Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4874results about How to "Prevent peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor light source apparatus and lighting unit

ActiveUS20110149549A1Easy to useIncrease brightnessPoint-like light sourceProjectorsPhosphorFluorescence

A semiconductor light source apparatus can emit various color lights having high brightness. The semiconductor light source apparatus can include a radiating substrate, at least one phosphor layer disposed on the radiating substrate and a semiconductor light source. The at least one phosphor layer can be composed of at least one of a glass phosphor and a phosphor ceramic and can include at least one of a red phosphor, a green phosphor and a blue phosphor. The light source can be located adjacent the phosphor layer so that light having high brightness emitted from the light source can be efficiently reflected on the radiating substrate via the at least one phosphor layer. Thus, the disclosed subject matter can provide a semiconductor light source apparatus that can emit various color lights having high brightness and a lighting unit using the light source apparatus, which can be used for general lighting, etc.

Owner:STANLEY ELECTRIC CO LTD

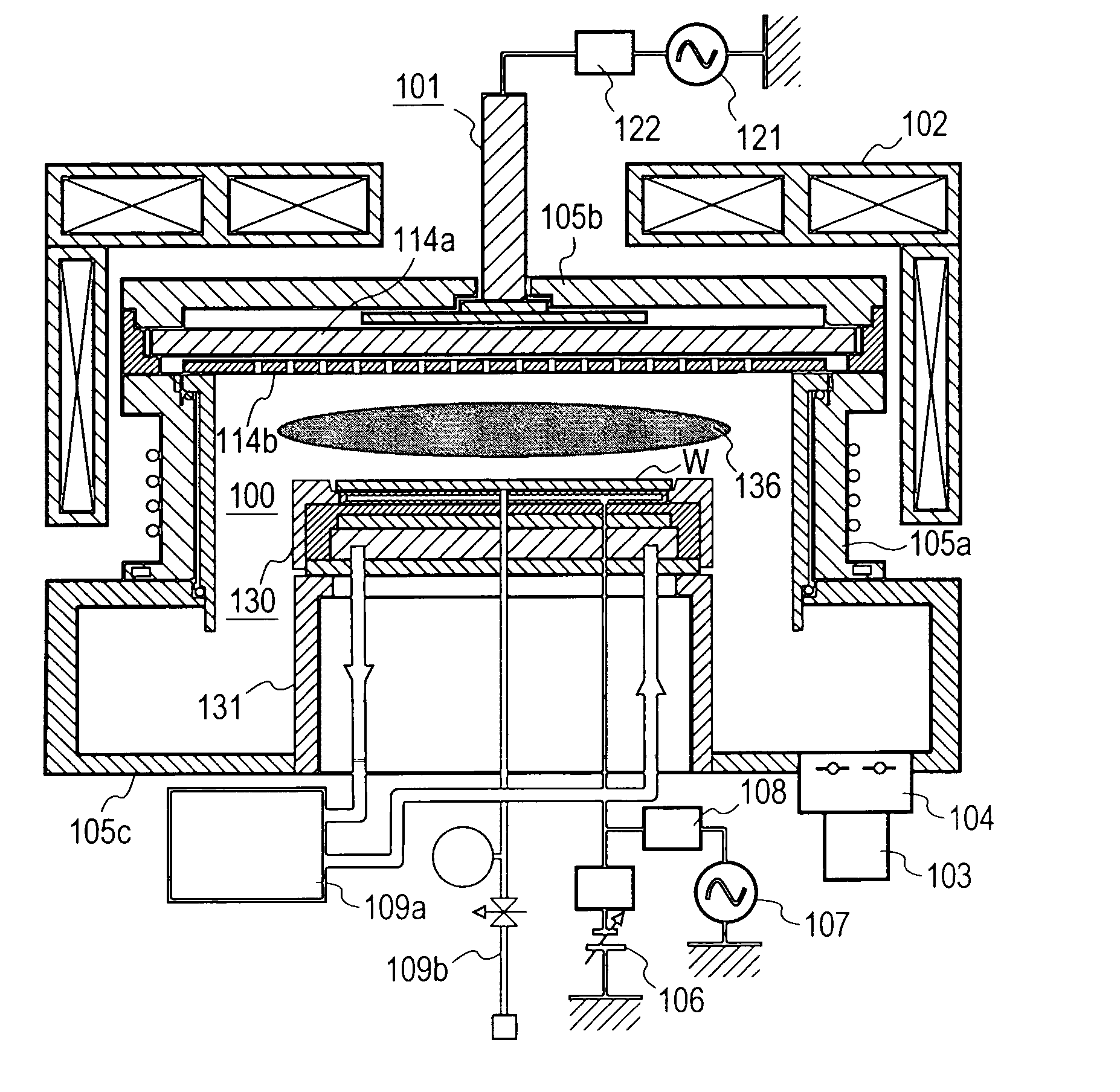

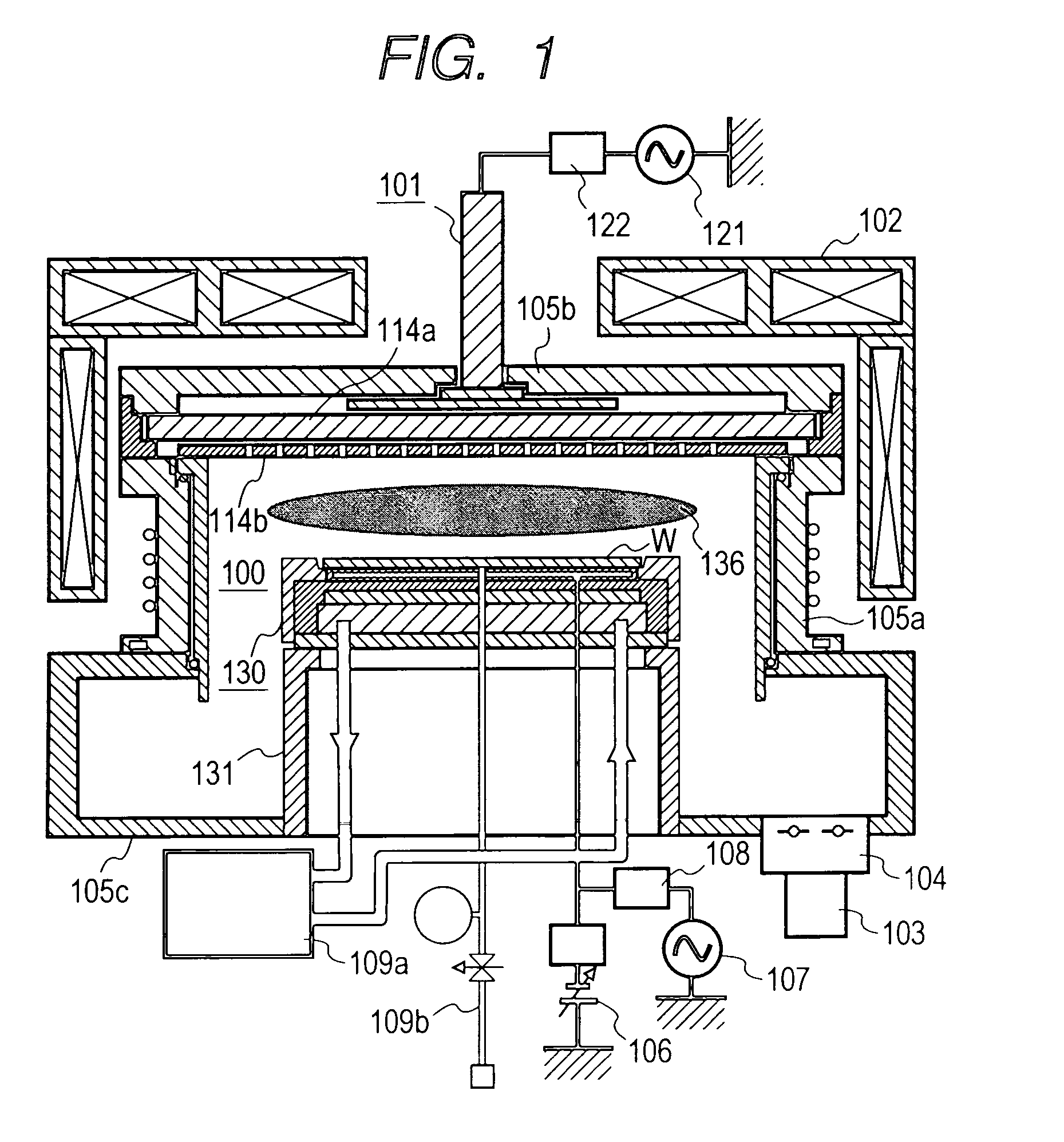

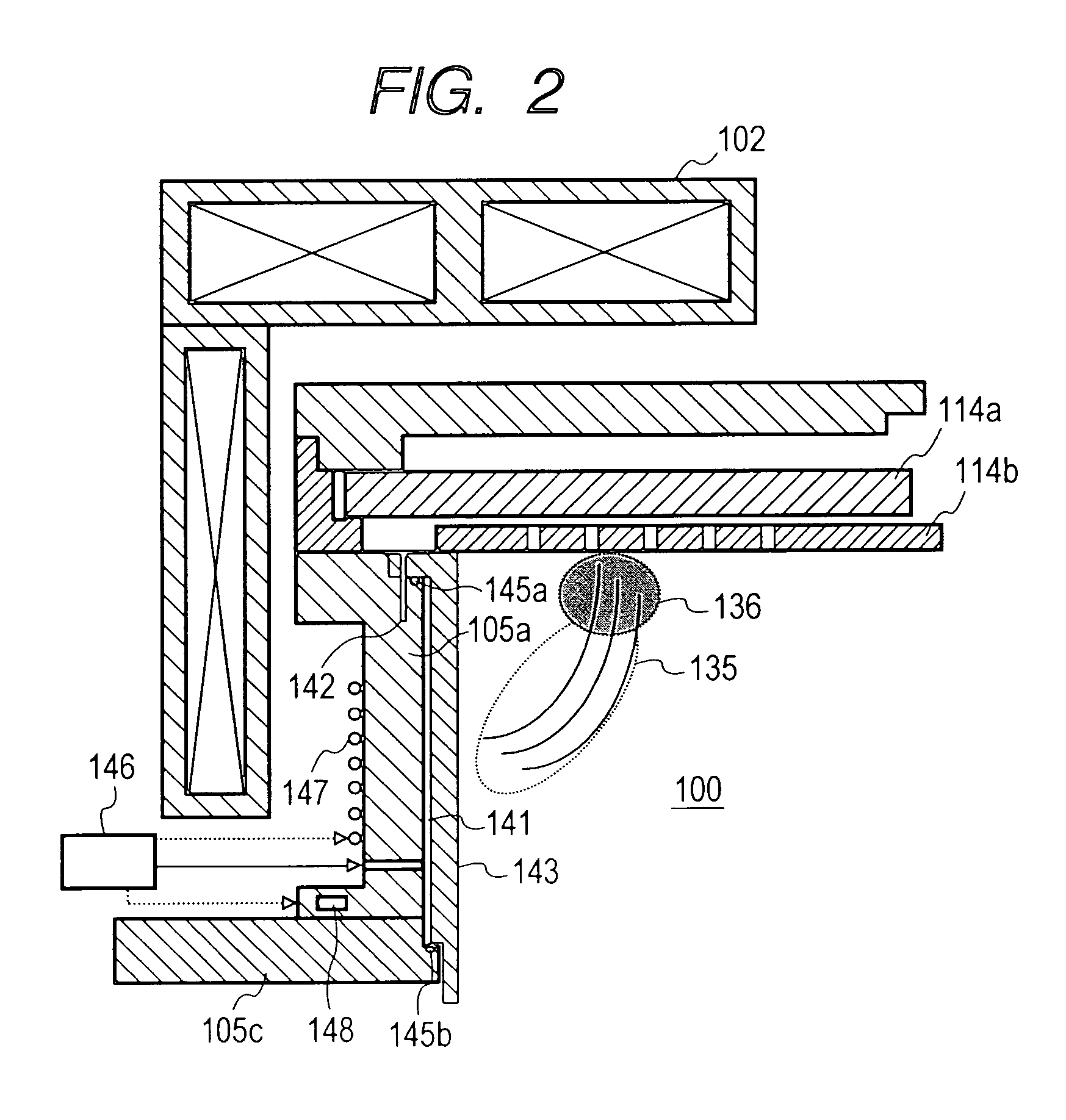

Plasma etching apparatus and method for forming inner wall of plasma processing chamber

InactiveUS20070215278A1Reduce corrosionDecreasing amountElectric discharge tubesSemiconductor/solid-state device manufacturingProduction rateHeat resistance

A plasma etching apparatus is provided which can prevent corrosion of an aluminum substrate constituting an etching processing chamber or an inside component thereof, thereby avoiding a reduction in productivity due to scattering of a sprayed coating. In the plasma etching apparatus, an anodic oxide film is disposed between a ceramic sprayed coating with excellent resistance to plasma, and the etching processing chamber and the inside component thereof made of aluminum alloy. The anodic oxide film has a thickness of 5 μm or less to have heat resistance.

Owner:HITACHI HIGH-TECH CORP

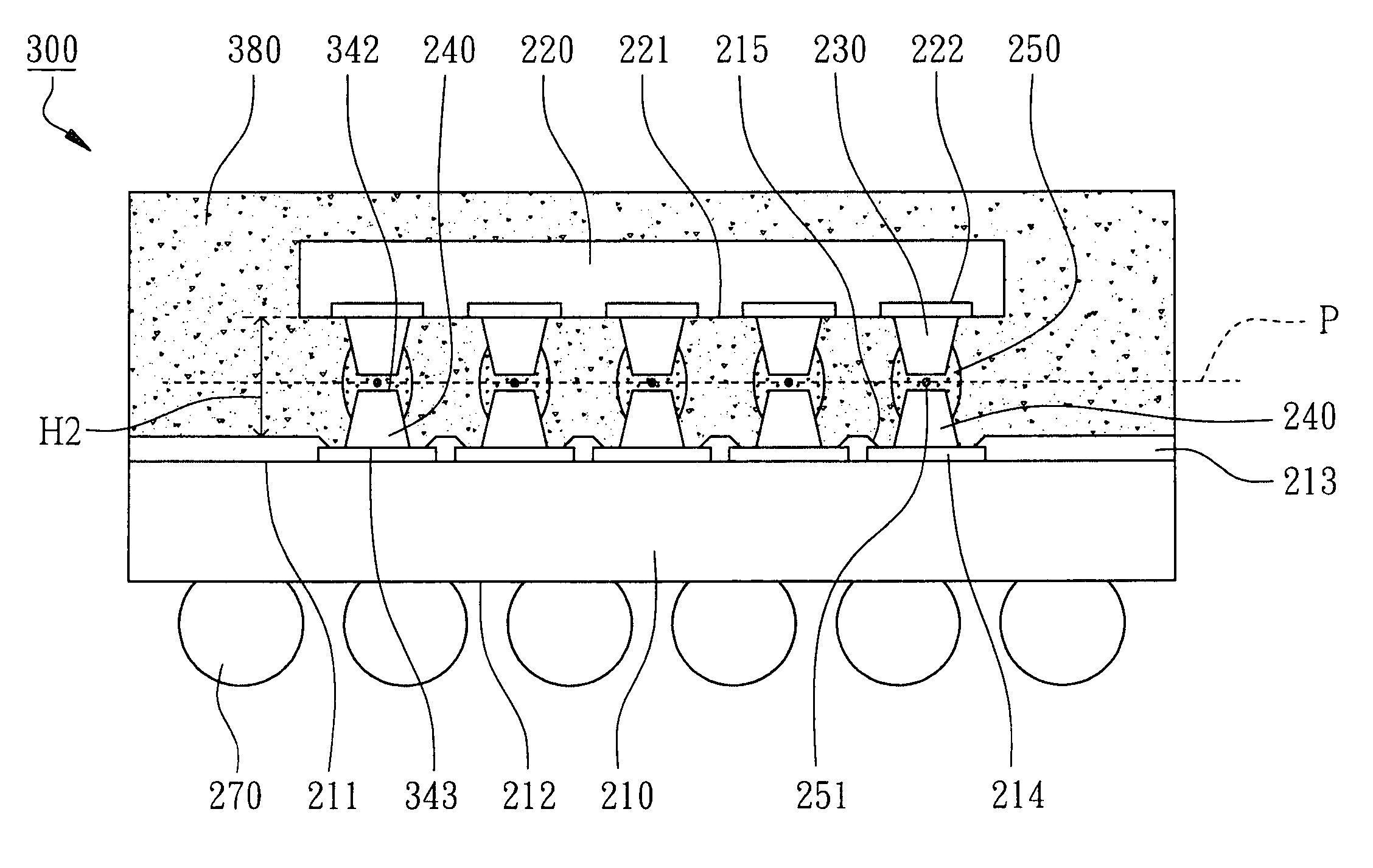

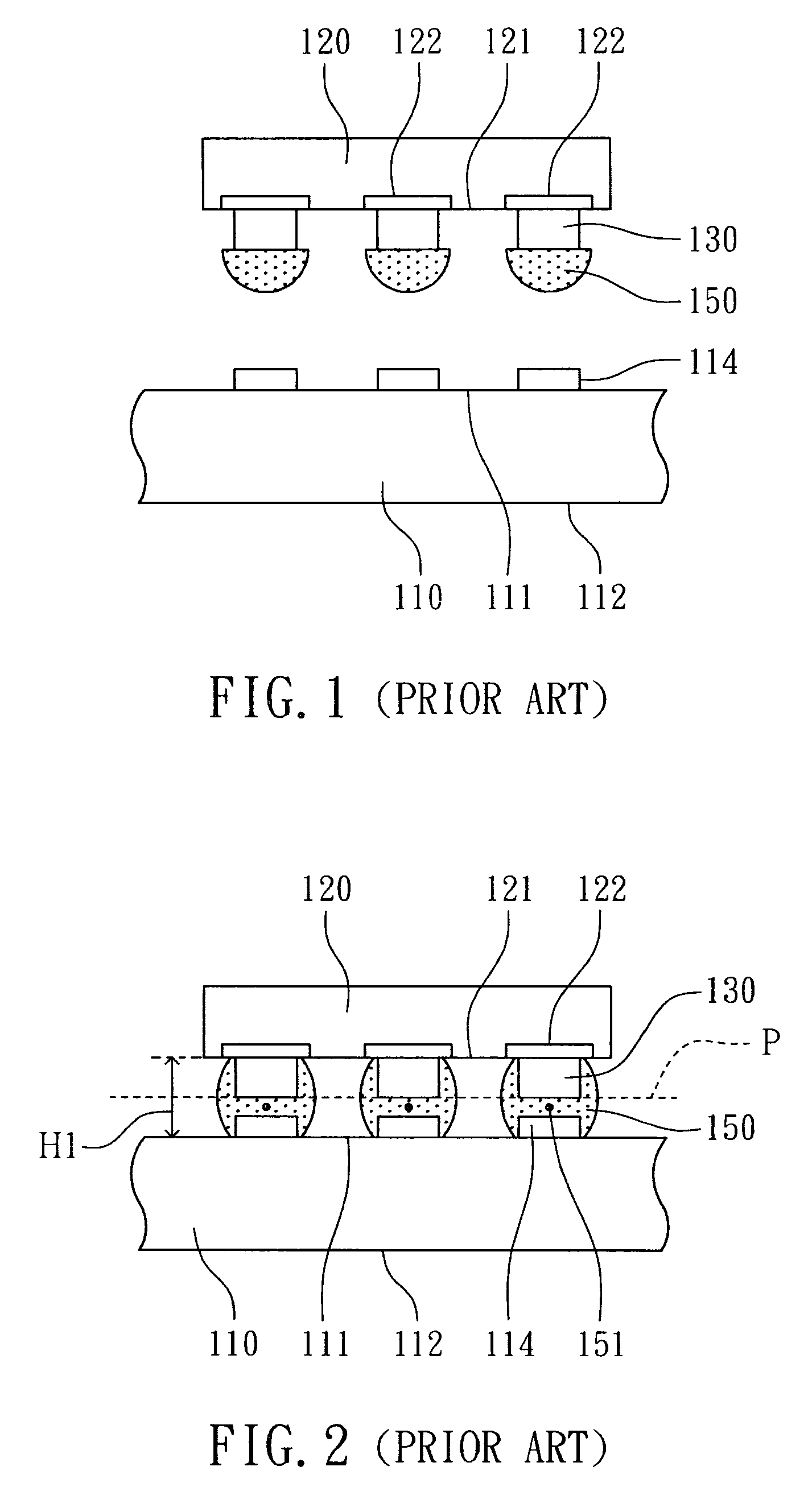

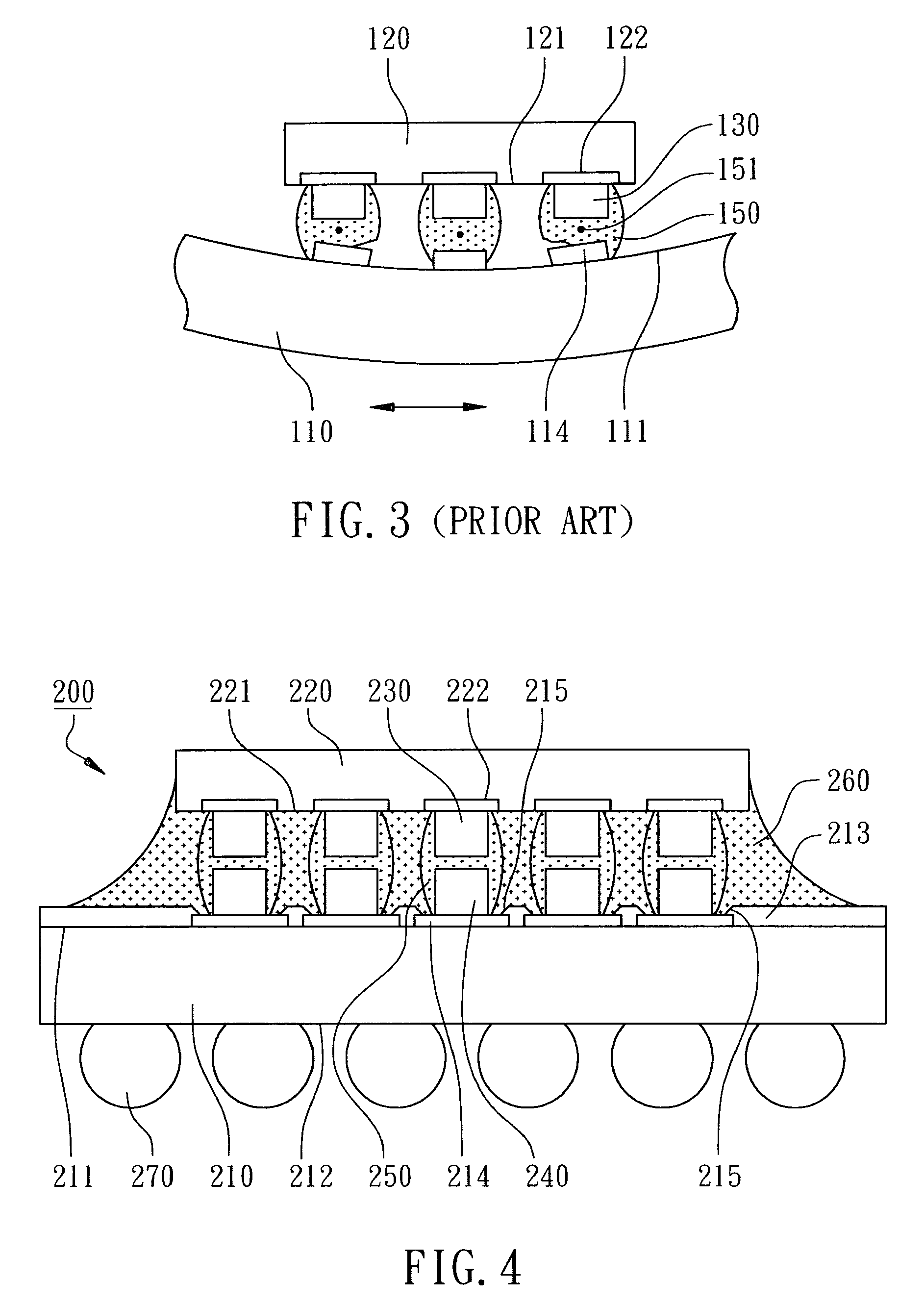

Pillar-to-pillar flip-chip assembly

ActiveUS7569935B1Reduce thermal stressPrevent peelingFinal product manufactureSemiconductor/solid-state device detailsSolder maskSolder ball

A pillar-to-pillar flip-chip assembly primarily comprises a substrate, a chip disposed on the substrate, a plurality of first copper pillars on the bonding pads of the chip, a plurality of second copper pillars on the bump pads of the substrate, and a soldering material. A first height of the first copper pillars protruding from the active surface of the chip is the same as a second height of the second copper pillars from the solder mask on the substrate. When the soldering material electrically and mechanically connects the first copper pillars to the second copper pillars, a plurality of central points of the soldering material are formed on an equal-dividing plane between the chip and the substrate to reduce the direct stresses exerted at the soldering material to avoid peeling or breaks from the bump pads. Moreover, each of conventional solder balls is replaced with two soldered copper pillars to meet the lead-free requirements with higher reliability and lower costs.

Owner:POWERTECH TECHNOLOGY

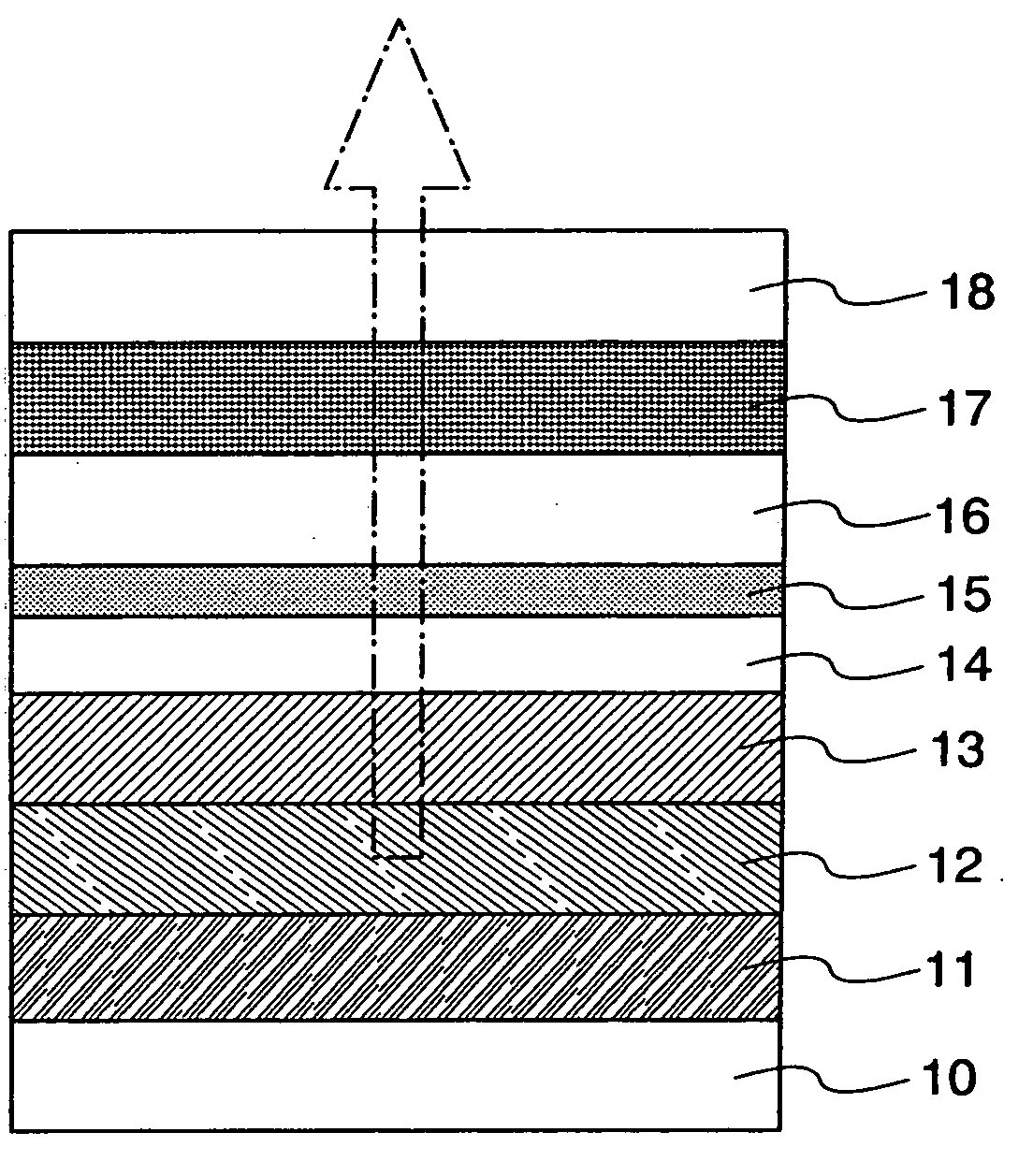

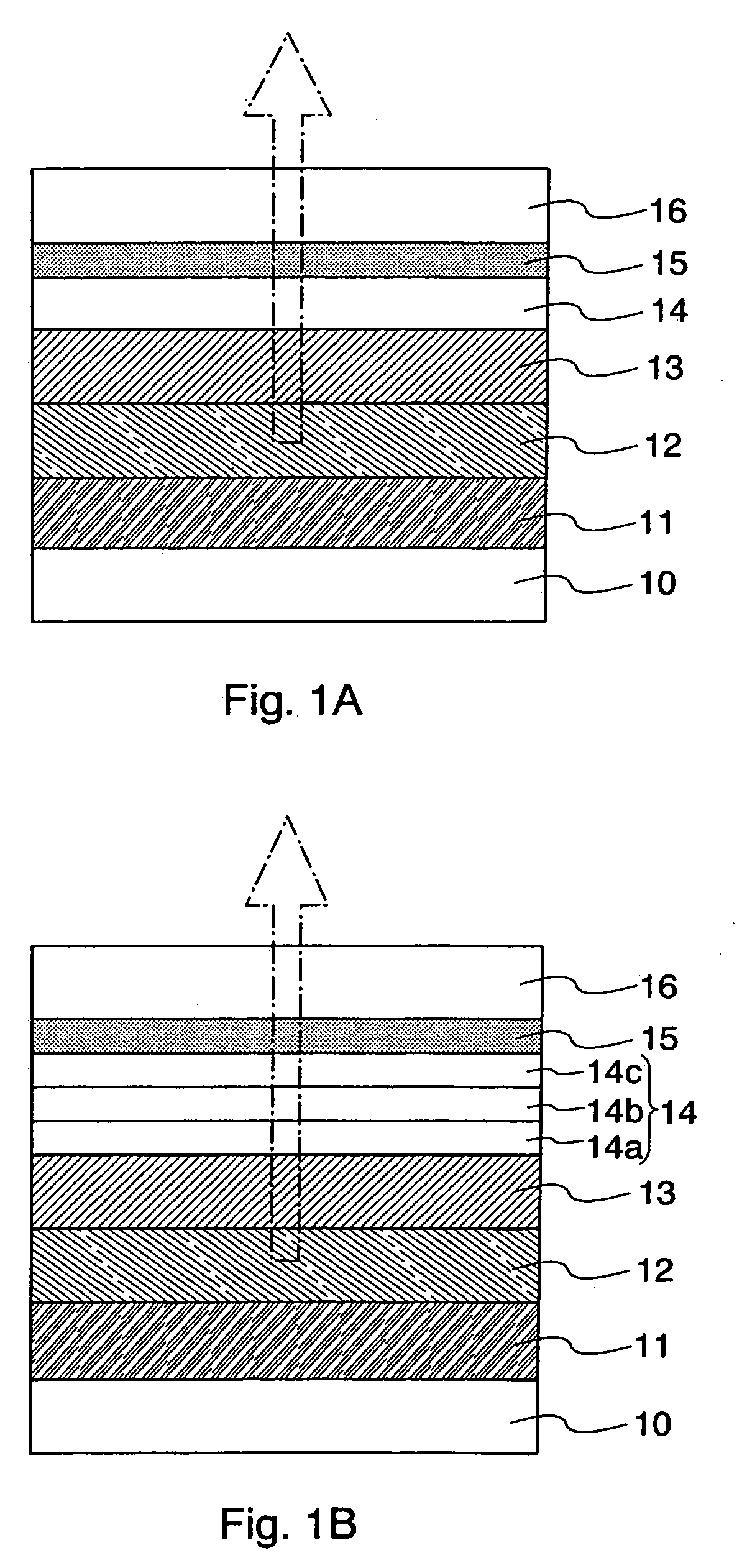

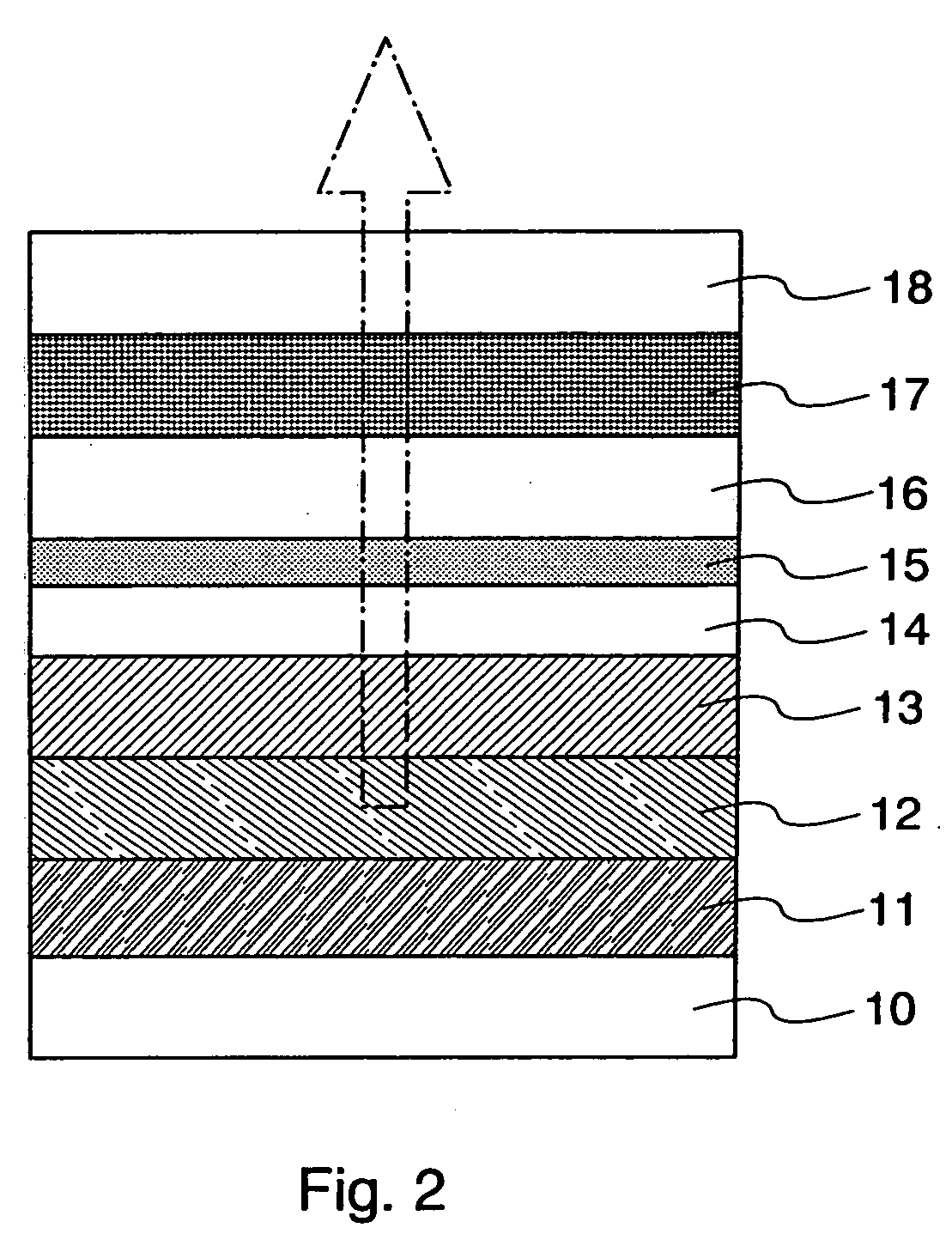

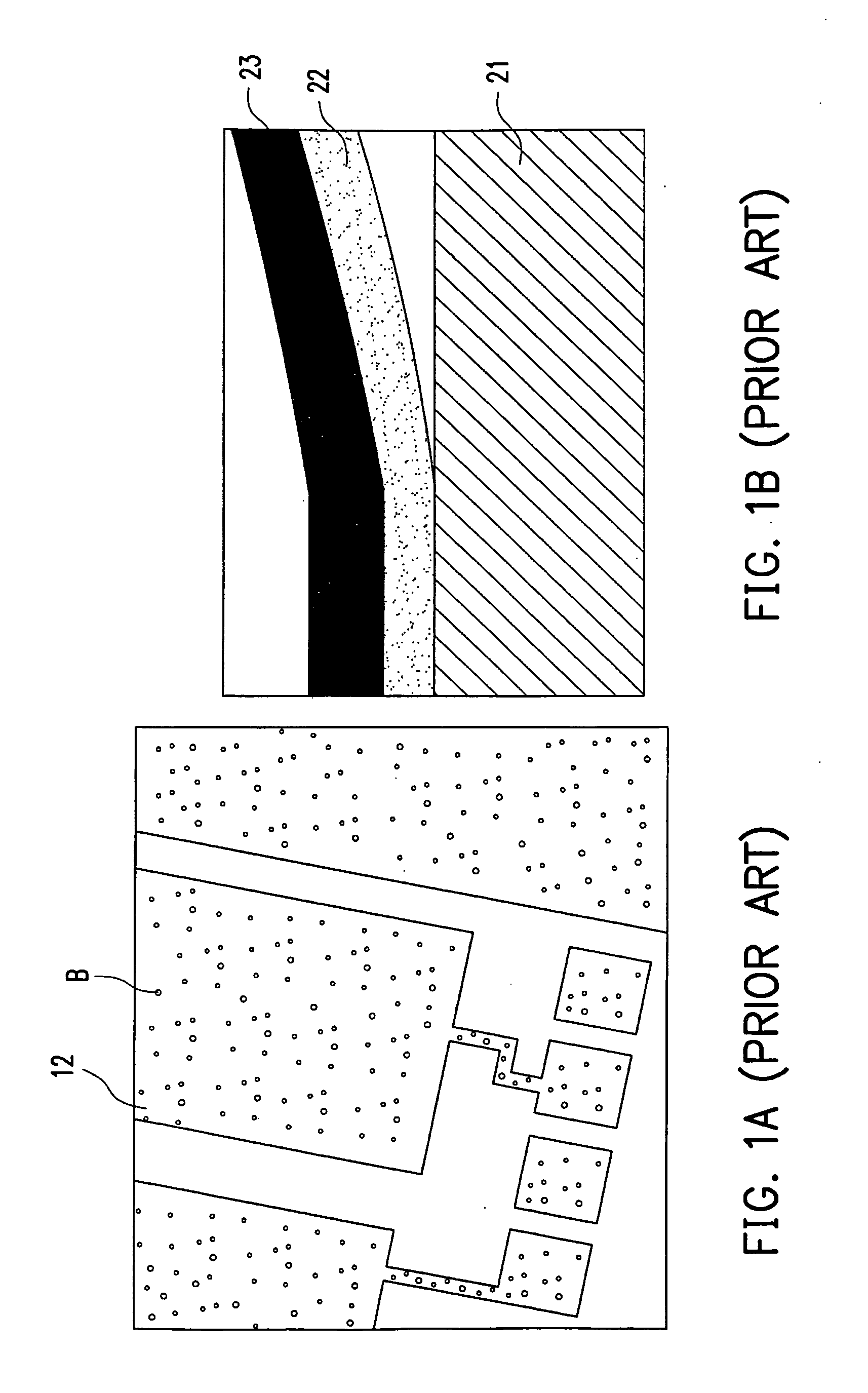

Light-emitting element and display device

InactiveUS20050263775A1Improve reliabilityImprove light extraction efficiencyStatic indicating devicesElectroluminescent light sourcesStress relievingRefractive index

There has been a problem that difference in refractive index between an opposite substrate or a moisture barrier layer (passivation film) such as SiN provided thereover, and air is maintained large, and light extraction efficiency is low. Further, there has been a problem that peeling or cracking due to the moisture barrier layer is easily generated, which leads to deteriorate the reliability and lifetime of a light-emitting element. According to the present invention, a light-emitting element comprises a pixel electrode, an electroluminescent layer, a transparent electrode, a passivation film, a stress relieving layer, and a low refractive index layer, all of which are stacked sequentially. The stress relieving layer serves to prevent peeling of the passivation film. The low refractive index layer serves to reduce reflectivity of light generated in the electroluminescent layer in emitting to air. Therefore, a light-emitting element with high reliability and long lifetime and a display device using the light-emitting element can be provided.

