Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3539 results about "Solid oxide fuel cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A solid oxide fuel cell (or SOFC) is an electrochemical conversion device that produces electricity directly from oxidizing a fuel. Fuel cells are characterized by their electrolyte material; the SOFC has a solid oxide or ceramic electrolyte.

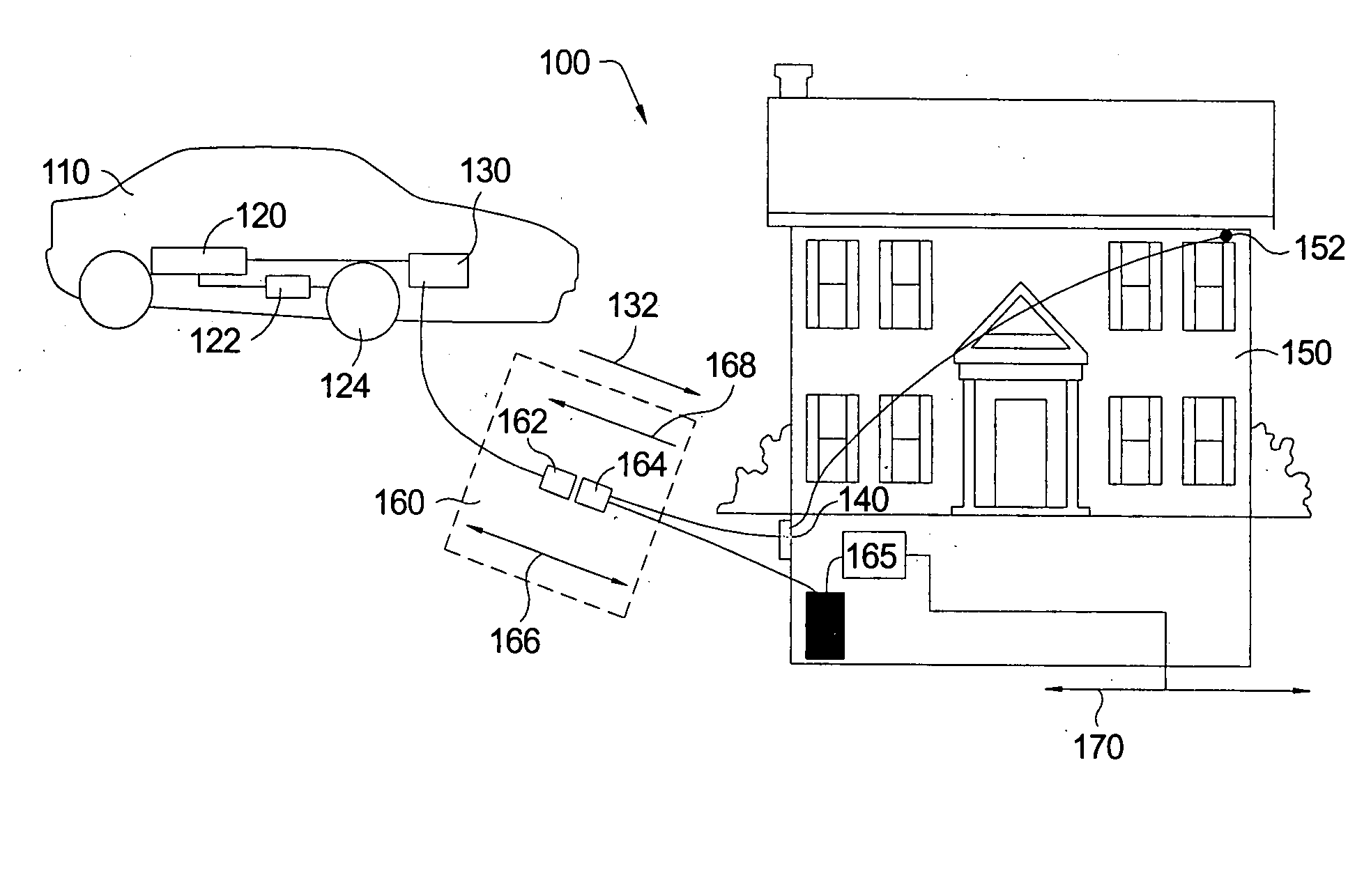

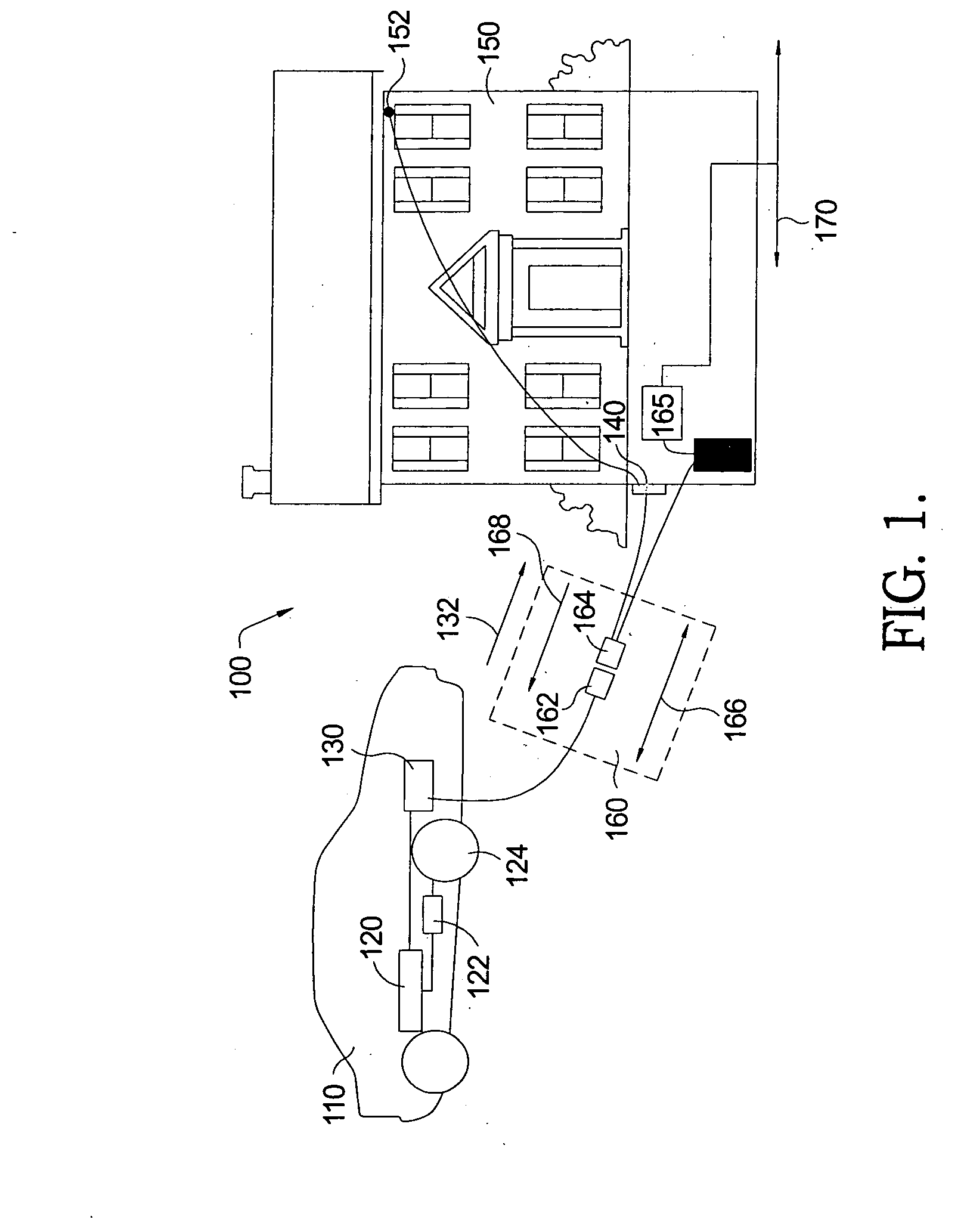

Electric vehicle having multiple-use APU system

ActiveUS20060219448A1Reducing net metered electricityIncrease powerAuxillary drivesBatteries circuit arrangementsElectricityFuel cells

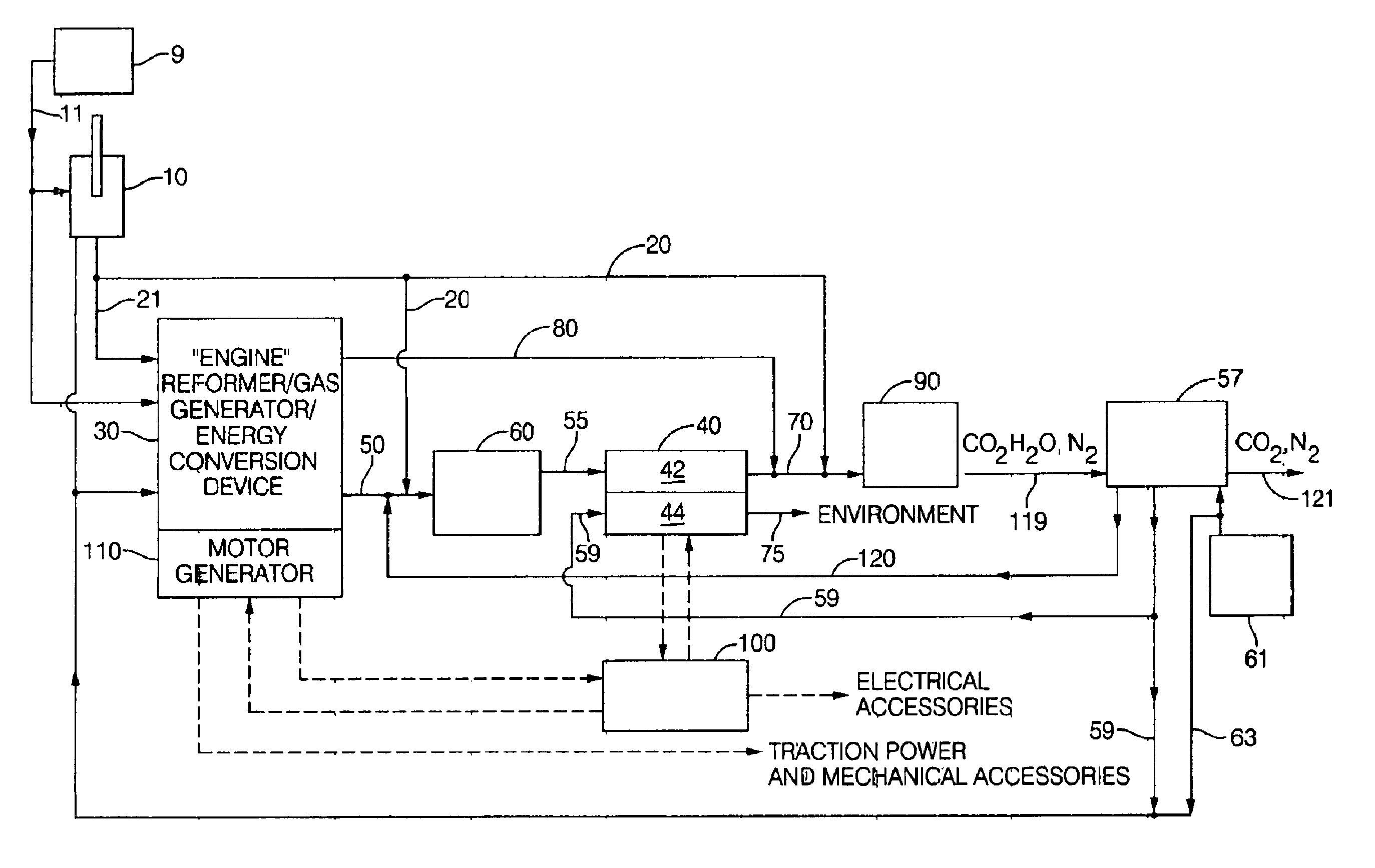

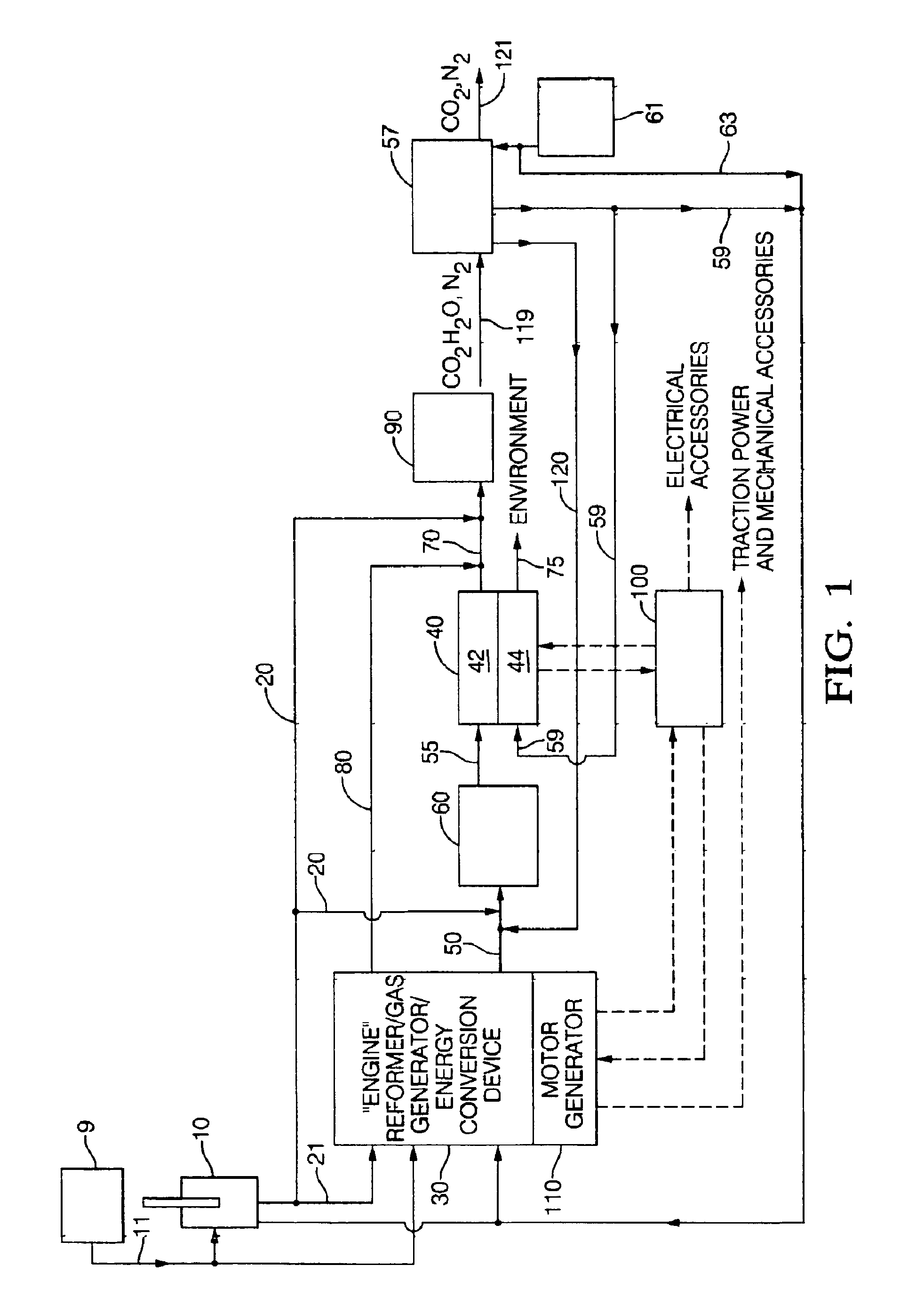

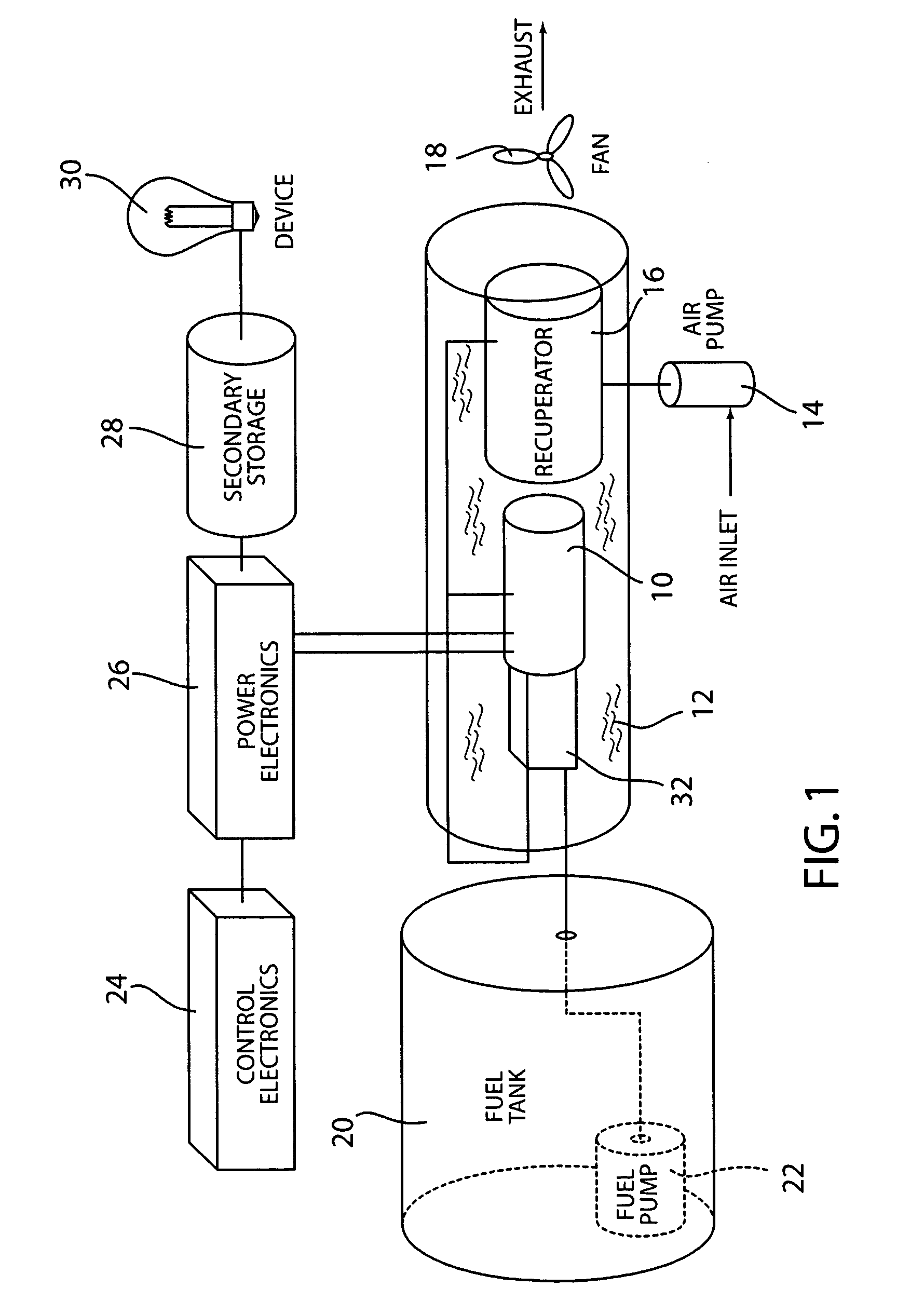

During periods of vehicle inactivity, a vehicle-based APU electric generating system may be coupled into a regional electric grid to send electricity into the grid. A currently-preferred APU is a solid oxide fuel cell system. When a large number of vehicles are thus equipped and connected, substantial electric buffering can be effected to the grid load. A vehicle-based APU can also function as a back-up generator to a docking facility in the event of power failure of the grid. Gaseous hydrocarbon is readily supplied by pipe in many locations as a commercial and residential heating fuel source, and a hydrocarbon reformer on the vehicle can be attached to the fuel source, enabling an APU to operate as a stationary power source indefinitely. An optional storage tank on the vehicle may be refueled with gaseous fuel, for example, while the battery is being electrically recharged by the grid.

Owner:APTIV TECH LTD

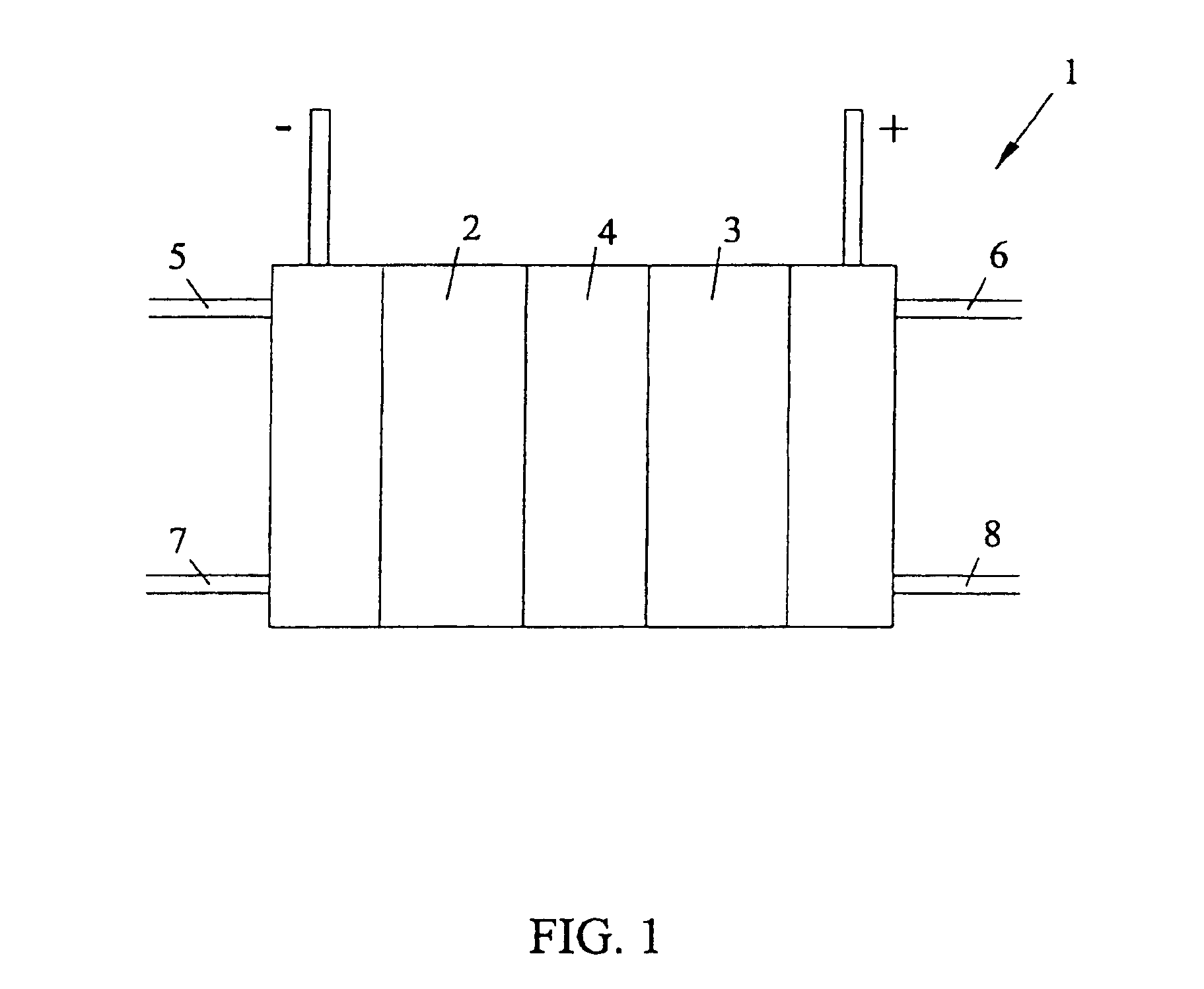

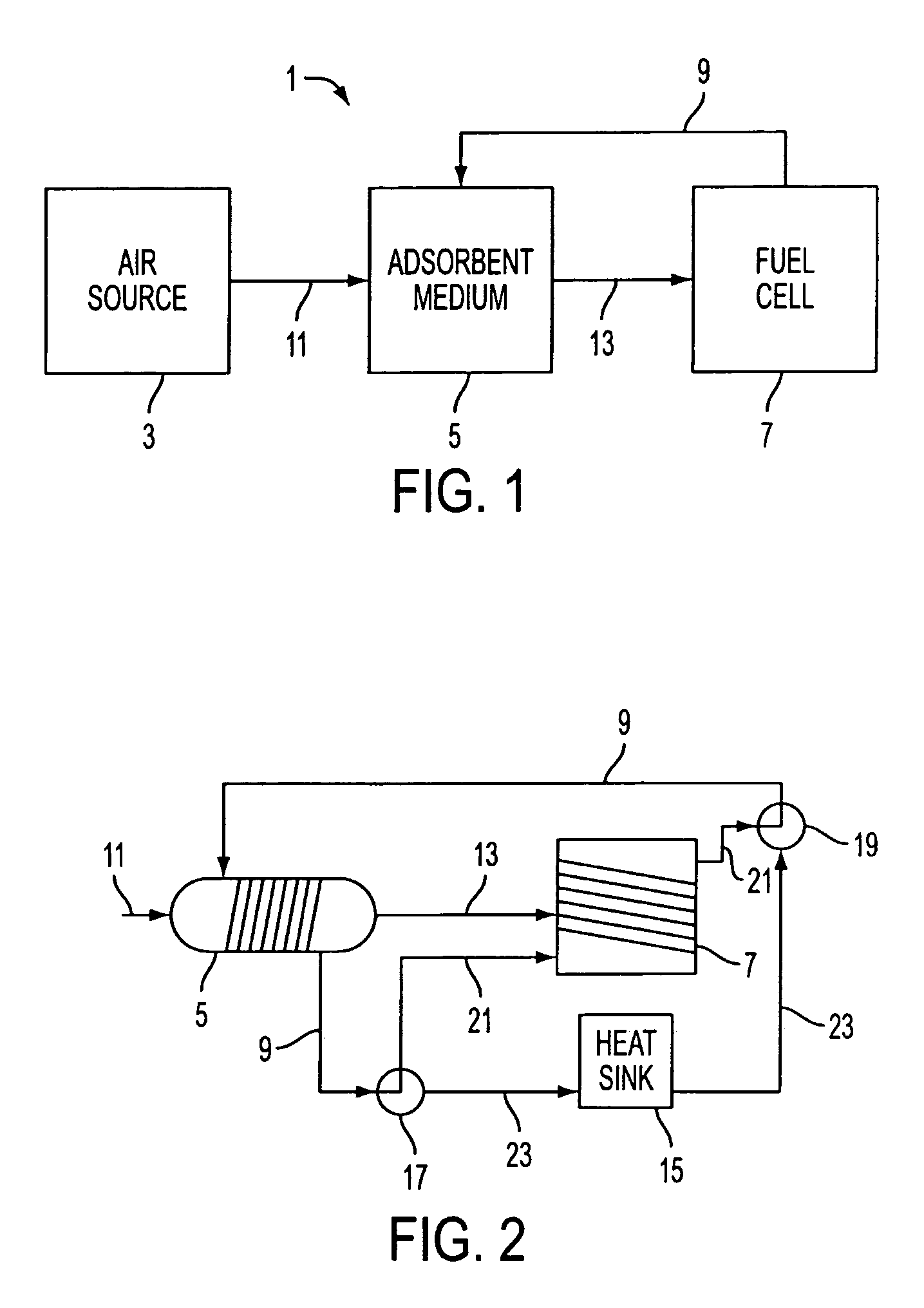

Energy efficient gas separation for fuel cells

InactiveUS20020142208A1Improve efficiencyReduce the ratioFuel cell heat exchangeFused electrolyte fuel cellsEngineeringDelivery system

