Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1172results about "Treads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

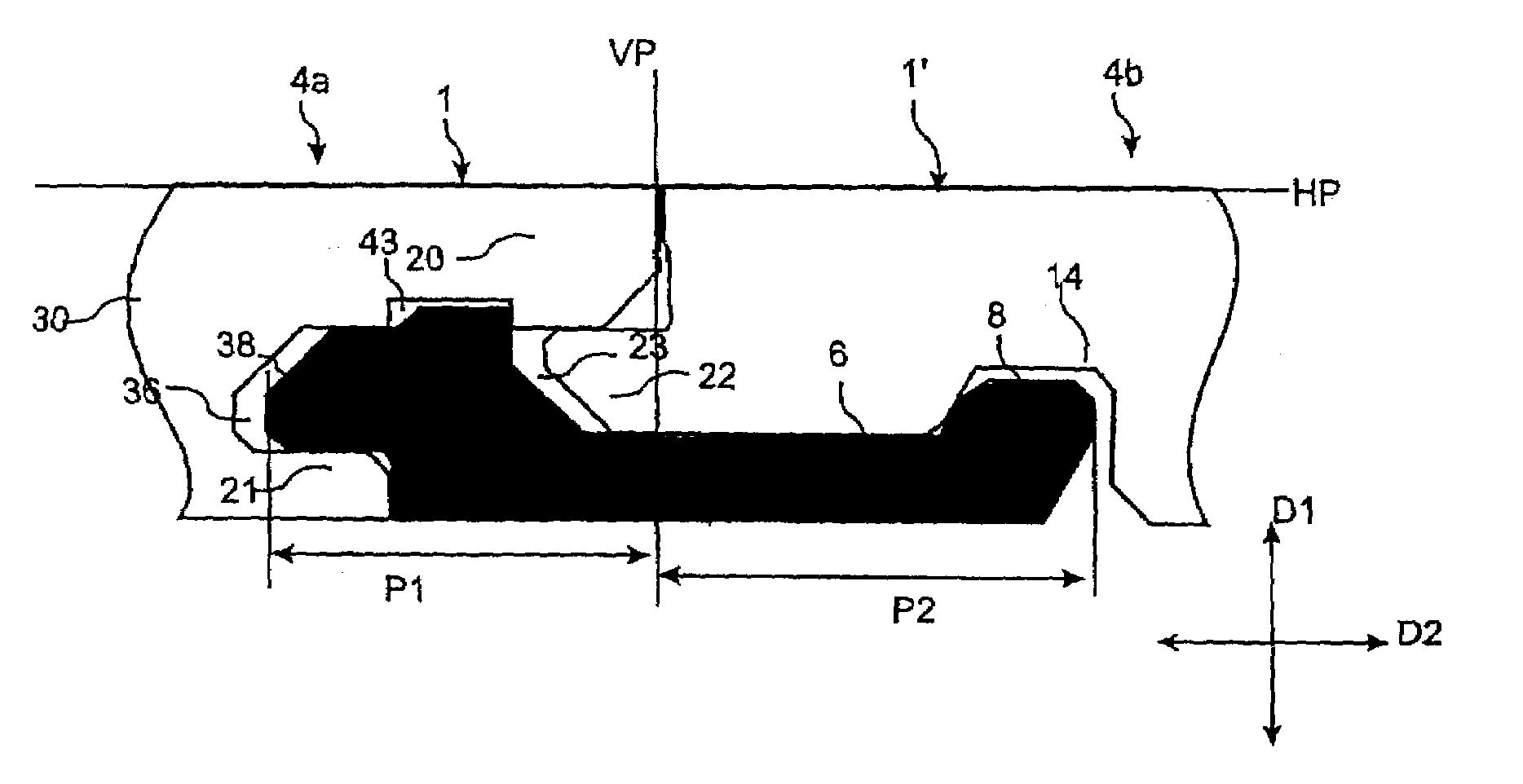

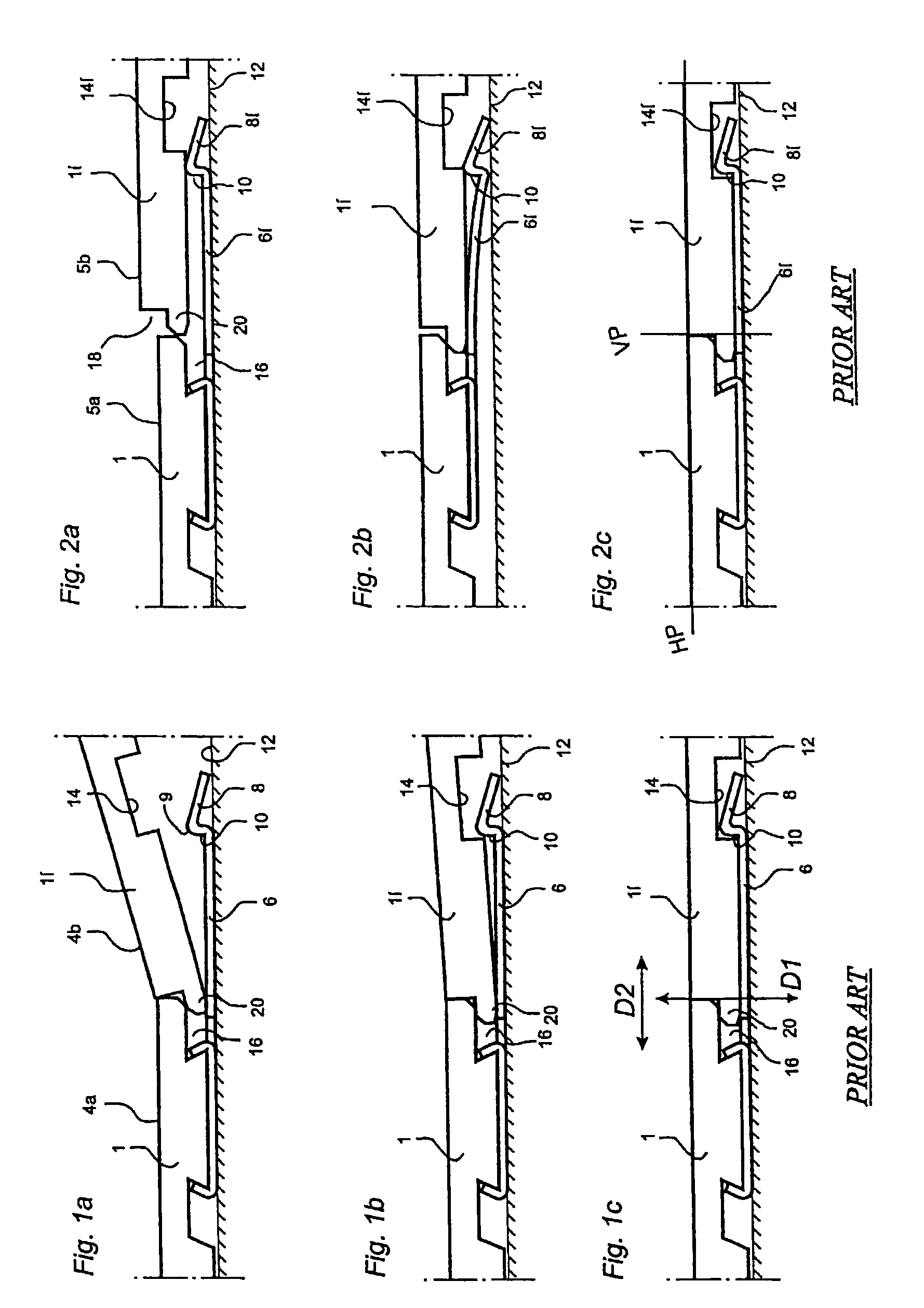

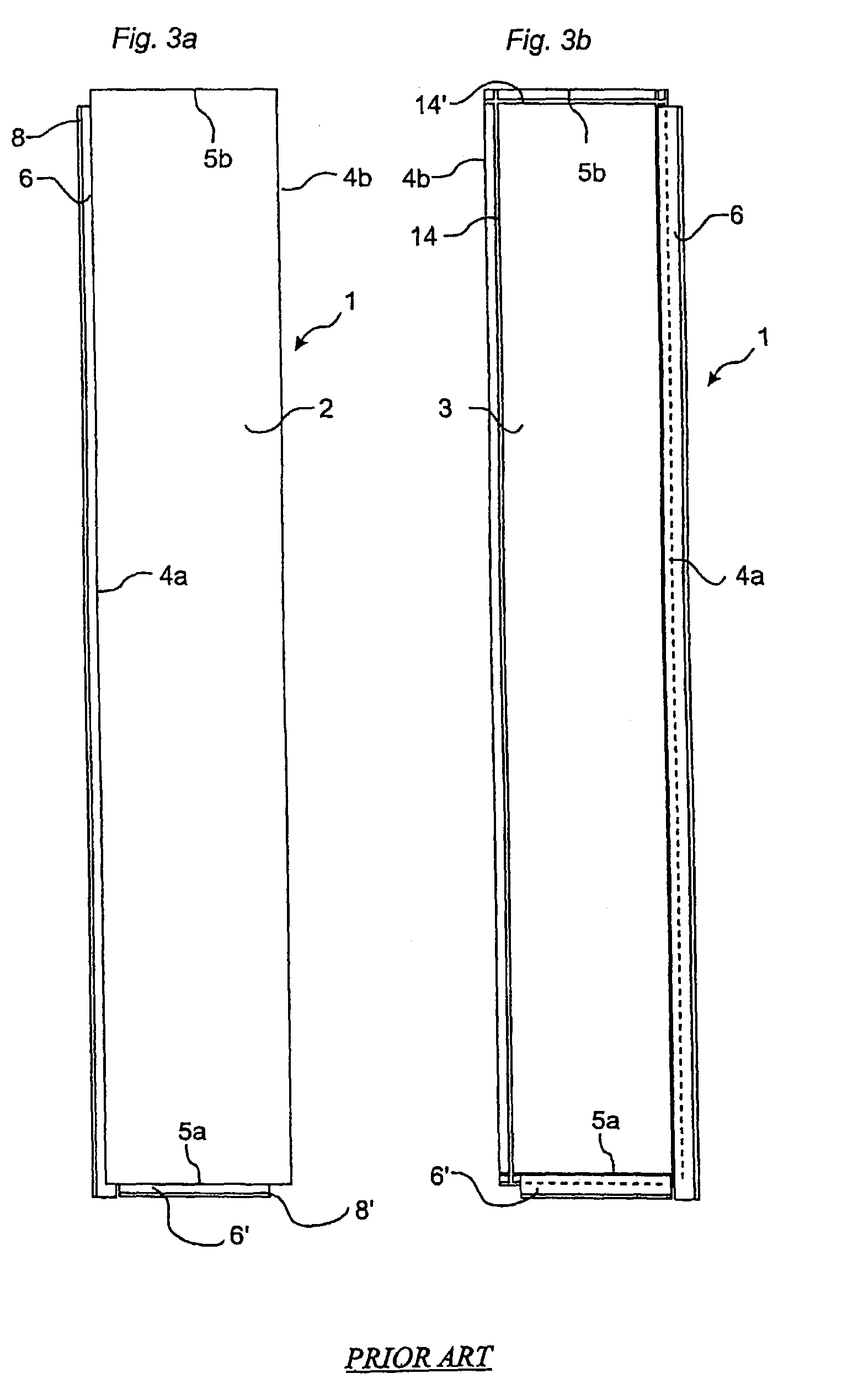

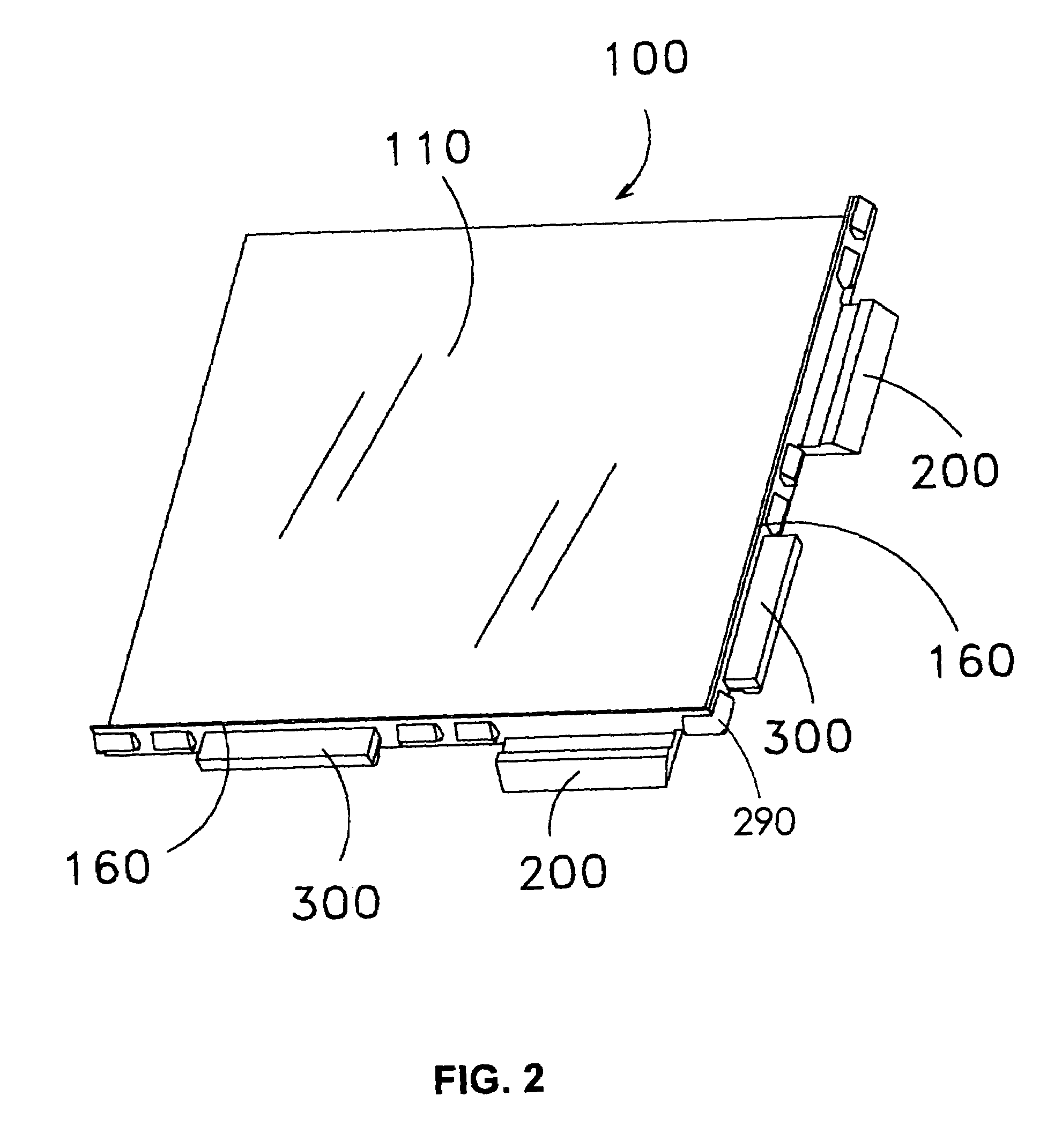

Mechanical locking system for floating floor

InactiveUS7051486B2Rational and cost-efficientReduce the amount requiredStrutsTreadsEngineeringFloating floor

Floorboards with a mechanical locking system having a separately machined strip which is mechanically joined with the floorboard.

Owner:VÄLINGE INNOVATION AB

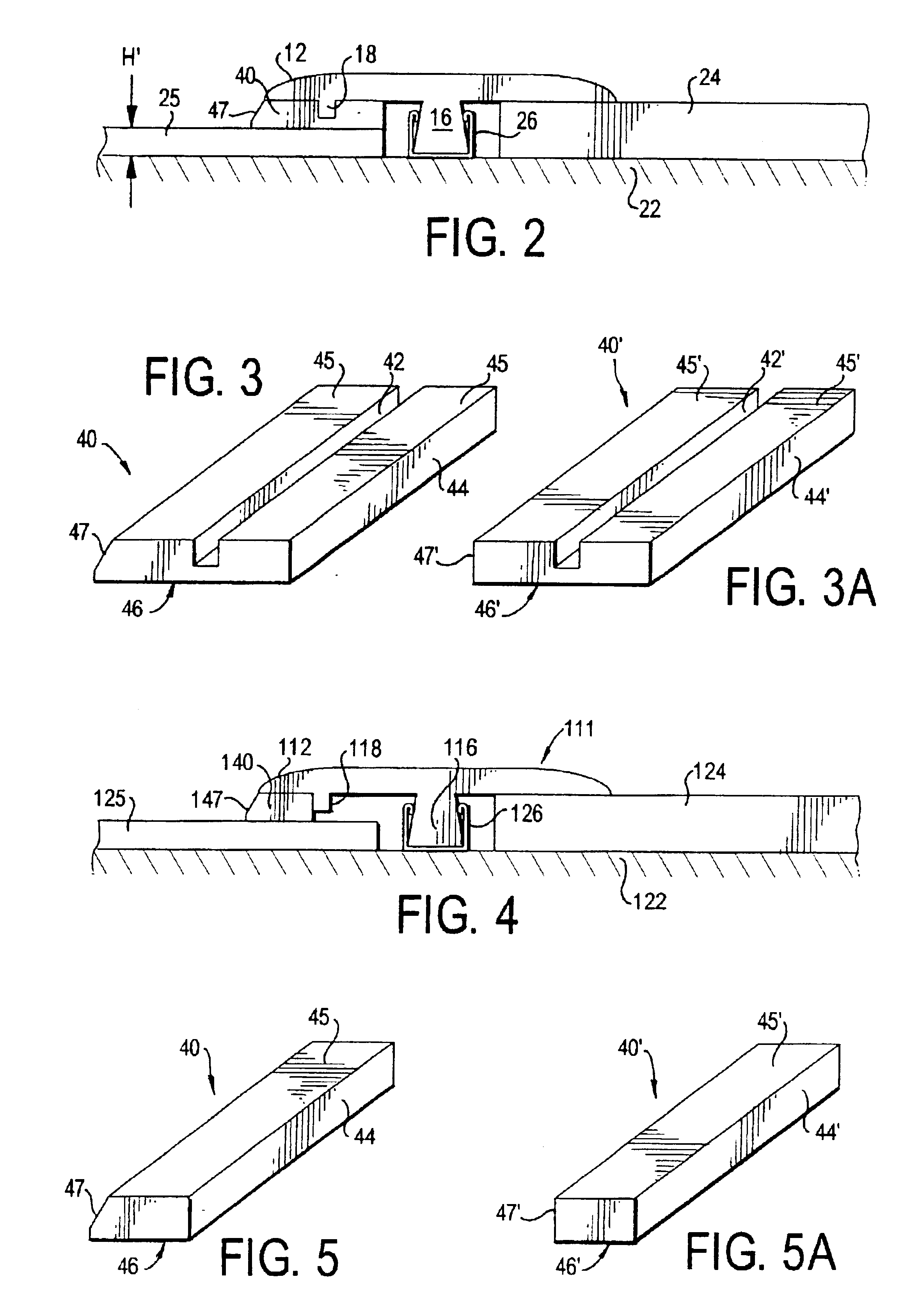

Glider bar for flooring system

A flooring system for use with floating floors is described which includes a glider bar having base portions including extending rails in the form of dovetail protrusions. The bases and rails are longitudinally moveable relative to anchoring plates, which anchoring plates are affixed to a subflooring. Flush finished floor moldings are slid longitudinally along the rails and are glued or mechanically fixed, at one side only, to the adjacent floating laminate flooring. By this assembly, smooth transitions between adjacent floating floors, or where floating floors meet another hard floor covering, or carpet, can be achieved. The system can also be used with flush stair nosing elements.

Owner:PERGO

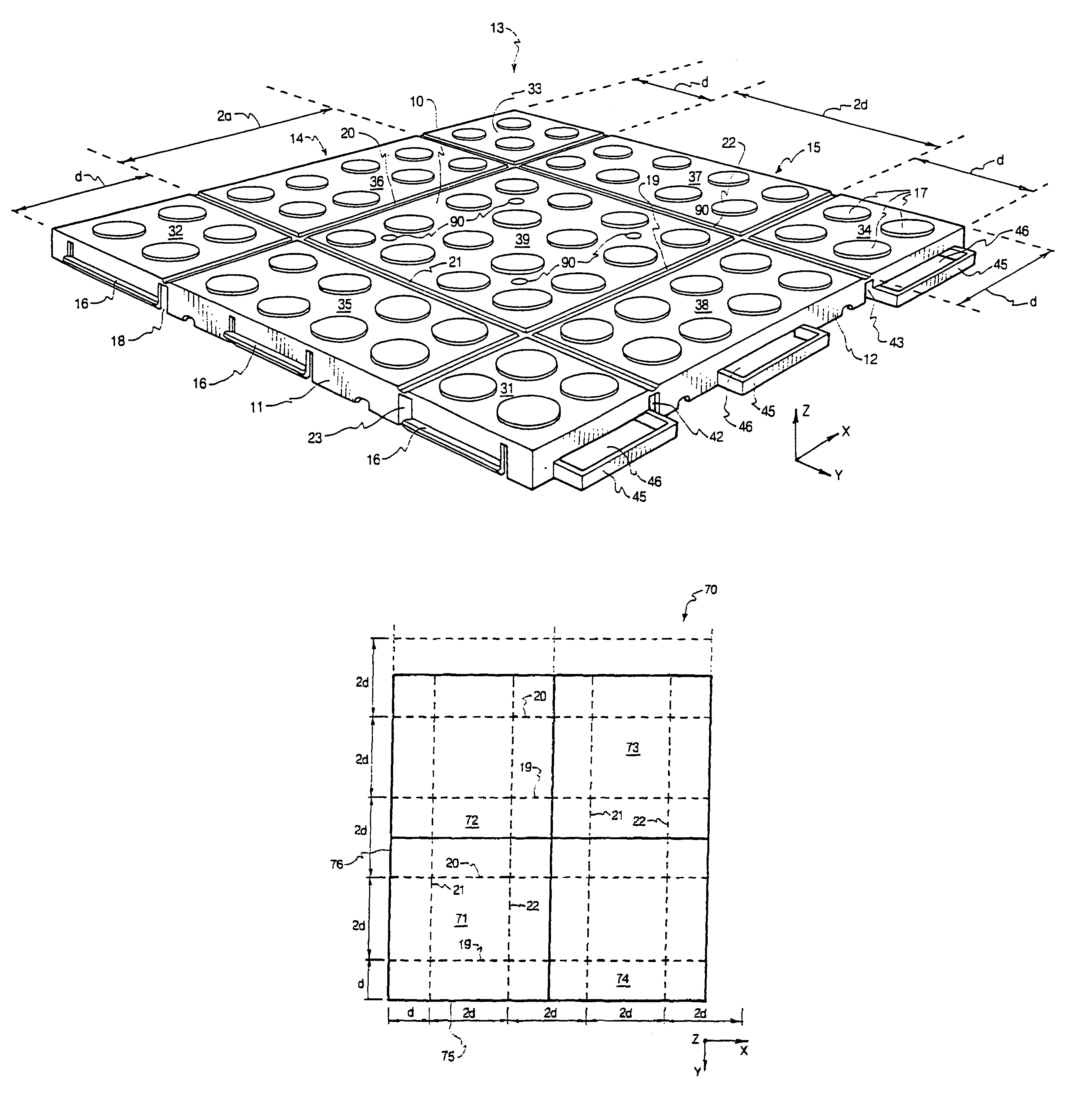

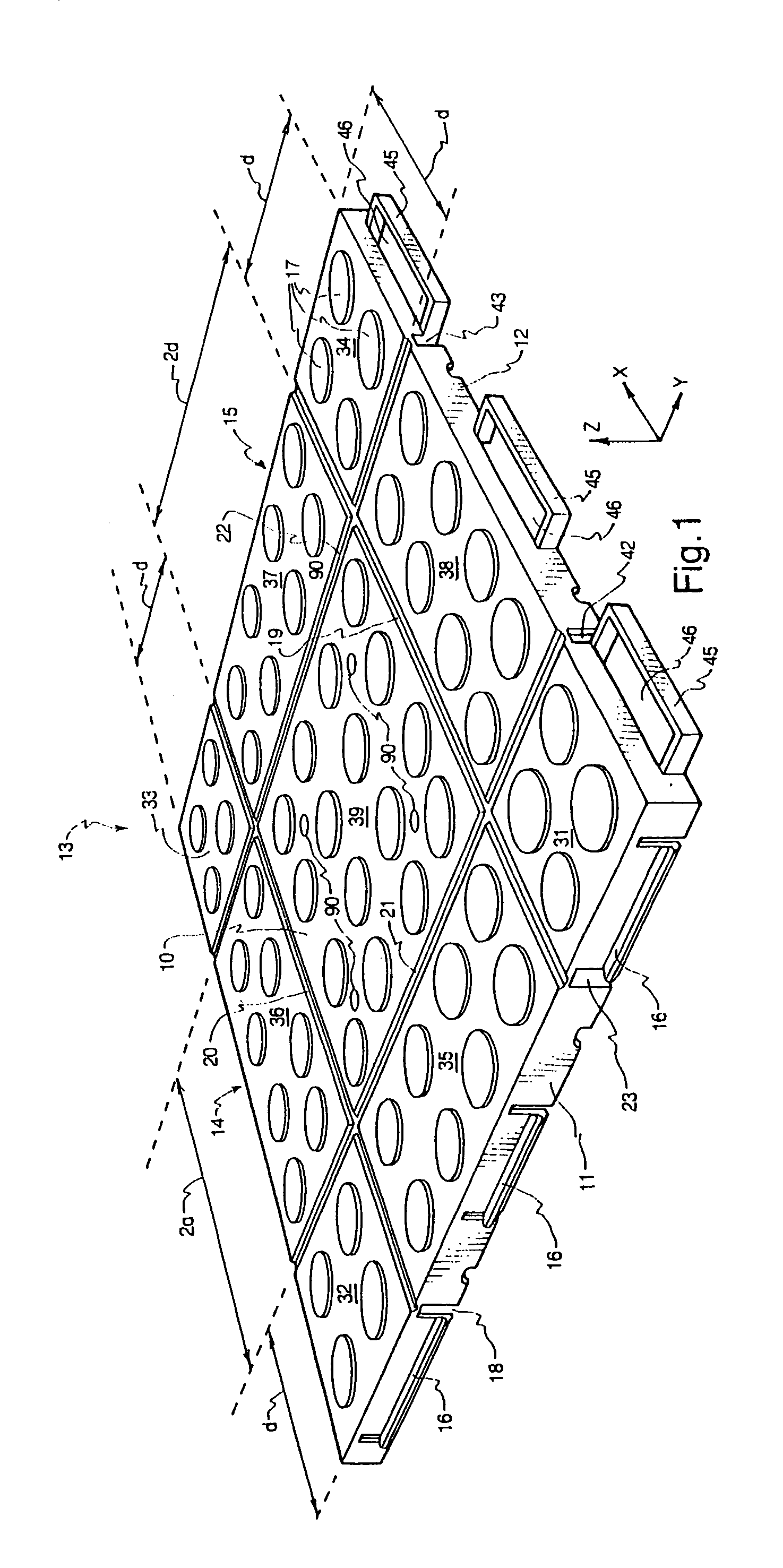

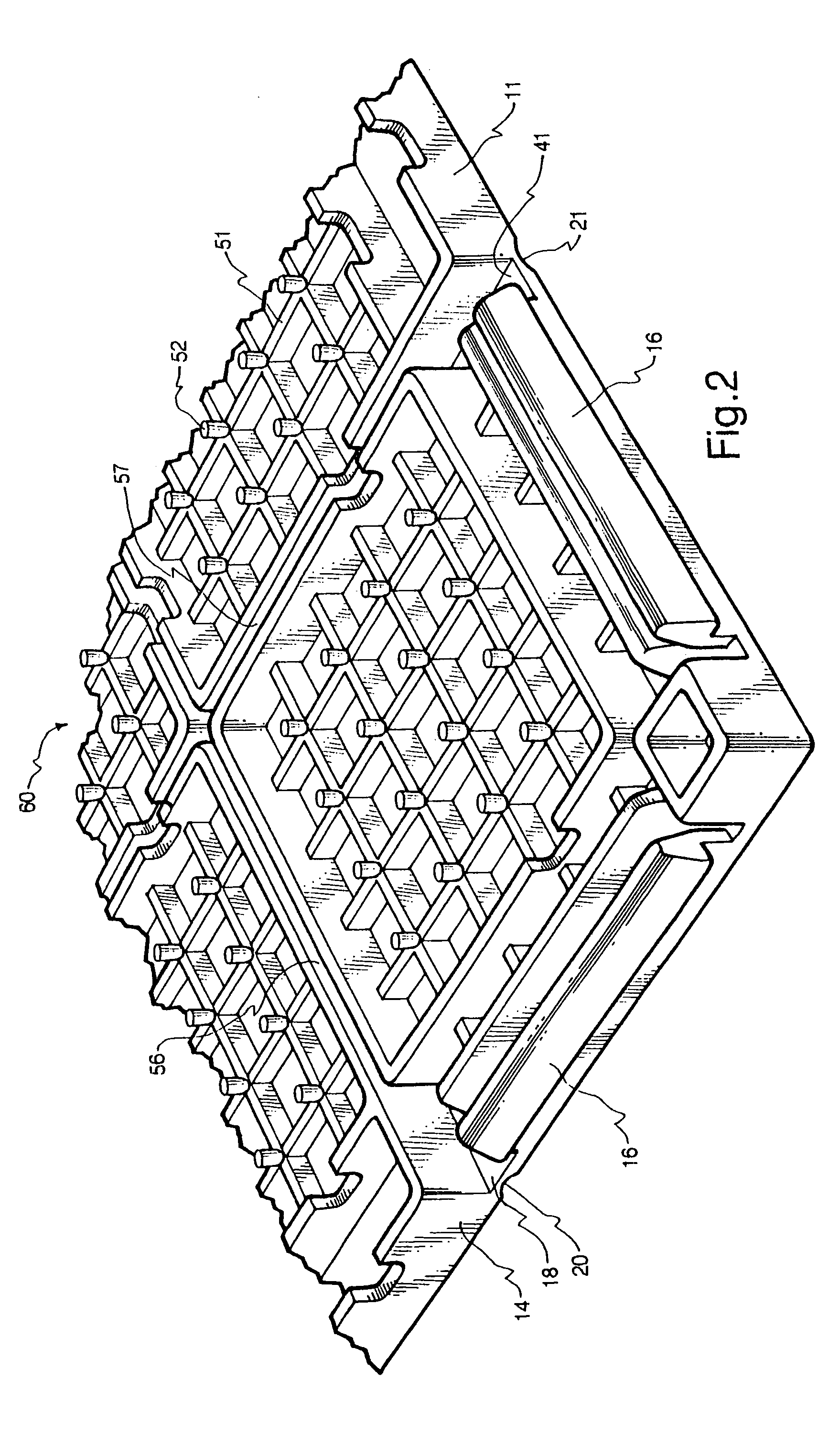

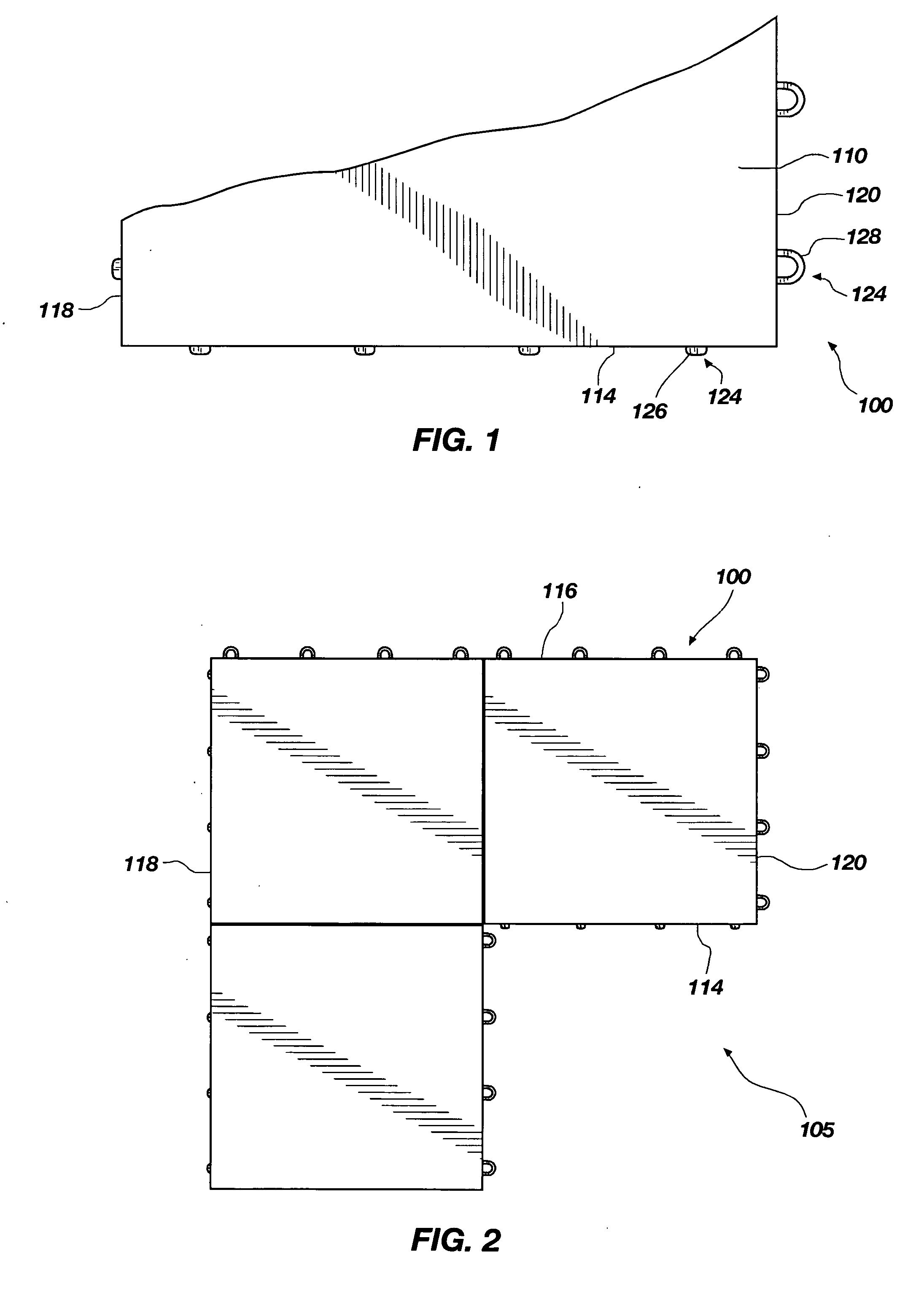

Roll-up floor tile system and method

A plurality of interlocking tile pieces form a generally flat traffic-carrying surface. The tile are locked together in a manner to form a plurality of non-bendable tile joints. The tile includes a hinge or fold line along a first axis and a hinge or fold line along a second axis. The hinges allow the multi-tile traffic carrying surface to be rolled up into a hollow tube from any direction along one of the axes, beginning at any edge of the traffic carrying surface. The rolled-up floor covering is made up of a plurality of tile panels.

Owner:SNAP LOCK INDS

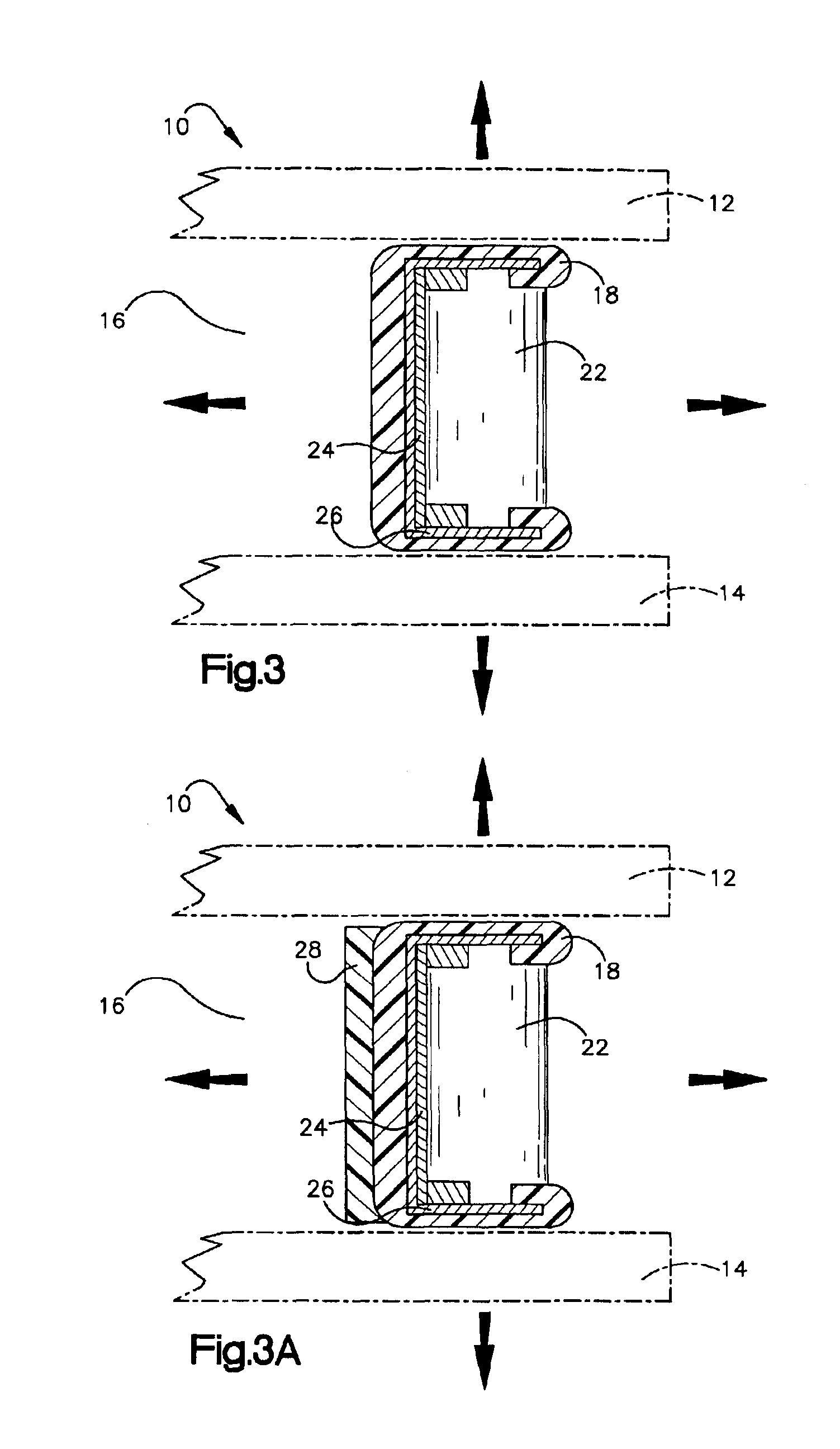

Transition molding

InactiveUS6860074B2Easy to useSmooth transitionTreadsRoof covering using tiles/slatesEngineeringSurface plate

The invention is a joint cover assembly for covering a gap adjacent an edge of a panel that covers a sub-surface, and a method of covering such a gap. The assembly includes a molding having a foot, a first arm, and a second arm. The foot is positioned along a longitudinal axis, and the first arm extends generally perpendicularly from the foot. The second arm extends generally perpendicularly from the foot. A tab depends generally perpendicularly from the first panel engaging surface. At least one of the tab and the foot engage the edge in order to tightly fit within the gap. The method includes the steps of placing the foot in the gap, pressing the respective panel engaging surfaces into contact with respective panels, and configuring at least one of the tab and the foot to cooperate to retain the molding in the gap when the assembly is in an installed condition.

Owner:PERGO

Silicone compositions, methods of manufacture, and articles formed therefrom

A method of manufacture of a silicone grip, comprising coating a solution of a silicone composition onto a substrate surface to form a silicone layer, wherein the solution comprises: a catalyst that promotes cure of the silicone composition, a higher molecular weight organopolysiloxane having at least two alkenyl groups per molecule, a lower molecular weight organopolysiloxane having at least two alkenyl groups per molecule, an organopolysiloxane having at least two silicon-bonded hydrogen atoms per molecule, and a solvent; and curing the silicone layer to form the silicone grip conformable with the substrate surface, wherein the cured silicone layer has a Shore A Durometer of less than or equal to about 60.

