Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4904 results about "Tool holder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

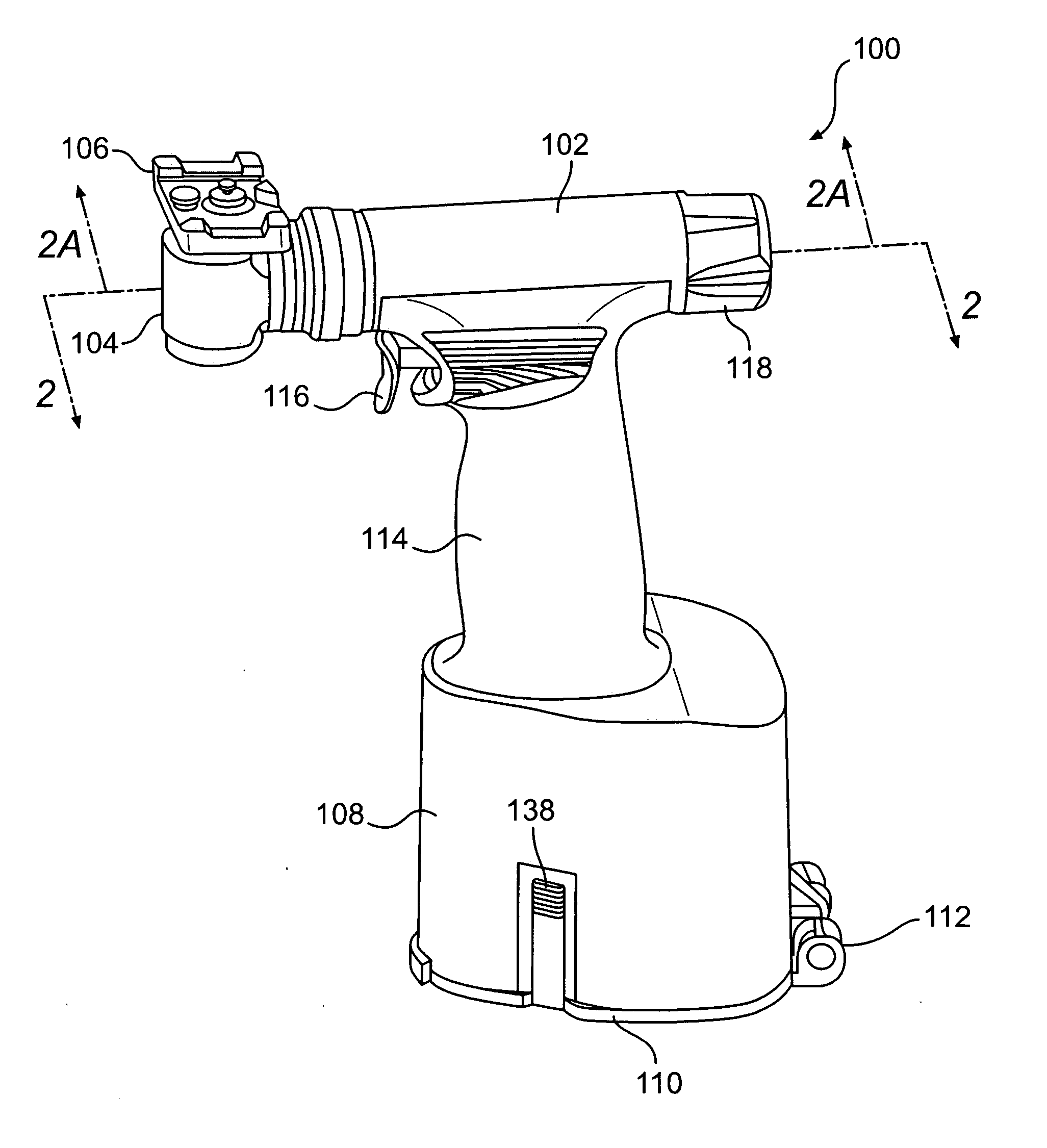

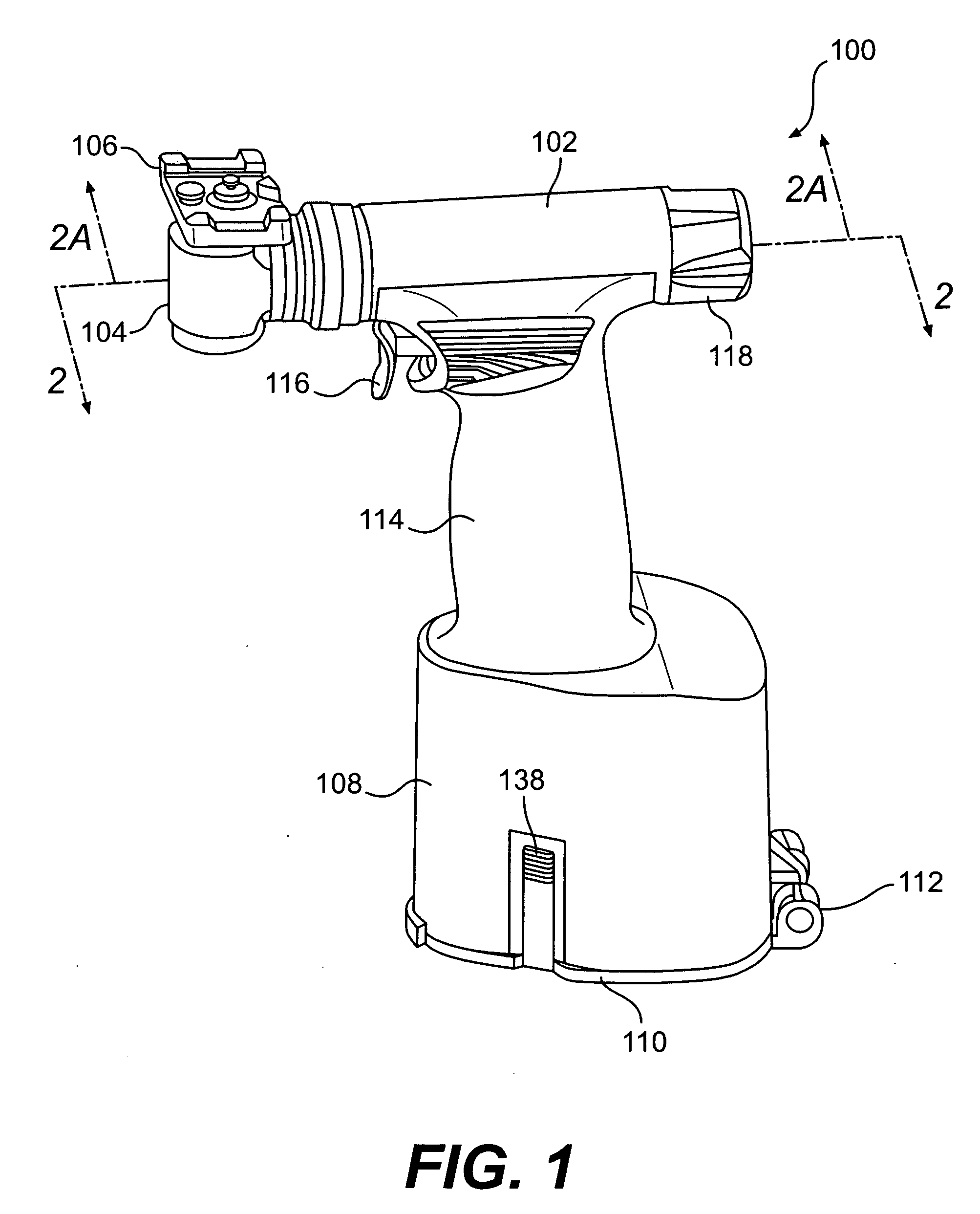

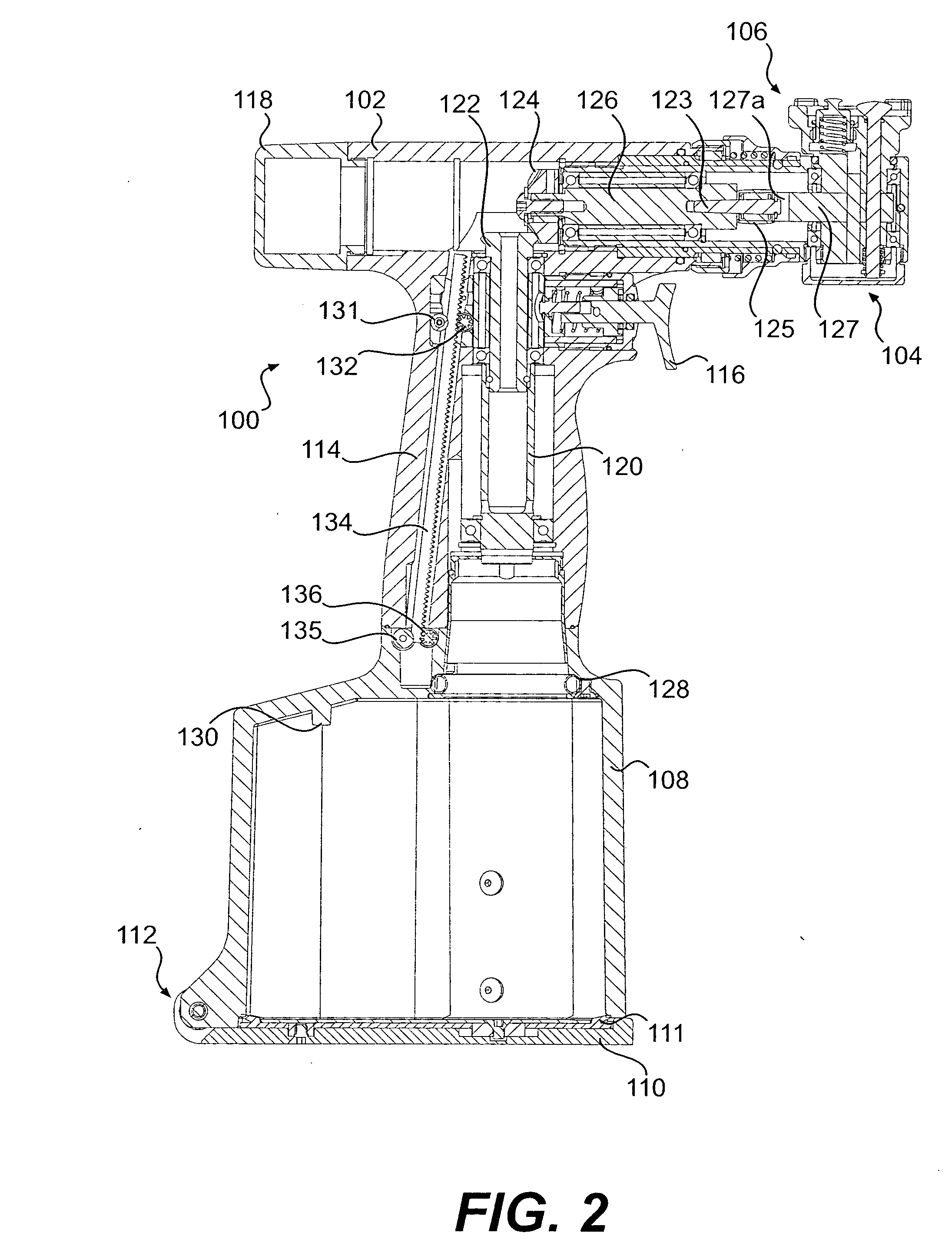

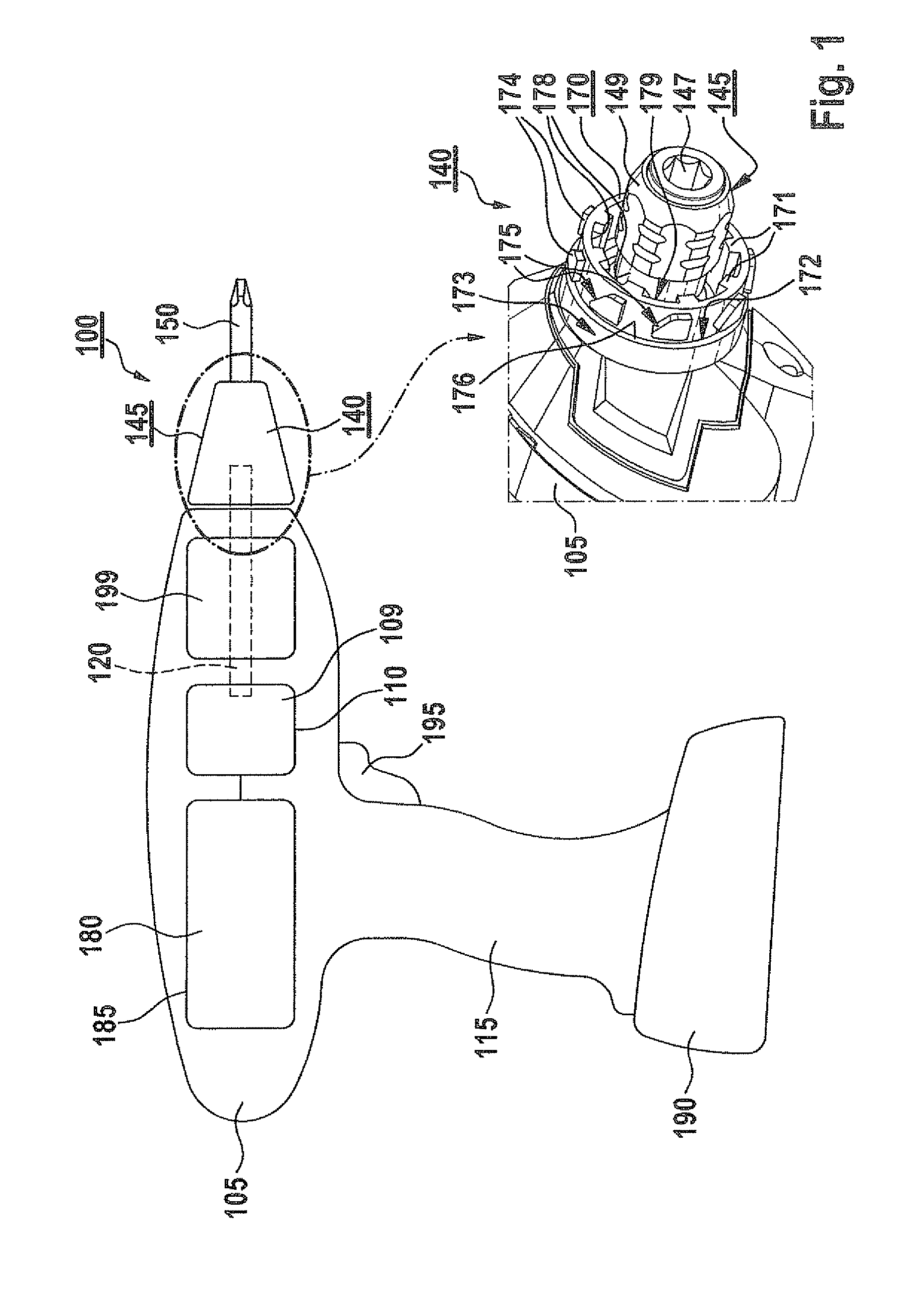

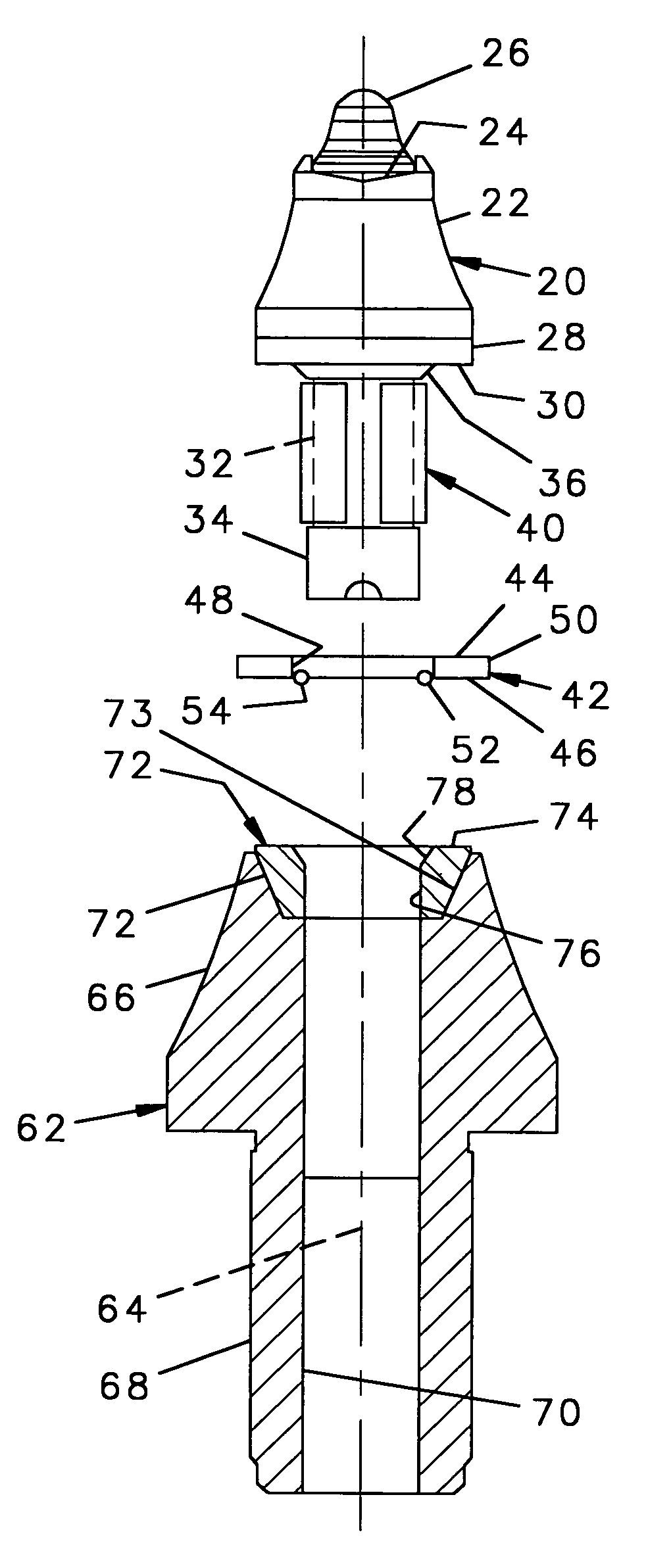

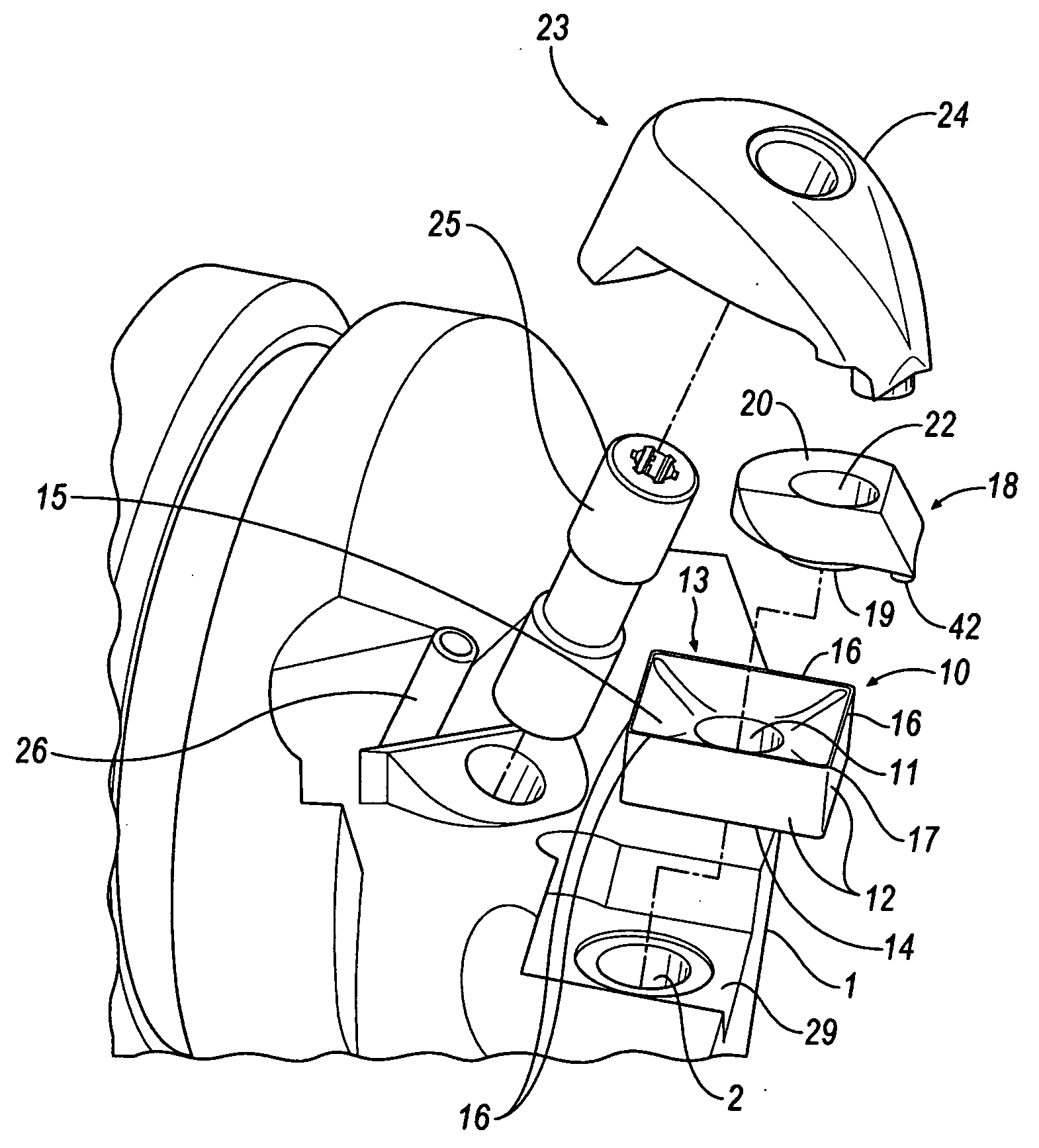

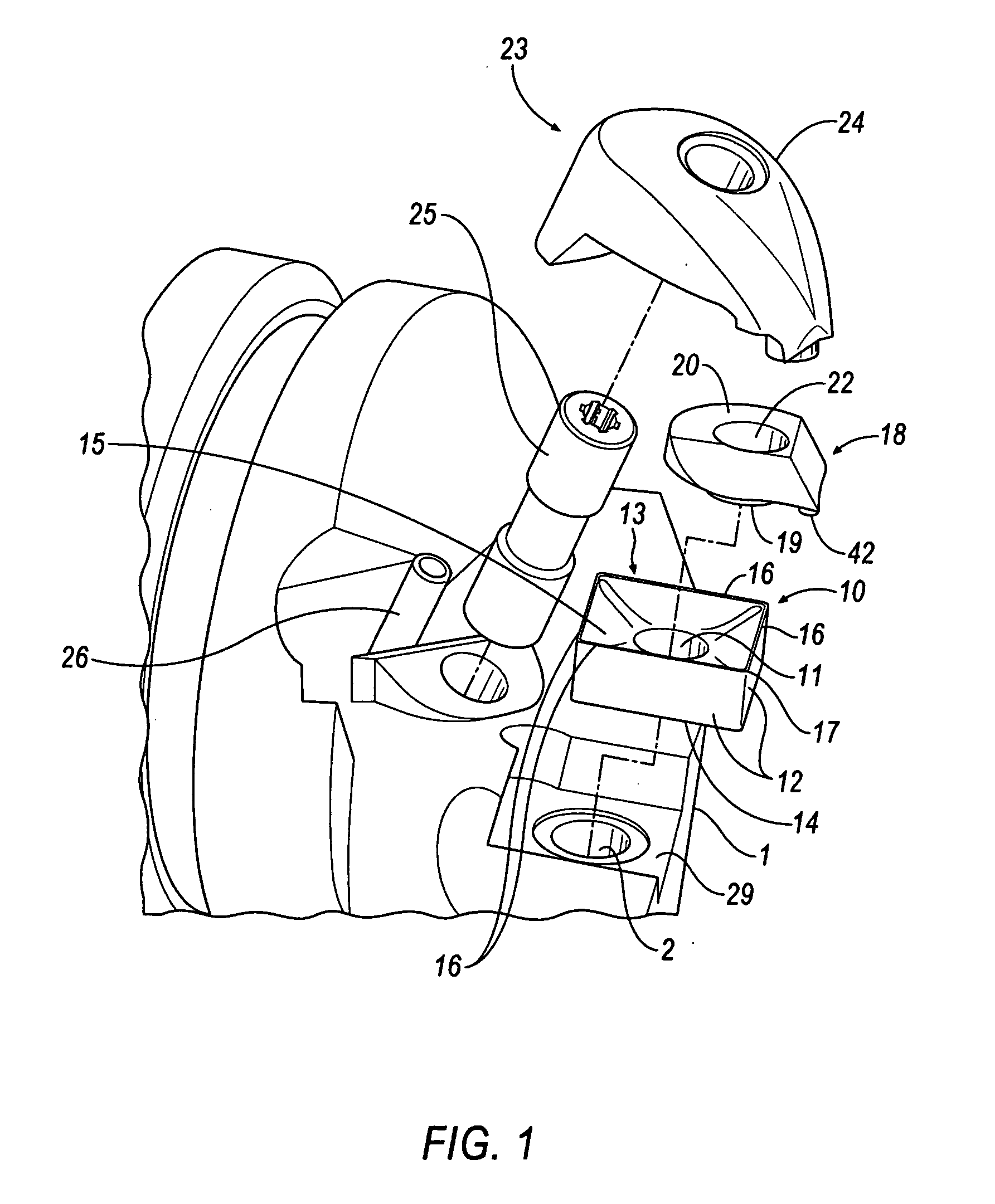

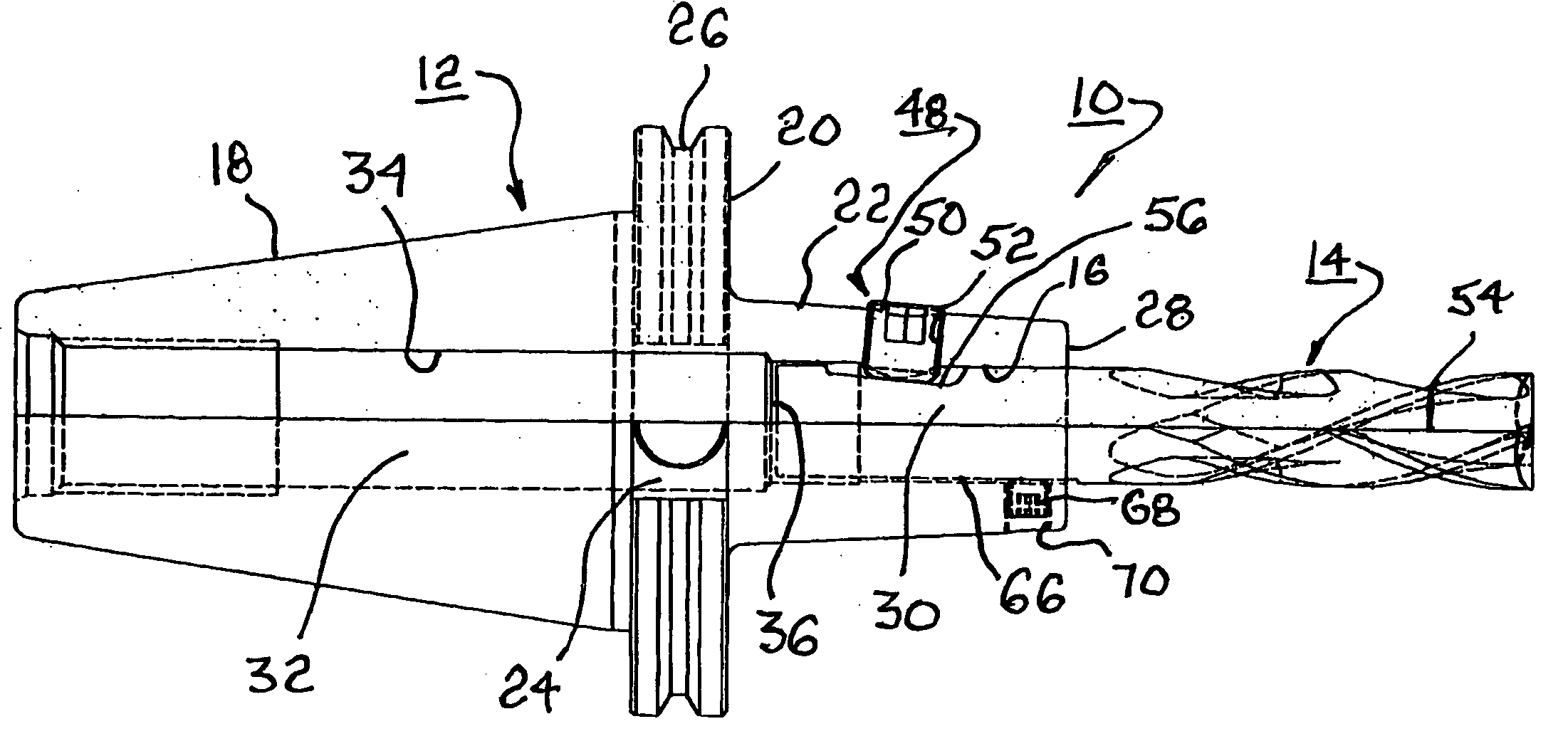

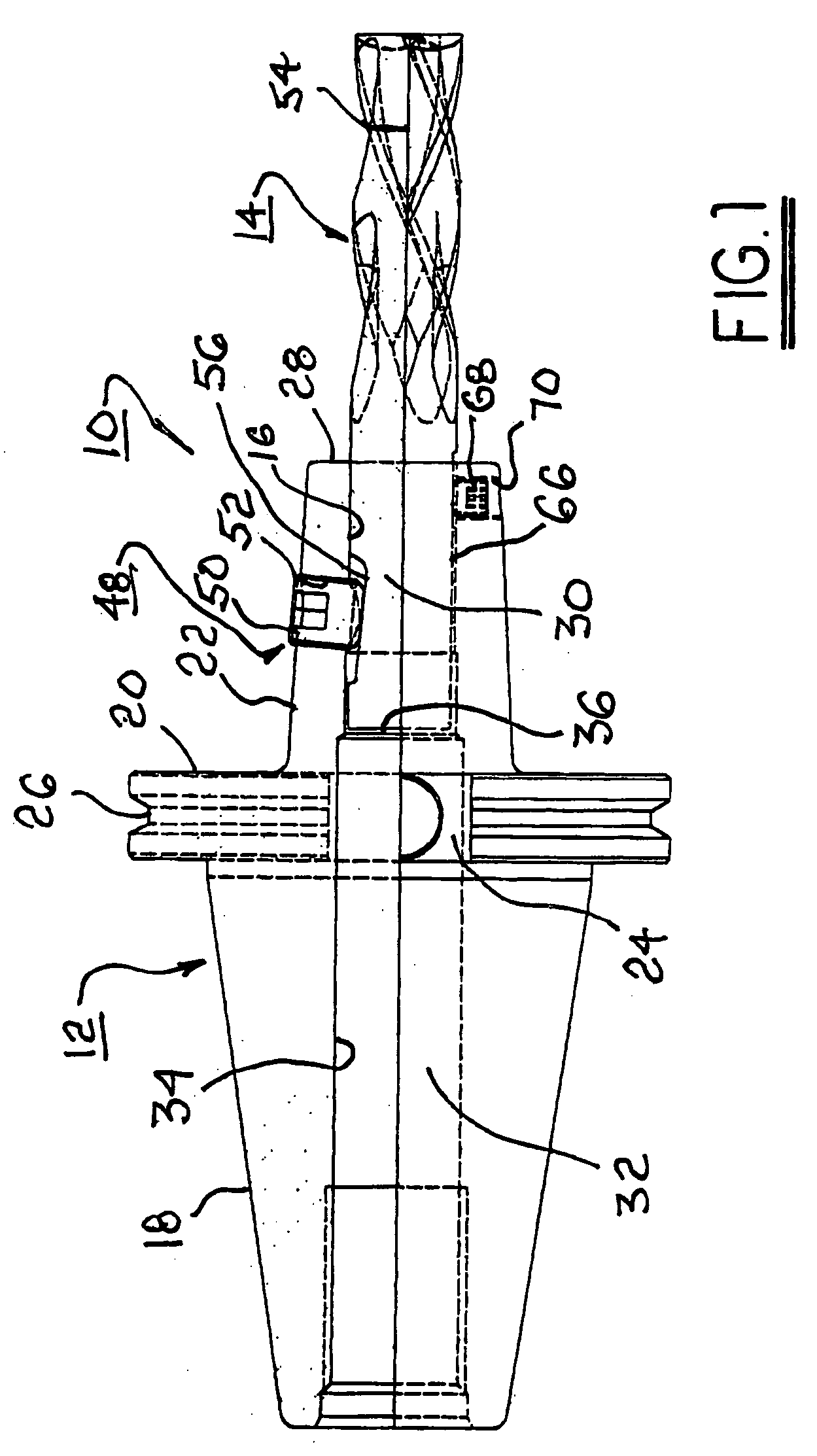

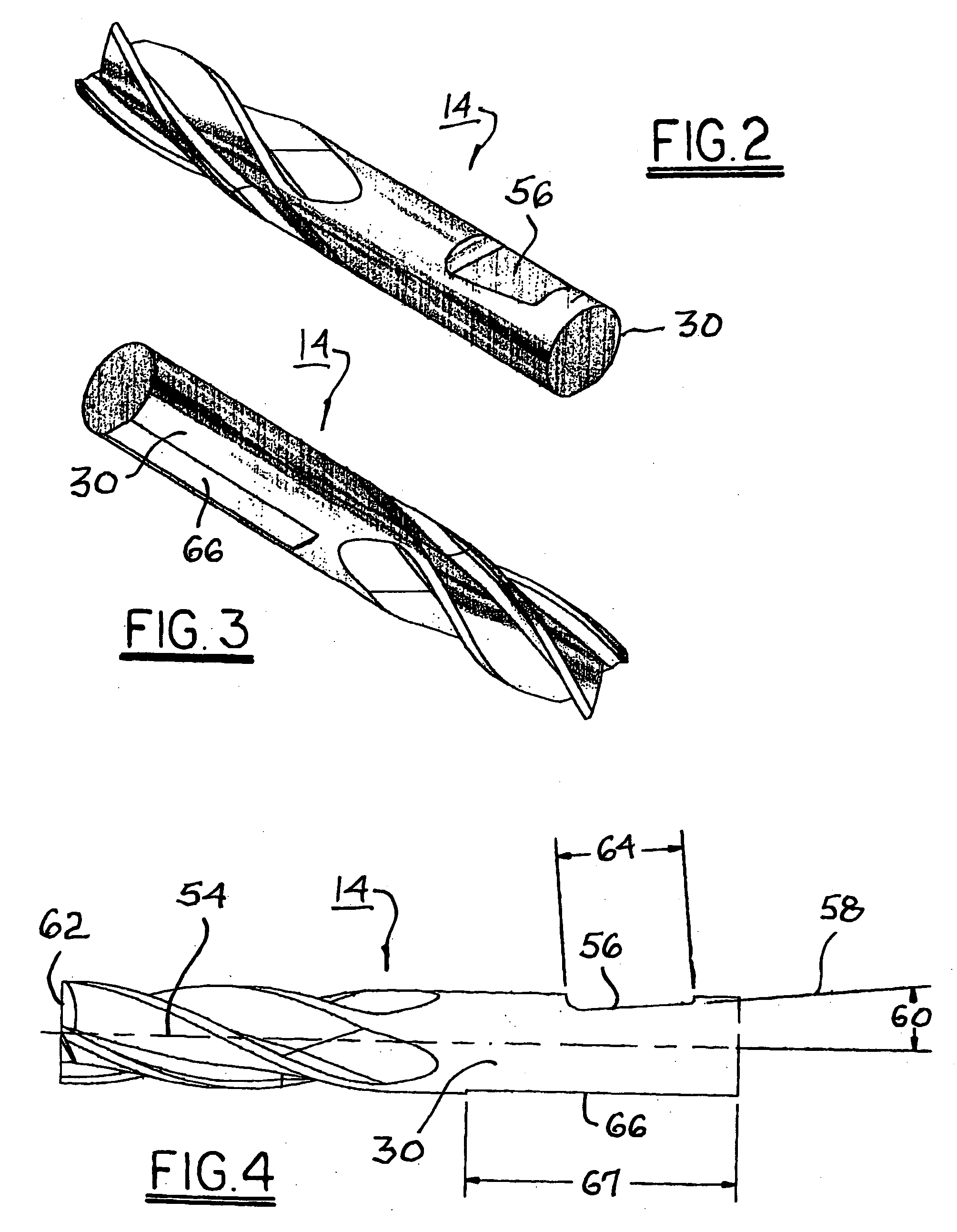

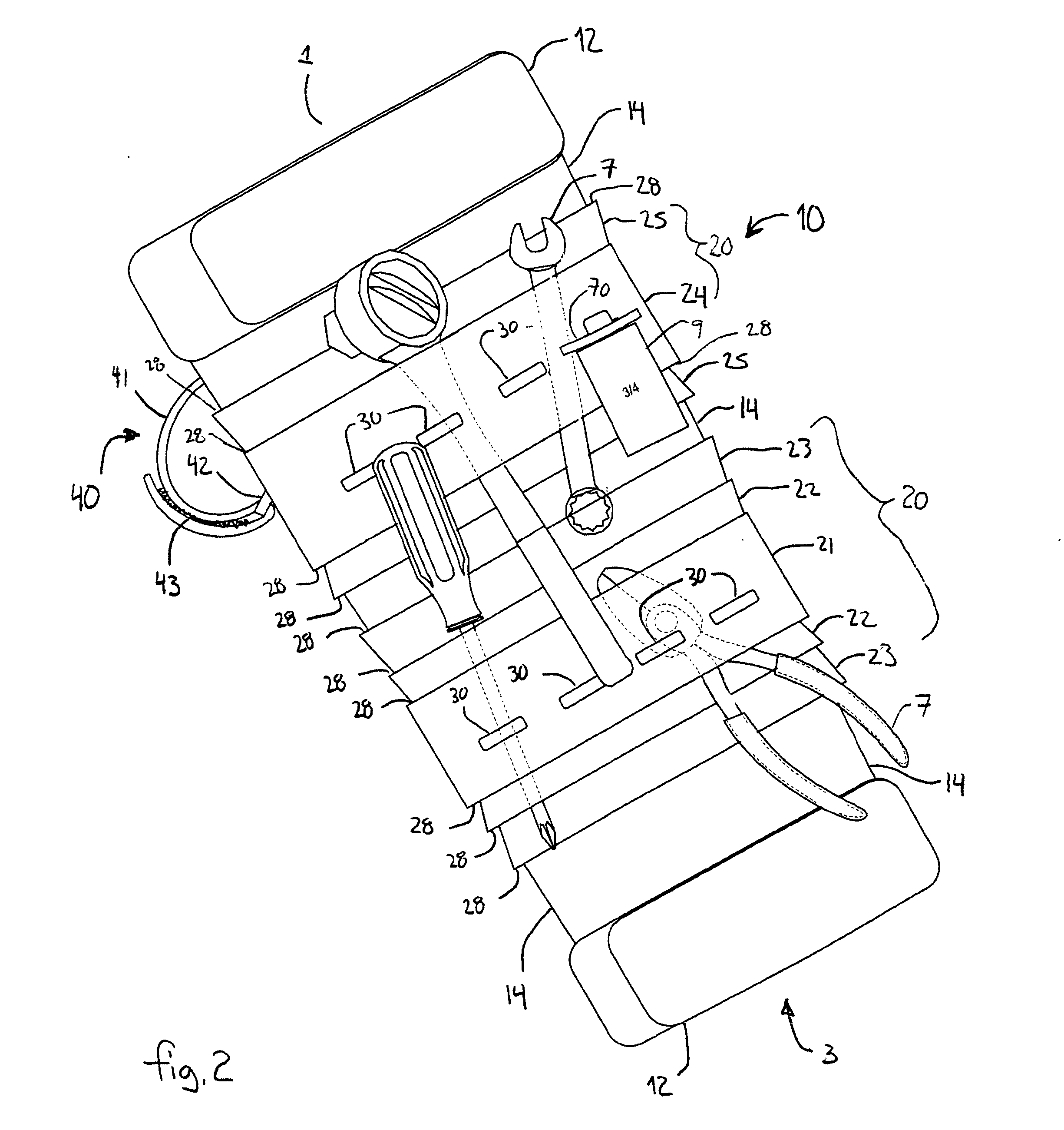

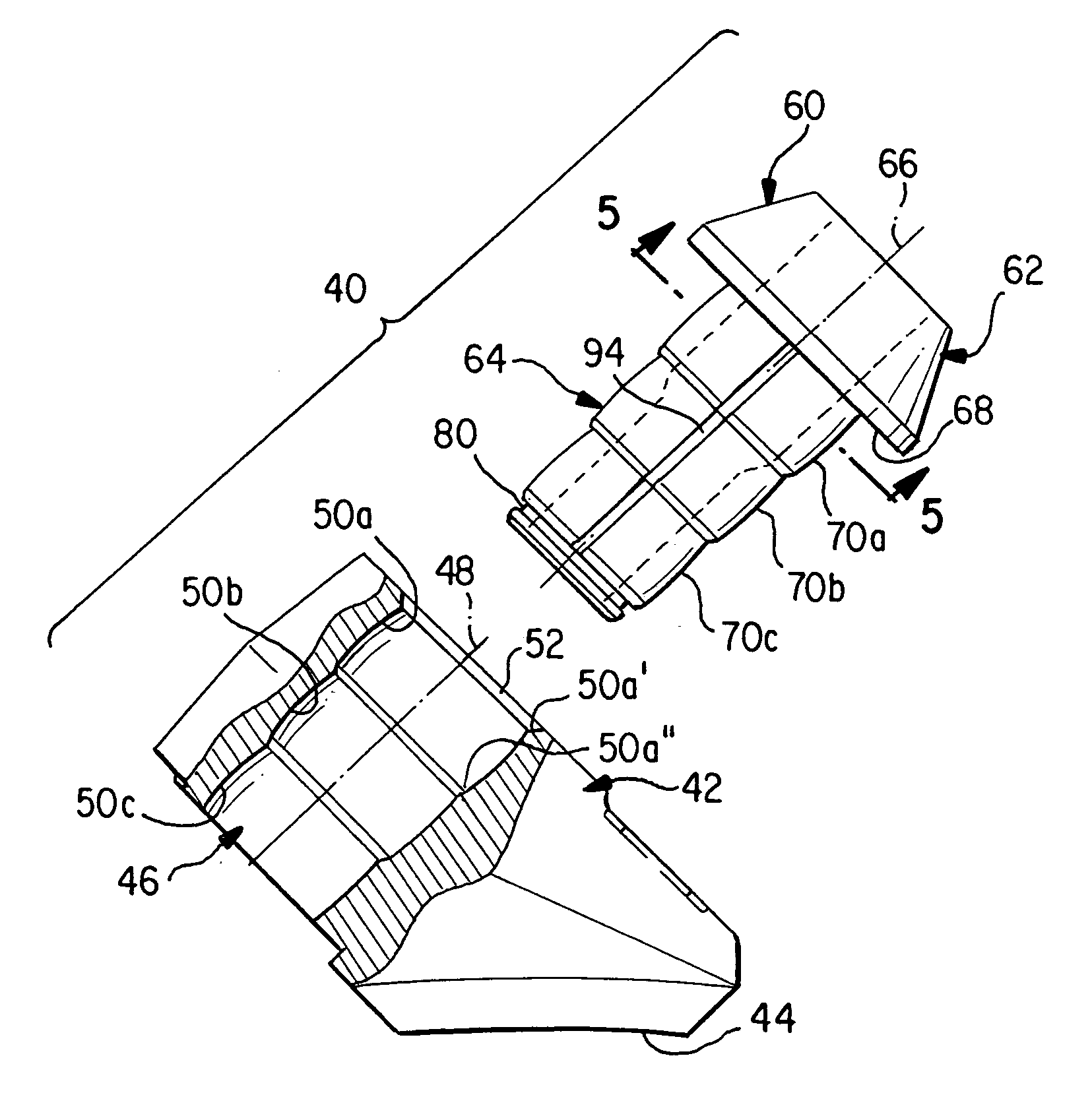

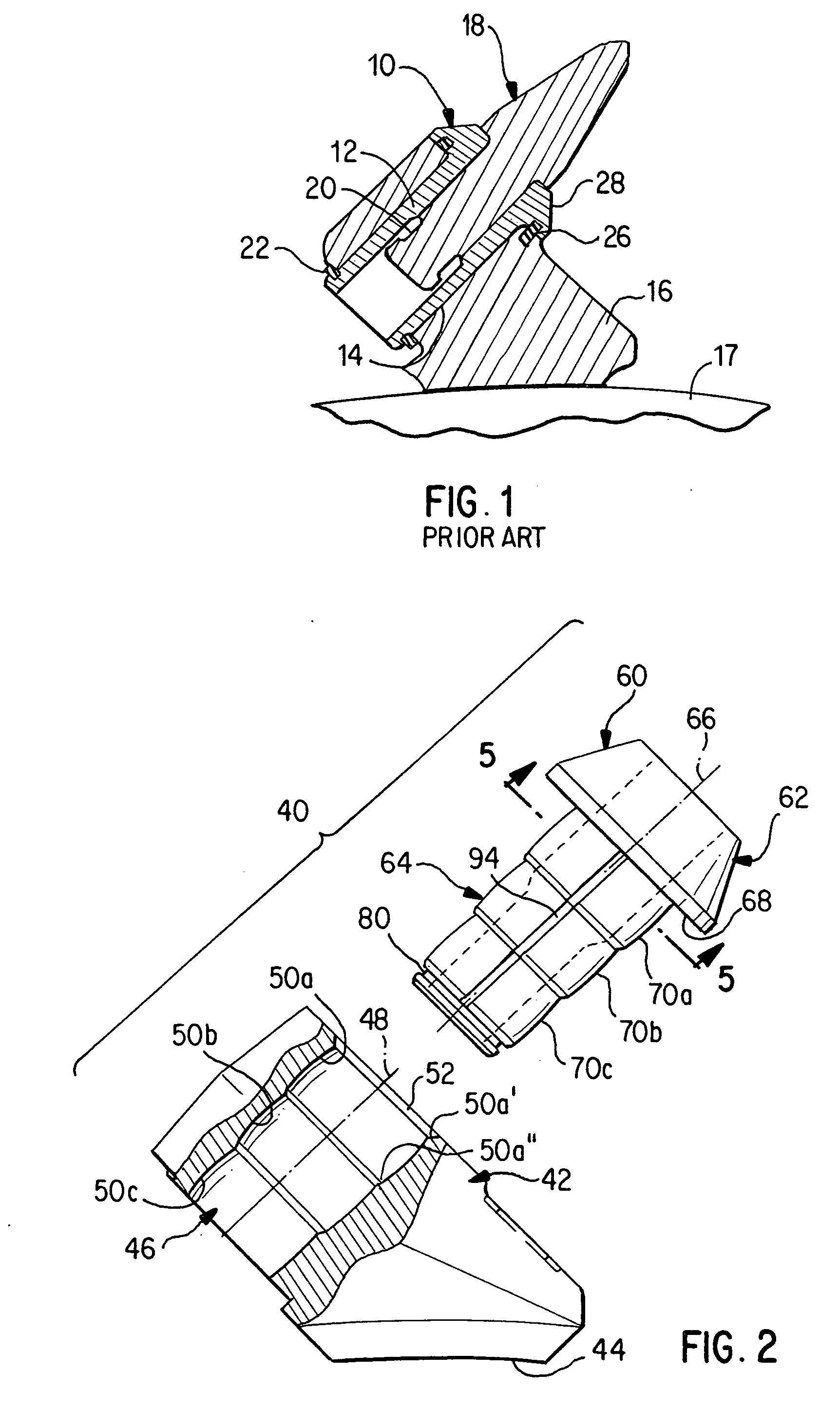

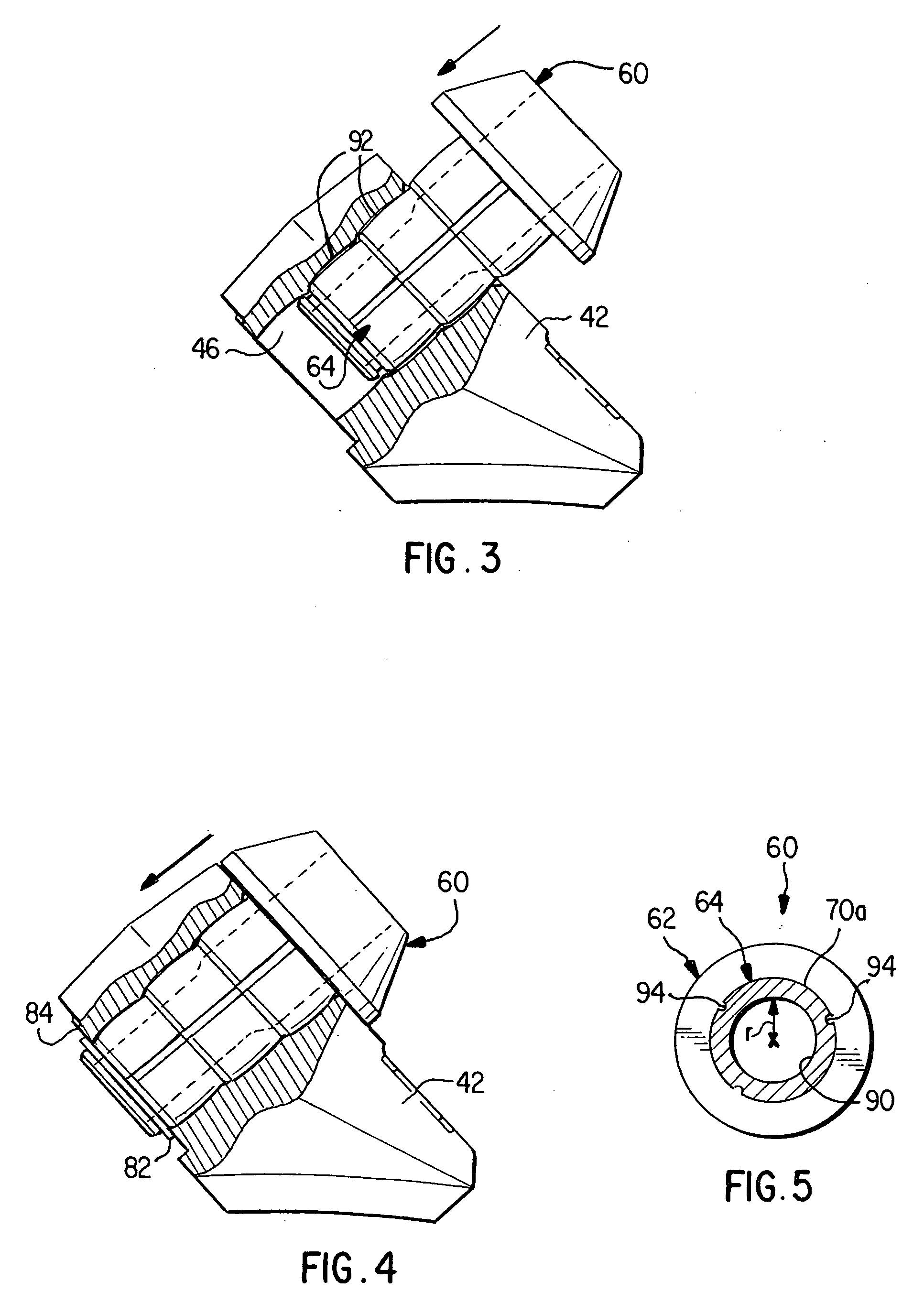

Surgical apparatus and tools for same

InactiveUS20060217729A1Easy to useNot easy to damageDiagnosticsSmall-sized cells cases/jacketsEngineeringPower tool

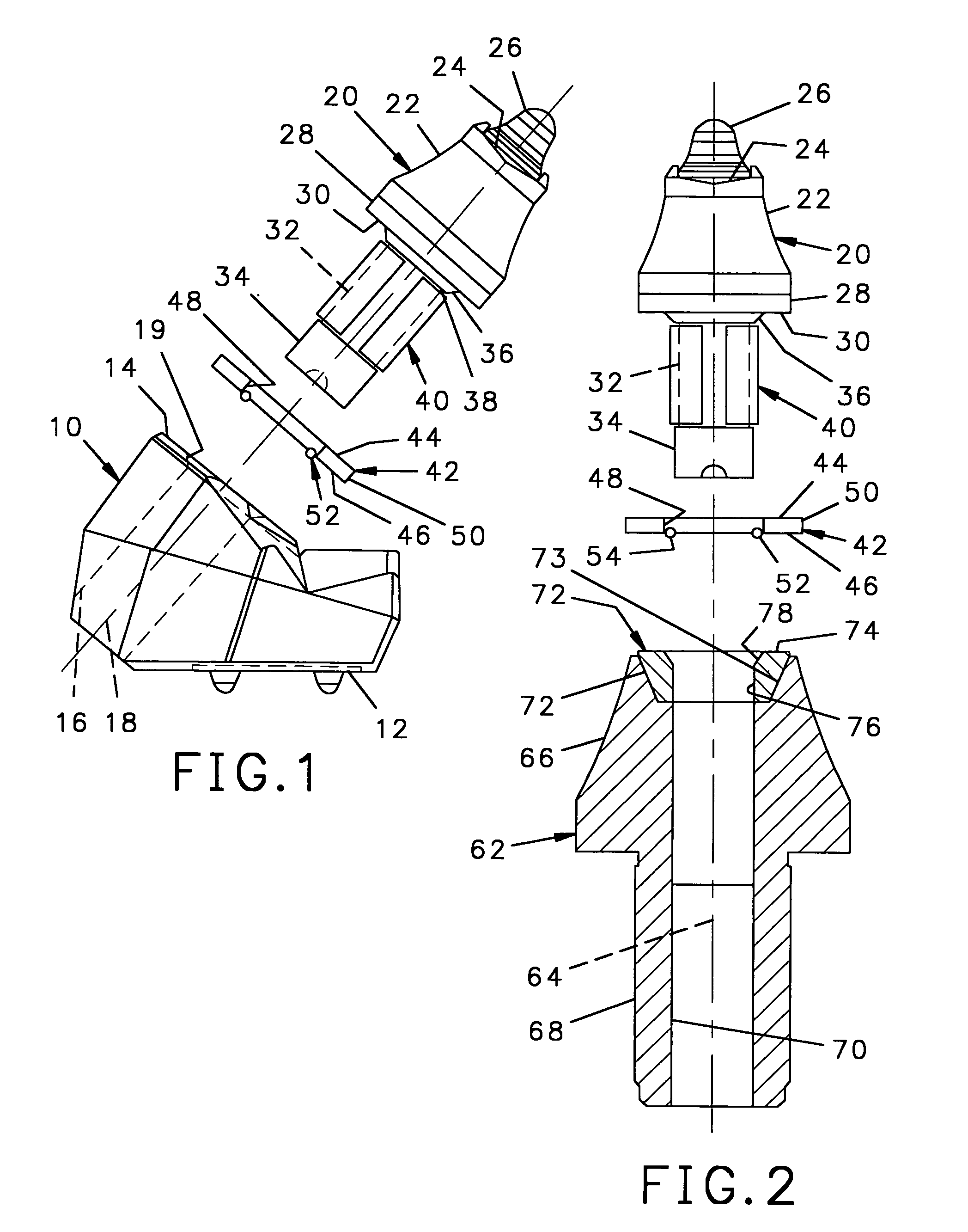

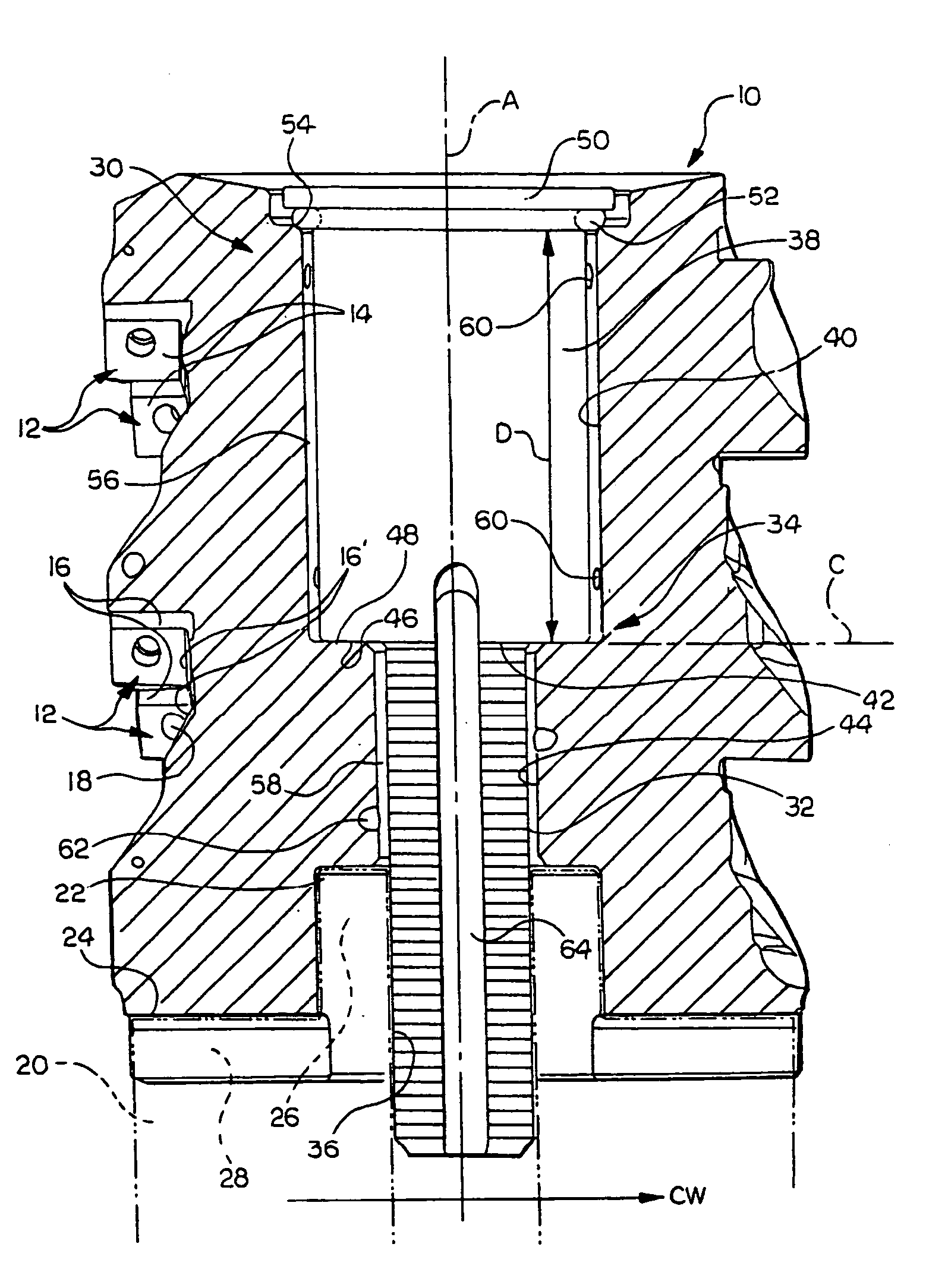

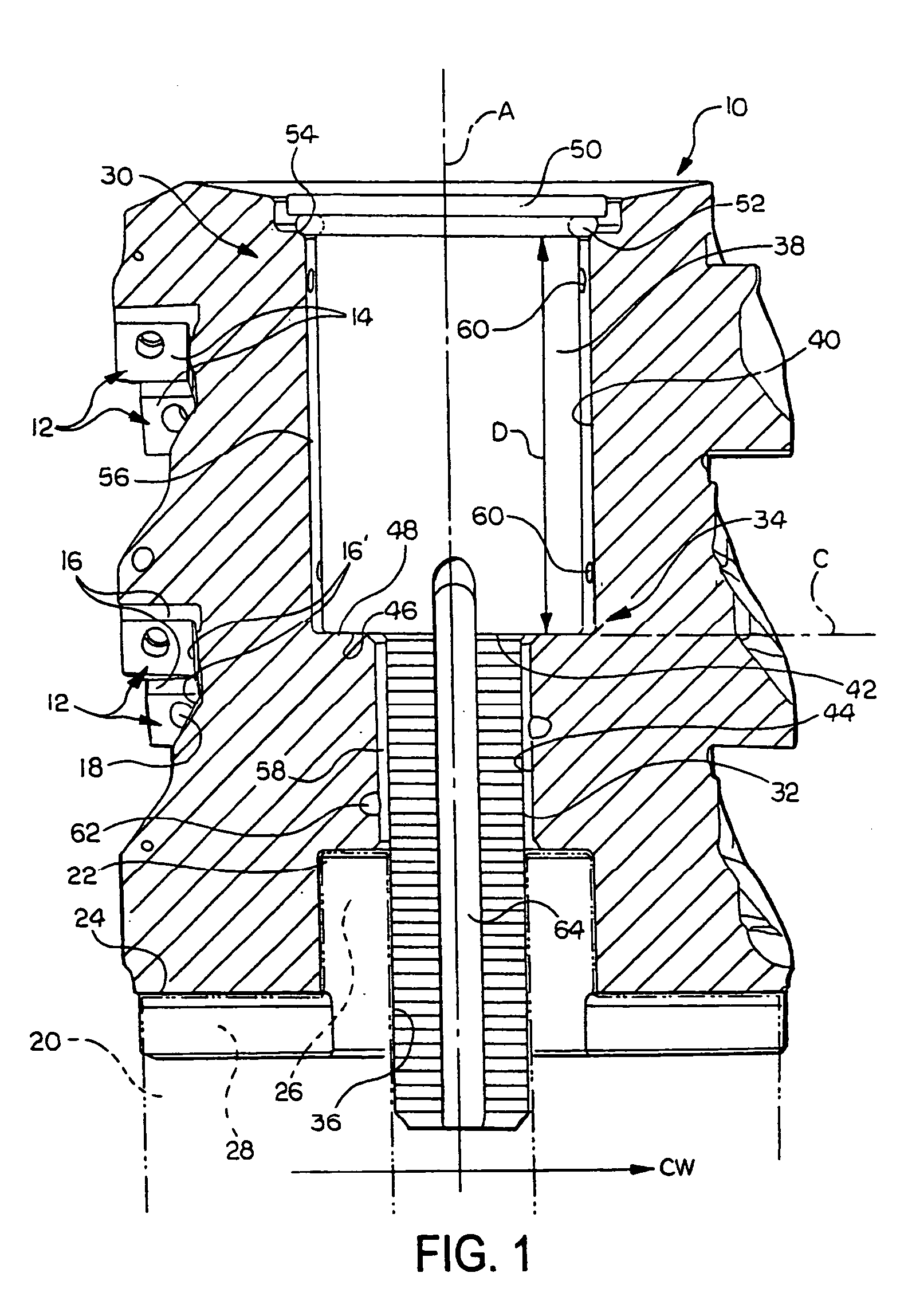

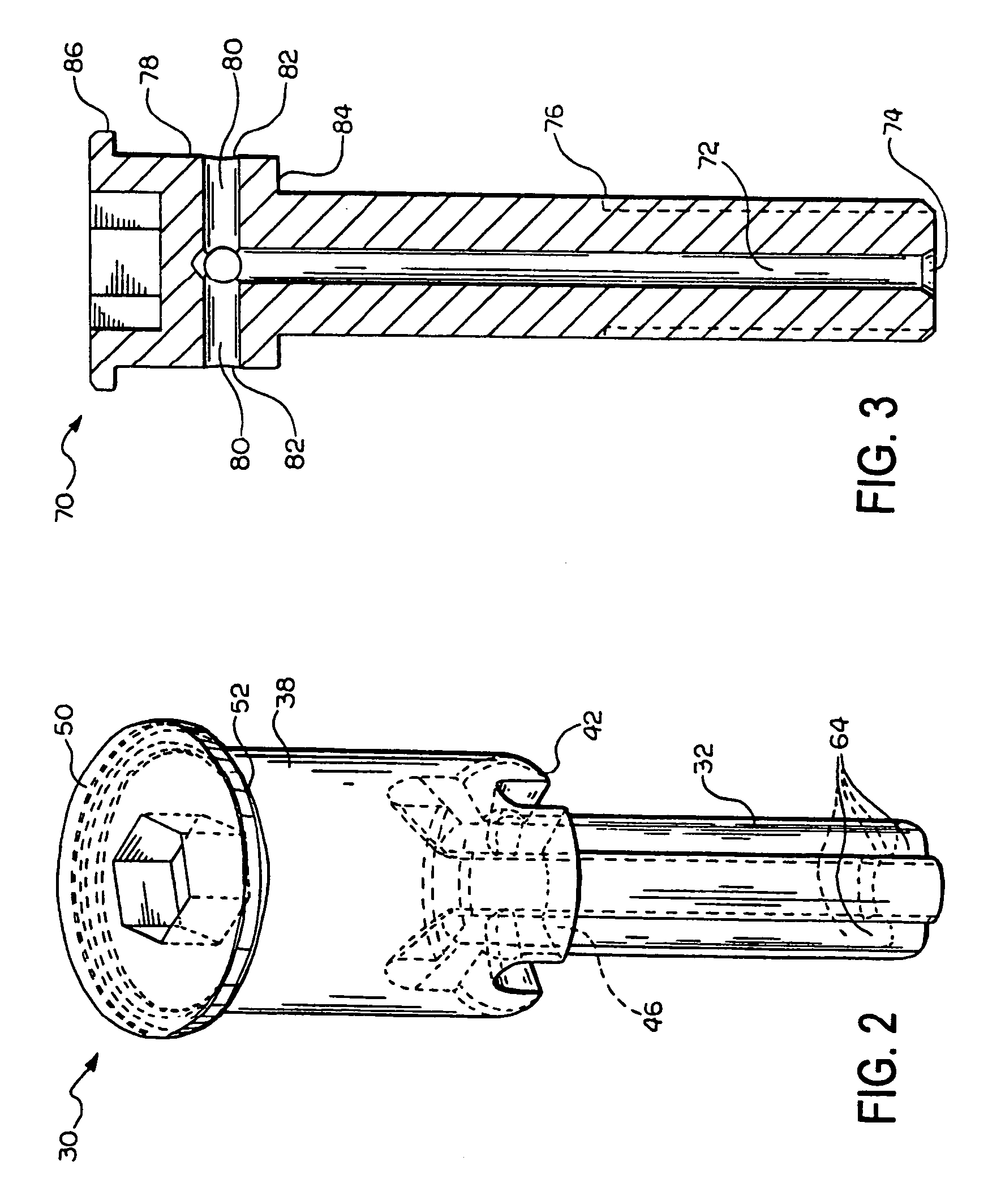

A surgical power tool includes a hand unit and a tool holder. The tool holder engages a hub of a tool to hold the tool during use. One tool holder includes a substantially planar support surface, a pair of spaced-apart sidewalls protruding from the support surface, each sidewall having at least one tab extending from the sidewall toward the other of the sidewalls. A tool clamp, including a post protrudes from the support surface with an enlarged head at a distal end thereof. A lock button protrudes from the support surface, the lock button being depressible toward the support surface. Another tool holder includes an output shaft having a driven end and a free end, the free end of the output shaft having a slot formed therein. A collet is disposed coaxially with the output shaft and is rotatable relative thereto. The collet has a