Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

530results about "Fused electrolyte fuel cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

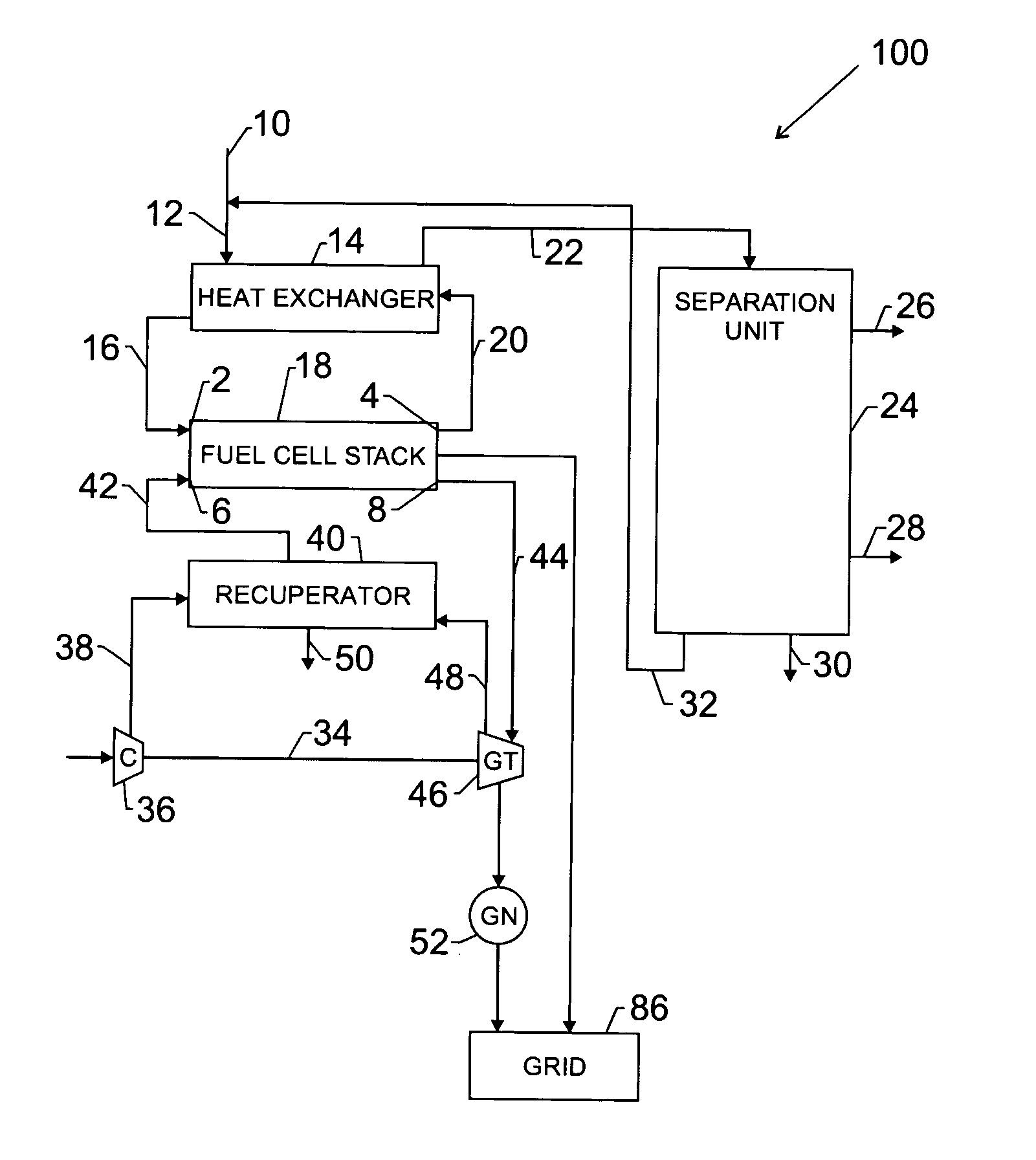

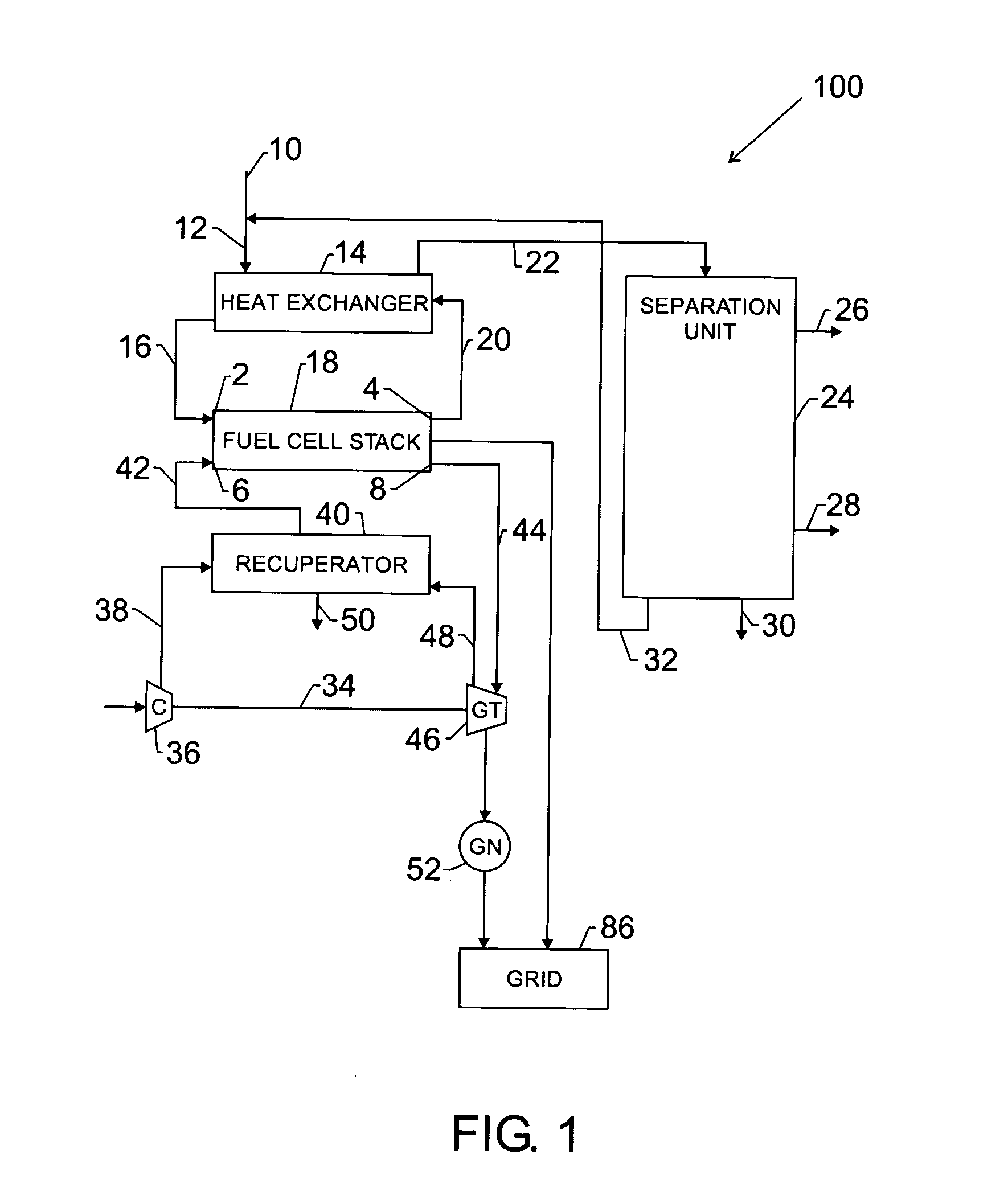

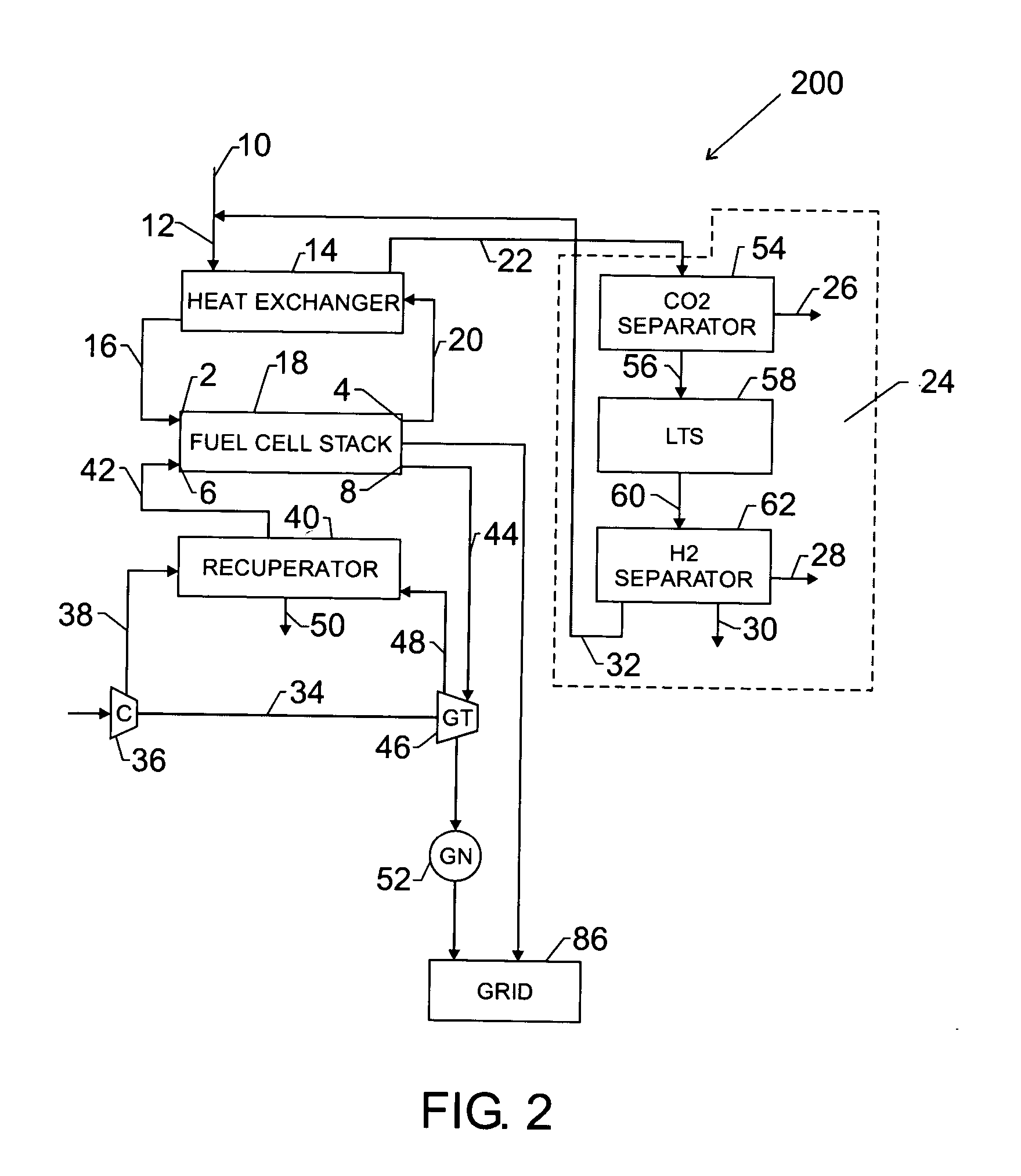

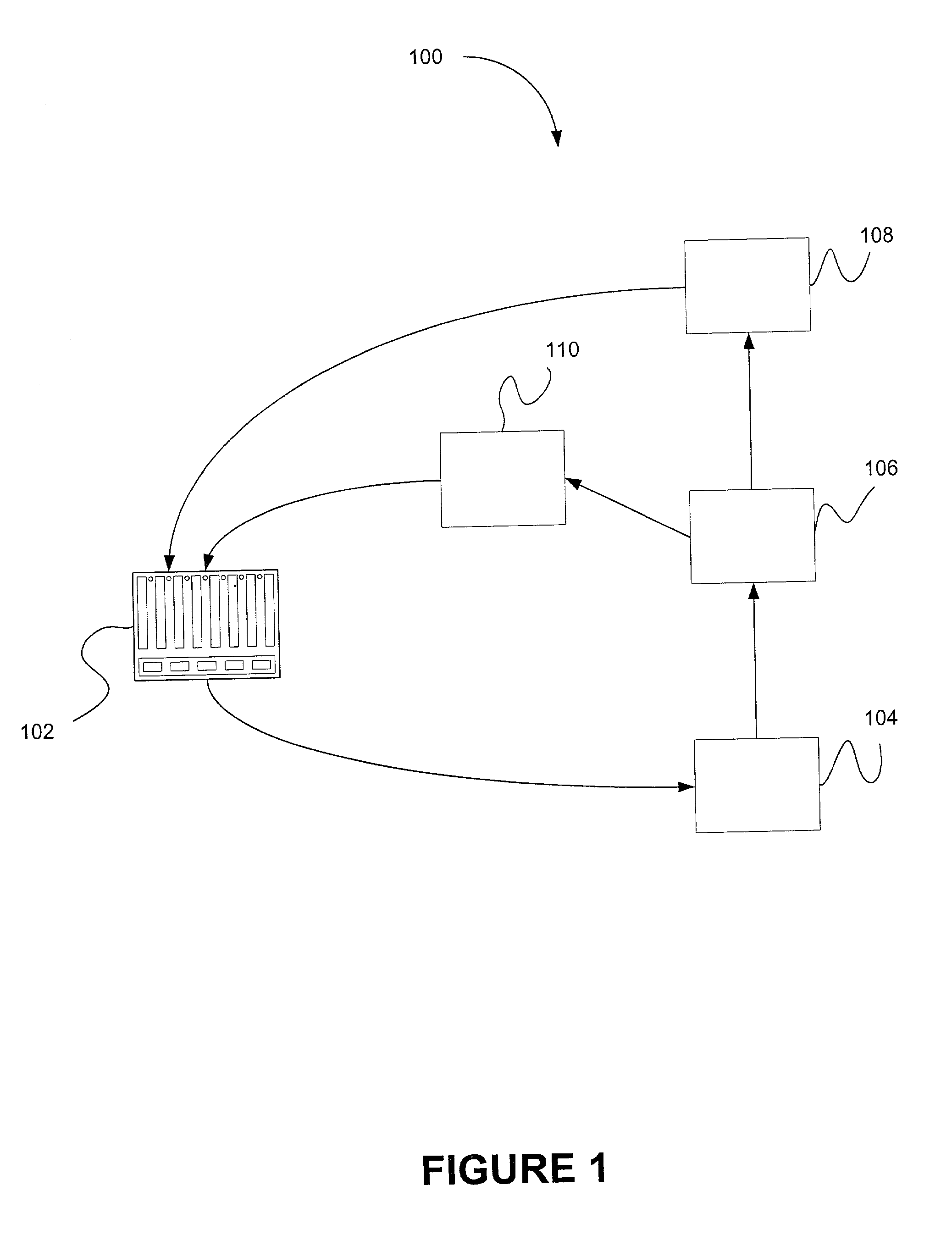

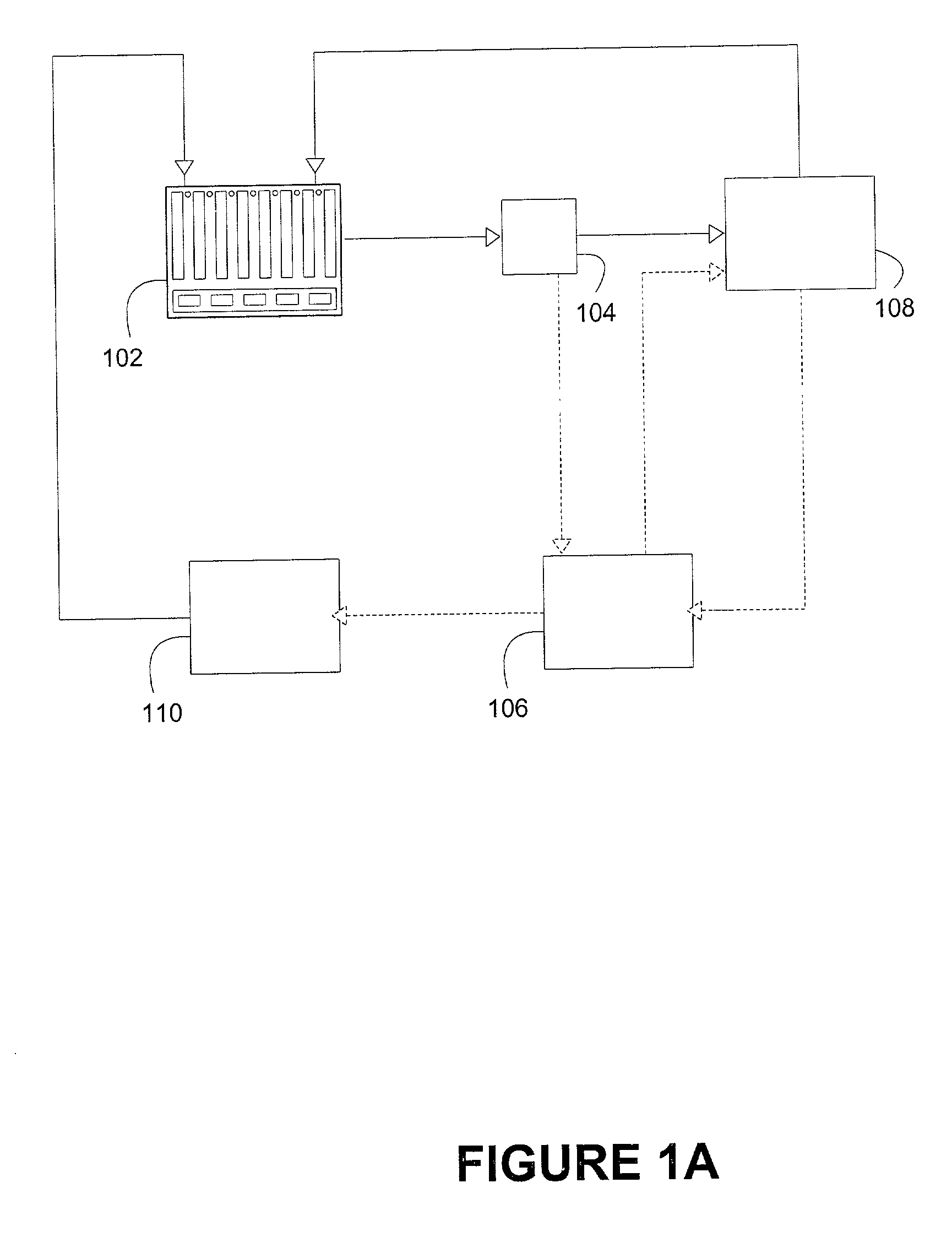

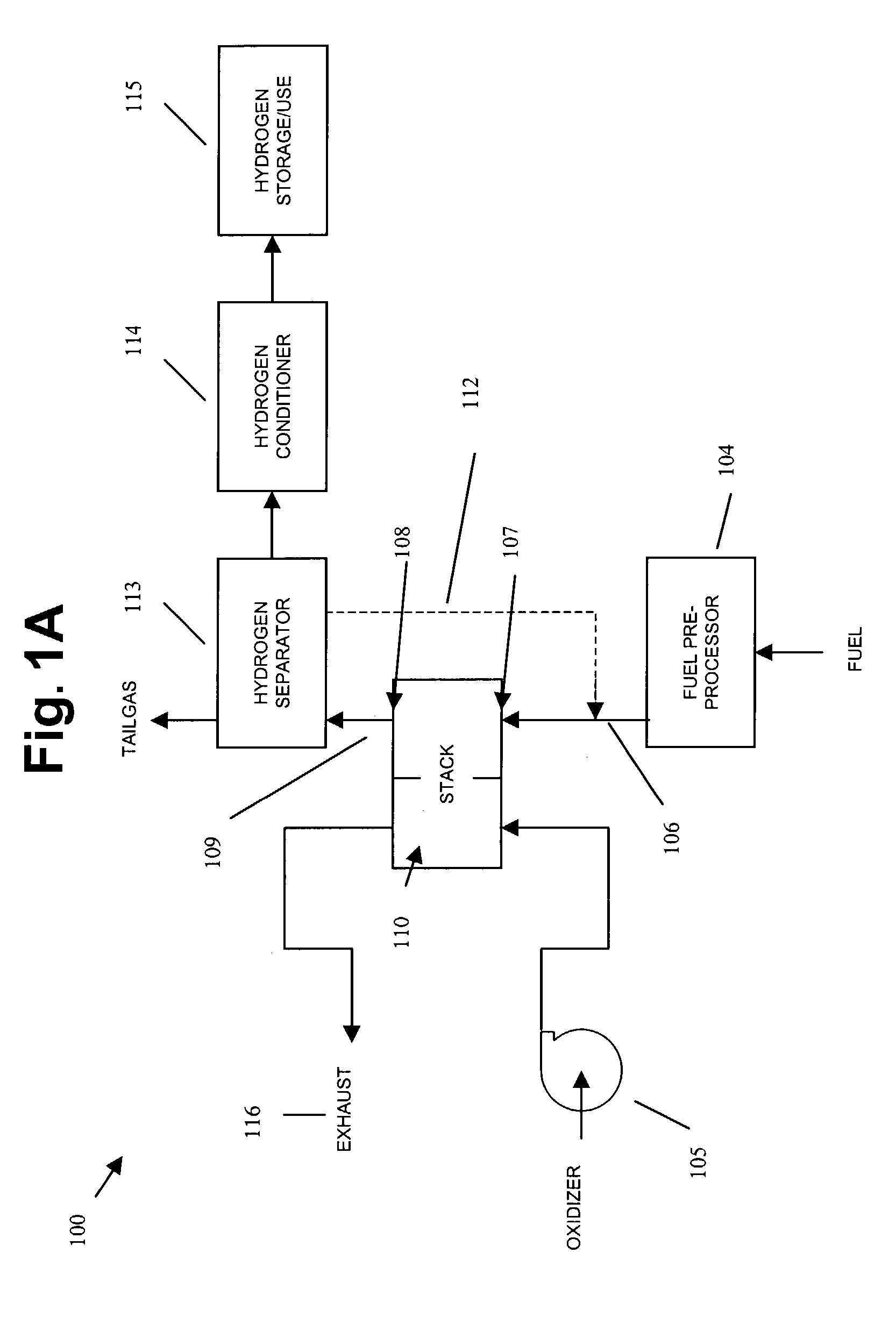

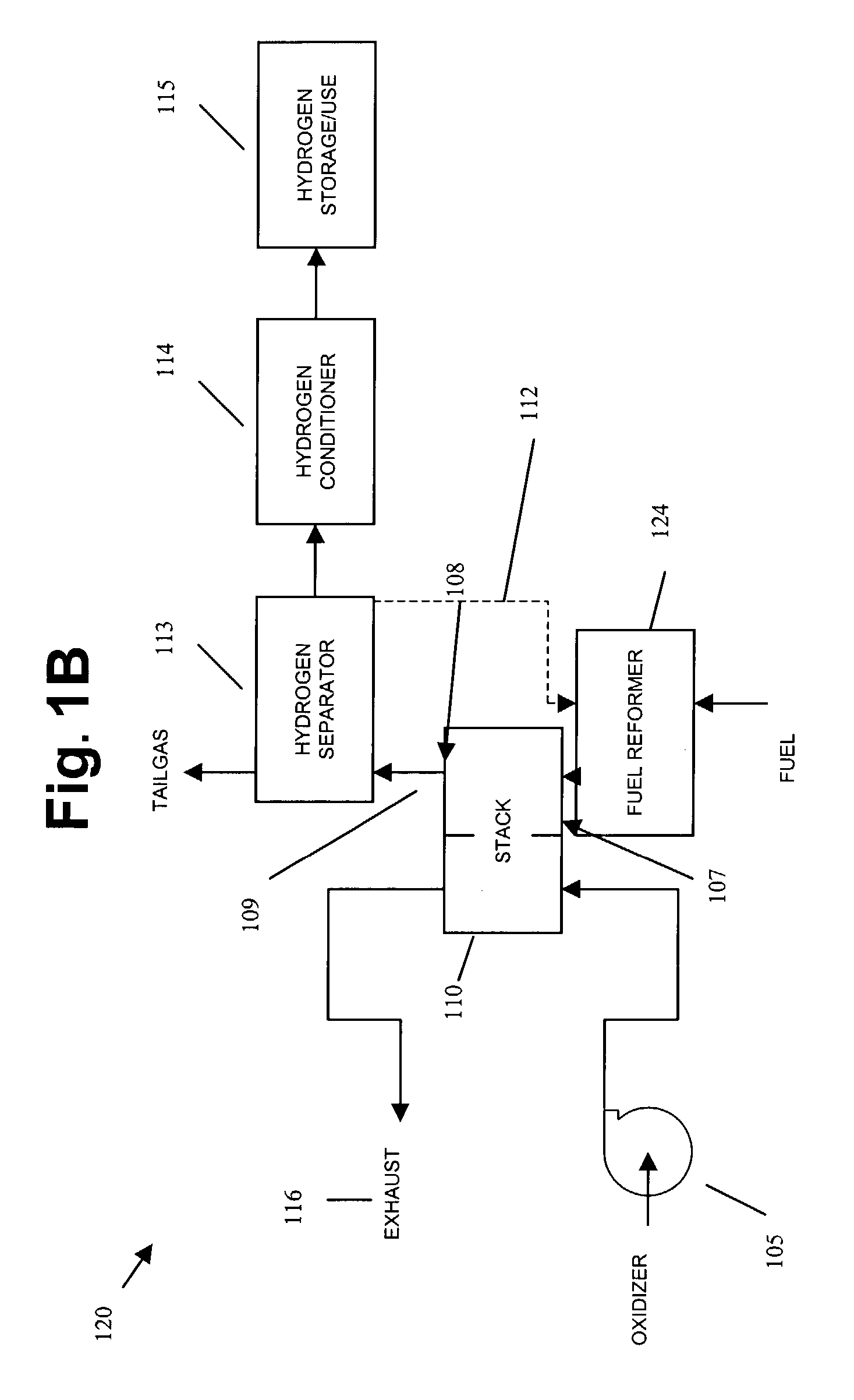

System and method for co-production of hydrogen and electrical energy

InactiveUS20050123810A1Fuel cell combinationsHydrogen separation at low temperatureHydrogenFuel cells

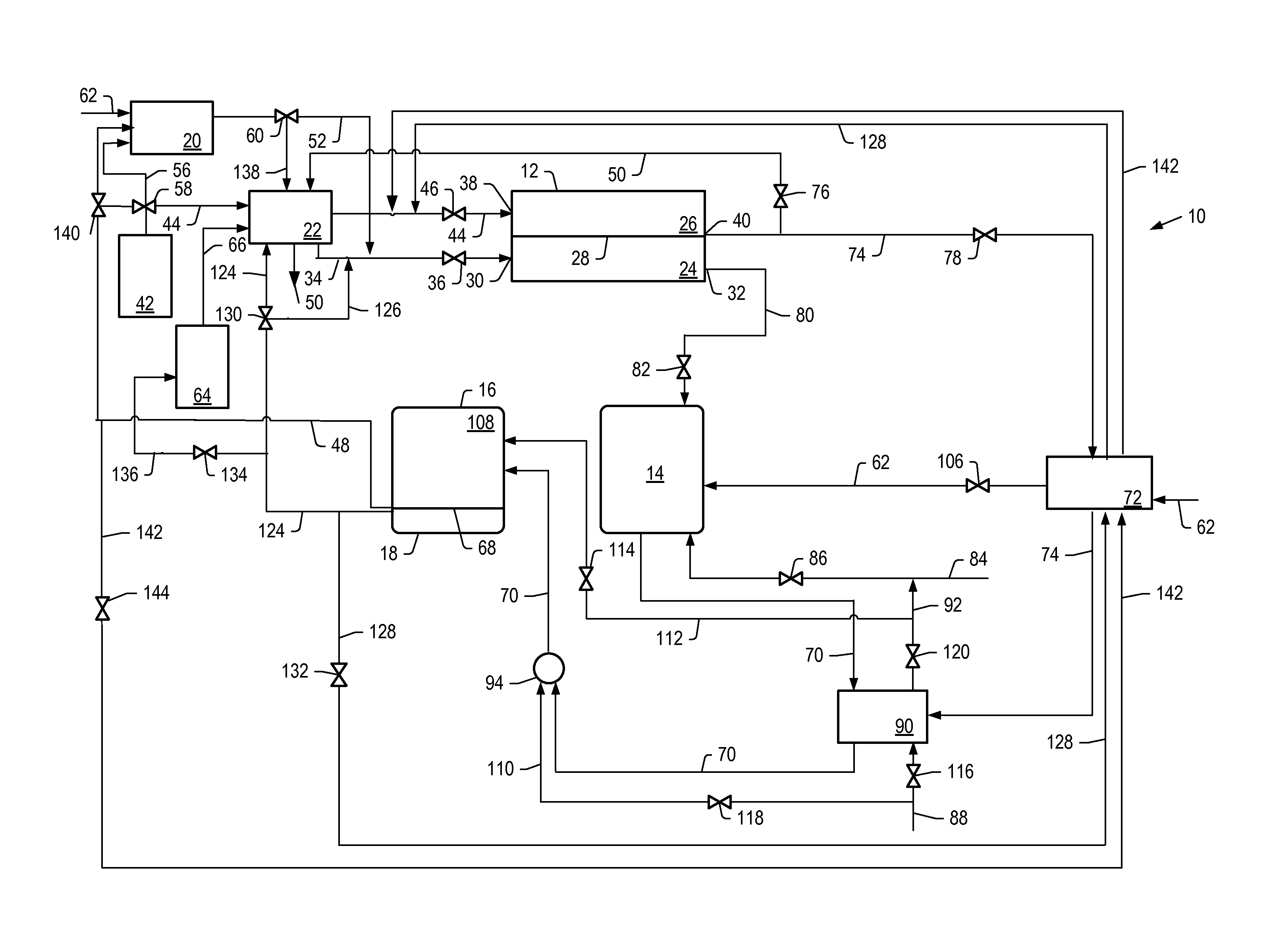

A system and method for co-production of hydrogen and electrical energy. The system comprises a fuel cell assembly comprising a plurality of fuel cells. The fuel cells further comprise a cathode inlet for receiving a compressed oxidant, an anode inlet for receiving a fuel feed stream, an anode outlet in fluid communication with an anode exhaust stream and a cathode outlet in fluid communication with a cathode exhaust stream. At least a portion of the fuel feed stream reacts with the oxidant to produce electrical power. The anode exhaust stream comprises hydrogen. The co-production system further comprises a separation unit in fluid communication with the fuel cell assembly. The separation unit is configured to receive the anode exhaust stream from the fuel cell assembly to separate hydrogen from the anode exhaust stream.

Owner:GENERAL ELECTRIC CO

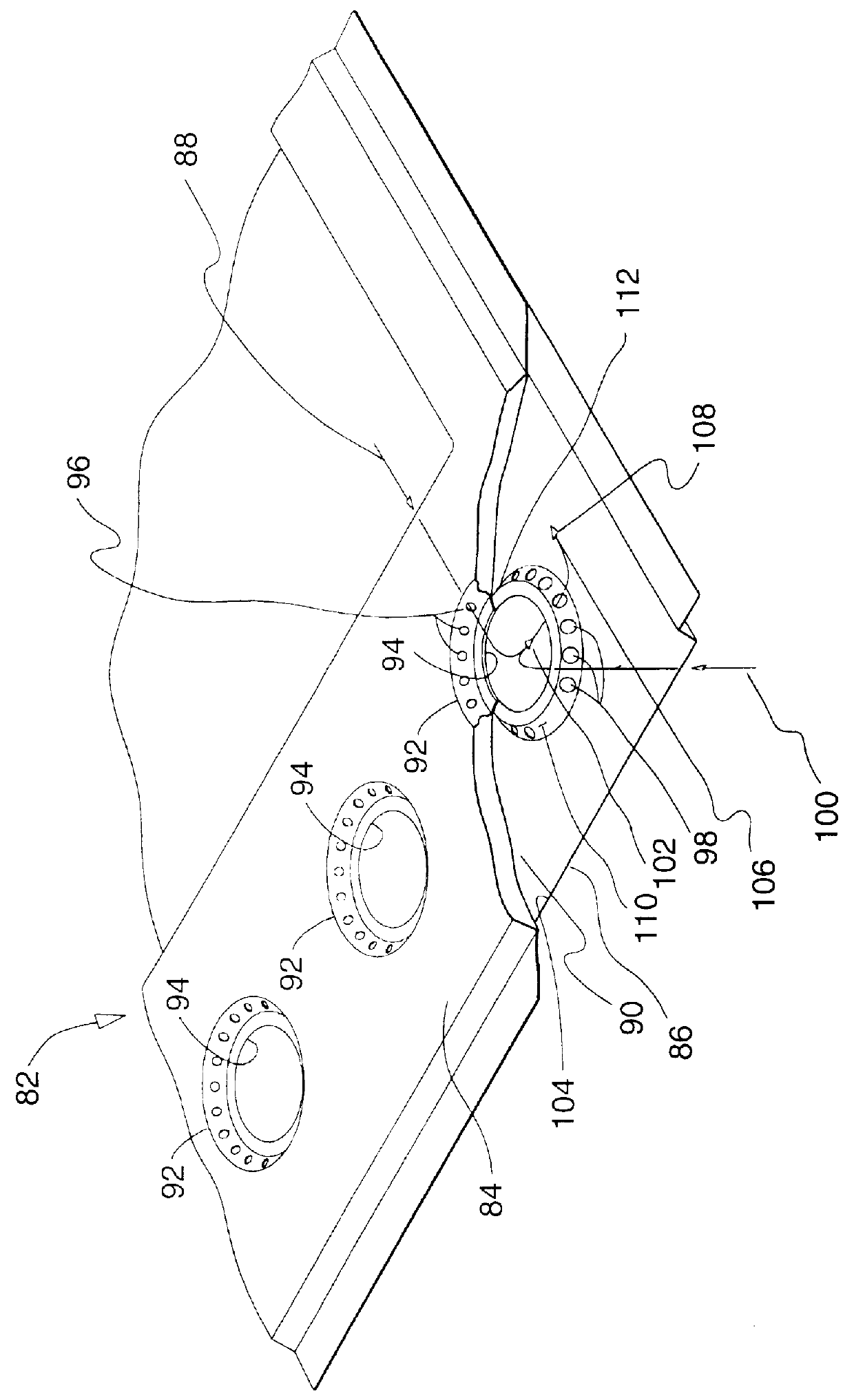

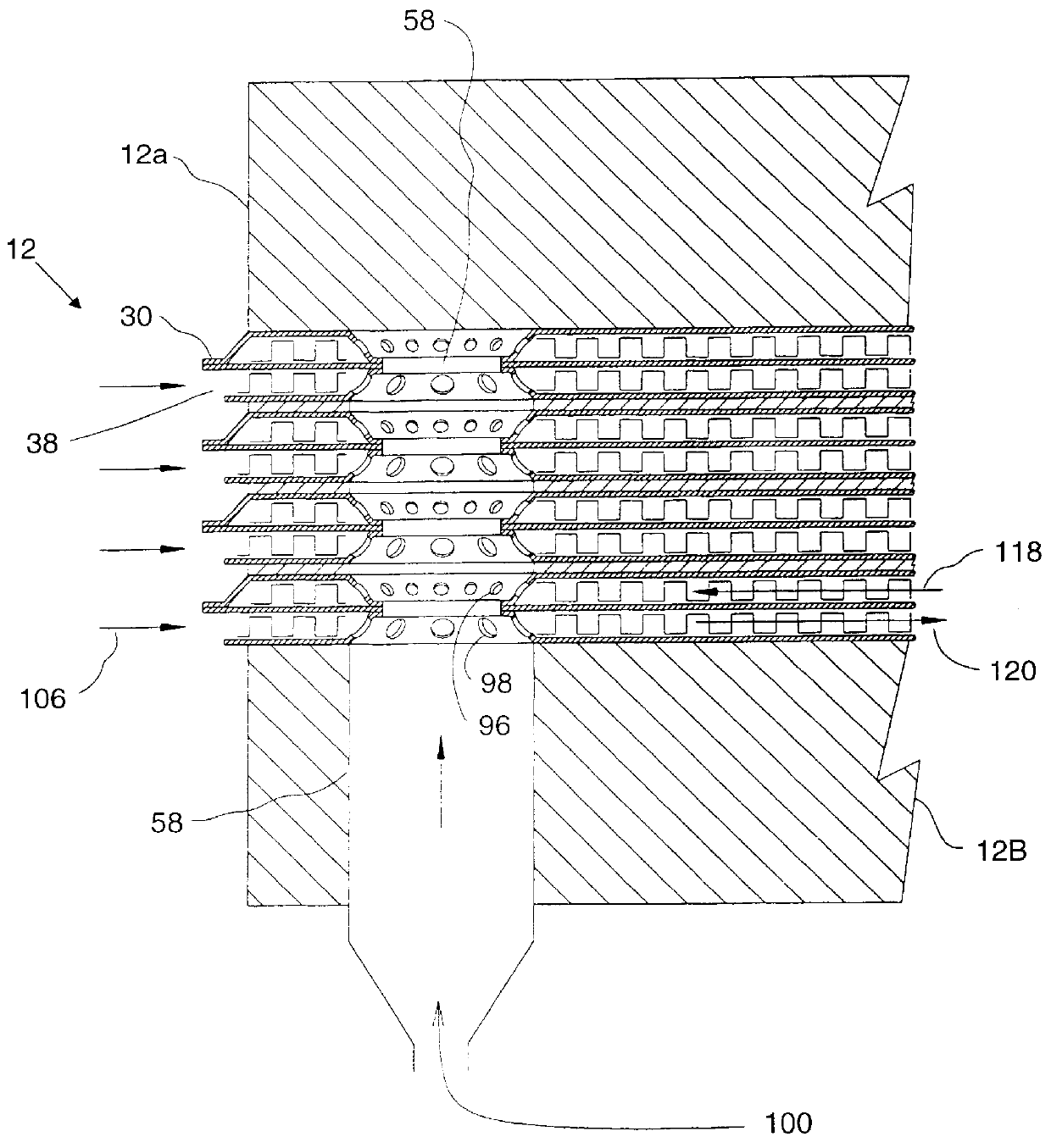

Energy efficient gas separation for fuel cells

InactiveUS20020142208A1Improve efficiencyReduce the ratioFuel cell heat exchangeFused electrolyte fuel cellsEngineeringDelivery system

