Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17071 results about "Temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The resistivity, ρ, and resistance, R, are temperature dependant, usually having a positive temperature coefficient (resistance increases as temperature increases), except for some metal oxides and semiconductors which have a negative temperature coefficient.

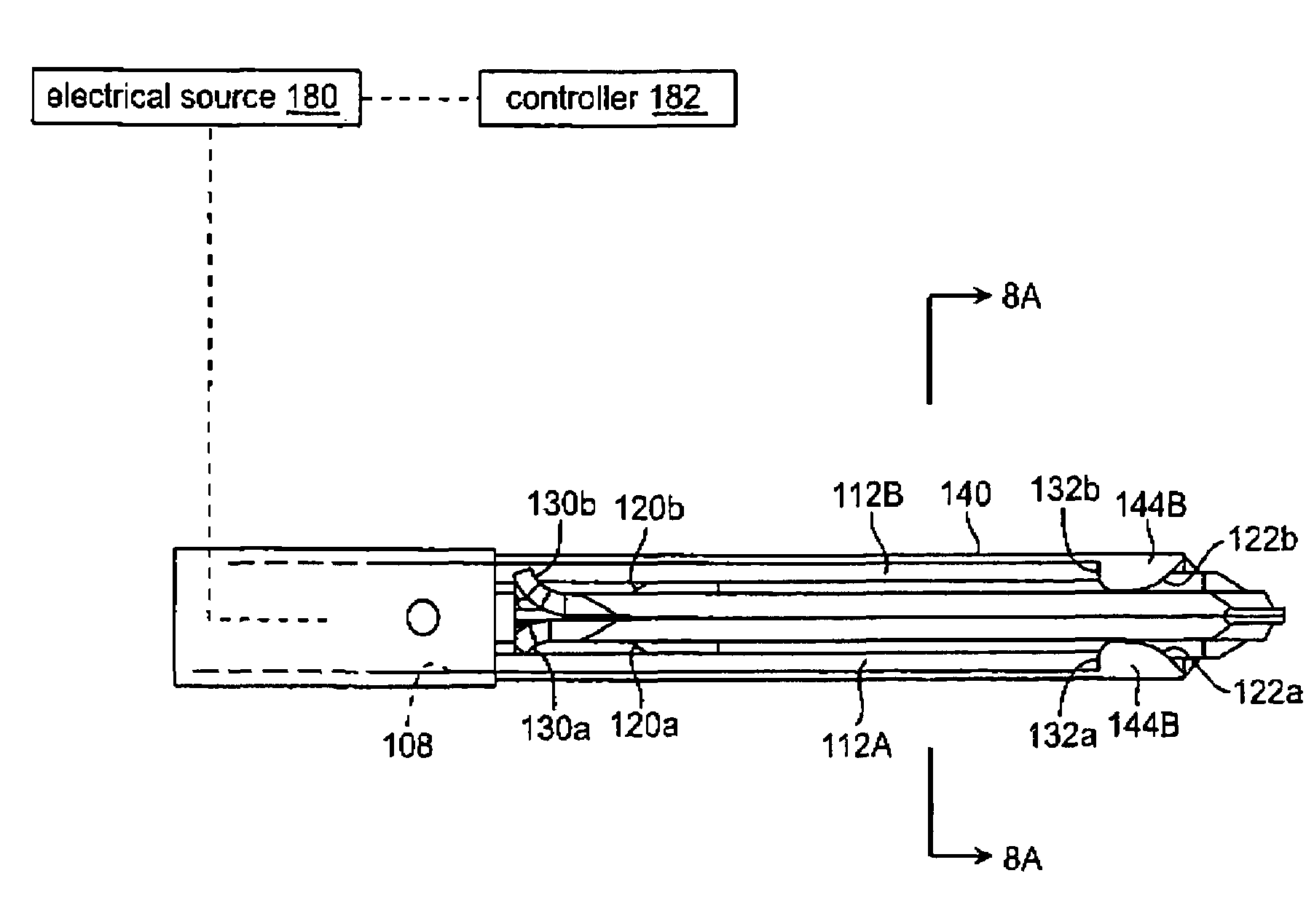

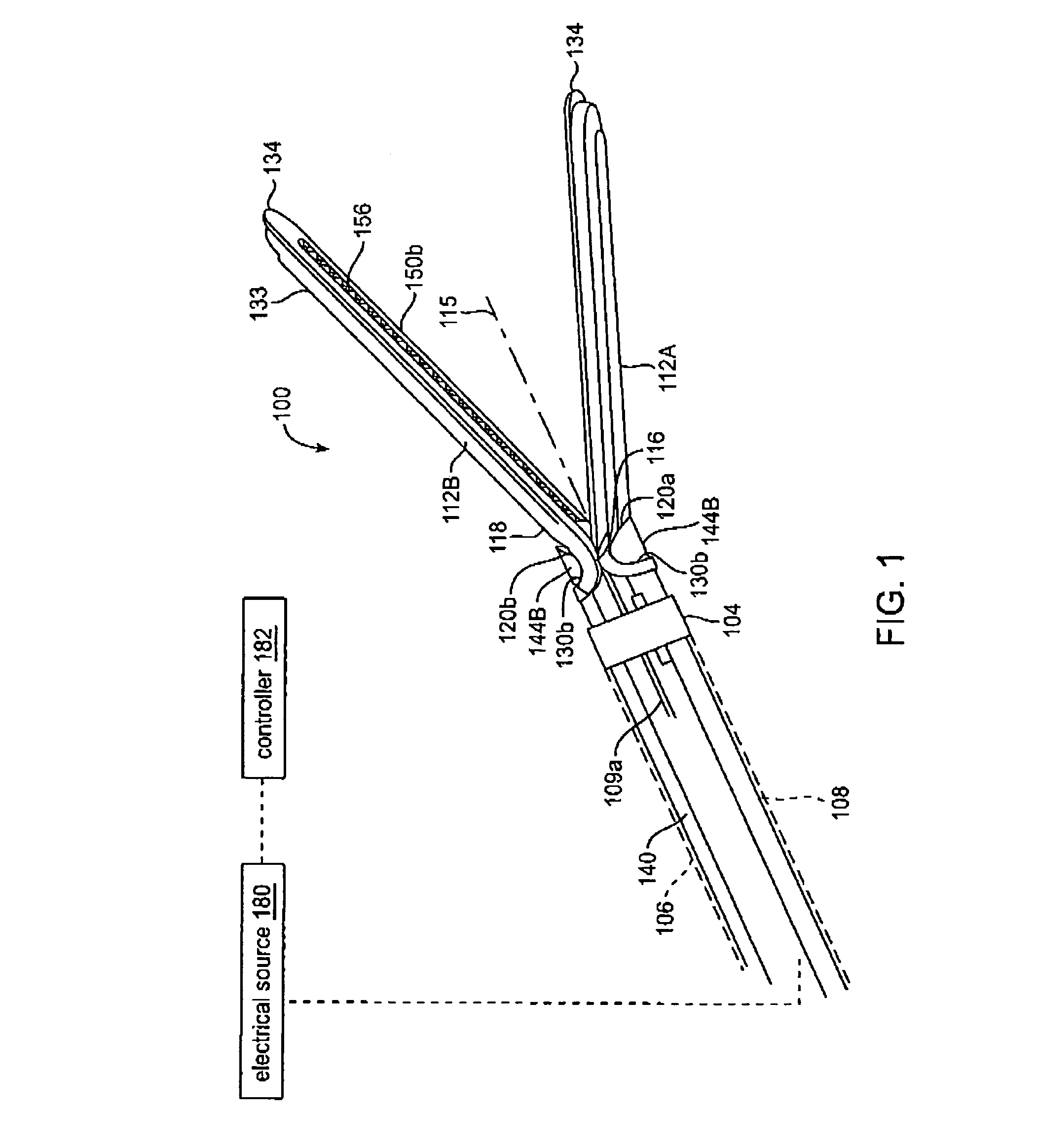

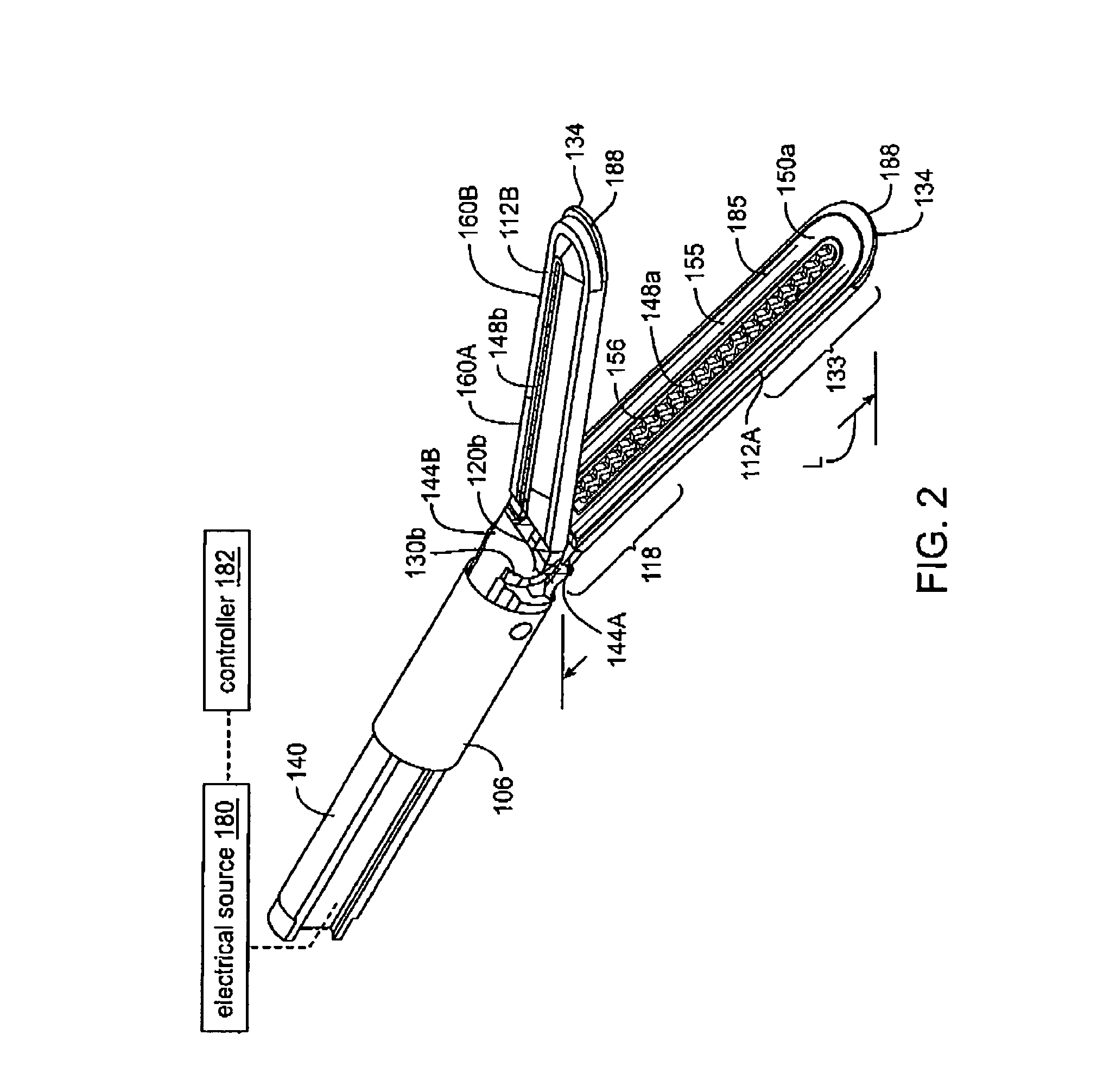

Jaw structure for electrosurgical instrument and method of use

InactiveUS7011657B2Improve the immunityEfficient weldingElectrotherapySurgical instruments for heatingTissue heatingVolumetric Mass Density

An electrosurgical medical device and technique for creating thermal welds in engaged tissue that provides very high compressive forces. In one exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying first and second surface portions that comprise (i) an electrically conductive material and (ii) a positive temperature coefficient (PTC) material having a selected increased resistance that differs at each selected increased temperature over a targeted treatment range. One type of PTC material is a doped ceramic that can be engineered to exhibit a selected positively sloped temperature-resistance curve over about 37° C. to 100° C. The 70° C. to 100° C. range can bracket a targeted “thermal treatment range” at which tissue welded can be accomplished. The engineered resistance of the PTC matrix at the upper end of the temperature range will terminate current flow through the matrix. In one mode of operation, the engagement plane cause ohmic heating within tissue from Rf energy delivery tissue PTC matrix is heated to exceed the treatment range. Thereafter, energy density in the engaged tissue will be modulated as the conductivity of the second portion hovers within the targeted treatment range to thereby provide optical tissue heating for purposes of tissue welding.

Owner:ETHICON ENDO SURGERY INC

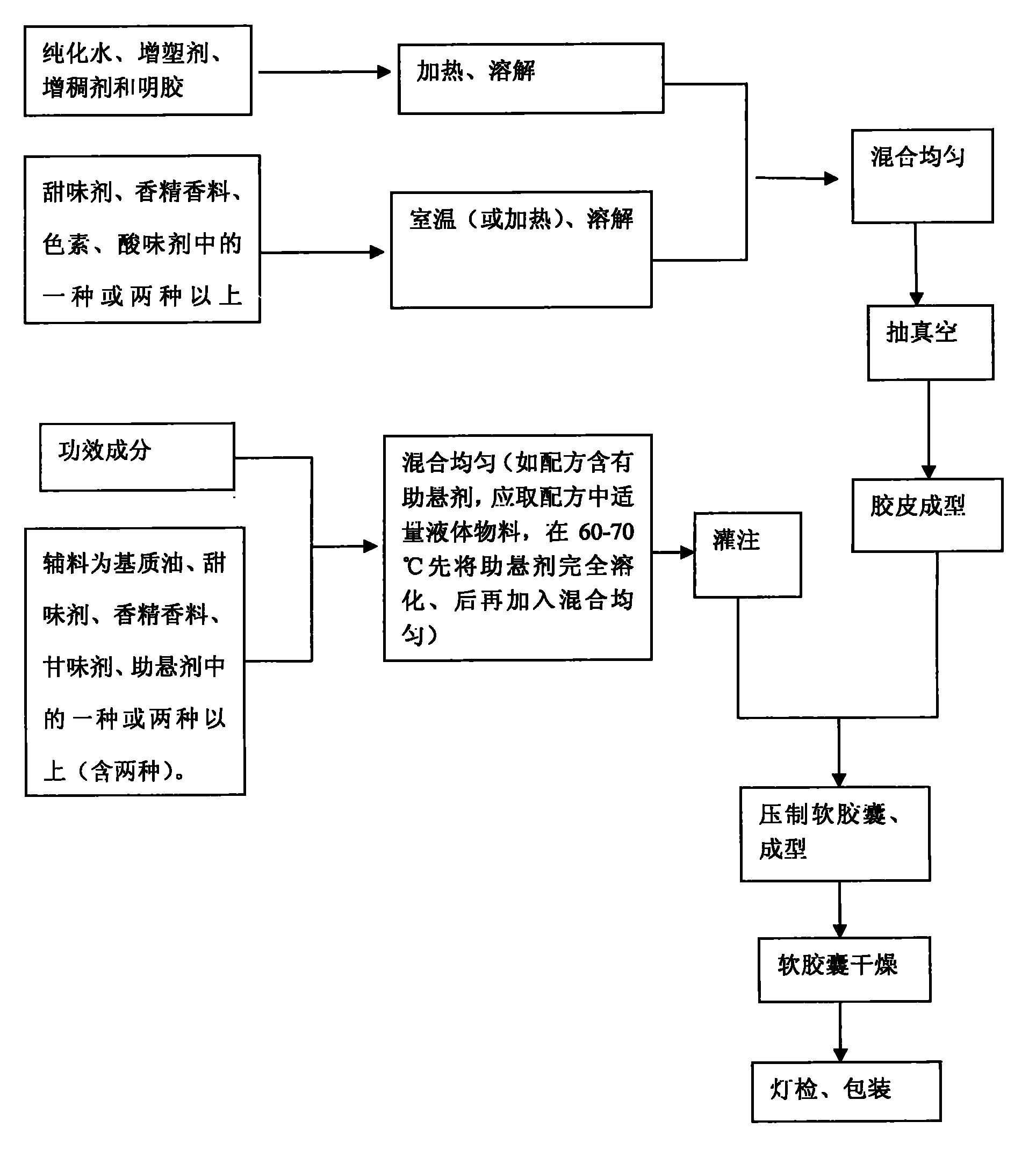

Chewable soft capsules and method for preparing same

ActiveCN101810336ADissolution stabilityRapid dissolutionFood shapingFood preparationFlavorPlasticizer

The invention discloses chewable soft capsules, which comprise capsule shells and contents sealed in the capsule shells. The chewable soft capsules are characterized by comprising the following raw materials in part by weight: 25 to 65 parts of glutin, 1 to 25 percent of thickening agent, 18 to 65 parts of plasticizer, 4 to 16 parts of water and a mixture containing one or more of 0.005 to 20 parts of sweetening agent, 0.005 to 2 parts of essence, 0.0001 to 10 parts of pigment and 0.0001 to 5 parts of acid additive. The invention also discloses a method for preparing the novel chewable soft capsules. The chewable soft capsules have the advantages of reasonable blending ratio, proper hardness, good temperature resistance, no adhesion, no deformation, stable storage, quick dissolution of effectively components and high chewiness; and when the chewing soft capsules are chewed, tastes of the capsule shells and the contents easily and uniformly spread in the mouth so as to cover up bad taste of raw materials.

