Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3708 results about "Chemical corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

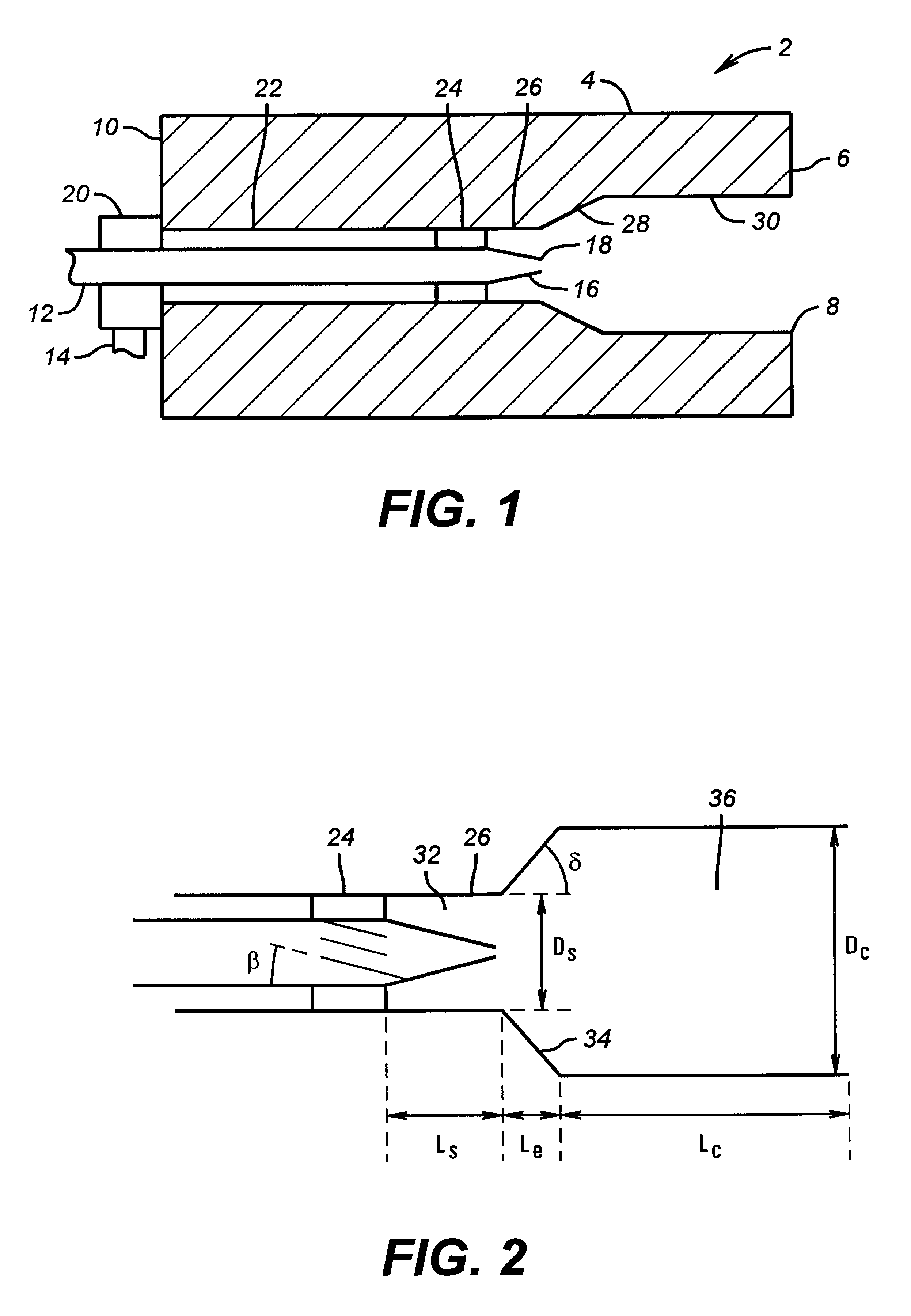

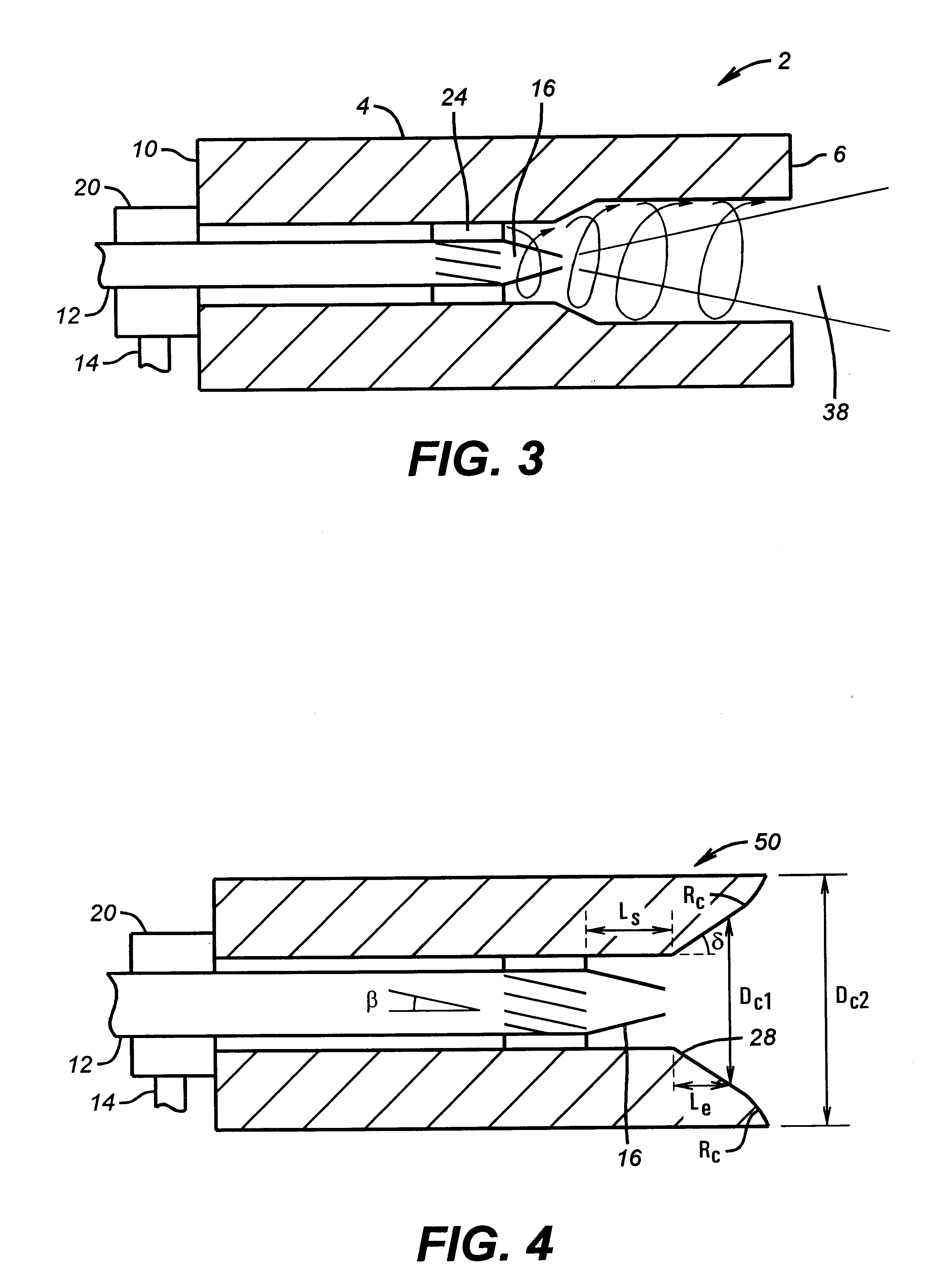

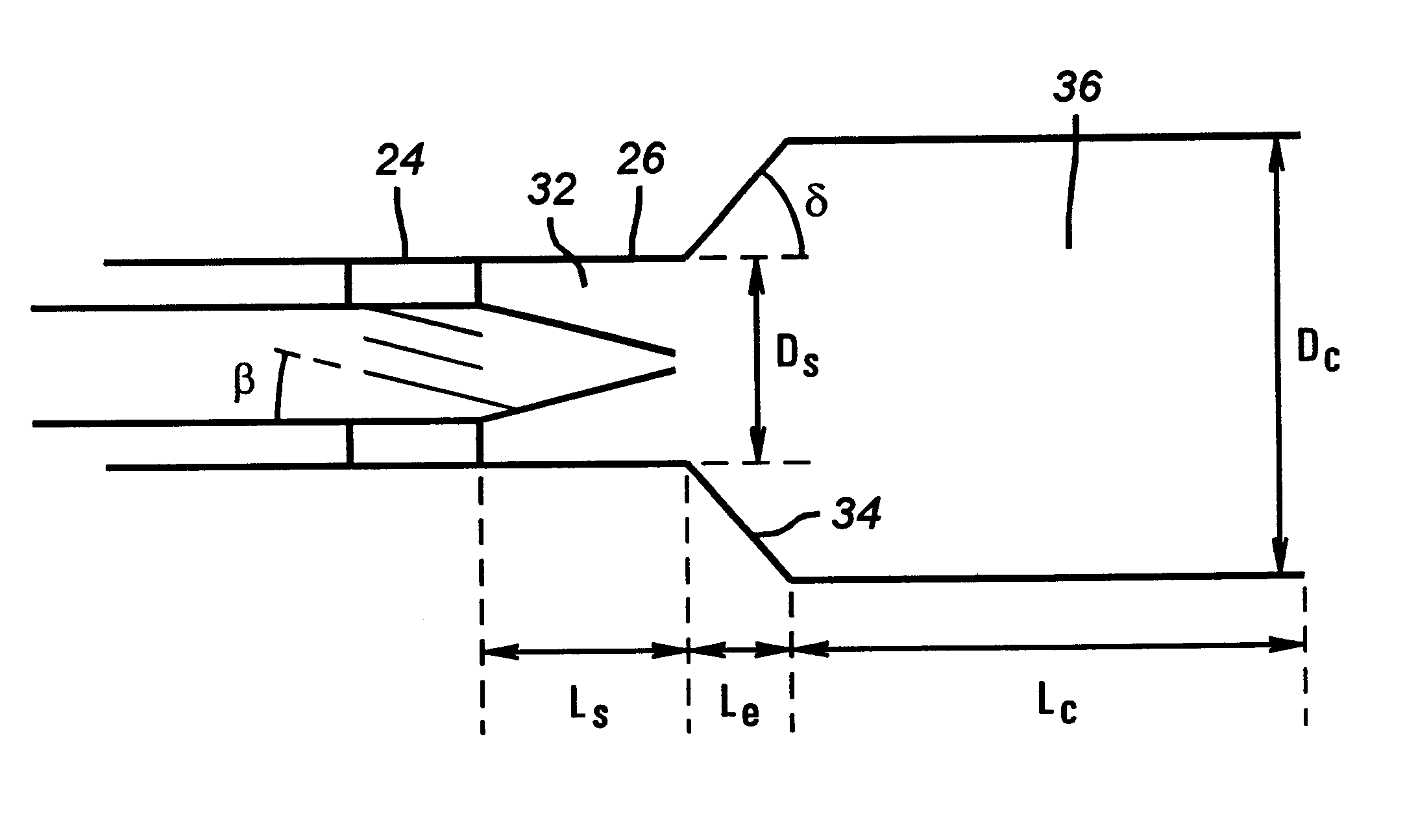

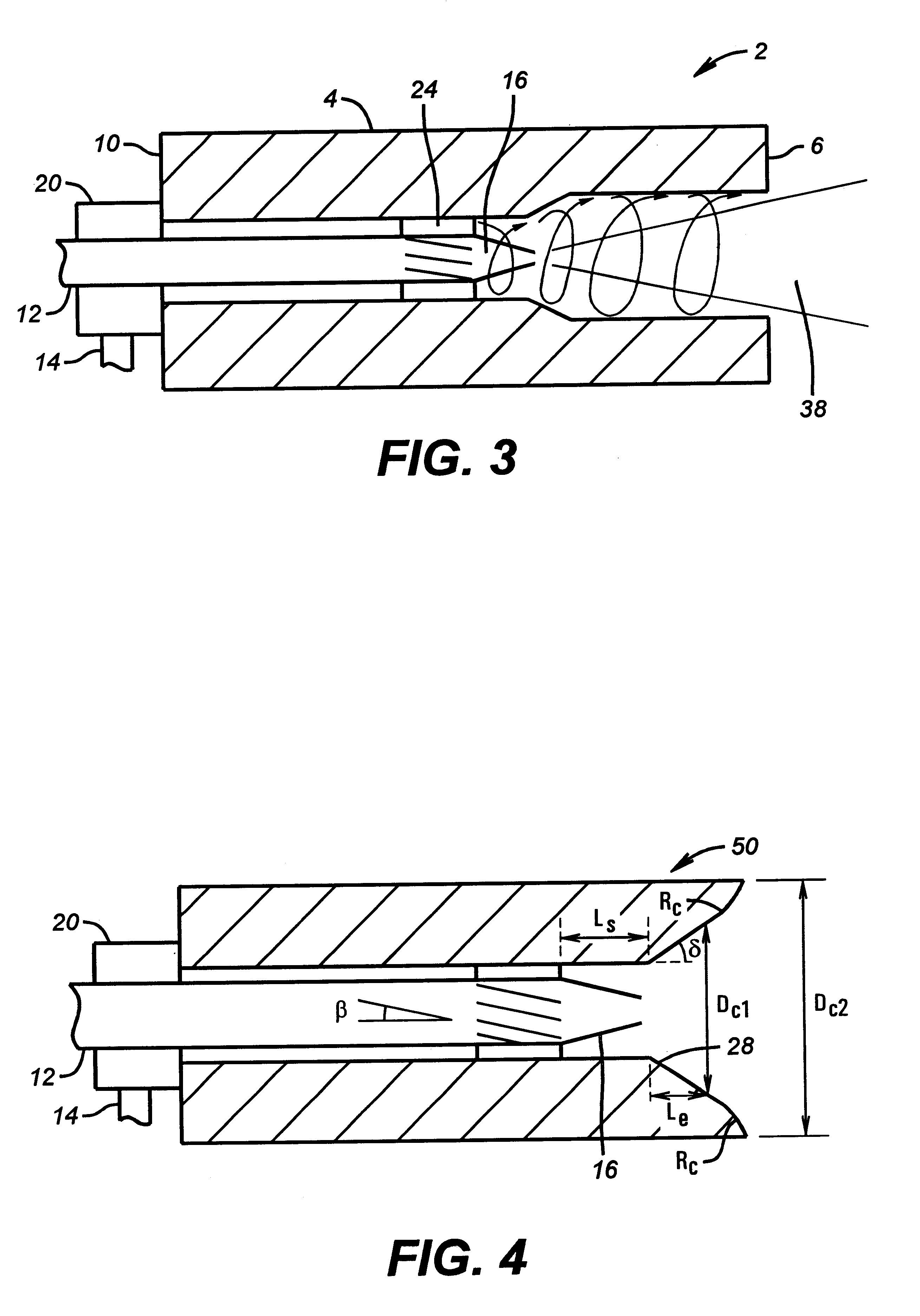

InactiveUS6123542AAvoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

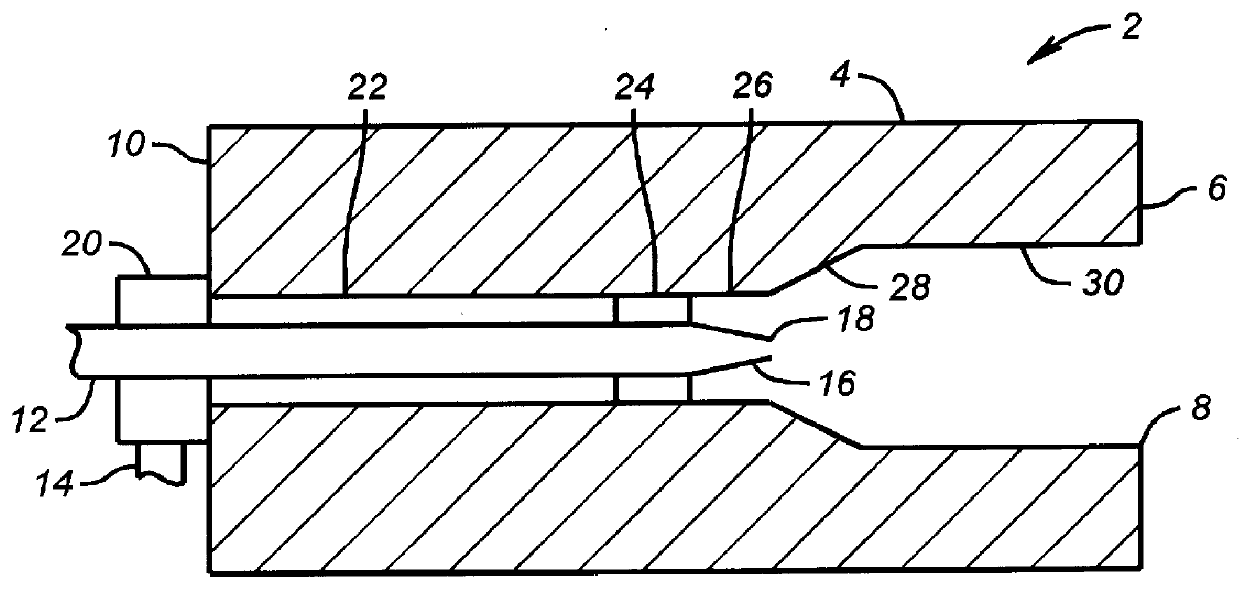

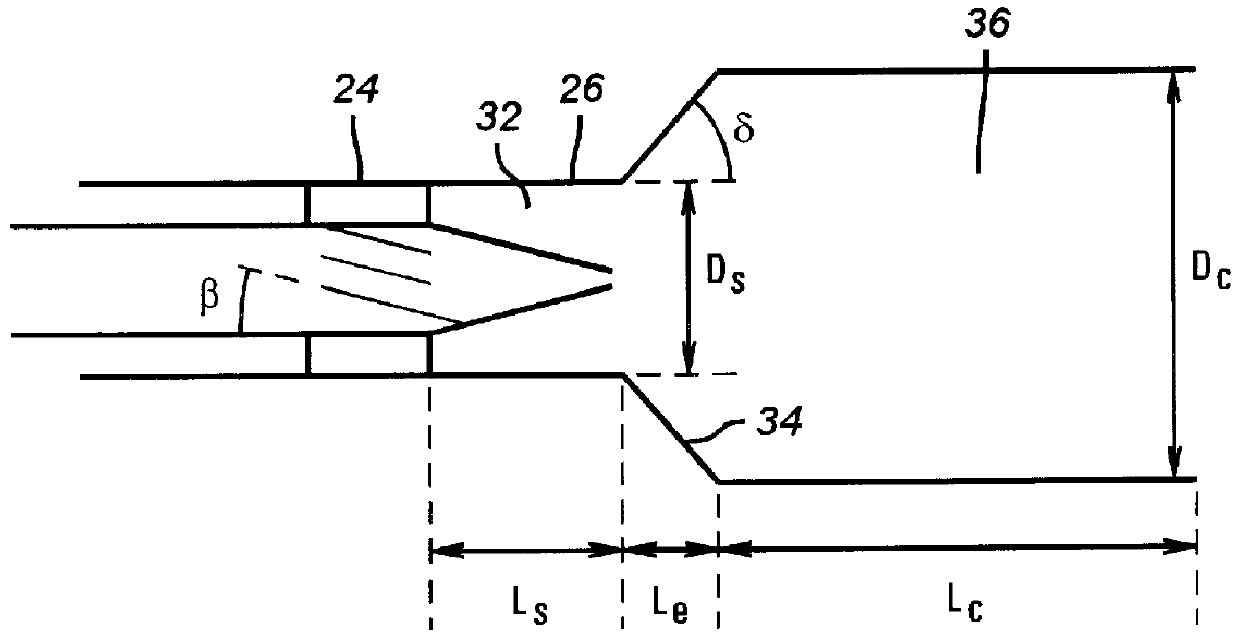

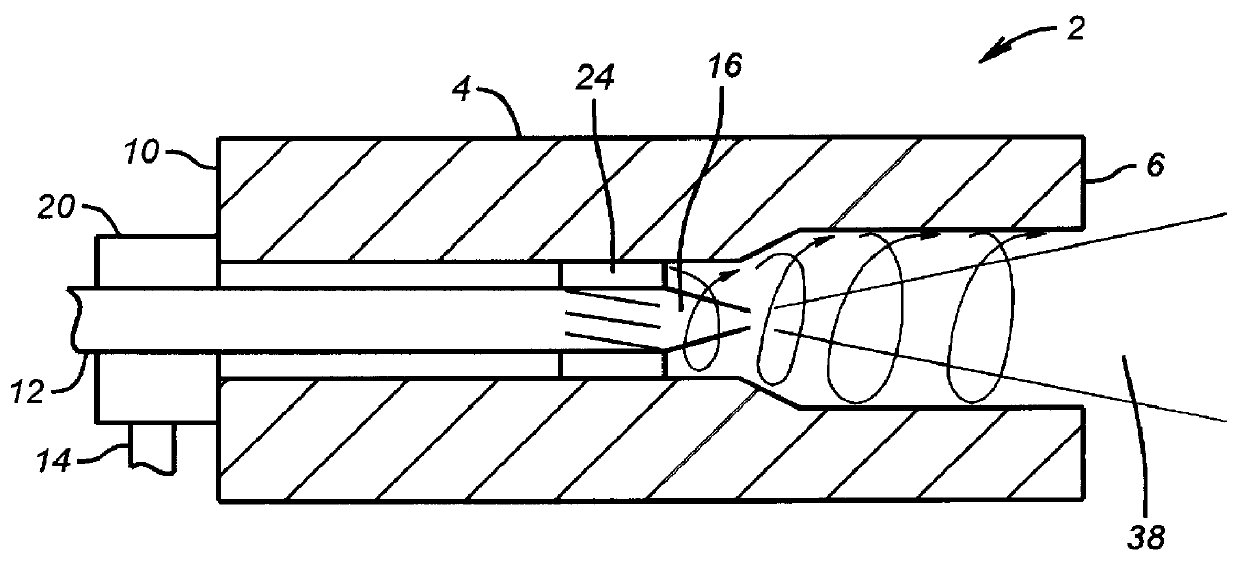

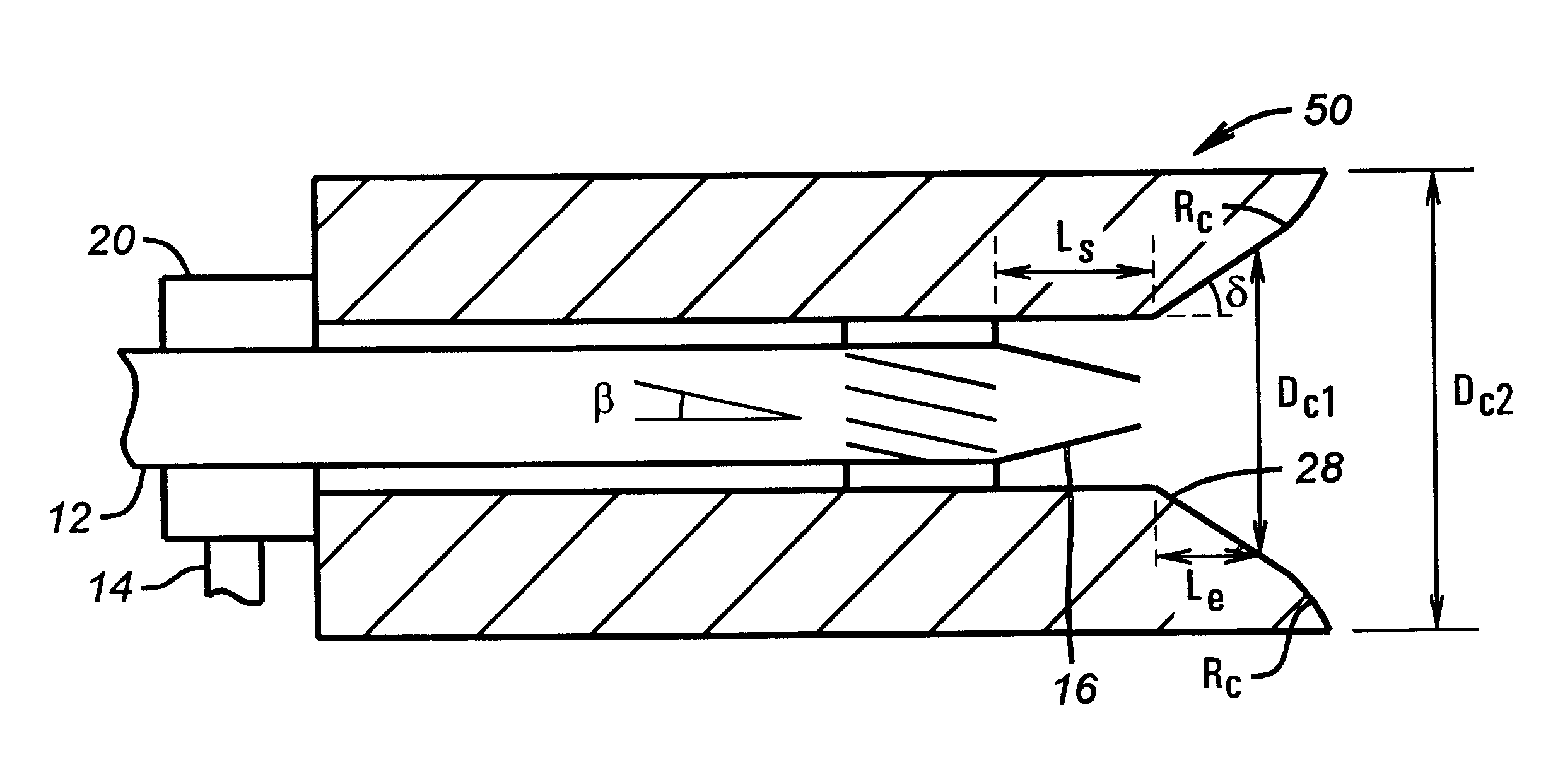

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200 DEG F. to 3000 DEG F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:LAIR LIQUIDE SA POUR L ETUD ET LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

Self-cooled oxygen-fuel for use in high-temperature and high-particulate furnaces

InactiveUS6276924B1Avoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

Internal member for plasma-treating vessel and method of producing the same

InactiveUS6884516B2Improve corrosion resistanceLiquid surface applicatorsMolten spray coatingInter layerChemical corrosion

It is to propose an internal member for a plasma treating vessel having excellent resistances to chemical corrosion and plasma erosion under an environment containing a halogen gas and an advantageous method of producing the same, which is a member formed by covering a surface of a substrate with a multilayer composite layer consisting of a metal coating formed as an undercoat, Al2O3 film formed on the undercoat as a middle layer and Y2O3 sprayed coating formed on the middle layer as a top coat.

Owner:TOCALO CO LTD +1

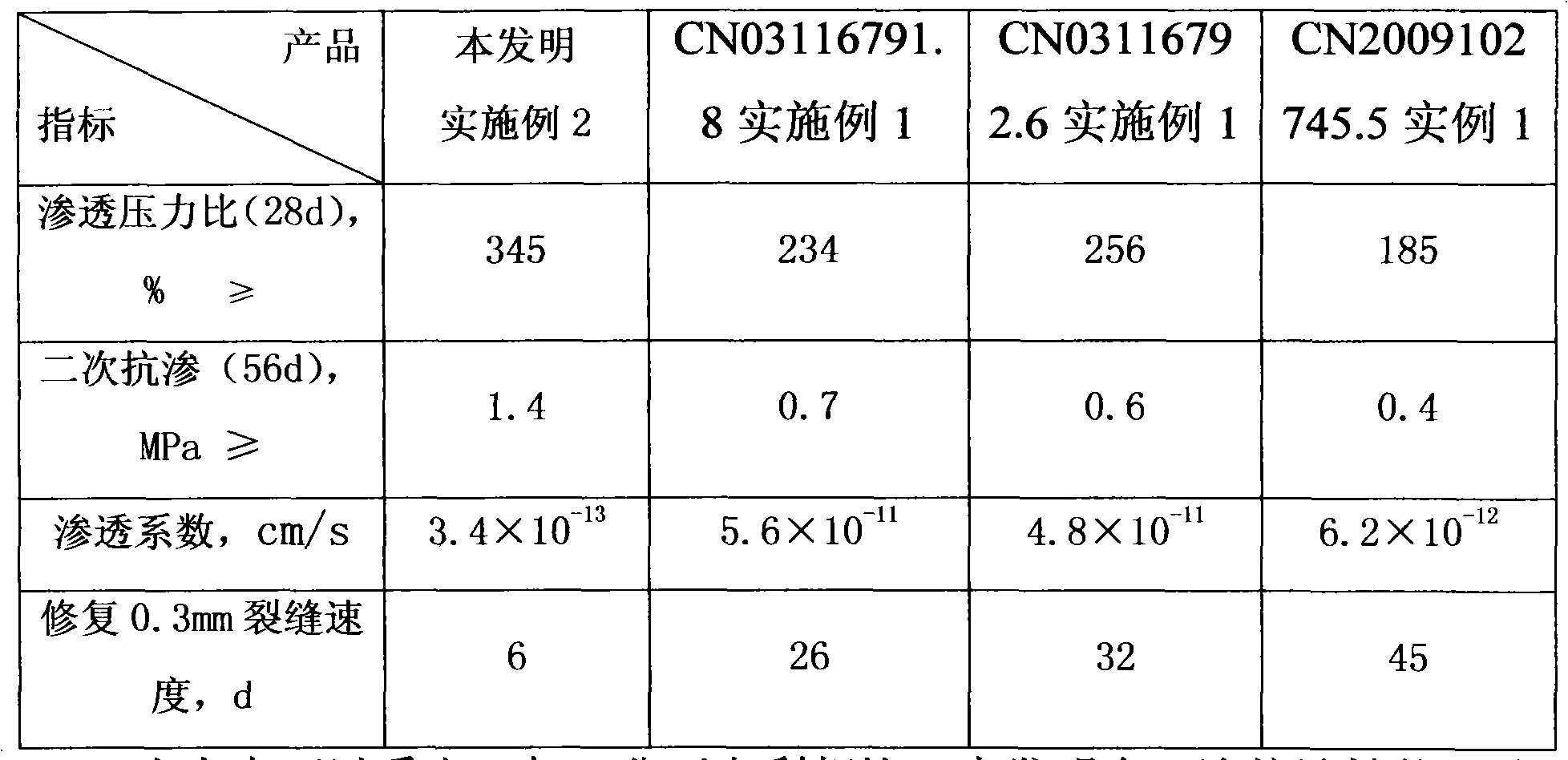

Cementitious capillary crystalline waterproof material capable of quickly repairing cracks

ActiveCN102167547AImprove impermeabilityImprove waterproof performanceSolid waste managementChemical corrosionCrystal growth

The invention relates to a cementitious capillary crystalline waterproof material, which comprises the following components in percentage by weight: 30 to 50 percent of cement, 5 to 10 percent of swelling agent, 8 to 20 percent of quartz sand, 5 to 12 percent of mineral additive, 20 to 35 percent of water reducer, 0.2 to 1.0 percent of retarder, 1 to 15 percent of crystal precipitator, 1 to 12 percent of complexing agent, 1 to 13 percent of calcium ion compensating agent and 0.1 to 1.0 percent of crystal growth promoter. The cementitious capillary crystalline waterproof material has double waterproof property, high cementitious capillary crystallization capacity, capacity of quickly repairing the cracks, and excellent chemical corrosion resistance.

