Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1749results about "Roof covering using flexible materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

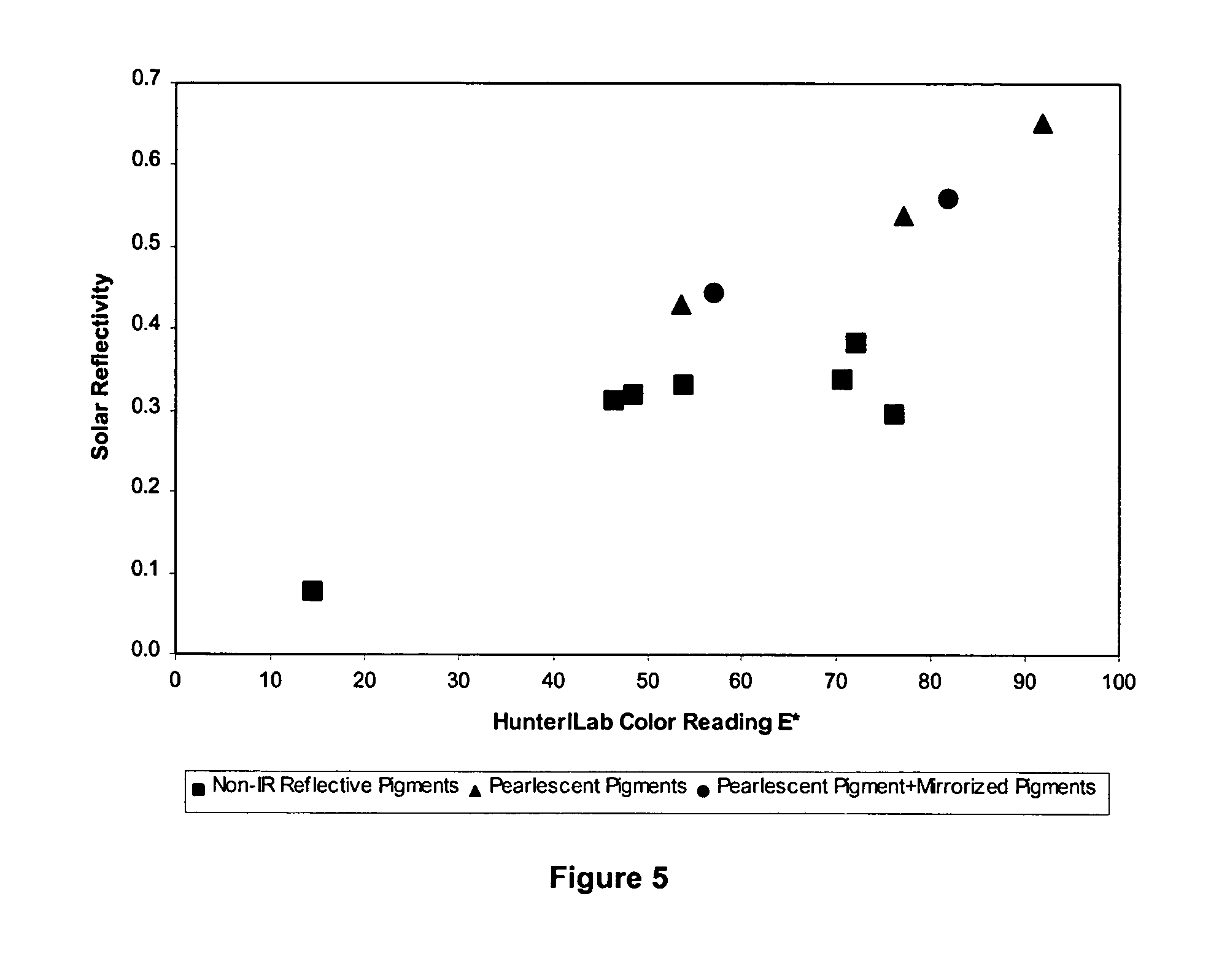

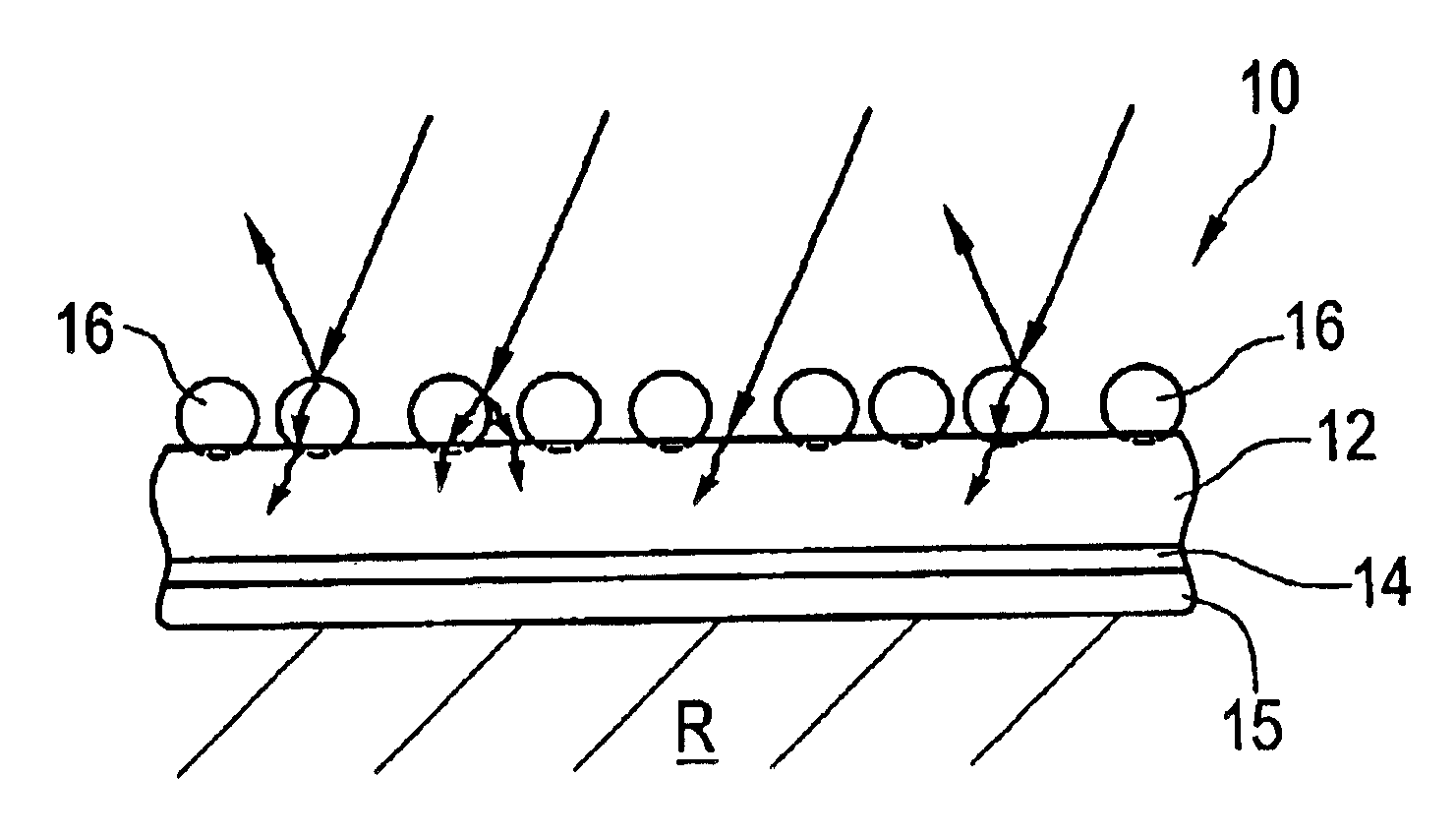

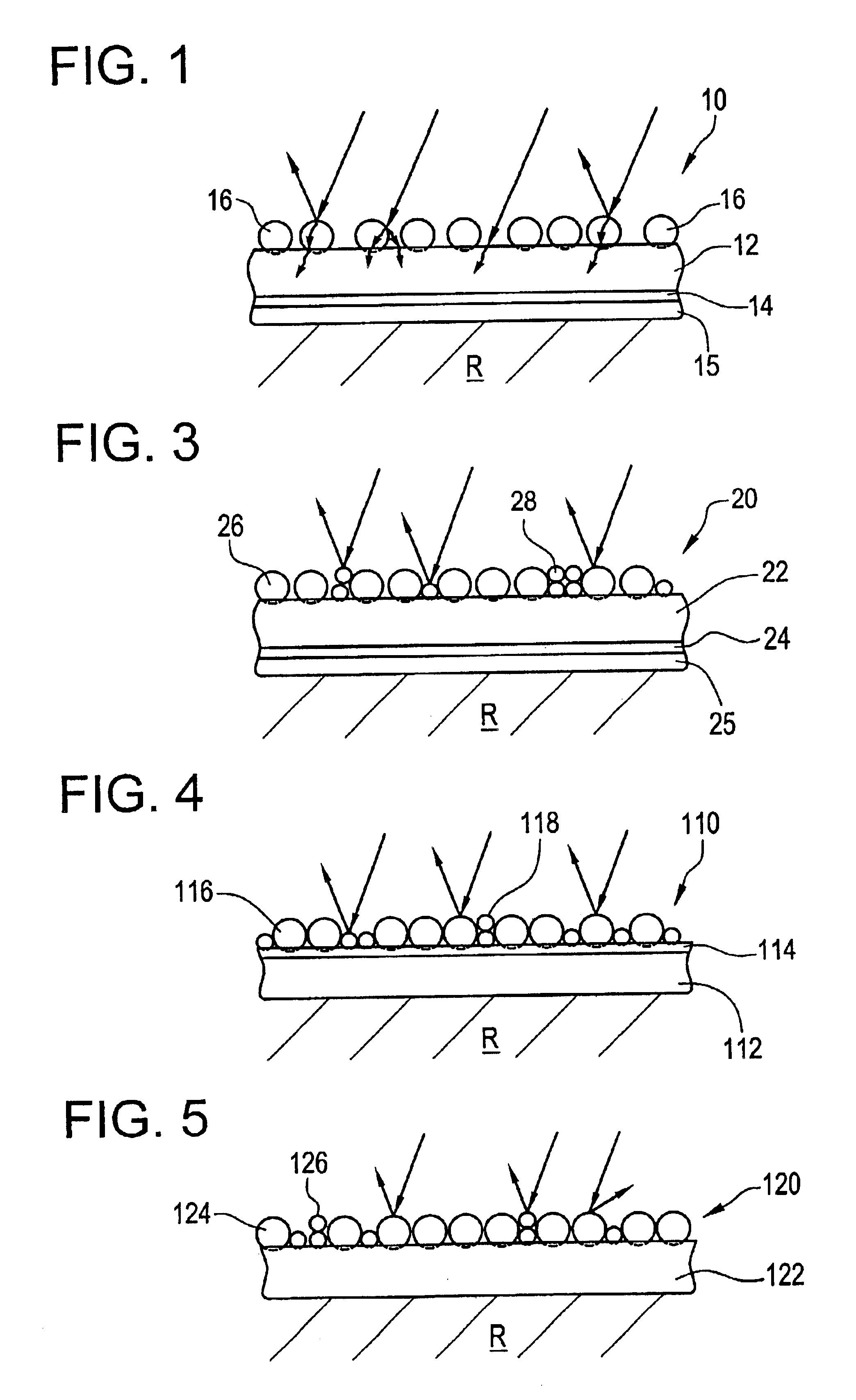

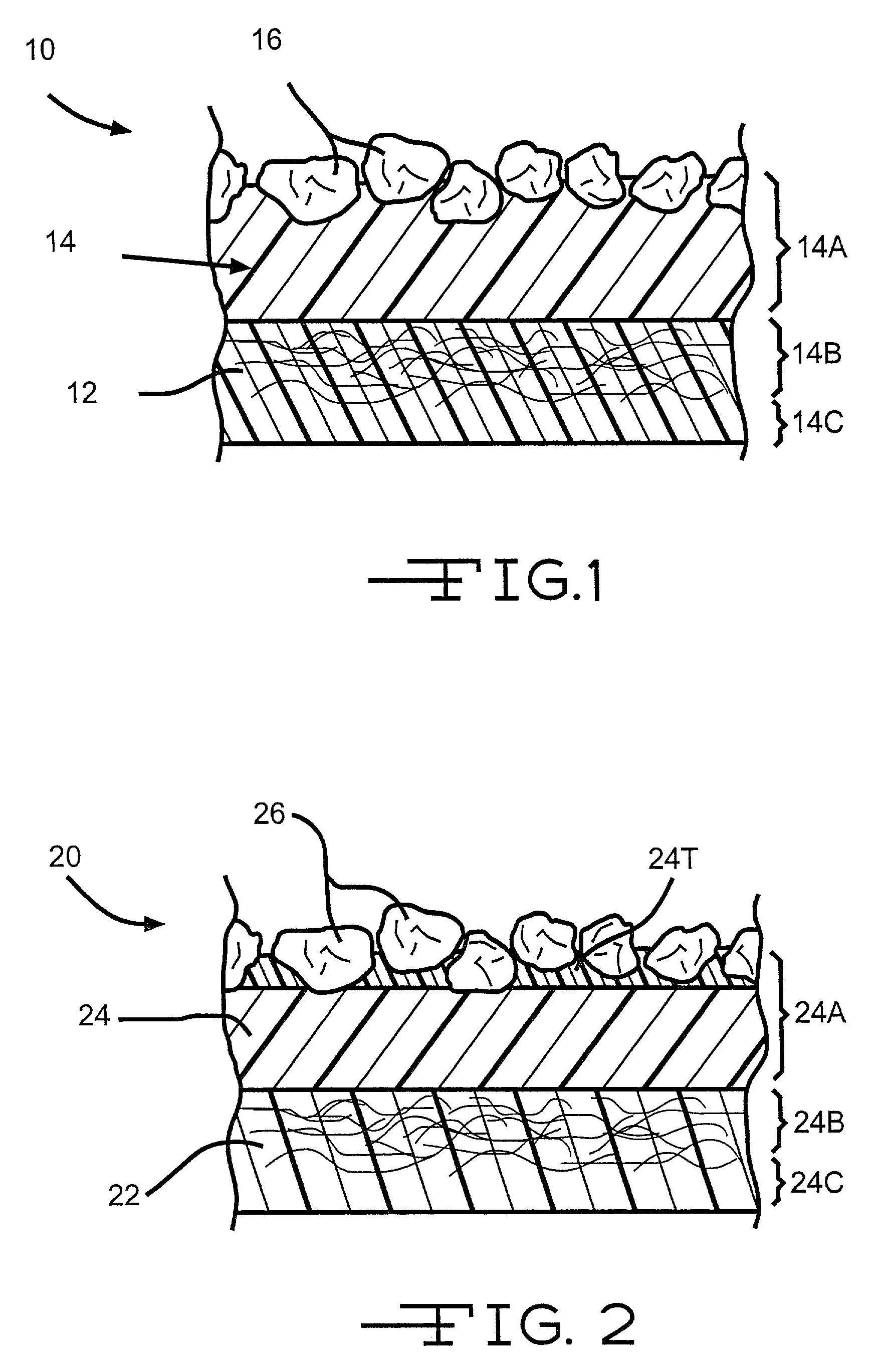

Colored roofing granules with increased solar heat reflectance, solar heat-reflective shingles, and process for producing same

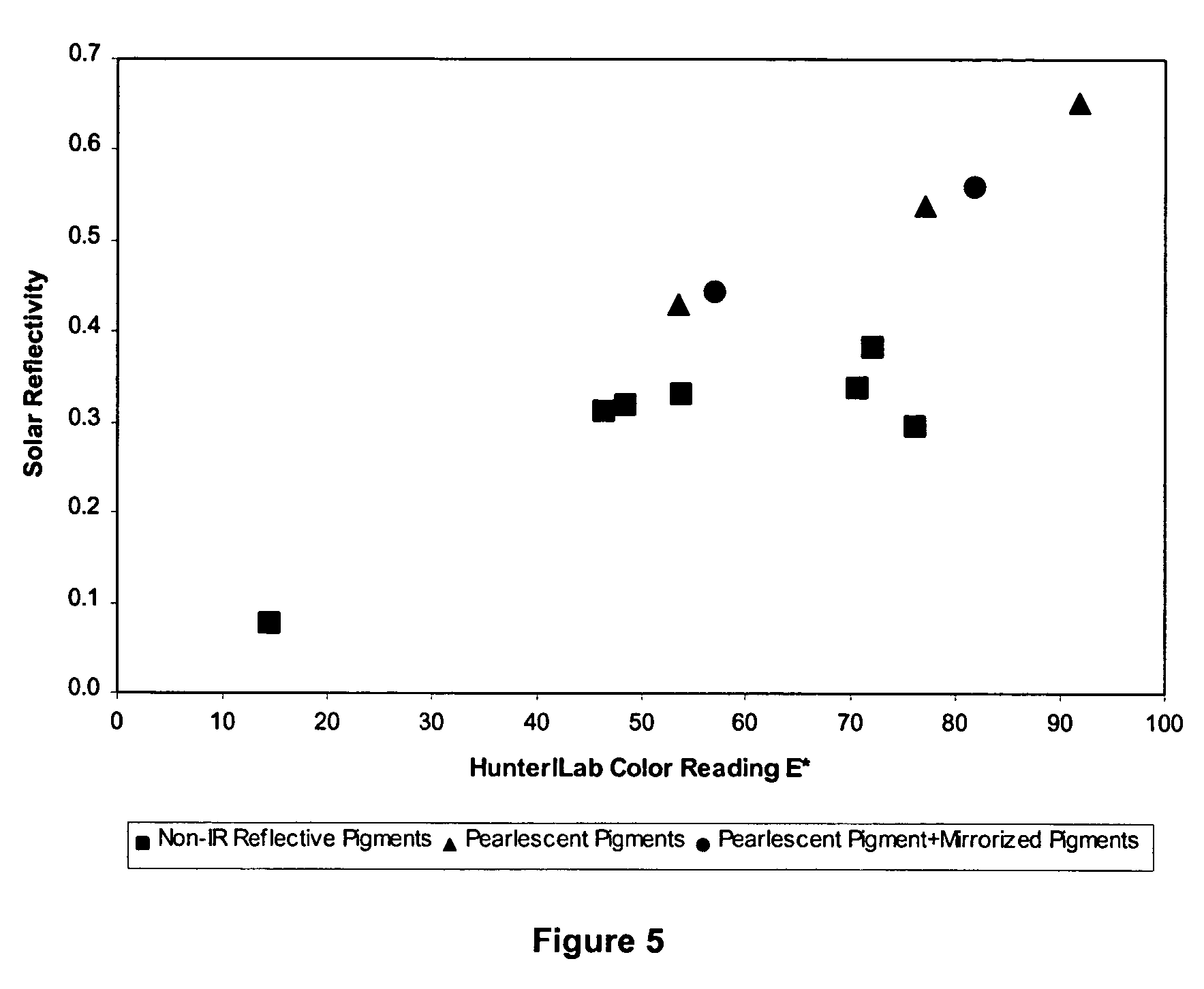

ActiveUS20050072114A1Improve solar heat reflectivityRoof improvementGlass/slag layered productsMineral particlesPigment

Owner:CERTAIN TEED LLC

Colored roofing granules with increased solar heat reflectance, solar heat-reflective shingles, and process for producing same

ActiveUS7241500B2Improve solar heat reflectivityRoof improvementGlass/slag layered productsMineral particlesPigment

Owner:CERTAIN TEED LLC

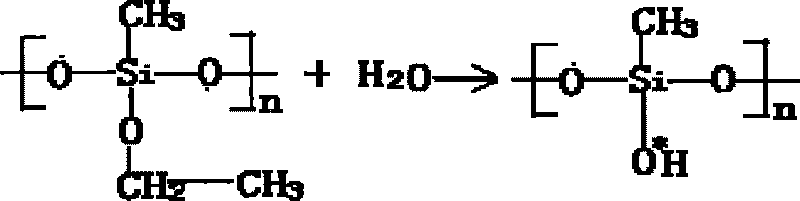

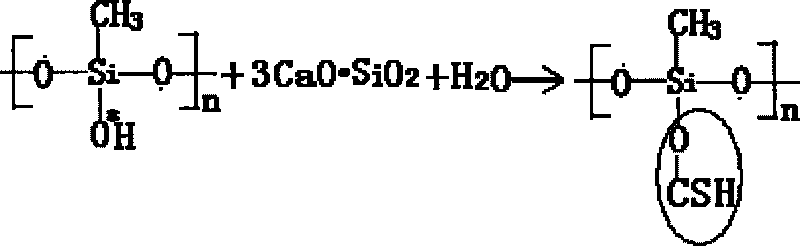

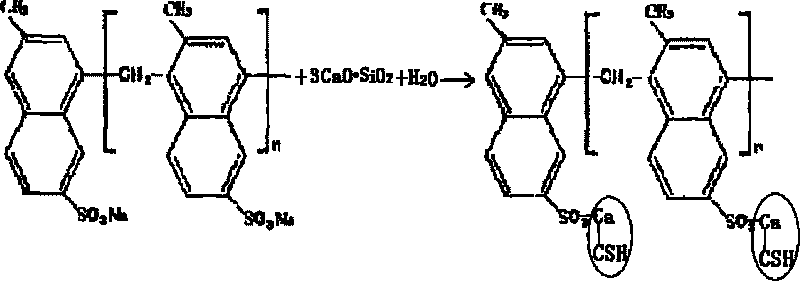

Waterproof roll capable of carrying out chemical bonding and physical crosslinking synergism with concrete

ActiveCN101694114AImprove stabilityIncreased durabilityRoof covering using flexible materialsTextiles and paperAntioxidantPlasticizer

The invention discloses a wet-laying and pre-laying waterproof roll which is made by the following processes: dipping and coating a modified asphalt compound on a blank body, controlling the thickness and sizing, coating a membrane, rolling, and the like, wherein the modified asphalt compound contains modified asphalt, a plasticizer, an antioxidant, a functional auxiliary agent and a filling gent. A preparation method of the waterproof roll comprises the following steps: putting substrate asphalt in a reaction pot, adding a thickening agent, irregular polyethylene and styrene-polybutadiene-styrene segmented copolymer, evenly mixing, heating and stirring for 1.5-2 hours, then reducing the temperature to about 180 DEG C, adding padding, the plasticizer, the antioxidant and the functional auxiliary agent into the reaction pot and stirring for 0.5-1h, evenly mixing and modifying, then conveying into a colloid mill for repeatedly milling to the material, then dipping and coating the modified asphalt on the blank body, controlling the thickness, sizing, coating the membrane and rolling, and finally preparing the waterproof roll which has excellent performance and can carry out chemical bonding and physical crosslinking synergism with the concrete, namely, a CPS waterproof roll for short.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

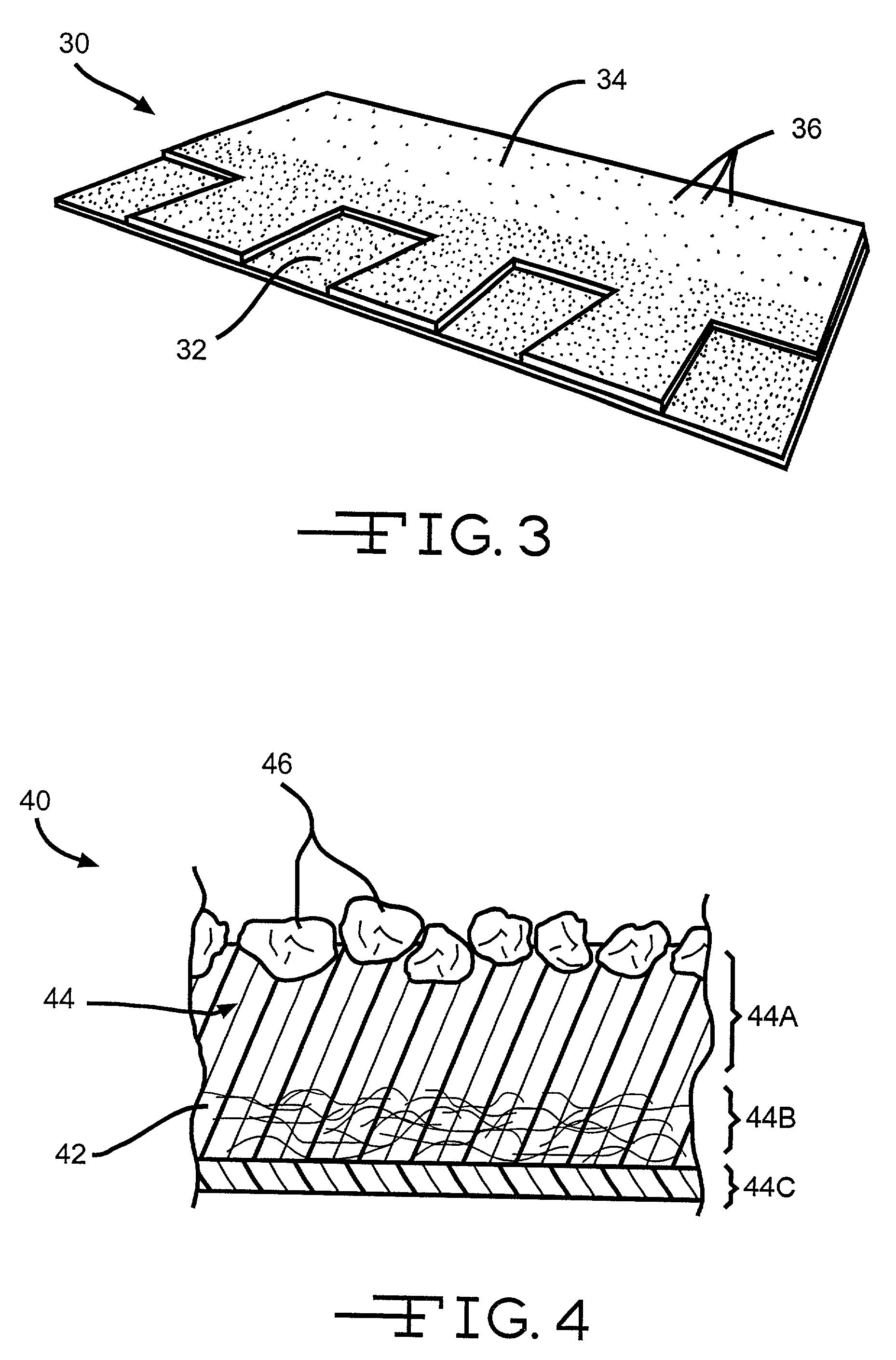

Mineral-surfaced roofing shingles with increased solar heat reflectance, and process for producing same

An infrared-reflective material is applied directly to the bituminous surface of a roofing product to increase the solar heat reflectance of the product, even when deep-tone roofing granules are used to color the product. The infrared-reflective material can be applied as a powder or in a carrier fluid or film, and can be applied along with infrared-reflective roofing granules.