Owner:WORLD PROPERTIES

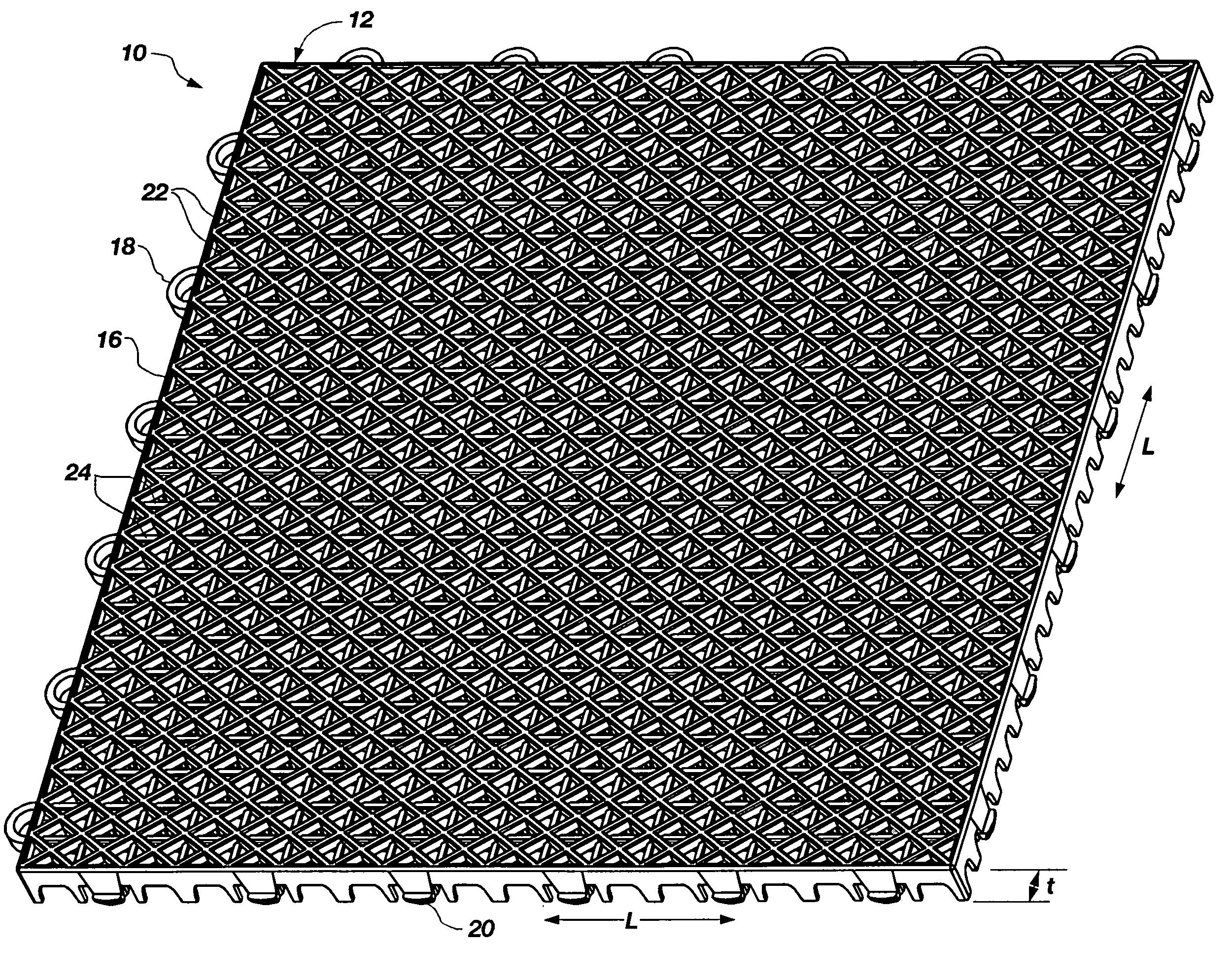

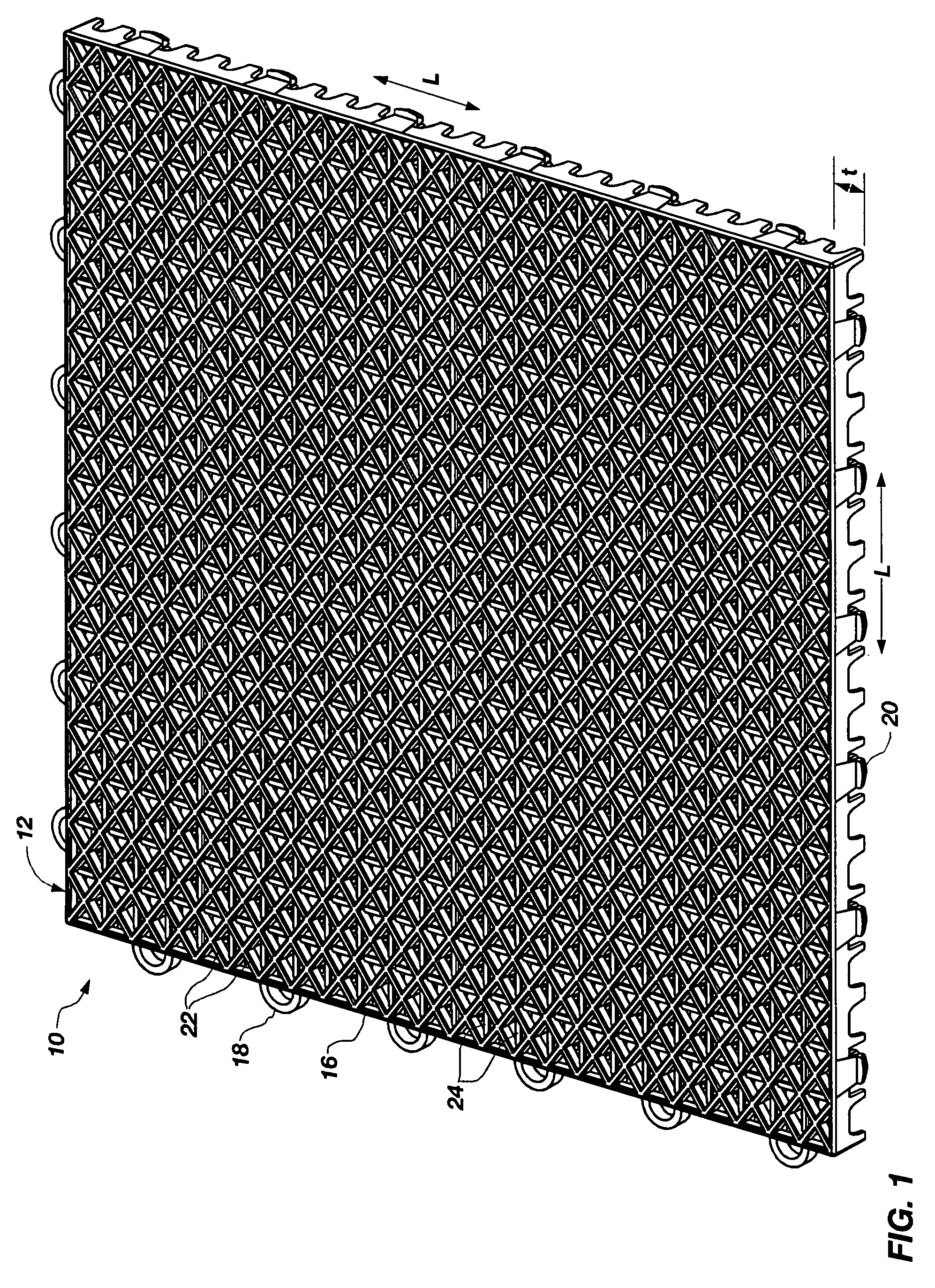

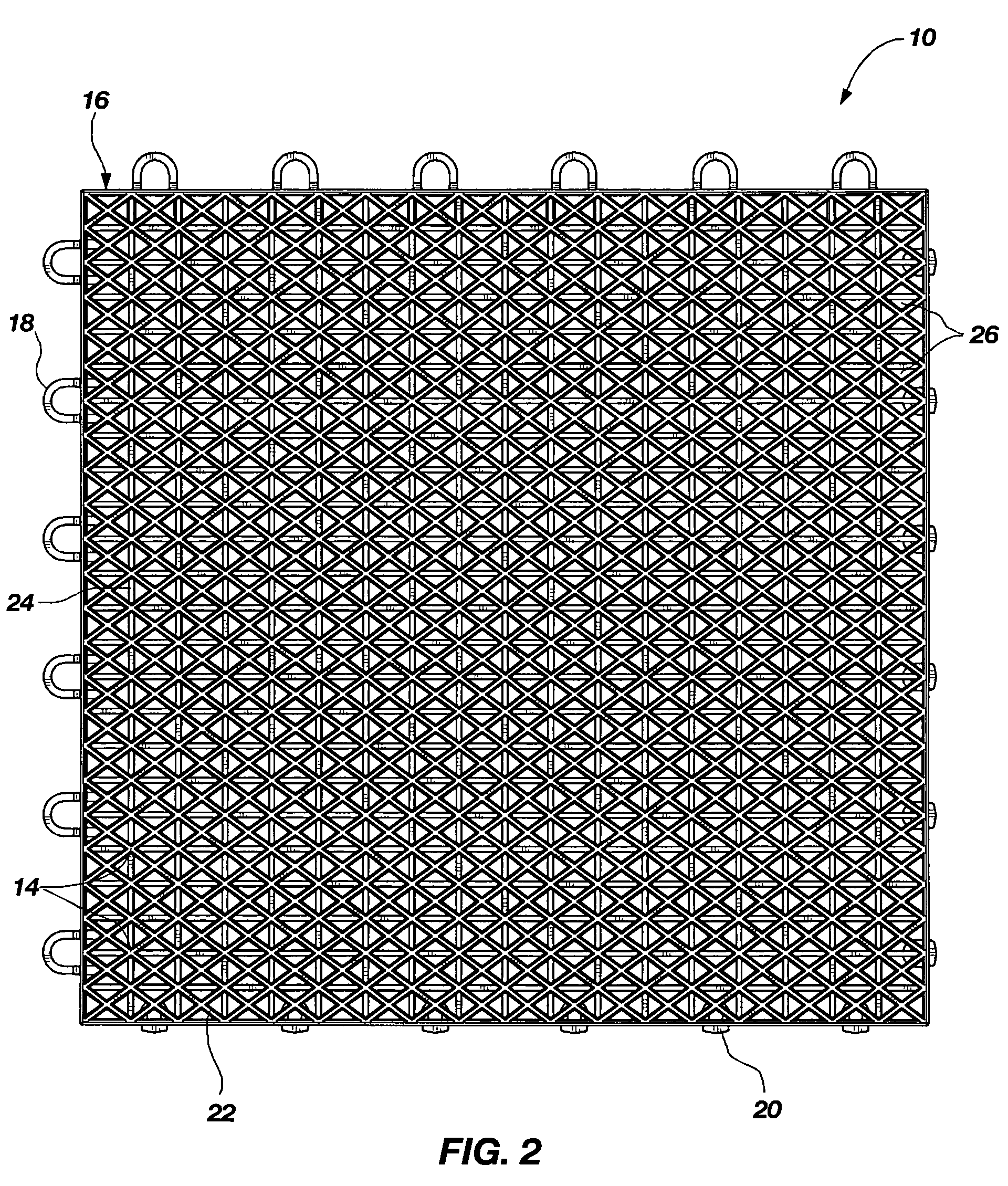

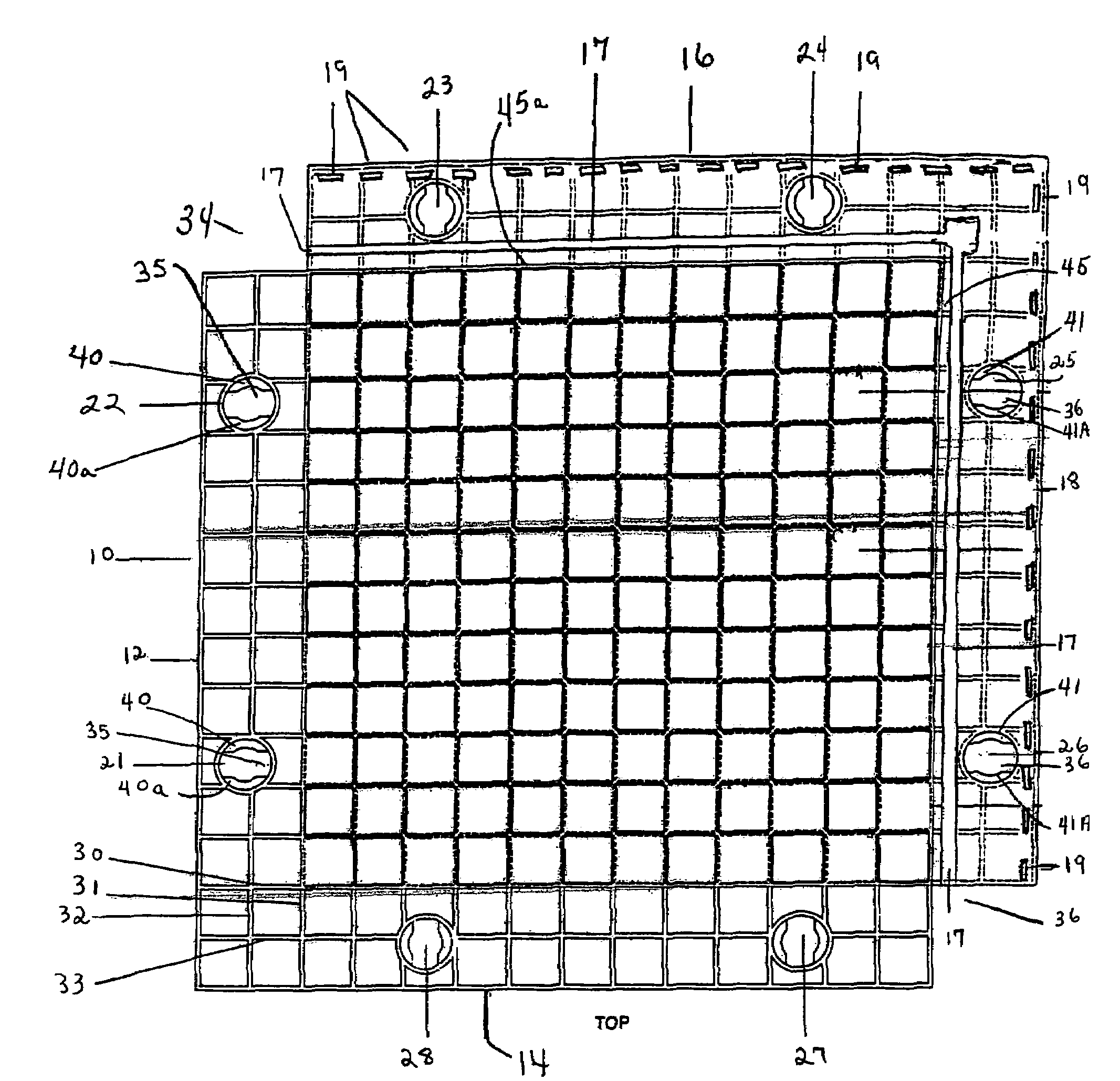

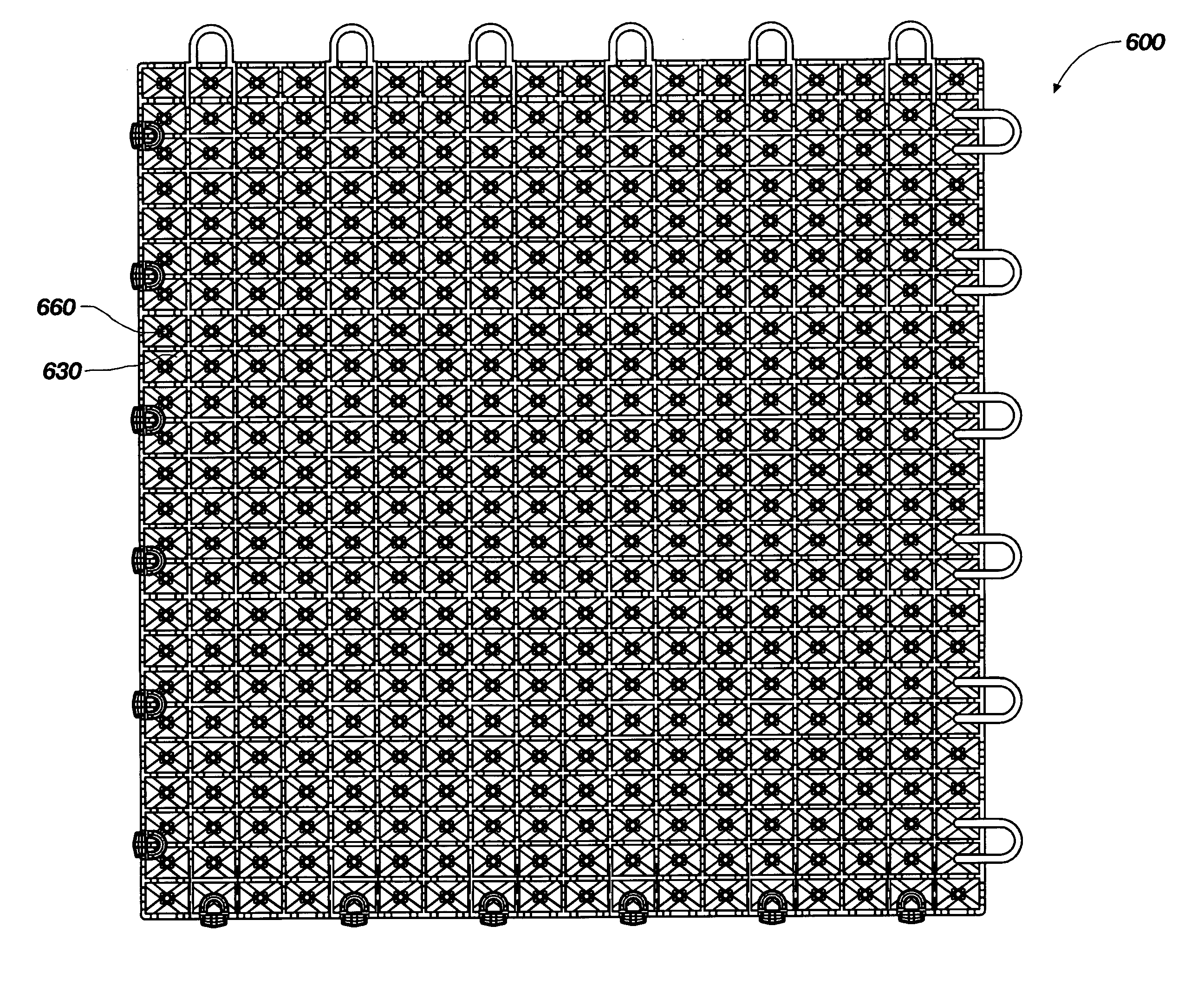

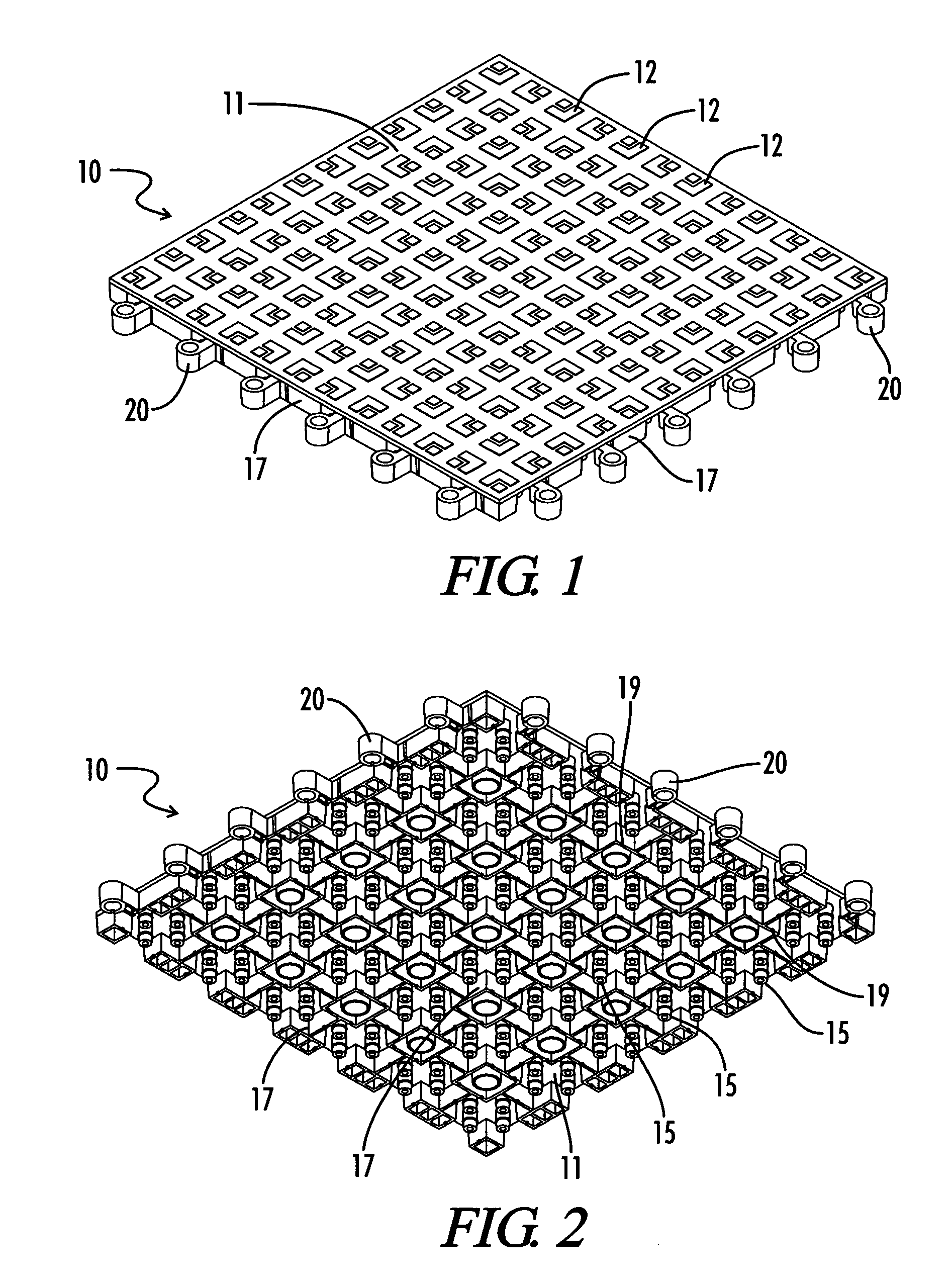

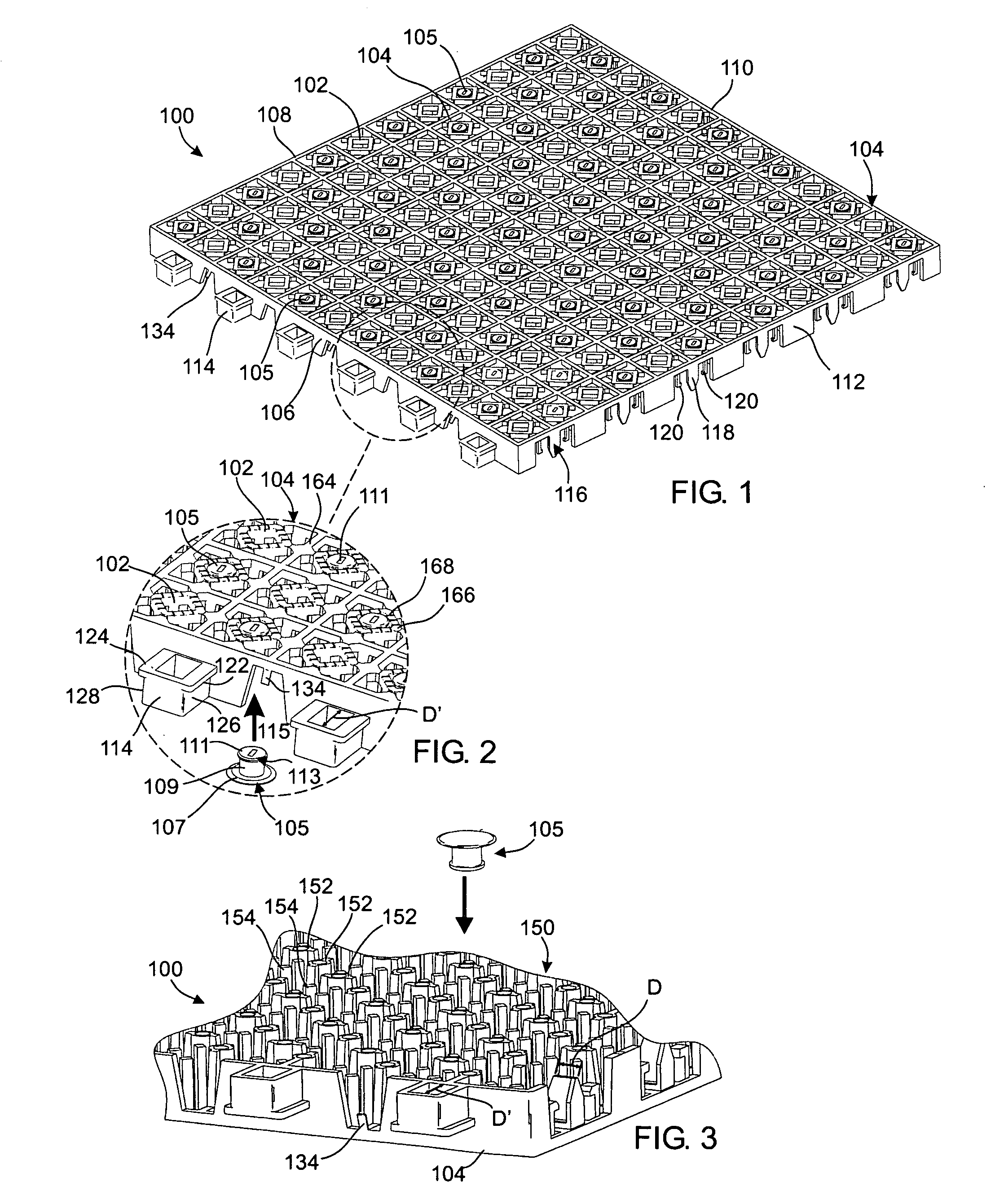

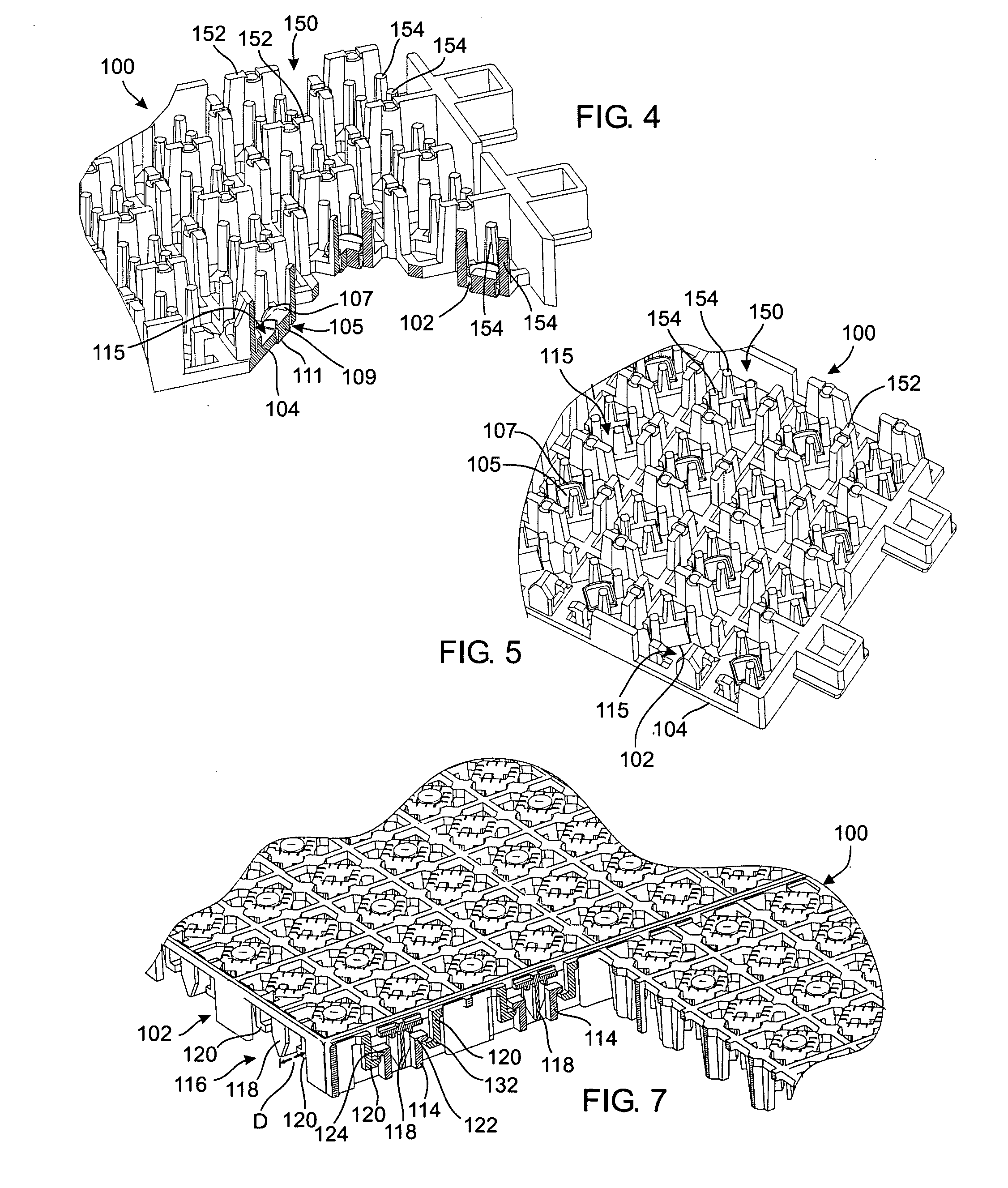

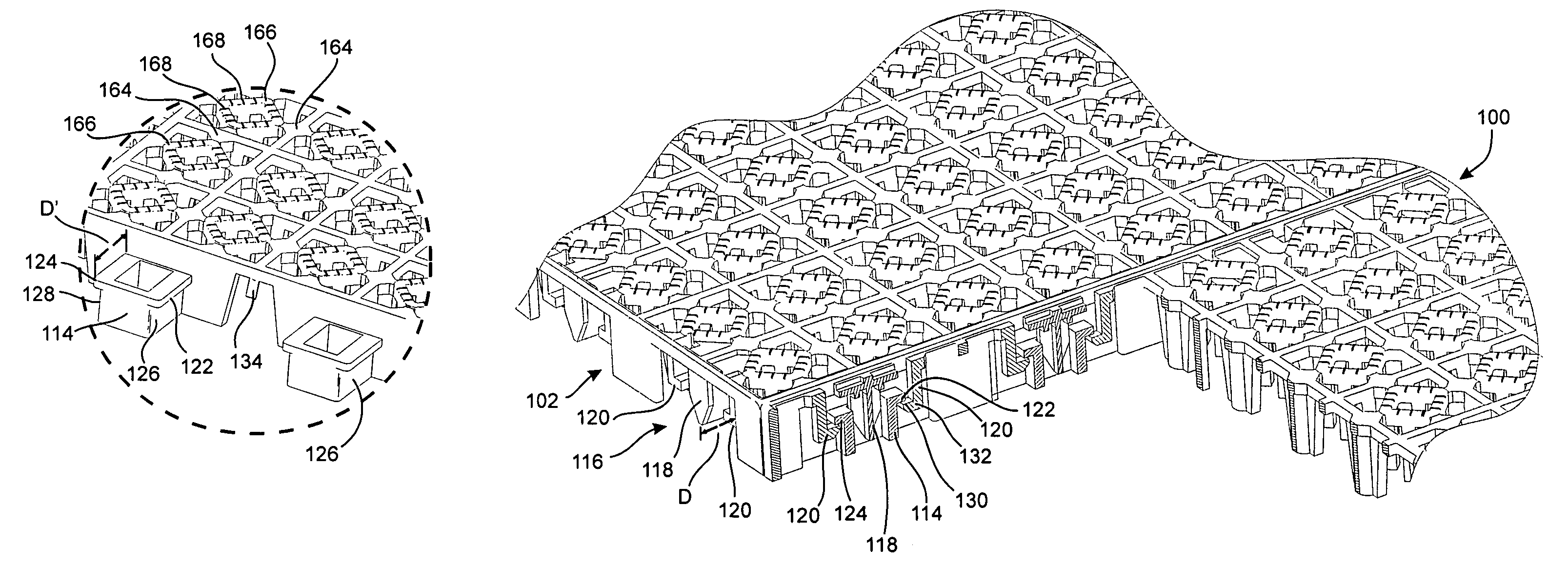

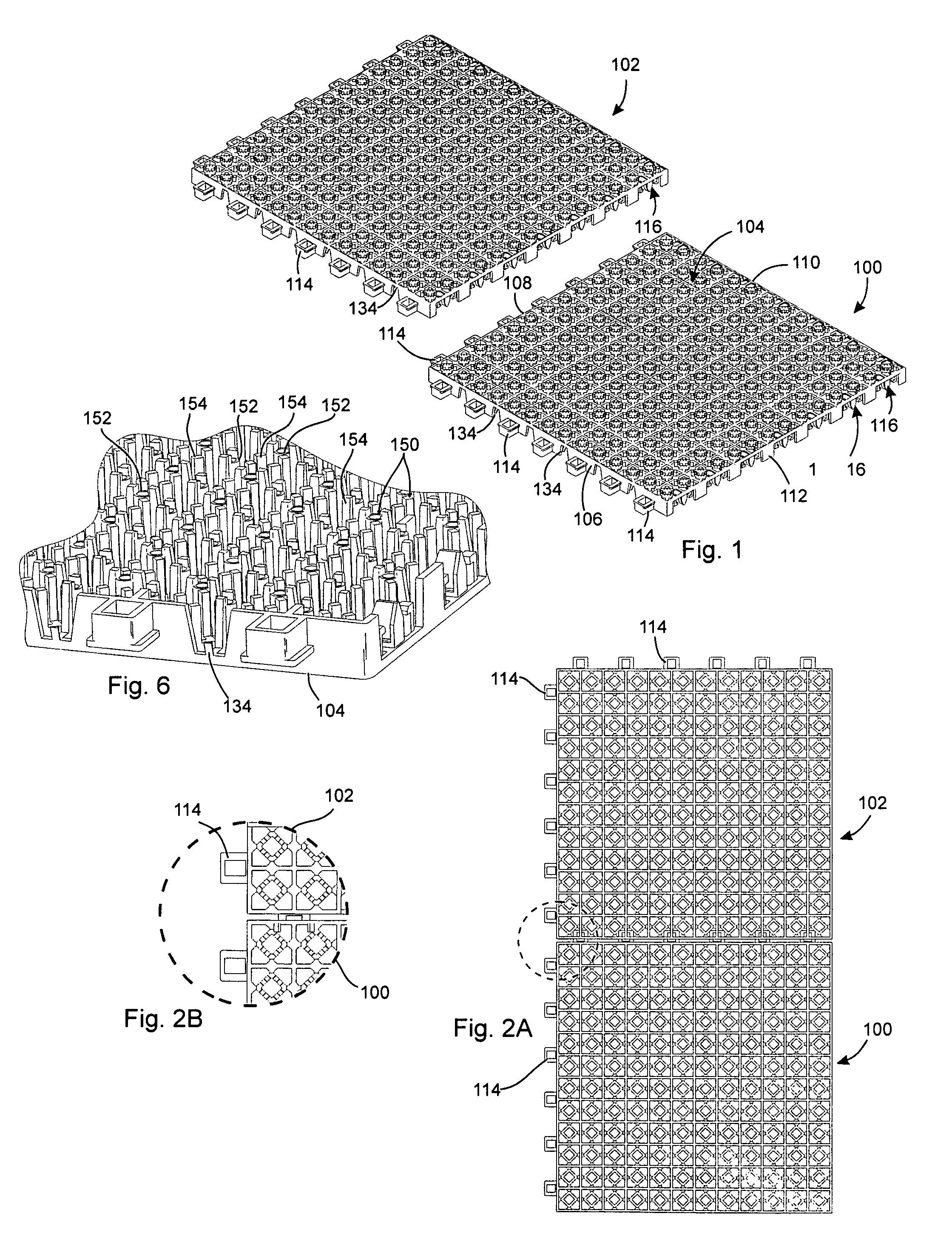

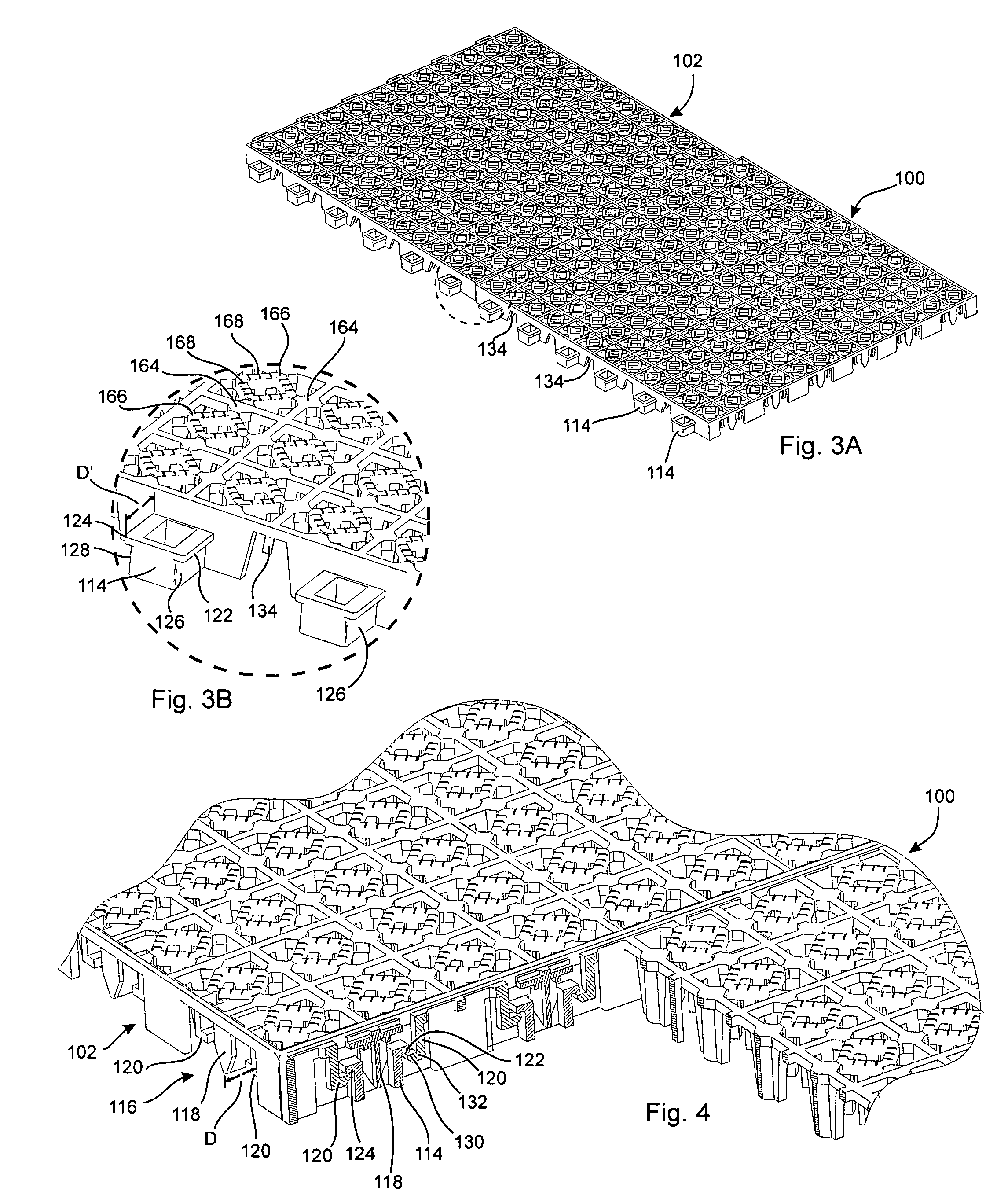

Tile with multiple-level surface

A grid-top floor tile for outdoor use includes a polymer tile having a grid-type top surface with multiple levels, such as a bi-level surface having an upper lattice and a lower lattice oriented generally transverse to the upper lattice. The multiple levels of the surface are preferably integrally formed with one another and provide drainage gaps therethrough. In a bi-level surface configuration, the lower lattice has a top surface below a top surface of the upper lattice, so as to draw residual moisture below the top surface of the upper lattice. The tile further includes a support structure, configured to support the tile on a support surface and provide drainage pathways beneath the top surface. The tile still further comprises various reinforcement members on each of the loop and pin connectors used to interlock the tiles when forming a flooring assembly.

