Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10075results about "Box making operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

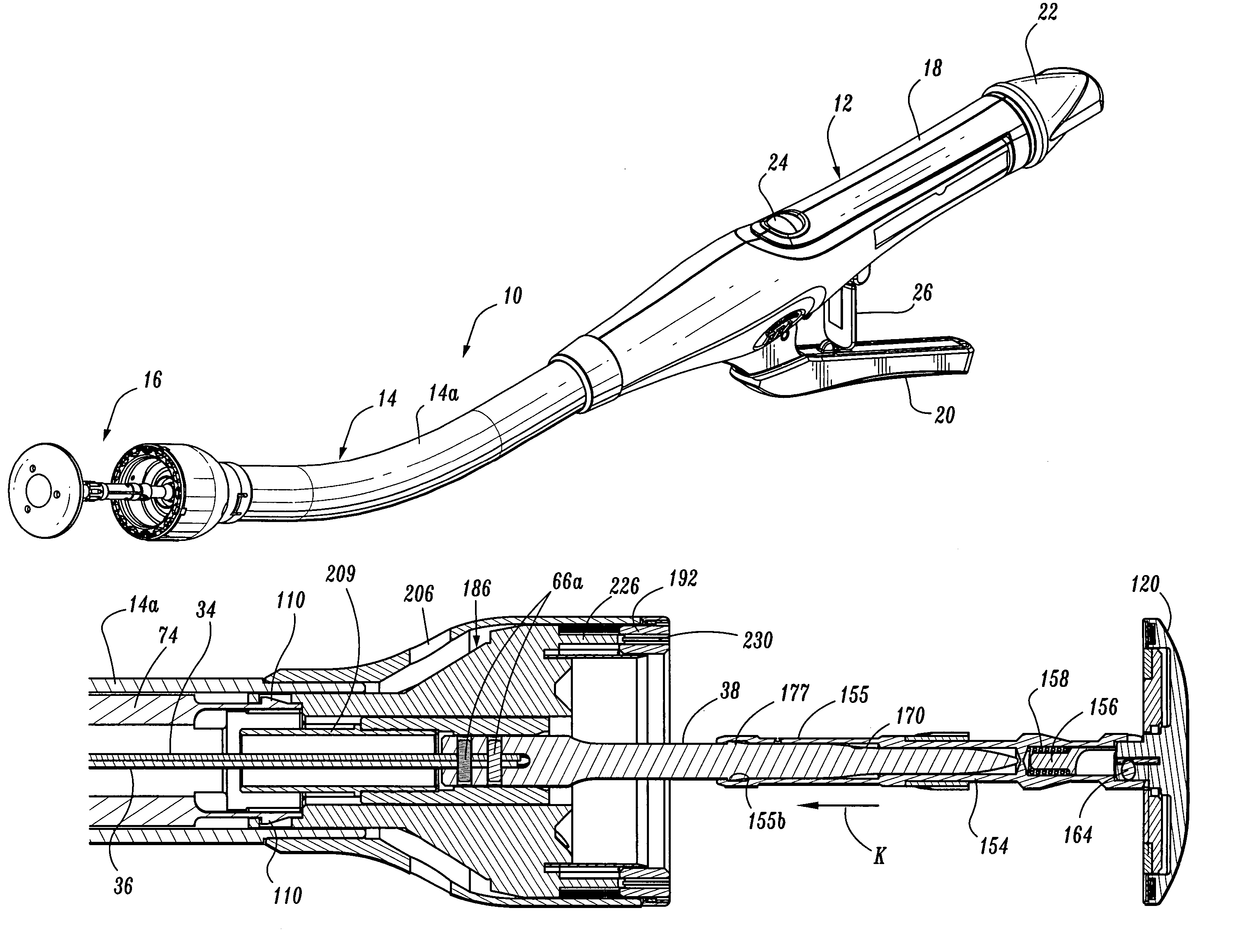

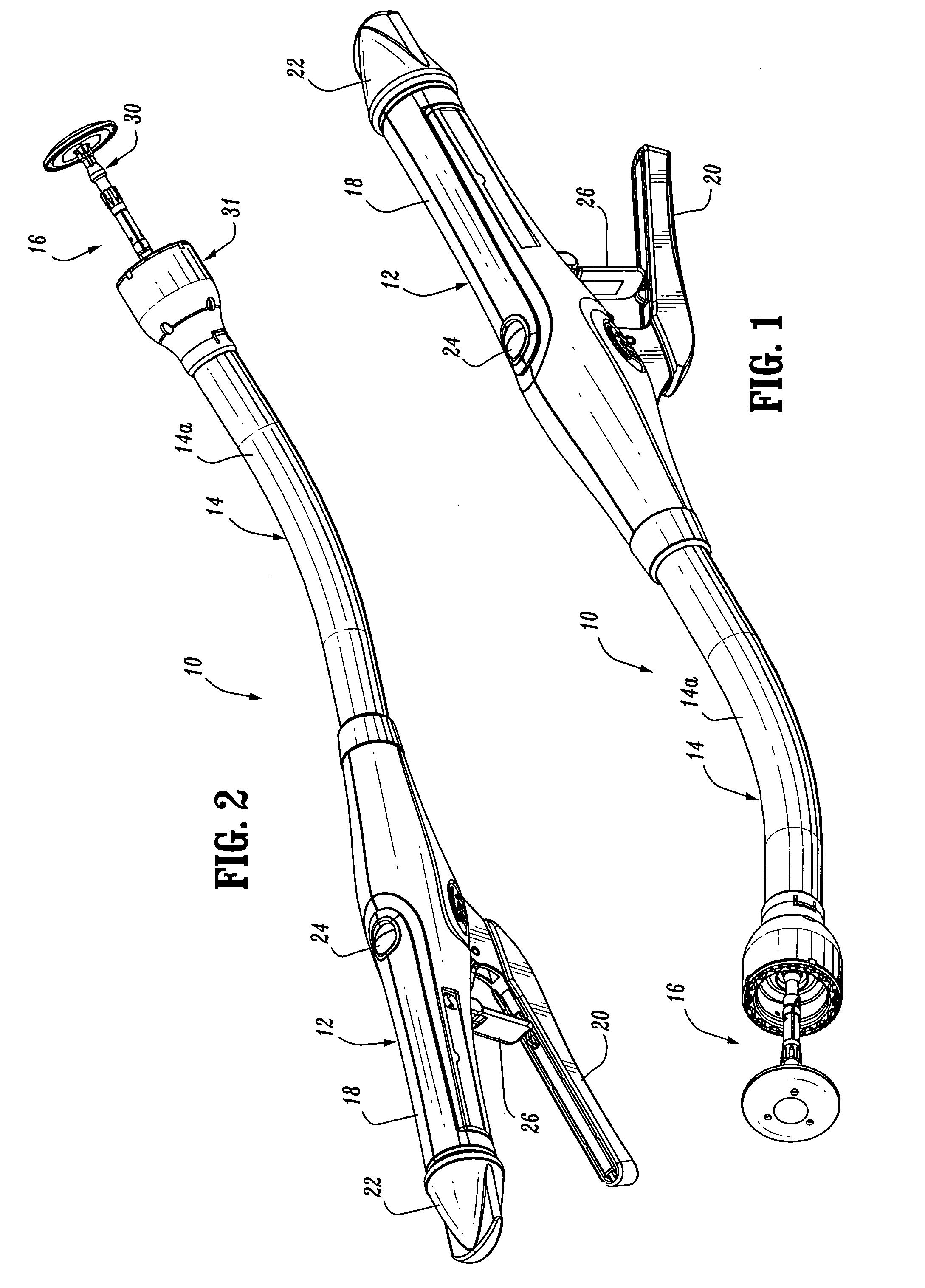

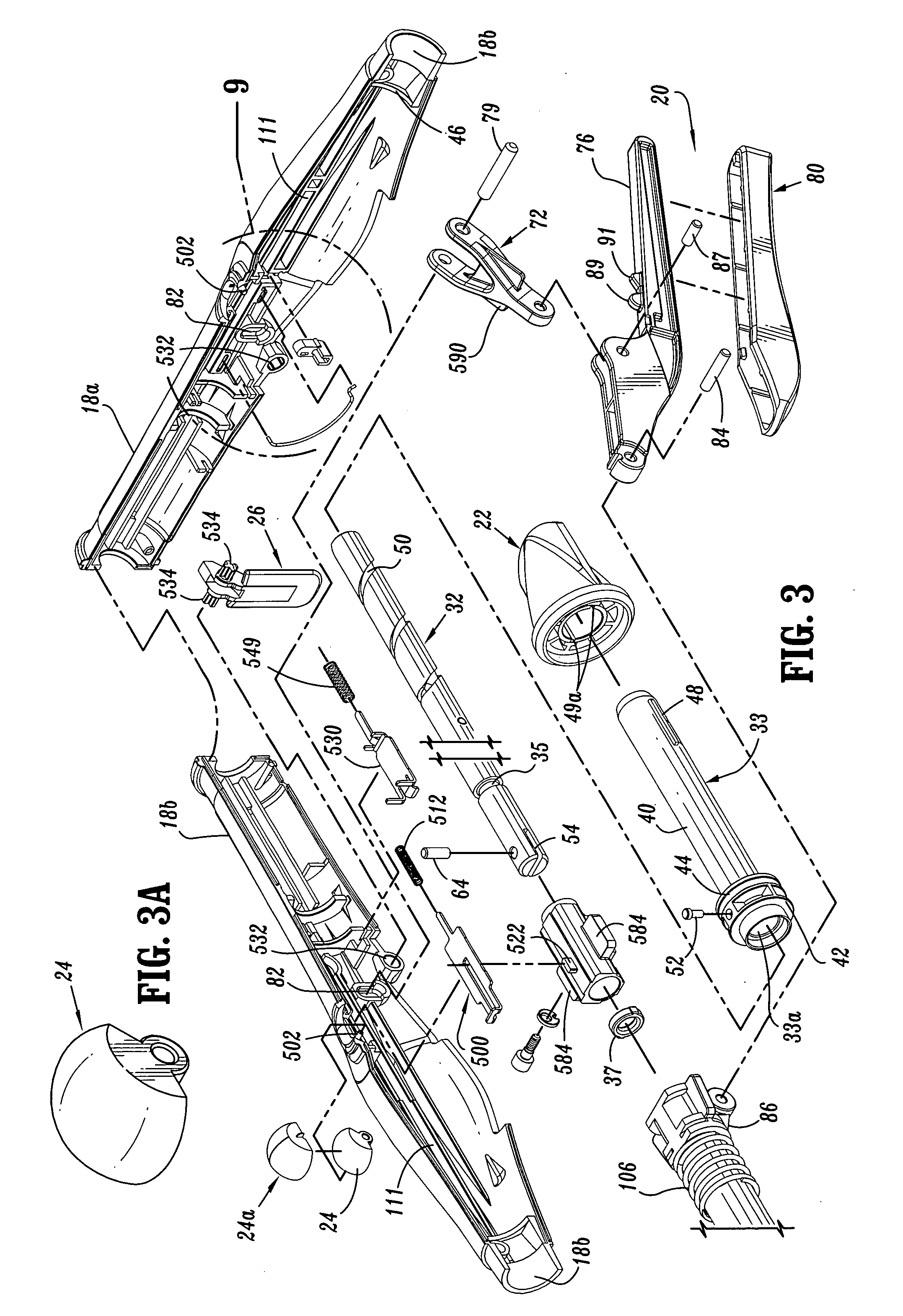

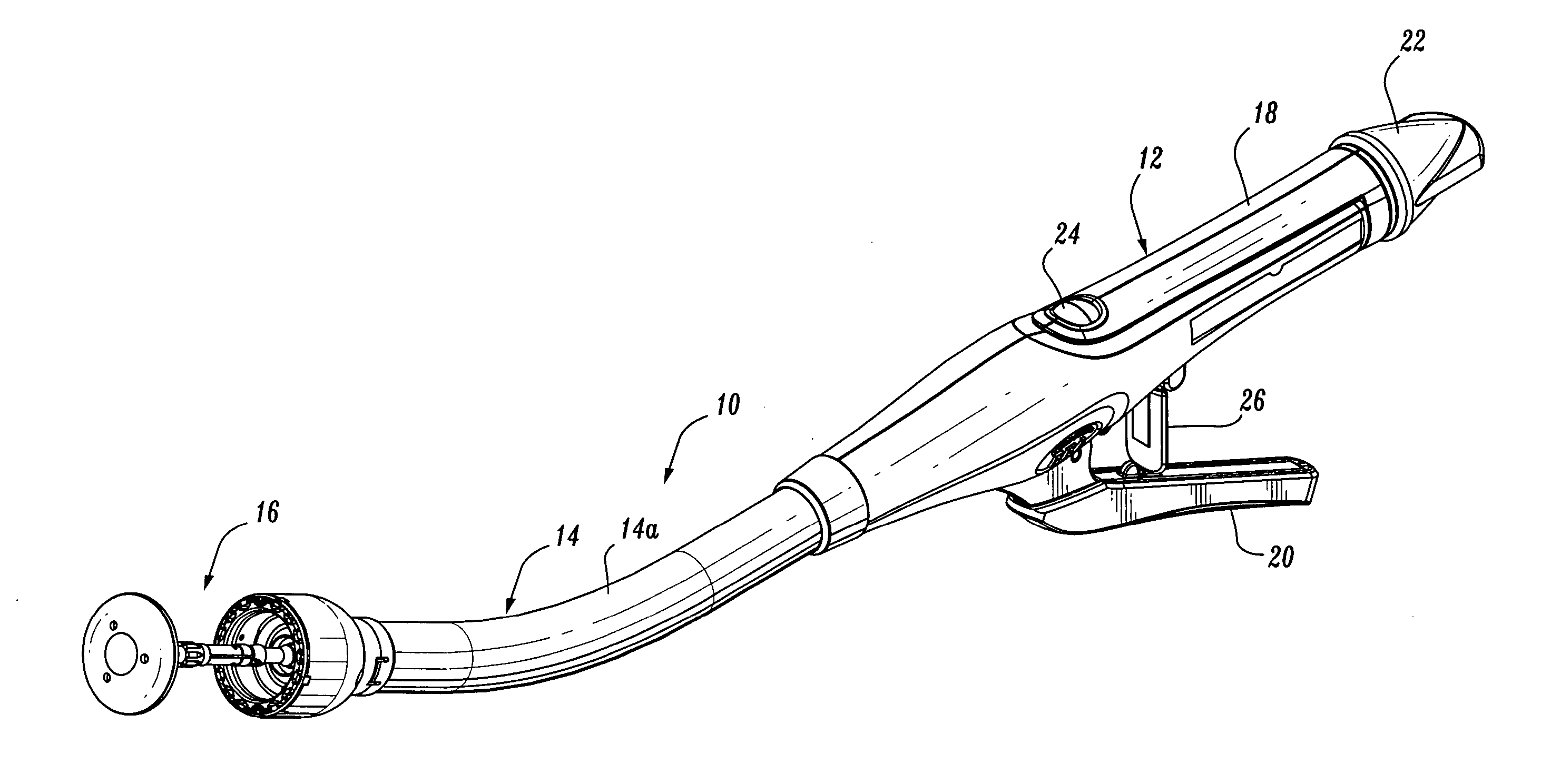

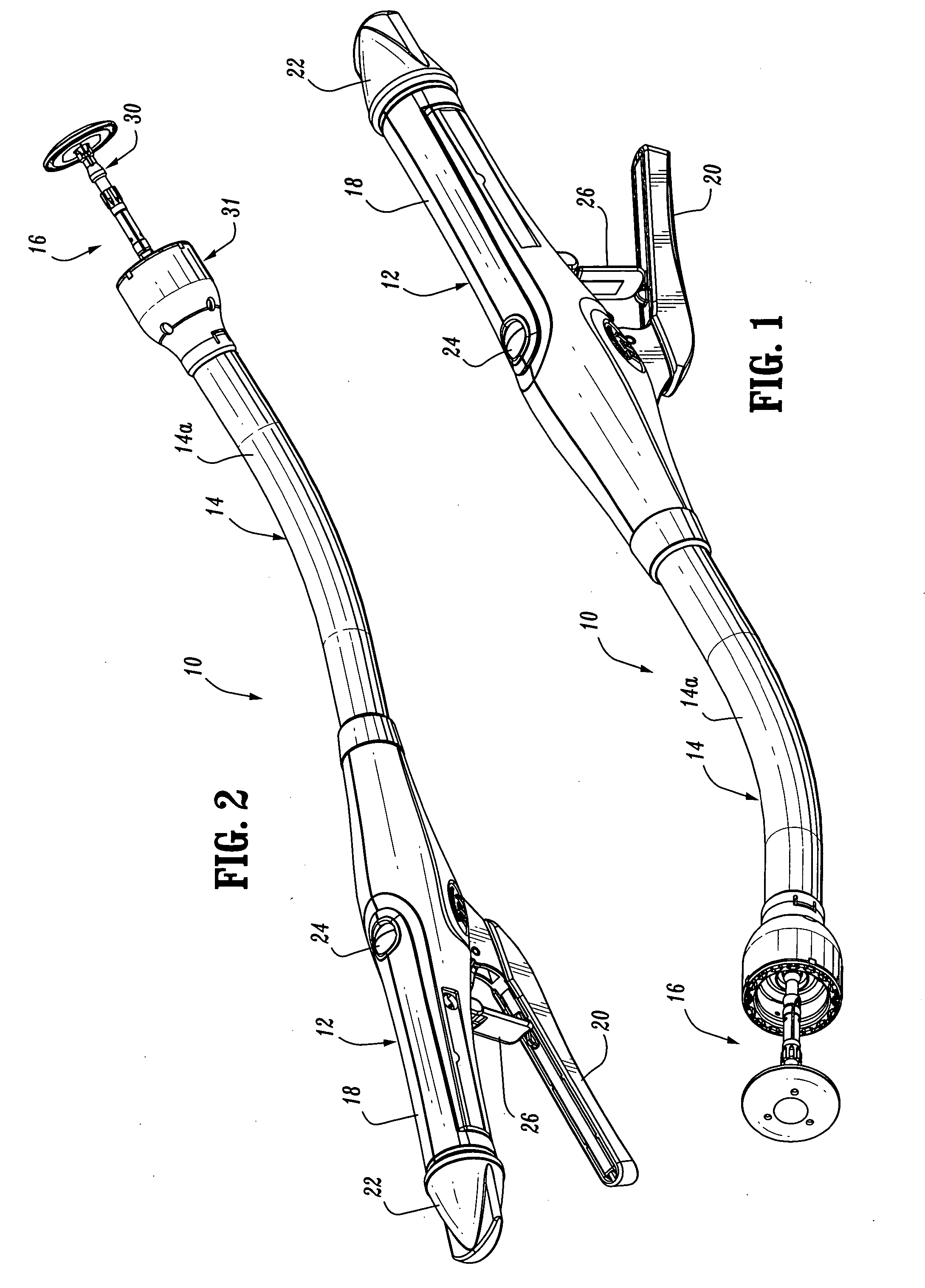

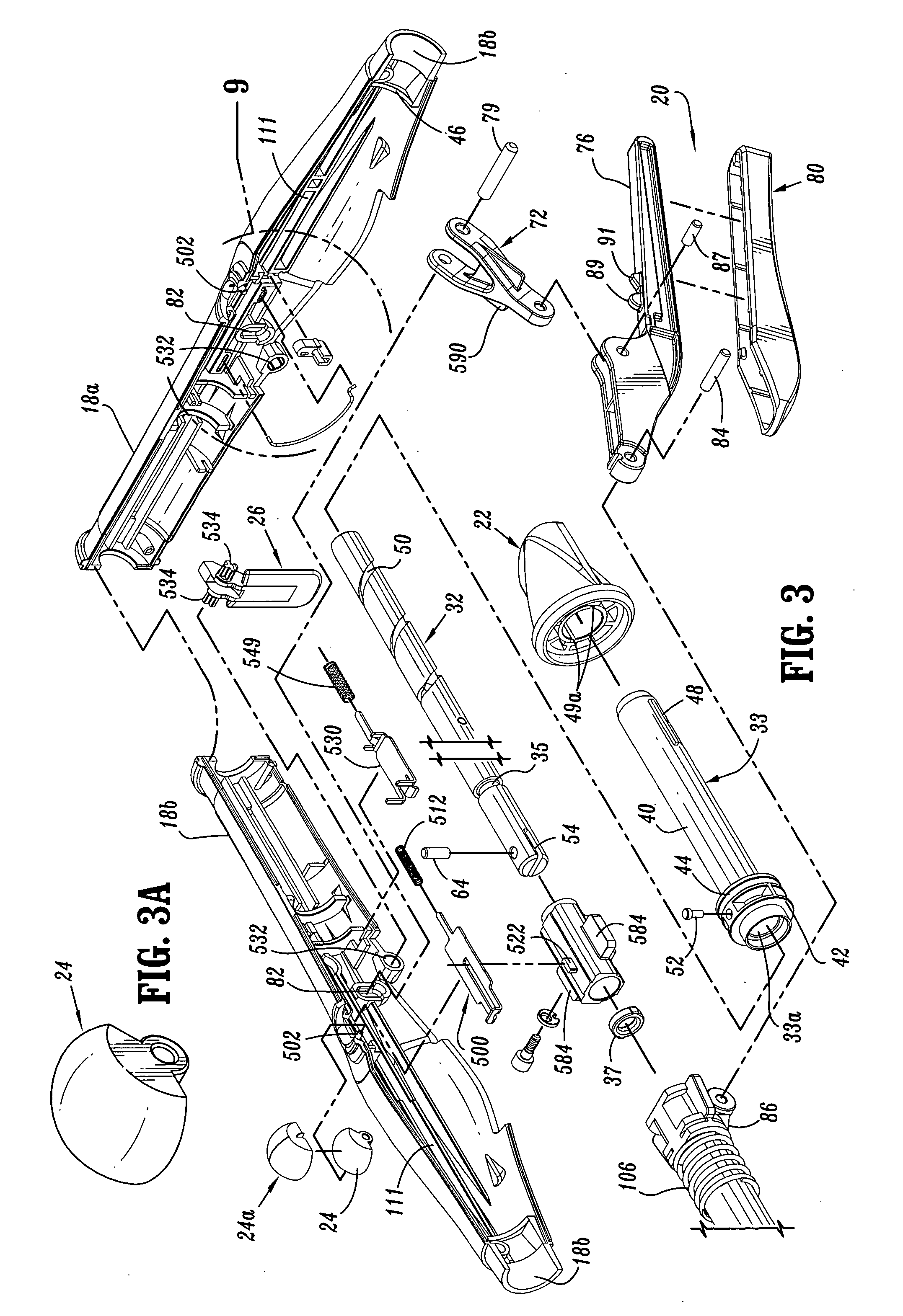

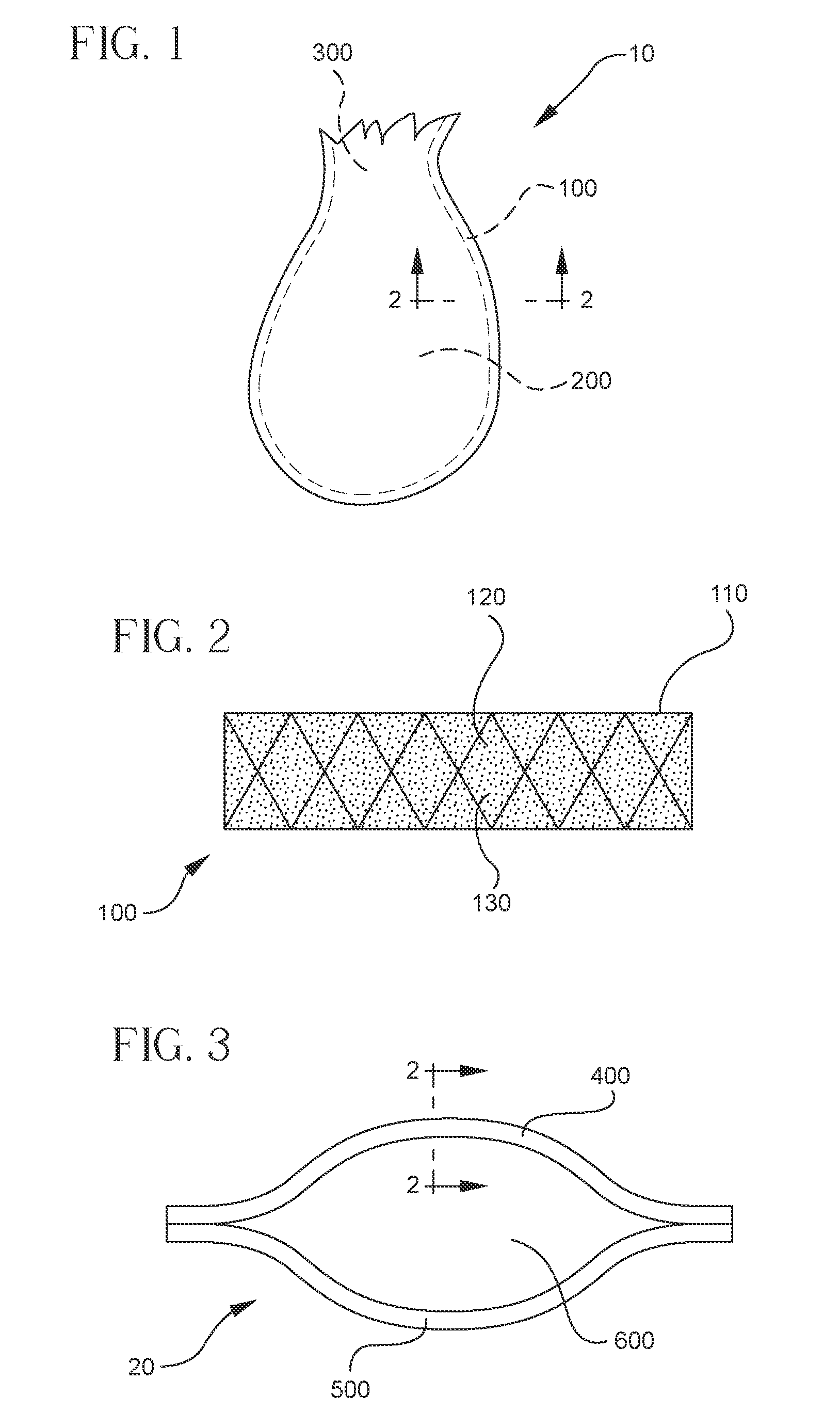

Surgical stapling device

ActiveUS7168604B2Enhanced advantageReduce firing forceSuture equipmentsStapling toolsDilatorSurgical site

A surgical stapling device is disclosed for the treatment of internal hemorrhoids. The surgical stapling device includes a handle portion, an elongated body portion and a head portion including an anvil assembly and a shell assembly. The head portion includes an anvil assembly including a tiltable anvil which will tilt automatically after the device has been fired and unapproximated. The tiltable anvil provides a reduced anvil profile to reduce trauma during removal of the device after the anastomoses procedure has been performed. The anvil assembly of the stapling device may include an approximation mechanism having an anvil retainer including an elongated distal extension dimensioned to be telescopingly received within a longitudinal bore of an anvil center rod of the anvil assembly. The elongated distal extension is of a length to provide telescopic engagement with the anvil center rod without obstructing visualization of the surgical site. A kit including a surgical instrument having a removable anvil assembly and an anvil assembly insertion handle is also disclosed. The kit may also include a speculum, an anal dialator and / or an obturator.

Owner:TYCO HEALTHCARE GRP LP

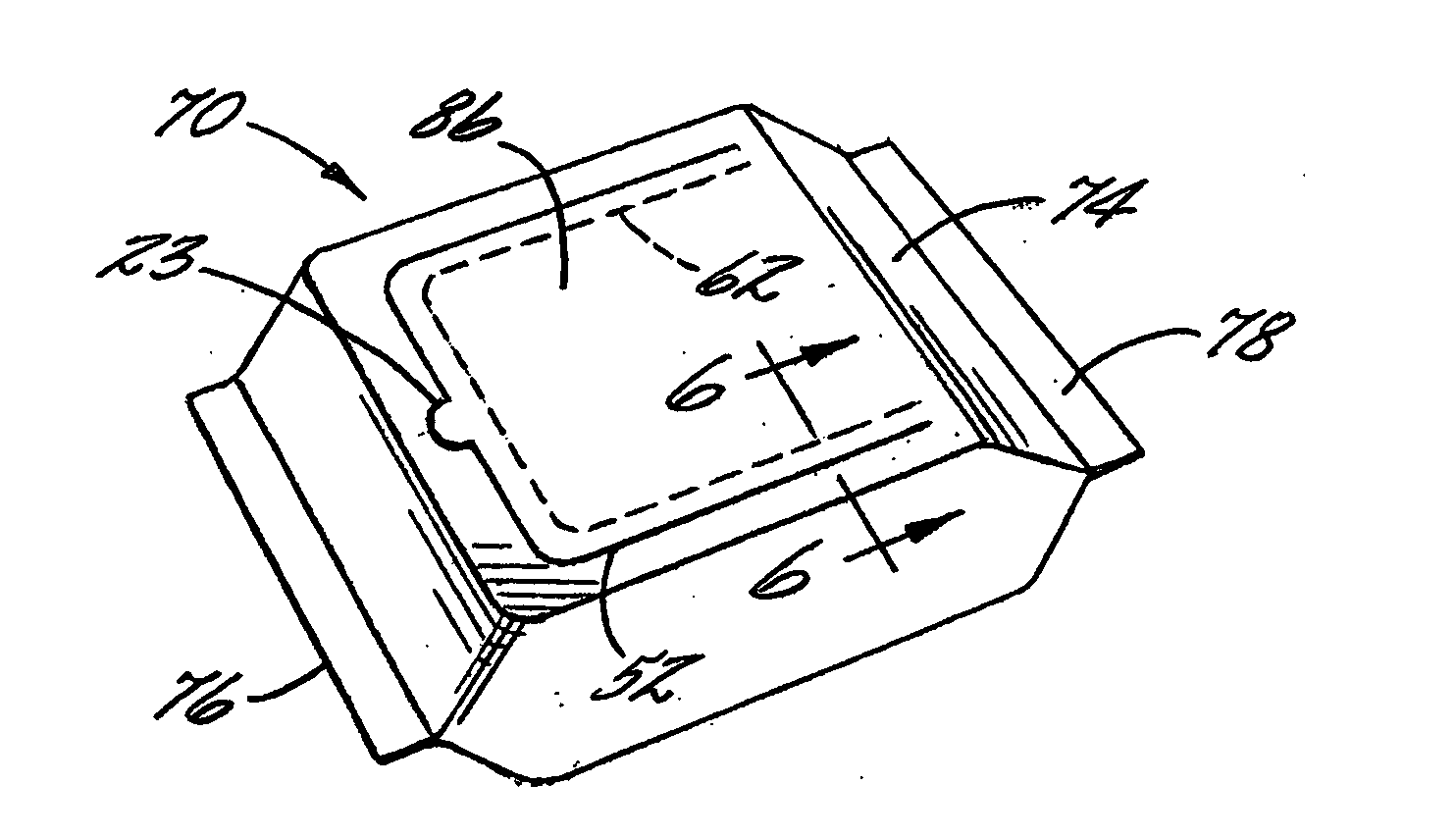

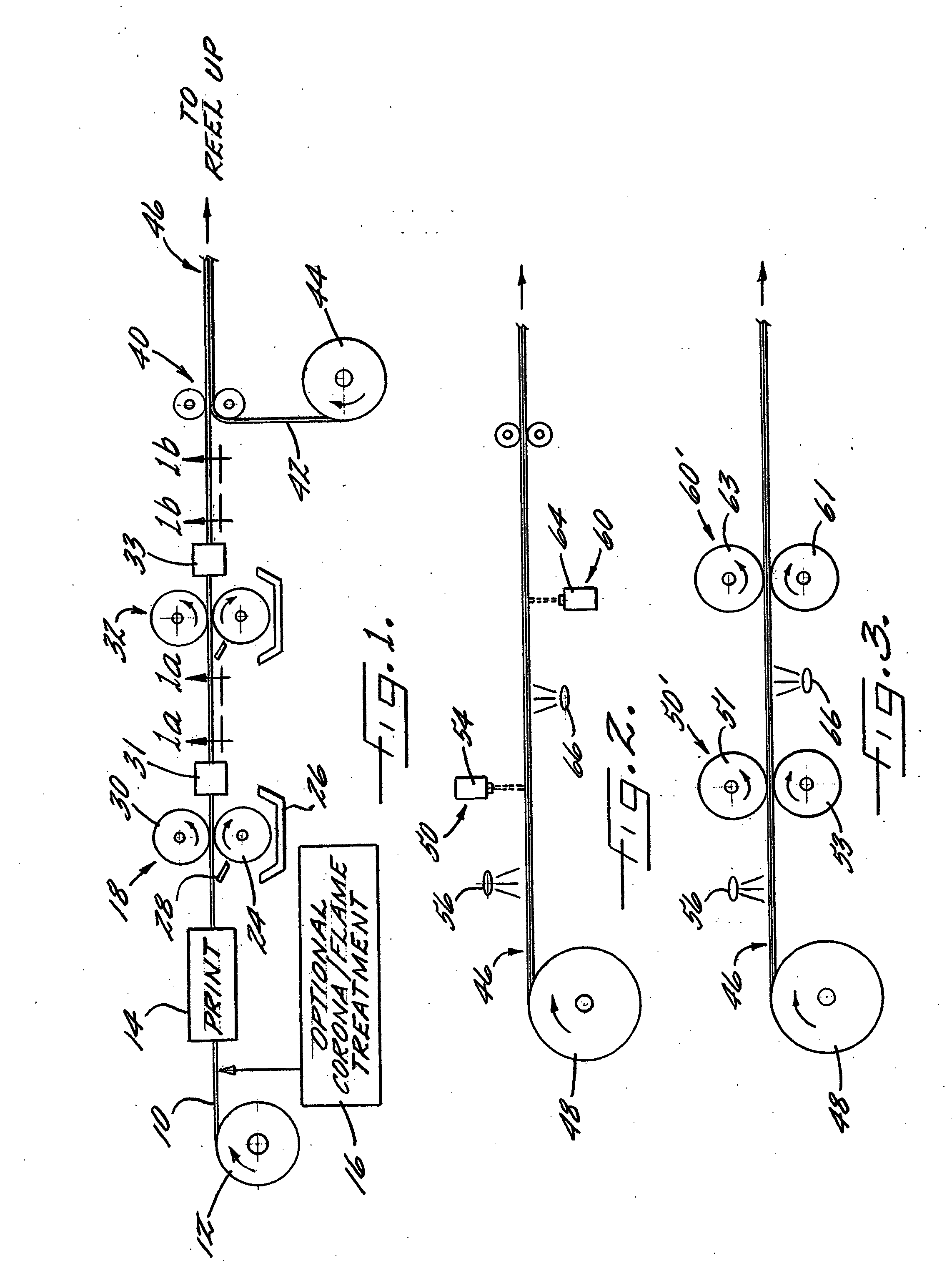

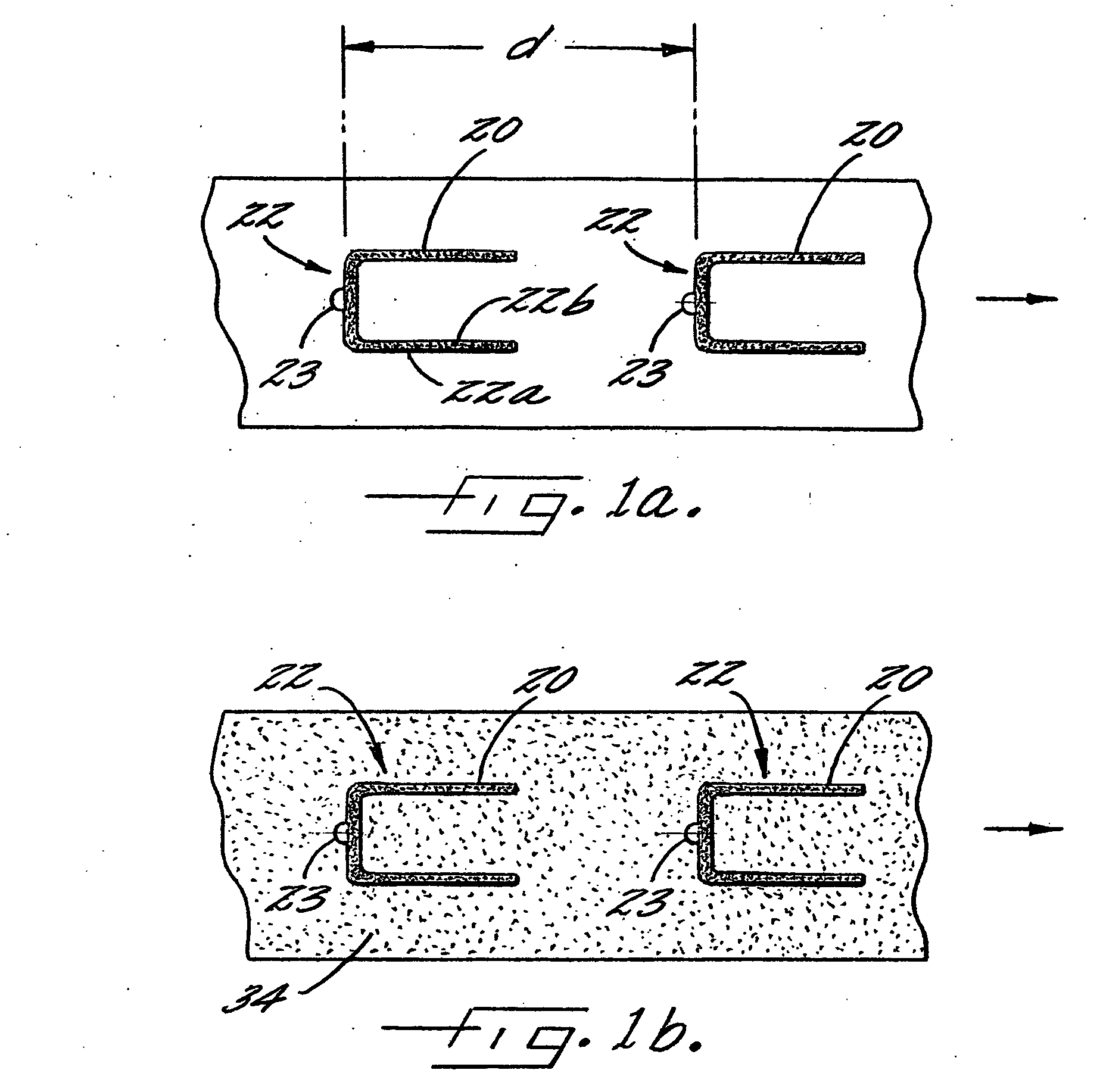

Flexible packaging structure with a built-in opening and reclose feature, and method for making same

ActiveUS20050276525A1Envelopes/bags making machineryWrappersMechanical engineeringPressure sensitive

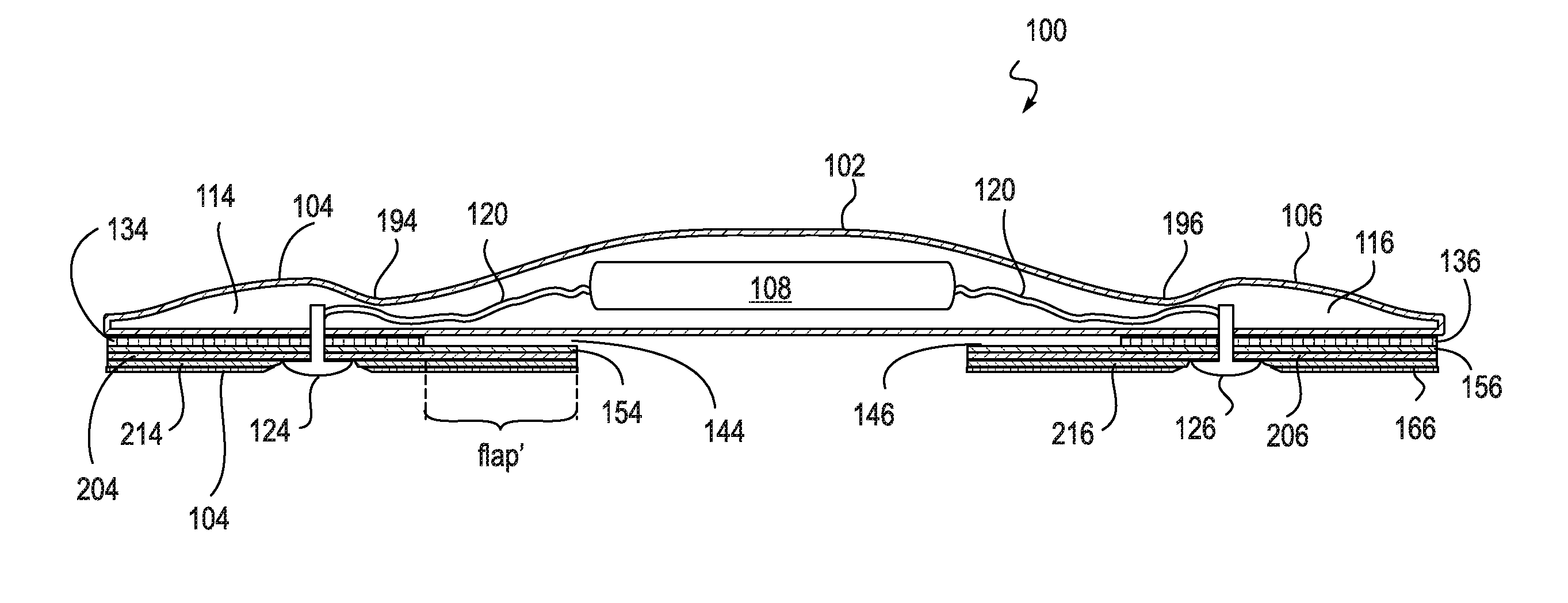

A flexible packaging laminate is formed to have a built-in opening and reclose feature by forming the laminate as a two-part structure having an outer structure joined in face-to-face relation with an inner structure. Score lines are formed in both structures to enable an opening to be formed through the laminate by lifting an opening portion (e.g., a flap or the like) of the two structures out of the plane of the laminate. The score line through the outer structure defines a larger opening than the score line through the inner structure, such that a marginal region of the outer structure extends beyond the edge of the opening portion of the inner structure. A pressure-sensitive adhesive is used to re-adhere the marginal region to an underlying surface of the inner structure adjacent the opening through the laminate.

