Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19892results about How to "Improve high temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fireproof insulating cementitious foam comprising phase change materials

ActiveUS8070876B1Improve fire resistanceImprove high temperature resistanceSolid waste managementSynthetic resin layered productsThermal energyThermal energy storage

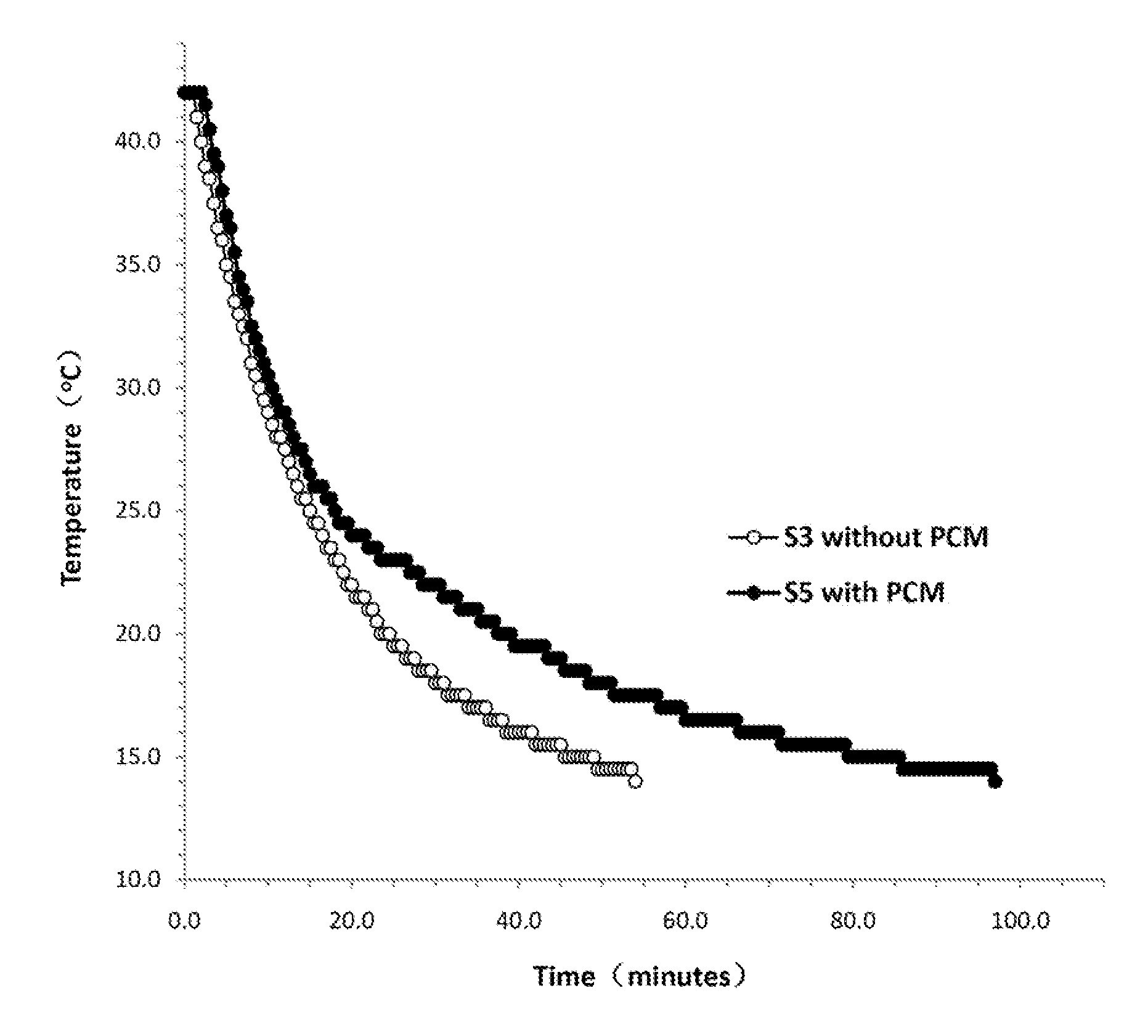

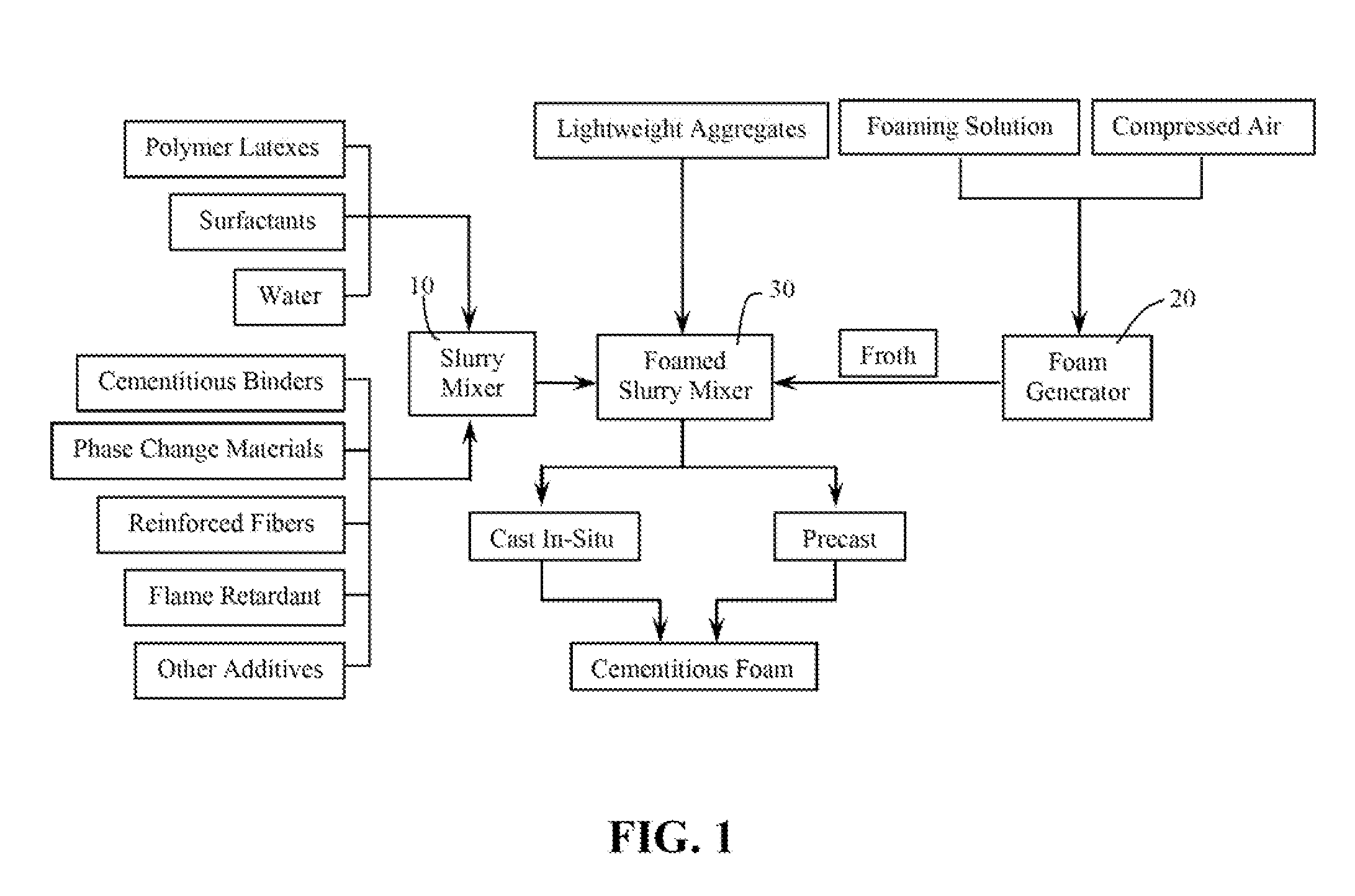

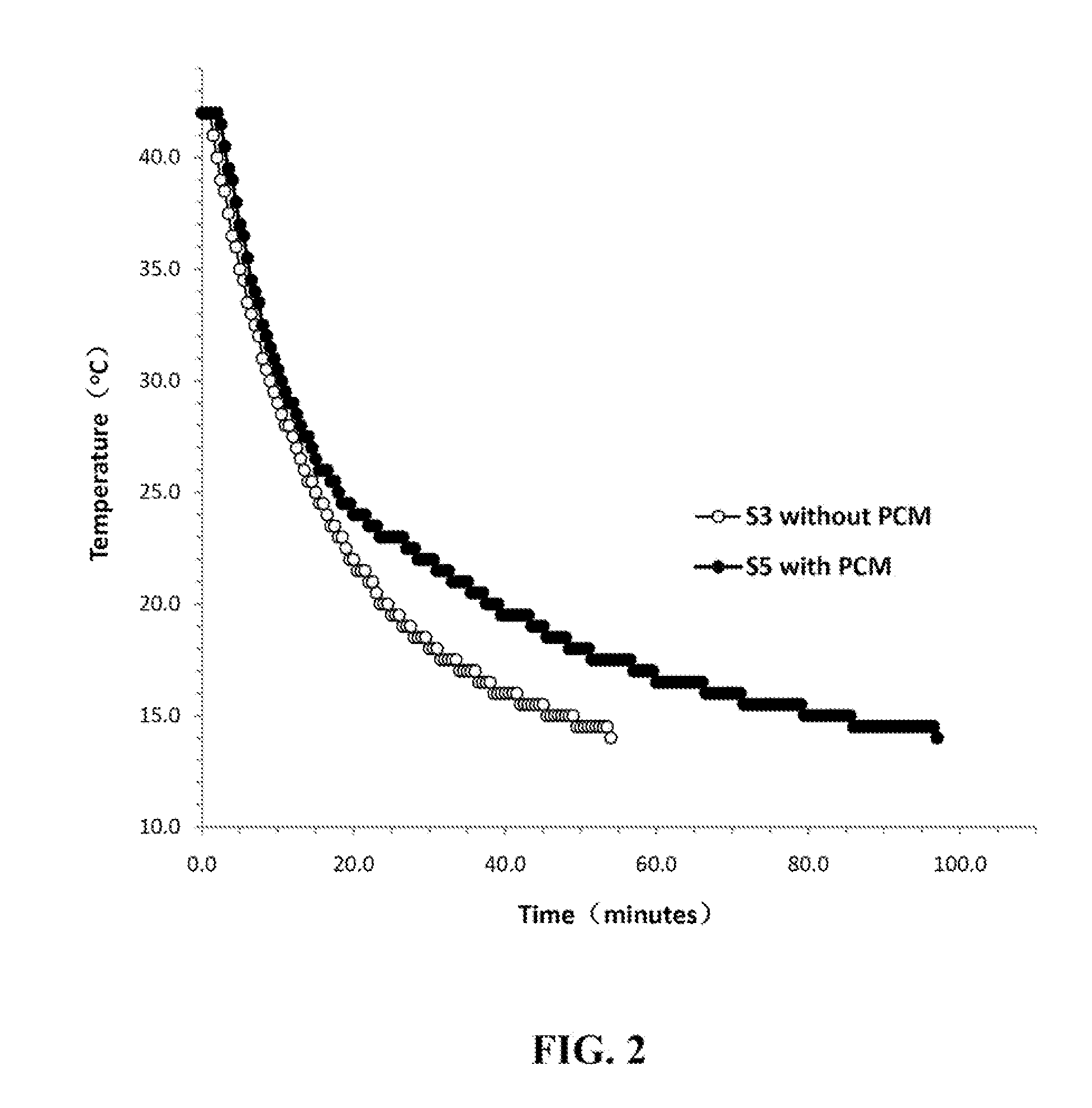

A fireproof insulating foamed cementitious composition with thermal energy storage capacity is provided for use in producing wall insulation boards, fireproof claddings for steel structures, inner cores of fire resistant wall or door panels, and the like. The composition demonstrates improved energy efficiency in which phase change materials, such as microencapsulates, are used in conjunction with a cementitious mixture of calcined gypsum and hydraulic cement, lightweight aggregates, a polymer latex, and a foaming solution to create stable air bubbles inside the cementitious matrix. The calcined gypsum and the hydraulic cement are present in a weight ratio range from about 1:3 to about 3:1. The composition may further include reinforced fibers, surfactants, inorganic flame retardants, and other additives. The presence of the phase change material not only increases energy efficiency of the cured cementitious foam material, but also improves compatibility between calcined gypsum and cement during slurry mixing and hardening.