Owner:东方雨虹民用建材有限责任公司 +3

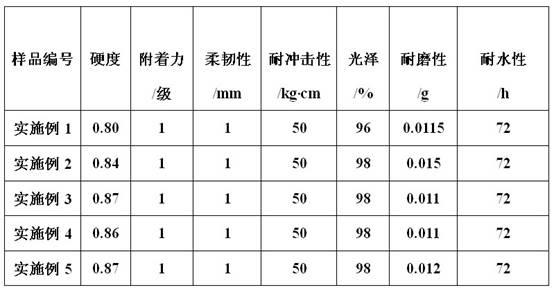

Ultraviolet cured paint for plastics and its production process

InactiveCN1772820AHigh hardnessImprove wear resistancePolyurea/polyurethane coatingsPolyester coatingsUltravioletDiluent

The present invention relates to one kind of ultraviolet cured paint for plastics and its production process. The paint includes matrix resin, active diluent, light initiator and solvent and features its antiwear hardness additive accounting for 0.1-8.0 wt% of the paint. The paint has high hardness, high antiwear performance, forms smooth paint coating through spraying, high toughness, high adhesion and high chemical corrosion resistance.

Owner:BYD CO LTD

Flame-retardant PP/nylon corrugated tube composite material and preparation method thereof

ActiveCN102050993AImprove flame retardant performanceImprove high temperature resistanceProcedure AgentsManufacturing technology

The invention relates to a corrugated tube material and particularly discloses a flame-retardant PP (Polypropylene) / nylon corrugated tube composite material and a preparation method thereof, aiming to overcome the shortcomings in the prior art that the mechanical property of the PP corrugated tube is bad, the nylon corrugated tube is not flame-retardant, the stability is bad, and the service lifeis short. The material disclosed by the invention comprises the following substances by weight percentage: 47-75 of PP, 3-40 of nylon, 5-30 of flame retardant, 5-20 of compatilizer, 1-40 of flexibilizer, 0-10 of filling master batches, 0.2-1.5 of heat stabilizer, and 0.2-1.5 of processing agent. The preparation method comprises the steps as follows: the filling master batches are firstly preparedand then added into a twin-screw extruder to melt and mix with other materials, and pelletings are extruded out to prepare the flame-retardant PP / nylon composite material. The invention has the advantages of favorable flame-retardant property, excellent high-temperature resistance, friction resistance, chemical corrosion resistance, long service life, high surface glossiness, high electrical insulativity, simple manufacturing technology, and low cost.