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

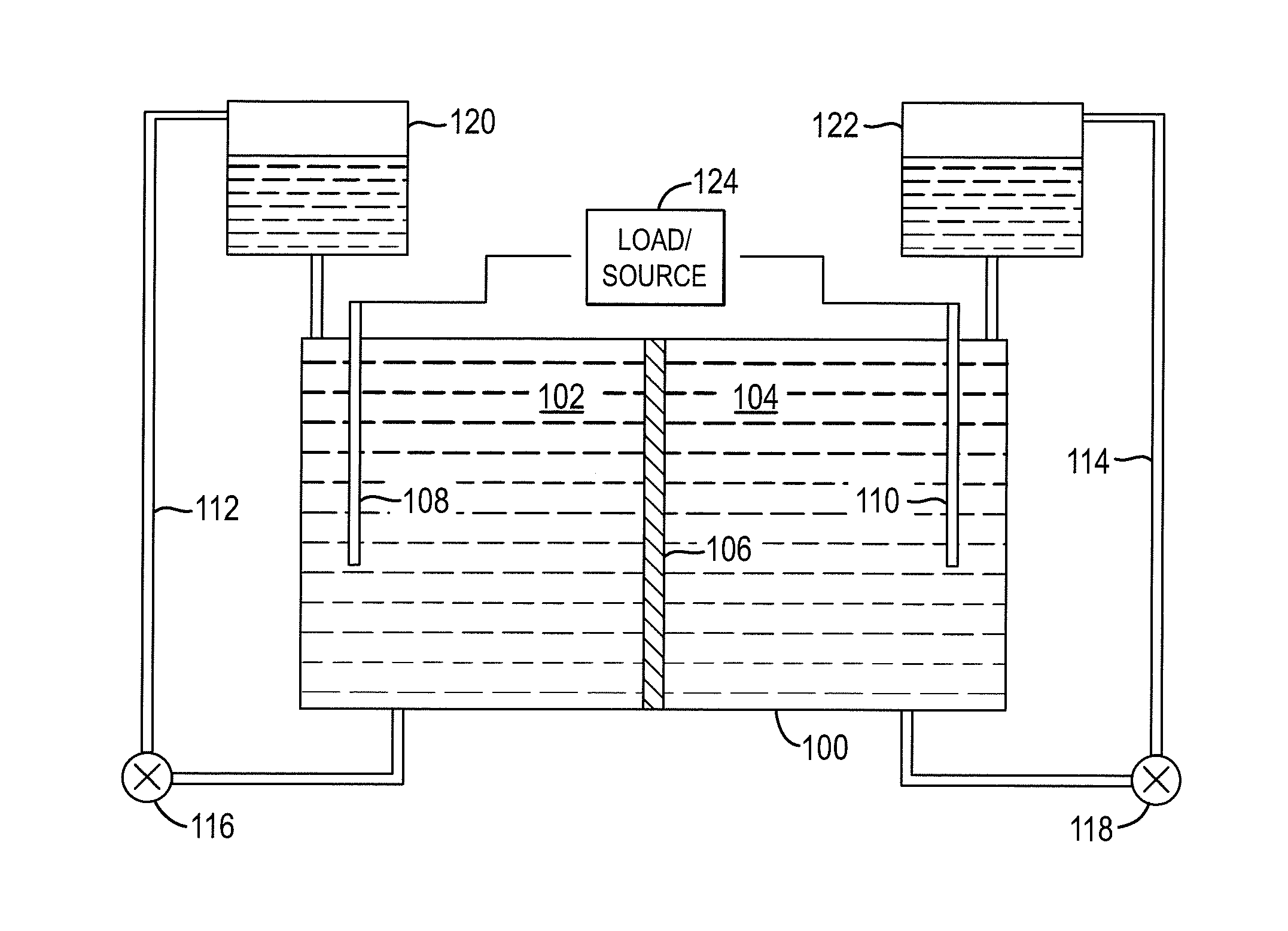

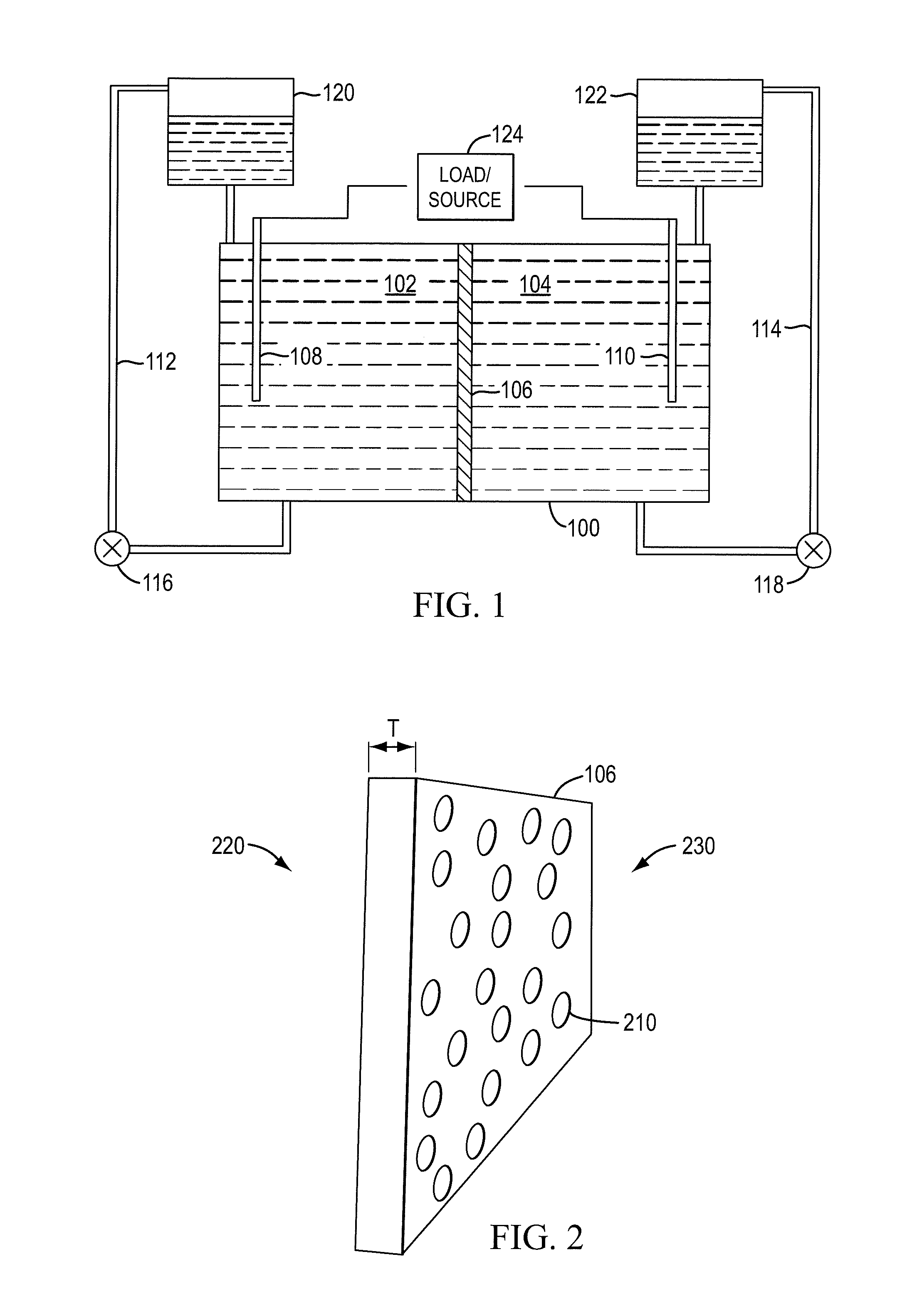

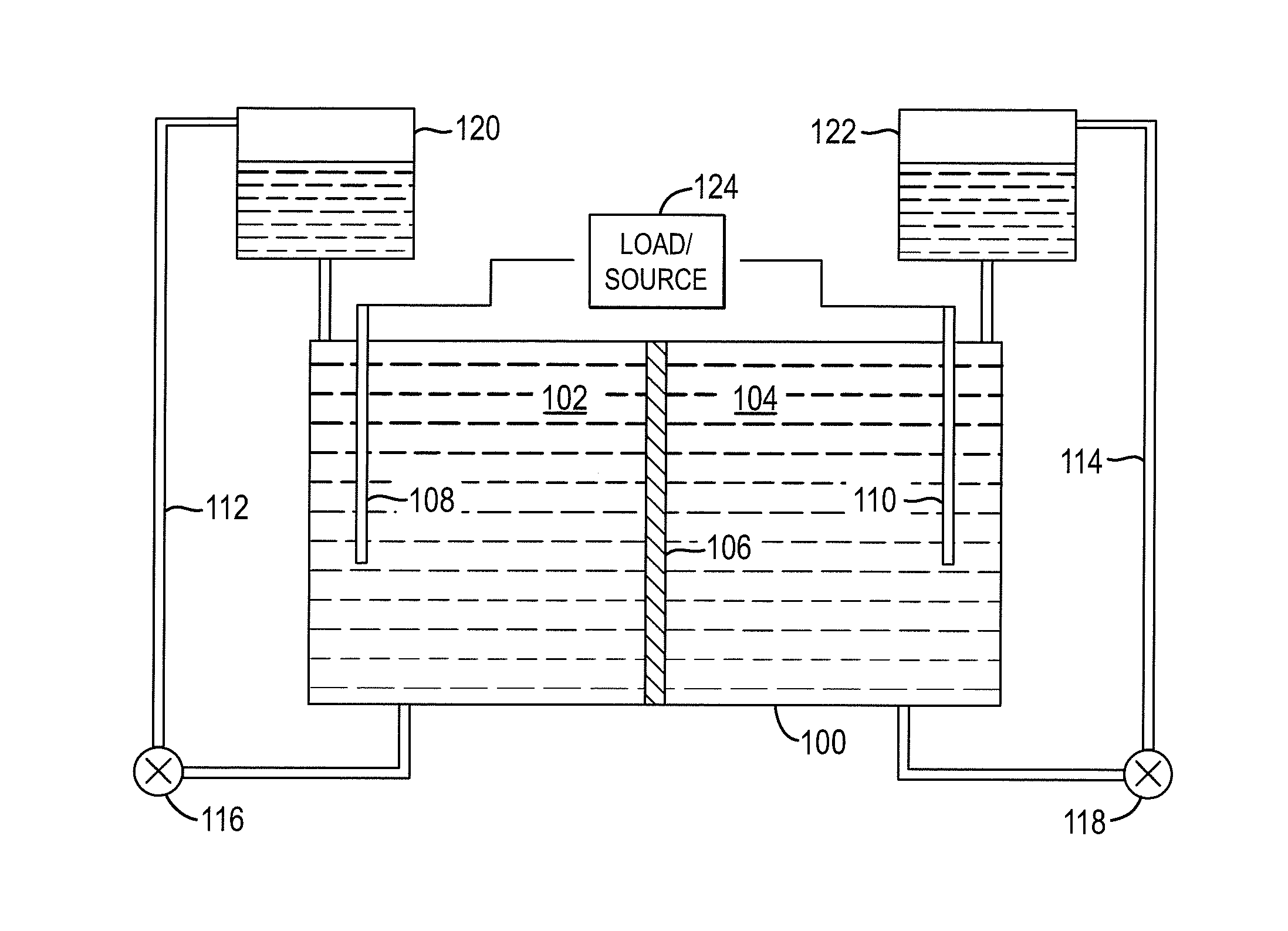

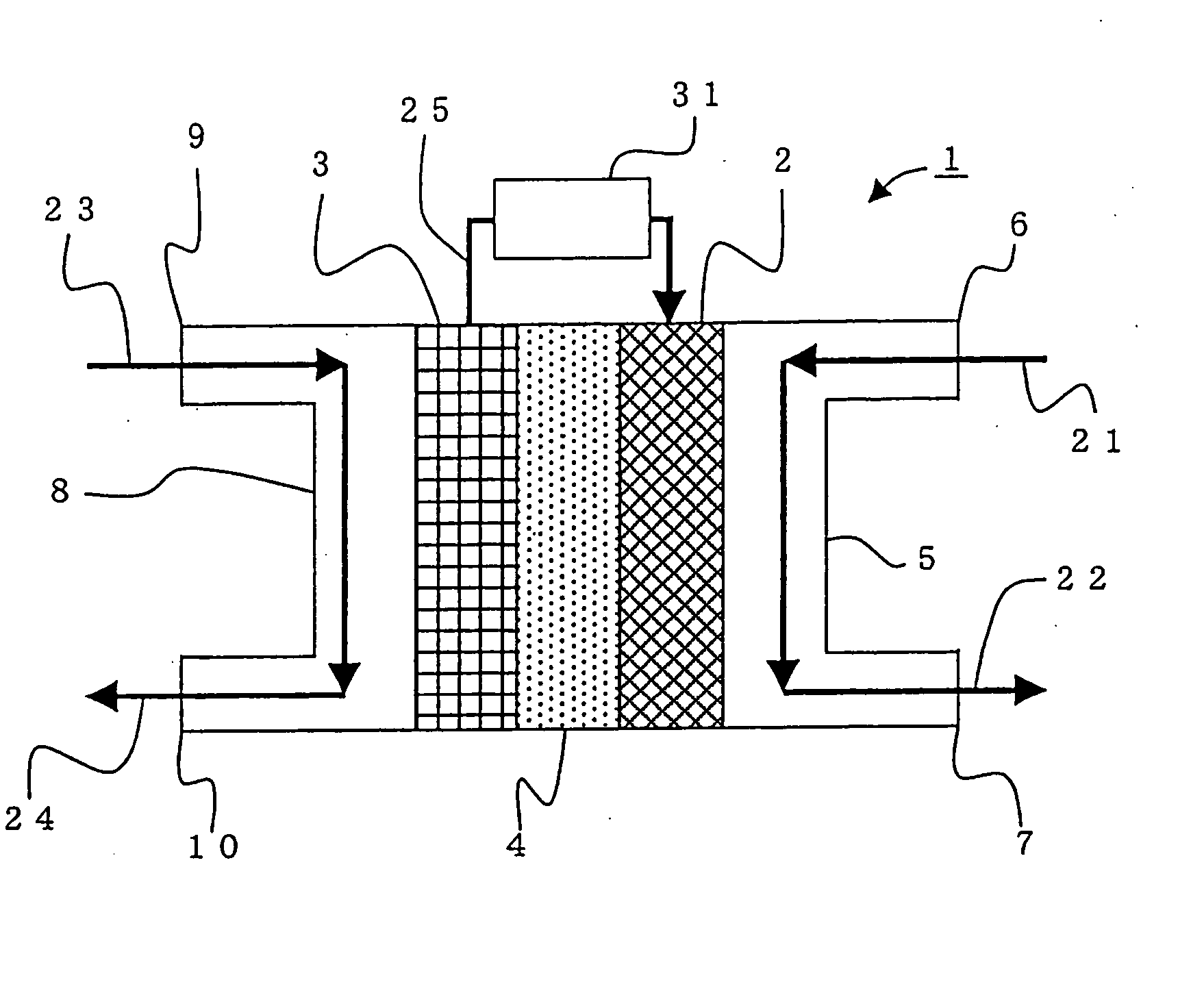

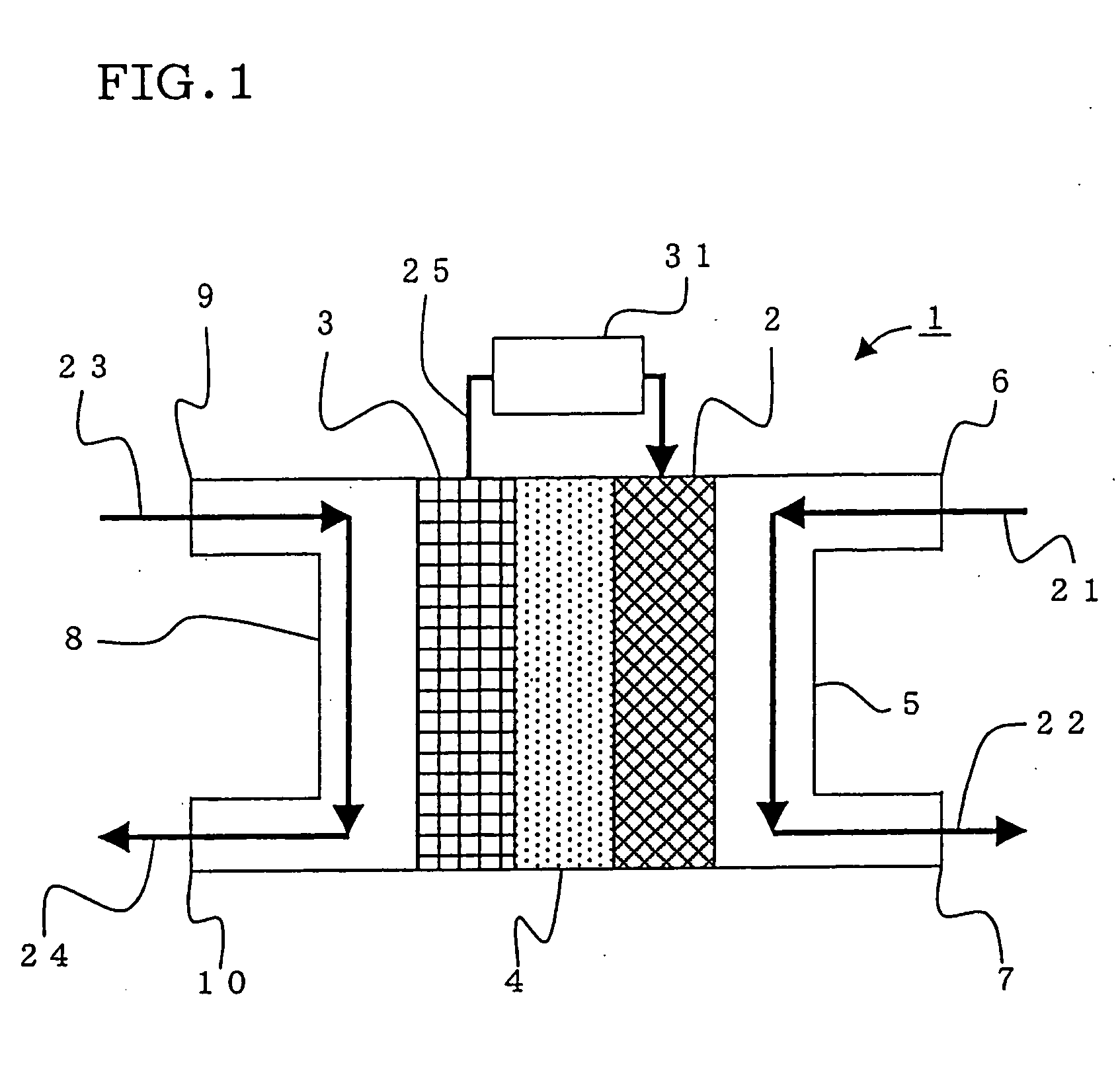

Redox flow cell

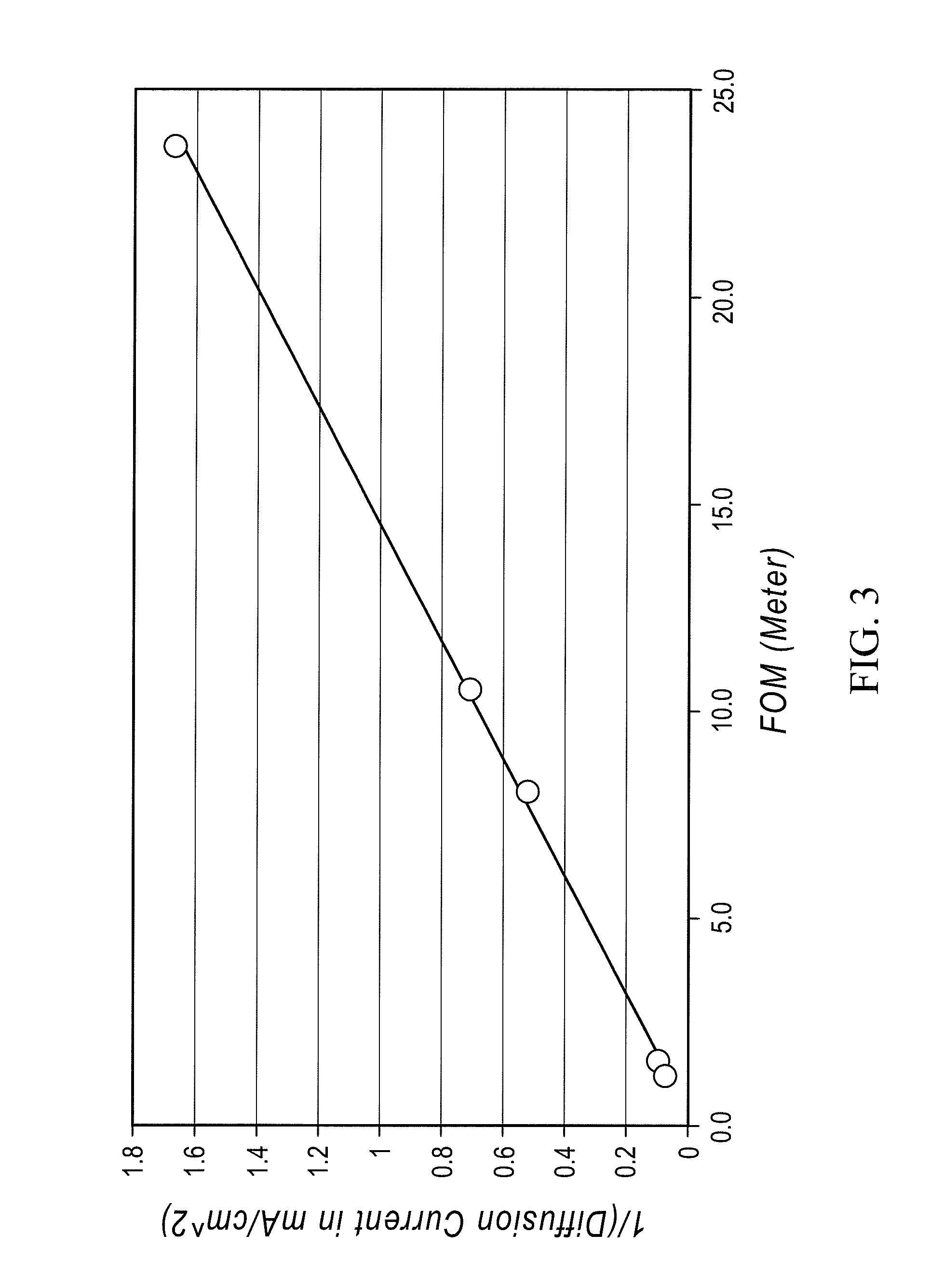

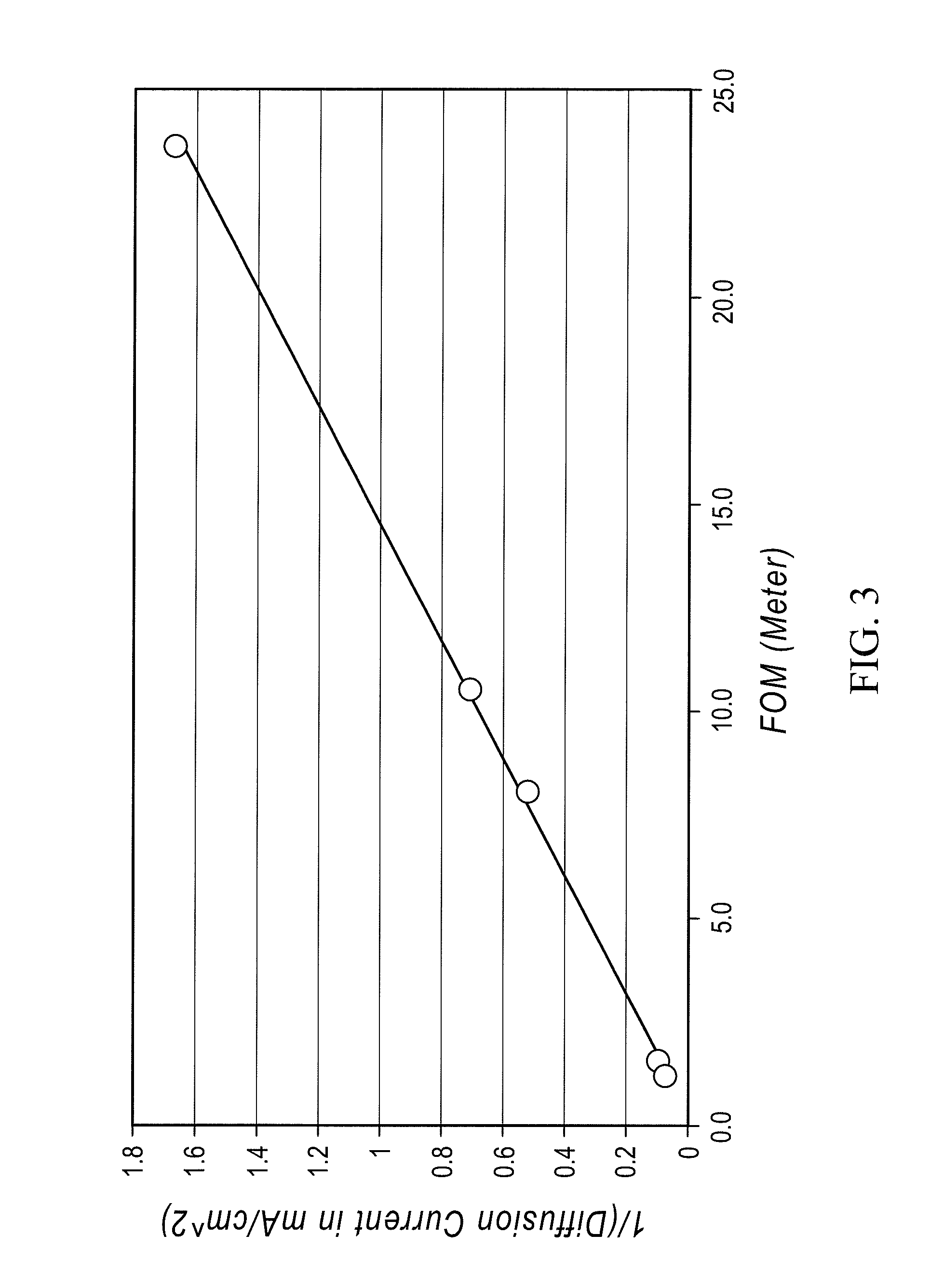

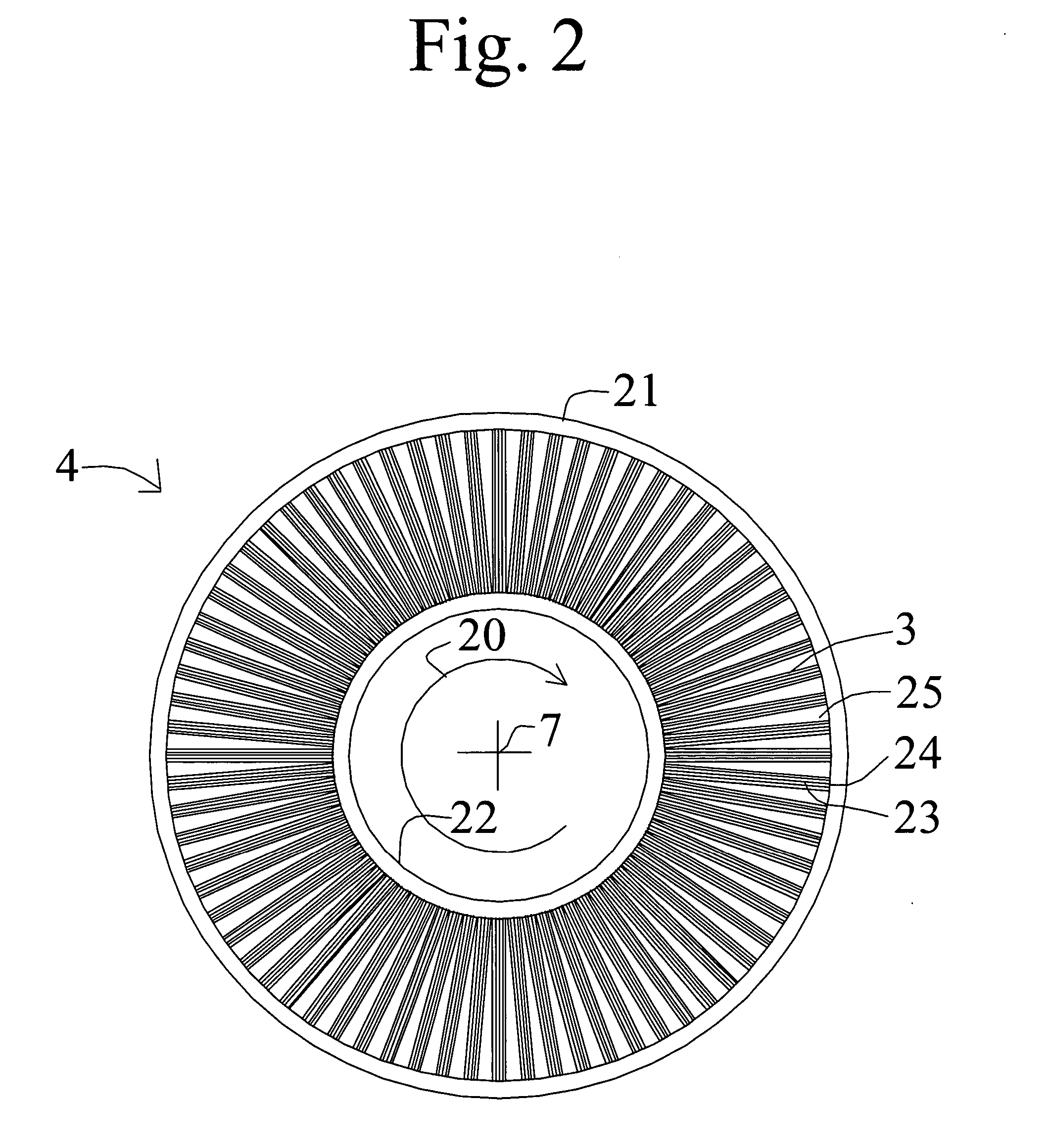

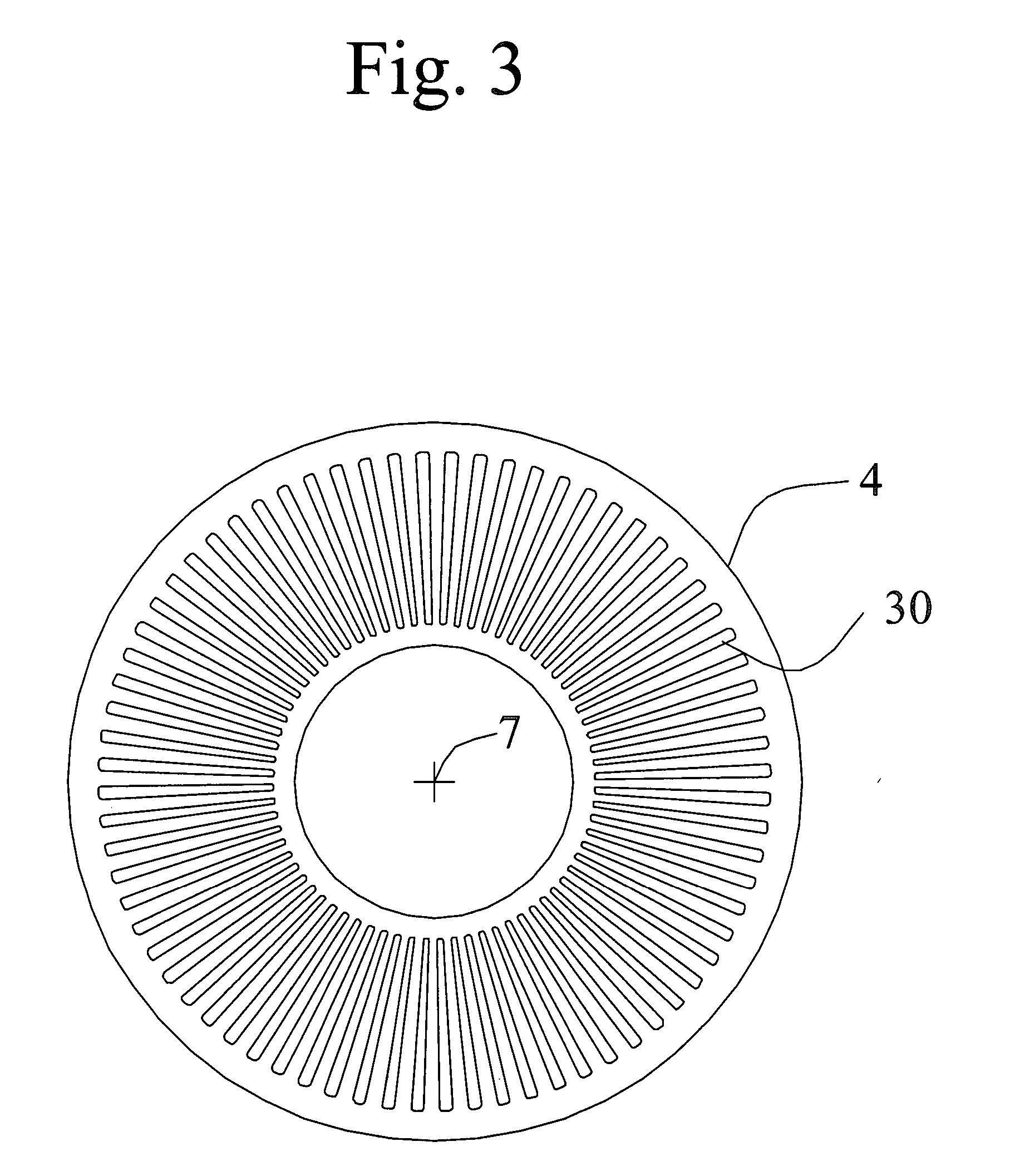

InactiveUS20100003586A1Facilitate ion exchangeCell electrodesFuel cell auxillariesFlow cellPorous membrane

A redox flow cell is presented that utilizes a porous membrane separating a first half cell and a second half cell. The porous membrane is chosen to have a figure of merit (FOM) is at least a minimum FOM. A method of providing a porous membrane for a flow cell can include determining a figure of merit; determining a first parameter from a pore size or a thickness for the porous membrane; determining a second parameter from the pore size or the thickness that is not the first parameter for the porous membrane, based on the figure of merit; and constructing a porous membrane having the pore size and the thickness.

