Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3461 results about "Resin composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

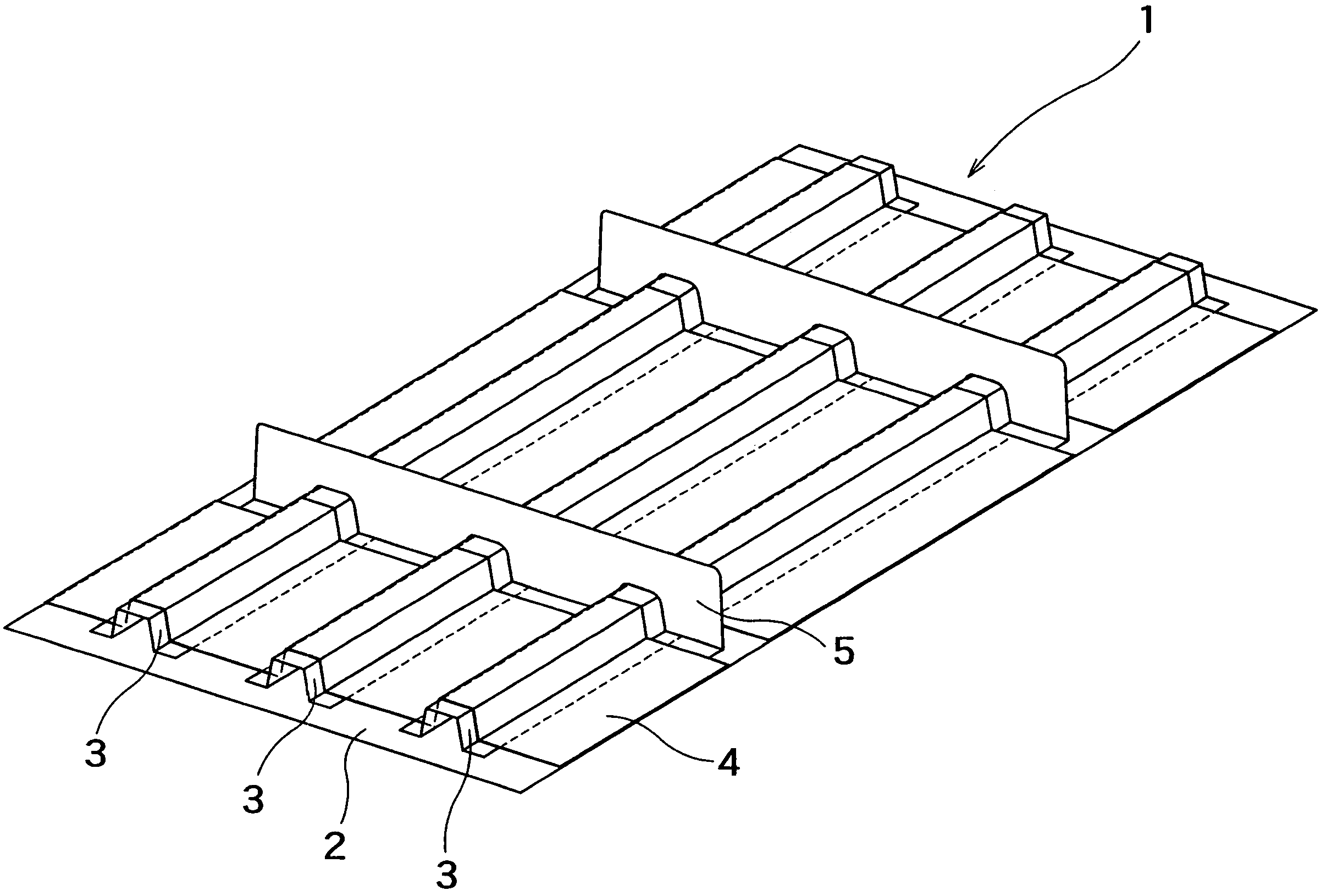

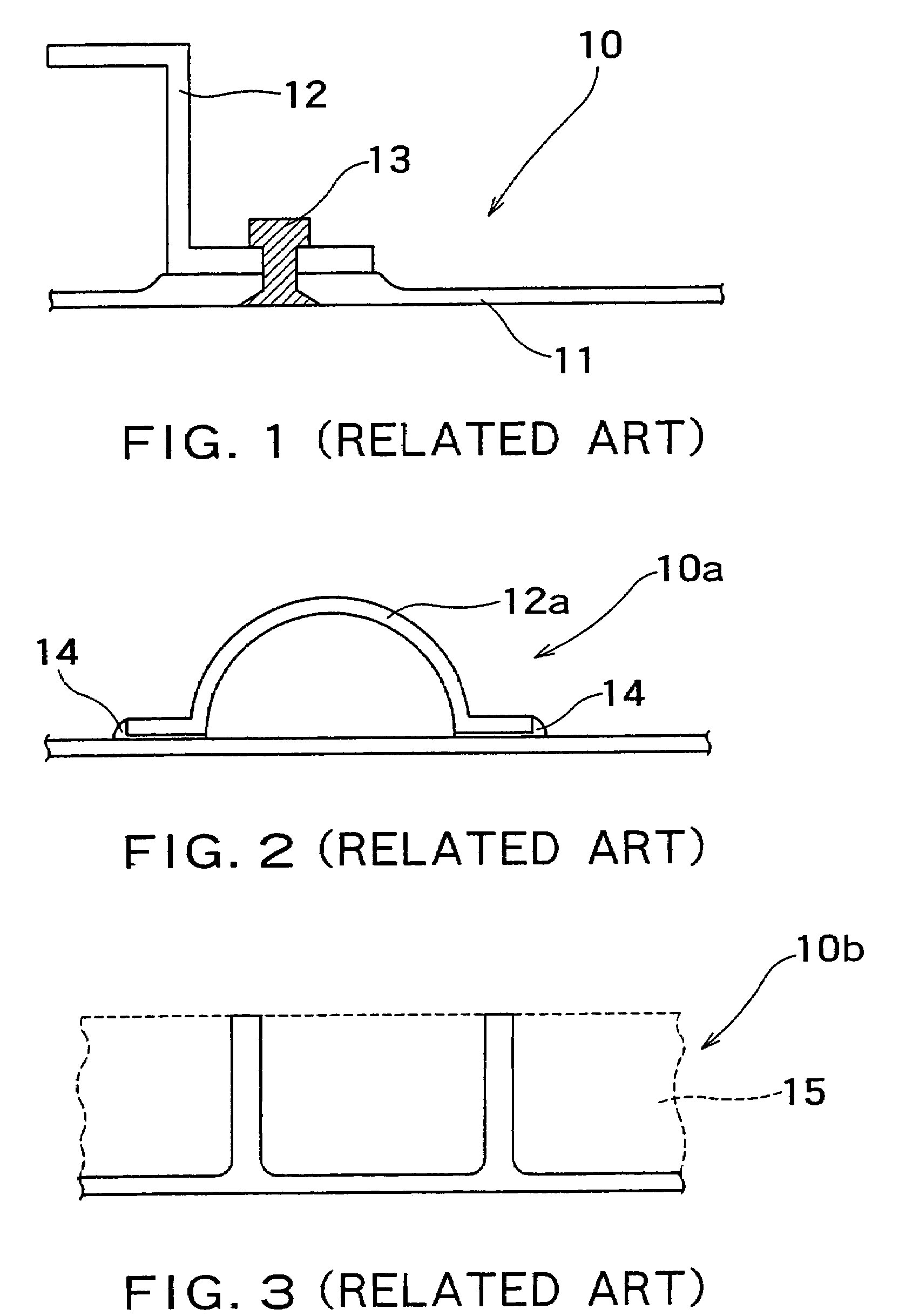

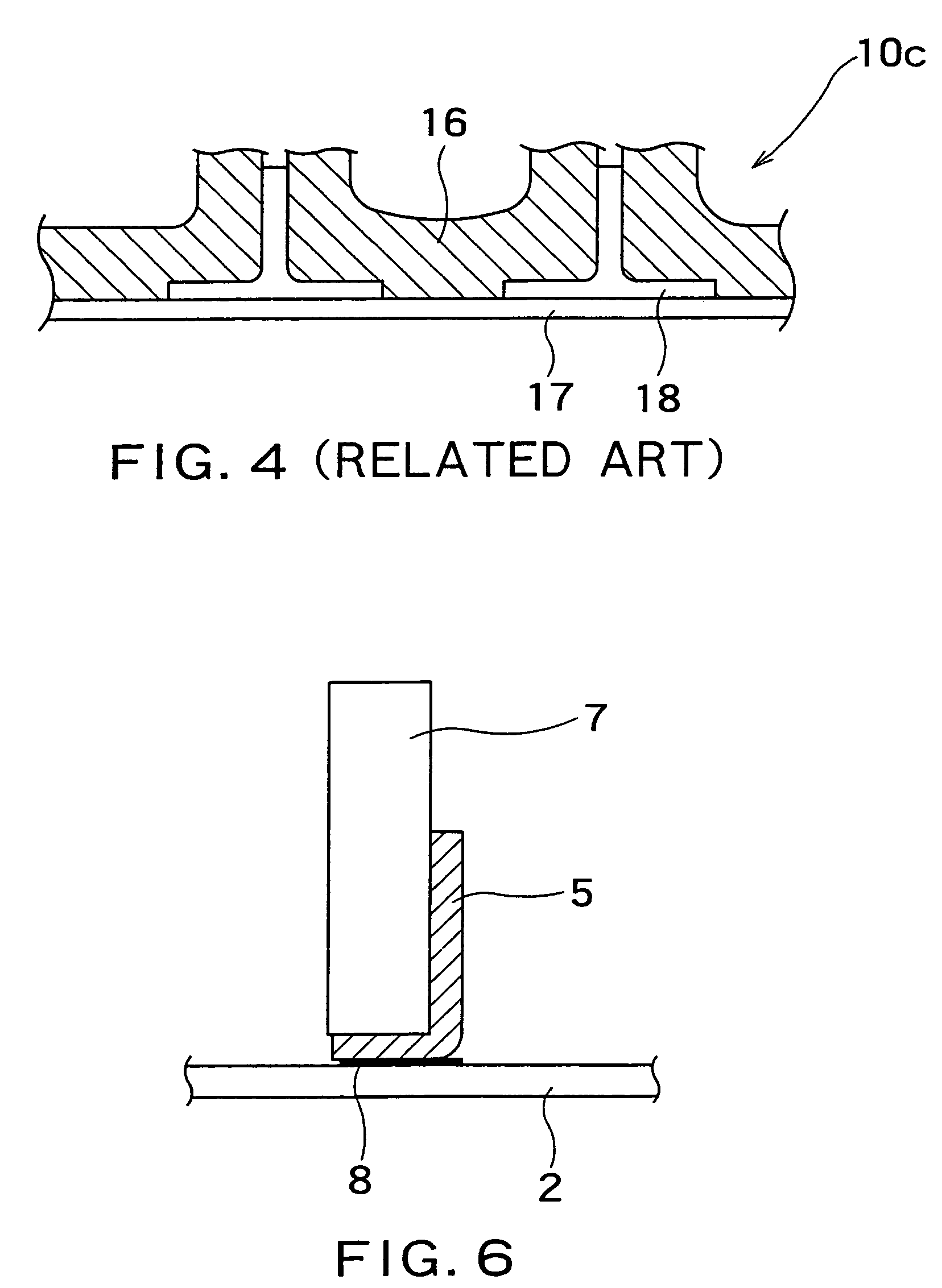

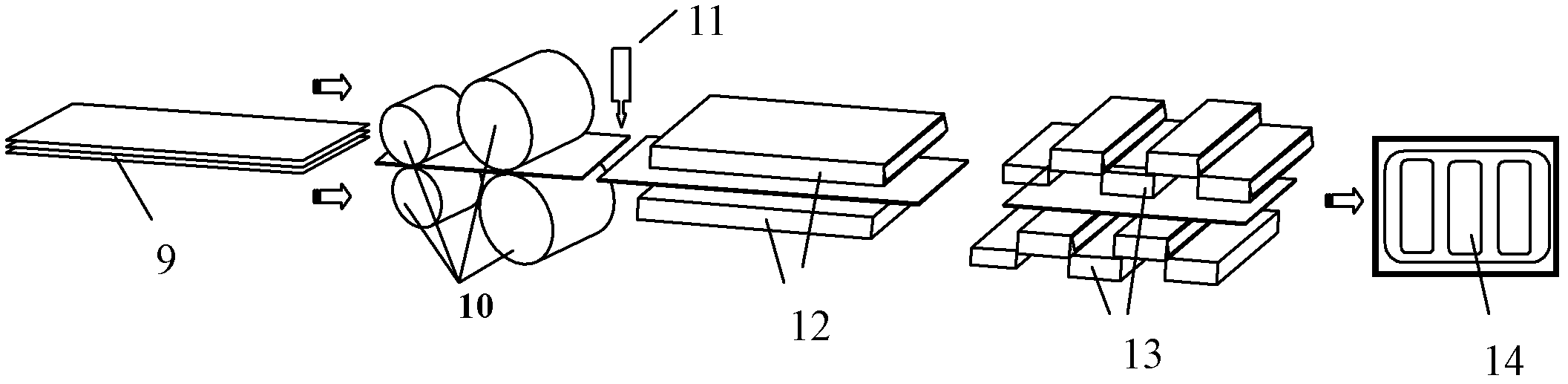

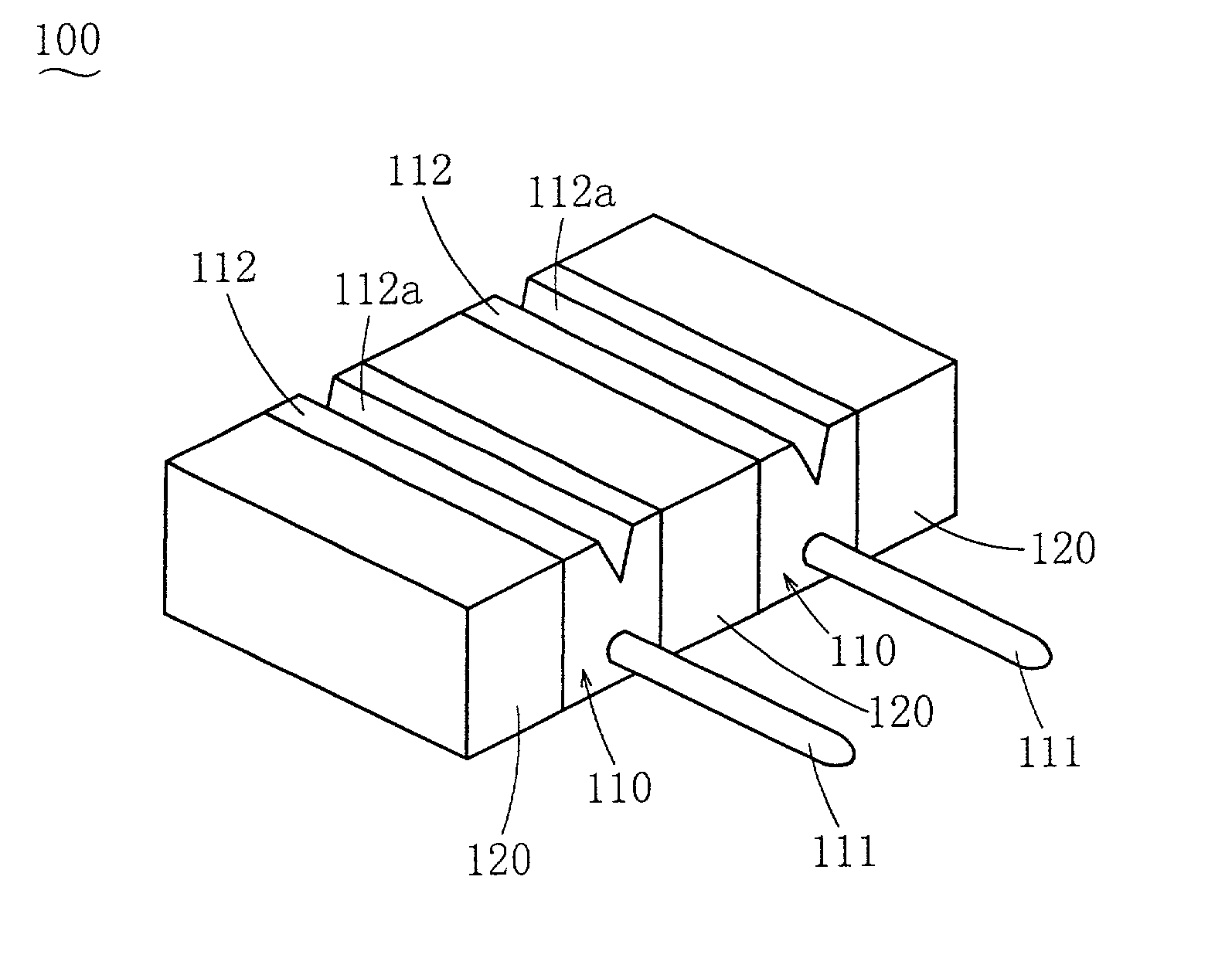

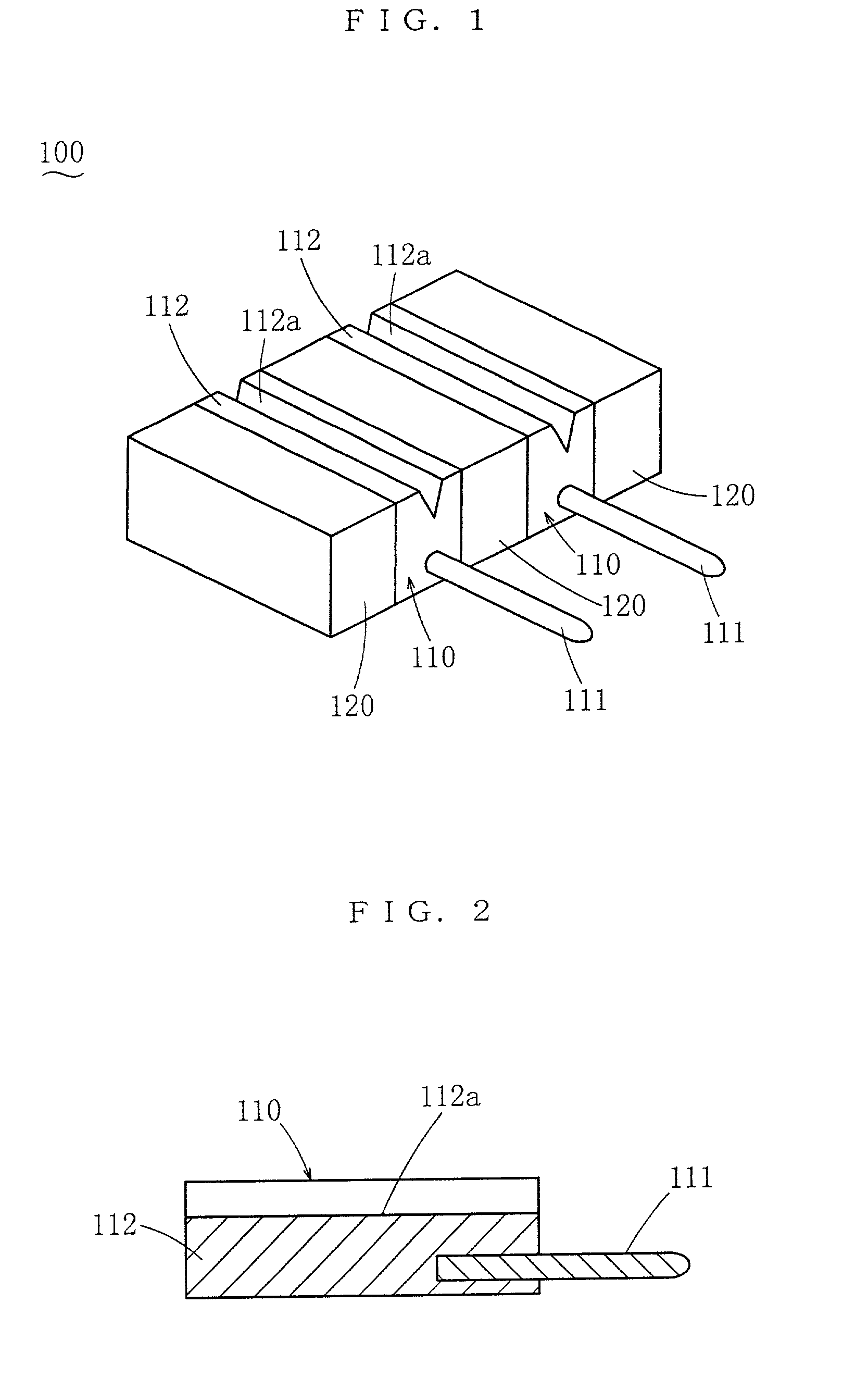

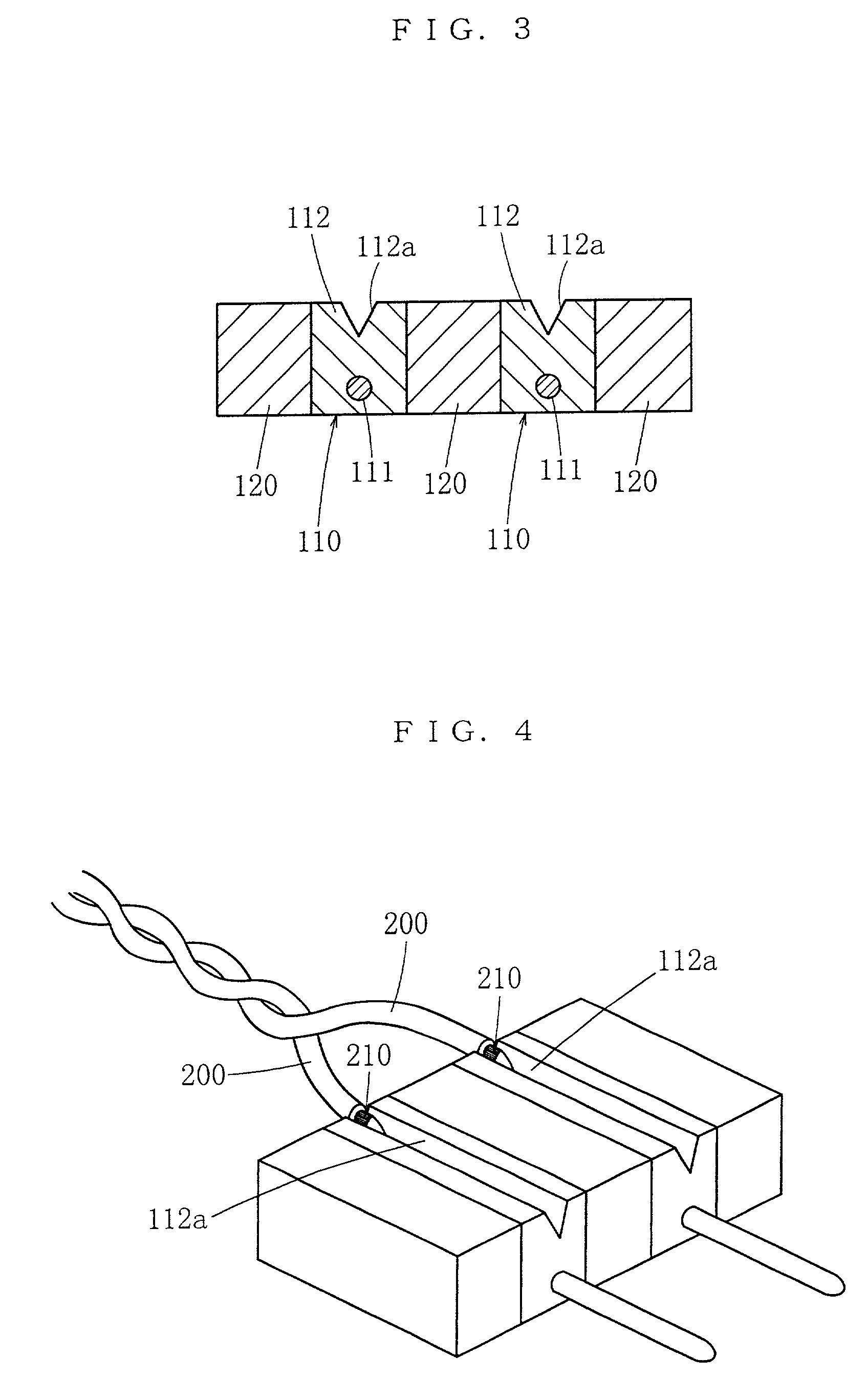

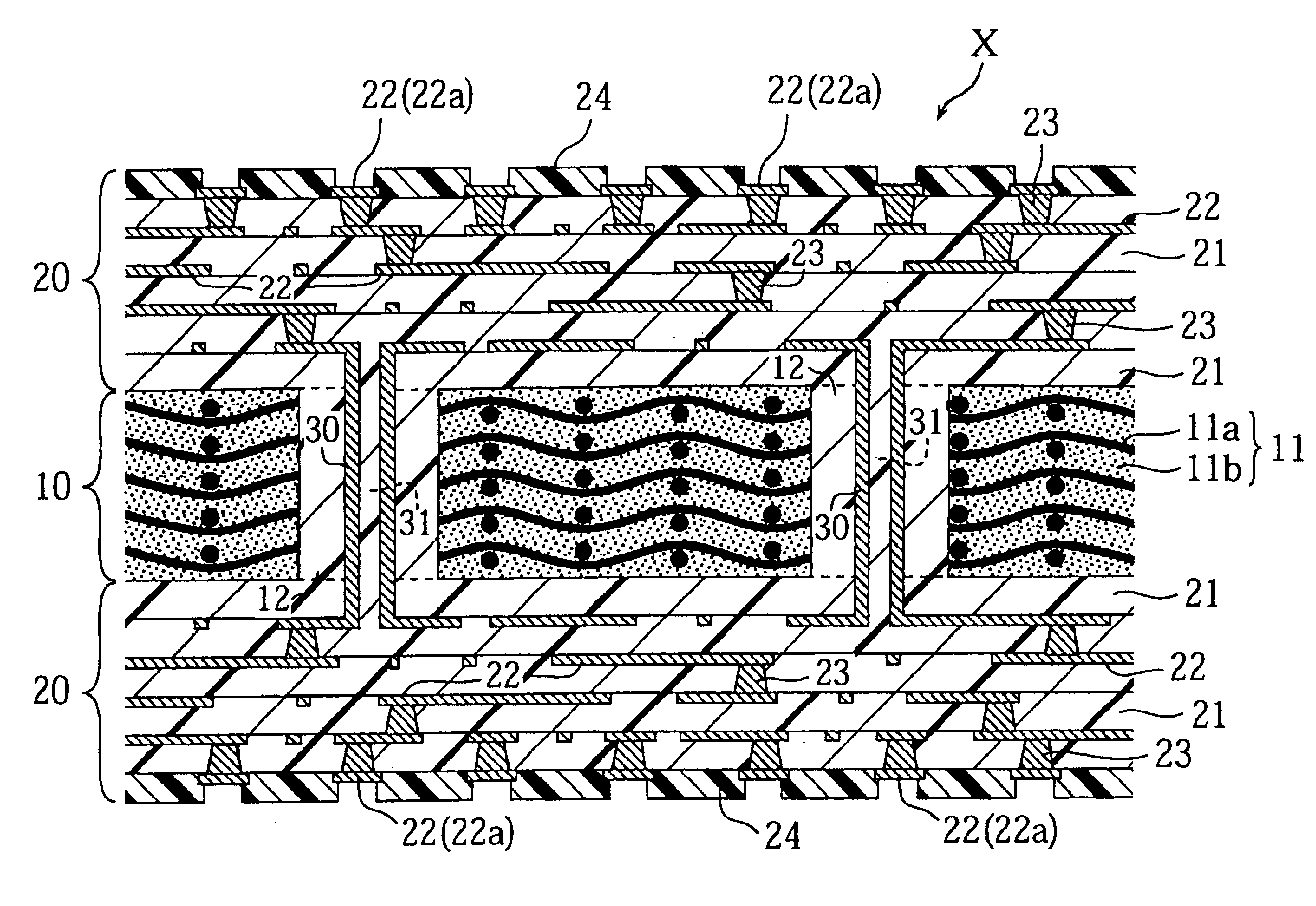

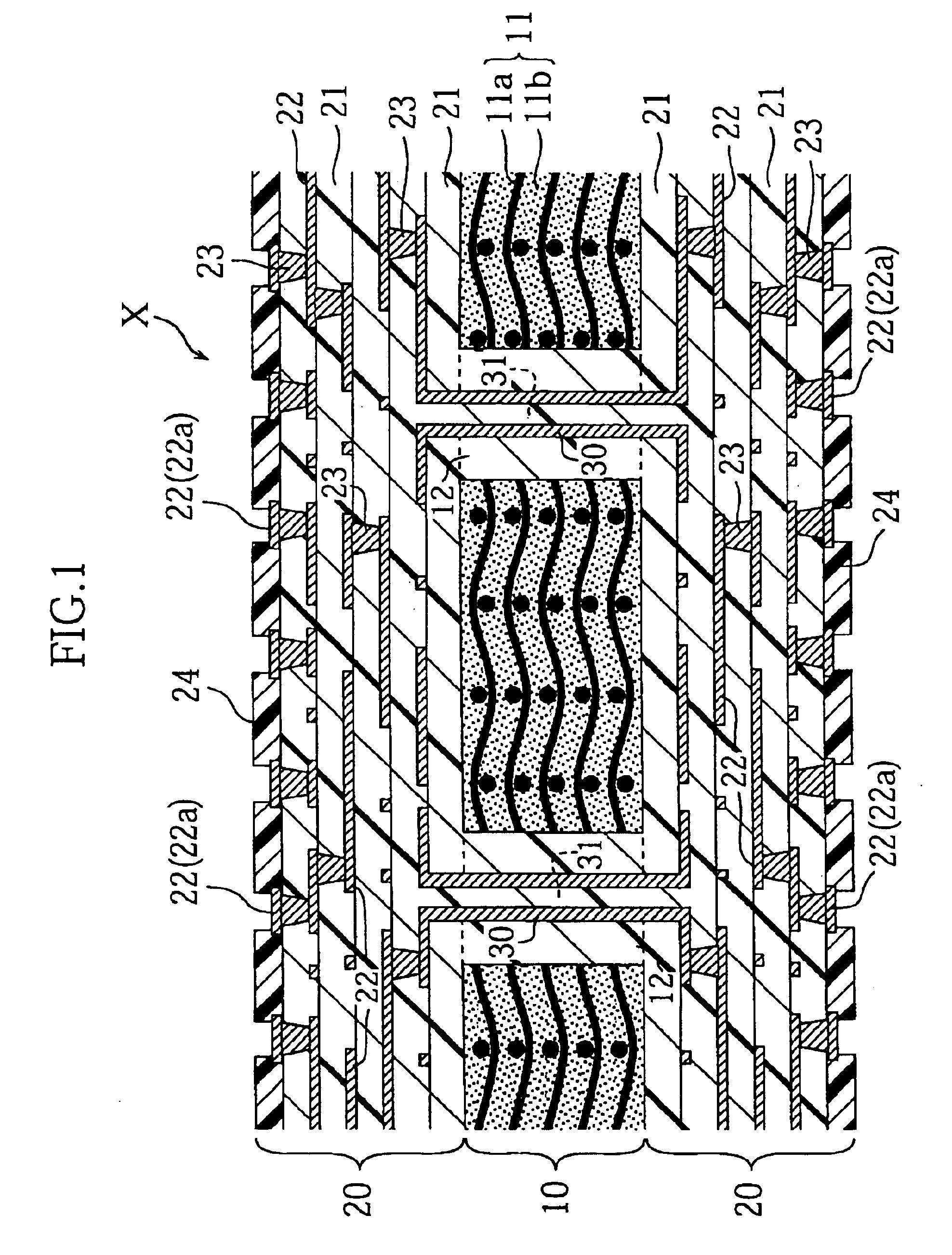

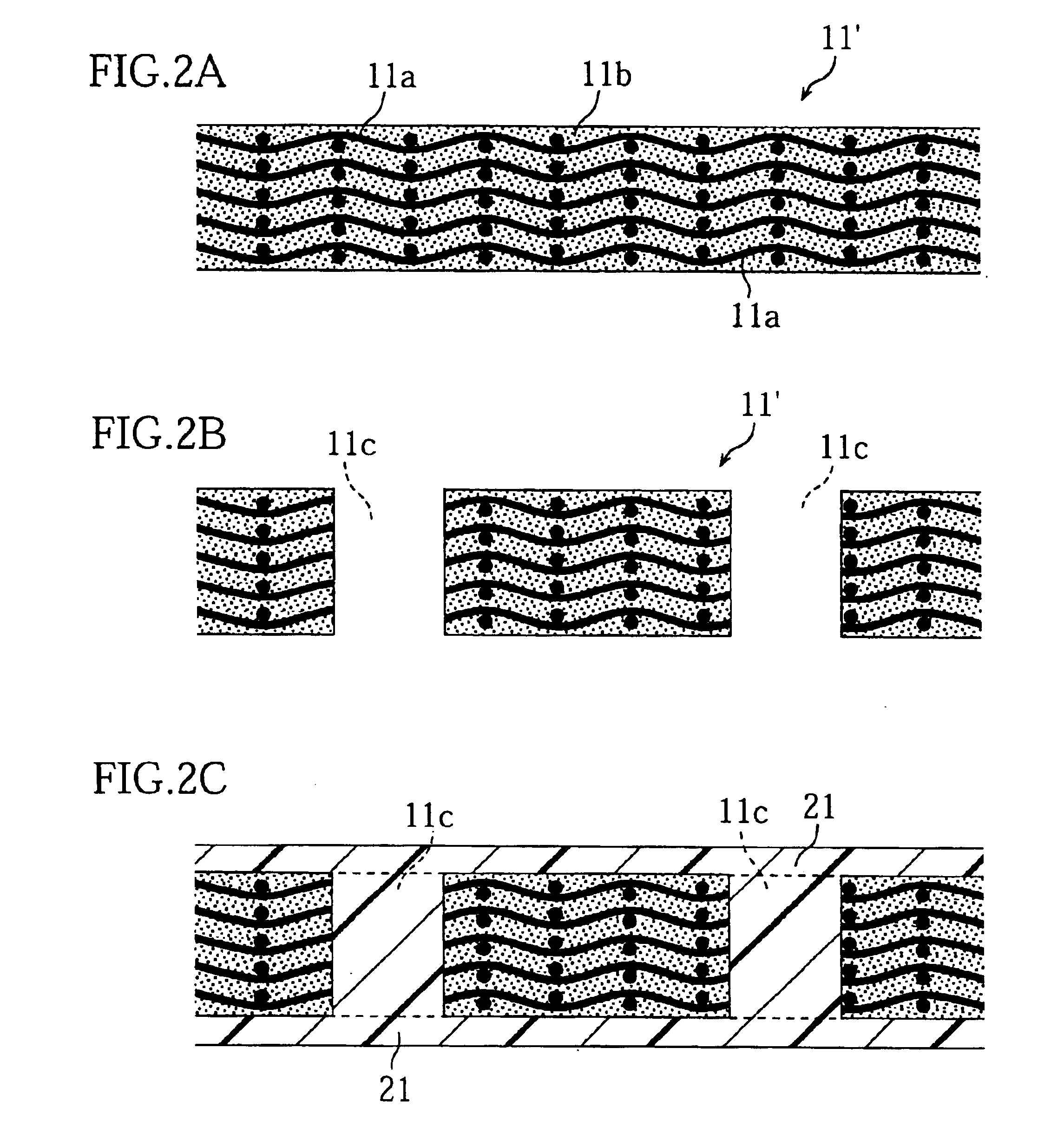

Composite material-stiffened panel and manufacturing method thereof

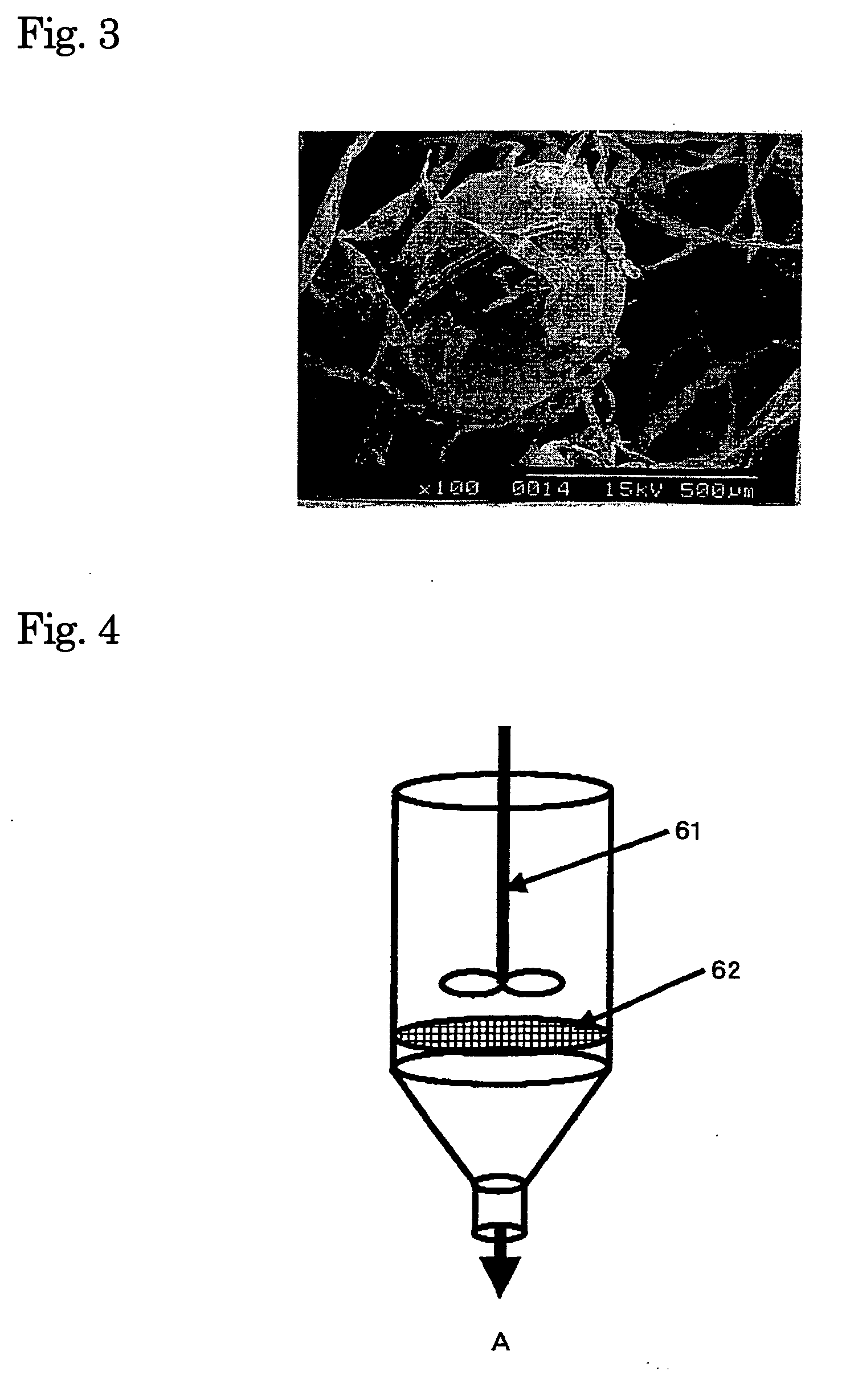

A composite material-stiffened panel has a skin obtained by molding a fiber-reinforced resin composite material into a flat skin, stiffeners arranged in rows on one surface of the skin, and a fiber-reinforced resin-composite material stitched on the skin covering the stiffeners. The composite material-stiffened panel can be manufactured as follows: A first fabric material is placed on a tool having a panel-shaped surface. Stiffeners are placed on the first fabric materials. A second fabric material is placed on the stiffeners to cover at least some of the stiffeners. The second fabric materials are reformed to match the shape of the stiffeners. The reformed second fabric material is stitched on the first fabric material along edges of the stiffeners. All the materials are covered with a bagging film for vacuum. Resin is infiltrated into the fabric materials by a RTM or a RFI method. The infiltrated resin is heated to be hardened.