Owner:SEMICON ENERGY LAB CO LTD

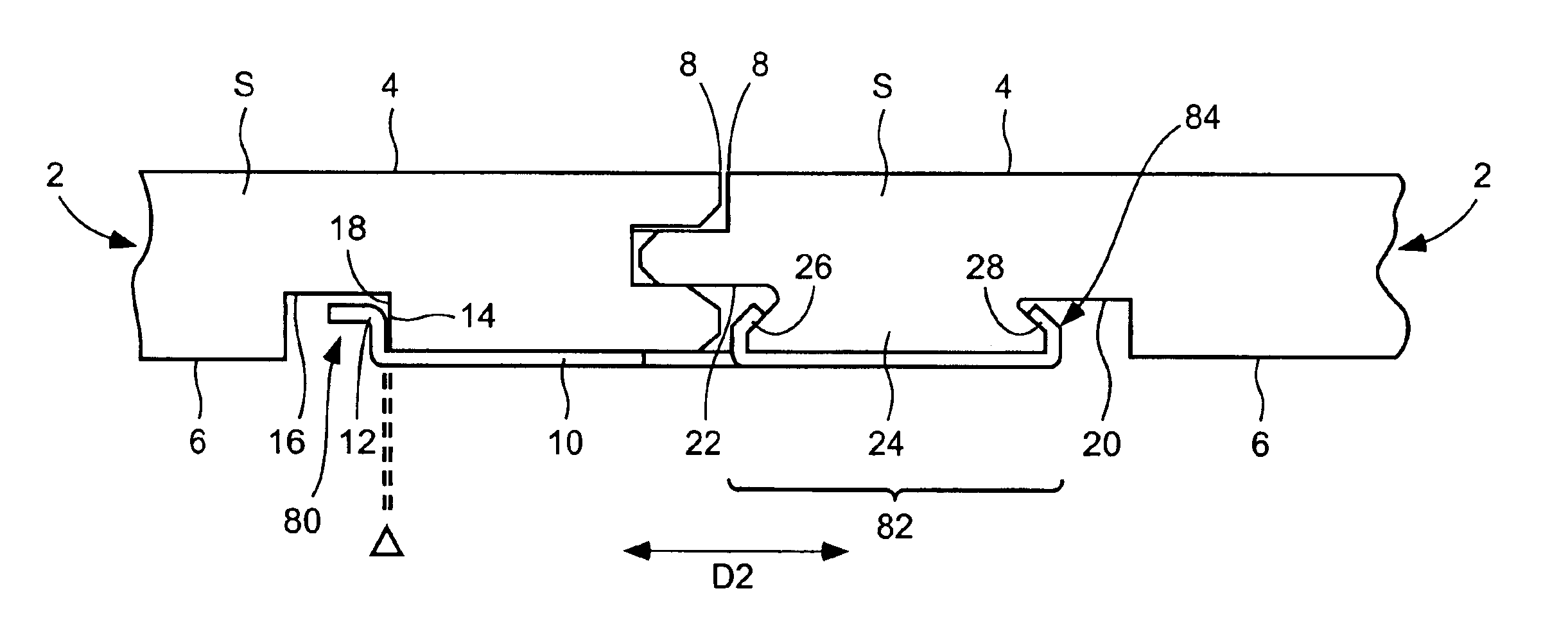

Metal strip for interlocking floorboard and a floorboard using same

InactiveUS6880305B2Not to damageUndesired joint gapCeilingsRoof covering using tiles/slatesMetal stripsMechanical engineering

Owner:VÄLINGE INNOVATION AB

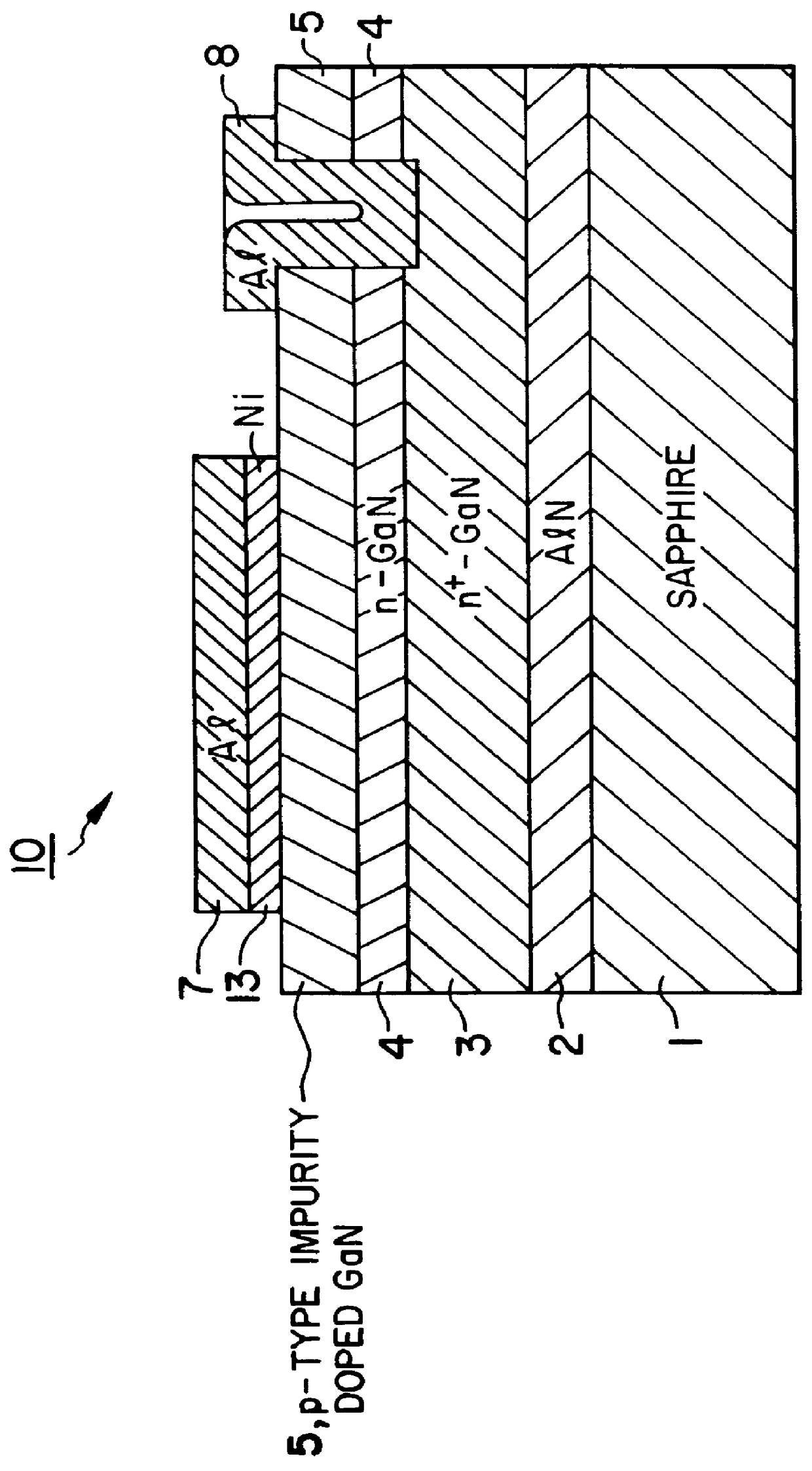

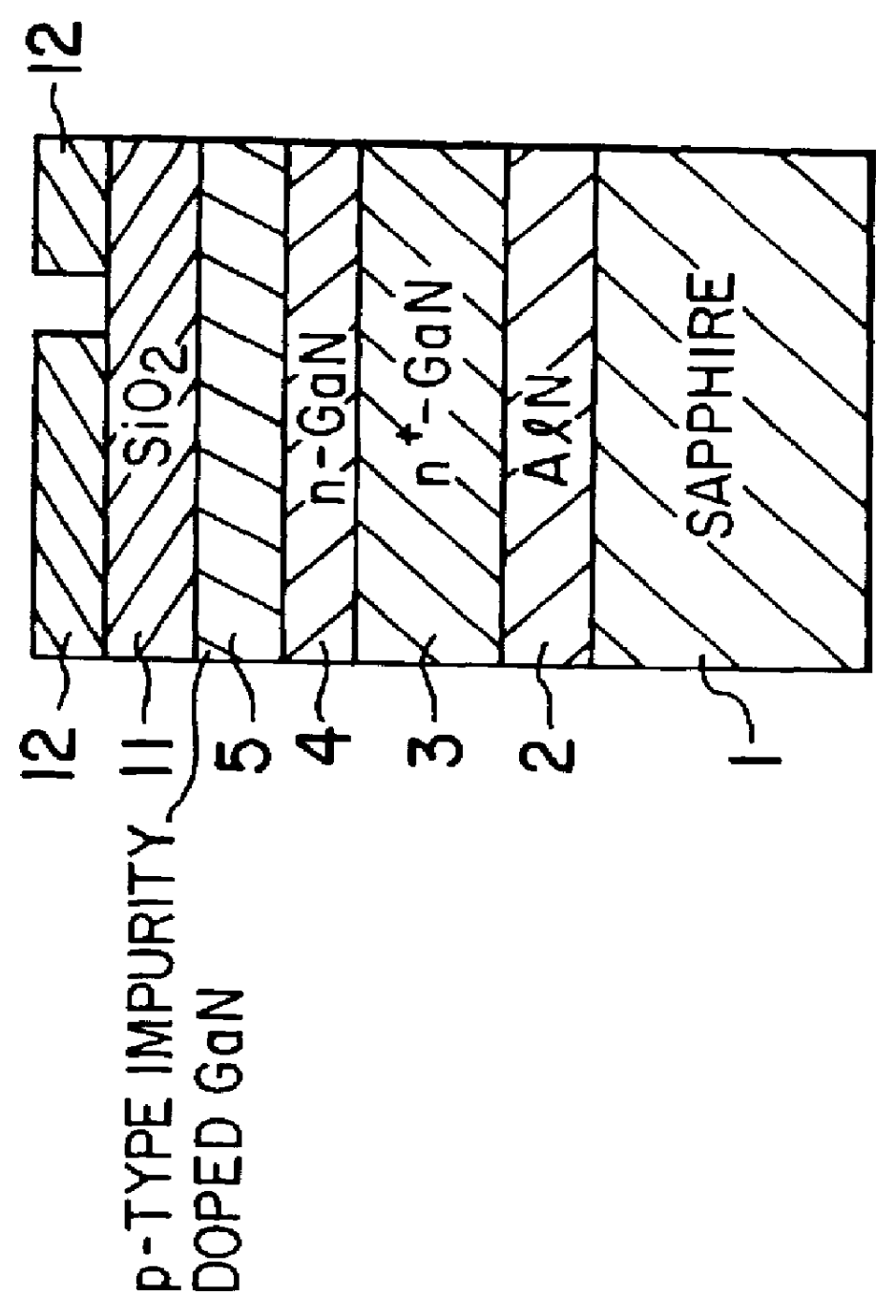

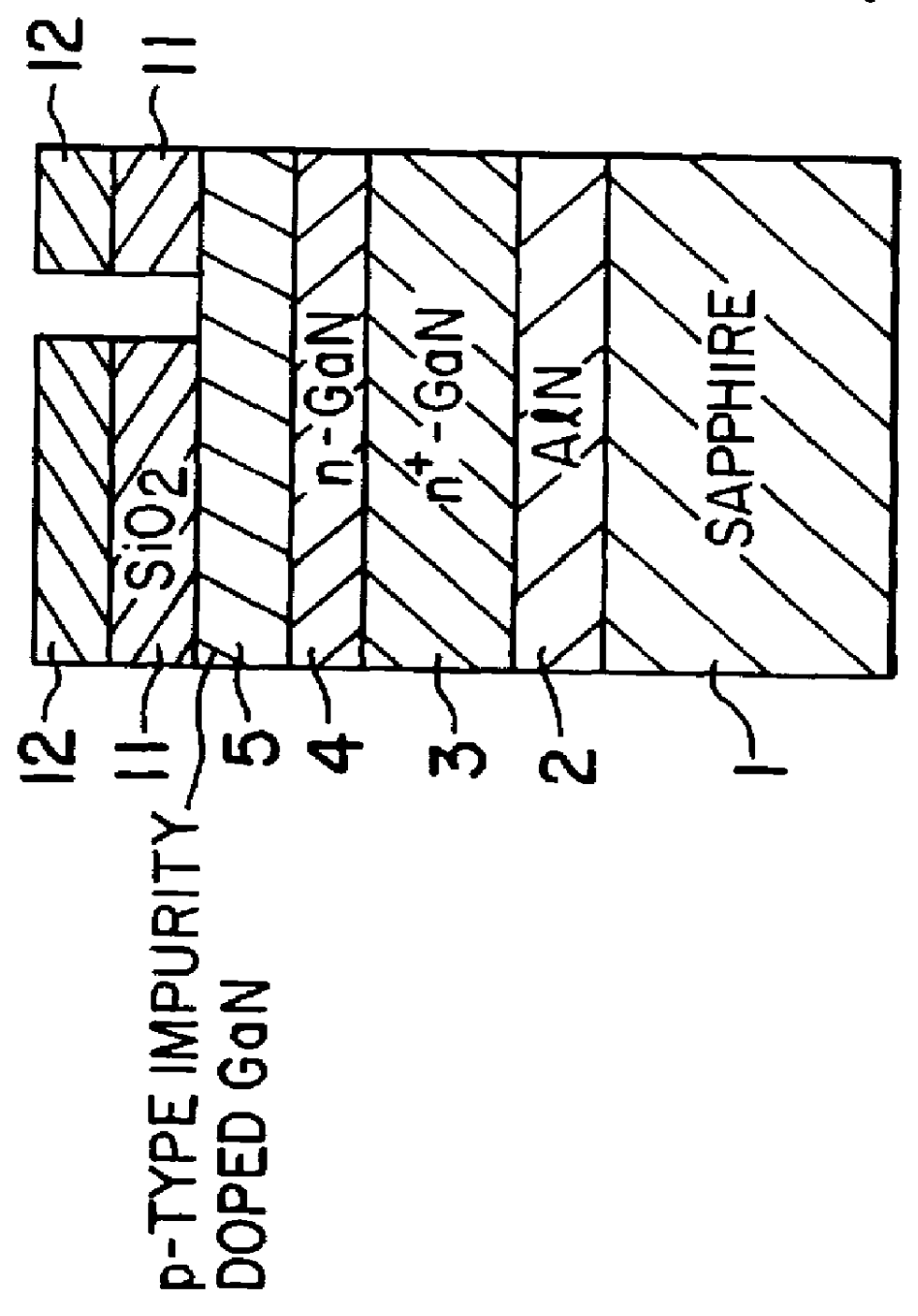

Light-emitting device of gallium nitride compound semiconductor

InactiveUSRE36747E1High luminous intensityReduce the driving voltageSemiconductor/solid-state device detailsSolid-state devicesLuminous intensityCharge carrier

A light-emitting diode of GaN compound semiconductor emits a blue light from a plane rather than dots for improved luminous intensity. This diode includes a first electrode associated with a high-carrier density n+ layer and a second electrode associated with a high-impurity density [iH-layer] H-layer. These electrodes are made up of a first Ni layer (110 ANGSTROM thick), a second Ni layer (1000 ANGSTROM thick), an Al layer (1500 ANGSTROM thick), a Ti layer (1000 ANGSTROM thick), and a third Ni layer (2500 ANGSTROM thick). The Ni layers of dual structure permit a buffer layer to be formed between them. This buffer layer prevents the Ni layer from peeling. The direct contact of the Ni layer with GaN lowers a drive voltage for light emission and increases luminous intensity.

Owner:TOYODA GOSEI CO LTD +1

Ceramic substrate, ceramic package for housing light emitting element

InactiveUS20060147746A1Reduce smoothnessIncrease costExtrusion containersSolid-state devicesGold layerCeramic substrate

A ceramic substrate comprising a metallic layer on its surface, wherein said metallic layer includes: a silver layer containing silver; a gold layer containing gold; and a nickel layer containing nickel, in this order from an outermost layer of said metallic layer.

Owner:NGK SPARK PLUG CO LTD

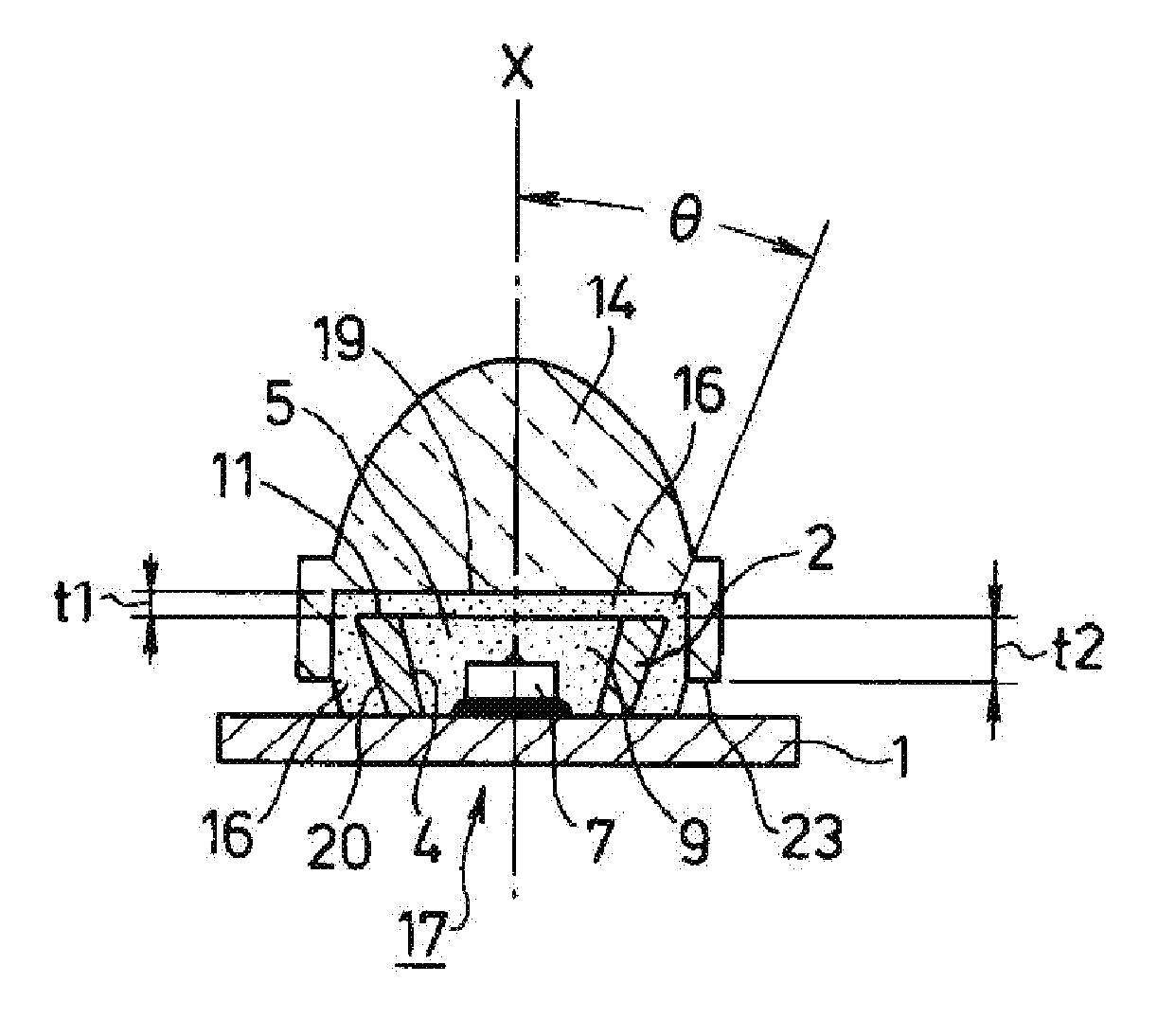

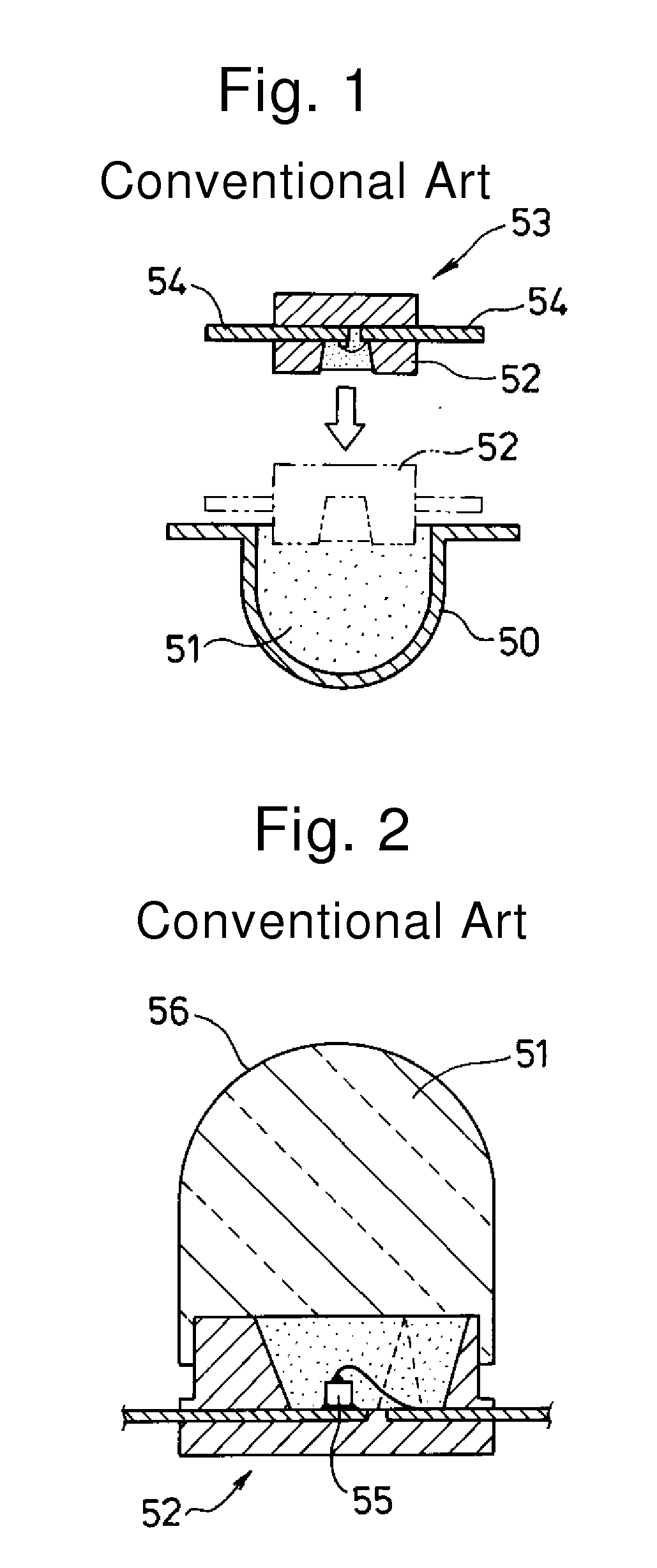

Semiconductor light-emitting device

InactiveUS20070205425A1Prevent peelingImprove reliabilitySolid-state devicesSemiconductor devicesOptical propertySubject matter

In a conventional semiconductor light-emitting device having a semiconductor light-emitting element-mounted body and an optical lens which are located adjacent each other, interfacial peeling sometimes occurs at the contact interfaces between components when the device is subjected to outside temperature changes. This may lead to the deterioration of optical characteristics and the reduction in reliability of the device. In accordance with an aspect of the disclosed subject matter, a semiconductor light-emitting element-mounted body can be integrated with the optical lens via a soft resin spacer. Hence, the soft resin spacer can serve as a thermal stress relaxation layer located between the semiconductor light-emitting element-mounted body and the optical lens, which are integrated together. The thermal stress relaxation layer can possibly prevent peeling, caused by thermal stresses due to outside temperature changes, from occurring at the interfaces between the components.

Owner:STANLEY ELECTRIC CO LTD

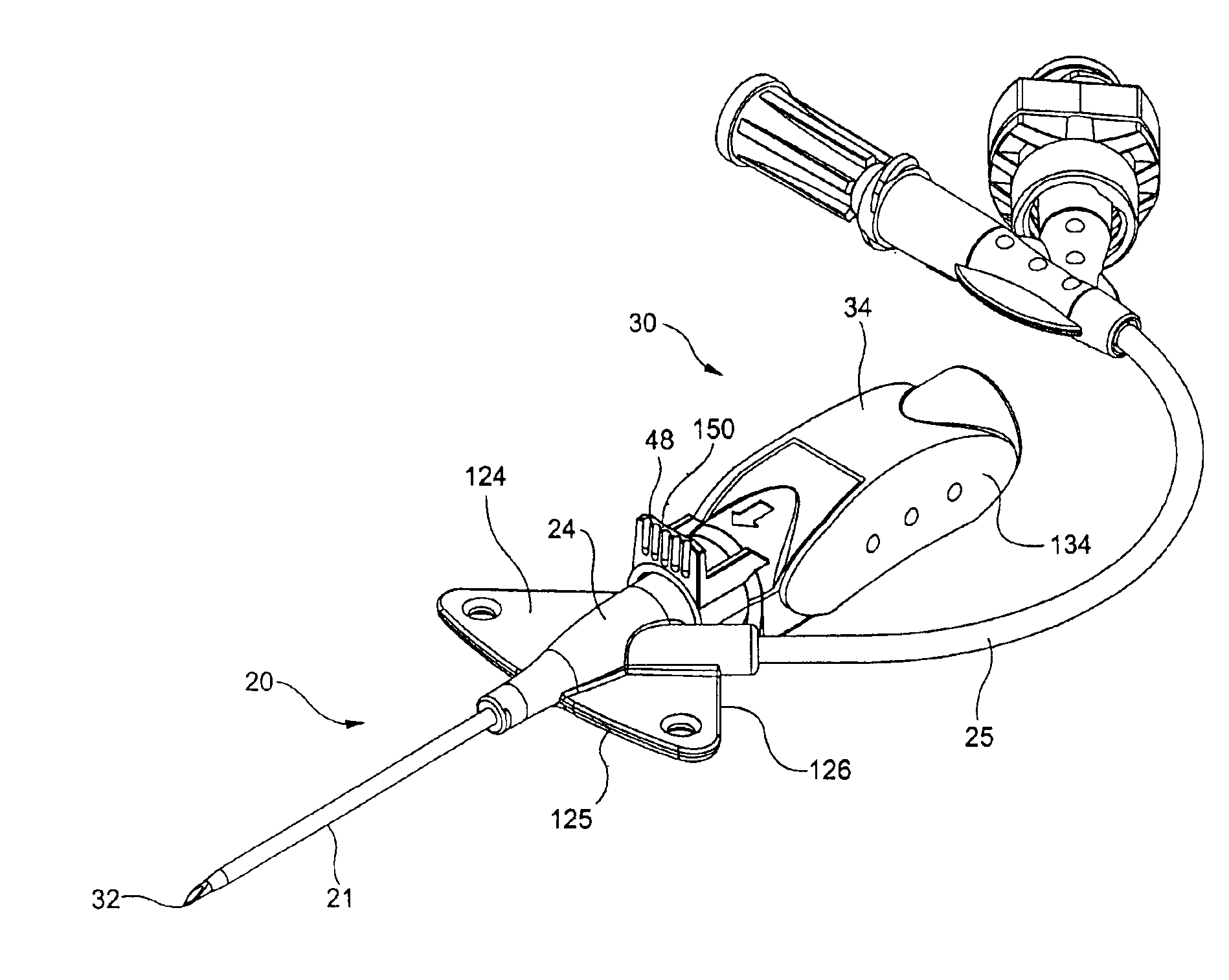

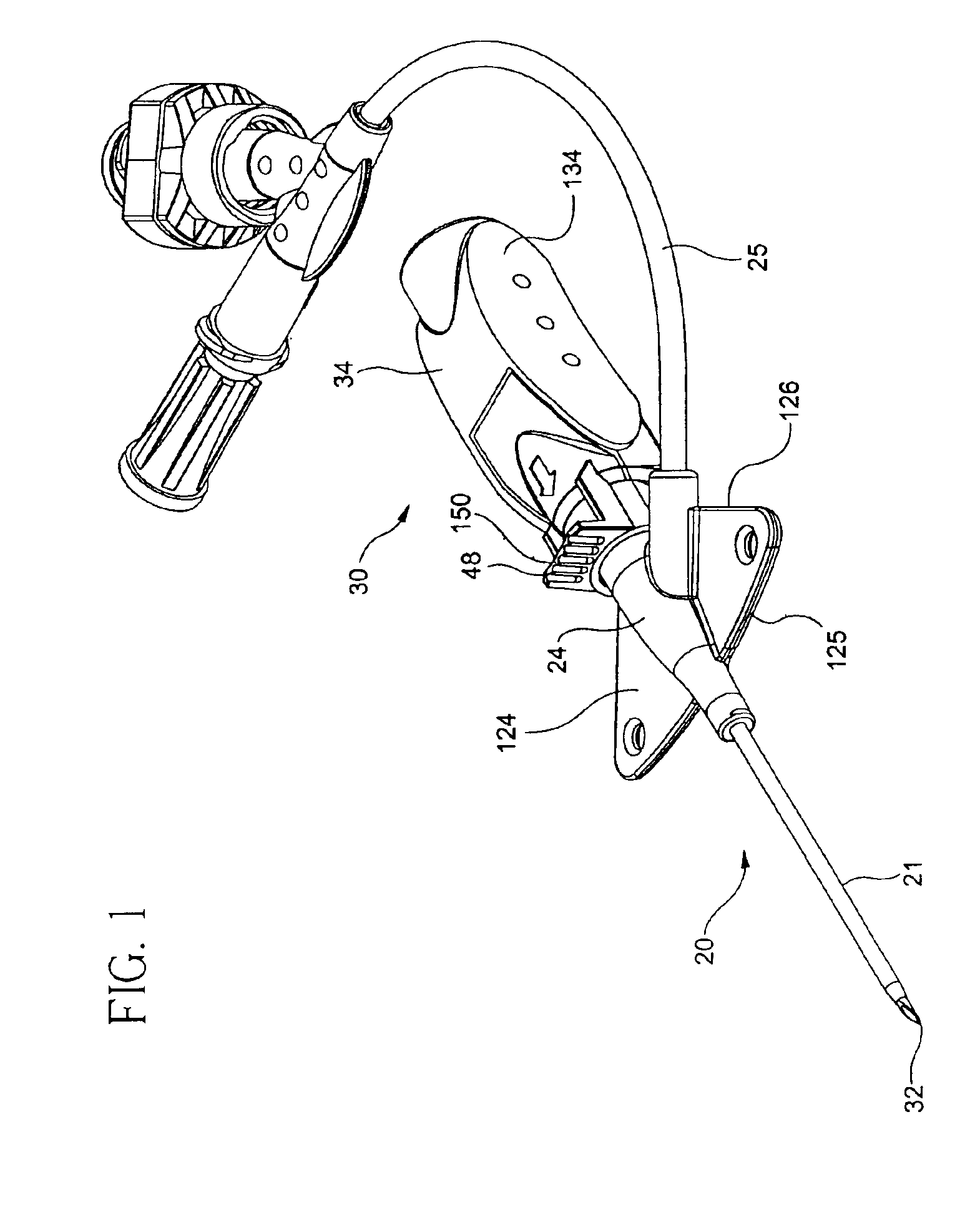

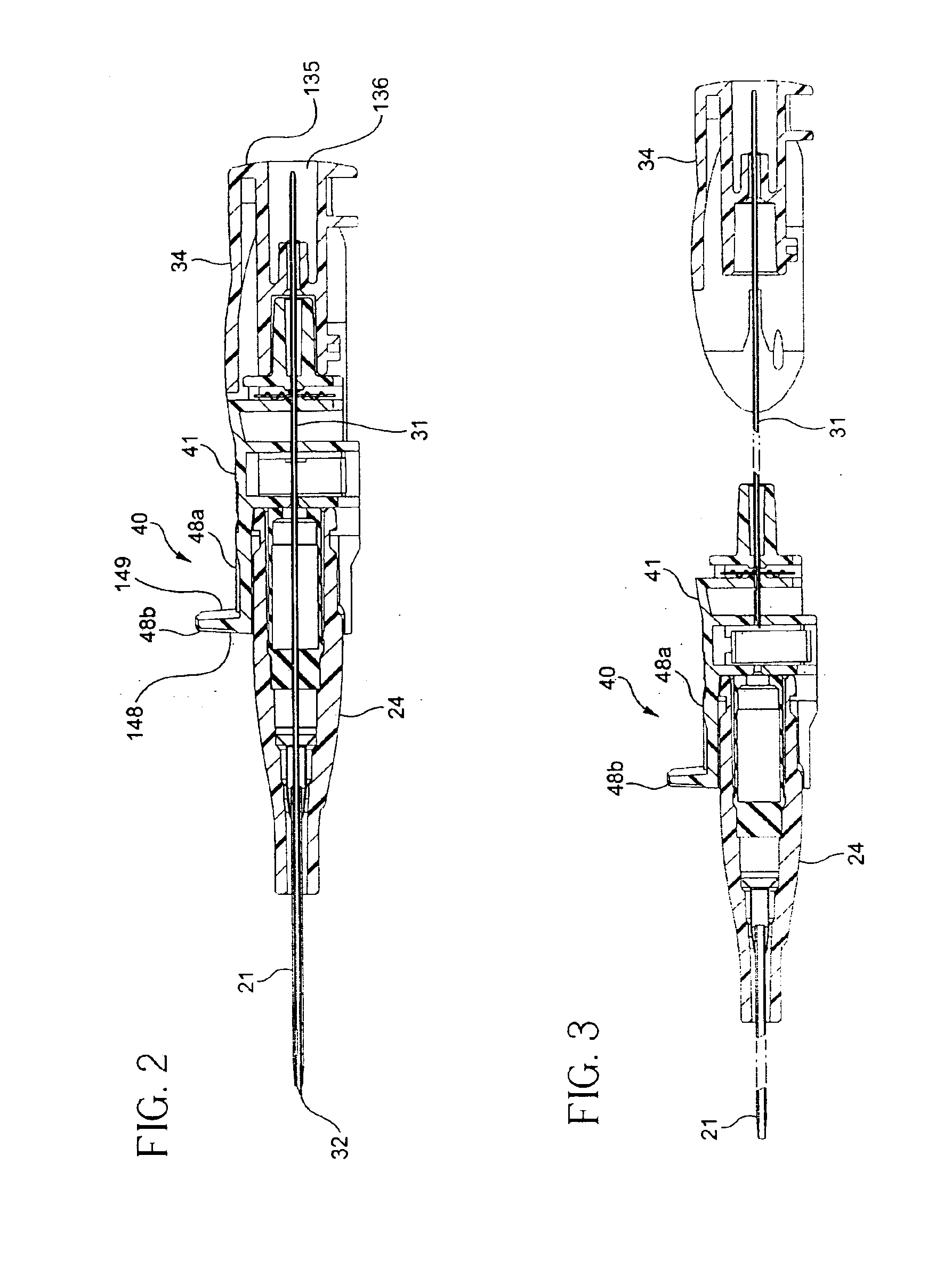

Cantilever push tab for an intravenous medical device

InactiveUS6953448B2Prevents unwanted distal movementPreventing unwanted proximal movementGuide needlesInfusion syringesVeinCATHETER ADAPTER

A combination cantilever push tab and finger rest is associated with the needle shield and extends distally from the distal end of the needle shield. The cantilever push tab and finger rest includes a cantilever portion that extends distally from the needle shield, preferably from an exterior surface of the needle shield, and an upstanding tab portion at the distal end of the cantilever portion. This configuration causes the upstanding tab to extend over the proximal portion of the catheter adapter and allows a clinician to insert a catheter using virtually any clinically acceptable technique for inserting a catheter into a patient.

