Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

682 results about "Carbon oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon Oxides. Carbon forms two important gases with oxygen: carbon monoxide, CO, and carbon dioxide, CO 2. Carbon oxides are important components of the atmosphere, and they are parts of the carbon cycle. Carbon dioxide is naturally produced by respiration and metabolism, and consumed by plants in their photosynthesis.

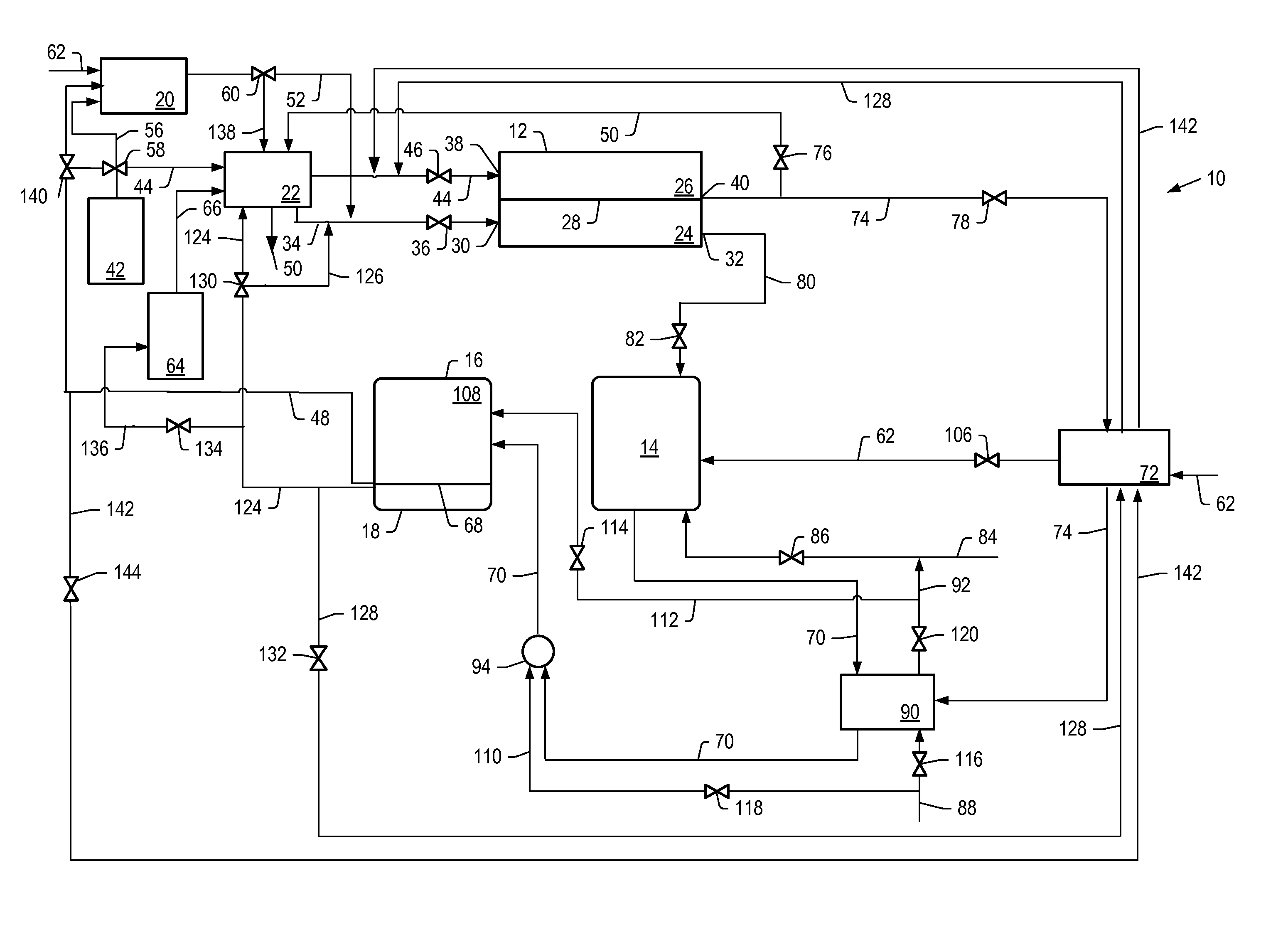

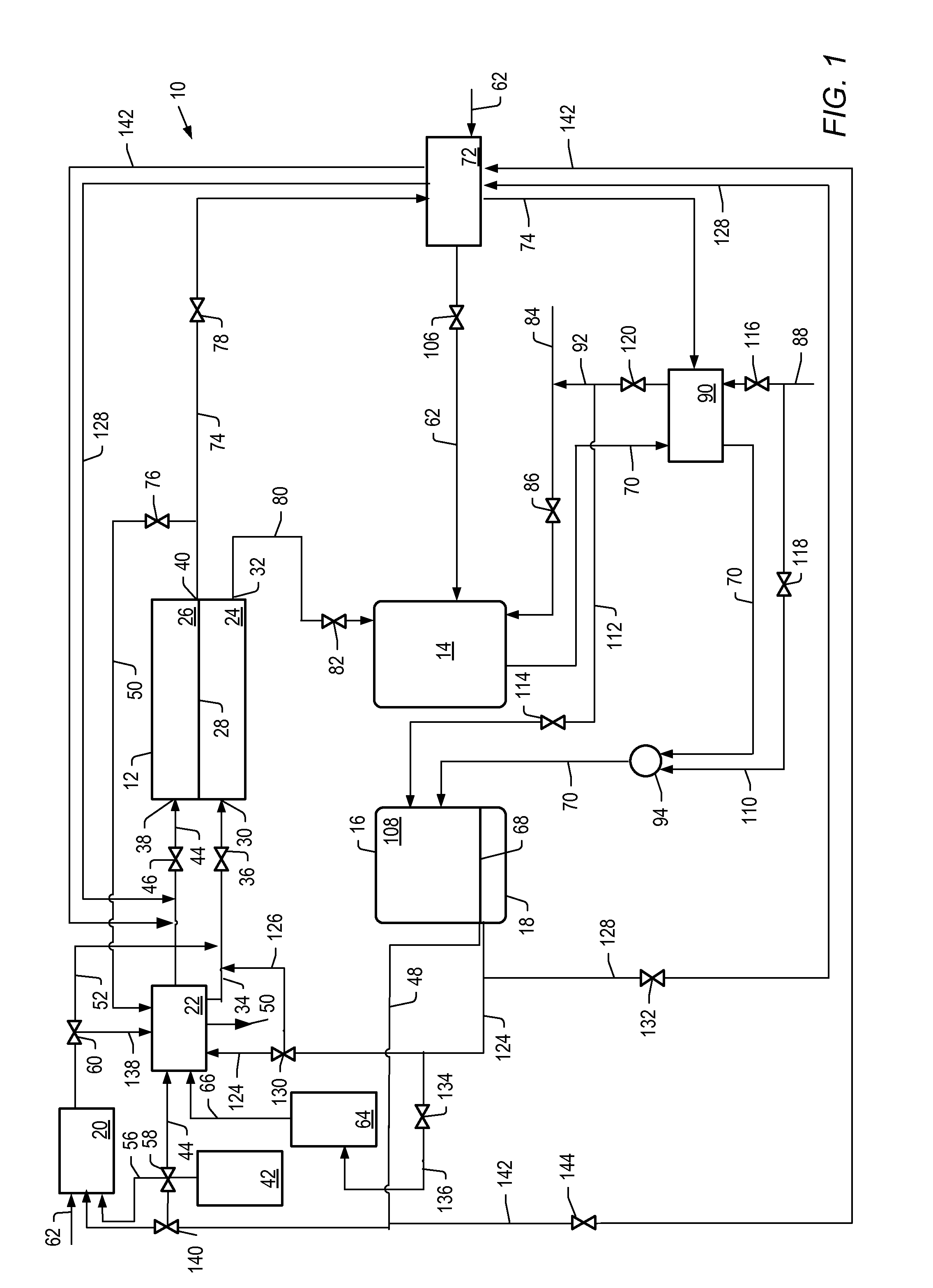

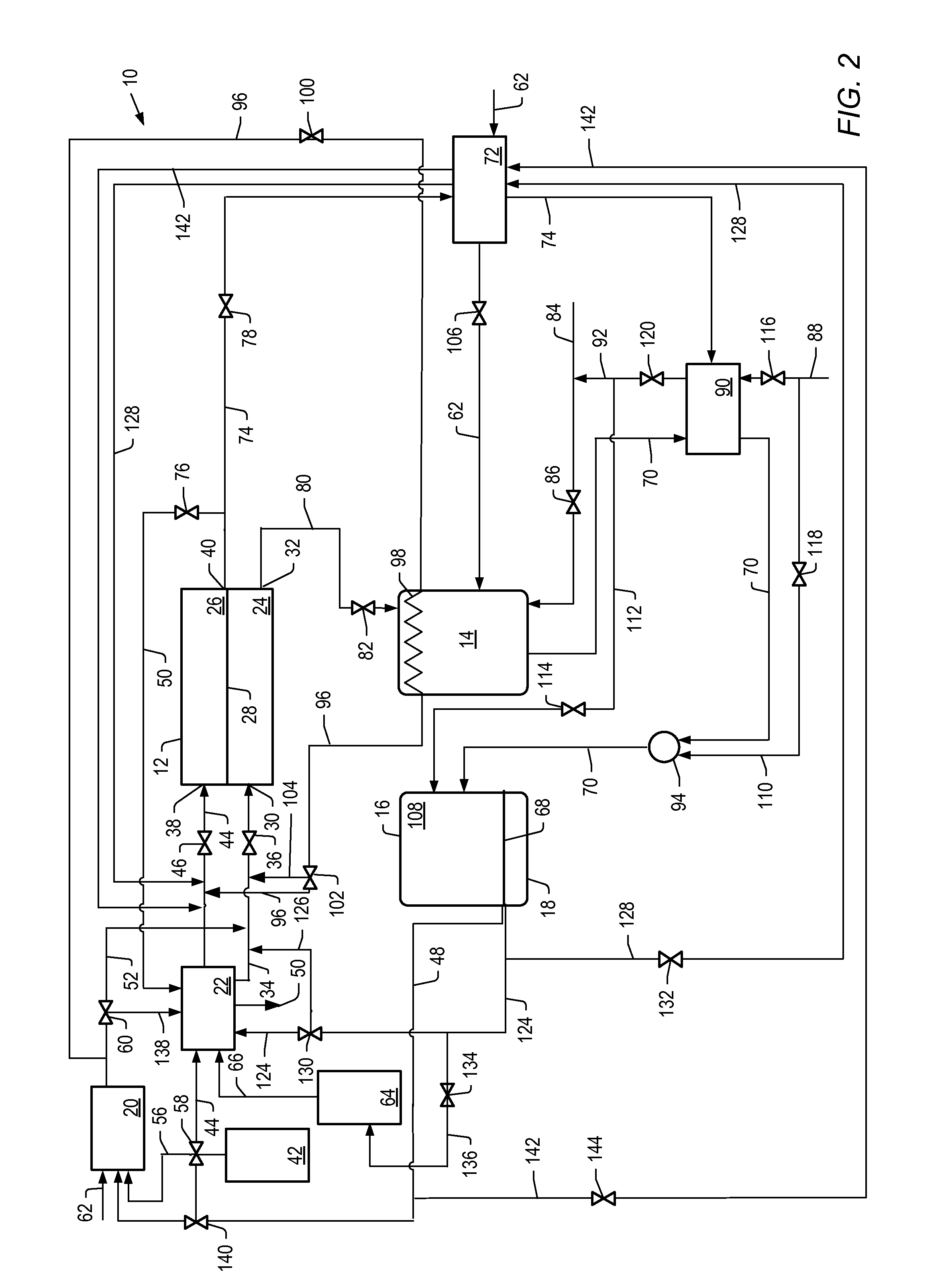

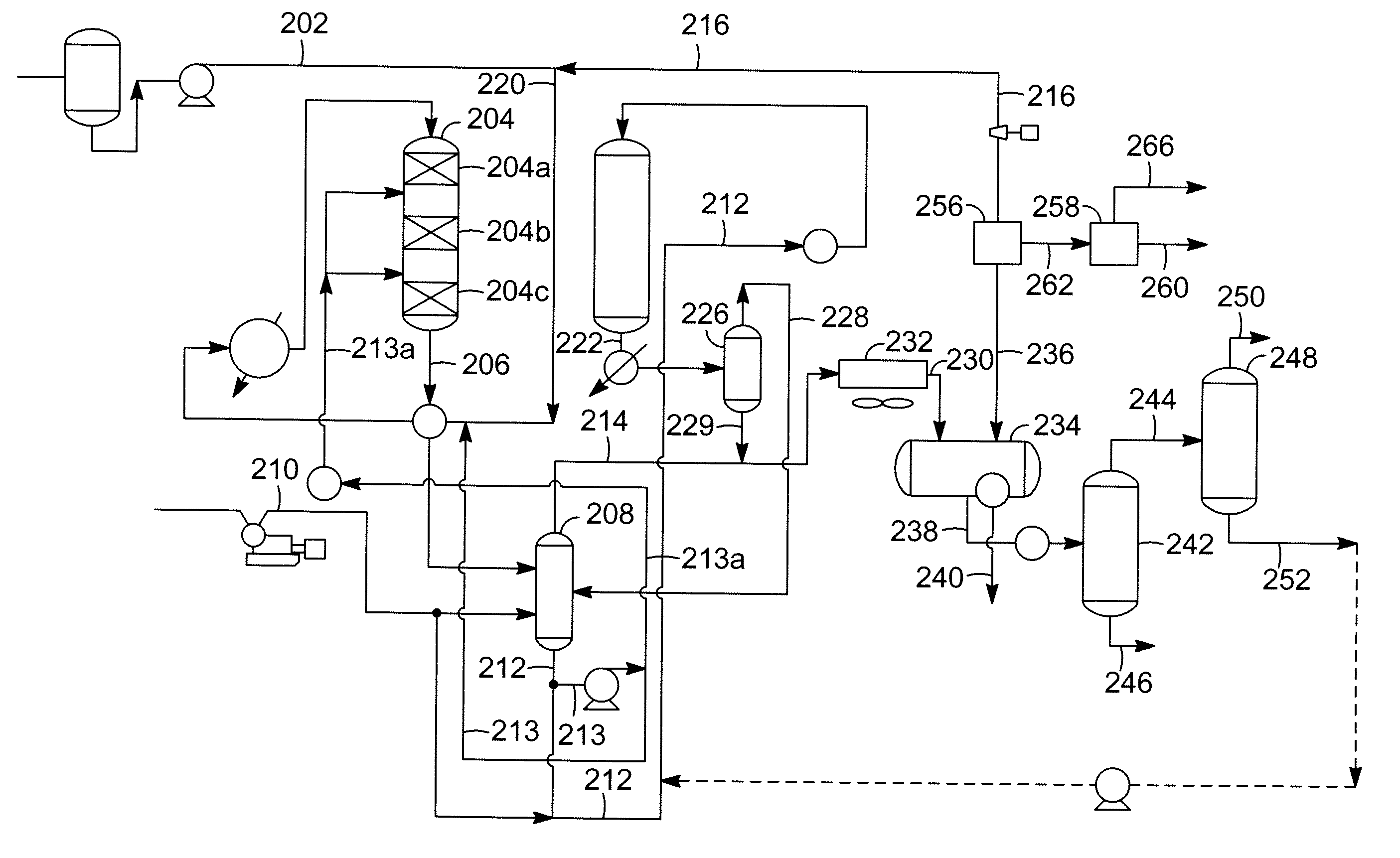

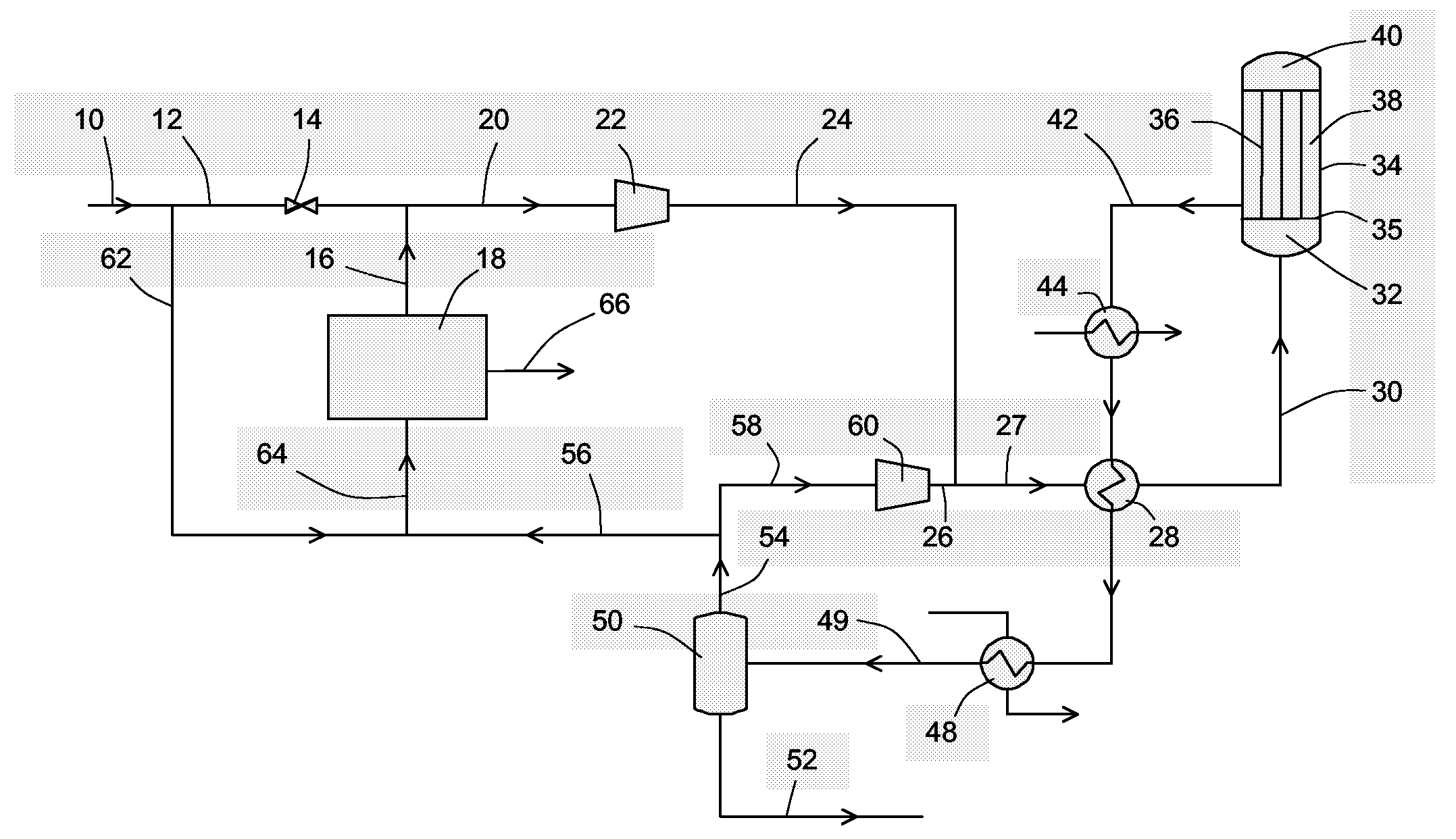

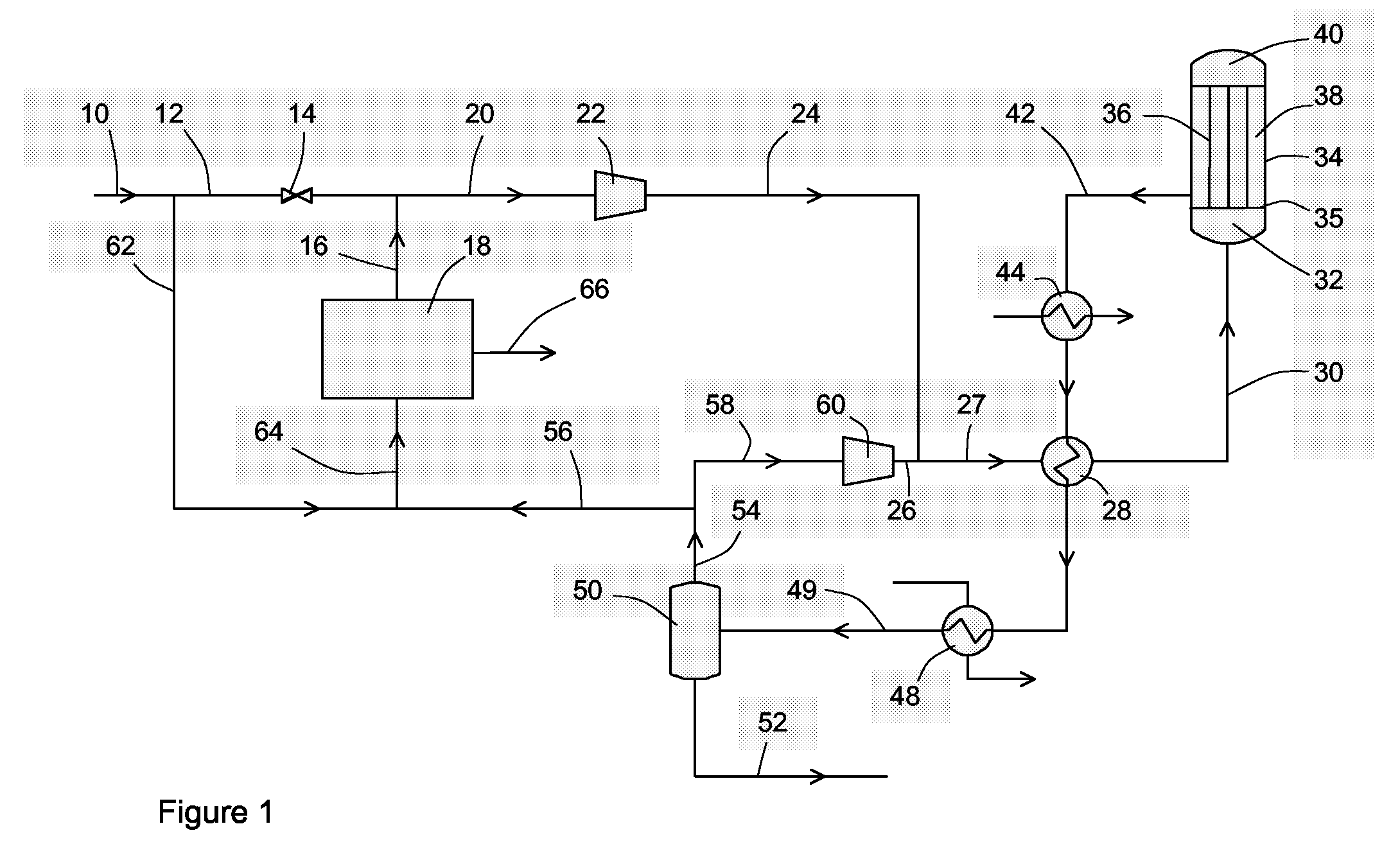

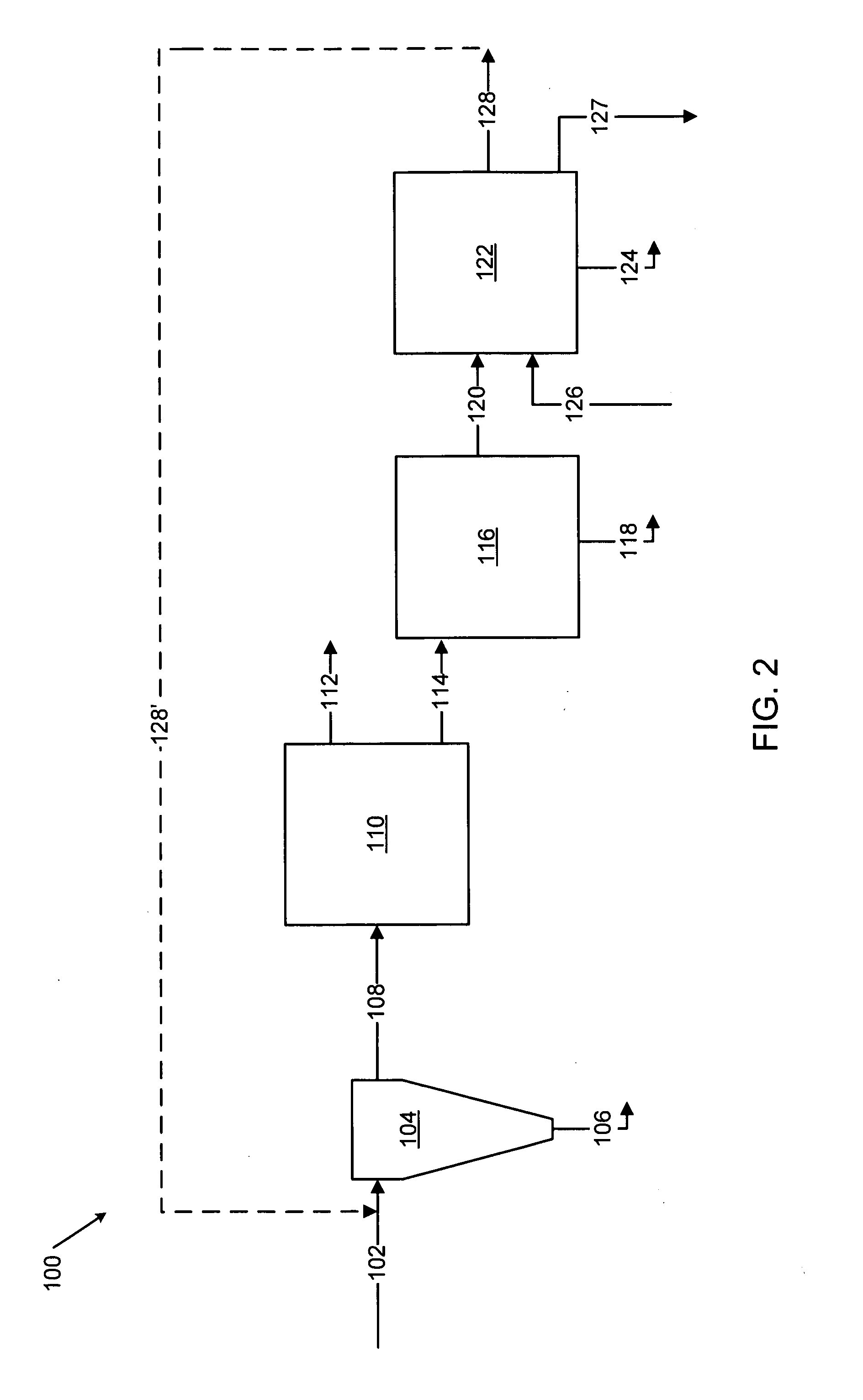

Systems and processes of operating fuel cell systems

InactiveUS20110111315A1Well mixedFuel cell auxillariesFused electrolyte fuel cellsSteam reformingFuel cells

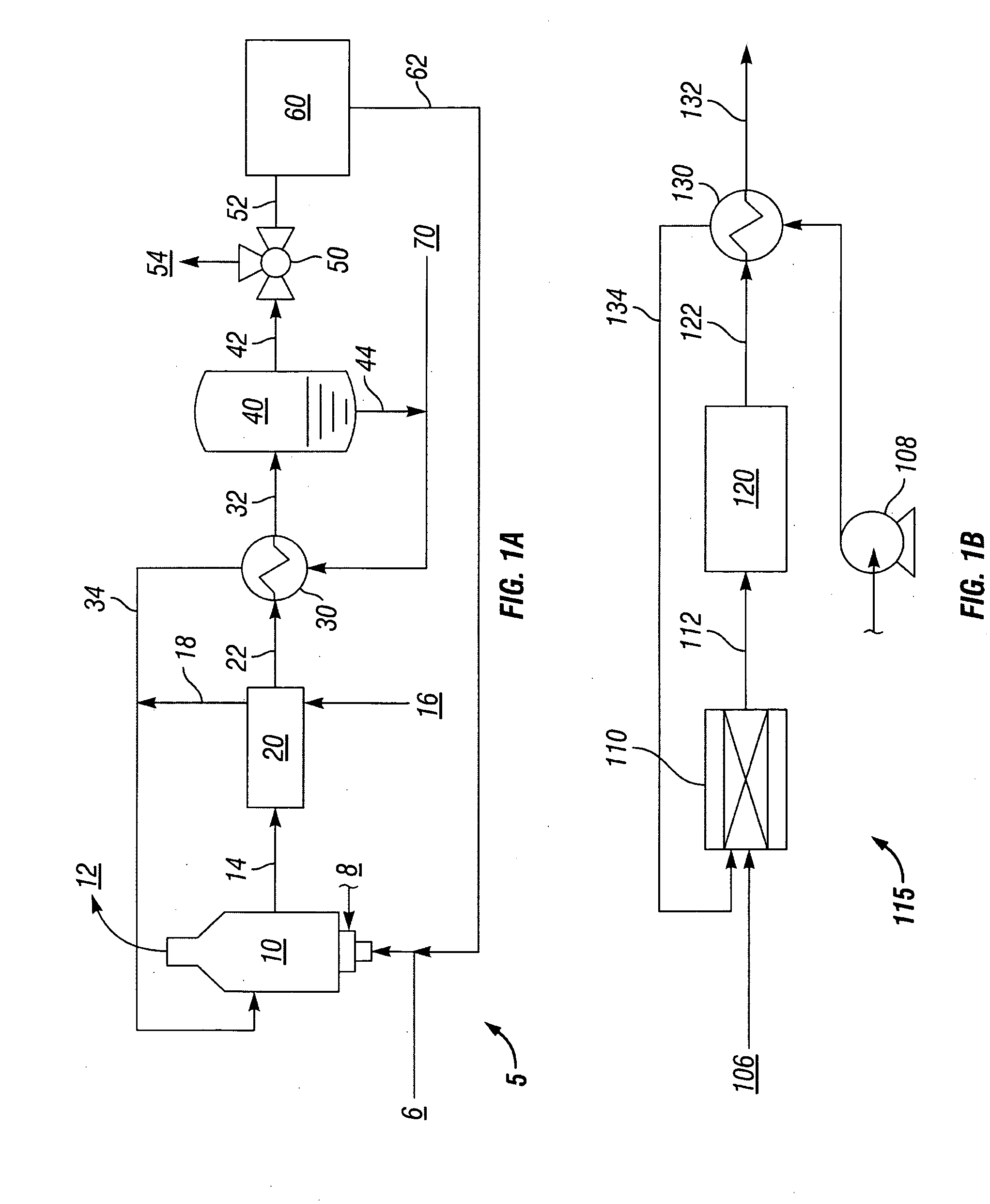

The present invention is directed to systems and processes for operating molten carbonate fuel cell systems. A process for operating the molten carbonate fuel cell includes providing a hydrogen-containing stream comprising molecular hydrogen to a molten carbonate fuel cell anode; heating a hydrocarbon stream, at least a majority of which is comprised of hydrocarbons that are liquid at 20° C. and atmospheric pressure, with a heat source comprising an anode exhaust from the molten carbonate fuel cell anode; contacting at least a portion of the heated hydrocarbon stream with a catalyst to produce a steam reforming feed comprising gaseous hydrocarbons, hydrogen, and at least one carbon oxide; separating at least a portion of the molecular hydrogen from the steam reforming feed; and providing at least a portion of the separated molecular hydrogen to the molten carbonate fuel cell anode as at least a portion of the stream comprising molecular hydrogen.

Owner:SHELL OIL CO

Terephthalic acid composition and process for the production thereof

InactiveUS7385081B1Reducing and eliminating resultantOrganic compound preparationCarboxylic compound preparationEtherCarbon oxide

Terephthalic acid is prepared by reacting a 2,5-furandicarboxylate with ethylene in the presence of a solvent to produce a bicyclic ether; and then dehydrating the bicyclic ether. The process of the present invention effectively produces terephthalic acid, while reducing or eliminating the impurities, color bodies and carbon oxides produced in commercial practice by the liquid-phase oxidation of methyl-substituted benzene feedstocks.