Owner:SONOCO DEV INC

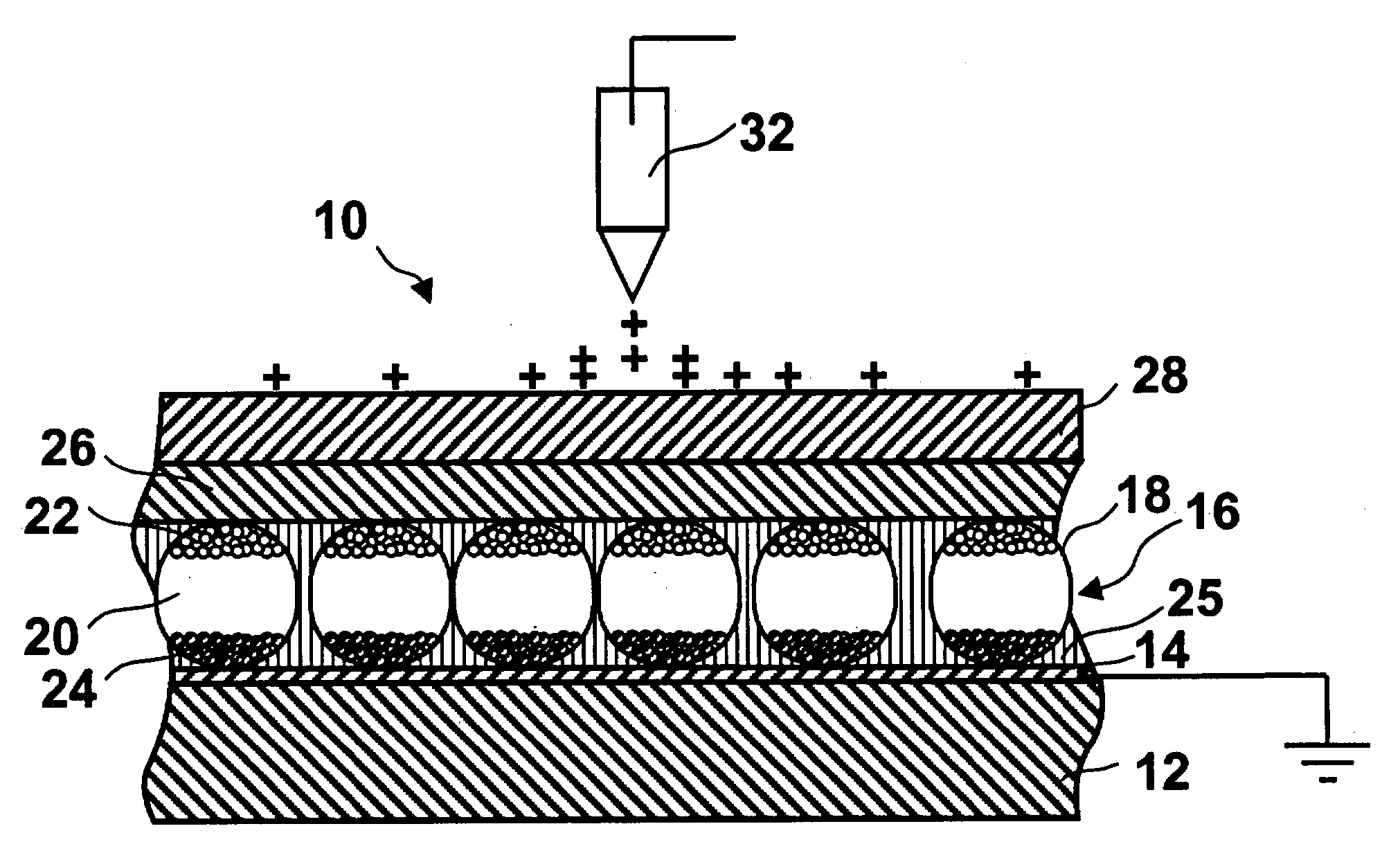

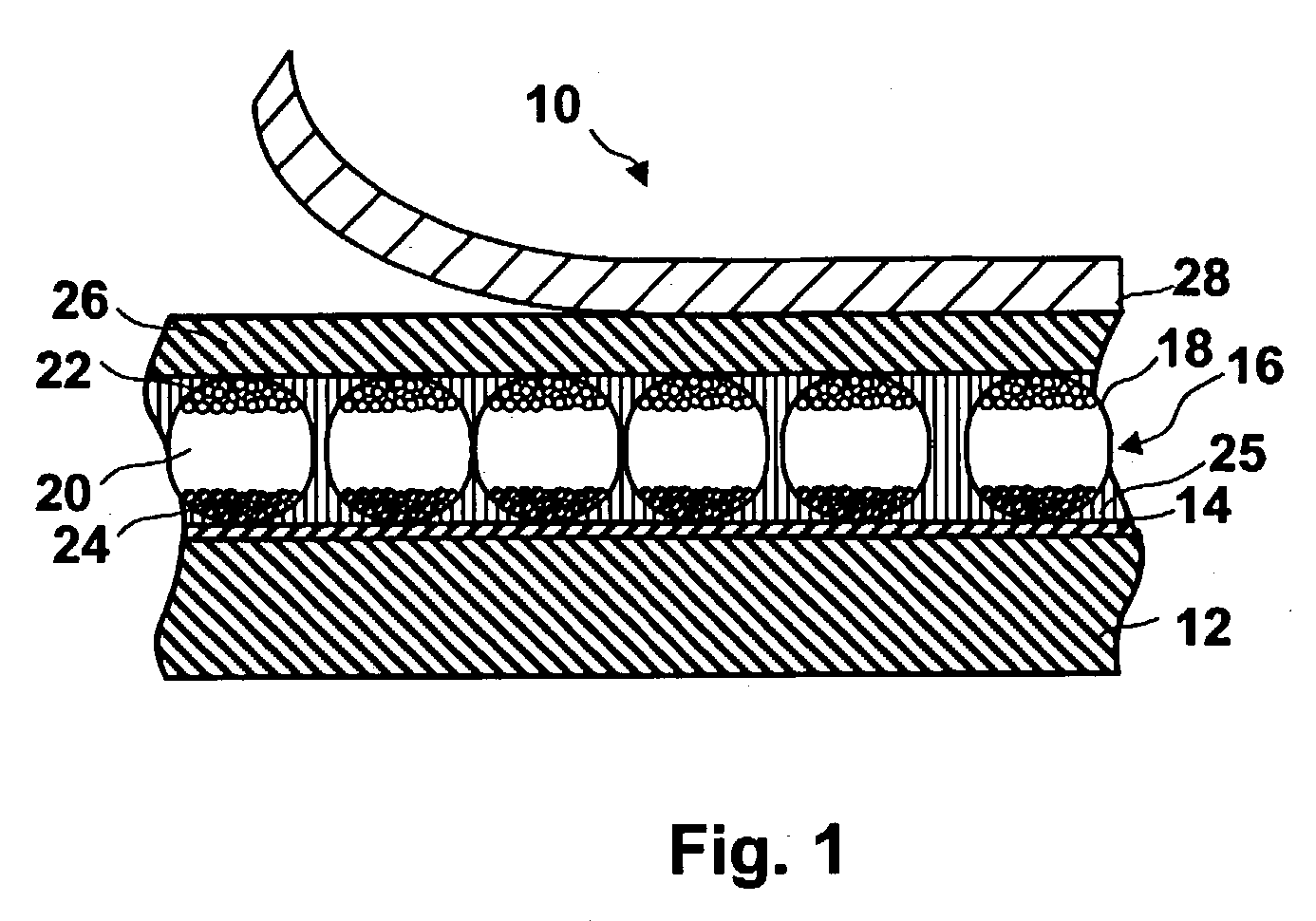

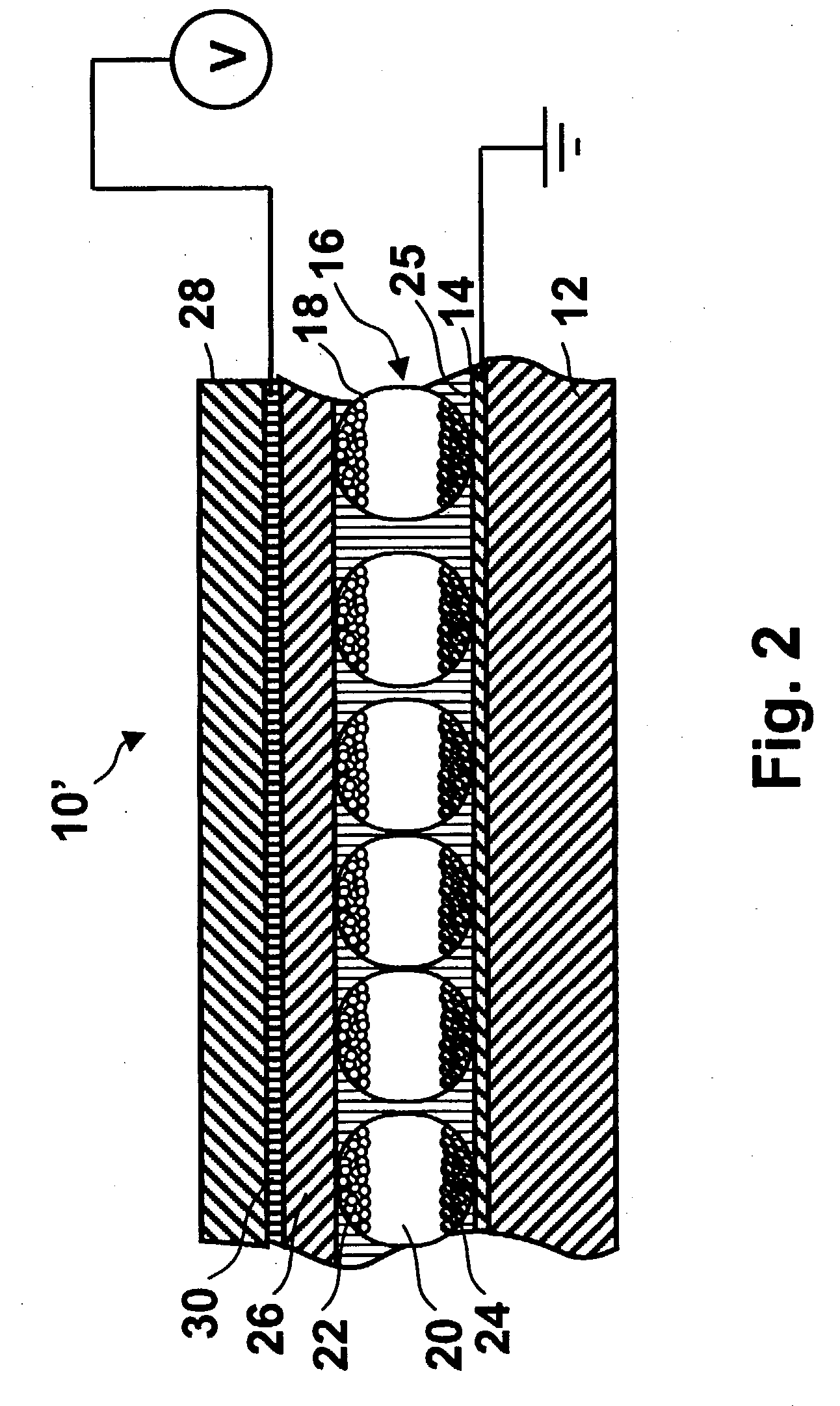

Components and methods for use in electro-optic displays

ActiveUS20040027327A1Avoid problemsLiquid surface applicatorsStatic indicating devicesElectricityDisplay device

A front plane laminate useful in the manufacture of electro-optic displays comprises, in order, a light-transmissive electrically-conductive layer, a layer of an electro-optic medium in electrical contact with the electrically-conductive layer, an adhesive layer and a release sheet. This front plane laminate can be prepared as a continuous web, cut to size, the release sheet removed and the laminate laminated to a backplane to form a display. Methods for providing conductive vias through the electro-optic medium and for testing the front plane laminate are also described.

Owner:E INK CORPORATION

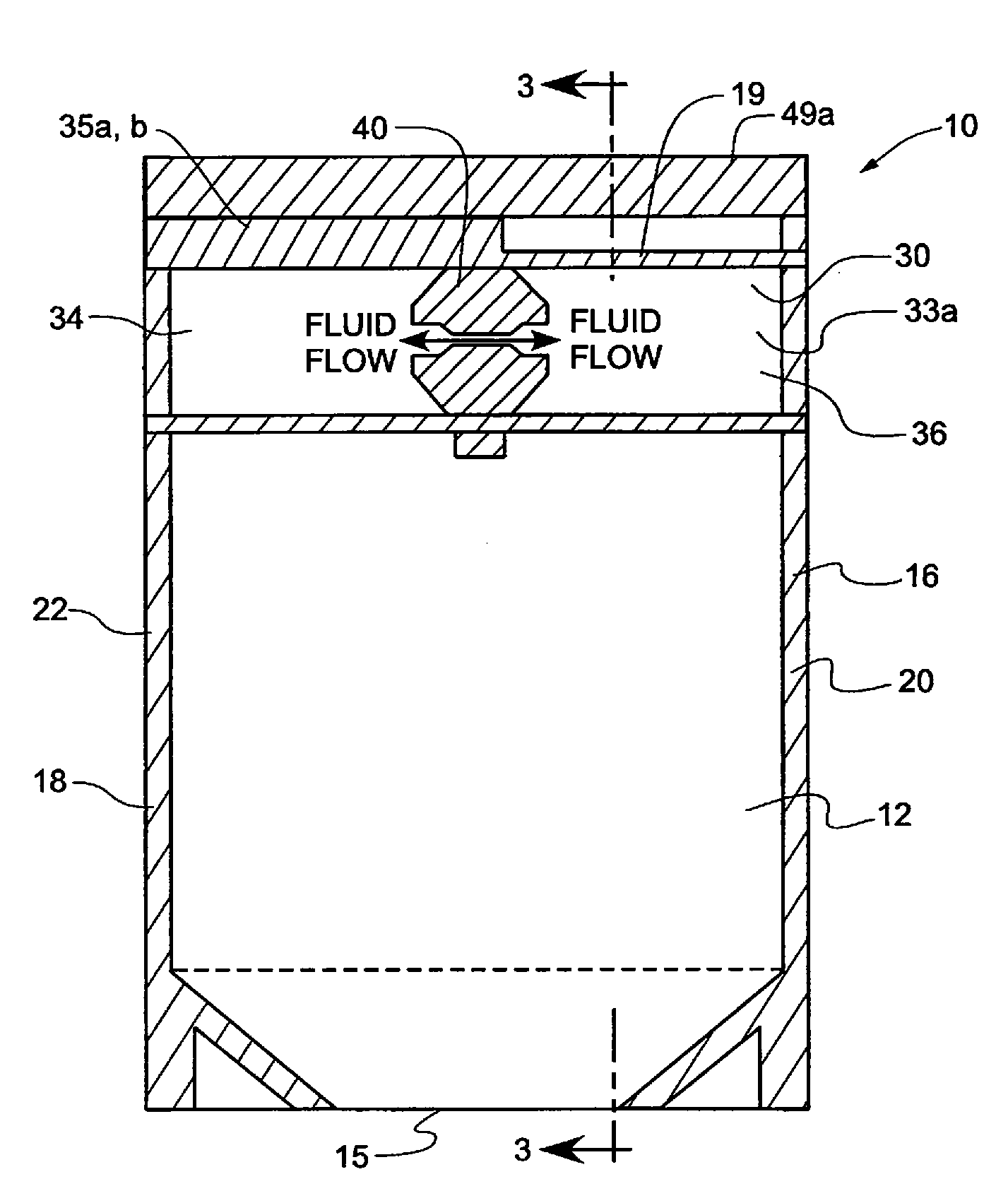

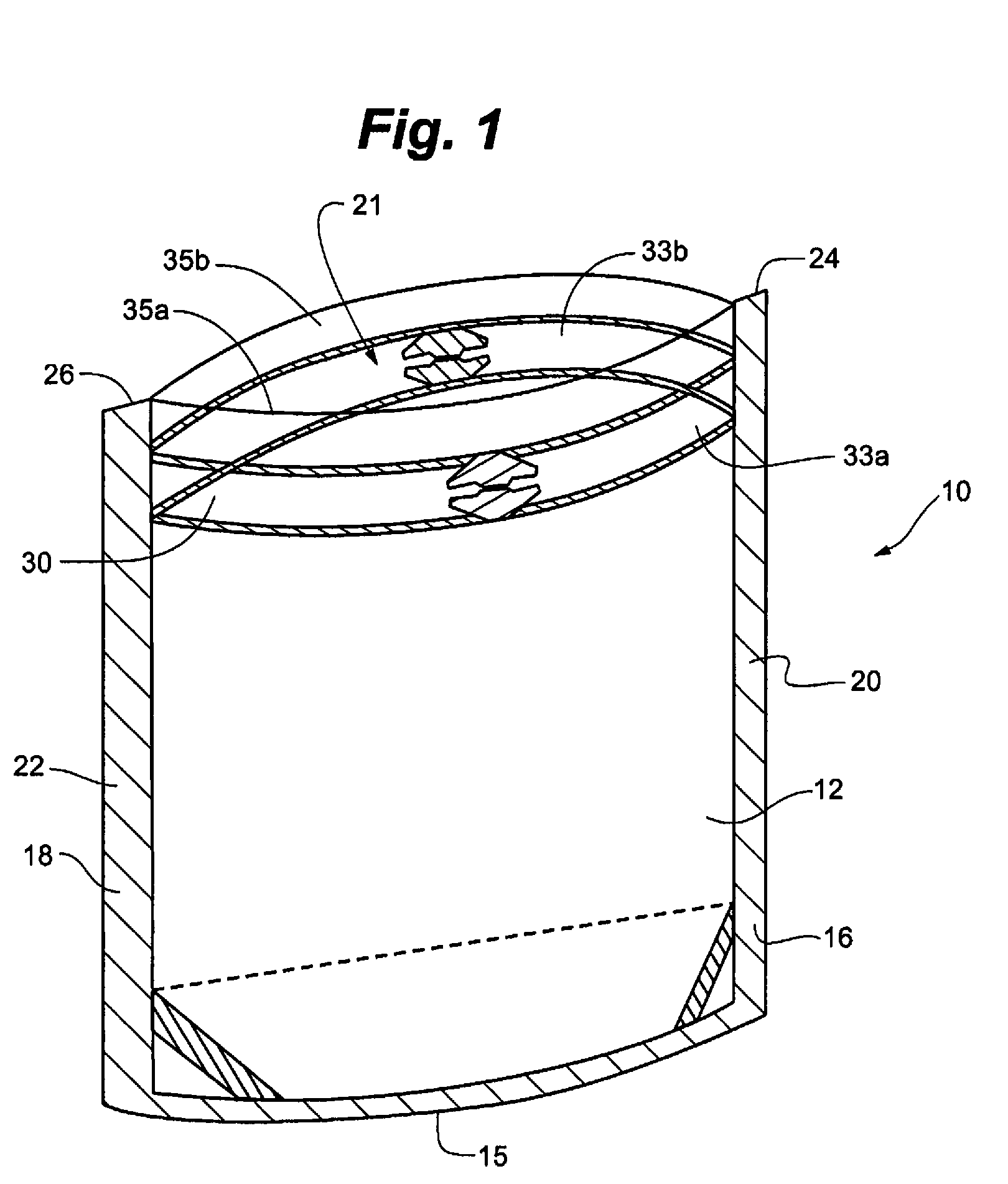

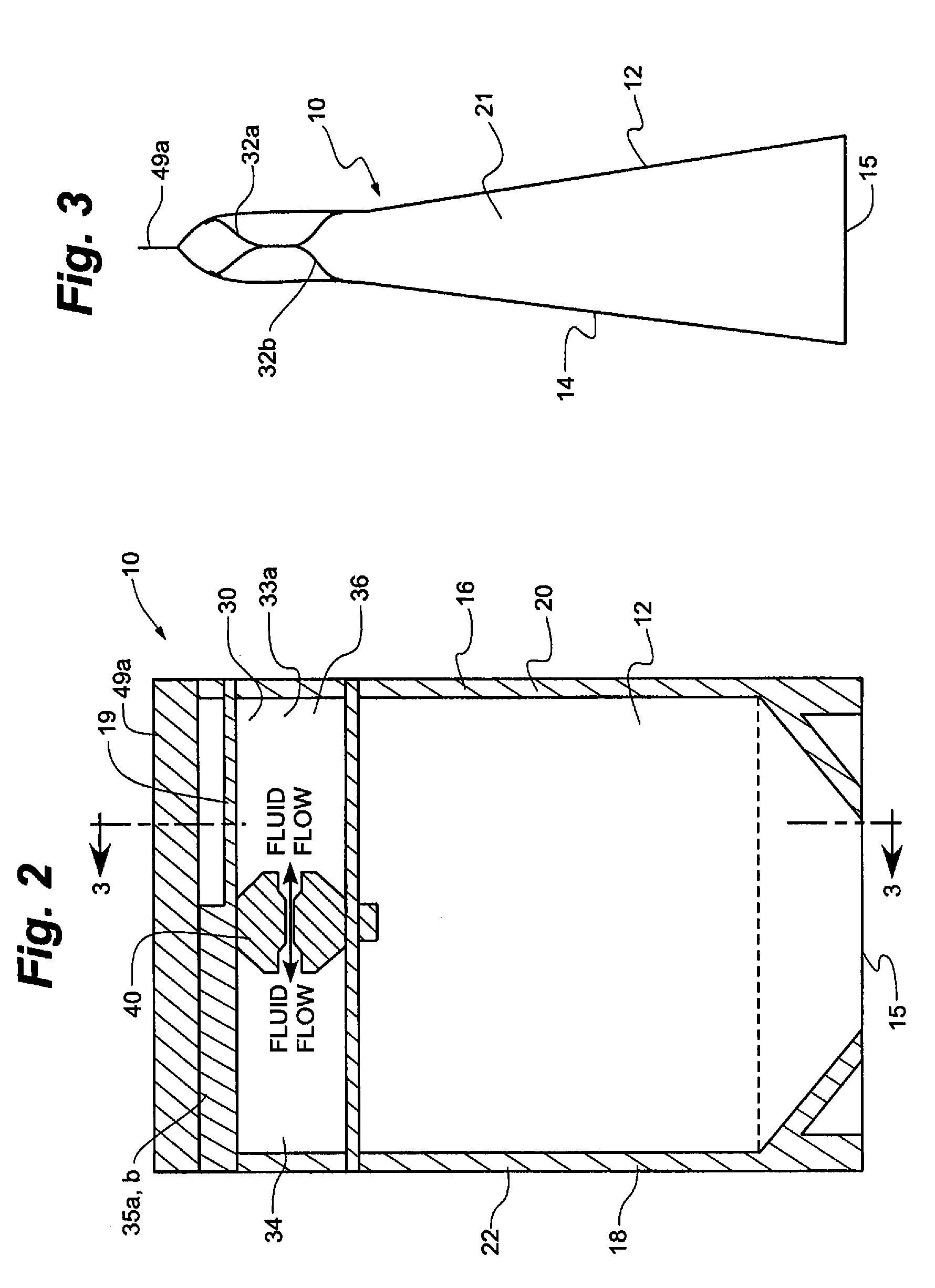

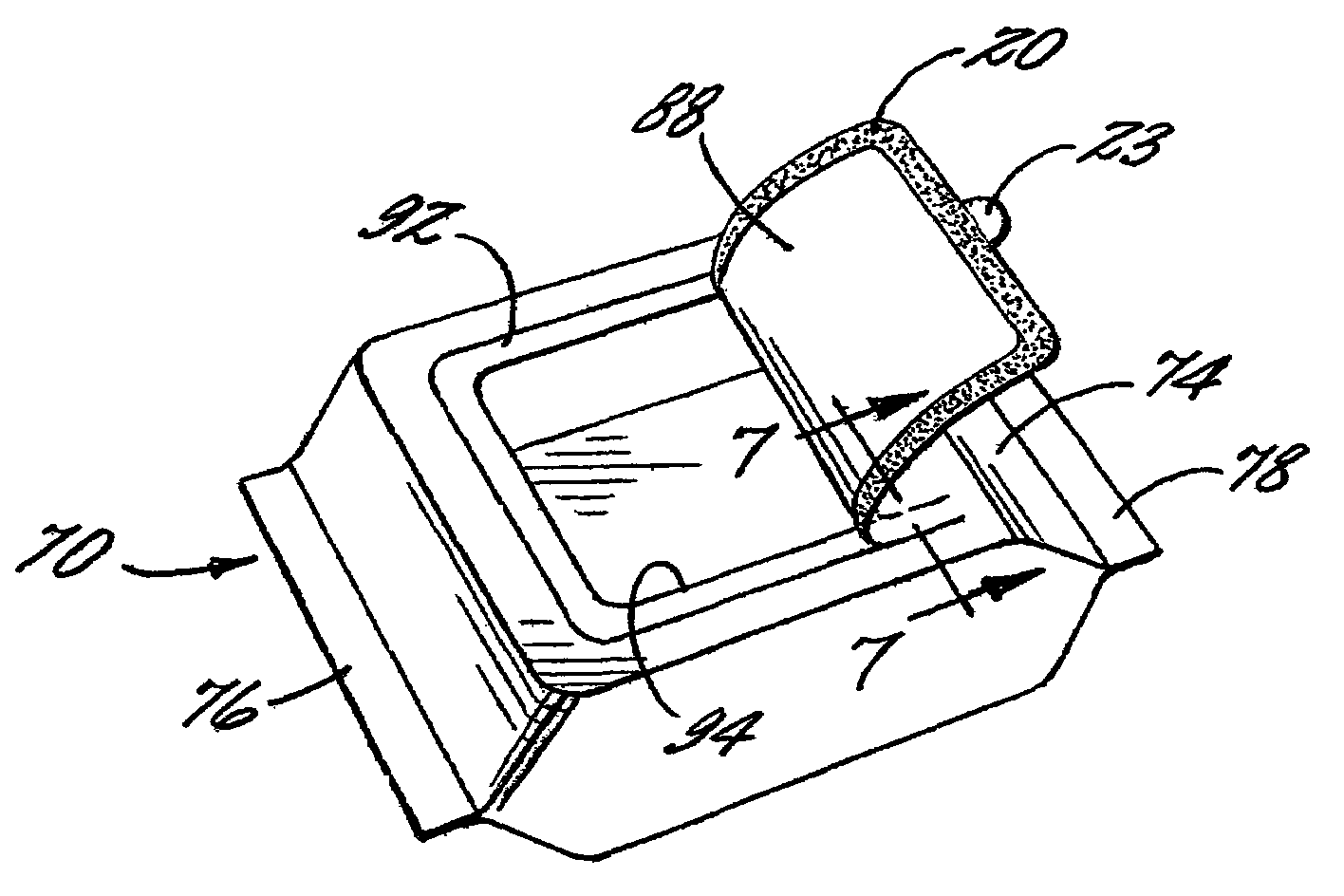

Package having a fluid actuated closure

ActiveUS7207717B2Solve the real problemEnvelopes/bags making machineryBag making operationsMechanical engineering

The package generally includes at least one front and back panel joined at least partially together to define an interior accessible through an access opening. The interior is capable of storing and dispensing product and other objects or materials. Further, at least one web member can be joined to each of the front and back panel portions respectively to form at least two generally parallel chambers and / or channels that extend generally along at least a portion of the access opening. In one embodiment, each of the chambers includes a reservoir or storage portion and a closure portion in fluid communication such that either the reservoir portion or the closure portion are generally inflated or expanded to correspondingly close or open the access opening.

Owner:STEELE MARK

Surgical stapling device

ActiveUS20050006433A1Increased mechanical advantageReduce firing forceSuture equipmentsStapling toolsSurgical siteEngineering

A surgical stapling device is disclosed for the treatment of internal hemorrhoids. The surgical stapling device includes a handle portion, an elongated body portion and a head portion including an anvil assembly and a shell assembly. The head portion includes an anvil assembly including a tiltable anvil which will tilt automatically after the device has been fired and unapproximated. The tiltable anvil provides a reduced anvil profile to reduce trauma during removal of the device after the anastomoses procedure has been performed. The anvil assembly of the stapling device may include an approximation mechanism having an anvil retainer including an elongated distal extension dimensioned to be telescopingly received within a longitudinal bore of an anvil center rod of the anvil assembly. The elongated distal extension is of a length to provide telescopic engagement with the anvil center rod without obstructing visualization of the surgical site. A kit including a surgical instrument having a removable anvil assembly and an anvil assembly insertion handle is also disclosed. The kit may also include a speculum, an anal dialator and / or an obturator.

