Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22730 results about "Impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition - What does Impact Resistance mean? Impact resistance is a material's ability to withstand intense force or shock applied to it over a short period of time.

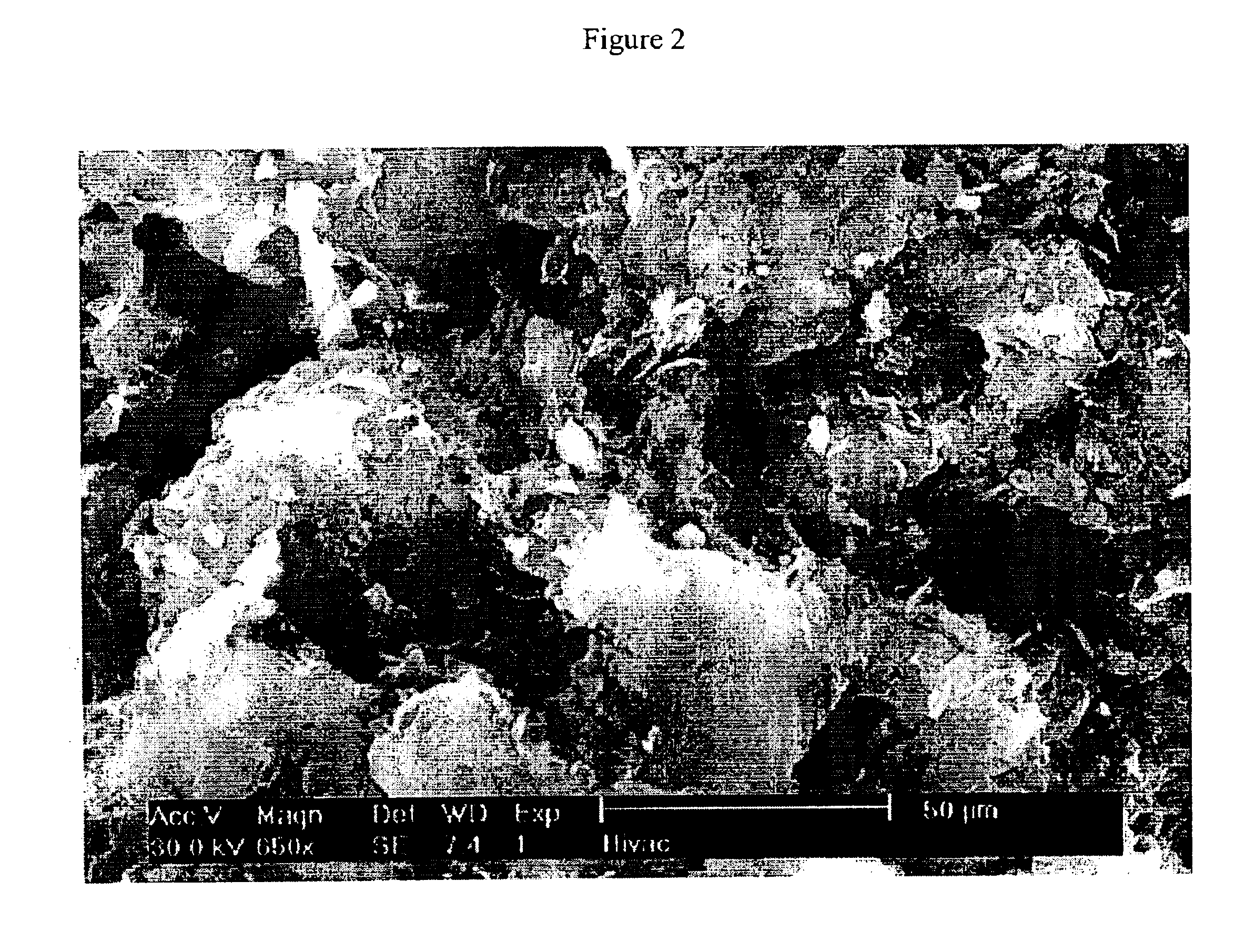

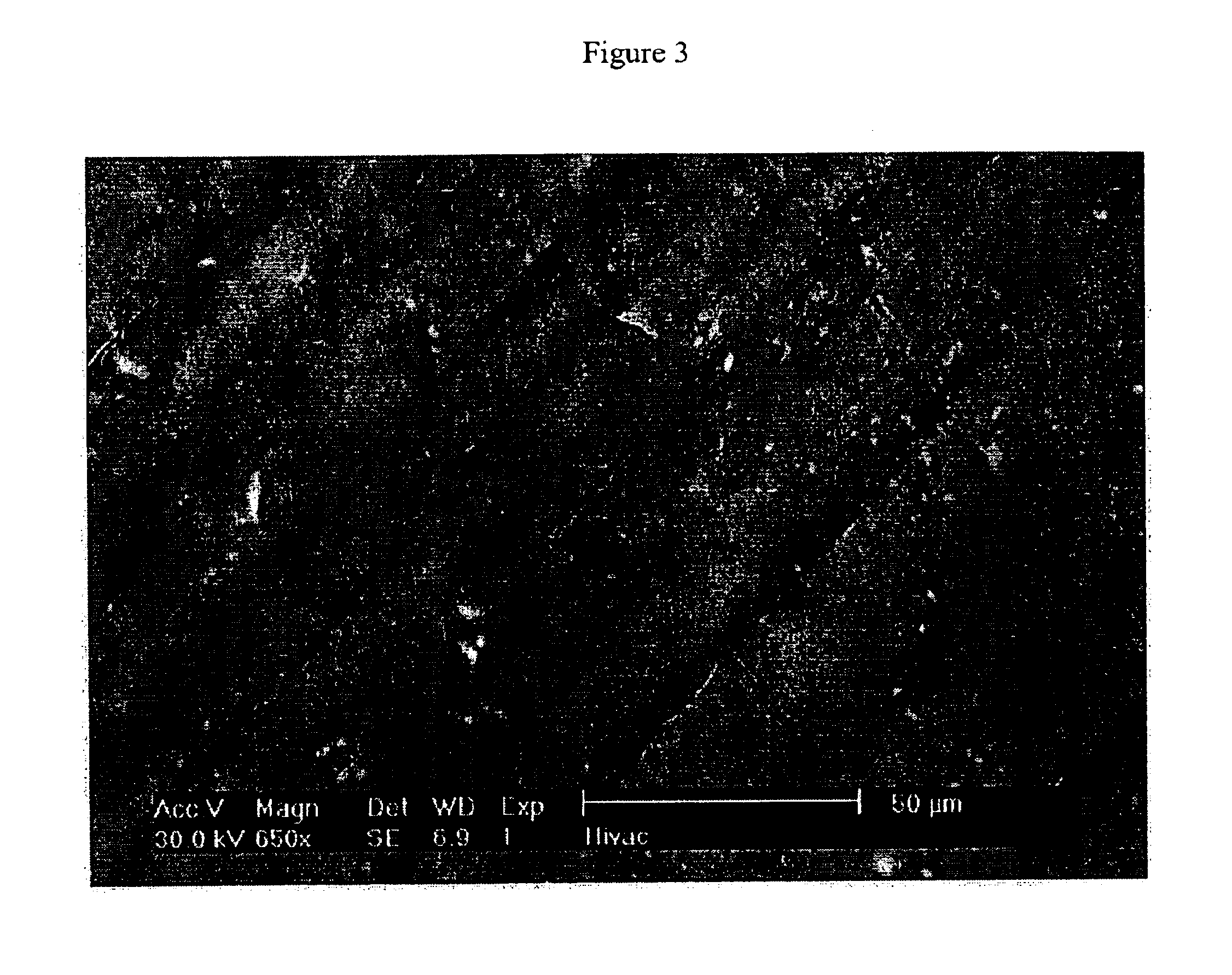

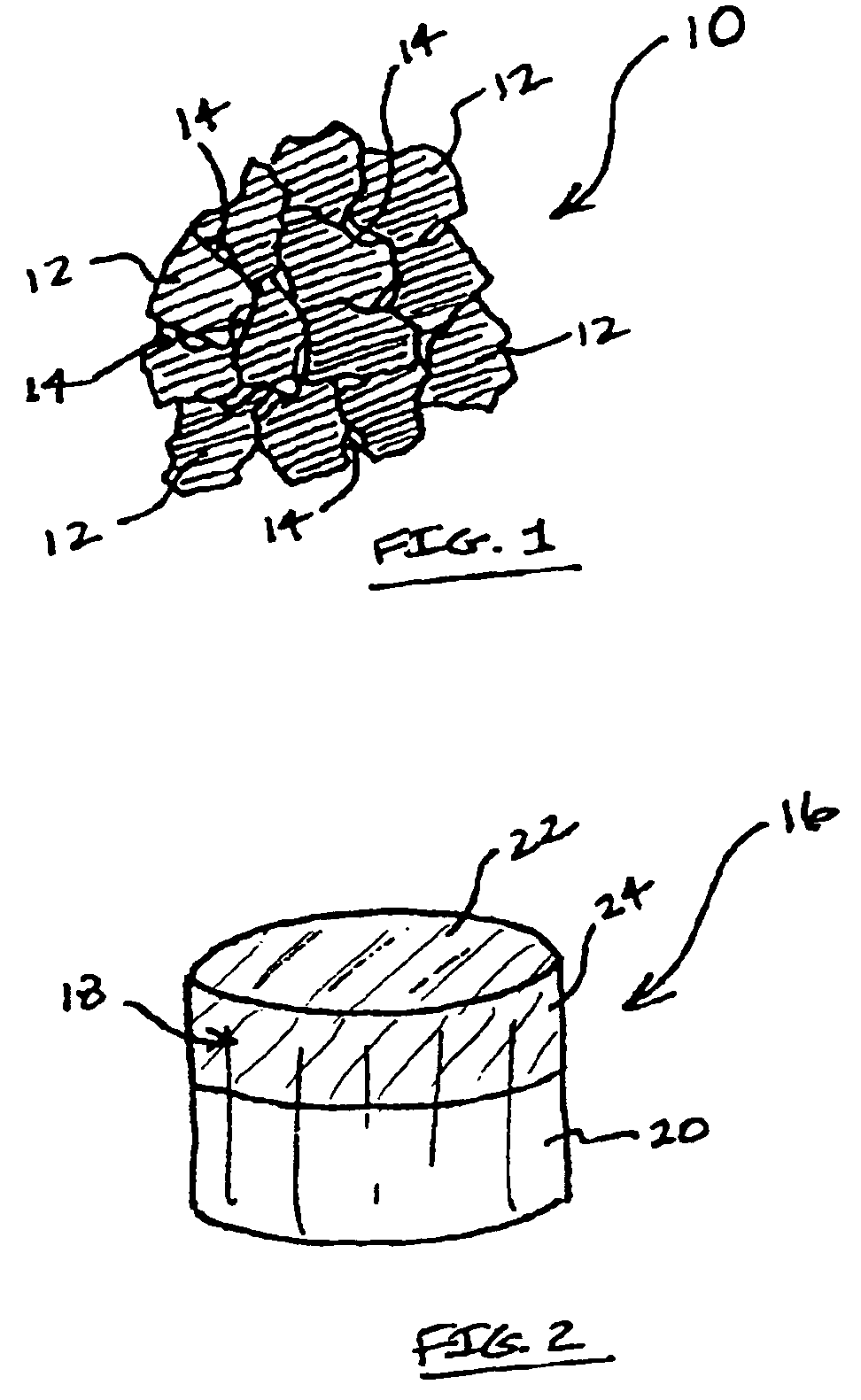

Entangled single-wall carbon nanotube solid material and methods for making same

InactiveUS6899945B2Material nanotechnologySynthetic resin layered productsCross-linkSolvent evaporation

Buckyrock is a three-dimensional, solid block material comprising an entangled network of single-wall carbon nanotubes (SWNT), wherein the block comprises greater than 75 wt % SWNT. SWNT buckyrock is mechanically strong, tough and impact resistant. The single-wall carbon nanotubes in buckyrock form are present in a random network of individual single-wall carbon nanotubes, SWNT “ropes” and combinations thereof. The random network of the SWNT or SWNT ropes can be held in place by non-covalent “cross-links” between the nanotubes at nanotube contact points. In one embodiment, SWNT buckyrock is made by forming a SWNT-water slurry, slowly removing water from the slurry which results in a SWNT-water paste, and allowing the paste to dry very slowly, such that the SWNT network of the SWNT-water paste is preserved during solvent evaporation. Buckyrock can be used in applications, such as ballistic protection systems, involving light-weight material with mechanical strength, toughness and impact resistance.

Owner:RICE UNIV

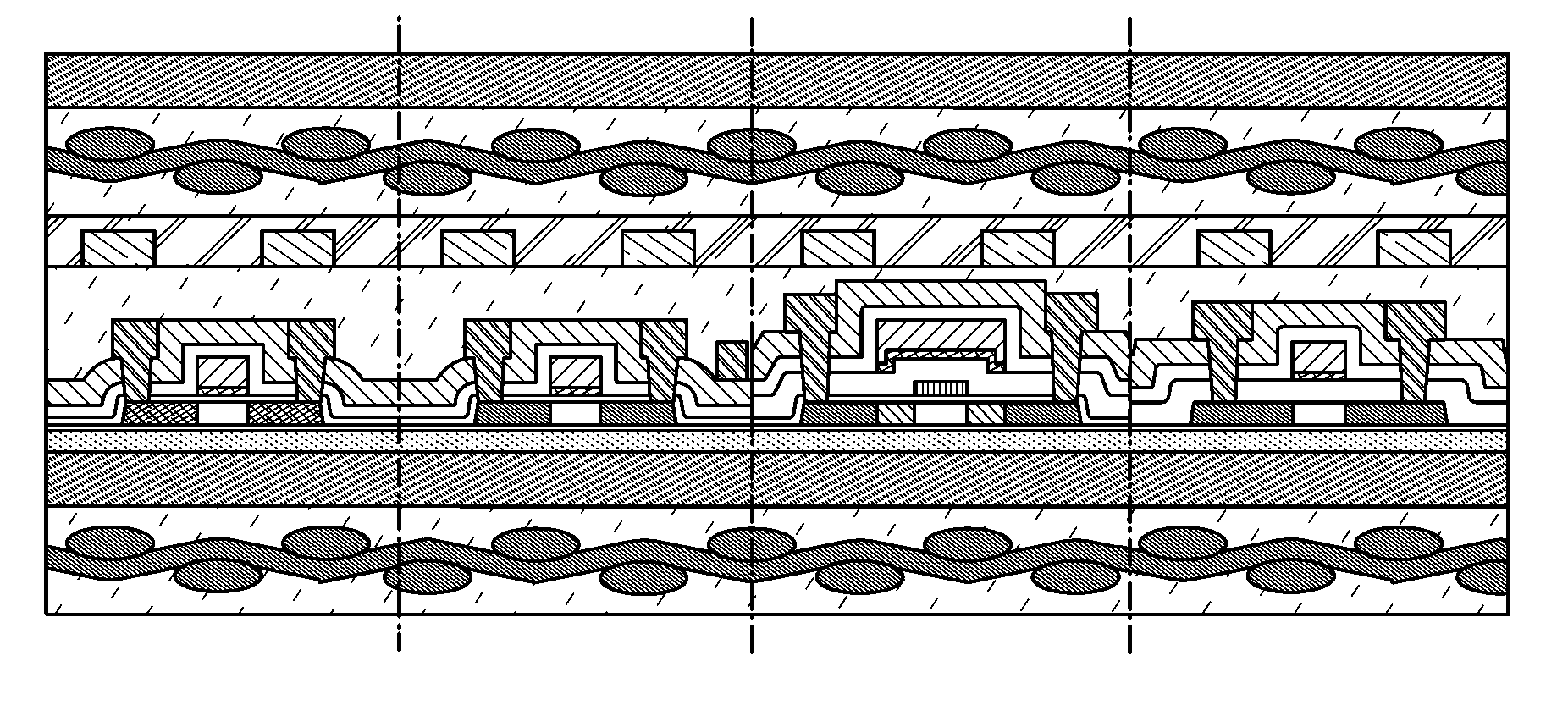

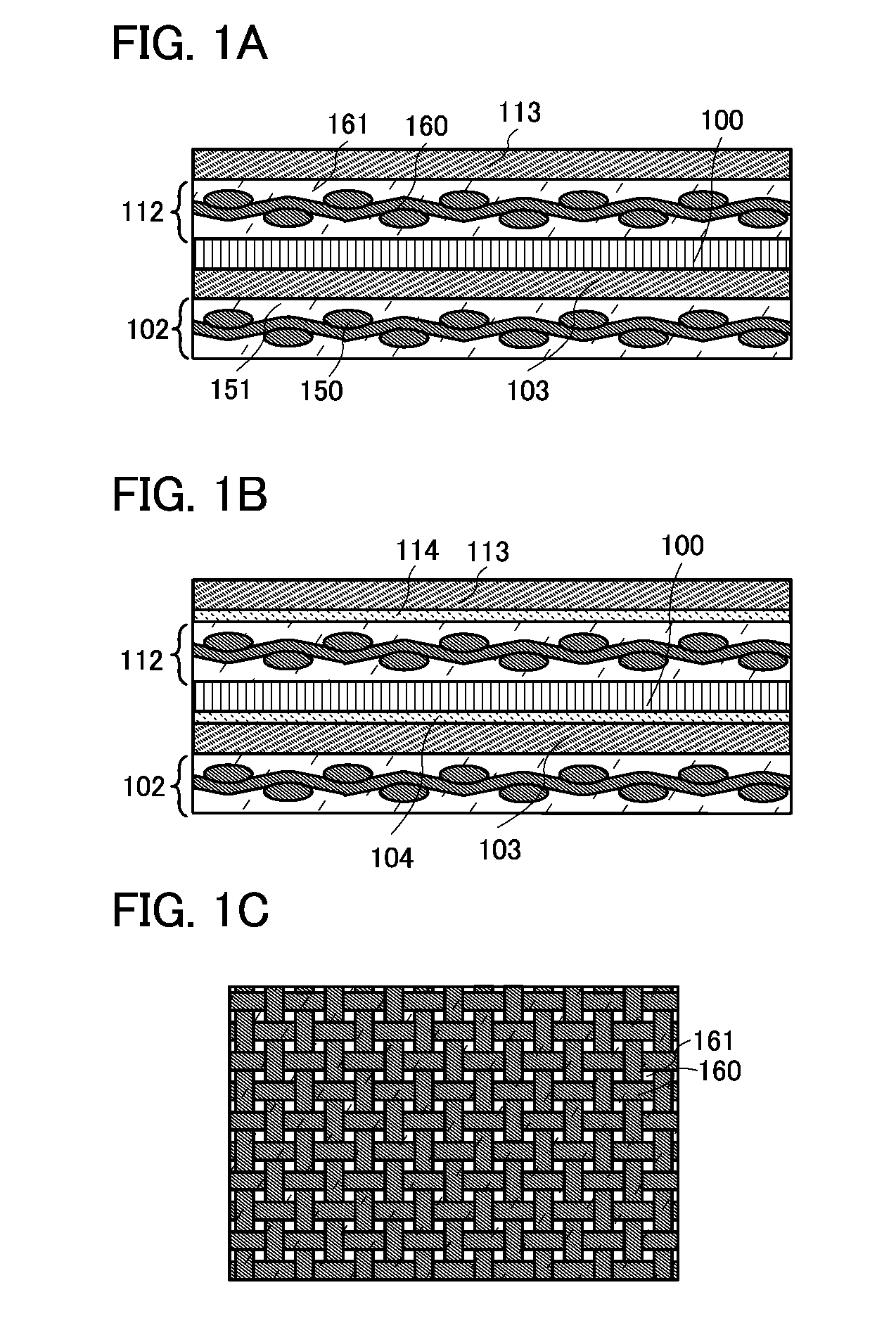

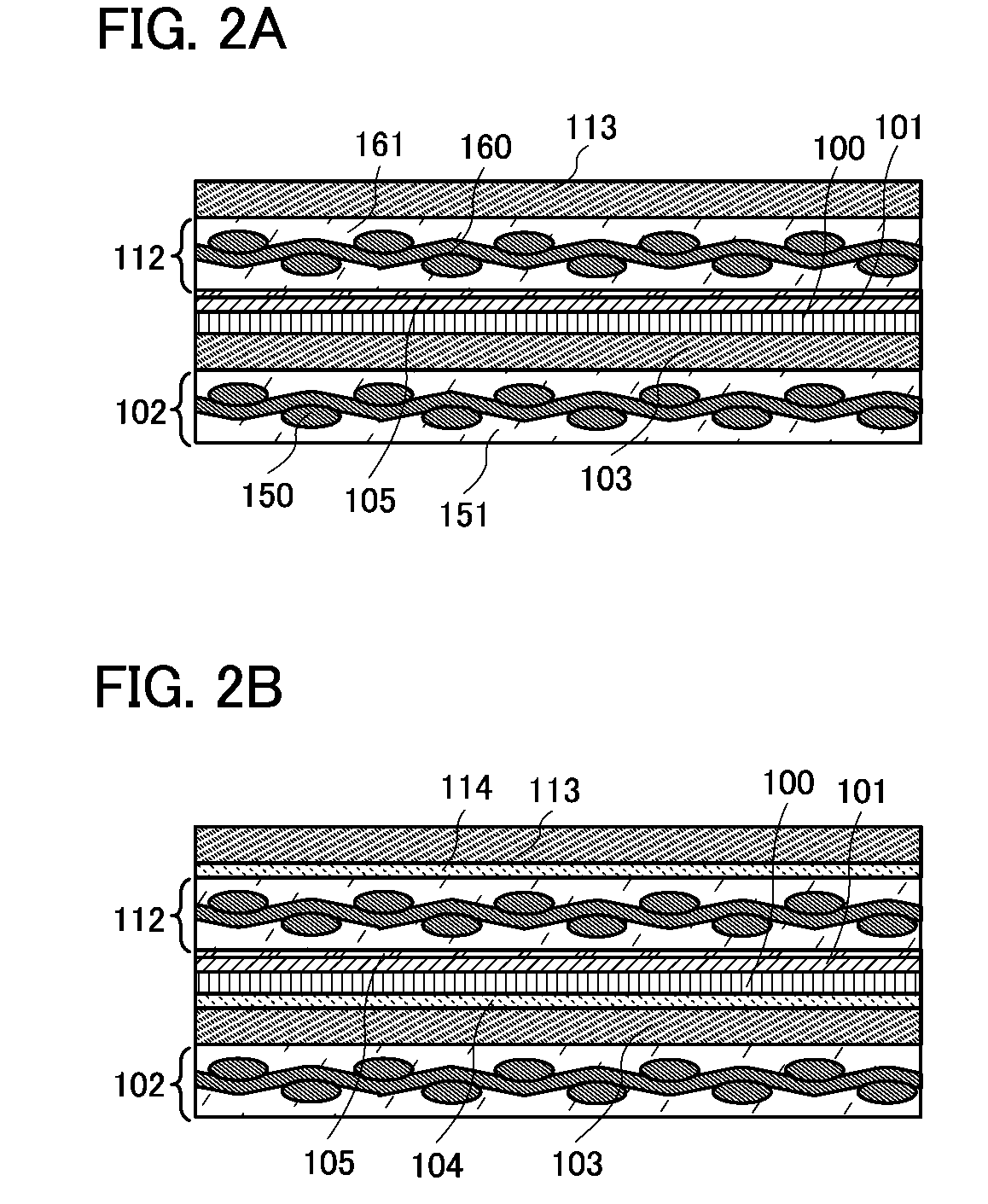

Semiconductor device and method for manufacturing the same

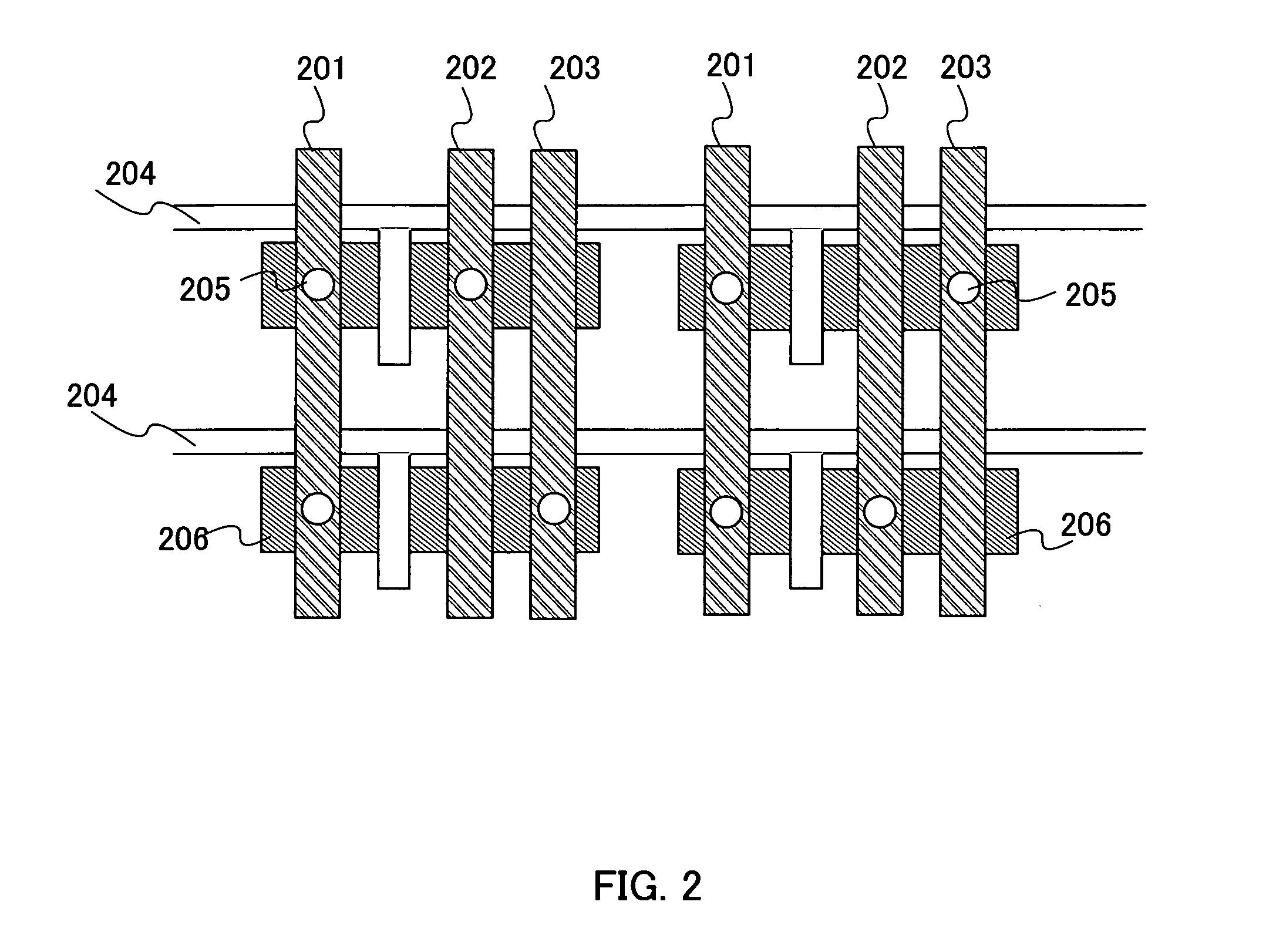

ActiveUS20090267225A1Reduce thicknessSmall sizeSemiconductor/solid-state device detailsSolid-state devicesShock resistanceDiffusion layer

In a semiconductor integrated circuit sandwiched between a pair of a first impact resistance layer and a second impact resistance layer, an impact diffusion layer is provided between the semiconductor integrated circuit and the second impact resistance layer. By provision of the impact resistance layer against the external stress and the impact diffusion layer for diffusing the impact, force applied to the semiconductor integrated circuit per unit area is reduced, so that the semiconductor integrated circuit is protected. The impact diffusion layer preferably has a low modulus of elasticity and high breaking modulus.