Owner:BP CORP NORTH AMERICA INC

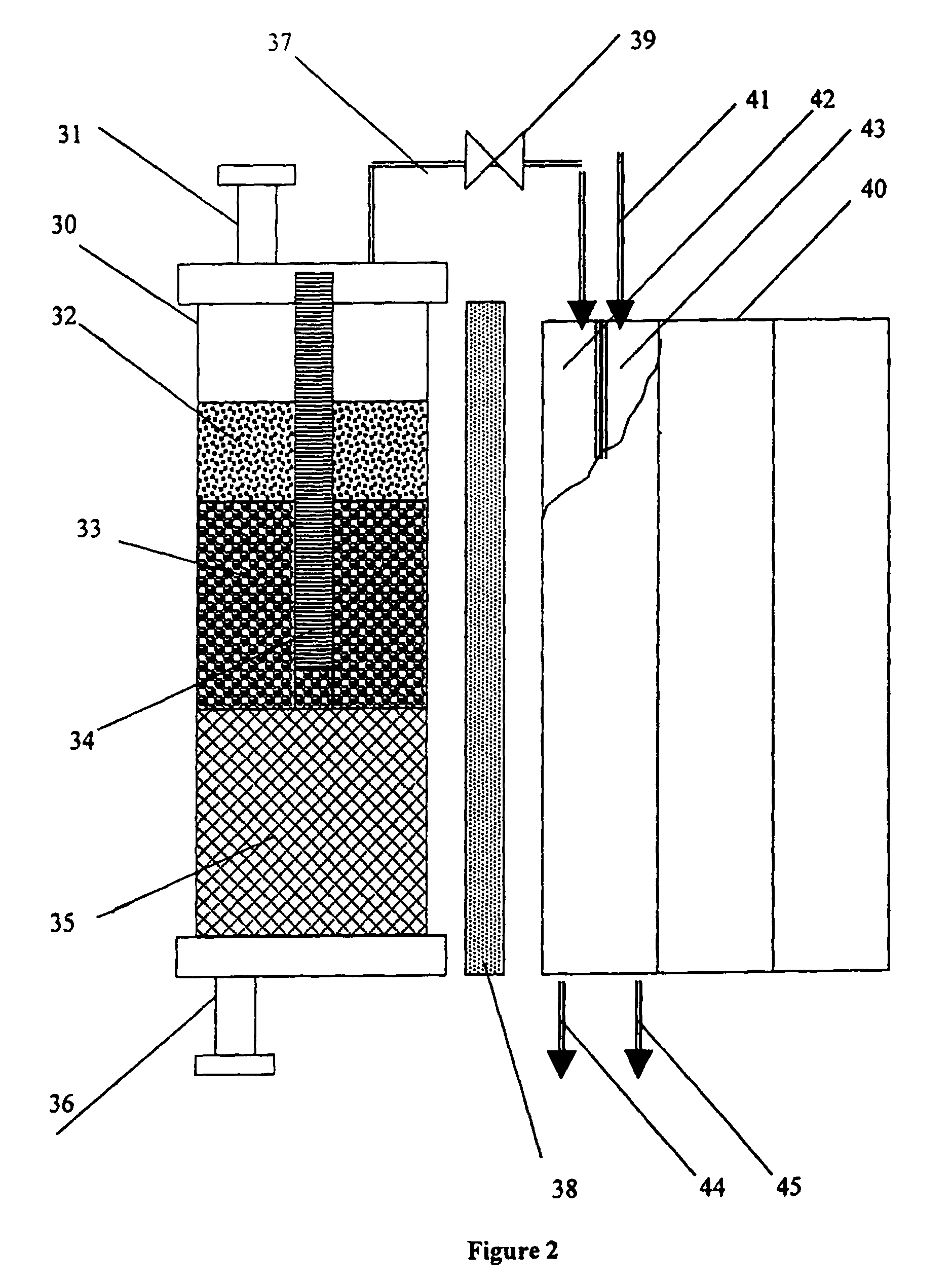

Portable hydrogen generator-fuel cell apparatus

InactiveUS6653005B1Increase specific energy and overall energy efficiencyHydrogenFuel cell auxillariesKeroseneImpurity

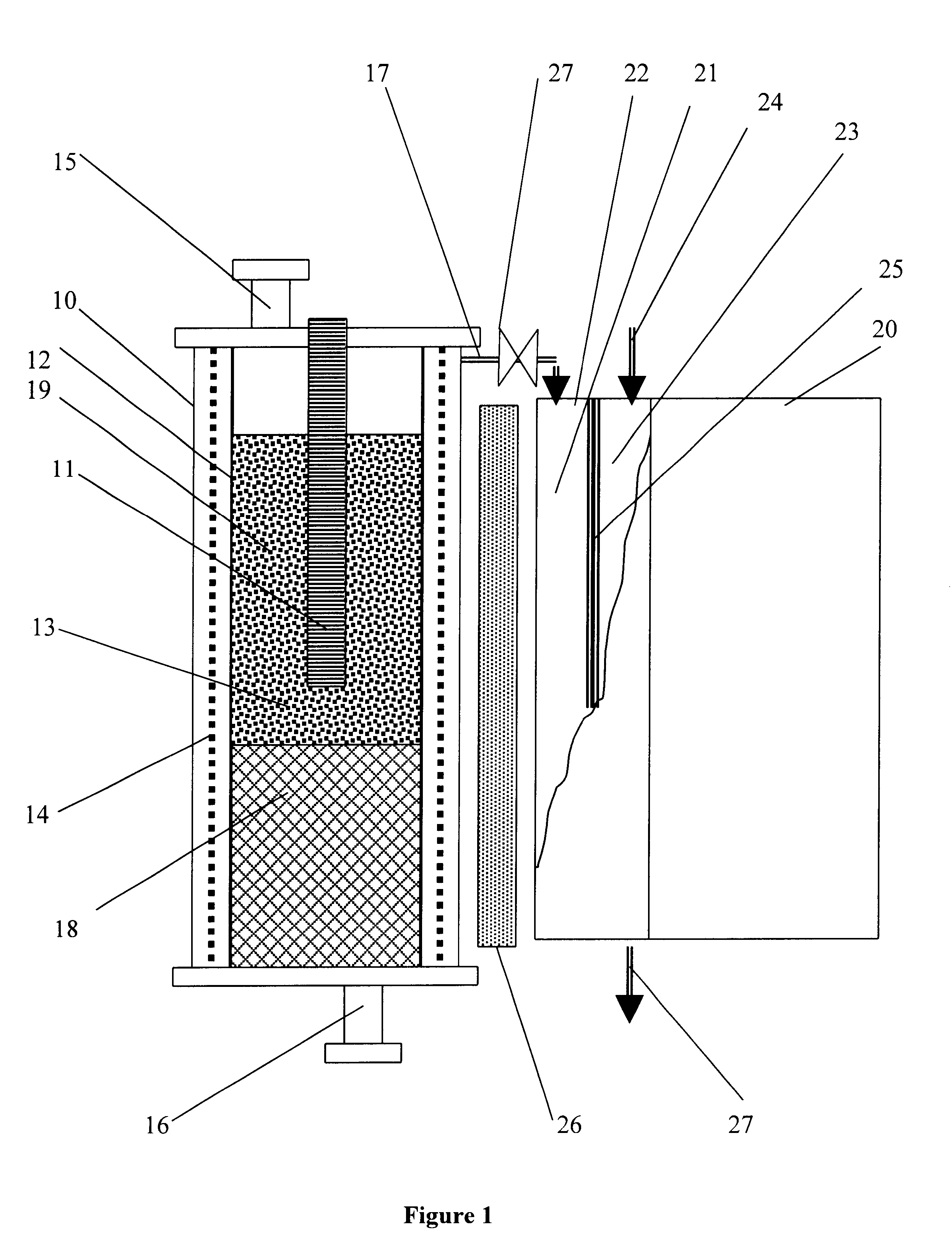

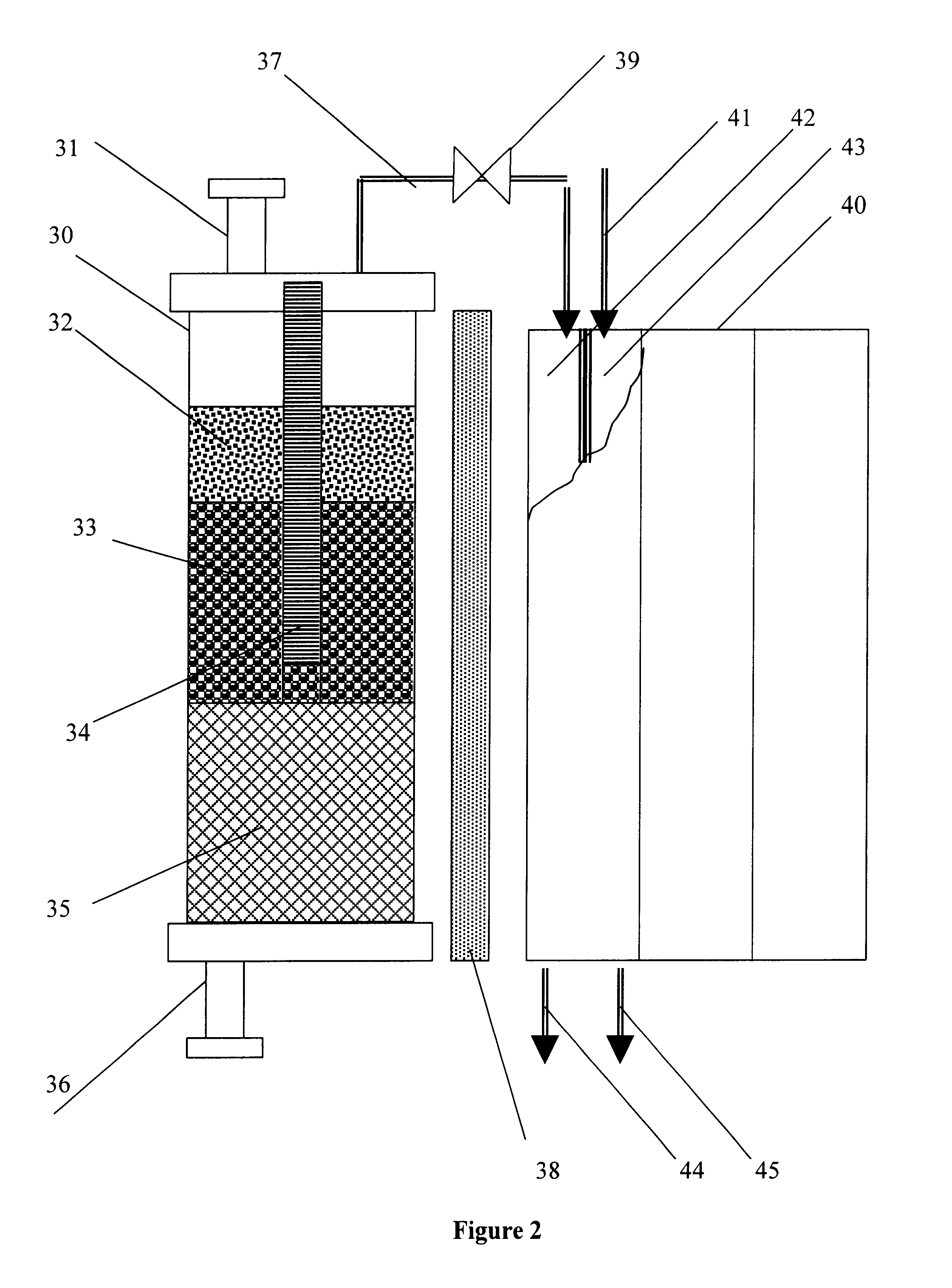

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. Hydrogen is produced via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in oxidant-free environment. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, kerosene, diesel fuel, crude oil (including sulfurous fuels). The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it could be directly fed to any type of a fuel cell. The catalysts for hydrogen production in the apparatus are carbon-based or metal-based materials and doped, if necessary, with a sulfur-capturing agent. Additionally disclosed are two novel processes for the production of two types of carbon filaments, and a novel filamentous carbon product. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