Owner:SIRIO PHARMA CO LTD

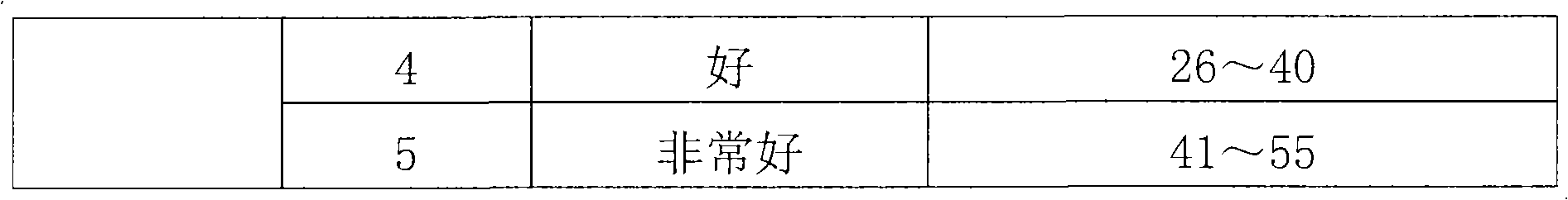

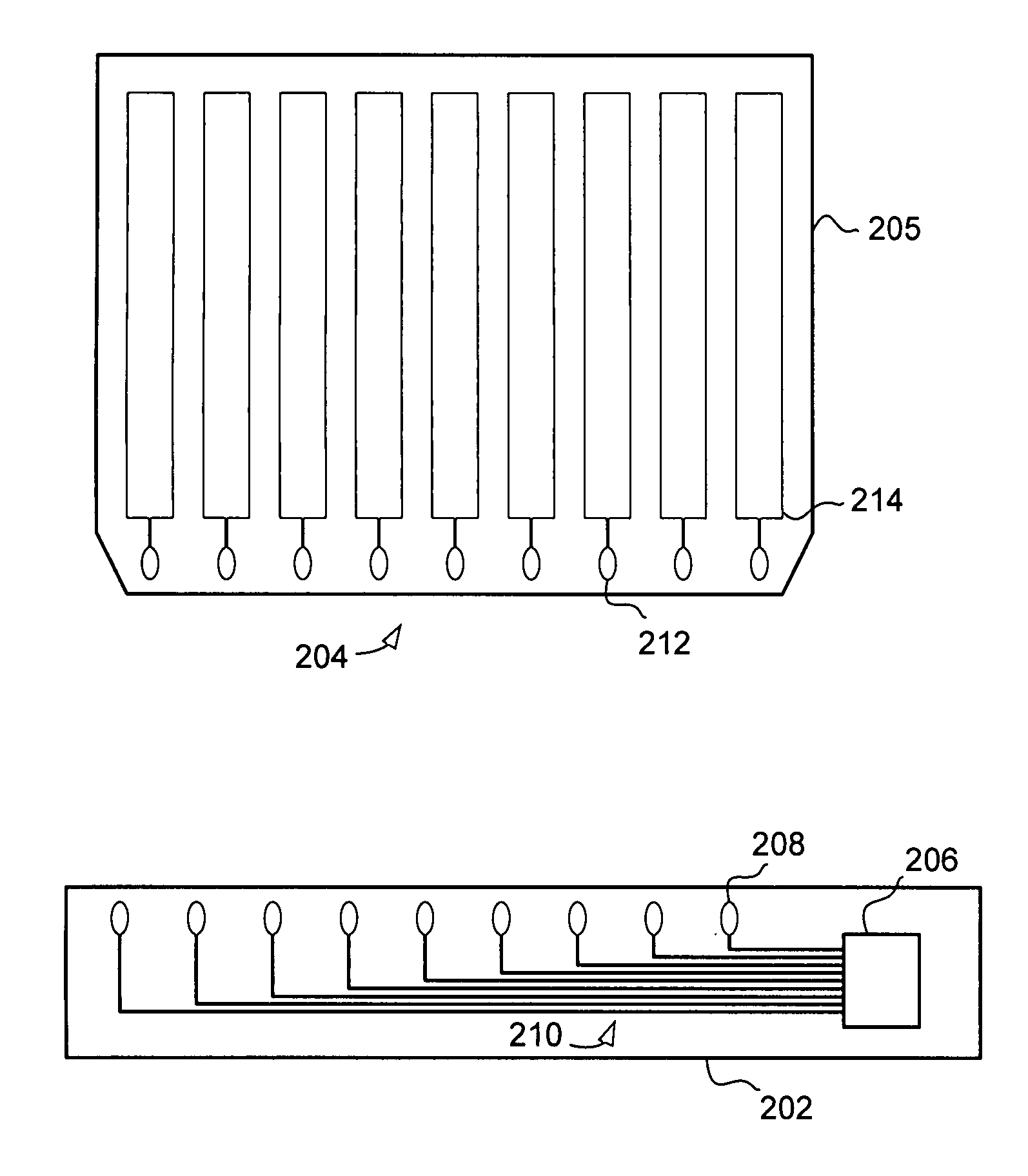

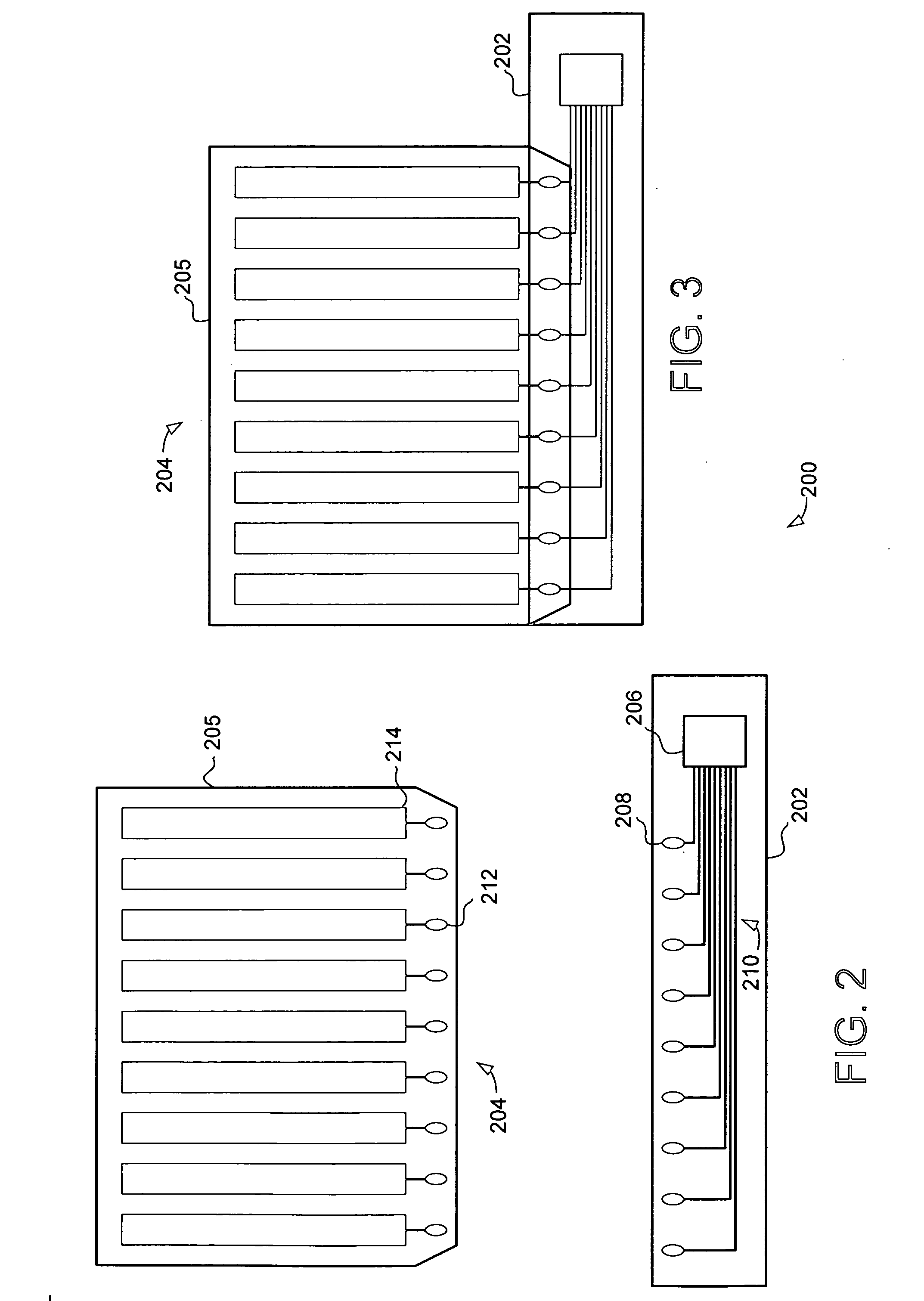

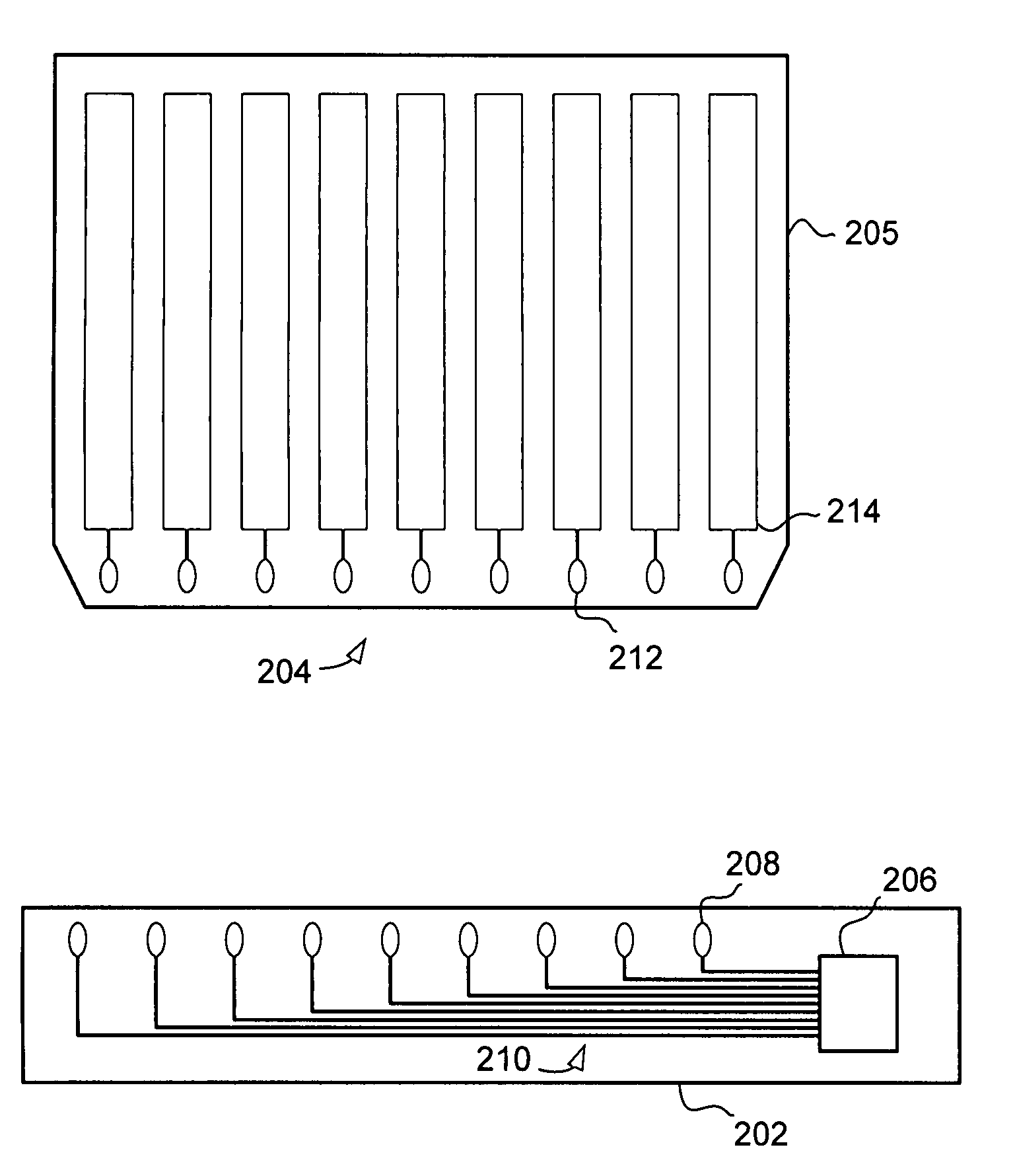

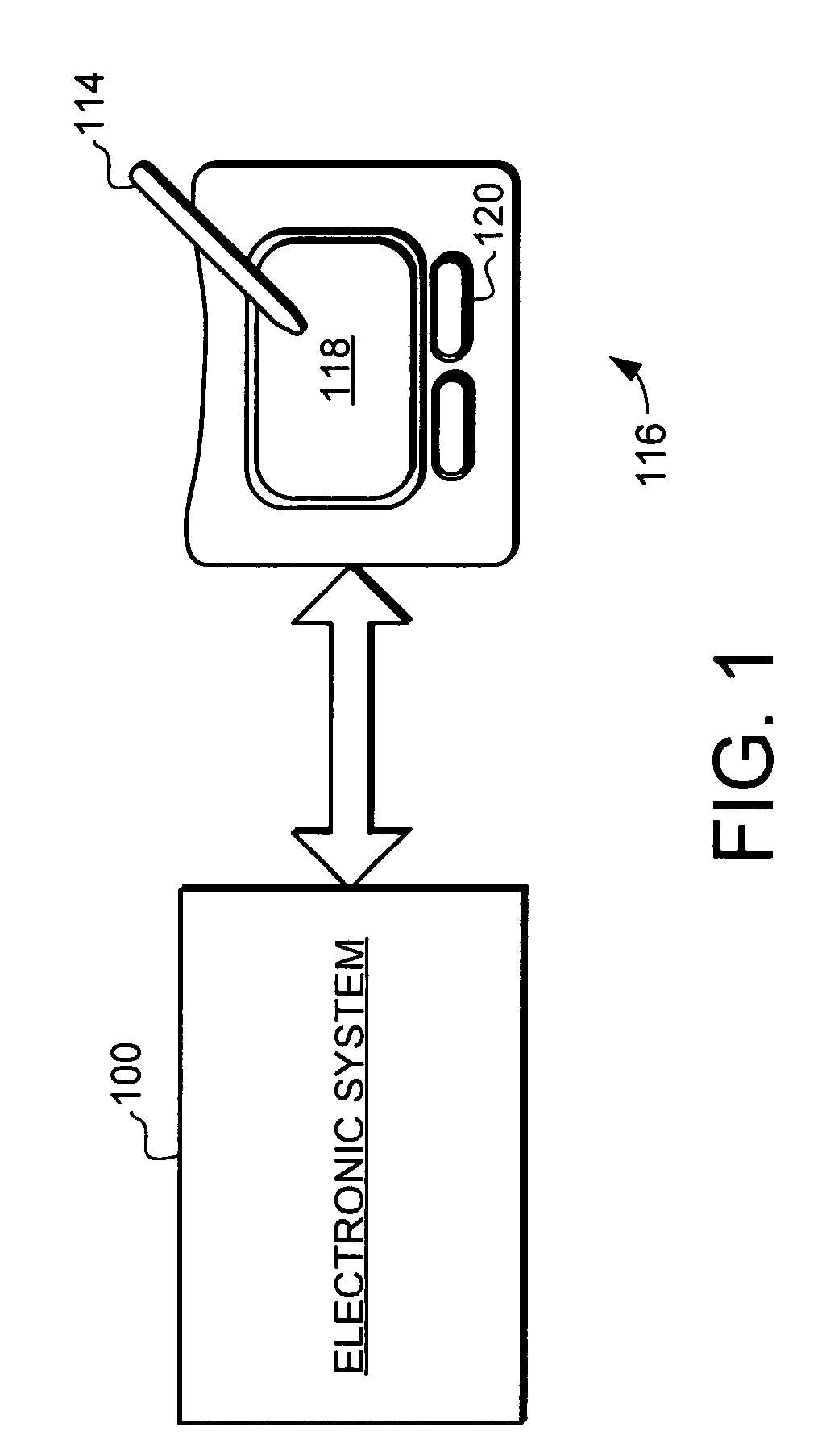

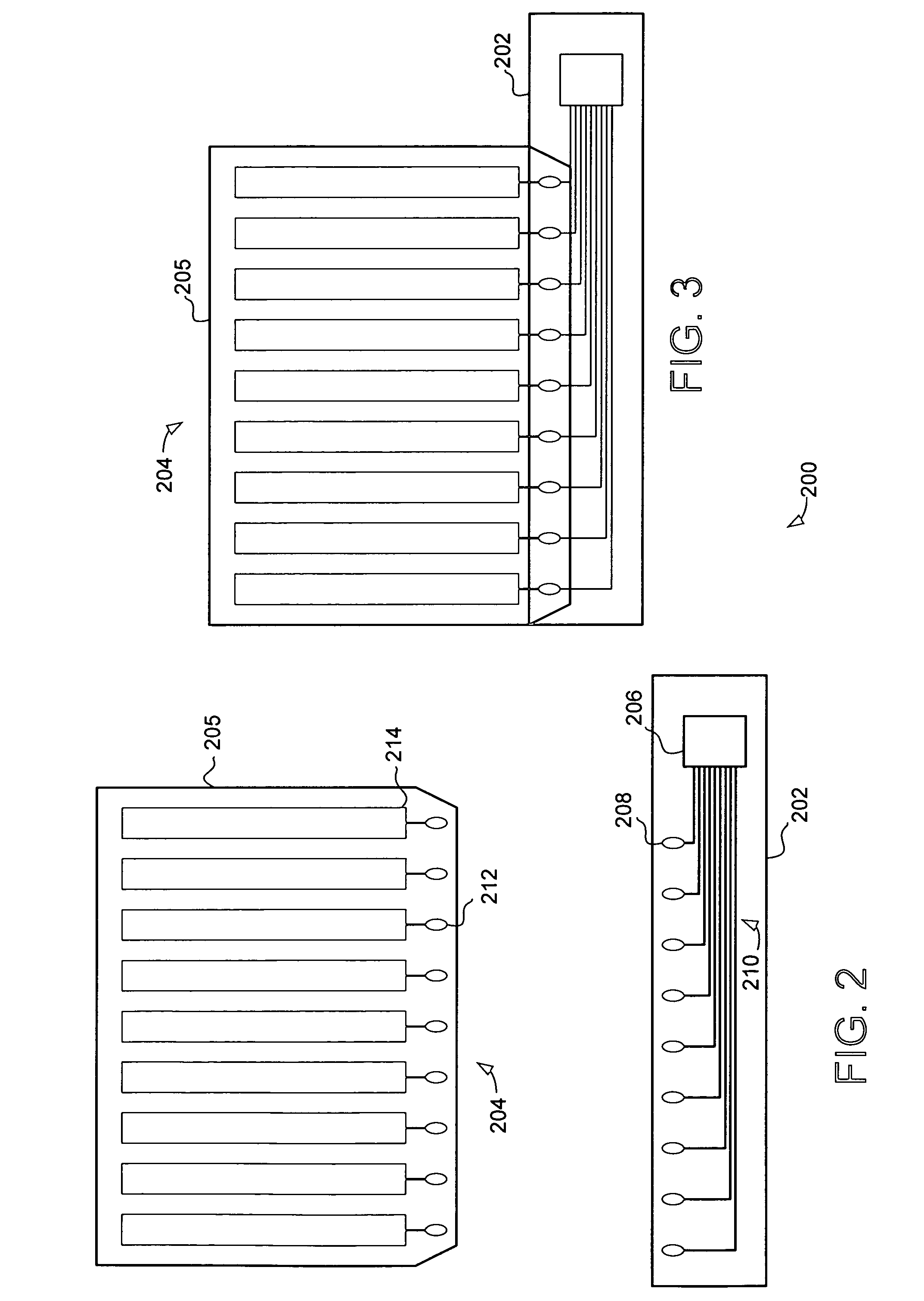

Touch pad with flexible substrate

ActiveUS20060274055A1High temperature resistanceIncrease flexibilityCircuit optical detailsCross-talk/noise/interference reductionEffective solutionFlexible circuits

A touch sensor device is provided that uses a flexible circuit substrate to provide an improved input device. Specifically, the present invention uses a touch sensor controller affixed to the flexible circuit substrate, which is coupled to a sensor component to provide a flexible, reliable and cost effective touch sensor suitable for a wide variety of applications. In one embodiment the touch sensor uses a flexible circuit substrate that provides relatively high temperature resistance. This allows the touch sensor controller to be affixed using reliable techniques, such as various types of soldering. The sensor component can comprise a relatively low-temperature-resistant substrate that can provide a cost effective solution. Taken together, this embodiment of the touch sensor provides reliability and flexibility at relatively low cost.