Owner:CERTAINTEED CORP

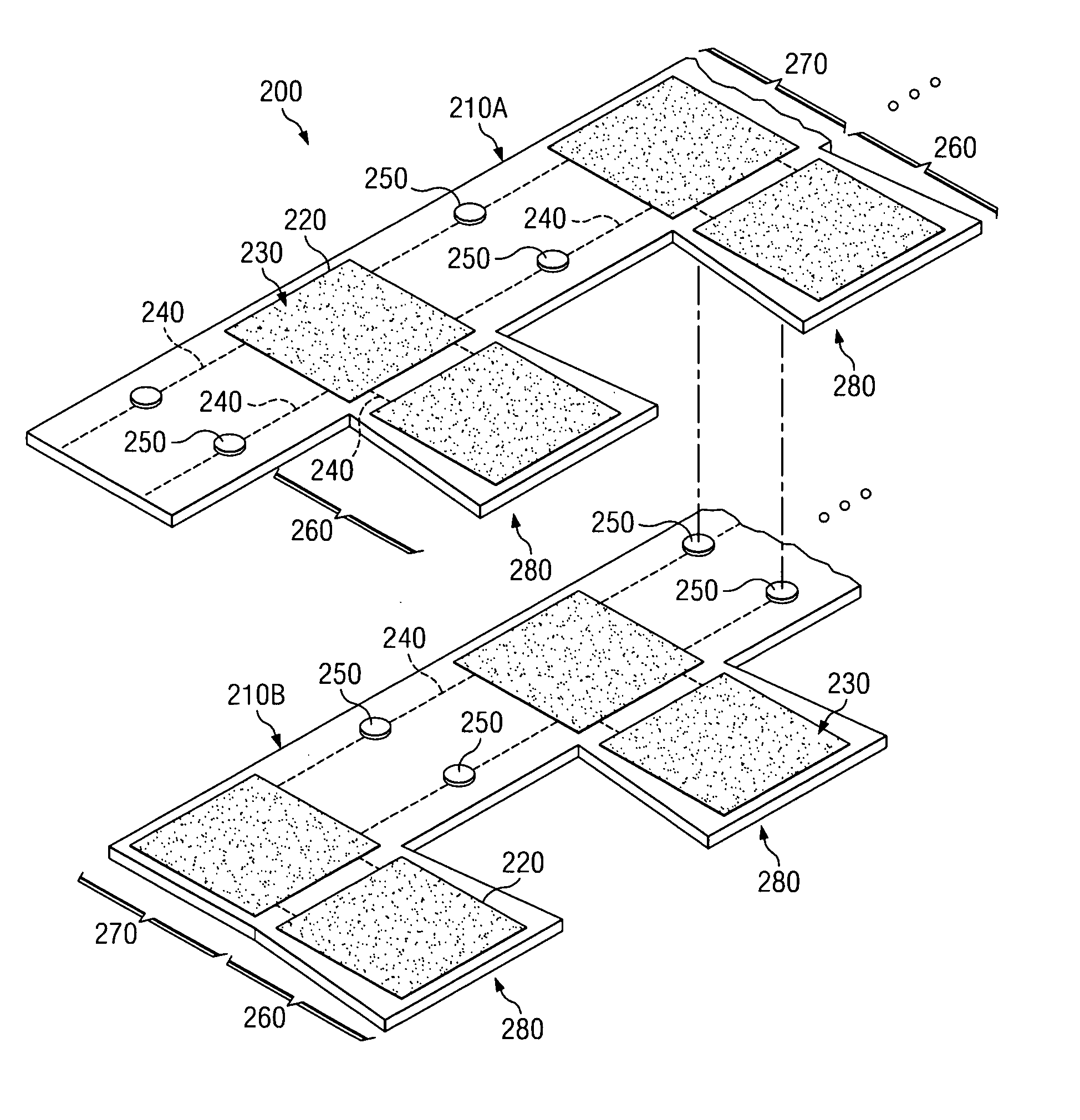

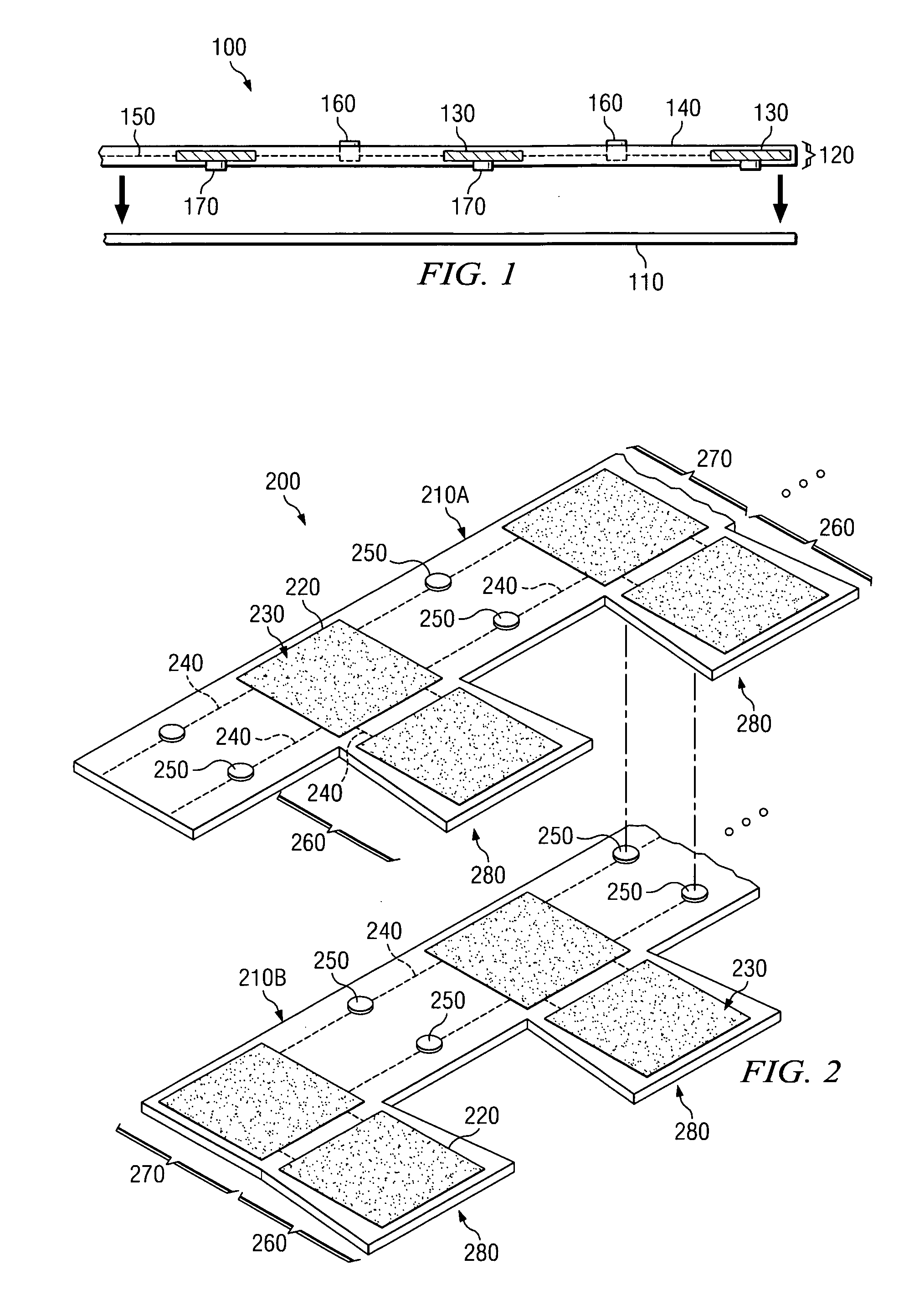

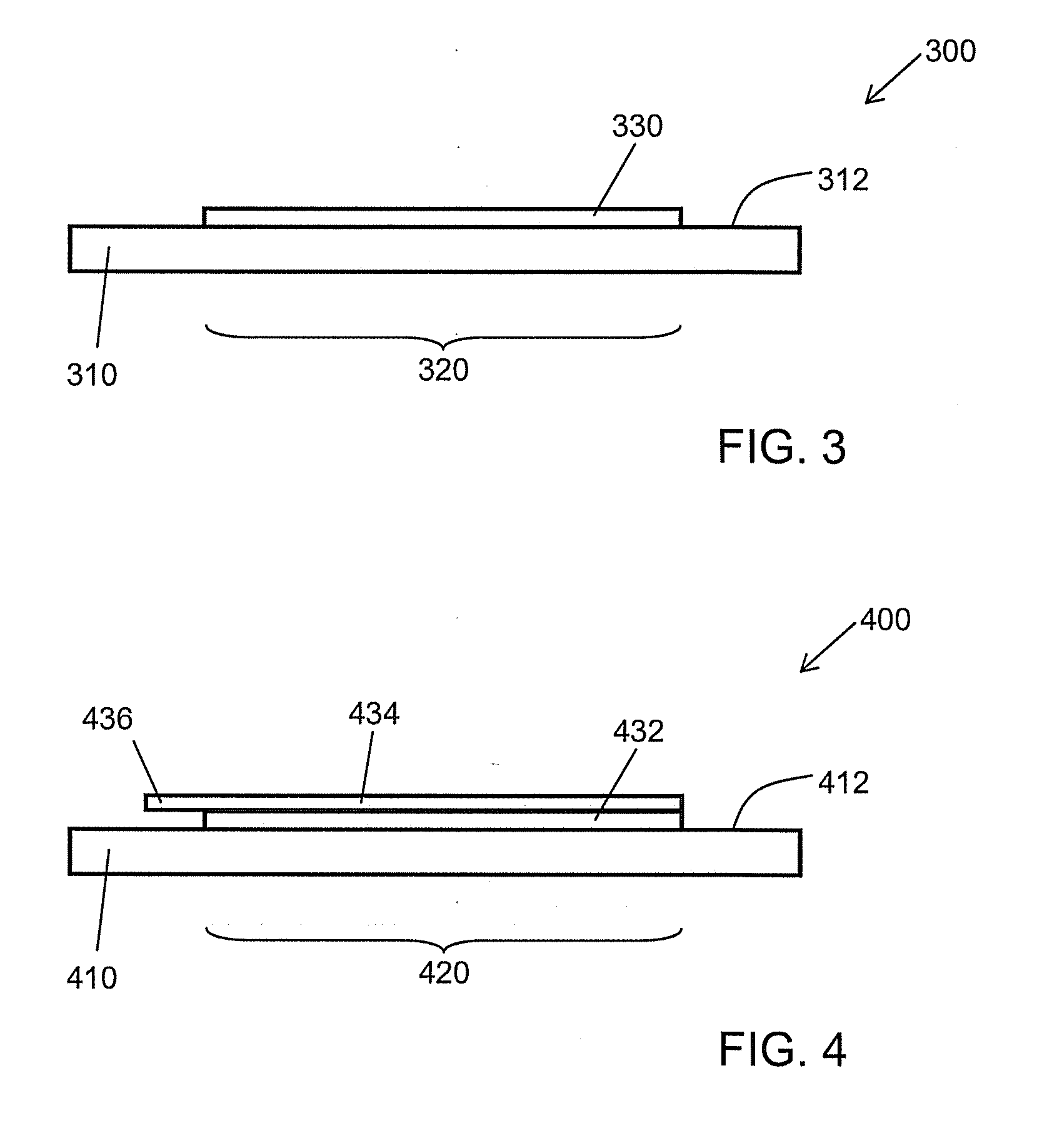

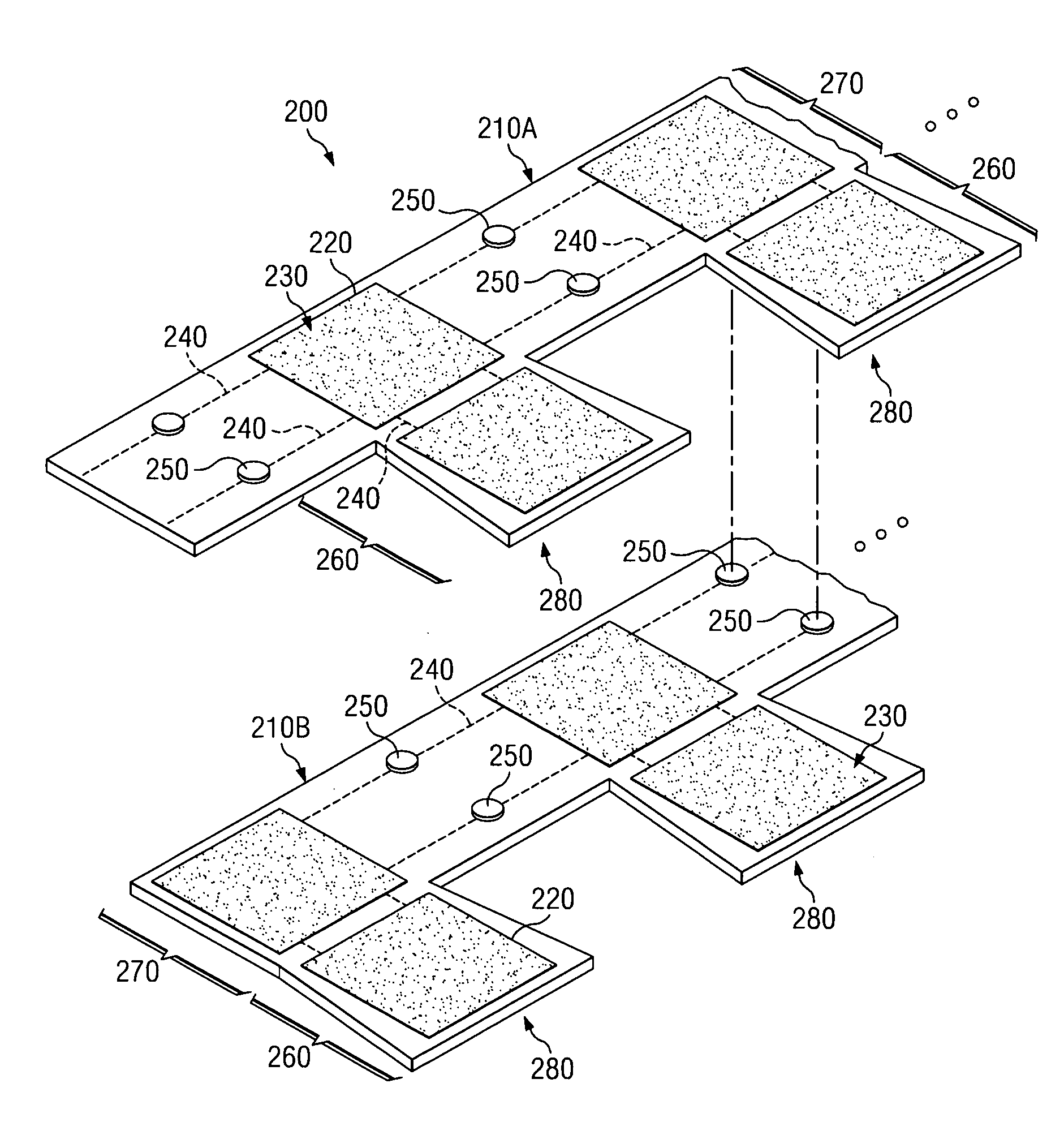

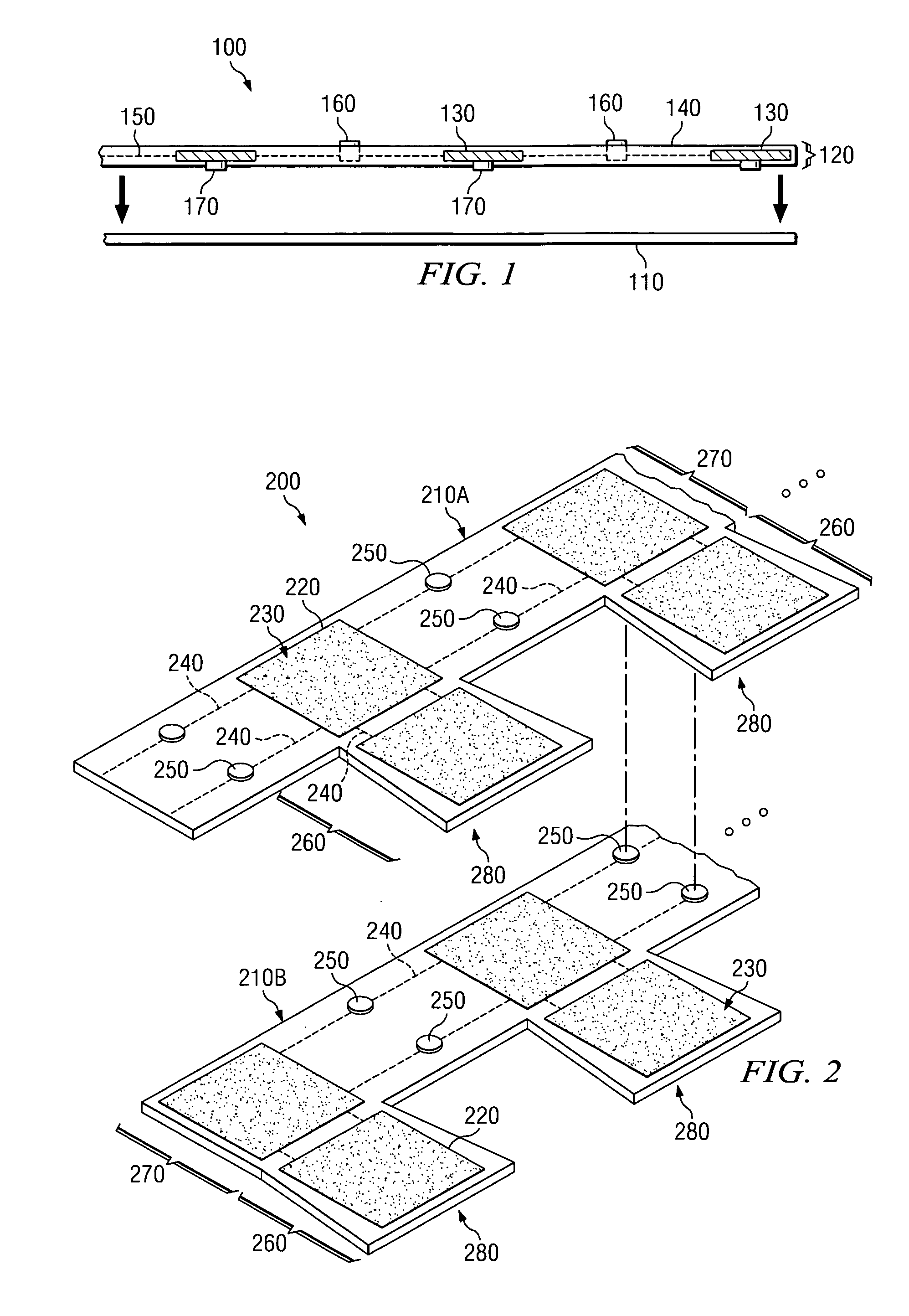

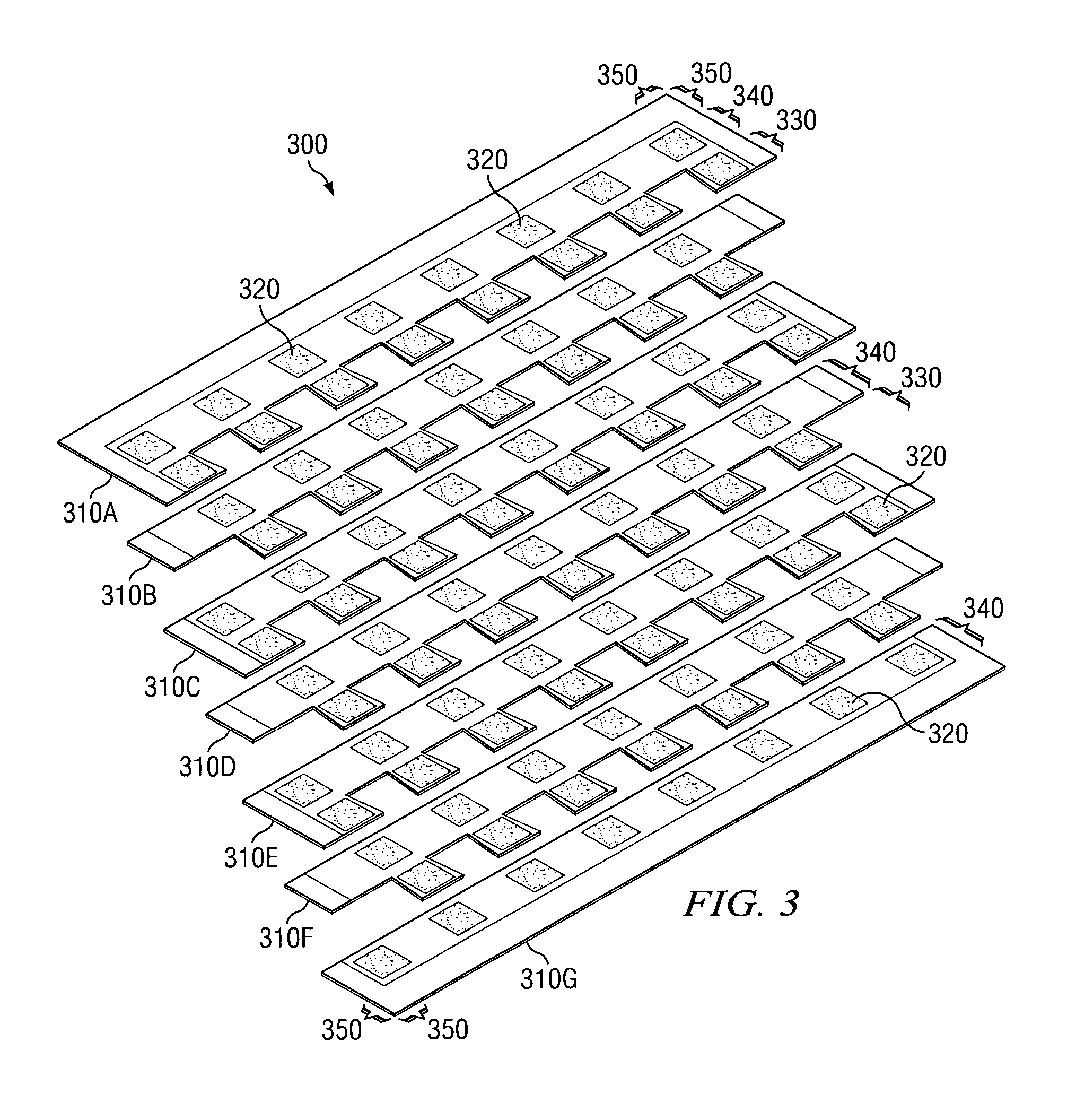

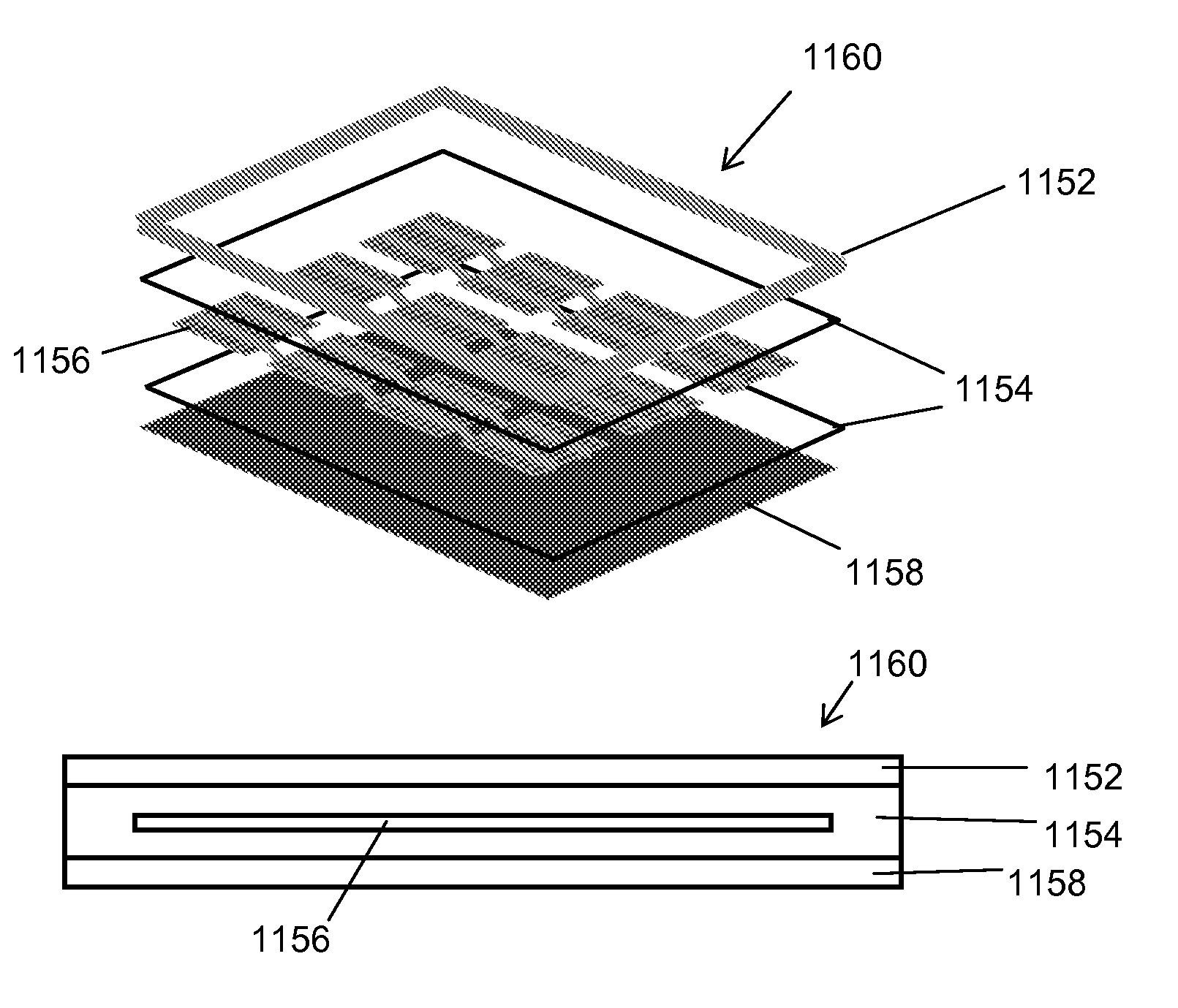

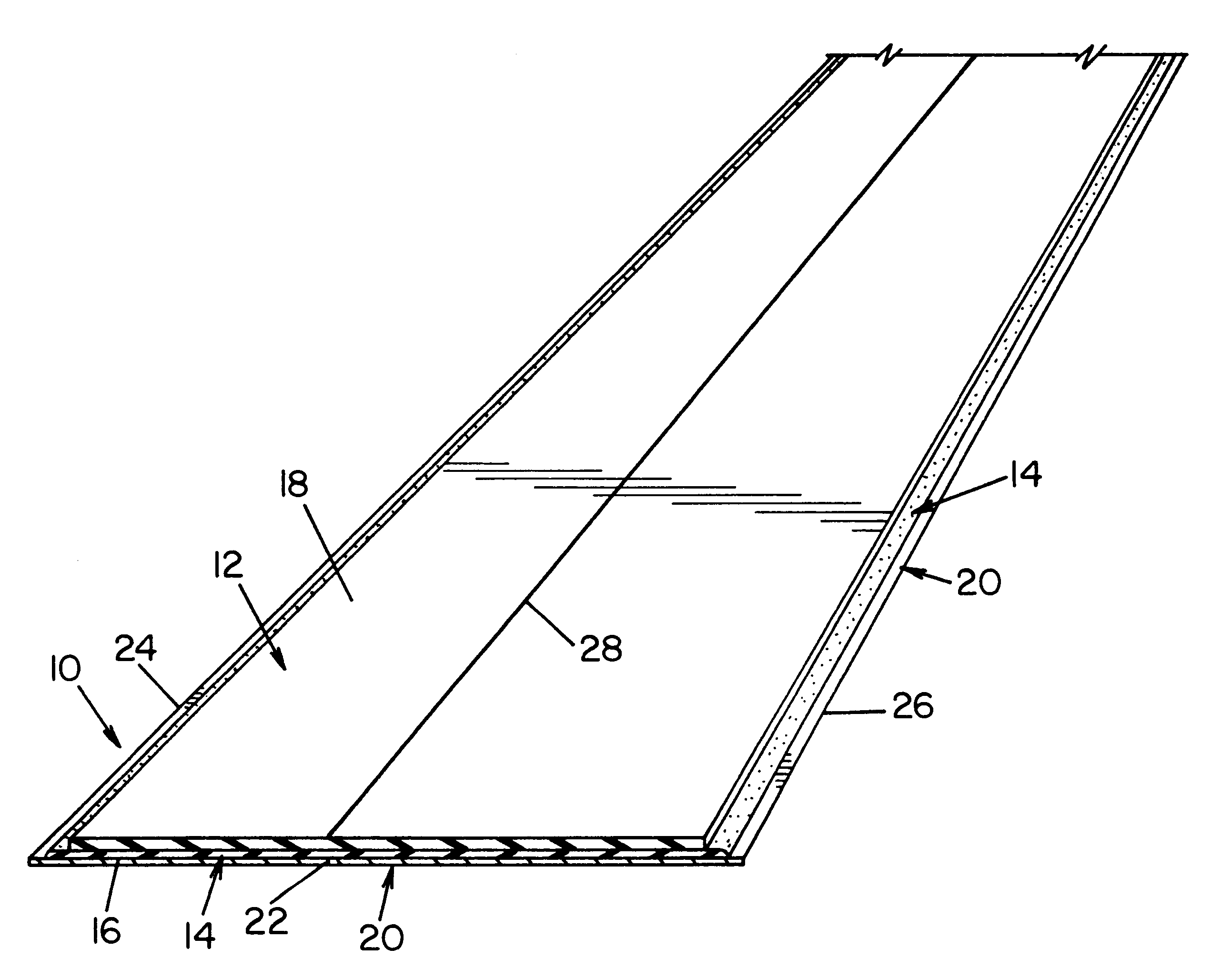

Flexible integrated photovoltaic roofing membrane and related methods of manufacturing same

ActiveUS20050178429A1Photovoltaic supportsRoof covering using slabs/sheetsElectricityPhotovoltaic solar energy

Disclosed herein are flexible, solar powered photovoltaic (PV) integrated roofing membrane and related methods of manufacturing such a membrane. The disclosed membrane and methods beneficially provide solar power to structures in either off-grid or on-grid connections. The roofing membrane may comprise multiple membrane strips or members having electrically interconnected photovoltaic solar elements. The membrane members preferably have distinct patterns for the solar elements located thereon that provide for coverage of entire sections, upon installation, as well as accommodate interconnections between the solar elements. Moreover, the membrane will appreciate the numerous types of patterns to achieve such purposed of full coverage and electrical coupling.

Owner:ELK PREMIUM BUILDING PROD

Method of forming an improved roofing material

InactiveUS6933007B2Improve reflectivityIncrease temperatureRoof covering using tiles/slatesCovering/liningsMaterials scienceReflectivity

A method of coating highly reflective granules on an adhering material of a roofing or siding material to form a roofing or siding material having an average resulting reflectivity on an upper surface of at least about 45%. The method includes the selecting of highly reflective granules and applying the highly reflective granules on an adhering material until over about 95% of a top surface of the adhering material is covered by the granules.

Owner:GARLAND INDS

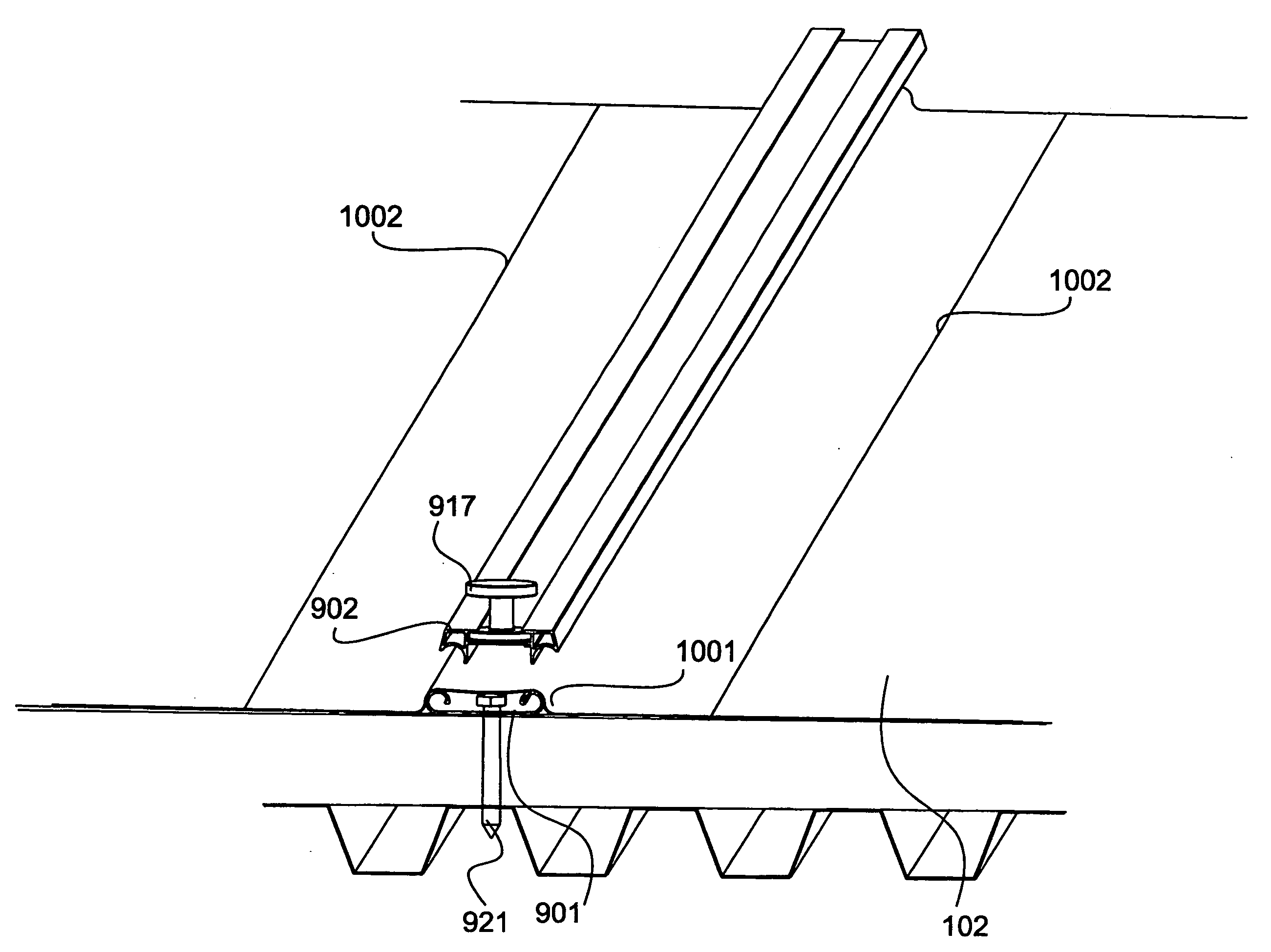

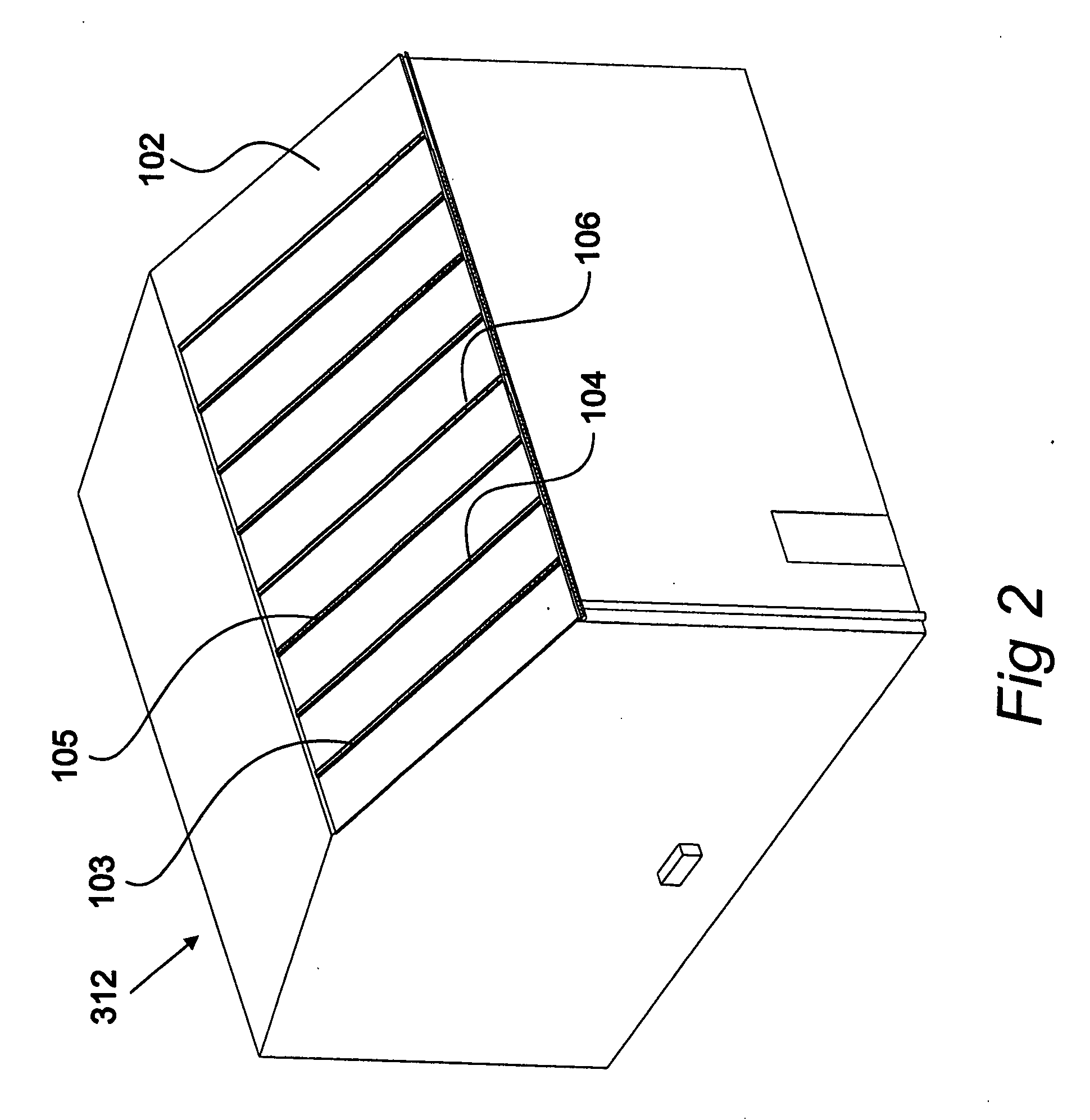

Solar panel roof mounting system

InactiveUS20070266672A1Photovoltaic supportsRoof covering using slabs/sheetsEngineeringSolar energy harvesting

Apparatus is provided for securing solar energy collection devices to a roof. A plurality of rails (103, 104) are provided. Each rail is attachable to a roof (102) at mutually displaced positions and defines a rail slot (702, 915). Attachment devices (917) are provided, each configured to engage with a rail slot (702, 915) such that in a first condition the devices are free to move along the slot and in the second condition the devices are secured within the slot. The attachment devices (917) include an engaging portion (919) that protrudes from the slot to engage with a solar energy collection device.