Owner:SHANGHAI KINGFA SCI & TECH +1

PP/PA composite material used for corrugated pipe and preparation method thereof

InactiveCN101724197ASolve heat resistanceSettle the priceFlexible pipesProcedure AgentsHeat resistance

The invention discloses a PP / PA composite material used for a corrugated pipe, which is prepared by processing polypropylene, nylon, compatilizer, toughening agent, filling master batch, light stabilizer, heat stabilizer and processing aid. The PP / PA composite material is prepared by feeding the components into mixing equipment according to a proportion, and melting, mixing, scattering, extruding and granulating the components at the temperature of between 210 and 280 DEG C. The PP / PA composite material not only has higher toughness, excellent high impact resistance and bending property and extremely good high temperature resistance, but also are excellent in the aspects of surface gloss, abrasion resistance, chemical corrosion resistance, electric insulation and the like, and solves the defect problems of insufficient heat resistance of the conventional PP corrugated pipe, over-high price of the PA corrugated pipe; and in addition, a preparation method for the PP / PA composite material is simple and meets the requirement of industrialized production.

Owner:SHANGHAI KINGFA SCI & TECH +1

High toughness filling reinforcement poly phenylene sulfide (PPS)/poly-p-phenylene oxide (PPO) alloy and method for preparing same

The invention relates to a high toughness filling reinforcement poly phenylene sulfide (PPS) / poly-p-phenylene oxide (PPO) alloy and a method for preparing the same. The alloy comprises 1-99 parts by weight of polyphenylene sulfide, 99-1 part by weight of polyphenyl ether, 10-200 parts by weight of glass fiber, 1-50 parts by weight of filler, 3-10 parts by weight of compatilizer, 5-30 parts by weight of toughening agent, 0.2-2 parts by weight of coupling agent, 0.2-2 parts by weight of antioxidant and 0.5-3 parts by weight of processing agent, wherein the sum of the parts by weight of the polyphenylene sulfide and the polyphenyl ether is 100 parts by weight. The alloy has the advantages of high toughness, impact cracking resistance, excellent strength and rigidity, excellent compatibility, high temperature resistance, inflaming retardance, chemical corrosion resistance, solvent resistance, stress cracking resistance, excellent processing performance and the like, and can be safely applied to various electrical and electronic equipment parts, vehicle equipment parts and chemical equipment parts and even ships, bridges and building materials.

Owner:张国庆 +1

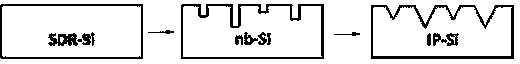

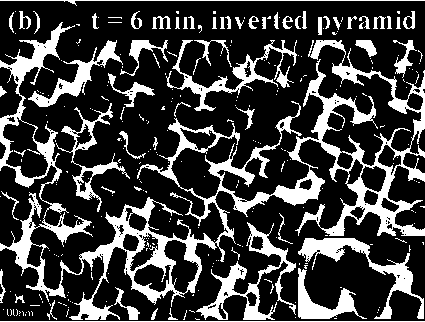

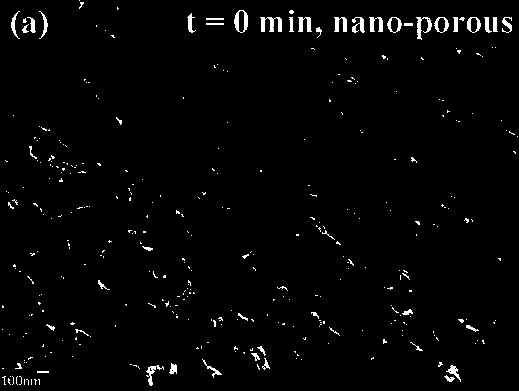

Method for forming inverted-pyramid porous surface nanometer texture on polycrystalline silicon and method for manufacturing short-wave reinforcing solar cell

InactiveCN103456804AExtend your lifeUniform and smooth microstructureFinal product manufacturePhotovoltaic energy generationCharge carrierSolar cell

The invention discloses a method for forming an inverted-pyramid porous surface nanometer texture on polycrystalline silicon and a method for manufacturing a short-wave reinforcing solar cell. The method for forming the inverted-pyramid porous surface nanometer texture on the polycrystalline silicon and the method for manufacturing the short-wave reinforcing solar cell are suitable for the technical field of solar photovoltaic batteries. By means of a metal catalytic chemical corrosion method, a nanometer porous surface structure is formed on the polycrystalline silicon through HF, AgNO3, H2O2, HNO3 and other solutions, then partial samples are placed in a NaOH corrosive liquid with the concentration of 0.1-1% for surface modification of a nanometer inverted pyramid, a nanometer inverted pyramid silicon structure is formed, and the micro structure appearance of the nanometer inverted pyramid silicon structure is even and smooth, so that service life of a few effective charge carriers is greatly prolonged, and ultimately, in the nanometer texture surface structure, by means of changes of the thickness of a silicon nitride layer in the solar cell manufacturing process, a nanometer inverted pyramid silicon solar photovoltaic cell which is low in surface reflection rate and high in short wave spectrum response is prepared. The method for forming the inverted-pyramid porous surface nanometer texture on the polycrystalline silicon and the method for manufacturing the short-wave reinforcing solar cell are simple in process, convenient to operate, low in cost and suitable for industrial production.

Owner:SHANGHAI UNIV

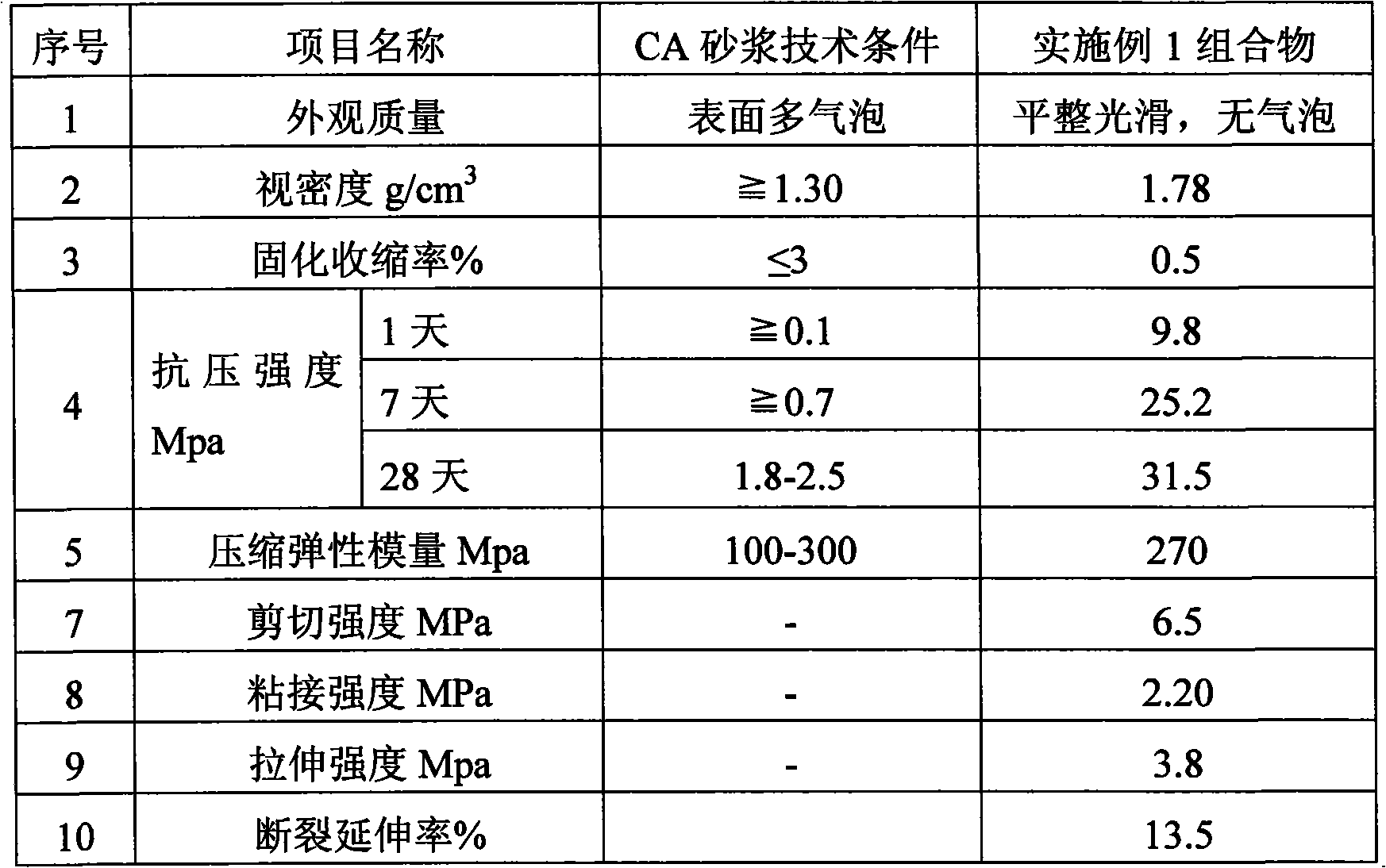

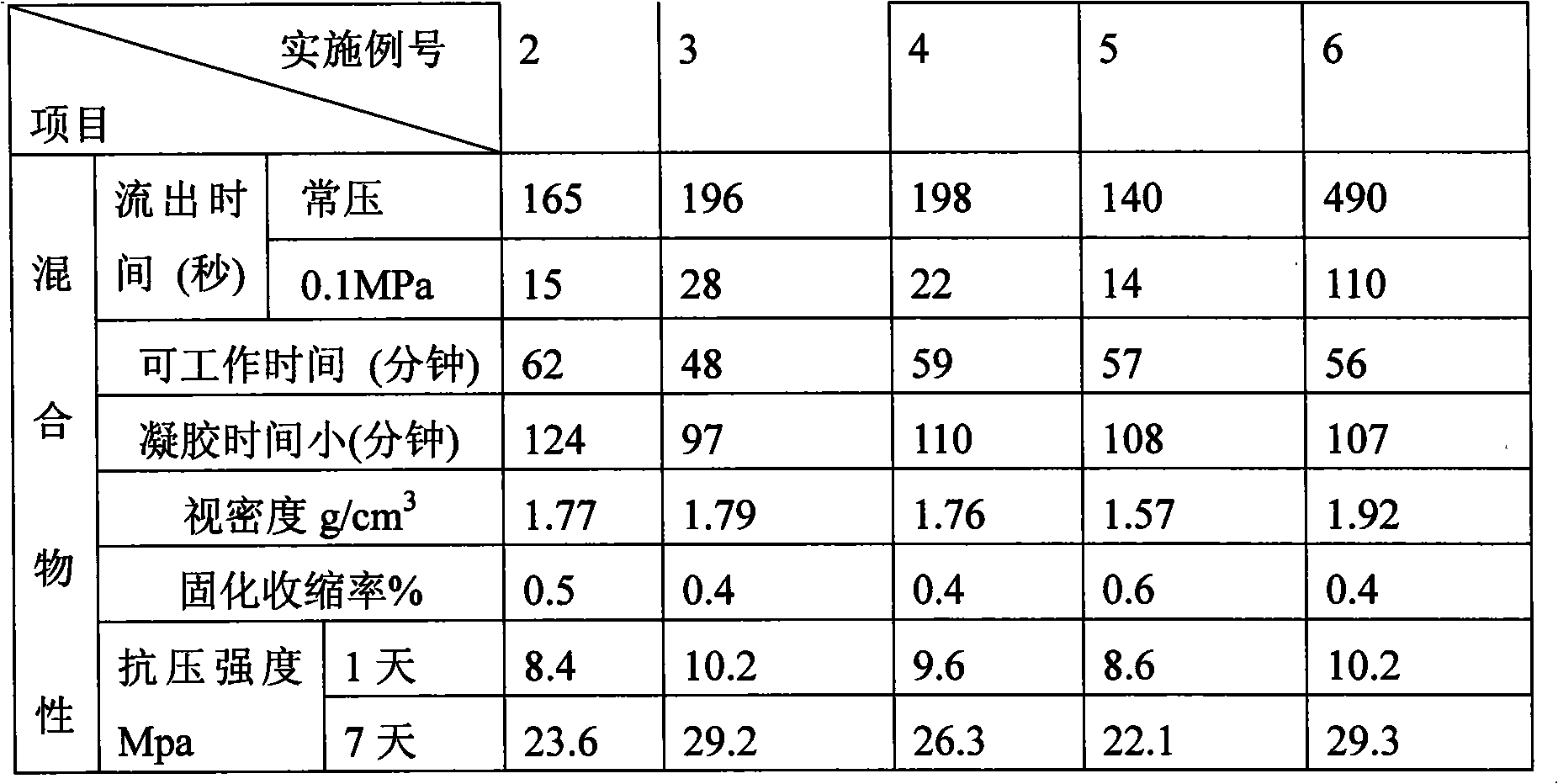

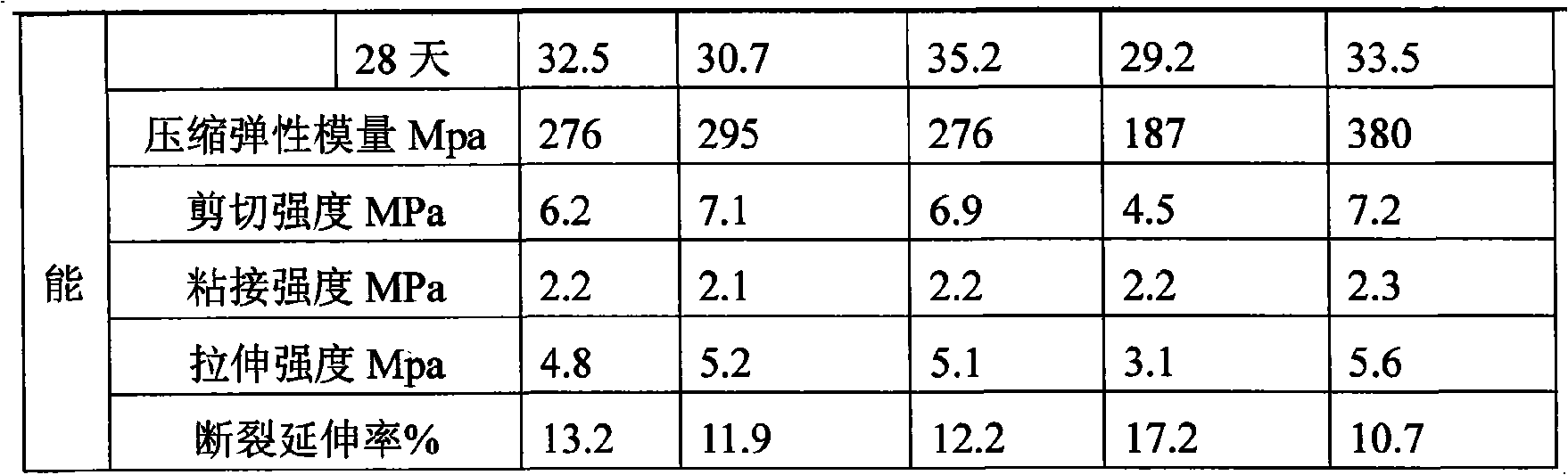

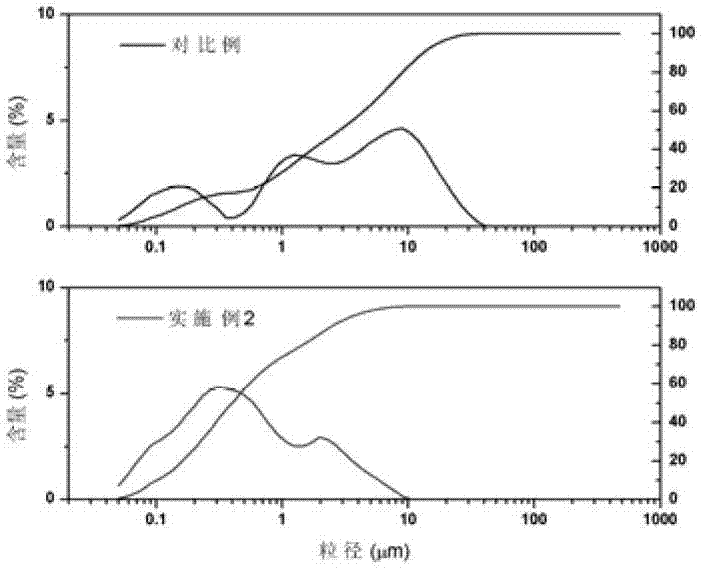

Epoxy resin mortar composite used for plate type fragment-free track

The invention discloses an epoxy resin mortar composite and an application of the composite for a filling material of railway plate type fragment-free track elastic adjusting layer, the epoxy resin mortar composite is composed of A, B and C three parts of materials, wherein part A is composed of the following materials according to parts by weight: 80-100 parts of epoxy resin, 1-10 parts of paint, 0-100 parts of diluent, 0-50 parts of toughening agent, 0-5 parts of ultraviolet absorbent, 0-5 parts of antioxidant, 0-2 parts of antifoaming agent and 0-5 parts of coupling agent; part B is curing agent; part C is filler, and the weight ratio of A, B and C parts is 80-100:5-100:50-600. Detection shows that the epoxy resin mortar composite provided by the invention has, for cement components, excellent adhesion stress, strong wet-heat aging resistance and chemical corrosion resistance and better elasticity and mechanical strength, thereby satisfying requirements of different climatic conditions and different construction conditions.