Owner:SYNAPTICS INC

Touch pad with flexible substrate

ActiveUS7439962B2Low costHigh temperature resistanceCircuit optical detailsTransmission systemsEffective solutionFlexible circuits

Owner:SYNAPTICS INC

Catalyst for preparing propylene by propane dehydrogenation and its prepn.

InactiveCN101015802AHigh selectivityImprove reaction stabilityCatalyst carriersHydrocarbonsAdhesiveDehydrogenation

The invention relates to a catalyst for dehydrogenating propane to prepare propone, which uses thermal-resistant oxide as carrier, uses palladium-group metal as main catalyst, uses IV A group metal and rare-earth metal as agents, uses halogen as modifier, and uses inorganic oxide with high temperature resistance as adhesive. The inventive catalyst under high temperature and low pressure has higher propane transfer rate, propone selectivity and reaction stability. And the preparation comprises that at 60-100Deg. C, immerging thermal-resistant oxide with rare-earth metal water solution for 2-10h, at 60-180Deg. C baking for 2-10h, at 400-600Deg. C baking for 3-10h, immerging said carrier and the water solution which contains palladium metal and IVA metal at 60-100Deg. C for 2-10h, and baking for 2-10h at 60-180Deg. C, adding adhesive, protruding agent and acid gel solvent, protruding and shaping, baking for 2-10h at 60-180Deg. C, activating for 3-10h at 400-600Deg. C, and reducing for 2-10h in hydrogen flow at 400-600Deg. C.

Owner:SOUTHEAST UNIV

Laser-cladding high-entropy alloy powder and preparation method of high-entropy alloy coating

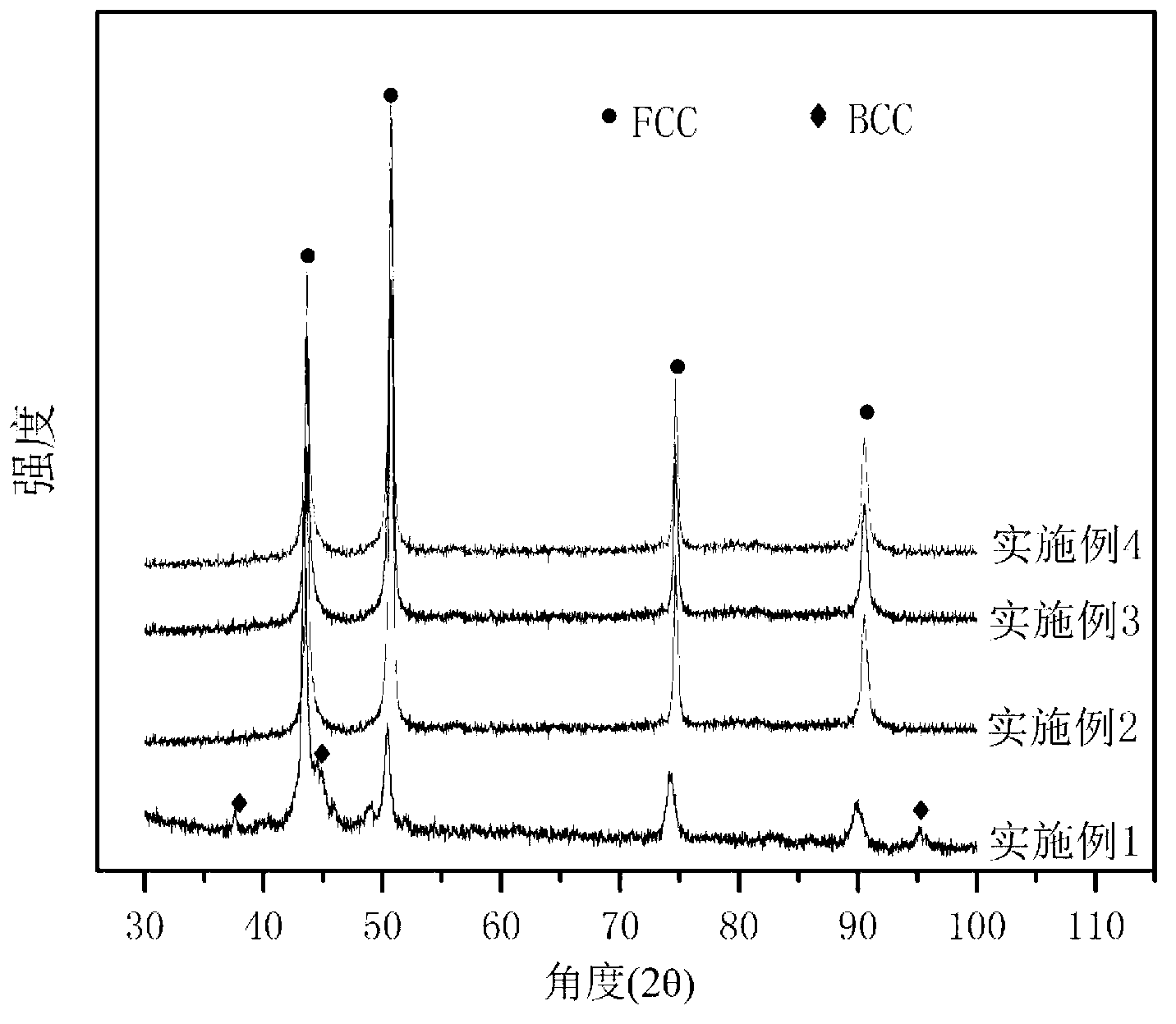

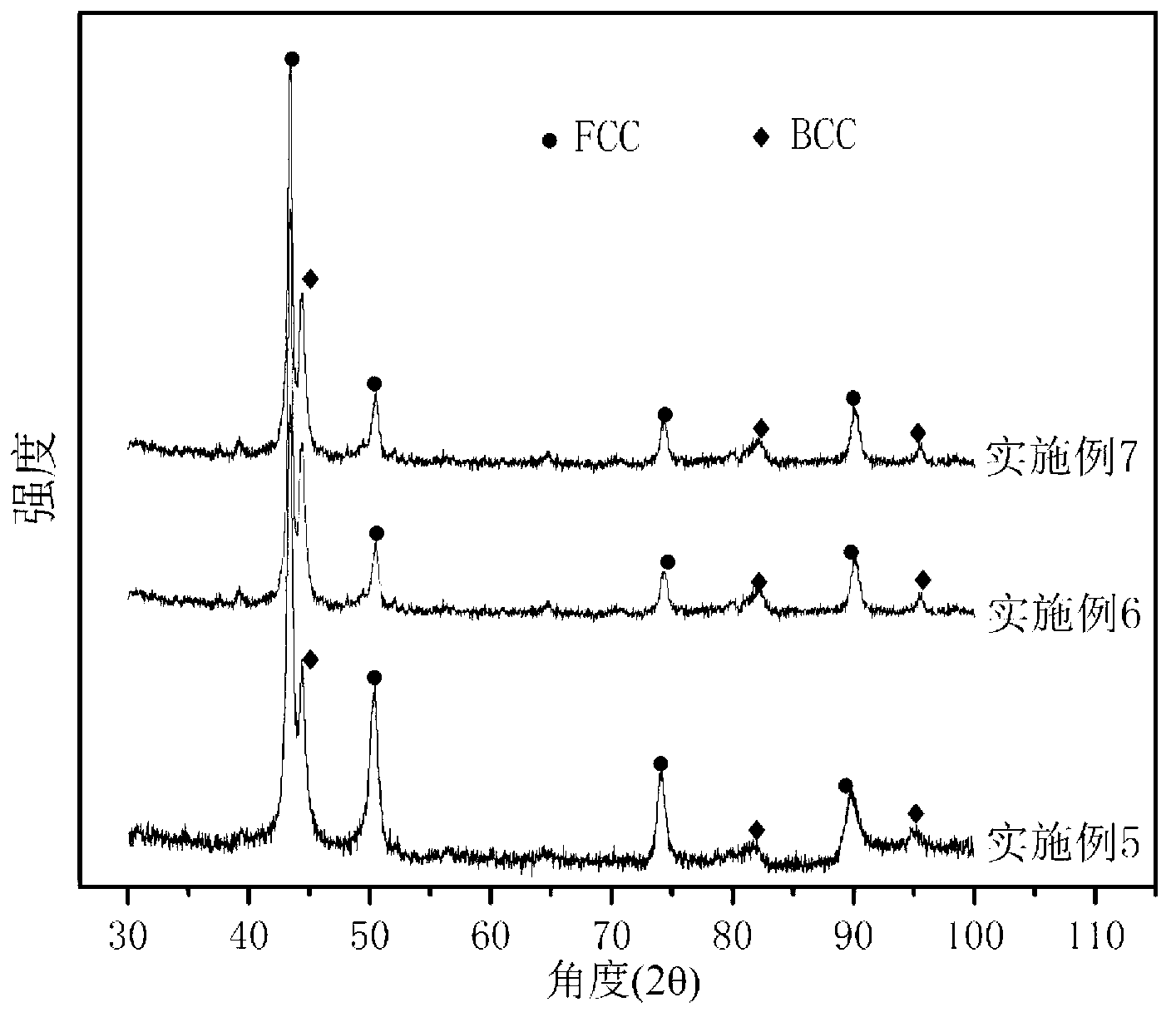

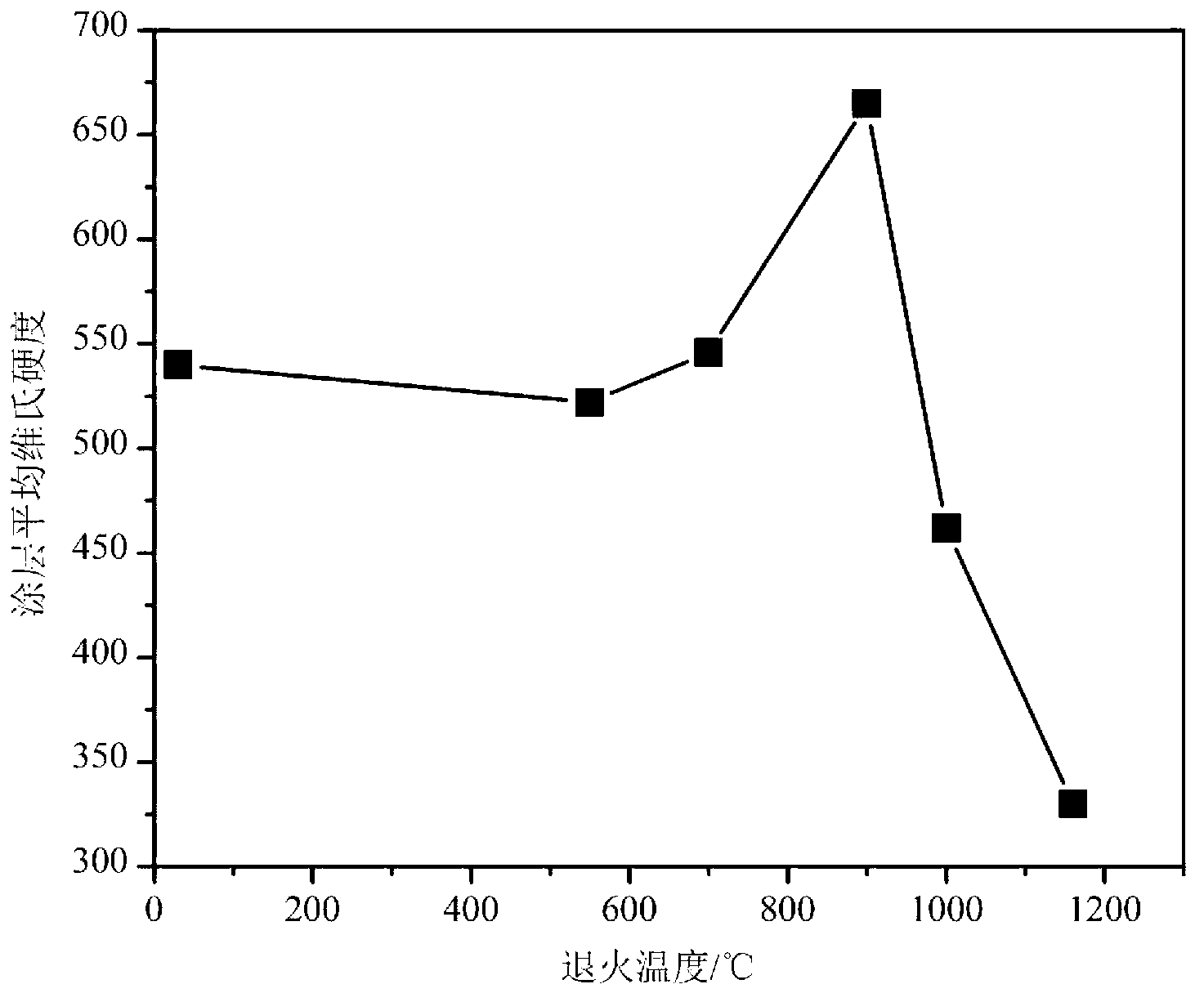

ActiveCN103290404AImprove coating qualityHigh hardnessMetallic material coating processesHigh entropy alloysOperability

The invention discloses laser-cladding high-entropy alloy powder. The laser-cladding high-entropy alloy powder comprises the following elements in percentage by weight: 10%-15% of Fe, 14%-17% of Cr, 22%-25% of Ni, 22%-24% of Co, 22%-24% of Mn, 0%-4% of Si and 0%-4% of B. The invention further discloses a scheme of adding another element Al based on the gradients of the scheme, and a method for preparing a high-entropy alloy coating by using the laser-cladding high-entropy alloy powder. According to the technical scheme, after laser cladding, good coating quality is realized; a phase structure of the coating retains peculiar solid solution structure of high-entropy alloy, and the atomic percent of each main metal element in the cladding coating satisfies nominal category of the high-entropy alloy; the coating has a plurality of excellent performances of high rigidity, high temperature resistance, wear resistance, corrosion resistance and the like; the technical repeatability and operability are both greatly improved, so that the high-entropy alloy is popularized and applied in surface modification of laser materials.

Owner:ZHEJIANG UNIV OF TECH +1

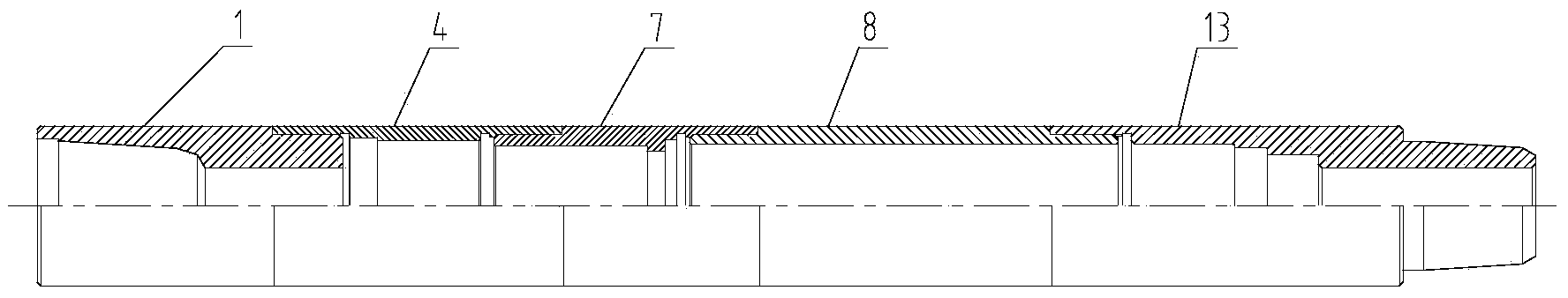

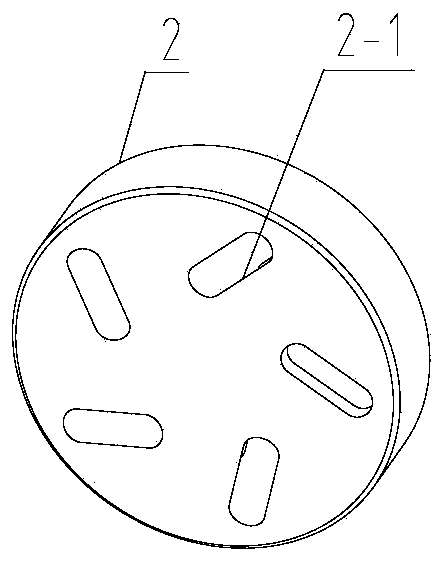

High-temperature resistant vibration tool for horizontal well

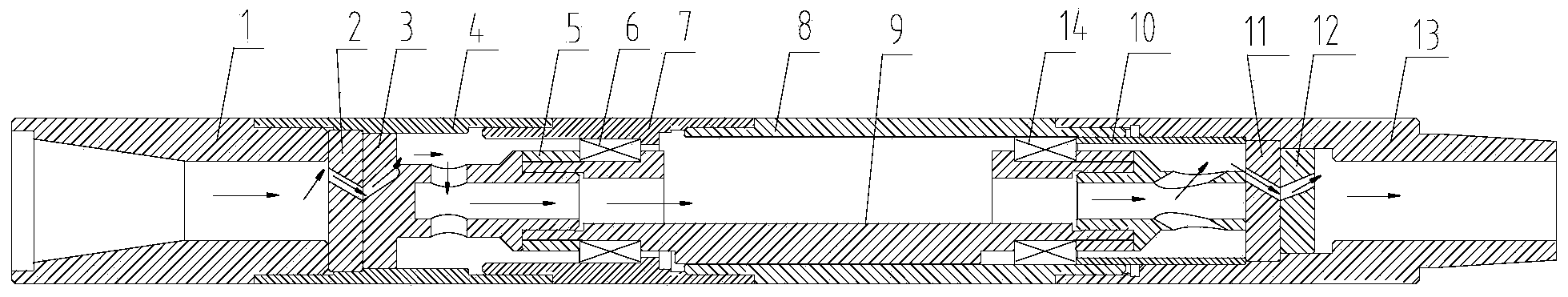

ActiveCN104234651AHigh working reliabilityImprove high temperature resistanceVibration devicesUpper jointTemperature resistance

The invention relates to a high-temperature resistant vibration tool for a horizontal well. The high-temperature resistant vibration tool for the horizontal well comprises a shell assembly and a vibration assembly arranged in the shell assembly and is characterized in that the shell assembly comprises an upper joint, an upper joint sleeve, a connection sleeve, a cover and a lower joint which sleeve from top to bottom in sequence; the vibration assembly comprises an upper end turbine, an eccentric shaft and a lower end turbine which are connected in sequence from top to bottom; the vibration assembly is arranged in the shell assembly by an upper end bearing and a lower end bearing; the upper end bearing and the lower end bearing respectively sleeve two end shafts of the eccentric shaft; an upper thrust ring and a lower thrust ring are respectively arranged at two ends of the vibration assembly and are respectively arranged in the upper joint sleeve and the lower joint; a channel for allowing fluid to flow is arranged in each of the shell assembly and the vibration assembly. The high-temperature resistant vibration tool for the horizontal well has the beneficial effects that the work reliability and high temperature resistance of the tool are improved, the deepening depth is increased, and enough drilling and pressing effects are applied.