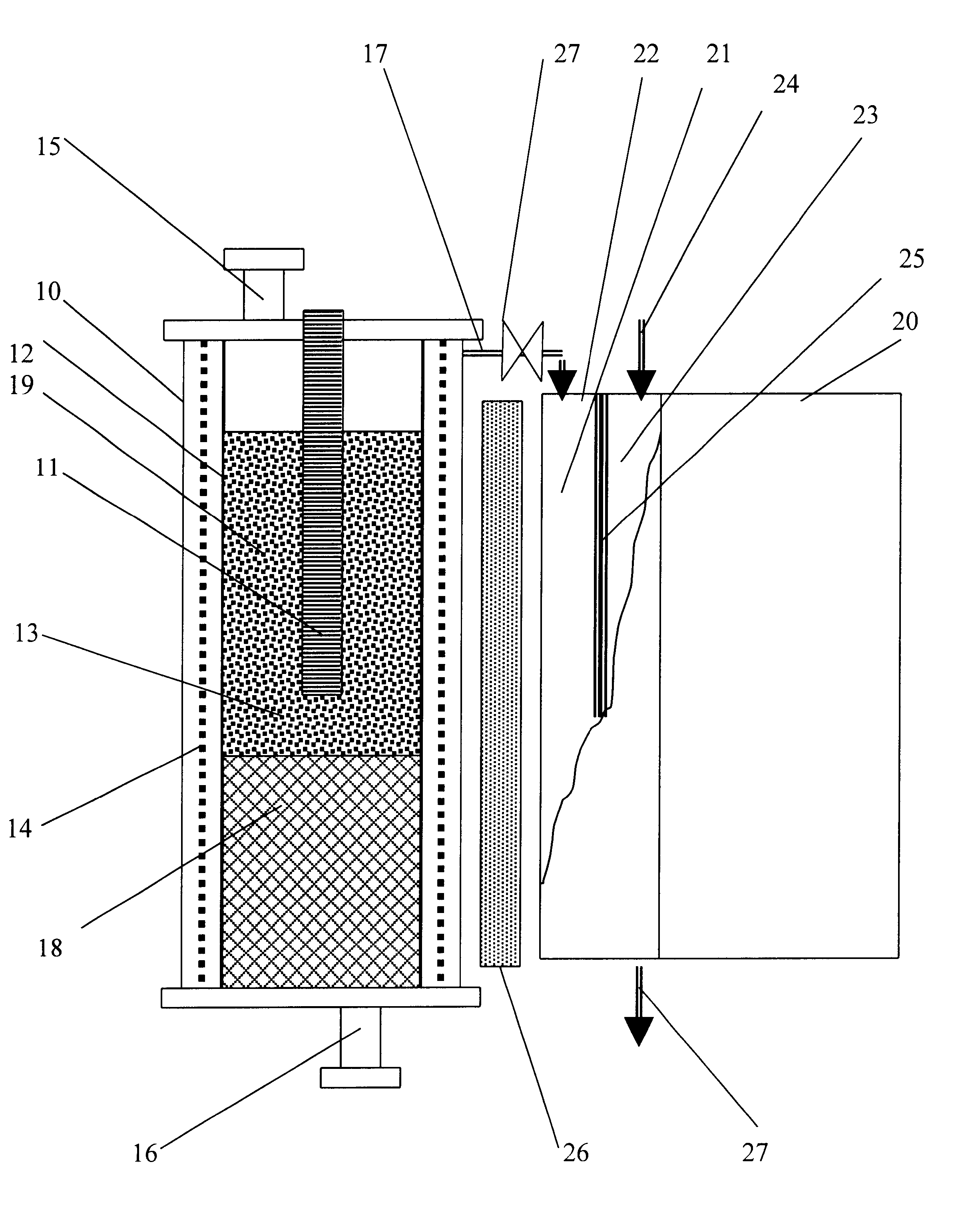

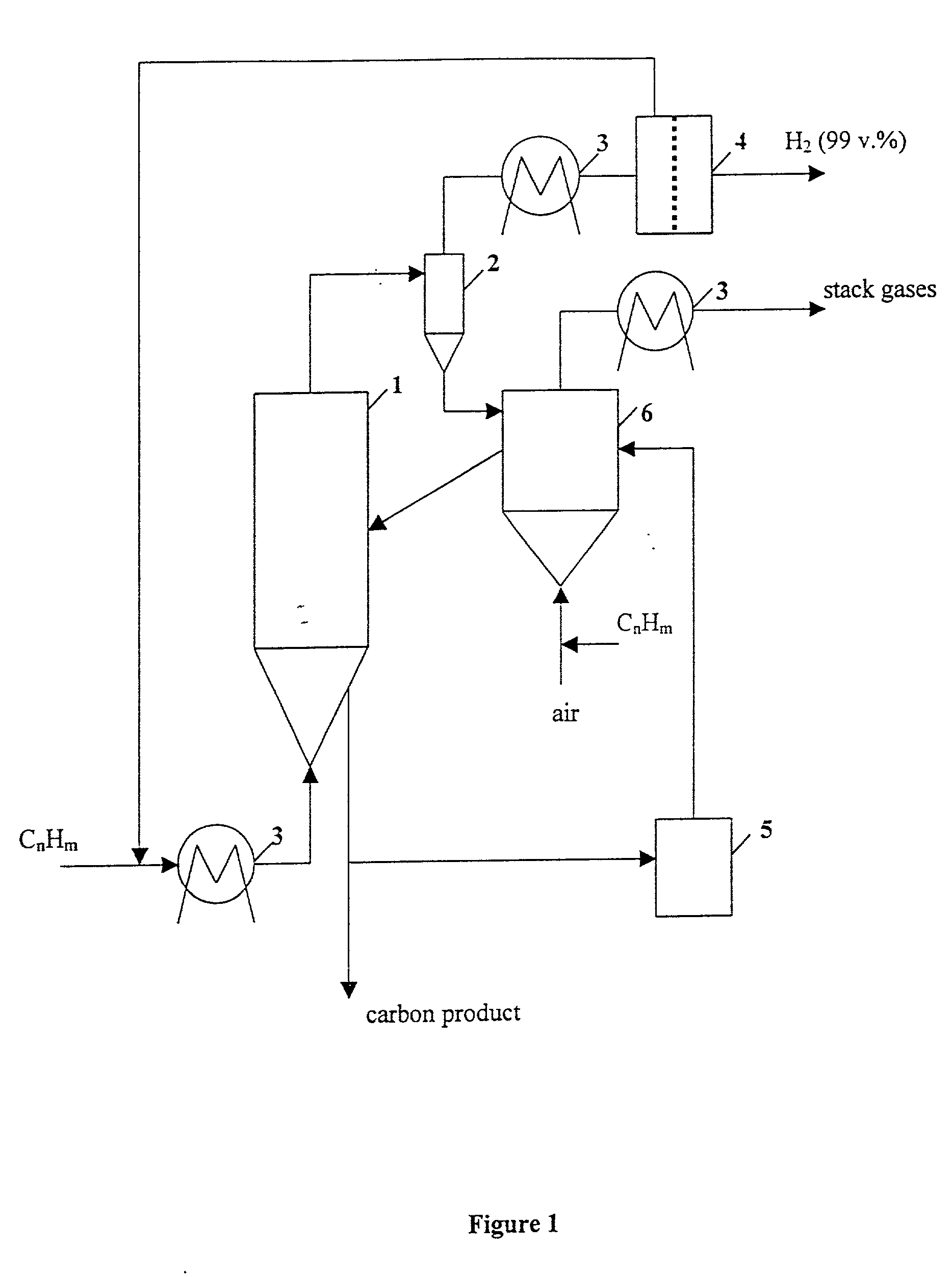

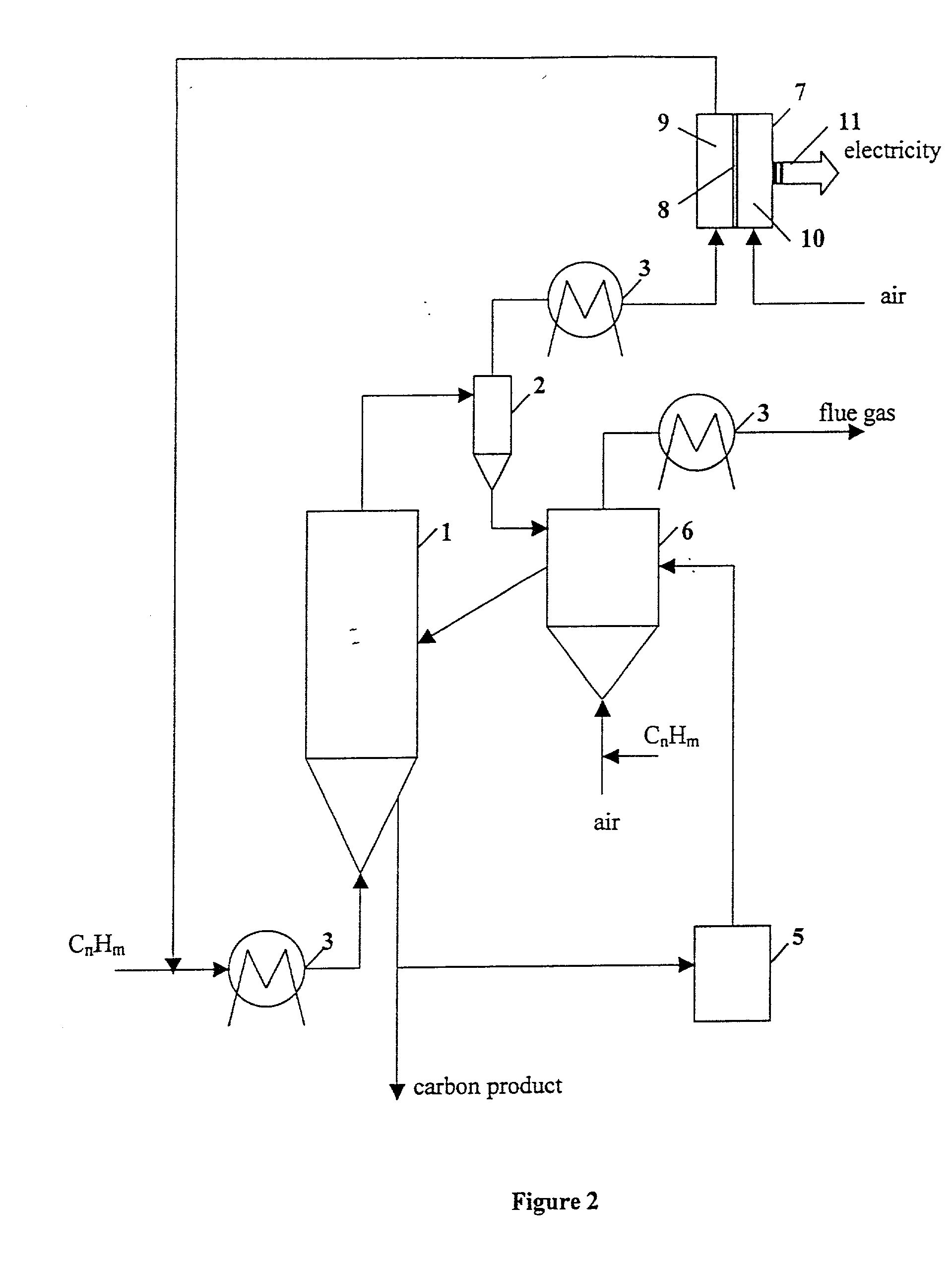

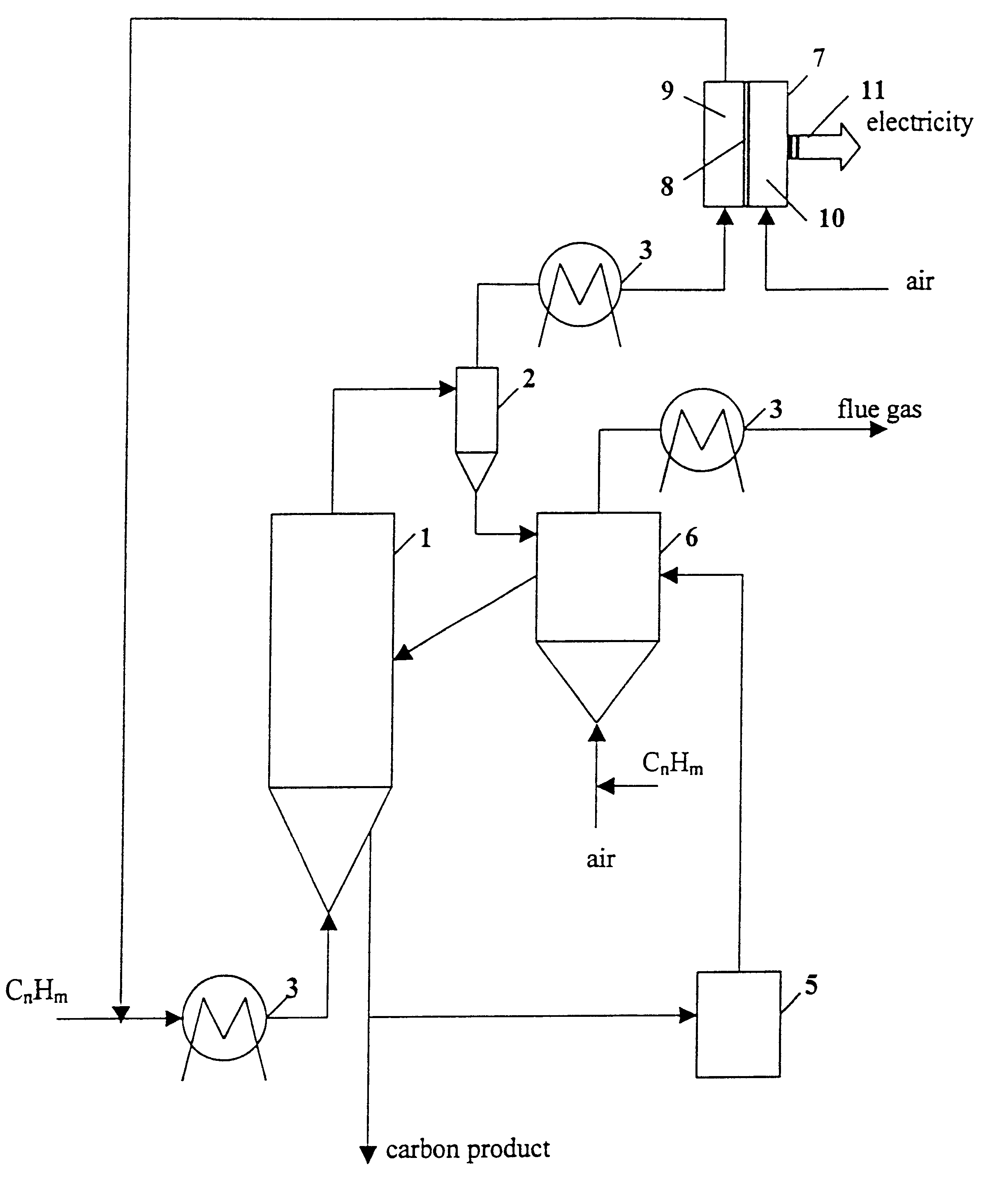

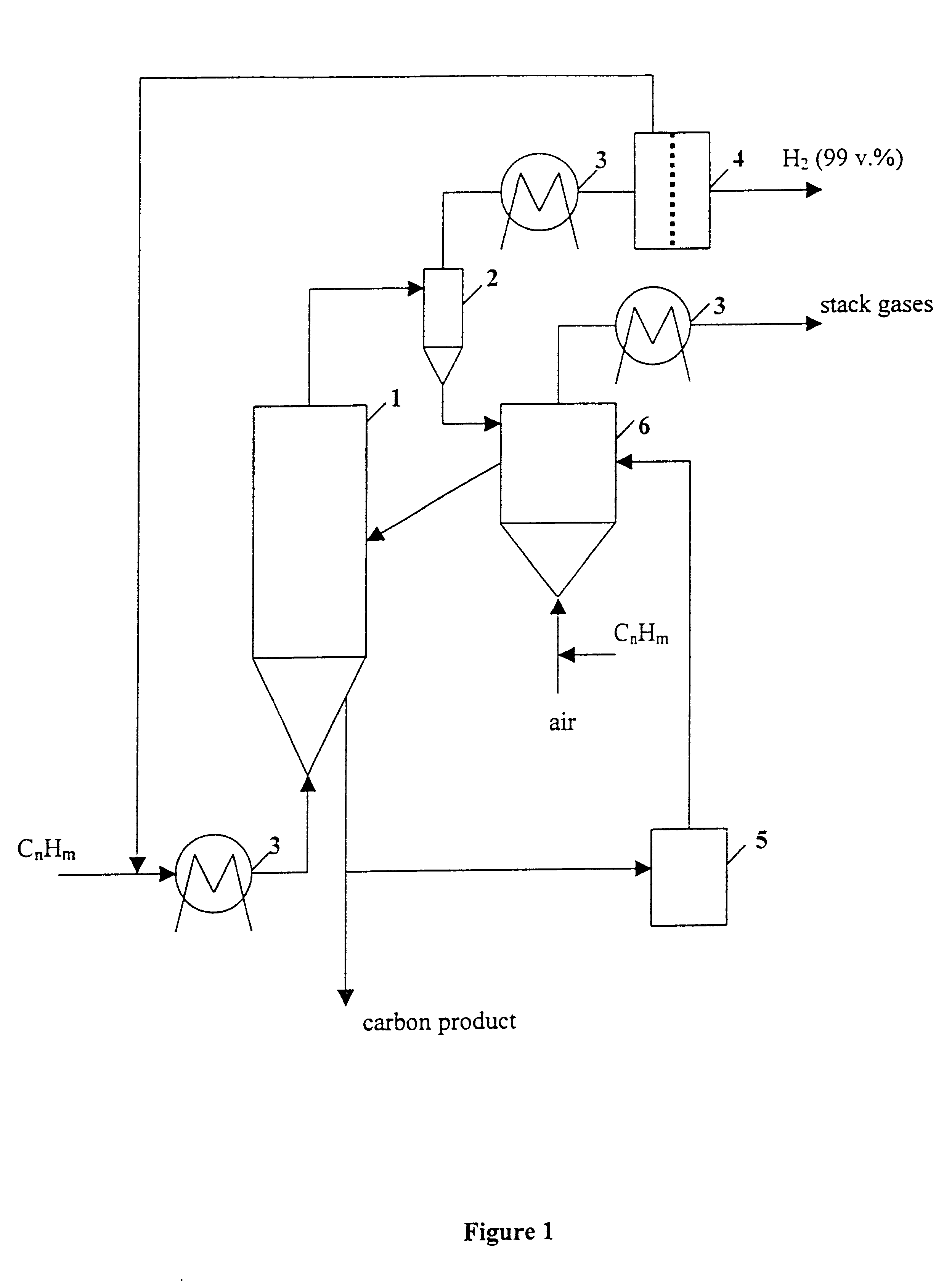

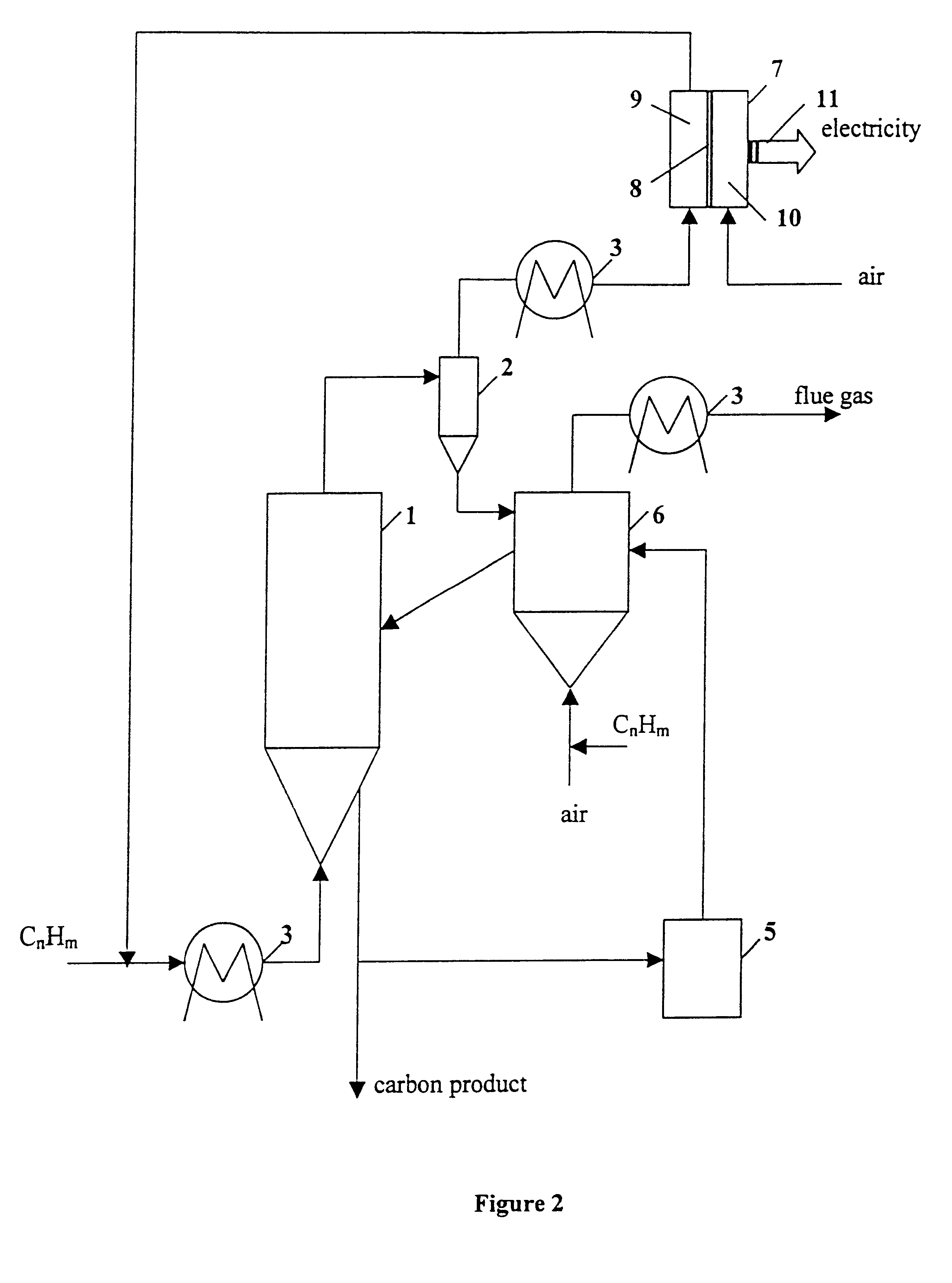

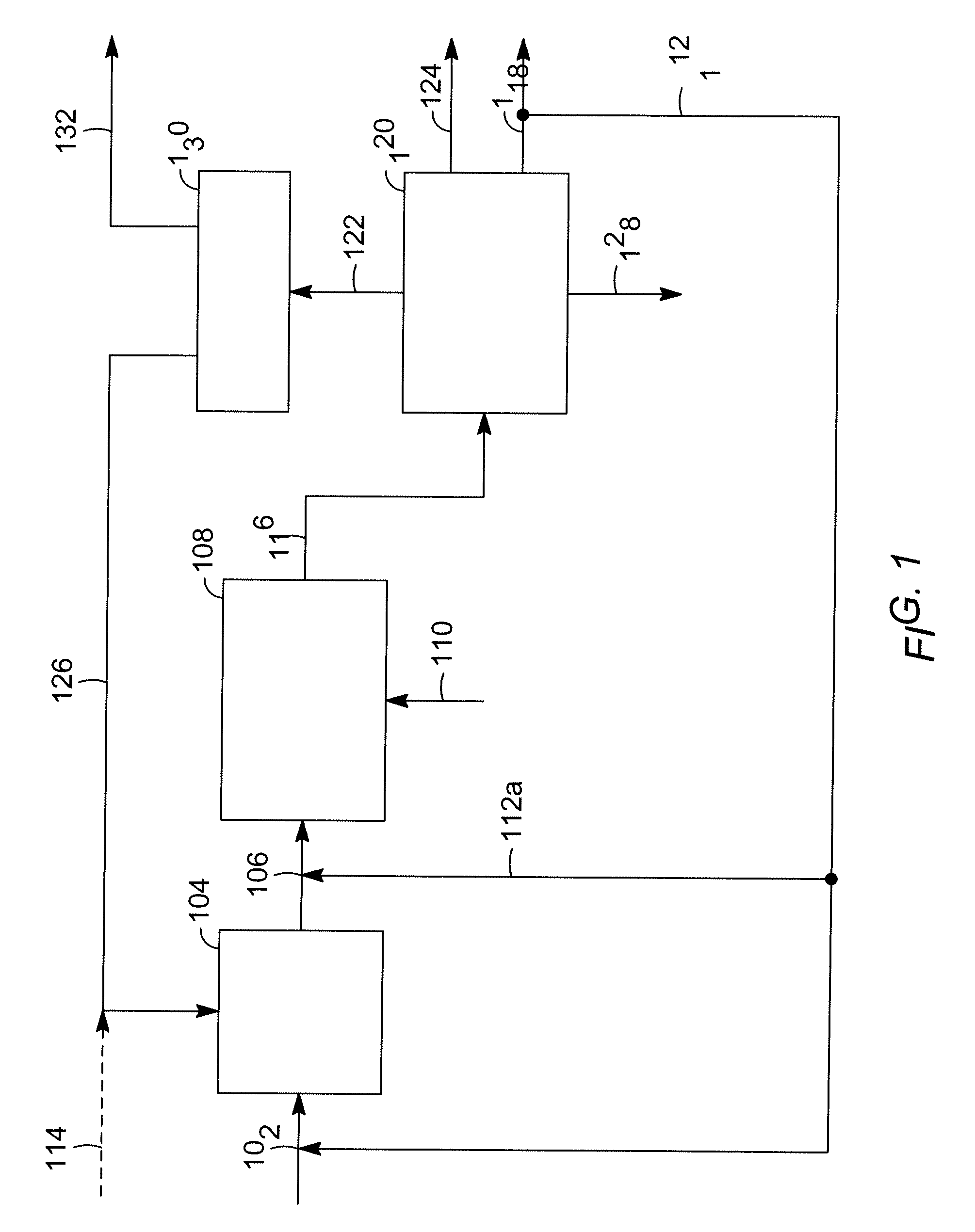

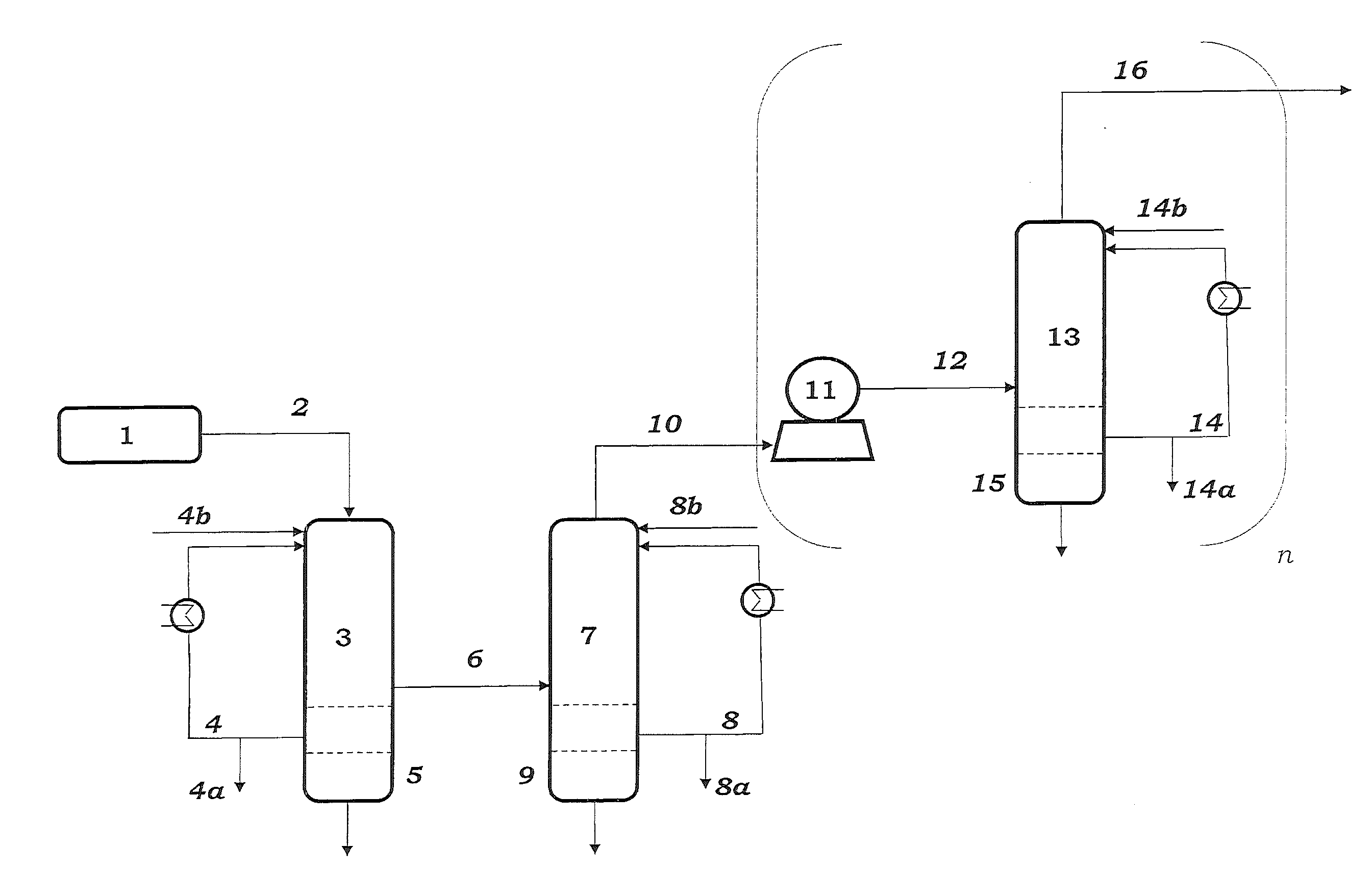

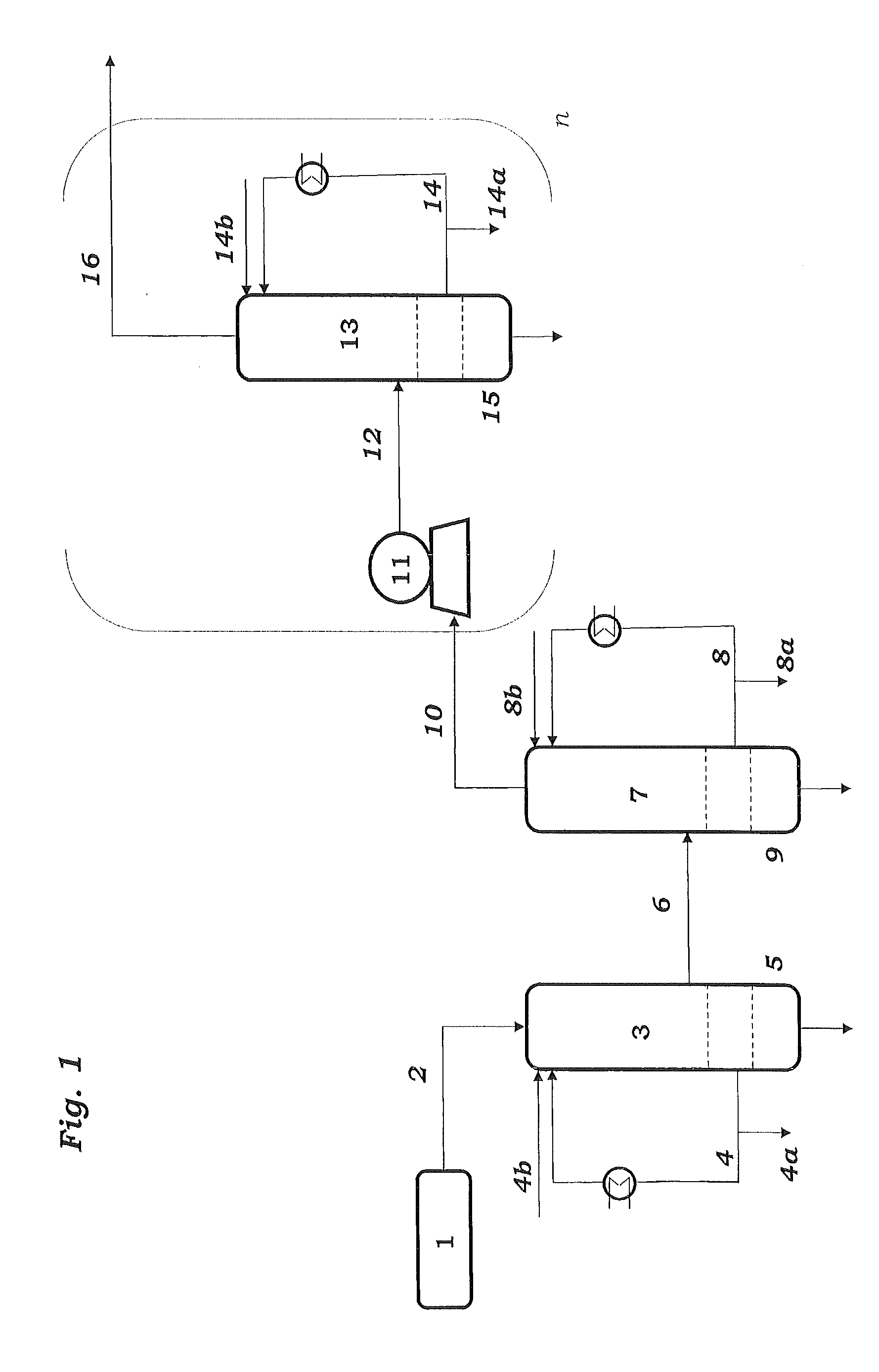

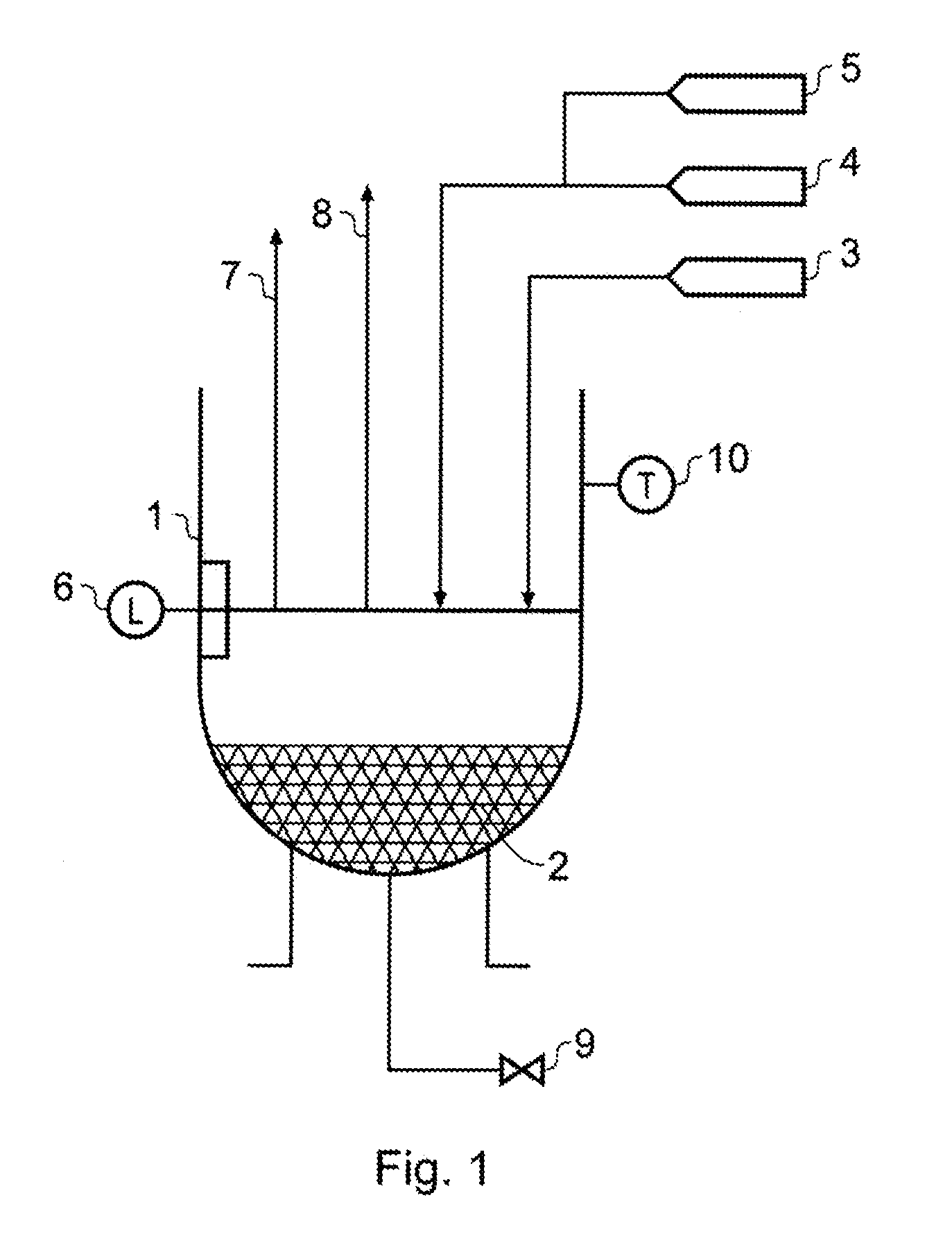

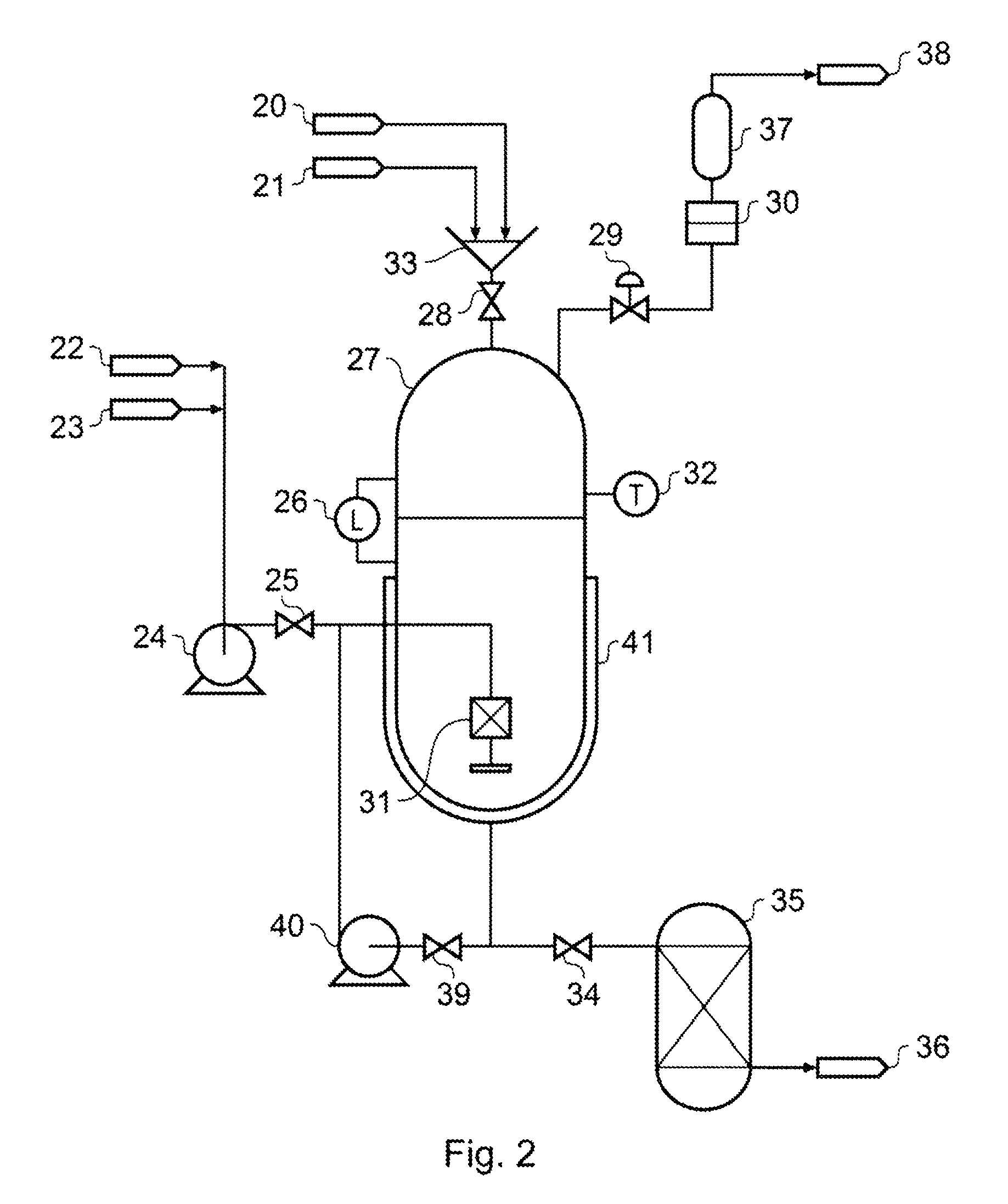

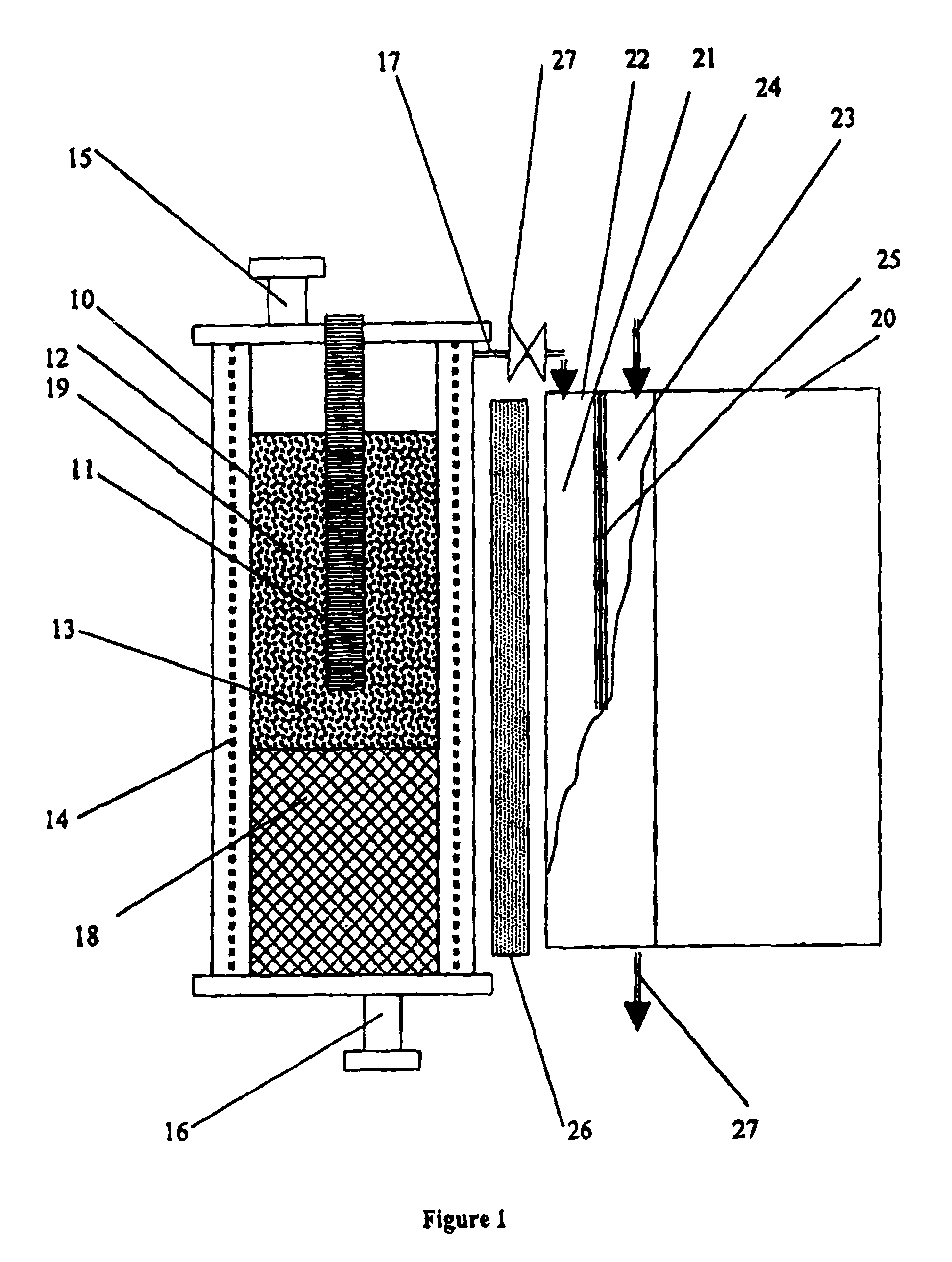

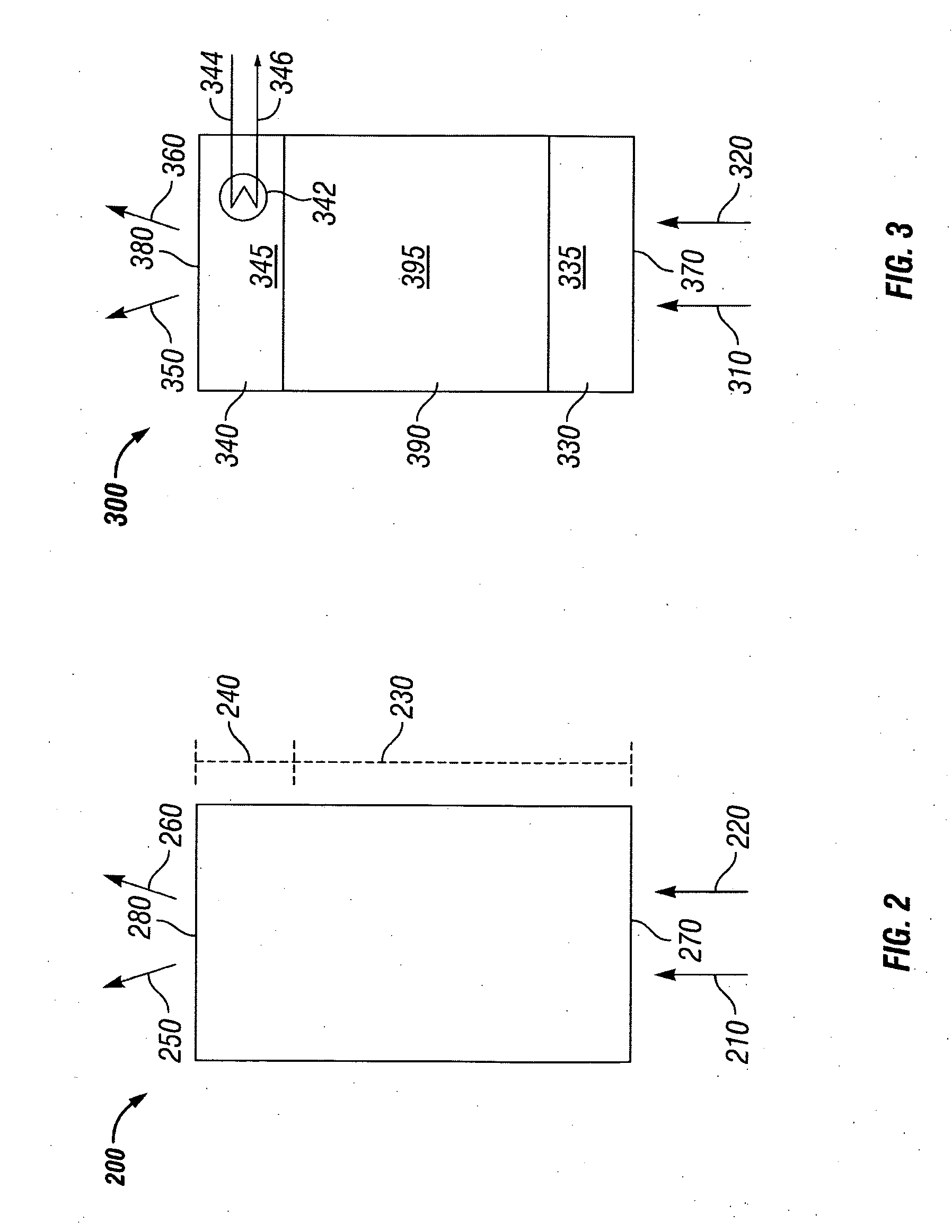

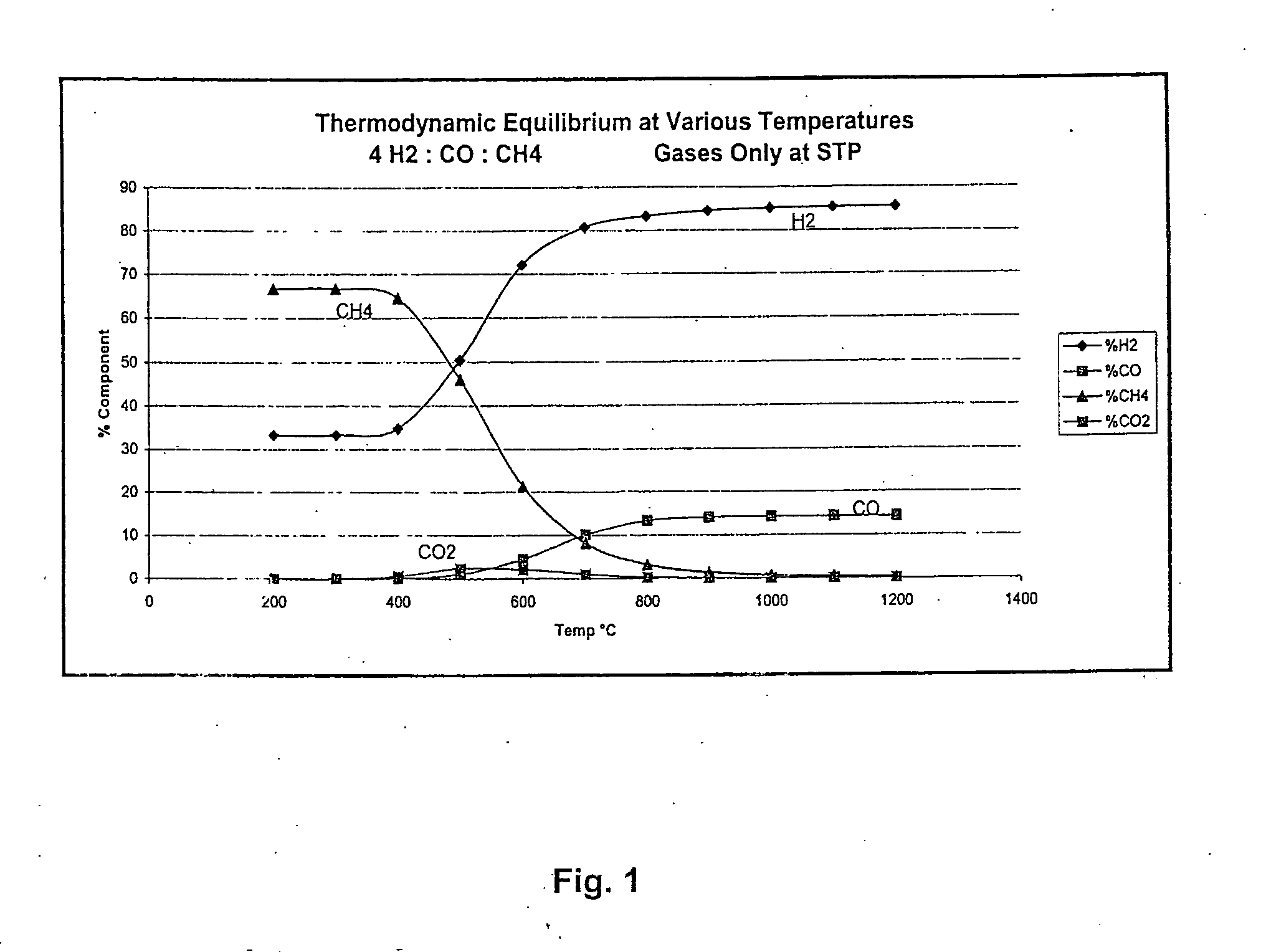

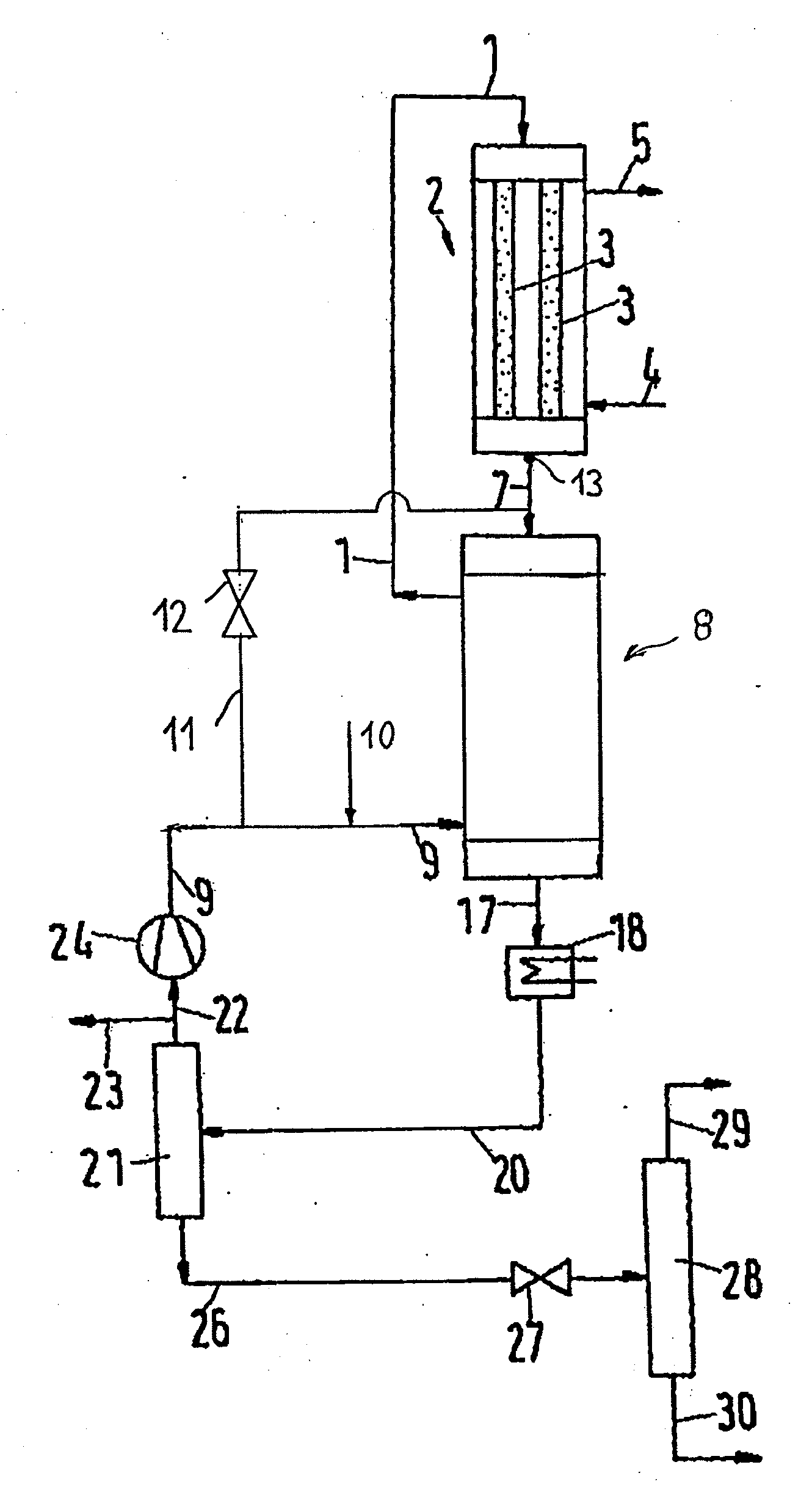

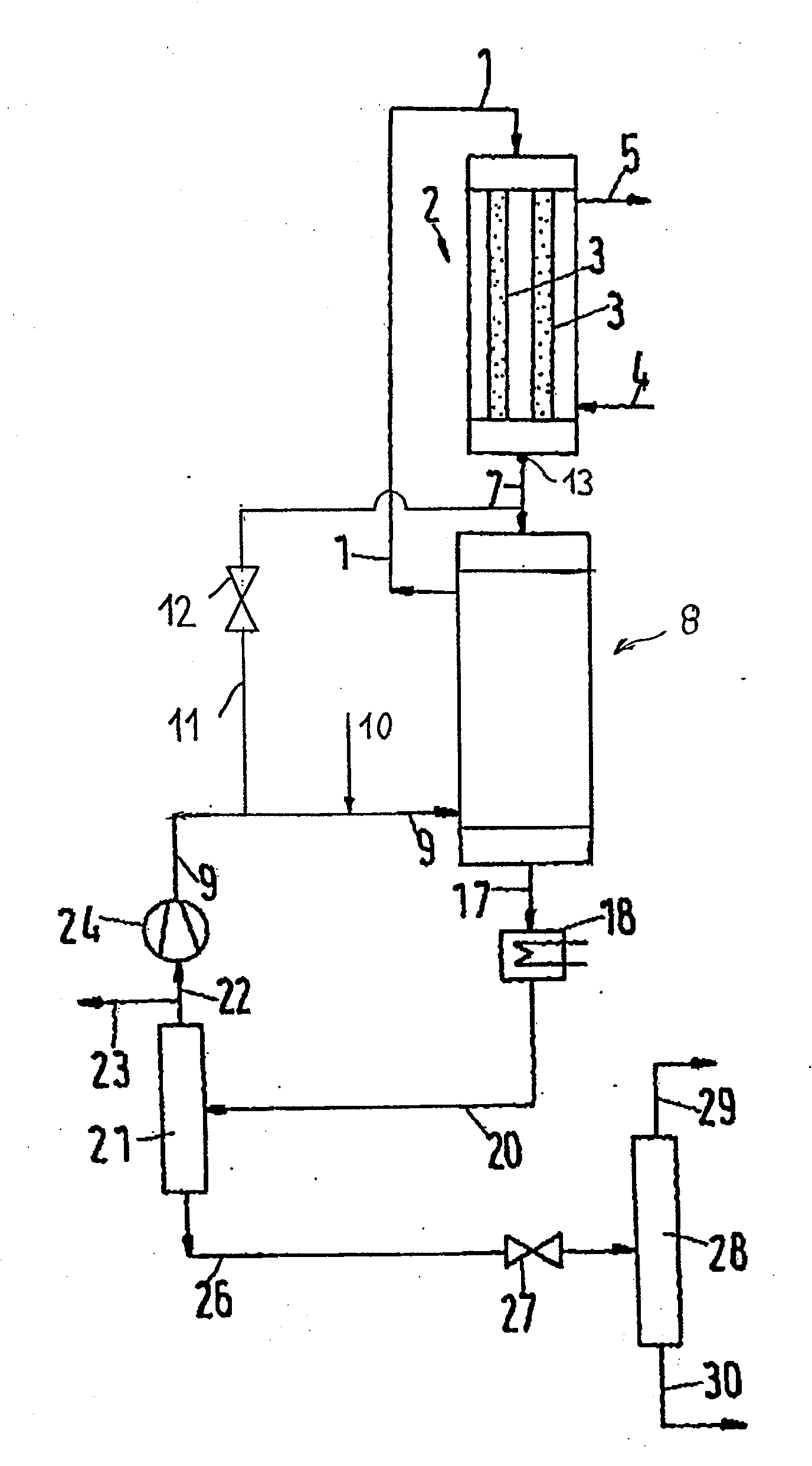

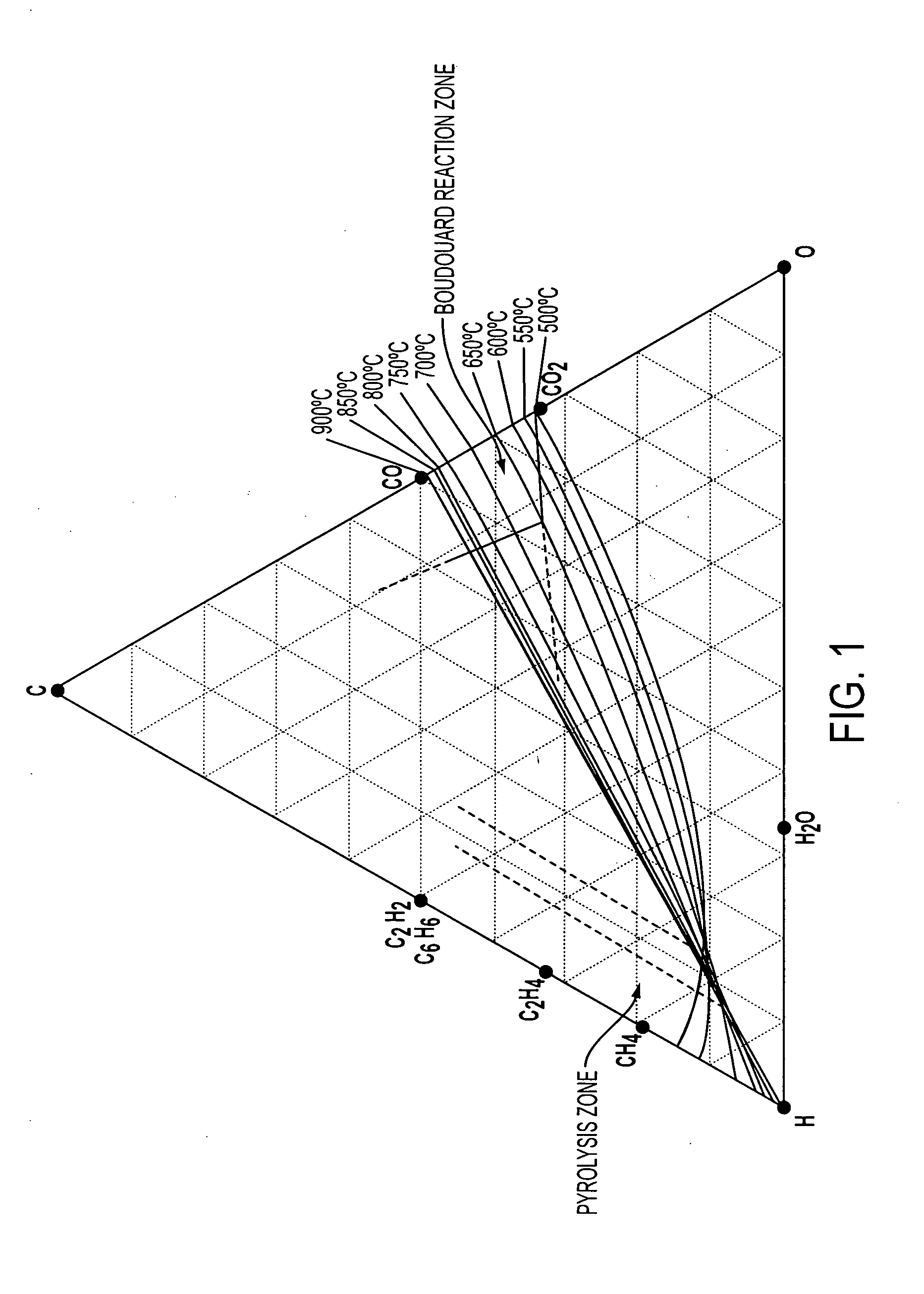

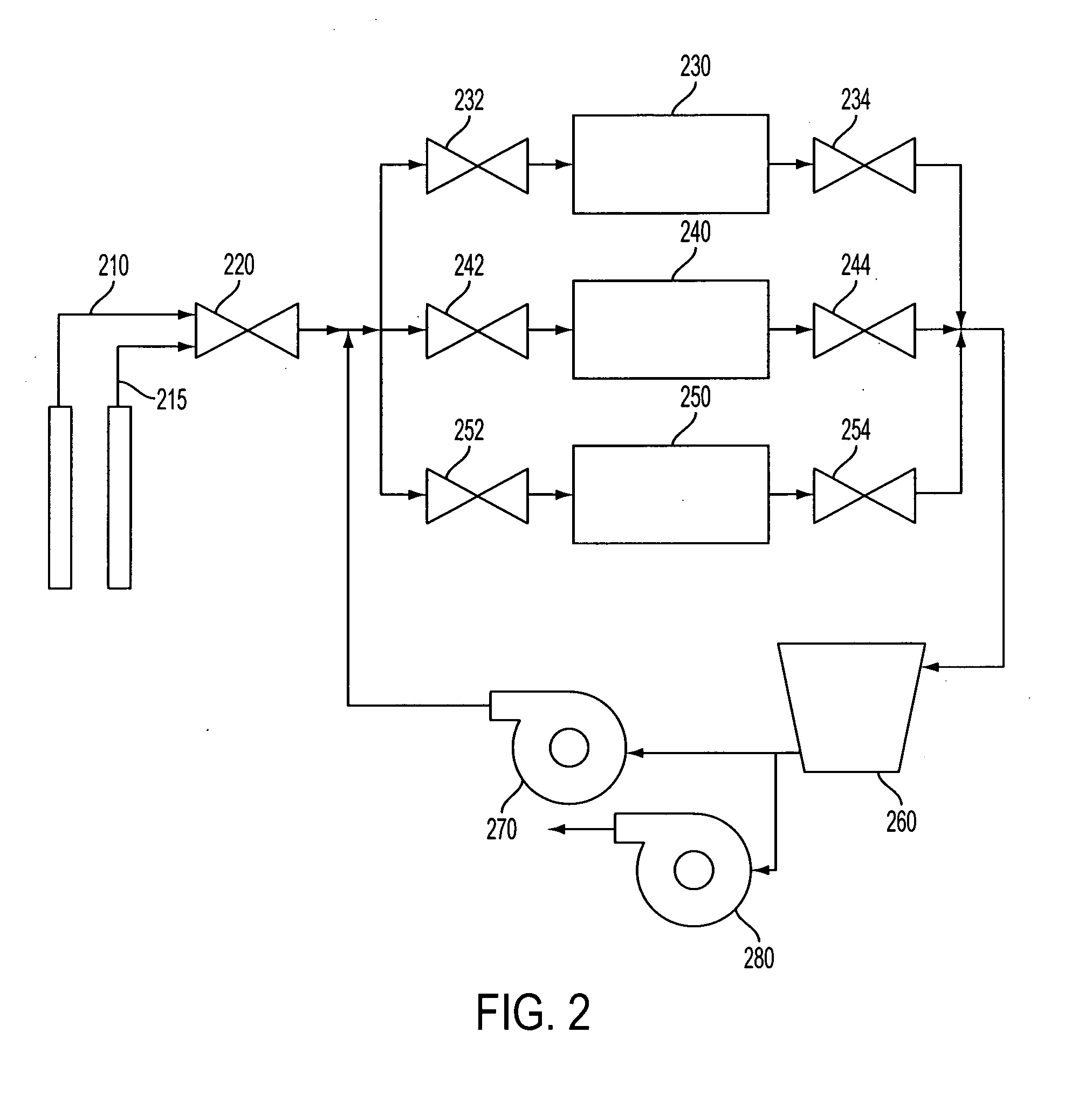

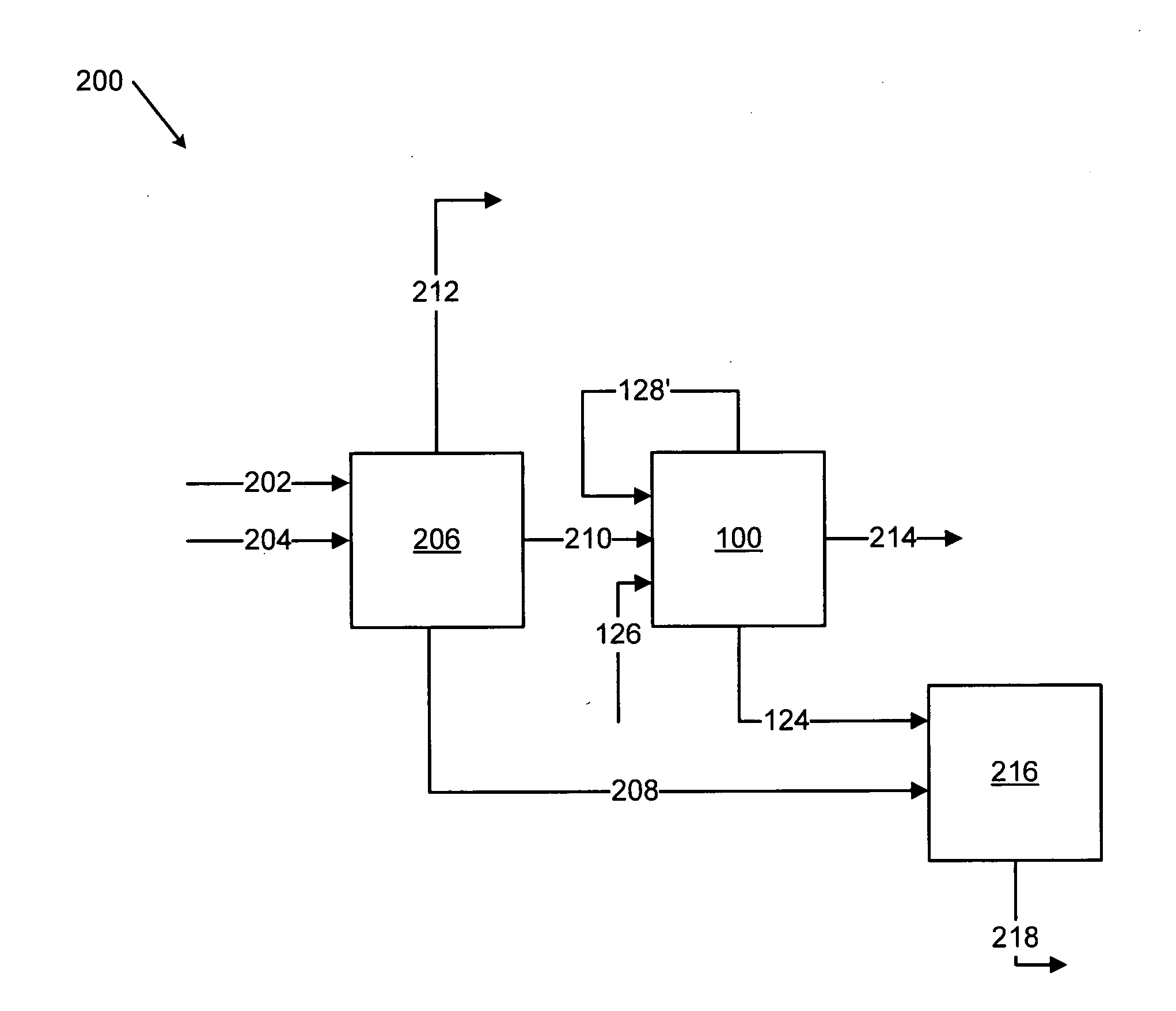

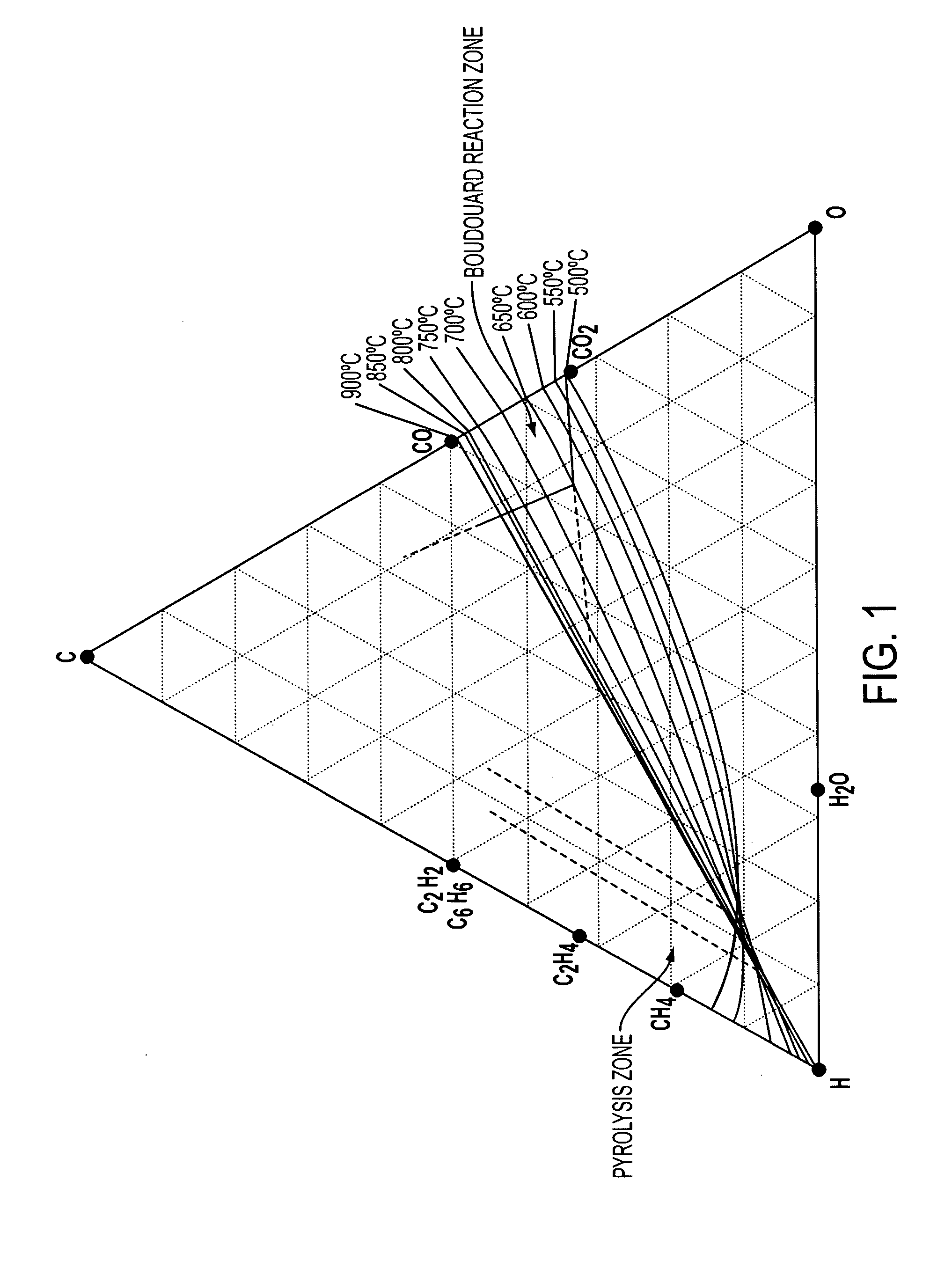

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

InactiveUS20020007594A1Pigmenting treatmentPressurized chemical processDecompositionBiological activation

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

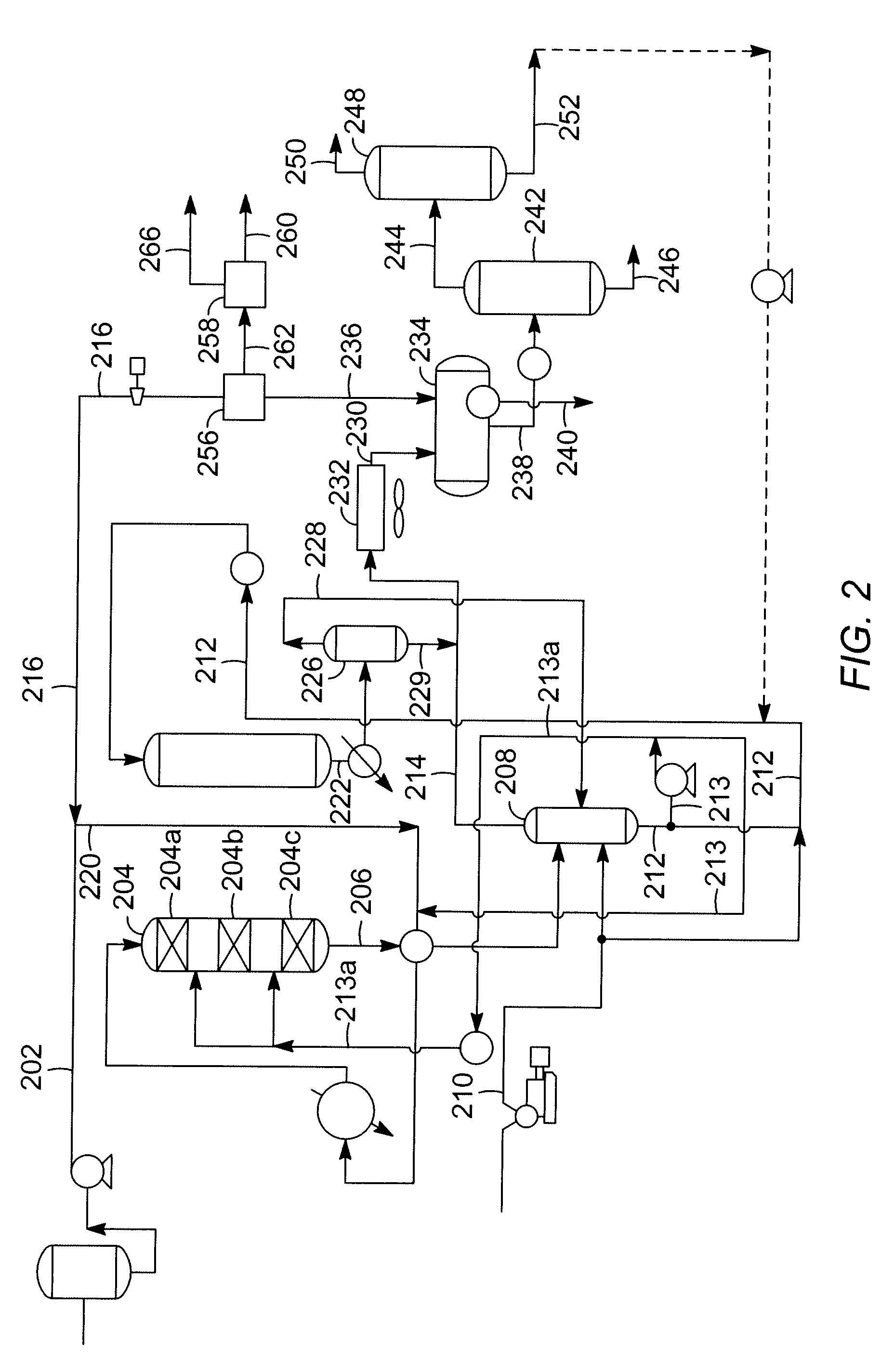

Production of Diesel Fuel from Biorenewable Feedstocks with Selective Separation of Converted Oxygen

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant and animal fats and oils, the process providing for sulfur management. The process involves catalytically treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel. The hydrocarbon fraction is isomerized to improve cold flow properties. A selective separation such as a hot high pressure hydrogen stripper is used to remove at least the carbon oxides from the first zone