Owner:TYCO HEALTHCARE GRP LP

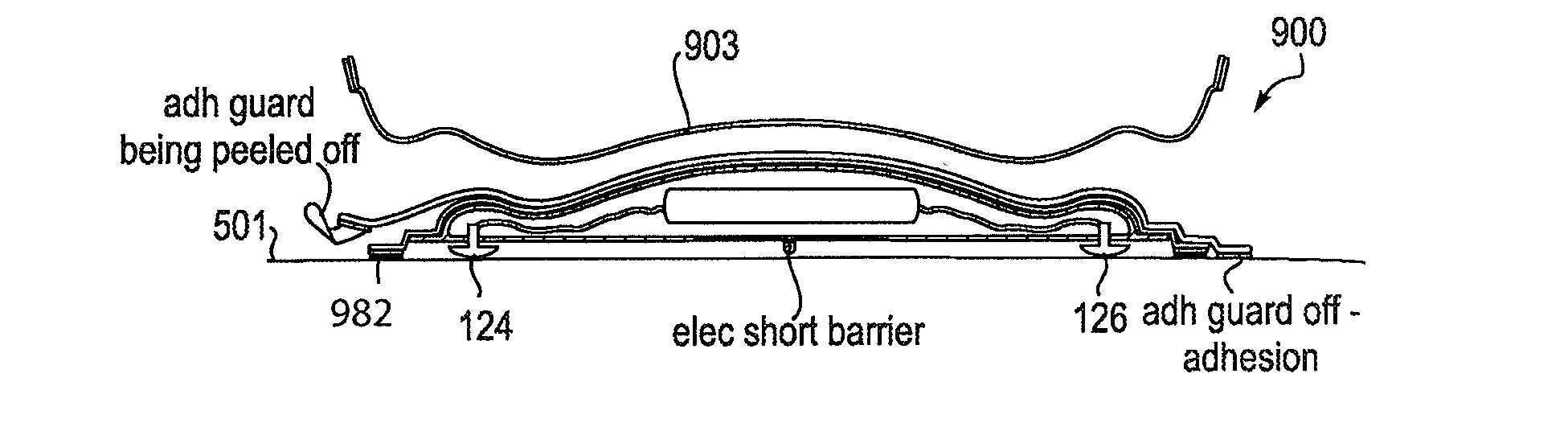

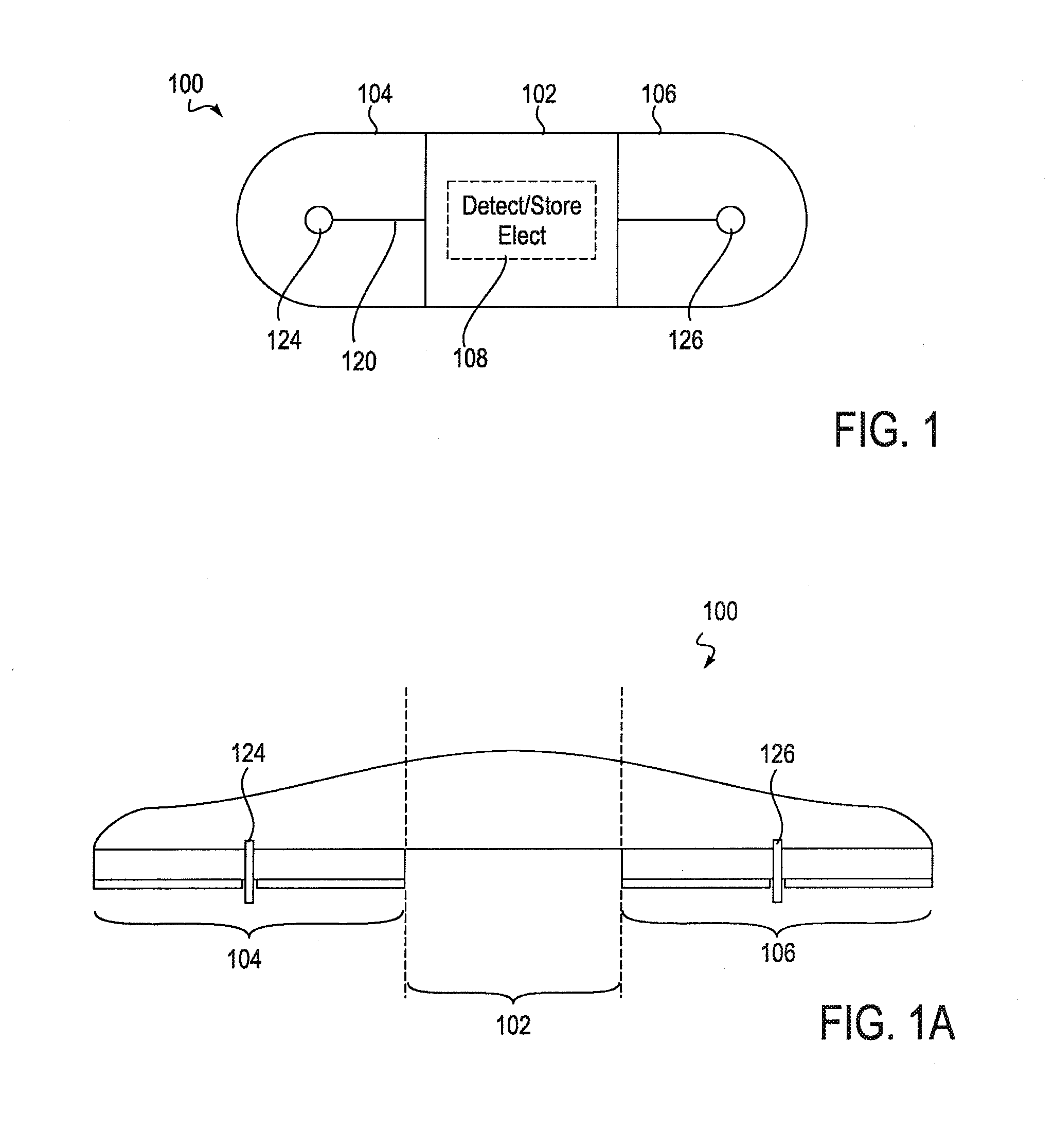

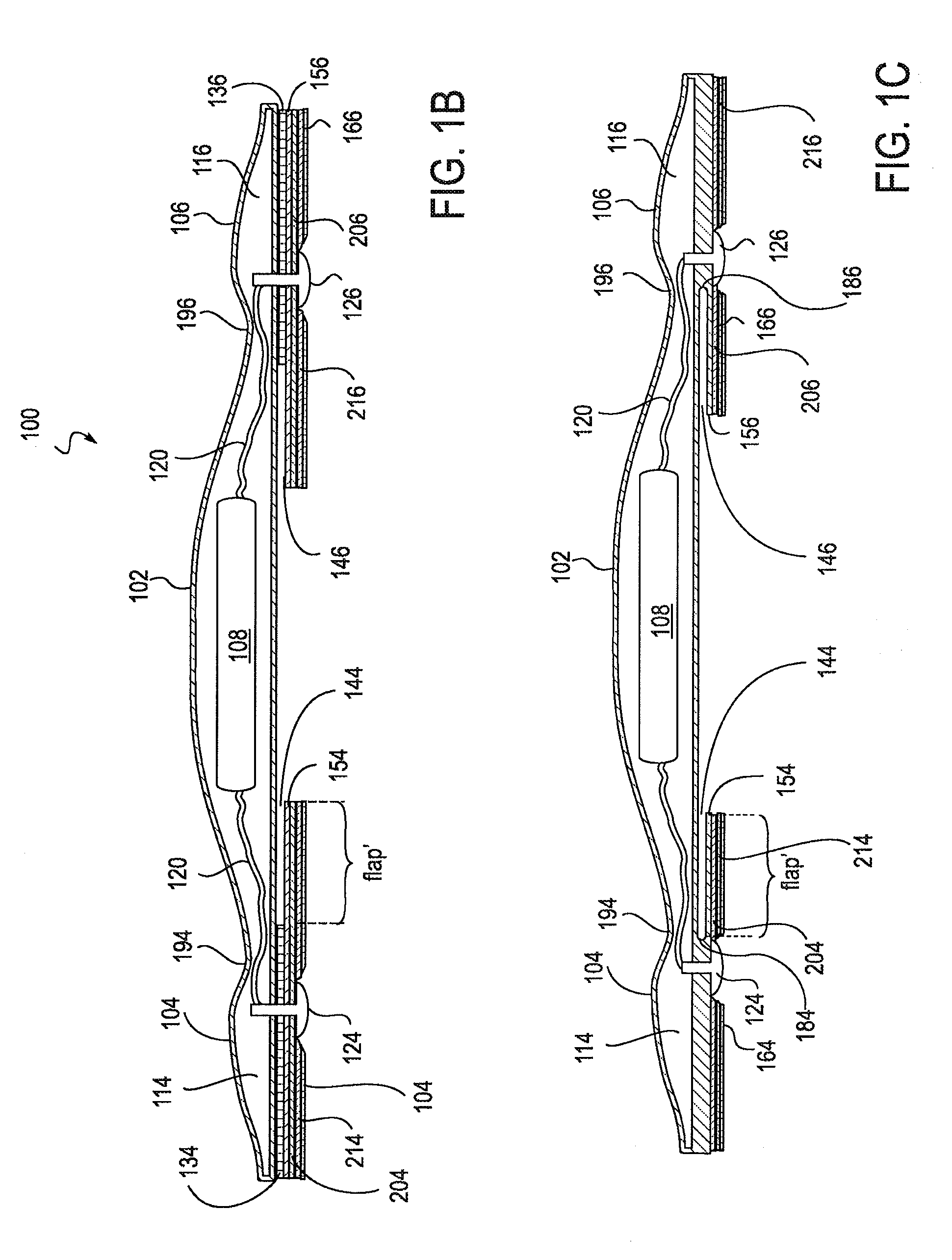

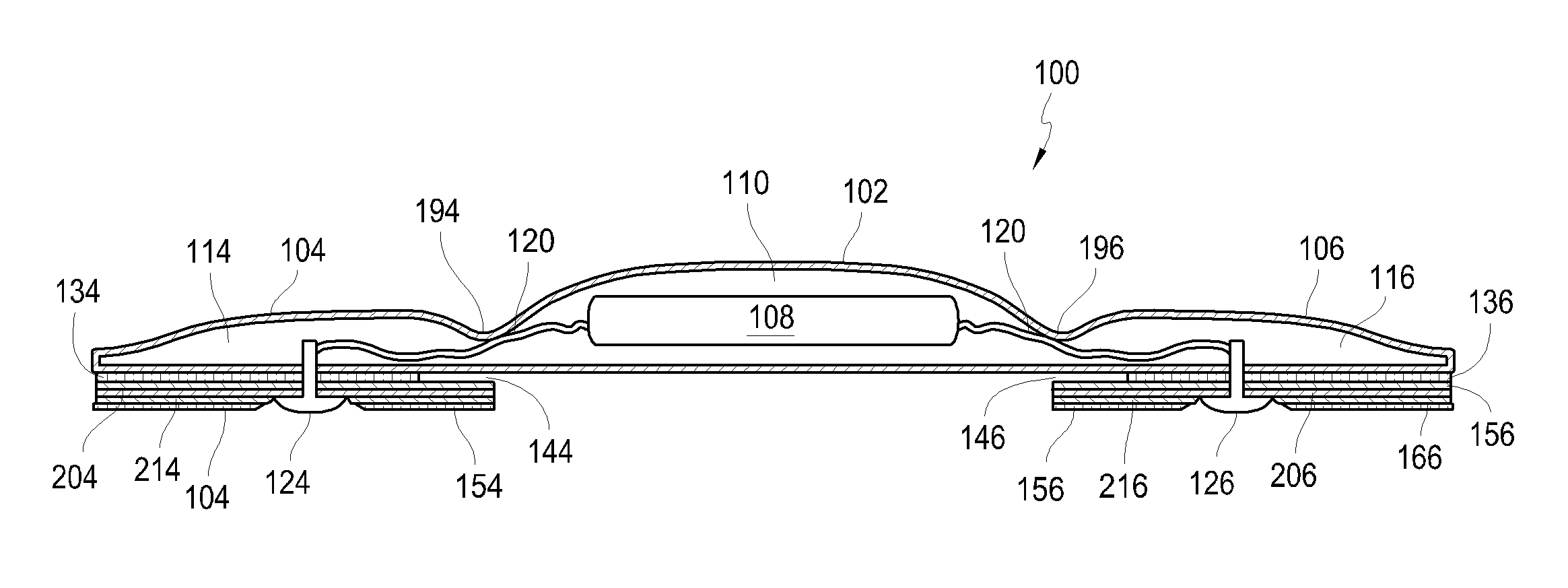

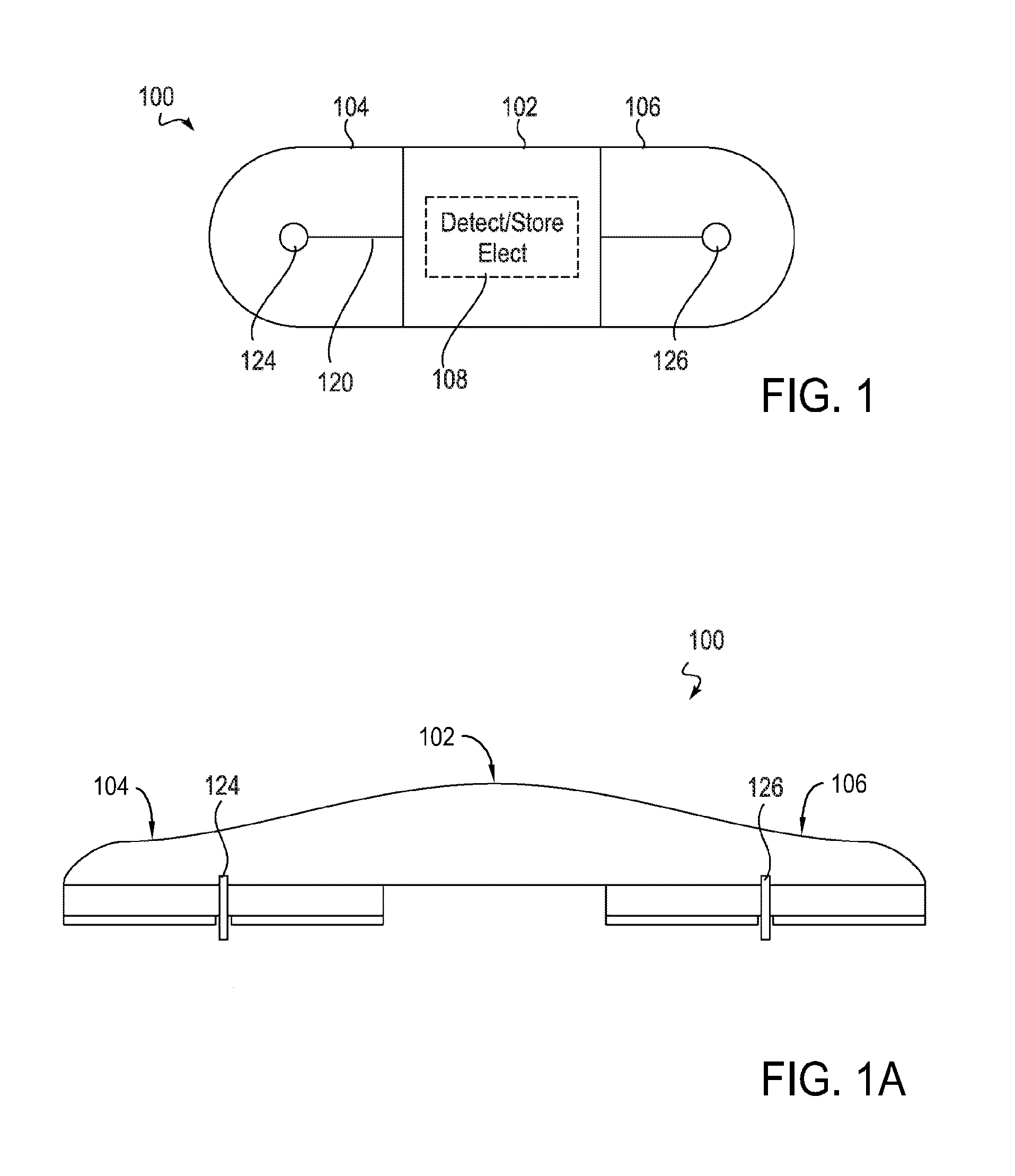

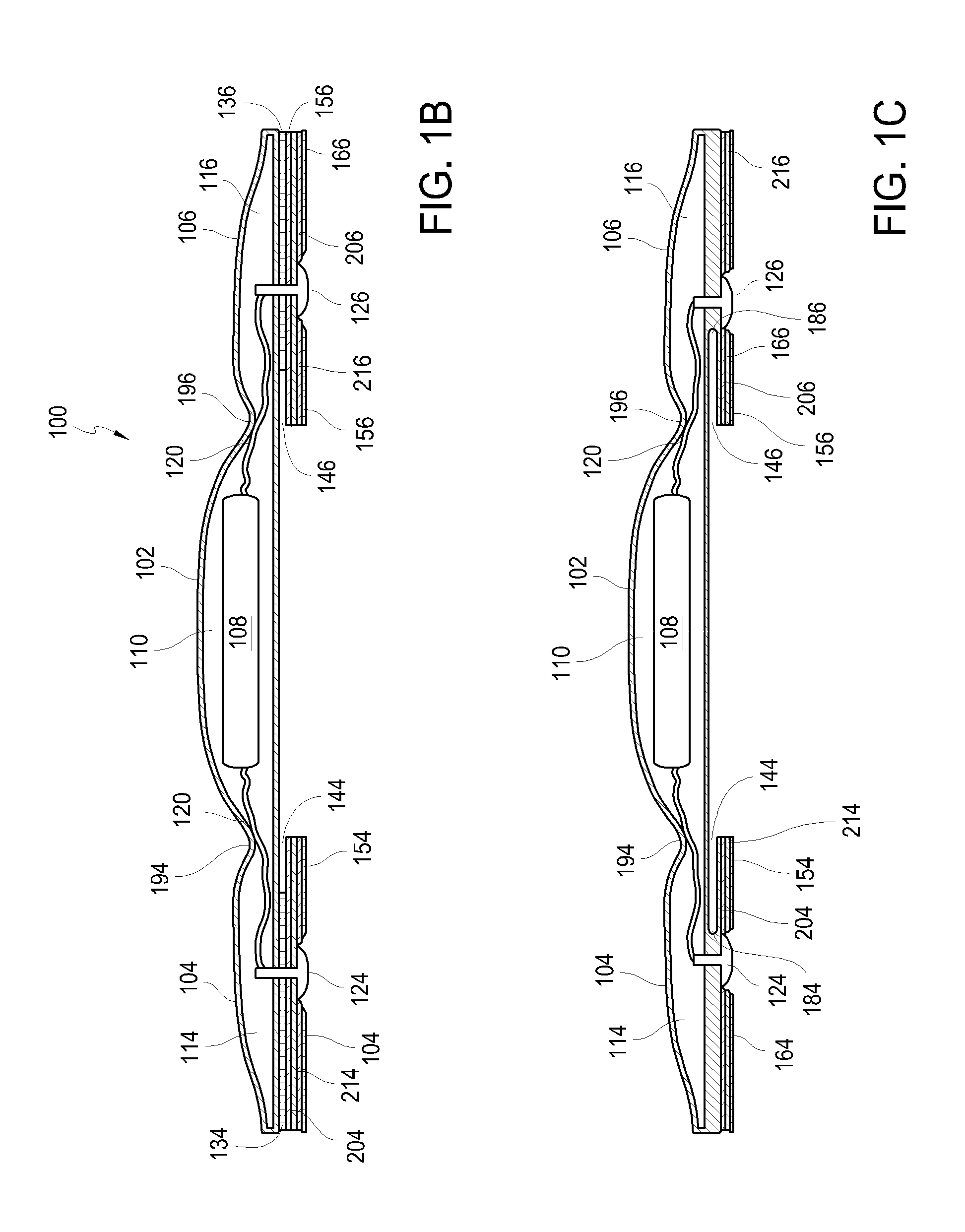

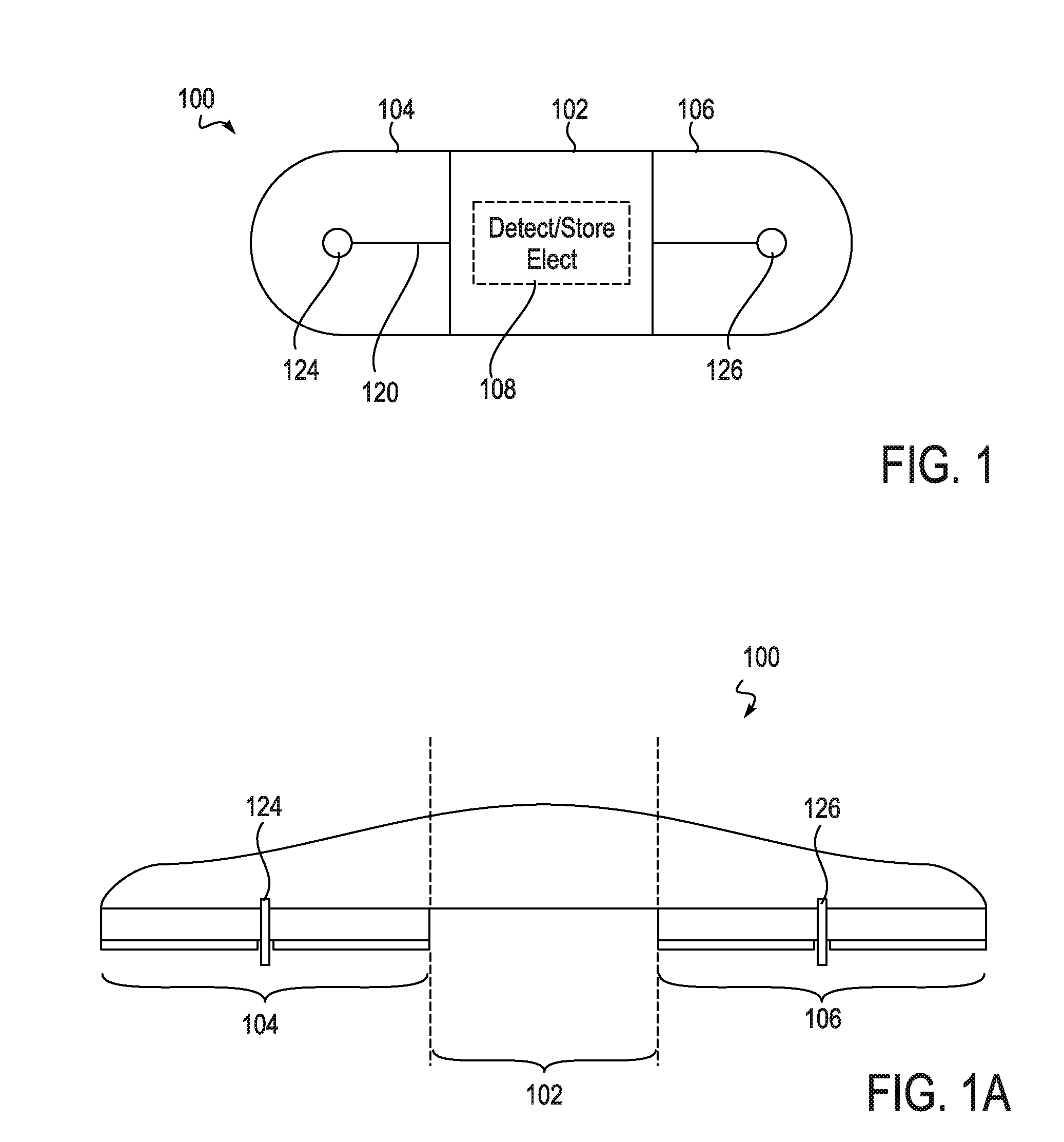

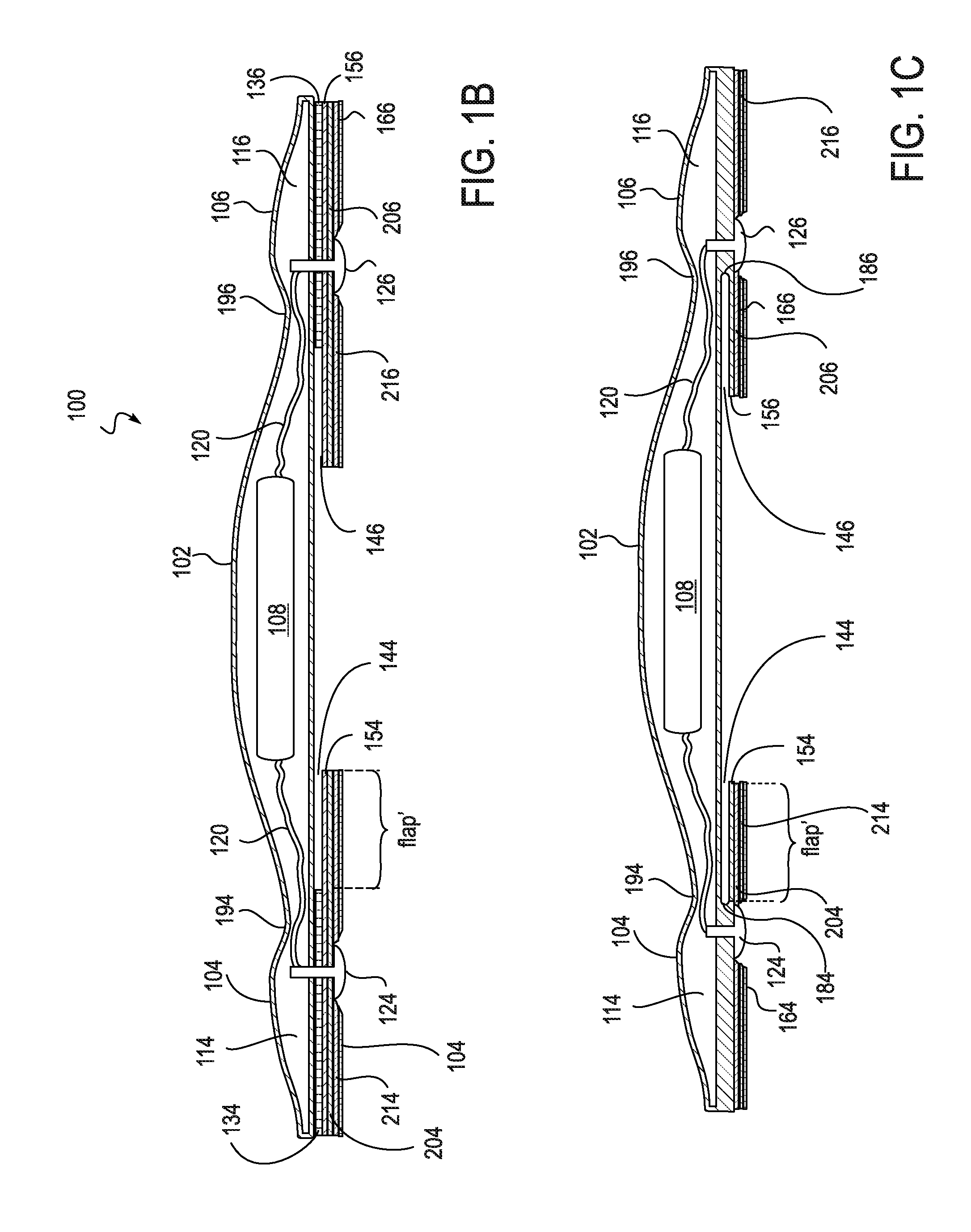

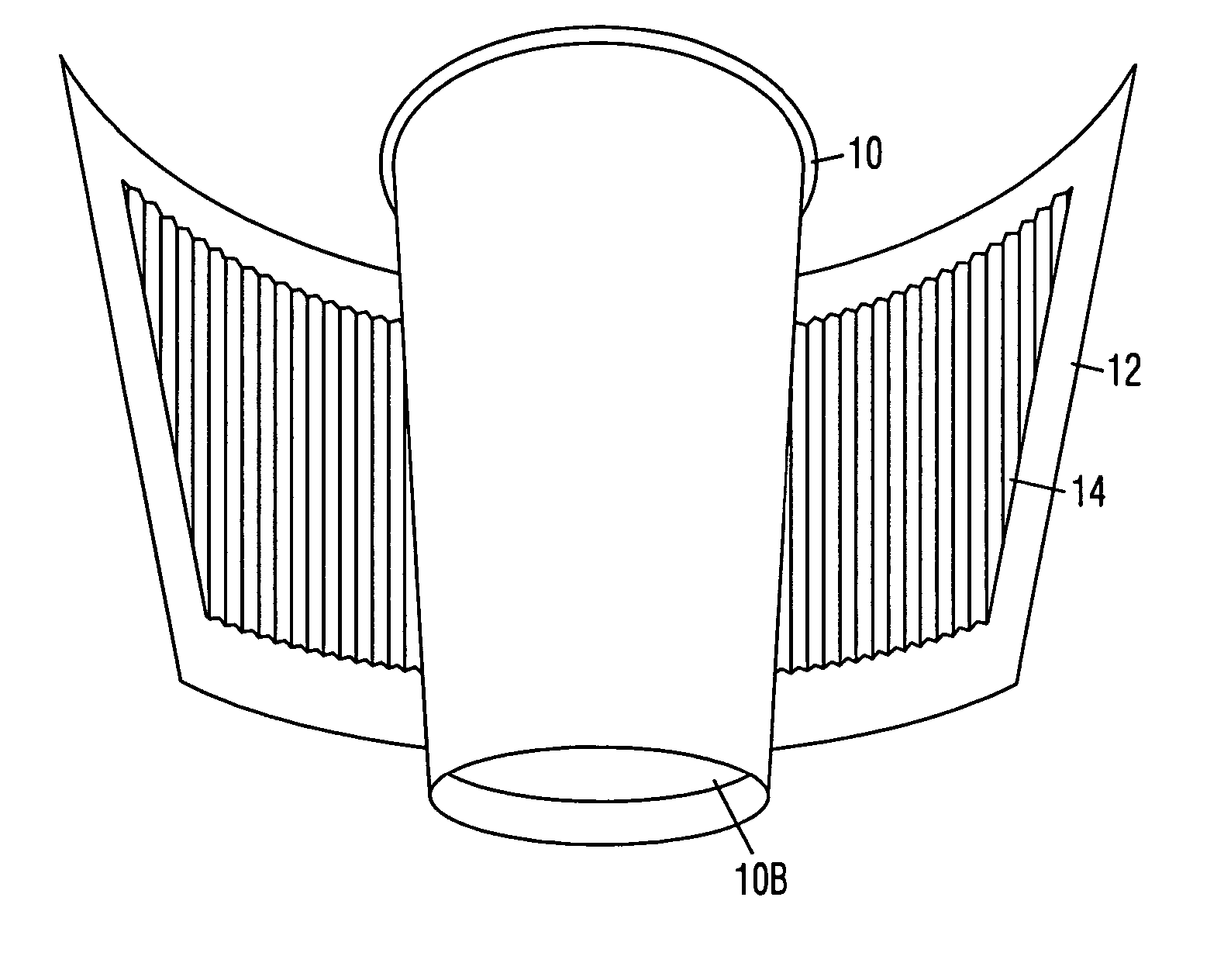

Device features and design elements for long-term adhesion

An electronic device for long-term adhesion to a mammal includes a housing with an electronic component. The electronic device may include a first wing and a second wing, each being integrally formed with the housing. An electrode is positioned on a bottom surface of each of the wings, the electrodes electrically connected to the electronic component. An adhesive layer is provided for adhesion to a surface of the mammal. The adhesive layer may cover a portion of the bottom surfaces of the wings but generally does not cover the electrode or a bottom surface of the housing. A method of applying an electronic device to a mammal includes removing first and second adhesive covers from first and second wings of the electronic device to expose an electrode and an adhesive coated on a bottom surface of each wing.

Owner:IRHYTHM TECH

Device features and design elements for long-term adhesion

An electronic device for long-term adhesion to a mammal includes a housing with an electronic component. The electronic device may include a first wing and a second wing, each being integrally formed with the housing. An electrode is positioned on a bottom surface of each of the wings, the electrodes electrically connected to the electronic component. An adhesive layer is provided for adhesion to a surface of the mammal. The adhesive layer may cover a portion of the bottom surfaces of the wings but generally does not cover the electrode or a bottom surface of the housing. A method of applying an electronic device to a mammal includes removing first and second adhesive covers from first and second wings of the electronic device to expose an electrode and an adhesive coated on a bottom surface of each wing.

Owner:IRHYTHM TECH

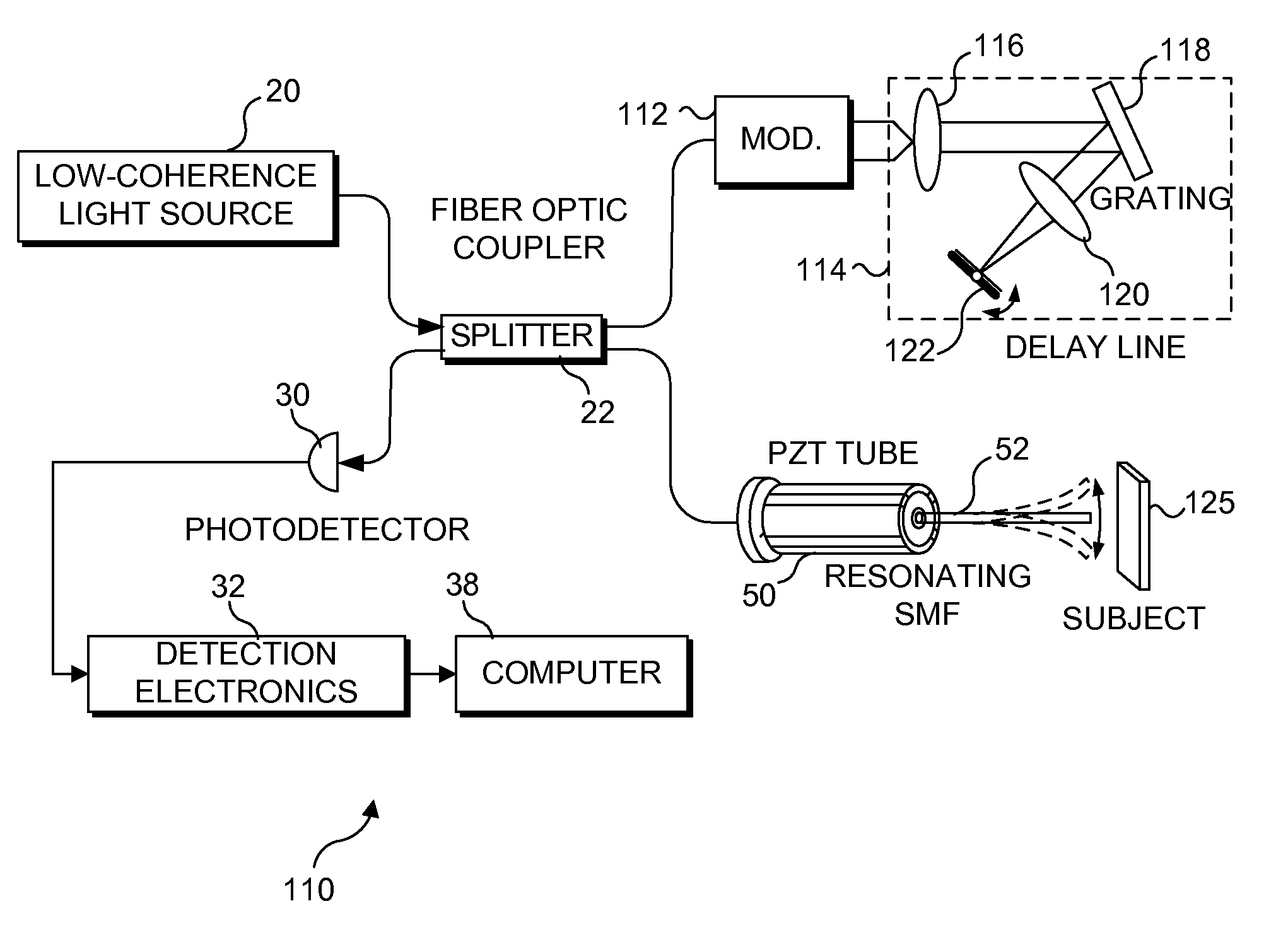

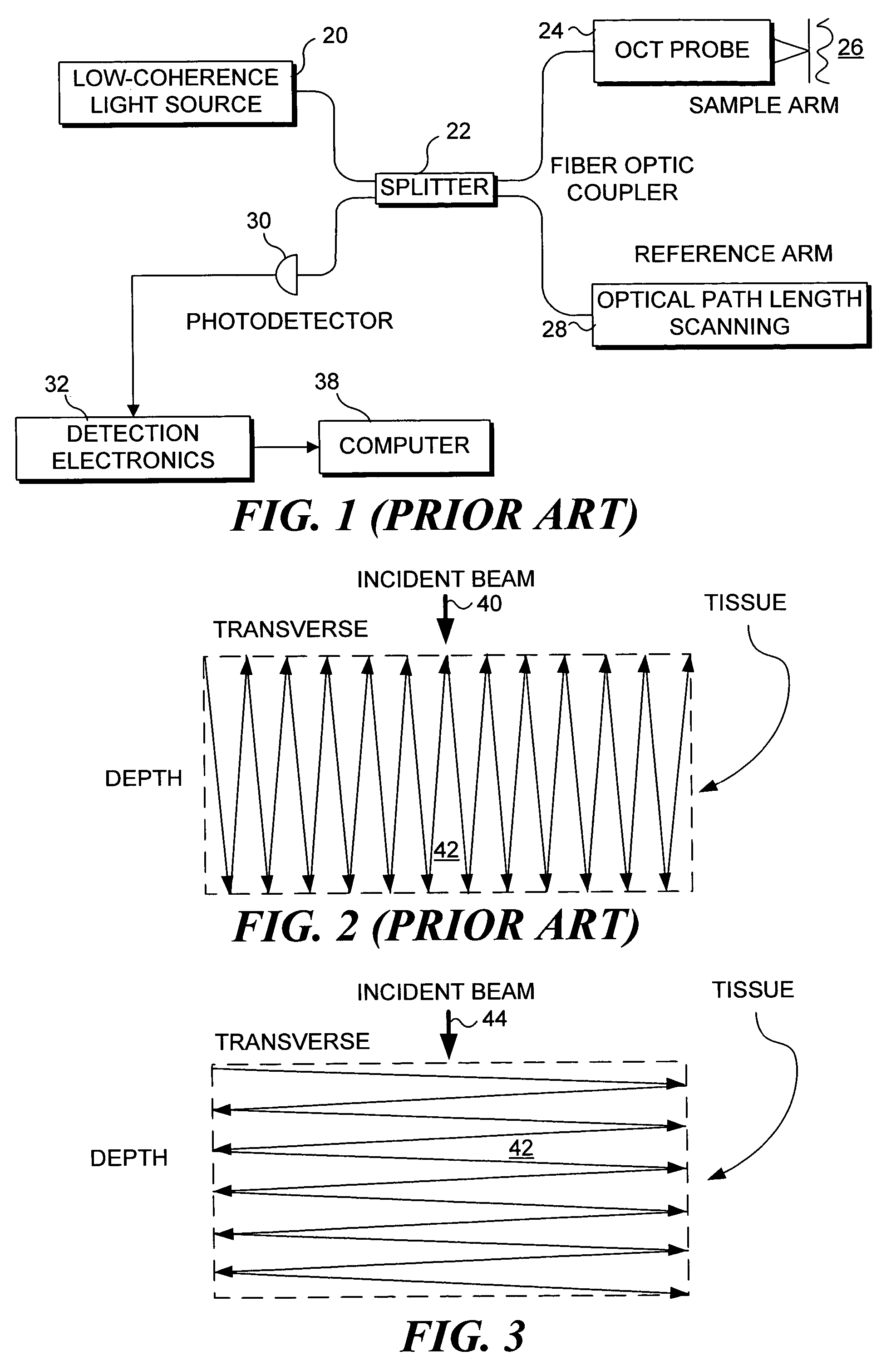

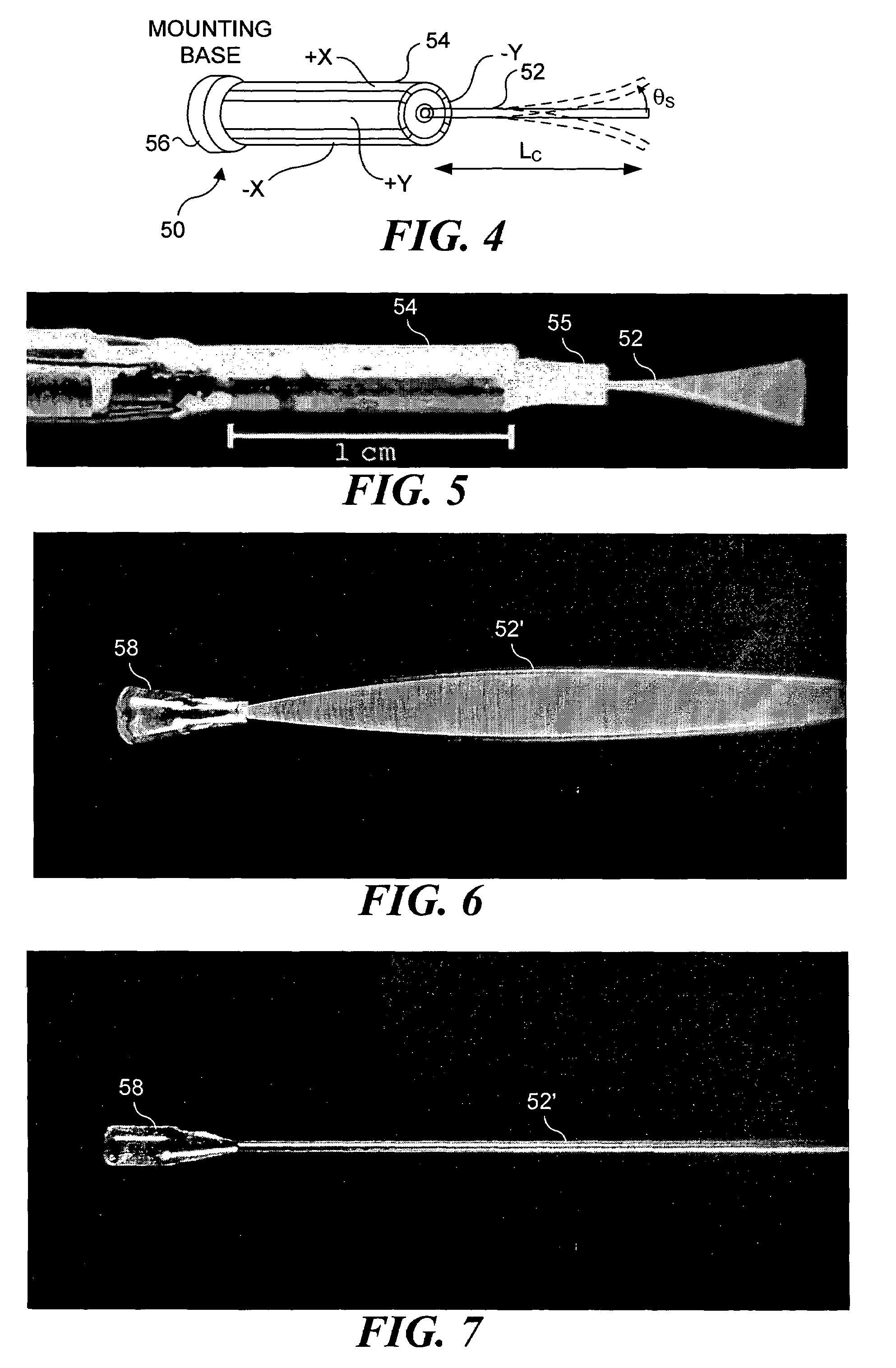

Optical fiber scanner for performing multimodal optical imaging

InactiveUS7616986B2Focus shiftReduce back reflectionBoxes/cartons making machineryBox making operationsActuatorFrequency modulation

An optical fiber scanner is used for multiphoton excitation imaging, optical coherence tomography, or for confocal imaging in which transverse scans are carried out at a plurality of successively different depths within tissue. The optical fiber scanner is implemented as a scanning endoscope using a cantilevered optical fiber that is driven into resonance or near resonance by an actuator. The actuator is energized with drive signals that cause the optical fiber to scan in a desired pattern at successively different depths as the depth of the focal point is changed. Various techniques can be employed for depth focus tracking at a rate that is much slower than the transverse scanning carried out by the vibrating optical fiber. The optical fiber scanner can be used for confocal imaging, multiphoton fluorescence imaging, nonlinear harmonic generation imaging, or in an OCT system that includes a phase or frequency modulator and delay line.

