Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160 results about "Carbon filaments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

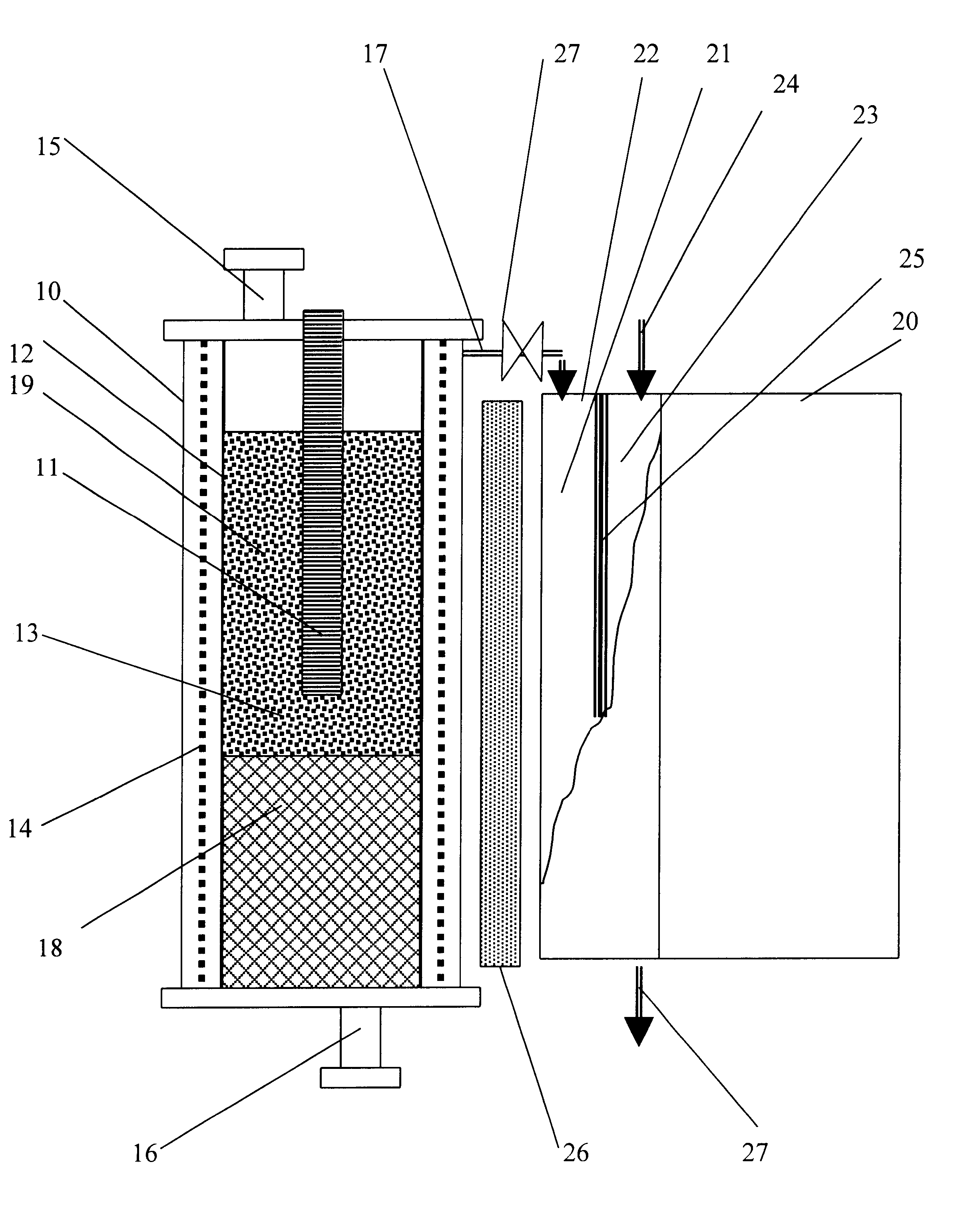

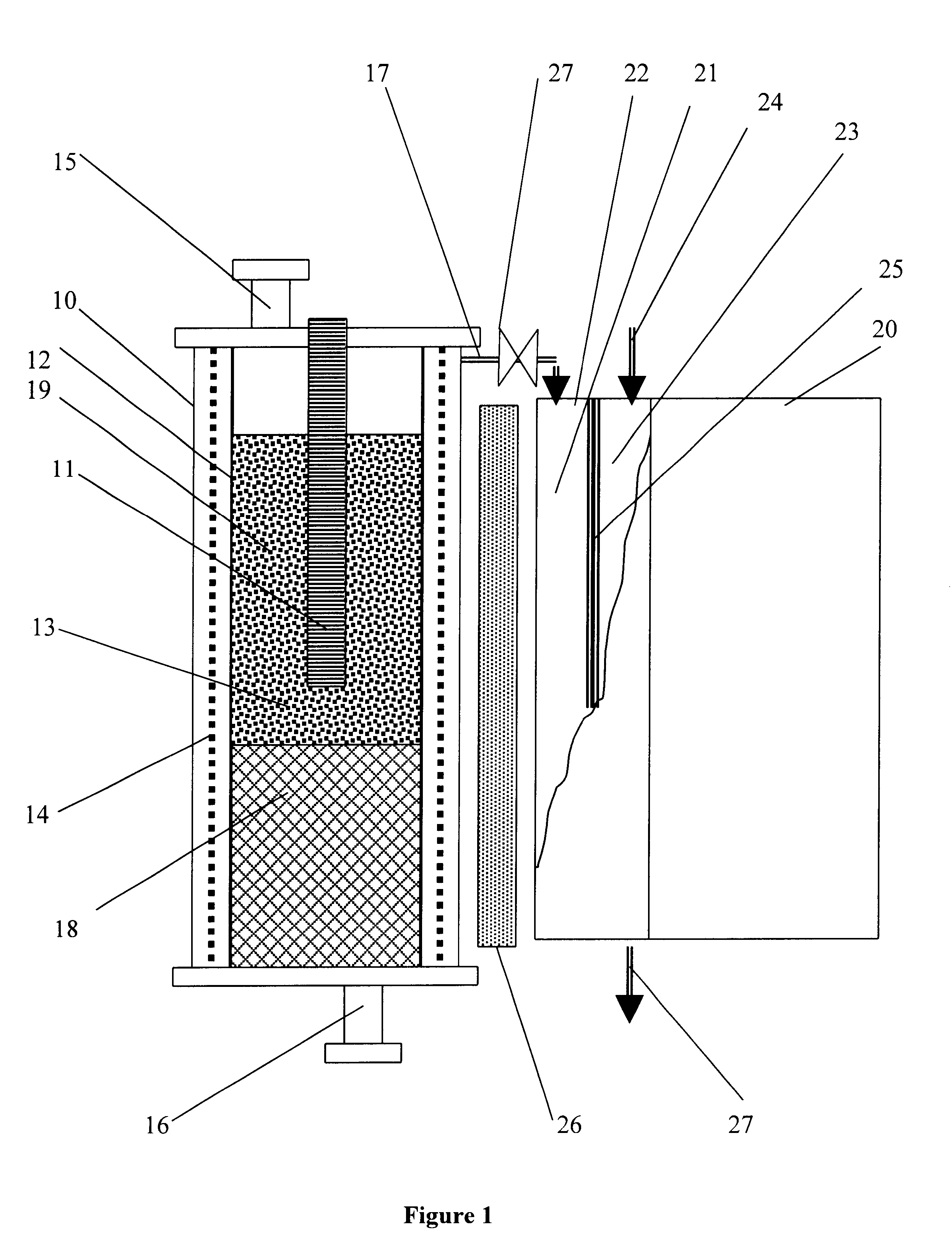

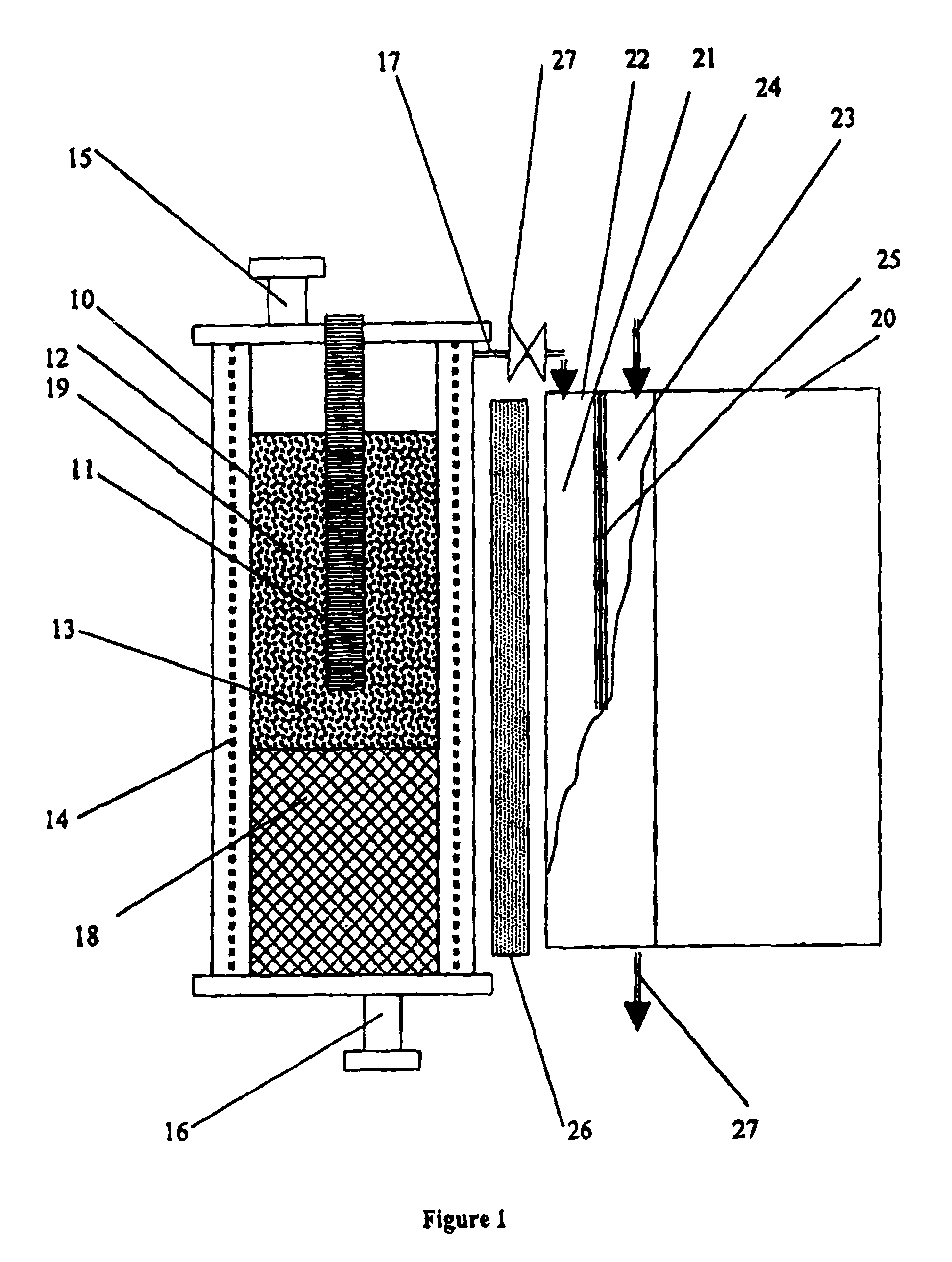

Portable hydrogen generator-fuel cell apparatus

InactiveUS6653005B1Increase specific energy and overall energy efficiencyHydrogenFuel cell auxillariesKeroseneImpurity