Owner:CONNOR SPORT COURT INT

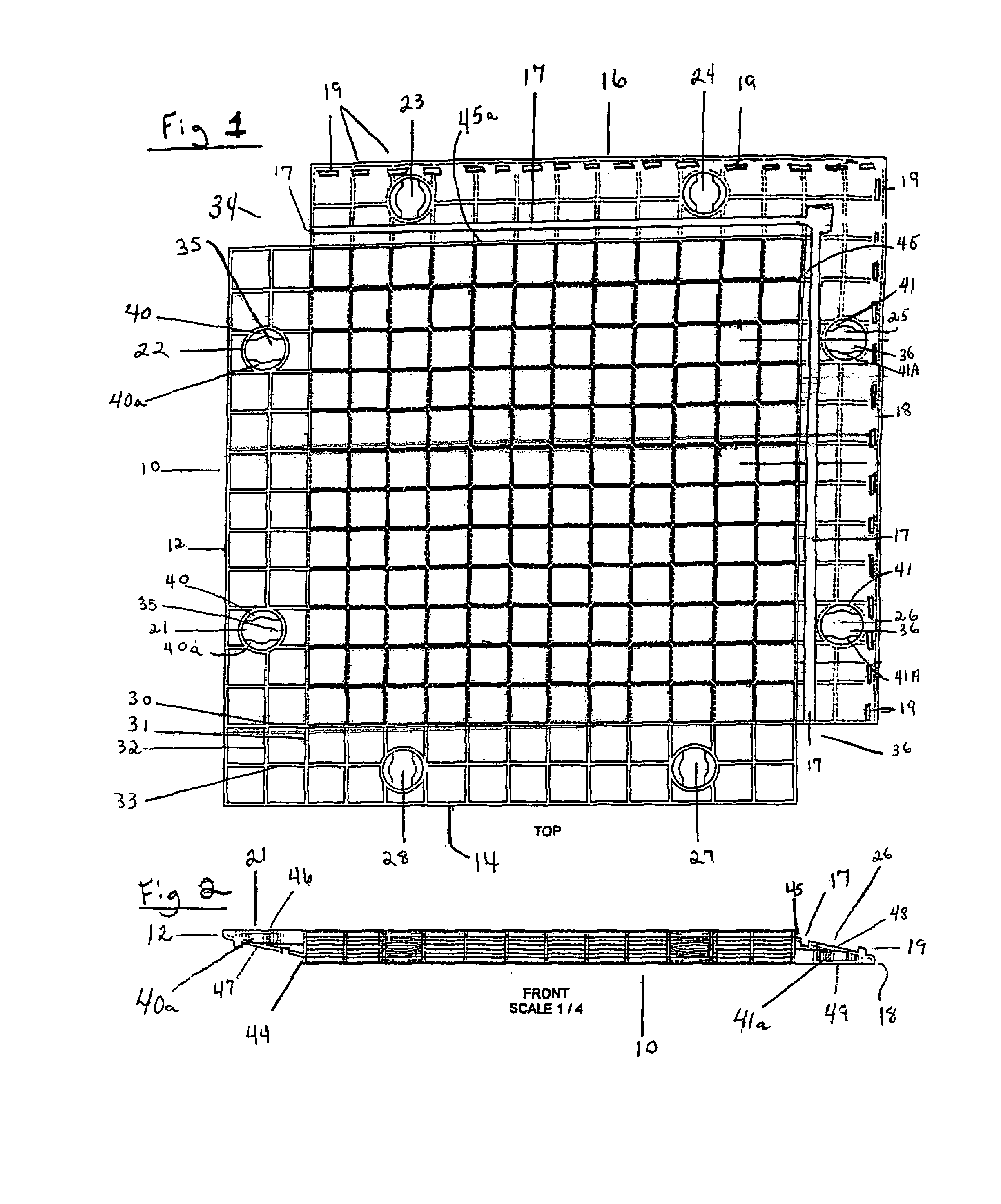

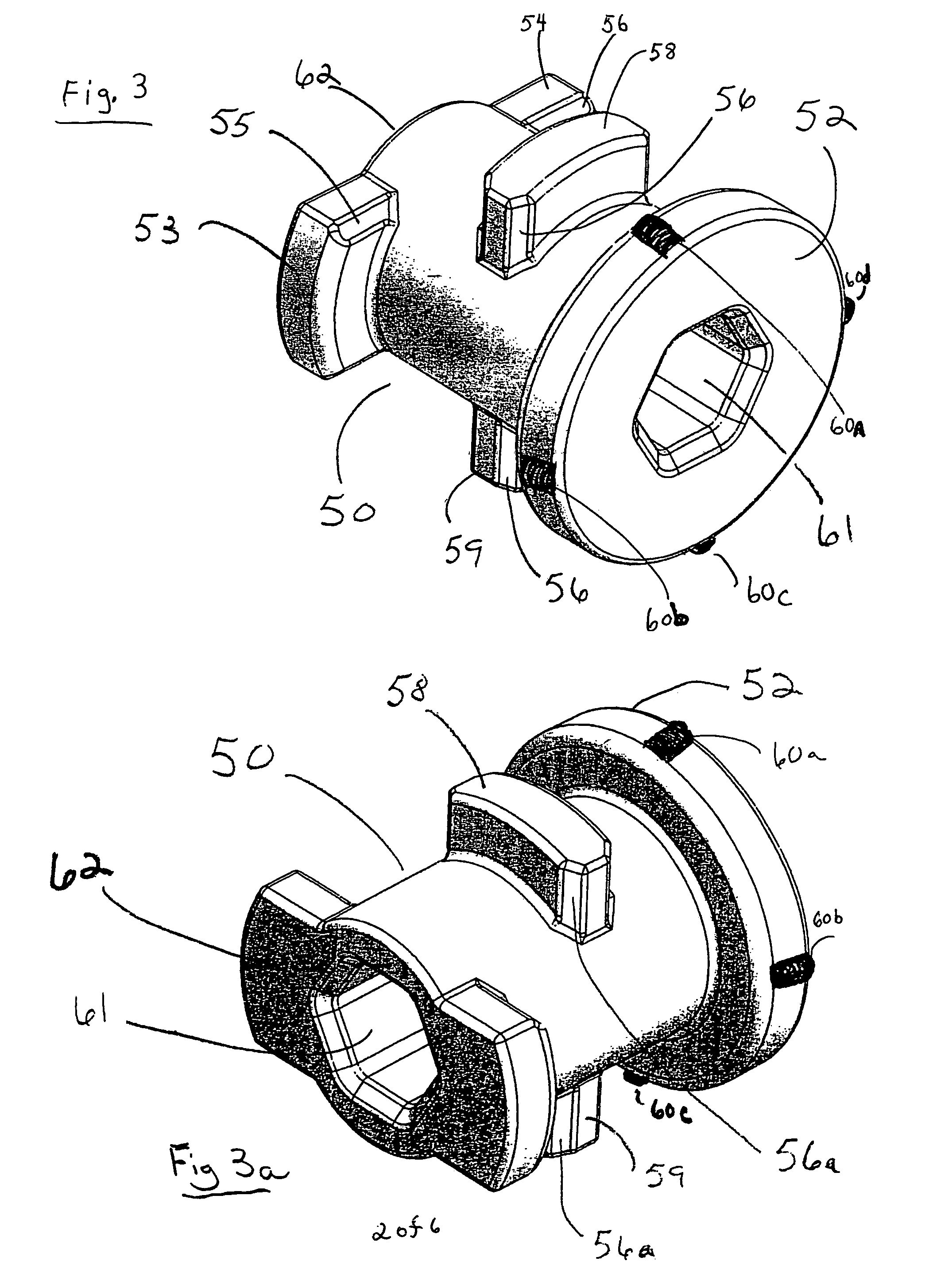

Interlocking mat

An mat system with each mat having sloping lips which overlap with an adjacent mat's sloping lips and are secured by interlocking joints in the mats' lips and / or by captive locking pins to form an easily assembled and interconnected flat surface. In use, opposing ledges forms a slot within holes in the top overlapping lips to receive a captive locking pin. The pin is captive by mid body prongs which fix underneath the ledges in a mat's upper lip's holes, and the pin locks and unlocks with rotary turning of the pin resulting in the pin's keeper feet fixing underneath the similar ledges in the holes of the lower lip of an adjacent mat.

Owner:SOLOCO LLC

Modular construction element

InactiveUS6199340B1Easily assembled togetherEasy to assembleConstruction materialTreadsEngineeringModular structure

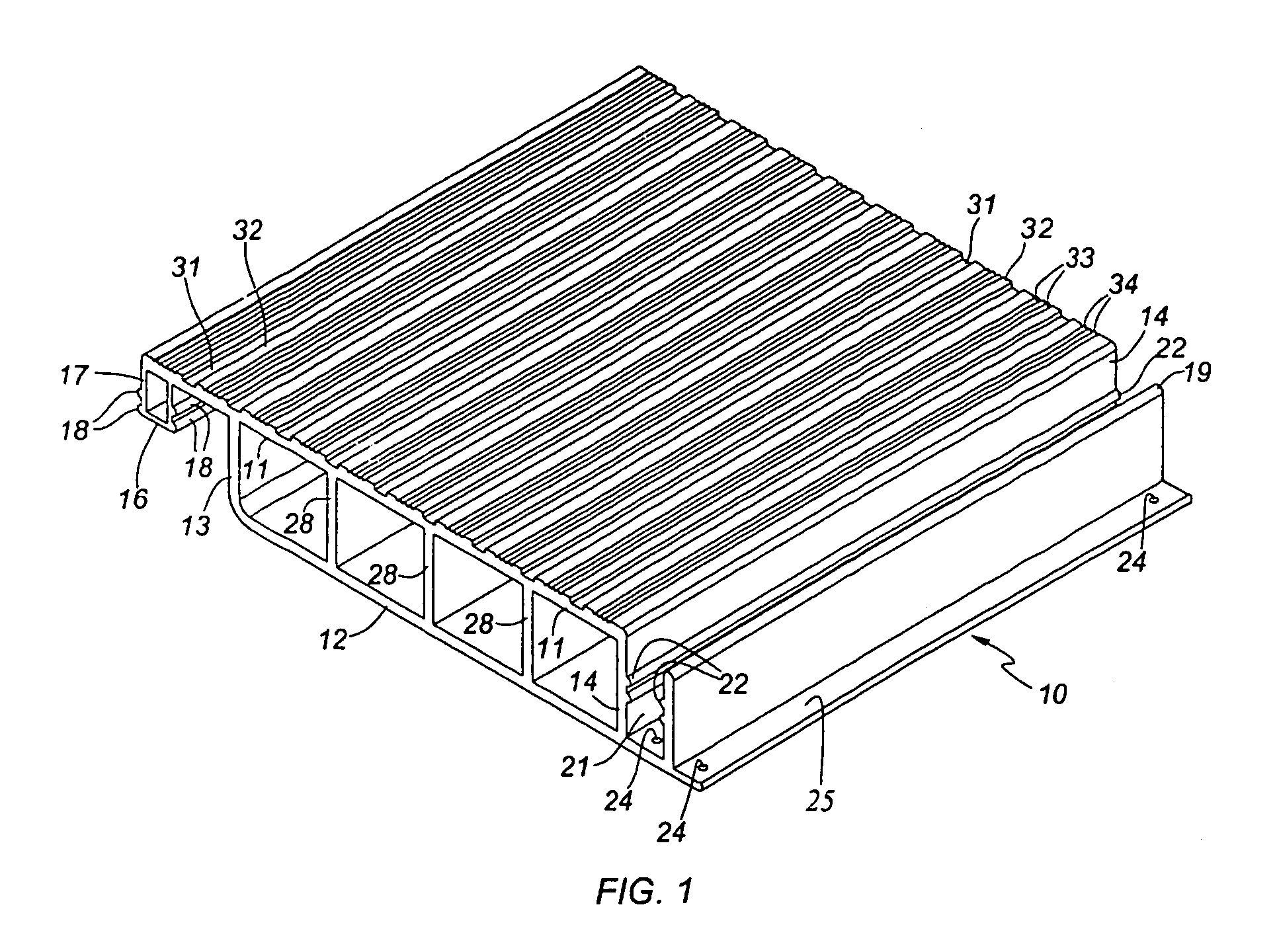

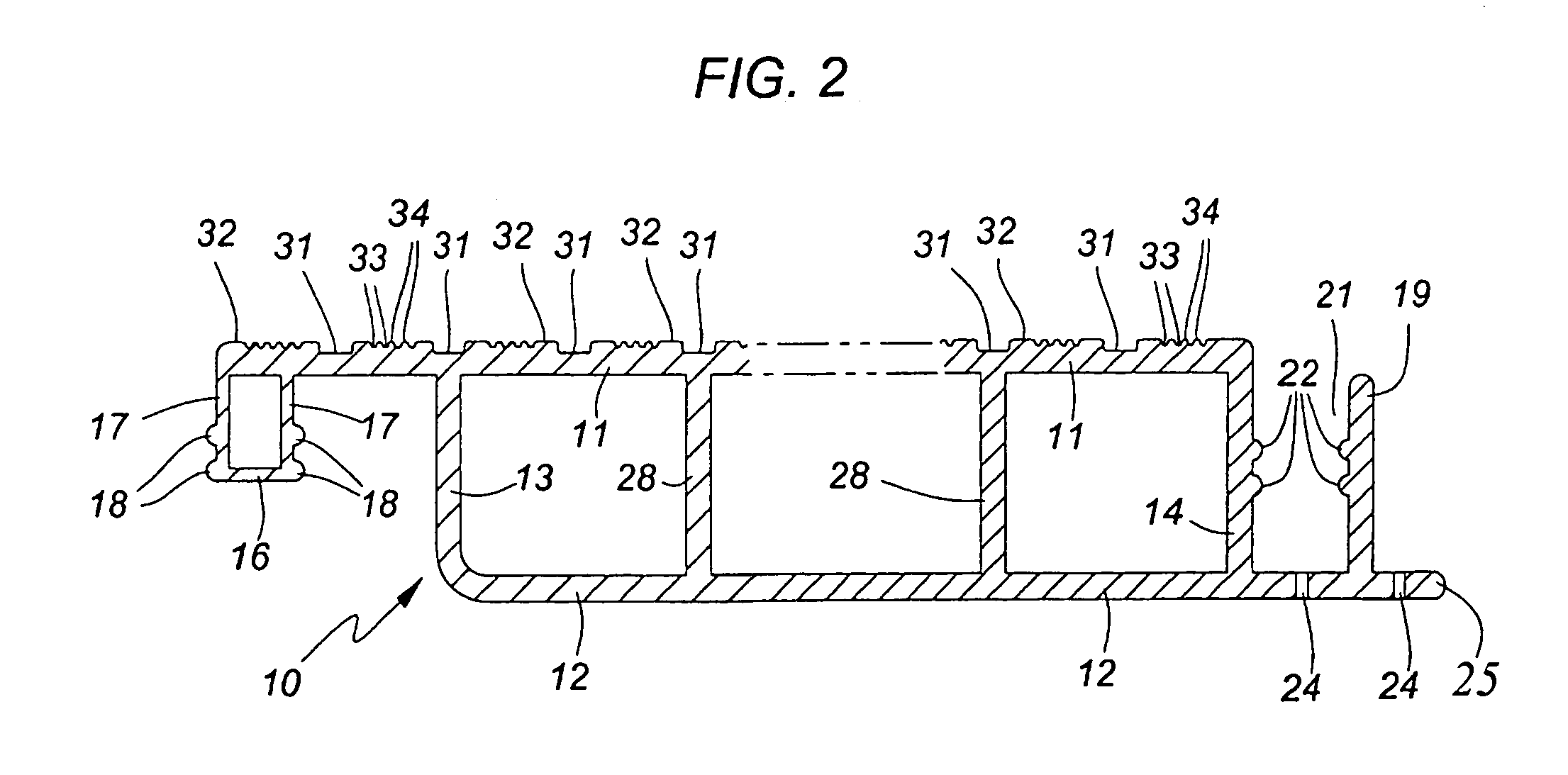

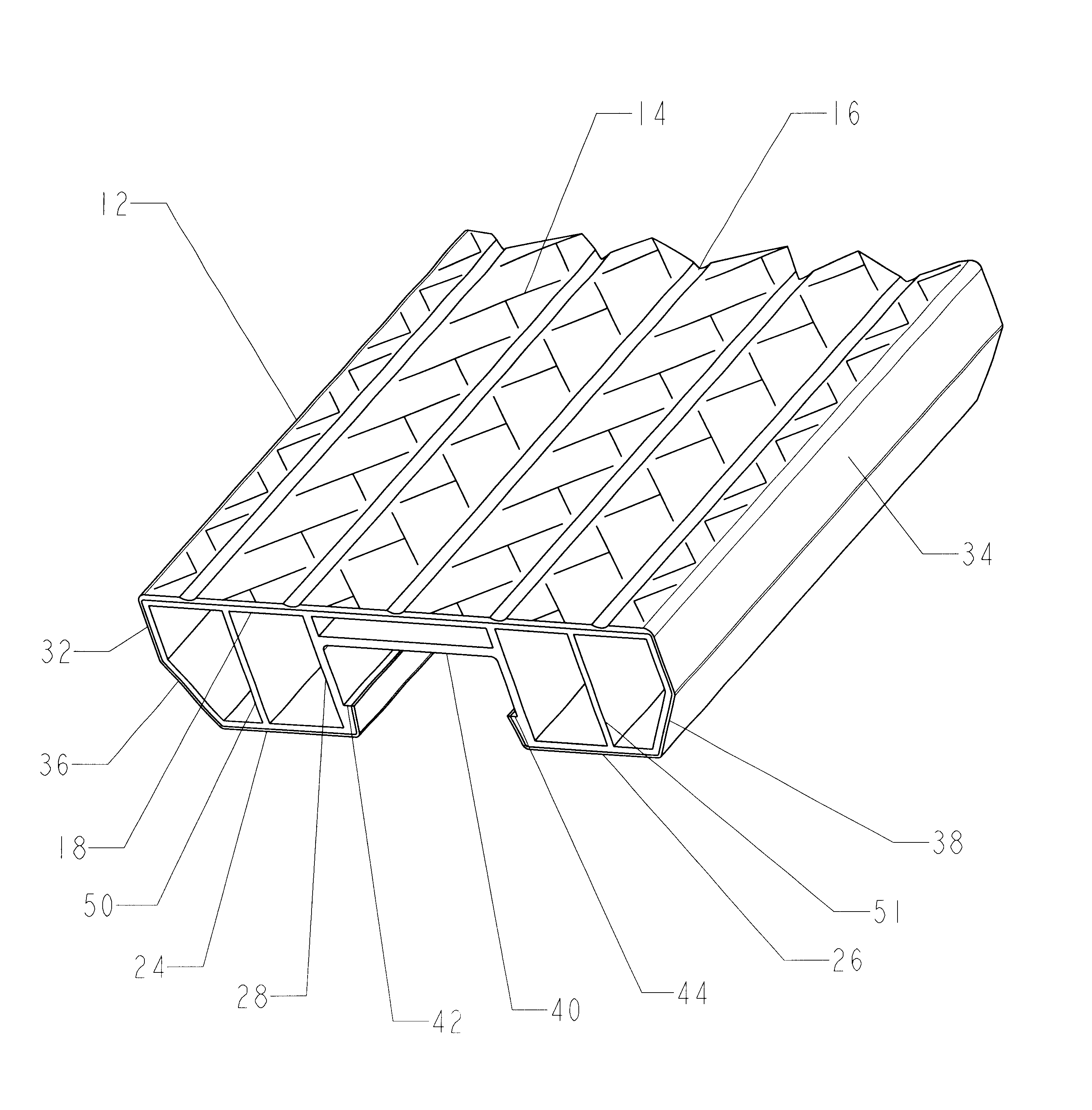

An elongate modular decking plank is provided for assembly on a supporting subfloor together with a plurality of like planks to form a decking structure. The decking plank has a top wall spaced-apart from a bottom wall, and opposing laterally spaced downwardly converging side walls interconnecting the top and bottom walls. An integrally-formed flange extends outwardly from the bottom wall on one of said sides of the decoding plank. The flange includes a fastening portion for receiving fasteners therethrough to the supporting subfloor to mount the decking plank on the supporting subfloor, and a connecting portion for connecting the plank to an adjacent like plank in a manner which permits limited lateral and angular adjustment between adjacent planks. The plank is preferably extruded from high-impact polymeric material, such as PVC plastic.

Owner:L B PLASTICS

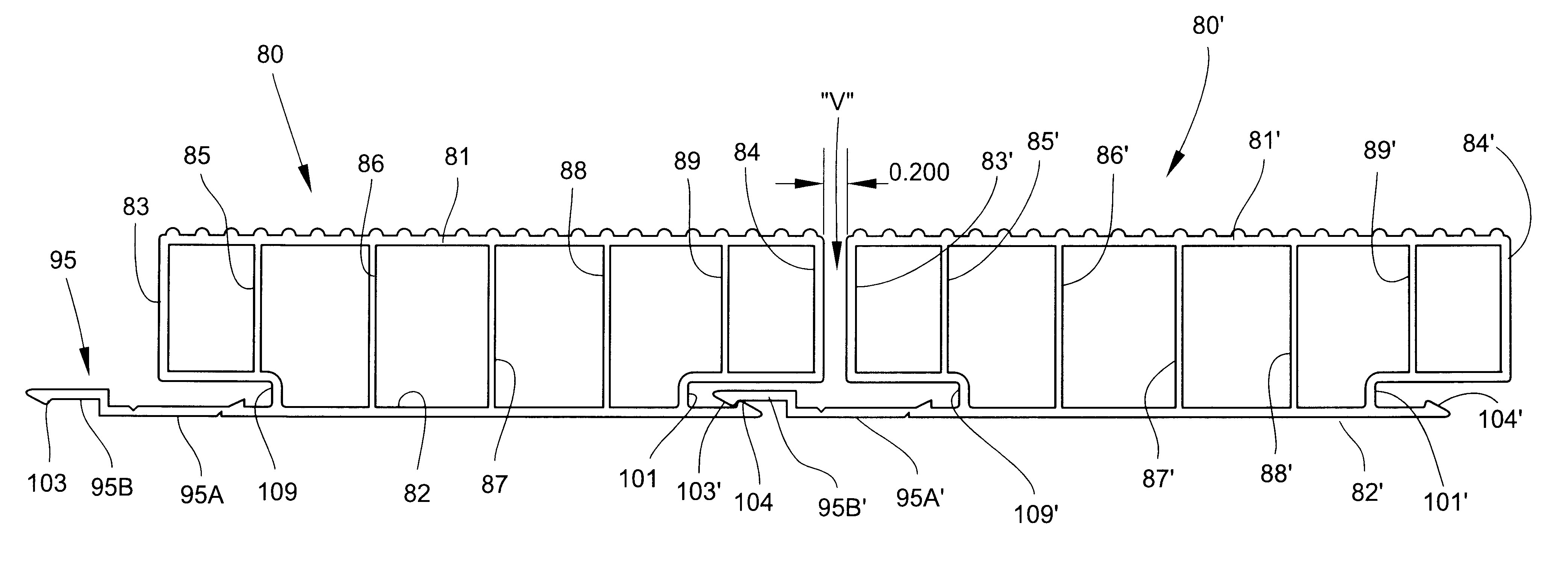

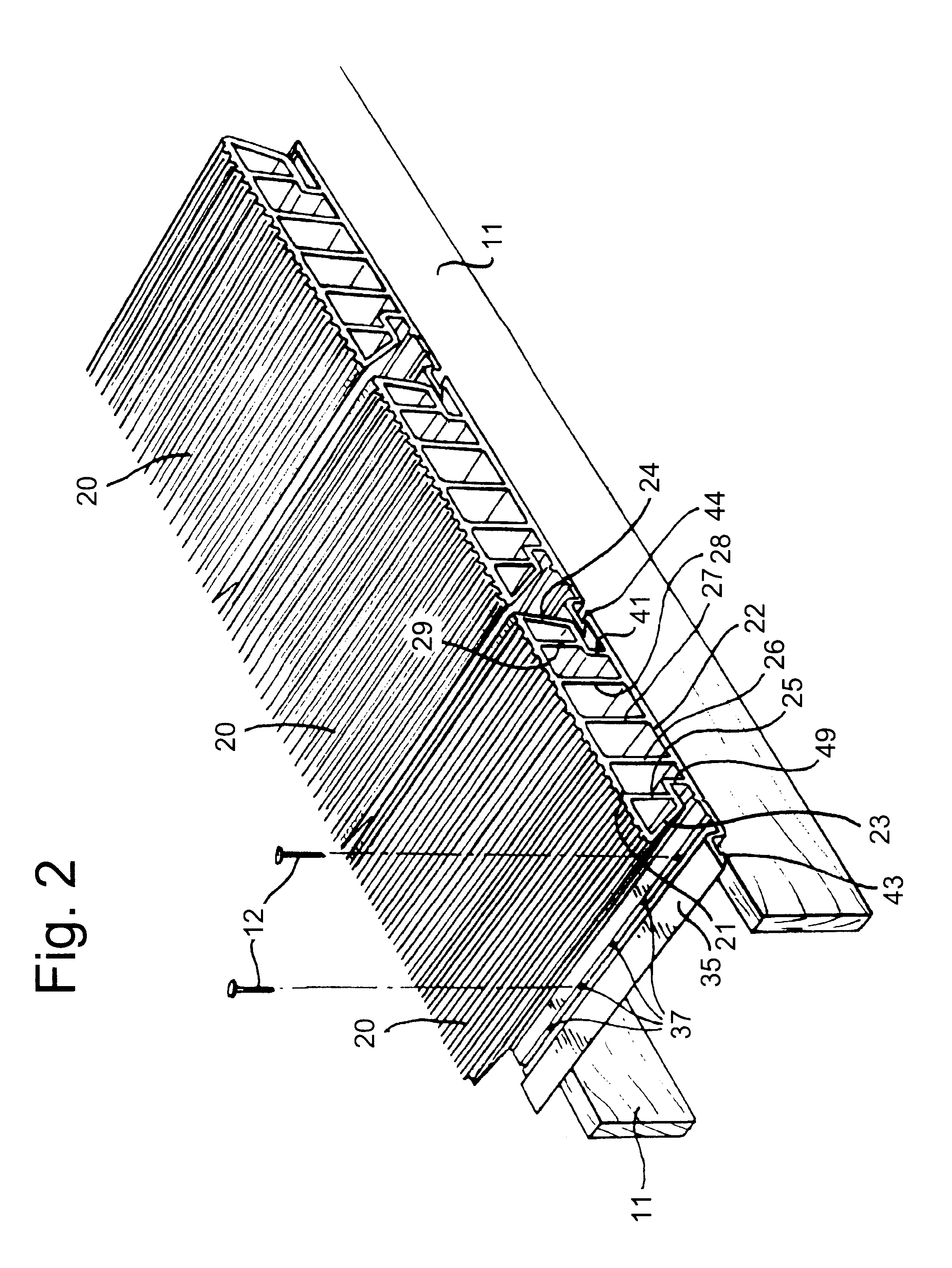

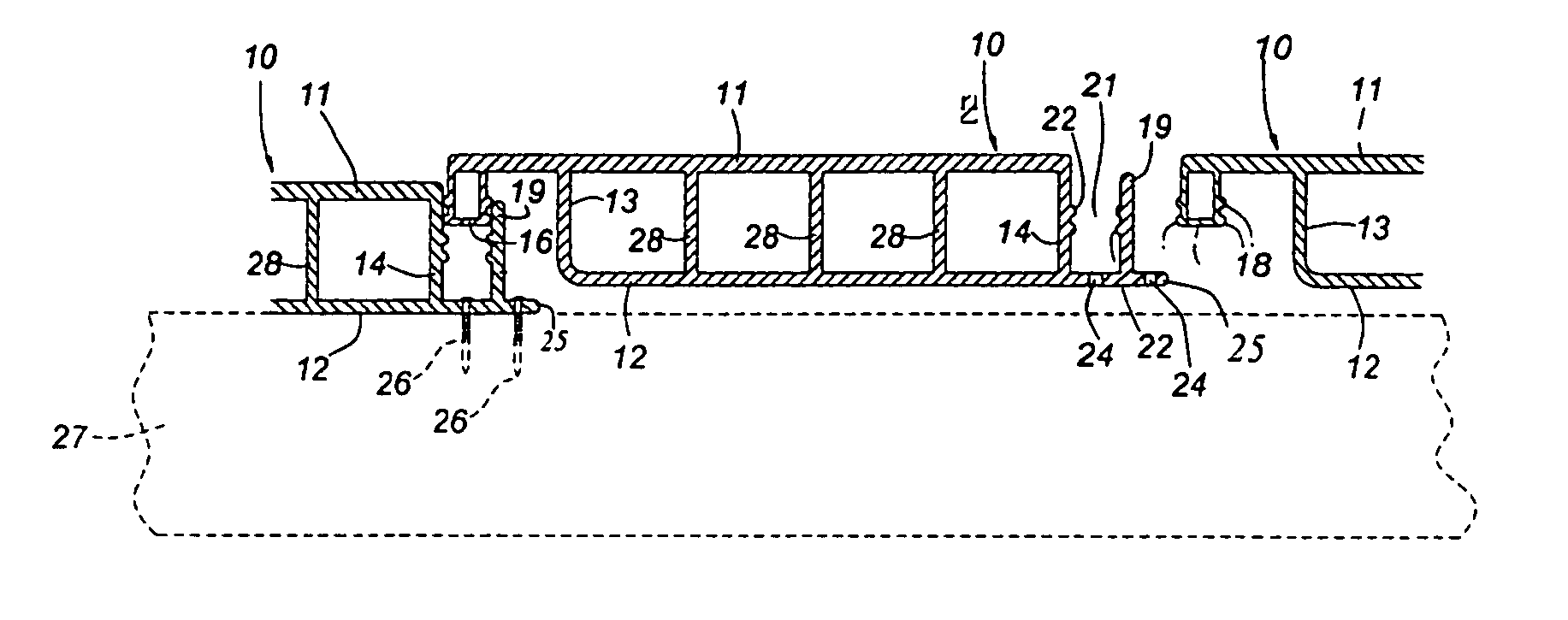

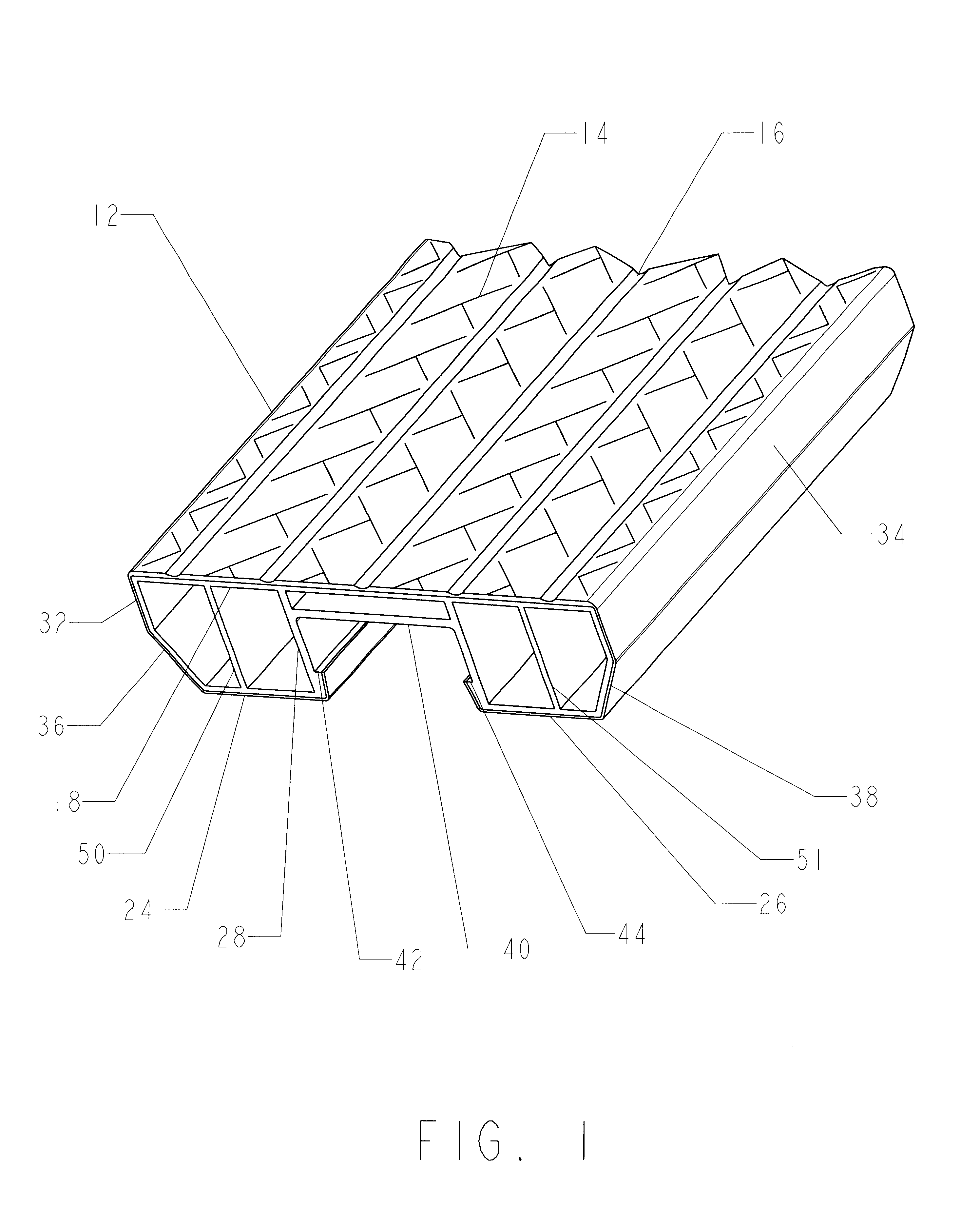

Modular decking planks

A decking system for placement on a subassembly having at least two spaced apart joists. A plurality of tubular elements for placement in lateral interlocking engagement with each other transversely of and spanning the distance between the joists. Each of the elements has a top portion, a bottom portion, and first and second side walls connecting said top and bottom portions. The top portion extends laterally beyond the first side wall and has formed thereon a downwardly extending longitudinal flange. The bottom portion extends laterally beyond the second side wall and has formed thereon an upwardly extending longitudinal wall defining an upwardly opening channel adjacent the second side wall adapted to receive therein in watertight relation the downwardly extending longitudinal flange. The bottom wall extends past the longitudinal flange, with the bottom portion having formed therein a plurality of apertures proximate the second side wall to receive fasteners engaging the joists.

Owner:HOMELAND VINYL PRODS

Modular tile with controlled deflection

A modular tile configured to interlock with multiple tiles to form a modular floor covering over a floor. The tile includes a top surface having a periphery defining side walls extending downward from the top surface, the side walls having a coupling portion configured to couple with other tiles adjacent thereto to form the modular floor covering. The tile also includes a bottom side, opposite the top surface, having a support grid including an array of downward extending polymeric post structures, at least some of the post structures including at least one resilient end portion with a radial end surface configured to be positioned against the floor to facilitate controlled deflection of the post structures. The post structures may comprise primary and secondary post structures, with the secondary post structures limiting the deflection of the primary post structures.

Owner:CONNOR SPORT COURT INT

Floor tile with load bearing lattice

A floor tile for use in a flooring system comprises an upper surface operable for use as a portion of a flooring installation and a support lattice operable to support the upper surface. The support lattice includes a plurality of support members extending downwardly from an underside of the upper surface and terminating in lower sections collectively defining a subfloor contact profile and a plurality of interconnecting members laterally interconnecting two or more of the support members. At least some of the plurality of support members extend downwardly at an oblique angle to the upper surface.

Owner:CONNOR SPORT COURT INT

Interlocking modular floor tile

An interlocking, modular floor tile that comprises a planar member defined by a perimeter having four sides and a top surface, a plurality of downwardly projecting support legs of common length dispersed pattern-wise inside the perimeter of the planar member and coupled with the top surface, and at least one female interlocking connector element that extends outside the perimeter of the planar member for receiving a support leg of a like tile and thereby forming an interlock with the like tile.

Owner:WEARWELL LLC

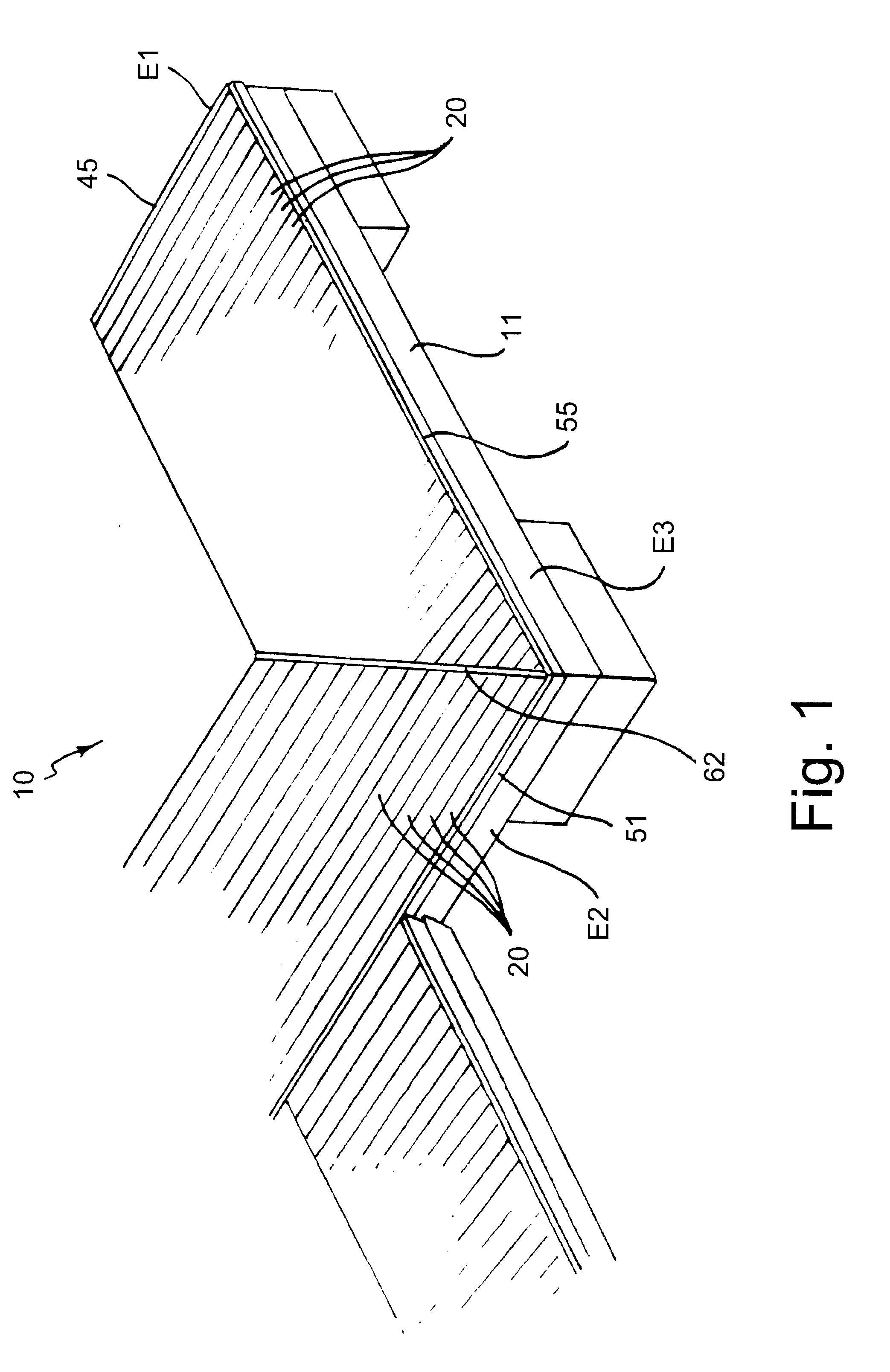

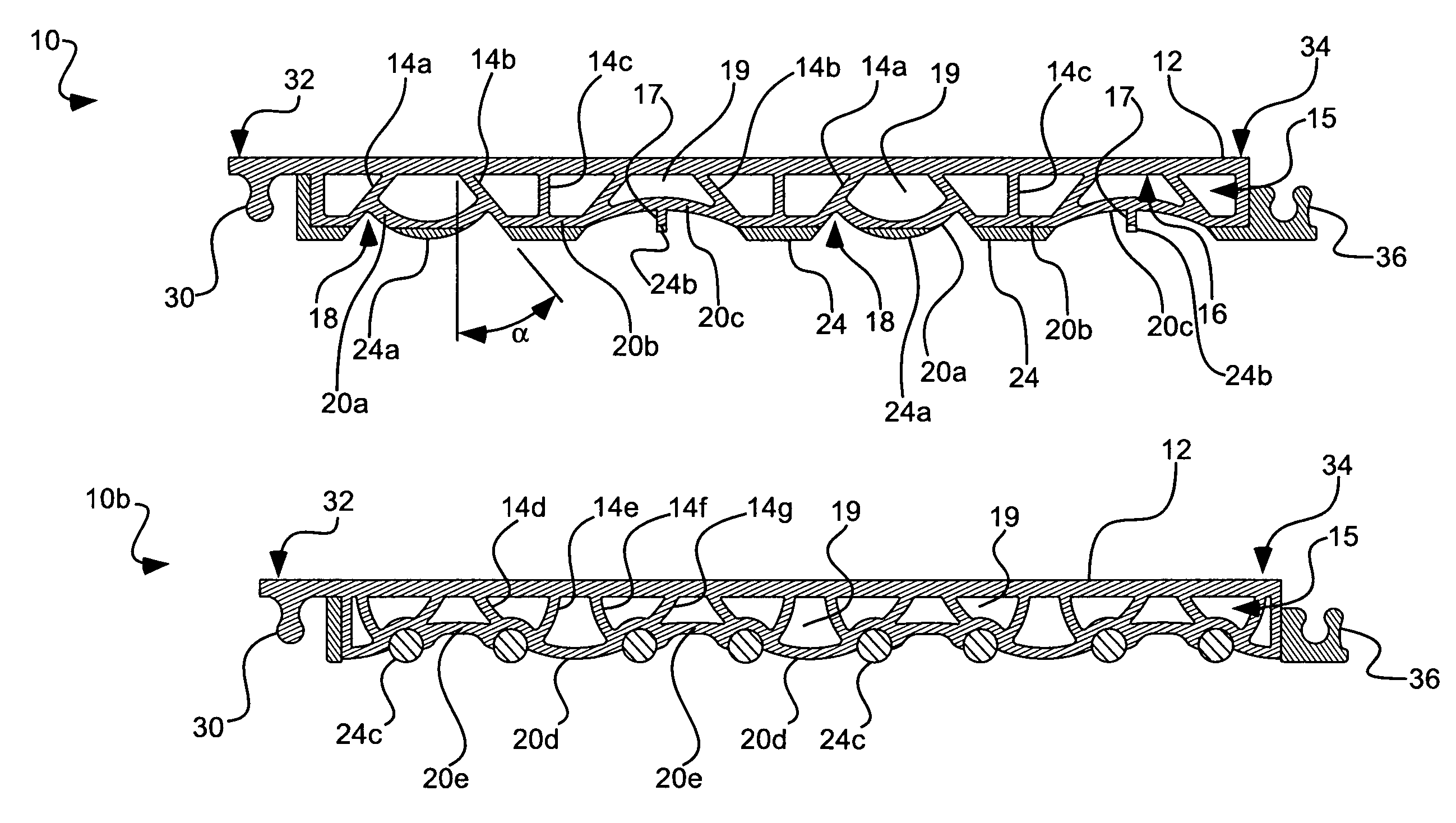

Connecting system for surface coverings

ActiveUS20070022694A1Excellent joint integrity in strengthExcellent in water-sealabilityStrutsTreadsEngineeringWood plank

A system and method for joining floor planks includes two or more planks wherein each plank includes a tongue, a groove, and optionally a shoulder, and optionally a protruding lip, that provide a mechanism for connecting two or more planks together. The tongue can be on the opposing side of each plank from the groove. The groove can be defined between a first flange extending along a first edge of the plank and from one side of the plank, and a second flange extending distally beyond a distal edge of the first flange from the first edge of the plank and from a second side of the plank opposite from the first side. The tongue can be S-shaped to form an interlocking relationship with the groove.