Owner:SUBARU CORP

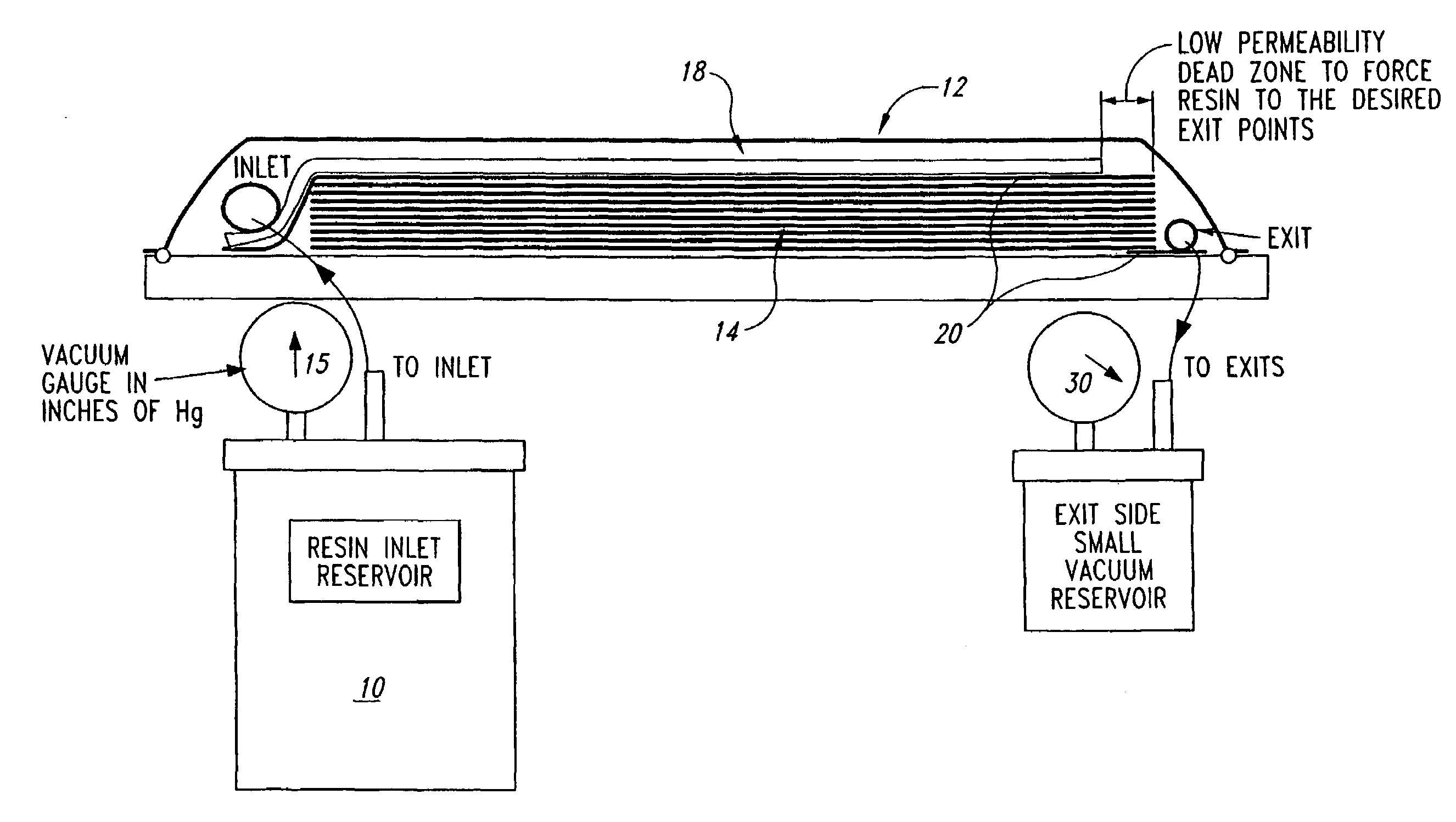

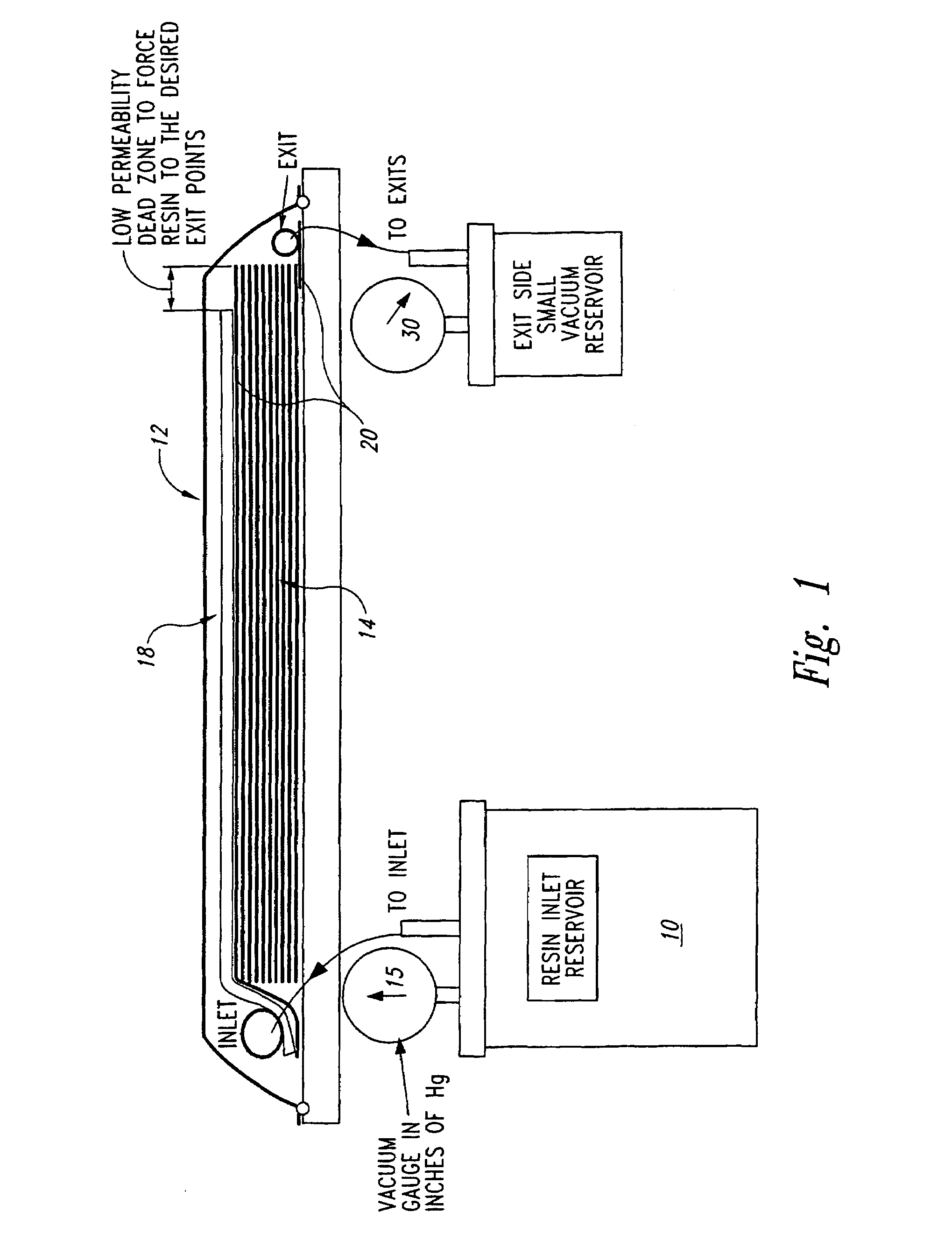

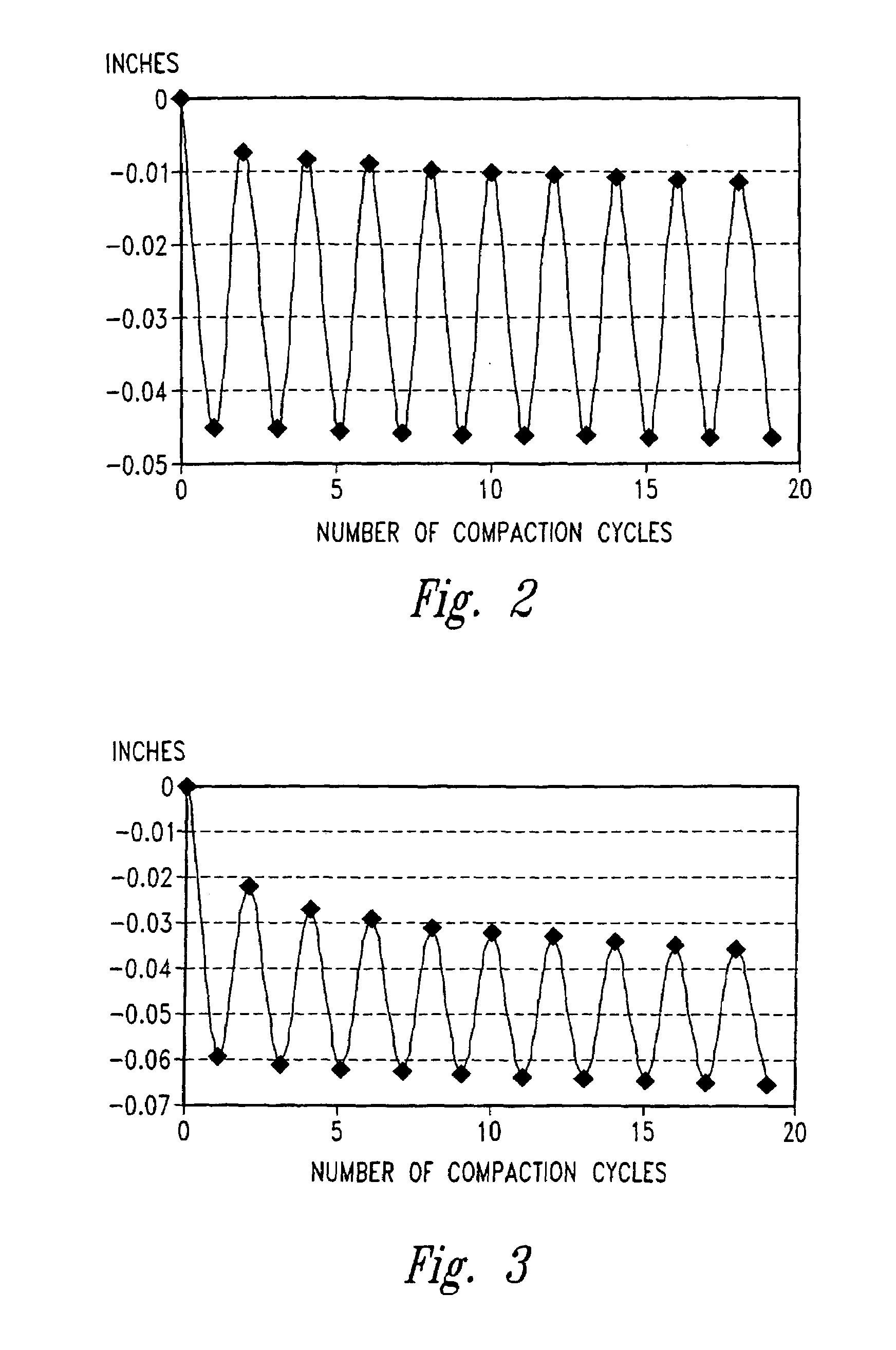

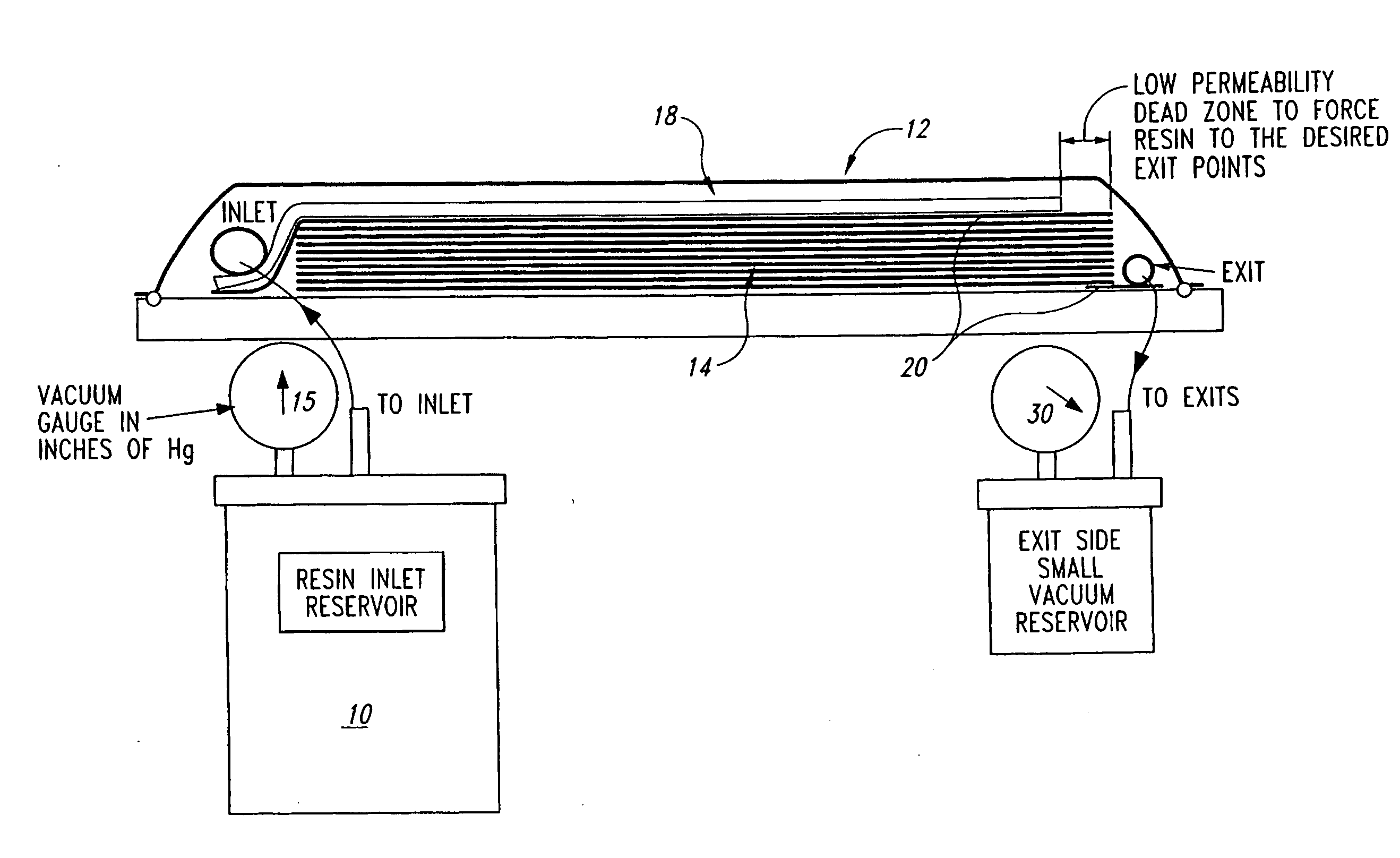

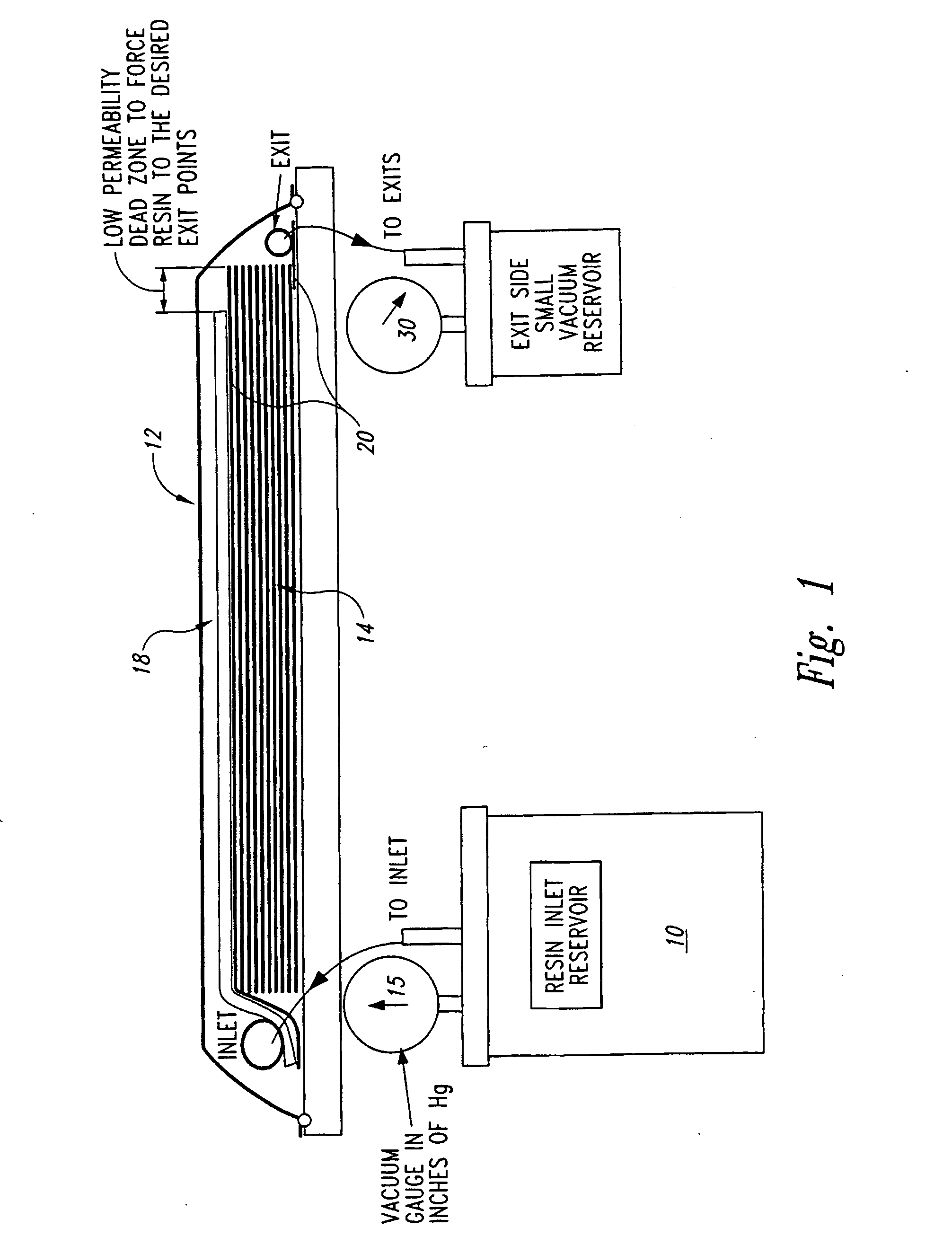

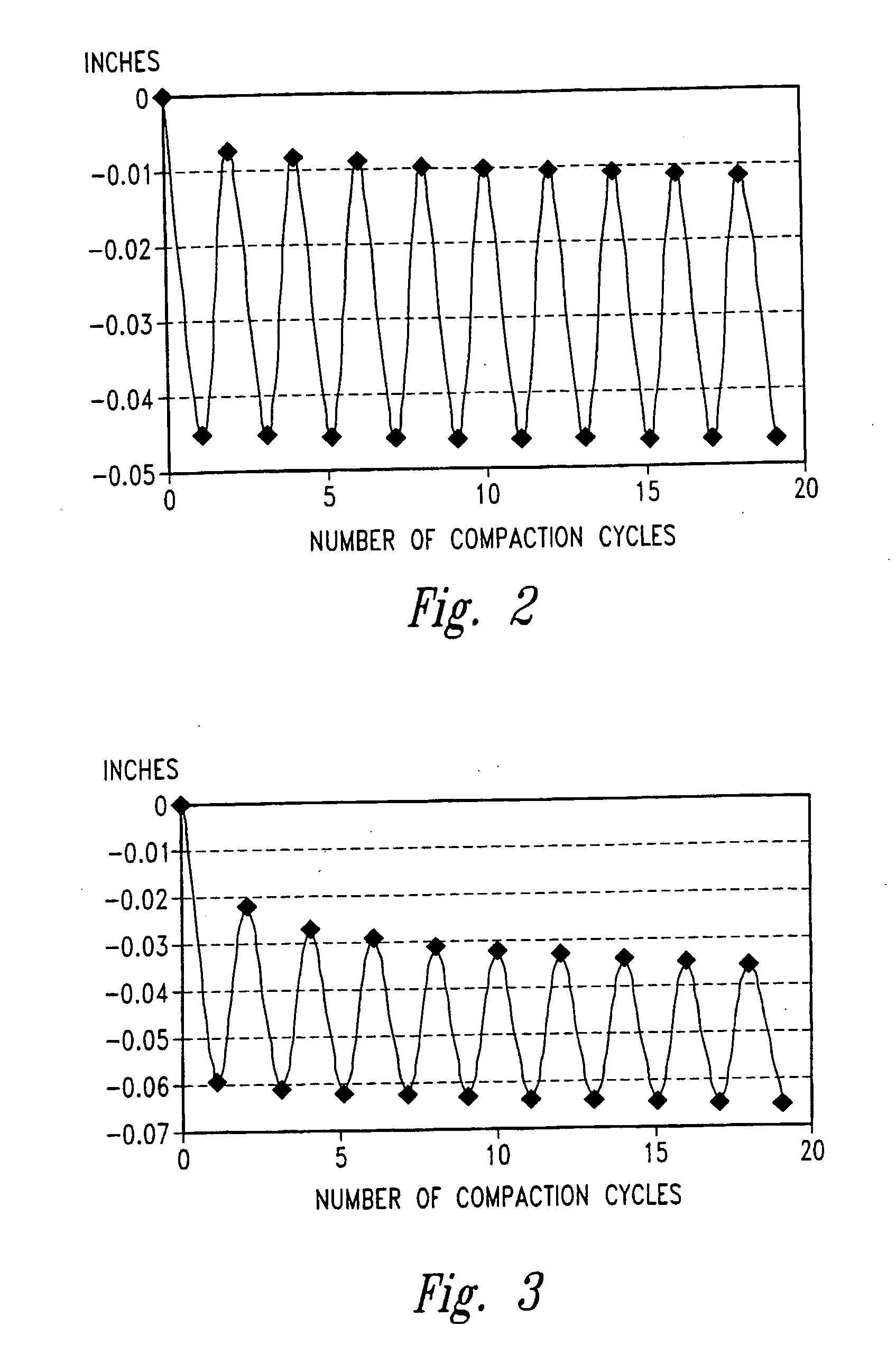

Controlled atmospheric pressure resin infusion process

By evacuating the resin feed tank to a pressure below atmospheric pressure, employing cyclic compaction, and controlling the net compaction pressure, we are better able to control a resin infusion process, particularly a vacuum assisted resin transfer molding process, and produce aerospace-grade fiber-reinforced resin composite having fiber volume fractions and tool-side surface finishes comparable to or exceeding those made using an autoclave.

Owner:THE BOEING CO

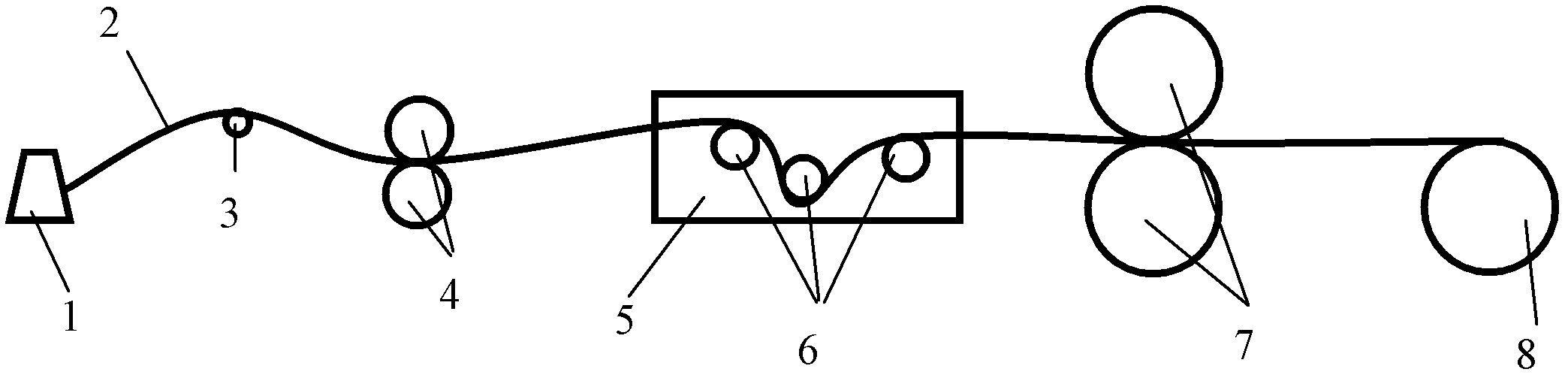

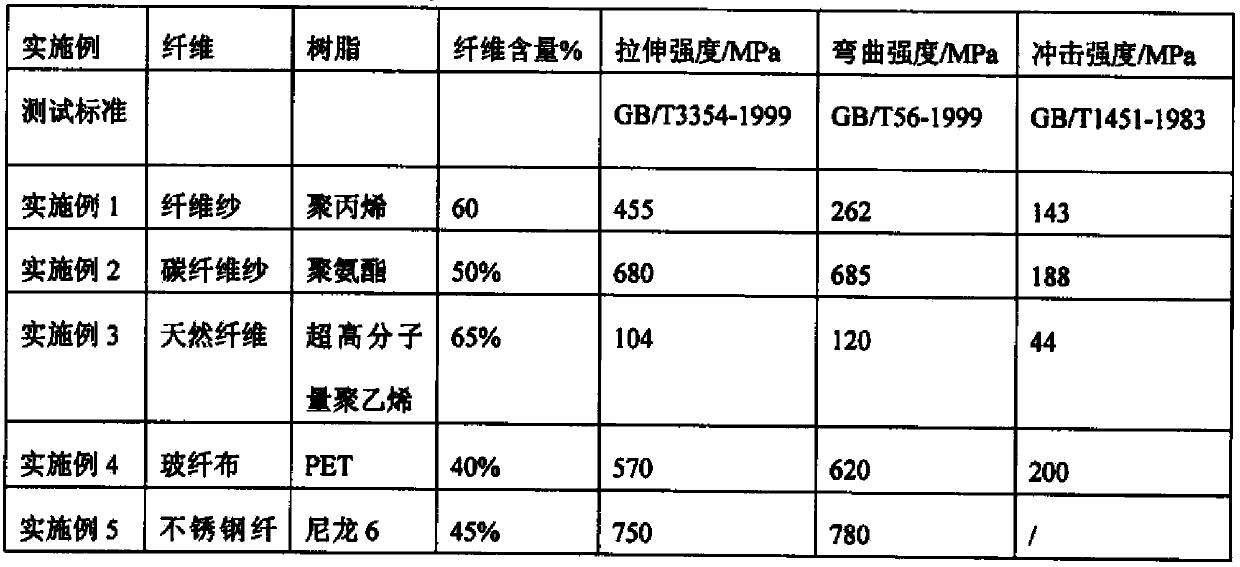

Thermoplastic resin composite material and preparation method and application thereof

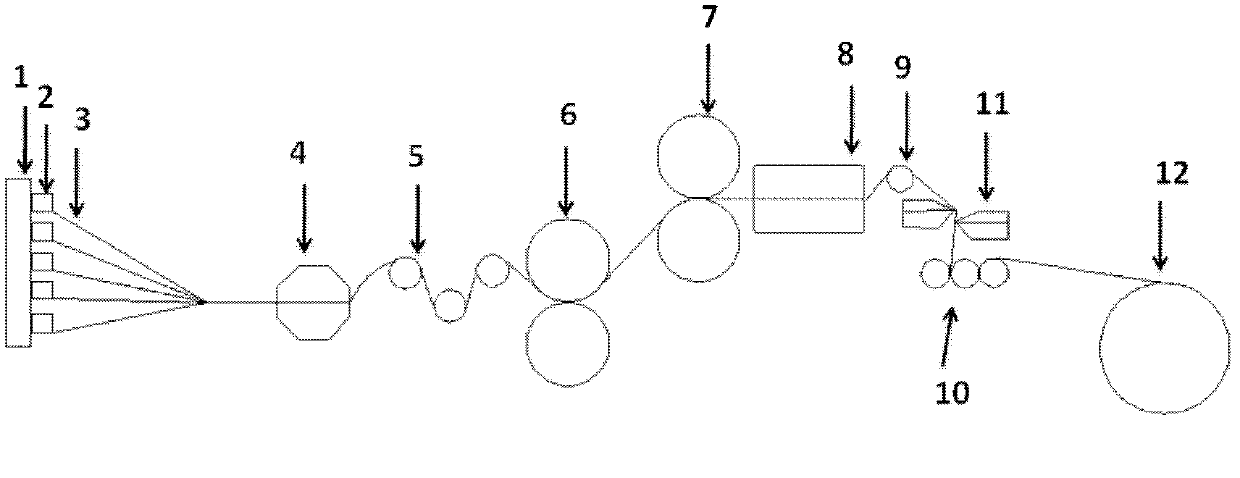

The invention falls into the technical field of resin material, and discloses thermoplastic resin composite material and a preparation method and application thereof. The thermoplastic resin composite material comprises 40-80 wt.% of continuous fibers, 20-30 wt.% of thermoplastic resin, 0-18 wt.% of a flame retardant, 0-9 wt.% of an anti-ultraviolet agent and 0-3 wt.% of an antioxidant. The preparation method of the thermoplastic resin composite material includes unreeling, spreading and laying fibers; impregnating unidirectional fiber fabrics; cooling and flattening; and coiling and forming. Also disclosed is a method for manufacturing an automobile door from the thermoplastic resin composite material, which includes laying impregnated unidirectional fiber tapes; molding the impregnated tapes under heating and pressing into composite sheet material; preheating the composite material; and press molding the composite material in a mold. The inventive composite automobile door has the advantages of integral molding, excellent overall properties, good impact resistance, resistance to damage, resistance to permanent deformation, etc.