Owner:SOLAR CENTURY HLDG

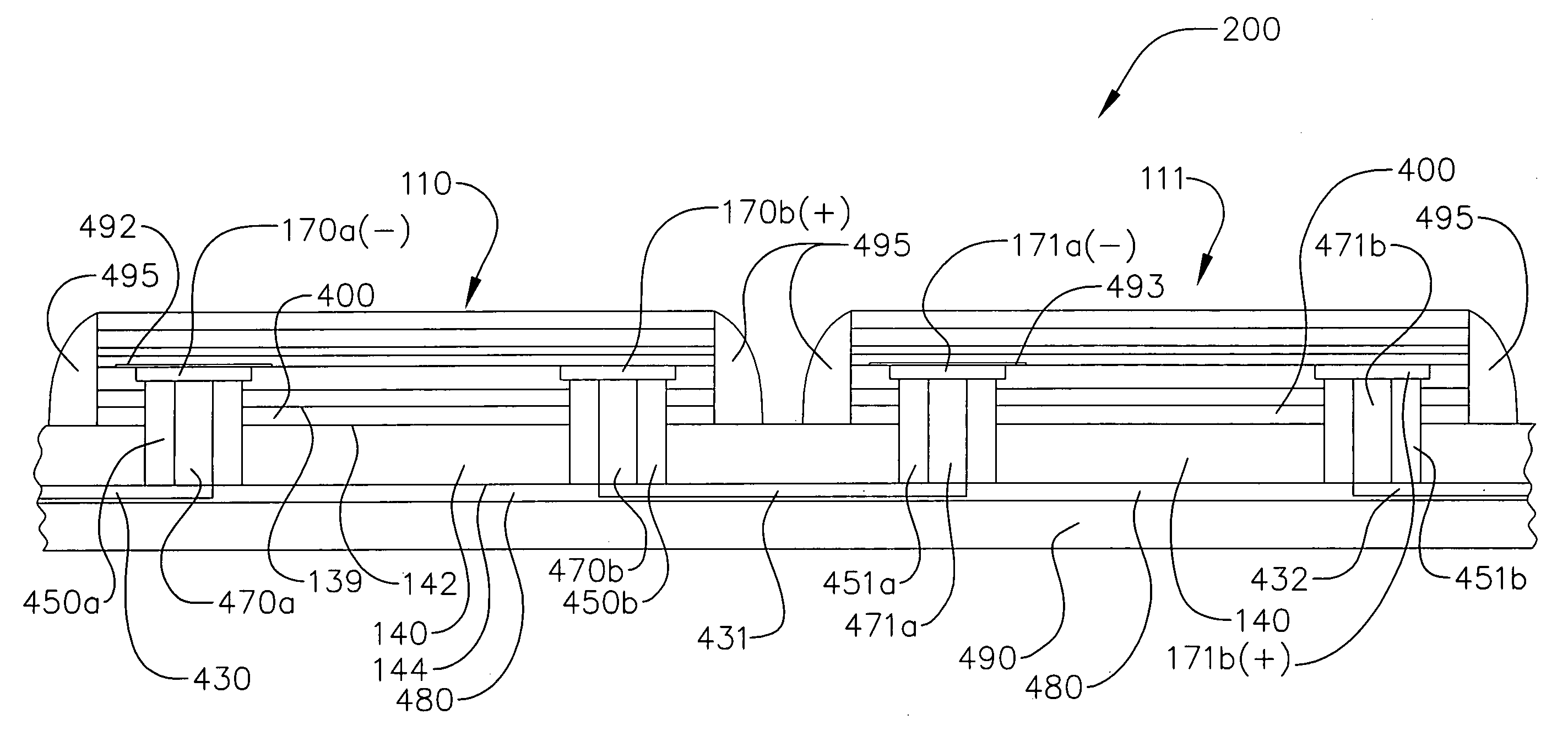

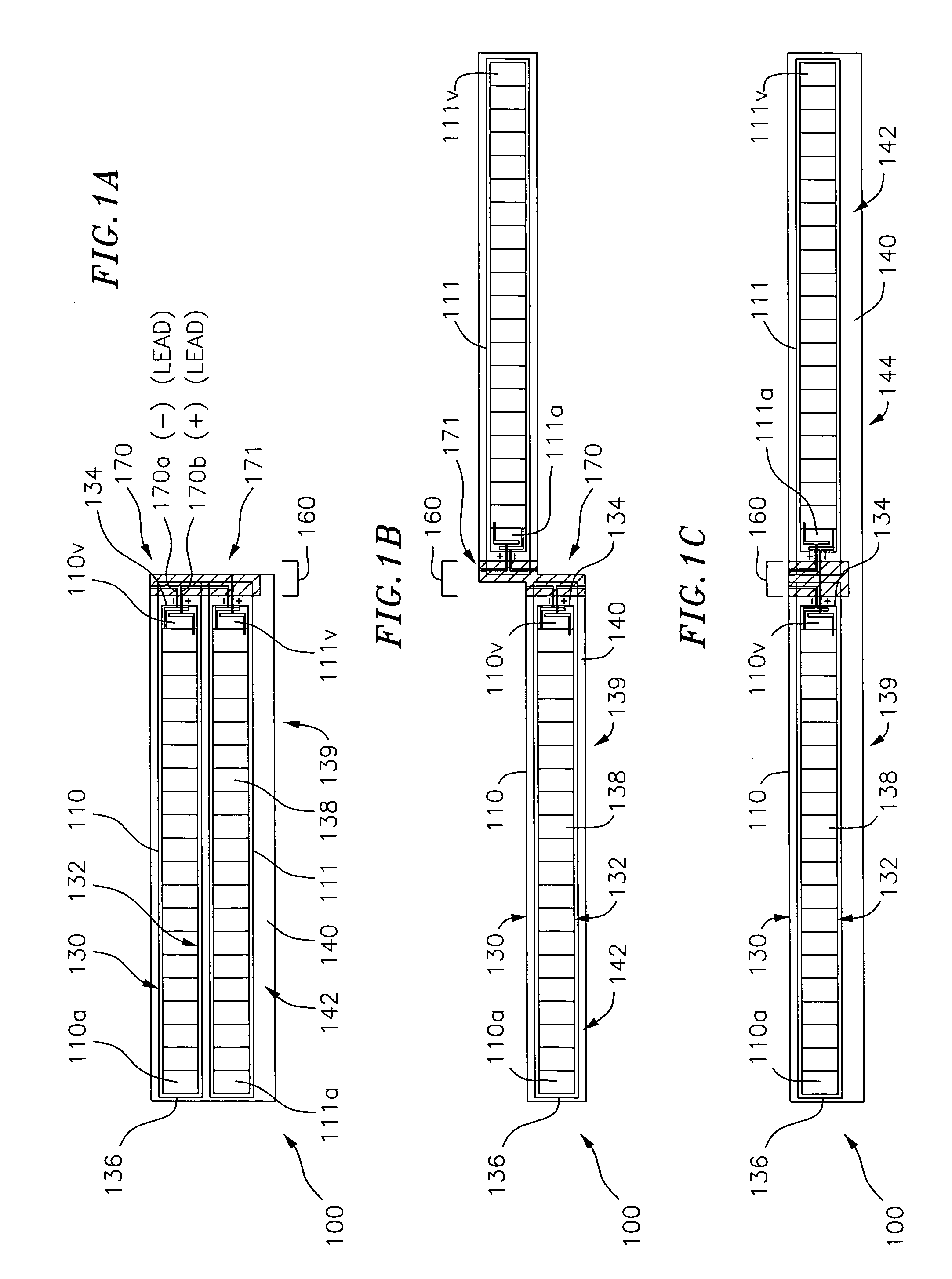

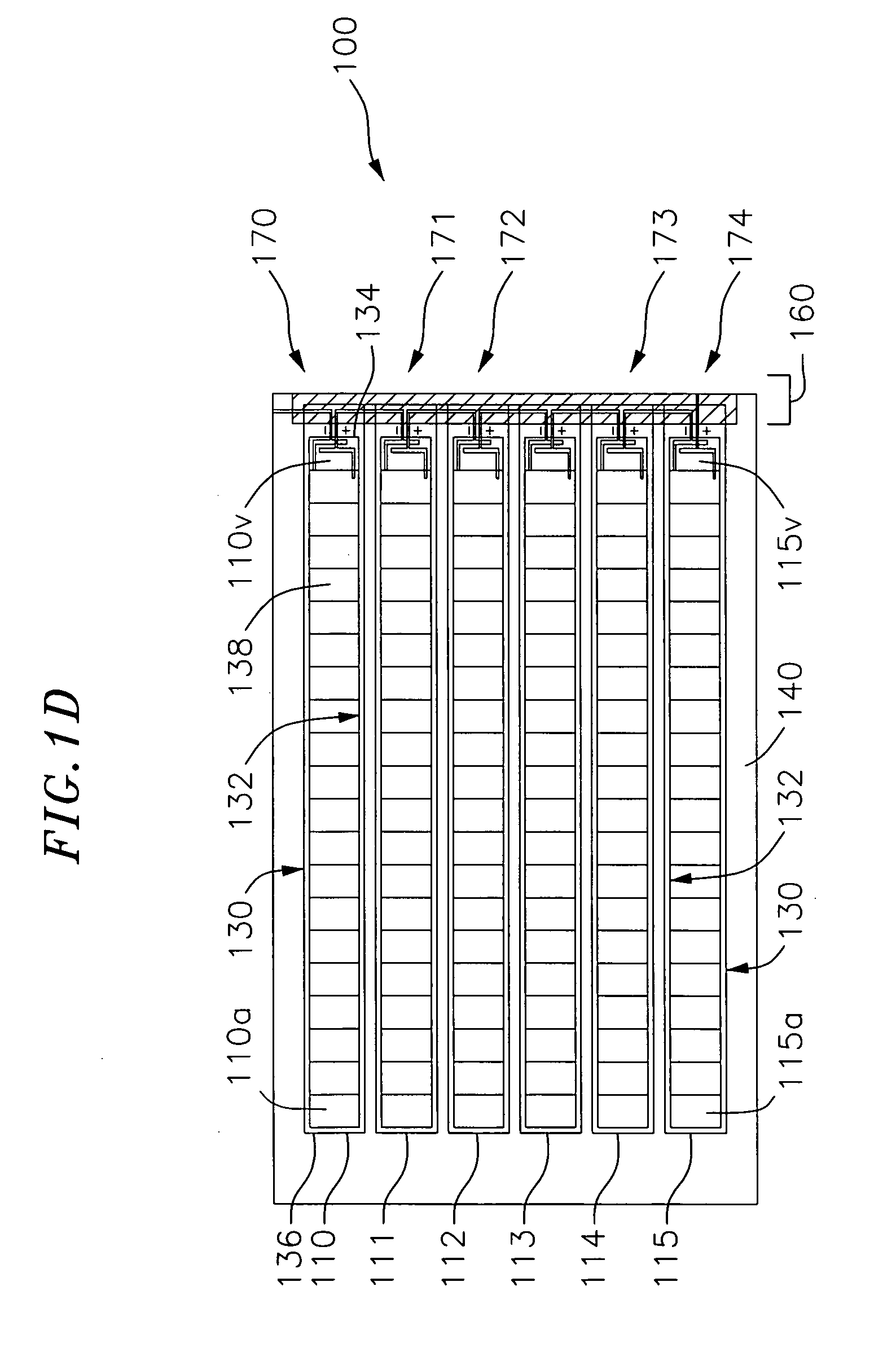

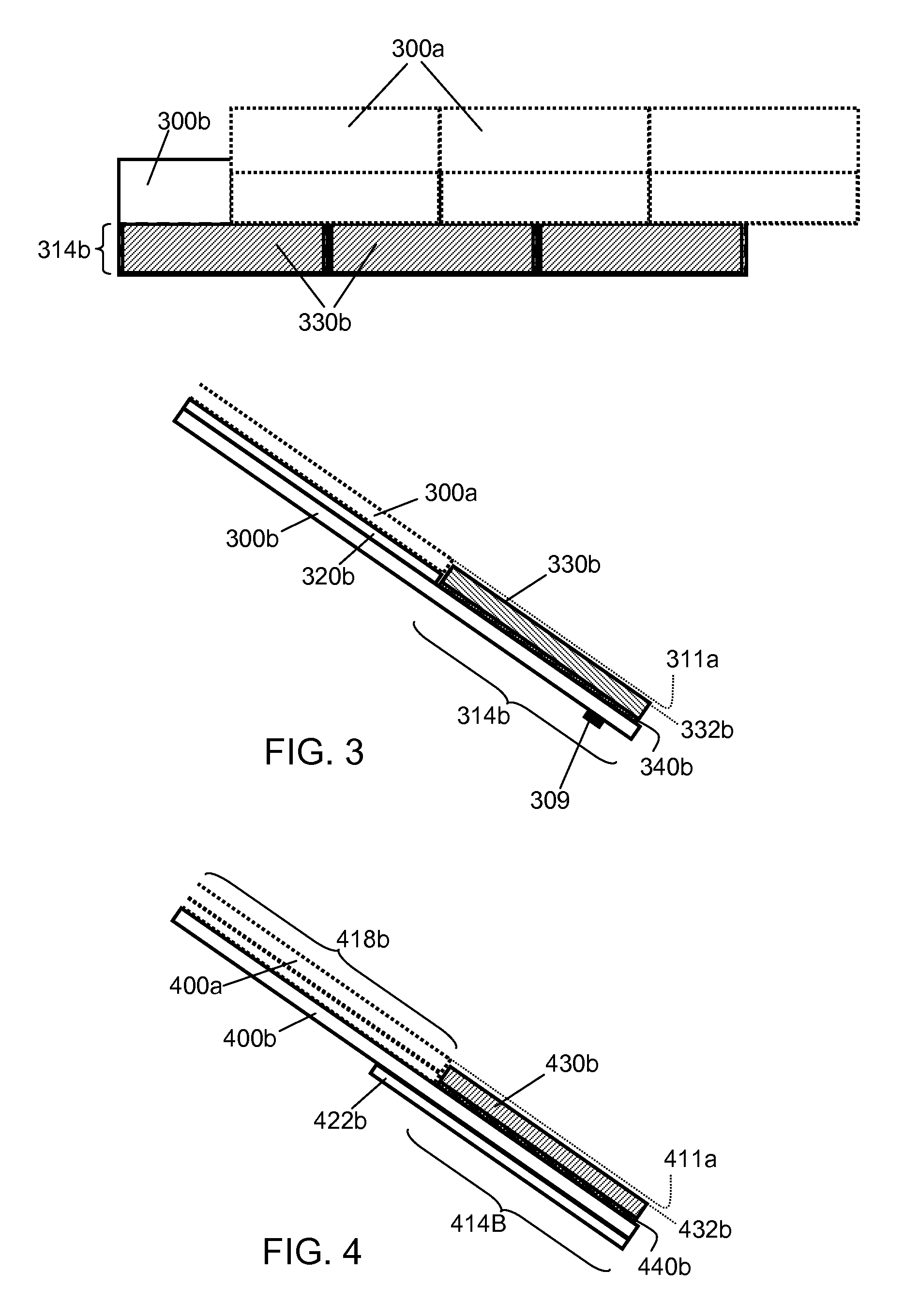

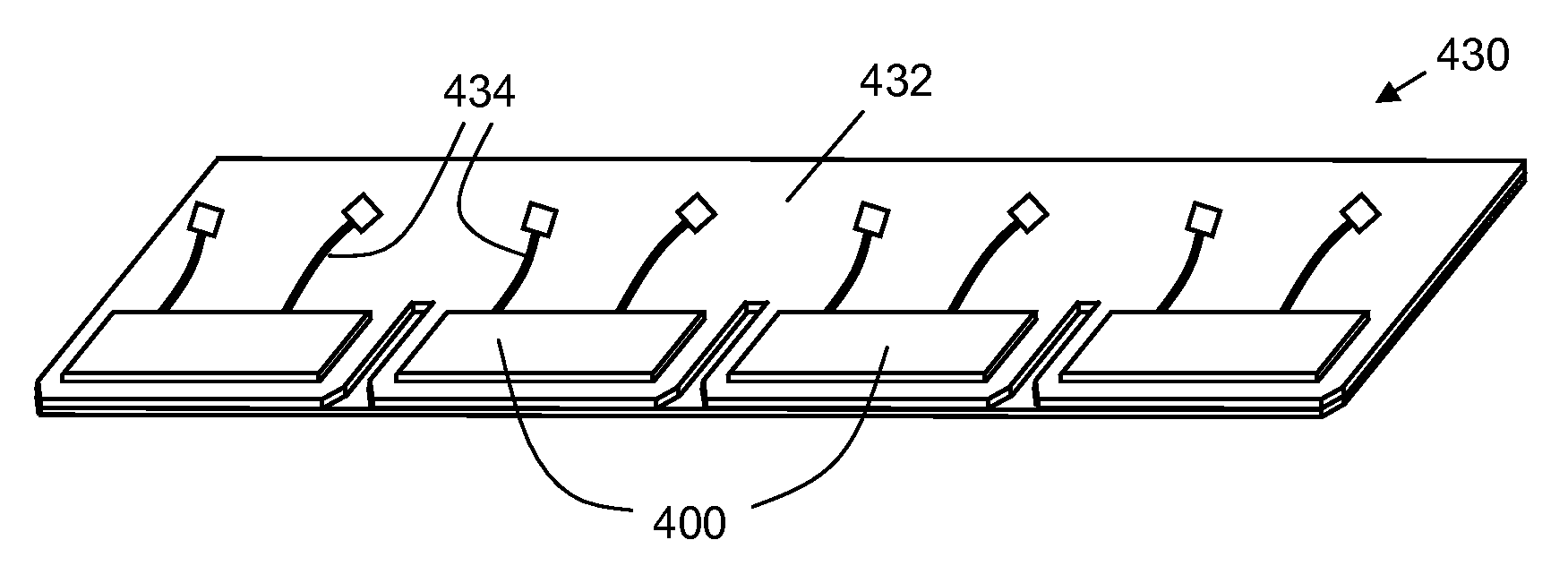

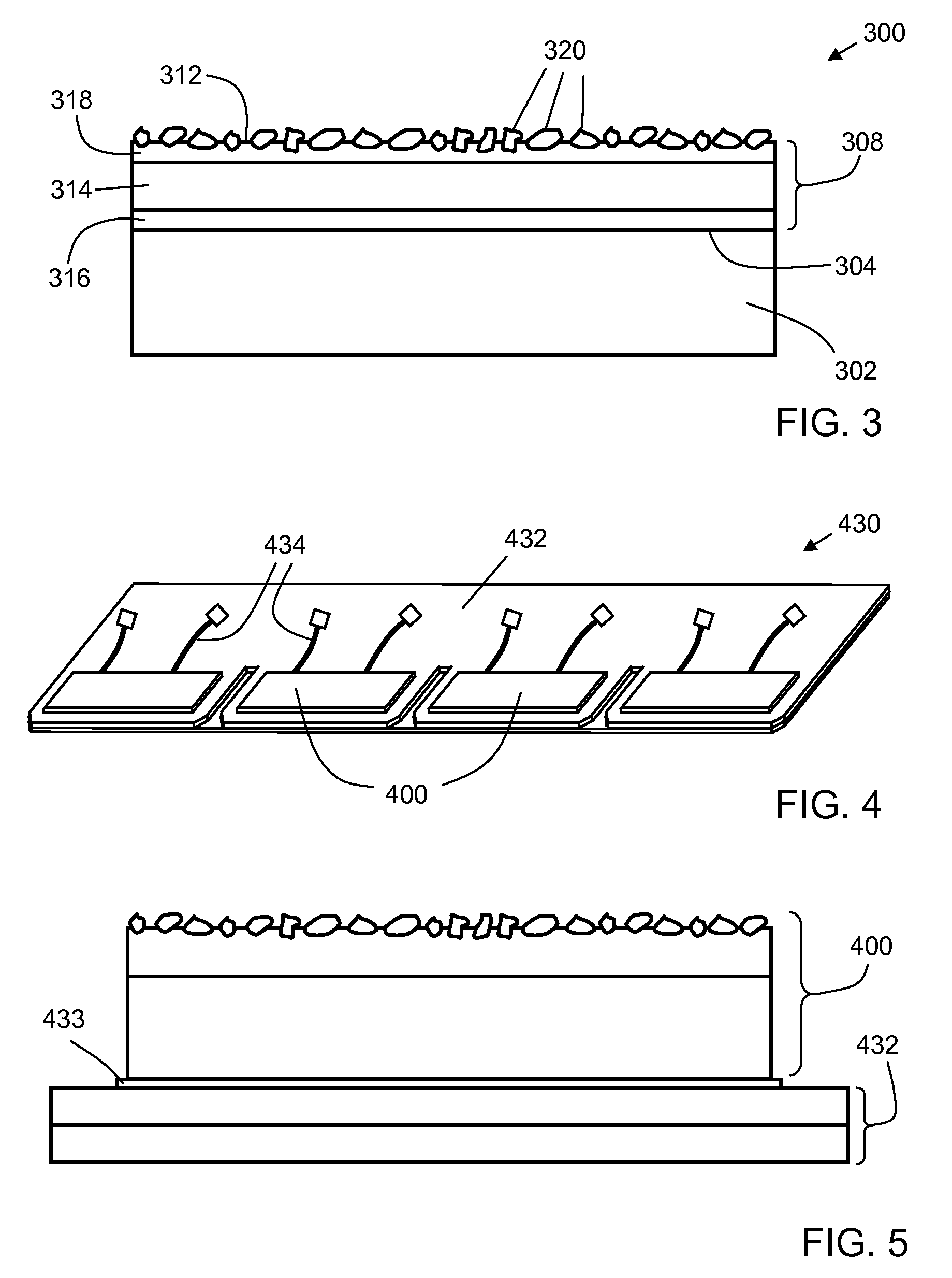

Integrated photovoltaic roofing component and panel

InactiveUS7342171B2Reducing electrical interconnectionPhotovoltaic supportsRoof covering using slabs/sheetsElectricityComputer module

A combination roofing panel and solar module includes a flexible membrane sheet, such as a single-ply membrane sheet, and a plurality of elongated solar or photovoltaic modules arranged side-by-side, end-to-end, or adjacent each other. The modules are adhered to the flexible membrane, and the edges of the modules having electrical connectors or electrodes are arranged to face each other or be aligned with each other. The electrical connectors are connected by a solder connection to module electrodes through apertures in a bottom surface of the flexible membrane and are connected in series. The series electrical connectors are connected directly to direct current (DC) electric devices, to a combiner box, to another panel or to an inverter which coverts direct current (DC) to alternating current electricity for use in residential, commercial or industrial building structures. The ends and elongated edges of a roofing component or panel having the flexible membrane and modules can be sealed for protection.