effluent before entering the isomerization zone, and to provide liquid recycle to the treating zone at pressure and temperature. A vapor stream is separated from the isomerization effluent and at least carbon dioxide is removed using at least one selective or flexible amine solution absorber. The resulting hydrogen-rich stream is recycled to the deoxygenation reaction zone

Owner:UOP LLC

Terephthalic Acid Composition and Process for the Production Thereof

ActiveUS20090124829A1Reducing and eliminating resultantOrganic compound preparationCarboxylic compound preparationEtherCarbon oxide

Terephthalic acid is prepared by reacting a 2,5-furandicarboxylate with ethylene in the presence of a solvent to produce a bicyclic ether; and then dehydrating the bicyclic ether. The process of the present invention effectively produces terephthalic acid, while reducing or eliminating the impurities, color bodies and carbon oxides produced in commercial practice by the liquid-phase oxidation of methyl-substituted benzene feedstocks.

Owner:BP CORP NORTH AMERICA INC

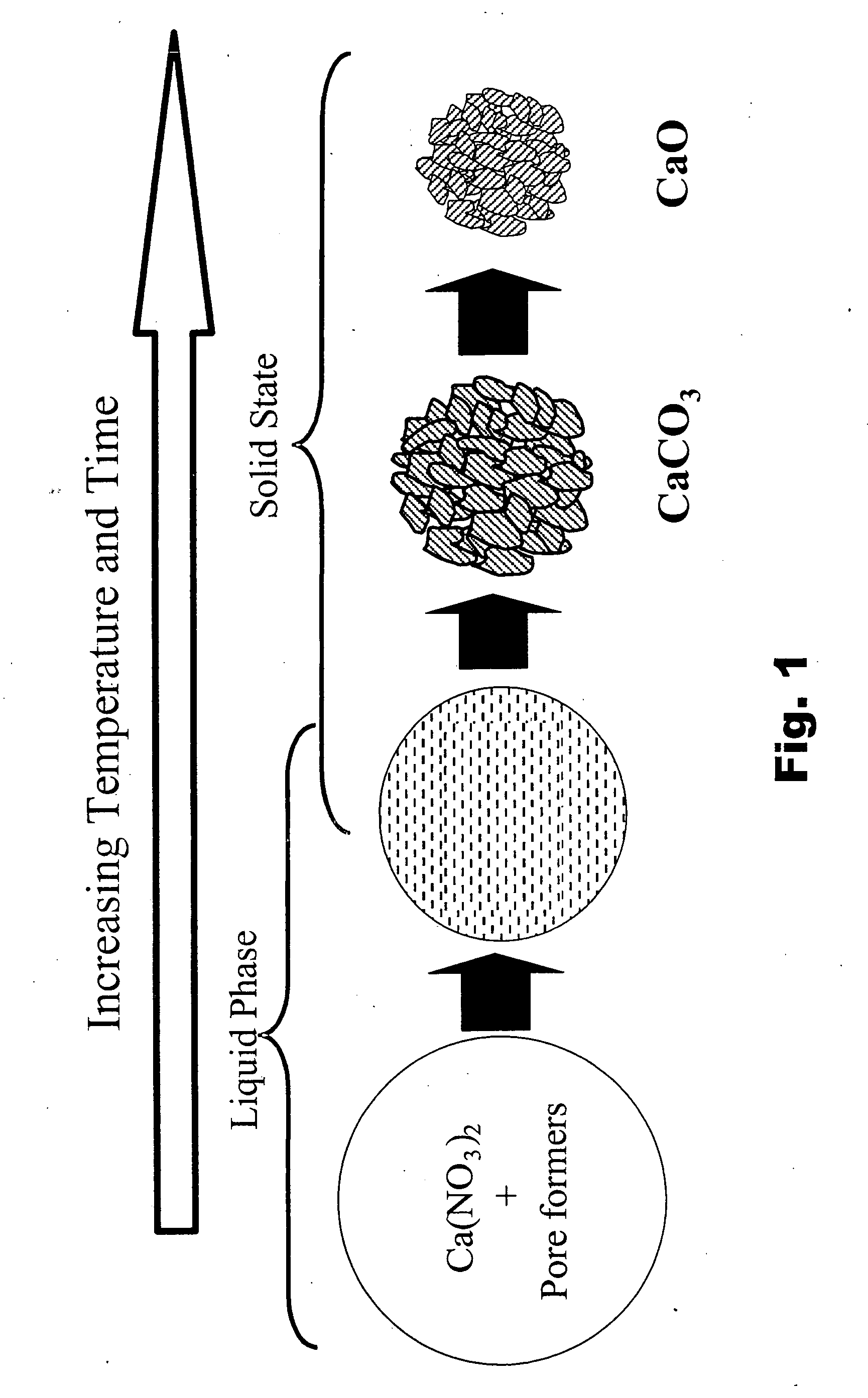

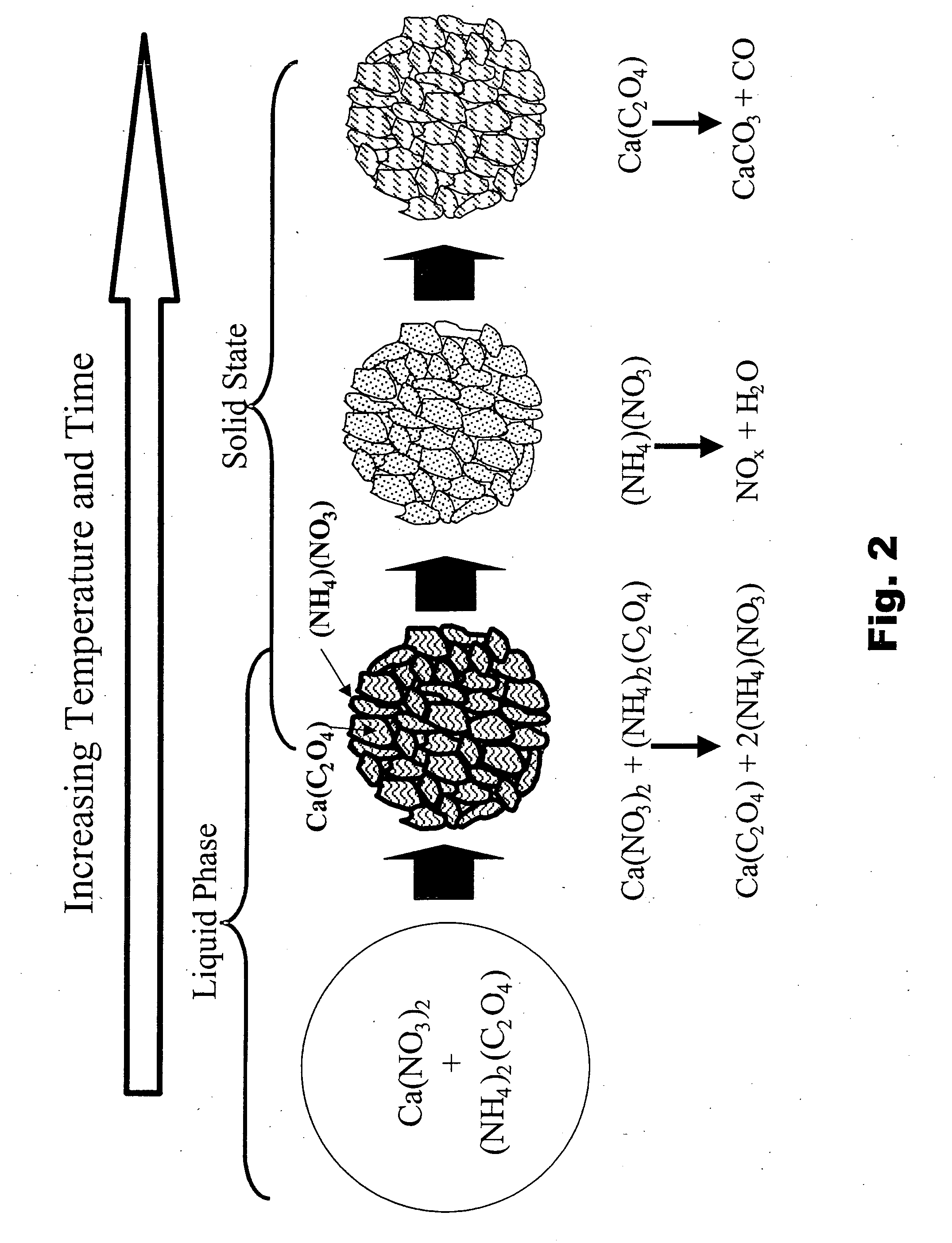

Fuel reformer catalyst and absorbent materials

InactiveUS20050112056A1Enhanced reformingOther chemical processesHydrogen separation using solid contactAbsorbent materialProduct gas

Materials that are useful for absorption enhanced reforming (AER) of a fuel, including absorbent materials and catalyst materials. The materials can be fabricated by spray processing. The use of the materials in AER can produce a H2 product gas having a high H2 content and a low level of carbon oxides.