Owner:滁州格美特科技有限公司

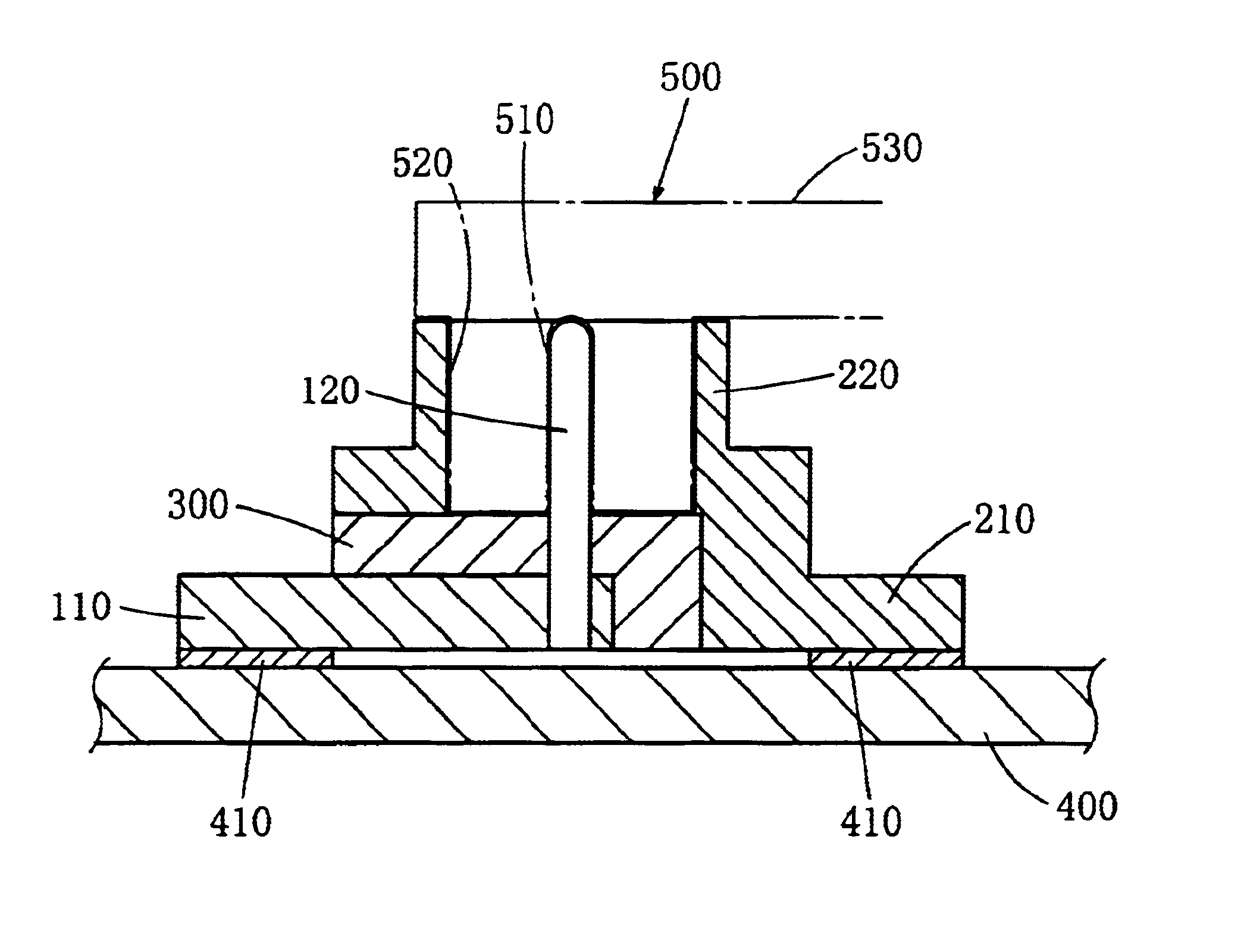

Electric connector for twisted pair cable using resin solder and a method of connecting electric wire to the electric connector

InactiveUS20020142676A1Firmly connectedIncrease the cross-sectional areaContact member assembly/disassemblySoldered/welded conductive connectionsElectricityElectrical conductor

The objectives of the present invention include to connect a twisted pair cable to the electric connector without undoing the twist of the end of the twisted pair cable, to accurately keep the twist of the twisted pair cable up to the end thereof, to make the twisted pair cable fully exhibit its noise cancellation effect, and to maximize impedance matching. The electric connector for twisted pair cable using resin solder according to the present invention comprises a pair of electric contacts having the first connecting part, which fits with the counterpart connector, and the second connecting part, to which the conductor of the electric wire is connected, and an insulating member, which insulates and holds these electric contacts. In each of the electric contacts, at least a part of the second connecting part, to which the conductor of the electric wire is connected, is made of a lead-free ultrahigh-conductive plastic being a conductive resin composite.

Owner:JST MFG CO LTD

Carbon fiber reinforced composite and preparation thereof

The invention discloses carbon fiber reinforced thermoplastic resin composite material which is composed of the components according to the percentage by weight: carbon fibers with the surface modified accounting for 5 percent to 50 percent, thermoplastic resin accounting for 44 percent to 75 percent, polytetrafluoroethylene accounting for 5 percent to 15 percent and processing auxiliary agent accounting for 1 percent to 5 percent; the carbon fibers with the surface modified is manufactured by processing the carbon fibers in specially mixed acidic solution under the temperature of 40 DEG C to 80 DEG C for 30 minutes to 120 minutes and dried at the temperature of 80 DEG C to 150 DEG C. The invention also discloses the preparation method of the carbon fiber reinforced thermoplastic resin composite material. The carbon fibers of the carbon fiber reinforced thermoplastic resin composite material provided by the invention are dispersed in a state of 3 mm to 5 mm in a resin matrix, the original high intensity of the carbon fibers is maintained to the maximum, so as to ensure the prepared composite material to have high intensity, high modulus, high heat resistant and high wear resistant performances.

Owner:宁波益德新材料有限公司

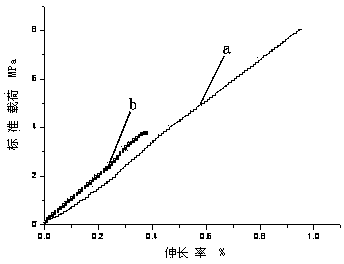

Graphene oxide/light cured resin composite and its preparation method and application

The invention provides a graphene oxide / light cured resin composite and its preparation method and application, the graphene oxide / light cured resin composite comprises two phases of graphene oxide and light cured resin, the graphene oxide is evenly dispersed in the light curing resin, the content of the graphene oxide is 0.1-1wt%, and the light cured resin comprises an oligomer, a light initiator and an active diluent. A graphene oxide nano material is dispersed in the light curing resin to obtain the graphene oxide / light cured resin nano composite, elongation at break and maximum bending strain of ordinary light cured resin is improved to a certain extent, and the impact strength of a coating film is increased by 2 times, so that a part printed by a 3D printer has better mechanical property.

Owner:QINGDAO UNIV OF SCI & TECH

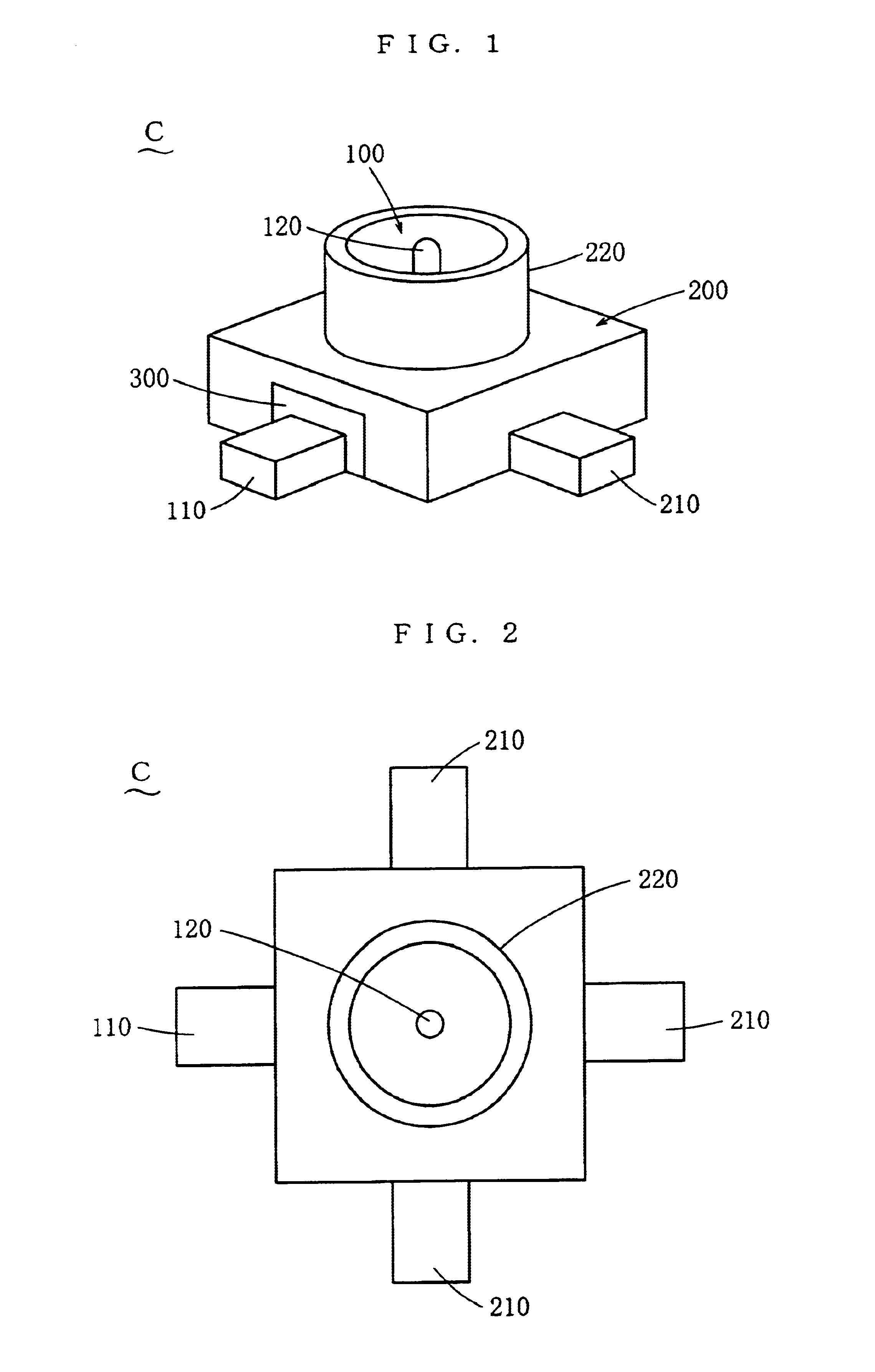

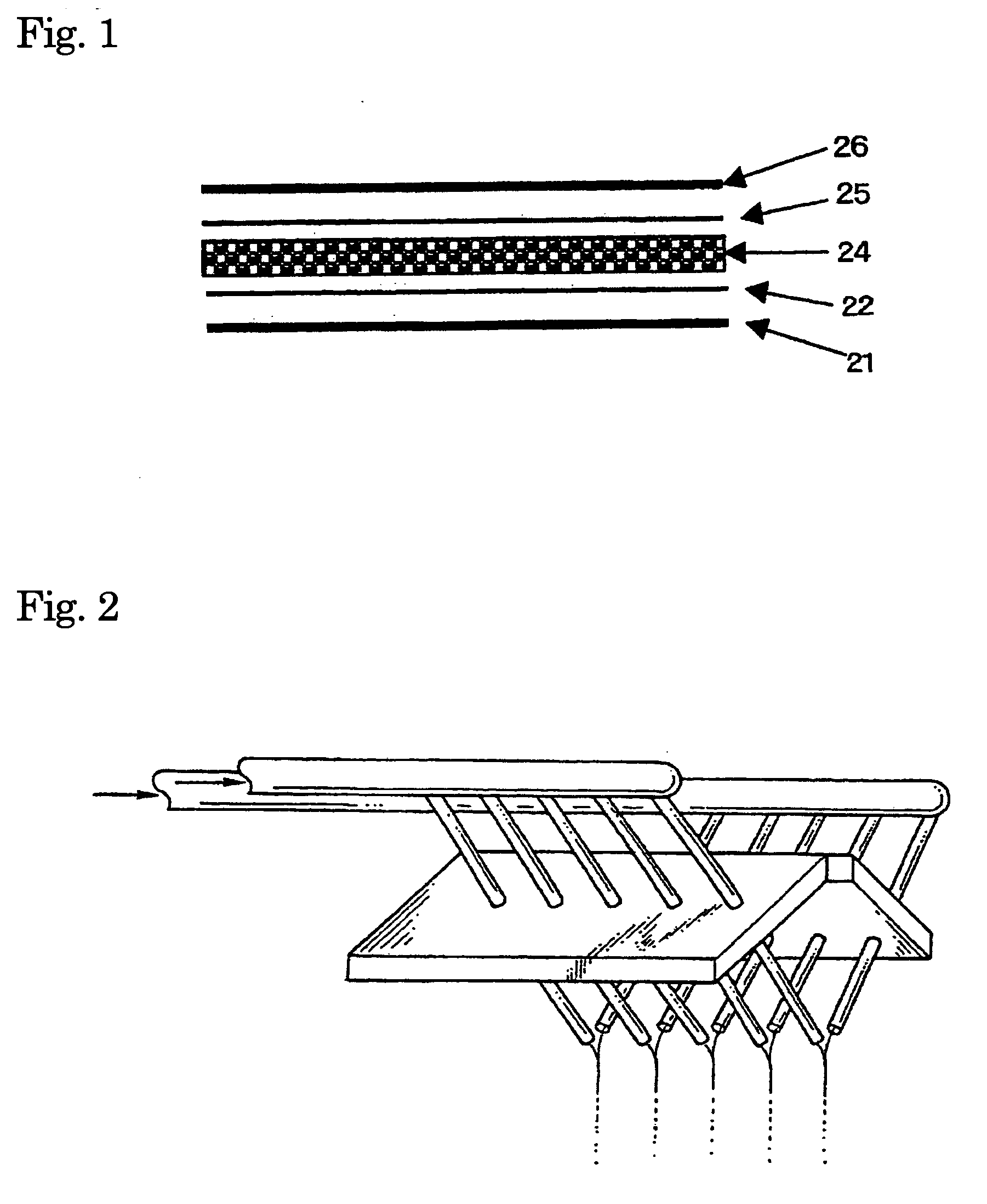

Wiring board with core layer containing inorganic filler

ActiveUS6869665B2Prevent the wiring board from being warpedSemiconductor/solid-state device detailsPrinted circuit aspectsFiberElectrical conductor

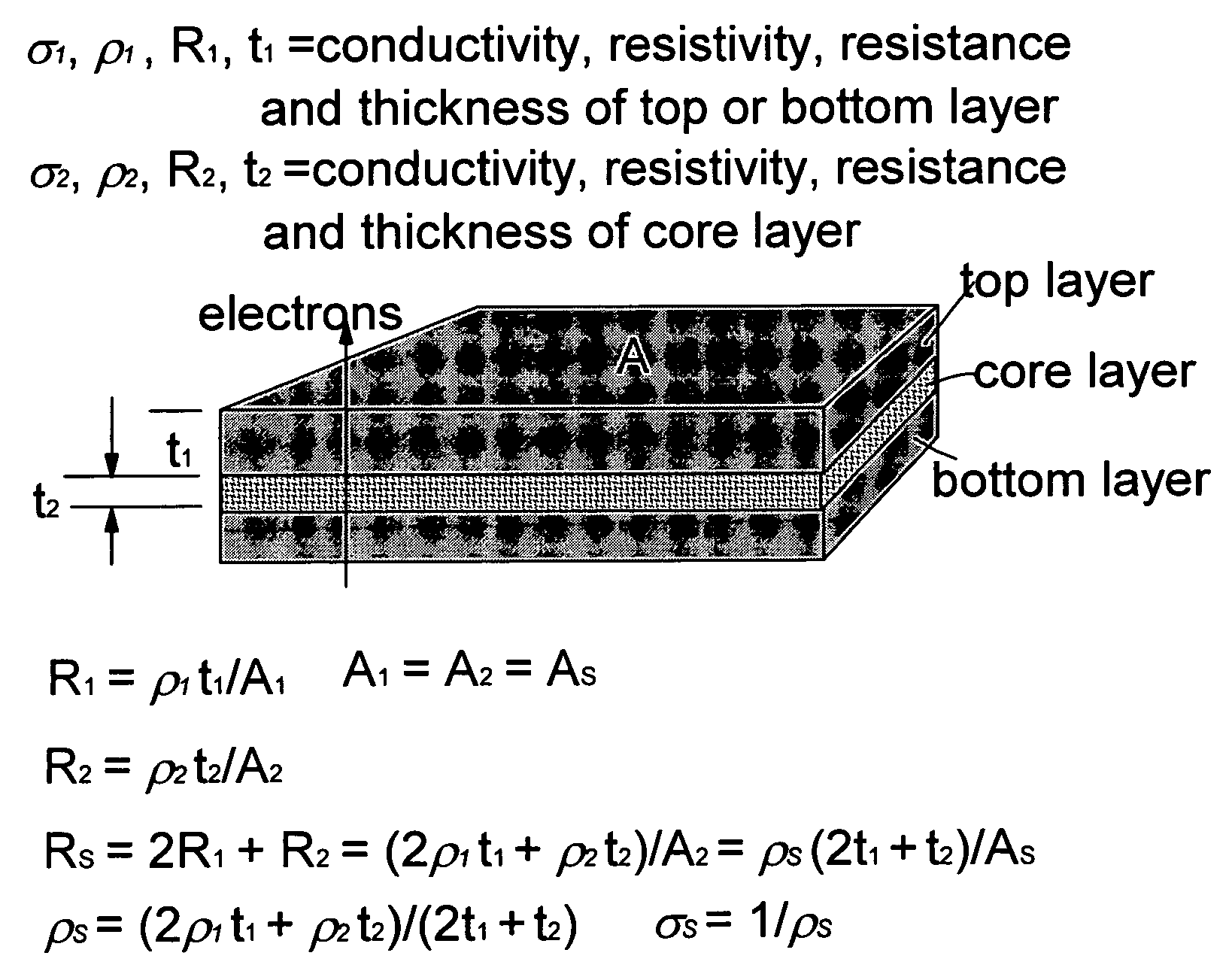

A wiring board includes a core layer and a pair of multilayer wiring portions. The core layer, having an upper surface and a lower surface, is formed from a resin composite which contains resin filler and encloses several pieces of carbon fiber cloth. One of the multilayer wiring portions is stacked on the upper surface of the core layer, while the other is stacked on the lower surface of the core layer. Each multilayer wiring portion is composed of a number of insulating layers and wiring patterns stacked alternately with the insulating layers. The wiring patterns of the upper and the lower wiring portions are connected to each other by conductors extending through the entire thickness of the core layer.

Owner:FUJITSU LTD

Electric contact and an electric connector both using resin solder and a method of connecting them to a printed circuit board

InactiveUS6717065B2Increase the cross-sectional areaGreat freedomTwo pole connectionsContact member assembly/disassemblyElectrical conductorEngineering

An electric contact using resin solder is connected to a printed circuit board, which has a conductor provided on a surface thereof. This electric contact comprises a leg, which contacts the conductor of the printed circuit board, and a connecting part, which is connected to the conductor of the counterpart member. At least a part of the leg, which contacts the conductor of the printed circuit board, is made of a lead-free ultrahigh-conductive plastic being a conductive resin composite. An electric connector includes the electric contact and an insulating housing, which holds the electric contact so that the part of the leg, which contacts the conductor of the printed circuit board, is exposed.

Owner:JST MFG CO LTD

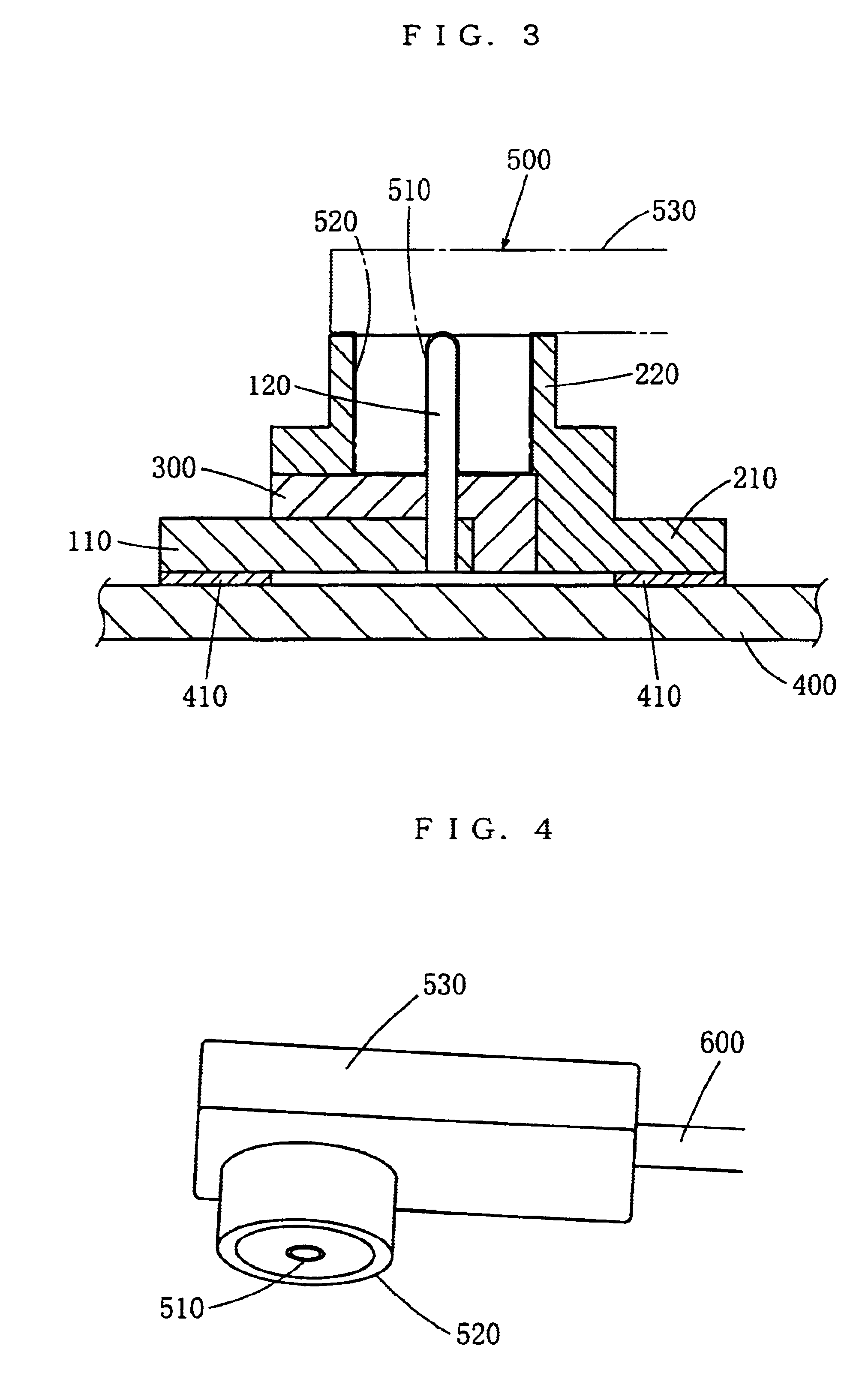

Method for chemically modifying inorganic filler with graphene oxide, product and application

InactiveCN103788413AImprove adhesionHigh mechanical strengthPigment treatment with organosilicon compoundsPigment physical treatmentEpoxySilanes

The invention discloses a method for chemically modifying inorganic filler with graphene oxide and a product. The method comprises the following steps: performing surface hydroxylation treatment and silane coupling agent treatment on the inorganic filler; maintaining the pH of a graphene oxide solution at 5.8-6.0 with an MES buffer solution; sequentially adding EDC and NHS, and performing ultrasonic treatment for 1-3 hours; adding the treated inorganic filler, and performing an amidation reaction at room temperature; and after the reaction, filtering, washing and drying to obtain the graphene oxide modified inorganic filler. The invention also discloses a method for preparing an inorganic filler / epoxy resin composite by use of the product. The process flow of the method disclosed by the invention is simple and environmentally friendly; the GO is connected to the surface of the inorganic filler by a chemical modification process, and the firm covalent bond combination between the GO and inorganic particles is generated, so that the interface adhesiveness and mechanical strength between the inorganic filler and the polymer are enhanced, and a new idea is provided to the modification of an inorganic filler surface and the preparation of a high-performance composite.

