Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10535results about "Building reinforcements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

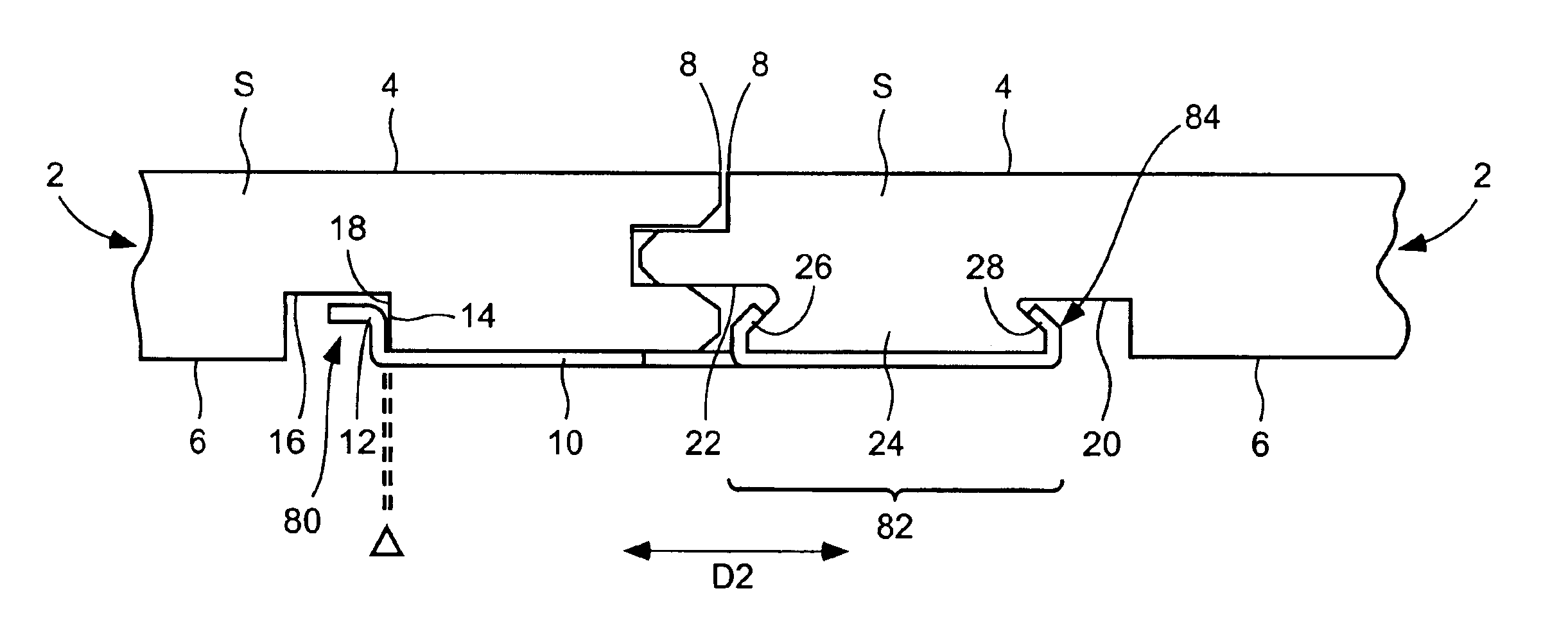

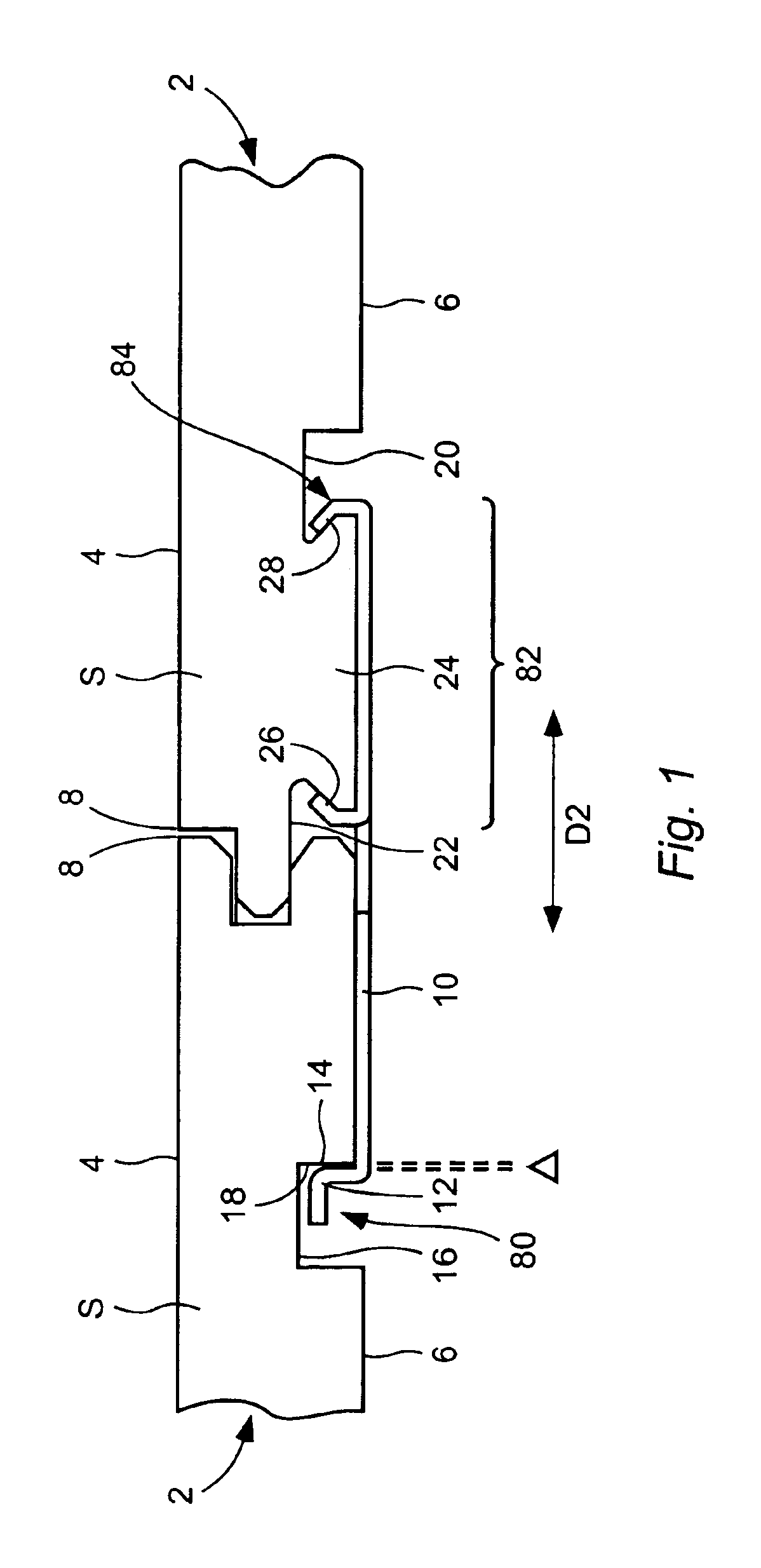

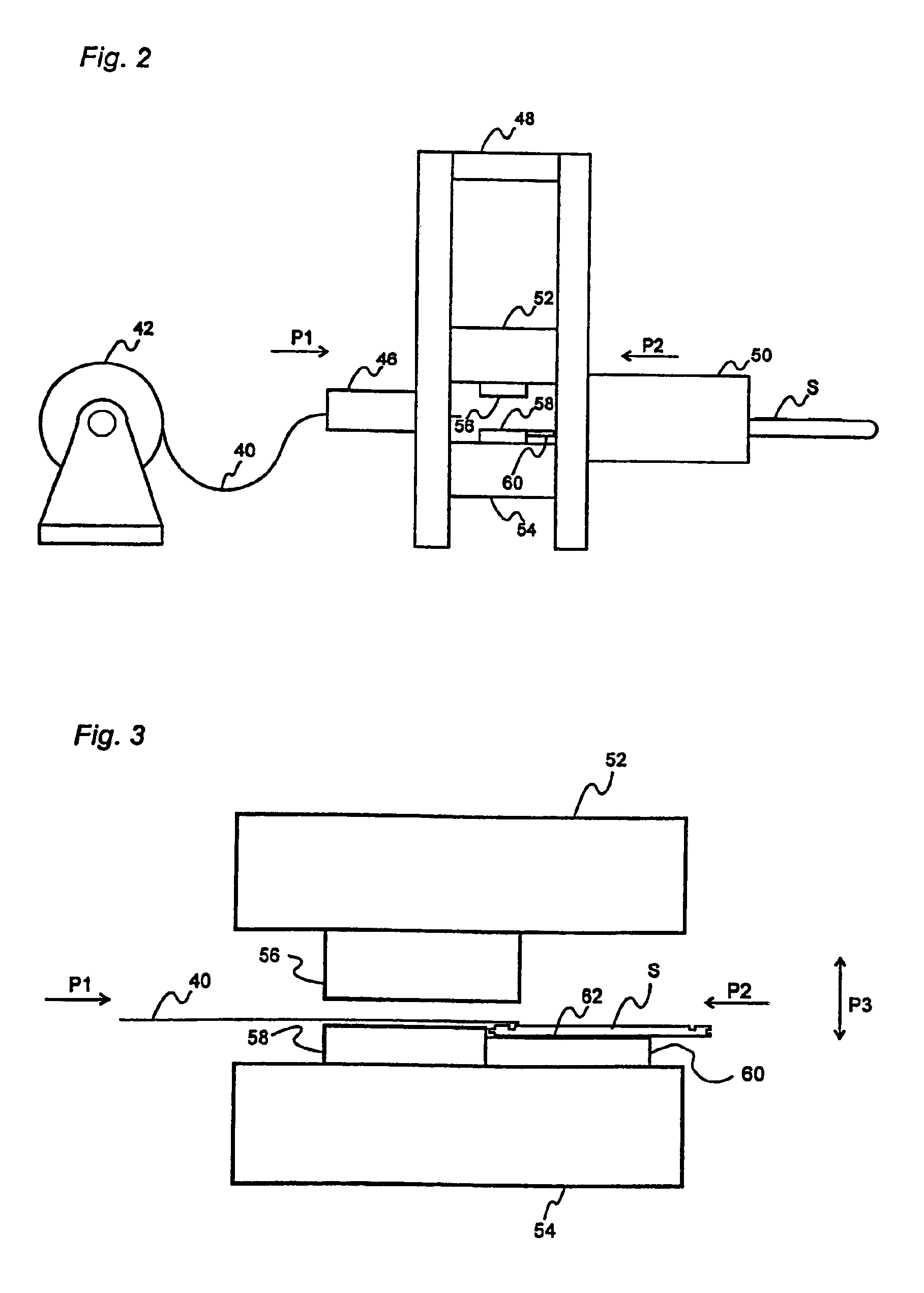

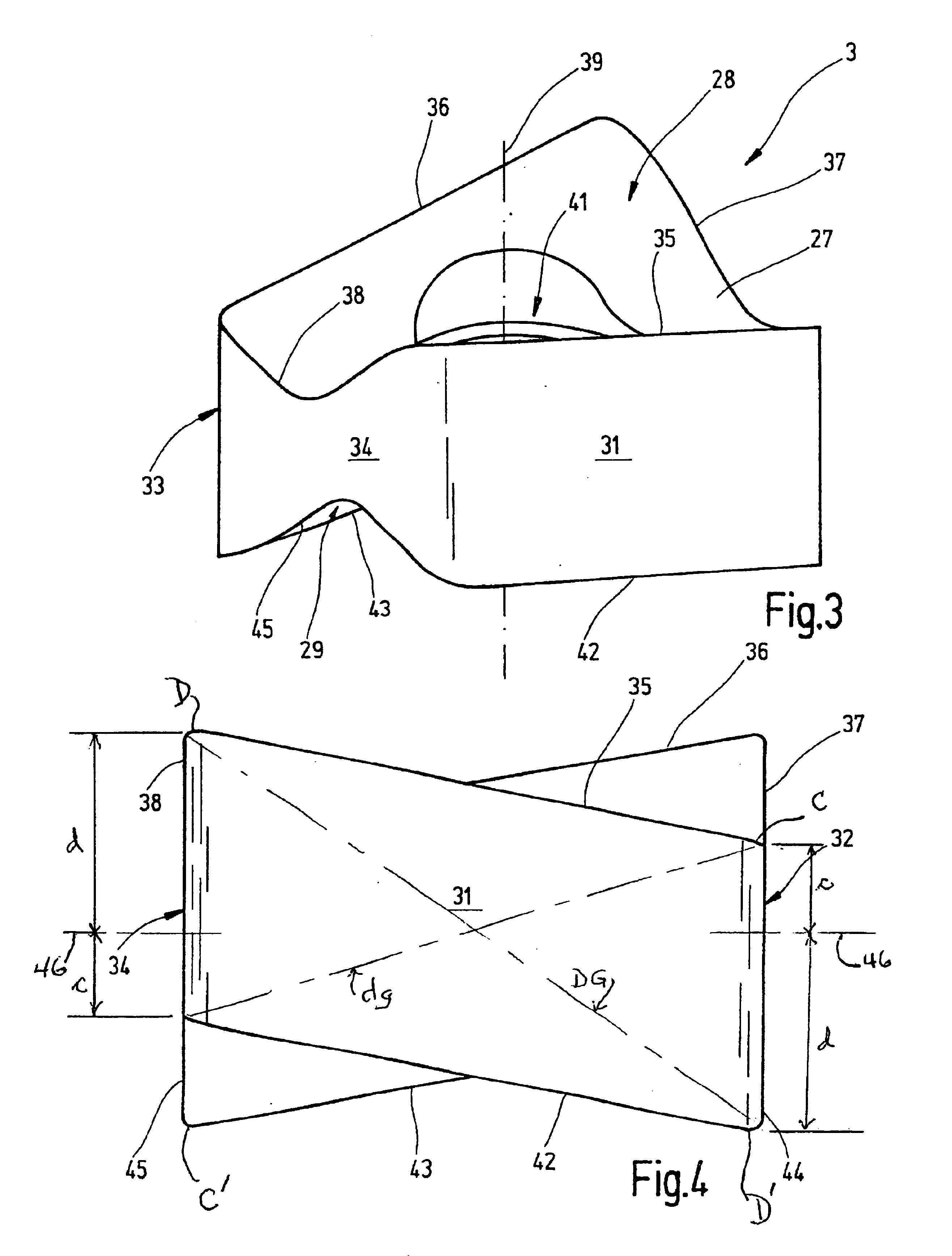

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipement to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