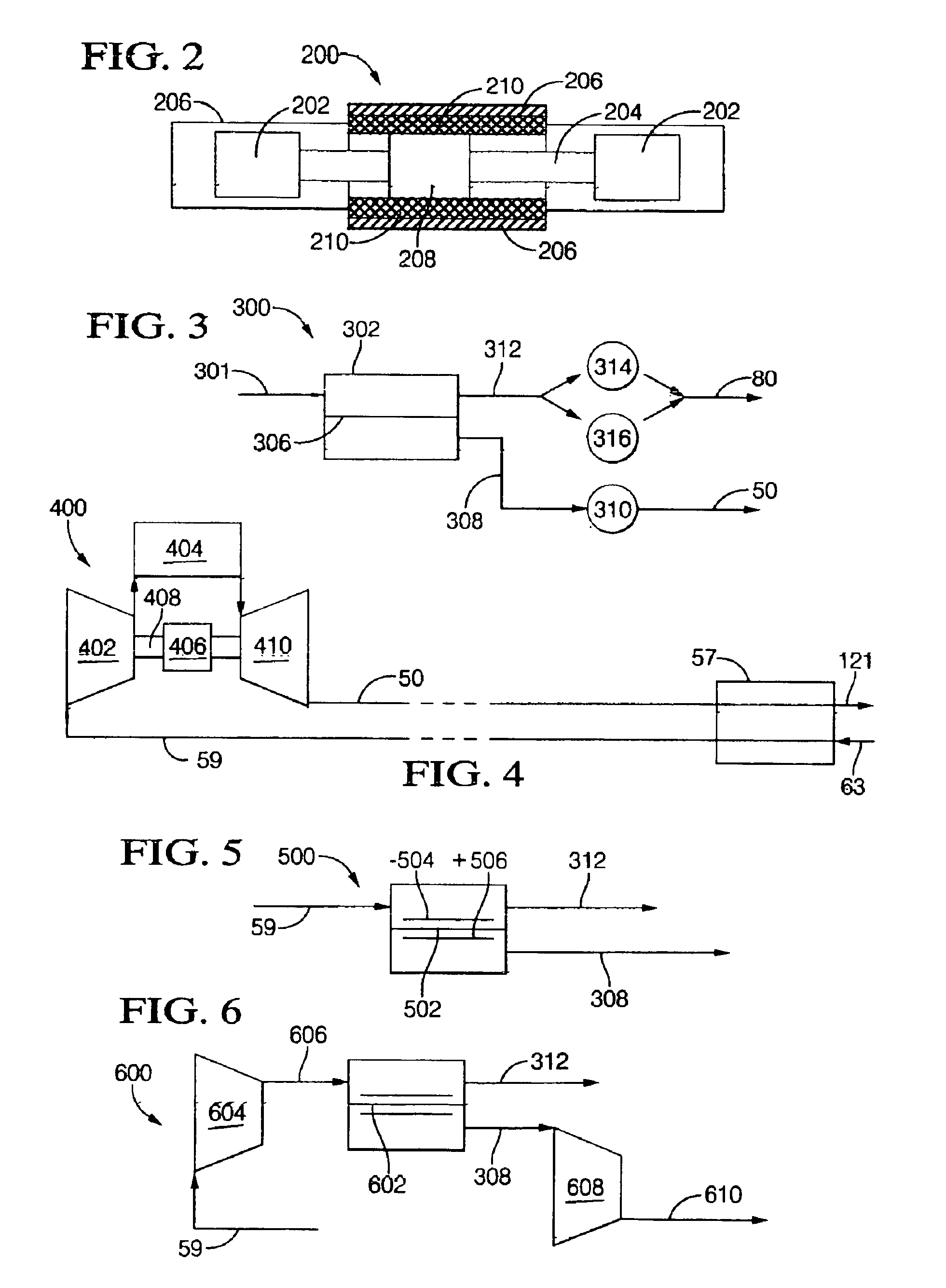

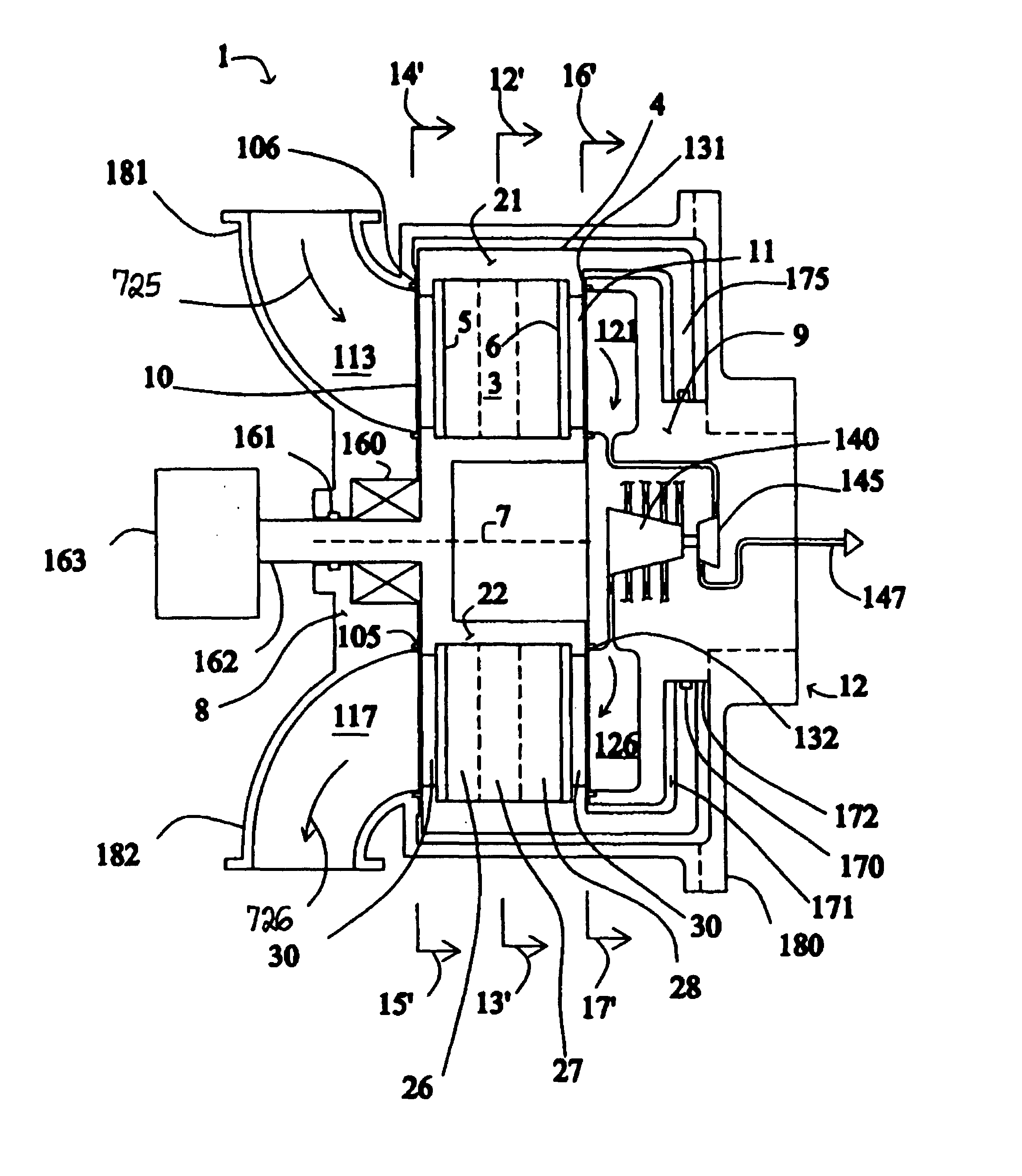

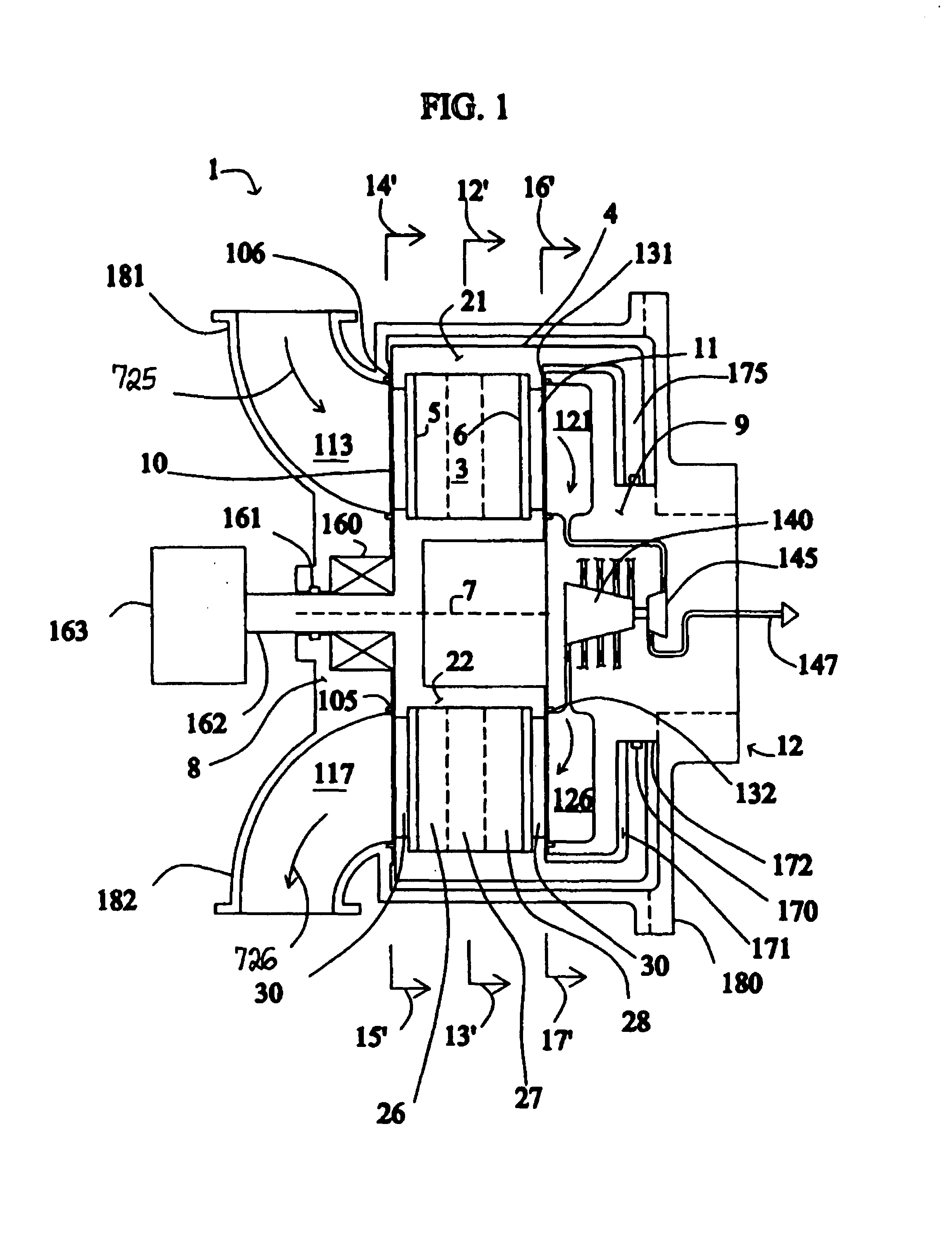

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

Power generation system and method

InactiveUS6915869B2Internal combustion piston enginesElectric propulsion mountingInternal combustion engineFuel supply

A power generation system and method providing an engine configured to produce hydrogen rich reformate to feed a solid oxide fuel cell includes an engine having an intake and an exhaust; an air supply in fluid communication with the engine intake; a fuel supply in fluid communication with the engine intake; at least one solid oxide fuel cell having an air intake in fluid communication with an air supply, a fuel intake in fluid communication with the engine exhaust, a solid oxide fuel cell effluent and an air effluent. Engines include a free piston gas generator with rich homogenous charge compression, a rich internal combustion engine cylinder system with an oxygen generator, and a rich inlet turbo-generator system with exhaust heat recovery. Oxygen enrichment devices to enhance production of hydrogen rich engine exhaust include pressure swing absorption with oxygen selective materials, and oxygen separators such as an solid oxide fuel cell oxygen separator and a ceramic membrane oxygen separator.

Owner:DELPHI TECH INC

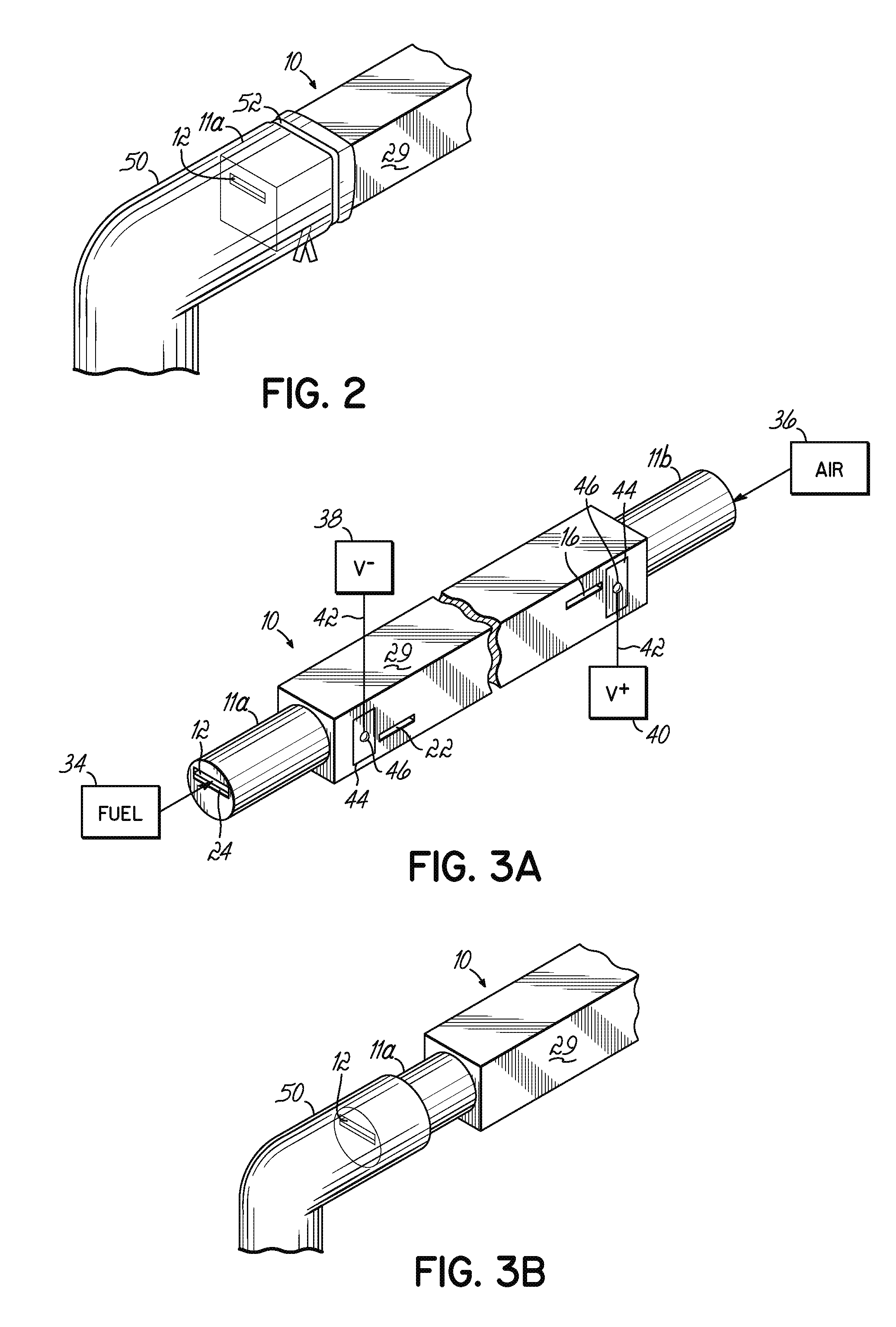

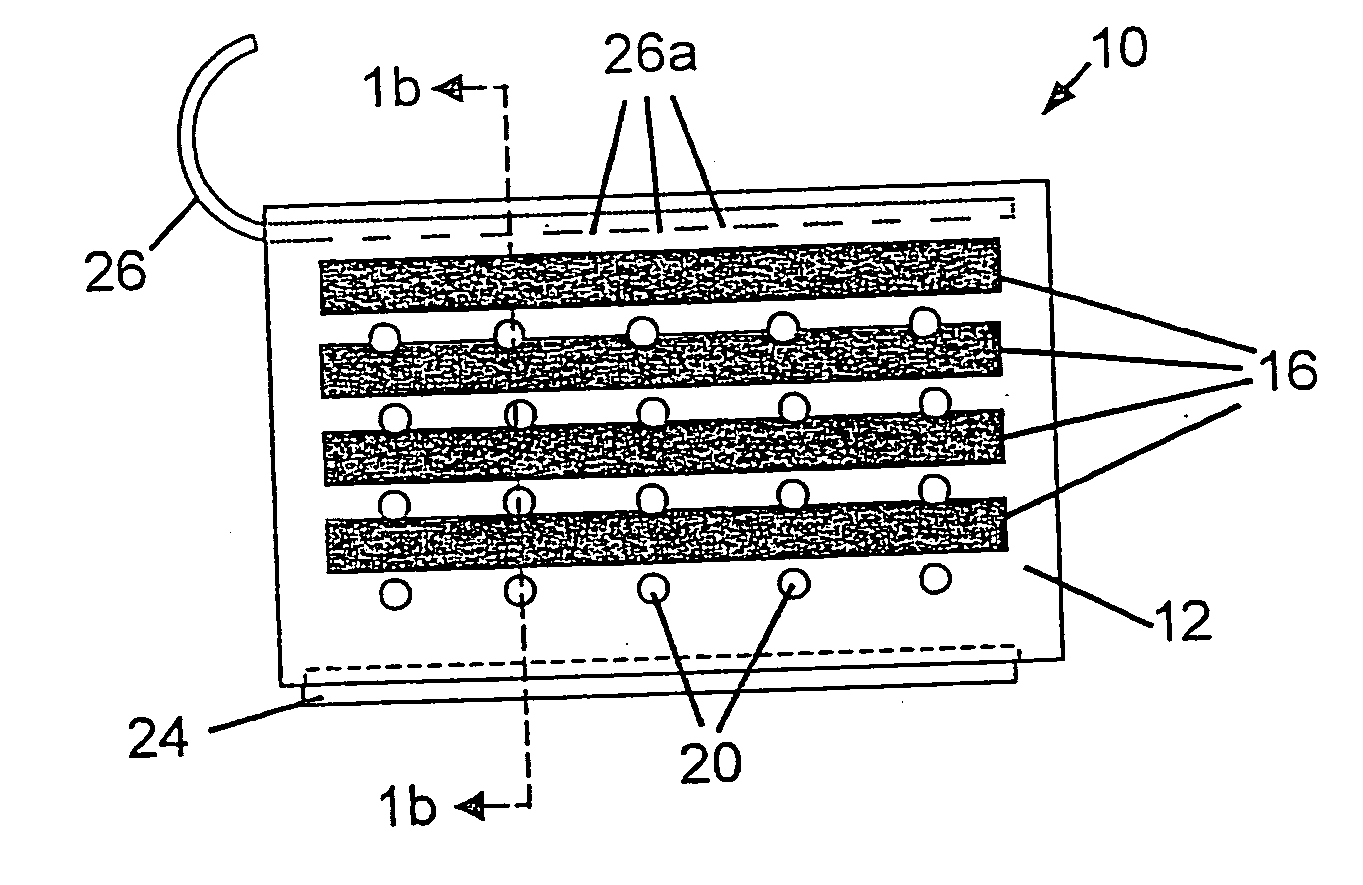

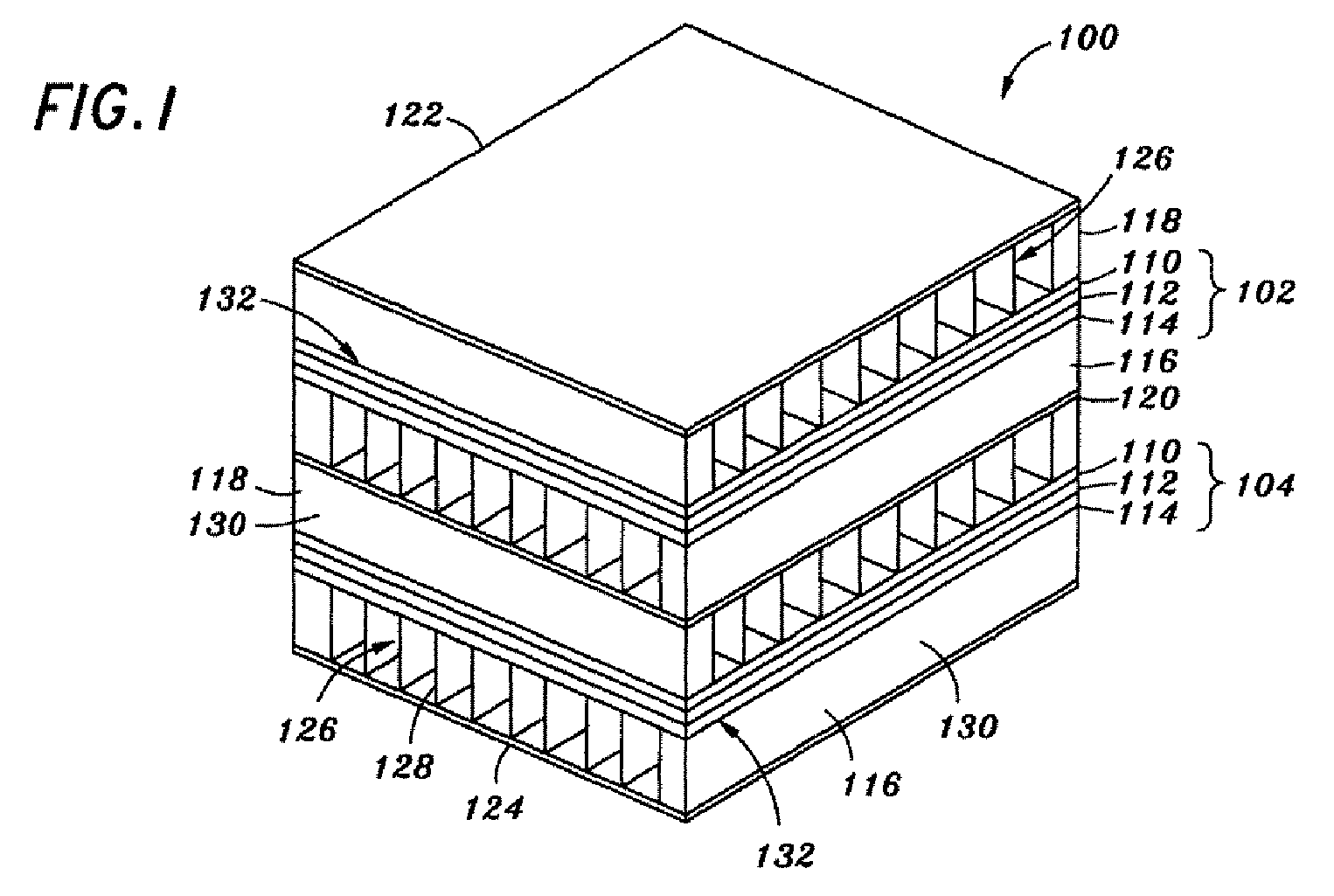

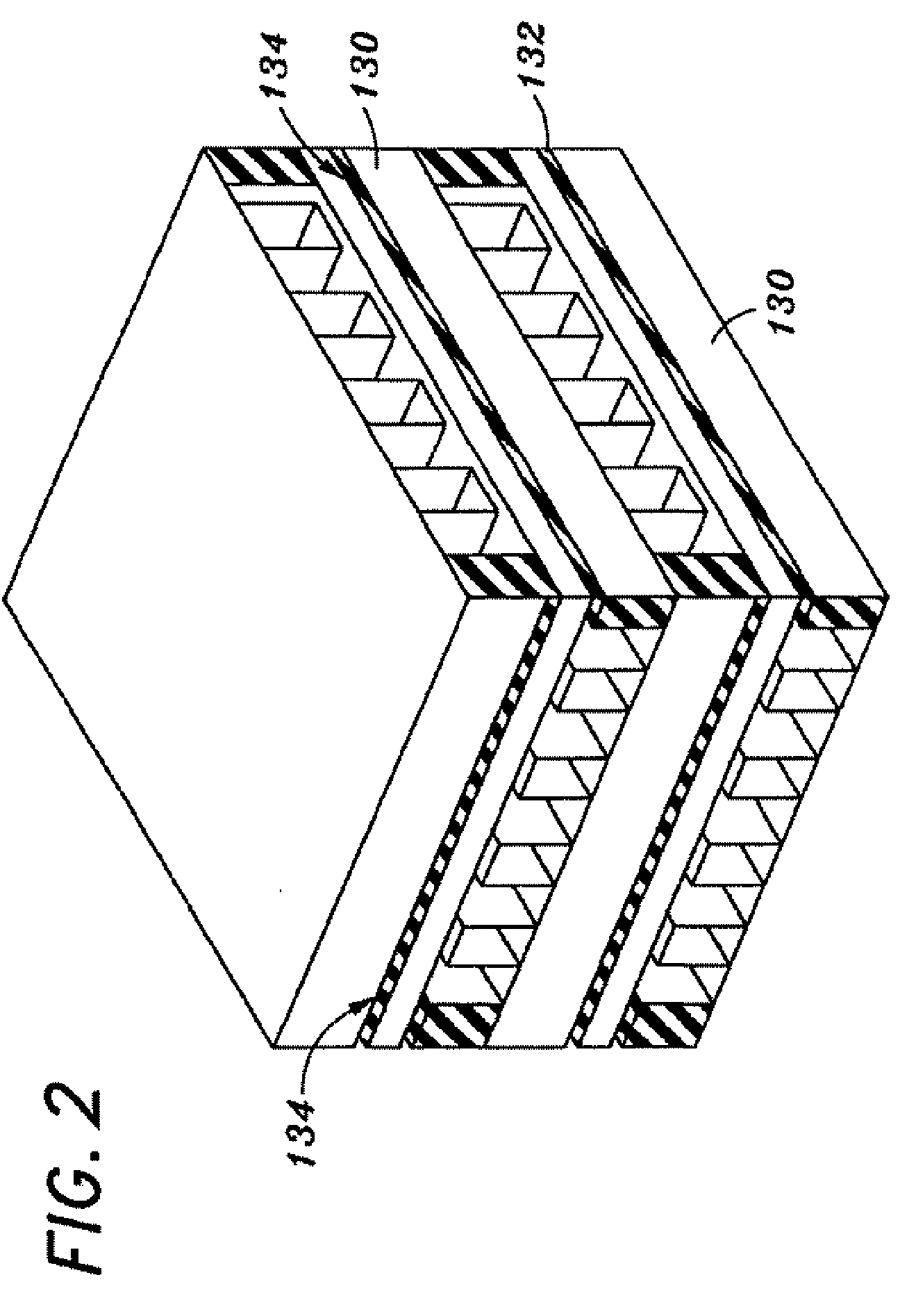

Solid oxide fuel cell stack

A fuel cell stack comprises a plurality of modules and each module comprises an elongate hollow member and one passage extending through the hollow member for the flow of a reactant. Each hollow member has a first flat surface and a second flat surface. At least one of the modules includes a plurality of fuel cells arranged on at least one of the first and second flat surfaces. Each module has a first and second integral feature to provide a spacer and a connection with its adjacent modules. The first integral feature comprises a third flat surface and the second integral feature comprises a fourth flat surface. The third flat surface is arranged at an intersecting angle to the first flat surface and the fourth flat surface is arranged at an intersecting angle to the second flat surface.