Owner:UNIV OF WASHINGTON

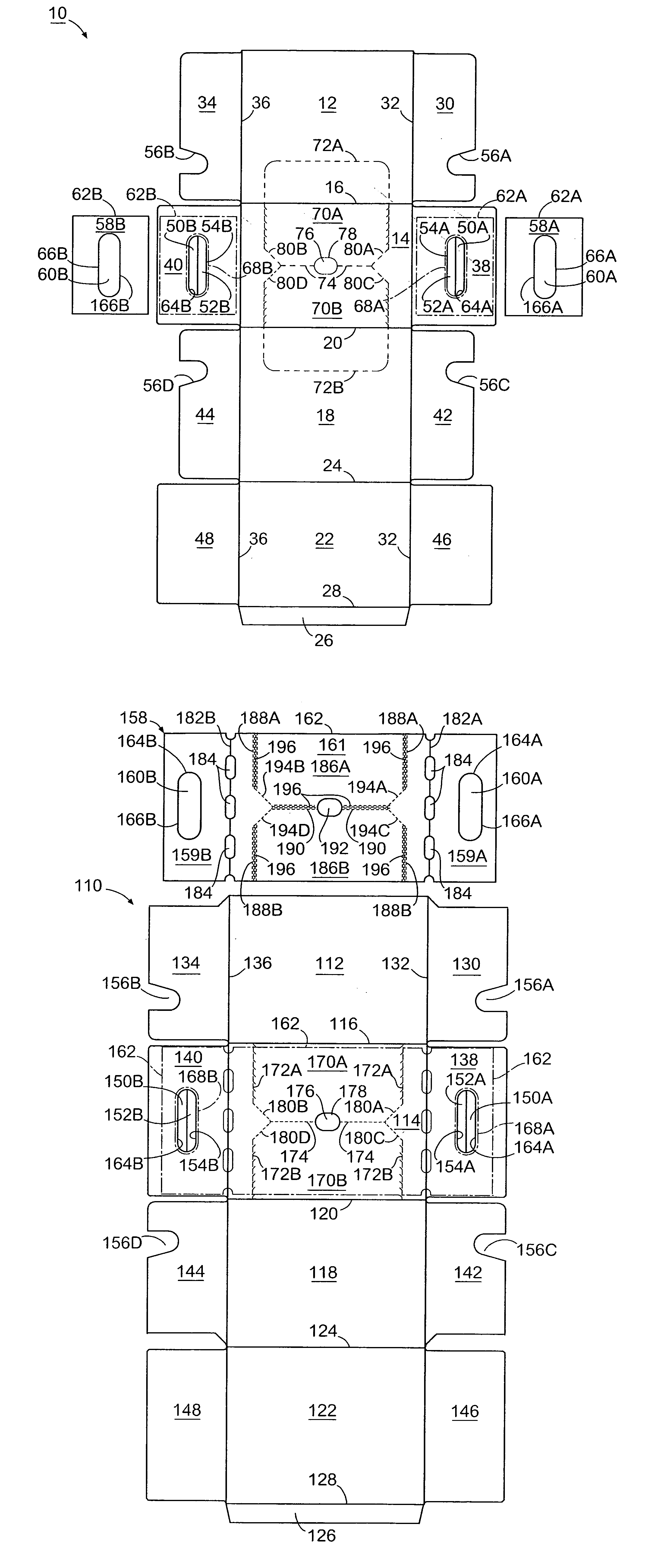

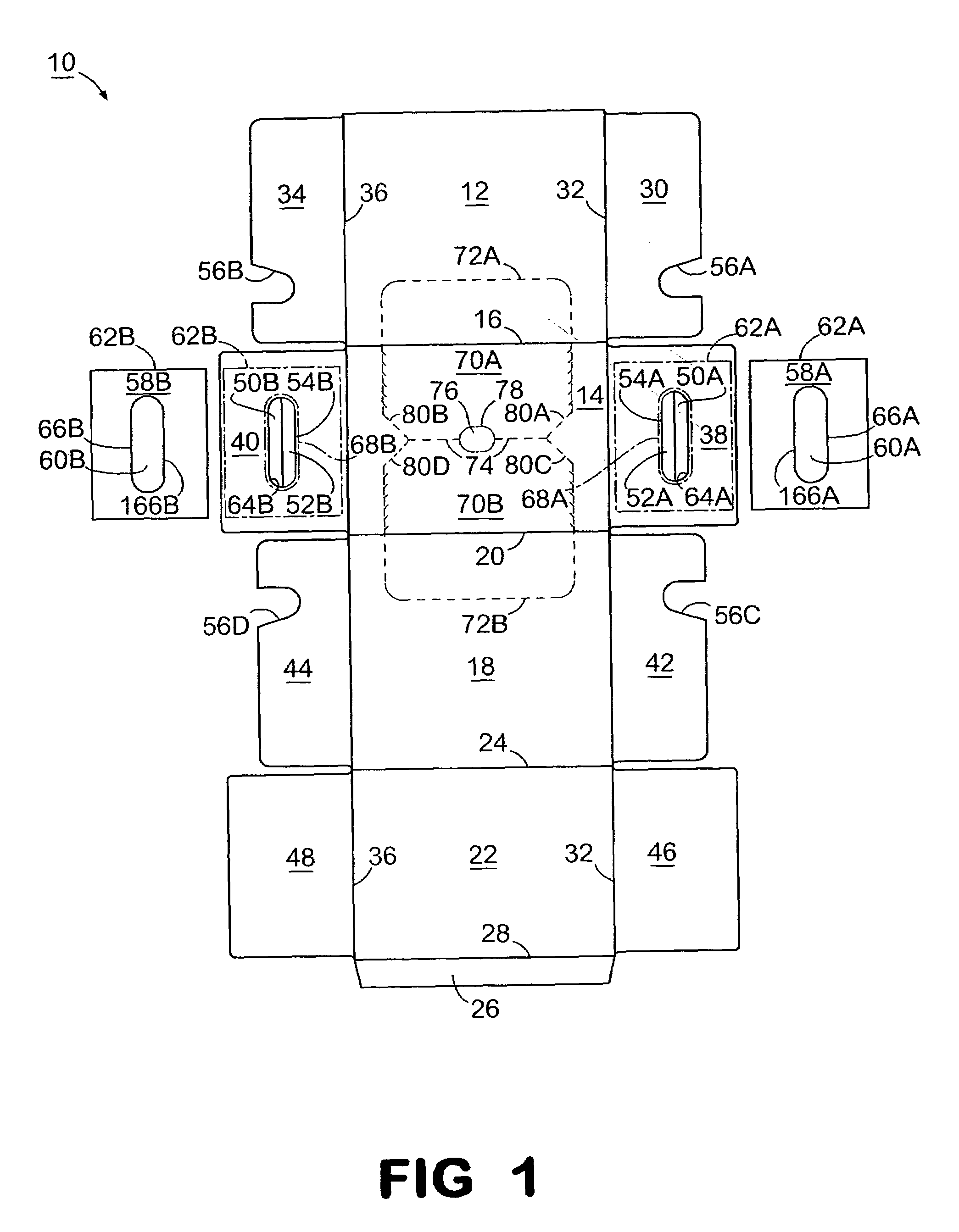

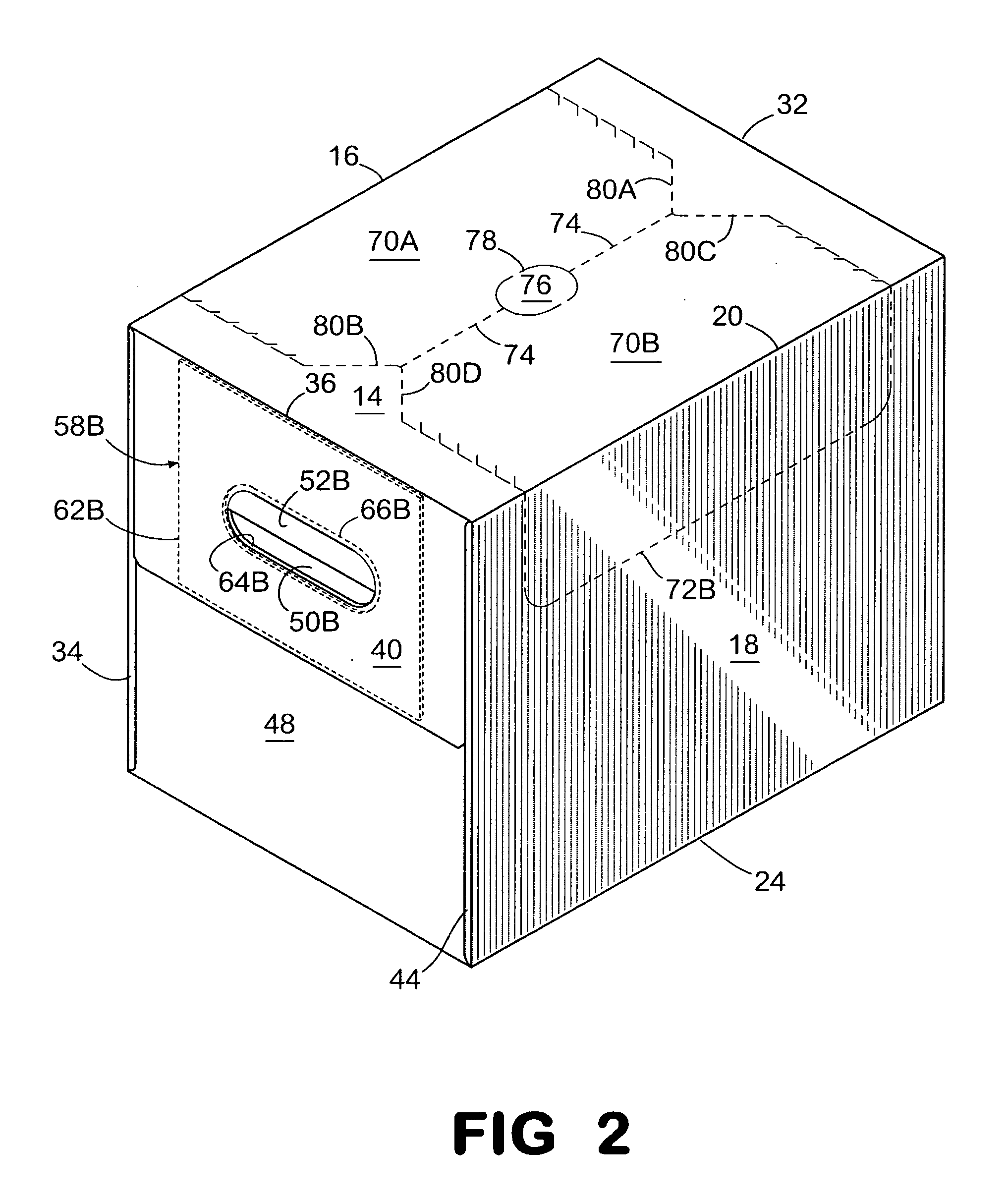

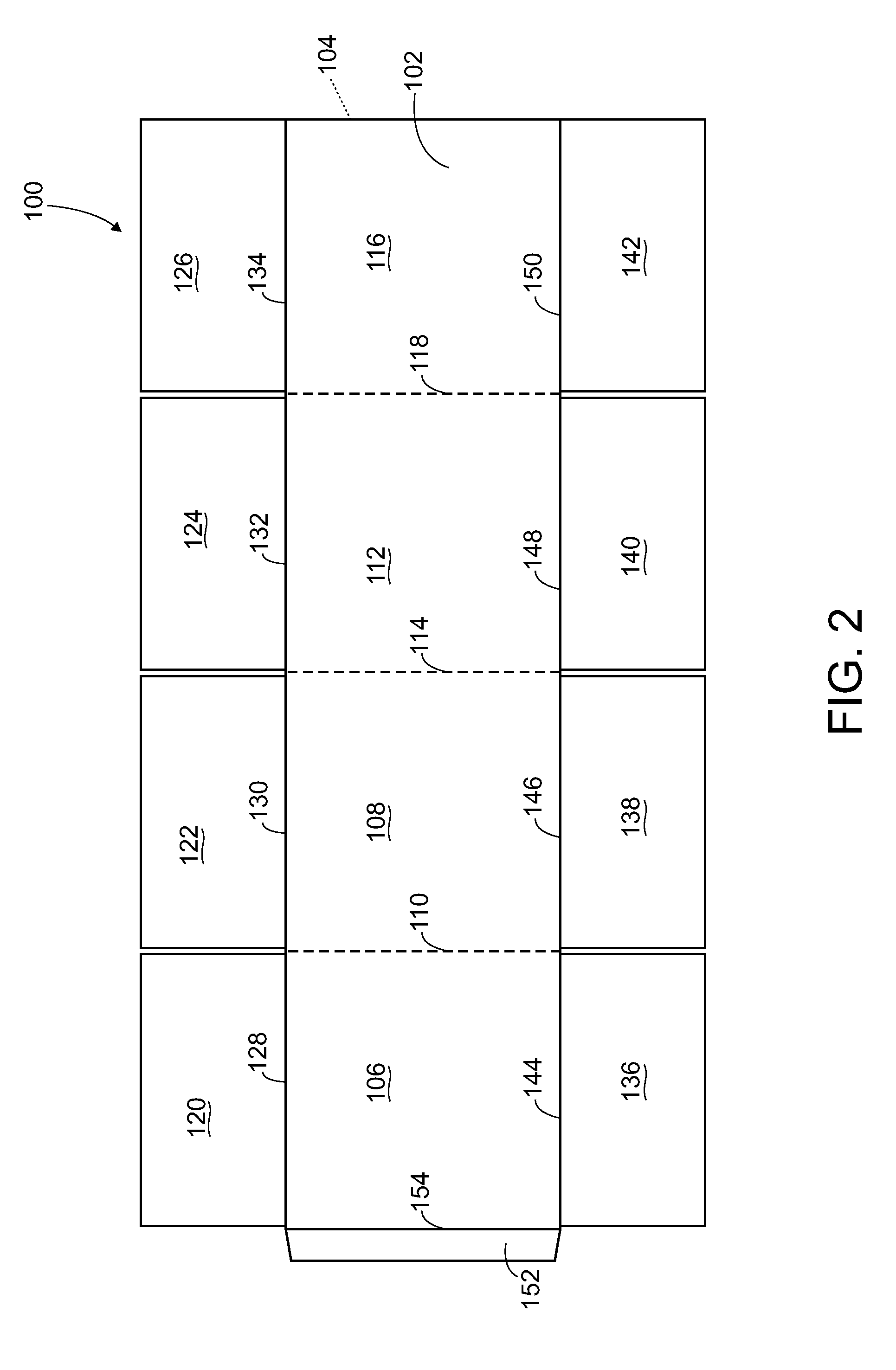

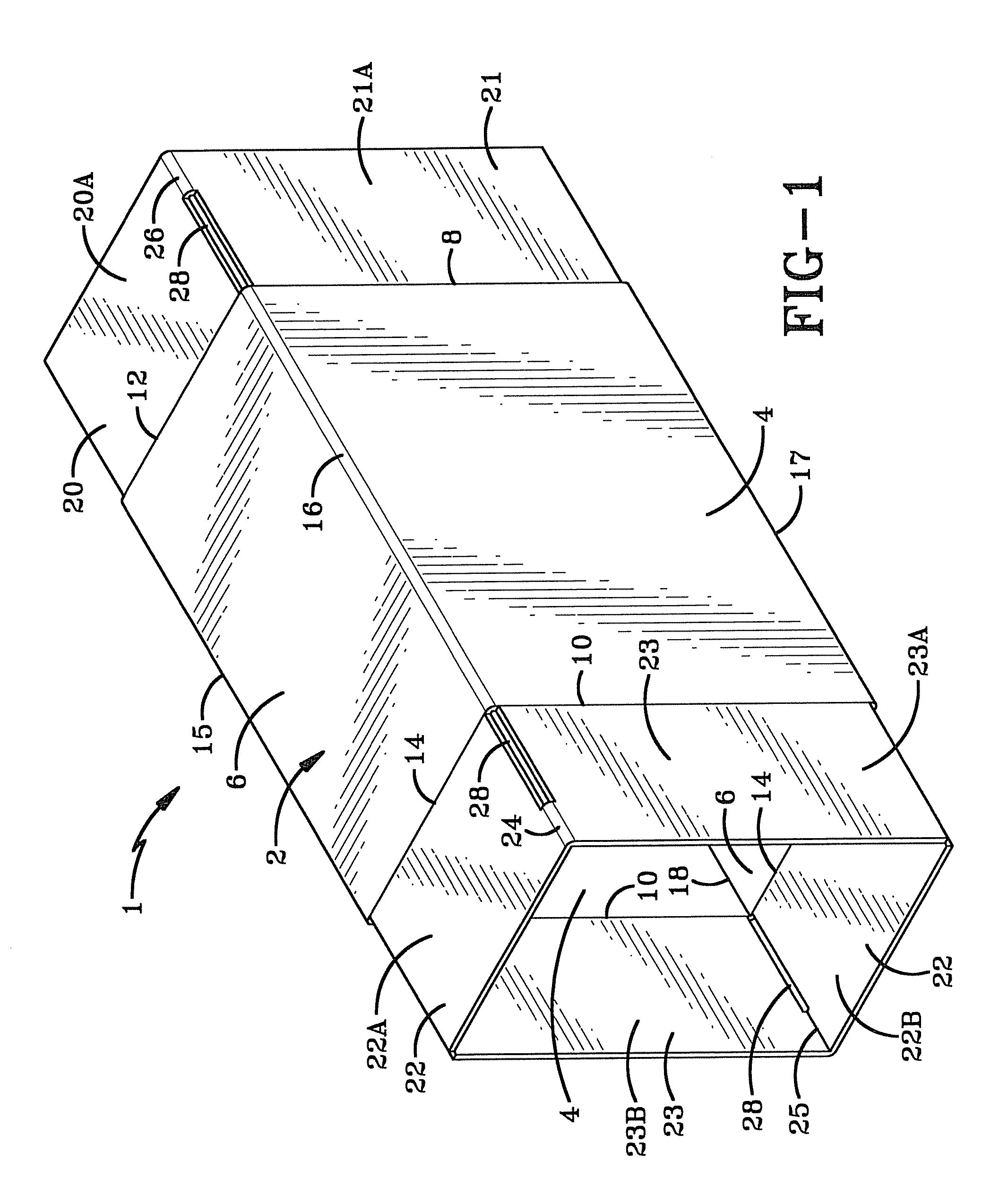

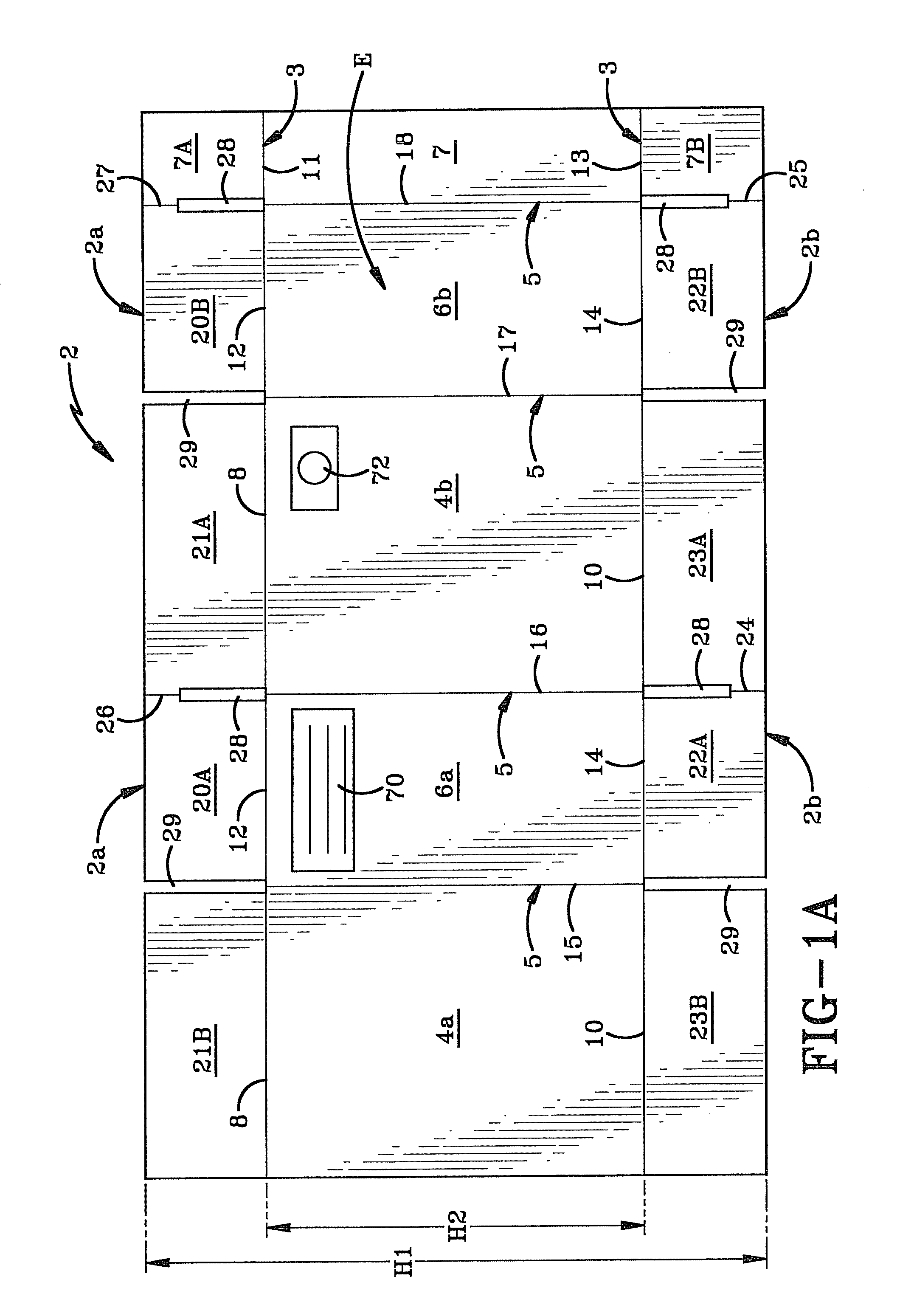

Handle and top handle reinforcement for a paperboard carton

A fully enclosed carton for carrying heavy loads with a reinforcement insert for the handle apertures located in the top end flaps of the carton. The paperboard reinforcing insert may be extended as a bridge across the top panel of the carton to prevent tearing of the handle apertures in the top end flaps and also tearing in the top panel of the carton when carrying a heavy load. The carton may have one or more dispensers in the top panel which may extend into an adjoining side panel. Multiple tear lines may be formed for the dispenser flap in the insert that extends across the top panel to permit easy access to the containers, such as bottles, in the carton.The paperboard reinforcing insert may have a larger aperture than the handle aperture in each top end flap to adjust for any imprecision in the alignment of the paperboard insert in forming the carton sleeve from the paperboard blank. When the paperboard insert extends across the top panel and one or more dispensers are formed in the top panel, multiple tear lines may be used to form the flaps in the insert to compensate for any imprecision in the insertion of the insert that extends across the top panel into the carton sleeve when it is being formed.

Owner:GRAPHIC PACKAGING INT

Device features and design elements for long-term adhesion

An electronic device for long-term adhesion to a mammal includes a housing with an electronic component. There is a first wing and a second wing, each being integrally formed with the housing. An electrode is positioned on a bottom surface of each of the wings, the electrodes electrically connected to the electronic component. An adhesive layer is provided for adhesion to a surface of the mammal. The adhesive layer is coated on a portion of the bottom surfaces of the wings. The adhesive layer is not coated on the electrode or on a bottom surface of the housing. A method of applying an electronic device to a mammal includes removing a first adhesive cover from a first wing of the electronic device to expose an electrode and an adhesive coated on a bottom surface of the first wing. There is a step of placing the exposed electrode into contact with the mammal by adhering the adhesive coated bottom of the first wing to the mammal. There is a step of removing a second adhesive cover from the second wing of the electronic device to expose an adhesive coated on a bottom surface of the second wing and another exposed electrode. There is a step of placing the another exposed electrode into contact with the mammal by adhering the adhesive coated bottom of the second wing to the mammal. After performing the removing and the placing steps, the housing is unattached to the mammal, but is held in position on the mammal using the adhesive coated bottoms of the first and the second wings.

Owner:IRHYTHM TECH

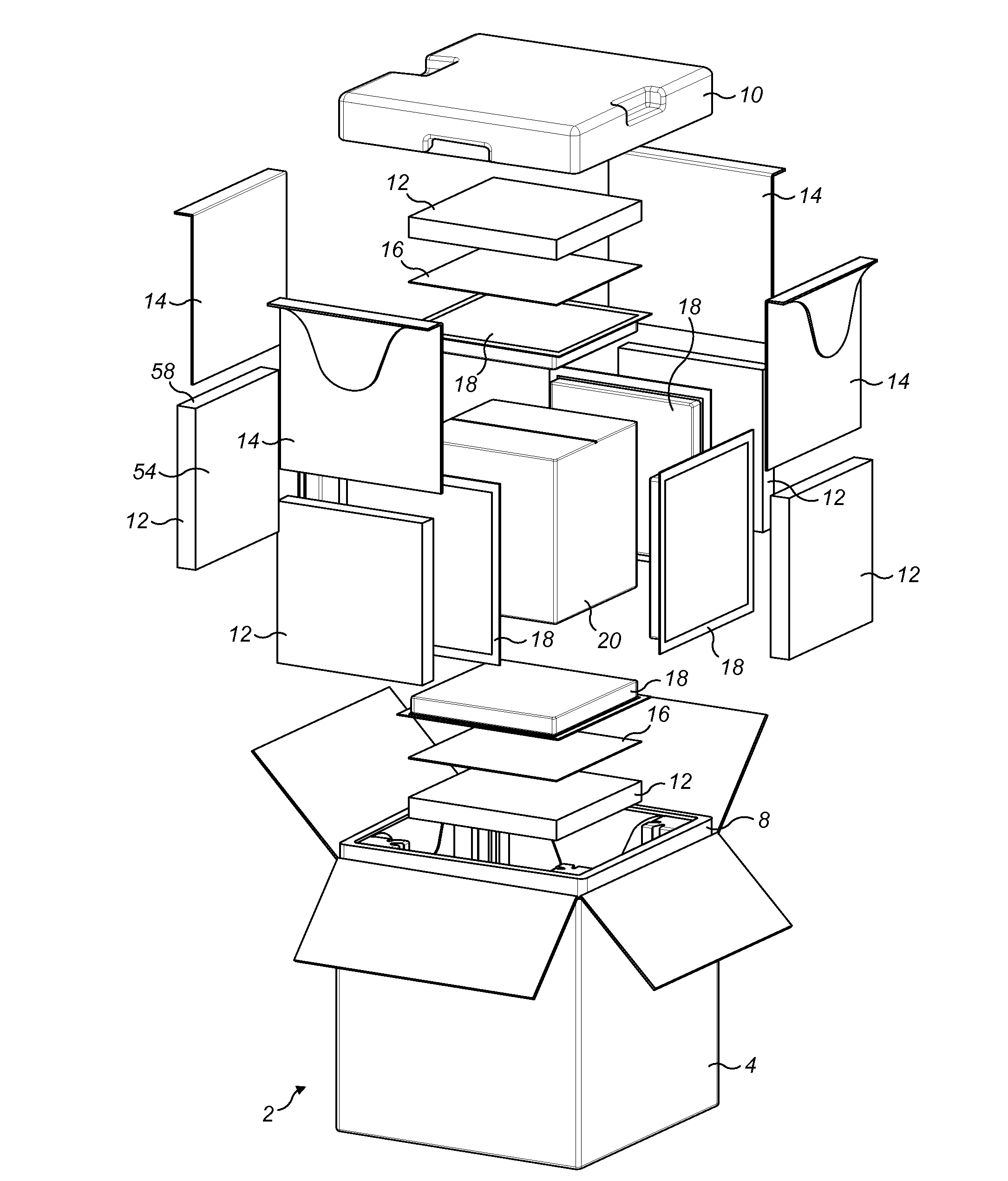

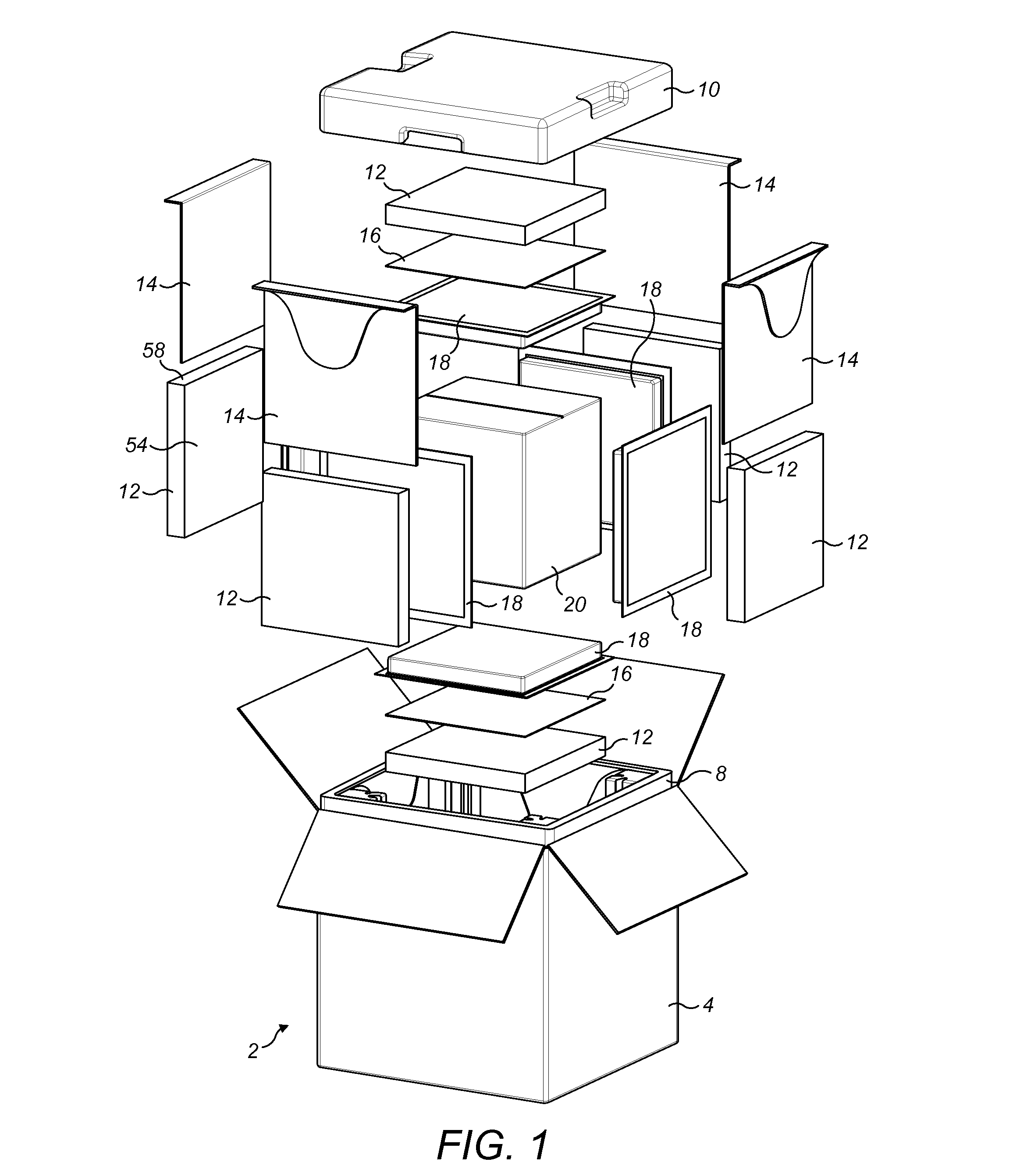

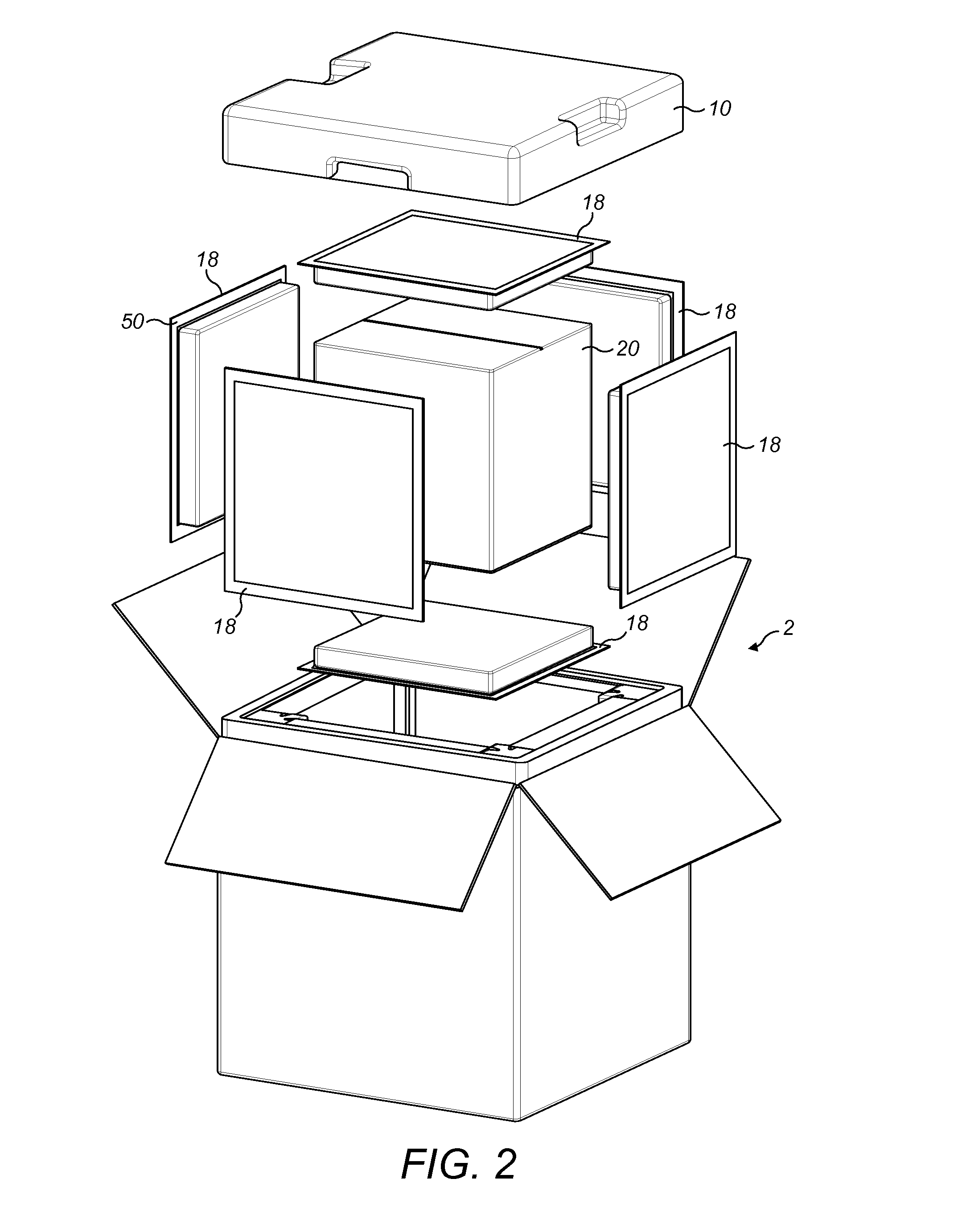

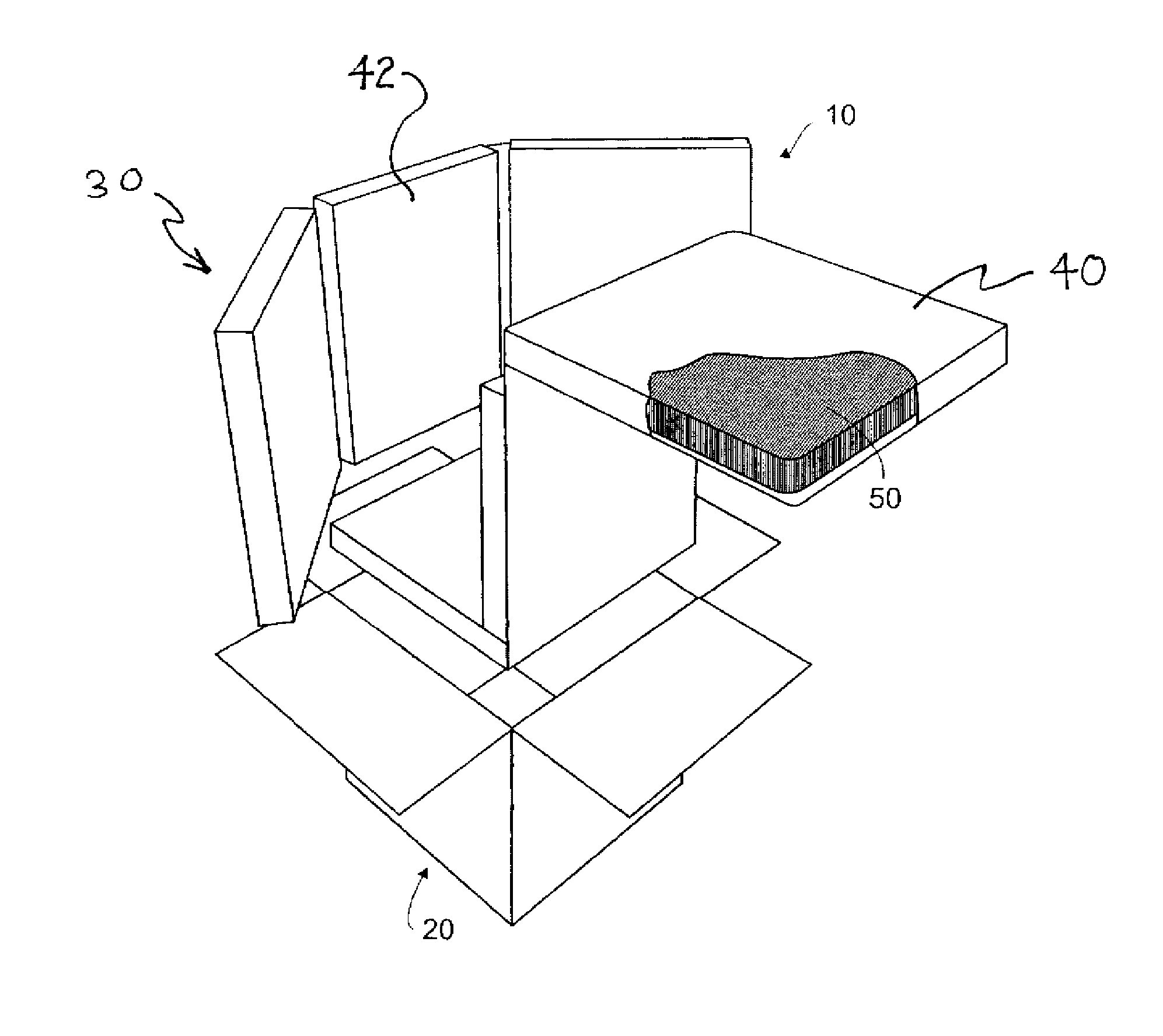

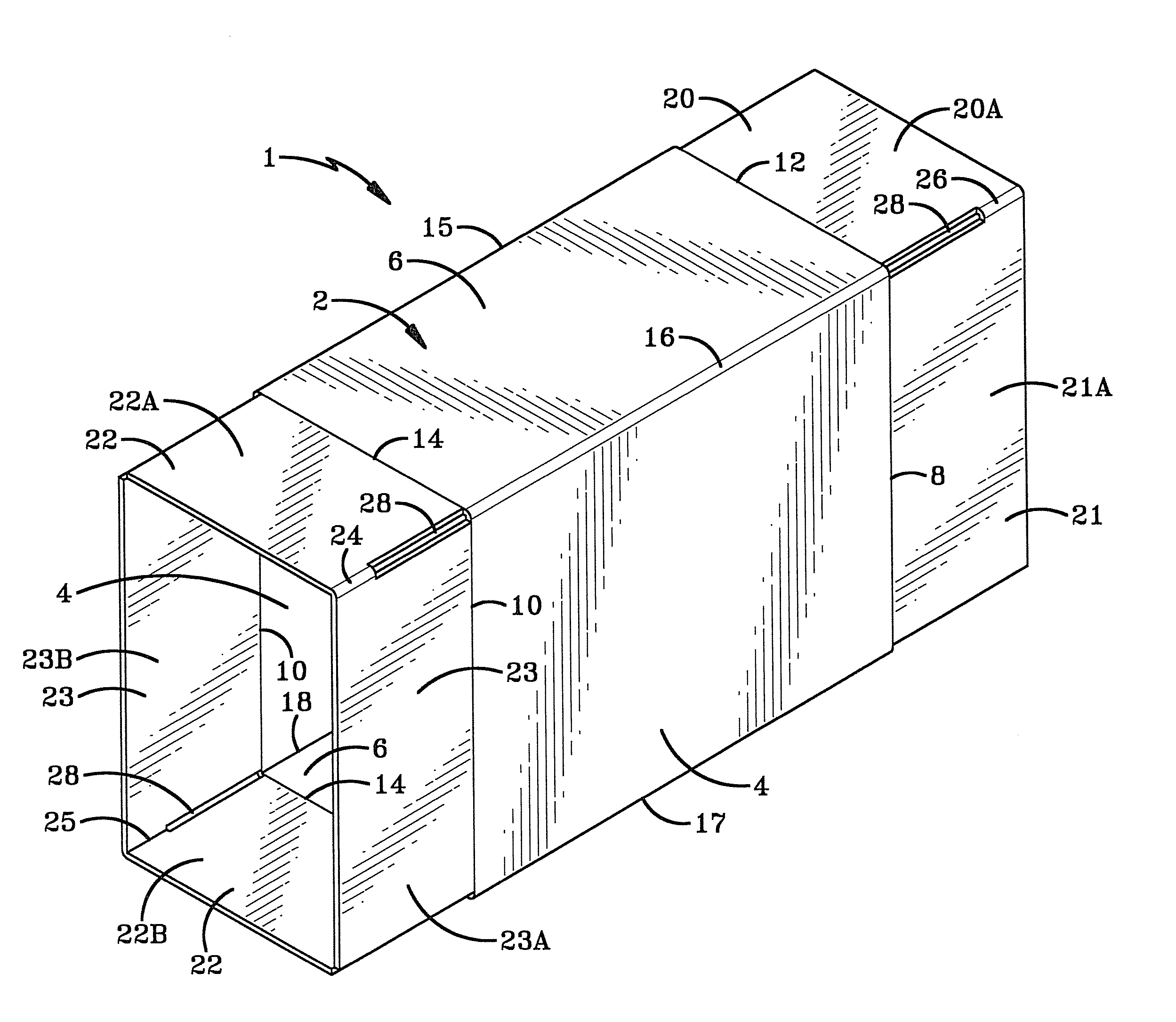

Thermally insulated package

ActiveUS20150166244A1Easy temperature controlLess expensiveLighting and heating apparatusBox making operationsEngineeringPhase-change material

A thermally insulating package comprises an outer shell (6) formed from a foam insulating material, a plurality of vacuum insulated panels (12) removably received on the walls of the outer shell (6) and a plurality of phase change material panels (18) arranged within the vacuum insulated panels (12) to define a payload space.

Owner:PELI BIOTHERMAL LLC (N D GES D STAATES DELAWARE)

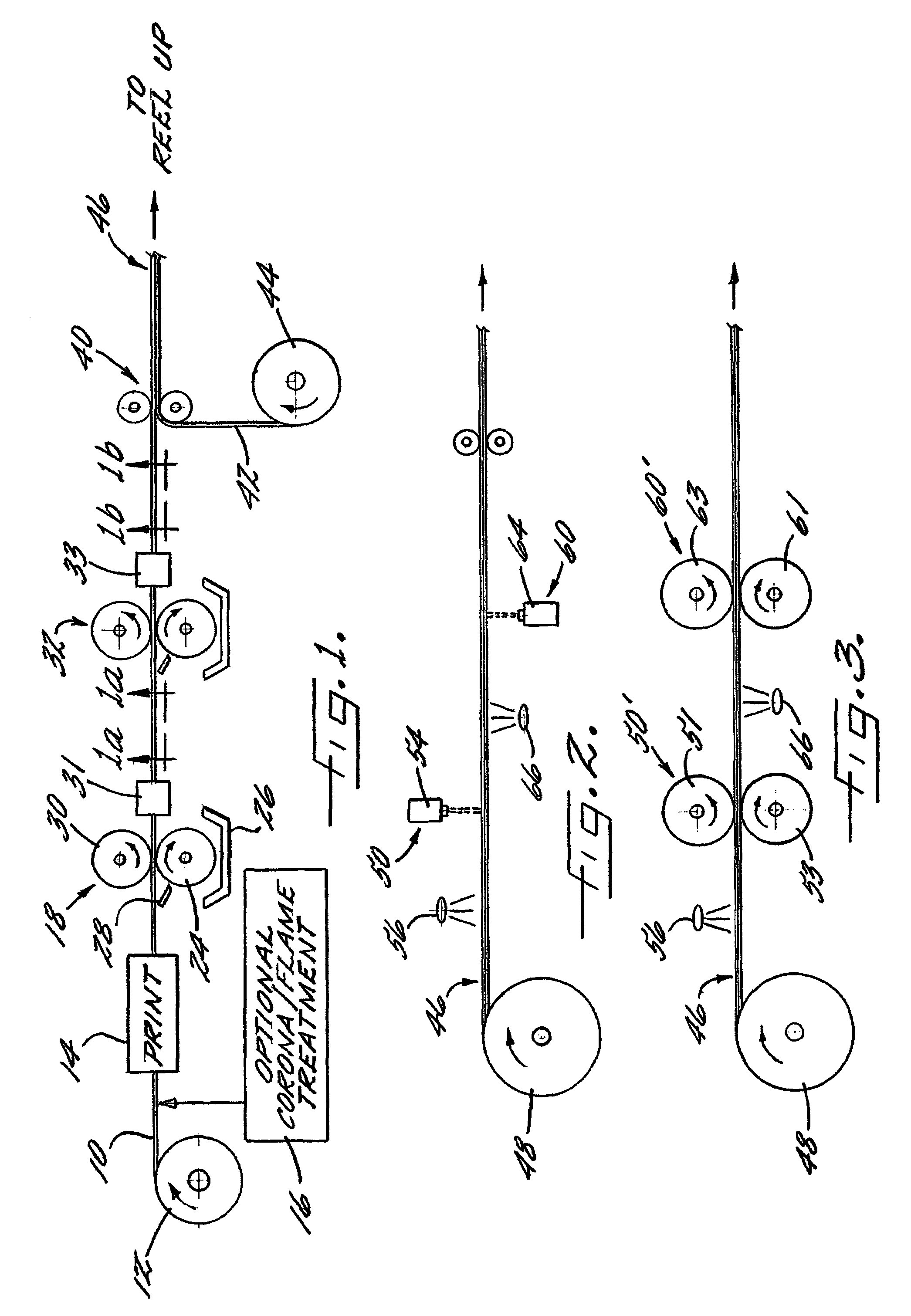

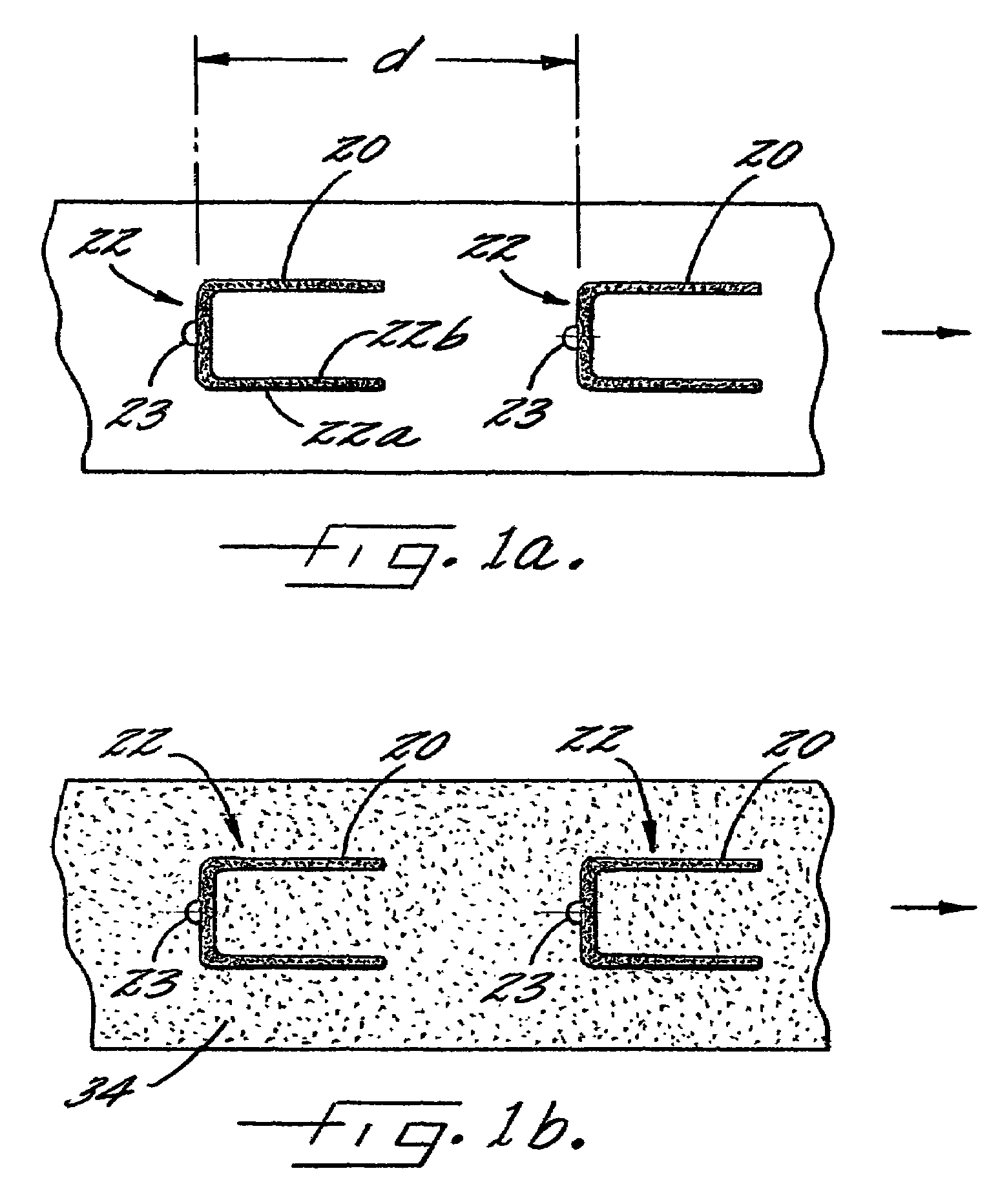

Flexible packaging structure with a built-in opening and reclose feature, and method for making same

A flexible packaging laminate is formed to have a built-in opening and reclose feature by forming the laminate as a two-part structure having an outer structure joined in face-to-face relation with an inner structure. Score lines are formed in both structures to enable an opening to be formed through the laminate by lifting an opening portion (e.g., a flap or the like) of the two structures out of the plane of the laminate. The score line through the outer structure defines a larger opening than the score line through the inner structure, such that a marginal region of the outer structure extends beyond the edge of the opening portion of the inner structure. A pressure-sensitive adhesive is used to re-adhere the marginal region to an underlying surface of the inner structure adjacent the opening through the laminate.

Owner:SONOCO DEV INC

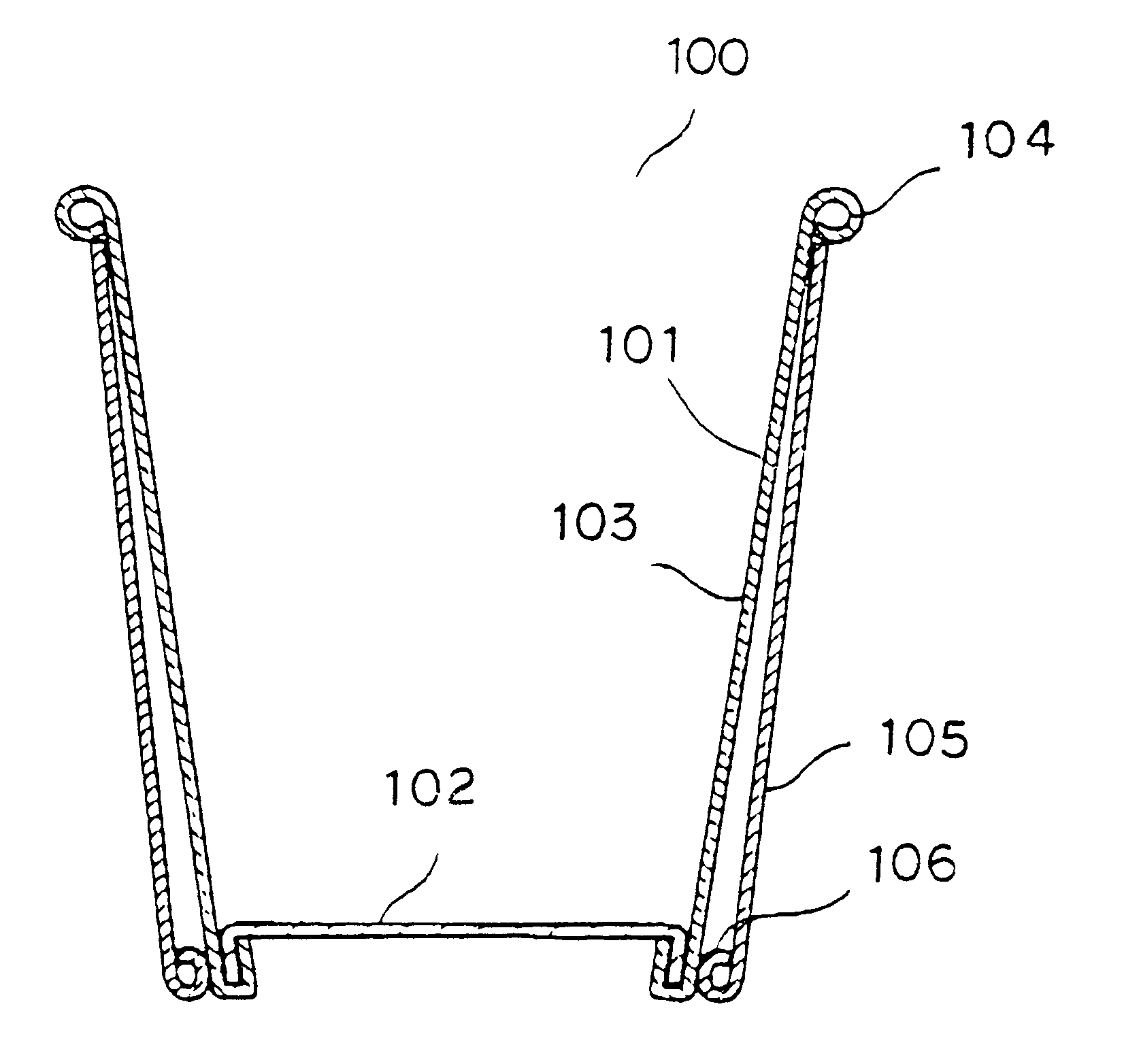

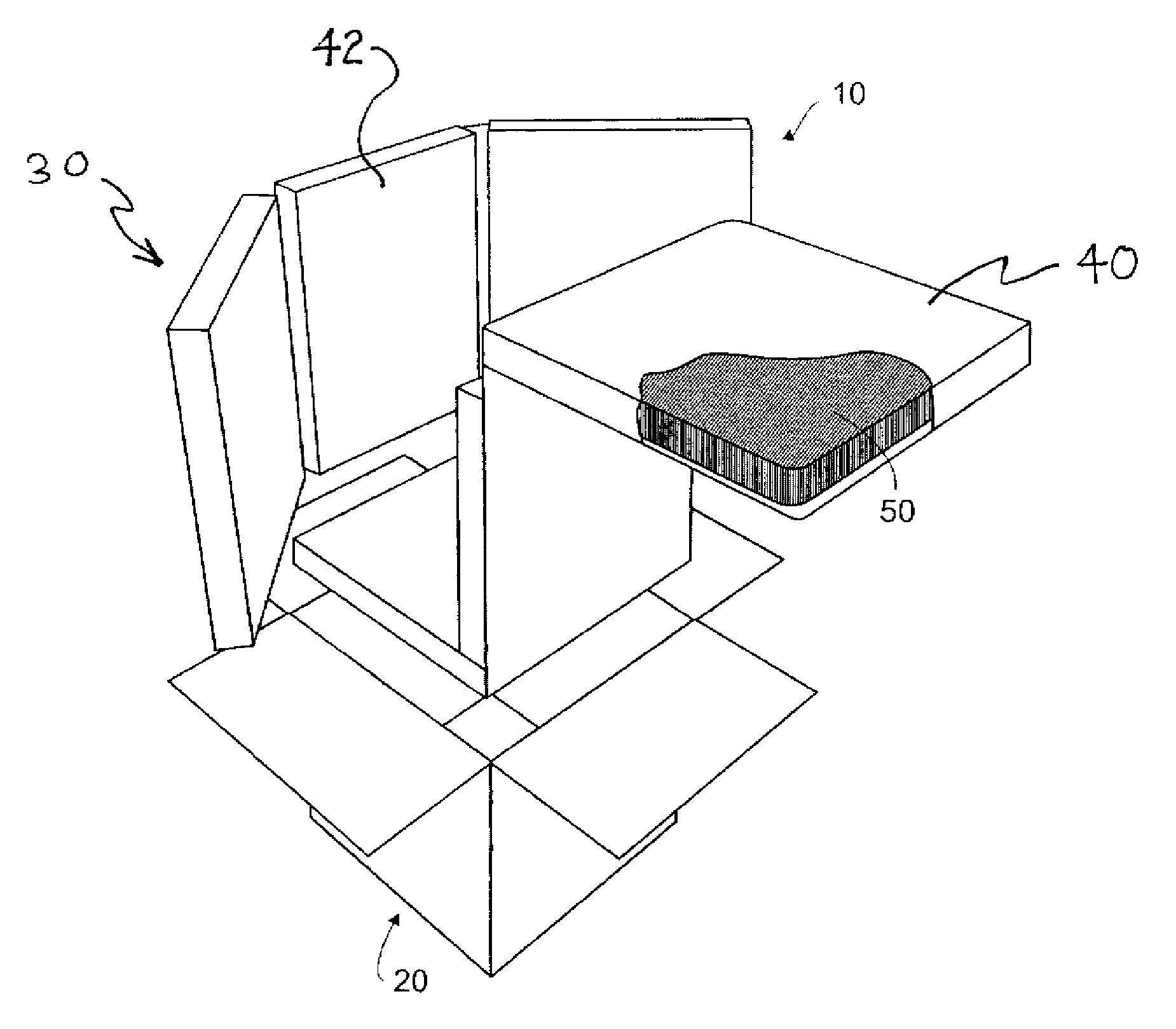

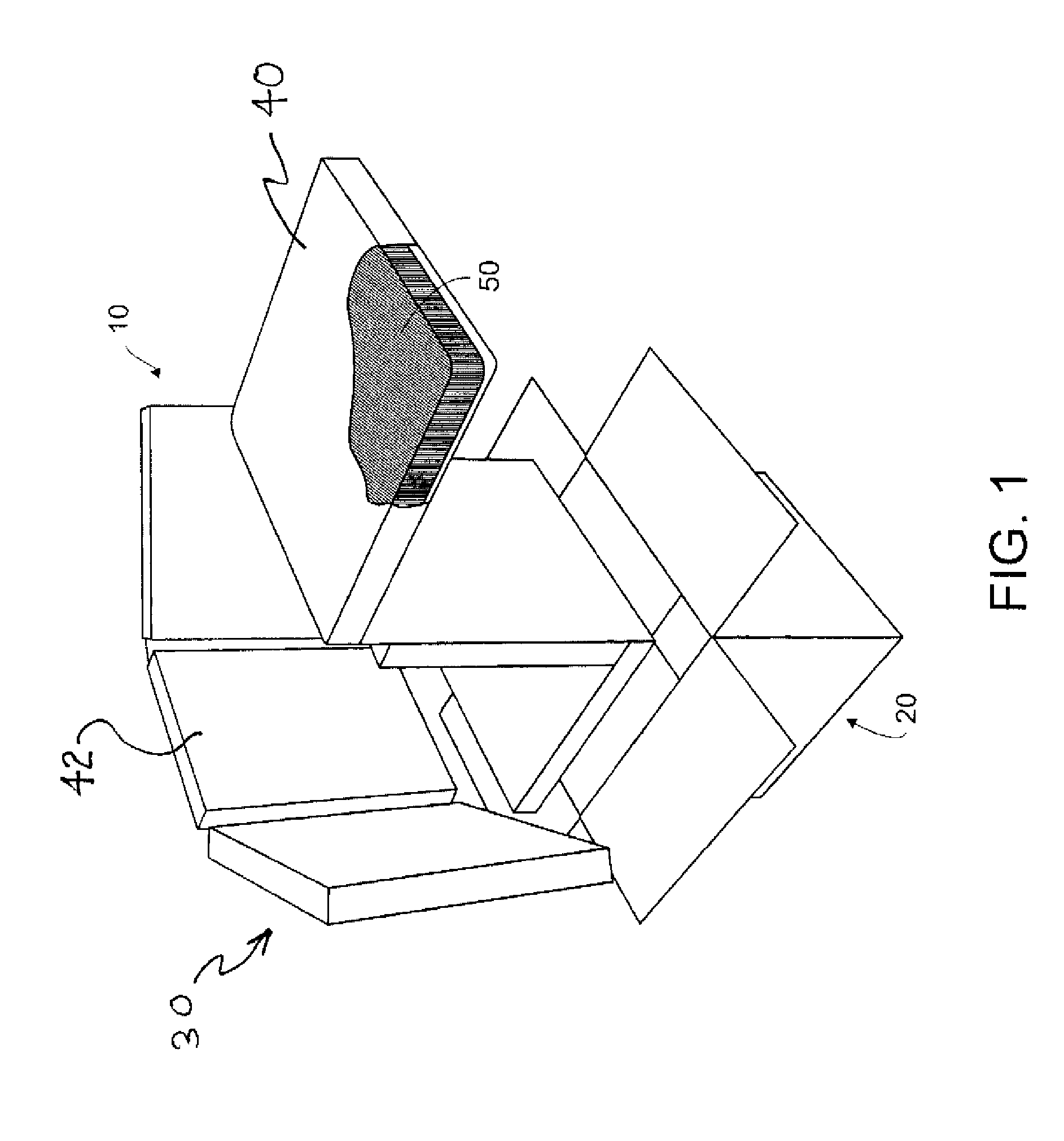

Container insert apparatus and method

InactiveUS20100284634A1Reduce laborLow costEnvelopes/bags making machineryWrappersInterior spaceEngineering