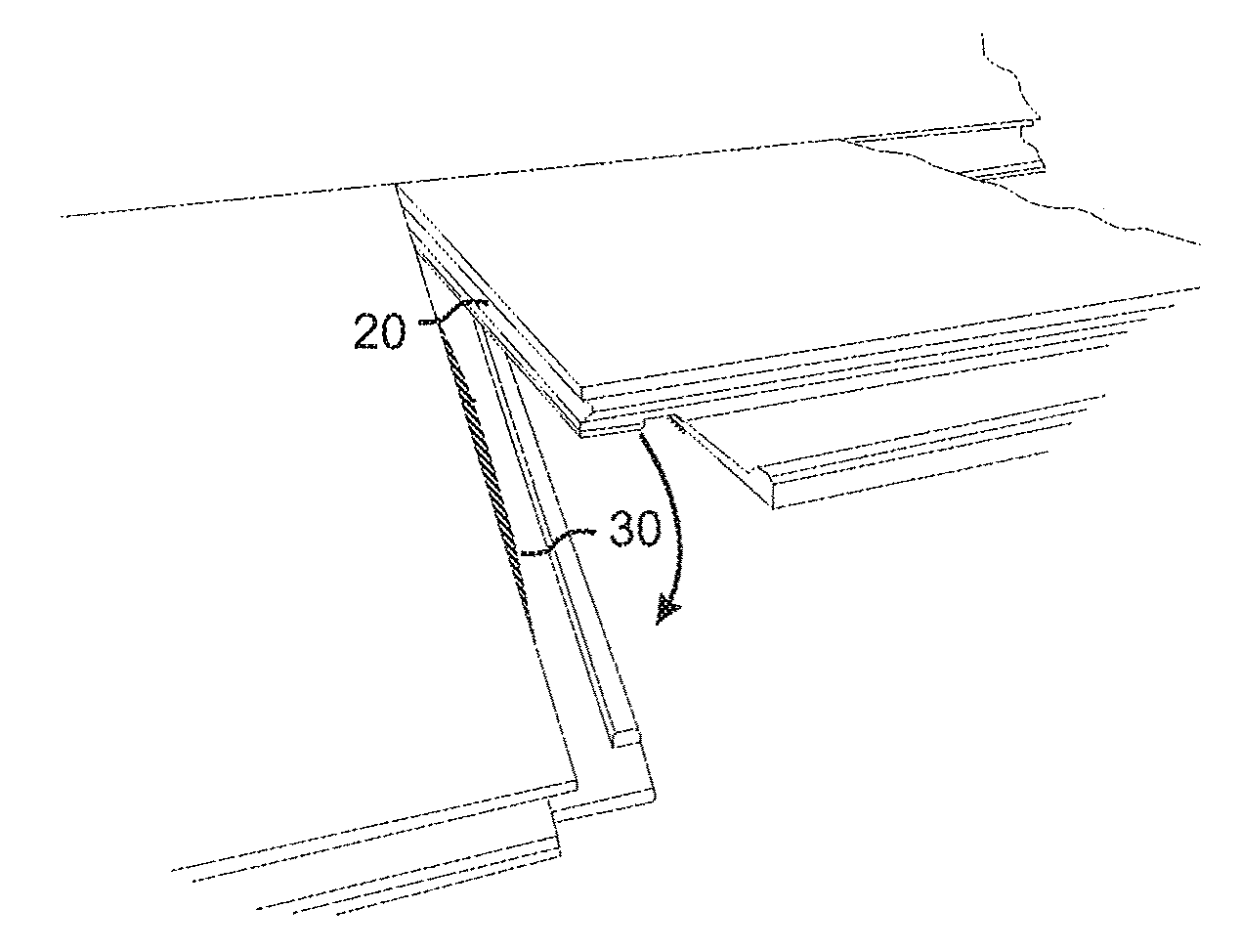

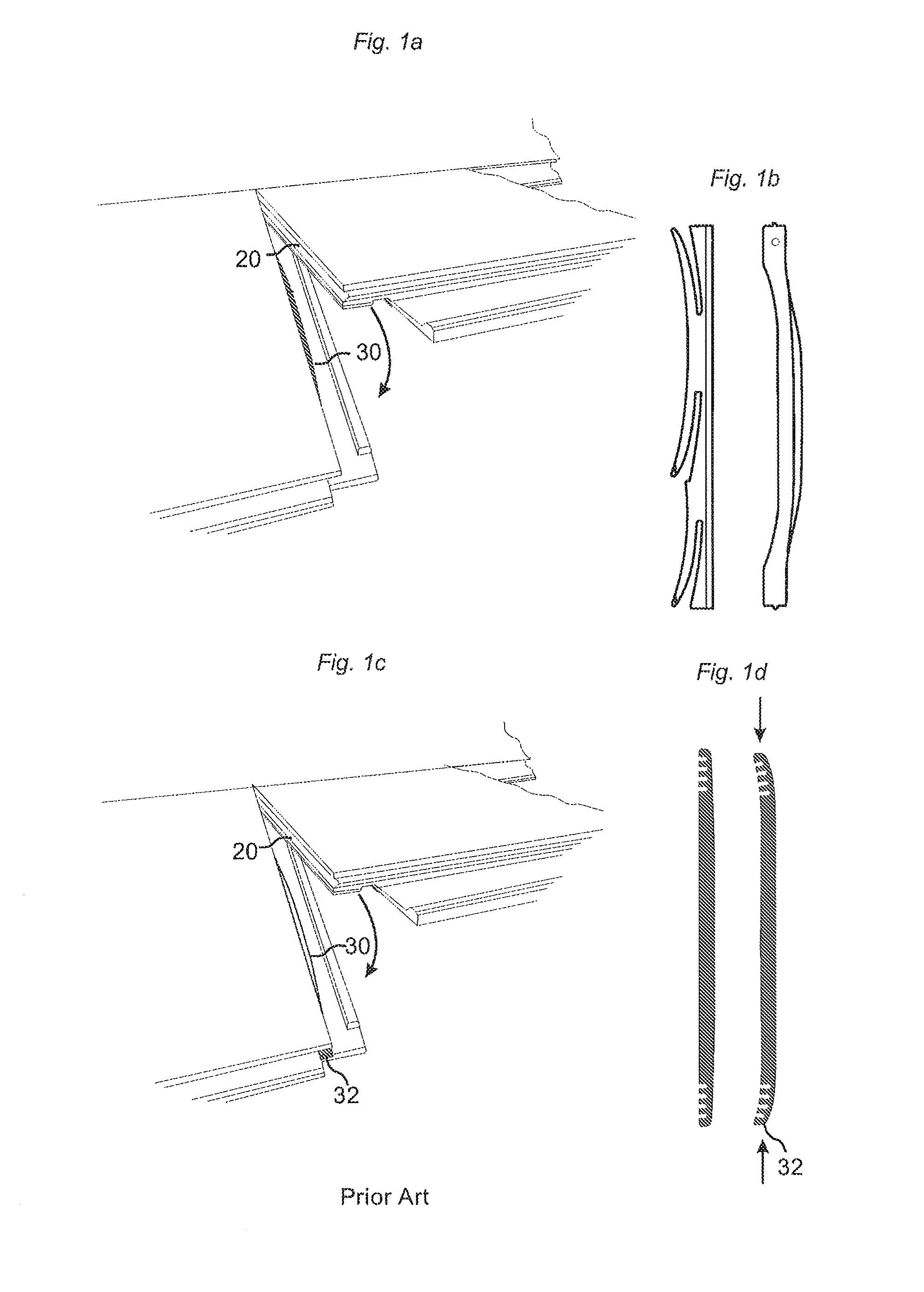

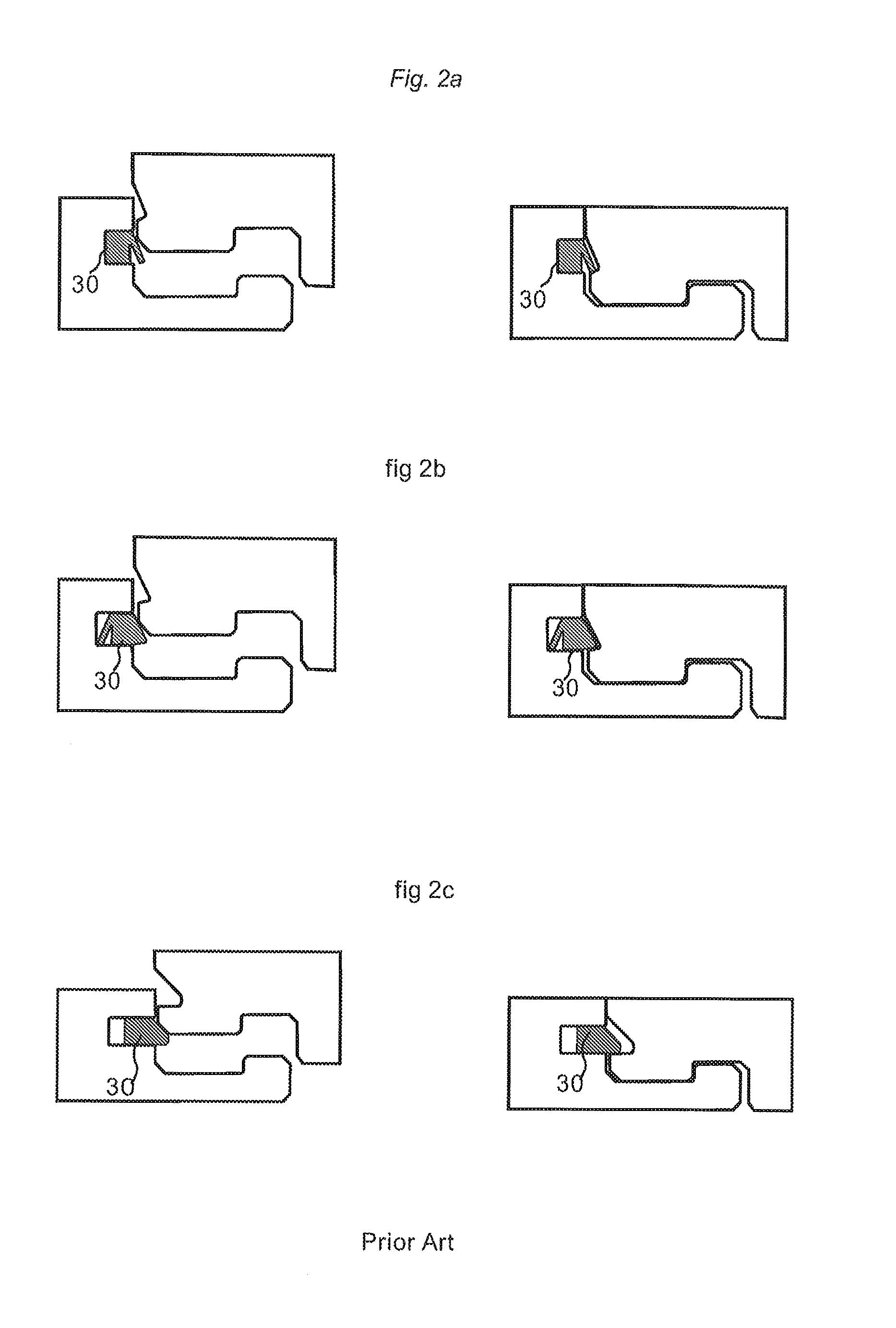

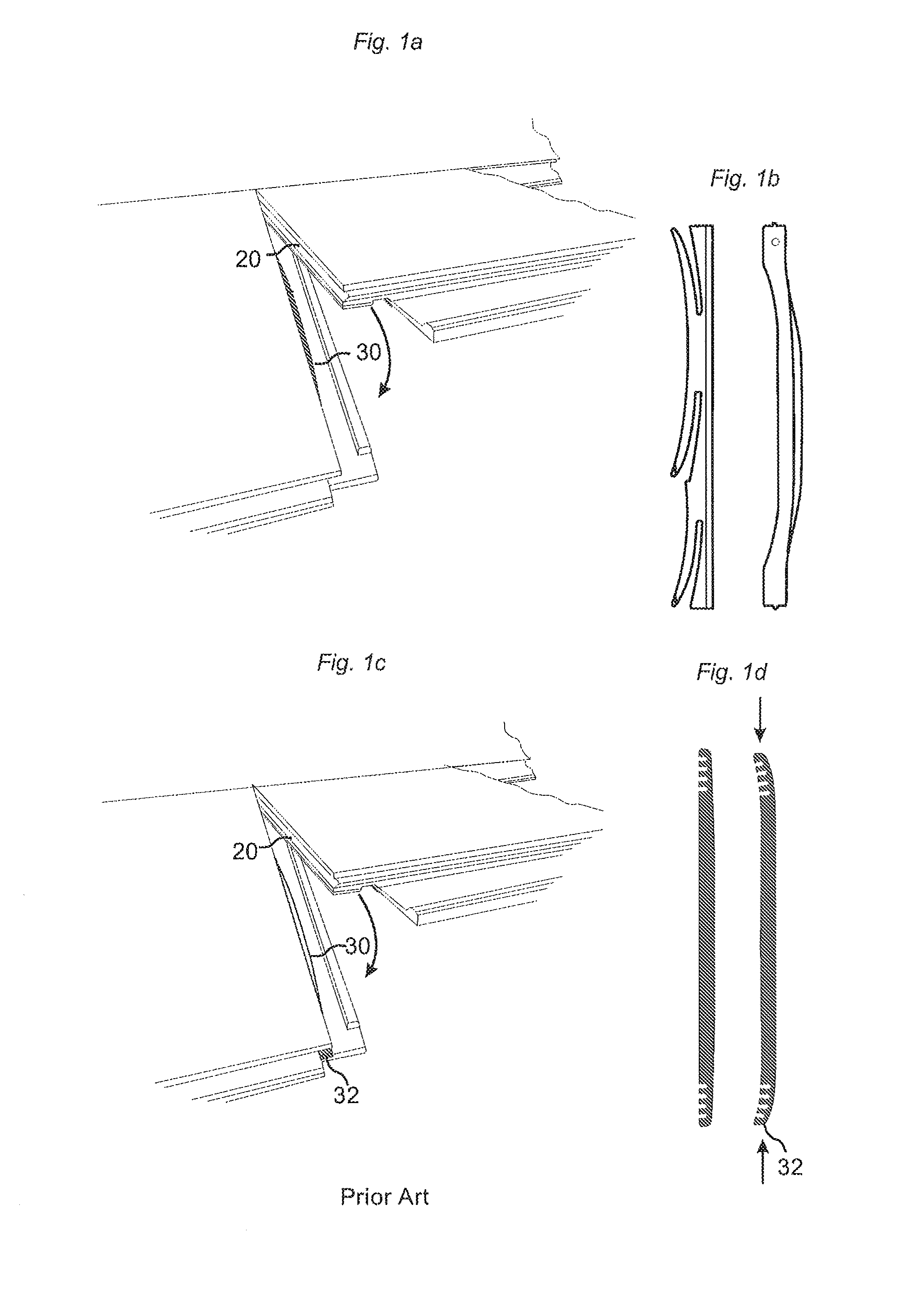

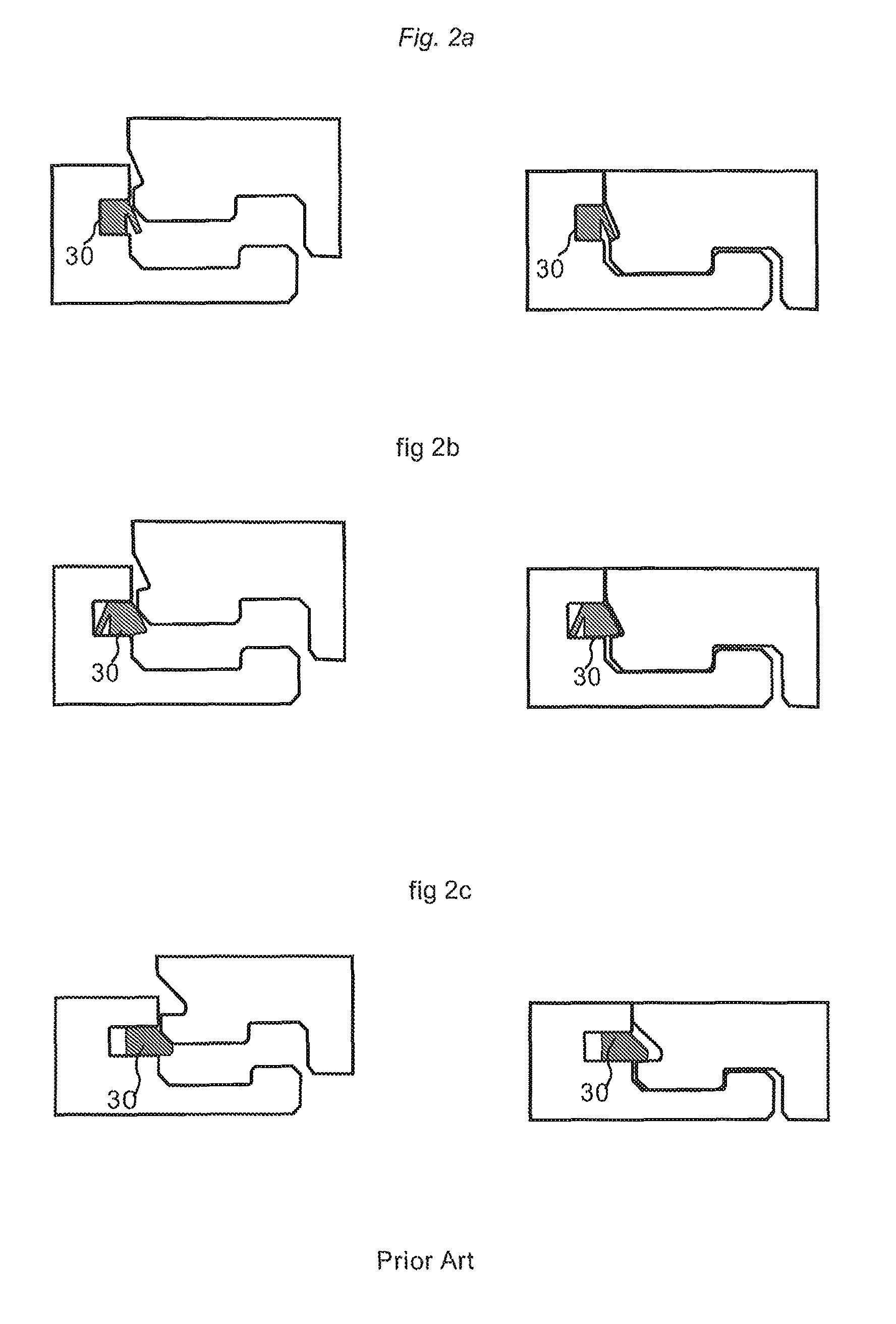

ActiveUS20110030303A1Avoid resistanceAvoid separationCovering/liningsTongue/grooves making apparatusTongue and grooveFace sheet

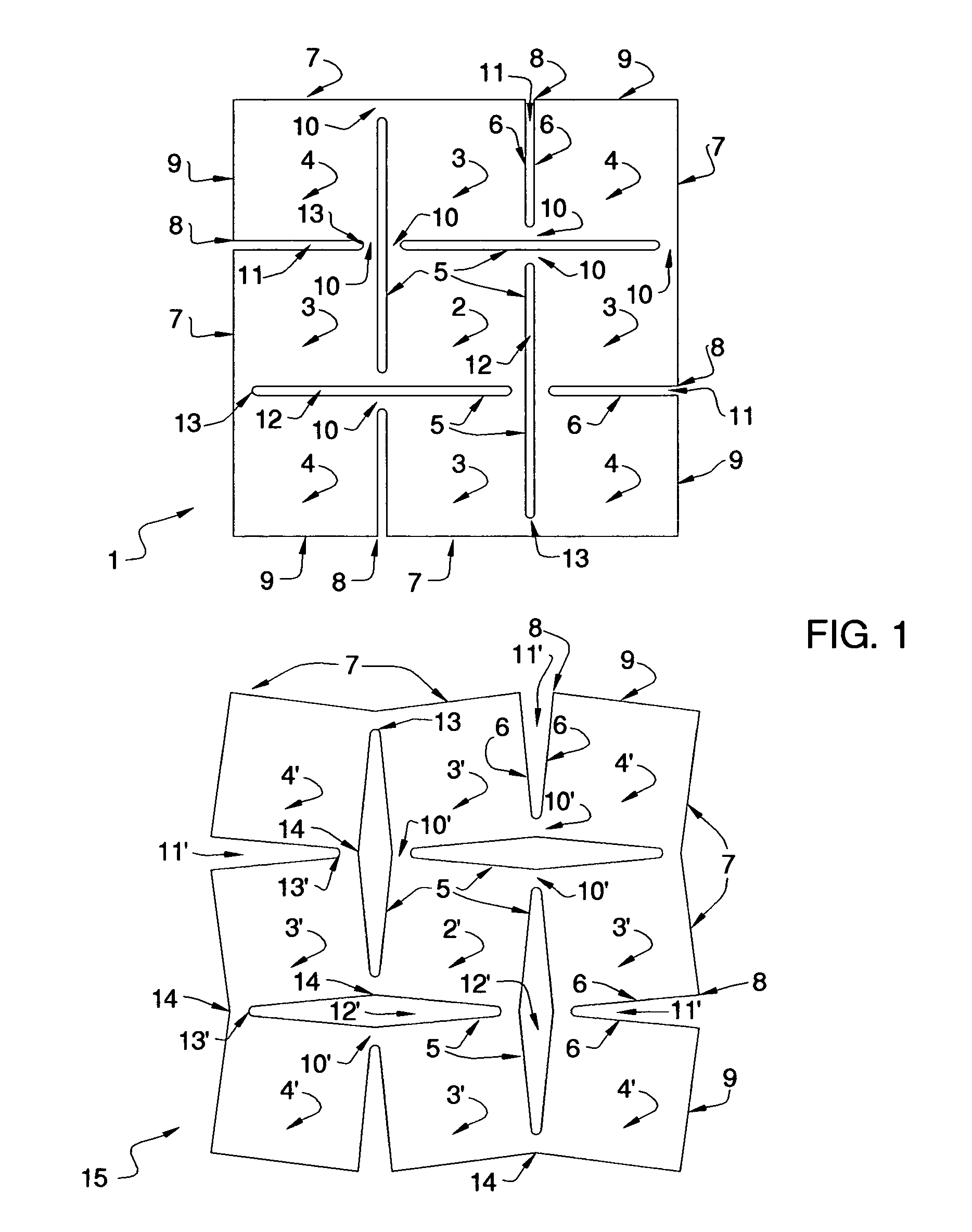

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

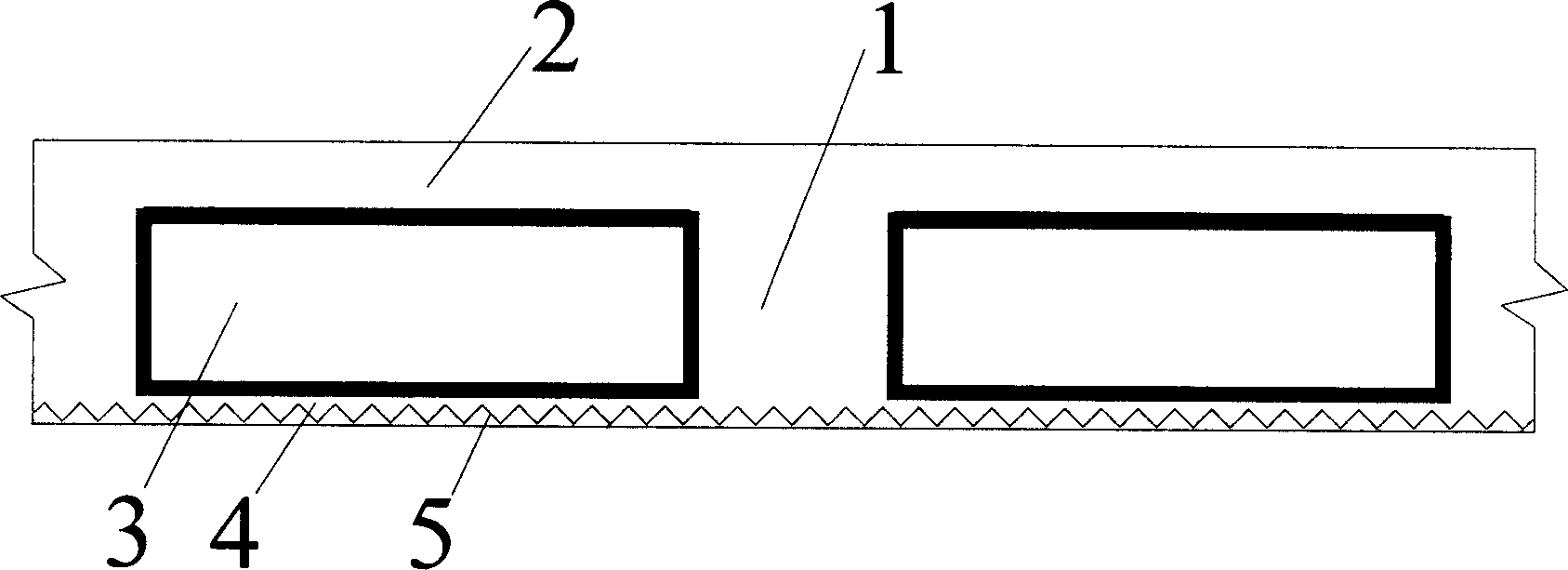

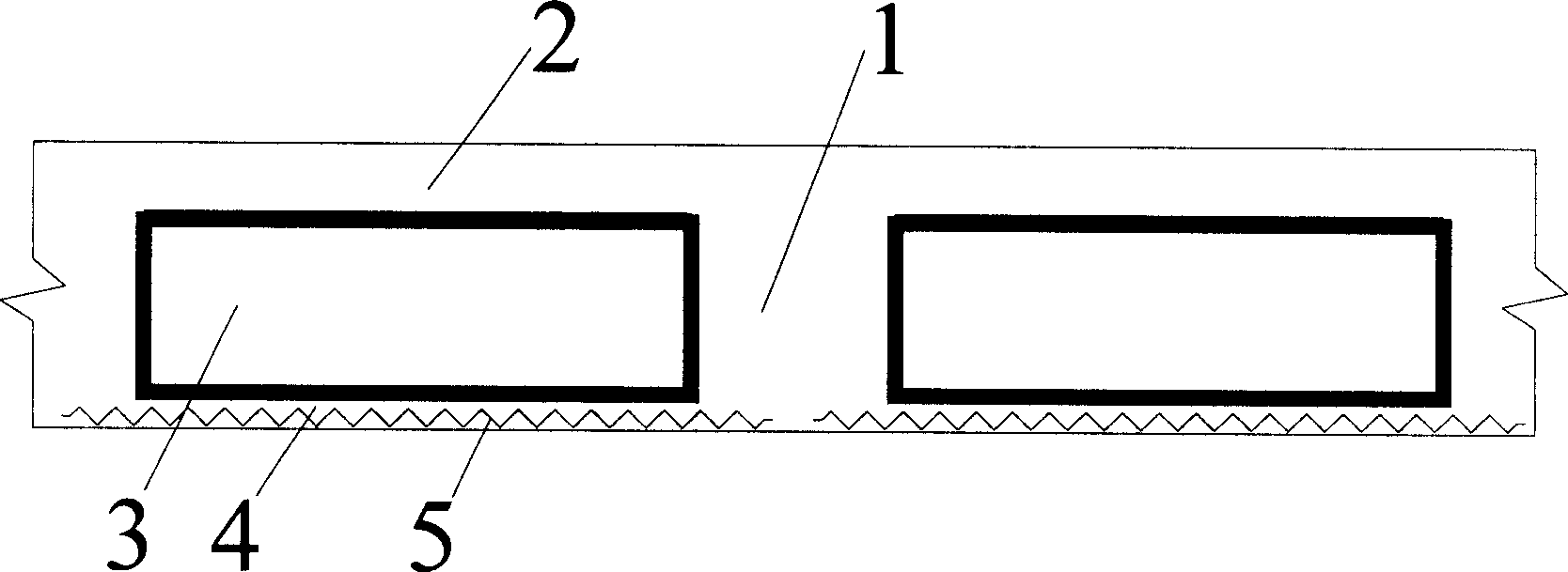

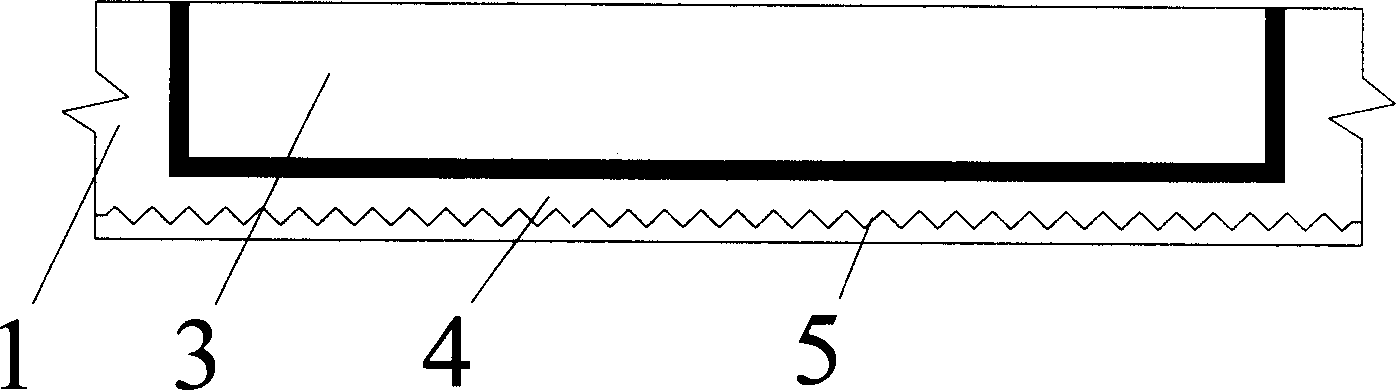

Hollow floor slab with small dense ribs and its production process

InactiveCN1637217ALarge spanSafe and reliable structureFloorsForms/shuttering/falseworksFloor slabLine tubing

The hollow floor slab includes column, solid belt, solid reinforced beam with dense ribs, reinforced facing board, and composite box with lower thin bottom board. The production process includes: a) laying and tying reinforcing steel bar in the floor slab formwork; b) laying the steel wire net and other reinforcing material; c) setting and fixing made composite thin box; d) tying reinforcing steel bar for the facing board; e) fixing reinforcing bars with iron wire; and f) embedding prefabricated pipeline inside the facing board and the dense ribs. The present invention may produce flat sealed floor slab cavity with dense ribs in once deposition.