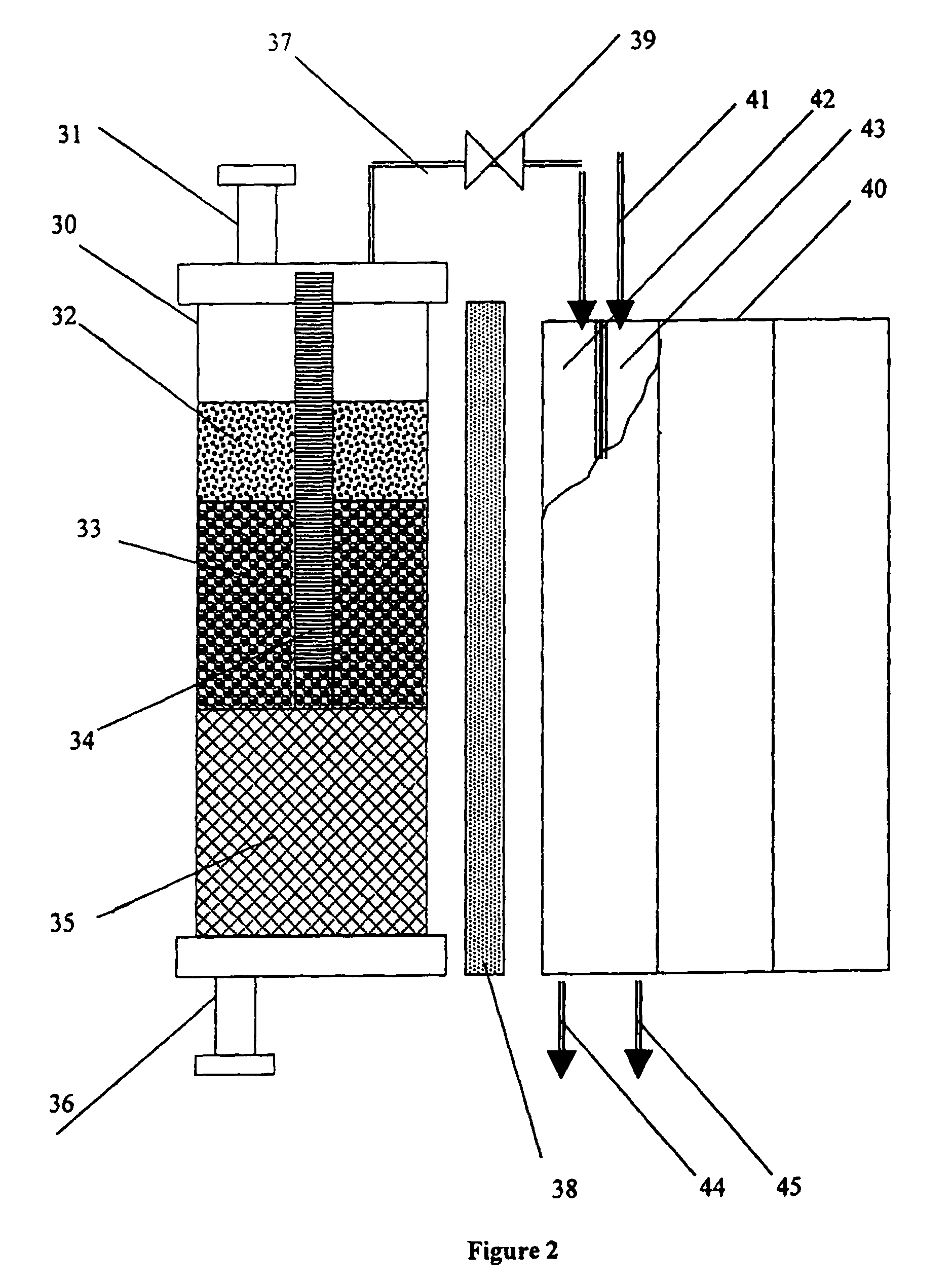

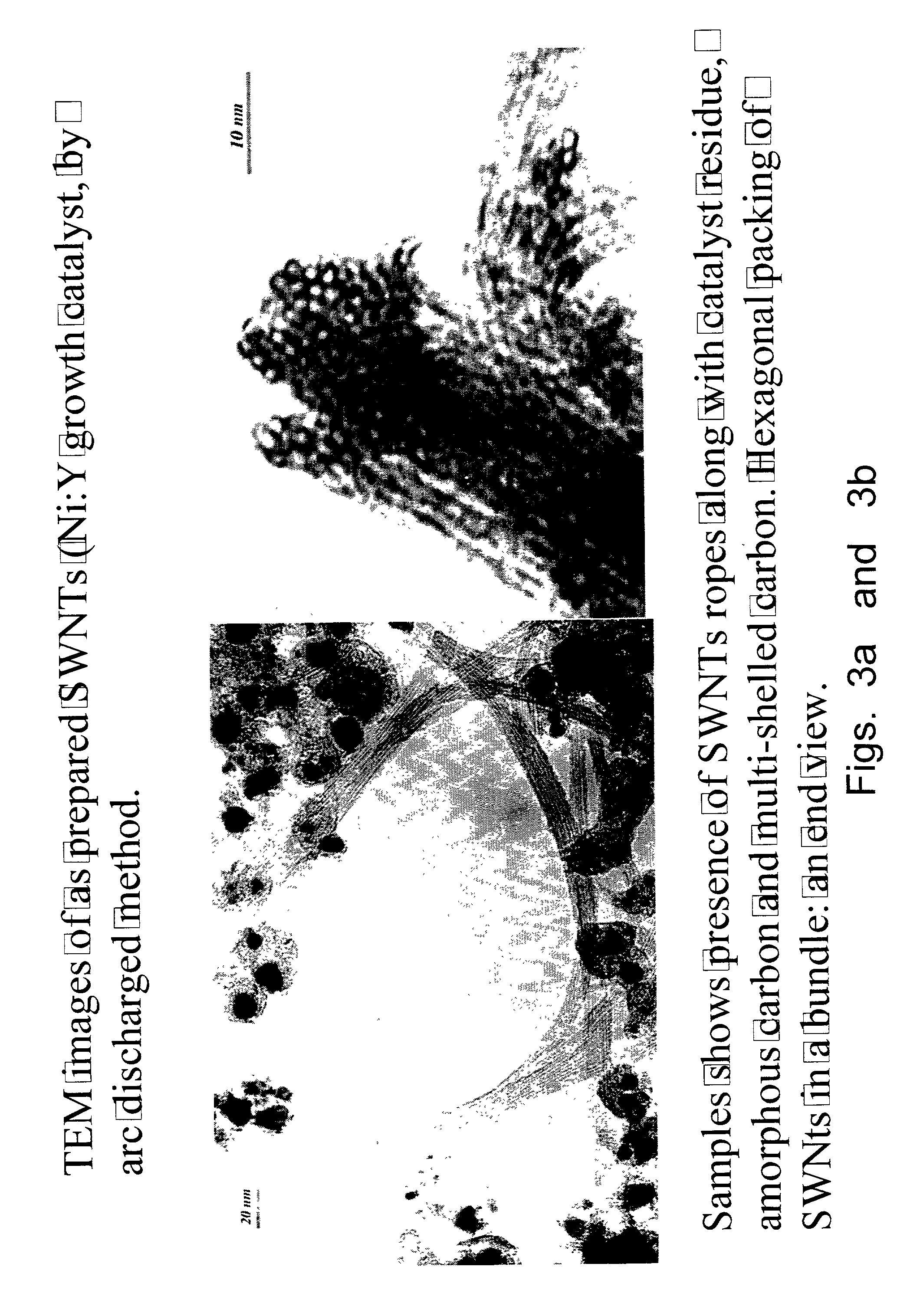

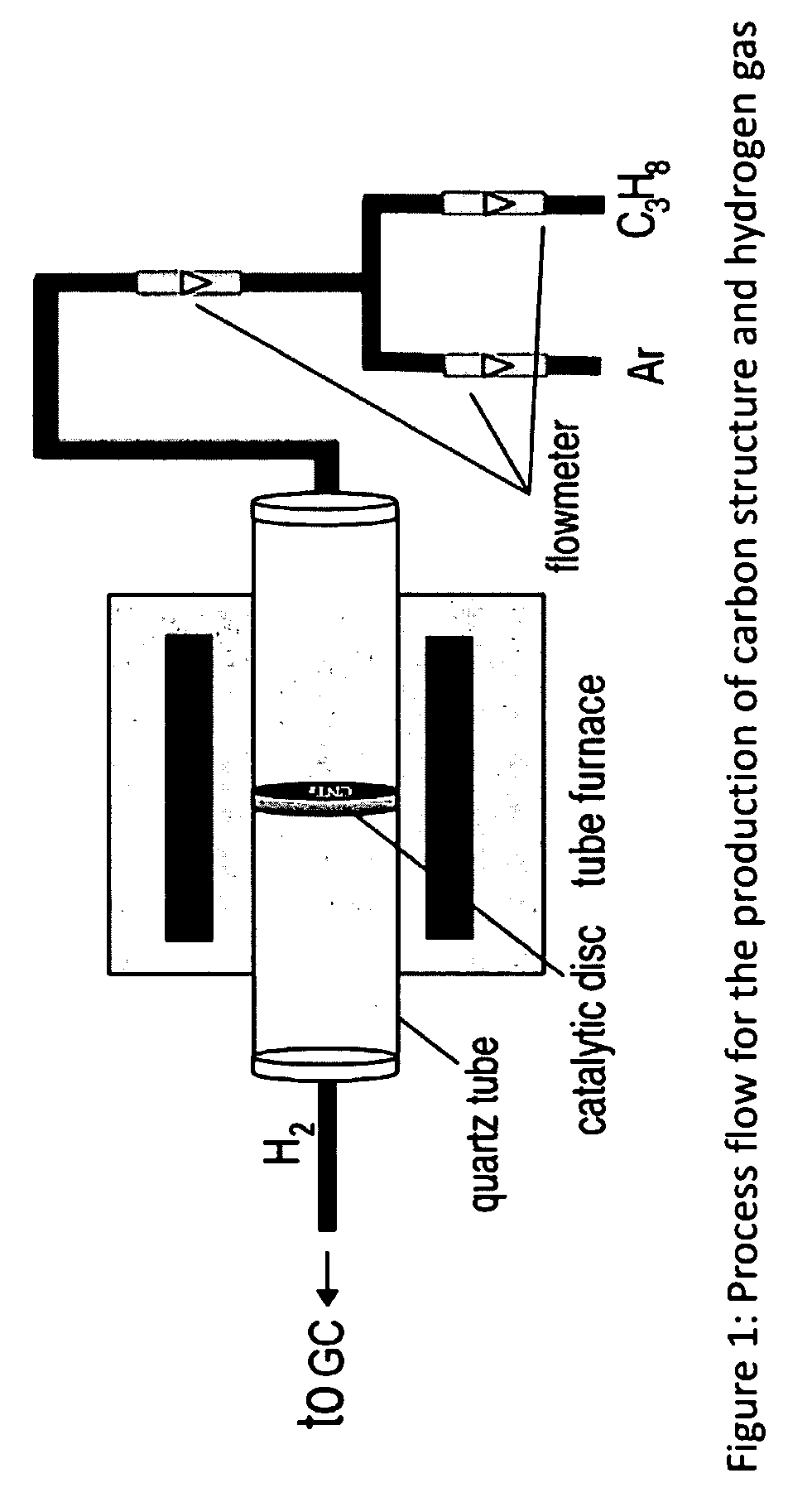

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. Hydrogen is produced via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in oxidant-free environment. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, kerosene, diesel fuel, crude oil (including sulfurous fuels). The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it could be directly fed to any type of a fuel cell. The catalysts for hydrogen production in the apparatus are carbon-based or metal-based materials and doped, if necessary, with a sulfur-capturing agent. Additionally disclosed are two novel processes for the production of two types of carbon filaments, and a novel filamentous carbon product. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

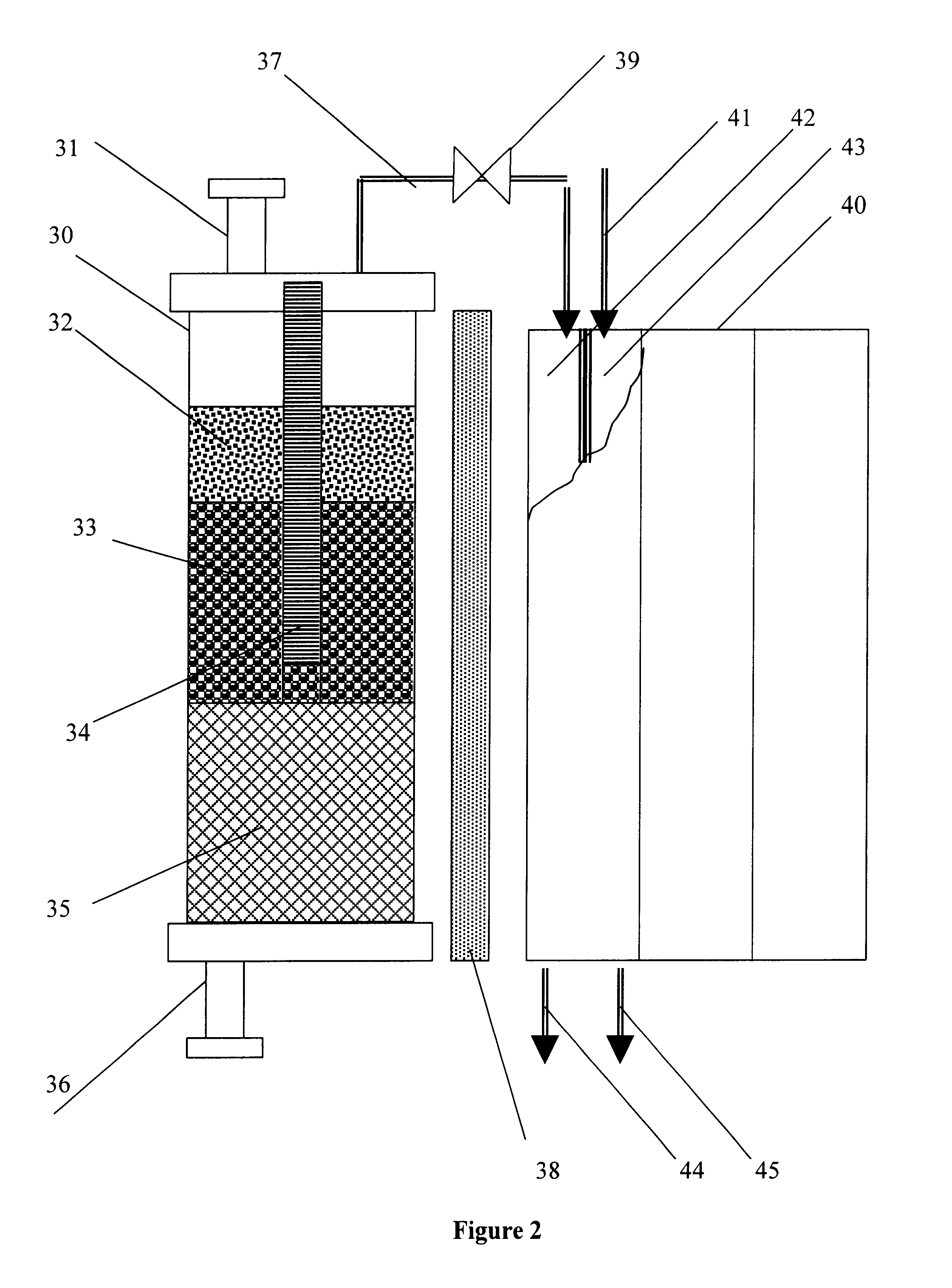

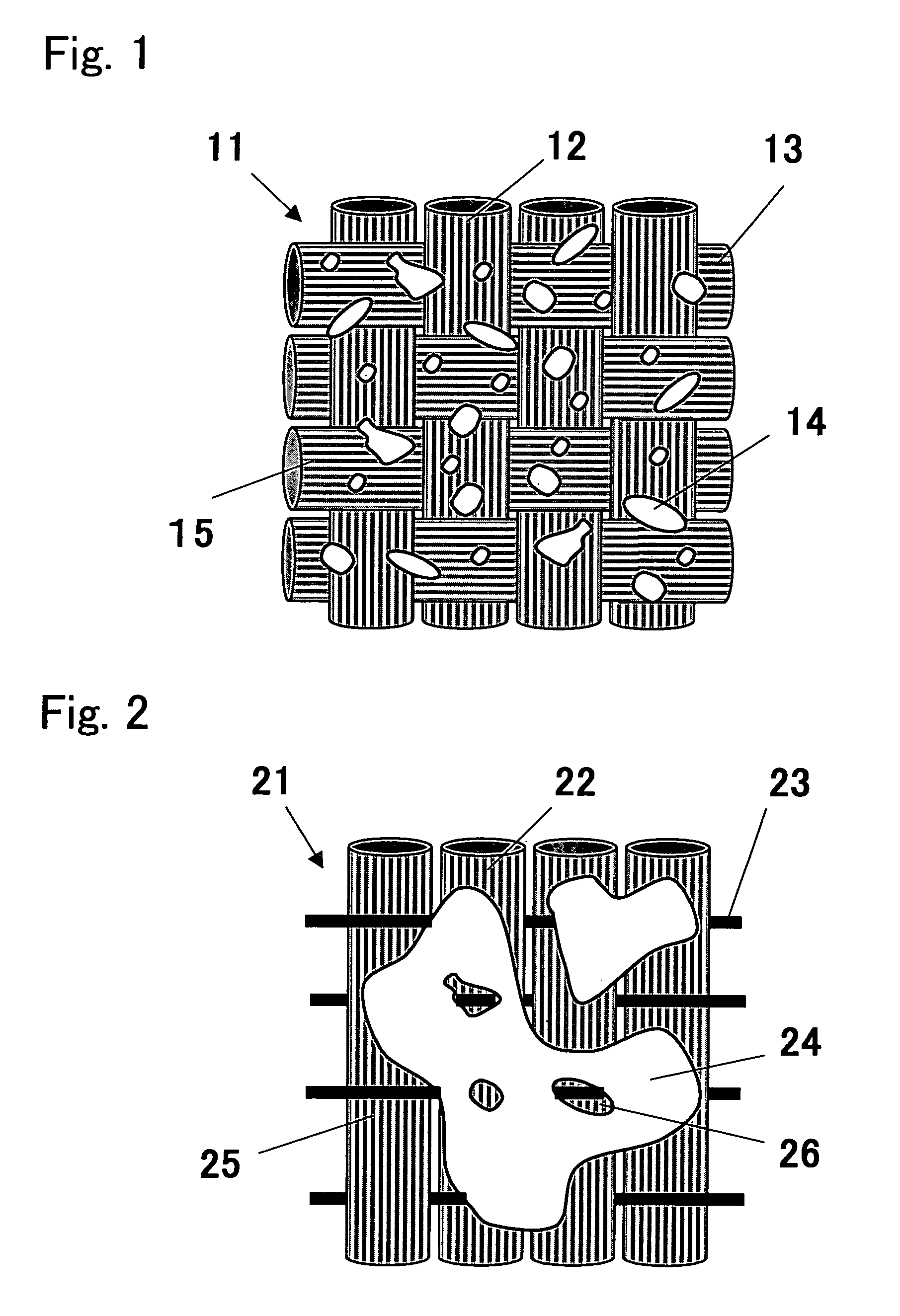

Discontinuous conductive filler polymer-matrix composites for electromagnetic shielding