Owner:UNIV OF JINAN

Composite particle for dielectrics, ultramicroparticulate composite resin particle, composition for forming dielectrics and use thereof

InactiveUS20030151032A1High dielectric constantSmall dielectric loss tangentSemiconductor/solid-state device detailsSolid-state devicesInorganic particleResin-Based Composite

The dielectric-forming composition according to the invention is characterized by consisting of: composite particles for dielectrics in which part or all of the surfaces of inorganic particles with permittivity of 30 or greater are coated with a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material; and (B) a resin component constituted of at least one of a polymerizable compound and a polymer. In addition, another dielectric-forming composition according to the invention is characterized by containing: ultrafine particle-resin composite particles composed of (J) inorganic ultra fine particles with the average particle size of 0.1 mum or smaller, and (B) a resin component constituted of at least one of a polymerizable compound and a polymer, wherein part or all of the surfaces of the inorganic ultrafine particles (J) are coated with the resin component (B), and the ultrafine particle-resin composite particles contain 20% by weight or more of the inorganic ultrafine particles (J); and inorganic particles with the average particle size of 0.1 to 2 mum and permittivity of 30 or greater, or inorganic composite particles in which a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material is deposited on the part or all of the surfaces of the inorganic particles.

Owner:JSR CORPORATIOON

Branched structure compound containing UV crosslinking reactive group and application thereof

The invention relates to a spherical branched compound containing UV crosslinking reaction group. Its core is trimerization isocyanates group, and the skeleton cotains a plurality of polar groups with their end being UV crosslinking group. The invention also provides the precursor of said compound and the application, such as adhesion promoter, photosensitive resin composite, and ink- jet ink. The hardness and water stability of ink- jet ink can be dramatically increased after ink jet.

Owner:IND TECH RES INST +1

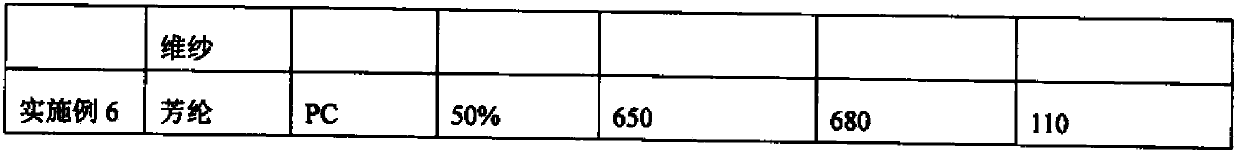

Resin composite material and its preparation method and use

The invention belongs to the technical field of polymers and discloses a resin composite material and its preparation method and use. The resin composite material comprises: by weight, 70 to 100 parts of one or more thermoplastic resins, 0 to 5 parts of one or more anti-oxidants, 0 to 5 parts of one or more fire retardants, 0 to 10 parts of one or more compatibilizers, 0 to 3 parts of one or more weather-resistant agents, 0 to 5 parts of one or more release agents and 0 to 2 parts of one or more assistants. The preparation method of the resin composite material comprises the following steps of fully mixing the raw materials in an intermediate-speed mixer according to the ratio for 3 to 7min, adding the mixture into an extruder, and carrying out extrusion cutting to obtain the resin composite material. A method for preparing a natural fiber / resin composite material prepreg tape from the resin composite material comprises the following steps of preparing natural fibers into a cord fabric, carrying out drawing, compaction and heating drying dehydration, carrying out pre-dipping of the resin composite material at a laminating extruder, carrying out gum dipping, carrying out cooling and carrying out wrapping-up. The prepreg tape obtained by the method has low porosity and high mechanical strength.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

High weather-proof thermosetting resin composite and prepreg and copper-clad laminate prepared thereby

InactiveCN101735456AImprove heat resistanceSmall coefficient of thermal expansionFibre treatmentPaper coatingEpoxyManufacturing technology

The invention relates to a high weather-proof thermosetting resin composite and prepreg and copper-clad laminate prepared thereby. The high weather-proof thermosetting resin composite comprises the following components in parts by weight: 10-40 parts of allyl compound, 8-80 parts of bismaleimide compound, 0-30 parts of epoxy resin and 0.05-5 parts of catalyst, wherein the molar ratio of allyl compound to bismaleimide compound is 1:2-4. The high weather-proof thermosetting resin composite provided by the invention has higher heat resistance, and the coefficient of thermal expansion (CTE) can be lowered to be below 2.0% to satisfy the requirements of manufacturing high multi-layer PCB. The prepreg prepared by the high weather-proof thermosetting resin composite has simple manufacture, better heat-resistant effect and high heat conductivity. The copper-clad laminate of the invention can be applied to heat-resisting and high multi-layer circuits and has simple manufacturing technology and low cost.

Owner:GUANGDONG SHENGYI SCI TECH

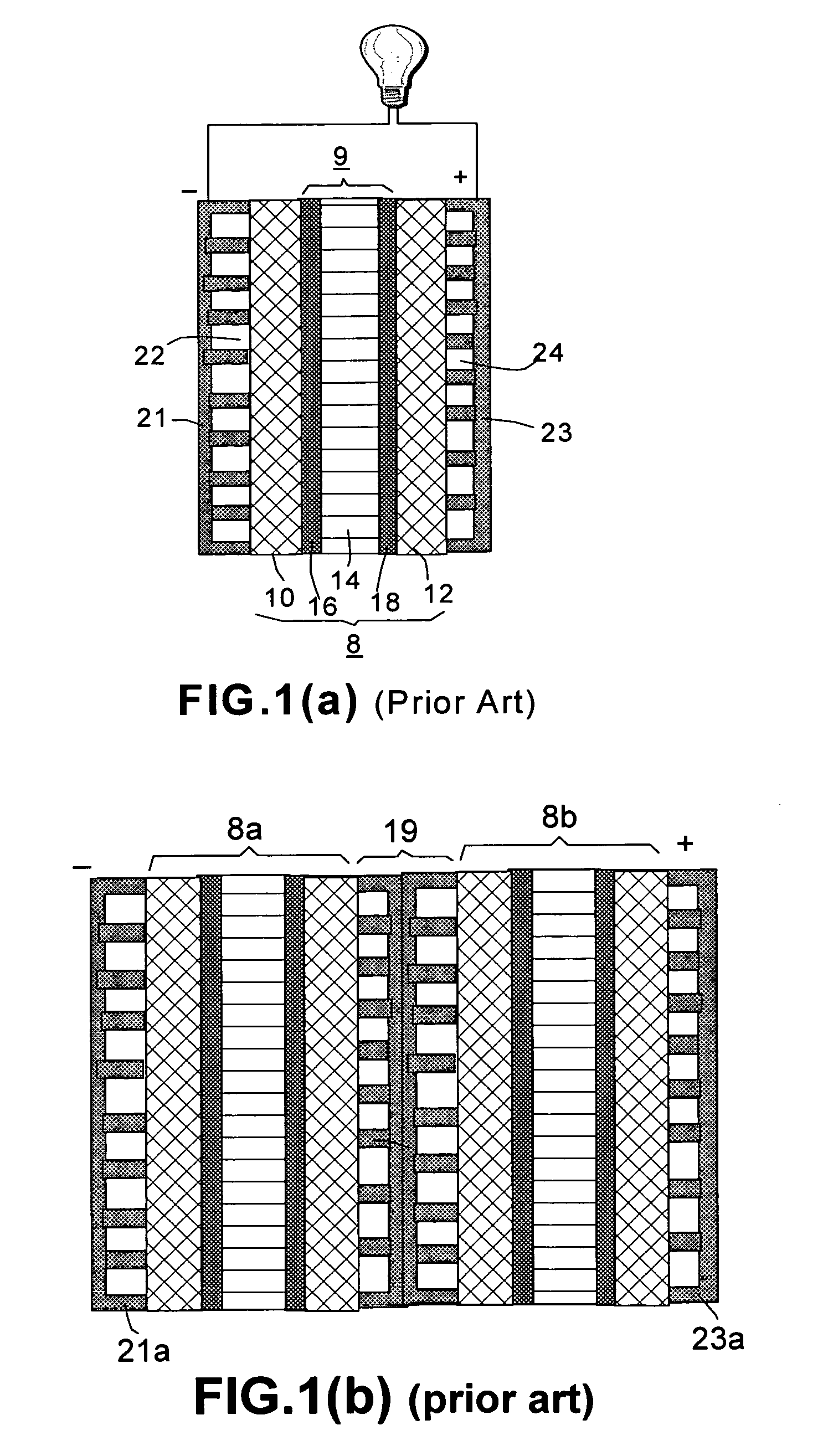

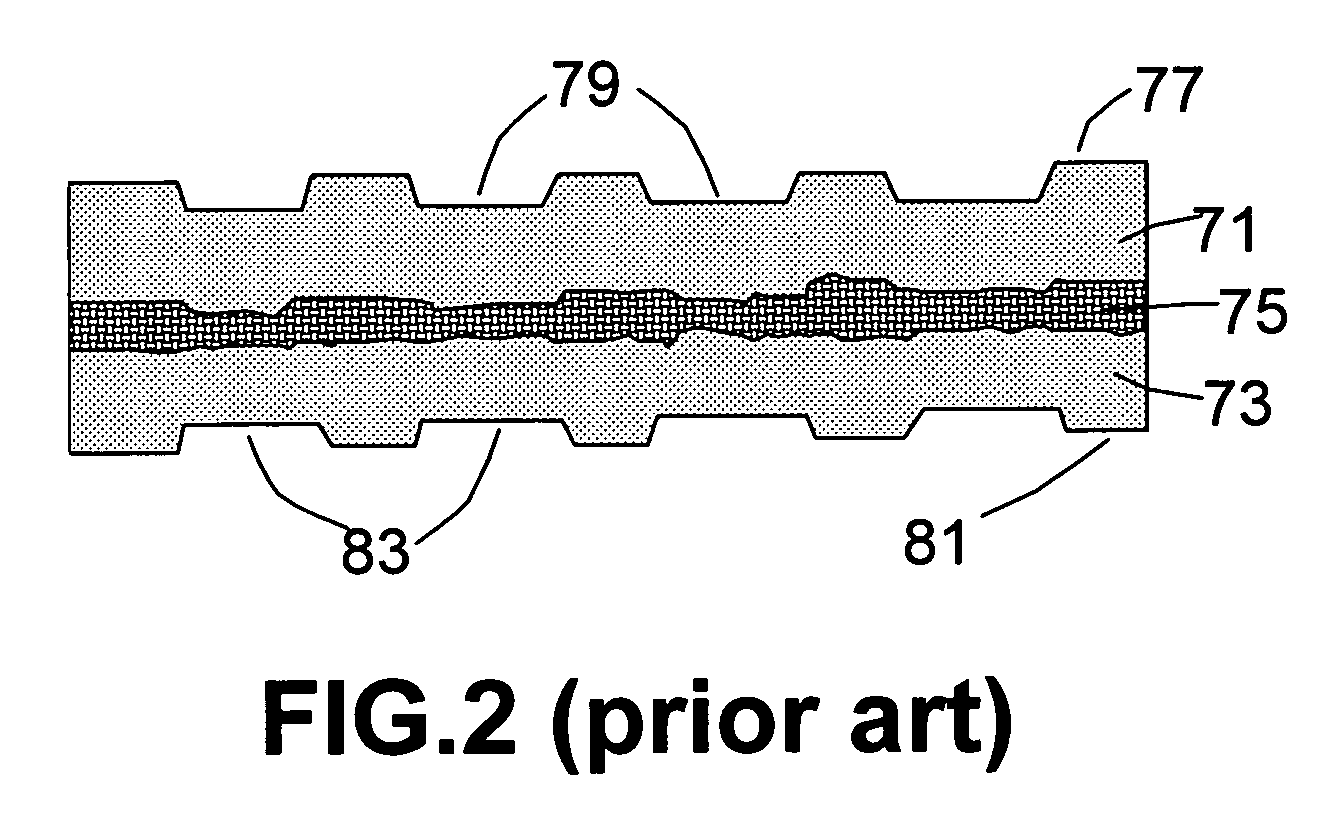

Process for producing carbon-cladded composite bipolar plates for fuel cells

The present invention provides a process for making a carbon-cladded composite composition for use as a fuel cell flow field plate or bipolar plate. In one preferred embodiment, the process comprises (a) providing a layer of conductive filler-resin composite having a first and a second primary surface; (b) depositing two clad layers of conductive carbon or graphite material onto the two primary surfaces, respectively, to produce a clad-composite-clad (three-layer) precursor structure; (c) creating flow field channels on the two primary exterior surfaces of the three-layer precursor; and (d) curing or solidifying the resin to form the desired bipolar plate. These steps are preferably integrated into a continuous roll-to-roll process for the mass production of bipolar plates. The conductive carbon or graphite material preferably comprises particles selected from the group consisting of carbon fibers, carbon nano-tubes, graphitic nano-fibers, nano-scaled graphene plates, carbon blacks, fine graphite powder, and combinations thereof.

Owner:NANOTEK INSTR GRP LLC

Water-absorbent article and method for producing the same

An absorbent article containing a water-absorbent resin composite comprising one nearly spherical water-absorbent resin particle and two or more fibers, wherein one or more of the fibers are partially embedded in the resin particle and are partially exposed from the resin particle, and wherein one or more of the fibers are never embedded in the resin particle but partially adhere to the surface of the resin particle. In the absorbent article, the water-absorbent resin particle is uniformly fixed on the fiber before, during and after water absorption, so that the water-absorbent resin can exist at a higher ratio to the fiber. Thus, the absorbent article characteristically has great softness and high shape stability.

Owner:MITSUBISHI CHEM CORP

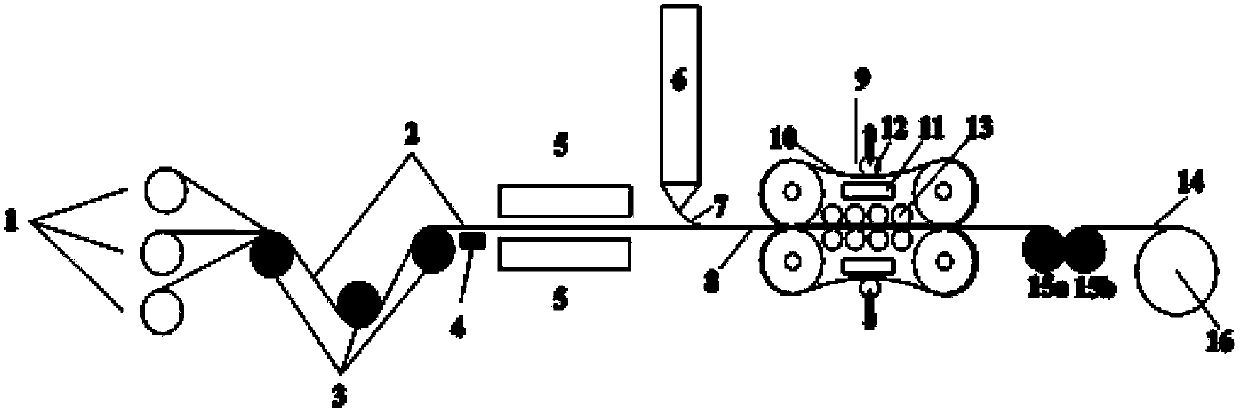

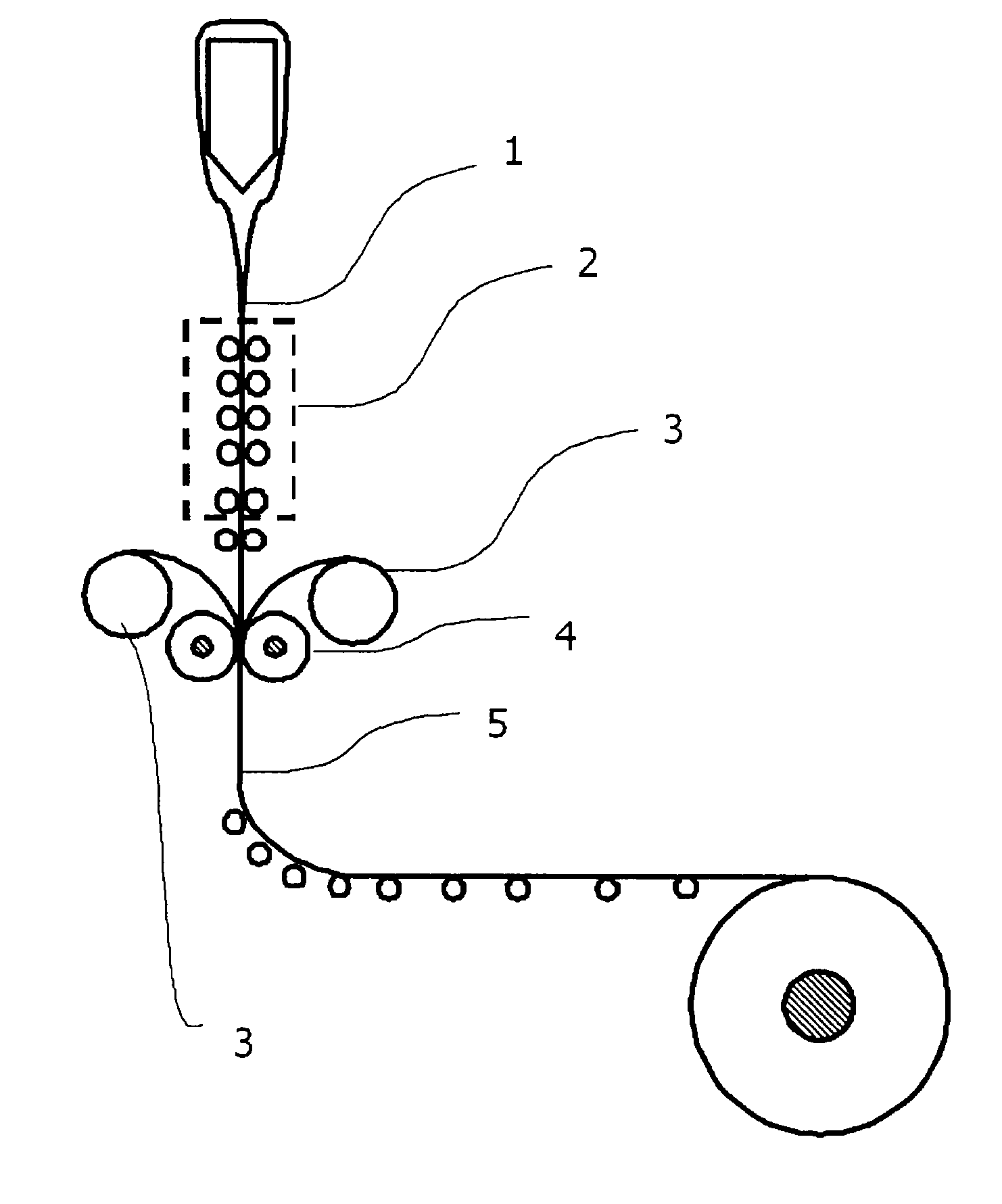

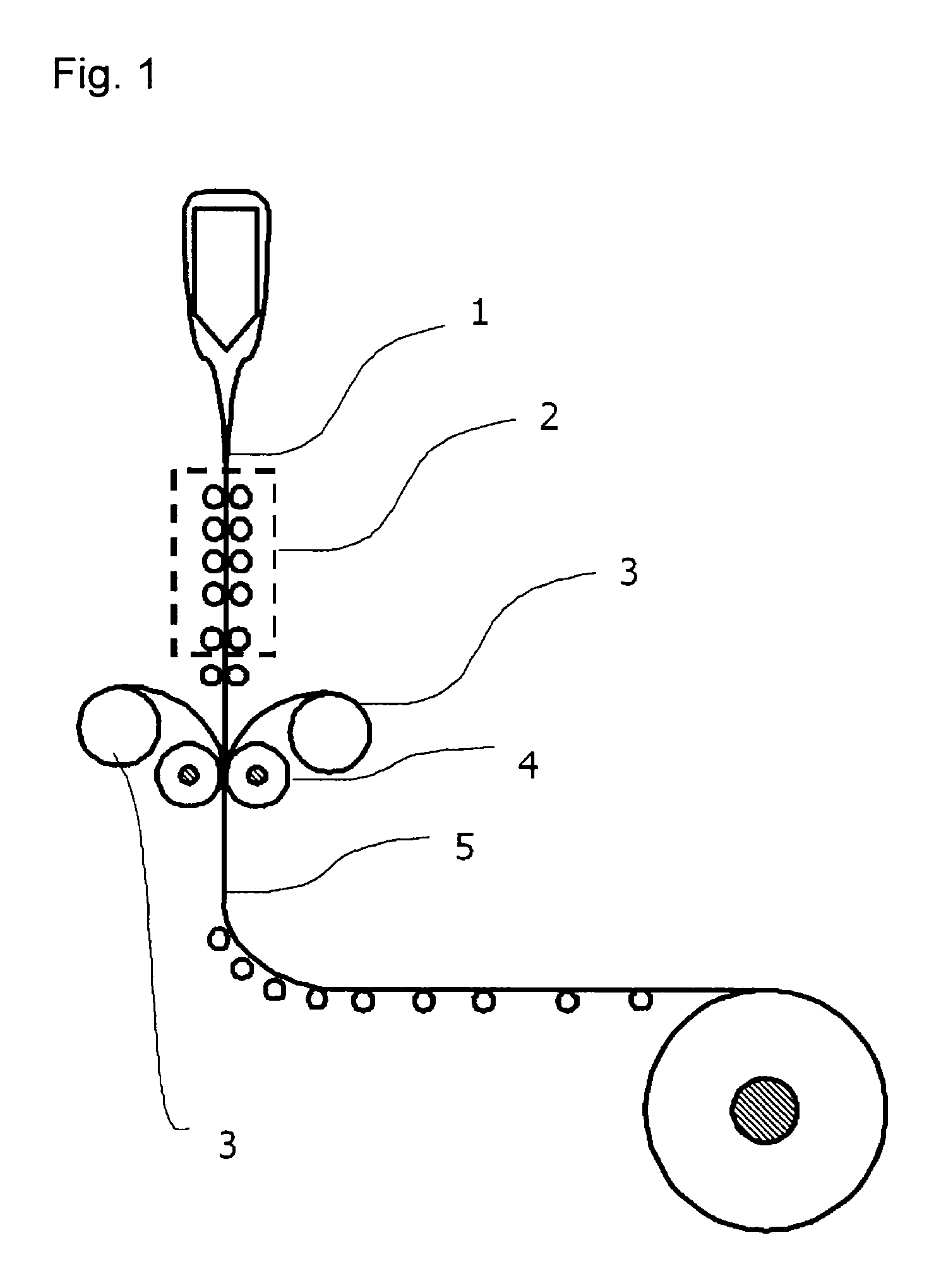

Continuous fiber fabric reinforced thermoplastic resin composite material and production method thereof

The invention relates to a continuous fiber fabric reinforced thermoplastic resin composite material and a production method thereof. The composite material is produced from continuous fiber through thermoplastic resin melting and impregnating, cooling and molding, with the thickness of 0.20mm-0.35mm, wherein the content of the continuous fiber reinforced fabric is 40wt%-65wt%, the continuous fiber fabric is uniformly spread out and subjected to tension adjustment and static electricity elimination, then enters thermoplastic resin for melting and impregnating, and finally is cooled in a cooling unit and wound and formed to obtain the continuous fiber fabric reinforced thermoplastic resin composite material. Compared with the prior art, the continuous fiber fabric reinforced thermoplastic resin composite material and the production method solve a series of problems caused by too high resin viscosity in the existing thermoplastic resin and fiber reinforcing process, such as complex equipment process, too high equipment cost, not environment-friendly technological operation process, dry gauze easily caused by poor impregnation and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Controlled atmospheric pressure resin infusion process

ActiveUS20050073076A1Specific strength of partLow costLaminationLamination apparatusSurface finishEngineering

By evacuating the resin feed tank to a pressure below atmospheric pressure, employing cyclic compaction, and controlling the net compaction pressure, we are better able to control a resin infusion process, particularly a vacuum assisted resin transfer molding process, and produce aerospace-grade fiber-reinforced resin composite having fiber volume fractions and tool-side surface finishes comparable to or exceeding those made using an autoclave.