Owner:JIANG HAIHONG

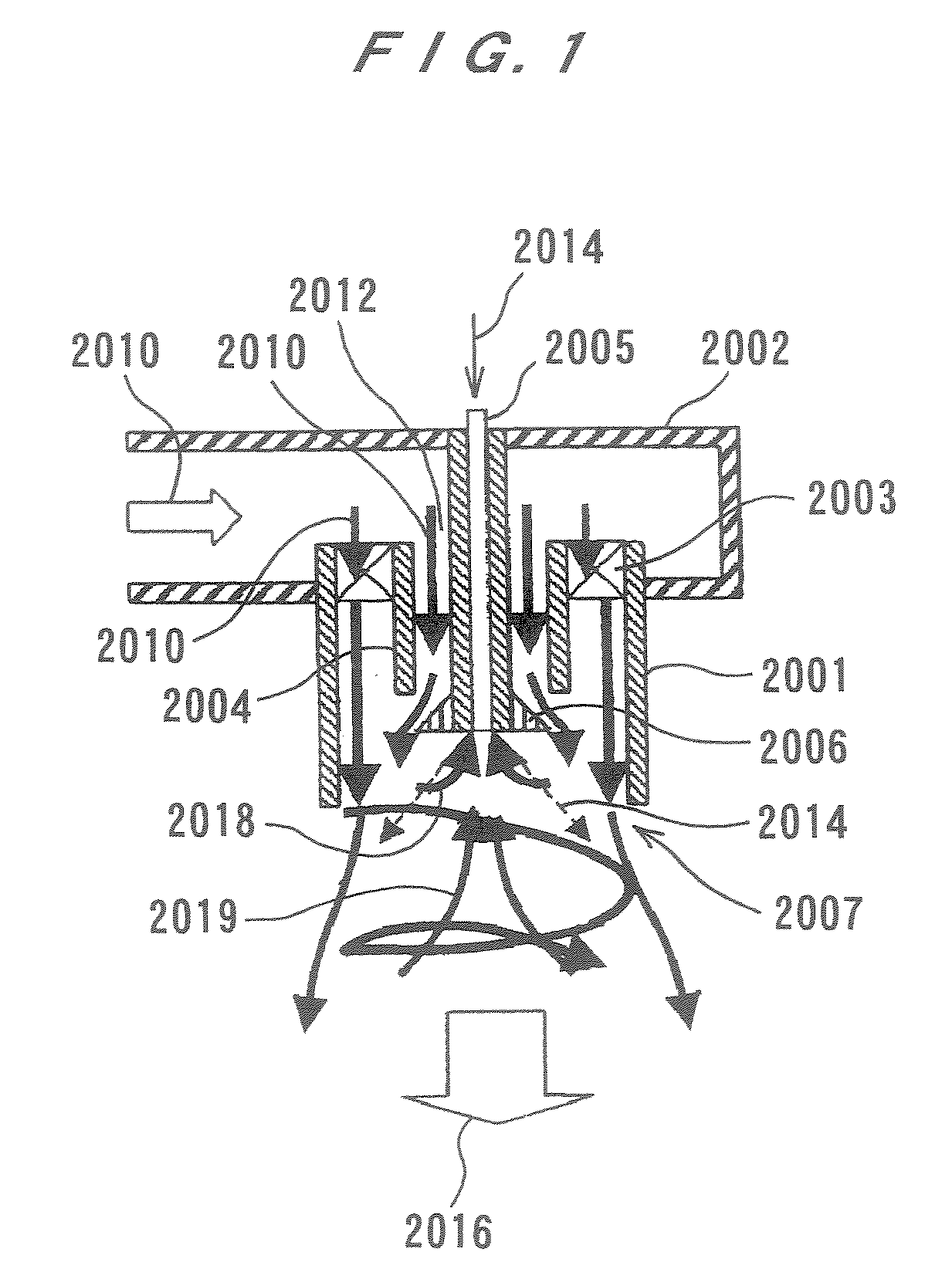

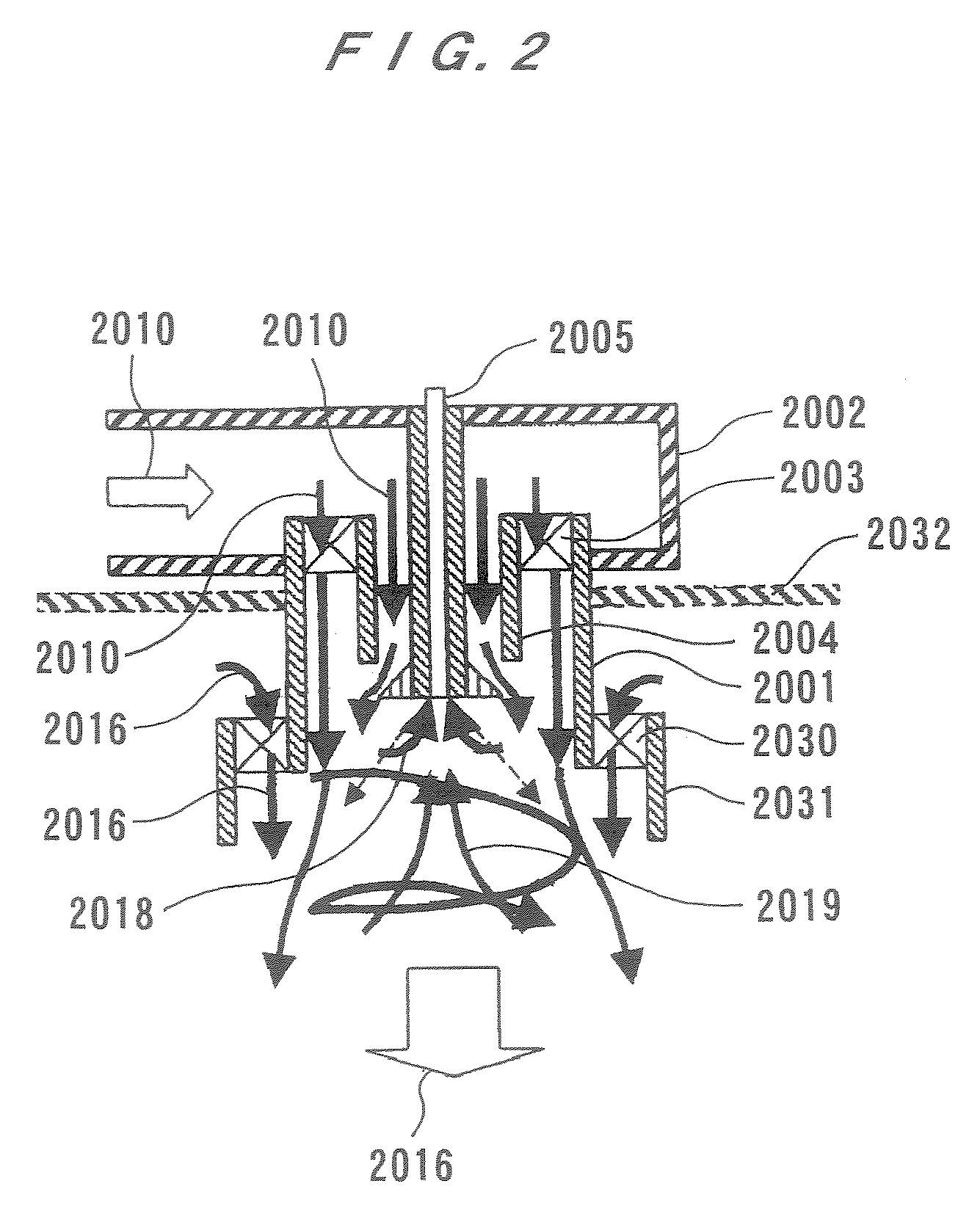

Combustion Apparatus and Combustion Method

InactiveUS20070272201A1Improve stabilityMaximize the effectContinuous combustion chamberCombustion enginesCombustion chamberEngineering

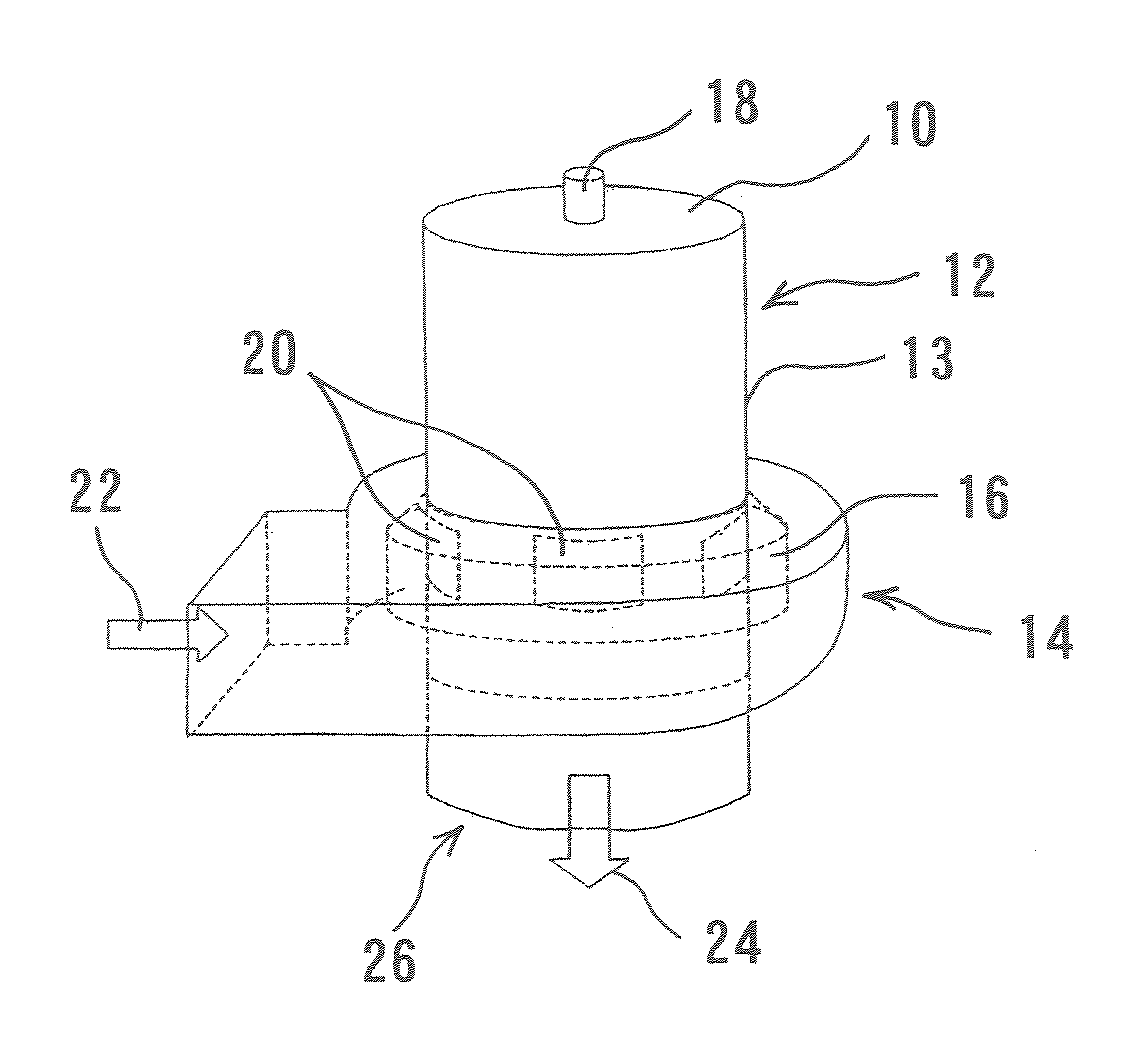

A combustion apparatus according to the present invention can positively control and generate burnt gas recirculation with a simple structure. The combustion apparatus has a cylindrical container (12) having a combustion chamber, a close end (10), and an open end (26), an inflow passages (20) for supplying combustion air into the combustion chamber in the cylindrical container (12), and a fuel nozzle (18) for supplying fuel into the combustion chamber in the cylindrical container (12). A flow (28) of air is formed so as to have a velocity component in a direction of a central axis (J) from the open end (26) to the close end (10) and a velocity component to swirl in a circumferential direction of said annular container (12). Fuel is injected so as to have a velocity component in the direction of the central axis (J) from the close end (10) to the open end (26) and a velocity component directed radially outward.

Owner:EBARA CORP

High-temperature thermal-insulation anticorrosive nano coating and its preparing method

InactiveCN1709988AImprove Radiation PerformanceGood heat insulationAlkali metal silicate coatingsPolymer scienceThermal insulation

The invention discloses a kind of new industry dope. It comprises such materials as 95 - 105 weight shares of Component A, and 1 - 3 weight shares of Component B; thereinto, Component A is made from following weight percents of materials: cementing agent 30-60%, pigment 12 - 30%, filling agent 10 - 30%, auxiliary agent 0.1 - 5%, compound nanometer dispersing agent 5 - 15% and solvent 10 - 25%; Component B is comprised of catalyzed membrane forming agent - nanometer Sb2O3 and mixed organic solvent carriers. The invention firstly brings nanometer Sb2O3 into high temperature heat preservation dope as catalyzer in dope membrane forming process. The dope of the invention has following advantages: it has high temperature heat preservation and heavy anticorrosion performances, and the coat has good acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:孙启明