Owner:JEREH ENERGY SERVICES

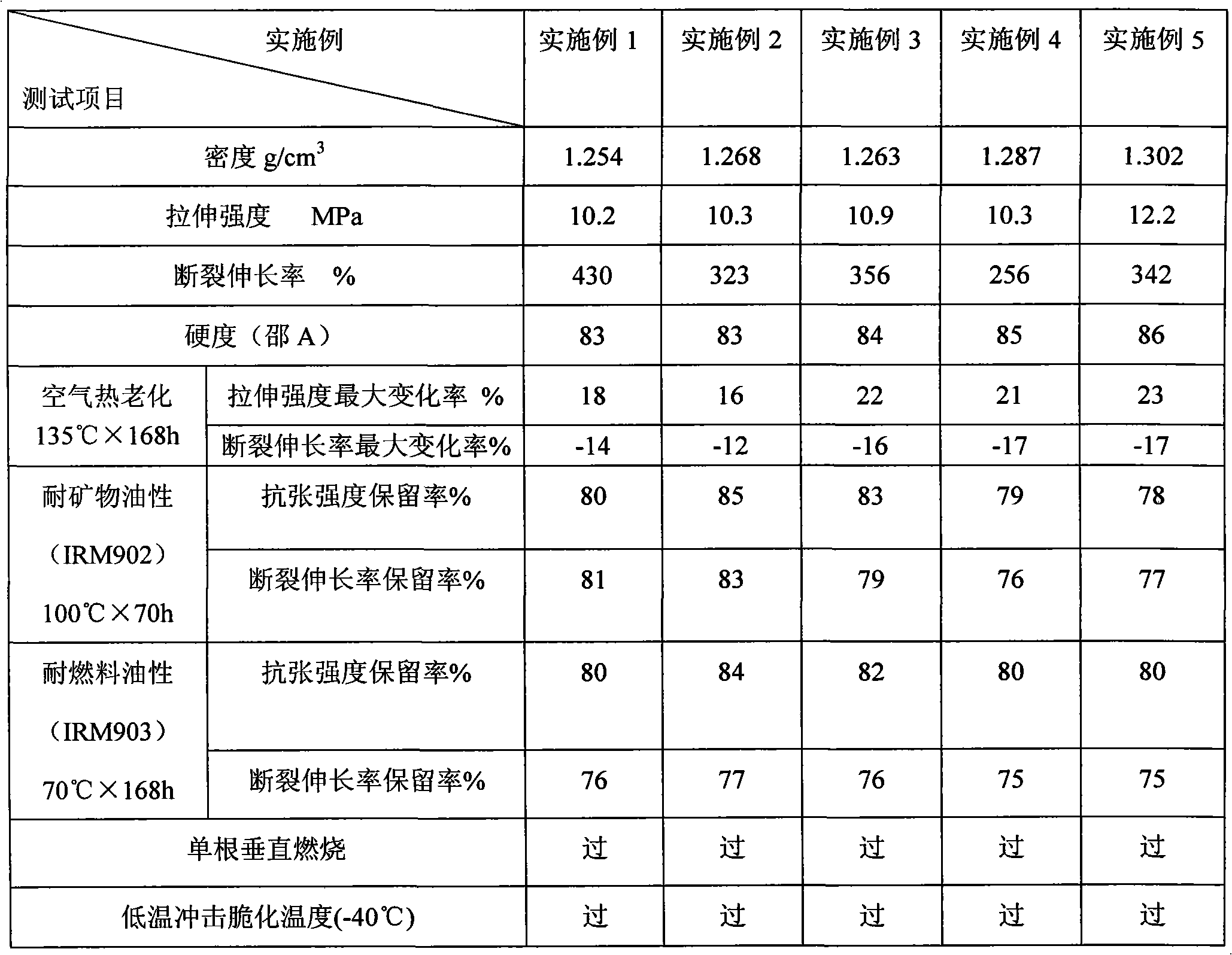

Irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material

ActiveCN102070821AGood oil resistanceGood flexibilityPlastic/resin/waxes insulatorsCross-linkSilanes

The invention provides an irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material which comprises the following components in parts by weight: 60-90 parts of ethylene-vinylacetate copolymer, ethylene-propylene-diene rubber and ethylene-octylene copolymer, 0-20 parts of nitrile rubber, 10-30 parts of interface compatilizer, 80-130 parts of flame retardant, 2-15 parts of flame-retardant synergist, 0.5-1.0 part of antioxidant, 1-2 parts of cross-linking sensitizing agent and 0.5-1.0 part of lubricant. The preparation method of the cable material in the invention mainly comprises the steps of silane surface modification treatment of the flame retardant, mixing and extruding of a double screw mixer-extruder unit or an internal mixer unit, brace water cooling or water ring particle cutting and the like. The cable material provided by the invention has the advantages of superior flame resistance (single cable can vertically burn), good mechanical properties, especially high softness, oil resistance, high-temperature resistance (the cable material can be used in a range of minus 40 DEG C-125 DEG C), low smoke, low toxicity and excellent processability.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

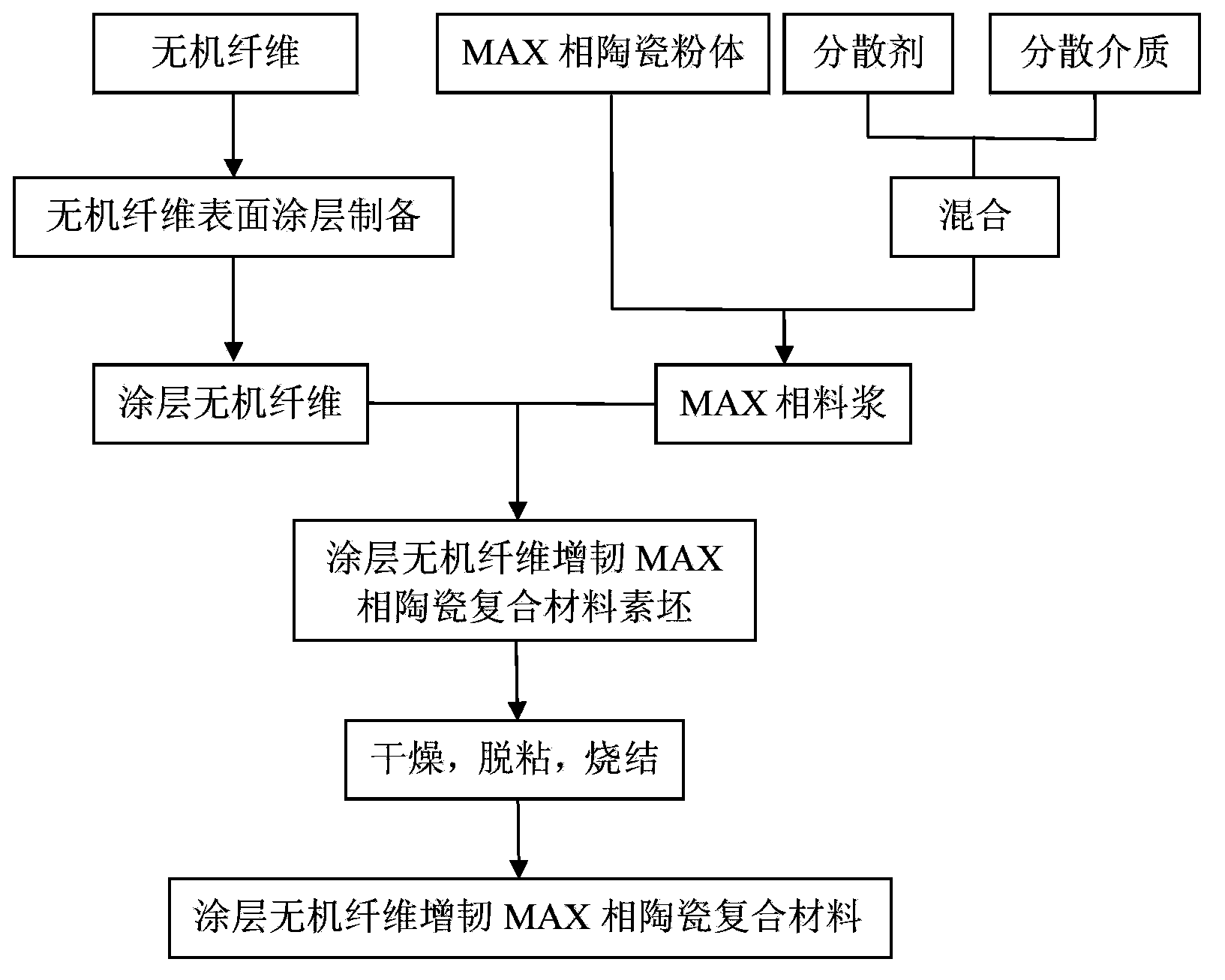

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

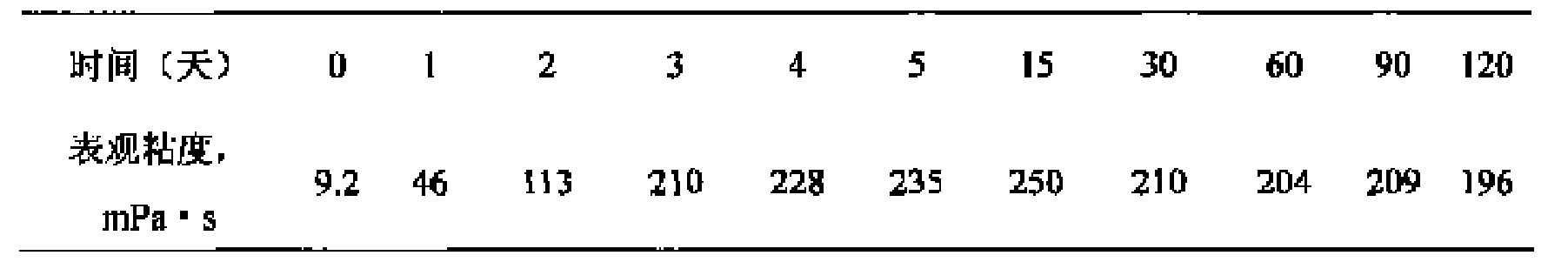

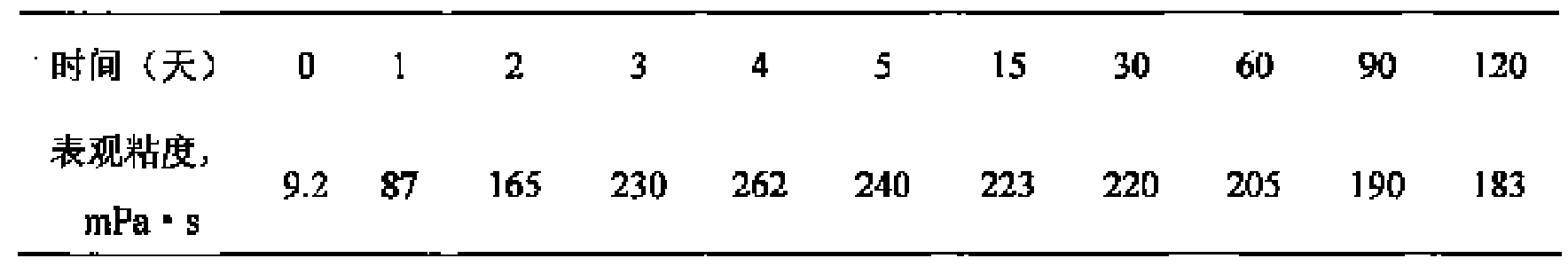

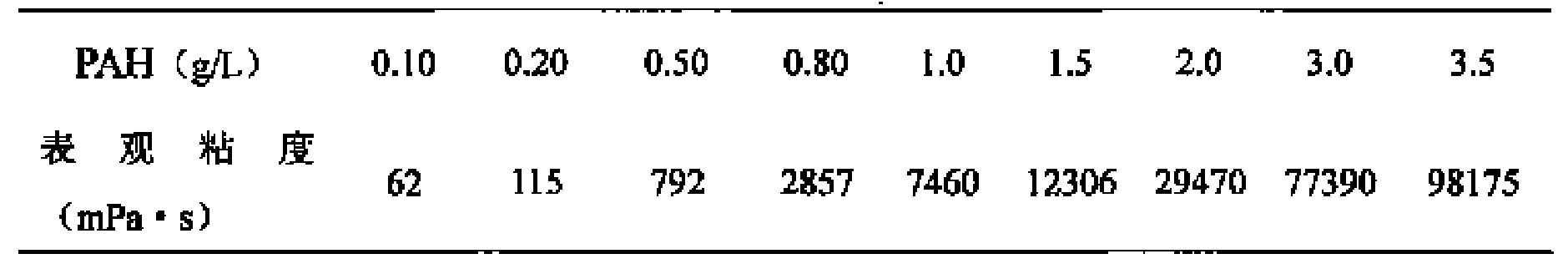

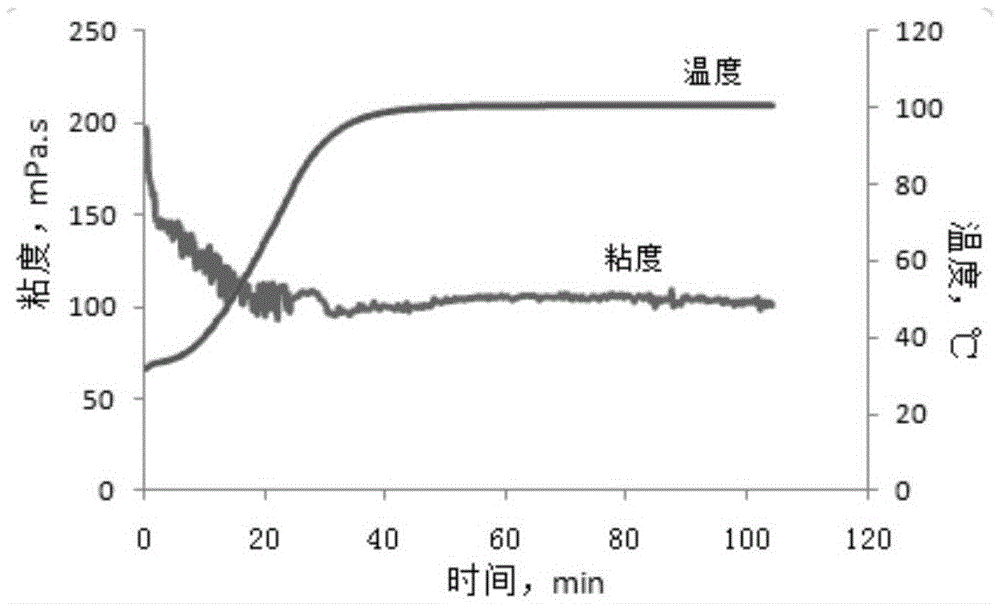

Temperature-resistant salt-resistant efficient gel, and preparation and use thereof

InactiveCN101475667AImprove solubilityGood viscosity increasing effectDrilling compositionSulfite saltAging resistance

The invention discloses a temperature resistant salt tolerant high efficiency gel and a preparation method and application thereof. The preparation method is characterized in that the preparation method comprises the following steps: preparing a comb-shaped associated copolymer PAH containing macromonomers and functional hydrophobic monomers into an aqueous solution having the concentration of 0.1 to 4g / L, the crosslinking agent concentration of 0.01 to 1.0g / L, the surfactant concentration of 0.01 to 8mmol / L and the sodium sulfite thermal stabilizer concentration of 0.005 to 1.0g / L; adding the aqueous solution into a mixing container with a stirring device; stirring the aqueous solution evenly at the room temperature; regulating the pH value of the solution to be equal to between 4 and 11, and obtaining a temperature resistant salt tolerant high efficiency gel polymer solution system used for tertiary oil recovery and scavenge, displacement modification, profile modification or water shutoff. The polymer solution system has micro-crosslinking to form the gel during the flowage inside the oil reservoir. The gel has good elasticity, not easy dehydration, stable gelling performance, and excellent tackification, temperature resistance, salt tolerance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

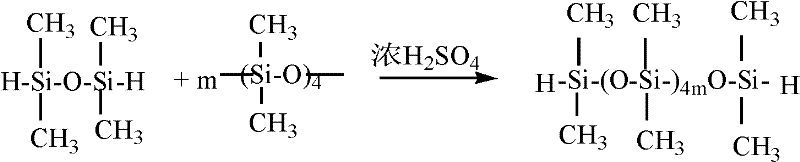

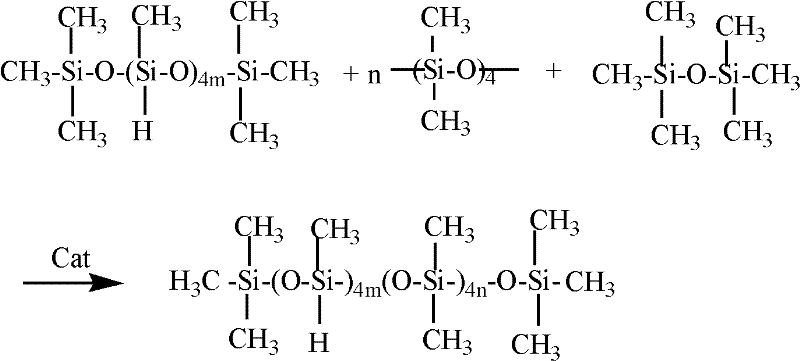

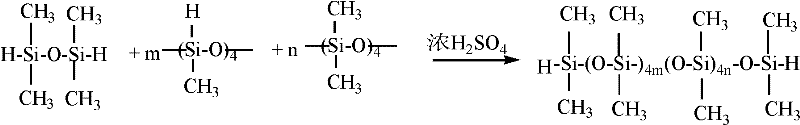

A kind of water-soluble polyether modified silicone defoamer and its preparation and compounding method

The invention relates to a water-soluble polyether modified silicone defoamer. The preparation method of the polyether-modified silicone defoamer comprises the following steps: firstly, adding terminal allyl polyoxyalkylene ether into a container for stirring, removing water; then adding solvent and low hydrogen-containing silicone oil into the above solution and stirring; then The catalyst is added to carry out stirring and heating reaction under N2 atmosphere and reflux condensation conditions; after the reaction is completed, the solvent and low boilers are removed to obtain the water-soluble polyether modified silicone. The invention also provides a compounding method of the water-soluble polyether modified silicone defoamer prepared by the above preparation method. The defoaming agent solves the problems that polysiloxanes are difficult to dissolve in water, have poor high temperature resistance and strong alkali resistance, and polyether defoaming agents have unsatisfactory defoaming speed and foam suppression time. The compounding method of water-soluble polyether-modified silicone defoamer solves the problems of incomplete emulsification of simethicone-type defoamer, demulsification when used, low temperature resistance and poor foam suppression ability.