Owner:CHANGSHU JIAFA CHEM

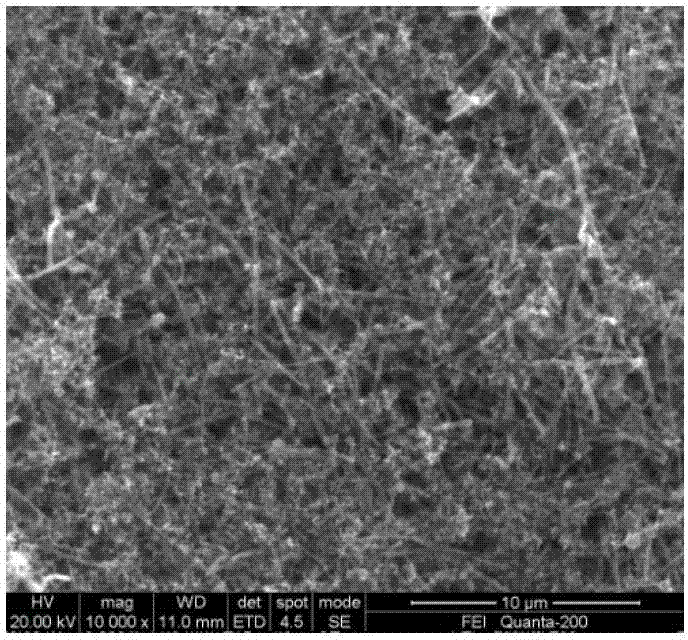

high-filling-content micro-nano powder/polymer composite material for 3D printing and preparation method and product thereof

ActiveCN103980592AEnhanced interactionImprove performance3D object support structuresCross-linkAntioxidant

The invention relates to a high-filling-content micro-nano powder / polymer composite material for 3D printing and a preparation method and a product thereof. The material contains the following raw materials, by weight, 10-30 parts of a polymer, 90-70 parts of a micro-nano powder, 0.05-0.2 part of an irradiation sensitizer and 0.01-0.02 part of an antioxidant. The micro nano powder is used as a main material and polymer resin is used as a binding agent, and moulding is finished by a 3D printing mode. Simultaneously, the irradiation sensitizer is added, and the polymer resin forms a three-dimensional cross-linked network after electron beam irradiation. Then, strength, heat resistance and chemical corrosion resistance are raised after resin bonding. The high-filling-content micro-nano powder endows the moulding material with excellent mechanical properties. In addition, according to changes of product usage environment and demand, types of the micro-nano powder are changed so as to obtain a material with special functionality, such as excellent conductivity, thermal conductivity, flame resistance, impact resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Current collector carbon coated aluminum foil and its preparation method

InactiveCN102832392AGood adhesionImprove conductivityElectrode manufacturing processesElectrolytic capacitorsInterface impedanceInternal resistance

The invention discloses a current collector carbon coated aluminum foil and its preparation method. A carbon-containing composite layer is arranged on the substrate of the current collector carbon coated aluminum foil, and is combined with the substrate through a binder, wherein the thickness of the carbon-containing composite layer is 1-100mum; the carbon-containing composite layer comprises granular conductive carbon black pre-dispersed by a dispersant, and fibrous conductive carbon; the granular conductive carbon black and the fibrous conductive carbon filled between the layers of the granular conductive carbon black form a netted node form conductive network. The composite layer is tightly combined with the substrate of the aluminum foil, so the conductivity and the corrosion resistance of the aluminum foil are improved, and the aluminum foil is protected from oxidation or chemical corrosion. The preparation method of the aluminum foil comprises the following operations: mixing the conductive carbon black with the dispersant in an organic solvent to pre-disperse, adding the fibrous conductive carbon, uniformly mixing, adding the binder to prepare a slurry, coating on the aluminum foil, and carrying out vacuum drying. The current collector carbon coated aluminum foil enables the interface impedances of the current collector and an active layer to be reduced, the internal resistance of a battery to be reduced, and the cycle life and the ratio performances of the battery to be improved when the aluminum foil is used as a lithium ion battery anode current collector. The aluminum foil has the advantages of simple technology, low cost and wide application prospect.

Owner:HUNAN CMAX NEW ENERGY TECH

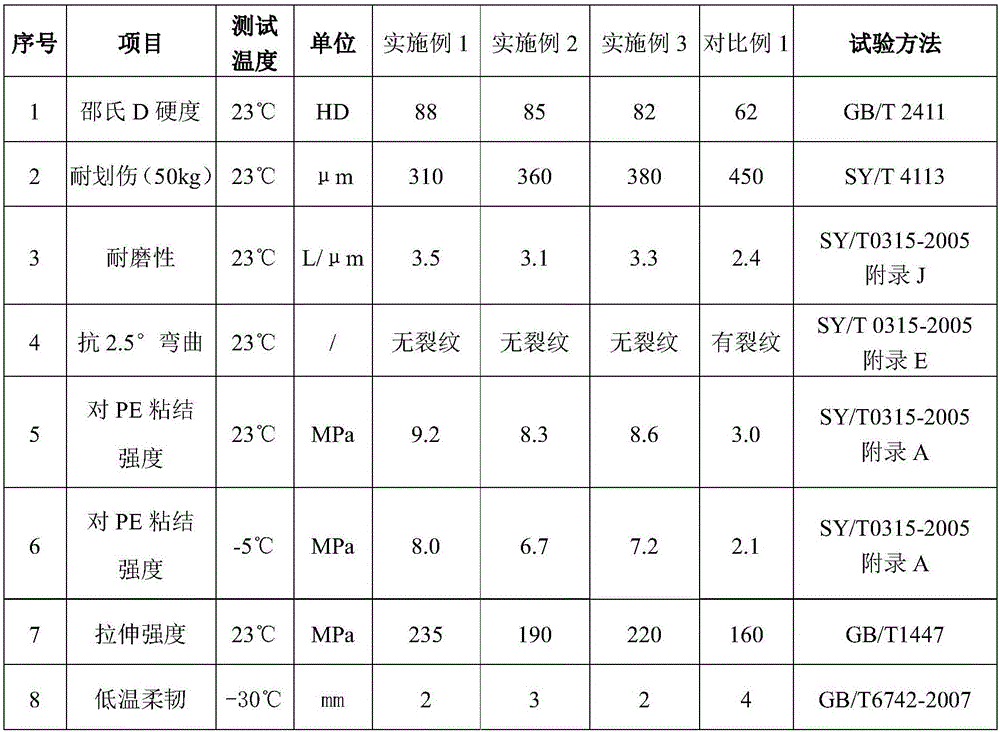

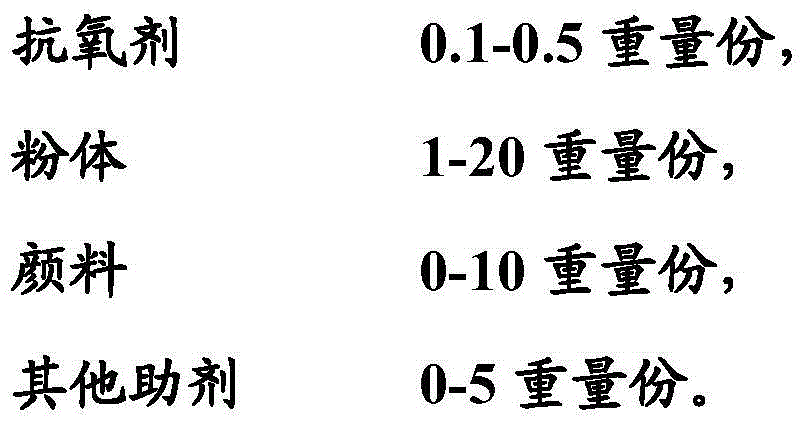

Electronic radiation crosslinked polymeric material for 3D printing, preparation method and product thereof

ActiveCN103980591AImprove heat resistanceGood chemical resistanceAdditive manufacturing apparatus3D object support structuresAnti oxidantMaterials science

The invention discloses an electronic radiation crosslinked polymeric material for 3D printing, a preparation method and a product thereof. The material includes following components, by weight, 100 parts of polymer resin, 0.5-5 parts of a radiosensitizer, 0.1-0.5 parts of an anti-oxidant agent, 1-20 parts of a powder and 1-10 parts of a pigment. With addition of the radiosensitizer, the polymer resin is subjected to a crosslinking reaction during a 3D printing process through electronic beam radiation to form a three-dimensional net structure so that a moulded material is significantly improved in heat resistant performance, chemical-corrosion resistant performance and mechanical strength. The polymer resin has a wider application prospect in 3D printing materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

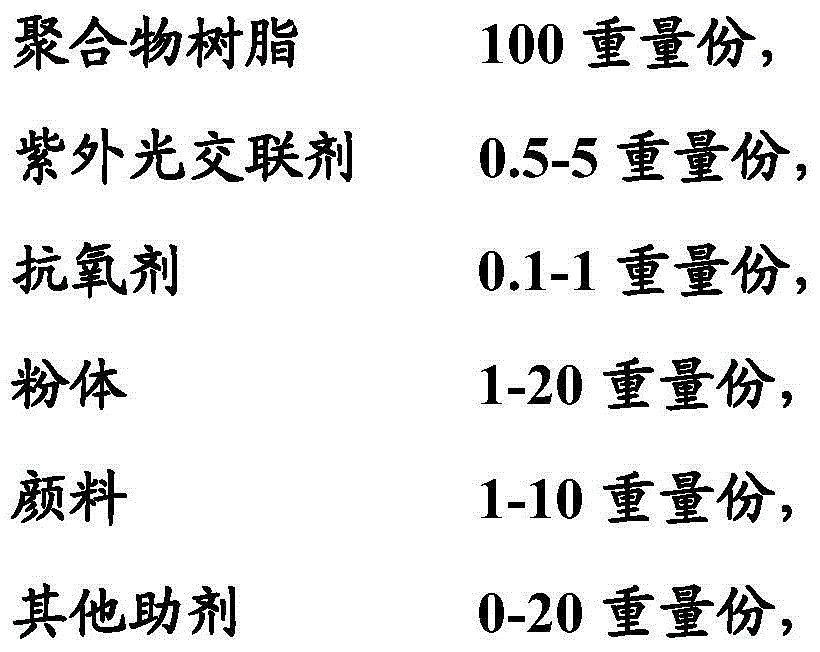

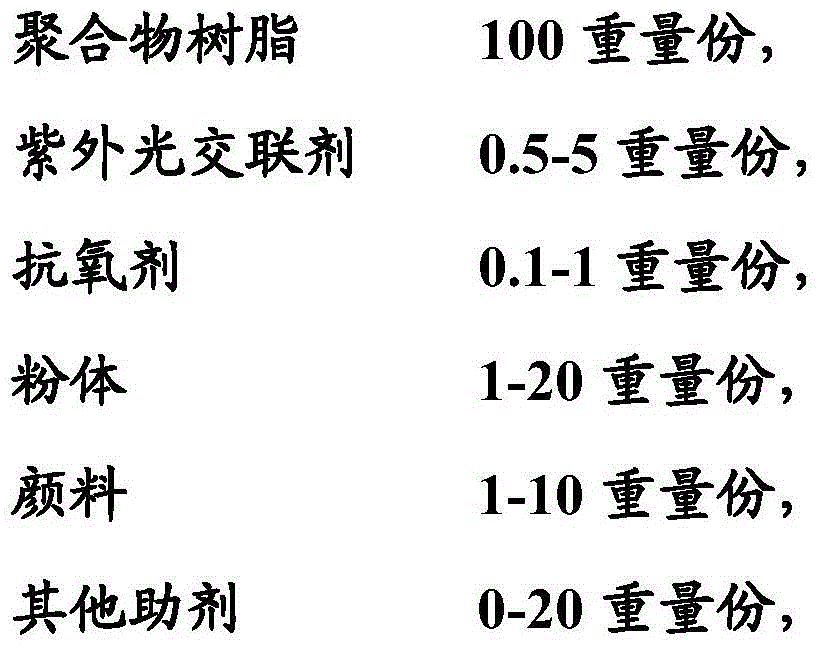

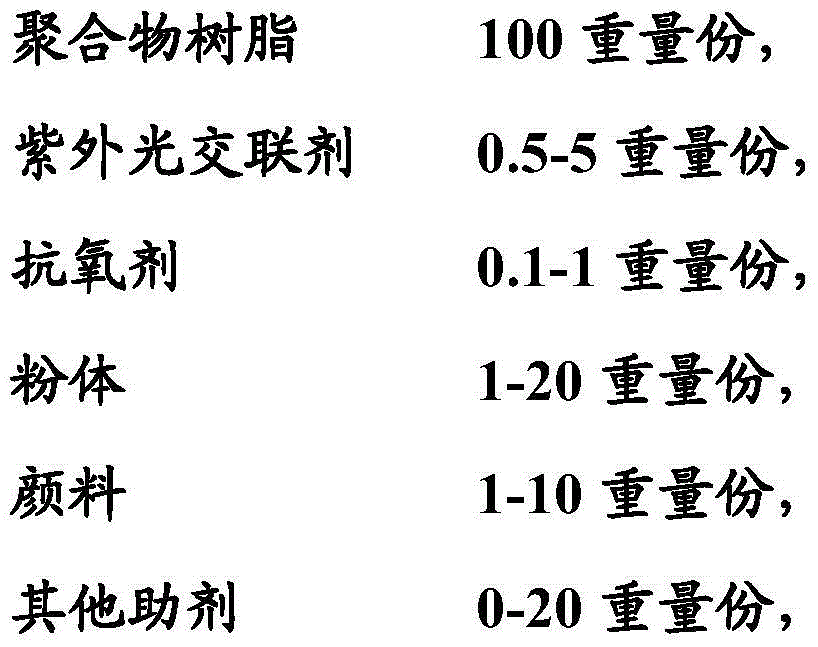

Ultraviolet light crosslinked polymer material used for 3D printing, and preparation method and application thereof

The invention relates to an ultraviolet light cross-linked polymer material used for 3D printing, and a preparation method and an application thereof. Raw materials of the material comprise, by weight, 100 parts of polymer resin, 0.5-5 parts of an ultraviolet light cross-linking agent, 0.1-0.5 parts of an antioxidant, 1-20 parts of powder, 1-10 parts of a pigment and 0-20 parts of other assistant. The light cross-linking agent absorbs ultraviolet lights with specific wavelengths under ultraviolet light irradiation to generate high molecular chain free radicals, so a series of a rapid polymerization reaction is generated to the polymer resin crosslink in a 3D printing process in order to form a three-dimensional net structure. The heat resistance, the chemical corrosion resistance and the mechanical strength of the cross-linked polymer material are greatly improved, so the polymer resin has a wide application prospect in 3D printing materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Solvent-free polyaspartate polyurea paint, and preparation method and application thereof

ActiveCN105670475AExcellent low temperature curingImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsLow temperature curingSolvent free

The invention provides a solvent-free polyaspartate polyurea paint, and a preparation method and application thereof. The solvent-free polyaspartate polyurea paint comprises a component A and a component B. The component A comprises the following ingredients in percentage by weight: 60-80% of hexamethylene diisocyanate and 20-40% of urethano modified HDI (hexamethylene diisocyanate) tripolymer. The component B comprises the following ingredients in percentage by weight: 60-70% of polyaspartate, 5-10% of pigment and filler, 10-20% of modified silicon micropowder, 1-3% of defoaming agent, 1-3% of leveling agent, 2-5% of adhesion promoter and 1-3% of coupling agent. The mass ratio of the component A to the component B is (3-5):1. The technical scheme provided by the invention greatly improves the low-temperature curing performance of the product and enhances the binding strength with the nonpolar material polyethylene; and the solvent-free polyaspartate polyurea paint has the advantages of high flexibility, high mechanical strength and high chemical corrosion resistance.