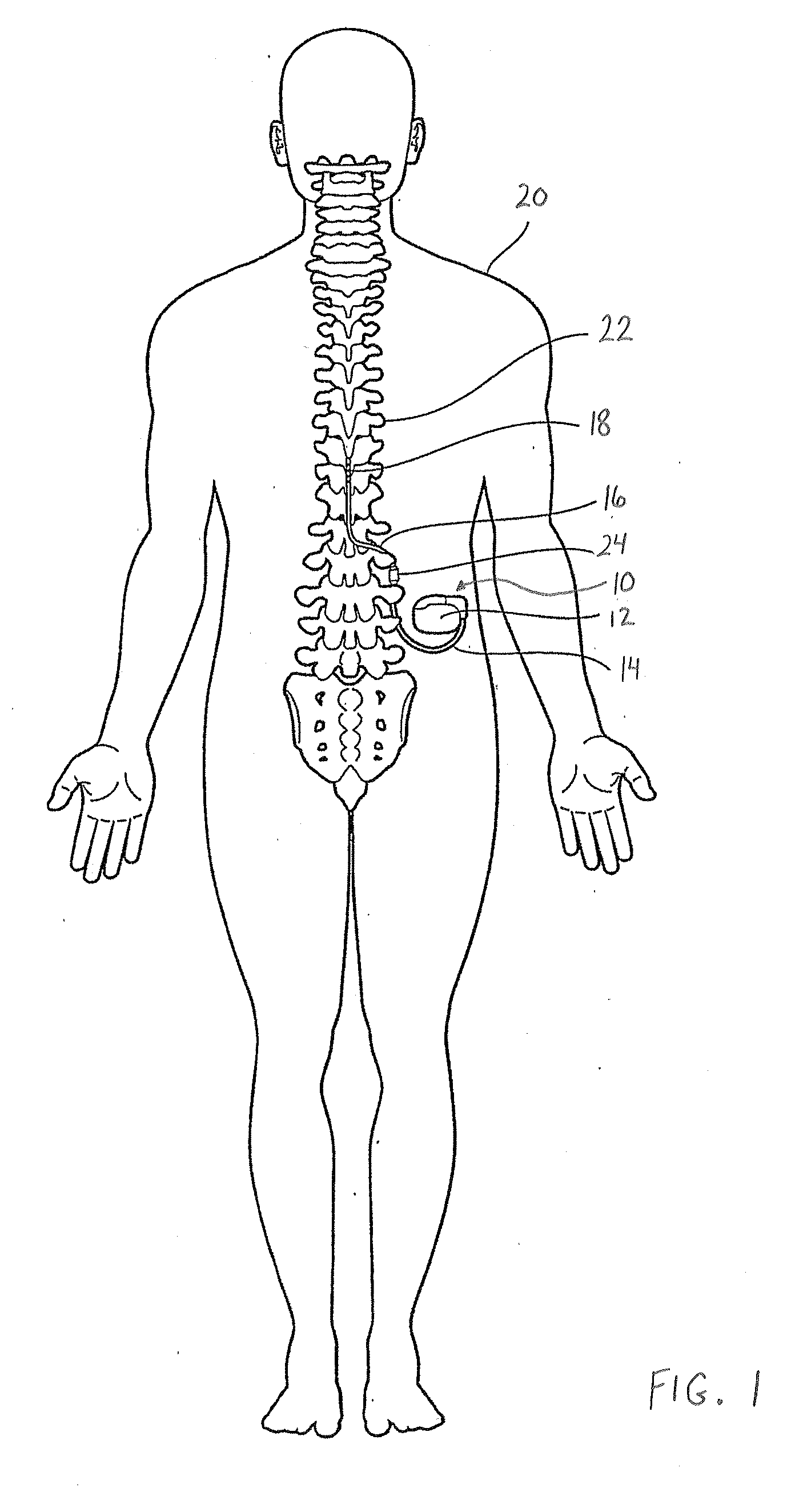

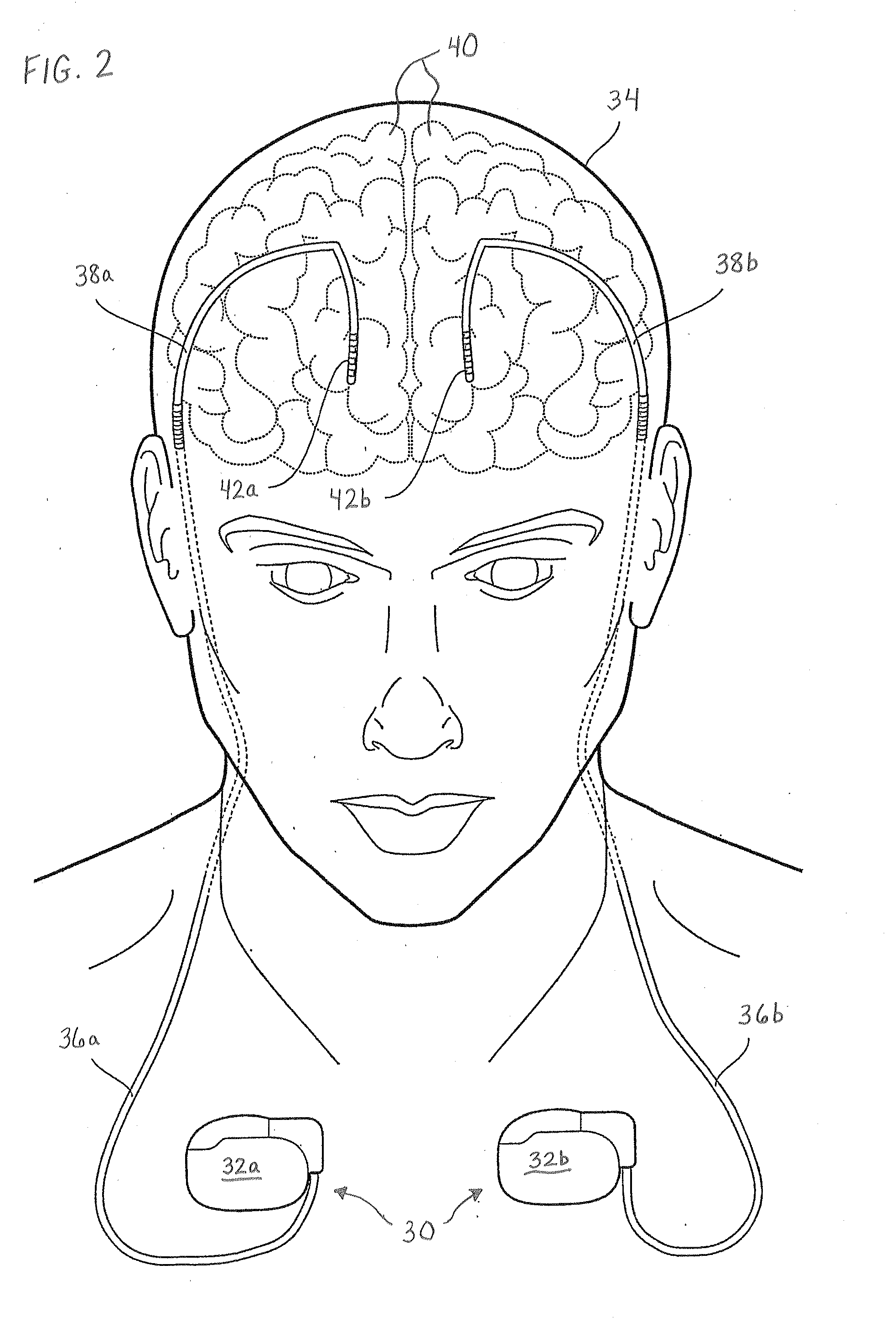

A medical electrical lead having a conductor assembly covered by an insulating layer, and a shield covering positioned adjacent or proximate to at least a portion of the insulating layer in order to shield the conductor assembly from one or more electromagnetic fields. The shield covering is formed of a polymer-matrix composite. The polymer-matrix composite includes a polymeric resin having discontinuous conductive fillers provided therein. The discontinuous conductive fillers include one or more of nano-sized metal structures and nano-sized non-metallic conductive structures. The nano-sized non-metallic conductive structures can have a coating formed of one or more metals. The nano-sized non-metallic conductive structures can be formed of carbon. In turn, the nano-sized non-metallic conductive structures can include one or more of carbon nanofibers, carbon filaments, carbon nanotubes, and carbon nanoflakes.

Owner:MEDTRONIC INC

Carbon fiber prepreg, and a production process thereof

InactiveUS6117551AImprove impact resistanceHigh tensile strengthDecorative surface effectsAdhesive processes with surface pretreatmentHigh concentrationFiber bundle

PCT No. PCT / JP97 / 04642 Sec. 371 Date Aug. 11, 1998 Sec. 102(e) Date Aug. 11, 1998 PCT Filed Dec. 16, 1997 PCT Pub. No. WO98 / 26912 PCT Pub. Date Jun. 25, 1998The present invention relates to a carbon fiber prepreg. The carbon fiber prepreg of the present invention is characterized in that a carbon fiber bundle comprising a plurality of continuous carbon filaments and having a hook drop value of 10 cm or more as the degree of fiber entanglement is impregnated with a base resin mainly composed of a thermosetting resin, and that particles of 150 mu m or less in particle size made of a thermoplastic resin account for 20 wt % or less based on the weight of the entire prepreg and distributed at a higher concentration in the surface zone than in the inside. The carbon fiber prepreg of the present invention is good in tackiness and less changing in tackiness with the lapse of time, and can form a composite with an excellent compression interlaminar shear strength (CILS) at high temperature after moisture absorption while maintaining good impact resistance. It also allows the production of a composite very higher than the conventional composite in the compressive strength (LCS) of a cross laminated panel. The carbon fiber prepreg of the present invention can be preferably used as a structural member in such areas as aerospace area, sporting area and civil engineering and architecture area.