Owner:BECTON DICKINSON & CO

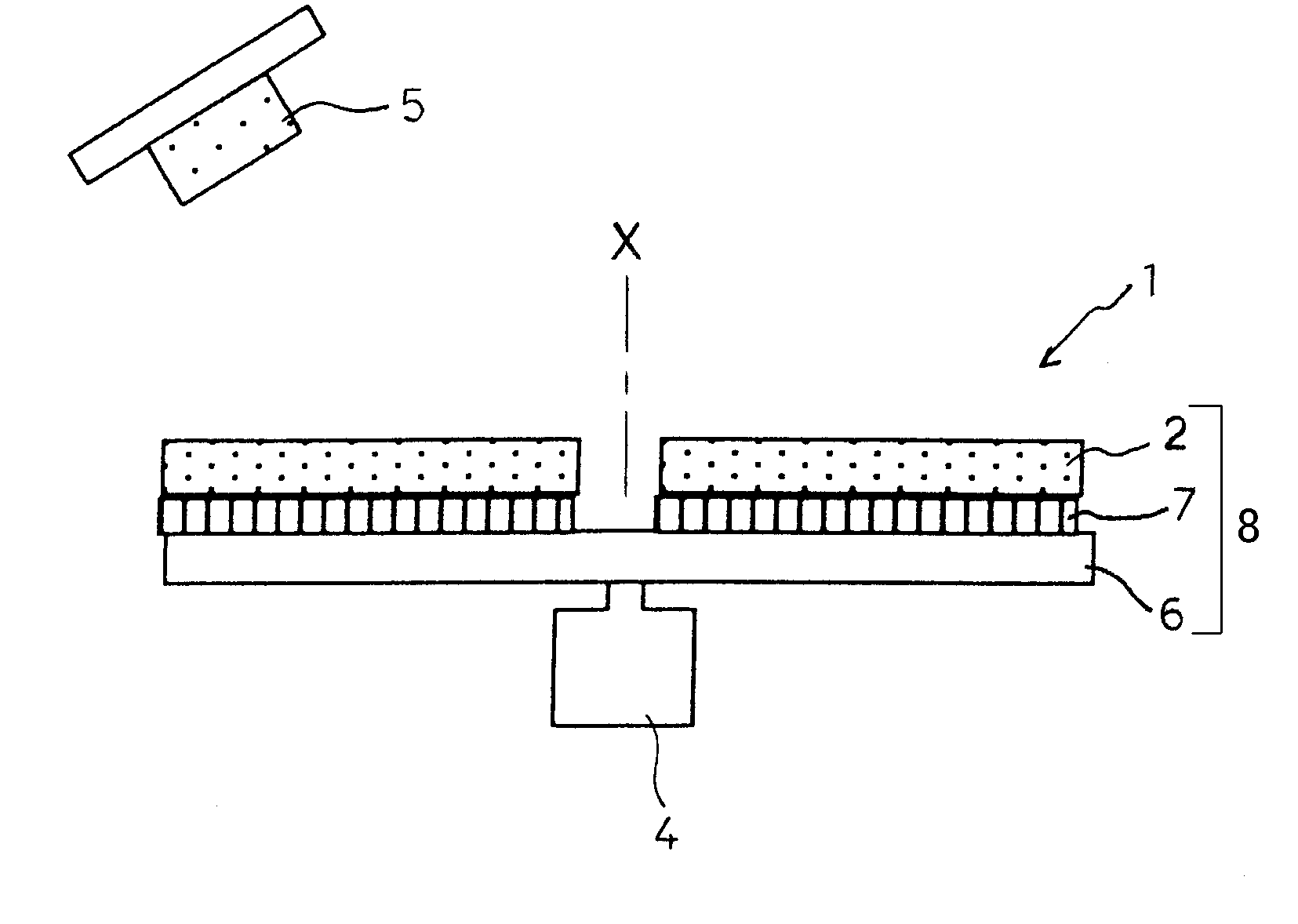

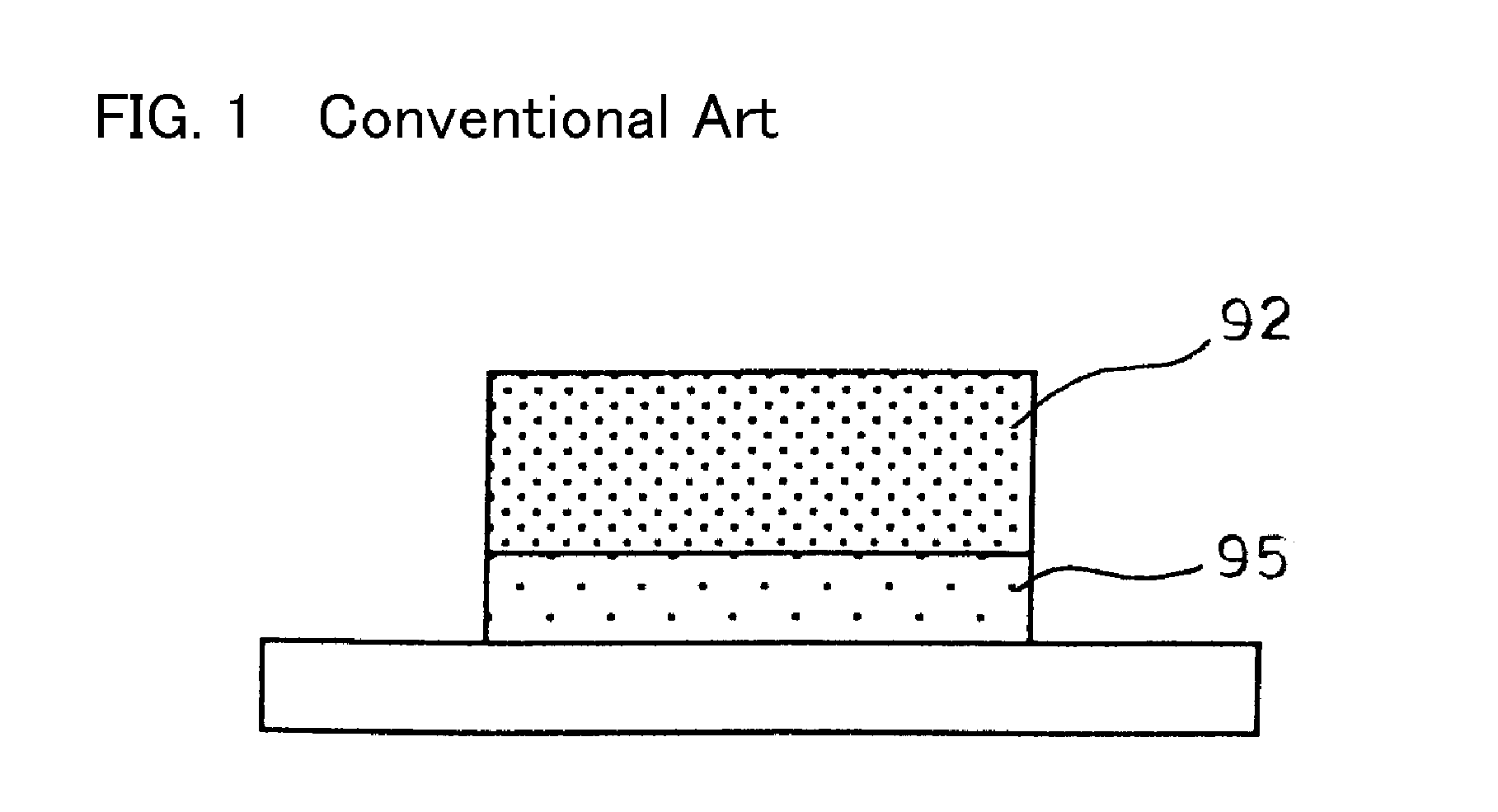

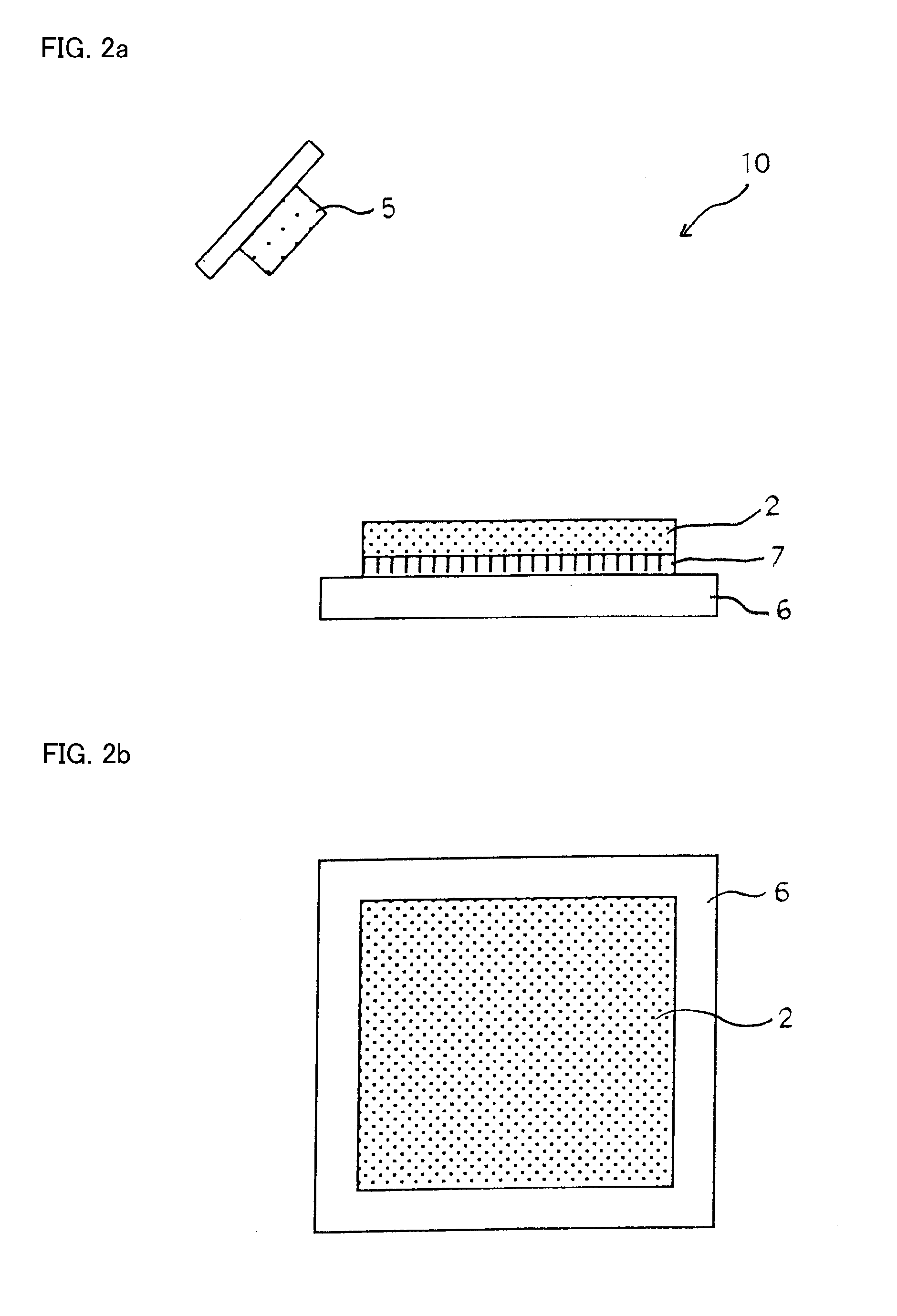

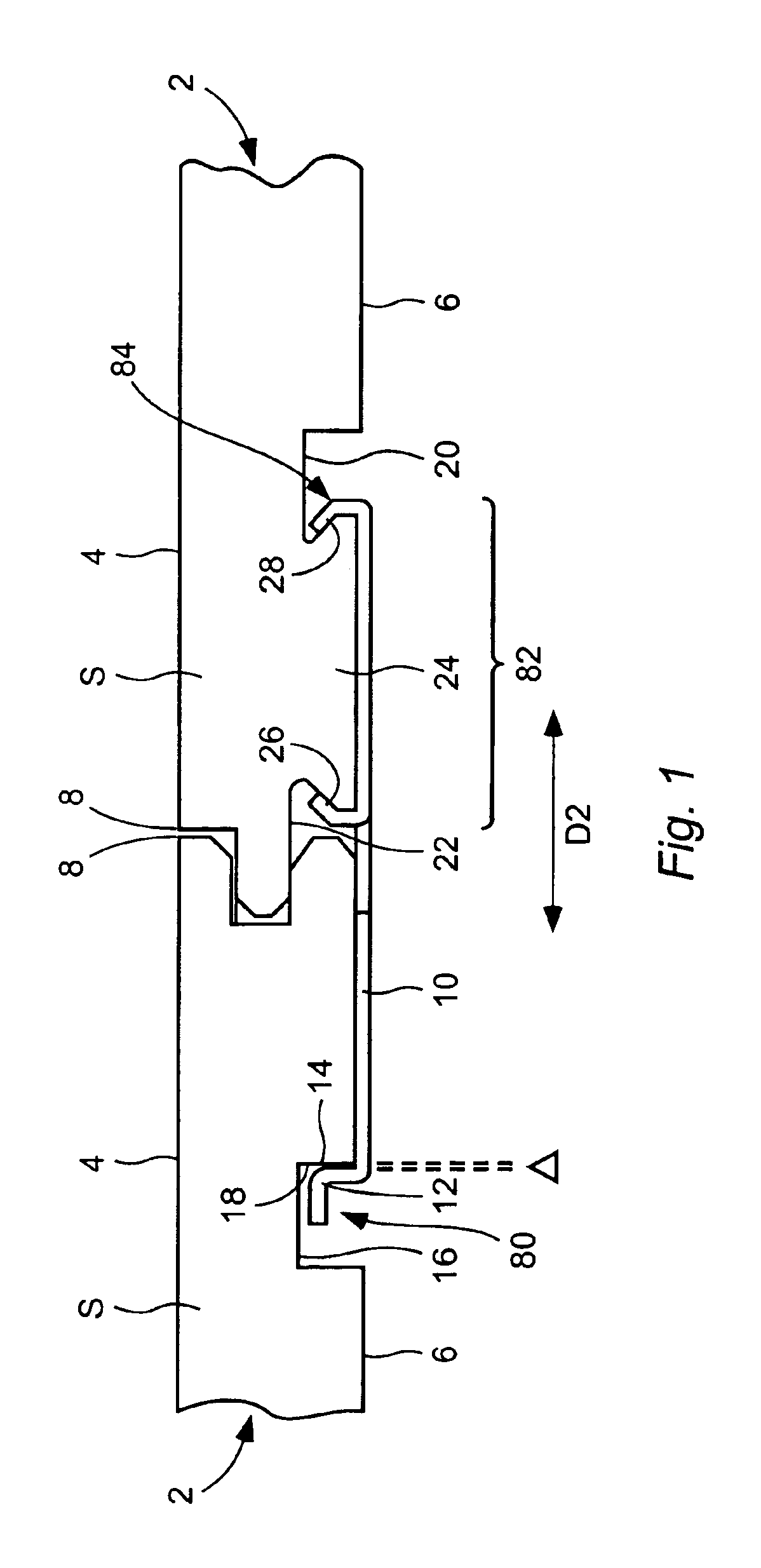

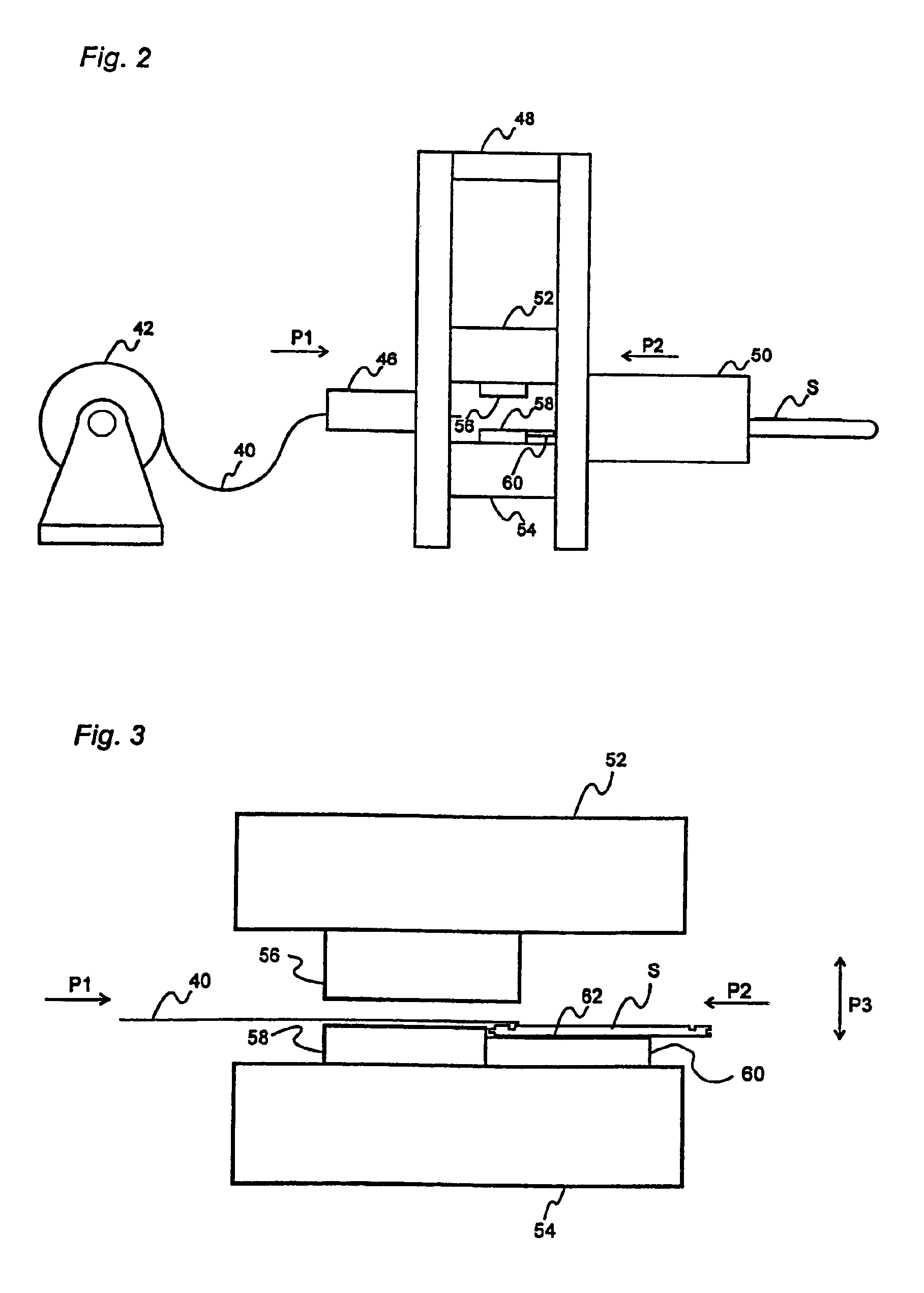

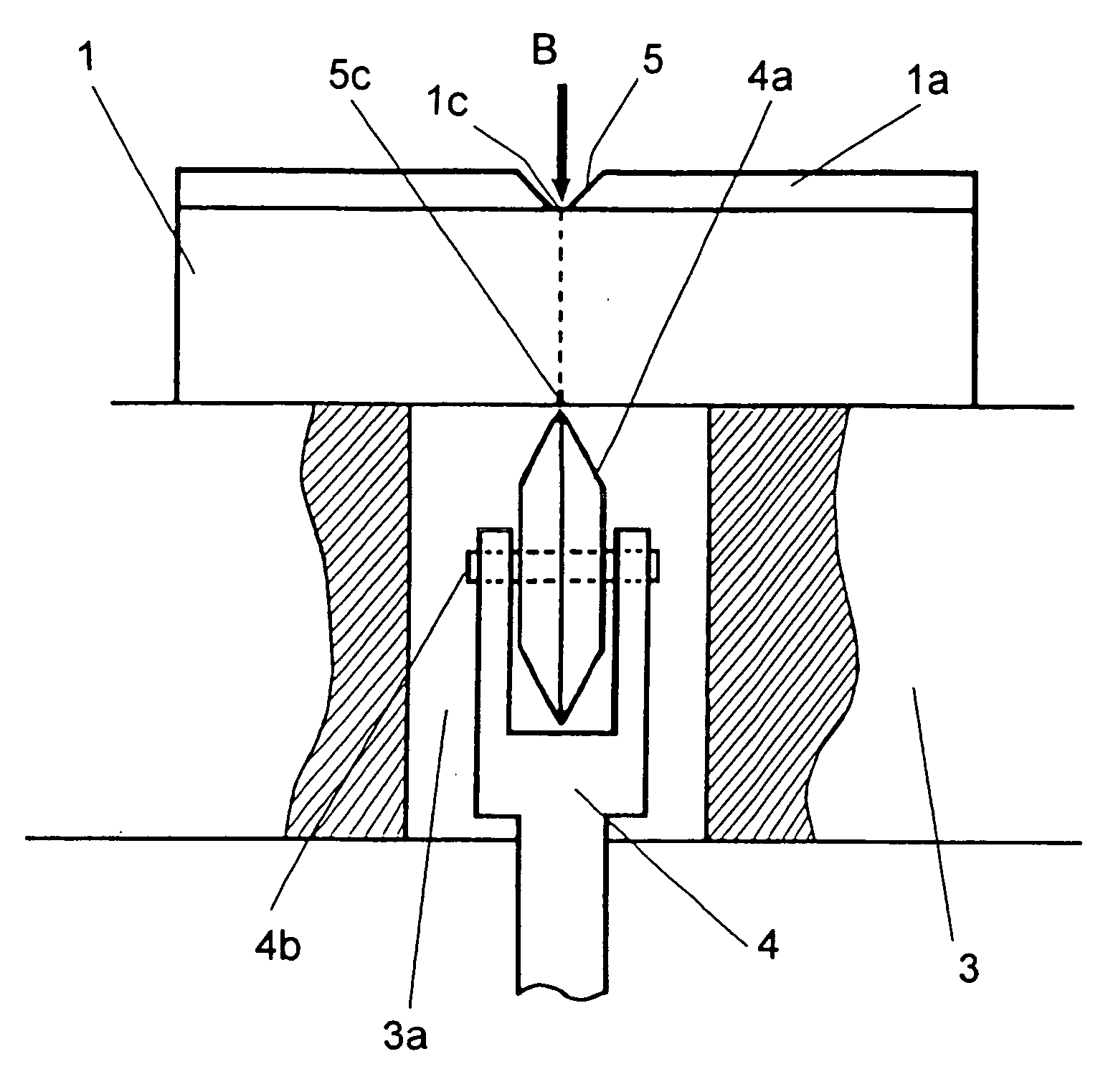

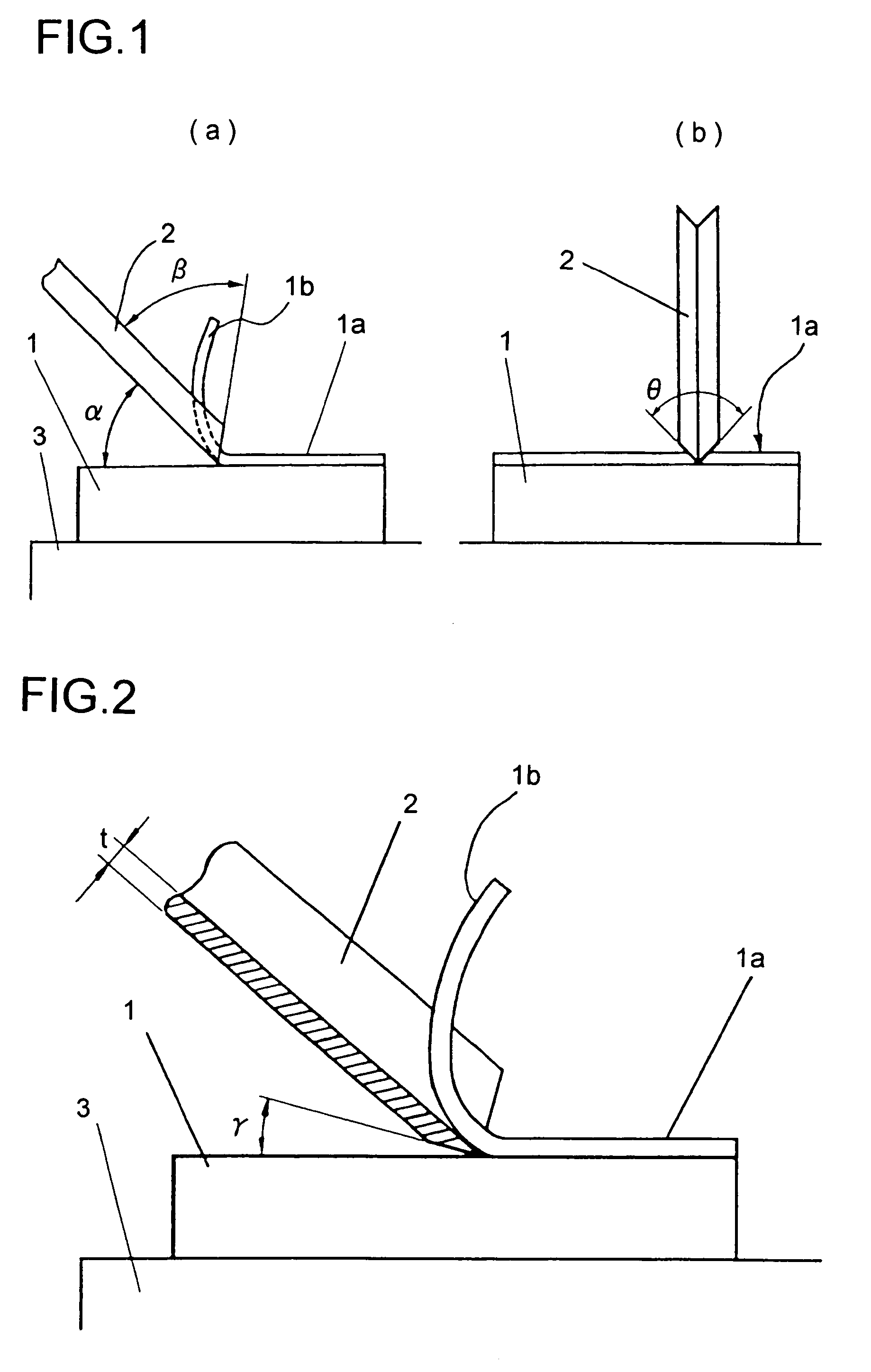

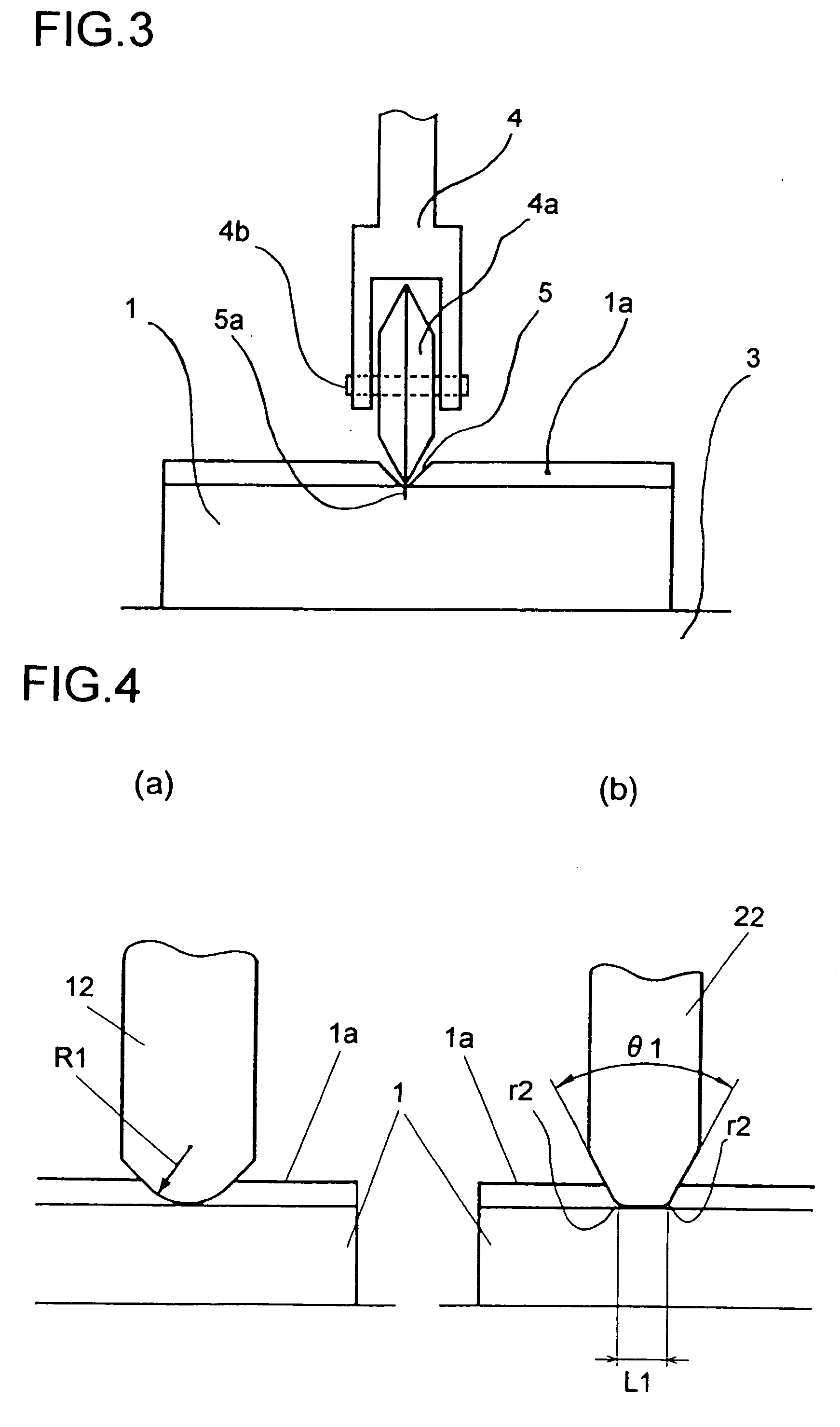

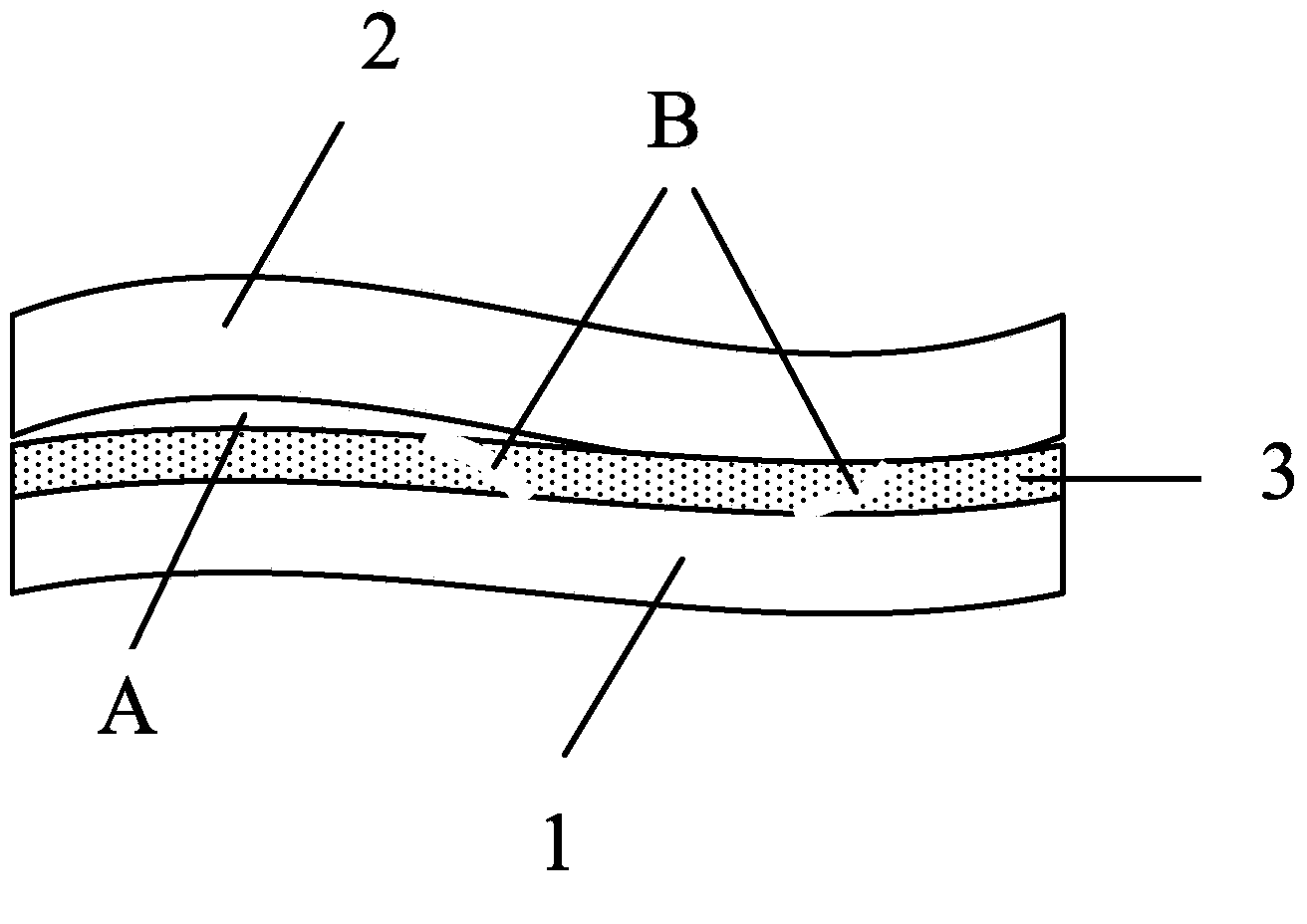

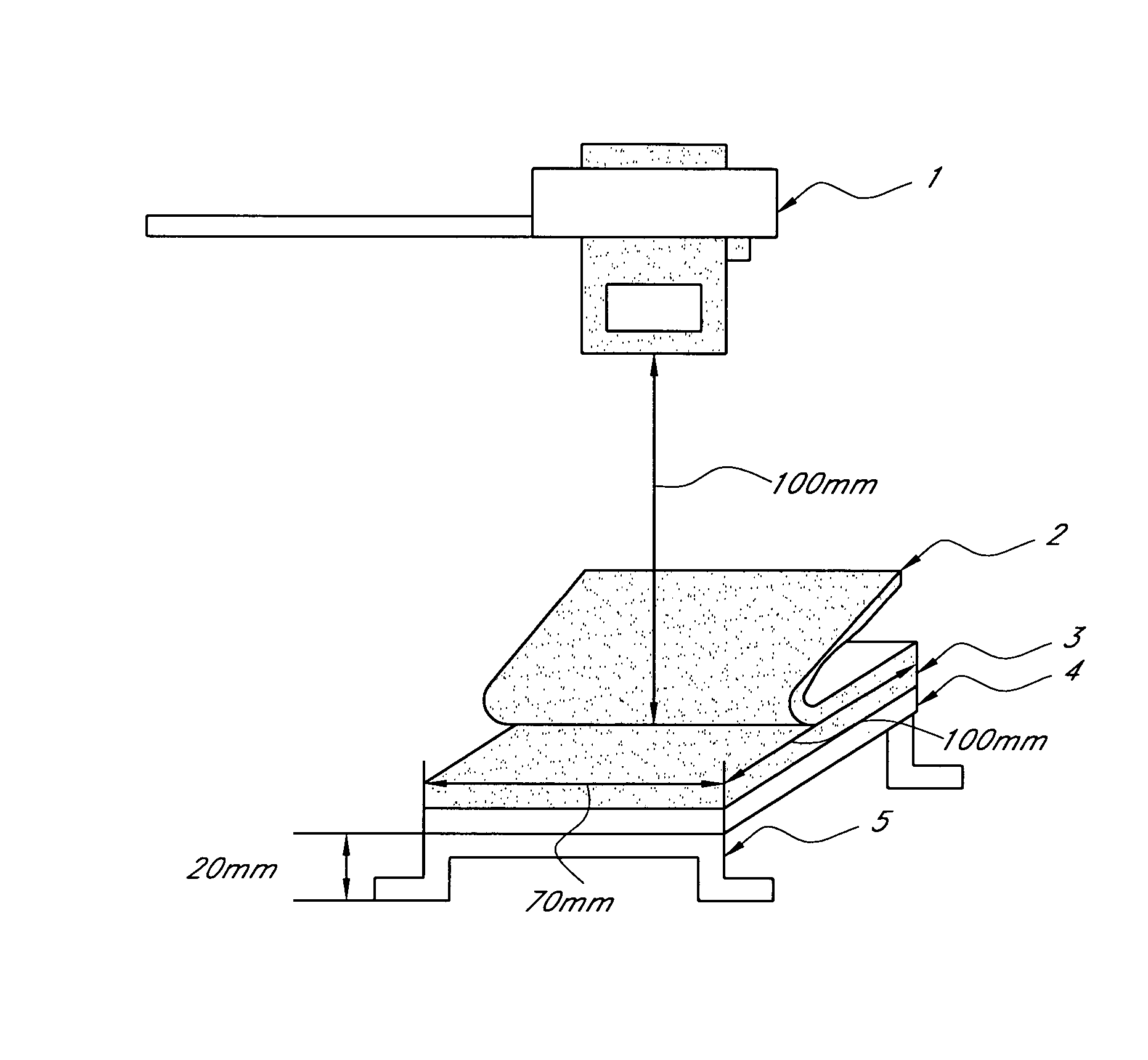

Method and device for parting glass substrate, liquid crystal panel, and liquid crystal panel manufacturing device

InactiveUS20050056127A1High mechanical strengthPrevent peelingLiquid crystal compositionsBox making operationsLiquid-crystal displayCutting glass

A method for cutting apart a glass substrate is provided whereby scribing of the glass substrate is possible without being affected by the presence or thickness of a deposited film formed thereon and without scratching the deposited film. To treat a glass substrate (1) having a deposited film (1a), such as a thin film or resin film, formed on one surface thereof, there are provided a shaving means (202), which is a blade that removes strip-shaped portions of the deposited film (1a) to expose strip-shaped regions on the glass substrate (1), and a wheel cutter (14a) that forms scribed lines along the strip-shaped regions exposed on the glass substrate (1). The glass substrate (1) is cut apart along the scribed lines.