Owner:THE BOEING CO

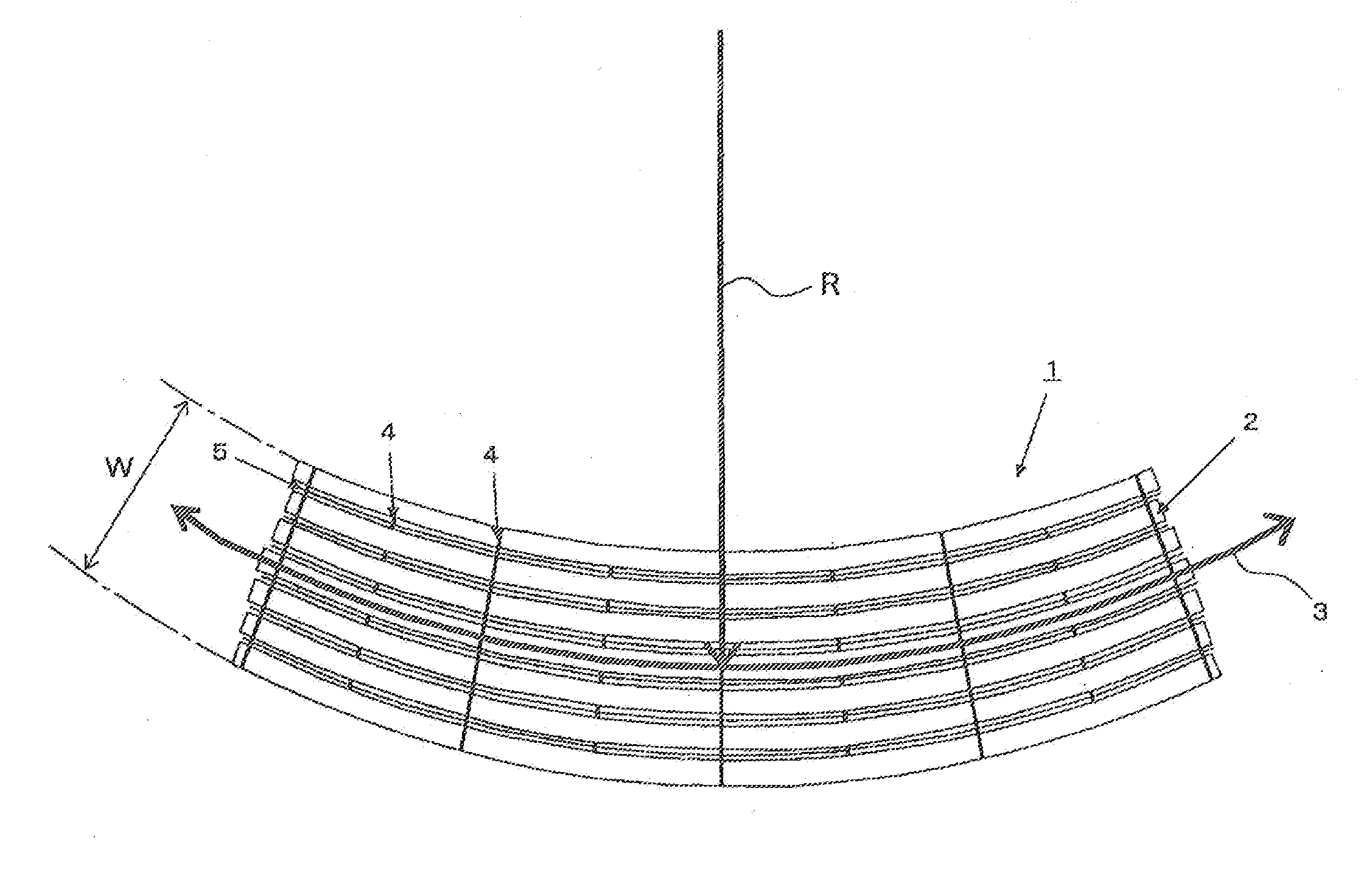

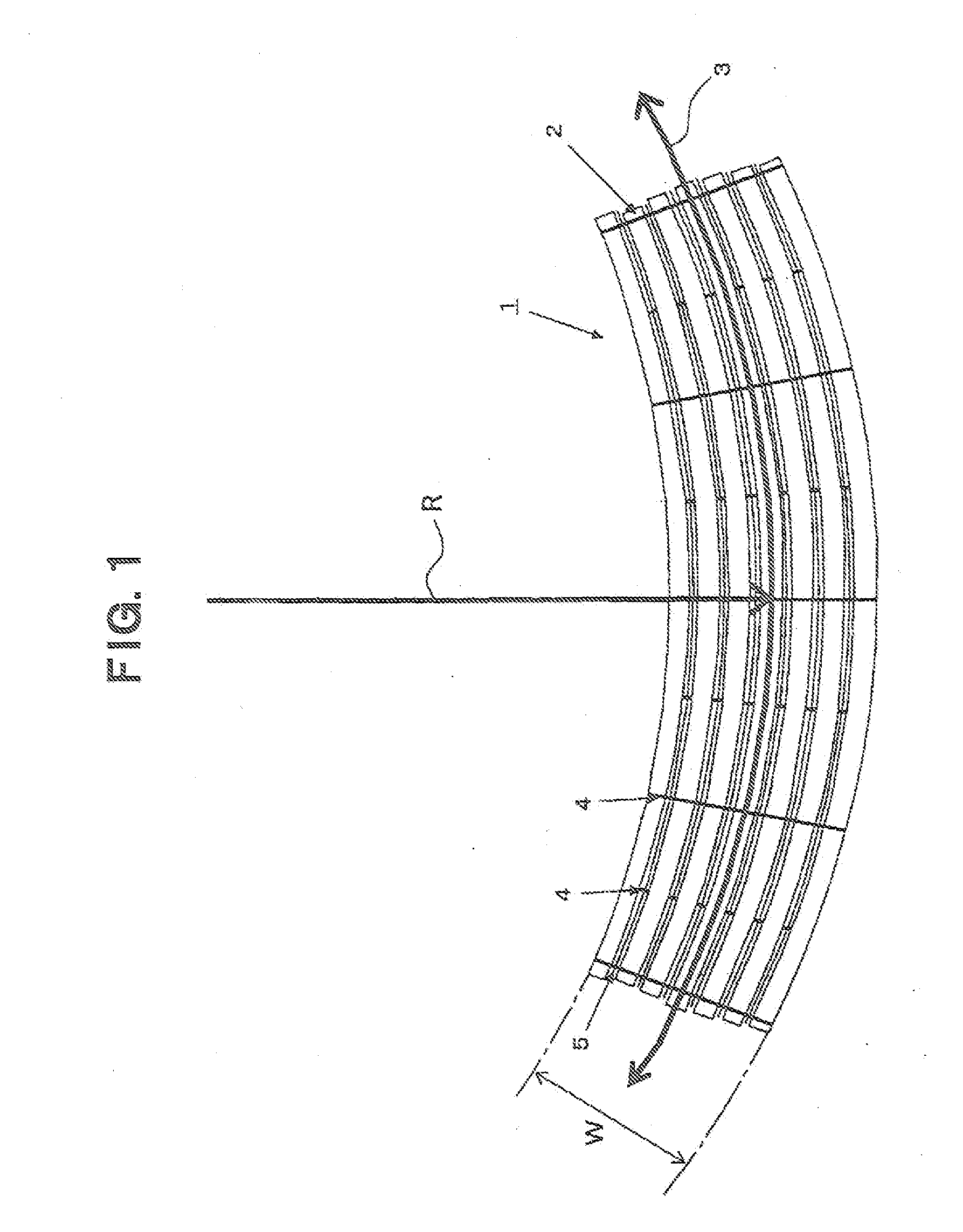

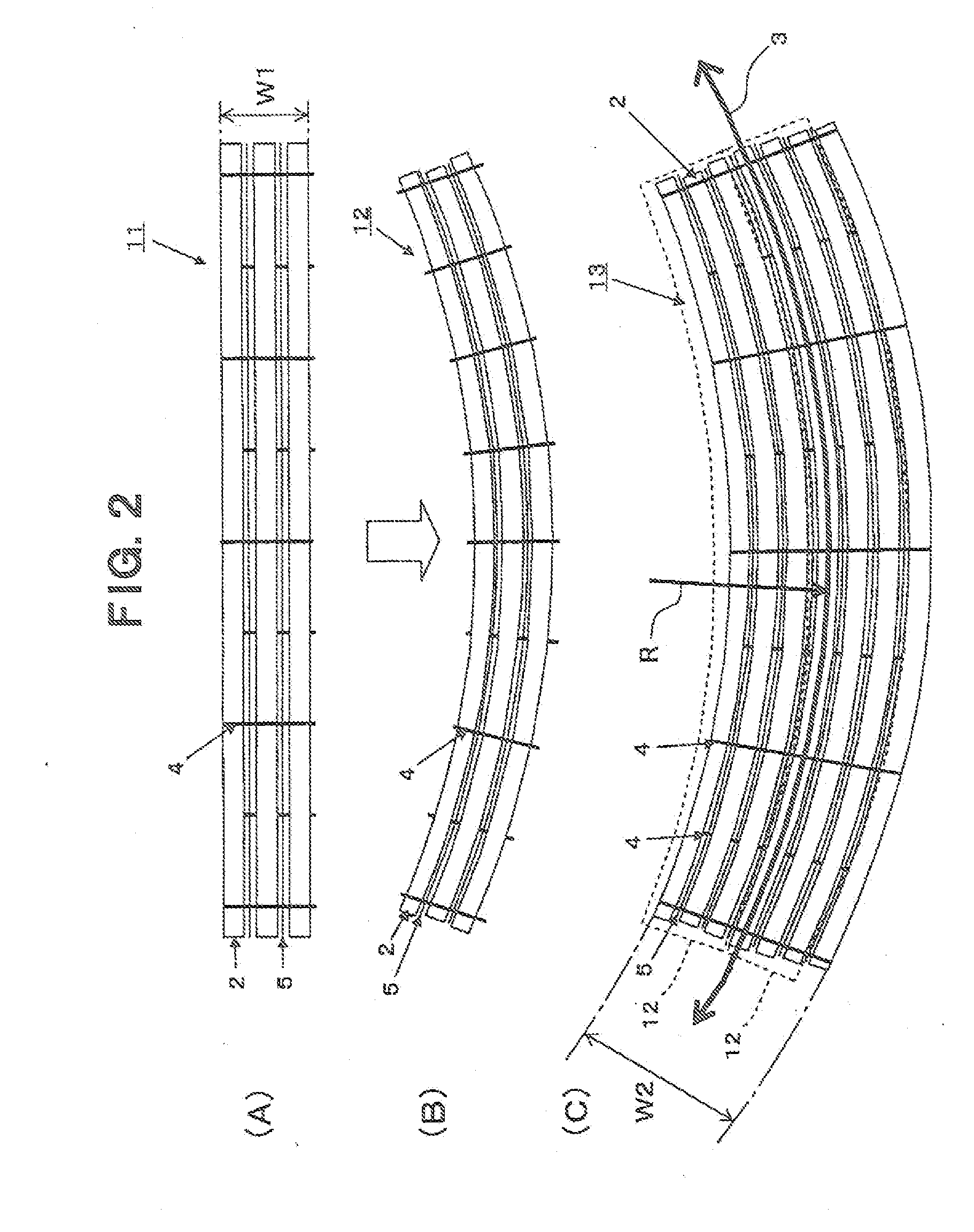

Reinforcing fiber substrate of curved shape, layered product using the same, preform, fiber-reinforced resin composite material, and processes for producing those

InactiveUS20100285265A1Efficient formationSimple structureLoomsSynthetic resin layered productsYarnCurve shape

A curved reinforcing fiber substrate having a curved planar shape comprising a plurality of reinforcing fiber yarns arranged parallel to a direction along a circumferential direction of the curved shape, and auxiliary weft yarns arranged in directions crossing the plurality of reinforcing fiber yarns each arranged in one direction of the circumferential direction.

Owner:TORAY IND INC

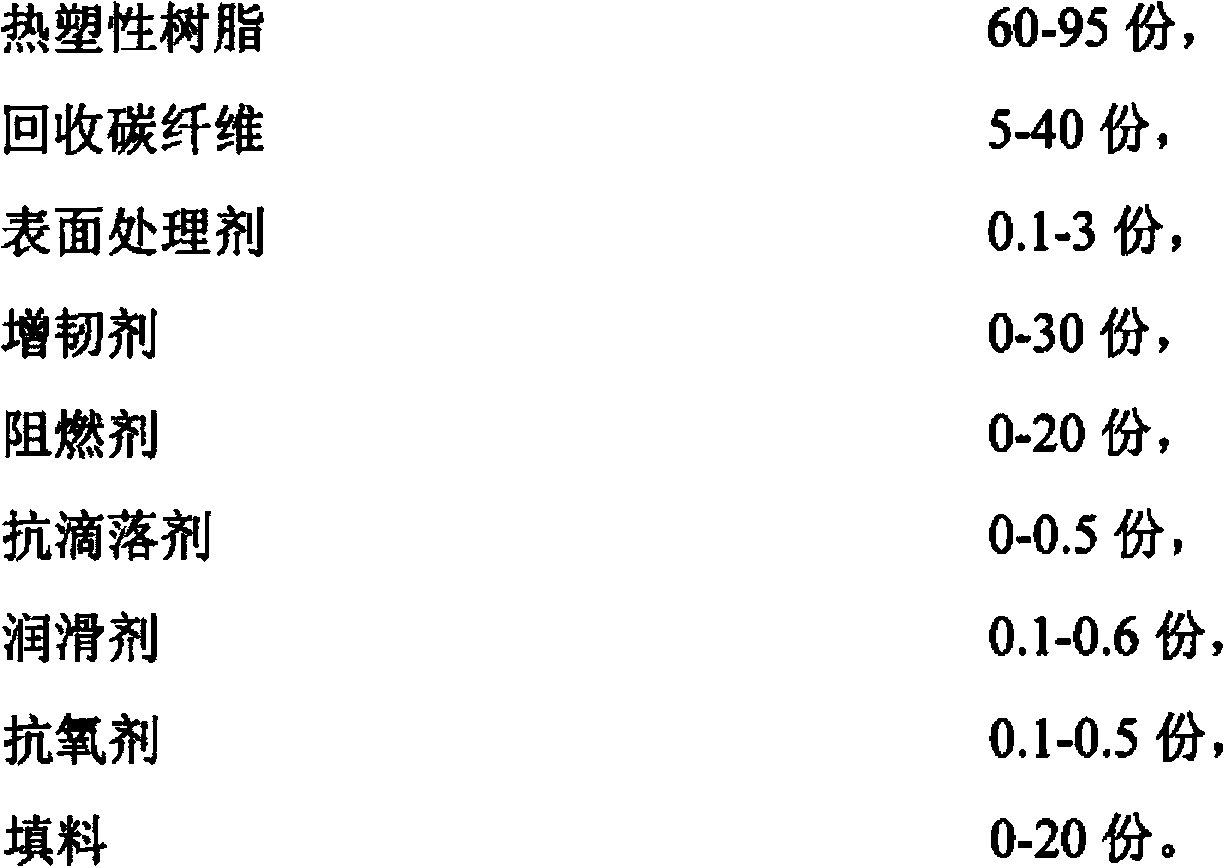

Recycled carbon fiber reinforced thermoplastic resin composite material and preparation method thereof

The invention relates to a recycled carbon fiber reinforced thermoplastic resin composite material and a preparation method thereof. The preparation method comprises the following steps: (1) weighing 5-40 parts of recycled carbon fiber according to a proportion, adding the recycled carbon fiber into a high-speed mixer, adding 0.1-3 parts of surface treating agent, and performing surface treatment on the recycled carbon fiber; (2) weighing 60-95 parts of thermoplastic resin, 0-30 parts of flexibilizer, 0-20 parts of fire retardant, 0-0.5 part of anti-drip agent, 0.1-0.6 part of lubricant, 0.1-0.5 part of antioxidant and 0-20 parts of filler according to the proportion, adding the raw materials into the high-speed mixer, and uniformly mixing the raw materials; (3) adding the uniformly mixed raw materials into a double-screw machine, and performing melt blending, extrusion, water cooling and strand pelletizing to obtain the recycled carbon fiber reinforced thermoplastic resin composite material. Compared with the prior art, the recycled carbon fiber reinforced thermoplastic resin composite material has the advantages of low density, excellent mechanical performance, low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

Process for producing glass/resin composite

InactiveUS20100192634A1High mechanical strengthReduce the possibilityLayered product treatmentLaminationCutting glassPolyresin

To provide a process for producing a glass / resin composite having a sufficient transportability, handling efficiency and processability, even though the thickness of the glass is very thin, without impairing excellent properties of glass.A process for producing a glass / resin composite, which comprises forming molten glass into a glass ribbon and forming a resin layer on at least one surface of the glass ribbon is provided. The resin layer is preferably formed by bonding to a glass ribbon, applying a heat melt resin or applying a curable resin. Further, a process for producing a glass / resin composite, wherein a cut glass substrate is bonded on a continuously supplied resin film is provided.

Owner:ASAHI GLASS CO LTD

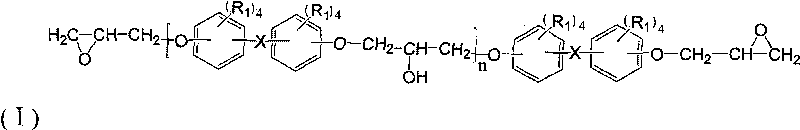

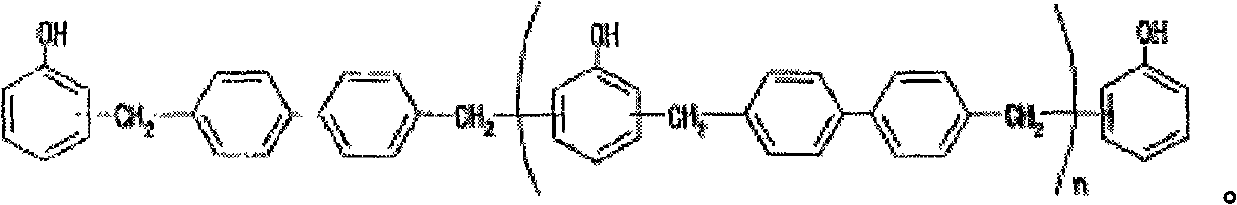

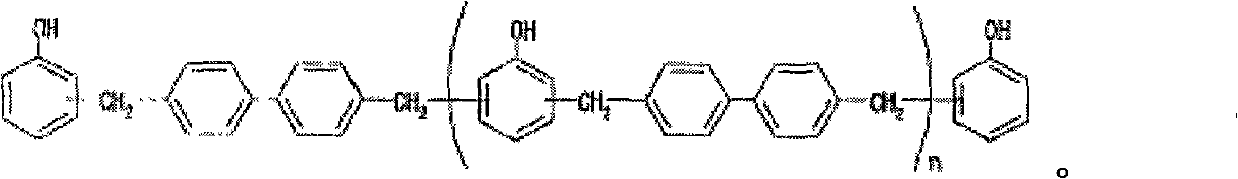

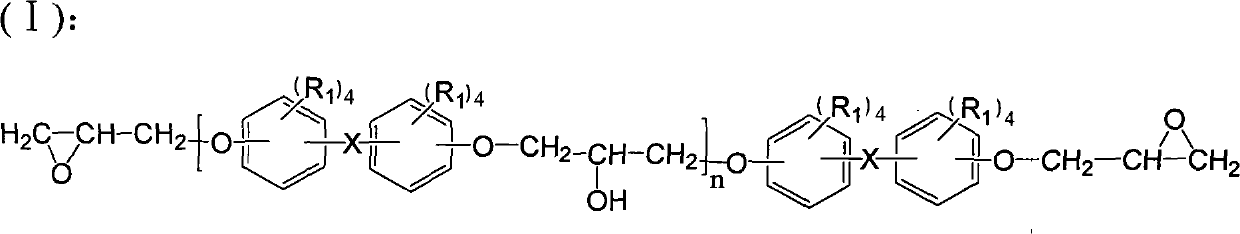

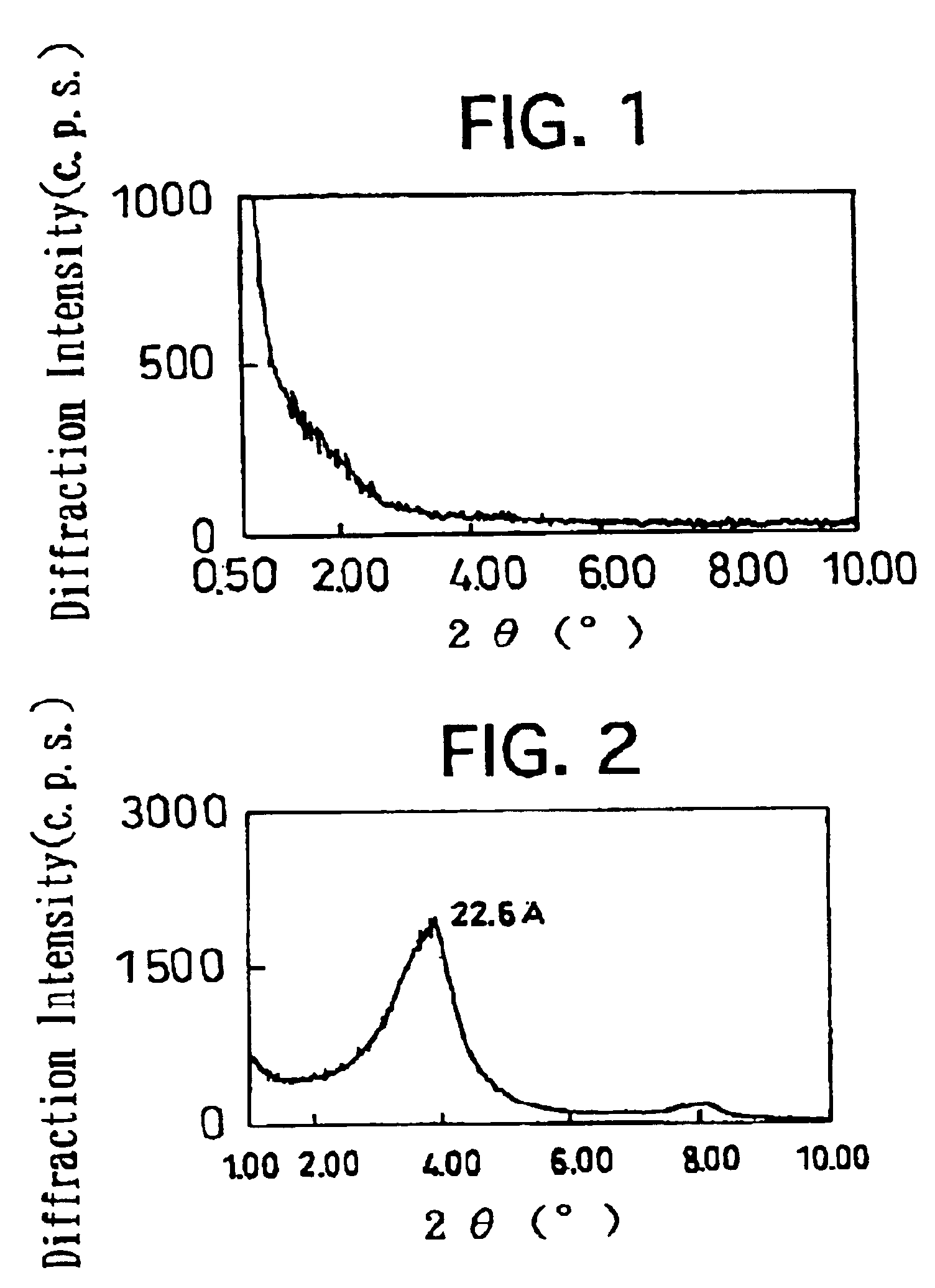

High thermal conductivity resin composition and high thermal conductivity coated metal foil board manufactured by using same