Owner:TORAY IND INC

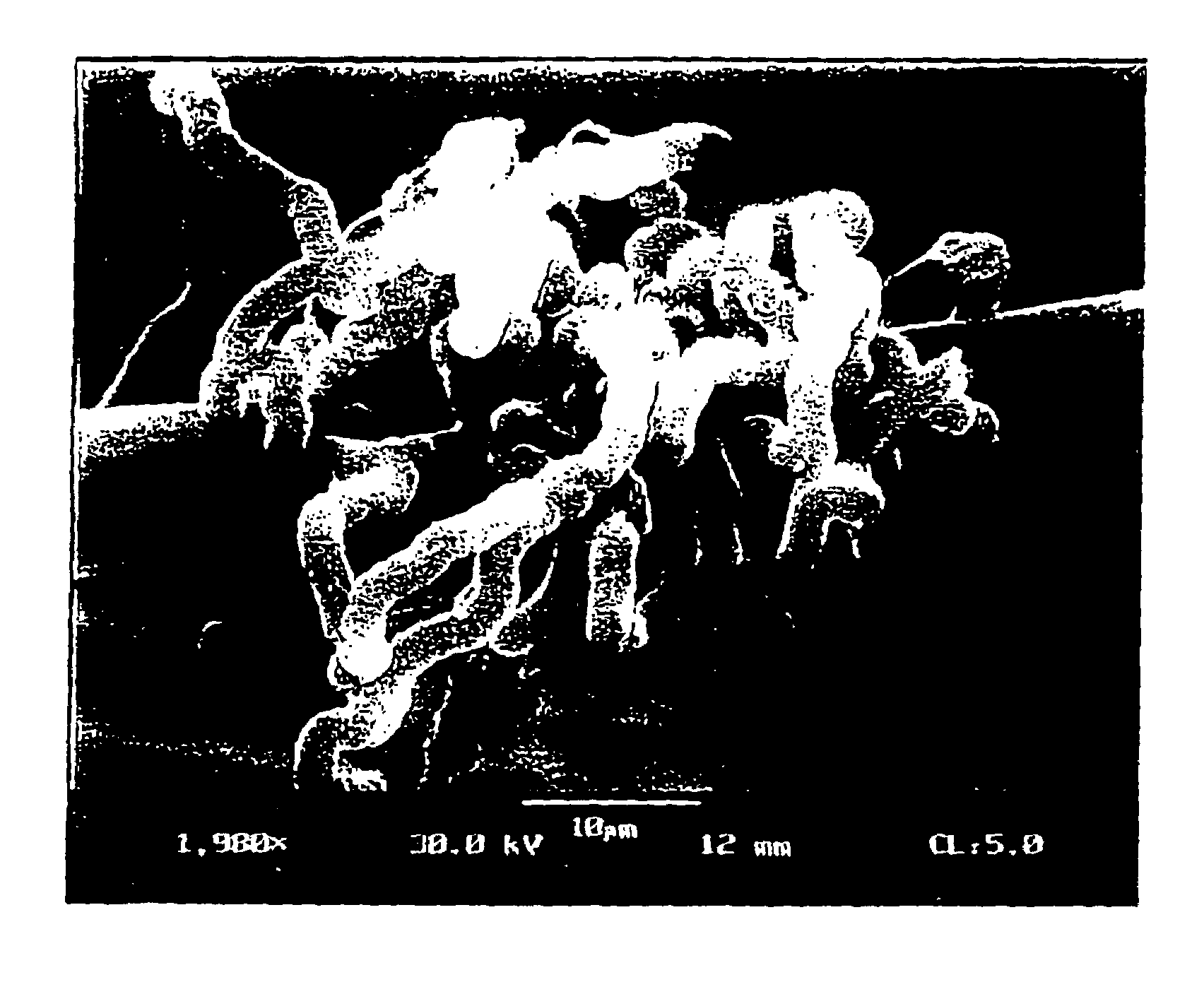

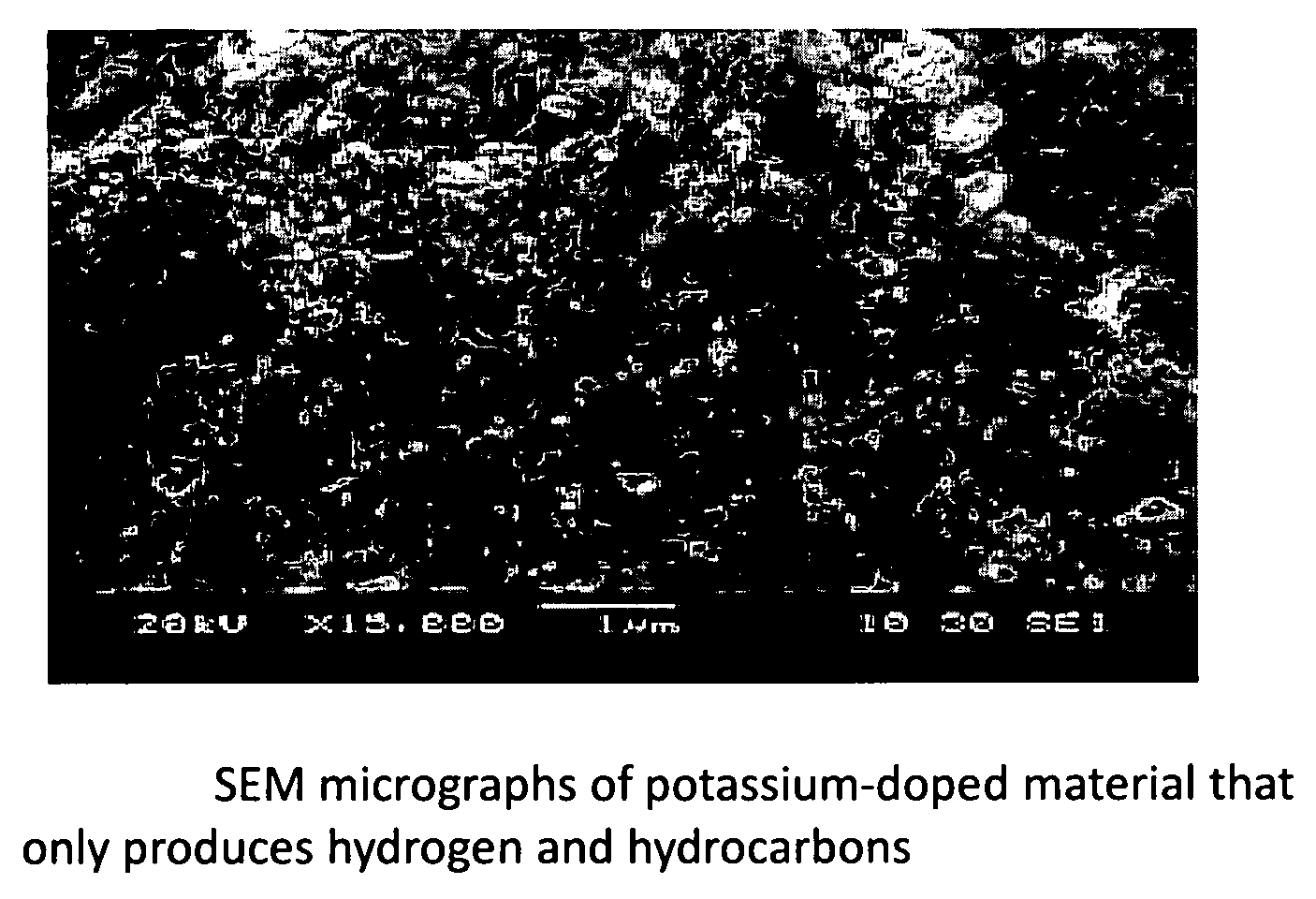

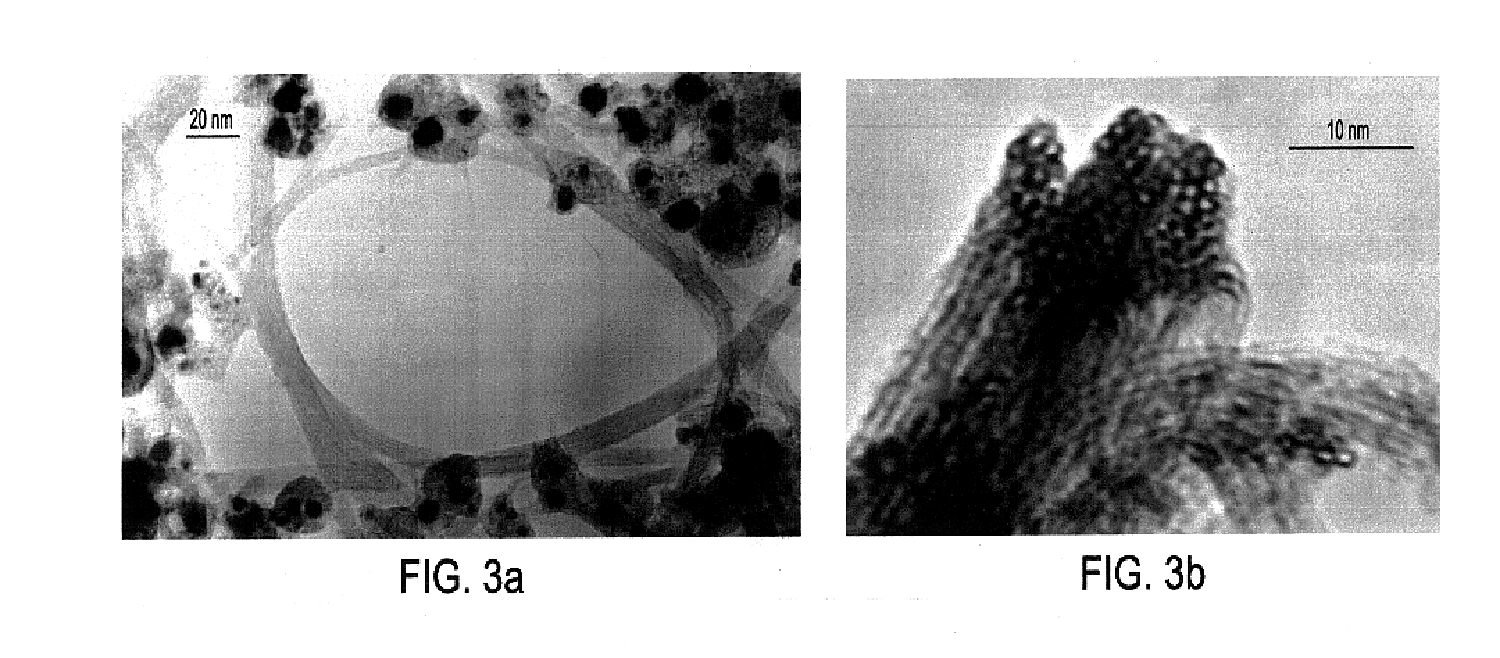

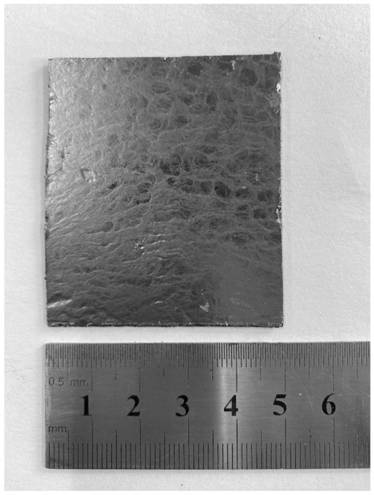

Filamentous carbon particles for cleaning oil spills and method of production

InactiveUS7473466B1Increase specific energy and overall energy efficiencyHydrogen/synthetic gas productionGlass/slag layered productsFiberCarbon nanotube

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. In the process of producing hydrogen for the generator via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in an oxidant-free environment, novel carbon products are produced with filamentary surfaces, “octopus”-like carbon filaments, single carbon nanotube fibers and the like. Two novel processes are disclosed for the production of carbon filaments and a novel filamentous carbon product useful in the clean-up of oil spills on the surface of water. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, and sulfurous fuels. The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it can be directly fed to any type of a fuel cell. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

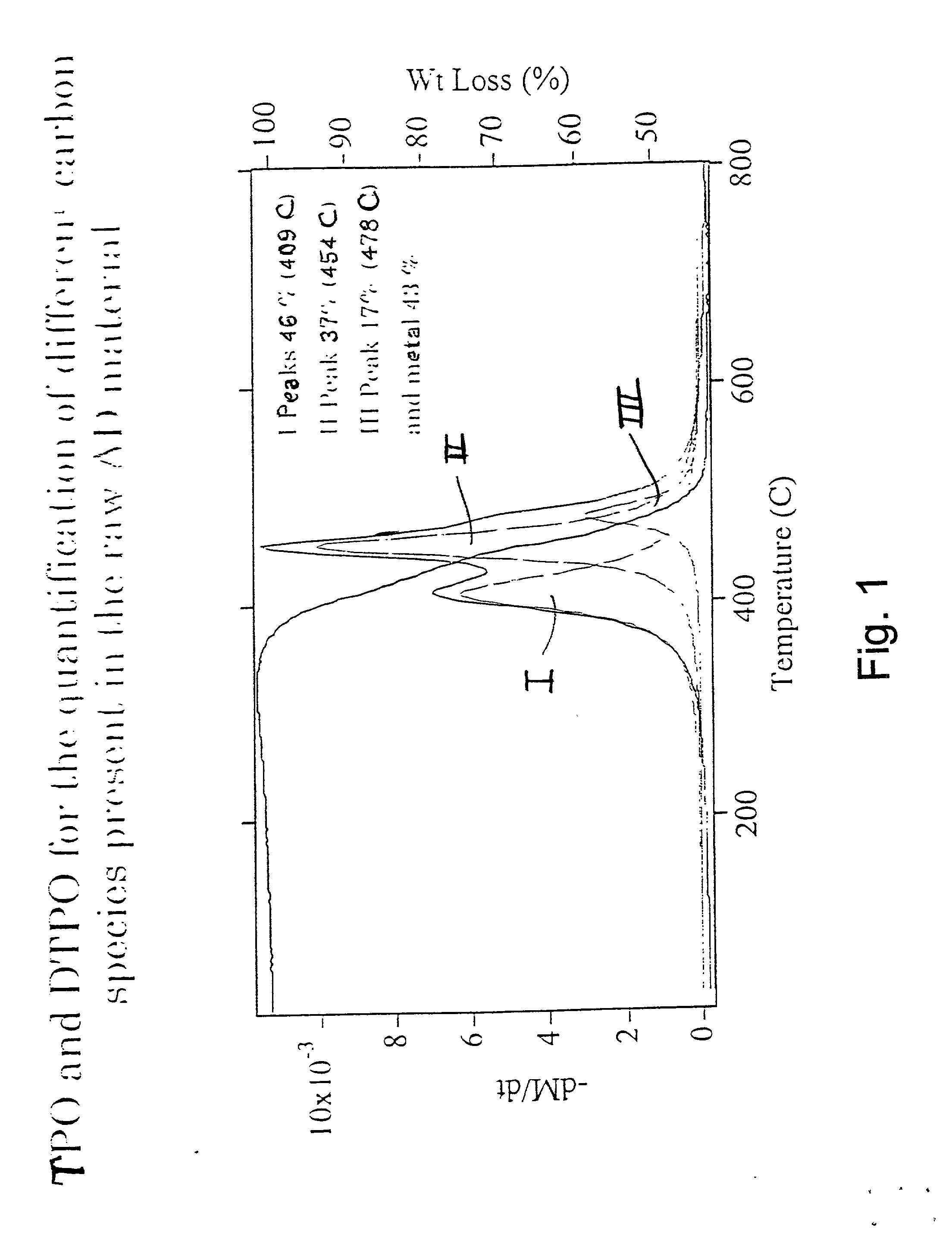

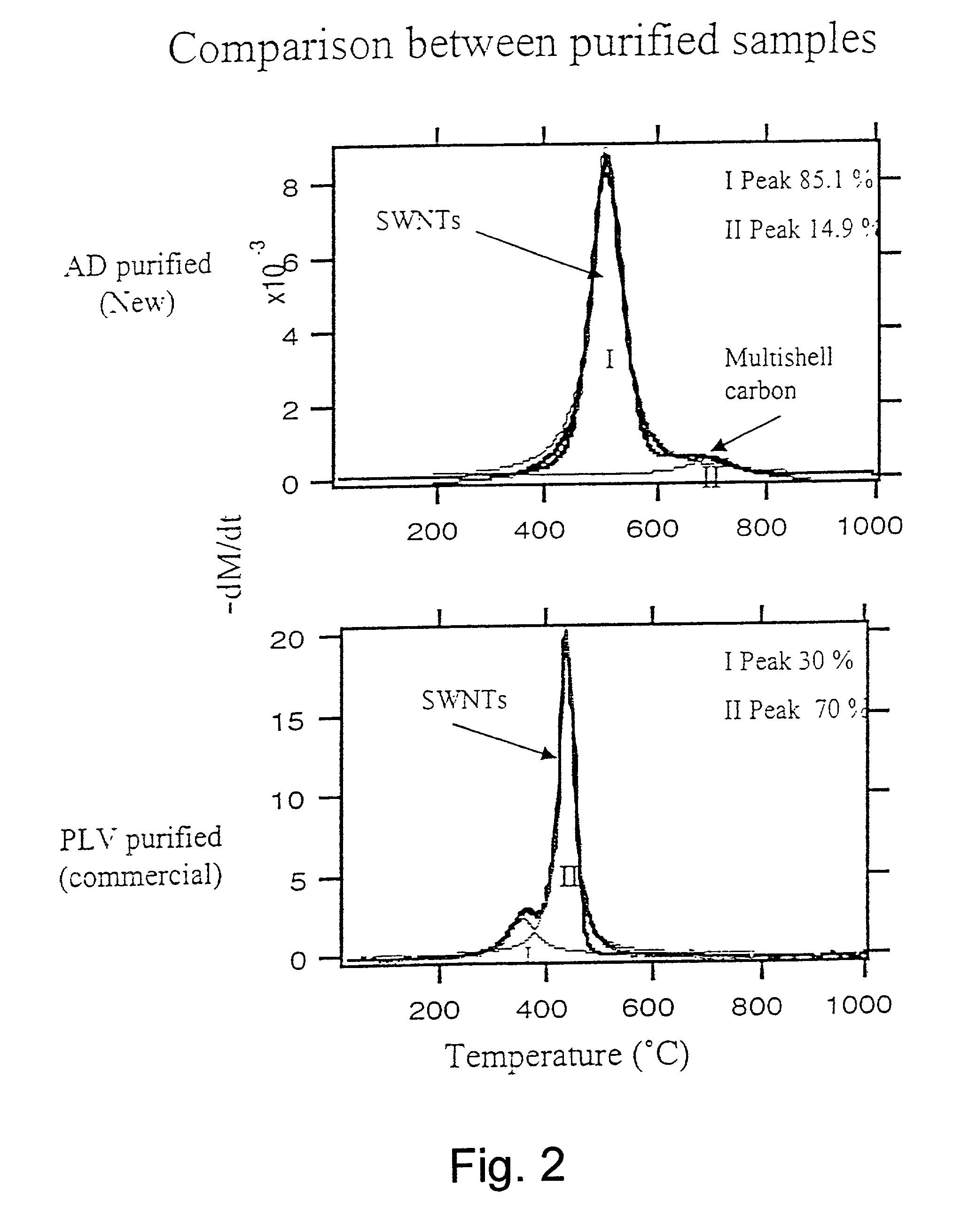

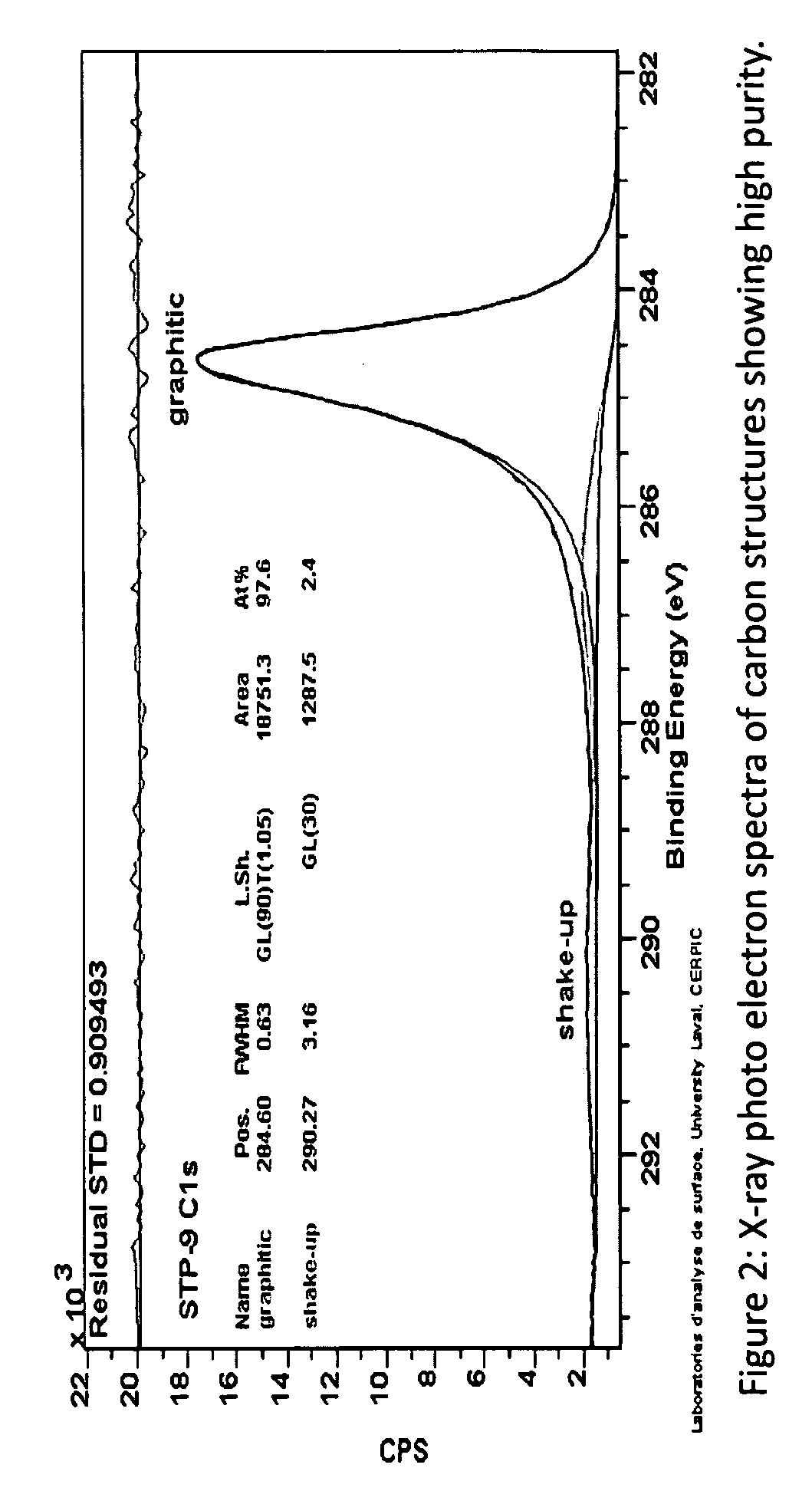

Purification of carbon filaments and their use in storing hydrogen

InactiveUS20030031620A1High yieldReduce the amount requiredMaterial nanotechnologyReversible hydrogen uptakeMetal impuritiesPhysical chemistry

Carbon structures, e.g. carbon nano-fibers, suitable for absorbing hydrogen at low pressures and low temperatures are produced by a selective oxidation and / or acid reflux process. The process includes heating an impure mixture containing a crystalline form of carbon in the presence of an oxidizing gas at a temperature and time sufficient to selectively oxidize and remove a substantial amount of any amorphous carbon impurities from the mixture. Metal containing impurities can be removed from the mixture by exposing the desired carbon and accompanying impurities to an acid to produce a carbon fiber that is substantially free of both non-fiber carbon impurities and metal impurities. Another aspect of the present invention includes purified carbon structures that can store hydrogen at low pressures and temperatures.