Owner:黄山市强力化工有限公司

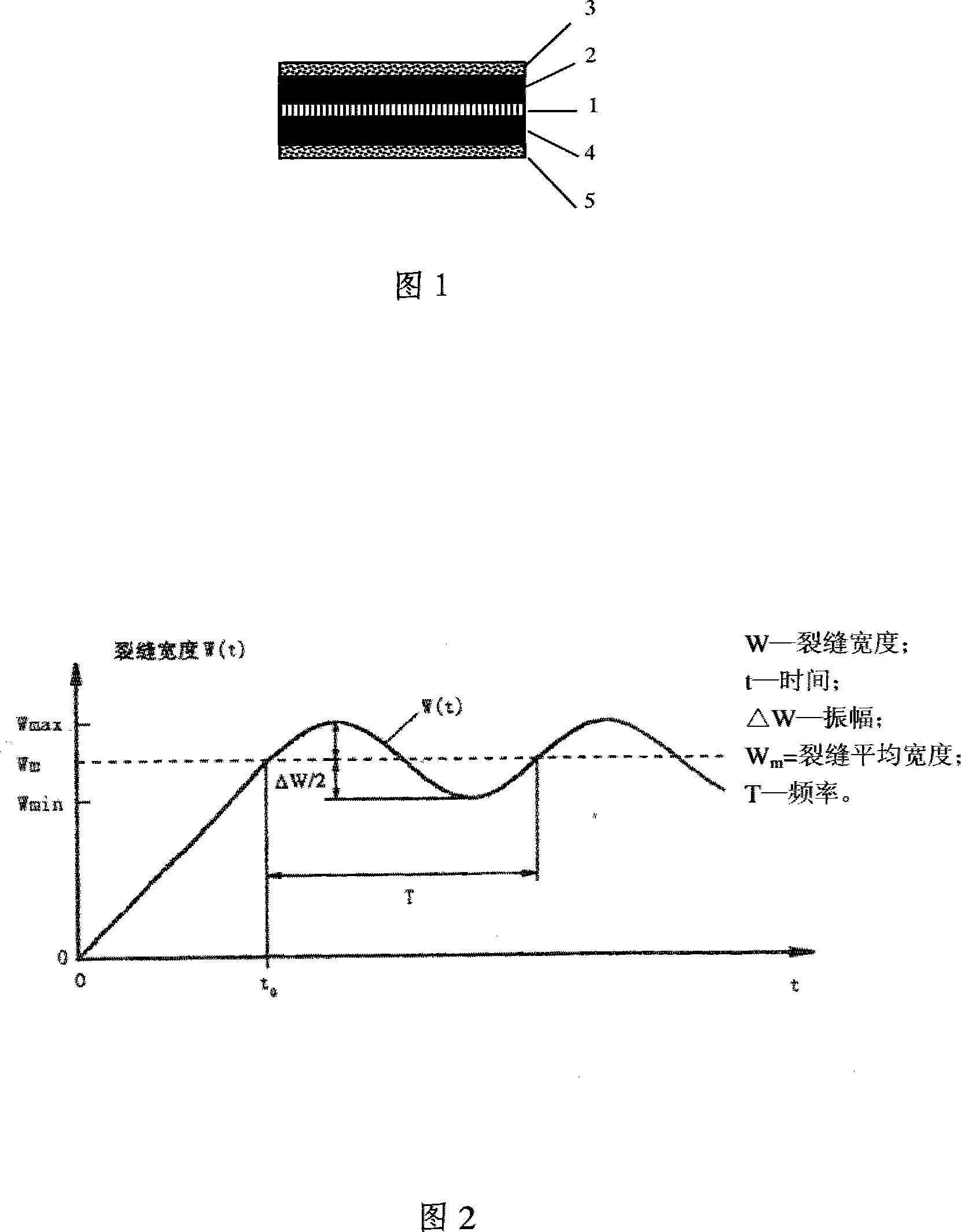

Channeling preventing and plugging agent and construction method for controlling plugging and sealing channeling by utilizing channeling preventing and plugging agent

ActiveCN105086967AExtend the production cycleEnhanced overall recoveryDrilling compositionSealing/packingEngineeringTemperature resistance

The invention provides a channeling preventing and plugging agent and a construction method for controlling plugging and sealing channeling by utilizing the channeling preventing and plugging agent. The channeling preventing and plugging agent comprises a high-temperature-resistance pre-plugging agent serving as a pre-posed pre-plugging plug, an enhanced gel plugging agent serving as an intermediate enhanced plug and a high-strength resin plugging agent serving as a postposed sealing plug. The channeling preventing and plugging agent has the characteristics of high temperature resistance, long-term stability, good plugging performance and the like. The invention further provides a construction method for controlling plugging and sealing channeling by utilizing the channeling preventing and plugging agent. The method has a simple constructing process, and can be used for constructing after the channeling preventing and plugging agent is directly prepared on the spot. The channeling preventing and plugging agent can be used for effectively solving the adverse impact of the steam / air channeling phenomenon of a heavy oil thermal production well on production, and has an important effect on prolonging the production cycle of a heavy oil well and improving the recovery efficiency.

Owner:PETROCHINA CO LTD

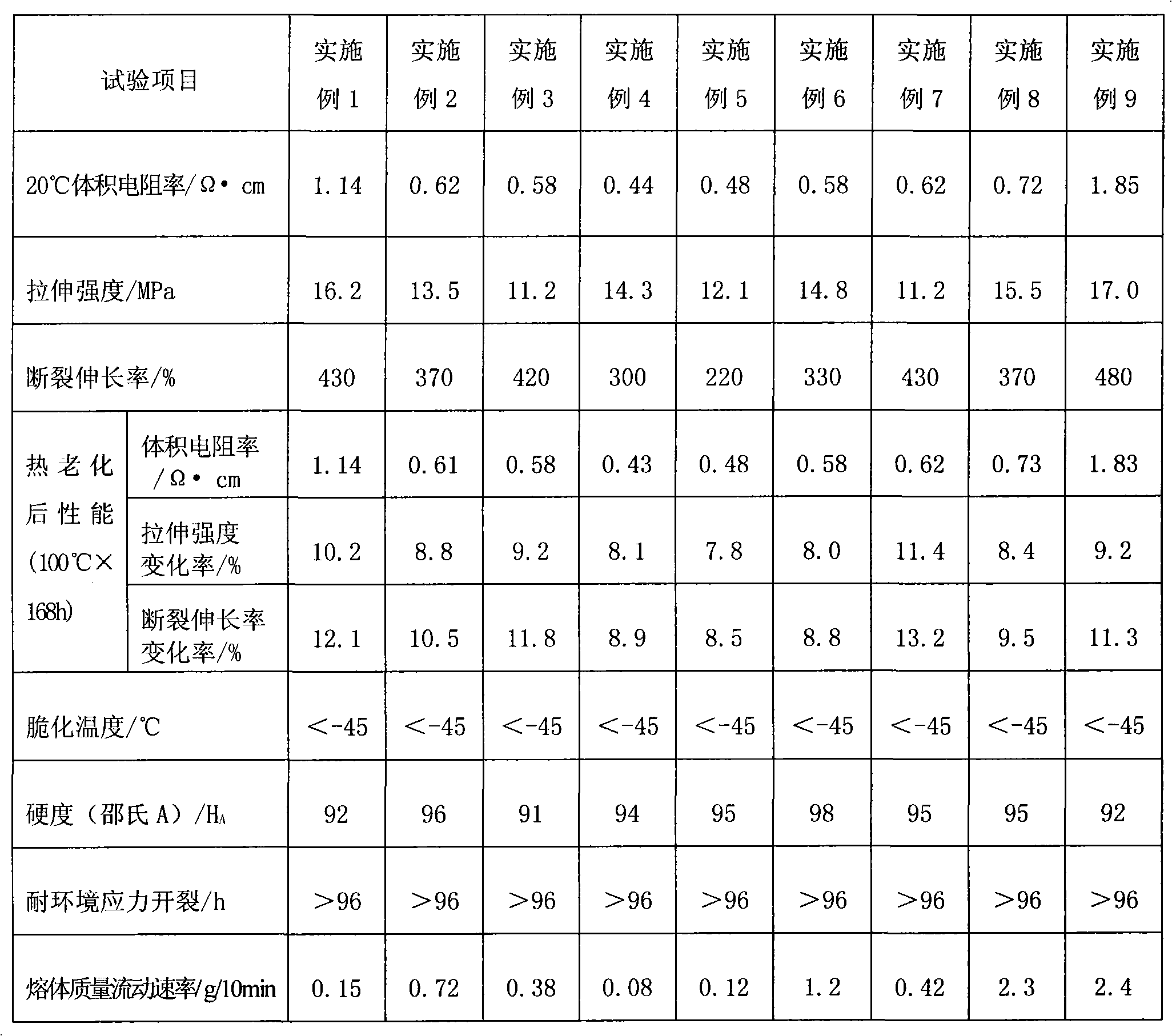

Composite type high-conductivity polymer material and preparation method thereof

ActiveCN101891914AImprove conductivityAvoid damageNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

The invention discloses a composite type high-conductivity polymer material and a preparation method thereof, which belongs to the technical field of new materials. The composite type high-conductivity polymer material is characterized by comprising the following raw materials in percentage by weight: 40-62 wt% of base resin compositions, 18-25 wt% of super conductive carbon black, 10-30 wt% of rubber filling oil, 1-3 wt% of low molecular wax, 0.2-0.8 wt% of fluoroelastomer processing aid (PPA), 0.5-2 wt% of lubricant, 1.5-3 wt% of inorganic filler and 0.5-2.5 wt% of other aids. The compositetype high-conductivity polymer material has the advantages of excellent high conductivity, environmental stress cracking resistance, weatherability, ozone resistance, ultraviolet resistance, favorable high temperature resistance, high impact resistance, oil resistance, solvent resistance and mechanical property, and can be used as an environment-friendly conductive polymer sheath material of an combined through earth line, a metal anticorrosive material of other ground cable, a conductive plastic cladding material of a conductive plastic cable positive wire, an optical cable flexible sheath material, and the like.

Owner:SHANDONG KEHONG WIRE & CABLE TECH CO LTD

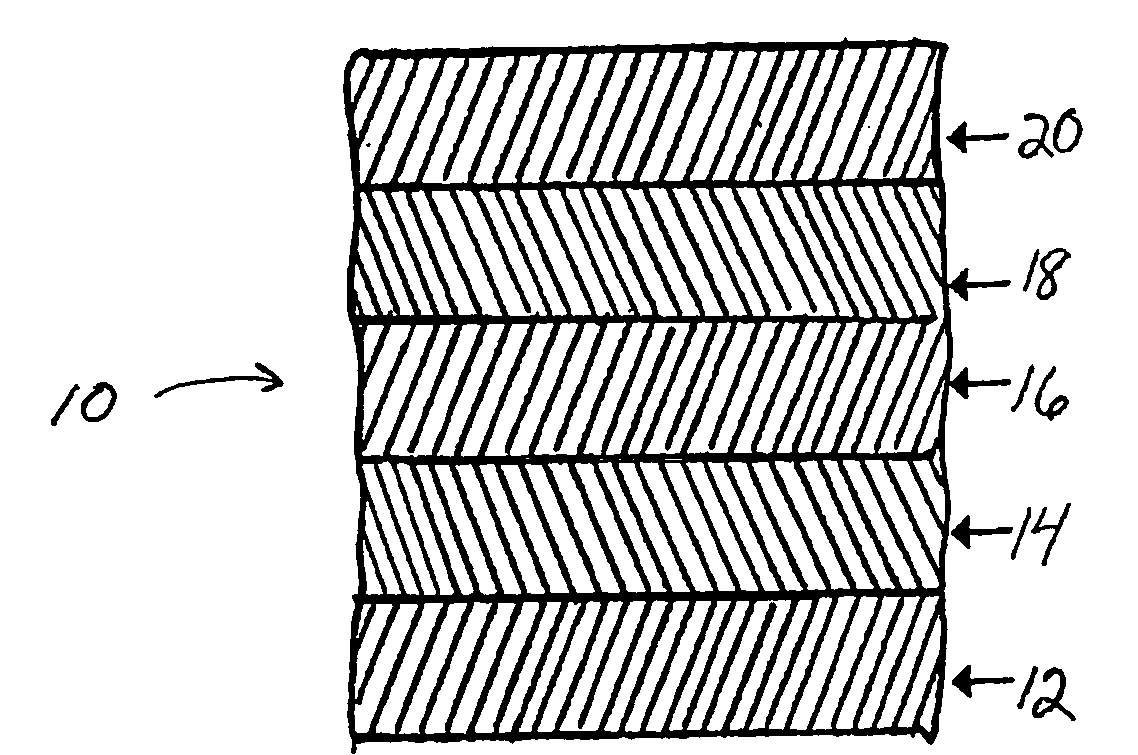

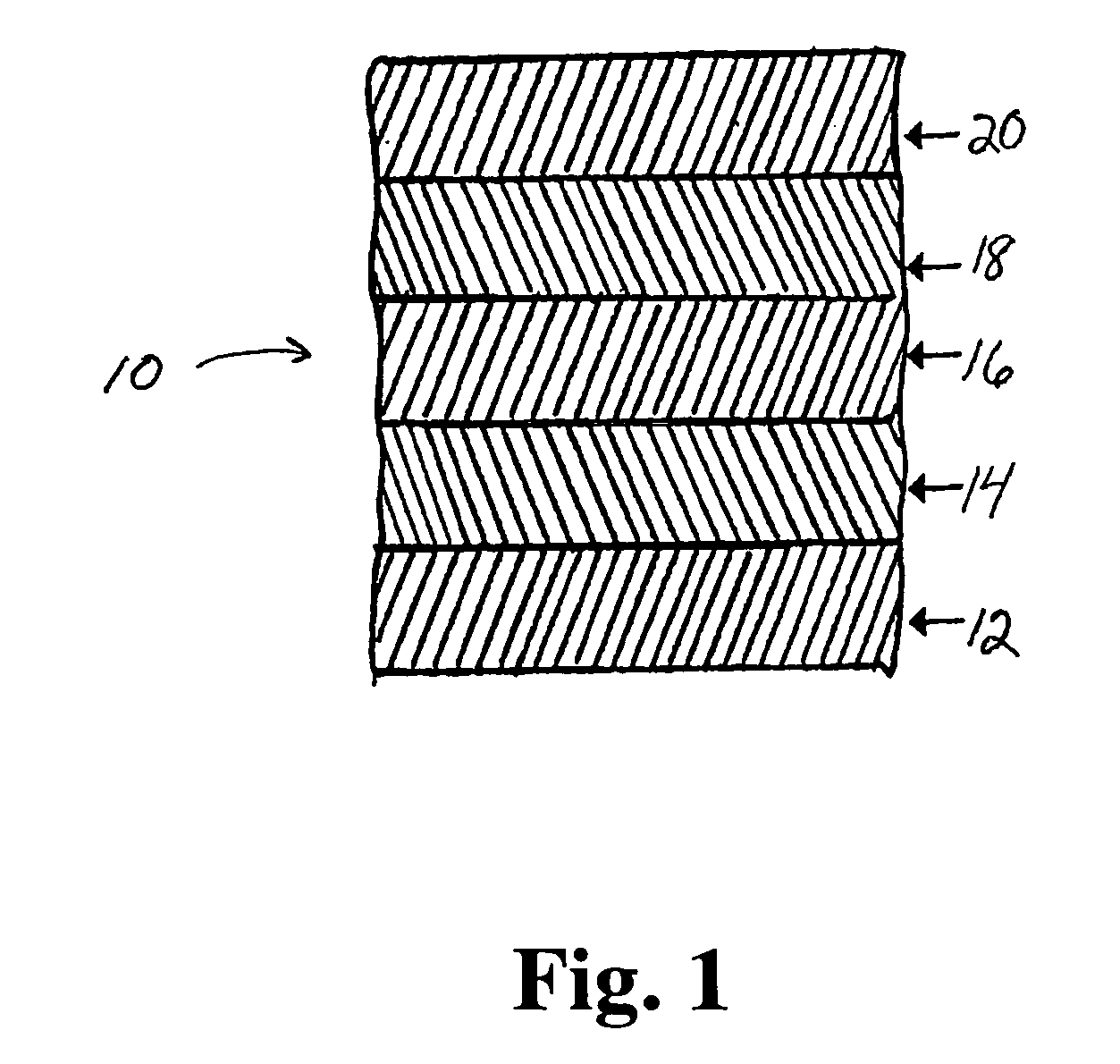

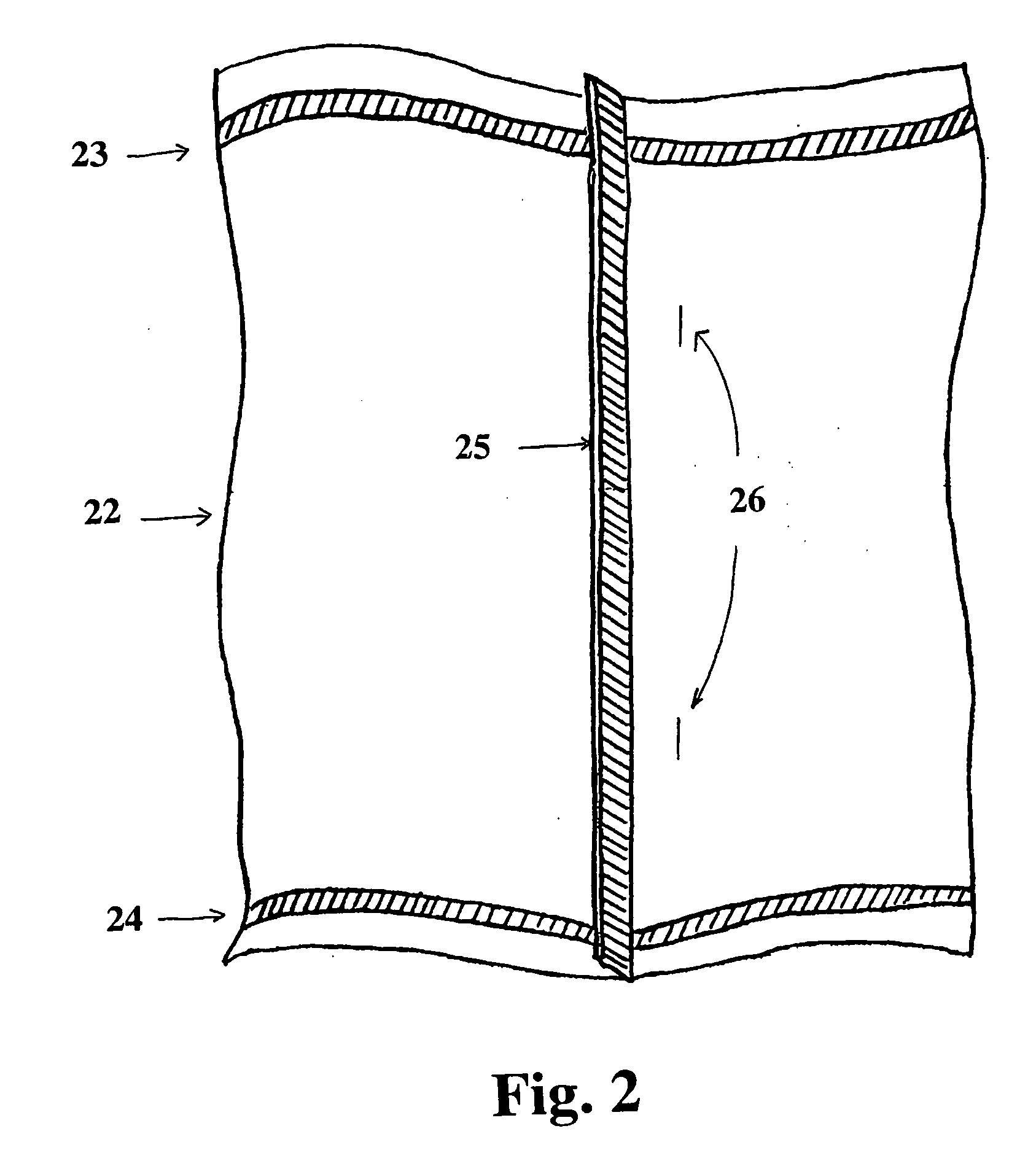

Freezable/microwavable packaging films and venting packages

InactiveUS20070215610A1Improve the immunityReduce the amount of solutionSynthetic resin layered productsBagsMicrowaveTemperature resistance