Owner:SHARP KK +1

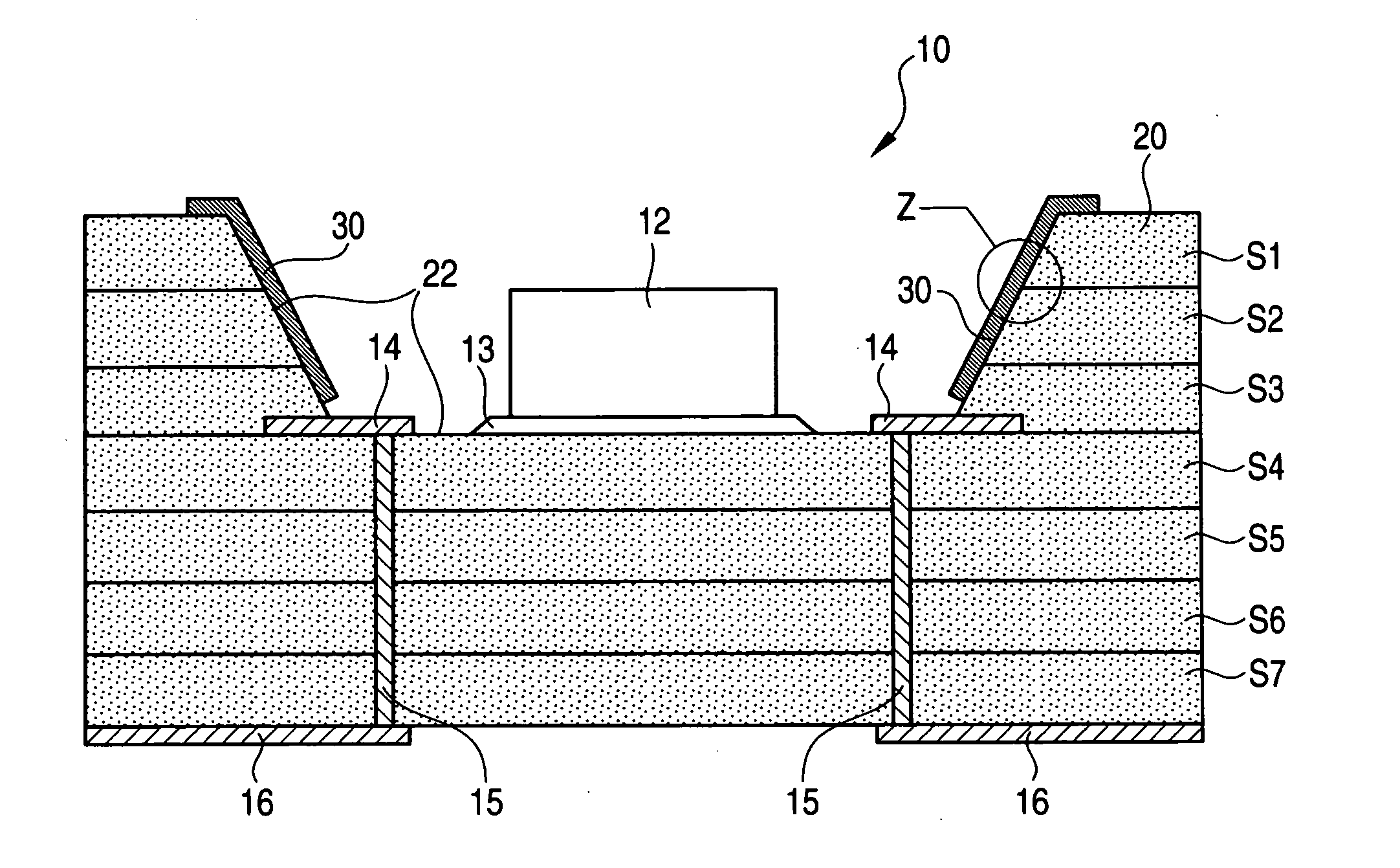

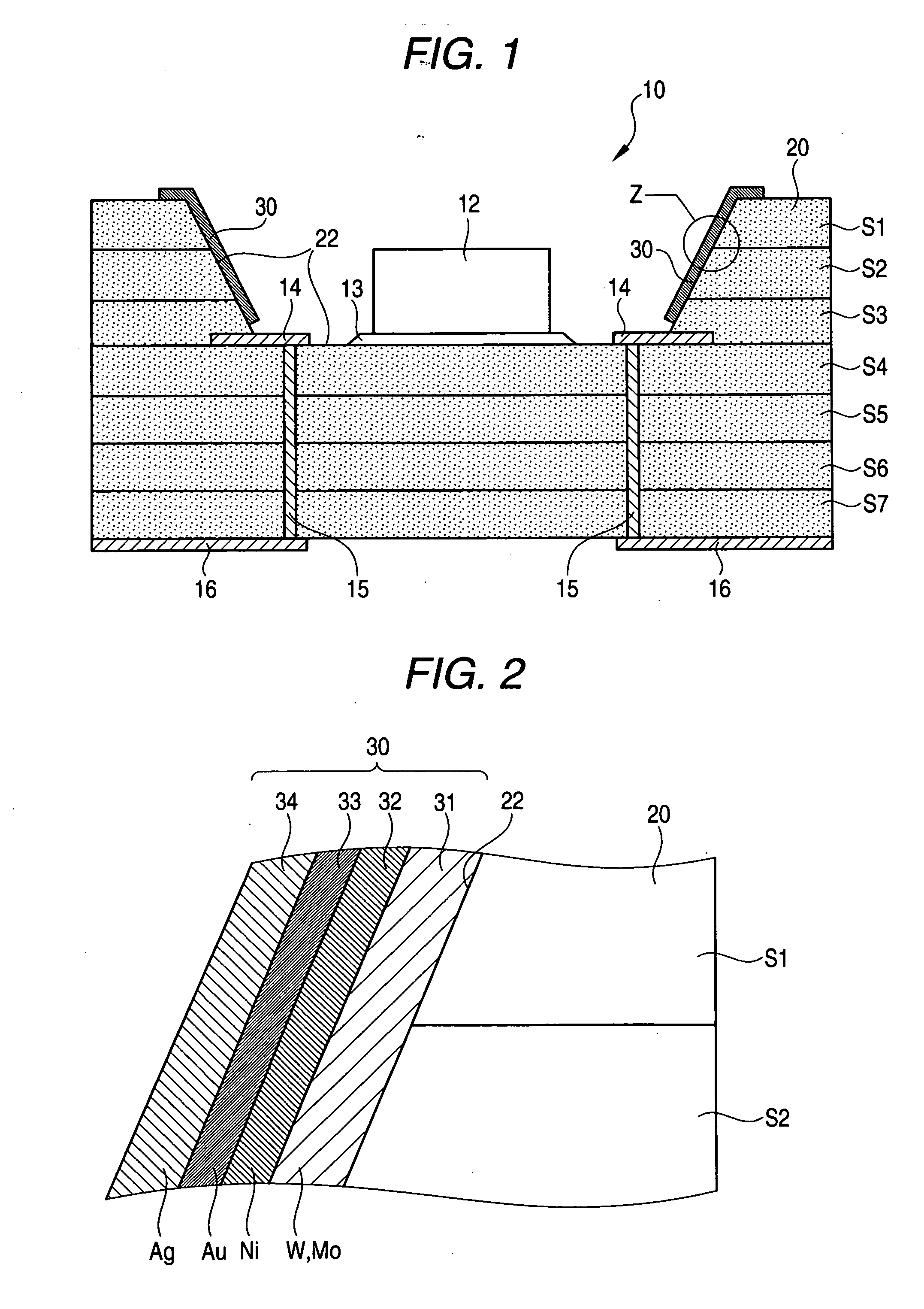

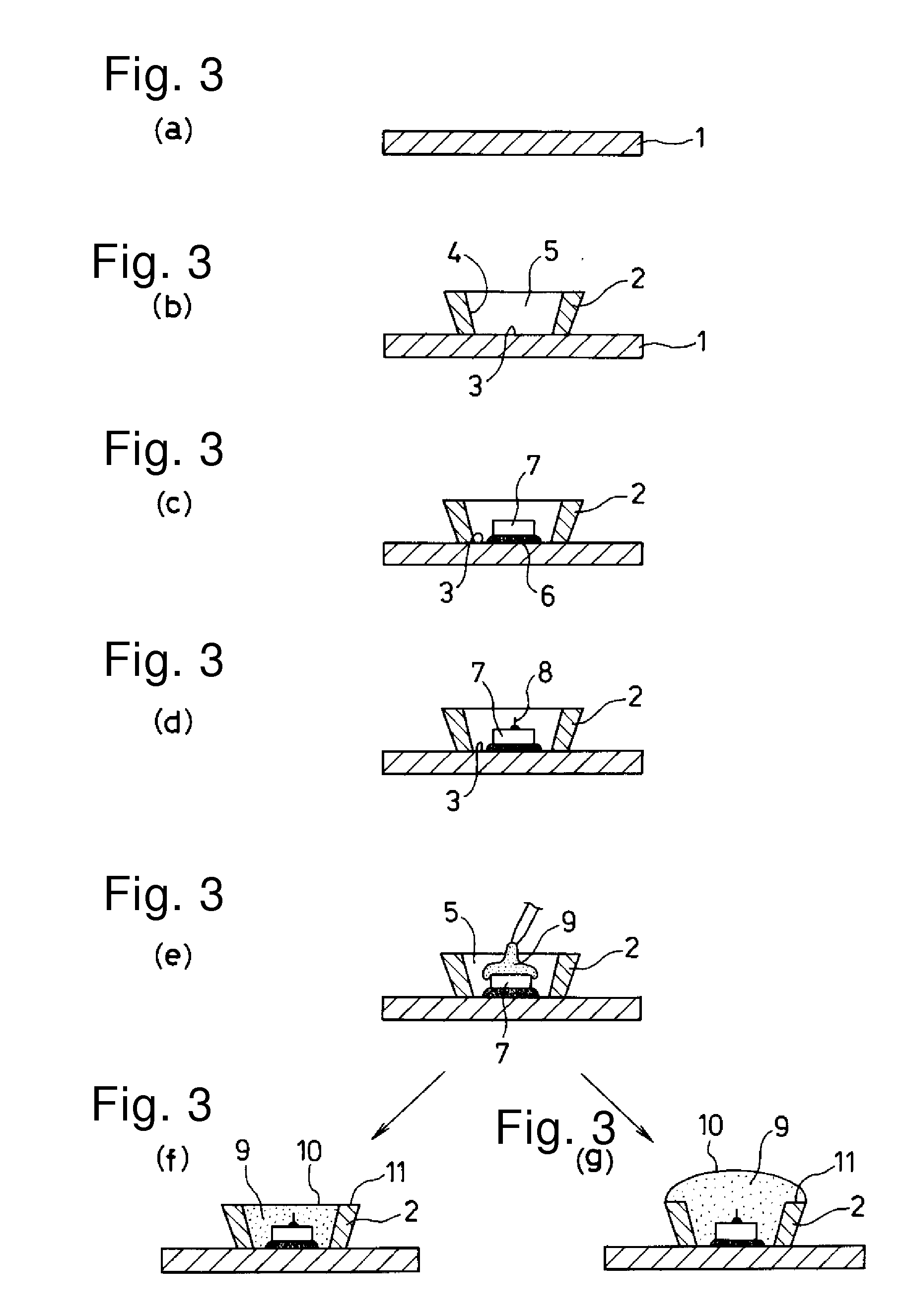

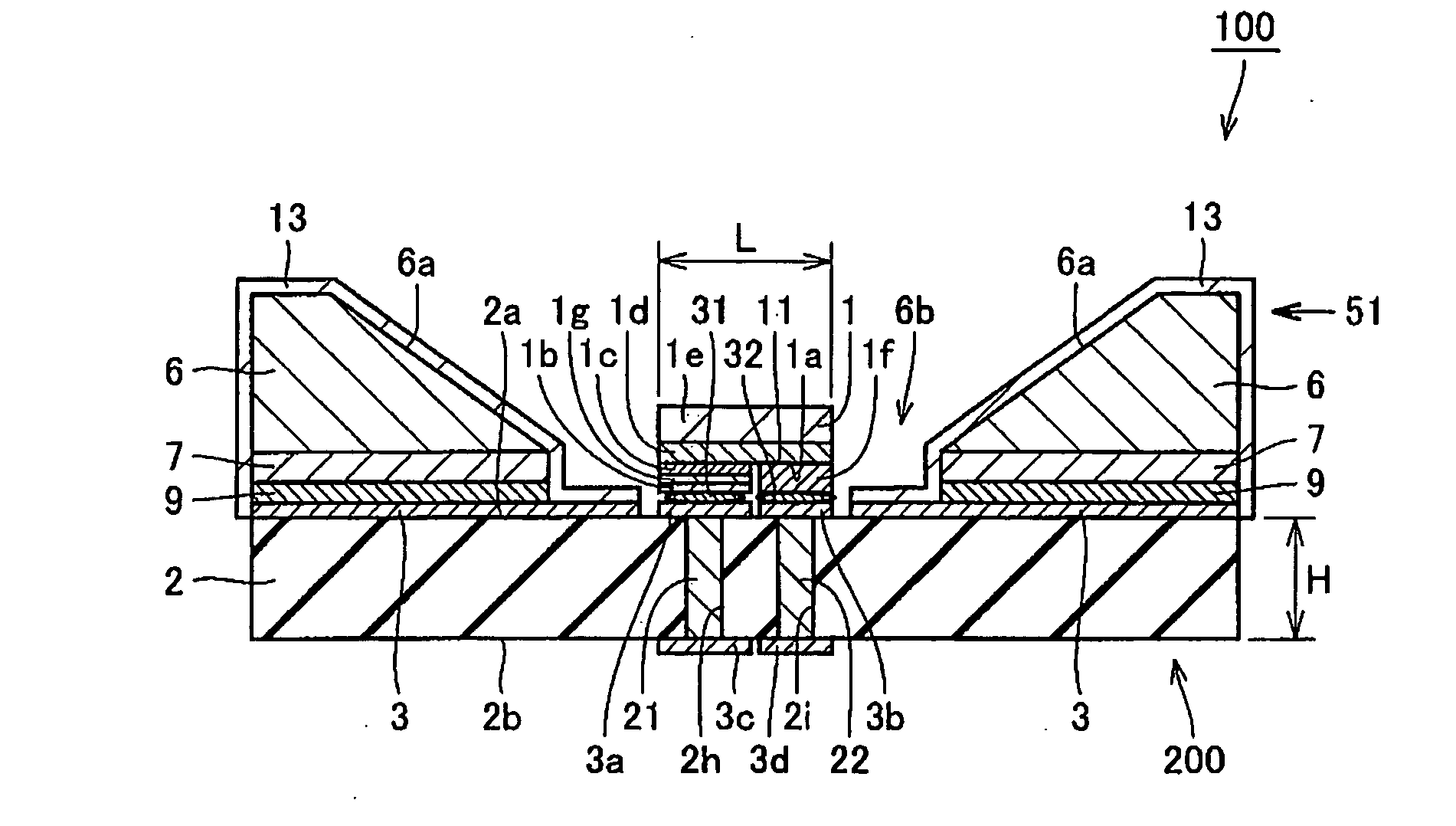

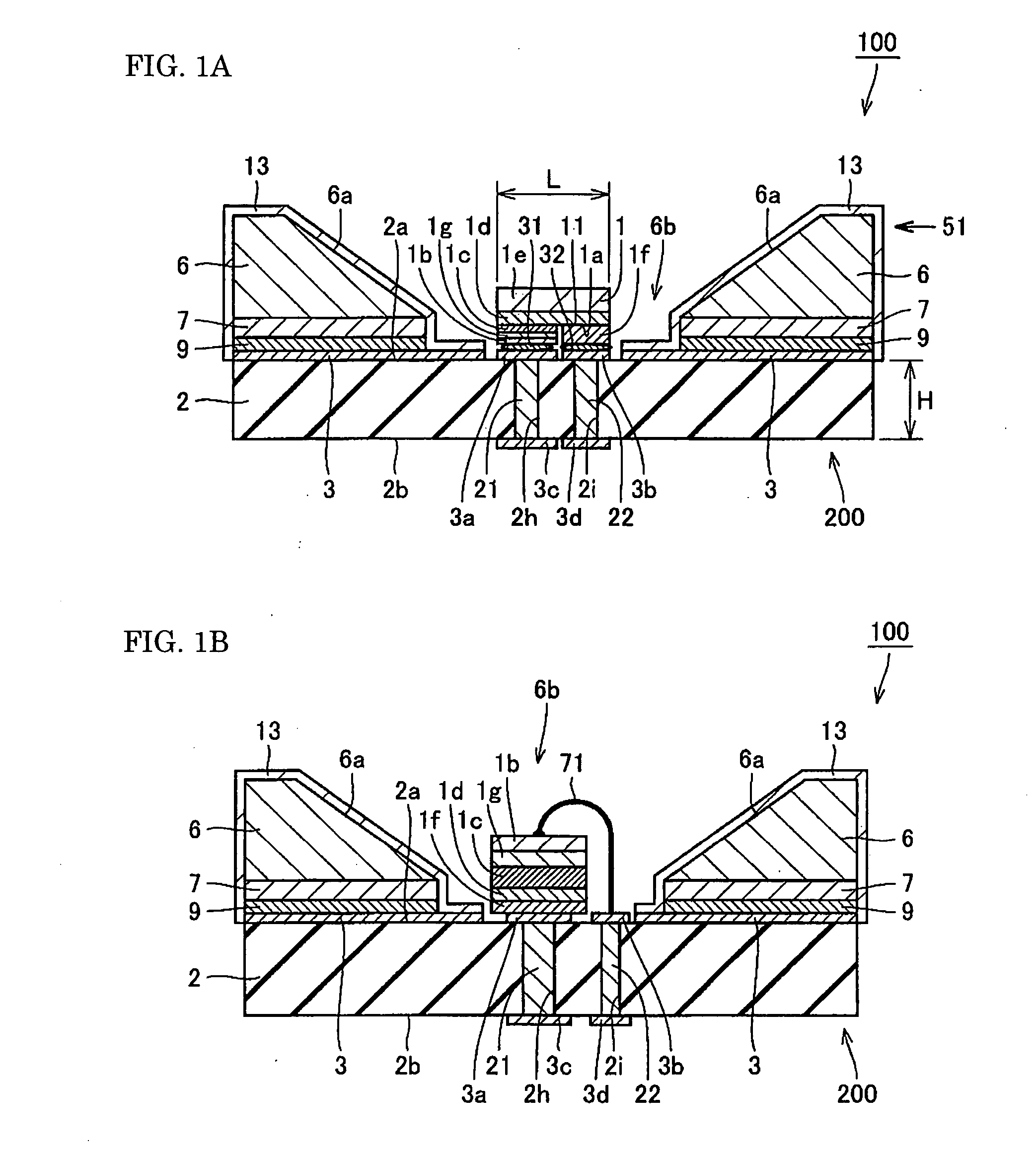

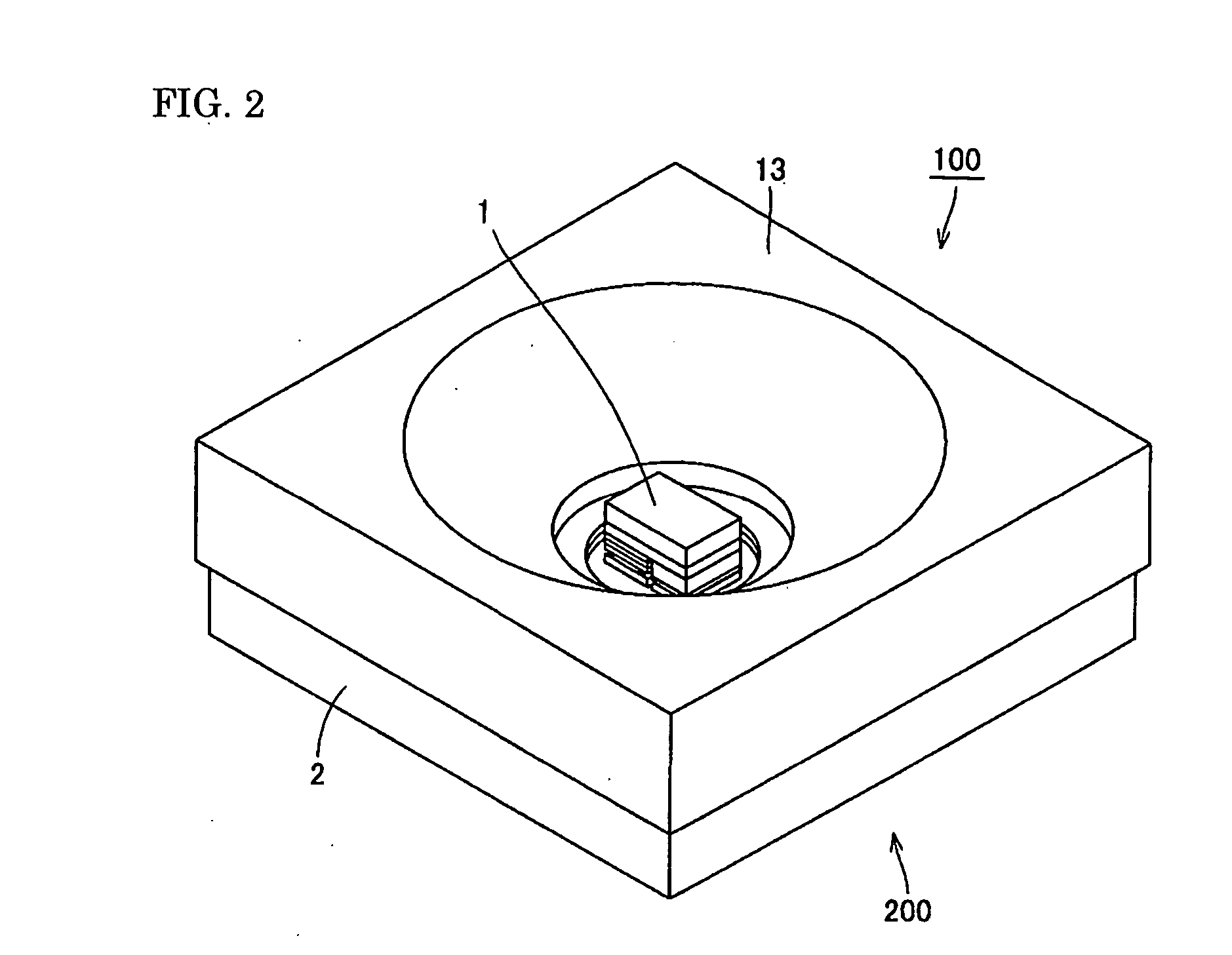

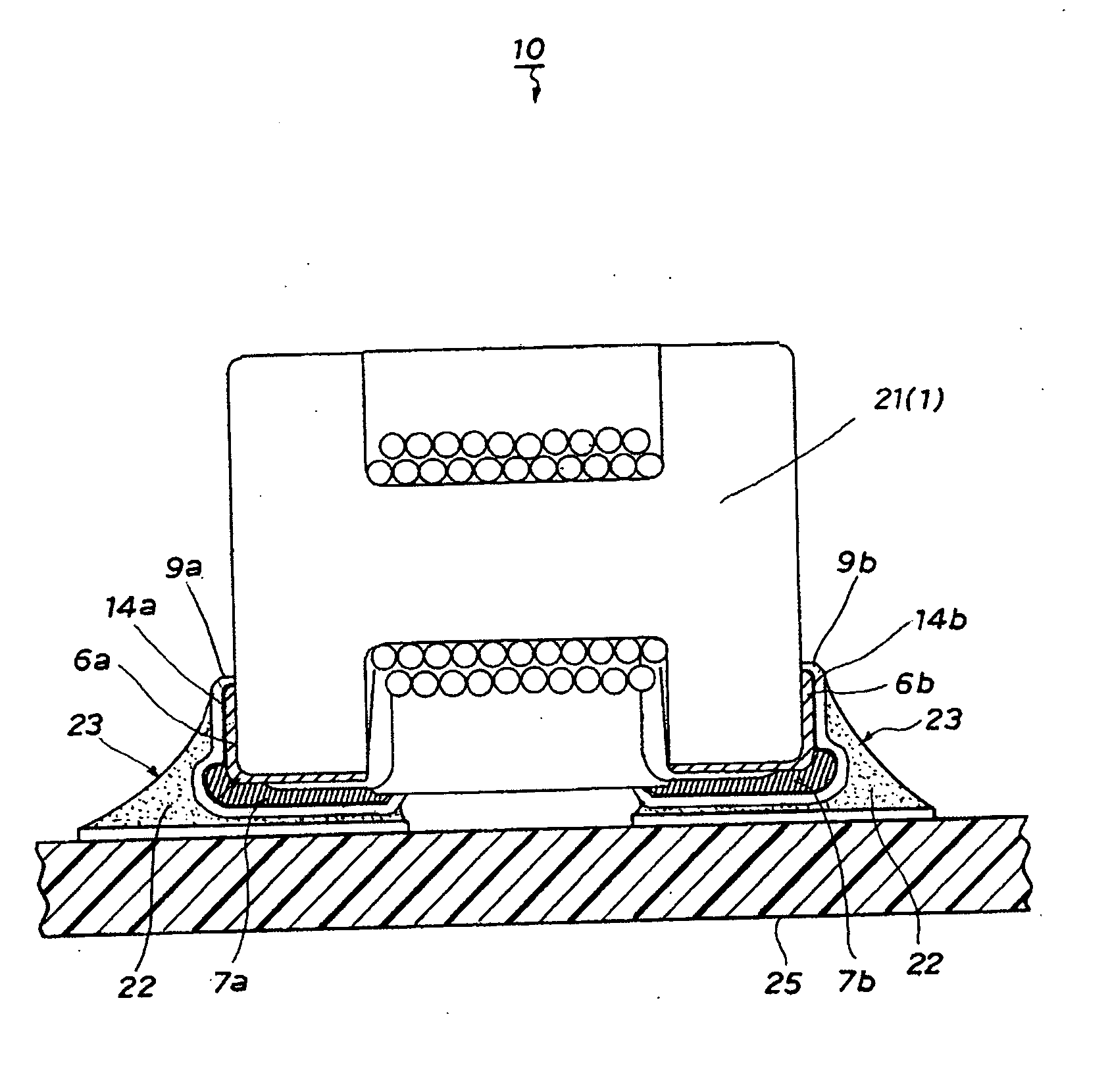

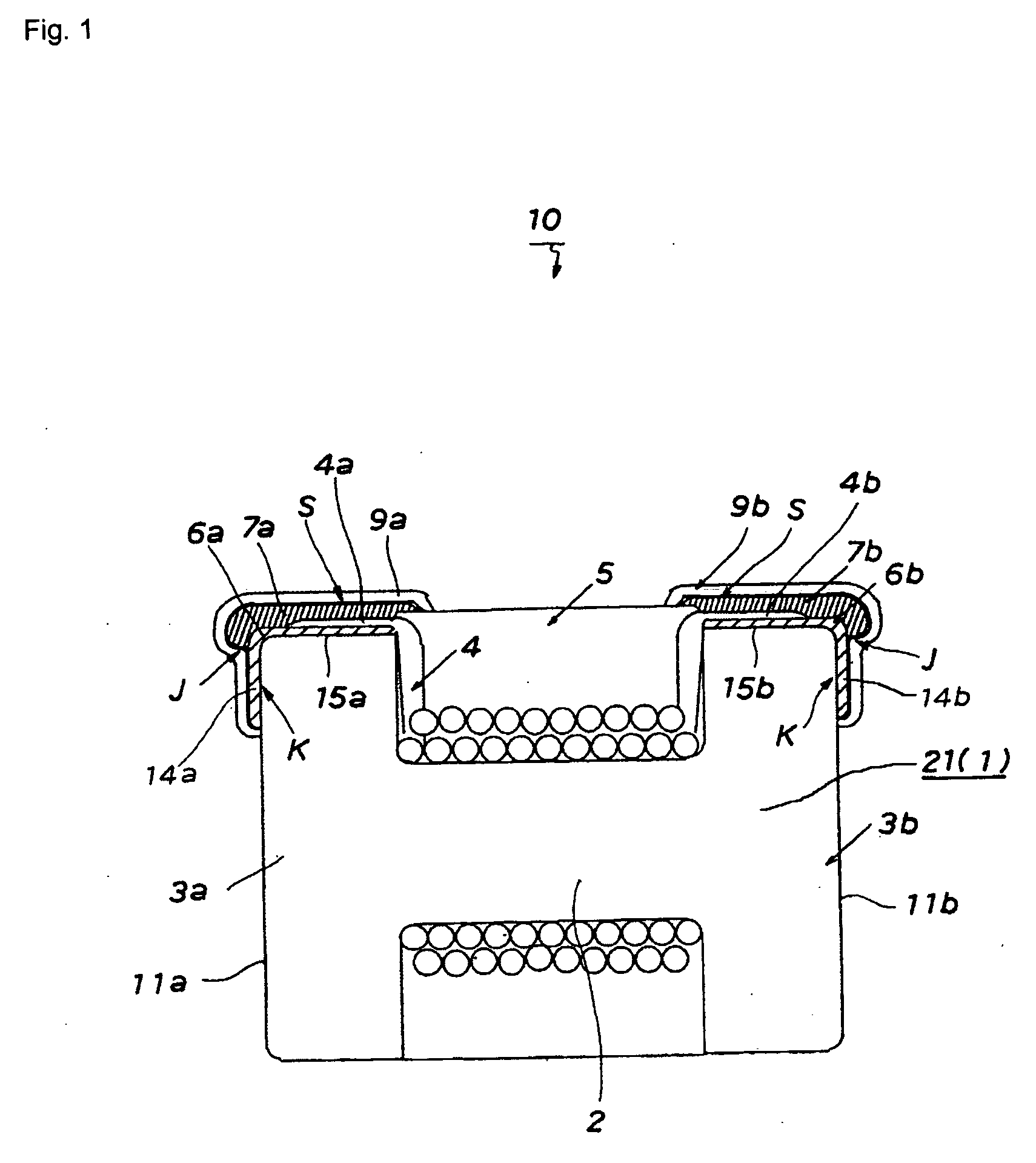

Light emitting element mounting member, and semiconductor device using the same

ActiveUS20060198162A1Efficiently dissipateSuperior cooling propertyLaser detailsDischarge tube luminescnet screensEngineeringSemiconductor

The object of the present invention is to provide a light-emitting element mounting member and a semiconductor device using the same that is easy to process and that allows adequate heat dissipation. A light-emitting element mounting member 200 includes: a substrate 2 including an element mounting surface 2a mounting a semiconductor light-emitting element 1 and first and second conductive regions 21, 22 disposed on the element mounting surface 2a and connected to the semiconductor light-emitting element 1; a reflective member 6 including a reflective surface 6a defining an internal space 6b for housing the semiconductor light-emitting element 1 and containing a metal disposed on the element mounting surface 1a; and a metal layer 13 disposed on the reflective surface 6a. The reflective surface 6a is sloped relative to the element mounting surface 2a so that a diameter of the internal space 6b is greater away from the element mounting surface 2a.

Owner:SUMITOMO ELECTRIC IND LTD

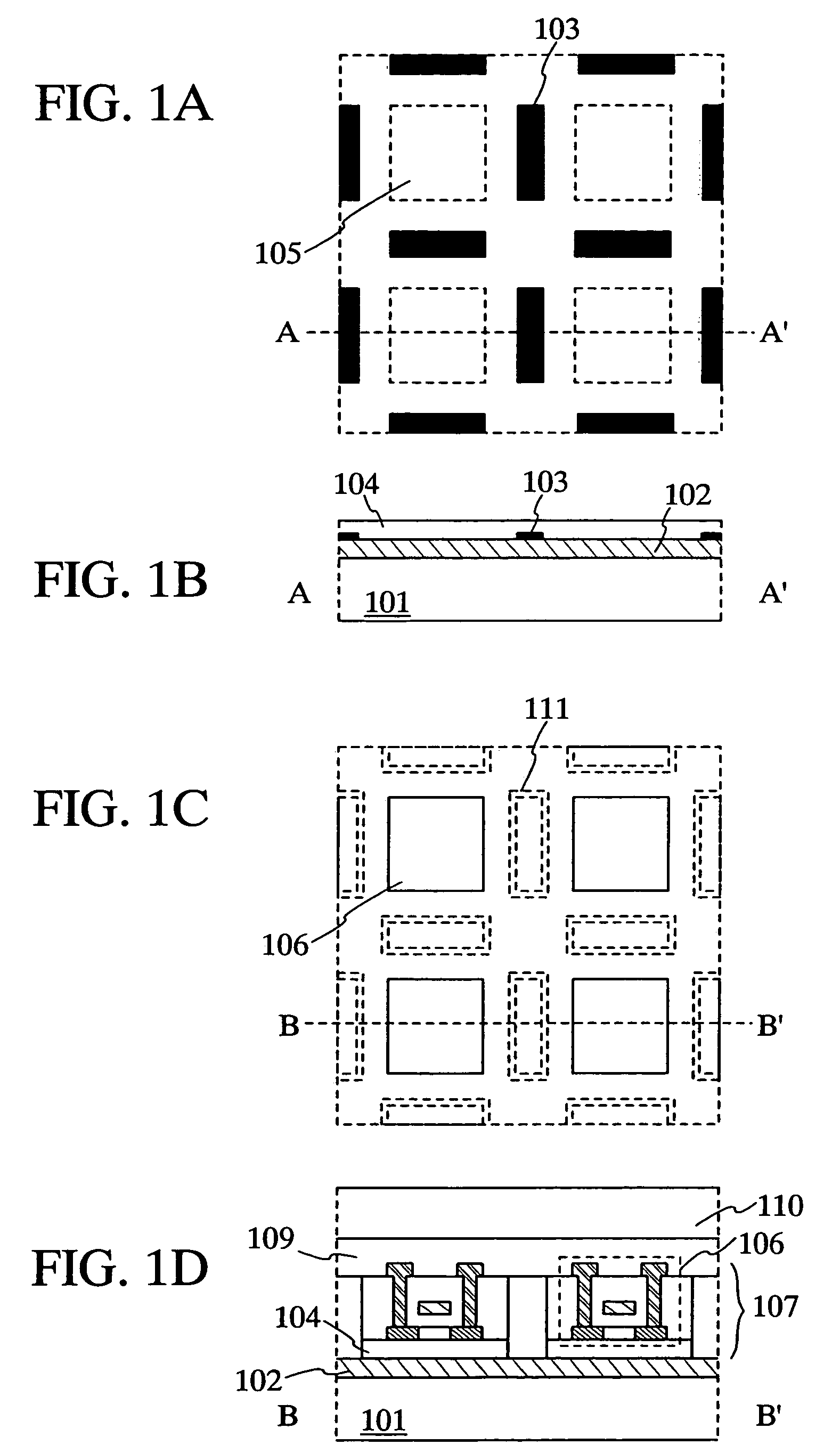

Semiconductor device and method of manufacturing the same

InactiveUS7091070B2Enhanced adhesivenessPrevent peelingTransistorSolid-state devicesIntegrated circuitEngineering

To provide a method for manufacturing a semiconductor device including a transfer step that is capable of controlling the adhesiveness of a substrate and an element-formed layer in the case of separating the element-formed layer including a semiconductor element or an integrated circuit formed over the substrate from the substrate and bonding it to another substrate. An adhesive agent made of a good adhesiveness material is formed between the semiconductor element or the integrated circuit comprising plural semiconductor elements formed over the substrate (a first substrate) and the substrate, and thus it is possible to prevent a semiconductor element from peeling off a substrate in manufacturing the semiconductor element, and further, to make it easier to separate the semiconductor element from the substrate by removing the adhesive agent after forming the semiconductor element.

Owner:SEMICON ENERGY LAB CO LTD

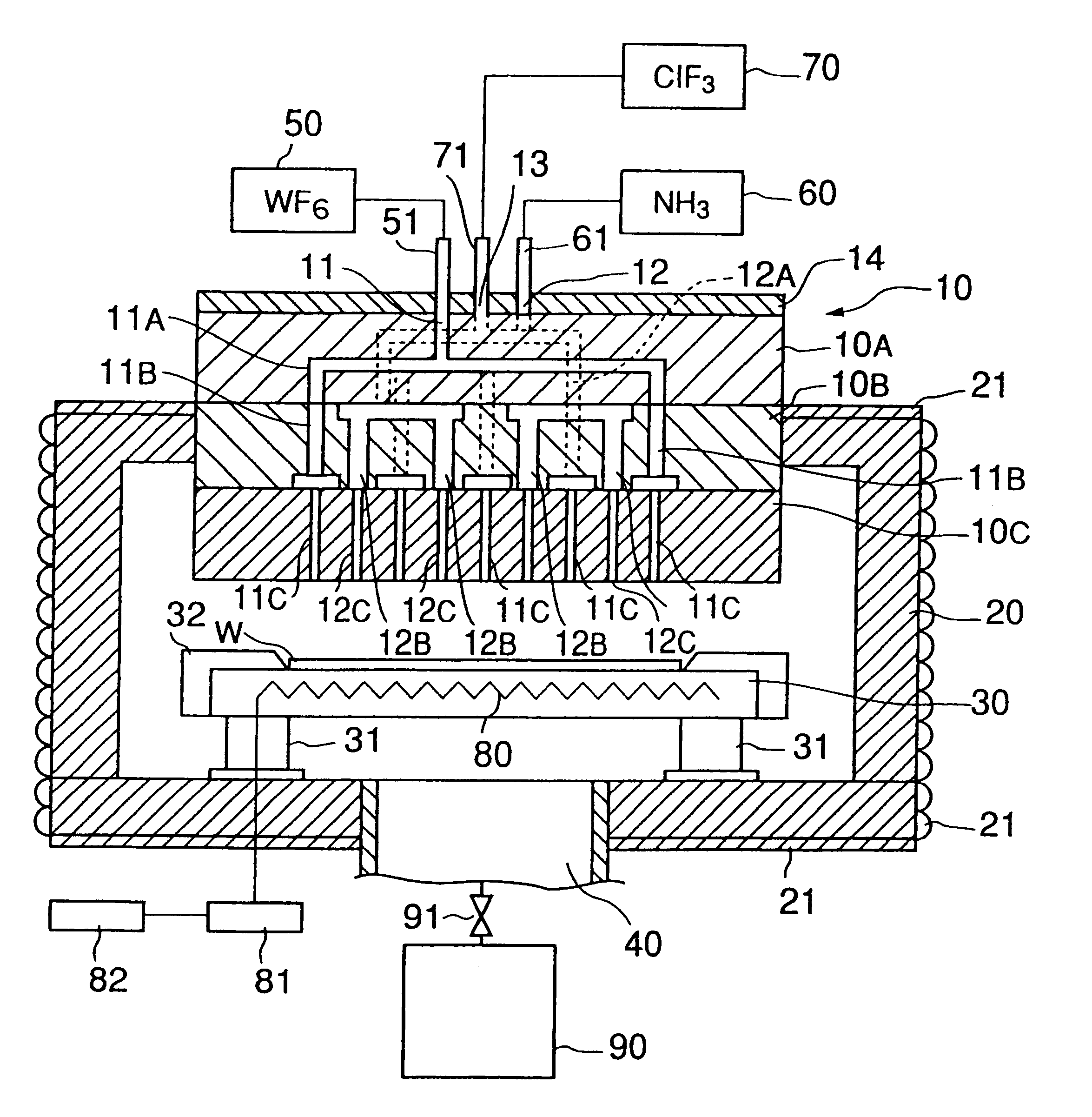

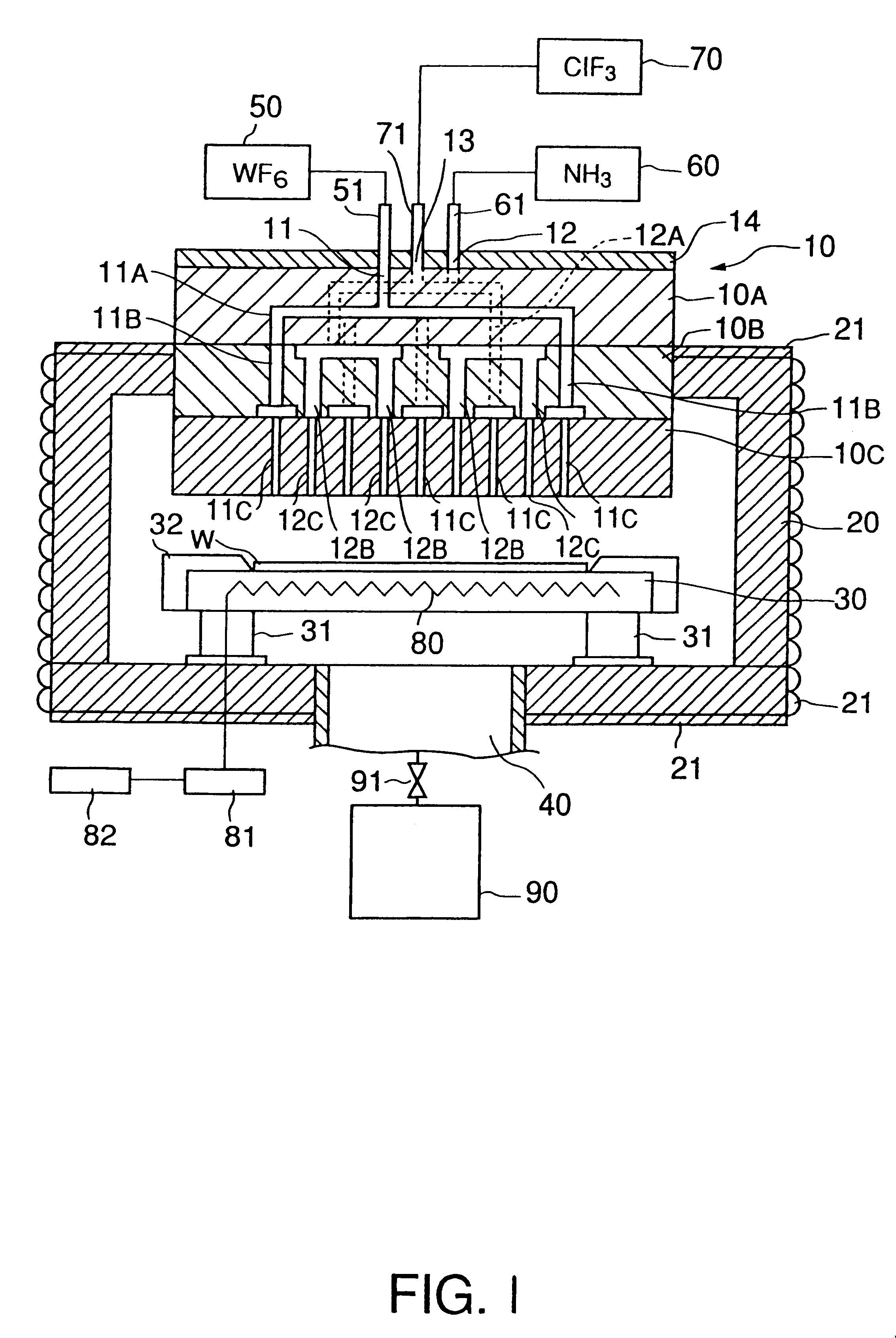

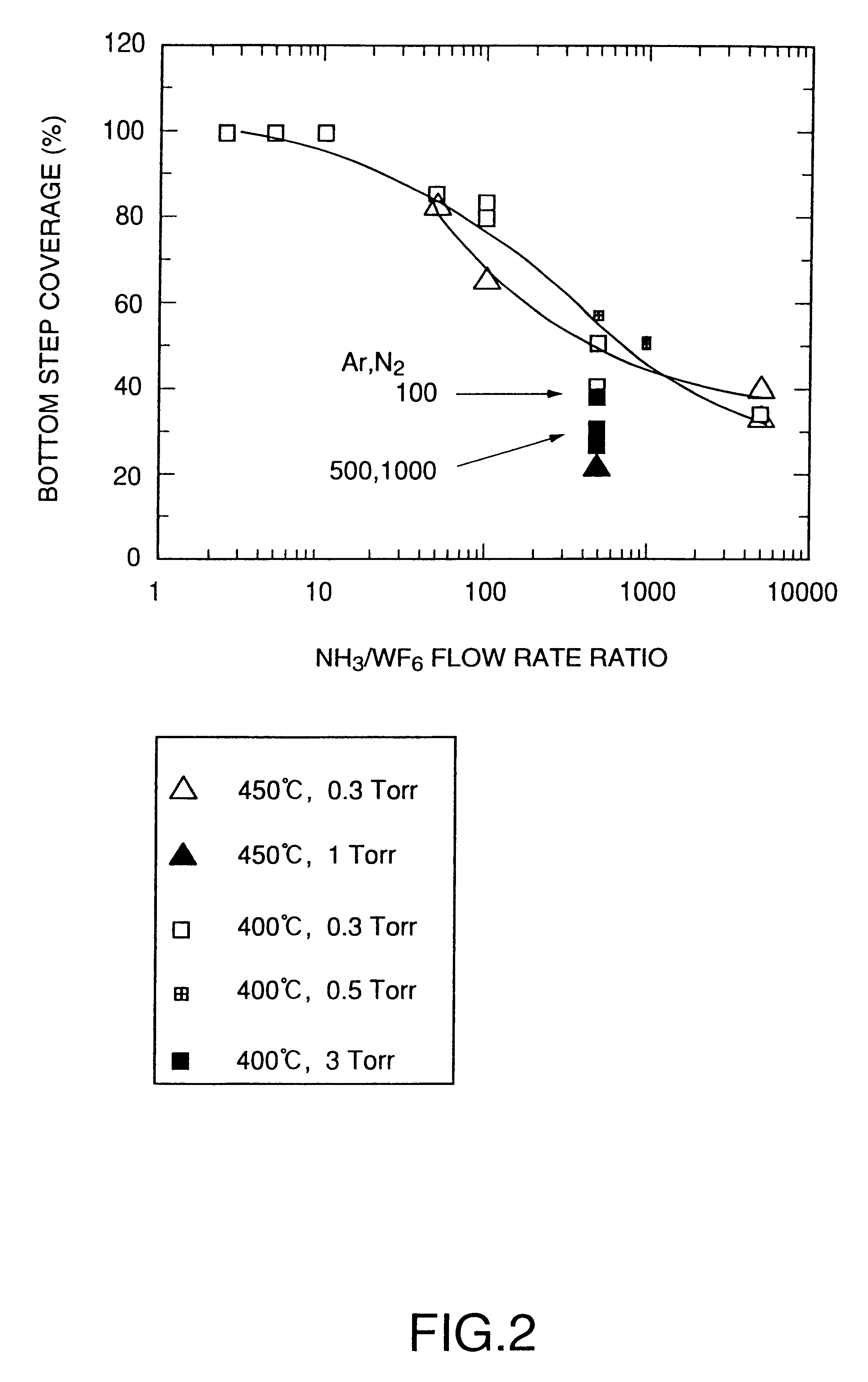

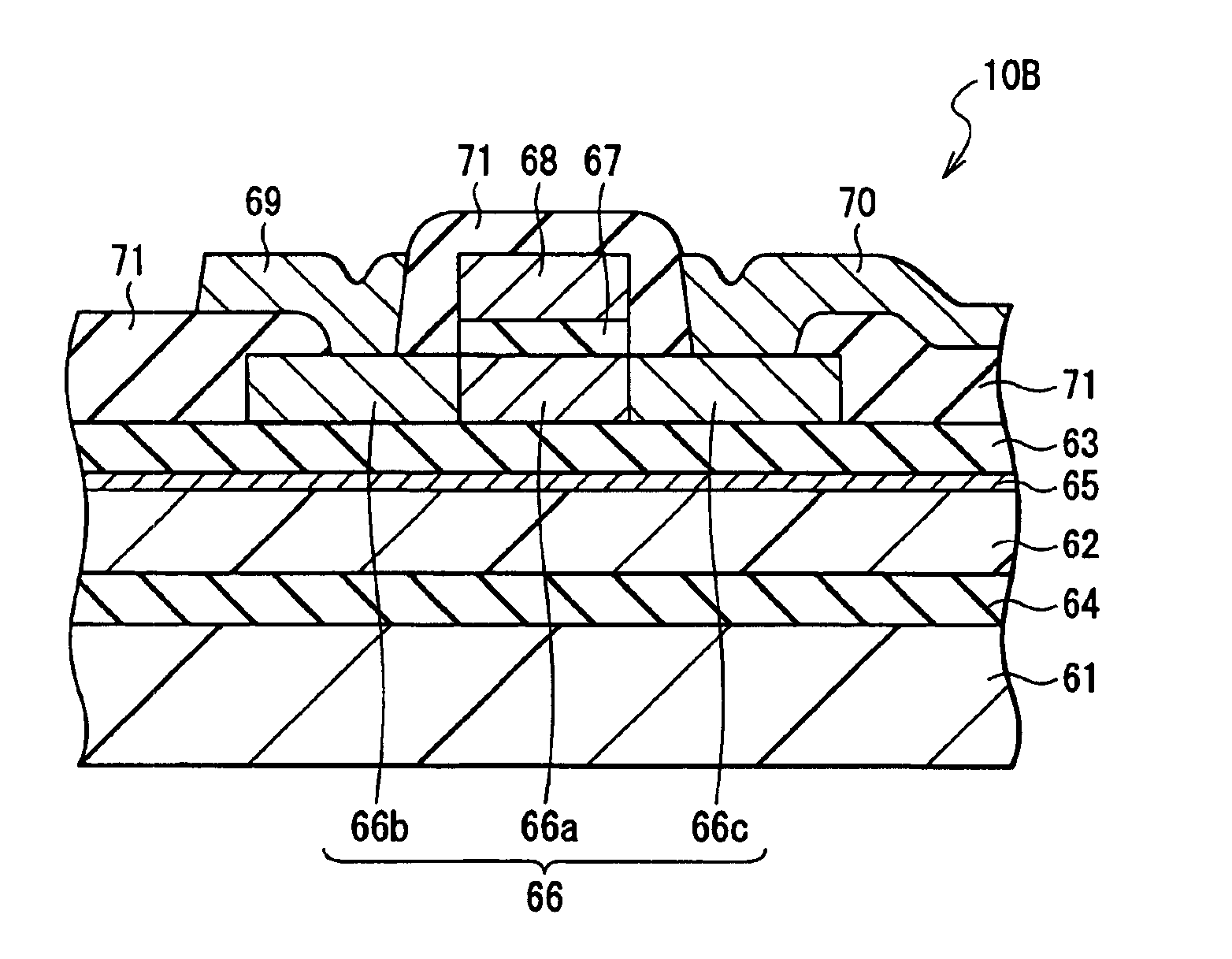

Semiconductor device fabricating method and system for carrying out the same

InactiveUS6399484B1Reduced form requirementsAvoid depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTungsten nitrideNitrogen

A semiconductor device fabricating method includes a preparatory process that brings a first source gas containing tungsten atoms into contact with a workpiece and that does not bring a second source gas containing nitrogen atoms into contact with the workpiece, and a film forming process that forms a tungsten nitride film on the workpiece by using the first and the second source gases so as to fabricate a semiconductor device. The semiconductor device fabricating method is capable of preventing the tungsten nitride film from peeling off from a layer underlying the same when the tungsten nitride film is subjected to heat treatment.