Owner:MANNINGTON MILLS

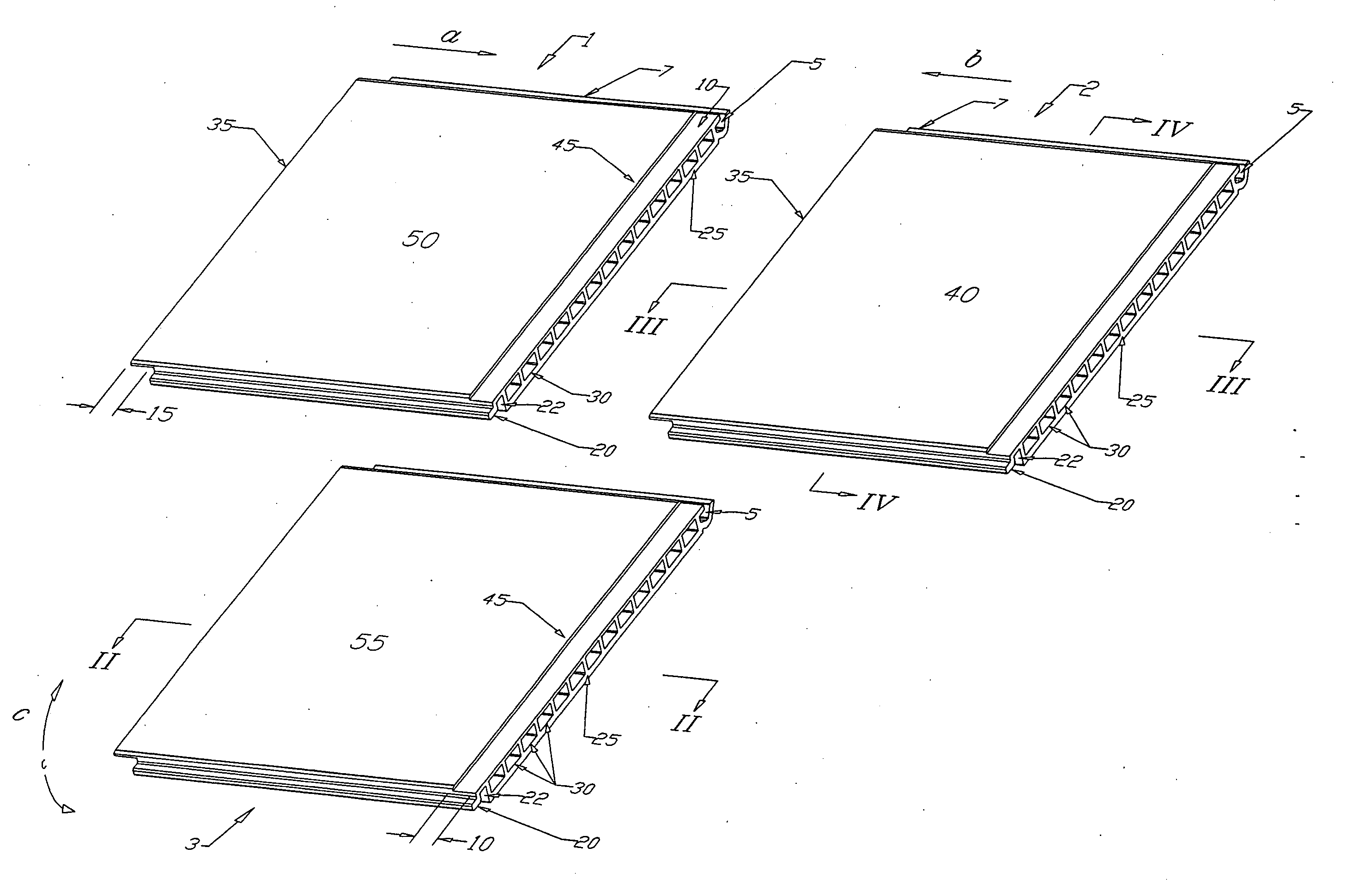

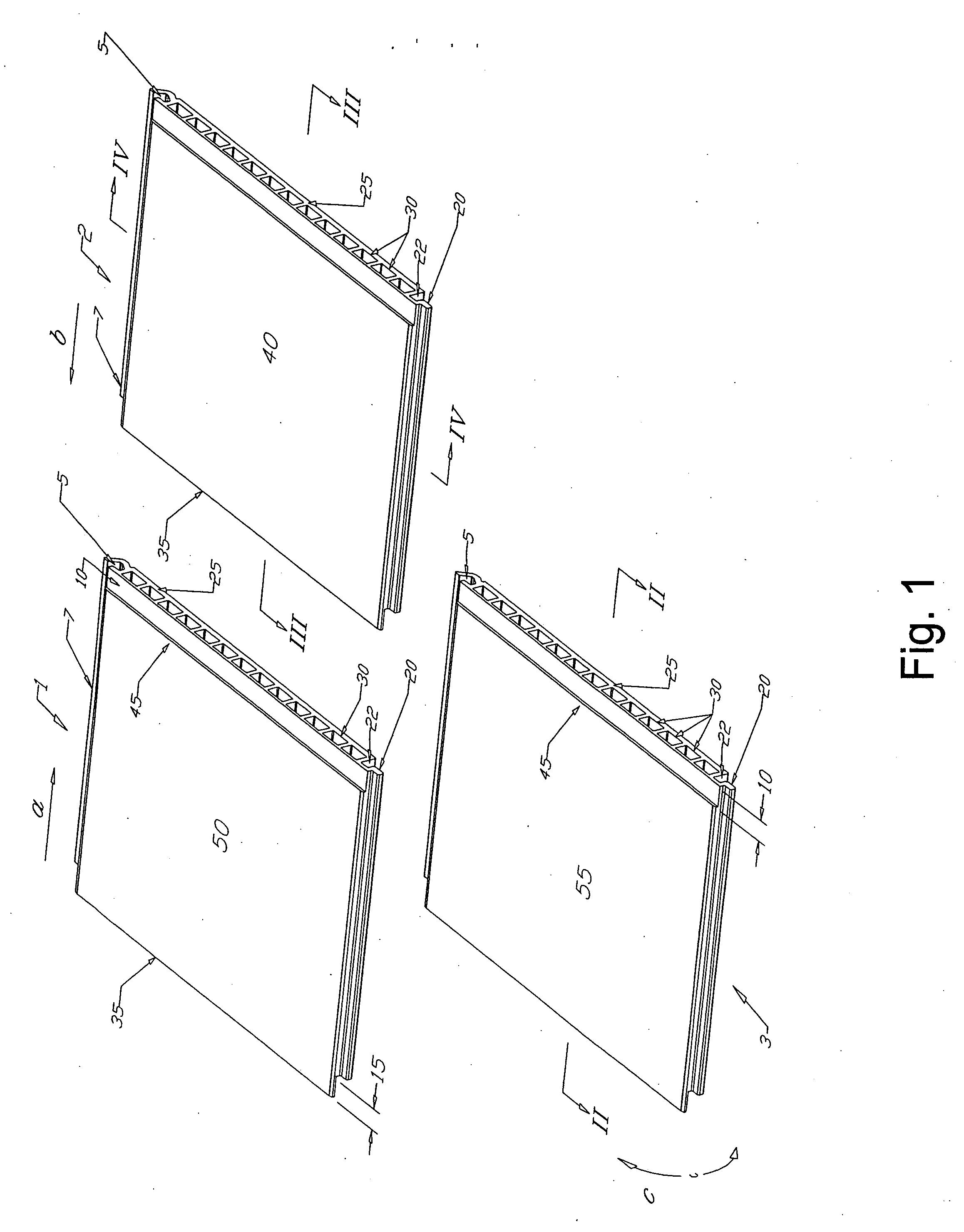

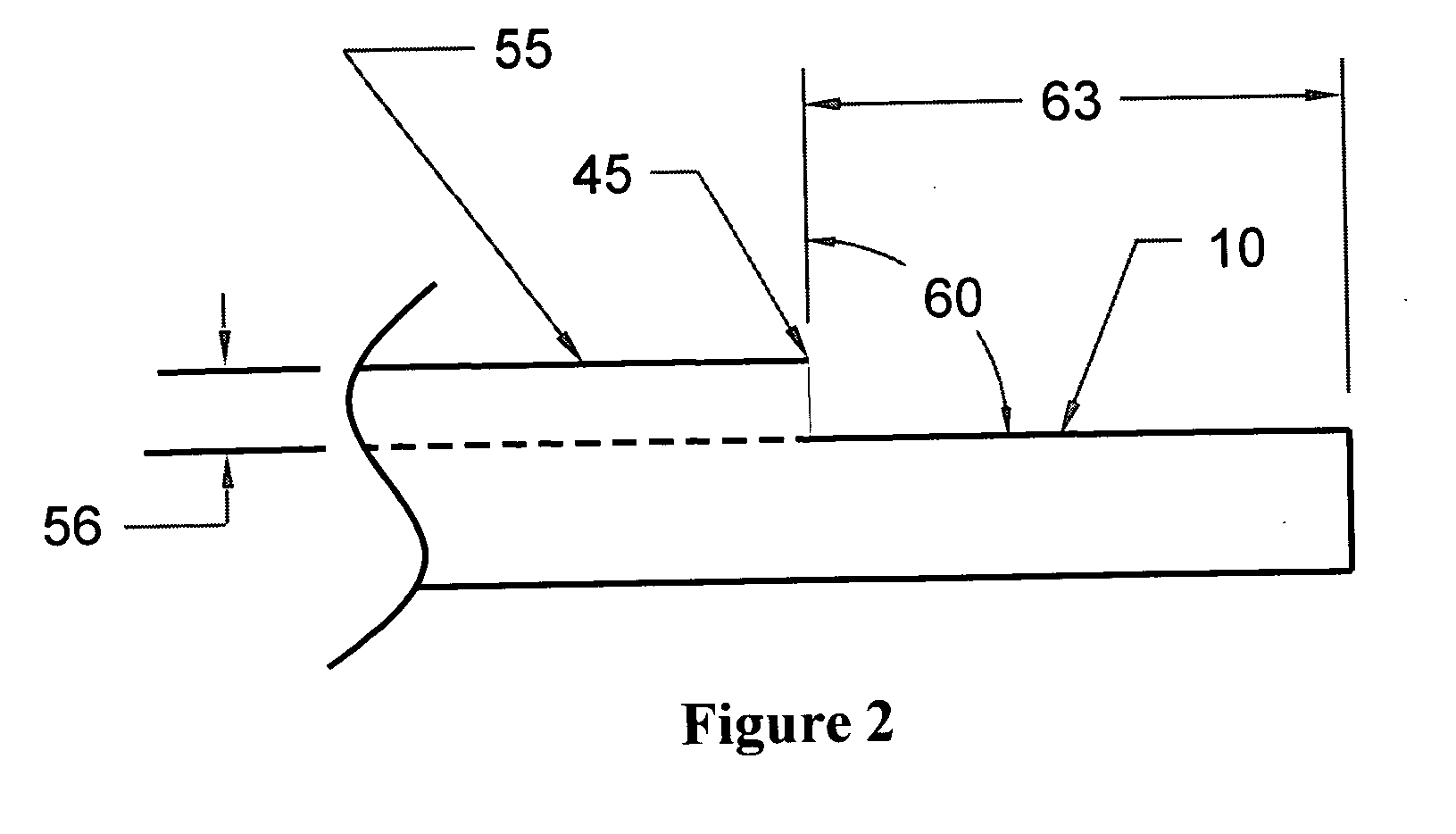

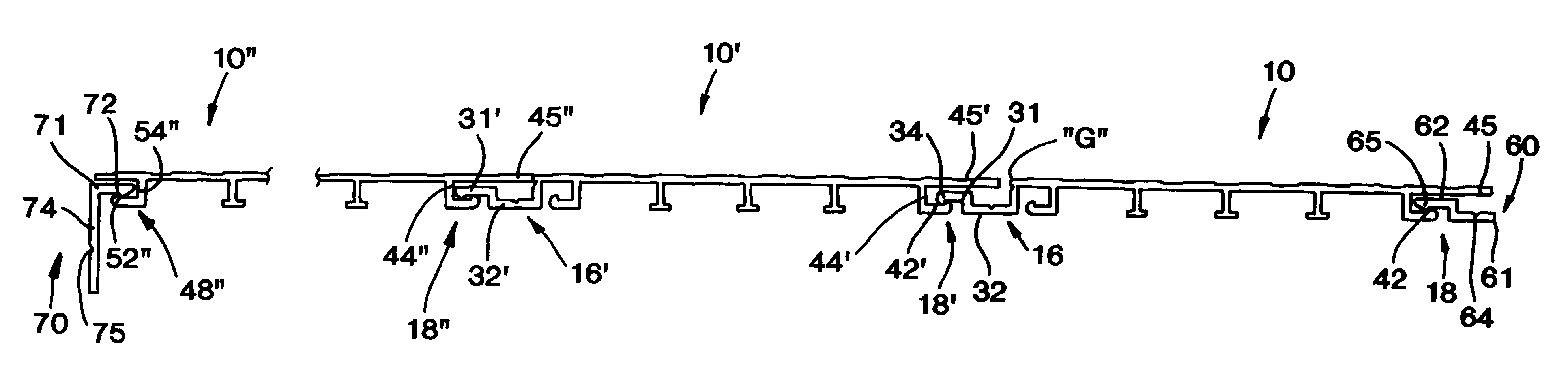

Modular cladding element

A modular cladding element cooperates with an assembly of cladding elements to clad a surface of an underlying structure. The cladding element includes a cladding panel having opposed inside and outside major surfaces, first and second opposed sides, and first and second opposed ends. A removable male fastener is integrally formed along the first side of the panel, and is adapted for entering a complementary fastener of an adjacent cladding element when positioned on the first side of the panel. The male fastener is removable in the absence of a complementary cladding element positioned on the first side of the panel. A first female fastener is integrally formed along the opposed second side of the panel, and defines a first opening adapted for receiving a complementary fastener of an adjacent cladding element positioned on the second side of the panel. A second female fastener is integrally formed adjacent the male fastener on the first side of the panel. Upon removing the male fastener, the second female fastener defines a second opening adapted for receiving a complementary fastener of an adjacent cladding element on the first side of the panel.