Owner:SEMICON ENERGY LAB CO LTD

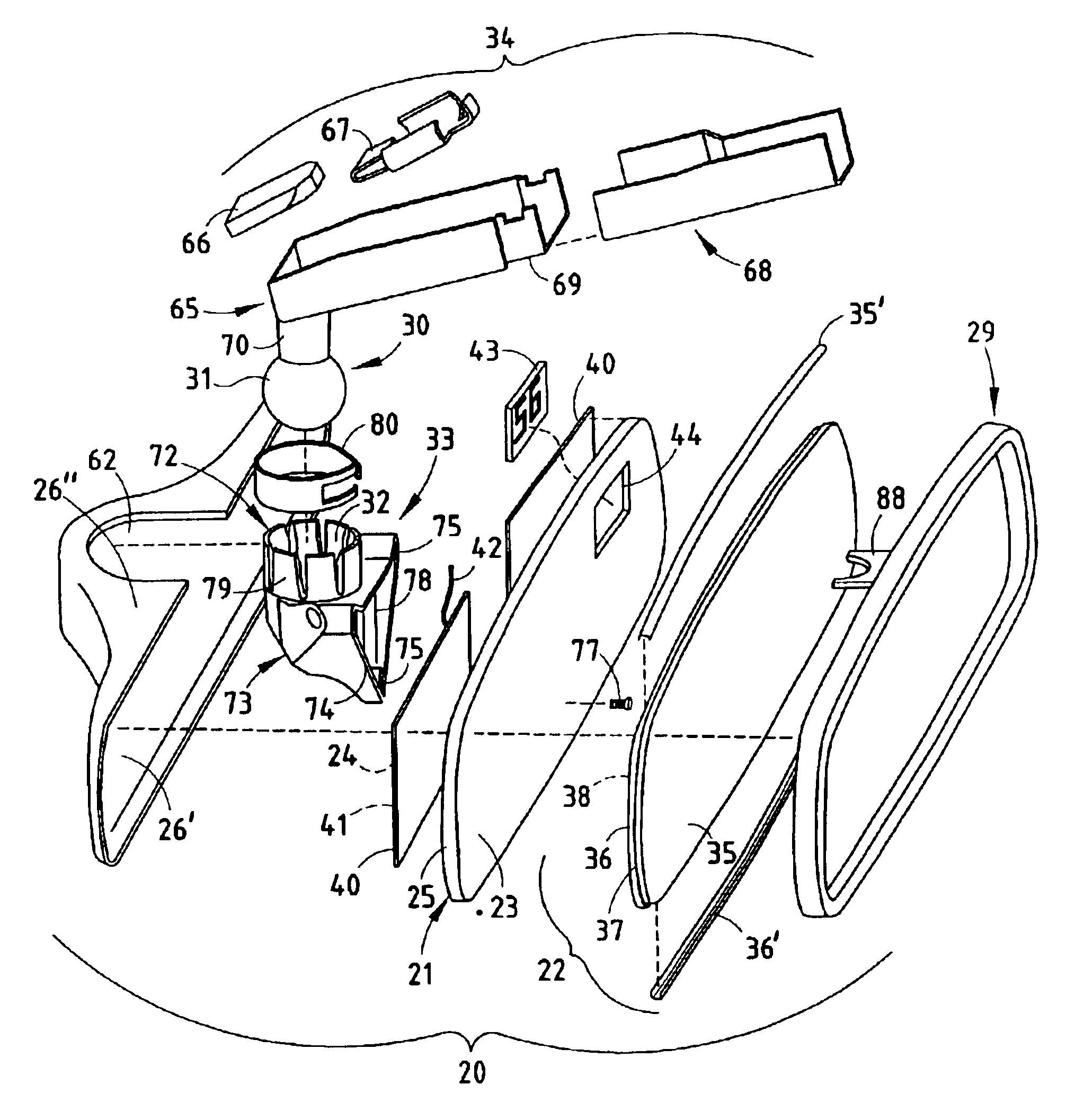

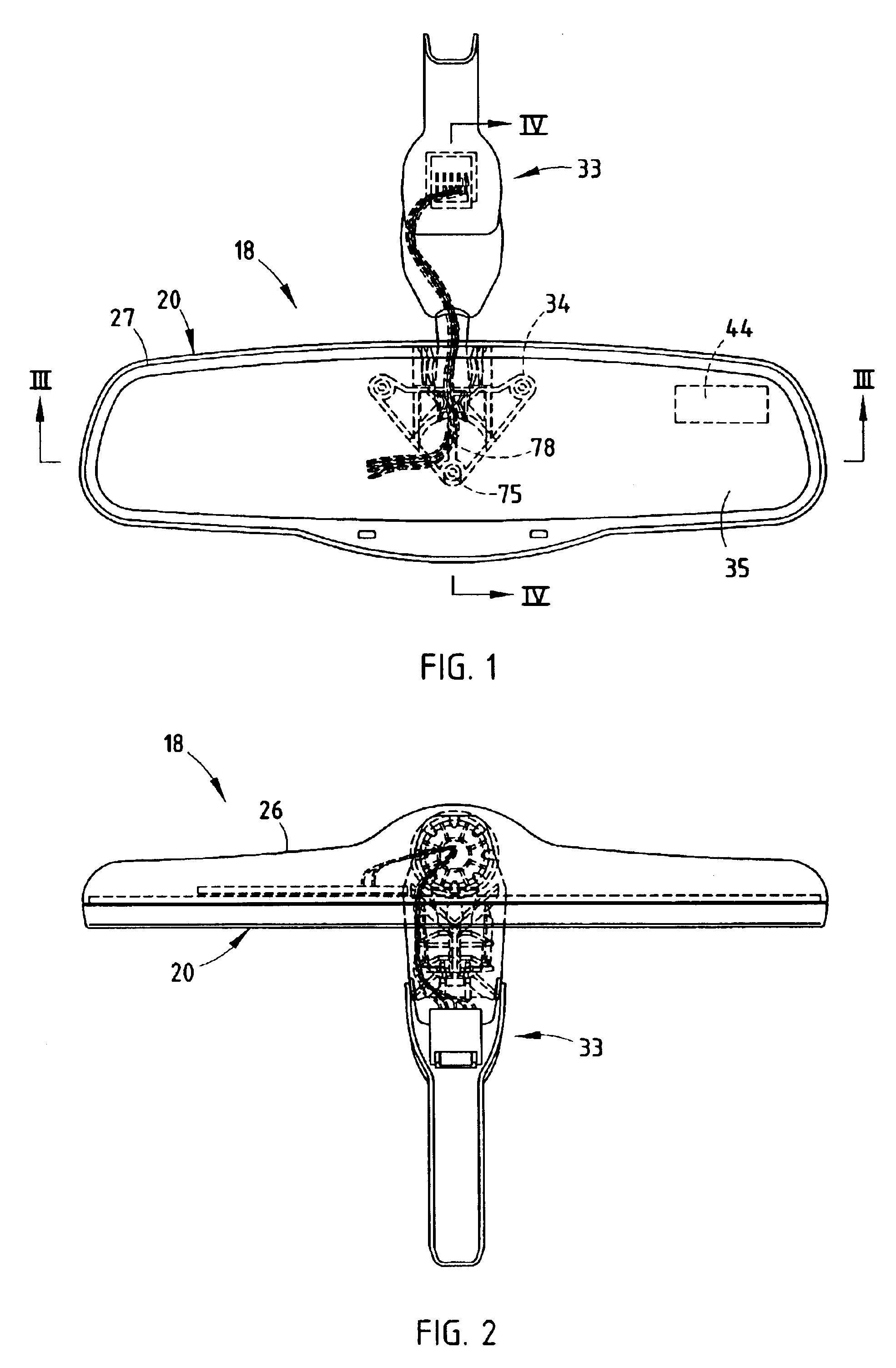

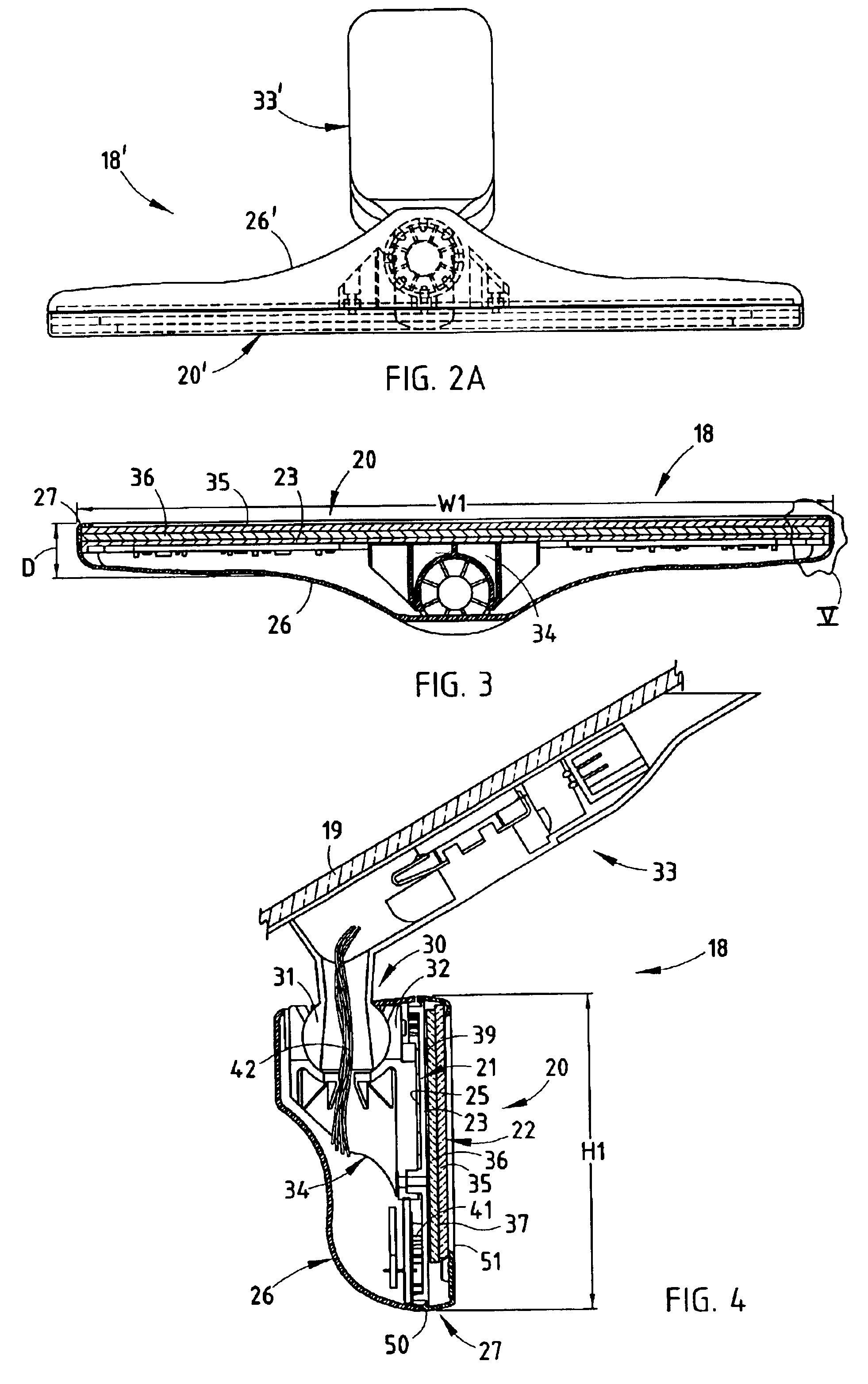

Rearview mirror with integrated frame

InactiveUS7287868B2Improve impact resistanceUniform supportMirrorsMountingsEngineeringRear-view mirror

Owner:GENTEX CORP

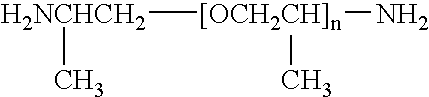

Structural modified epoxy adhesive compositions

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

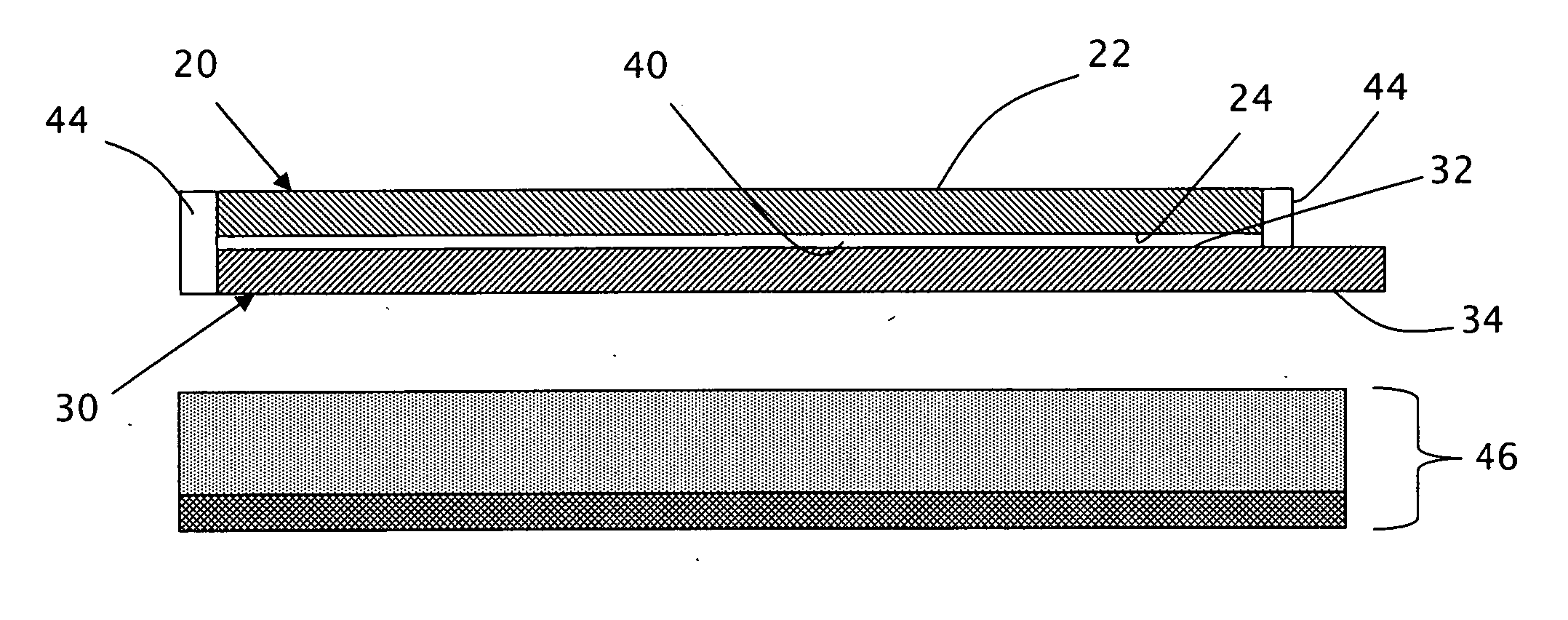

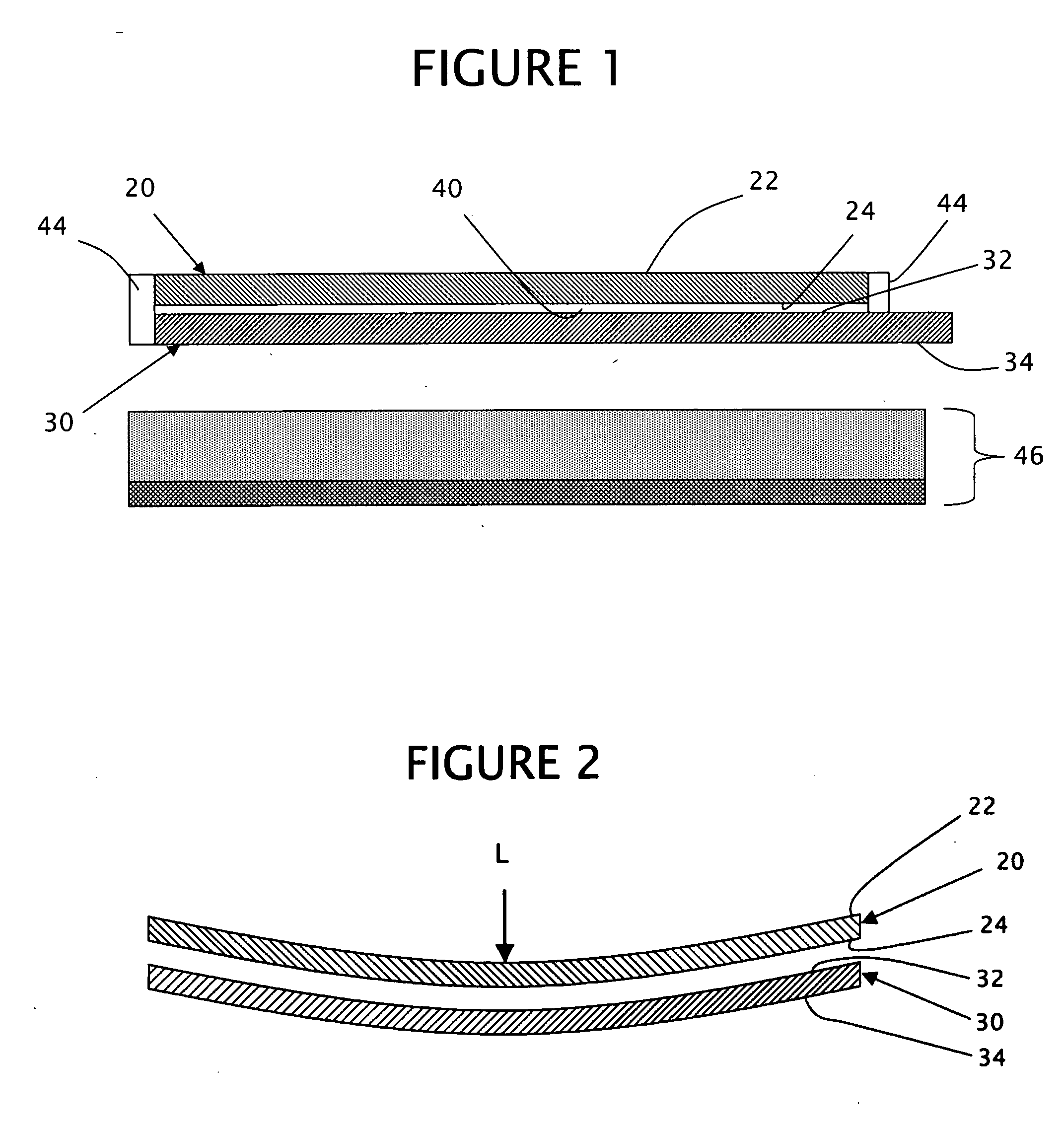

Glass laminate substrate having enhanced impact and static loading resistance

ActiveUS20060127679A1Increased resistance to impactIncrease static loadLiquid crystal compositionsGas-filled discharge tubesDisplay deviceThermal expansion

A glass laminate substrate for electronic substrates, such as flat panel displays, includes a transparent glass core bounded by transparent glass skin layers, wherein the coefficient of thermal expansion of the core is greater than the coefficient of thermal expansion of the skin layers thereby forming a residual compressive stress in the skin layers and a residual tensile stress in the core. The relative thickness of the skin layers can be selected to enhance the strength of the glass laminate substrate while maintaining a sufficiently low residual tensile stress in the core to allow scribing and separating of the substrate to size. Interlayers can be located between the core and the skin layers, wherein the interlayers include a residual compressive stress, and produce a reduced residual tensile stress in the core.