Owner:SOLAR INTEGRATED TECH

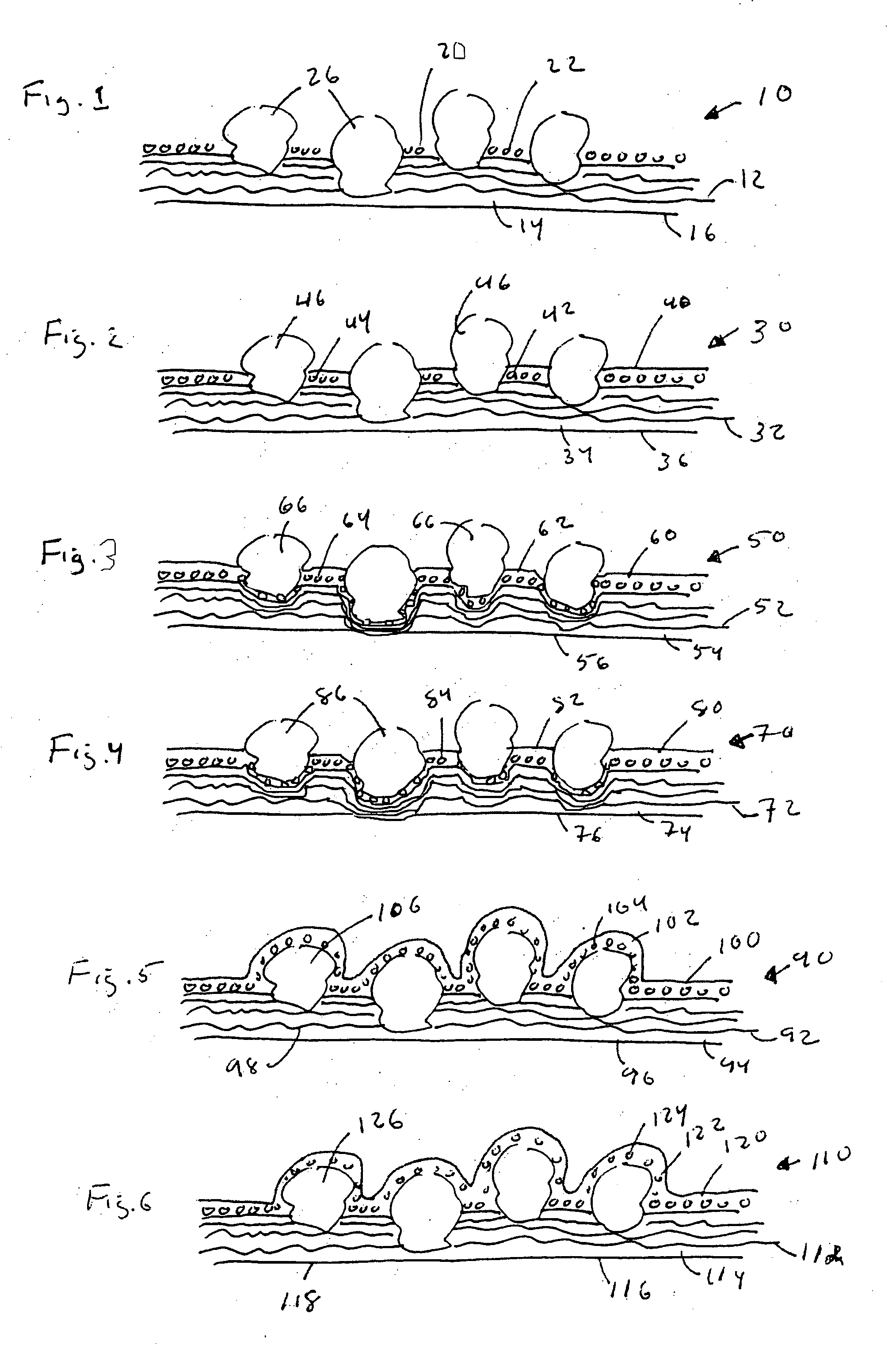

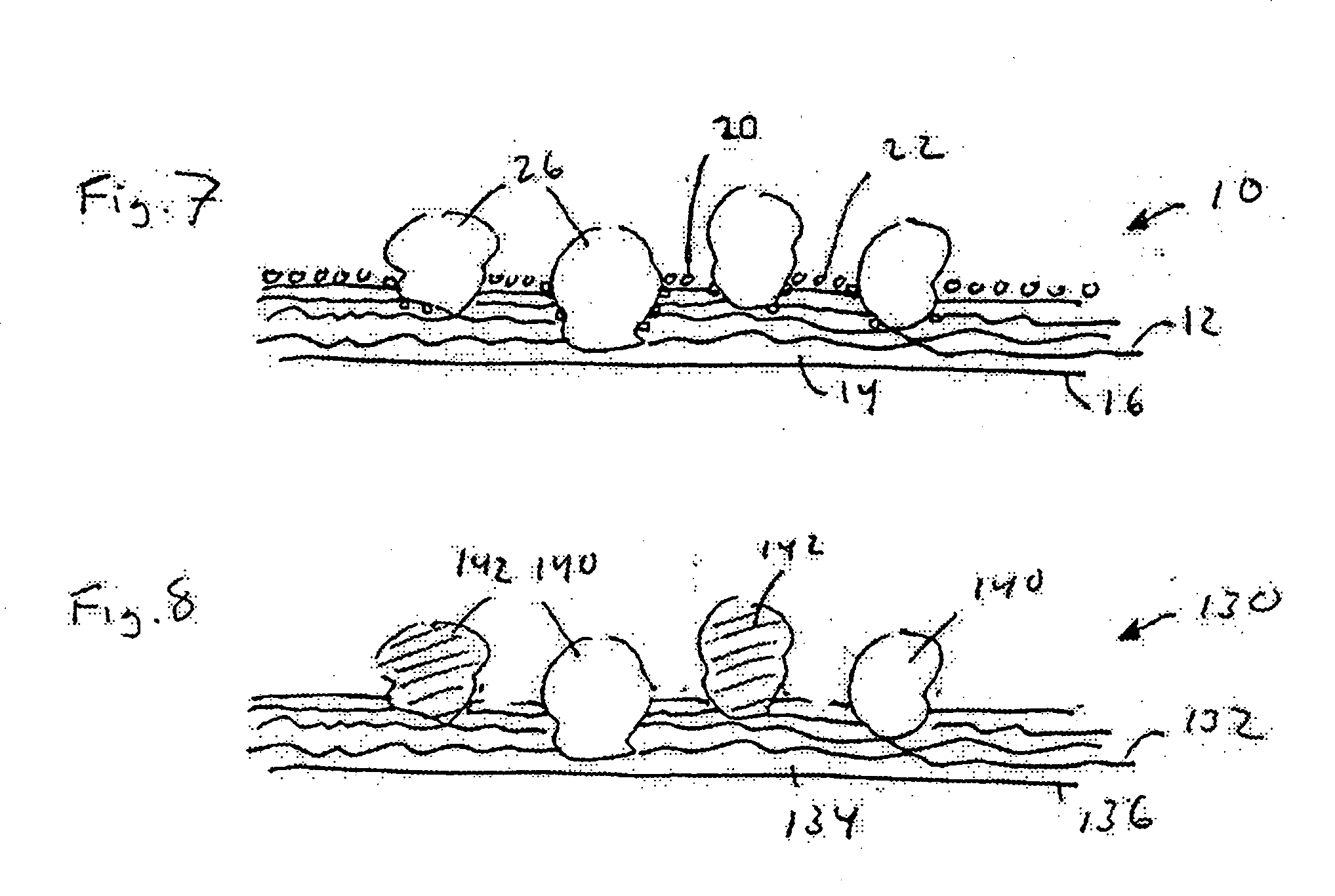

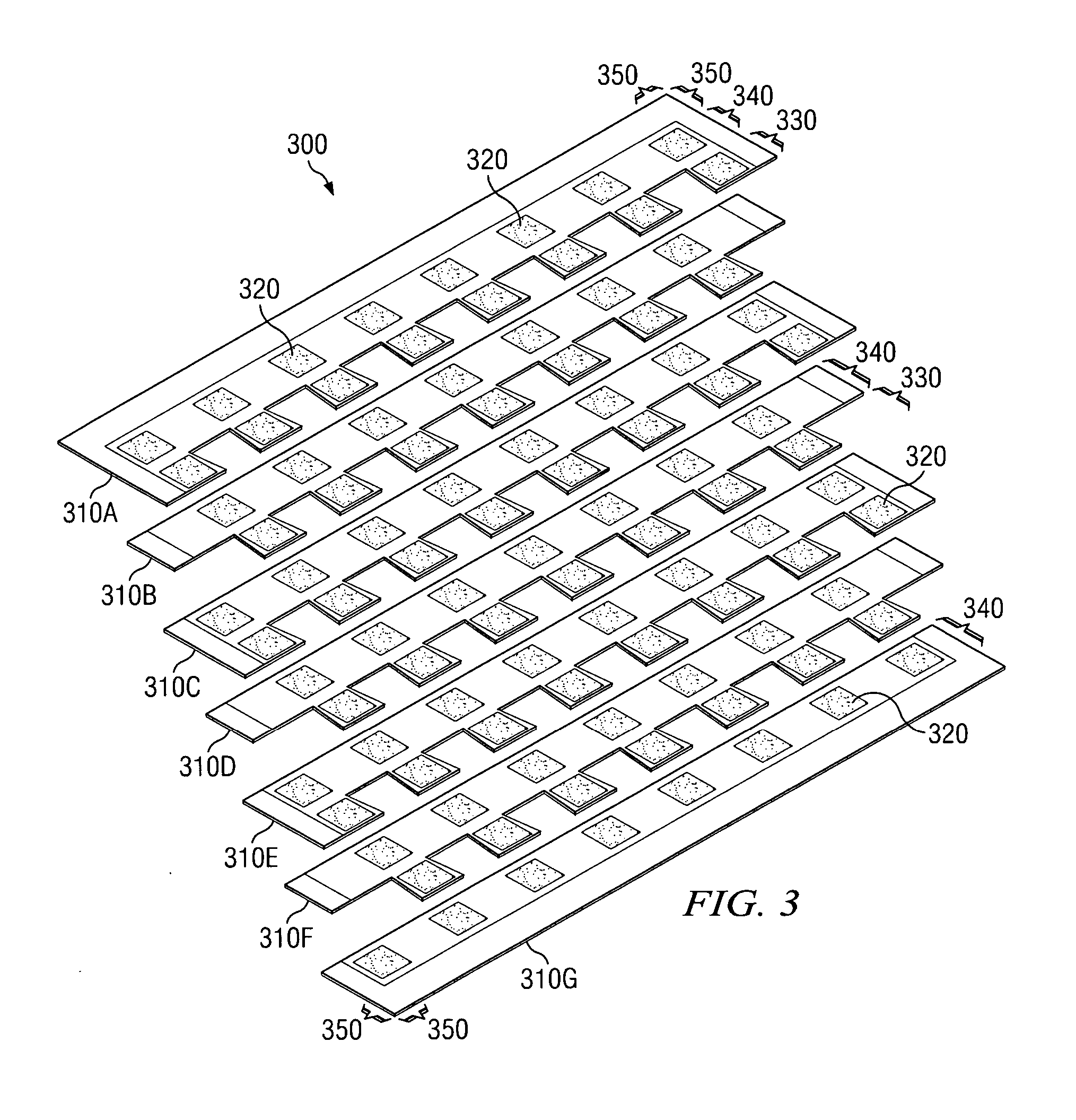

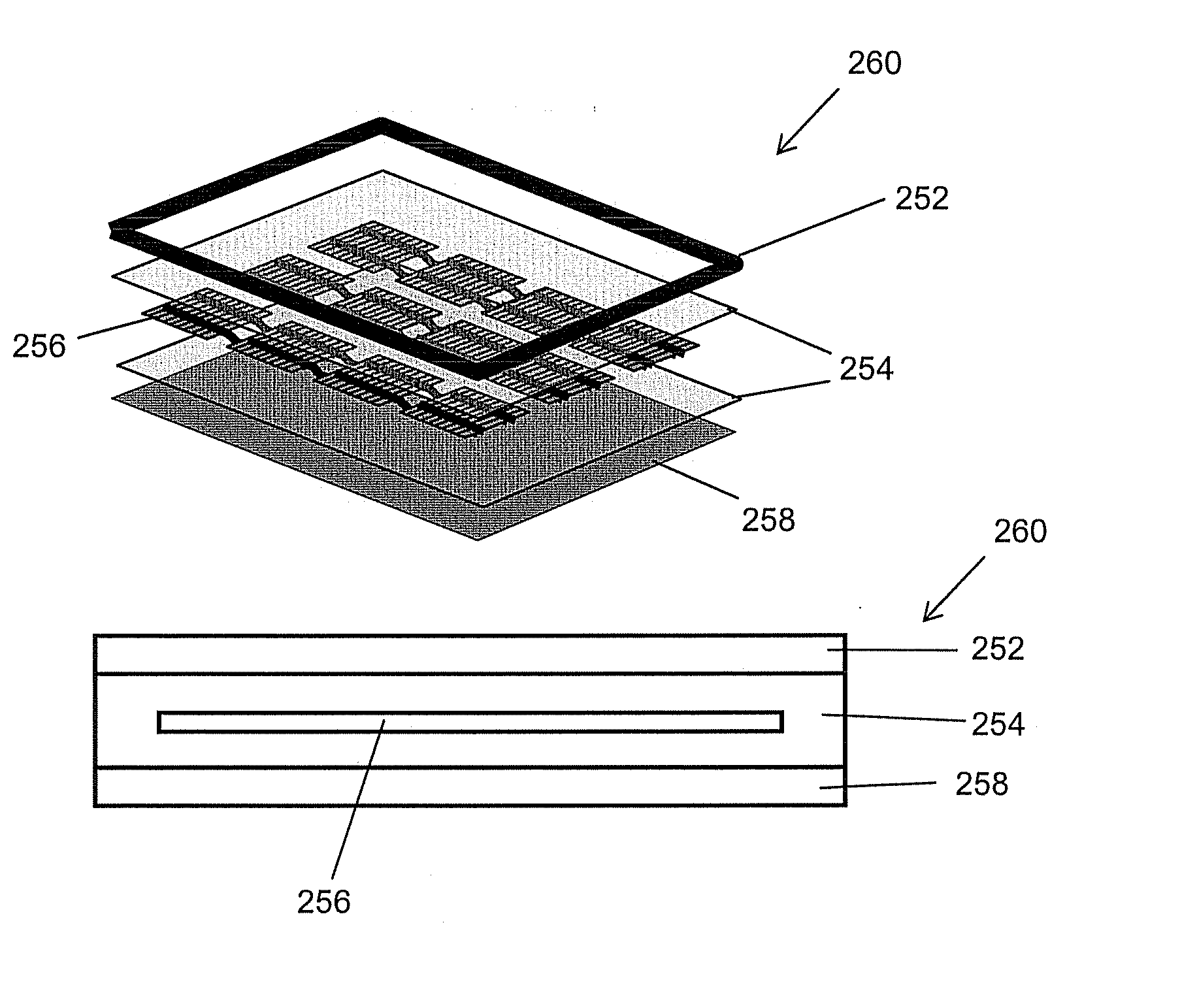

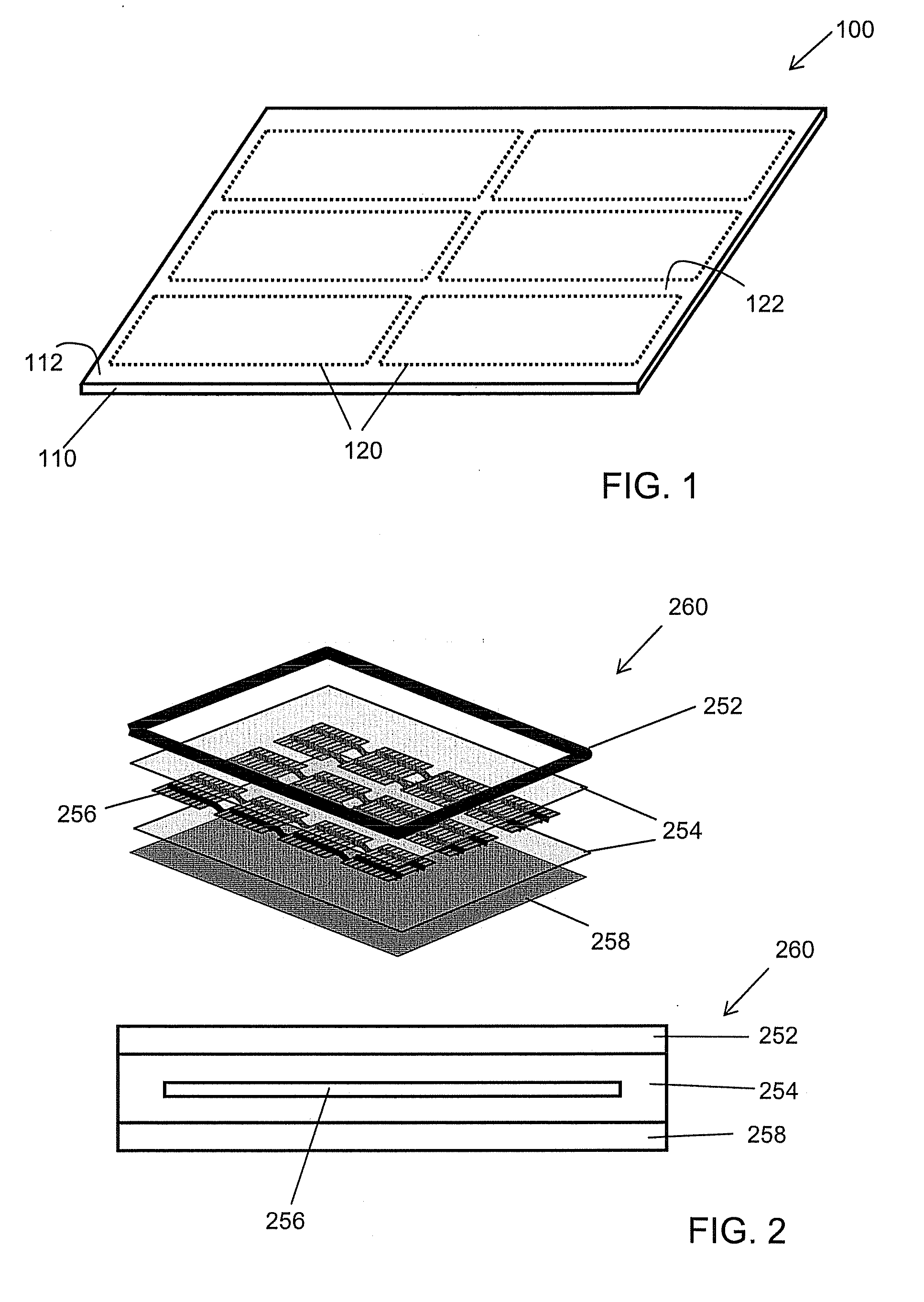

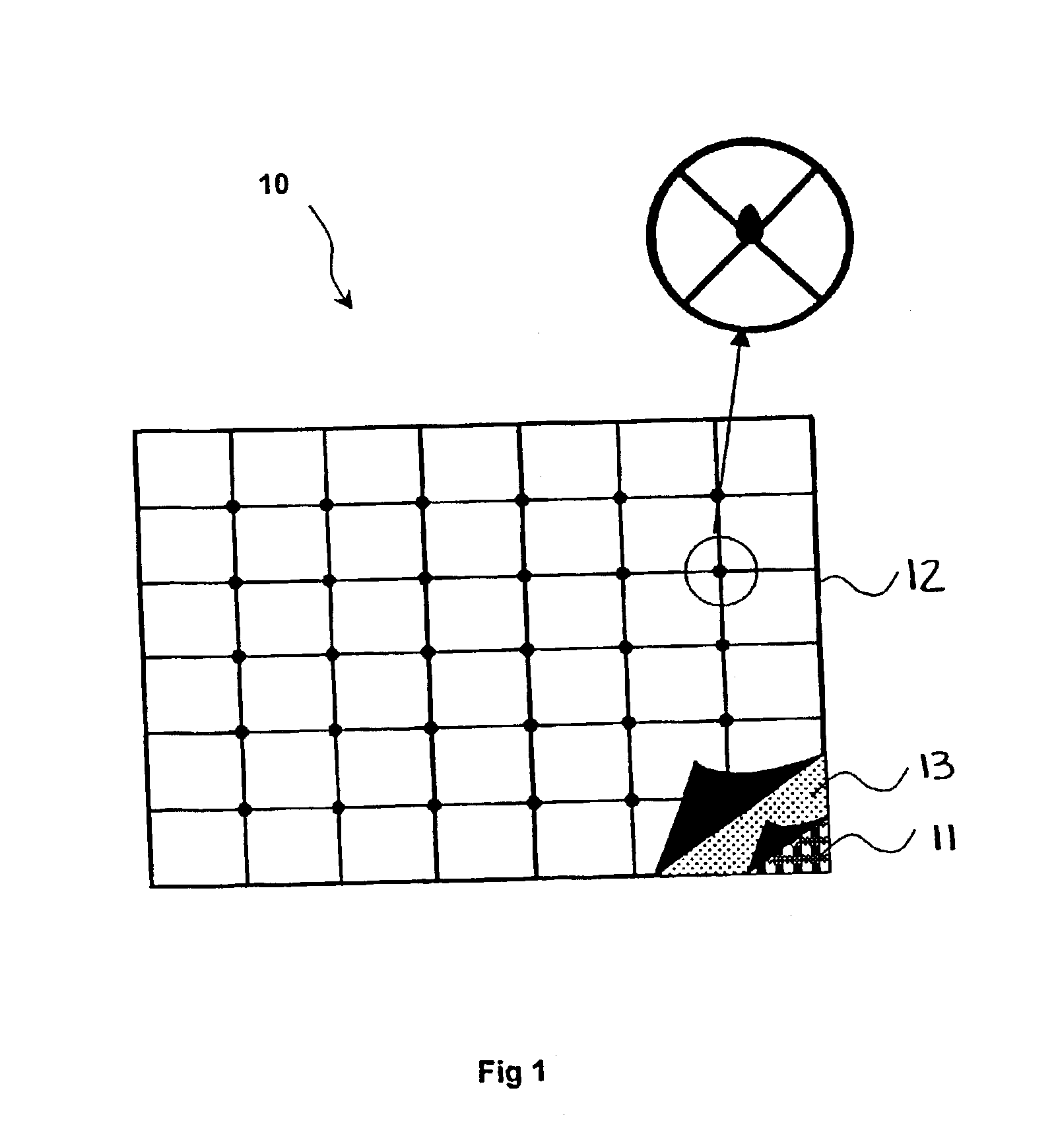

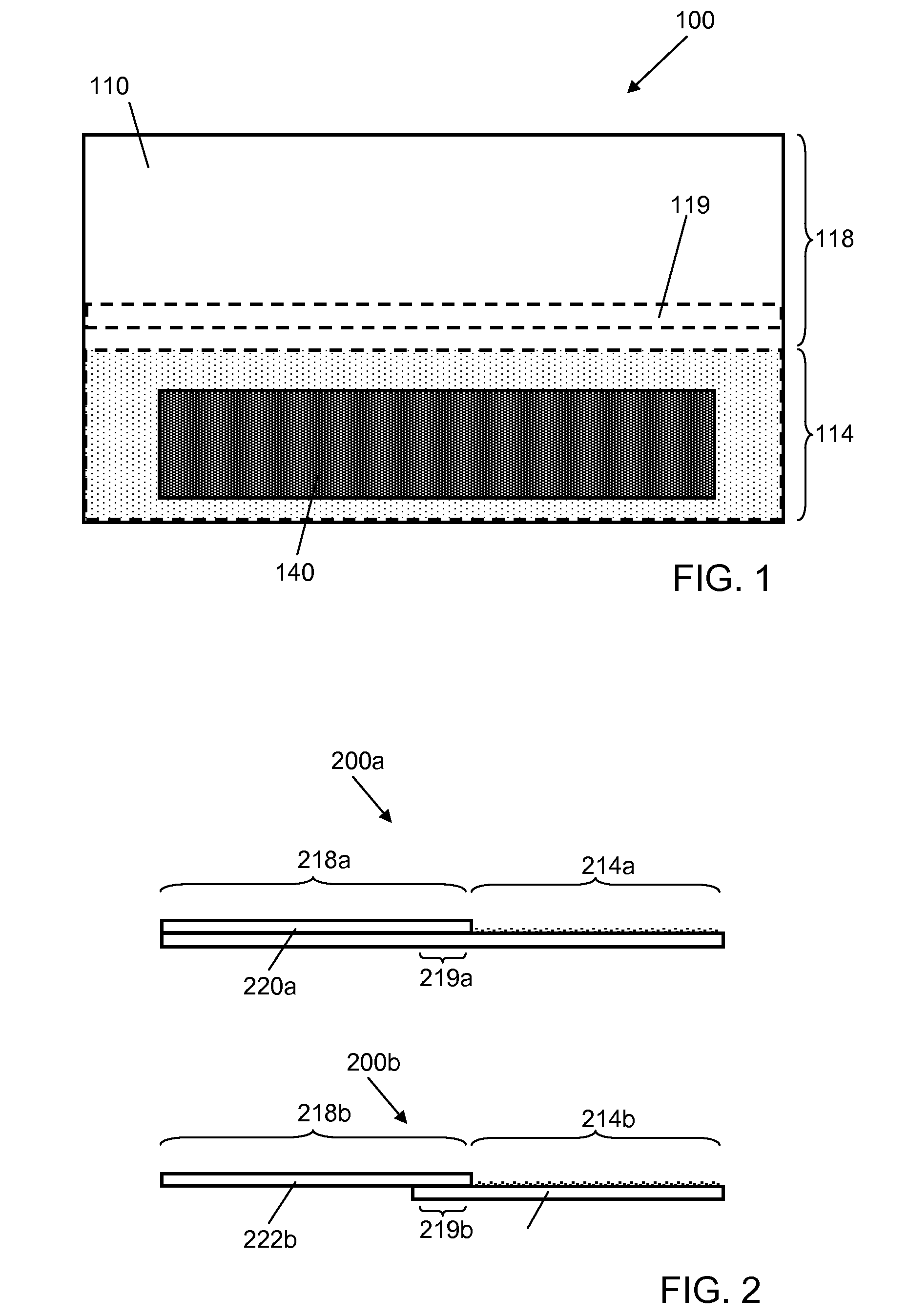

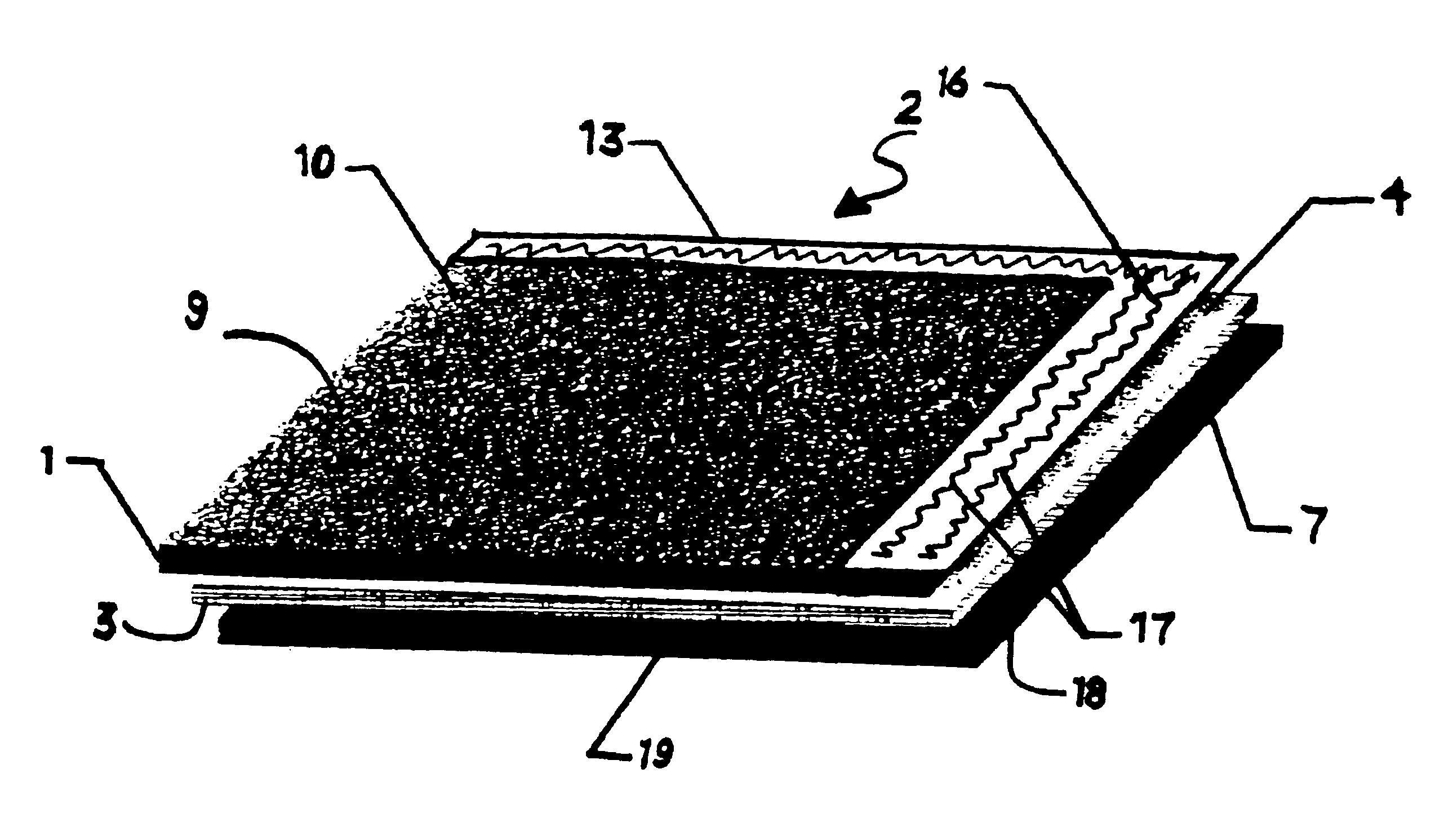

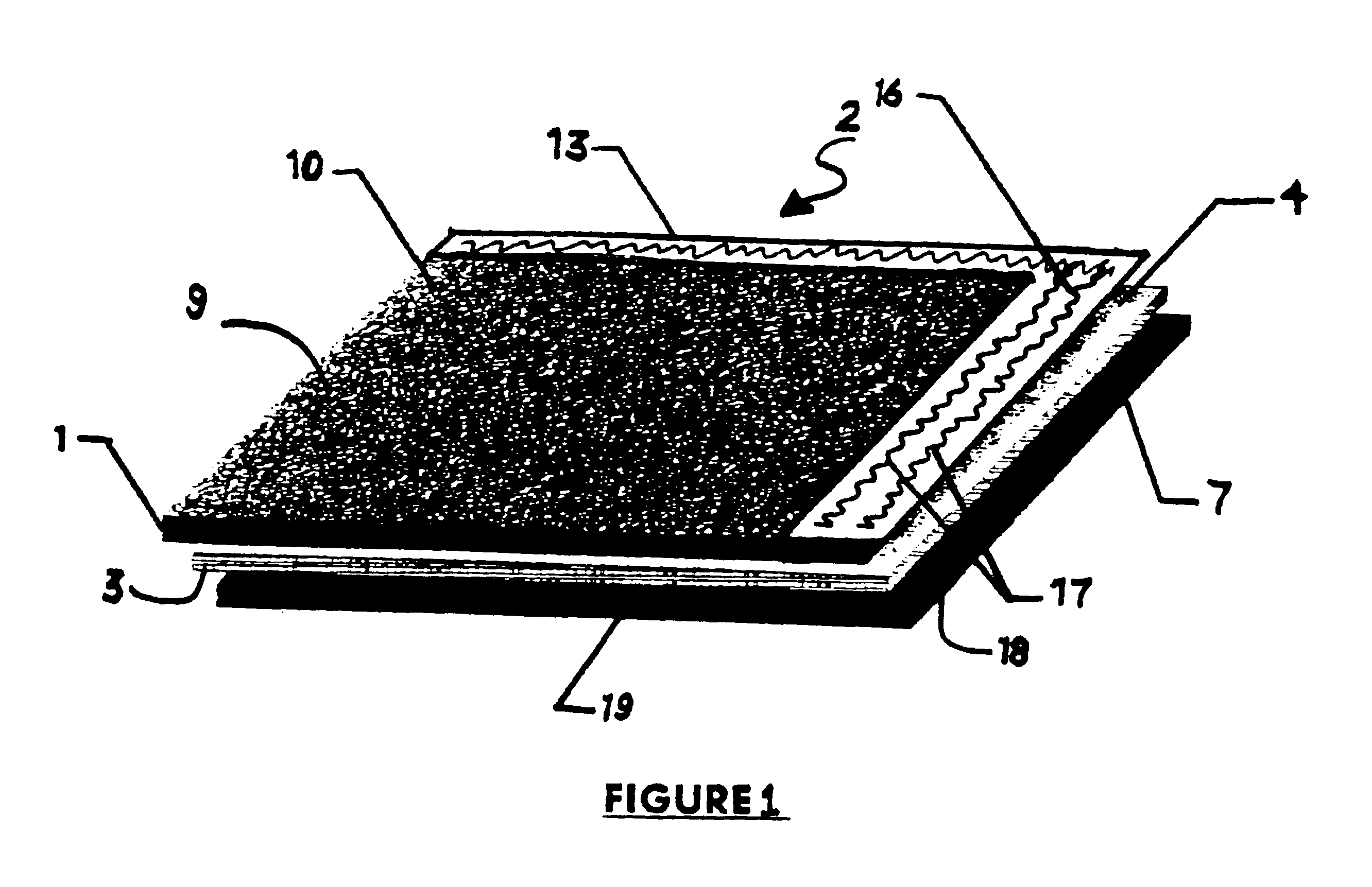

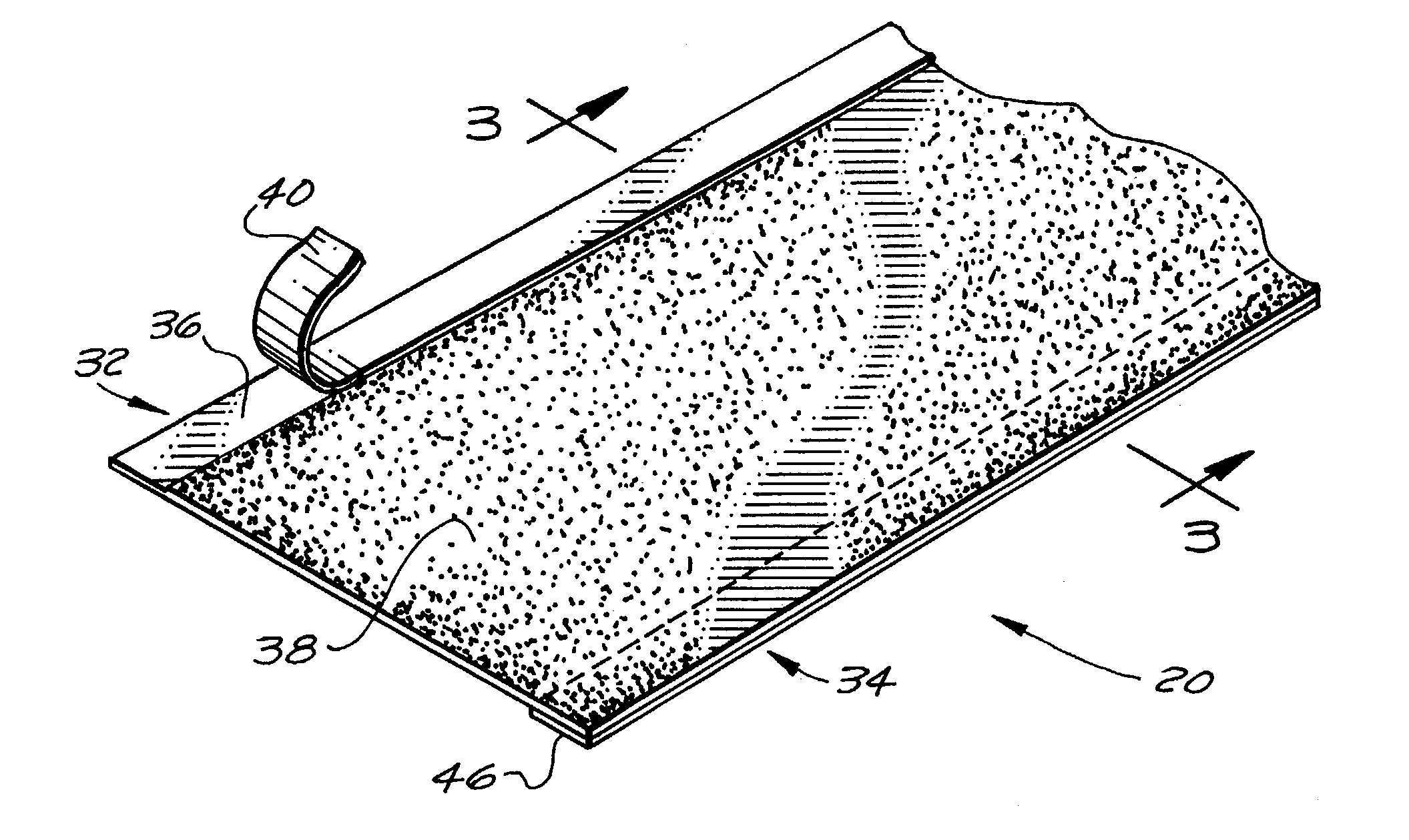

Roofing Products Having Receptor Zones and Photovoltaic Roofing Elements and Systems Using Them

InactiveUS20090159118A1Improve adhesionPhotovoltaic supportsPV power plantsPhotovoltaicsCivil engineering

The present invention relates generally to roofing products. The present invention relates more particularly to roofing products for use with photovoltaic elements, and to photovoltaic systems that include one or more photovoltaic elements is joined to a roofing substrate. In one embodiment, a roofing product includes a flexible roofing substrate having a top surface, the top surface having one or more receptor zones thereon, each receptor zone being adapted to receive one or more photovoltaic elements, each receptor zone having a different surfacing than the area of the top surface adjacent to it.

Owner:CERTAINTEED CORP

Flexible integrated photovoltaic roofing membrane and related methods of manufacturing same

Disclosed herein are flexible, solar powered photovoltaic (PV) integrated roofing membrane and related methods of manufacturing such a membrane. The disclosed membrane and methods beneficially provide solar power to structures in either off-grid or on-grid connections. The roofing membrane may comprise multiple membrane strips or members having electrically interconnected photovoltaic solar elements. The membrane members preferably have distinct patterns for the solar elements located thereon that provide for coverage of entire sections, upon installation, as well as accommodate interconnections between the solar elements. Moreover, the membrane will appreciate the numerous types of patterns to achieve such purposed of full coverage and electrical coupling.