collet wall extending between the first and second ends of the collet. The collet has a plurality of slots in the first end of the collet, a plurality of grooves in an inner surface of the collet wall, and a plurality of internal ridges protruding from the inner surface of the collet wall.

Owner:BRASSELER USA MEDICAL

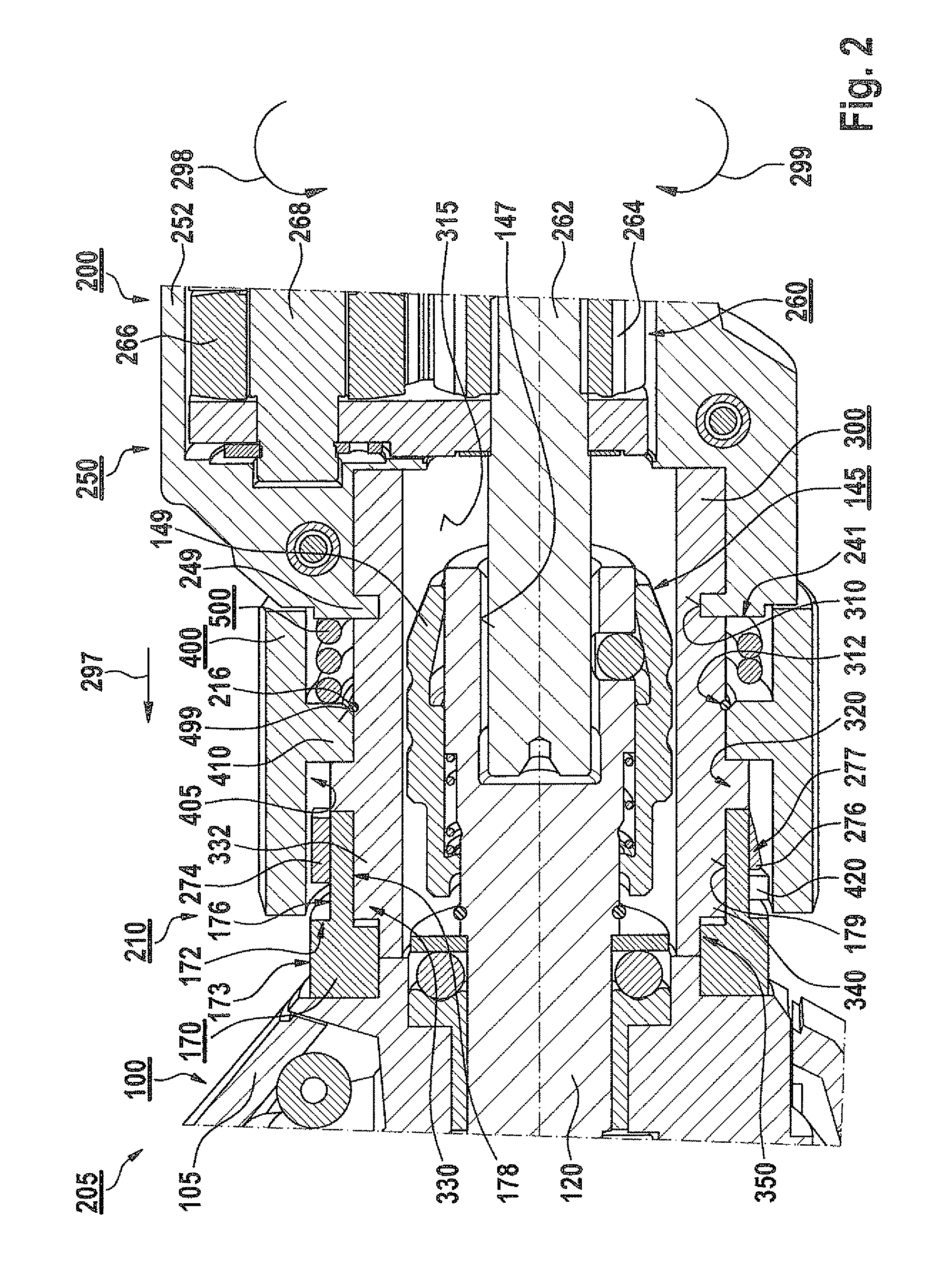

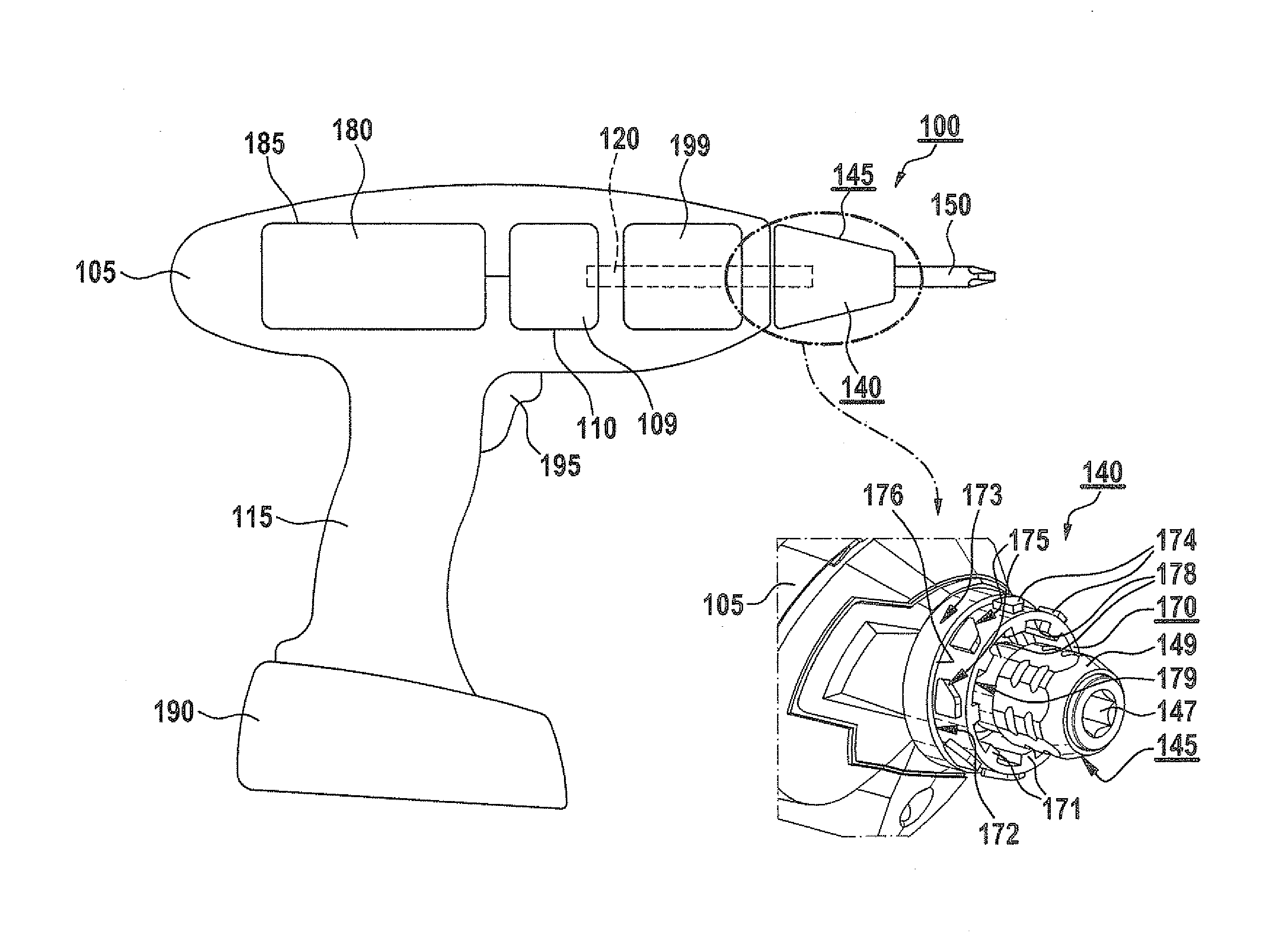

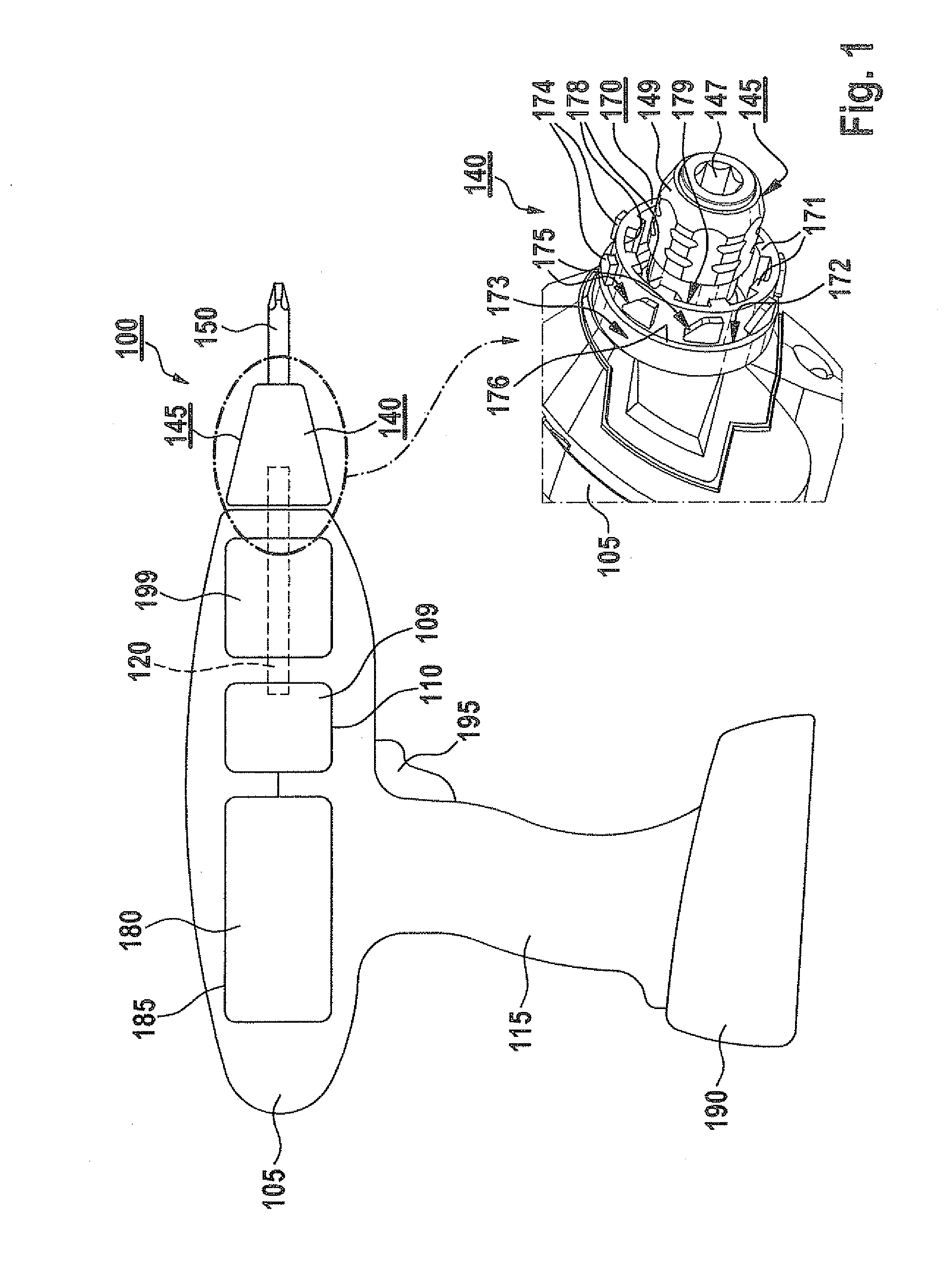

Tool attachment

A tool attachment for mounting on a hand-held machine tool provided with a tool holder, the tool attachment having an output shaft and a base body at whose outer circumference a locking sleeve is disposed in a manner allowing it to rotate to release at least one assigned locking element; at the outer circumference of the base body, an anti-rotation unit is formed for the twist-proof mounting of the base body on a fastening unit assigned to the hand-held machine tool; on the anti-rotation unit and at an inner circumference of the fastening unit, complementary geometrical forms are provided which are configured to mesh with each other for the releasable, twist-proof mounting of the base body on the fastening unit.

Owner:ROBERT BOSCH GMBH

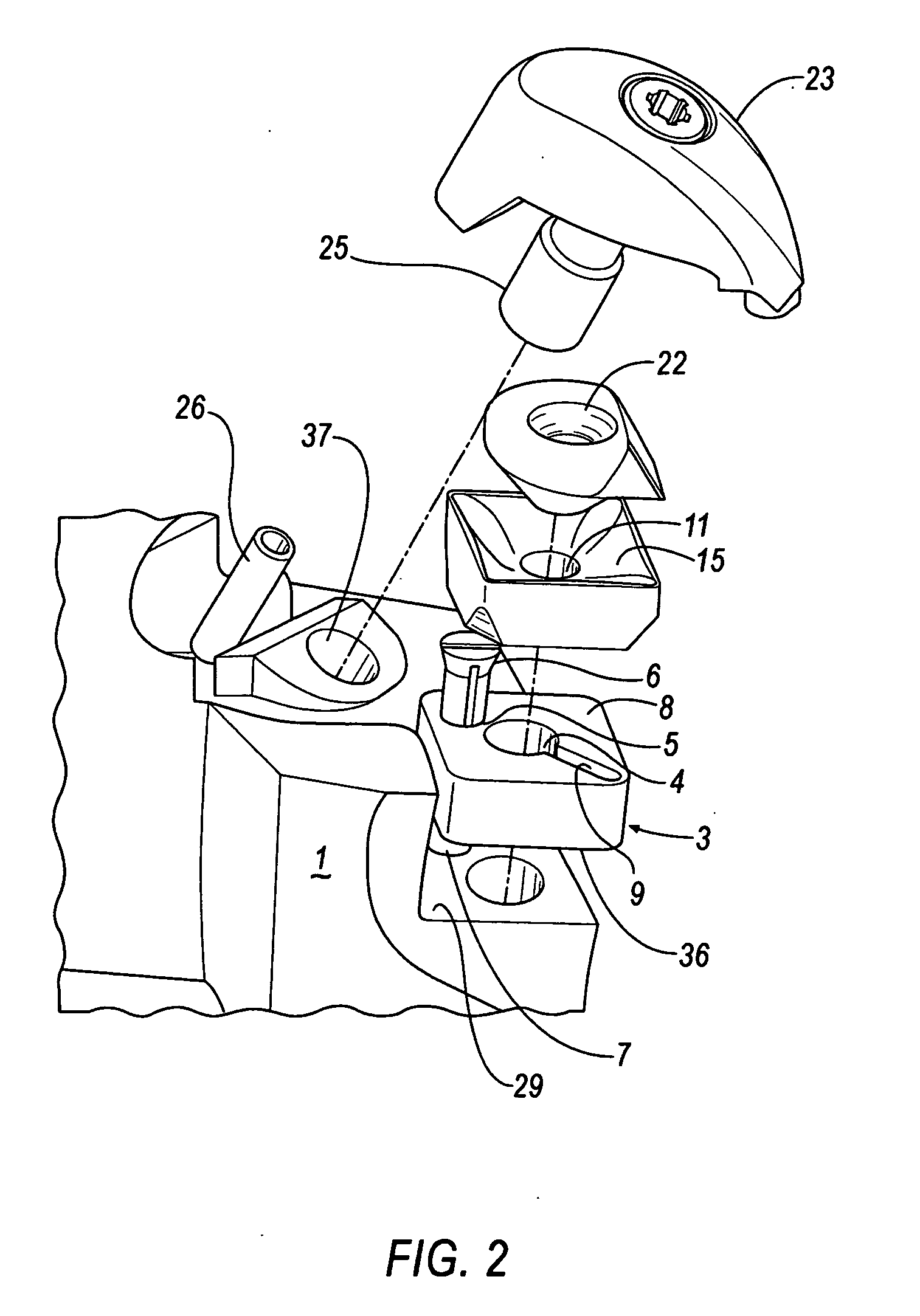

Surgical coupling device

InactiveUS20070179477A1Simple structureSimple and safe operationDiagnosticsSpannersCouplingEngineering

A surgical coupling device detachably connects a tool holder to a surgical instrument, wherein the tool holder is provided with a recess into which a coupling portion of the instrument can be inserted detachably, wherein a locking recess is provided in an inner wall of the recess, with which a locking member can be engaged detachably, the locking member being supported at the instrument, wherein the locking member is selectively movable into a locking position and a release position by a servo drive.