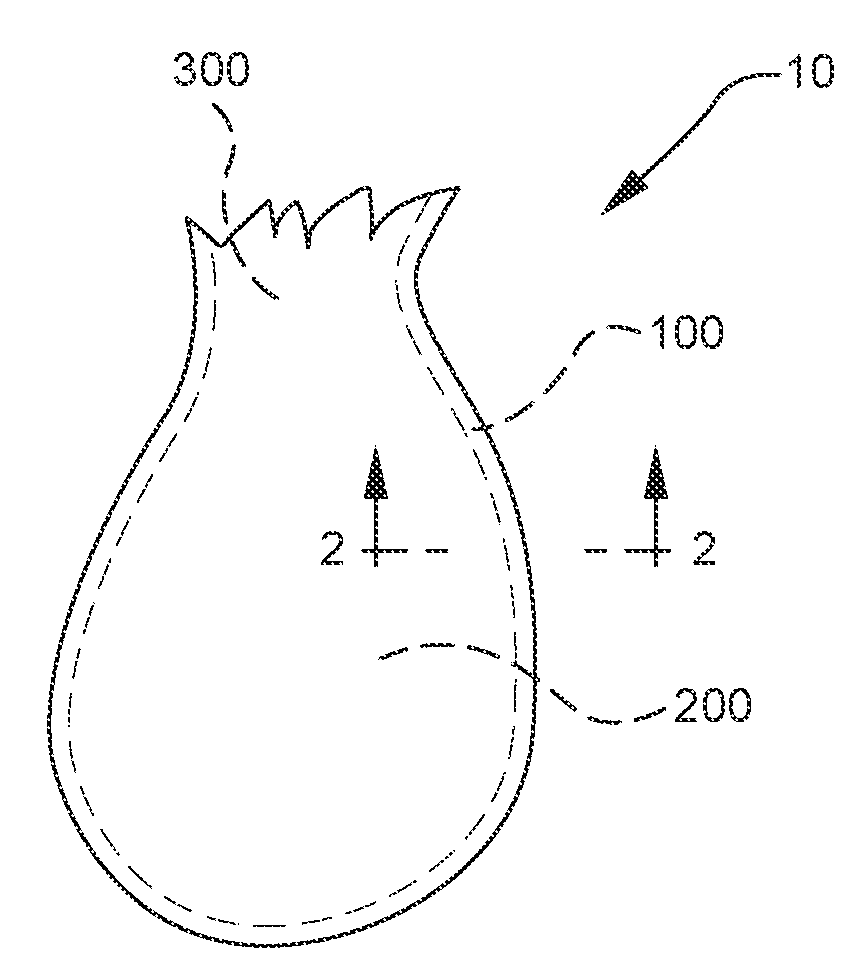

A container insert, and an apparatus and a method of producing the container insert. The container insert is formed as a deformable pouch adapted to be received in an interior of an associated container. The pouch has a closed lower end, an open upper end, and spaced apart sealed edges. The lower end of the pouch includes two leg portions. The pouch is manipulatable to generally conform to the interior of the contained and form a hollow interior space therein for receiving an object and providing a lining for the interior of the container. The apparatus and the method for producing the insert provides for a substantially automatic and continuous production of the insert from a roll of material.

Owner:CUTTING EDGE CONVERTED PROD

Film Embedded Packaging and Method of Making Same

The present invention relates to packaging in the form of a pouch, which may contain active substances, such as food products, pharmaceutical agents, nutraceuticals and cosmetic agents, or the like. More specifically, in some embodiments, the present invention provides a pouch, which includes at least one porous substrate encompassing a closed volume and at least one water-soluble film at least partially embedded in the at least one porous substrate. The pouch may contain an active substance within the closed volume, as well as an active substance in the water-soluble film. The present invention also relates to methods of making and using the pouches.

Owner:MONOSOL RX

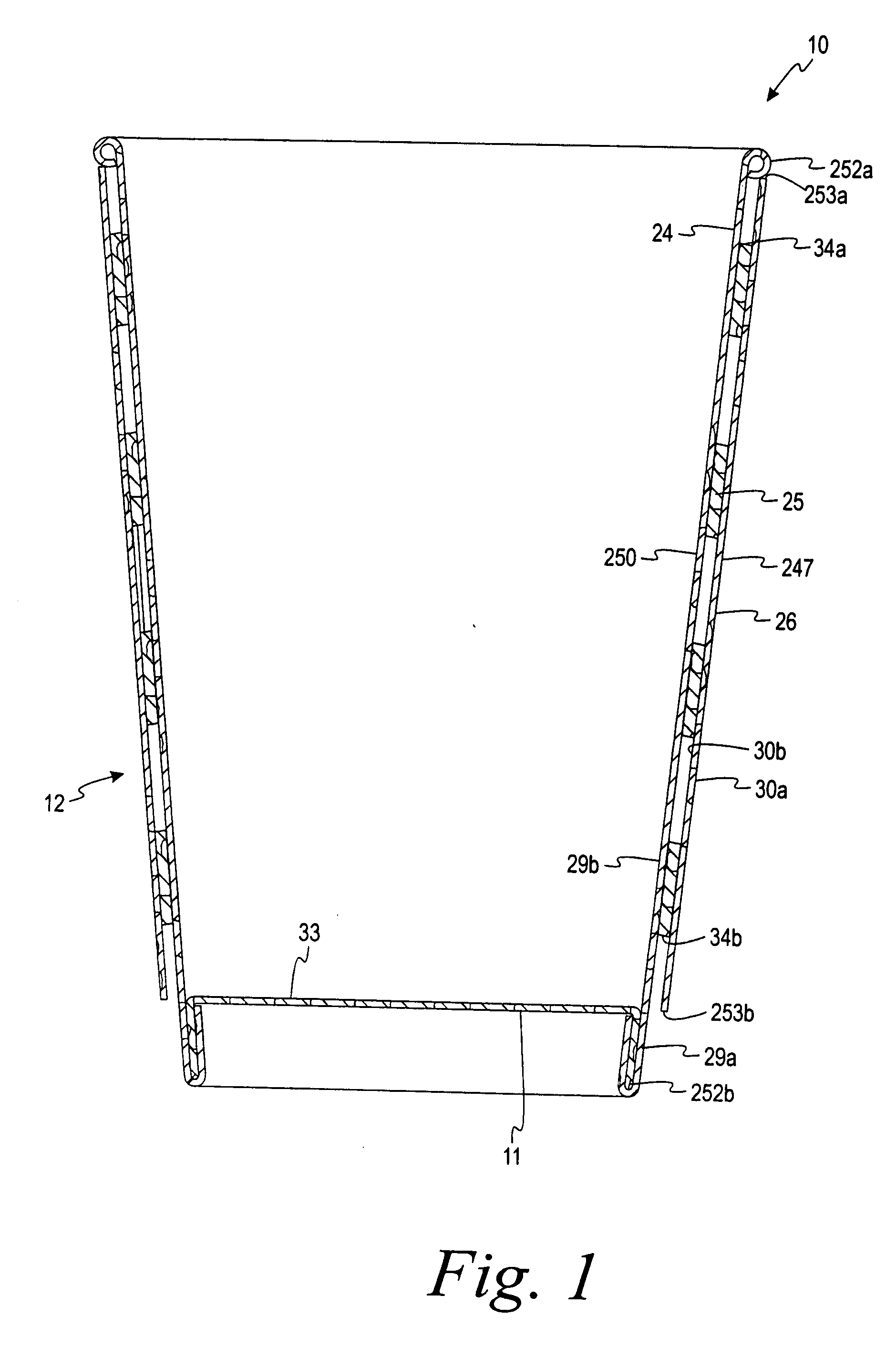

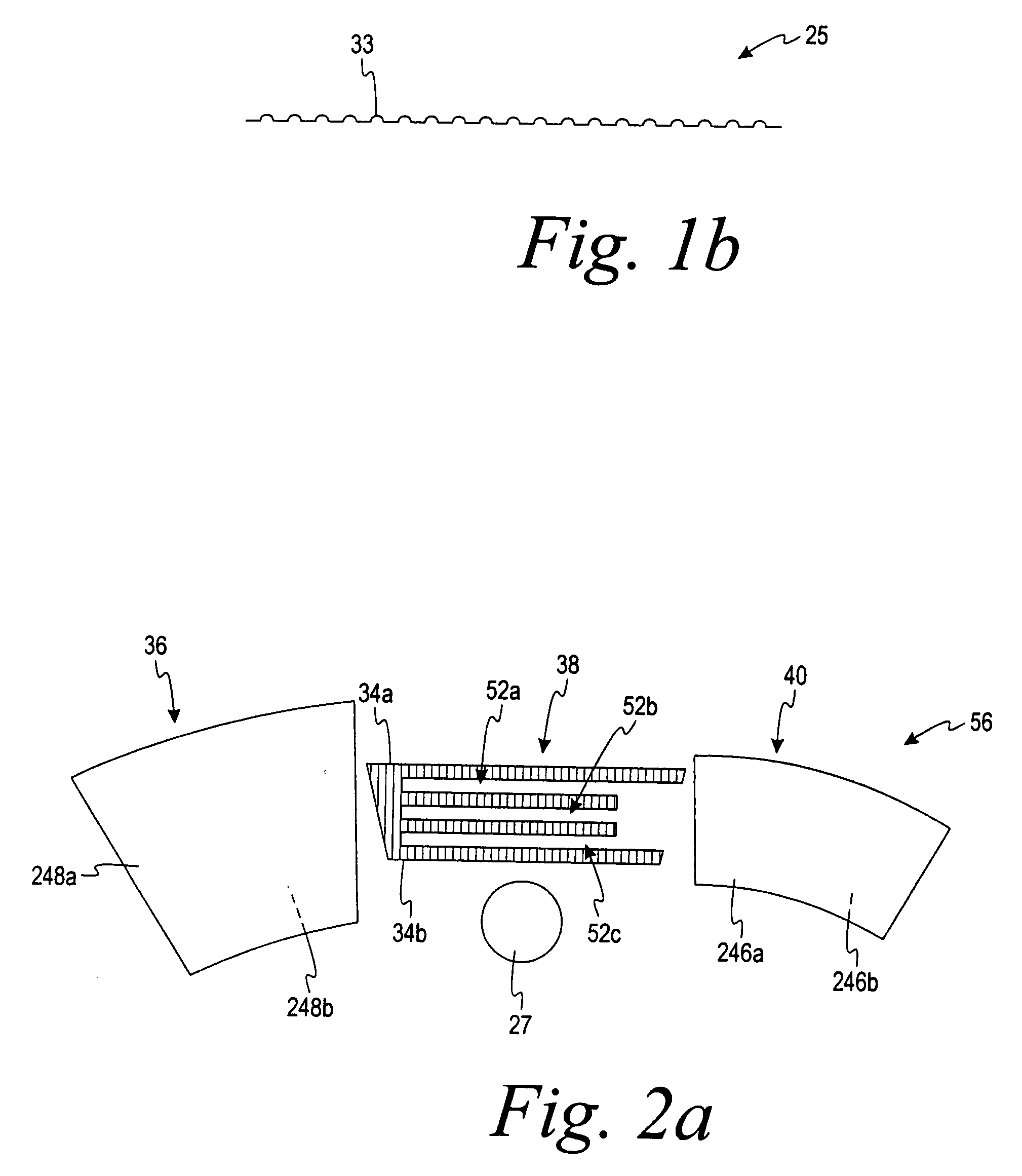

Flexible container having flat walls

InactiveUS7207716B2Improve stabilitySimple methodEnvelopes/bags making machineryBoxes/cartons making machineryPlastic materialsFlat panel

Owner:NESTEC SA

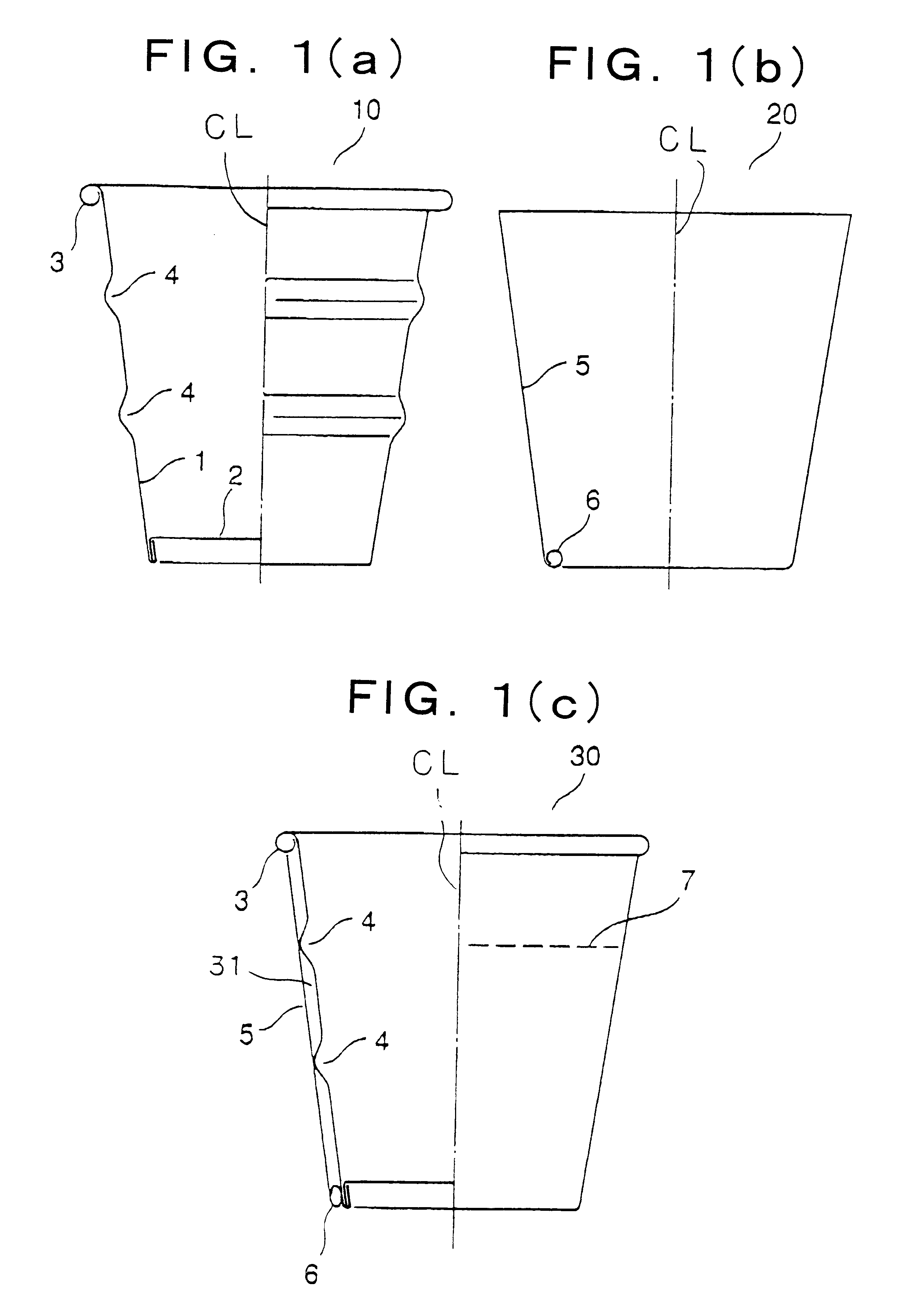

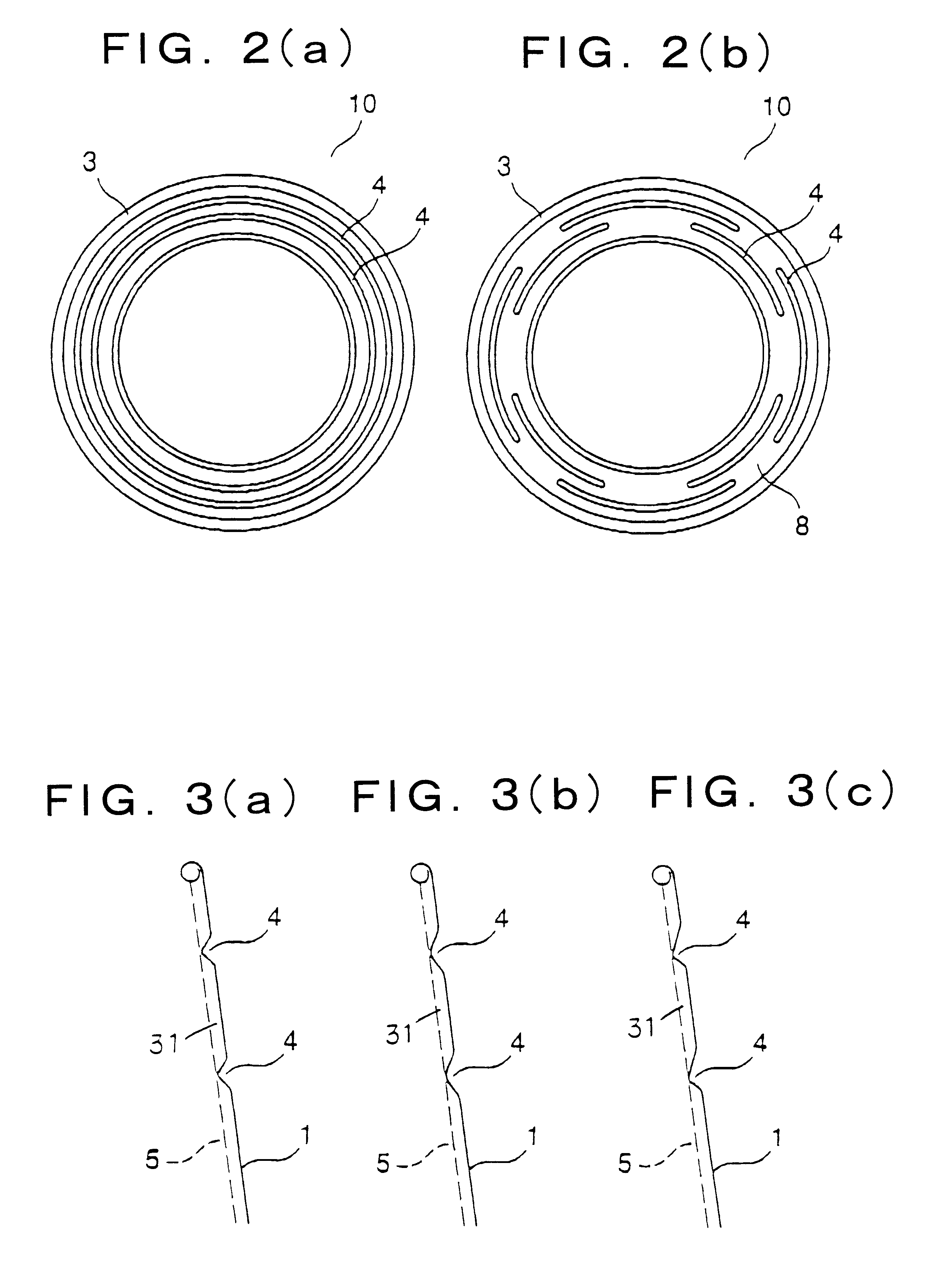

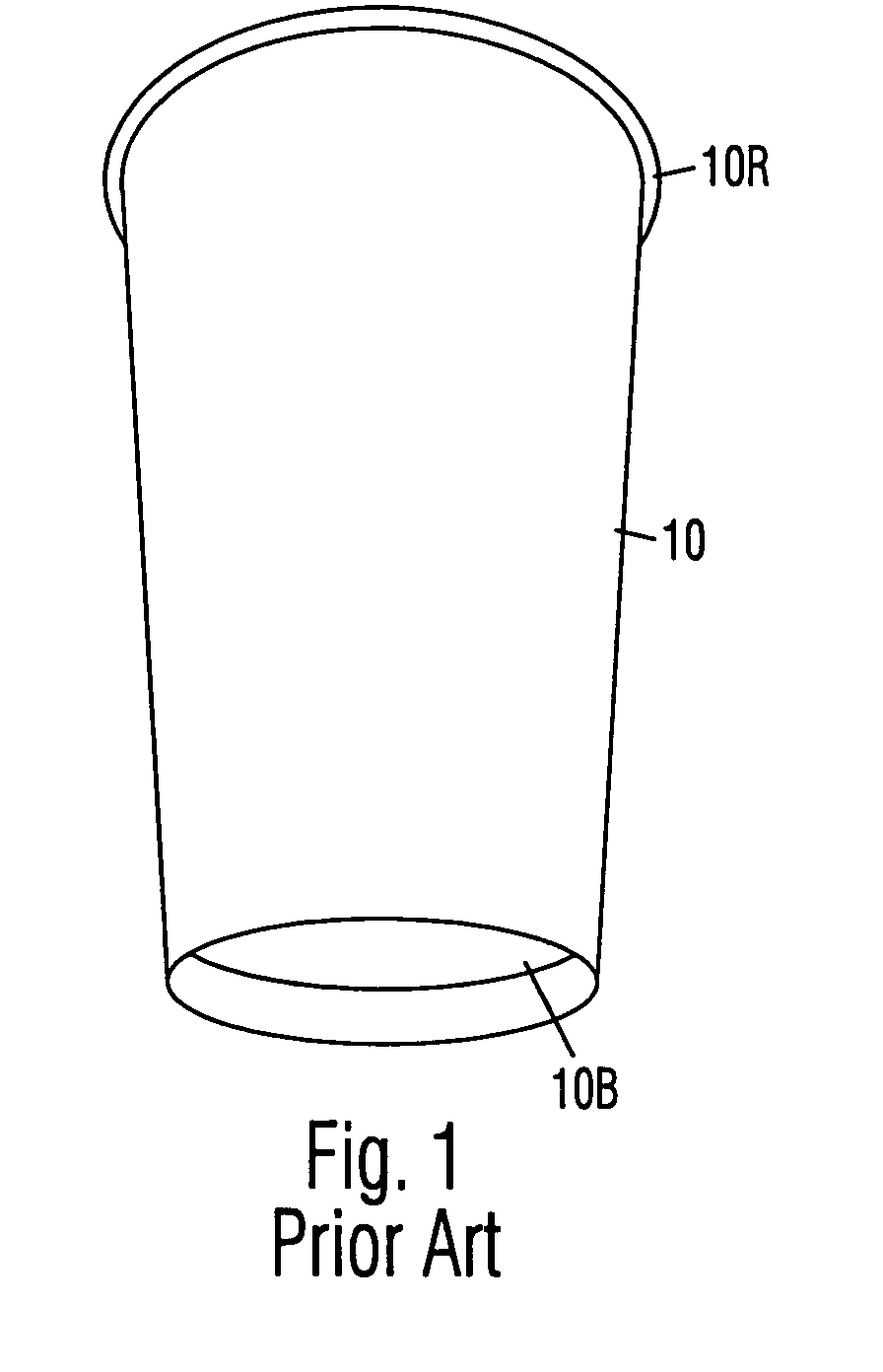

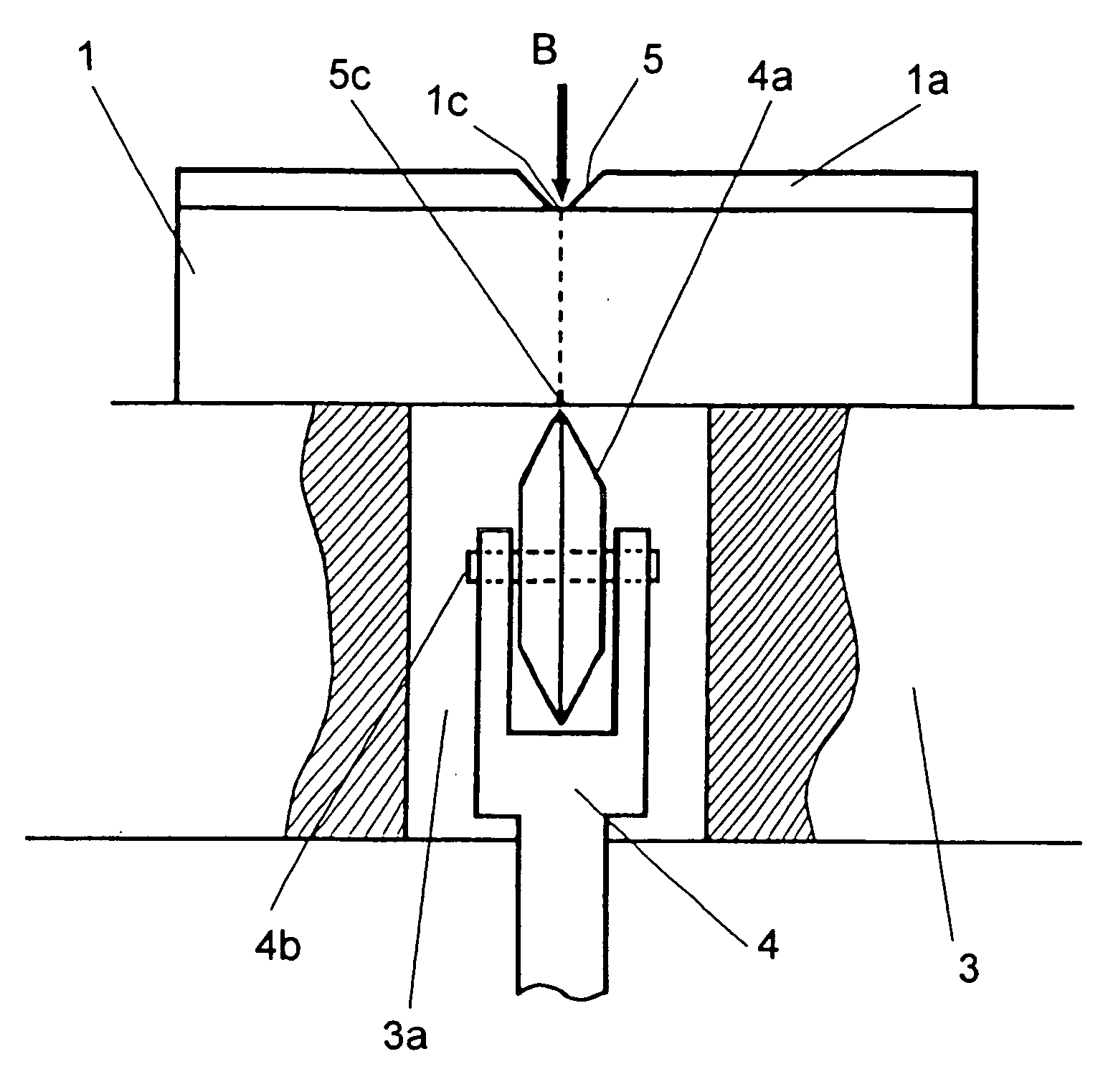

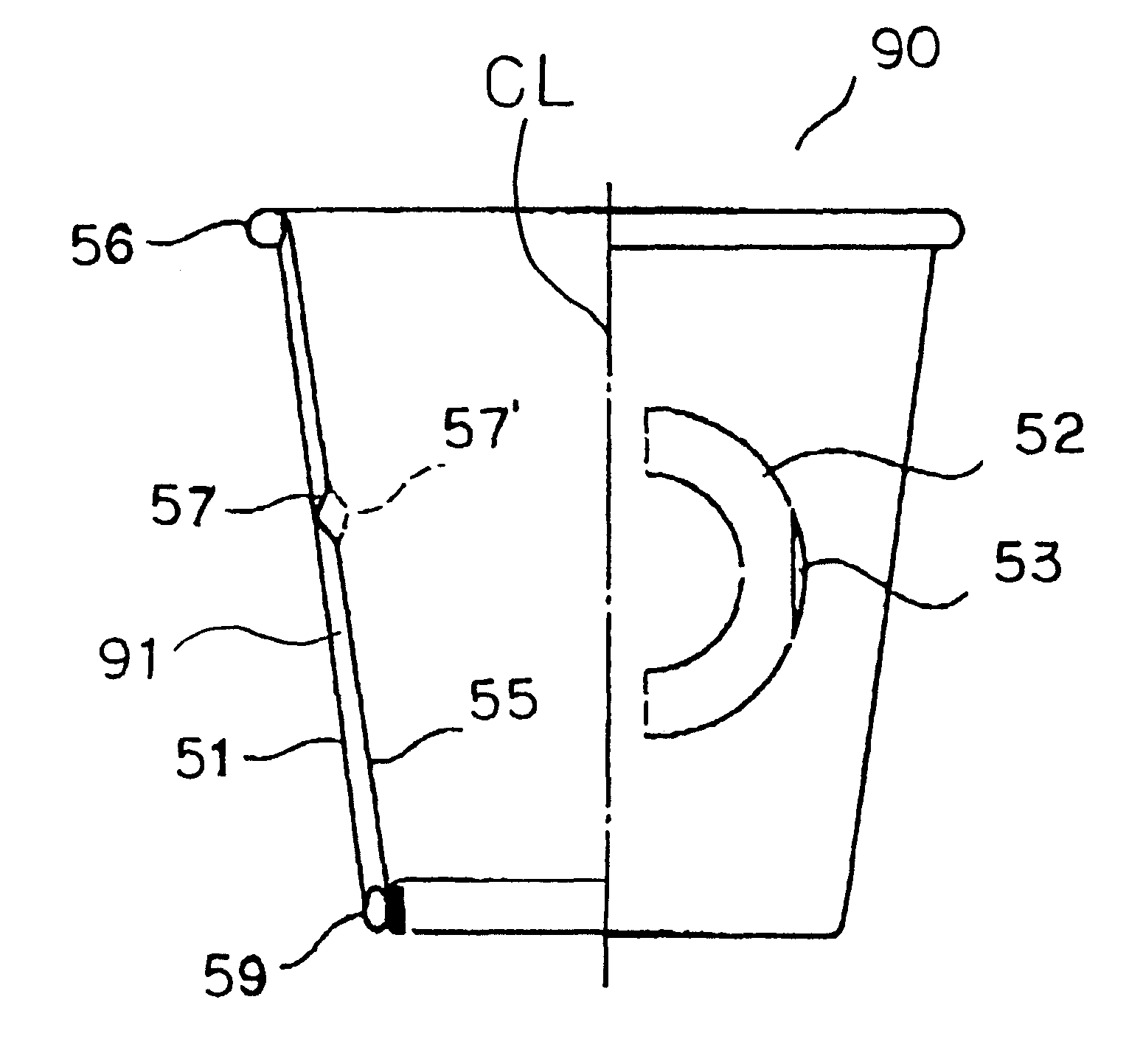

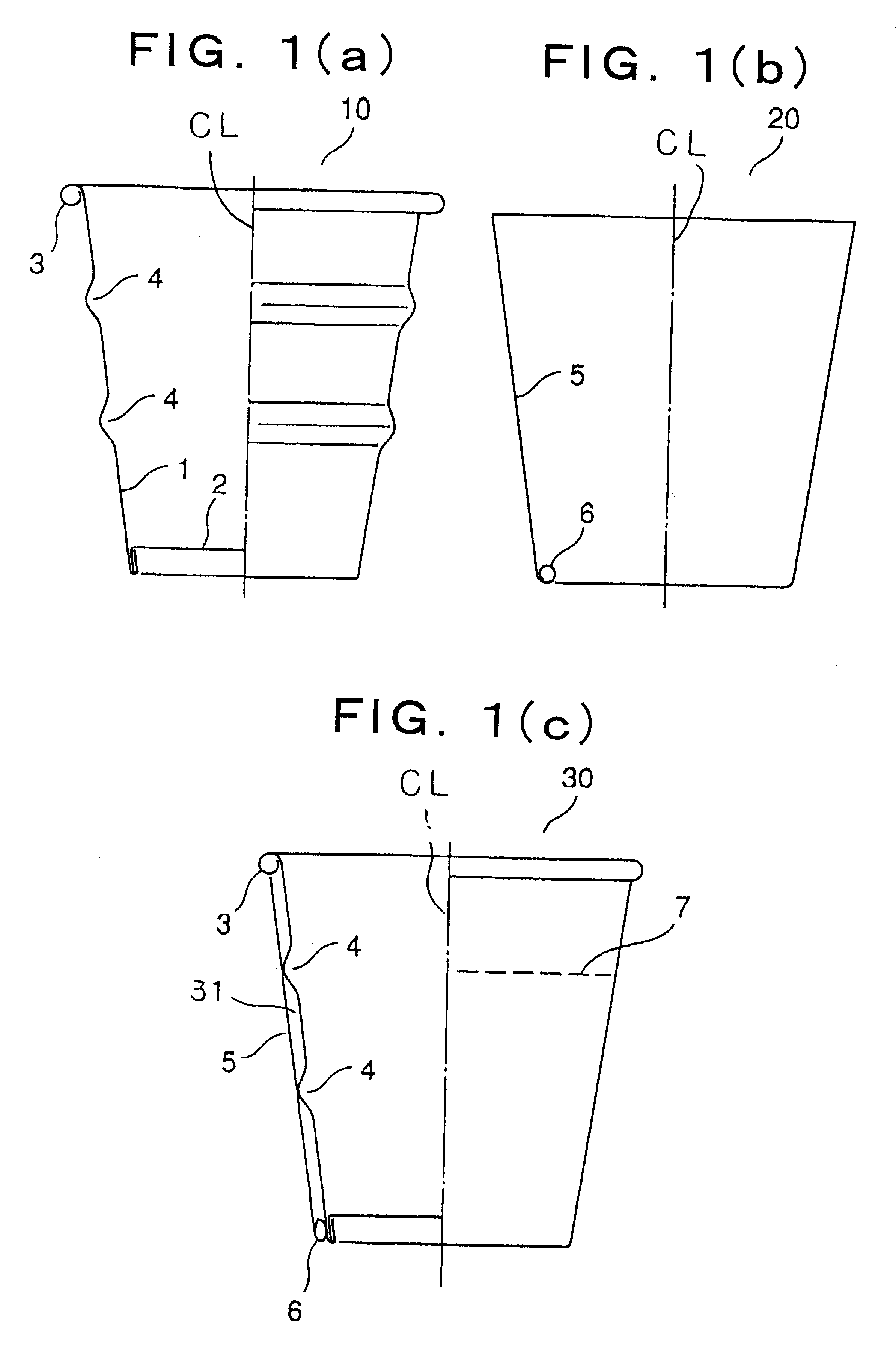

Insulating container

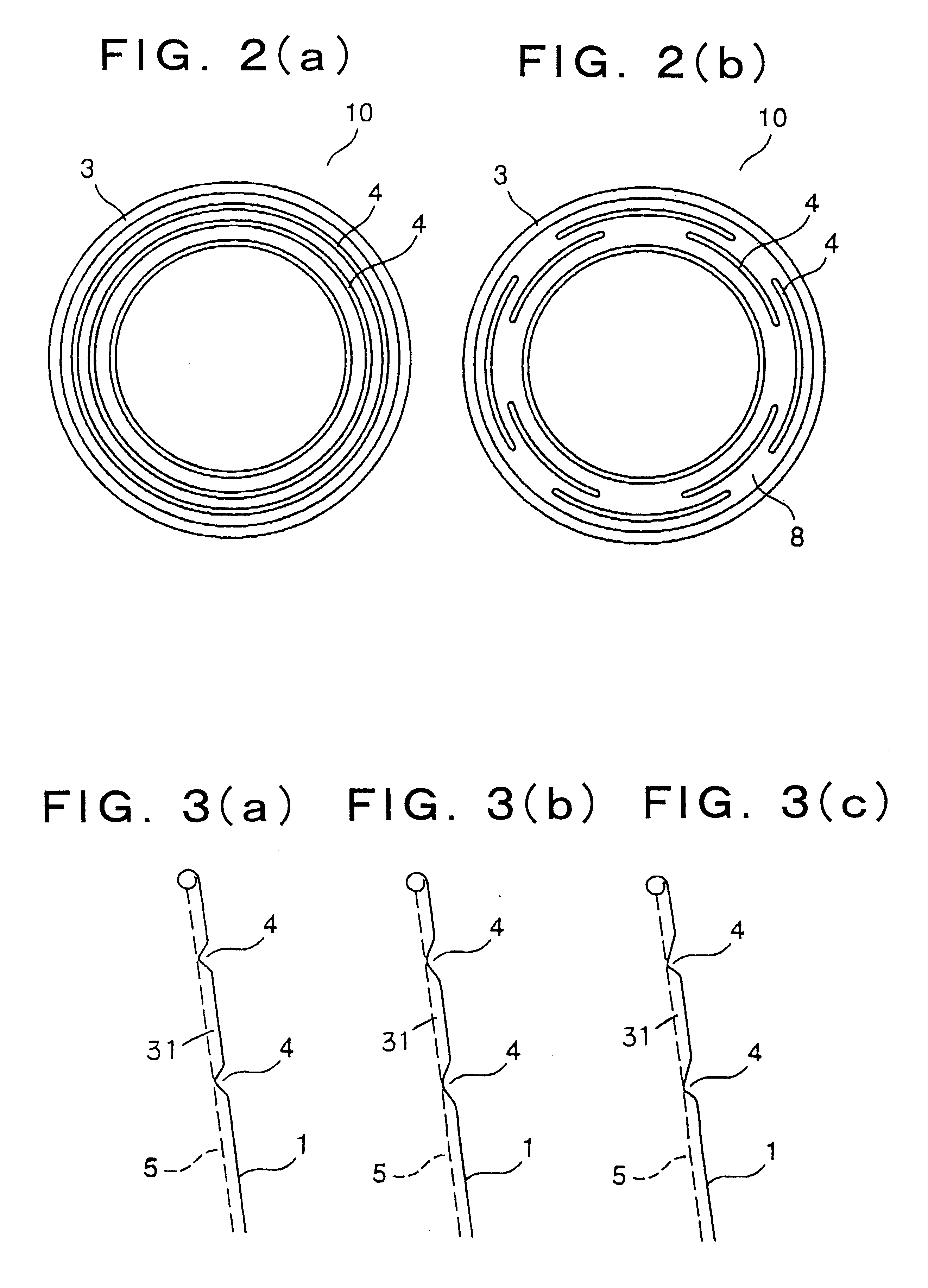

InactiveUS6193098B1Improve insulation performanceImprove securityBoxes/cartons making machineryDomestic cooling apparatusEngineeringPaper cup

A heat-insulating container comprises a paper cup body having an inner surface, an upper open end, a shell member and a bottom, the inner surface being coated with polyolefine resin, the upper open end having an outward curled portion and the shell member having a side wall on which at least one rib is formed; and a tubular member being formed of paper and having an inverse truncated conical shape, the tubular member having at a lower end thereof an inward curled portion. The tubular member is combined with an outer periphery of the paper cup body so as to come into contact with the paper cup body in contact portions provided on the at least one rib of the paper cup body and on an outer periphery of an lower end of the side wall of the shell member. According to such a structure, it is possible to provide the heat-insulating container, which has a stable heat-insulating property, a high grade design, a high degree of freedom in indication by printing on the outer surface of the container, and a lower production cost.

Owner:DAI NIPPON PRINTING CO LTD

Insulating shipping system

An insulating shipping system may include a container and an insert assembly which may include an insert configured to be inserted into the container. The insert may have a first blank that may include a center panel, two bottom panels emanating from opposite side edges, wherein each bottom panel has at least one slot, at least one top panel emanating from a top edge of each of the bottom panels, wherein each top panel has at least one tab or flange, and at least one foldable line of weakness disposed between each top panel and bottom panel, wherein the at least one slot is sized to receive the at least one tab or flange. The insert further may include a second blank have a center panel, wherein the center panel is configured to couple to the center panel of the first blank to form at least one walled cavity.