Owner:TOKYO ELECTRON LTD

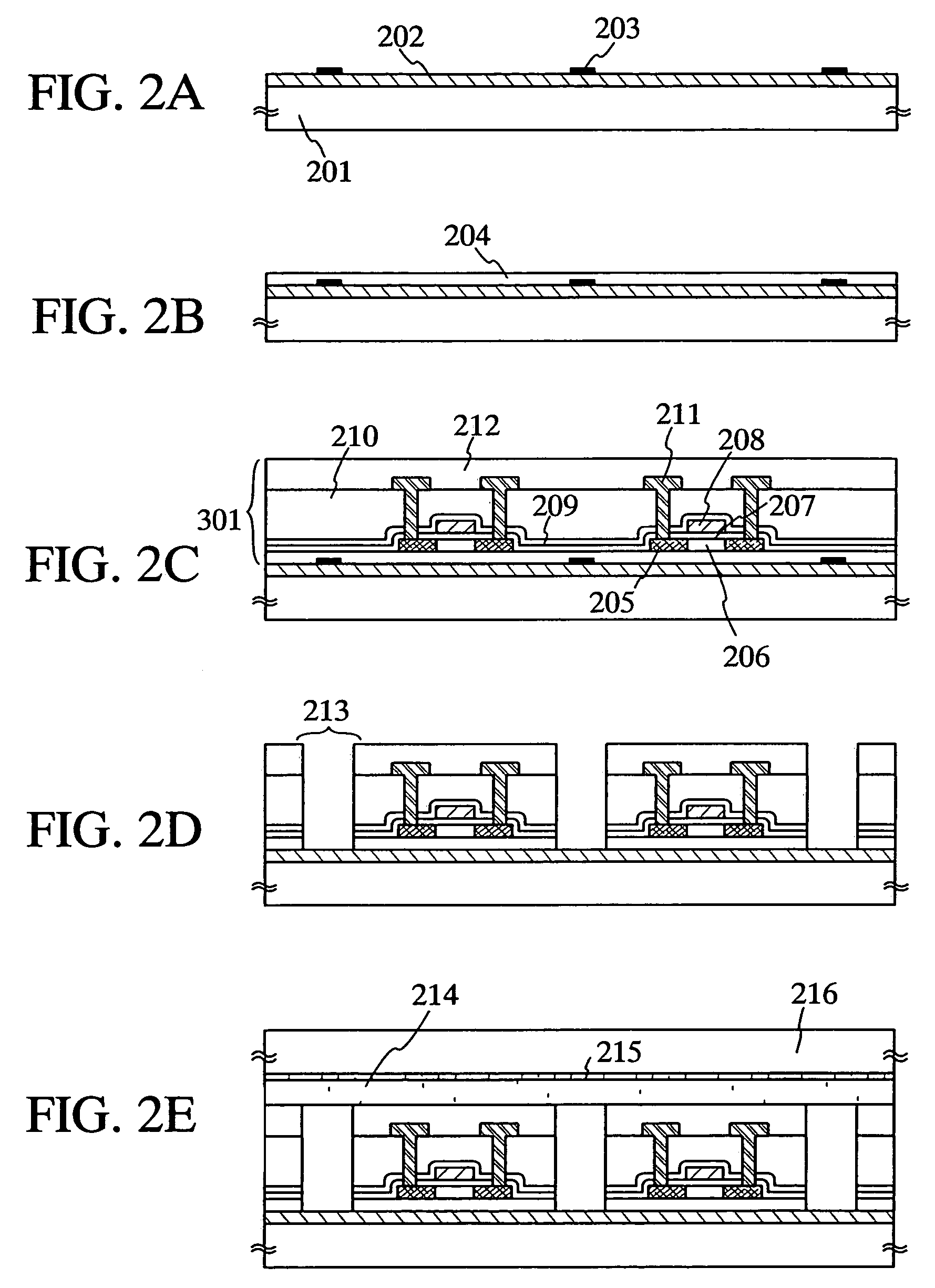

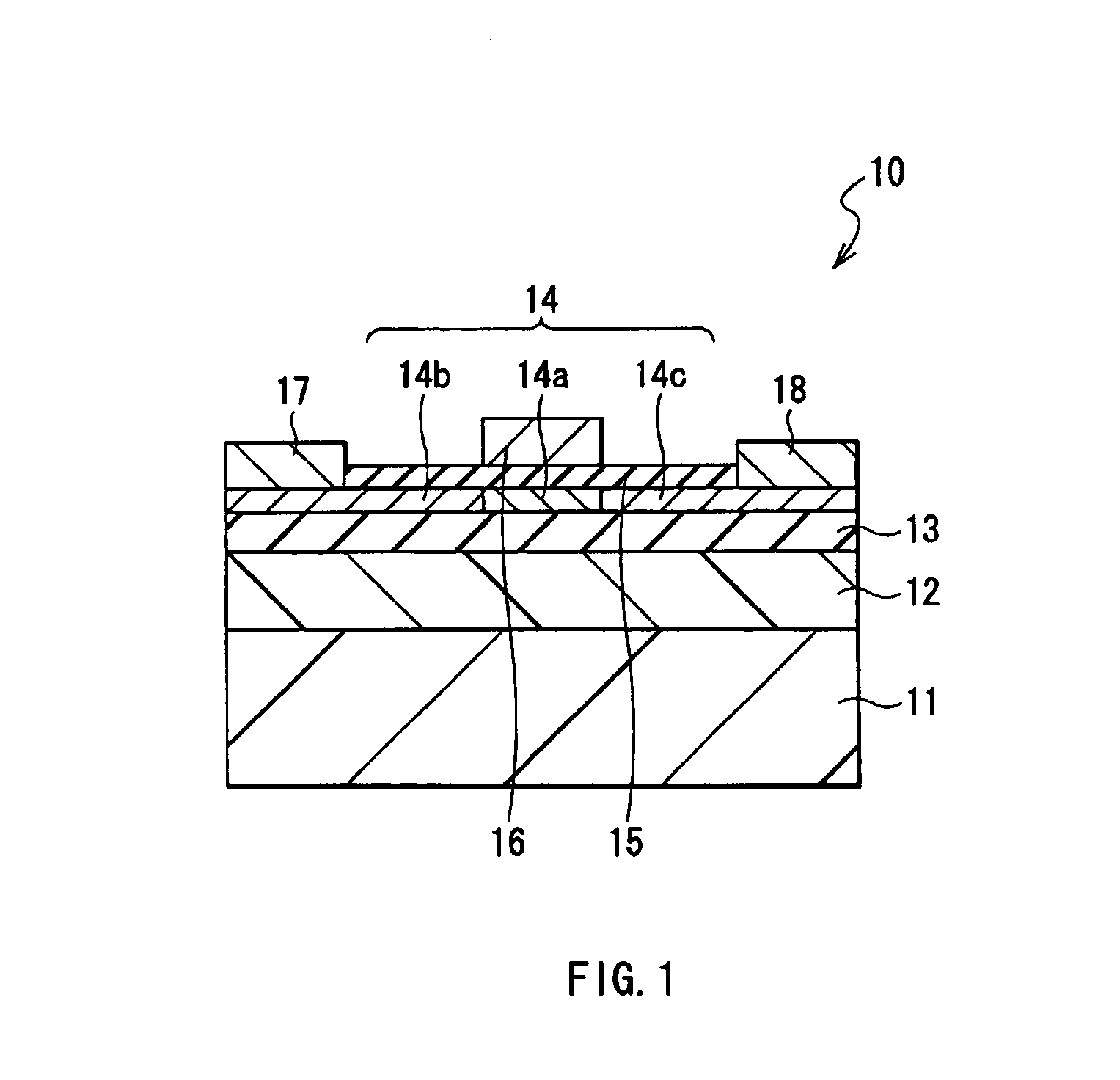

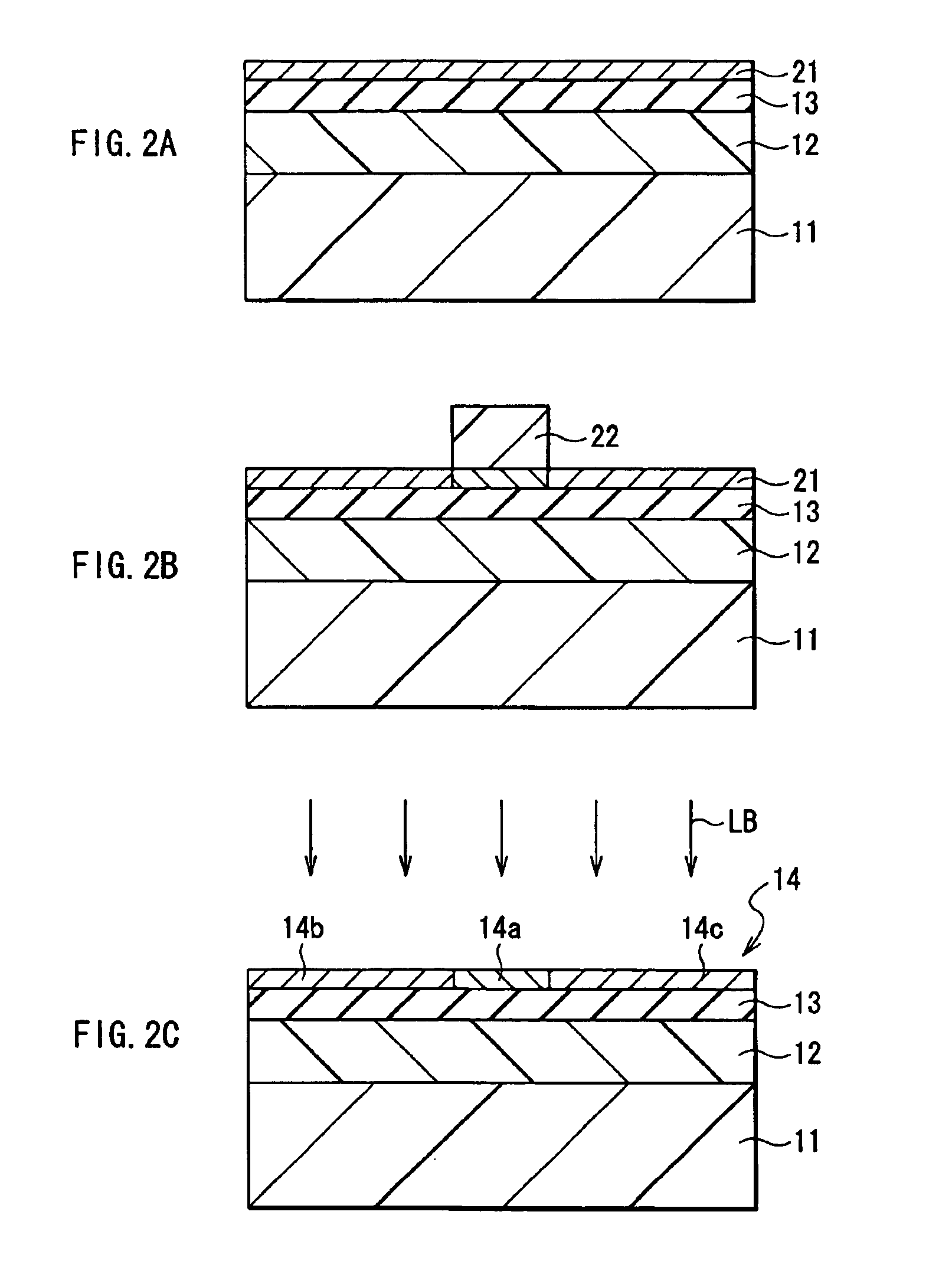

Functional device and method of manufacturing the same

InactiveUS6953754B2Avoid layeringOccurrence can be preventedTransistorLayered productsEpoxyAcrylic resin

The invention provides a functional device having no cracks and capable of delivering good functional characteristics and a method of manufacturing the same. A functional layer (14) is formed by crystallizing an amorphous silicon layer as a precursor layer by laser beam irradiation. A laser beam irradiation conducts heat up to a substrate (11) to cause it to try to expand; a stress to be produced by the difference in thermal expansion coefficient between the substrate (11) and the functional layer (14) is shut off by an organic polymer layer (12) lower in thermal expansion coefficient than the substrate (11), thereby causing no cracks nor separations in the functional layer (14). The organic polymer layer (12) is preferably made of an acrylic resin, an epoxy resin, or a polymer material containing these that is deformed by an optical or thermal process to undergo a three-dimensional condensation polymerization, for higher compactness and hardness. Inserting a metal layer and an inorganic heat resistant layer between the substrate (11) and the functional layer (14) will permit a more powerful laser irradiation.

Owner:SONY CORP

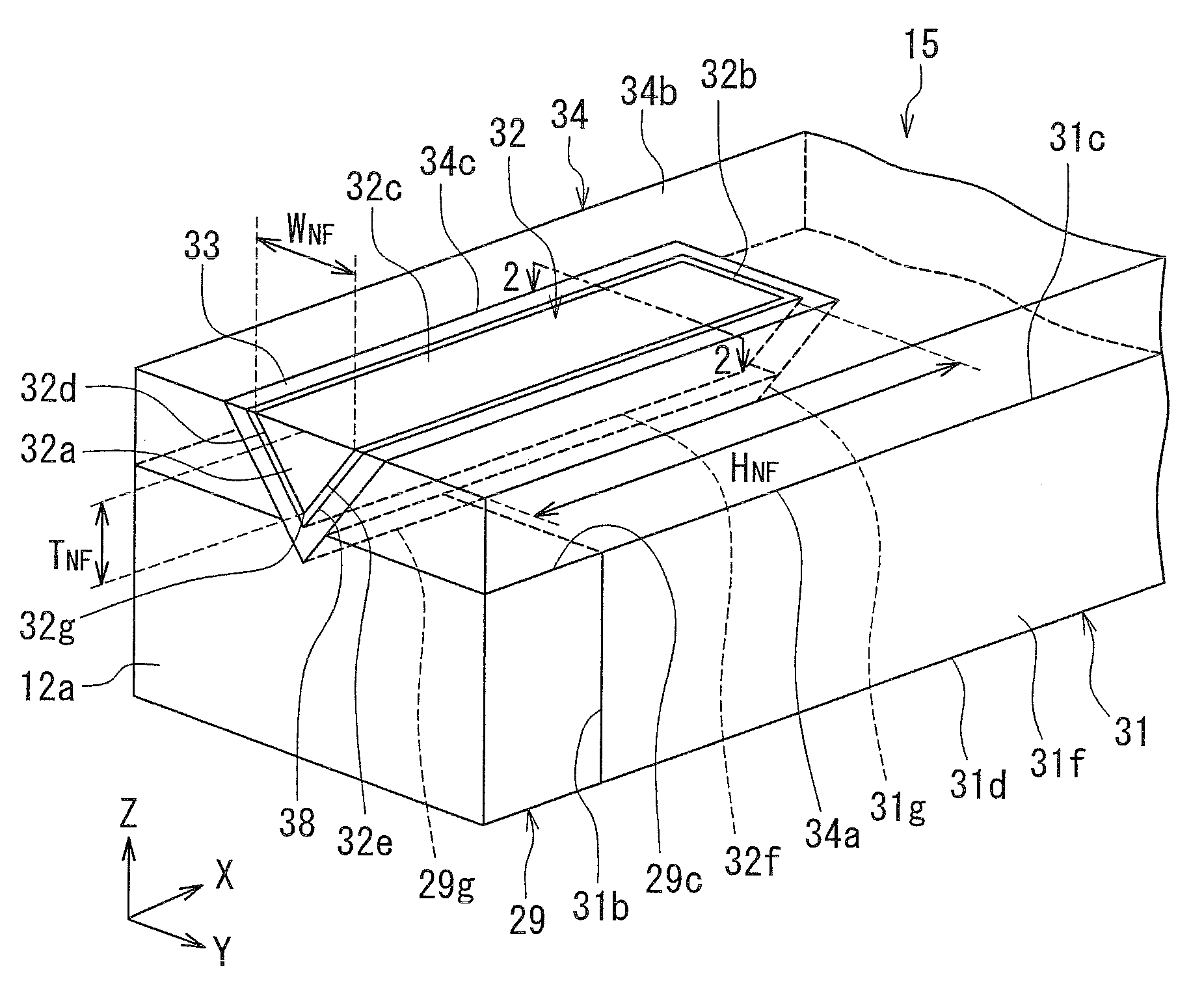

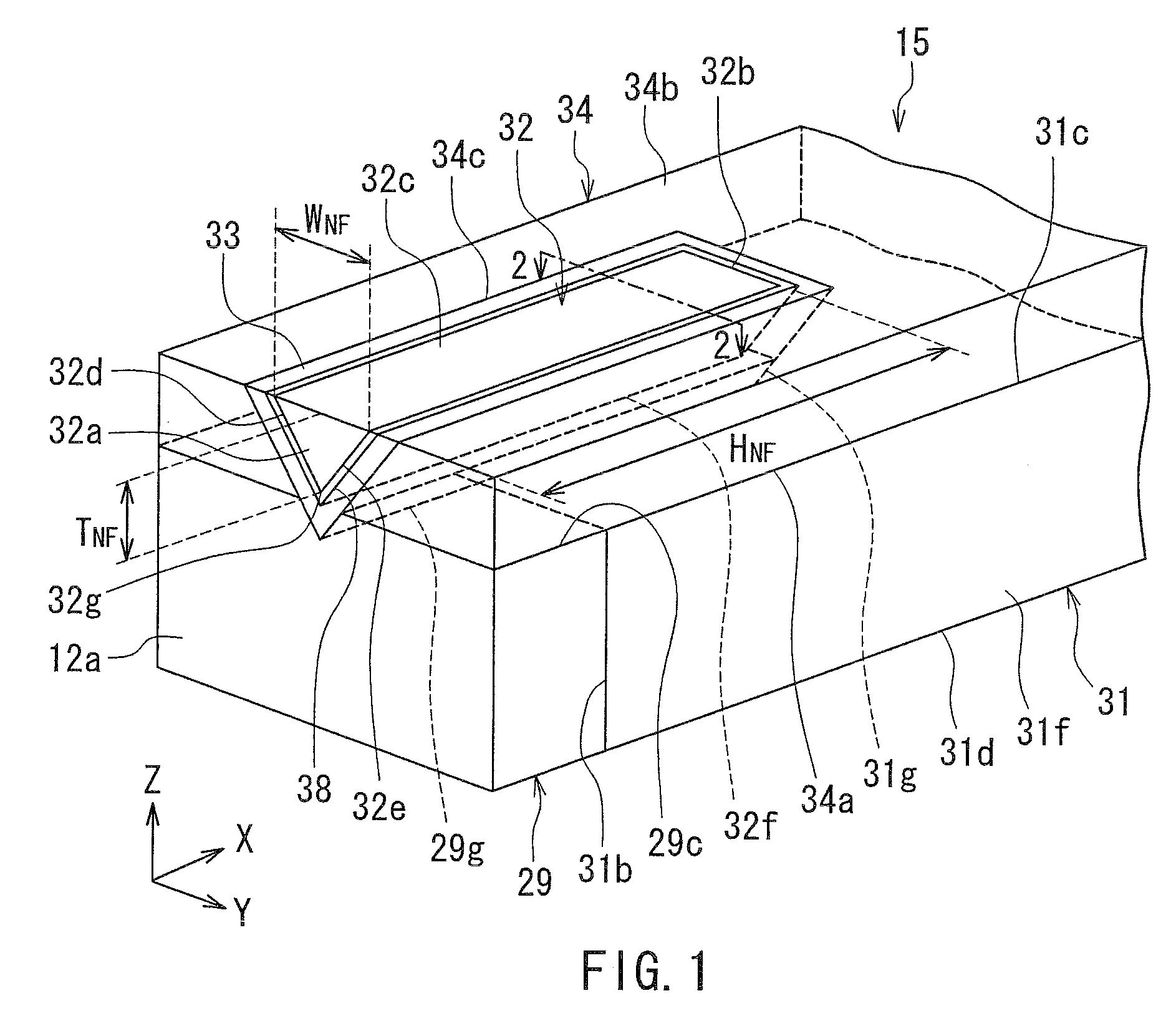

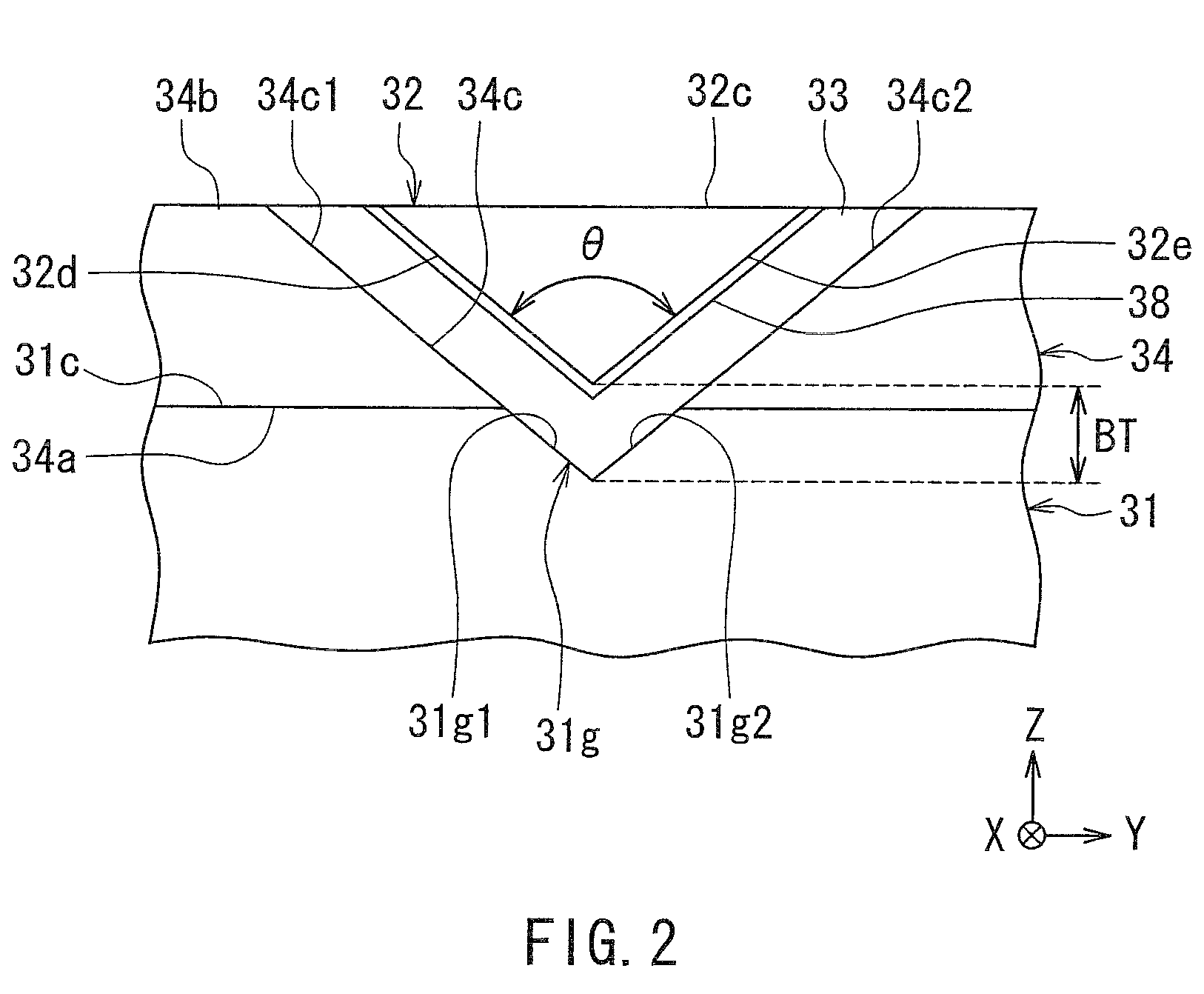

Near-field light generating device including near-field light generating element disposed over waveguide with buffer layer and adhesion layer therebetween

ActiveUS8040761B2Prevent peelingSuppressing drop use efficiencyCombination recordingRecord information storageElectrical resistance and conductanceAdhesive

Owner:TDK CORPARATION

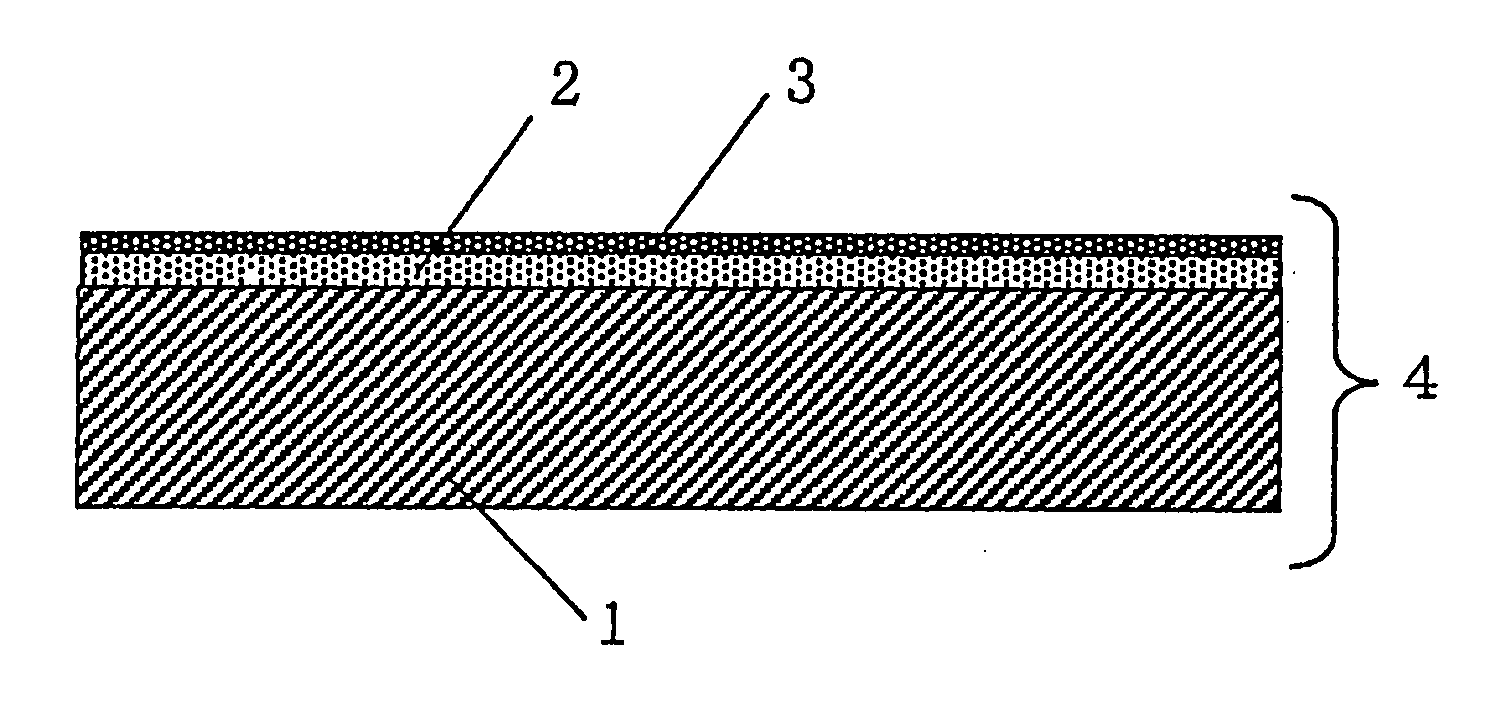

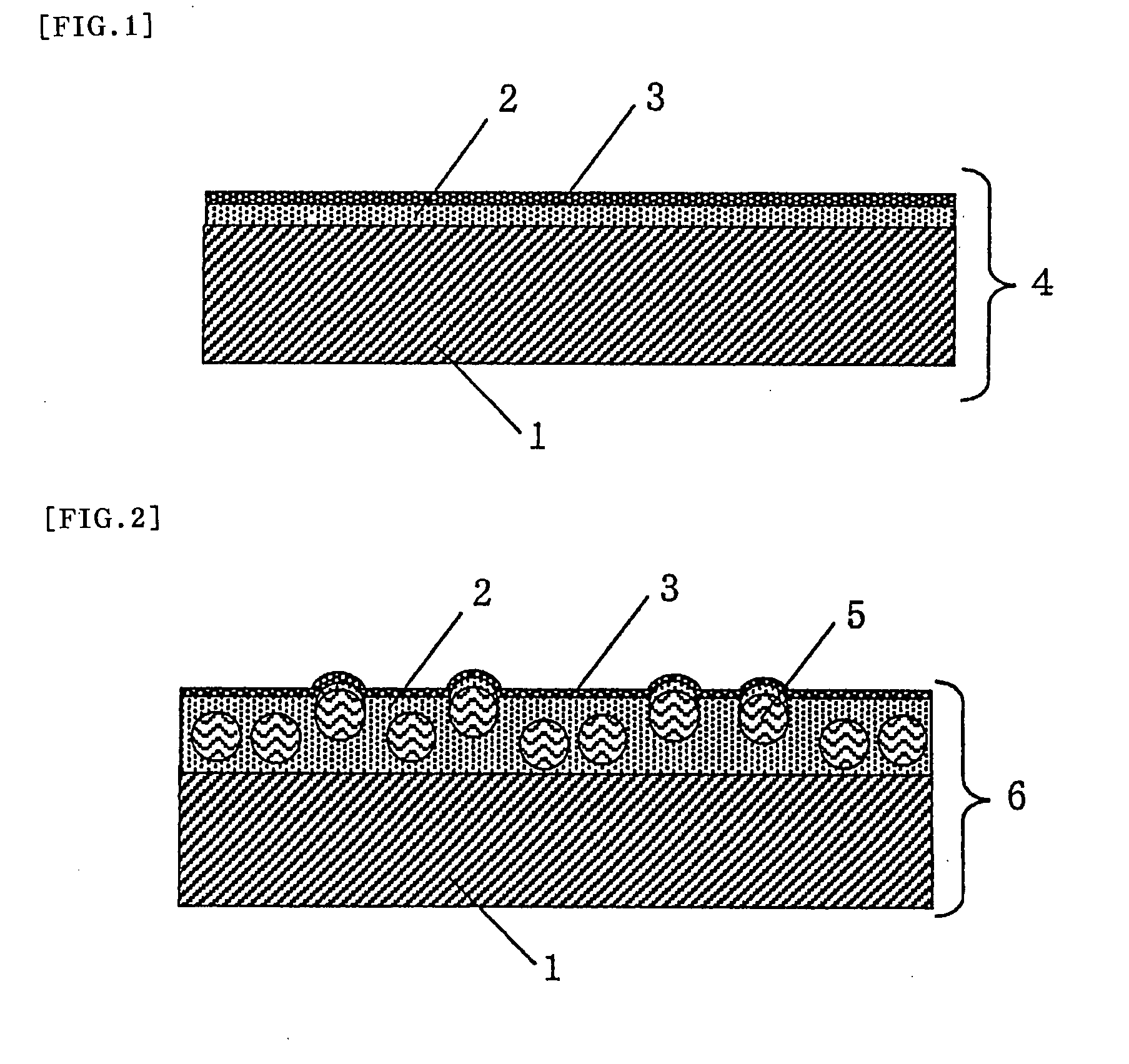

Antireflection Hard Coating Film, Optical Element and Image Display

ActiveUS20080160257A1Improve suppression propertiesImprove adhesionRoof covering using sealantsSynthetic resin layered productsMeth-Display device

An antireflection hard coating film of the invention comprises: a transparent plastic film substrate; and at least one hard coating layer of a cured coating layer and at least one antireflection layer that are formed in this order on at least one side of the transparent plastic film substrate, wherein a hard coating layer-forming material contains 100 parts by weight of a (meth)acrylate group-containing curable compound (A) and 0.01 to 3 parts by weight of a (meth)acrylate group-containing reactive silicone (B), and an antireflection layer-forming material contains a siloxane component-containing compound, at the interface between the hard coating layer and the antireflection layer being in direct contact with each other. The antireflection hard coating film has good adhesion between the hard coating layer and the antireflection layer, high hardness, and good scratch resistance without a reduction in antireflection properties.

Owner:NITTO DENKO CORP

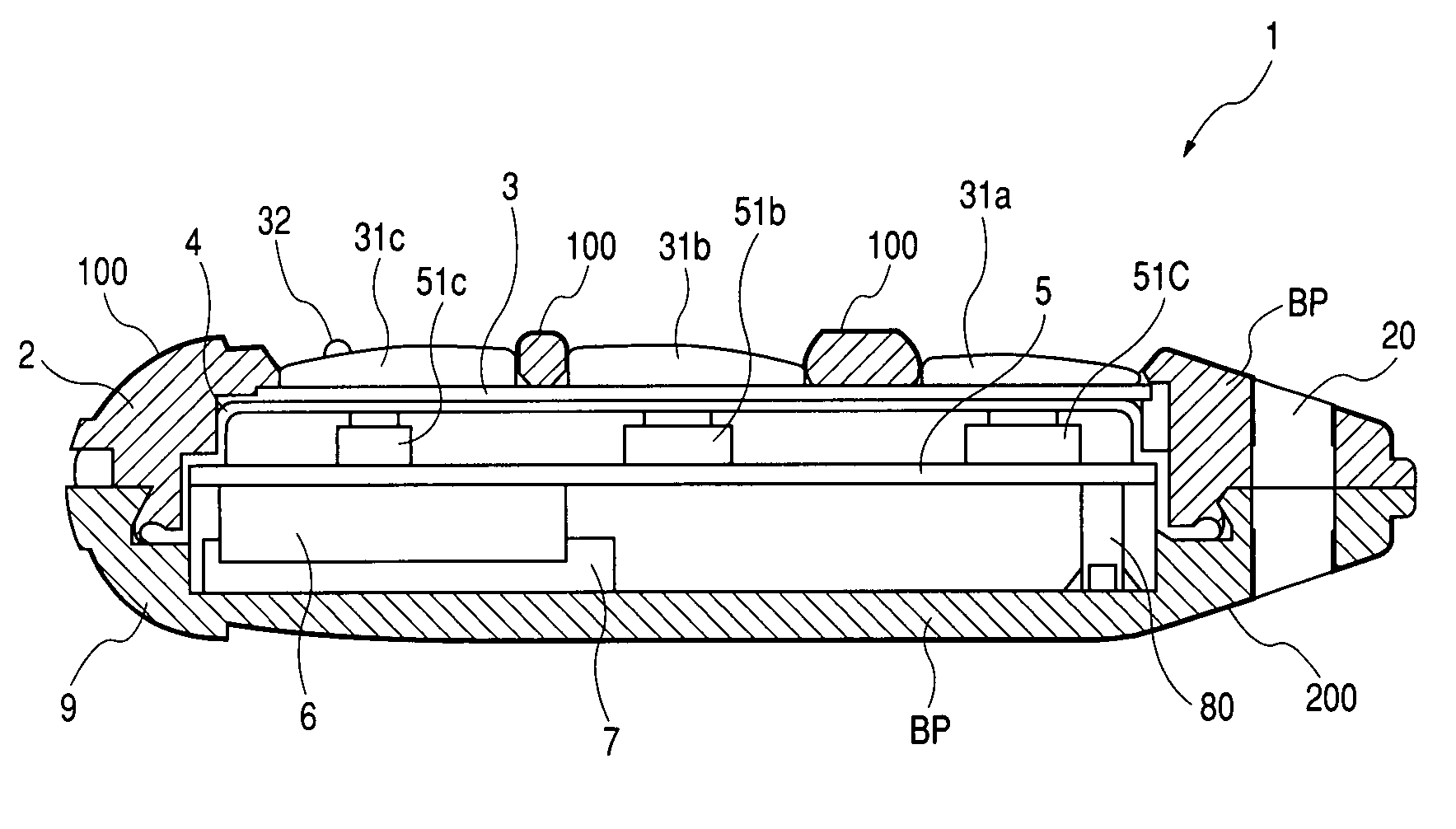

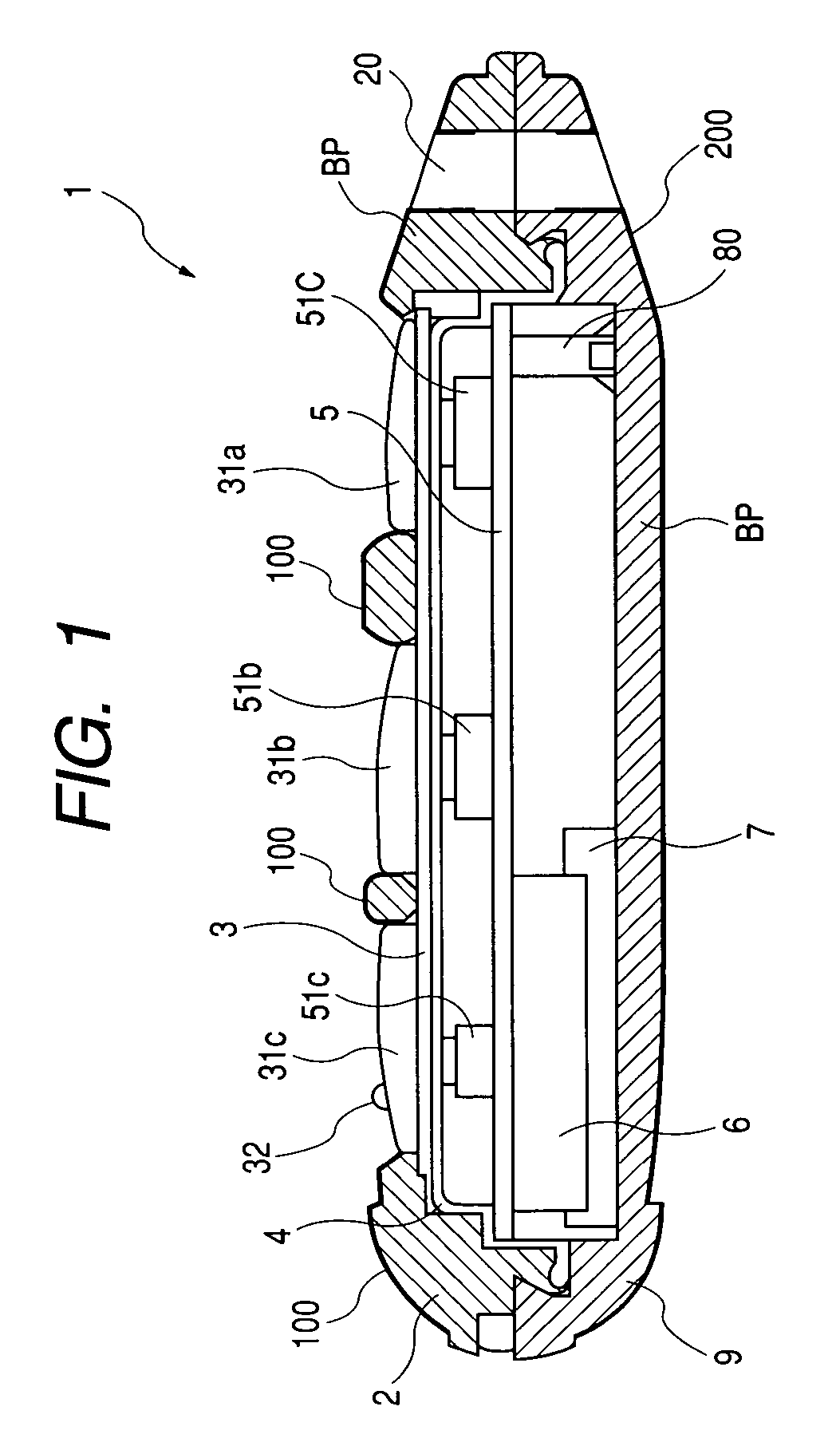

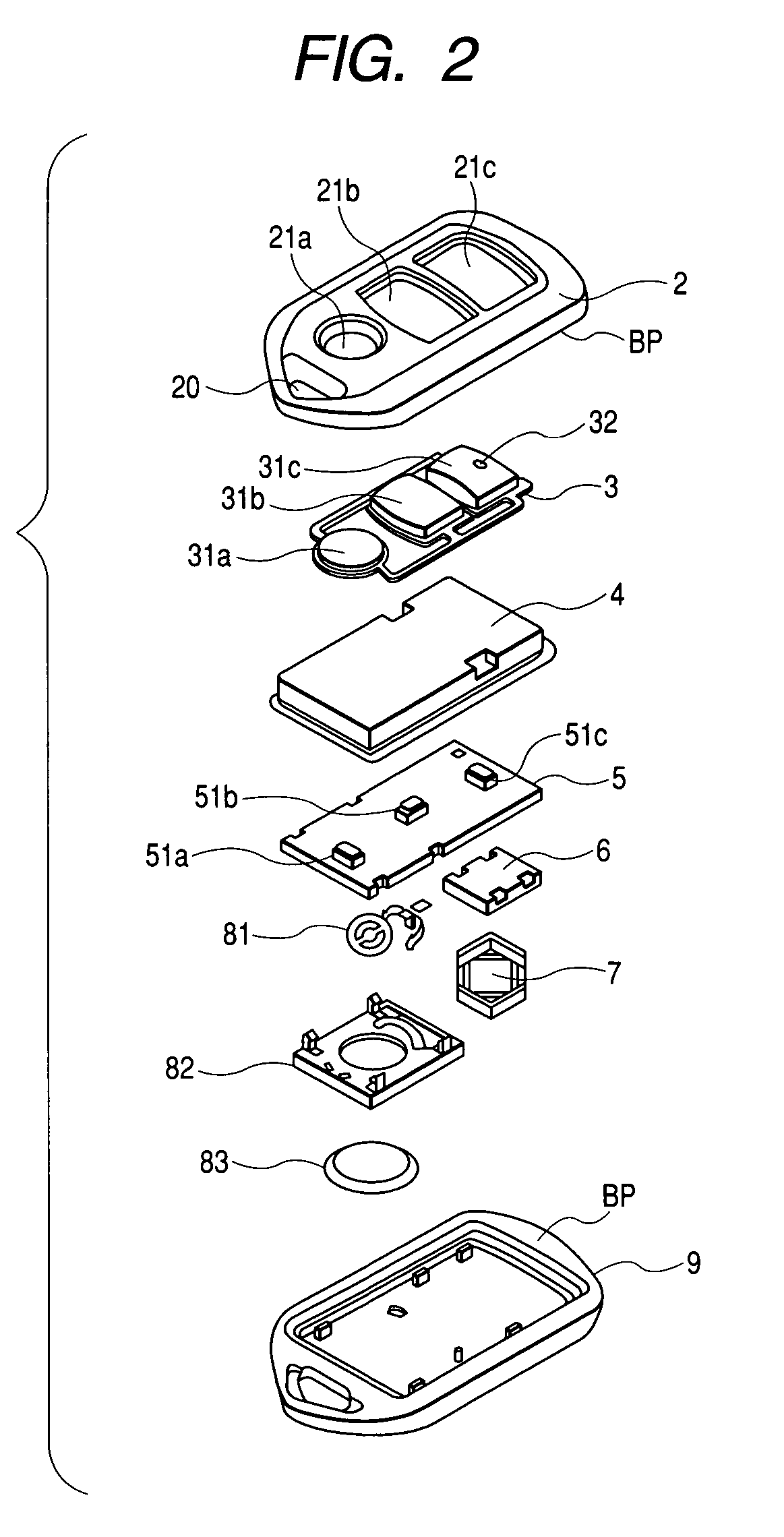

Case for portable equipment

ActiveUS7050292B2Prevent peelingEasy to manufactureContact surface shape/structureDigital data processing detailsEngineeringElectrical and Electronics engineering

A case of a portable equipment for communication to an external system comprises a body portion and an operation portion acting as a function member. At least a portion of the case is provided with a decorative film having a resin film having transparency and a print layer printed on a back surface of the resin film in a predetermined pattern, and a resin base member formed on a back surface of the decorative film so as to contact the print layer. The front surface of the decorative layer is exposed as a most outside surface of the case.