Owner:CYG CHANGTONG NEW MATERIAL

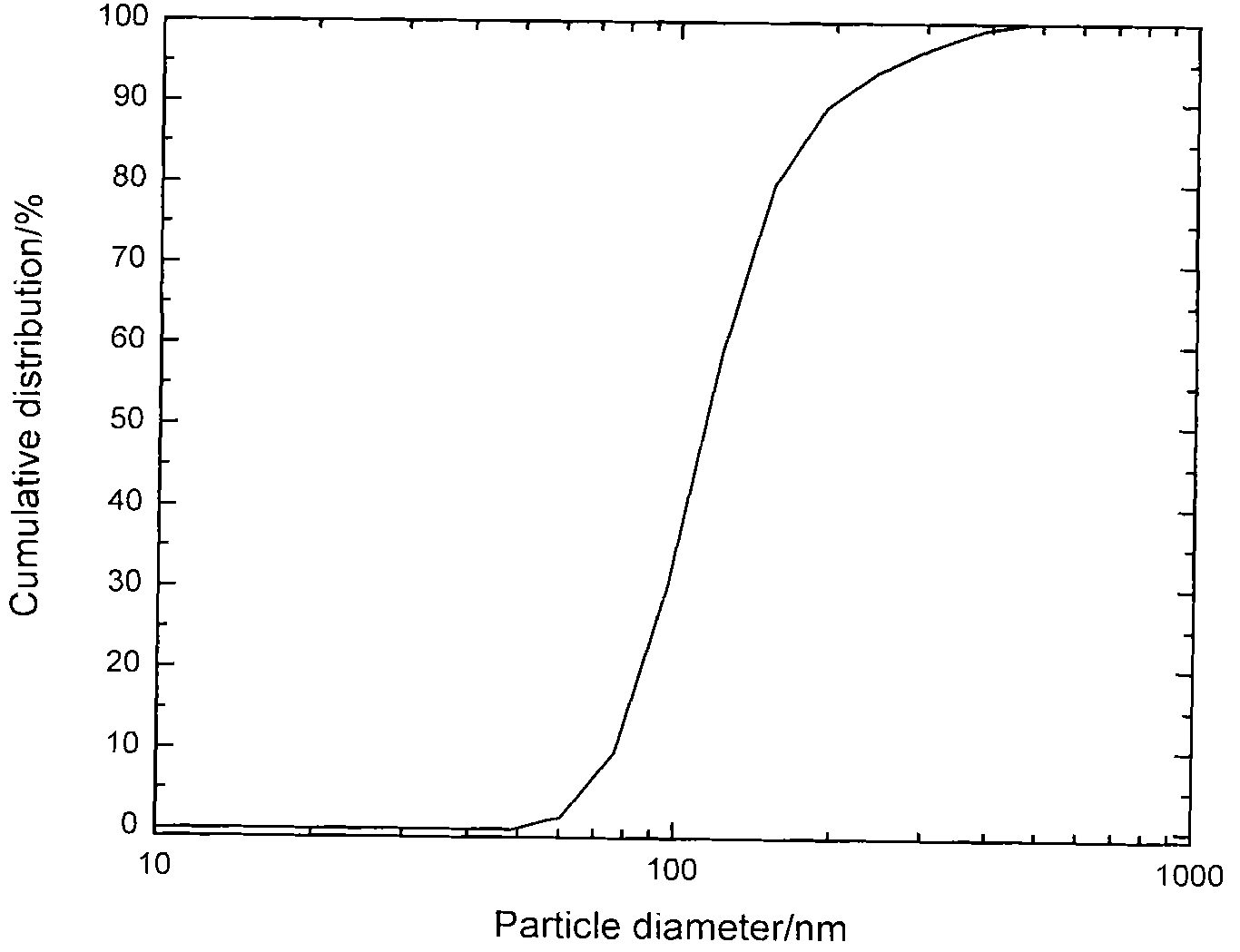

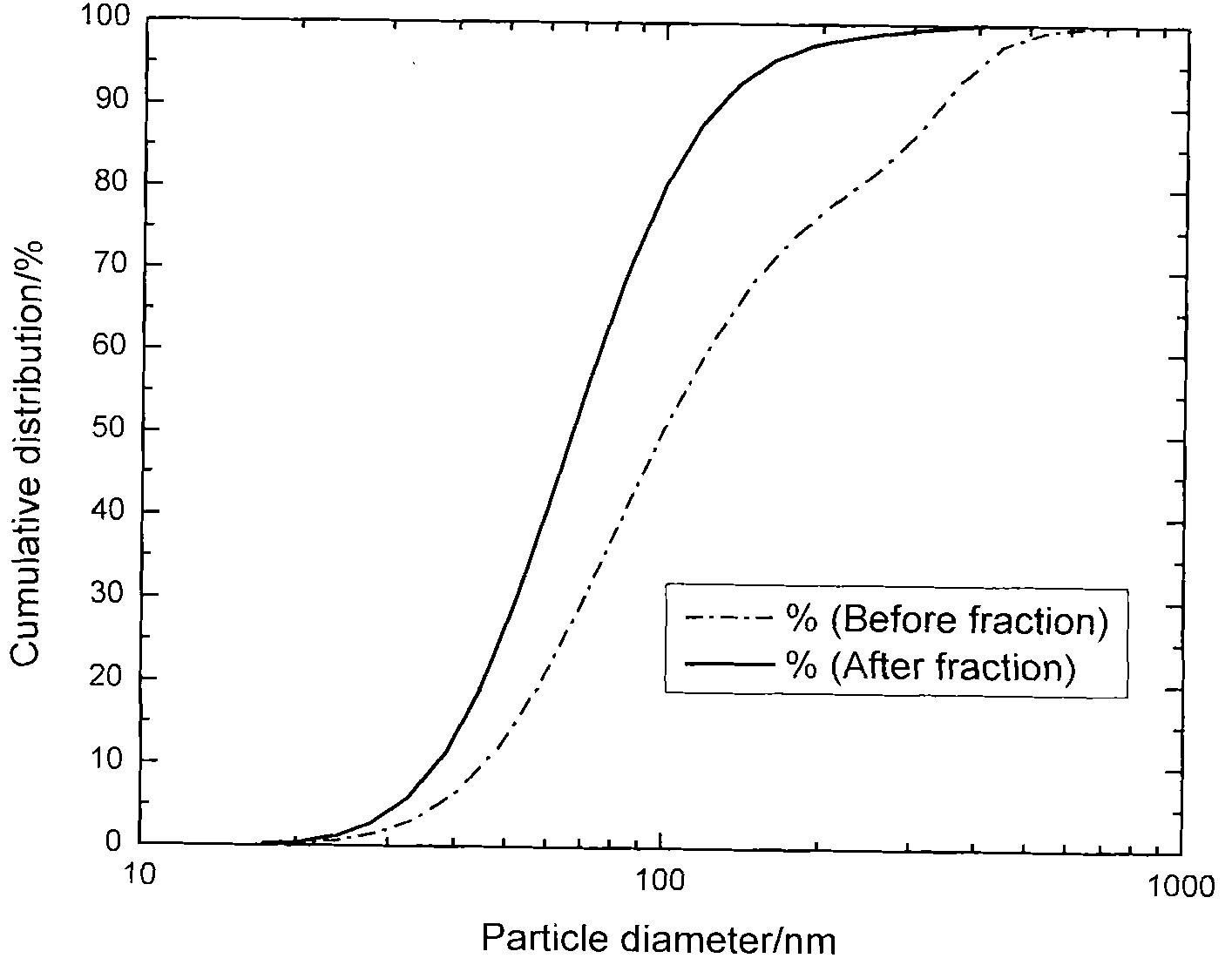

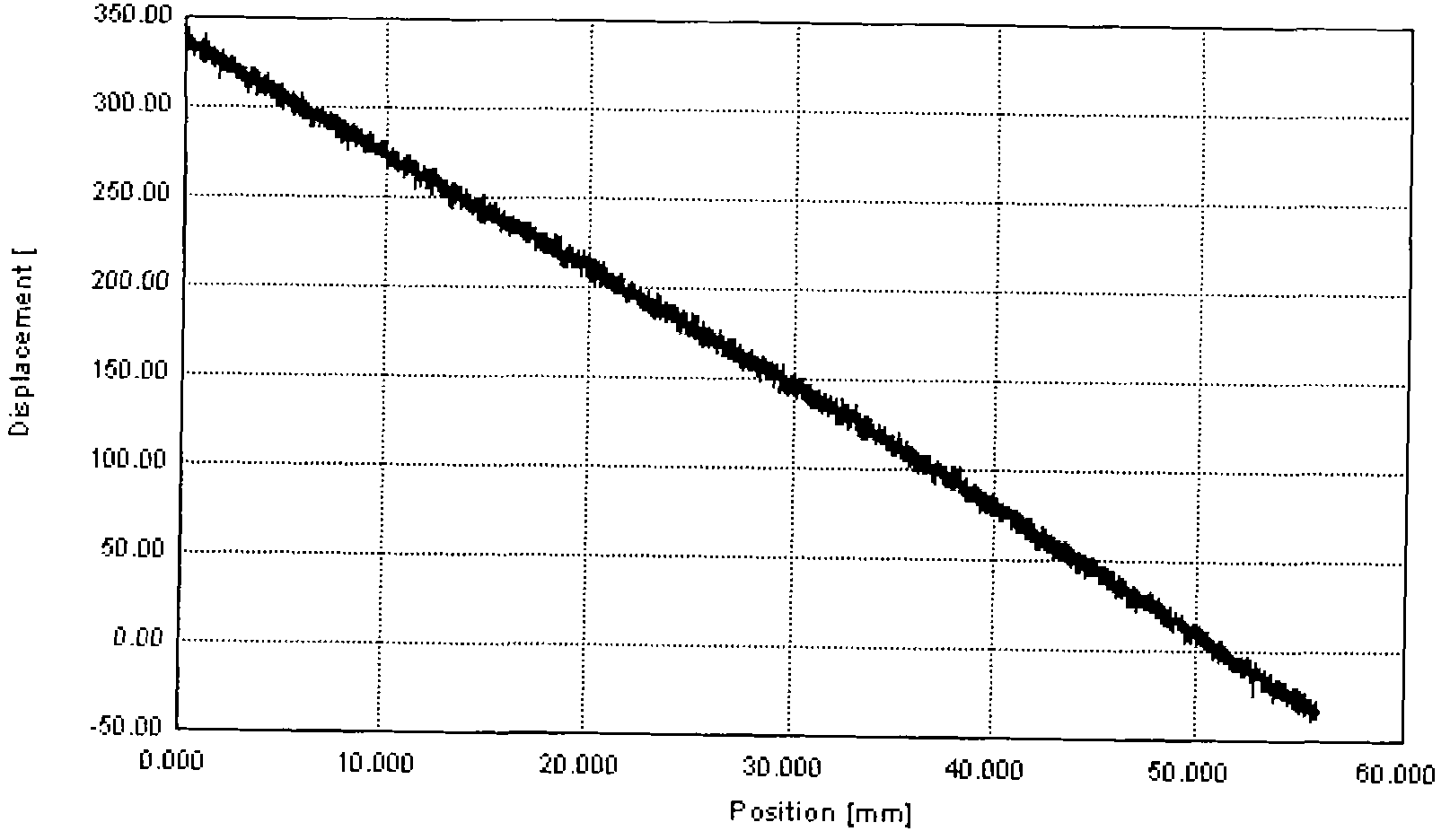

High-precision non-water-based nano-diamond grinding fluid and preparation method and application thereof

InactiveCN101831243AStrict control of particle size distributionTight control of particle morphologyPolishing compositions with abrasivesWater basedAlloy

The invention provides a high-precision non-water-based nano-diamond grinding fluid and a preparation method and application thereof. The high-precision non-water-based nano-diamond grinding fluid comprises main components of nano-diamond particles, a dispersion stabilizing agent, a suspension agent, a pH value regulator, an antistatic agent, an antioxidant, a dispersion medium and the like. In the invention, the particle size distribution is 130nm or smaller D50 particle size; the ratio of D10 to D50 is 50 percent or more; and the ratio of D90 to D50 is 200 percent or less. The preparation method comprises the following steps of: thinning diamond raw materials; carrying out modifying processing; deeply purifying; separating particle size; and finally mixing components according to a certain ratio. The invention has the advantages of completely eliminating deliquesce, hydrolization, chemical corrosion and electrochemical corrosion during the premise polishing and improving the polishing efficiency and the polishing quality to be maximum extent. The products have wide application to hard alloys, disk moulds, computer magnetic heads, computer disks, solar batteries and the like.

Owner:CHINA JILIANG UNIV

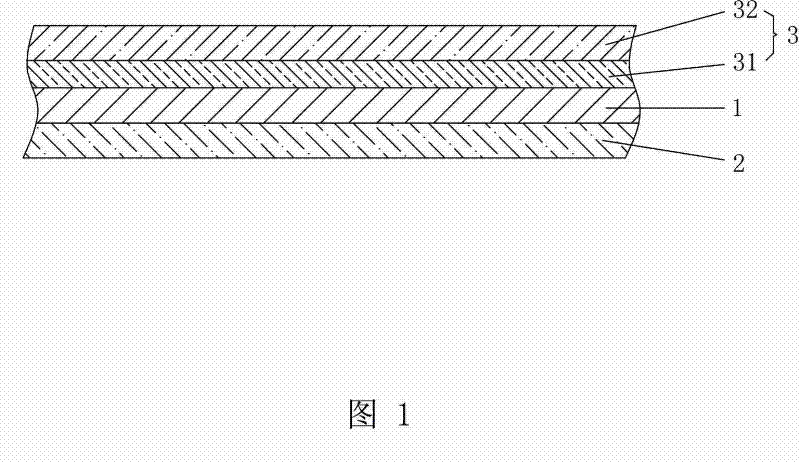

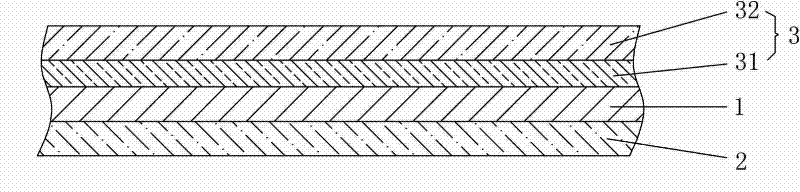

Membrane and preparation method thereof as well as lithium ion battery

ActiveCN102412377AImprove heat resistanceGood chemical resistanceSecondary cellsCell component detailsFiberCarbon fibers

The invention provides a membrane and a preparation method thereof as well as a lithium ion battery. The membrane comprises a substrate and size layers arranged on two sides of the substrate, wherein the size layers comprise ceramic particles, a silane coupling agent and an adhesion agent, and the substrate is an insulating carbon fiber non-woven fabric. The membrane disclosed by the invention has the advantages of good heat-resistant property, chemical corrosion resistant property, high strength and capability of effectively avoiding short circuit in the battery caused by puncture of lithium dendrites. The lithium ion battery prepared from the membrane disclosed by the invention has the advantages of excellent safety performance and high temperature resistance and long service life.

Owner:BYD CO LTD

Modified epoxy resin adhesive and preparation method thereof

ActiveCN101654605AGood flexibilityHigh peel strengthInsulating substrate metal adhesion improvementCarboxyl rubber adhesivesEpoxyPliability

The invention discloses a modified epoxy resin adhesive, which comprises the following components in portion by weight: 10 to 50 portions of epoxy resin, 20 to 80 portions of toughening agent, 0.2 to 5 portions of curing agent, 0 to 2 portions of curing accelerant, 0 to 1 portion of assistant, 2 to 15 portions of inorganic filler and 20 to 80 portions of solvent. In order to overcome the defects in the prior art, the invention provides the modified epoxy resin adhesive with strong flexibility, high peeling strength, good flexure property, good size stability, strong chemical corrosion resistance and excellent electric performance, and a method for producing the modified epoxy resin adhesive.

Owner:ZHONGSHAN DONGYI HIGH TECH MATERIAL

Ultra violet radiation cross-linking polymeric material for 3D printing and preparation method and product thereof

ActiveCN103980594AImprove heat resistanceGood chemical resistance3D object support structuresCross-linkAntioxidant

The invention discloses an ultra violet radiation cross-linking polymeric material for 3D printing and a preparation method and a product thereof. Main components of the material contain, by weight, 100 parts of unsaturated resin and 0.5-5 parts of an UV cross-linking agent. In addition, the material also contains, by weight, 0.1-0.5 part of an antioxidant, 1-20 parts of a powder, 0-10 parts of a pigment and 0-5 parts of other auxiliary agents, which help enhance a printing effect of the material. With the addition of the UV cross-linking agent and by the utilization of ultraviolet irradiation, unsaturated resin is subjected to crosslinking after 3D printing extrusion so as to form a three-dimensional net structure. Heat resistance, resistance to chemical corrosion and mechanical strength of a moulding material are all raised to a large extent. Thus, unsaturated resin has a wider application prospect in 3D printing materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Fluorosilicone rubber nano composite alloy three-proof paint and production method thereof

InactiveCN101230224AImprove anti-corrosion performanceExcellent anti-fouling flashEpoxy resin coatingsCross-linkPolymer science

The invention discloses a fluorosilicone rubber nano-composite alloy triplicate-prevention paint and the production method. The organic silicon provided with hydroxyl is introduced into the carbon resin, and is dispersed into resin polymerize and cross-linked by a variety of polymer resin via nano-particle which is processed by nano-dispersion solution; and then the fluorosilicone rubber nano-composite alloy triplicate-prevention paint which can resist salt spray, acid, alkali and impact; has strong adhesive attraction, strong resistance to elements, and heavy corrosion resistance; can prevent pollution flashover , and can drain for anti-icing is produced by modifying the obtained resin. The invention has high reaction energy and ultra-low surface energy, can resist chemical corrosion and electrochemical corrosion, has ability for resisting strong corrosion medium, has strong adhesive attraction and high reliability between paint film layers, can prevent water, oxygen and other corrosion mediums from destructing, can resist ultraviolet radiation, can resist temperature change, has super resistance to elements, has long coating maintenance usage duration, and is applicable to bad weather conditions and all kinds of strong corrosive environments.