Owner:EKOPAK INC

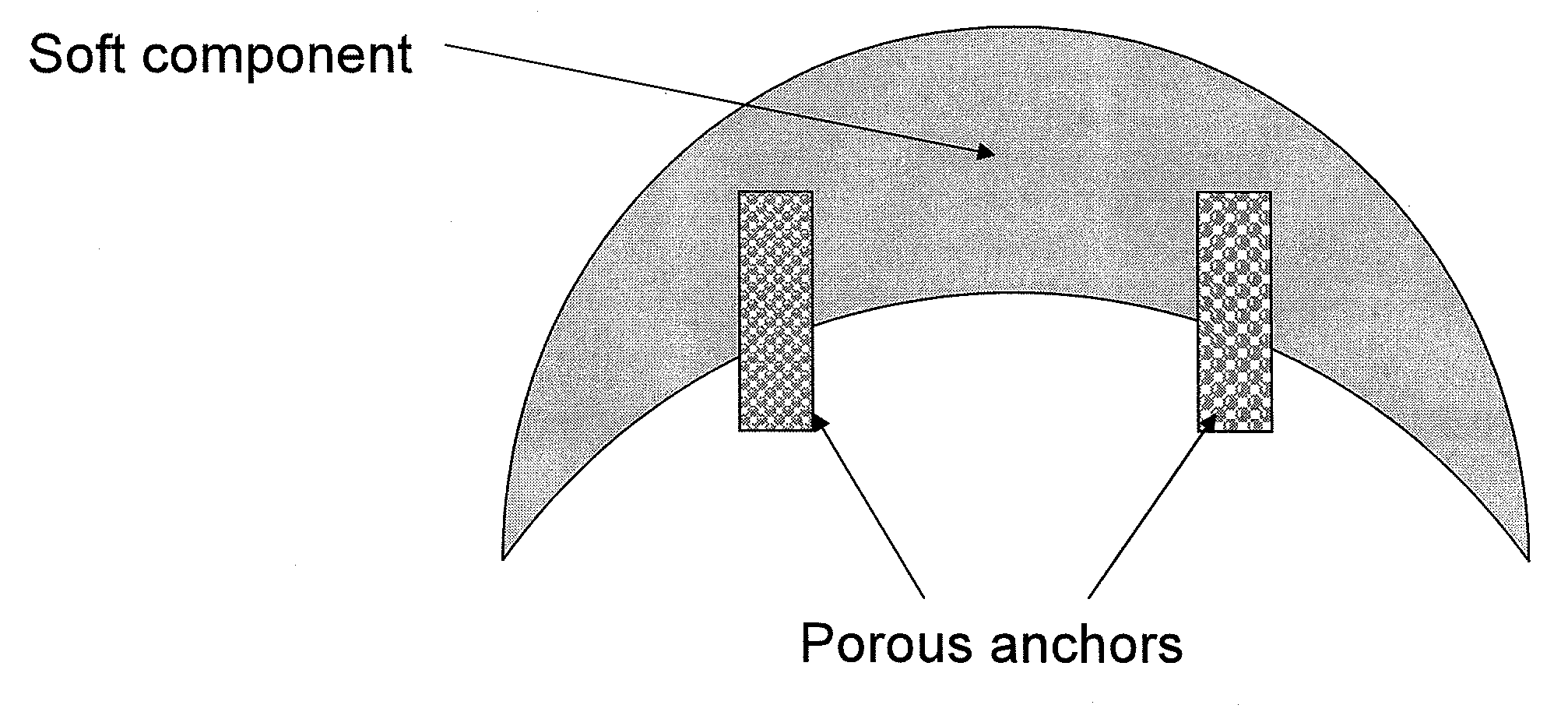

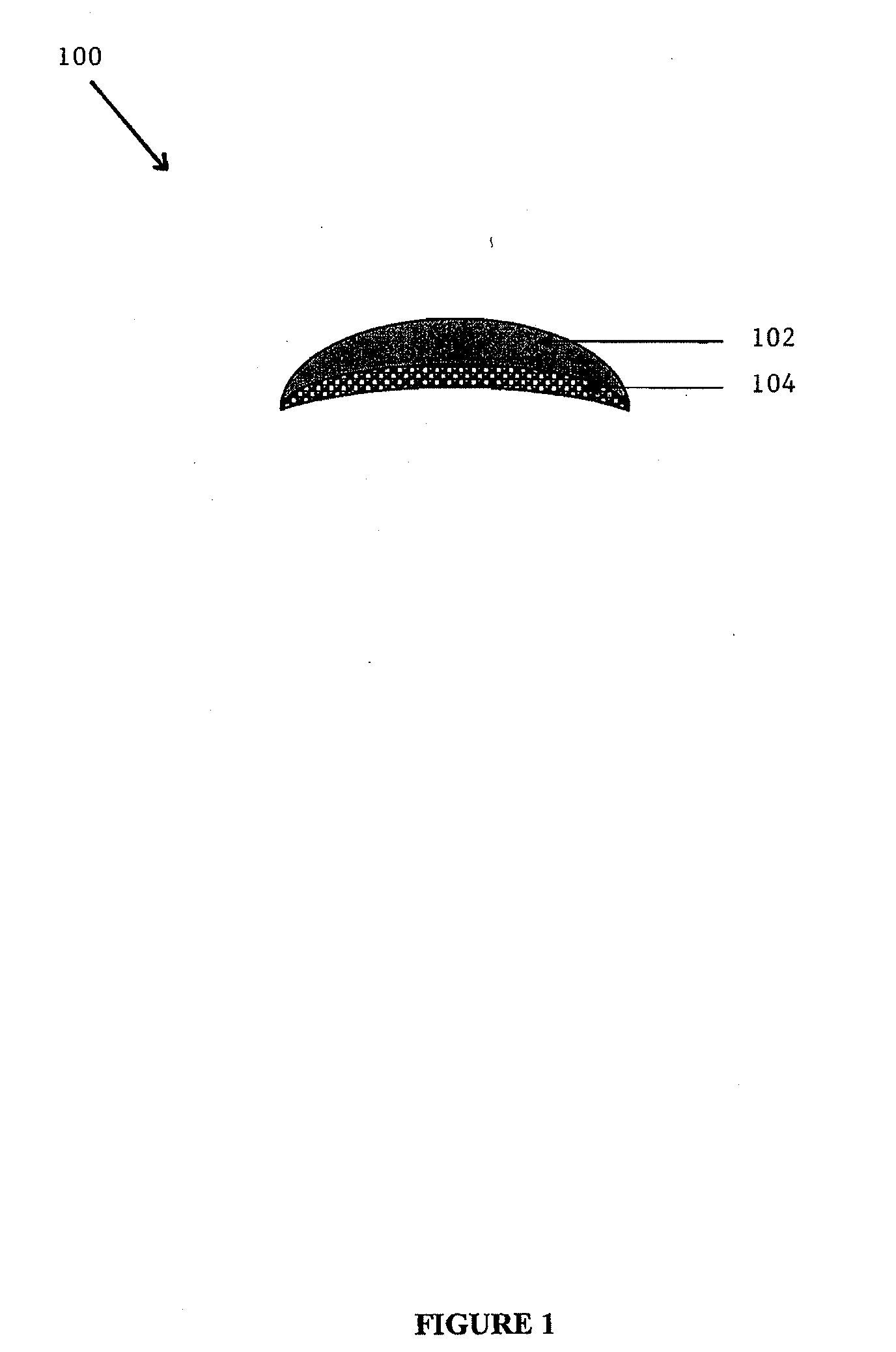

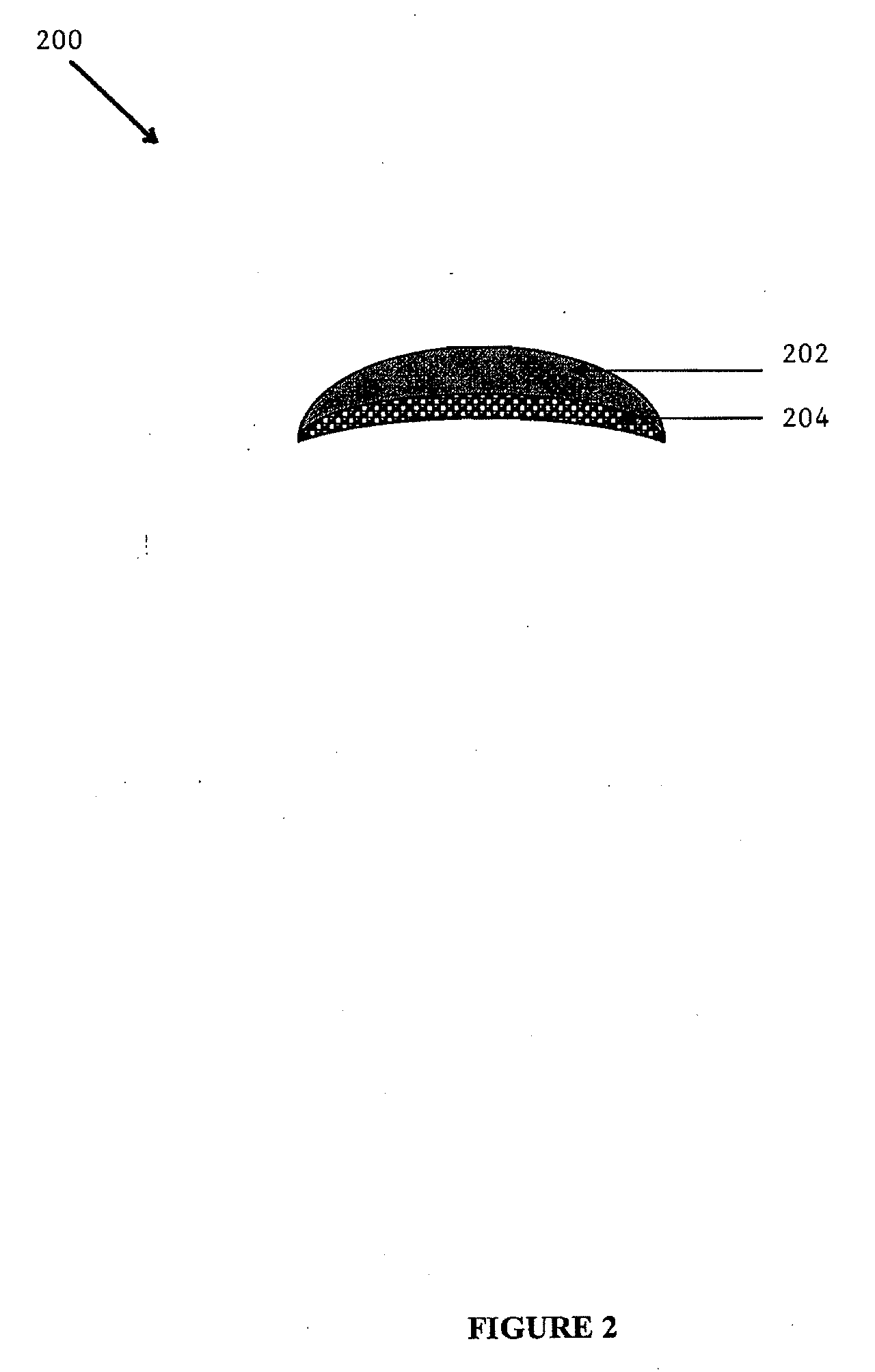

Composite Implants and Methods of Making and Using the Same

ActiveUS20100023130A1Reduce and preclude implant motionSmall sizeBone implantBox making operationsMaterials sciencePolymer

The present invention provides composite implants for the replacement or augmentation of non-load bearing or load bearing soft tissues, and methods of making and using these implant compositions. In one embodiment, a composite implant of the present invention comprises a soft polymeric component coupled to a porous polymeric substrate

Owner:ORTHOVITA INC

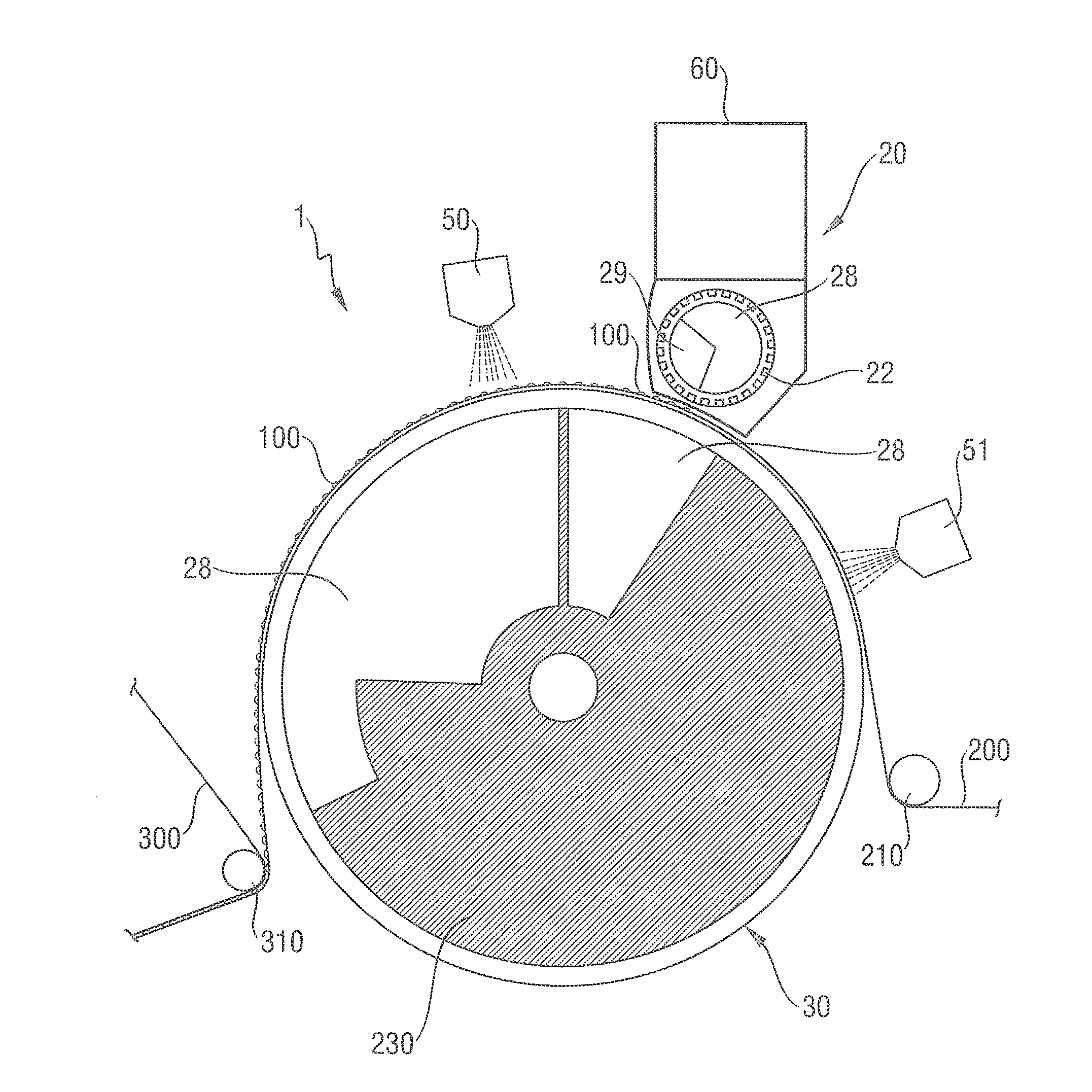

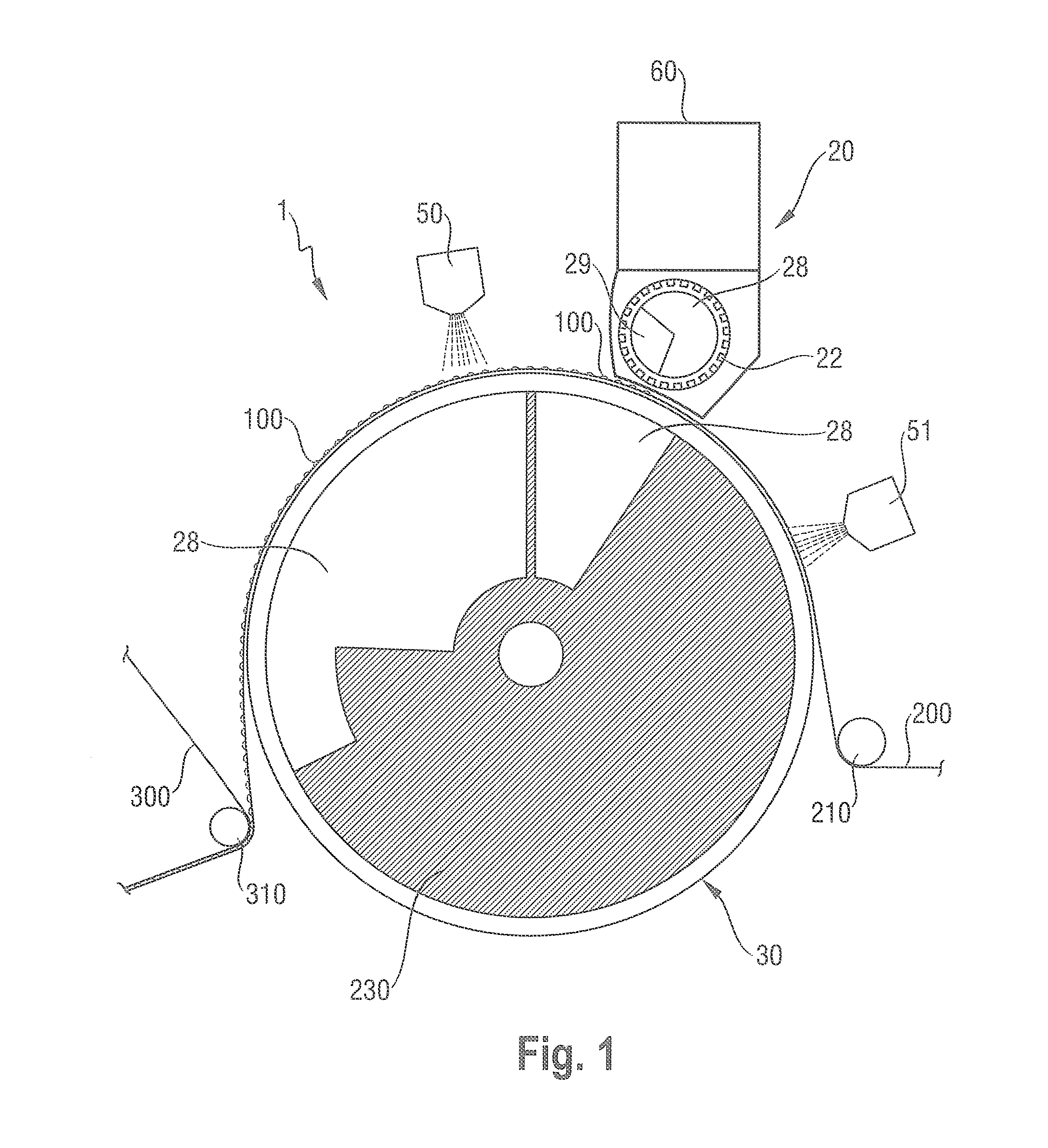

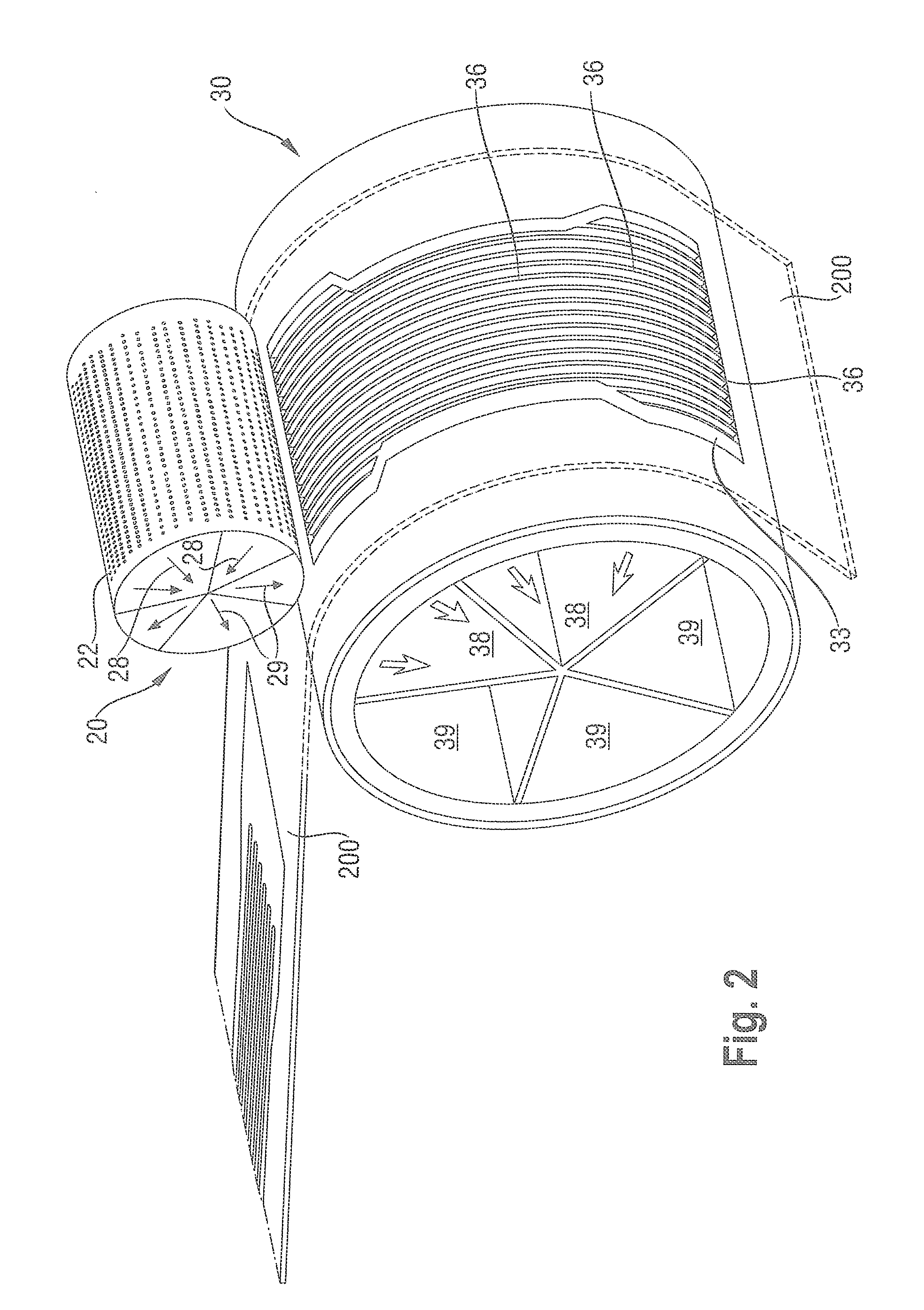

Method and Apparatus for Making Absorbent Structures with Absorbent Material

ActiveUS20120316046A1Boxes/cartons making machineryPaper/cardboard articlesAbsorbent materialMechanical engineering

A method and apparatus for making specific absorbent structures with an absorbent layer with absorbent material with therein substantially longitudinally extending strips that are free of absorbent material, using or having thereto a moving endless surface with receptacle(s) with specific longitudinally extending rods; and specific absorbent structures obtained therewith, suitable for absorbent articles, such as diapers and sanitary napkins.