Owner:CORNING INC

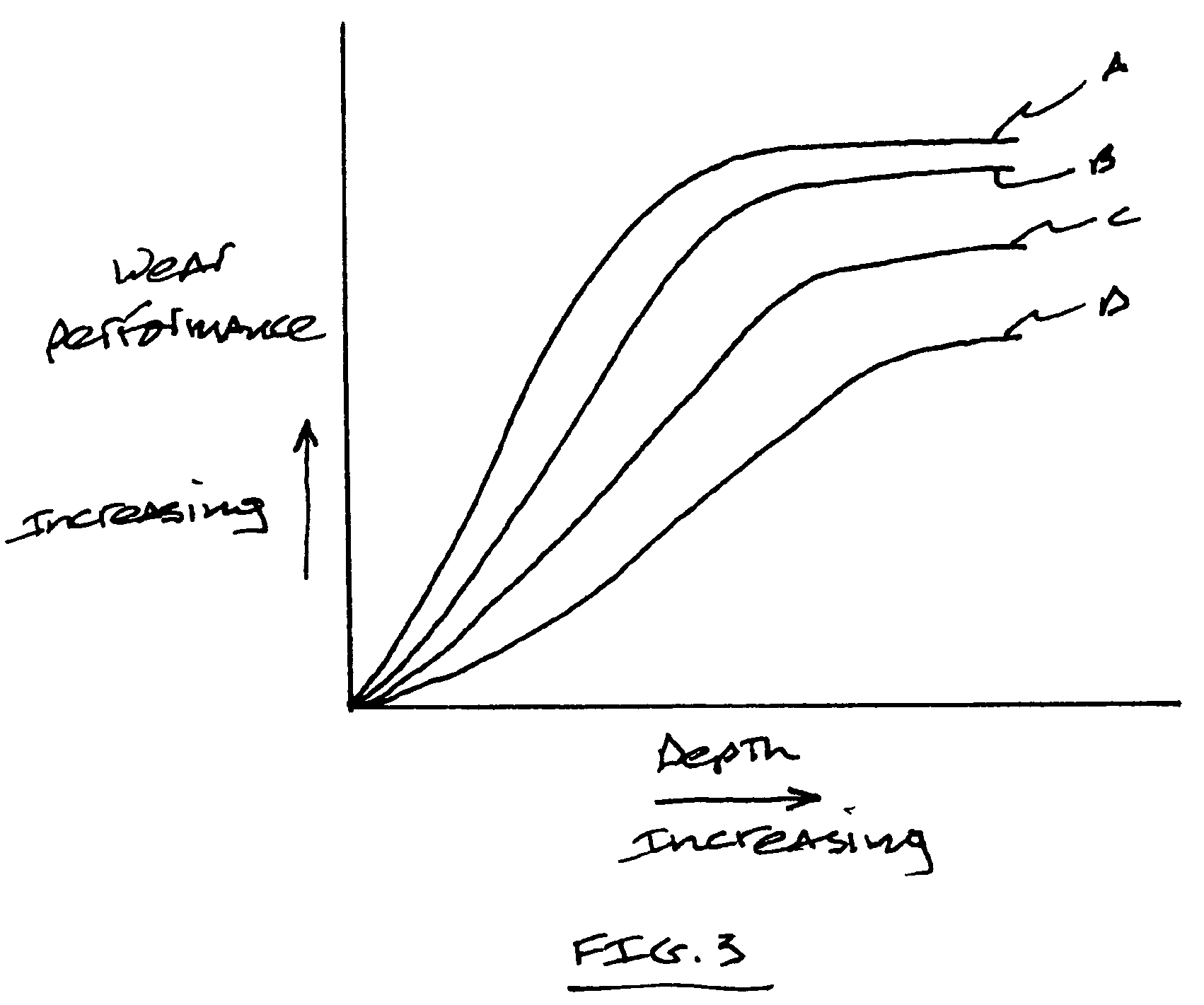

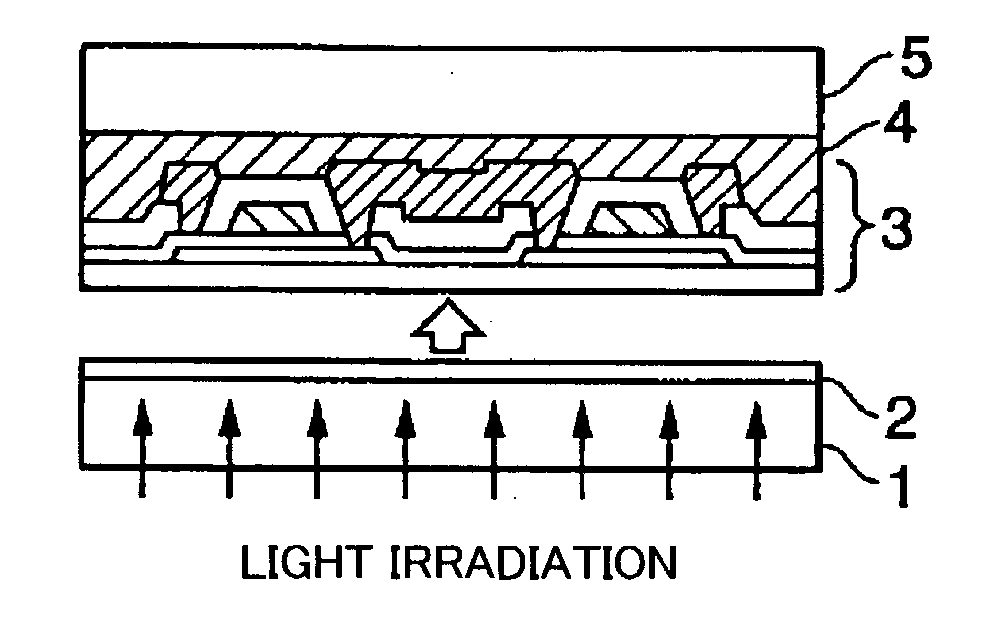

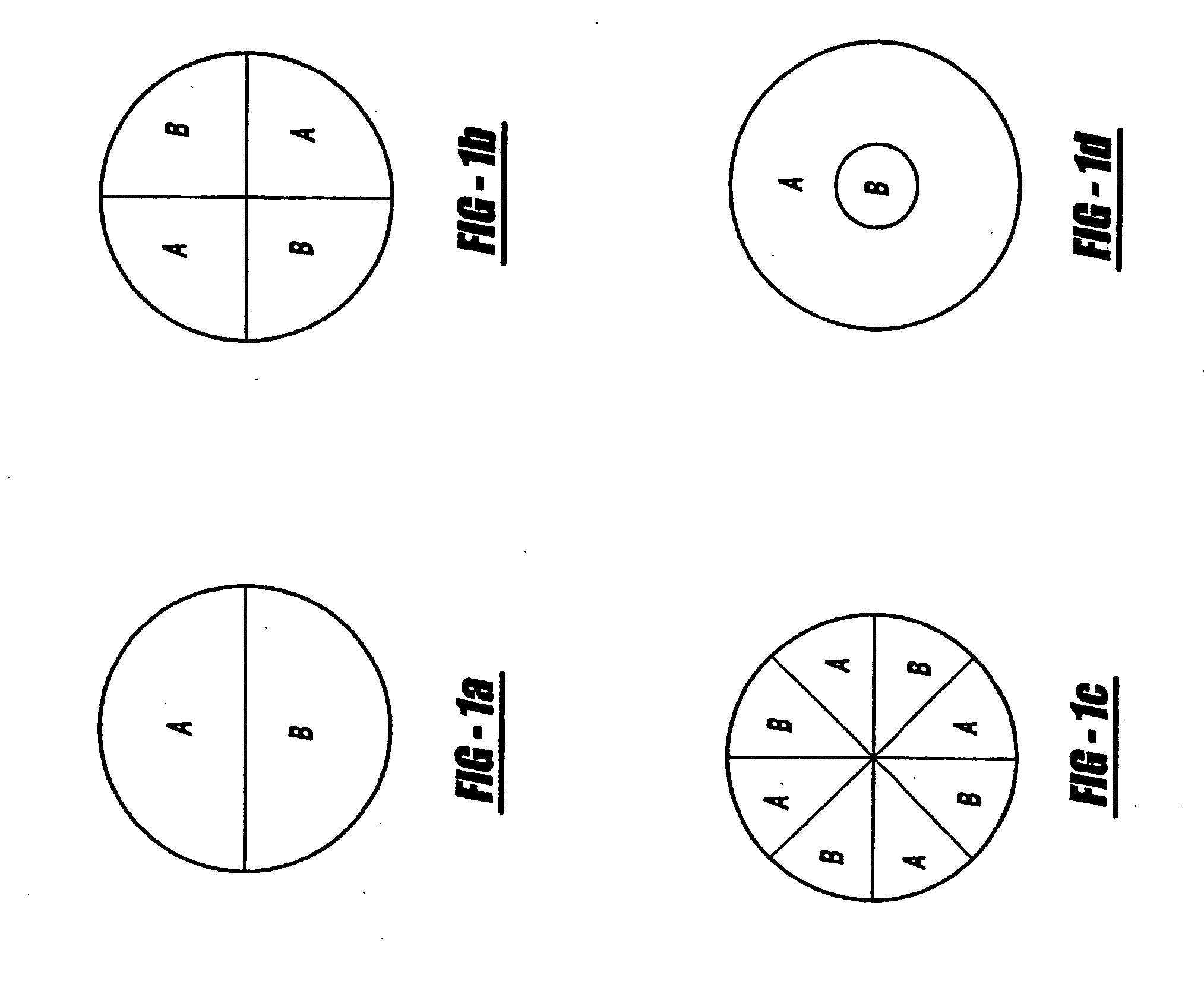

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

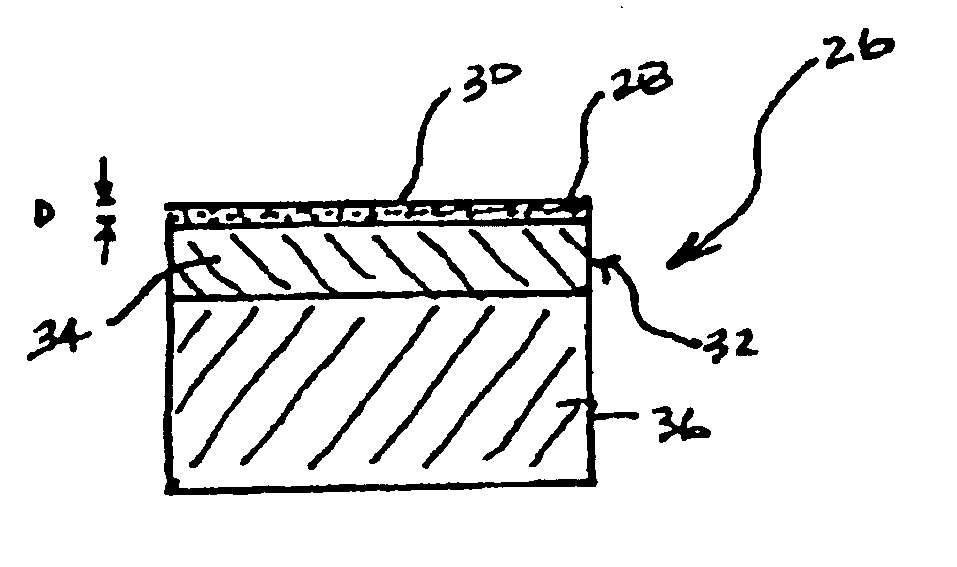

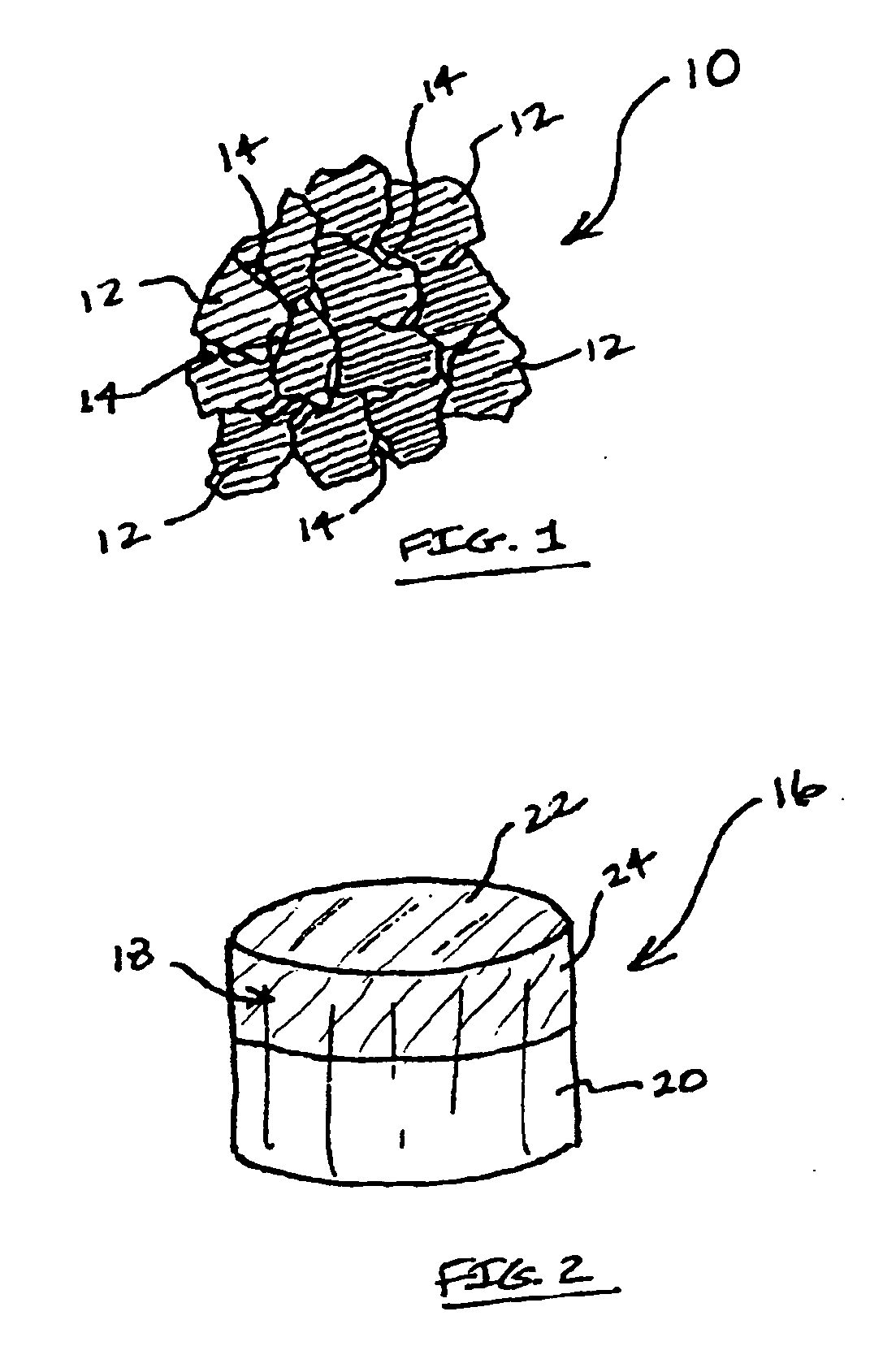

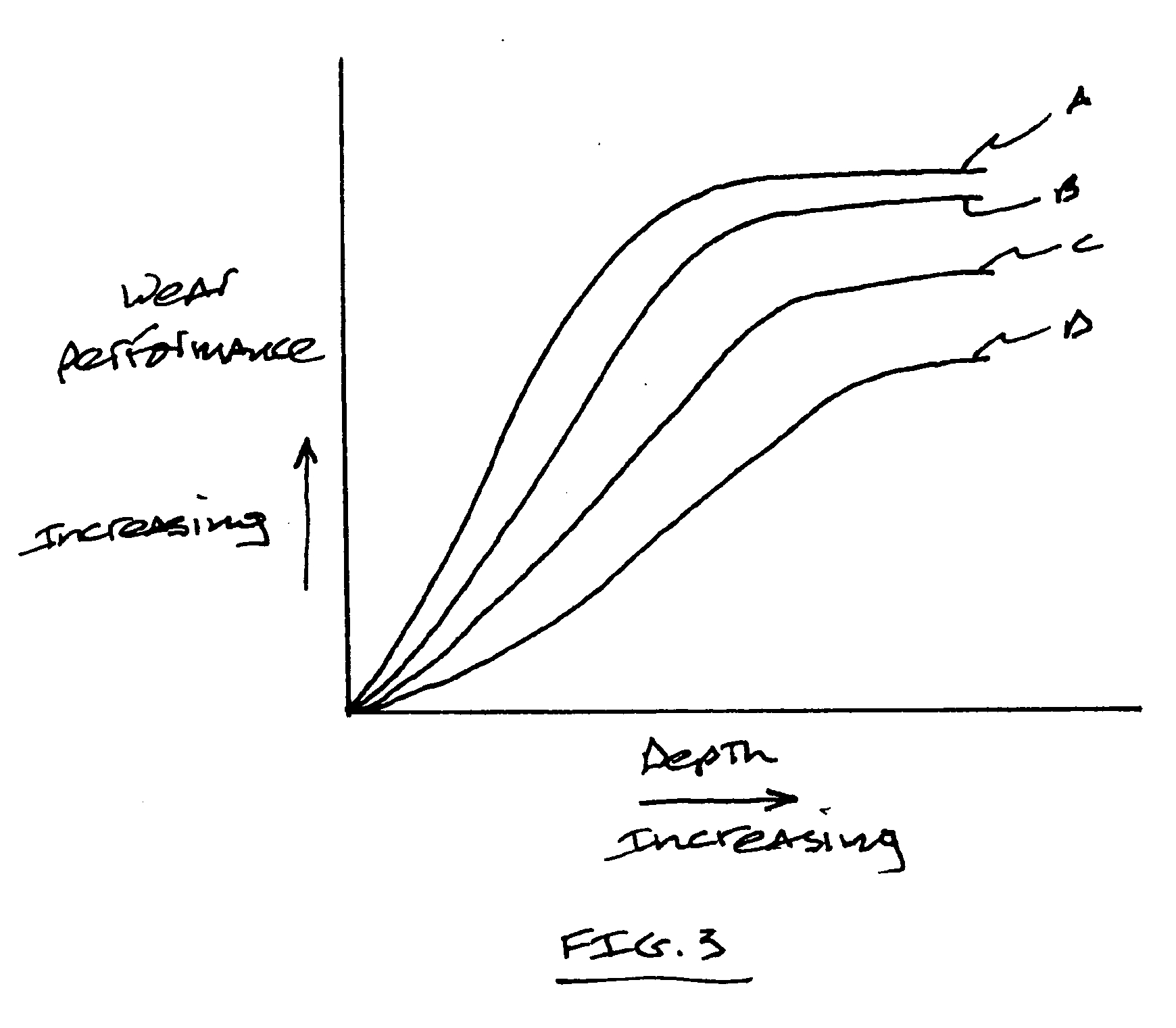

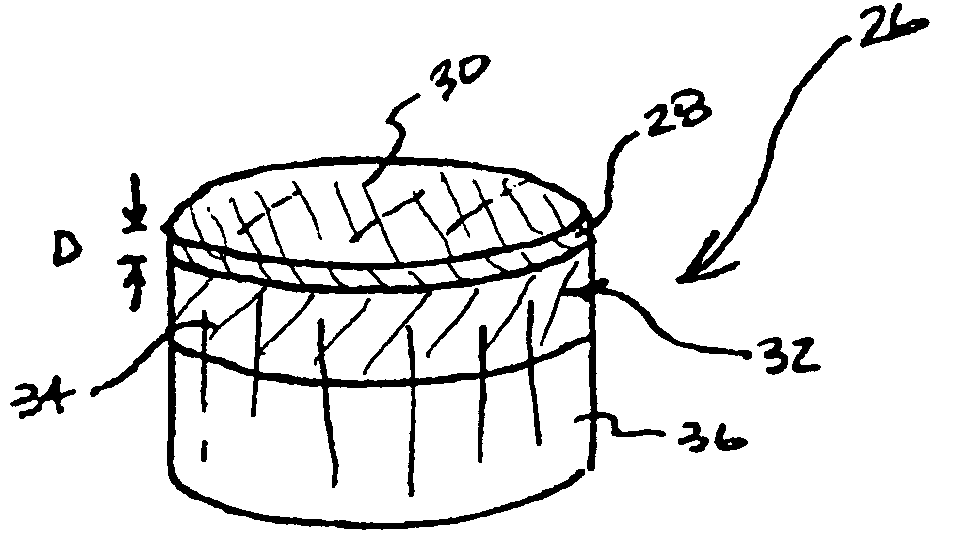

ActiveUS20060266559A1Improve propertiesDrill bitsConstructionsDiamond crystalPolycrystalline diamond

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

Thermoset materials with improved impact resistance

The present invention relates to a thermoset material with improved impact resistance comprising:99 to 20% of a thermoset resin, and1 to 80% of an impact modifier comprising at least one copolymer comprising S-B-M, B-M and M-B-M blocks,wherein:each block is connected to the other by means of a covalent bond or of an intermediate molecule connected to one of the blocks via a covalent bond and to the other block via another covalent bond,M is a PMMA homopolymer or a copolymer comprising at least 50% by weight of methyl methacrylate,B is incompatible with the thermoset resin and with the M block and its glass transition temperature Tg is less than the operating temperature of the thermoset material, andS is incompatible with the thermoset resin, the B block and the M block and its Tg or its melting temperature is greater than the Tg of B.S is advantageously polystyrene and B polybutadiene. The thermoset resin advantageously originates from the reaction of a thermosetting epoxy resin and of a hardener.

Owner:ATOFINA

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

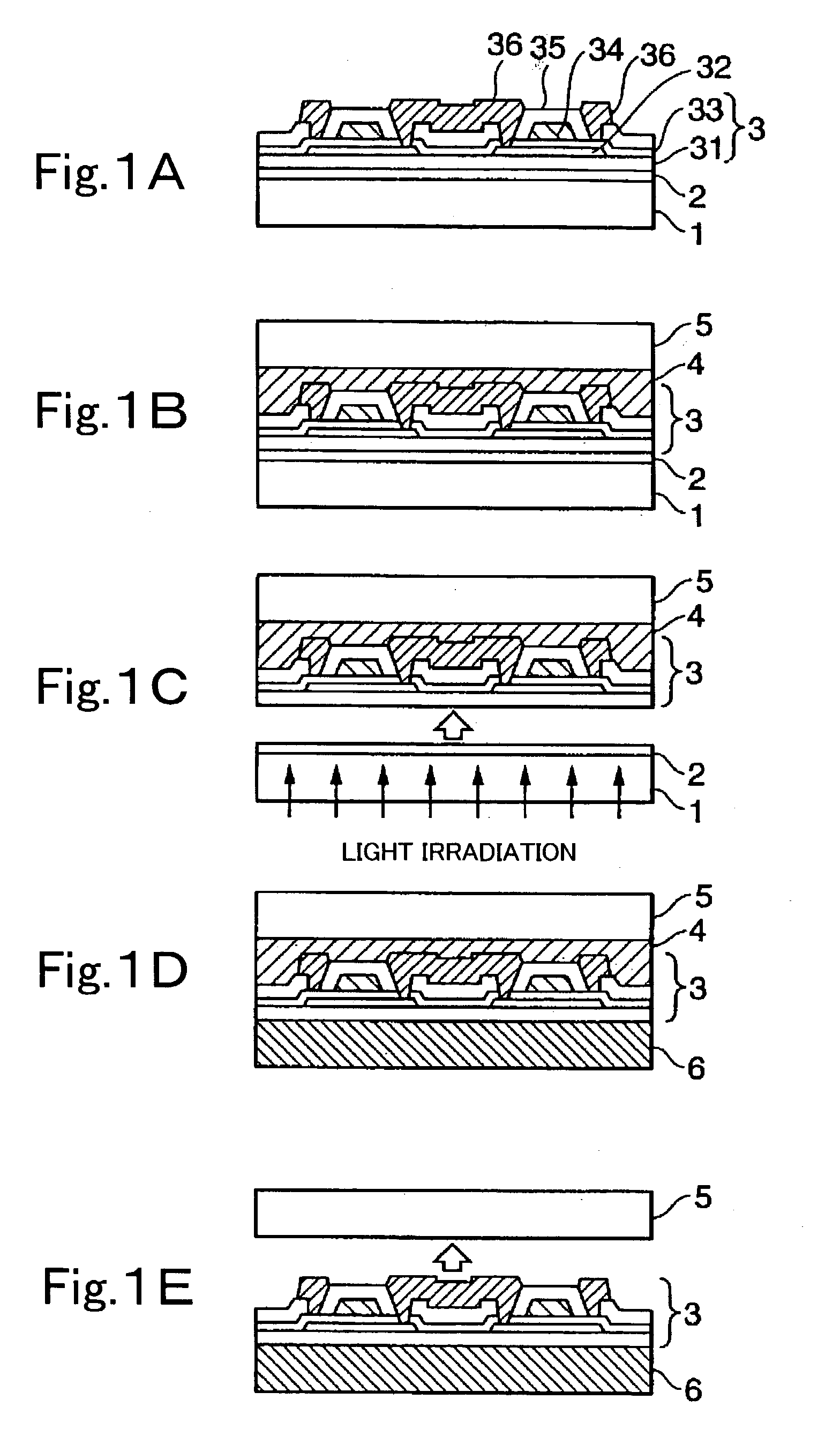

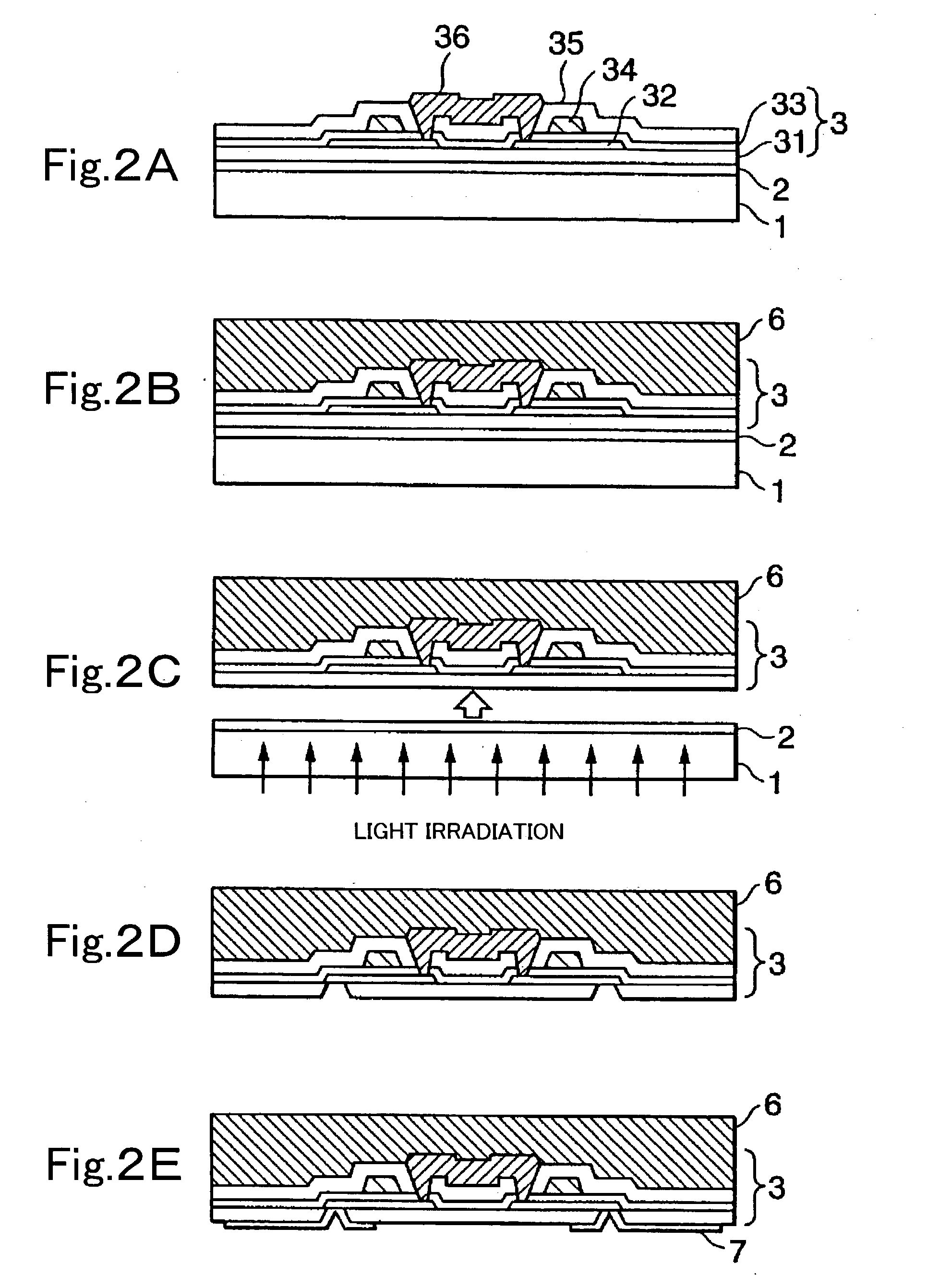

Method for transferring element, method for producing element, integrated circuit, circuit board, electro-optical device, IC card, and electronic appliance

InactiveUS20030024635A1Thinner semiconductor deviceMinimize cracksLamination ancillary operationsDecorative surface effectsDevice materialEngineering

A peeling layer 2 is formed on an element-forming substrate 1, an element-forming layer 3 including an electrical element is formed on the peeling layer, the element-forming layer is joined by means of a dissolvable bonding layer 4 to a temporary transfer substrate 5, the bonding force of the peeling layer is weakened to peel the element-forming layer from the element-forming substrate, the layer is moved to the temporary transfer substrate 5 side, a curable resin 6 is applied onto the element-forming layer 3 which has been moved onto the temporary transfer substrate 5, the resin is cured to form a transfer substrate 6, and the bonding layer 4 is dissolved to peel the temporary transfer substrate 5 from the transfer substrate 6, resulting in a structure in which a transfer substrate is formed directly on the element-forming layer 3. The separation and transfer technique can be used to form a substrate with better flexibility and impact resistance directly on a semiconductor element, without an adhesive layer on the semiconductor device that is produced.