Owner:IMERGY POWER SYST

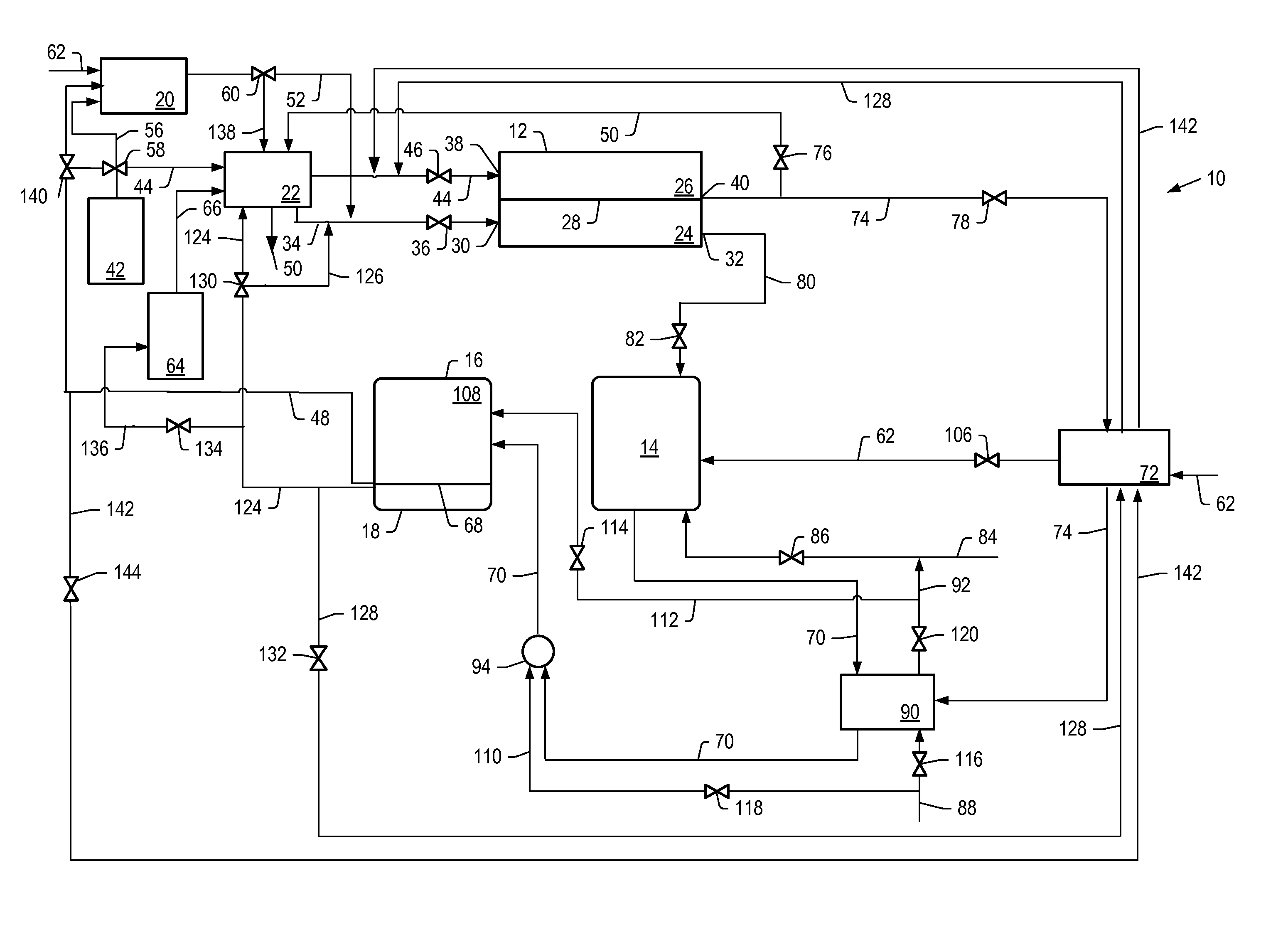

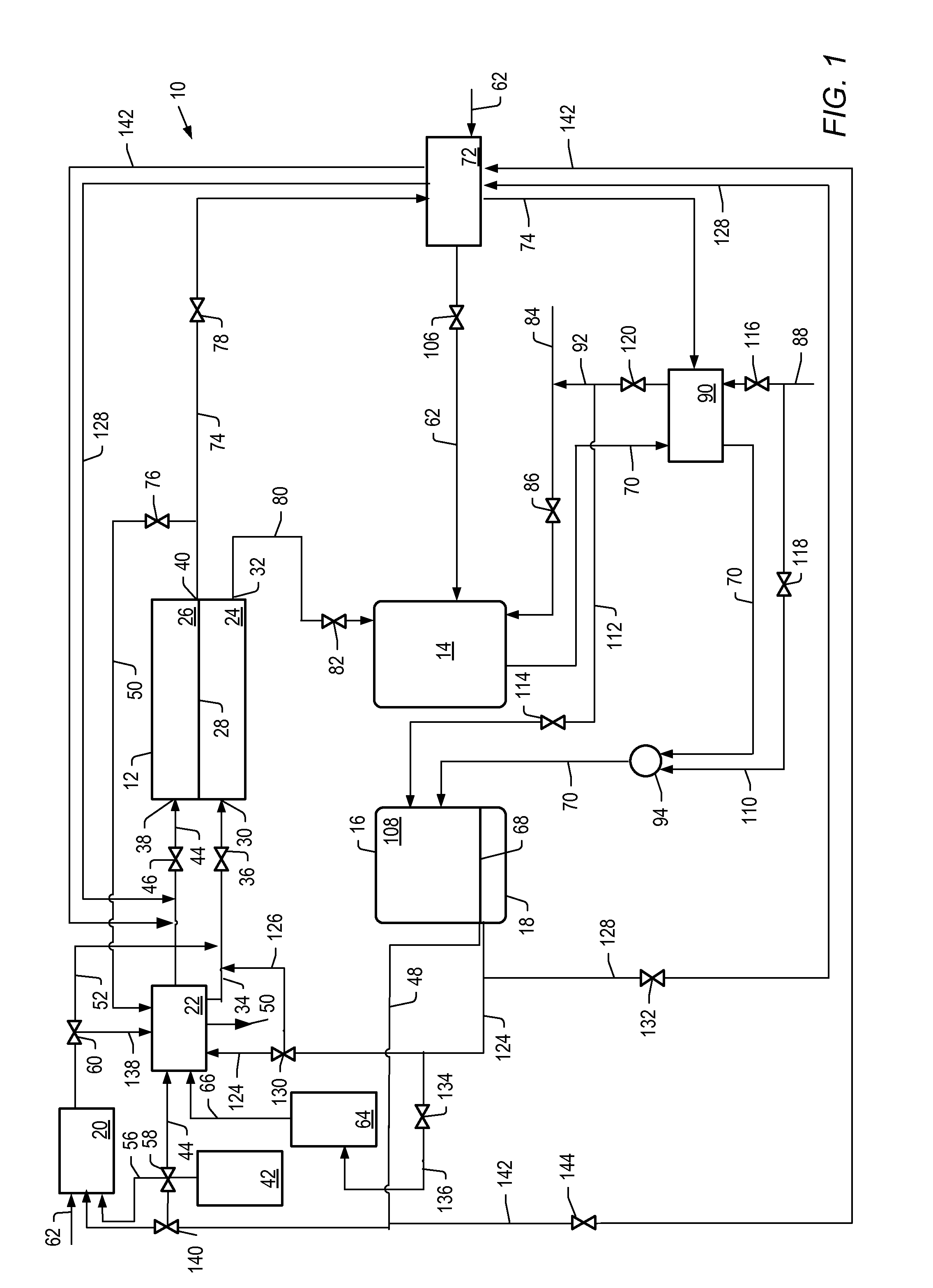

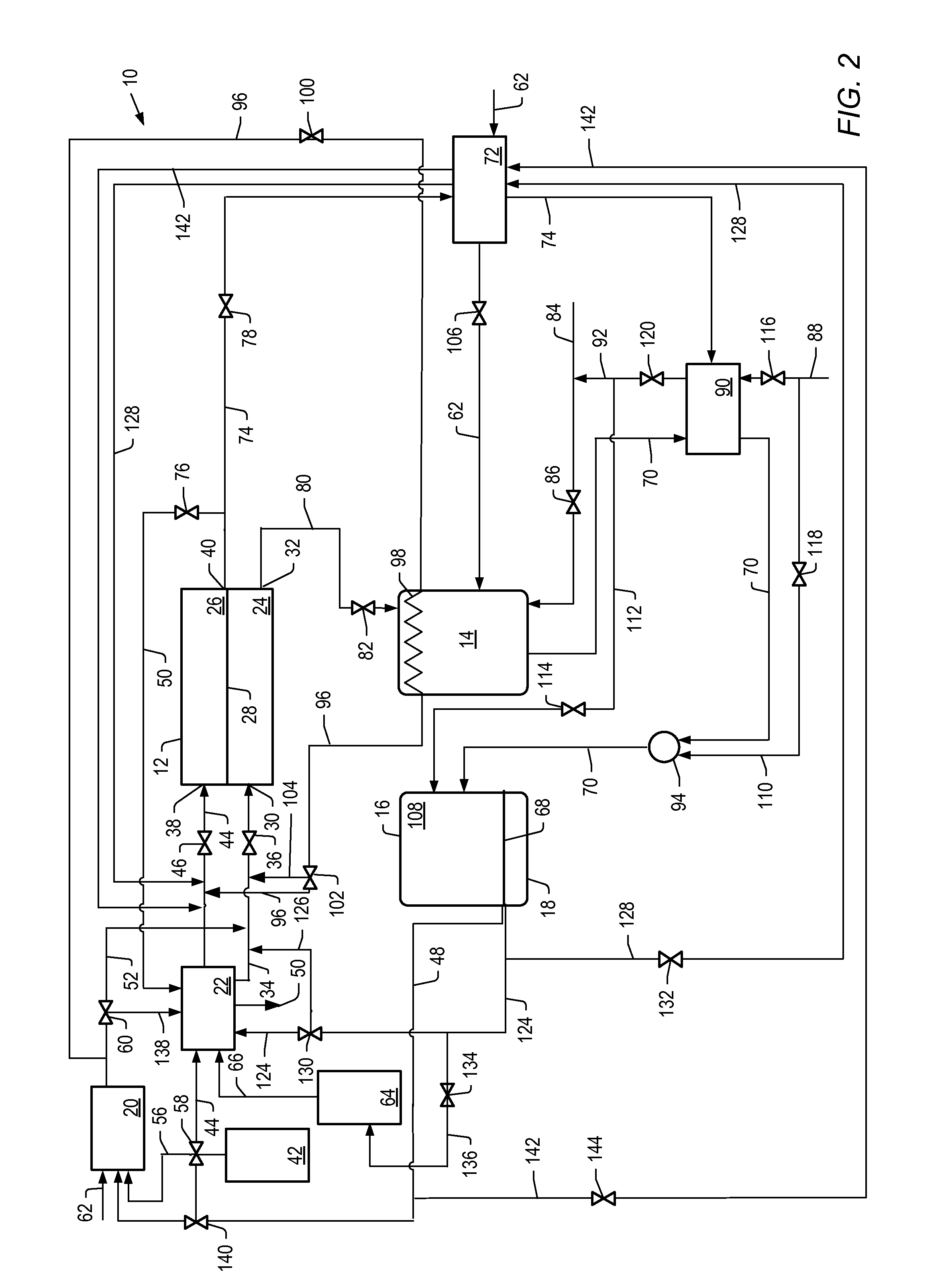

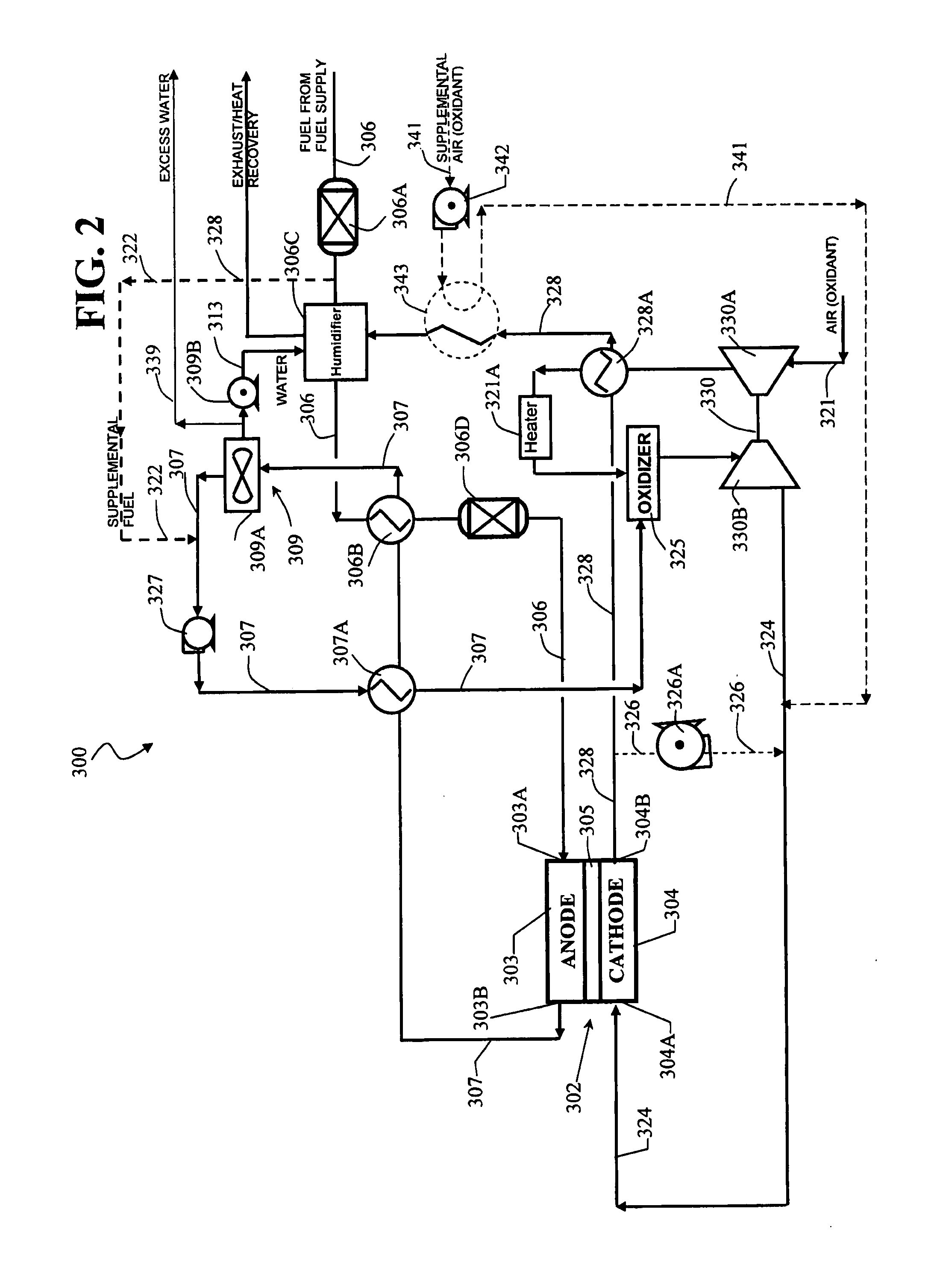

Systems and processes of operating fuel cell systems

InactiveUS20110111315A1Well mixedFuel cell auxillariesFused electrolyte fuel cellsSteam reformingFuel cells

The present invention is directed to systems and processes for operating molten carbonate fuel cell systems. A process for operating the molten carbonate fuel cell includes providing a hydrogen-containing stream comprising molecular hydrogen to a molten carbonate fuel cell anode; heating a hydrocarbon stream, at least a majority of which is comprised of hydrocarbons that are liquid at 20° C. and atmospheric pressure, with a heat source comprising an anode exhaust from the molten carbonate fuel cell anode; contacting at least a portion of the heated hydrocarbon stream with a catalyst to produce a steam reforming feed comprising gaseous hydrocarbons, hydrogen, and at least one carbon oxide; separating at least a portion of the molecular hydrogen from the steam reforming feed; and providing at least a portion of the separated molecular hydrogen to the molten carbonate fuel cell anode as at least a portion of the stream comprising molecular hydrogen.

Owner:SHELL OIL CO

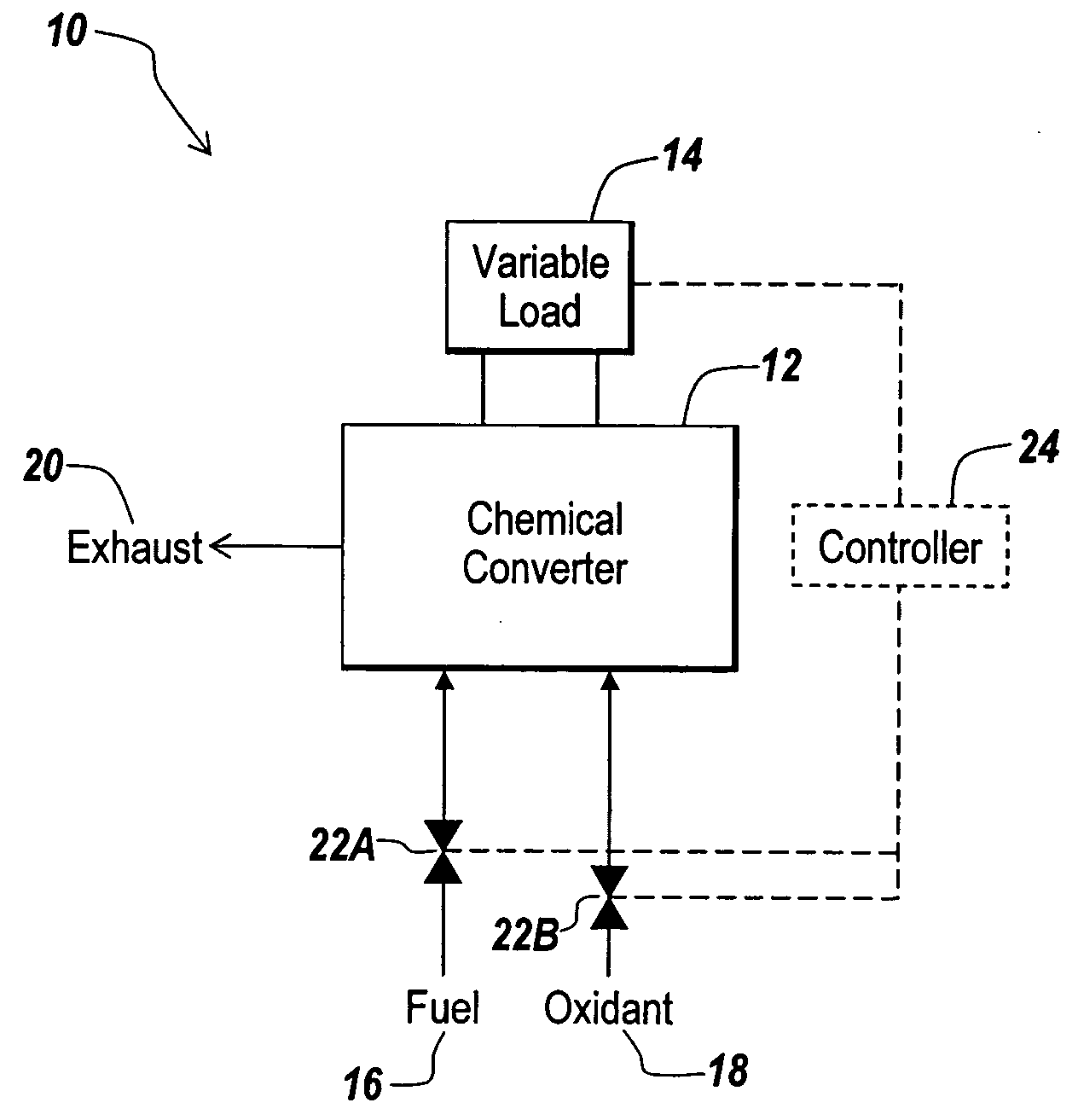

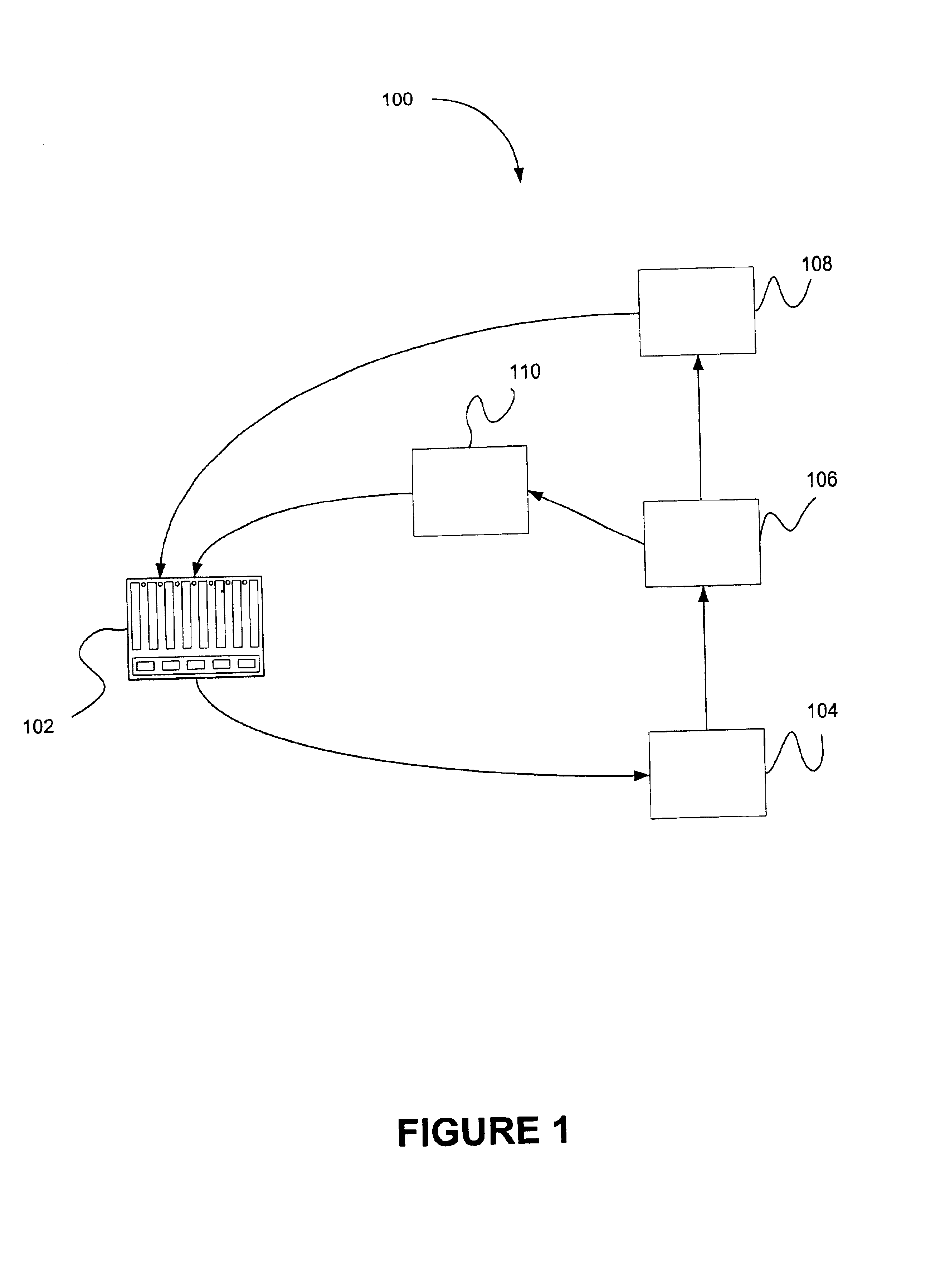

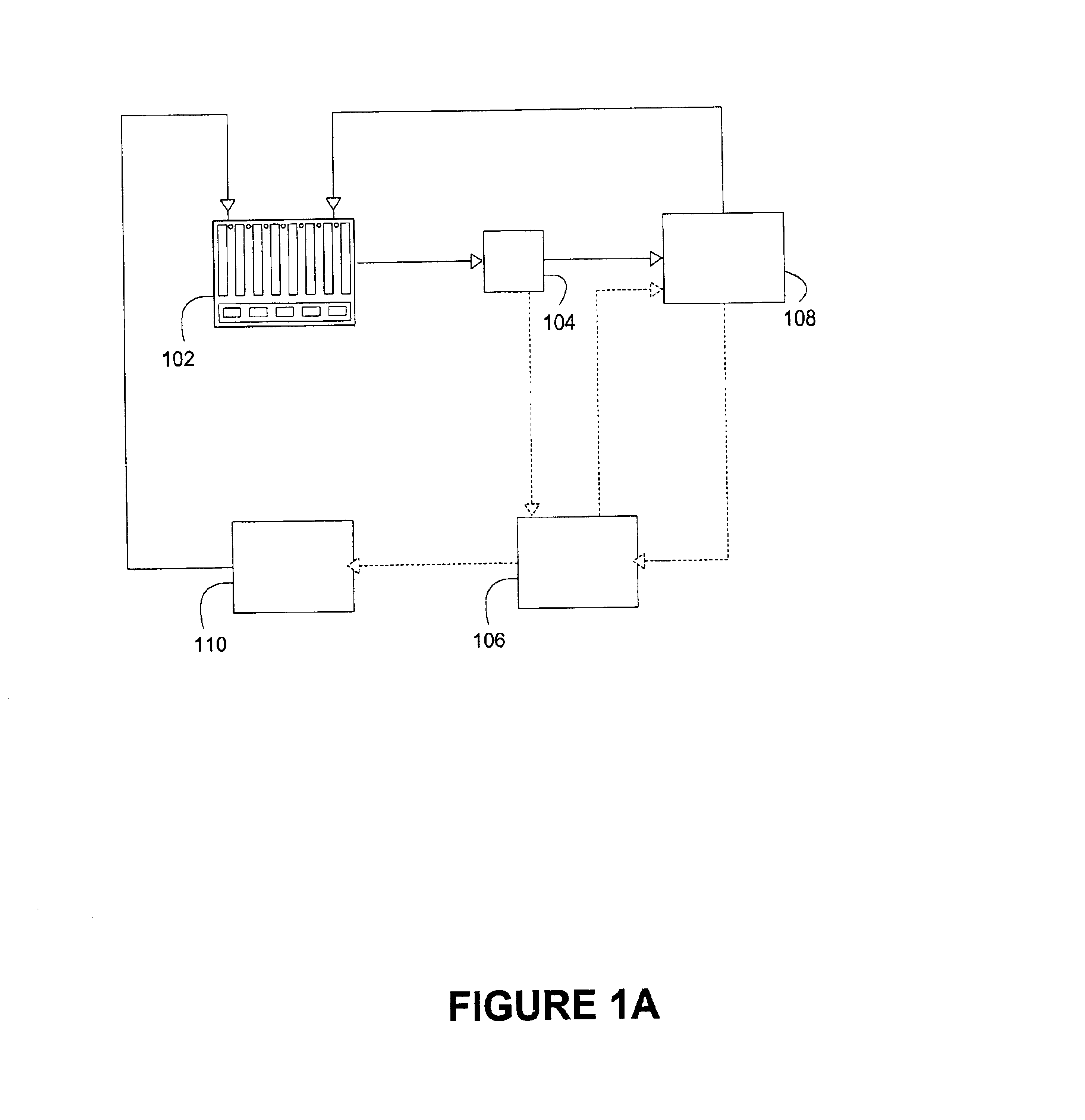

Methods of using fuel cell system configured to provide power to one or more loads

A fuel cell system is described for providing primary and / or auxiliary / backup power to one or more loads selected from the group comprising: lawn & garden equipment; radios; telephone; targeting equipment; battery rechargers; laptops; communications devices; sensors; night vision equipment; camping equipment; stoves; lanterns; lights; vehicles; cars; recreational vehicles; trucks; boats; ferries; motorcycles; motorized scooters; forklifts; golf carts; lawnmowers; industrial carts; passenger carts (airport); luggage handling equipment (airports); airplanes; lighter than air crafts; blimps; dirigibles; hovercrafts; trains; locomotives; submarines (manned and unmanned); torpedoes; security systems; electrical energy storage devices for solar-based, tidal-based, hydro-based, wind-based, and other renewable energy source; equipment for which a primary and / or backup power source is necessary or desirable to enable the equipment to function for its intended purpose, military-usable variants of above, and suitable combinations of any two or more thereof. The system provides power to the one or more loads upon the occurrence of a power outage condition, which includes a disruption or discontinuation in the delivery of primary power (i.e., power from a system-external primary source, namely, a source other than the fuel cell system) to, or power demand condition by, the one or more loads. A controller senses outage of primary power to, or demand for primary power by, the one or more loads, and, responsive thereto, operatively engages one or more fuel cells to provide power to the one or more loads.