Owner:LG FUEL CELL SYST

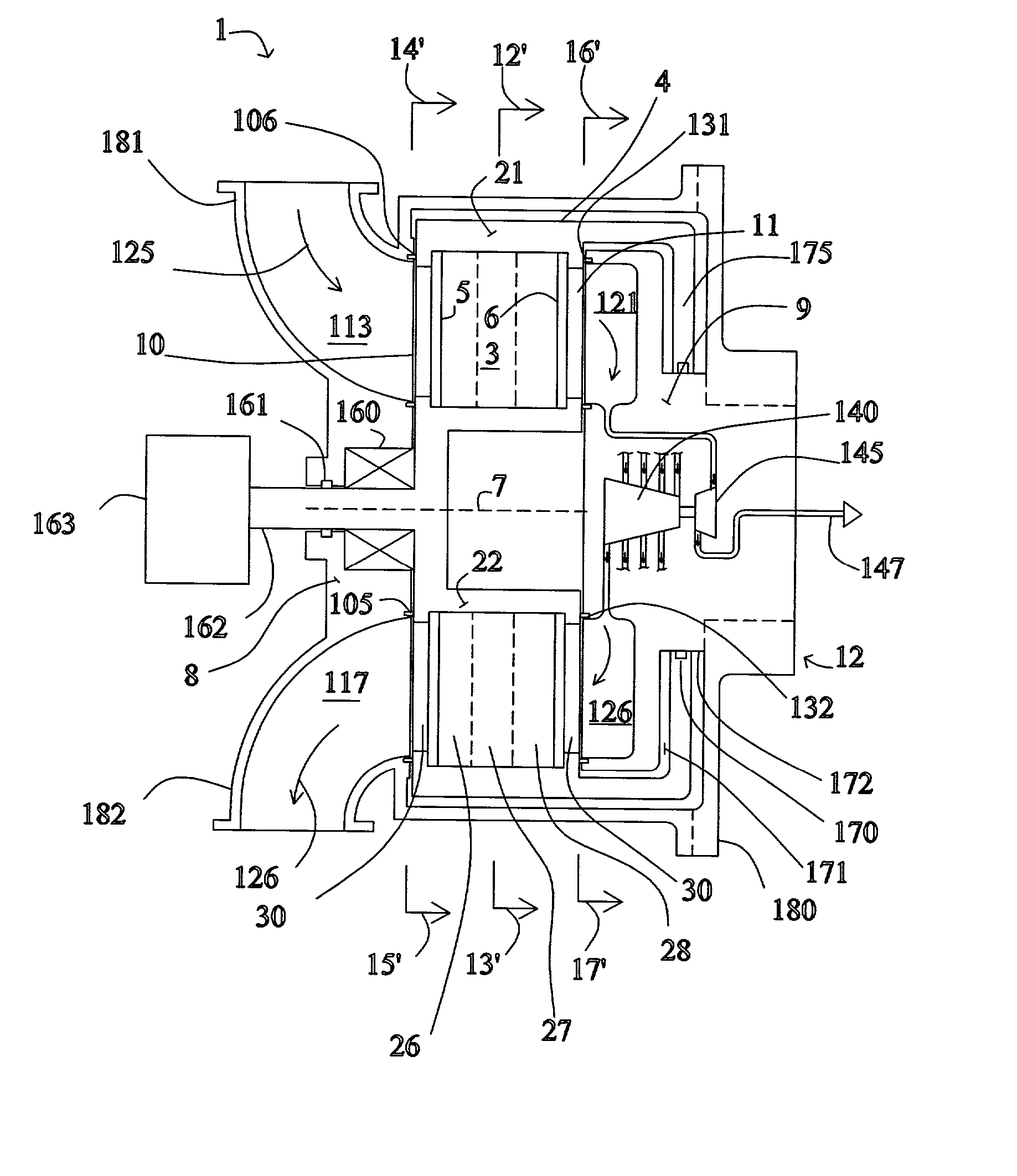

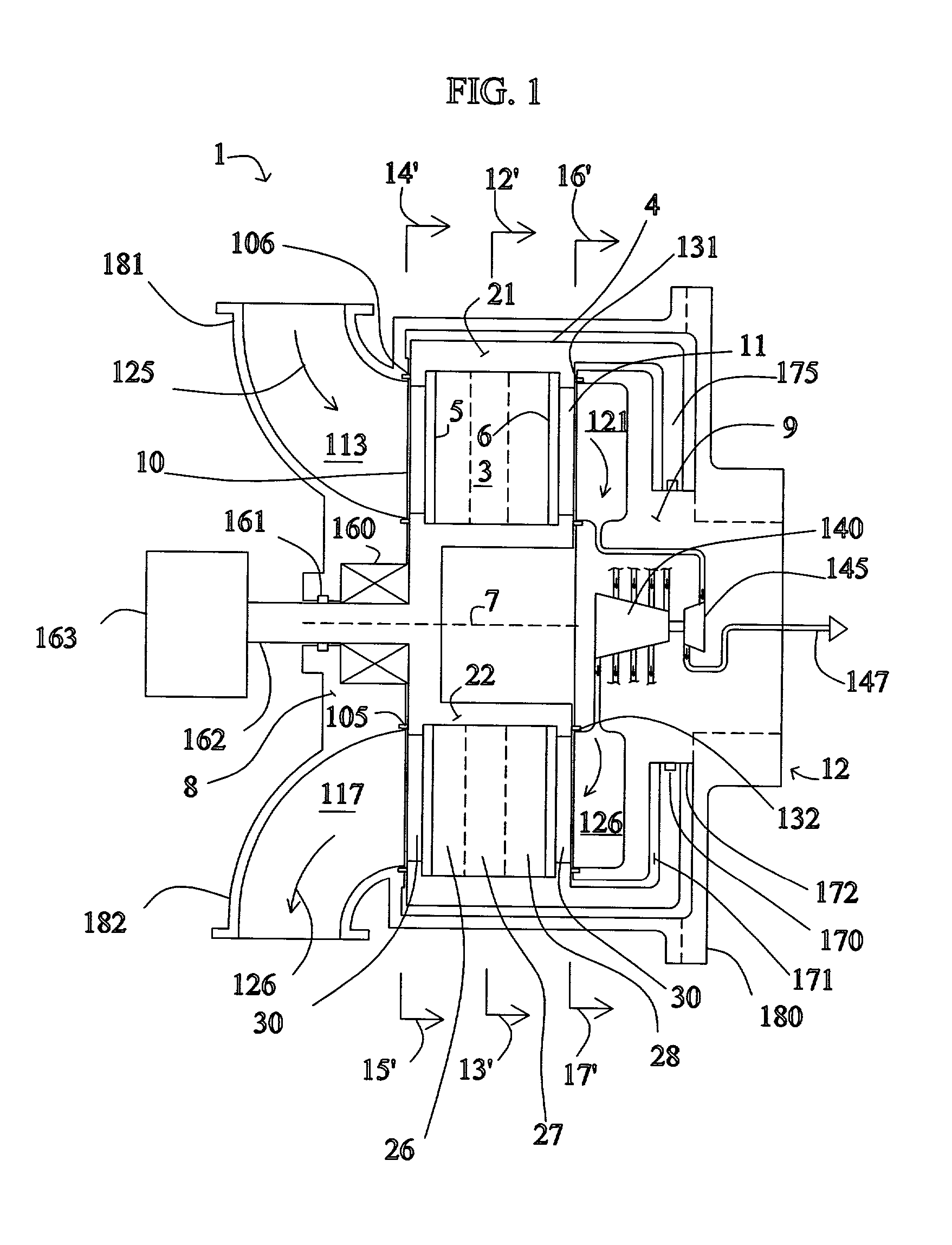

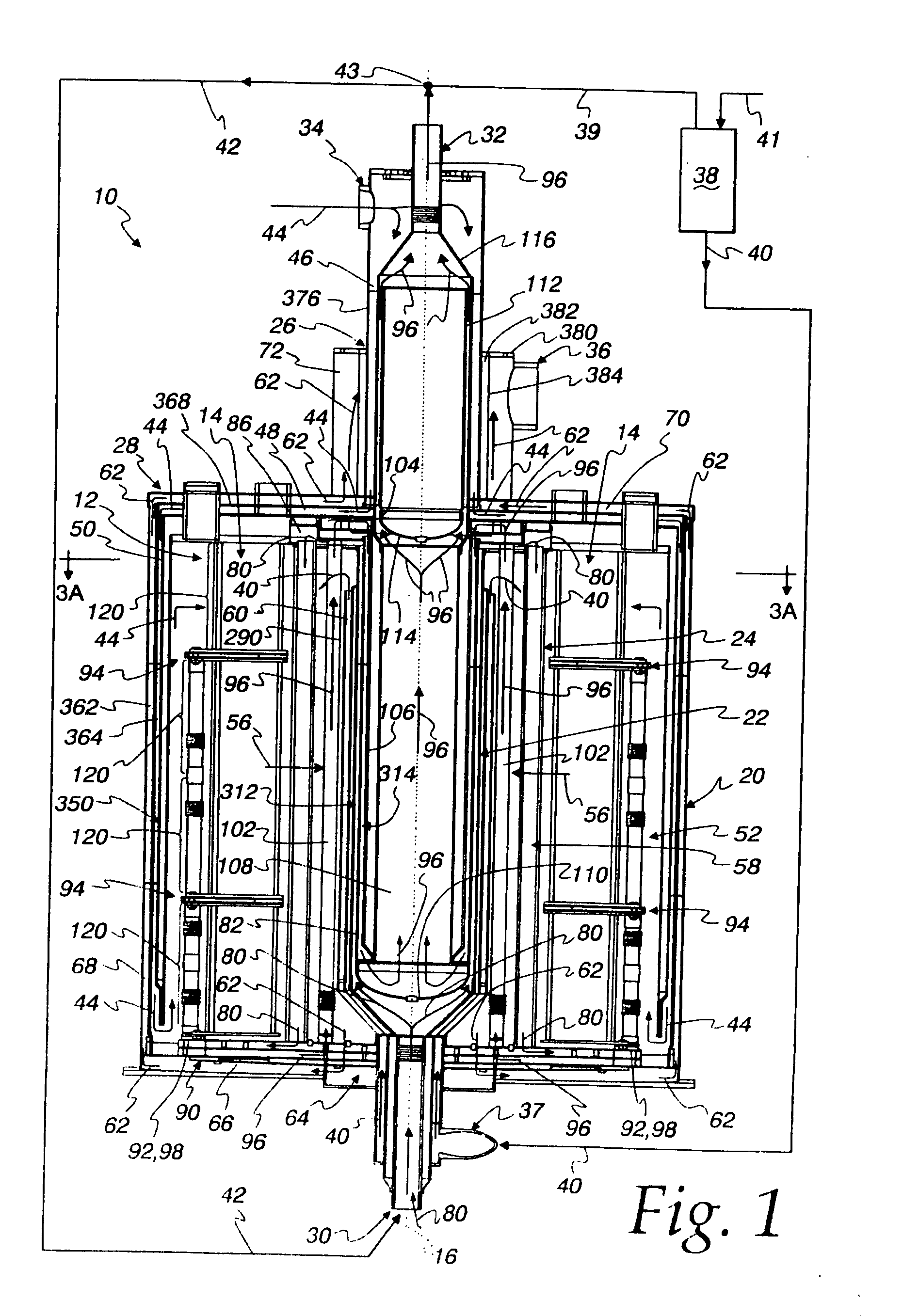

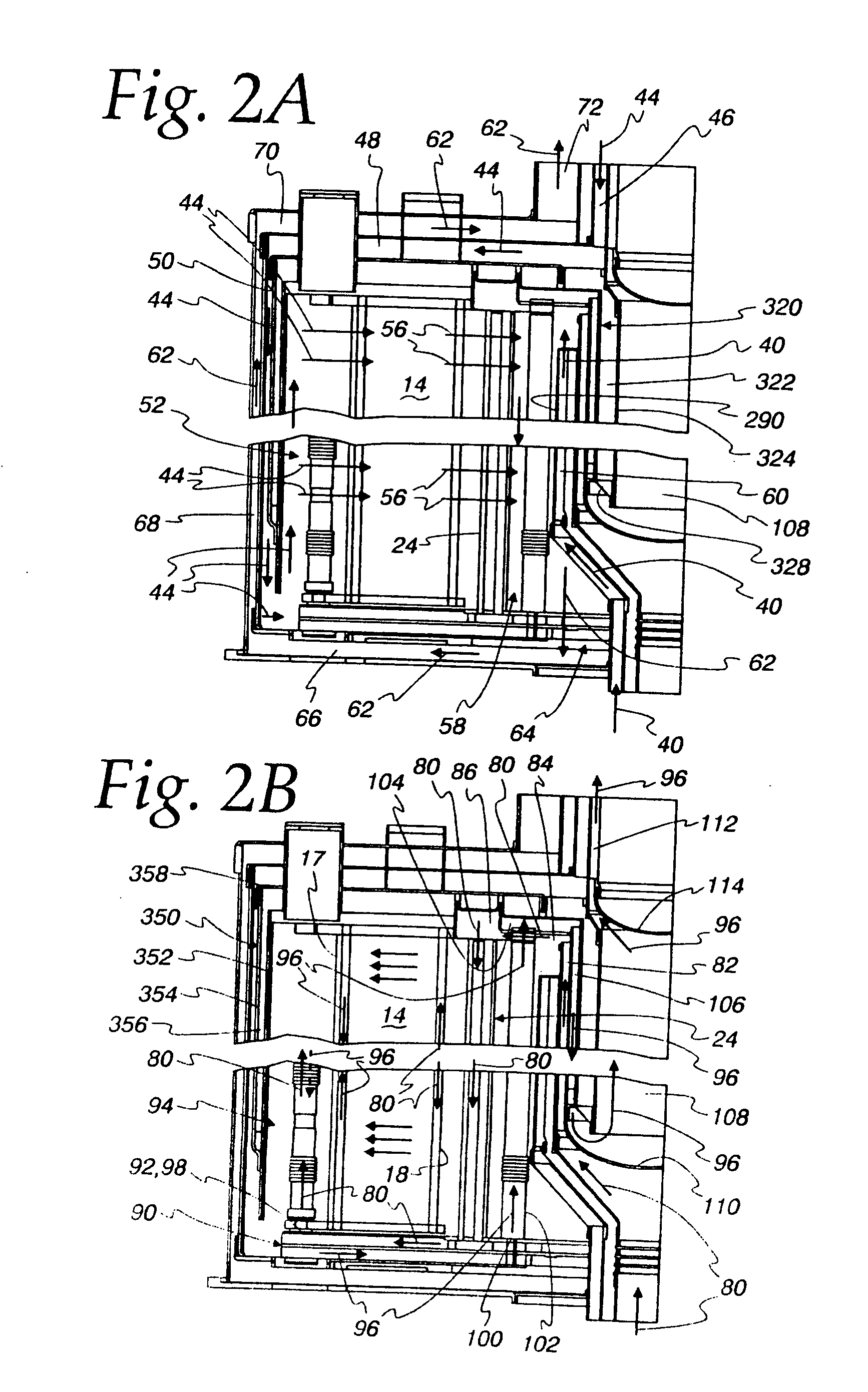

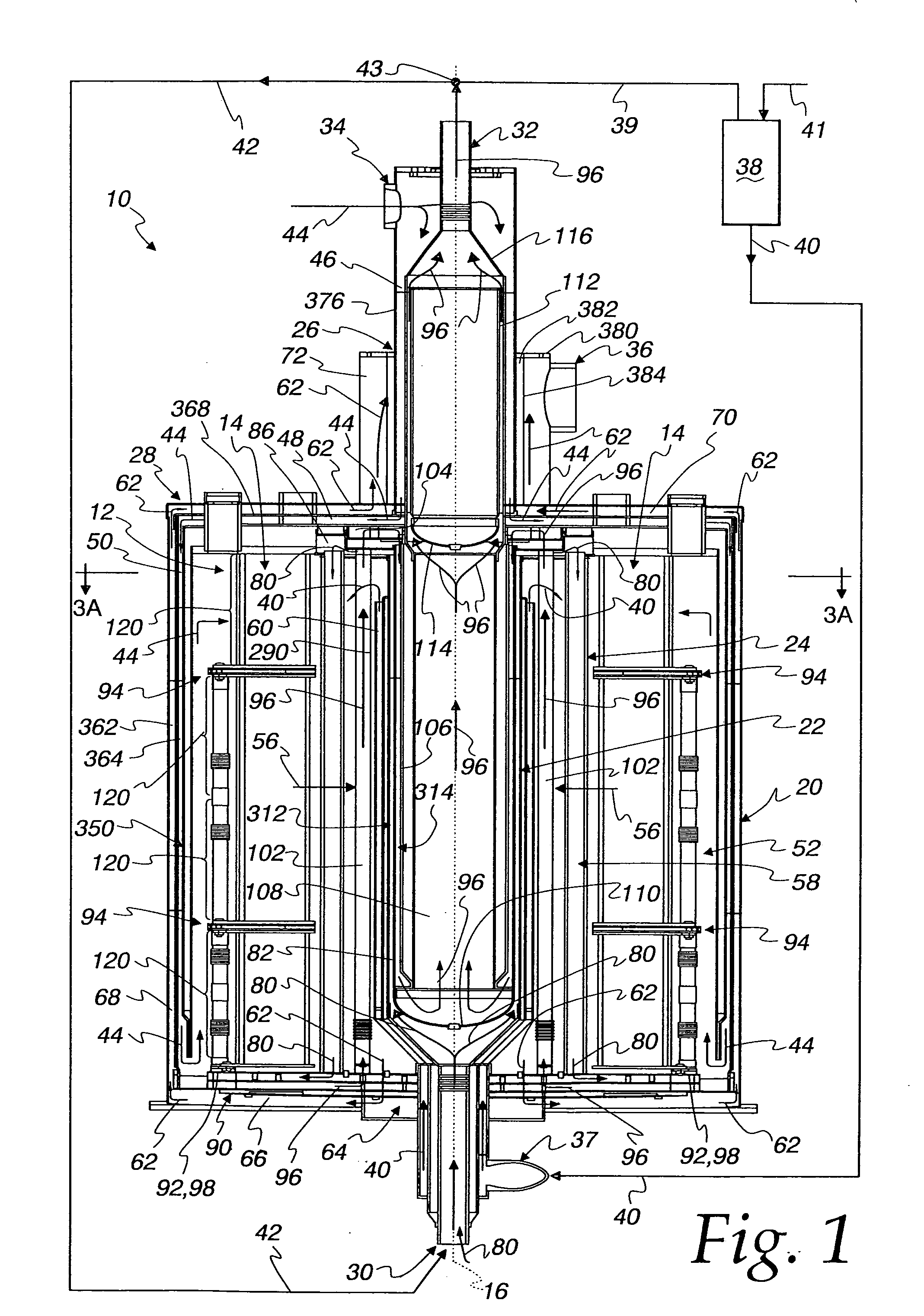

Intergrated solid oxide fuel cell and fuel processor

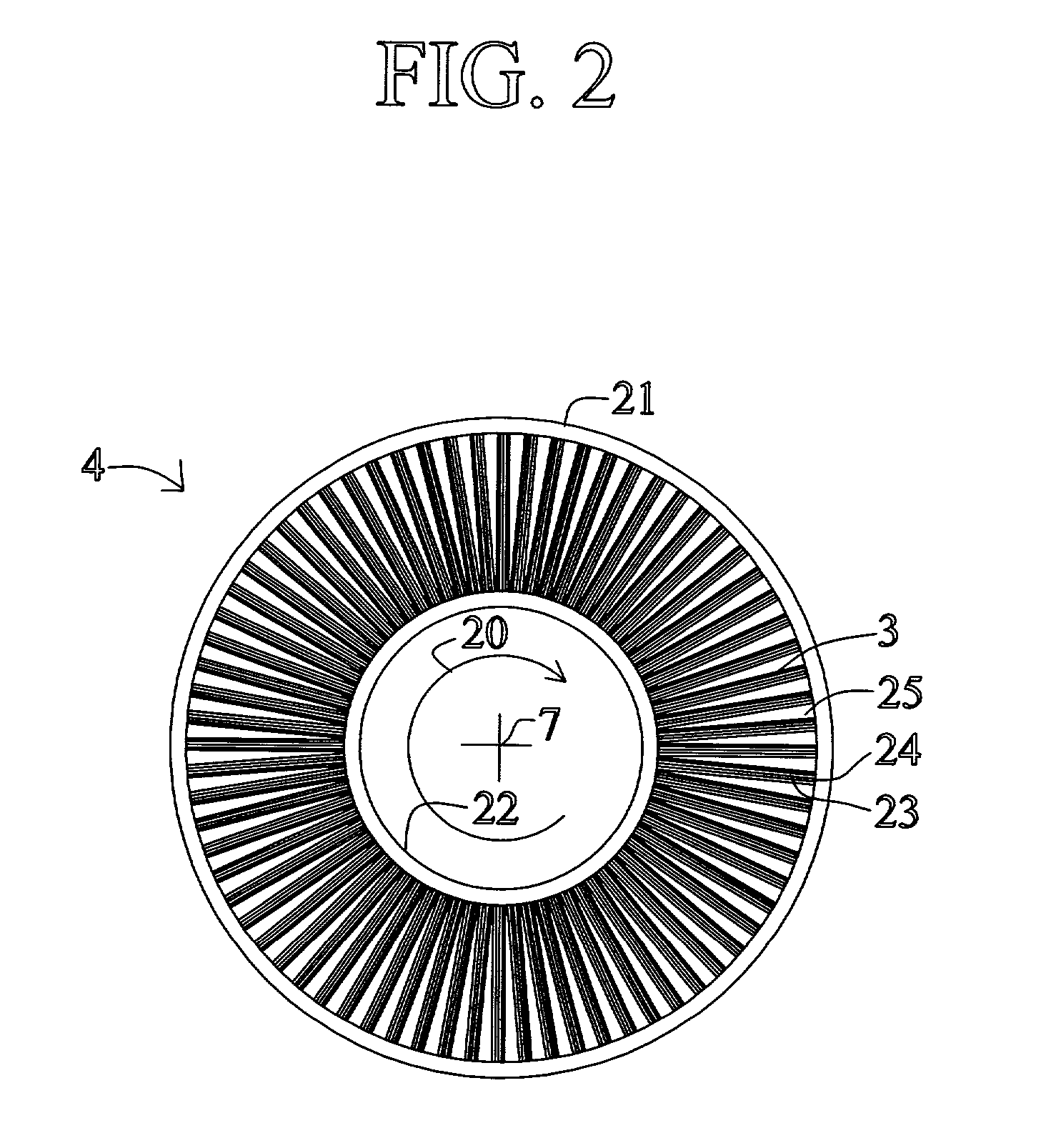

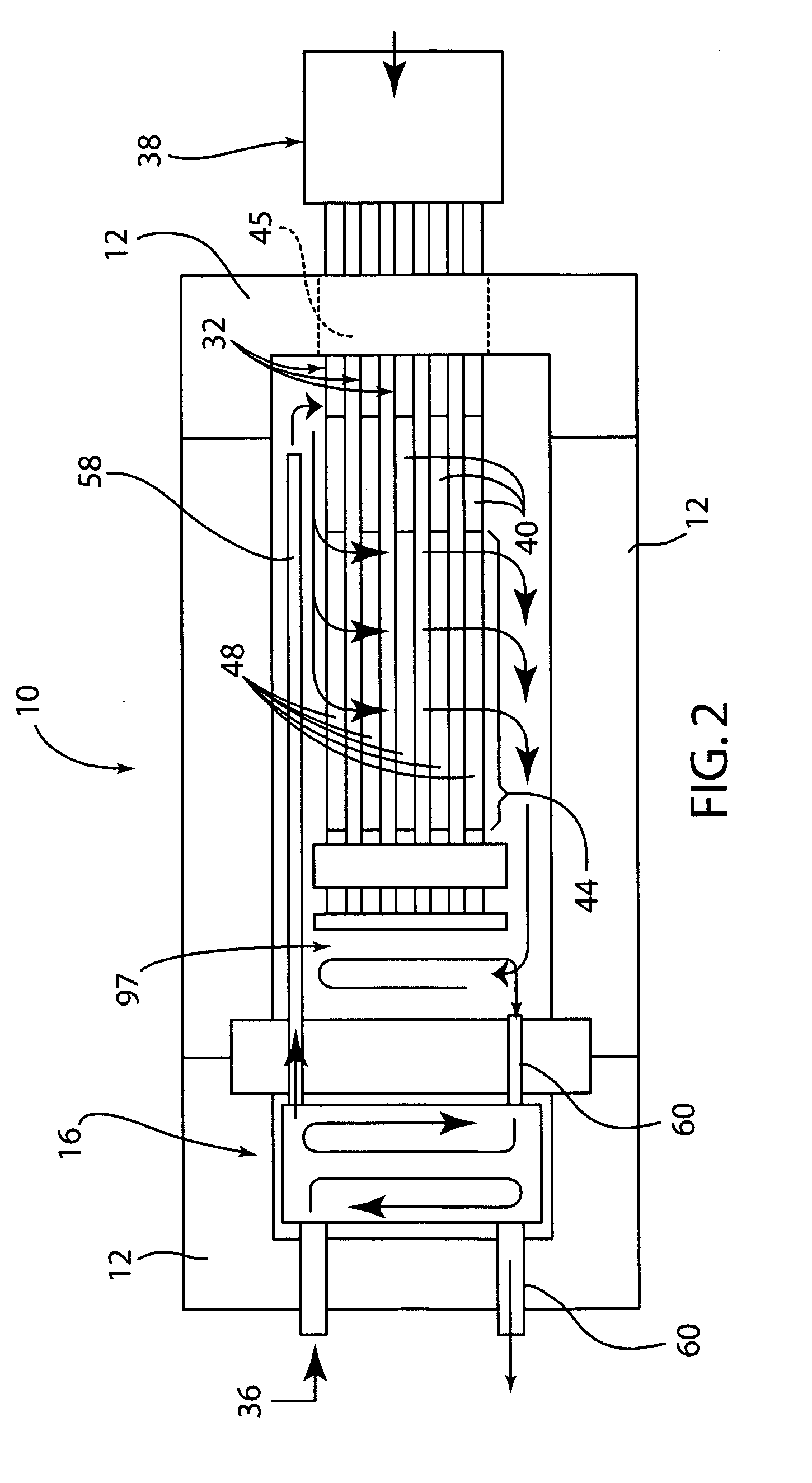

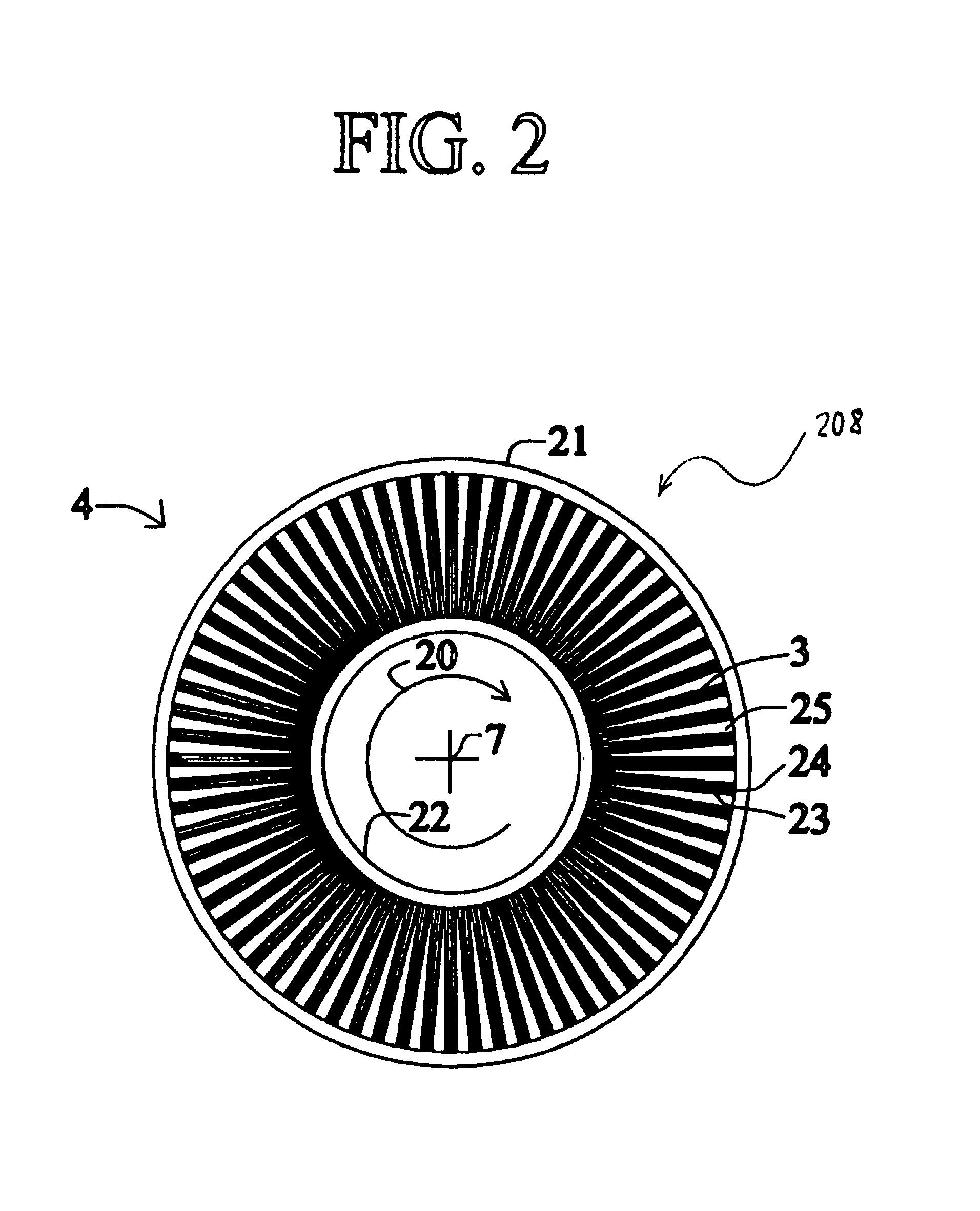

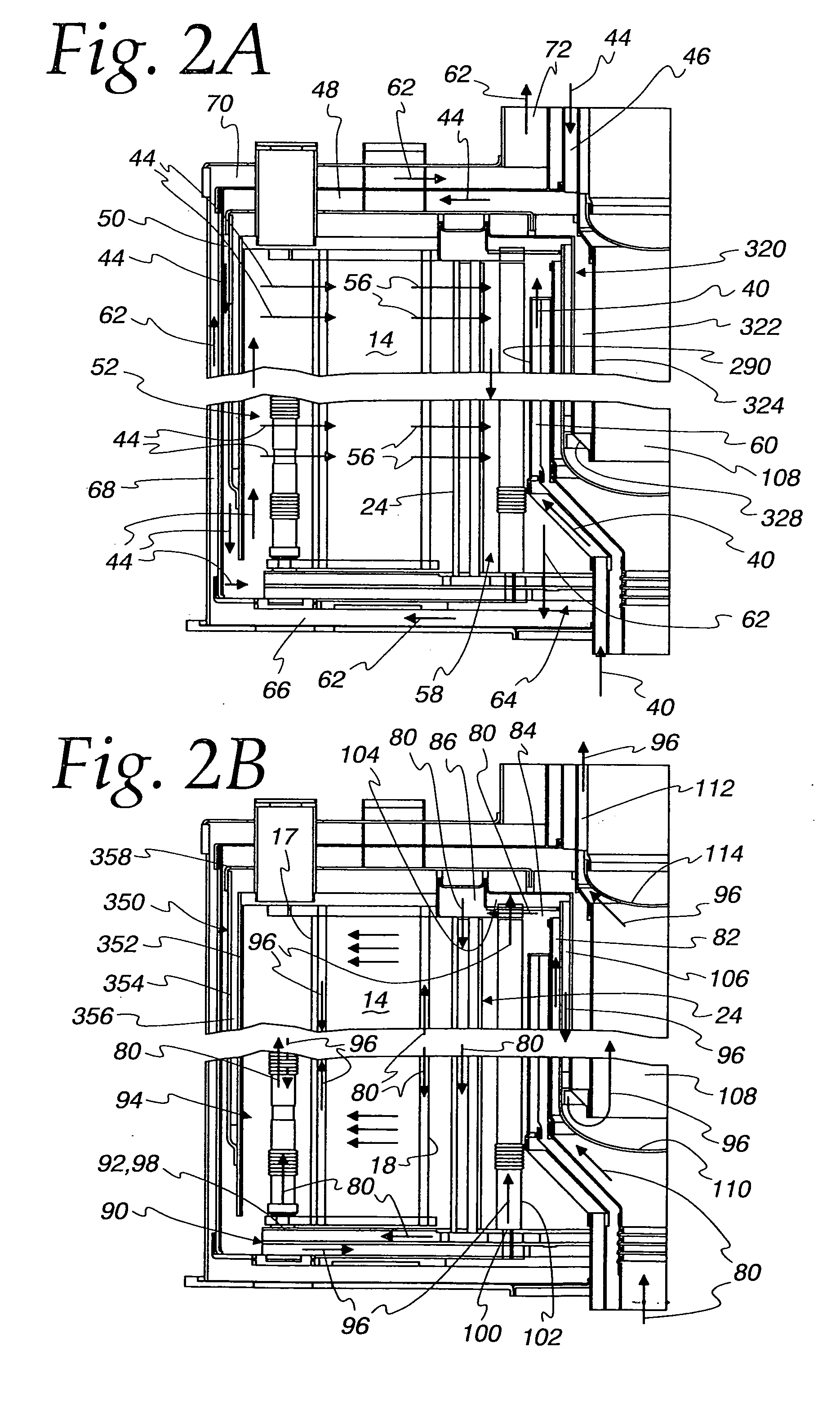

An integrated fuel cell unit (10) includes an annular array (12) of fuel cell stacks (14), an annular cathode recuperator (20), an annular anode recuperator (22), a reformer (24), and an anode exhaust cooler (26), all integrated within a common housing structure (28).

Owner:BLOOM ENERGY CORP

Solid polymer fuel cell with improved voltage reversal tolerance

In a solid polymer fuel cell series, various circumstances can result in the fuel cell being driven into voltage reversal. For instance, cell voltage reversal can occur if that cell receives an inadequate supply of fuel (for example, fuel starvation). In order to pass current during fuel starvation, reactions other than fuel oxidation may take place at the fuel cell anode, including water electrolysis and oxidation of anode components. The latter may result in significant degradation of the anode. Such fuel cells can be made more tolerant to cell reversal by promoting water electrolysis over anode component oxidation at the anode. This can be accomplished by incorporating a catalyst composition at the anode to promote the water electrolysis reaction, in addition to the typical anode electrocatalyst for promoting fuel oxidation.