Owner:L B PLASTICS

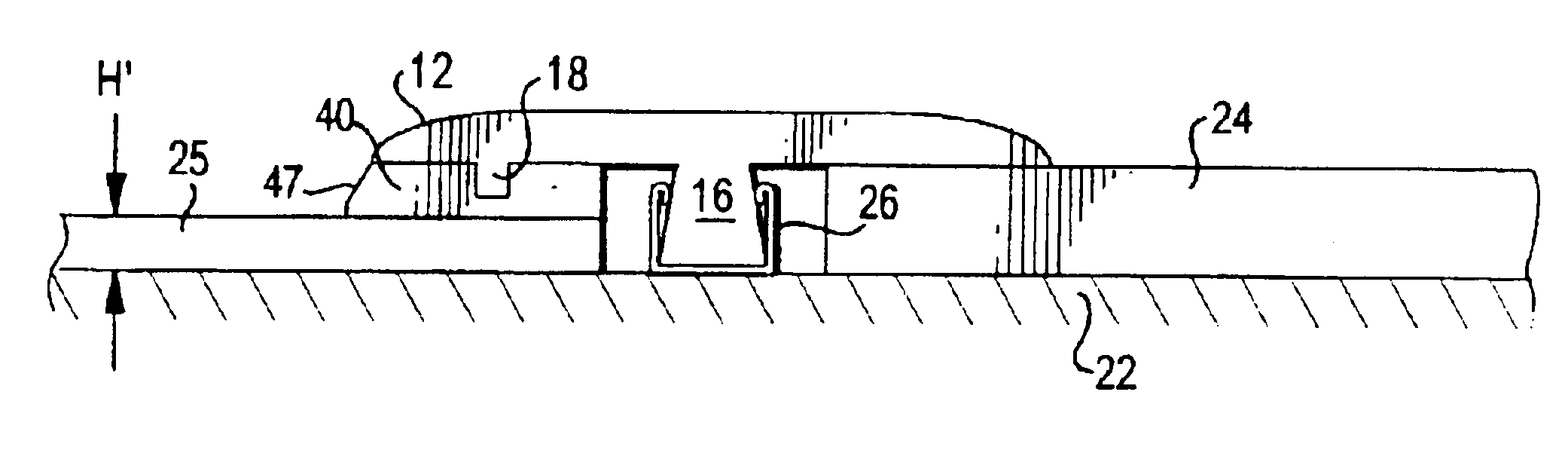

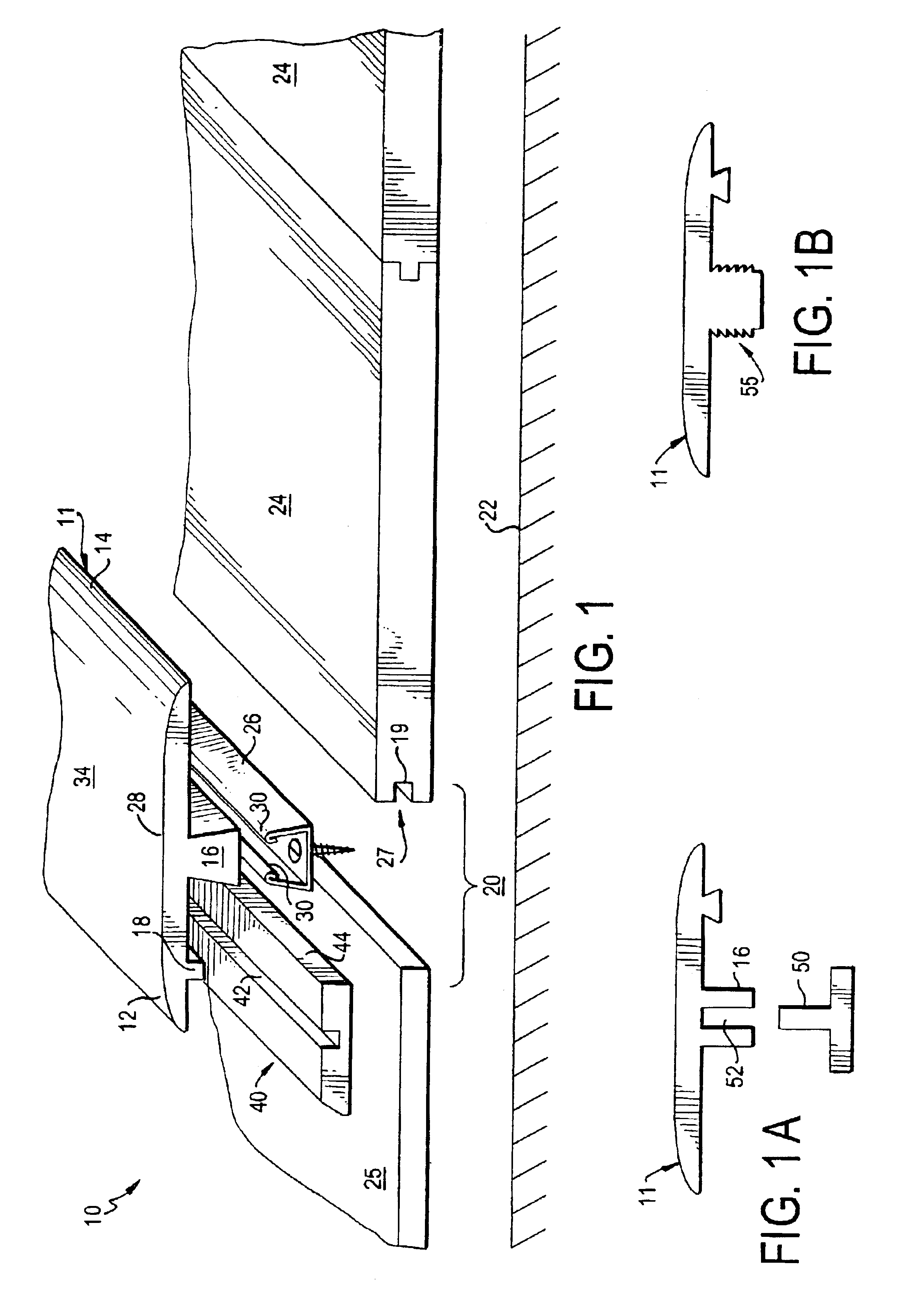

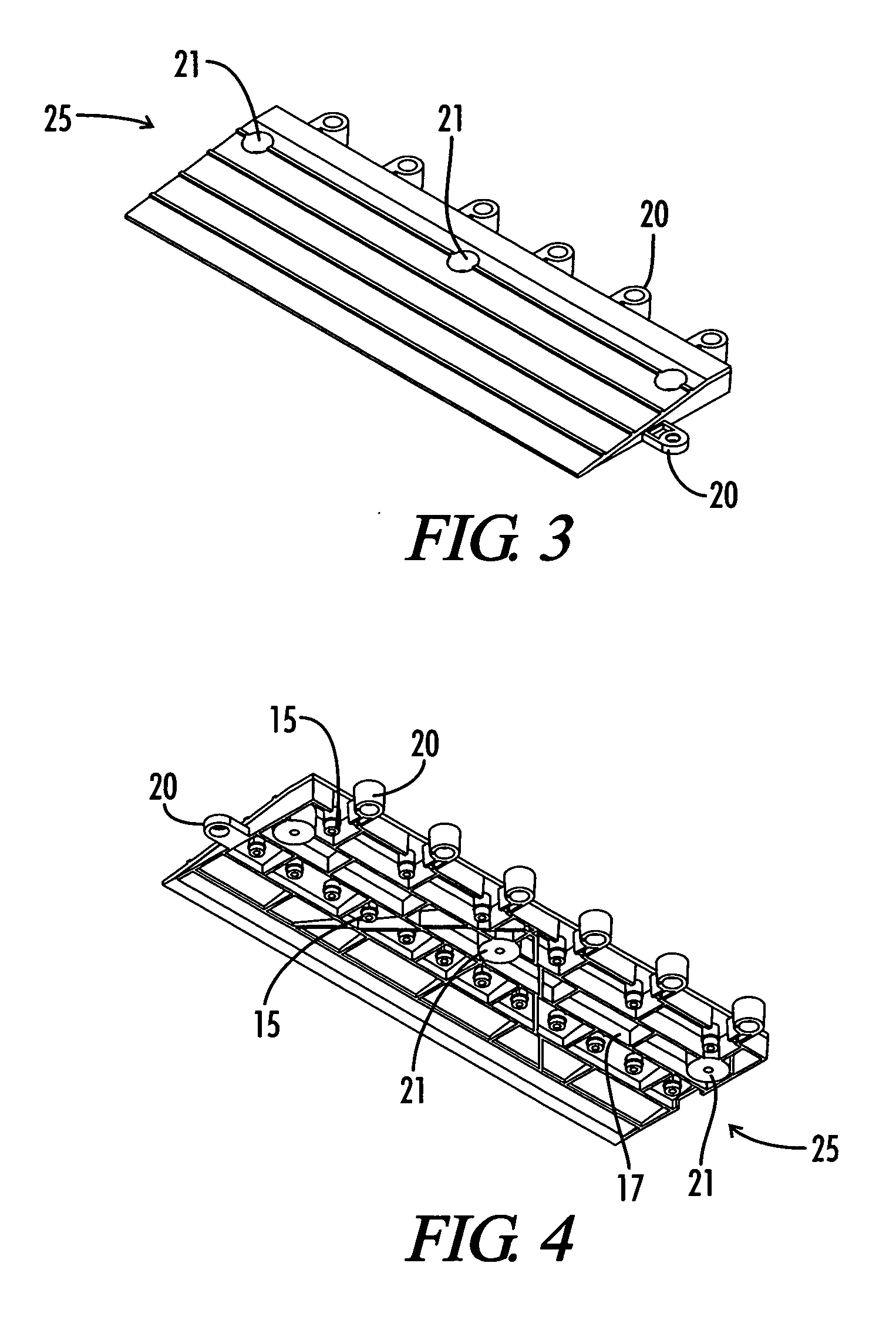

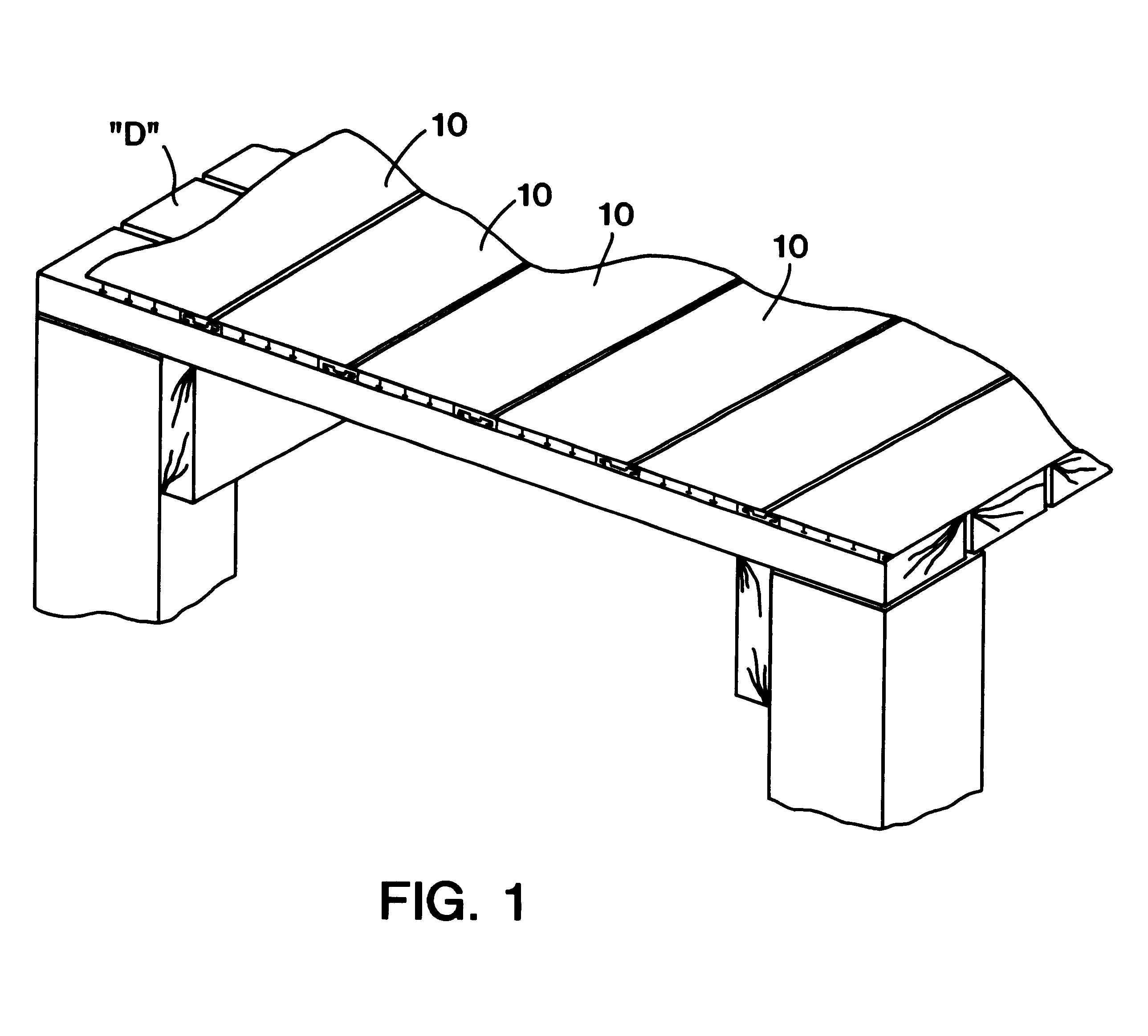

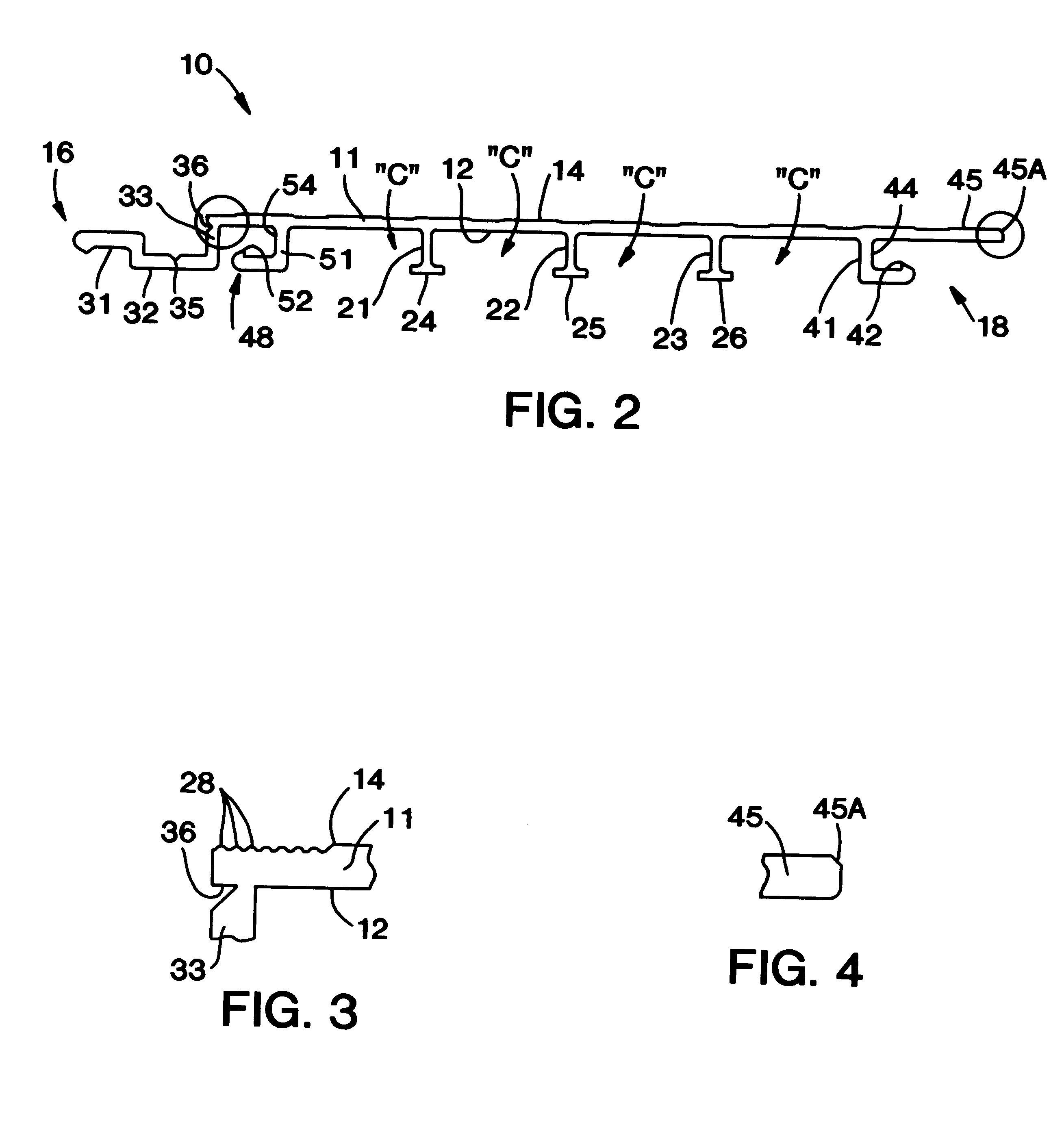

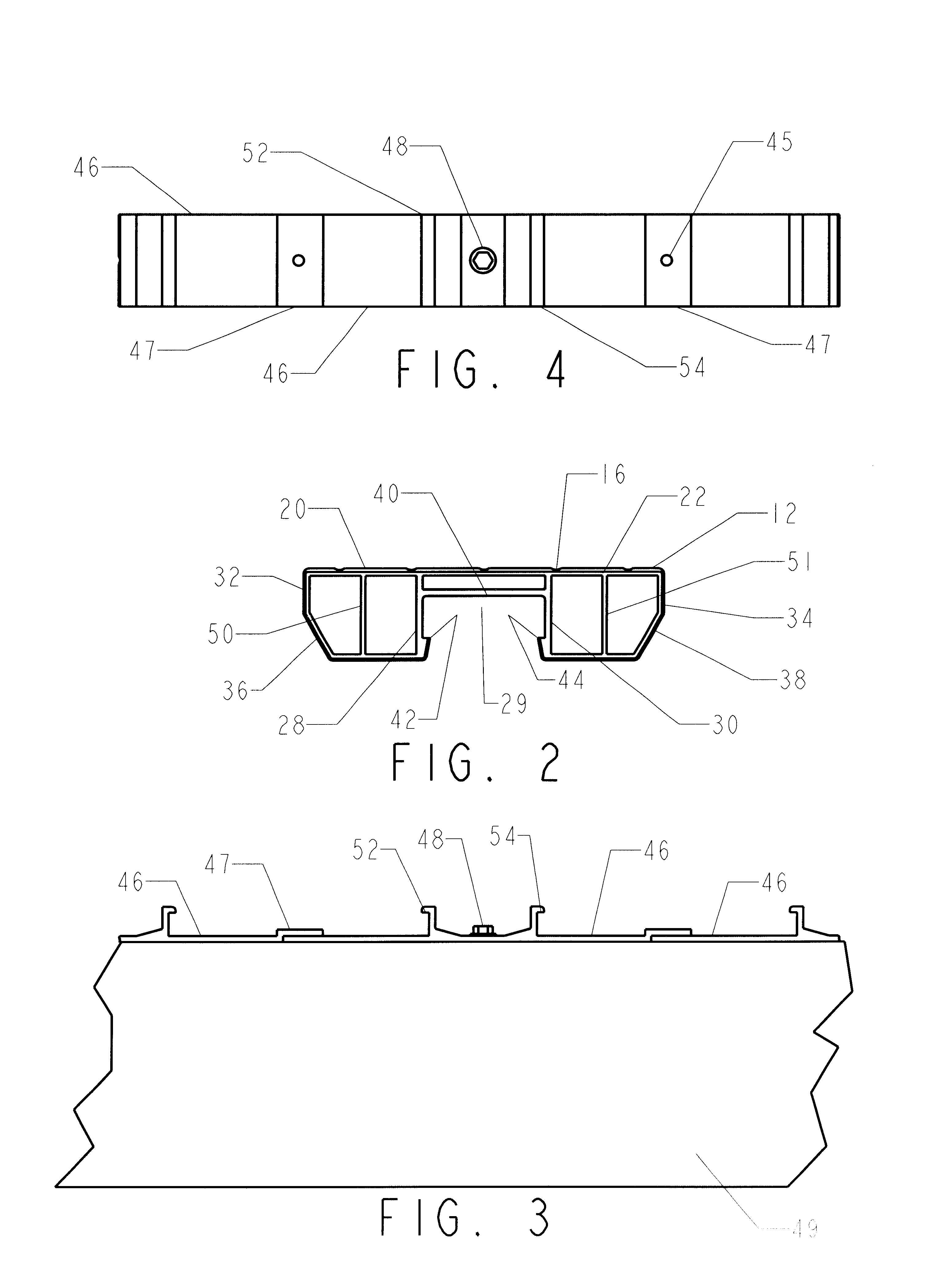

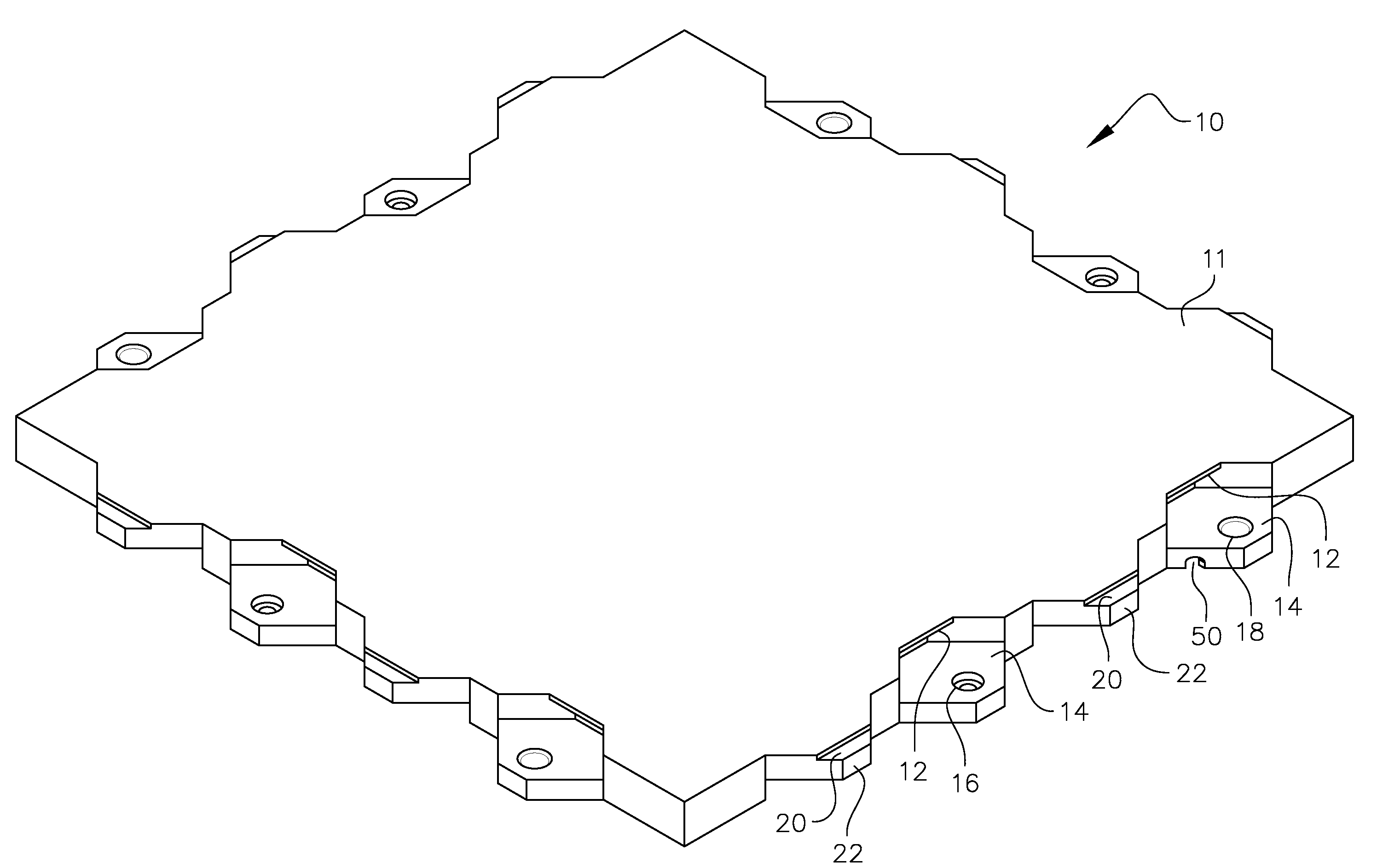

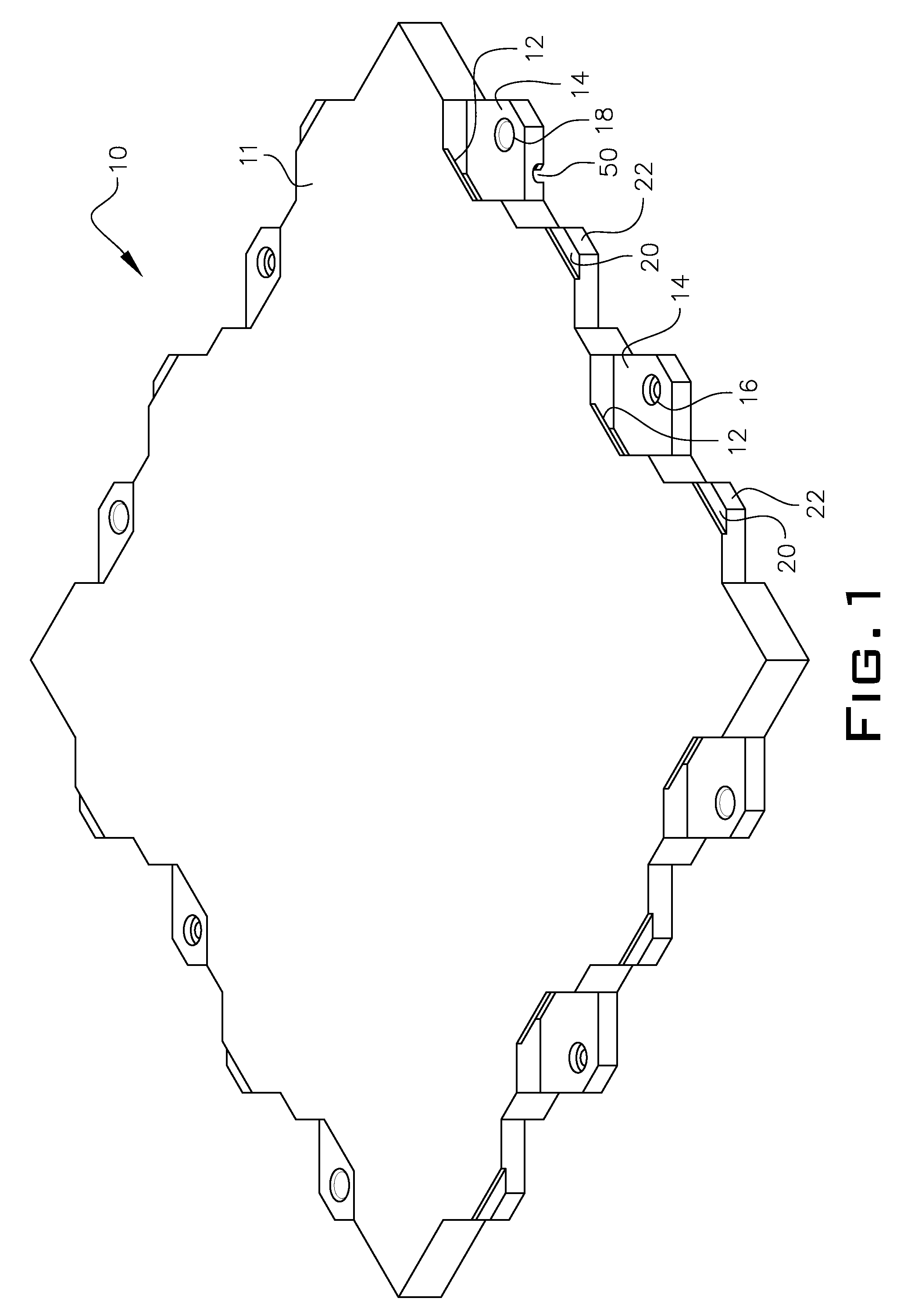

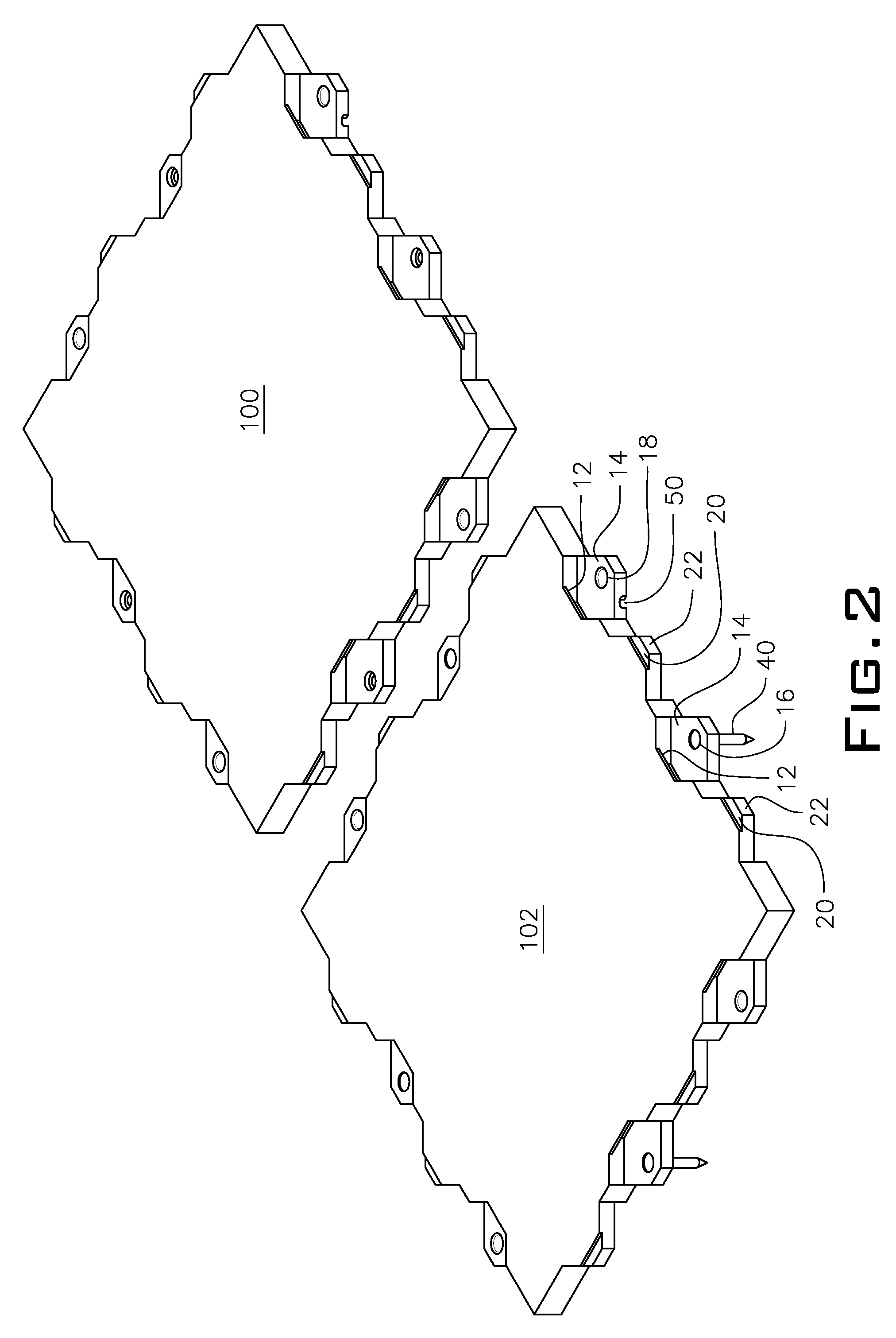

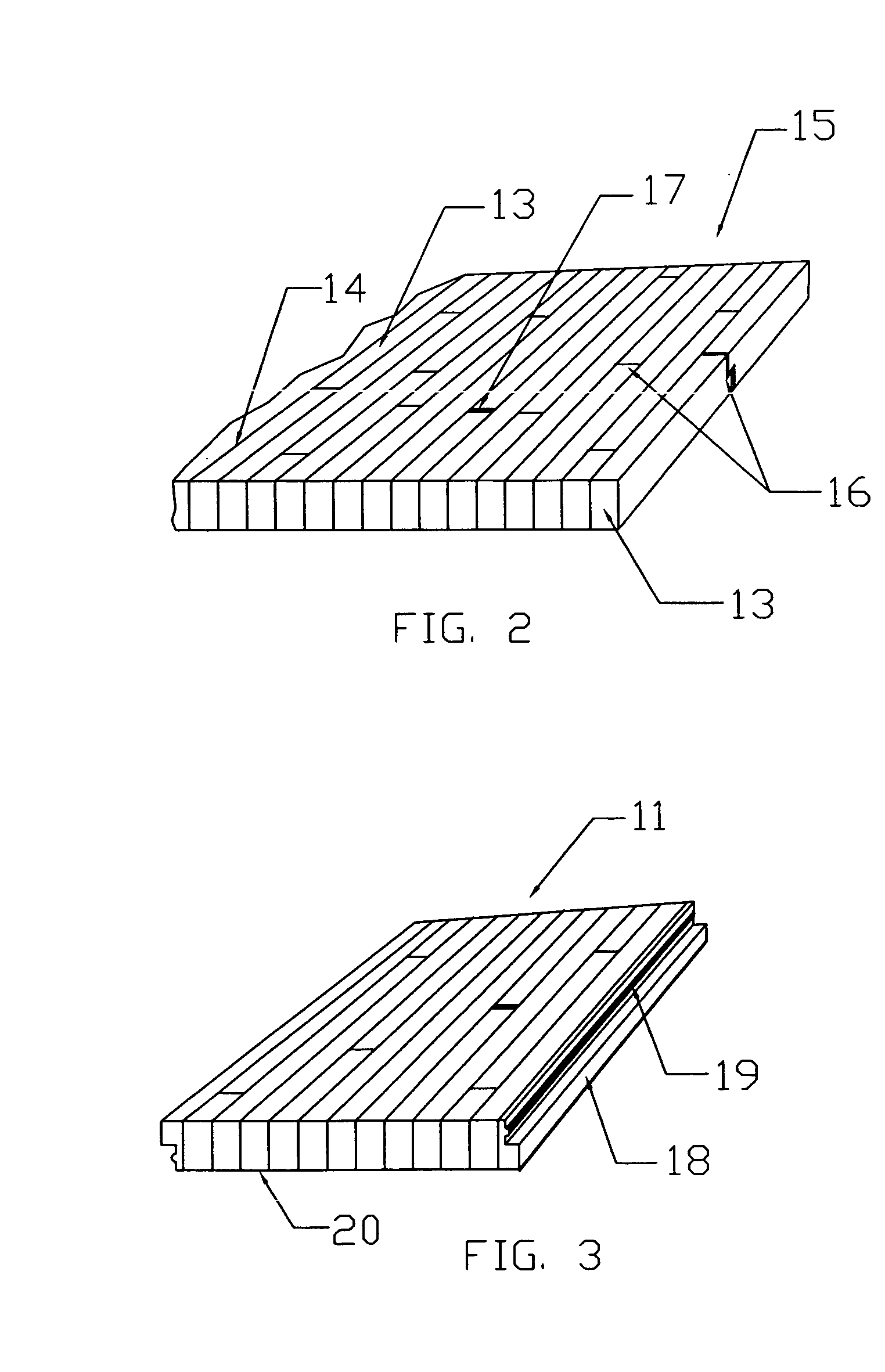

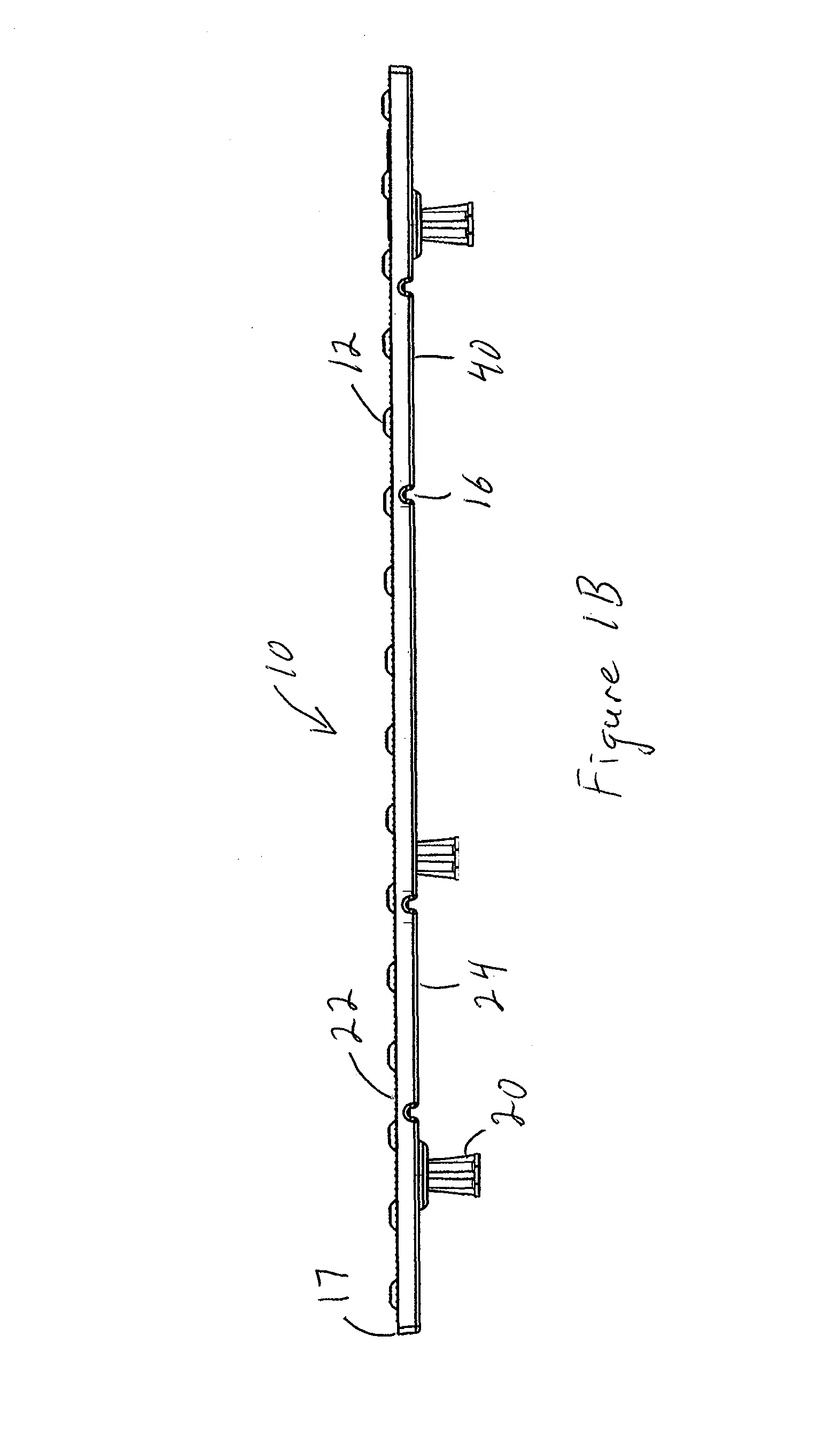

Deck plank extrusion and retaining clip

A deck plank (12) readily attaches to an engagement clip (46) when force is applied over the plank. When a plurality of clips are attached to underlying joists in parallel with the joists, and a plurality of deck planks are oriented to the clip perpendicular to the joist and pushed down over clips, a secure deck structure is provided. Each clip has a pair of horizontal flanges (52 and 54), which snap over a plurality of ledges (42 and 44) in a channel under each plank. The deck planks (12) are embossed (14) so as to form a slip resistant surface to be walked upon. The plastic extruded deck plank (12) resists rot, deterioration and insect infection found in current wood products. The deck plank assembly is simple enough so that a homeowner or do-it-yourselfer can install or alter it with minimal effort and direction.

Owner:LEINES RICHARD ALAN

Interlocking floor system

ActiveUS7516587B2Easy to disassembleEasy to assembleRoof covering using tiles/slatesTreadsBrickEngineering

Multiple polymeric panels molded as a rigid integral body having a planar top surface and a bottom grid structure are interlocked together mechanically along side edges. Each side edge has alternating upwardly and downwardly facing steps with concave dimples on one and mating convex projections on the other for securely interlocking adjacent panels to each other. The steps of adjacent panels interlock with each other to form a complete floor system. The multiple polymeric panels can be molded to simulate flooring materials such as brick or overlaid with sections of linoleum, carpet, synthetic grass, tile or wood flooring. Alternately, the assembled panels can be covered with a sheet of decorative material.