Owner:METALLIC POWER INC

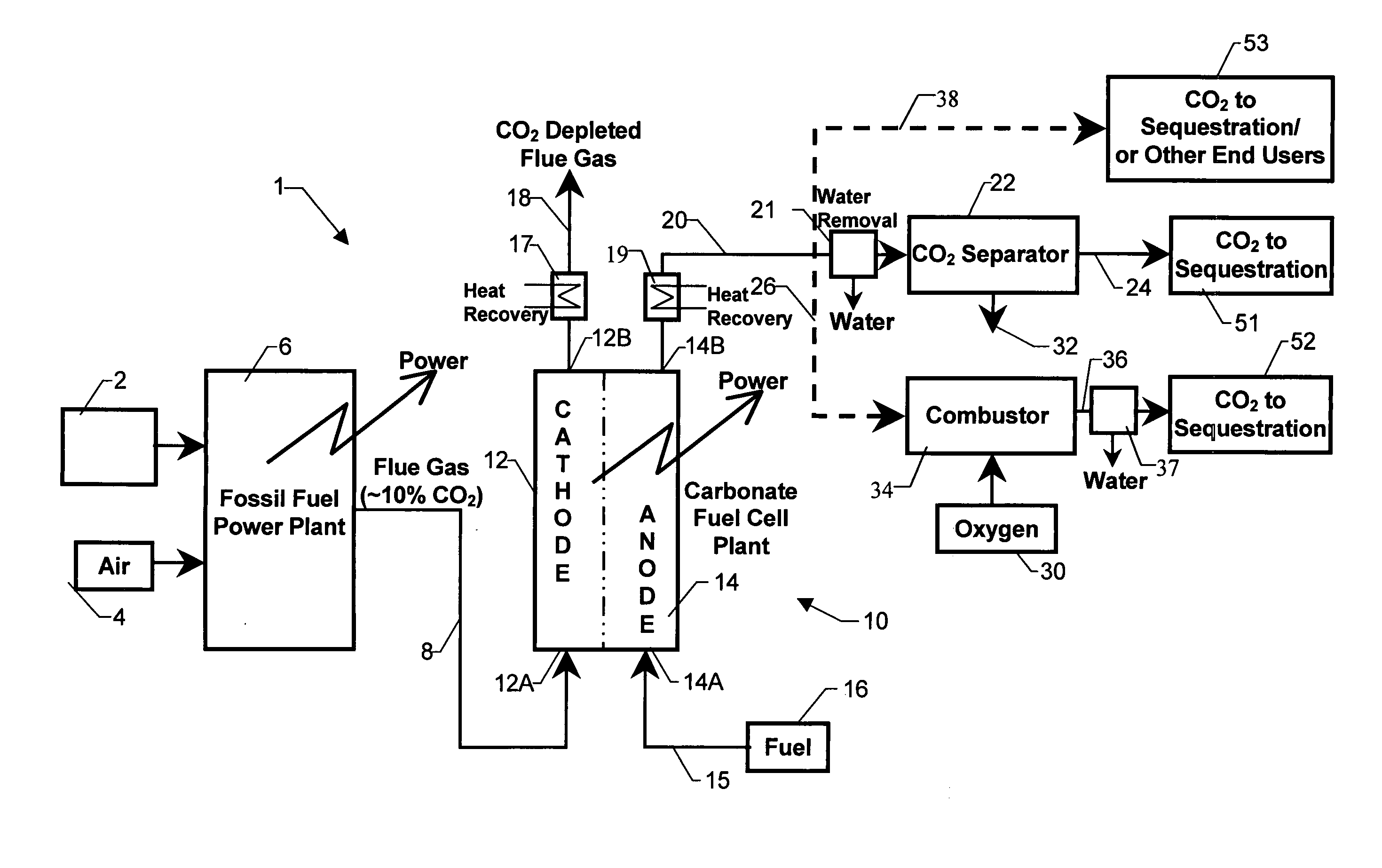

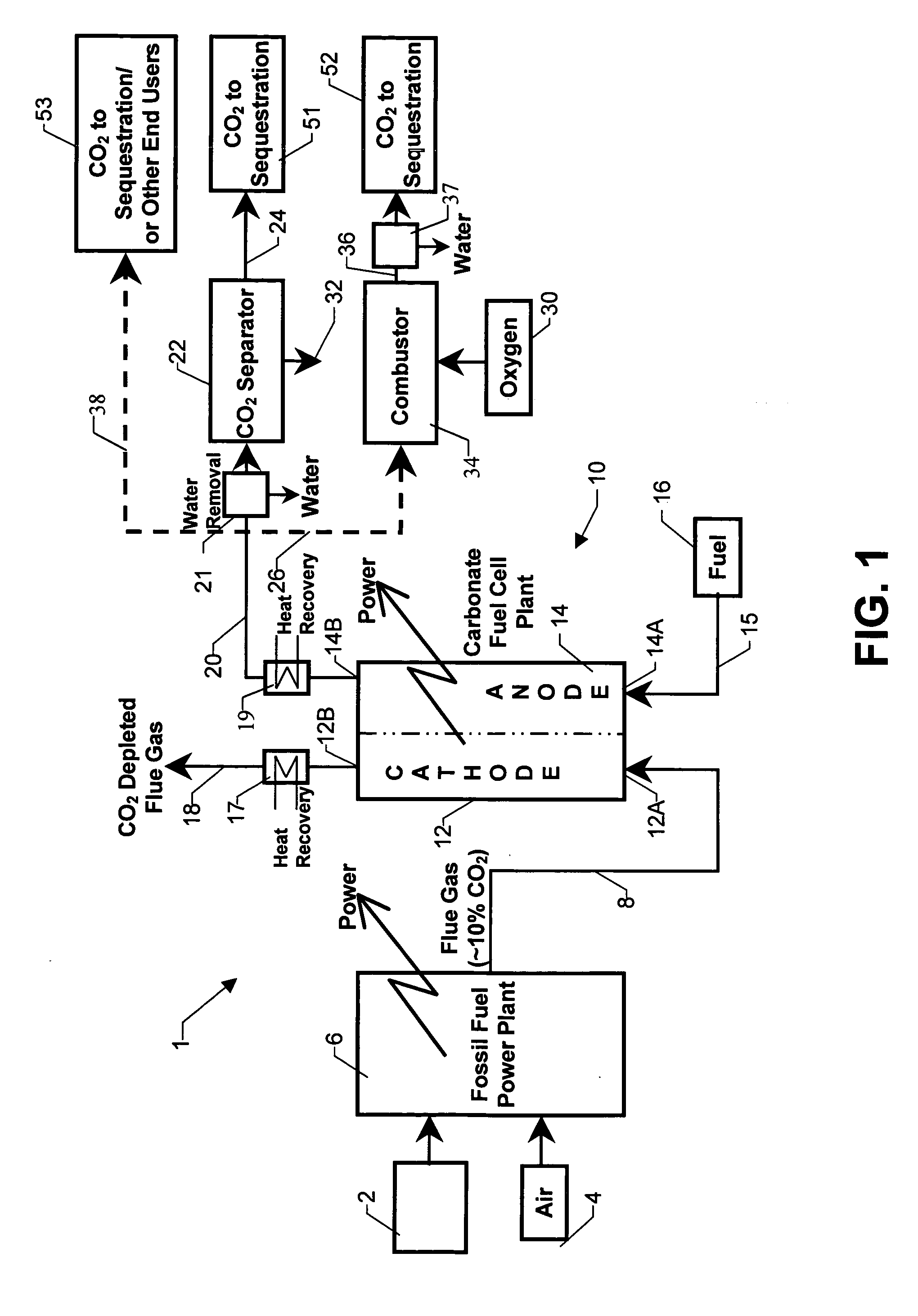

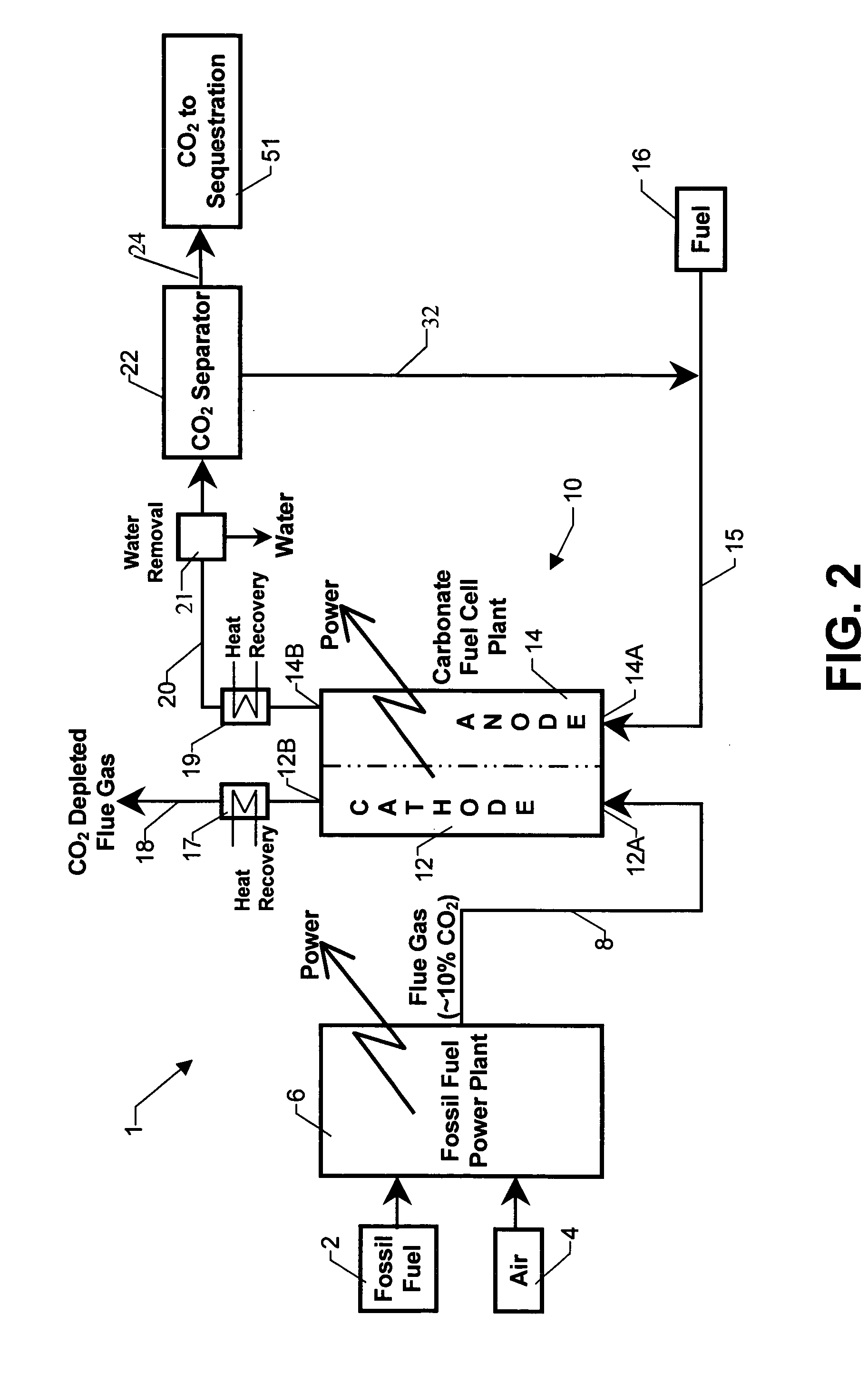

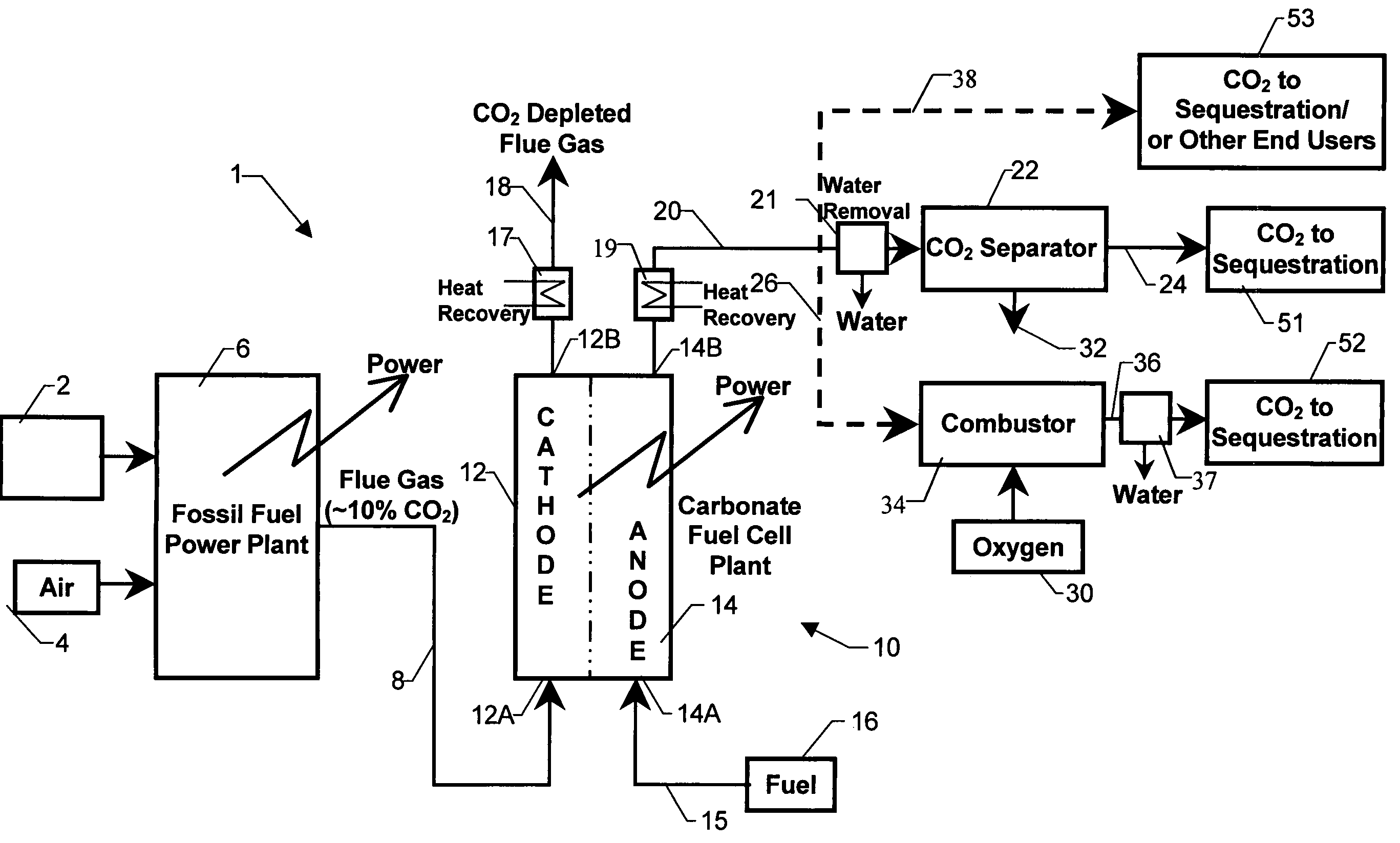

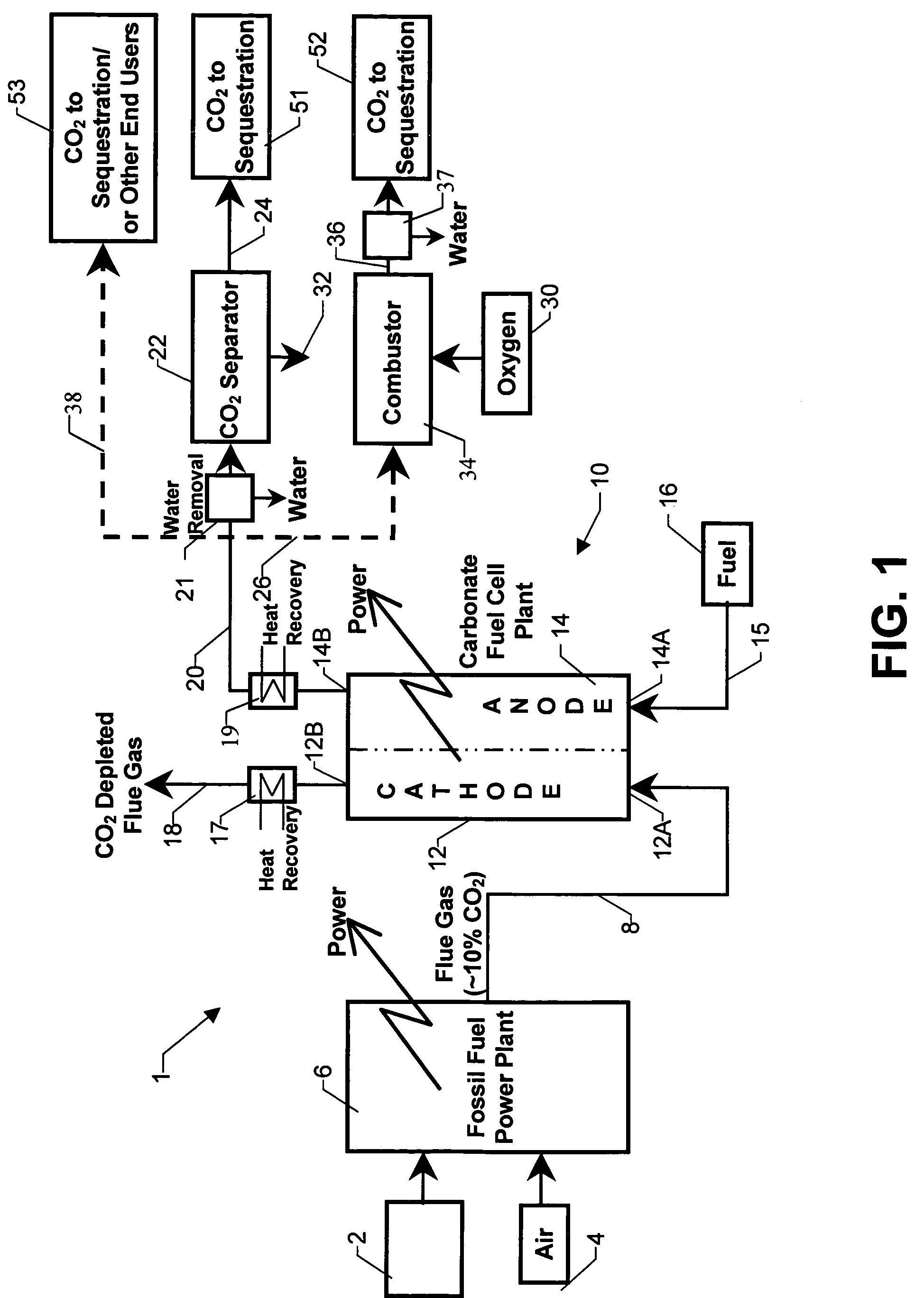

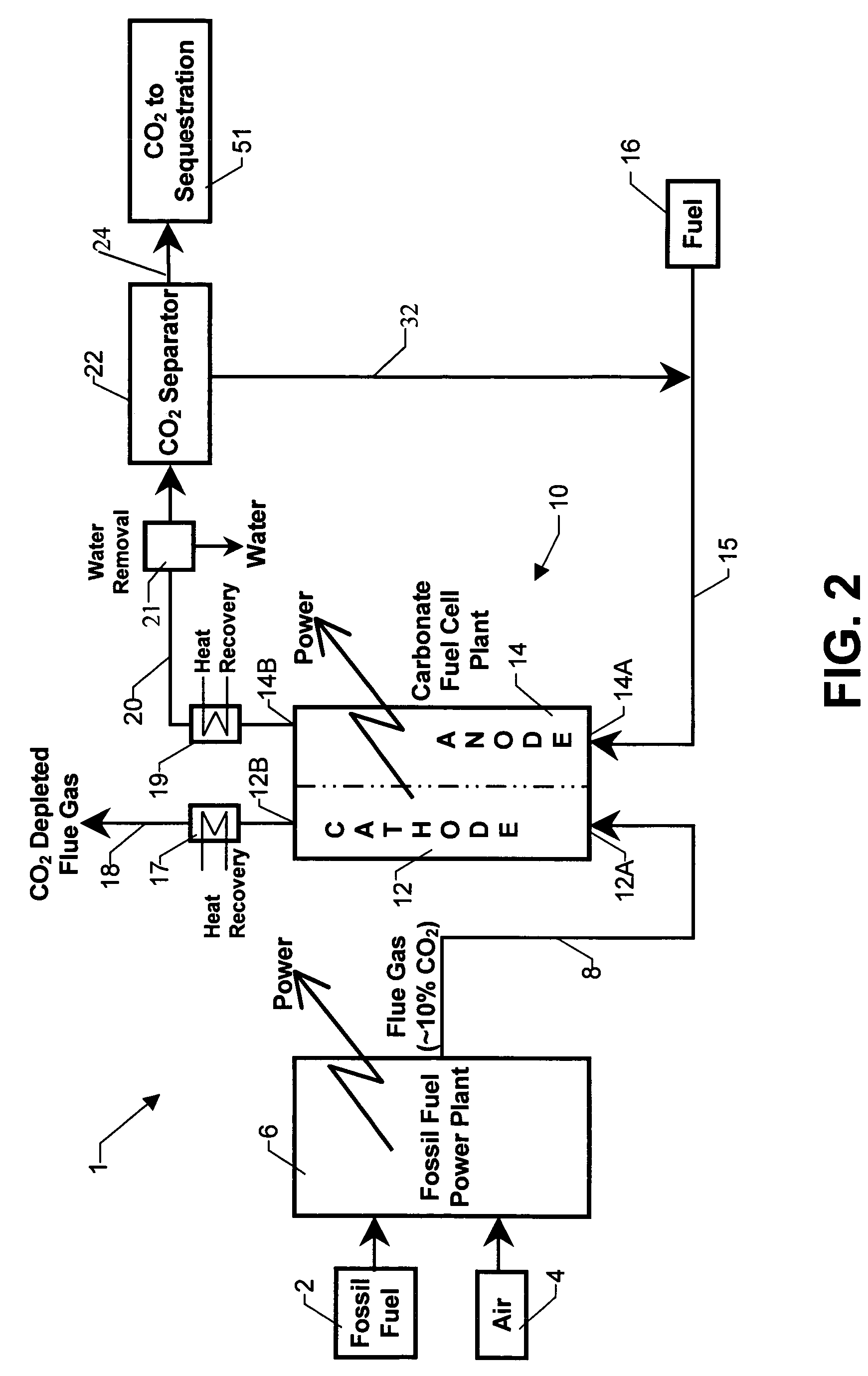

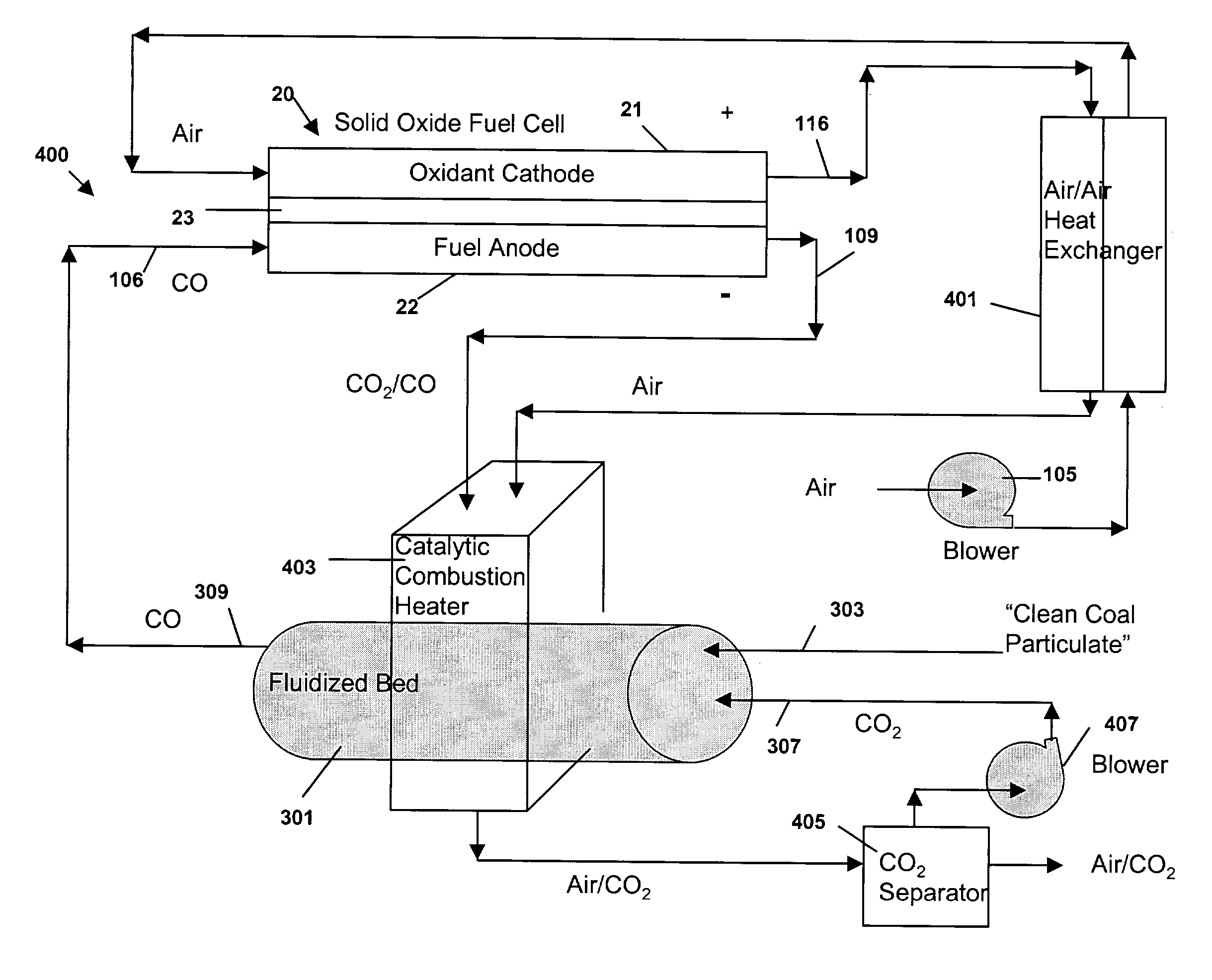

Integrated high efficiency fossil fuel power plant/fuel cell system with CO2 emissions abatement

An integrated power production system including a fossil fuel power plant for processing fossil based fuel such as coal or natural gas arranged in tandem with a carbonate fuel cell having an anode and a cathode section. The flue gas of the power plant serves exclusively as the inlet gas for the cathode section of the fuel cell. Anode exhaust gas leaving the anode section of the fuel cell is subjected to processing including sequestration of the carbon dioxide in the exhaust gas.

Owner:FUELCELL ENERGY INC

Integrated high efficiency fossil fuel power plant/fuel cell system with CO2 emissions abatement

ActiveUS7396603B2Fuel cell heat exchangeElectricity cogenerationNuclear engineeringEmission abatement

Owner:FUELCELL ENERGY INC

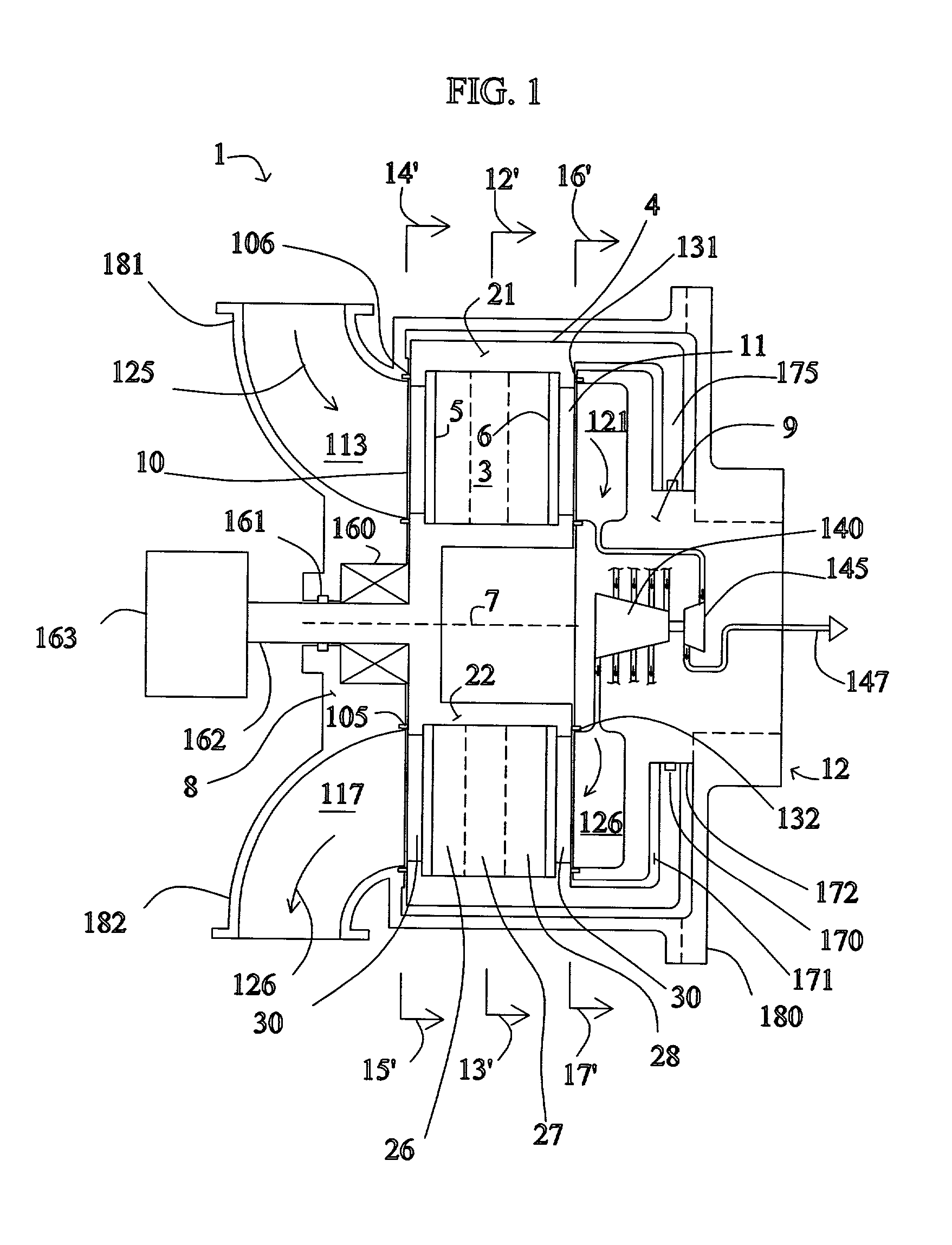

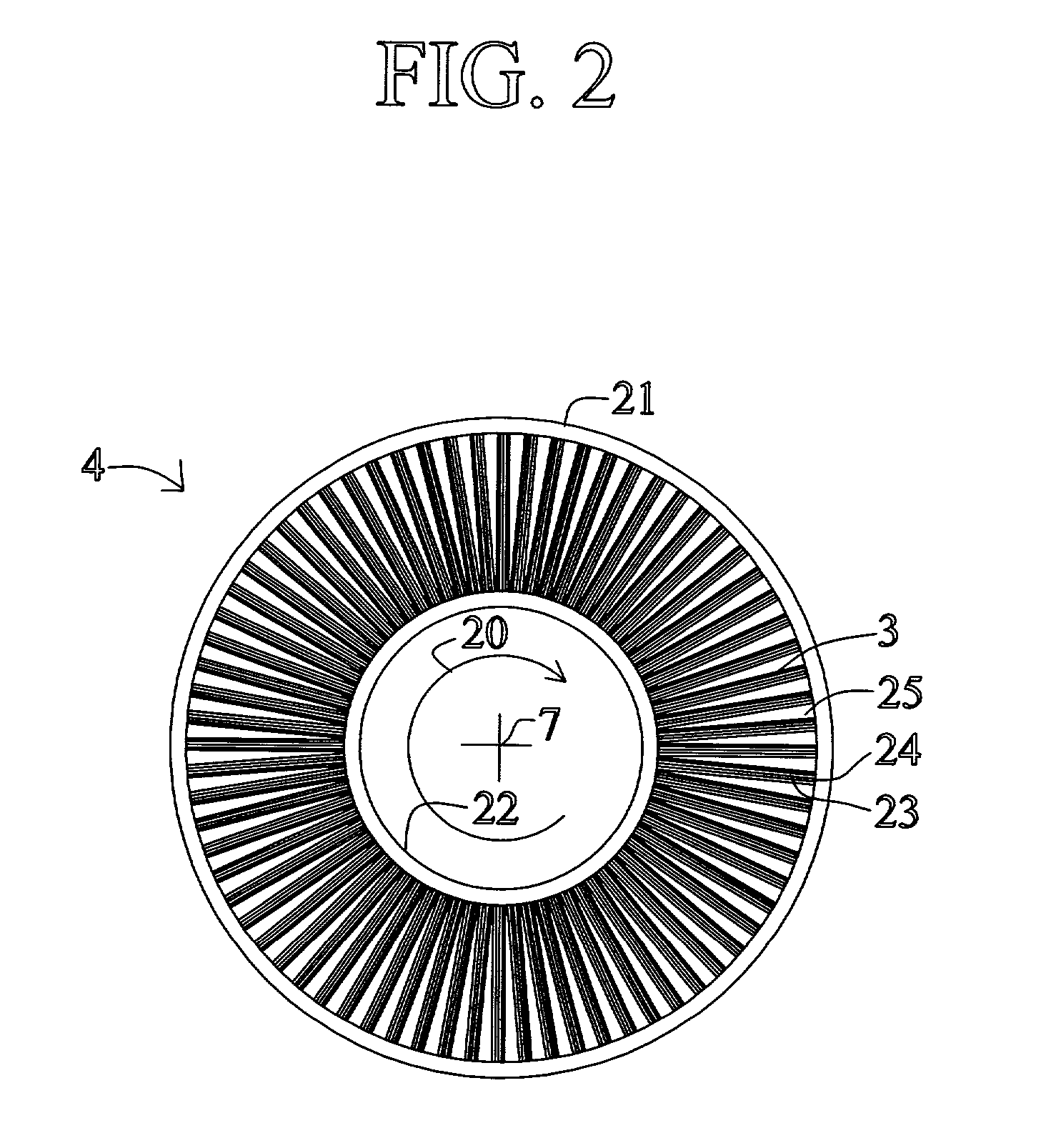

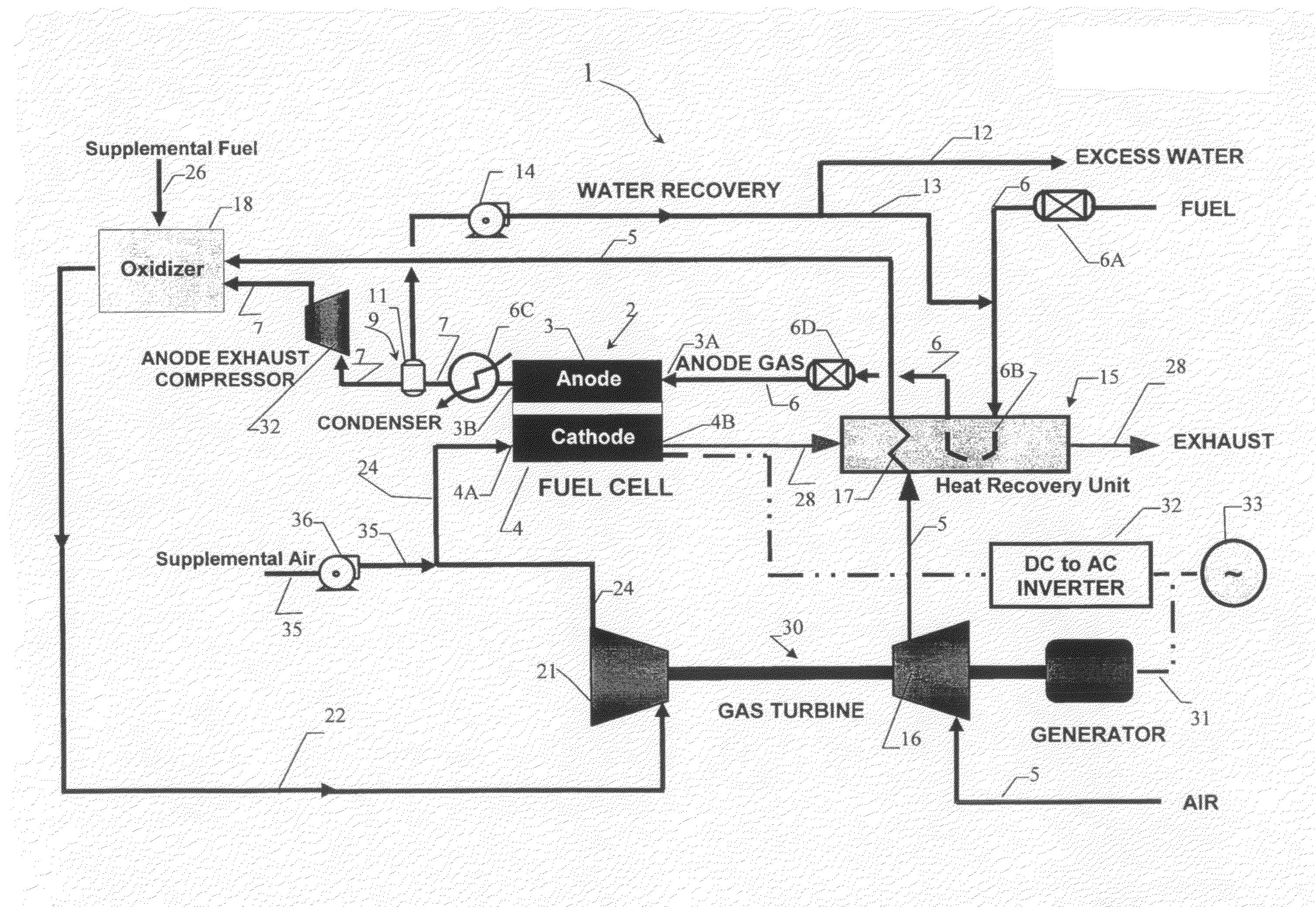

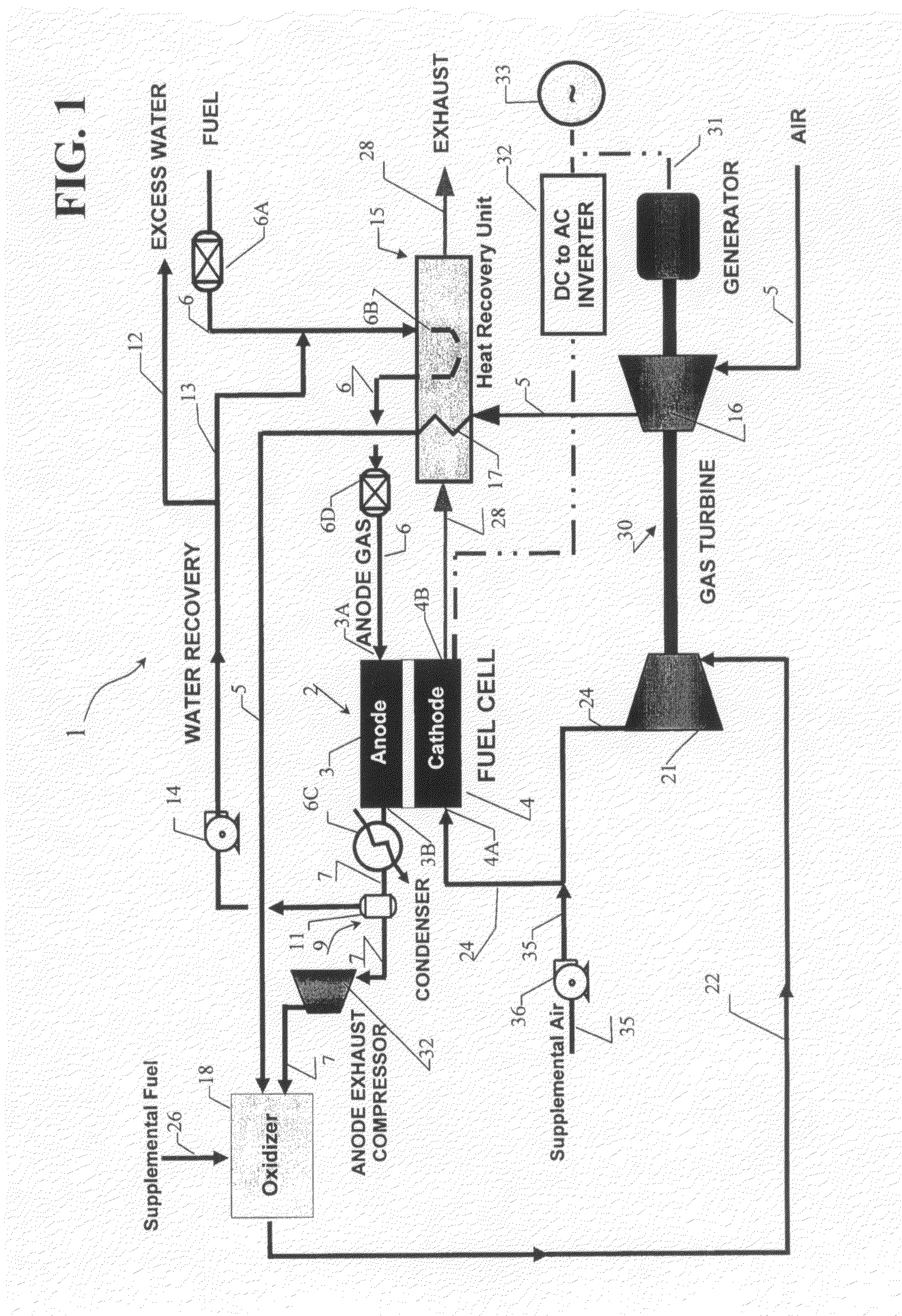

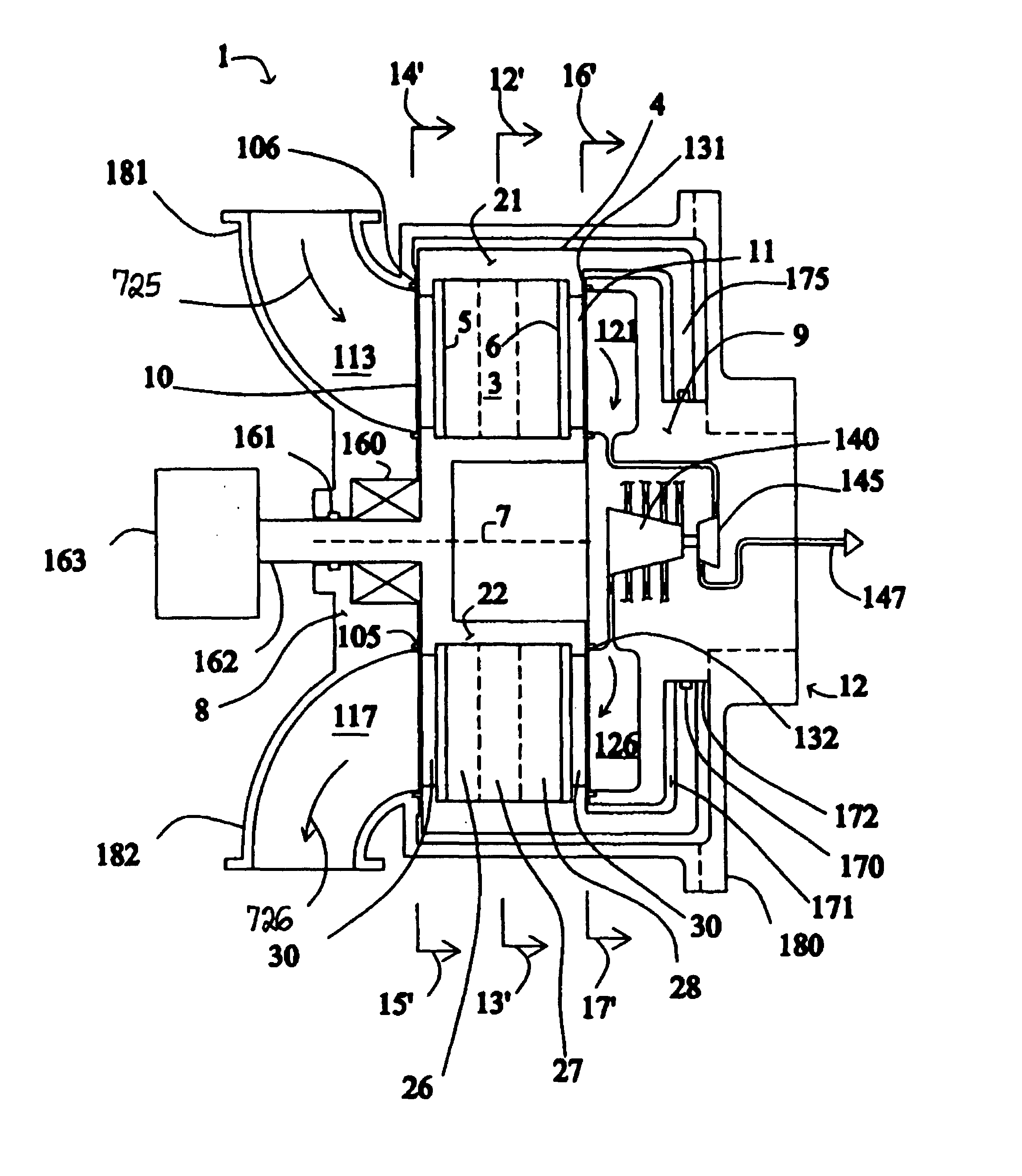

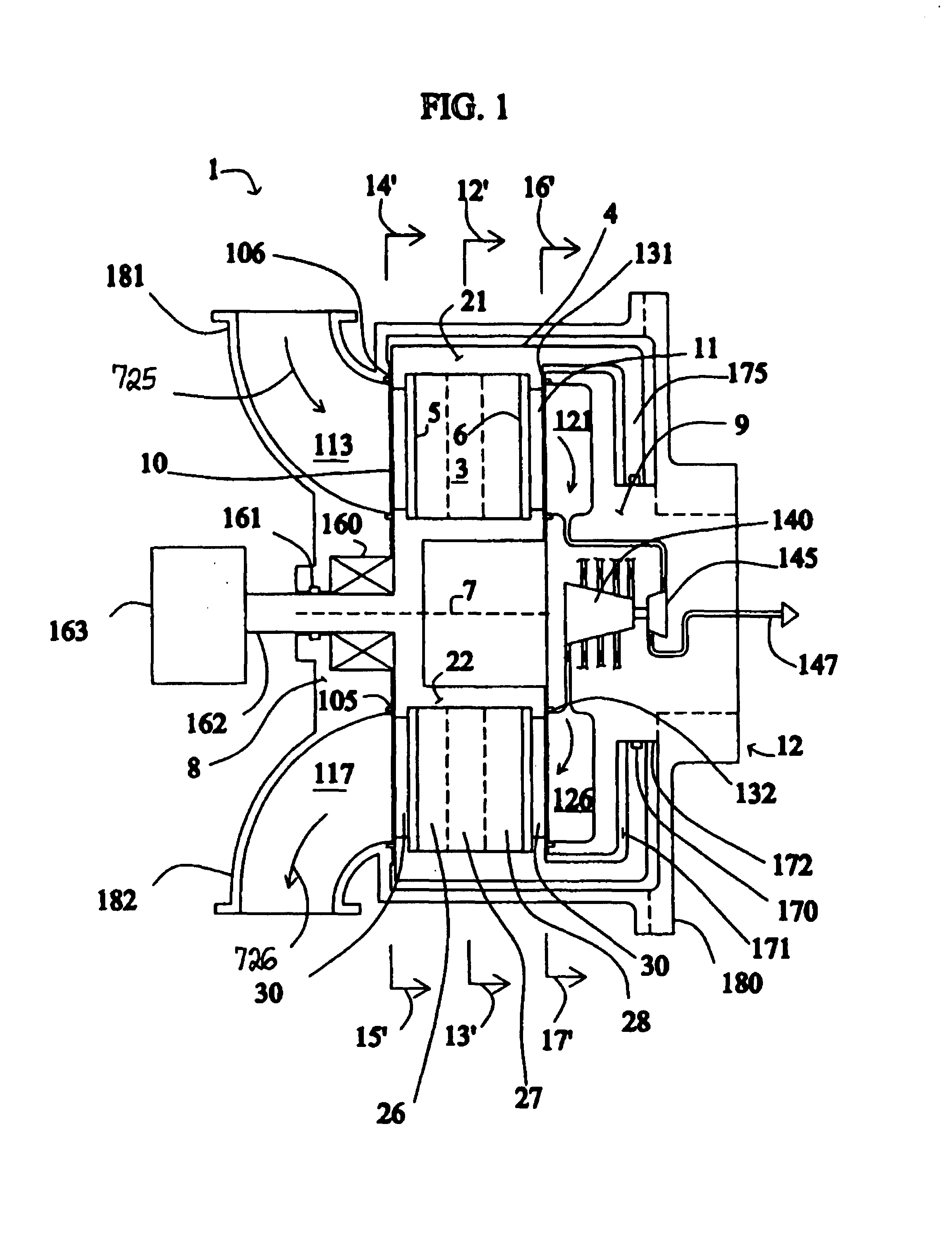

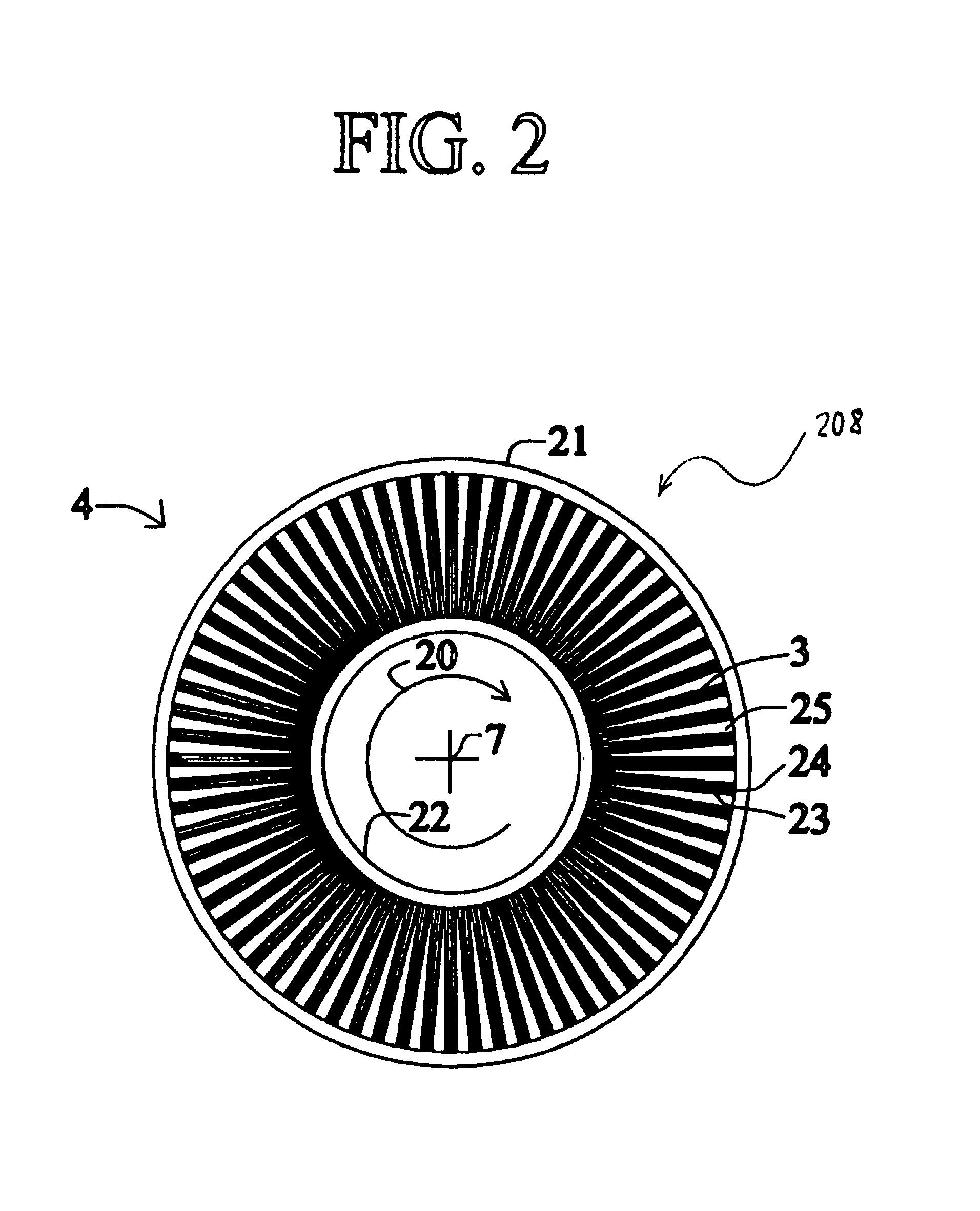

Integrated fuel cell and heat engine hybrid system for high efficiency power generation

ActiveUS20080187789A1Improve system efficiencyImprove efficiencyFuel cell heat exchangeElectricity cogenerationFuel cellsHybrid system

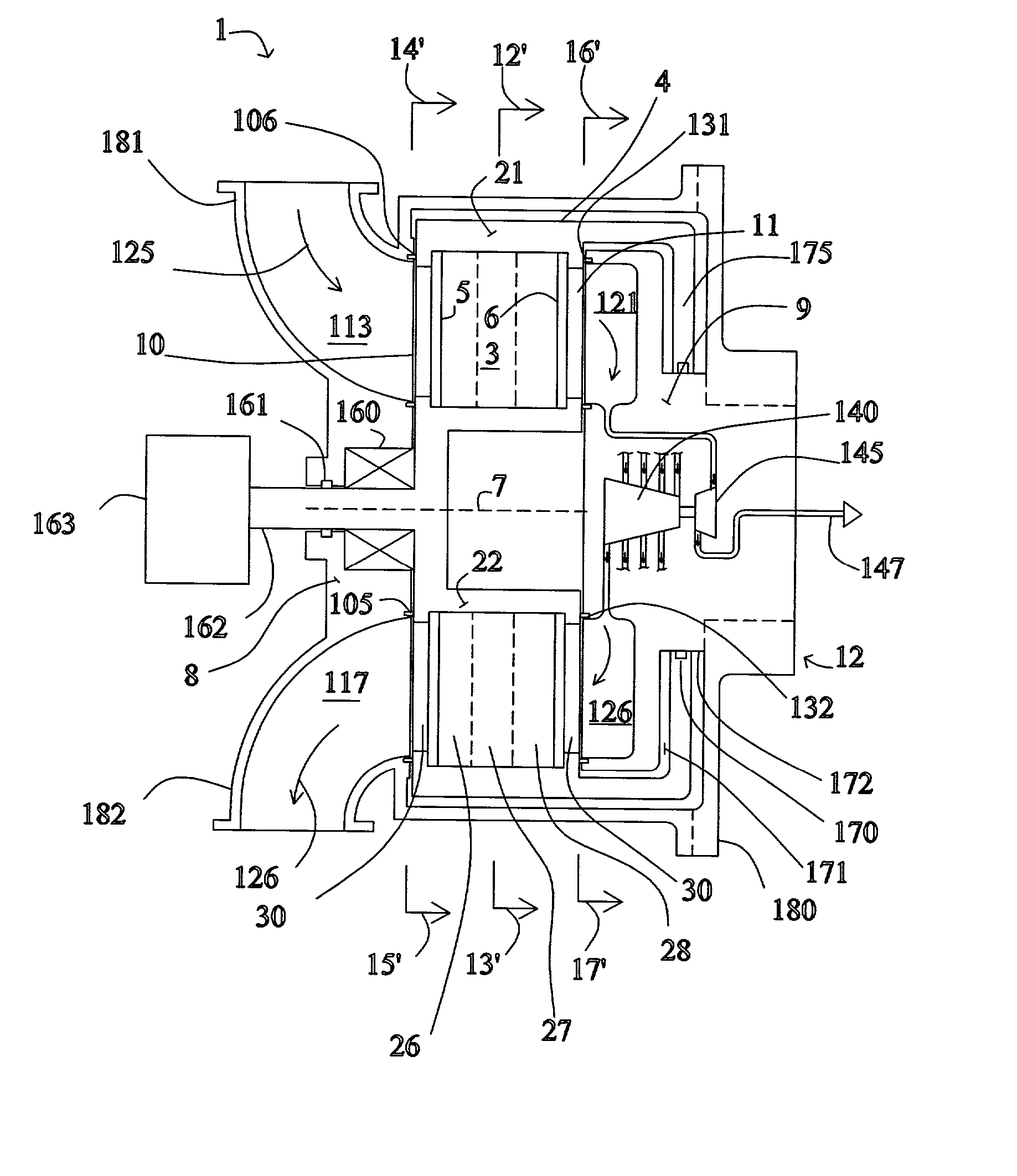

A fuel cell and heat engine hybrid system using a high-temperature fuel cell having an anode compartment adapted to receive fuel from a fuel supply path and to output anode exhaust gas and a cathode compartment adapted to receive oxidant gas and to output cathode exhaust gas. A heat engine assembly is adapted to receive oxidant gas and a further gas comprising one of the anode exhaust gas and a gas derived from the anode exhaust gas and to cause oxidation of the further gas and generate output power, the heat engine also generating heat engine exhaust including oxidant gas. The heat engine exhaust is then used to provide oxidant gas to the cathode compartment of the fuel cell.