Owner:HUNAN BDF ENERGY SAVING TECH

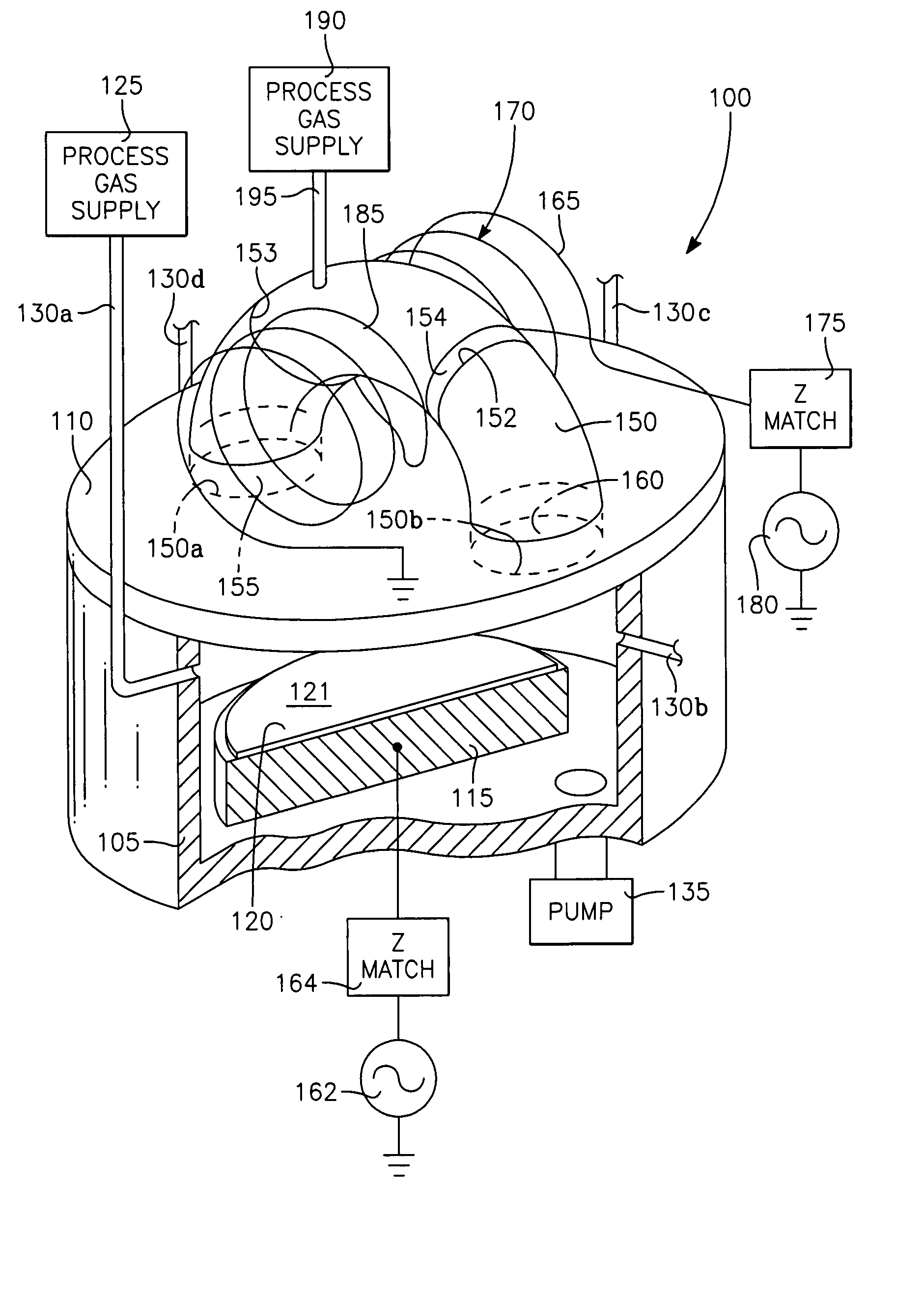

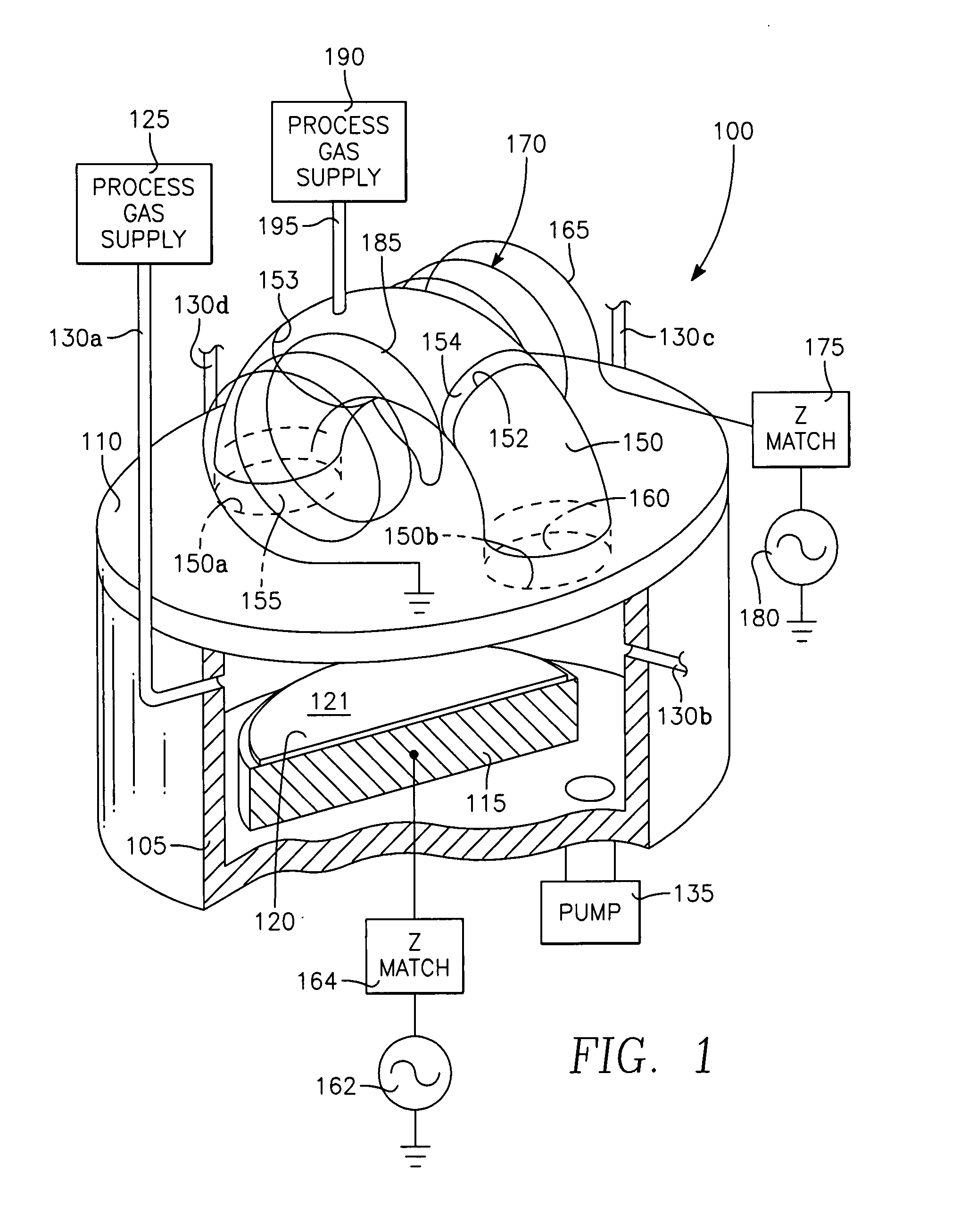

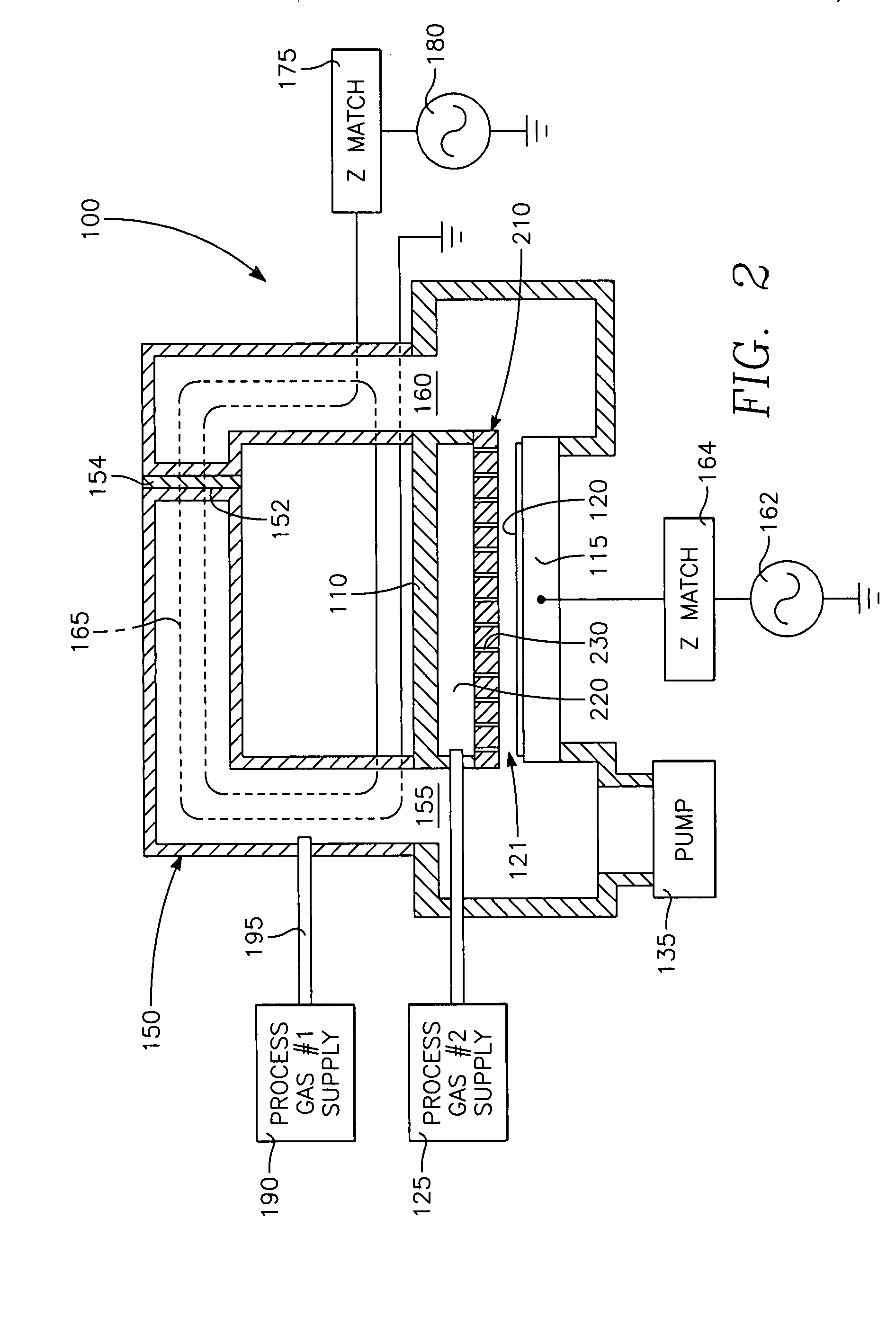

Low temperature CVD process with selected stress of the CVD layer on CMOS devices

Device-enhancing coatings are deposited on CMOS devices by successively masking with photoresist each one of the sets of N-channel and P-channel devices while unmasking or leaving unmasked the other set, and after each step of successively masking one of the sets of devices, carrying out low temperature CVD steps with a toroidal RF plasma current while applying an RF plasma bias voltage. The temperature of the workpiece is held below a threshold photoresist removal temperature. The RF bias voltage is held at a level at which the coating is deposited with a first stress when the unmasked set consists of the P-channel devices and with a second stress when the unmasked set consists of N-channel devices.