Owner:BALLARD POWER SYSTEMS +1

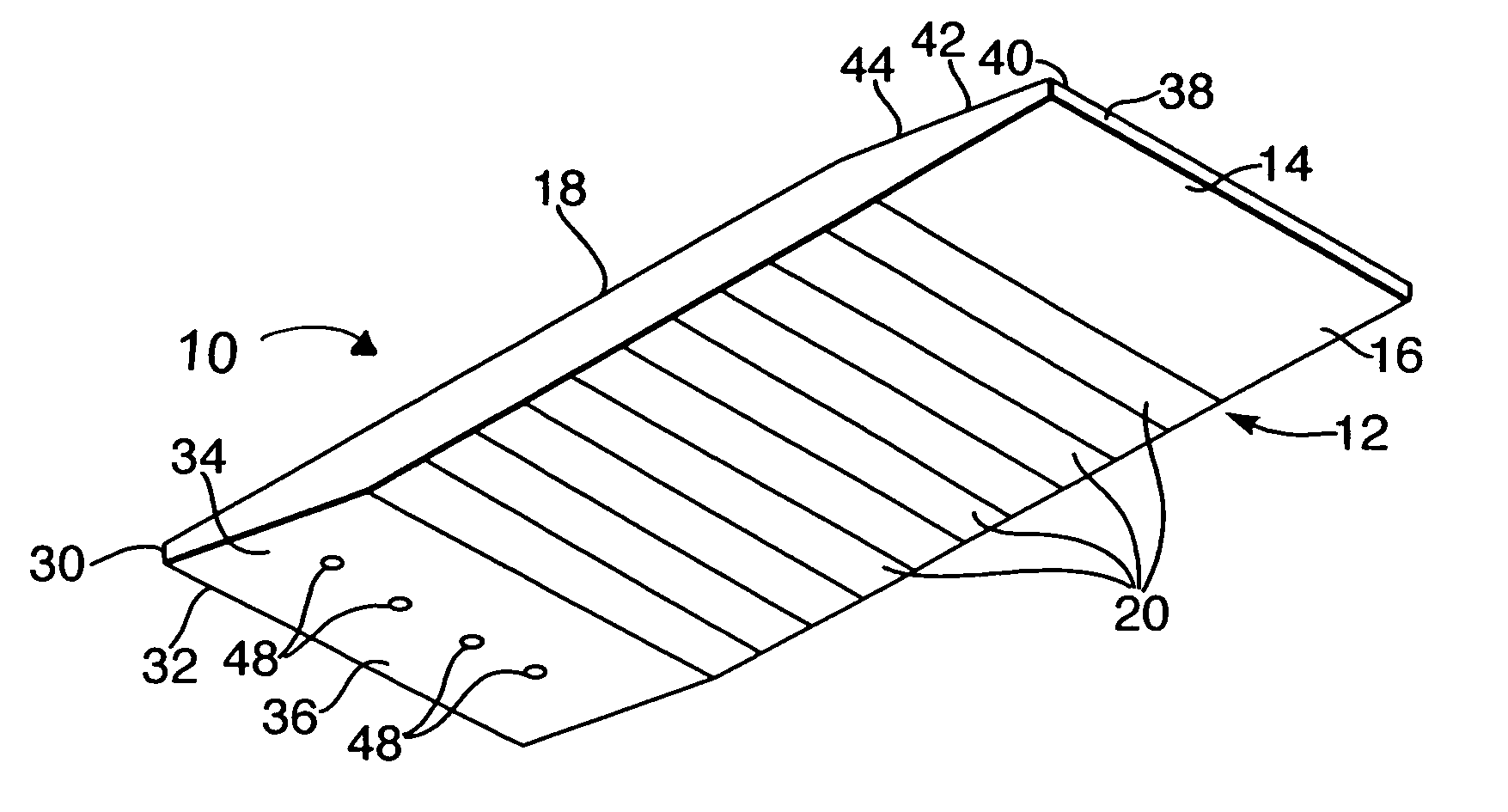

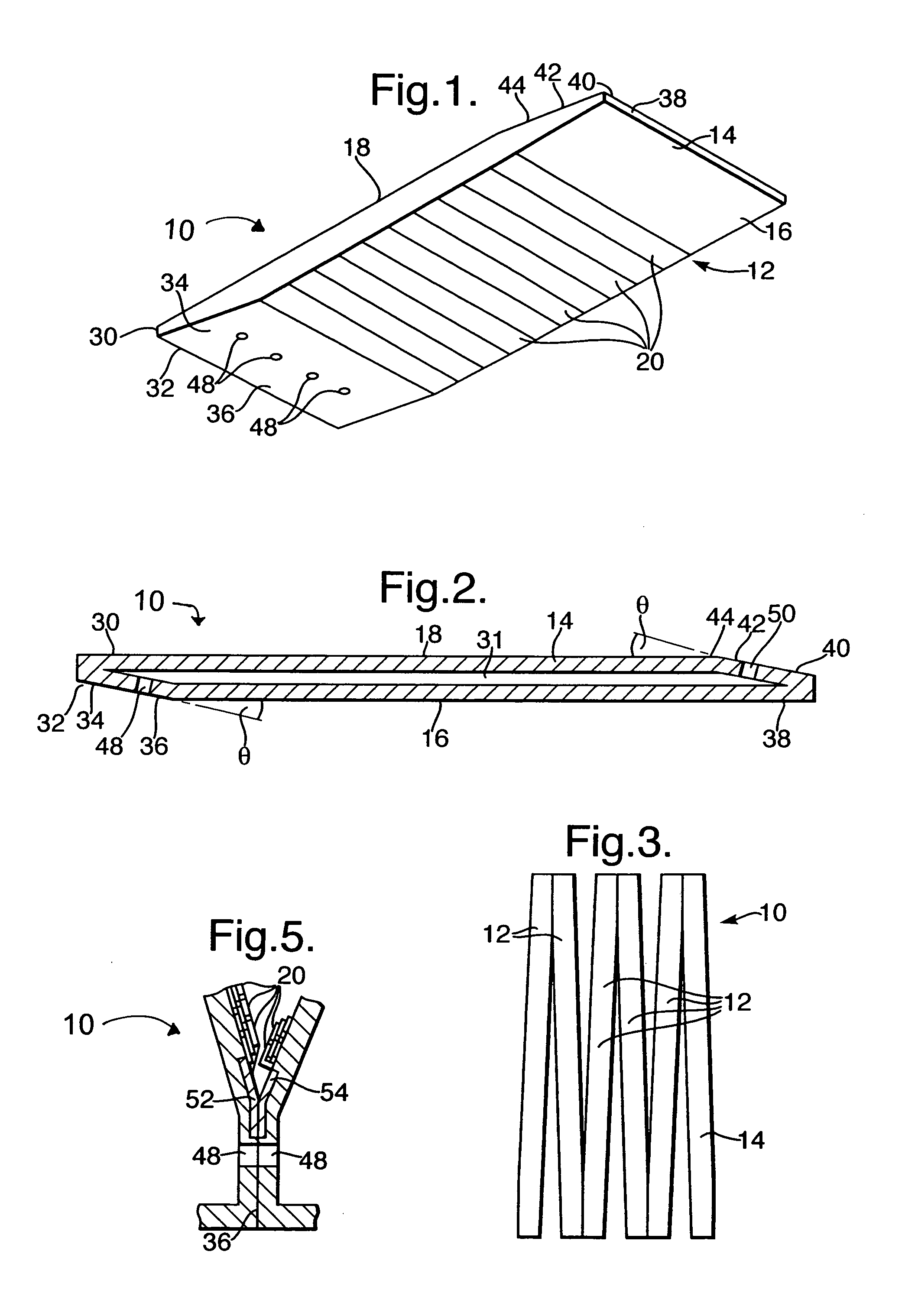

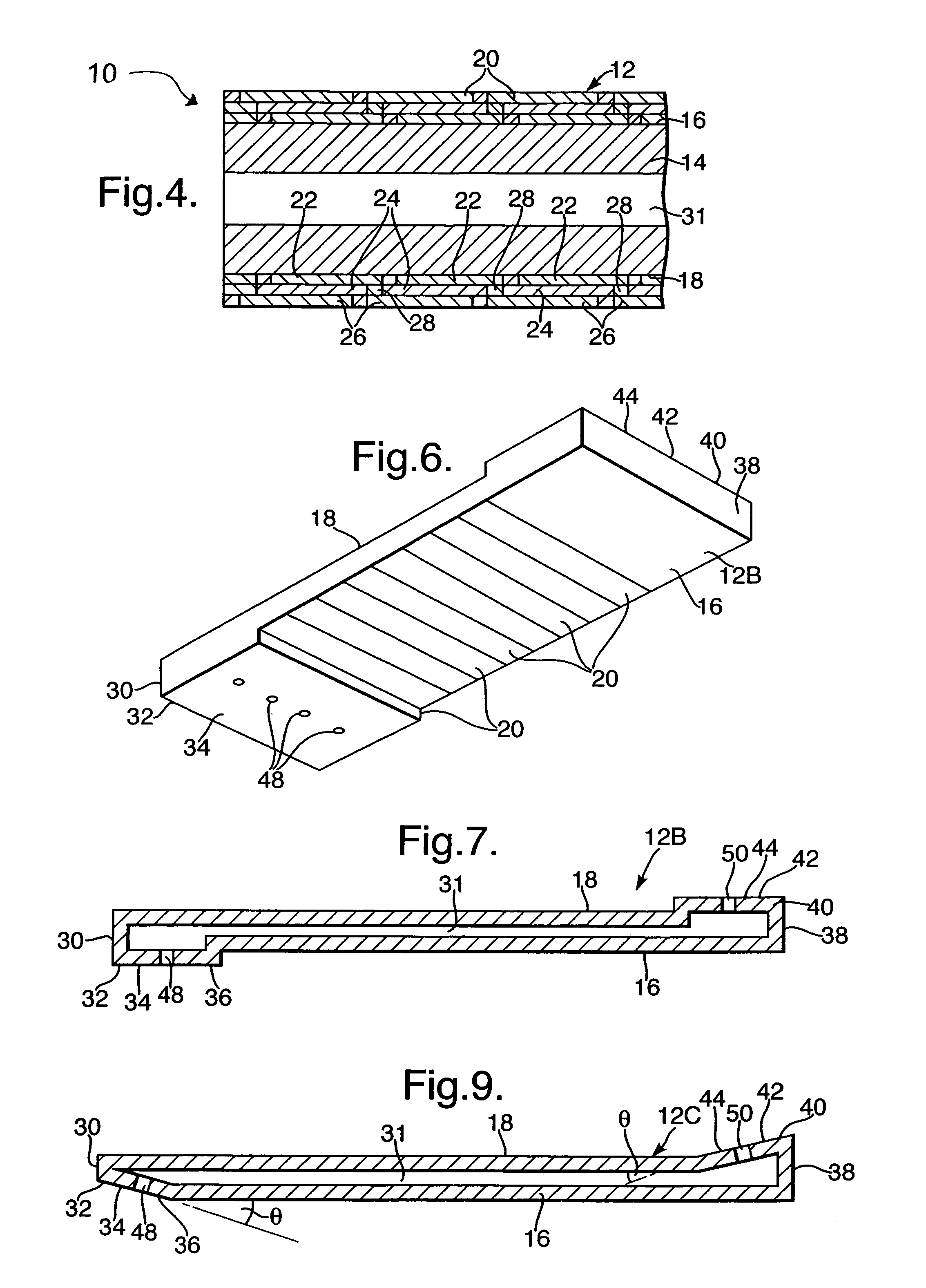

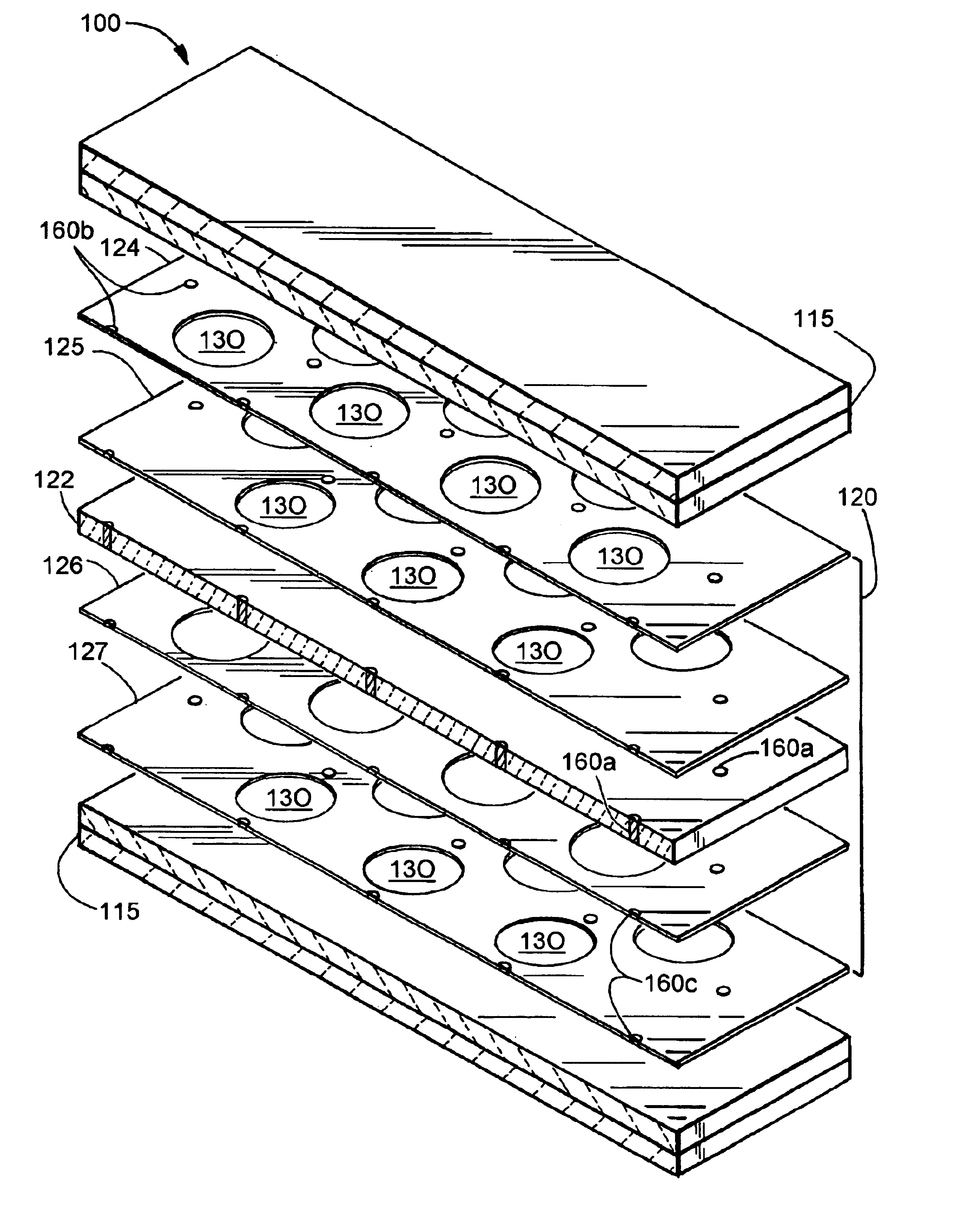

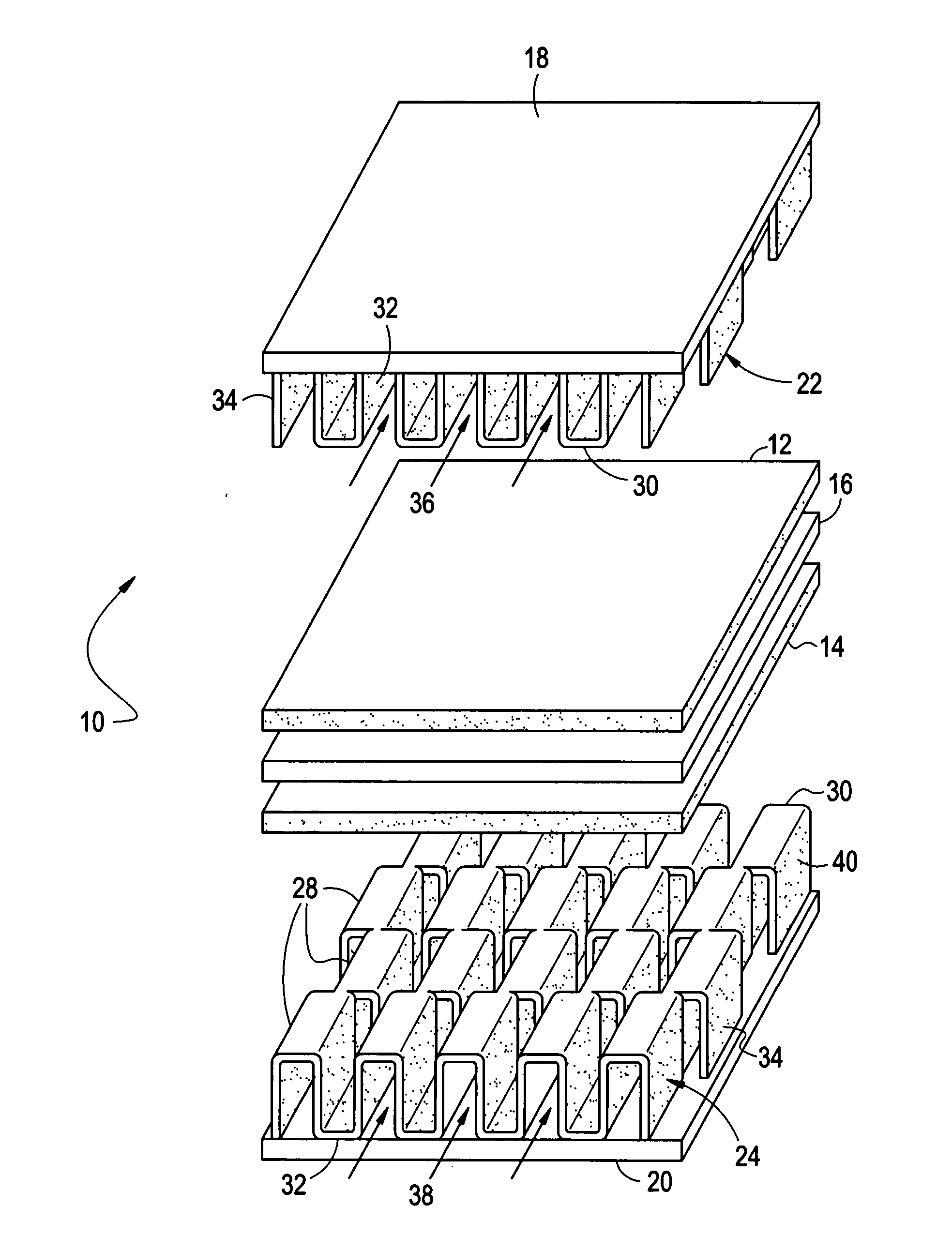

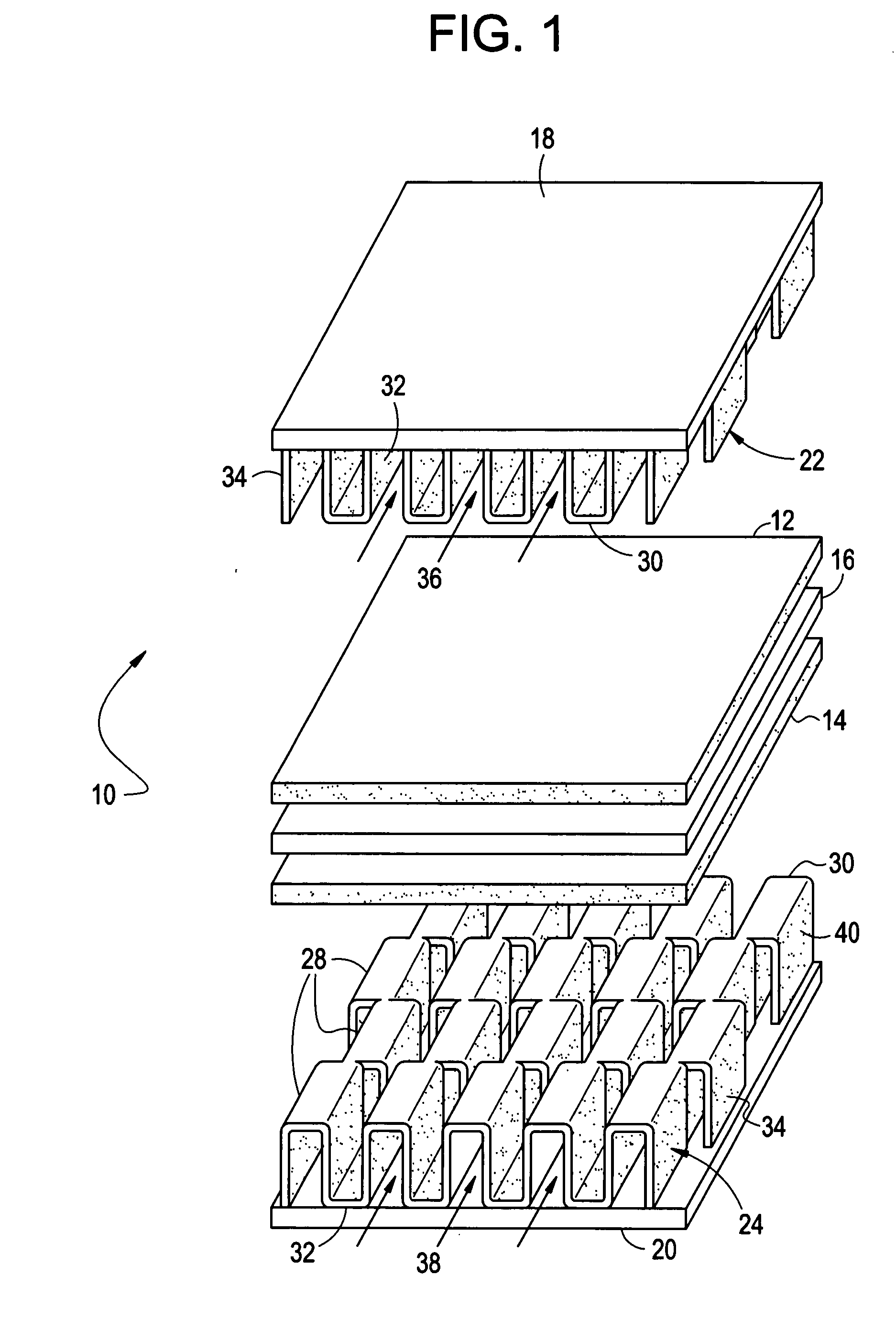

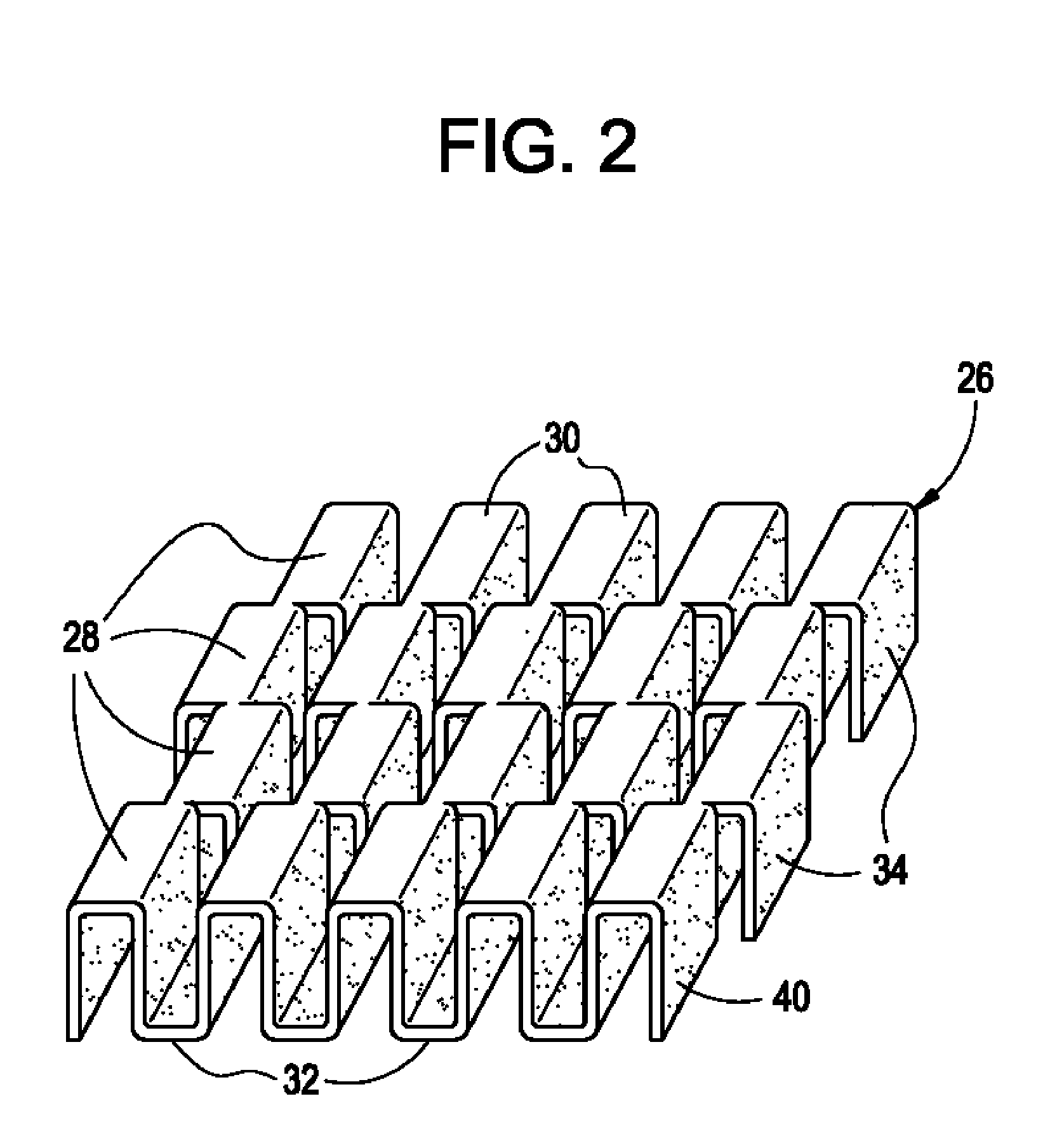

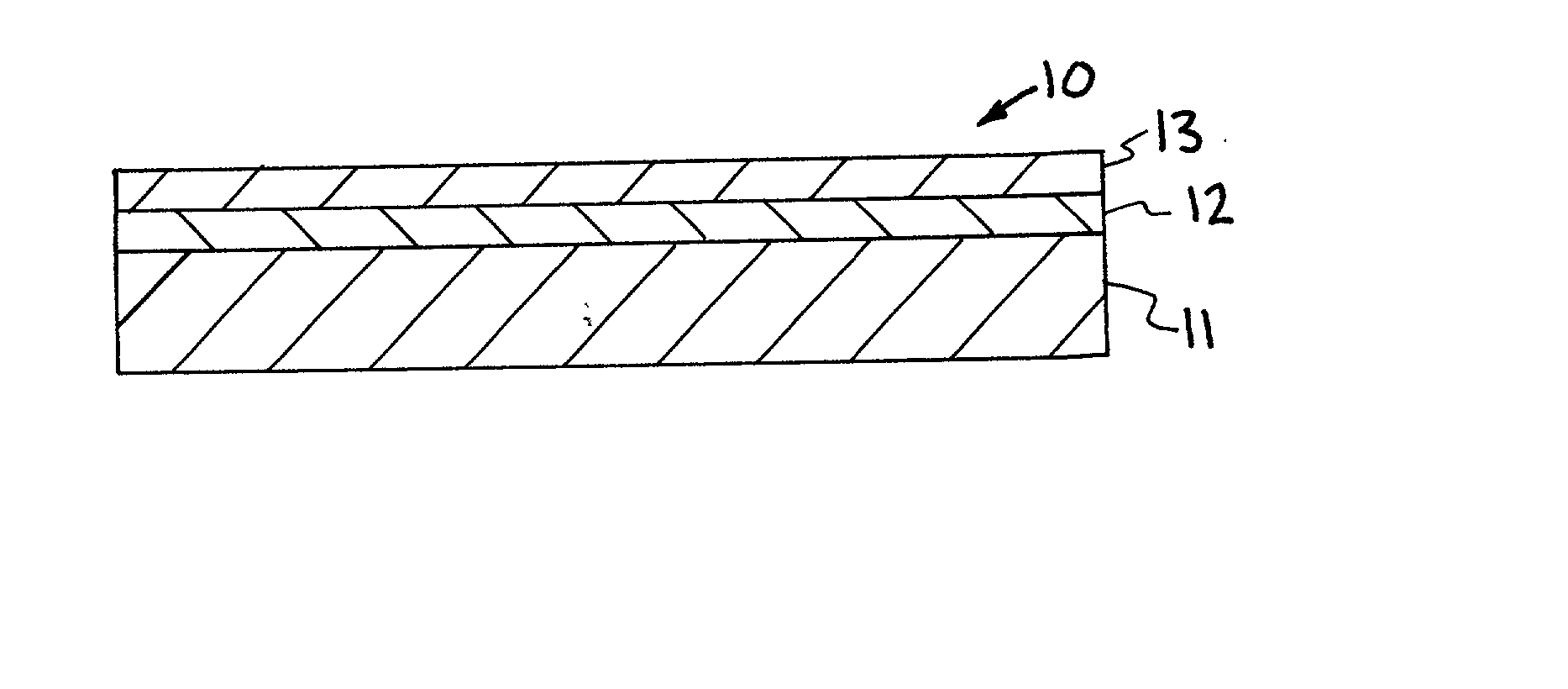

Planar solid oxide fuel cell stack with metallic foil interconnect

A solid oxide fuel cell stack having a plurality of integral component fuel cell units, each integral component fuel cell unit having a porous anode layer, a porous cathode layer, and a dense electrolyte layer disposed between the porous anode layer and the porous cathode layer. The porous anode layer forms a plurality of substantially parallel fuel gas channels on its surface facing away from the dense electrolyte layer and extending from one side to the opposite side of the anode layer, and the porous cathode layer forms a plurality of substantially parallel oxidant gas channels on its surface facing away from the dense electrolyte layer and extending from one side to the opposite side of the cathode. A flexible metallic foil interconnect is provided between the porous anode and porous cathode of adjacent integral component fuel cell units.

Owner:VERSA POWER SYST

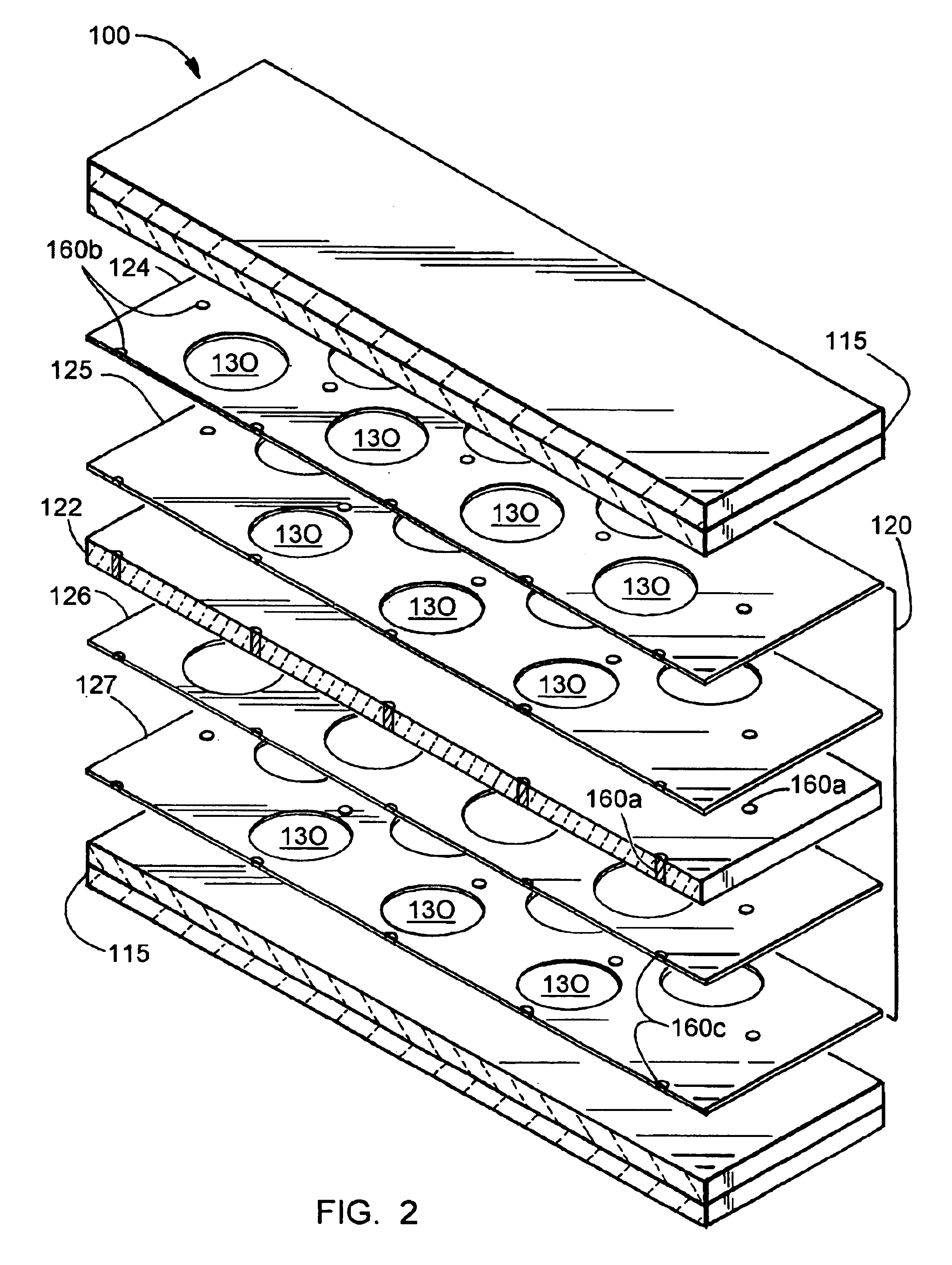

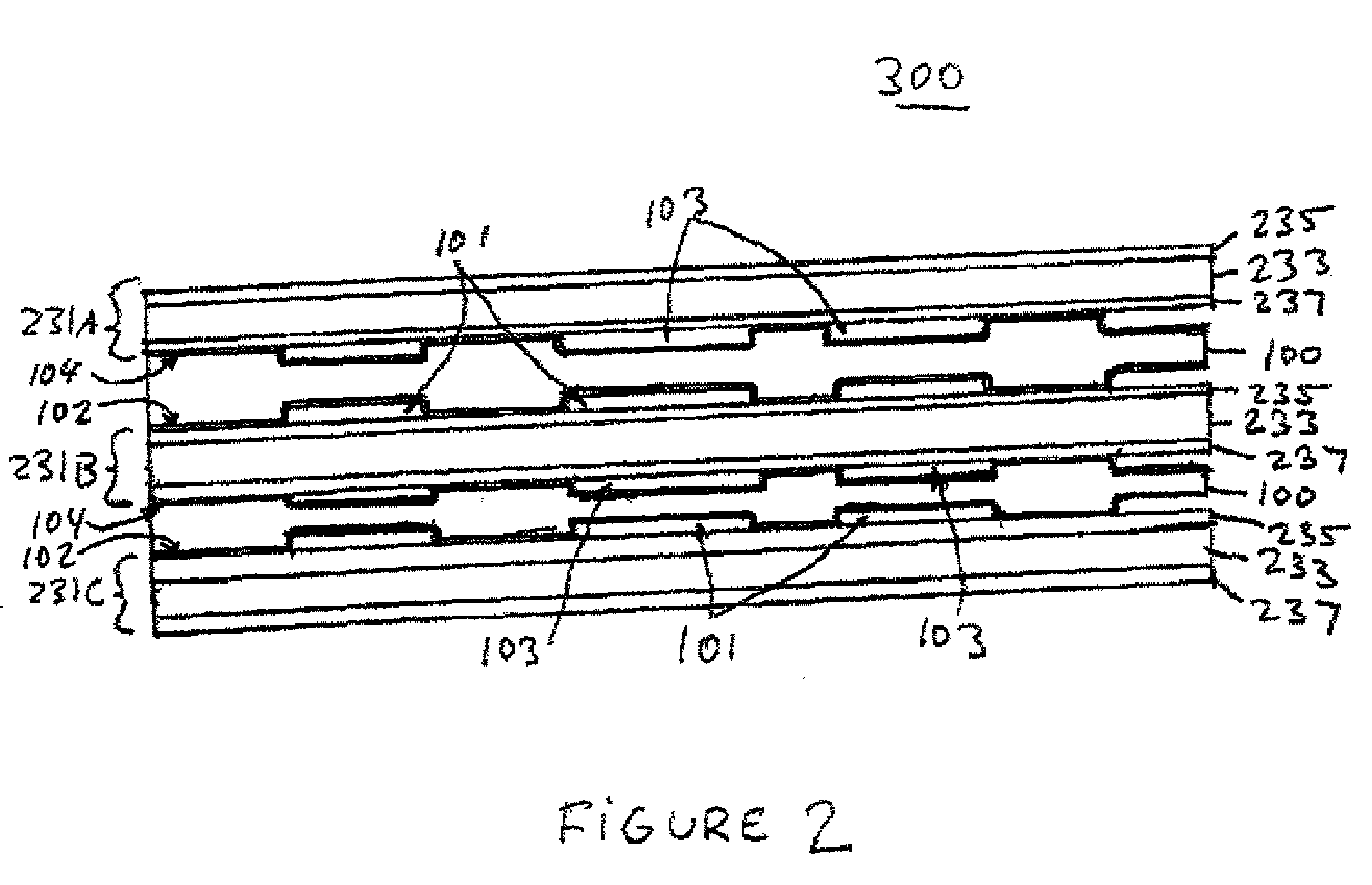

Offset interconnect for a solid oxide fuel cell and method of making same

InactiveUS20050227134A1Fuel cells groupingFinal product manufactureFuel cellsElectrically conductive

An interconnect for a solid oxide fuel cell includes a non-ionically and non-electrically conductive ceramic gas separator plate comprising at least two ceramic layers, a plurality of first vias extending through the first separator plate ceramic layer but not through the second separator plate ceramic layer and a plurality of second vias extending through the second separator plate ceramic layer but not through the first separator plate ceramic layer. The second vias are offset from the first vias. The interconnect also includes a plurality of electrically conductive first fillers located in the plurality of first vias and a plurality of electrically conductive second fillers located in the plurality of second vias. Each of the plurality of first fillers is electrically connected to at least one second filler.

Owner:BLOOM ENERGY CORP

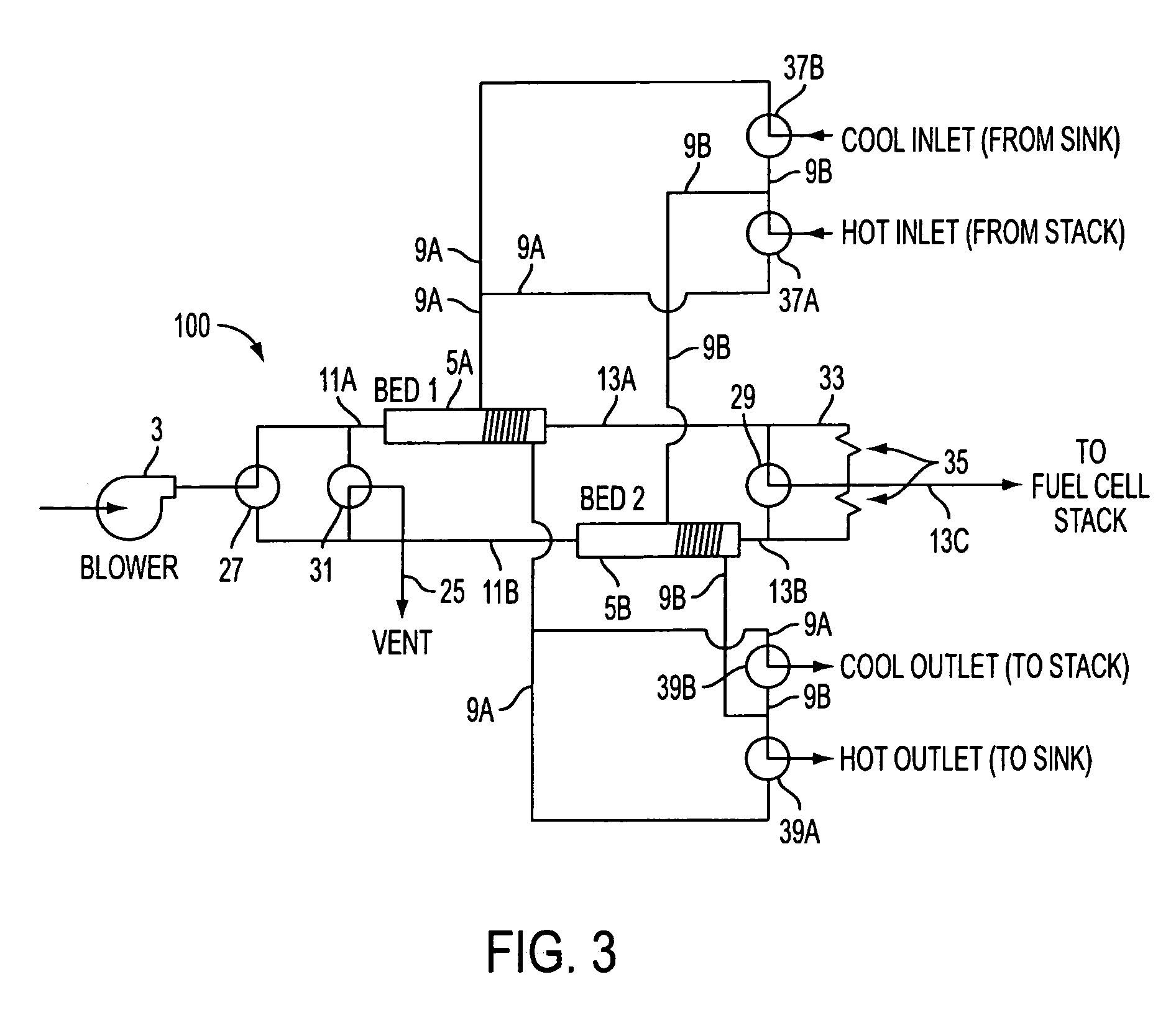

Solid oxide fuel cell systems having temperature swing reforming

InactiveUS7503948B2Improve efficiencySpeed up the processHydrogenChemical industrySyngasThermodynamics

The present invention provides an improvement in the process of producing energy from fuel cells. A cyclic reforming process, referred to as temperature swing reforming, provides an efficient means for producing a hydrogen containing synthesis gas for use in solid oxide fuel cell applications. In one embodiment, at least some synthesis gas which is first produced in the temperature swing reforming process is combusted with air to provide the heat for the regeneration step of the temperature swing reforming process. The syngas produced in TSR is particularly well suited for use in solid oxide fuel cell applications.