Owner:THE PROCTER & GAMBLE COMPANY

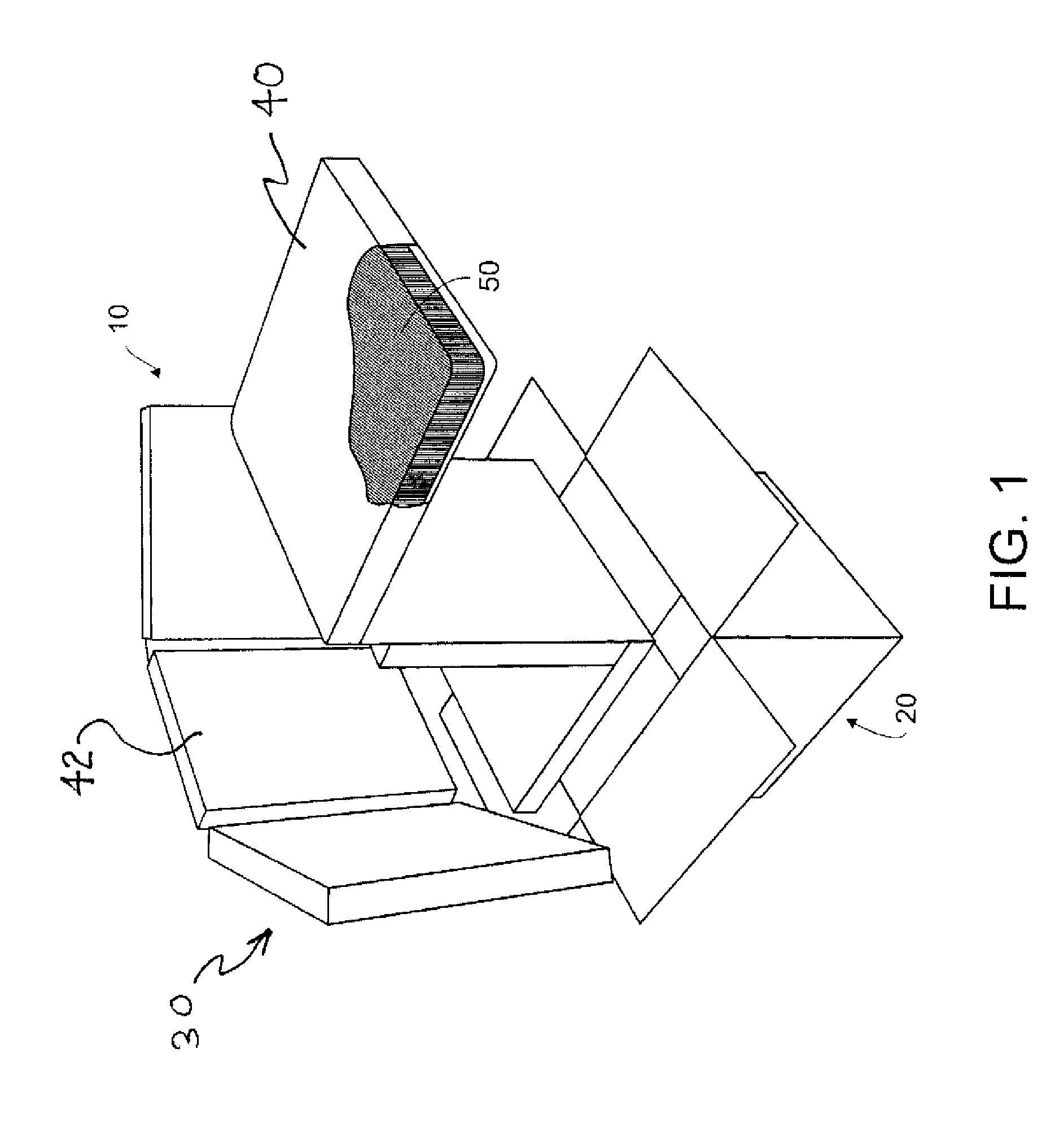

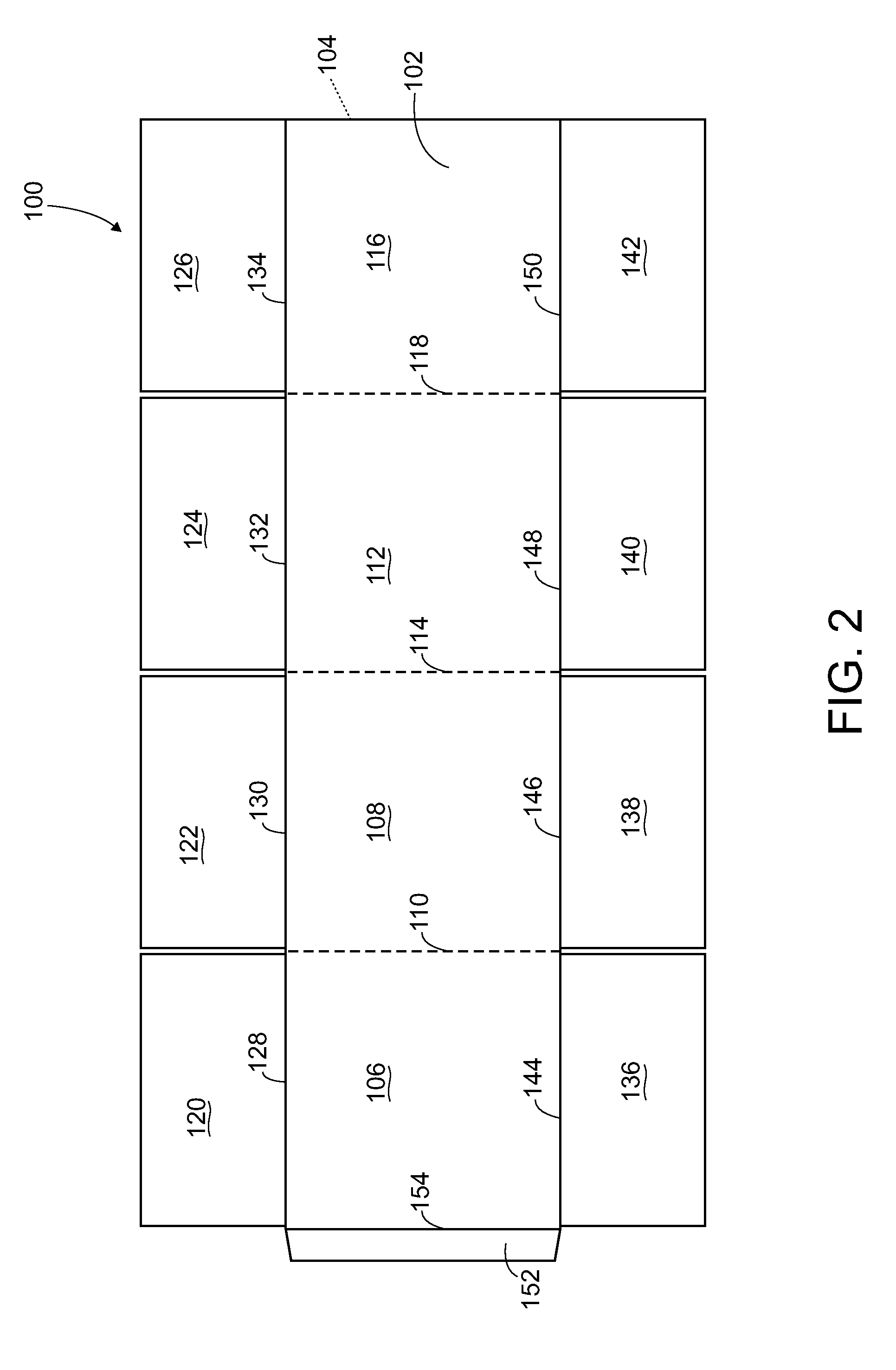

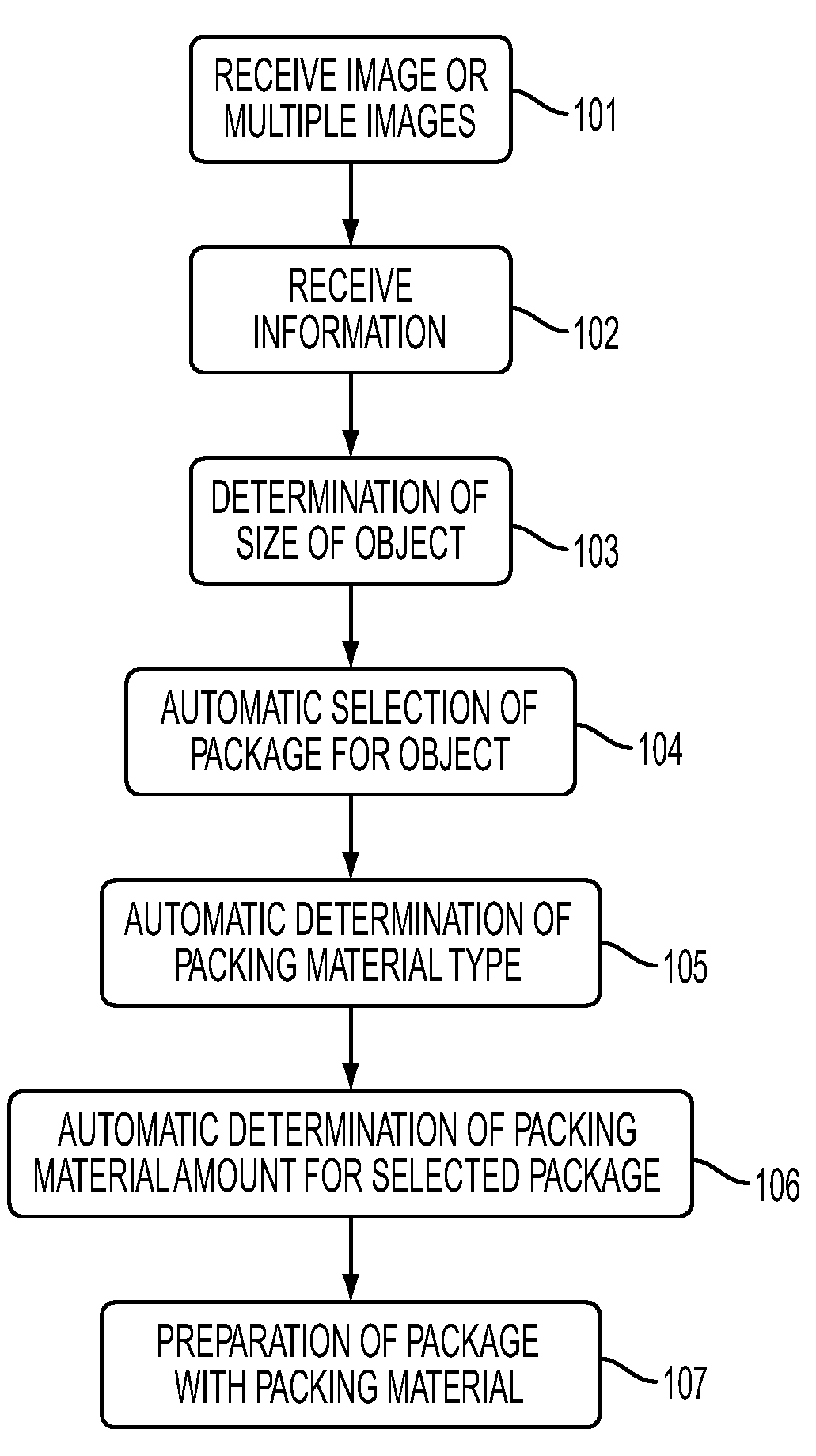

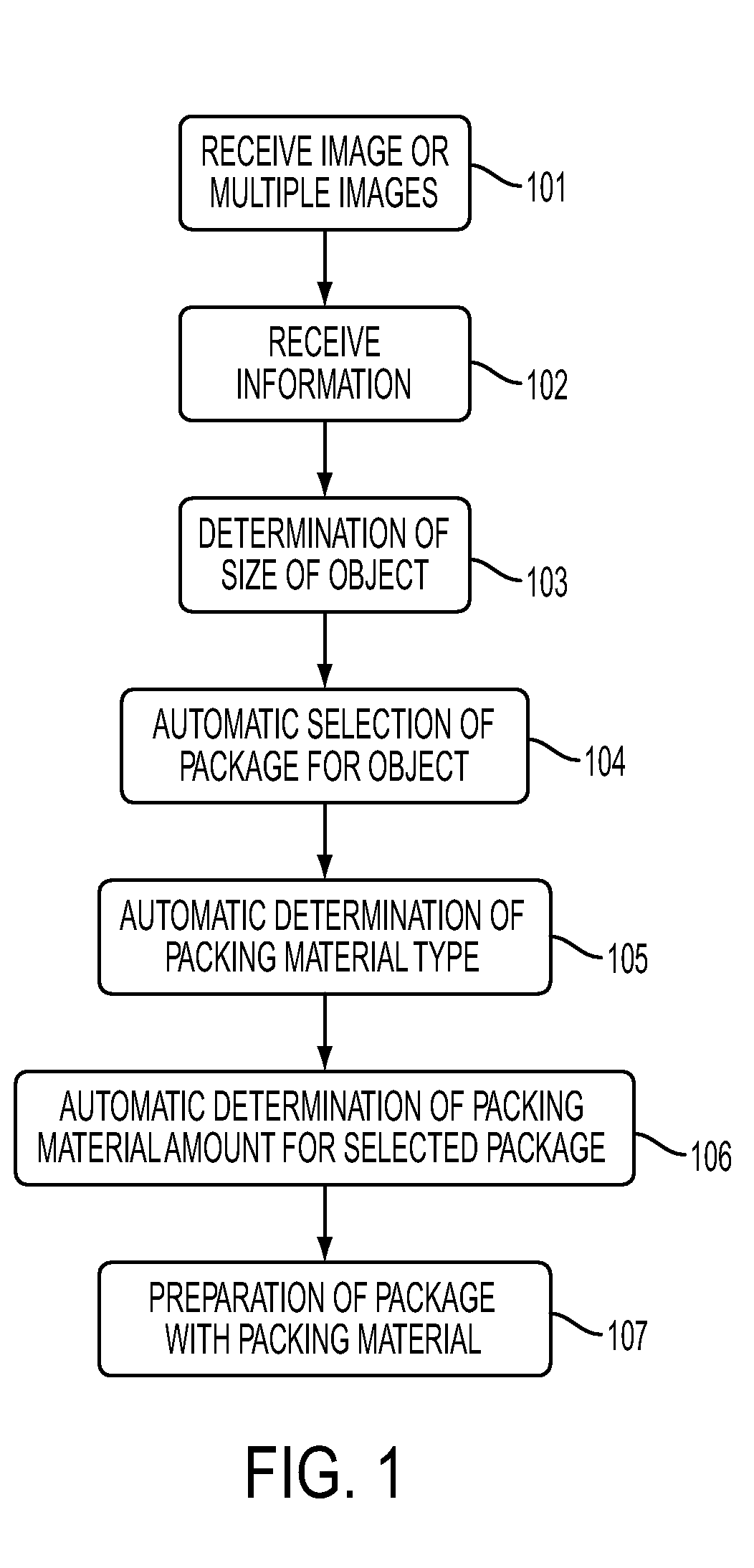

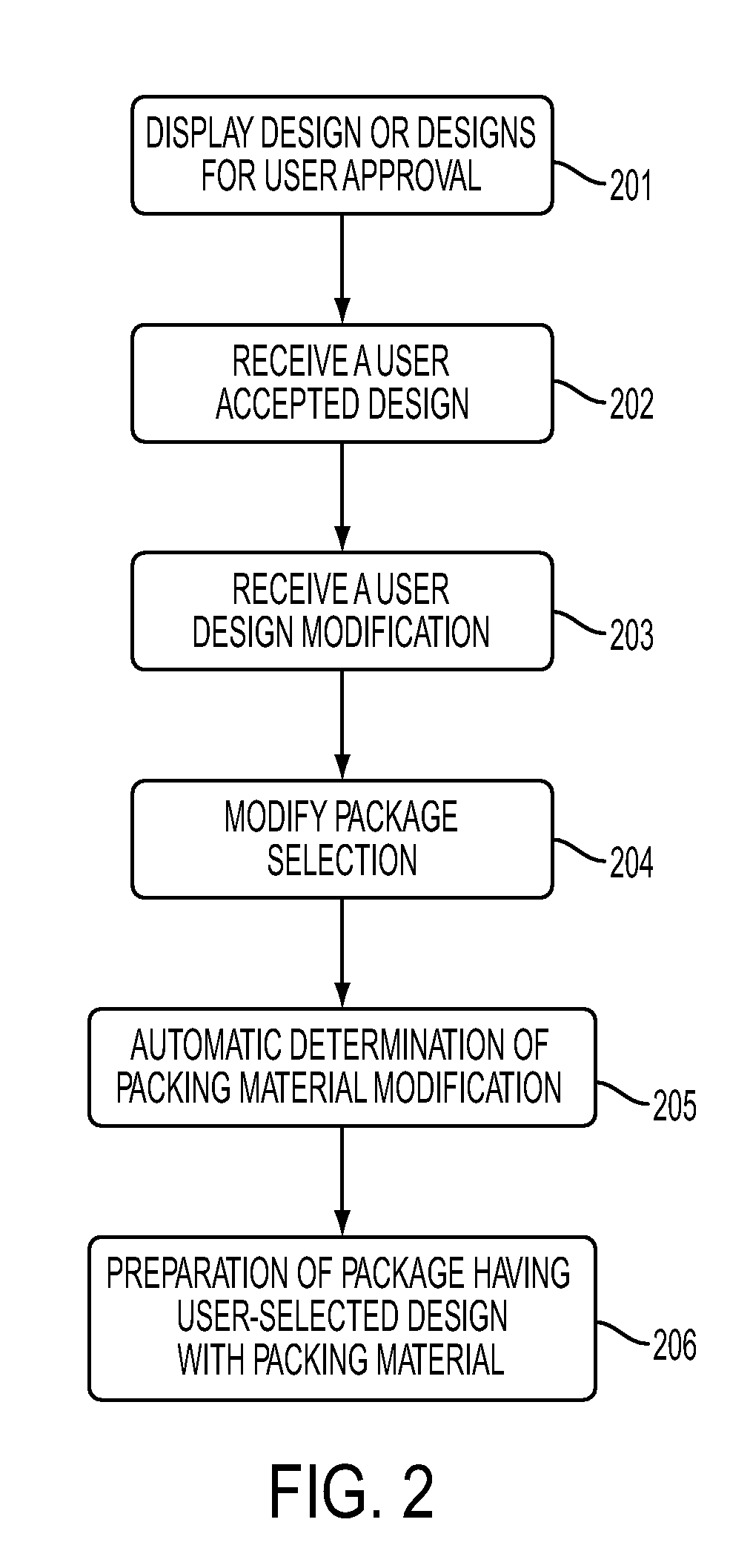

Custom packaging solution for arbitrary objects

Owner:XEROX CORP

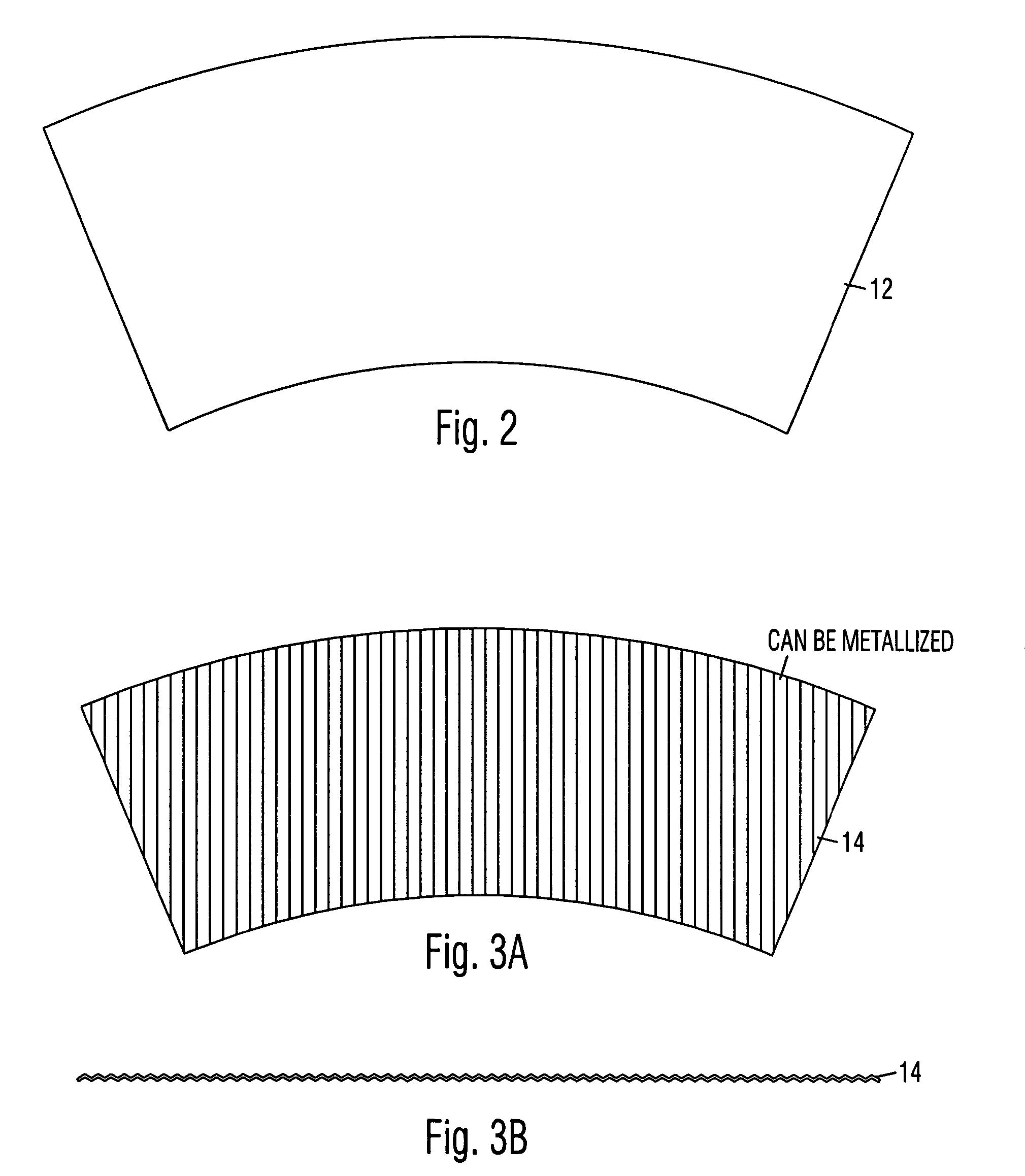

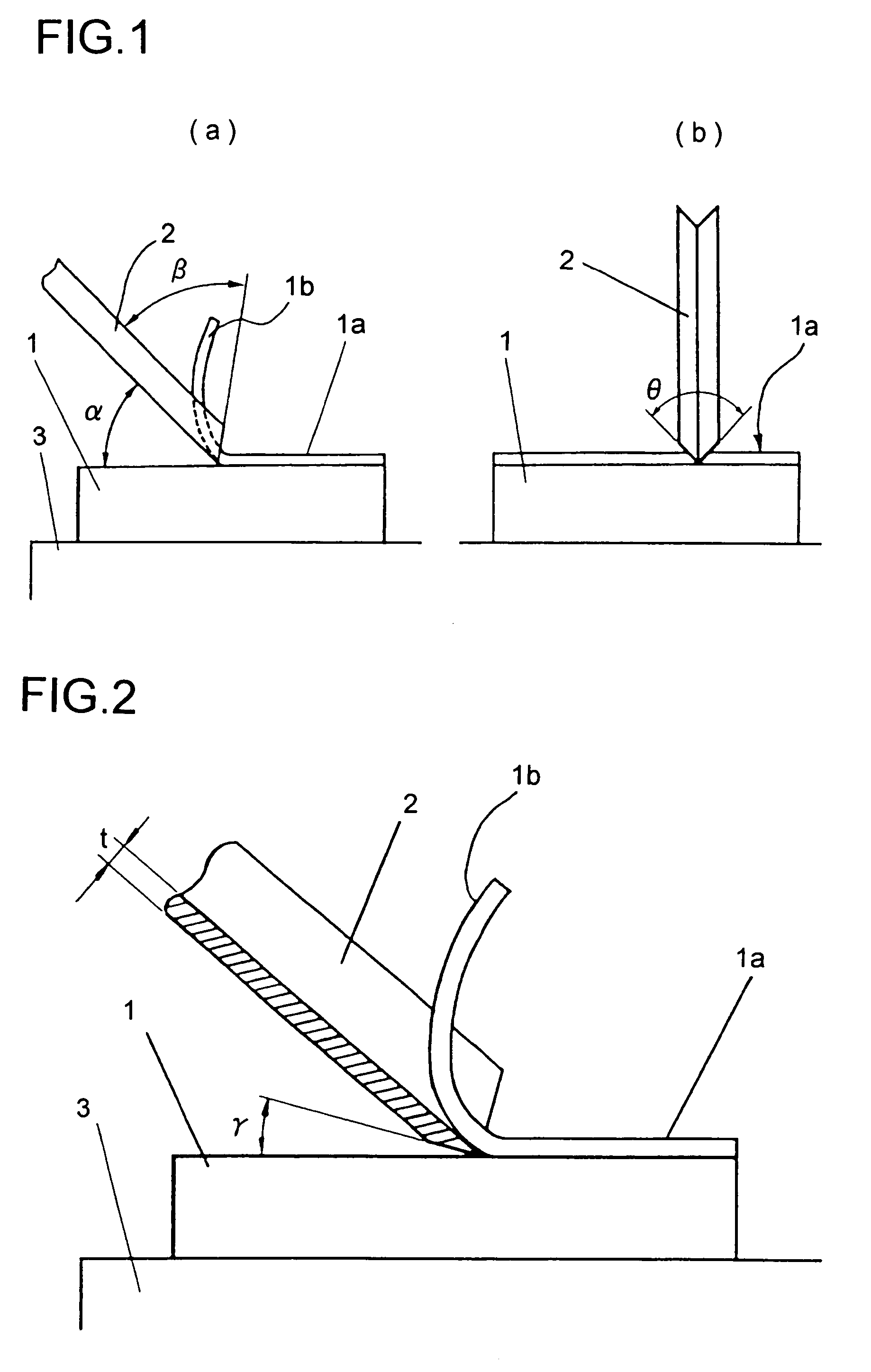

Insulating cup wrapper and insulated container formed with wrapper

A thermally insulated cup is formed from a single-walled paper or plastic inner cup and an insulating outer wrapper. The insulating outer wrapper comprises a paper base sheet or outer sidewall blank, optionally printed on one side, and a corrugated paper or foamed plastic insulating insert. The insulating insert is similar in shape to the outer sidewall blank but smaller in size. The insert is glued in a centered position to the non-printed side of the sidewall blank to form a two-layered insulating wrapper. Less than 20% of the area of the insert is glued to the base sheet. Specifically, no glue is applied to the area adjacent to the cut side edges of the insert, and as such these edges are not attached to the base sheet. The wrapper is then wrapped around the single walled inner cup. The side edges of the base sheet of the wrapper overlap and are sealed directly together to form a side seam. The side seam is itself adhesively secured to the side wall of the inner cup. The side edges of the insert do not come between the seal between the side seam of the base sheet and the inner cup. The wrapper can also be adhered to the inner cup by one or more beads of cold glue (paste adhesive) or a thin layer of polyethylene (or similar heat sealing material) can be pre-applied to the inside cut edges of the base sheet. This is then heat-activated immediately prior to wrapping the wrapper around the inner cup, and pressing the overlapping side seam to the sidewall of the inner cup to simultaneously glue the side seam together, and to glue the insulating wrapper to the side wall of the cup.

Owner:GPCP IP HLDG LLC

Insulating Shipping System

An insulating shipping system may include a container and an insert assembly which may include an insert configured to be inserted into the container. The insert may have a first blank that may include a center panel, two bottom panels emanating from opposite side edges, wherein each bottom panel has at least one slot, at least one top panel emanating from a top edge of each of the bottom panels, wherein each top panel has at least one tab or flange, and at least one foldable line of weakness disposed between each top panel and bottom panel, wherein the at least one slot is sized to receive the at least one tab or flange. The insert further may include a second blank have a center panel, wherein the center panel is configured to couple to the center panel of the first blank to form at least one walled cavity.

Owner:EKOPAK INC

Custom packaging solution for arbitrary objects

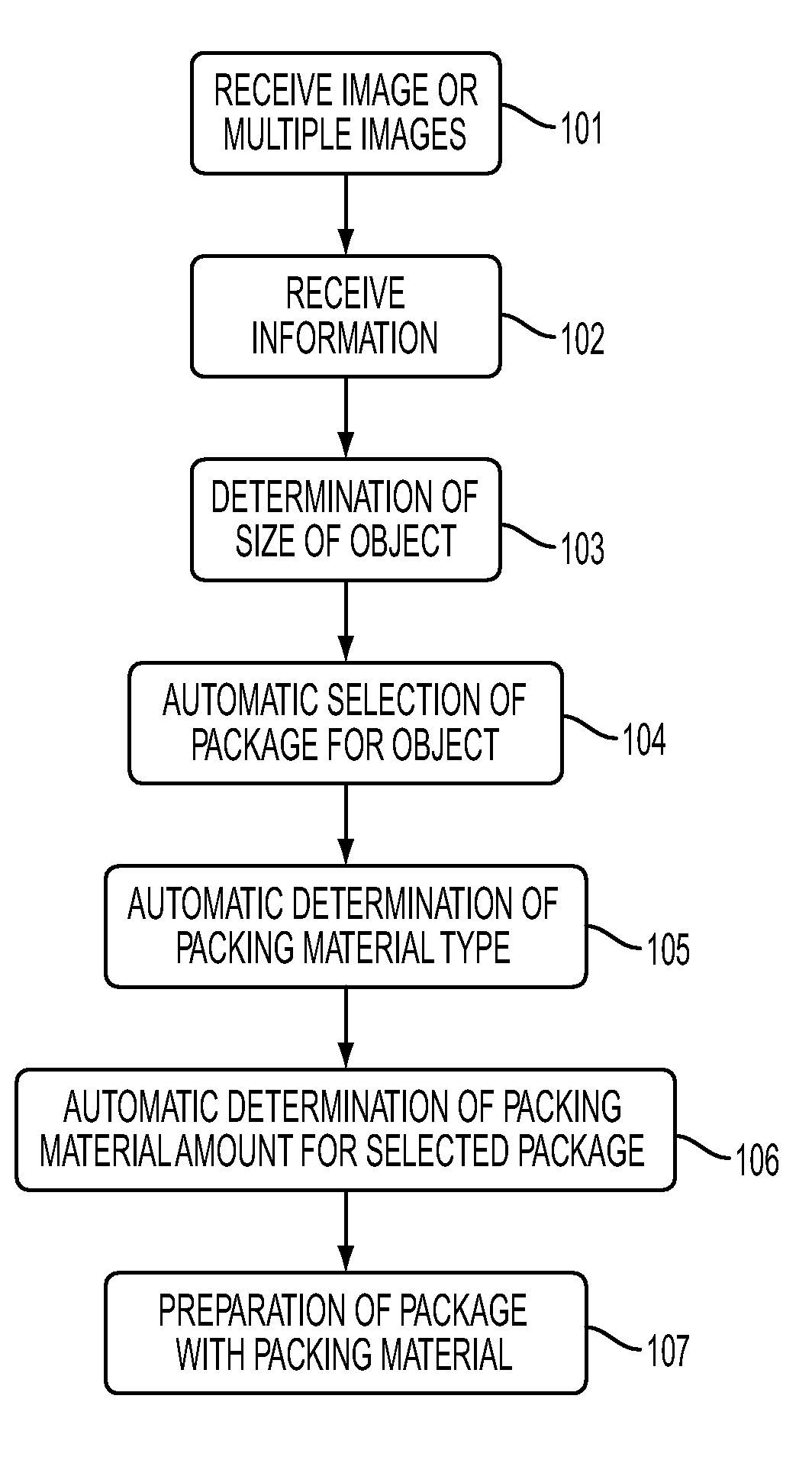

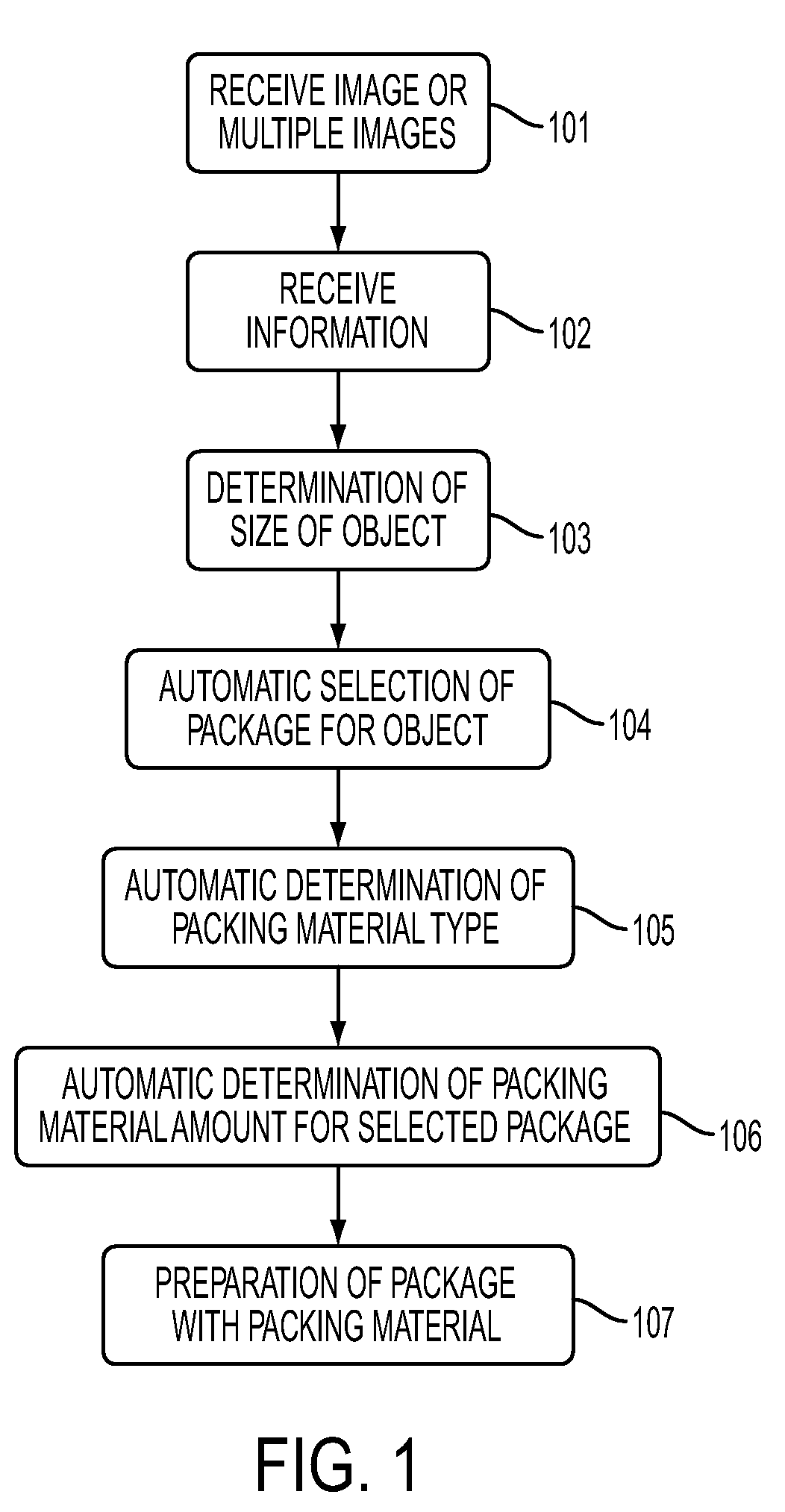

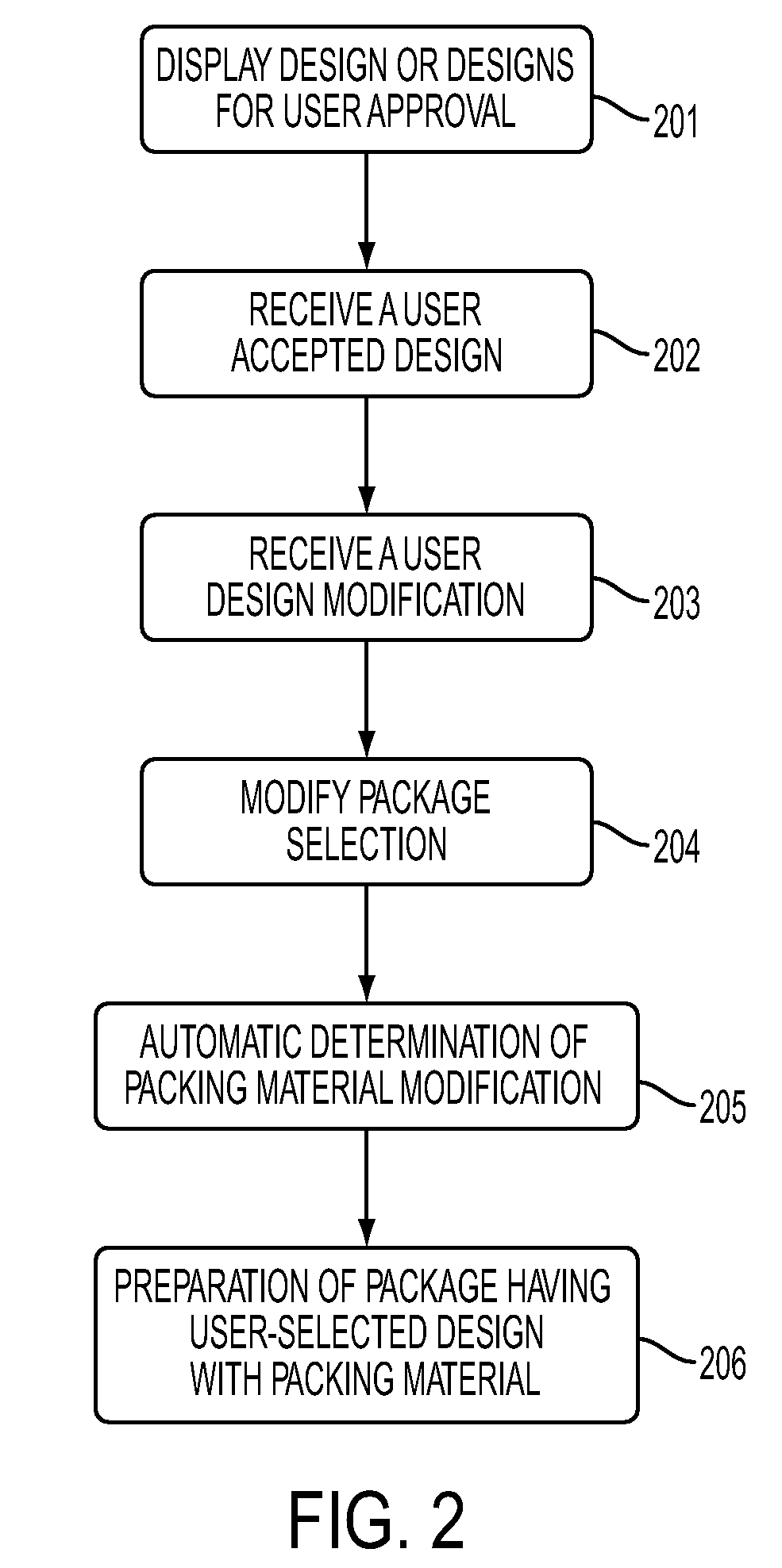

A method of producing a custom packaging system for arbitrary objects. A first image of an object to be packaged is received via an electronic user interface. Information relating to the material properties of the object may be received as well via the interface. A three dimensional size for the object is determined. At least one package for the object is automatically selected. Based on the material properties, a packing material type is automatically determined. Based upon the size and the selected package, a packing material amount is determined. Further printing options are permitted.

Owner:XEROX CORP

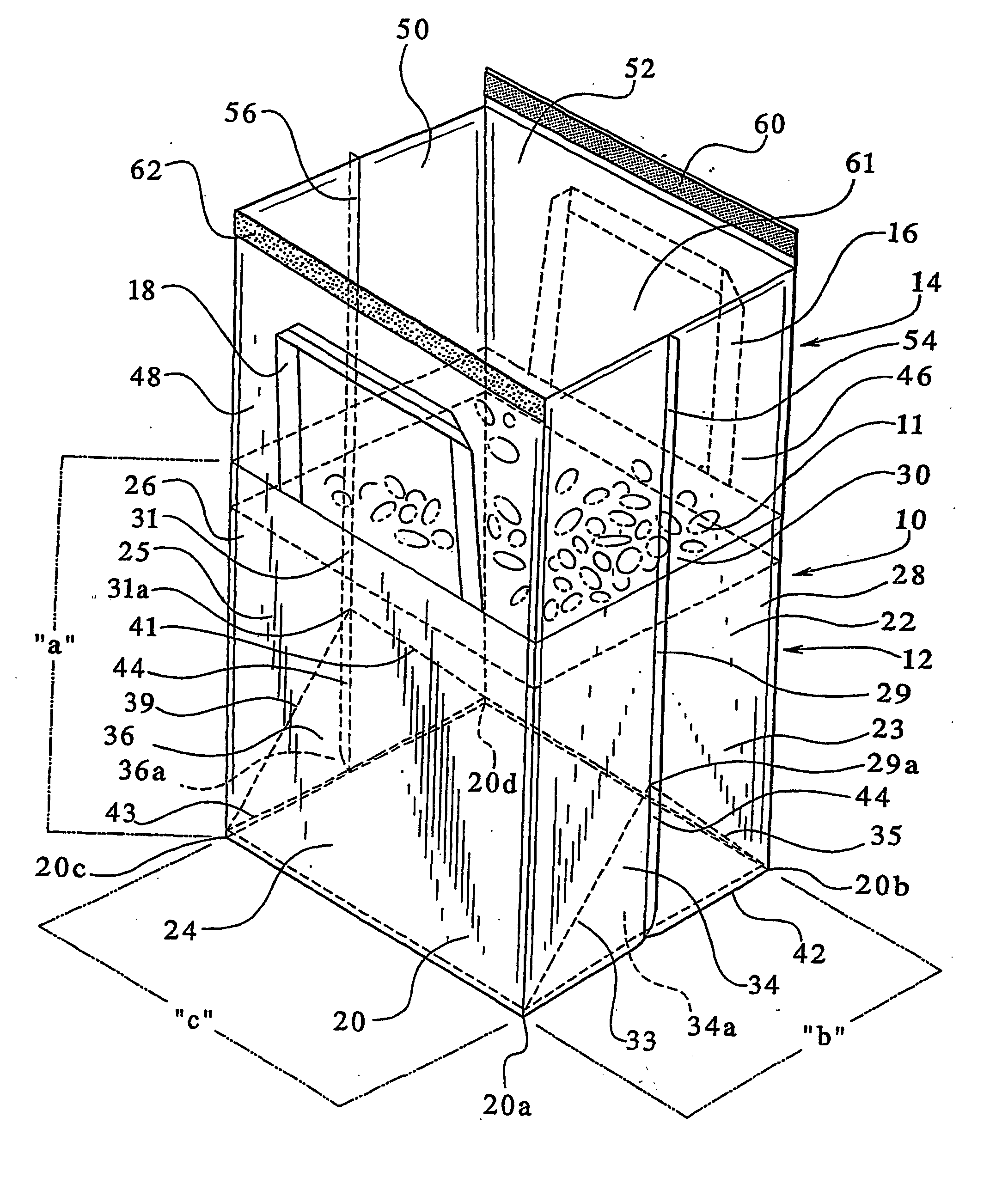

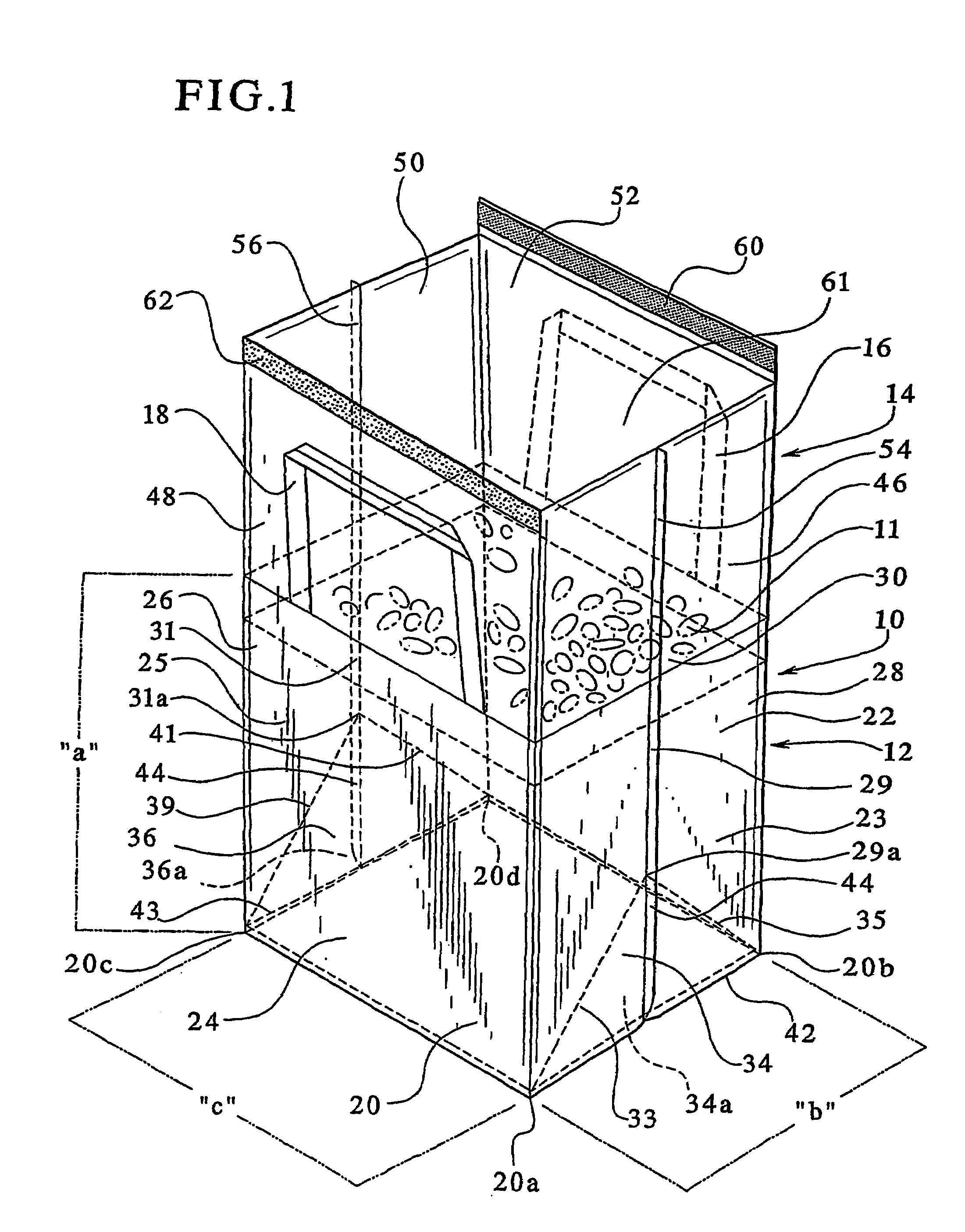

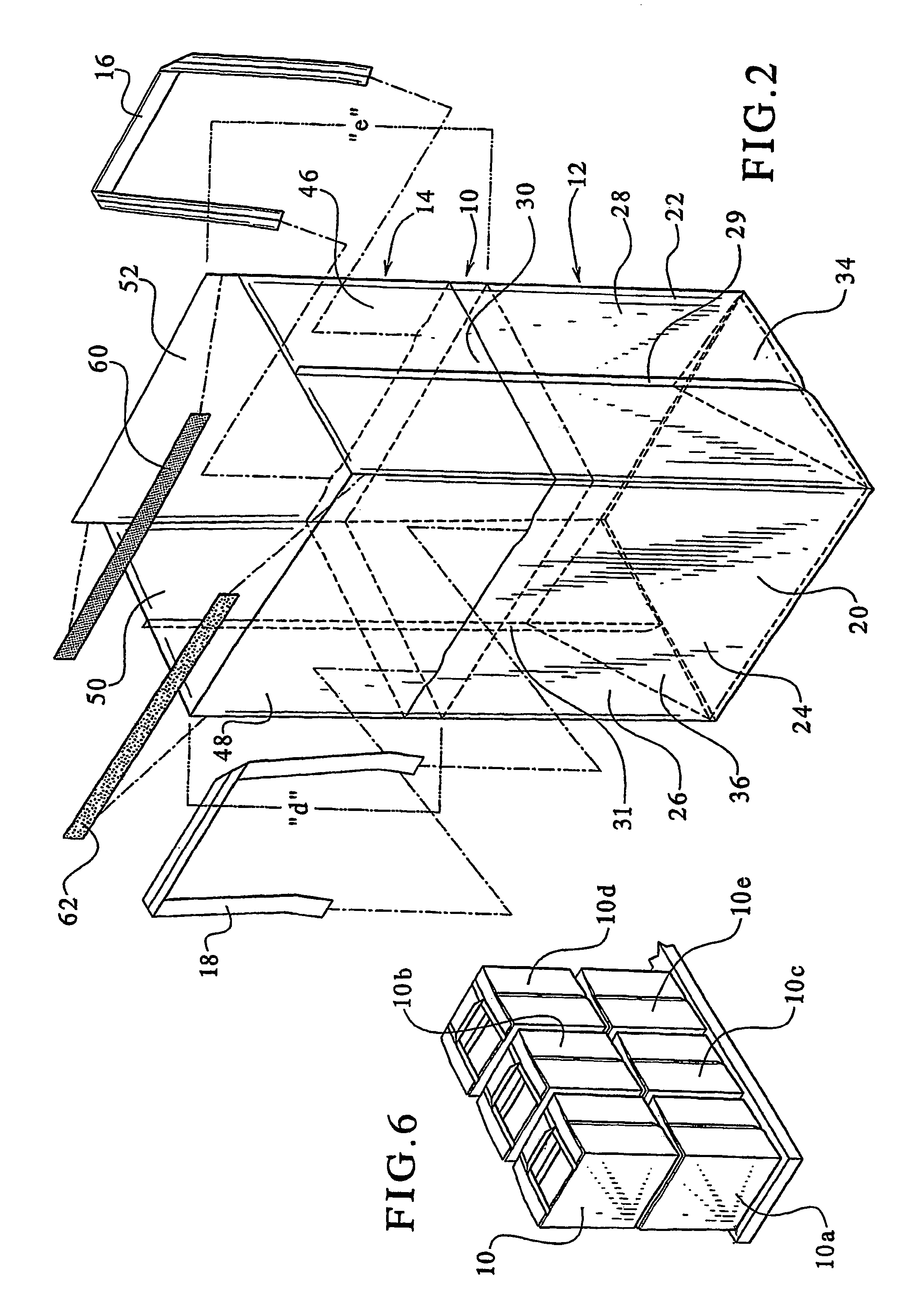

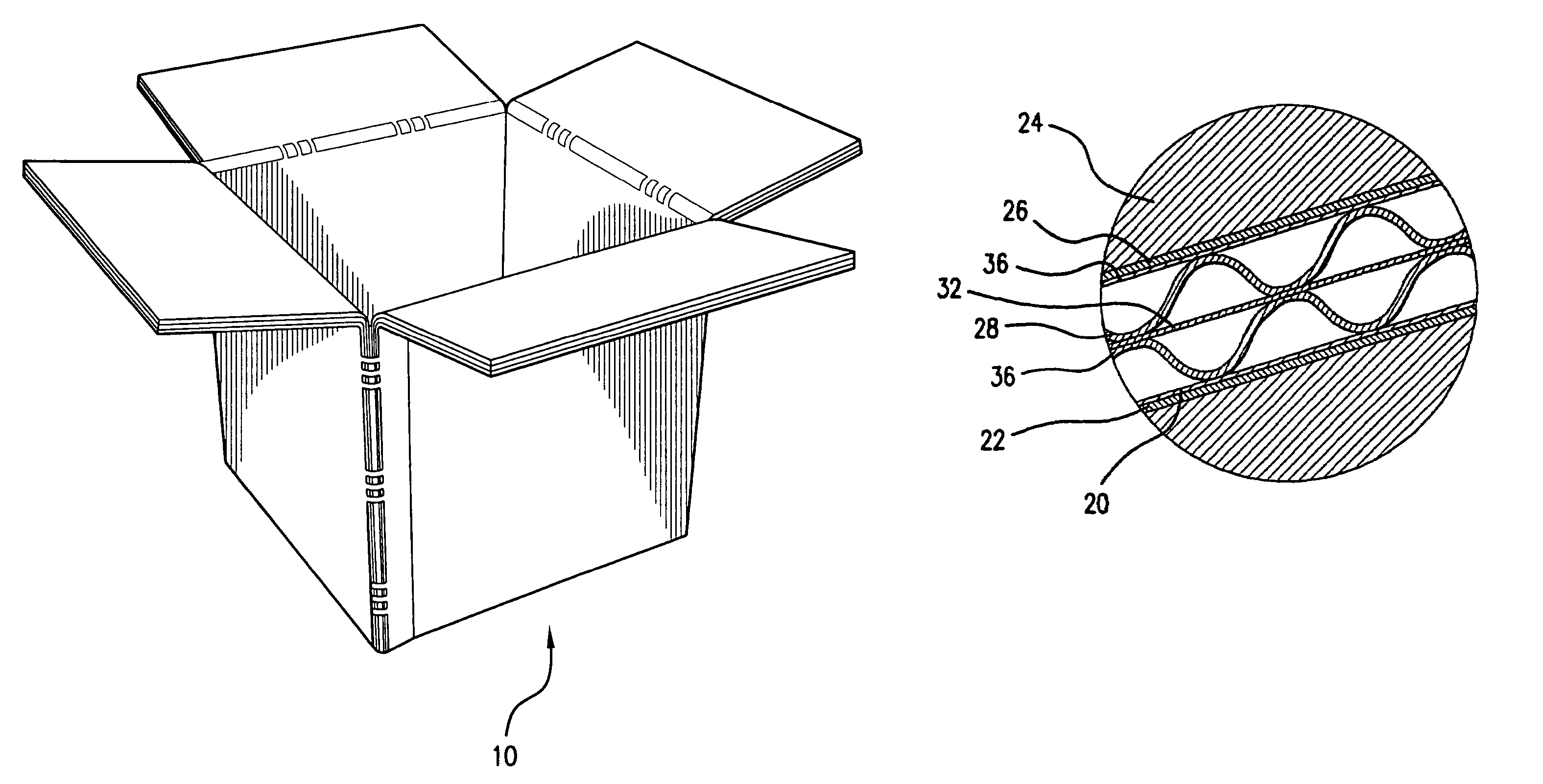

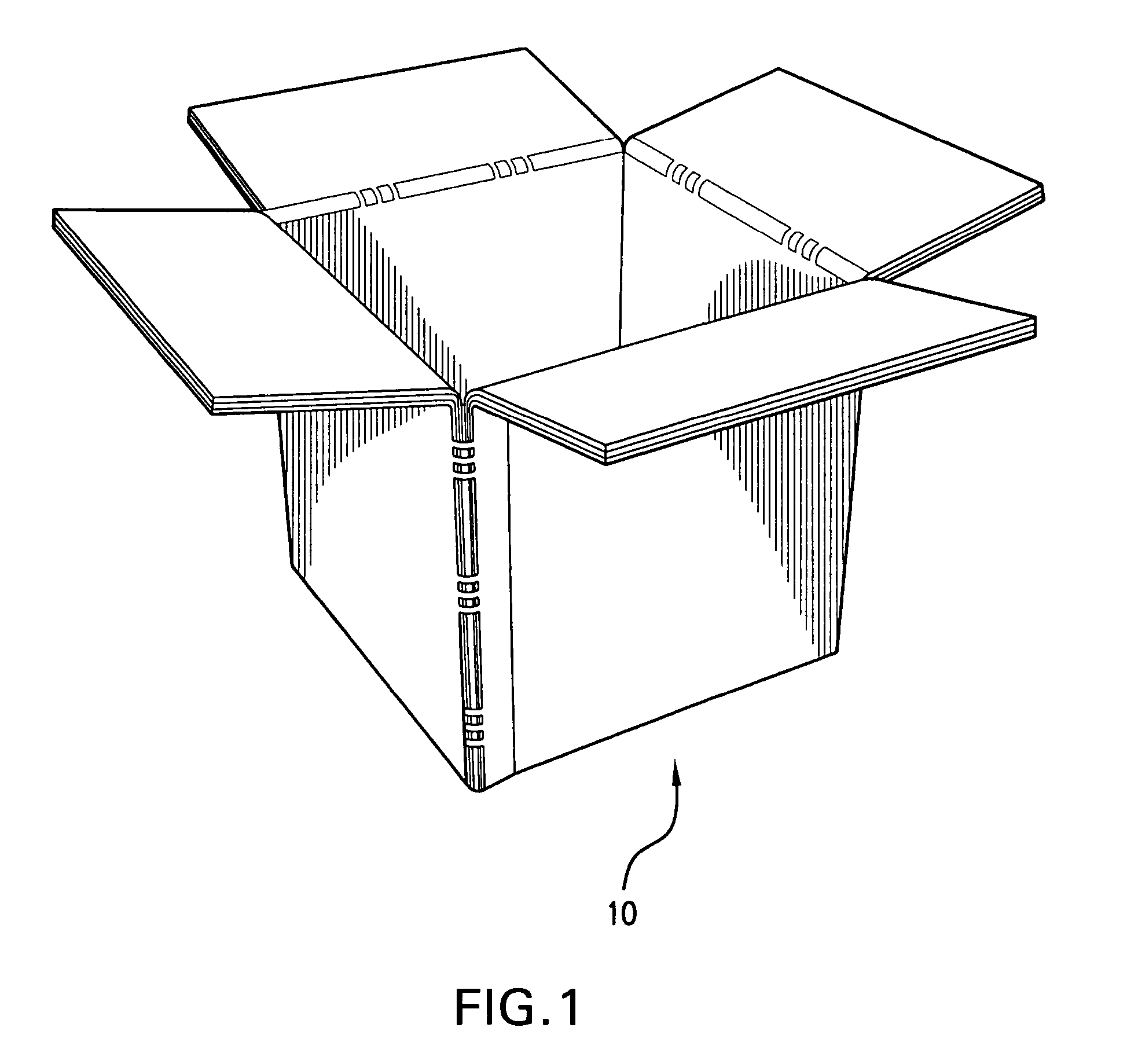

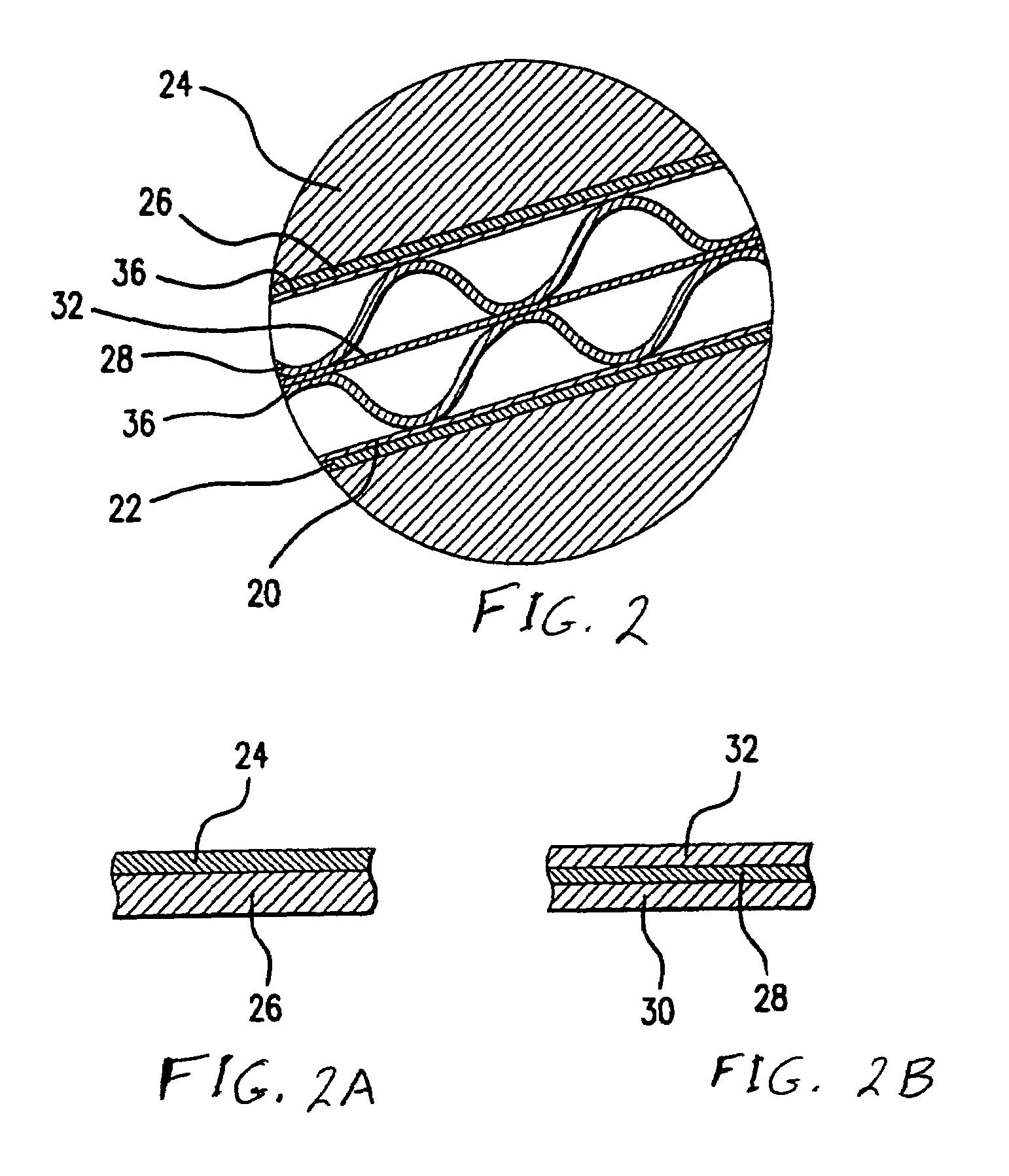

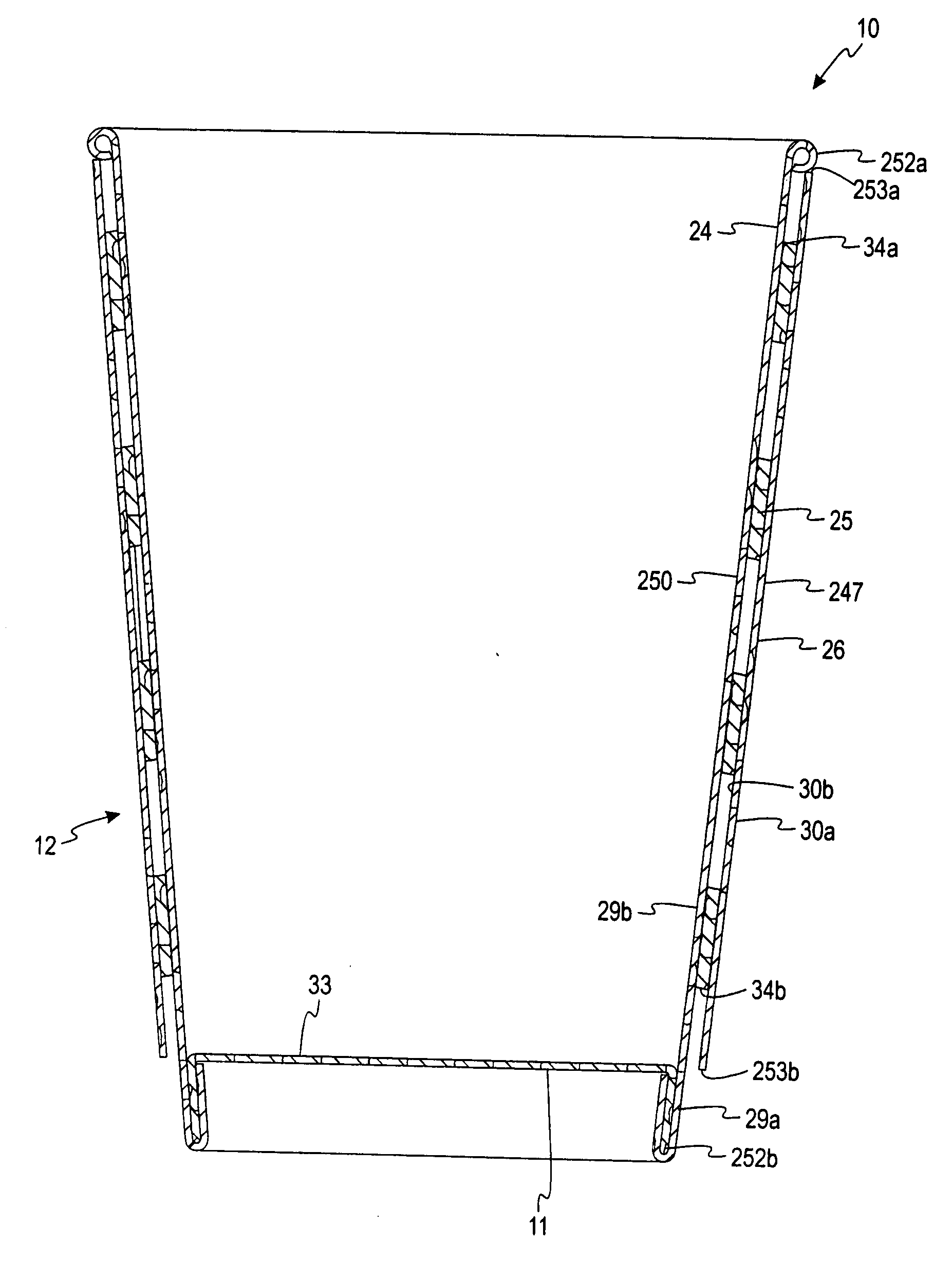

Knockdown corrugated box for temperature control and method of making

ActiveUS7094192B2Envelopes/bags making machineryBoxes/cartons making machineryTemperature controlFlute

A box for shipping temperature sensitive or perishable goods made from a double walled combined web having an inside barrier layer, a first paper liner bonded to the inside barrier layer, a first paper flute medium bonded to the first paper liner, an outside barrier layer, a second paper liner bonded to the outside barrier layer, a second paper flute medium bonded to the second paper liner, and a sandwich of a barrier layer bonded between third and fourth paper liners. The flute mediums are bonded, respectively, to the third and fourth paper liners.