Owner:GEBR BRASSELER GMBH & CO KG

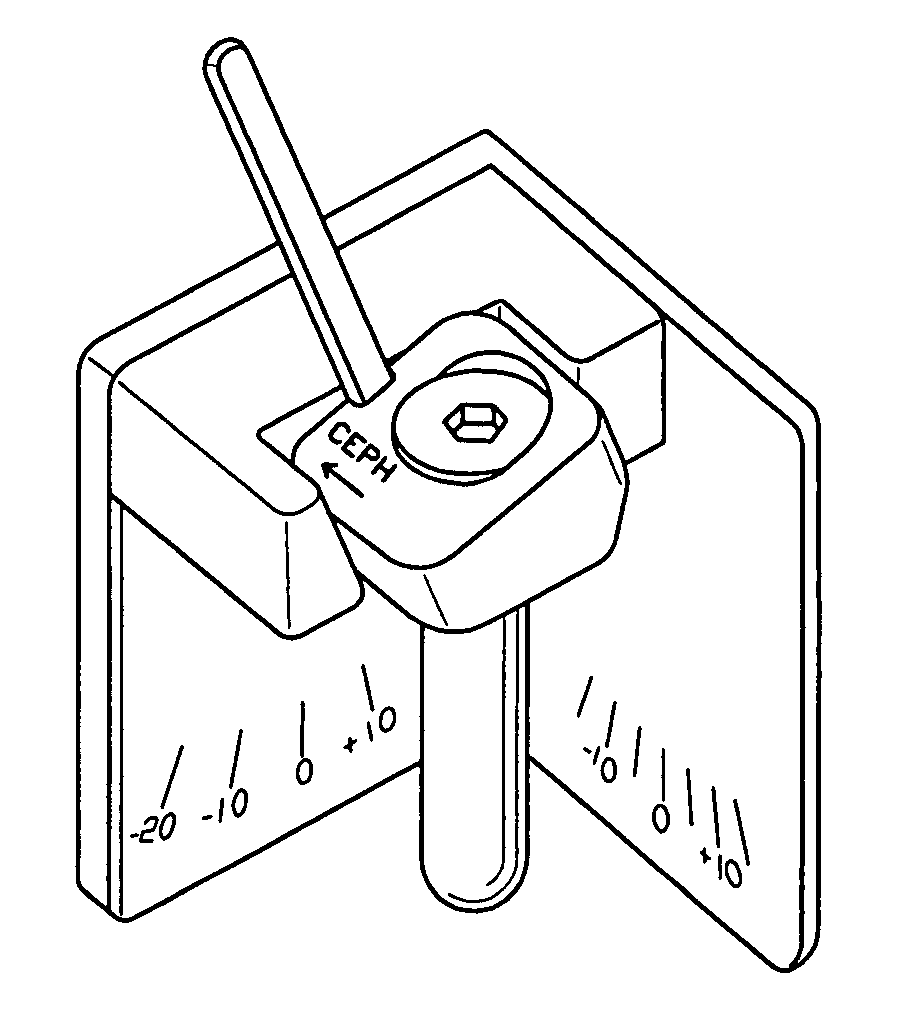

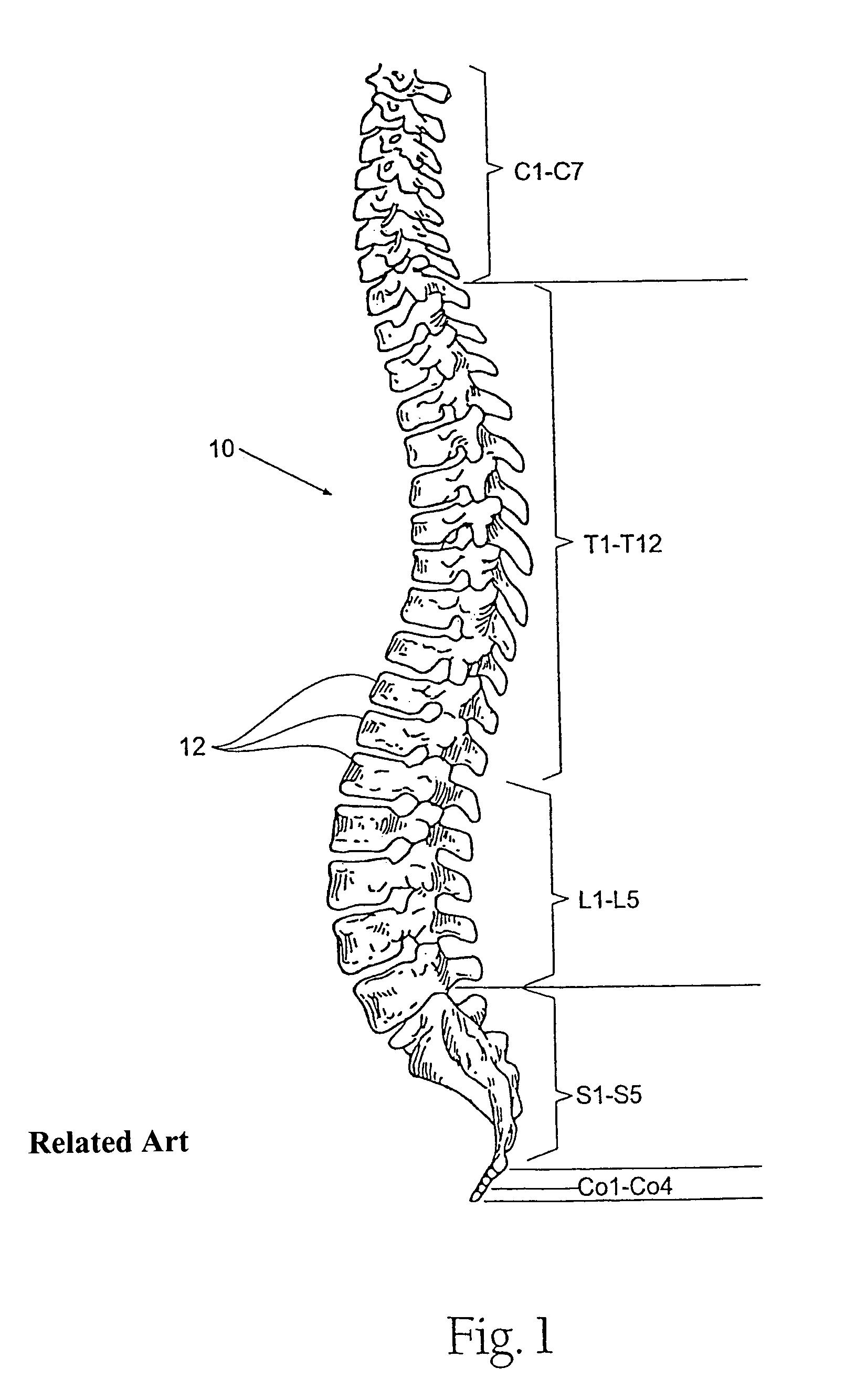

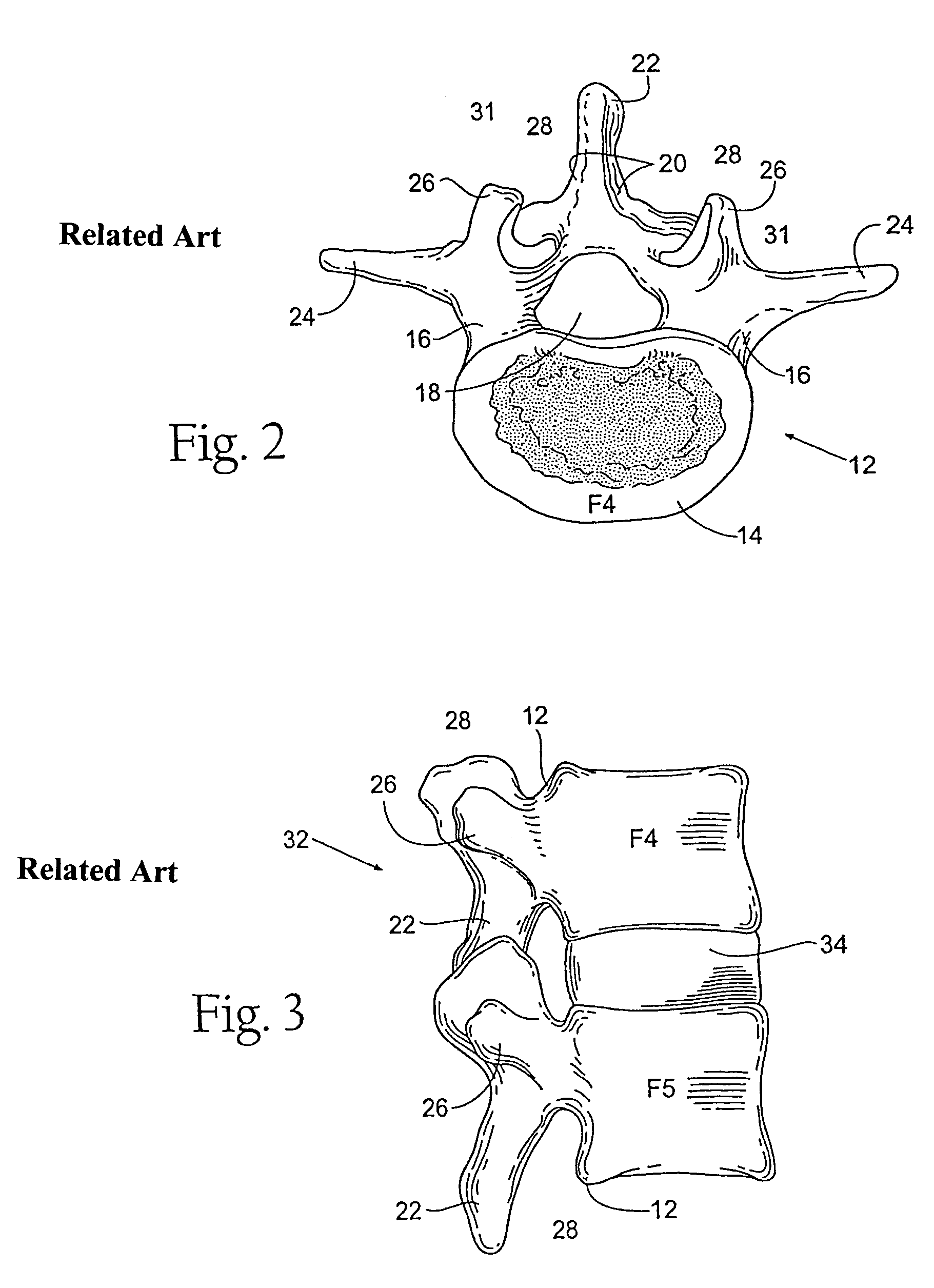

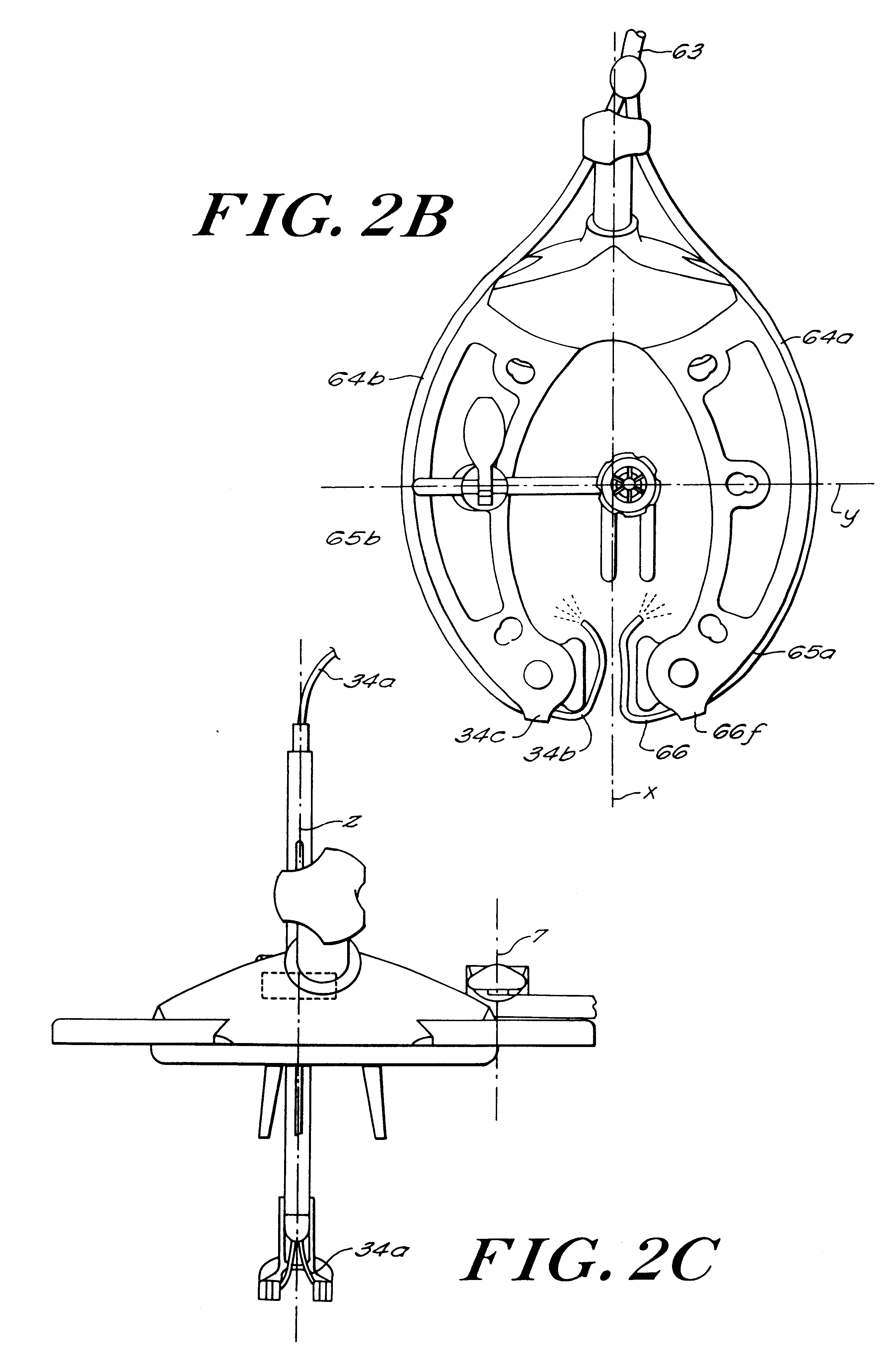

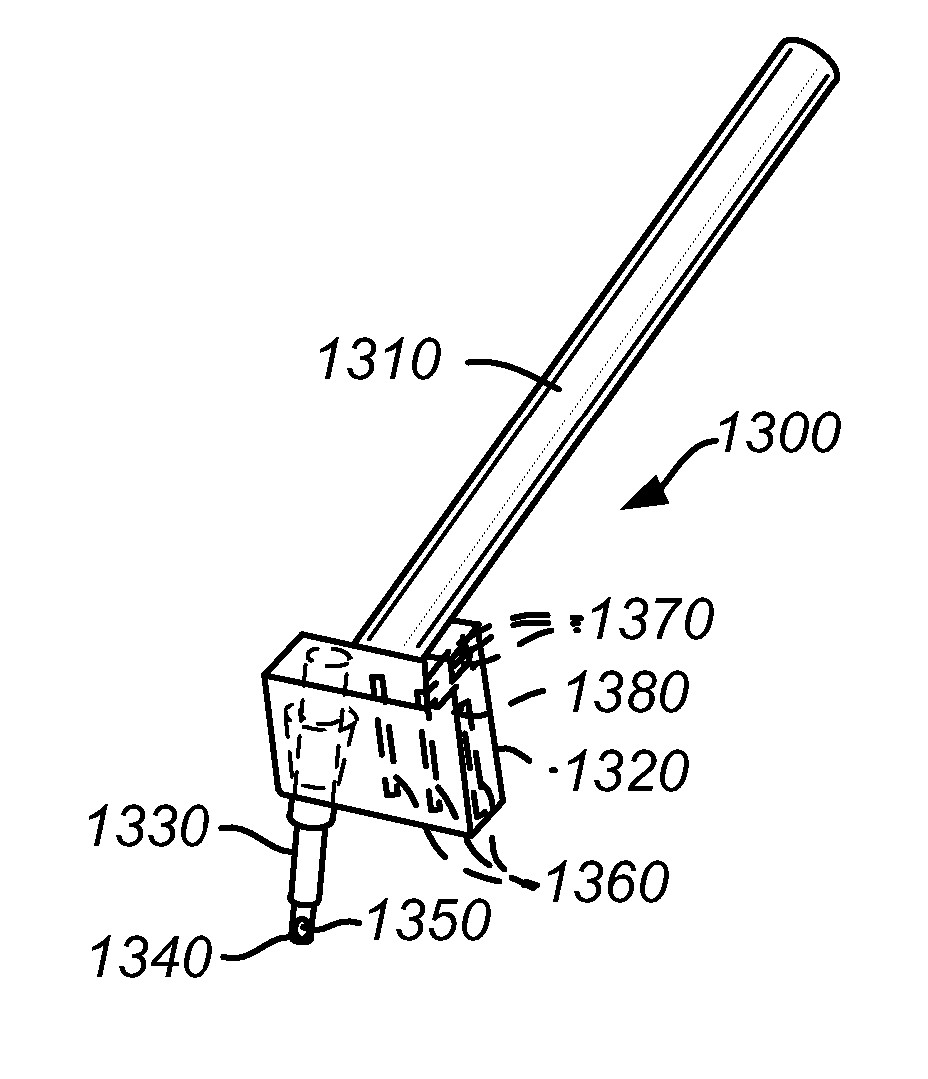

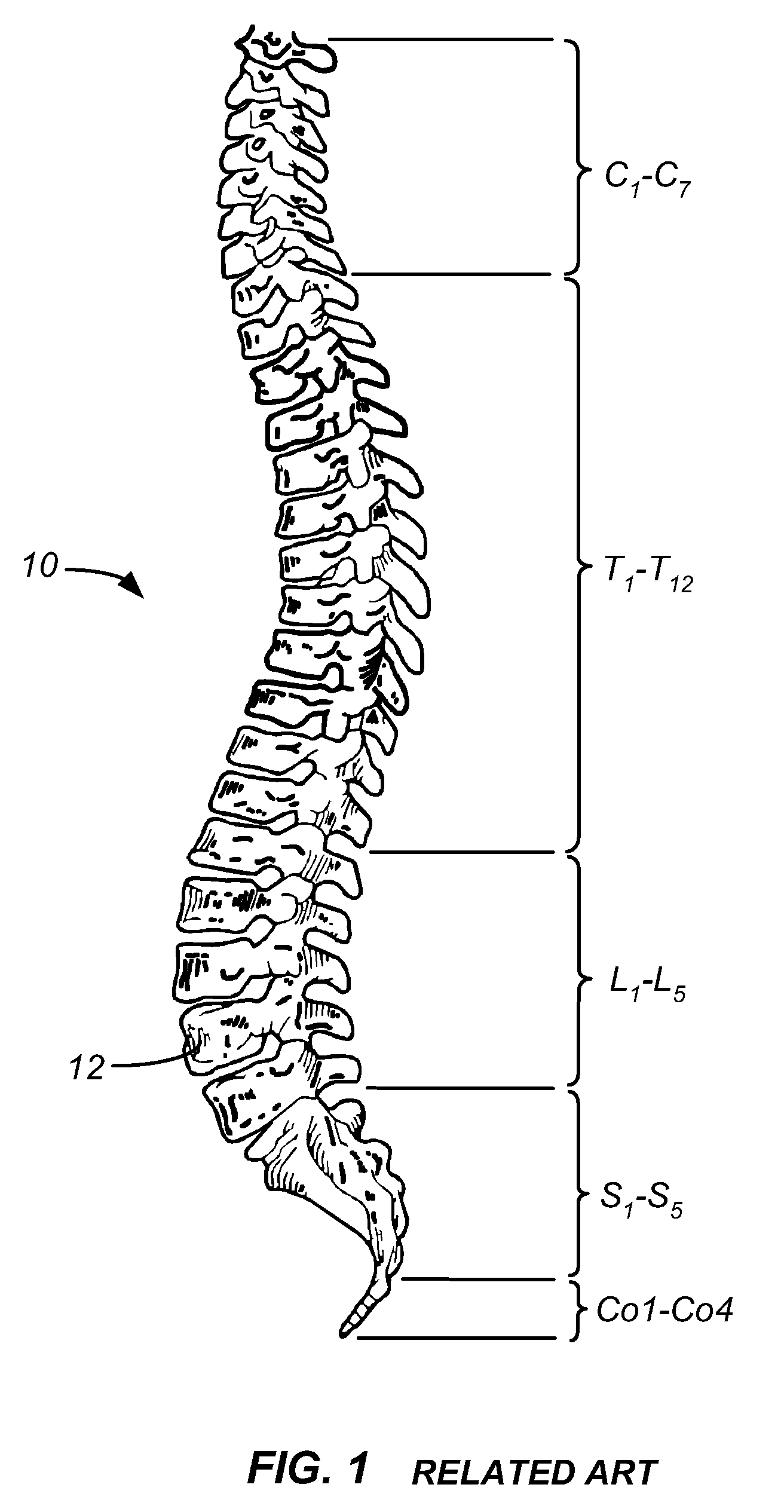

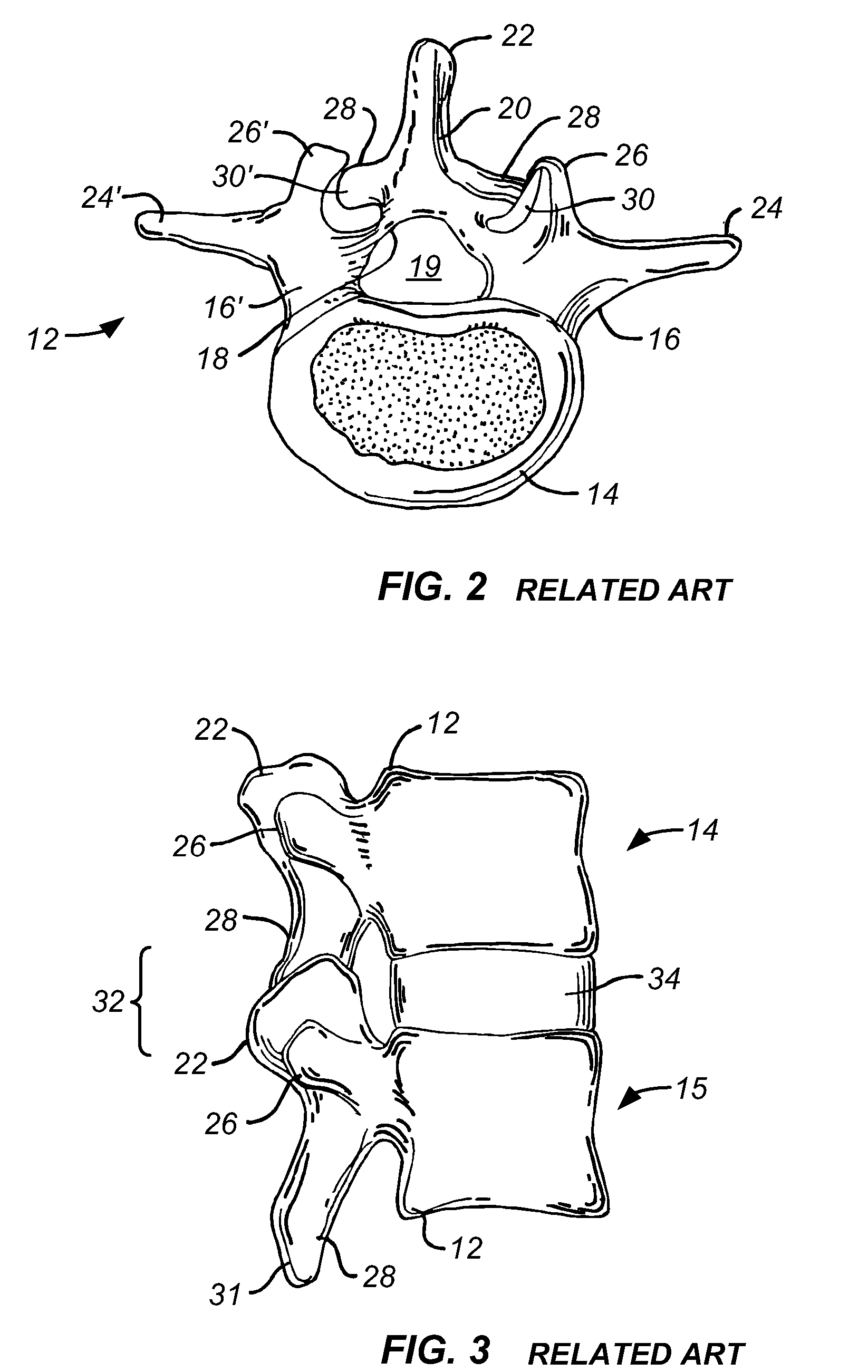

Facet joint prosthesis measurement and implant tools

ActiveUS7051451B2Easy to measureAngles/taper measurementsInternal osteosythesisFacet joint prosthesisProsthesis

The present invention provides tools and methods designed to aid in the placement of facet joint prosthesis at virtually all spinal levels. One aspect of the present invention is a measurement tool for installing a cephalad facet joint prosthesis including a fixation measurement element and a support arm element. This measurement tool assists in the selection and / or configuration of a cephalad facet joint prosthesis for implantation in a patient. Another aspect is a measurement tool for installing a caudal facet joint prosthesis including a stem element and a trial caudal bearing surface element. This measurement tool assists in the selection and / or configuration of a caudal facet joint prosthesis for implantation in a patient. Yet another aspect is a measurement tool holder including a measurement surface connected to a holder element. This tool holder assists in determining the measurements obtained with the caudal facet joint prosthesis measurement tool.