Owner:EXXON RES & ENG CO

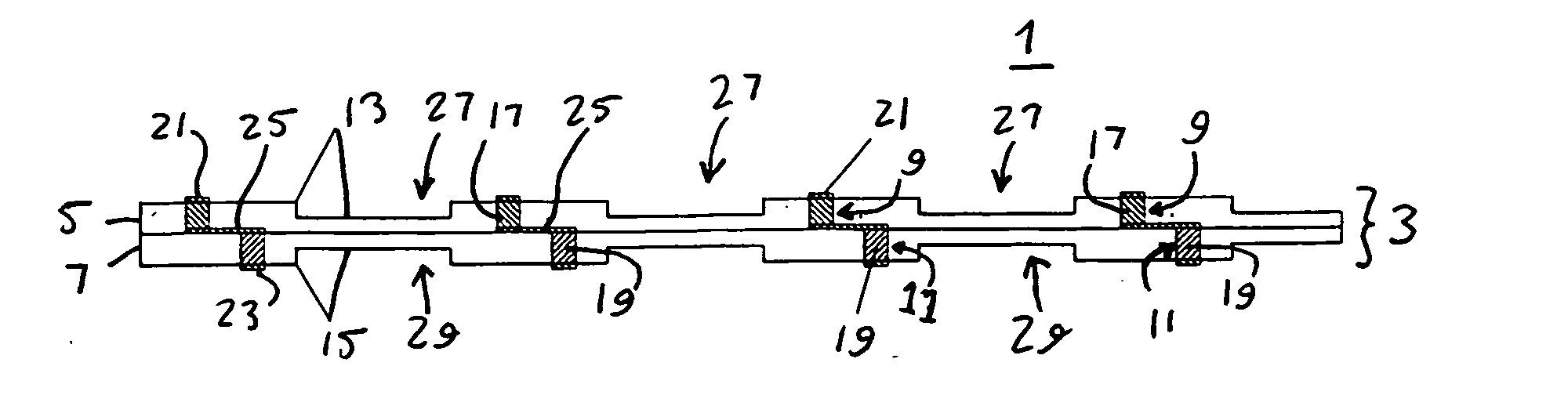

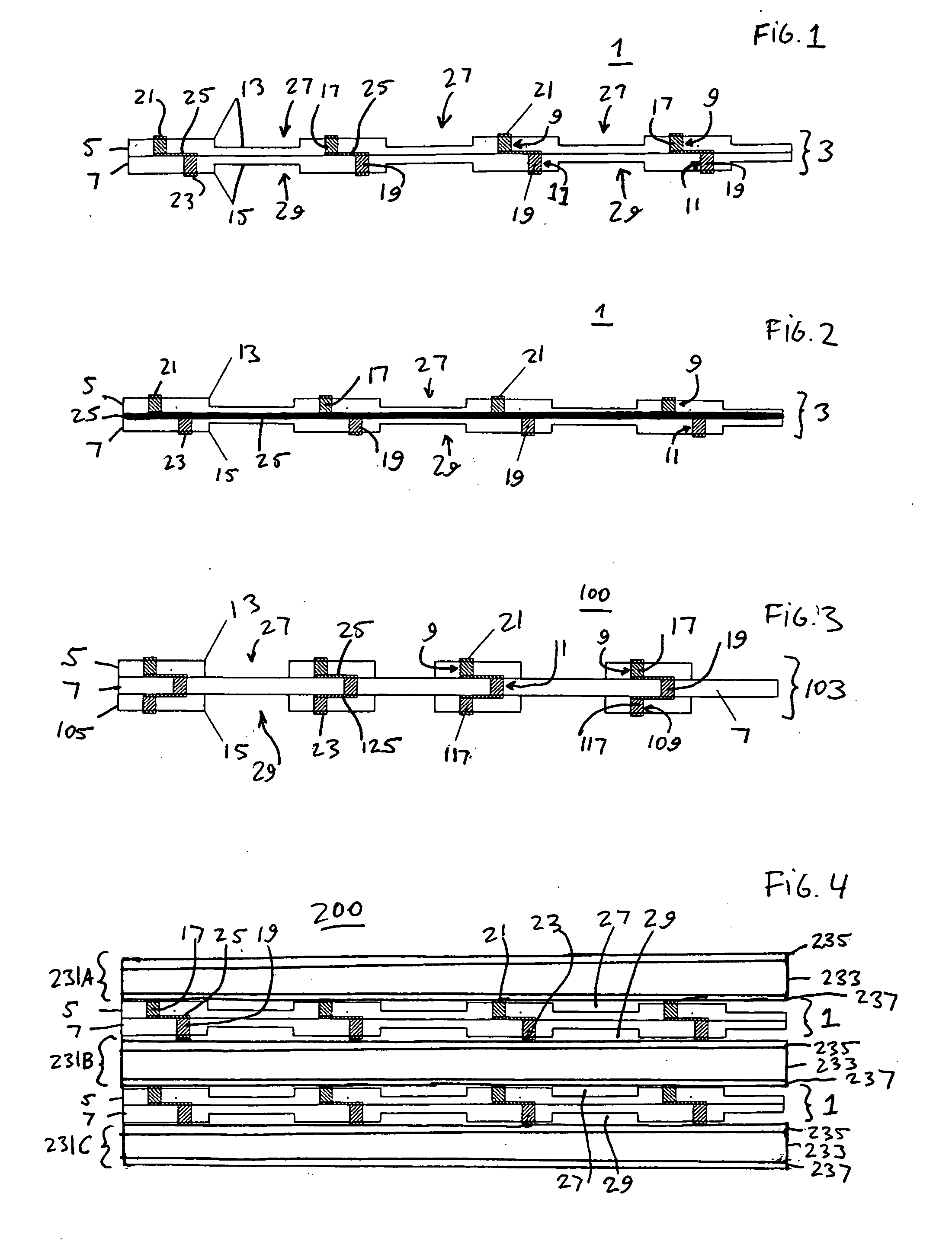

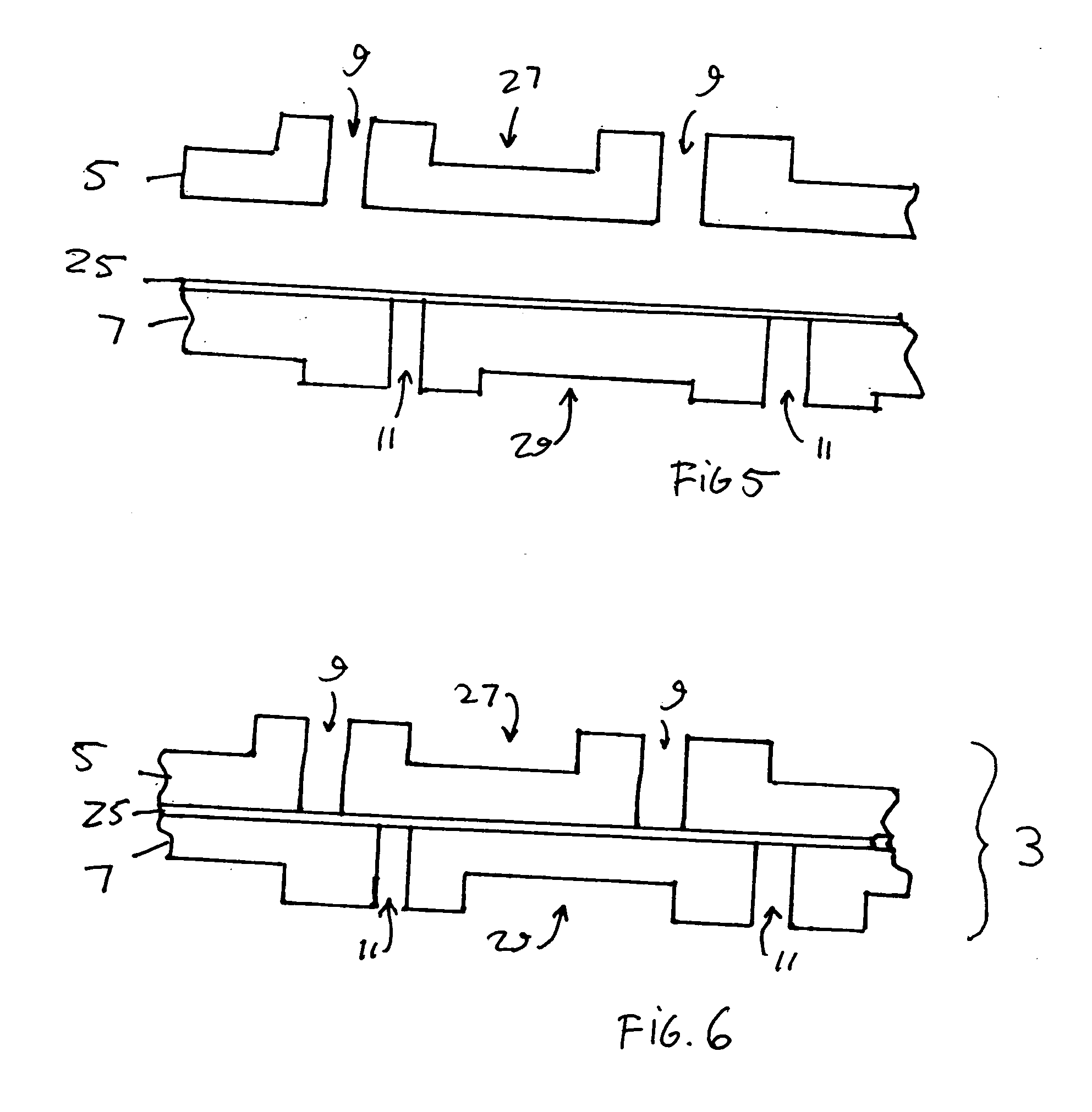

Solid Oxide Fuel Cell Device and System

The invention provides solid oxide fuel cell devices and a fuel cell system incorporating a plurality of the fuel devices, each device including an elongate substrate having a reaction zone for heating to an operating reaction temperature, and at least one cold zone that remains at a low temperature below the operating reaction temperature when the reaction zone is heated. An electrolyte is disposed between anodes and cathodes in the reaction zone, and the anode and cathode each have an electrical pathway extending to an exterior surface in a cold zone for electrical connection at low temperature. In one embodiment, the device is a multi-layer anode-cathode structure, and in another embodiment, the device is an electrode-supported device. The system further includes the devices positioned with their reaction zones in a hot zone chamber and their cold zones extending outside the hot zone chamber. A heat source is coupled to the hot zone chamber to heat the reaction zones to the operating reaction temperature, and fuel and air supplies are coupled to the substrates in the cold zones.

Owner:DEVOE ALAN +1

Anode with remarkable stability under conditions of extreme fuel starvation

A solid oxide fuel cell (SOFC) includes a cathode electrode, a solid oxide electrolyte, and an anode electrode having a first portion and a second portion, such that the first portion is located between the electrolyte and the second portion. The anode electrode comprises a cermet comprising a nickel containing phase and a ceramic phase. The first portion of the anode electrode contains a lower porosity and a lower ratio of the nickel containing phase to the ceramic phase than the second portion of the anode electrode.

Owner:BLOOM ENERGY CORP

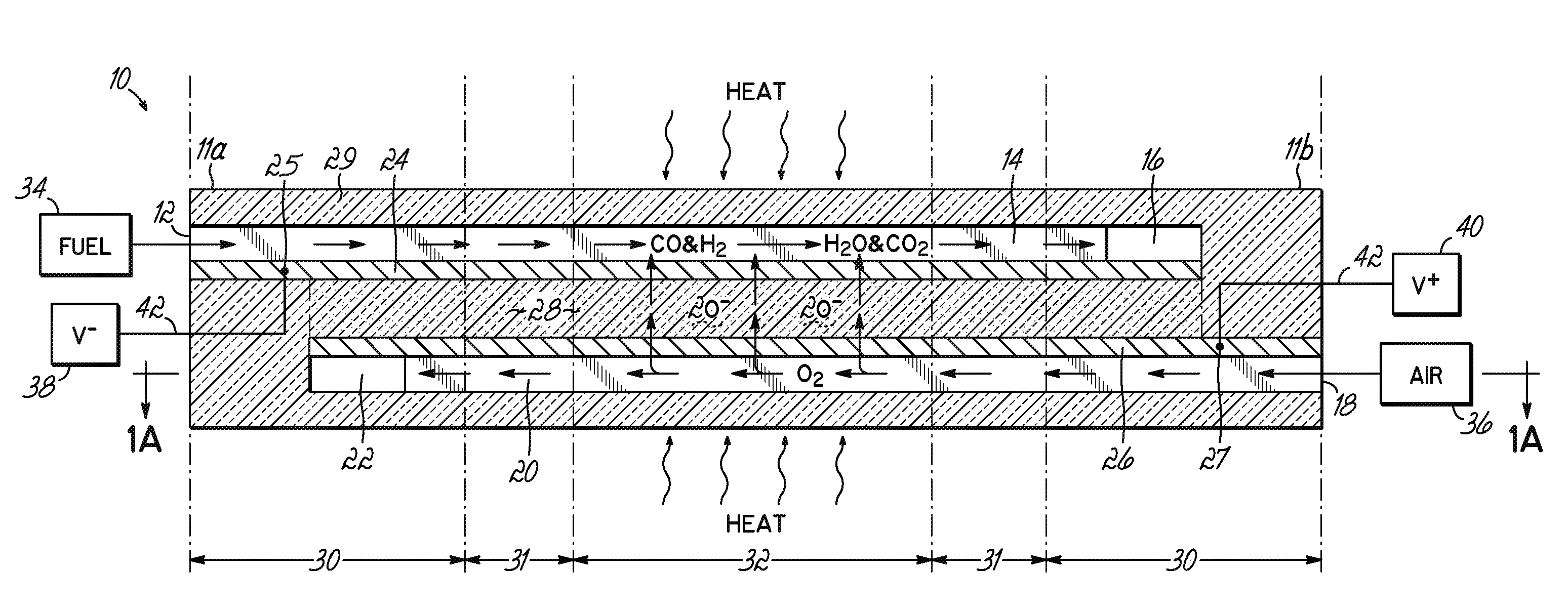

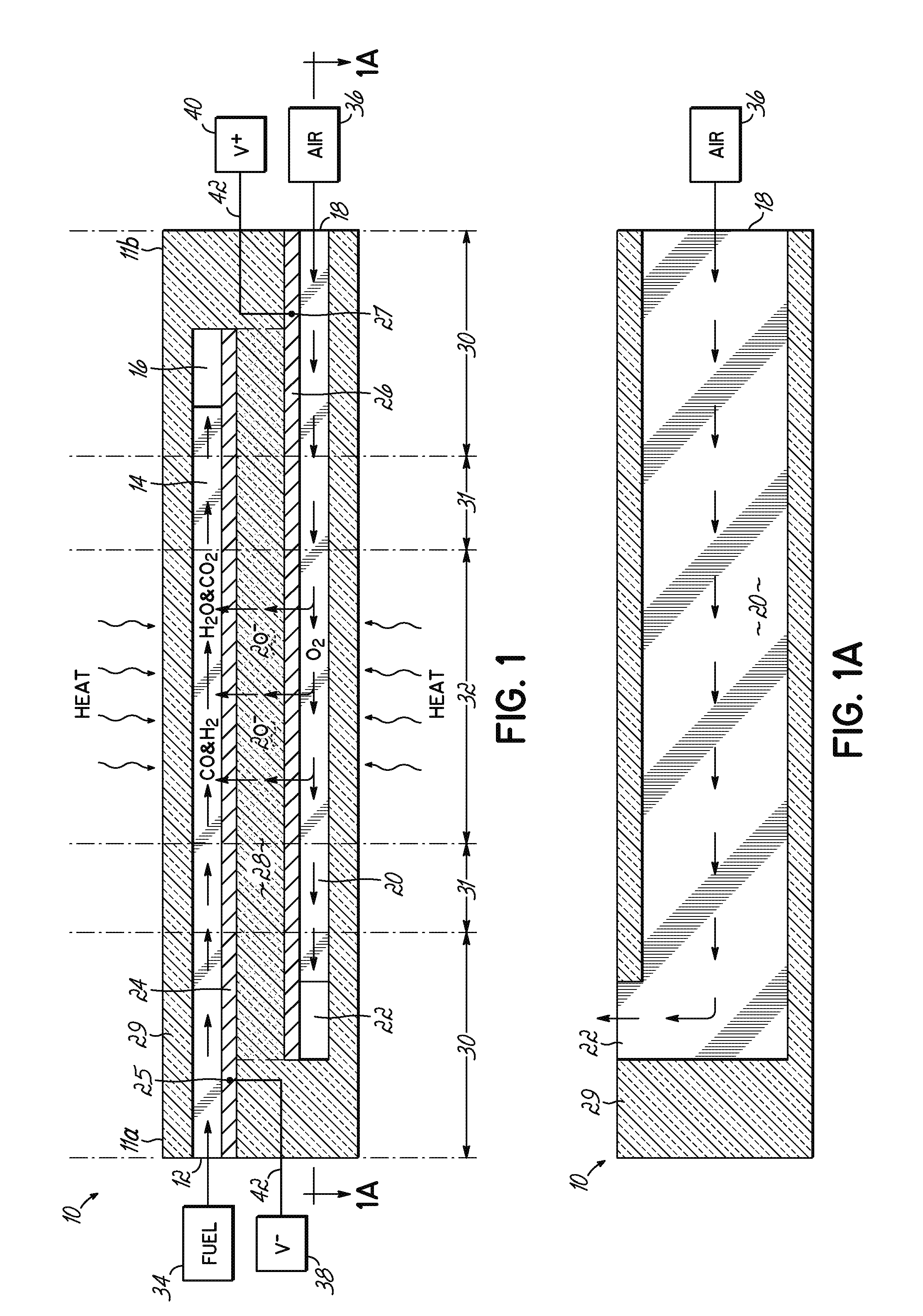

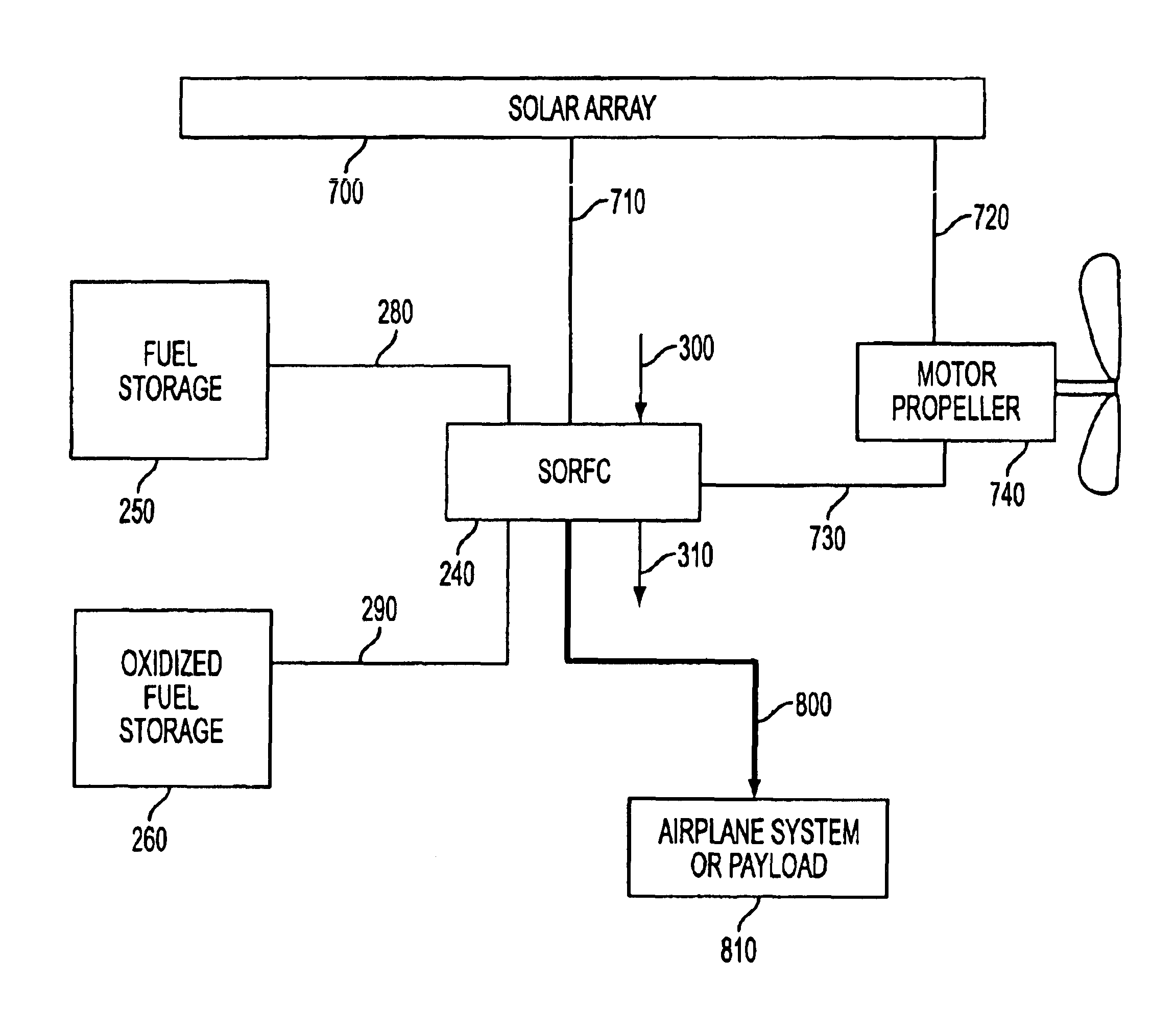

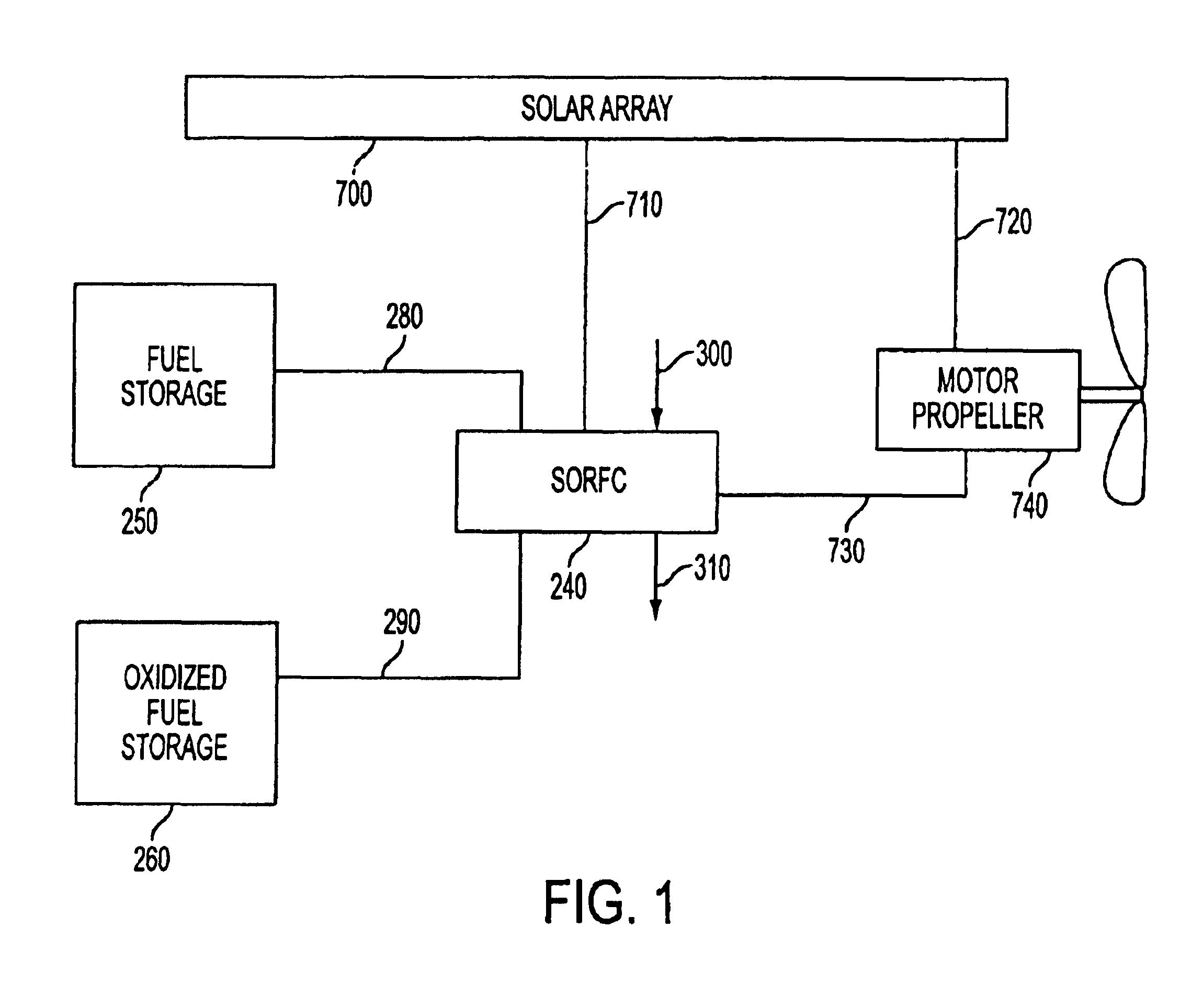

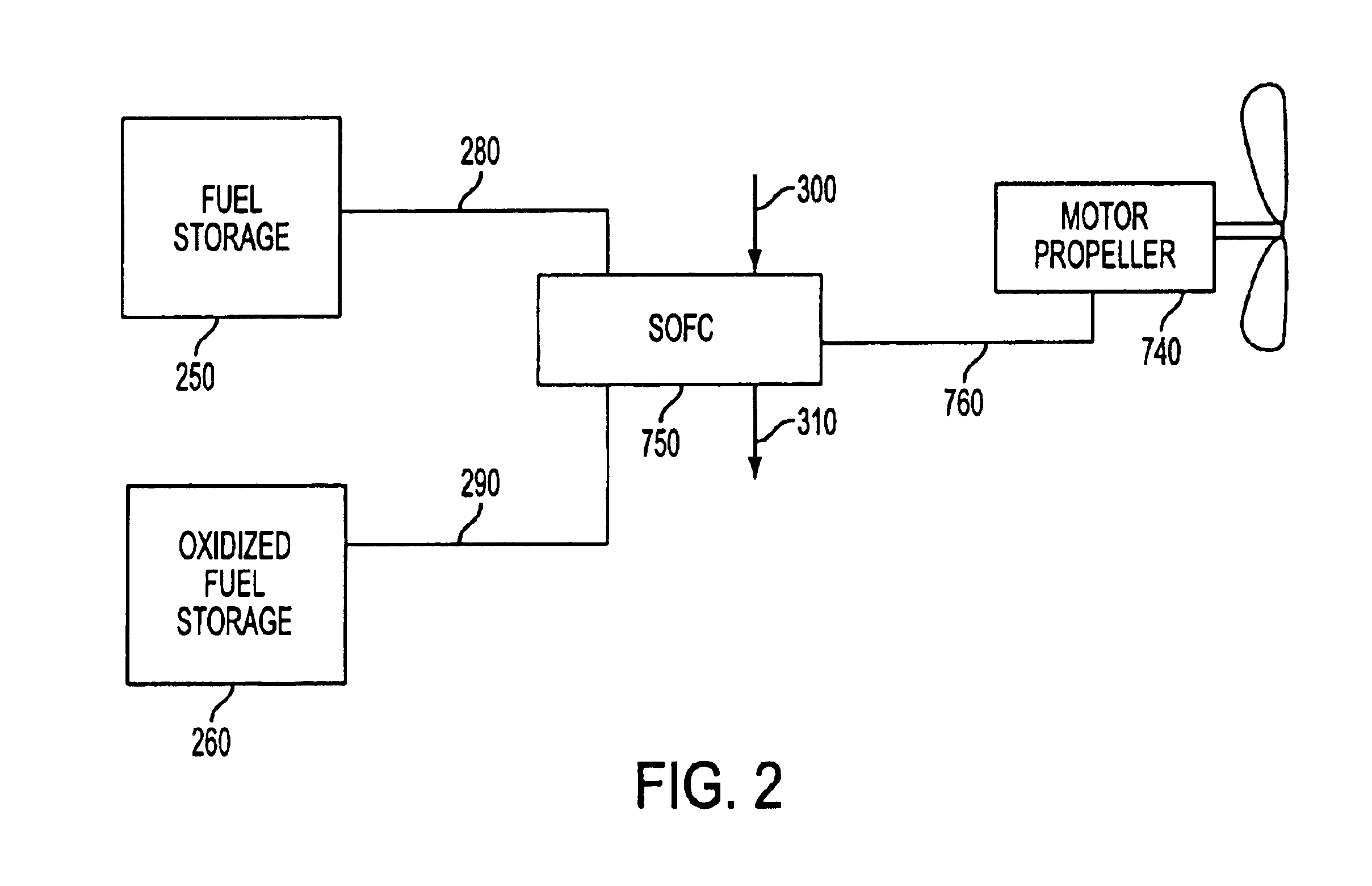

Solid oxide regenerative fuel cell for airplane power generation and storage

InactiveUS6854688B2Reactant parameters controlFuel cells groupingUnitized regenerative fuel cellElectrolysis

A Solid Oxide Regenerative Fuel Cell (SORFC) or a Solid Oxide Fuel Cell (SOFC) is incorporated into an electrically powered airplane to provide either regenerative or primary electrical energy. The SORFC, the SOFC, or any other suitable fuel cell within an airplane may also be used to heat payload or equipment within the airplane. The SORFC is not only capable of generating electrical energy from fuel and a suitable oxidizer, but can also generate fuel through electrolysis of oxidized fuel. Thus, the SORFC system powering an airplane can obtain oxygen oxidant reactant from the air and avoid the complexity, weight, volume, and cost associated with oxygen storage.

Owner:BLOOM ENERGY CORP

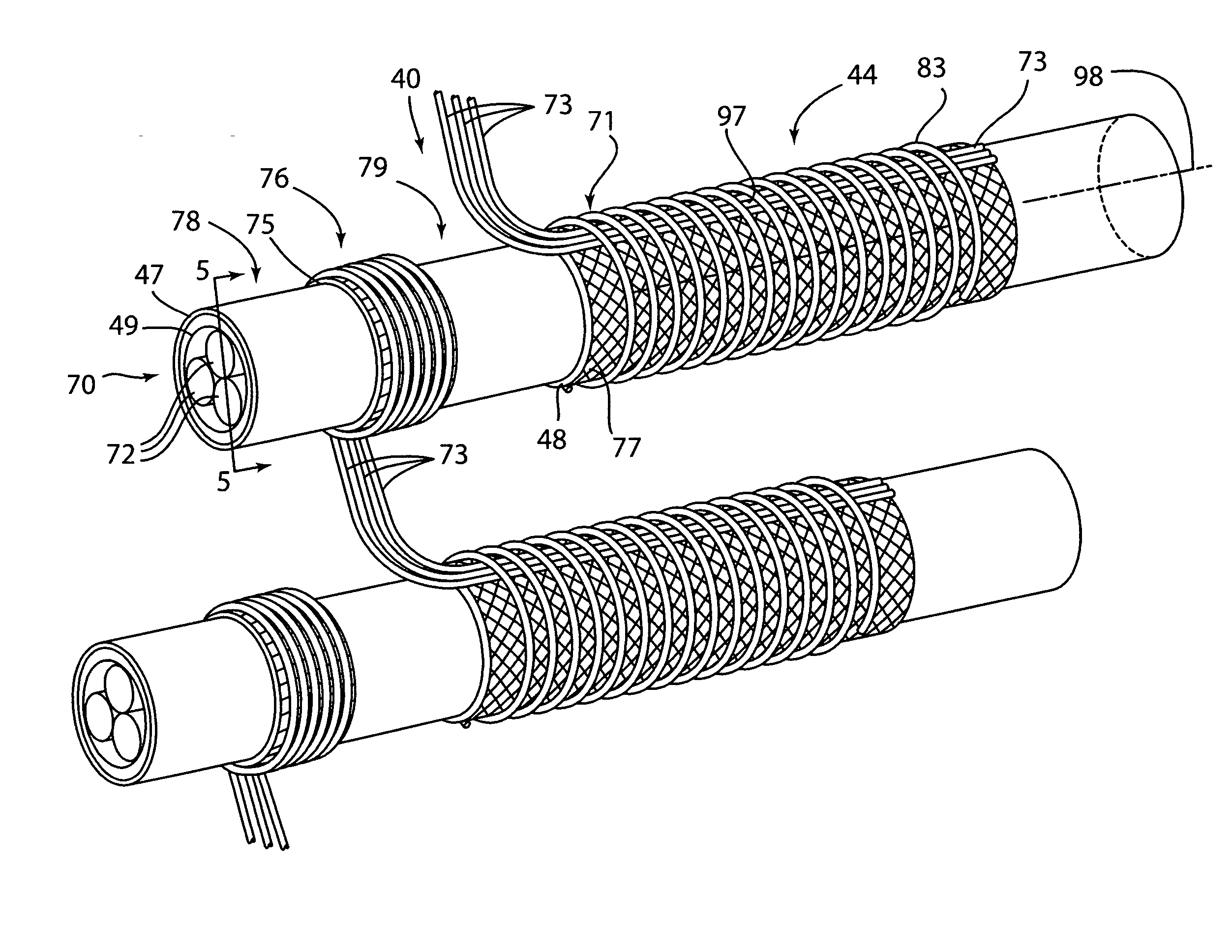

Solid oxide fuel cell with improved current collection

A solid oxide fuel cell comprises a plurality of tubes, each having an anode, electrolyte and cathode. Anode and cathode current collectors are mounted on the tubes. The anode current collector electrically connects to the anode and can have a contact with the anode. The cathode current collector electrically connects to the cathode and can have a contact with the cathode. An electrically conductive sealant may be positioned between the anode of one tube and the cathode current collector of another tube.