Owner:APPLIED MATERIALS INC

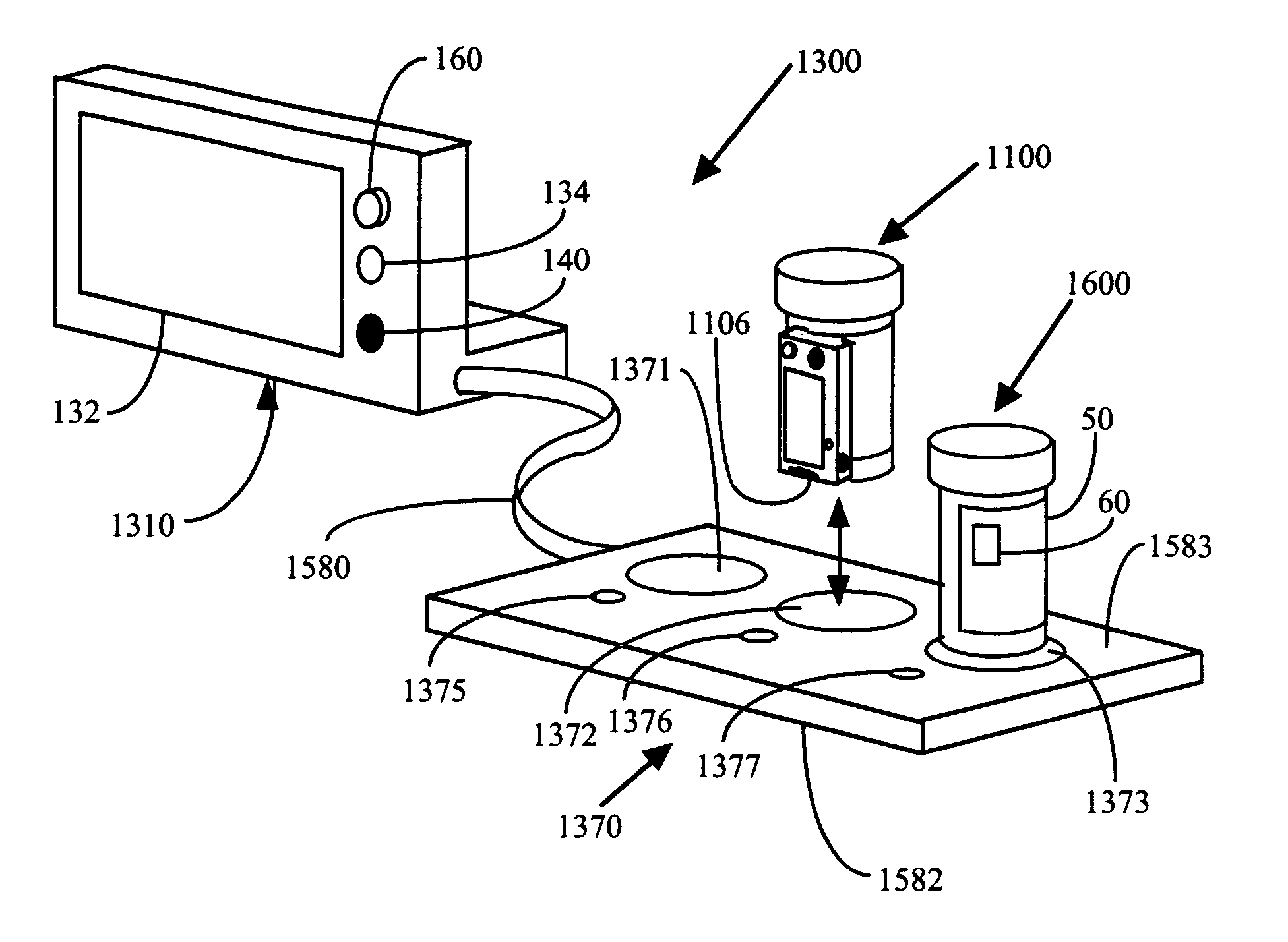

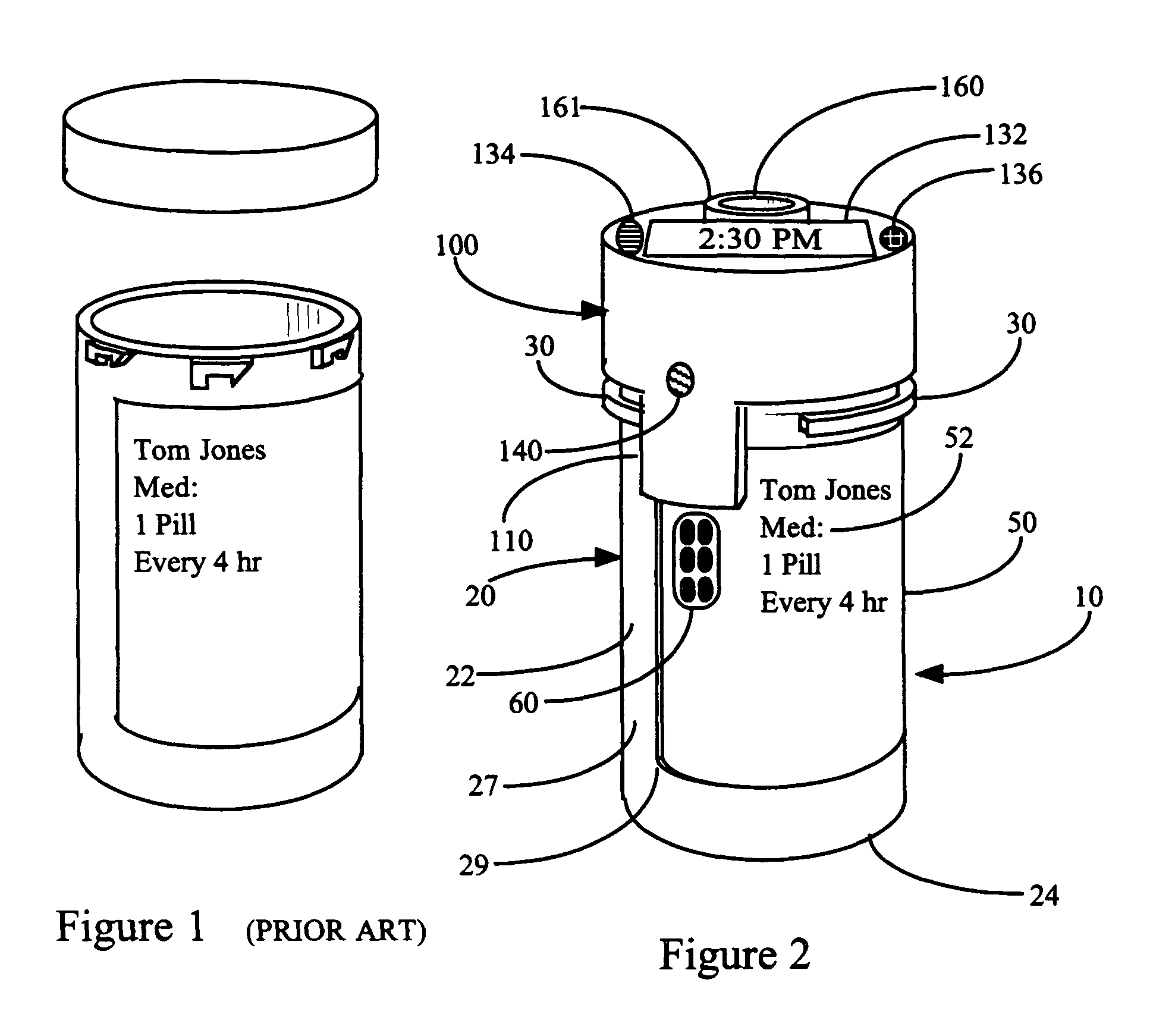

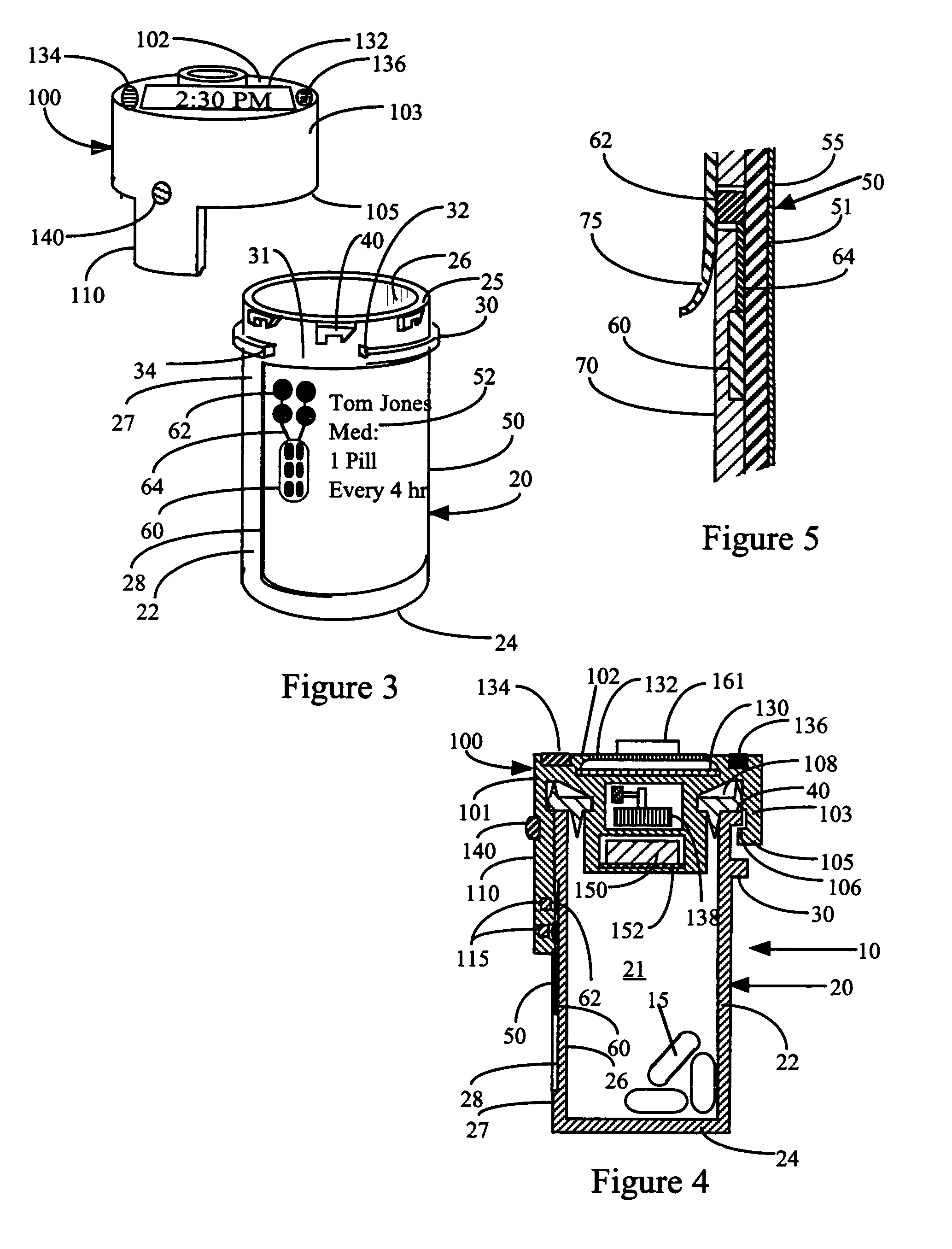

Interactive medication container

InactiveUS7978564B2Patient compliance is goodLow costMechanical clocksCoin-freed apparatus detailsPatient inputDosing regimen

This invention relates to an interactive medication container or console that hold or otherwise organizes one or more medication vials or containers. Each vial has a memory strip containing medication and prescription information. Each vial can also include a reminder unit that is attached to and portable with the individual vials. The console or reminder unit reads the information strip of the vial and communicates this information to or interacts with a patient to remind them to take the medication. The medication container or reminder unit also gathers or tracks information such as consumption time, quantity remaining, patient feedback, and contraindication information. The medication container or reminder unit interacts with the patient by displaying questions or receiving and recording input from the patient before, during or after a dose of medication is taken. The patient input can be used to modify the dosing regimen for future doses of medication. The medication container reorders medication when the quantity remaining reaches a threshold level. Contraindication information in the memory strip is downloaded to a personal home computer or a hospital or nursing home computer.