Multilayer freezable / microwaveable films and packages having both low temperature resistance to withstand subzero freezer storage temperatures and high temperature resistance to withstand microwave cooking temperatures. The freezable / microwaveable films and packages include, for example, a film having at least three coextruded layers comprising an inner heat sealable layer, at least one core layer adjacent to the heat sealable layer, and an outer skin layer adjacent the core layer opposite the heat sealable layer. Preferably, the films and packages further include an outer protective layer laminated to the outer skin layer. The freezable / microwaveable packages can include a venting system, such as vent slits or a vent valve in the package, or vents in at least one seal of the package, to facilitate microwave heating or cooking of the package contents.

Owner:ABX SOLUTIONS LLC

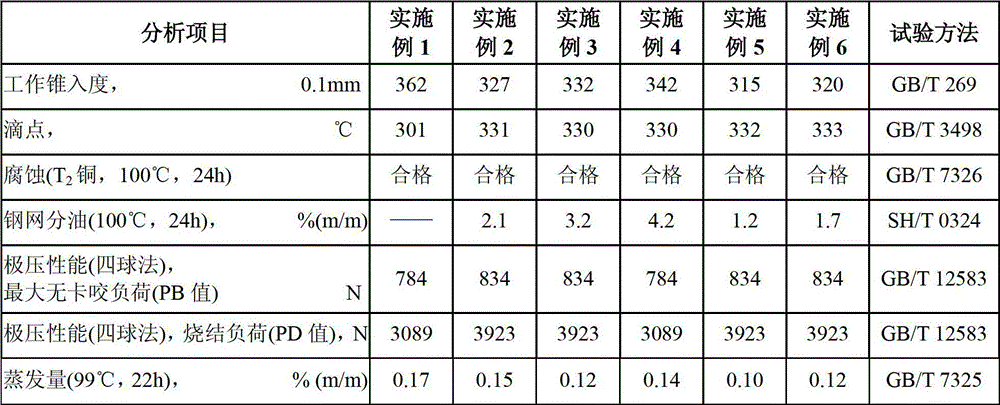

High-temperature-resistant extreme pressure type lubricating grease composition and preparation method

The invention relates to a high-temperature-resistant extreme pressure type lubricating grease composition and a preparation method of the high-temperature-resistant extreme pressure type lubricating grease composition. The preparation method comprises steps as follows: mixing high-base-value calcium naphthenate, high-base-value sulfoacid calcium, and 35 to 65% of base oil; agitating; then adding a transforming agent; heating to reach 75 to 105 DEG C; maintaining the temperature for 40 to 120 minutes until the materials are thick; continuously heating the material until the temperature reaches more than 200 DEG C; removing the water completely, wherein the rest base oil is added during heating; continuously heating the materials until the temperature reaches 220 to 240 DEG C; agitating for 5 to 30 minutes at constant temperature until the materials are thick; and cooling and homogenizing to obtain the product as requirements. The lubricating grease prepared by the preparation method is high in comprehensive performance, excellent in high-temperature resistance, and high in extreme-pressure wear resistance, and can be used for lubricating high-temperature equipment with high load; and the requirements on use in high-temperature and high-load lubricating situations in the ferrous metallurgy industry can be met.

Owner:CHINA PETROLEUM & CHEM CORP

Polyolefin and Ceramic Battery Separator for Non-Aqueous Battery Applications

InactiveUS20110171523A1Improve heat resistanceImprove carrying capacityCell component detailsVehicular energy storagePolyolefinPolymer science

A ceramic microporous polyolefin battery separator membrane, high in air permeability, low in shrinkage and improved temperature resistance addresses the safety requirements of lithium ion batteries. The separators made by the current invention consists of one or more polyolefin polymers and kaolin fillers comprised of aluminum oxide and silicon oxide. The membranes of current invention have a thickness of 5-200 microns, air permeability of 1-200 sec / 10 cc (Gurley seconds), and average pore diameter of less than 1 micron.

Owner:ADVANCED MEMBRANE SYST INC

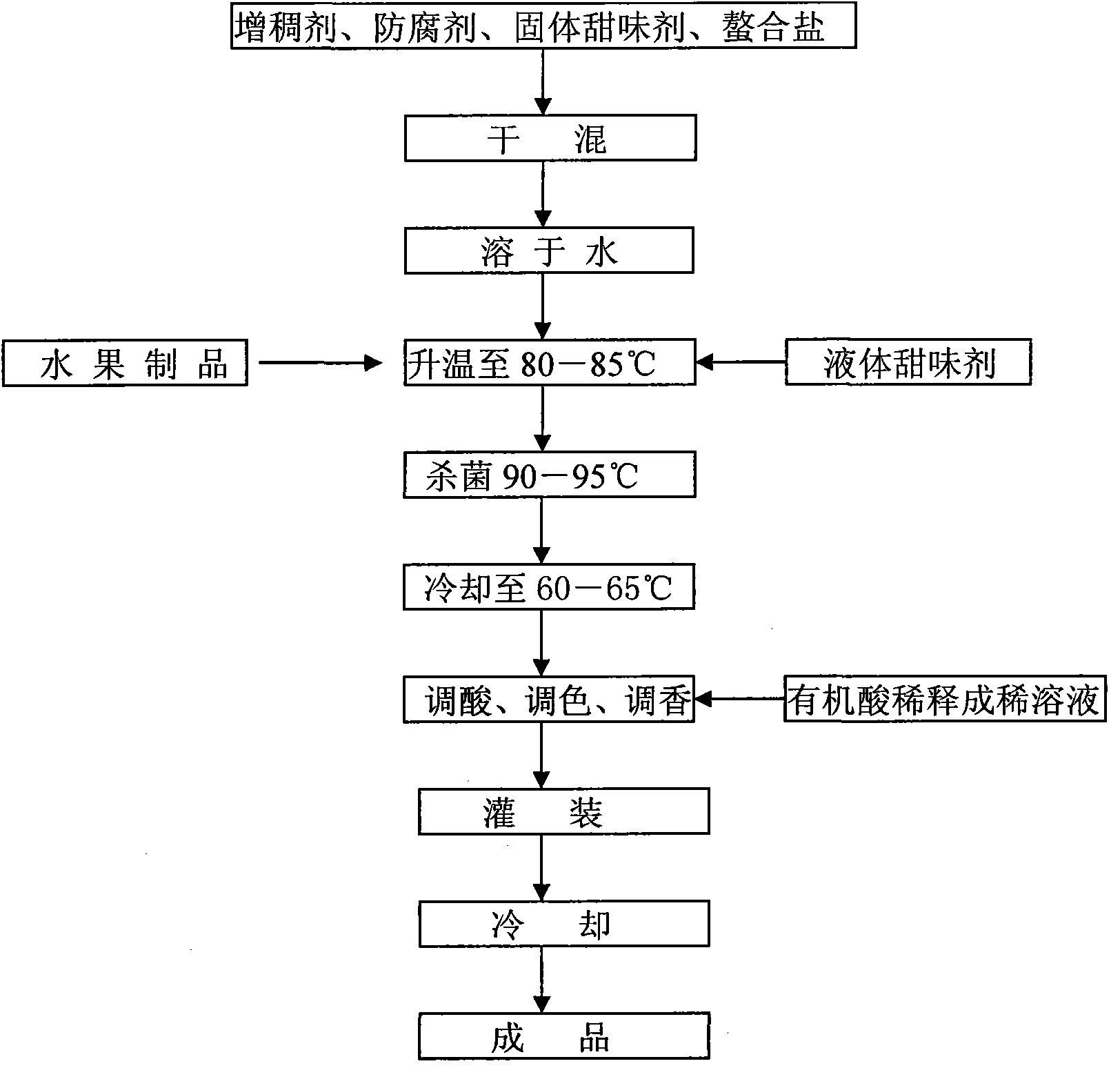

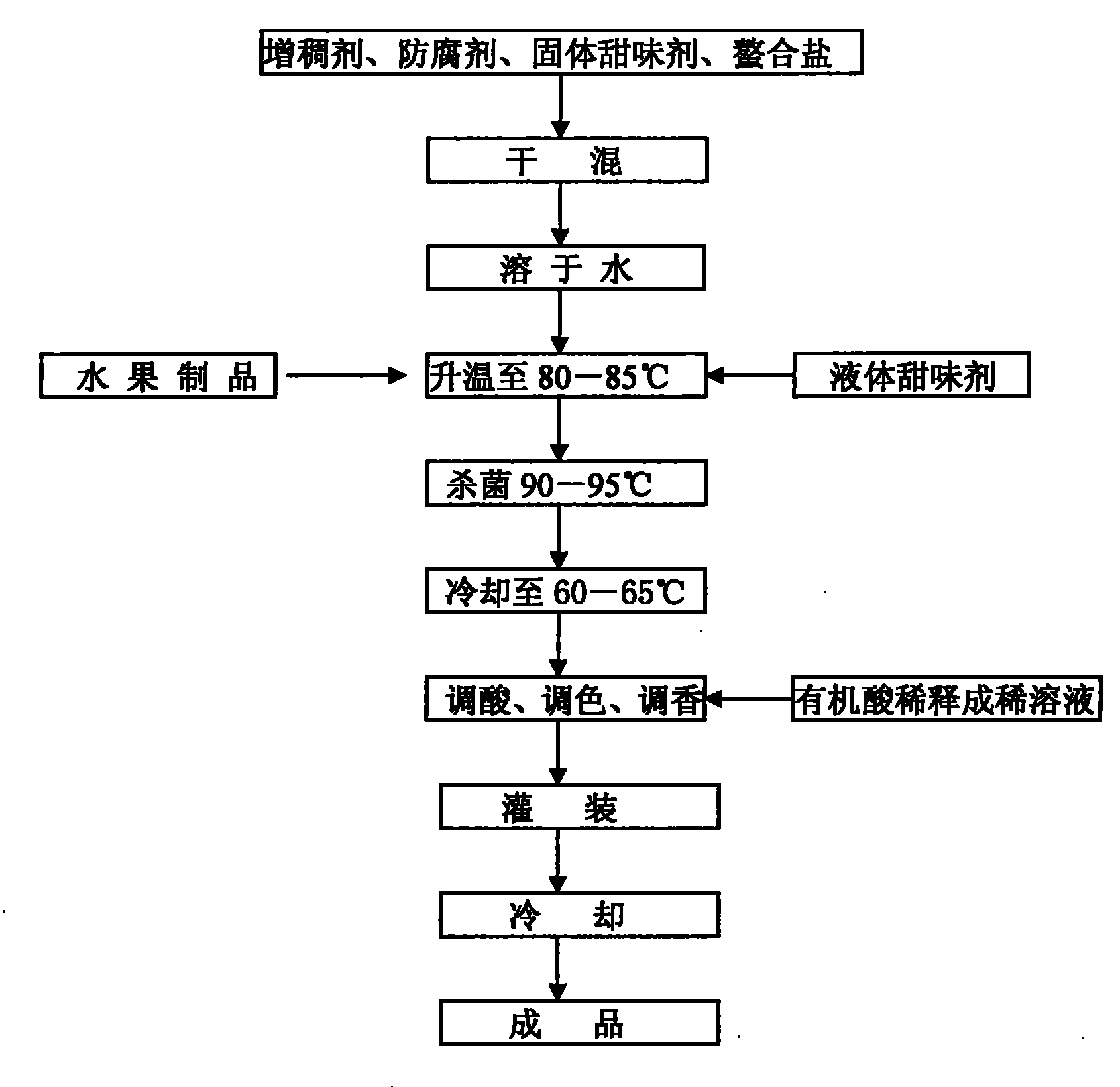

High-temperature baking resistant jam and preparation method and application thereof

ActiveCN101843306AImprove high temperature resistanceSolve prone to collapseBakery productsFood preparationOrganic acidFlavor

The invention discloses a high-temperature baking resistant jam and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly mixing a thickening agent, a preservative, a solid sweetening agent and chelated salt, and dissolving the mixture in water; raising the temperature to a temperature of between 80 and 85 DEG C with continuous stirring, adding a liquid sweetening agent and fruit products, and sterilizing at the temperature of between 90 and 95 DEG C for 10 to 15 minutes; and cooling to the temperature of between 60 and 65 DEG C, and adding a food flavor, a food color and prepared organic acid solution to obtain the high-temperature baking resistant jam. The jam has good high temperature resistance, can be baked at a high temperature for more than 20 minutes without deformation, off-flavor and discoloration, has high transparency, and is suitable to be used as sandwich, stuffing, surface decoration and seasoning of baked goodssuch as cakes, bread and the like. The high-temperature baking resistant jam has the advantages of simpleness and wide sources of raw materials, simpleness and easy operation of the preparation method, and no need of complicated equipment, and can be produced by slightly adjusting the conventional production lines of manufacturers for fruit drinks and seasonings.

Owner:广州合诚实业有限公司

Calcium oxide-based ceramic core for casting titanium alloy and manufacturing method thereof

The invention discloses a calcium oxide-based ceramic core for casting titanium alloy and a manufacturing method of the calcium oxide-based ceramic core. The calcium oxide-based ceramic core comprises the following components by weight percent: 1.0-15.0% of zirconium dioxide, 0.5-10.0% of yttrium oxide, 0.05-0.1% of thorium oxide and the balance of calcium oxide, and the sum of the contents of the above the component is 100%. According to the ceramic core, the bending strength is 15-30Mpa at room temperature, the bending strength is 5-10Mpa at high temperature, the high-temperature deflection is 0.2-0.5%, the firing shrinkage ratio is 1-1.5%, and the porosity is 40-50%. Compared with the existing commercial alumina-based ceramic core and silicon oxide-based ceramic core, the calcium oxide-based ceramic core of the invention greatly reduces the reactivity with molten titanium, and has the advantages of high temperature resistance, easiness in core leach, low in cost and the like.

Owner:BEIHANG UNIV

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

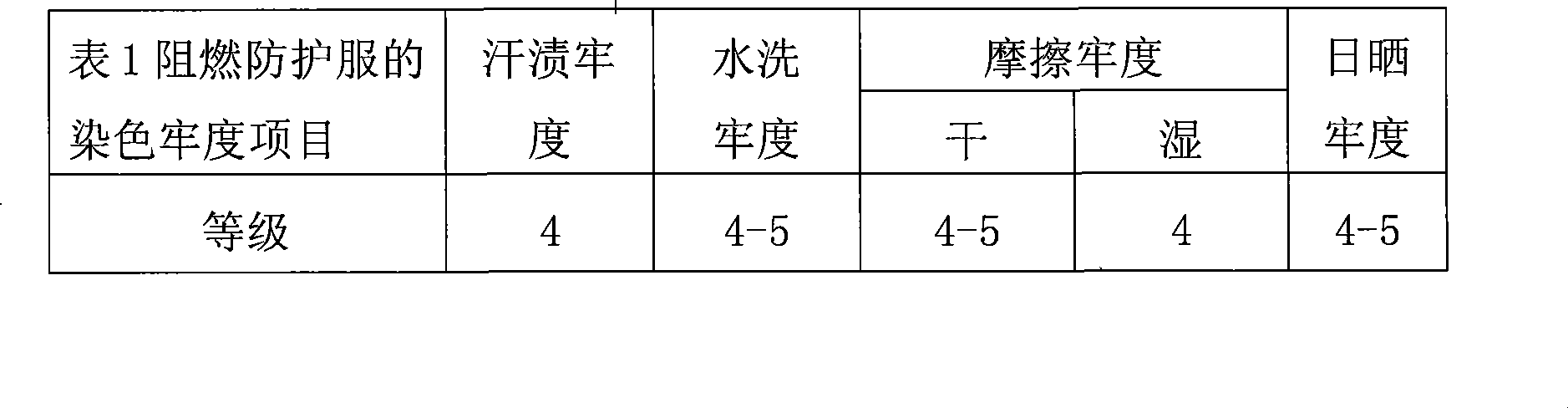

Industrial flame-retardant protection suit fabric, production method thereof and flame-retardant protection suit thereof

The invention relates to an industrial anti-flaming exposure suit fabric and a manufacturing method and an exposure suit thereof. Yarns used in the industrial anti-flaming exposure suit fabric are formed by the blending of anti-flaming viscose, wool fibers and nylon fibers. The blending proportions (weight percentage) of the anti-flaming viscose, the wool fibers and the nylon fibers are respectively 45 percent to 55 percent, 35 percent to 45 percent and 5 percent to 15 percent. The industrial anti-flaming exposure suit fabric used in front of electric welding and metallurgy smelting furnaces has the functions of permanent anti-flaming performance, high temperature resistance, heat convection resistance, molten metal splashing resistance, and the like. The fabric is not only suitable for firefighter uniforms, flying protective clothing, and the like, realizes permanent anti-flaming performance and high temperature resistance, but also meets the requirements of the anti-flaming exposure suit fabric used in front of the electric welding and metallurgy smelting furnaces for the functions of heat convection resistance, molten metal splashing resistance, and the like.