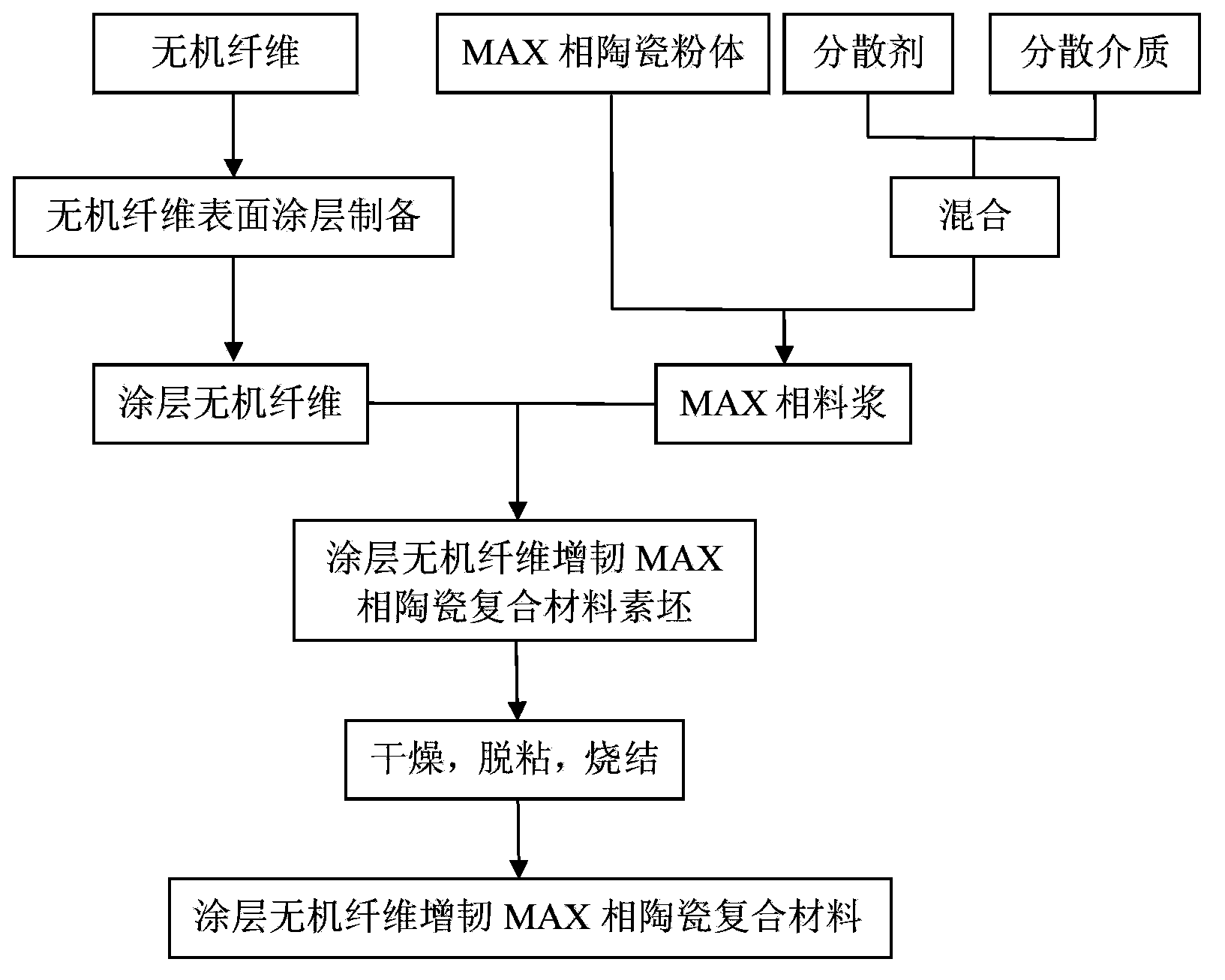

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

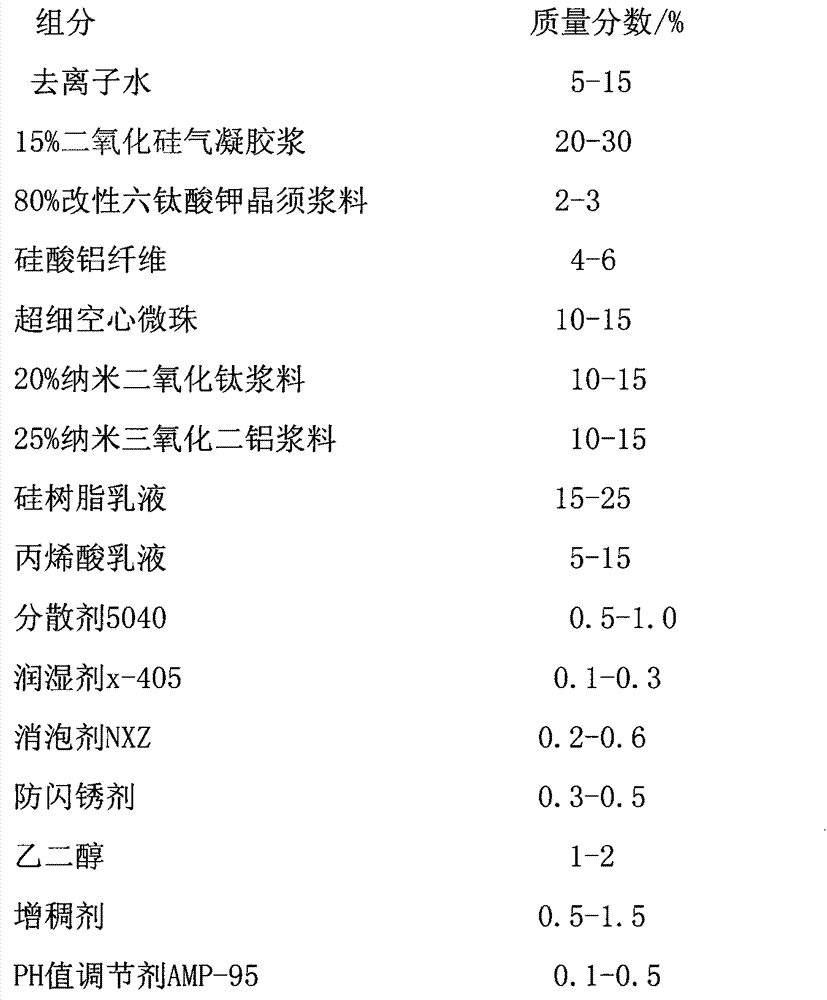

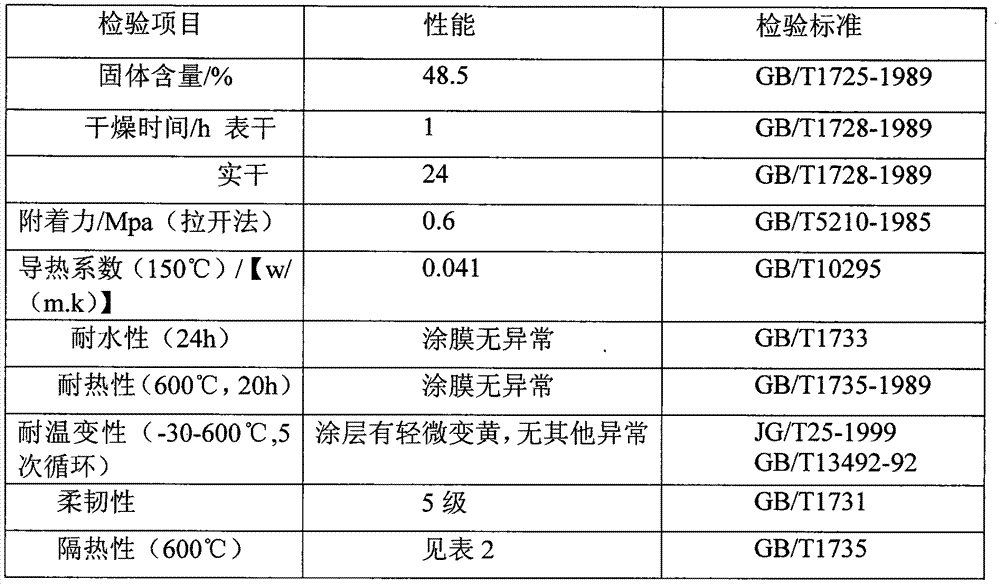

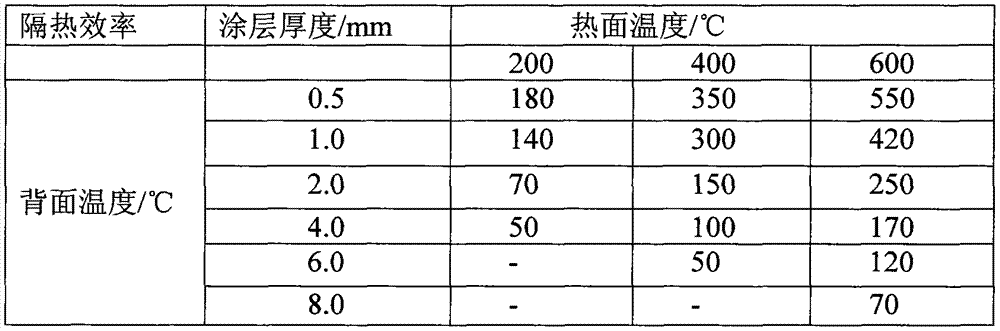

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

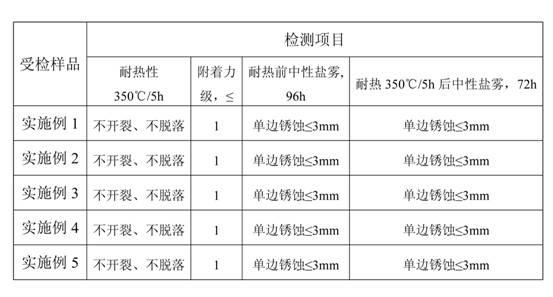

Heat-resisting organic silicon antiseptic inner tank coating

InactiveCN101935498AGood high temperature resistanceGood adhesionAnti-corrosive paintsEpoxy resin coatingsSolventFilling materials

The invention discloses a heat-resisting organic silicon antiseptic inner tank coating which comprises the following components in part by mass: 5-30 parts of organic silicon resin, 5-15 parts of modified organic silicon resin, 1-5 parts of amino resin, 0-18 parts of epoxy resin, 0-8 parts of phenolic resin, 11-43 parts of antiseptic pigment, 8-20 parts of filling material and 4-22 parts of solvent. The heat-resisting organic silicon antiseptic inner tank coating has good heat resistance and can work for long term at the high temperature of 350 DEG C; the coating has good adhesion force, good corrosion resistance and excellent performance; and a coating film still has good corrosion resistance after working at high temperature.

Owner:JIANGMEN PAINT FACTORY

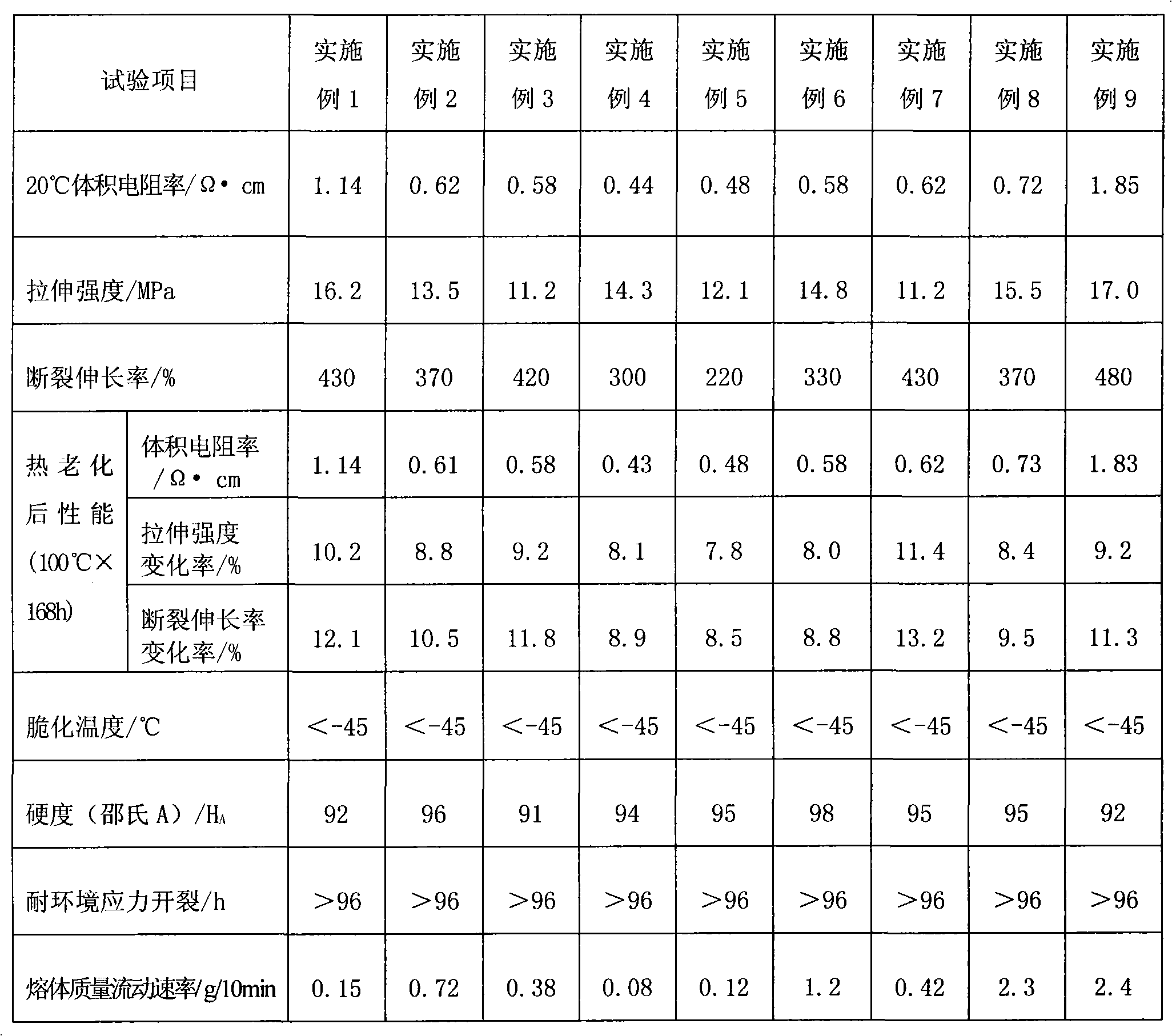

Composite type high-conductivity polymer material and preparation method thereof

ActiveCN101891914AImprove conductivityAvoid damageNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

The invention discloses a composite type high-conductivity polymer material and a preparation method thereof, which belongs to the technical field of new materials. The composite type high-conductivity polymer material is characterized by comprising the following raw materials in percentage by weight: 40-62 wt% of base resin compositions, 18-25 wt% of super conductive carbon black, 10-30 wt% of rubber filling oil, 1-3 wt% of low molecular wax, 0.2-0.8 wt% of fluoroelastomer processing aid (PPA), 0.5-2 wt% of lubricant, 1.5-3 wt% of inorganic filler and 0.5-2.5 wt% of other aids. The compositetype high-conductivity polymer material has the advantages of excellent high conductivity, environmental stress cracking resistance, weatherability, ozone resistance, ultraviolet resistance, favorable high temperature resistance, high impact resistance, oil resistance, solvent resistance and mechanical property, and can be used as an environment-friendly conductive polymer sheath material of an combined through earth line, a metal anticorrosive material of other ground cable, a conductive plastic cladding material of a conductive plastic cable positive wire, an optical cable flexible sheath material, and the like.

Owner:SHANDONG KEHONG WIRE & CABLE TECH CO LTD

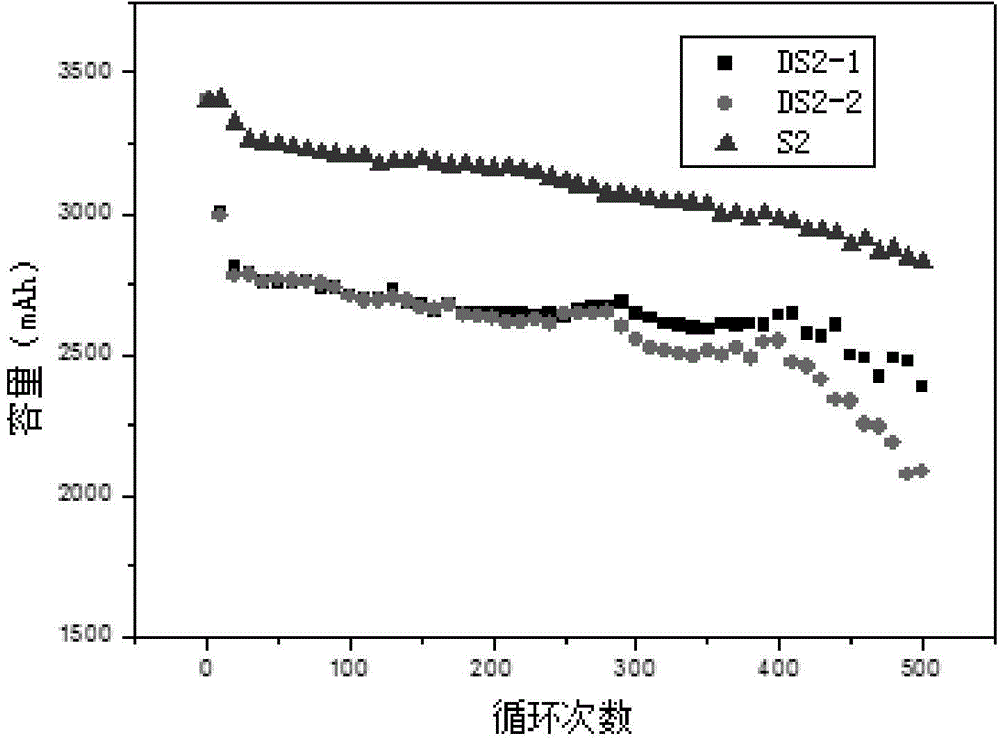

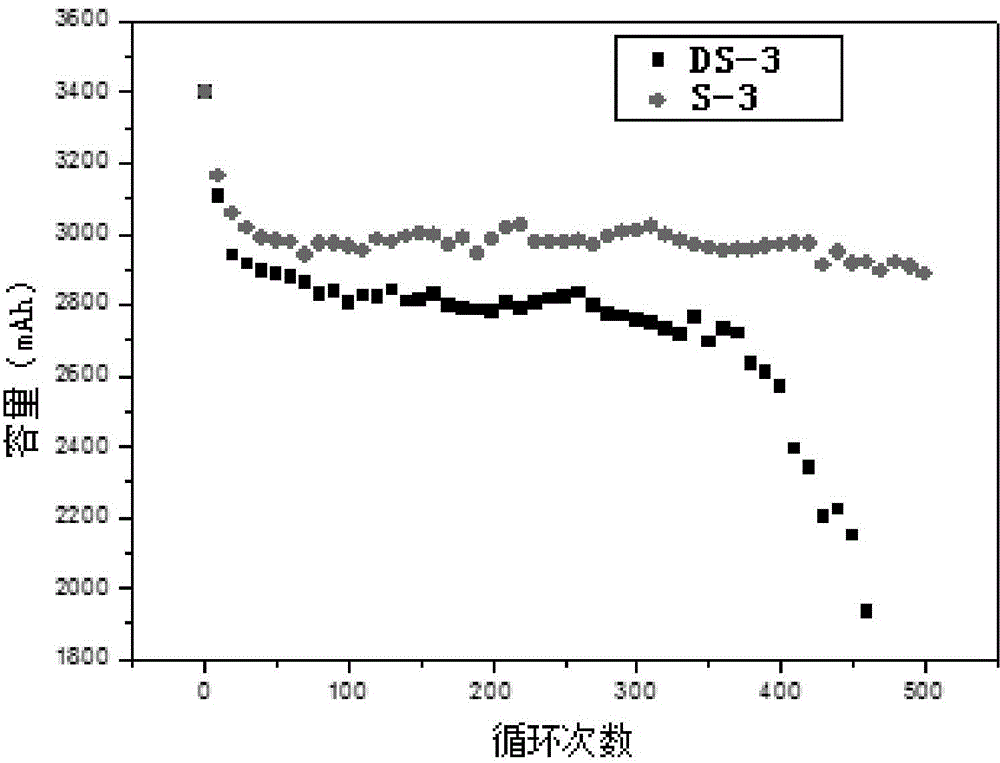

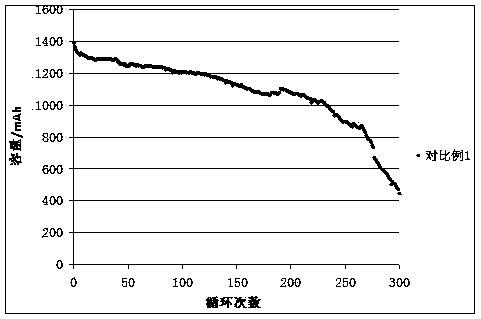

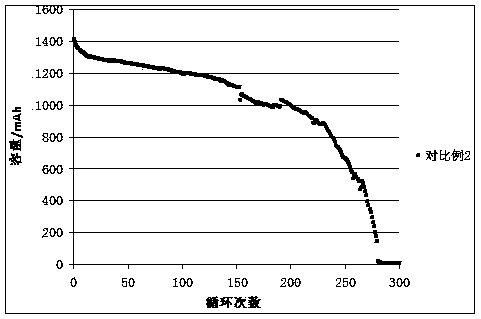

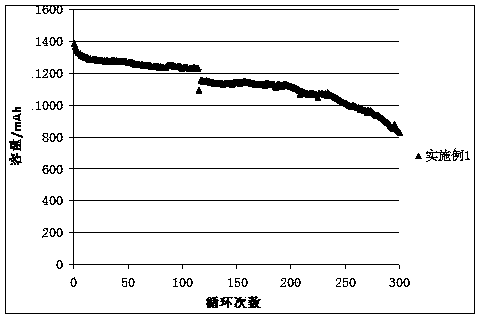

Electrolyte solution for high-capacity lithium-ion battery, preparation method and lithium-ion battery

InactiveCN104900916AAvoid direct contactInhibit cathode decompositionFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentElectrical battery

The invention discloses an electrolyte solution for a high-capacity lithium-ion battery. The electrolyte solution includes non-aqueous solvent, lithium hexafluorophosphate, negative electrode film forming additive, positive electrode surface activity inhibiting additive and transition metal ion complexant; the negative electrode film forming additive includes organic ester negative electrode film forming additive of 1 to 10wt% of the total electrolyte solution and inorganic lithium salt negative electrode film forming additive of 0.5 to 2wt% of the total electrolyte solution; the positive electrode surface activity inhibiting additive includes fluorinated ether additive of 1 to 5wt% of the total electrolyte solution and nitrile additive of 0.1 to 5wt% of the total electrolyte solution; the transition metal ion complexant is of 0.1 to 1.0wt% of the total electrolyte solution. The electrolyte solution is adaptive to the high-capacity lithium-ion battery and is capable of optimizing the circulating performance and high-temperature storage performance of the lithium-ion battery. The invention further provides a preparation method of the electrolyte solution and the high-capacity lithium-ion battery adopting the electrolyte solution.