Owner:PENN STATE RES FOUND

Carbon fiber reinforced base material, preform and composite material comprising the same

A carbon fiber reinforced substrate comprising a fabric composed of carbon fiber bundles and a first resin adhering to the fabric. Each of the carbon fiber bundles comprises numerous continuous carbon filaments, has the tensile modulus of 210 GPa or more, and has the fracture strain energy of 40 MJ / m3 or more. The amount of the first resin adhering to the fabric is in a range from 1 to 20 parts by weight per 100 parts by weight of said fabric. A preform comprising a laminate composed of plural layers of the carbon fiber reinforced substrate, wherein the layers are integrated by means of the first resin. A composite comprising the preform impregnated with a matrix resin.

Owner:TORAY IND INC

Discontinuous conductive filler polymer-matrix composites for electromagnetic shielding

ActiveUS9044593B2Internal electrodesDiagnostic recording/measuringElectrical conductorCarbon nanofiber

Owner:MEDTRONIC INC

Metal loaded carbon filaments

InactiveUS20050042163A1Material nanotechnologyCarbon-silicon compound conductorsElectronic componentChemical vapor deposition

Metal loaded carbon filaments and a process for making the same are provided. This process includes forming metal on carbon filaments produced from at least one carbon-containing compound, e.g., an alkane or an alkene. The metal may be formed on surfaces of previously formed carbon filaments by, for example, electroplating, impregnation, or chemical vapor deposition. Alternatively, the carbon filaments and the metal may be formed concurrently, resulting in the metal being incorporated in the carbon filaments. An article of manufacture is also provided that includes a carbon filament having metal disposed thereon. The article of manufacture may be, for example, a high surface area catalyst, an electronic element, and a composite material having enhanced electrical properties.

Owner:CONOCOPHILLIPS CO

Carbon fiber, process for production thereof, prepregs, and golf club shafts

InactiveUS20070196648A1High compressive strengthTensile modulusSynthetic resin layered productsMonocomponent synthetic polymer artificial filamentCarbonizationGolf Ball

A carbon fiber tow composed of many carbon filaments and having a strand tensile strength of 3.8 to 5.5 GPa, a strand tensile modulus of 180 to 220 GPa and a carbon crystal size (Lc) of 13 to 18 Å. This carbon fiber tow can be produced by subjecting a precursor fiber tow composed of many polyacrylonitrile filaments which have a lightness difference (ΔL) of 50 or below and fineness of 1.1 to 1.7 dtex to oxidative stabilization and subjecting the stabilized fiber tow to carbonization with the maximum temperature within the range of 1,100 to 1,300° C. in an inert atmosphere while raising the temperature from 1,000° C. to the maximum temperature at a temperature rise rate of 100 to 2,000° C. / min.

Owner:TORAY IND INC

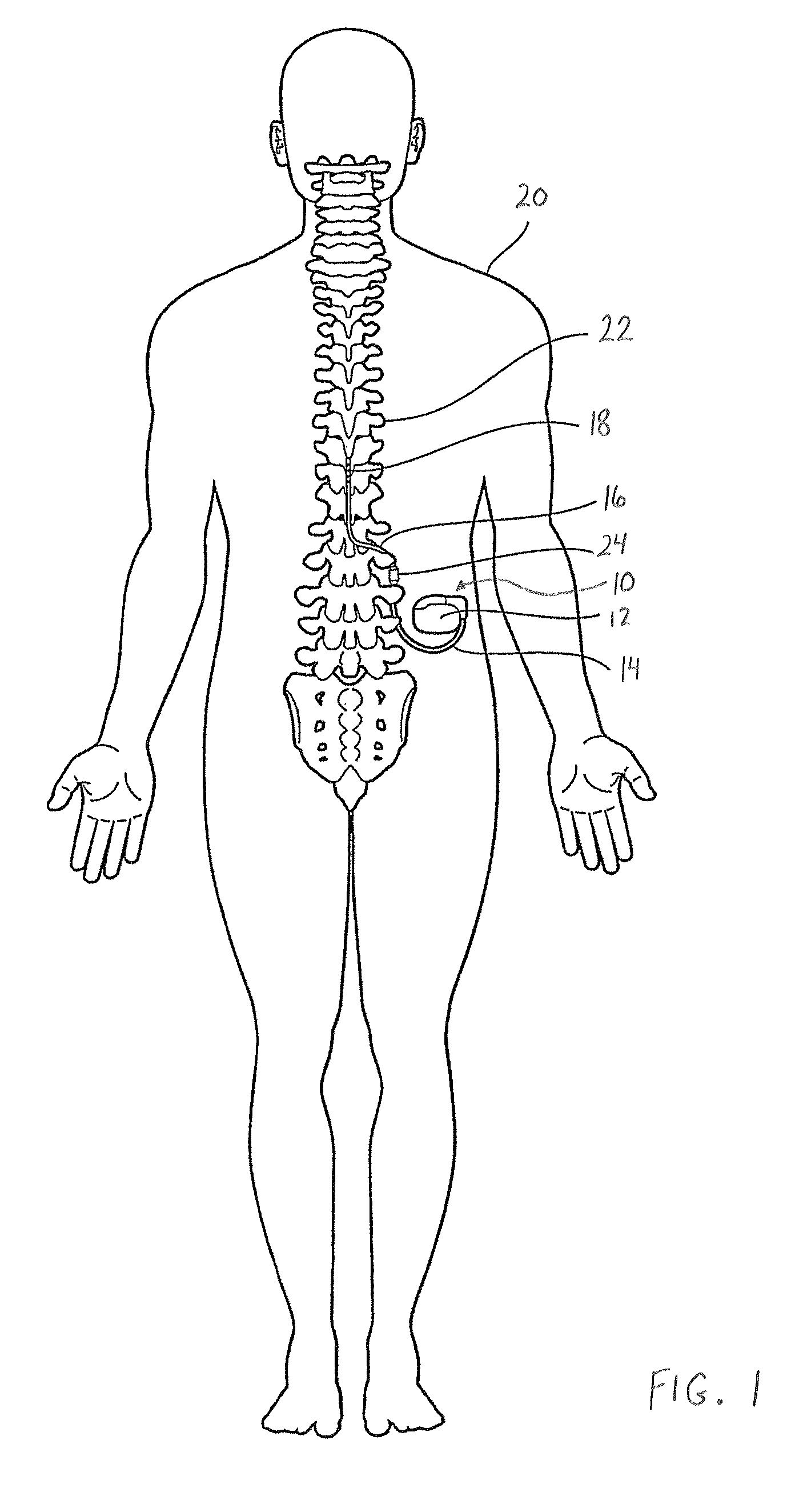

Pneumatic vehicle

A pneumatic vehicle is provided with a first sub- assembly with a chassis, part of the vehicle body, a pair of B-pillars, a pair of rear rails, wheels, an elongate aluminum compressed load bearing air tank oriented longitudinally in the chassis, side panels connected to the tank and the wheels, a heat exchanger to heat the compressed air, and an air motor driven by the heated, compressed air and connected to a wheel. A ventilation system has a restrictive solenoid valve for directing air to the heat exchanger. The air tank is provided with a carbon filament reinforced plastic layer, and a fiberglass and aramid-fiber layer. A second sub-assembly includes part of the vehicle body bonded to the first-sub-assembly using a structural adhesive, a pair of A-pillars, and a pair of roof rails. Seating includes inflatable components for adjustment.

Owner:DEAKIN UNIVERSITY

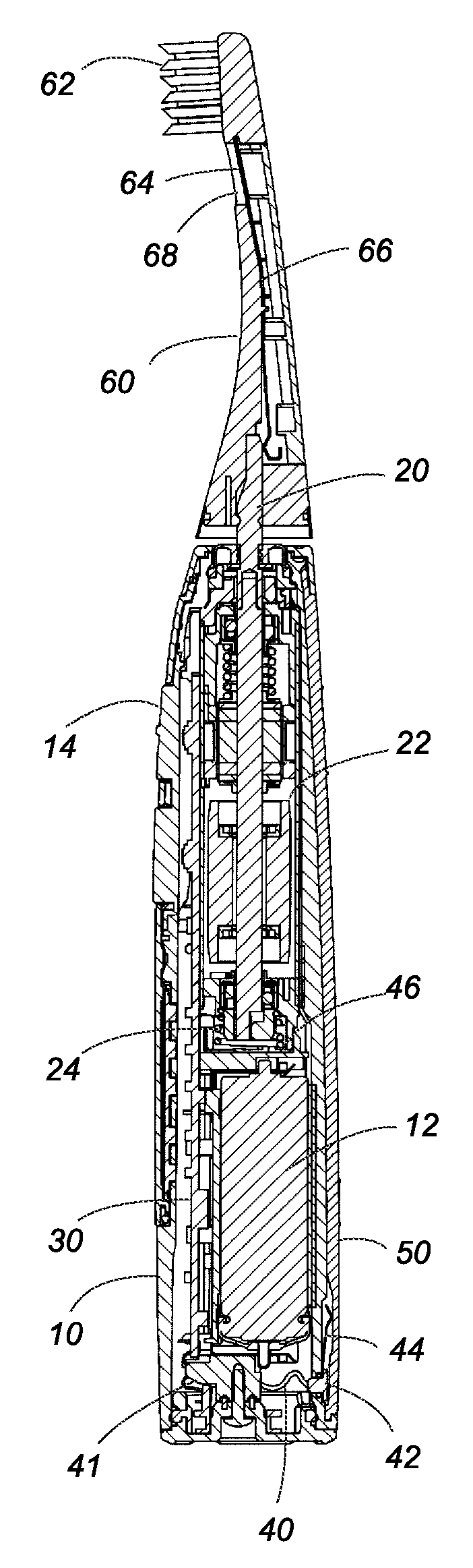

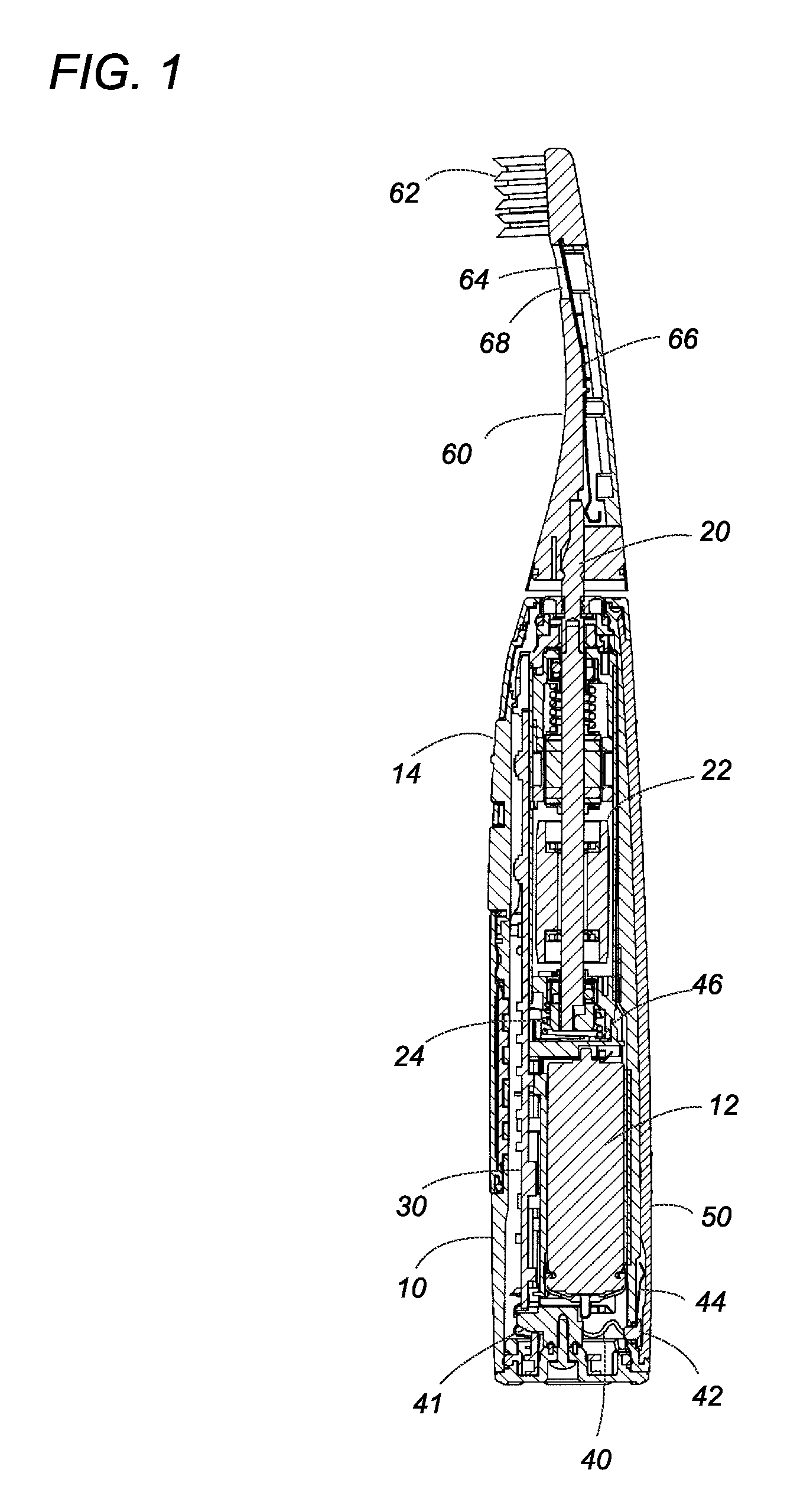

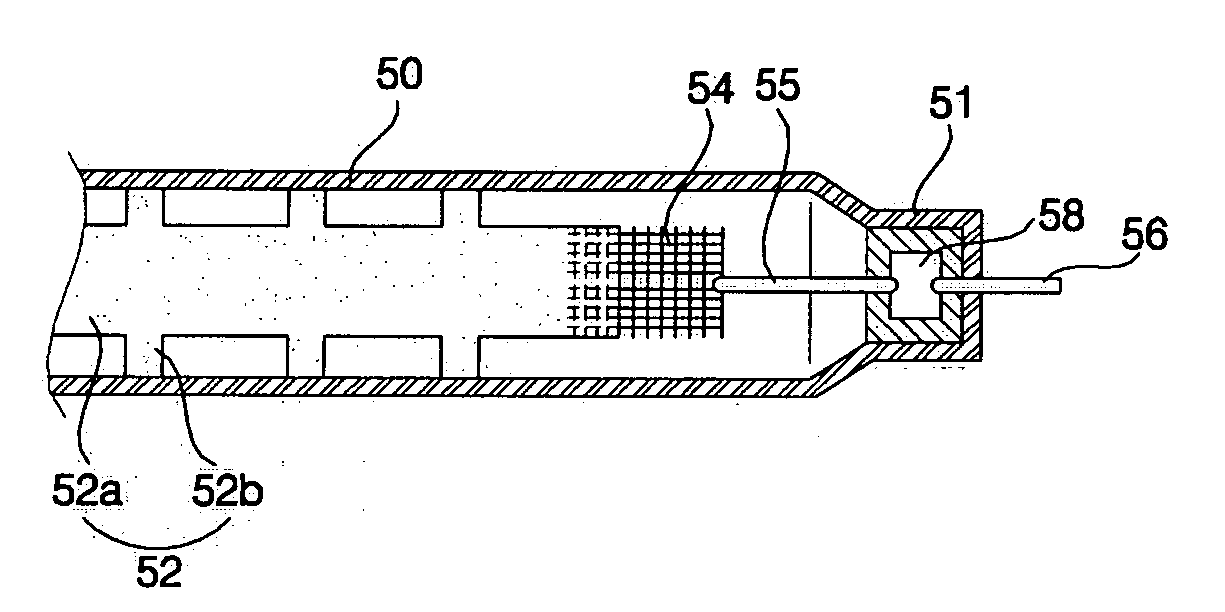

Oral care device

InactiveUS20080183249A1Without deterioration of appearance and performanceEasy to useElectrotherapyCarpet cleanersMouth careMetallic materials