Owner:DENSO CORP

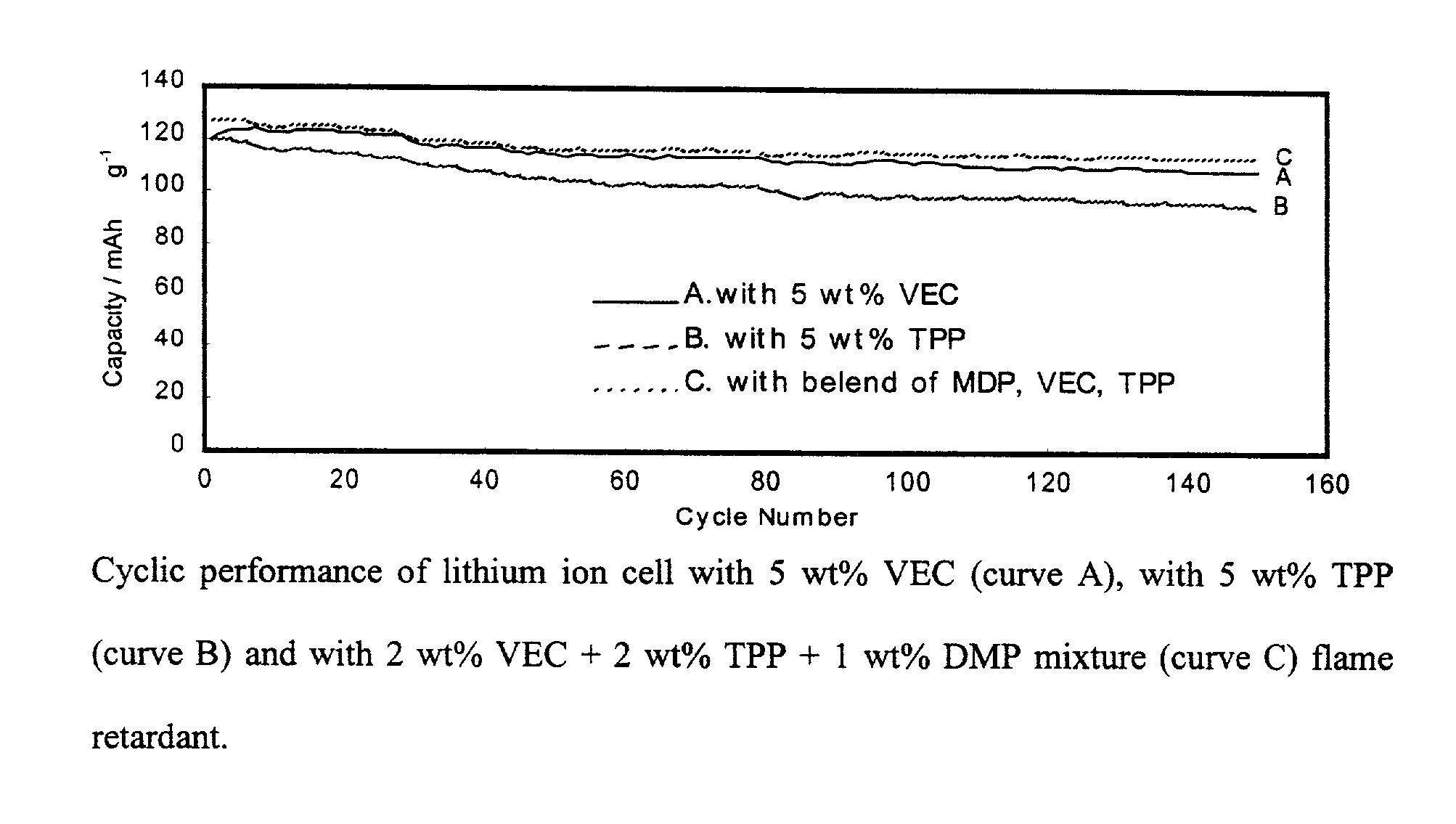

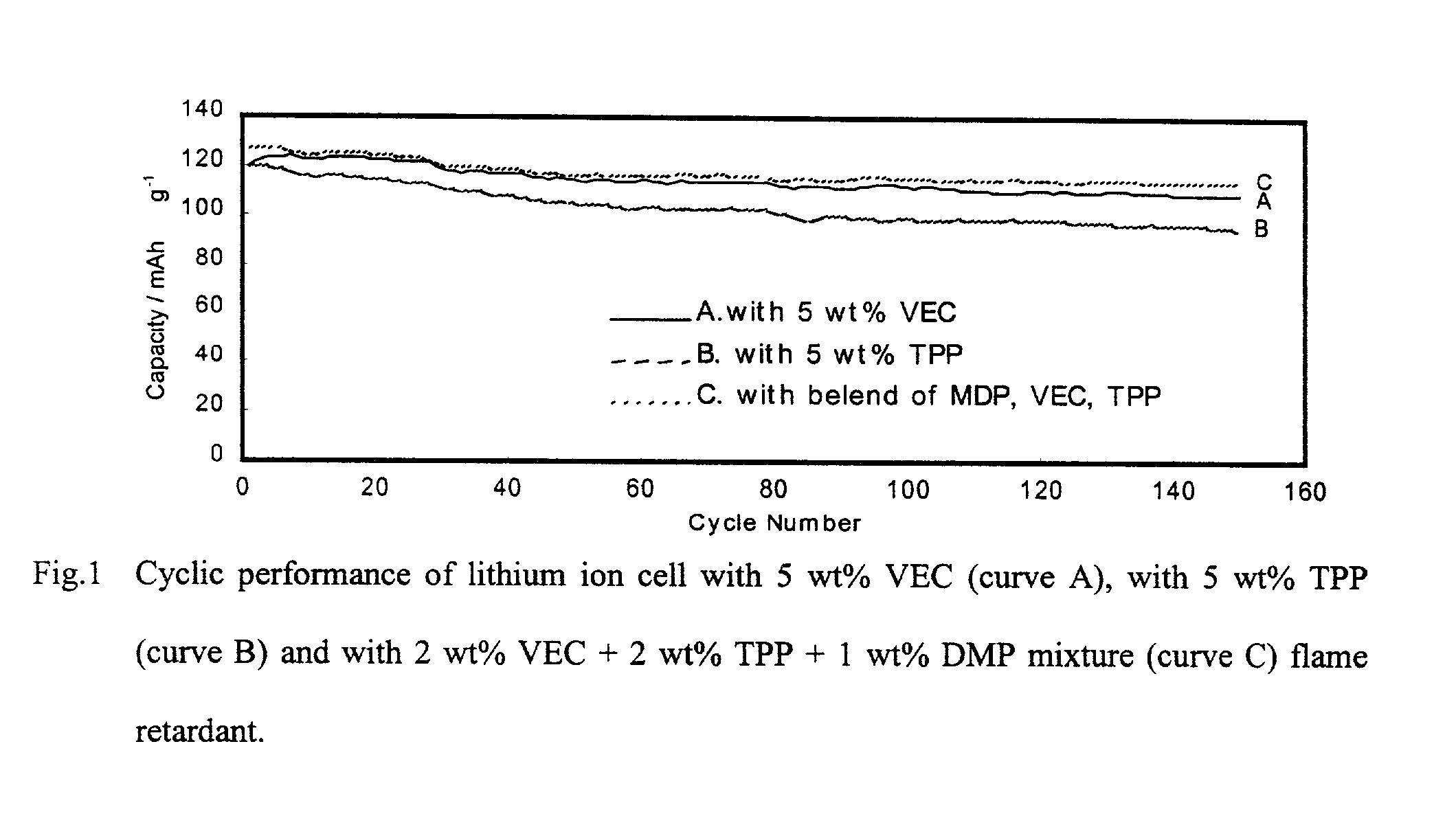

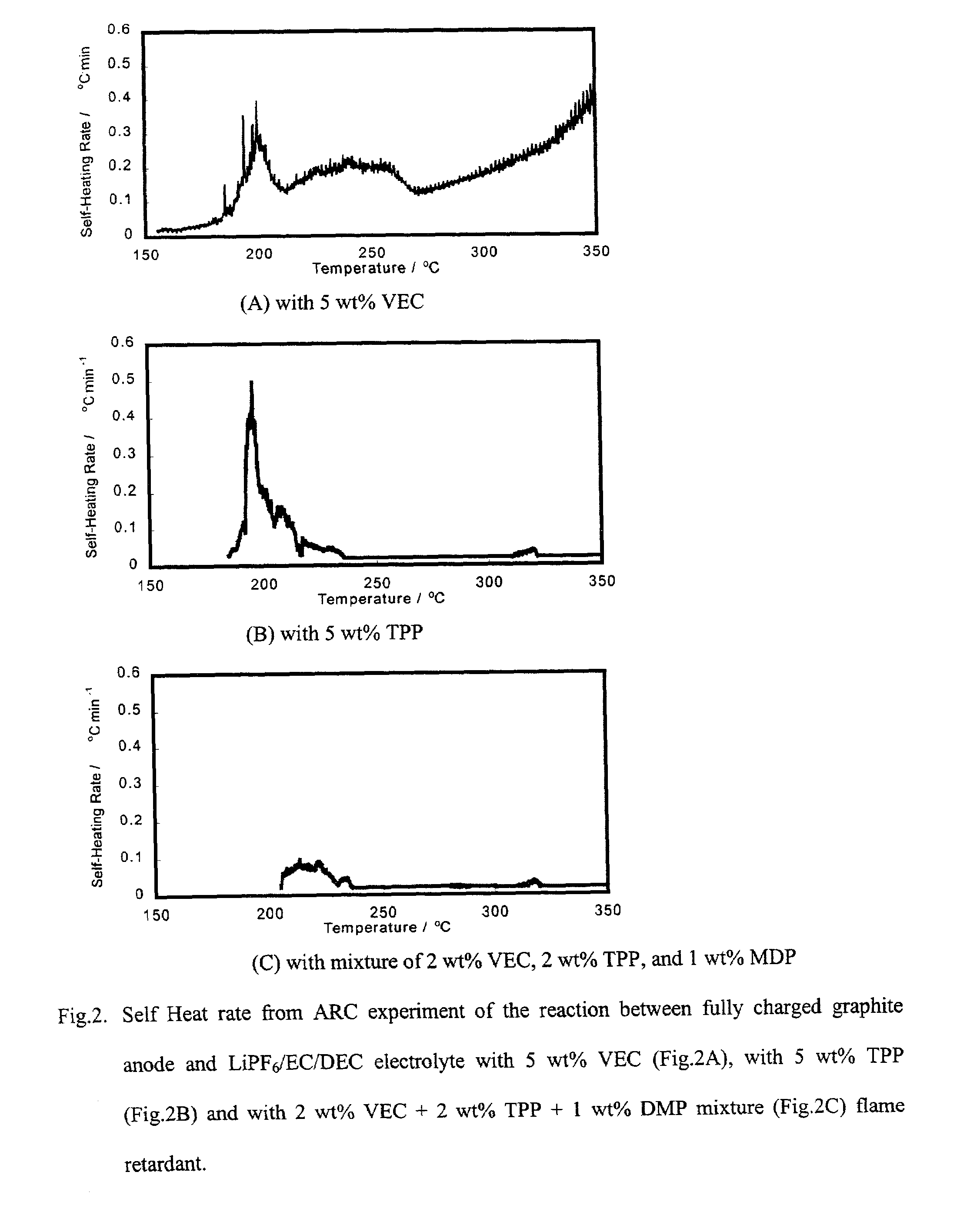

Lithium ion battery with improved safety

InactiveUS7026074B2Superior thermal safety behaviorSuppress gas productionOrganic electrolyte cellsLi-accumulatorsOrganic solventGraphite electrode

A lithium battery with improved safety that utilizes one or more additives in the battery electrolyte solution wherein a lithium salt is dissolved in an organic solvent, which may contain propylene, carbonate. For example, a blend of 2 wt % triphenyl phosphate (TPP), 1 wt % diphenyl monobutyl phosphate (DMP) and 2 wt % vinyl ethylene carbonate additives has been found to significantly enhance the safety and performance of Li-ion batteries using a LiPF6 salt in EC / DEC electrolyte solvent. The invention relates to both the use of individual additives and to blends of additives such as that shown in the above example at concentrations of 1 to 4-wt % in the lithium battery electrolyte. This invention relates to additives that suppress gas evolution in the cell, passivate graphite electrode and protect it from exfoliating in the presence of propylene carbonate solvents in the electrolyte, and retard flames in the lithium batteries.

Owner:UCHICAGO ARGONNE LLC

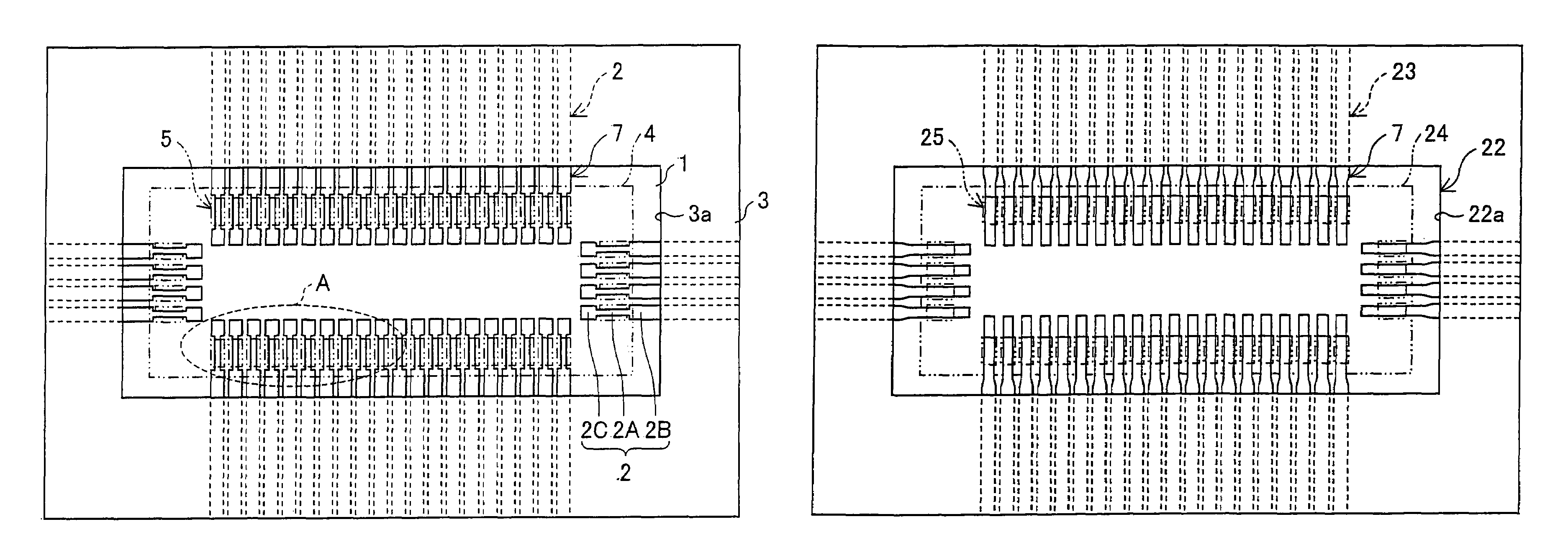

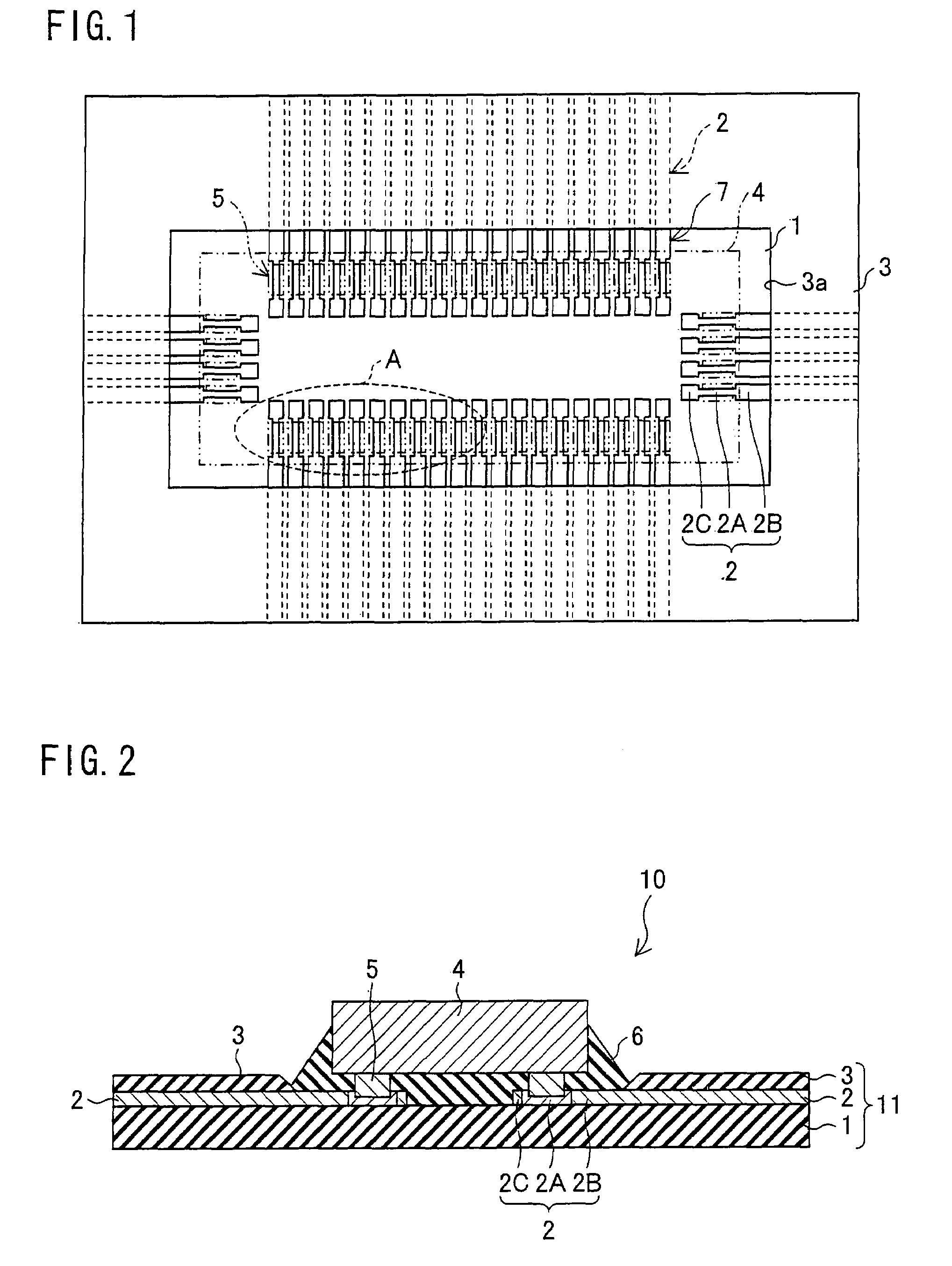

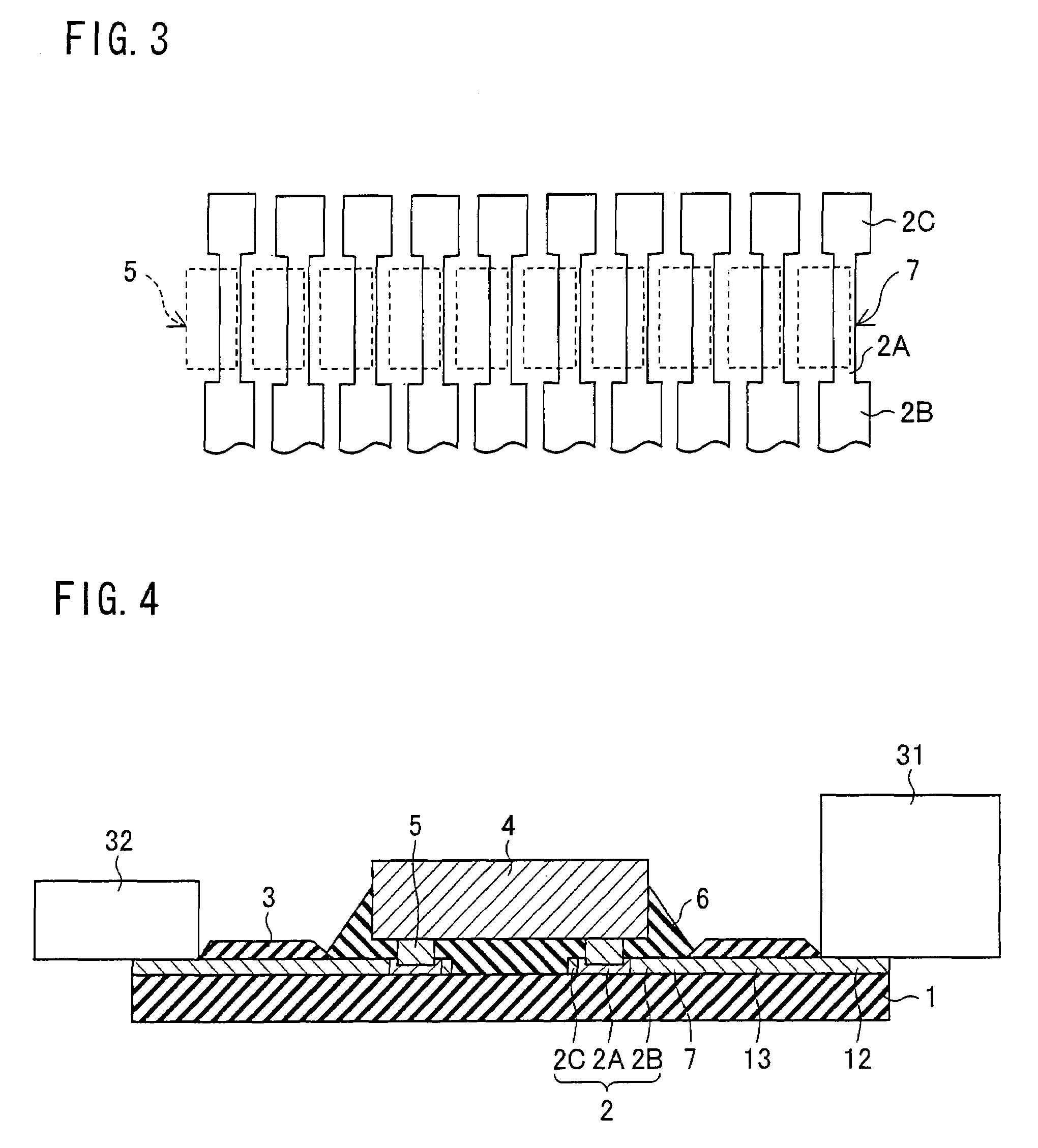

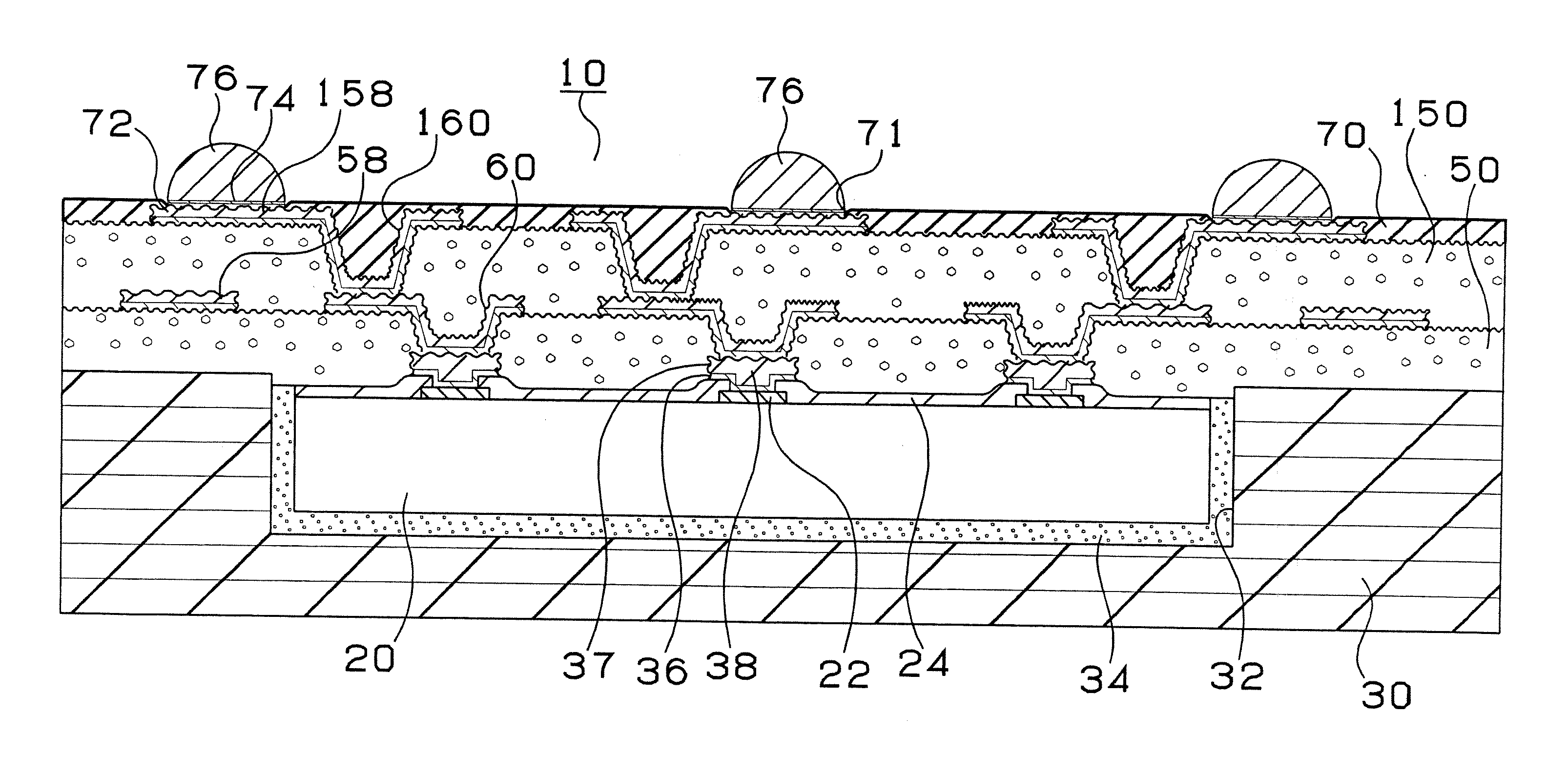

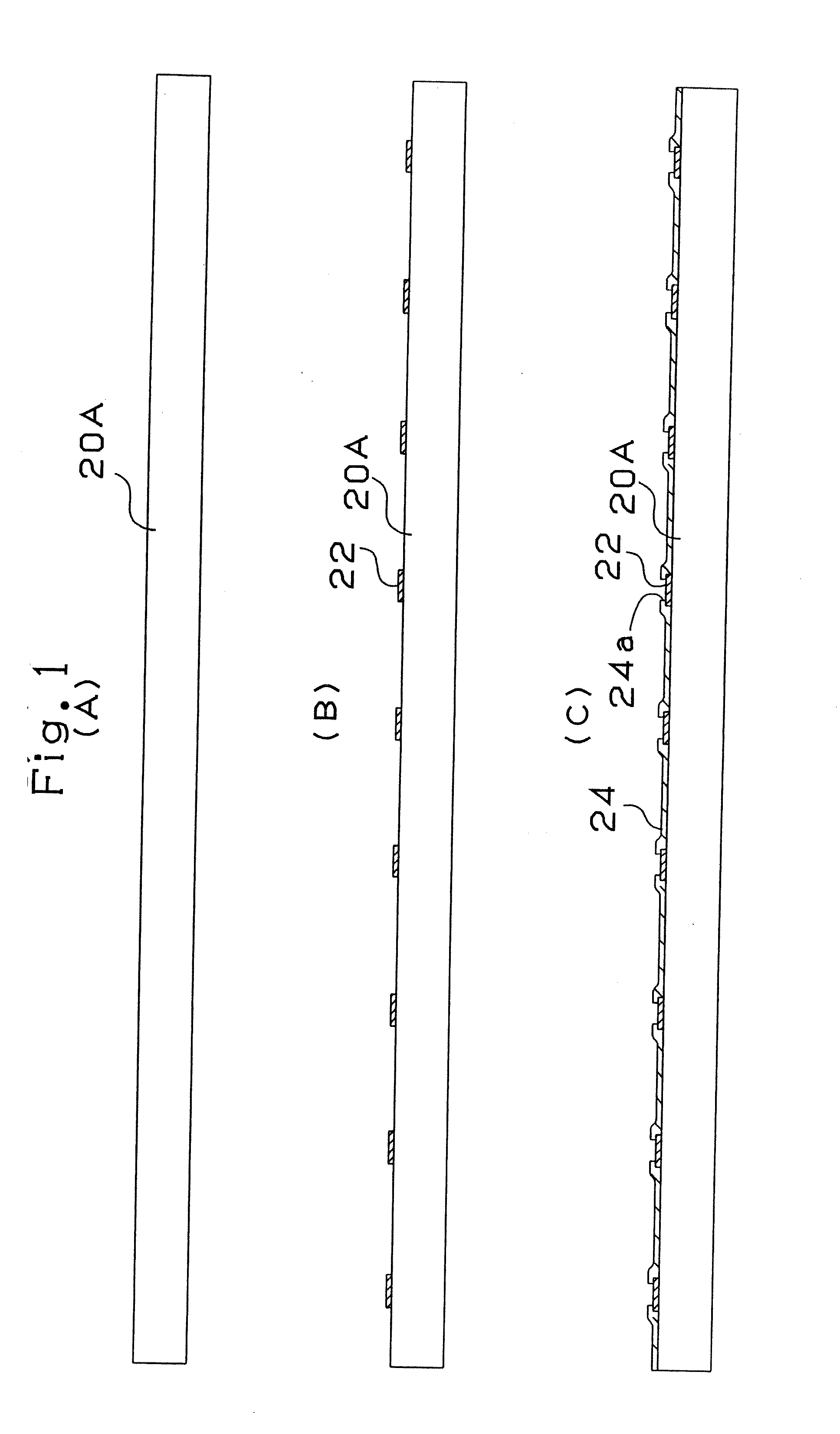

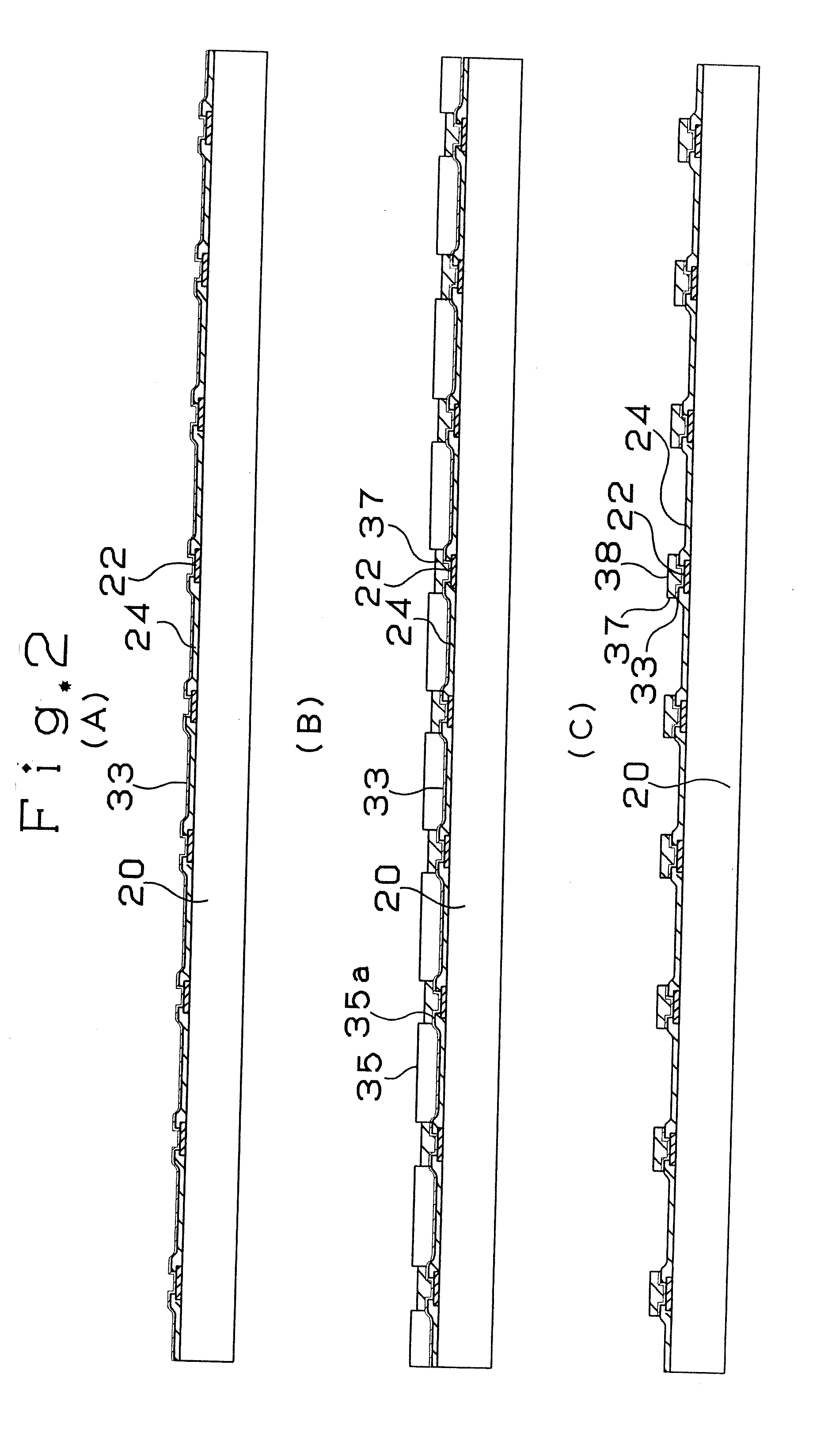

Tape carrier, semiconductor apparatus, and semiconductor module apparatus

ActiveUS7671454B2Prevent peelingAvoid defectsFinal product manufactureSemiconductor/solid-state device detailsWire widthEngineering

A tape carrier of the present invention includes an insulating tape and a wiring pattern formed on the insulating tape. The wiring pattern includes a connecting section via which the wiring pattern is connected to a bump electrode. The connecting section is provided at a part of an overlap part of the wiring pattern, which overlap part overlaps a semiconductor device when the semiconductor device is mounted on the wiring pattern. The connecting section of the wiring pattern is smaller in wiring width than the remaining part of the overlap part, which remaining part is other than the connecting section.

Owner:SHENZHEN TOREY MICROELECTRONIC TECH CO LTD

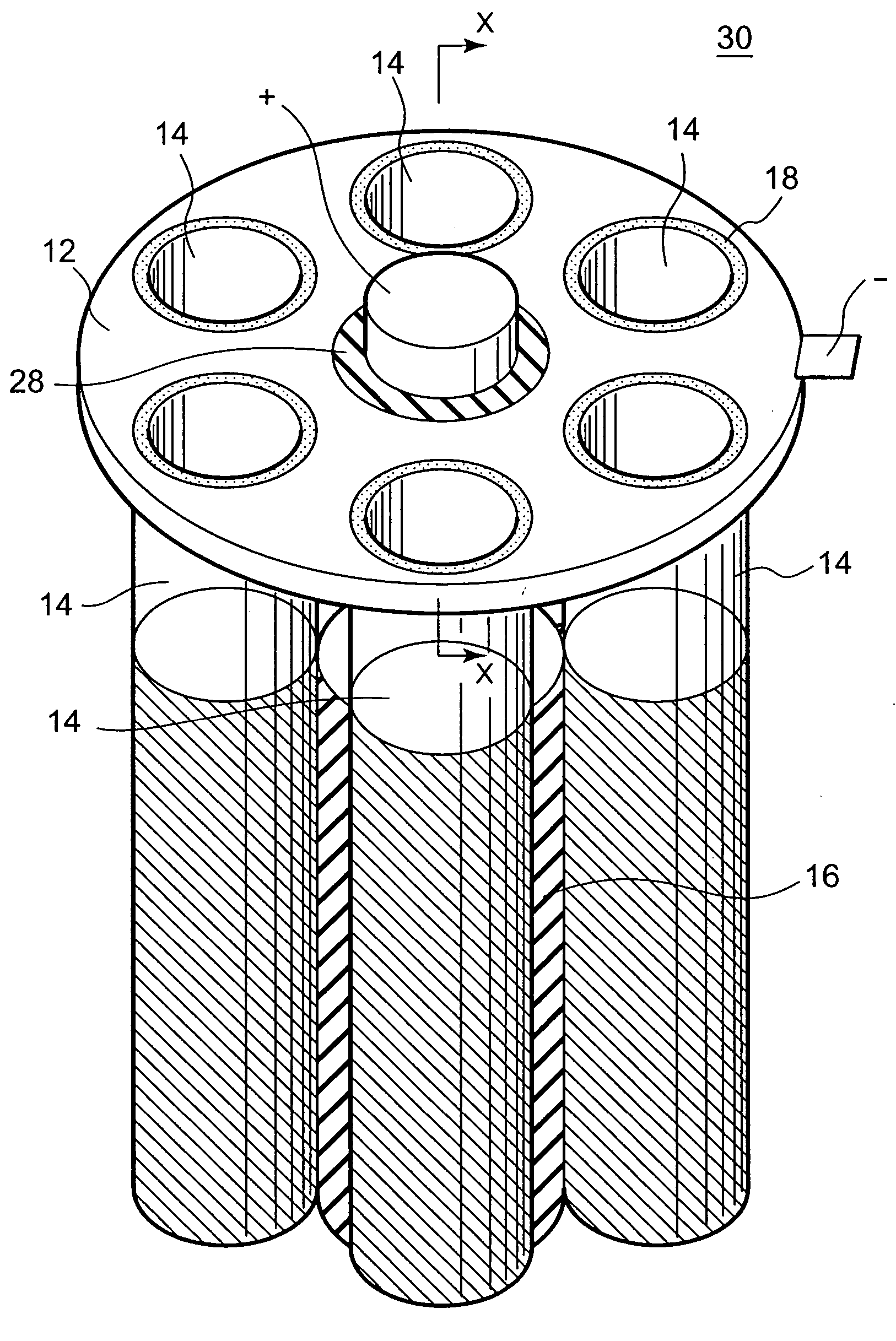

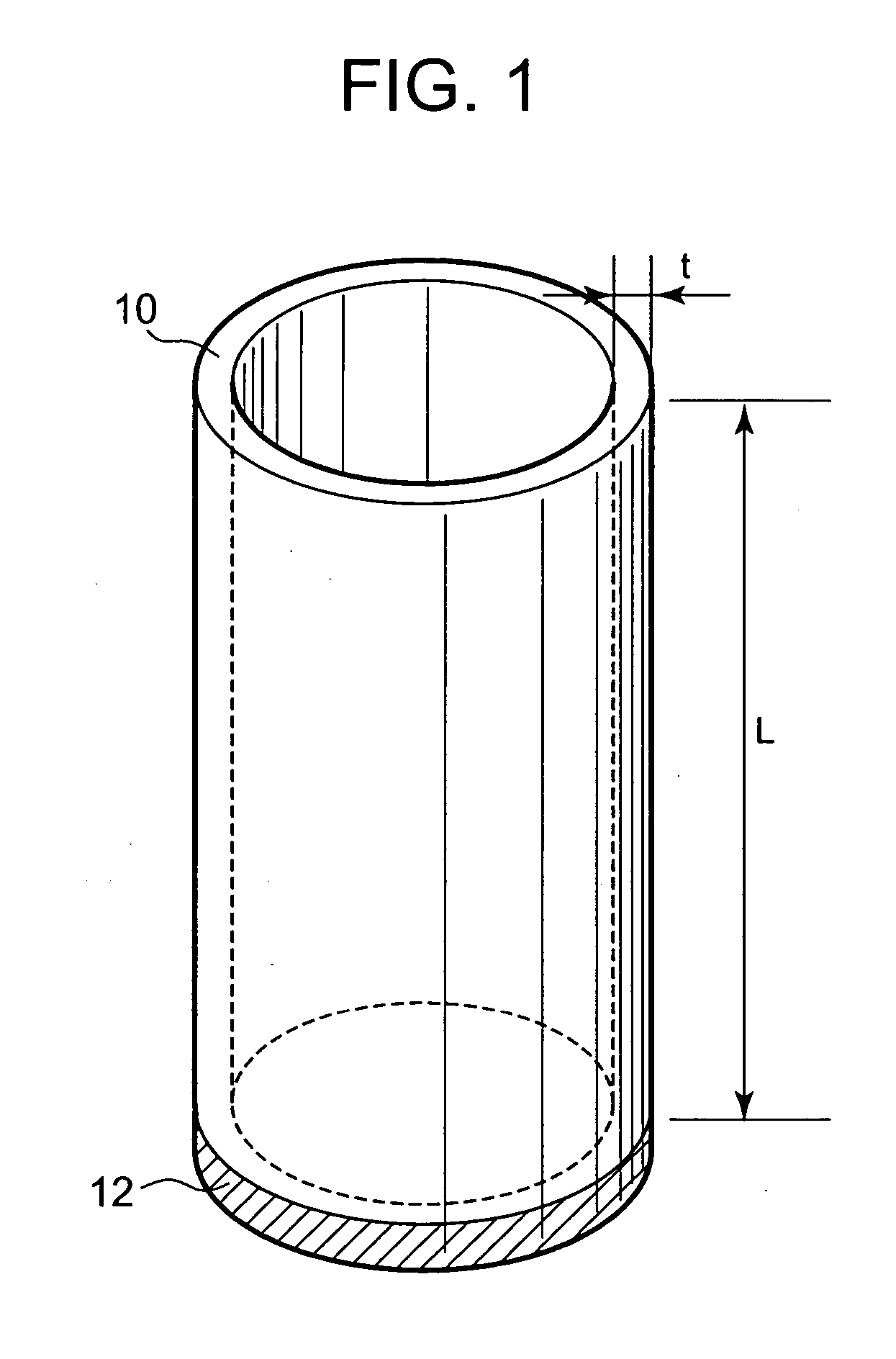

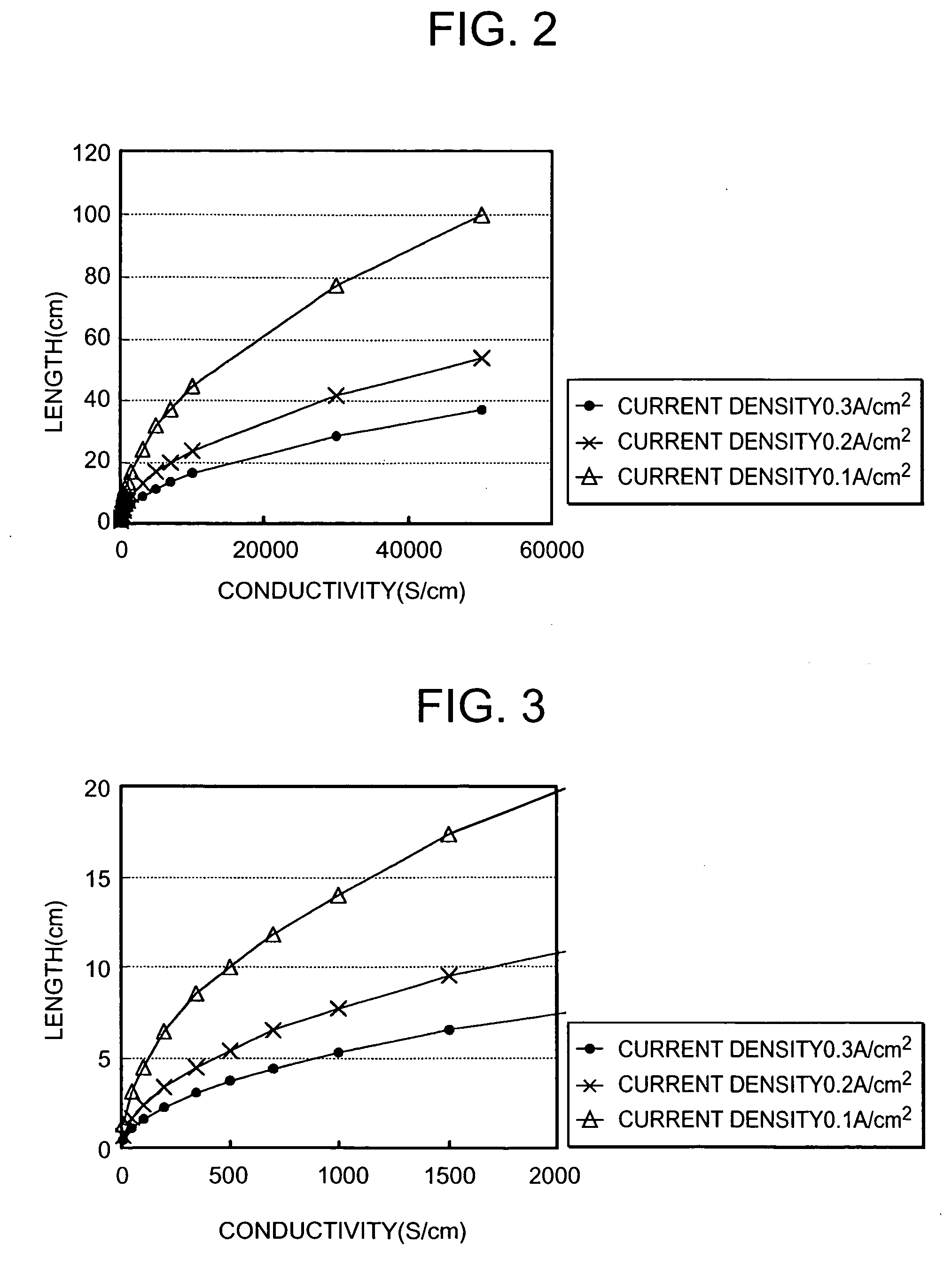

Solid oxide fuel cell, solid oxide fuel cell assembly, solid oxide fuel cell module, and solid oxide fuel cell power generator

InactiveUS20050008916A1Improve startup performanceIncrease temperatureFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A shape and conductivity of a cylindrical porous metal substrate of low power collection losses are defined, and a solid oxide fuel cell of a high output or high start-up performance is provided by using the cylindrical porous metal substrate. In the solid oxide fuel cell of the invention, the cylindrical porous metal substrate which has a conductivity of 130 S / cm or more is used, and a power collecting section is connected to a position which does not exceed 100 cm from any place thereof. A first electrode, a solid electrolytic layer, and a second electrode are formed on a full periphery of the cylindrical porous metal substrate. Thus, it is possible to obtain a solid oxide fuel cell of easy cell formation and low power collection losses, i.e., high durability and a high output.