Owner:ELK PREMIUM BUILDING PROD

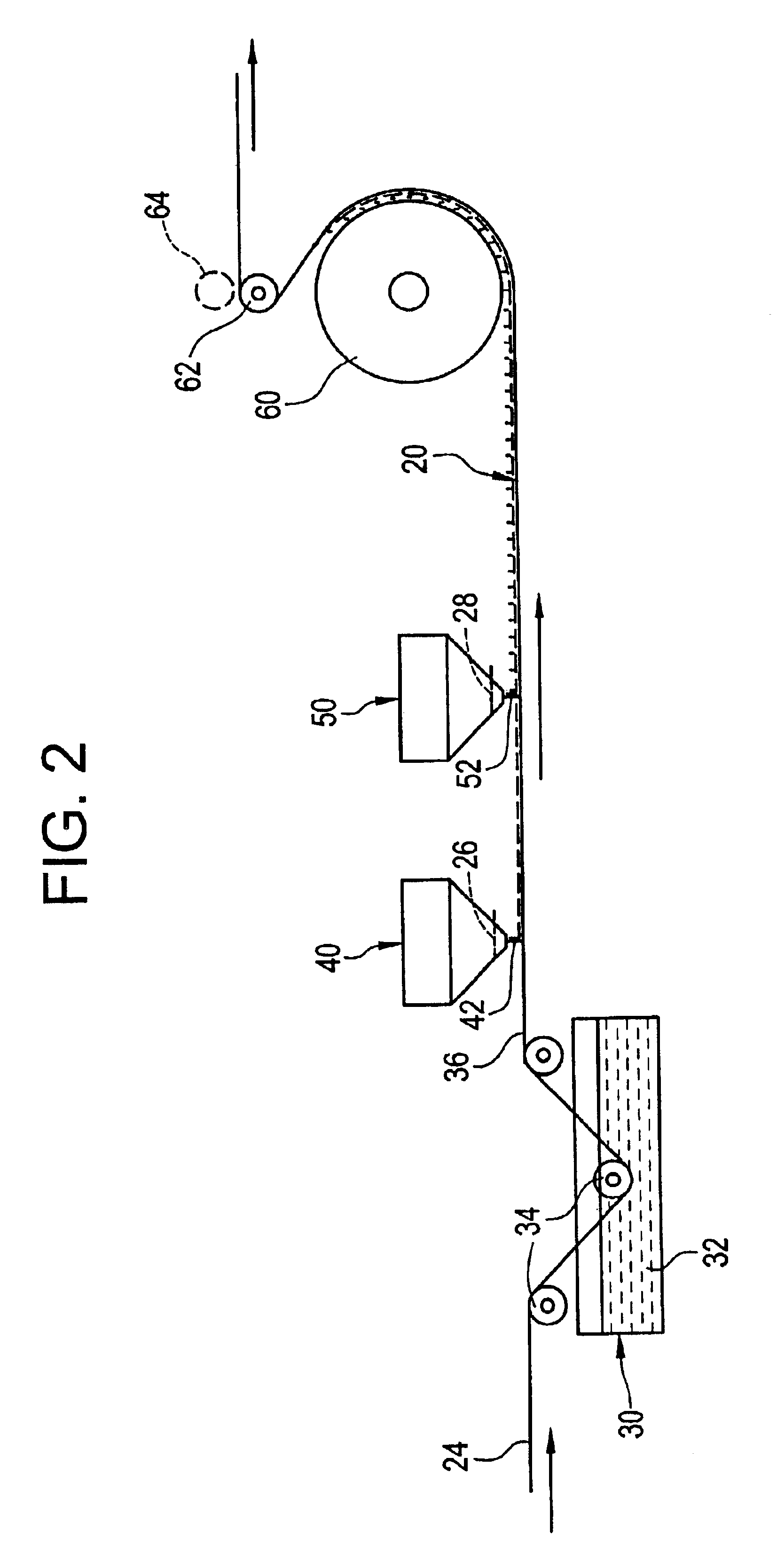

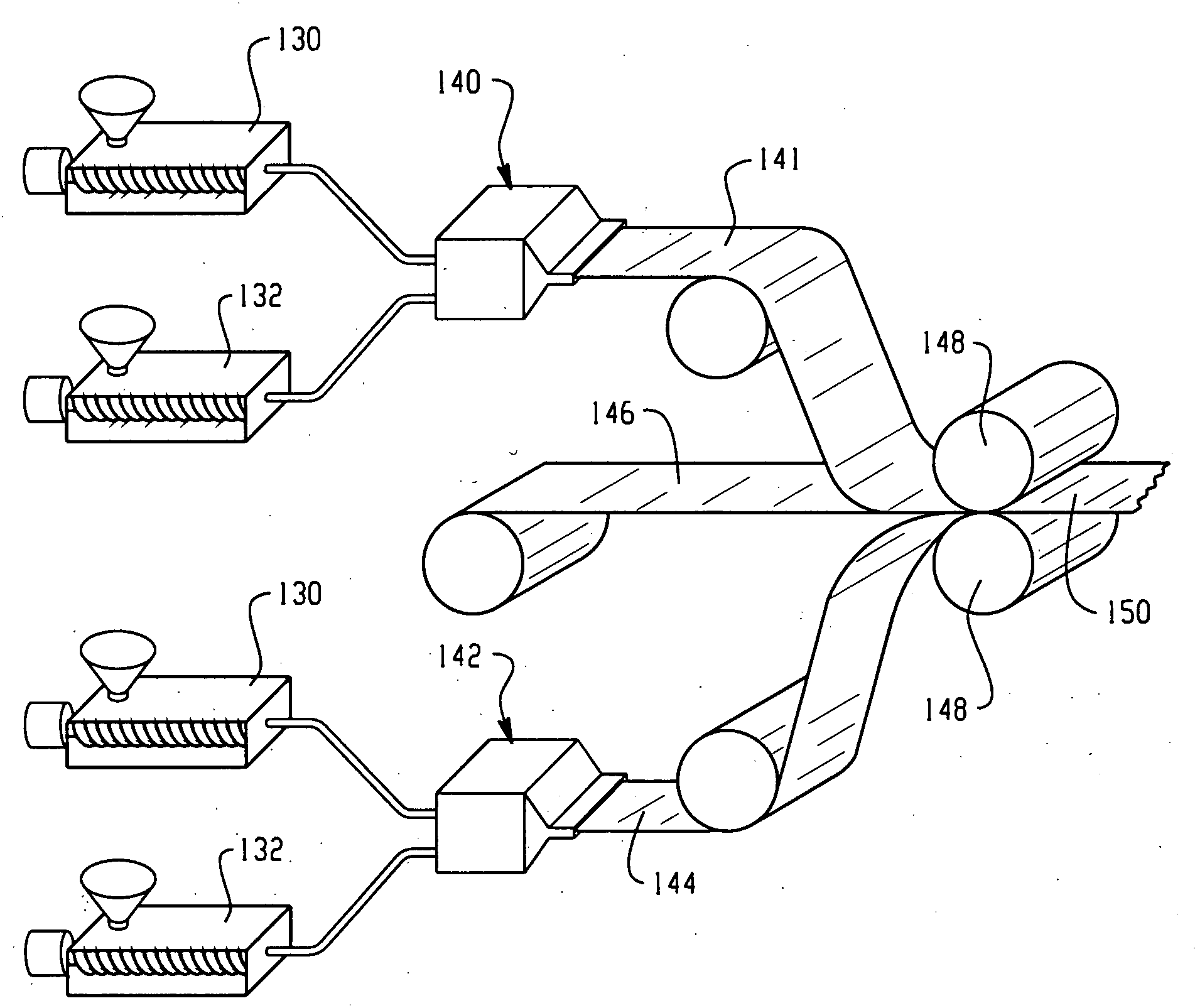

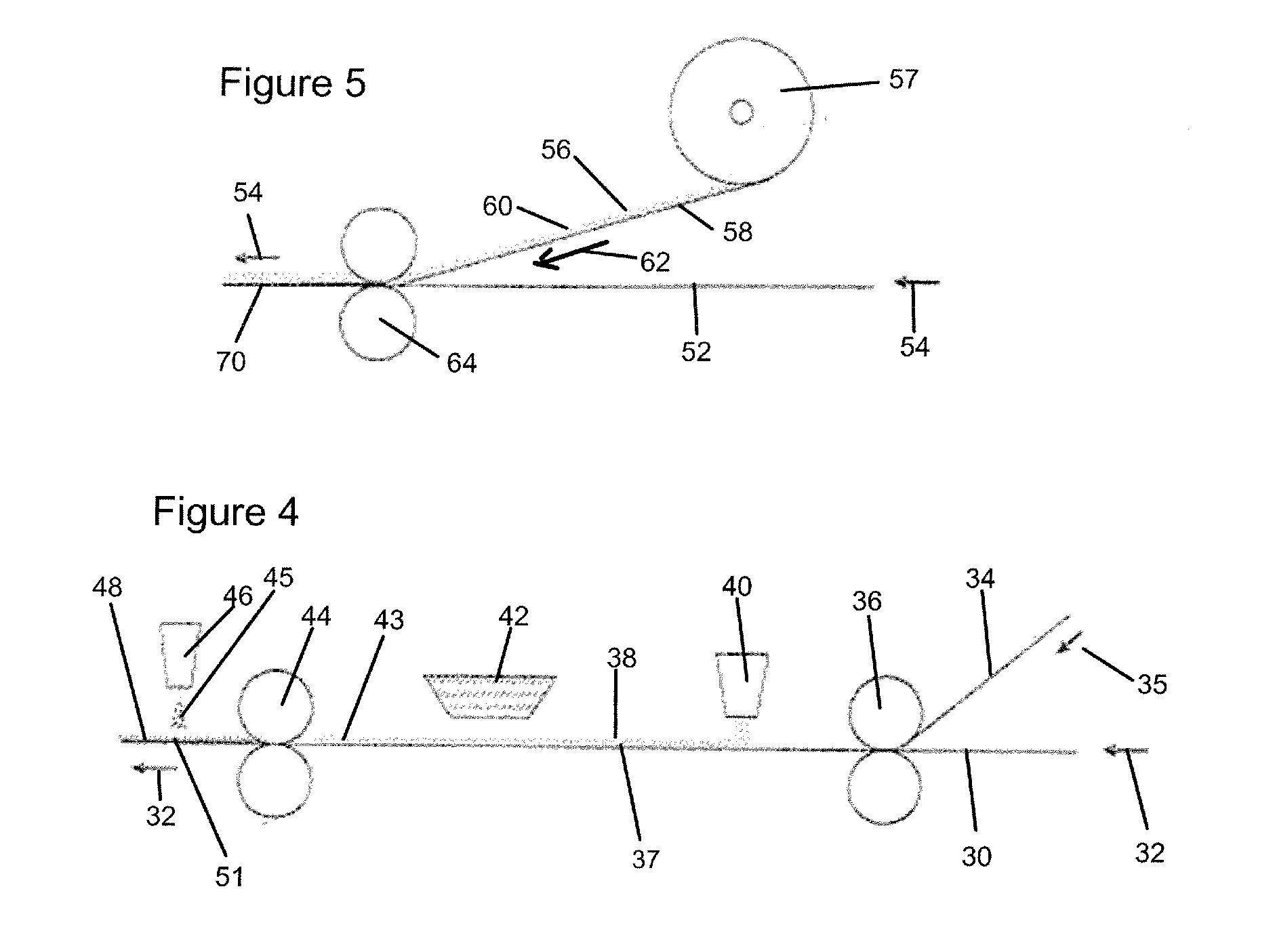

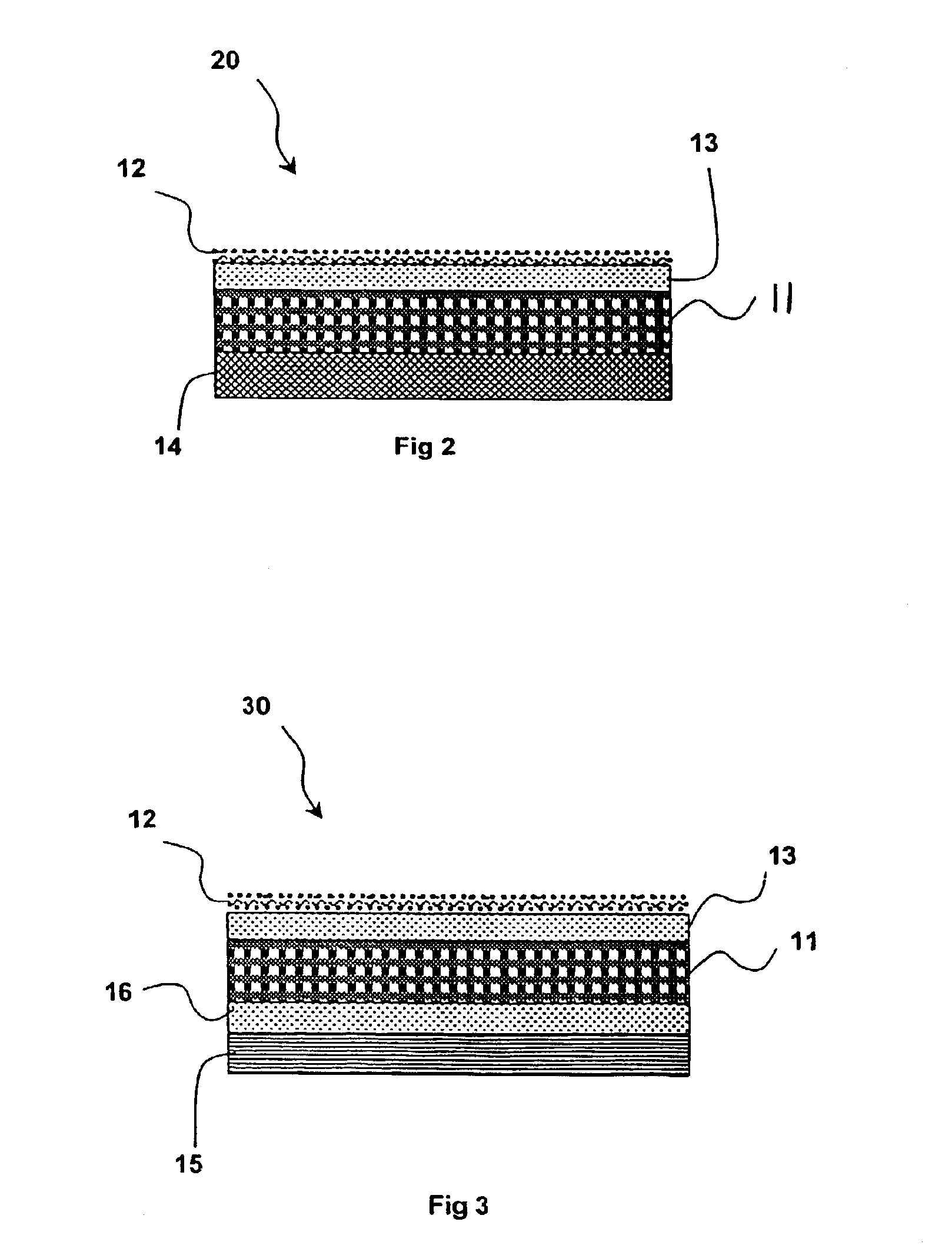

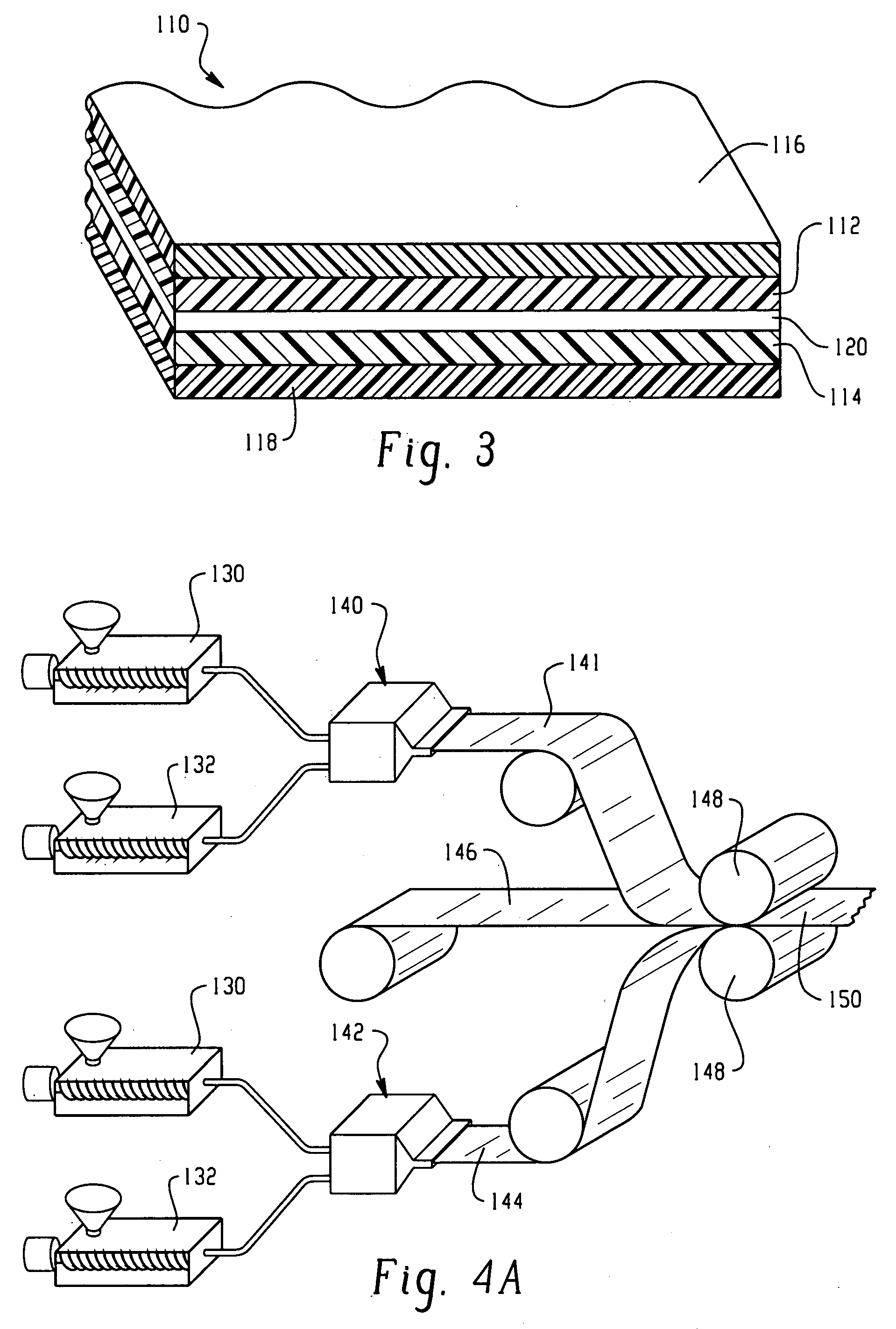

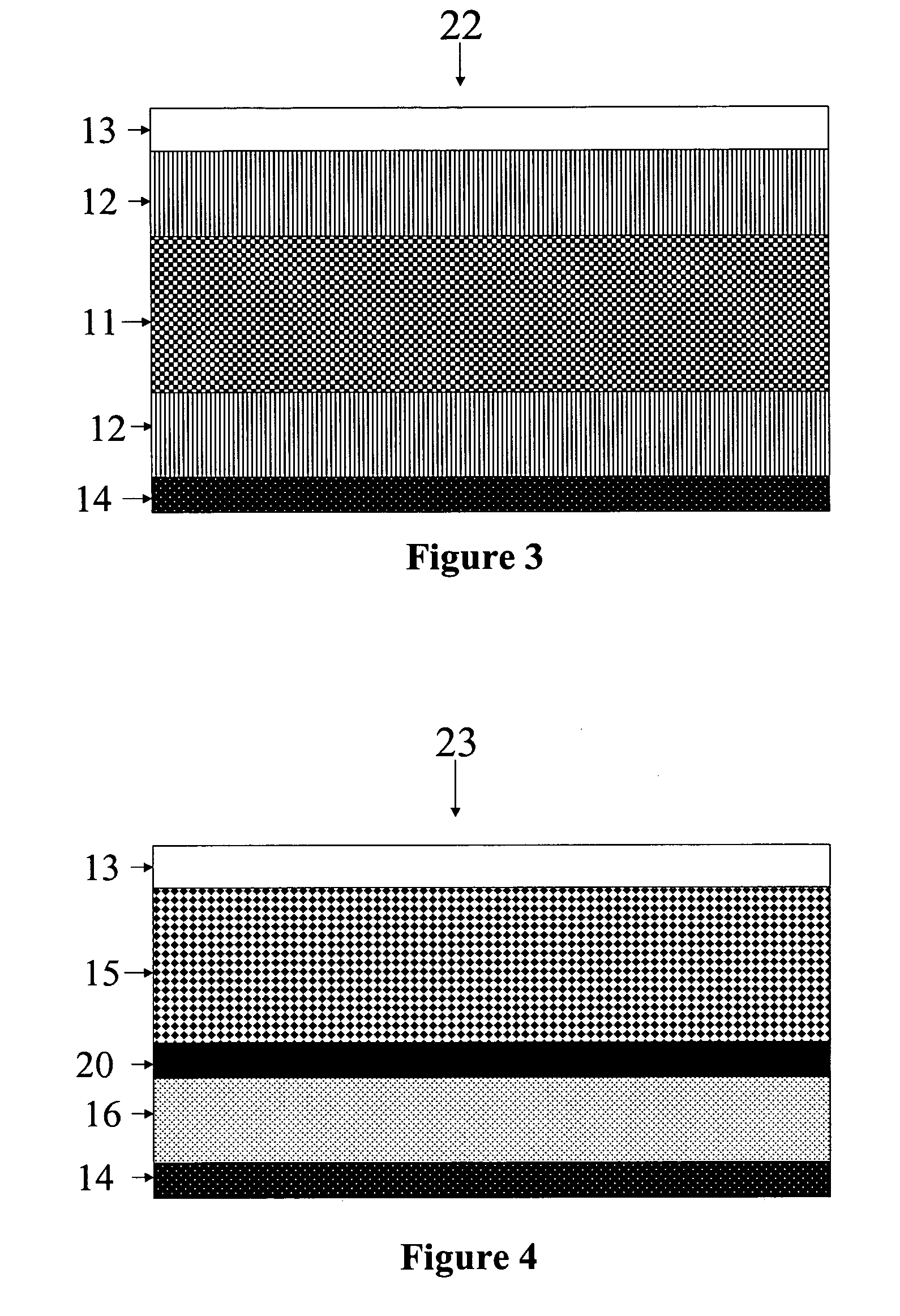

Co-extrusion process for preparing roofing membranes

InactiveUS20070194482A1Roof covering using flexible materialsSynthetic resin layered productsCo extrusionBiomedical engineering

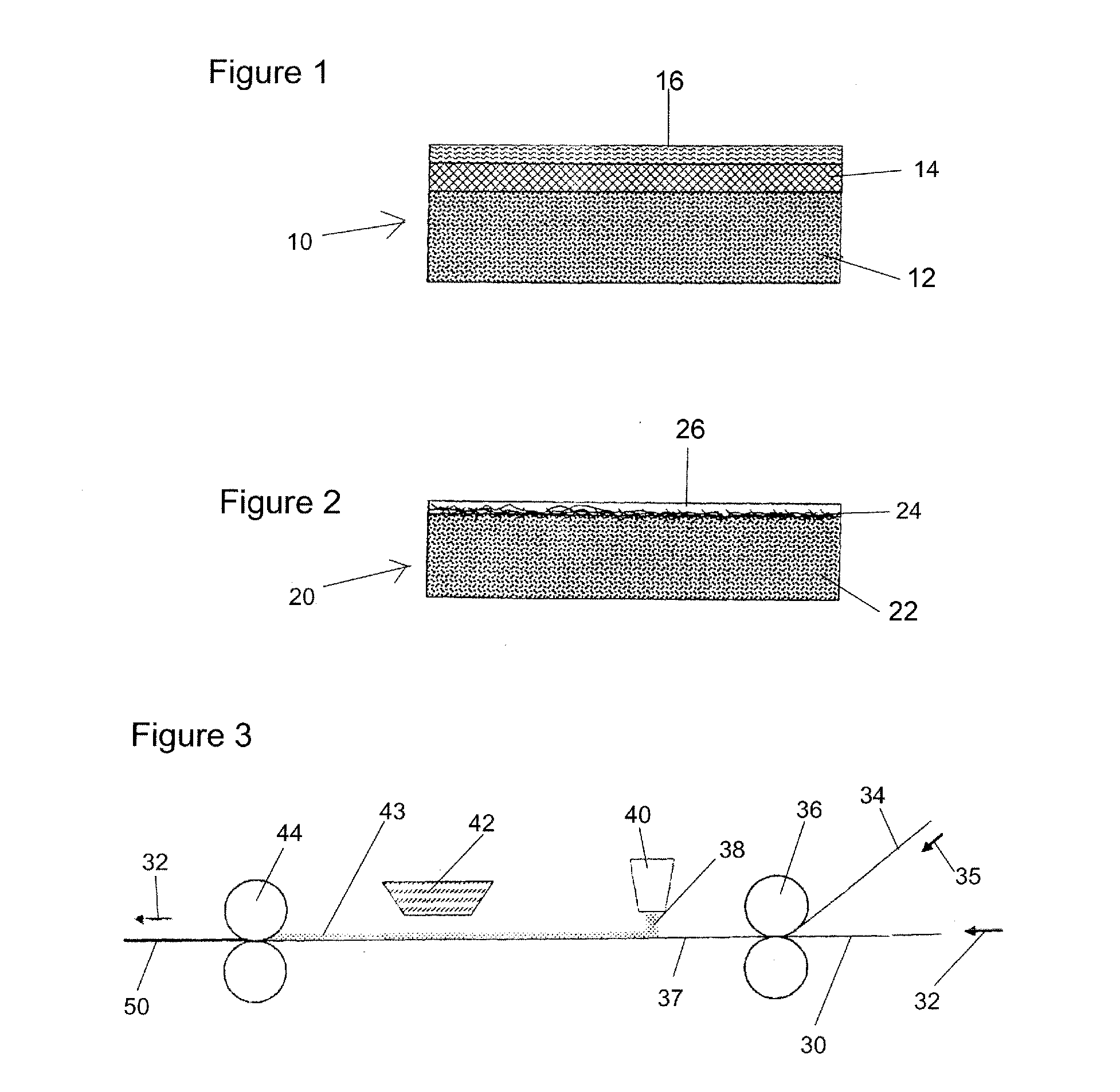

A process for preparing a multi-layer roofing or structural membrane is provided including a top sheet including co-extruding a cap and inner layer and bonding the top sheet to a bottom sheet. The use of the co-extrusion process allows for multi-layer sheets that reduce the need for expensive fillers in all but a cap layer of the membrane. A scrim reinforcement layer is optionally embedded in the membrane. When installed on a roof substrate, the membrane can be sealed by heat welding the seams of the membrane sheets or by other means.

Owner:FIRESTONE BUILDING PRODS

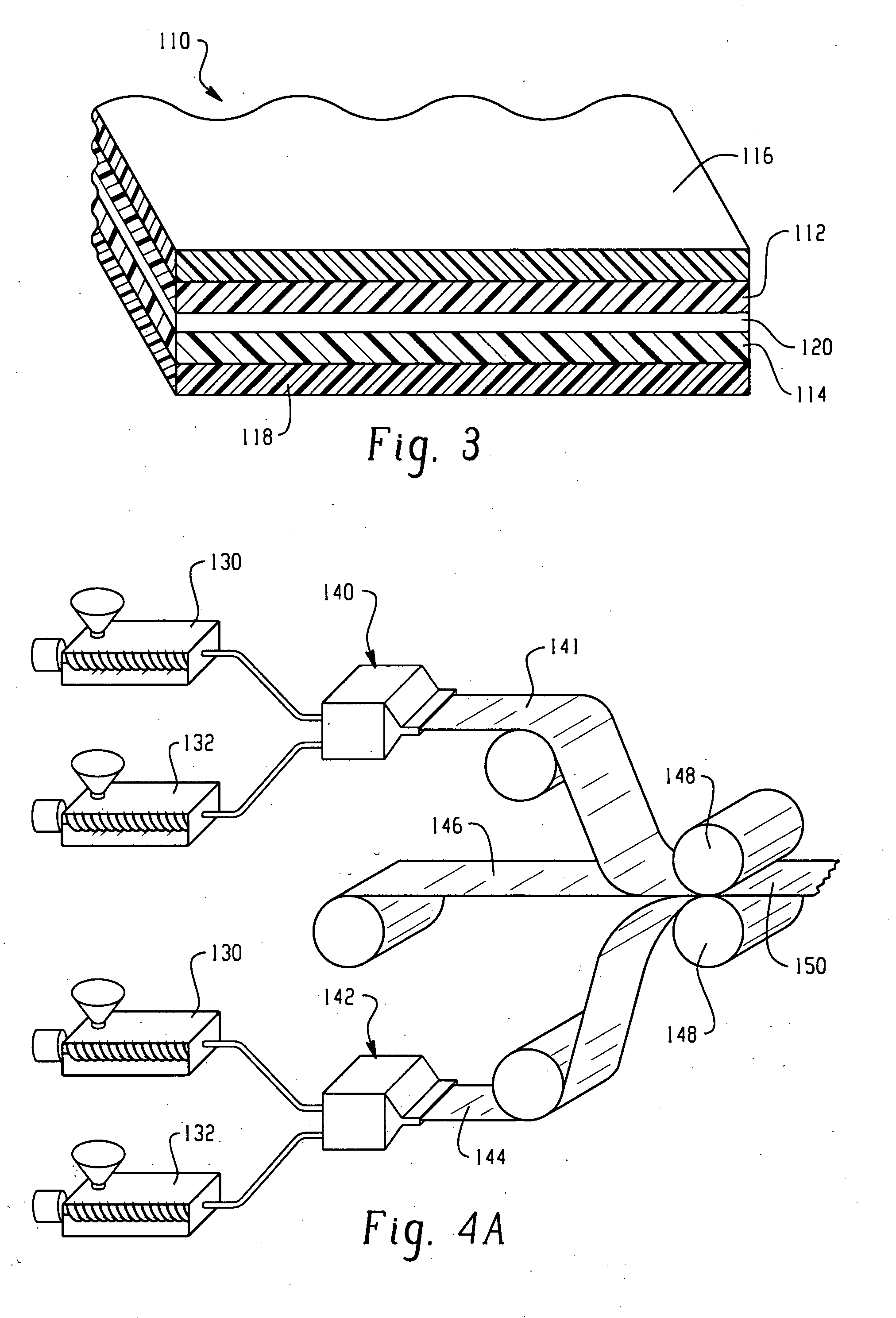

Heat weldable roofing membrane

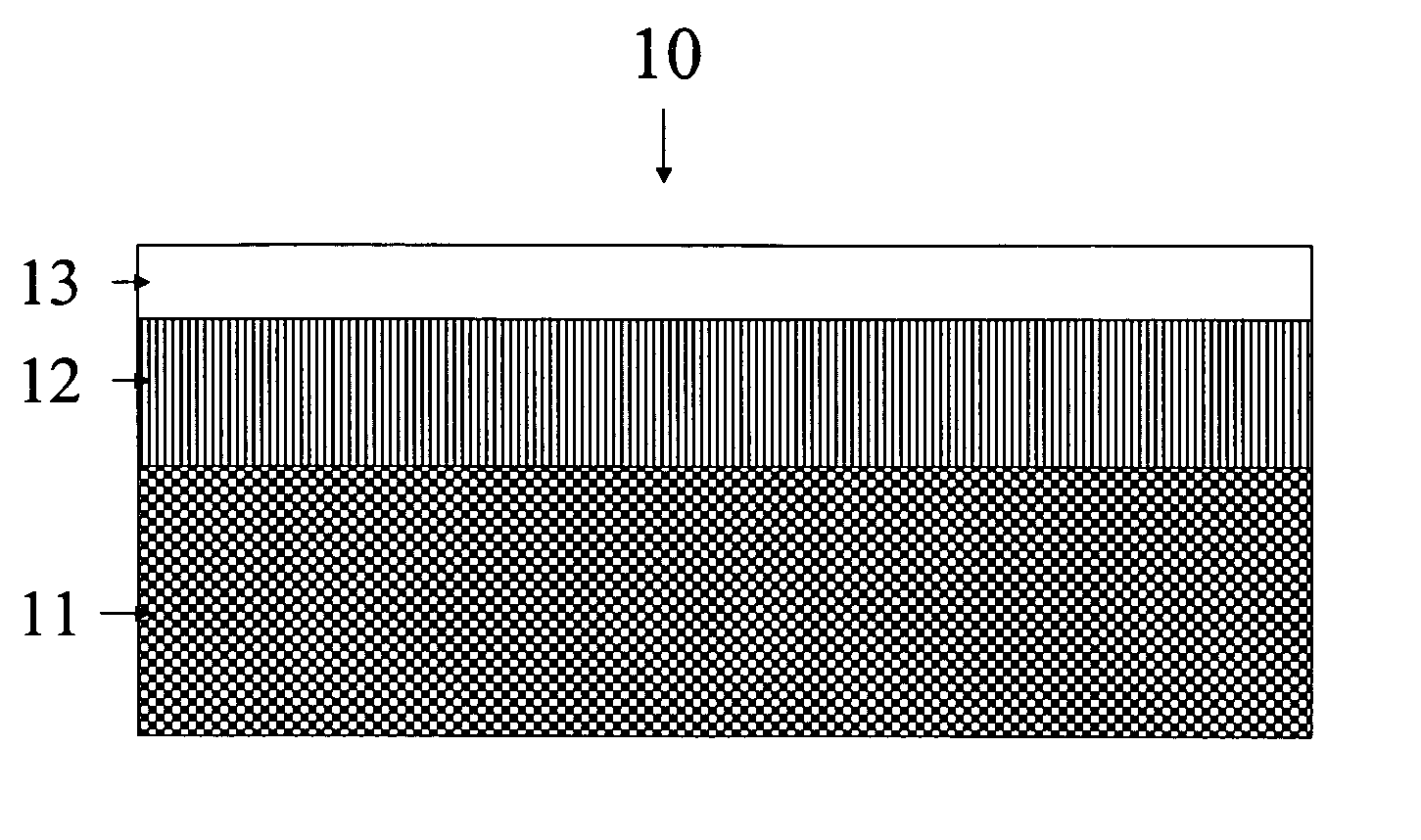

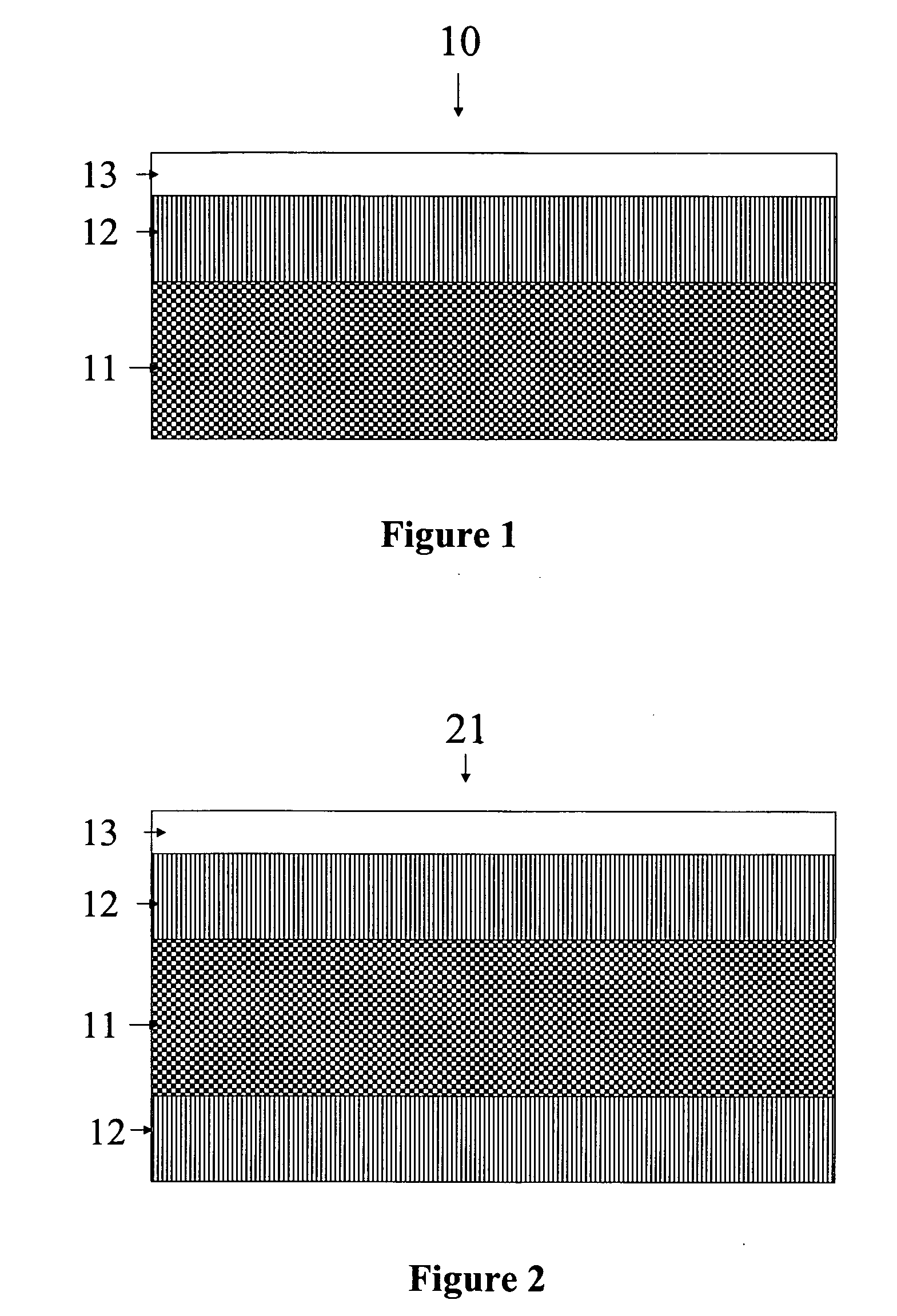

InactiveUS6864195B2Roof covering using flexible materialsSynthetic resin layered productsThermoplasticPolyolefin

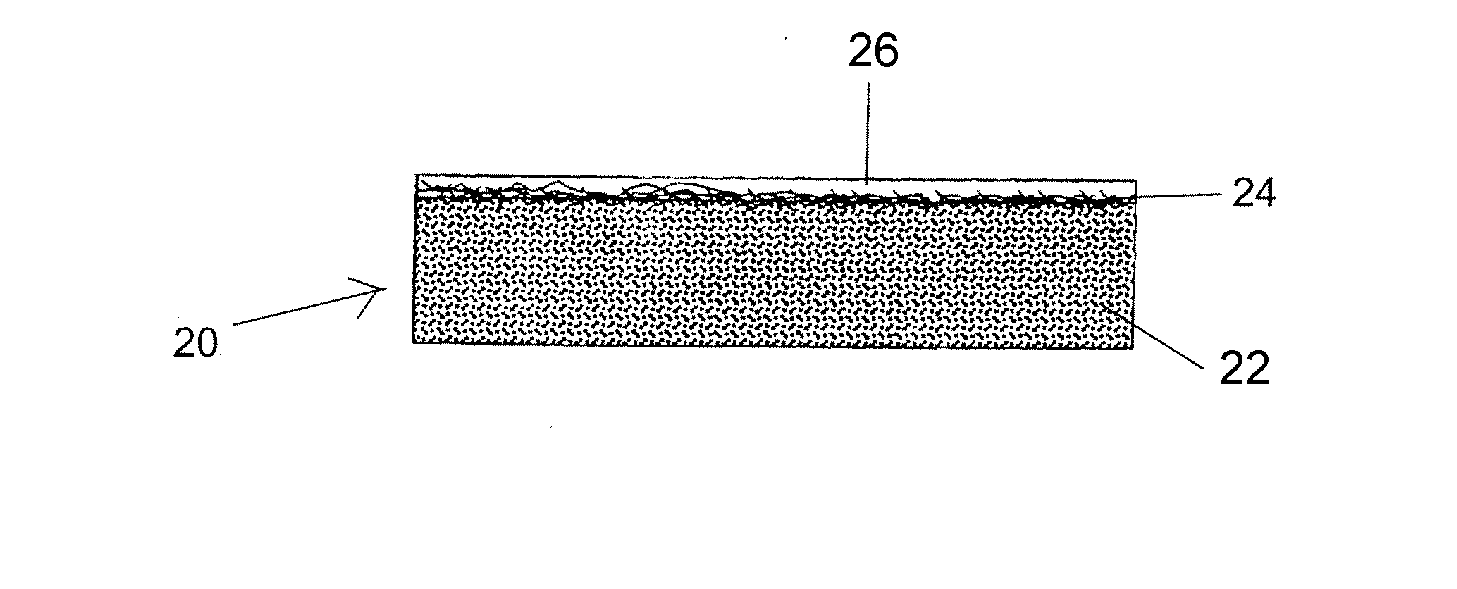

A roofing membrane includes a substrate sheet formed of a thermoplastic vulcanizate (TPV) and a film layer of thermoplastic polyolefin (TPO) adhered to at least one surface of the substrate sheet. The TPV preferably includes a copolymer of ethylene and a carbonyl containing monomer dynamically vulcanized in a polyolefin thermoplastic, preferably metallocene-catalyzed polyethylene. A scrim reinforcement layer is optionally embedded in the TPV layer. When installed on a roof substrate, the membrane can be sealed by heat welding the seams of the membrane sheets.

Owner:HOLCIM

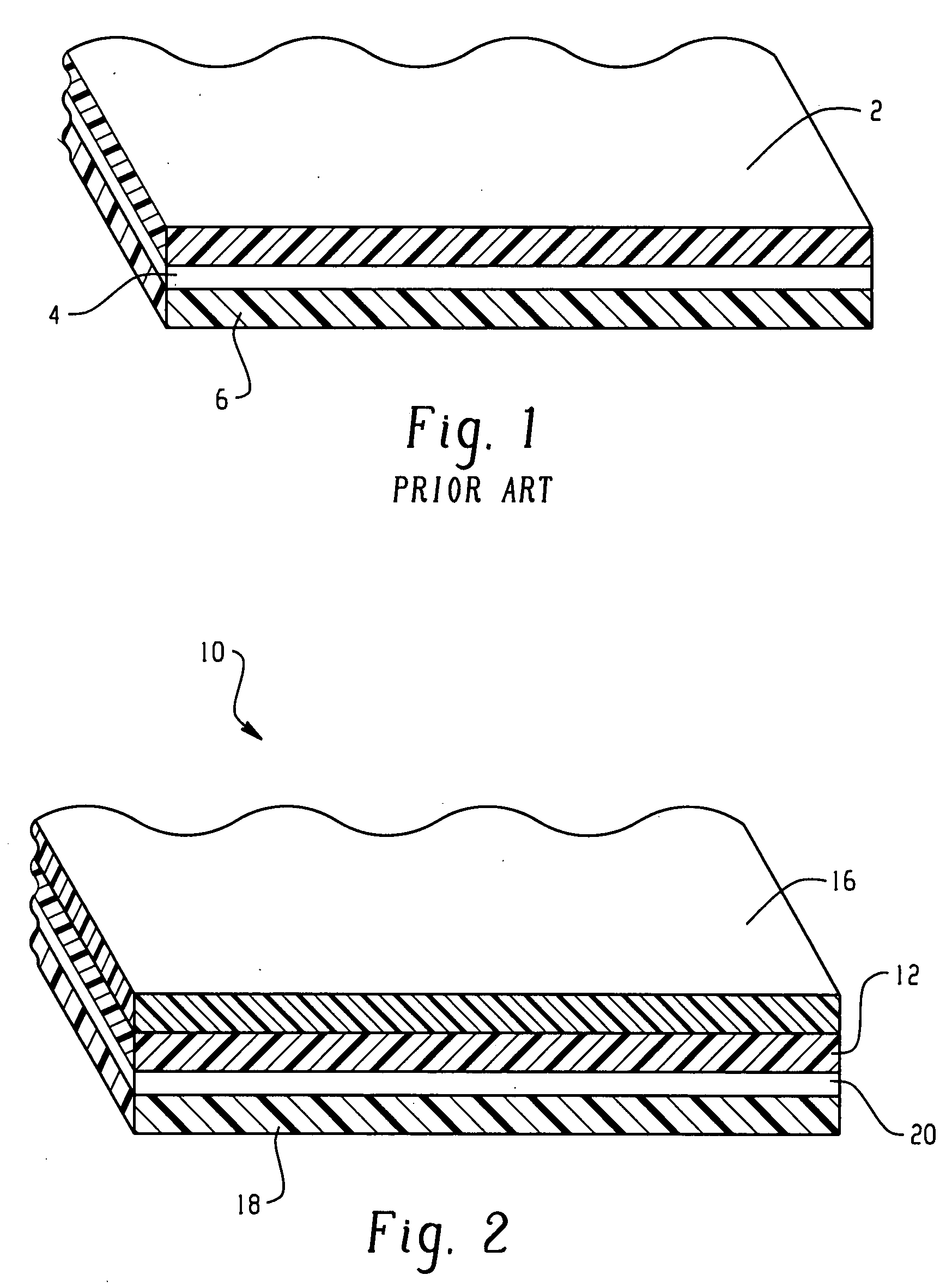

Solar Heat Reflective Roofing Membrane and Process For Making the Same

ActiveUS20070054129A1High solar heat resistanceRoof covering using flexible materialsClimate change adaptationEngineeringSolar heat