Owner:CABOT CORP

Process for Preparing Butadiene by Oxidative Dehydrogenation of N-Butenes with Monitoring of the Peroxide Content During Work-Up of the Product

InactiveUS20140200381A1Analysis using chemical indicatorsHydrocarbon by hydrogenationWater vaporDesorption

The invention relates to a process for preparing butadiene from n-butenes, which comprises the following steps:A) provision of a feed gas stream a comprising n-butenes;B) introduction of the feed gas stream a comprising n-butenes and an oxygen-comprising gas into at least one dehydrogenation zone and oxidative dehydrogenation of n-butenes to butadiene, giving a product gas stream b comprising butadiene, unreacted n-butenes, water vapor, oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases;C) cooling and compression of the product gas stream b in at least one cooling stage and at least one compression stage, with the product gas stream b being brought into contact with a circulated coolant to give at least one condensate stream c1 comprising water and a gas stream c2 comprising butadiene, n-butenes, water vapor, oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases;D) separation of incondensable and low-boiling gas constituents comprising oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases as gas stream d2 from the gas stream c2 by absorption of the C4-hydrocarbons comprising butadiene and n-butenes in a circulated absorption medium, giving an absorption medium stream loaded with C4-hydrocarbons and the gas stream d2, and subsequent desorption of the C4-hydrocarbons from the loaded absorption medium stream to give a C4 product gas stream d1;E) separation of the C4 product stream d1 by extractive distillation using a solvent which is selective for butadiene into a stream e1 comprising butadiene and the selective solvent and a stream e2 comprising n-butenes;F) distillation of the stream e1 comprising butadiene and the selective solvent to give a stream f1 consisting essentially of the selective solvent and a stream f2 comprising butadiene;where samples are taken from the circulated coolant in step C) and / or the circulated absorption medium in step D) and the peroxide content of the samples taken is determined by means of iodometry, differential scanning calorimetry (DSC) or microcalorimetry.

Owner:BASF AG

Functional fluid and a process for the preparation of the functional fluid

A functional fluid for the removal of contaminates such as but not limited to, acid causing components in gas, sulfur components and carbon oxides from fluid streams, and removal and treatment of NOX & SOX from post combustion emissions. Also described is the manufacturing process to produce the functional fluid both in a batch atmospheric process system as well as a closed system capable of operating at above or below atmospheric conditions.

Owner:SPECIALIST PROCESS TECH

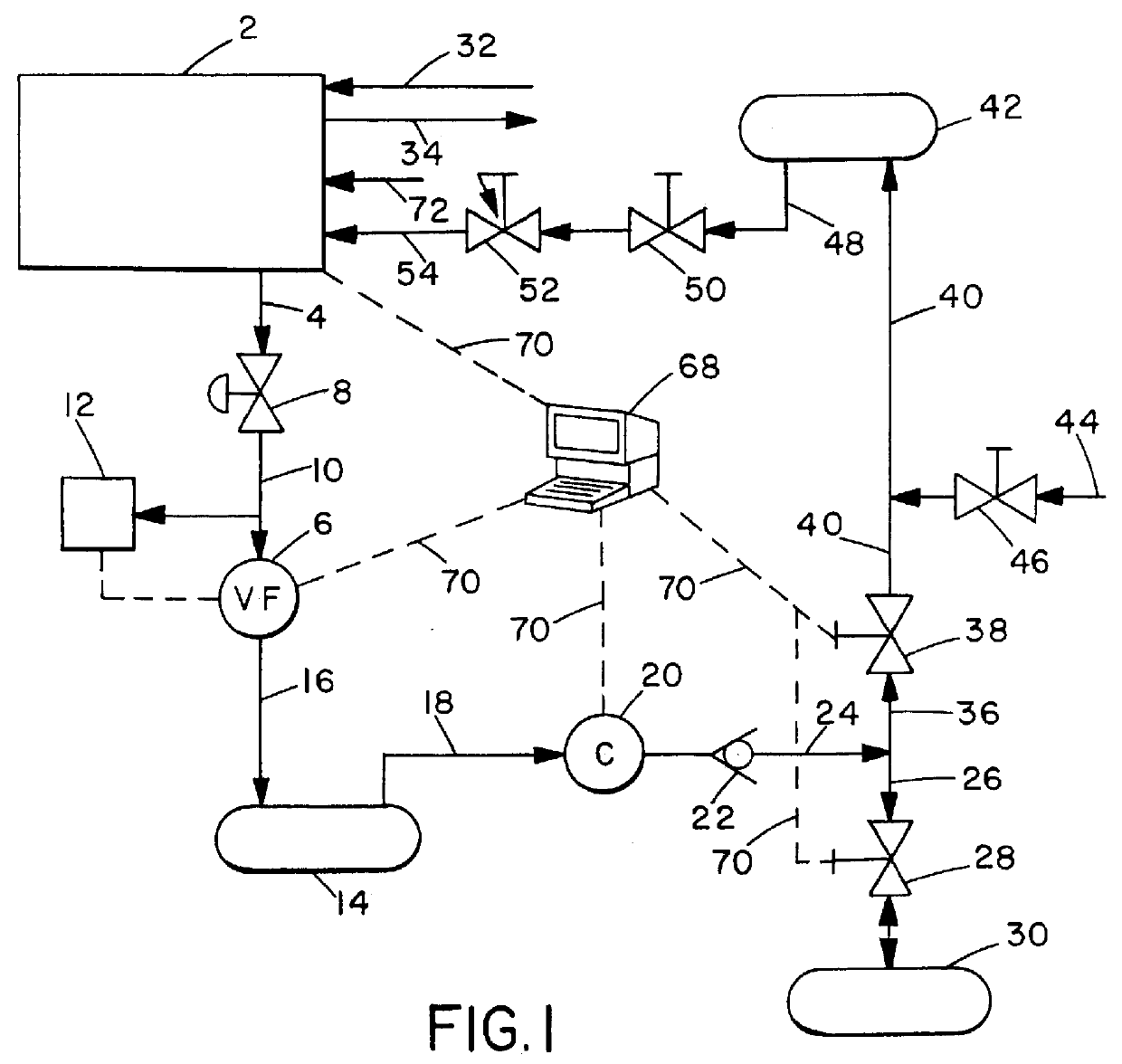

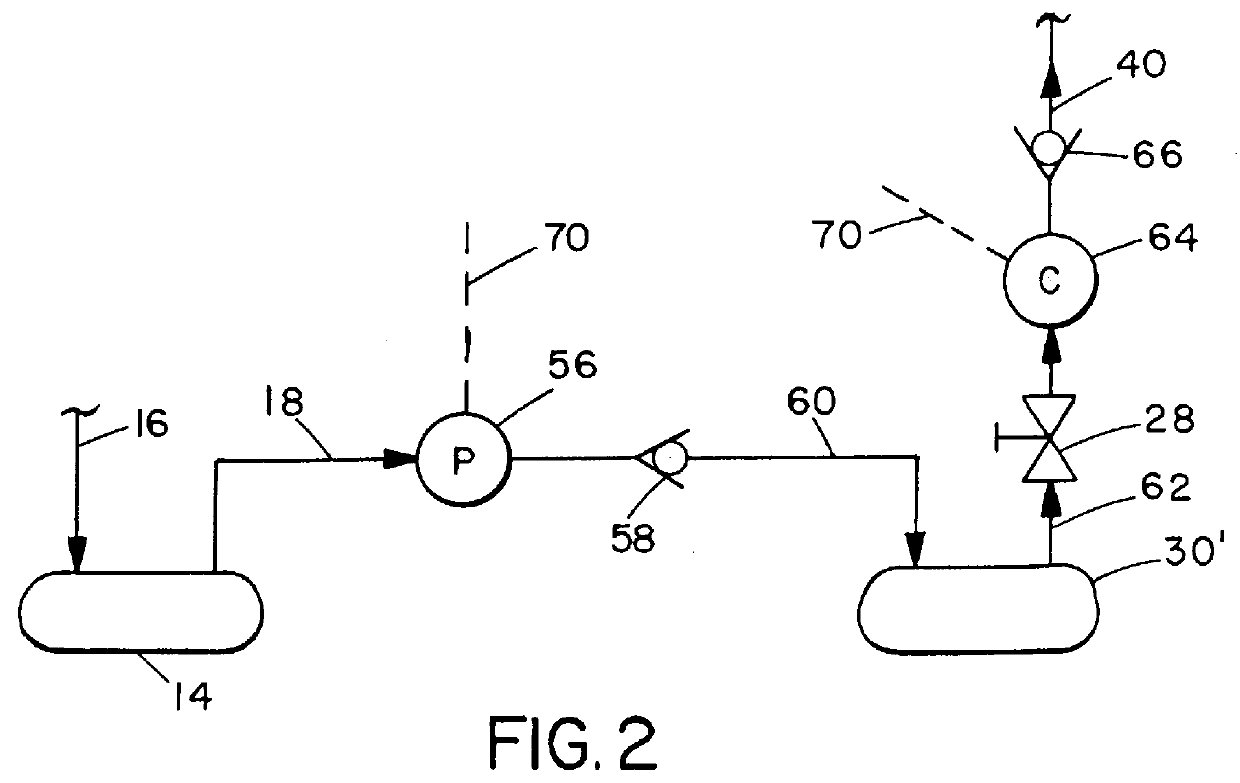

Method for recovery and reuse of gas

A gas recovery and reuse / recycle method is disclosed which can readily and economically recover valuable and / or environmentally hazardous gases from a manufacturing or chemical process and then return the gas to the process for reuse, and repeat this many times without significant contamination or degradation of the gas or the produced products. All gas transport, compression and storage equipment is designed and maintained so that it is non-contaminating to the process gas. Commonly the process gas will be a Group VIII gas, preferably He, Ne, Kr or Xe, or a gas which comprises a hazard to the ambient environment or beings therein, such as a carbon oxide gas, a halocarbon gas, an acid-precursor gas, a biologically hazardous gas, or a radioactive gas.

Owner:ENTEGRIS INC

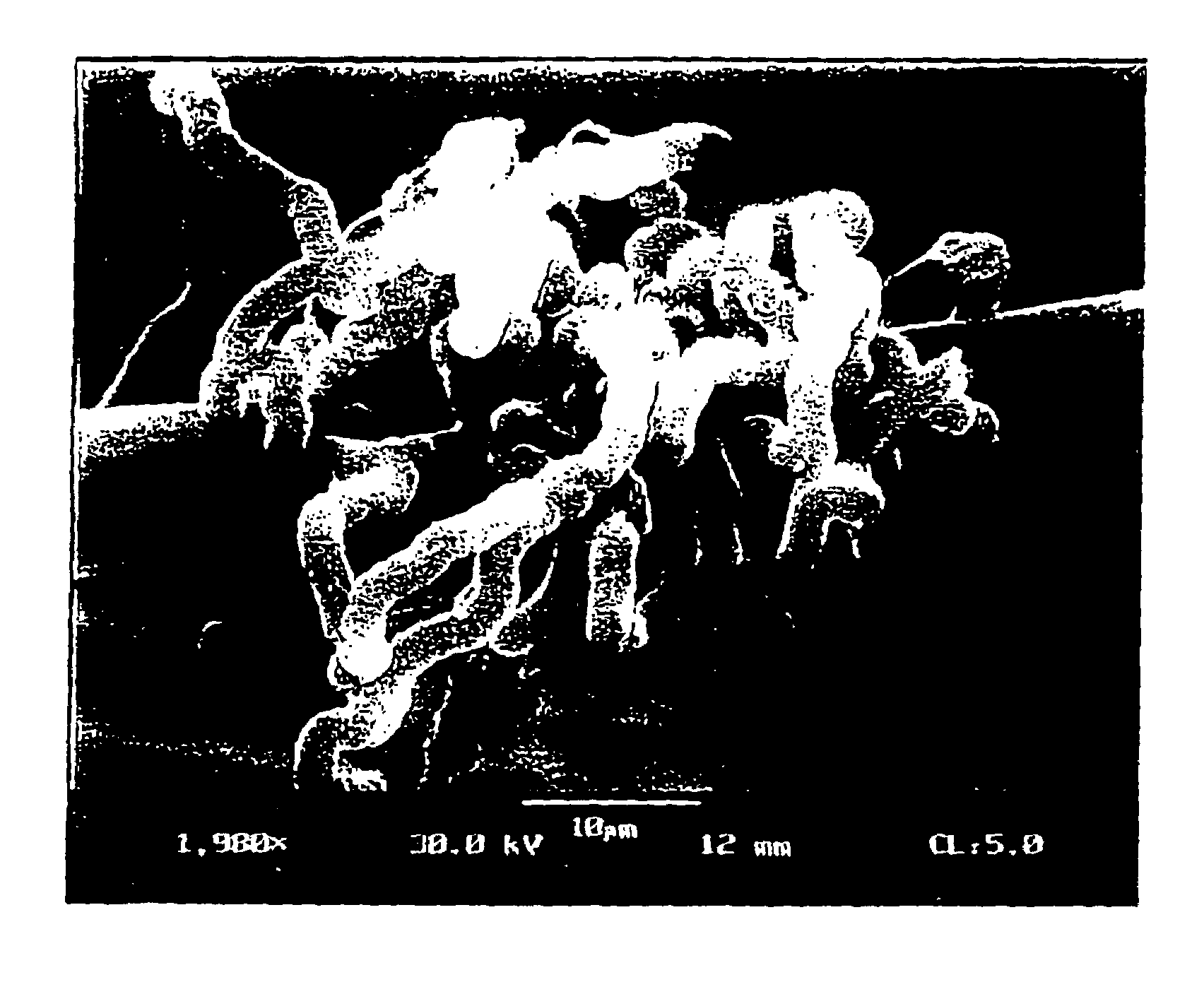

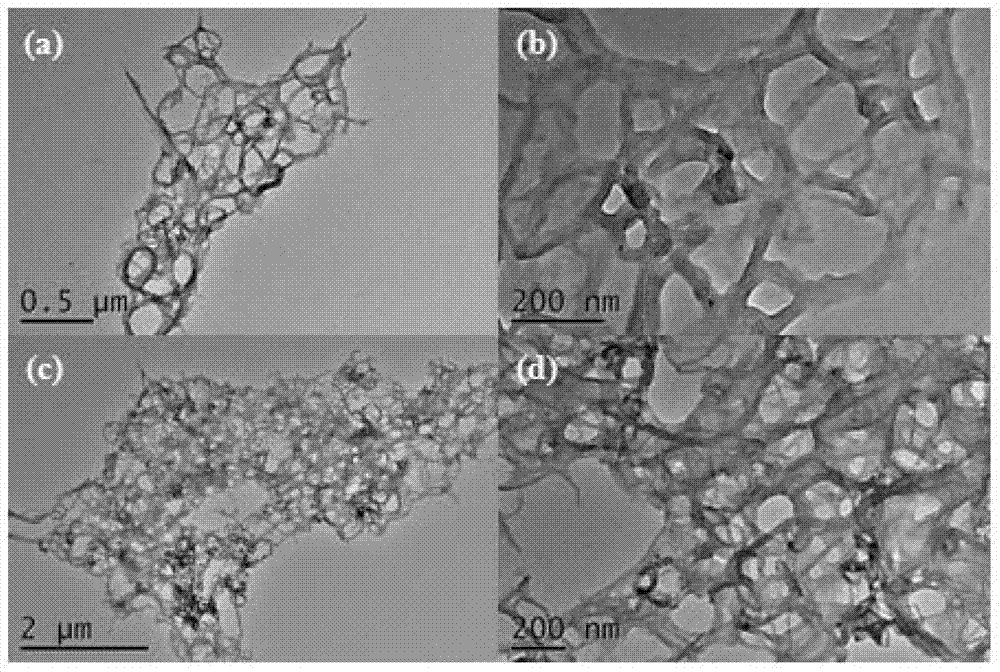

Filamentous carbon particles for cleaning oil spills and method of production

InactiveUS7473466B1Increase specific energy and overall energy efficiencyHydrogen/synthetic gas productionGlass/slag layered productsFiberCarbon nanotube

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. In the process of producing hydrogen for the generator via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in an oxidant-free environment, novel carbon products are produced with filamentary surfaces, “octopus”-like carbon filaments, single carbon nanotube fibers and the like. Two novel processes are disclosed for the production of carbon filaments and a novel filamentous carbon product useful in the clean-up of oil spills on the surface of water. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, and sulfurous fuels. The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it can be directly fed to any type of a fuel cell. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