An oral care device has a handle with a touch electrode and a brush handle with a brush electrode for flowing a minute current into an oral cavity of a user by way of the user's body for removing plaque. The touch electrode is made of a non-metal material filled with carbon filaments, and is free from any metal elution or corrosion while it is in contact with the user's hand, which assures to keep the oral care device in good appearance and performance over a prolonged use.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Carbon fiber heating element assembly and methods for making

An electrical resistance heating element has an axially elongated flat carbon fiber tow, which includes a multiplicity of continuous axially parallel carbon filaments. The tow is sandwiched between two layers of polyester sheet material and bonded to only one of the layers. The other of the layers overlies the tow in direct contacting engagement with and unconnected relation to the tow and is connected to longitudinally extending marginal portions of the one layer along transversely opposite sides of the tow. The heating element may be produced by a continuous forming process.

Owner:METHODE ELETRONICS INC

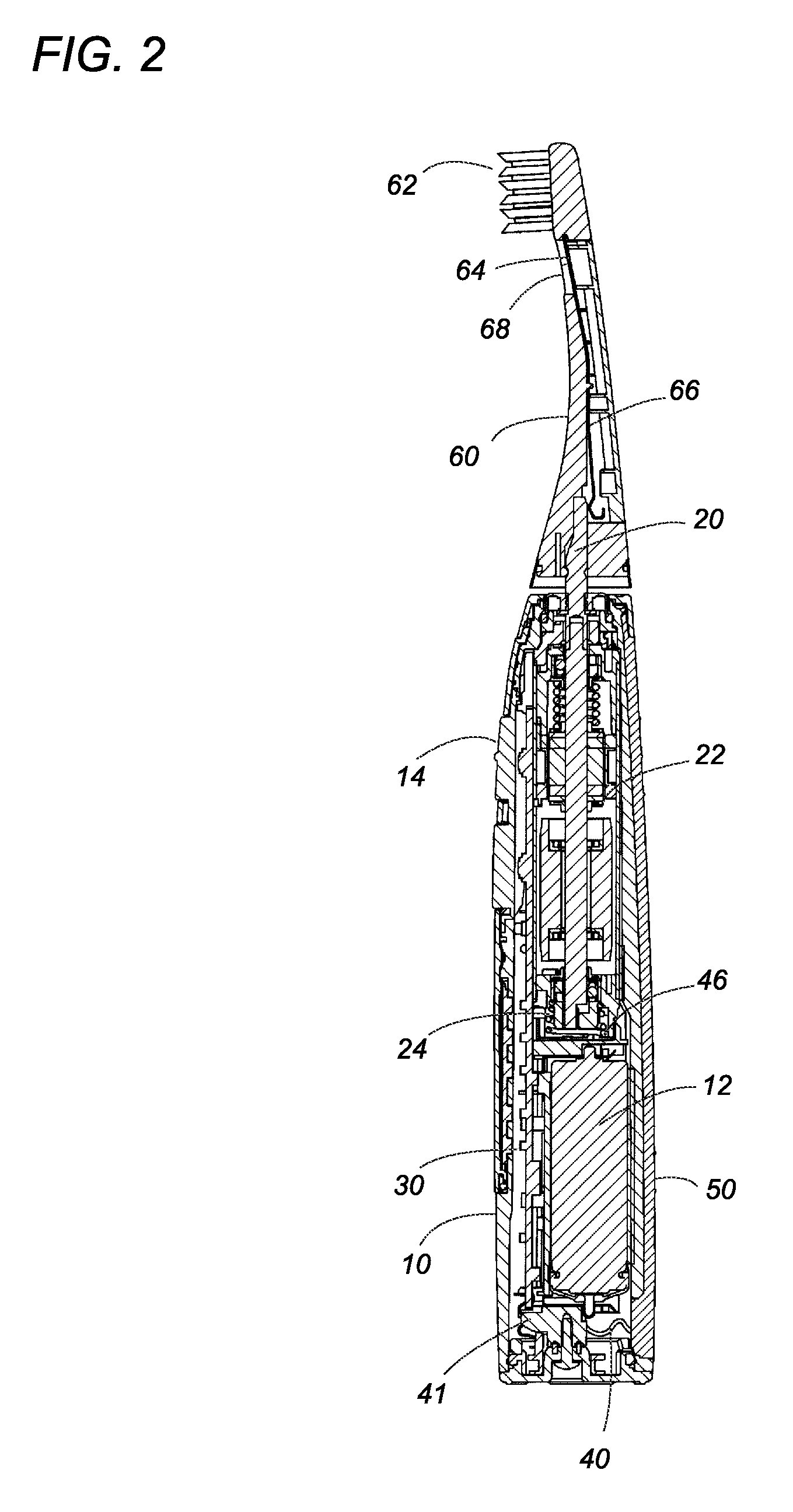

Method for bonding carbon fiber pipe with metal flanges internally and externally

InactiveCN102278342AFirmly connectedImprove carrying capacityAdhesive processes with adhesive heatingFastening meansFiberAdhesive

The invention provides a method for bonding a carbon fiber pipe with metal flanges internally and externally. The method comprises the following steps of: step 1, carrying out surface treatment on the carbon fiber pipe and the metal flanges to be connected; step 2, connecting the carbon fiber pipe after the surface treatment with an outer metal flange through carbon filaments; step 3, connecting an inner metal flange through the carbon filaments, and locating the inner metal flange and the outer metal flange through flange hole dowel pins; step 4, taking off the flange hole dowel pins and removing excessive adhesive; and step 5, bonding, heating and curing the carbon fiber pipe and the metal flanges. According to the method for bonding the carbon fiber pipe with the metal flanges internally and externally, disclosed by the invention, a new connection manner is provided for the carbon fiber pipes and metal connecting pieces, the method is simple and convenient, the connection capability between the carbon fiber pipes and metal joints is effectively improved and the safety and the reliability of a structural system are increased.

Owner:BEIHANG UNIV

Novel catalyst to manufacture carbon nanotubes and hydrogen gas

This invention relates primarily to a novel method to manufacture single / multi / fibers carbon filaments (nano tubes) in pure form optionally with antiferromagnetic and electrical property wherein the byproduct is hydrogen gas resulting in reduction of environmental carbon emissions by at least 20%; both carbon filaments and resultant exhaust are useful products.

Owner:QUAID E AZAM UNIV

Process for producing shaped bodies comprising fiber-reinforced ceramic materials

Process for producing shaped bodies comprising fiber-reinforced ceramic materials, where a green body is produced in a first step by introducing a press moulding composition into a mold, where the press moulding composition comprises carbon fibers and / or carbon filaments and pitch and / or resins which, when treated thermally and with the exclusion of oxidizing agents, form carbon-containing residues, the green body is cured in a second step by heating to a temperature of from 120° C. to 280° C. under pressure, the cured green body, also referred to as intermediate body, is carbonized in a third step by heating in a nonoxidizing atmosphere to a temperature of from about 750° C. to about 1100° C. to form a C / C body, wherein heating in the first, second and / or third step is at least partly effected by an electric current being passed through the pressable composition, the green body and / or the cured green body, shaped bodies produced according to this process and their use as brake disks, clutch disks and friction disks

Owner:AUDI AG

Purification of carbon filaments and their use in storing hydrogen

InactiveUS6869583B2High yieldReduce the amount requiredMaterial nanotechnologyReversible hydrogen uptakeRefluxHydrogen

Carbon structures, e.g. carbon nano-fibers, suitable for absorbing hydrogen at low pressures and low temperatures are produced by a selective oxidation and / or acid reflux process. The process includes heating an impure mixture containing a crystalline form of carbon in the presence of an oxidizing gas at a temperature and time sufficient to selectively oxidize and remove a substantial amount of any amorphous carbon impurities from the mixture. Metal containing impurities can be removed from the mixture by exposing the desired carbon and accompanying impurities to an acid to produce a carbon fiber that is substantially free of both non-fiber carbon impurities and metal impurities. Another aspect of the present invention includes purified carbon structures that can store hydrogen at low pressures and temperatures.

Owner:PENN STATE RES FOUND

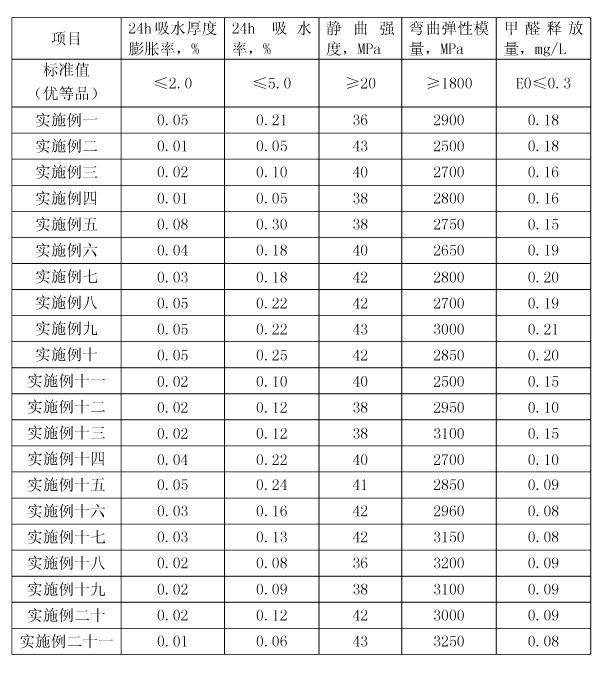

Zero-carbon high-fiber environment-friendly sheet synthesized by waste circuit board powder and production process thereof

The invention discloses a zero-carbon high-fiber environment-friendly sheet synthesized by waste circuit board powder and a preparation process thereof. The pressing raw materials of the environment-friendly sheet comprise: circuit board recycled powder, wood fiber powder, a cross-linking agent, a waterproofing agent, and carbon filament fiber; the production process of the sheet comprises the following steps of: drying the circuit board recycled powder at a constant temperature; converting high fiber auxiliary materials into wood fiber powder above 80 meshes, drying, and then stirring under 180 DEG C to form carbon fiber powder; adding a processing assistant and blending uniformly again; and feeding materials, paving pressing plates, pressurizing, standing, complementing pressure, and gently decompressing to produce the sheet. The pressure during the production process is controlled so that the sheet is stable in quality and high in intensity; the sheet synthesized by wood fiber powder obtained by recycling crop straw, bamboo and wood saw powder and the like with the waster circuit board powder can be sawn, drilled, processed, and shaped easily; furthermore, the sheet is excellent in waterproof and fireproof performances, and high in static bending strength; and the utilization of waste materials reaches the purposes of environmental protection and low carbon.

Owner:清远炬众节能环保科技有限公司

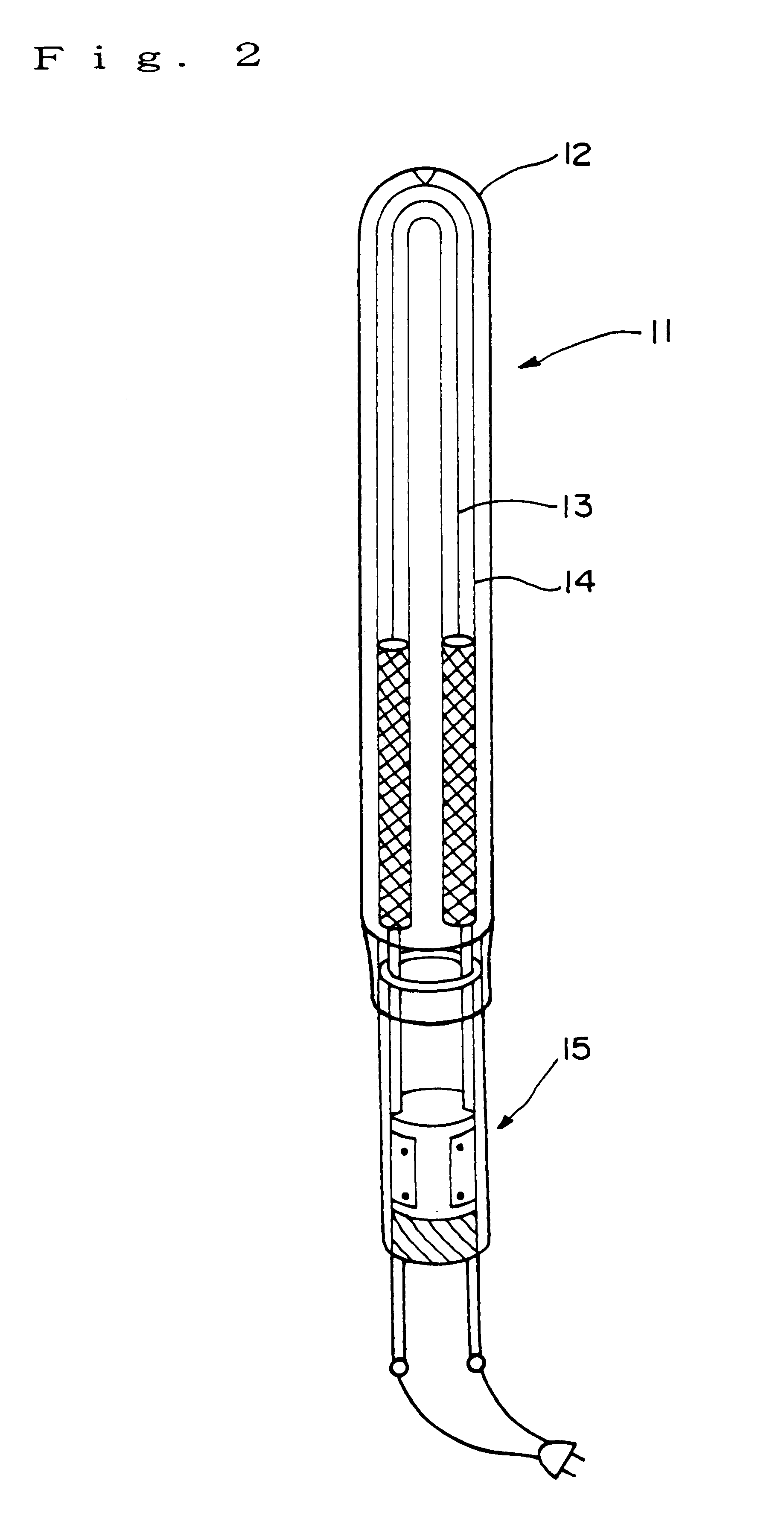

Heater sealed with carbon wire heating element

InactiveUS6584279B2Quality improvementExcellent anti-aging stability of electric resistanceDomestic stoves or rangesIncandescent ignitionSingle fiberCrystal structure

A heater sealed with carbon wire heating element has a carbon wire heating element sealed with a quartz glass member, the carbon wire being prepared by knitting carbon single fibers into a knitted cord of a braid, each wire having a crystal structure with a interlayer spacing d (002) thereof being 0.343 or less and crystallite size Lc (002) thereof being 4.0 nm or more.