Owner:SHANGHAI IBENA TEXTILE PROD

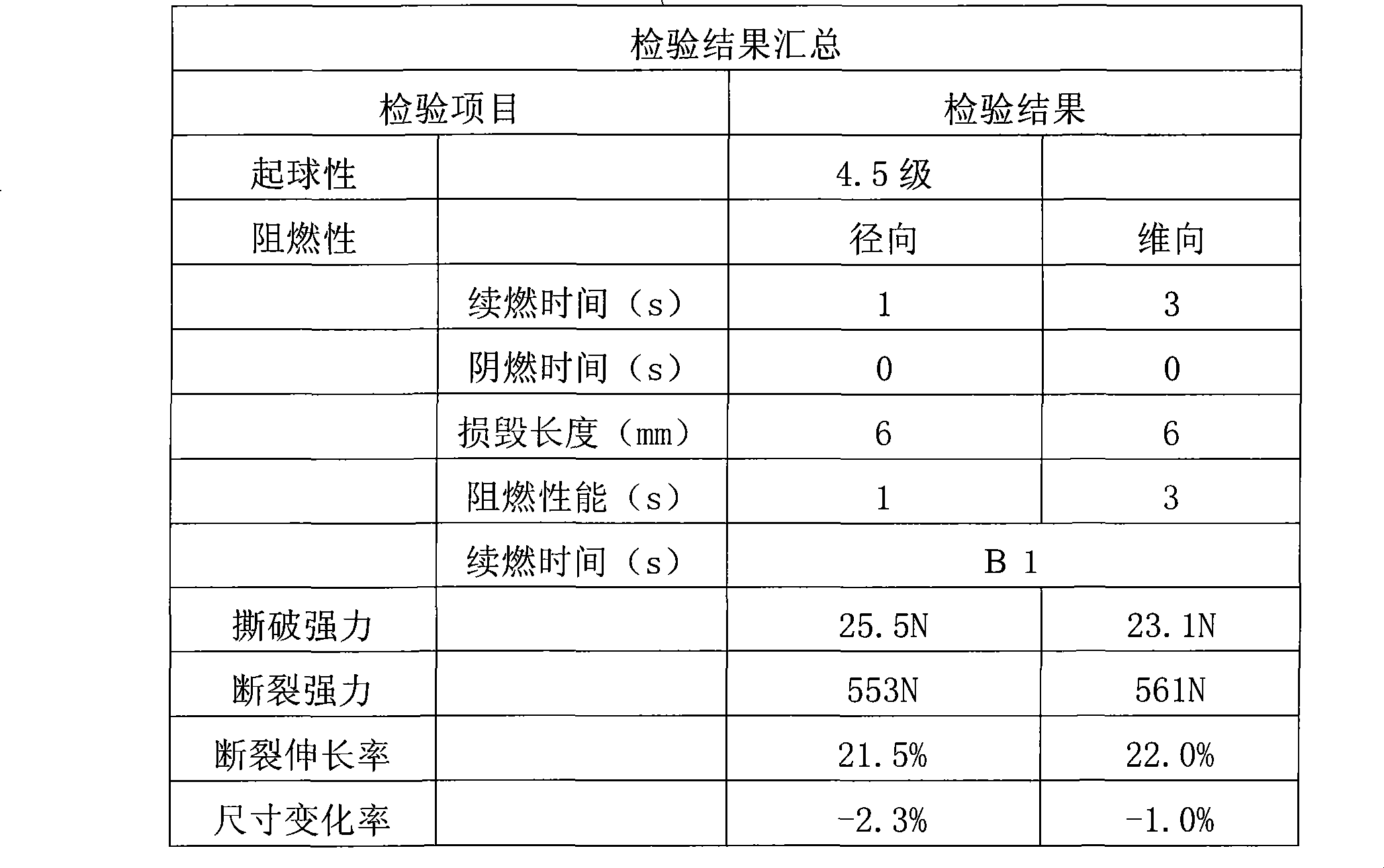

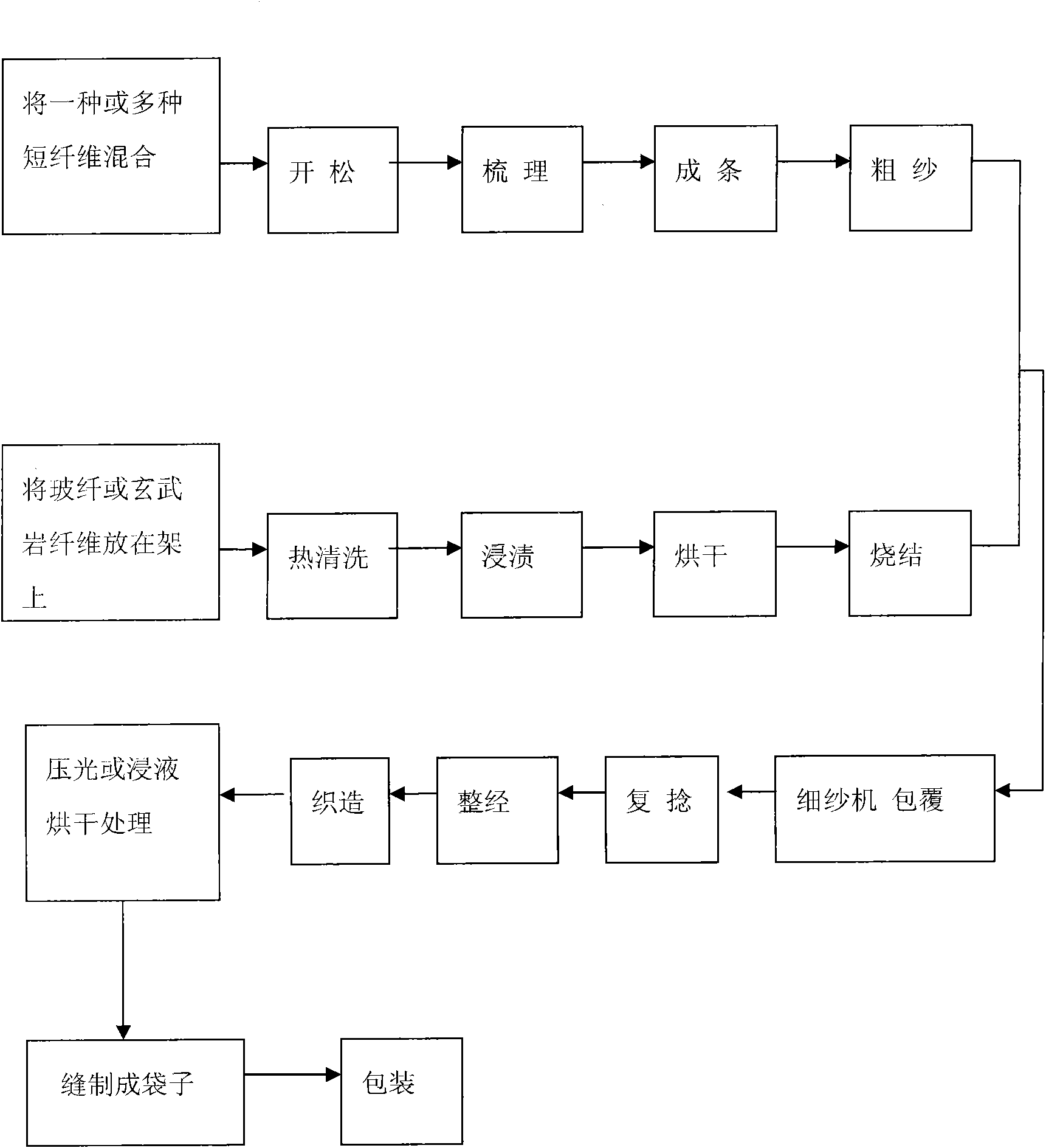

Composite covered yarn, and manufacturing method and use thereof

The invention relates to a composite covered yarn and a manufacturing method thereof and also relates to a high-temperature filter cloth. The composite covered yarn comprises an outer layer of coveredyarn made of short fiber and an inner layer of reinforcing rib made of long fiber, wherein the composite covered yarn is formed by using the covered yarn, made of one or a plurality of types of shortfibers, to cover the reinforcing rib or the metal wire reinforcing rib made of one or a plurality of types of long fibers by thermal cleaning, dipping, drying and sintering. The composite covered yarn manufactured by the method not only saves cost, but also combines the characteristics of high strength of the long fiber and good abrasion resistance and toughness of the short fiber and enhances service life, strength, high-temperature resistance and stability of the composite covered yarn. The composite covered yarn can be made into the filter cloth.

Owner:辽宁新洪源环保材料有限公司

Polyurethane resin composition, preparation method and application thereof

InactiveCN101735595AImprove water resistanceImprove featuresBallastwayTrack maintainencePolyolefinAlcohol

The invention provides a polyurethane resin composition, a preparation method and application thereof. The polyurethane resin composition comprises a component A and a component B, wherein the component A contains polyolein polyatomic alcohol, a plasticizer, an anti-settling agent and other auxiliary agents; the component B is isocyanate or prepolymer of the isocyanate; and the mass ratio of the A to the B is 10:1-1:10. A pouring material containing the resin composition can be used as a patching material for a cement road bed, a boss resin layer and a mortar packing layer of a railway plate-type unballasted track and has the advantages of high water resistance, ageing resistance and low temperature resistance, long service life and capability of being used at a low temperature.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

High-polymer modified pitch, its water-proof roll material and use thereof

ActiveCN101070434AImprove standardsHigh standard waterproof functionOther chemical processesRoof covering using flexible materialsPolymer modifiedCrack resistance

The invention provides a polymer modified asphalt, and the weight of the components comprising as follows :45-55% matrix asphalt, 4 - 8% blend oil, 12 - 14% of SBS ,5-9 % APAO, 2-7% of High-temperature improvement and 15-20% filler. It also offers polymer modified asphalt, which made of waterproof membrane and the railway bridge, highway bridge deck waterproofing project applications. The invention of these waterproofing membrane have a high standard of waterproof function, it can withstand high intensity of railway bridge and particularly high stress dynamic load .It also have excellent performance on water-resistance, high and low temperature resistance, adhesion, crack resistance, fatigue resistance and other aspects .it can be used for railway bridge and the road deck waterproofing works.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS +1

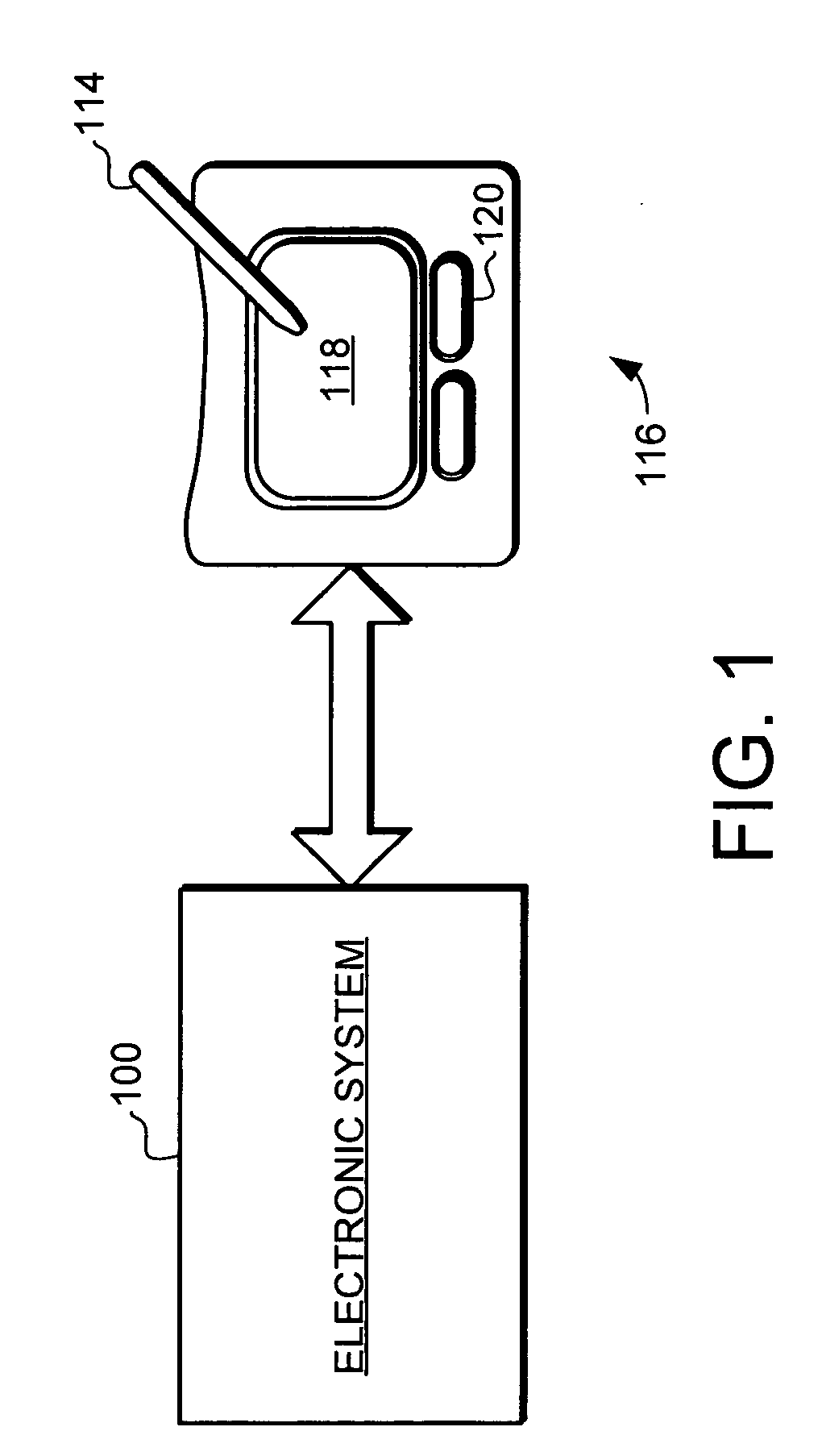

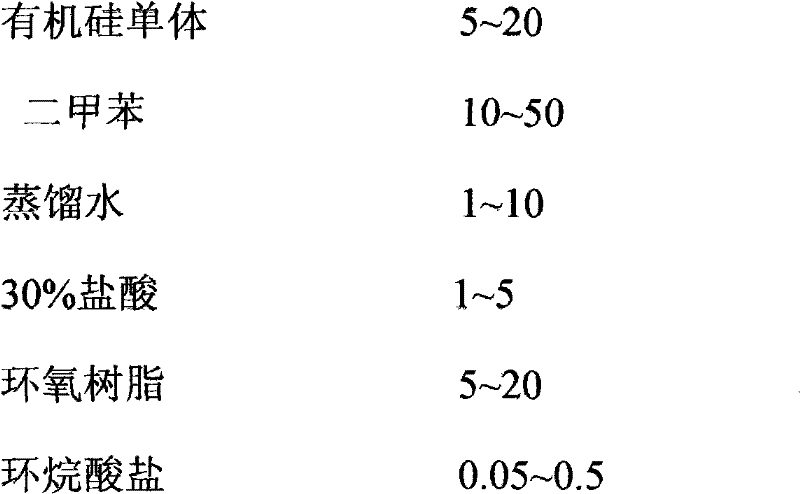

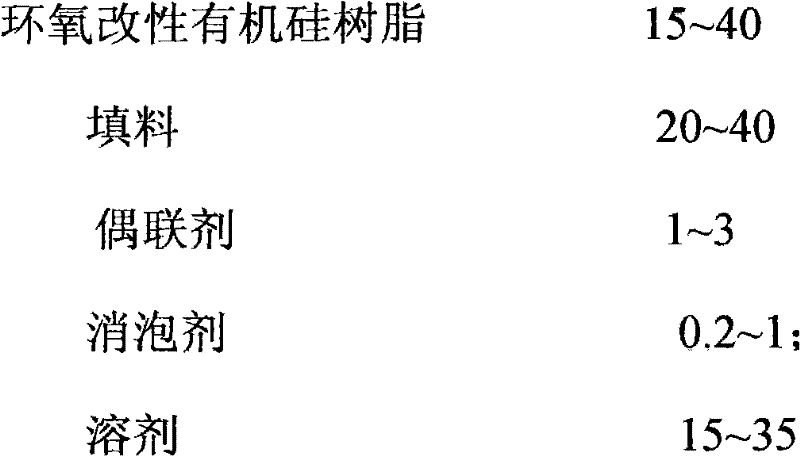

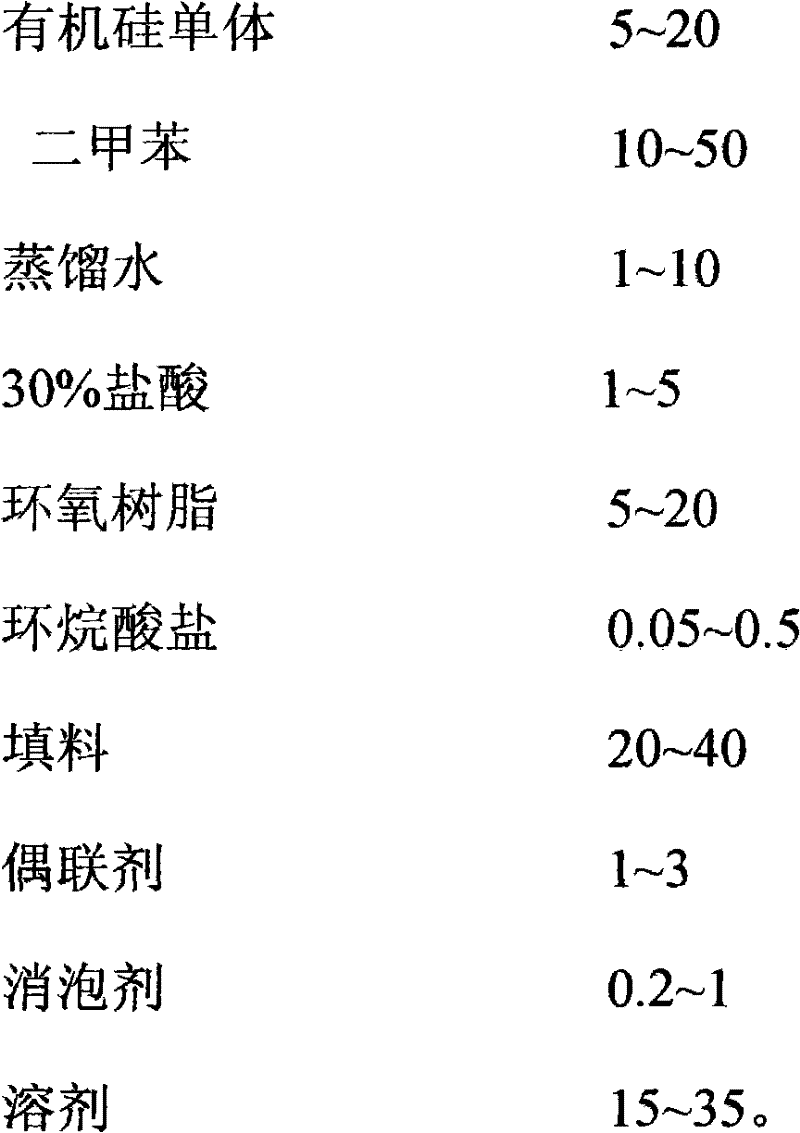

Preparation method of epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating and its products