Owner:ADAPTIVE MATERIALS

Energy efficient gas separation for fuel cells

InactiveUS7087331B2Intuitive effectFully purifiedFuel cell heat exchangeFused electrolyte fuel cellsDelivery systemSolid oxide fuel cell

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

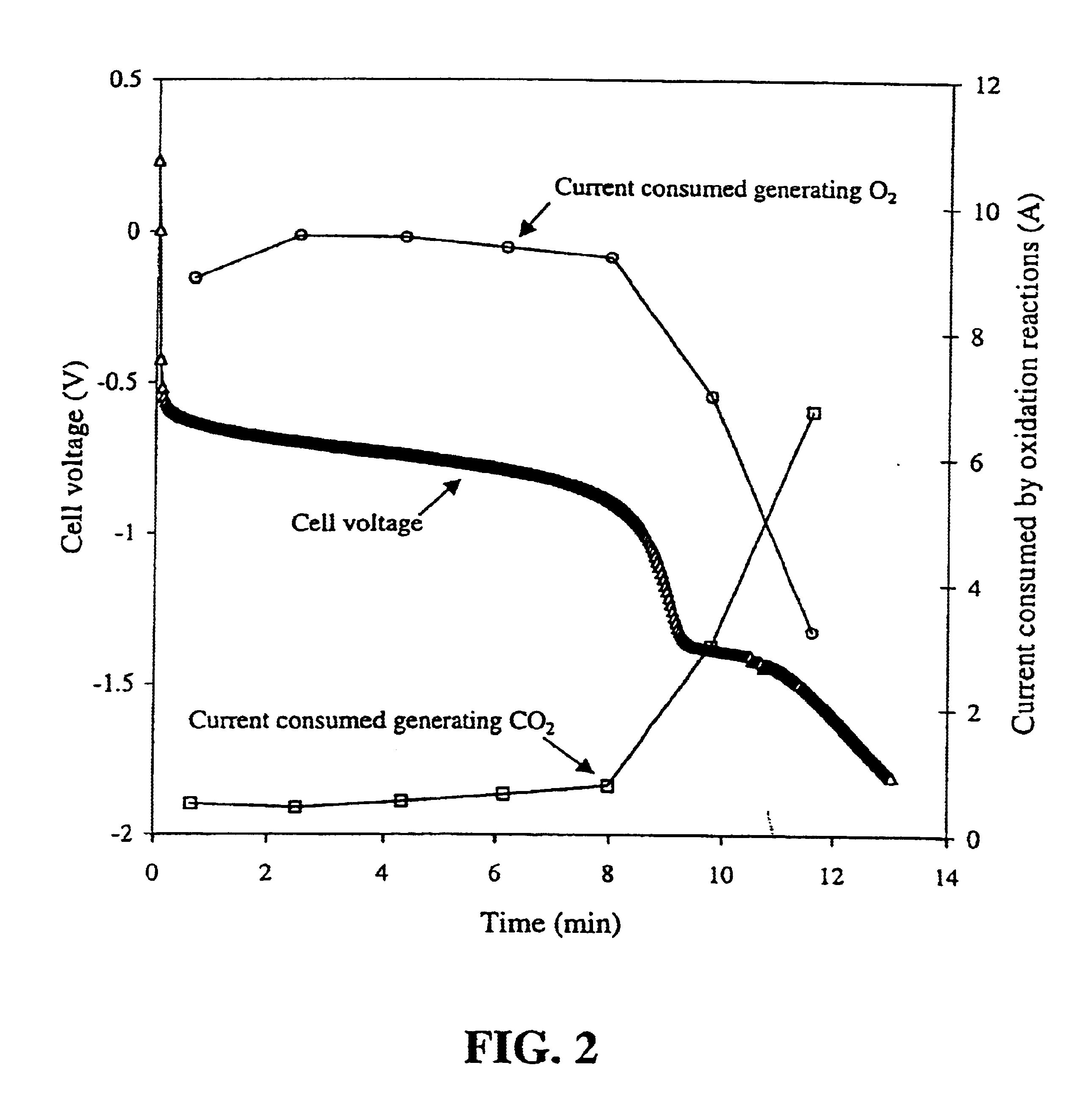

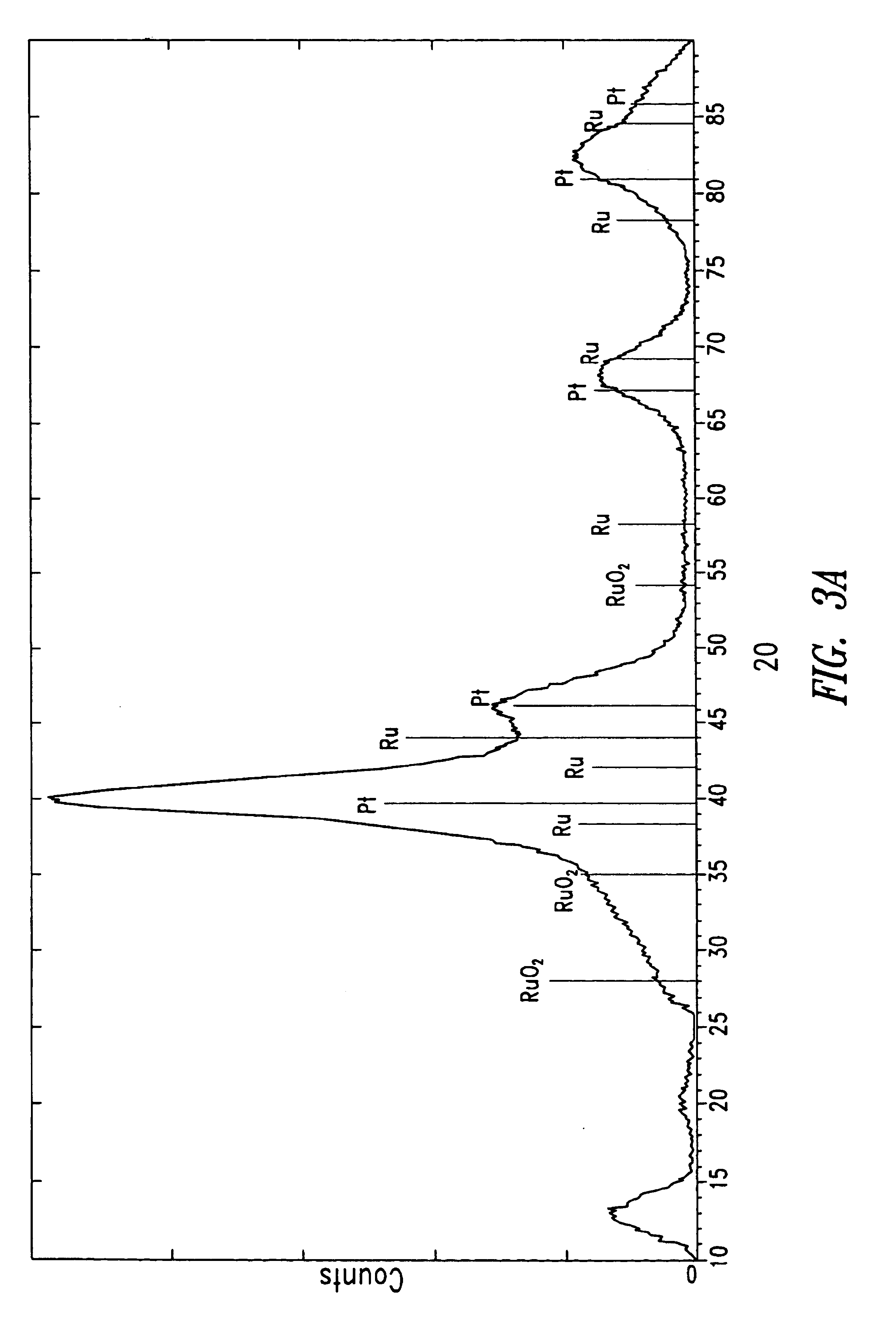

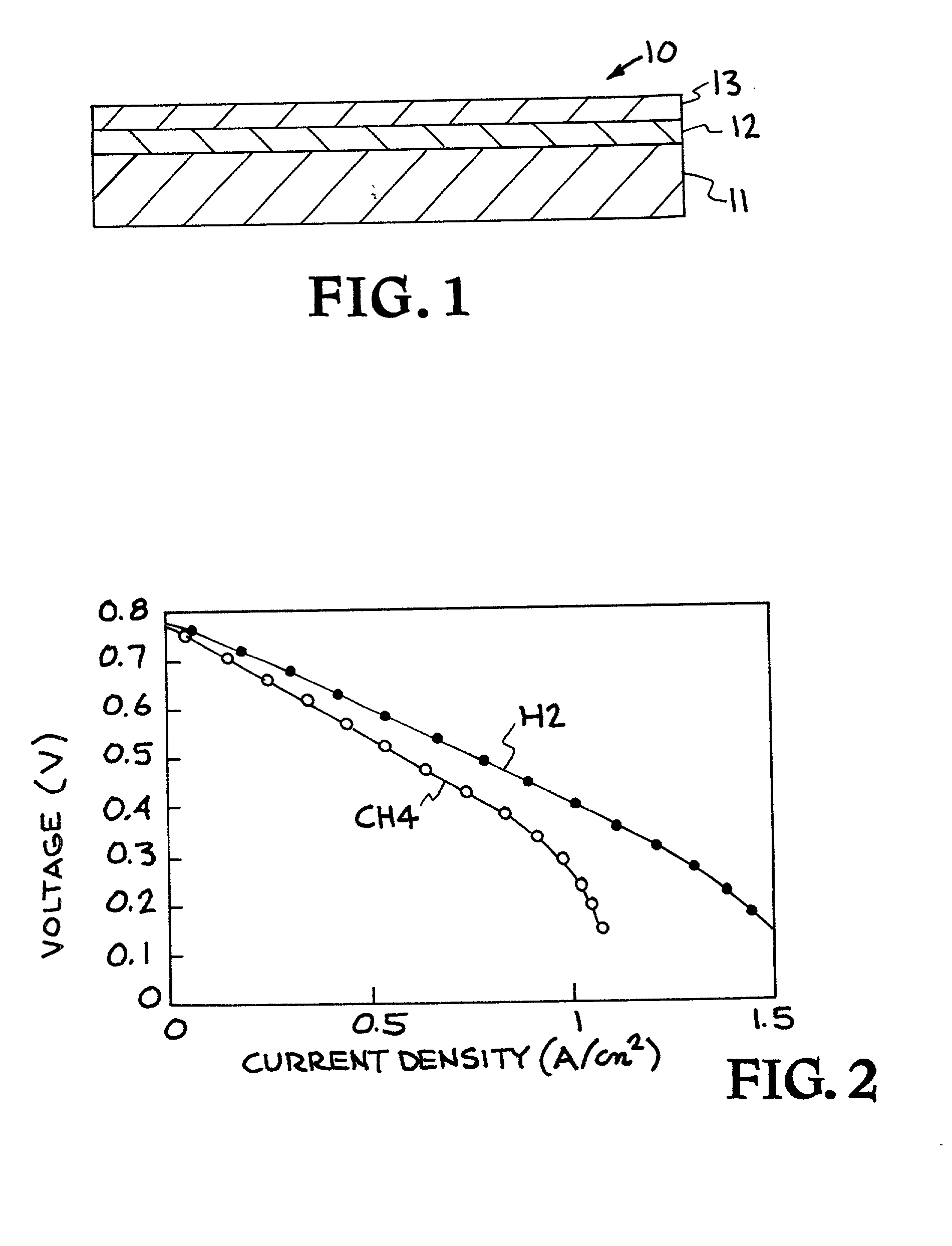

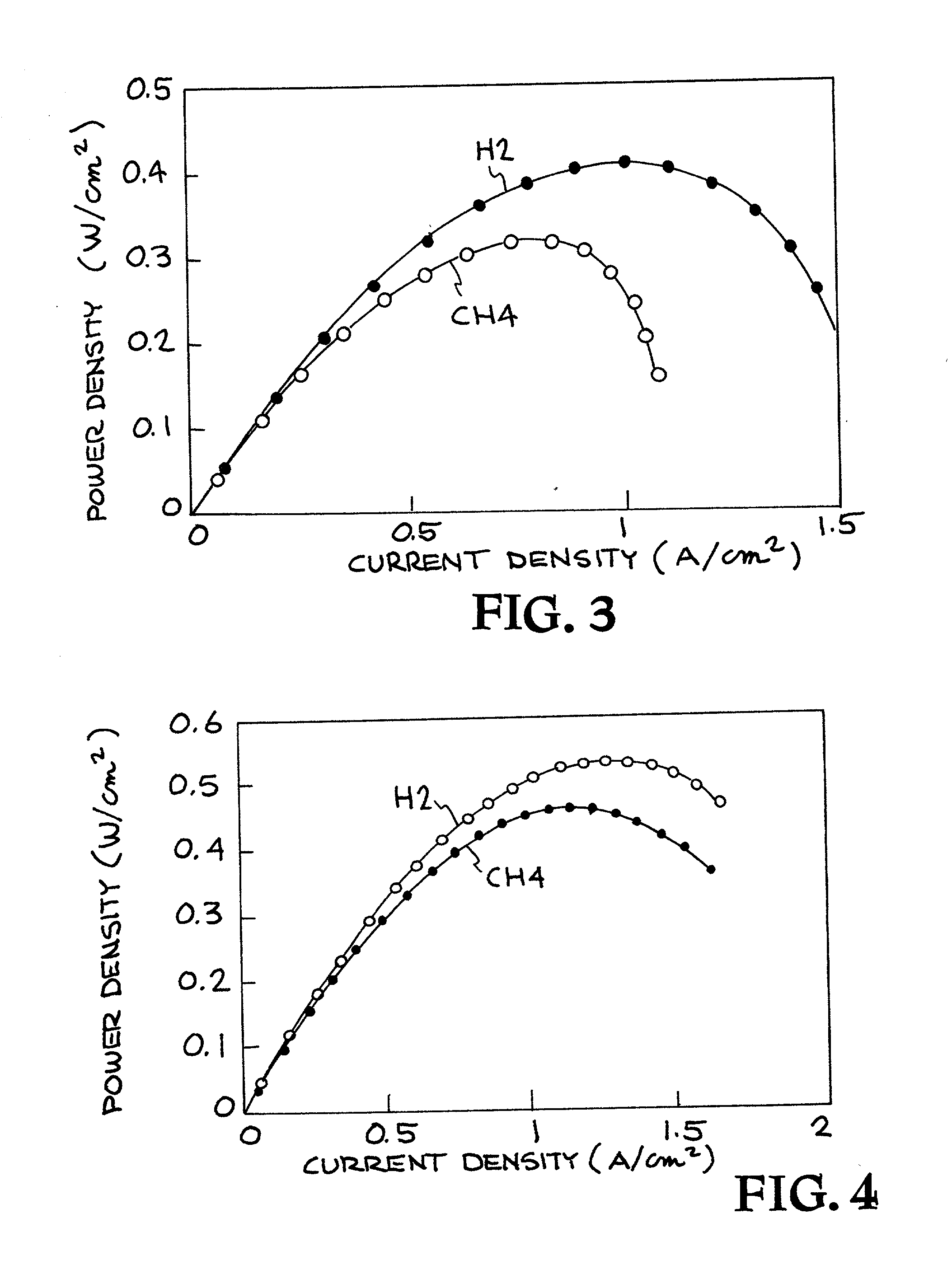

Direct hydrocarbon fuel cells

InactiveUS6214485B1Increase ratingsUseful power densityFuel cells groupingFinal product manufactureFuel cellsHydrogen

The direct electrochemical oxidation of hydrocarbons in solid oxide fuel cells, to generate greater power densities at lower temperatures without carbon deposition. The performance obtained is comparable to that of fuel cells used for hydrogen, and is achieved by using novel anode composites at low operating temperatures.

Owner:NORTHWESTERN UNIV

Textured electrolyte for a solid oxide fuel cell

ActiveUS7045237B2Decreases cost per wattImprove adhesionFuel cell heat exchangeFuel cells groupingFuel cellsMaterials science

A ceramic electrolyte for a solid oxide fuel cell includes at least one non-uniform surface portion. Preferably, the electrolyte surface is textured.

Owner:BLOOM ENERGY CORP

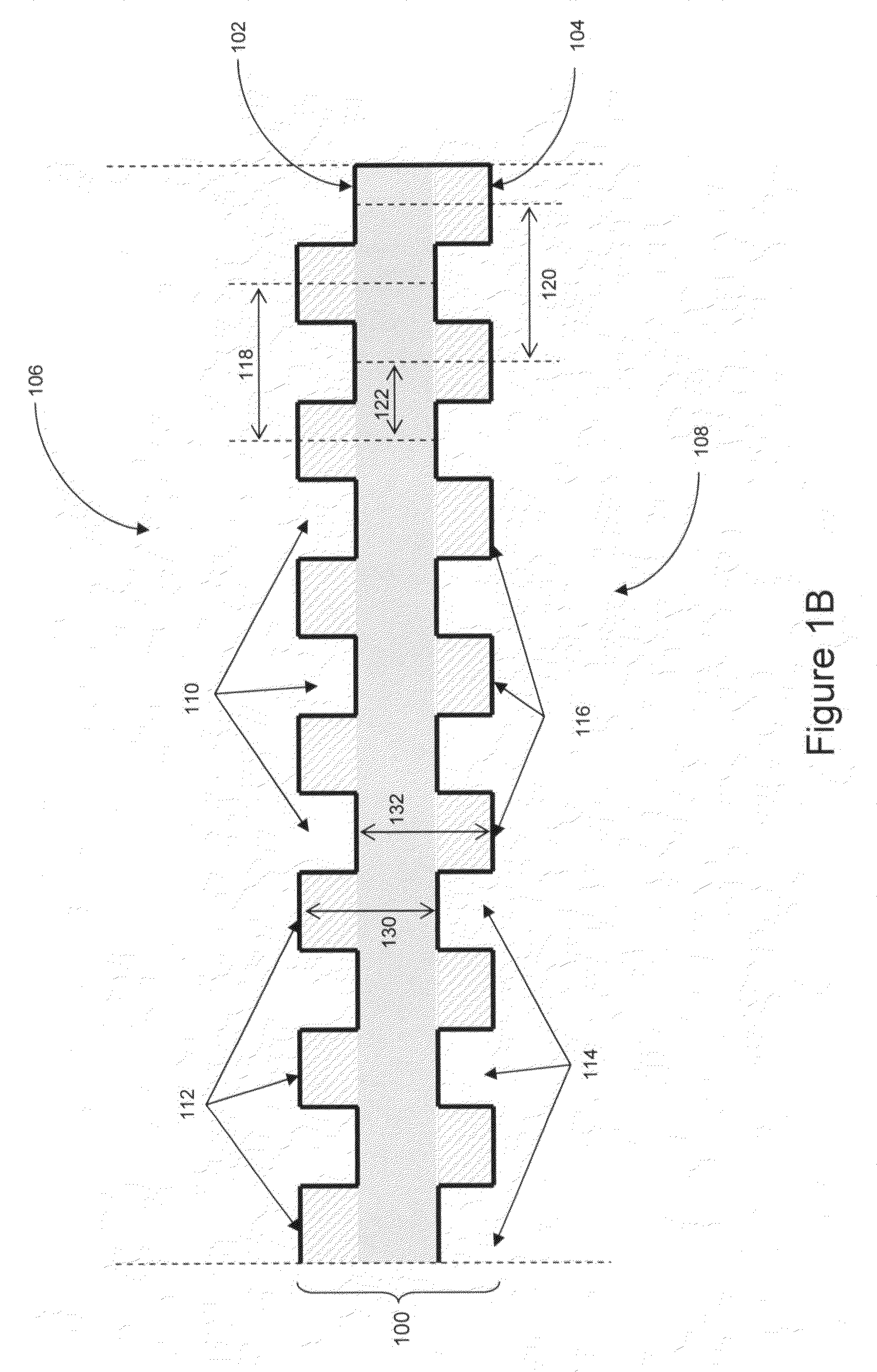

Solid oxide fuel cell interconnect

InactiveUS20080199738A1Fuel cells groupingFuel cell auxillariesFuel cellsElectrical and Electronics engineering

A fuel cell interconnect includes a first surface containing a first plurality of channels and a second surface containing a second plurality of channels. The first and second surfaces are disposed on opposite sides of the interconnect. The first plurality of channels is offset from the second plurality of channels. The thickness of the interconnect measured between the first and second surfaces is substantially constant

Owner:BLOOM ENERGY CORP

Solid oxide fuel cell

InactiveUS20060035130A1High operating temperatureLower operating temperatureFuel cell heat exchangeFinal product manufactureFuel cellsOperating temperature

One embodiment of the present invention provides a solid oxide fuel cell, which includes: an anode; a cathode; and an ionically conducting solid oxide electrolyte disposed between the anode and the cathode; wherein the solid oxide electrolyte includes at least one first region having a relatively high operating temperature and at least one second region having a relatively low operating temperature; and wherein the composition of the solid oxide electrolyte is different in the first and second regions. Other embodiments of the invention provide methods for making and using the fuel cell, and also the solid oxide electrolyte.

Owner:AISIN SEIKI KK

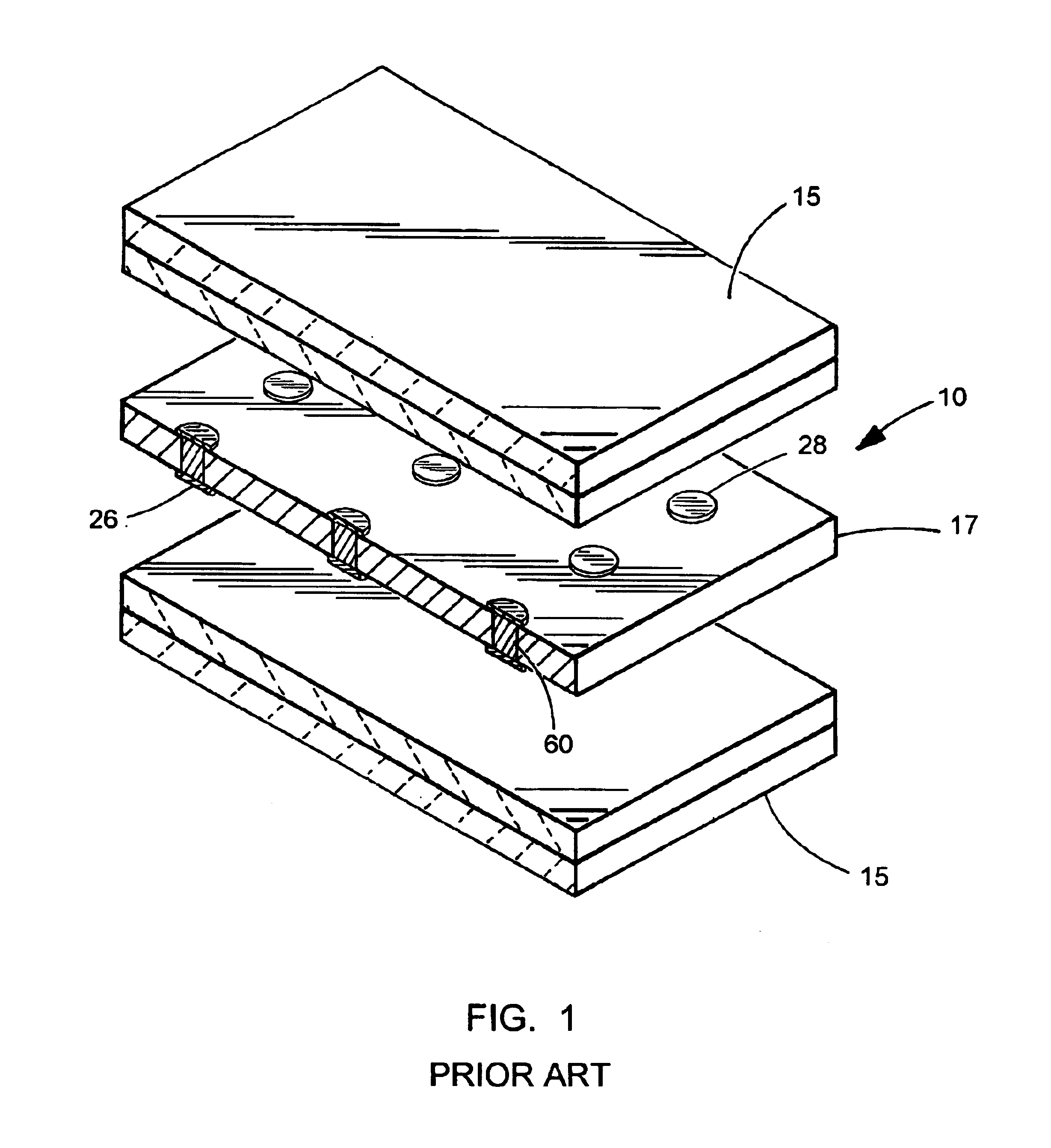

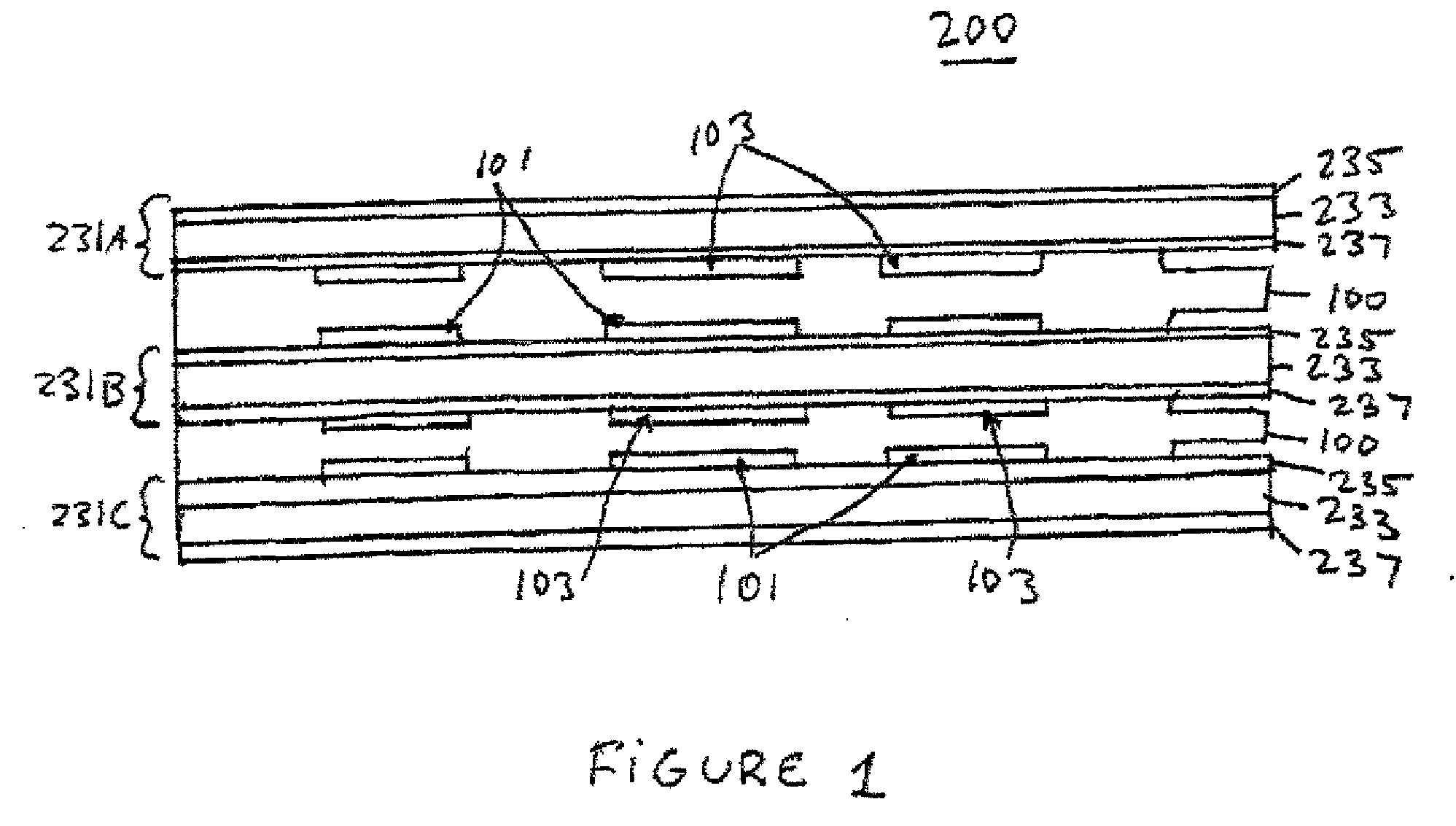

High performance ceramic fuel cell interconnect with integrated flowpaths and method for making same

InactiveUS6949307B2Overcome lack of conductivityMinimal resistive lossesFuel cells groupingFinal product manufactureFuel cellsElectrical connection

A method, apparatus and assembly related to solid oxide fuel cell interconnects is disclosed. In its broadest embodiment, the invention contemplates a multi-layered ceramic interconnect having integrated flow fields and electrical connections. The method of making this interconnect includes judicious selection of materials, formation of appropriate apertures for the flow fields and electrical connectors, and the joining of the layers through a firing and / or sealing process.

Owner:LG FUEL CELL SYST

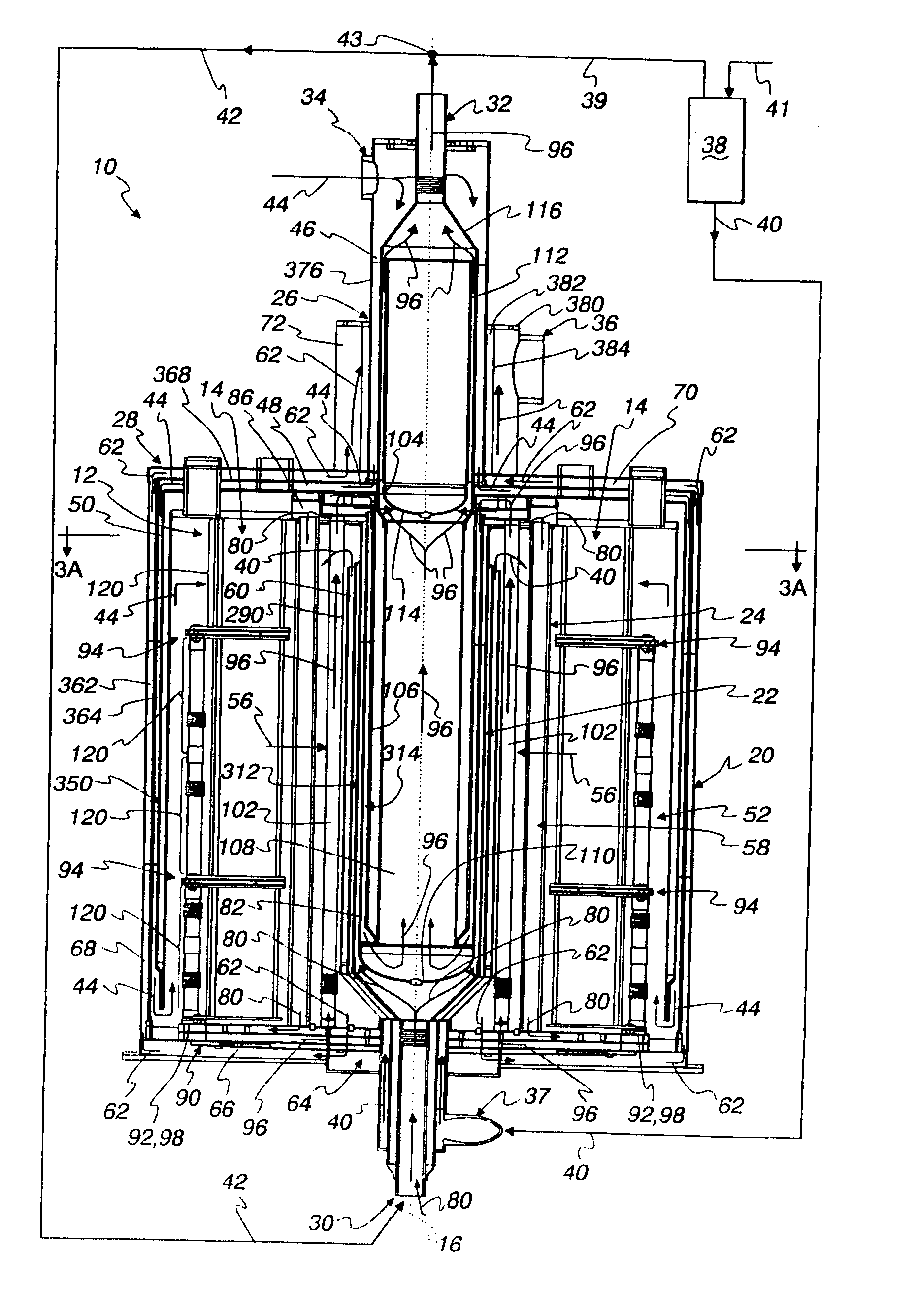

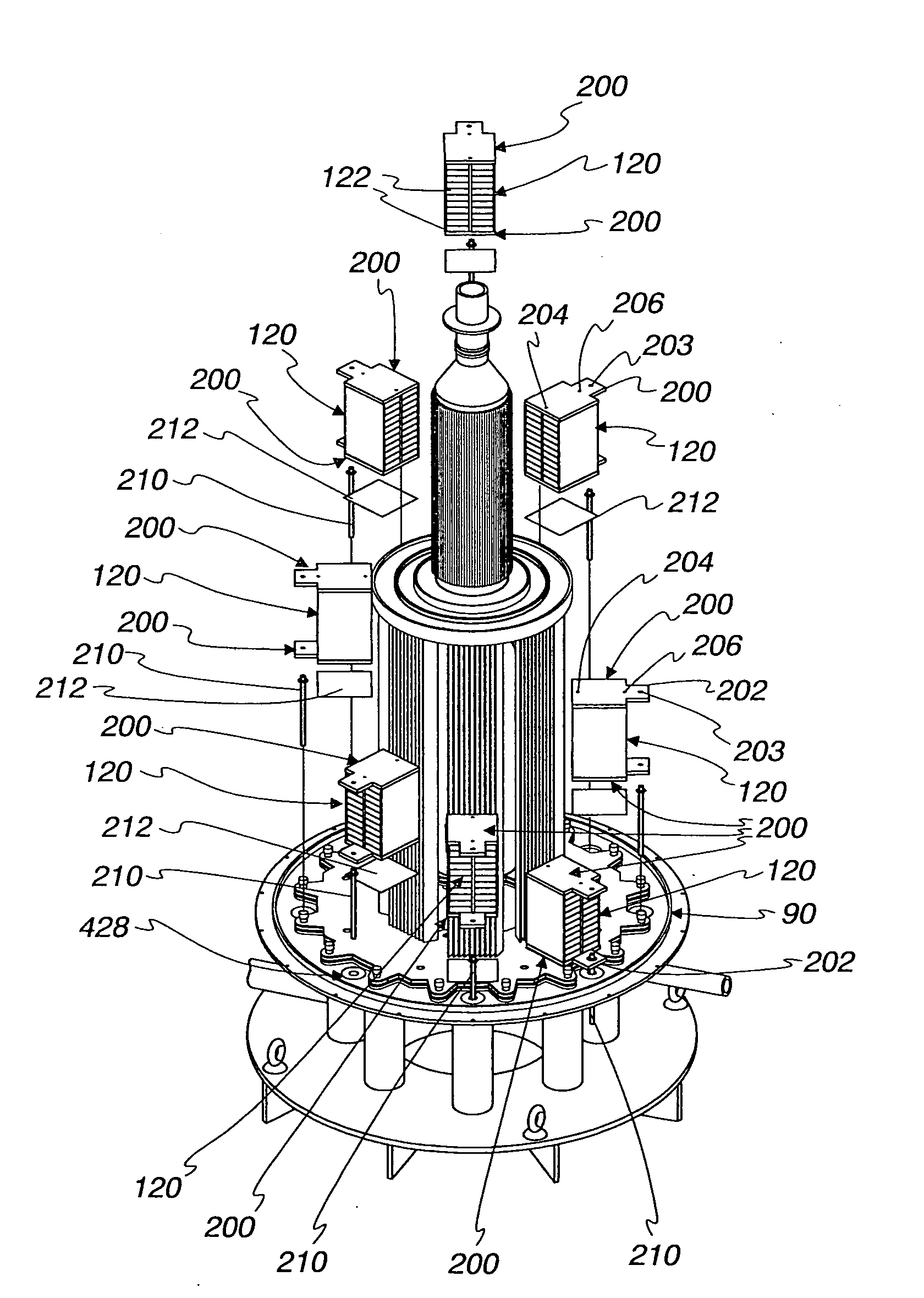

Integrated solid oxide fuel cell and fuel processor

An integrated fuel cell unit (10) includes an annular array (12) of fuel cell stacks (14), an annular cathode recuperator (20), an annular anode recuperator (22), a reformer (24), and an anode exhaust cooler (26), all integrated within a common housing structure (28).