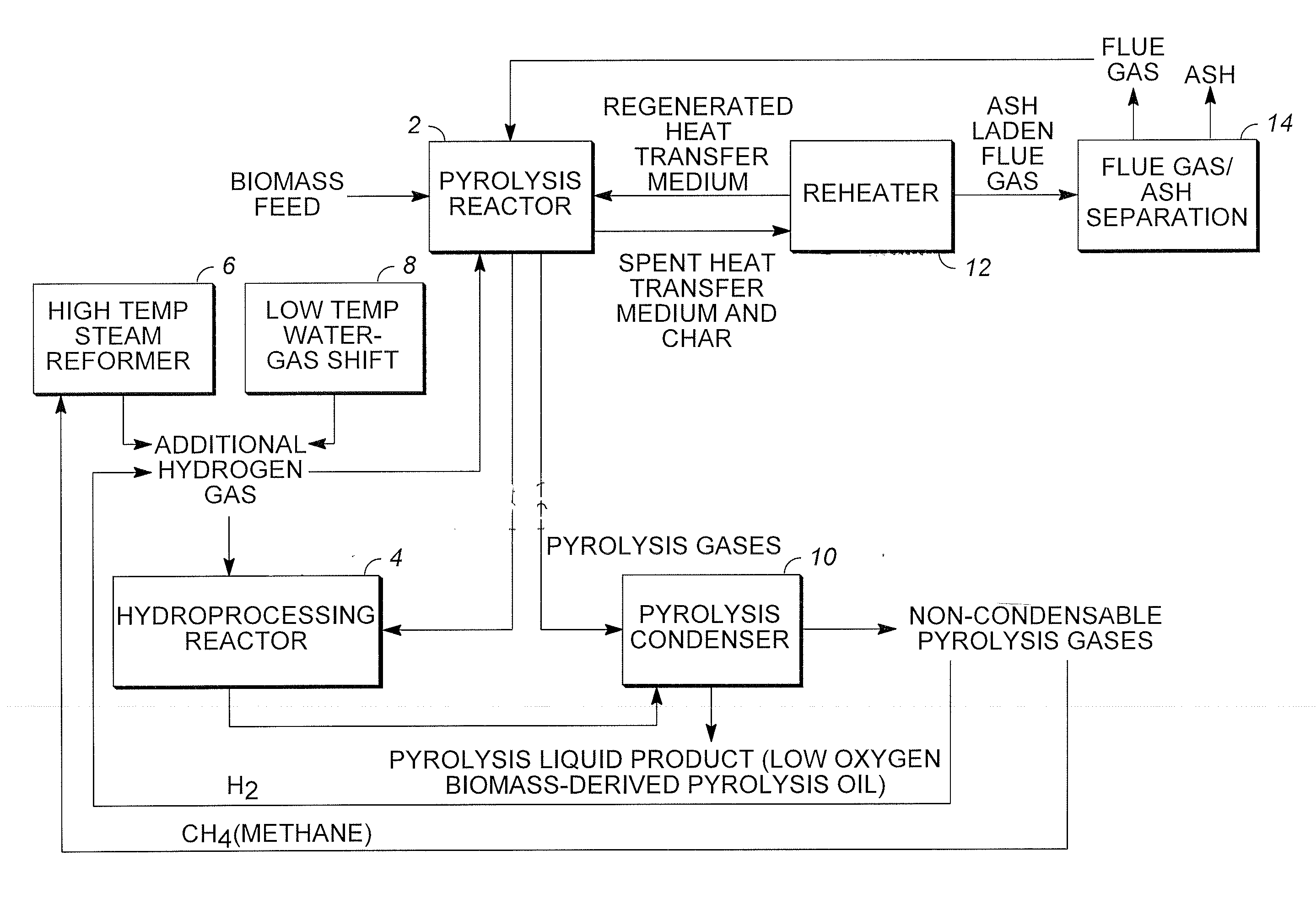

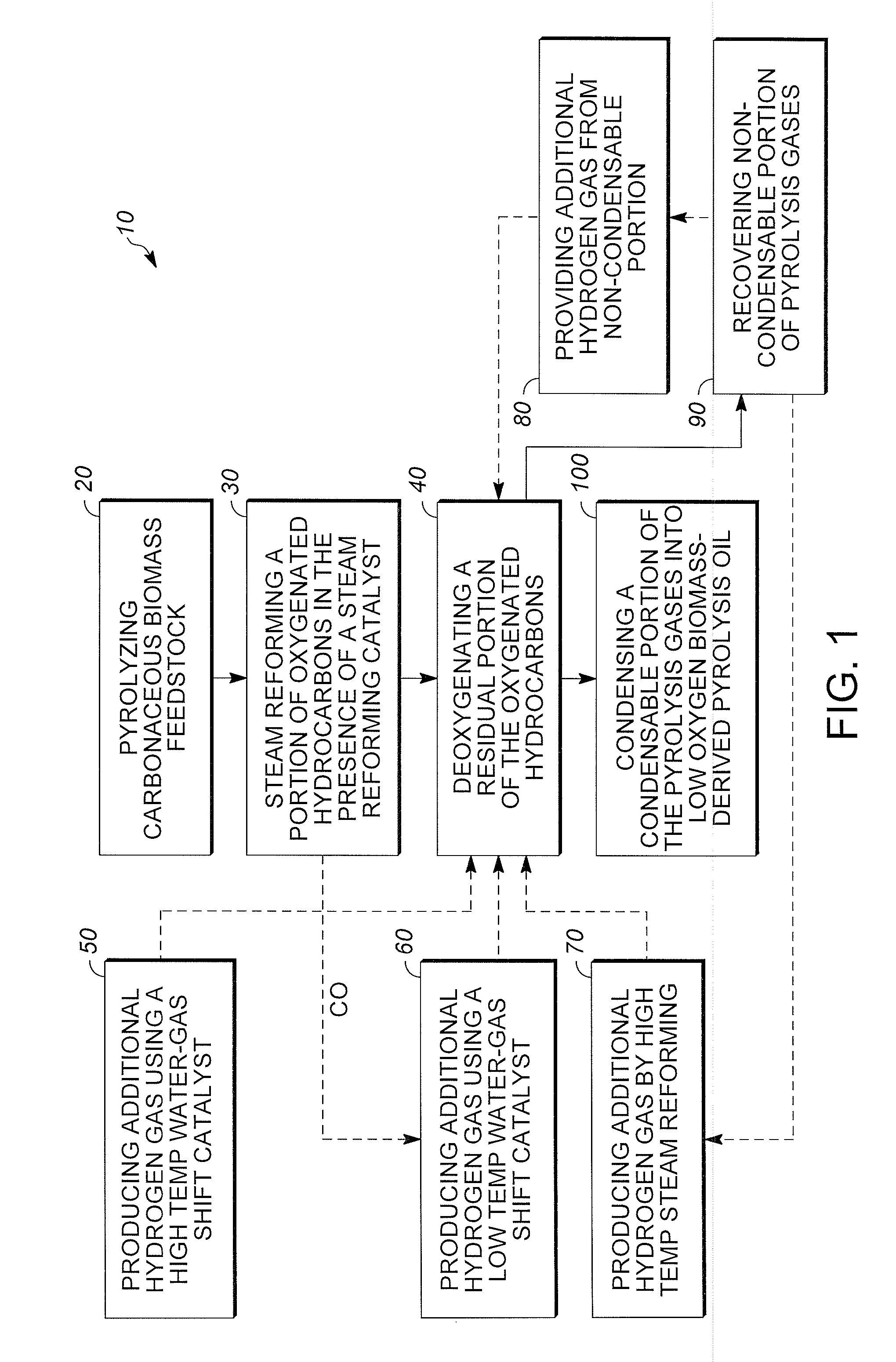

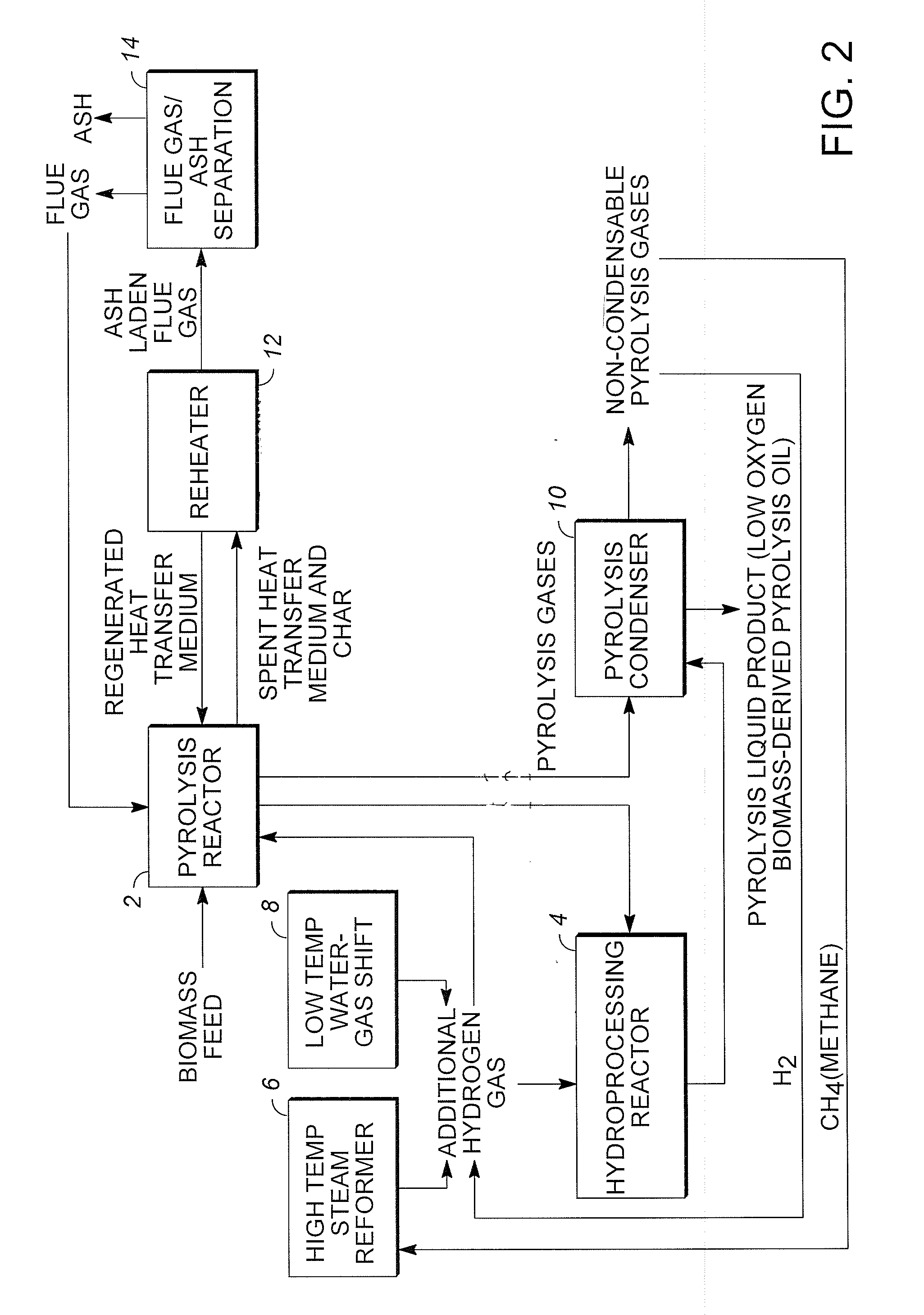

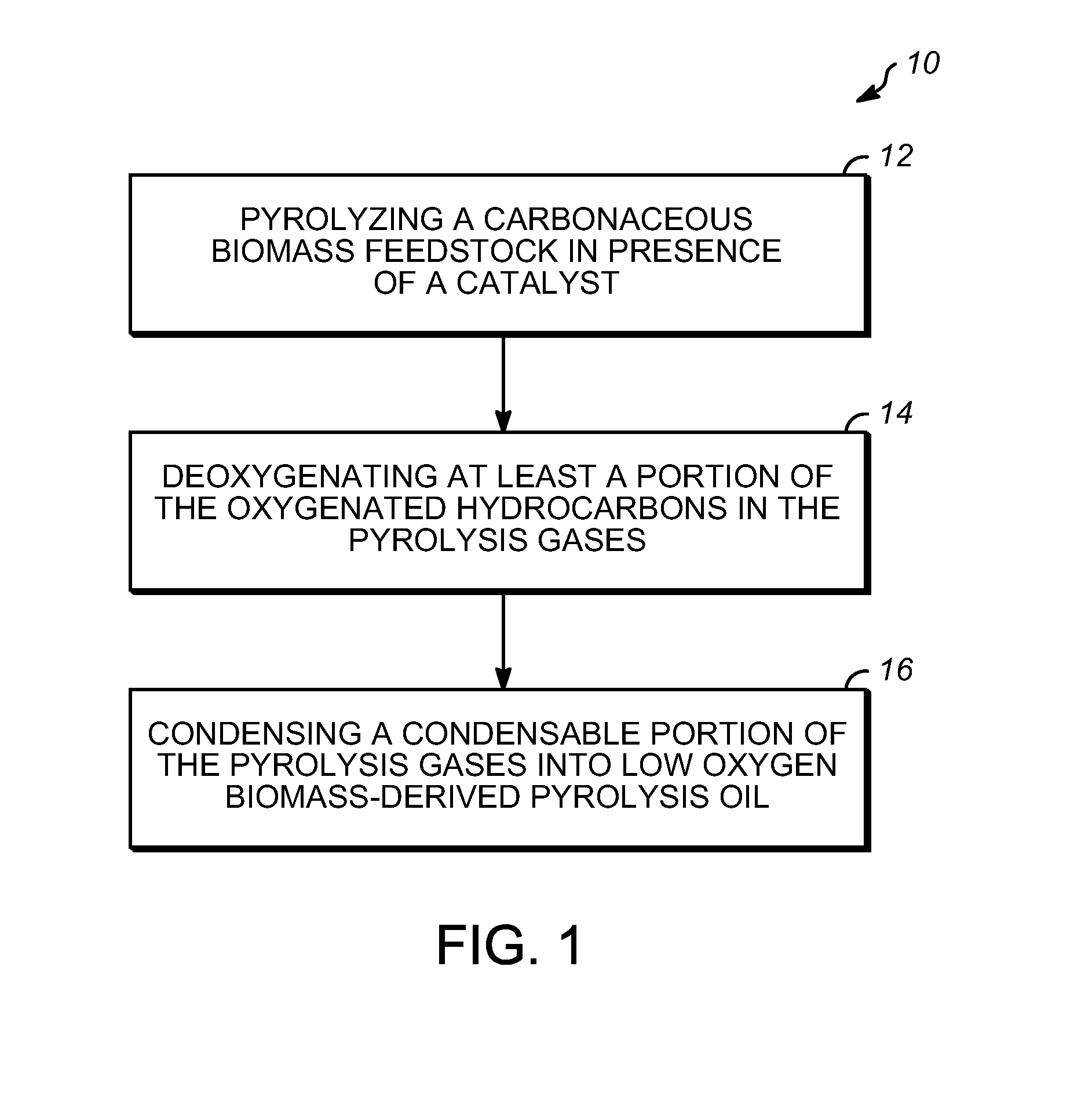

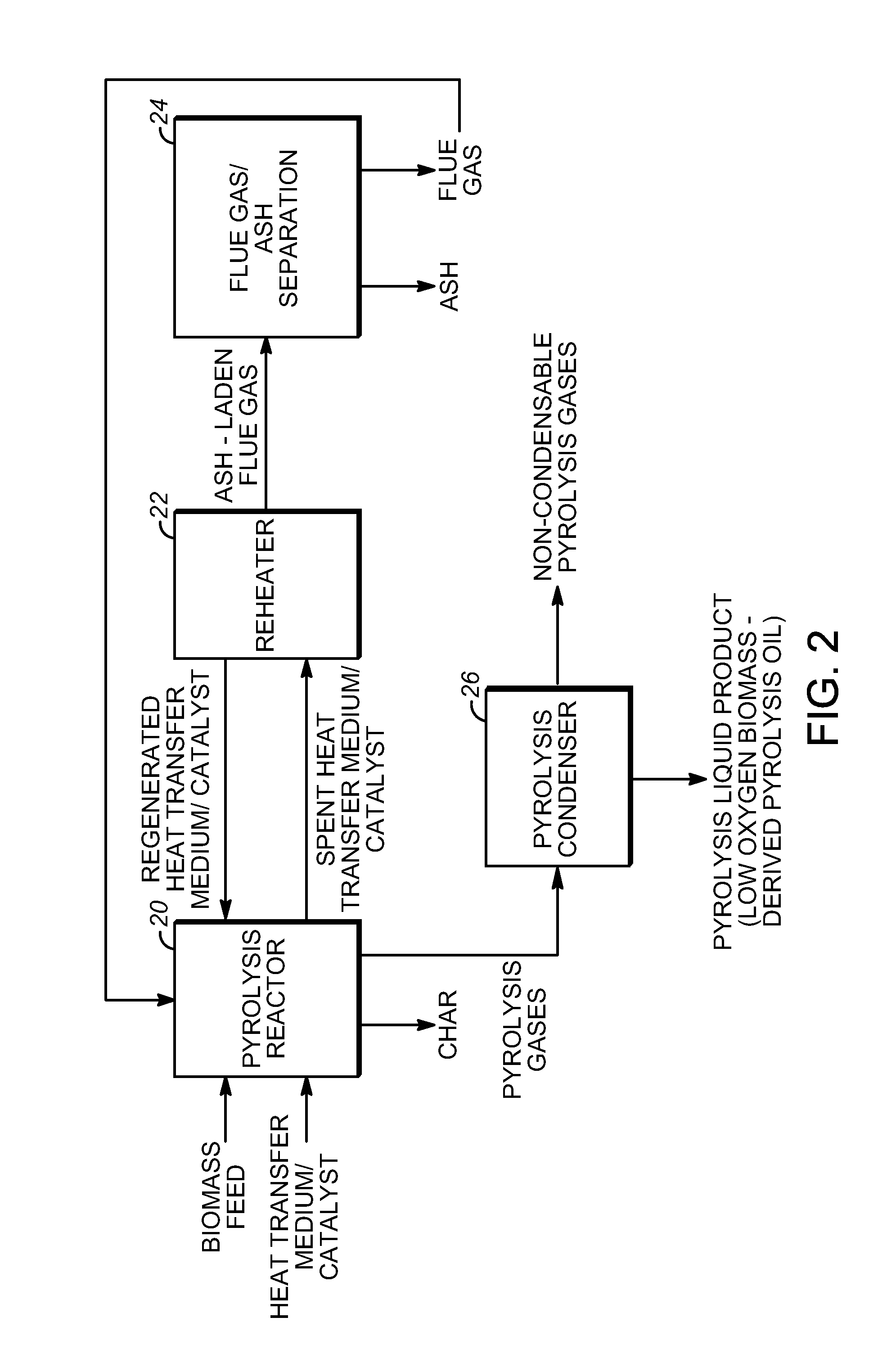

Low oxygen biomass-derived pyrolysis oils and methods for producing the same

InactiveUS20110201854A1Direct heating destructive distillationBiofuelsSteam reformingPartial oxidation

Methods are provided for producing low oxygen biomass-derived pyrolysis oil from carbonaceous biomass feedstock. The carbonaceous biomass feedstock is pyrolyzed in the presence of a steam reforming catalyst to produce char and pyrolysis gases. During pyrolysis, a portion of the oxygenated hydrocarbons in the pyrolysis gases is converted into hydrocarbons by steam reforming also yielding carbon oxides and hydrogen gas. The hydrogen gas at least partially deoxygenates a residual portion of the oxygenated hydrocarbons. Additional hydrogen gas may also be produced by water-gas shift reactions to deoxygenate the residual portion of the oxygenated hydrocarbons in the pyrolysis gases. Deoxygenation may occur in the presence of a hydroprocessing catalyst. A condensable portion of the pyrolysis gases is condensed to form low oxygen biomass-derived pyrolysis oil.

Owner:UOP LLC

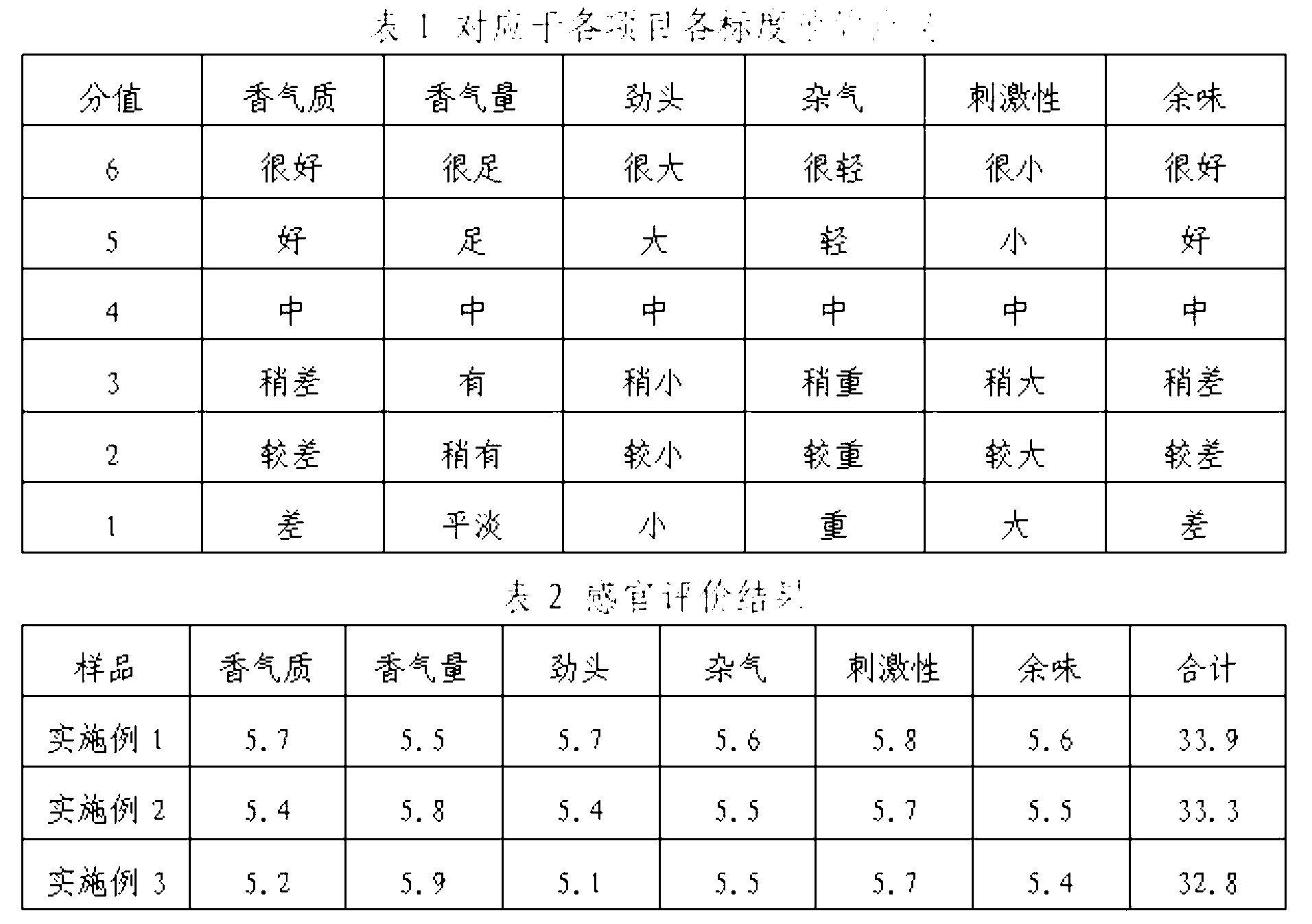

Electronic cigarette liquid capable of effectively improving sensory quality of electronic cigarette

The invention discloses electronic cigarette liquid capable of effectively improving sensory quality of an electronic cigarette, and the electronic cigarette liquid is prepared by uniformly mixing 5 to 10 percent of extract of red-flower Dajinyuan tobacco leaves produced in Yunnan province, 5 to 9 percent of essence for cigarettes, 1 to 5 percent of spice for the cigarettes, 5 to 15 percent of deionized water, 10 to 20 percent of glycerol and balance of propylene glycol. The electronic cigarette liquid is used for atomizing the electronic cigarette, no tar and carbon oxide (CO) is produced, harm on consumers can be greatly reduced, and no harm of second-hand smoking is produced through the application of the product; the extract of the red-flower Dajinyuan tobacco leaves not only provide nicotine, but also provide abundant tobacco characteristic fragrant substances, so that the sensory quality of the electronic cigarette is closer to that of the traditional cigarette; and due to the adoption of the essence and the spice for the cigarette, the fragrance quality and the fragrance quantity of the electronic cigarette can be enhanced, and the satisfactory of the consumers can be improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

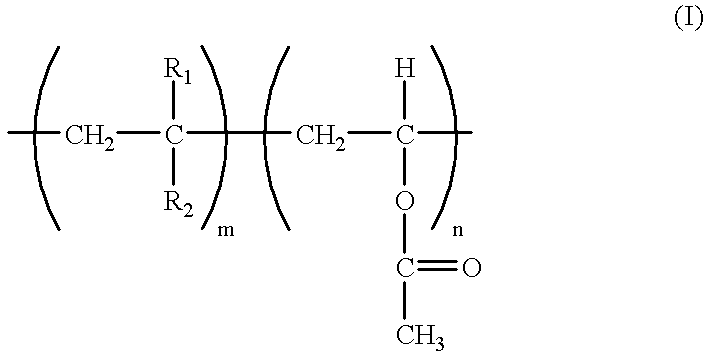

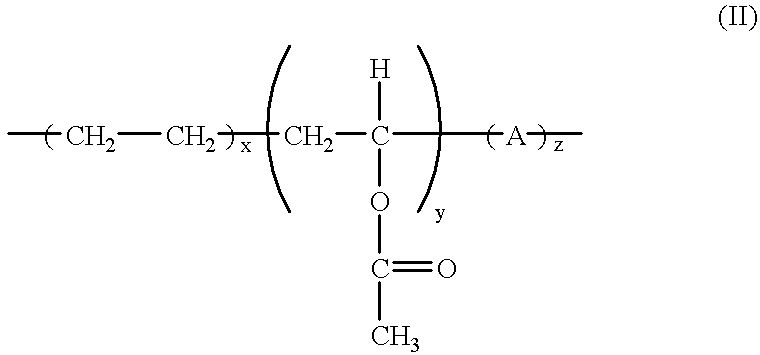

Gel polymer electrolyte of vinyl acetate

InactiveUS6268088B1Enhanced interactionImprove ionic conductivityOrganic electrolyte cellsSolid electrolyte cellsSolventFluid electrolytes

A gel polymer electrolyte according to the present invention comprises a polymer selected from the group consisting of vinyl acetate copolymer, poly(ethylene / vinylacetate / carbon oxide: EVACM), and poly(ethylene / vinylacetate / maleic acid anhydride: EVAMA); an inorganic filler; and a liquid electrolyte that a lithium salt is dissolved in an aprotic solvent. It is preferable that the polymer material in a gel polymer electrolyte according to the present invention is in the range of 20 to 30% by weight, the inorganic material filler is in the range of 5 to 20% by weight, and the liquid electrolyte is in the range of 60 to 80 % by weight. As a specific functional group which has a high compatibility with a liquid electrolyte in the present invention is contained in the polymer material, a lithium ion becomes to move with ease in electrolyte, and the ionic conductivity is over 0.5 mS / cm which is the demand level of a gel polymer electrolyte. Also, it provides the gel polymer electrolyte material with a high film formability, a good property of containing an electrolyte, a good adhesion, and a good mechanical strength.

Owner:CHEIL IND INC

Methanol synthesis

A process for synthesising methanol comprises the steps of: (i) reforming a hydrocarbon feedstock and separating water to generate a make-up gas comprising hydrogen and carbon oxides, the make-up gas mixture having a stoichiometric number, R, R=([H2]−[CO2]) / ([CO2]+[CO]) of less than 2.0, (ii) combining the make up gas with an unreacted synthesis gas to form a synthesis gas mixture, (iii) passing the synthesis gas through a bed of methanol synthesis catalyst to generate a product stream, (iv) cooling the product stream to recover a crude methanol stream from the unreacted synthesis gas, (v) removing a portion of the unreacted synthesis gas as a purge gas, and (vi) feeding the remaining unreacted synthesis gas to step (ii), wherein hydrogen is recovered from a portion of the purge gas and the make up gas, and the recovered hydrogen is included in the synthesis gas mixture.

Owner:JOHNSON MATTHEY PLC

Systems and processes of operating fuel cell systems

The present invention is directed to systems and processes for operating molten carbonate fuel cell systems. A process for operating the molten carbonate fuel cell includes providing a hydrogen-containing stream comprising molecular hydrogen to a molten carbonate fuel cell anode; heating a hydrocarbon stream, at least a majority of which is comprised of hydrocarbons that are liquid at 20° C. and atmospheric pressure, with a heat source comprising an anode exhaust from the molten carbonate fuel cell anode; contacting at least a portion of the heated hydrocarbon stream with a catalyst to produce a steam reforming feed comprising gaseous hydrocarbons, hydrogen, and at least one carbon oxide; separating at least a portion of the molecular hydrogen from the steam reforming feed; and providing at least a portion of the separated molecular hydrogen to the molten carbonate fuel cell anode as at least a portion of the stream comprising molecular hydrogen.