Owner:GLOBUS MEDICAL INC

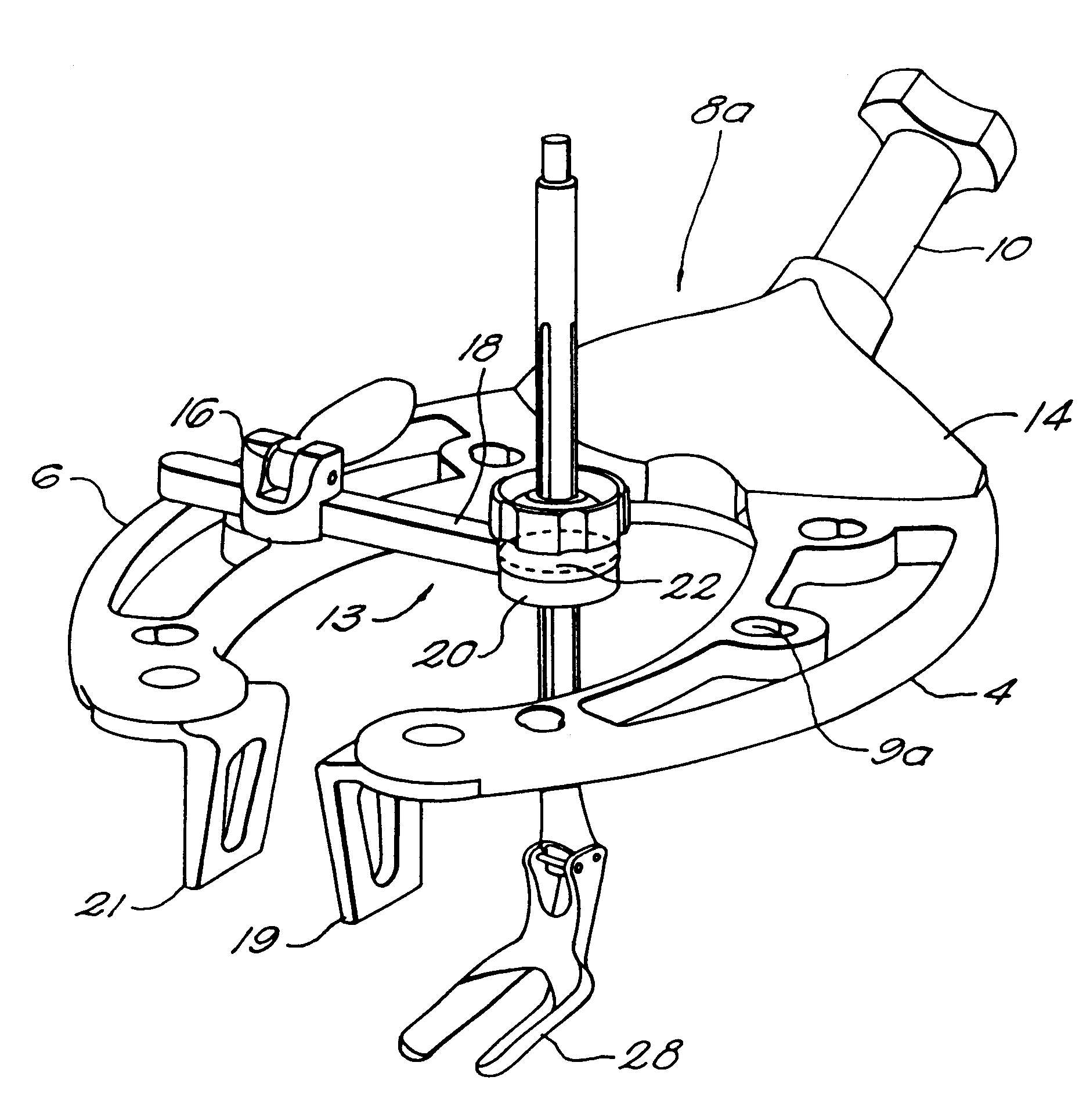

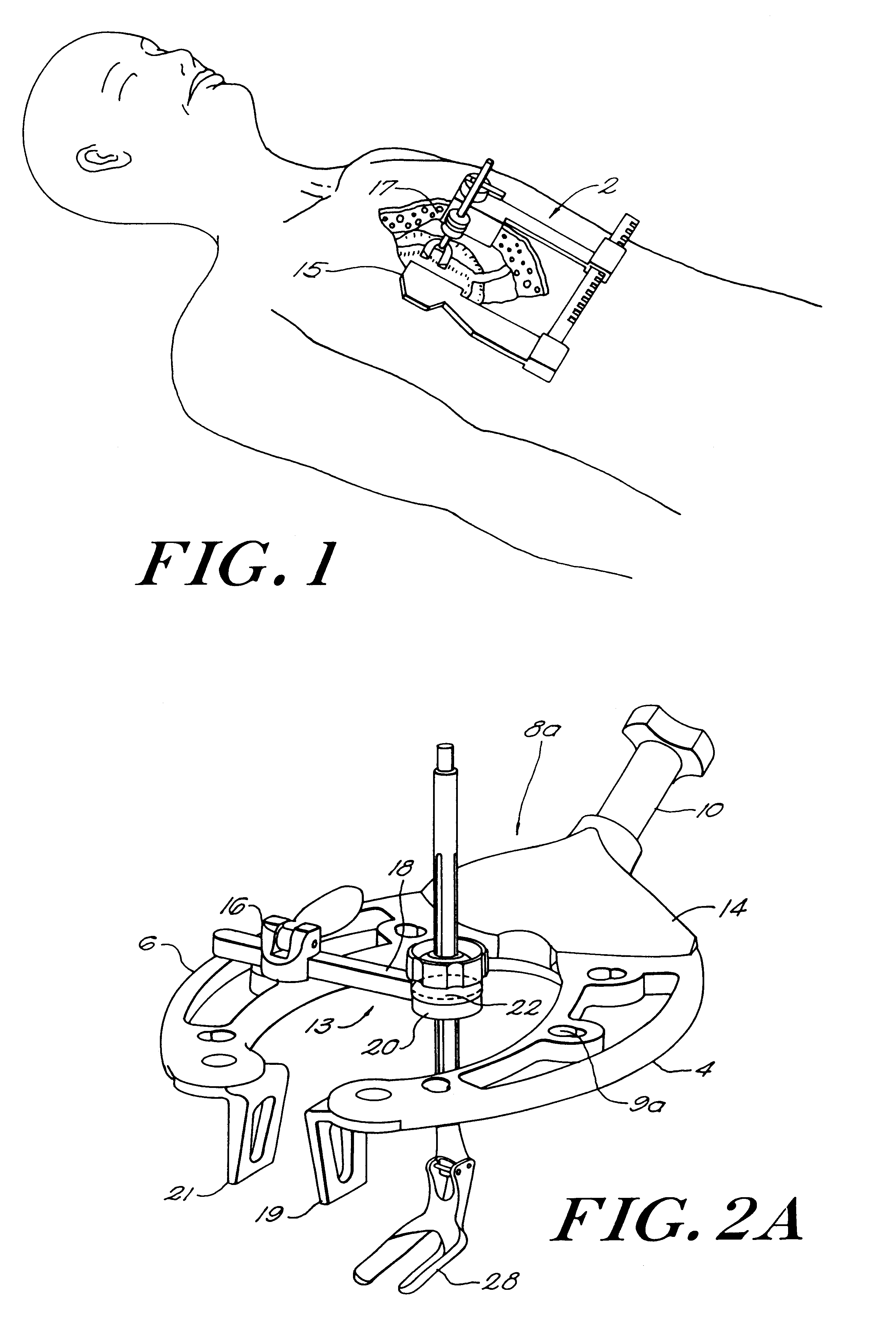

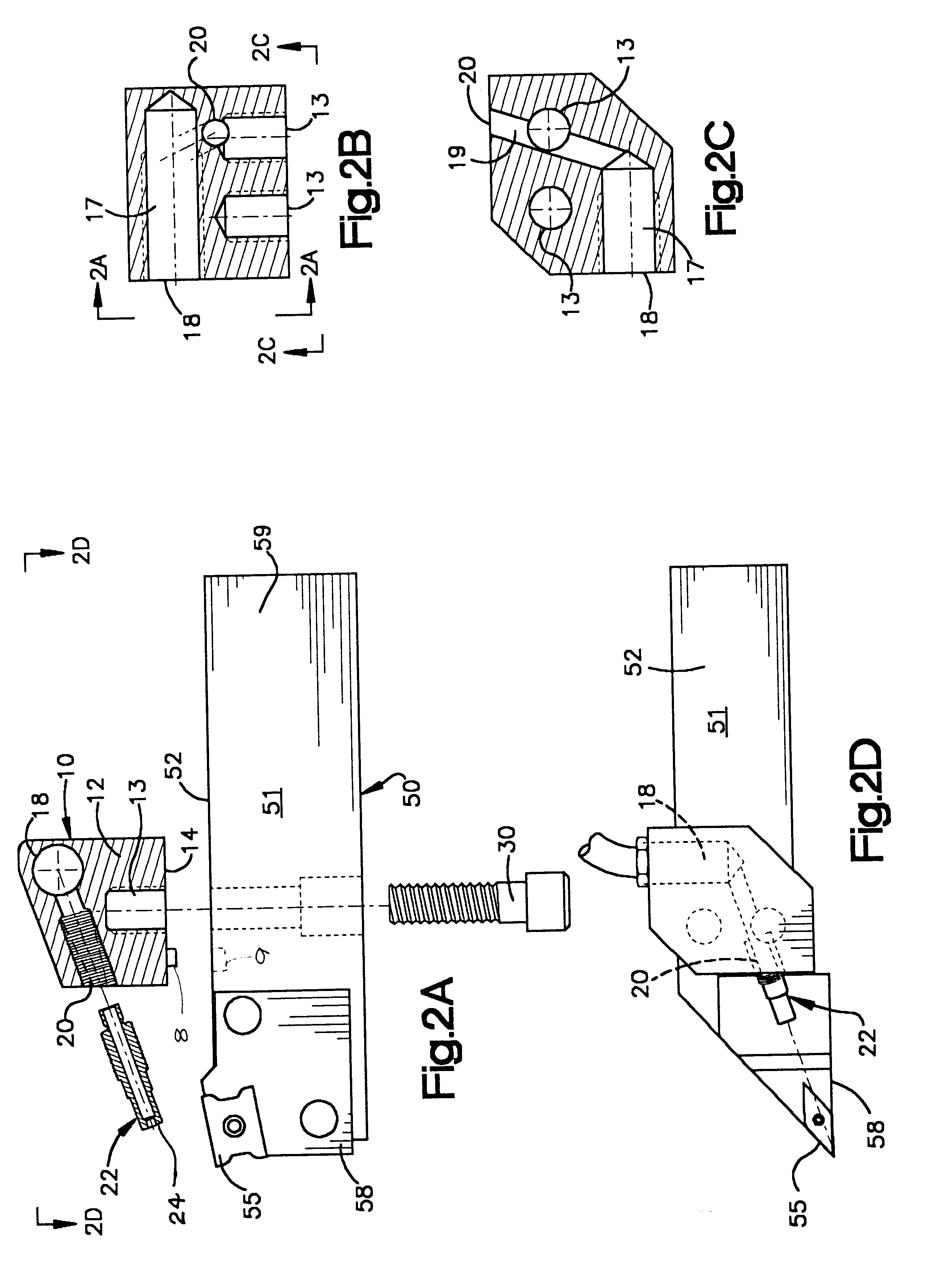

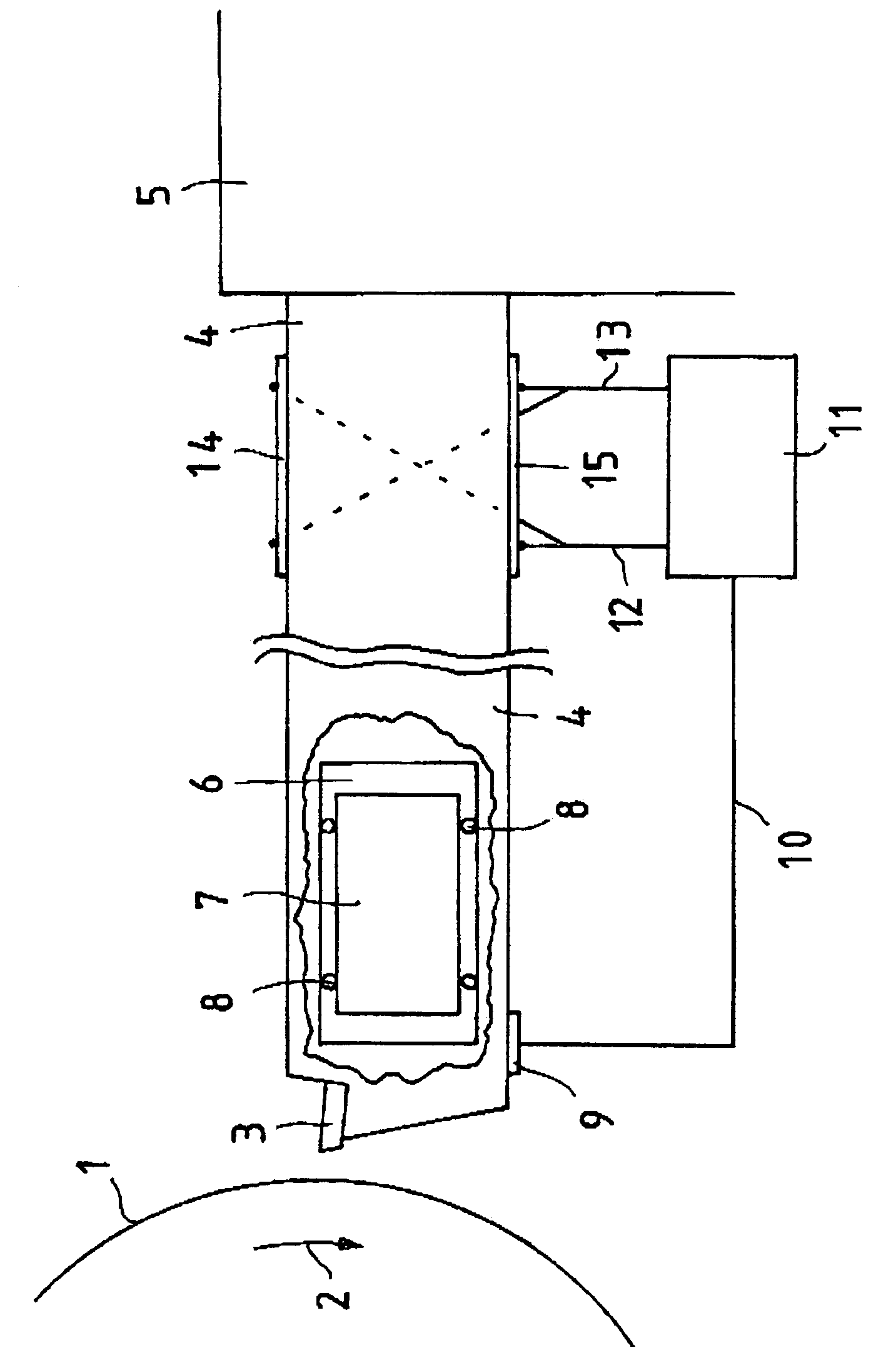

Minimally invasive surgical apparatus

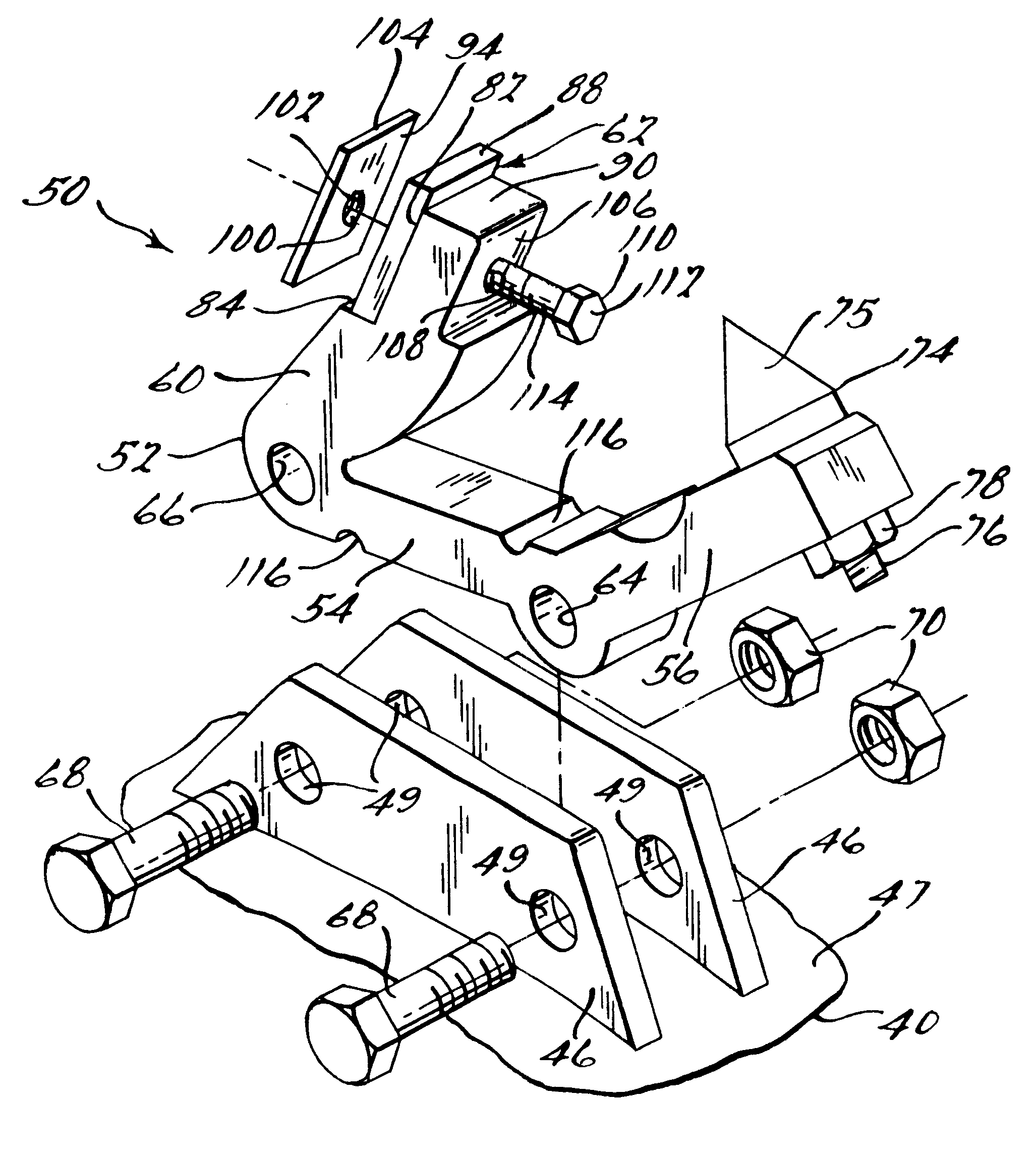

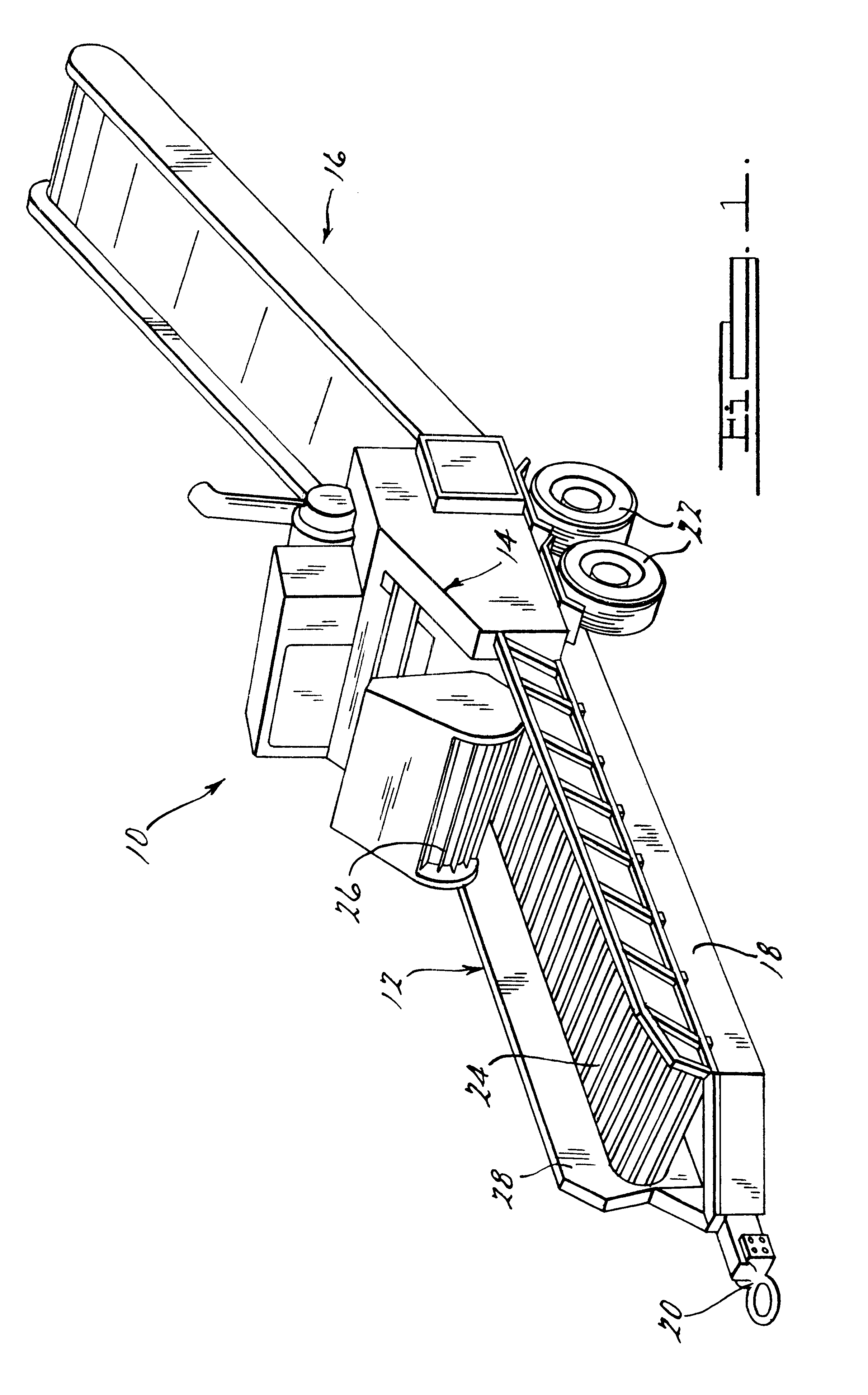

The present invention encompasses tools and a tool-holding retractor assembly. The retractor assembly spreads an incision and holds the incision open. At least one extension device, having a tool holder on one end, attaches to the assembly. The holder includes a selectively locking multi-axis adjustable mounting element adapted to grip a tool shaft. The mounting element acts as a universal mounting providing rotational and sliding movement of the tool shaft. The extension device adjusts to position the tool holder peripherally of the surgical field. Once the retractor is placed, the extension device provides full access to regions below the incision. The extension device allows the surgeon to chose the insertion point and insertion angle of the tool shaft.

Owner:SMITH & NEPHEW INC +1

Tool attachment

ActiveUS20130093149A1Improve usabilitySleeve/socket jointsPortable power-driven toolsTool holderMachine tool

A tool attachment for mounting on a hand-held machine tool provided with a tool holder, the tool attachment having an output shaft and a base body at whose outer circumference a locking sleeve is disposed in a manner allowing it to rotate to release at least one assigned locking element; at the outer circumference of the base body, an anti-rotation unit is formed for the twist-proof mounting of the base body on a fastening unit assigned to the hand-held machine tool; on the anti-rotation unit and at an inner circumference of the fastening unit, complementary geometrical forms are provided which are configured to mesh with each other for the releasable, twist-proof mounting of the base body on the fastening unit.

Owner:ROBERT BOSCH GMBH

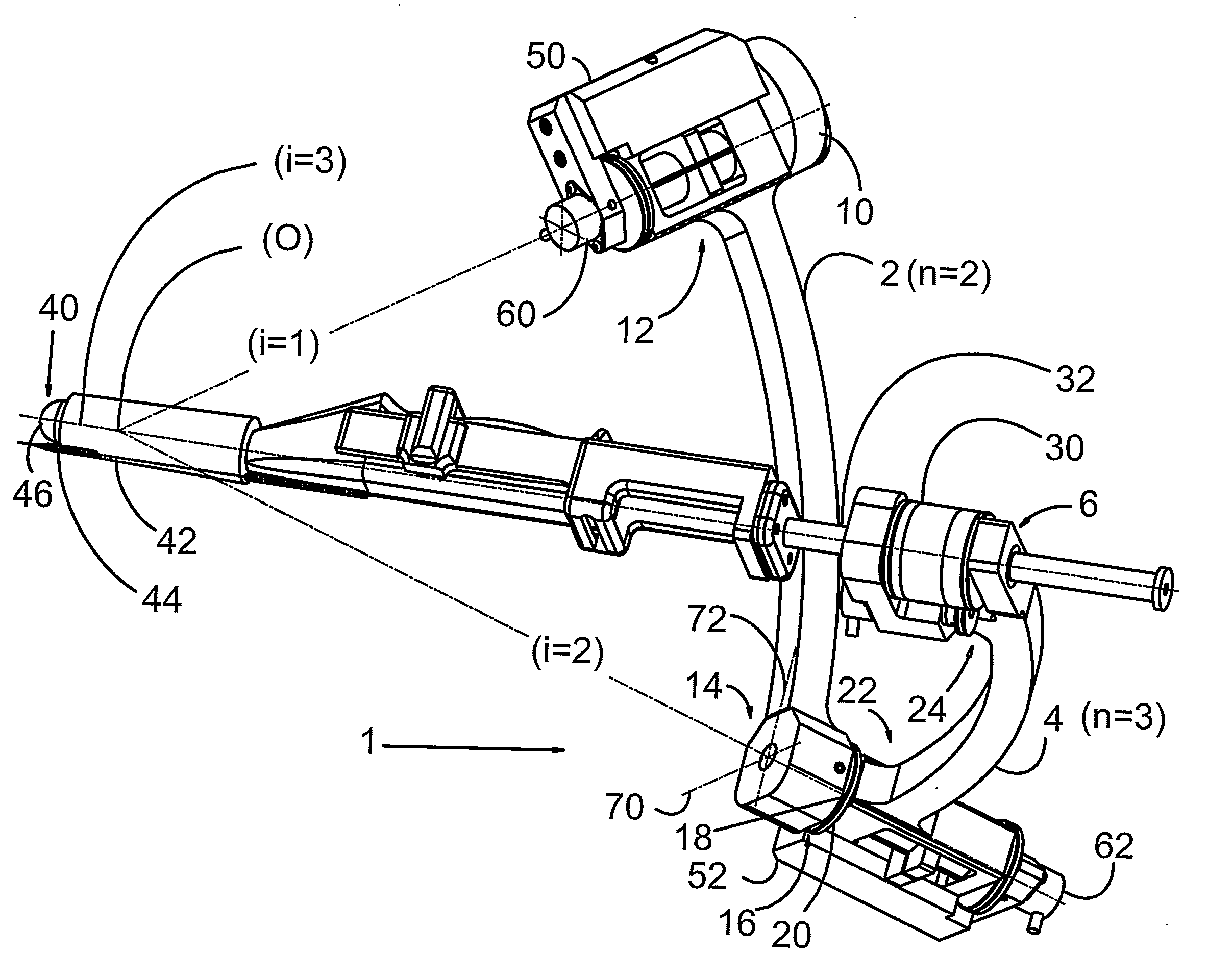

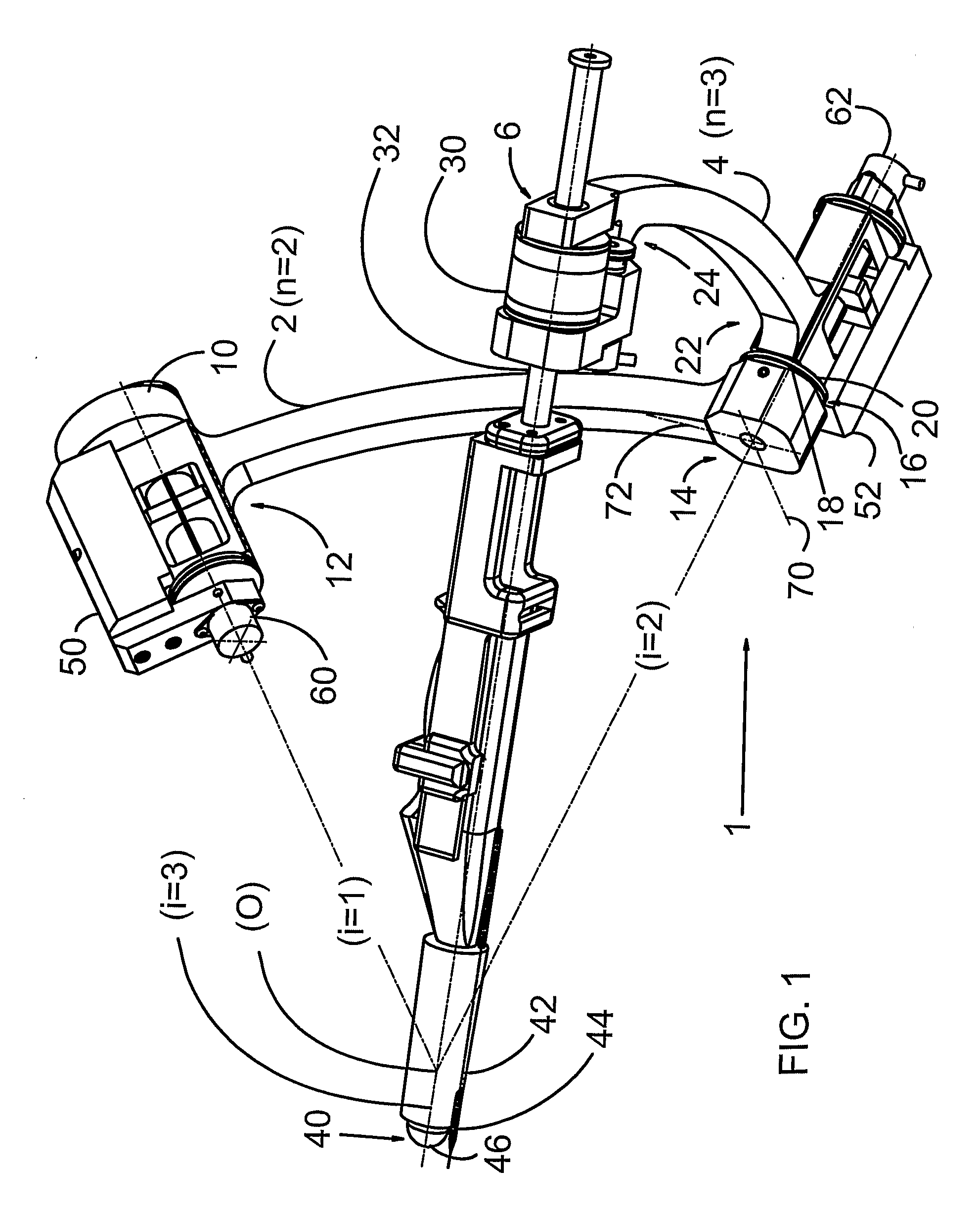

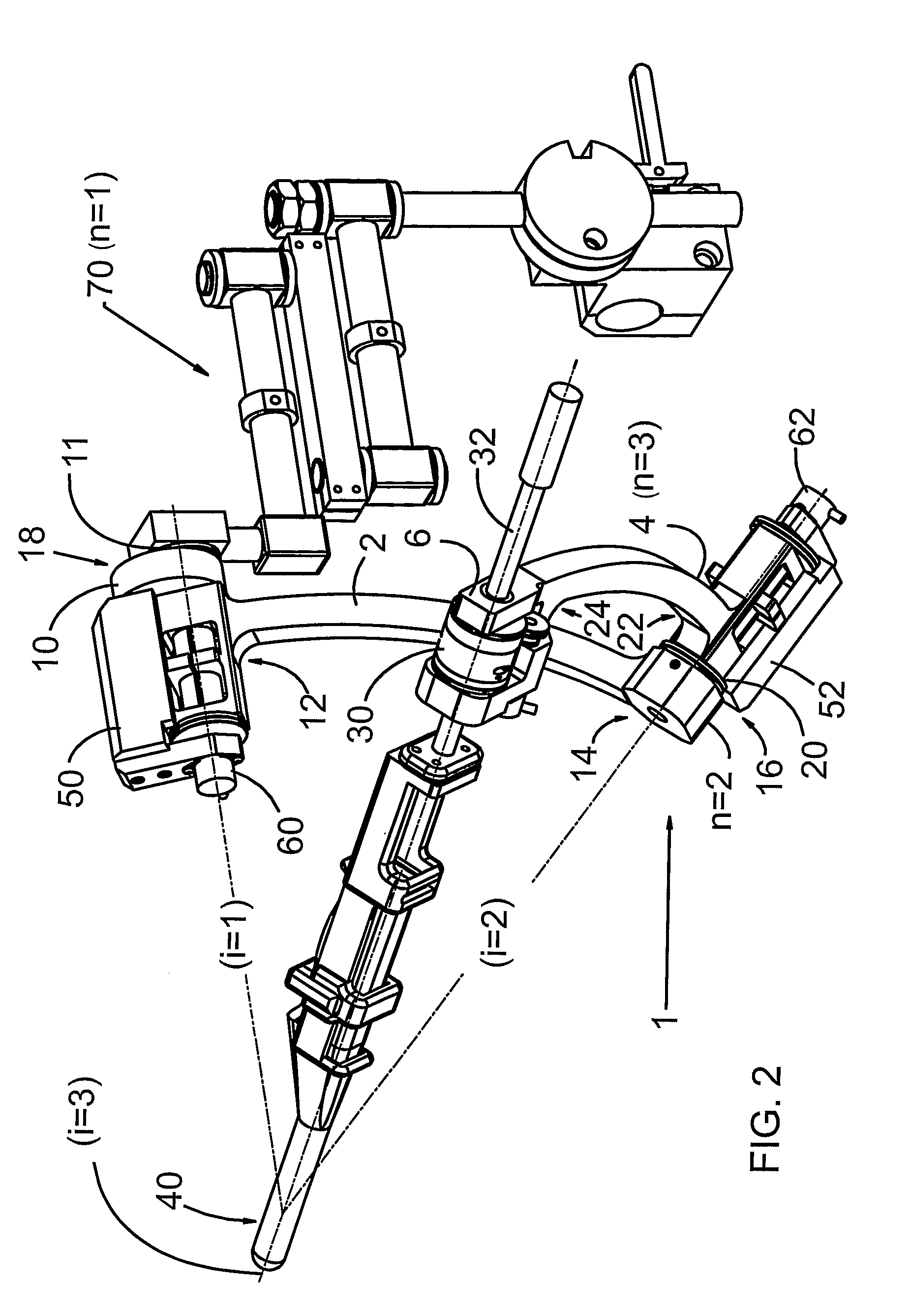

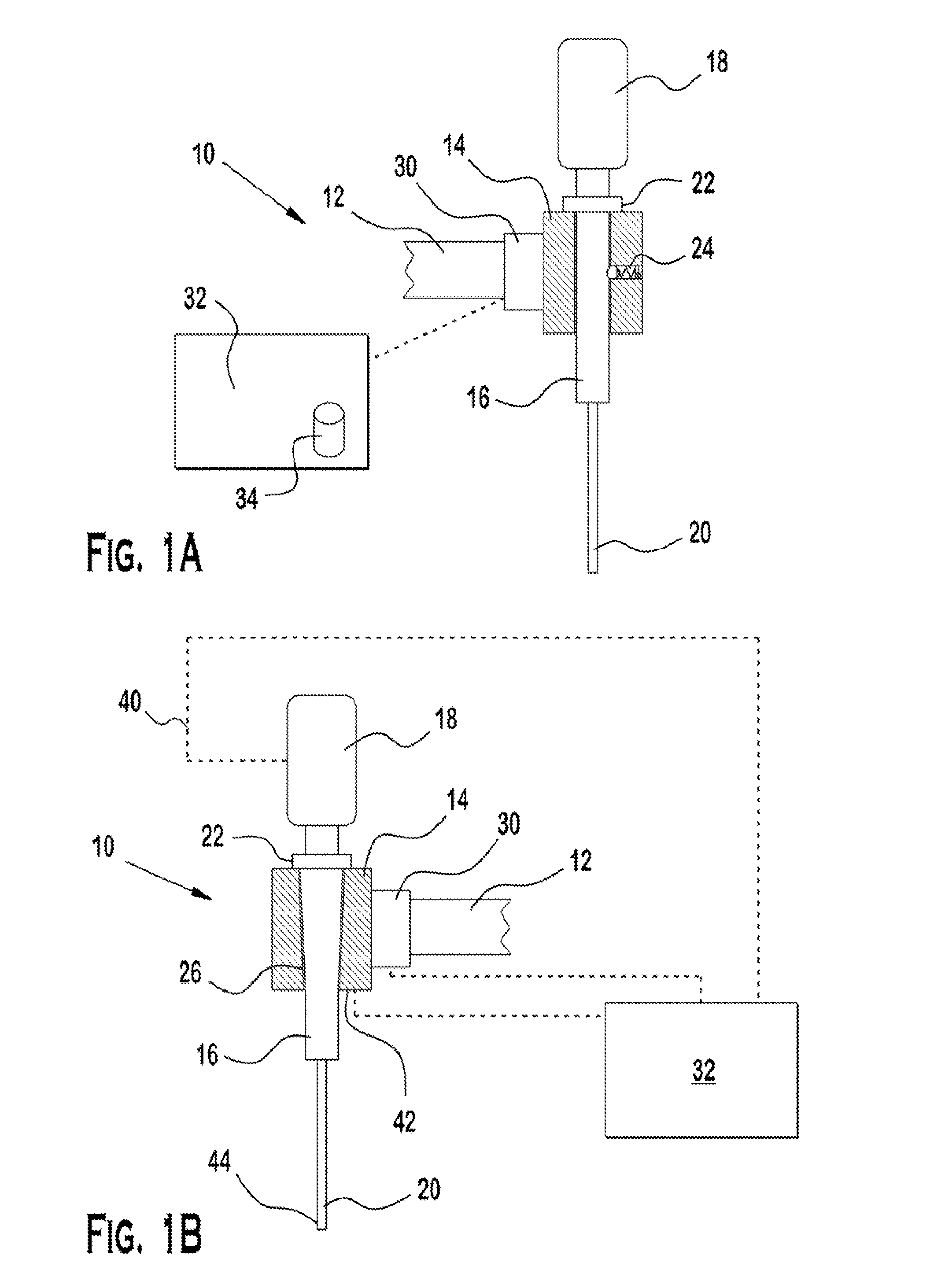

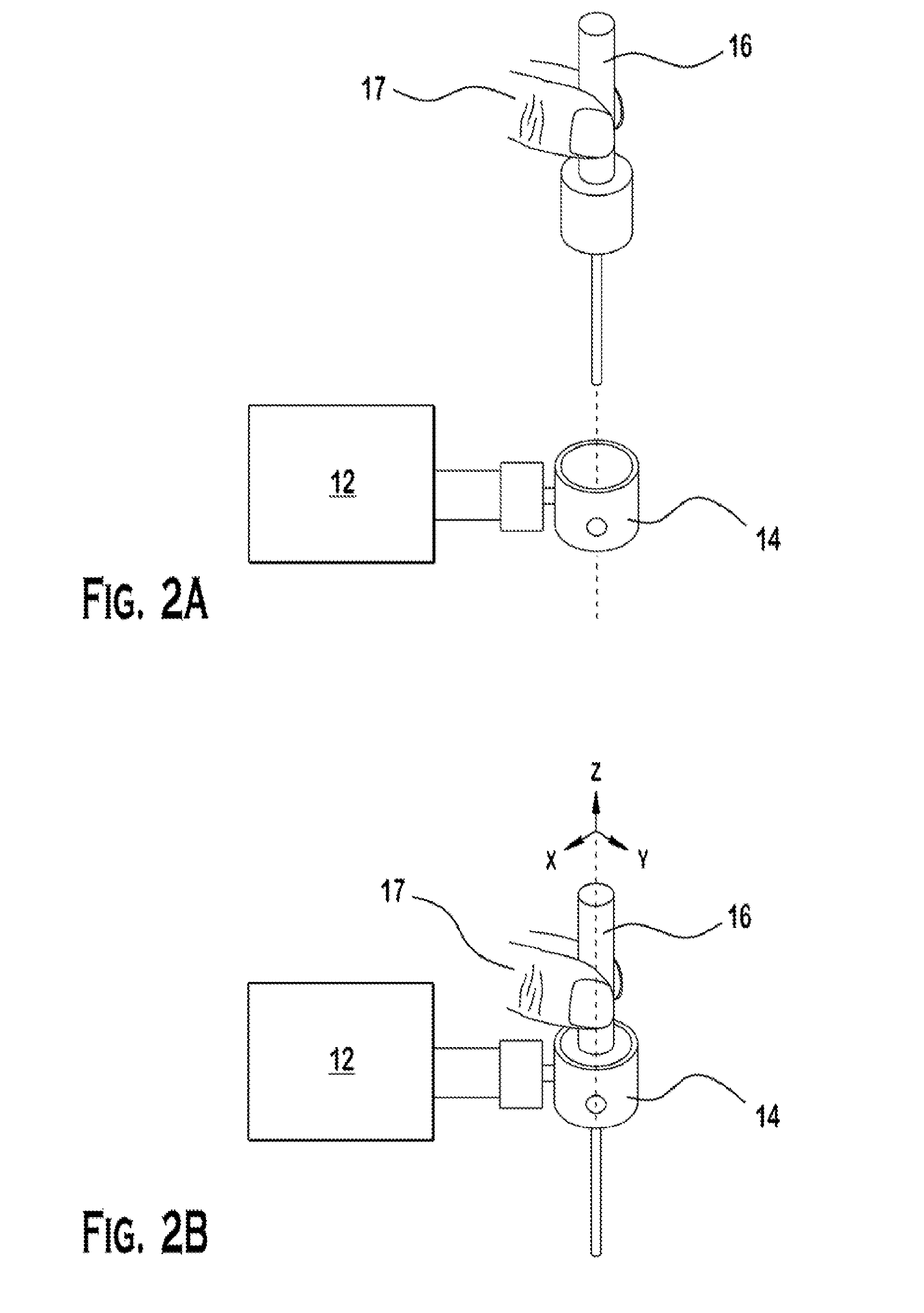

Apparatus for guiding a medical tool

InactiveUS20090234369A1Ultrasonic/sonic/infrasonic diagnosticsSurgical needlesRotational axisCoupling

There is provided a guide apparatus for orienting a medical tool relative to and through a remote fulcrum or remote center of motion. The guide apparatus may comprise: at least one crank arm comprising at least a portion of a first hinged coupling for hinged coupling to a stabilizer; at least one link arm comprising at least a portion of a second hinged coupling for hinged coupling to the crank arm at a location spaced from the first hinged coupling; a tool holder for supporting a medical tool on the link arm at a location spaced from the first hinged coupling; wherein the rotational axes of the first and second hinged couplings intersect to define a remote fulcrum. The guide apparatus may be configured to be an open-loop spherical chain or a closed-loop spherical chain.

Owner:UNIV OF WESTERN ONTARIO

Implantable orthopedic device component selection instrument and methods

ActiveUS7406775B2Easy to measureInternal osteosythesisMeasurement devicesSpinal levelSacroiliac joint

The present invention provides tools and methods designed to aid in the placement of artificial facet joints at virtually all spinal levels. One aspect of the present invention is a measurement tool for installing an artificial cephalad facet joint including a fixation measurement element and a support arm element. This measurement tool assists in the selection and / or configuration of an artificial cephalad facet joint for implantation in a patient. Another aspect is a measurement tool for installing a caudad facet joint including a stem element and a trial caudad bearing surface element. This measurement tool assists in the selection and / or configuration of a caudad facet joint for implantation in a patient. Yet another aspect is a measurement tool holder including a measurement surface connected to a holder element. This tool holder assists in determining the measurements obtained with the caudad facet joint measurement tool.

Owner:GLOBUS MEDICAL INC

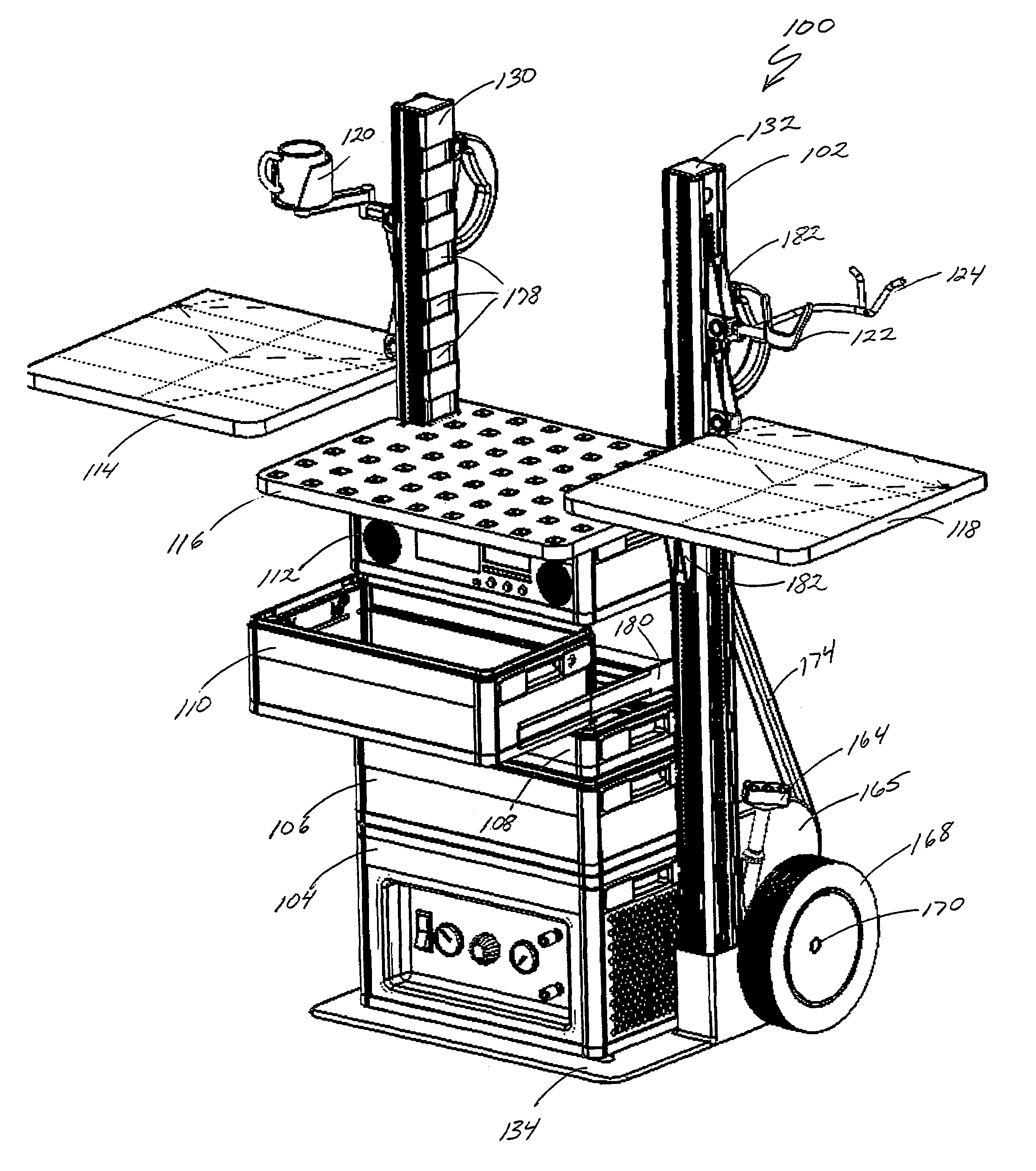

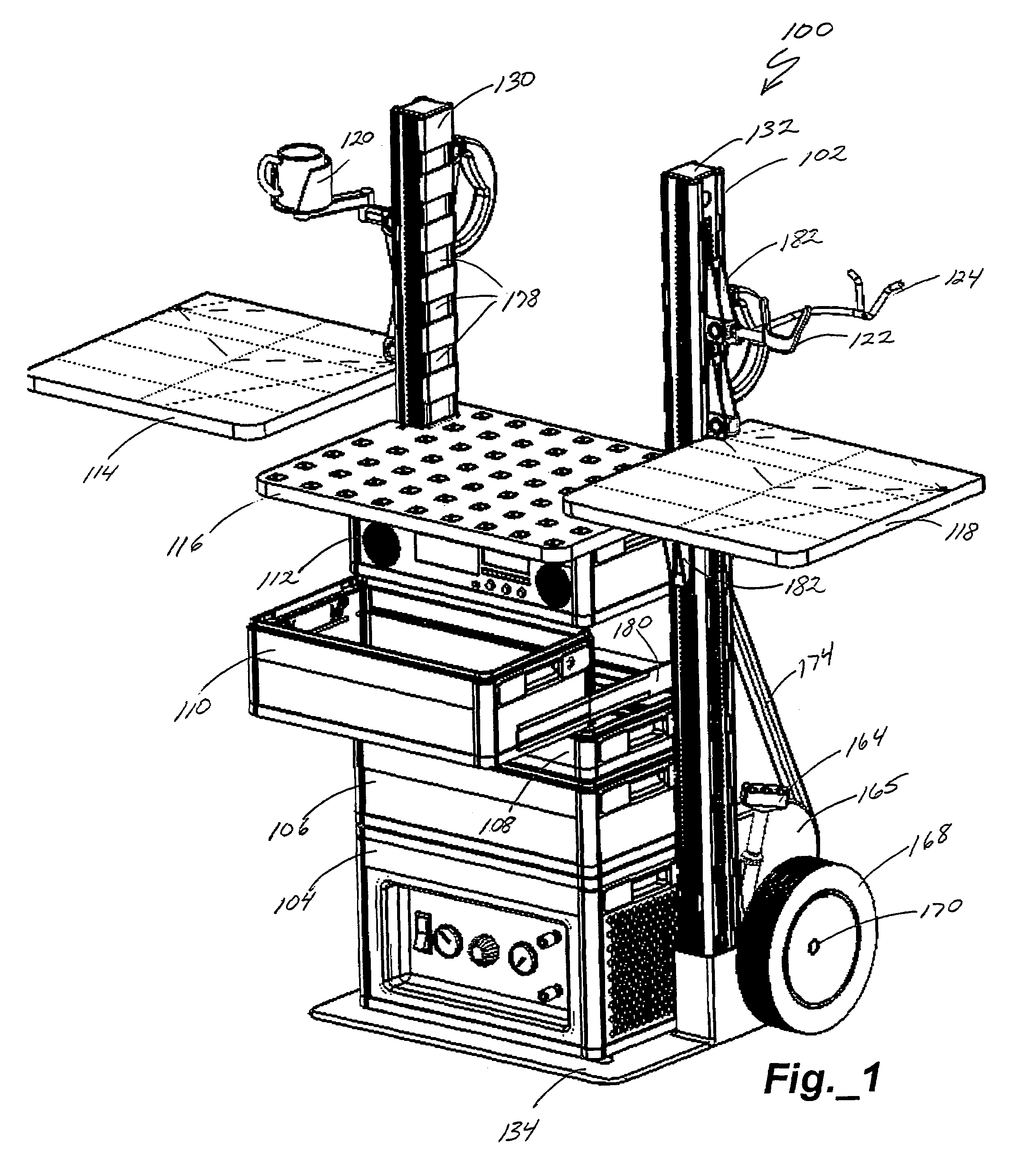

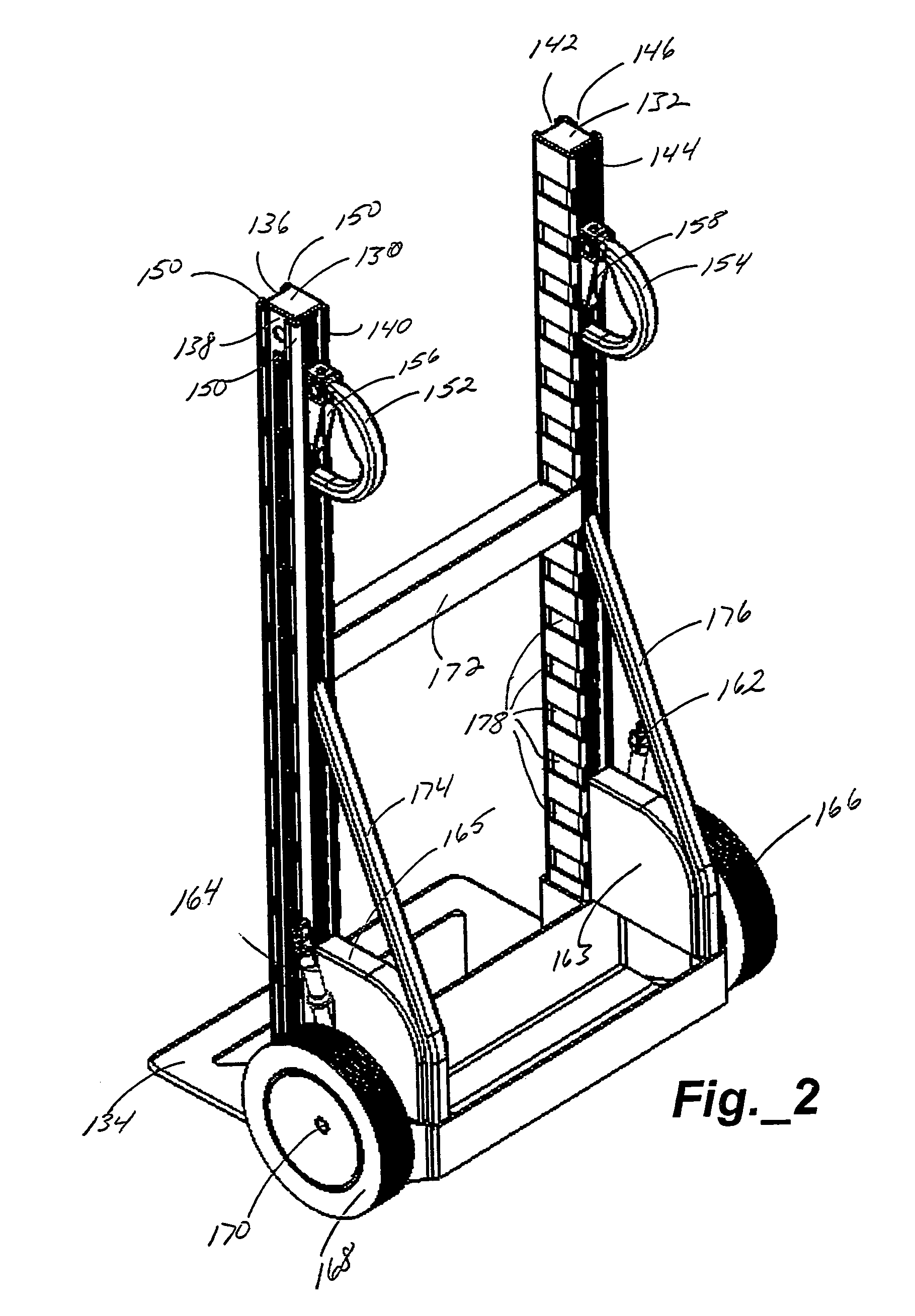

Tool and task box storage, transport, and workbench system

InactiveUS7367571B1Easy to liftCarriage/perambulator with single axisWork benchesMachine toolWorkbench

A machine tool stand and / or workbench, electrical outlet panel, light supply, and modular task box system, combined into an integrated system that includes a support structure having a support base on wheels and side rails disposed on the surface of the support base. The side rails include structure for attaching tool holders, work pieces holders, work surfaces, and the like.