Owner:SANYO ELECTRIC CO LTD

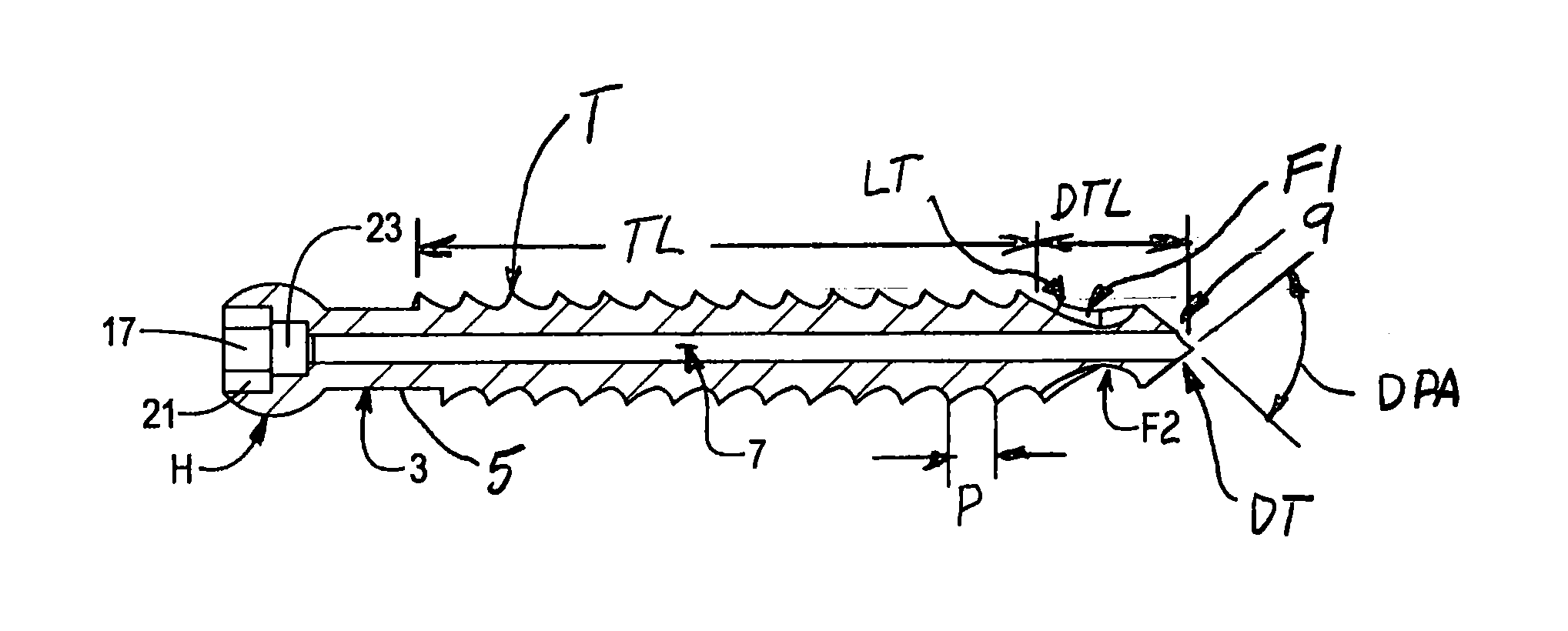

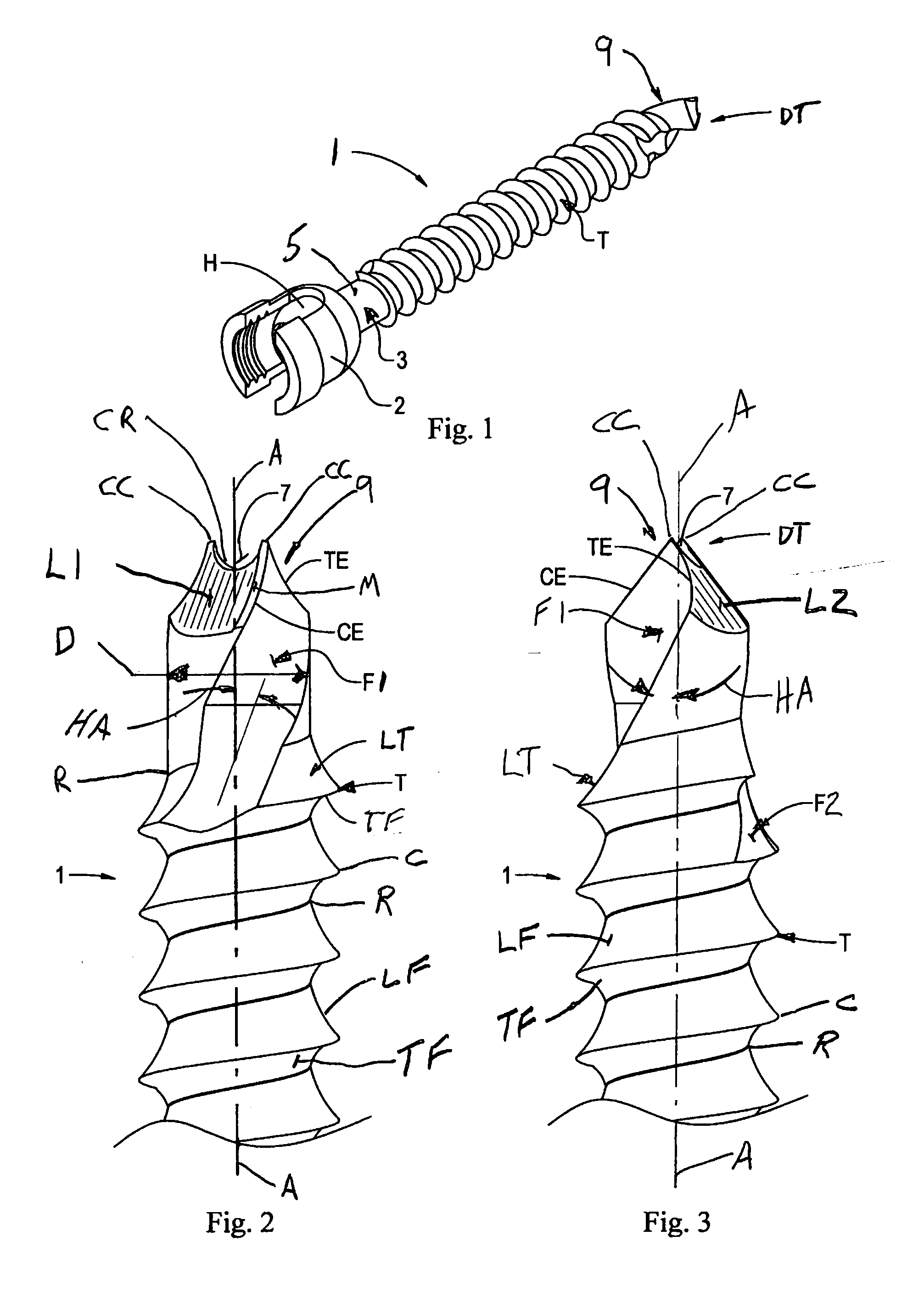

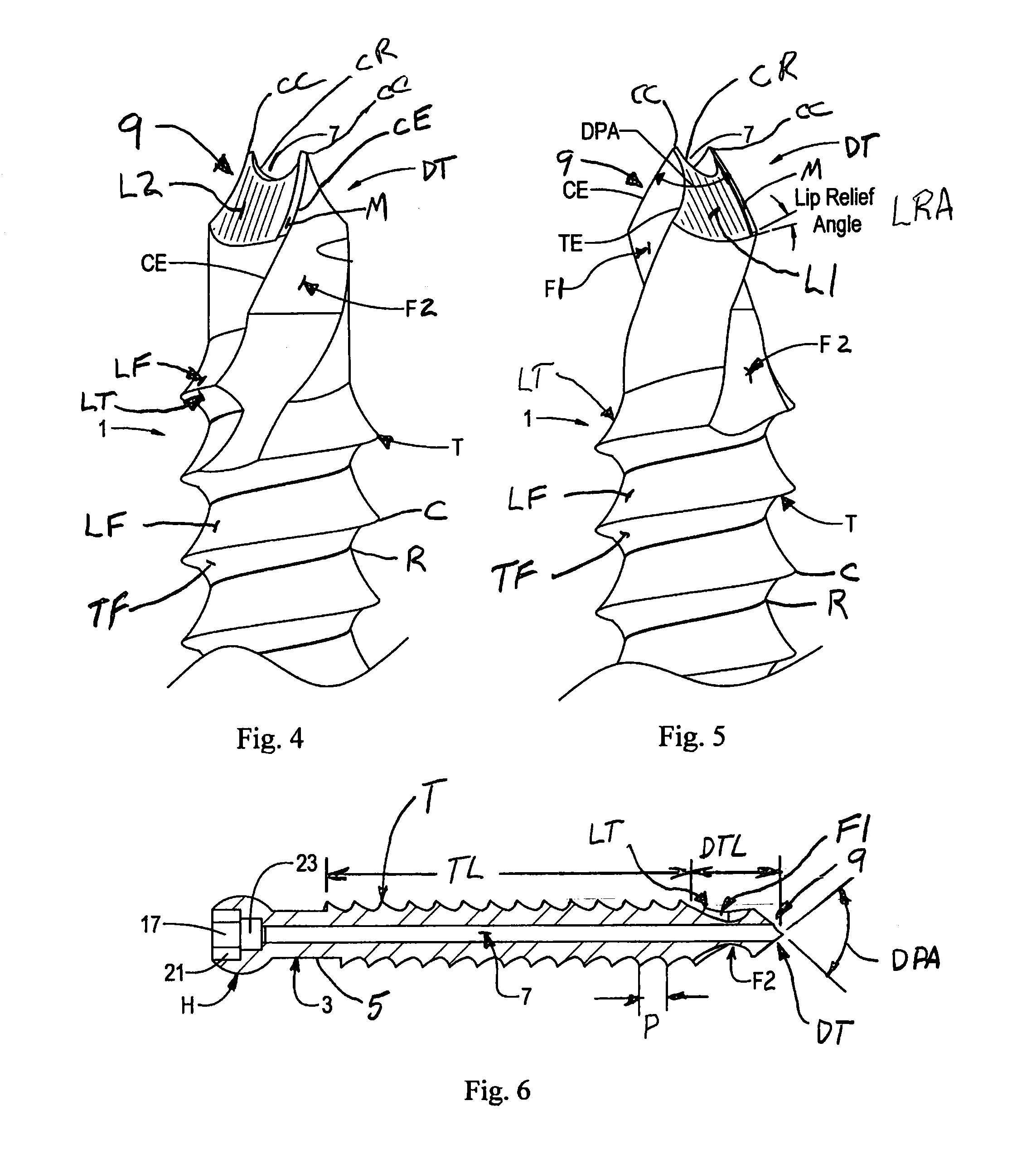

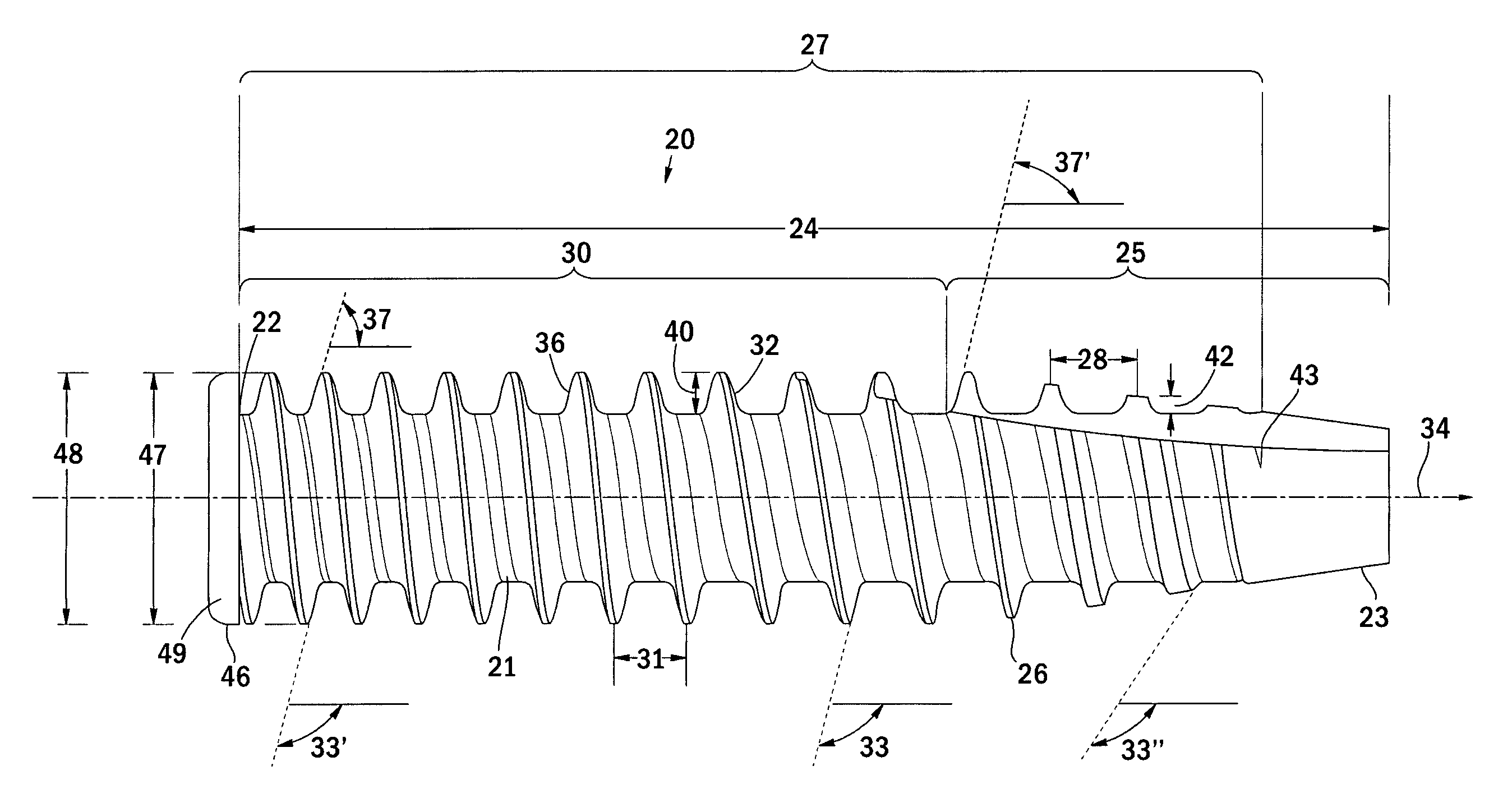

Self drilling, self-tapping bone screw and method of installing for bicortical purchase

ActiveUS20140277188A1Improve productivityShorten the timeSuture equipmentsInternal osteosythesisBone CortexIliac screw

A self-drilling, self-tapping bone screw is described in which the bone screw has a drill tip free of threads and having a length at least as great as about the thickness of a proximal cortical bone layer, with the drill tip having opposed lands and a helical flute between each of the lands with each of the lands having a cutting edge configured to cut bone as the drill tip is rotated into the bone with the flutes conveying the bone debris away from the drill tip, where a lead thread begins to self-tap internal threads in the proximal cortical bone layer after the drill tip has drilled through the proximal cortical bone layer so as to avoid stripping the threads formed in the bone layer. A method of installation is also disclosed.

Owner:POULOS NICHOLAS

Flexible display panel, production method for same, and flexible display device

ActiveCN103985321AImprove bendabilityAvoid breakingSolid-state devicesIdentification meansElastic componentEngineering

The invention discloses a flexible display panel, a production method for the same, and a flexible display device. The flexible display panel comprises a flexible substrate and a transparent flexible cover plate which are oppositely arranged; the flexible display panel is provided with a display area and a border area surrounding the display area; a rubber layer is arranged in the border area, and used for bonding and fixing the flexible substrate and the transparent flexible cover plate; a plurality of elastic components are arranged in the rubber layer. The flexible display panel is good in bendability. The production method can be used for producing the flexible display panel with good bendability, and the flexible display device is produced by the flexible display panel and good in bendability.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

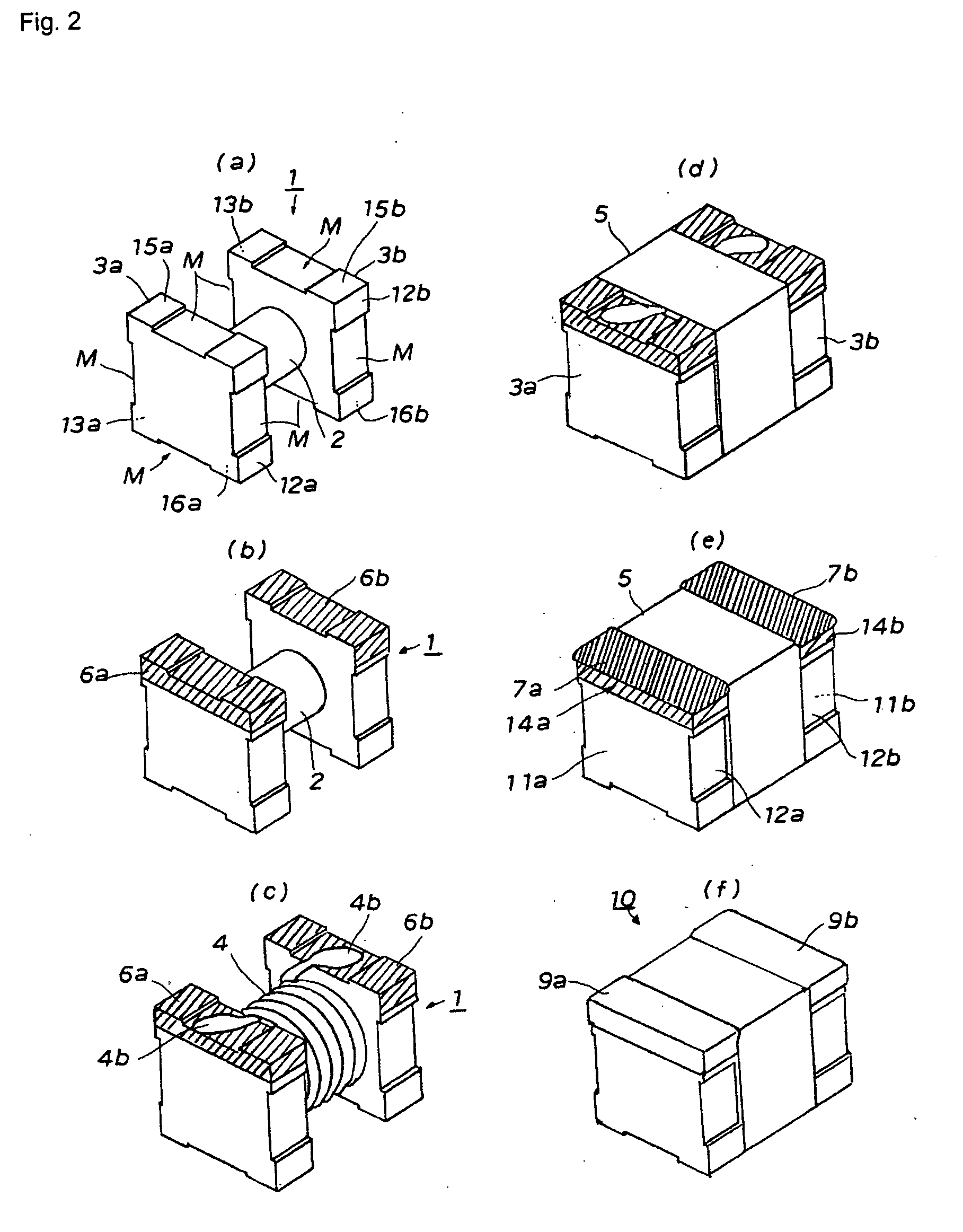

Surface mount coil component and surface mount coil component mounted substrate

ActiveUS20060071749A1High in cohesion strengthImprove cohesionTransformers/inductances casingsPrinted circuit manufactureElectrical conductorSurface mounting

A surface mount coil component has an electrode part including: internal electrodes mounted on both flanges of a drum type core over bottom surfaces and wraparound portions extending from the bottom surfaces to the end surfaces and parts of both sides. The coil conductor is conductively joined to the internal electrodes at both ends thereof. Intermediate electrodes cover from the top sides of wraparound portions of the internal electrodes on the sides of the flanges through top sides of the wraparound portion thereof on the end surfaces of the flanges to top sides of the wraparound portion thereof on the other sides of the flanges so as to leave C-shaped cross section of exposed areas of the internal electrodes. Also, plating conductive films extend from surfaces of the exposed areas of the internal electrodes to surfaces of the intermediate electrodes.

Owner:TAIYO YUDEN KK

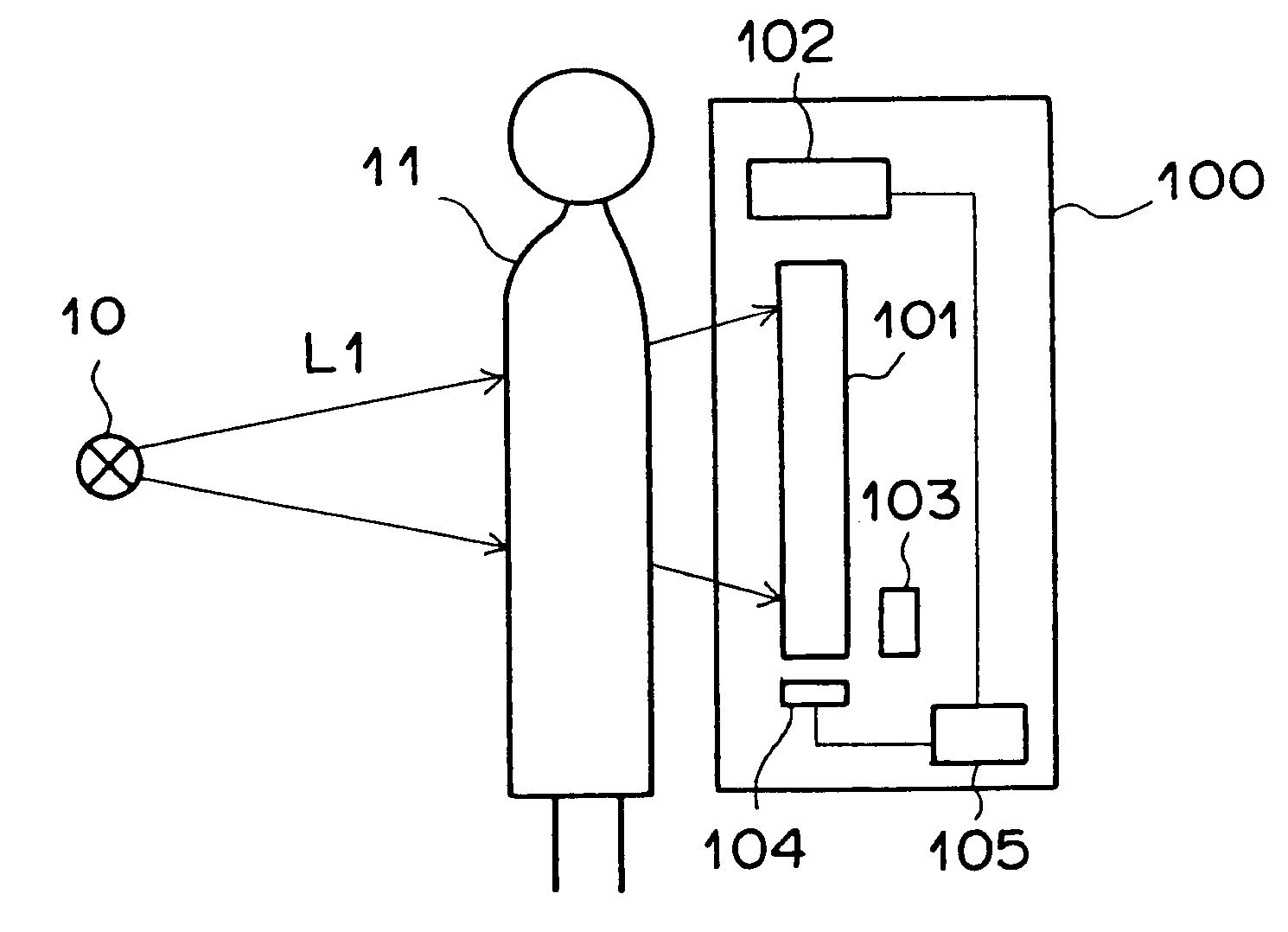

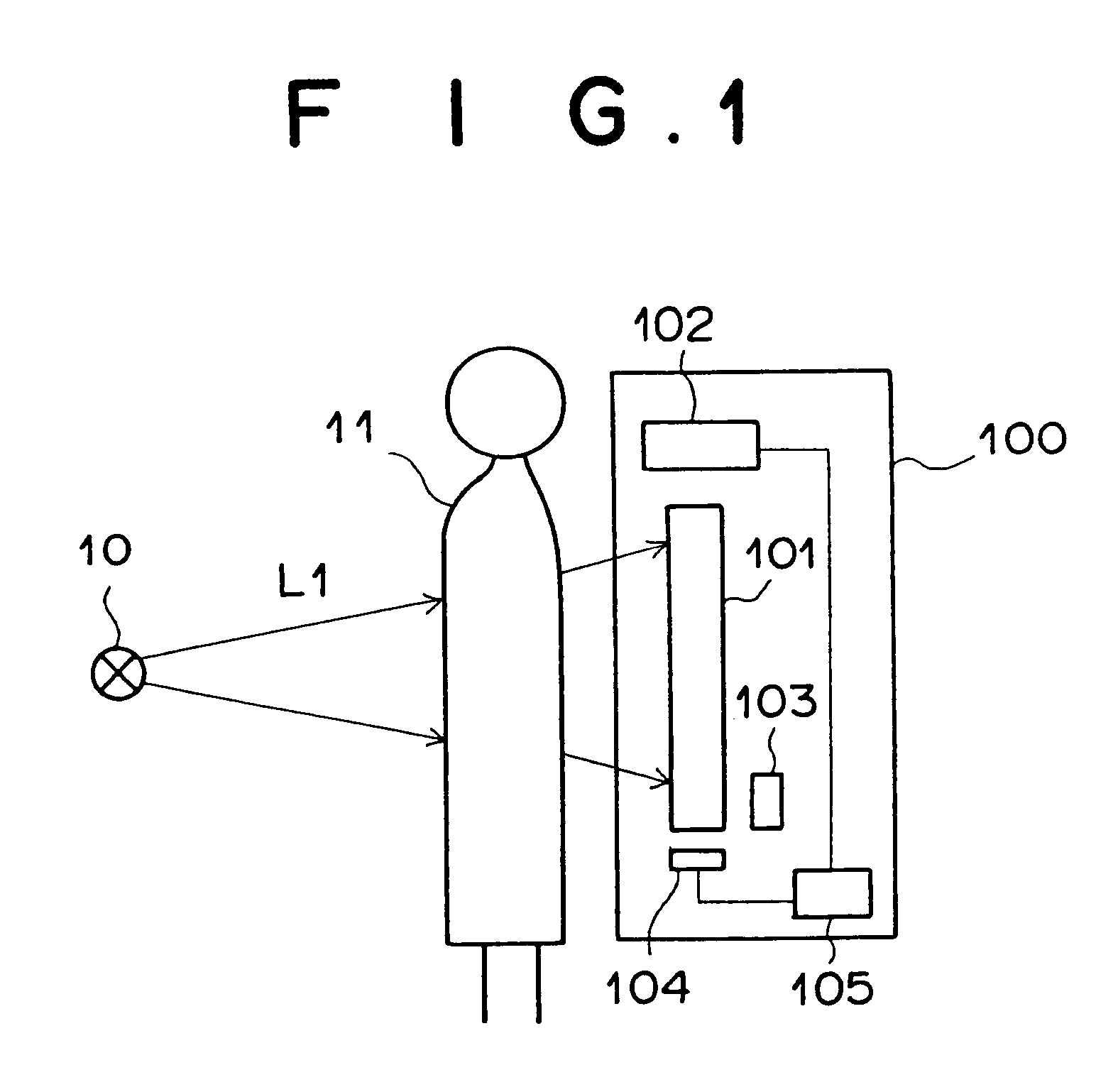

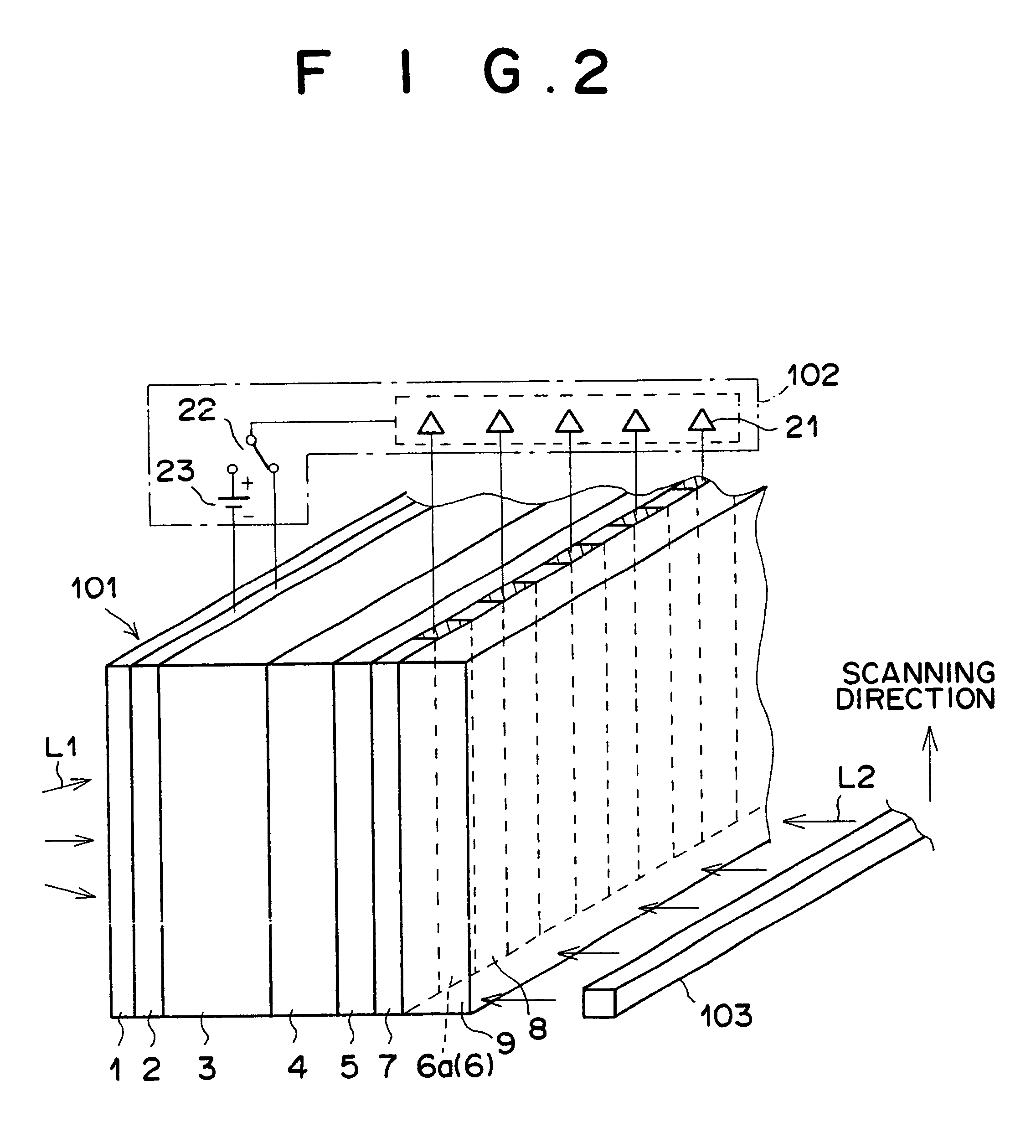

Energetic-beam detection apparatus including temperature-controlled selenium detector

InactiveUS6469312B2Decrease in the practical lifetime of a selenium detectorPrevent peelingX-ray/infra-red processesElectroluminescent light sourcesTemperature controlSe element

In an energetic-beam detection apparatus having a selenium detector which includes a substrate and an energetic-beam absorber being formed on the substrate and containing selenium, a temperature detecting unit detects a temperature of the selenium detector, and a temperature control unit controls the temperature of the selenium detector so that the temperature is maintained in a predetermined range when the selenium detector is in operation. Alternatively, when the temperature of the selenium detector is outside a predetermined range, an operation suppressing unit suppresses the operation of the selenium detector, or a notification unit notifies a user of the deviation of the temperature of the selenium detector from the predetermined range.

Owner:FUJIFILM CORP +1

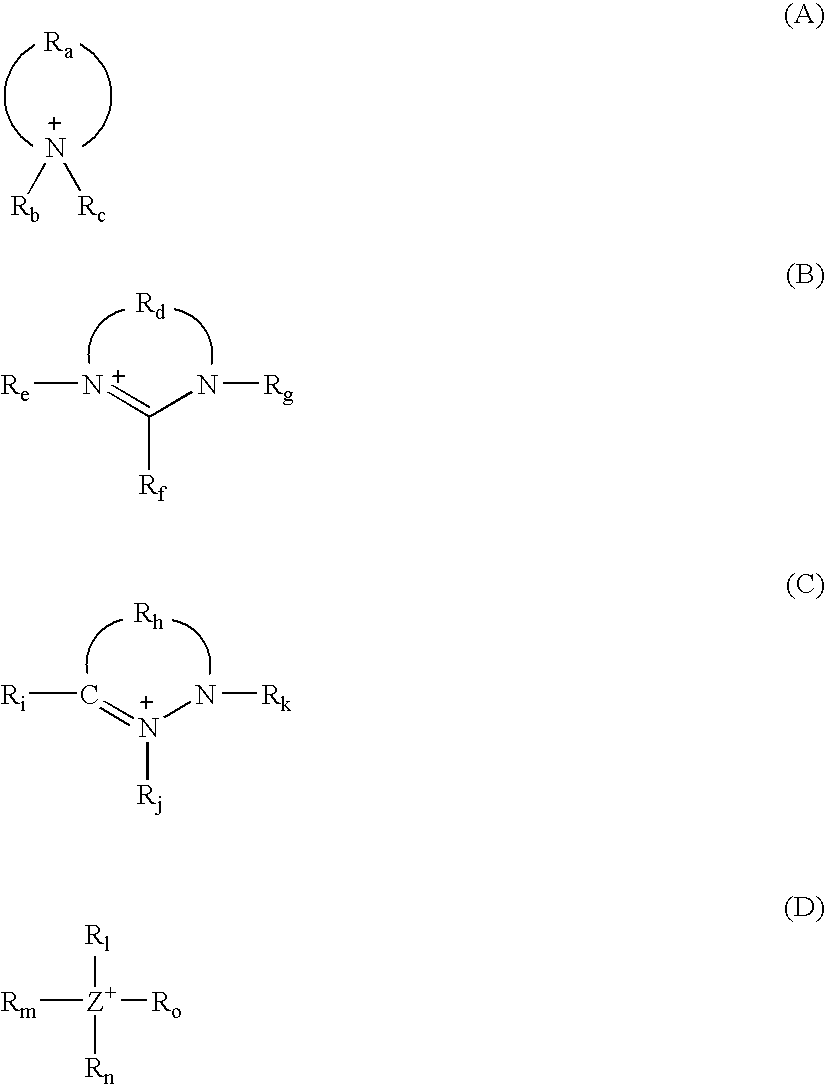

Pressure-sensitive adhesive composition, pressure-sensitive adhesive sheets, and surface protecting film

InactiveUS20060024494A1Improve antistatic performanceReduced stainabilityNon-macromolecular adhesive additivesFilm/foil adhesivesMeth-Oxygen

An object of the present invention is to provide a pressure-sensitive adhesive composition which is excellent in antistatic property of a non-electrification-prevented adherend (subject to be protected) upon peeling, and has reduced stainability in an adherend and is excellent in adhesion reliance, and electrification preventing pressure-sensitive adhesive sheets using the same. There is provided a pressure-sensitive composition comprising an ionic liquid, and a (meth)acryl-based polymer containing, as a monomer component, 0.1 to 100% by weight of a (meth)acrylic acid alkylene oxide. In addition, there is provided a pressure-sensitive composition comprising an ionic liquid, and a polymer containing, as a monomer component, 0.5 to 30% by weight of a nitrogen-containing monomer and having a glass transition temperature Tg of no higher than 0° C. Furthermore, there is provided a pressure-sensitive composition comprising an ionic liquid, and a (meth)acryl-based polymer containing, as a monomer component, 0.01 to 20% by weight of a reactive surfactant.

Owner:NITTO DENKO CORP

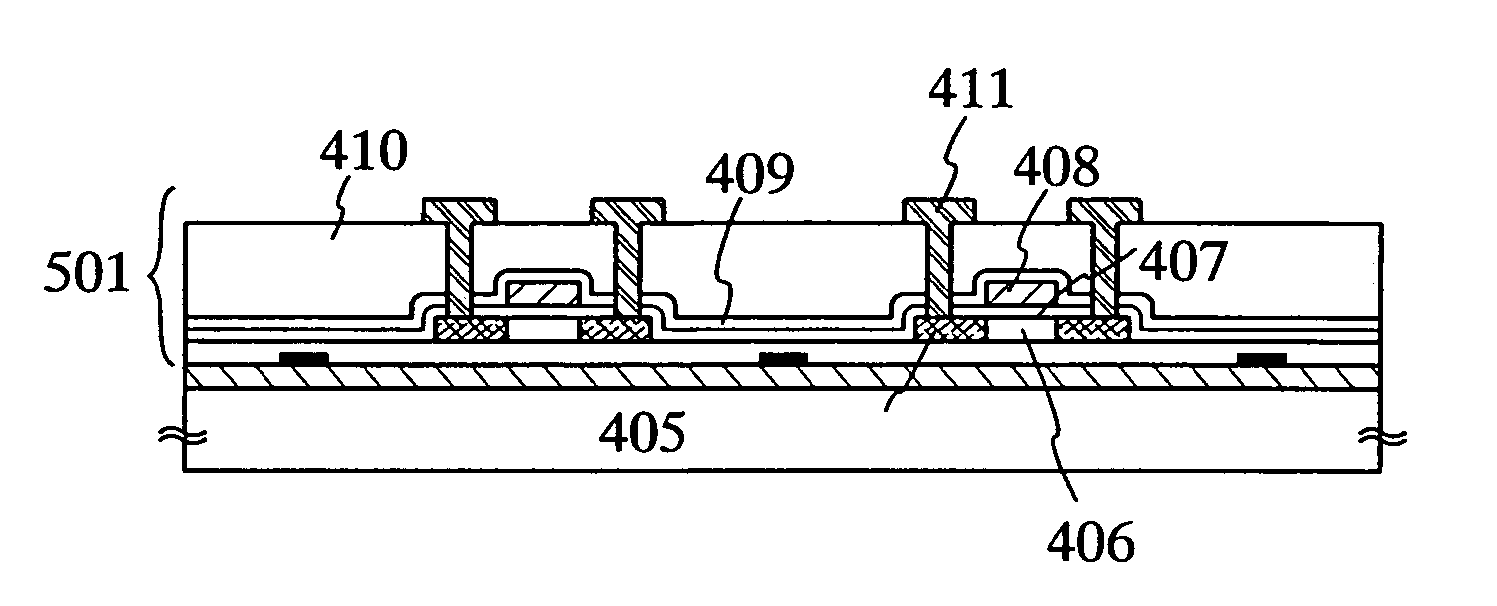

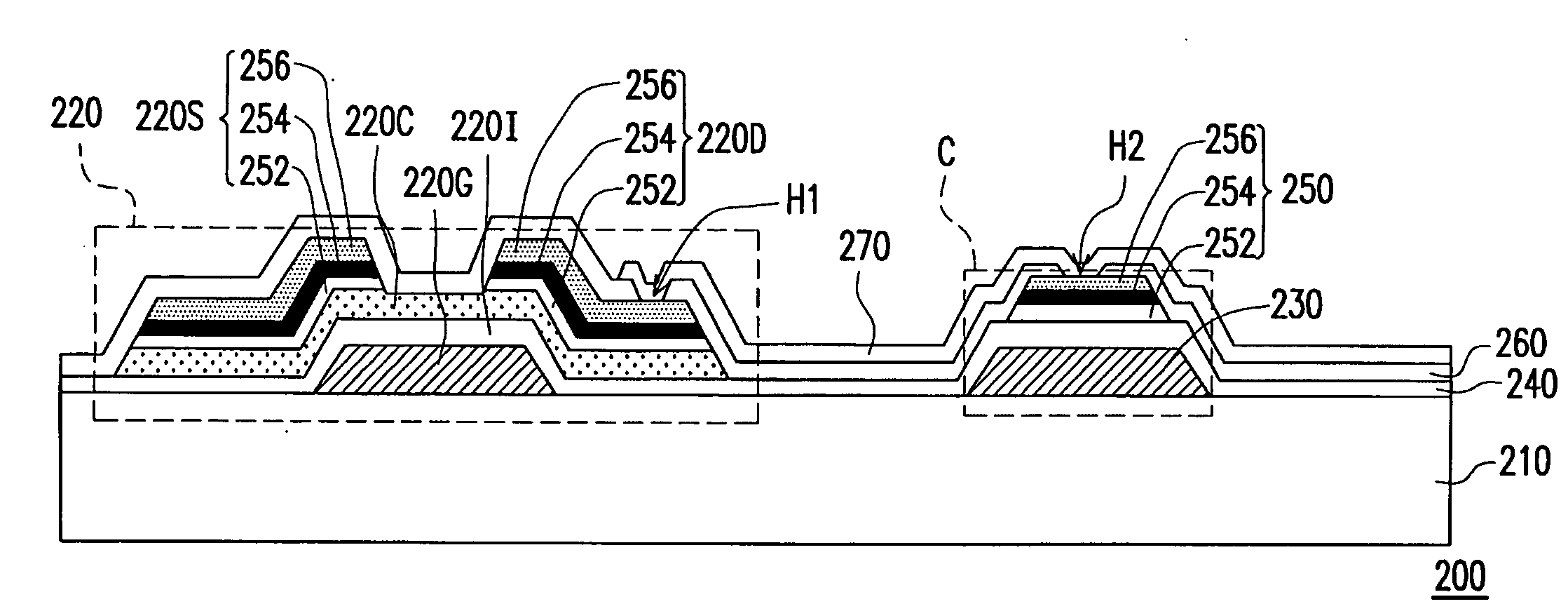

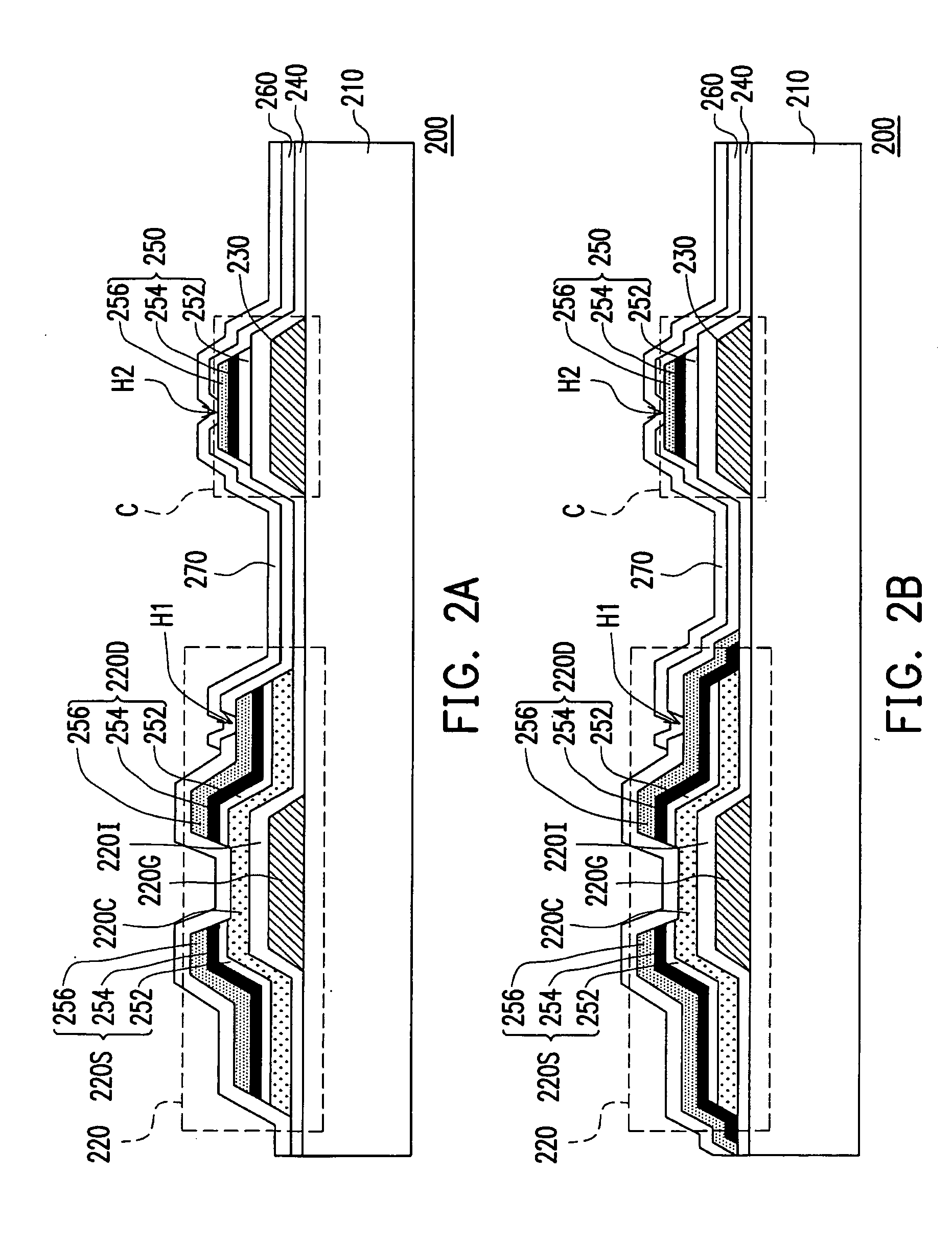

Pixel structure, display panel, eletro-optical apparatus, and method thererof

ActiveUS20090153056A1Prevent peelingTube/lamp screens manufactureSolid-state devicesEngineeringSemiconductor

A pixel structure disposed on a substrate including a thin film transistor (TFT), a bottom capacitor electrode, a dielectric layer, an upper capacitor electrode, a passivation layer, and a pixel electrode is provided. The TFT having a source / drain and the bottom capacitor electrode are disposed on the substrate. The dielectric layer is disposed on the bottom capacitor electrode. The upper capacitor electrode has a semiconductor layer, a barrier layer, and a metal layer. The semiconductor layer is disposed on the dielectric layer above the bottom capacitor electrode. The barrier layer is disposed on the semiconductor layer. The metal layer whose material includes copper, a copper alloy, or a combination thereof is disposed on the barrier layer. The passivation layer covers the TFT and the upper capacitor electrode and has a first opening exposing the source / drain. The pixel electrode is electrically connected to the TFT through the first opening.