Owner:SOUTHWEST TECH INNOVATIONS +2

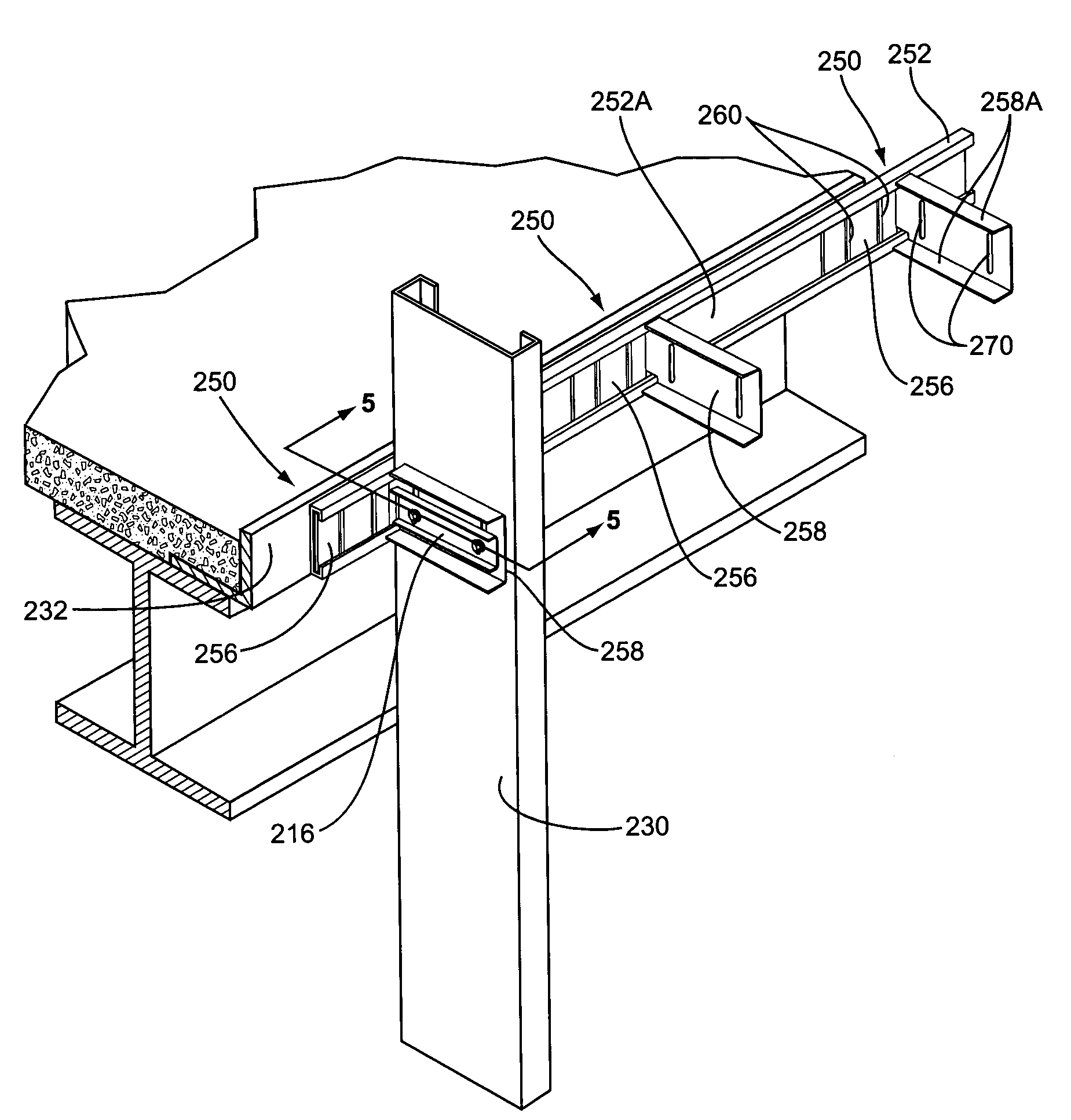

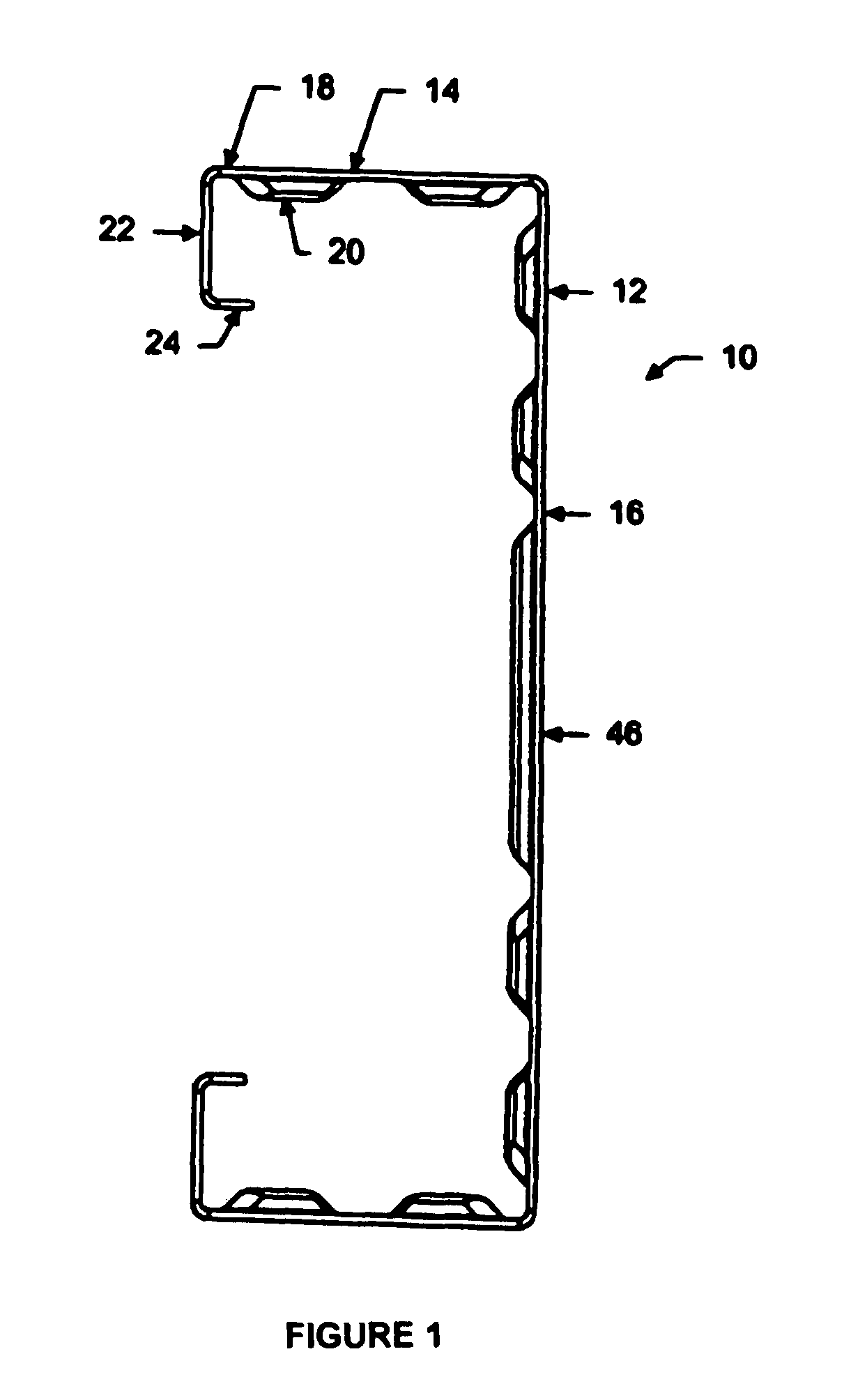

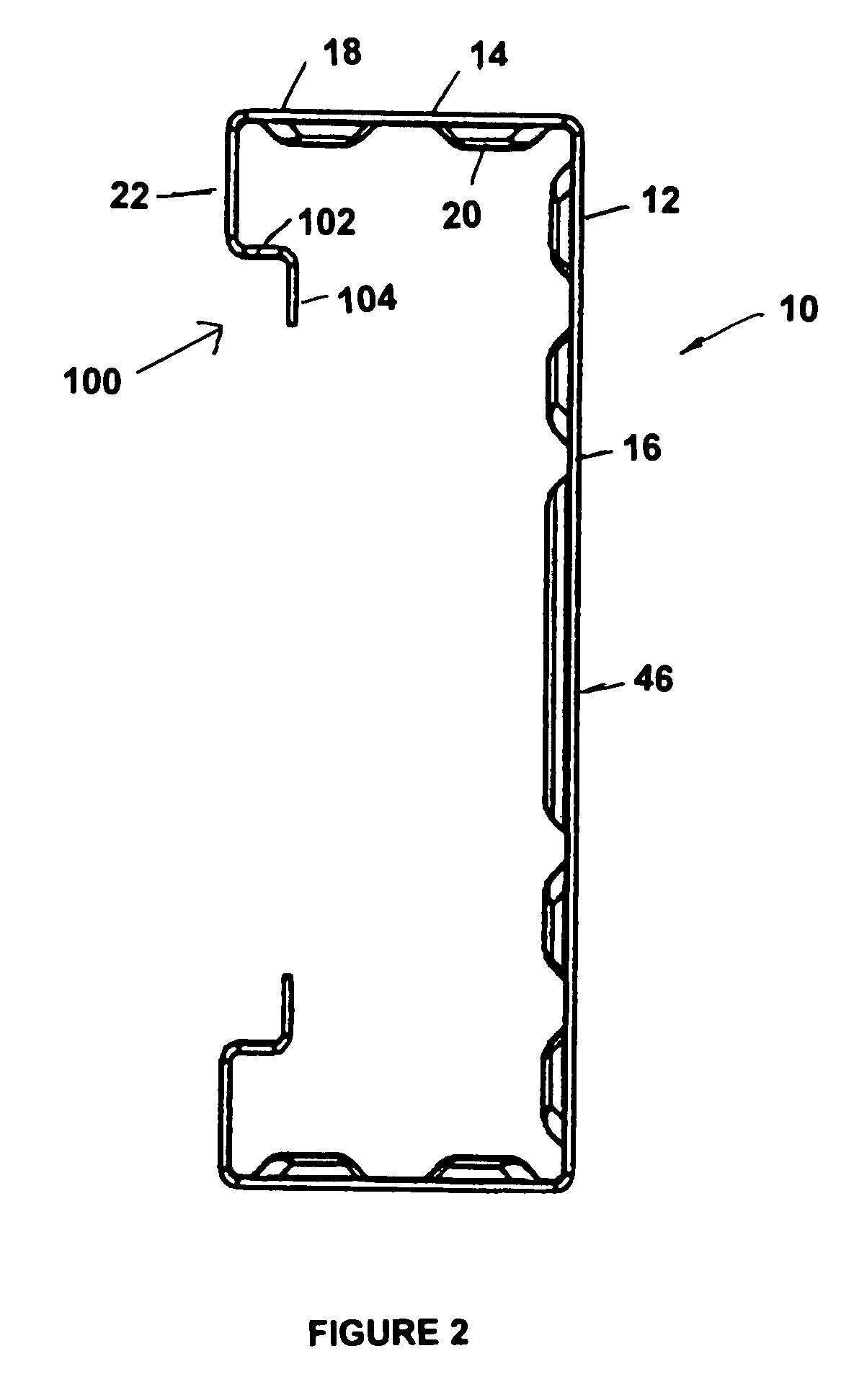

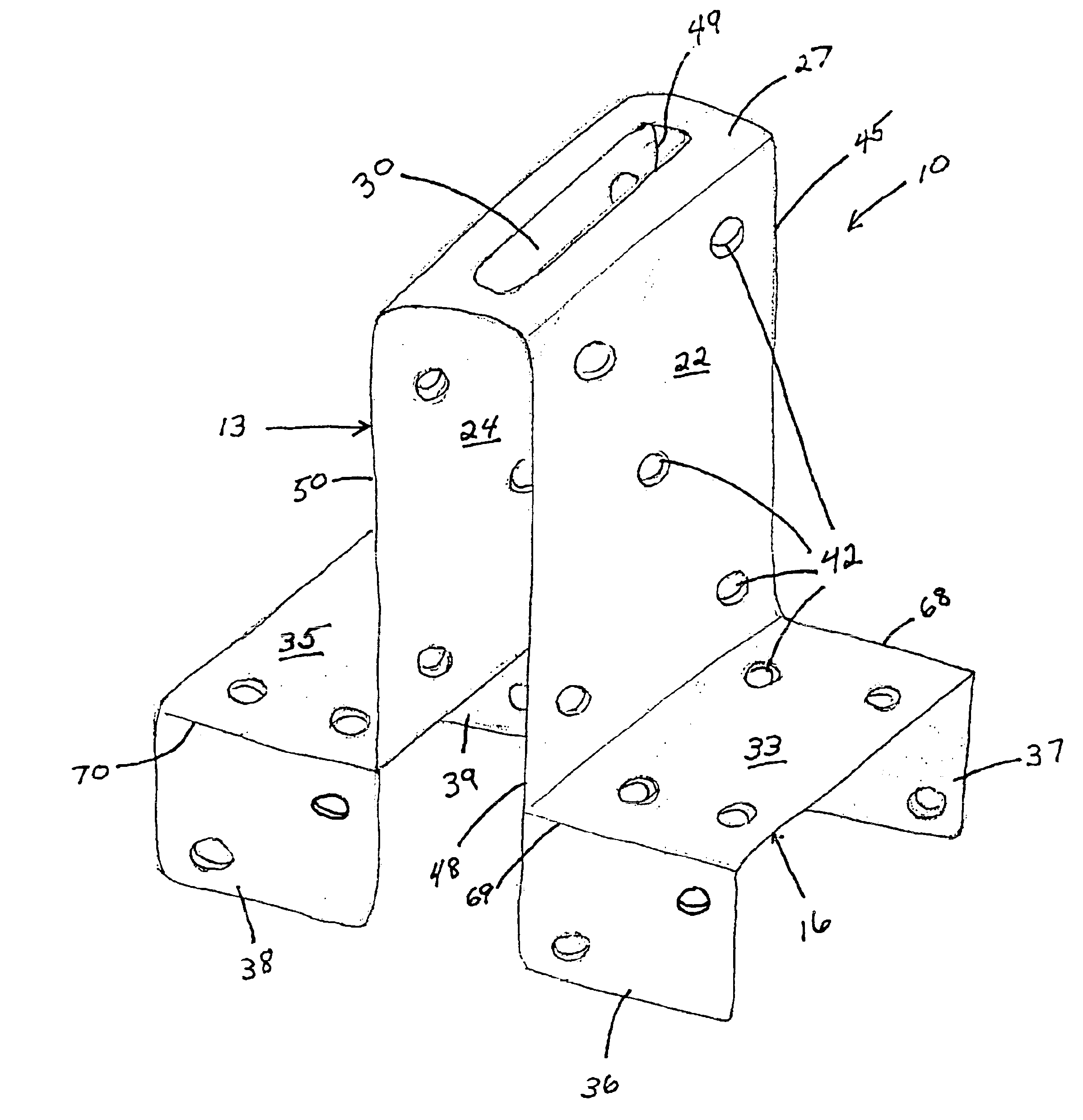

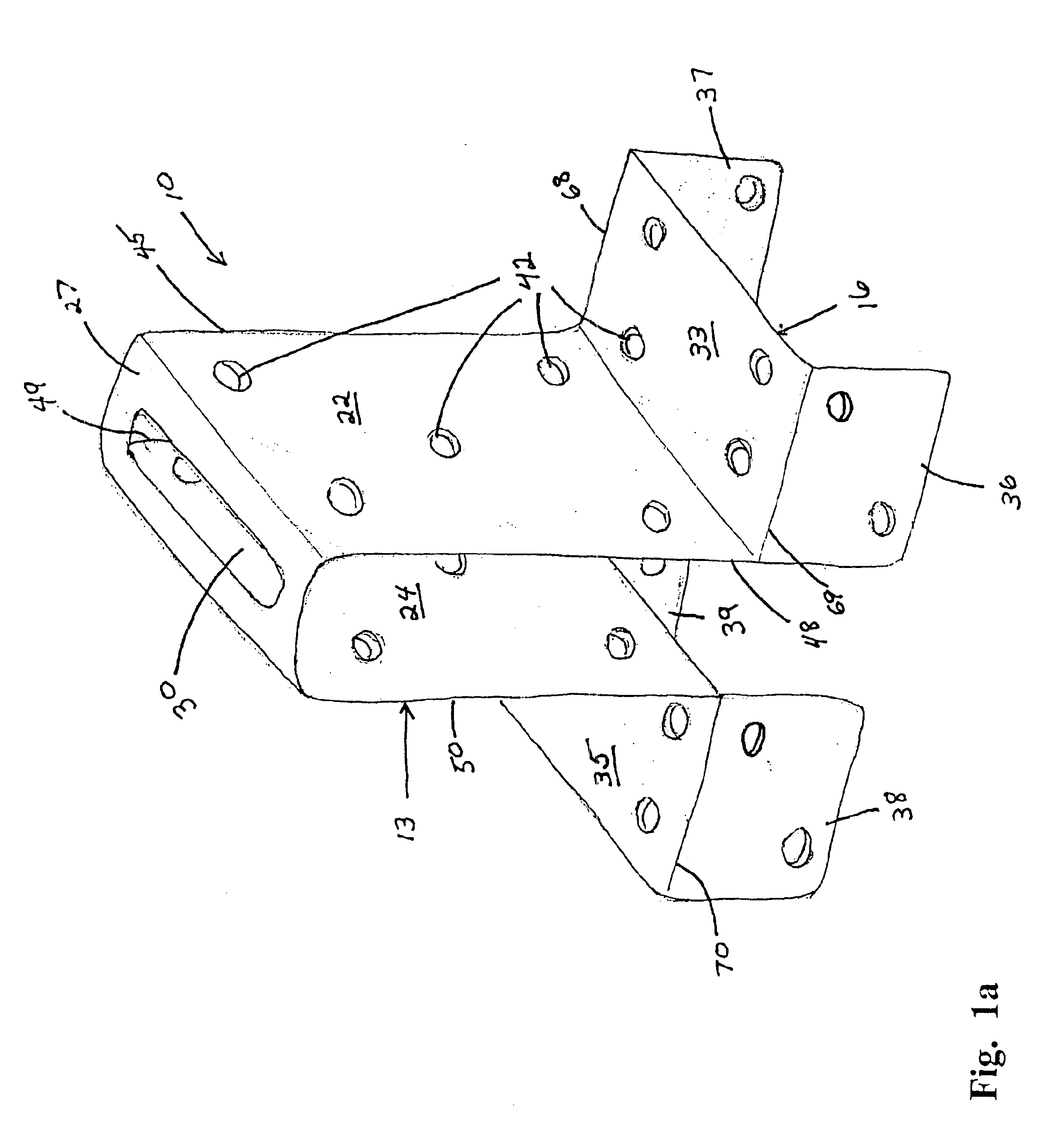

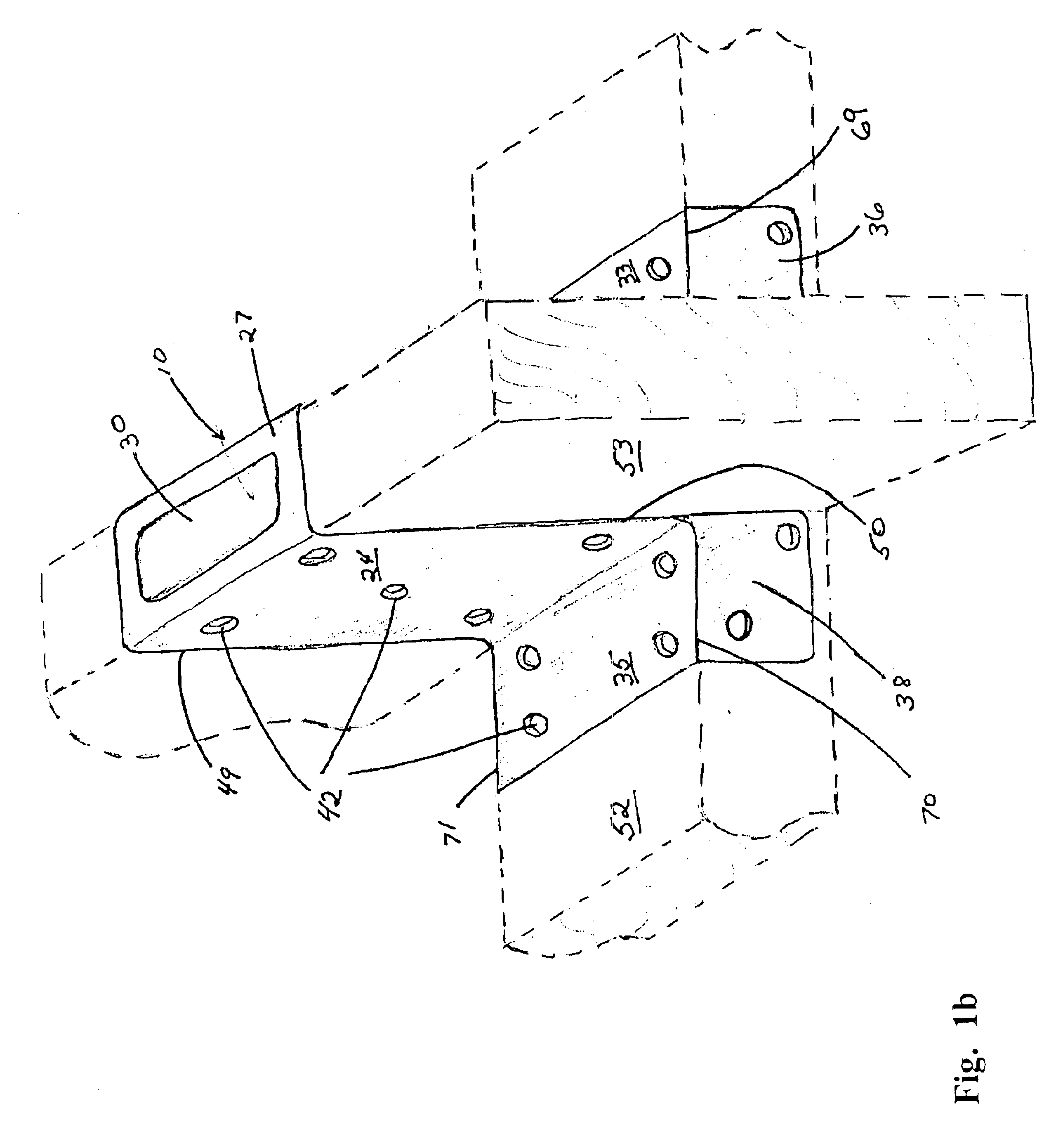

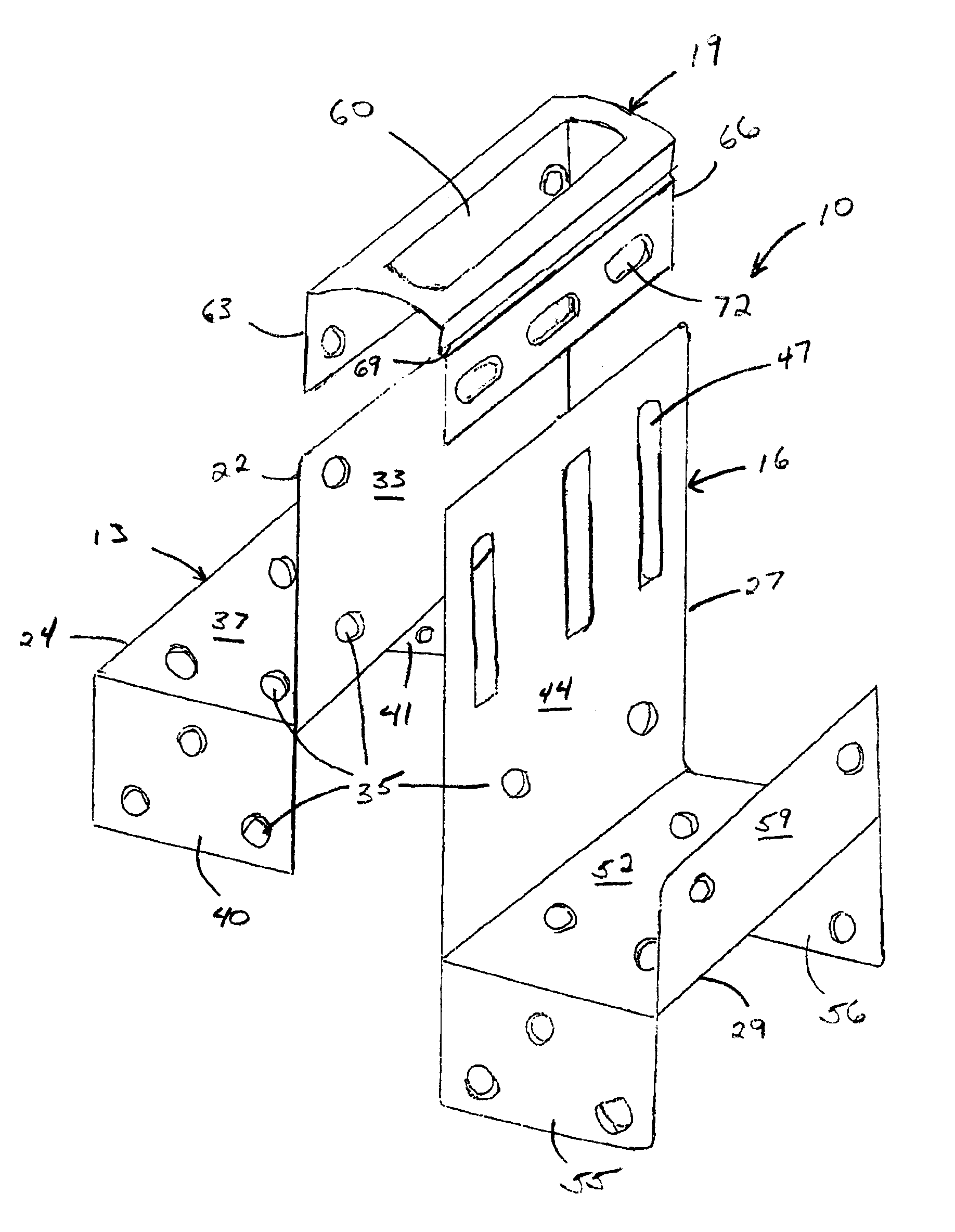