Owner:孟中

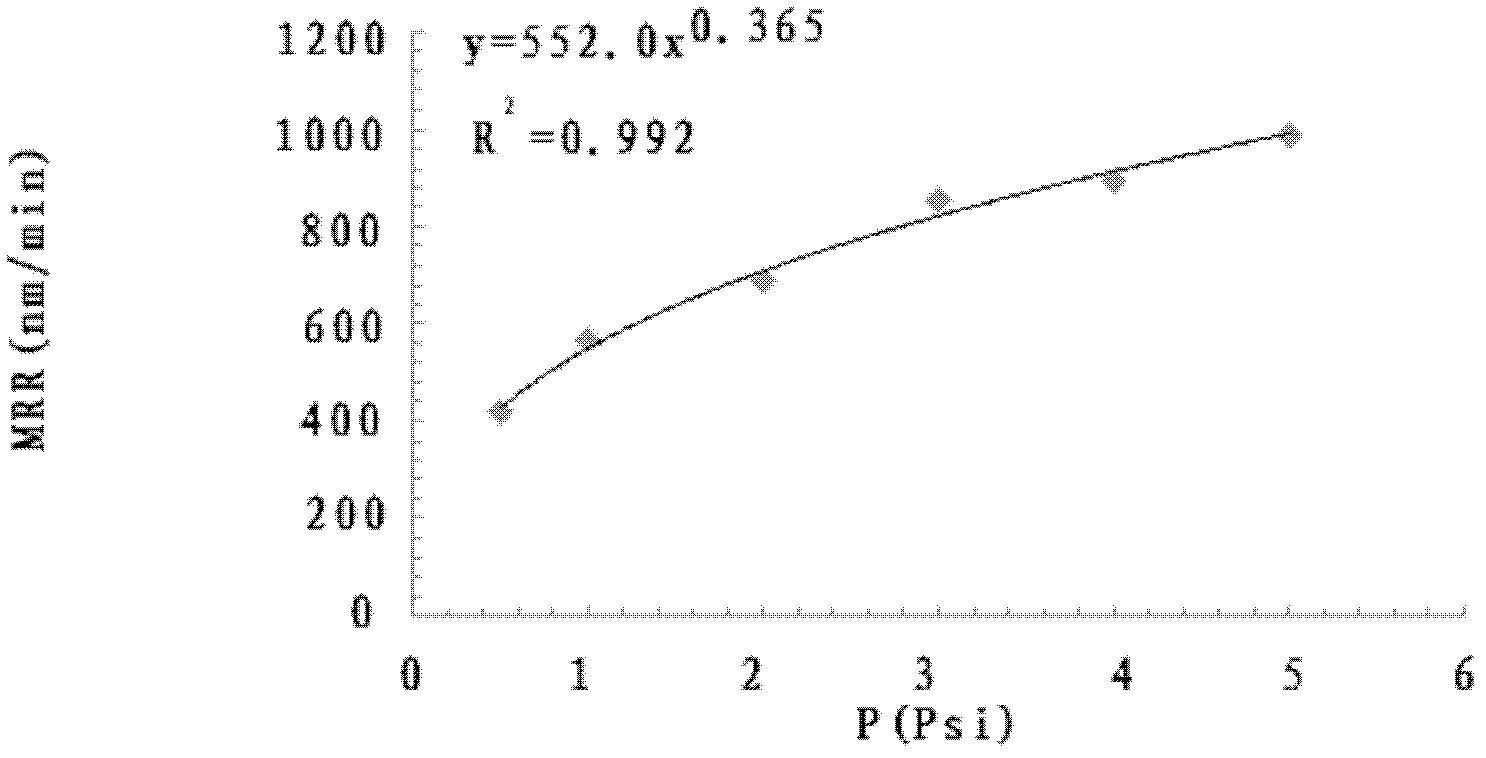

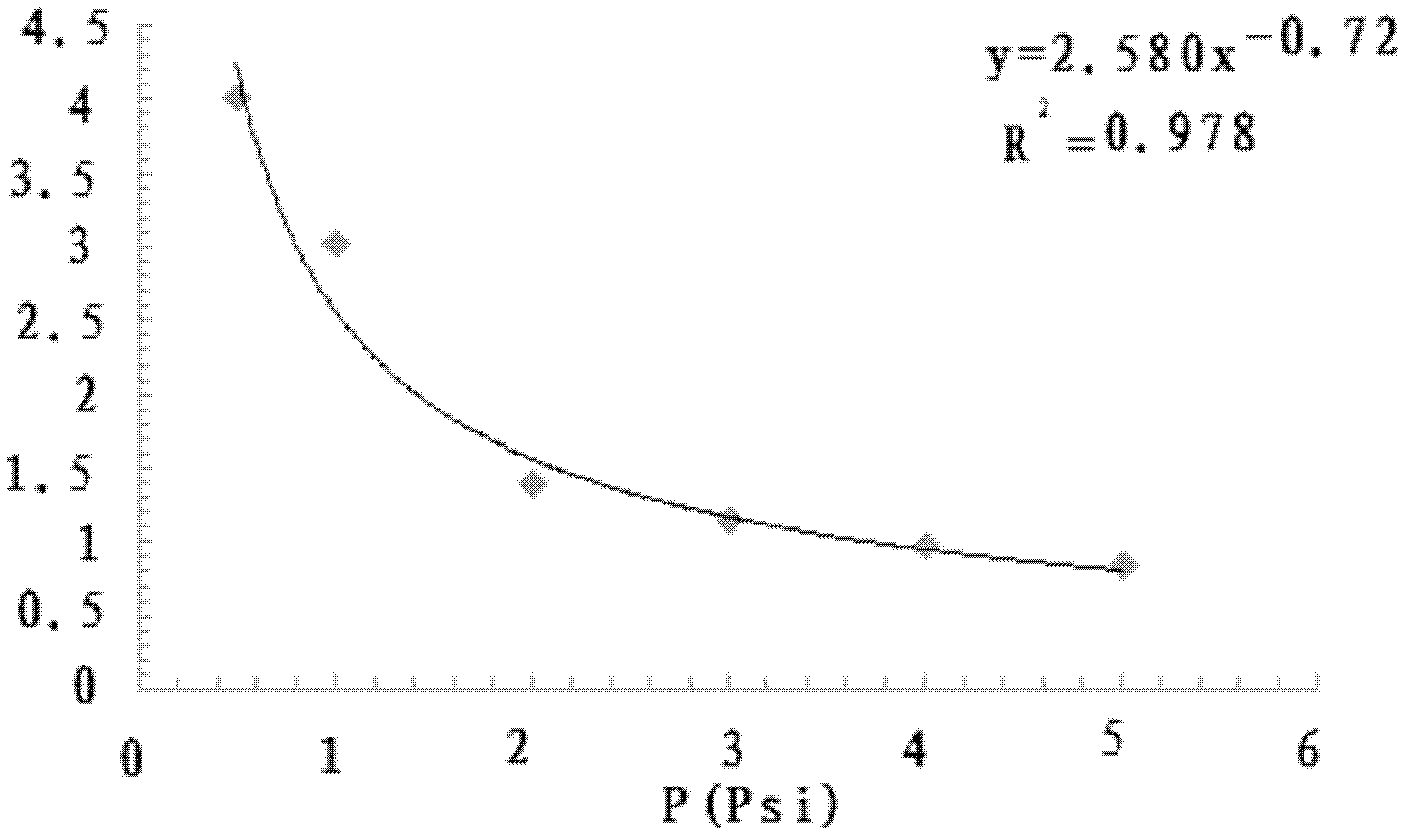

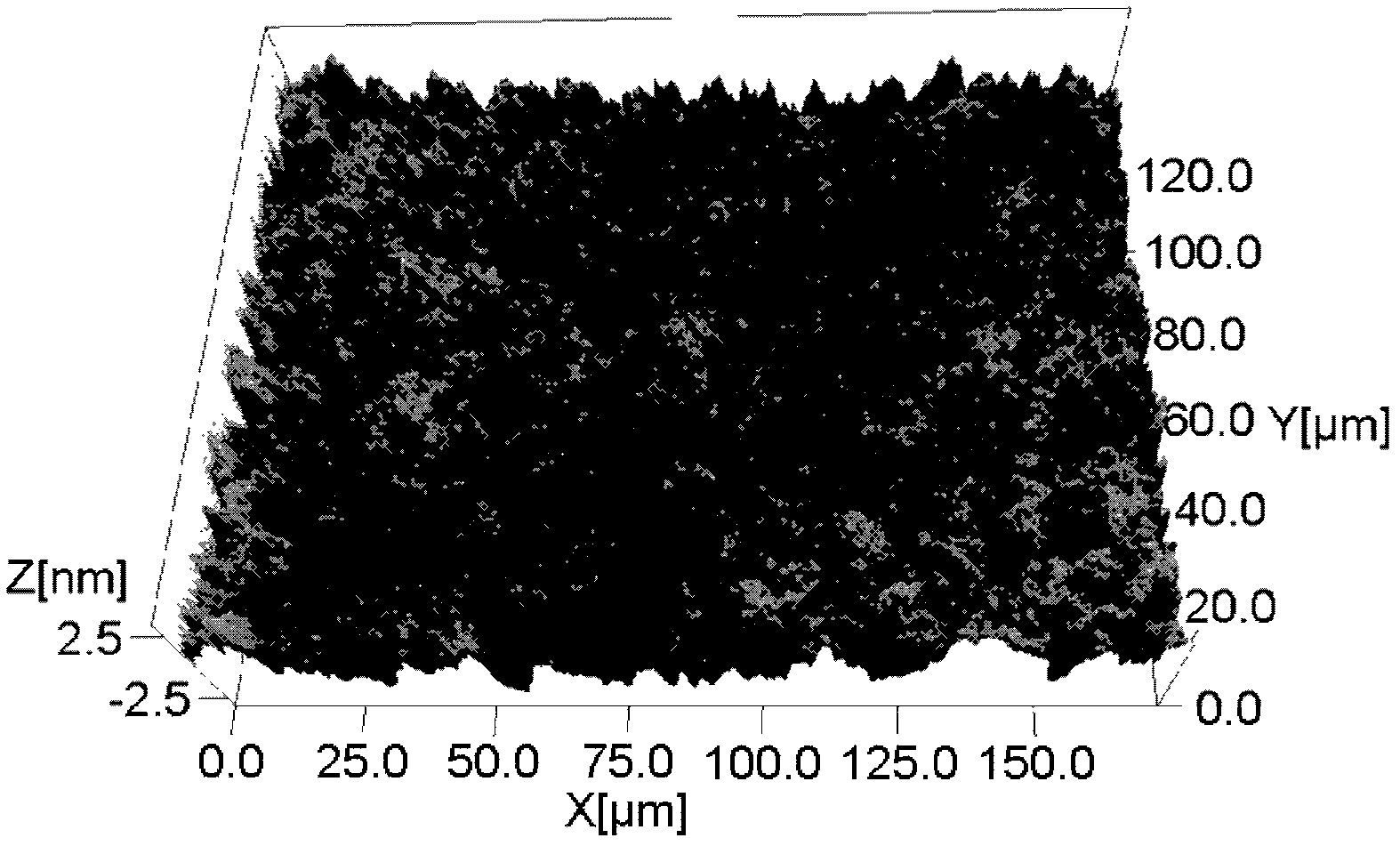

Acidic chemical and mechanical polishing composition

ActiveCN102585706AEasy to polishBoost rateOther chemical processesPolishing compositions with abrasivesColloidal silicaOrganic film

The invention provides an acidic chemical and mechanical polishing composition. The pH value of the acidic chemical and mechanical polishing composition is 2-7, and the acidic chemical and mechanical polishing composition comprises 1-20% by weight of abrasive material, 0.5-10% by weight of oxidant, 0.1-10% by weight of complexing agent, 0.001-1% by weight of corrosion inhibitor, 0.001-5% by weight of organic film-forming auxiliaries and the balance of pH regulator and deionized or distilled water, wherein the abrasive material is of colloidal silica sol after modification in the special step, and the average particle size is of 10-200nm. According to the chemical and mechanical polishing composition provided by the invention, the abrasive material is refined and modified; by using the method, the stability of the abrasive material in polishing slurry can be effectively upgraded, and polishing removal rate and surface roughness degree are respectively optimized to a certain extent; and the unique adding effect of the organic film-forming auxiliaries can well balance the strength of chemical corrosion action and the strength of mechanical grinding action, and achieve the effects of improving polishing removal efficiency and performing global planarization.