Owner:STAINBROOK & STAINBROOK

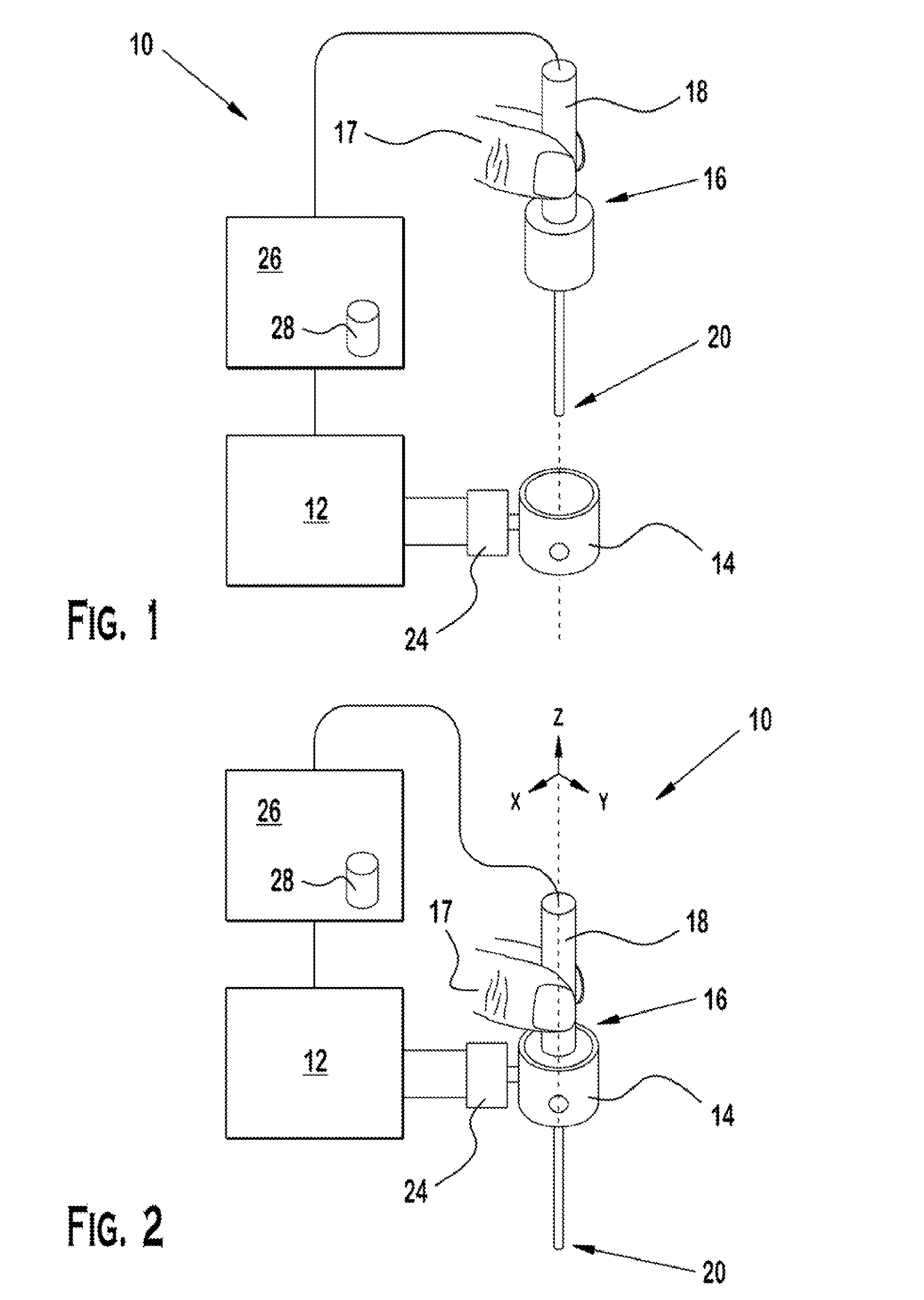

Tool exchange interface and control algorithm for cooperative surgical robots

A system and method for tool exchange during surgery for cooperatively controlled robots comprises a tool holder for receiving a surgical tool adapted to be held by a robot and a surgeon, a tool holding element for constraining downward motion of the tool while allowing low force removal of the surgical tool from the holder, a first sensor for detecting if the surgical tool is docked within the tool holder, and a selector for automatically selecting different movements or actions of the tool holder to be performed based upon information detected by the first sensor. The system and method of the present invention provides an advantage to an often slow moving cooperative robot, by increasing the speed by which the tool holder may move in the direction away from the patient.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

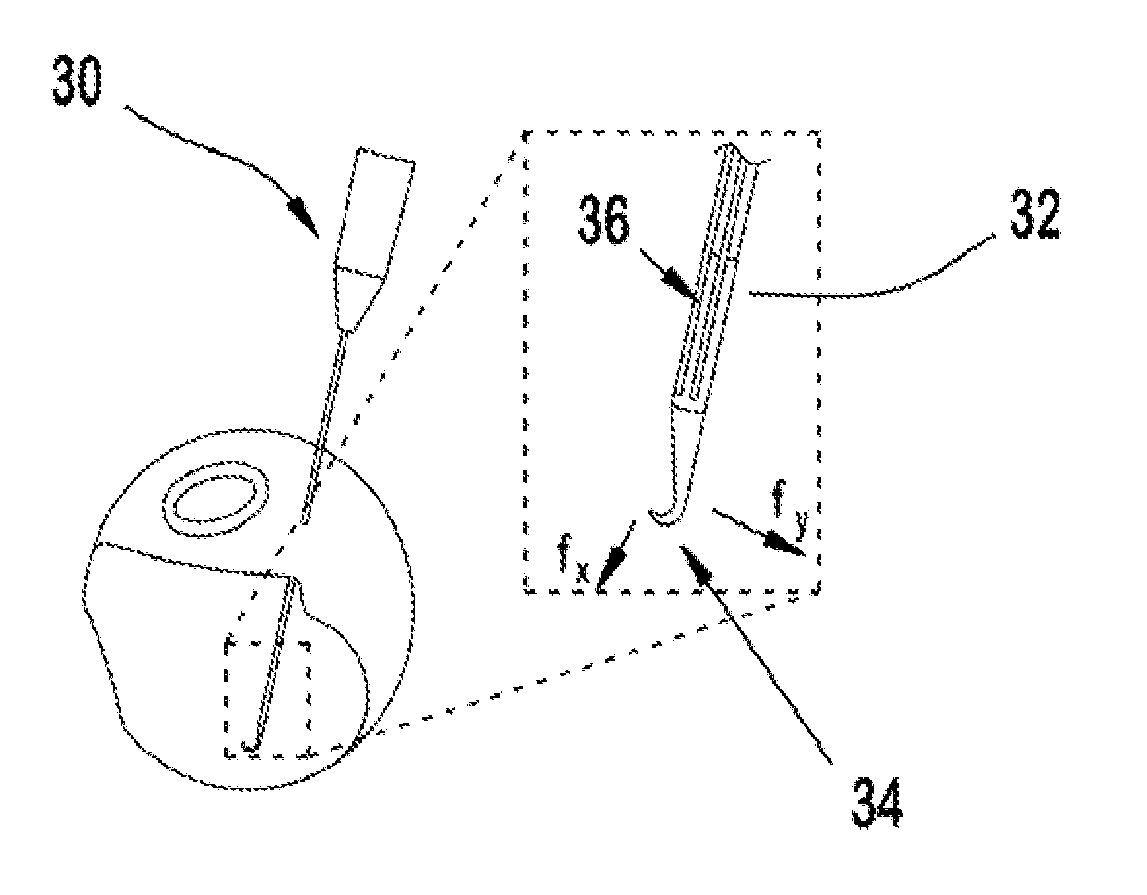

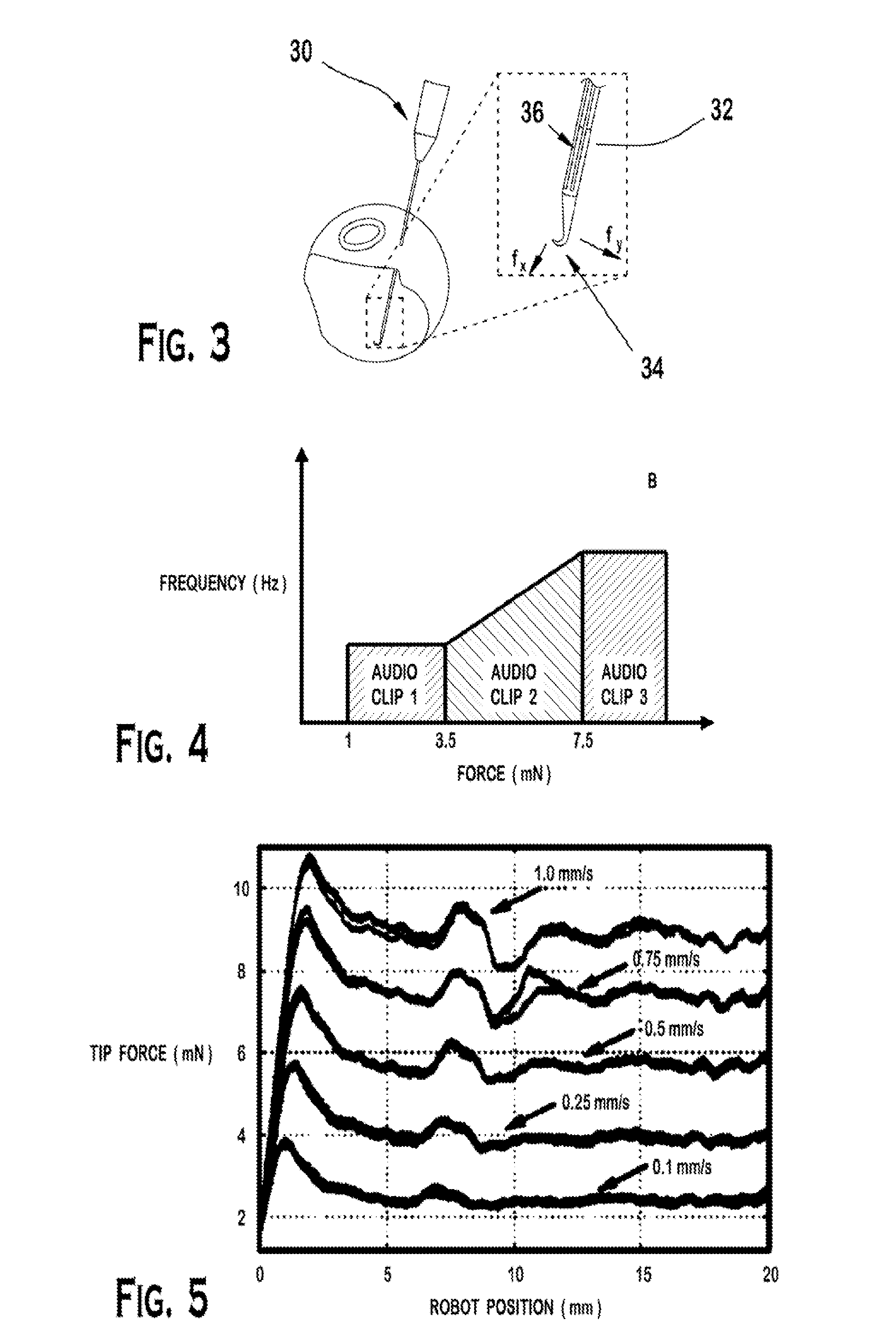

Method for presenting force sensor information using cooperative robot control and audio feedback

InactiveUS20140052150A1Limiting robot velocityHaptic feedback can be providedMechanical/radiation/invasive therapiesEye surgeryRelative intensityEngineering

A system and method for cooperative control of surgical tool includes a tool holder for receiving a surgical tool adapted to be held by a robot and a surgeon, a sensor for detecting a force based on operator input and / or tool tip forces, a controller for limiting robot velocity based upon the force detected so as to provide a haptic feedback, a selector for automatically selecting one level of a multi-level audio feedback based upon the detected force applied, the audio feedback representing the relative intensity of the force applied, and an audio device for providing the audio feedback together with the haptic feedback. The audio feedback provides additional information to the surgeon that allows lower forces to be applied during the operation.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Rotatable tool assembly

A tool assembly includes an axially symmetric tool having a tapered forward end, a radial flange, and a cylindrical shank. A retainer is fitted around the cylindrical shank, a washer is fitted around the retainer, and an annular elastomeric member is bonded to the inner surface of the washer. When the rotatable shank is fitted into a cylindrical mounting bore of a tool holder, the annular elastomeric member prevents the washer from rotating with the tool.

Owner:THE SOLLAMI COMPANY

Universal tool holder coolant delivery adapters

InactiveUS6299388B1Increase COOOptimized coolant deliveryTurning toolsShaping cuttersLine tubingSpray nozzle

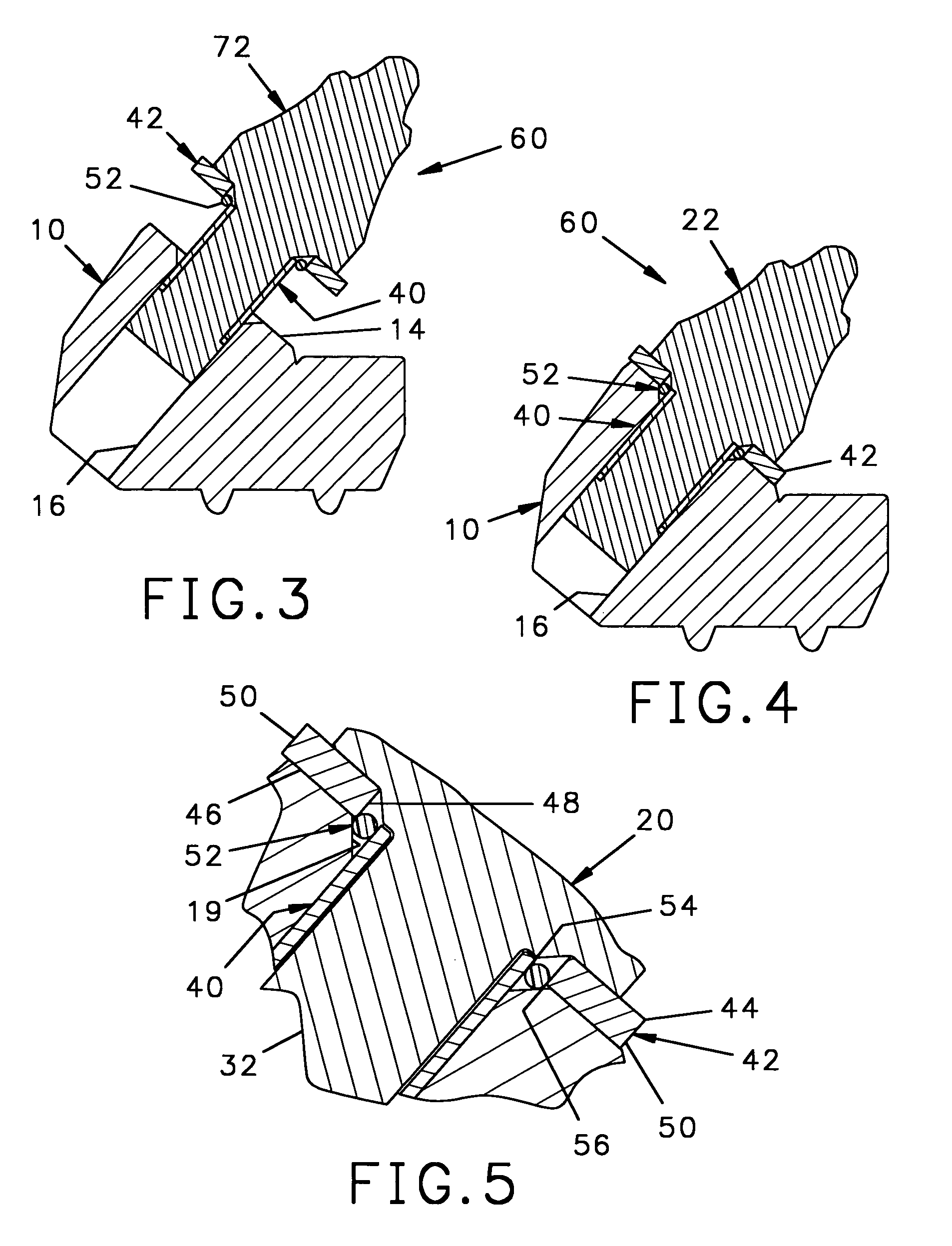

Universal tool holder coolant delivery adapters have adapter bodies which are removably attachable to a tool holder by at least one fastening device, the adapter located between an attachment end of the tool holder and a distal end of the tool holder, the distal end of the tool holder having a cutting tool attached thereto, the adapter bodies having an internal coolant passageway including an intake port and an exit port, the intake port adapted for attachment to a pressurized coolant supply line and the outlet port adapted for attachment to or configured in the form of a coolant spray nozzle, the coolant spray nozzle being closely positioned and substantially aligned with the cutting interface of the cutting tool and a workpiece.

Owner:SLABE MACHINE PROD

Device for applying cryogenic composition and method of using same

A device of the present invention for applying a cryogenic composition includes a machining tool or tool holder having a channel positioned therethrough and a capillary tube positioned within the channel. A dense cryogenic fluid is passed through the capillary tube while a diluent or propellant fluid is passed through the channel. The diluent or propellant fluid flows within the channel and about the capillary tube. Upon exiting the capillary tube, the dense fluid admixes with the diluent or propellant fluid to form a cryogenic composite fluid or spray. The cryogenic composite fluid or spray is selectively directed onto a substrate for cooling or lubrication purposes, or onto the machining tool for cooling purposes.

Owner:COOL CLEAN TECH

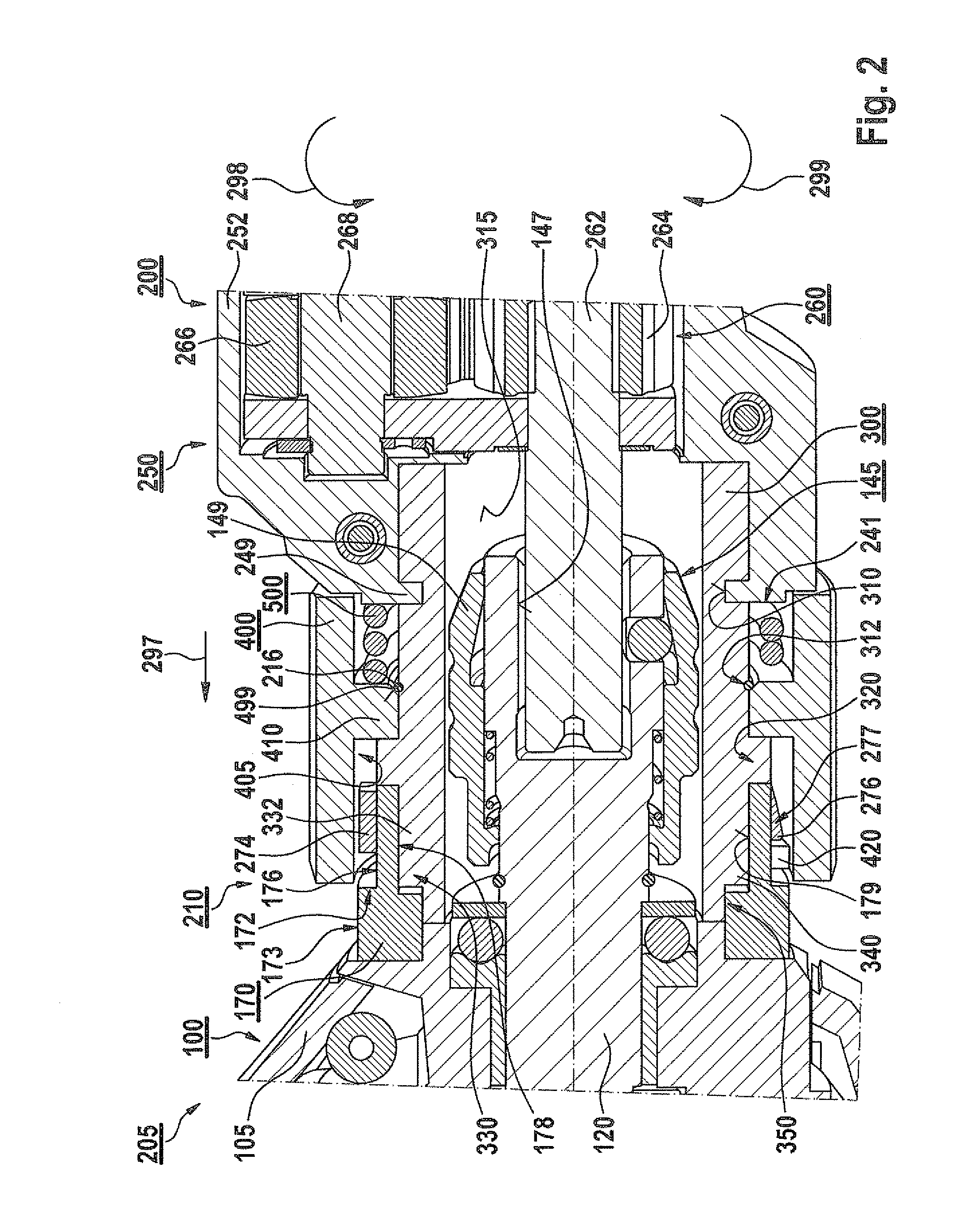

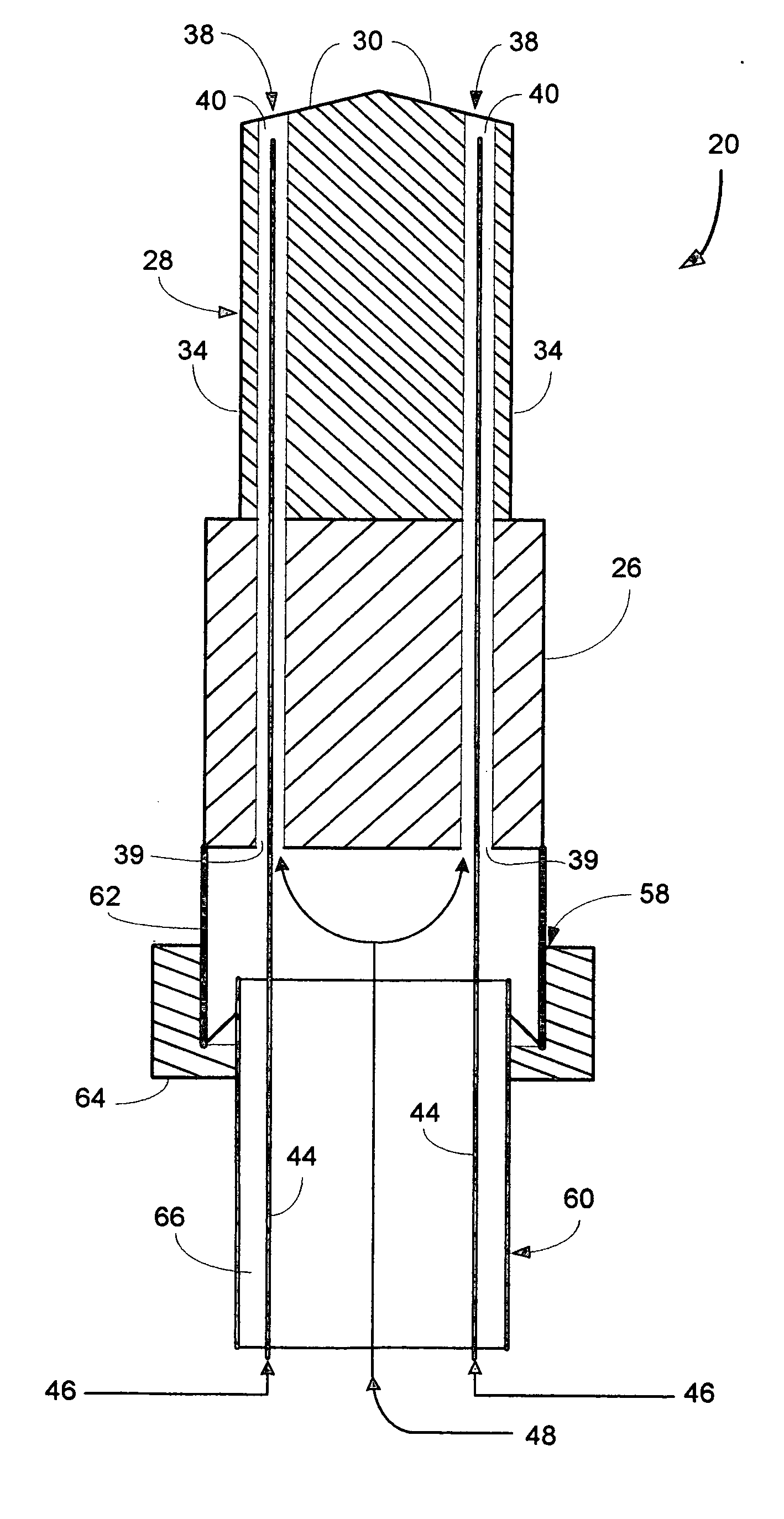

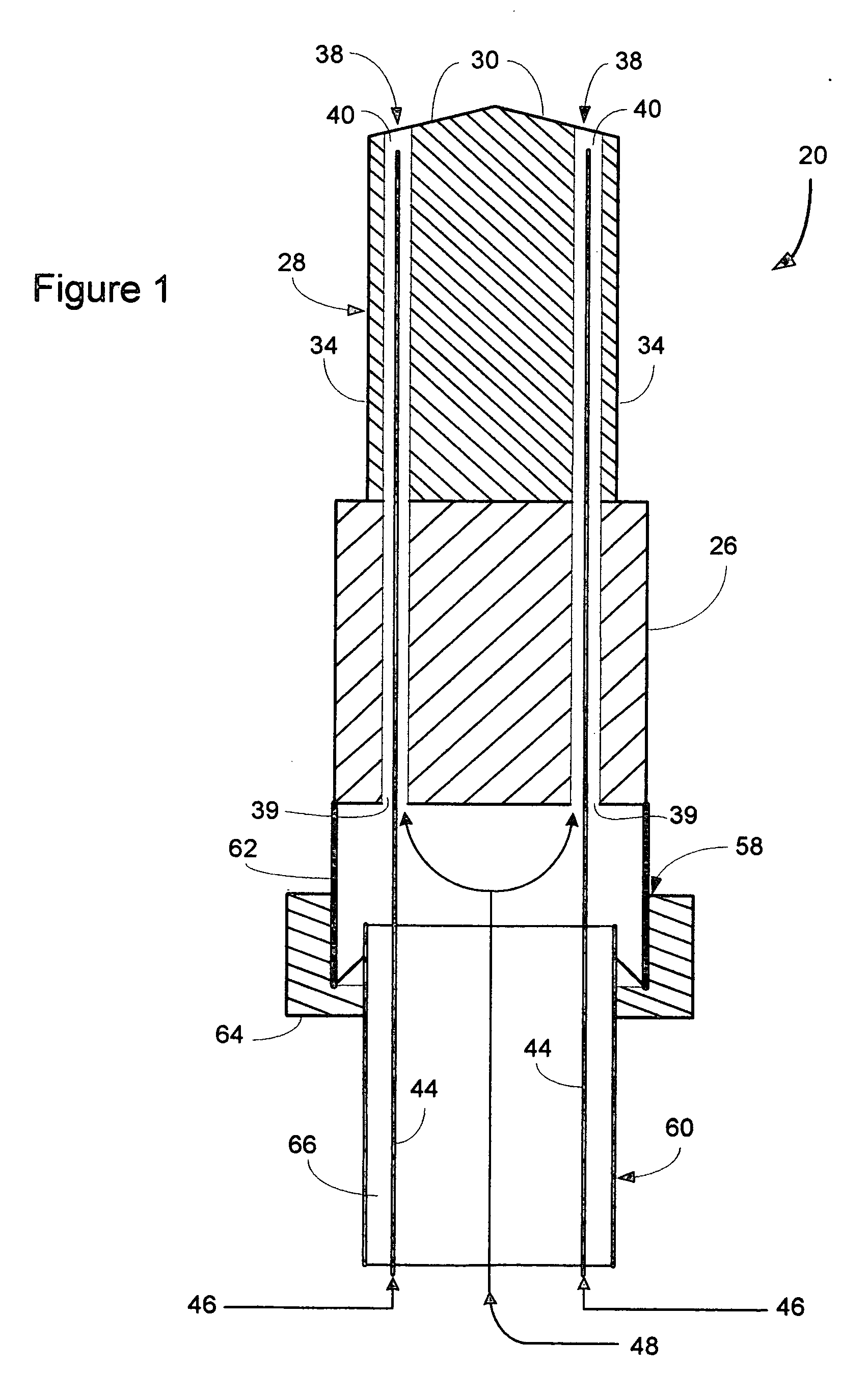

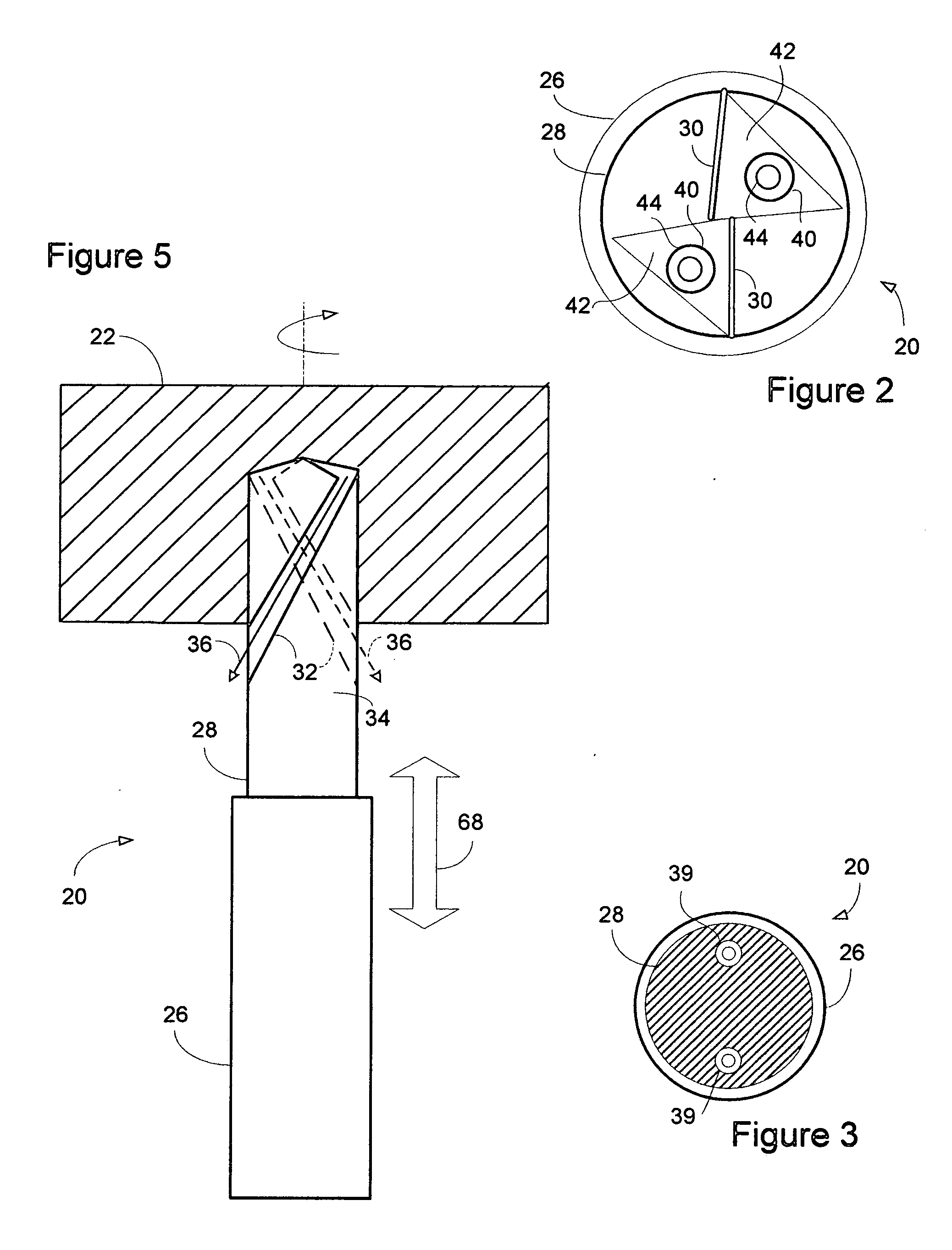

High-speed, hand-held reciprocating method for cutting, carving, sawing, chiseling, filing, sanding, and engraving

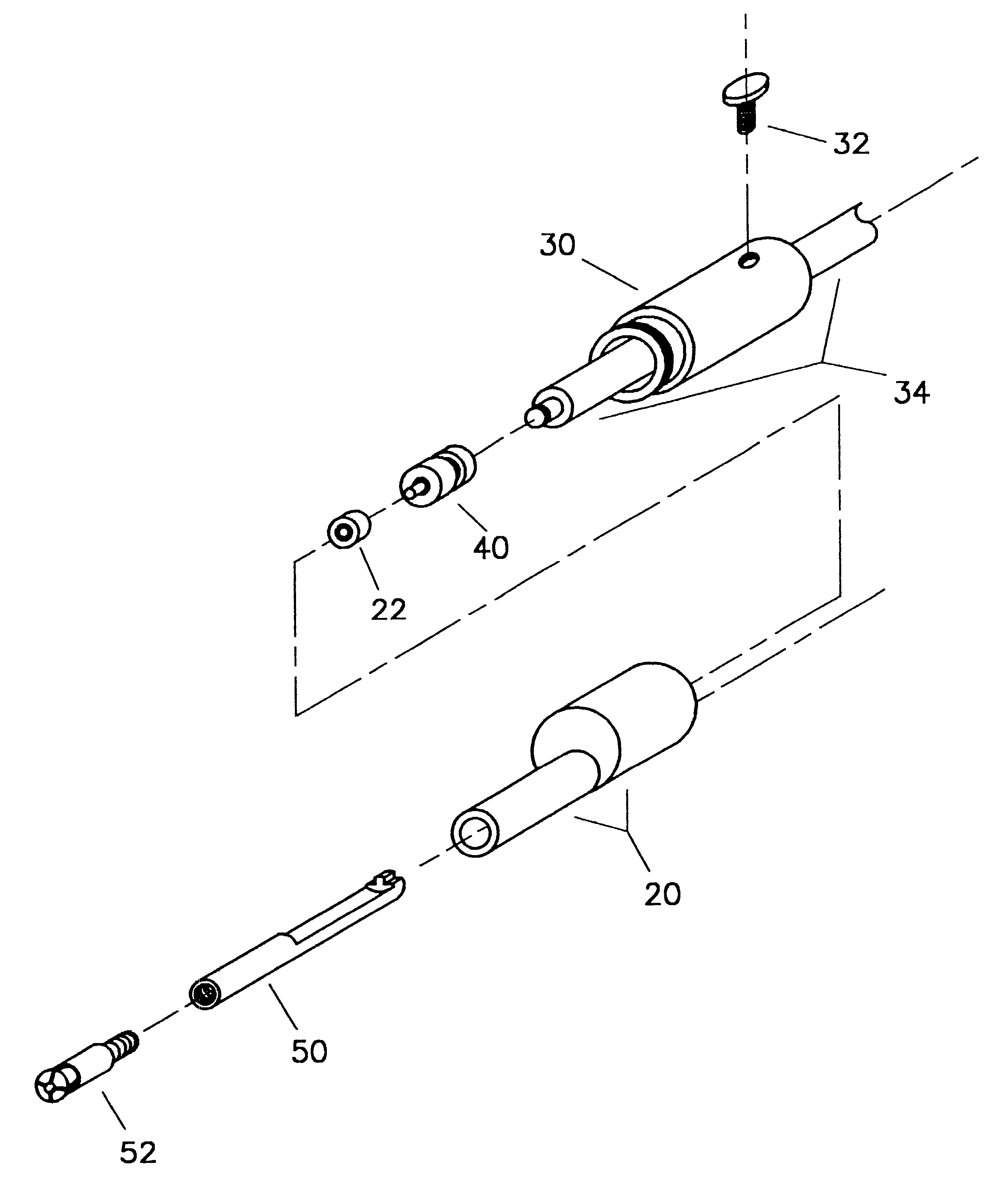

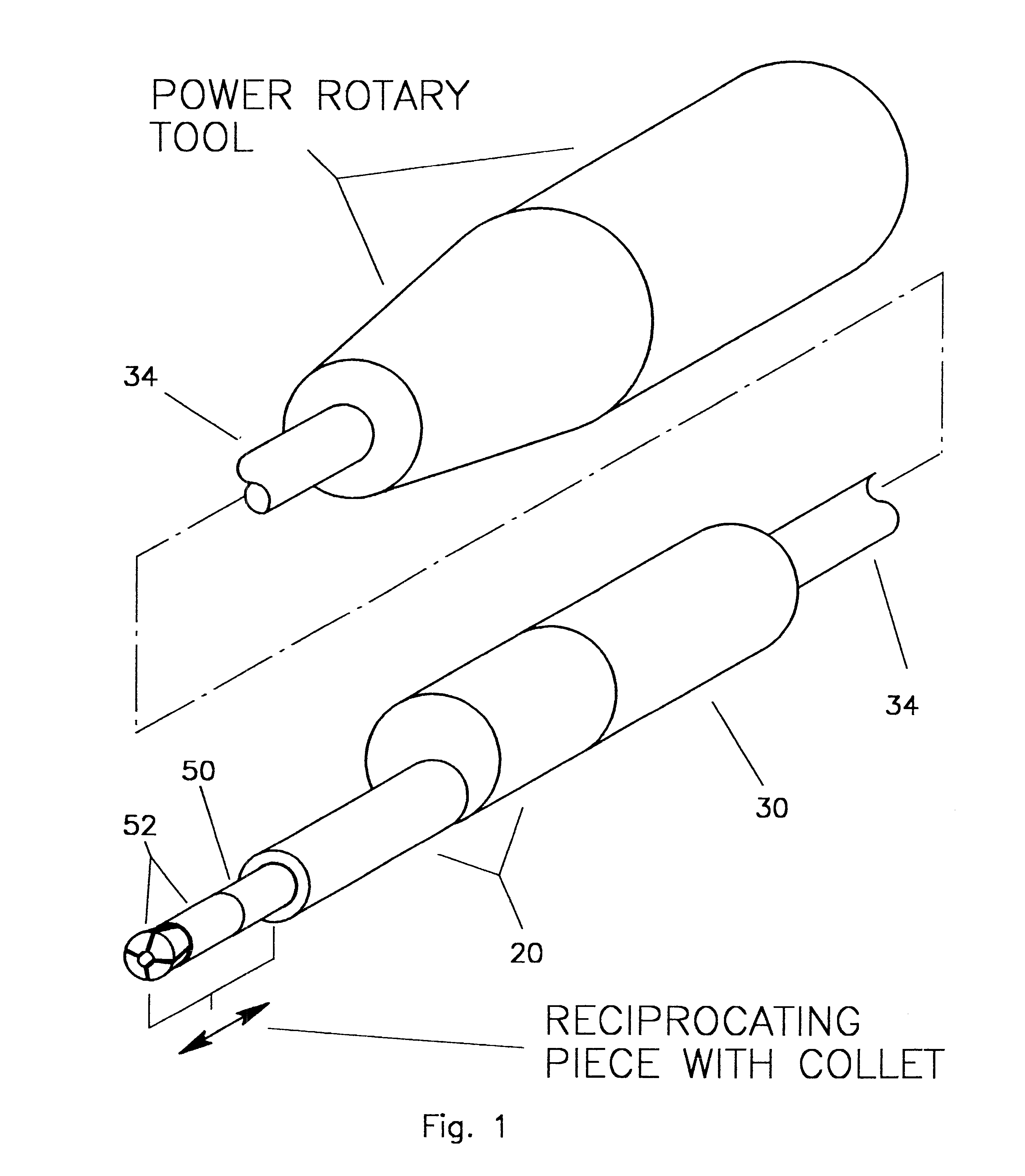

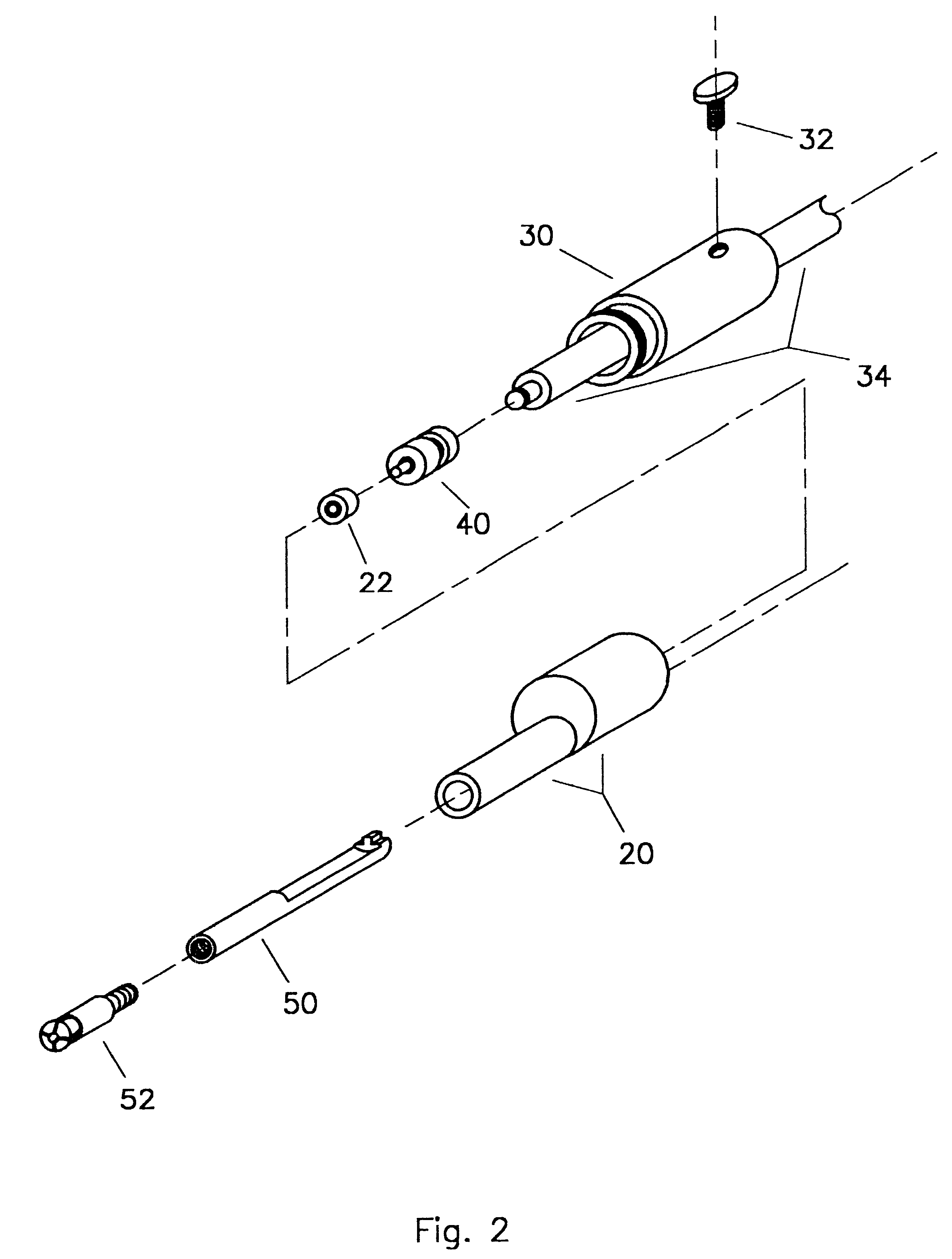

A high-speed, hand-held attachment for flex rotor shafts of power rotary tools, and also for direct attachment to power rotary tools without flex rotor shafts, that converts rotary motion to reciprocating motion for precision control of cutting, carving, sawing, chiseling, filing, sanding, and engraving on delicate work pieces. The attachment is one assembly comprising a one-piece front one-piece enclosure (20), a rear one-piece enclosure (30), a high-speed bearing (22), a one-piece rotating piece (40) with integral cam groove, a one-piece reciprocating piece (50) with an integral cam follower on one end and with its other, exposed end accomodating the attachment of a chuck or collet and with geometry to prevent rotation, and a thumbscrew (32). Rotating piece (40) attaches directly to the rotary power source and provides the cam action drive to reciprocating piece (50). Bearing (22) provides rotative support for the other end of rotating piece (40). Reciprocating piece (50) slidably mounts in front one-piece enclosure (20). Front one-piece enclosure (20) and rear one-piece enclosure (30) are attached to each other and maintain proper alignment for rotating piece (40), bearing (22), and reciprocating piece (50). Thumbscrew (32) secures the attachment to the flex rotor shaft of a power rotary tool. A tool holder / collet is attached to the exposed end of reciprocating piece (50) whereby numerous types of cutting tools may be utilized. Alternative versions of the rear one-piece enclosure, (30A) and (30B), described herein, allow for attachment directly to power rotary tools without flex rotor shafts. Alternative versions of the reciprocating piece, (50A), (50B), and (50C), and of the rotating piece, (40A), are also described herein.