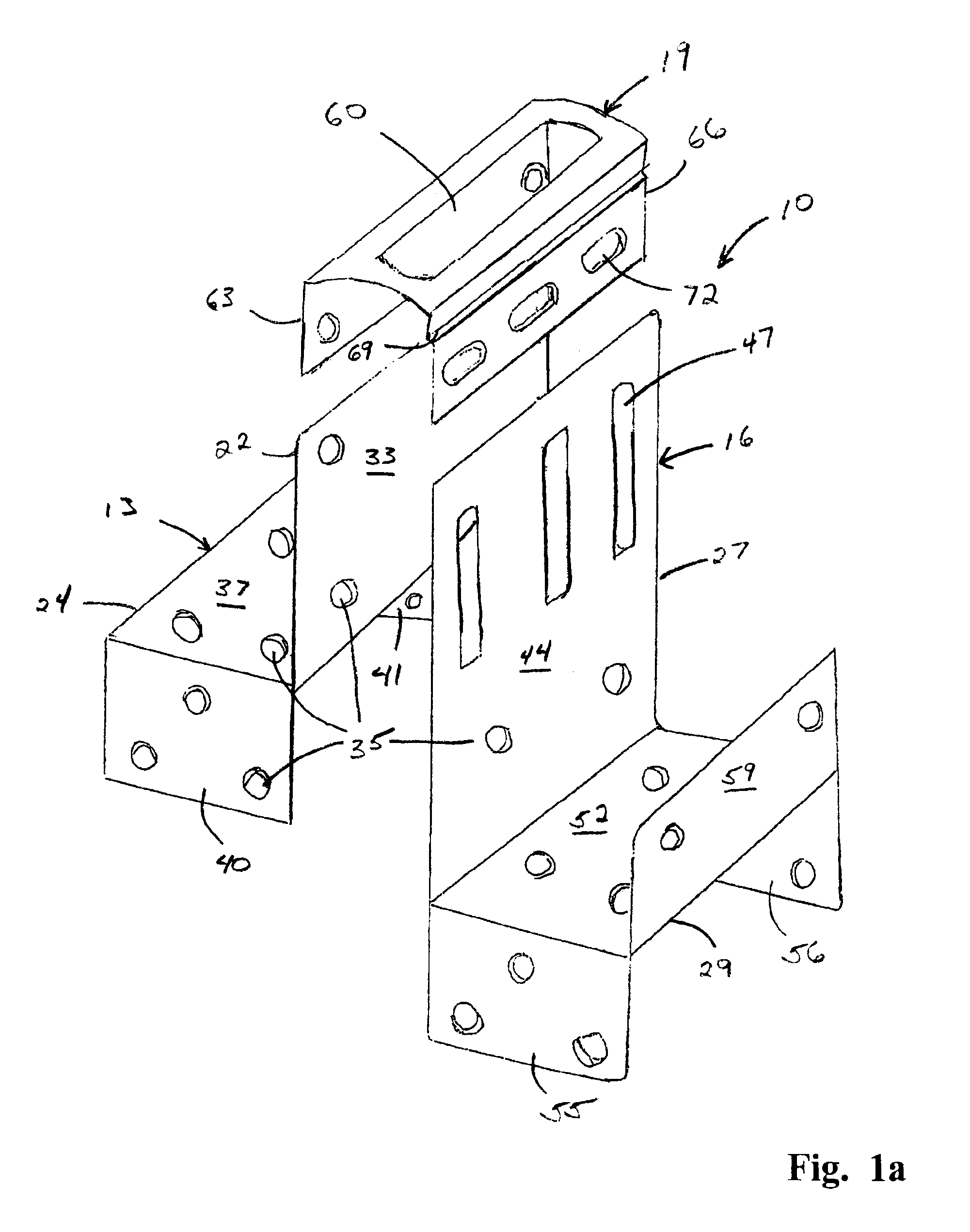

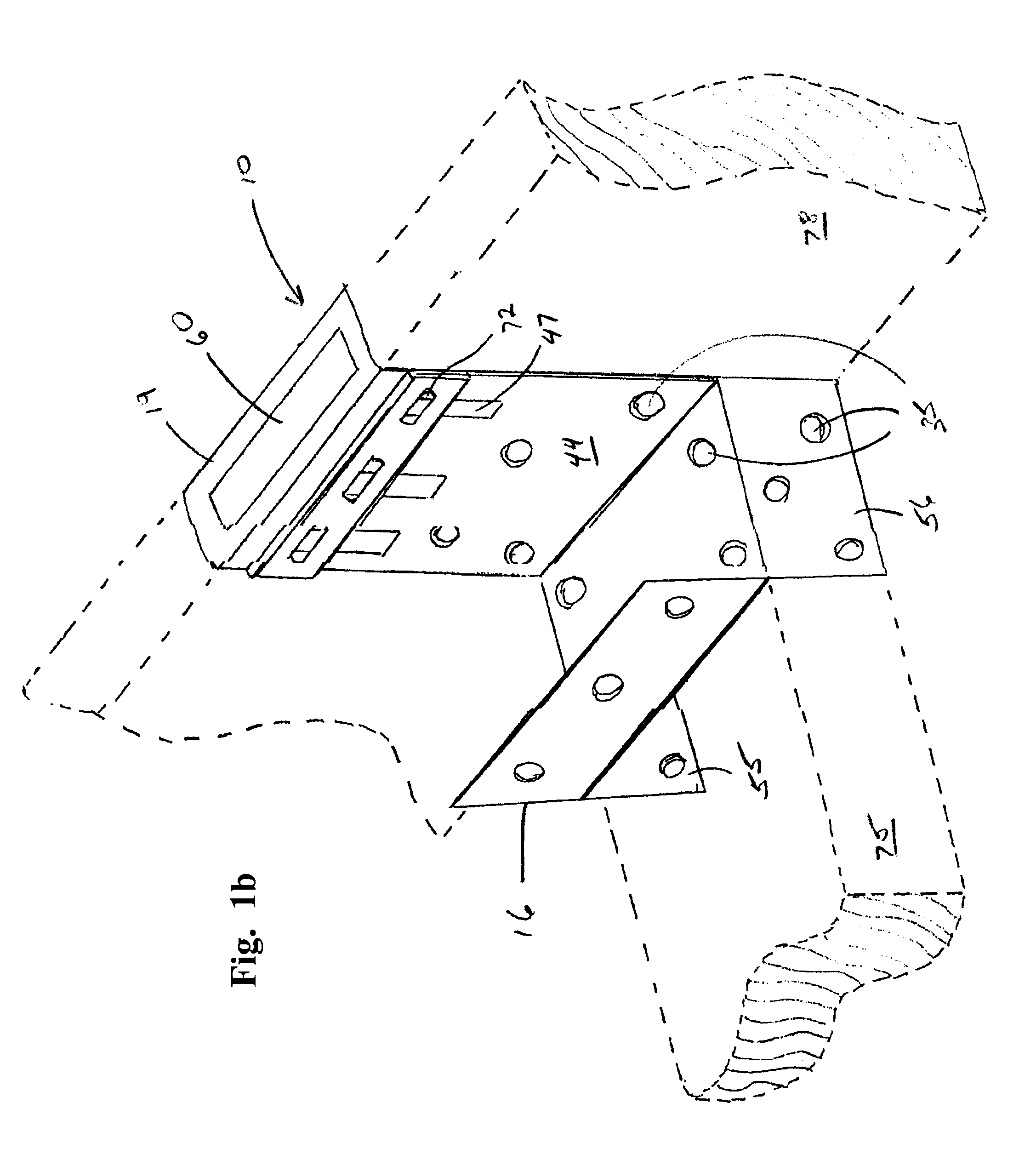

Connector for connecting two building members together that permits relative movement between the building members

ActiveUS7104024B1Permit some movementScaffold connectionsWallsArchitectural engineeringRelative motion