Owner:FUELCELL ENERGY INC

Energy efficient gas separation for fuel cells

InactiveUS7087331B2Intuitive effectFully purifiedFuel cell heat exchangeFused electrolyte fuel cellsDelivery systemSolid oxide fuel cell

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

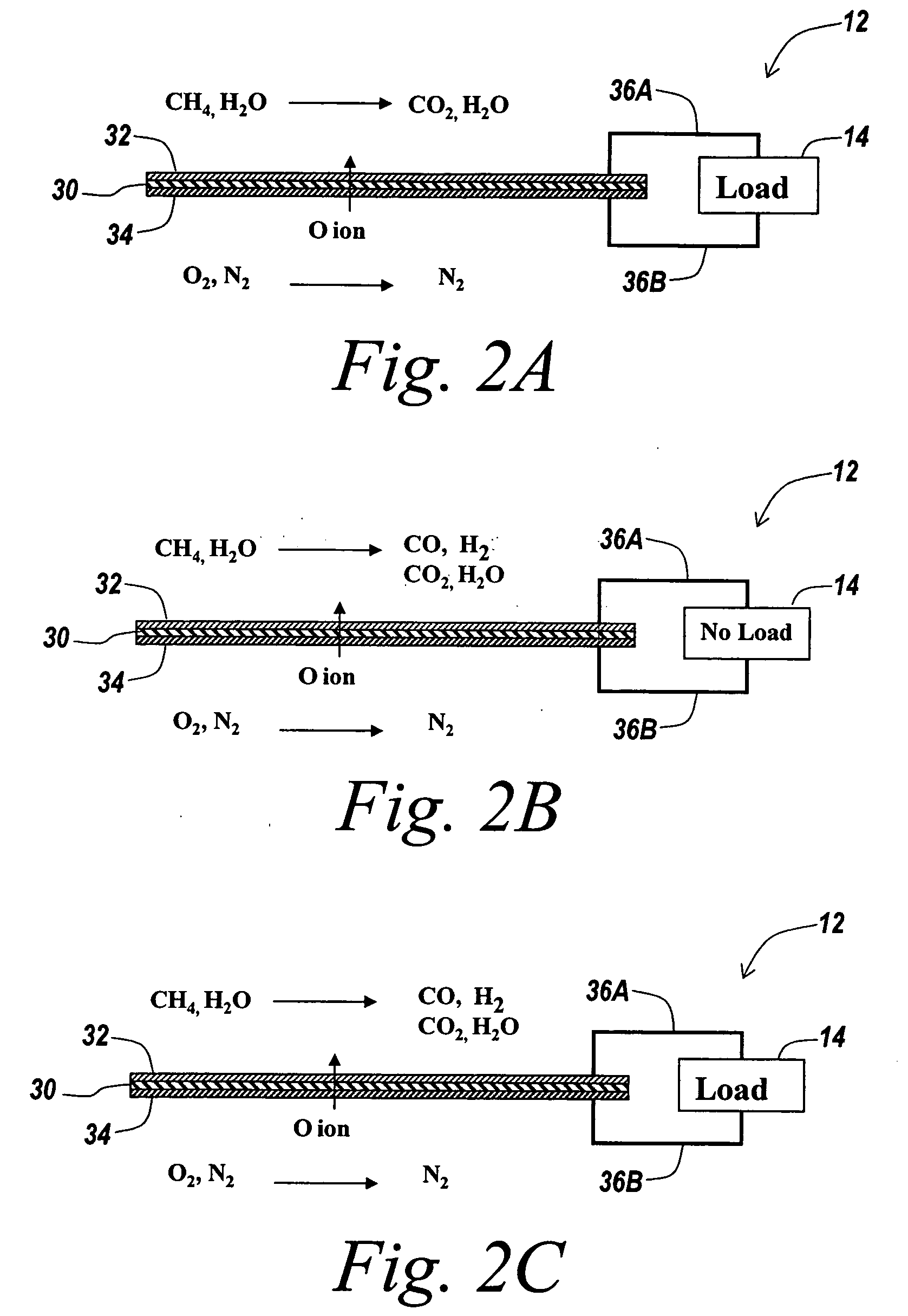

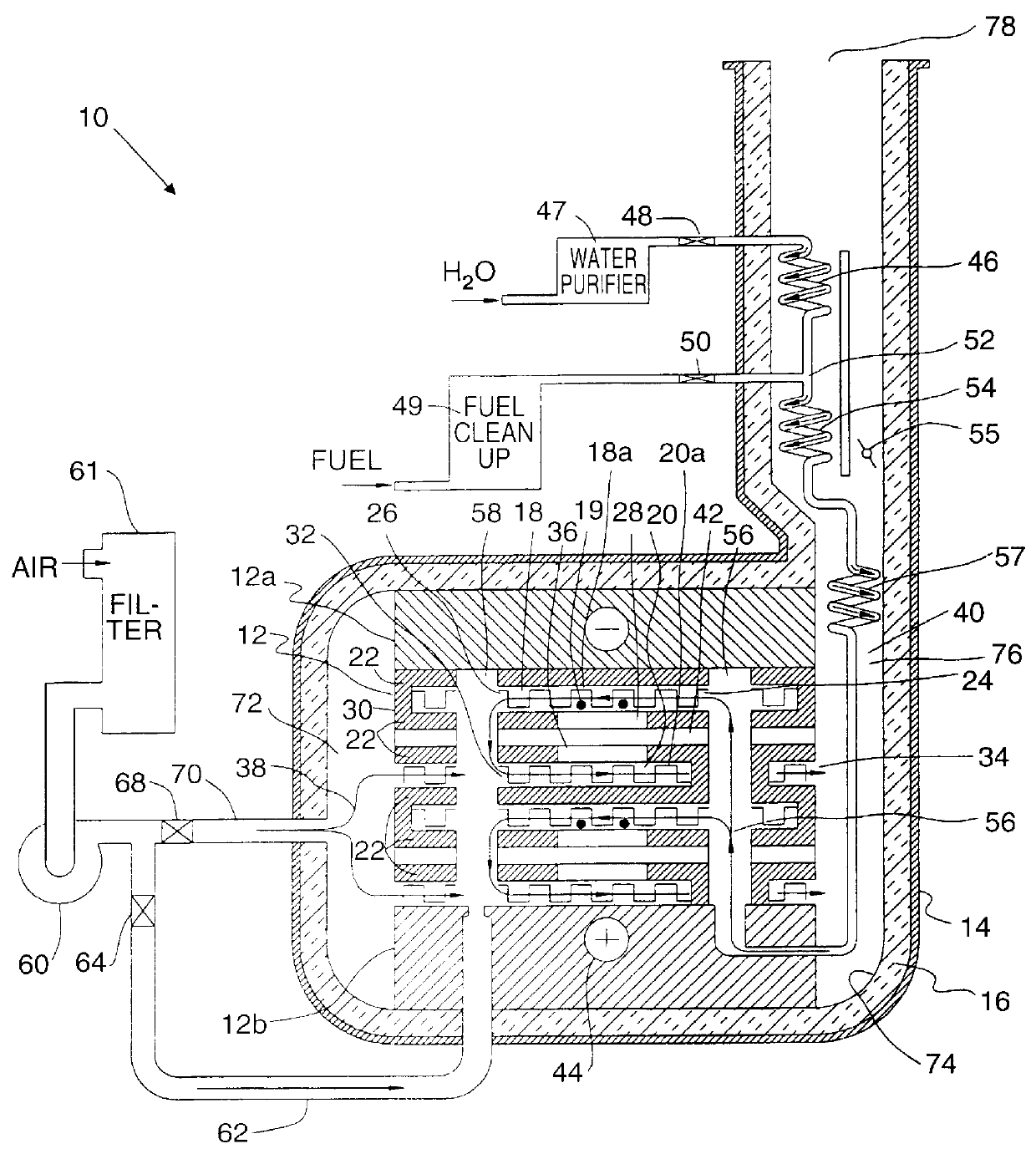

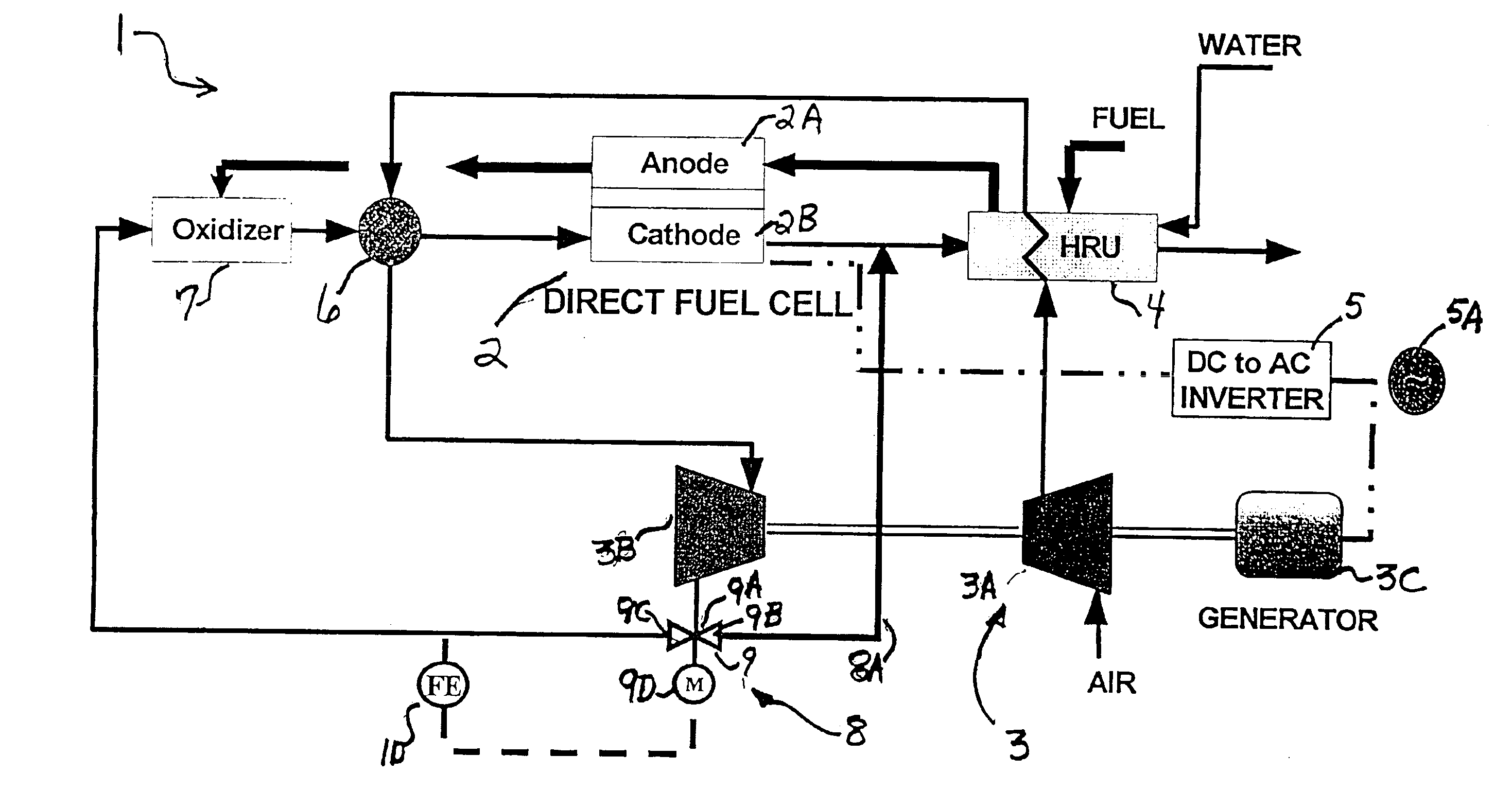

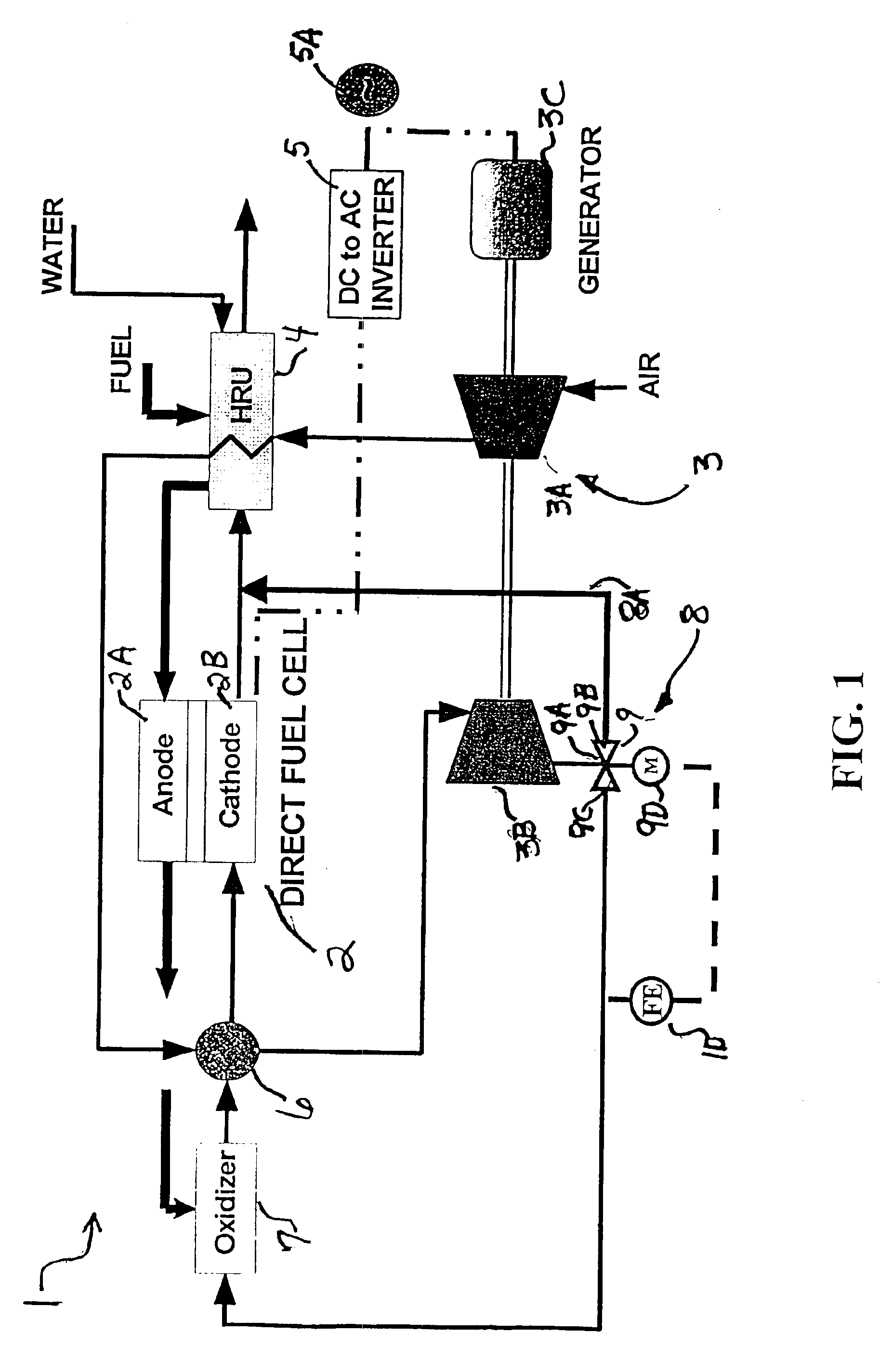

Fuel cell for hydrogen production, electricity generation and co-production

InactiveUS20050112425A1Amount be controlFuel cell combinationsHydrogenElectricityElectrochemical response

A hydrogen-electricity co-production (HECP) system utilizes a fuel cell to produce hydrogen, electricity, or a combination of both hydrogen and electricity. In a first mode, the fuel cell performs an electrochemical reaction by reacting a hydrogen-containing fuel with oxygen to produce electricity, water and heat. In a second mode, the fuel cell utilizes heat released by an electrochemical reaction of the fuel cell to reform a hydrogen-containing fuel to produce hydrogen rich gas. In a third mode, both hydrogen and electricity are co-produced by the fuel cell. The HECP system can control an amount of hydrogen and / or electricity produced and switch between modes by varying an electrical load on the system.

Owner:ZTEK

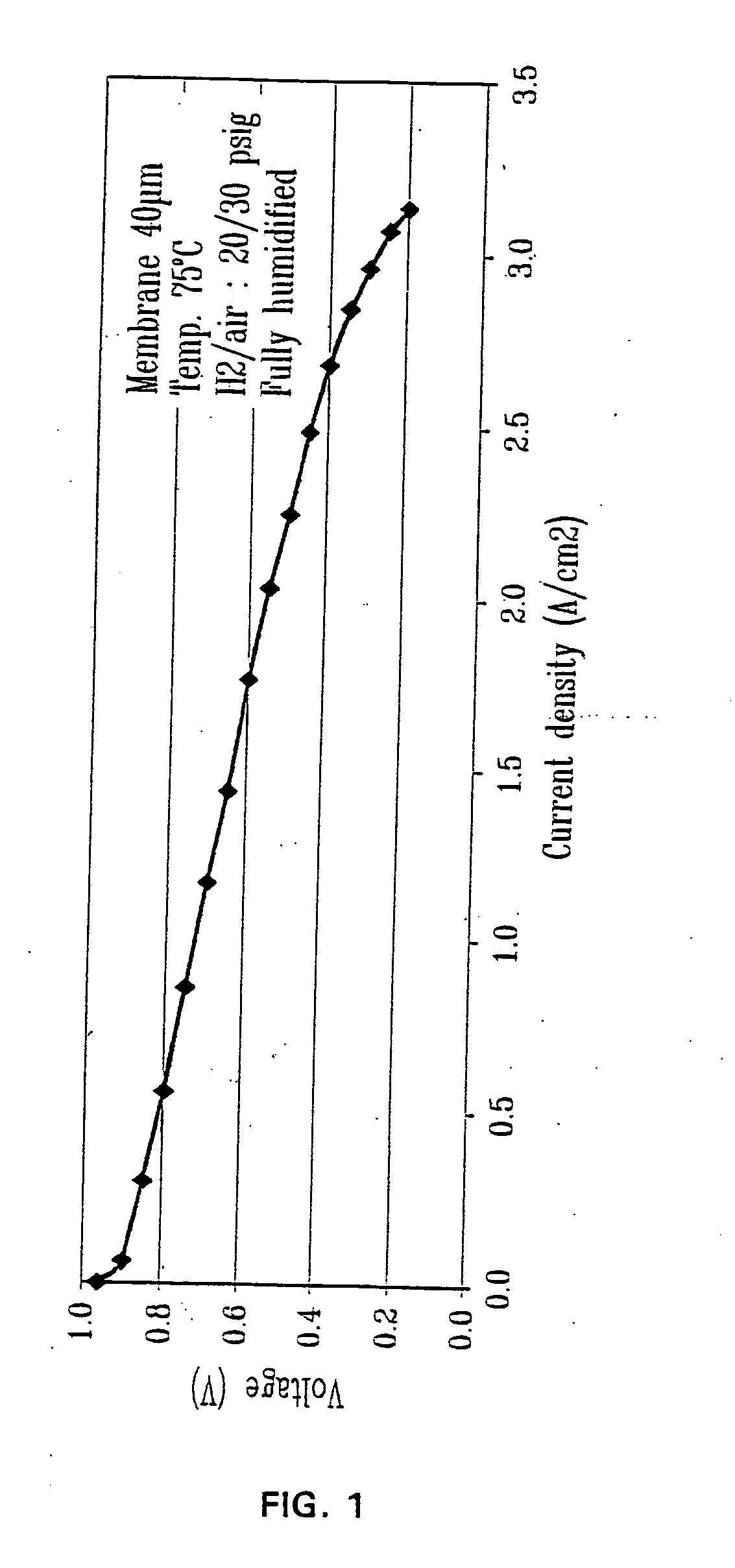

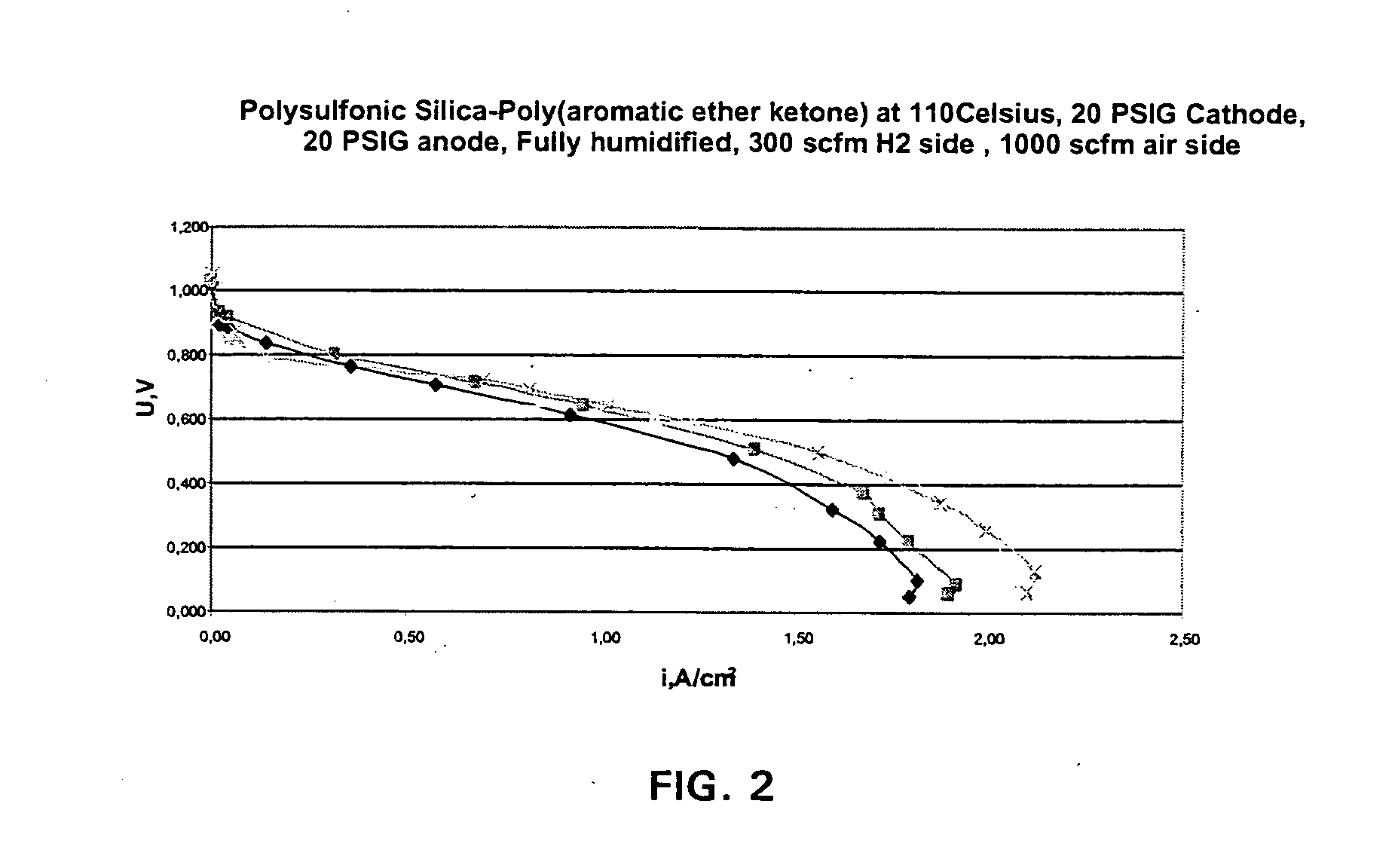

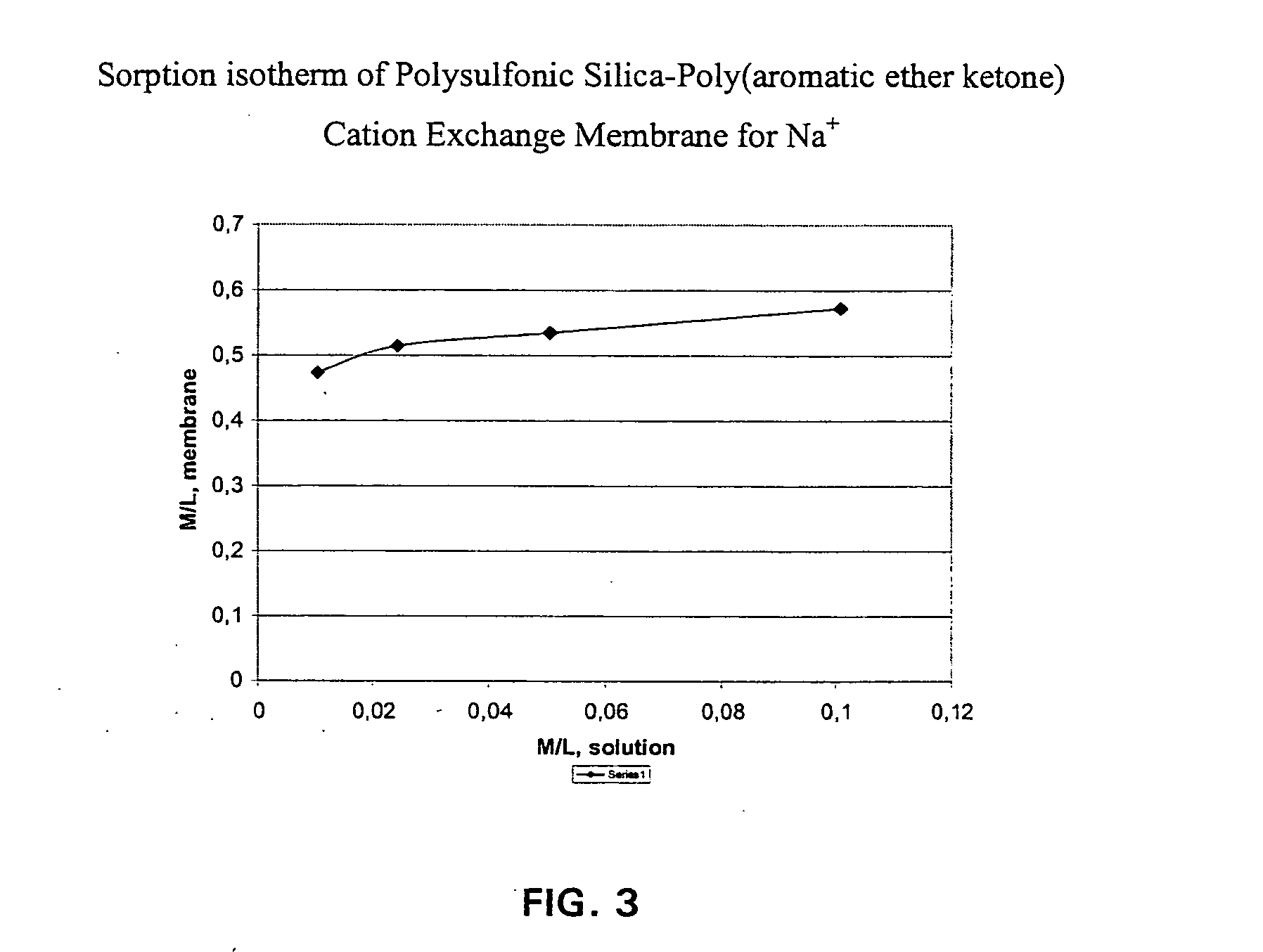

Ion exchange composite material based on proton conductive functionalized inorganic support compounds in a polymer matrix

InactiveUS20050053818A1Improve mechanical propertiesImprove impermeabilitySemi-permeable membranesSolid electrolytesIon exchangeLiquid fuel

The composite material comprise acid functionalized inorganic supports such as silica dispersed in a functionalized and / or non-functionalized polymer matrix that is based on numerous polymers such as poly(aromatic ether ketones), or poly(benzoyl phenylene), or derivatives thereof. The composite material is characterized by good water retention capabilities due to the acidic functions and the hydrophilicity of the silica particles. Moreover, a good impermeability to gas and liquid fuels commonly used in fuel cell technology, like hydrogen gas or methanol solution, is also obtained due to the presence of silica particles. Good mechanical properties of the composite material let the material to be formed easily in thin film or membrane form. In that form, the composite material is usable for proton exchange membrane for fuel cells, for drying or humidifying membrane for gas or solvent conditioning, or as acid catalytic membrane.

Owner:SIM COMPOSITES INC

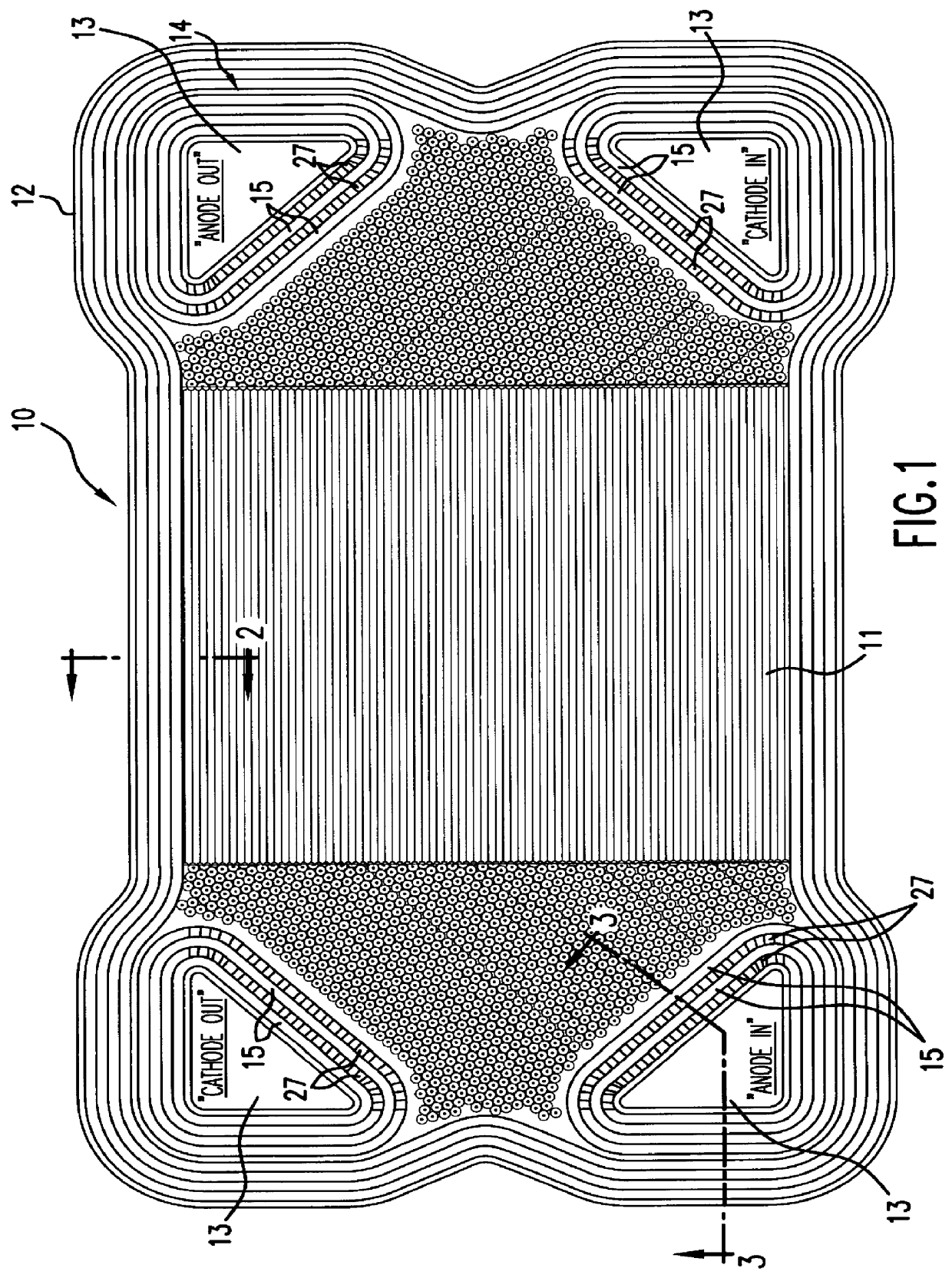

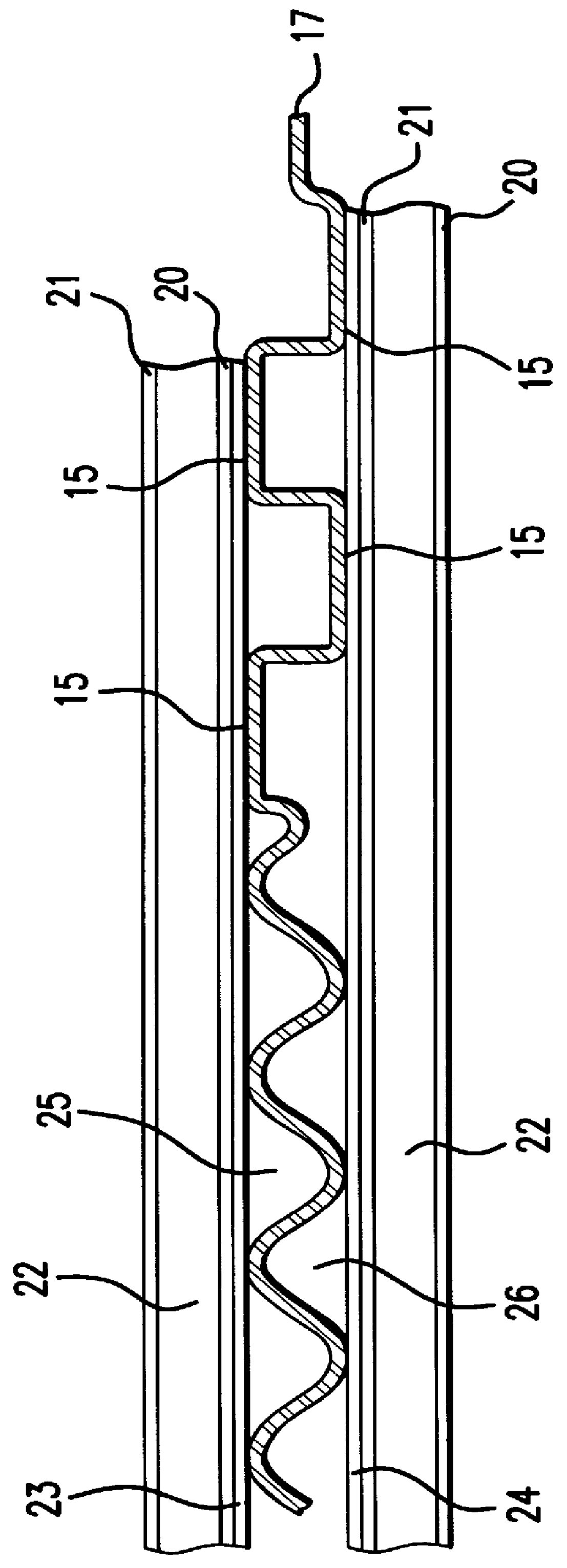

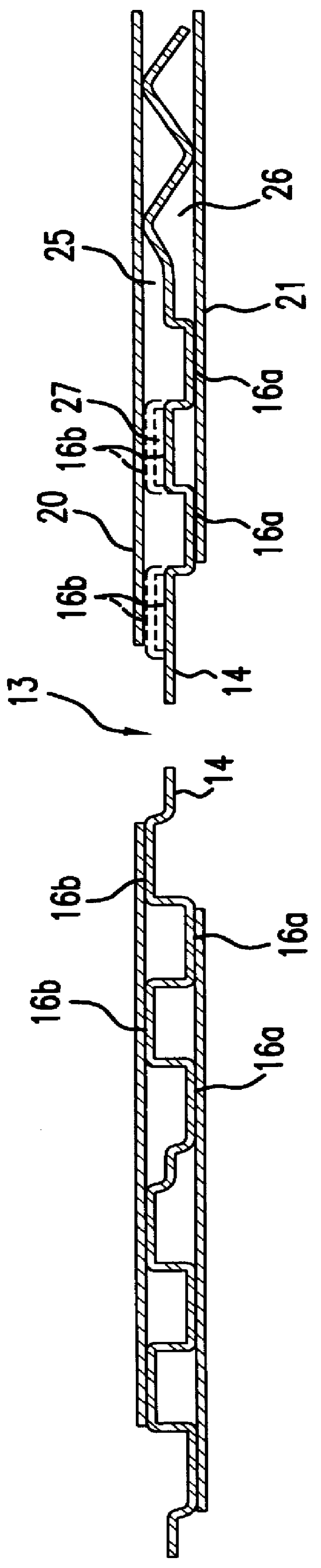

One piece fuel cell separator plate

InactiveUS6040076AShorten assembly timeImprove sealingFuel cells groupingFused electrolyte fuel cellsFuel cellsGuide tube

A separator plate for an internally manifolded fuel cell stack comprising a centrally disposed active region, a peripheral seal region, and forming at least one pair of perforations substantially geometrically disposed on opposite sides of the centrally disposed active region. The peripheral seal region comprises a peripheral seal structure on each face of the separator plate completely around the periphery of each said face. A manifold seal region in each face completely encloses each perforations, the manifold seal region comprising conduits on one of said faces for communication of a gas between the centrally disposed active region and at least the one pair of perforations. The separator plate is comprised of one sheet of a material suitable for use as a separator plate, preferably a pressed sheet metal.

Owner:INST OF GAS TECH

Redox flow cell

A redox flow cell is presented that utilizes a porous membrane separating a first half cell and a second half cell. The porous membrane is chosen to have a figure of merit (FOM) is at least a minimum FOM. A method of providing a porous membrane for a flow cell can include determining a figure of merit; determining a first parameter from a pore size or a thickness for the porous membrane; determining a second parameter from the pore size or the thickness that is not the first parameter for the porous membrane, based on the figure of merit; and constructing a porous membrane having the pore size and the thickness.