Owner:JONES WILLIAM RANDOLPH

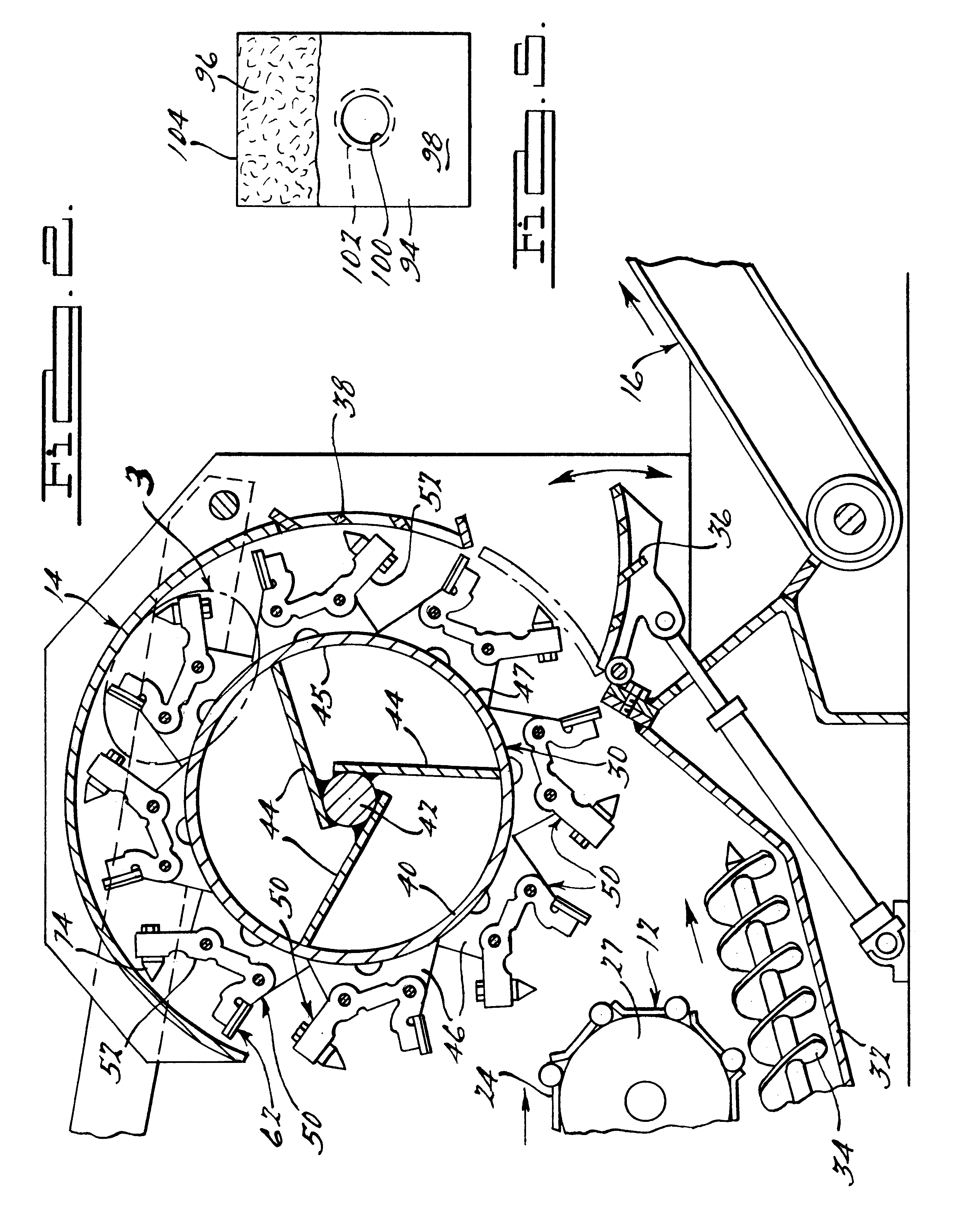

Replaceable raker assembly for processing tool of waste processing machine

A replaceable raker assembly for a processing tool of a waste processing machine includes a tool holder for attachment to a rotor assembly of the waste processing machine. The replaceable raker assembly also includes a raker removably attached to the tool holder to rake reduced waste material.

Owner:SMORACY

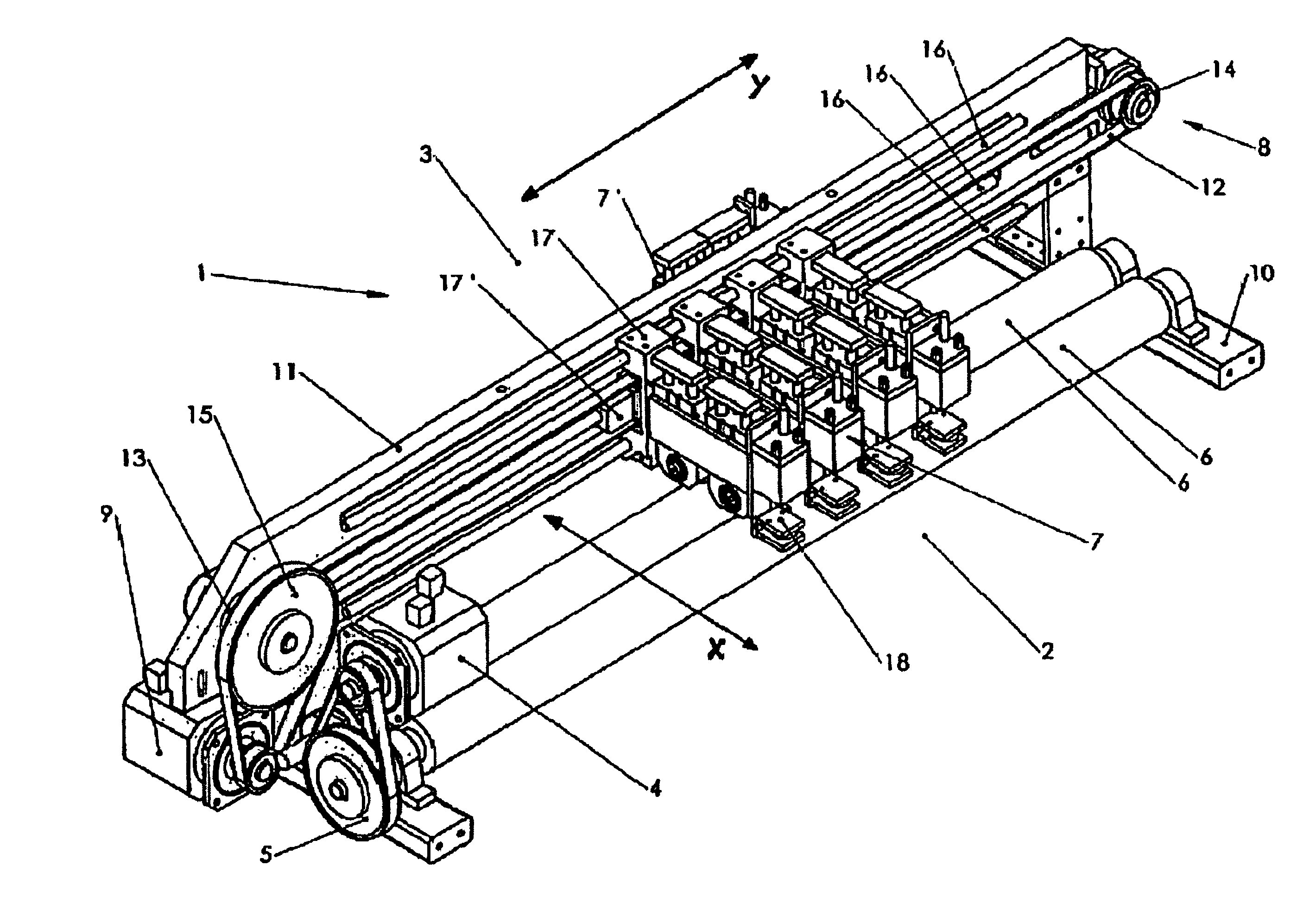

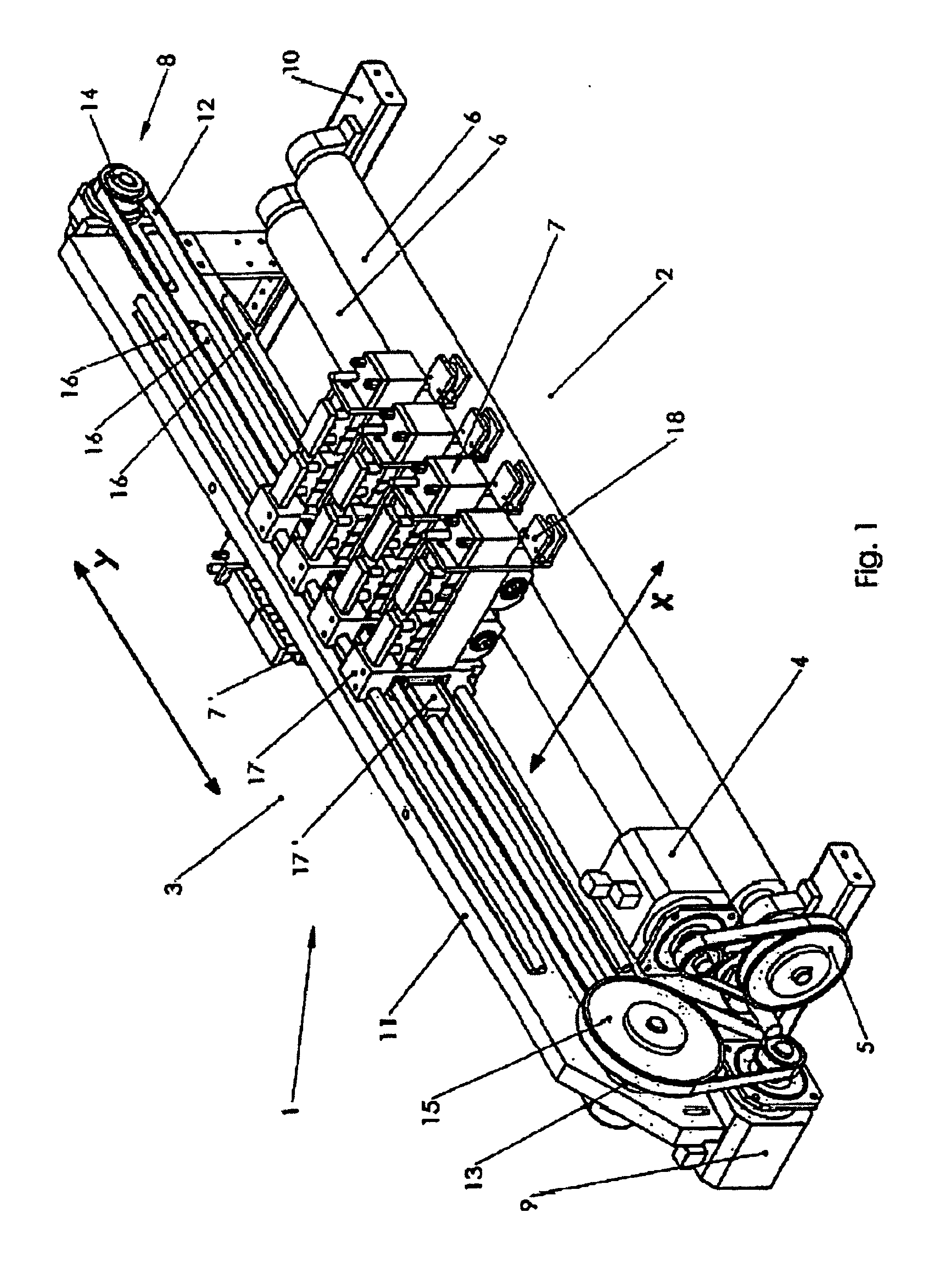

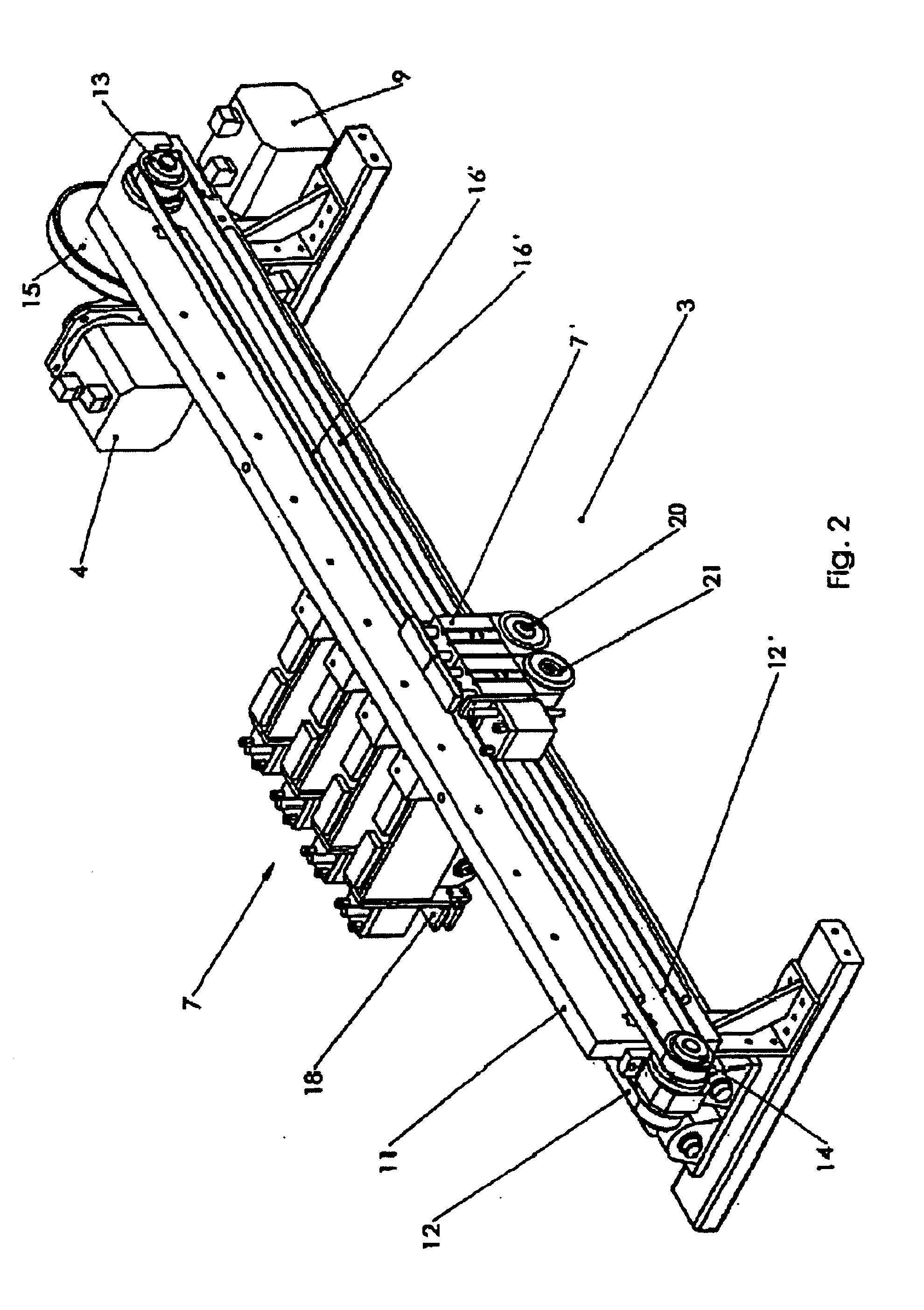

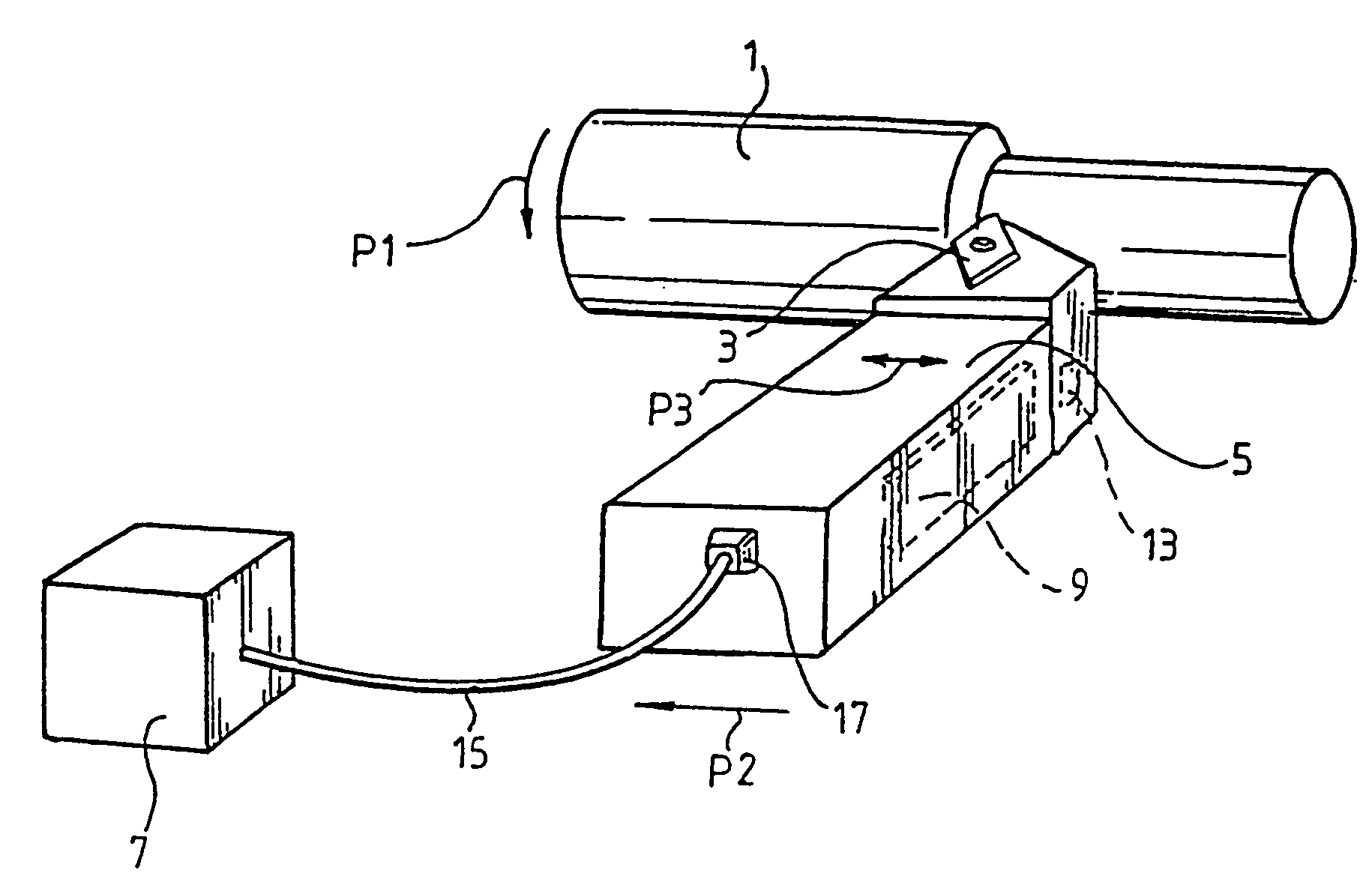

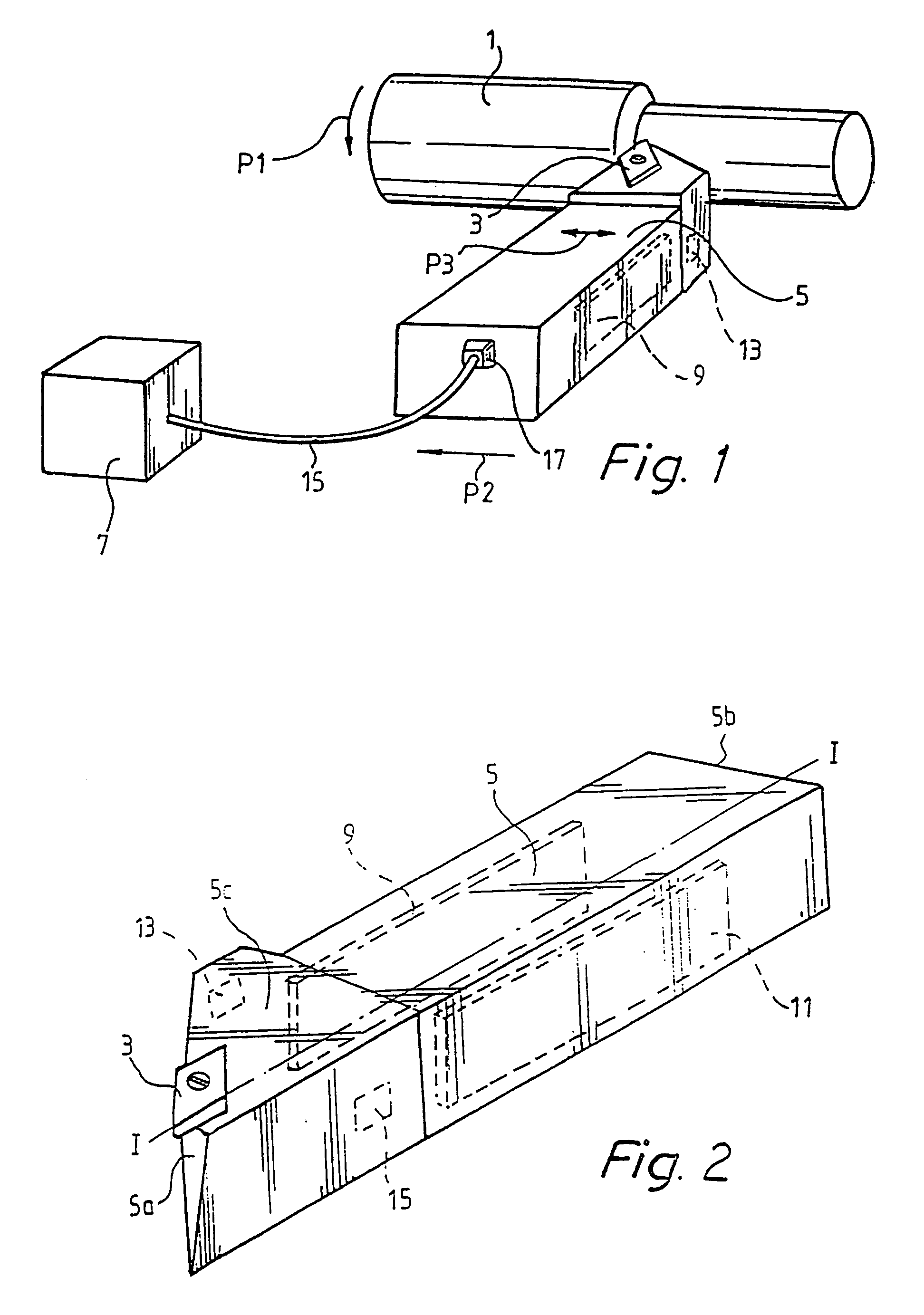

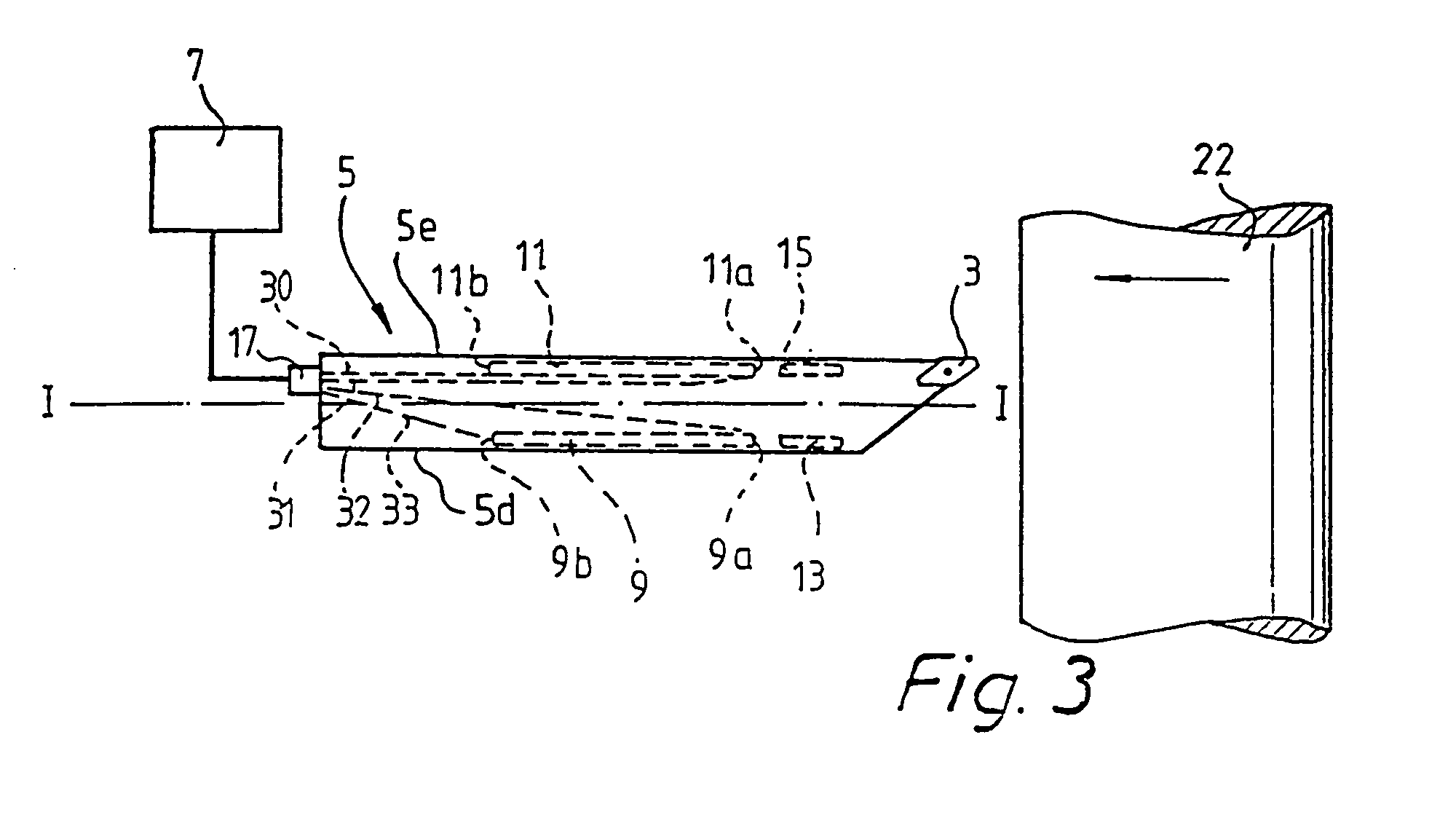

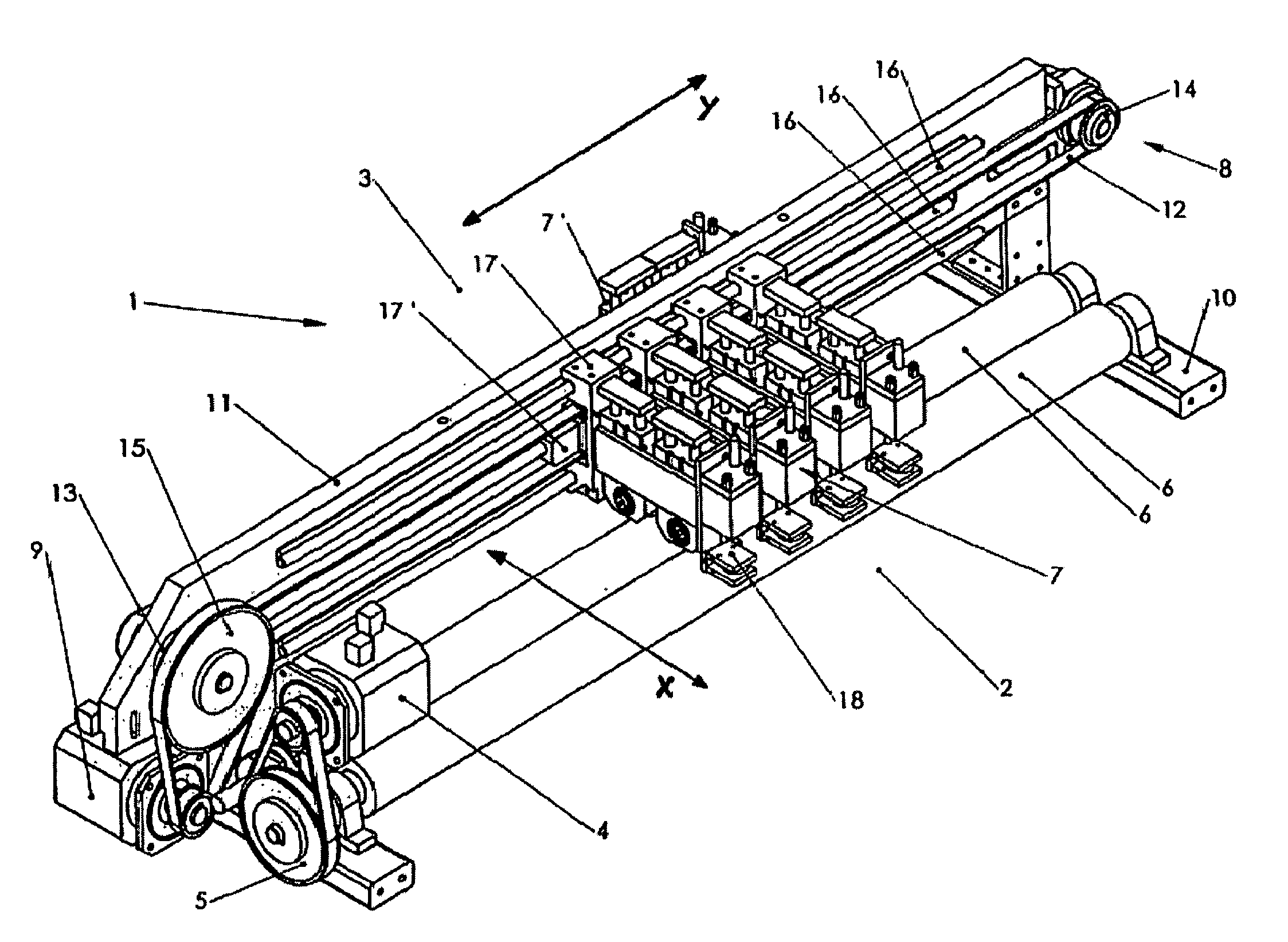

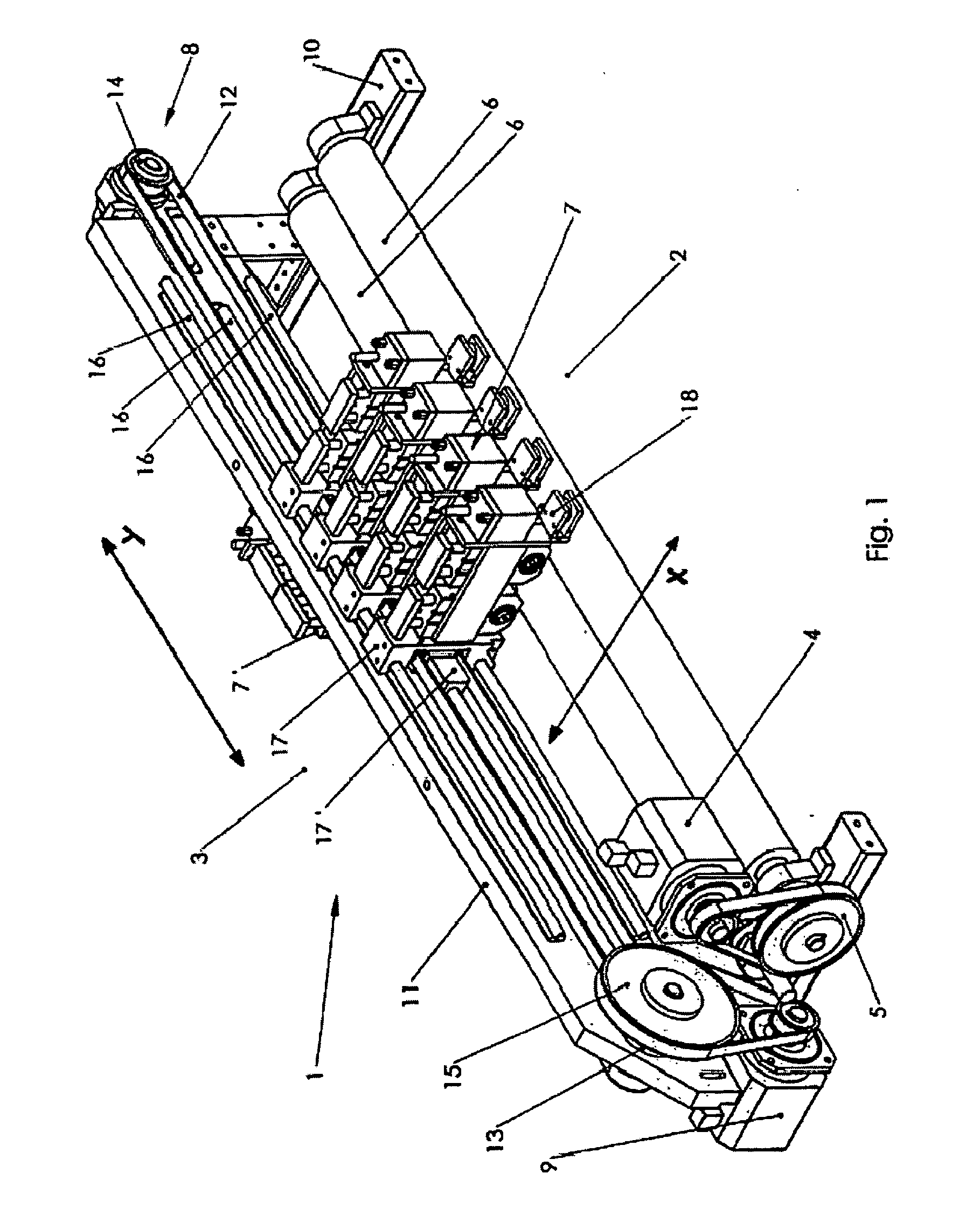

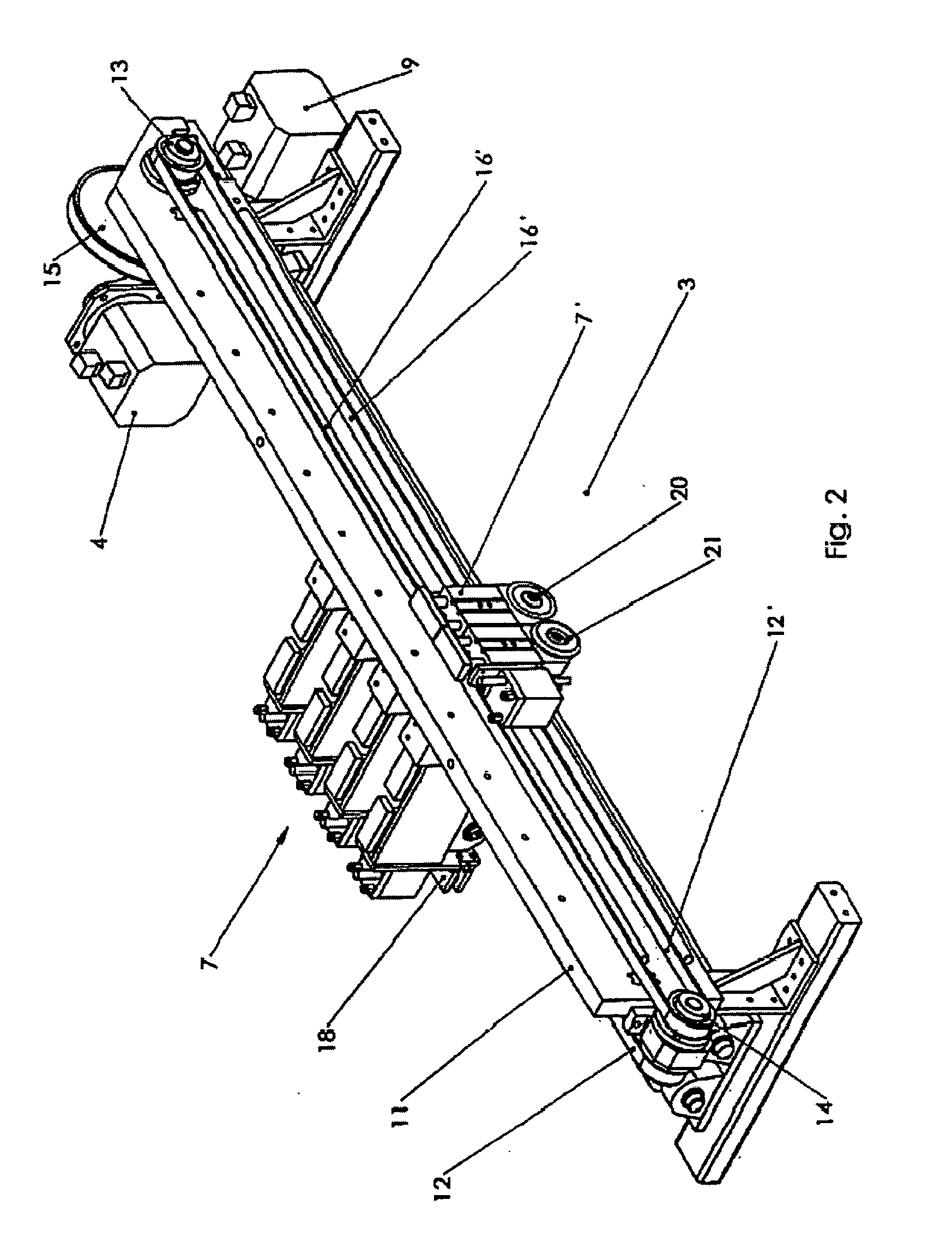

Apparatus for the positioning of a tool or a tool holder in a machine designed for processing a sheet material

InactiveUS6840898B2Accurate versatile controlled positioningEnvelopes/bags making machineryBox making operationsMachine designKnife holder

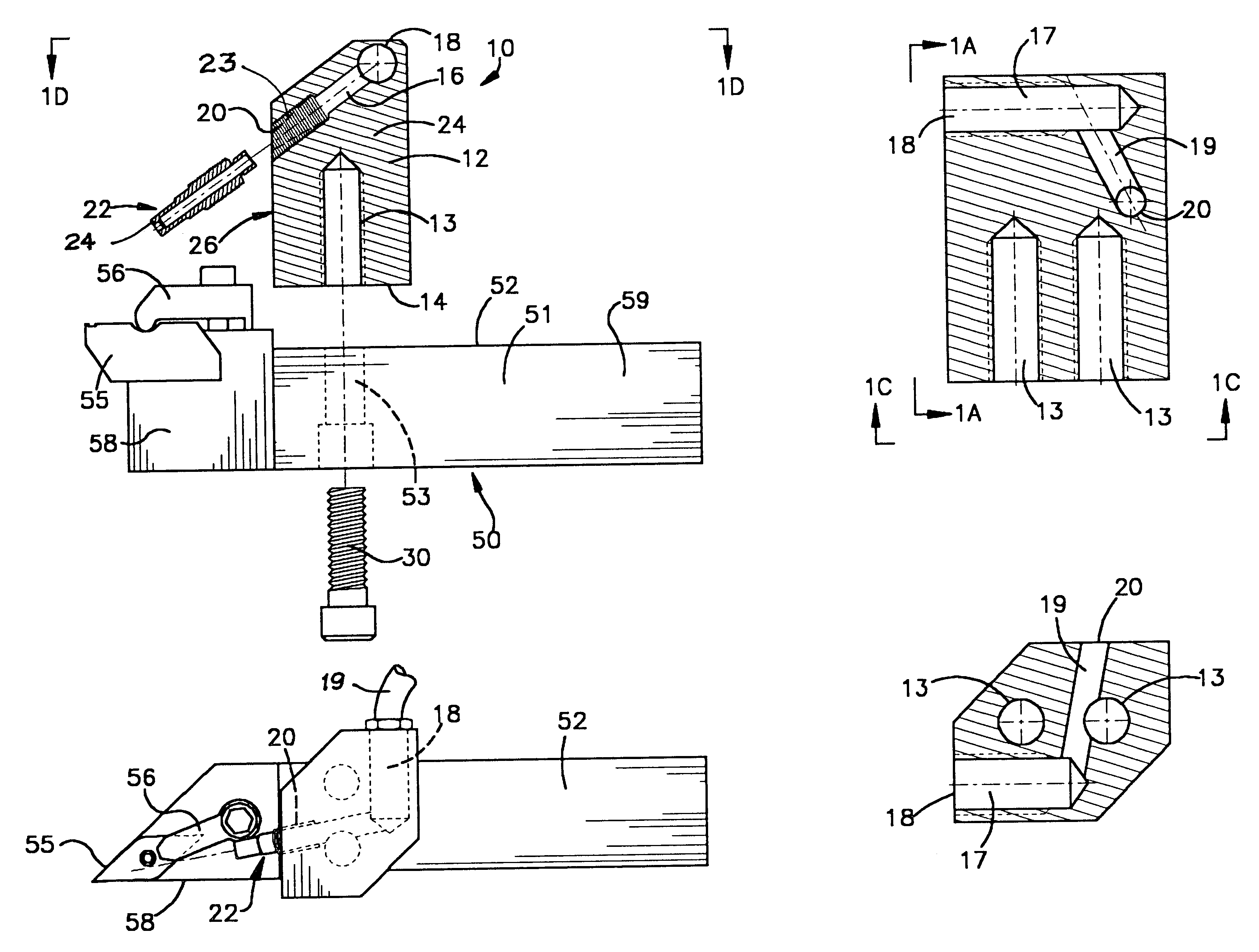

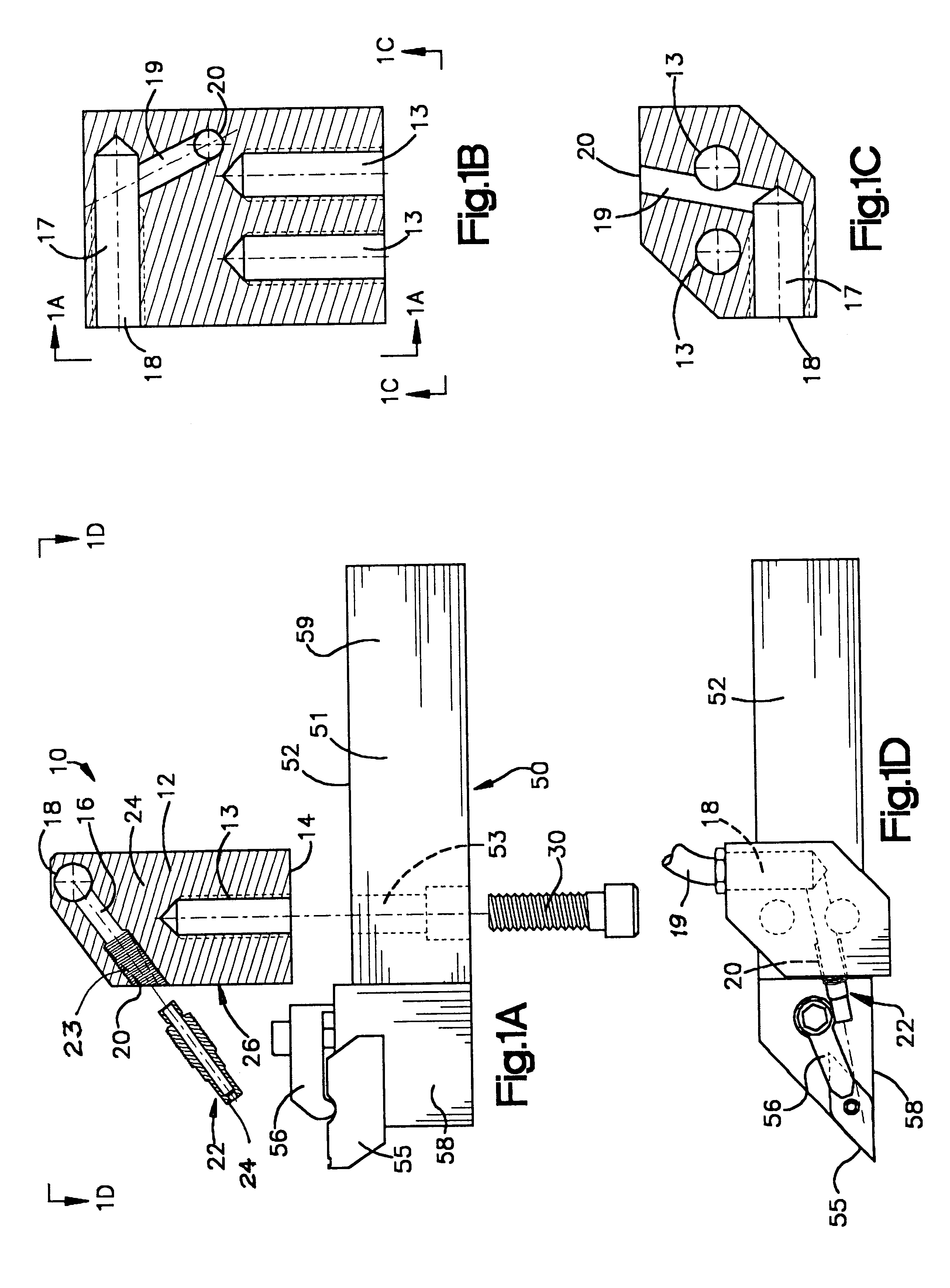

Arrangement for the positioning and shifting of tools, specifically the tools of a machine designed for shaping sheet material while being advanced relative to the arrangement, the arrangement having fixed guides (16,19) for guiding the tools in transverse motion relative to the travel direction (X) of the material, the tools or holders (7,7′) for the tools comprising means (22,23) by which a continuous or intermittently running drive (Y) across the material travel direction (X) is used for shifting the tool holders, individually or in combination, by alternately connecting one or several tool holders (7,7′) to the running drive.