Owner:COORSTEK INC +1

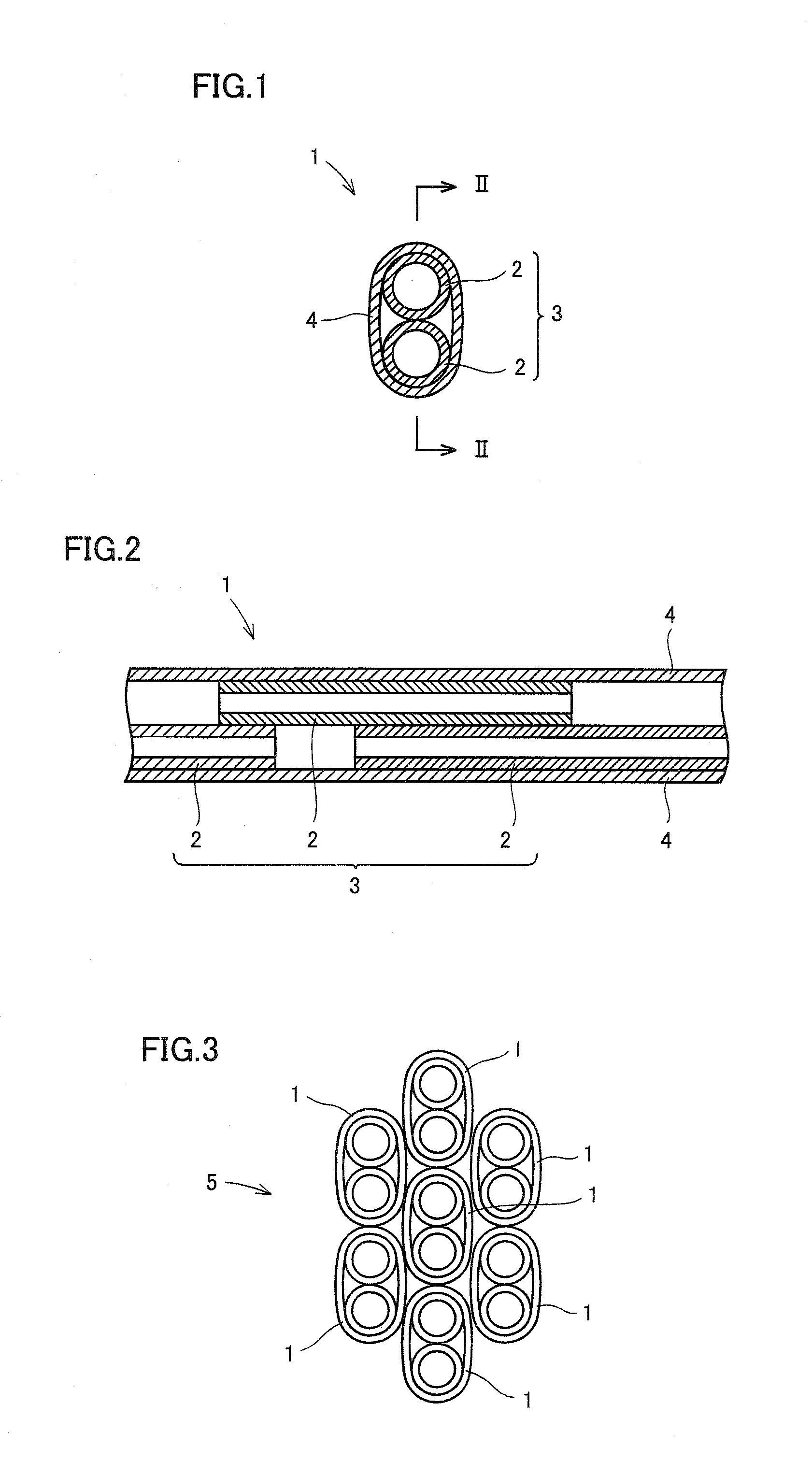

Carbon wire and NANO structure formed of carbon film and method of producing the same

InactiveUS20110003174A1Lower resistanceLarge light transmissionMaterial nanotechnologyFinal product manufactureCarbon filmElectrical resistance and conductance

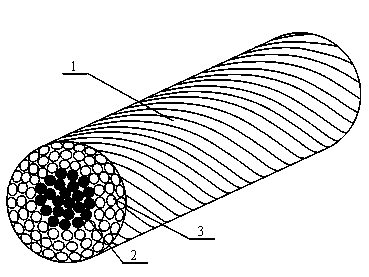

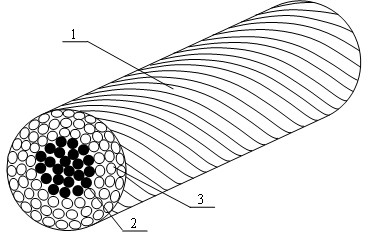

There are provided a carbon wire using CNT or a similar carbon filament having a sufficiently low electrical resistance value, and a wire assembly employing that carbon wire. A carbon wire includes an assembly portion and a graphite layer. The assembly portion is configured of a plurality of carbon filaments implemented as carbon nanotubes in contact with one another. The graphite layer is provided at an outer circumference of the assembly portion.

Owner:SUMITOMO ELECTRIC IND LTD

Steel pipeline corrosion proof reinforcing method

The invention relates to a method for reinforcing and antisepticising steel pipeline, comprising the following steps of: processing the surface of steel pipeline to be reinforced and antisepticised, preparing epoxy ethylene resin and resin mortar, using the mortar to fill and block the crack and perforation part of the pipeline, sticking bidirectional carbon fiber cloth on the patching part, finally winding and sticking the unidirectional carbon fiber cloth on the pipeline in circularity when the surface of the pipeline is being coating by the prepared resin, the direction of the carbon filament should be right angle of 90 degrees with the axes of the pipeline, and then winding and brushing, recoating a layer of resin surface layer after the surface of the resin gel is dry. The invention has the advantages that the adopted carbon fiber epoxy ethylene resin composite material system has the excellent performances of high strength, light weight, corrosion resistance and humidity resistant, evident dual effect of reinforcing and antisepticising, and practical and reliable method for patching crack and perforation, which can greatly prolong the service life of the pipeline.

Owner:上海华夏化工材料有限公司

Carbon fiber, process for production thereof, prepregs, and golf club shafts

InactiveCN1930332AImprove flexibilityLow flexural modulusMonocomponent synthetic polymer artificial filamentNon-woven fabricsPolymer scienceUltimate tensile strength

A carbon fiber tow composed of many carbon filaments and having a strand tensile strength of 3.8 to 5.5 GPa, a strand tensile modulus of 180 to 220 GPa and a carbon crystal size (Lc) of 13 to 18 AA. This carbon fiber tow can be produced by subjecting a precursor fiber tow composed of many polyacrylonitrile filaments which have a lightness difference (DeltaL) of 50 or below and fineness of 1.1 to 1.7dtex to oxidative stabilization and subjecting the stabilized fiber tow to carbonization with the maximum temperature within the range of 1,100 to 1,300 1 / 2 C in an inert atmosphere while raising the temperature from 1,000 1 / 2 C to the maximum temperature at a temperature rise rate of 100 to 2,000 1 / 2 C / min.

Owner:TORAY IND INC

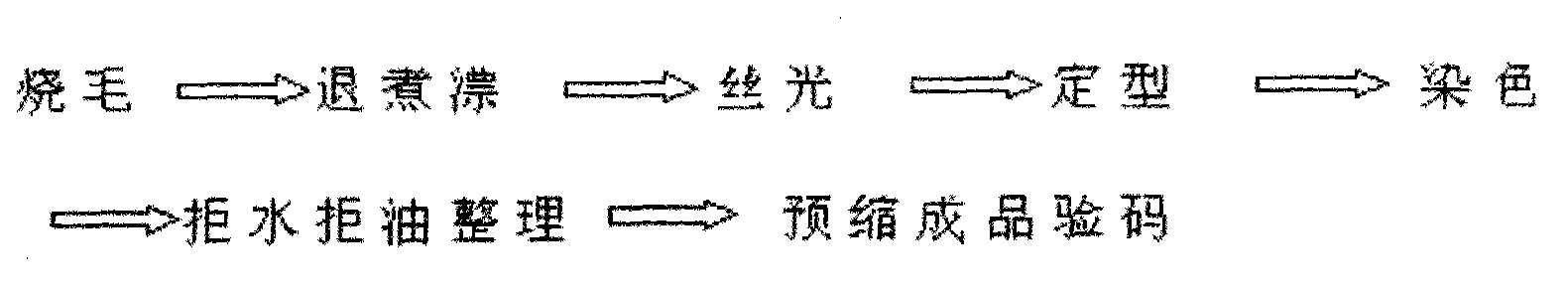

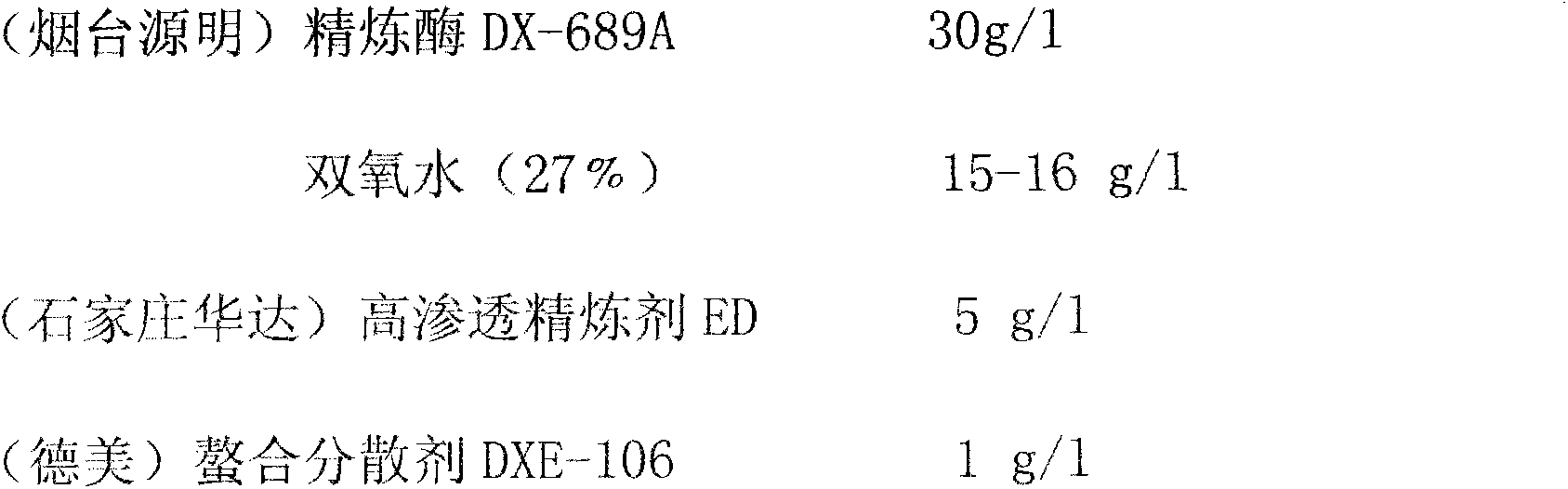

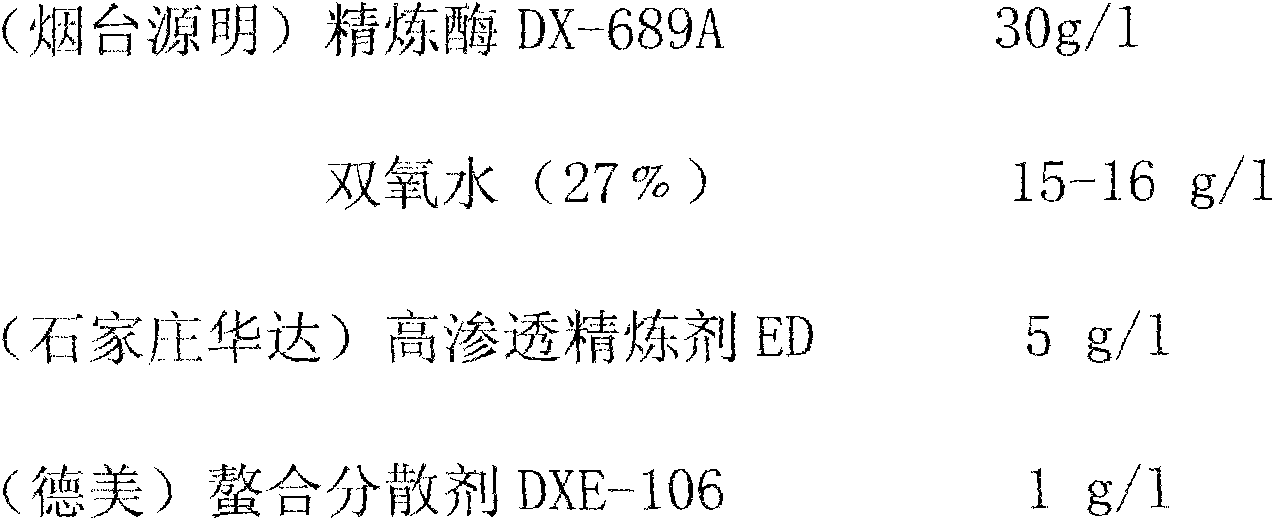

Polyester and cotton blended novel carbon filament anti-static water and oil repellent composite functional fabric

ActiveCN103015106AExcellent long-lasting anti-static effectOvercoming the fatal shortcoming of catalytic hydrogen peroxide splittingSucessive textile treatmentsMercerising of indefinite length fabricsCooking & bakingFiber

The invention relates to the field of textile, and in particular relates to a functional fabric. A polyester and cotton blended novel carbon filament anti-static water and oil repellent composite functional fabric is prepared by blending polyester, cotton and conductive carbon fibers through singeing, annealing, boiling, blanching, grinding, sizing, dyeing and water and oil repellent treatment; the dyed fabric is subjected to water and oil repellent treatment; the mangle expression is 60 percent; infrared is completely open; a pre-baking chamber I has the temperature of 80 DEG C, and a pre-baking chamber II has the temperature of 100 DEG C; the baking temperature is 190 DEG C; the baking time is 45 seconds; and a finished product checking code is pre-condensed. The conductive carbon fiber has the advantages and the water and oil repellent theory that the novel conductive carbon fiber has a good and durable anti-static effect; the critical defect of metal conductive fiber catalytic hydrogen peroxide decomposition is avoided; the refining and blanching resistance is relatively high; square grids formed by the conductive fiber on the surface of the fabric cannot be seen from the appearance of the fabric; and the composite functional fabric is more attractive than the metal conductive fiber.