Owner:IMERGY POWER SYST

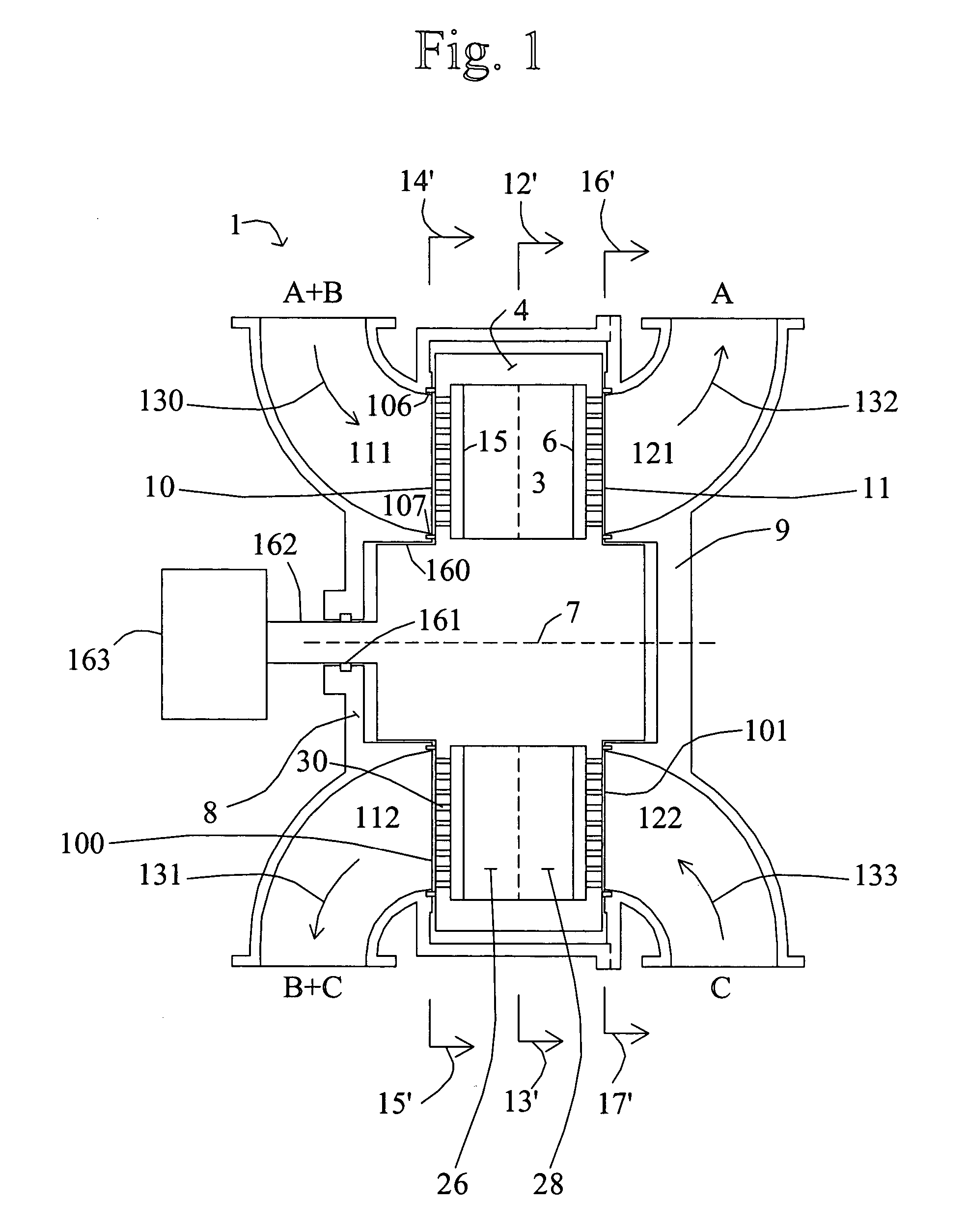

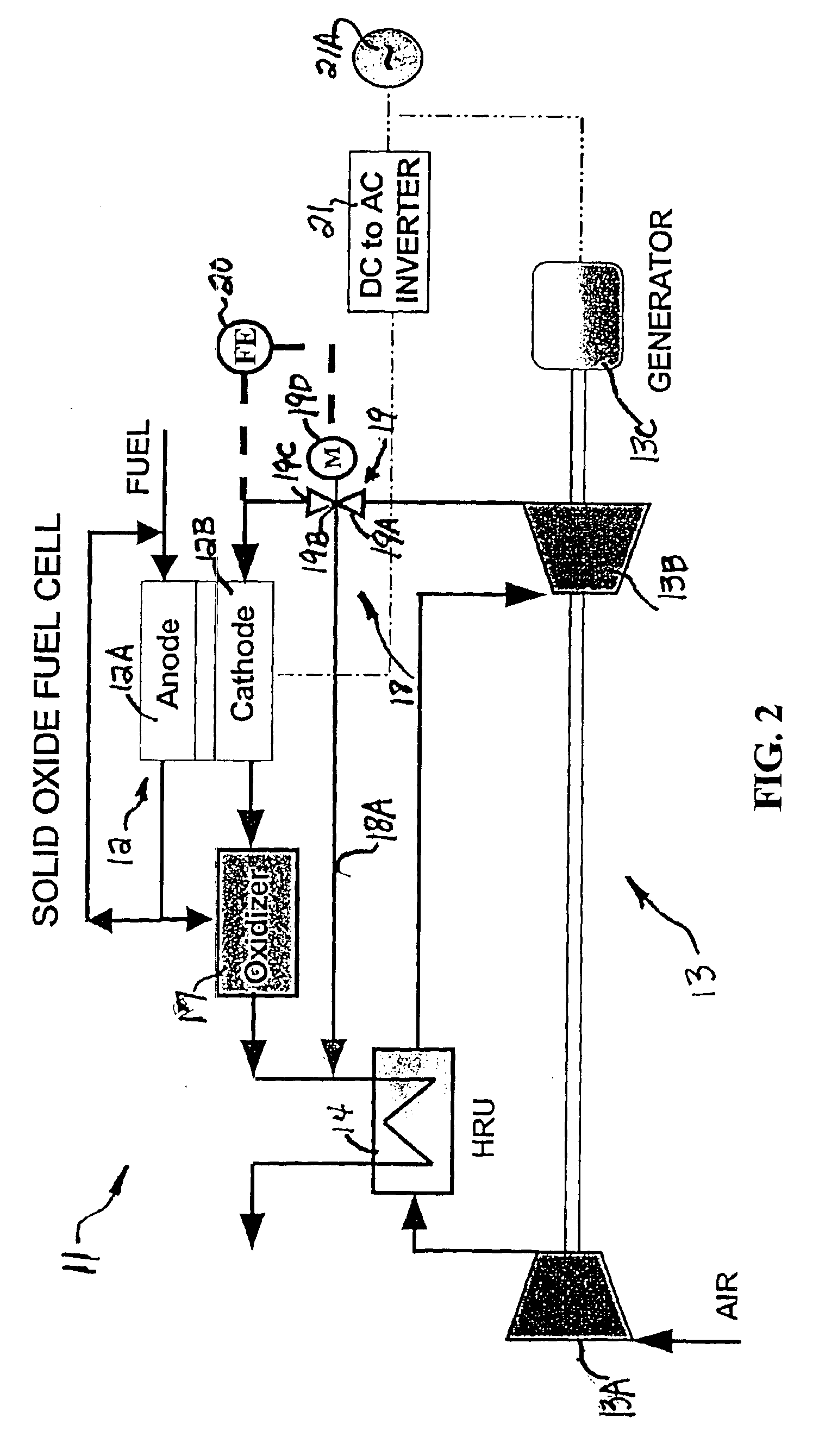

Hydrogen recycle for high temperature fuel cells

InactiveUS20040197612A1Improve efficiencyImprove sustainabilityGas treatmentRegenerative fuel cellsOxygenContamination

High temperature fuel cell electrical generation systems are provided that are adapted to enable selective generation of electrical power, and / or hydrogen fuel, and / or useable heat, allowing flexible operation of the generation system. In such embodiments, the high temperature fuel cell may be either a MCFC or a SOFC. The disclosed systems relate to high temperature fuel cells exploiting gas separation devices in which a first gas mixture is to be separated so that a first product of the separation is enriched in a first component, while a second component is mixed with a displacement purge stream to form a second gas mixture, with provision to prevent cross contamination of purge gas components into the first product stream. The process may be applied to hydrogen (component A) enrichment from syngas mixtures such as fuel cell anode exhaust, where dilute carbon dioxide (component B) is to be rejected such as to the atmosphere or for recycle to the fuel cell cathode in the case of molten carbonate fuel cells, by purging with cathode exhaust oxygen-depleted air (as component C).

Owner:QUSIR TECH

Fuel cell with internal combustion chamber

InactiveUS6124053AImprove performanceFacilitate fuel combustionFuel cells groupingFuel cell auxillariesFuel cellsCombustion chamber

A novel fuel cell design is provided having a combustion chamber manifold internal to a fuel cell stack and interfacing one or more anode passage outlets and cathode passage inlets. The combustion chamber is equipped to combine a primary source of oxidant gas with an anode exhaust stream and to combust the mixture, if desired, for use as fuel within the cathode passage. The fuel cell design also provides an external gas manifold for directing carrier gas to the cathode passages upstream of the cathode passage inlets for combining with the combustion chamber exhaust prior to entry into the cathode passages.

Owner:FUEL CELL TECH

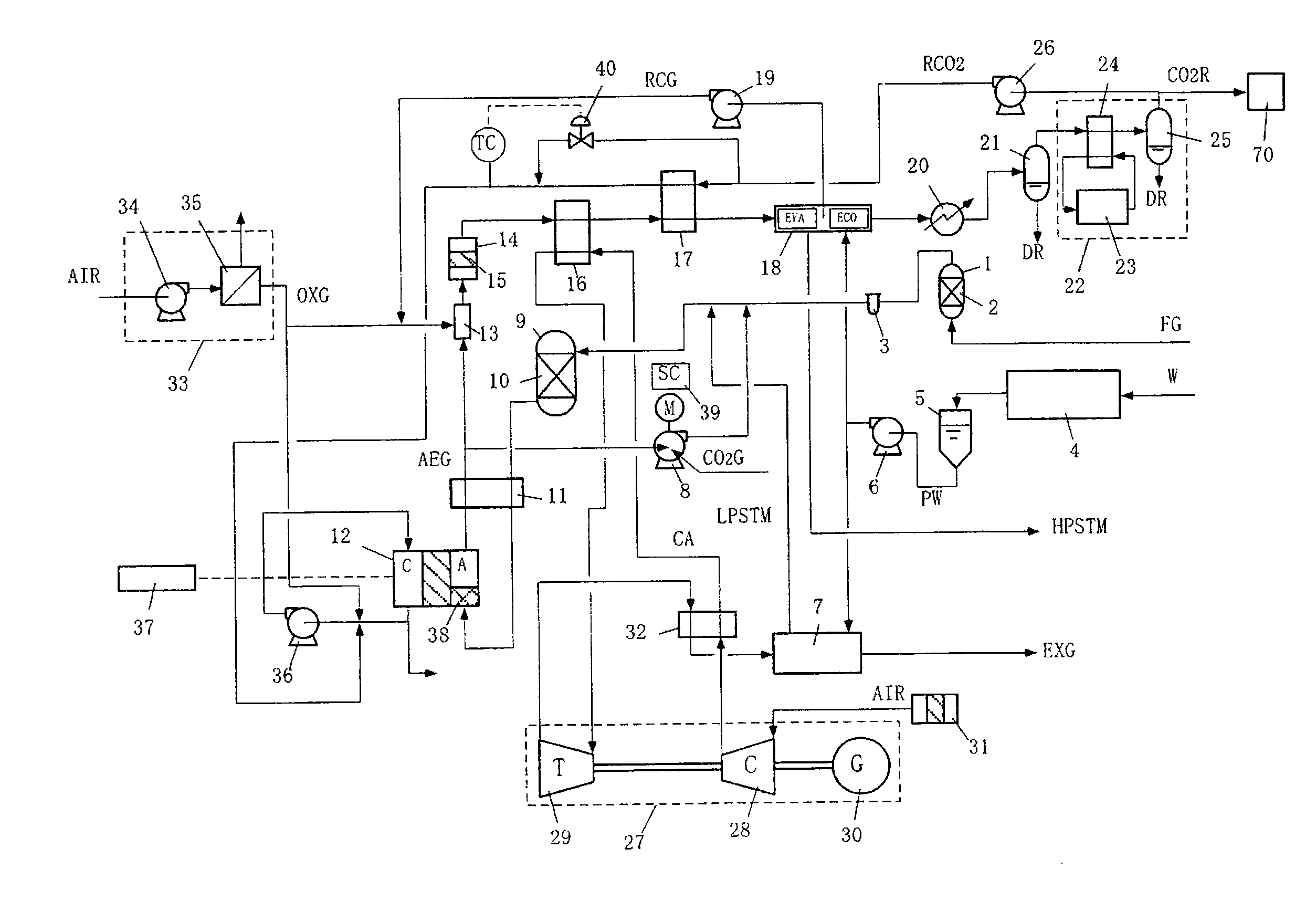

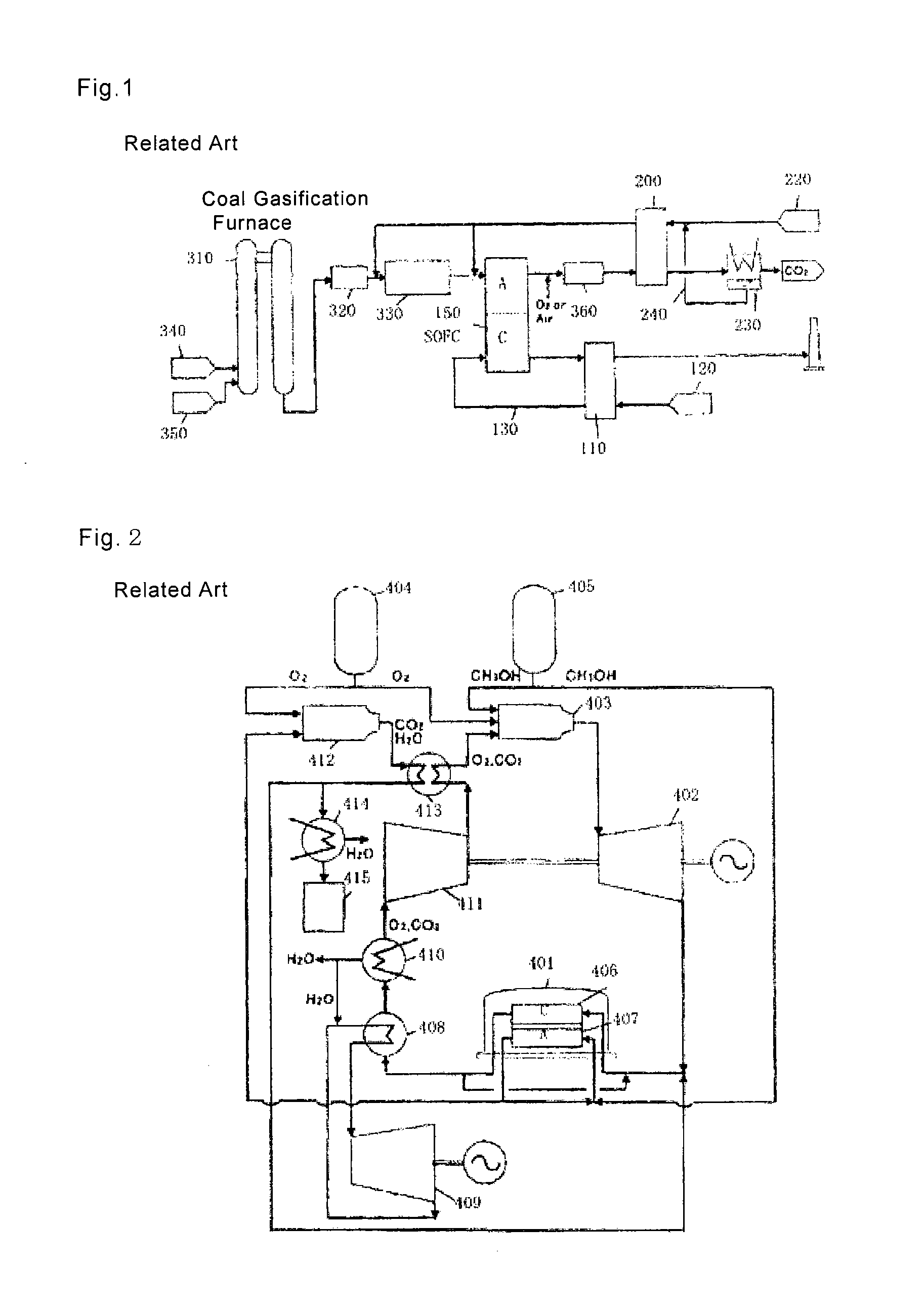

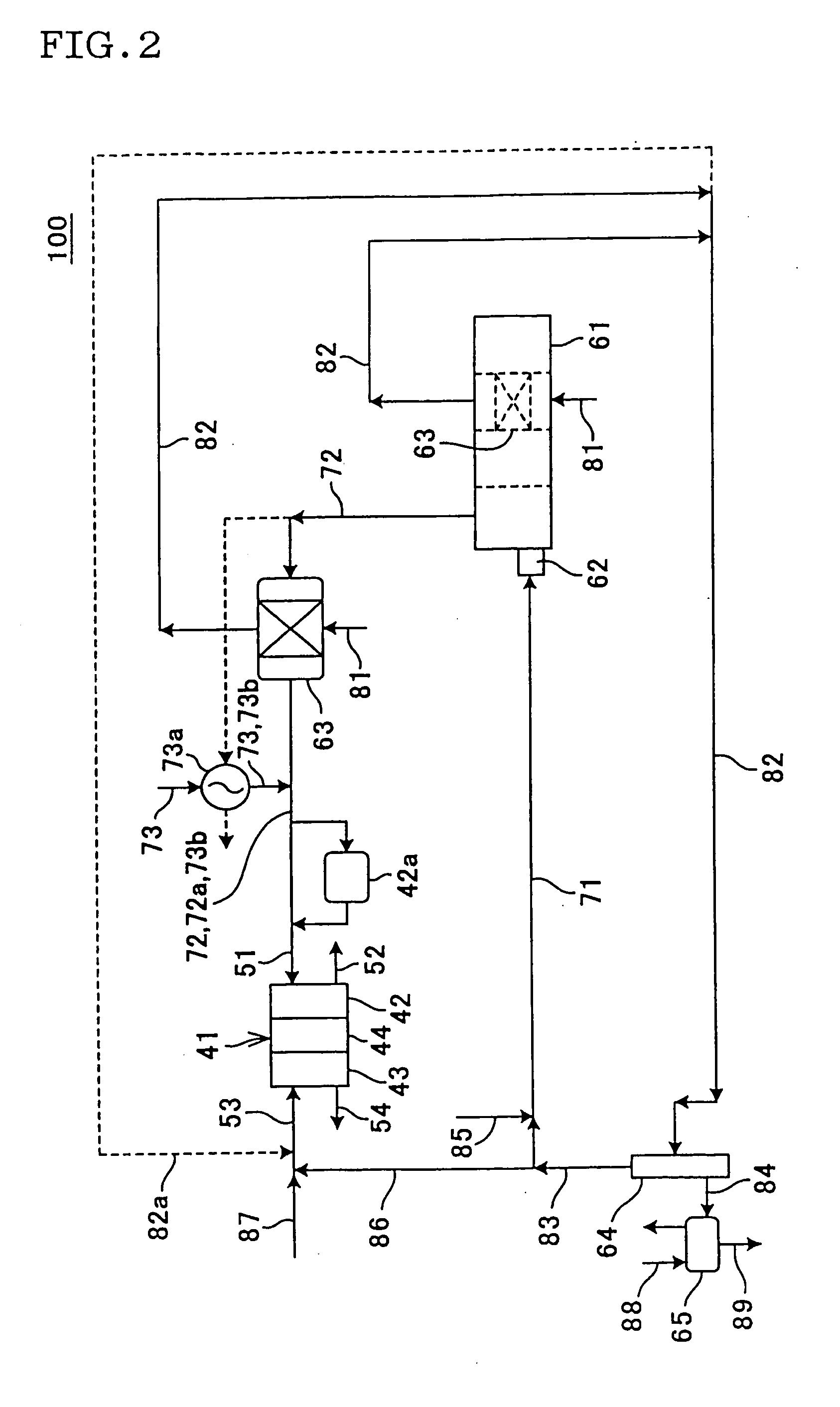

Mcfc power generation system and method for operating same

InactiveUS20110223500A1Reduce the amount of fuelReduce the amount requiredFuel cell heat exchangeRegenerative fuel cellsElectricityFuel cells

Disclosed is an MCFC power generation system and a method for operating the same enabling significant reduction of CO2 emission or substantially zero CO2 emission by minimizing the equipment added to a general power generation facility to a minimum, enabling both high power generation efficiency and high heat recovery efficiency, enabling adjustment of the voltage and output of the fuel cell in a certain range by adjusting the cathode gas composition, enabling great variation of the ratio between the heat and electricity, and thereby enabling variable thermoelectric operation. The MCFC generation system includes a cathode gas circulation system in which the cathode gas is circulated by a cathode gas recycle blower, and a closed loop is formed. Oxygen consumed by power generation is supplied from an oxygen supply plant, and CO2 is supplied from recycled CO2. Combustible components in anode exhaust are burned with oxygen, the resultant gas is cooled, and water is removed. The fuel gases in the anode exhaust is recycled.

Owner:TOKYO GAS CO LTD

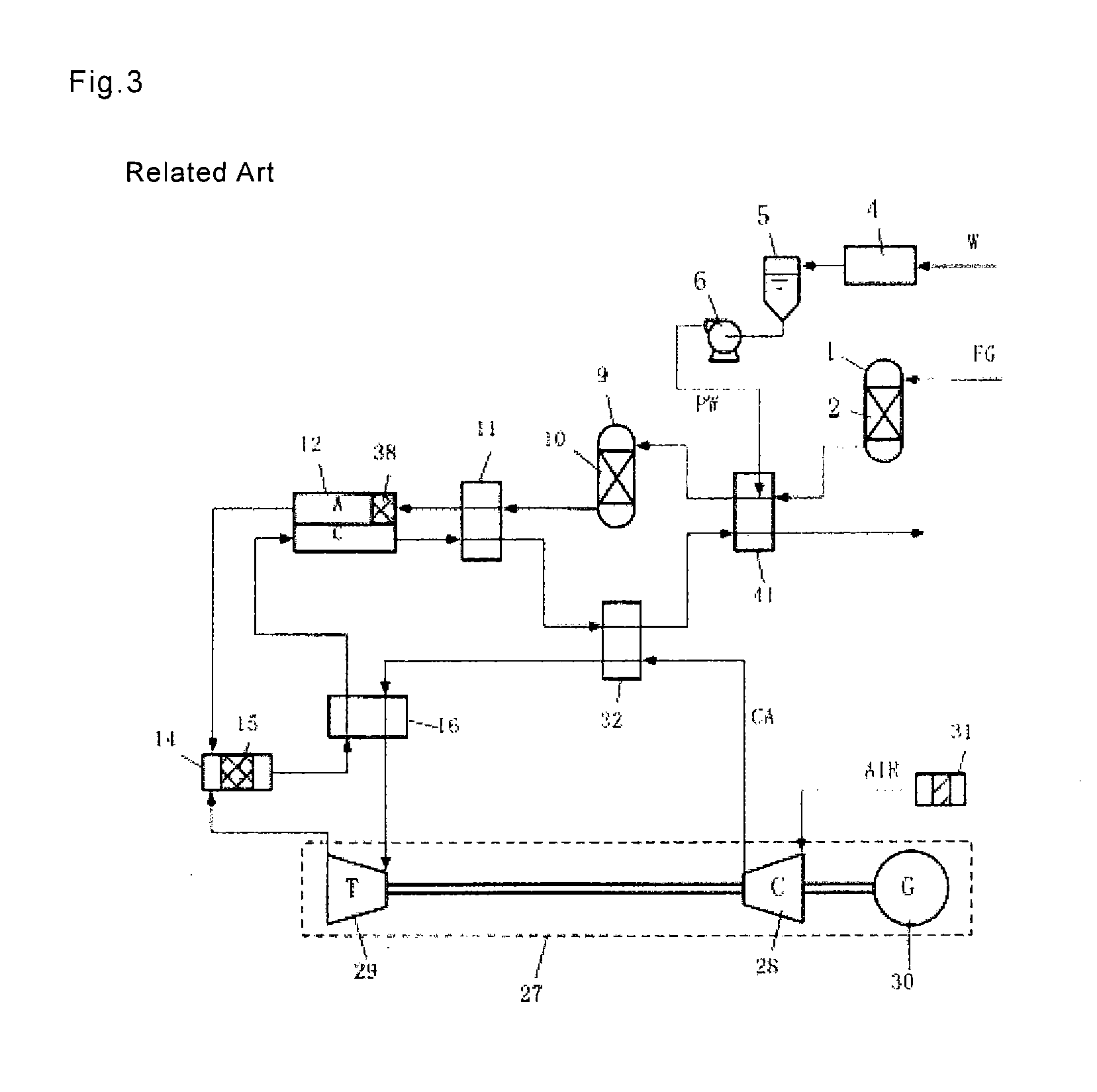

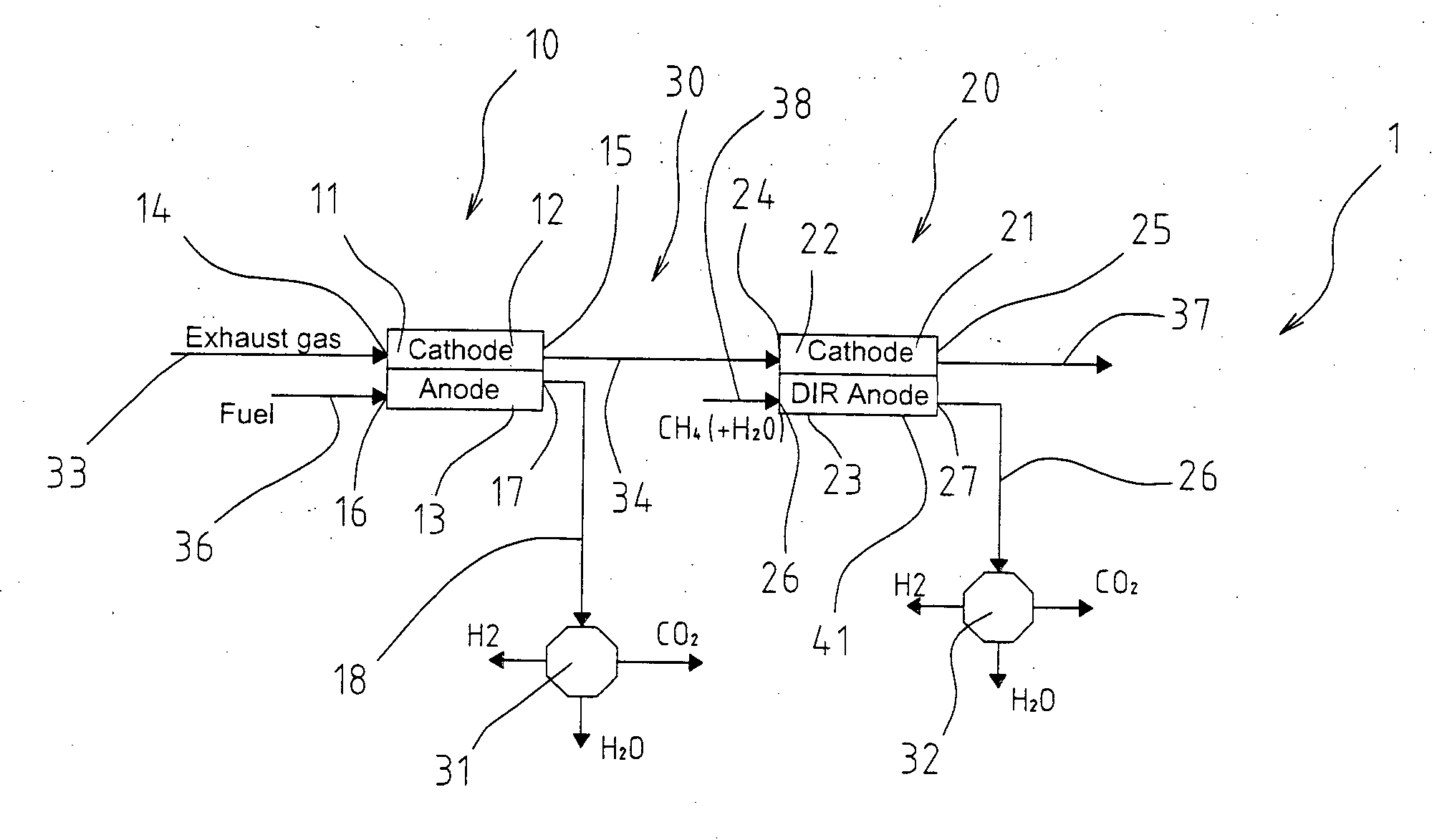

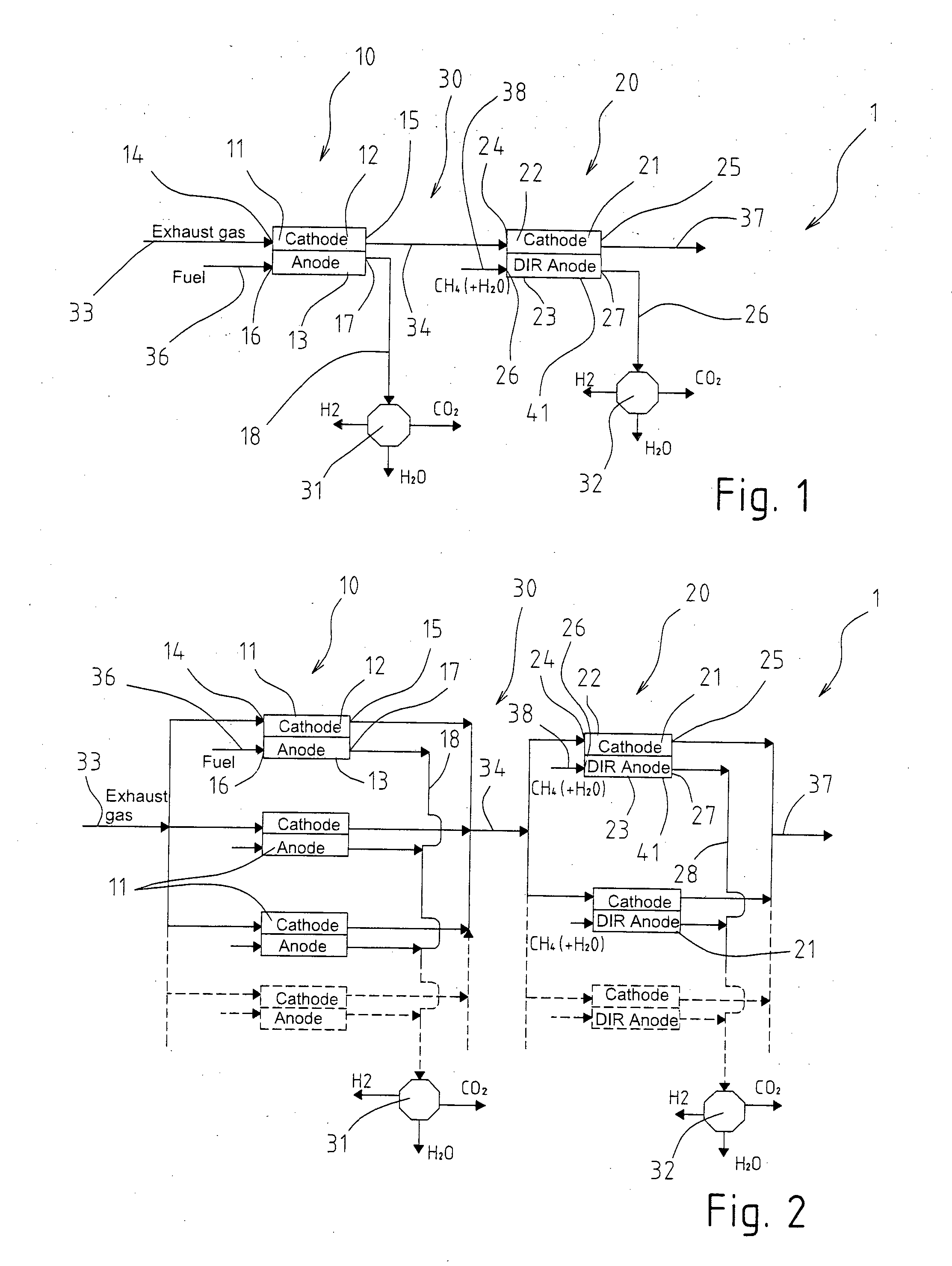

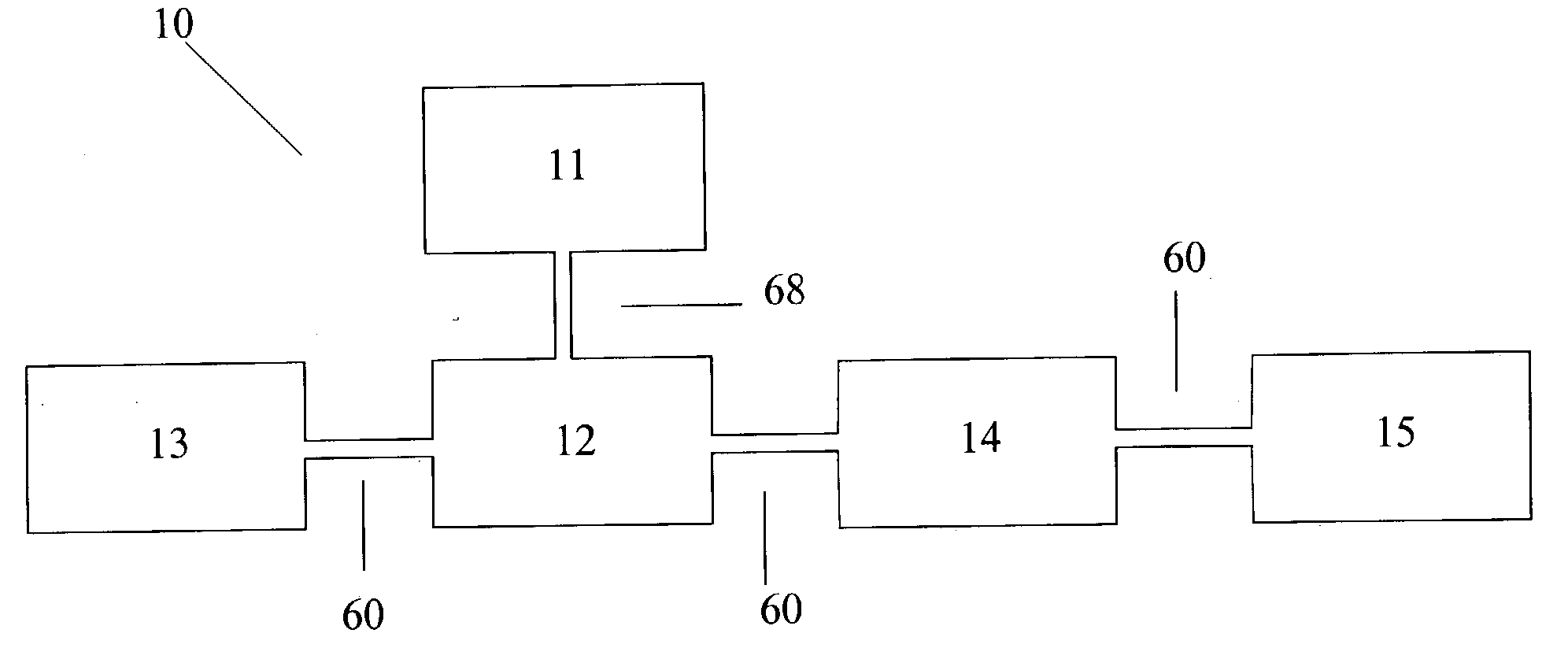

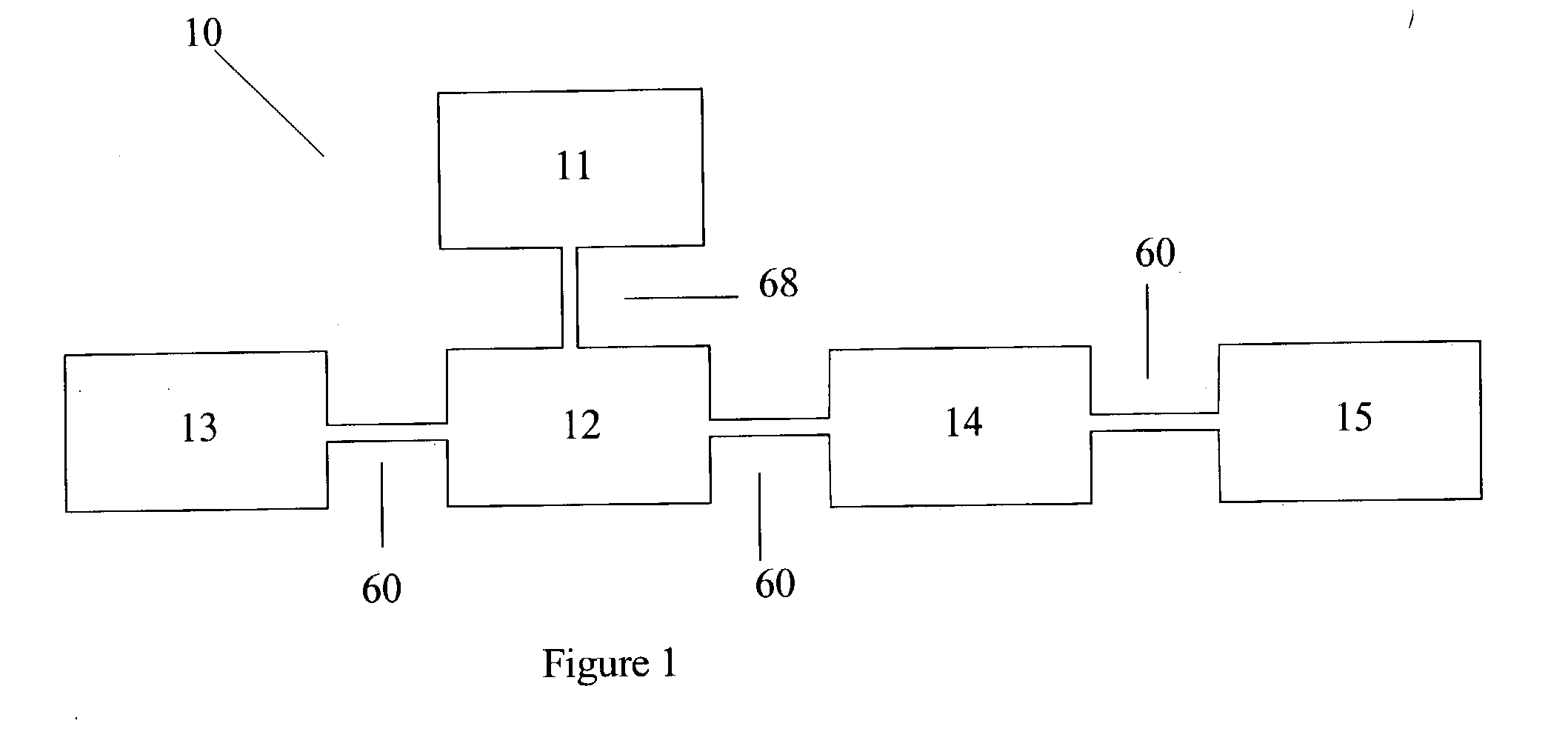

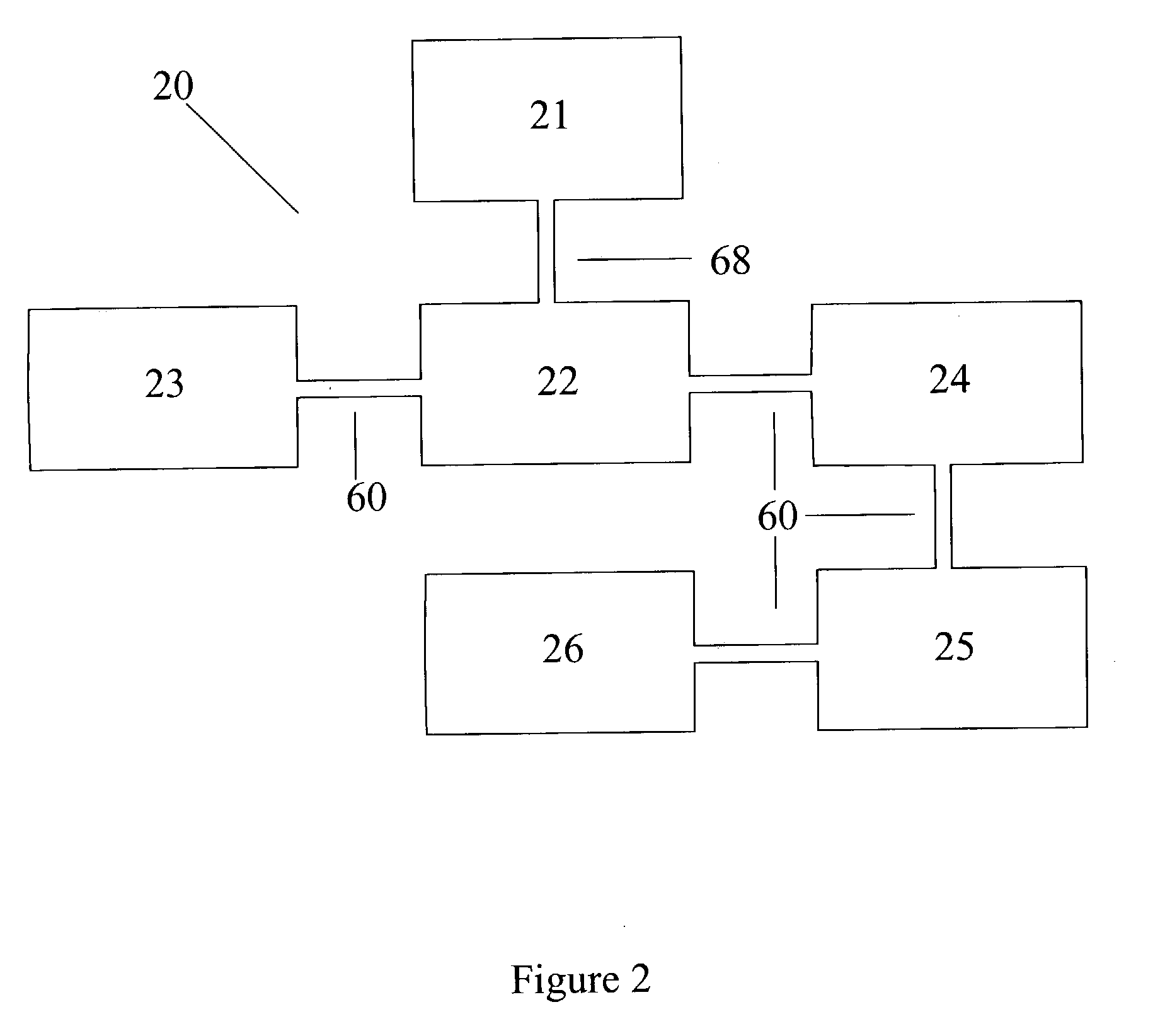

System and method for separating co2 from combustion exhaust gas by means of mcfc multistacks

InactiveUS20130014484A1Improve performanceSimplify water managementFuel cells groupingDispersed particle separationCombustionEngineering

A system for separating CO2 from combustion exhaust gas by means of MCFC multistacks comprises: a first MCFC unit (10) and a second MCFC unit (20), having respective cells (11, 21) with respective cathodic compartments (12, 22) and respective anodic compartments (13, 23); at least one CO2-capture unit (31, 32); and a connection network (30) that connects the units (10, 20) to one another and to the CO2-capture unit (31,32); the first unit (10) is formed by one or more MCFC cells (11) without active direct internal reformer; and the second unit (20) is formed by one or more MCFC cells (21) with active direct internal reformer; the units (10, 20) are connected in such a way that the exhaust gas to be treated are supplied to the cathodic compartments (12) of the cells (11) of the first unit (10), and the cathodic compartments (22) of the cells (21) of the second unit (20) are supplied with cathodic exhaust of the first unit (10), either alone or with additions that do not include portions of exhaust gas that have not previously passed into the cathodic compartments (12) of cells (11) of the first unit (10).