Owner:PACKSIZE

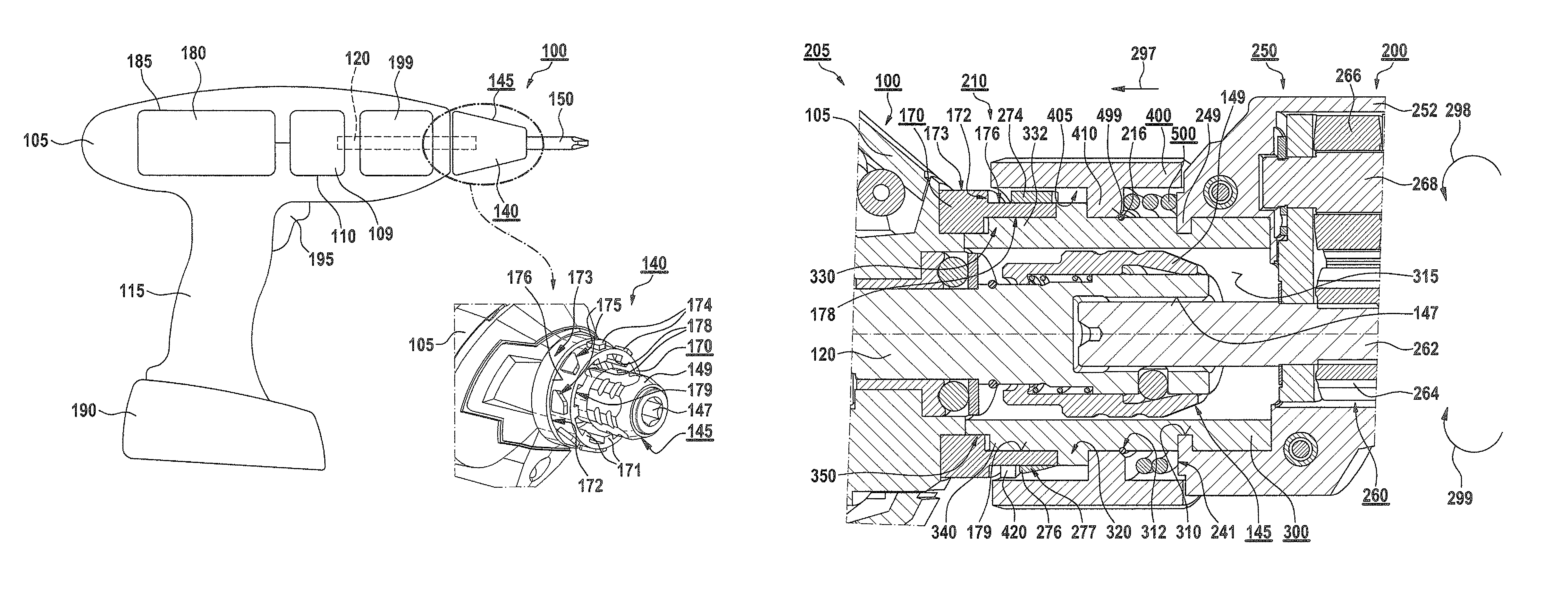

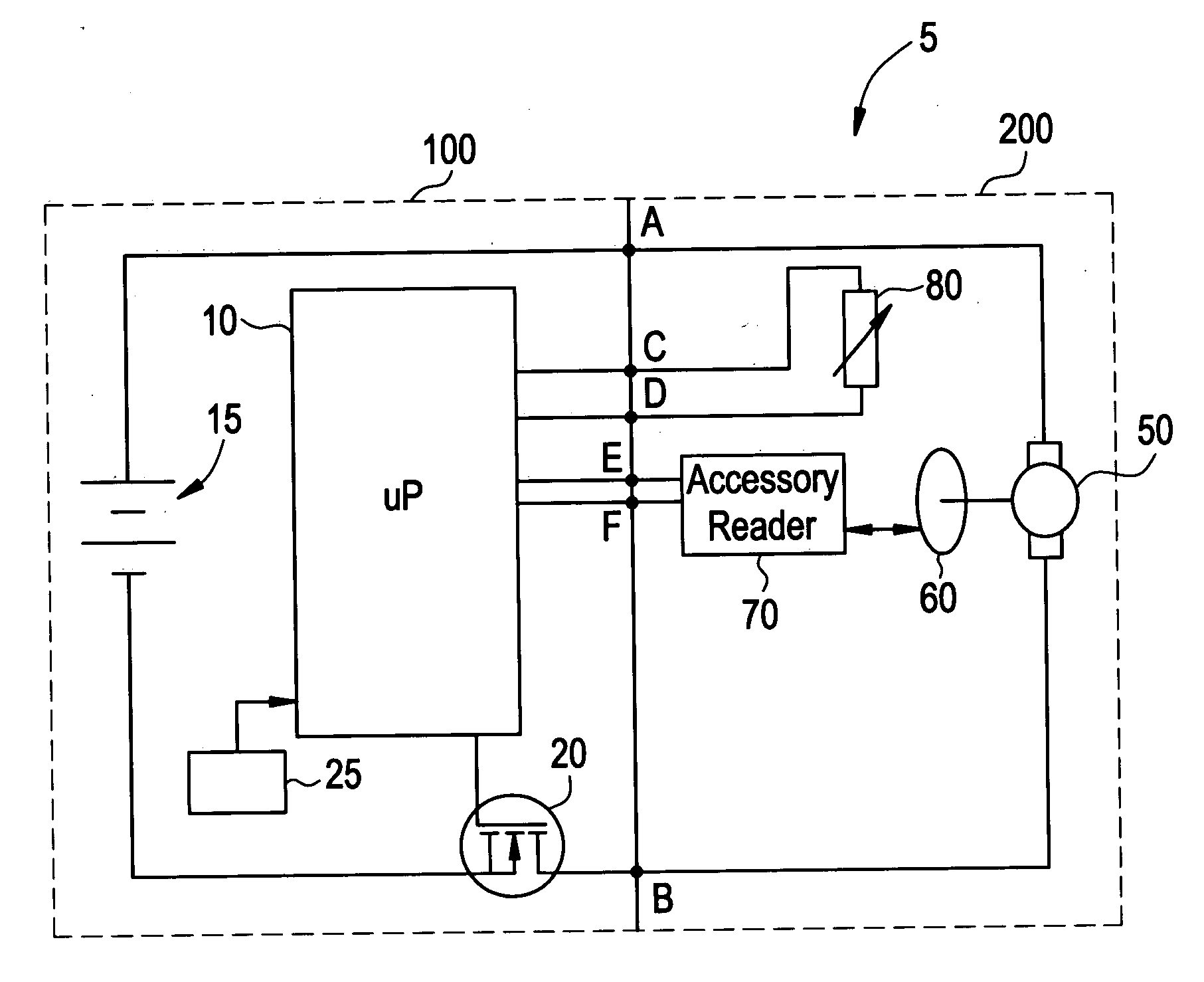

Power tool accessory identification system

A power tool accessory identification system includes a power tool which has a motor, an output spindle actuatable by the motor, and a tool holder connected to the spindle and configured to hold an accessory therein. The power tool includes an accessory reader to decoding an identification device on the accessory. In a method of controlling the power tool with an accessory operatively coupled thereto, the accessory is inserted in the tool and a communication interface between the accessory and tool is read. An accessory identification is decoded via an accessory reader of the tool. A tool setting for the power tool is accessed based on the decoded accessory identification.

Owner:BLACK & DECKER INC

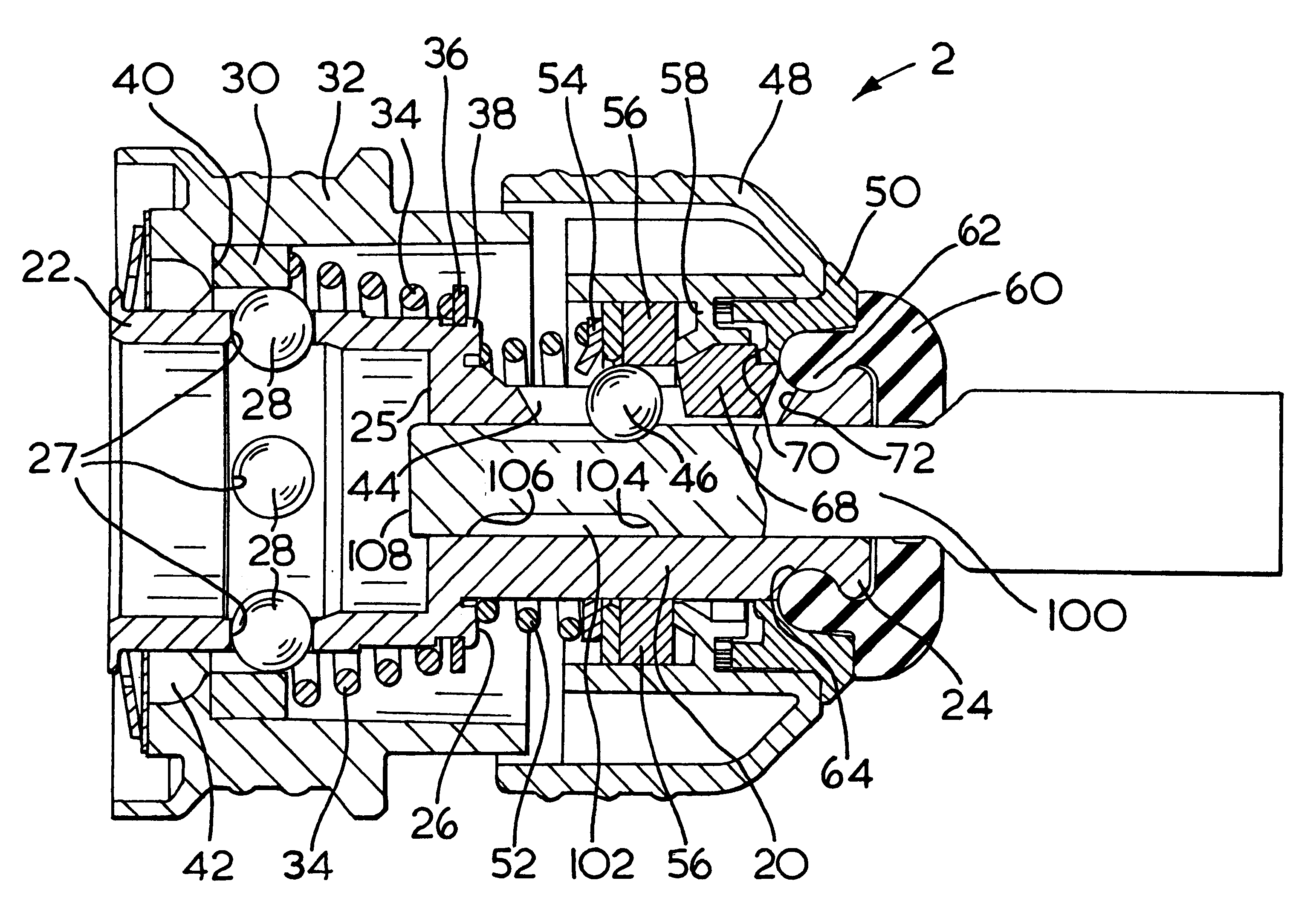

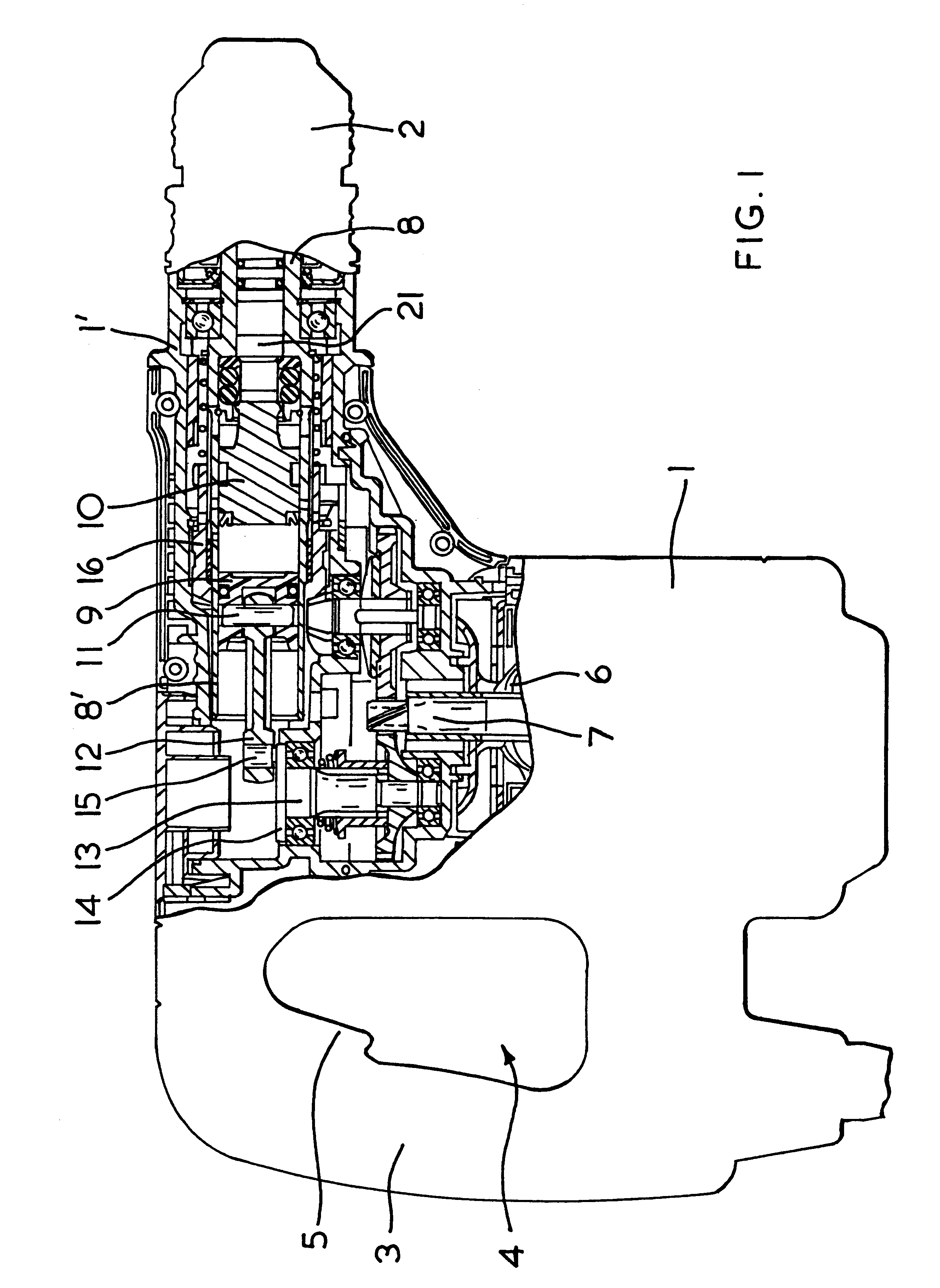

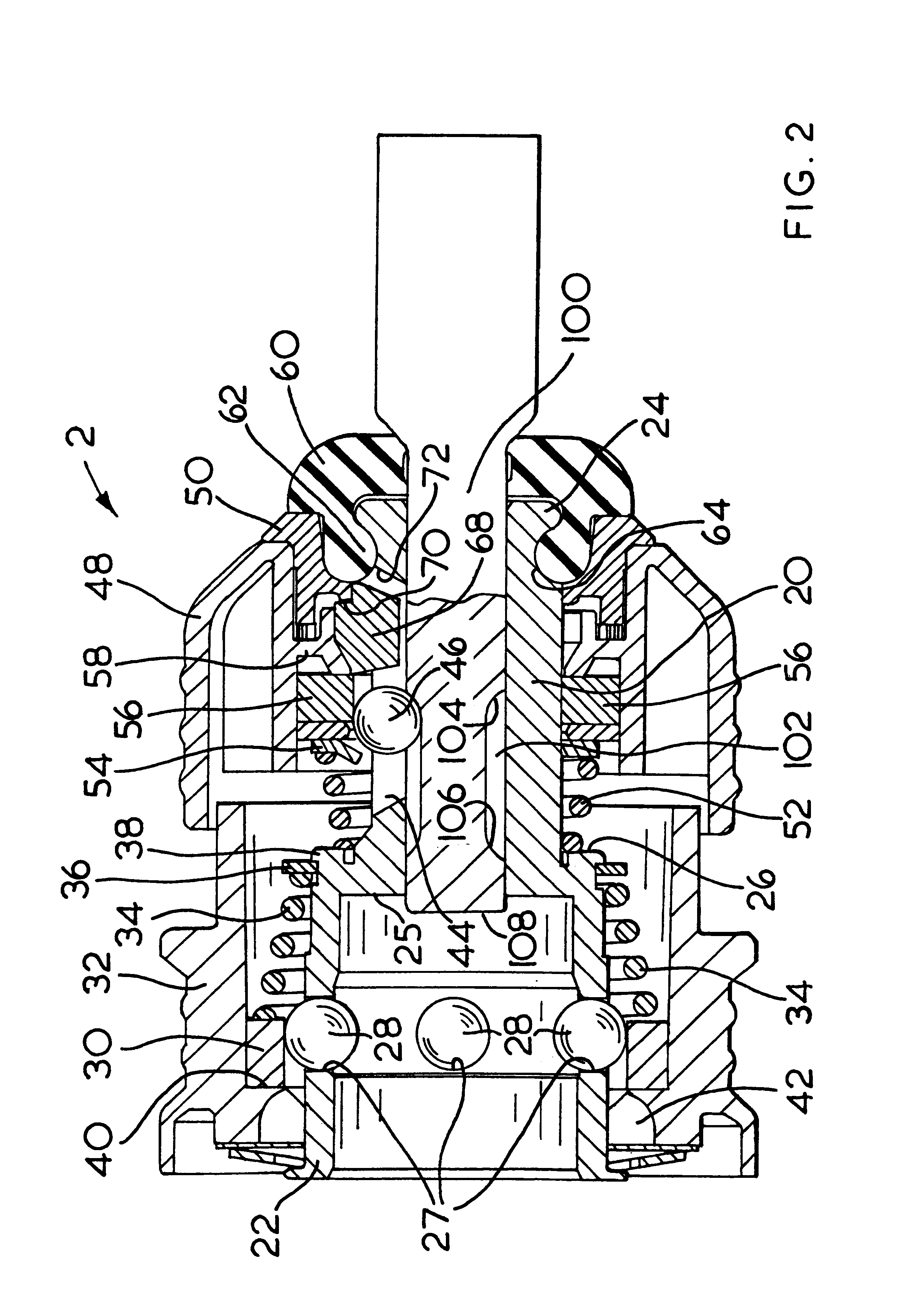

Rotary hammer

InactiveUS6241026B1Weakening rangeReduce risk of damageConstructionsChucksEngineeringFront and back ends

A tool holder attachable to a spindle of a hammer and which can receive a bit, the bit having a shank with at least one retaining groove extending along part of the shank, the retaining groove having a defined length, a front end and a rear end that limit axial movement of the bit in the tool holder, which tool holder comprises a hollow cylinder having an axis, an axial bore, a rear end that can be attached to the spindle of the hammer, and a front end that can receive the shank of the bit so that the bit is slidable within the cylinder in an axial direction, at least one retaining element that is located so that it can extend radially into the bore of the cylinder and into the at least one retaining groove of the bit so that the retaining element can be hit by the rear end of the retaining groove during the transition to idling and limit the extent of axial movement of the bit within the cylinder, at least one radial restraining element limiting movement of the retaining element in the radial direction, at least one axial restraining block limiting movement of the retaining element in the axial direction, when hit by the retaining element the axial restraining block movable to a limited extent in the axial direction with respect to the radial restraining element, and a resilient element located forward of the axial restraining block and arranged so as to attenuate the impact transmitted through the axial restraining block from the retaining element.

Owner:BLACK & DECKER INC

Metal cutting system for effective coolant delivery

A metal cutting system with a tool holder, a shim, an insert with a top depression, a top piece and a clamp. A rake face cooling channel for fluid delivery is formed between the top piece and the depression in the insert. A primary discharge slot at the end of the rake face cooling channel delivers fluid from below the cutting edge of the insert. A second cooling channel for delivery of fluid to the flank face is formed between the insert and the shim or is formed between the shim and the tool holder with a portion of the cooling channel passing through the shim.

Owner:KENNAMETAL INC

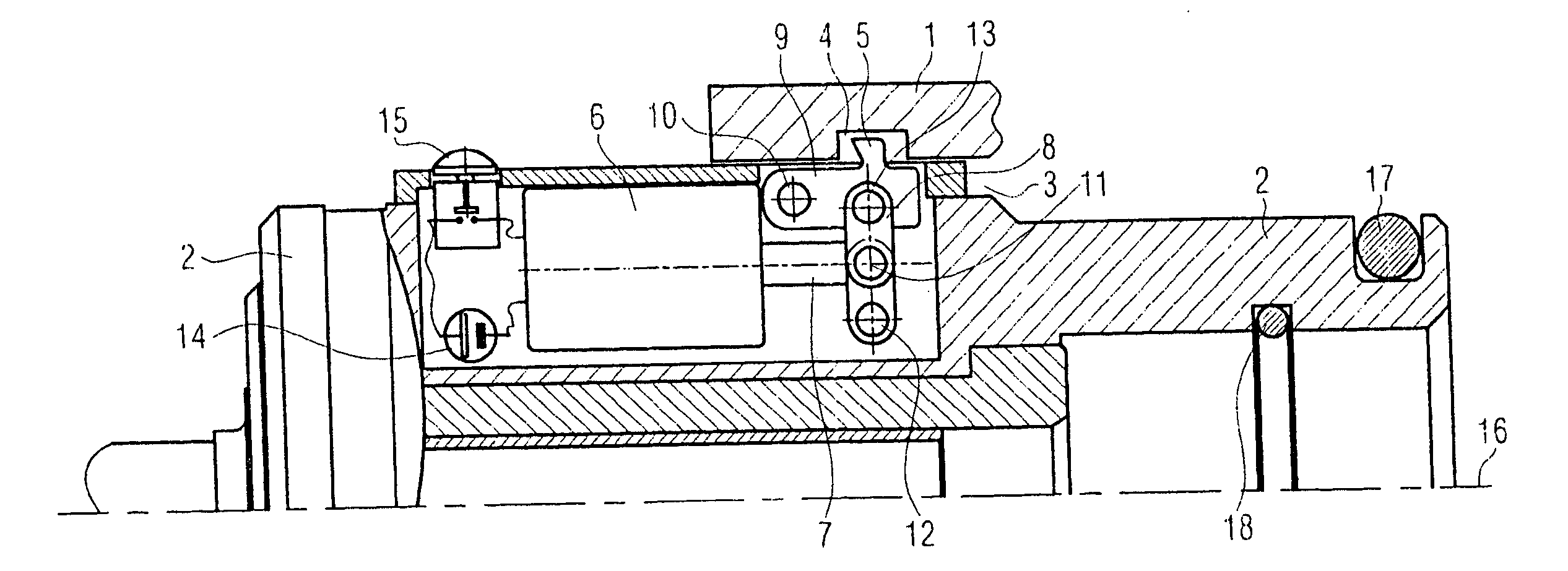

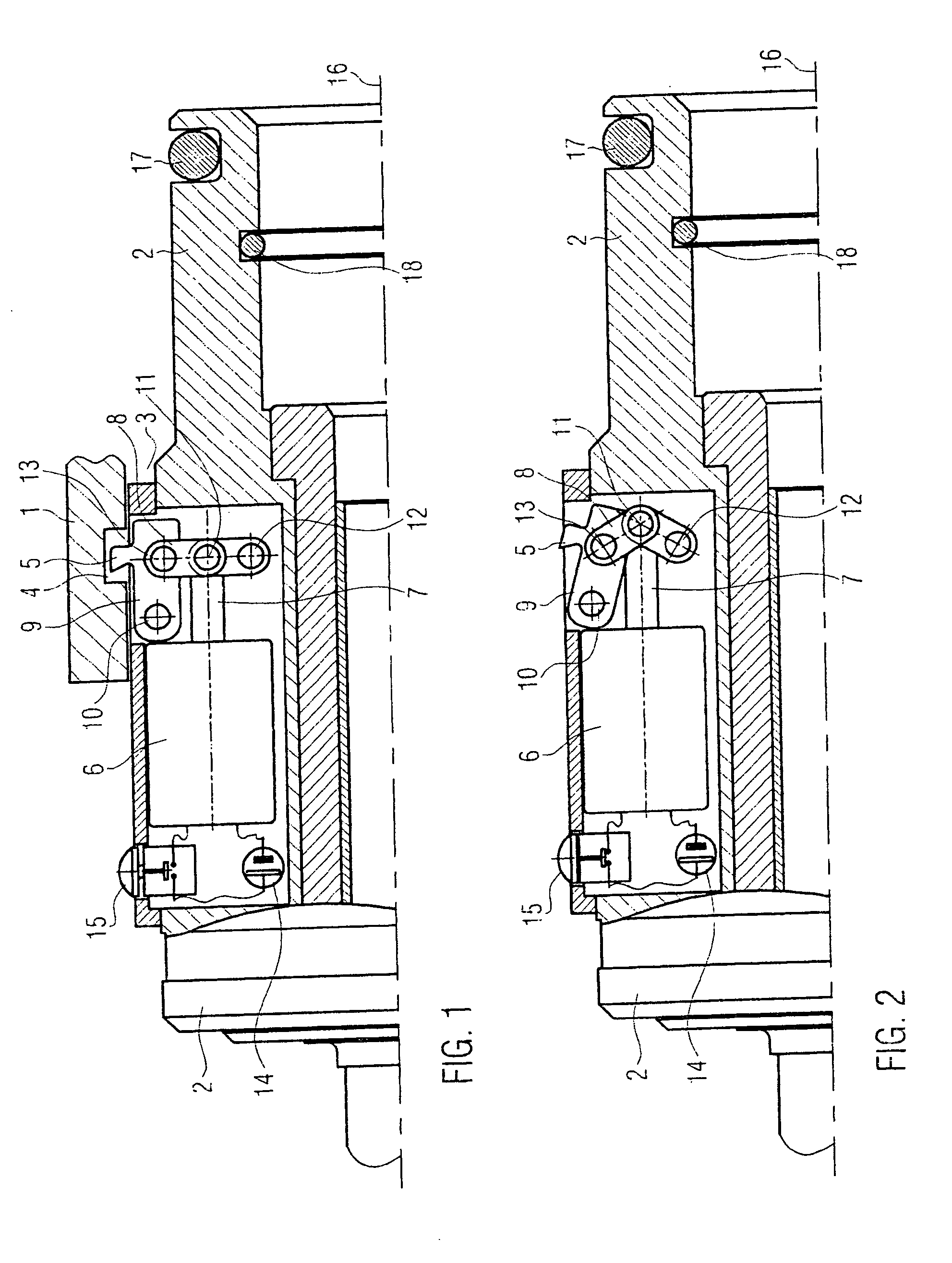

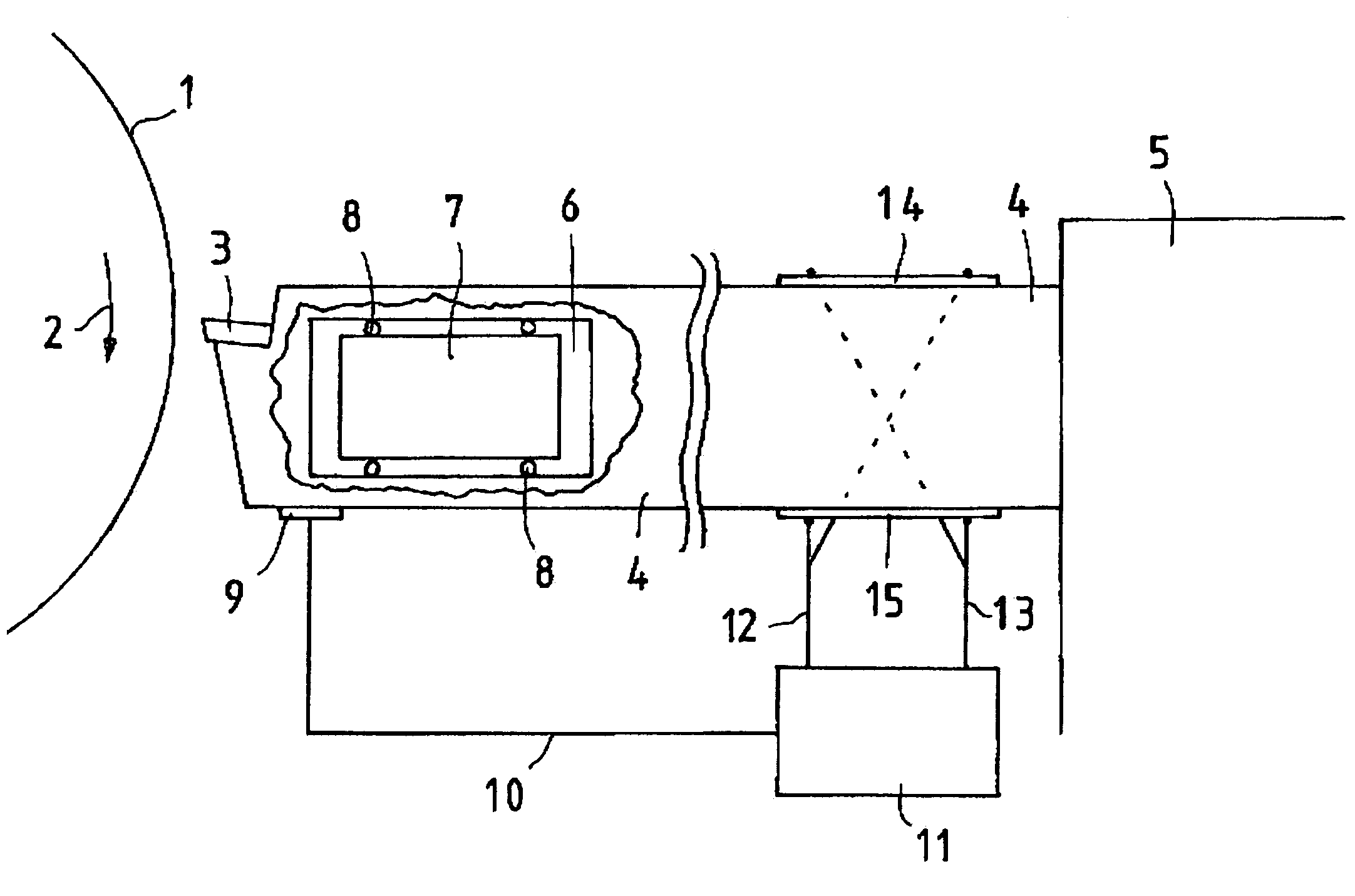

Device and a method for preventing or reducing vibrations in a cutting tool

An arrangement for reducing vibrations in a tool holder (4) with a cutting tool (3) and has a vibration sensor on the tool holder (4) that is connected to a guide unit (11). The tool holder (4) has further two piezo-electric actuators 14 and 15.Under the influence of the vibration sensor (9), the guide unit (11) provides an electric alternating current that is actively guided over time so that the actuators movably affect the tool holder (4) to reduce the vibrations in this. To also be able to dampen transients in the tool holder (4) this is movably connected with a passive dampening arrangement that is independent of the guide unit (11) and that is based on the principle of a springing (8) suspended mass (7). The invention also relates to a method for reducing vibrations. The vibrations in the tool holder are sensed and a corresponding signal is provided to a guide unit that over time provides actively guided signals to the actuators. The tool holder is also passively influenced by a dampening arrangement that is independent of the guide unit.

Owner:CLAESSON INGVAR +4

System for mounting a machine tool in a tool holder

InactiveUS20050238451A1Accurate centerAvoid turningSleeve/socket jointsTransportation and packagingSet screwEngineering

A system for mounting a tool in a tool holder combining a means for high-precision centering of the tool and a means for positive restraint of the tool from rotation within the tool holder. The tool holder includes a cylindrical aperture having a diameter slightly less than the diameter of the shank of a cylindrical tool. The tool is installed into the tool holder by heating the tool holder to a temperature sufficient to increase the pocket diameter sufficiently to accept the tool shank. In a first shrink-fit embodiment, the tool shank is further provided with an angular flat for engagement with a set screw to prevent the tool from being turned in the holder in use. In a second shrink-fit embodiment, a groove extending partially around the tool receives a tangential pin through a passage in the tool holder. The tool is rotated in the holder until the pin binds in the groove, thus preventing any further rotation of the tool in the holder during use.