Owner:MODINE MFG CO

Solid oxide fuel cell assembly with replaceable stack and packet modules

InactiveUS20060166053A1Continuous operationFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A method of replacing a fuel cell packet module in a fuel cell stack, said method comprising: (i) powering down the fuel cell stack; (ii) electrically disconnecting the fuel cell packet module from external power load, (iii) mechanically disconnecting the fuel cell packet module from the fuel cell stack; and (iv) removing the fuel cell packet module from the stack.

Owner:CORNING INC

Cermet and ceramic interconnects for a solid oxide fuel cell

An interconnect and gas separator for a solid oxide fuel cell includes a cermet material comprising a first conductive phase and a second ceramic phase or a multi-component ceramic material including a first ceramic ionically conductive and electrically non-conductive component and a second ceramic electrically conductive component.

Owner:BLOOM ENERGY CORP

Expanded nickel screen electrical connection supports for solid oxide fuel cells

InactiveUS6379831B1Primary cell to battery groupingFuel cells groupingEastern InterconnectionFuel cells

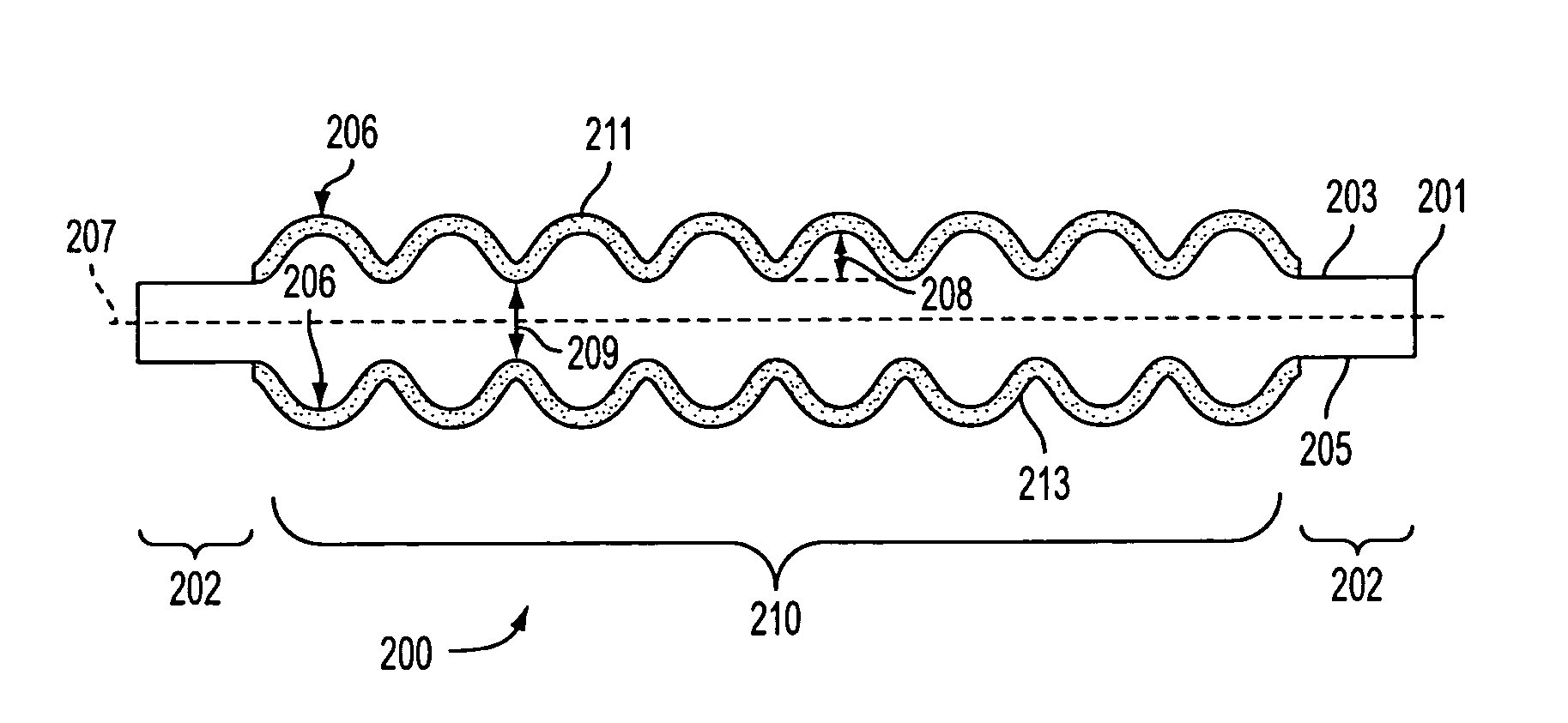

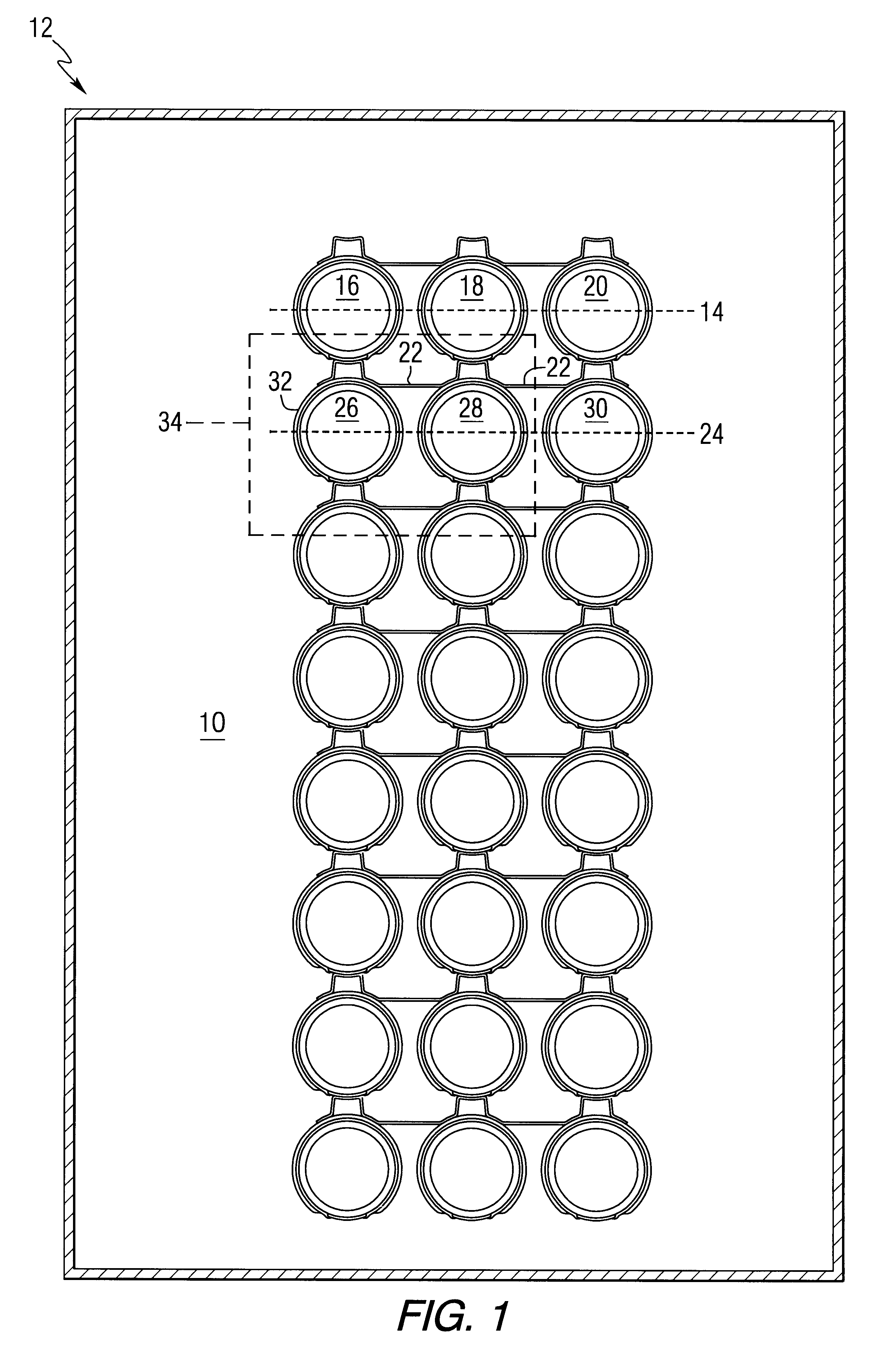

A solid oxide fuel assembly is made, wherein rows (14, 24) of fuel cells (16, 18, 20, 26, 28, 30), each having an outer interconnection (36) and an outer electrode (32), are disposed next to each other with corrugated, electrically conducting expanded metal mesh (22) between each row of cells, the corrugated mesh (22) having top crown portions (40) and bottom shoulder portions (42), where the top crown portion (40) contacts outer interconnections (36) of the fuel cells (16, 18, 20) in a first row (14), and the bottom shoulder portions (42) contacts outer electrodes (32) of the fuel cells in a second row (24), said mesh electrically connecting each row of fuel cells, and where there are no metal felt connections between any fuel cells.

Owner:SIEMENS ENERGY INC

Solid Oxide Fuel Cell With Internal Reforming, Catalyzed Interconnect For Use Therewith, and Methods

ActiveUS20050170234A1Improve internal efficiencyMinimizesElectrolyte holding meansFinal product manufactureFuel cellsMetallic substrate

A catalyzed interconnect for an SOFC electrically connects an anode and an anodic current collector and comprises a metallic substrate, which provides space between the anode and anodic current collector for fuel gas flow over at least a portion of the anode, and a catalytic coating on the metallic substrate comprising a catalyst for catalyzing hydrocarbon fuel in the fuel gas to hydrogen rich reformate. An SOFC including the catalyzed anodic inter-connect, a method for operating an SOFC, and a method for making a catalyzed anodic interconnect are also disclosed.

Owner:CUMMINS ENTERPRISE LLC

Proton conducting solid oxide fuel cell systems having temperature swing reforming

ActiveUS7875402B2Improve efficiencySpeed up the processFuel cells groupingFuel cell auxillariesSyngasThermodynamics

The present invention provides an improvement in the process of producing energy from fuel cells. A cyclic reforming process, referred to as temperature swing reforming, provides an efficient means for producing a hydrogen containing synthesis gas for use in proton conducting solid oxide fuel cell applications. In one embodiment, at least some synthesis gas which is first produced in the temperature swing reforming process is combusted with air to provide the heat for the regeneration step of the temperature swing reforming process. The syngas produced in TSR is particularly well suited for use in proton conducting solid oxide fuel cell applications.

Owner:EXXON RES & ENG CO

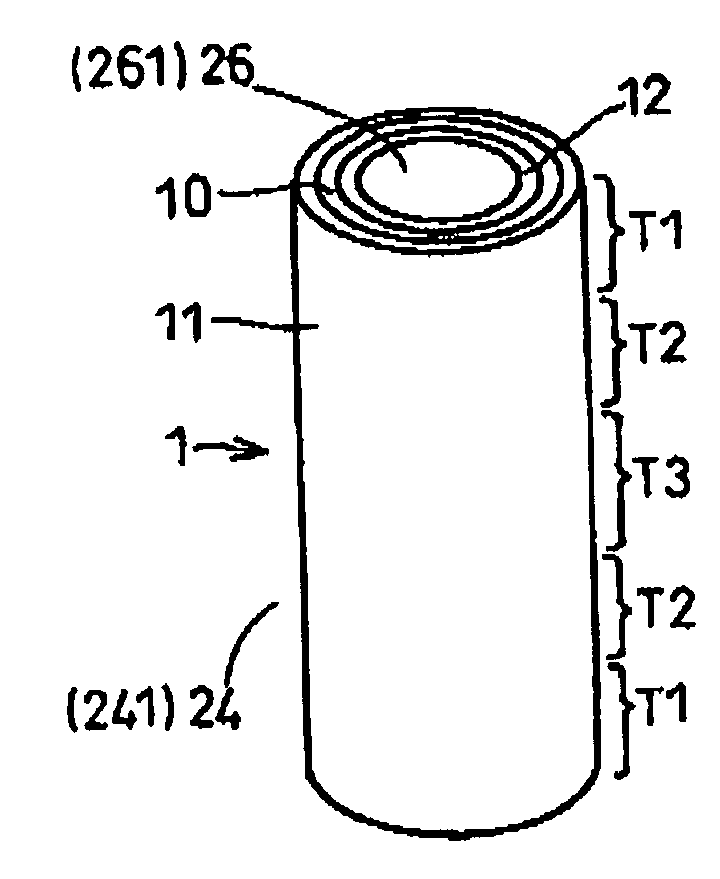

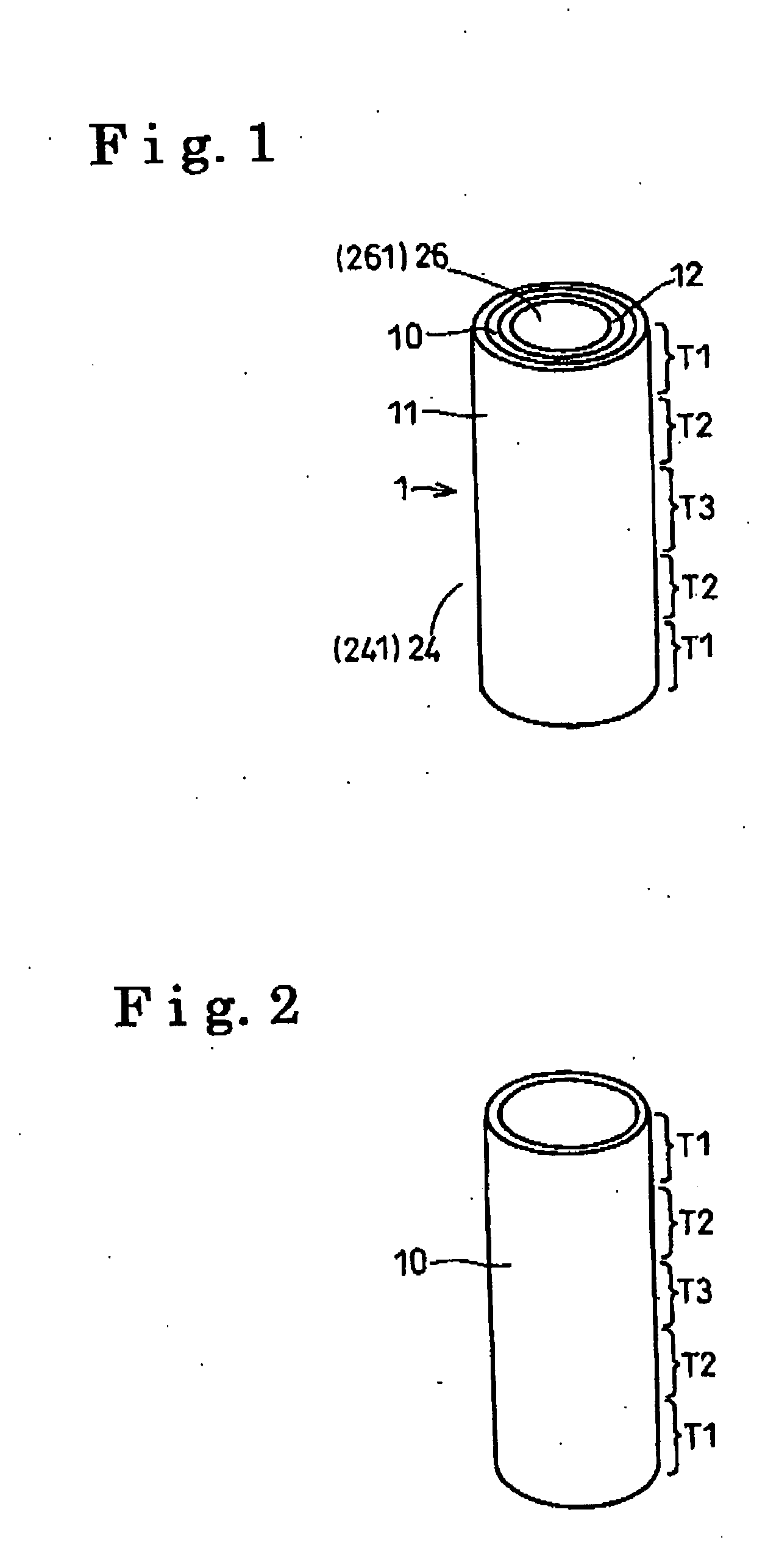

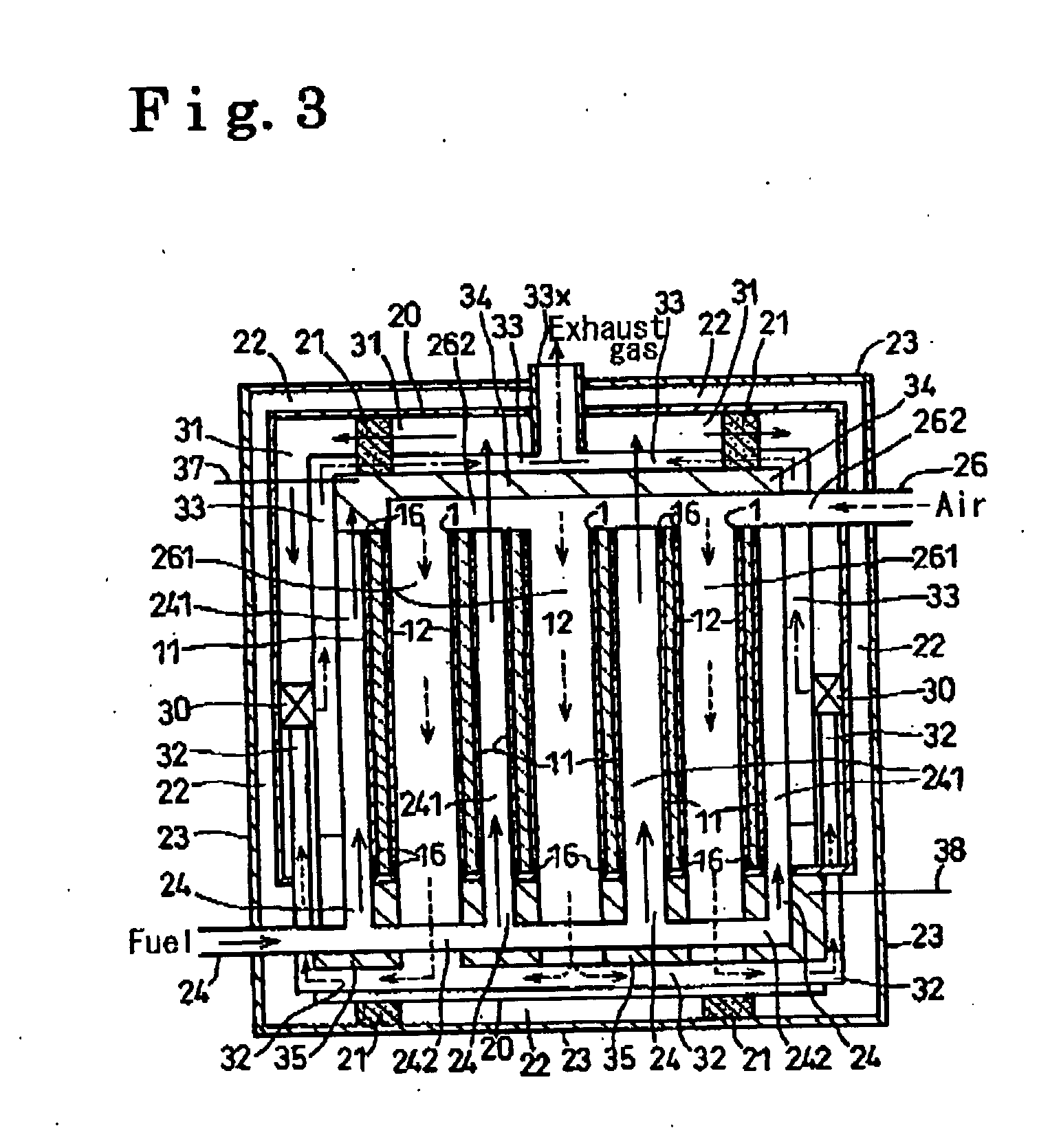

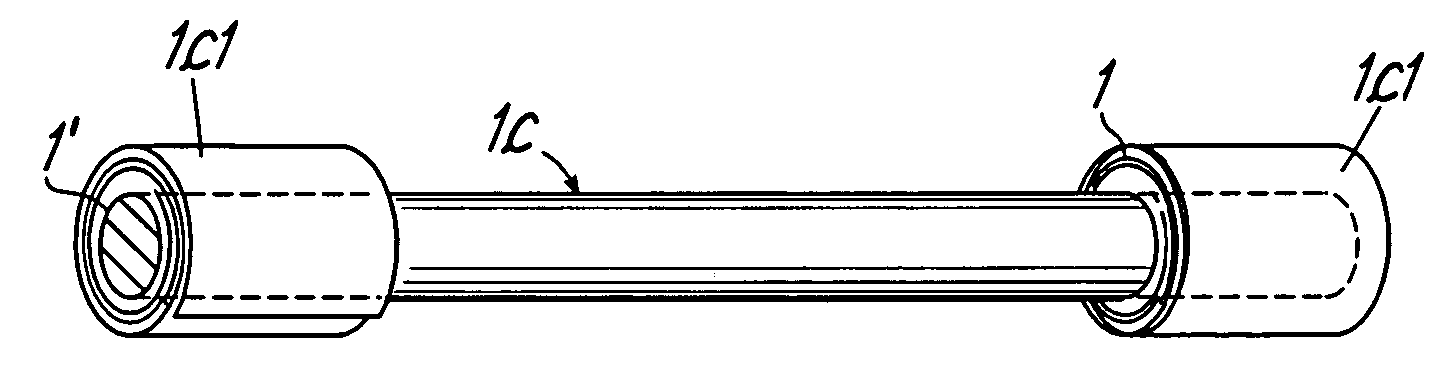

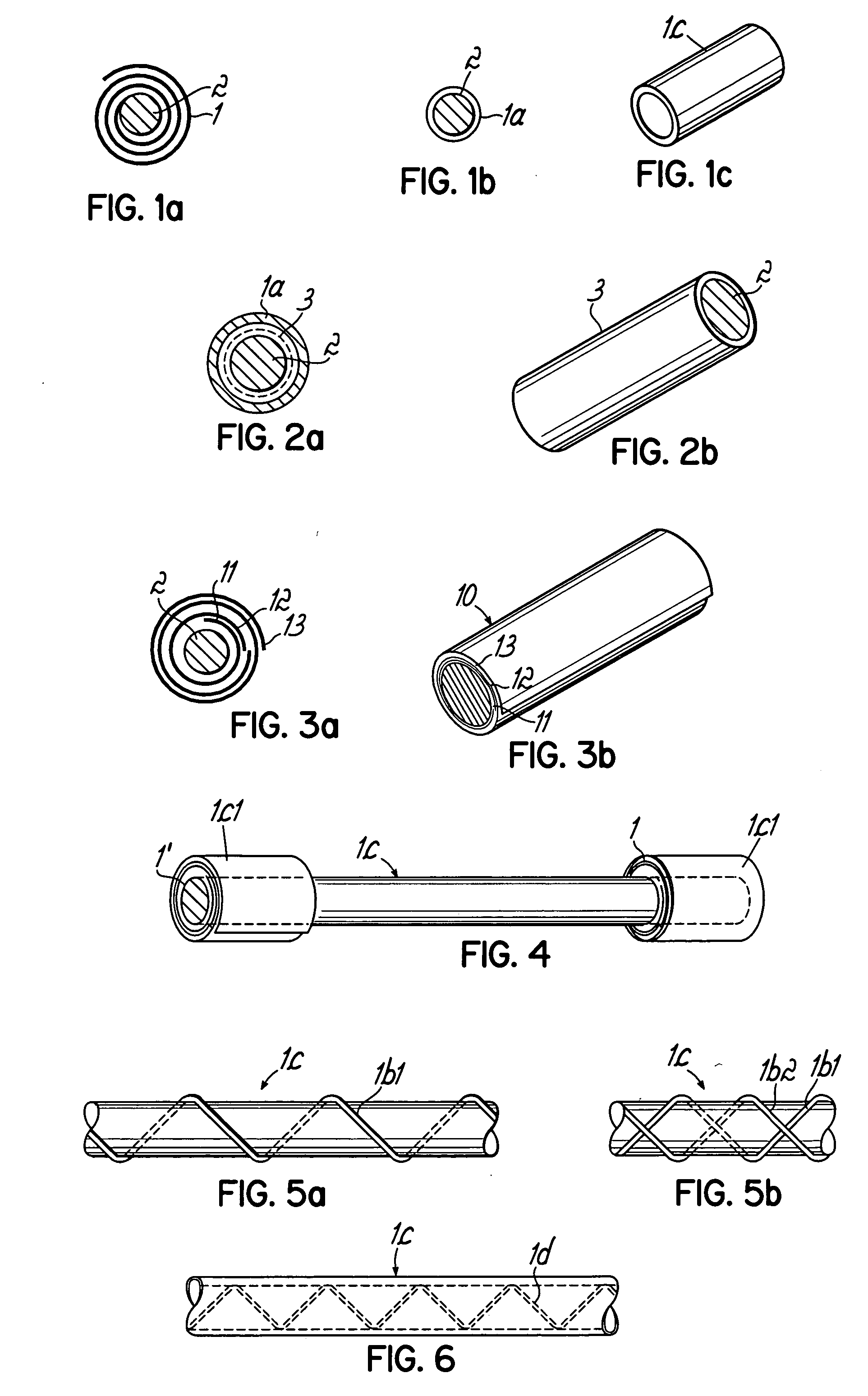

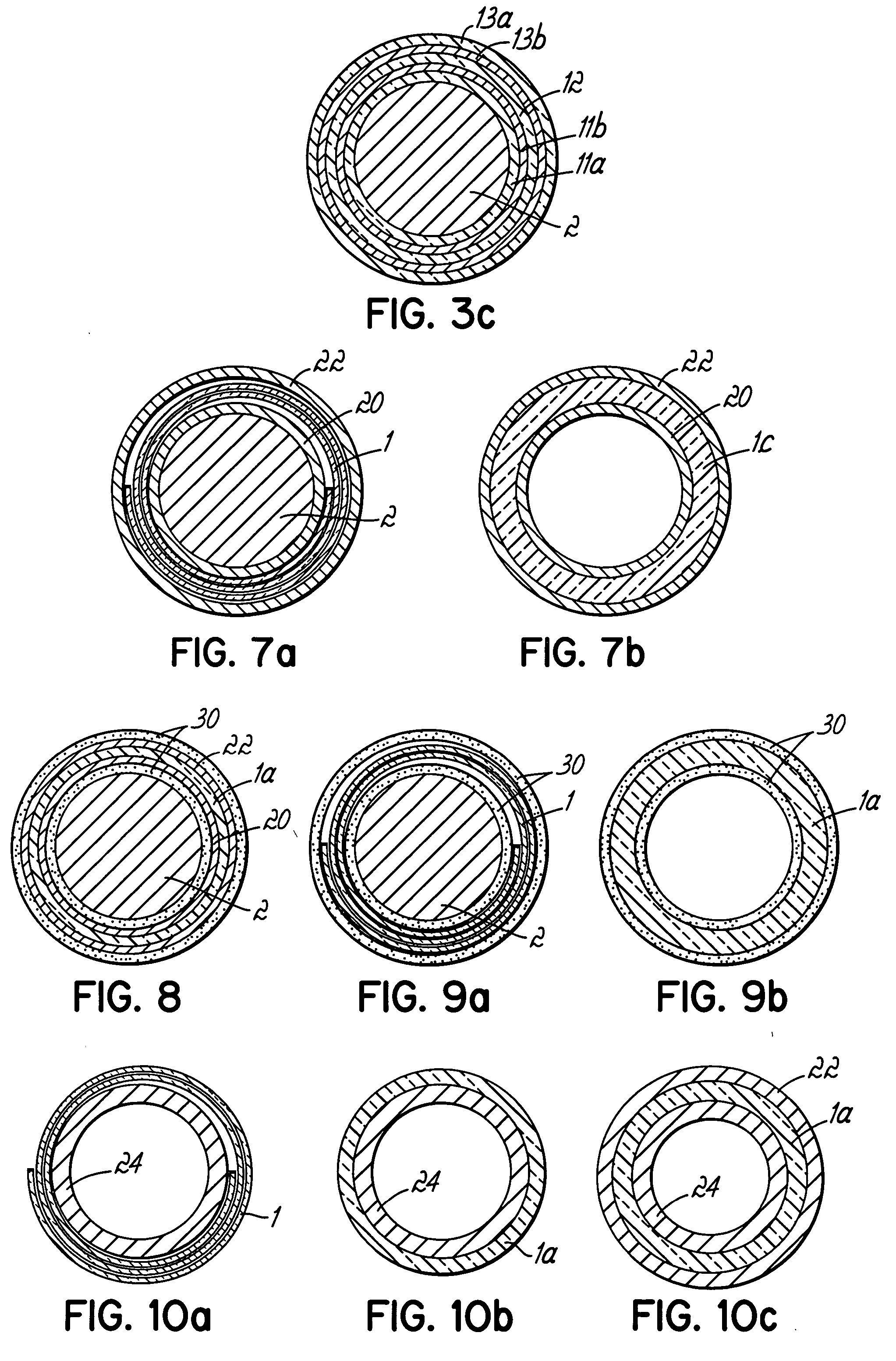

Method of making laminate thin-wall ceramic tubes and said tubes with electrodes, particularly for solid oxide fuel cells

InactiveUS20050000621A1Additional green thicknessHigh strengthPaper/cardboard wound articlesLayered productsFuel cellsMaterials science

A method of fabricating a ceramic tube with electrodes thereon suitable for use as a tubular reaction chamber for a fuel cell. In one embodiment, the method includes wrapping a first electrode material around a mandrel, then wrapping a green ceramic material over the first electrode material, and then wrapping a second electrode material over the green ceramic material. The wrapped layers are laminated together, and then removed from the mandrel and sintered, in either sequence, to produce the laminated ceramic tube having an inner first electrode and an outer second electrode. Alternatively, a first electrode tube is provided in place of the mandrel and around which the green ceramic material is wrapped. The outer second electrode may be produced by wrapping a second electrode material around the green ceramic material, before or after laminating, or by printing the electrode material onto the sintered ceramic tube. The present invention further provides a method of making a ceramic tube in which a sacrificial organic material is first wrapped around the mandrel to a desired thickness prior to wrapping the green ceramic material to increase the green material thickness. During sintering, the organic material is burned away leaving only a laminated ceramic tube, optionally with electrodes thereon.

Owner:PRESIDIO COMPONENTS

Alkali-Free Composite Sealant Materials for Solid Oxide Fuel Cells

A sealant composition for use in sealing solid oxide fuel cells is provided which comprises a glass component which comprises a mixture of alkali-free inorganic oxides, and an optional filler component dispersed in the glass component, said filler component being up to 40% by weight of the composition. The glass component can include, on a mole basis, 20 to 50% BaO, 1 to 10% Y2P3, 5 to 20% B2O3, 10 to 30% SiO2, 3 to 35% MgO, 2 to 20% CaO, 1 to 10% ZnO, and 0 to 5% ZrO2, and exemplary filler components include zirconia, alumina, barium titanate, strontium titanate, and combinations thereof.