ActiveCN101974208AImprove thermal conductivityImprove heat resistanceMetal layered productsPolyesterEpoxy

The invention relates to a high thermal conductivity resin composition and a high thermal conductivity coated metal foil board manufactured by using the same. The high thermal conductivity resin composition comprises the following components of: epoxy resin, at least one phenoxy resin or carboxy terminal butadiene acrylonitrile, biphenyl phenolic resin and a high thermal conductivity packing material, wherein the biphenyl phenolic resin has the structure shown in the specification. The high thermal conductivity coated metal foil board manufactured by using the high thermal conductivity resin composition comprises a high thermal conductivity adhesive film and metal foils coated on both sides of the high thermal conductivity adhesive film, wherein the high thermal conductivity adhesive film comprises a carrier film and the high thermal conductivity resin composition coated on the carrier film, and the carrier film is a polyester film or a polyimide film. The high thermal conductivity coated metal foil board comprises a resin composite metal foil and a metal foil or another resin composite metal foil coated on the previous resin composite metal foil, and the resin composite metal foil comprises a metal foil and the high thermal conductivity resin composition coated on the metal foil.

Owner:GUANGDONG SHENGYI SCI TECH

Wood decorative material coated with resin composite film and process for producing the same

InactiveUS6352784B1High bonding strengthCrack and breakOther plywood/veneer working apparatusSynthetic resin layered productsSurface layerLacquer

A wood decorative material coated with resin composite film, comprising a laminate of, arranged in the following order, a wood substrate; a heat bonding layer (A) formed from a heat bonding resin composition comprising 100 parts by weight of a thermoplastic resin (a-1) and 0.001 to 80 parts by weight of a tackifier resin (a-2), the above heat bonding resin composition having a melting point or softening temperature of 170° C. or below and exhibiting a melt flow rate (MFR) at 190° C. of 1 to 500 g / 10 min; and a mar-proof surface layer (B). Not only can beautiful appearance be obtained while retaining natural texture without the application of lacquer but also surface protection and bending working properties are improved.

Owner:TOHCELLO CO LTD (JP)

Phenolic resin composite material

InactiveUS6838509B2Improve heat resistanceHigh mechanical strengthMaterial nanotechnologyPigmenting treatmentClay mineralsHeat resistance

A phenolic resin composite material includes a phenolic resin, a filler dispersed in the phenolic resin and being a reinforcement member and an organized layered clay mineral being different from the filler and dispersed uniformly in the phenolic resin. The phenolic resin composite material is improved in terms of the heat resistance as well as the mechanical strengths.

Owner:TOYOTA IND CORP

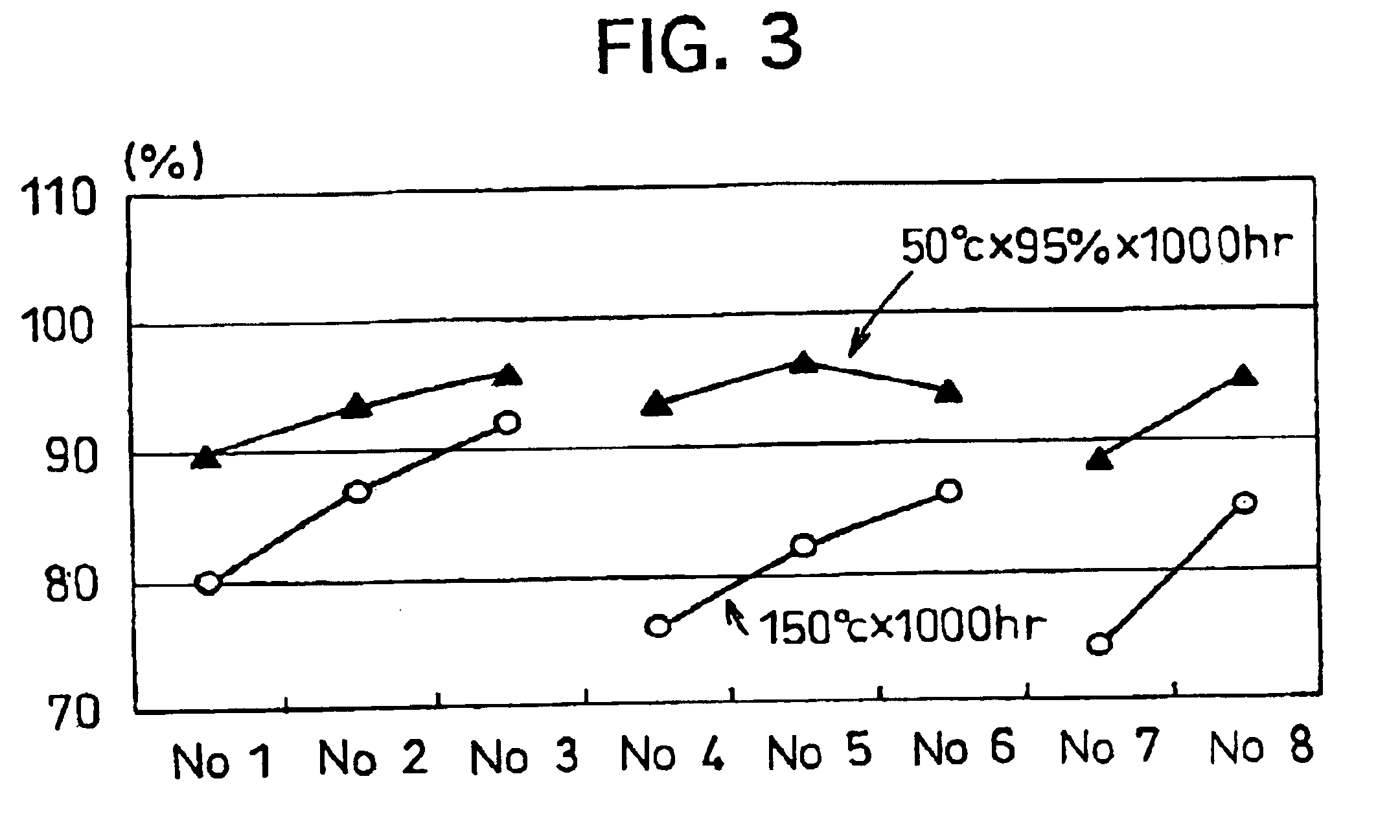

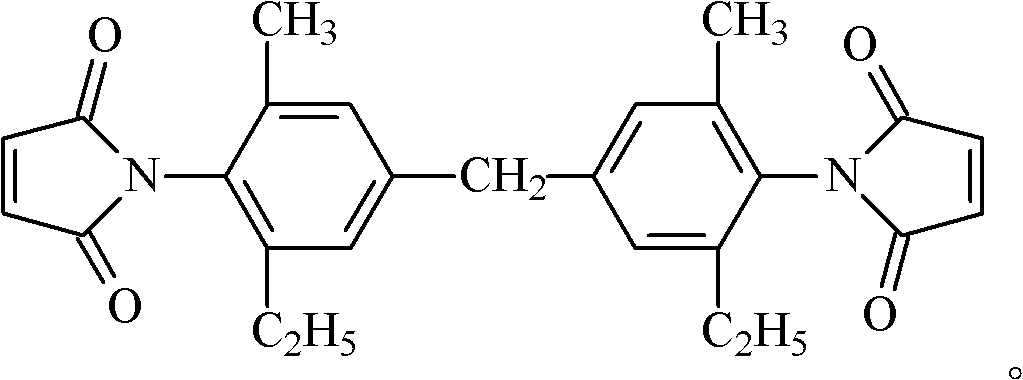

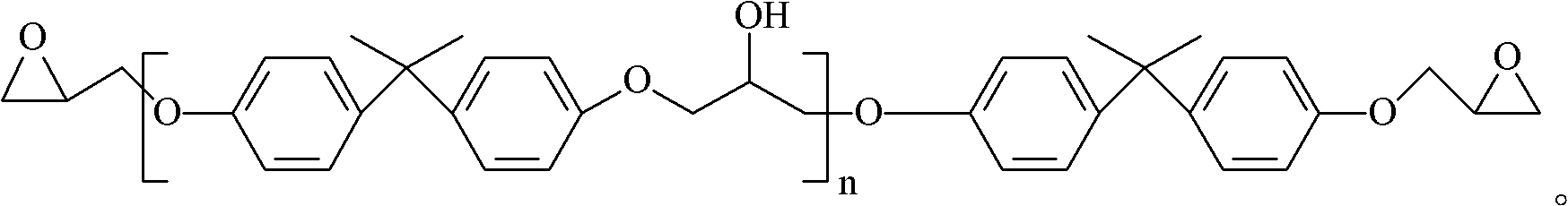

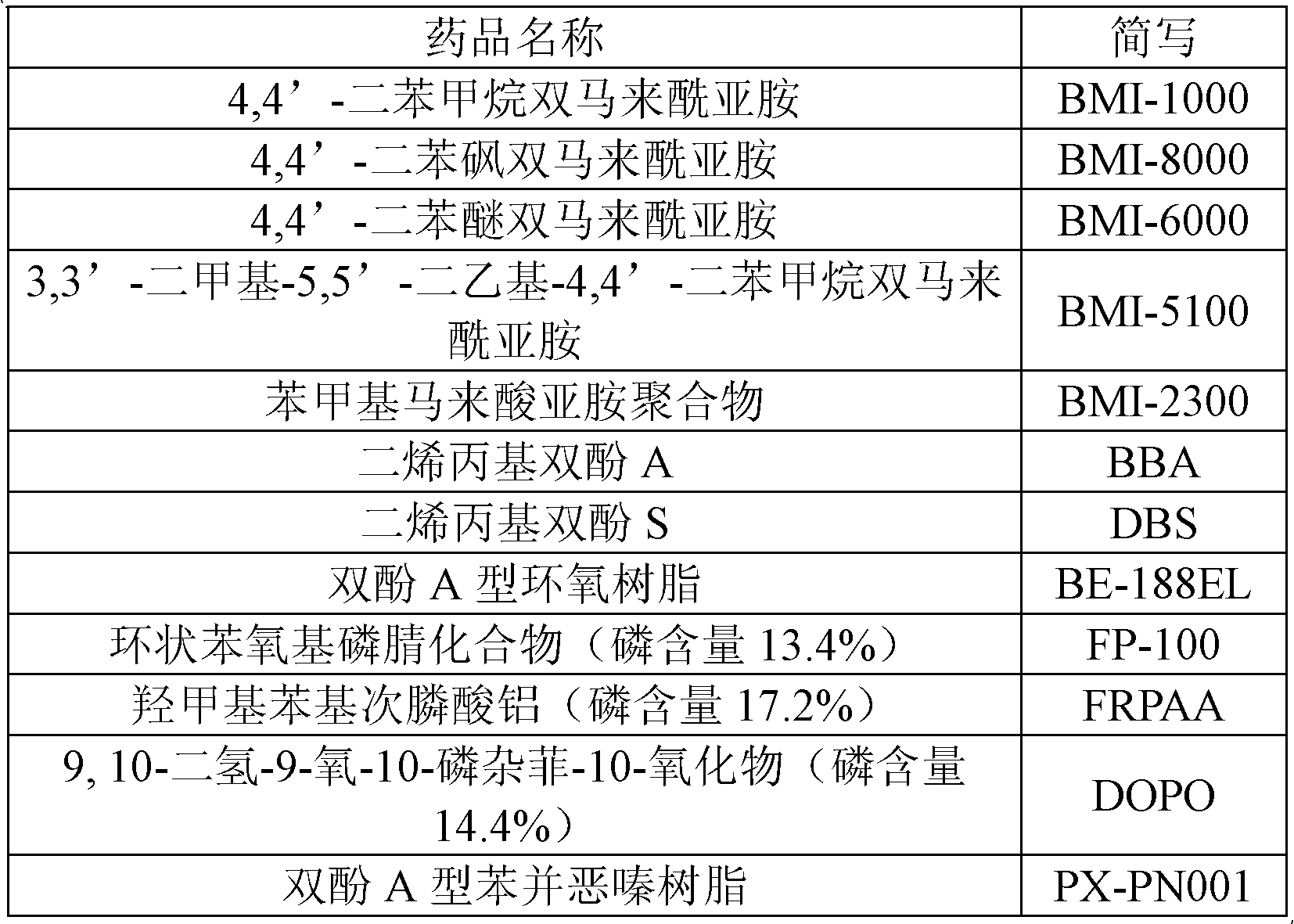

Halogen-free phosphorus-containing flame-retardant polyimide resin composition and preparation method thereof

ActiveCN102276837AImprove flame retardant performanceImprove toughnessGlass/slag layered productsMetal layered productsHalogenCopper

The invention relates to a halogen-free phosphorus-containing flame retardant polyimide resin composite, which is characterized by comprising the following components in part by weight: 150 to 180 parts of bismaleimide, 90 to 110 parts of allyl compound, 10 to 20 parts of bisphenol A epoxy resin and 10 to 50 parts of phosphorus-containing compound. The invention also relates to a preparation method for the halogen-free phosphorus-containing flame retardant polyimide resin composite. The method comprises the following steps of: adding the bismaleimide, the allyl compound, the bisphenol A epoxyresin and the phosphorus-containing compound into a reaction kettle, and reacting at the temperature of between 120 and 140 DEG C for 3 to 5 hours to obtain the halogen-free phosphorus-containing flame retardant polyimide resin composite. The halogen-free phosphorus-containing flame retardant polyimide resin composite is synthesized in one step and does not contain halogens and has high flame retardant performance; according to UL94 V0 flame retardant grade tests, the toughness of the cured composite is improved; and the moist heat resistant performance of the composite is high, and the composite meets the requirements of flame retardance and processing in the process of processing copper-clad plates and has high the storage stability.

Owner:INNOTEK TECH CHINA

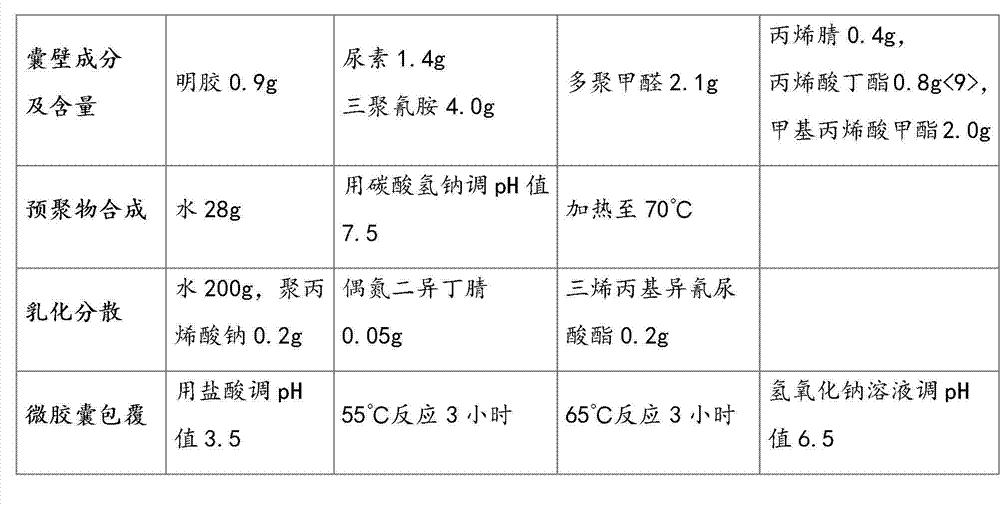

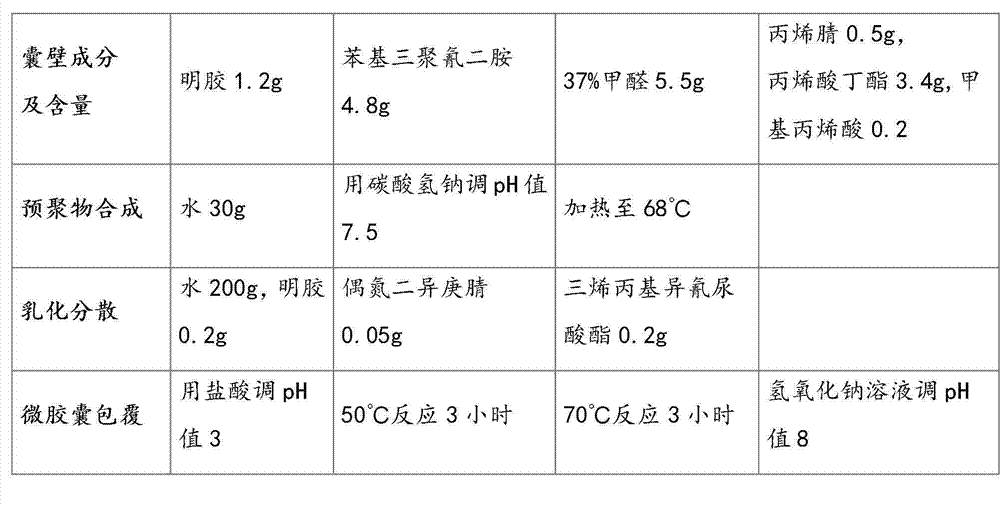

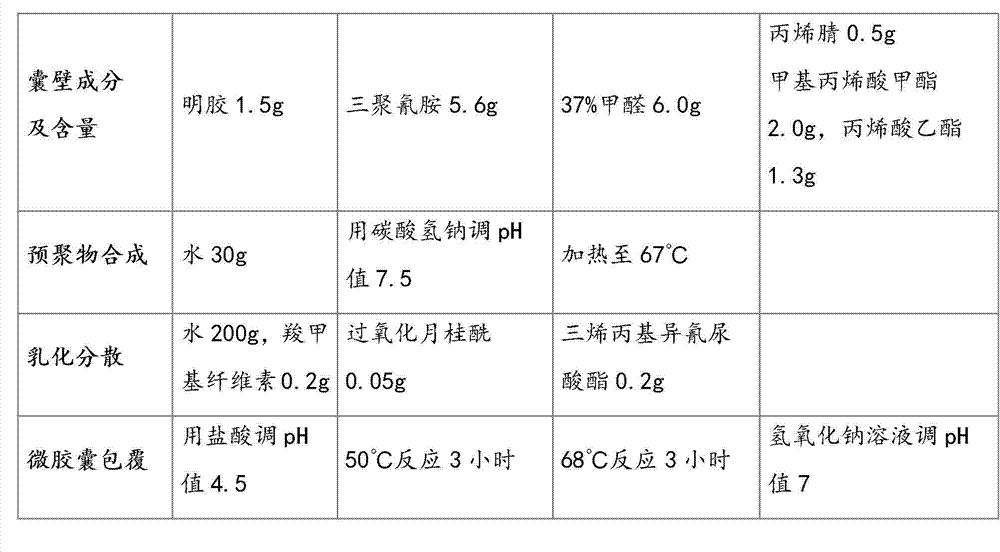

Double-layer coated essence microcapsule and preparation method thereof

ActiveCN102899168AMeet heat resistanceFulfil requirementsEssential-oils/perfumesMicroballoon preparationAcrylate polymerMechanical property

The invention discloses a double-layer coated essence microcapsule and a preparation method thereof. The essence microcapsule takes an oil soluble liquid essence as a capsule core, a gelatin modified amino resin composite material as a first-layer capsule wall and an acrylate polymer as a second-layer capsule wall, wherein a grafting transition area is formed by graft copolymerization of gelatin and acrylate between the first-layer capsule wall and the second-layer capsule wall. The preparation method comprises a step of prepolymer compounding, emulsification dispersion, microcapsule continuous double-layer coating and post-treatment. Compared with a single-layer coated microcaposule, the essence microcapsule has the advantages that the slow release performance, the heat resistance performance and the capsule wall material mechanical property are greatly improved, and the essence microcapsule can be used for most of microencapsulated essence products processed by heat extrusion molding of high molecular materials.