Owner:PARLEC

Universal tool holder

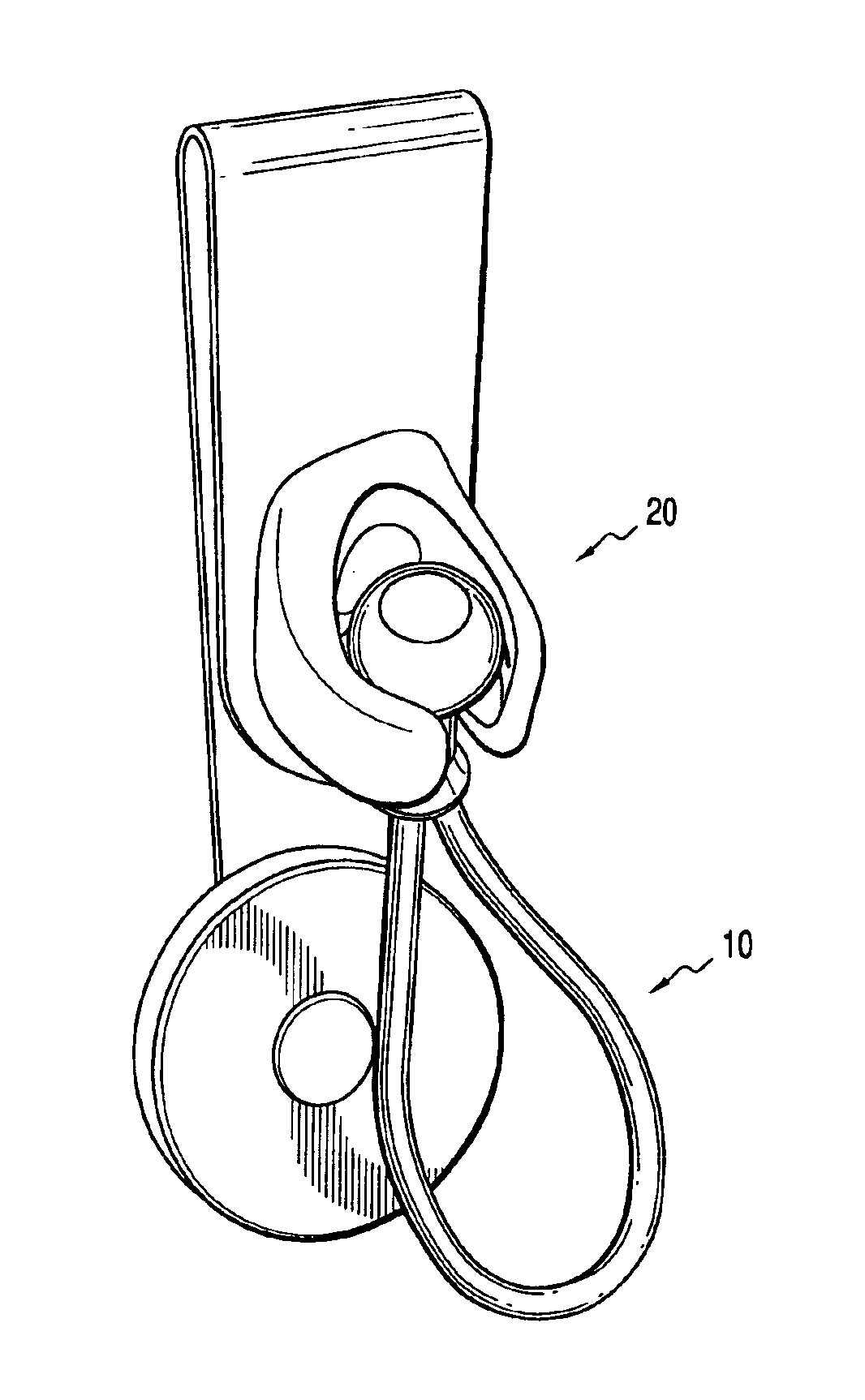

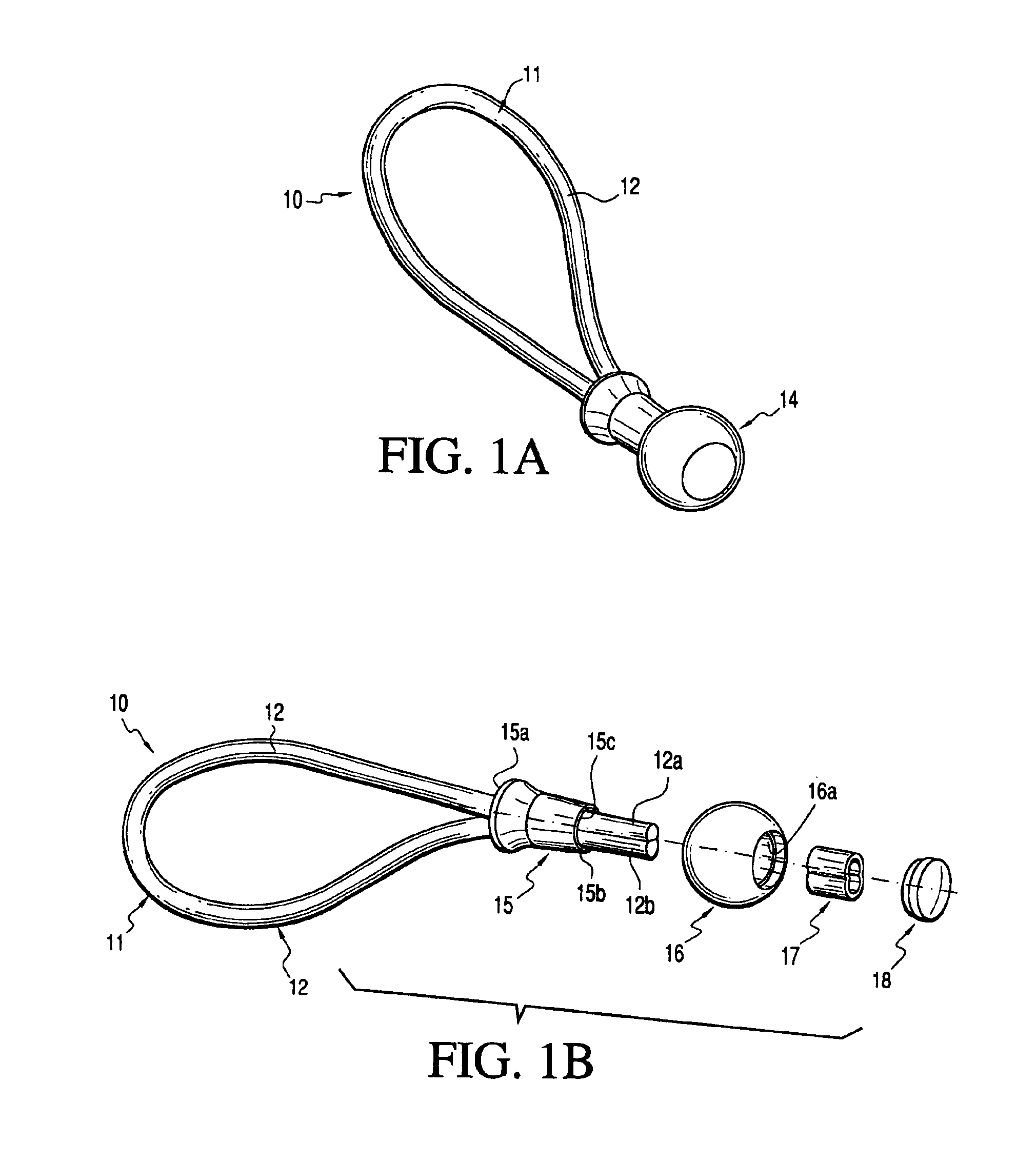

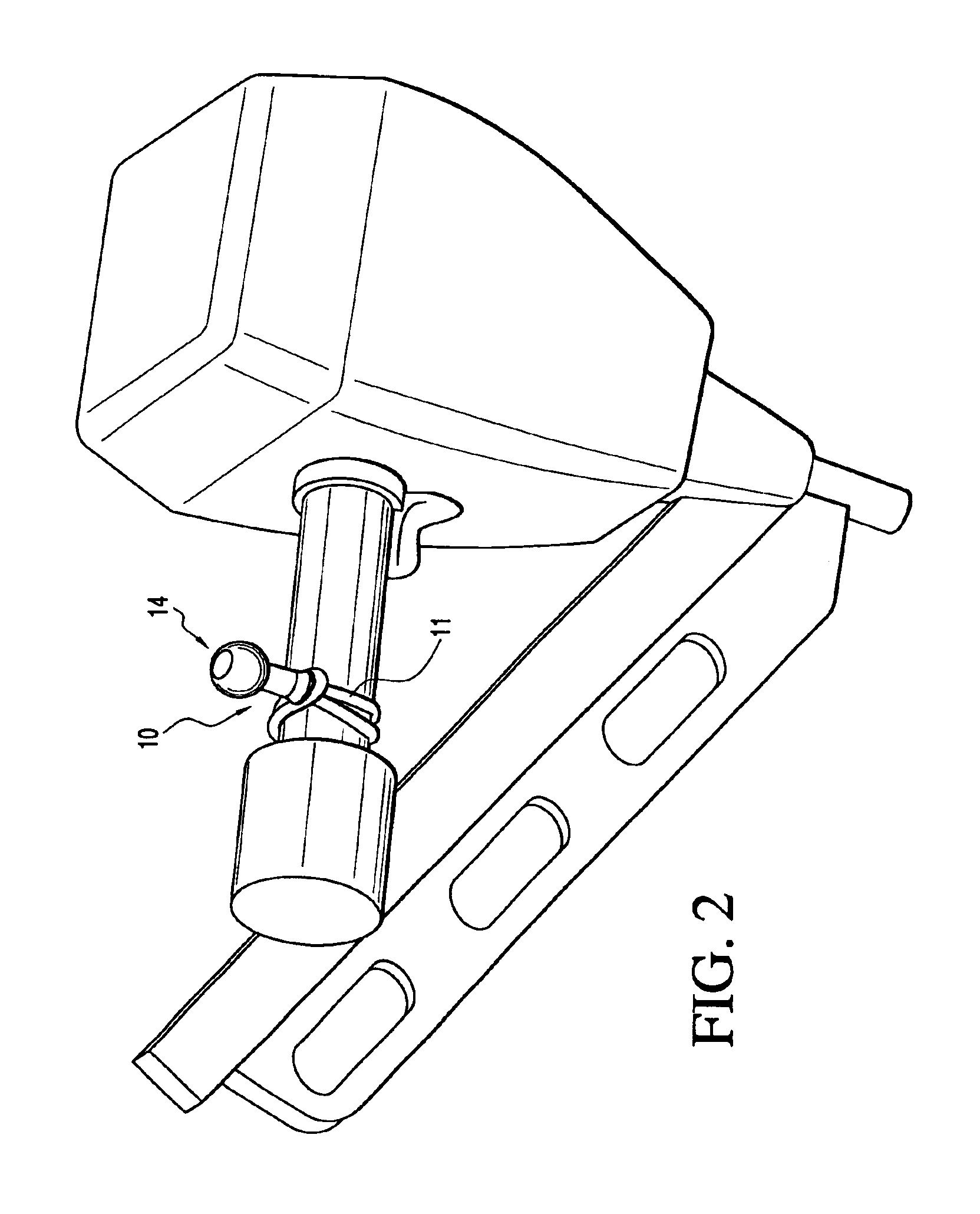

ActiveUS6880794B1Removably attachEasily and quickly introduced into retaining receiverSnap fastenersTravelling carriersDrillWall mount

A universal tool holder for carrying a tool or other article, for example, a cordless drill, nail gun, hammer or shovel is provided comprising a stretchable cord that is formed into a looped end and adapted to be wrapped about the handle of a tool in such a manner that it tightly engages the tool, and a second end having a retainable object, such as a ball, that is configured to be safely and securely held within a retaining receiver. The retaining receiver is in the form of a socket-type receiver configured to correspond to the geometrical shape of the retainable object such it can removably secure the retainable object. The socket-shaped retaining receiver can be incorporated into a variety of articles usefull in carrying and storing tools, including a belt clip, a wall mounting implement or a ladder mounting implement. By integrating the retaining receiver into such a variety of articles, any tool carried by the universal tool holder can be removably secured to the retaining receiver, thereby enabling a user to suspend the tool from a belt clip, ladder or wall.

Owner:KAHN PETER P

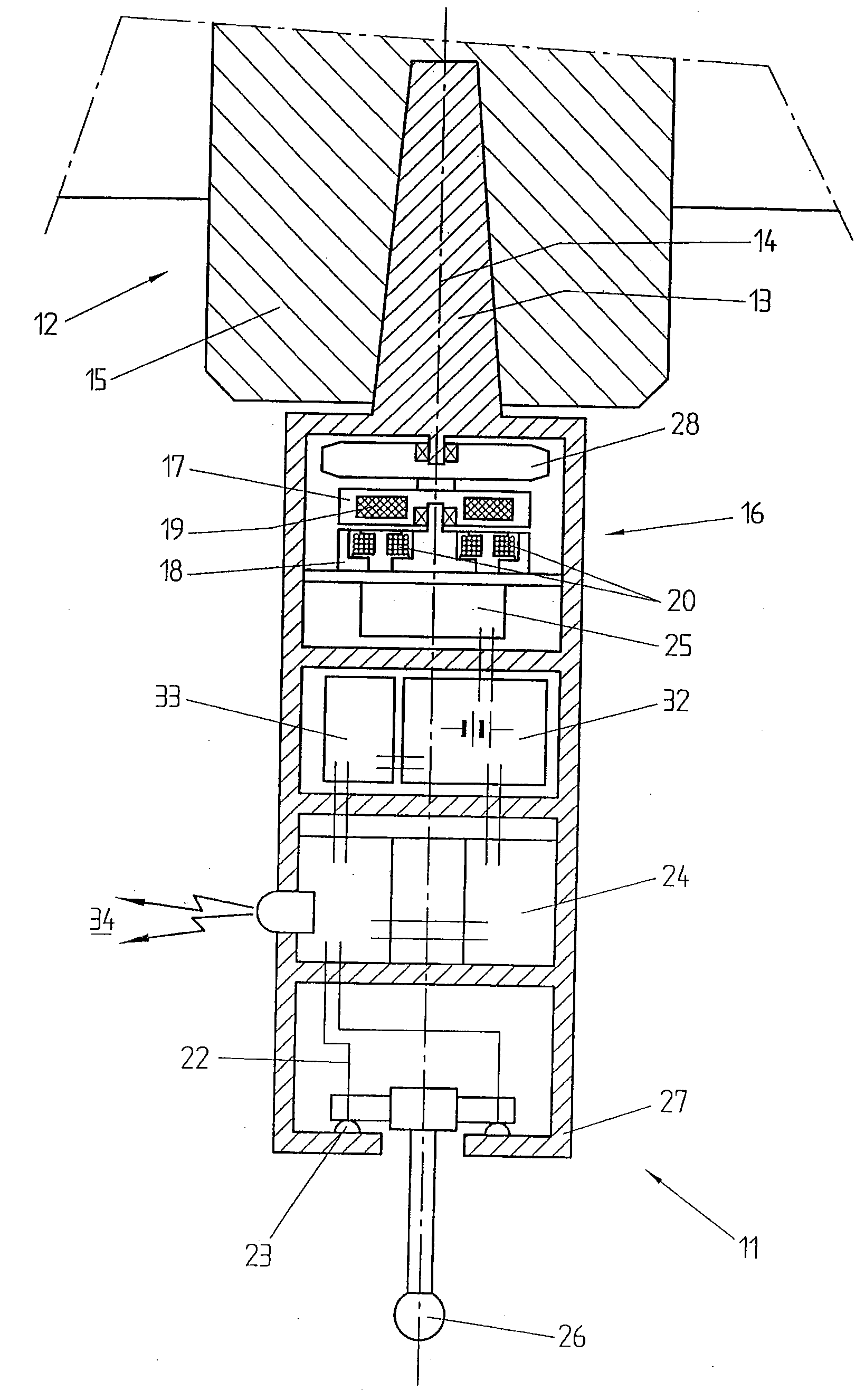

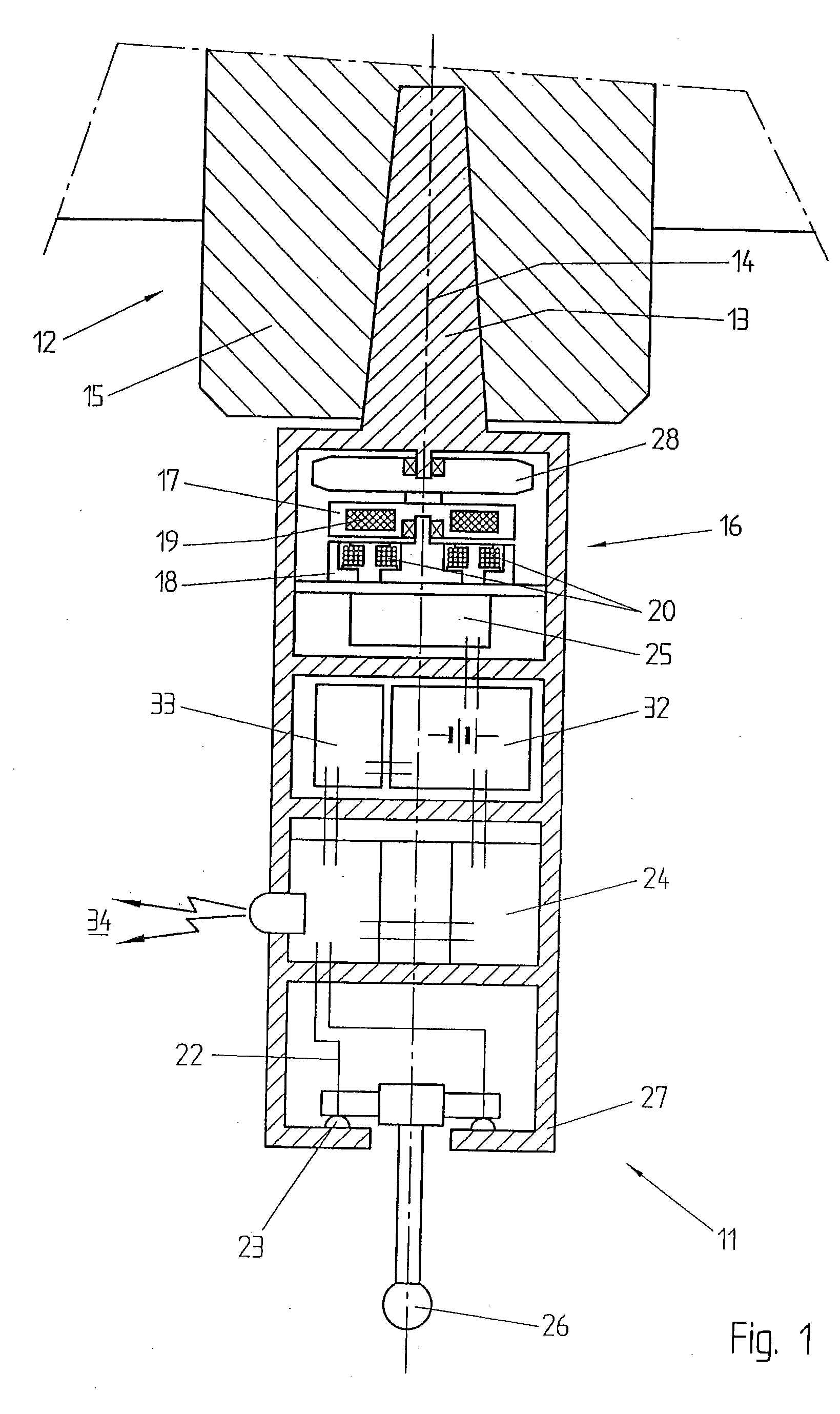

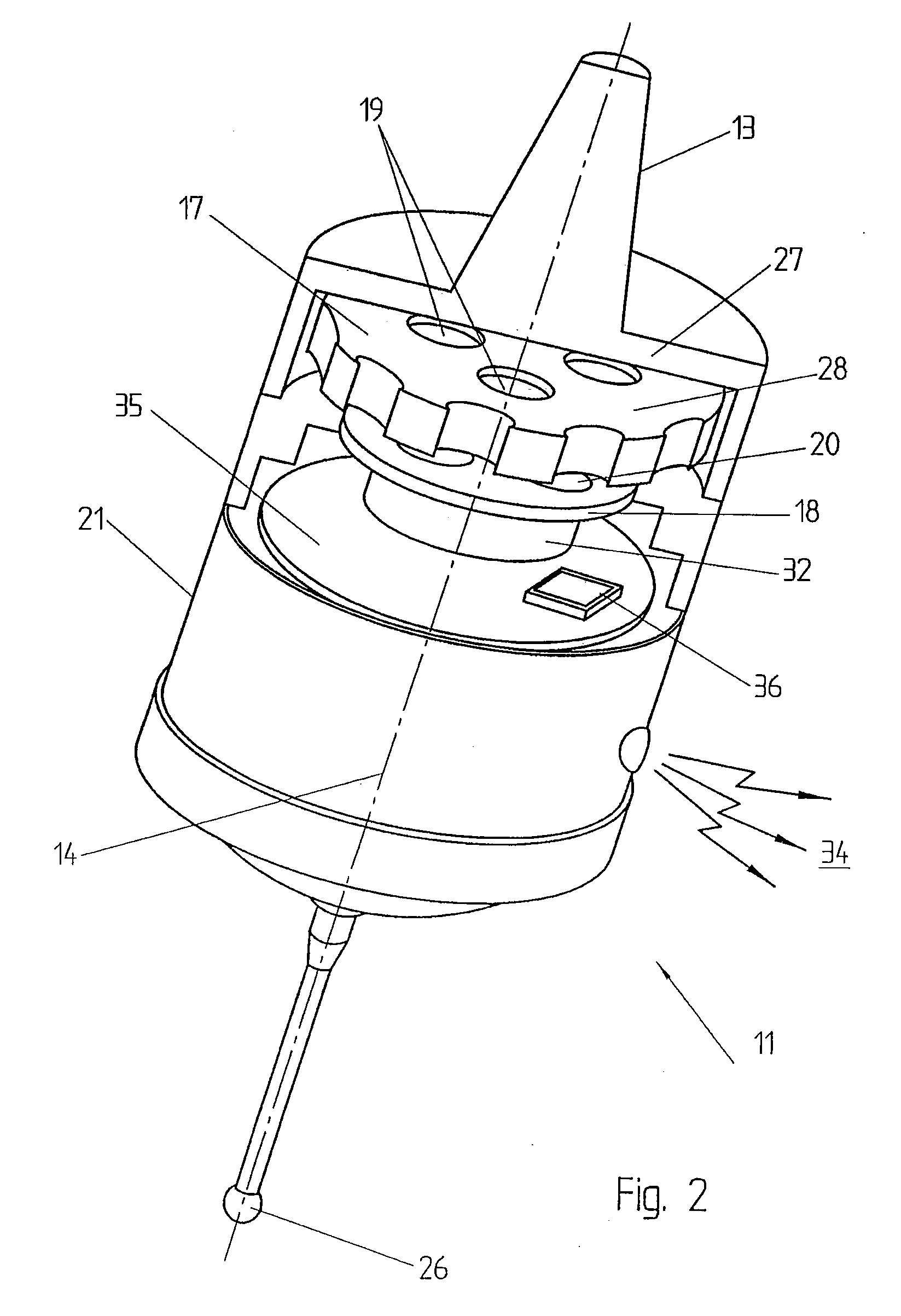

Self-powered coordinate probe

InactiveUS20090265946A1Improve system efficiencyMaximize the effectMachines/enginesMechanical energy handlingExternal energyEngineering

A probe, connectable to a machine tool, having an electric generator (16), supplying an electric or electronic circuit (22) with electric power, and a driving element (28), capable of relative rotation with respect to the stator of the electric generator. The rotation axis of the driving element is preferably a symmetry axis of the probe itself. The driving element is not connected to any external energy source, and can be set in rotation simply by activating the rotary axis of the machine tool.Advantageously, the driving element of the present invention is not directly connected with any mobile element of the machine tool, but is either rotatably mounted on the probe itself, or fixed on the reference table of the machine tool. Importantly, the inventive probe requires no additional connections to the machine tool on which it is mounted, besides the connection to the rotary spindle, which can be realized with a conventional tool-holder with a standardised tapered shank. In this way the inventive probe is fully compatible with standard probes, and can be mounted and used with standard tool-holders, without any adaptation. The self-powering function of the probe can be activated simply by sending appropriate rotation instructions to the machine tools.

Owner:HEXAGON TECH CENT GMBH

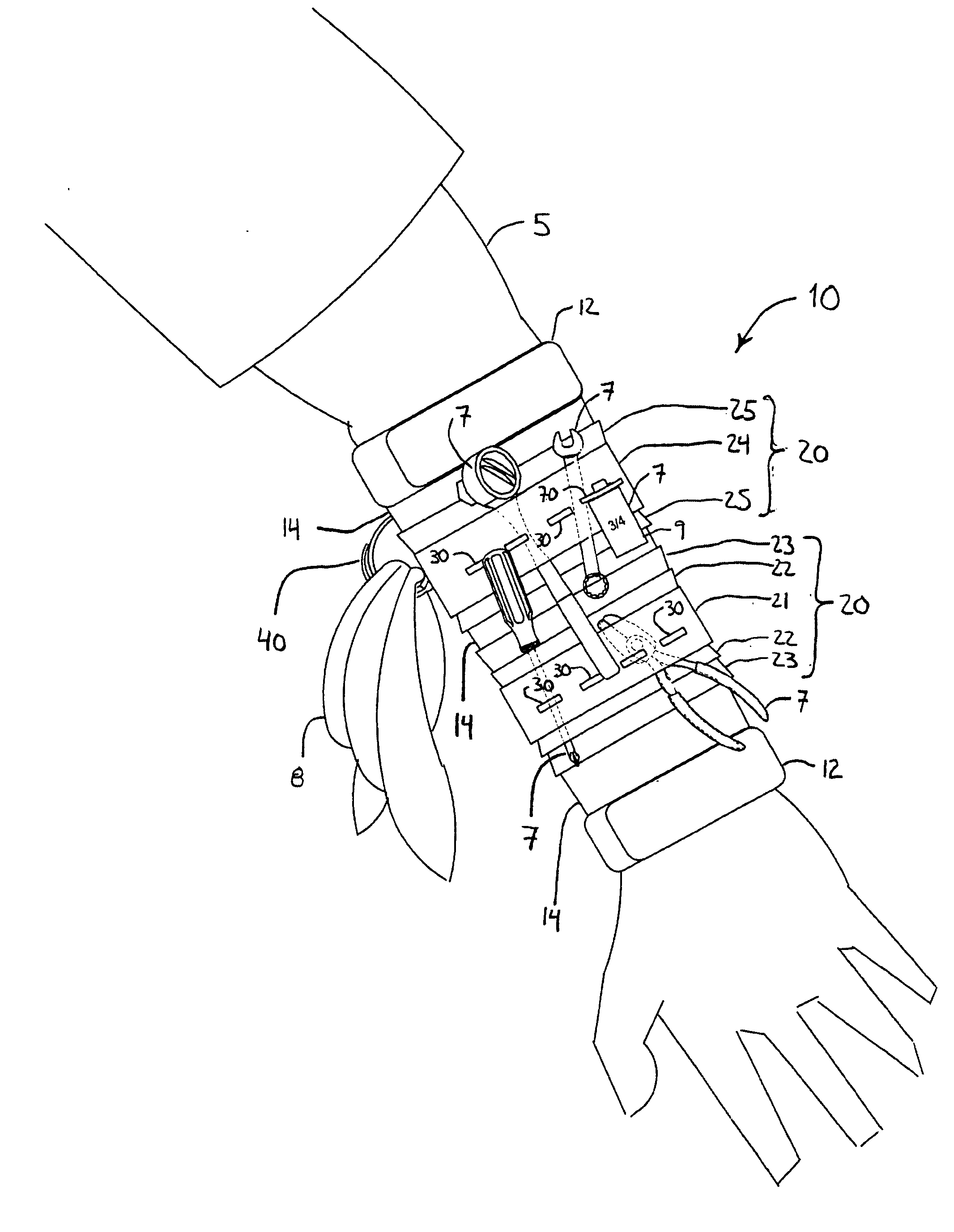

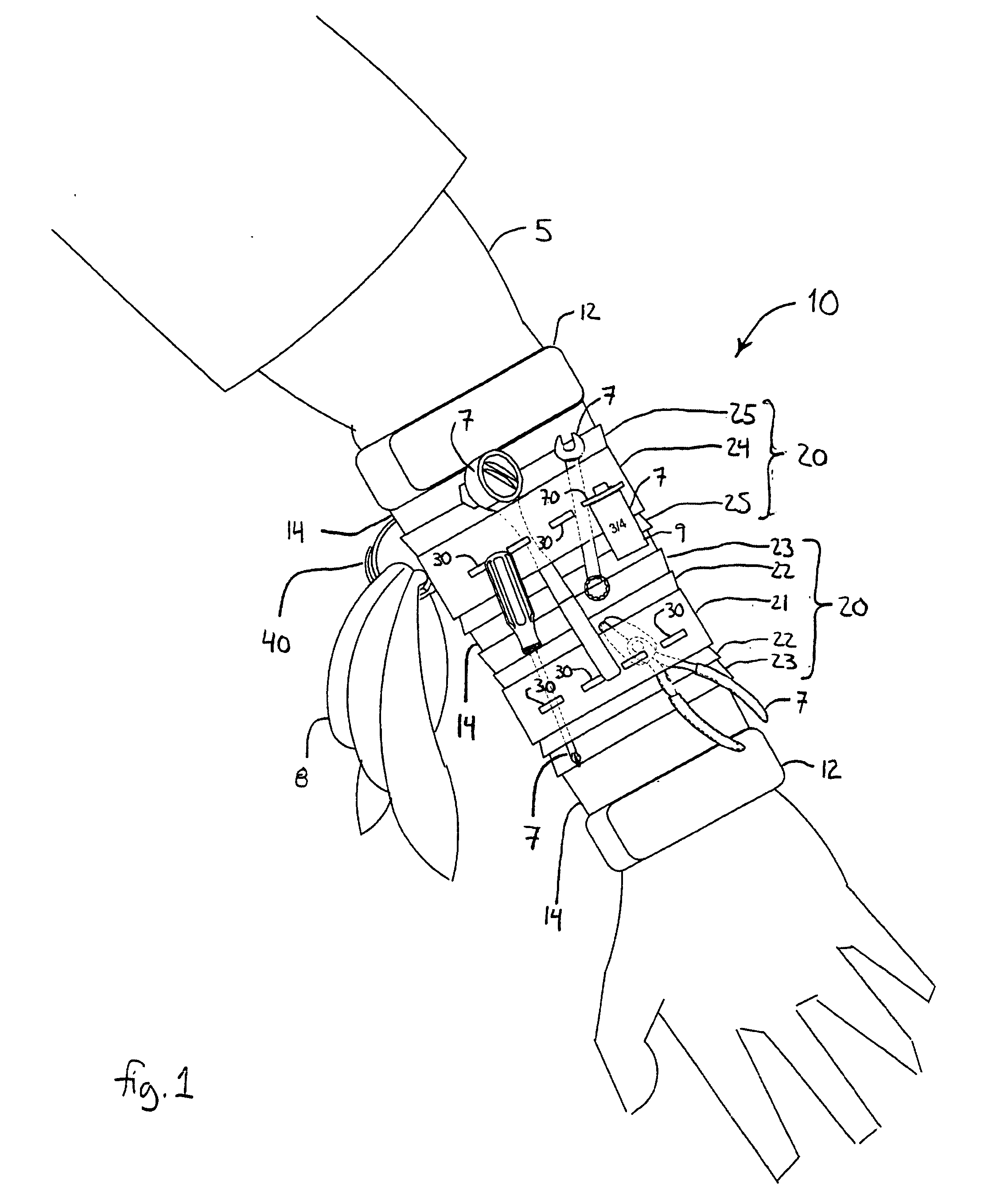

Wrist tool holder

The present invention comprises an apparatus for removably holding tools. The apparatus includes an armband arranged to removably fasten around a user's forearm. At least one tool holder is attached to the armband. The at least one tool holder is arranged to removably receive and hold a tool. In other aspects of the invention the tool holder includes a magnet as a band a tool can be removably slid under.

Owner:OHAIR KEITH

Method and device for controlling a turning operation

InactiveUS6925915B1Improve surface smoothnessLathesAutomatic/semiautomatic turning machinesControl systemActuator

A device increases the surface smoothness of a turned surface. The device comprising a control system with a control unit and an actuator connectible to the control unit and connectible with a tool holder. The actuator in adapted to impart a vibrating motion in the lateral direction to the tool holder. A method will also increase the surface smoothness of a turned surface, comprising the step of controlling the vibrations of the tool holder during turning. The method also comprises the step of imparting a vibrating motion in the lateral direction to the tool holder. Moreover, a turning lathe and a turning tool holder which like the device are designed to generate vibrating motion in the lateral direction.

Owner:STAFFANSBODA CIE

Tool holder block and sleeve retained therein by interference fit

InactiveUS20060186724A1Effective interference fitSlitting machinesCutting machinesInterference fitEngineering

A hollow sleeve is mounted in a hole of a holder block to receive a rotary cutter bit. The sleeve includes a front flange and a shank extending rearwardly from the front flange and defining a longitudinal axis. The shank includes an outer periphery having a radially stepped configuration, wherein an outer surface of the shank includes a plurality of axially adjacent surface sections that become successively smaller in cross-section in a direction away from the flange. Each surface section occupies one-third of the hole length. Each surface section has longitudinally spaced front and rear ends, wherein a portion of each surface section situated between its front and rear ends is spaced farther from the axis than are the front and rear ends. Each surface section has a generally longitudinally extending groove formed therein.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Apparatus for the positioning of a tool or a tool holder in a machine designed for processing a sheet material

InactiveUS20040082453A1Accurate versatile controlled positioningEnvelopes/bags making machineryBox making operationsEngineeringMachine design

Arrangement for the positioning and shifting of tools, specifically the tools of a machine designed for shaping sheet material while being advanced relative to the arrangement, the arrangement having fixed guides (16,19) for guiding the tools in transverse motion relative to the travel direction (X) of the material, the tools or holders (7,7') for the tools comprising means (22,23) by which a continuous or intermittently running drive (Y) across the material travel direction (X) is used for shifting the tool holders, individually or in combination, by alternately connecting one or several tool holders (7,7') to the running drive.

Owner:PACKSIZE

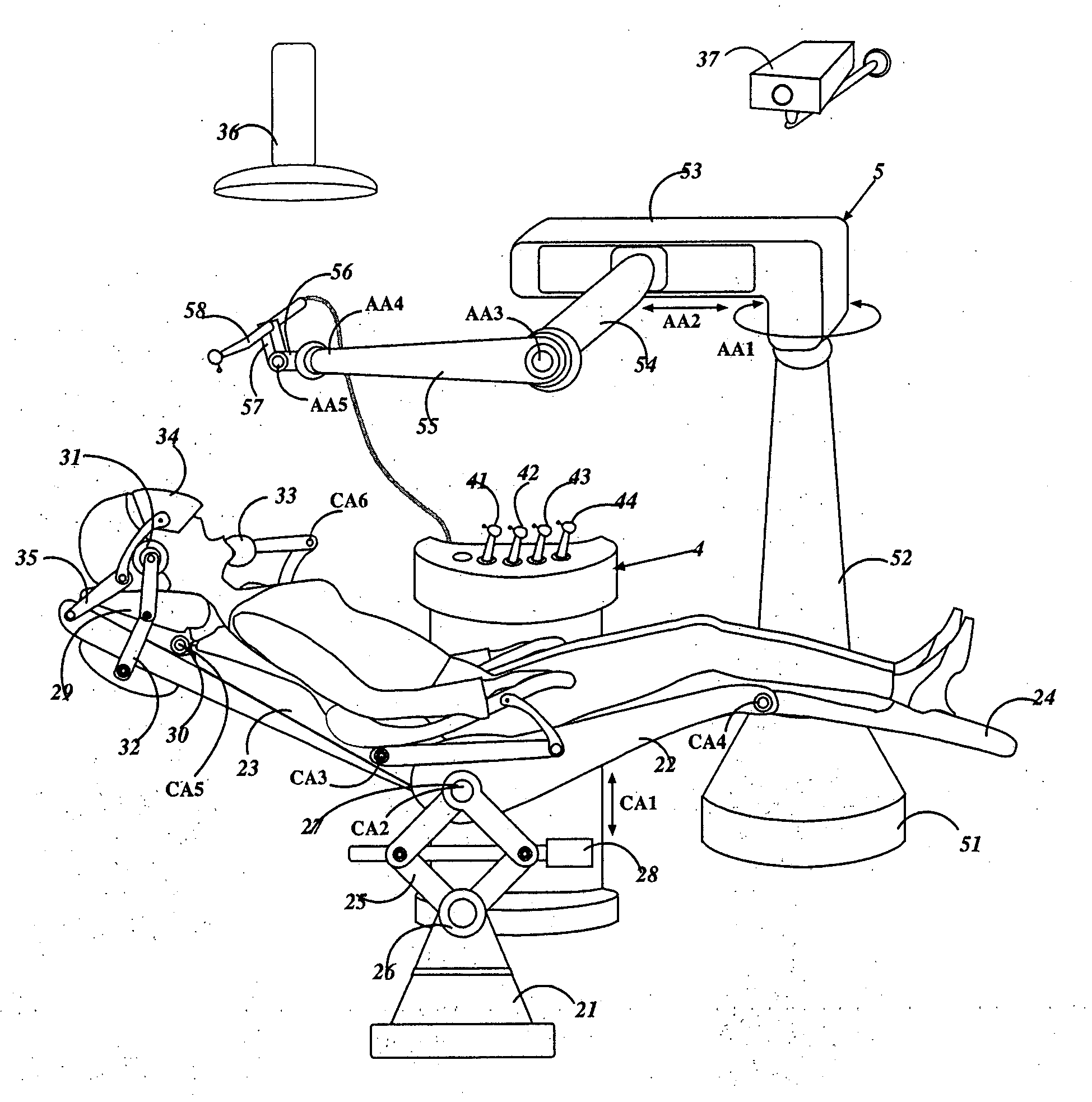

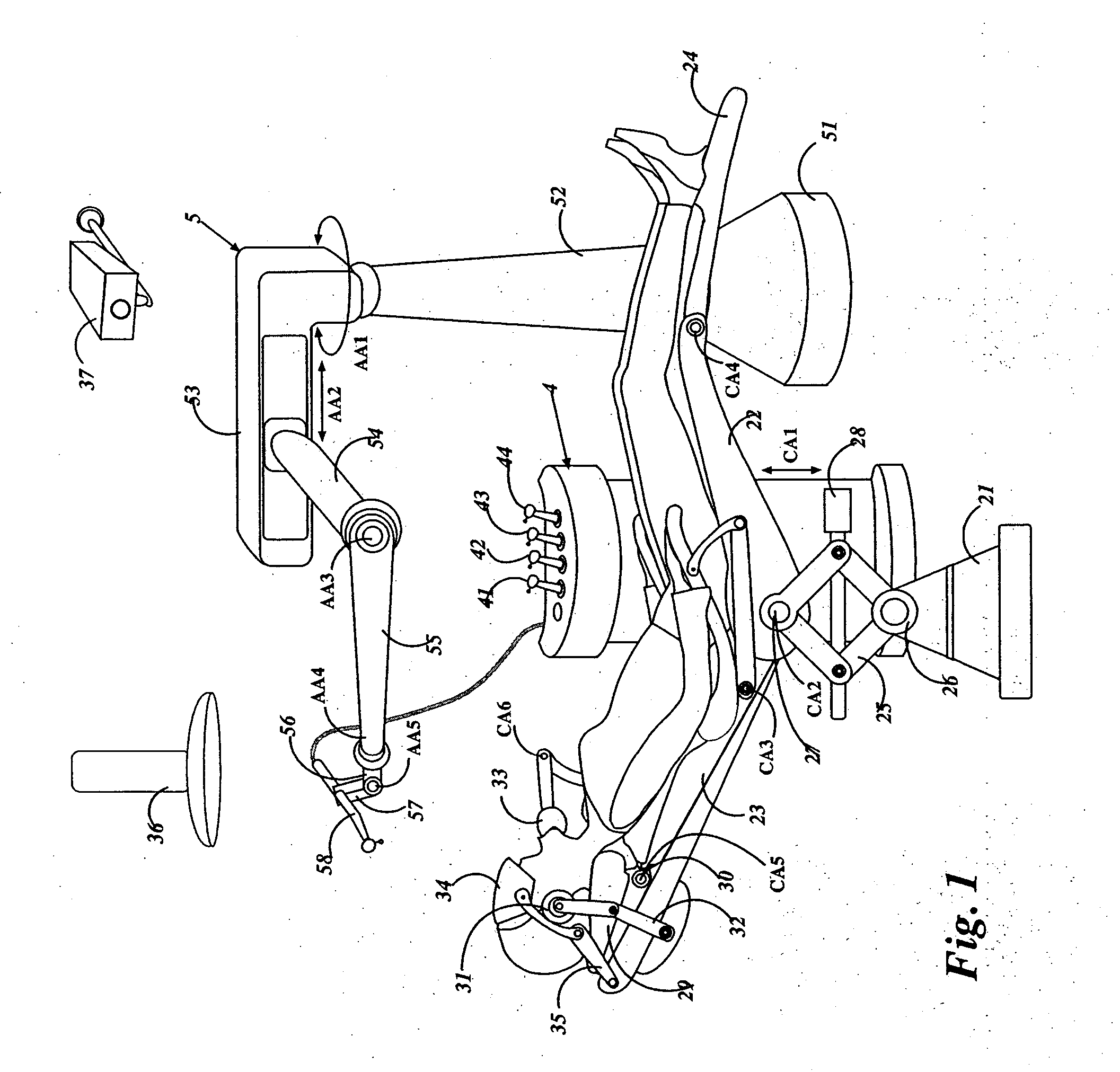

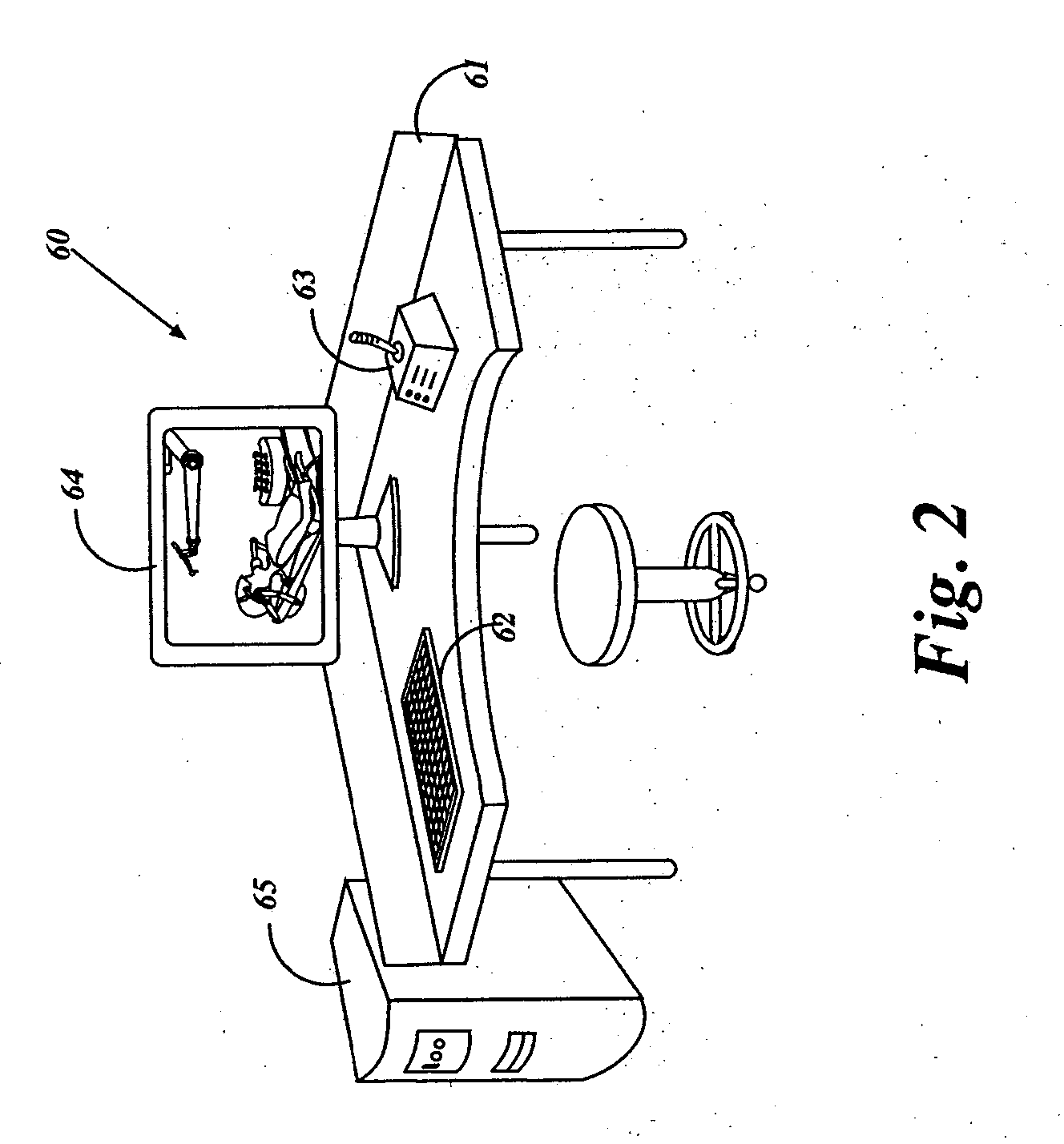

Computer-controlled dental treatment system and method

A computer-controlled dental treatment system, includes: a dental chair for receiving a patient to be treated; a robotic arm carrying a dental tool holder for holding a dental tool to be used in rendering a selected dental treatment, and for manipulating the dental tool with respect to the patient's head during the dental treatment; and a control system programmable to control the robotic arm to manipulate the dental tool in accordance with the selected dental treatment to be rendered to the patient.

Owner:COHEN YECHIEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com