Owner:GUANGZHOU TINCI MATERIALS TECH

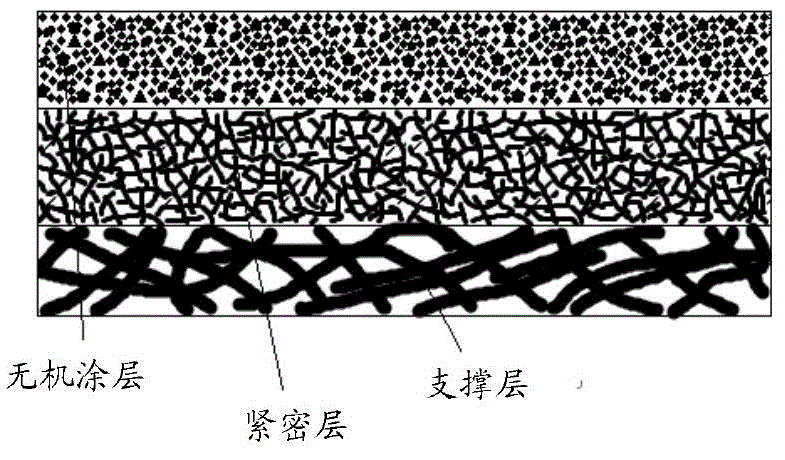

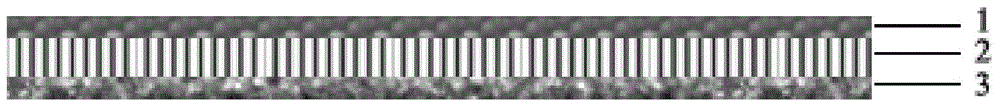

Lithium ion battery diaphragm, preparation method of lithium ion battery diaphragm and lithium ion battery

ActiveCN104157812ARequirements to ensure the strength of the diaphragmMeet the requirements of diaphragm strengthCell seperators/membranes/diaphragms/spacersSecondary cellsPorosityElectrical battery

The invention provides a lithium ion battery diaphragm, a preparation method of the lithium ion battery diaphragm and a lithium ion battery. The lithium ion battery diaphragm comprises a support layer, wherein either or both of a dense layer or an inorganic coating are compounded on the support layer; the average quantity of the lithium ion battery diaphragm is 8-25g / m<2>, the thickness is 15-60 mu m, the average aperture is 50-500nm, and the porosity is 78-82%. The lithium ion battery diaphragm provided by the invention is good in isolating property and excellent in electrolyte absorbing property, is further relatively high in tension strength, is capable of realizing high power capacity of a battery, and can meet the requirement of rapid large-current charge and discharge of the lithium ion battery.

Owner:SOUTH CHINA UNIV OF TECH

Lithium ion battery composite diaphragm and preparation method and application thereof

InactiveCN104157811AGood air permeabilityImprove securitySecondary cellsCell component detailsLithium electrodePolymer

The invention discloses a lithium ion battery composite diaphragm and a preparation method and an application thereof, belonging to the technical field of lithium ion batteries. The composite diaphragm comprises a polyolefin microporous membrane, a polymer microsphere based coating on one side surface of the polyolefin microporous membrane, and an inorganic ceramic-based coating on the other side surface of the polyolefin microporous membrane. The lithium ion battery composite diaphragm has good air permeability, liquid retaining capability and high-temperature resistance and can remarkably improve the security and the circulation property of the battery. The melting point or softening point of the polymer microsphere-based coating in the composite diaphragm is 90-140 DEG C, and when the temperature of the battery is increased, the polymer microsphere based coating is molten or swelled within a short time, then the apertures of the polyolefin microporous membrane are blocked rapidly, the thermal turn-off effect of the diaphragm is achieved, a lithium ion conveying channel is cut off, and short circuit inside the battery is prevented; meanwhile as ceramic grains inside the inorganic ceramic-based coating have the high-temperature resistance property, the polyolefin microporous membrane is effectively prevented from shrinkage, and the situation that positive and negative films directly come into contact to cause short circuit of the battery.