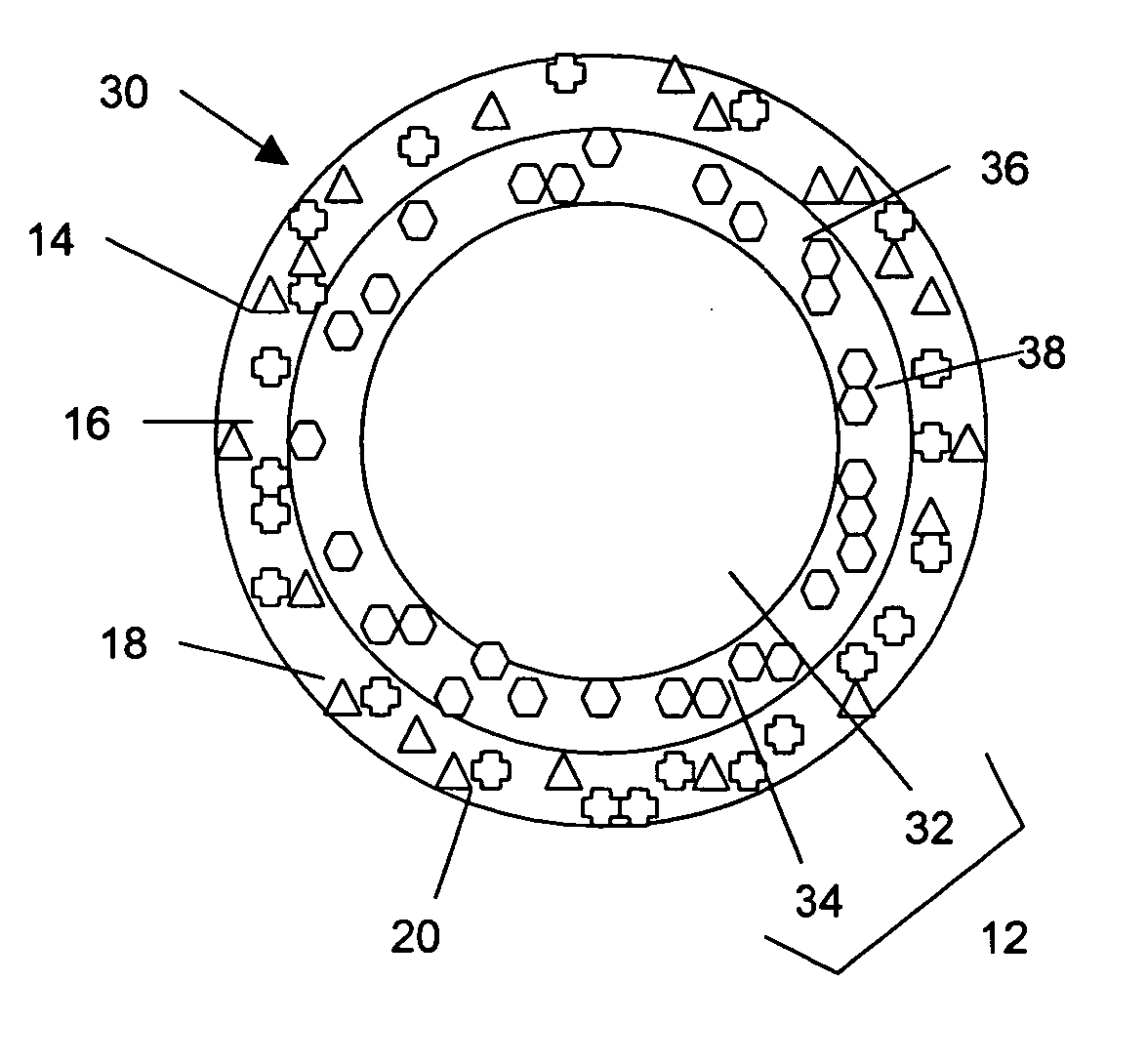

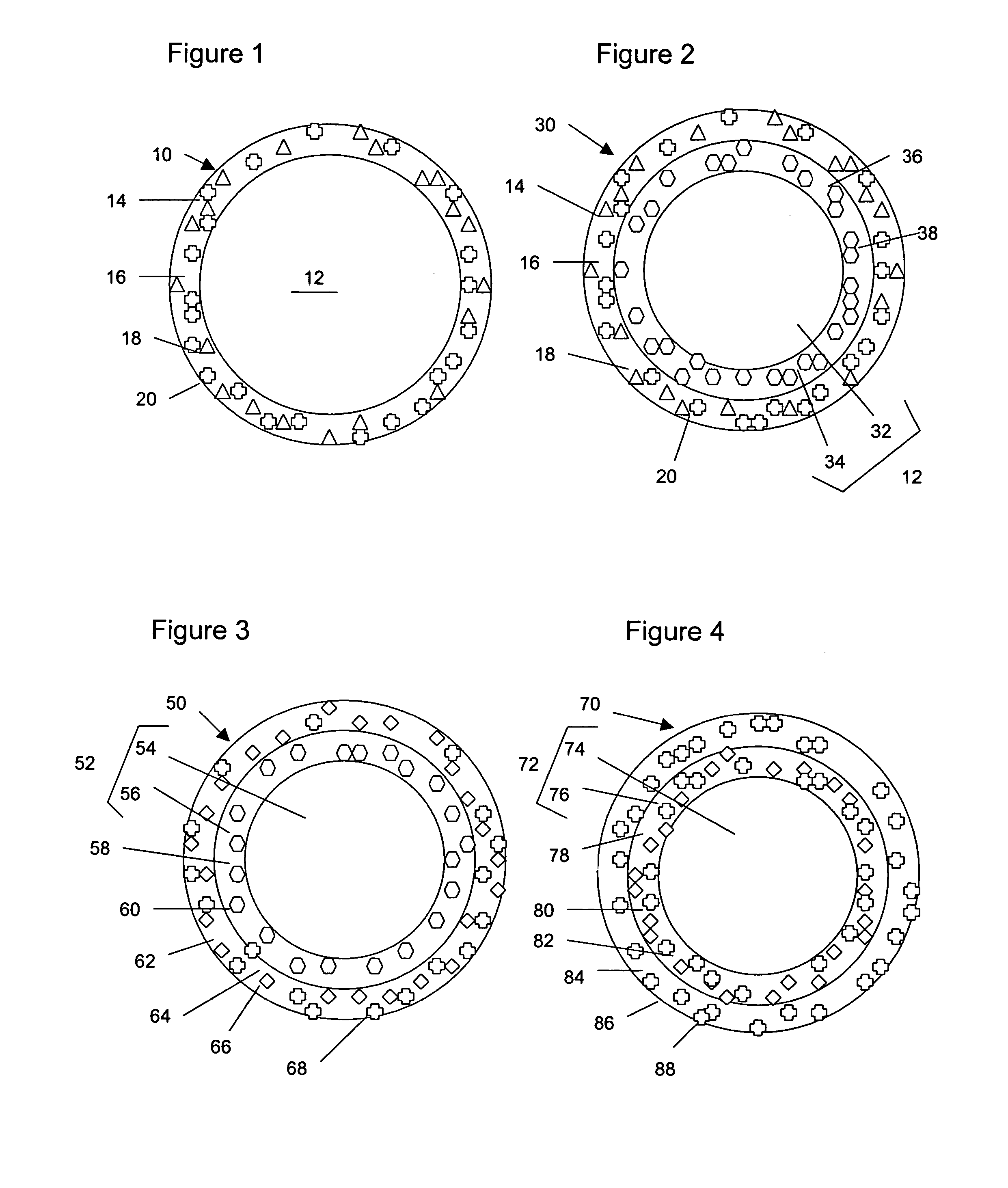

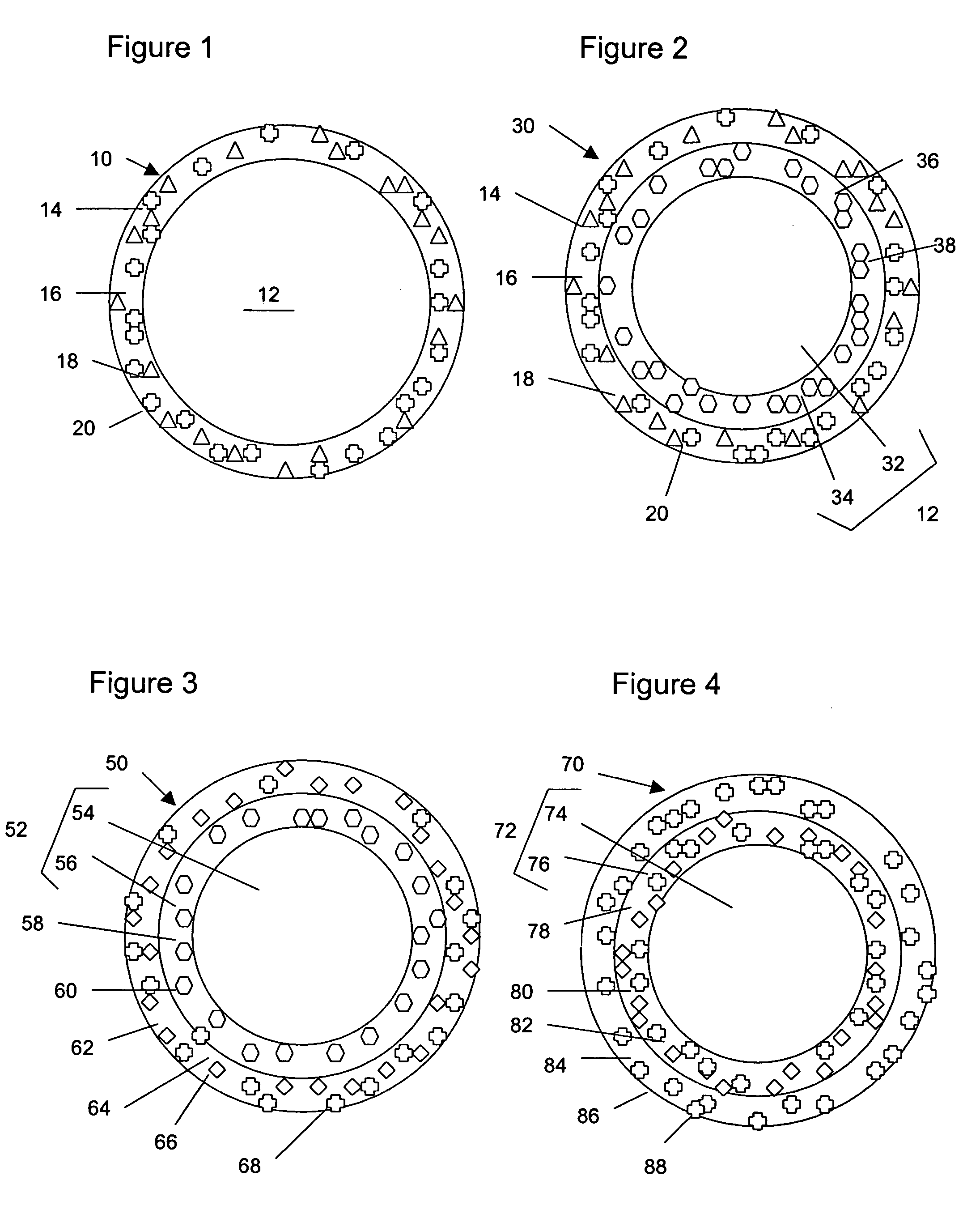

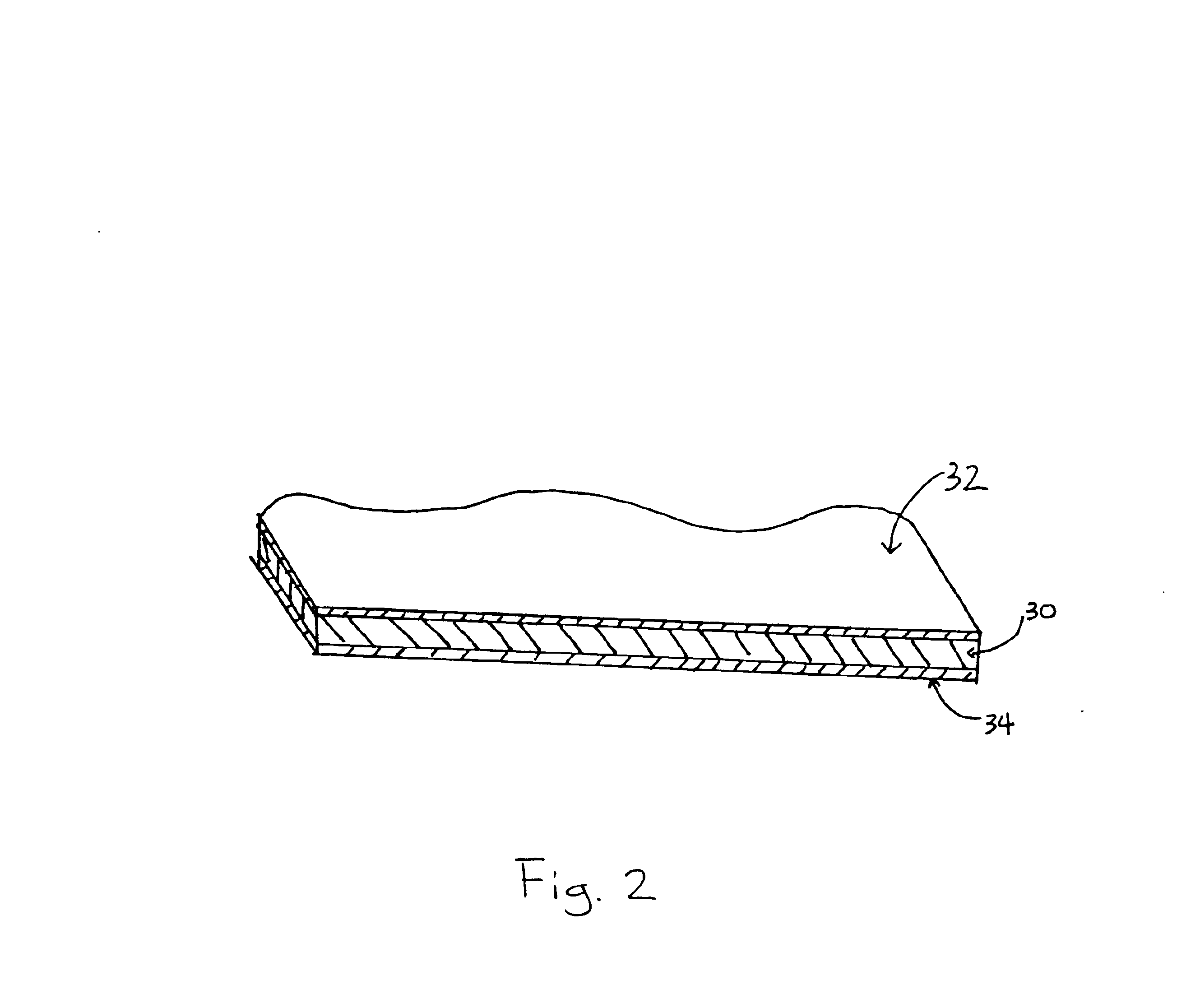

A roofing membrane with high solar heat reflectance includes a bituminous base sheet, a tie-layer with a reinforcement material, and a solar heat-reflective upper layer.

Owner:CERTAINTEED CORP

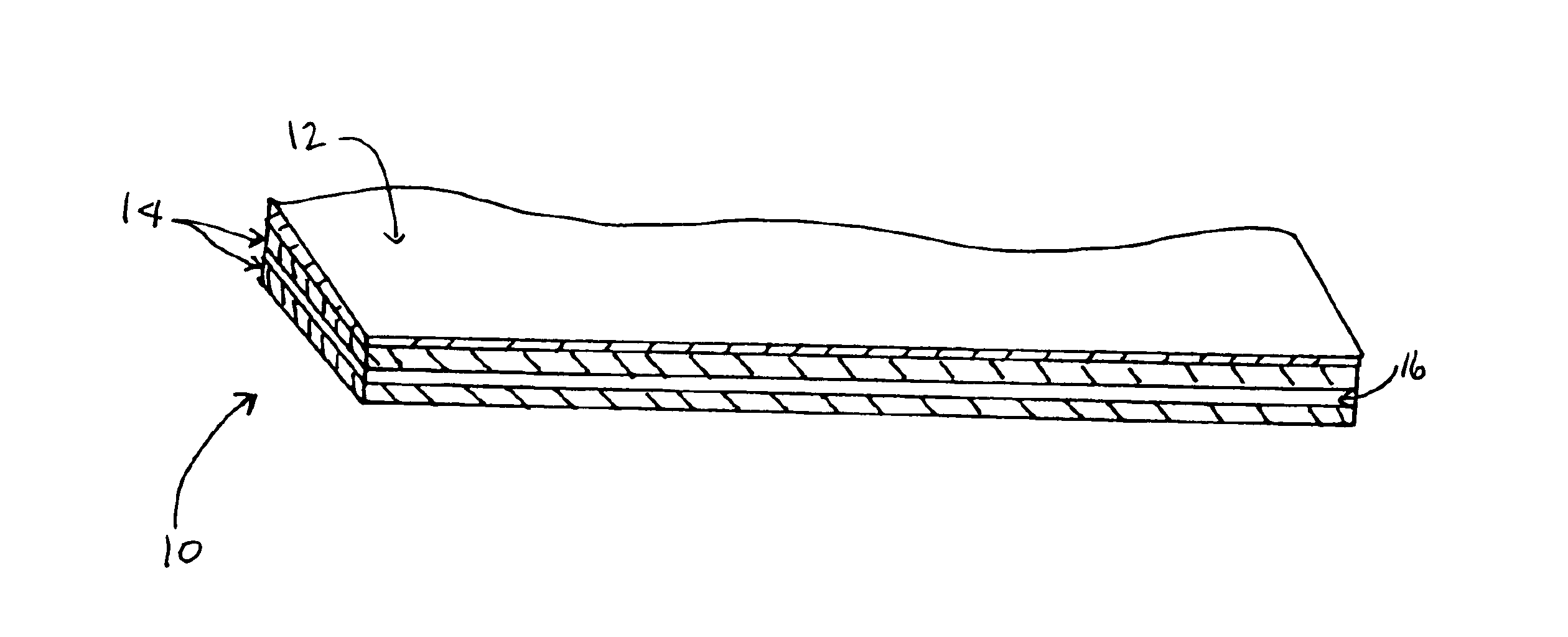

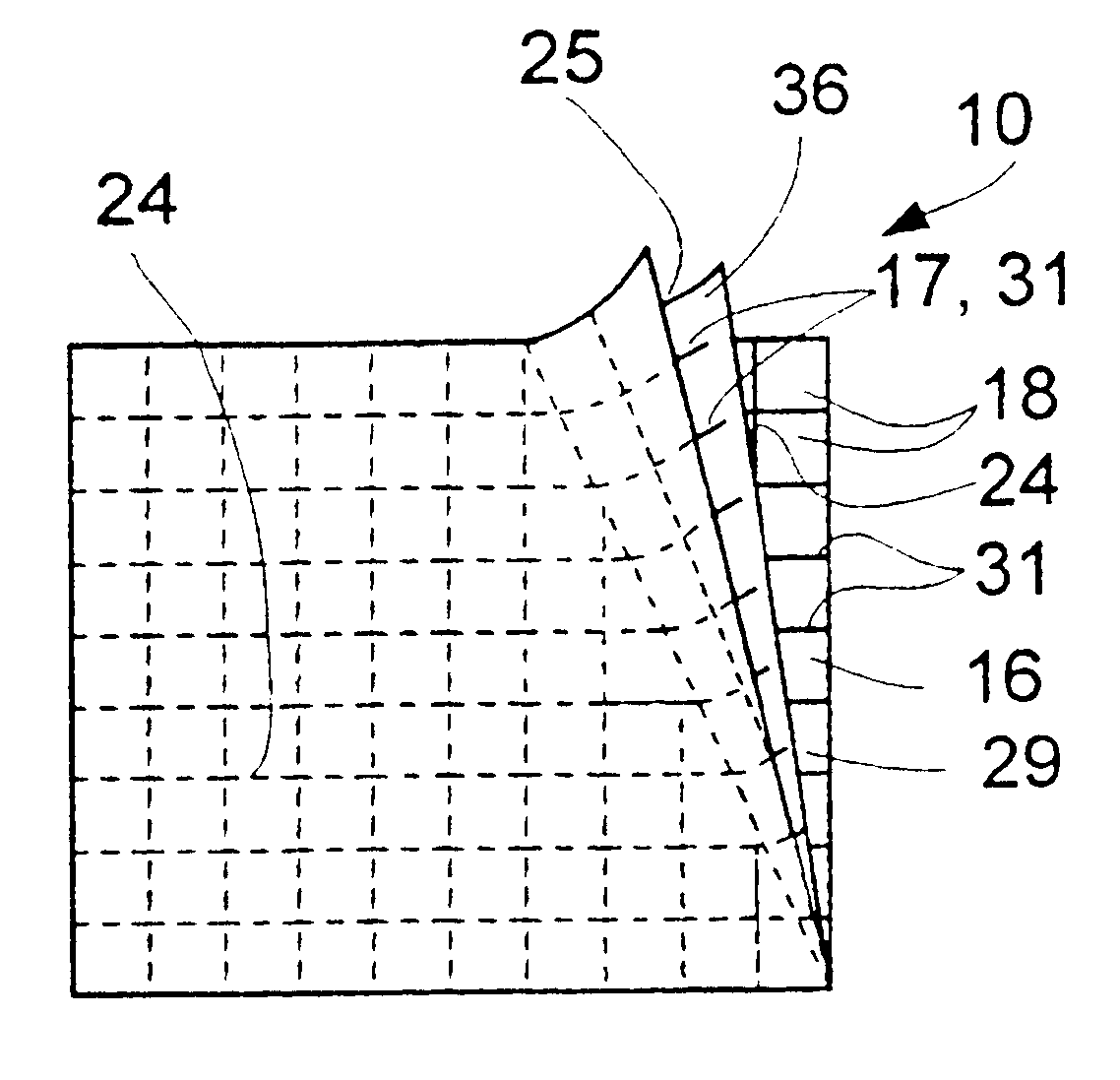

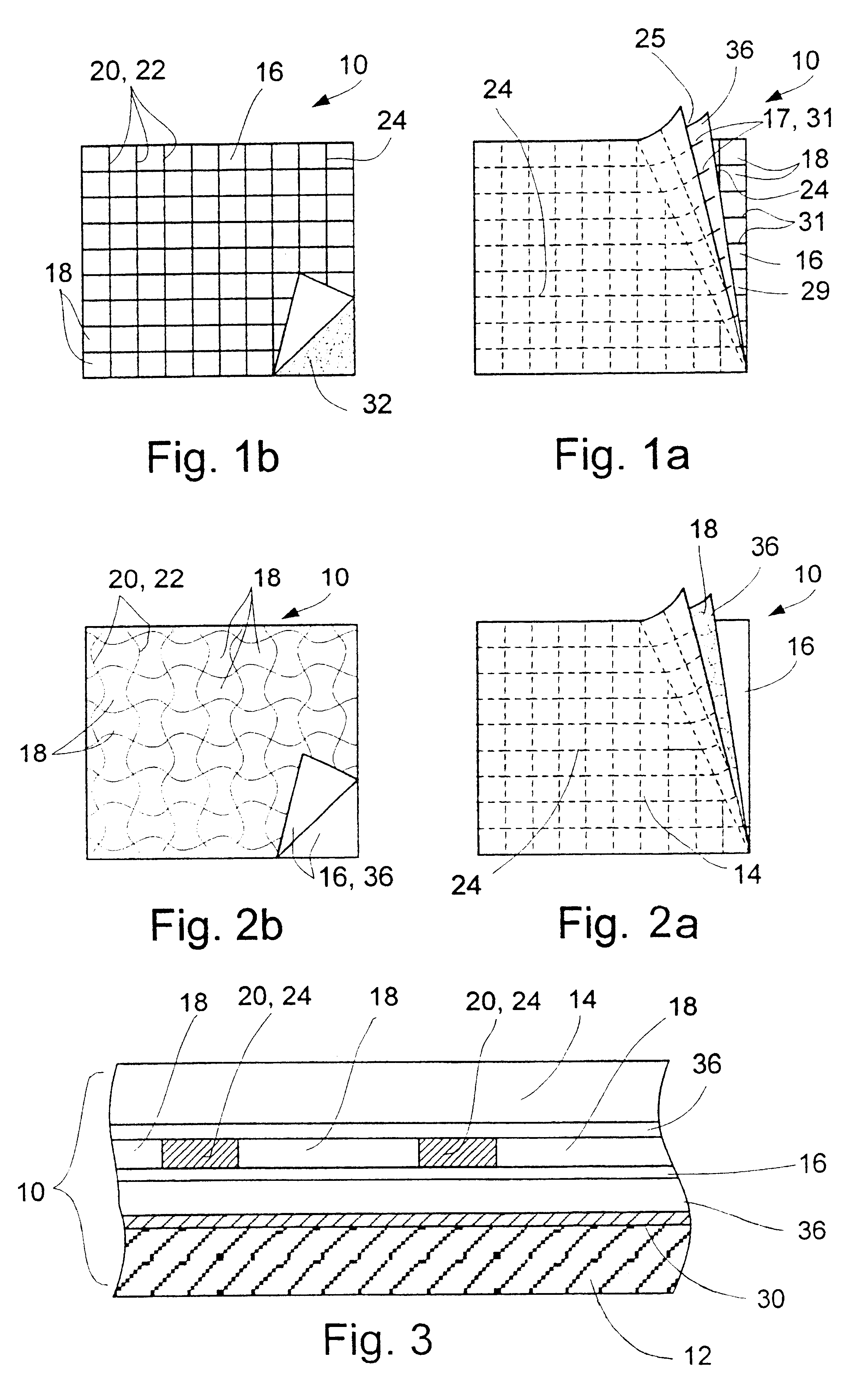

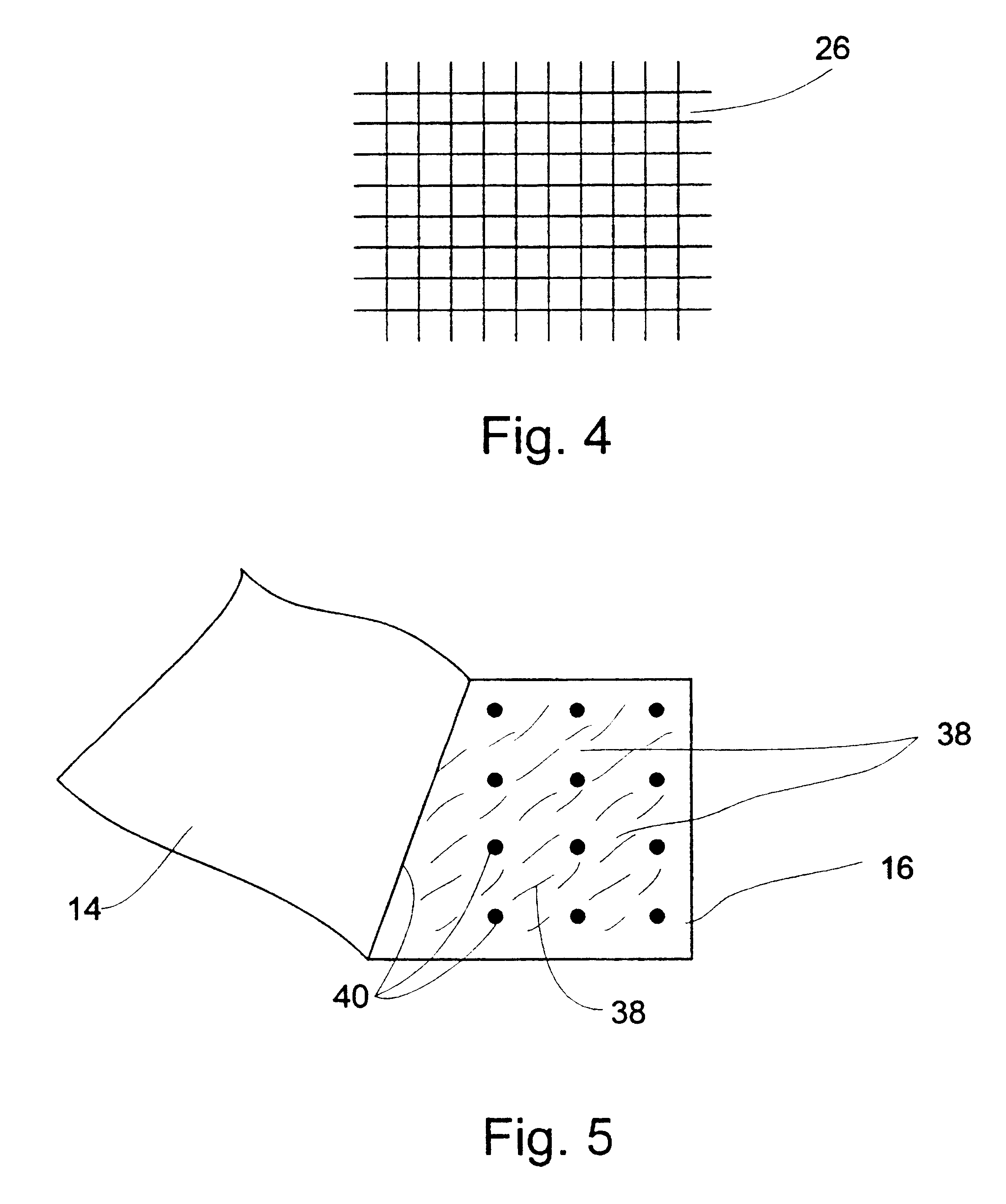

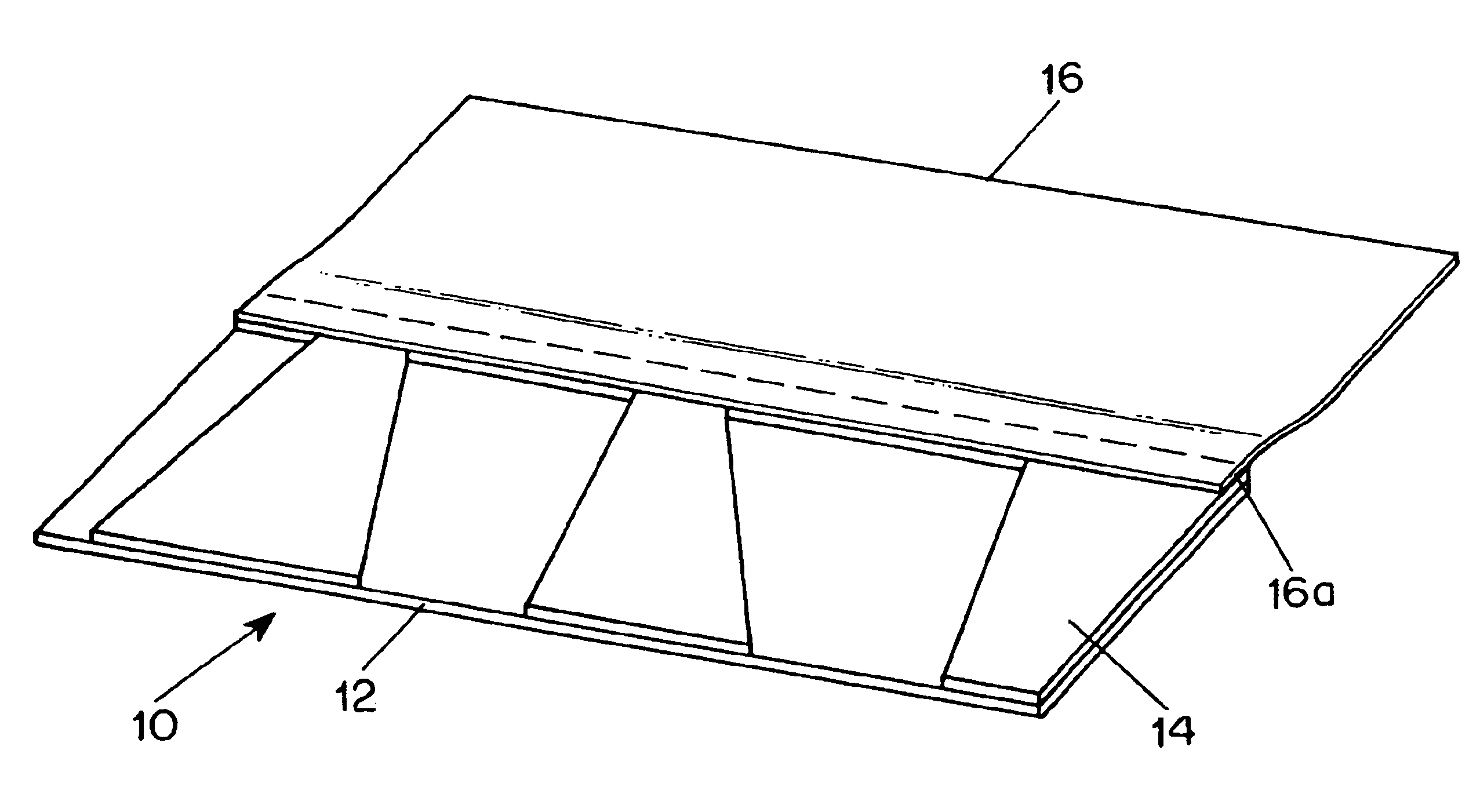

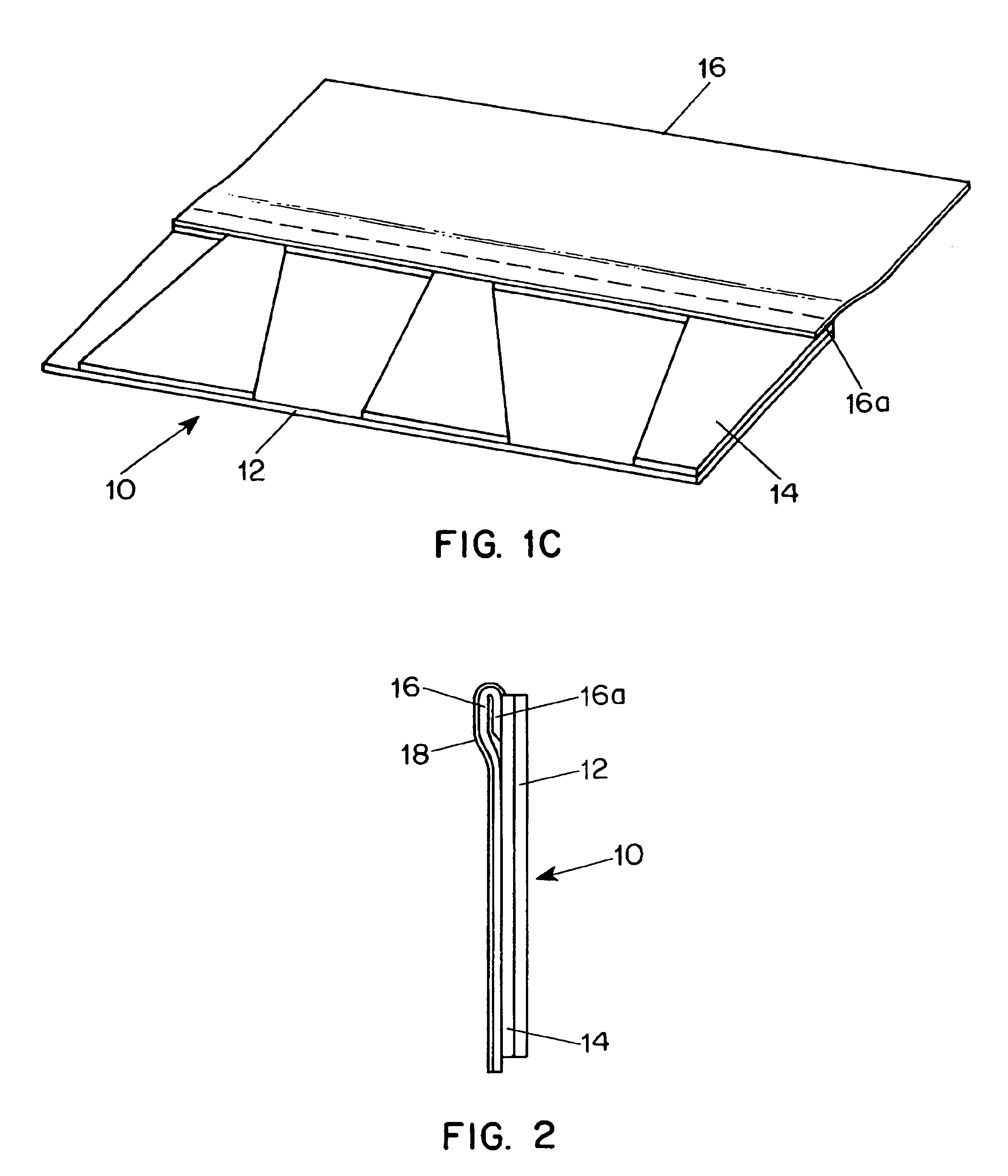

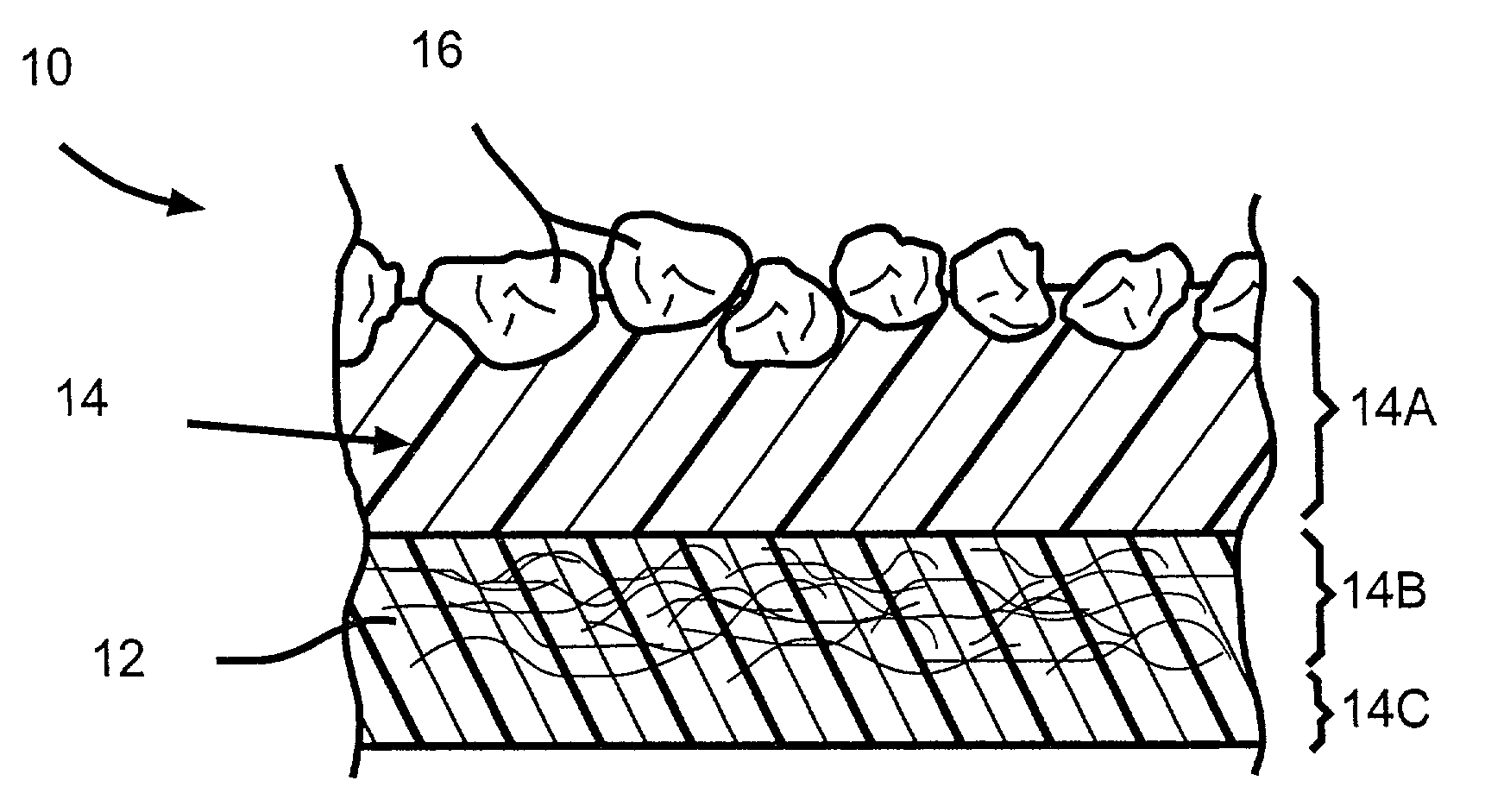

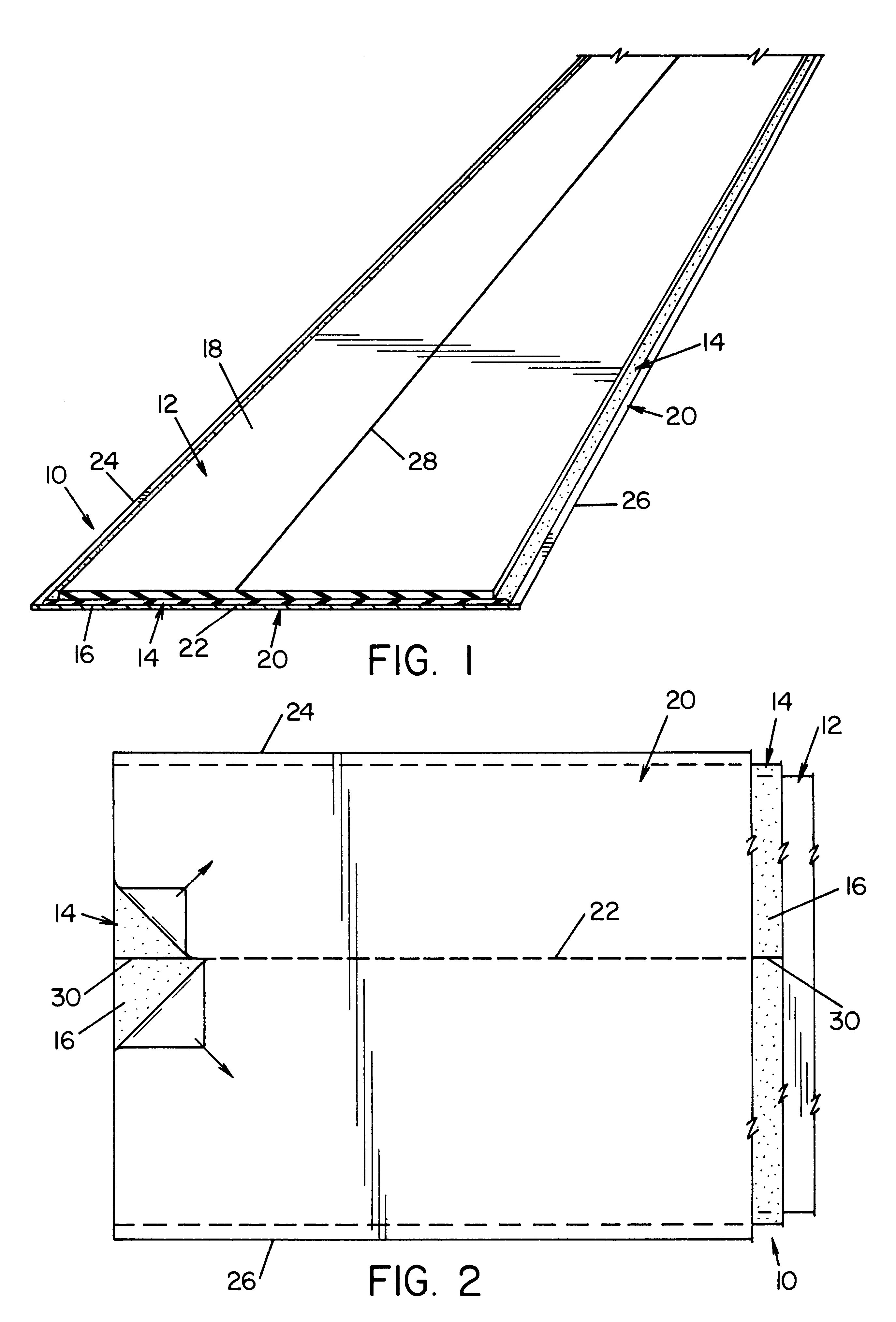

Sealing sheet assembly for construction surfaces and methods of making and applying same