Owner:湖南方税达科技有限公司 +1

Fluorescent carbon quantum dot, its light-emitting polymer based composite material and preparation method

ActiveCN103382389APromote formationImprove luminous performanceLuminescent compositionsPtru catalystSolar cell

The invention discloses a fluorescent carbon quantum dot, its light-emitting polymer based composite material and a preparation method thereof. More specifically, the invention provides a method for preparation of the fluorescent carbon quantum dot and its light-emitting polymer based composite material by taking a small molecule compound as a carbon source and an organosilicone monomer as a catalyst and stabilizer. By means of the combined action of the polymerizable organosilicone monomer and the small molecule carbon source, the carbon quantum dot can be formed in one step. Without purification, the reaction product only needs solvent removal to undergo further reaction so as to form a carbon quantum dot-organosilicone resin composite material. The organosilicone monomer involved in the invention can promote formation of the carbon quantum dot, and can play a role of stabilizing the carbon quantum dot, and also can be used as a polymer matrix monomer. Therefore, the obtained carbon quantum dot has stable luminescent properties, is well compatible with the polymer matrix and keeps the original luminescent properties. The method disclosed in the invention has a simple process and is easy to implement, and can be widely applied in the fields of solar cells and LED devices.

Owner:SUN YAT SEN UNIV

Biodegradable resin composites

InactiveUS20110229698A1More rigidityMore strengthAdhesive processesDecorative surface effectsPolymer scienceResin composite

Owner:E2E MATERIALS

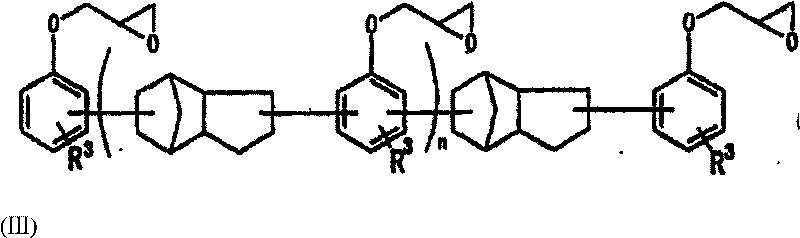

Thermosetting resin composition, prepreg and laminated board

ActiveCN102199351AGood workmanshipExcellent heat and humidity resistanceSynthetic resin layered productsLaminationEpoxyThermal expansion

The invention discloses a thermosetting resin composition which is characterized by comprising the following components in parts by weight: 10-65 parts of alkyl modified bismaleimide resin prepolymer, 5-60 parts of composite cyanate resin and 5-65 parts of halogen-free epoxy resin, wherein the total weight of the resins is 100 parts; the alkyl modified bismaleimide resin prepolymer is obtained byreacting a bismaleimide resin with a diallyl compound for 20-120 minutes at the temperature of 110-160 DEG C and then cooling; and the weight ratio of bismaleimide resin to diallyl compound is 100: (15-120). A prepreg and a laminated board can be prepared by using the composition. The composition, the prepreg and the laminated board have the characteristics of good manufacturability, halogen-free inflaming retardance, excellent humidity resistance and heat resistance, low thermal expansion coefficient and low dielectric constant and dielectric loss, and are suitable for the fields of integrated circuit package, high-frequency, high-speed and high-density interconnection and the like.

Owner:SHENGYI TECH SUZHOU

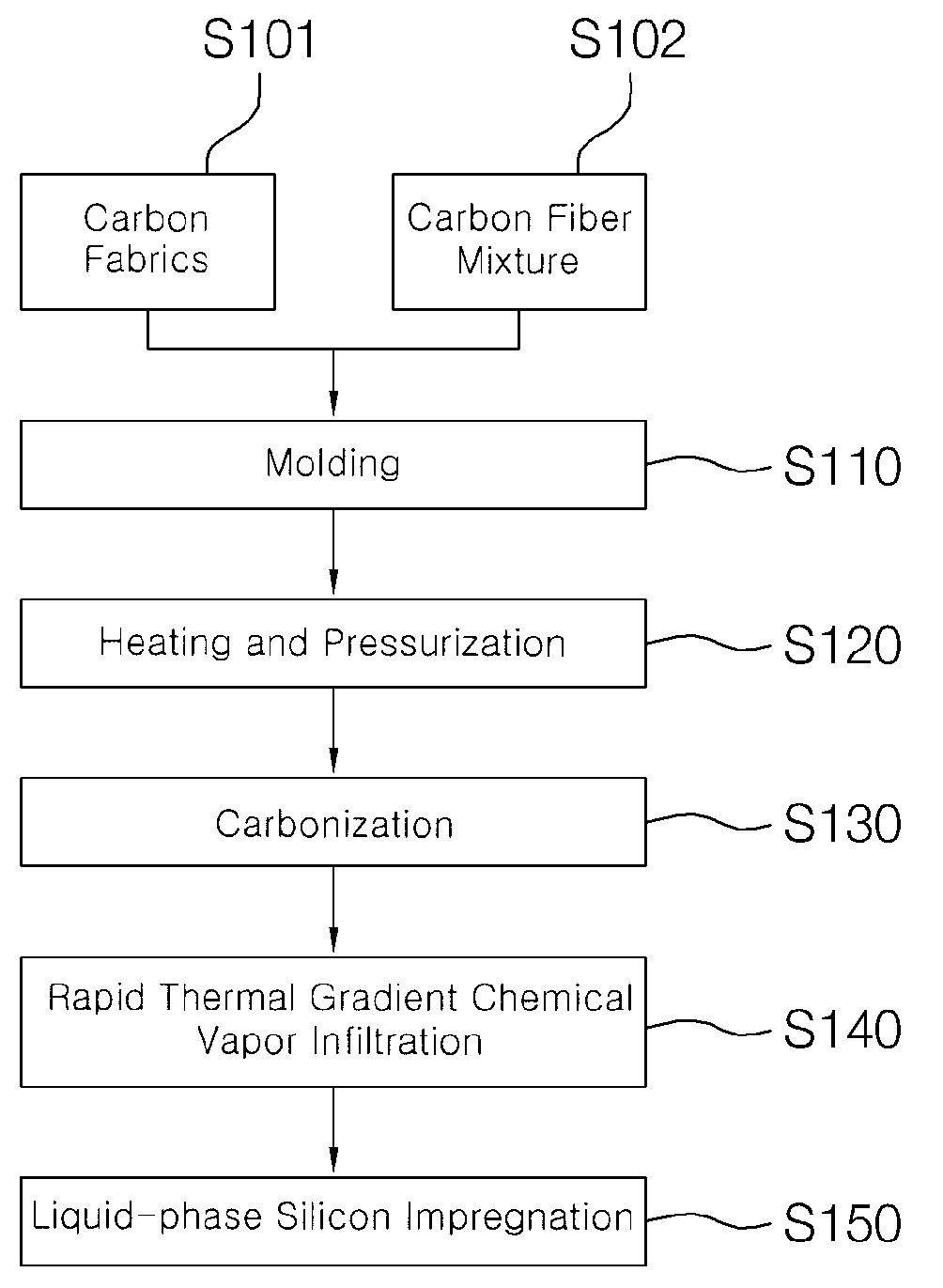

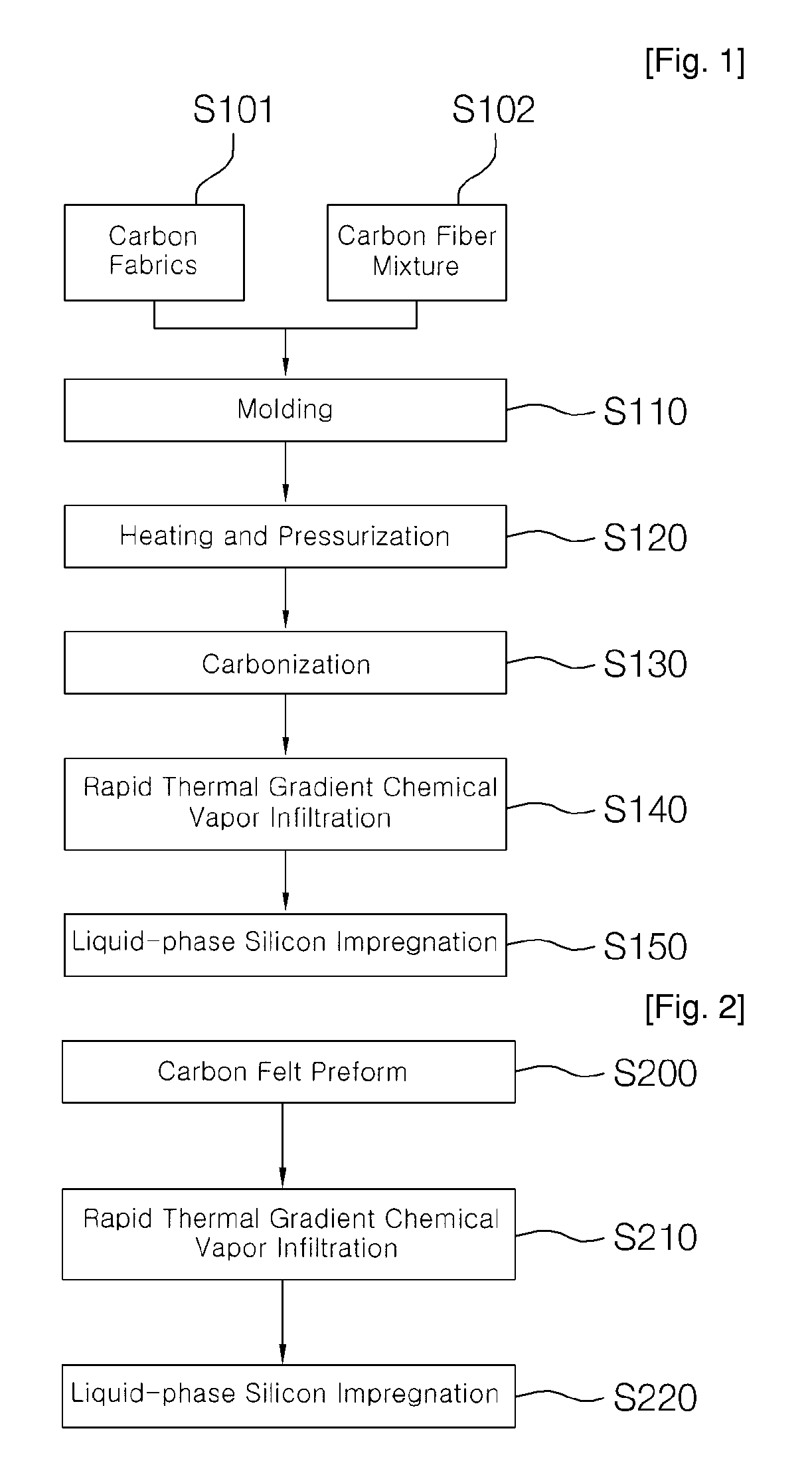

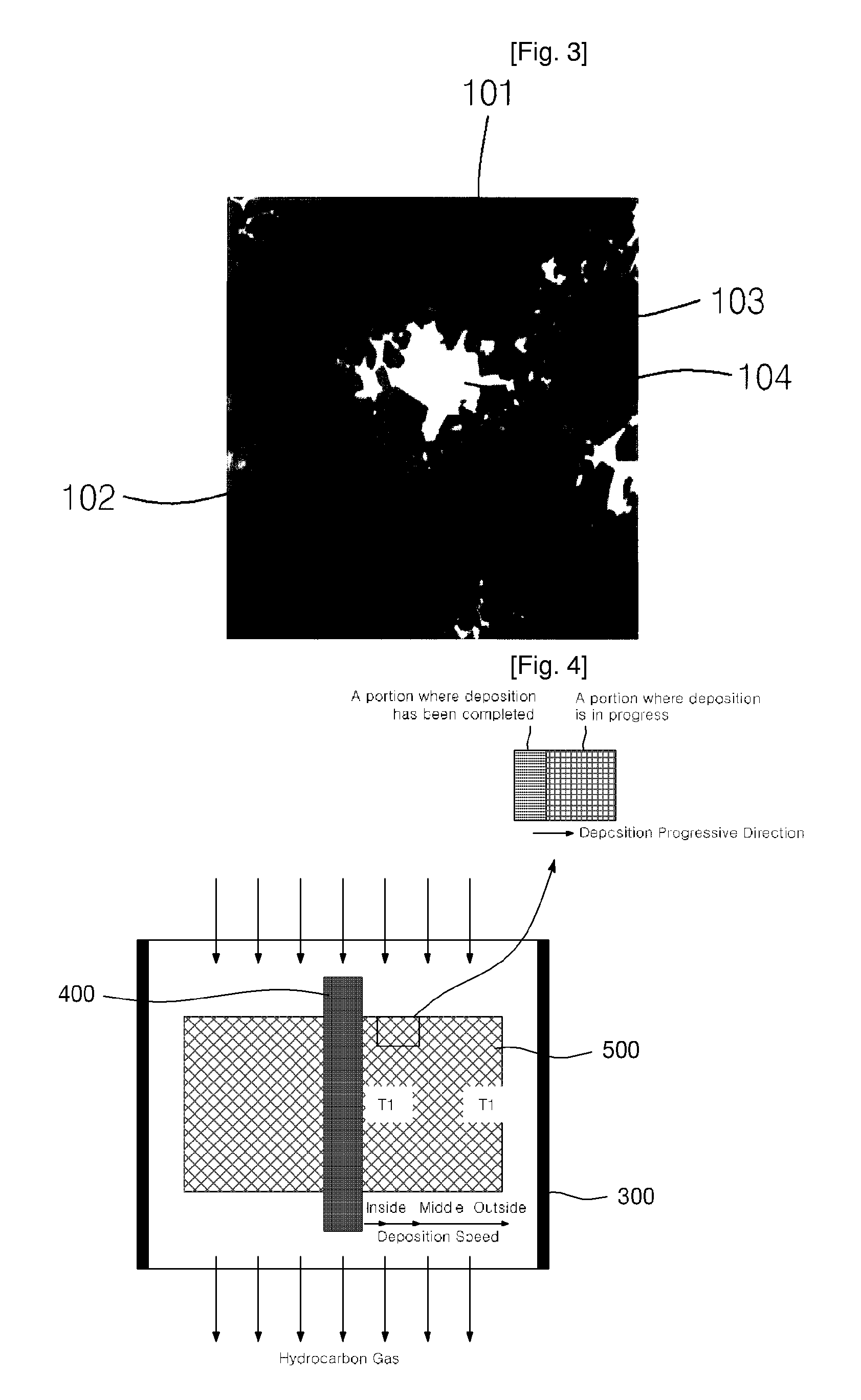

Method of Producing Carbon Fiber Reinforced Ceramic Matrix Composites

InactiveUS20080143005A1Improve propertiesRapid depositionFibre chemical featuresFriction liningCarbon compositesCarbon fibers

The present invention relates to a method of producing carbon fiber reinforced ceramic matrix composites, the method of producing carbon fiber reinforced ceramic matrix composites according to the present invention is characterized in that the method comprises the steps of: producing a carbon fiber reinforced resin composite that is molded with a mixture in which carbon fibers and polymer precursors containing carbon are mixed; producing a carbon fiber reinforced carbon composite by depositing pyrolytic carbon during a rapid thermal gradient chemical vapor infiltration process while increasing the deposition speed in a direction from the inside to the outside by performing a thermal treatment on said carbon fiber reinforced resin composite at high temperature; and infiltrating liquid-phase silicon into the pores of said carbon fiber reinforced carbon composite. The method of producing carbon fiber reinforced ceramic matrix composites according to the present invention as described above has the effect of improving the properties of carbon fiber reinforced ceramic matrix composites, and it is possible to deposit a pyrolytic carbon layer at a deposition speed 5-10 times faster than other conventional chemical vapor infiltration processes, thereby showing a remarkably improved effect in terms of manufacturing process, time, and cost.

Owner:DACC

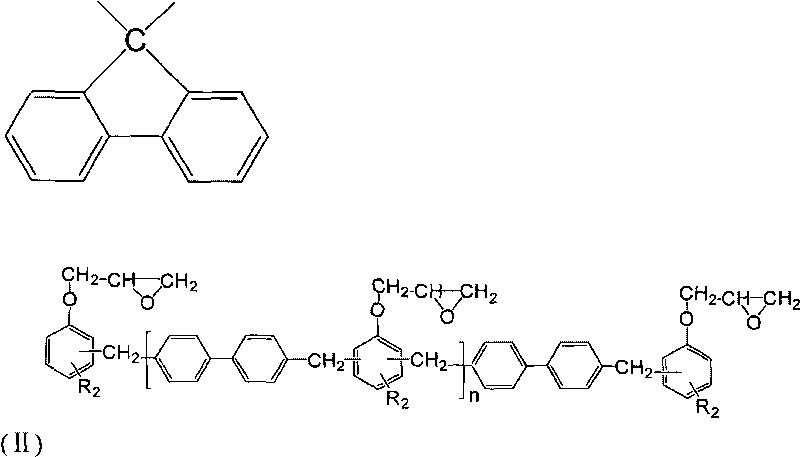

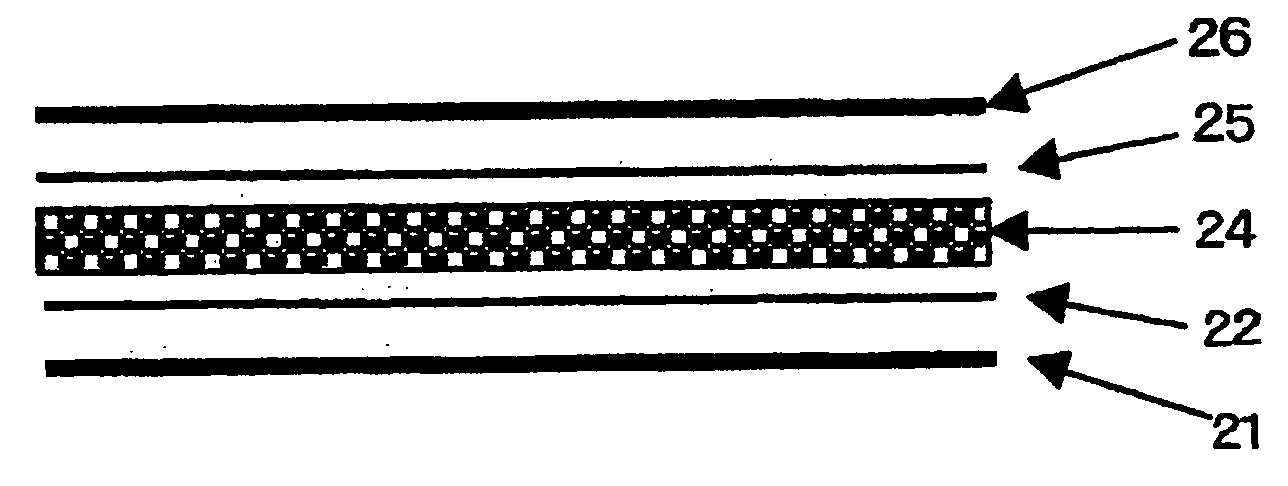

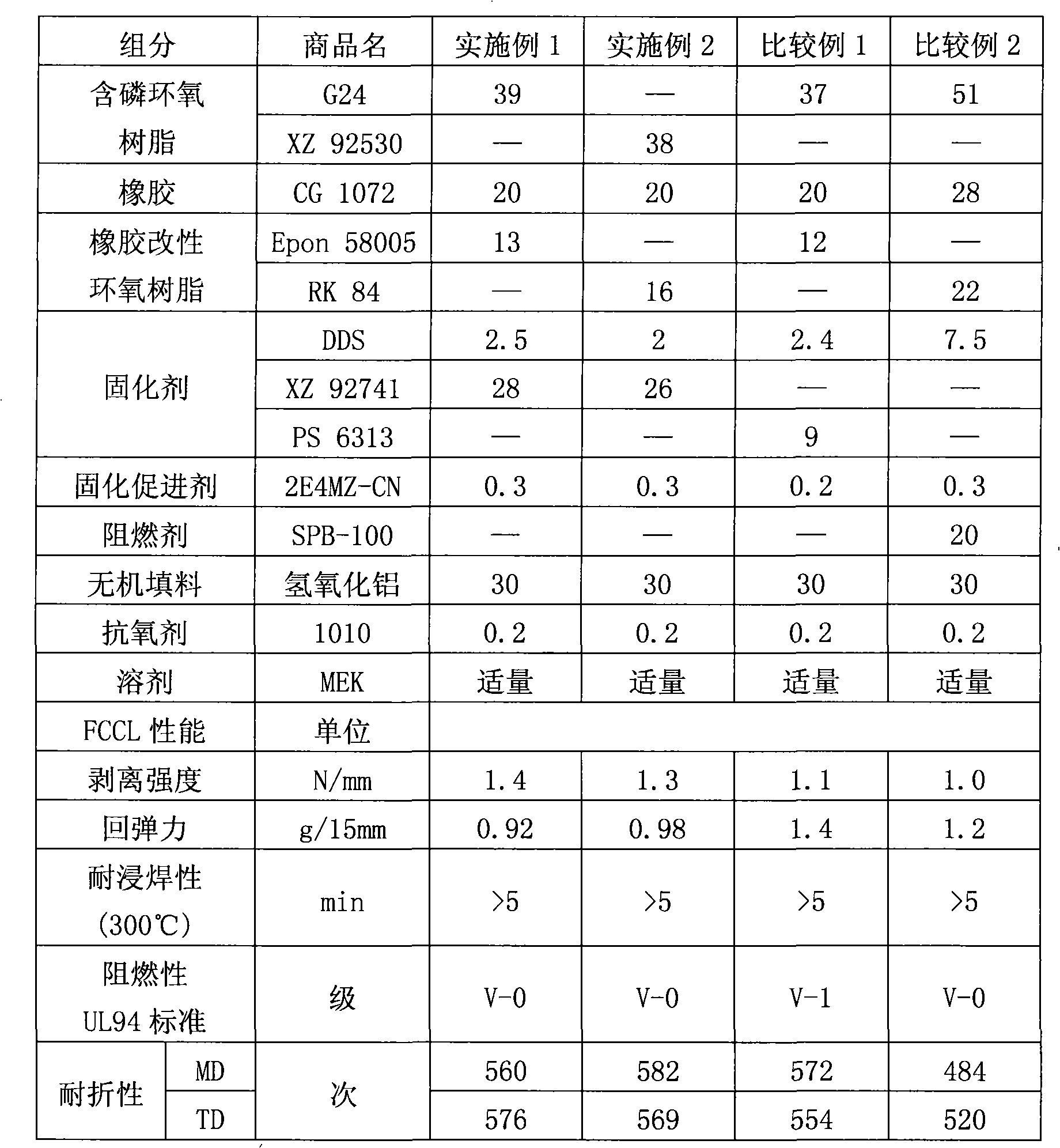

Halogen-free flame-retardant epoxy resin composition, flexible copper clad laminate made therefrom and preparation of the flexible copper clad laminate

InactiveCN101280093AGood compatibilityImprove mechanical propertiesCircuit susbtrate materialsSolid componentEpoxy

The invention relates to a halogen-free flame-retardant epoxy resin composite, the flexible copper clad laminate made from the epoxy resin composite and the production method. The halogen-free flame-retardant epoxy resin composite is composed of solid components and organic solvents, wherein, the solid components include: phosphorus epoxy resin, synthetic rubber, rubber-modified epoxy resin and composite curing agent. The flexible copper clad laminate made from the halogen-free flame-retardant epoxy resin composite is a three-layer flexible copper clad laminate, including a polyimide insulation film, a coating of halogen-free flame-retardant epoxy resin composite coated on the polyimide insulation film, and a copper foil pressed on the coating of halogen-free flame-retardant epoxy resin composite. The resin composite of the invention is halogen-free and dispenses with other organic phosphorus flame retardants; the flexible copper clad laminate made from the composite has the flame retardancy up to UL94 V-0-level and has the advantages of high peeling strength, excellent dimensional stability, softness, good ion migration resistance and processing performance.

Owner:GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com