Owner:SHANGHAI FANNENG NEW MATERIAL TECH CO LTD

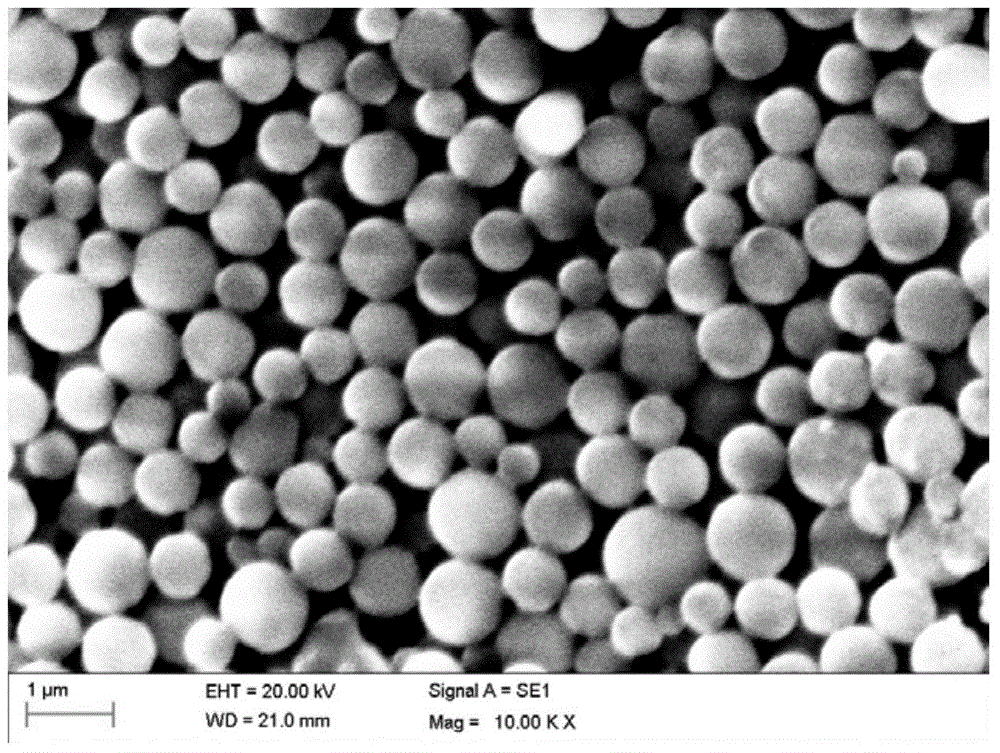

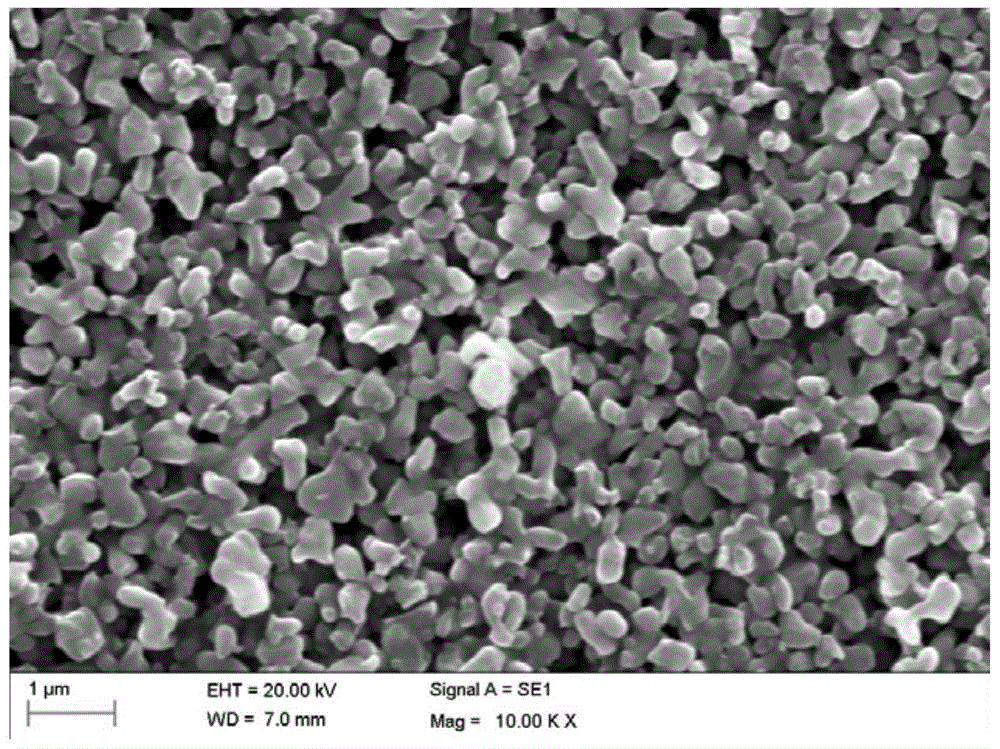

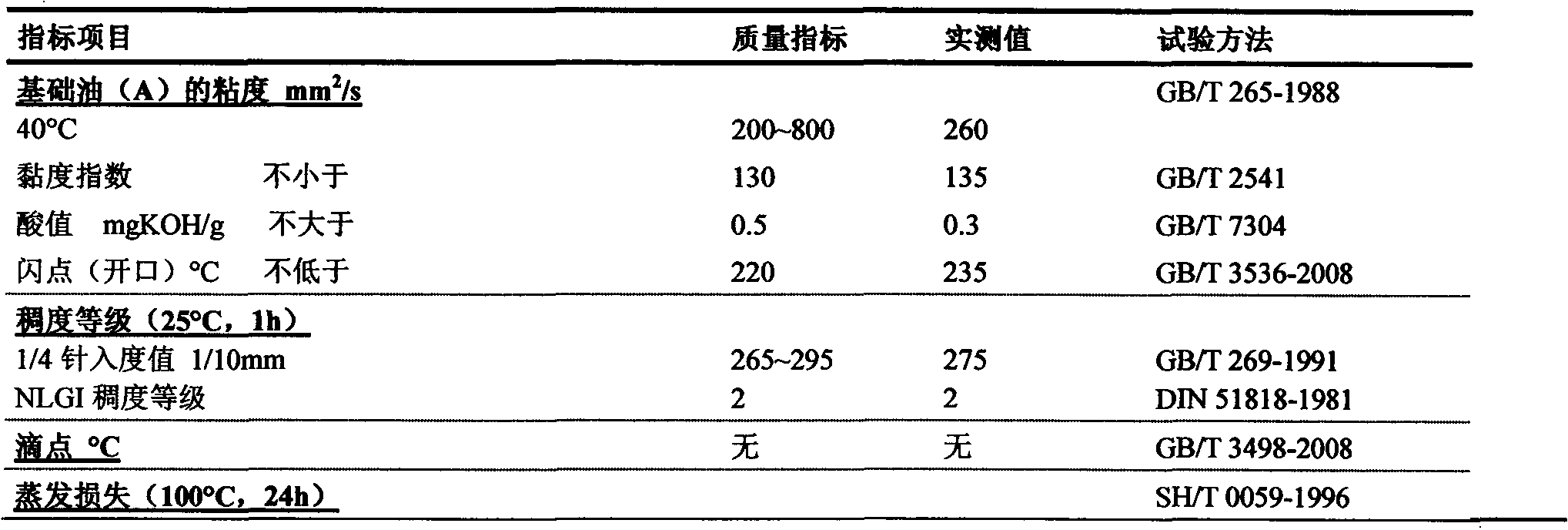

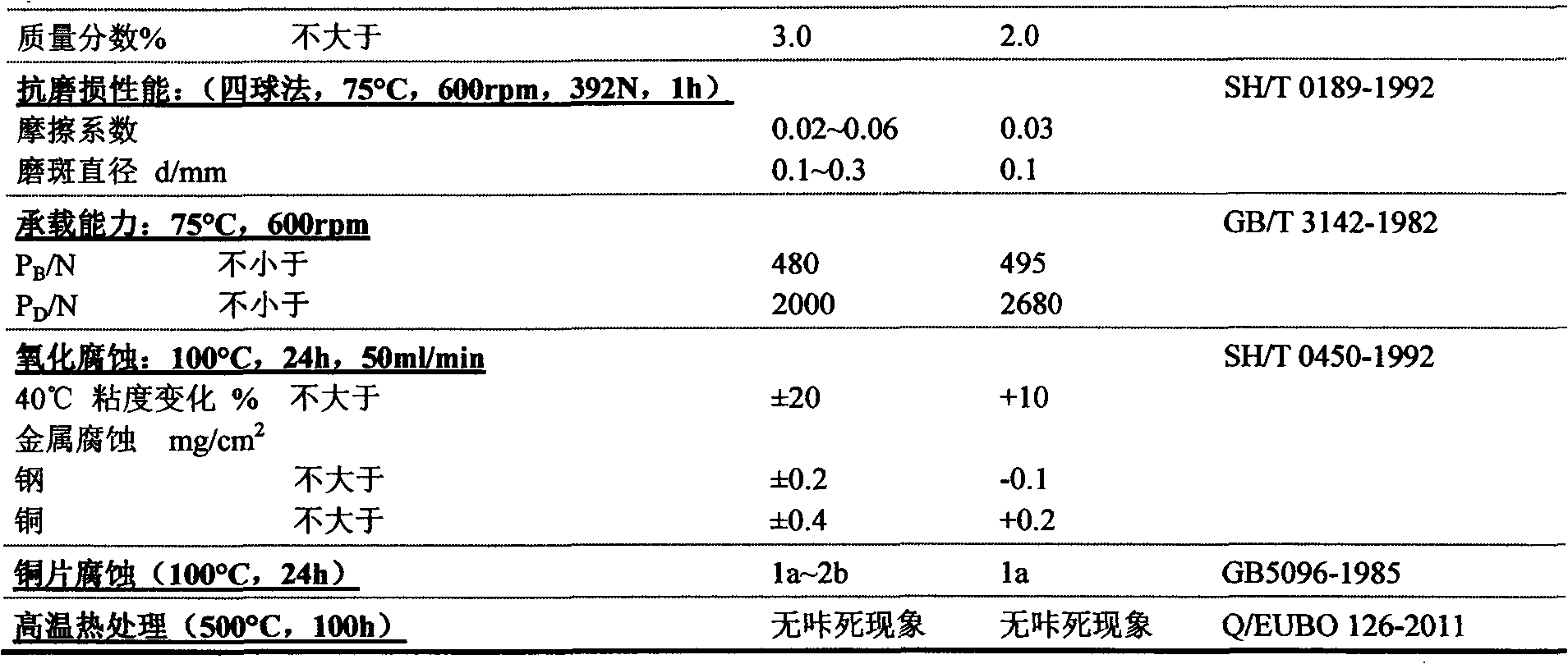

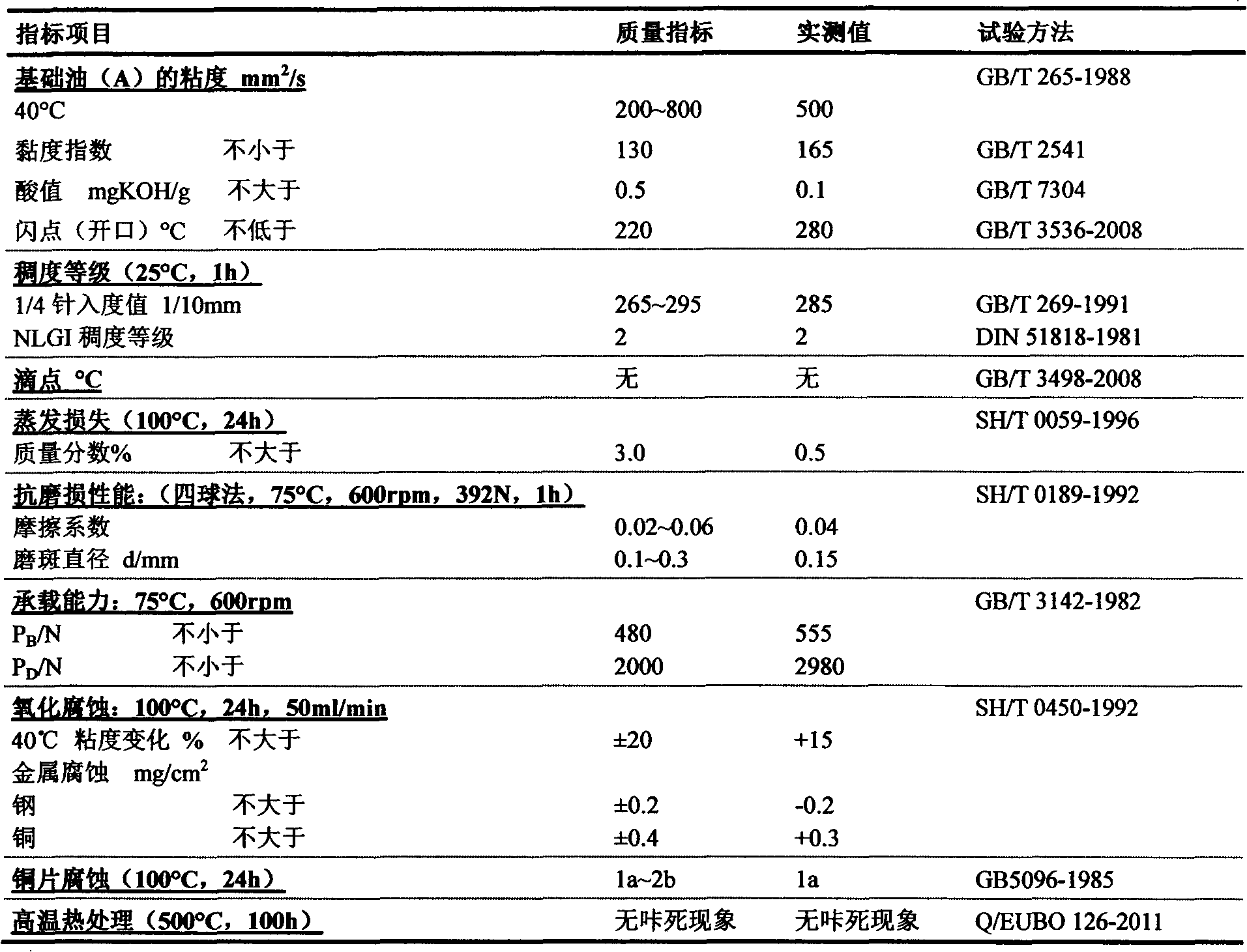

Valve element sealing lubricating agent composition

InactiveCN102433204ASimple production methodImprove high temperature resistanceLubricant compositionBase oilWear resistance

The invention relates to the field of lubricating materials, in particular to a valve core sealing lubricating agent composition, which comprises: (A) 100.0 weight parts of base oil; (B) 5.0 to 35.0 weight parts of thickening agent; (C) 3.0 to 55.0 weight parts of solid lubricating agent; (D) 0.1 to 3.0 weight parts of surfactant; (E) 0.1 to 2.5 weight parts of antioxygen; (F) 0.1 to 4.0 weight parts of extreme pressure antiwear agent; (G) 0.1 to 2.0 weight parts of metal passivating agent; and (H) 0.1 to 1.5 weight parts of antimicrobial agent. The finished lubricating agent prepared according to the mixing ratio has high high-temperature resistance, high antiwear and wear-resistance performance and high dead-locking-preventing performance. Meanwhile, the production and preparation method of the lubricating agent are simple, convenient and easy to implement and is suitable for large-scale batch production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

High-strength stretch-proof flame-retardant textile

InactiveCN101748549ASolve the difficulty of weavingSolve not easy to dyeWoven fabricsYarnCompound aEngineering

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

Preparation method of high-temperature-resistant aerogel and aerogel-type porous ceramics

PendingCN107098352AImprove high temperature resistanceAvoiding Densification ProblemsSilicaZirconium compoundsThermal insulationWhiskers

The invention discloses a preparation method of high-temperature-resistant aerogel. The method comprises: adding high-temperature-resistant powder or crystal whiskers to sol, performing in-situ compounding of sol and high-temperature-resistant powder or crystal whiskers, and performing aging, modification and drying to obtain high-temperature-resistant aerogel. The invention further discloses a preparation method of aerogel-type porous ceramics. Porous ceramics having an aerogel hole structure kept is obtained by sintering the high-temperature-resistant aerogel. The prepared high-temperature-resistant aerogel and aerogel-type porous ceramics can resist high temperature of 1000-1800 DEC C or more, keep the nanometer hole structure from collapse, have high porosity and strength and have hole diameters which can be adjusted from micropores to large holes. The aerogel and aerogel-type porous ceramics can be used as a super thermal insulation material and can be widely applied to fields of purification separation, adsorption, chemical industrial catalytic carriers, sound absorption and damping, sensing elements and electrochemistry. The method is simple and easy to carry out and suitable for massive production, and allows high temperature resistance of aerogel to be improved and application fields of aerogel to be broadened.

Owner:浙江圣润纳米科技有限公司

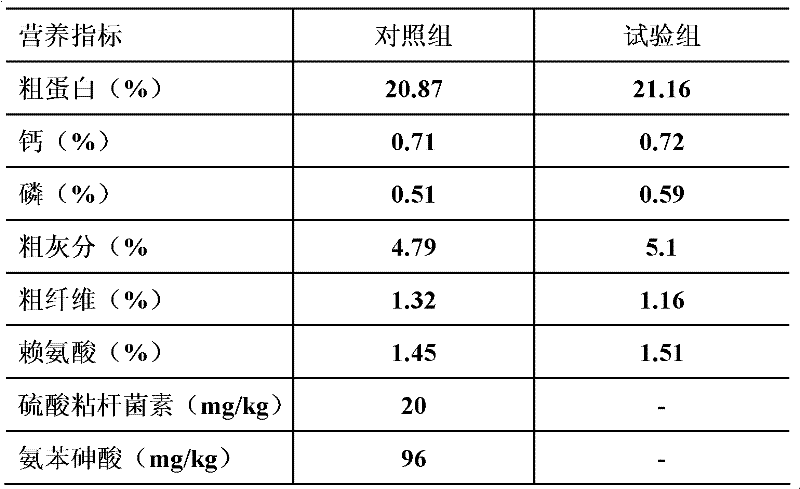

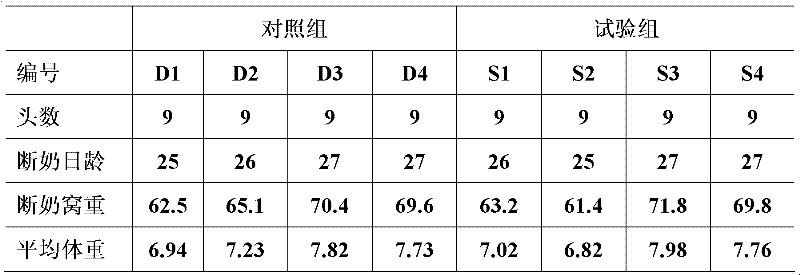

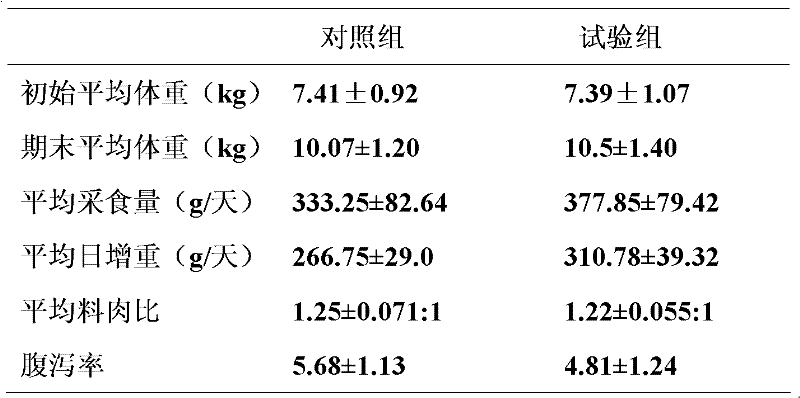

Feed for early weaned suckling pigs

ActiveCN102265984AGood enzyme productionImprove acid resistanceFood processingAnimal feeding stuffWeight gainingAdditive ingredient

The invention relates to a feed for early weaned piglets, which belongs to the field of the feed. Main ingredients of the feed comprise expanded corn, full-fat soybean, fat powder, steam fish meal, acidified whey powder, fermented soybean meal, a complex enzyme preparation, a micro-ecological preparation, amino acids, complex vitamins, complex trace elements and the like. The digestive physiological characteristics of the weaned piglets are fully considered on the selection and the processing of raw materials, thereby greatly improving the palatability and the digestion rate of the feed; simultaneously, through the synergistic compatibility of an egg yolk antibody, lactein, sodium humate and the complex micro-ecological preparation, the diarrhea rate of the weaned piglets is reduced, the effects are superior to those of adding antibiotics into the feed, and the feed is the green, environmentally-friendly and nuisanceless feed. An animal feeding experiment proves that the feeding effects are ideal, the palatability is good, the piglets after weaning are high in average feed intake, fast in daily weight gain and low in diarrhea rate, and the feed has a good promoting effect for growth and health conditions of the weaned piglets and can meet the demands of most of raisers at present.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

High-temperature-resistant, anti-corrosion and thermal-insulation coating and preparation technology thereof

ActiveCN104673063AReduce internal stressImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentCross linker

The invention discloses a high-temperature-resistant, anti-corrosion and thermal-insulation coating which comprises components in parts by weight as follows: 45-60 parts of film-forming resin, 20-30 parts of a pigment and filler, 15-30 parts of an aid and 25-30 parts of a solvent. The invention further designs a preparation technology of the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The technology comprises steps as follows: firstly, mixing the film-forming resin with the pigment and the filler, sequentially adding an antifoaming agent, a leveling agent, a coupling agent, a crosslinking agent and a curing agent, and evenly stirring the mixture at the normal temperature to obtain the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The coating has the advantages of environment-friendliness, low cost, high hardness, long service life, good heat resistance, good flexibility, good high-temperature resistance and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