Owner:MILLER DRAYTON +1

Three-layered containers and methods of making the same

ActiveUS20080121681A1Boxes/cartons making machineryDomestic cooling apparatusEngineeringElectrical and Electronics engineering

Owner:PACTIV CORP

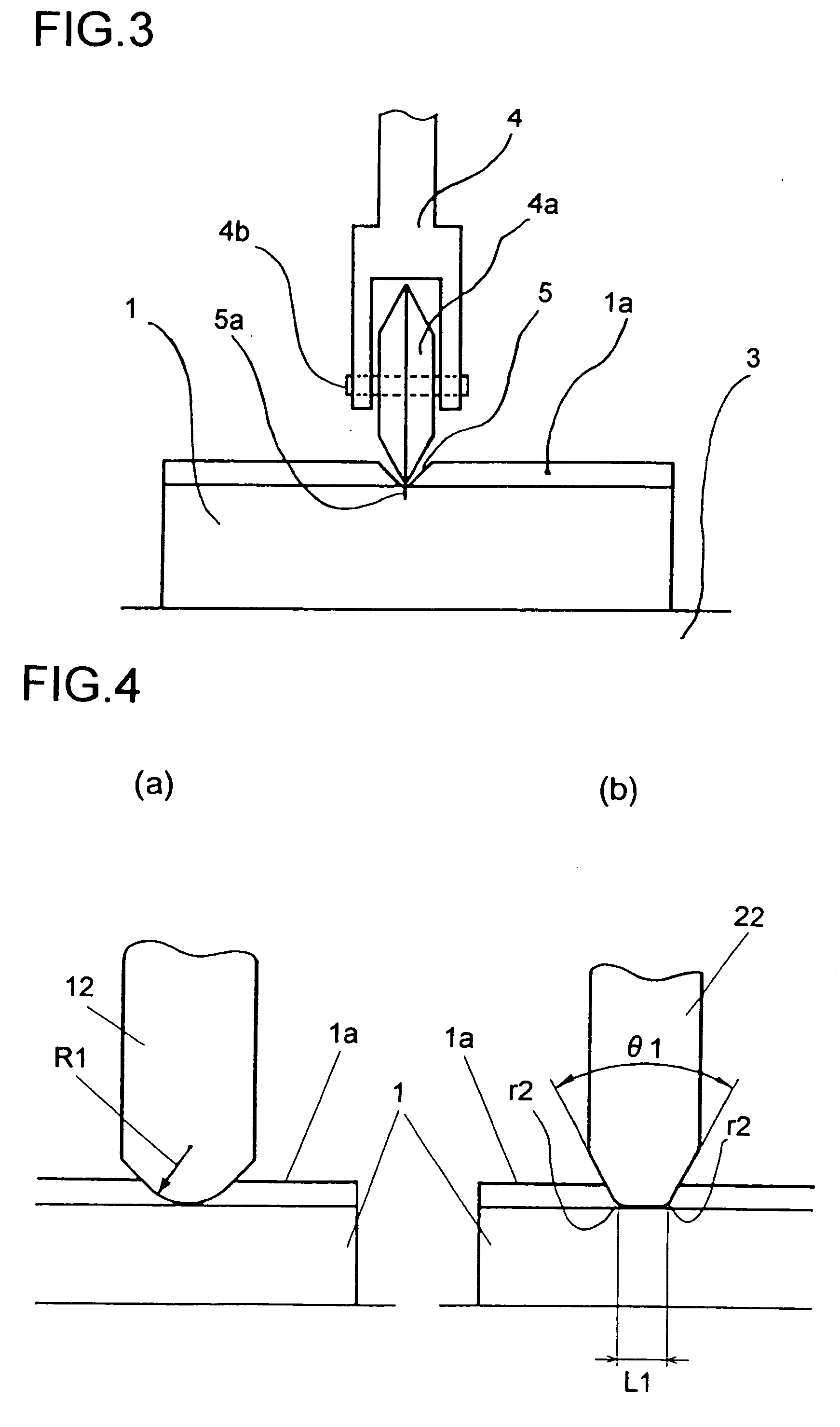

Method and device for parting glass substrate, liquid crystal panel, and liquid crystal panel manufacturing device

InactiveUS20050056127A1High mechanical strengthPrevent peelingLiquid crystal compositionsBox making operationsLiquid-crystal displayCutting glass

A method for cutting apart a glass substrate is provided whereby scribing of the glass substrate is possible without being affected by the presence or thickness of a deposited film formed thereon and without scratching the deposited film. To treat a glass substrate (1) having a deposited film (1a), such as a thin film or resin film, formed on one surface thereof, there are provided a shaving means (202), which is a blade that removes strip-shaped portions of the deposited film (1a) to expose strip-shaped regions on the glass substrate (1), and a wheel cutter (14a) that forms scribed lines along the strip-shaped regions exposed on the glass substrate (1). The glass substrate (1) is cut apart along the scribed lines.

Owner:SHARP KK +1

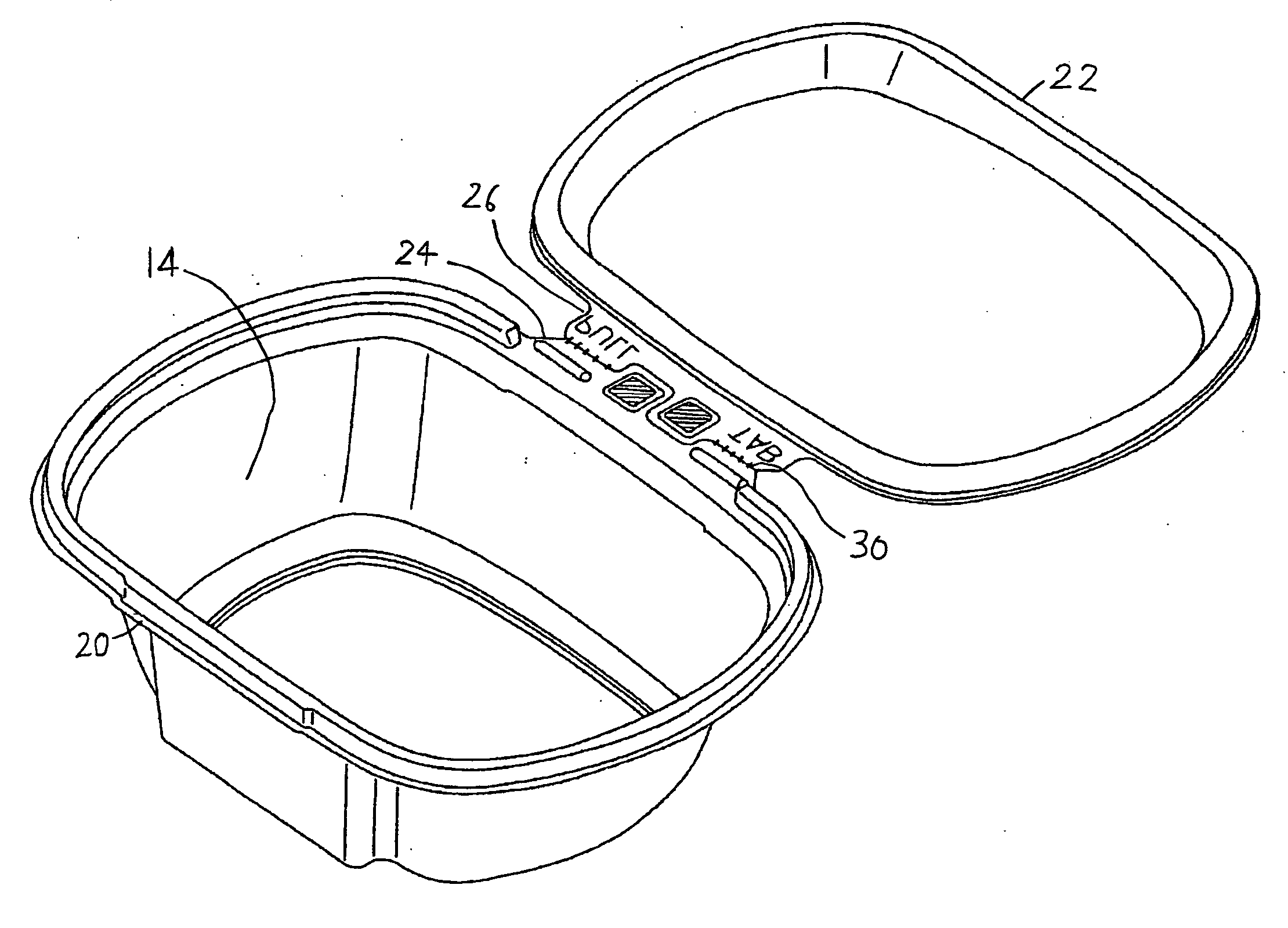

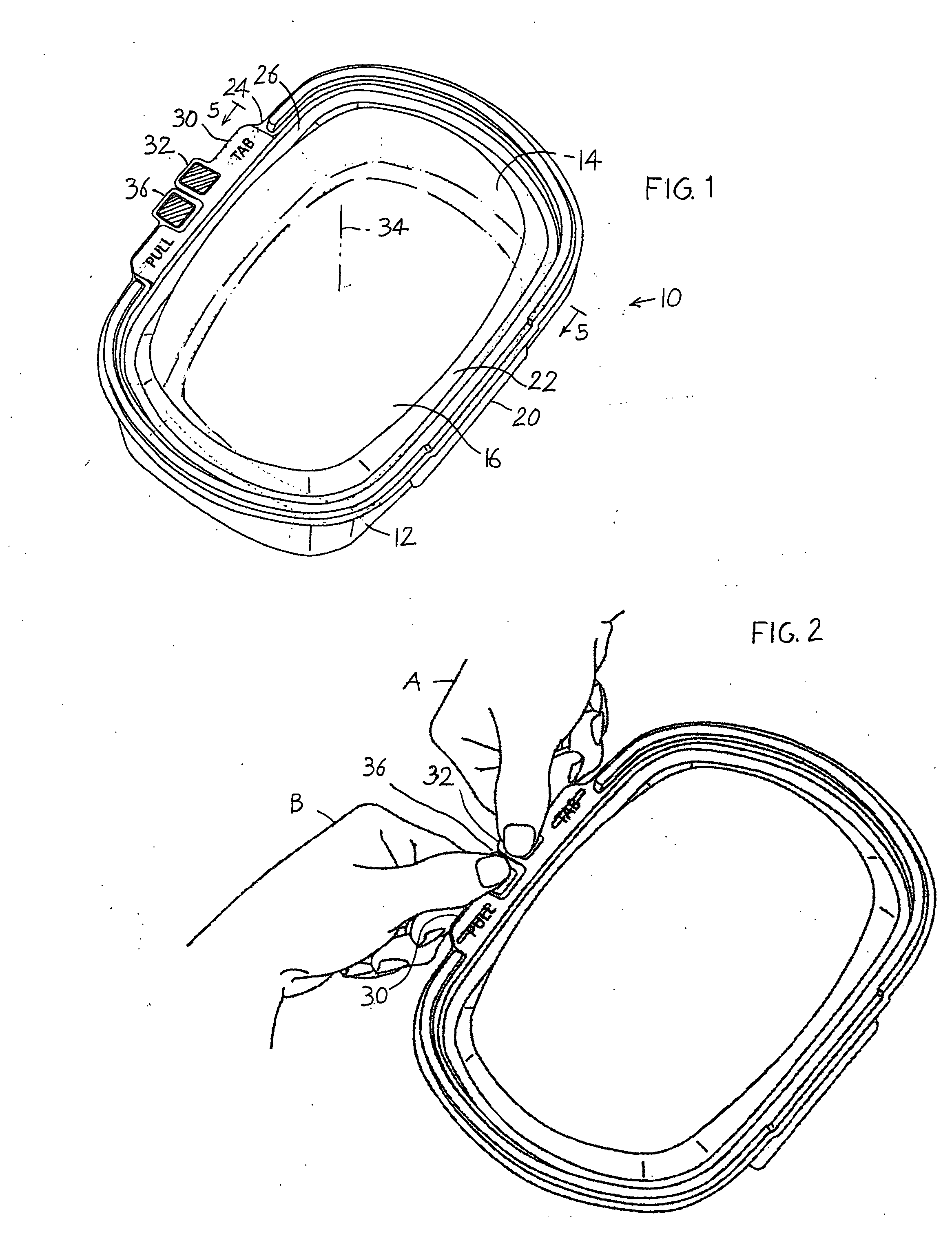

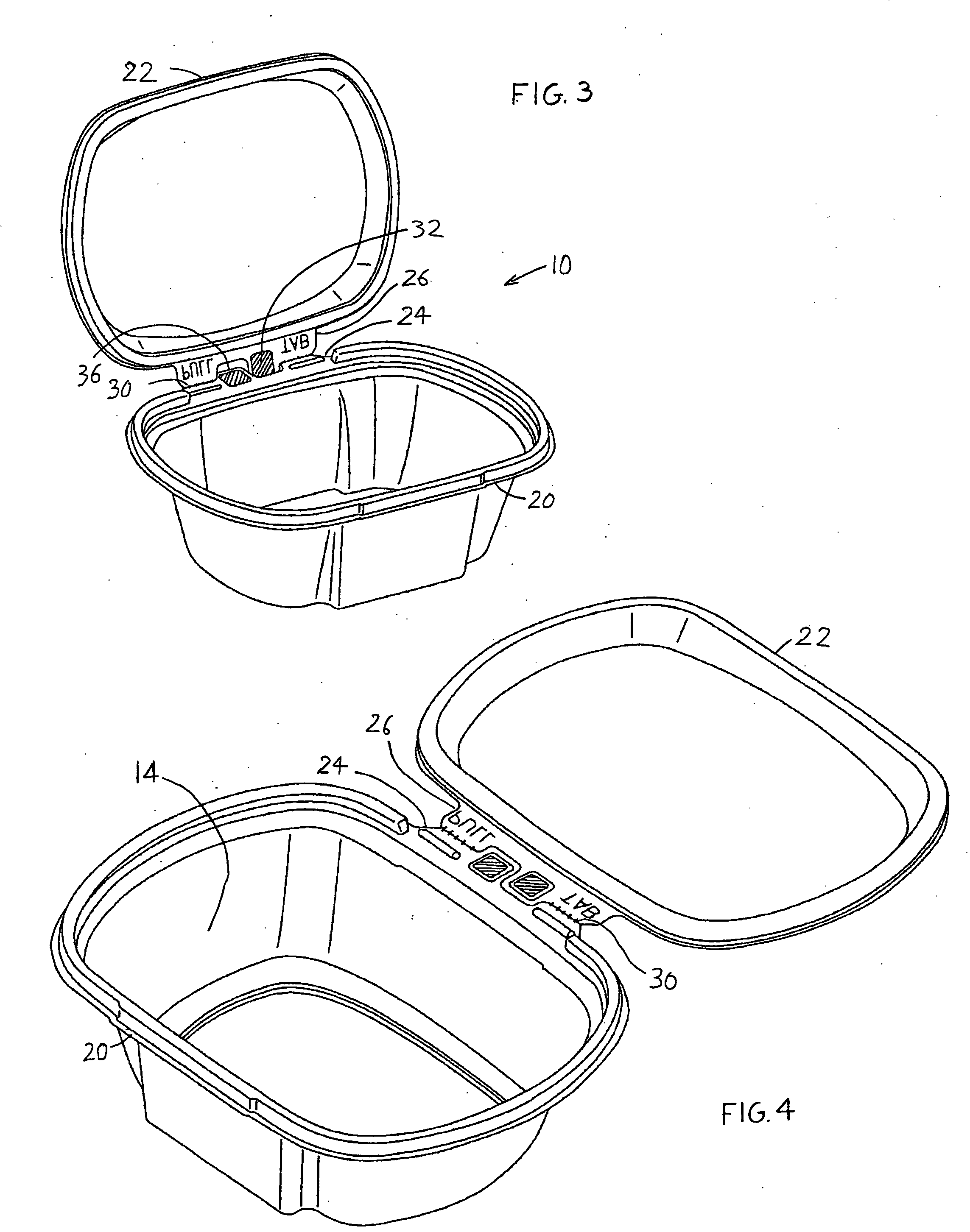

Edge-tearing tamper-evident container

A food container formed from plastic, can be loaded with food and then closed by a clerk, and thereafter cannot be opened without tearing apart first sides (24, 26) of the base (12) and lid (16). The container is formed by a single sheet of plastic that forms a base and lid with second sides (20, 22) that are latched together and with adjacent first sides that are joined by a joint line (30) in the plastic that is creased and that has slits (40). At the joint line, the lid has a projecting lid tab (32) and the base has a projecting base tab (36). A person grasps both tabs, and lifts only the lid tab to tear apart the first sides of the base and lid along the joint line (30). Thereafter, the lid can be easily closed and reopened on the base.

Owner:PACTIV PACKAGING

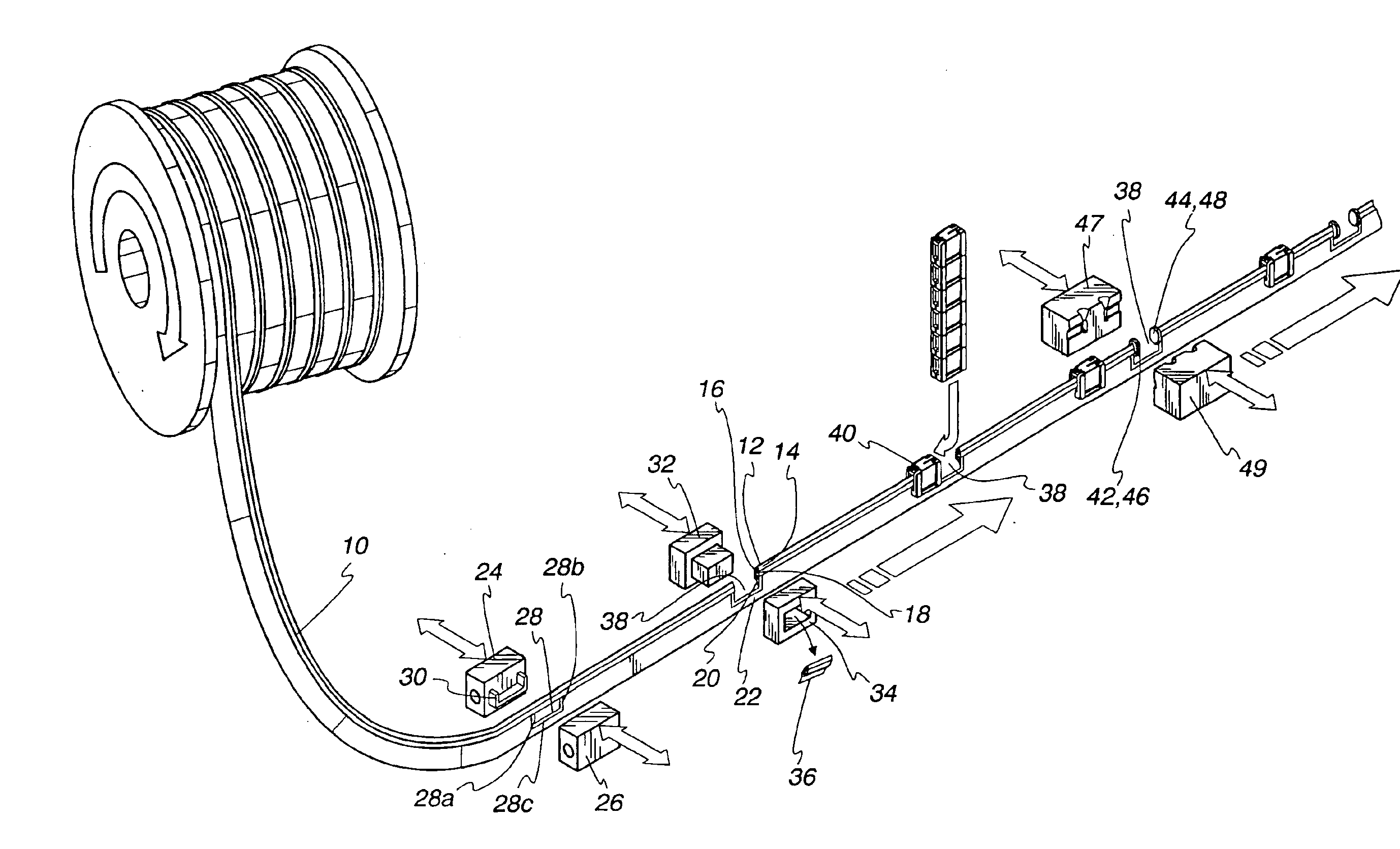

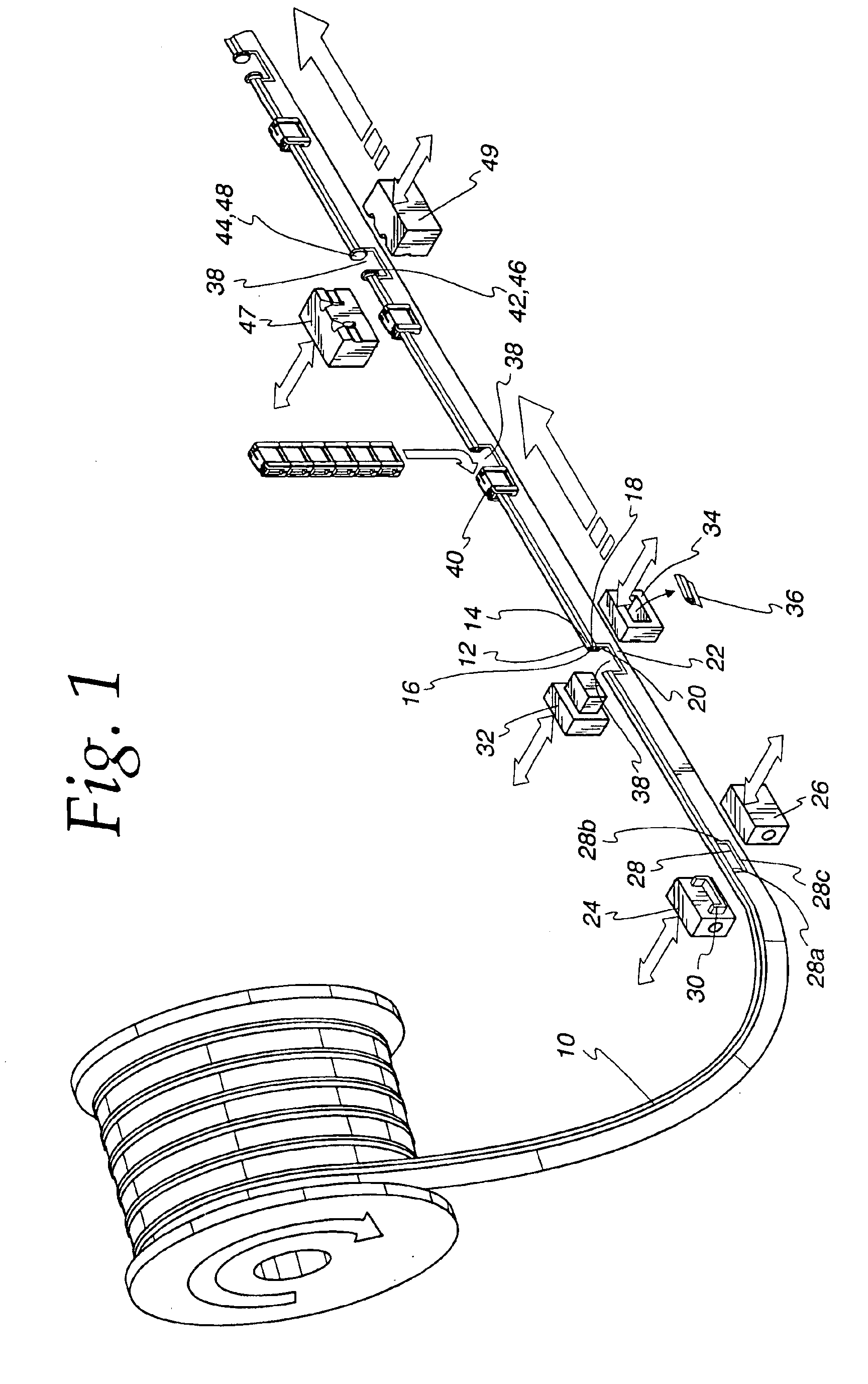

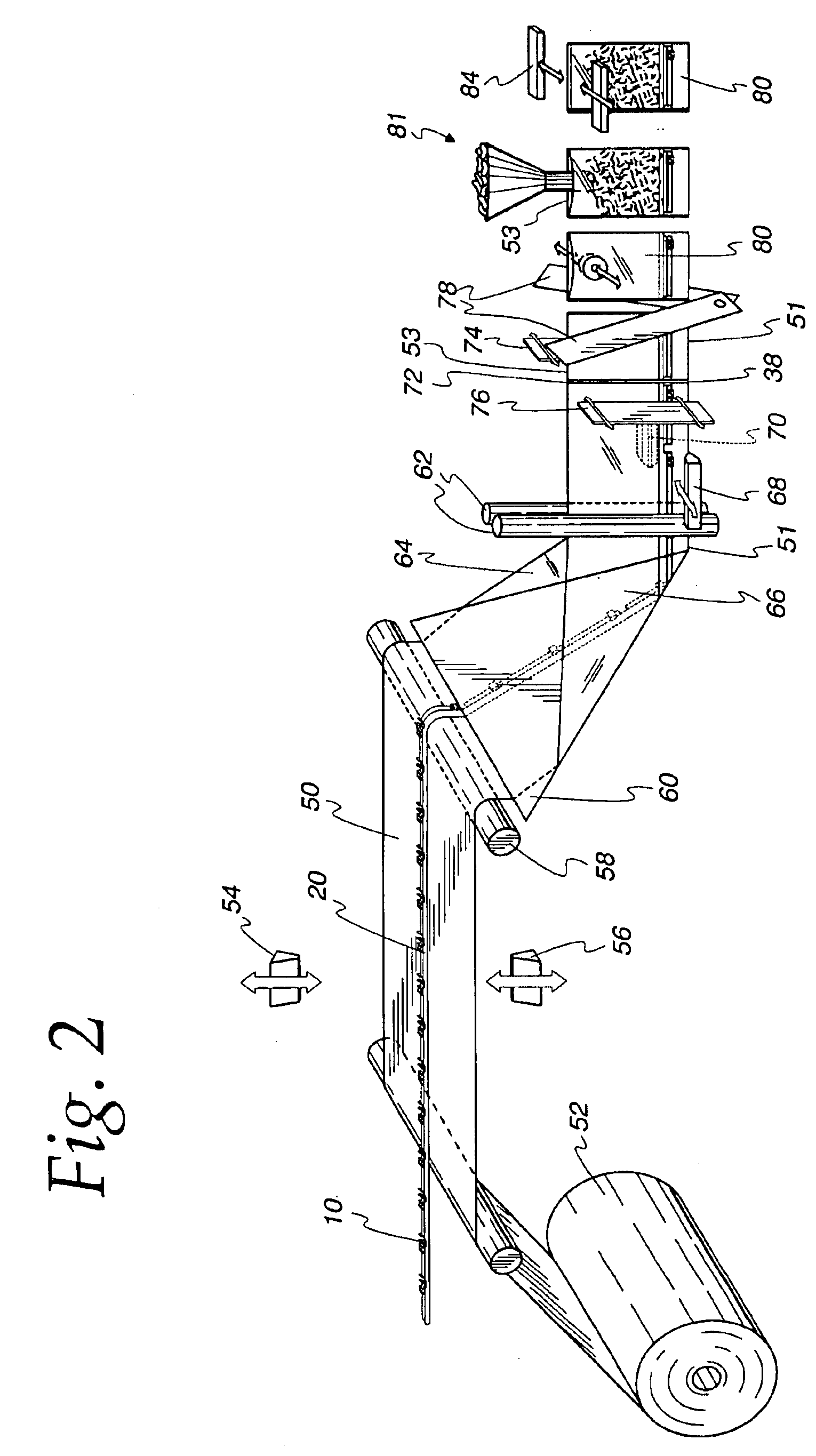

Method and apparatus for making reclosable plastic bags using a pre-applied slider-operated fastener

InactiveUS6871473B1Not adversely impactEasy to modifyEnvelopes/bags making machineryWire articlesThin membraneEngineering

A method and apparatus for making reclosable plastic bags is provided. In the method and apparatus, a fastener is attached to a moving flat web of plastic film, preferably in the direction of web movement and near the center of the web. A plurality of sliders are mounted to the fastener either before or after the fastener is attached to the flat web, but prior to conveying the web to a FFS machine. The flat web, with the slider-operated fastener already attached thereto, is then conveyed to a vertical or horizontal FFS machine where the flat web is formed into bags, and the bags are successively filled and sealed.

Owner:REYNOLDS PRESTO PRODS

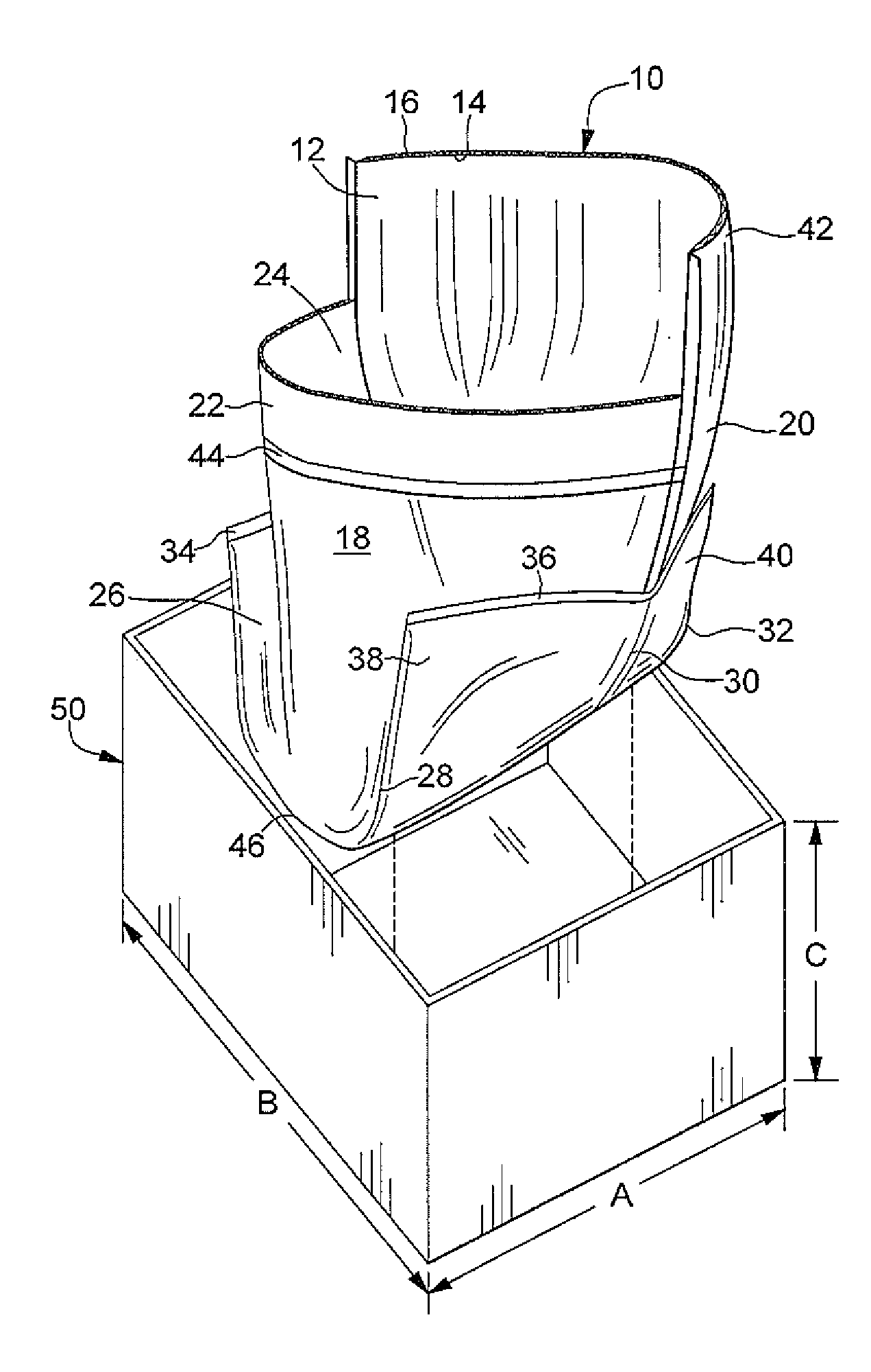

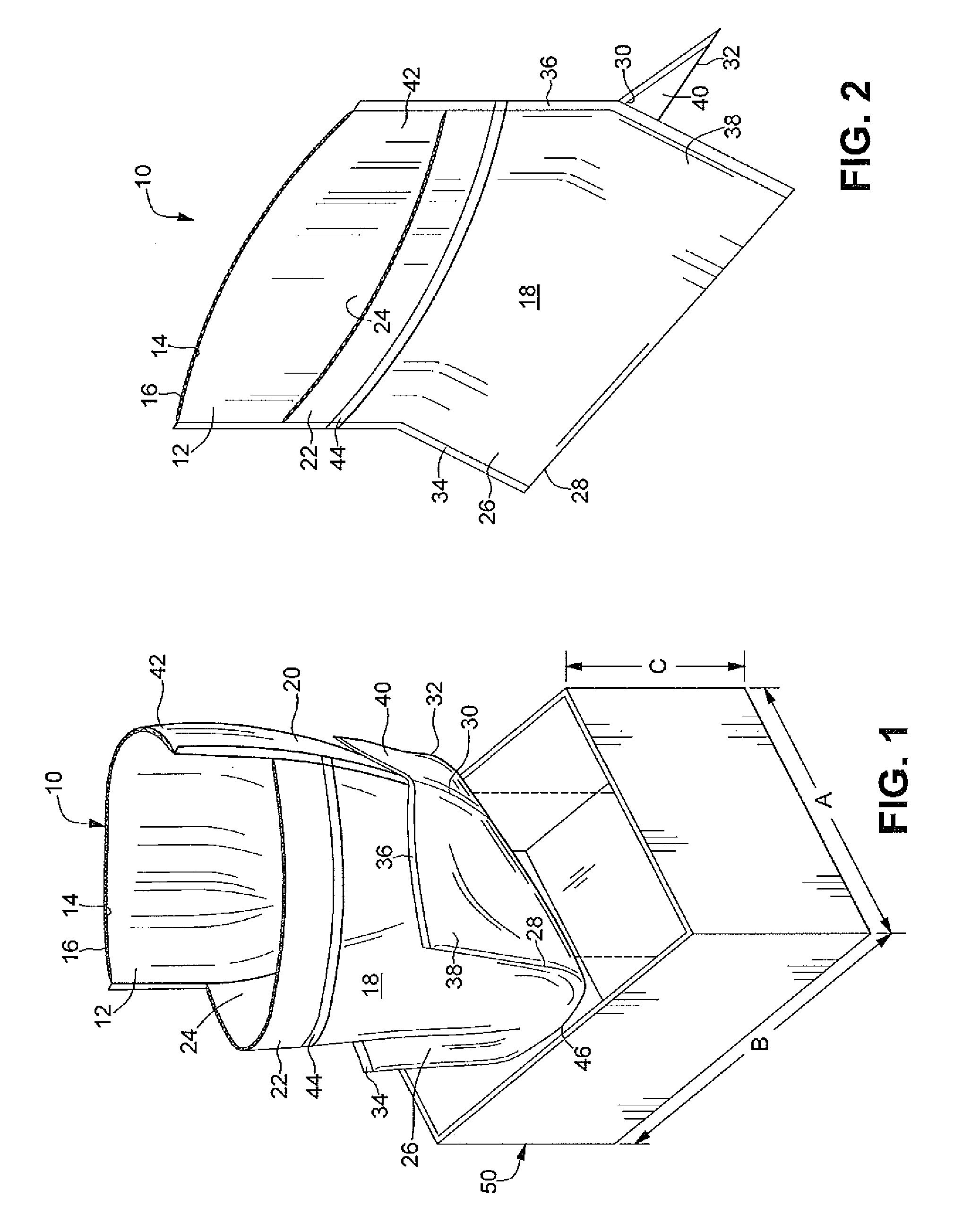

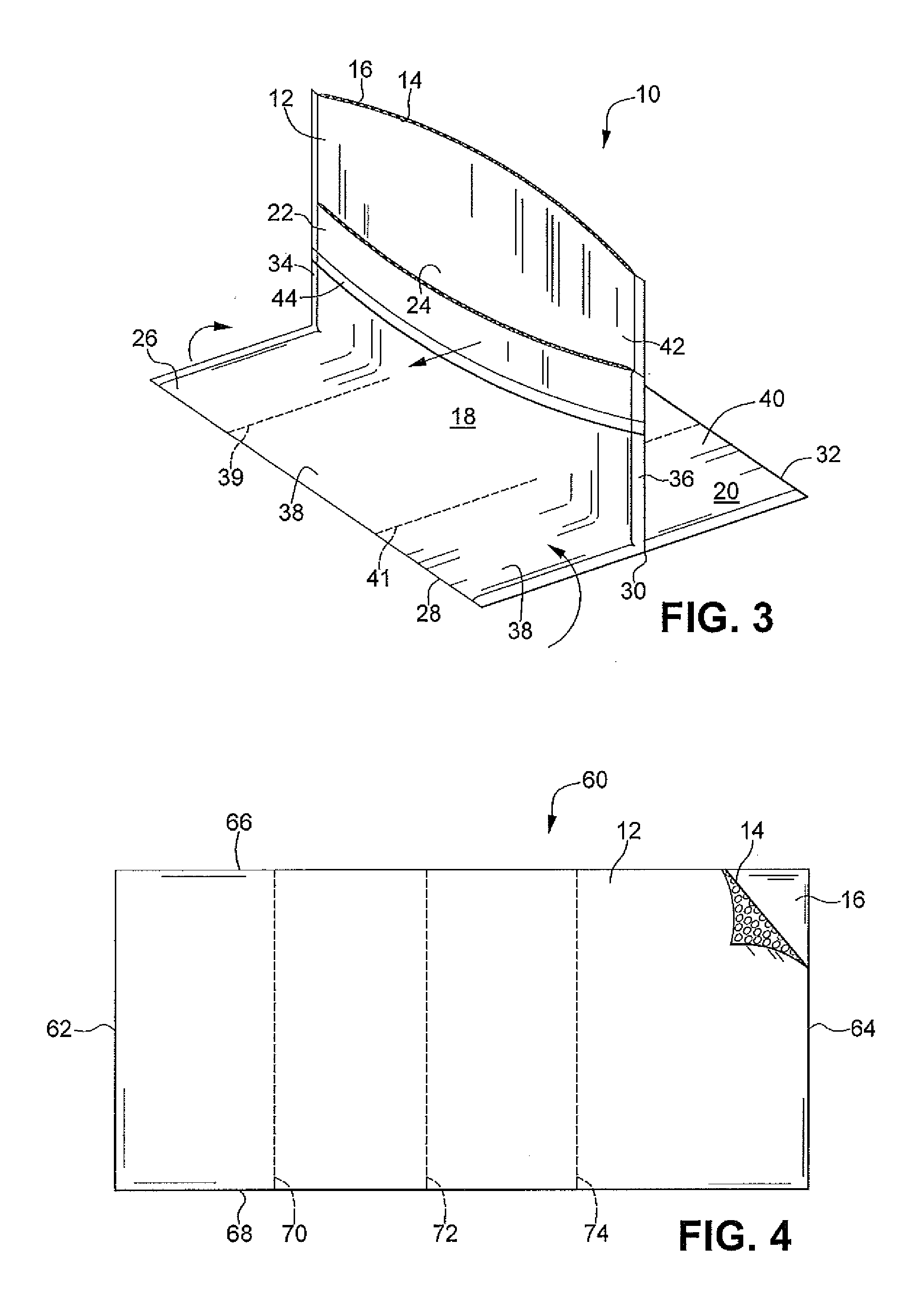

Method and apparatus for making, shipping and erecting boxes

InactiveUS20100001056A1Reduce the overall heightPaper-makingBox making operationsEngineeringFace sheet

A cardboard box with four side panels, four bottom flaps and four top flaps. The box is made from a blank having a first height measured between the outermost edges of the top and bottom flaps. The flaps are rotated into abutting contact with the exterior surface of the panels thereby reducing the overall height of the box to the height of the panel. Adjacent pairs of top and bottom flaps are provided with living hinges that enable them to remain in this position when the box is collapsed. The collapsed box is shipped through the mail in this diminished size and then erected into a box of the same height as the panels.

Owner:KITARU INNOVATIONS

Heat-insulating container

InactiveUS6260756B1Improve insulation performanceIncrease freedomBoxes/cartons making machineryDomestic cooling apparatusPolyolefinEngineering

A heat-insulating container comprises a paper cup body having an inner surface, an upper open end, a shell member and a bottom, the inner surface being coated with polyolefine resin, the upper open end having an outward curled portion and the shell member having a side wall on which at least one rib is formed; and a tubular member being formed of paper and having an inverse truncated conical shape, the tubular member having at a lower end thereof an inward curled portion. The tubular member is combined with an outer periphery of the paper cup body so as to come into contact with the paper cup body in contact portions provided on the at least one rib of the paper cup body and on an outer periphery of an lower end of the side wall of the shell member. According to such a structure, it is possible to provide the heat-insulating container, which has a stable heat-insulating property, a high grade design, a high degree of freedom in indication by printing on the outer surface of the container, and a lower production cost.

Owner:DAI NIPPON PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com