Owner:CH3 SOLUTIONS LLC

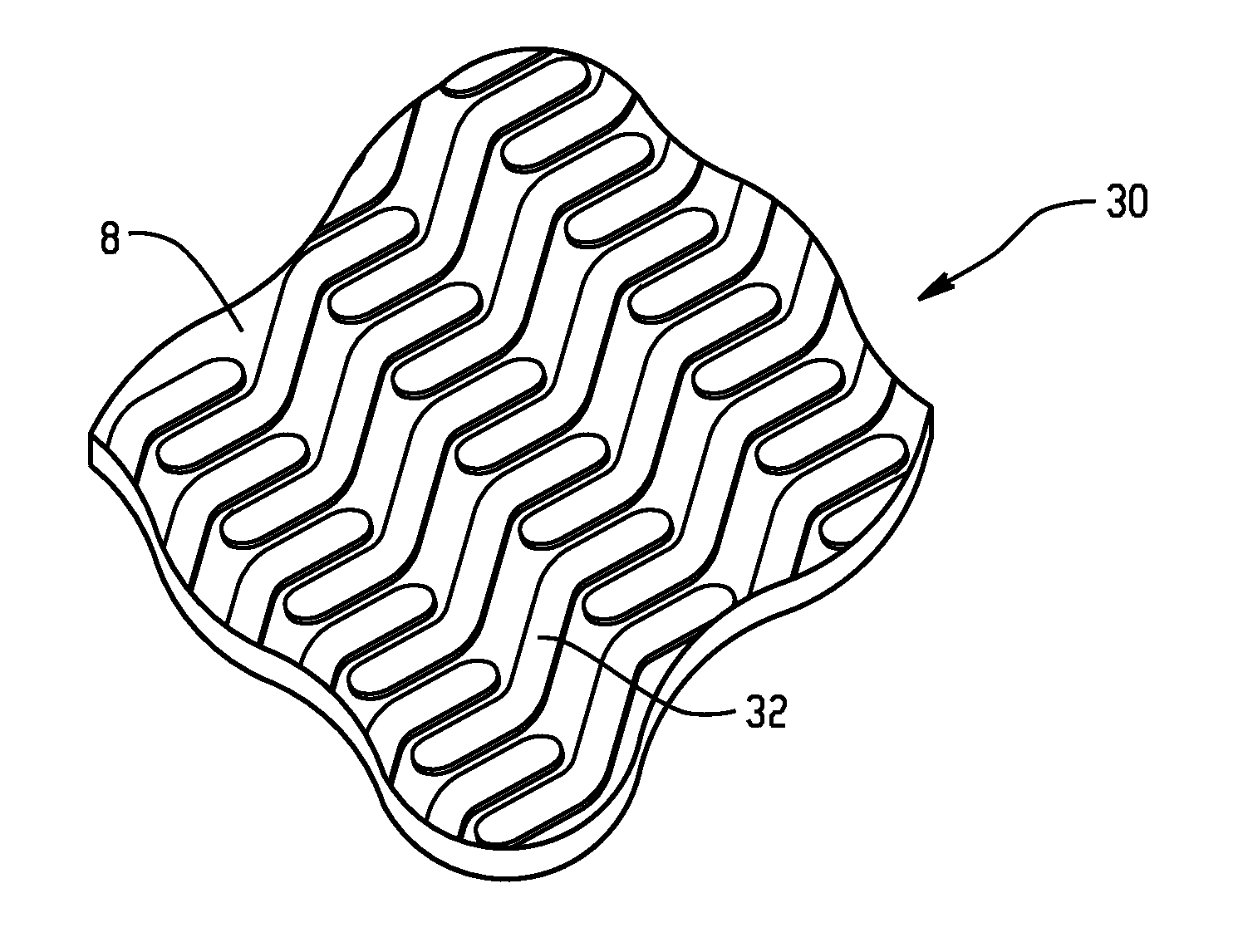

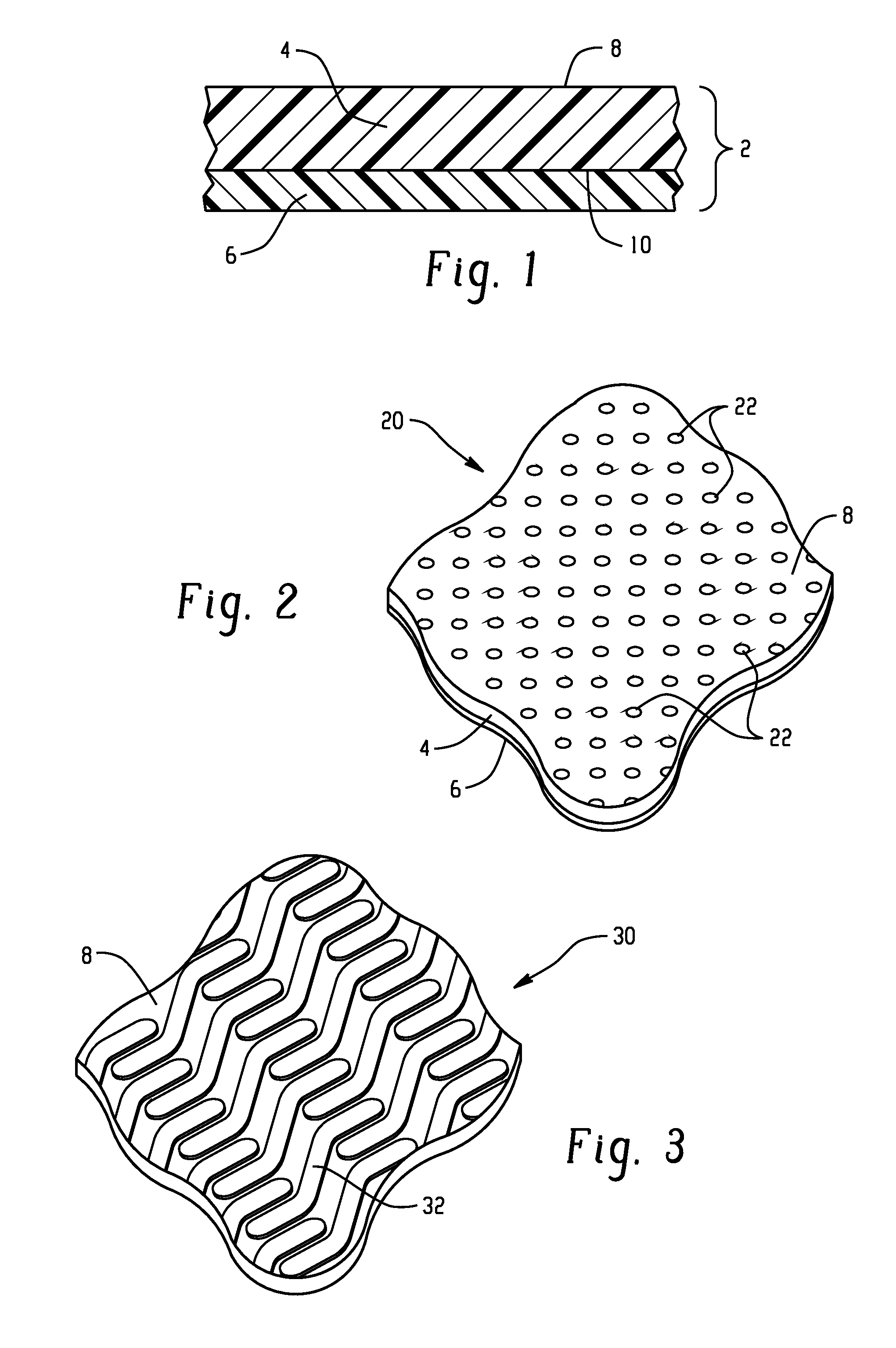

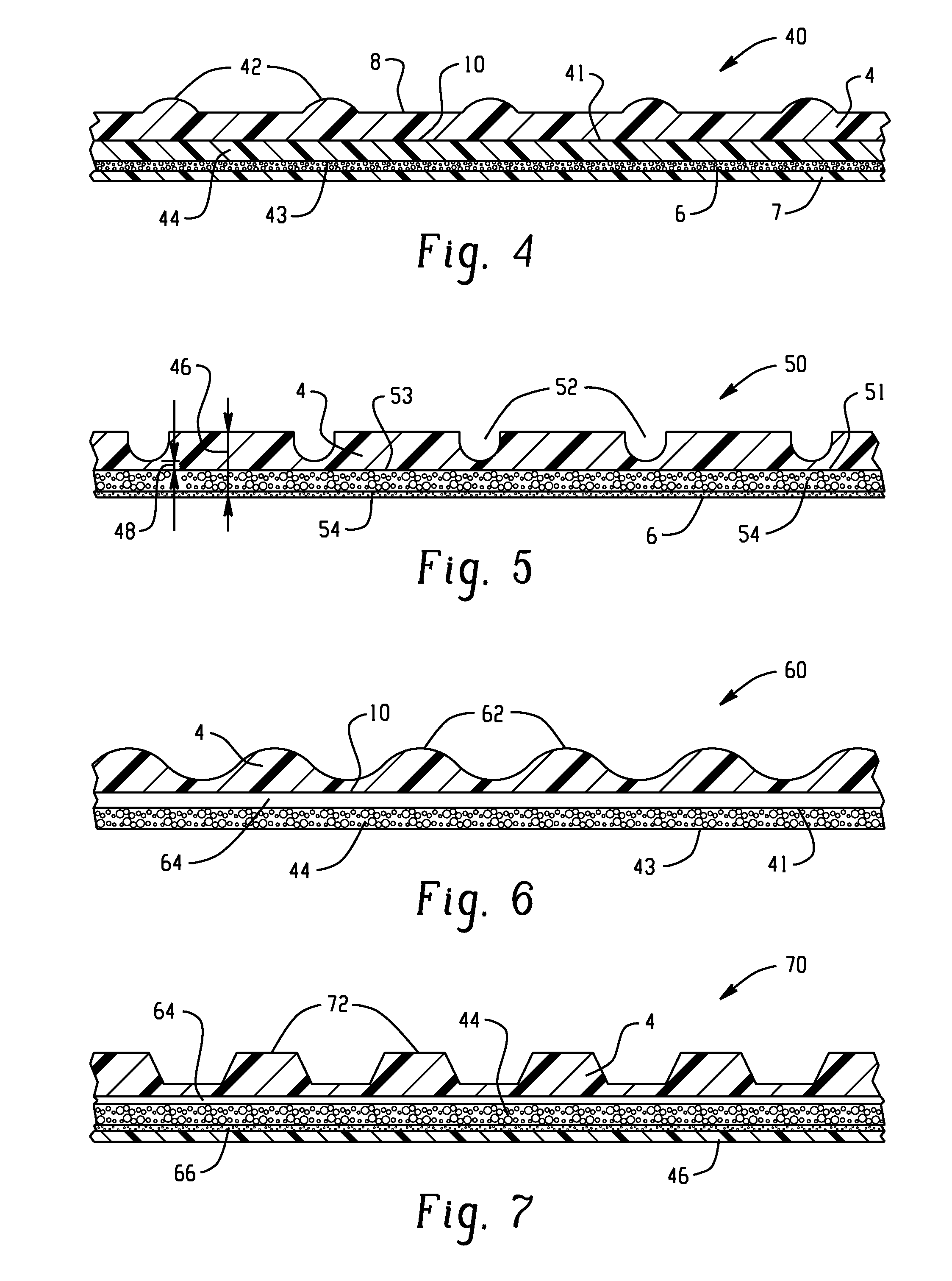

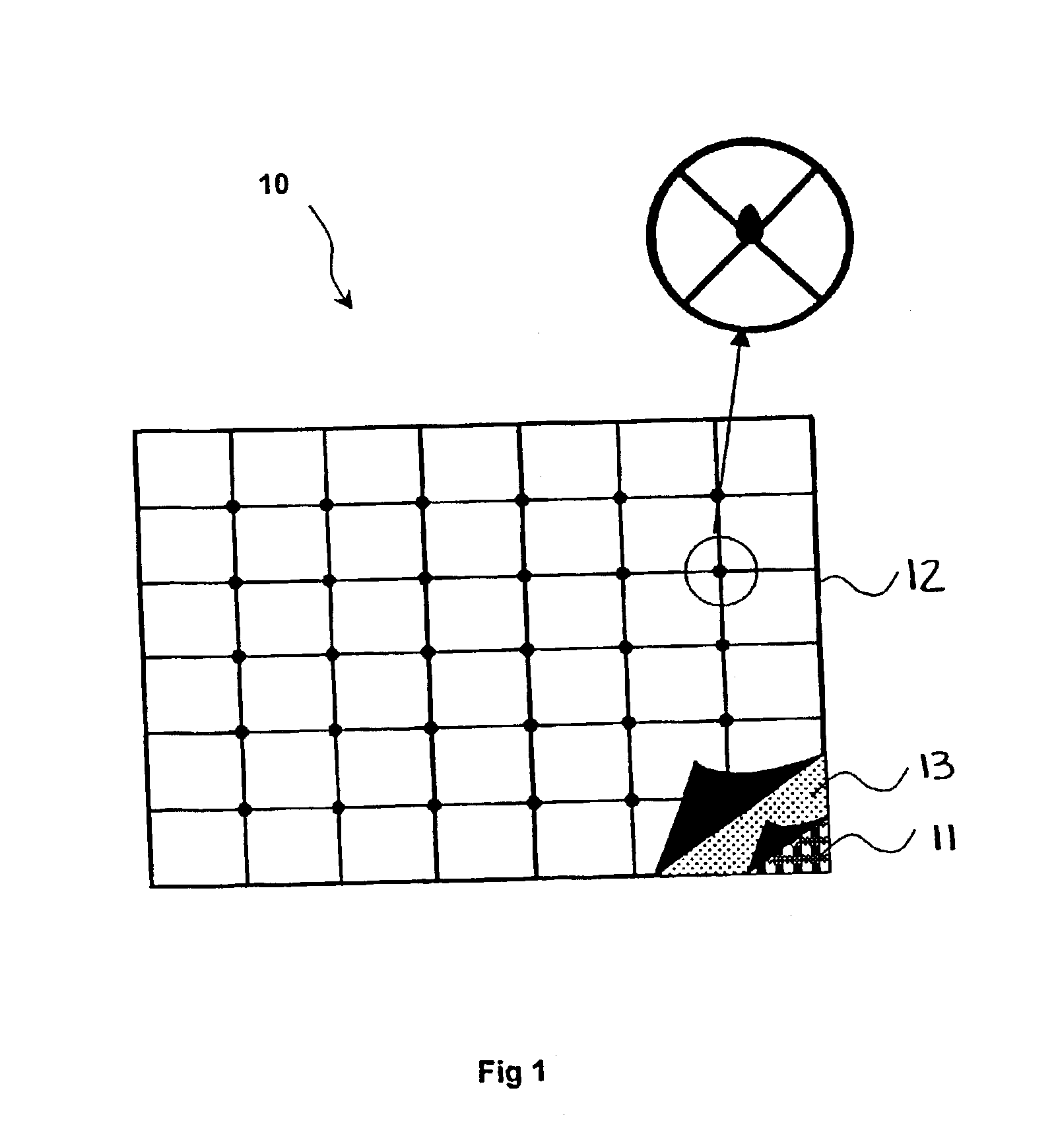

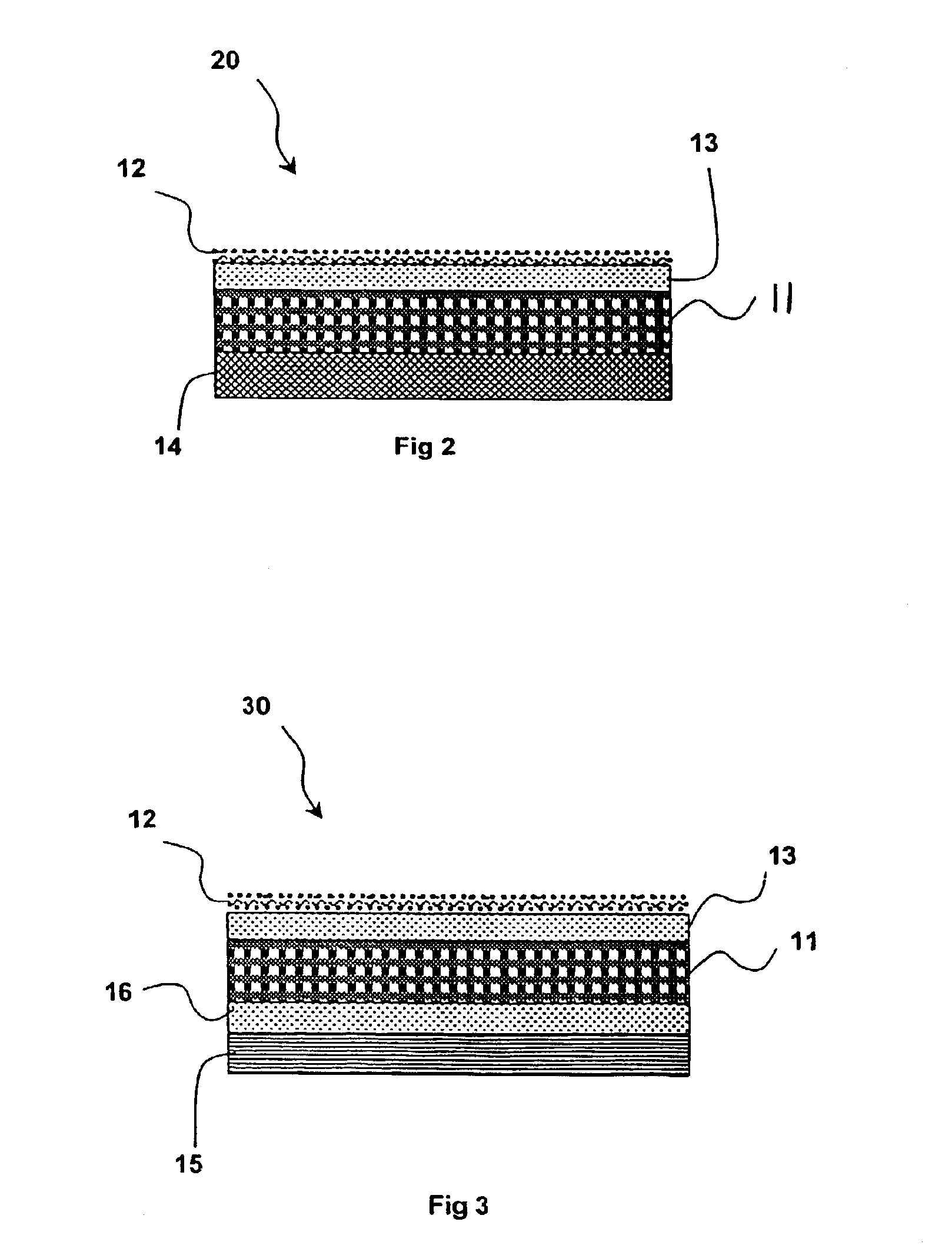

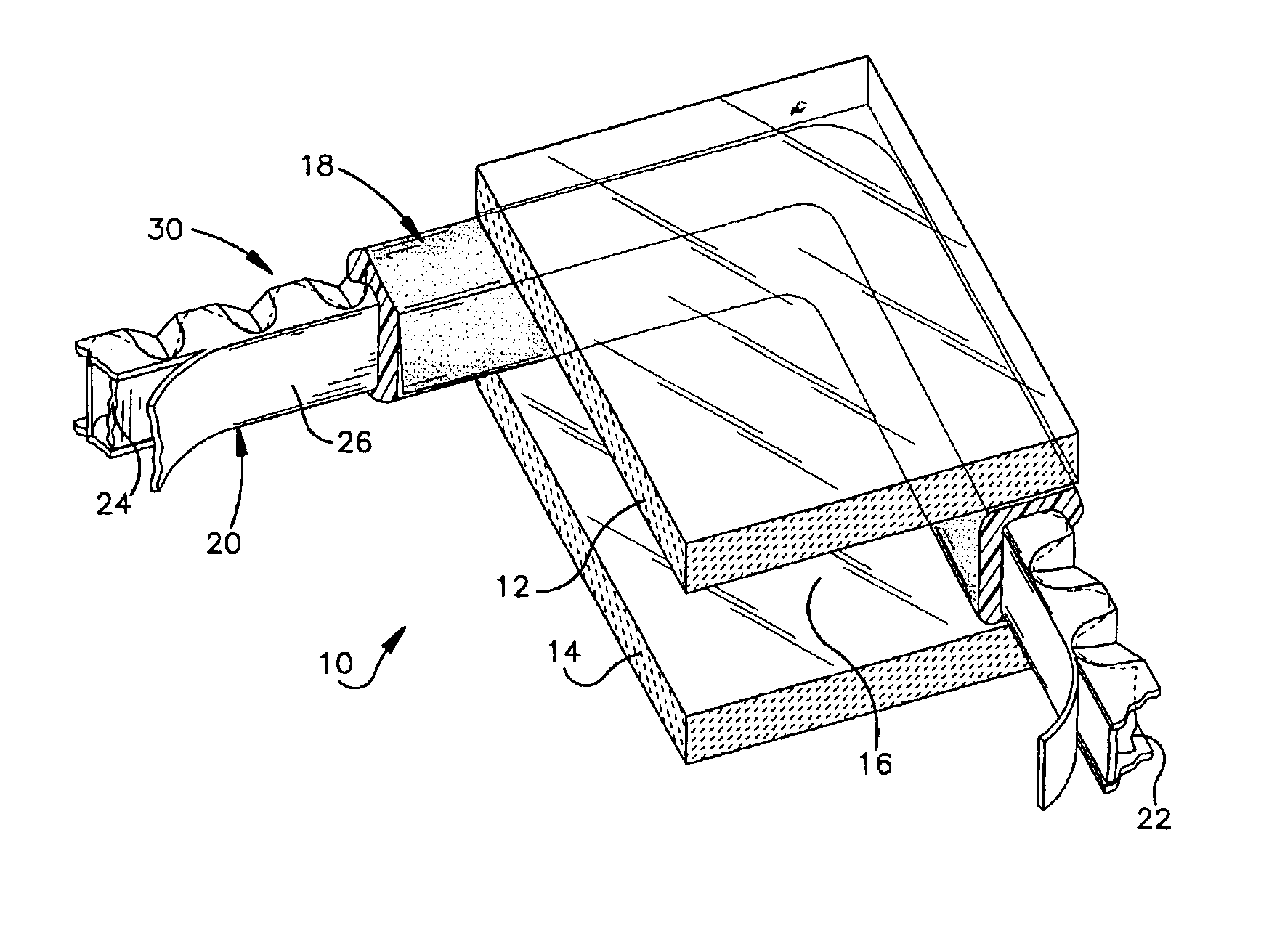

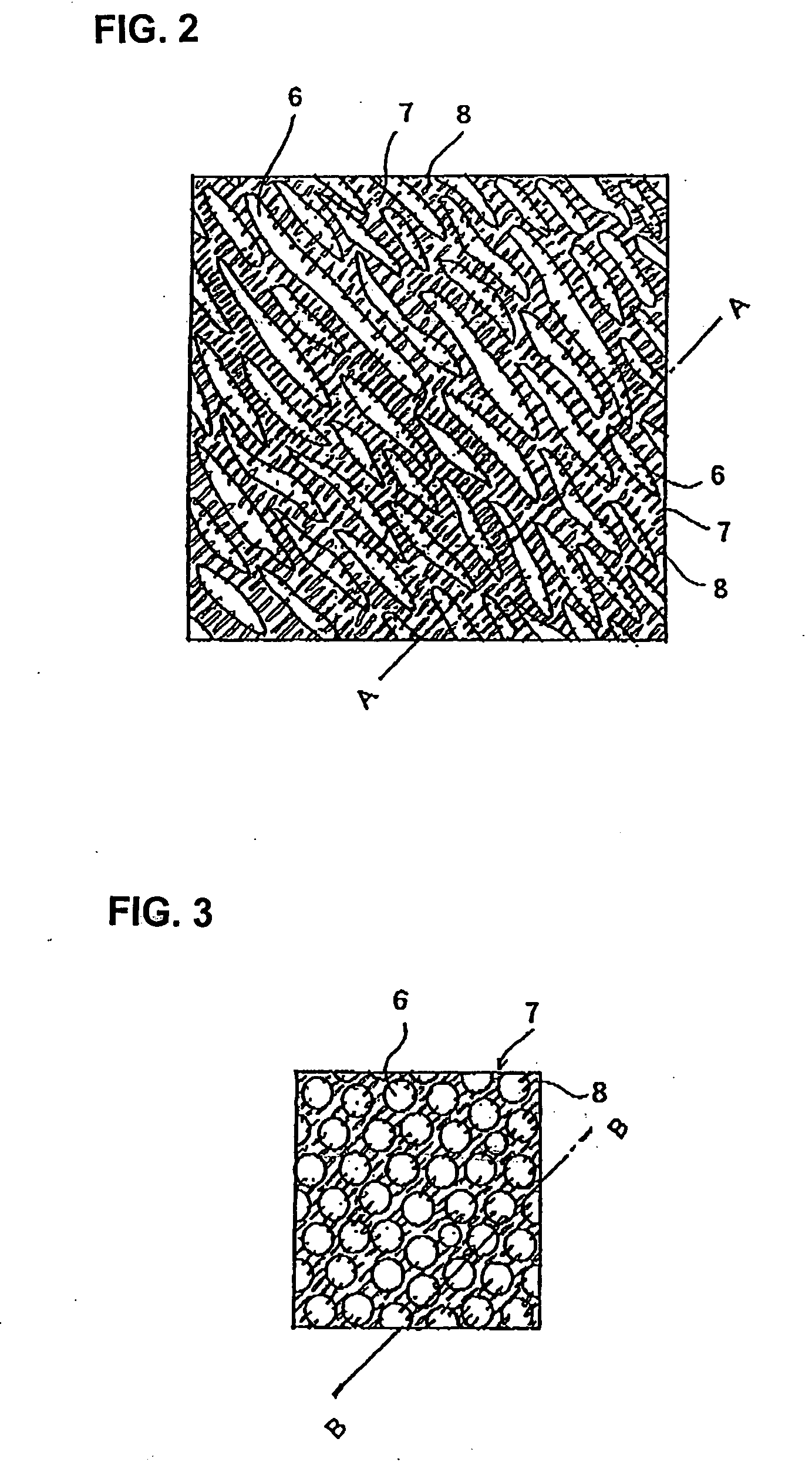

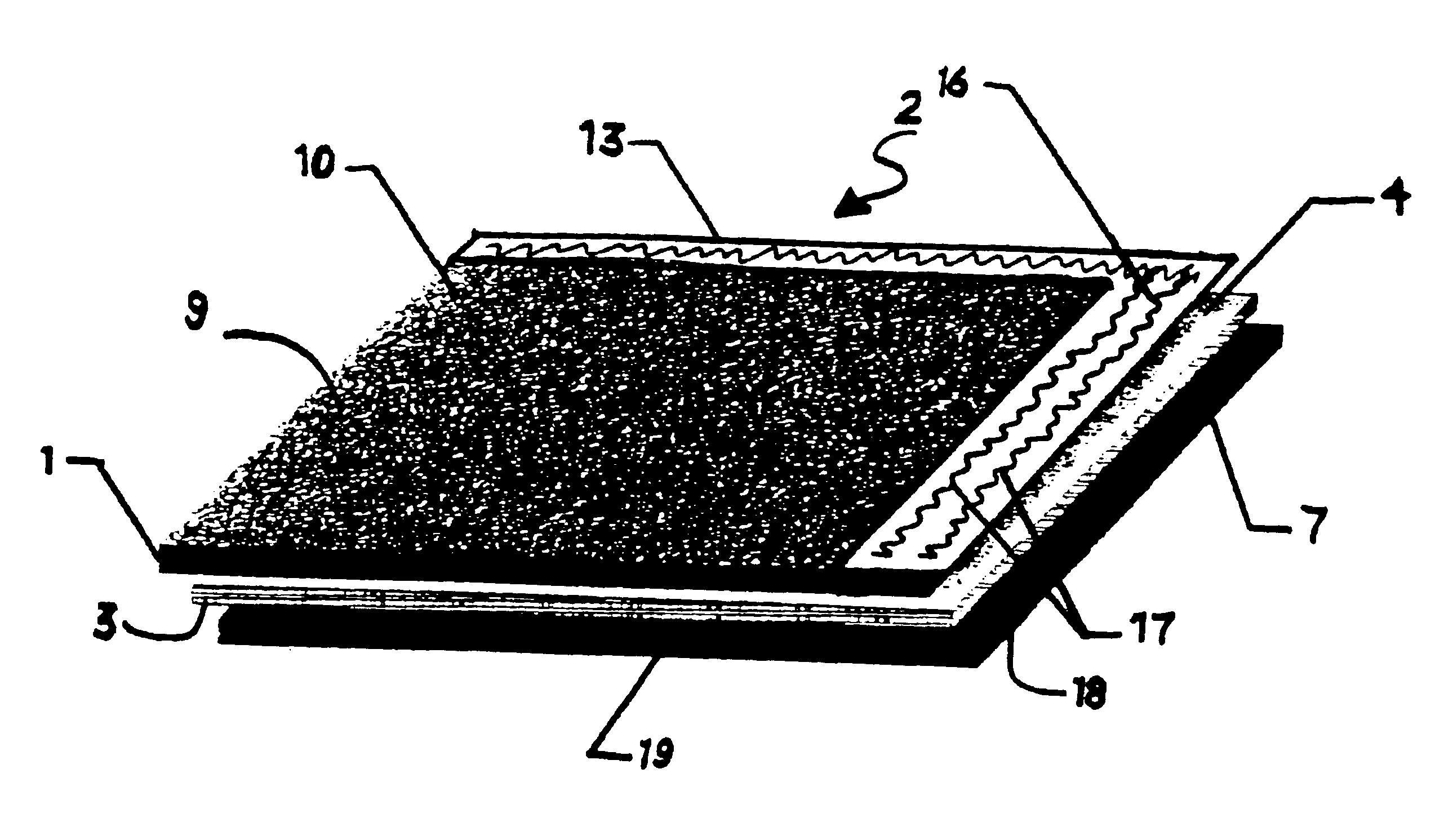

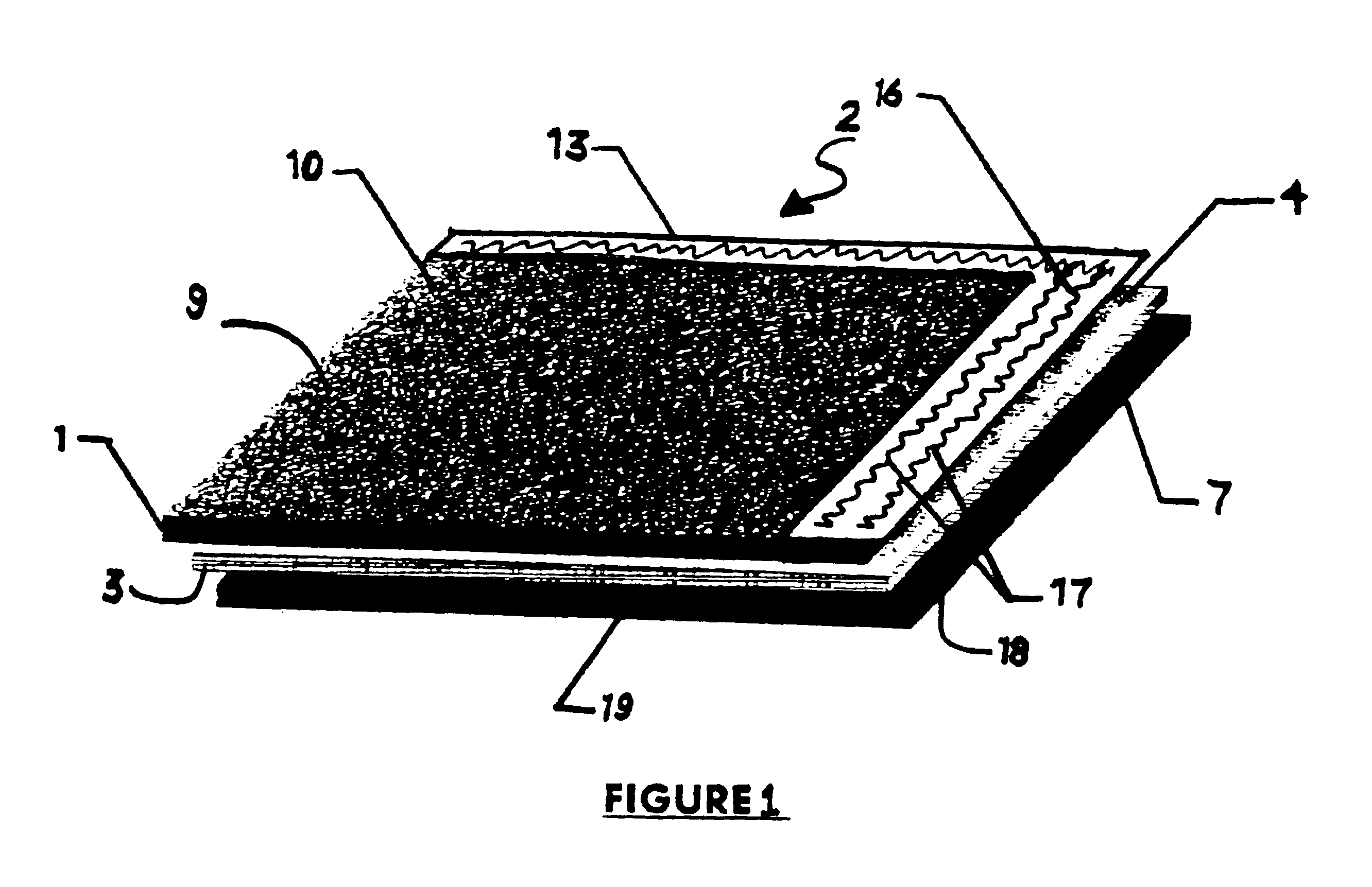

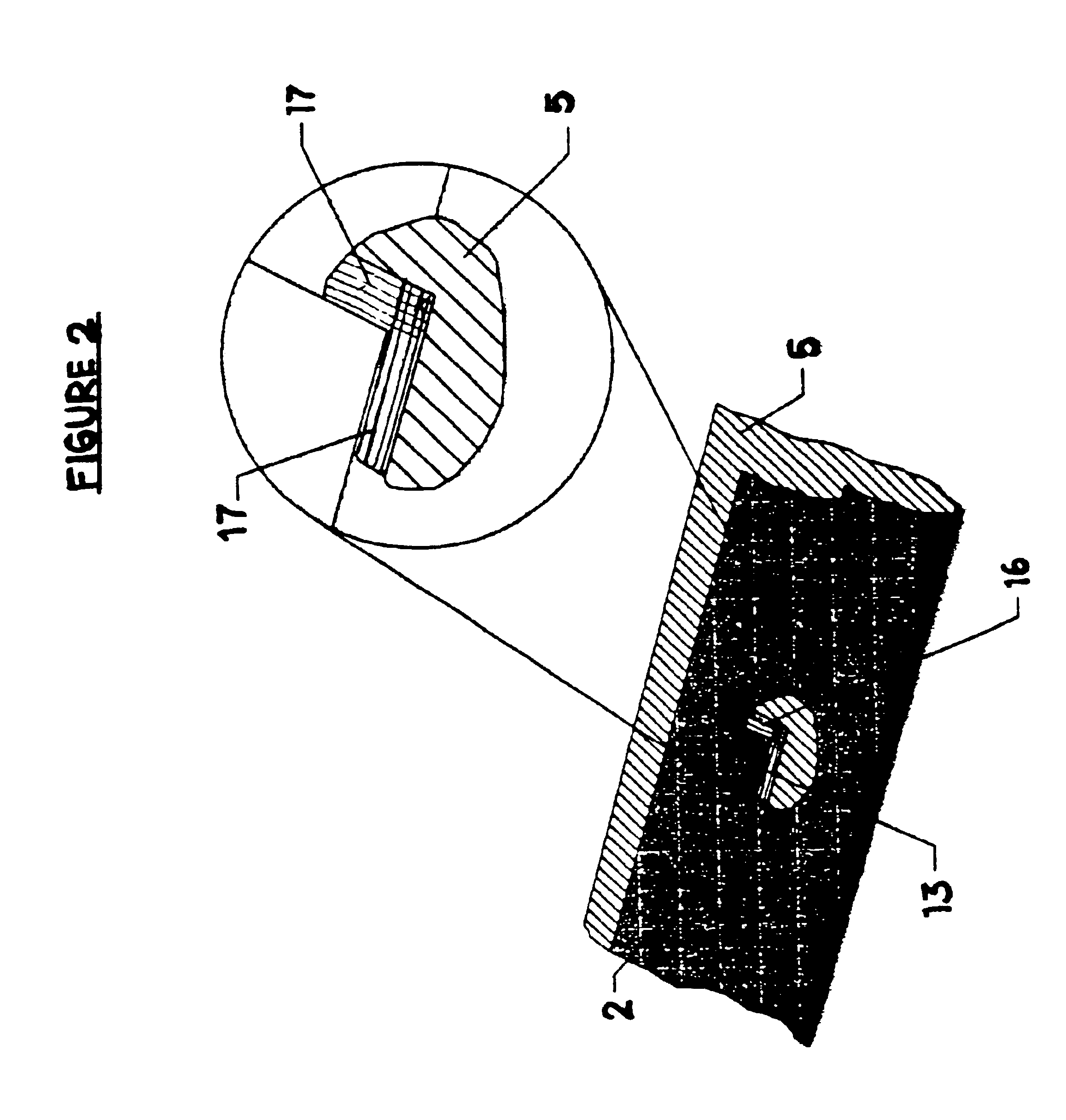

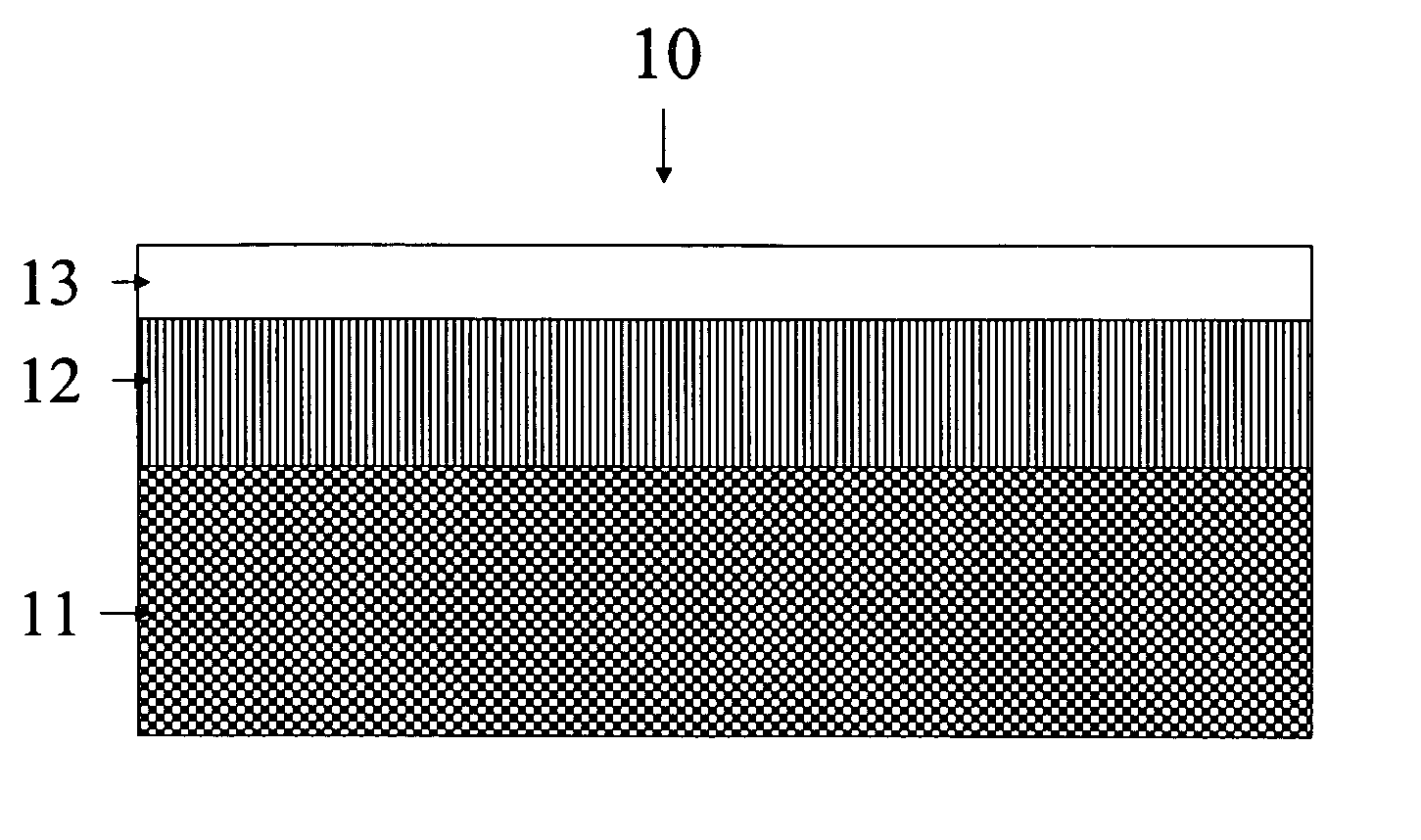

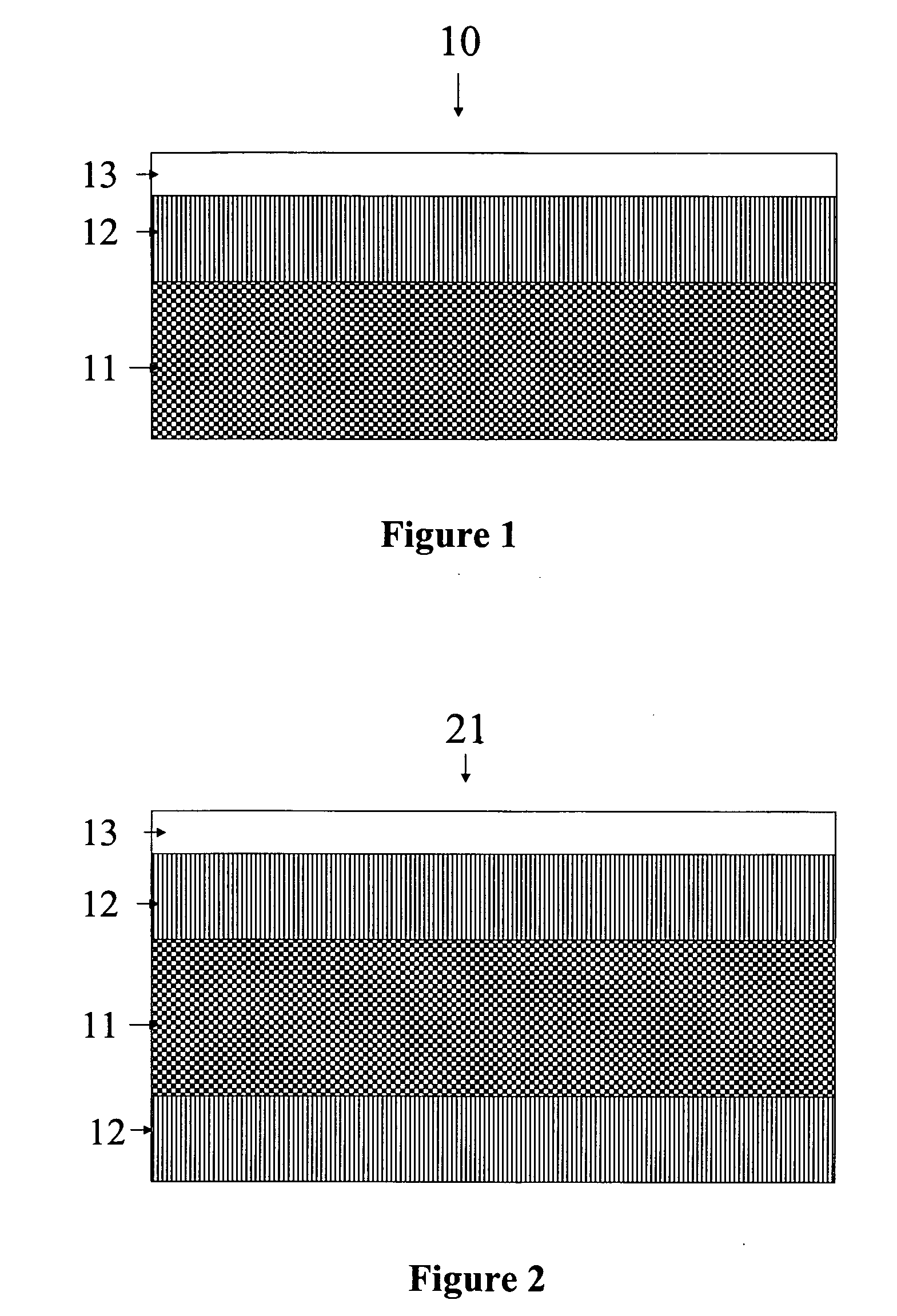

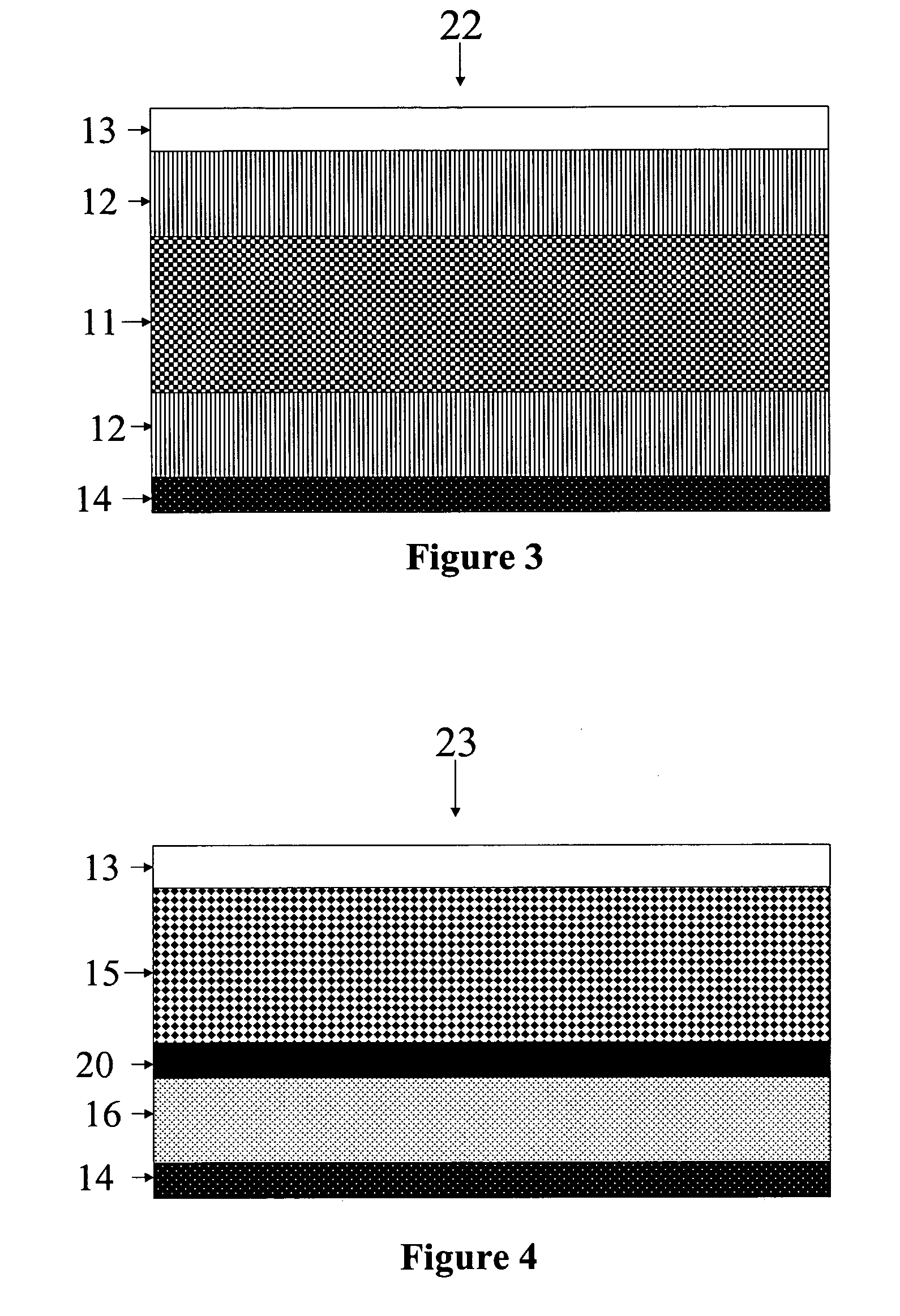

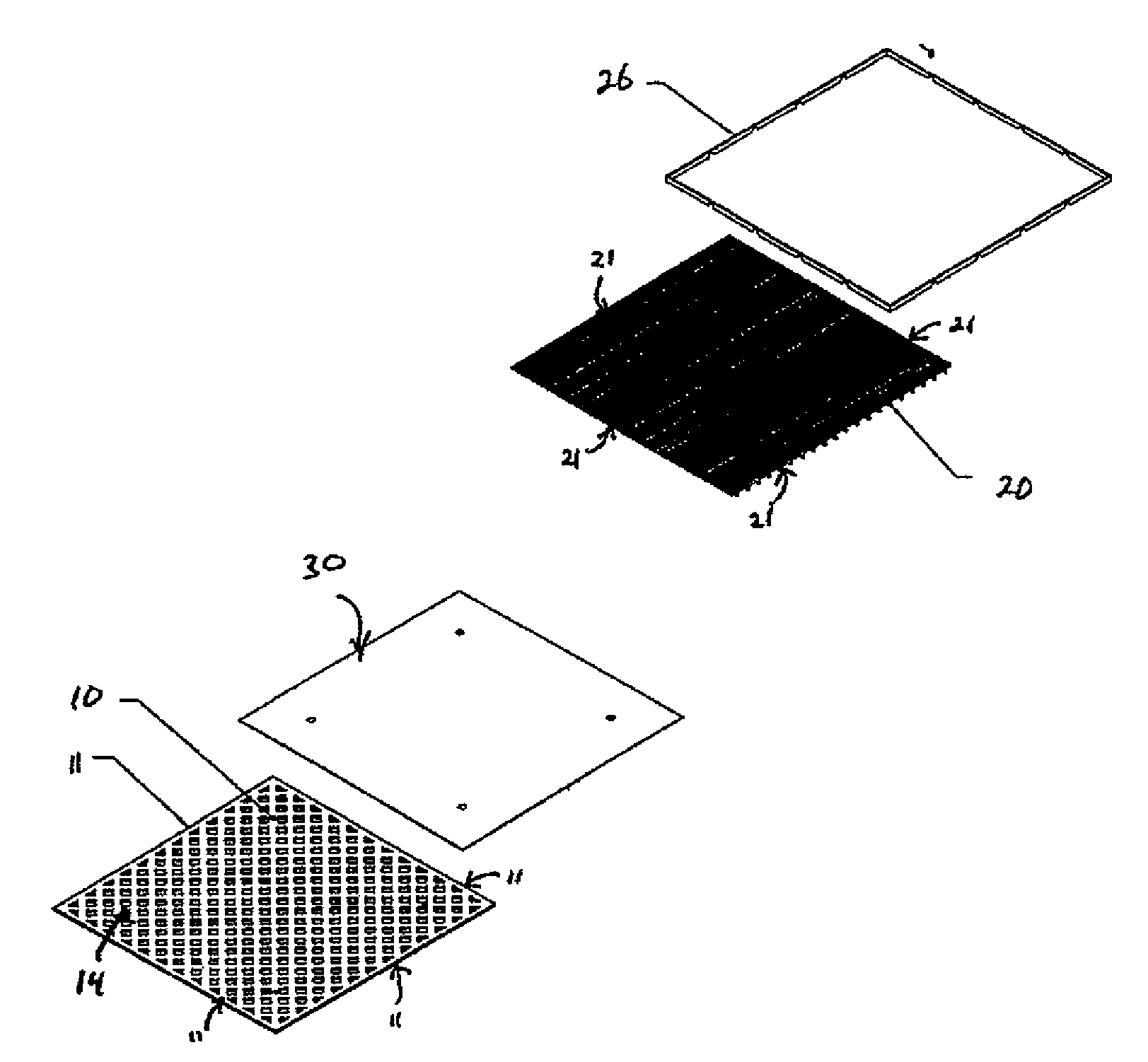

Multilayer slip resistant sheet material

InactiveUS6925766B2Increase coefficient of frictionGood walkabilityRoof covering using tiles/slatesTreadsEngineeringSlip resistance

There is provided a sheet material having a walking surface with high slip resistance. The sheet material has a flexible structural layer laminated to a mesh layer which has interconnected reinforced strands and protruding nodes to impart a high coefficient of friction. The high coefficient of friction of the sheet material provides a roofing underlayment which is safe to walk upon in dry, wet or dusty conditions, and on steeply sloped surfaces. The sheet material may also be used as an industrial wrapping material or a fabric.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

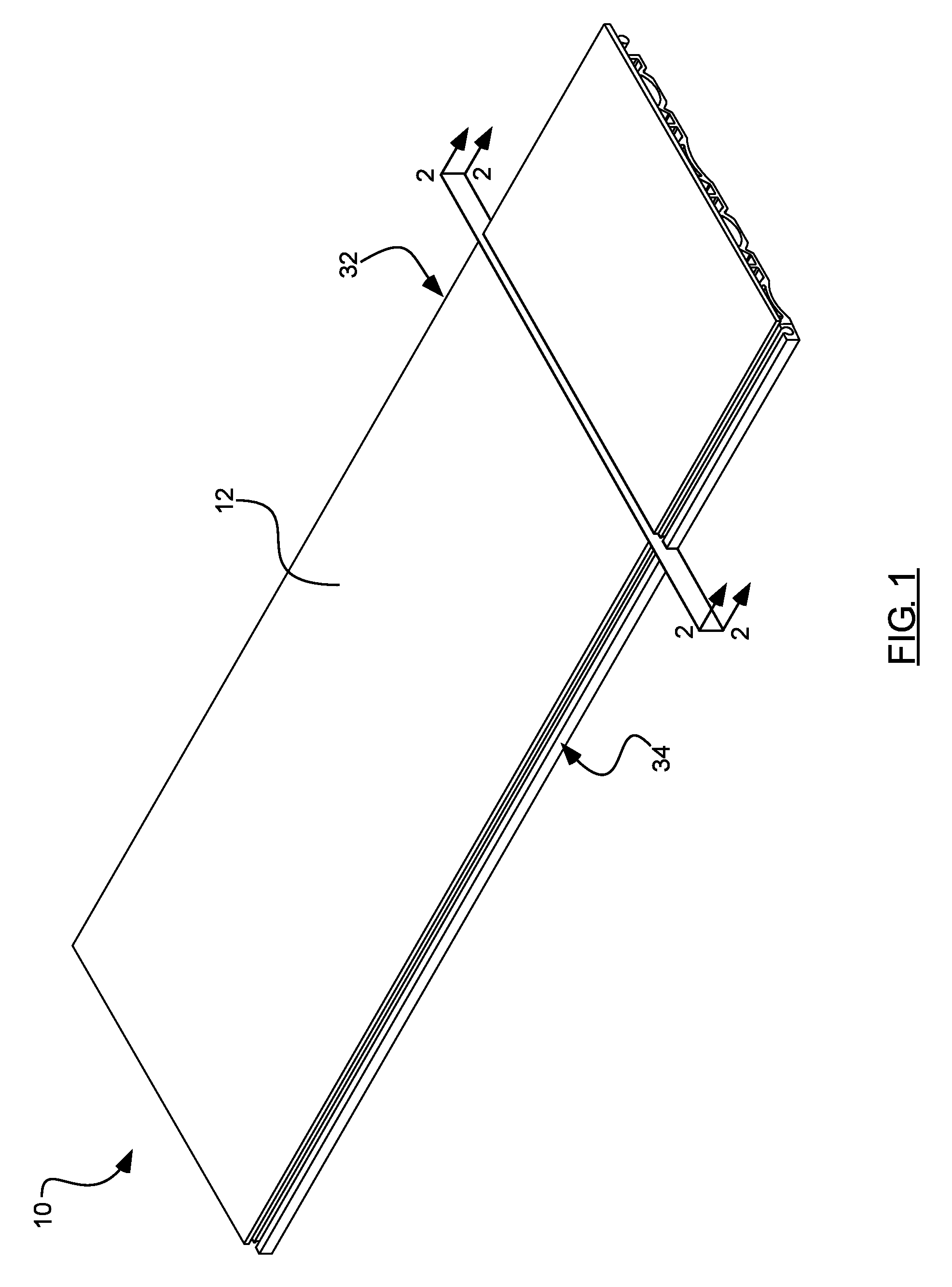

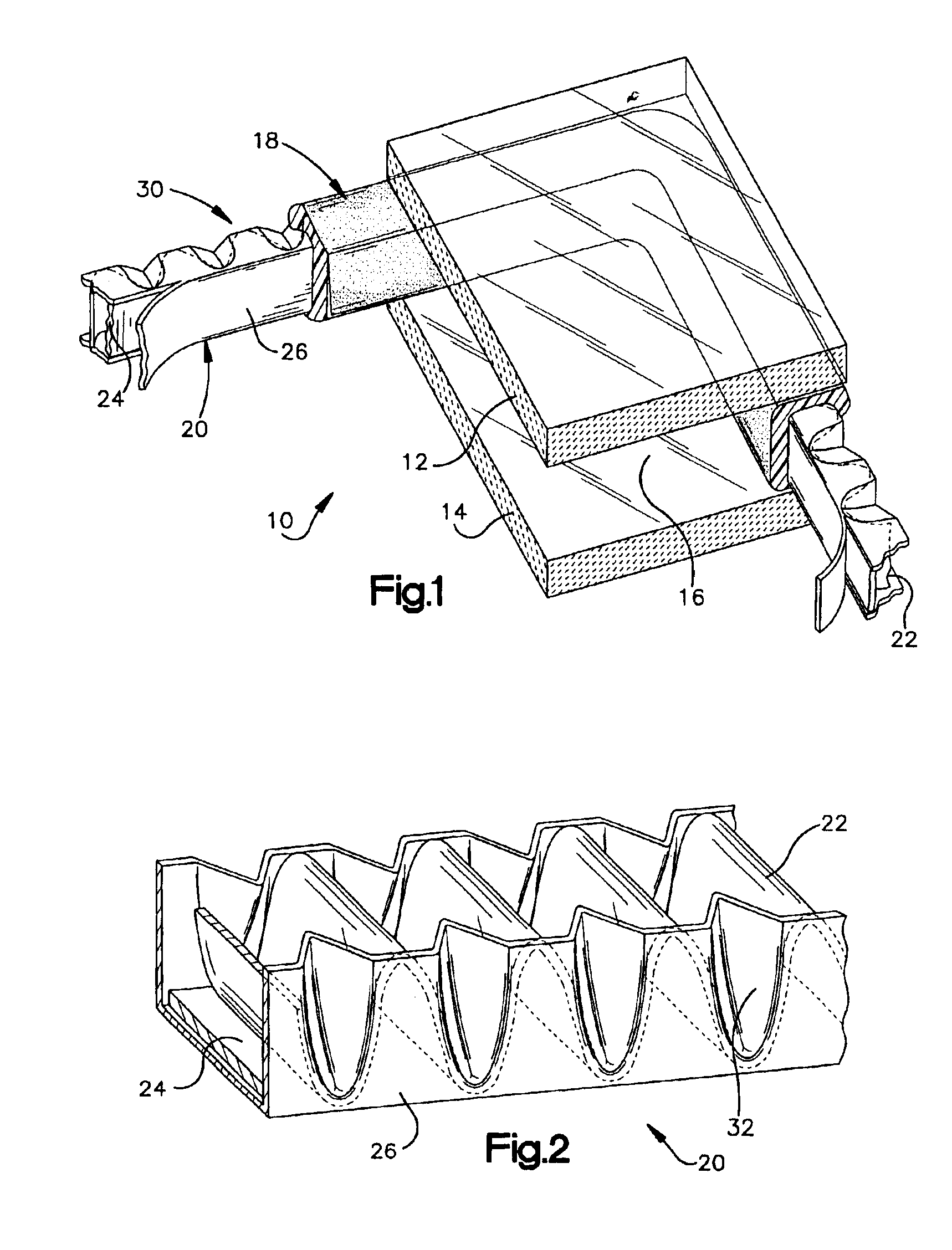

Continuous flexible spacer assembly having sealant support member

InactiveUS6877292B2Easy to produceImprove lateral stabilityTreadsCurtain accessoriesEngineeringSealant

A spacer and sealant assembly comprising a stretchable sealant support member having a planar surface bounded by first and second edges wherein said first and second edges have at least one pleated portion, a plastic shim having at least one undulating portion in contact with said first and second edges of said stretchable sealant support member so that said at least one pleated portion is oriented concavedly inward into said at least one undulating portion of said shim, a sealant joined to at least said first and second edges of said sealant support member.

Owner:QUANEX IG SYST INC

Bathroom floor panel

InactiveUS20080190048A1Prevent slippingReduce the average velocityTreadsFlooringWater flowEngineering

A bathroom floor panel for use in an airtight and water tight space is configured to be efficiently dried in a few hours under ambient conditions. When water drops onto the floor panel, the surface tension of the water is broken by irregular-shaped portions and the water spreads without forming waterdrops. Also, the irregular-shaped portions reduce the flow velocity of the water due to a gradient of the panel, so as to prevent the water flowing in channels to a drain from being discontinued. With this, although the drain velocity of the water is low, substantially no water remains as isolated drops. Further, even if some water remain on the irregular-shaped portions after the water flows out the channels to the drain, any amount of water remaining in the channels is evaporated in a relatively short period of time because the amount of the remaining water is very small.