The invention provides a preparation method of an epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating, comprising the following steps: preparing raw materials; synthesizing an organosilicon pre-polymer; synthesizing an epoxy-modified organosilicon resin; and preparing the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating. The invention also provided the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating prepared by the method. The coating is composed by the epoxy modified organosilicon resin, fillers, a coupling agent and solvents. The coating prepared by the method in the invention takes account of insulation, thermal-conductivity, and high-temperature resistance at the same time, has coating adhesion of first level, hardness of 5H, a breakdown voltage of 1800V / 0.5mA, 2 seconds, a heat transfer coefficient of larger than 100W / (m<2>.K), and no obviously changed coating at a temperature of 250 DEG C for 24 hours, therefore the coating can be widely used in various industrial equipment and household appliances.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN +2

PP/PA composite material used for corrugated pipe and preparation method thereof

InactiveCN101724197ASolve heat resistanceSettle the priceFlexible pipesProcedure AgentsHeat resistance

The invention discloses a PP / PA composite material used for a corrugated pipe, which is prepared by processing polypropylene, nylon, compatilizer, toughening agent, filling master batch, light stabilizer, heat stabilizer and processing aid. The PP / PA composite material is prepared by feeding the components into mixing equipment according to a proportion, and melting, mixing, scattering, extruding and granulating the components at the temperature of between 210 and 280 DEG C. The PP / PA composite material not only has higher toughness, excellent high impact resistance and bending property and extremely good high temperature resistance, but also are excellent in the aspects of surface gloss, abrasion resistance, chemical corrosion resistance, electric insulation and the like, and solves the defect problems of insufficient heat resistance of the conventional PP corrugated pipe, over-high price of the PA corrugated pipe; and in addition, a preparation method for the PP / PA composite material is simple and meets the requirement of industrialized production.

Owner:SHANGHAI KINGFA SCI & TECH +1

High toughness filling reinforcement poly phenylene sulfide (PPS)/poly-p-phenylene oxide (PPO) alloy and method for preparing same

The invention relates to a high toughness filling reinforcement poly phenylene sulfide (PPS) / poly-p-phenylene oxide (PPO) alloy and a method for preparing the same. The alloy comprises 1-99 parts by weight of polyphenylene sulfide, 99-1 part by weight of polyphenyl ether, 10-200 parts by weight of glass fiber, 1-50 parts by weight of filler, 3-10 parts by weight of compatilizer, 5-30 parts by weight of toughening agent, 0.2-2 parts by weight of coupling agent, 0.2-2 parts by weight of antioxidant and 0.5-3 parts by weight of processing agent, wherein the sum of the parts by weight of the polyphenylene sulfide and the polyphenyl ether is 100 parts by weight. The alloy has the advantages of high toughness, impact cracking resistance, excellent strength and rigidity, excellent compatibility, high temperature resistance, inflaming retardance, chemical corrosion resistance, solvent resistance, stress cracking resistance, excellent processing performance and the like, and can be safely applied to various electrical and electronic equipment parts, vehicle equipment parts and chemical equipment parts and even ships, bridges and building materials.

Owner:张国庆 +1

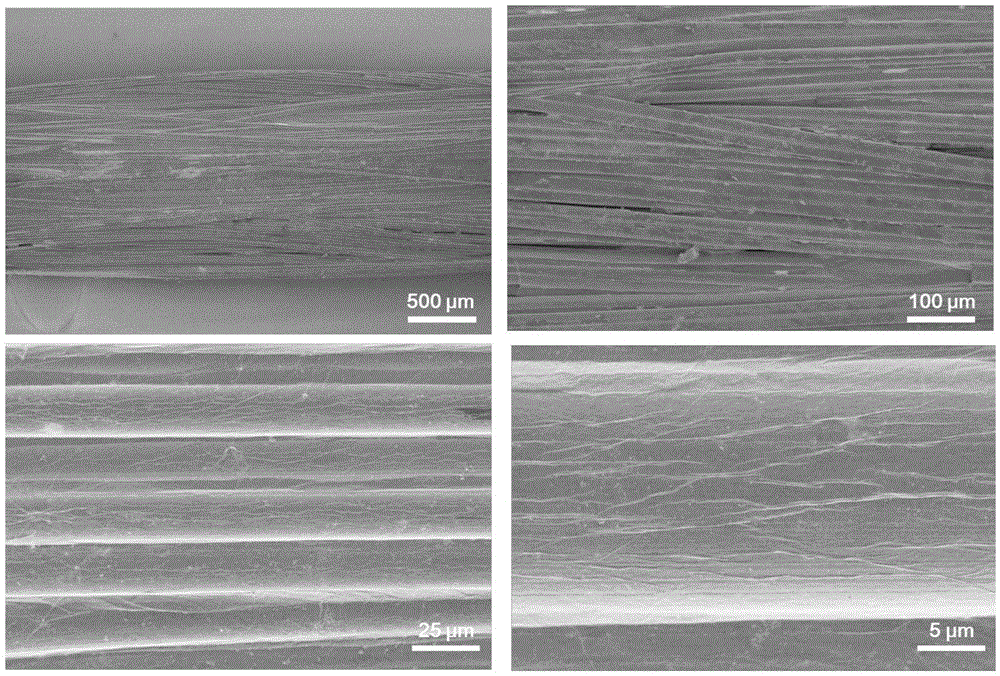

Preparation method of graphene composite conductive fiber

The invention discloses a preparation method of a graphene composite conductive fiber and relates to the technical field of graphene. The method comprises the following steps: processing a common textile polymer fiber with an organic solvent to remove impurities such as an oiling agent on the fiber surface; dipping the textile polymer fiber into an alkali liquor and an oxidized graphene solution, and enabling the fiber surface to fully contact the oxidized graphene; and dipping the dried fiber with an oxidized graphene coating into a solution containing a reducing agent to obtain the graphene composite conductive fiber. By adopting a simple dip coating method, the obtained composite fiber has mechanical property, high temperature resistance and flexibility performance of a traditional high polymer material and also has good conductivity. The method is easy to operate, environment-friendly and convenient to industrialize.

Owner:宁国市龙晟柔性储能材料科技有限公司

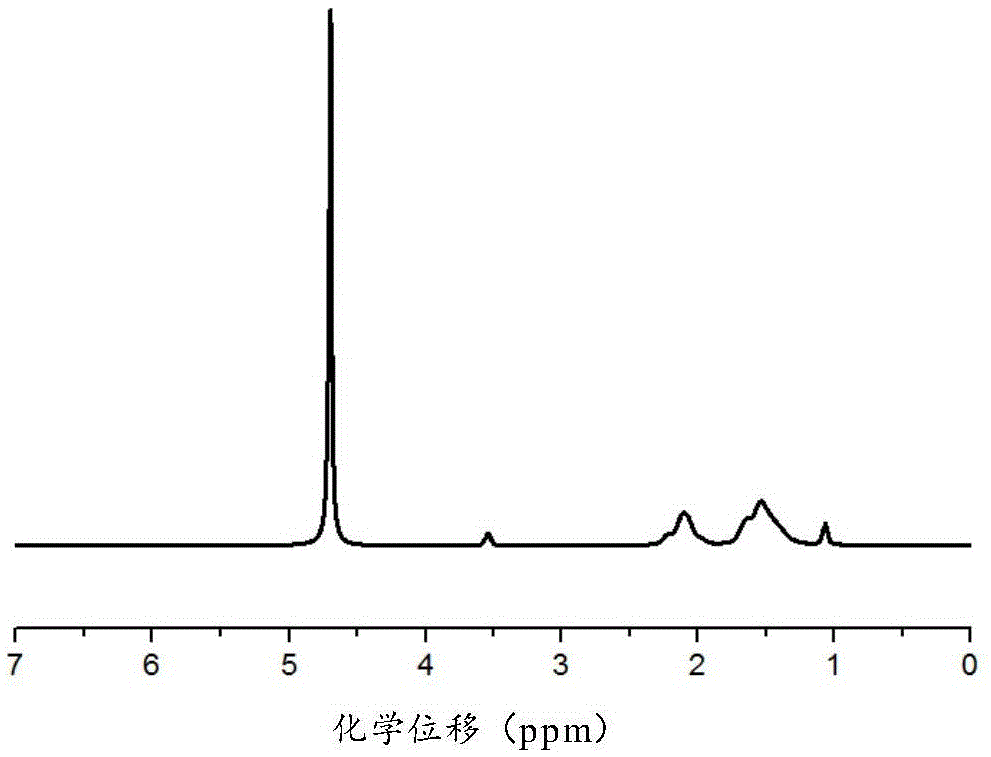

Hydrophobic associated polymer and preparation method thereof

InactiveCN105646777AGood temperature and salt resistanceImprove shear resistanceDrilling compositionSolubilityPolymer science

The invention provides a hydrophobic associated polymer, comprising repeating units shown in formula (I) and formula (II), wherein x: y = 1: (0.001 to 0.06); A is a monomeric unit of a hydrophobic monomer; the viscosity average molecular weight of the hydrophobic associated polymer is 5 to 35 million. Compared with the prior art, the hydrophobic associated polymer comprises two monomeric units, and a hydrophilic unit is a monomeric unit of acrylamide, can provide a hydrophilic group for a hydrophobic associated polymer, and ensures that the polymer has good water solubility; a hydrophobic unit is a monomeric unit of the hydrophobic monomer, can provide a hydrophobic side group for the hydrophobic associated polymer, and ensures that a polymer chain has a certain hydrophobic character, and hydrophobic groups gather in water due to a hydrophobic interaction to form a spatial network structure, thereby providing necessary viscoelasticity for a solution; under the combined action of the two units, the temperature resistance and salt tolerance and shear resistance of the hydrophobic associated polymer are improved.

Owner:SICHUAN GUANGYA POLYMER CHEM

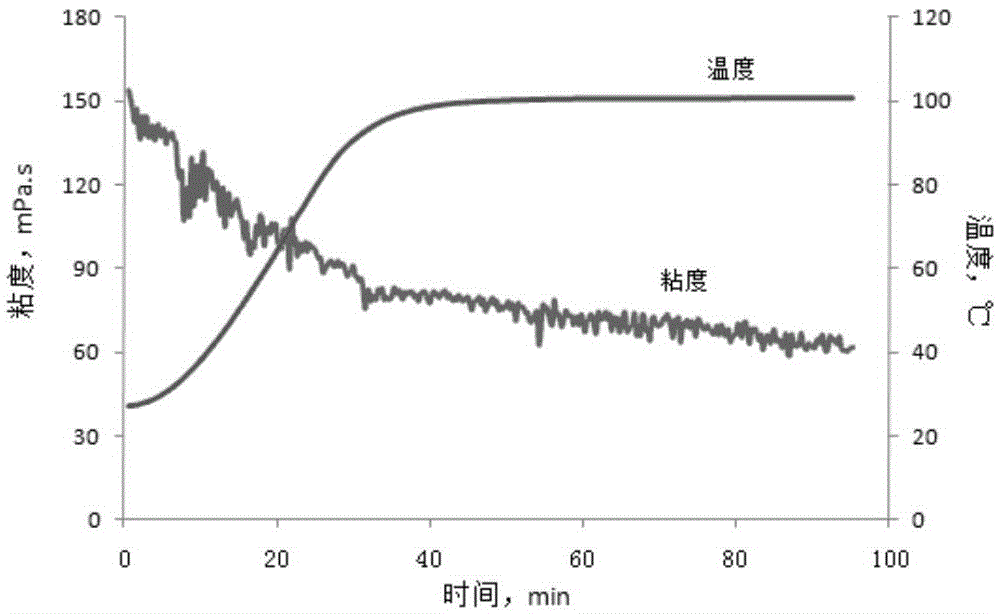

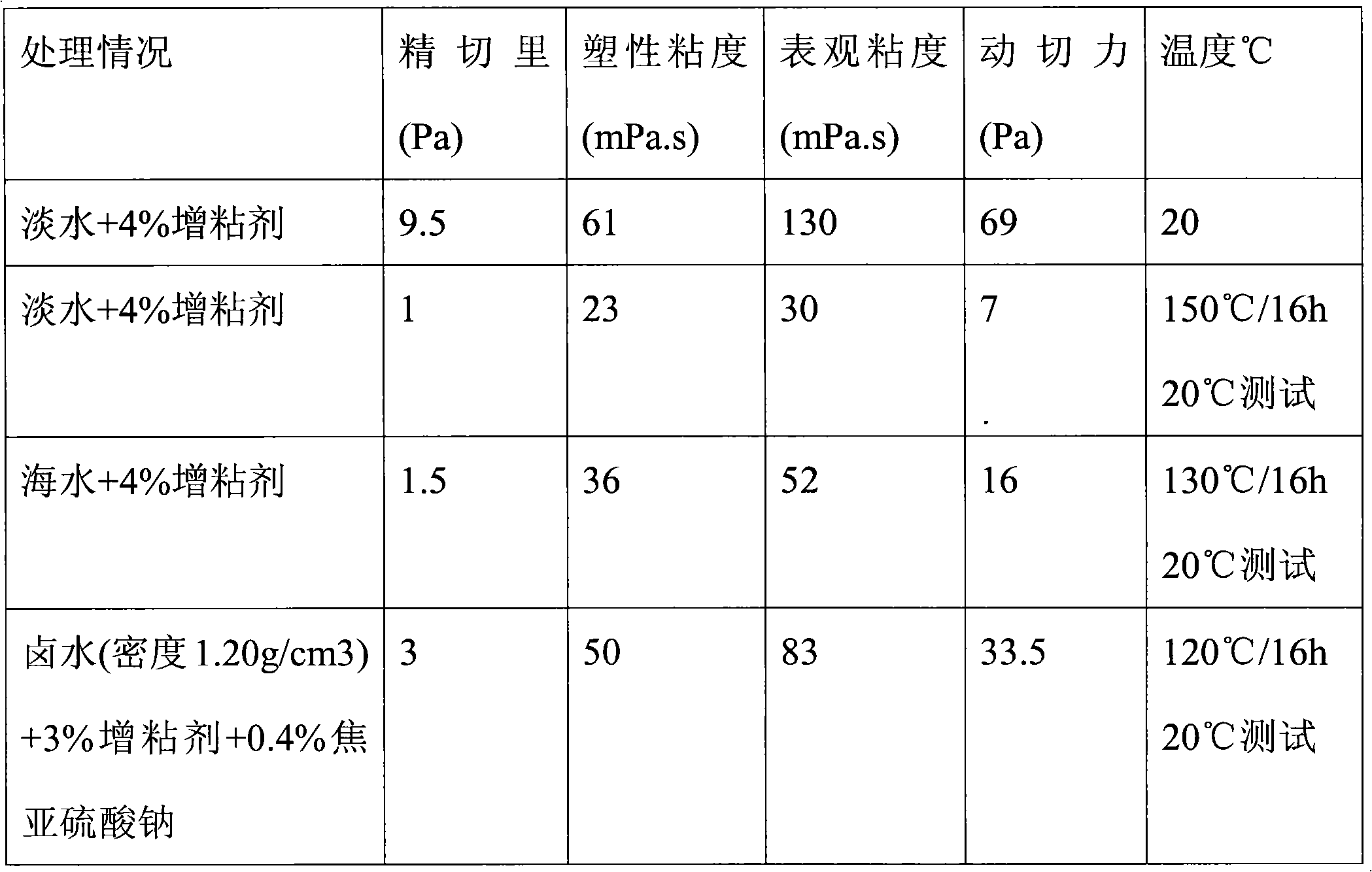

High-temperature resistance tackifier for drilling fluid and preparation method thereof

ActiveCN102127401AGood resistance to salt and viscosity increaseImprove temperature resistanceDrilling compositionTemperature resistanceSolvent

The invention relates to a petroleum drilling fluid, in particular to a high-temperature resistance tackifier for a drilling fluid and a preparation method thereof. The high-temperature resistance tackifier for the drilling fluid comprises the following components in parts by mass: 1 part of starch, 0.05-5 parts of guar gum, 0.01-2 parts of alkaline hydroxides, 0.02-6 parts of epoxide and 0-9 parts of alcohol solvent. The preparation method of the high-temperature resistance tackifier for the drilling fluid comprises the following steps of: adding the starch and the guar gum to a vessel, thenadding the epoxide and the alcohol solvent and stirring for 10-30min, then adding a water solution of alkaline hydroxides, continuously stirring and reacting for 20min-3h at 0-120 DEG C, discharging,drying and crushing to obtain a finished product. The tackifier prepared by adopting the preparation method disclosed by the invention achieves the purpose of improving the temperature resistance of a solid-free drilling fluid for a deep well and the viscosity and the shearing force of the drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Weak solvent aliphatic polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for synthetic leather, in particular to weak solvent aliphatic polyurethane resin for synthetic leather and a preparation method thereof. The weak solvent aliphatic polyurethane resin for synthetic leather is prepared from the following components by weight percent: 2-30 percent of aliphatic diisocyanate compound, 5-40 percent of polyester or polyether polyalcohol compound, 0-10 percent of micromolecule polyol chain extender, 0.1-13 percent of micromolecule polyamine chain extender, 0.01-1.0 percent of catalyst, 0.05-5.0 percent of assistant and 45-85 percent of organic mild solvent. The invention also discloses the preparation method of the weak solvent aliphatic polyurethane resin for synthetic leather. By adopting the technical scheme, the polyurethane resin with different solid contents, different viscosities and different modulus can by synthesized, the requirement of the synthetic leather is satisfied, and the synthetic leather product with high temperature resistance, cold resistance, anti-sticking performance and better external tensility of pigment can be prepared.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com