InactiveUS6586080B1Low costReduce thicknessBuilding roofsRoof covering using flexible materialsRelative displacementClassical mechanics

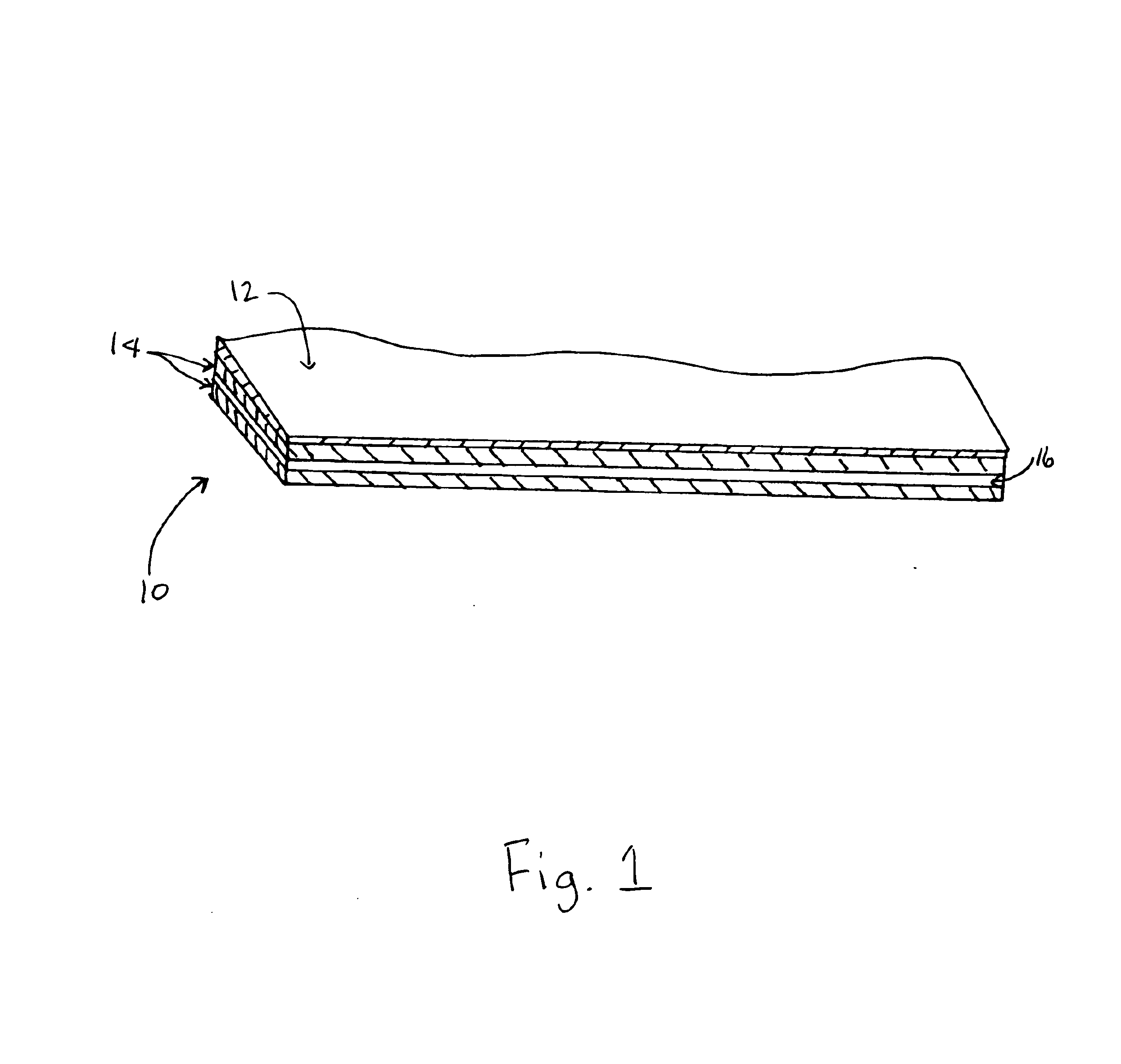

A sealing sheet (10) assembly bondable to a construction surface comprising (a) an upper layer (14) of a first substance, the upper layer being selected fluid impermeable; and (b) a lower flexible layer (16) of a second substance, the lower flexible layer being bondable to the construction surface. The upper layer and the lower flexible layer are at least partially attached to one another, wherein a combination of the upper layer, the lower layer and the attachment or the partial attachment of the layers to one another are selected such that tensile forces resulting from constructional movements acting upon the sealing sheet result in a local detachment or relative displacement of the upper layer and the lower flexible layer, thereby the ability of the lower flexible layer of transmitting the forces onto the upper layer is remarkably reduced, resulting in improved service of the sealing cover as a whole. The attachment is selected such that a spread of a leakage between the layers via a tear formed in the upper layer is locally restricted.

Owner:HEIFETZ RAPHAEL

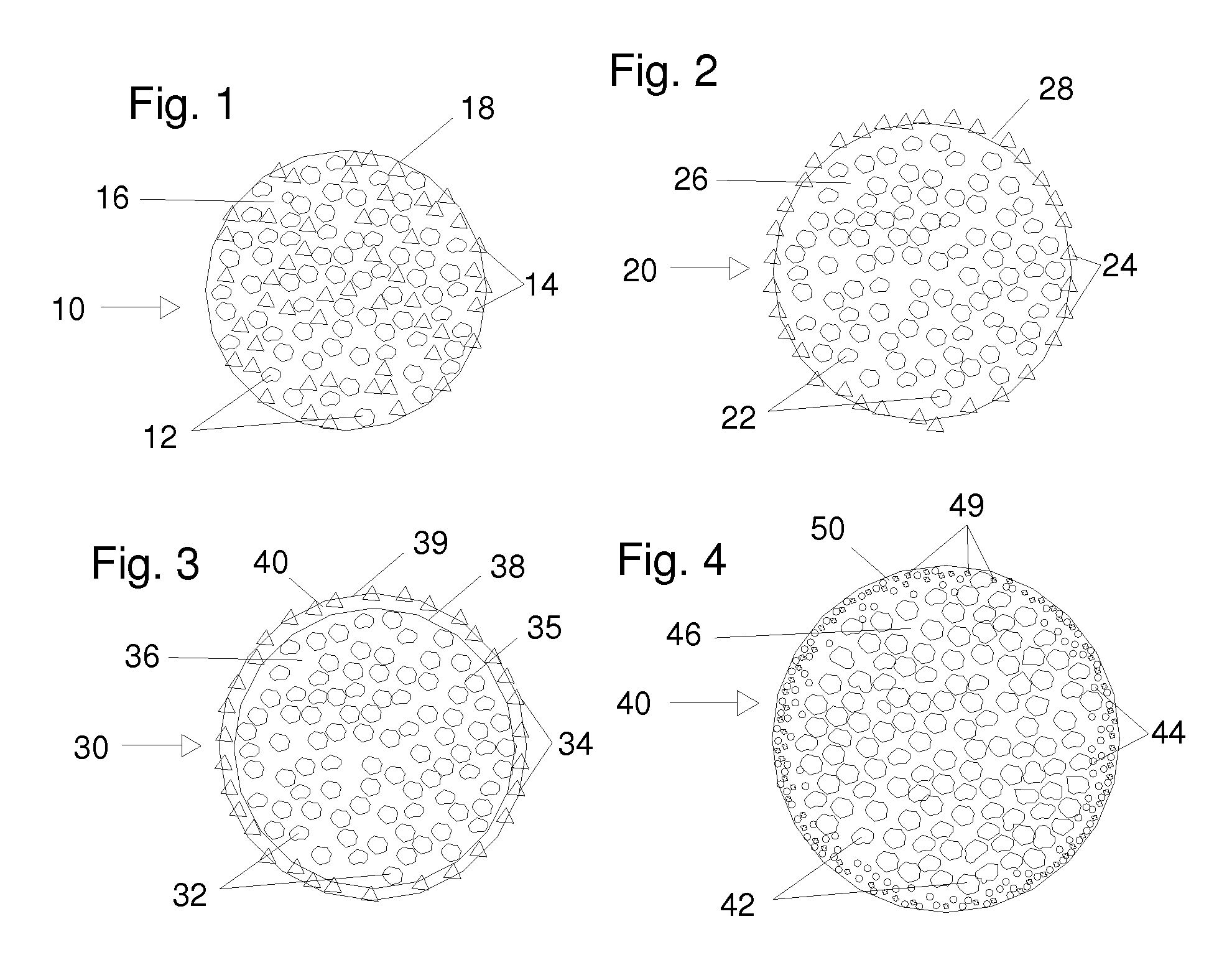

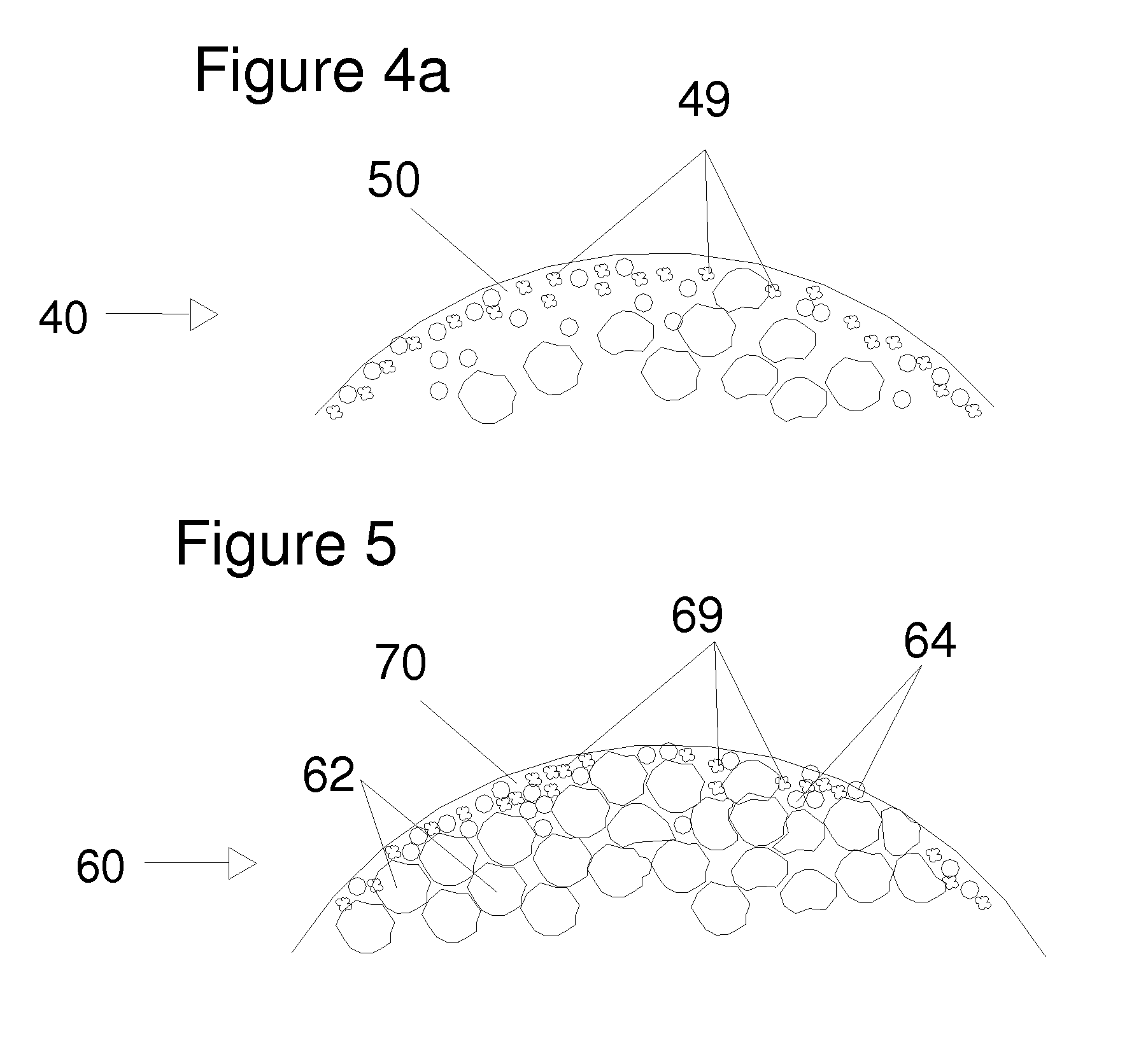

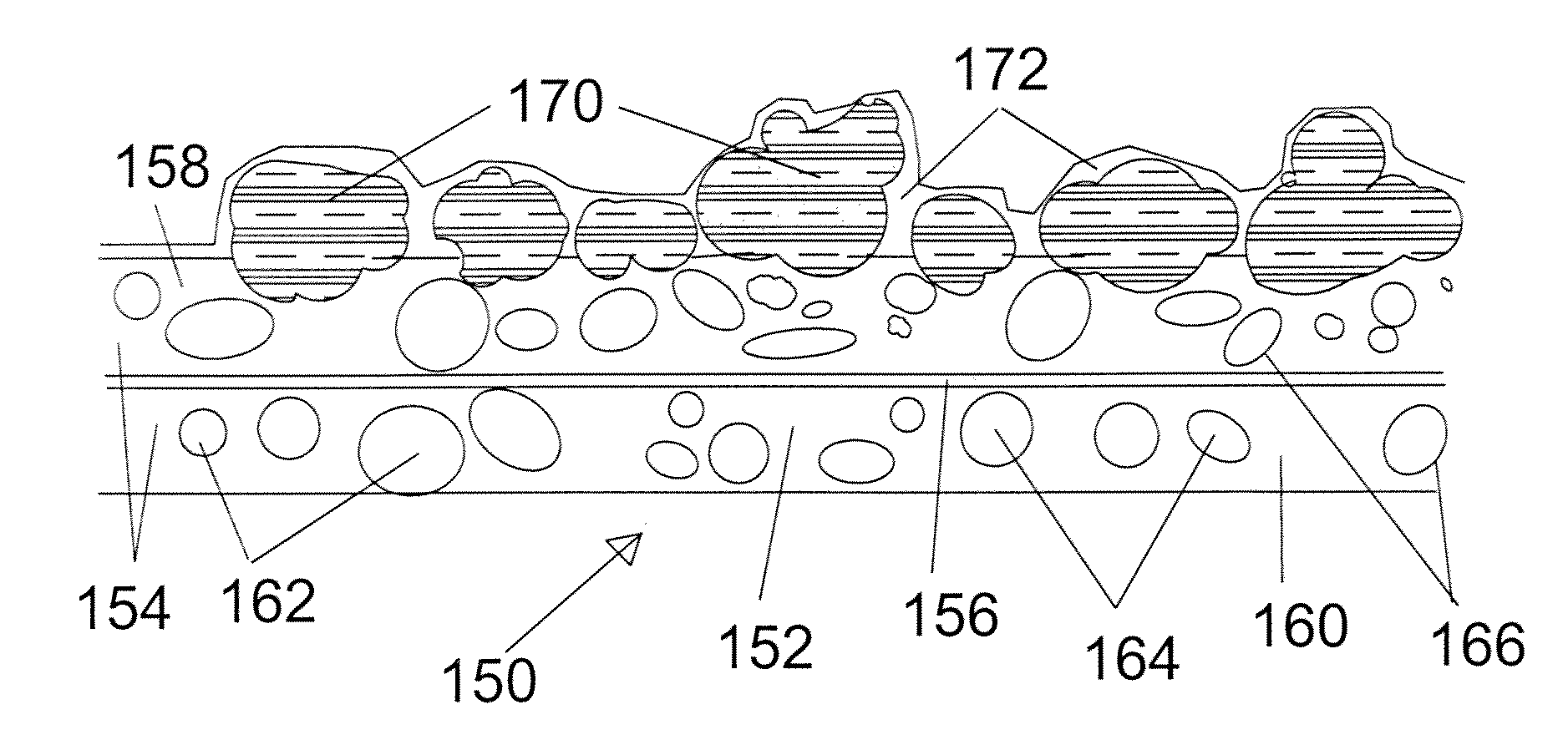

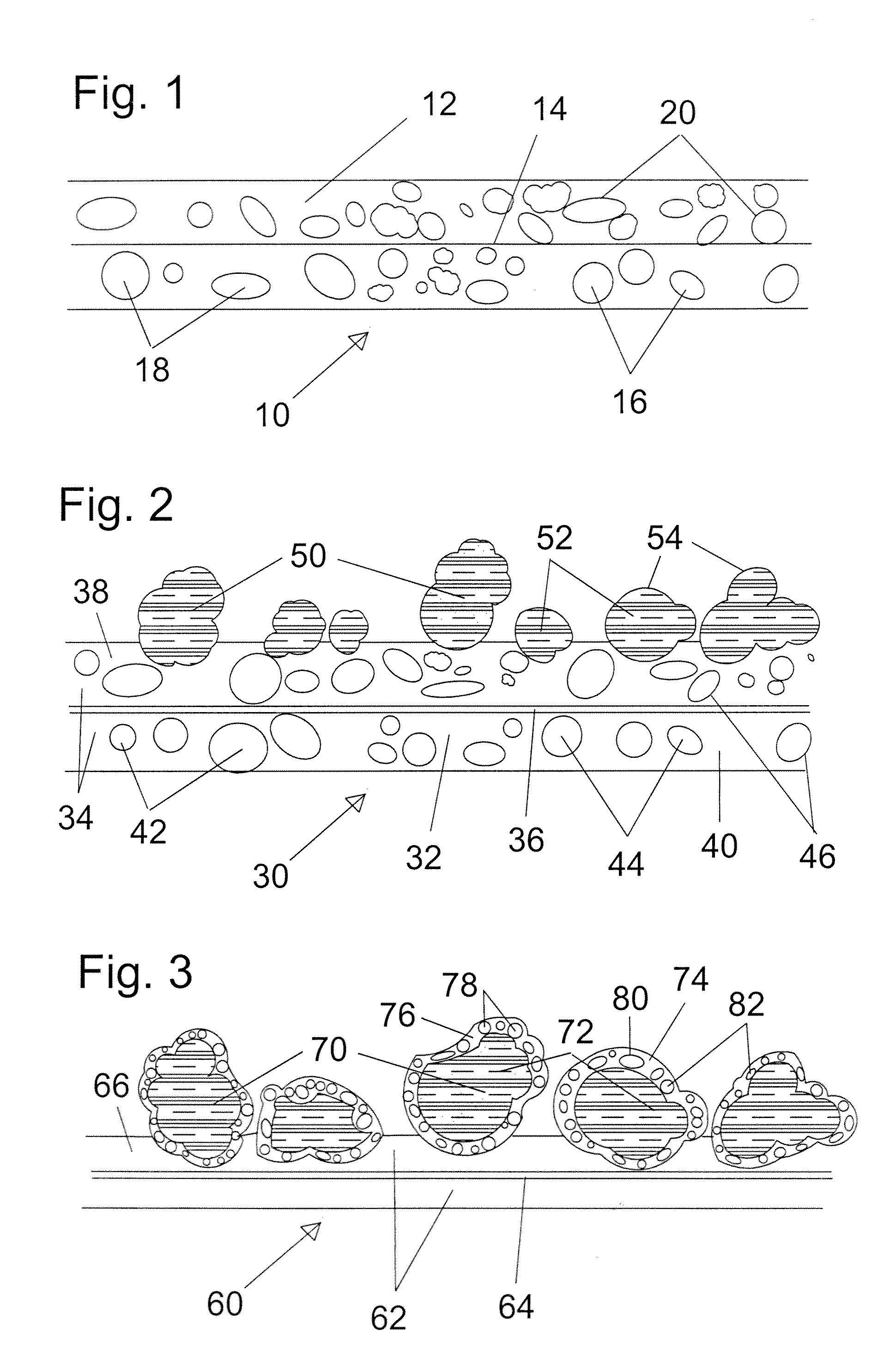

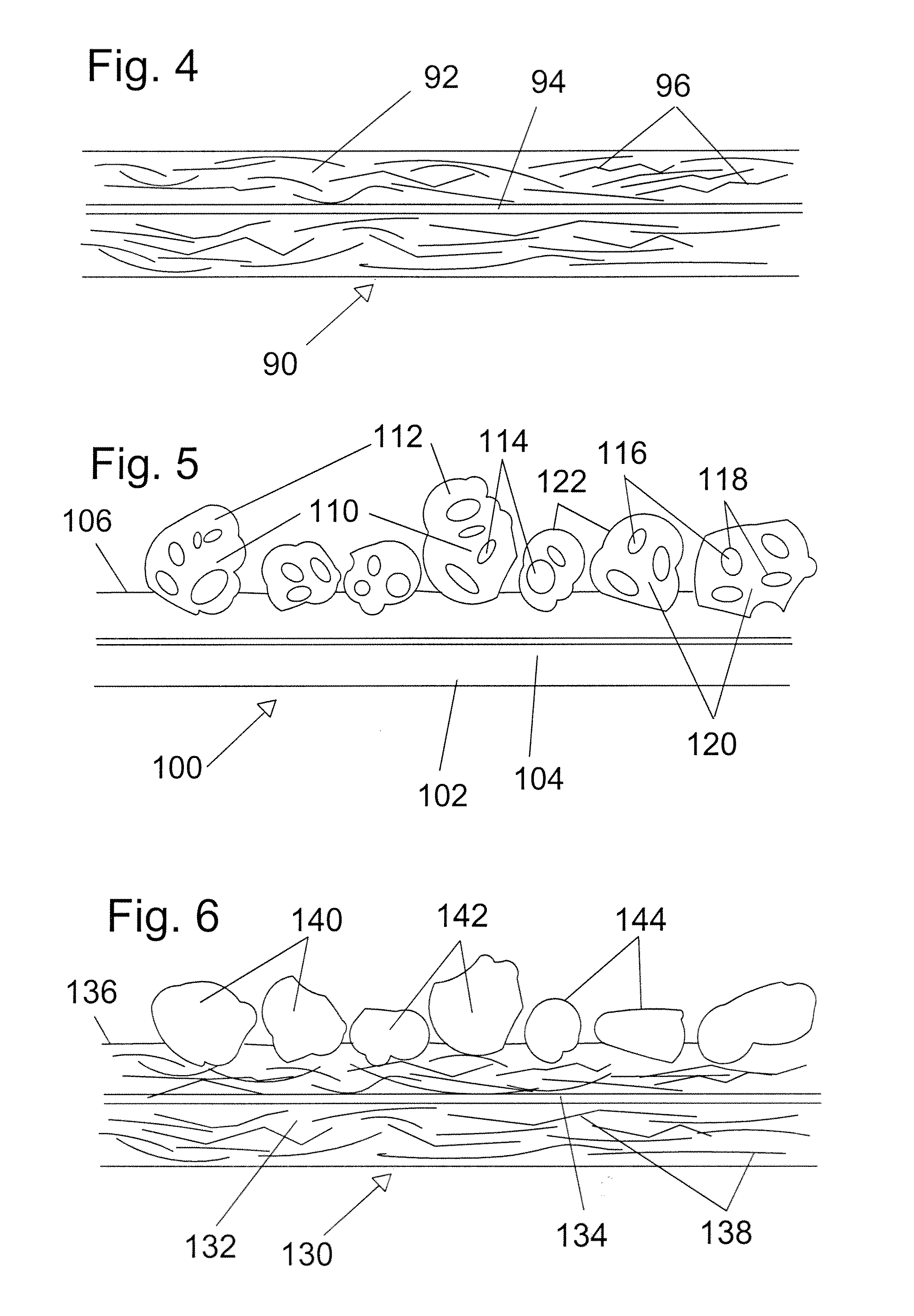

Roofing Granules With Improved Surface Coating Coverage And Functionalities And Method For Producing Same

InactiveUS20060251807A1Easy to packGood optical performanceLiquid surface applicatorsRoof covering using sealantsMineral particlesMaterials science

Roofing granules are produced by suspending selected mineral particles in a selected medium to separate the individual particles, uniformly depositing a coating material, and curing the coating material.

Owner:CERTAINTEED CORP

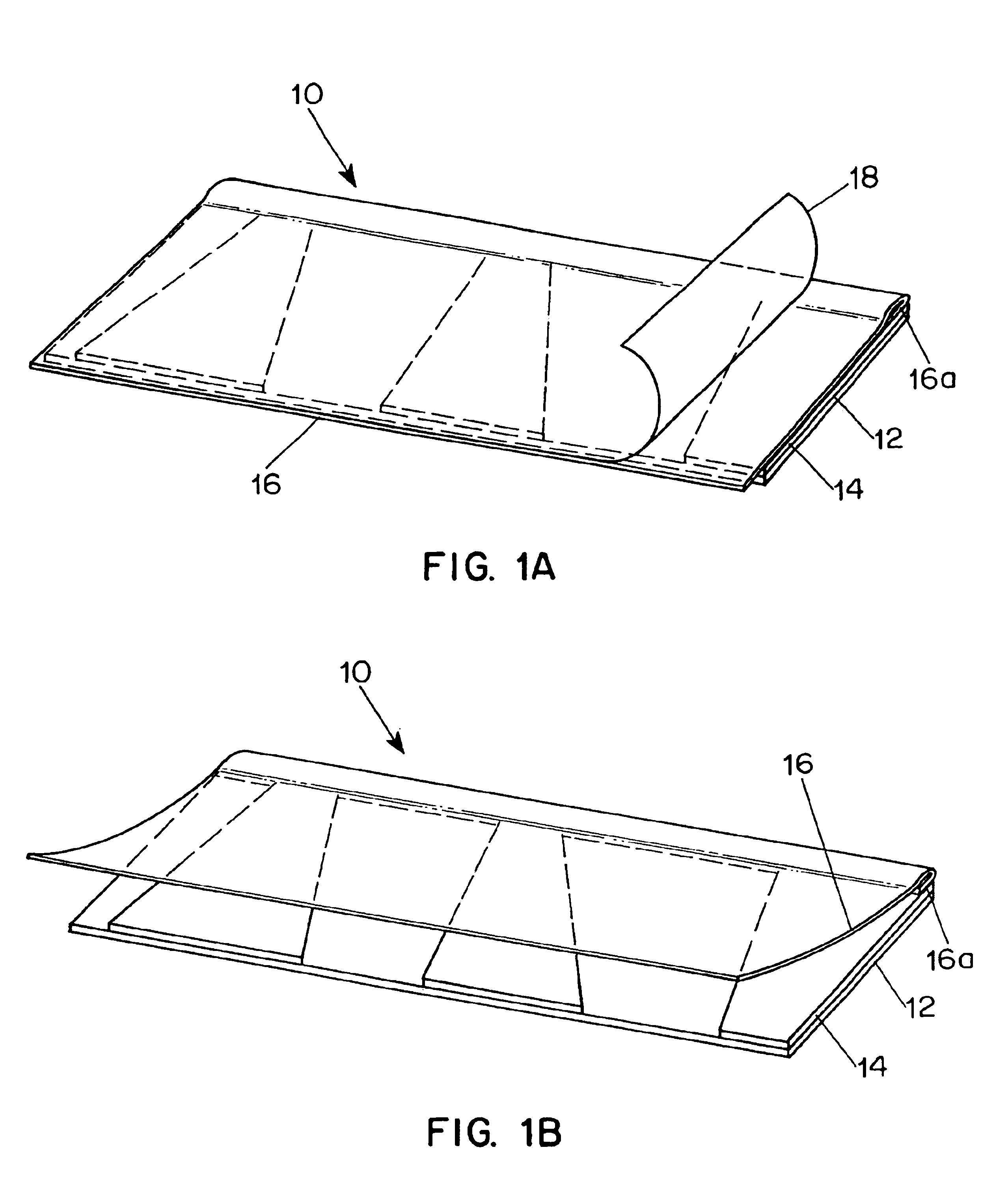

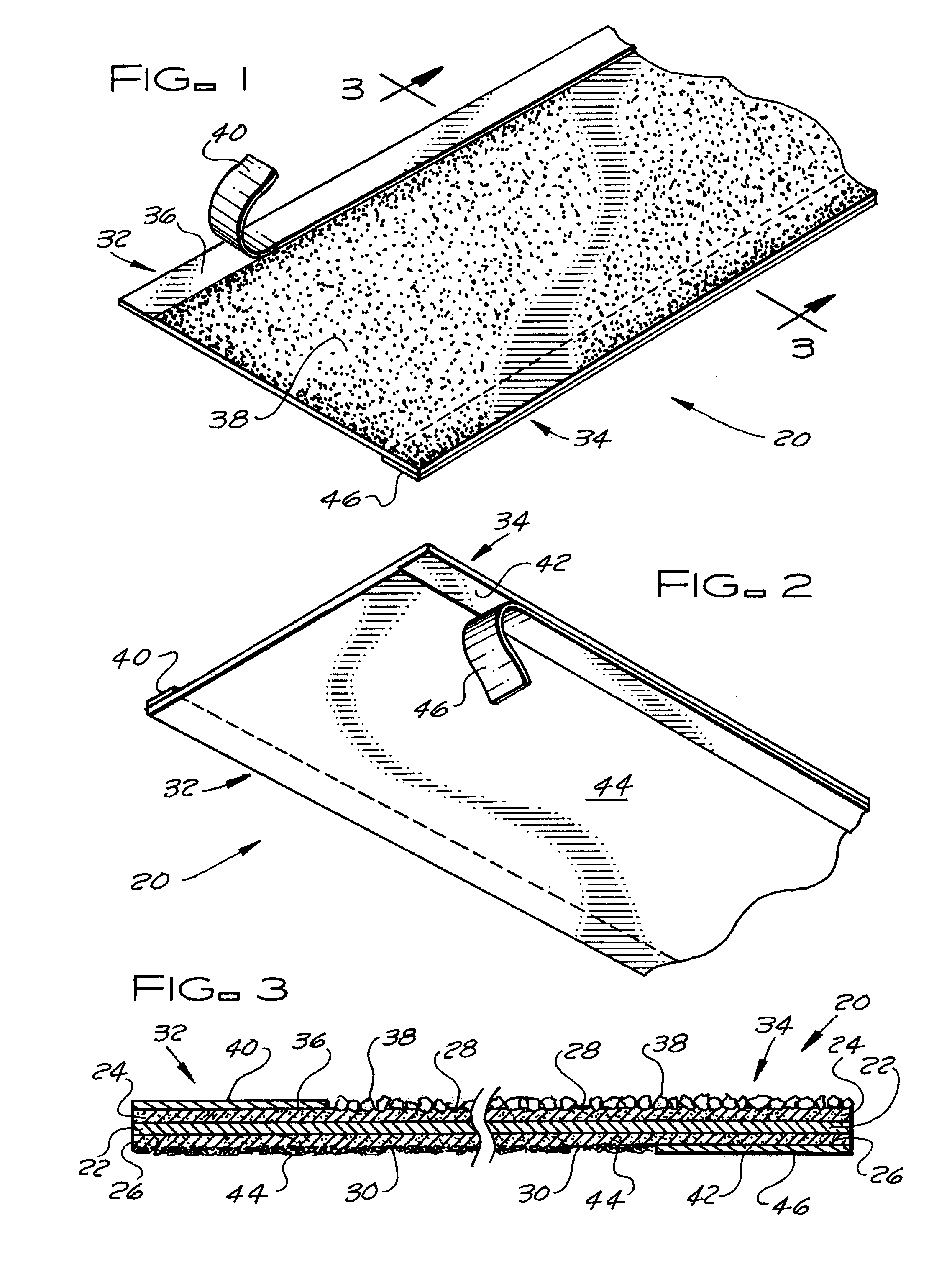

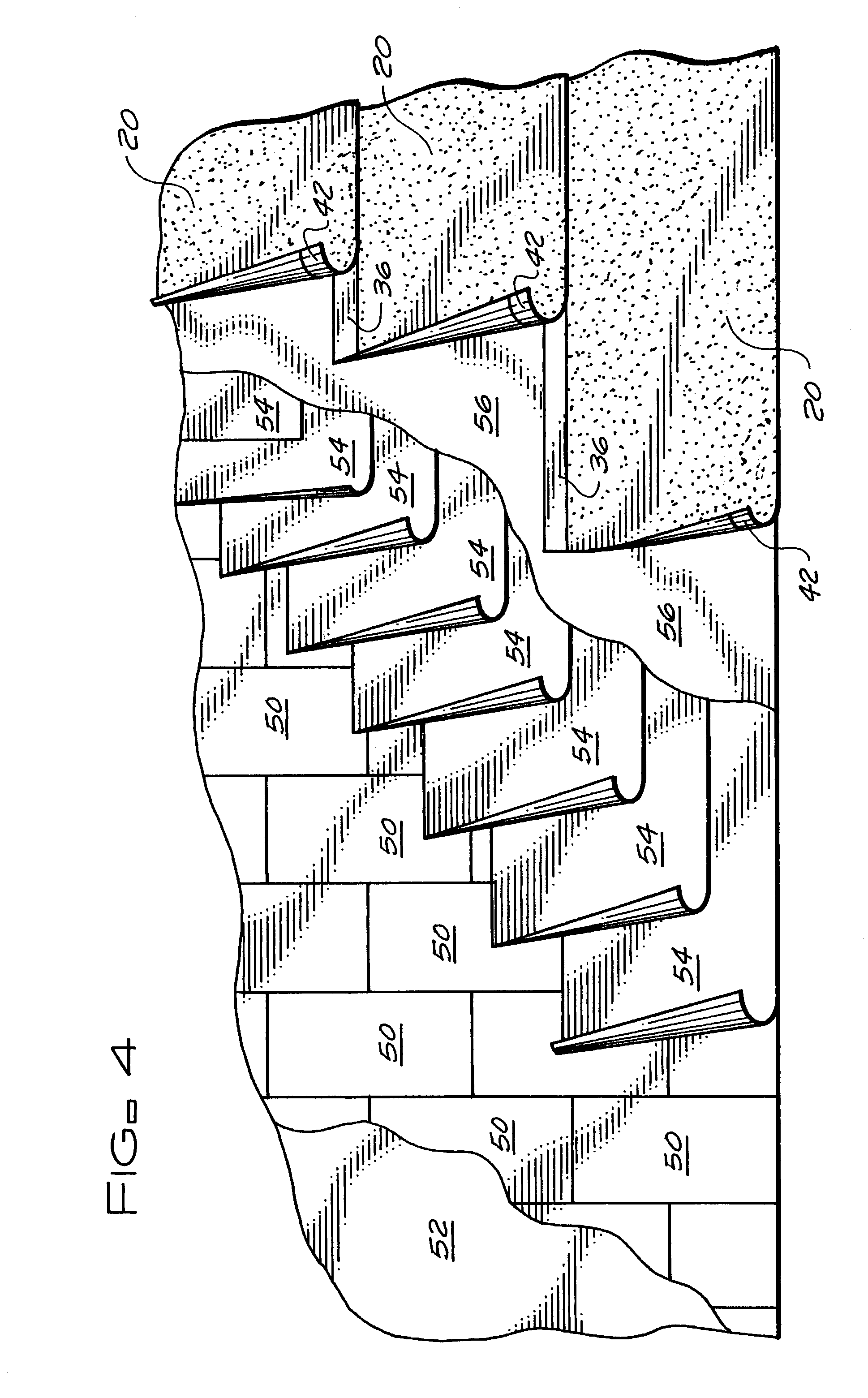

Fastener-free composite roofing product

InactiveUS6936329B2Wider exposed surfaceRecord information storageMagnetic recordingAdhesiveWater resistant

A fastener-free composite roofing product comprising a roofing material and an interply material attached to the roofing material, wherein the interply material includes an adhesive coating on one side. The interply material is attached adjacent to an edge of the roofing material to permit a major portion of the interply material to be folded away from the roofing material for application to a roof. The adhesive is effective to secure the roofing product to the roof without the use of nails or other fasteners. The roofing material may be a roofing shingle or roll roofing, and the interply material is comprised of a water resistant material.