Owner:TOTO LTD

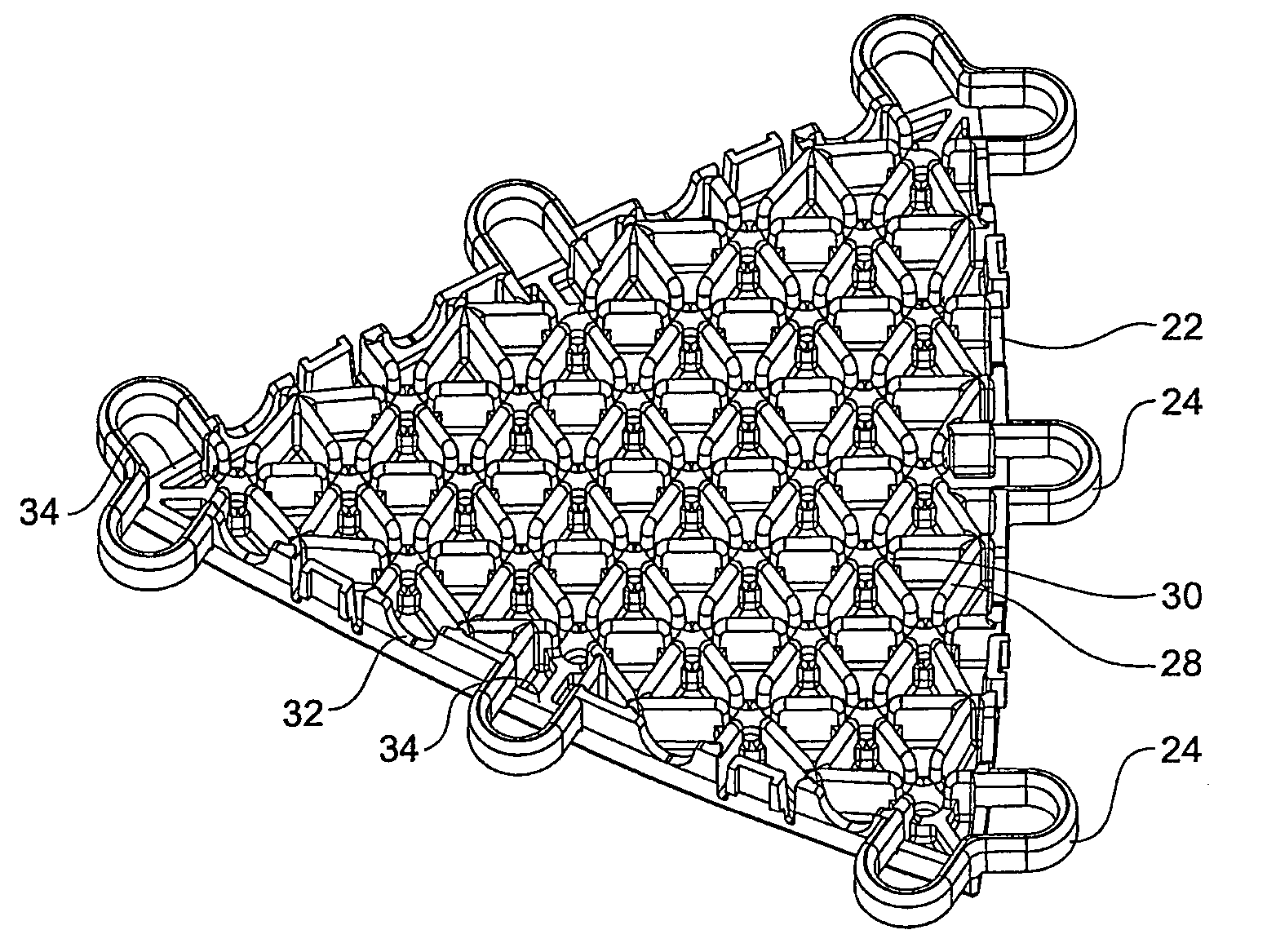

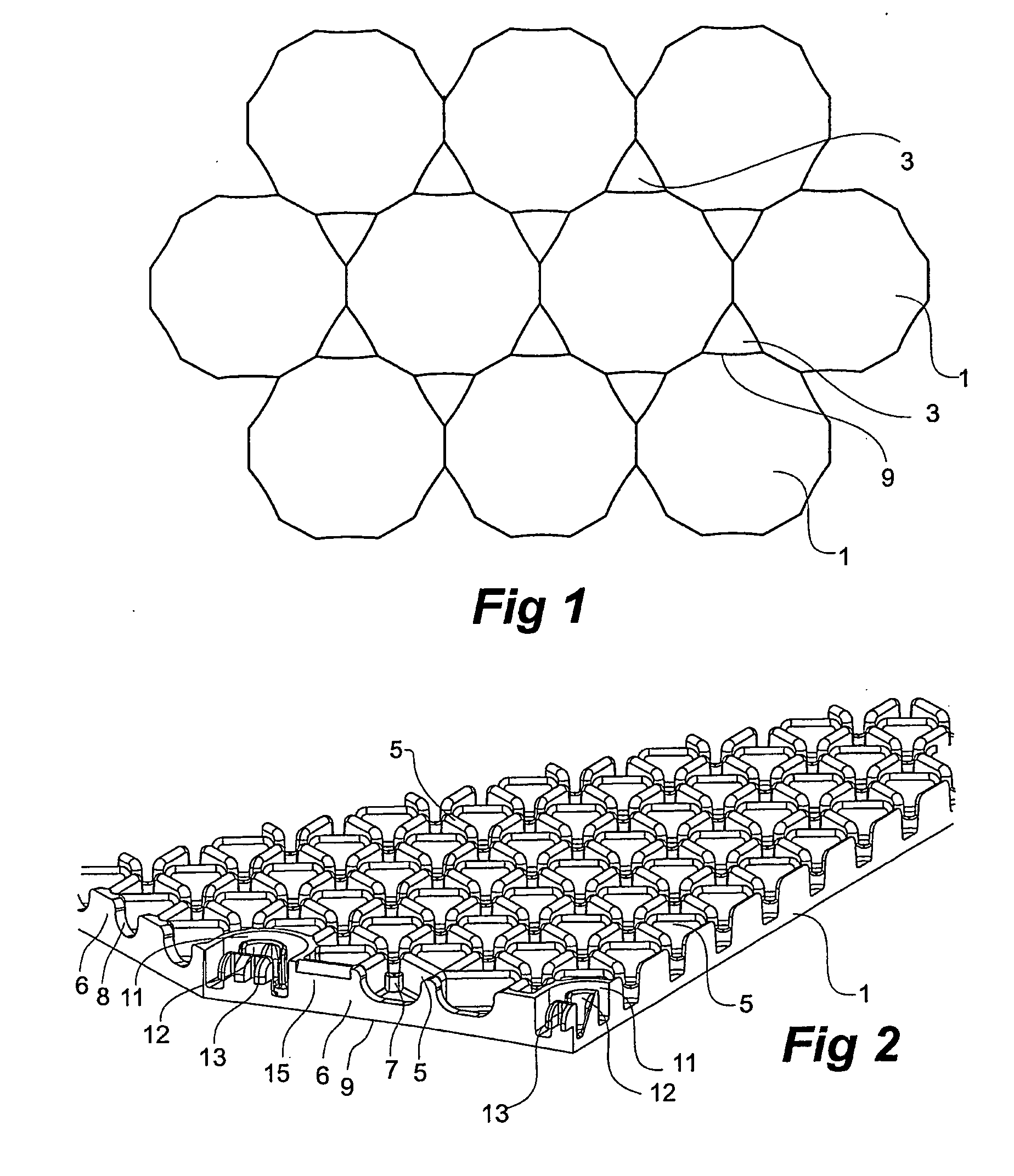

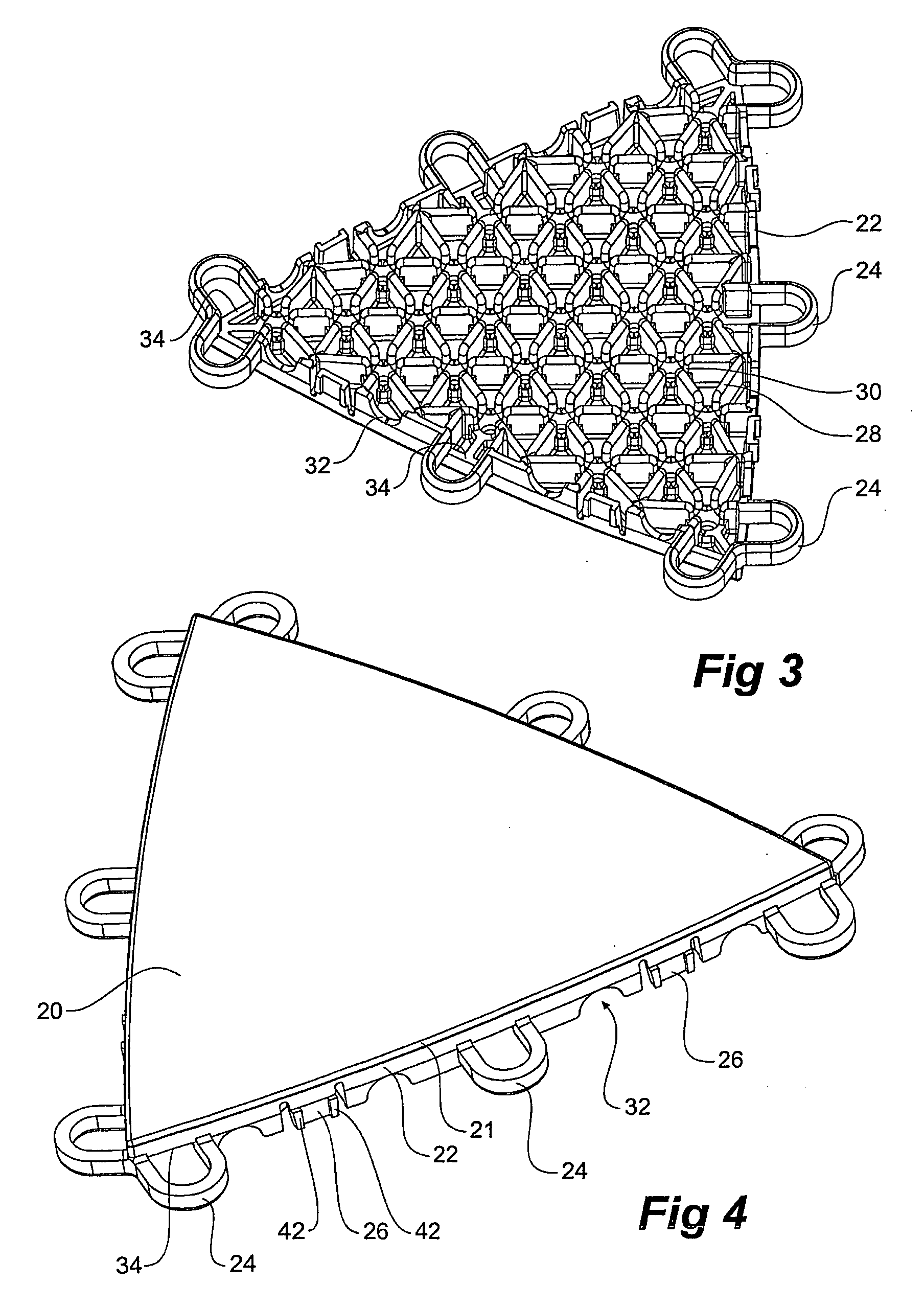

Modular plastic flooring

A modular plastic floor assembly formed from a plurality of shaped tiles (1) and a plurality of shaped connector tiles (3). The shape tiles are substantially larger than the shaped connector tiles and the shaped connector tiles fit into interstices between the shaped tiles when the floor assembly is formed. Each of the shaped tiles and the shaped connector tiles have a substantially planar upper surface (20) and a support array (5, 28) extending from a lower surface of the body. The shaped tiles have connectors (11) and the shaped connector tiles have complementary connectors (24). The connectors are adapted to interengage to interlock the shaped tiles to adjacent shaped connector tiles. Resiliently loaded fingers (118) allow for expansion and contraction between the adjacent tiles. The support array may include resiliently moulded shock absorbing portions (141). The upper surface may have in-mould decoration to provide a surface with changed appearance, frictional properties and / or surface hardness.

Owner:DESIGN DEV COMMLISE

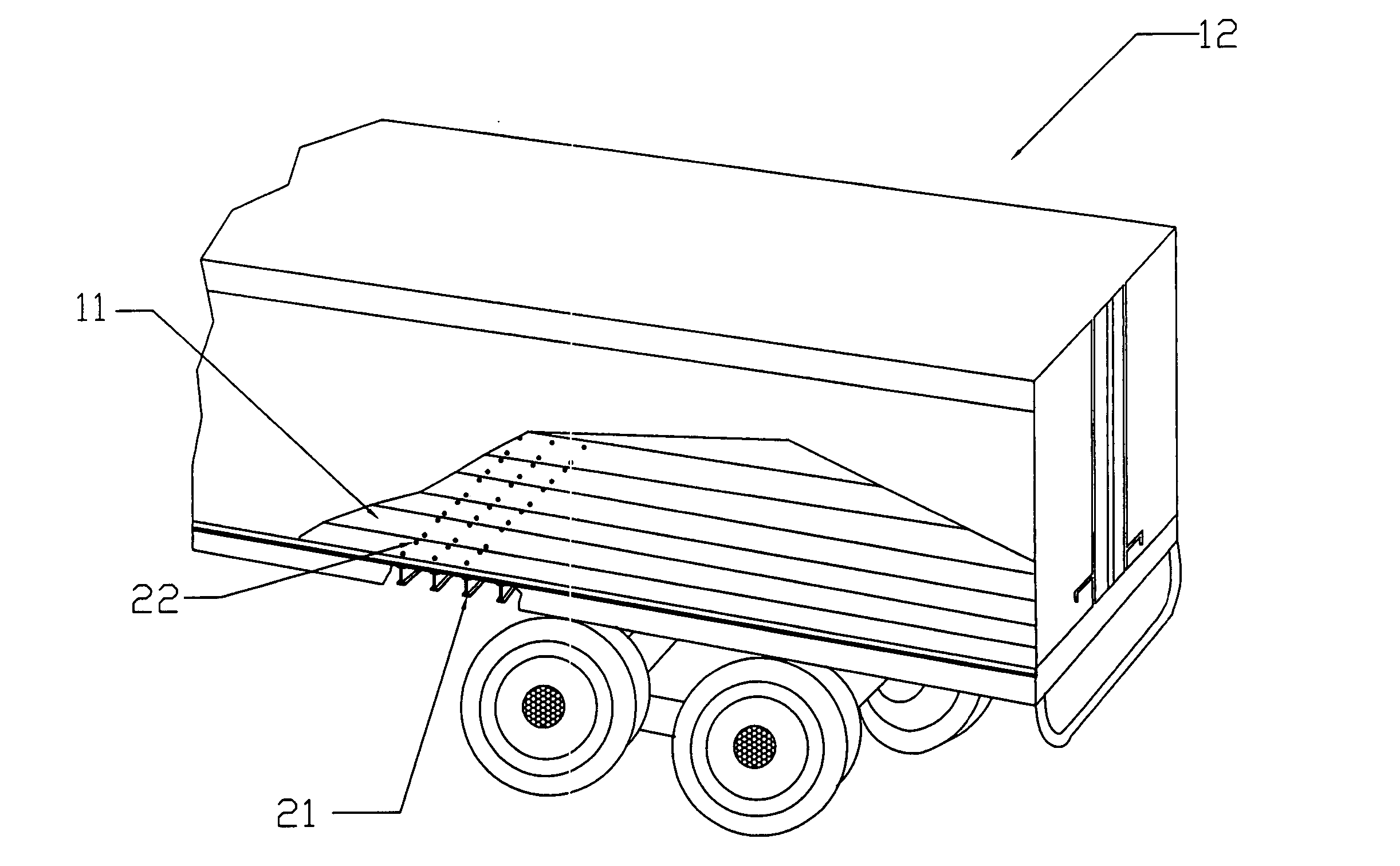

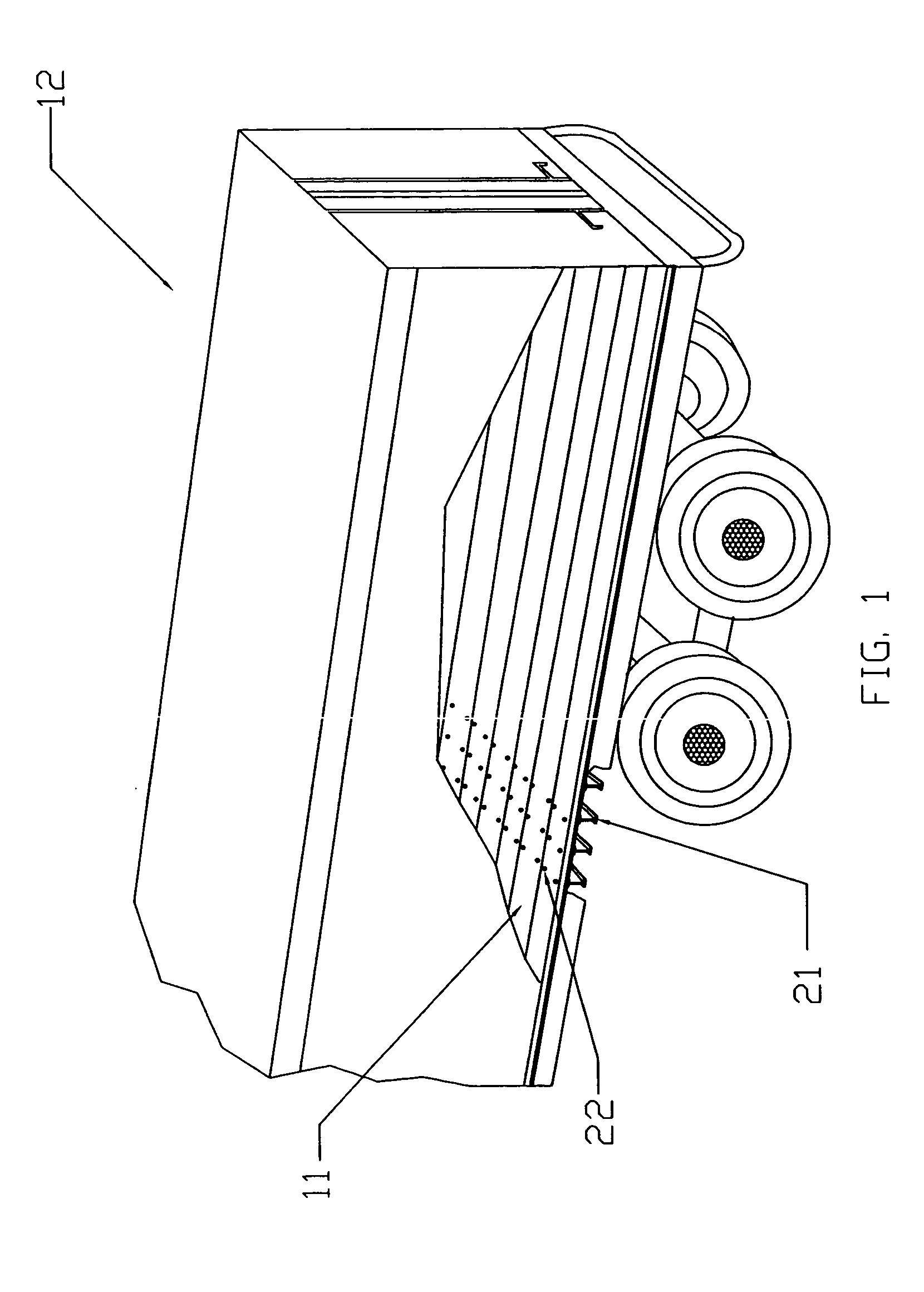

Durable wood-plastic composite flooring for trailers

InactiveUS20060179733A1Little and no structural defectLow costTreadsSynthetic resin layered productsEngineeringThermoplastic composites

A composite wood flooring system for a vehicular trailer floor comprising: a plurality of wood boards, each wood board comprising a top surface and a bottom surface opposite the top surface; and a filled thermoplastic composite layer comprising a thermoplastic polymer and a discontinuous filler, the thermoplastic layer being substantially bonded to the top surface of each wood board.

Owner:HAVCO WOOD PRODS

Modular flooring assemblies

Owner:COMC

Modified bitumen roofing membrane with enhanced sealability

InactiveUS6924015B2Reduce the possibilityImprove the noise reduction effectTreadsRoof covering using flexible materialsThermoplasticEngineering

A self-adhering modified bituminous roof covering composite that comprises a thermoplastic (APP), elastomeric (SBS) or TPO modified bitumen compound on the front side, and a factory-applied self-adhesive compound on the back side of a reinforcement carrier sheet, with factory-applied tracts of adhesive on the side lap and end lap sections of each roll to enhance adhesion. A method of manufacturing such composite comprising coating an APP or SBS or TPO compound on the upper surface and affixing a self-adhesive compound to the lower surface of a reinforcement carrier support sheet, coating an adhesive on the side lap and end lap areas, applying a release liner to the tacky self-adhesive layer, and applying release films to the side and end laps during manufacture, stripping the release liner, selvage release film and end lap film from the membrane immediately prior to use, subsequently placing the exposed self-adhesive side of the membrane directly on to the end lap areas and side lap areas of adjacent rolls and applying force directly to the sheet to enhance the bond between the two sheets, resulting in a continuous roof covering. The present invention relates generally to residential and commercial roofing membranes.

Owner:POLYGLASS

Skid resistant surfaces

InactiveUS20070044397A1Good for scrollingExcellent skidTreadsRoof covering using flexible materialsPressure sensitiveCivil engineering

Skid-resistant surfaces as described having either a pressure-sensitive adhesive layer or a highly filled, textured binder to reduce skidding. The surfaces are applied to trafficable surfaces such as roof and floors. Products such as roof underlyments bearing the surfaces are described in particular.

Owner:WR GRACE & CO CONN

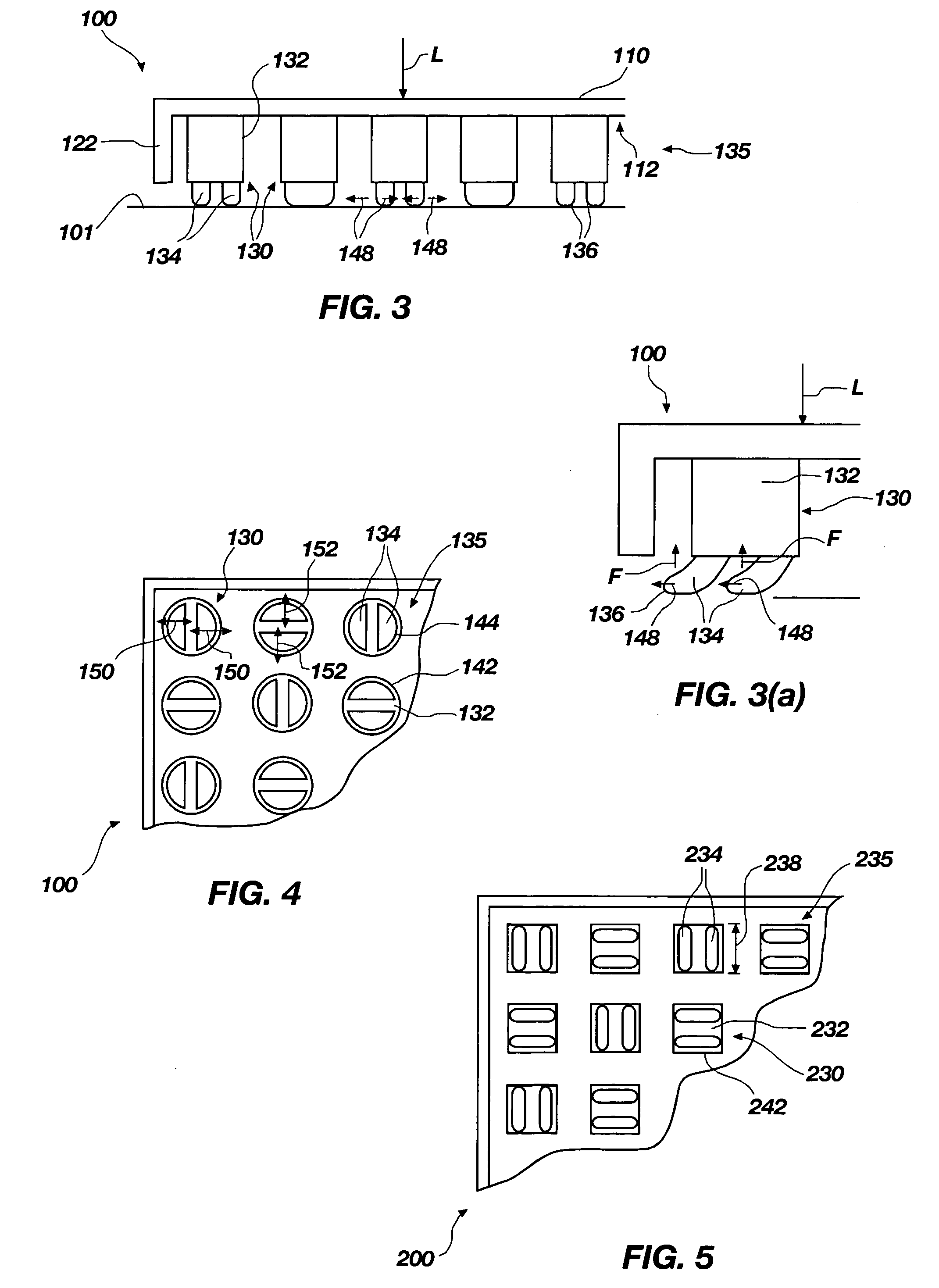

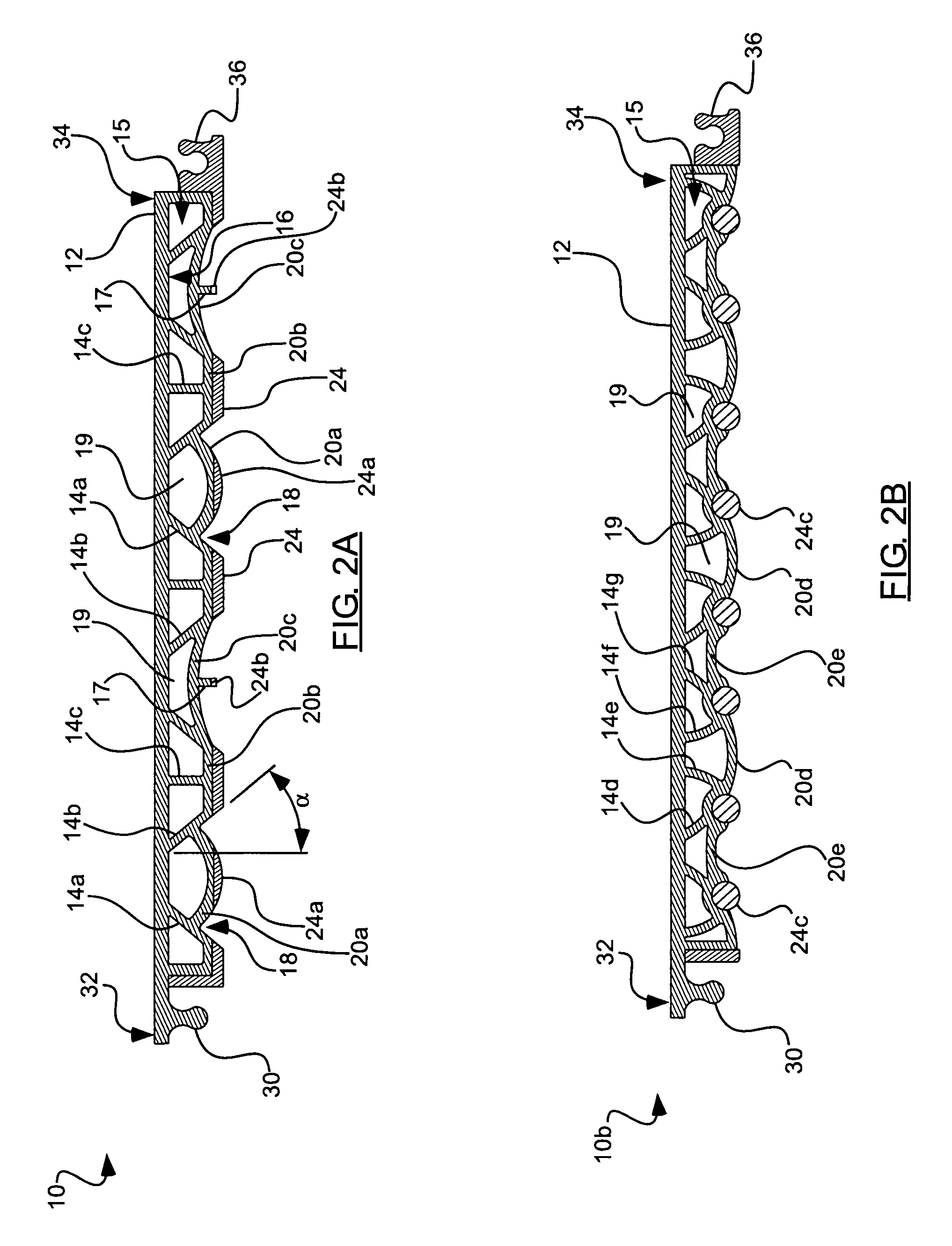

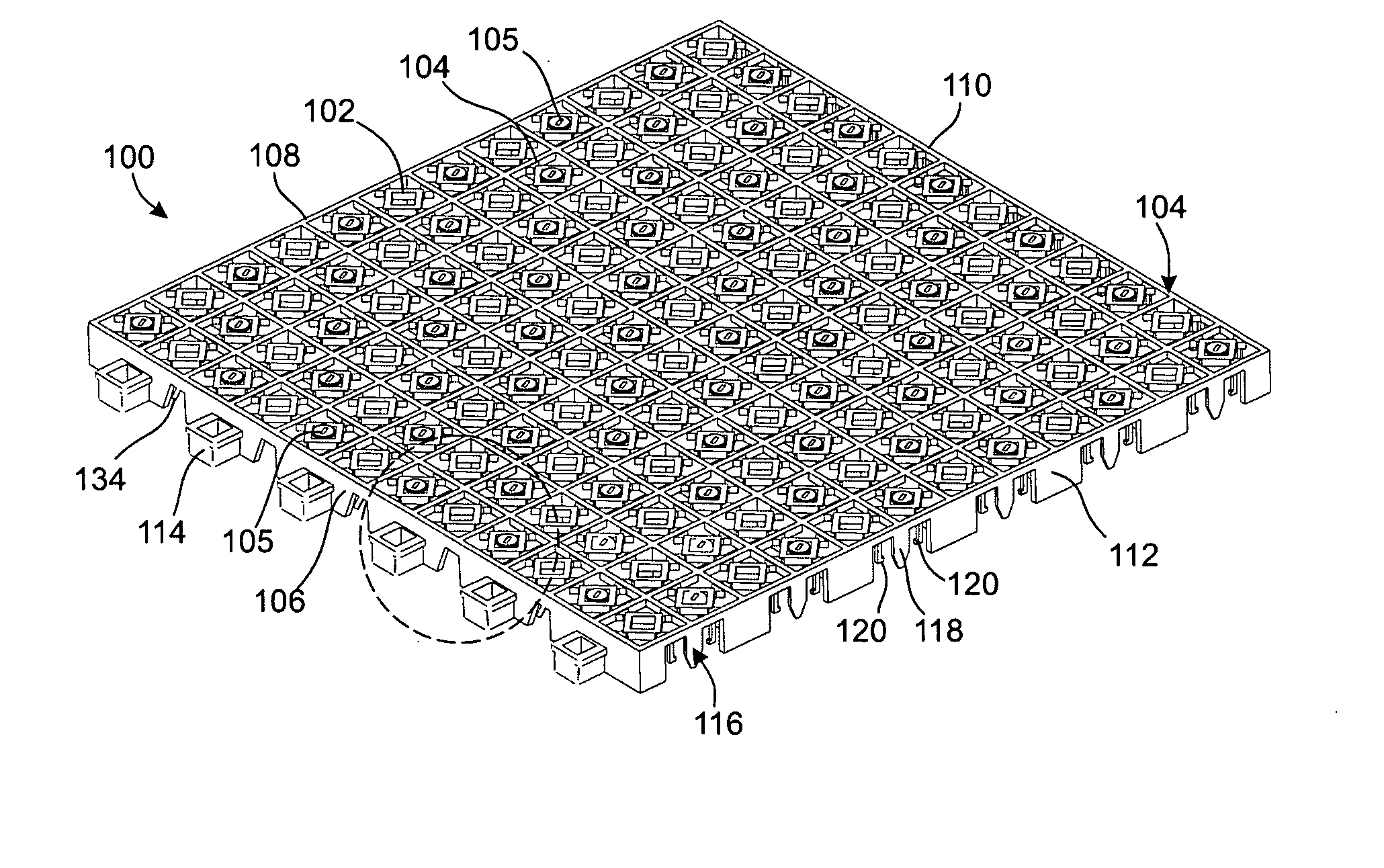

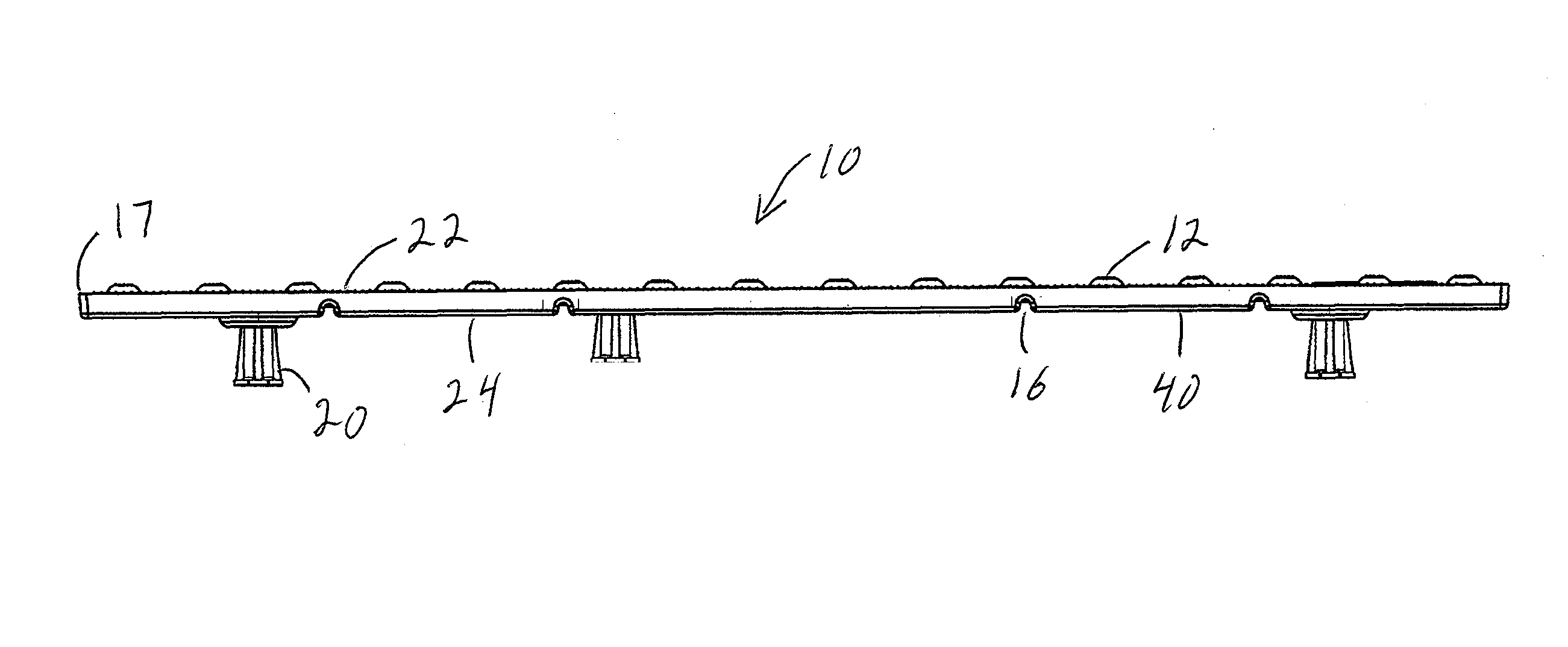

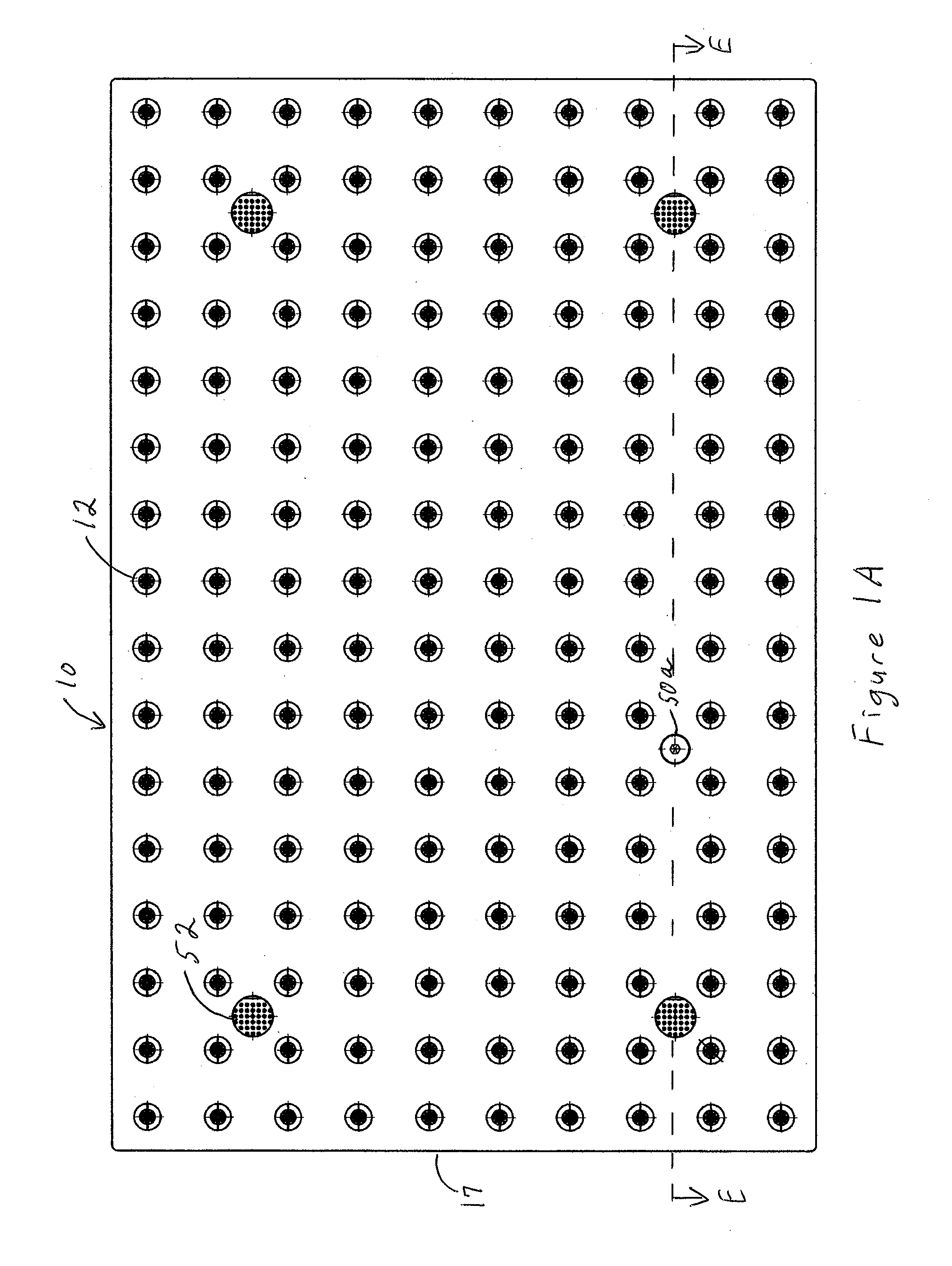

Modular floor tile with nonslip insert system

The principles described herein provide floor tiles and modular floors. The floor tiles include inserts that increase traction. The inserts may be removable and protrude from a top surface of the floor tiles. The tiles may include a locking system that allows adjacent tiles to interlock, while also permitting a predetermined amount of lateral sliding relative to one another. The modular tiles may be injection molded and the inserts may comprise an elastomer. The floor tiles may also provide four layers of traction, providing more sure footing than previous flooring systems.

Owner:UNITED TECH CORP +1

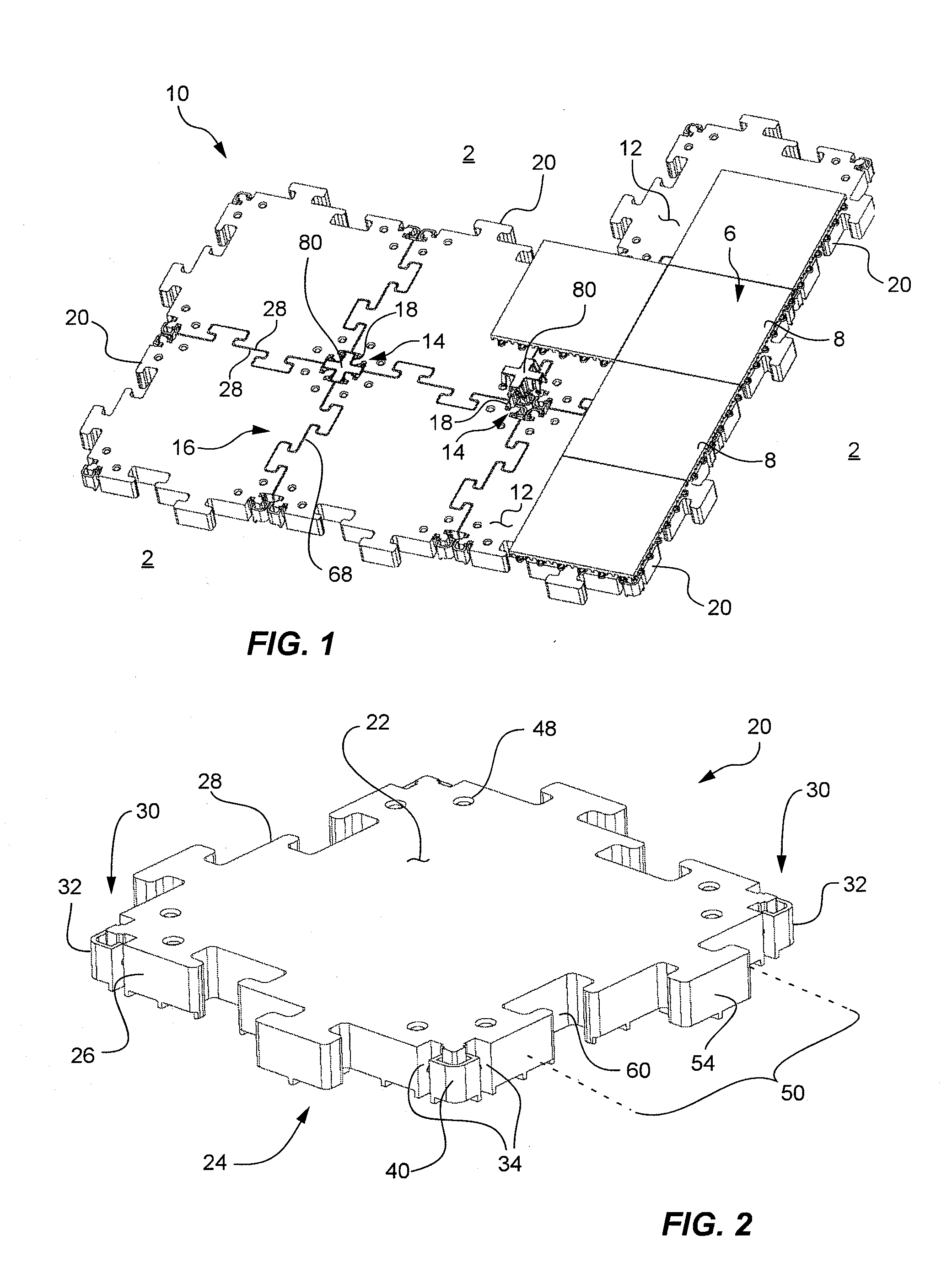

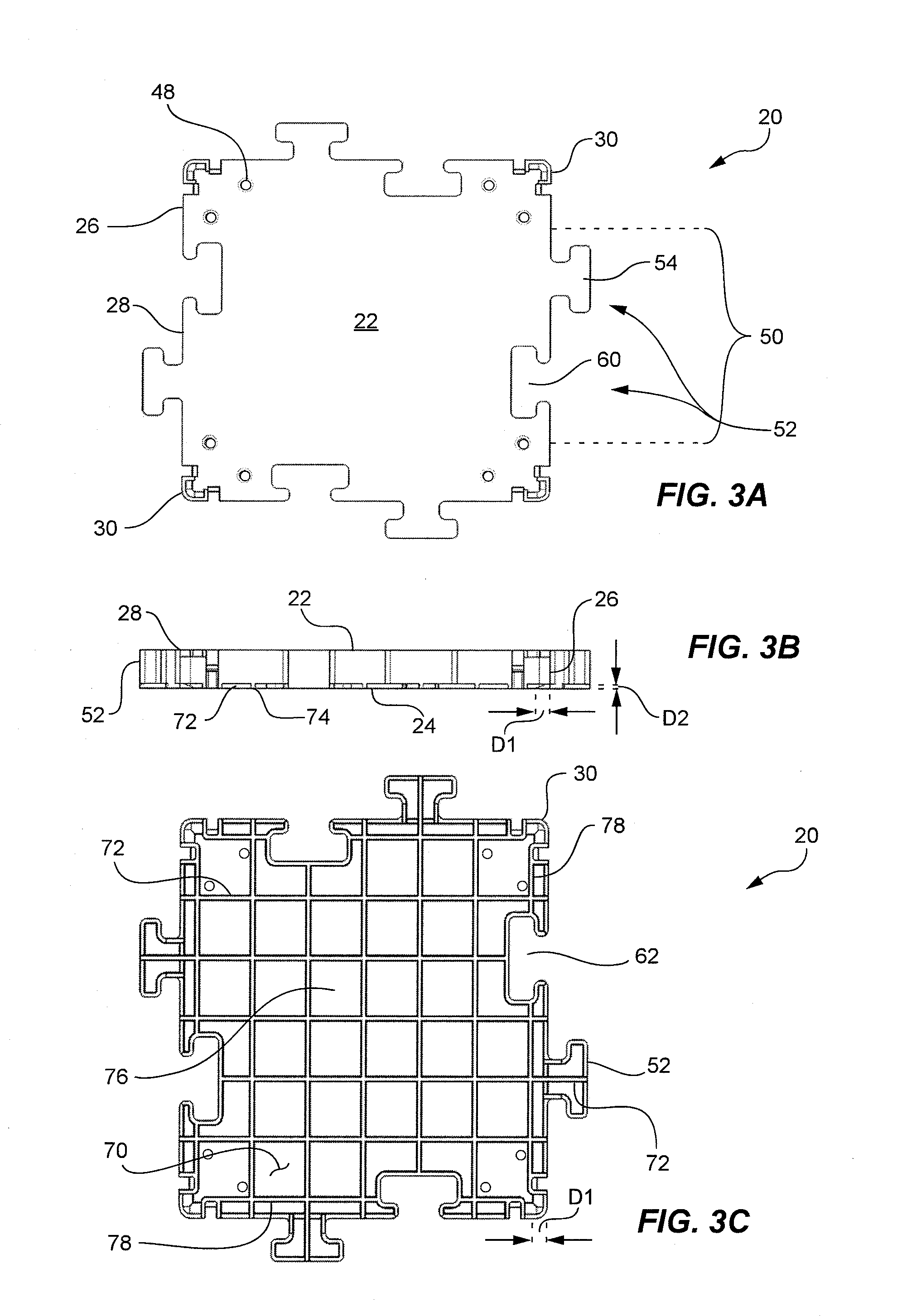

Modular floor tile system with sliding lock

The present invention provides floor tiles and modular floors. The floor tiles may include a locking system that allows adjacent tiles to interlock, while also permitting a predetermined amount of lateral sliding relative to one another. The modular tiles may be injection molded, and a minor change in the mold facilitates variation to the amount of lateral slide allowed between interlocked tiles. The floor tiles may also provide three layers of traction, providing more sure footing than previous flooring systems. In addition, the floor tiles may comprise a two-tier suspension system that yields a flex or spring-like effect.