Owner:AU OPTRONICS CORP

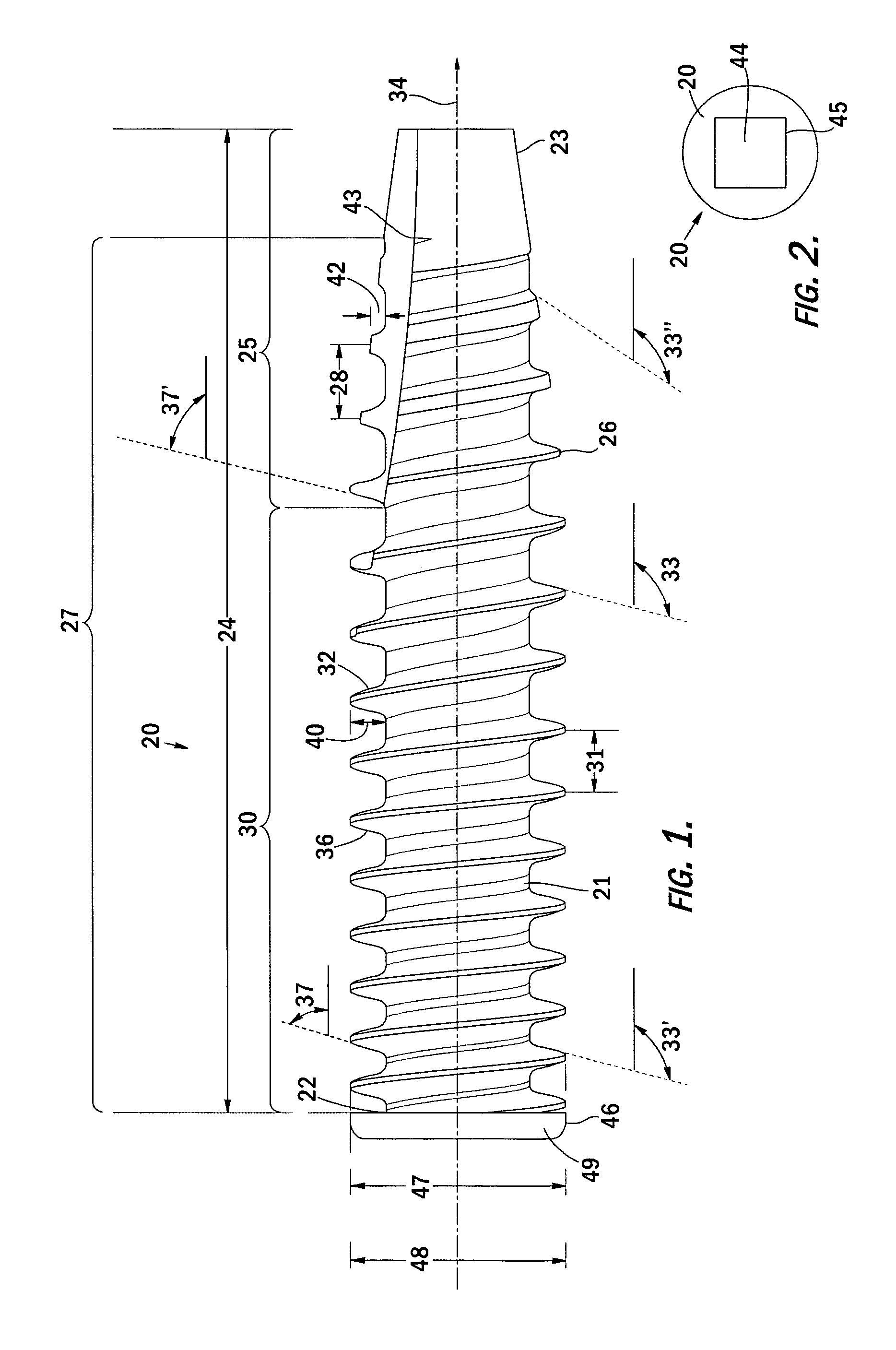

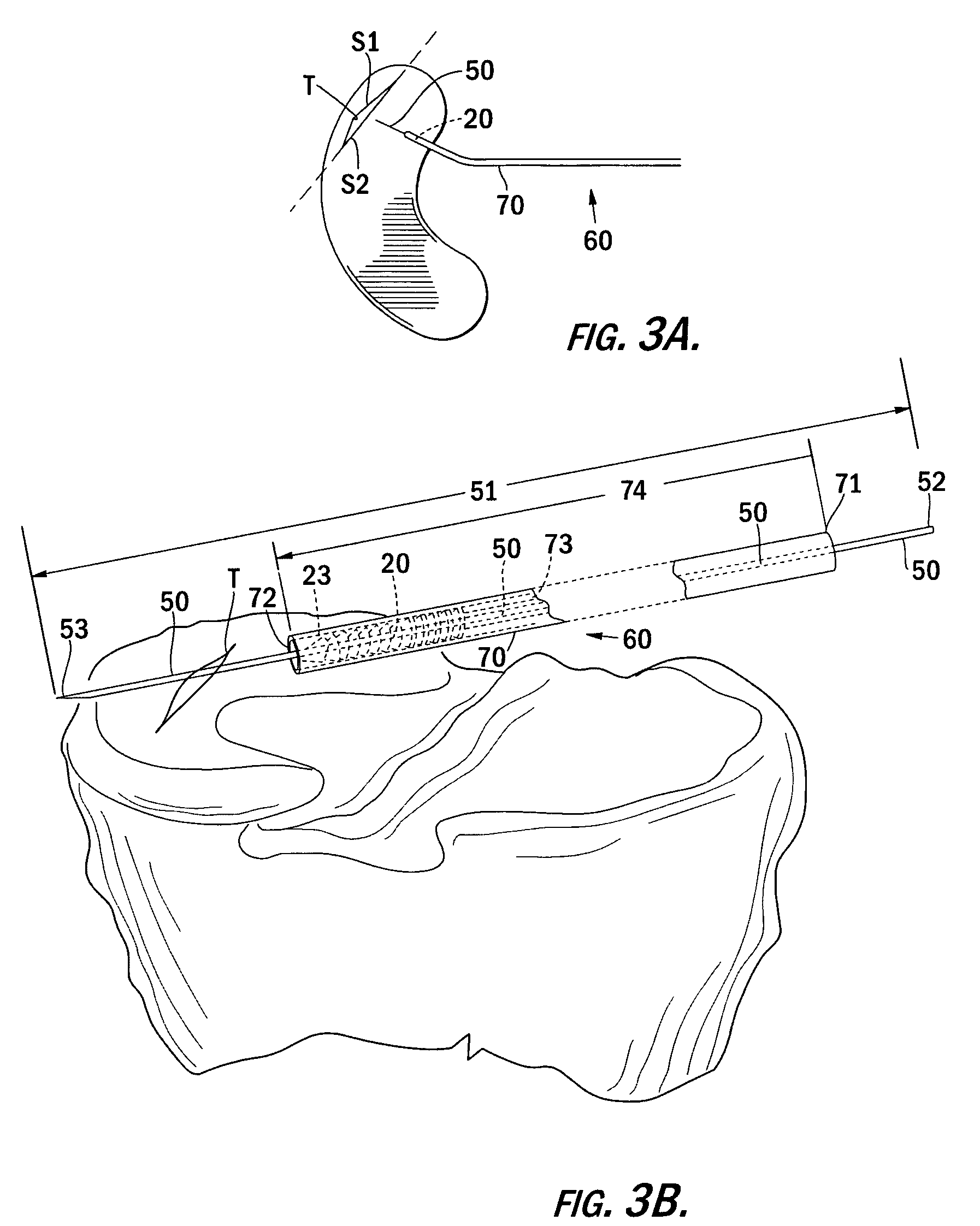

Orthopedic screw and method

InactiveUS7578836B2Avoid scratchesMaintain structural integritySuture equipmentsNutsMeniscal tearsIliac screw

A screw, driving device, and method are provided for repairing a tissue injury of a patient, such as a meniscal tear in a knee or osteochondritis dissecans. The screw has a root, a distal section having a narrowing cross section toward the distal end, and a thread along at least a portion of the root between the proximal end and the distal end. Along a leading section extending from the distal end, the helical pitch is substantially constant; along a trailing section between the leading section and the root's proximal end, the helical pitch decreases. The substantially constant pitch along the leading section assists in preventing a stripping of the helical section. At the proximal end is a head having a diameter greater than a major root diameter of the central section. The head is for improving the tissue retention characteristics of the screw.

Owner:DEPUY MITEK INC

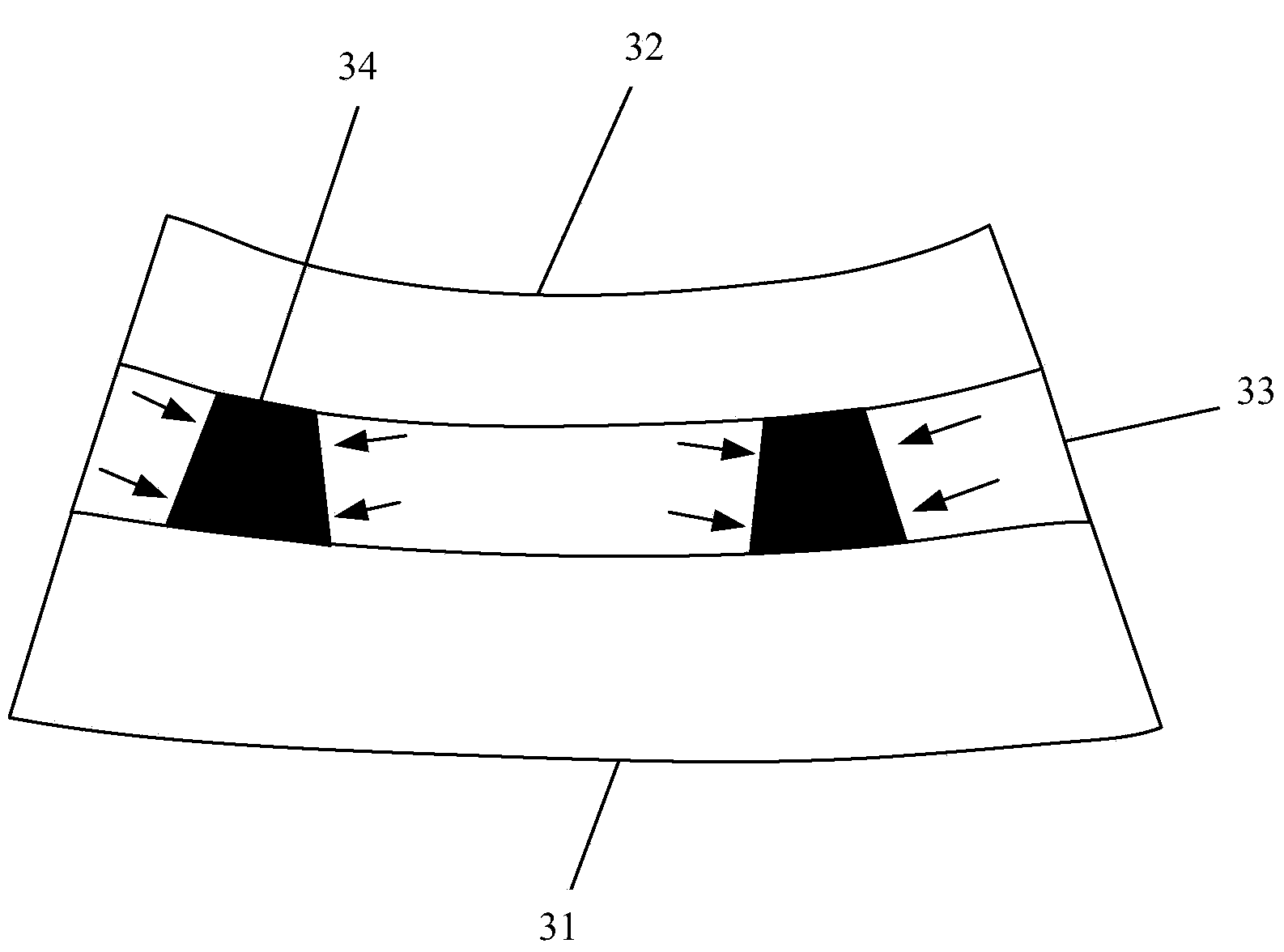

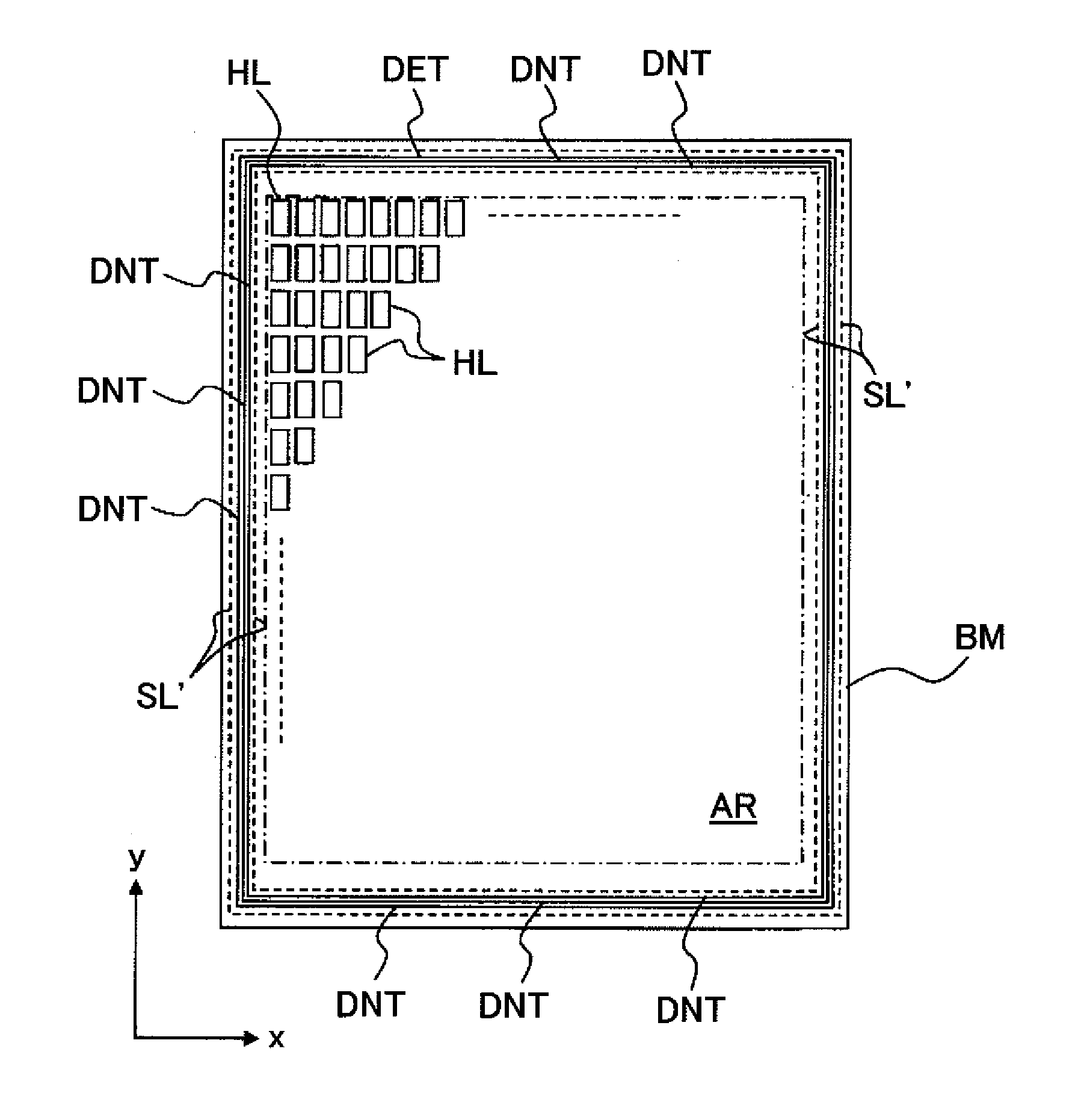

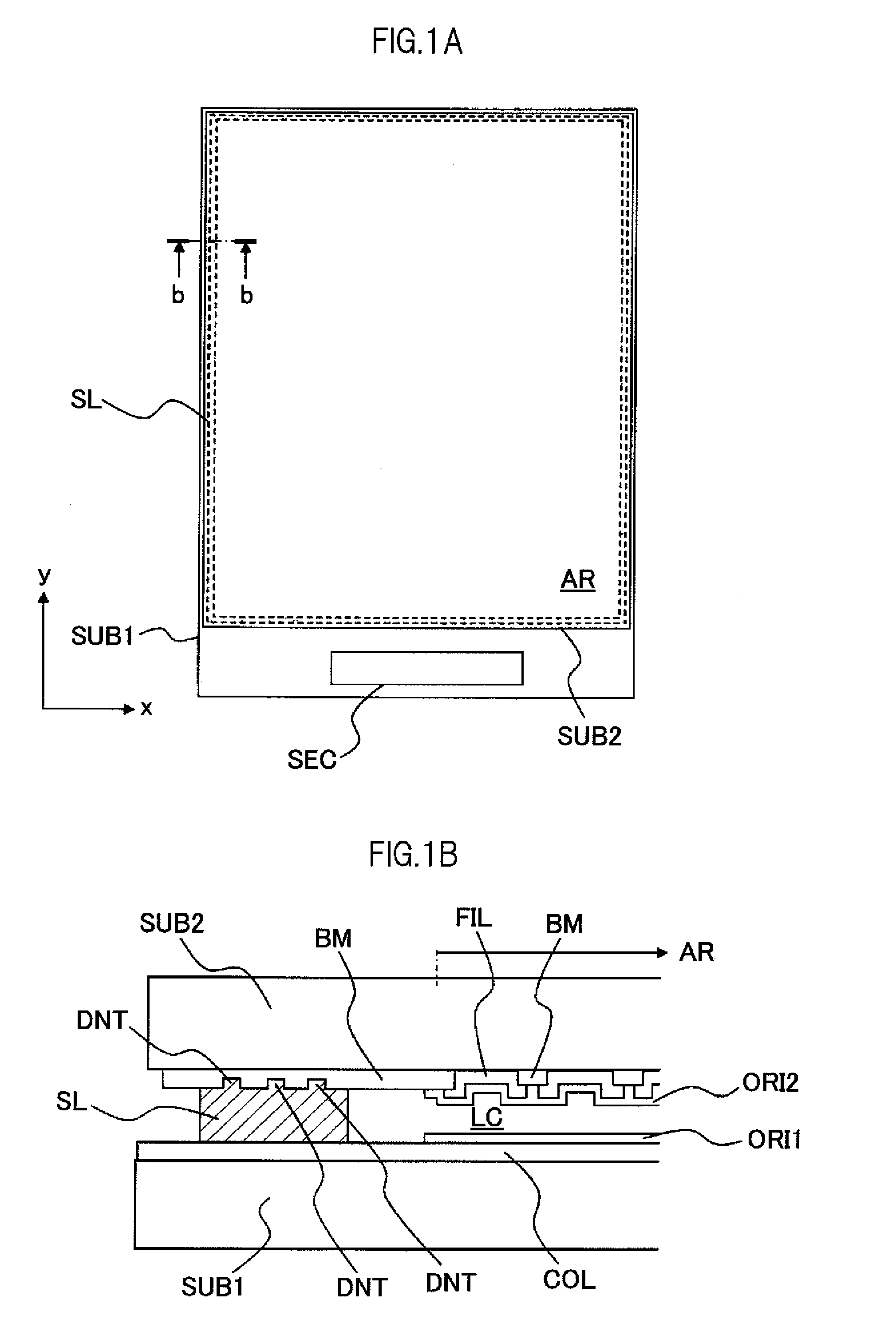

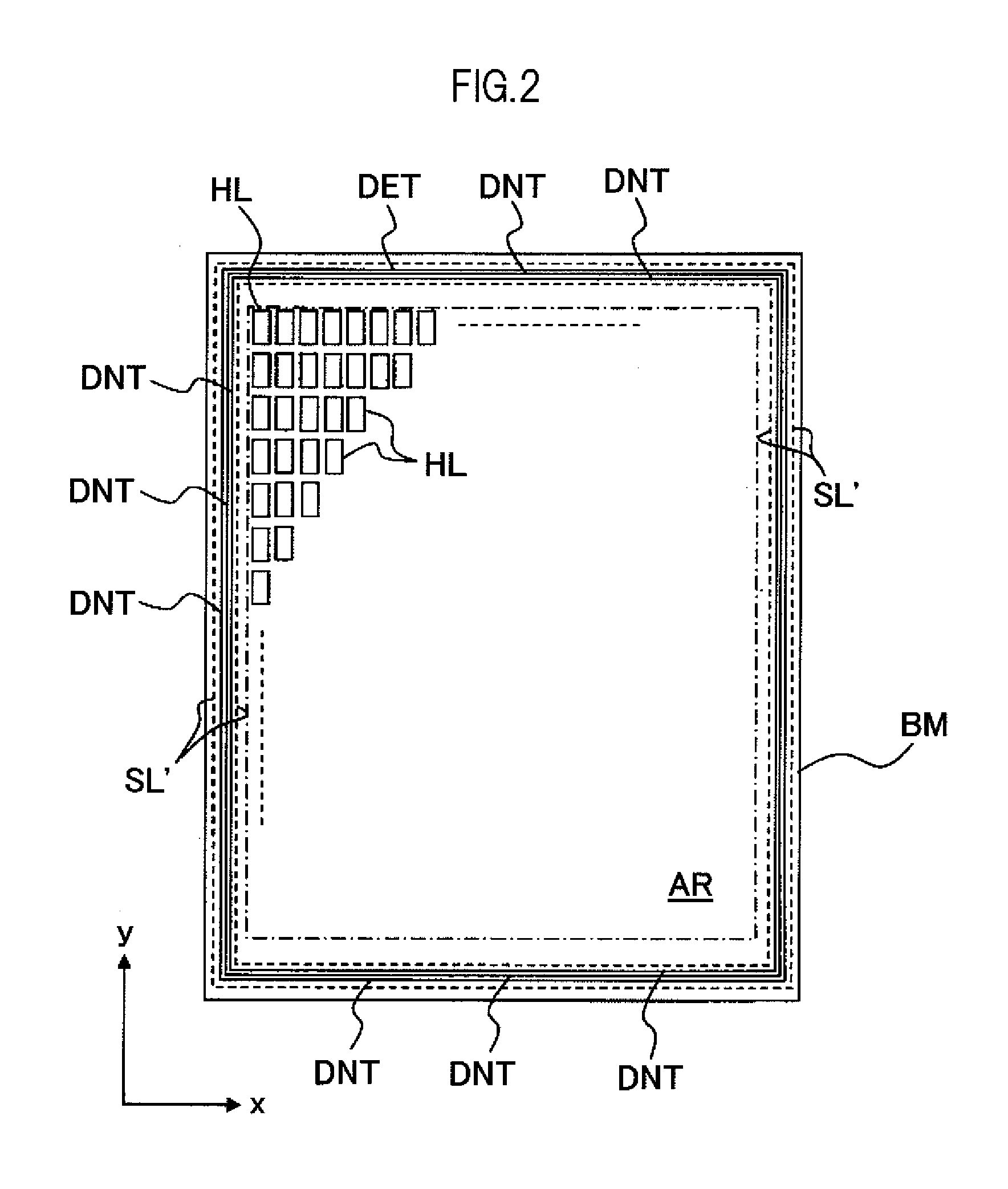

Liquid crystal display device

ActiveUS20100079718A1Improve adhesionPrevent peelingNon-linear opticsLiquid-crystal displayEngineering

Provided is a liquid crystal display device including: a first substrate and a second substrate which are arranged so as to be opposed to each other for sandwiching a liquid crystal; an image display portion; a sealing material which seals the liquid crystal; and a light-shielding film which is formed on a liquid crystal side of the second substrate so that a part of the light-shielding film extends beyond the image display portion to overlap with the sealing material, and which has openings in the image display portion, at least in regions of the multiple pixels, in which the part of the light-shielding film that overlaps with the sealing material has a recessed portion formed on a sealing material side of the light-shielding film continuously or discontinuously along a circumferential direction of the sealing material, to a depth that is smaller than a thickness of the light-shielding film.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

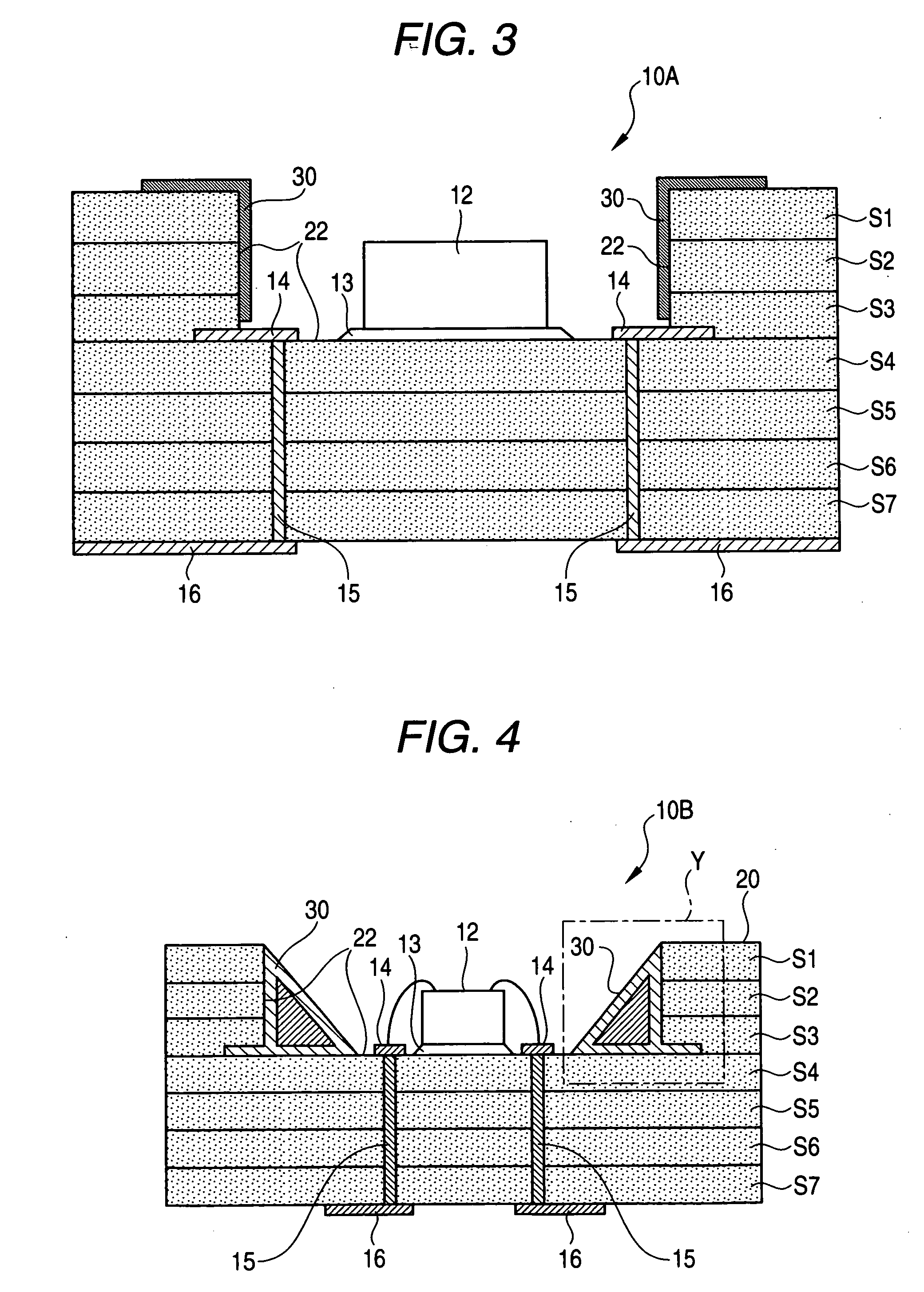

Semiconductor element, method of manufacturing semiconductor element, multi-layer printed circuit board, and method of manufacturing multi-layer printed circuit board

InactiveUS20070209831A1Improve adhesionAvoid crackingPrinted electric component incorporationSemiconductor/solid-state device detailsEngineeringCopper

A transition layer 38 is provided on a die pad 22 of an IC chip 20 and integrated into a multilayer printed circuit board 10. Due to this, it is possible to electrically connect the IC chip 20 to the multilayer printed circuit board 10 without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on an aluminum pad 24, it is possible to prevent a resin residue on the pad 24 and to improve connection characteristics between the die pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

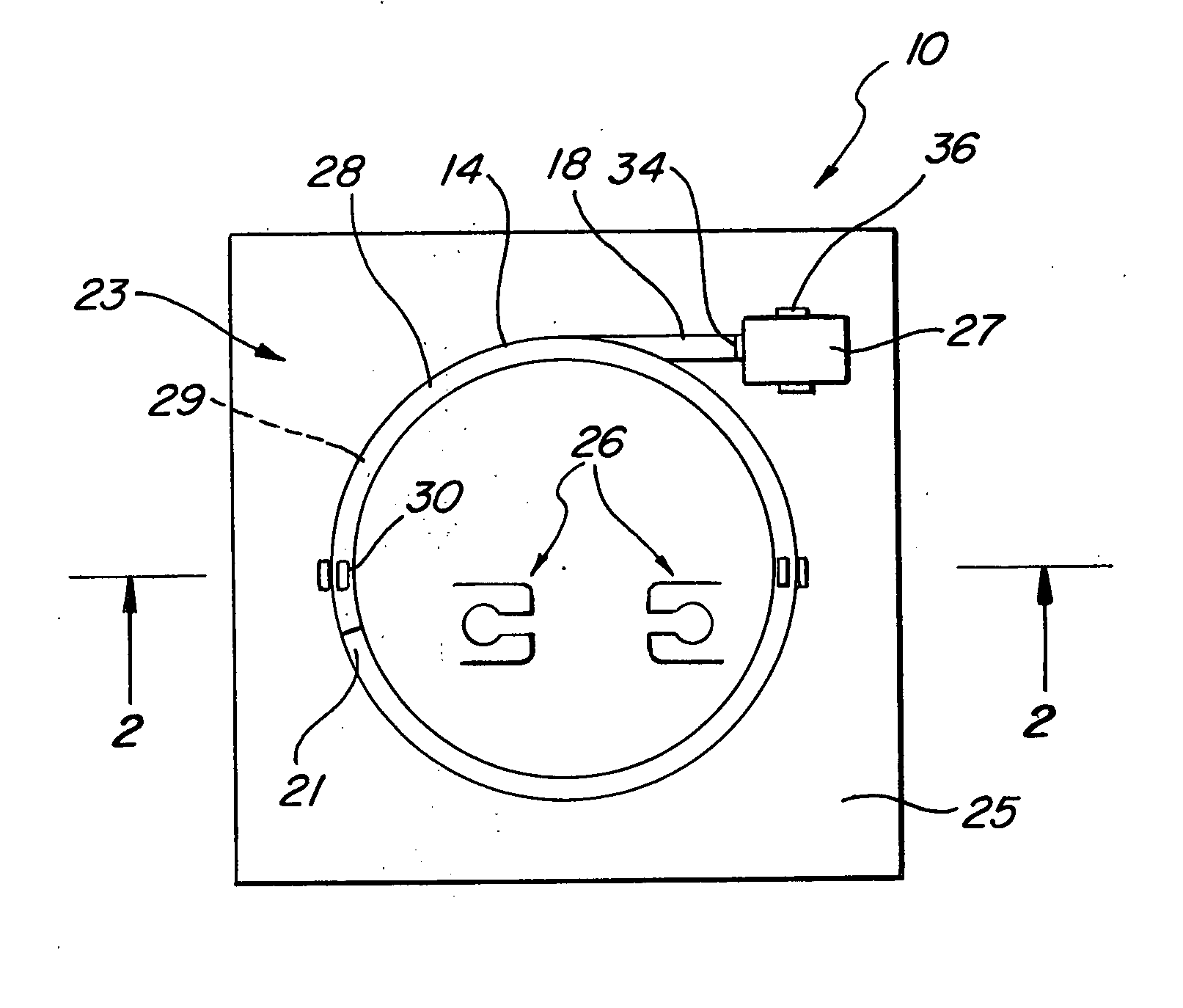

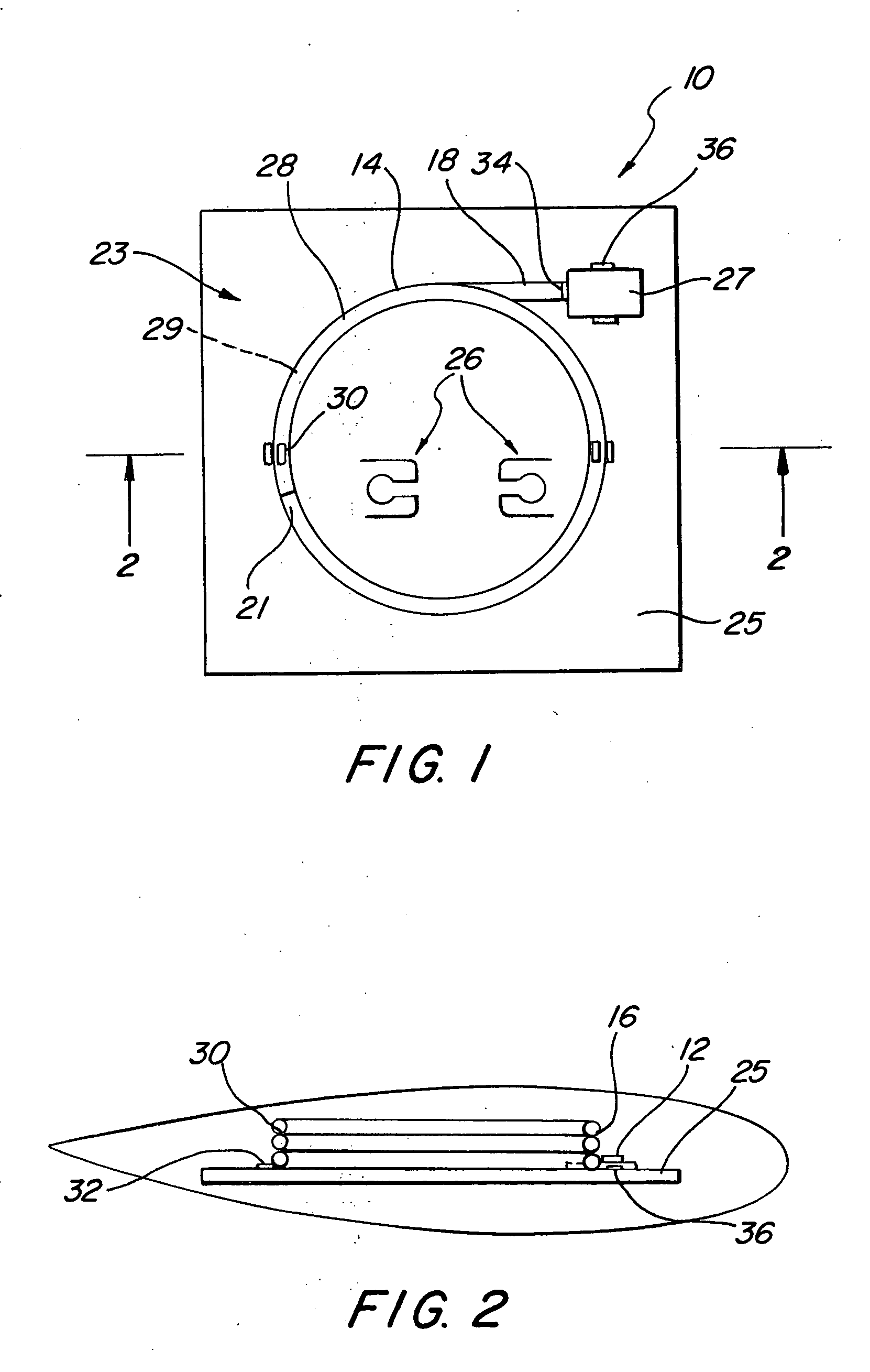

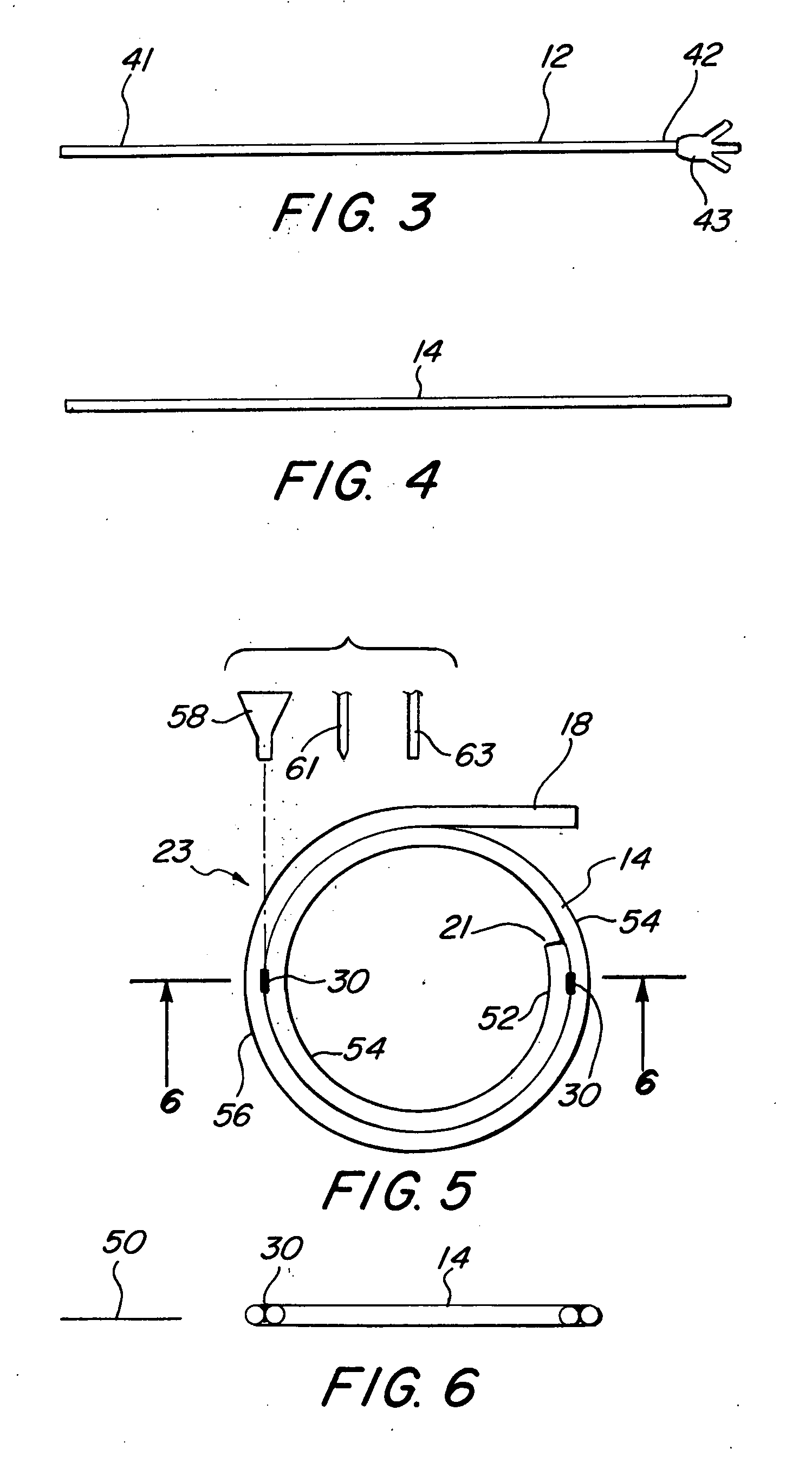

Apparatus and method for packaging elongate surgical devices

A package for an elongate surgical device, such as a catheter, includes an elongate tube formed into a coil configuration with a first coil portion disposed adjacent to a second coil portion. A thermal weld bonds the coil portions in a fixed relationship and with a strength sufficient to prevent peeling the first coil portion from the second coil portion. The surgical device can then be loaded into the tube, pouched and sterilized for ultimate distribution. In an associated method, the tube is coiled on a turntable and moved relative to heating stations where the thermal bonds can be formed.

Owner:OLIVER HEALTHCARE PACKAGING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com