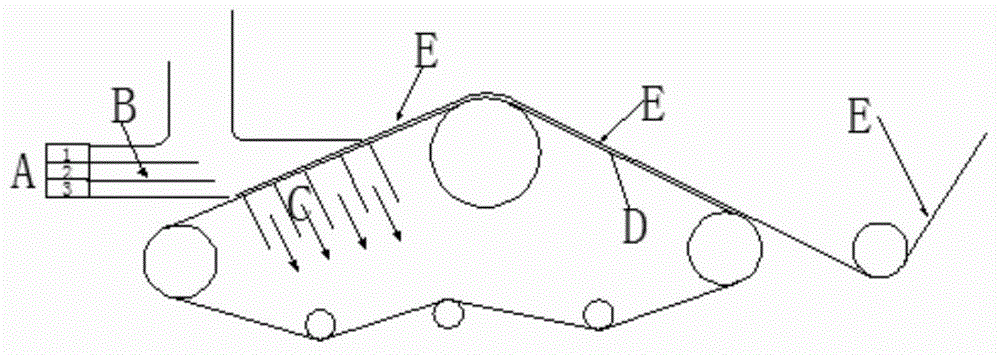

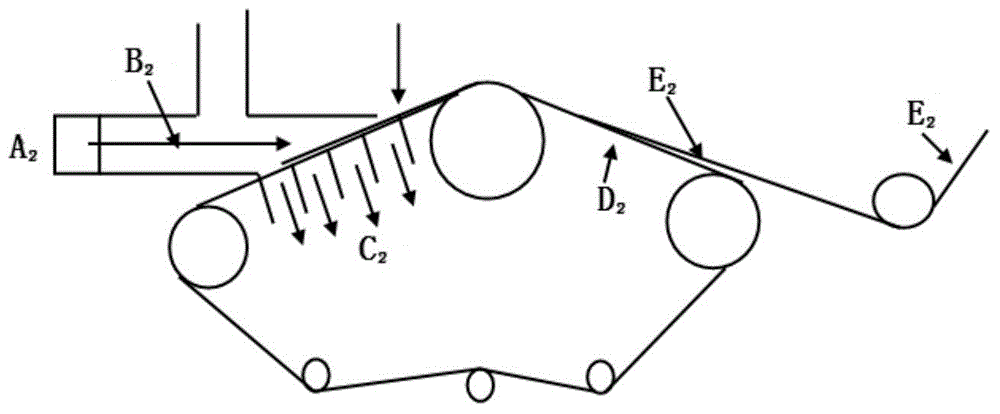

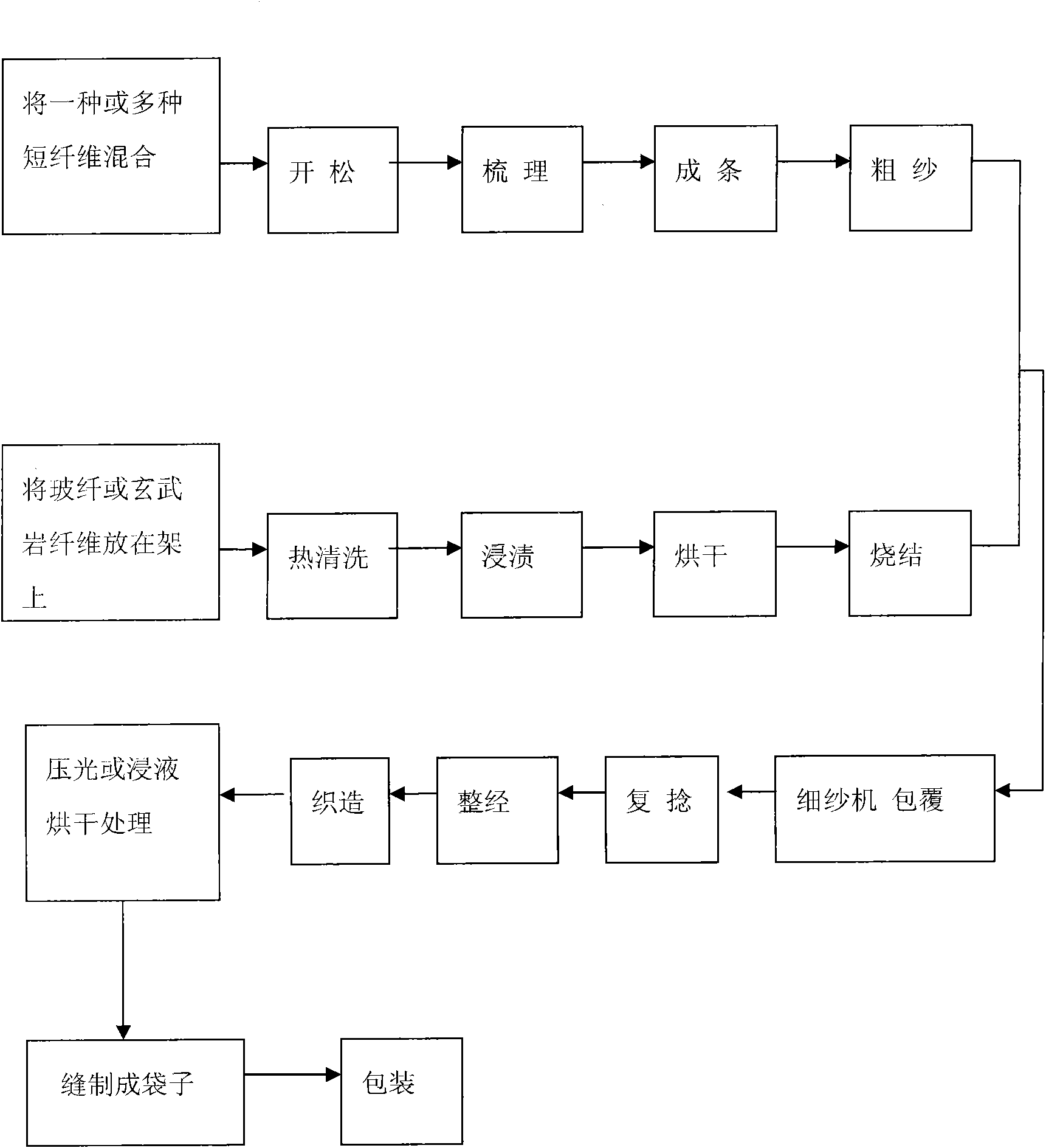

Composite covered yarn, and manufacturing method and use thereof

The invention relates to a composite covered yarn and a manufacturing method thereof and also relates to a high-temperature filter cloth. The composite covered yarn comprises an outer layer of coveredyarn made of short fiber and an inner layer of reinforcing rib made of long fiber, wherein the composite covered yarn is formed by using the covered yarn, made of one or a plurality of types of shortfibers, to cover the reinforcing rib or the metal wire reinforcing rib made of one or a plurality of types of long fibers by thermal cleaning, dipping, drying and sintering. The composite covered yarn manufactured by the method not only saves cost, but also combines the characteristics of high strength of the long fiber and good abrasion resistance and toughness of the short fiber and enhances service life, strength, high-temperature resistance and stability of the composite covered yarn. The composite covered yarn can be made into the filter cloth.

Owner:辽宁新洪源环保材料有限公司

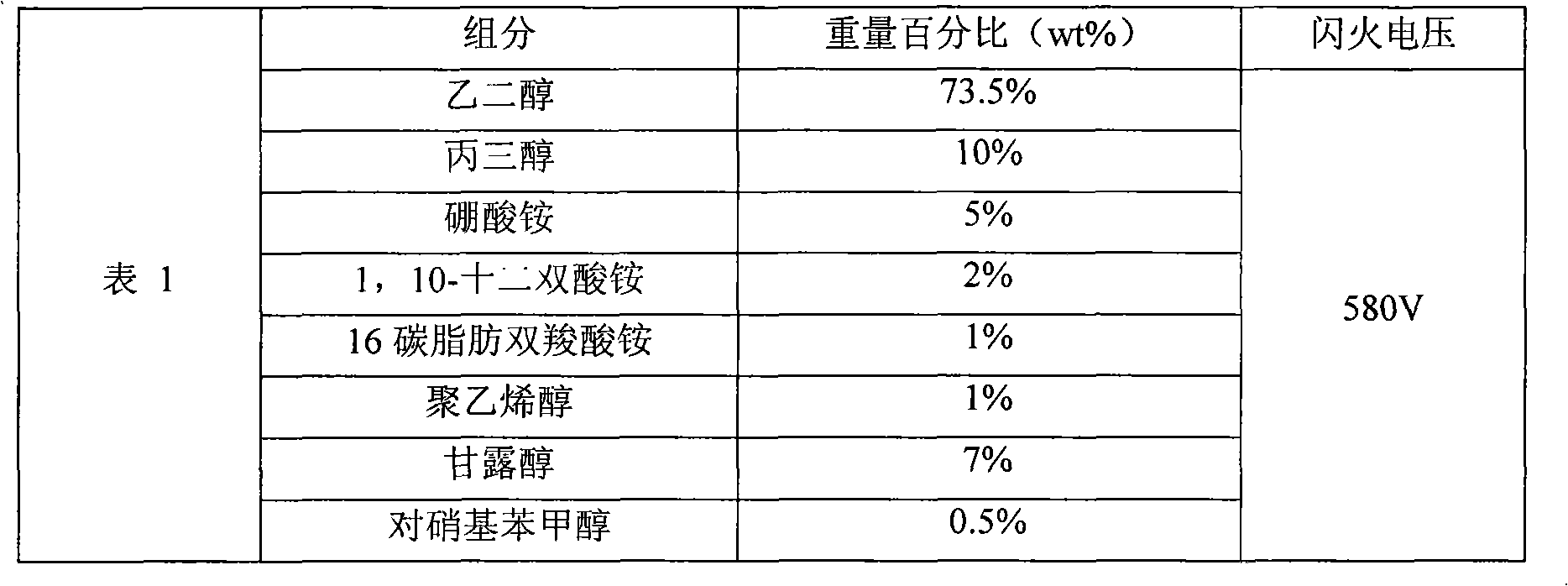

Aluminium electrolytic capacitor working electrolyte and capacitor obtained thereof

ActiveCN1744247AGood high pressureImprove high temperature resistanceElectrolytic capacitorsAmmonium pentaborateSolvent

The electrolyte includes solvent, solute, additive for corrosion resistance and property modifying additive. The additive for corrosion resistance includes 8-hydroxy quinoline, mannitol, phosphate monoester and one or more matters selected from organic acids. Compositions of property modifying additive include polyvinyl alcohol and / or carbowax, boracic acid and / or ammonium pentaborate, and glycol etc. Moreover, the electrolyte also includes dehydrogenation agent and waterproof mixture. The electrolyte improves capabilities of high temperature and high pressure resistant, and corrosion proof for aluminum electrolytic capacitor, reduces generation of hydrogen so as to prevent capacitor from blowing up, and hydration causing invalidation of capacitor. The invention also discloses the aluminum electrolytic capacitor of using the electrolyte. The capacitor is operable under rated operational voltage 315V-500V, and temperature 125 deg.C as upper limit.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

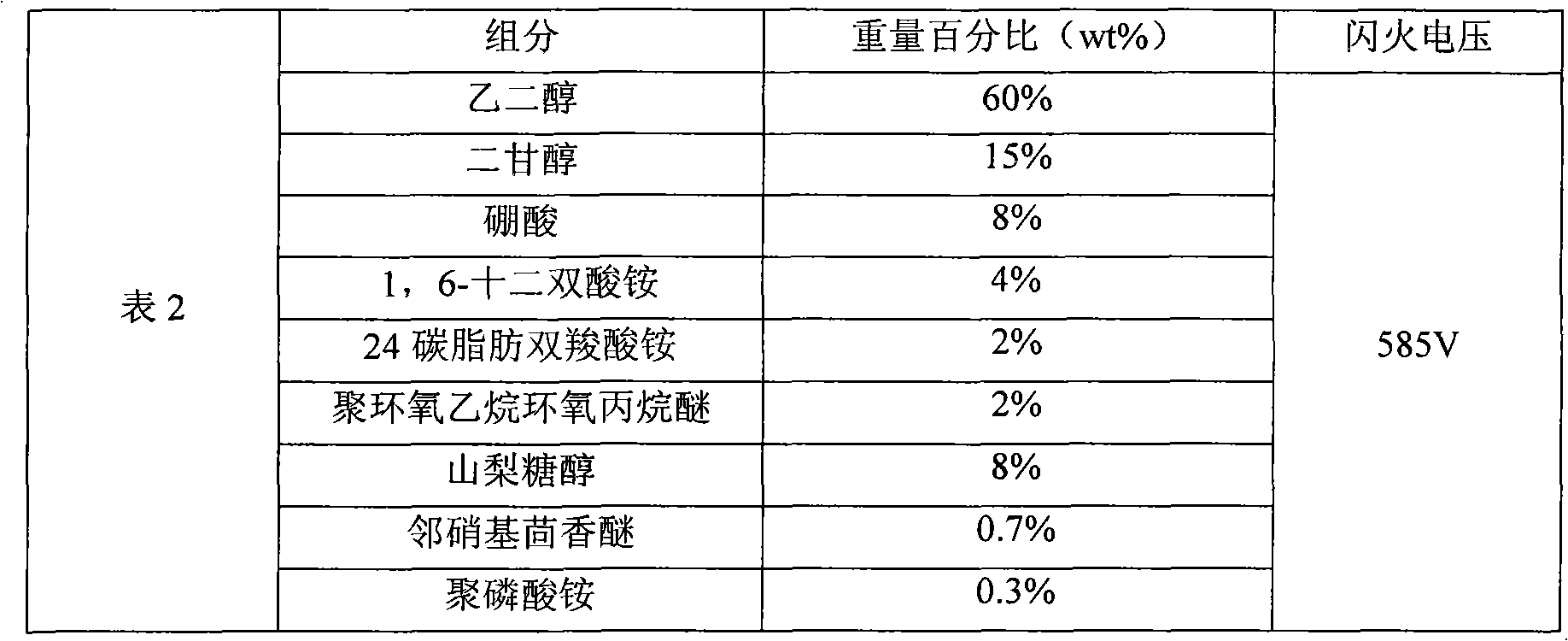

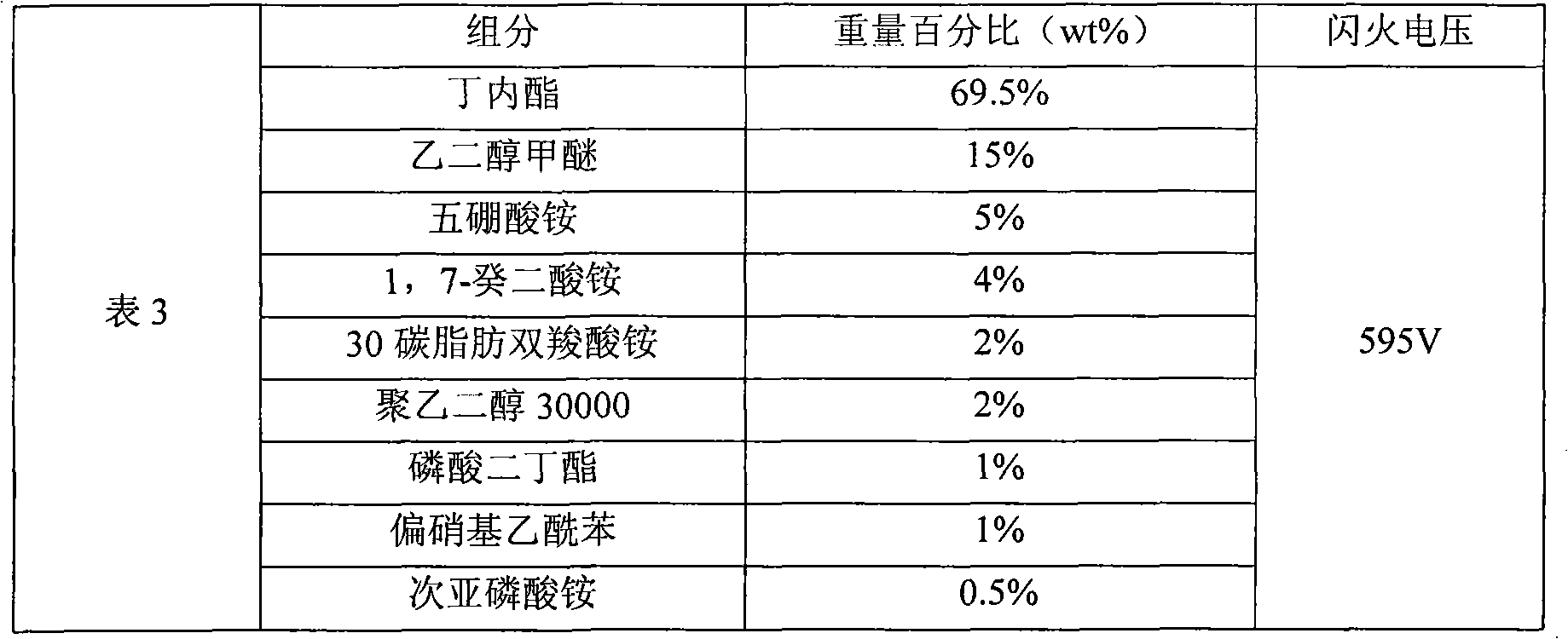

600V extra-high voltage aluminum electrolyte capacitor working electrolyte and preparation and application thereof

ActiveCN101599367AImprove high pressure resistanceImprove high temperature resistanceLiquid electrolytic capacitorsElectrolytic agentHydrogen

The invention relates to a 600V extra-high voltage aluminum electrolyte capacitor working electrolyte and a preparation and an application thereof; the working electrolyte comprises the following materials: 44.5-80.3% of main solvent, 5-15% of auxiliary solvent, 8-15% of solute, 0.5-2.5% of sparking voltage enhancer, 6-10% of stabilizer and 0.2-3% of hydrogen absorbent; the preparation method comprises the following steps: mixing the main solvent and the auxiliary solvent evenly, heating the mixture to 60-90 DEG C; adding sparking voltage enhancer, heating the mixture to 135-155 DEG C; cooling the heated mixture to 65-80 DEG C by circulating water, adding the solute and the stabilizer, heating the product to 105-135 DEG C; finally, adding the hydrogen absorbent and natural cooling to obtain the working electrolyte. Proper sparking voltage enhancer and stabilizer are added in the electrolyte to improve the high voltage resistant and high temperature resistant properties of electrolyte and to ensure the electrolyte to have low aerogenesis property; the aluminum electrolyte capacitor prepared by using the electrolyte has long service life and high voltage resistant property, and can not be broken down as the sparking voltage of the electrolyte is unstable.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

Method for preparing aramid composite diaphragm

ActiveCN103242556AImprove breathabilityImprove mechanical propertiesCell component detailsCoatingsLithium-ion batteryAramid

The invention discloses a method for preparing an aramid composite diaphragm. The method comprises the following steps of: (1) uniformly mixing aramid fibers, a solvent, a cosolvent and a pore forming agent so as to prepare membrane forming liquid; (2) coating the membrane forming liquid on a diaphragm of a lithium-ion battery so as to obtain a wet diaphragm; and (3) drying the wet diaphragm so as to obtain the aramid composite diaphragm; or firstly baking the wet diaphragm, soaking the wet diaphragm in water and then drying so as to obtain the aramid composite diaphragm. According to the method, the diaphragm is prepared through mixing and coating the aramid fibers and the pore forming agent; the prepared diaphragm has the characteristics of good air permeability, good mechanical properties and strong high-temperature resistance; and the method is simple and convenient, and the preparation cost is saved.