Owner:CUMMINS ENTERPRISE LLC

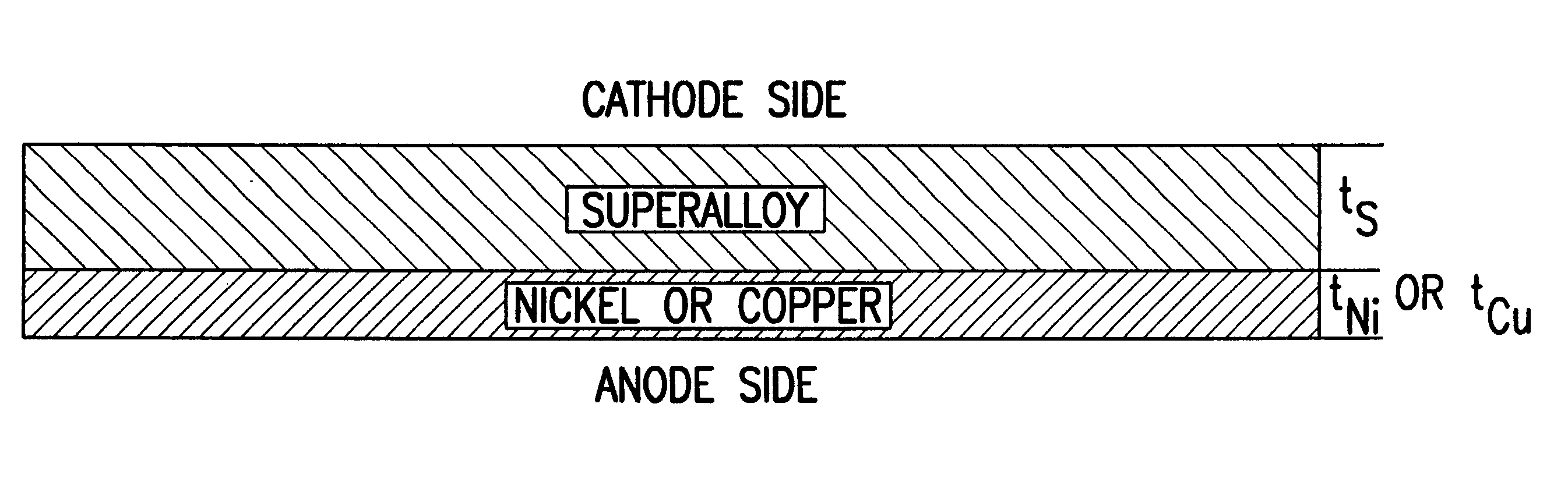

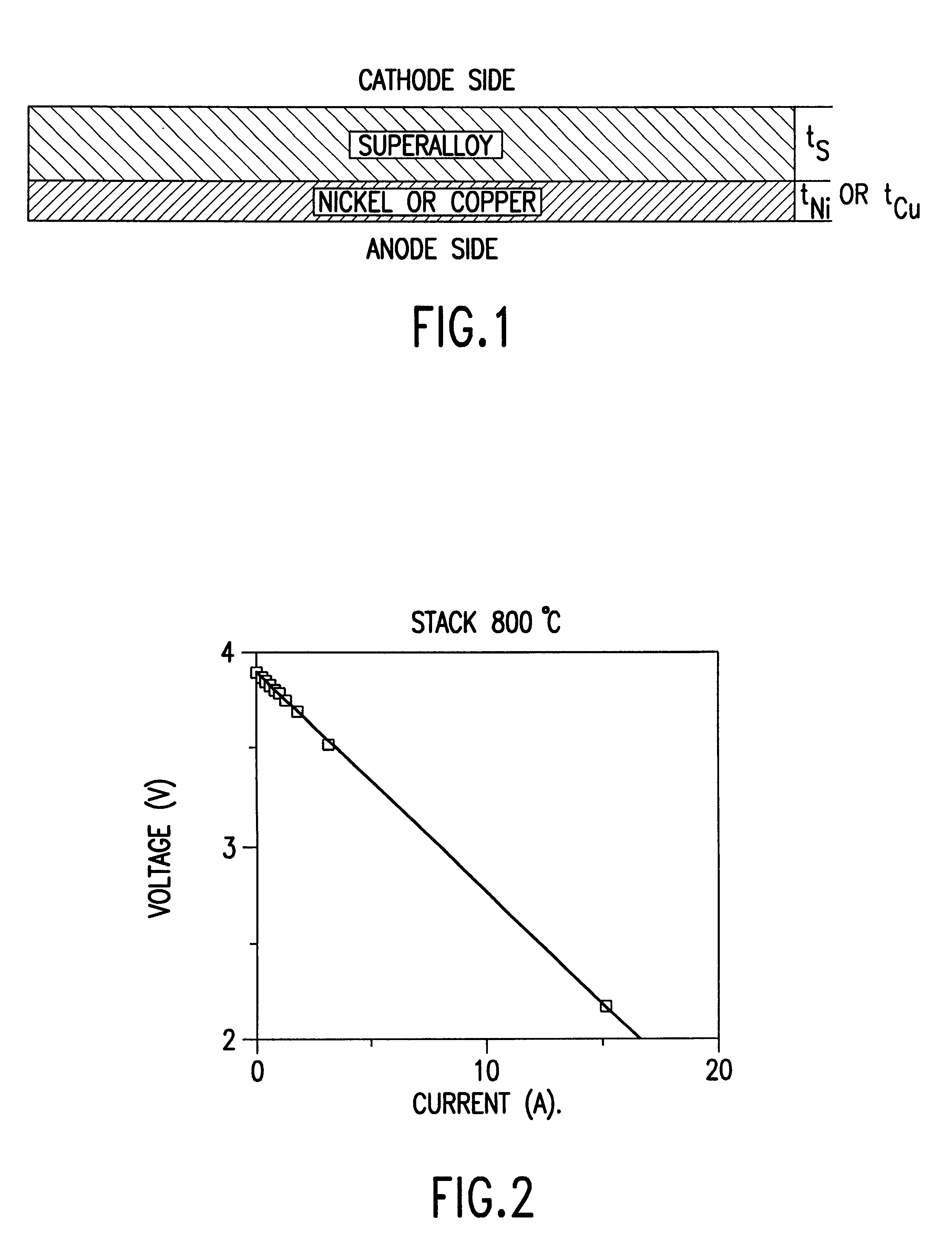

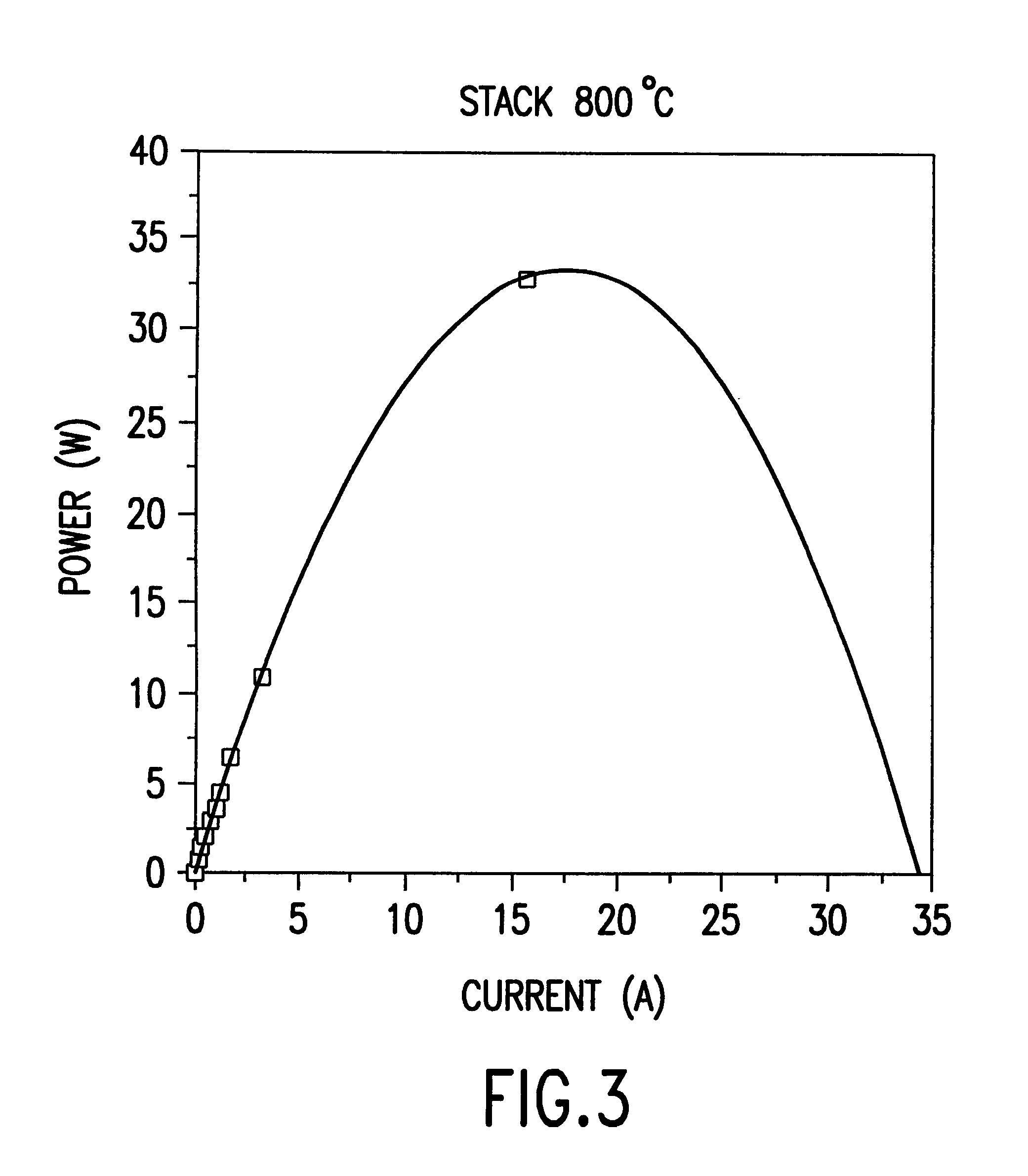

Solid oxide fuel cell interconnector

A solid oxide fuel cell interconnector having a superalloy metallic layer with an anode-facing face and a cathode-facing face and metal layer on the anode-facing face of the superalloy metallic layer. The metal layer is a metal which does not oxidize in a fuel atmosphere, preferably nickel or copper.

Owner:VERSA POWER SYST

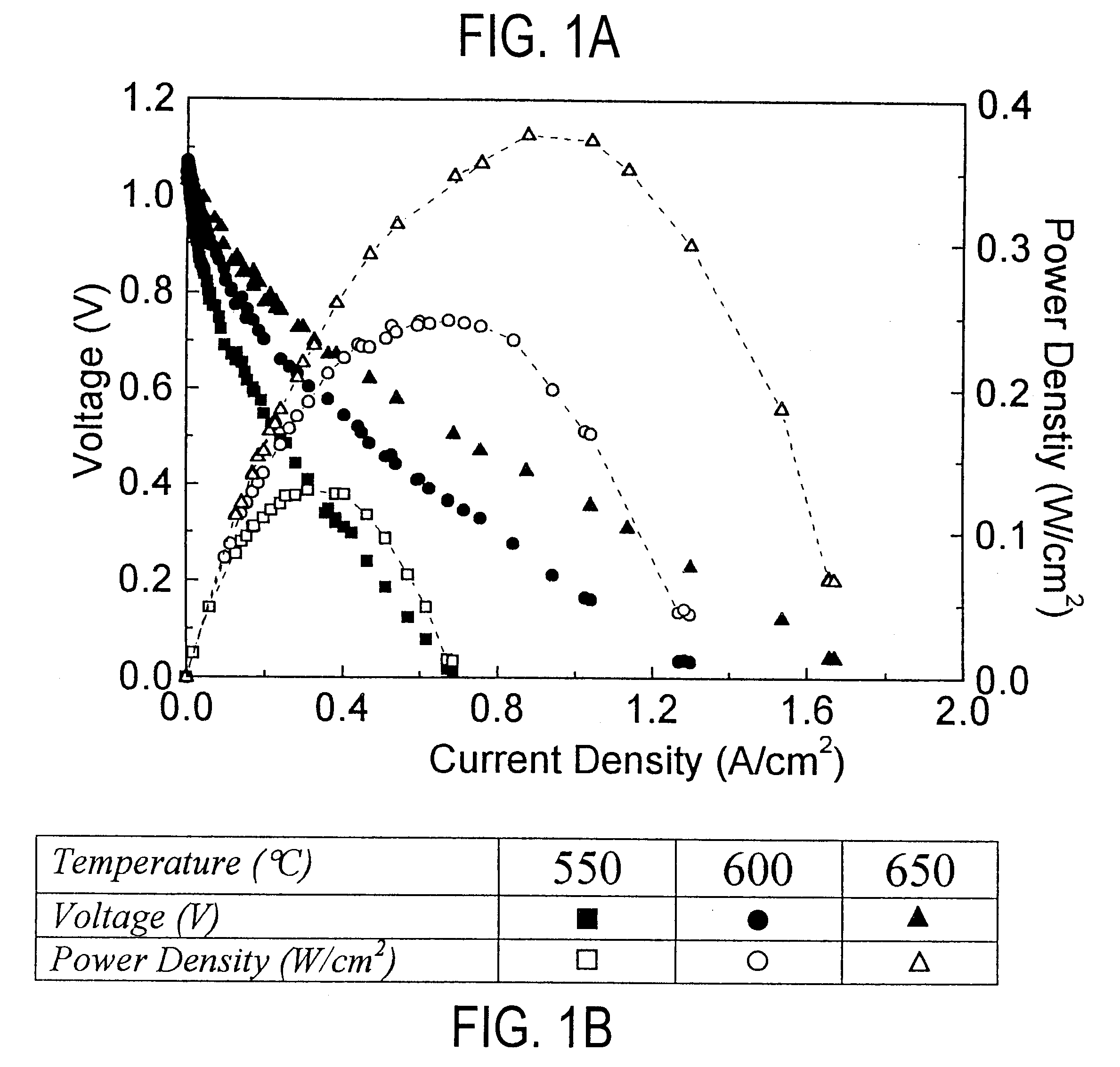

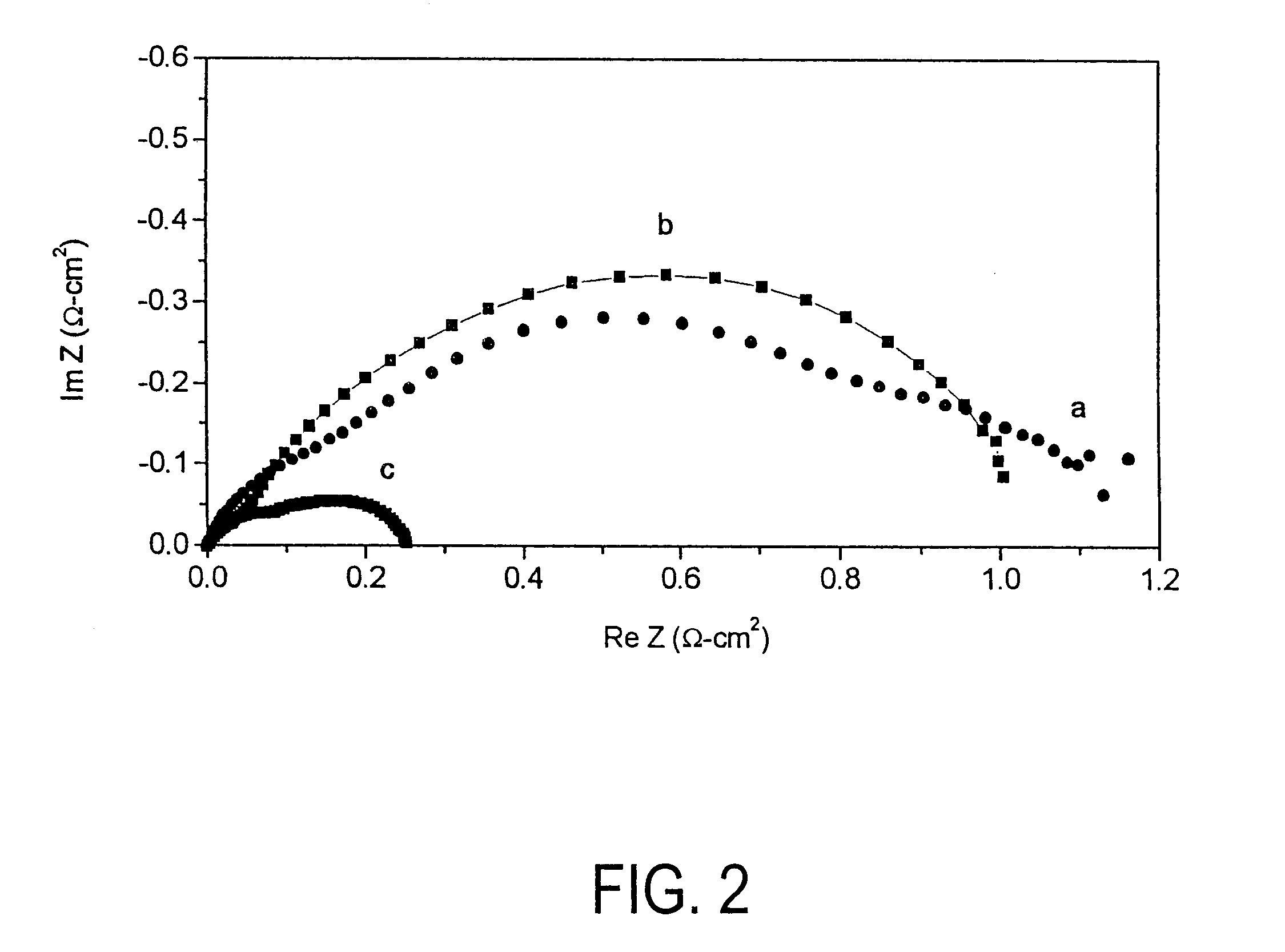

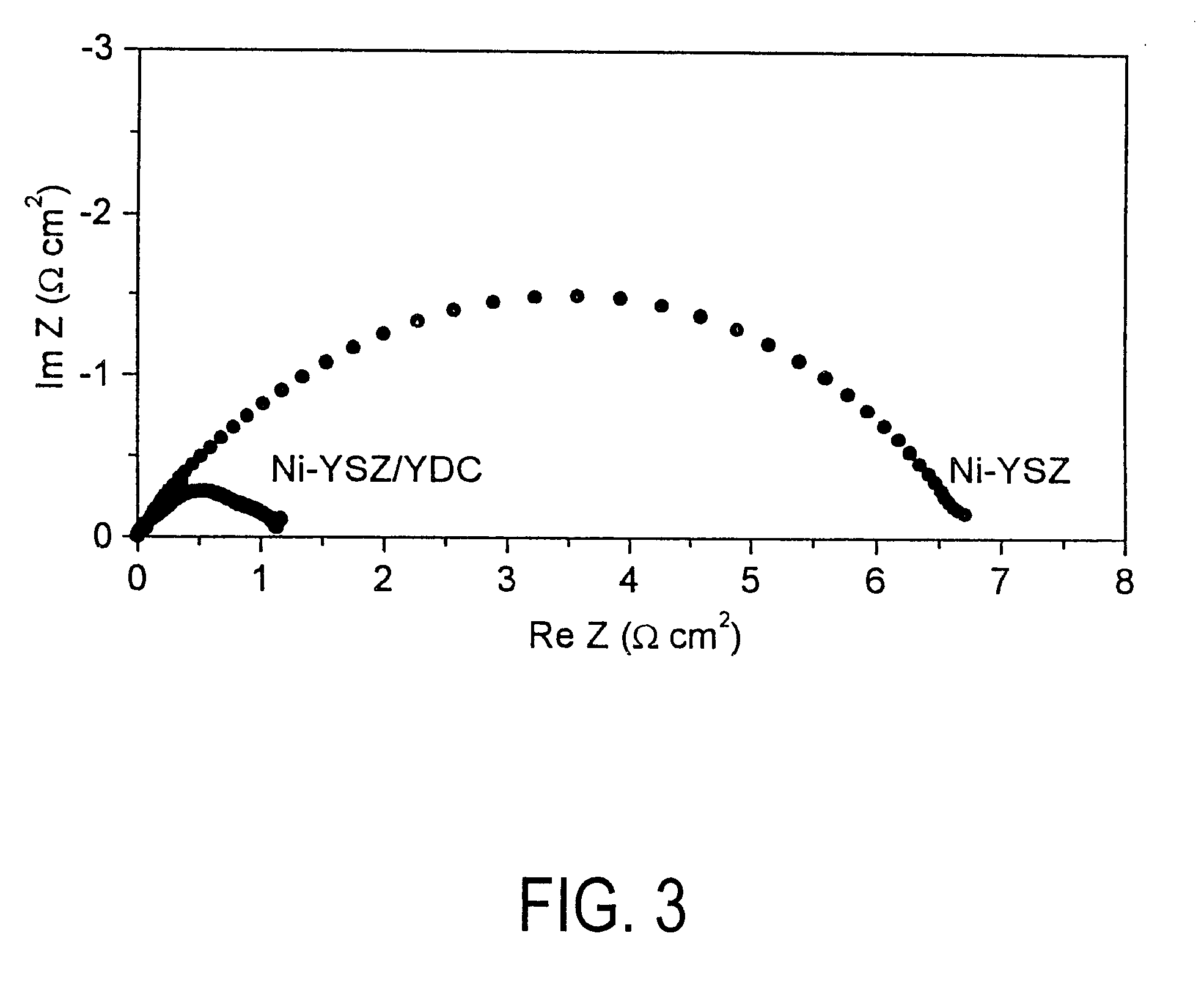

Ceria-based solid oxide fuel cells

InactiveUS20020127455A1Improve power densityMore option for sealingCell electrodesFuel cell auxillariesCerium(IV) oxideCobalt

High-performance intermediate temperature solid oxide fuel cells (SOFCs). The SOFCs are ceria-based structures that can achieve a power output of 300 mW / cm.sup.2 at an operating temperature below 600.degree. C. By way of example, the fuel cell as an anode made of NiO / doped-ceria, a thin film of doped-ceria and / or doped zirconia electrolyte is deposited on the anode, and a cathode of cobalt iron based material, such as (La, Sr)(Co, Fe)O.sub.3 or cobalt, ion, magnesium based material, is deposited on top of the electrolyte, and can operate at a temperature of 550.degree. C. The various layers may be deposited by colloidal spray deposition or aerosol spray casting.

Owner:RGT UNIV OF CALIFORNIA

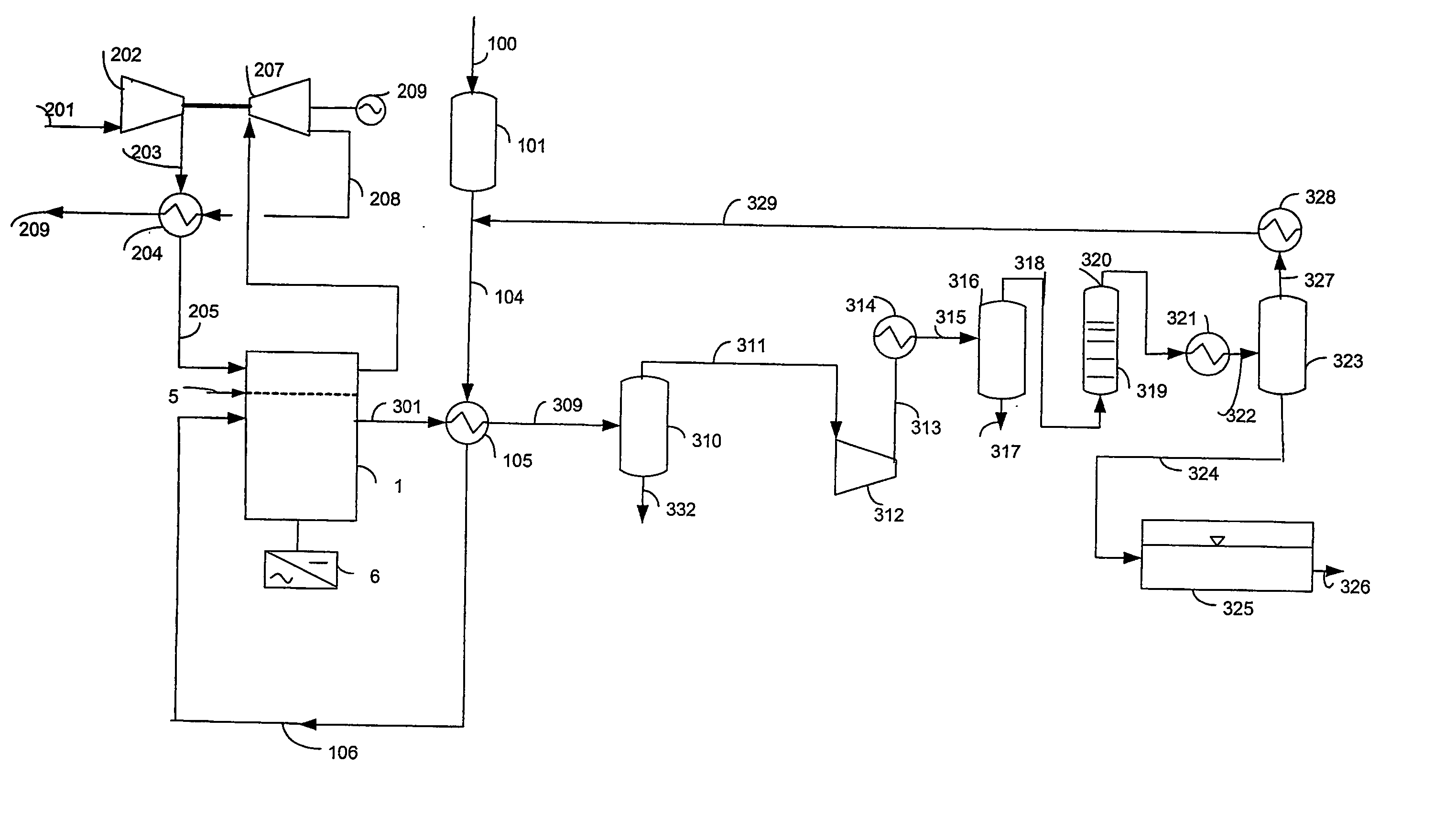

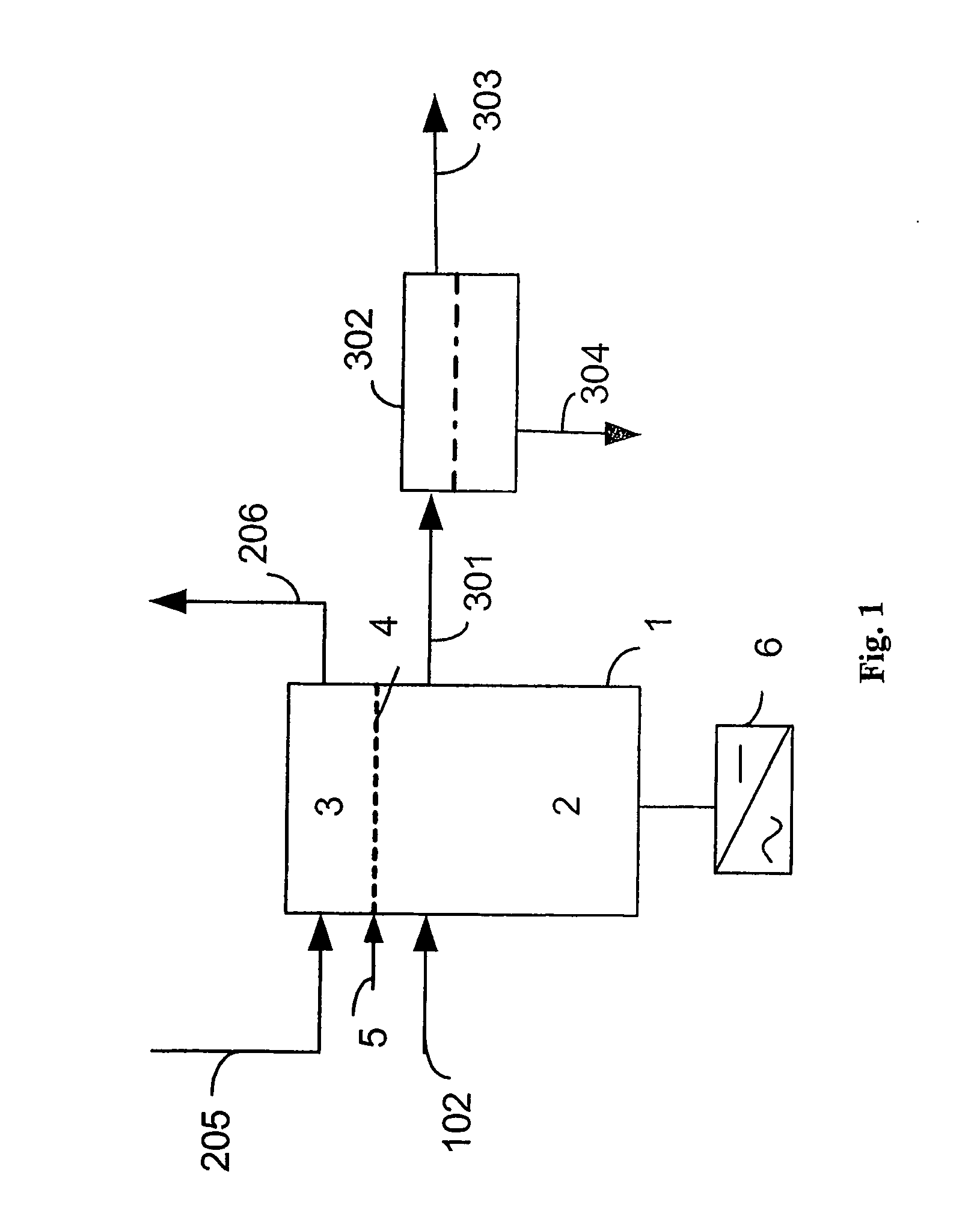

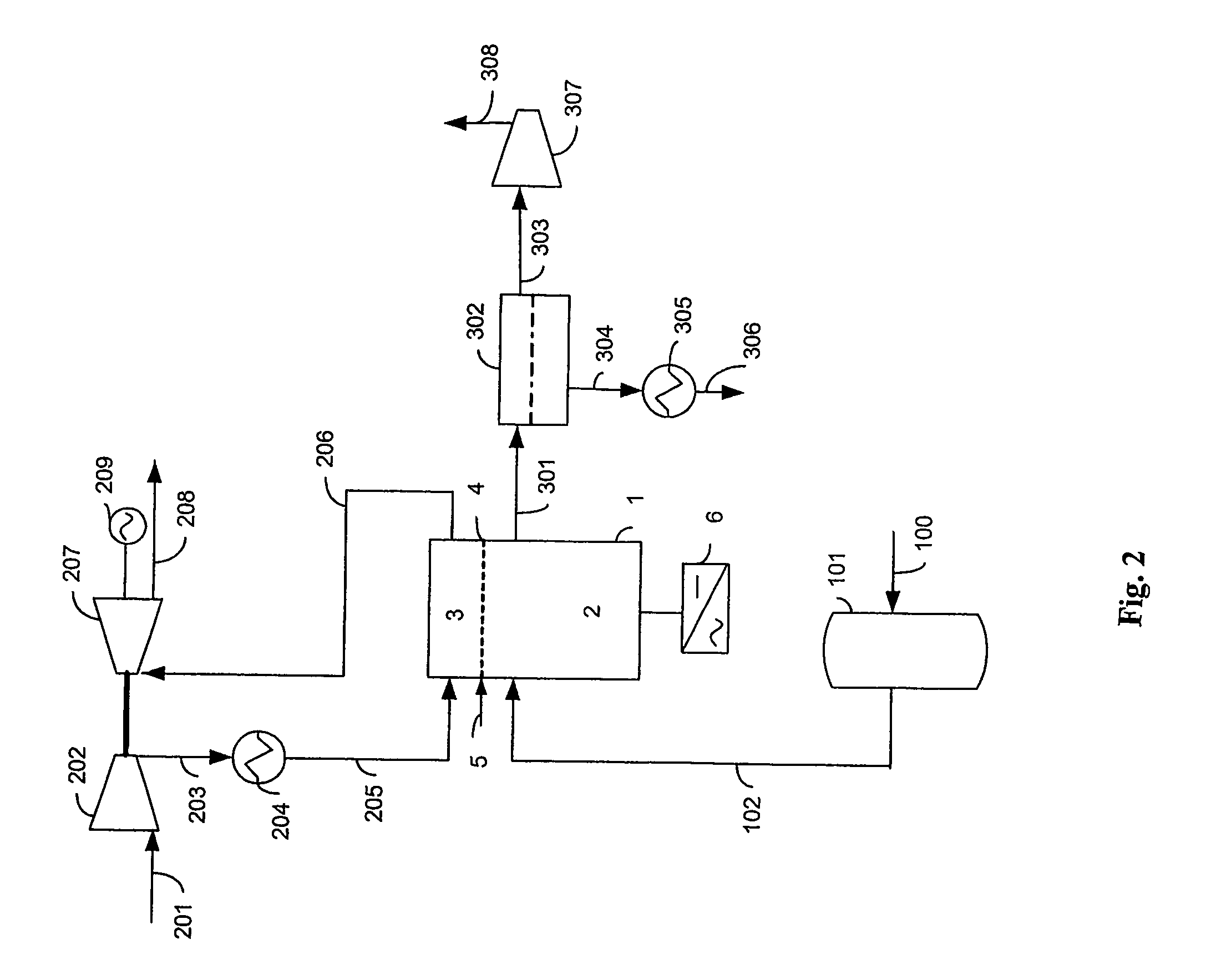

Method for exhaust gas treatment in a solid oxide fuel cell power plant

InactiveUS20060115691A1Improve electricity efficiencySimple and preferably cheapSolidificationLiquefactionFuel cellsPower station

The invention relates to anode exhaust gas treatment methods for solid oxide fuel cell power plants with CO2 capture, in which the unreacted fuel in the anode exhaust (301) is recovered and recycled, while the resulting exhaust stream (303) consists of highly concentrated CO2. It is essential to the invention that the anode fuel gas (102) and the cathode air (205) are kept separate throughout the solid oxide fuel cell stacks (1). A gas turbine (202,207) is included on the air side in order to maximise the electrical efficiency.

Owner:AKER KVRNER ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com