Owner:SAMSUNG ELECTRONICS CO LTD

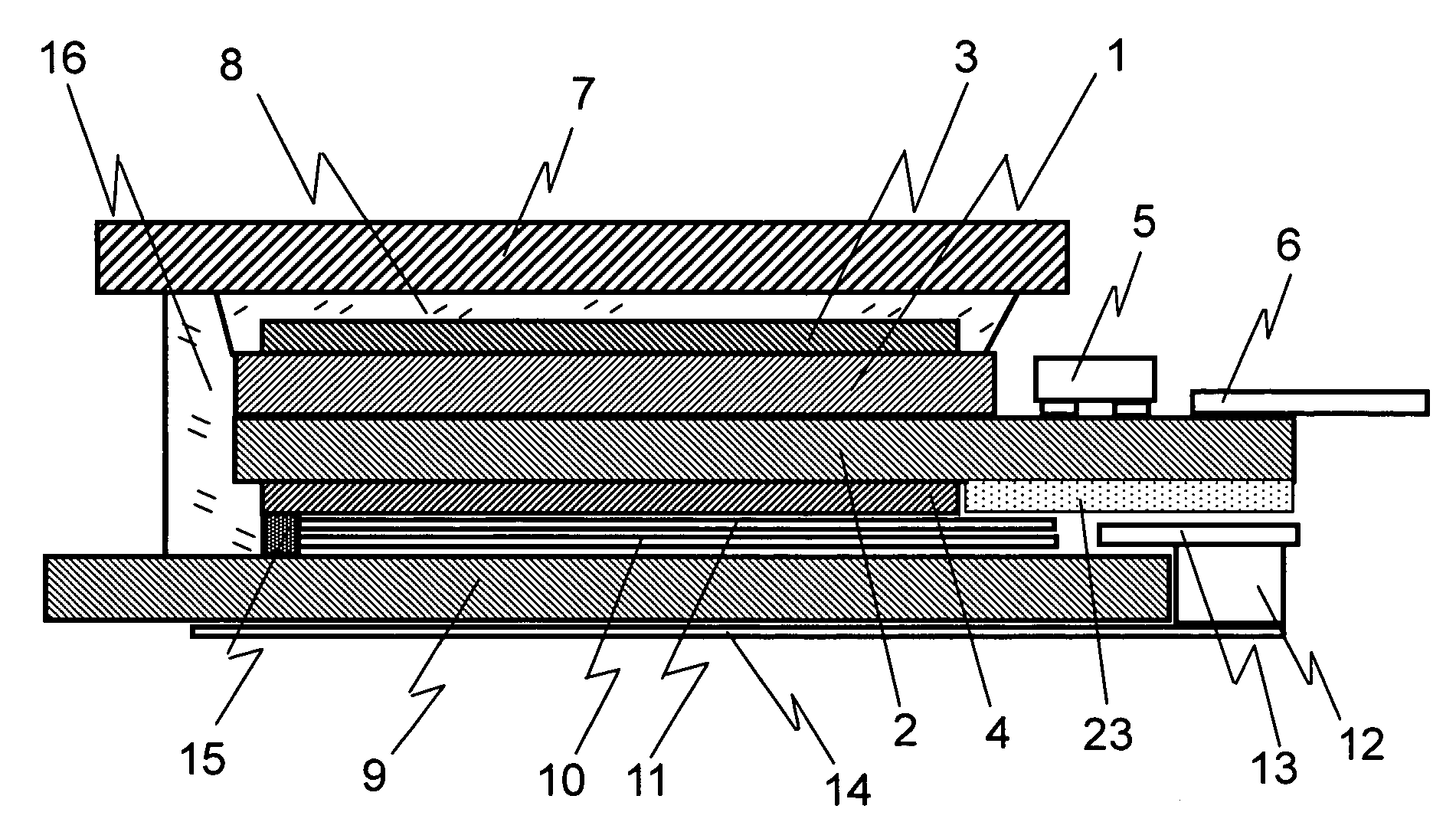

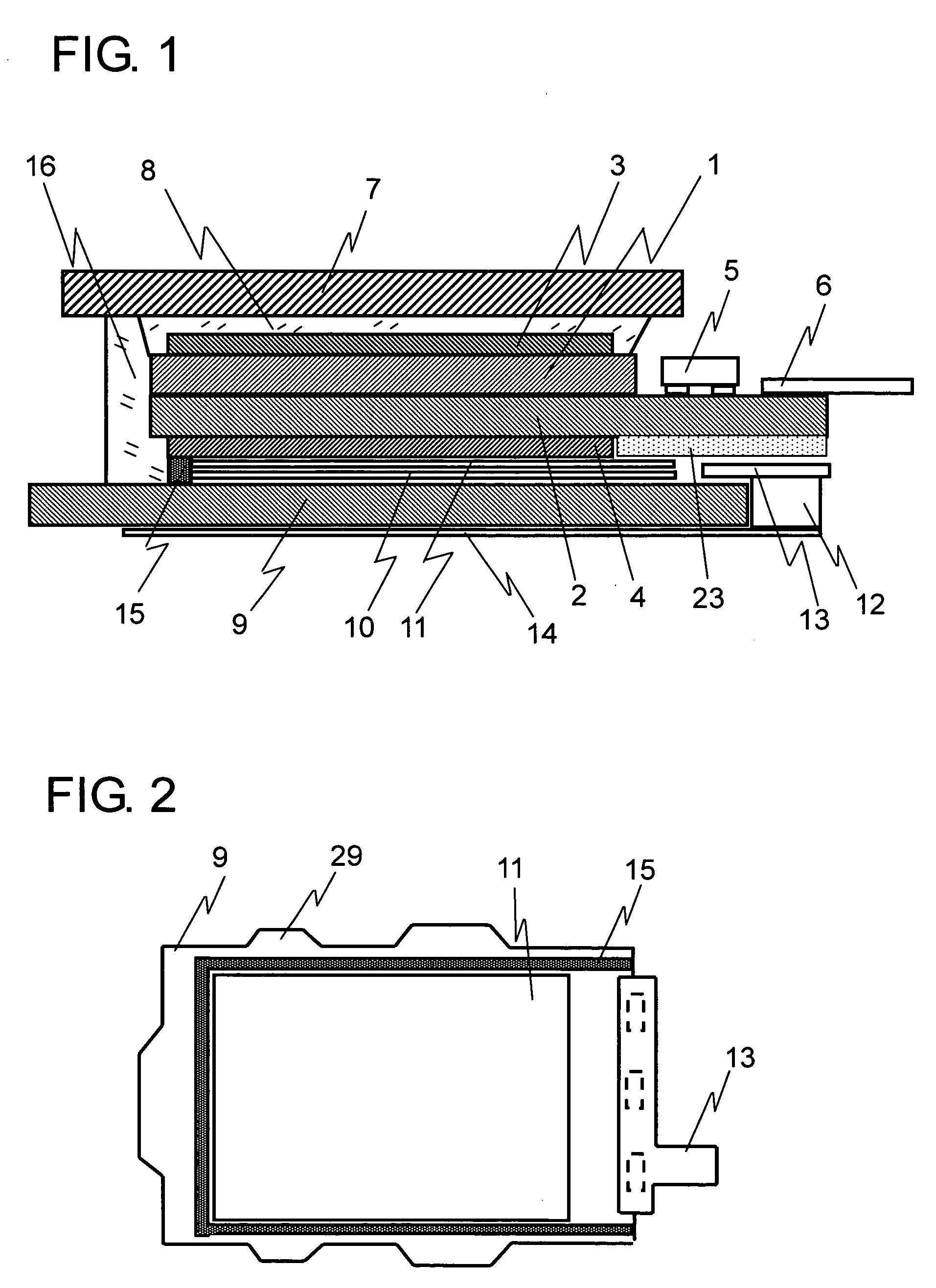

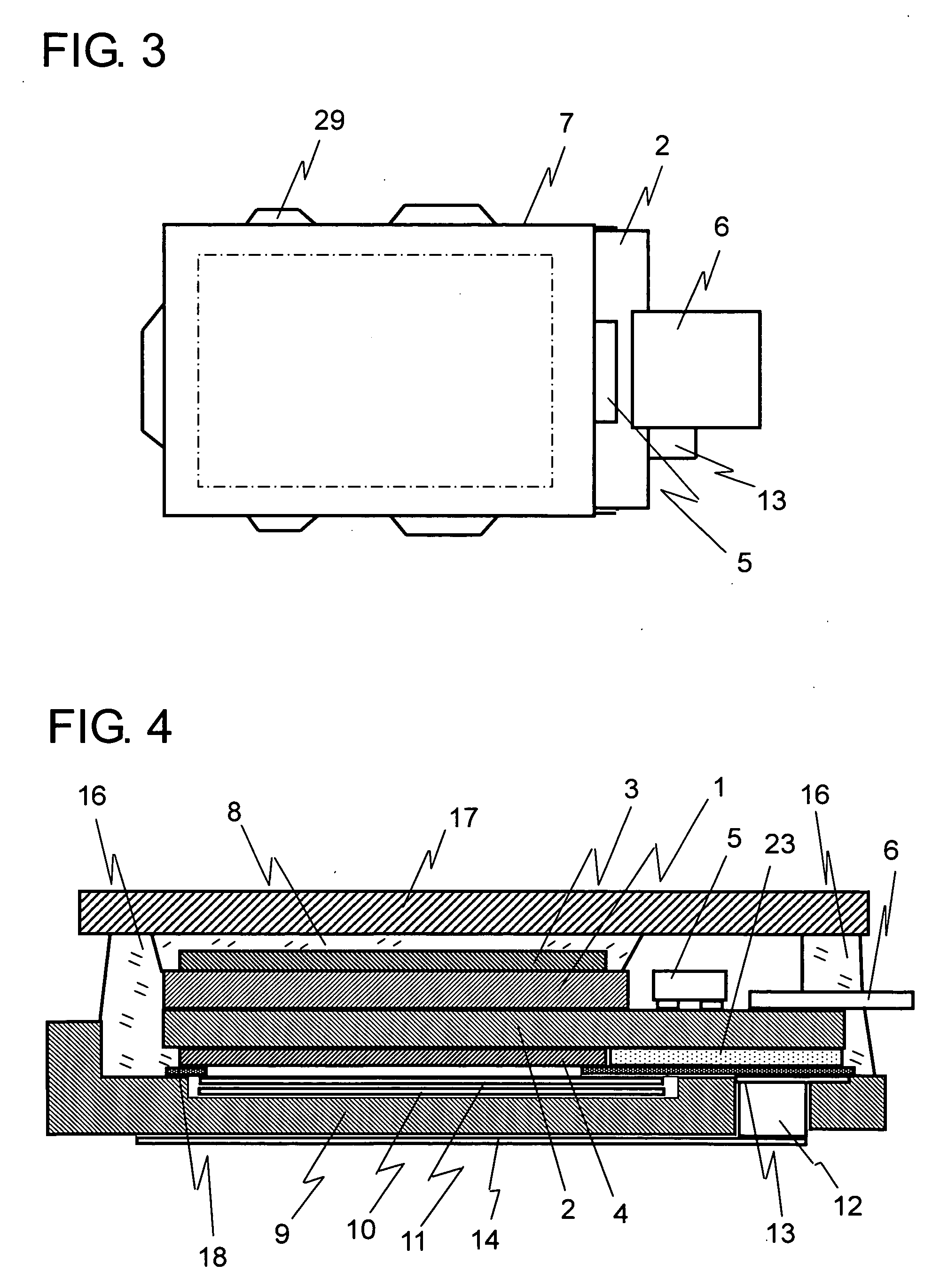

Display device

ActiveUS20090185100A1Lower resistanceImprove impact resistanceDigital data processing detailsPlanar/plate-like light guidesAdhesiveDisplay device

To solve deterioration of an impact resistance caused in a thinned liquid crystal panel, a display device includes a display panel held between a transparent plate arranged on a display surface side and a plate-like member on a rear surface side in a sandwiched manner, and the transparent plate and the plate-like member are bonded and fixed to each other with an adhesive (16) in an outer periphery of the display panel.

Owner:DAWNCREST IP LLC

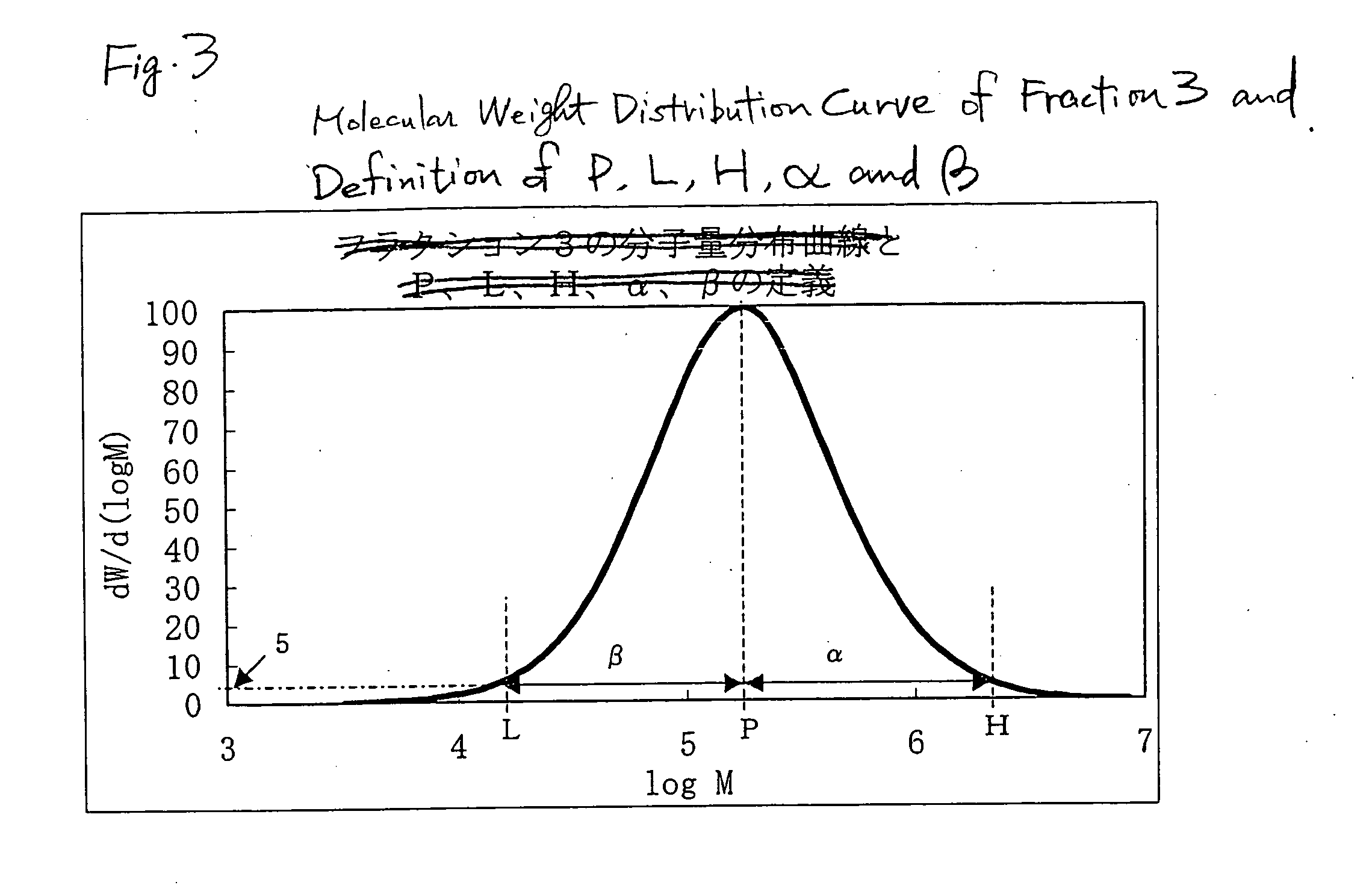

Polypropylene block-copolymer resin and process for producing it

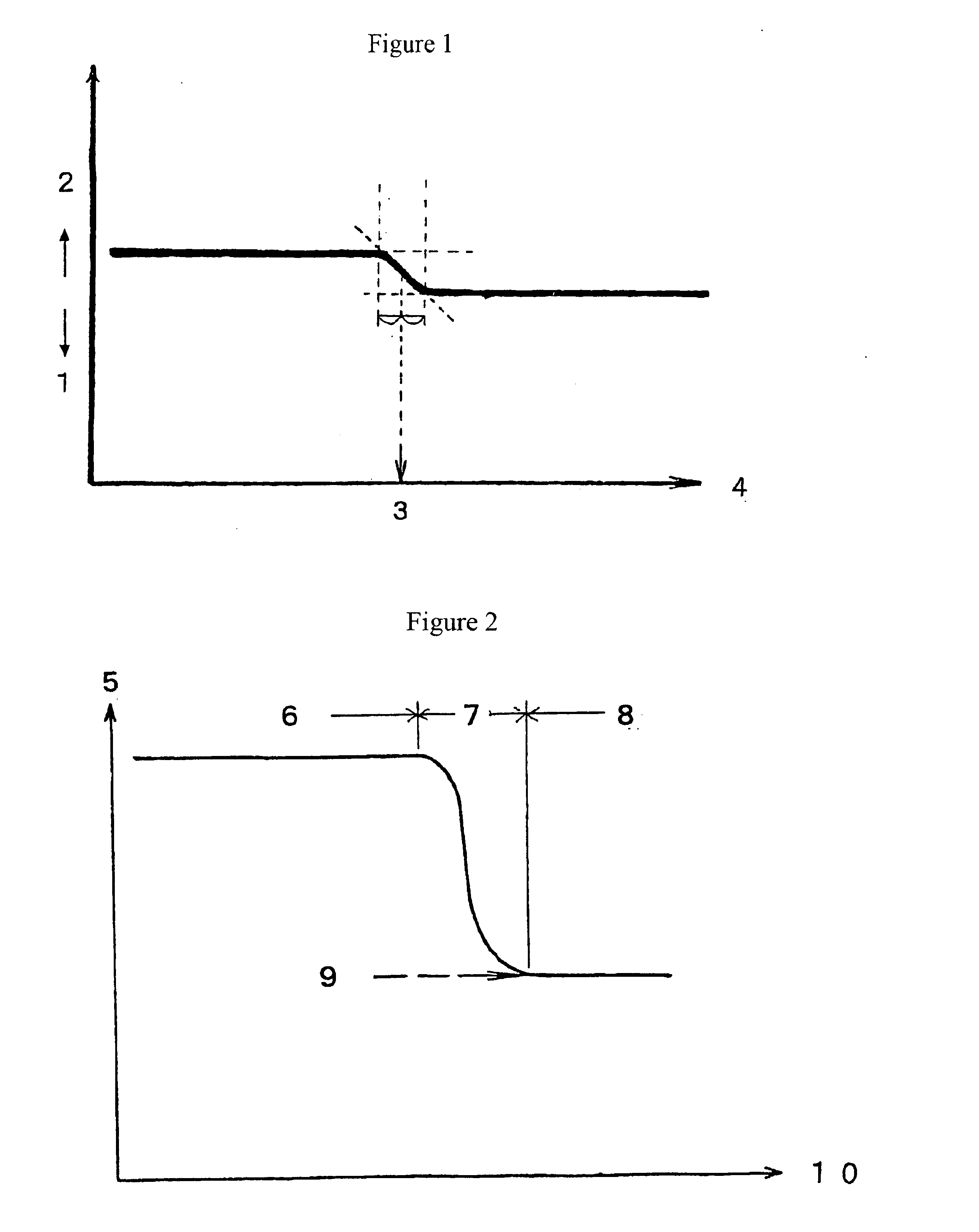

Polypropylene block-copolymer resin exhibiting high melt tension and improved moldability with balanced stiffness and impact resistance may be molded at high speed into large-sized articles, including, stretched films, with good appearance and resistance to deformation. The block copolymer includes a higher molecular weight polypropylene segment, a lower molecular weight polypropylene segment and an ethylene alpha-olefin copolymer segment. When subjected to dissolution fractionation m paraxylene, a large proportion is insoluble at 23° C. but soluble at 135° C., and a smaller portion is soluble at 23° C. The block copolymer has a melt flow rate of 0.01 to 5 g / 10 min at 230 C. (2.16 kg) and a molecular weight distribution Mw / Mn of 6-20 and Mz / Mw of at least 3.5. A continuous multistage polymerization may be used to form the block copolymer.

Owner:PRIME POLYMER CO LTD

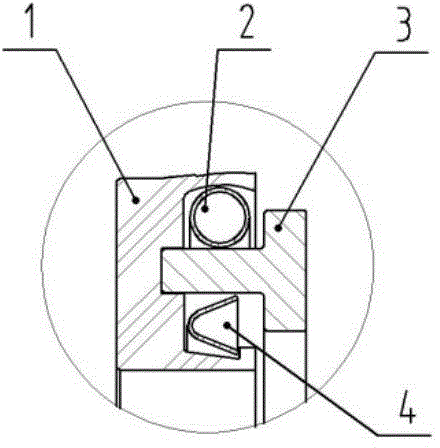

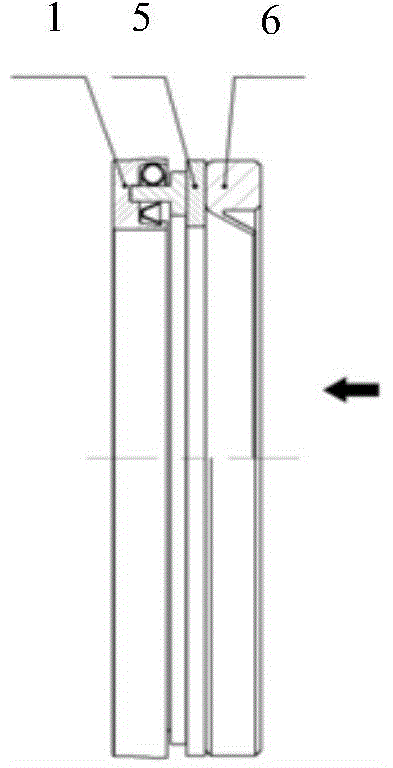

Sealing device and sealing ring thereof

InactiveCN104595493AClose contactAvoid deformationEngine sealsPositive displacement pump componentsEngineeringHigh pressure

The invention discloses a sealing ring, which comprises a base body, a first elastic element and a support element used for supporting, wherein the base body is provided with a groove, the support element is fixedly arranged in the groove, the first elastic element is arranged between the support element and the inner side wall of the groove in a clamping way, and in addition, the first elastic element exerts the force in the direction towards the axis center when receiving the impact by fluid. When the sealing ring provided by the invention is adopted, and when the sealing ring receives the impact by the fluid, on one hand, the base body has a certain impact resistance effect on the fluid, and on the other hand, the elastic element receives the impact effect of the fluid and exerts the force in the direction towards the axis center on the base body, so that the contact of the base body and the part passing through the shaft hole is tighter, so that a good sealing effect is achieved. Therefore the sealing ring has the excellent high-pressure fluid dynamic sealing performance, and in addition, the service life is long. The invention also discloses a sealing device comprising the sealing ring.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Propylene block copolymer

InactiveUS20050009993A1Extensive and intensive investigationImprove heat resistancePolymer scienceHeat resistance

To provide a propylene based block copolymer that, when used as a molding material, exhibits an extremely good stiffness-impact resistance balance and has good heat. resistance and excellent moldability, and therefore, in molding, good appearance is revealed. That is, the invention provides a propylene based block copolymer obtained through a preceding stage step of producing a propylene polymer component (PP) and a subsequent stage step of producing a propylene-ethylene copolymer component (EP) using a metallocene catalyst, wherein the block copolymer satisfies specific requisites.