Owner:ADVANCED ELECTRONICS ENERGY LIMITED GUANGDONG

Flame-retardant PP/nylon corrugated tube composite material and preparation method thereof

ActiveCN102050993AImprove flame retardant performanceImprove high temperature resistanceProcedure AgentsManufacturing technology

The invention relates to a corrugated tube material and particularly discloses a flame-retardant PP (Polypropylene) / nylon corrugated tube composite material and a preparation method thereof, aiming to overcome the shortcomings in the prior art that the mechanical property of the PP corrugated tube is bad, the nylon corrugated tube is not flame-retardant, the stability is bad, and the service lifeis short. The material disclosed by the invention comprises the following substances by weight percentage: 47-75 of PP, 3-40 of nylon, 5-30 of flame retardant, 5-20 of compatilizer, 1-40 of flexibilizer, 0-10 of filling master batches, 0.2-1.5 of heat stabilizer, and 0.2-1.5 of processing agent. The preparation method comprises the steps as follows: the filling master batches are firstly preparedand then added into a twin-screw extruder to melt and mix with other materials, and pelletings are extruded out to prepare the flame-retardant PP / nylon composite material. The invention has the advantages of favorable flame-retardant property, excellent high-temperature resistance, friction resistance, chemical corrosion resistance, long service life, high surface glossiness, high electrical insulativity, simple manufacturing technology, and low cost.

Owner:SHANGHAI KINGFA SCI & TECH +1

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

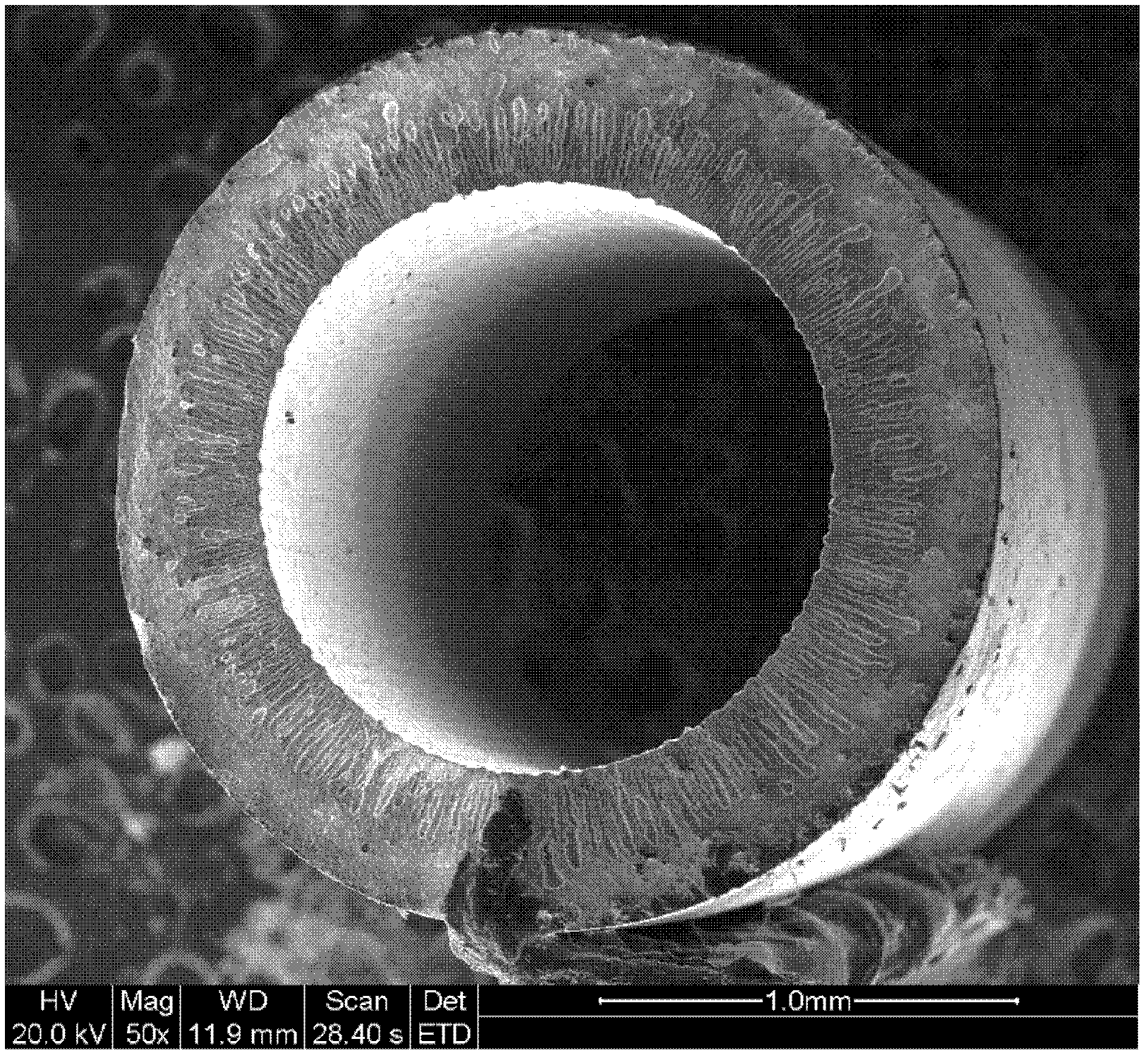

Preparation method for organic and inorganic hollow fiber composite membrane

ActiveCN102350226AImprove high temperature resistanceInhibit swellingSemi-permeable membranesHollow fibreFiber

The invention relates to a preparation method for an organic and inorganic hollow fiber composite membrane. An inorganic ceramic hollow fiber serves as a support body on which one layer of organic high molecular polymer membrane is coated; the layer of the polymer membrane can be hydrophilic polymer, hydrophobic polymer or amphipathy polymer, and is mainly used for separating close-boiling or constant-boiling organic solvent in a pervaporation mode and removing tract components in the solution. The average aperture of the inorganic ceramics hollow fiber support is 0.2-0.8 microns, and the inorganic ceramics hollow fiber support has higher mechanical strength. The composite membrane is prepared on the macropore inorganic ceramics support by the bridging effect and solvent prewetting, and the problems that the organic membrane layer is easily stripped from the inorganic support with larger curvature, hole leakage is serious to cause the organic matter to excessively block the duct of the inorganic support can be solved. Compared with a micropore support of 0.02-0.2 microns, the method is more convenient, and a technical support is provided for the large-scale application of the organic and inorganic hollow fiber composite membrane.

Owner:NANJING TECH UNIV

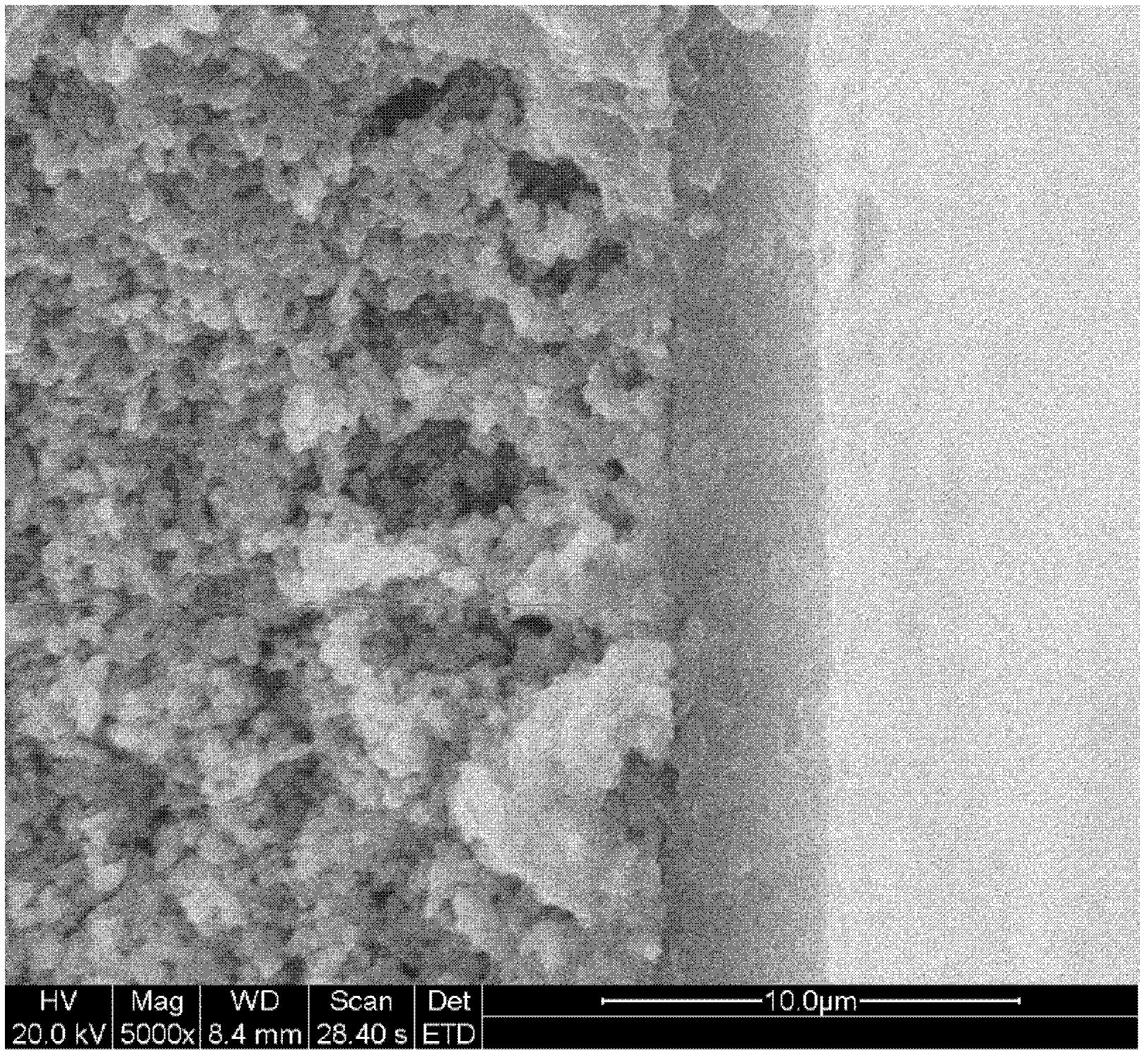

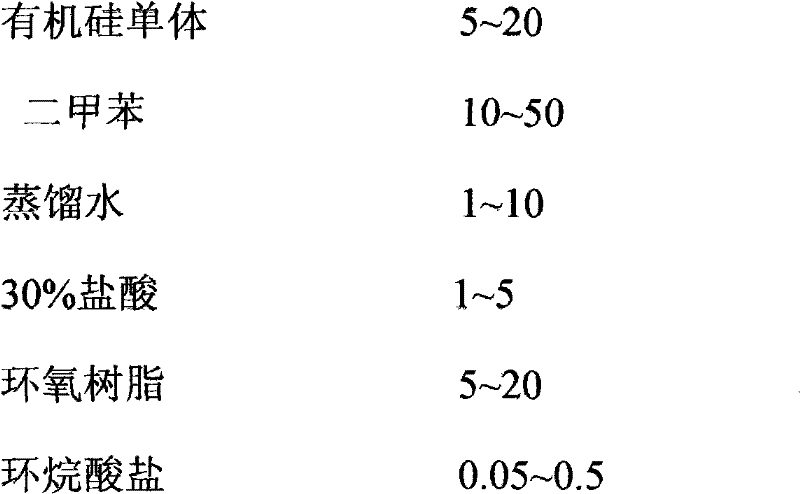

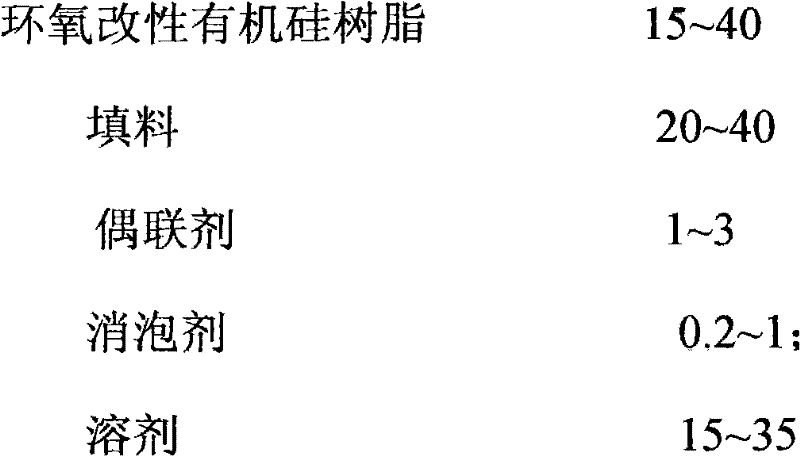

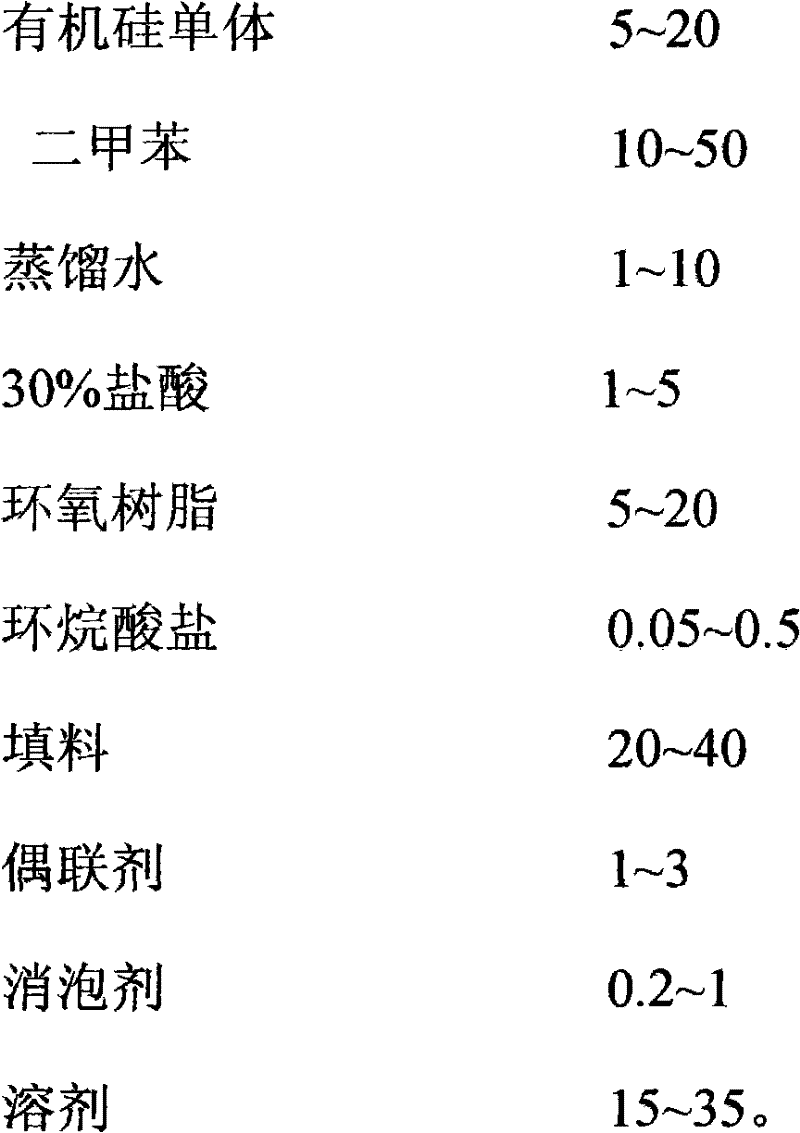

Preparation method of epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating and its products

