Thermoplastic resin composite material and preparation method and application thereof

A thermoplastic resin and composite material technology, applied in the field of preparation and thermoplastic resin composite materials, can solve the problems of difficult recycling and reuse, poor impact resistance, and difficult to repair damage, and achieve easy acquisition, good impact resistance, and easy repair. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Continuous Glass Fiber Reinforced Polypropylene Composites for Minivan Doors

[0051] formula:

[0052] Continuous glass fiber (fiber length: 120 meters): 10 kg (40% by weight)

[0053] Polypropylene resin: 7.5 kg (30% by weight)

[0054] Flame retardant decabromodiphenylethane: 3.5 kg (14% by weight)

[0055] Flame retardant antimony trioxide: 1 kg (4% by weight)

[0056] Anti-ultraviolet agent UV531: 2.25 kg (9% by weight)

[0057] Antioxidant 168: 0.75 kg (3% by weight)

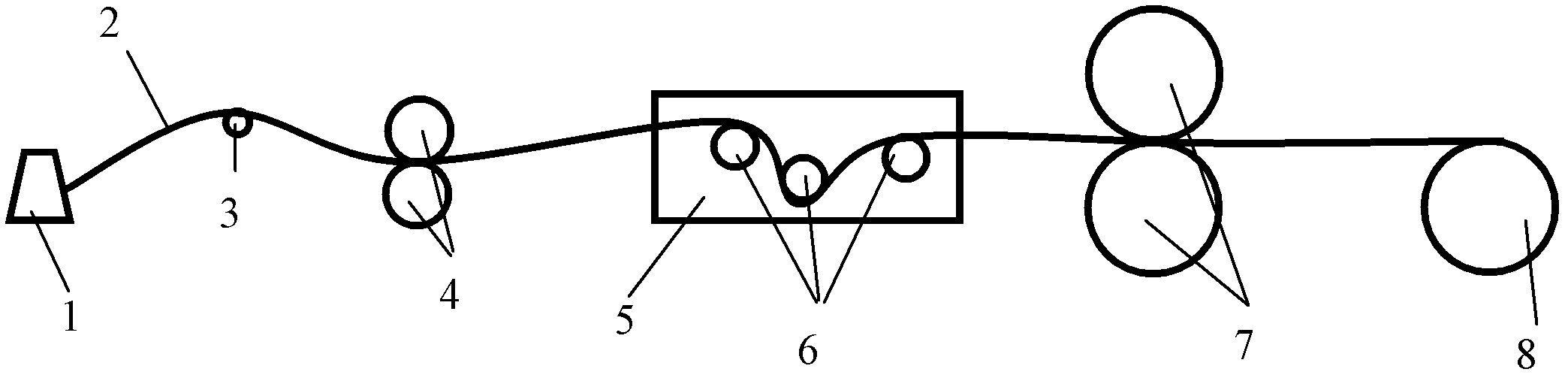

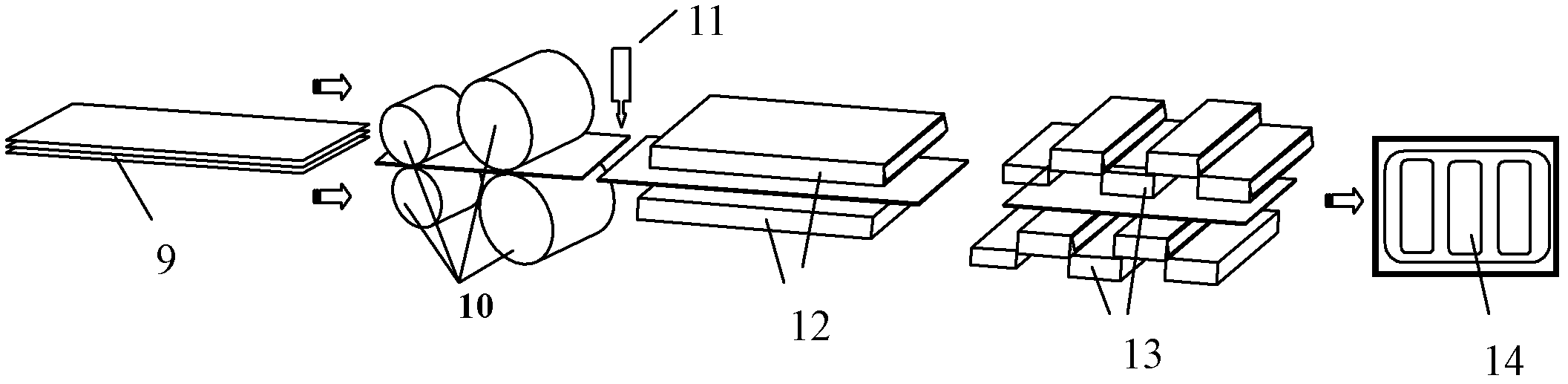

[0058] Such as figure 1 As shown, the thermoplastic resin composite material, that is, the unidirectional glass fiber polypropylene impregnated tape, was prepared first. Unwind the continuous glass fiber roll 1 and pull out the continuous glass fiber bundle 2, through the godet roller 3 and the godet roller 4 rely on the action of tension to make the glass fiber bundle open and flatten to form a unidirectional glass fiber cloth. The number of required fiber bundles is 60. Mix polypropylene r...

Embodiment 2

[0064] Continuous glass fiber reinforced polypropylene composite freight train door

[0065] formula:

[0066] Continuous glass fiber (fiber length 250 meters): 30 kg (60% by weight)

[0067] Polypropylene resin: 12.5 kg (25% by weight)

[0068] Flame retardant decabromodiphenylethane: 3.5 kg (7% by weight)

[0069] Flame retardant antimony trioxide: 1 kg (2% by weight)

[0070] Anti-ultraviolet agent UV531: 1.25 kg (2.5% by weight)

[0071] Anti-ultraviolet agent light stabilizer 944: 1 kg (2.0% by weight)

[0072] Antioxidant 1010: 0.75 kg (1.5% by weight)

[0073] First, a thermoplastic resin composite material, that is, a unidirectional glass fiber polypropylene impregnated tape, is prepared. Unwind the continuous glass fiber roll and pull out the continuous glass fiber bundles, through the godet roller and the godet roller rely on the action of tension to make the glass fiber bundles open and flatten to form a unidirectional glass fiber cloth. The number of require...

Embodiment 3

[0079] Carbon fiber reinforced nylon 66 high strength bulletproof door

[0080] formula:

[0081] Carbon fiber T300 (fiber length 300 meters): 16 kg (80% by weight)

[0082] Nylon 66: 4 kg (20% by weight)

[0083] Flame retardant: 0

[0084] Anti-UV agent: 0

[0085] Antioxidant: 0

[0086]Firstly, a thermoplastic resin composite material, that is, a unidirectional carbon fiber polypropylene impregnated tape, is prepared. Unwind the continuous carbon fiber roll and pull out the continuous carbon fiber bundle, through the godet roller and the godet roller rely on the action of tension to make the carbon fiber bundle open and flatten to form a unidirectional carbon fiber cloth. The number of required fiber bundles was 50. Nylon 66 is melted and extruded by a screw extruder and injected into the dipping tank, and then the unidirectional carbon fiber cloth after the stretched yarn is laid flat is passed through the dipping tank to impregnate the unidirectional carbon fiber c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com