Owner:JAPAN POLYPROPYLENE CORP

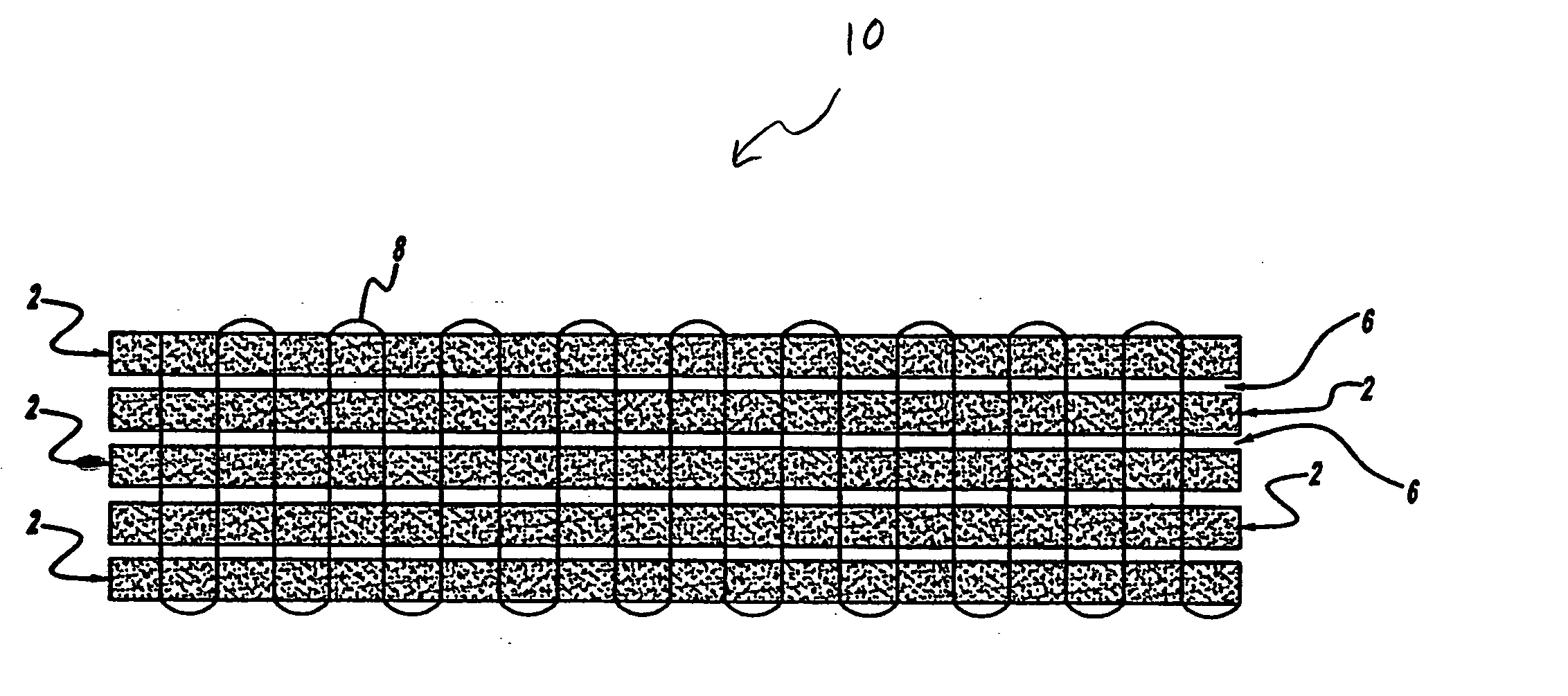

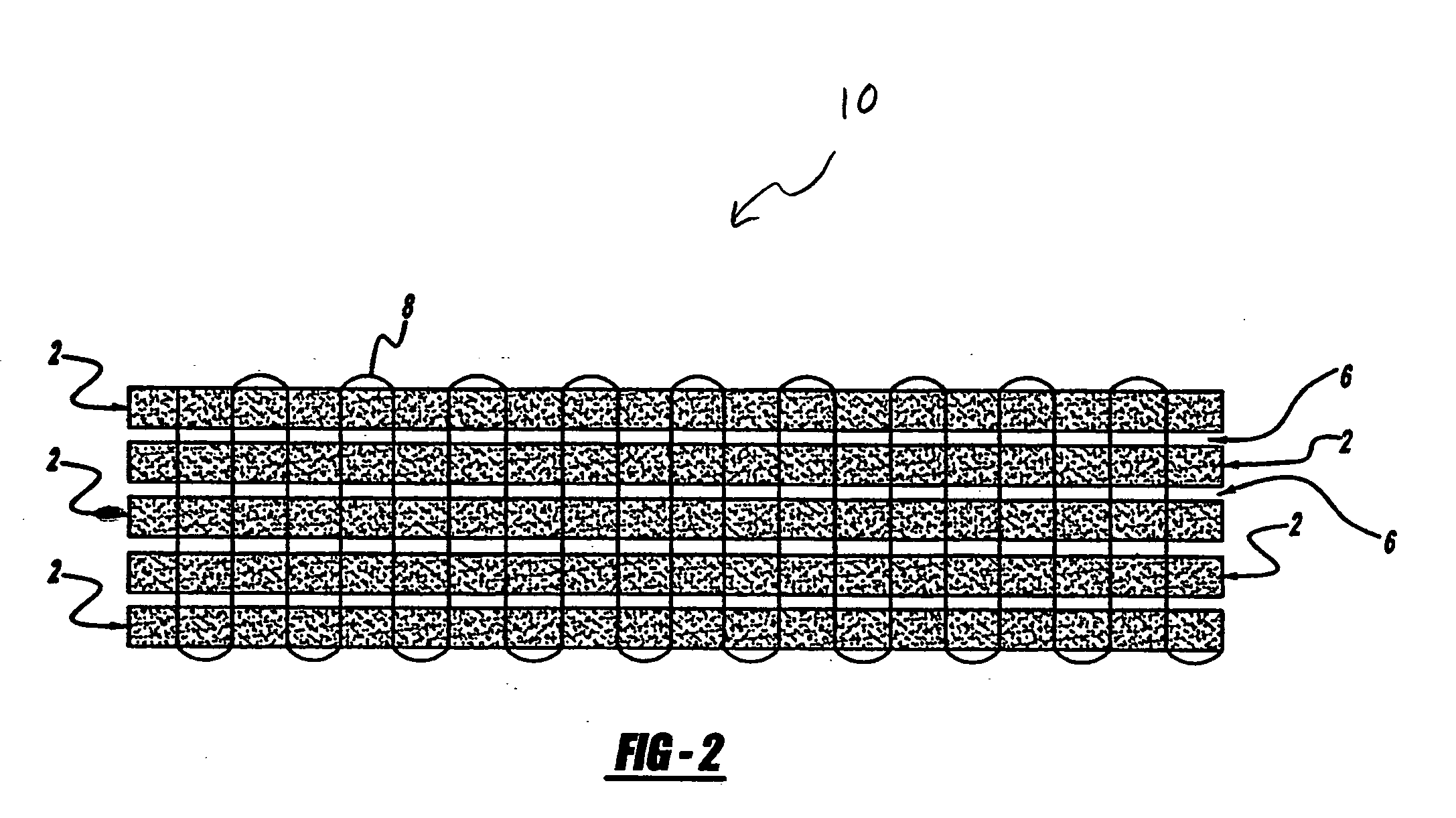

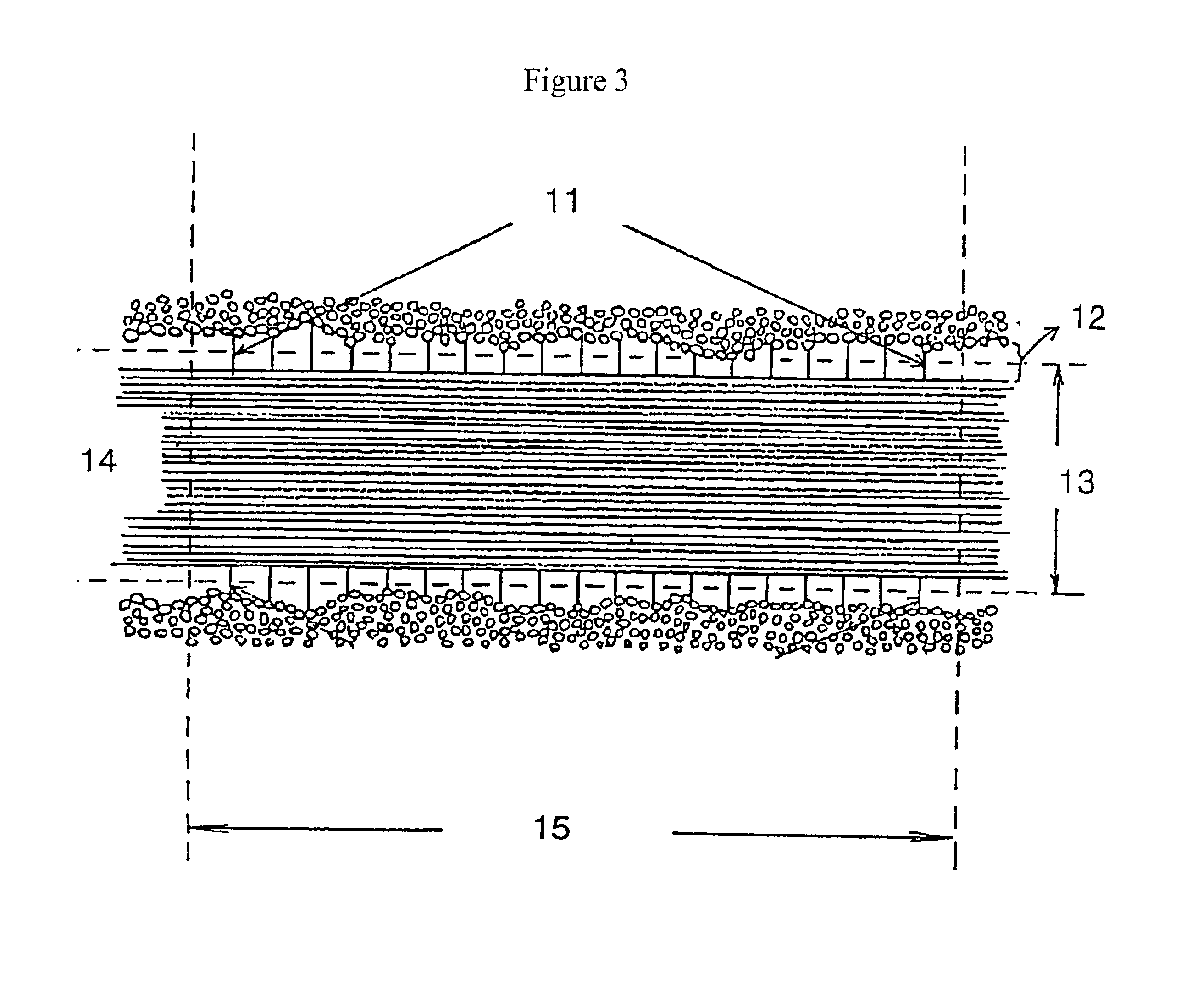

Methods and preforms for forming composite members with interlayers formed of nonwoven, continuous materials

ActiveUS20050059309A1Improve impact resistanceLayered productsWoven fabricsShell moldingMaterials science

Materials and methods are provided for producing preform materials for impact-resistant composite materials suitable for liquid molding. Interlayers formed of nonwoven, continuous fibers, such as spunbonded, spunlaced, or mesh fabric, are introduced between non-crimped layers of unidirectional reinforcing fibers to produce a preform for use in liquid-molding processes to produce a composite member. Curing of the preform provides increased impact resistance by increasing the amount of energy required to propagate localized fractures due to impact.

Owner:THE BOEING CO

Epoxy resin composition for fiber-reinforced composite material prepreg, and fiber-reinforced composite material

The present invention relates to an epoxy resin composition for a fibre reinforced composite material, which is thermosetting resin composition where the glass transition temperature Tg of the cured material obtained by heating for 2 hours at 180° C. is at least 150° C., and the modulus of rigidity G'R in the rubbery plateau in the temperature region above the aforesaid Tg is no more than 10 MPa. In accordance with the present invention, it is possible to provide a fibre-reinforced composite material which is outstanding in its resistance to hot-wet environmental condition, impact resistance, and strength characteristics such as tensile strength and compression strength, and furthermore it is possible to provide a thermosetting resin composition and a prepreg outstanding in terms of their peel strength to a honeycomb core.

Owner:TORAY IND INC

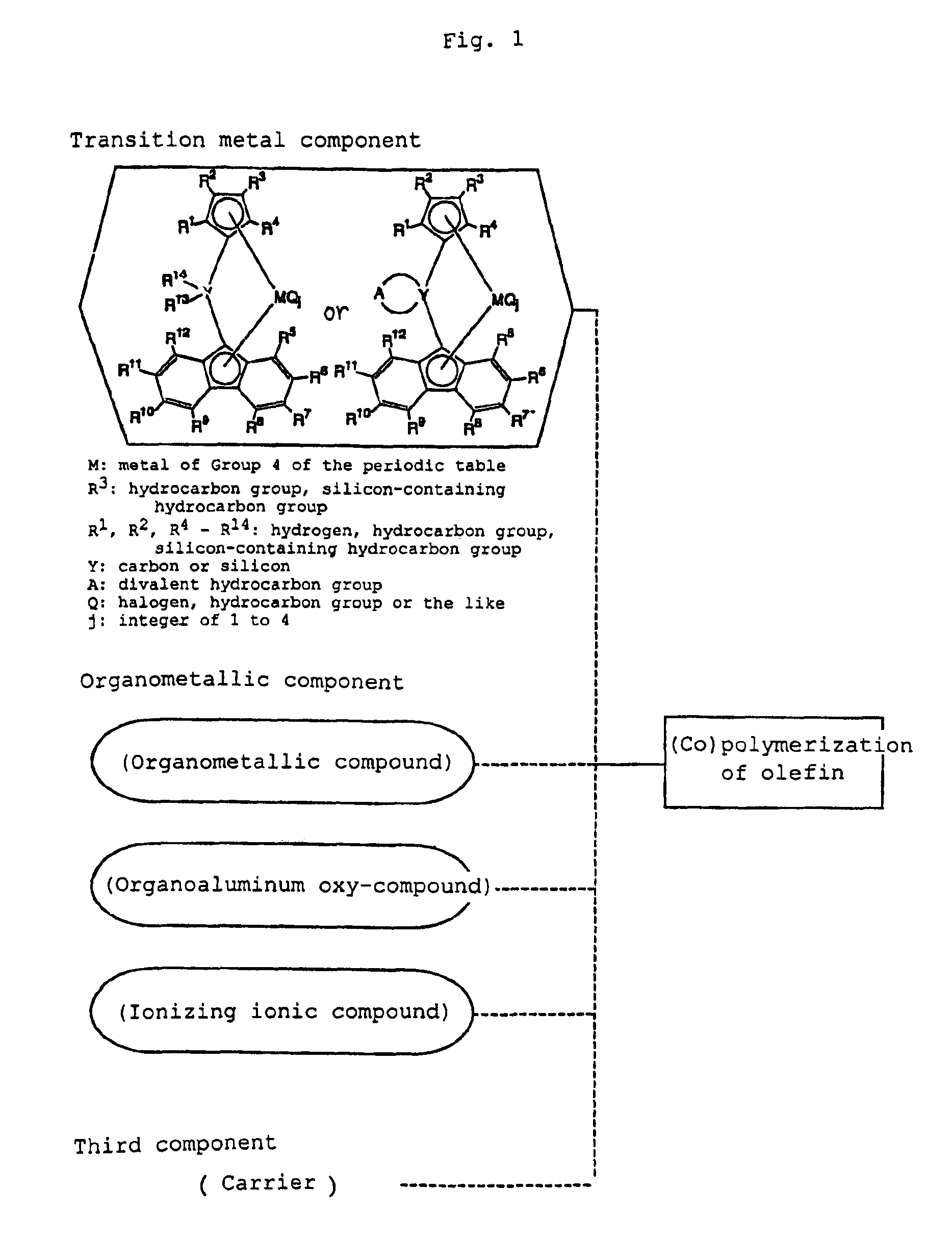

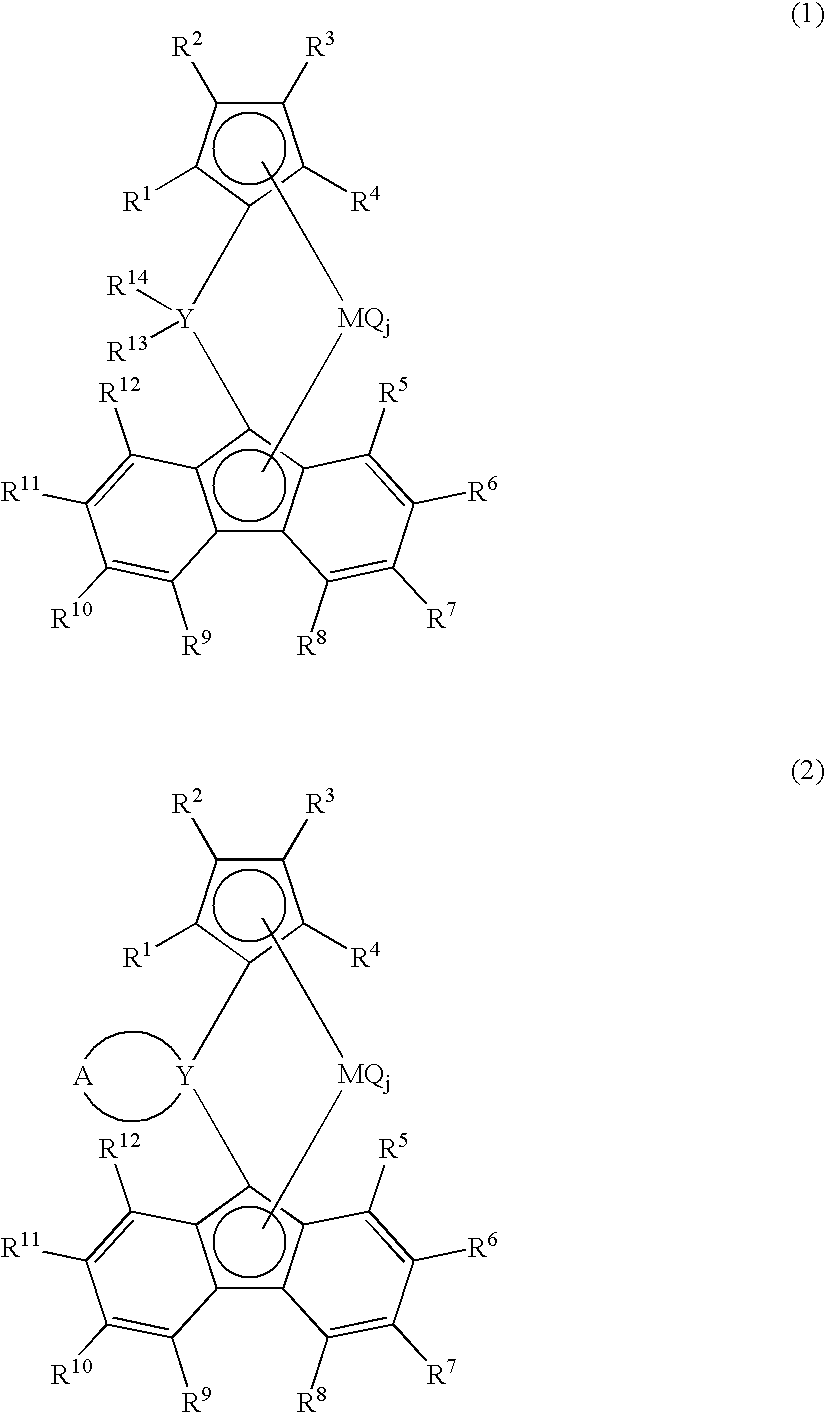

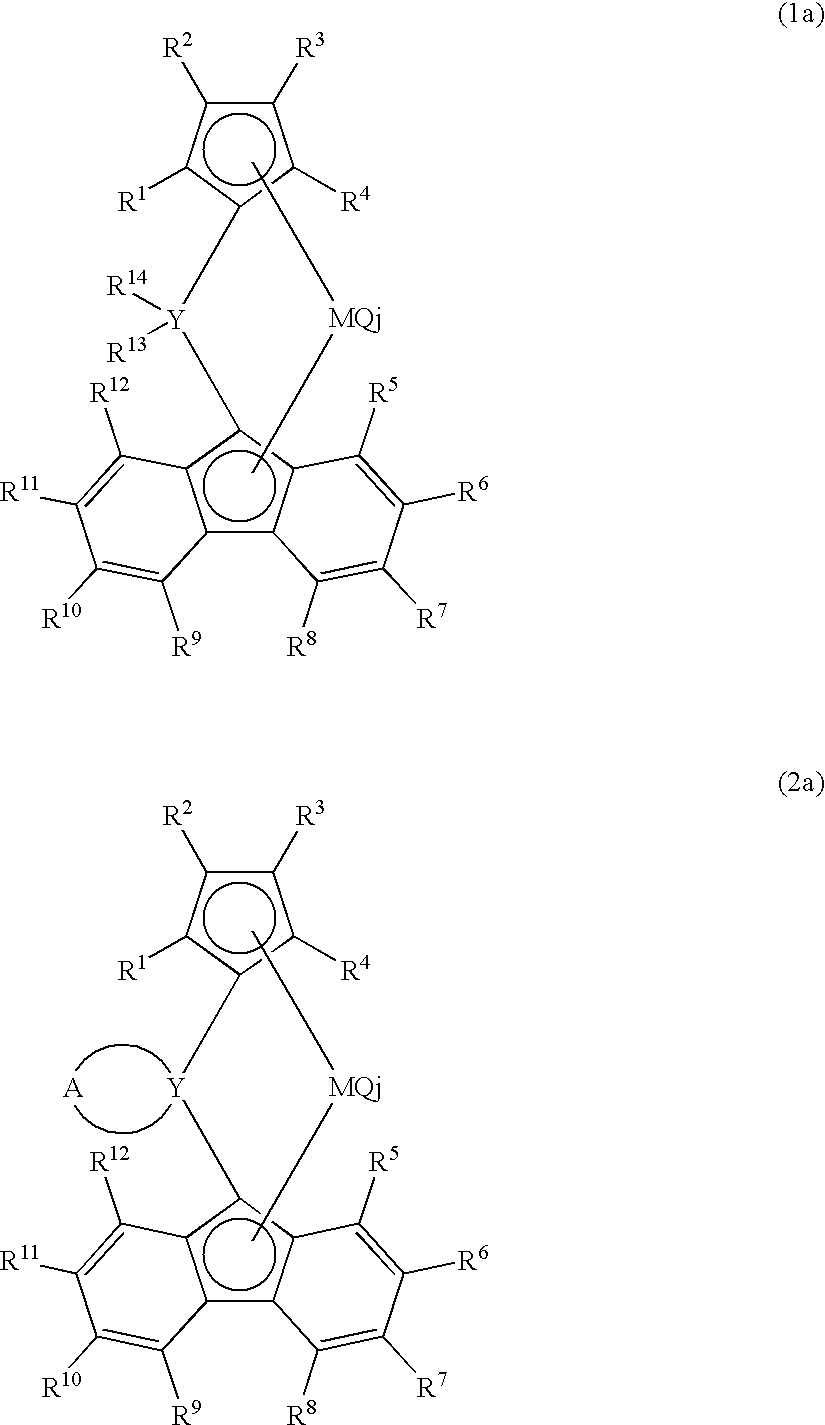

Metallocene compound, process for producing metallocene compound, olefin polymerization catalyst, process for producing polyolefin, and polyolefin

InactiveUS6939928B1High activityModulus improvementSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolyolefin

The metallocene compound according to the invention and the olefin polymerization catalyst containing the compound are intended to produce a catalyst capable of preparing an isotactic polymer with a high polymerization activity. The metallocene compound contains a substituted cyclopentadienyl group and a (substituted) fluorenyl group and has a structure wherein these groups are bridged by a hydrocarbon group or the like. The process for preparing a metallocene compound according to the invention is intended to selectively prepare a specific metallocene compound so as not to produce an isomer, and in this process an intermediate product is synthesized by a specific method. The process for preparing a polyolefin according to the invention is intended to prepare a polyolefin having excellent impact resistance and transparency, and this process comprises homopolymerizing an α-olefin of 3 to 8 carbon atoms or copolymerizing an olefin of 3 to 8 carbon atoms and another α-olefin in the presence of an olefin polymerization catalyst containing the above-mentioned metallocene compound.

Owner:MITSUI CHEM INC

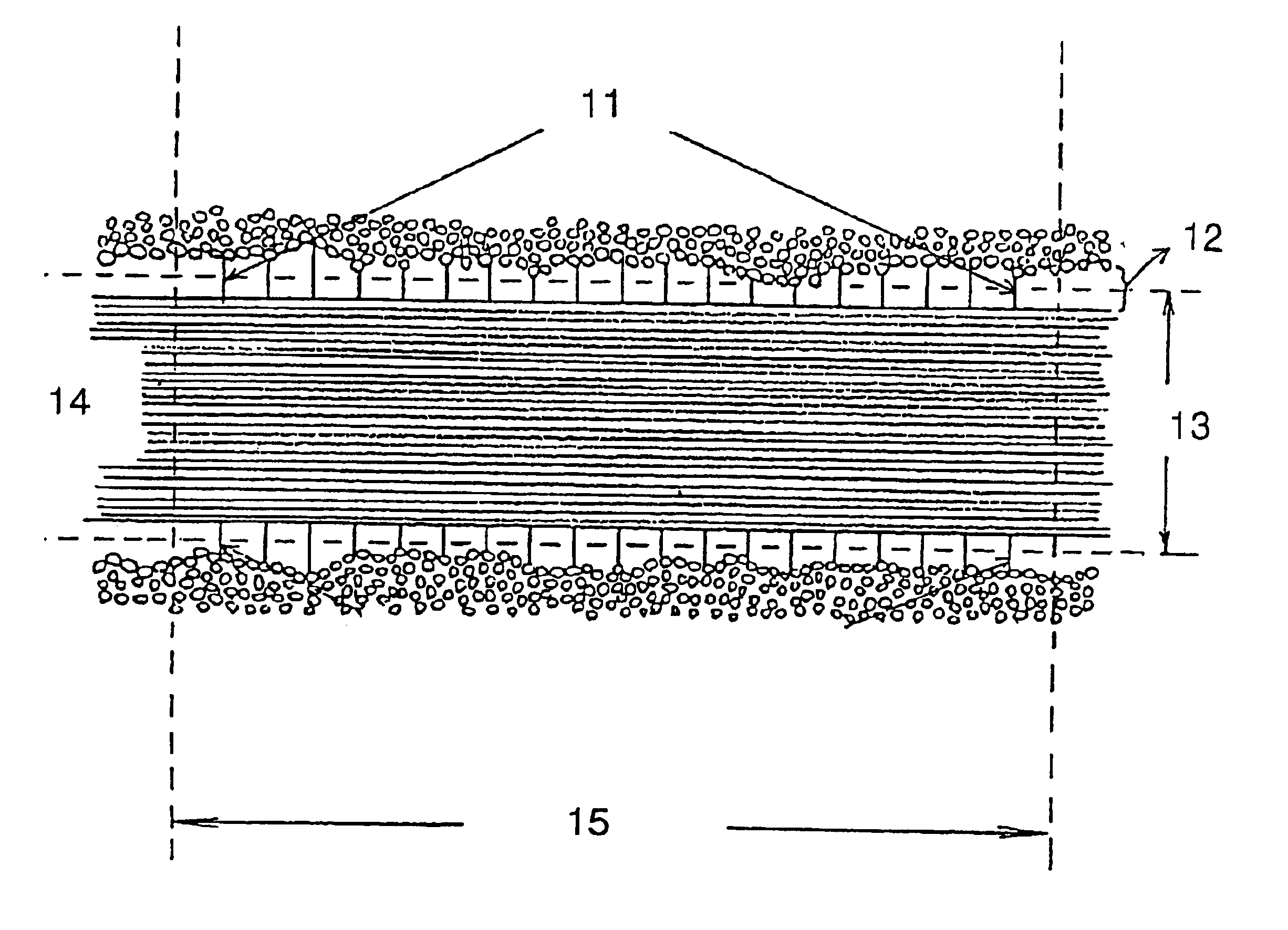

Resin compositions for fiber-reinforced composite materials and processes for producing the same, prepregs, fiber-reinforced composite materials, and honeycomb structures

InactiveUS6045898ASufficient self adhesivenessReduce porosityLayered productsNon-woven fabricsPorosityFiber-reinforced composite

PCT No. PCT / JP97 / 00250 Sec. 371 Date Jan. 5, 1998 Sec. 102(e) Date Jan. 5, 1998 PCT Filed Jan. 31, 1997 PCT Pub. No. WO97 / 28210 PCT Pub. Date Aug. 7, 1997The present invention provides a prepreg having an excellent self adhesiveness to a honeycomb core, a low porosity when used as skin panels, an excellent surface smoothness due to a low surface porosity, and good tackiness and drapability. This invention also provides a honeycomb sandwich panel having a skin panel peel strength, an excellent impact resistance and an excellent hot water resistance, and a composition for a fiber reinforced composite material made from the prepreg and honeycomb sandwich panel. The fiber reinforced composite material made from the prepreg of the present invention can be used for airplanes, automobiles and other industrial applications, particularly as structural materials of airplanes, because of its excellent mechanical properties.