Owner:ANSALDO ENERGIA SPA

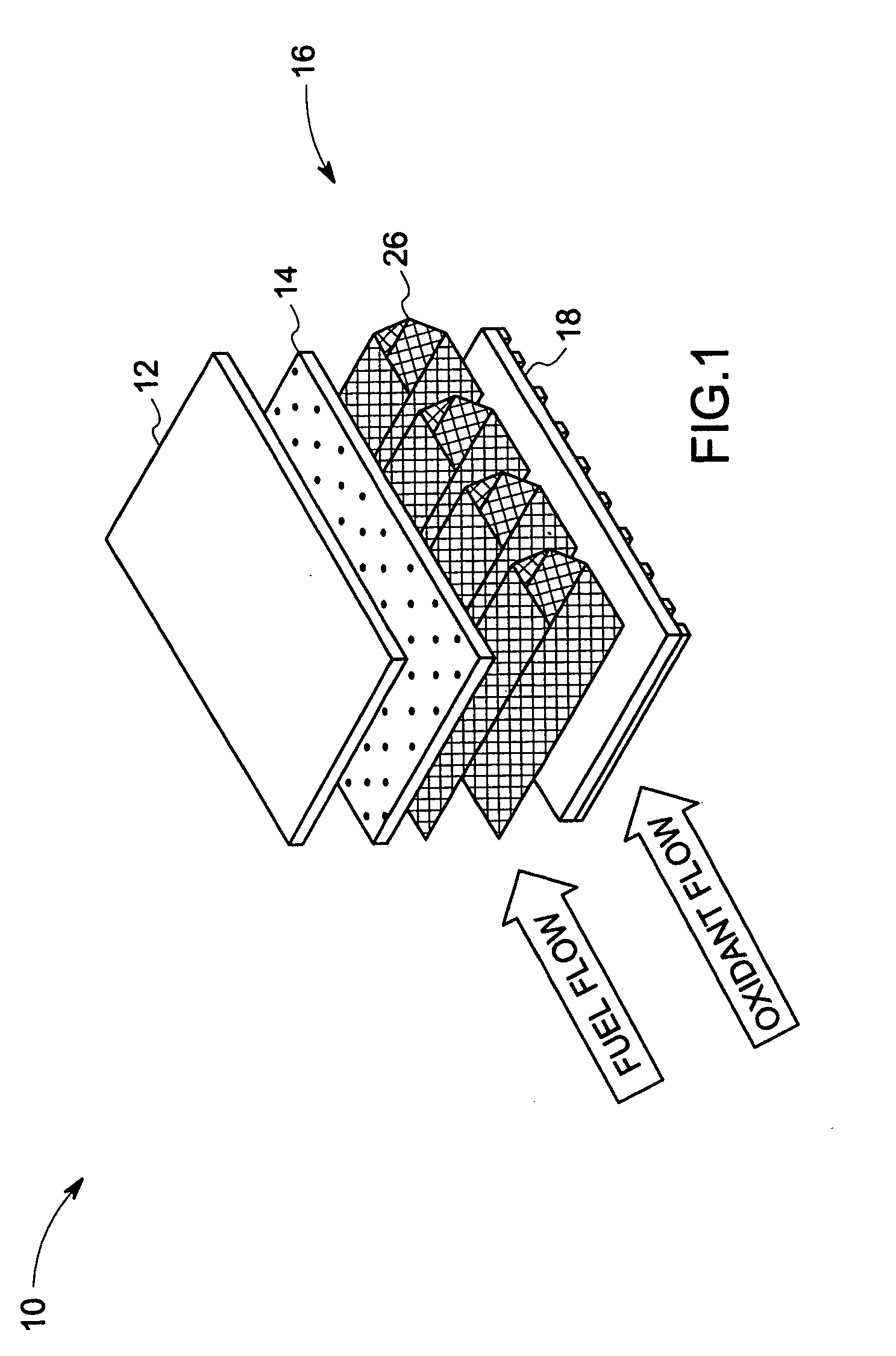

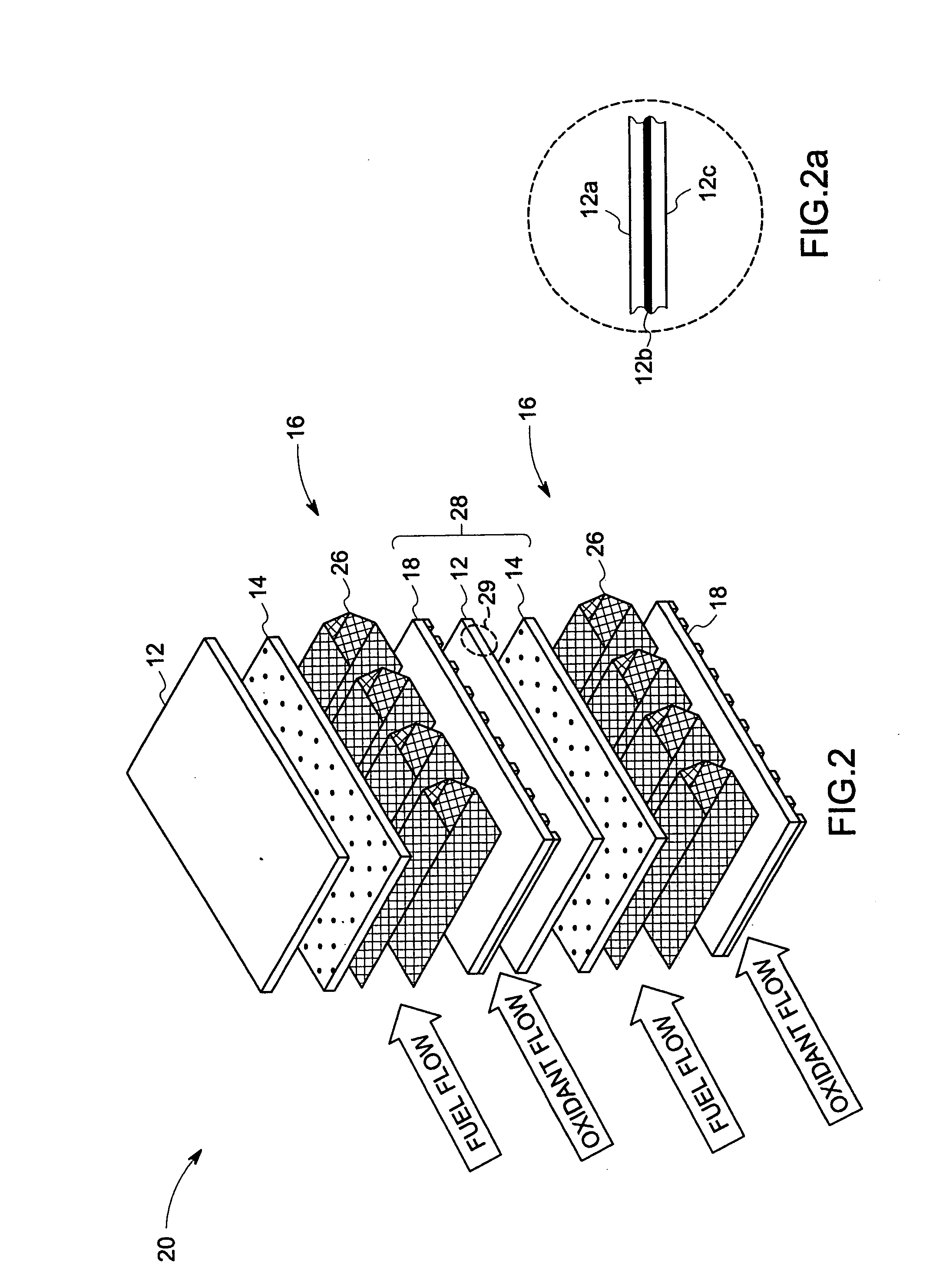

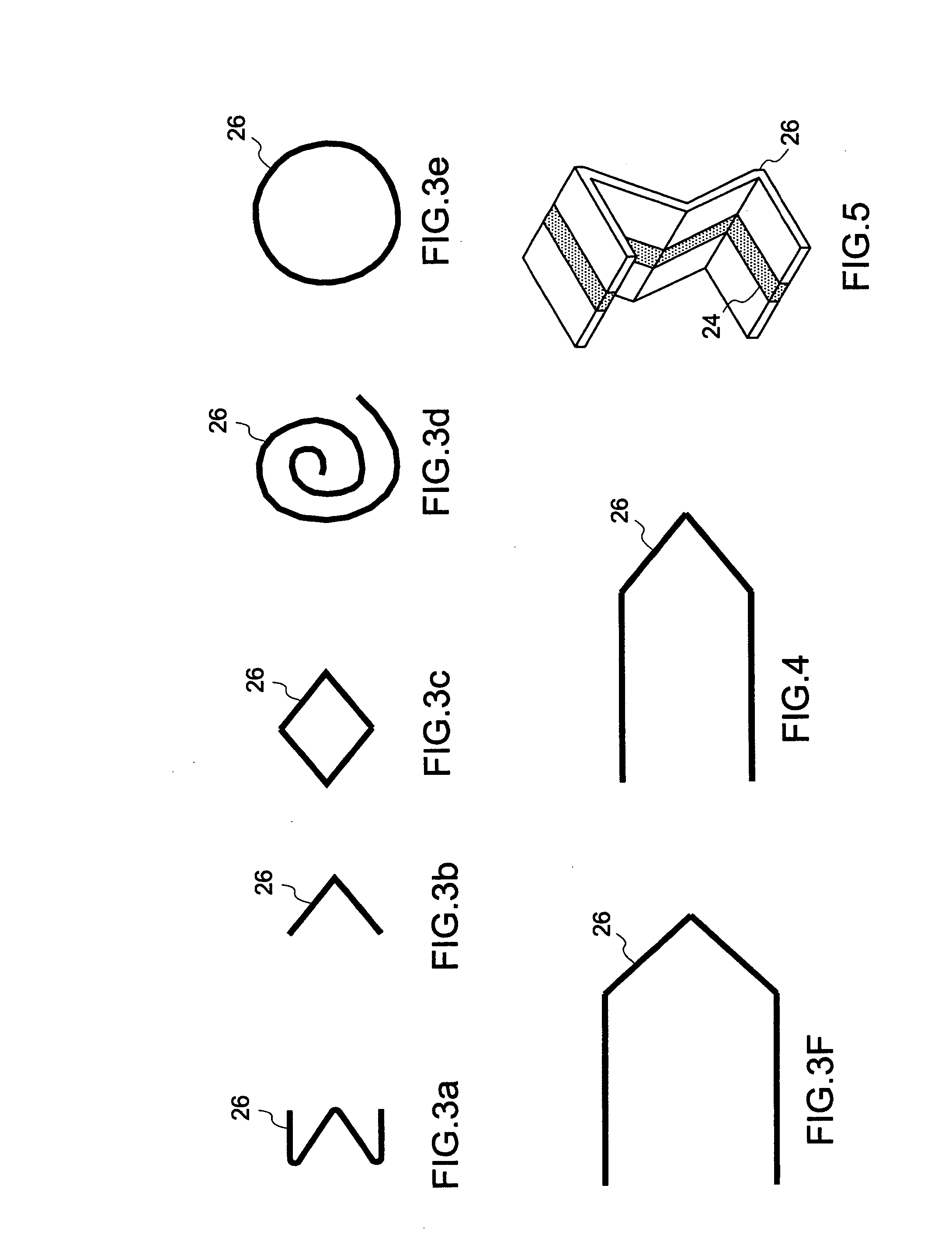

Compliant fuel cell system

A fuel cell, comprising a first electrode layer, a second electrode layer and an electrolyte interposed therebetween. The fuel cell further comprises a first electrode interconnect for supporting the first electrode layer. The first electrode interconnect is in intimate contact with the first electrode layer. The fuel cell also comprises a separator plate incorporating a second electrode interconnect for supporting the second electrode layer, which second electrode interconnect is in intimate contact with the second electrode layer, and at least one compliant structure disposed between the first electrode interconnect and the separator plate. In operation, the compliant structure deforms to accommodate motion in the fuel cell.

Owner:GENERAL ELECTRIC CO

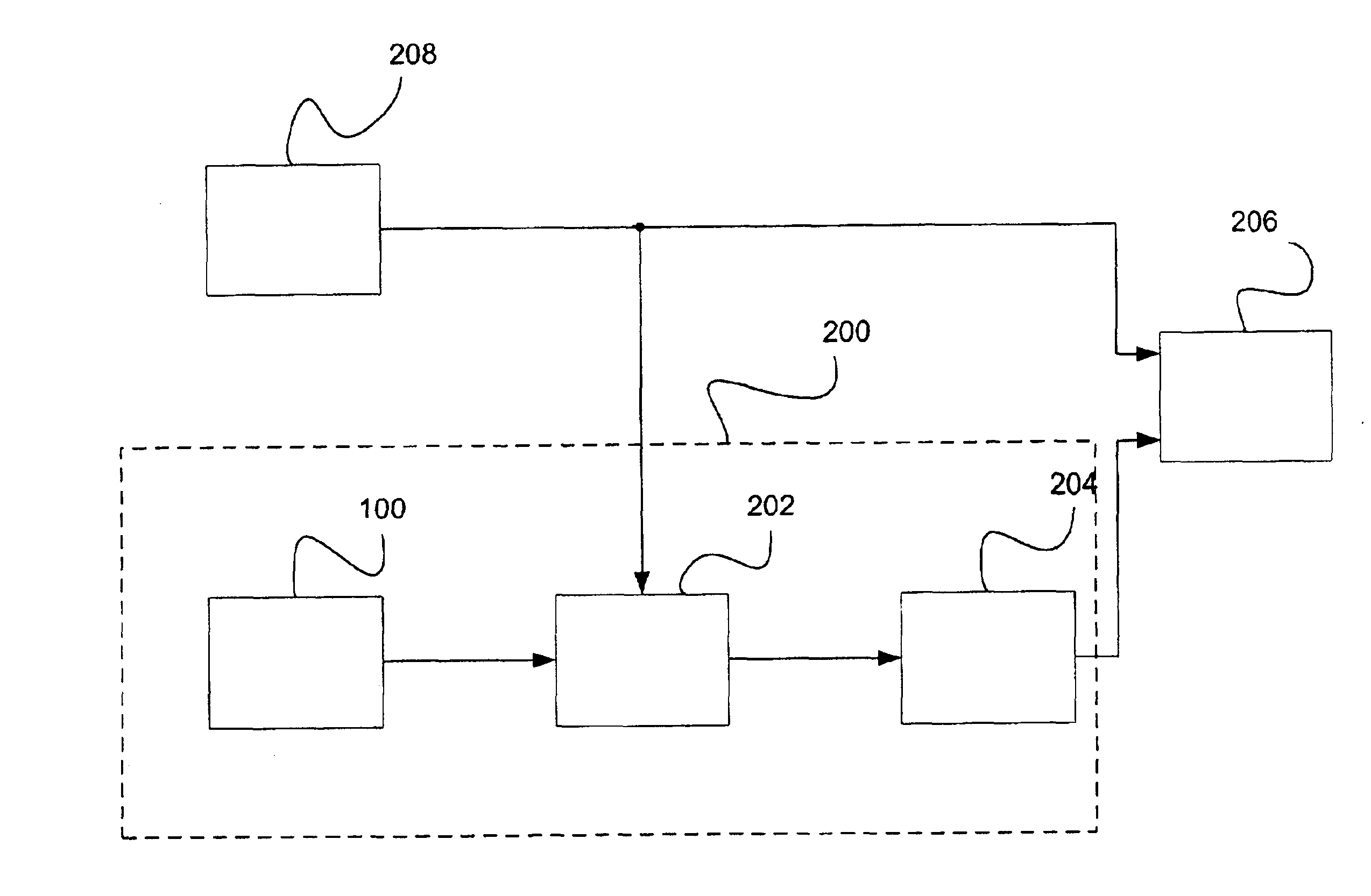

Co-production of hydrogen and electricity in a high temperature electrochemical system

A high temperature electrochemical system, such as a solid oxide fuel cell system, generates hydrogen and optionally electricity in a fuel cell mode. At least a part of the generated hydrogen is separated and stored or provided to a hydrogen using device. A solid oxide regenerative fuel cell system stores carbon dioxide in a fuel cell mode. The system generates a methane fuel in an electrolysis mode from the stored carbon dioxide and water by using a Sabatier subsystem. Alternatively, the system generates a hydrogen fuel in an electrolysis mode from water alone.

Owner:BLOOM ENERGY CORP

Enhanced high efficiency fuel cell/turbine power plant

ActiveUS6896988B2Improve efficiencyElectricity cogenerationFuel cell heat exchangePower stationCell system

A hybrid fuel cell system having a fuel cell and a heat engine having an expansion cycle and a compressor cycle and which is further adapted to include a bypass assembly for segmenting expanded oxidant supply gas from the expansion cycle of the heat engine into a first expanded oxidant supply gas portion and a second expanded gas portion and in which the first expanded oxidant supply gas portion is used for the fuel cell and the second expanded gas portion bypassed around the fuel cell.

Owner:FUELCELL ENERGY INC

Urea based composition and system for same

InactiveUS20030219371A1Safe handlingLow degreeGas turbine plantsFused electrolyte fuel cellsNitrogenNitrogen gas

A method and apparatus for generating energy from a composition comprising urea and water are described. The method in one embodiment includes: (a) reacting the urea with water to form ammonia; and (b) oxidizing the ammonia formed in step (a) to form water and nitrogen generating energy. The apparatus in one embodiment contains: (a) a first container for providing the composition; (b) a second container for reacting the urea with water to form ammonia, wherein the second container is connected to the first container by means for delivering the composition from the first container to the second container; (c) a third container for providing ammonia, wherein the third container is connected to the second container by means for delivering ammonia from the third container to the second container; and (d) a fourth container for oxidizing ammonia to form water and nitrogen generating energy, wherein the fourth container is connected to the second container by means for delivering ammonia from the second container to the fourth container. The method and apparatus are used to generate energy for use in stationary and mobile applications.

Owner:AMENDOLA STEVEN C

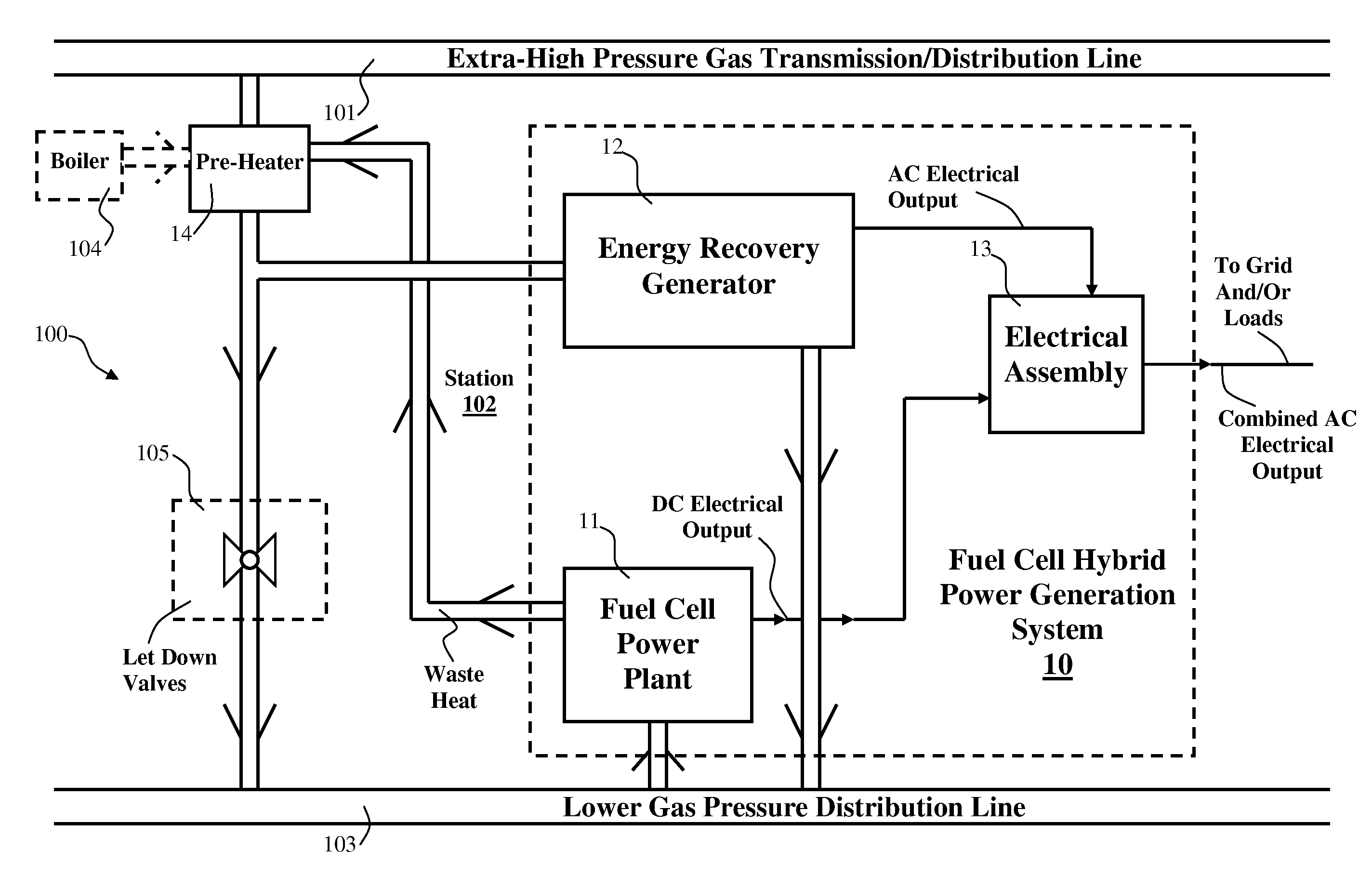

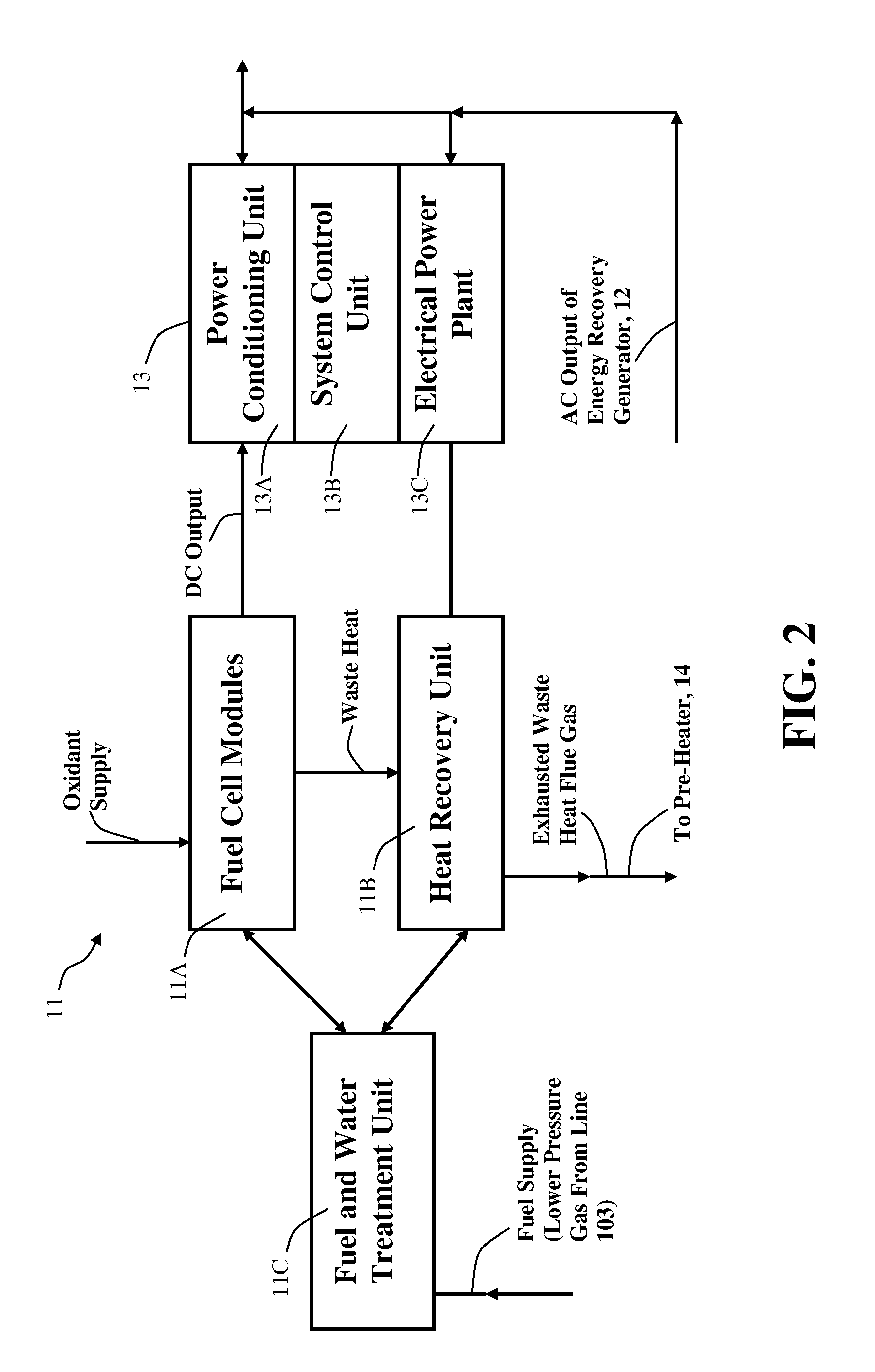

Fuel cell hybrid power generation system

A fuel cell hybrid power generation system for use in a gas distribution system in which a higher pressure gas is transported / distributed and reduced to a lower pressure gas for a gas distribution or transmission line and a pre-heater is used to heat the higher pressure gas before it is reduced in pressure. The power generation system includes: (i) a fuel cell power plant that generates electricity while producing heat that is used to preheat high pressure gas; (ii) an energy recovery generator that uses the pre-heated higher pressure gas to generate electricity while reducing the gas pressure to a lower gas pressure; and (iii) an electrical assembly combining the electrical outputs of the energy recovery generator and the fuel cell power plant. The fuel cell power plant makes the waste heat available to the gas pre-heater without using a combustion unit thereby increasing the system's electrical efficiency.

Owner:FUELCELL ENERGY INC +1

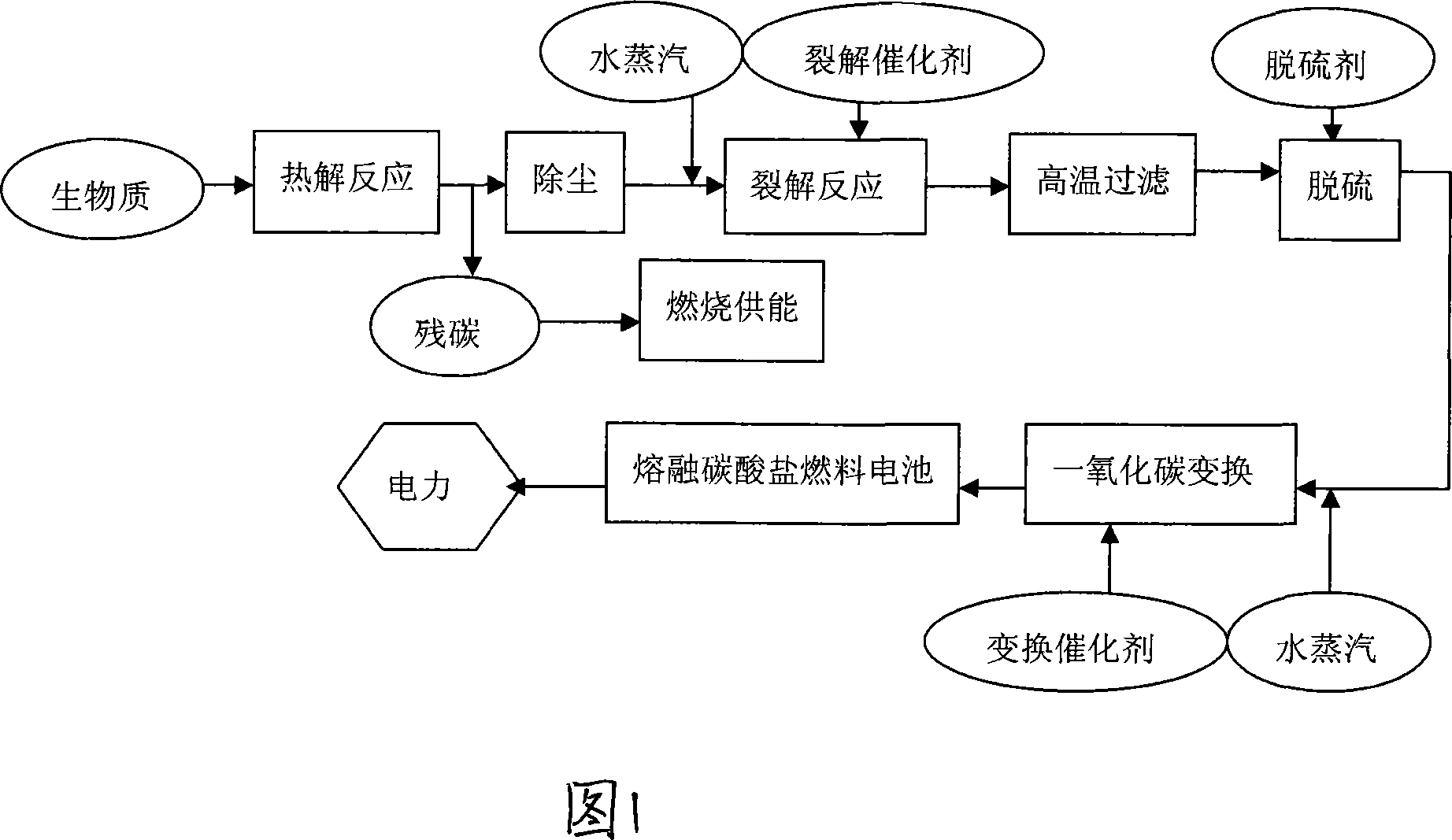

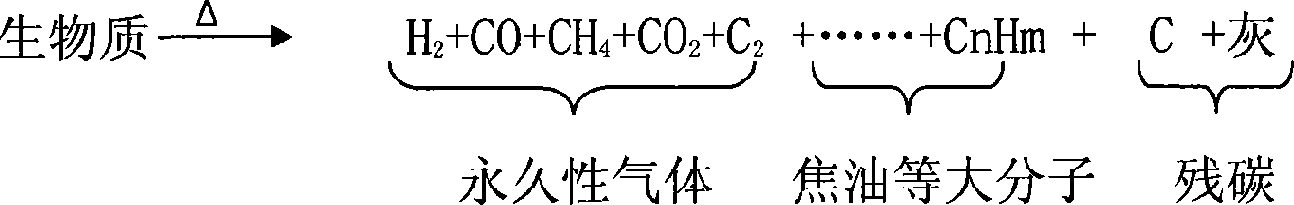

Biomass hydrogen energy electric generation method

InactiveCN101098022AIncrease profitOptimize layoutEnergy inputFused electrolyte fuel cellsElectricityHydrogen

A biomass hydrogen energy generating method is characterized in that using biomass thermal chemical hydrogen generating method to convert biomass into clean high-temperature hydrogen-abundant fuel gas, which can be directly used in fusion carbonate fuel battery without purification to generate electricity.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

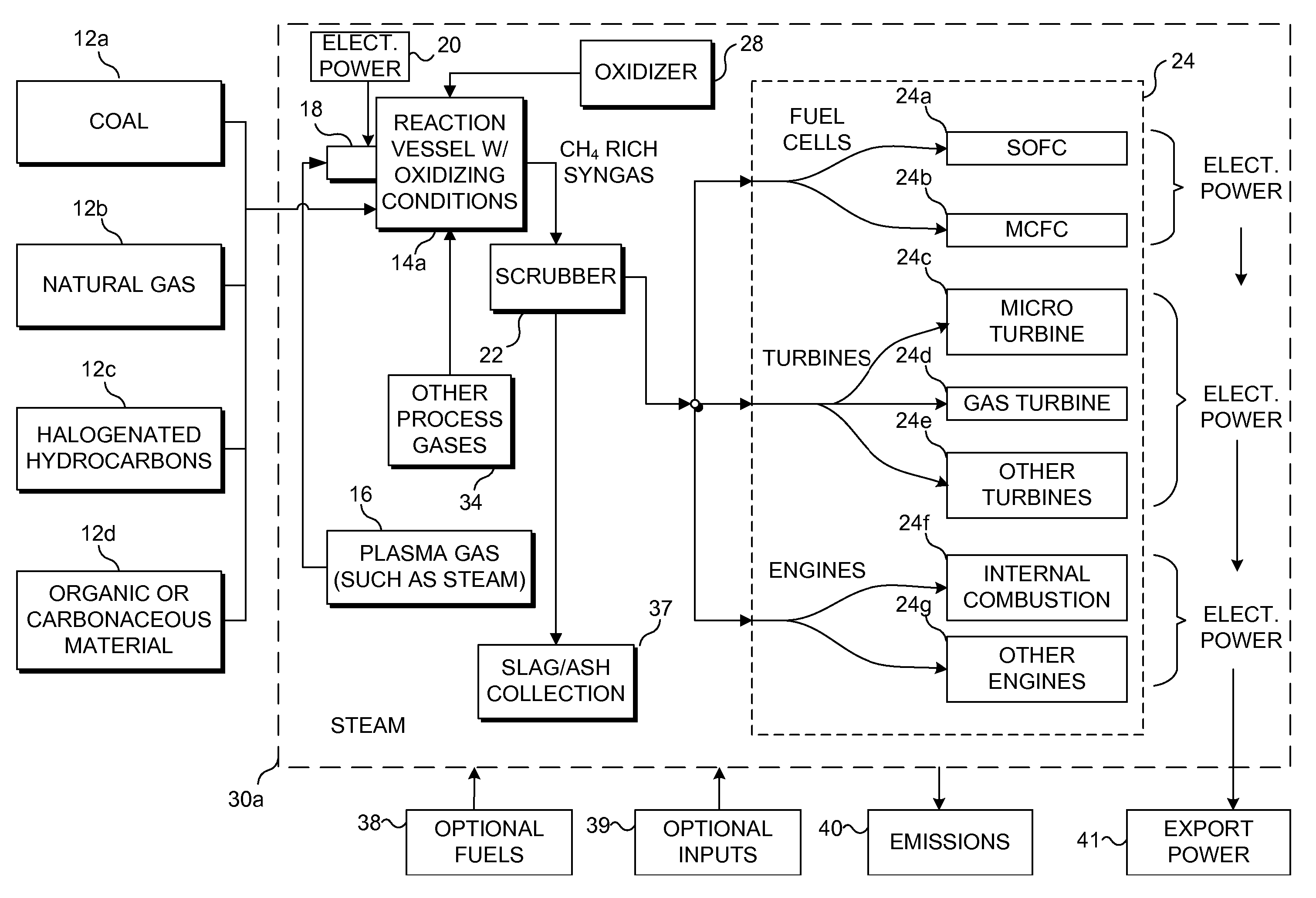

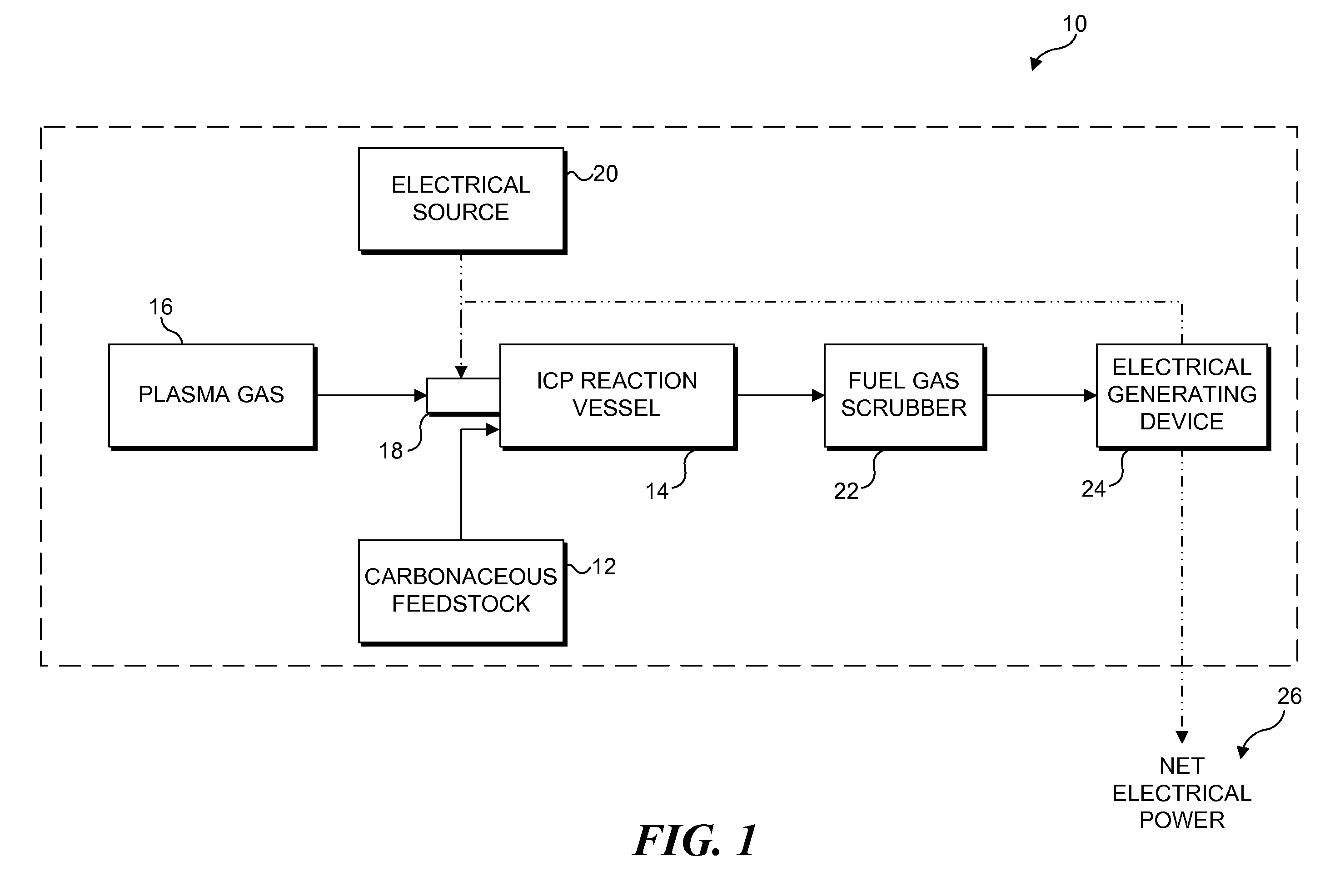

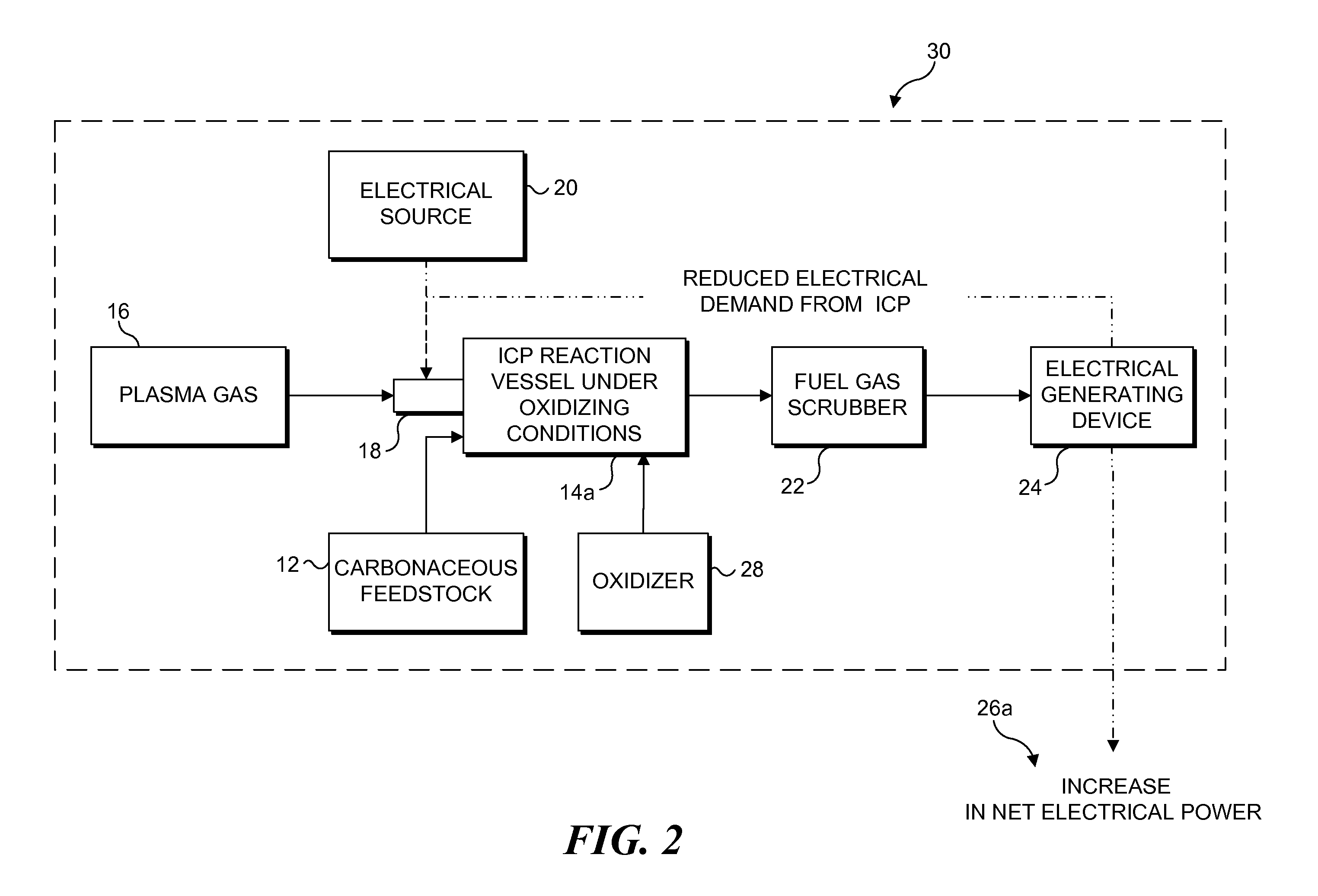

Inductively coupled plasma/partial oxidation reformation of carbonaceous compounds to produce fuel for energy production

