Silicon carbide ceramic tubular product and preparation method thereof

A technology for silicon carbide ceramics and tubular products is applied in the field of silicon carbide ceramic materials and their preparation. Strong interaction, easy to process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

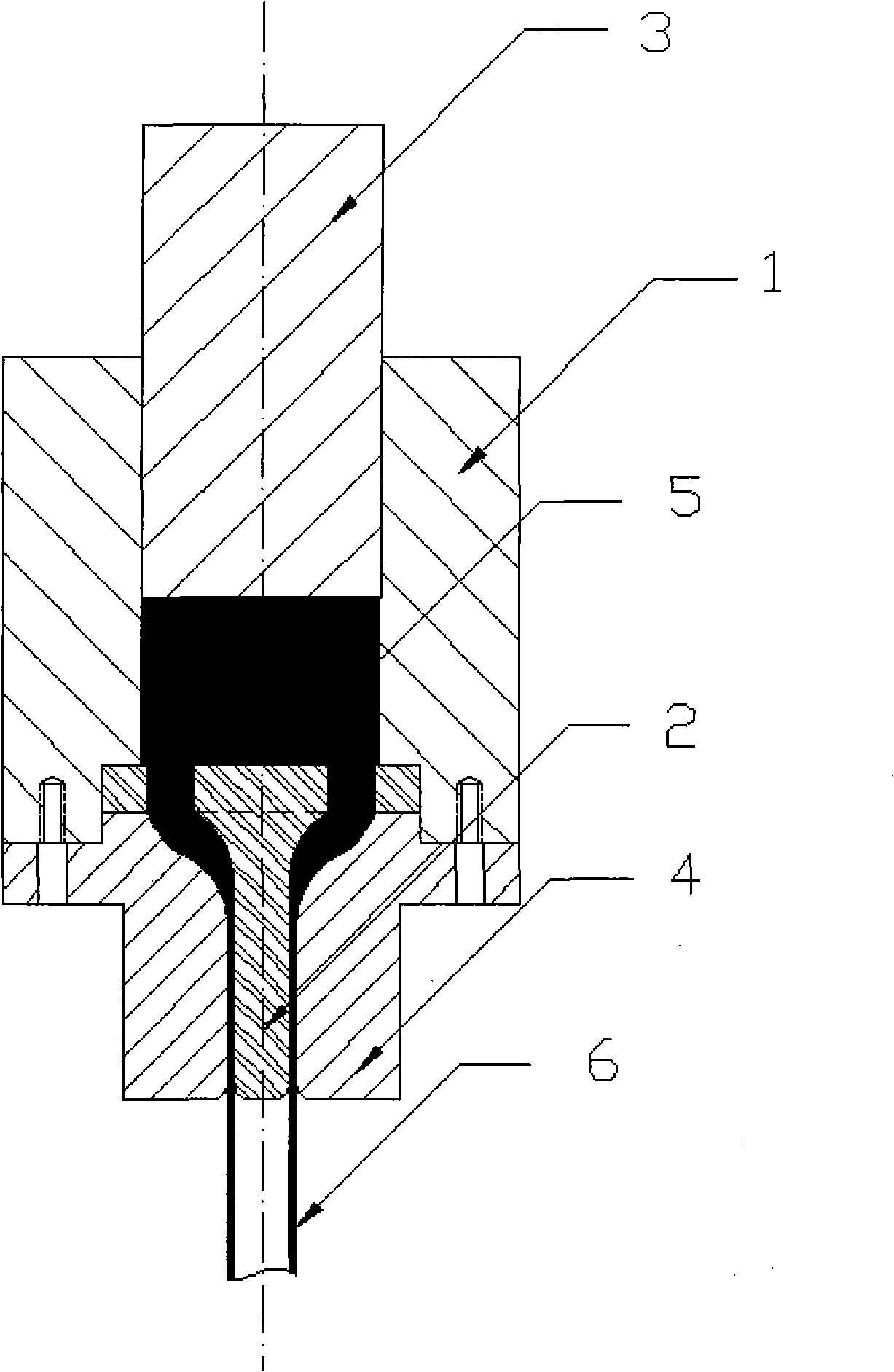

[0045] The preparation method of the silicon carbide ceramic tube of the present invention has a simple process and mainly includes raw material preparation, extrusion molding, drying, high-pressure densification and homogenization, pyrolysis and firing processes.

[0046] The preparation method uses solid particle powder and high-molecular materials with high carbon yield as raw materials. After air-drying and aging treatment, a tubular prefabricated body is prepared in an extrusion molding die, and then a high-pressure compaction is carried out in a hot isostatic press. After melting, pyrolysis and sintering, the specific preparation process is as follows:

[0047] (1) Mix solid particle powder (silicon carbide powder, silicon powder or both mixed powder), polymer material, curing agent and organic solvent in a certain proportion, ball mill after mechanical stirring, and filter to obtain slurry. Slurry solution solute is 5~70% (preferably range is 40~70%) of total mass; Afte...

Embodiment 1

[0060] Blend silicon carbide powder with an average particle size of 5 μm and phenolic resin with a mass ratio of 65%: 35%, and then add p-toluenesulfonic acid (accounting for 5% of the resin mass), and then co-dissolve in absolute ethanol, and mechanically stir After ball milling and filtering, the slurry is obtained, and the solute of the slurry solution is 70% of the total mass; air-dried to remove certain ethanol in the slurry, so that the air-dried organic solvent mass content is 1%, and then the above-mentioned slurry is heated at room temperature Aging for 20 hours. Put the above-mentioned raw materials into the inner cavity of the extrusion mold and extrude them, so that the raw materials are extruded from the annular outlet under the mold to form a tubular prefabricated body, and then dried in an oven at 50°C for 60 minutes; then the dried The tubular prefabricated body is subjected to 1000MPa, 240°C high-pressure densification and homogenization in a hot isostatic pr...

Embodiment 2

[0064] Blend silicon carbide powder with an average particle size of 5 μm and silicon powder with an average particle size of 3 μm and phenolic resin with a mass ratio of 50%: 10%: 40%, and then add toluenesulfonic acid (accounting for 2% of the mass of the resin), and then co-dissolve In absolute ethanol, after mechanical stirring, ball milling, filtering, to obtain a slurry, the solute of the slurry solution is 60% of the total mass; air-drying removes a certain amount of ethanol in the slurry, so that the mass content of the organic solvent after air-drying is 5% %, then the above slurry was aged at 35°C for 20 hours. Put the above-mentioned raw materials into the inner cavity of the extrusion mould, extrude the raw materials from the annular outlet under the mold to form a tubular prefabricated body, and then dry them in an oven at 80°C for 20 minutes; The tubular prefabricated body is subjected to 600MPa, 400°C high-pressure densification and homogenization in a hot isost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com