Owner:SHELL OIL CO

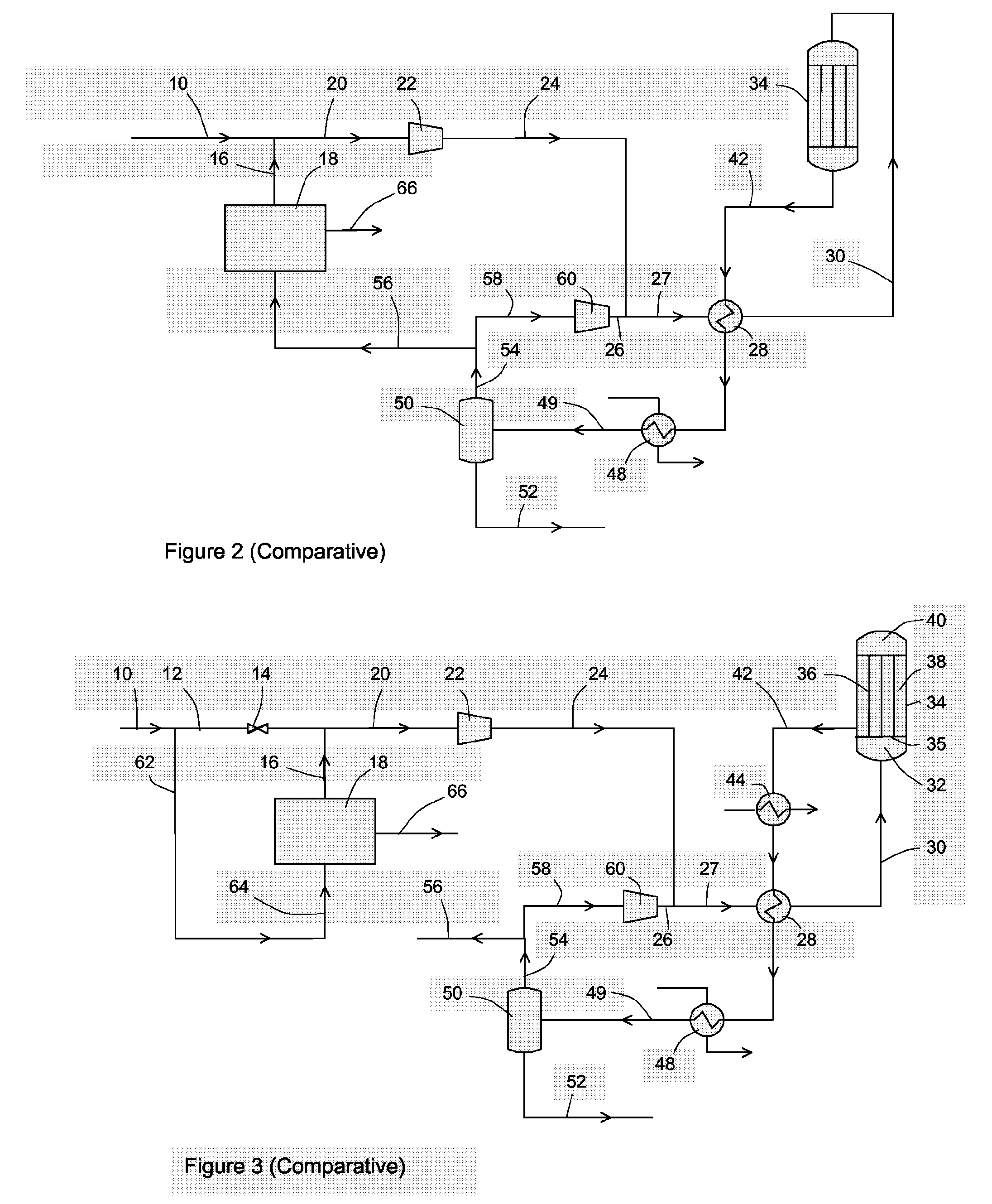

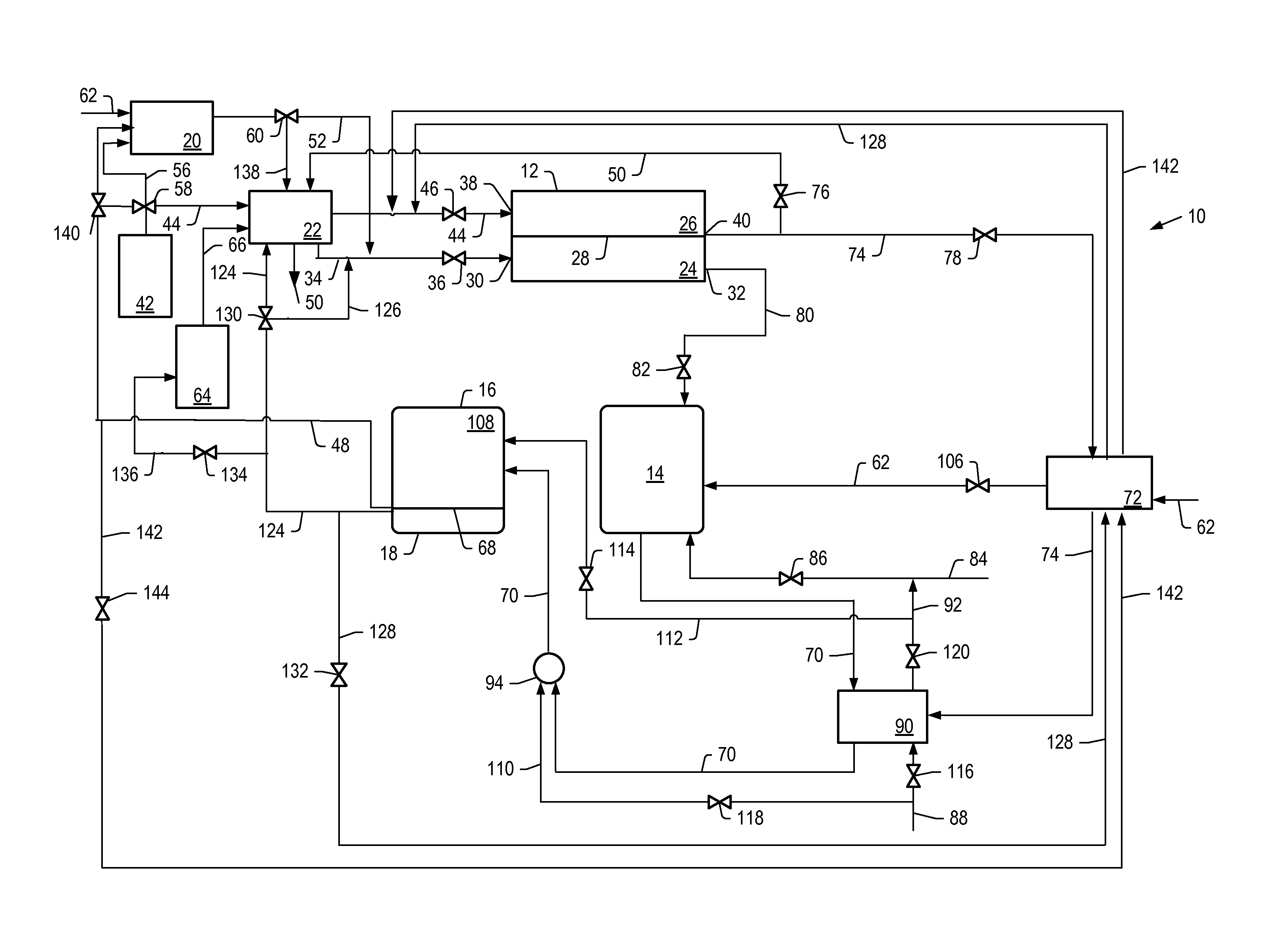

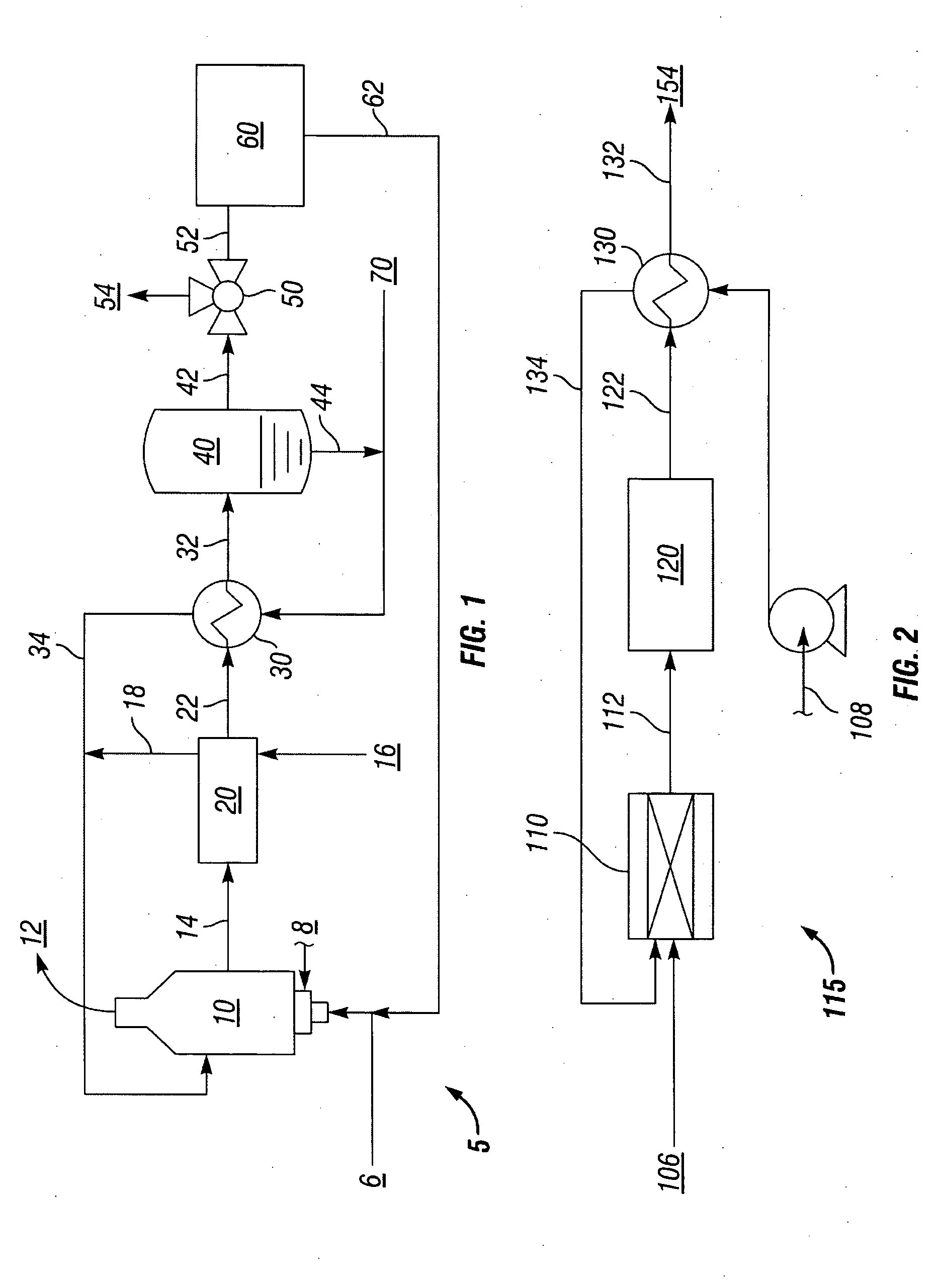

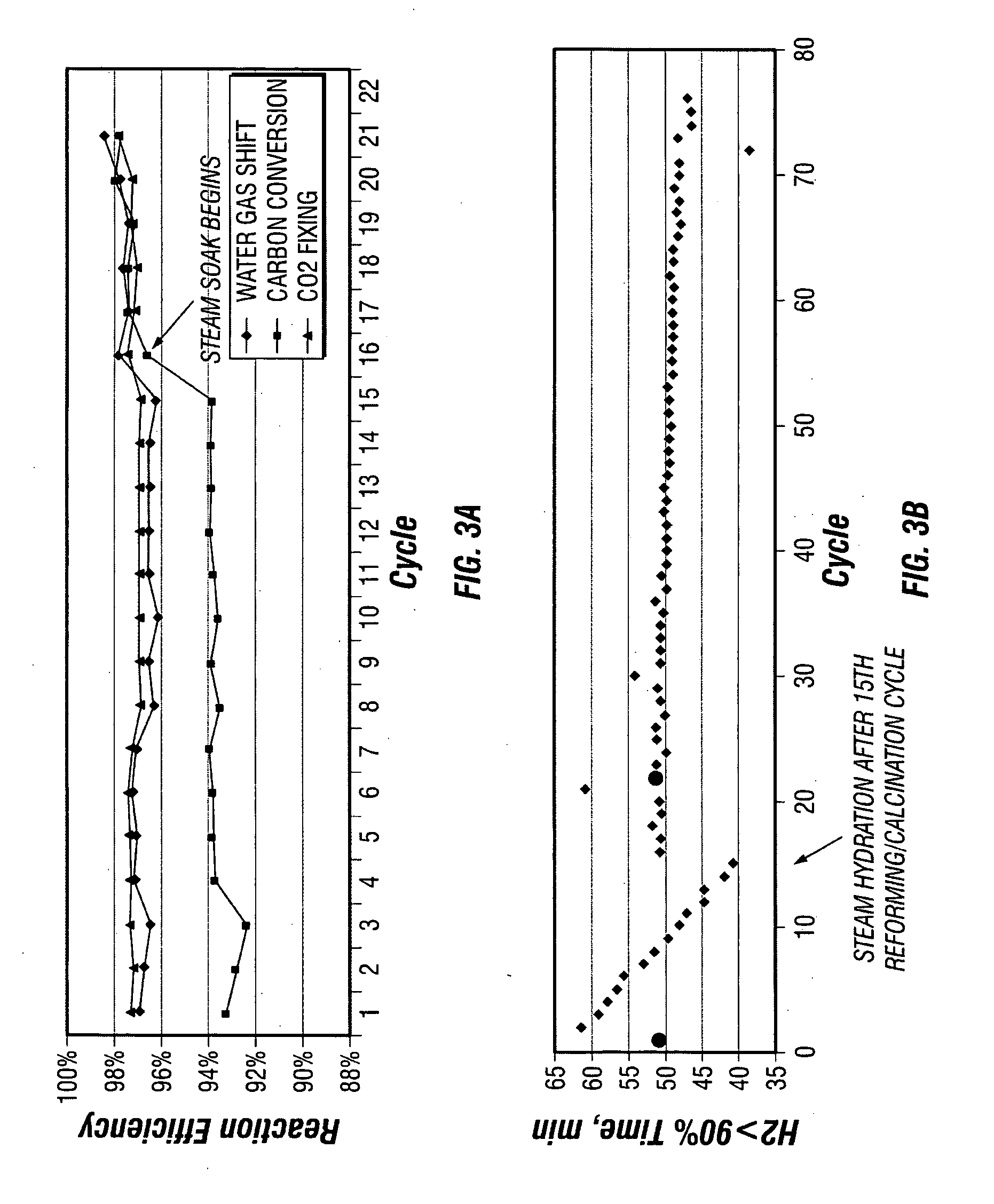

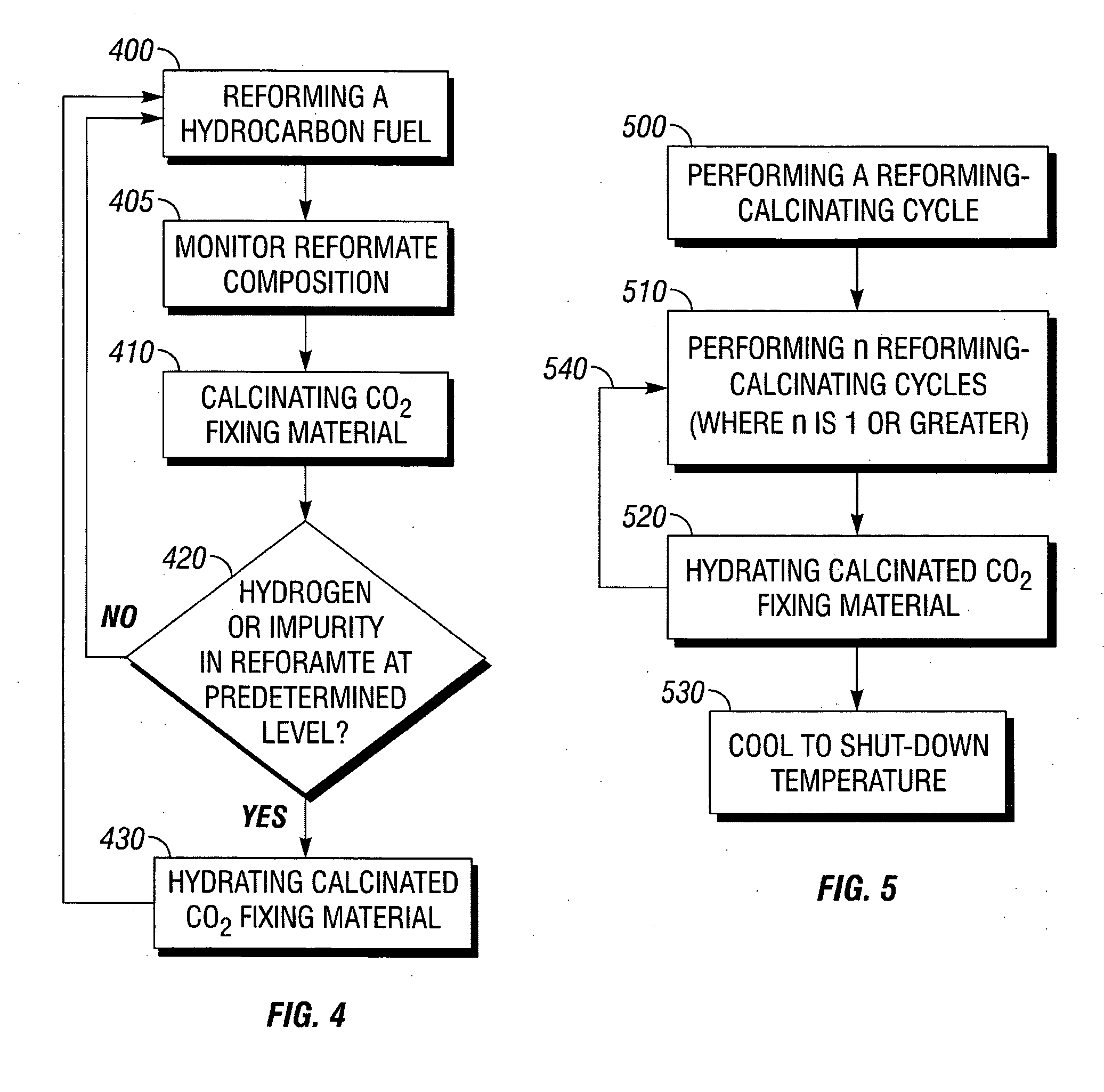

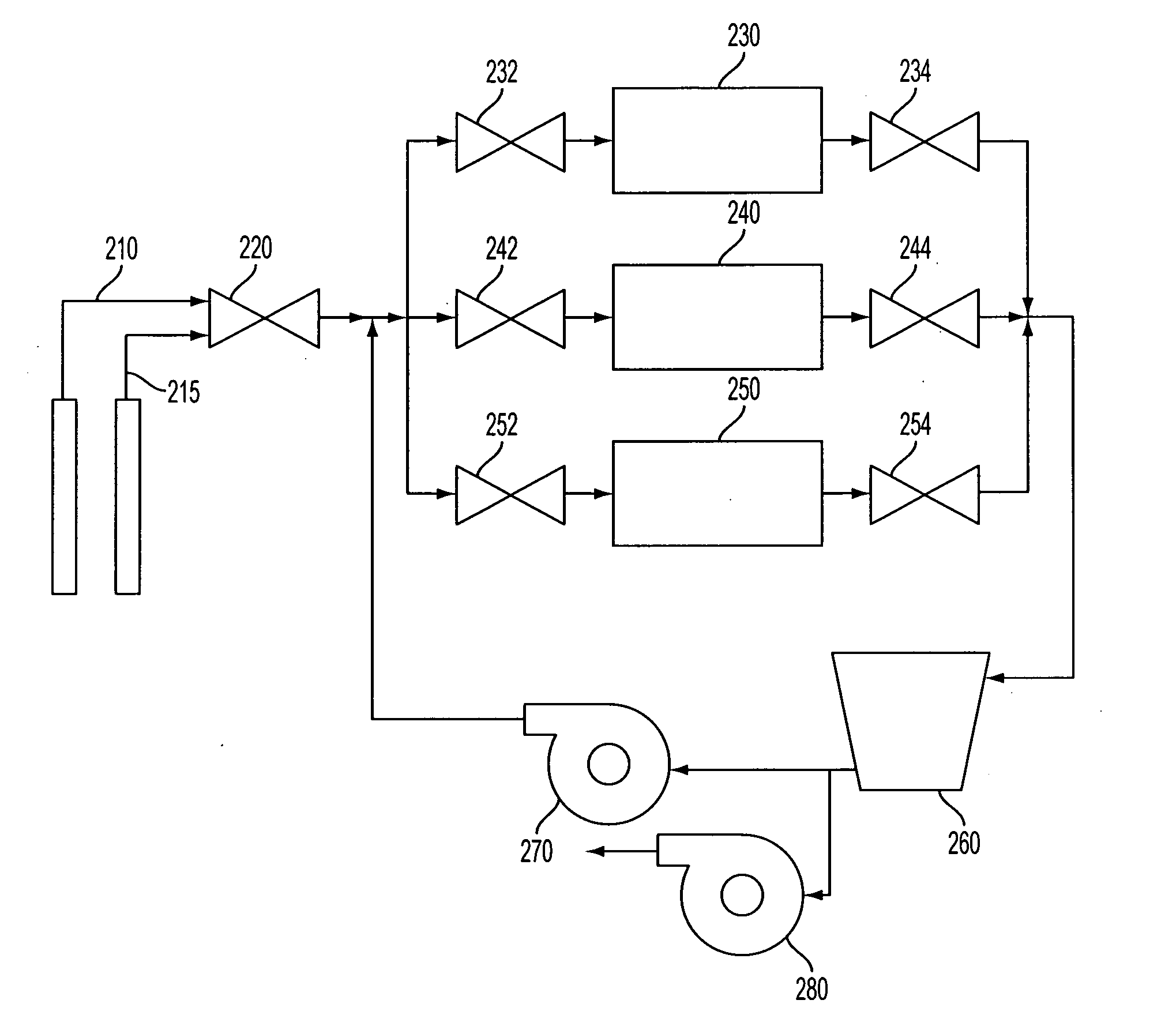

Reforming with hydration of carbon dioxide fixing material

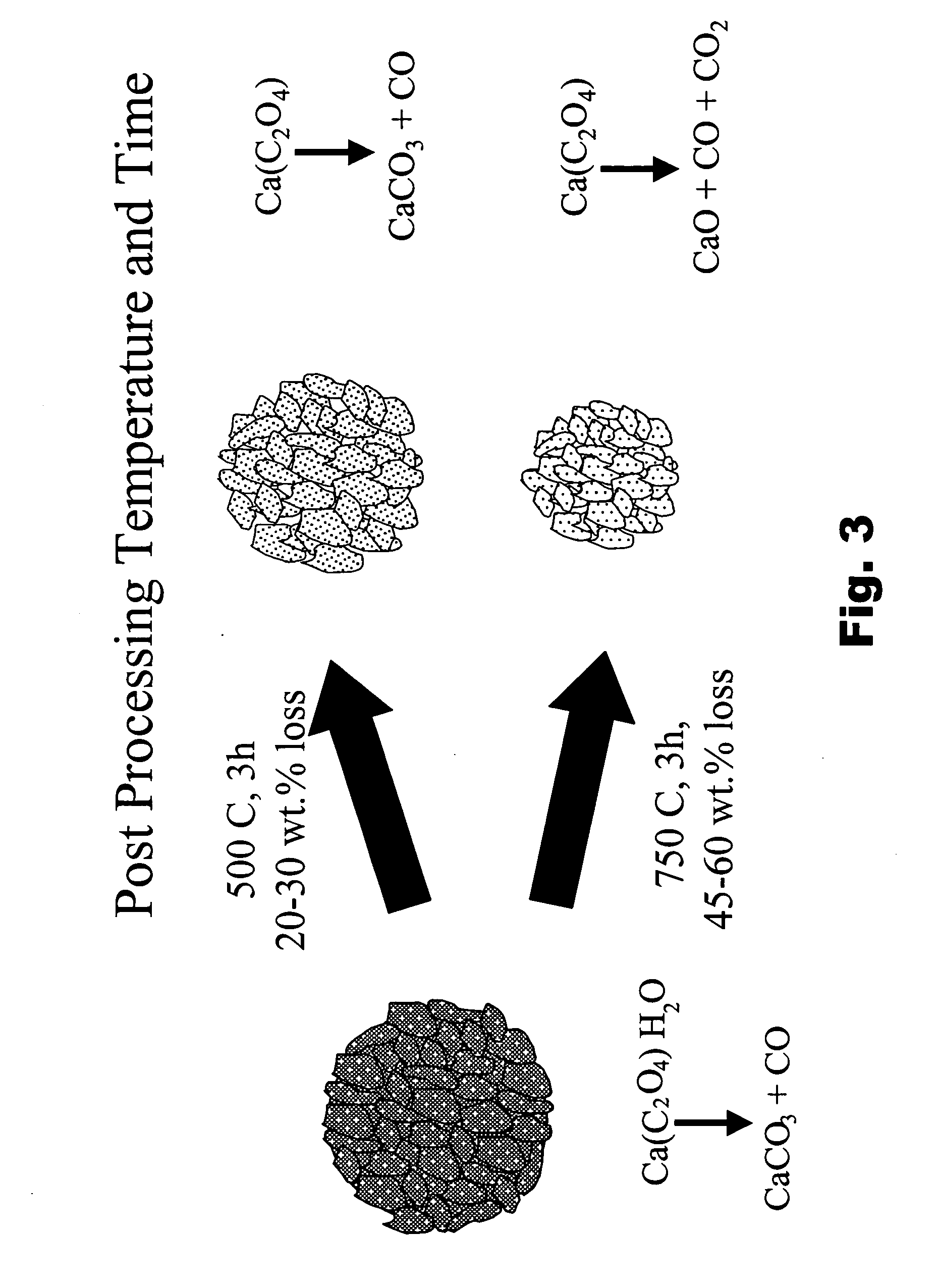

InactiveUS20050232856A1Carbon compoundsHydrogen separation using solid contactDesorptionHydrocotyle bowlesioides

Methods for converting hydrocarbon fuels to hydrogen-rich reformate that incorporate a carbon dioxide fixing mechanism into the initial hydrocarbon conversion process. The mechanism utilizes a carbon dioxide fixing material to remove carbon dioxide from the reformate product stream. The removal of carbon dioxide from the product stream shifts the reforming reaction equilibrium toward higher hydrocarbon conversion with only small amounts of carbon oxides produced. Repeated absorption / desorption of carbon dioxide by the fixing materials tends to decrease the fixing capacity of the materials. Hydration of the carbon dioxide fixing materials between one or more cycles serves to sustain their fixing capacity and to enhance the efficiencies of the reforming and shift reactions occurring in the catalyst bed. Hydration can occur during reactor start-up or shut down, periodically over a number of cycles, and / or upon a monitored change in the reformate composition.

Owner:TEXACO INC & TEXACO DEV CORP

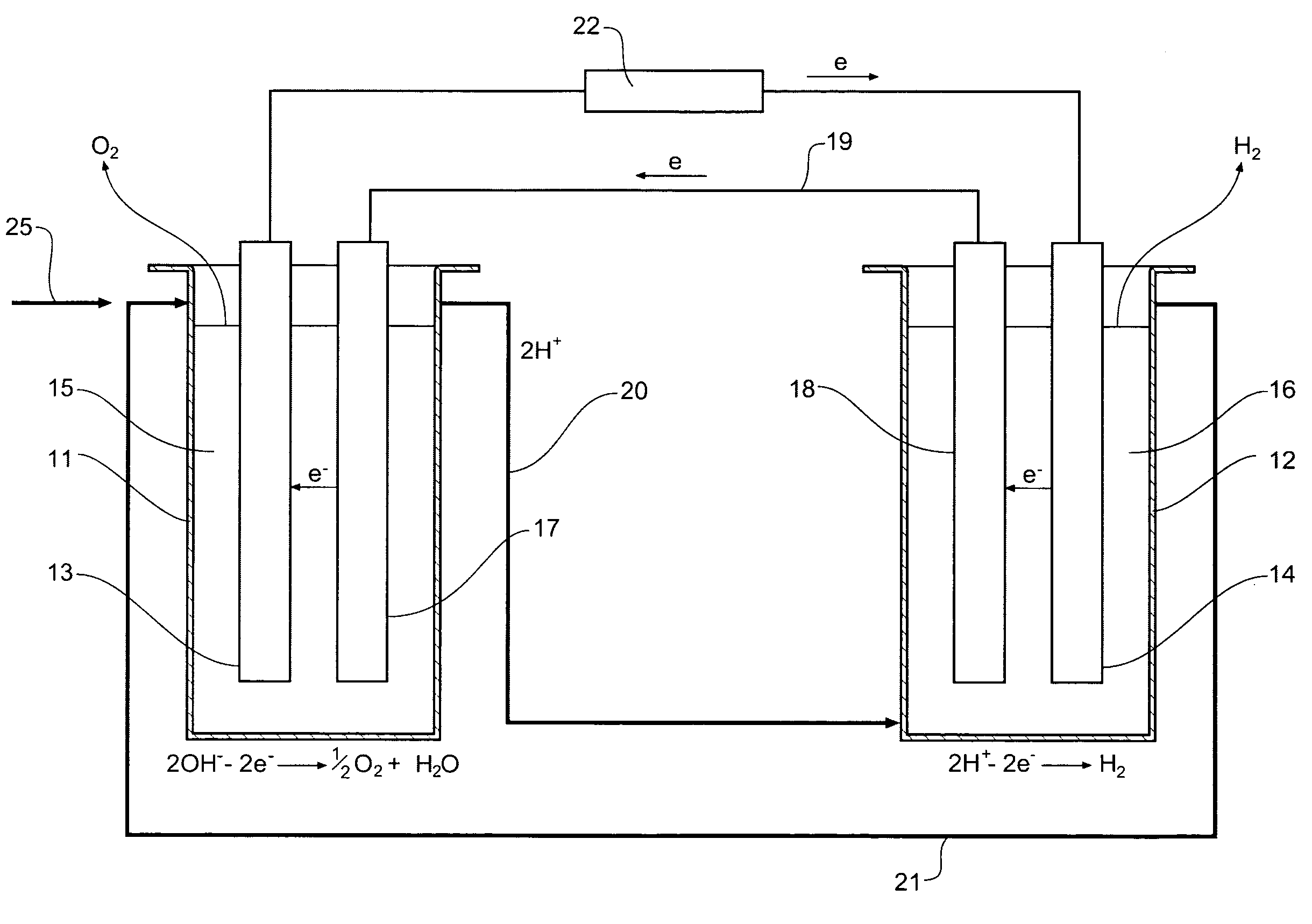

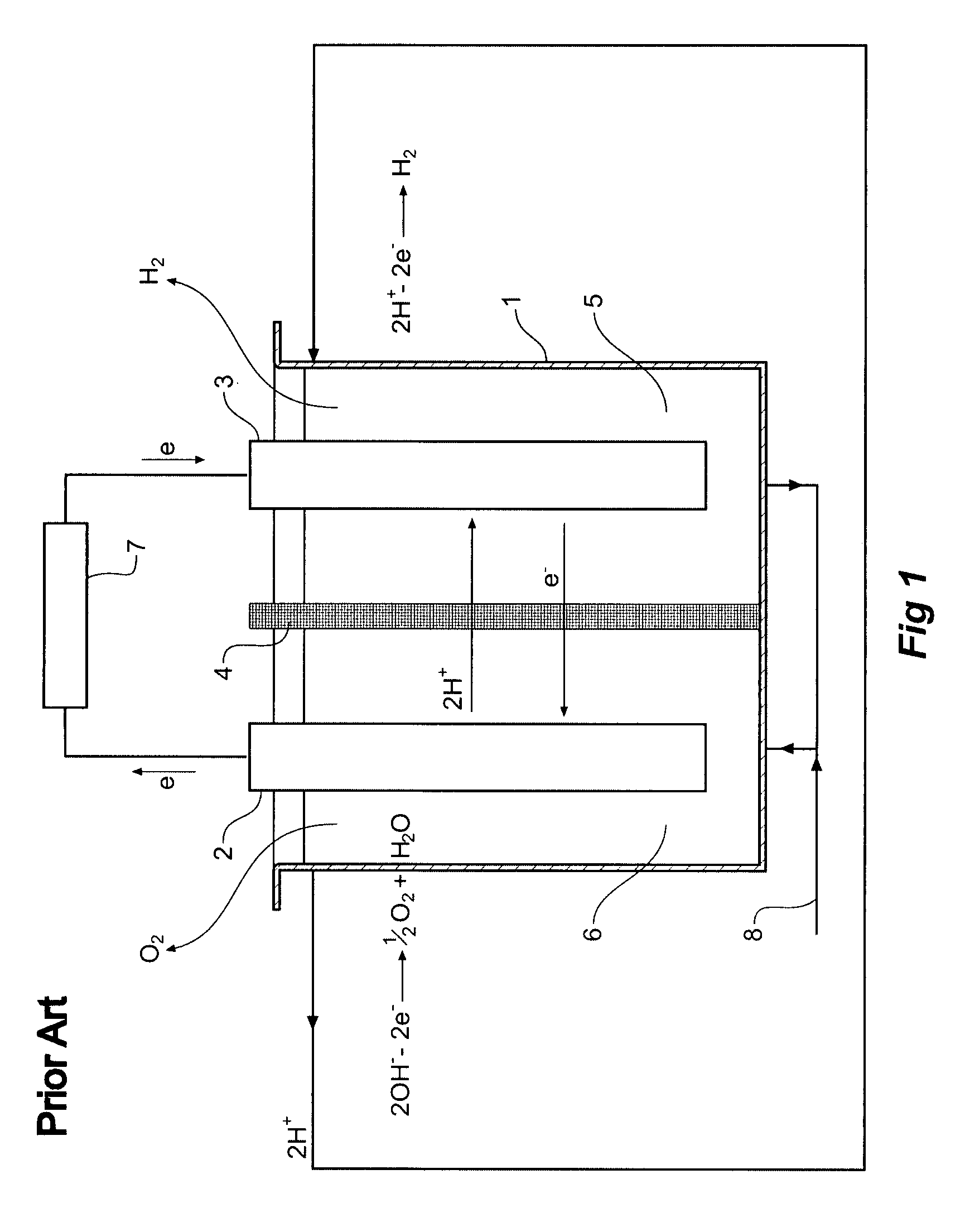

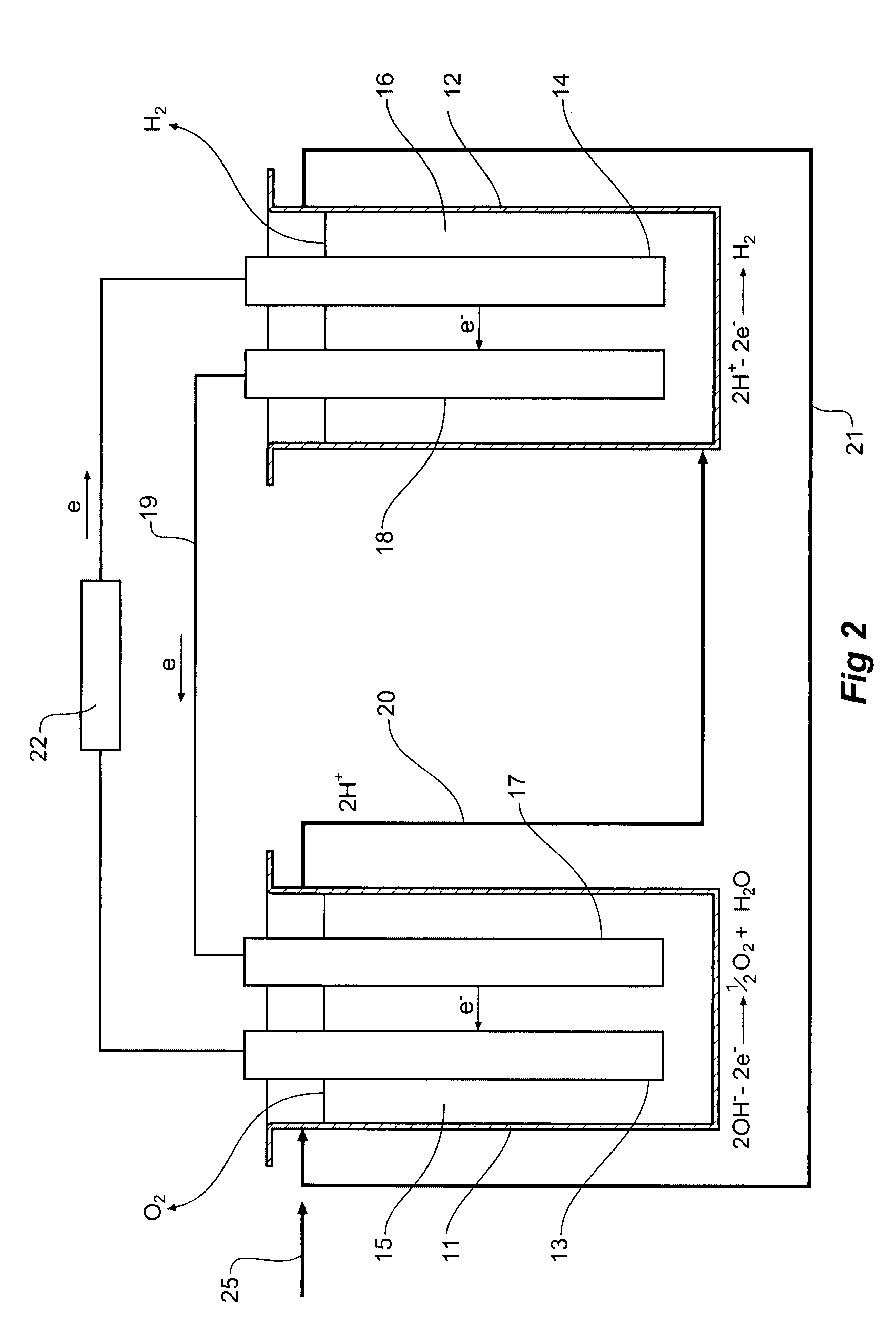

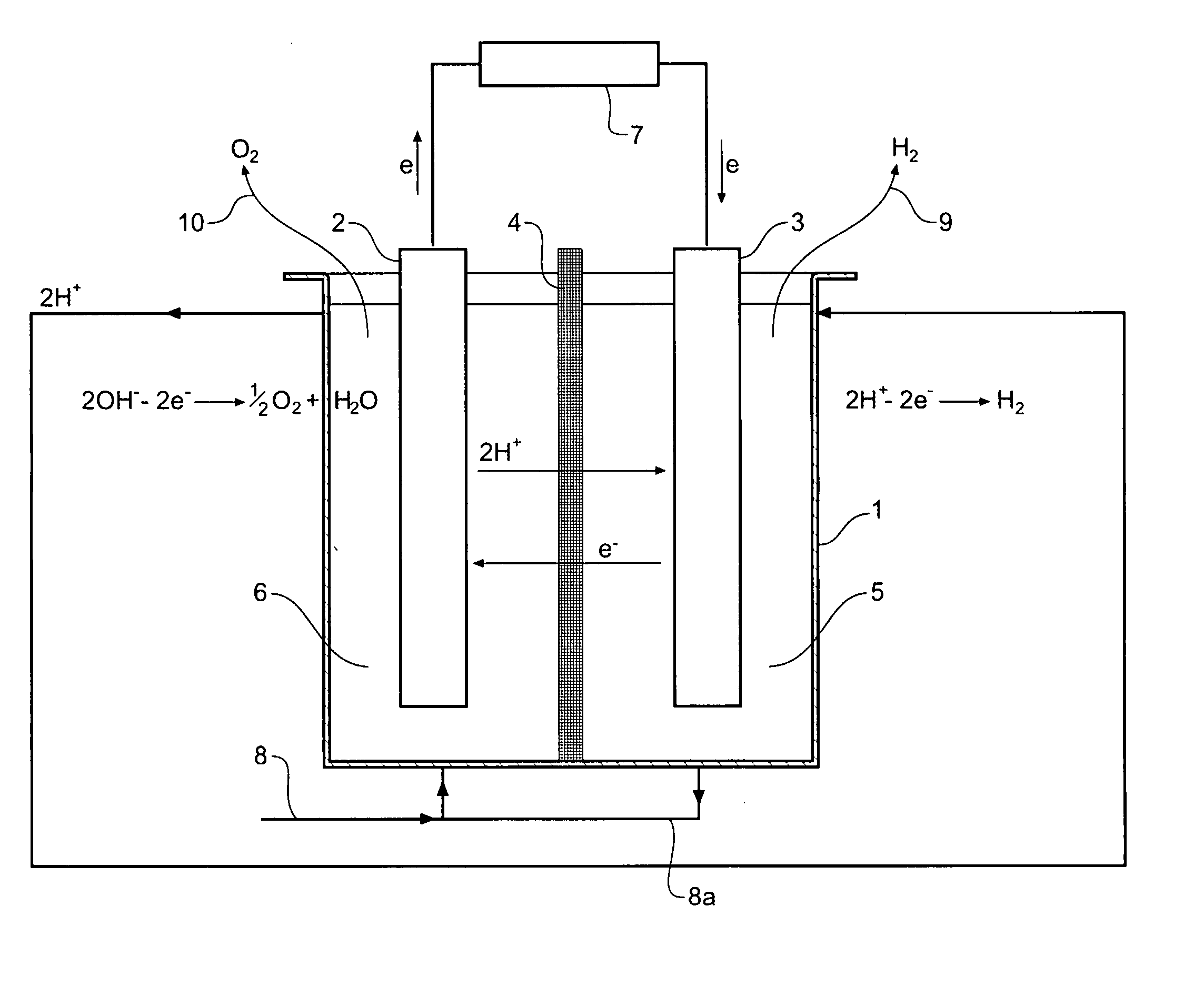

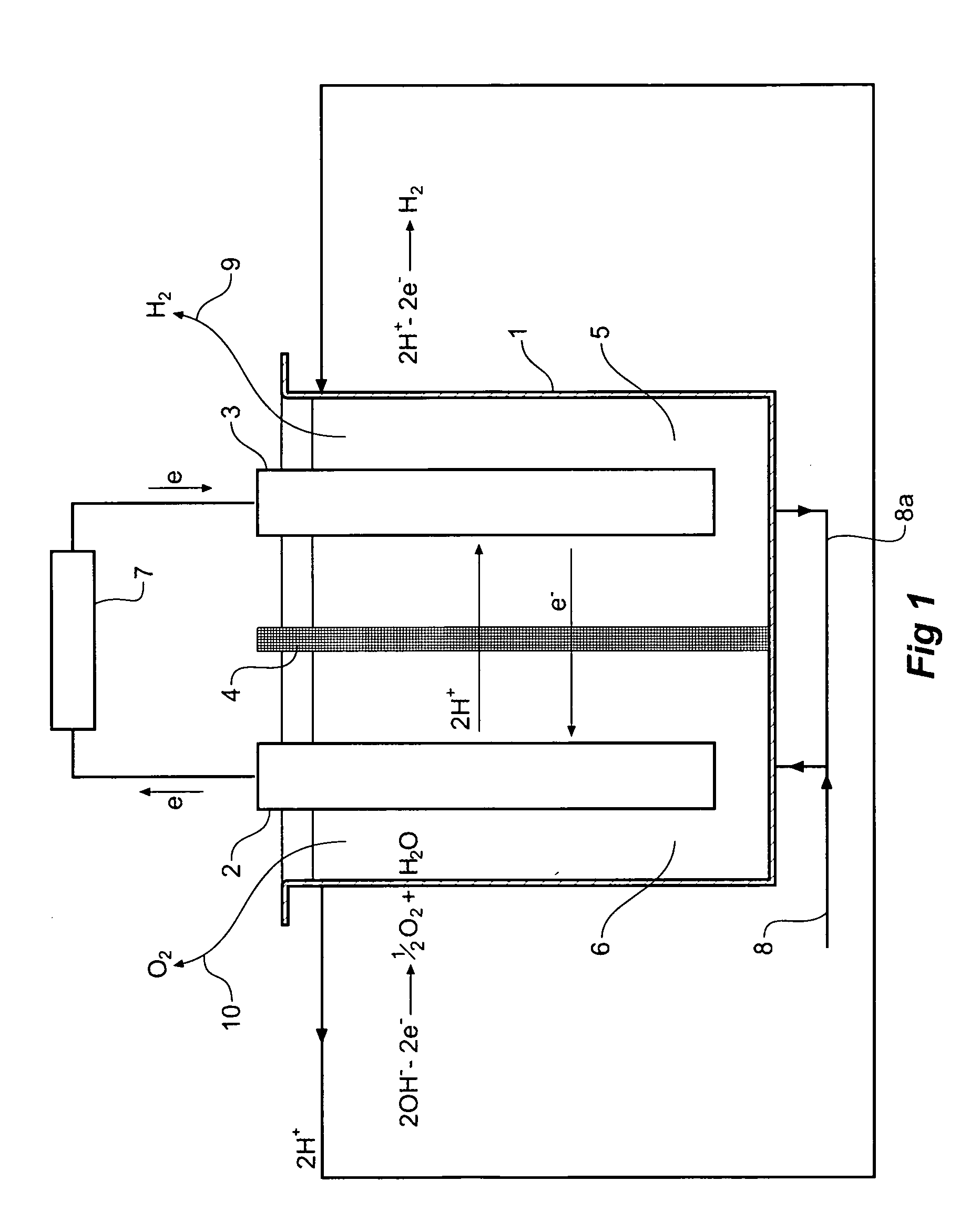

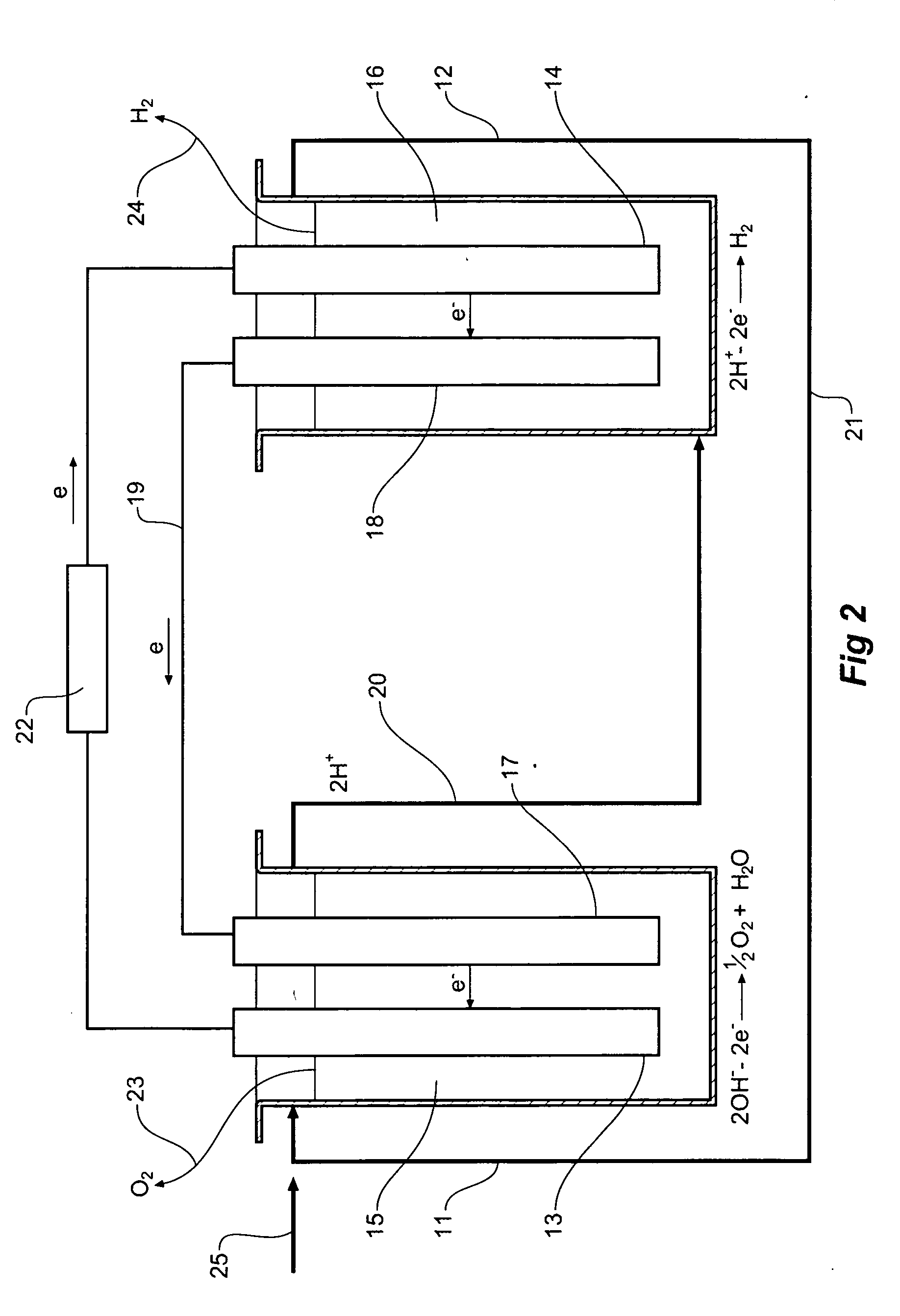

Commercial production of hydrogen from water

InactiveUS7326329B2Minimizing energyReduce voltageCellsPhotography auxillary processesWater useElectrical conductor

Large quantities of low cost hydrogen free of carbon oxides are required as fuel for the hydrogen economy. Commercial quantities of hydrogen can be produced from the electrolysis of water using a diaphragm-less electrolytic cell. The electrolytic cell has an anode cell (31) and a cathode cell (32) connected by a DC power source (53) and an external conductor (52). An alternate apparatus method to produce hydrogen is to electrolyze water using unipolar activation. Unipolar activation uses separate anode and cathode circuits and can use secondary cathode (132) and anode (139) cells to recover energy and produce further hydrogen.