The invention provides a preparation method of an epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating, comprising the following steps: preparing raw materials; synthesizing an organosilicon pre-polymer; synthesizing an epoxy-modified organosilicon resin; and preparing the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating. The invention also provided the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating prepared by the method. The coating is composed by the epoxy modified organosilicon resin, fillers, a coupling agent and solvents. The coating prepared by the method in the invention takes account of insulation, thermal-conductivity, and high-temperature resistance at the same time, has coating adhesion of first level, hardness of 5H, a breakdown voltage of 1800V / 0.5mA, 2 seconds, a heat transfer coefficient of larger than 100W / (m<2>.K), and no obviously changed coating at a temperature of 250 DEG C for 24 hours, therefore the coating can be widely used in various industrial equipment and household appliances.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN +2

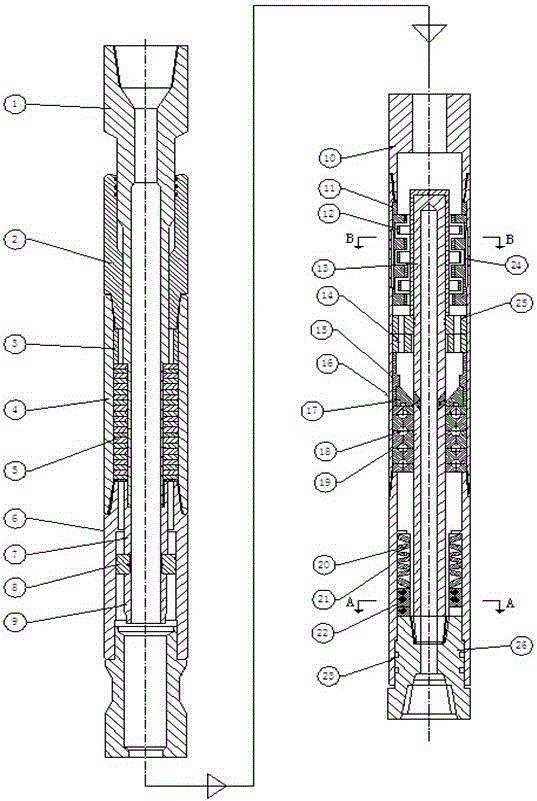

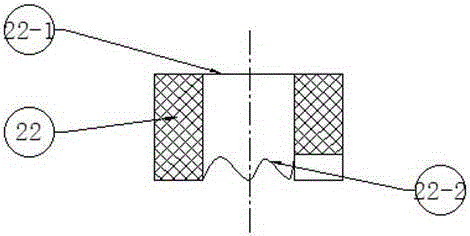

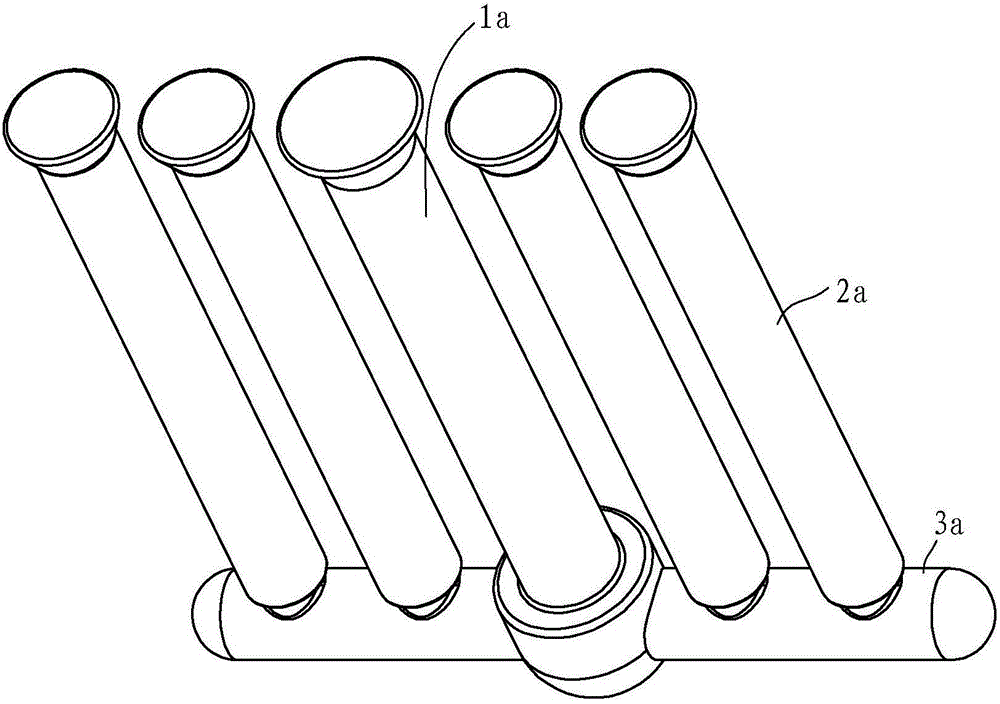

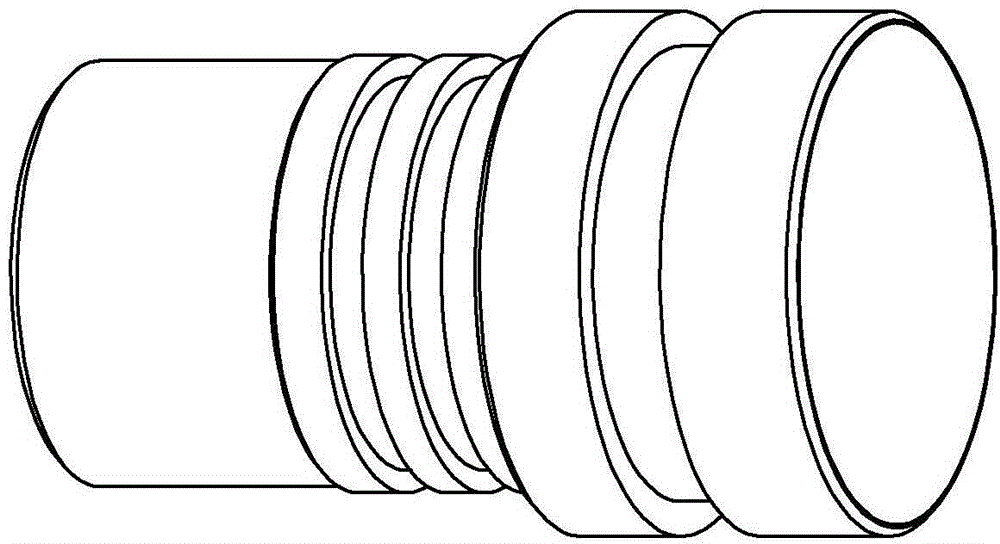

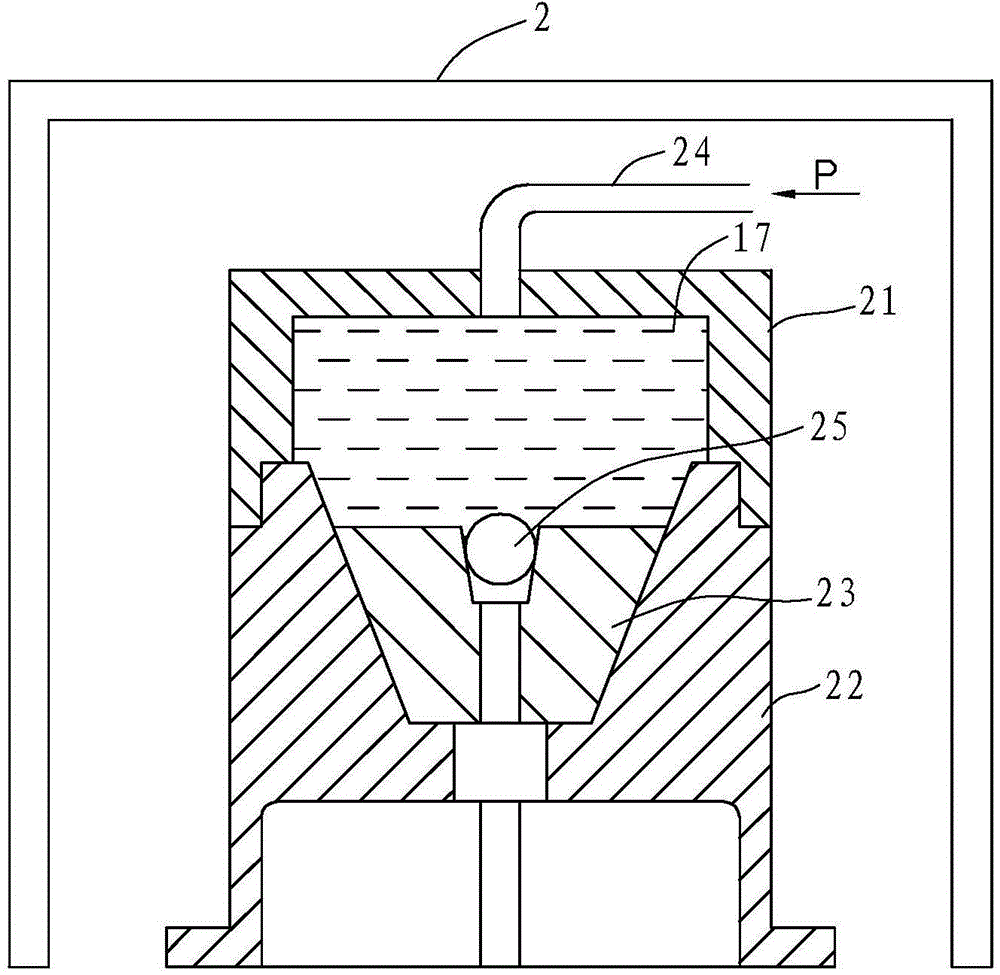

Downhole tool for achieving efficient rock breaking through spin vibration

InactiveCN105239929AQuality improvementImprove high temperature resistanceBorehole drivesVibration drillingDrive shaftSpins

The invention relates to a downhole tool for achieving efficient rock breaking through spin vibration, and belongs to the technical fields of petroleum and natural gas exploitation and drilling tools. According to the technical scheme, drilling fluid drives a turbine to rotate, a turbine rotor drives a transmission shaft to rotate to drive a disc valve set to periodically rotate, the open area changes, a periodic pressure pulse is generated to act on a vibration nipple to generate reciprocating vibration, the friction resistance between a drilling column and the well wall is effectively improved, and mechanical drilling speed is increased; the lower end of a tooth-shaped impact hammer head is provided with a tooth-shaped curved surface which is meshed with a tooth-shaped curved surface of a lower-end transmission connector, and the lower-end transmission connector is driven by a transmission shaft to generate rotating motion, so that the tooth-shaped impact hammer head is driven to rotate to generate axial reciprocating impact on the lower-end transmission connector under the joint action of the tooth-shaped impact hammer head and a force accumulating spring. According to the downhole tool, the structure is simple, the friction resistance is small, effective bit pressure and effective vibration are increased, the mechanical rotating speed is increased, and the cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

High-voltage lithium ion battery electrolyte

ActiveCN103401020AIncrease oxidation potentialSolve severe flatulenceSecondary cellsElectrolytic agentInternal resistance

The invention specifically relates to a high-voltage lithium ion battery electrolyte, which belongs to the technical field of lithium ion battery electrolytes. The high-voltage lithium ion battery electrolyte provided by the invention comprises a non-aqueous solvent, a lithium salt and an additive, wherein the additive comprises a mixture of a fluoro-ether additive and an alkyl dinitrile additive. A lithium ion battery using the high-voltage lithium ion battery electrolyte has stable cycle performance at normal temperature, no gas generation at a high temperature condition and small changes of internal resistance. A preparation process for the high-voltage lithium ion battery electrolyte is simple and easy to implement and has good market prospects.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

PP/PA composite material used for corrugated pipe and preparation method thereof

InactiveCN101724197ASolve heat resistanceSettle the priceFlexible pipesProcedure AgentsHeat resistance

The invention discloses a PP / PA composite material used for a corrugated pipe, which is prepared by processing polypropylene, nylon, compatilizer, toughening agent, filling master batch, light stabilizer, heat stabilizer and processing aid. The PP / PA composite material is prepared by feeding the components into mixing equipment according to a proportion, and melting, mixing, scattering, extruding and granulating the components at the temperature of between 210 and 280 DEG C. The PP / PA composite material not only has higher toughness, excellent high impact resistance and bending property and extremely good high temperature resistance, but also are excellent in the aspects of surface gloss, abrasion resistance, chemical corrosion resistance, electric insulation and the like, and solves the defect problems of insufficient heat resistance of the conventional PP corrugated pipe, over-high price of the PA corrugated pipe; and in addition, a preparation method for the PP / PA composite material is simple and meets the requirement of industrialized production.

Owner:SHANGHAI KINGFA SCI & TECH +1

Weak solvent aliphatic polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for synthetic leather, in particular to weak solvent aliphatic polyurethane resin for synthetic leather and a preparation method thereof. The weak solvent aliphatic polyurethane resin for synthetic leather is prepared from the following components by weight percent: 2-30 percent of aliphatic diisocyanate compound, 5-40 percent of polyester or polyether polyalcohol compound, 0-10 percent of micromolecule polyol chain extender, 0.1-13 percent of micromolecule polyamine chain extender, 0.01-1.0 percent of catalyst, 0.05-5.0 percent of assistant and 45-85 percent of organic mild solvent. The invention also discloses the preparation method of the weak solvent aliphatic polyurethane resin for synthetic leather. By adopting the technical scheme, the polyurethane resin with different solid contents, different viscosities and different modulus can by synthesized, the requirement of the synthetic leather is satisfied, and the synthetic leather product with high temperature resistance, cold resistance, anti-sticking performance and better external tensility of pigment can be prepared.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Battery diaphragm and its preparation method and lithium ion secondary battery containing the diaphragm

InactiveCN101000951AGood chemical stabilityNo ruptureSecondary cellsCell component detailsLithiumPower battery

A battery separator includes the substrate and holes distributed on it, in which, the substrate contains polyimide. The battery separator of this invention uses polyimide which is a new material bearing high temperature as substrate, so that it has excellent chemical stability, high temperature, good permeability and high mechanical strength. The lithium-ion rechargeable batteries using this invention don't appear short circuit even in 150 deg. C, thus this battery separator can be used for high-capacity and power batteries.

Owner:BYD CO LTD

Rapidly degradable magnesium alloy material as well as manufacturing method and application thereof

ActiveCN104651691AModerate densitySolve the pollution problemFluid removalWell/borehole valve arrangementsEnvironmental resistanceSlag

The invention discloses a rapidly degradable magnesium alloy material. The material comprises the following components: elements such as Al, Li, Ca, Y, Si, Ni, Cu and Fe. The invention also discloses a preparation method and the application of the rapidly degradable magnesium alloy material. Compared with the prior art, the rapidly degradable magnesium alloy material has the advantages that the problems of failure in resisting high temperatures and failure in meeting high-temperature and high-bearing operation requirements of the existing easily degradable materials or easily degradable magnesium alloy materials and products thereof are solved, meanwhile, the material is controllable in density, the slag or the corrosion product of the material meets the requirements of flowback operations, and multiple technical effects of simplicity and high efficiency, low cost, energy conservation, environmental protection and the like can be achieved.

Owner:NINGBO HIGH NEW DISTRICT RONGCHUANG NEW MATERIAL SCI & TECH

Modified hydrogenated nitrile-butadiene rubber and its preparing method

The present invention relates to the preparing technology of composite rubber material. Carbon nanotube via surface treatment and liquid rubber are ultrasonically mixed and added into partial hydrogenated nitrile-butadiene rubber to prepare mother rubber; the mother rubber is mixed with the rest hydrogenated nitrile-butadiene rubber, carbon black, zinc oxide and sulfurizing agent, and the mixture is mixed in a rolling mixer or a Banbury mixer and sulfurized to obtain the carbon nanotube modified hydrogenated nitrile-butadiene rubber. The present invention has the beneficial effects of raised heat performance, antiwear performance, mechanical strength, antiageing performance, etc. raised use performance and expanded application range.

Owner:SINOPEC OILFIELD EQUIP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com