InactiveUS20080041829A1Increase the amount of carbonMore electricityElectricity cogenerationFuel cell auxillariesThermal energyPartial oxidation

Owner:SEQUOYAH FINANCE ONE

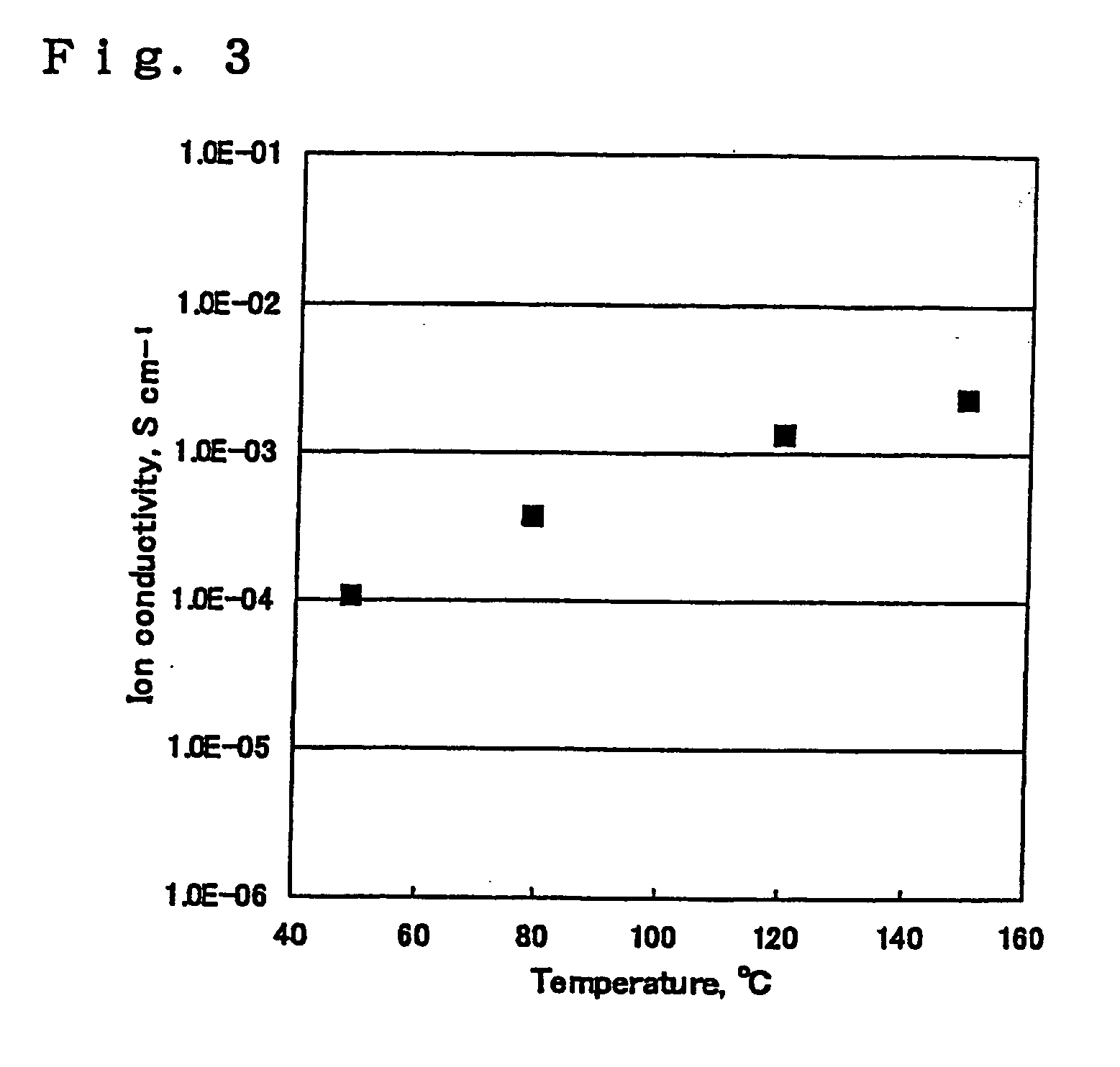

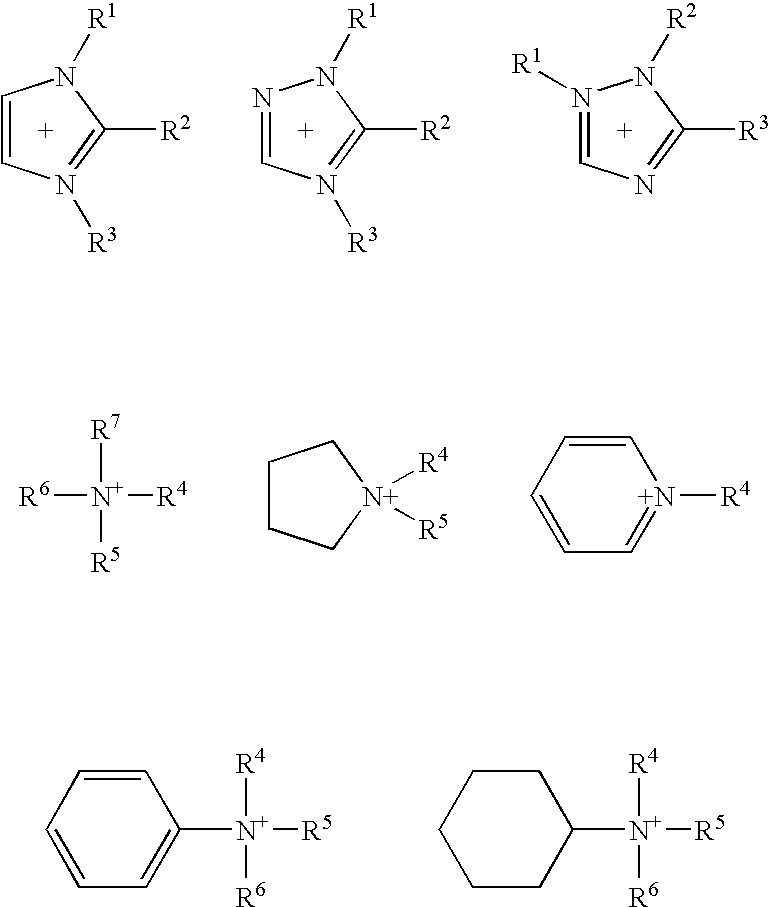

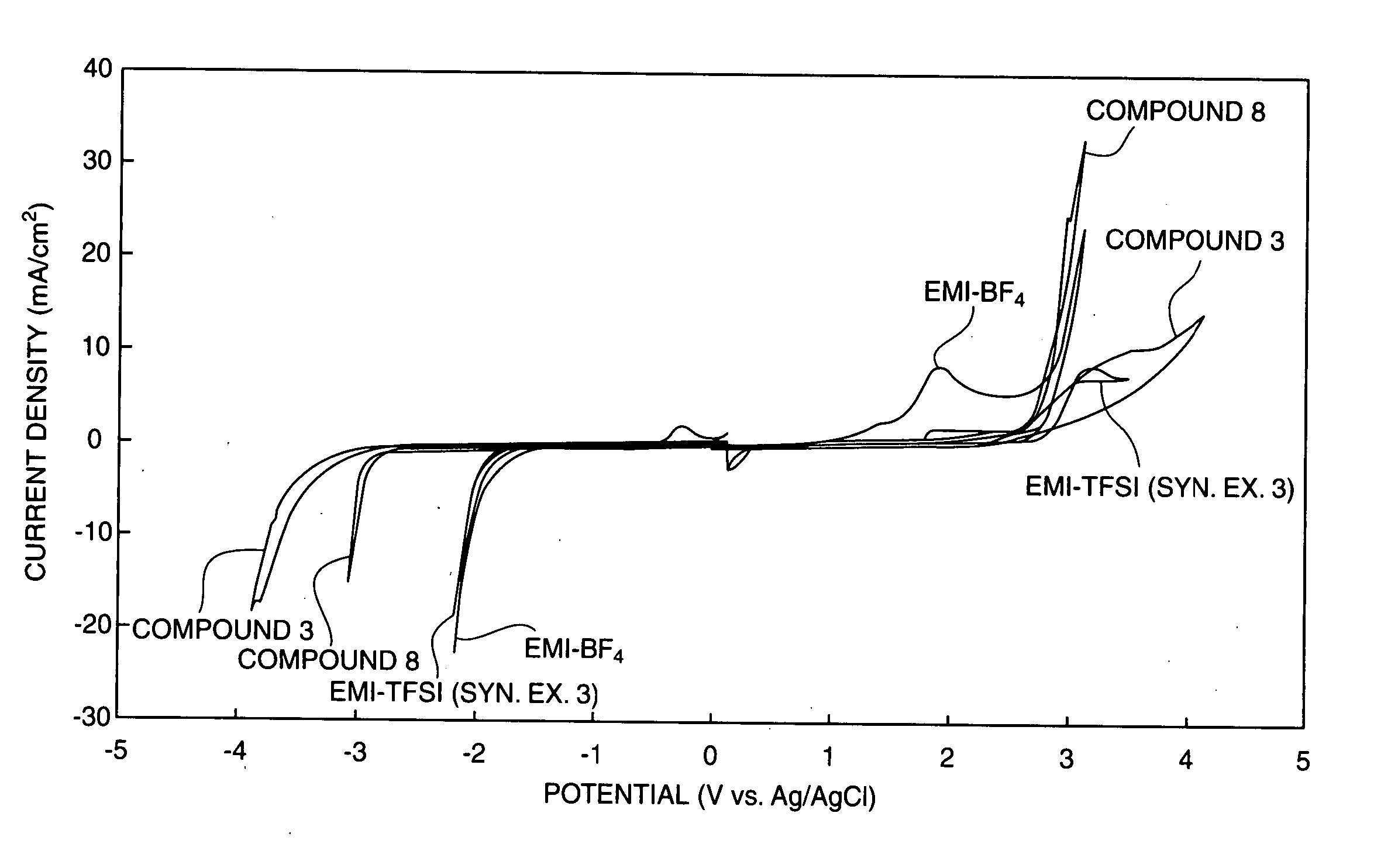

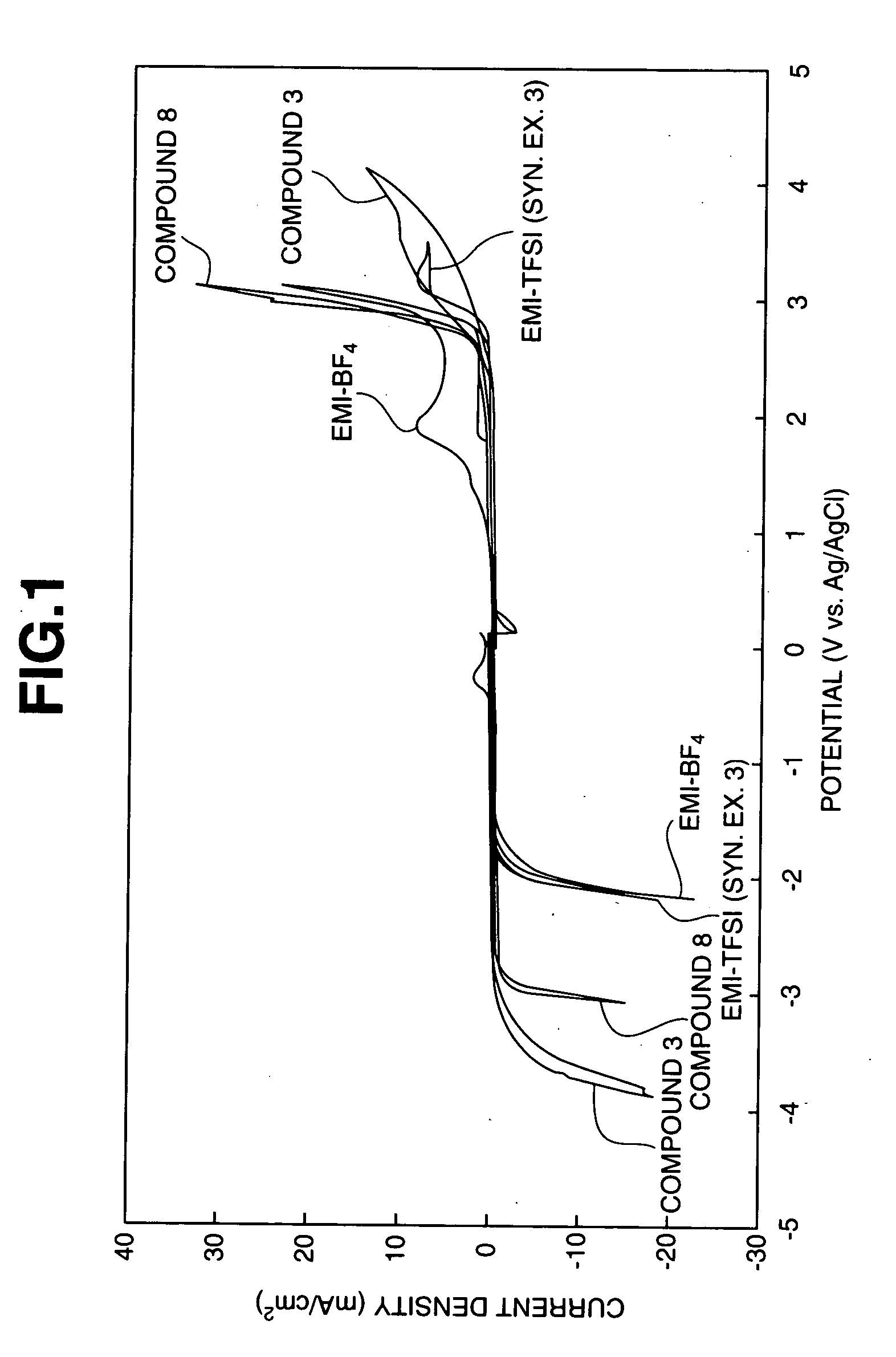

Polyelectrolyte membrane and production method therefor

InactiveUS20050221193A1High mechanical strengthSecures high ion conductivityCell electrodesFuel cell auxillariesPolymer scienceElectrolysis

A polymer electrolyte membrane comprising a microporous polymer membrane having pores penetrating through the opposite sides thereof. The microporous polymer membrane holds a mixture of a polymer and a molten salt at a weight ratio of 1 / 99 to 99 / 1 and / or a molten salt. The polymer electrolyte membrane is inexpensive, durable, excellent in mechanical strength, excellent in structural retention in high temperatures, and capable of stably holding a molten salt in its porous polymer membrane structure, shows high heat resistance, and secures high ionic conductivity in the absence of water or a solvent and is therefore useful in fuel cells, secondary batteries, electric double layer capacitors, electrolytic capacitors, and the like.

Owner:UBE IND LTD

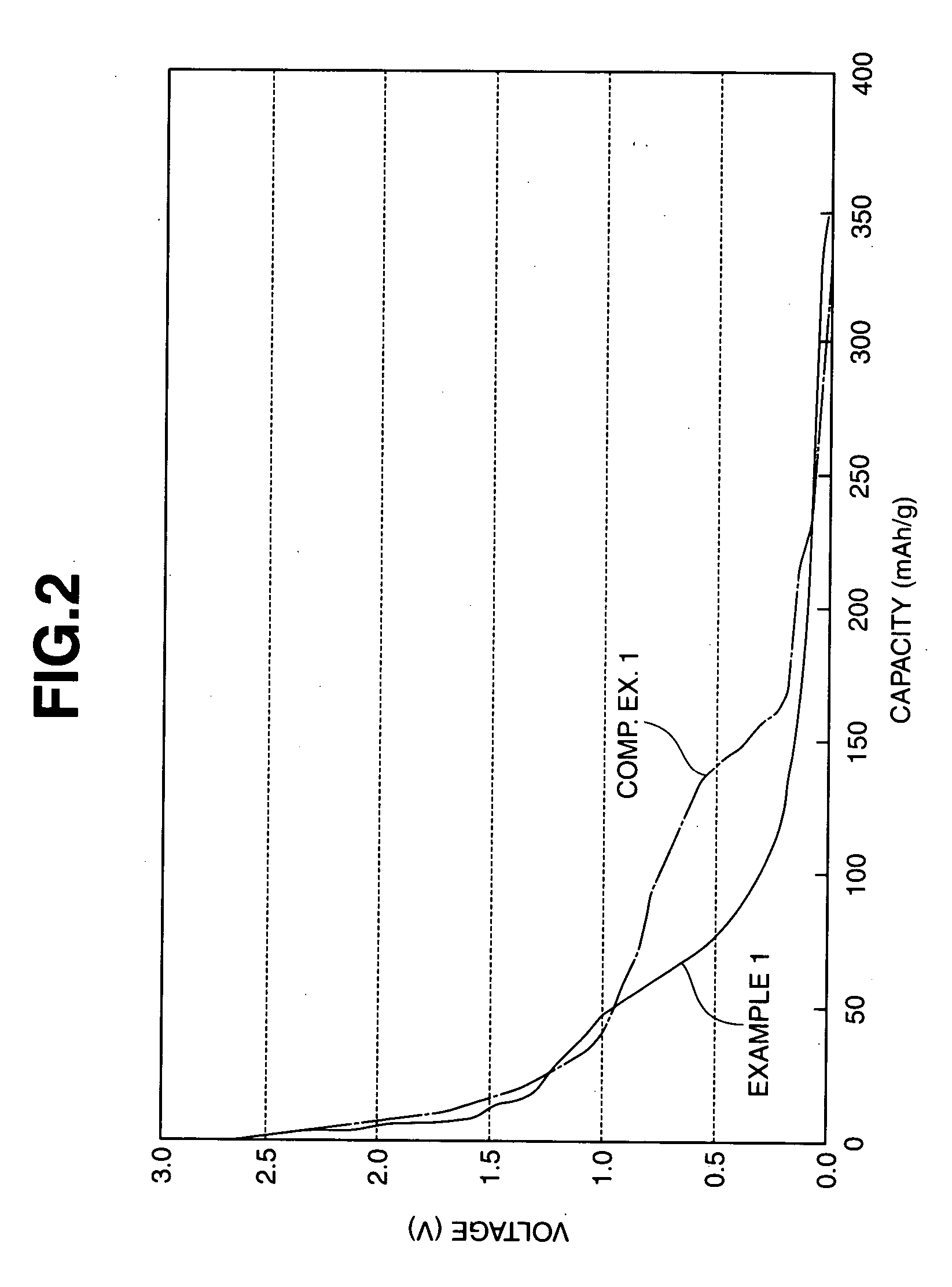

Nonaqueous electrolyte and nonaqueous-electrolyte secondary battery

InactiveUS20060035137A1Good low temperatureLow melting pointOrganic chemistryOrganic electrolyte cellsLithiumMethyl group

A nonaqueous electrolyte which contains an ionic liquid having general formula (1) below and a melting point not higher than 50° C., a compound which reductively decomposes at a more noble potential than the ionic liquid, and a lithium salt. In formula (1), R1 to R4 are each independently an alkyl group of 1 to 5 carbons or an alkoxyalkyl group of the formula R′—O—(CH2)n— (R′ being methyl or ethyl, and the letter n being an integer from 1 to 4), and any two from among R1, R2, R3 and R4 may together form a ring, with the proviso that at least one of R1 to R4 is an alkoxyalkyl group of the above formula. X is a nitrogen atom or a phosphorus atom, and Y is a monovalent anion.

Owner:NISSHINBO IND INC

Fuel cell, operating method thereof, sintering furnace, and power generator

InactiveUS20060127718A1Increase carbon dioxide concentrationEfficient heatingHydrogen separationChemical industryFuel cellsMetallurgy

A molten carbonate fuel cell, operating method of the fuel cell, sintering furnace equipped with the fuel cell, and power generator, wherein a cathode gas with a high carbon dioxide concentration can be obtained without a process of increasing the carbon dioxide concentration, and the heat of furnace exhaust gas can be effectively reclaimed and the fuel consumption can be reduced. The cathode gas is a gas containing a furnace exhaust gas discharged from an industrial furnace for heating materials, a mixed gas of the furnace exhaust gas and a gas for cathode use or a preheated gas for cathode use, which is a gas for cathode use preheated using the furnace exhaust gas as a heating source, or the preheated gas for cathode use, and the carbon dioxide concentration of the cathode gas is 0.1-50 vol %.

Owner:NGK INSULATORS LTD

Systems and processes of operating fuel cell systems

The present invention is directed to systems and processes for operating molten carbonate fuel cell systems. A process for operating the molten carbonate fuel cell includes providing a hydrogen-containing stream comprising molecular hydrogen to a molten carbonate fuel cell anode; heating a hydrocarbon stream, at least a majority of which is comprised of hydrocarbons that are liquid at 20° C. and atmospheric pressure, with a heat source comprising an anode exhaust from the molten carbonate fuel cell anode; contacting at least a portion of the heated hydrocarbon stream with a catalyst to produce a steam reforming feed comprising gaseous hydrocarbons, hydrogen, and at least one carbon oxide; separating at least a portion of the molecular hydrogen from the steam reforming feed; and providing at least a portion of the separated molecular hydrogen to the molten carbonate fuel cell anode as at least a portion of the stream comprising molecular hydrogen.

Owner:SHELL OIL CO

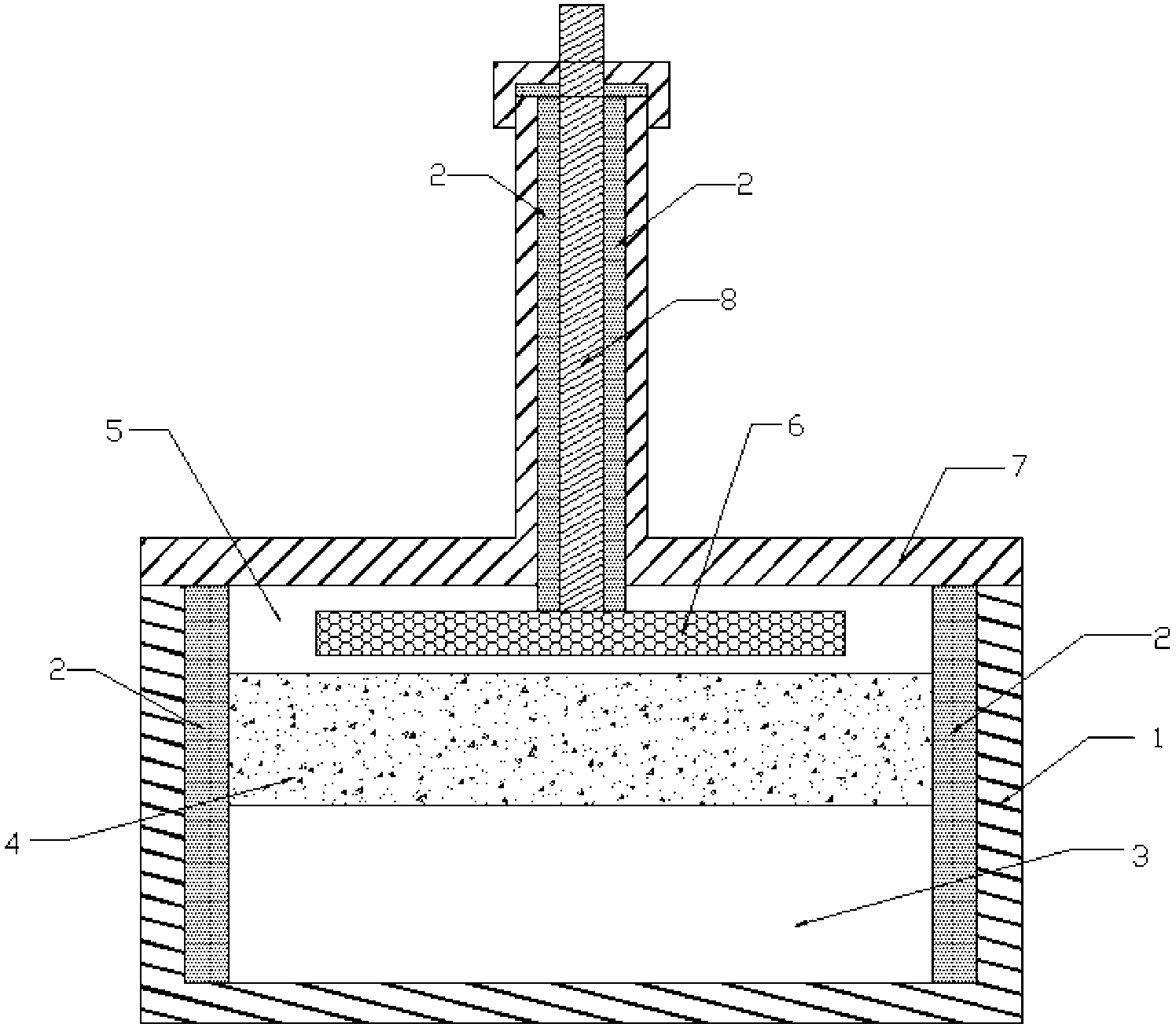

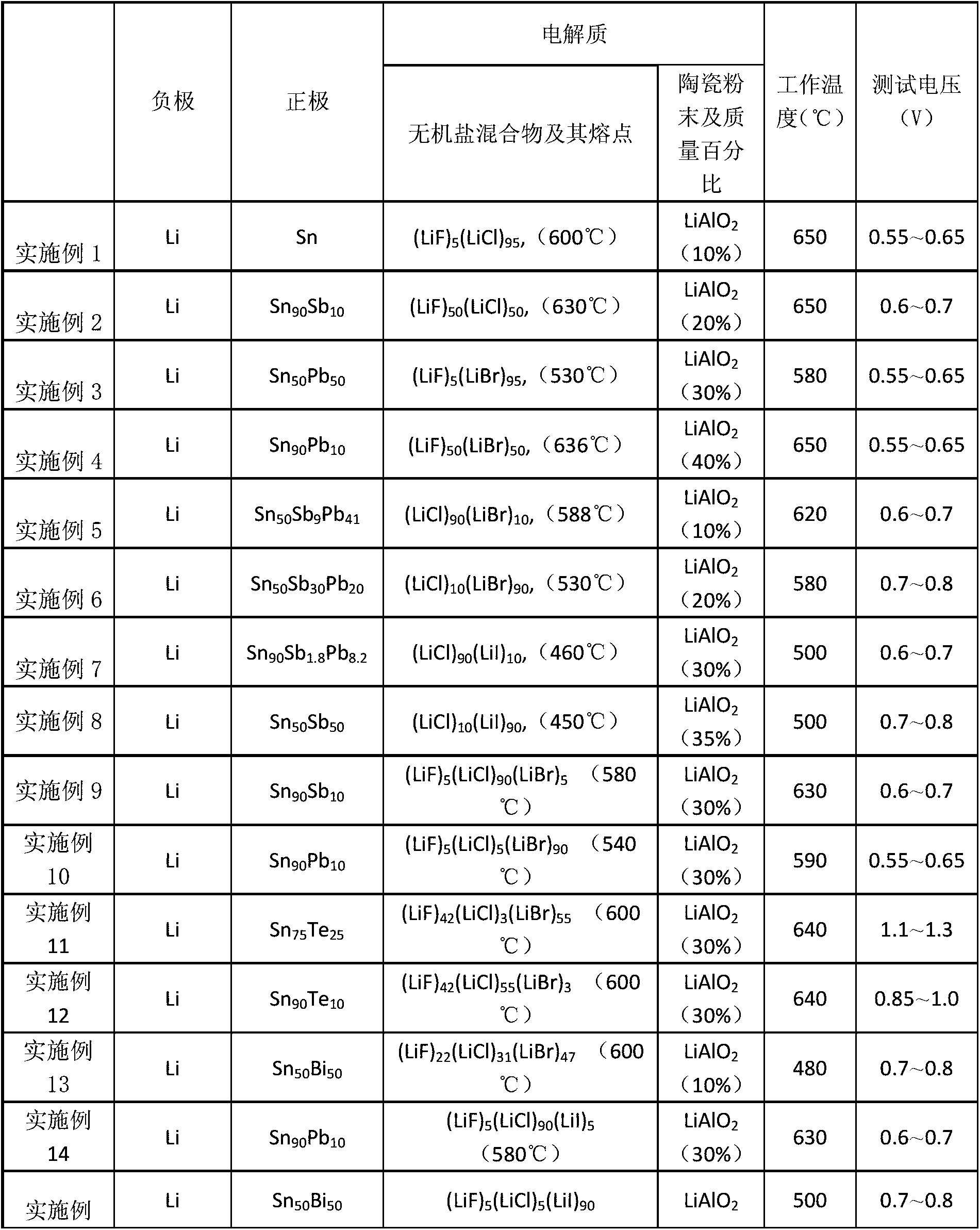

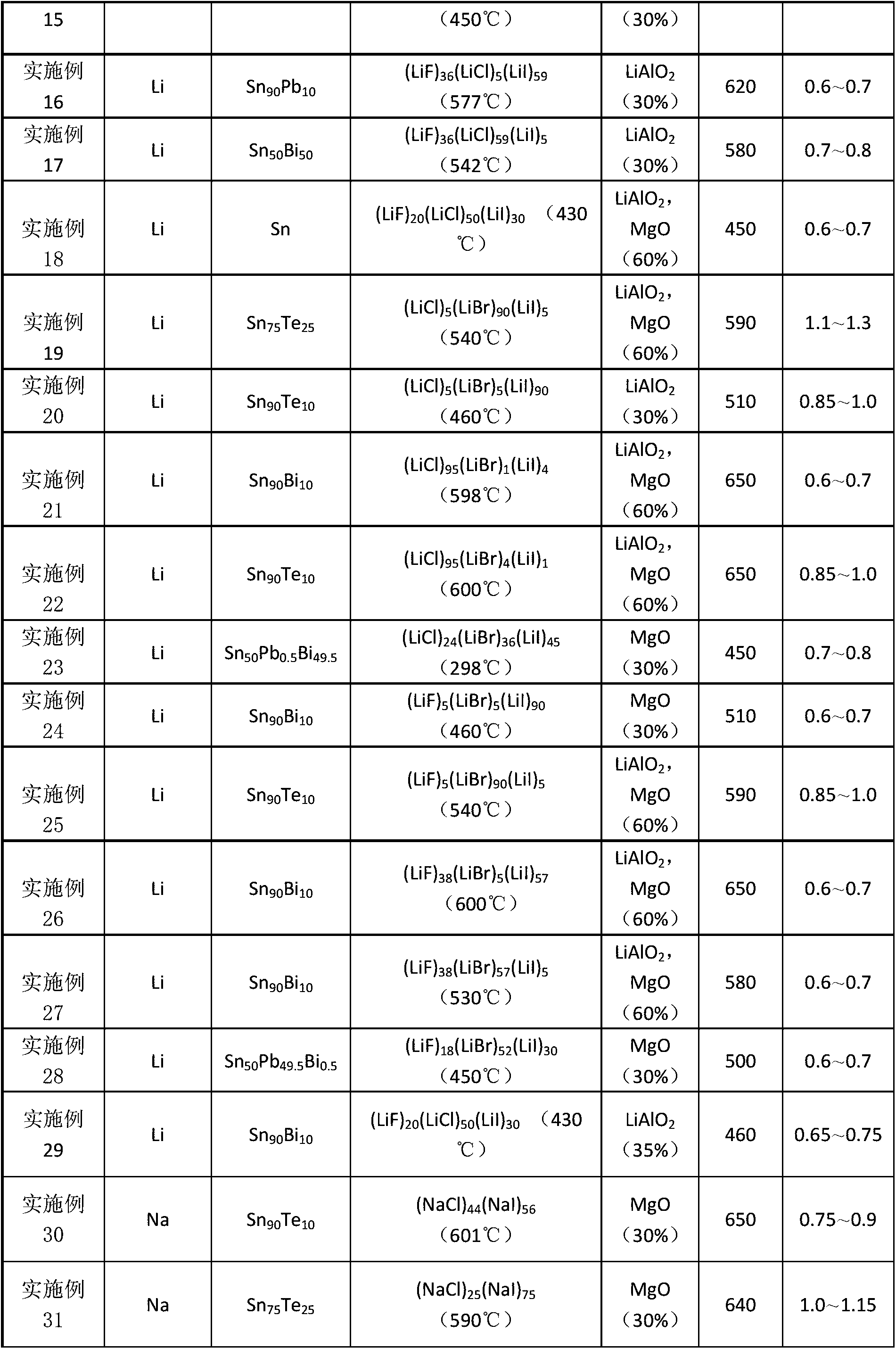

Semi-liquid metal electrode energy storage battery

ActiveCN103259033AAvoid short circuitIncrease profitCell electrodesFused electrolyte fuel cellsElectric power systemWorking temperature

The invention relates to a semi-liquid metal electrode energy storage battery, belonging to the field of an energy storage battery, and aiming at solving the problems that the all-liquid metal battery is narrow in battery material selection range and high in running temperature, and has potential safety problem. The semi-liquid metal electrode energy storage battery comprises a shell, a positive pole, electrolyte, a negative pole and a collector, wherein the positive pole is alloy made from one or more of Sn, Sb, Pb, Bi and Te; the negative pole is alloy made from one or more of Li, Na, Mg and Ca; and the electrolyte is a mixture of inorganic salt mixture and ceramic powder. When the semi-liquid metal electrode energy storage battery runs, the positive pole is in a semi-liquid state structure with alloy solid phase distributed in liquid phase, and the electrolyte is melted into semi-liquid state paste, so that the short circuit of the positive pole and the negative pole can be effectively prevented, the energy storage cost is lowered, the working temperature of the battery is reduced, the corrosion speed of the shell is slowed down, the service life of the battery is prolonged, the safety and the reliability of running can be improved, and the semi-liquid metal electrode energy storage battery is suitable for storing energy for new energy power generation grid-connection, frequency modulation and peak-load regulation of an electrical power system as well as smart power grid construction.

Owner:HUAZHONG UNIV OF SCI & TECH

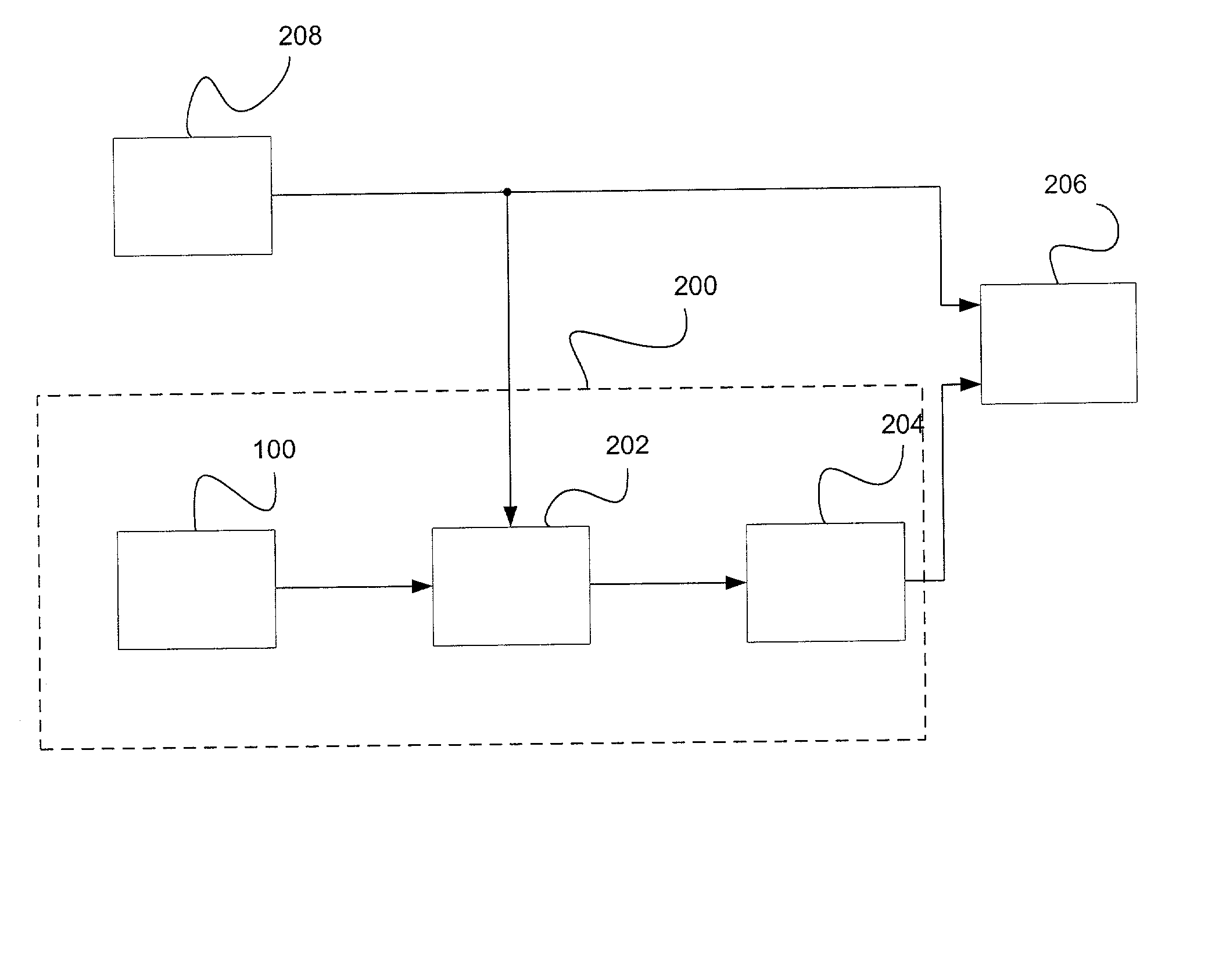

Methods of using fuel cell system configured to provide power to one or more loads

A fuel cell system for providing primary and / or auxiliary / backup power to one or more loads for which a primary and / or backup power source is desirable to enable equipment to function for its intended purpose. The system provides power to the one or more loads upon the occurrence of power outage condition, which includes a disruption in the delivery of primary power to, or power demand condition by, the one or more loads. A controller senses outage of primary power to, or demand for primary power by, the one or more loads, and, responsive thereto, operatively engages one or more fuel cells to provide power to the one or more loads.

Owner:METALLIC POWER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com