Owner:TSINGHUA UNIV

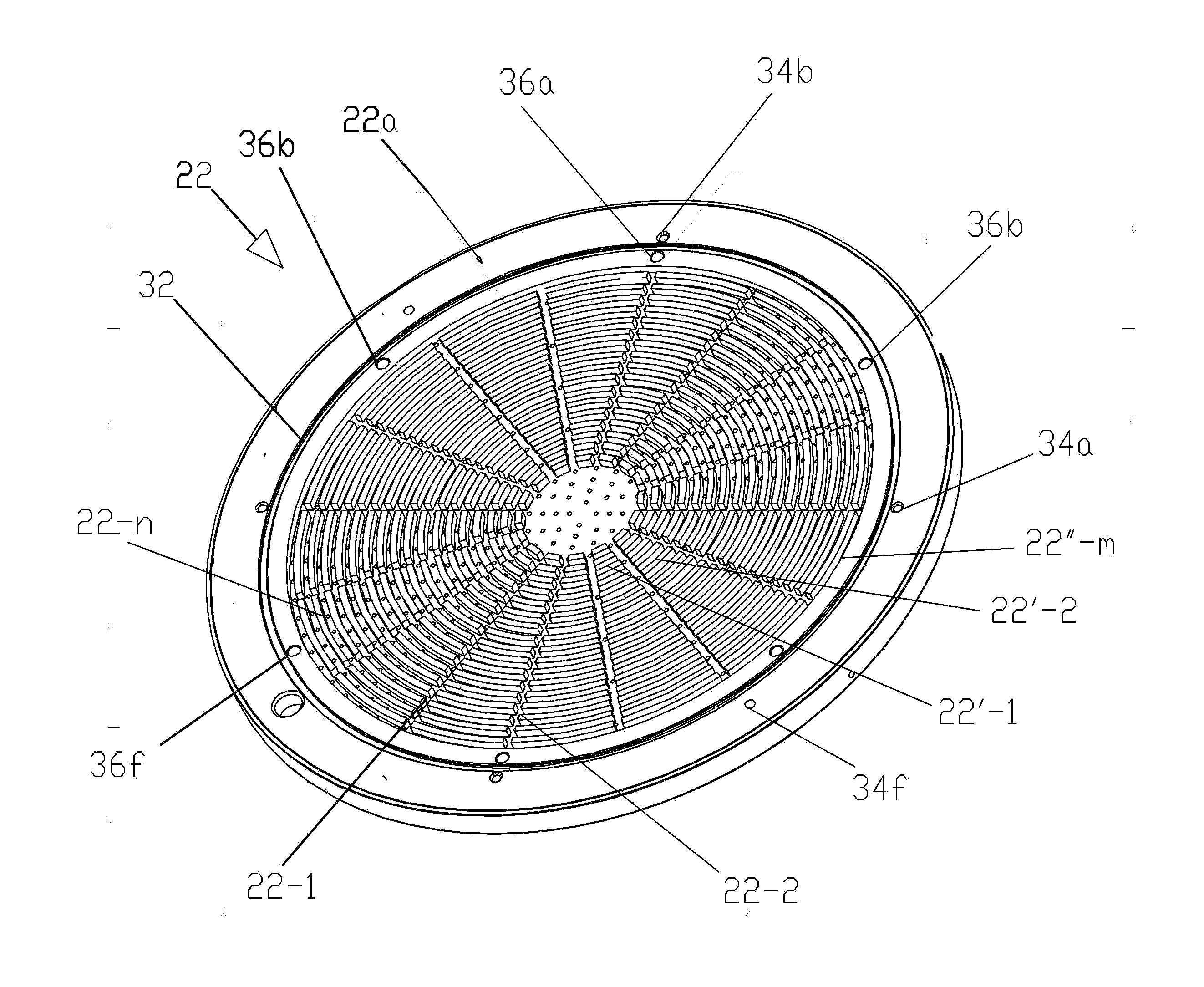

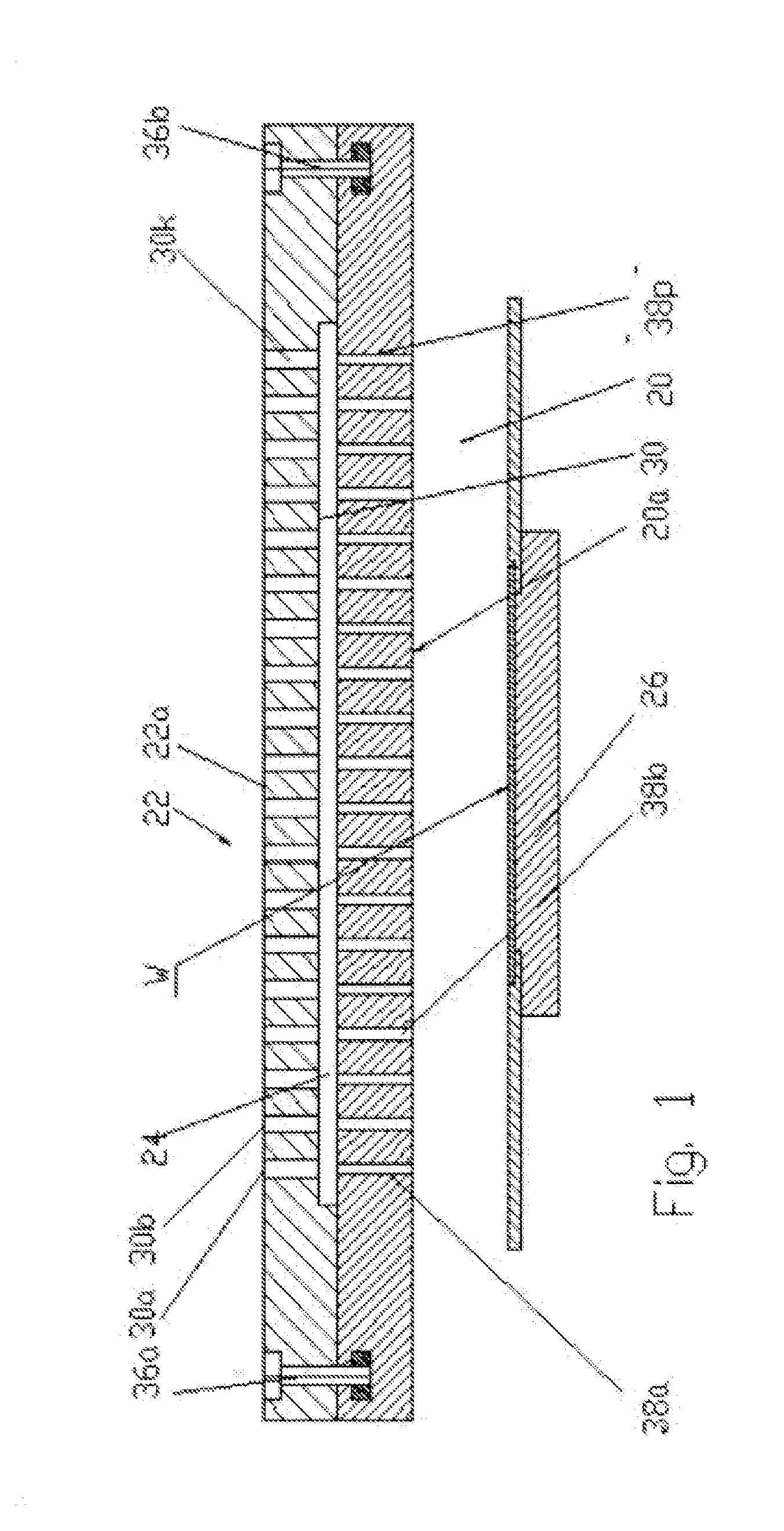

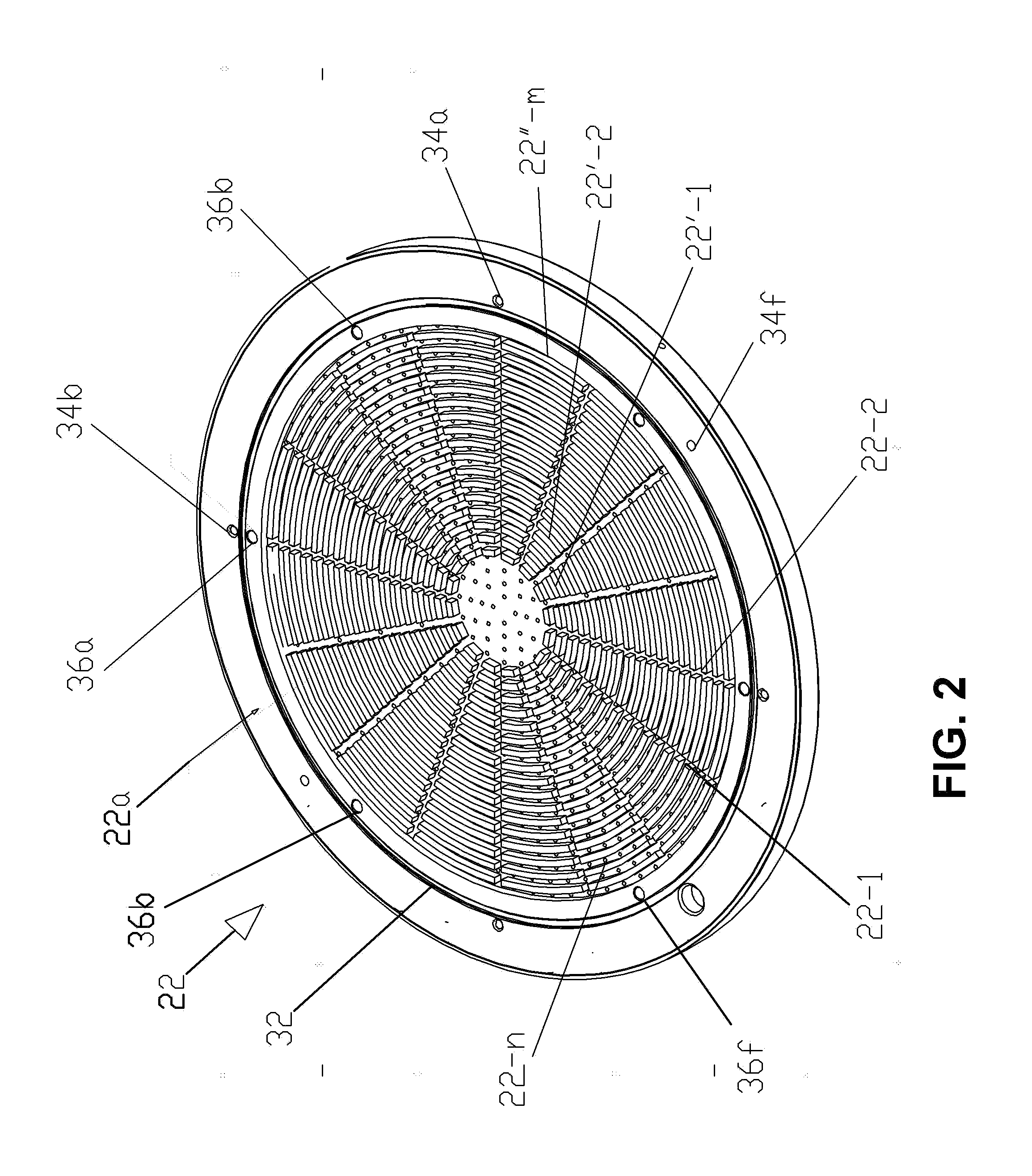

Method for providing uniform distribution of plasma density in a plasma treatment apparatus

ActiveUS20150214013A1High plasma uniformityEvenly distributedLiquid surface applicatorsElectric discharge tubesElectricityPlasma density

Proposed is a method for providing uniform distribution of plasma density in a CCP plasma processing apparatus. According to the method the through gas holes of the showerhead of used in the plasma processing chamber of the apparatus are provided with conical nozzles formed on the side of the gas holes that face the gas reservoir of the cooler plate. The cone angle θ of the nozzles decreases in the direction from the peripheral portion to the central area of the showerhead in the range from 120° to 0°. Since the conical nozzles increase the gas gap between the showerhead and the cooler plate, more favorable conditions are created for electric breakdown. In order to protect the surfaces of the conical nozzles and gas holes from deterioration by hollow cathode discharge, these surface are coated by a protective coating resistant to electrical breakdown and chemical corrosion.

Owner:GLUKHOY YURI

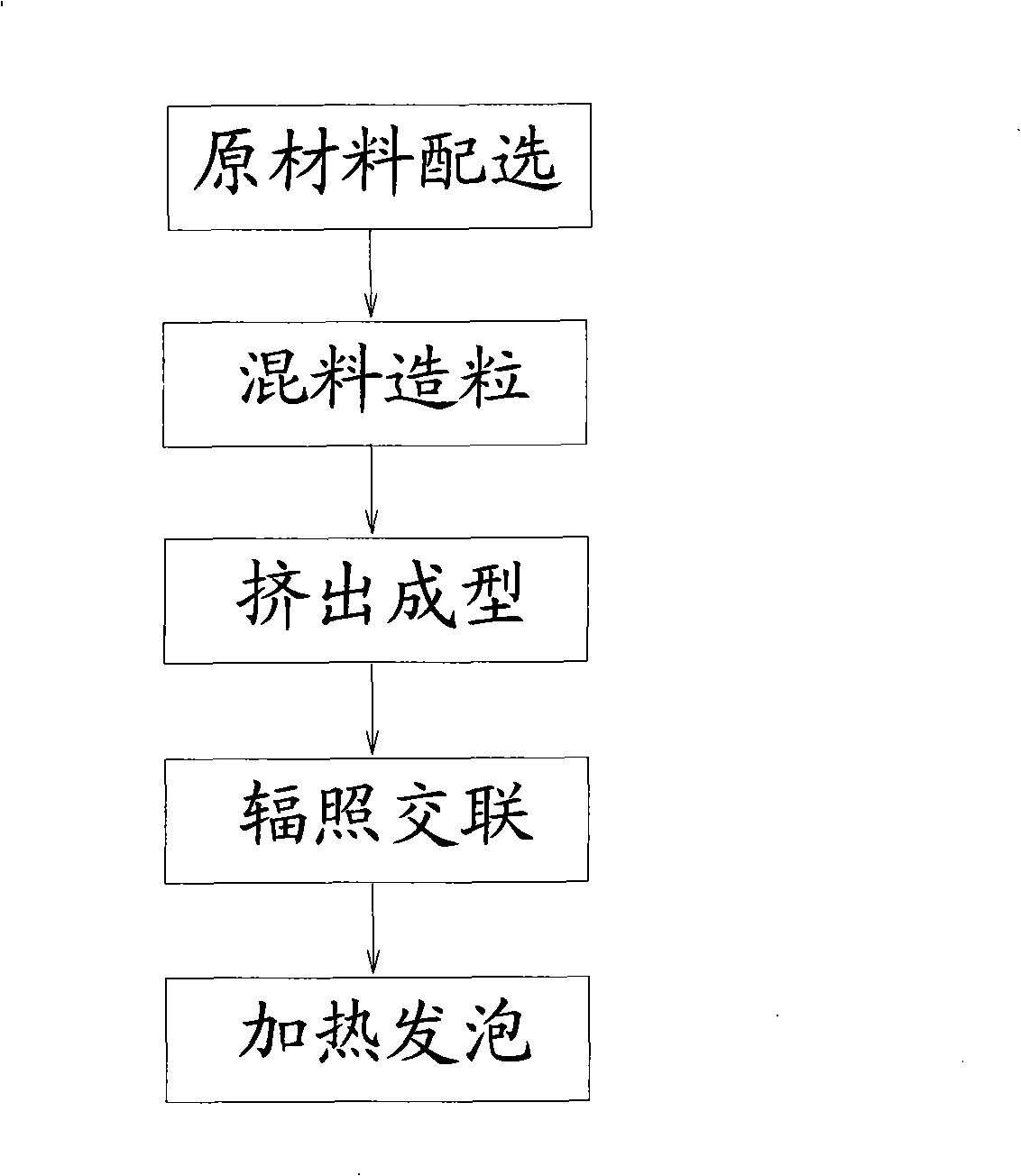

IXPE electron radiation on crosslinking polyethylene conductive foam and preparation method thereof

The invention relates to an IXPE electronic radiation crosslinked polyethylene conductive foam and a preparation method thereof. The IXPE electronic radiation crosslinked polyethylene conductive foam mainly contains the mother batch: low density polyethylene; accessories: ethylene-vinyl acetate copolymer, azodicarbonamide blowing agent, polyethylene wax lubrication additive, titanate ester coupling agent and conductive carbon black which are mixed for processing, extruded for molding, radiated for crosslinking, heated for foaming, and treated by secondary processing, etc, to produce the IXPE electronic radiation crosslinked polyethylene conductive foam. The crosslinking of the product of the invention can be easily controlled, the foaming process is stable, the foam pores are fine and even, the quality of the surface is high without unpleasant odor, the foam pores are obstructed, the production can be carried out continually, the electrical conductivity is stable, the product is lightweight, non-toxic, extremely less absorbent; the thermal conductivity is slow, aging resistant, chemical corrosion resistant, pulverization resistant, and a plurality of porous foam materials can be easily achieved; in addition, the product has good properties to be treated by the secondary processing procedures, such as bonding, machining, hot forming, etc.