Owner:TORAY IND INC

Thermoplastic composite material, and preparation method and application thereof

The invention belongs to the field of polymer composite materials, and discloses a thermoplastic composite material, and a preparation method and an application thereof. The composite material is composed of the components of, by weight: 1-99 parts of a prepreg and 1-99 parts of a thermoplastic composition or thermoplastic resin. The preparation method comprises the steps that: the 1-99 parts of thermoplastic composition or thermoplastic resin is added into a feeding hopper of an injection molding machine, and is mixed with the 1-99 parts of prepreg already in an injection mold; and injection molding is carried out. The invention also discloses an application of the thermoplastic composite material in car bumpers, car door inner panels, car bumper beams, cars toe-boards, car hood, car rear lift door, building templates, biogas digesters, train sidings, train wall panels, or train roof panels. The composite material provided by the invention has the advantages of smooth outer surface, high gloss, good appearance, excellent mechanical performance, high strength, and good impact resistance.

Owner:HEFEI GENIUS NEW MATERIALS

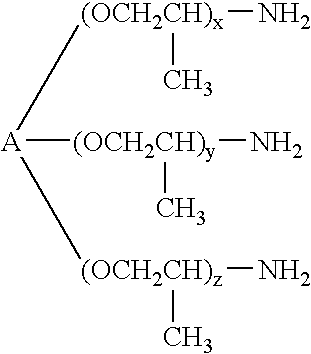

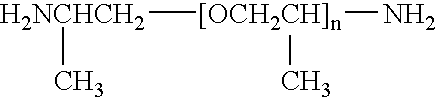

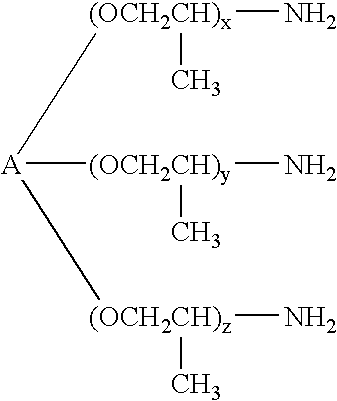

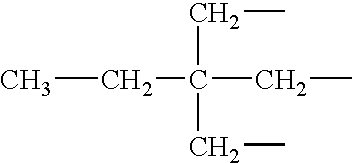

Epoxy adhesive having improved impact resistance

InactiveUS20030196753A1Polyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyphenolExpandable microsphere

In the preparation of an improved adhesive composition, an epoxy-based prepolymer is obtained by the reaction of one or more epoxy resins with amino-terminated polyethers and / or carboxyl-terminated butadiene-nitrile rubbers. In one embodiment of the invention, both a solid epoxy resin and a liquid epoxy resin, each of which is a diglycidyl ether of a polyphenol such as bisphenol A, are used. The epoxy-based prepolymer is mixed with an acrylate-terminated urethane resin (preferably, one based on a polyol having a number average molecular weight of at least about 400) and a heat-activated latent curing agent to make an adhesive composition which can be pumpable at room temperature. Curable adhesives capable of expansion to about 100% with high impact resistance after curing may be obtained by inclusion of expanding agents such as expandable microspheres.

Owner:HENKEL KGAA

Thermoplastic resin composition and elastomer composition

Provided are a thermoplastic resin composition which is excellent in oil resistance, heat resistance, weatherability, impact resistance, transparency, and moldability, and which can be produced economically, an elastomer composition with low hardness and high tensile strength which is excellent in oil resistance and compression set, and a molded object produced by molding the thermoplastic resin composition or elastomer composition. The composition is produced by compounding a thermoplastic resin or an elastomer with a block copolymer having at least one methacrylic ester polymer block and at least one acrylic ester polymer block. Also provided are a process for producing a methacrylic ester-acrylic ester-methacrylic ester block copolymer which requires hardly any purification, which is excellent in heat resistance and weatherability, and in which the molecular weight and the molecular-weight distribution are controlled, and a methacrylic ester-acrylic ester-methacrylic ester block copolymer produced by the process.

Owner:KANEKA CORP

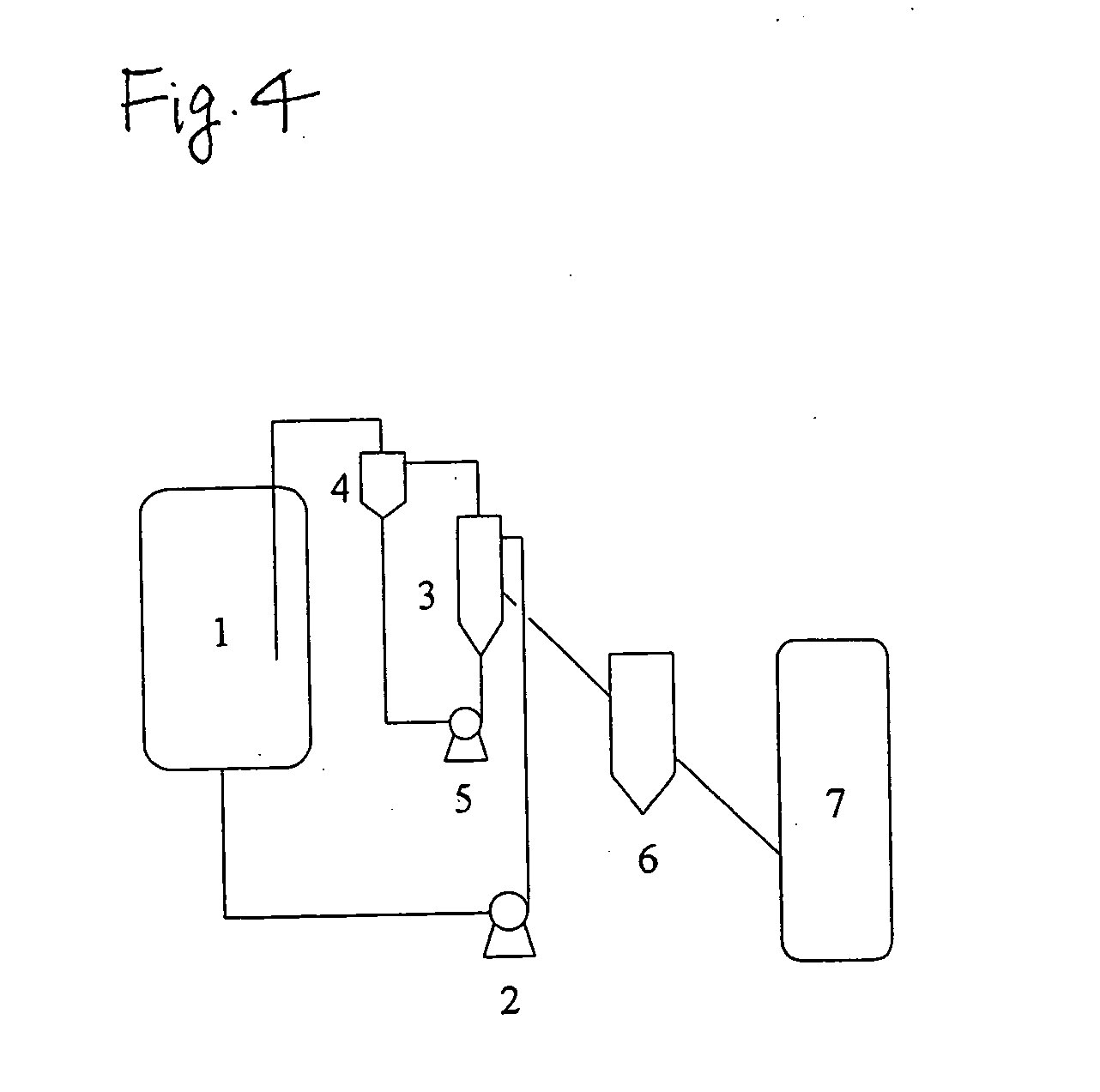

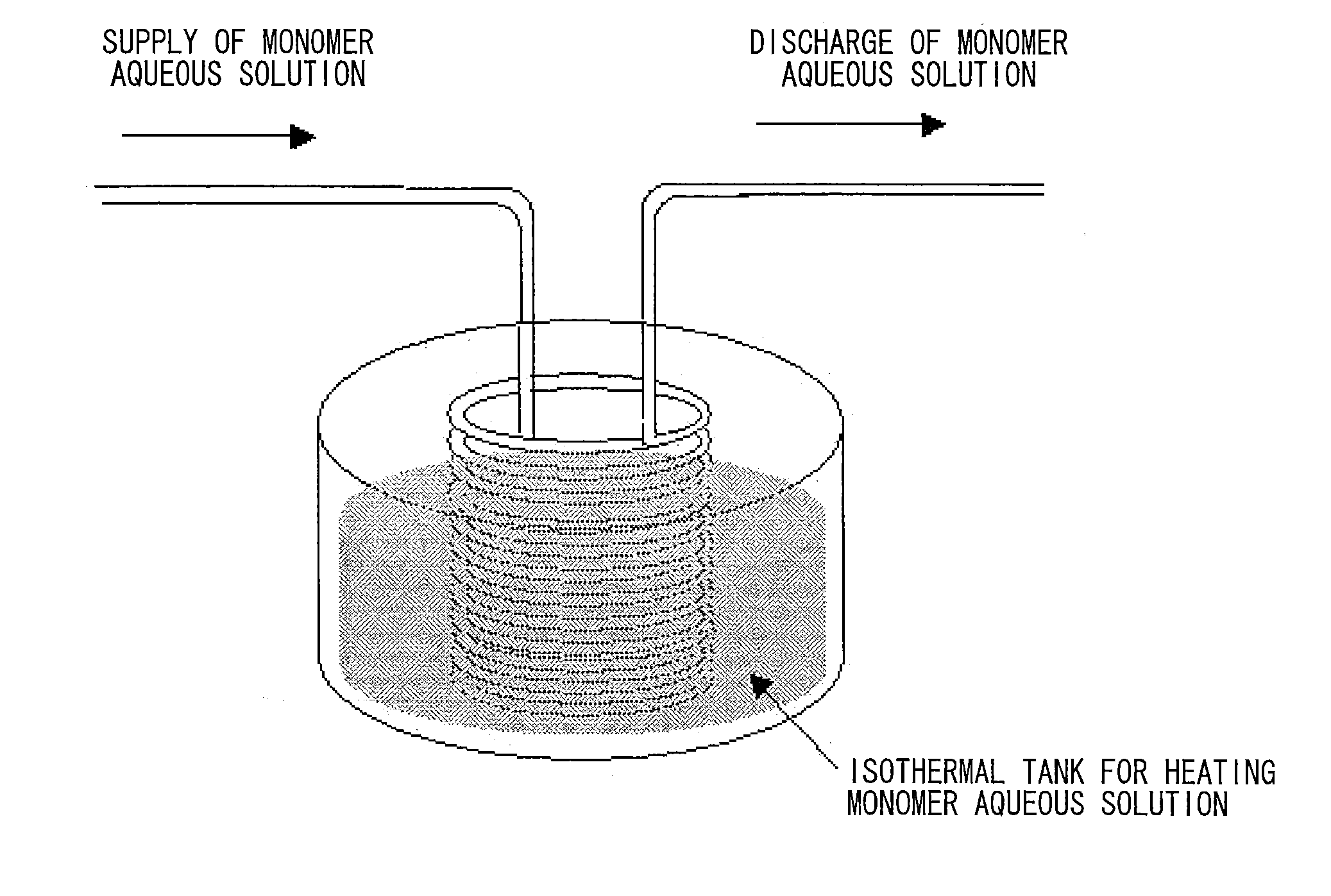

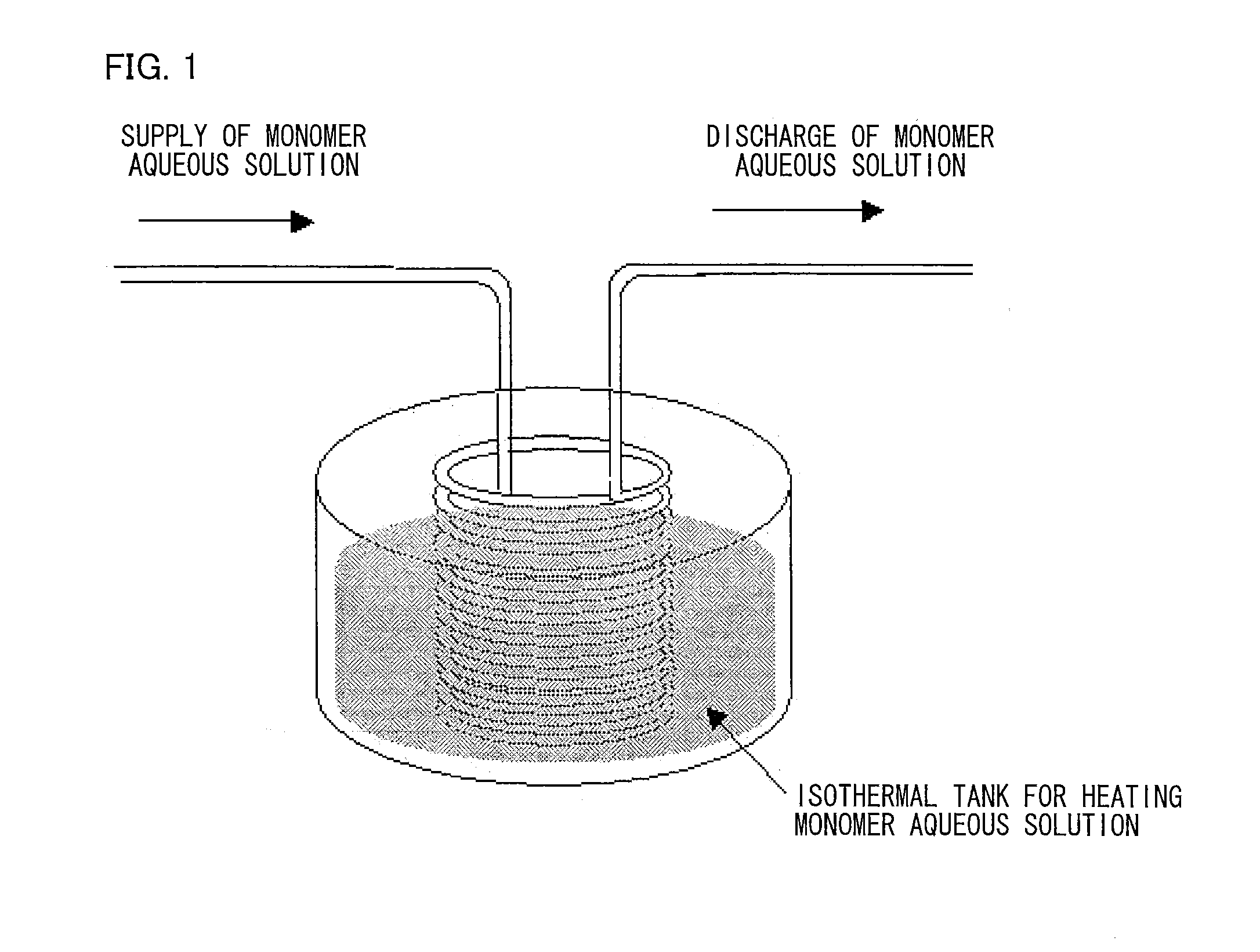

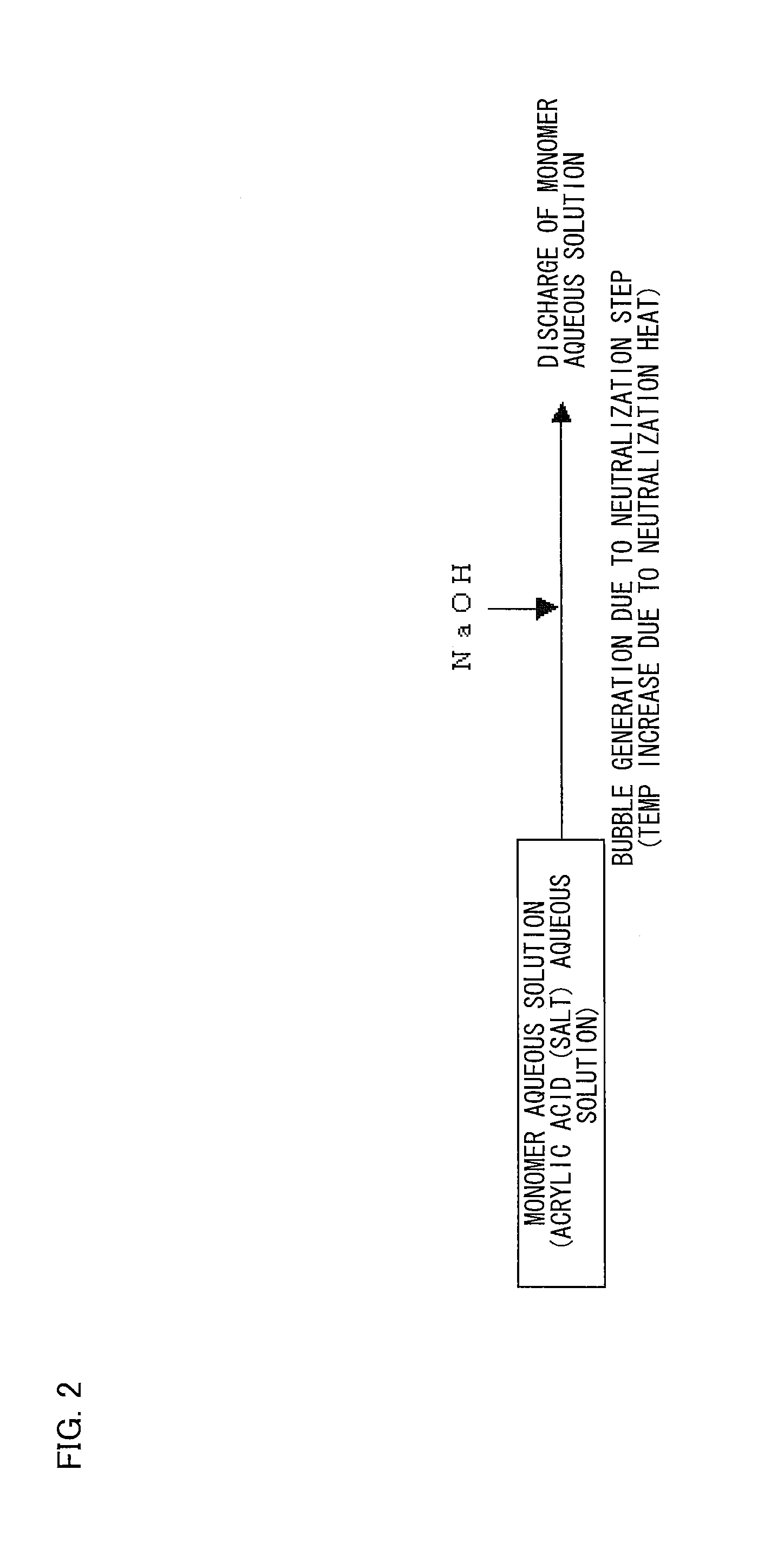

Water-absorbable polyacrylic acid resin powder, and process for production thereof

ActiveUS20120258851A1Improve water absorptionImprove impact resistanceOther chemical processesCatalyst activation/preparationSolubilityCrosslinked polymers

A process according to the present invention for production of water-absorbable polyacrylic acid resin powder, including: (a) polymerizing an acrylic acid-based monomer aqueous solution containing bubbles, and (b) drying a hydrogel crosslinked polymer thus obtained in the step of polymerizing, further includes (c) lowering solubility of dissolved gas in a monomer aqueous solution in the presence of a surfactant and / or a dispersing agent, so as to generate the bubbles in the acrylic acid-based monomer aqueous solution. With this arrangement, it is possible to provide white water-absorbable resin with better water absorbing rate, keeping or without significantly losing the other properties (permeability potential, bulk specific gravity, surface tension, absorbency against pressure, impact resistance, etc.)