Owner:辽宁宏润源印染有限公司

Method suitable for carrying out consolidation forming on polyacrylonitrile carbon fiber precursor by dry-wet method

ActiveCN104264286AImprove applicabilityPositive supportArtificial filament chemical after-treatmentDouble diffusionResidence time

The invention relates to a method suitable for carrying out consolidation forming on a polyacrylonitrile carbon fiber precursor by a dry-wet method. The method comprises the following preparation steps: in a low-temperature low-concentration coagulating bath with a consolidation temperature of 20 DEG C below zero to 25 DEG C and mass concentration of 5 to 40 percent, enabling spinning solution to pass through a spinneret plate and jetting the spinning solution by an air layer so as to enable the spinning solution to enter the coagulating bath, wherein residence time in the coagulating bath is 2 to 10s; rapidly quenching the surface of stock solution to generate a hard film; by the hard film and the conditions of low temperature, low concentration and the like, slowing down a double diffusion rate, improving the orientation degree of nascent fibers by the hard film to realize homogenizing of consolidation forming and avoid a skin-core structure so as to obtain the nascent fibers with pre-draft times of 2.3 to 4.0 times, wherein the nascent fibers have orientation degree of 65 to 70 percent. The protofilament prepared by the method disclosed by the invention has high homogeneity; high-quality protofilaments and carbon filaments can be obtained; moreover, in the dry-wet technology, the method has strong universality and can be popularized and used in the dry-wet production.

Owner:ZHONGFU SHENYING CARBON FIBER

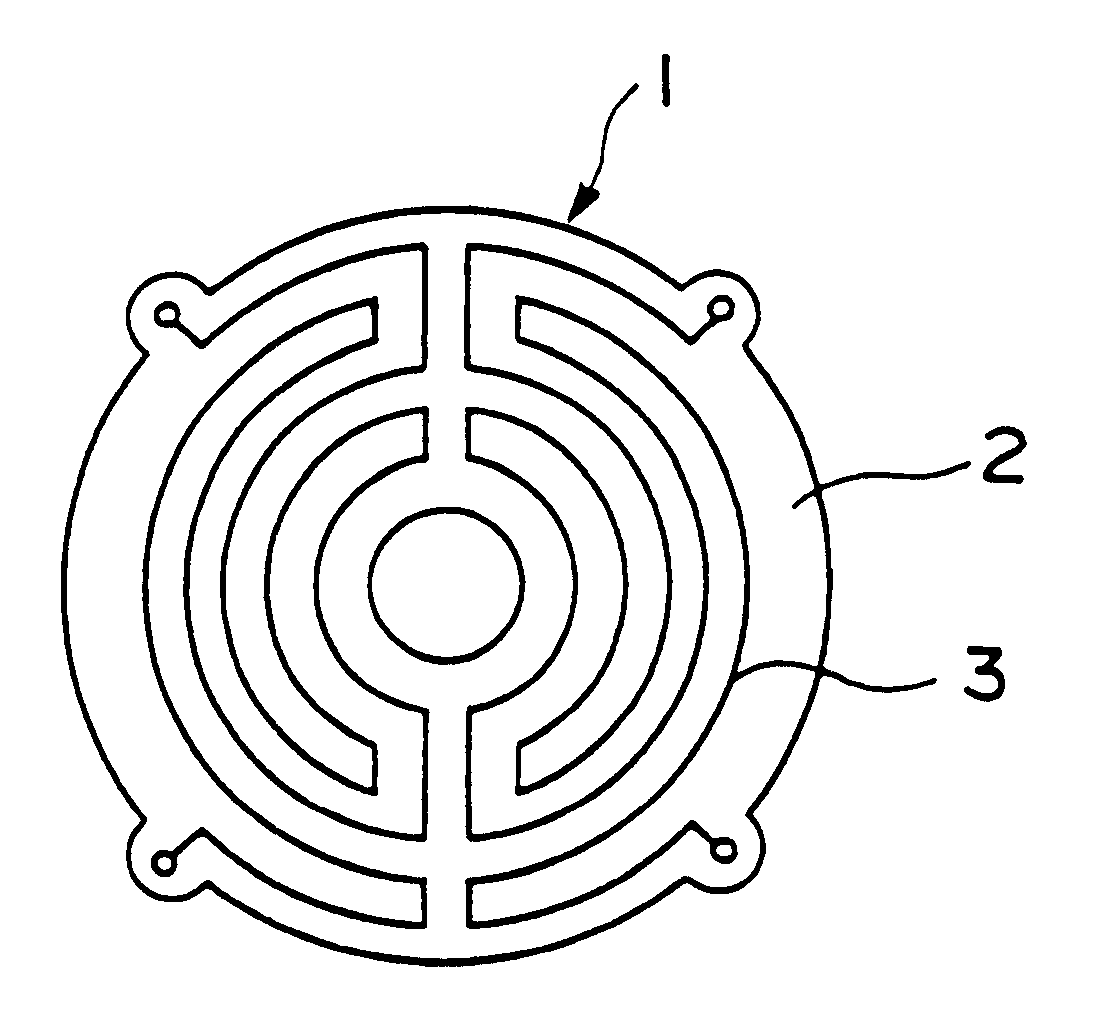

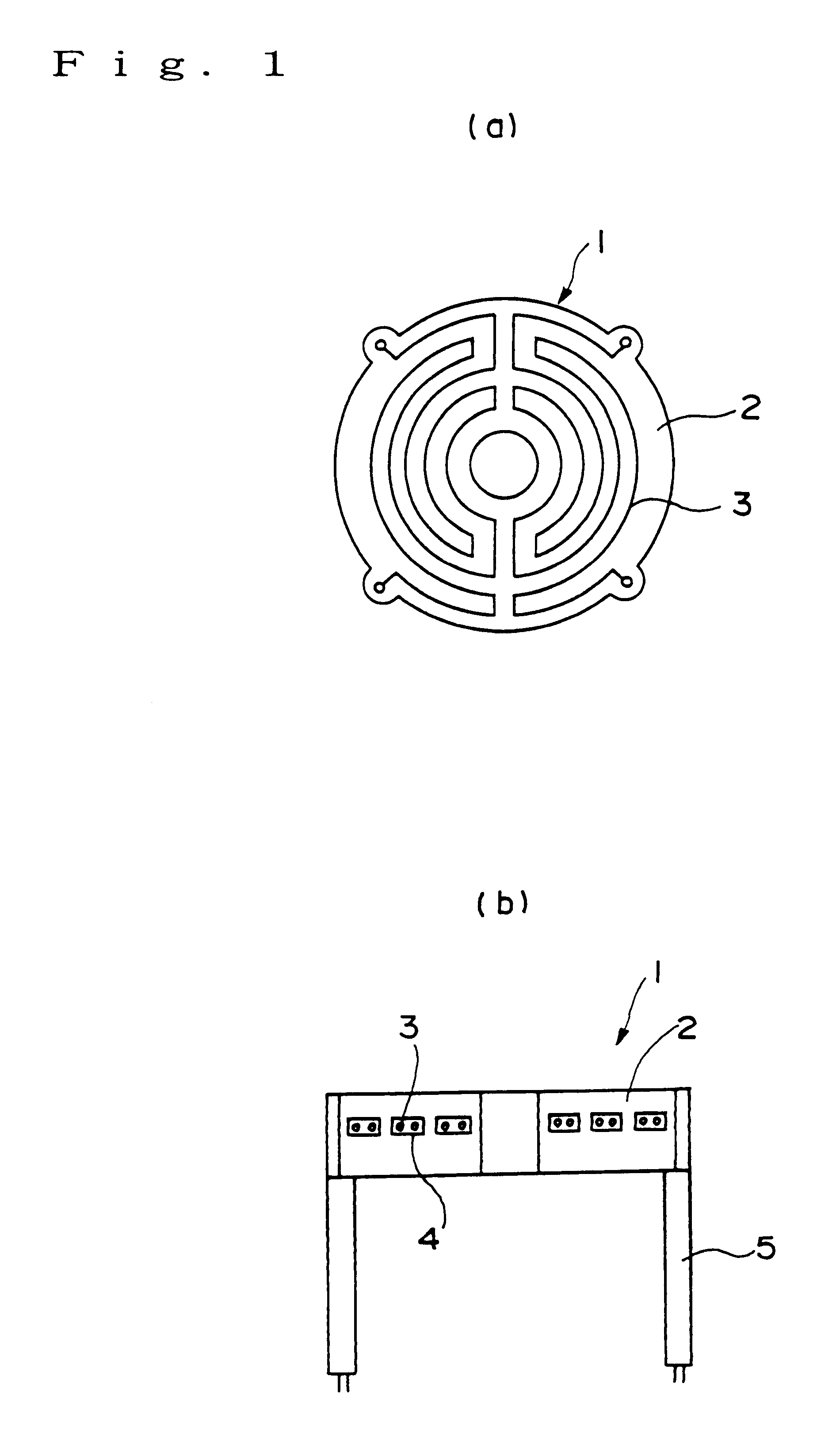

Carbon heater

ActiveUS20060032847A1Simple connection structureReduce manufacturing costFluid heatersDomestic stoves or rangesNanotechnologyCarbon filaments

Disclosed herein is a carbon heater. The carbon heater comprises a carbon filament disposed in a tube for serving as a heating element. The carbon filament has support parts integrally formed at the carbon filament while being protruded from the carbon filament in the direction perpendicular to the longitudinal direction of the carbon filament such that the support parts are supported inside the tube. Consequently, the carbon filament is more stably supported in the tube by the support parts, whereby the service life of the carbon heater is increased, and easy and convenient design and assembly of the carbon heater is accomplished.

Owner:LG ELECTRONICS INC

Flame-resistant, high visibility, Anti-static fabric and apparel formed therefrom

InactiveUS20140041107A1High tensile strengthImprove energy absorptionChemical protectionHeat protectionFiberYarn

A fabric for use in safety apparel comprising a first set of yarns comprising at least 60 percent modacrylic fibers, and a second set of yarns comprising at least some anti-static carbon filaments. The fabric meets at least the high visibility standard ANSI / ISEA-107-2010; the vertical flame test ASTM 1506-10w; and the Federal Test Method Standard 191A, Method 5931 for electrostatic decay, and the Electrostatic Discharge Association Advisory ADV11.2-1995 voltage potential.

Owner:GLEN RAVEN INC

Method for preparing carbon fibre braided packing

The invention relates to a method for preparing braided packing, in particular to a method for preparing carbon fiber braided packing, which mainly aims to solve problems of causing equipment to be frequently shutdown for inspection and affecting the normal operation of the production due to low tensile strength, easy scouring during the use, short service life, and the need of frequent replacement existing in the prior art. The method also solves the technical problems that certain materials with better strength have no electric conductivity and heat conductivity and can be overheated and burnt when the materials are used under working conditions of high pressure, high temperature and high speed, thereby easily producing dielectric leakage, frequently causing process shutdown, bringing great loss to the production and economy and so on. The method comprises the steps: the adoption of a polyacrylonitrile fiber, constant-temperature filament unwinding, multi-stage pre-oxidation, middle-temperature carbonization, the protection of high temperature carbonization by a micro-oxygen carbon corrosion method, sizing, filament winding, one-step carbon filament pretreatment, pipe inversion, the adjustment of spindle tension, fixed temperature constant control braiding, negative pressure filling and soaking, drying, shaping, inspection, packing and warehouse entry.

Owner:浙江国泰密封材料股份有限公司

Composite current collector and preparation method thereof

ActiveCN104200997AReduce manufacturing costReduce investmentSolid electrolytic capacitorsElectrode carriers/collectorsCarbonizationShielding gas

The invention discloses a composite current collector and a preparation method thereof. The method includes: coating mixture formed by nano carbon material, nano metal powder, metal catalyst, adhesive resin and organic solvent on one surface of a light foil, and rolling and pressing to form a conductive coating after drying; under a vacuum or protective gas atmosphere, performing high-temperature carbonization on the conductive coating to obtain the composite current collector. The method has the advantages that the conductive coating mixed by the nano carbon material, the nano metal powder, the metal catalyst and the adhesive resin, the adhesive resin is carbonized under catalyzing of the metal catalyst and under high temperature, and whisker-shaped carbon filaments which allow the nano metal powder and the nano carbon material to be connected, wrap the nano metal powder and the nano carbon material and is tightly combined with the light foil; no magnetic control sputtering equipment is needed, high equipment investment is avoided, no methane atmosphere is needed, and danger in production is lowered.

Owner:SAMXON ELECTRONICS DONG GUAN +1

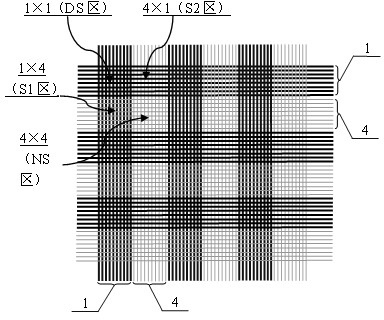

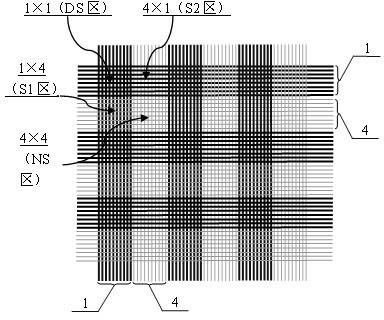

Wave absorbing machine woven fabric of cladding type carbon fiber filament composite yarns and application thereof

InactiveCN102425023BOvercoming the weakness of easily forming burrsWoven fabricsCarbon filamentsNanotechnology

The invention provides a wave absorbing machine woven fabric of cladding type carbon fiber filament composite yarns and application thereof. The cladding type carbon fiber filament composite yarns comprise warp yarns and weft yarns and are characterized in that: the whole or part of at least one of the warp yarns and the weft yarns consist of the cladding type carbon fiber filament composite yarns. The cladding type carbon fiber filament composite yarns overcome the defect that carbon fibers are easily burred in the process of weaving to make the carbon fiber filaments weaved on a common weaving machine like common yarns. The wave absorbing woven fabric can be used for manufacturing electromagnetic wave shielding and protective clothing and other textiles and widens application range of carbon filament fibers.

Owner:DONGHUA UNIV

Wave absorbing machine woven fabric of cladding type carbon fiber filament composite yarns and application thereof

InactiveCN102425023AOvercoming the weakness of easily forming burrsWoven fabricsCarbon filamentsNanotechnology

The invention provides a wave absorbing machine woven fabric of cladding type carbon fiber filament composite yarns and application thereof. The cladding type carbon fiber filament composite yarns comprise warp yarns and weft yarns and are characterized in that: the whole or part of at least one of the warp yarns and the weft yarns consist of the cladding type carbon fiber filament composite yarns. The cladding type carbon fiber filament composite yarns overcome the defect that carbon fibers are easily burred in the process of weaving to make the carbon fiber filaments weaved on a common weaving machine like common yarns. The wave absorbing woven fabric can be used for manufacturing electromagnetic wave shielding and protective clothing and other textiles and widens application range of carbon filament fibers.

Owner:DONGHUA UNIV

Heat-conducting gasket and preparation method thereof

PendingCN113337253AImprove thermal conductivityEnsure ultra-high filler contentHeat-exchange elementsModifications by conduction heat transferPolymer sciencePolymer chemistry

The invention provides a heat-conducting gasket, which comprises a heat-conducting filler and a reinforcing material. The heat-conducting filler is a two-dimensional heat-conducting filler arranged along the thickness direction of the heat-conducting gasket, and the reinforcing material is filaments formed by high-molecular polymer wire drawing and / or carbon filaments formed by heat treatment of the filaments formed by high-molecular polymer wire drawing. The two-dimensional heat-conducting filler is tightly connected by the polymer filaments and / or the carbon filaments to form a filler / polymer and / or filler / carbon filament network structure.

Owner:CHANGZHOU FUXI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com