Owner:RODOLFO ANTONIO M GOMEZ

Low oxygen biomass-derived pyrolysis oils and methods for producing the same

Low oxygen biomass-derived pyrolysis oils and methods for producing them from carbonaceous biomass feedstock are provided. The carbonaceous biomass feedstock is pyrolyzed in the presence of a catalyst comprising base metal-based catalysts, noble metal-based catalysts, treated zeolitic catalysts, or combinations thereof to produce pyrolysis gases. During pyrolysis, the catalyst catalyzes a deoxygenation reaction whereby at least a portion of the oxygenated hydrocarbons in the pyrolysis gases are converted into hydrocarbons. The oxygen is removed as carbon oxides and water. A condensable portion (the vapors) of the pyrolysis gases is condensed to low oxygen biomass-derived pyrolysis oil.

Owner:UOP LLC

Multi-component super-molecular hydrogel and preparation method thereof

ActiveCN103242656AAchieve multi-functionalityUniversalNon-macromolecular adhesive additivesPhotometryCross-linkPolyvinyl alcohol

The invention discloses multi-component super-molecular hydrogel and a preparation method of the multi-component super-molecular hydrogel. The hydrogel is formed by a component containing a strong hydrogen bond, a component containing a weak hydrogen bond and water, wherein the component containing the strong hydrogen bond is one or more of a carbon oxide nano tube, graphene oxide, a carboxylated ferroferric oxide nano particle, a carboxylated silver nano particle, a carboxylated quantum dot, polyacrylic acid, polypropylene glycol, polyvinyl alcohol, polyurethane, polyamide and poly(p-styrene) sodium sulfonate; and the component containing the weak hydrogen bond is a small-molecular compound or a high-molecular compound. A lot of cross-linking force of the hydrogel disclosed by the invention comes from the weak hydrogen bond so that the hydrogel is very sensitive to the stimulation of an external environment; when chemical components are proper, gel-sol conversion can be carried out under the effects of temperature rising, near-infrared light illumination and acids; and the conversion is reversible, namely the gel-sol conversion can be carried out under the effects of temperature reduction, removing of a near-infrared light source and alkalis.

Owner:PEKING UNIV

Commercial production of hydrogen from water

InactiveUS20050126924A1Minimizing energyReduce voltageCellsPhotography auxillary processesWater useElectrical conductor

Large quantities of low cost hydrogen free of carbon oxides are required as fuel for the hydrogen economy. Commercial quantities of hydrogen can be produced from the electrolysis of water using a diaphragm-less electrolytic cell. The electrolytic cell has an anode cell (31) and a cathode cell (32) connected by a DC power source (53) and an external conductor (52). An alternate apparatus method to produce hydrogen is to electrolyze water using unipolar activation. Unipolar activation uses separate anode and cathode circuits and can use secondary cathode (132) and anode (139) cells to recover energy and produce further hydrogen.

Owner:RODOLFO ANTONIO M GOMEZ

Reactor with carbon dioxide fixing material

InactiveUS20050232855A1Increase temperatureHydrogen separation using solid contactHydrogen/synthetic gas productionHydrocotyle bowlesioidesCarbon oxide

Apparatus and methods for converting hydrocarbon fuels to hydrogen-rich reformate that incorporate a carbon dioxide fixing mechanism into the initial hydrocarbon conversion process. The mechanism utilizes a carbon dioxide fixing material within the reforming catalyst bed to remove carbon dioxide from the reformate product. The removal of carbon dioxide from the product stream shifts the reforming reaction equilibrium toward higher hydrocarbon conversion with only small amounts of carbon oxides produced. Fixed carbon dioxide may be released by heating the catalyst bed to a calcination temperature. A non-uniform distribution of catalysts and carbon dioxide fixing material across catalyst bed yields higher conversion rates of hydrocarbon to hydrogen-rich reformate.

Owner:TEXACO INC & TEXACO DEV CORP

Method for conversion of atmospheric carbon dioxide into useful materials

A method for converting carbon dioxide in a gaseous environment, including air into useful materials by use of renewable energy sources which comprises:(1) extracting carbon dioxide from a gaseous source using a sorbent such as sodium hydroxide, calcium hydroxide, or potassium hydroxide;(2) utilizing wind power, solar power, or other renewable energy sources to regenerate said sorbent by membrane cell electrolysis or other similar method, simultaneously producing hydrogen (H2) gas;(3) releasing carbon dioxide from said sorbent; and(4) utilizing the Fischer Tropsch process, Mobil process, ICI process, or related or similar processes to convert carbon oxides to a hydrocarbon concomittantly with or after effecting the reverse water-gas shift reaction to convert said CO2 and H2 gas into carbon monoxide for reaction in said Fischer Tropsch process, Mobil process or ICI process.

Owner:KAPLAN THOMAS PROGER

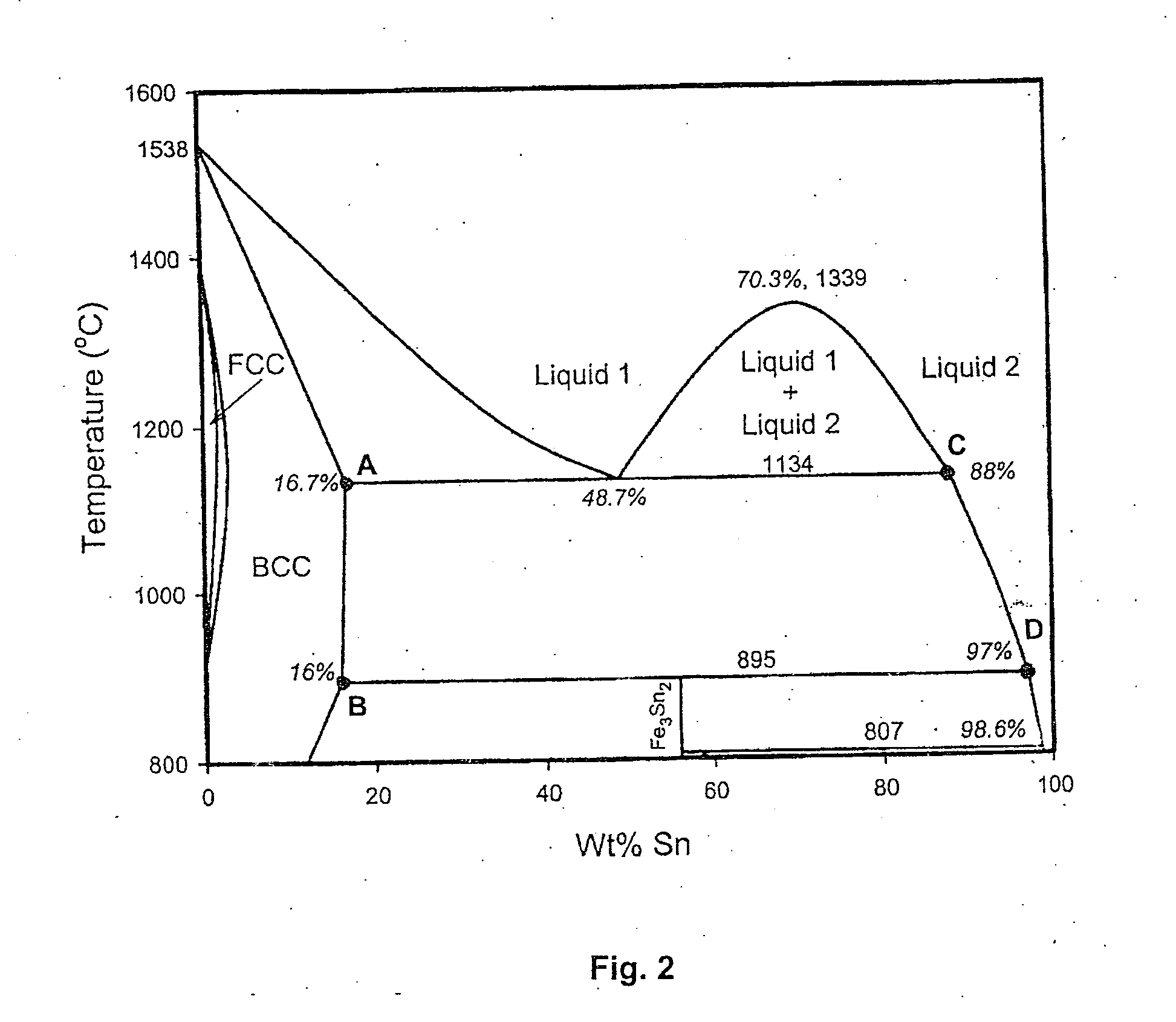

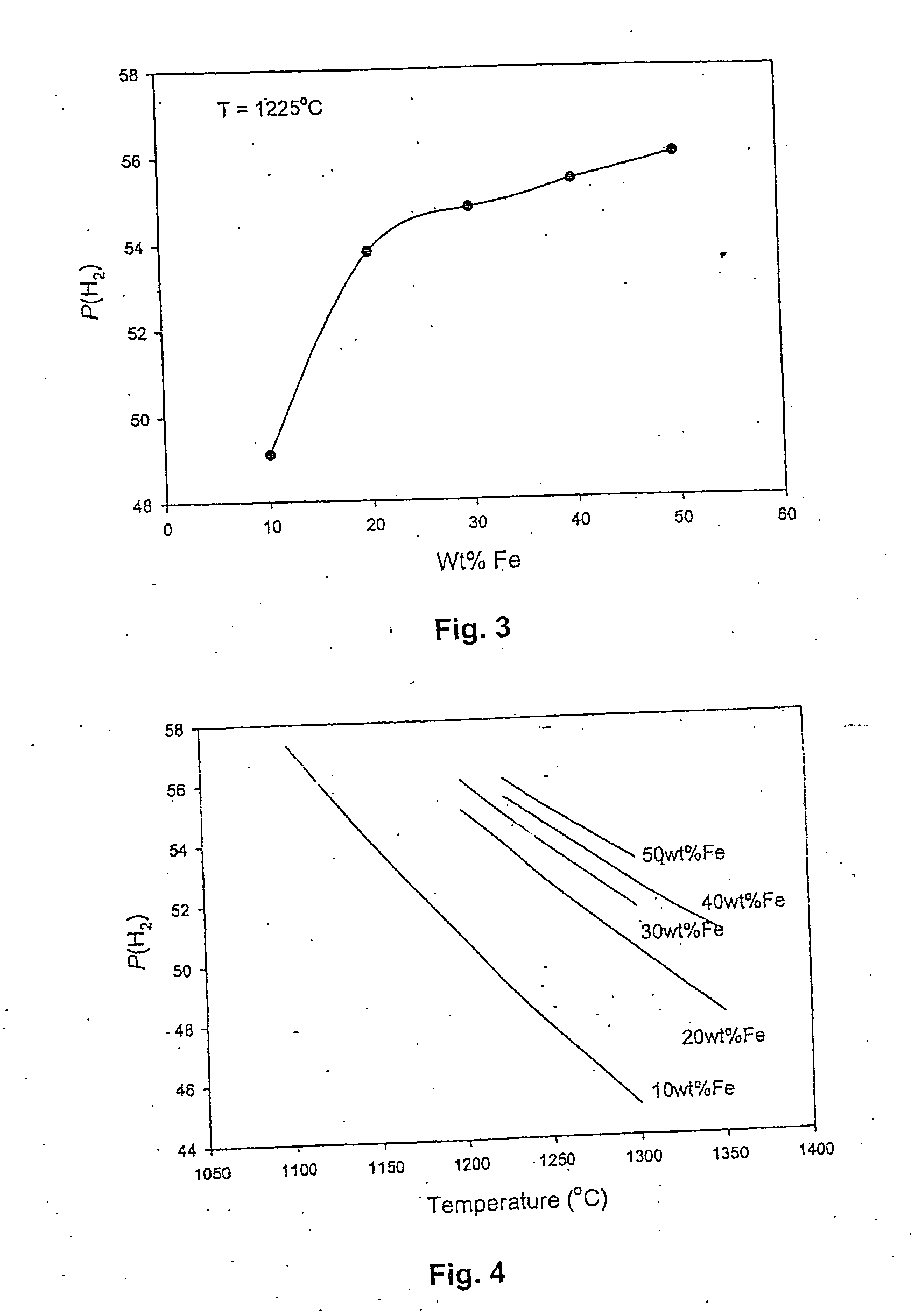

Method for the production of hydrogen-containing gaseous mixtures

InactiveUS20050042166A1Cheap productionDirect heating destructive distillationWaste based fuelSyngasGas composition

A method for the production of a hydrogen-containing gas composition, such as a synthesis gas including hydrogen and carbon monoxide. The molar ratio of hydrogen to carbon monoxide (H2:CO) in the synthesis gas can be well-controlled to yield a ratio that is adequate for the synthesis of useful products such as methane or methanol, without the need to remove carbon oxides from the gas stream to adjust the ratio.

Owner:ALCHEMIX CORP

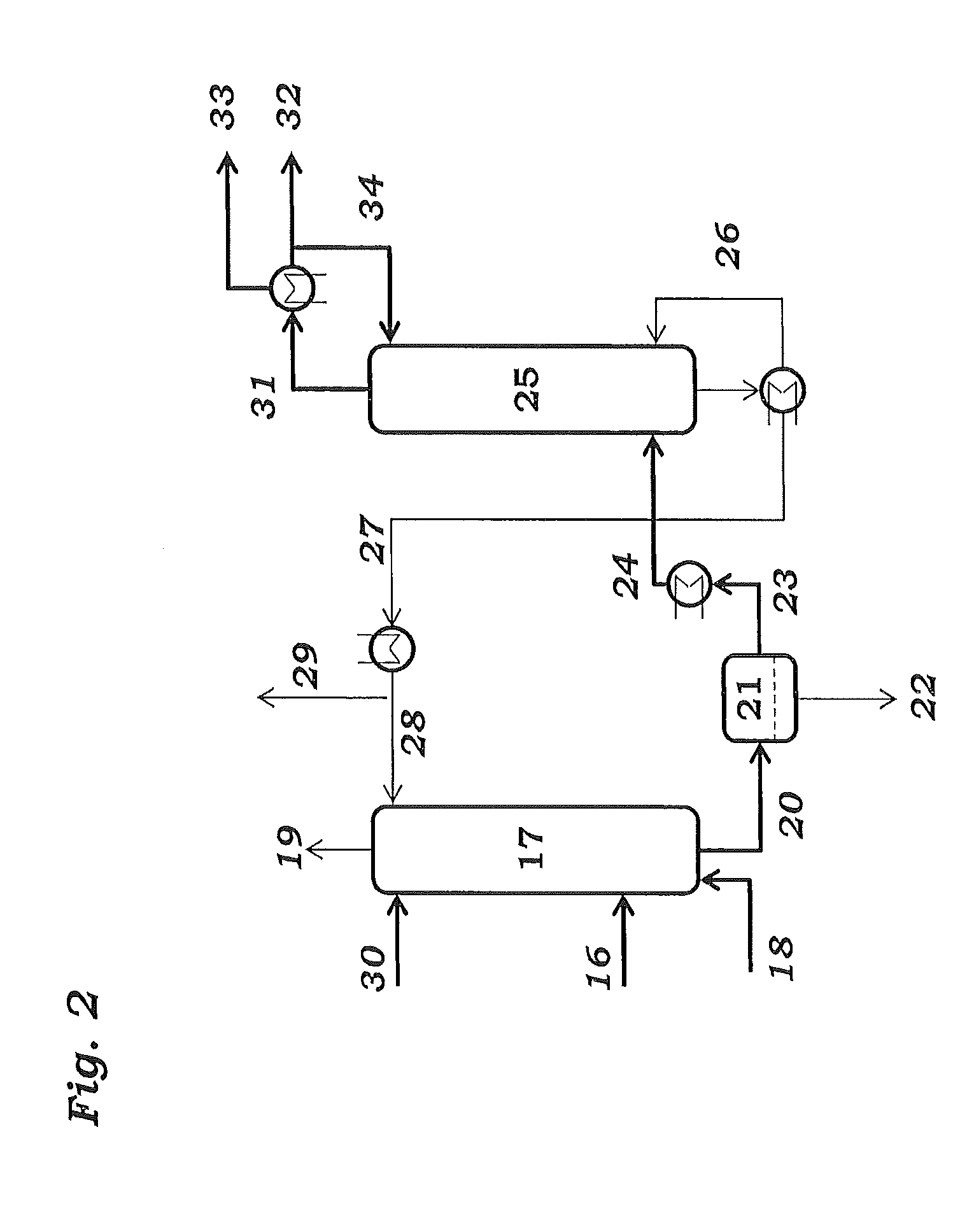

Process and plant for producing methanol

ActiveUS20110065966A1Raise the outlet temperatureHigh yieldOrganic compound preparationOxygen compounds preparation by reductionHydrogenCarbon oxide

In the production of methanol from a synthesis gas containing hydrogen and carbon oxides, the synthesis gas is passed through a first, preferably water-cooled reactor, in which a part of the carbon oxides is catalytically converted to methanol. The obtained mixture containing synthesis gas and methanol vapor is supplied to a second, preferably gas-cooled reactor, in which a further part of the carbon oxides is converted to methanol. Subsequently, methanol is separated from the synthesis gas, and the synthesis gas is recirculated to the first reactor. To achieve a maximum methanol yield even with an aged catalyst, a partial stream of the synthesis gas is guided past the first reactor and introduced directly into the second reactor.

Owner:LURGI

Methods and reactors for producing solid carbon nanotubes, solid carbon clusters, and forests

InactiveUS20150064092A1Promote lowerReduce metal oxideMaterial nanotechnologyOxygen-containing compound preparationSolid carbonBi modal

Methods of producing fibrous solid carbon forests include reacting carbon oxides with gaseous reducing agents in the presence of a catalyst having a predetermined grain size to cause growth of fibrous solid carbon forests upon a surface of the metal. The fibrous solid carbon forests are substantially perpendicular to the surface of the metal thus creating the “forests”. A bi-modal forest composition of matter is described in which a primary distribution of fibrous solid carbon comprises the forest and a secondary distribution of fibrous solid carbon is entangled with the primary distribution. A reactor includes a catalyst, a means for facilitating the reduction of a carbon oxide to form solid carbon forests on a surface of the catalyst, and a means for removing the solid carbon forest from the surface of the metal catalyst.

Owner:SEERSTONE

Methods for treating an offgas containing carbon oxides

ActiveUS20150059527A1Cheap sourceIncrease valueMaterial nanotechnologyPigmenting treatmentParticulatesSolid carbon

A method of treating an offgas includes purifying the offgas to remove particulate matter, water, undesirable gaseous components and inert gases to produce a dried carbon oxide gas feedstock, and converting at least a portion of carbon oxides in the dried carbon oxide gas feedstock into solid carbon. In other embodiments, a method includes passing a dried carbon oxide gas feedstock through a multi-stage catalytic converter. A first stage is configured to catalyze methane-reforming reactions to convert methane into carbon dioxide, carbon monoxide and hydrogen with residual methane. A second stage is configured to catalyze the Bosch reaction and convert carbon oxides and hydrogen to solid carbon and water.

Owner:SEERSTONE

Hydrophilic polyvinylidene fluoride modified separation membrane and preparation method thereof

The invention discloses a hydrophilic polyvinylidene fluoride modified separation membrane and a preparation method thereof. The separation membrane is prepared from polyvinylidene fluoride, a polyvinylidene fluoride solvent, a carbon oxide carbon nano tube / graphene oxide and a pore-forming agent. According to the hydrophilic polyvinylidene fluoride modified separation membrane, on one hand, hydrophilicity of the separation membrane is enhanced through oxygen-containing functional groups in the carbon oxide carbon nano tube and graphene oxide, on the other hand, graphene oxide of a sheet structure enters a carbon oxide carbon nano tube network of a tubular structure for mutual intercalation to form a stable sandwich layered structure, therefore, agglomeration of the same nano structure bodies can be effectively inhibited, and migration and assembly of graphene oxide to the surface of a composite membrane are facilitated, and the contact area of the carbon oxide carbon nano tube and graphene oxide and macromolecule matrix in the composite membrane is remarkably improved, and thus, the hydrophilicity and anti-pollution capacity of the membrane are enhanced, so that the water flux of the membrane is substantially improved. In addition, the preparation method is simple in operation technology and is easily carried out.

Owner:TIANJIN POLYTECHNIC UNIV

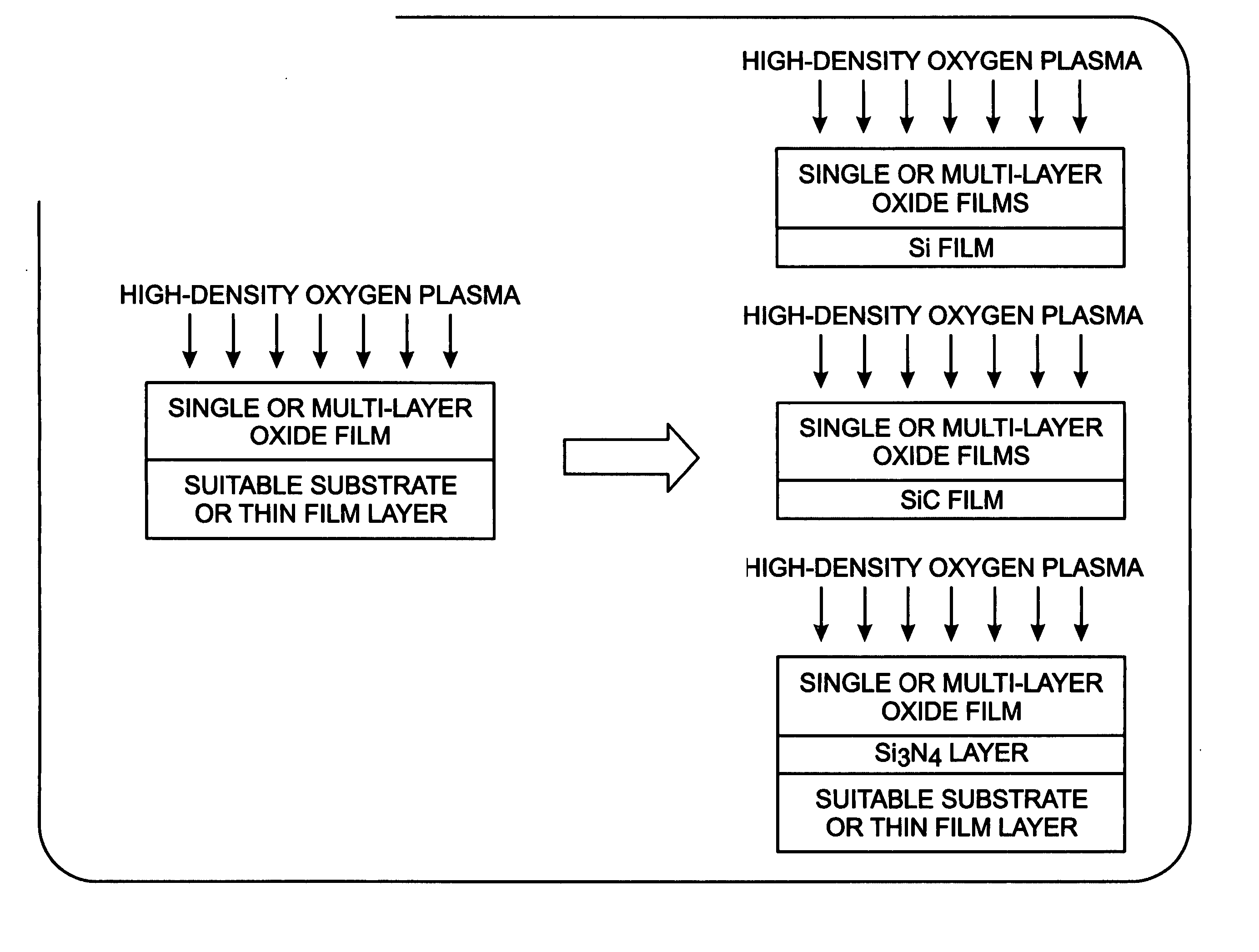

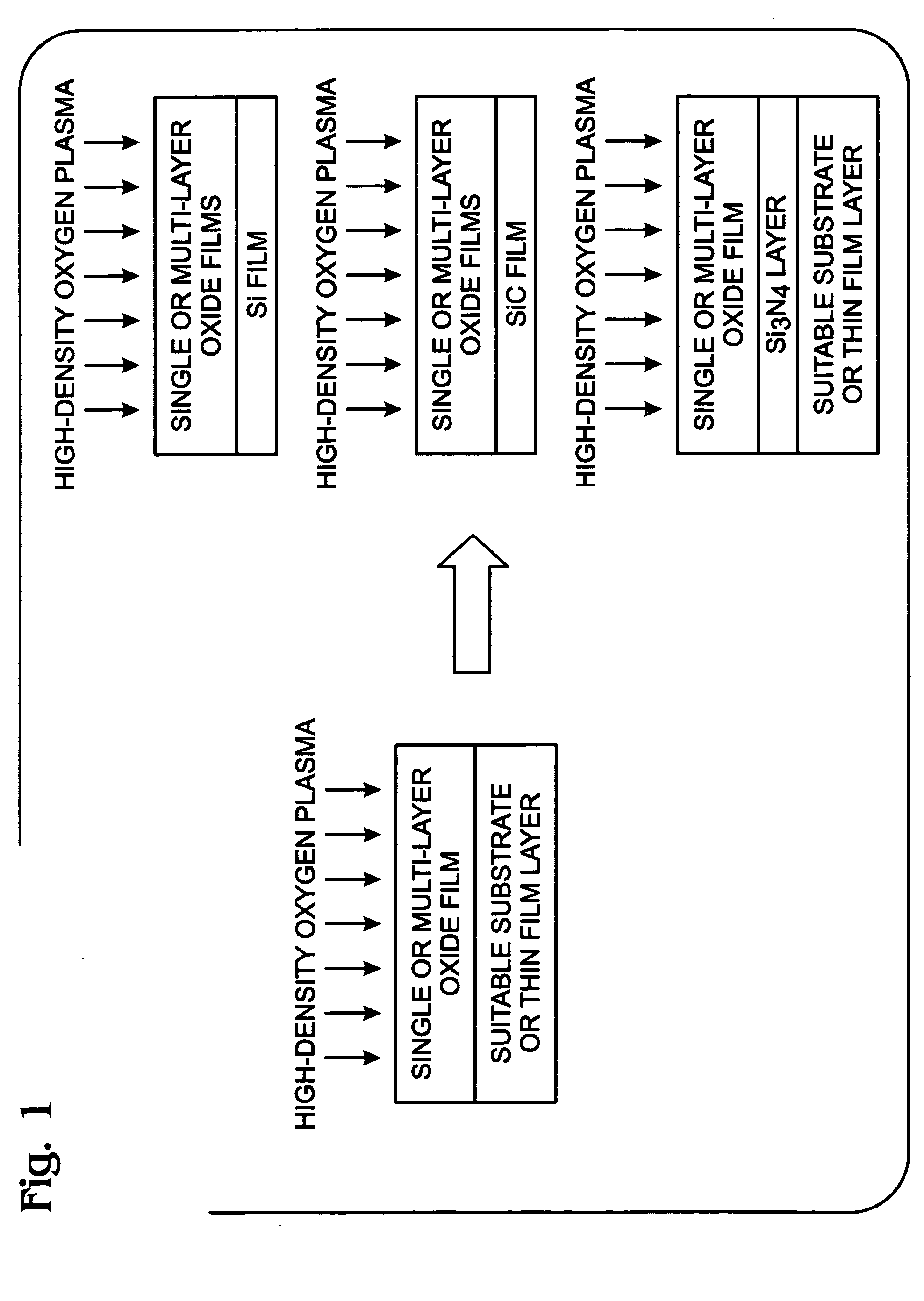

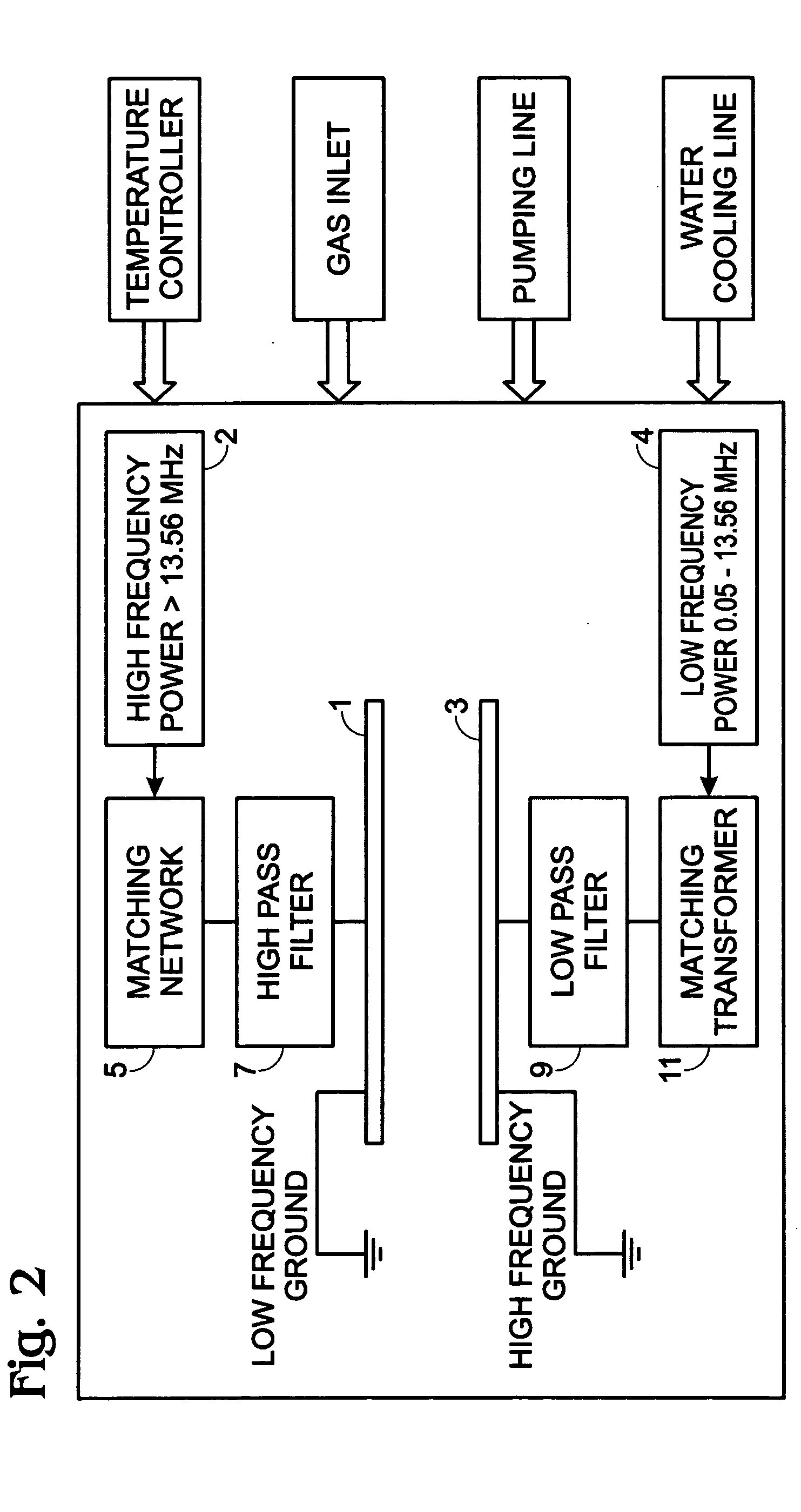

Enhanced thin-film oxidation process

InactiveUS20060110939A1Significant damageEffective controlSemiconductor/solid-state device manufacturingHigh densityOxidation state

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com