Owner:SHENZHEN CHANGYUAN TEFA TECH CO LTD

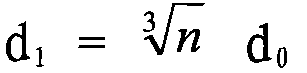

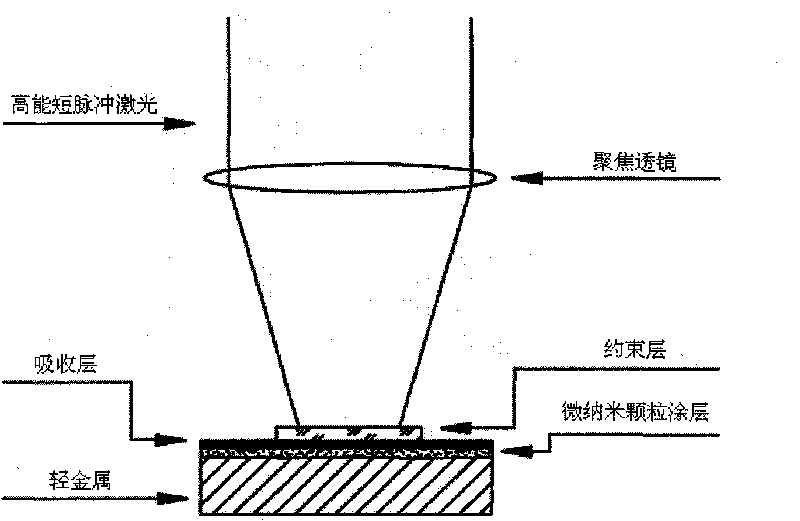

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

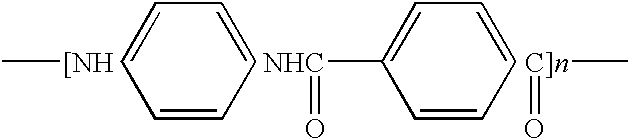

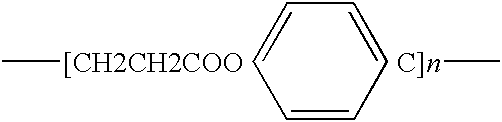

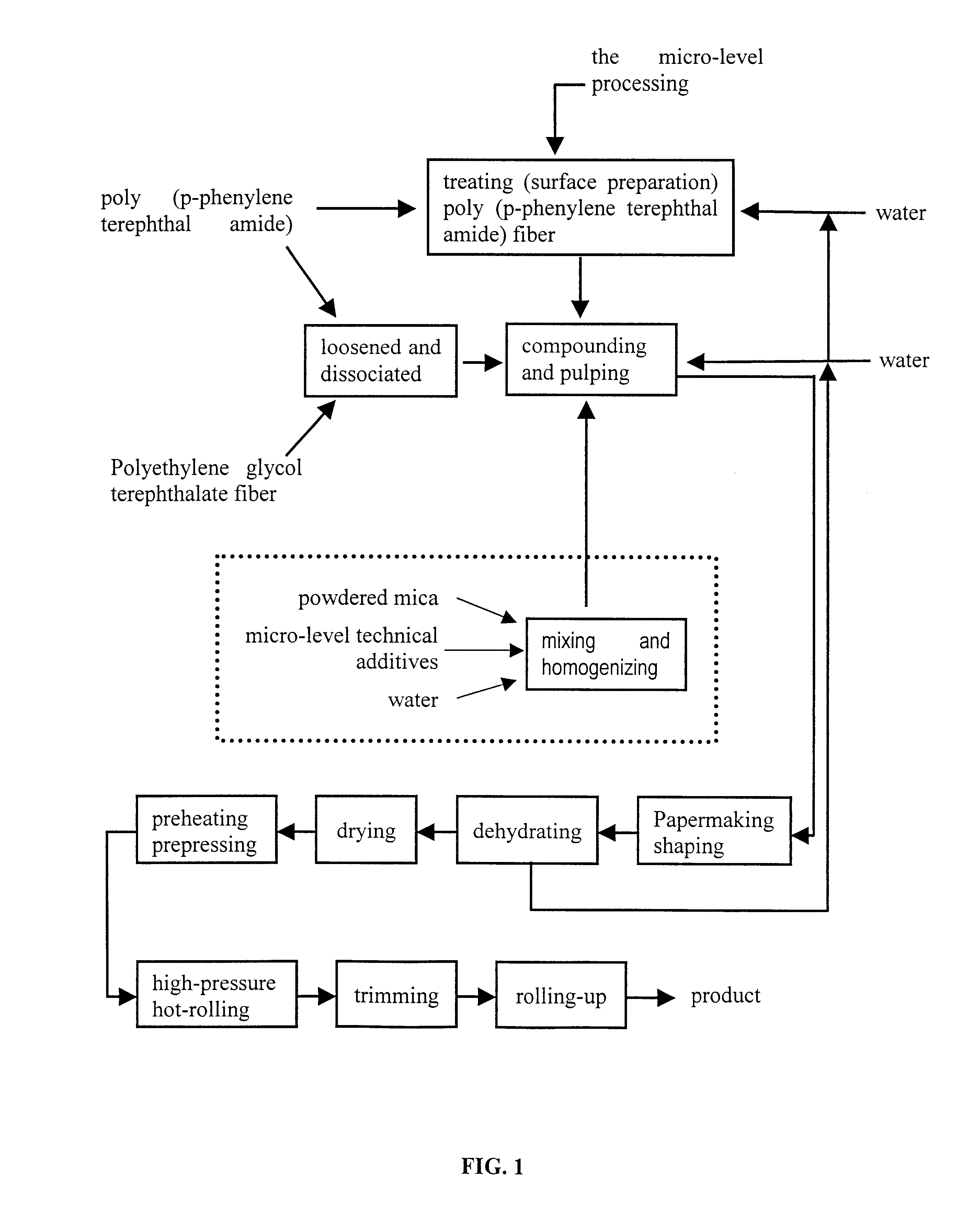

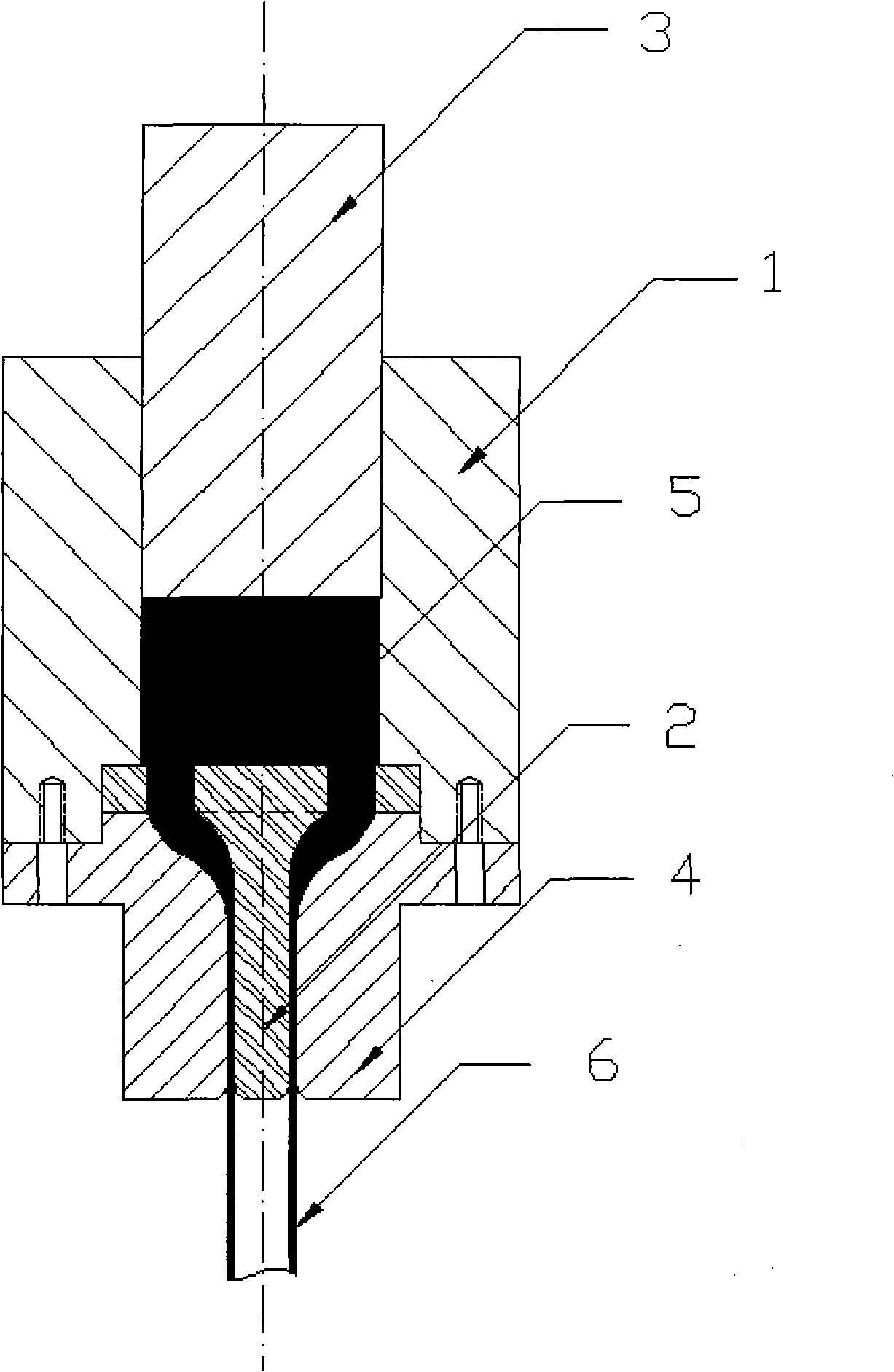

Synthetic fiber paper

The present invention provides a synthetic fiber paper, the synthetic fiber paper comprises poly (phenylene terephthal amide) fiber, polyethylene glycol terephthalate fiber and powdered mica. The synthetic fiber paper has high-temperature resistance, high strength, low-deformability, resistivity against fire, burning resistance, resistance to chemical corrosion and excellent property of electric insulation, it can be widely applied in the field of mechano-electronics product, aviation, aerospace, military project for national defence, high-tech areas for civil use, high-voltage equipment, high-temperature circumstance as insulting material, it often can be used in composite materials with special use as structural material. The present invention also provides a process for preparing this synthetic fiber paper.

Owner:SICHUAN FOREIGN ECONOMIC RELATIONS & TRADE CORP

Silicon carbide ceramic tubular product and preparation method thereof

InactiveCN101580390AExcellent extrusion formabilityControllable tube shapeThermal expansionHigh pressure

The invention belongs to the technical fields of a silicon carbide ceramic material and a preparation method thereof, in particular relates to a silicon carbide ceramic tubular product with high strength, high thermal conduction, low expansion, high thermal-shock resistance performance and controllable external dimensions and a preparation method thereof. The silicon carbide ceramic tubes have even texture and uniform tubular wall thickness; the thickness of each tubular wall can be controlled from 0.5 mm to 20 mm, each tubular outer diameter can be from 5 mm to 100 mm, the silicon carbide ceramic tube with the longest length is limited by a sintering furnace, and each tubular wall can be in a compact structure or a micropore structure. The silicon carbide ceramic tubular product uses organic resin and SiC powder as main raw materials and utilizes an extrusion molding technology to prepare a tubular precast blank which is compacted and equalized at a high temperature, pyrolysed to form a final product after reaction, infiltration and sintering. The silicon carbide ceramic tubular product has the fundamental characteristics of SiC ceramics, such as high strength, low thermal expansion coefficient, high thermal conduction, chemical corrosion resistance, oxidation resistance, good high temperature stability, strong thermal-shock resistance performance, and the like. The preparation method has simple technology, convenient operation, no complicated equipment and low manufacture cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method for light-heat dual-cured woodware UV varnish coating

InactiveCN102321424AOvercome depthOvercoming the difficulty in application in colored systemsEpoxy resin coatingsEpoxyPtru catalyst

Owner:SOUTH CHINA UNIV OF TECH

Multi-layer thermal transfer ribbon and manufacturing method thereof

The invention relates to a multi-layer thermal transfer ribbon and a manufacturing method thereof, and the multi-layer thermal transfer ribbon comprises a membranous base band, a heat-resistant printing ink layer and a heat transfer printing ink layer, wherein the heat-resistant printing ink layer is coated on one side of the base band, the heat transfer printing ink layer is coated on the other side of the base band, the heat transfer printing ink layer comprises a stripping printing ink layer and an adhesive printing ink layer, the stripping printing ink layer is directly coated on the surface of the base band, the adhesive printing ink layer is coated on the stripping printing ink layer, printing ink in the striping printing ink layer is hot-melting type printing ink, and the printing ink in the adhesive printing ink layer is the hot-melting type printing ink or solvent type printing ink. The heat transfer printing ink layer of the multi-layer mixed-based ribbon can be easily completely stripped off the base band, and the great adhesive ability is realized on a smooth medium; in addition, the multi-layer thermal transfer ribbon further has the advantages of high resolution, clear printing, anti-friction property, moisture resistance, chemical corrosion resistance, environment friendliness and the like.

Owner:泉州市山水电脑耗材有限公司

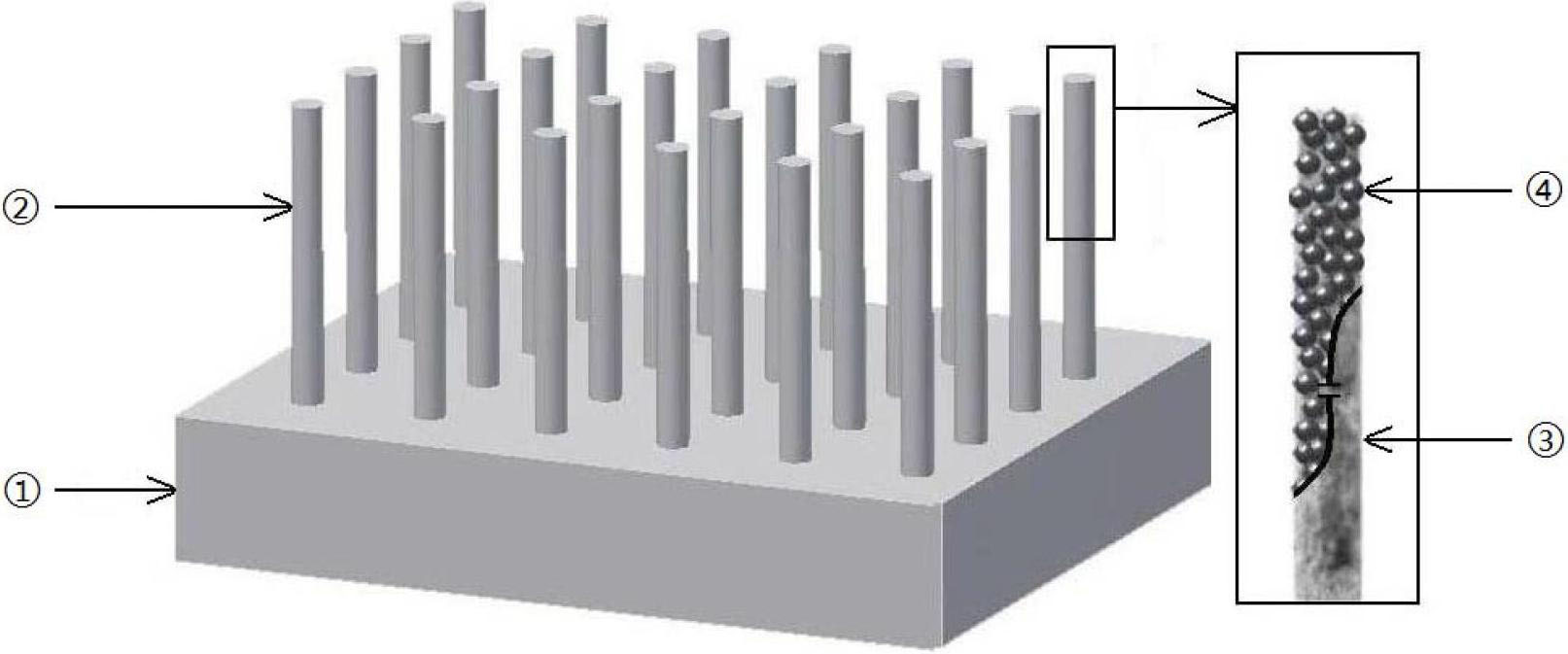

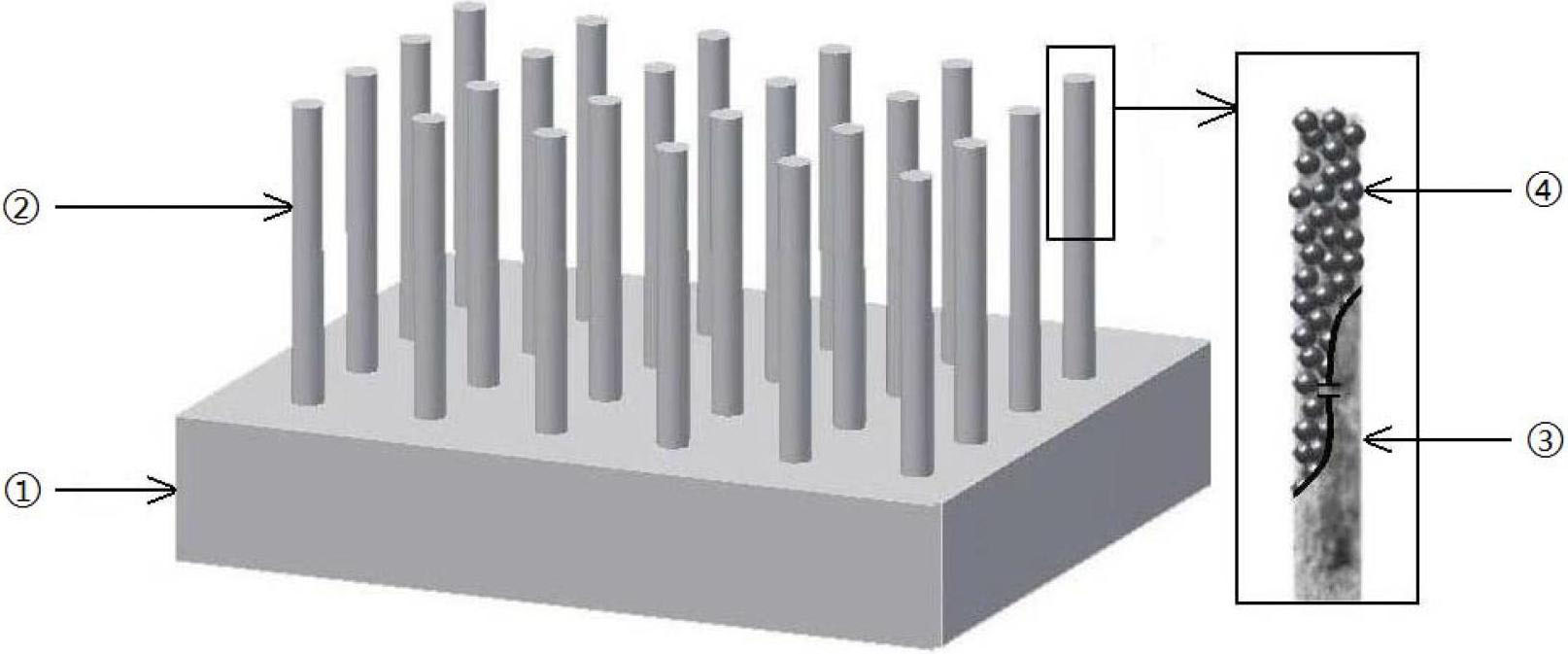

Preparation method of surface-enhanced Raman scattering substrate of metal particle array

The invention provides a preparation method of a surface-enhanced Raman scattering substrate of a metal particle array. The preparation method comprises the following steps of: preparing a porous silicon nanometer wire array (PSNWA) as a substrate material through a metal-assisted chemical corrosion method; reducing metal ions in a metal salt solution to elementary substance through an impregnation-reduction method, and obtaining the surface-enhanced Raman scattering substrate after uniformly depositing the elementary substance on the surface of the PSNWA in a nanometer particle manner; and inducing a substance to be detected into an active substrate surface through an infiltration or titration method, namely carrying out Raman spectrum detection. The preparation method provided by the invention has the advantages of low cost, simple process, simplicity and convenience in operation, high sensitivity of SERS (Surface-Enhanced Raman Scattering) signals, and good repeatability; and an SERS light spectrum has very good stability and repeatability. The invention provides a molecule detection and trace quantity analysis method with high speed, high sensitivity and high reliability. The preparation method provided by the invention needs extremely less sample amount, is suitable for various liquid samples, and has wide application prospects of rapid identification of clinical biological molecules, trace quantity chemical substance detection, biological sample analysis and the like.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com