Owner:SNAP LOCK INDS

Replaceable wet-set tactile warning surface unit and method of installation and replacement

A replaceable, wet-set tactile warning surface unit having a body defining an upper surface and a lower surface, the body defining a series of raised projections on its upper surface, and defining a plurality of spaced through-holes from the top to the bottom surface, in which the raised projections are spaced from one another and the through-holes are located between projections. An anchor member such as a threaded insert is coupled to the bottom surface of the unit member directly below each of the through-holes by fasteners such as bolts that pass through the through-holes.

Owner:ADA SOLUTIONS

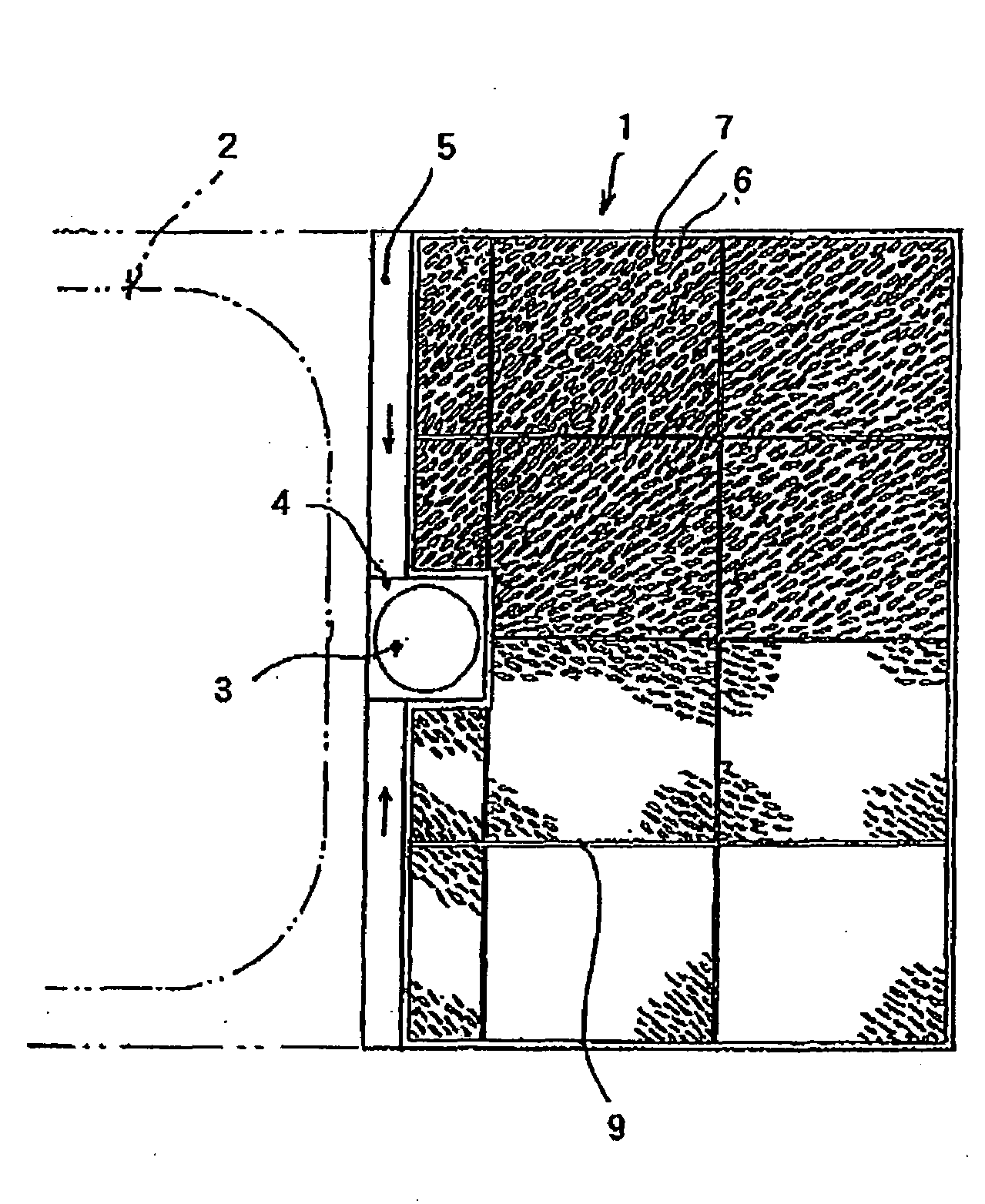

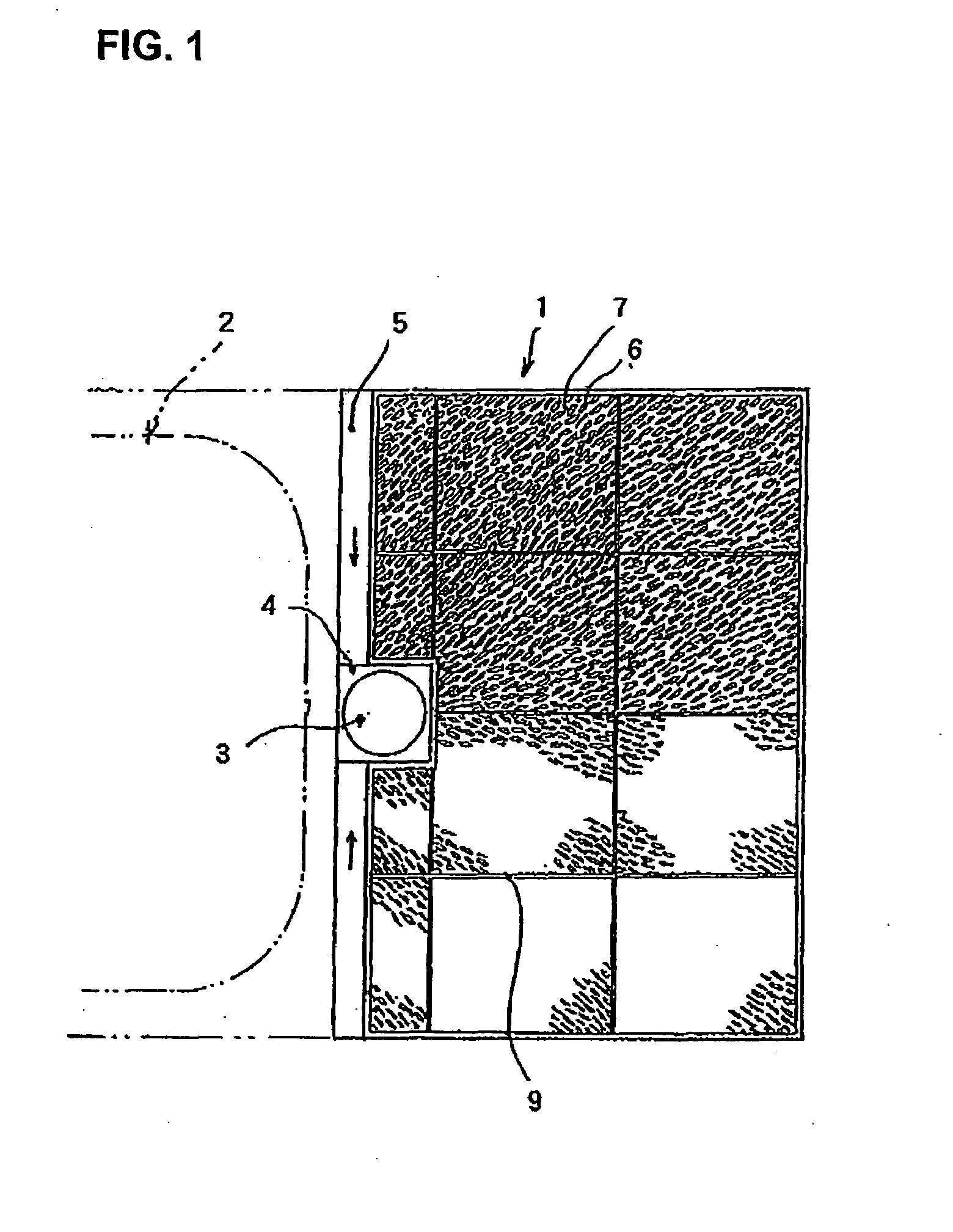

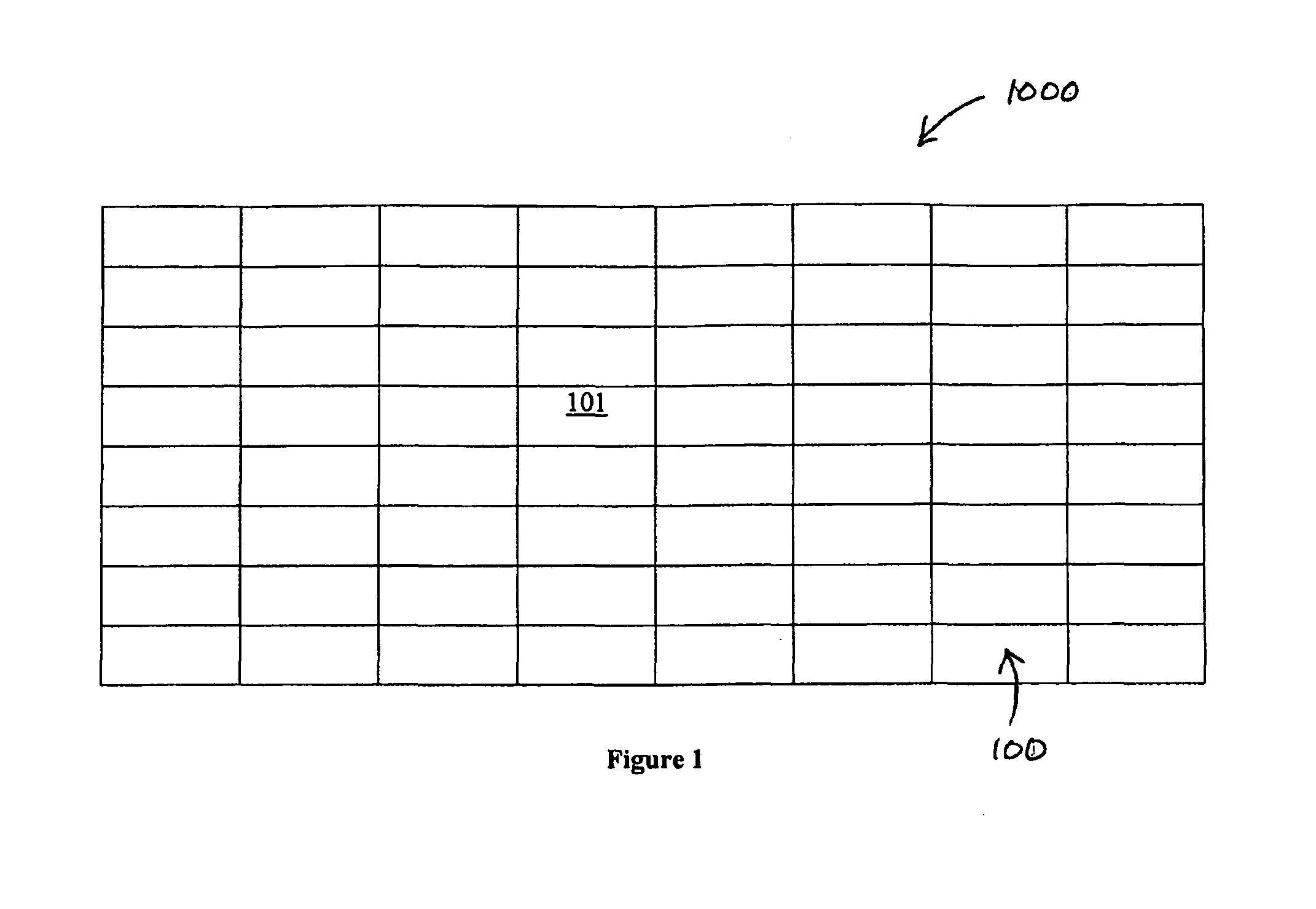

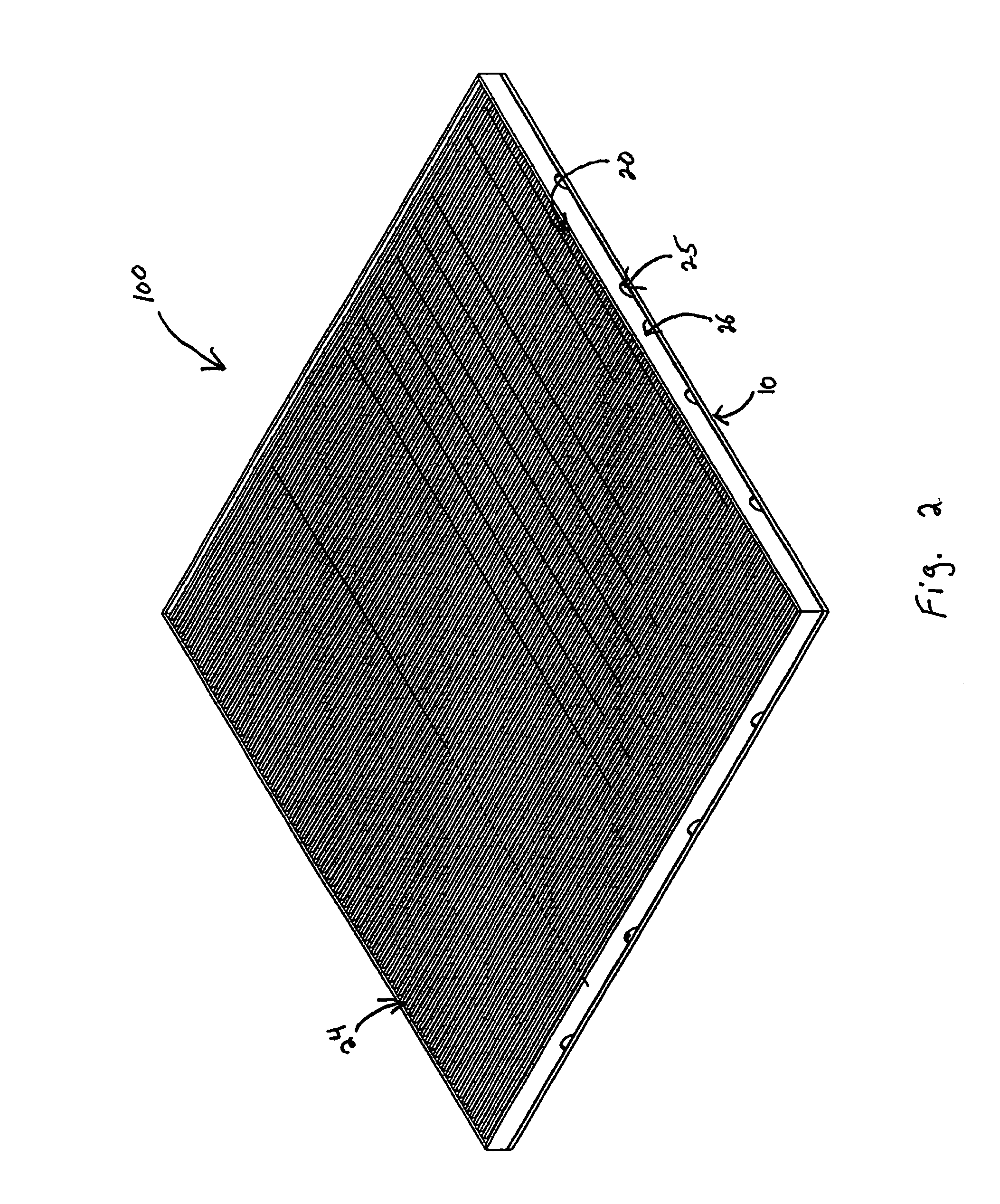

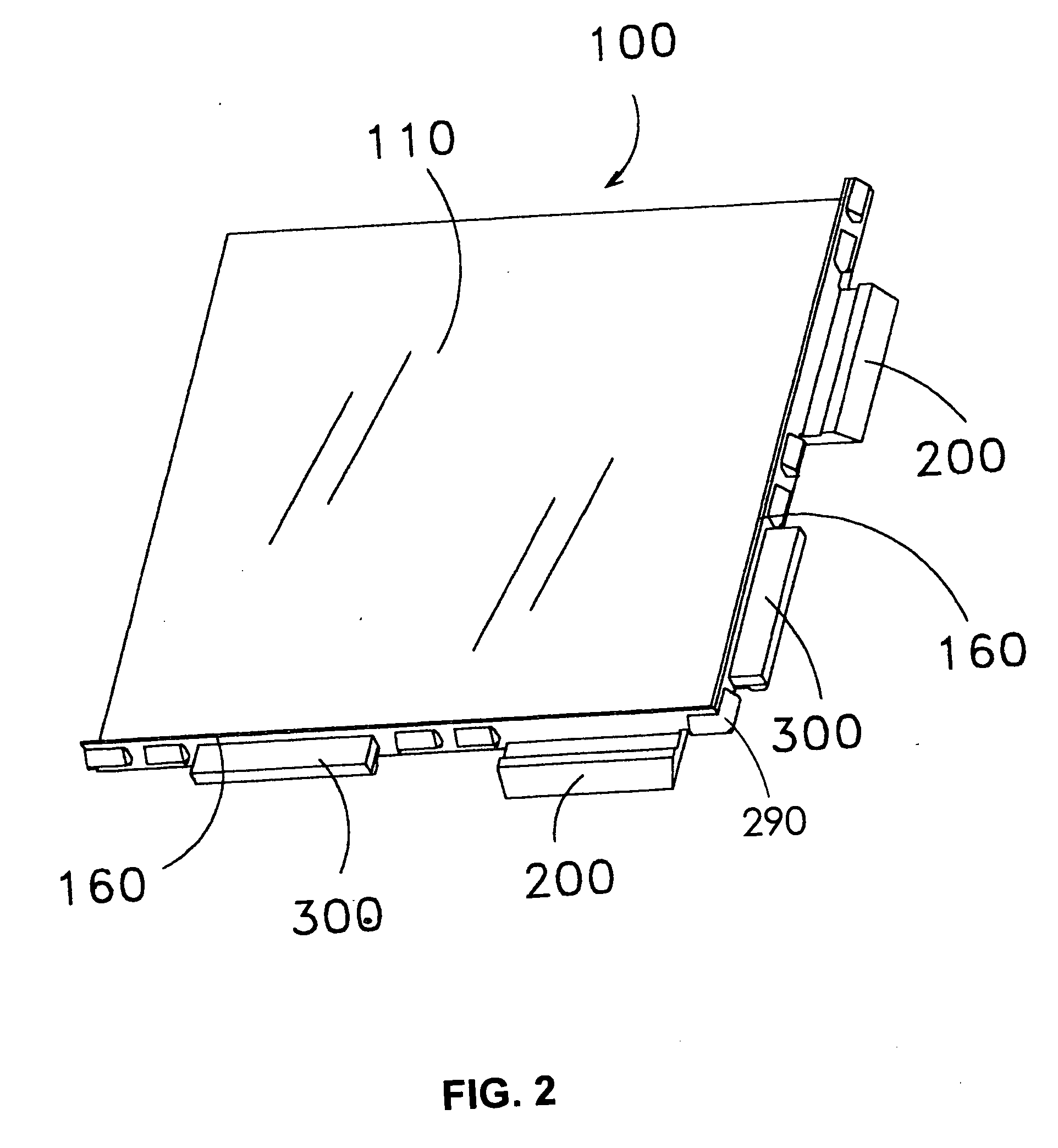

Modular entrance floor system

A modular entrance floor system comprising a plurality of floor sections, the plurality of floor sections being disposed adjacent each other and defining a perimeter of an entrance floor area. Each floor section includes a base plate permanently coupled to a foundation, and a surface plate removably attached to the base plate. The surface plate has at least one drain feature. The plurality of floor sections are configured such that the surface plate of a first floor section is interchangeable with the surface plate of a second floor section, independent of the adjacent floor sections.

Owner:E M E H

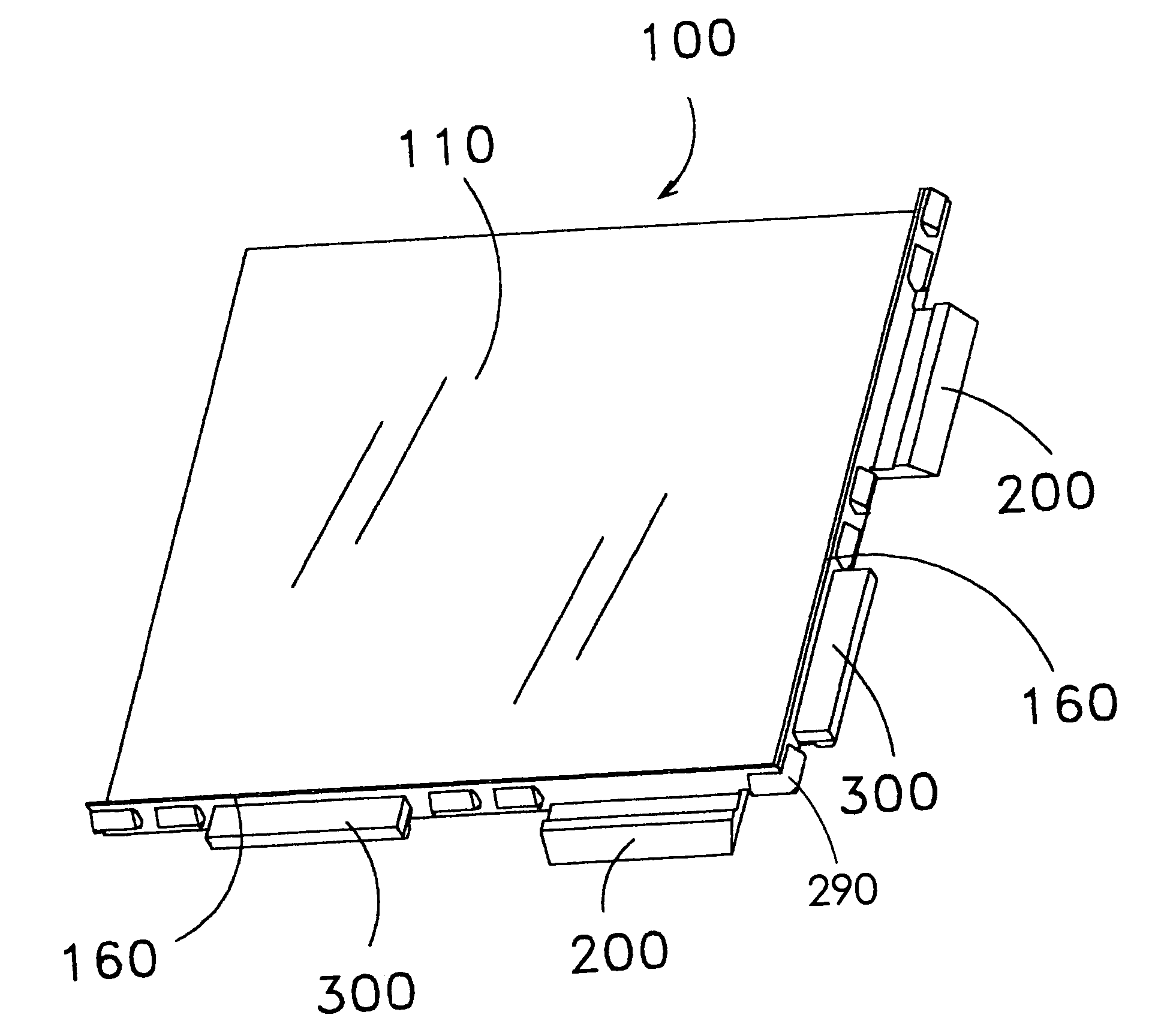

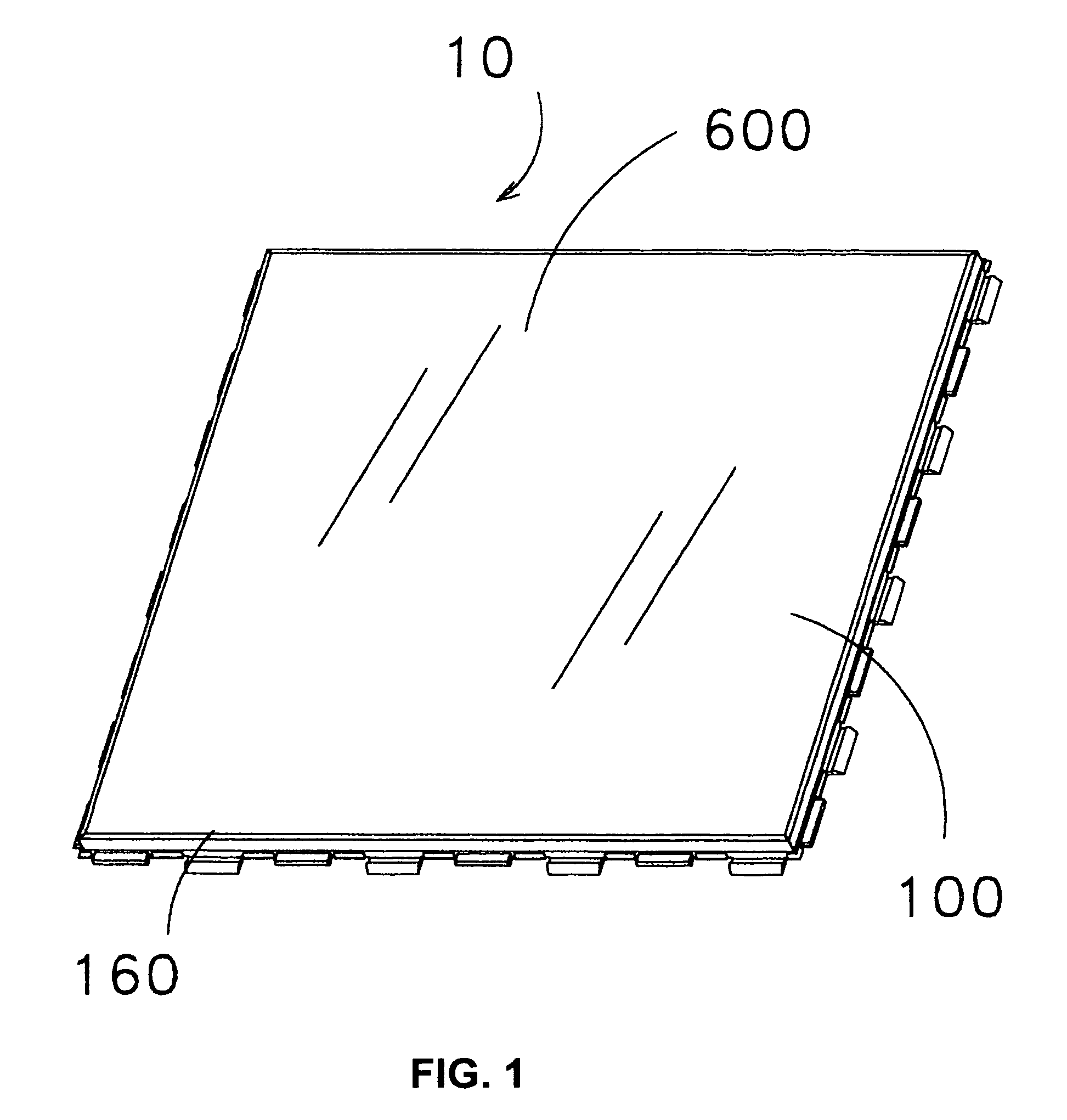

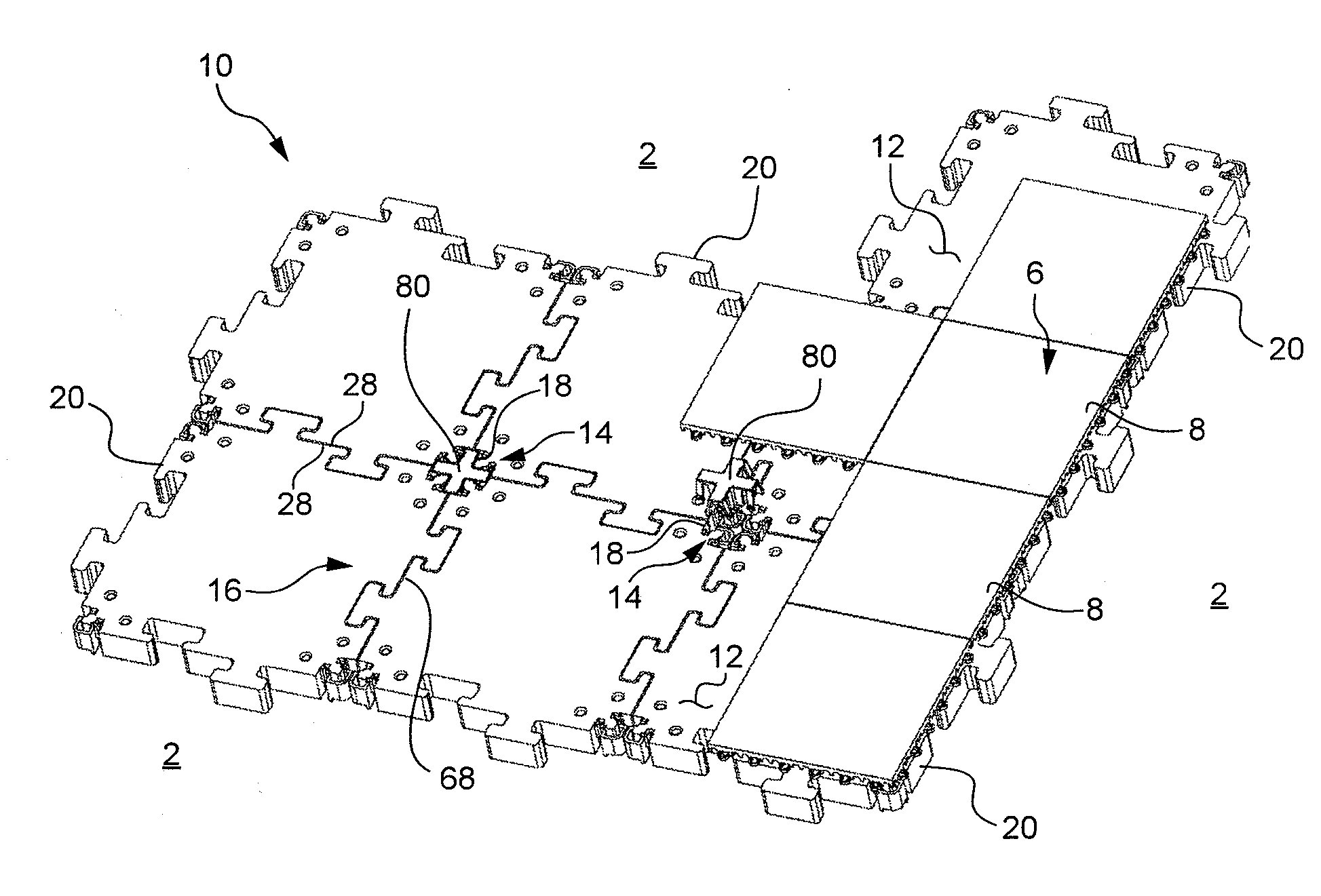

Modular flooring system

ActiveUS20130167458A1Facilitate controlled relative lateral movementAvoid vertical movementTreadsSingle unit pavingsModularityLateral movement

A modular flooring system includes a plurality of floor tiles situated about a ground surface, with each floor tile having a substantially-flat top surface and a connection interface with opposing engagement surfaces. The flooring system also includes a plurality of removable bridge connectors, with each of the bridge connectors having a plurality of tile interfaces, and with each tile interface having complimentary engagement surfaces configured to engage with the opposing engagement surfaces of the connection interfaces. The tile interfaces of the bridge connectors couple to the respective connection interfaces of any adjacent floor tiles to restrain the relative vertical movement between the adjacent floor tiles while facilitating controlled relative lateral movement between the floor tiles.

Owner:CONNOR SPORT COURT INT

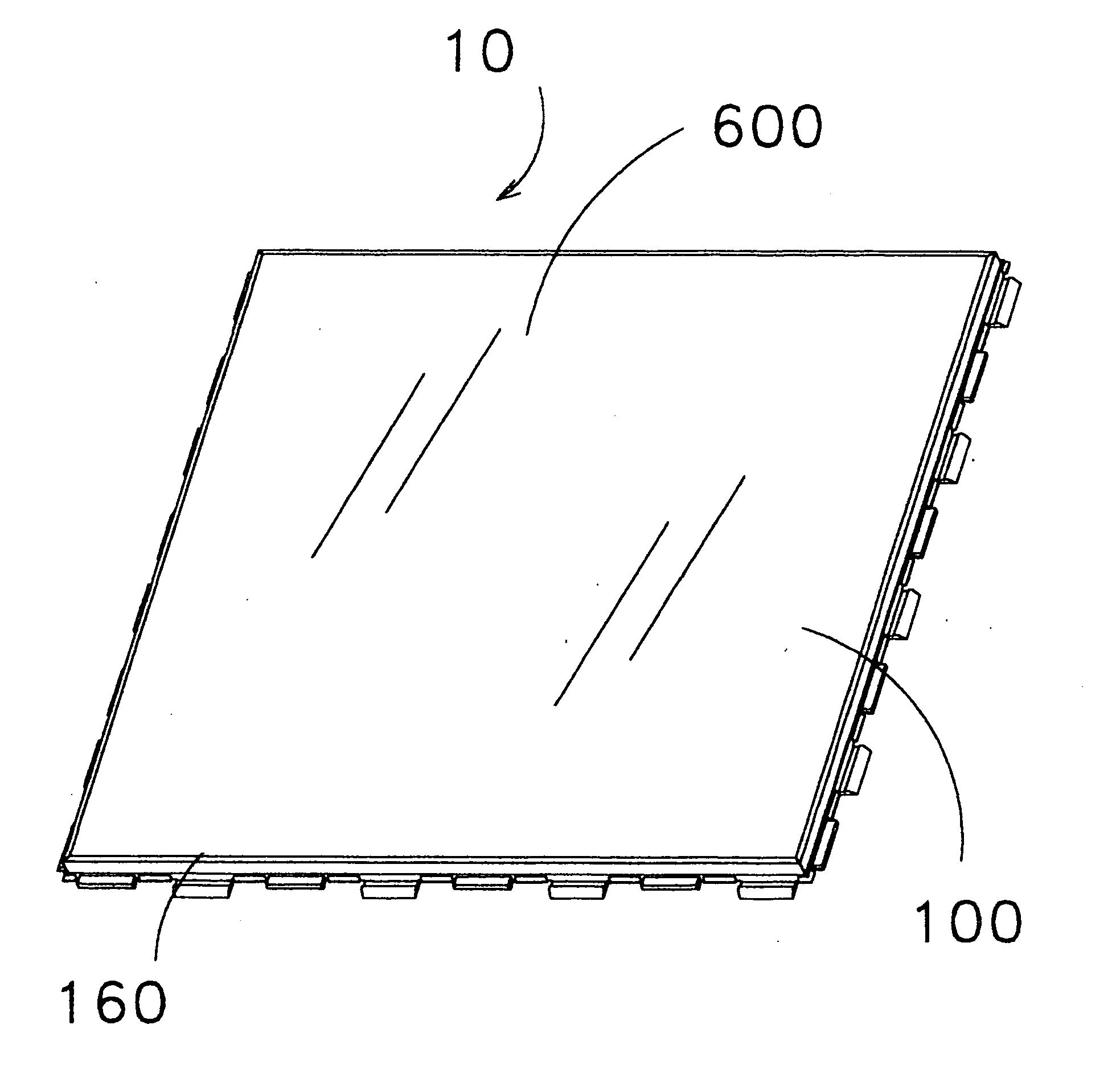

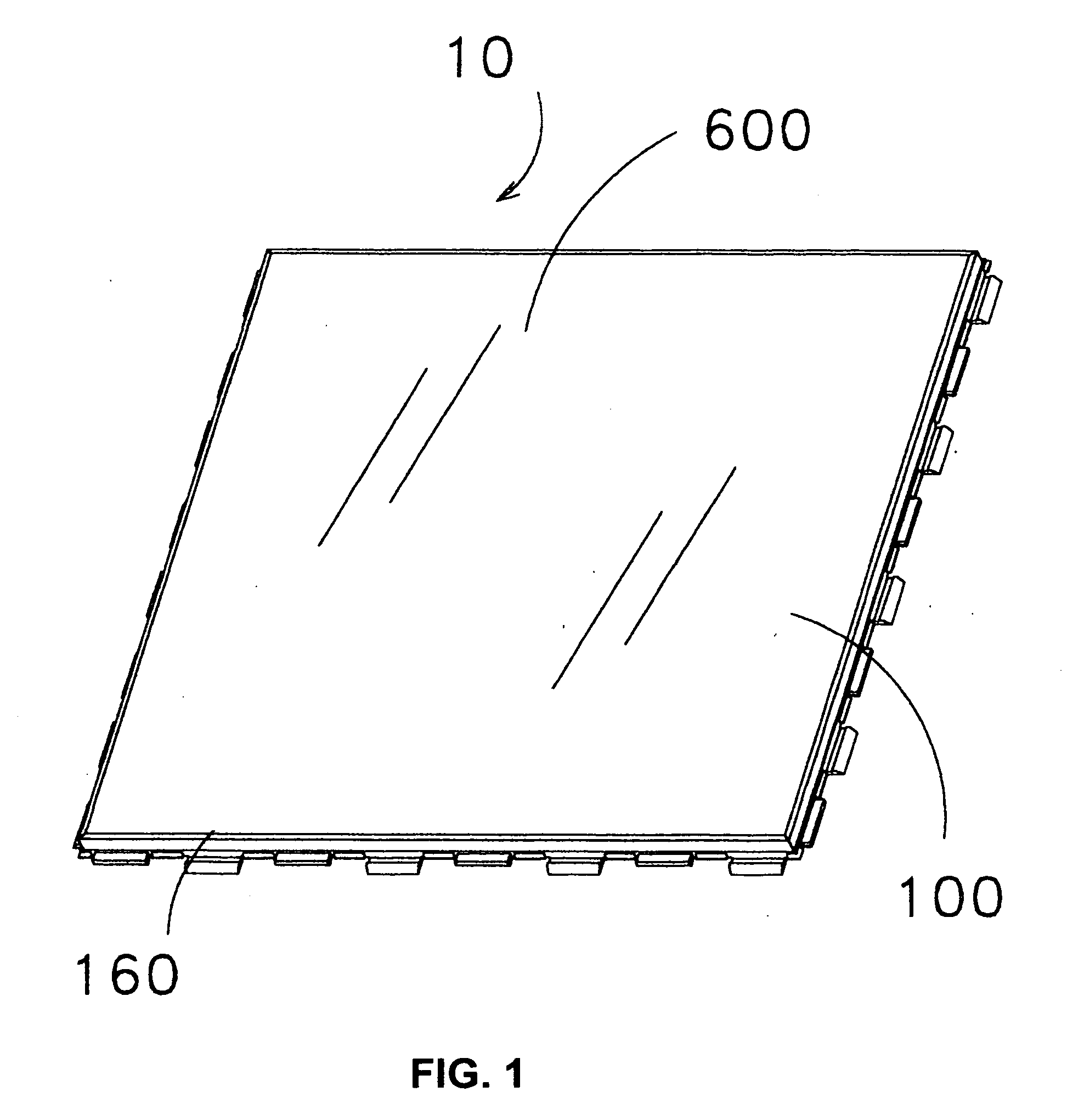

Modular flooring assemblies

A modular flooring assembly including a flooring component adhered to a tray substrate is described. The modular flooring assembly may be interconnected with additional modular flooring assemblies to form a modular floor suitable for most flooring applications. The flooring component may be tile or wood or other materials commonly used in flooring applications. Convention fill-in grout or a snap-in grout may be used with the modular flooring assemblies. One suitable snap-in grout is a right angle grout member.

Owner:COMC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com