Owner:NIPPON SHOKUBAI CO LTD

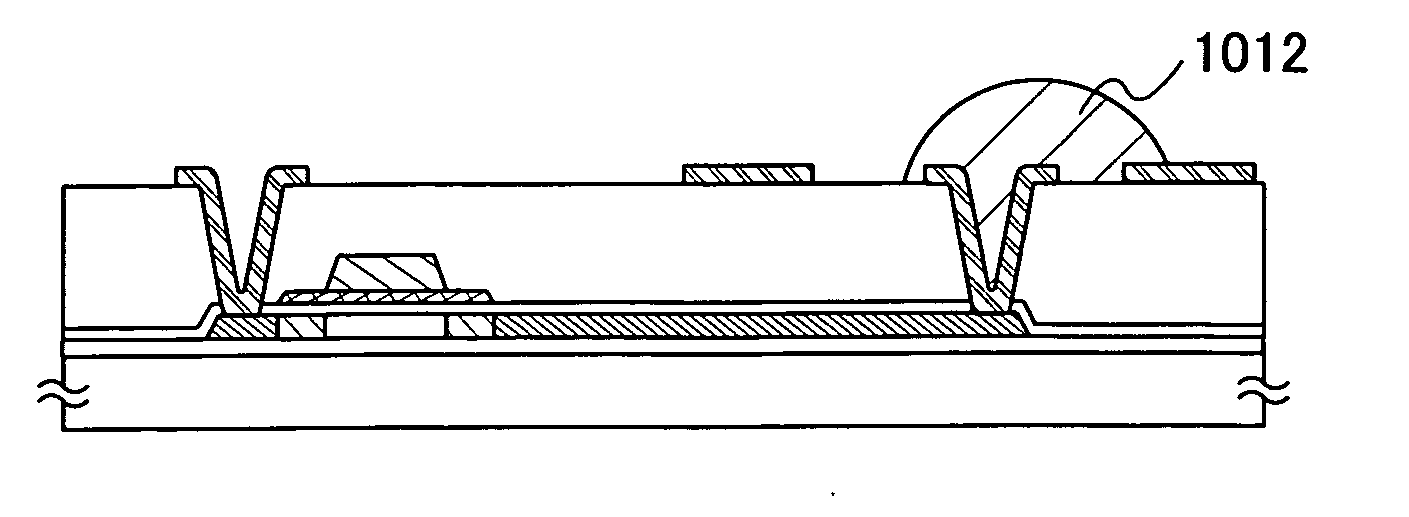

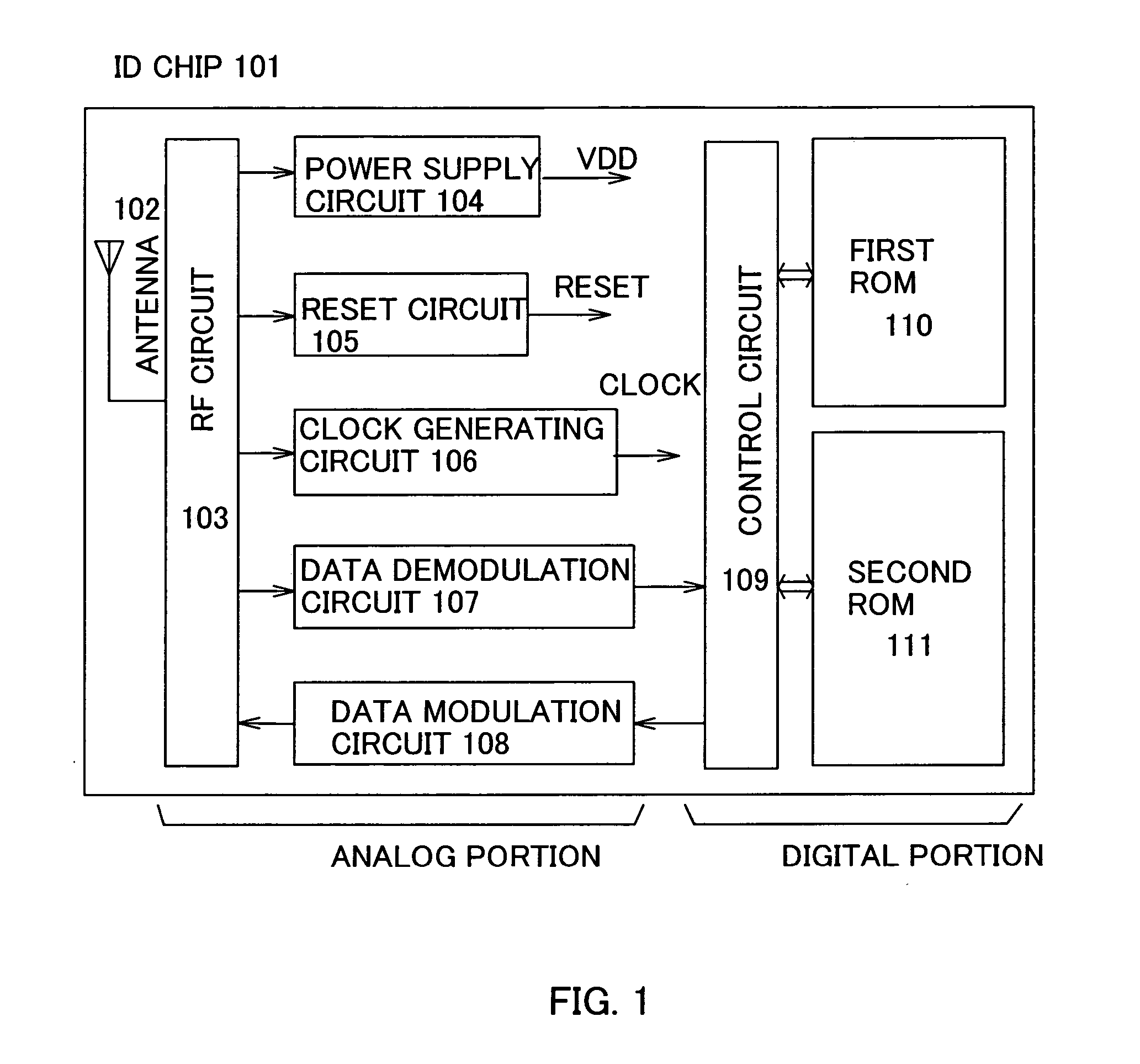

Semiconductor integrated circuit, semiconductor device, and manufacturing method of the semiconductor integrated circuit

InactiveUS20050133790A1Improve efficiencySmall amount of wasteTransistorSolid-state devicesDevice materialLaser cutting

A chip with increased impact resistance, attractive design and reduced cost, and a manufacturing method thereof are provided. A semiconductor integrated circuit is formed on a large glass substrate, and a part of data of a ROM included therein is determined by an ink jet method or a laser cutting method. Accordingly, the cost can be reduced without requiring a photomask, resulting in an inexpensive ID chip. Further, depending on the application, the semiconductor integrated circuit is transposed to a flexible substrate, thereby an ID chip with improved impact resistance and more attractive design can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

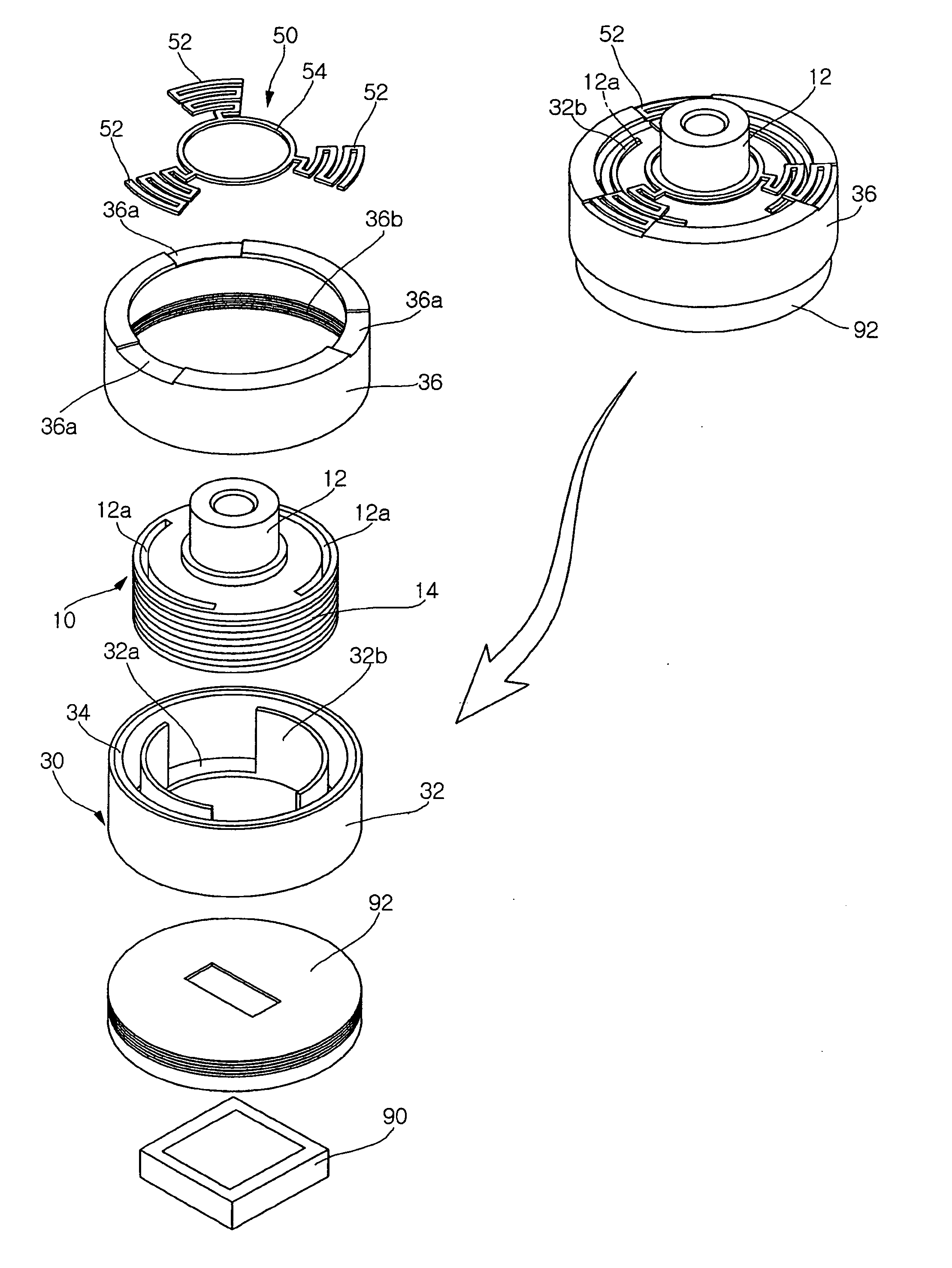

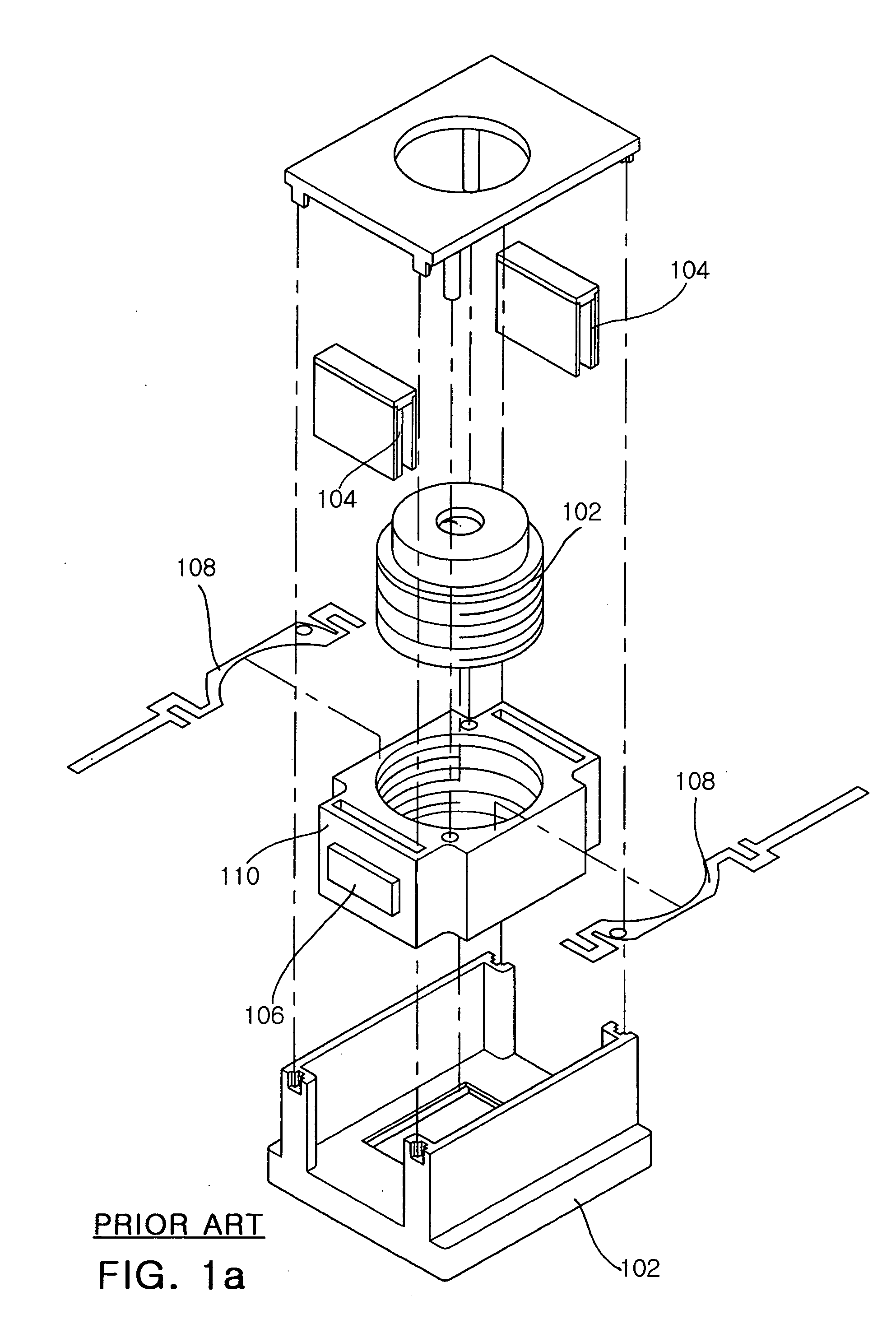

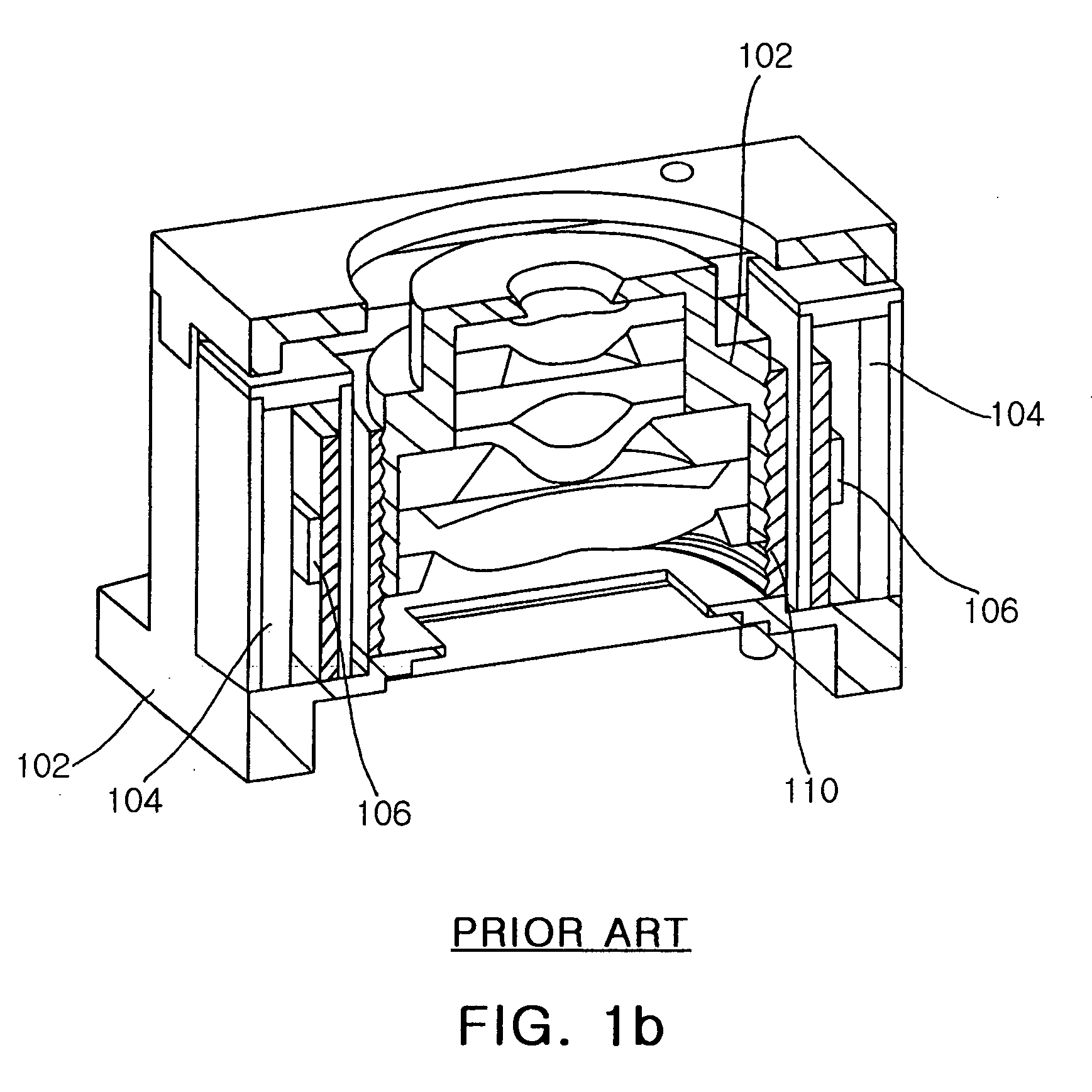

Focal length adjustment apparatus with improved vibration and impact-resistance properties

InactiveUS20060153556A1Improve damping effectHigh magnetic flux densityProjector focusing arrangementPliersUltrasound attenuationMagnetic flux

Disclosed herein is a focal length adjustment apparatus in which a magnetic fluid that serves as attenuation means is injected between a magnet and a coil to achieve an improvement in a magnetic flux density and damping effect. The apparatus comprises a moving unit including a lens barrel that contains at least one lens therein, and a coil arranged on an outer circumference of the lens barrel, a fixed unit including a yoke formed with an opening for receiving the lens barrel, a case into which the yoke is inserted and mounted, and a magnet affixed to the yoke to be arranged adjacent to the coil, a supporting member used to elastically support the moving unit relative to the case, and attenuation means interposed between the coil and the magnet to attenuate vibration of the moving unit.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Thermoset materials with improved impact resistance

The present invention relates to a thermoset material with improved impact resistance comprising: 99 to 20% of a thermoset resin, 1 to 80% of an impact modifier comprising at least one copolymer chosen from copolymers comprising S-B-M, B-M and M-B-M blocks, in which: each block is connected to the other by means of a covalent bond or of an intermediate molecule connected to one of the blocks via a covalent bond and to the other block via another covalent bond, M is a PMMA homopolymer or a copolymer comprising at least 50% by weight of m thyl methacrylate, B is incompatible with the thermoset resin and with the M block and its glass transition temperature Tg is less than the operating temperature of the thermoset material, S is incompatible with the thermoset resin, the B block and the M block and its Tg or its melting temperature M.t. is greater than the Tg of B. S is advantageously polystyrene and B polybutadiene. The thermoset resin advantageously originates from the reaction of a thermosetting epoxy resin and of a hardener.

Owner:ATOFINA

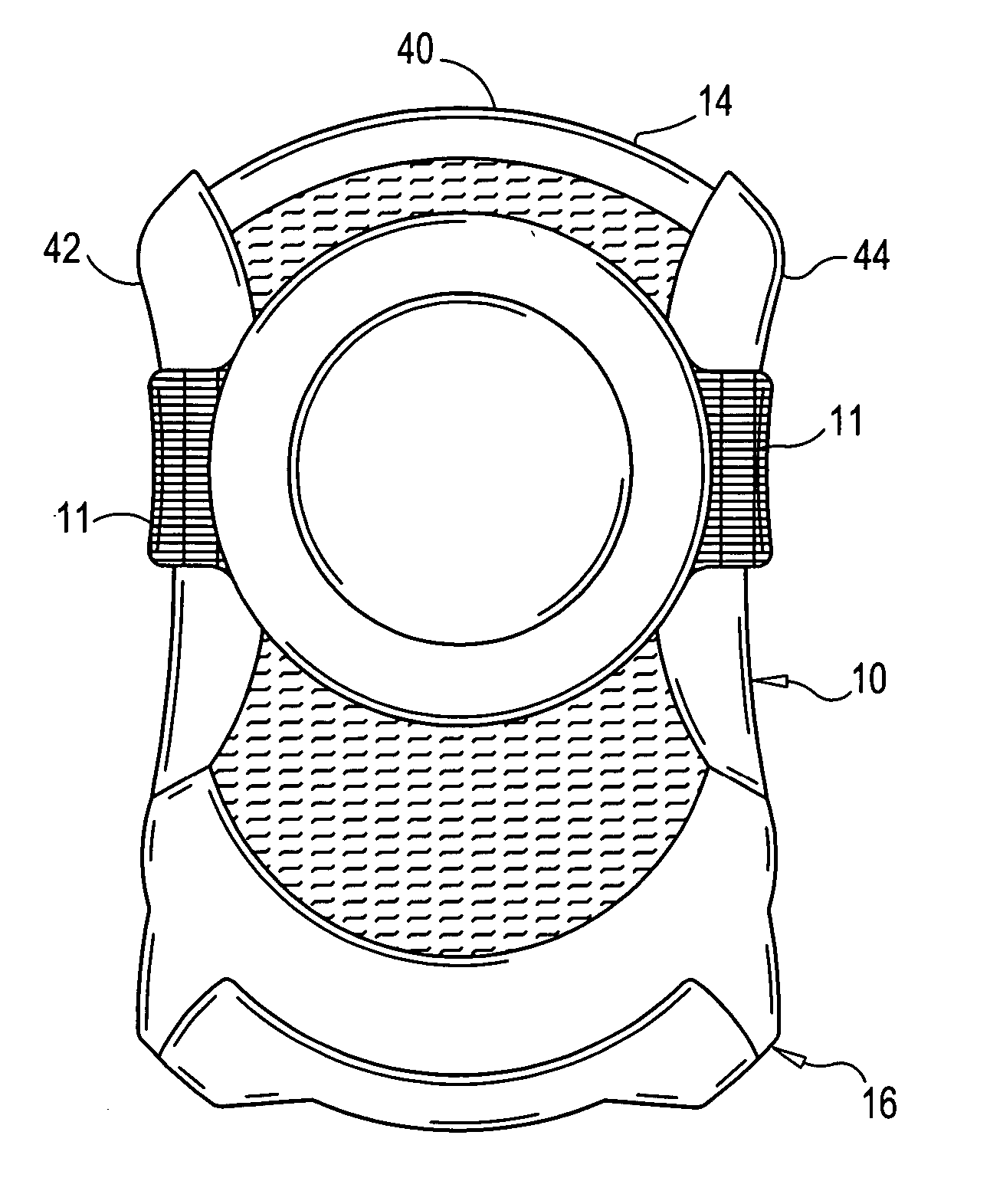

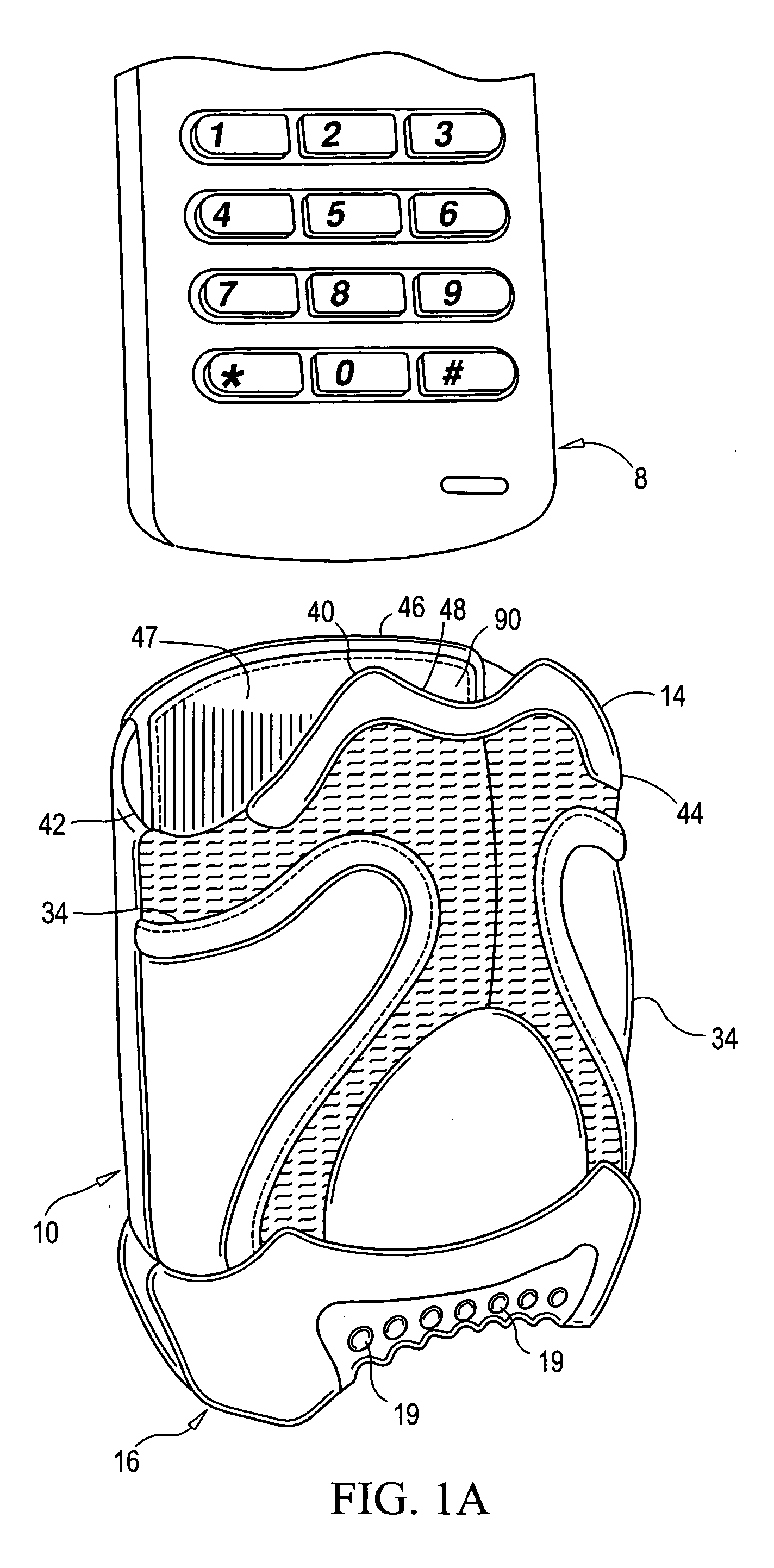

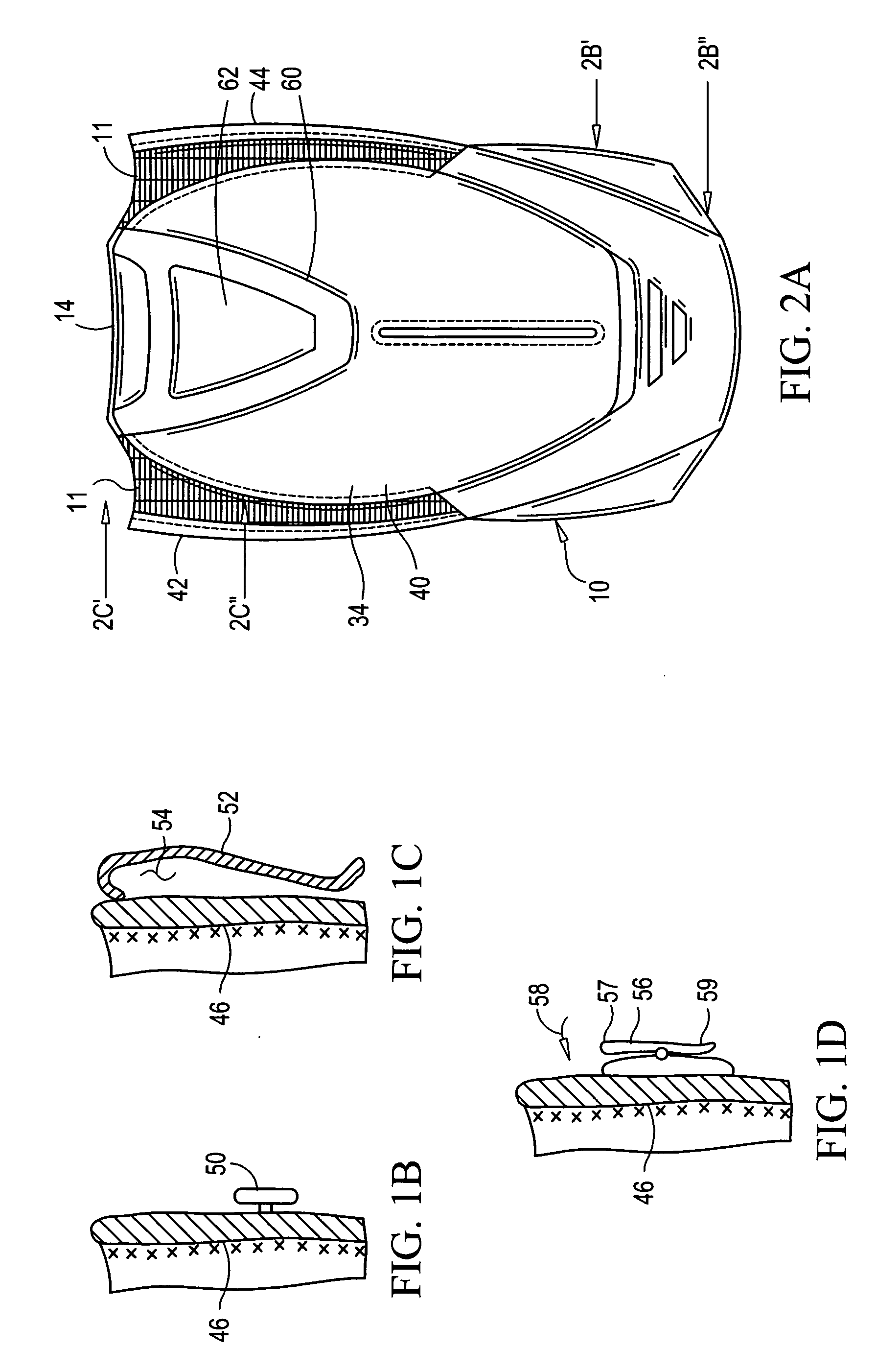

Carrying case for cell phone or other device with protective end cap and cushioning

InactiveUS20060052064A1Improve impact resistanceProvide tactile response structureTravelling carriersHoldersCushioningEngineering

The carrying case for a cell phone or other small electronic device includes a front, a rear, two opposing sides and a bottom. A resilient plastic bottom end cap forms a protective shield at the bottom. The end cap may include recessed grooves and / or raised lands to enhance impact resistance and / or provide a tactile response structure. The front side wall of the carrier may include a soft cushion edge pad along its upper edge to facilitate phone or device removal and insertion into the carrier. A carrier may also include bands of cushioning material about its sides which define shock resistant elements to protect the intermediate portions of the carried device. To better grip the device or phone, the case may include a swath of elastic with or without a releasable fastener system extending over the swath of elastic.