Owner:ELCOR CORP

Multilayer slip resistant sheet material

InactiveUS6925766B2Increase coefficient of frictionGood walkabilityRoof covering using tiles/slatesTreadsEngineeringSlip resistance

There is provided a sheet material having a walking surface with high slip resistance. The sheet material has a flexible structural layer laminated to a mesh layer which has interconnected reinforced strands and protruding nodes to impart a high coefficient of friction. The high coefficient of friction of the sheet material provides a roofing underlayment which is safe to walk upon in dry, wet or dusty conditions, and on steeply sloped surfaces. The sheet material may also be used as an industrial wrapping material or a fabric.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

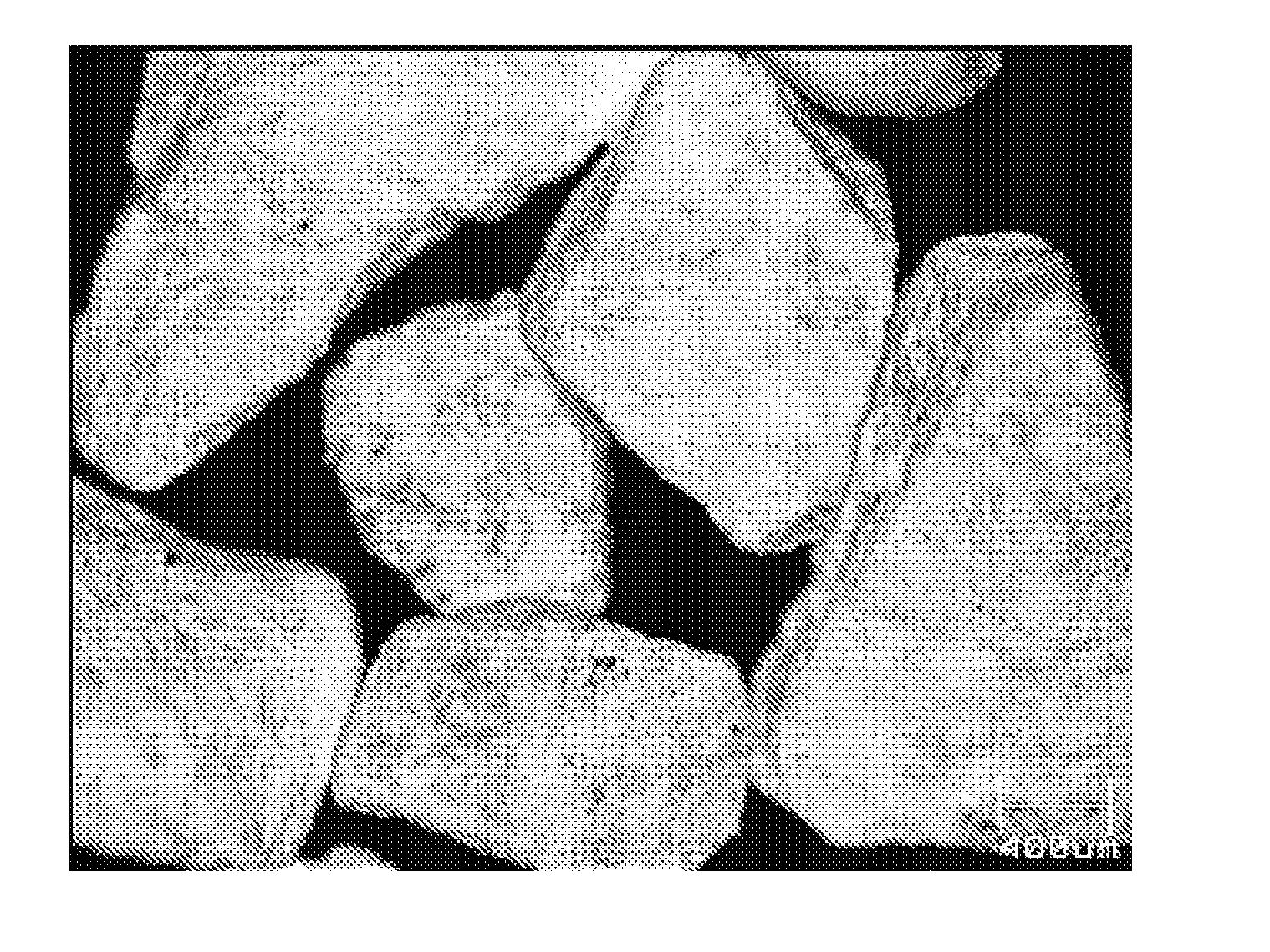

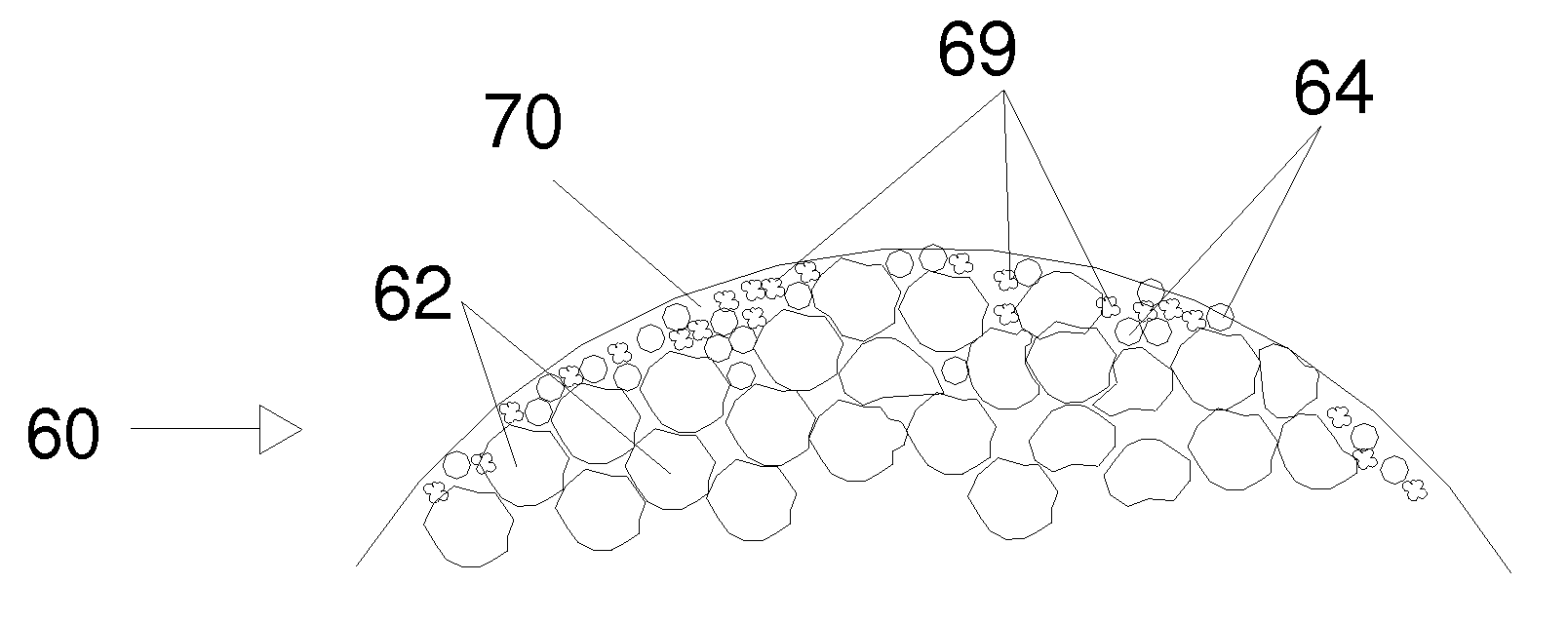

Roofing granules with high solar reflectance, roofing products with high solar reflectance, and processes for preparing same

InactiveUS20100203336A1Improve solar reflectivityRoof improvementWood working apparatusMineral particlesOptoelectronics

Solar reflective roofing granules include a binder and inert mineral particles, with solar reflective particles dispersed in the binder. An agglomeration process preferentially disposes the solar reflective particles at a desired depth within or beneath the surface of the granules.

Owner:CERTAINTEED CORP

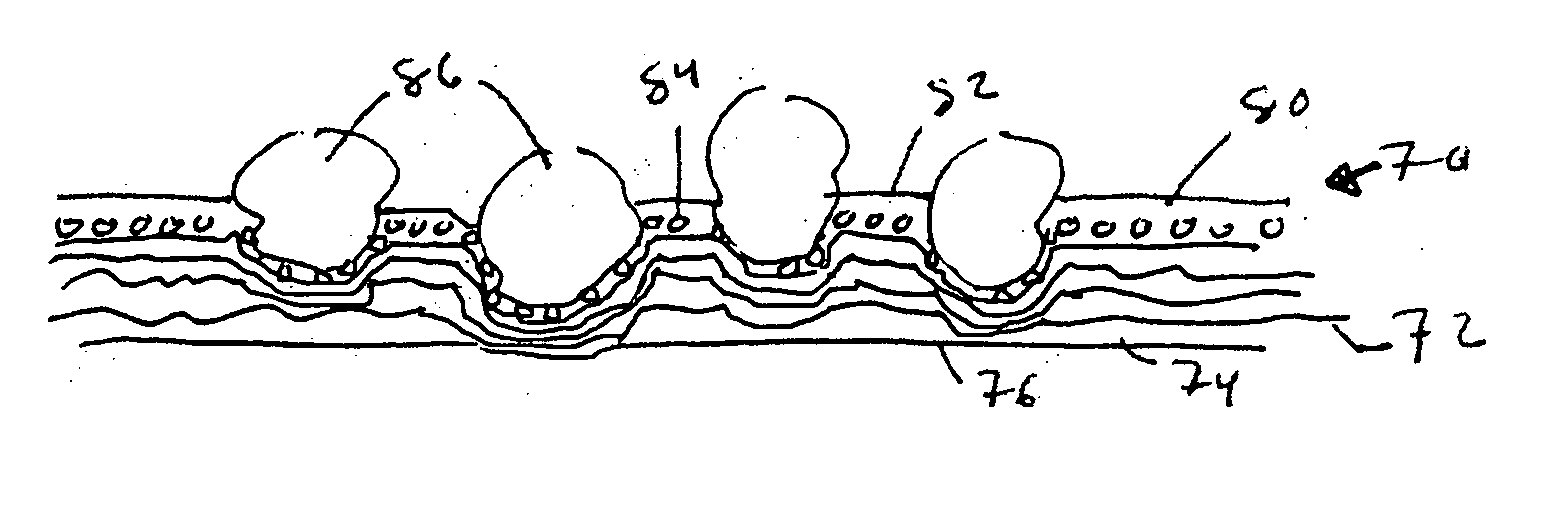

Roofing products, photovoltaic roofing elements and systems using them

InactiveUS20110030761A1Improve adhesionPhotovoltaic supportsSolar heating energyEngineeringPhotovoltaics

The present invention relates generally to roofing products. The present invention relates more particularly to roofing products for use with photovoltaic elements, and to photovoltaic systems that include one or more photovoltaic elements joined to a roofing substrate. In one embodiment, a roofing product includes a flexible roofing substrate having a top surface, the top surface having one or more granule-coated zones thereon capable of acting as a receptor zone or an exposure zone, each zone being adapted to receive one or more photovoltaic elements; and an adhesive suitable for securing photovoltaic elements to one or more of the granule-coated zones, the adhesive capable of forming a bond to the granules and the top surface of the flexible roofing substrate and to the bottom surface of the photovoltaic elements.

Owner:CERTAINTEED CORP

Highly reflective asphalt-based roofing membrane

ActiveUS20050053745A1Efficient use ofImprove reflectivitySpecial ornamental structuresCeramic layered productsEngineeringAsphalt

A prefabricated asphalt-based waterproof roofing membrane for use in a multi-ply asphalt-based commercial roofing system, e.g. a cap sheet that forms the exposed layer of a multi-ply built-up roofing system, is manufactured at a factory to have a highly reflective non-asphalt based elastomeric top coating layer with an upper surface that meets current EPA Energy Star requirements. Preferably, a polymer primer layer is interposed between the highly reflective coating layer and an asphalt saturated and coated reinforcing substrate to keep oils and other colored components in the asphalt from exuding into the highly reflective coating layer.

Owner:JOHNSON MANVILLE INT

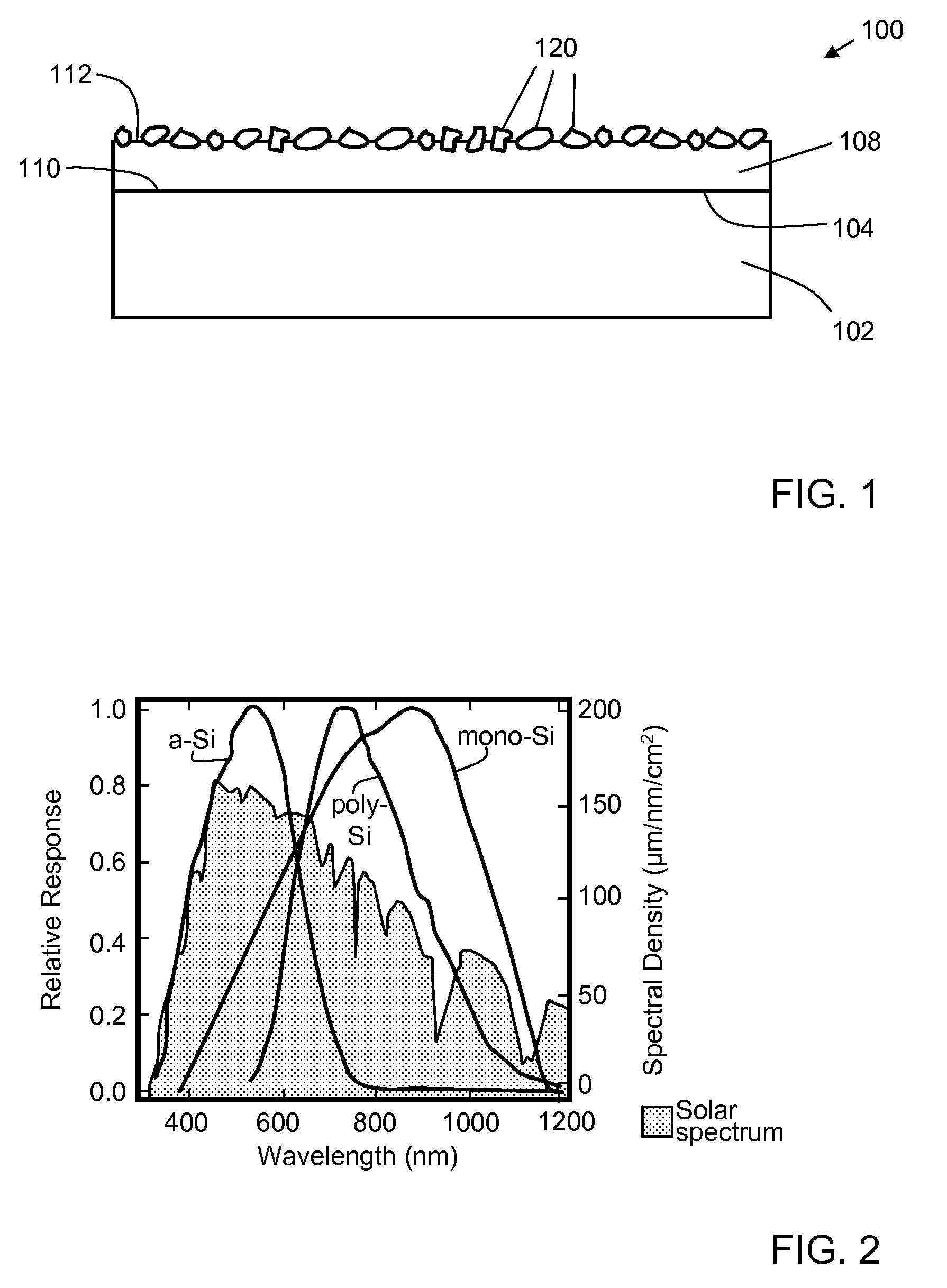

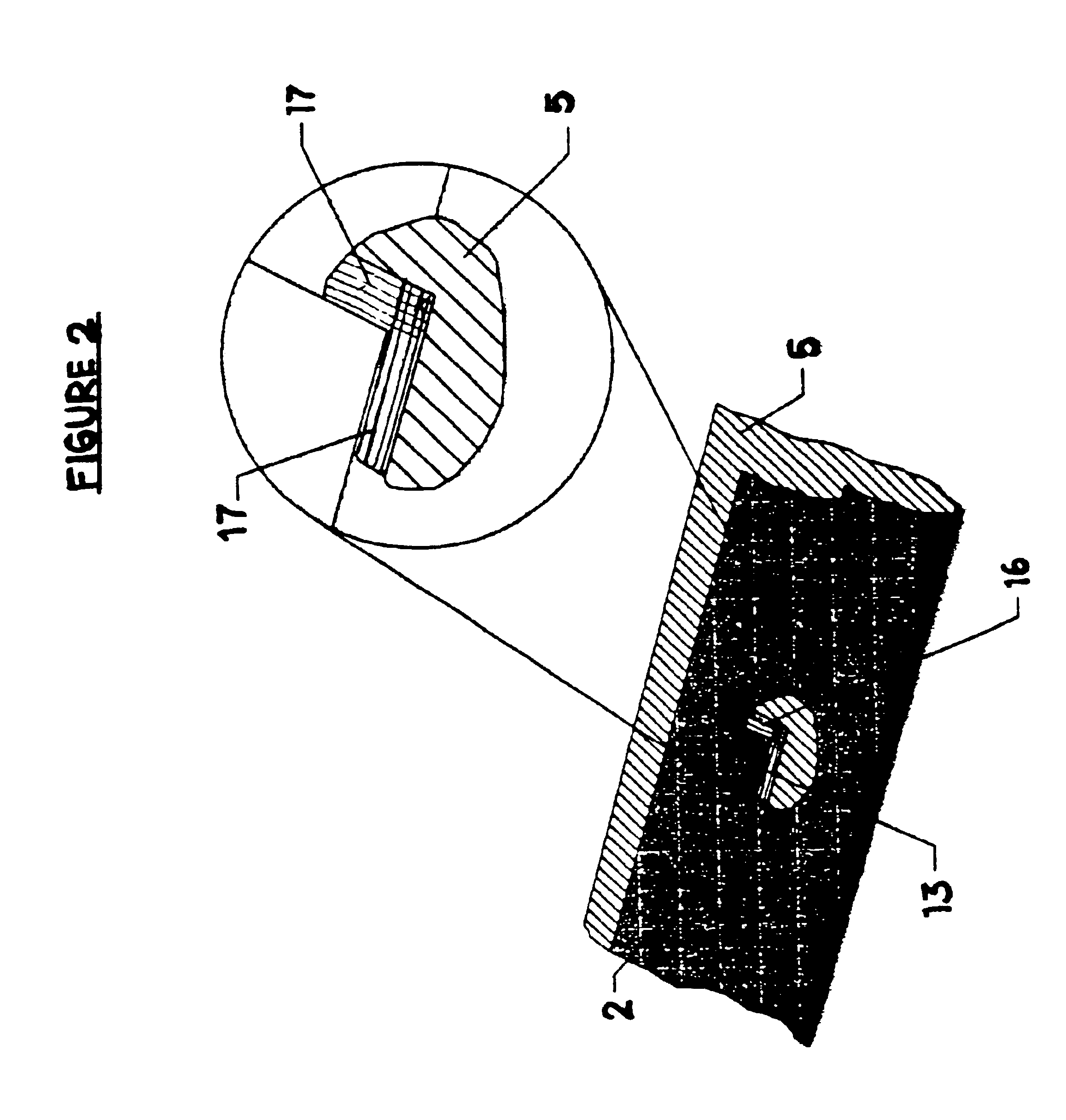

Photovoltaic Devices and Photovoltaic Roofing Elements Including Granules, and Roofs Using Them

InactiveUS20080271773A1Generate significant photovoltaic powerAesthetically pleasingPhotovoltaic supportsRoof covering using tiles/slatesEngineeringWavelength range

The present invention includes photovoltaic devices and photovoltaic roofing elements comprising a photovoltaic element having an active face and an operating wavelength range; a polymer structure having (a) a bottom surface disposed on the active face of the photovoltaic element and (b) a top surface; and a plurality of granules disposed on the top surface of the polymer structure. Roofs including the photovoltaic devices and photovoltaic roofing elements of the present invention may be configured to have an aesthetically desirable appearance while retaining high photovoltaic efficiency.

Owner:CERTAINTEED CORP

Manufacture of composite roofing products with matrix formulated microbiocide

InactiveUS6245381B1Good dispersionEliminate the problemBiocideLiquid surface applicatorsAsphalt shingleBlue green algae

This invention discloses improved residential roofing products with durable active protection against algae discoloration. Versatile organometallic salts and chelates for this purpose are incorporated in manufacture of composite concrete tile and asphalt shingle products via integrated process modifications. These chemically stable non-volatile microbiocides, with exceptional effectiveness against both green and blue green algae, are tailored for specific matrix compatibility. By virtue of their composition and surface activity they serve a dual function in process improvement and product performance. The control of microbiocide activity, long term, significantly advances the state-of-the-art protection against algae and the service life of these products.

Owner:TAMKO BUILDING PRODS

Roofing materials having engineered coatings

InactiveUS7238408B2Improve toughnessImprove impact resistanceRoof covering using tiles/slatesRoof improvementPliabilityAsphalt

An asphalt-based roofing material includes a coating having a top portion containing a mixture of asphalt and igneous and / or metamorphic rock particles, while the mat portion of the coating contains a mixture of asphalt and a filler which contains less than 10% igneous and / or metamorphic rock particles. In other embodiments, the top portion but not the bottom portion of the coating meets or exceeds a pliability standard, passes a weathering performance test, or has a high solar reflectance. In another embodiment relating to a laminated roofing material, the top portion but not the bottom portion has viscoelastic properties effective to prevent the coating from sticking to an adjacent shingle in a bundle. The invention also relates to a continuous process of applying first and second coatings to a mat for manufacturing a roofing material. In a first coating operation, a first asphalt-based coating is continuously applied to a first surface of the mat so that the first coating saturates the mat and forms a layer on the first surface. In a second coating operation, a second asphalt-based coating is continuously applied to a second surface of the mat so that the second coating forms a layer on the second surface. The second coating has different properties from the first coating.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Flexible polypropylene roofing membrane

InactiveUS20060046084A1Good flexibilityExcellent heat welding strengthRoof covering using flexible materialsSynthetic resin layered productsElastomerPolyolefin

A thermoplastic polyolefin (TPO) roofing membrane is made by blending a new polypropylene based elastomer (PBE) or plastomer (PBP) and polyolefin copolymers. The new PBE or PBP offers superior flexibility over conventional polypropylene roofing membranes for easy installation. The new narrow molecular weight distribution and broad crystallinity distribution of the PBE or PBP results in excellent heat welding strength and wide heat welding windows of the said TPO membrane.

Owner:BUILDING MATERIALS INVESTMENT

Roofing Products Containing Phase Change Materials

InactiveUS20080008858A1Improve the immunityAttractive appearanceRoof covering using tiles/slatesRoof covering using flexible materialsDegree CelsiusPhase change

Owner:CERTAINTEED CORP

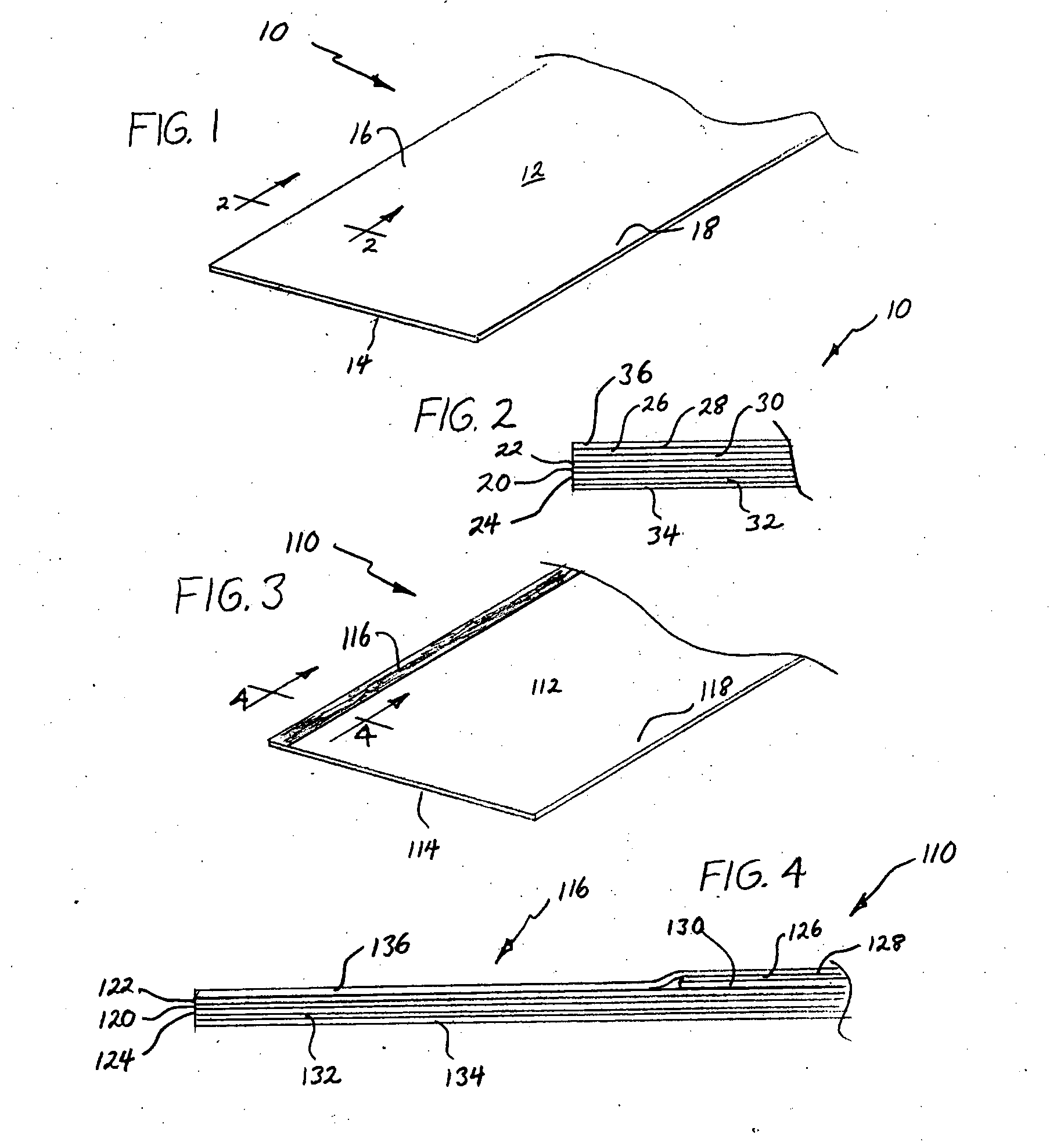

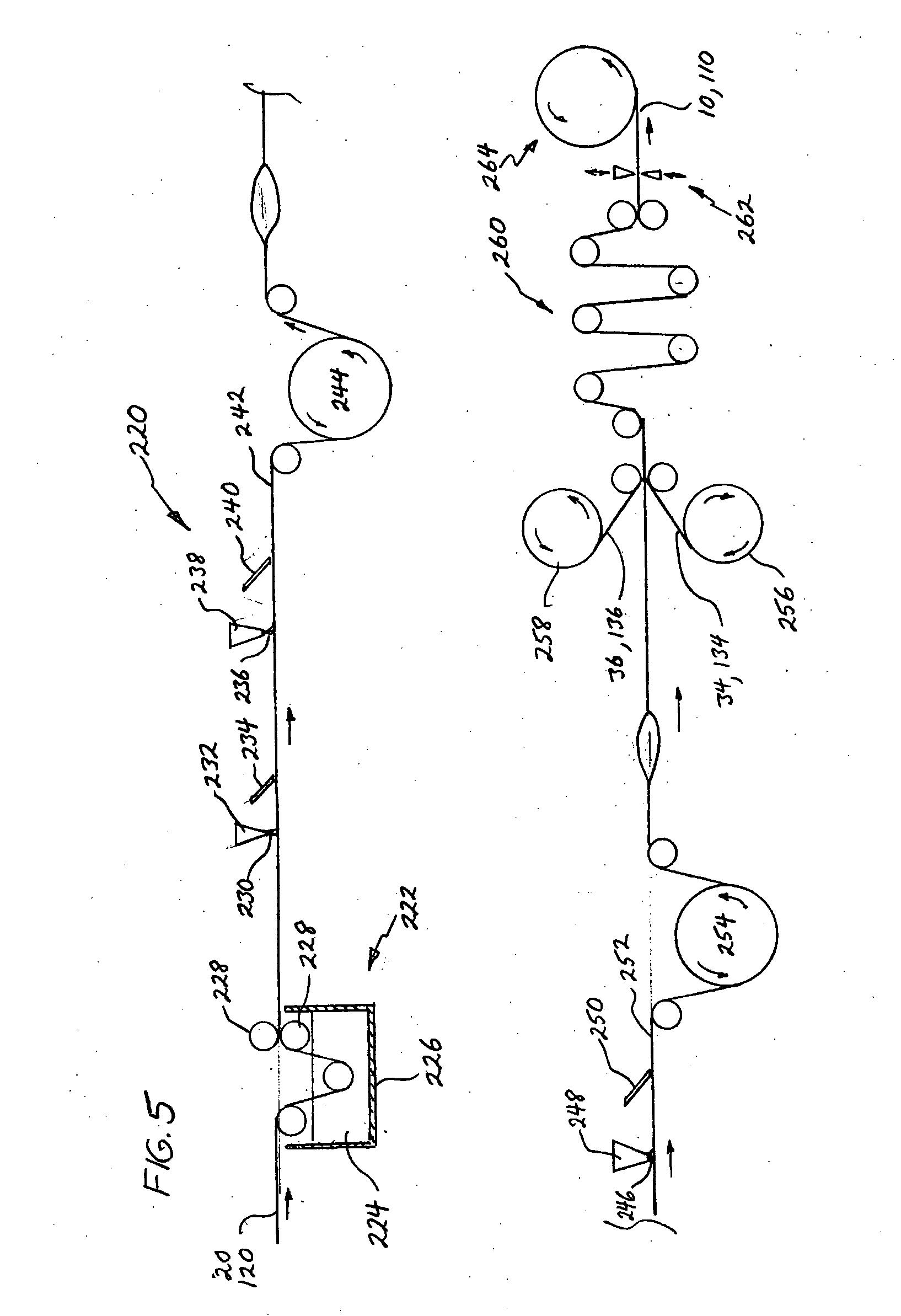

Adhesive rubber article having scored released liner and guide to facilitate field application and related methods

An adhesive rubber article of the type having a release liner covering its tacky, adhesive surface to prevent the adhesive rubber article from adhering to various substrates or to itself prior to its intended use includes an impression or mark presented on one or more surfaces for facilitating the alignment and application of the adhesive rubber article on one or more substrates. The release liner has been scored, perforated or otherwise cut in a longitudinal direction of the article such that the scoring of the release liner further produces a visual guide on the adhesive rubber article. Thus, upon removal of the release paper, the guide may be used to align and apply the adhesive rubber article to the various substrates. These adhesive rubber articles are particularly useful within the roofing industry for bonding panels of rubber membranes together or for use as flashing.

Owner:FIRESTONE BUILDING PRODS

Multi-layer co-extruded roofing membrane

A multi-layer roofing membrane is provided including a top sheet including a co-extruded cap and inner layer and a bottom sheet. The use of a co-extrusion die allows for multi-layer sheets that reduce the need for expensive fillers in all but a cap layer of the membrane. A scrim reinforcement layer is optionally embedded in the membrane. When installed on a roof substrate, the membrane can be sealed by heat welding the seams of the membrane sheets or by other means.

Owner:HOLCIM

Modified bitumen roofing membrane with enhanced sealability

InactiveUS6924015B2Reduce the possibilityImprove the noise reduction effectTreadsRoof covering using flexible materialsThermoplasticEngineering

A self-adhering modified bituminous roof covering composite that comprises a thermoplastic (APP), elastomeric (SBS) or TPO modified bitumen compound on the front side, and a factory-applied self-adhesive compound on the back side of a reinforcement carrier sheet, with factory-applied tracts of adhesive on the side lap and end lap sections of each roll to enhance adhesion. A method of manufacturing such composite comprising coating an APP or SBS or TPO compound on the upper surface and affixing a self-adhesive compound to the lower surface of a reinforcement carrier support sheet, coating an adhesive on the side lap and end lap areas, applying a release liner to the tacky self-adhesive layer, and applying release films to the side and end laps during manufacture, stripping the release liner, selvage release film and end lap film from the membrane immediately prior to use, subsequently placing the exposed self-adhesive side of the membrane directly on to the end lap areas and side lap areas of adjacent rolls and applying force directly to the sheet to enhance the bond between the two sheets, resulting in a continuous roof covering. The present invention relates generally to residential and commercial roofing membranes.

Owner:POLYGLASS

Skid resistant surfaces

InactiveUS20070044397A1Good for scrollingExcellent skidTreadsRoof covering using flexible materialsPressure sensitiveCivil engineering

Skid-resistant surfaces as described having either a pressure-sensitive adhesive layer or a highly filled, textured binder to reduce skidding. The surfaces are applied to trafficable surfaces such as roof and floors. Products such as roof underlyments bearing the surfaces are described in particular.

Owner:WR GRACE & CO CONN

Cap sheet, roofing installation, and method

ActiveUS7146771B2Reduce the amount of adhesionEffective combinationRoof covering using tiles/slatesRoof covering using flexible materialsEngineeringMechanical engineering

A cap sheet for cold-applied adhesive roof installations includes a reinforcement mat saturated with and encapsulated within SBS modified bitumen. Bitumen layers above and beneath the mat have top and bottom major surfaces. The top surface of the top bituminous layer has a first edge portion extending inward from and along a first lateral edge. The bottom surface of the bottom bituminous layer has a second edge portion extending inward from and along a second lateral edge. The bitumen in the edge portions is a pressure-sensitive adhesive that is covered by release liners for protection prior to installation. When the cap sheets are installed, the release liners are removed from the edge portions and overlapping edge portions of the cap sheets are pressed and adhesively bonded together to immediately form effective watertight, weather-secure seams.

Owner:JOHNS MANVILLE INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com