Owner:FINDINGS & MFG

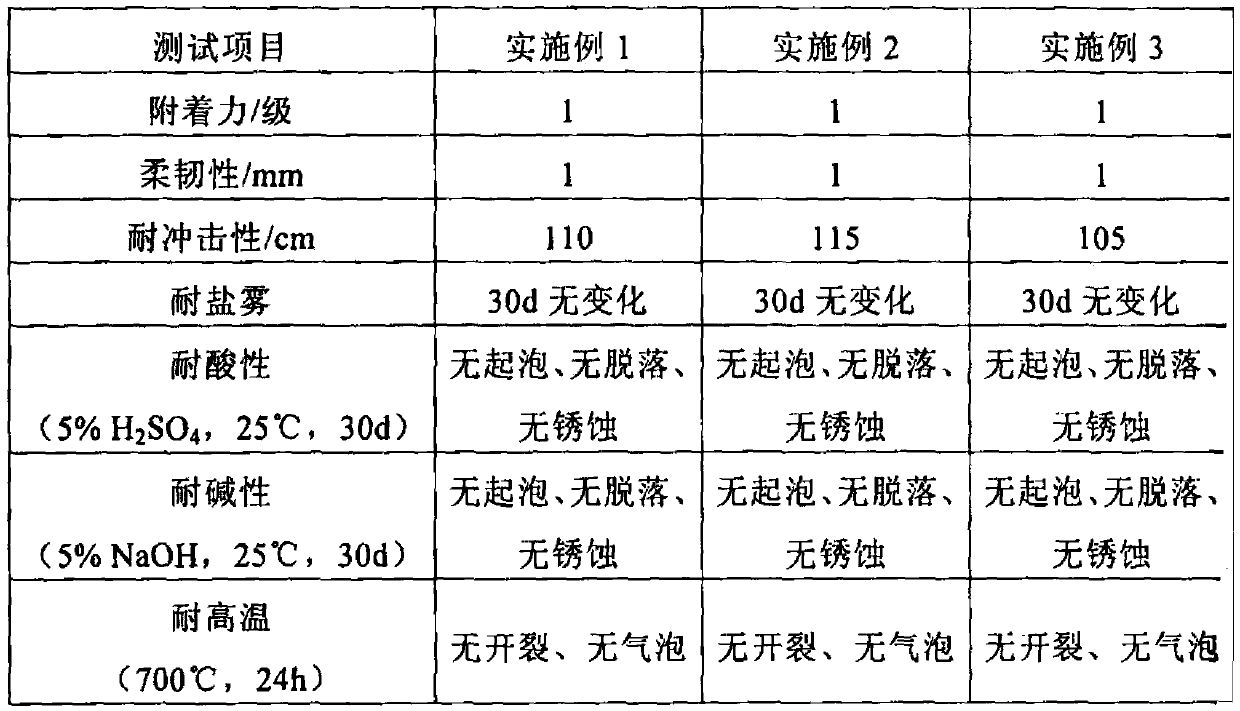

High temperature resistant anticorrosion coating based on graphene and preparation method thereof

InactiveCN103589281AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

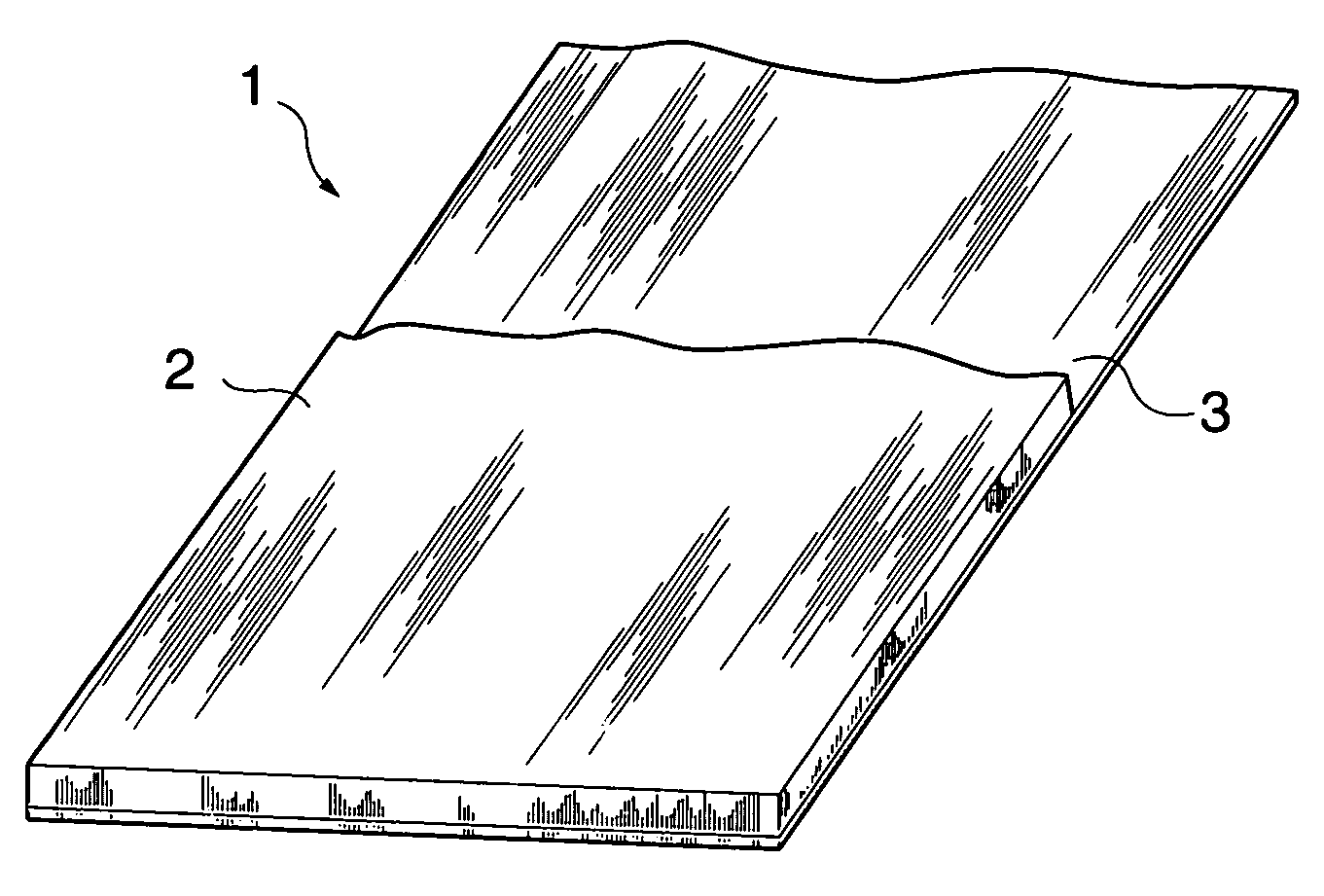

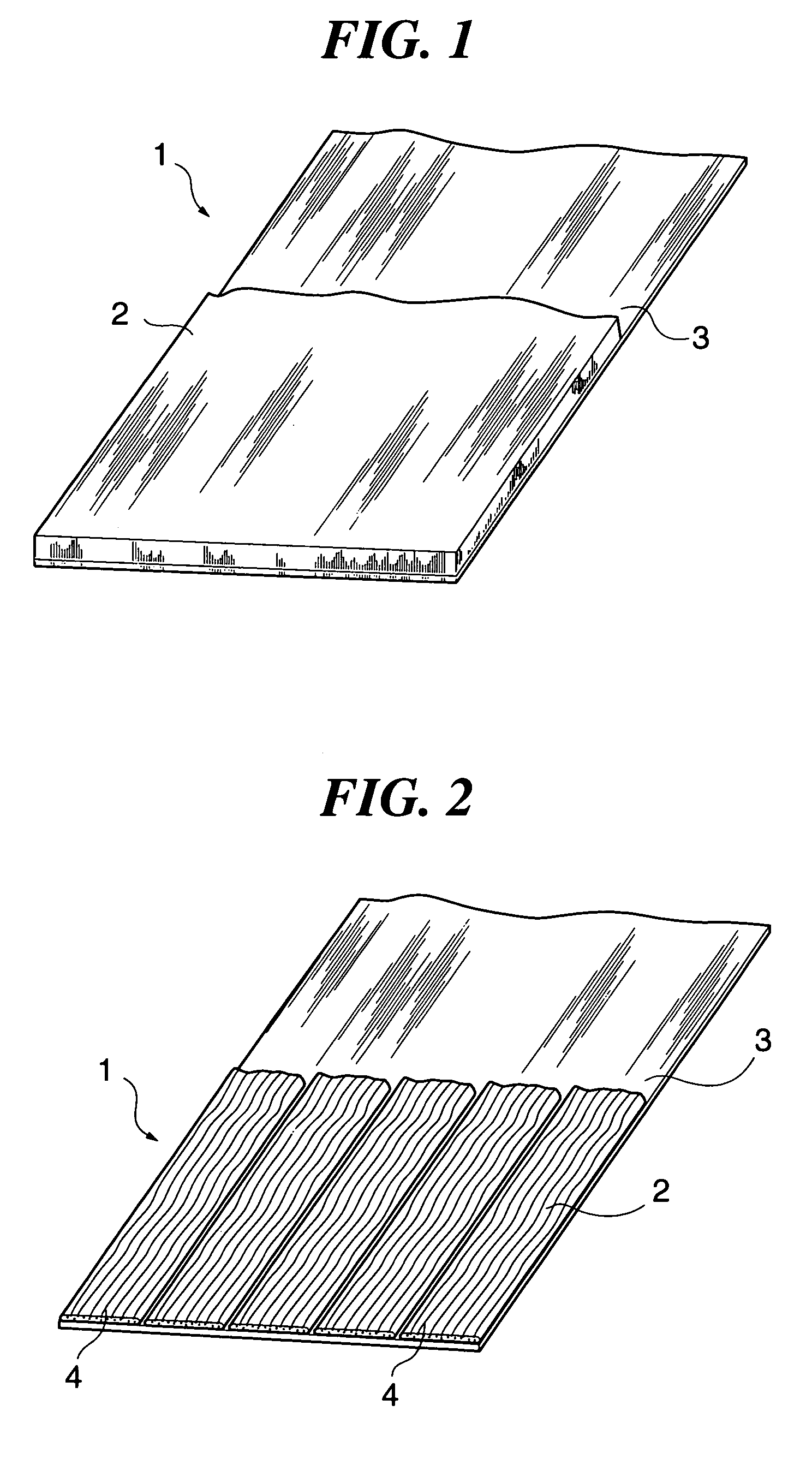

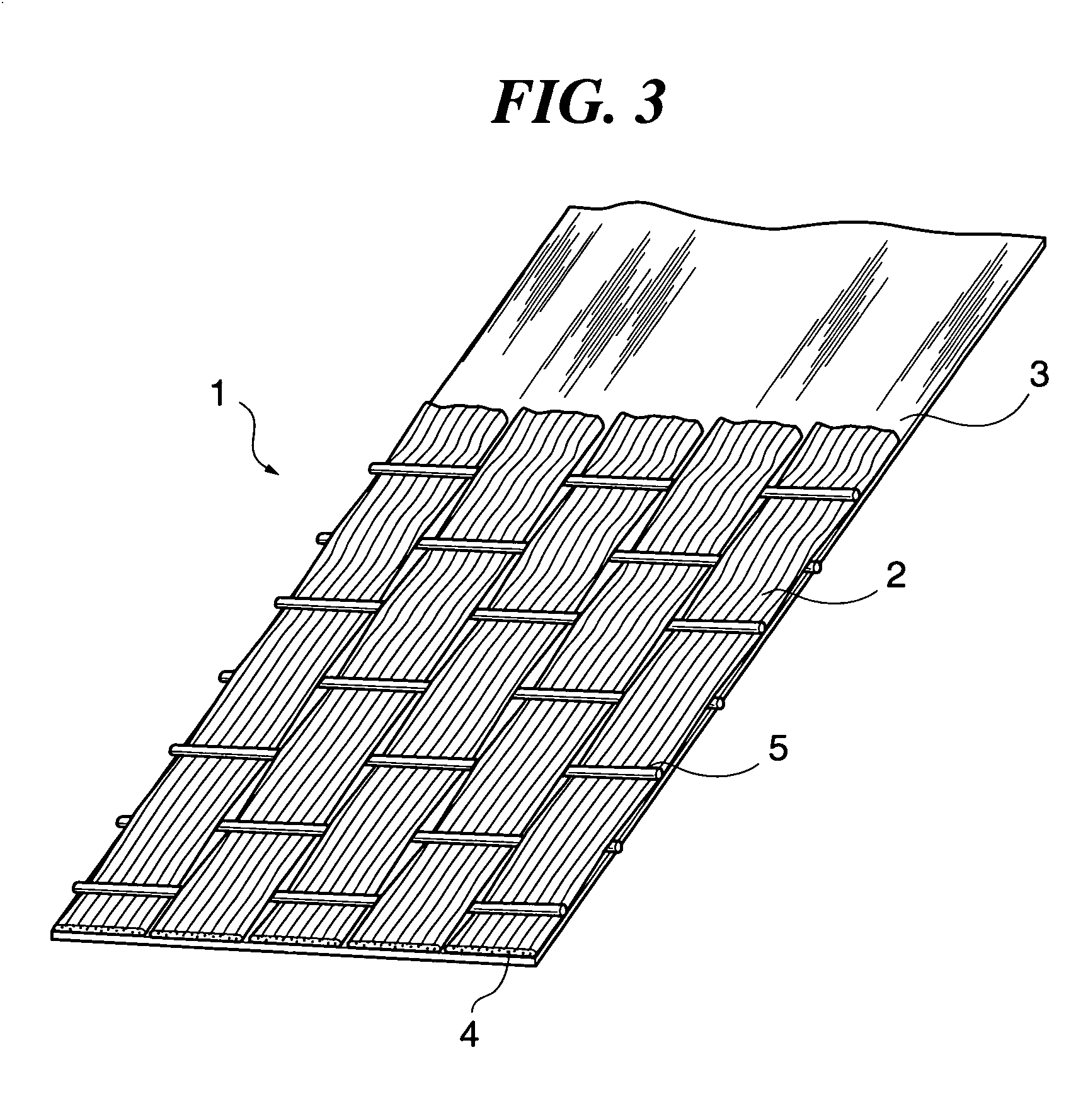

Composite reinforcing fiber base material, preform and production method for fiber reinforced plastic

InactiveUS6995099B1Excellent shaping propertyImprove impact resistanceLayered productsVehicle componentsMaterials scienceFiber reinforcement

The present invention is aimed at providing FRP formed by integrating a fiber reinforcing material and a non-woven fabric, and having excellent shaping ability, impact resistance after molding, and excellent reliability and low cost.The aim of the present invention is achieved by a complex fiber reinforcing material including a sheet-shaped fiber reinforcing material composed of reinforcing fibers, and a non-woven fabric laminated on at least one side of the fiber reinforcing material, wherein the fibers constituting the non-woven fabric pass through the fiber reinforcing material to integrate the non-woven fabric with the fiber reinforcing material.

Owner:TORAY IND INC

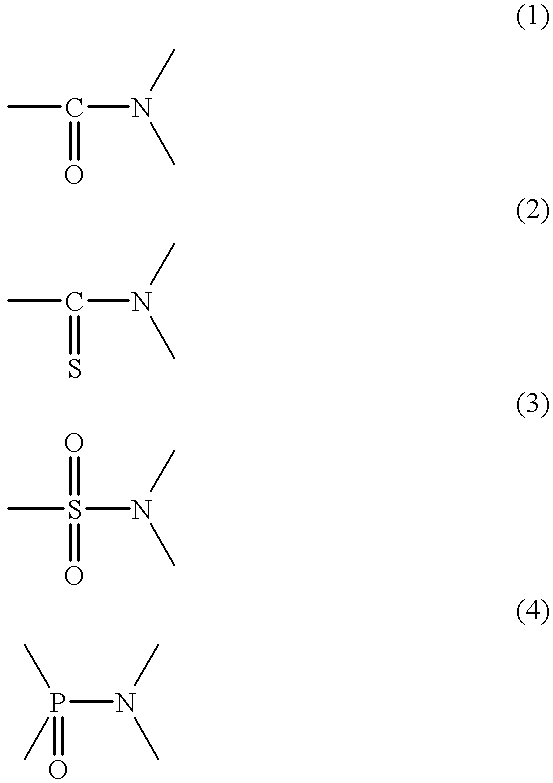

Epoxy resin composition for fiber-reinforced composite material, prepreg, and fiber-reinforced composite material

InactiveUS20020007022A1Synthetic resin layered productsThin material handlingInterlaminar shearFiber-reinforced composite

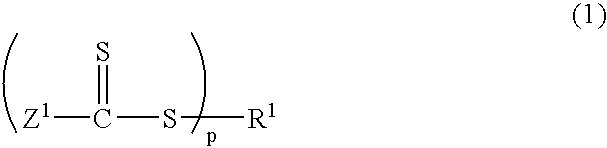

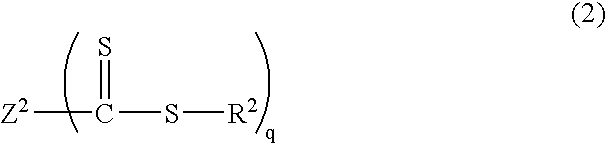

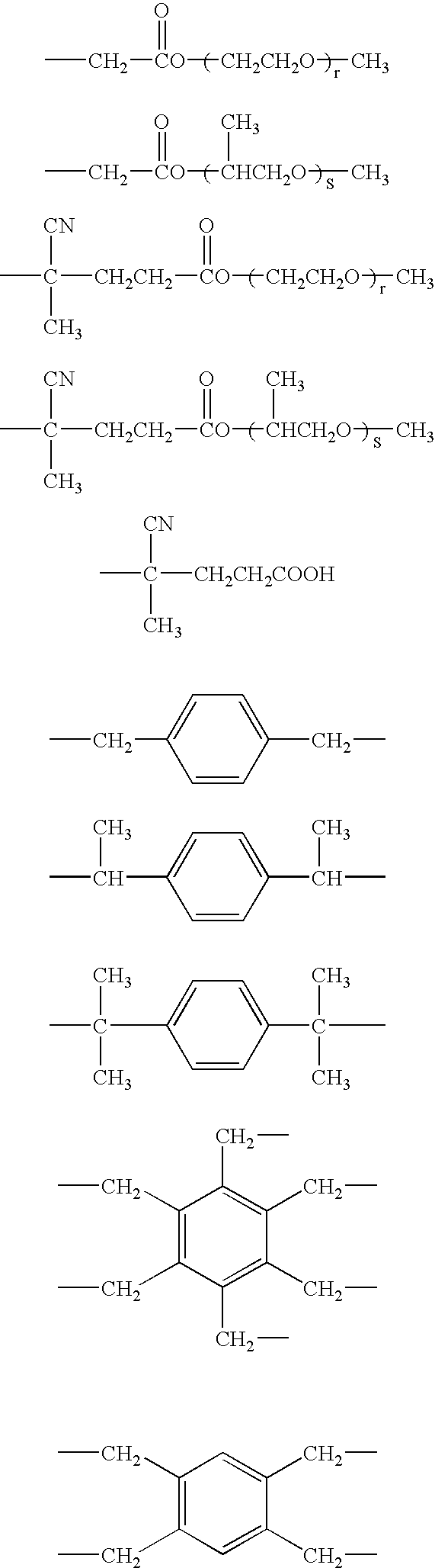

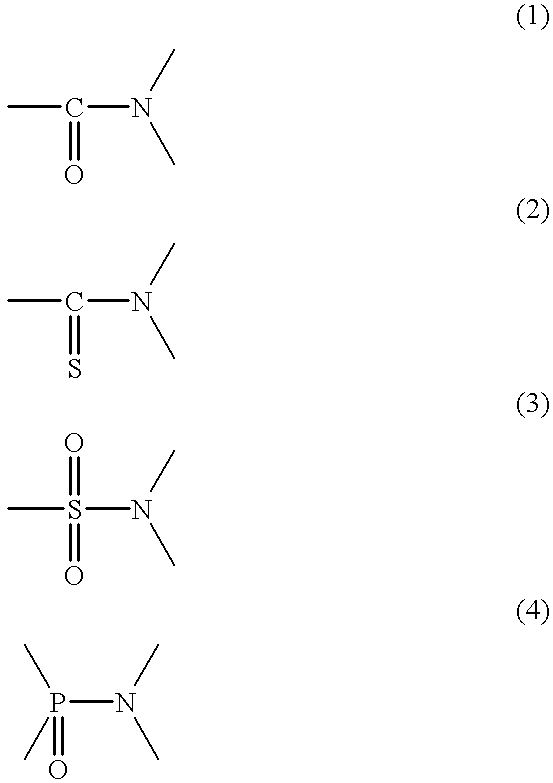

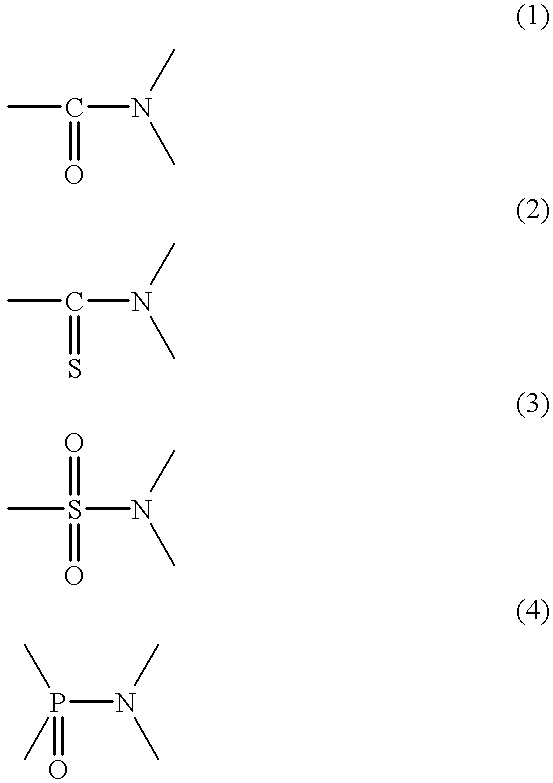

In order to realize the objectives stated above, the thermosetting resin composition for carbon fiber reinforced composite materials of the present invention chiefly comprises the following components. (A) Thermosetting resin (B) Compound containing one functional group which can react with thermosetting resin (A) or its curing agent, and a moiety selected from the following formulae (1) to (4) Furthermore, the present invention also relates to a prepreg formed by impregnating reinforcing fiber with the aforesaid resin composition and to carbon fiber reinforced composite materials comprising reinforcing fiber and a cured aforesaid thermosetting resin composition. In accordance with the present invention, there can be obtained a thermosetting resin composition where the adhesion to reinforcing fiber by the cured material and the elastic modulus of the cured material are excellent, and by using this resin composition there can be obtained carbon fiber reinforced composite materials which are excellent in their 0° compressive strength, 90° tensile strength and interlaminar shear strength, and which also have outstanding impact resistance.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com