Owner:THE STEEL NETWORK

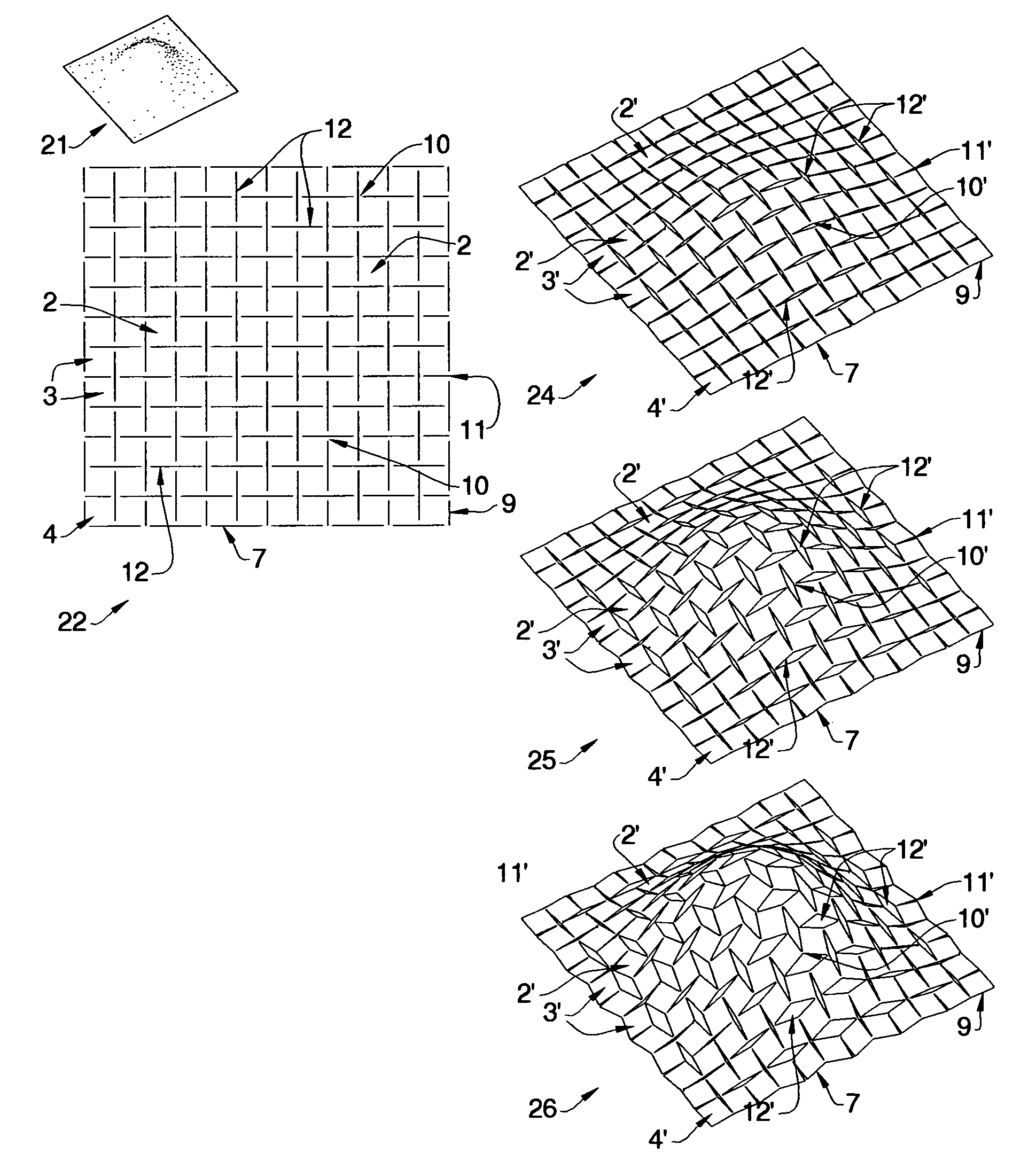

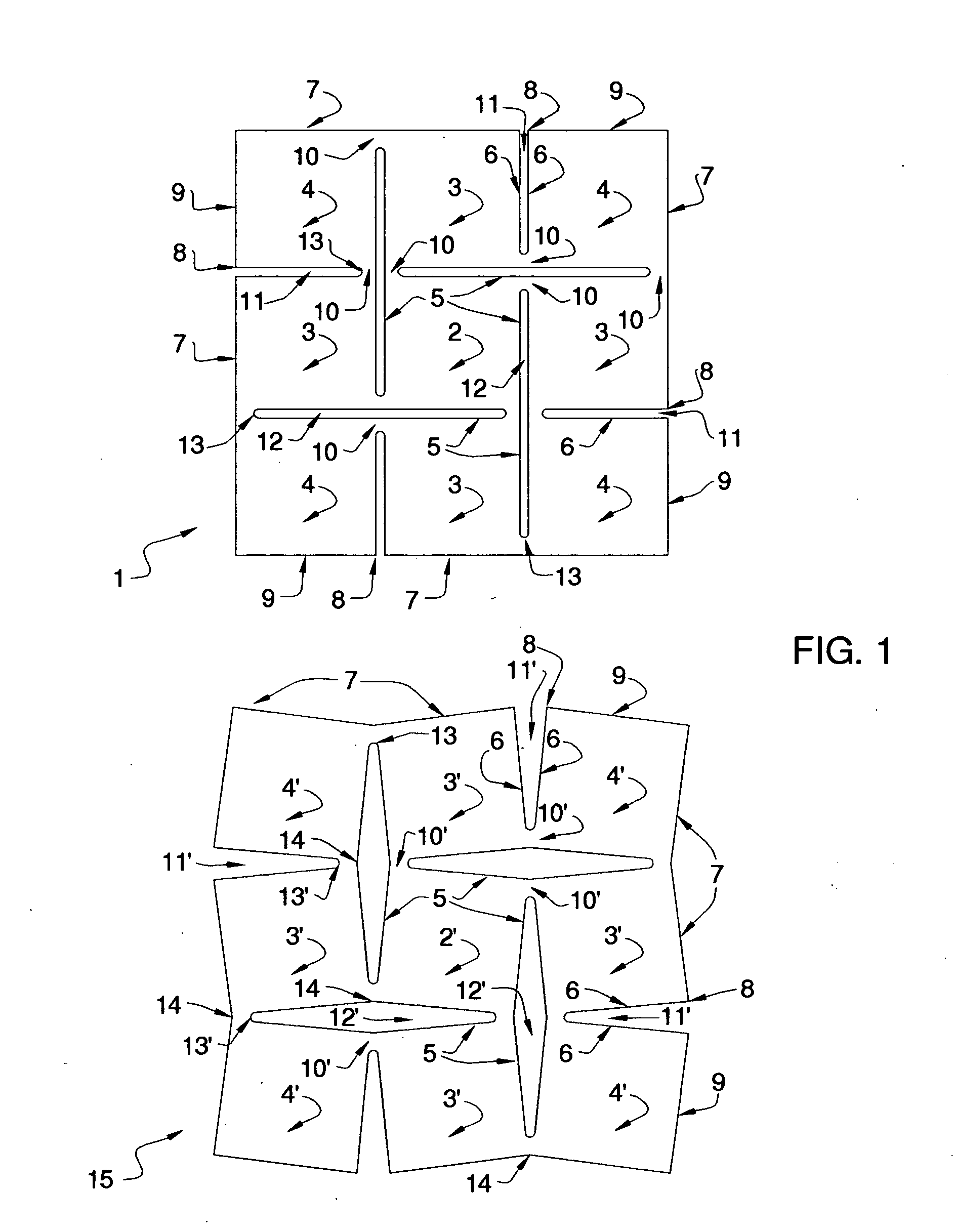

Multi-directional and variably expanded sheet material surfaces

ActiveUS8084117B2Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingMulti directional

Owner:LALVANI HARESH

Light steel structural members

Owner:PARADIGM FOCUS PROD DEV

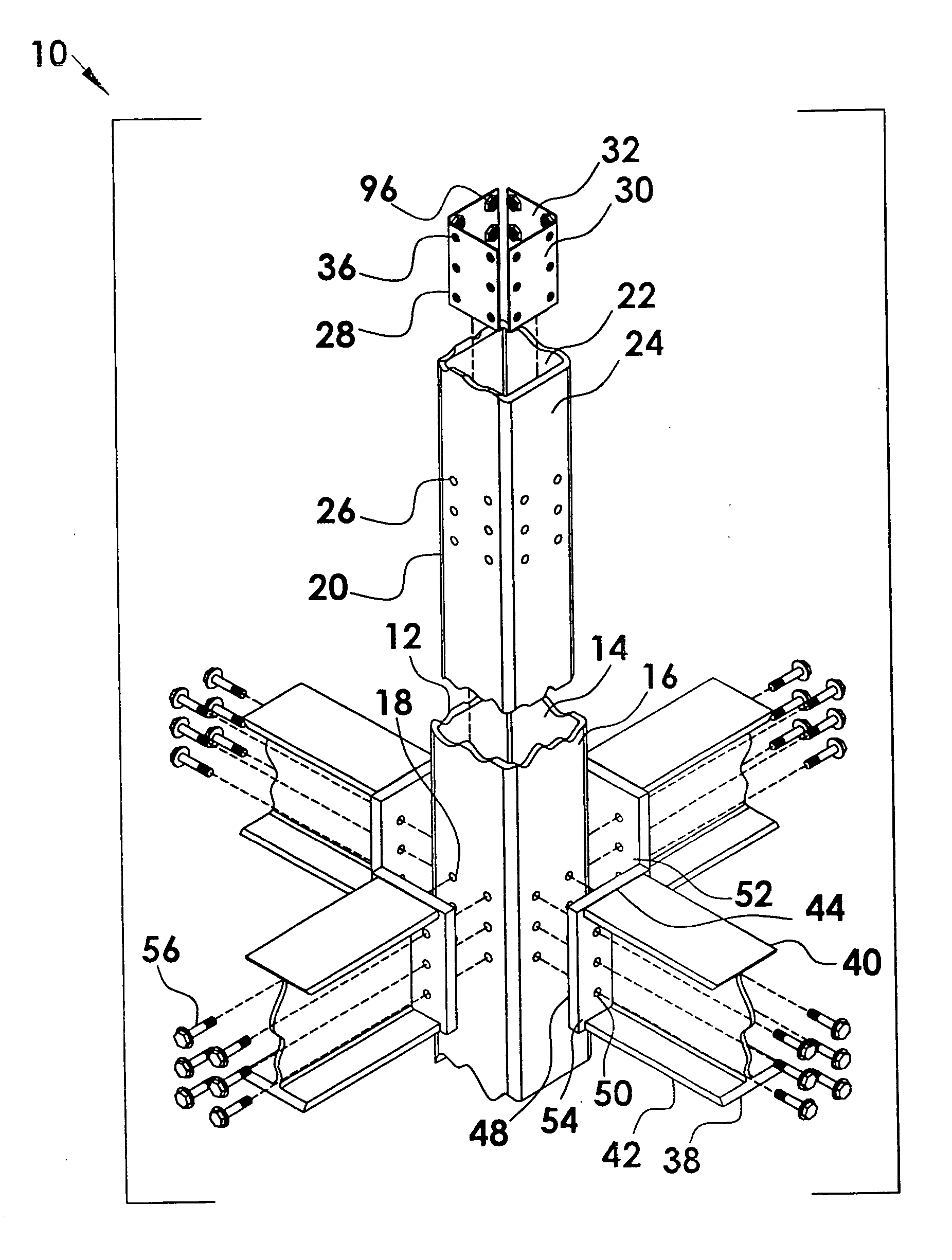

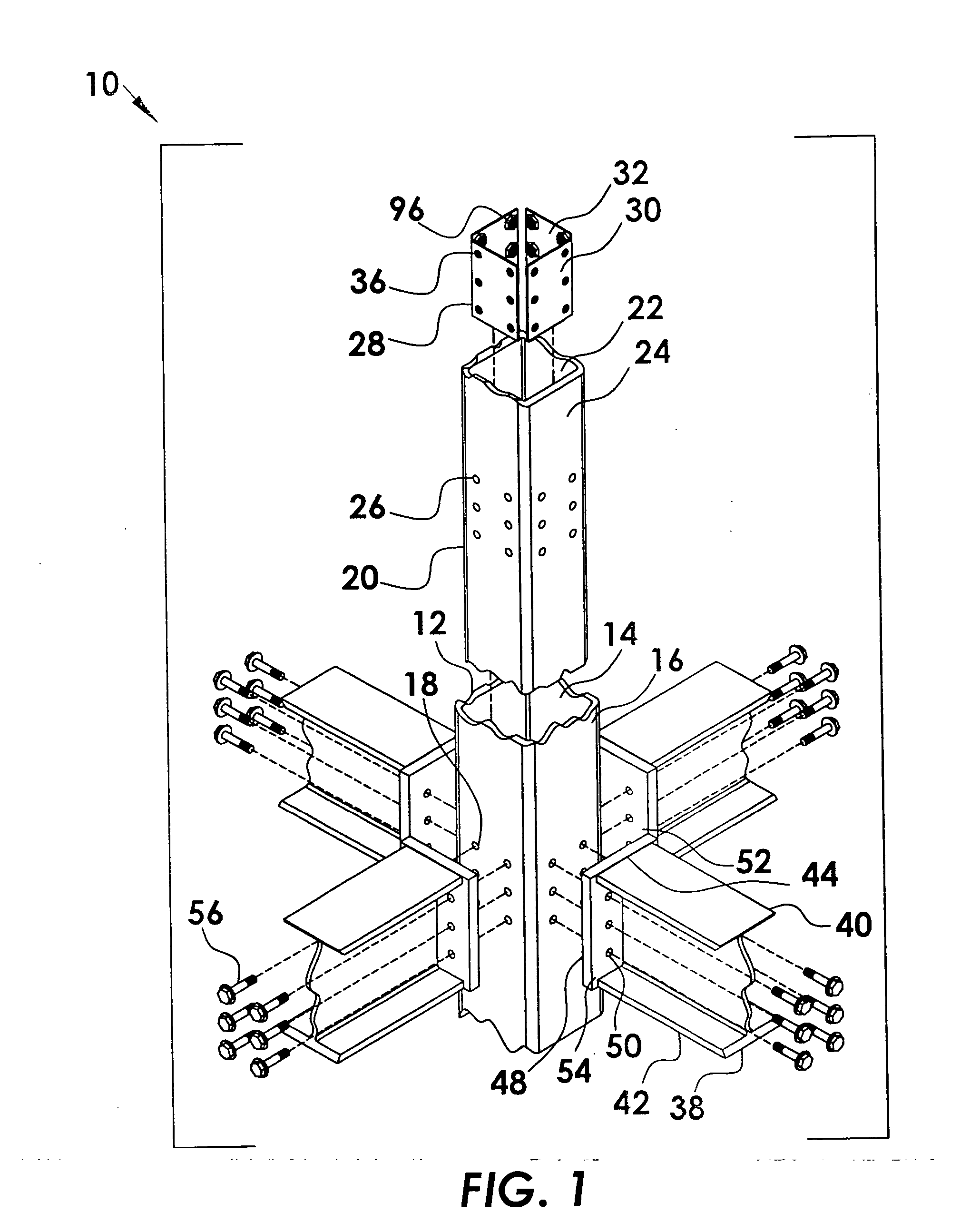

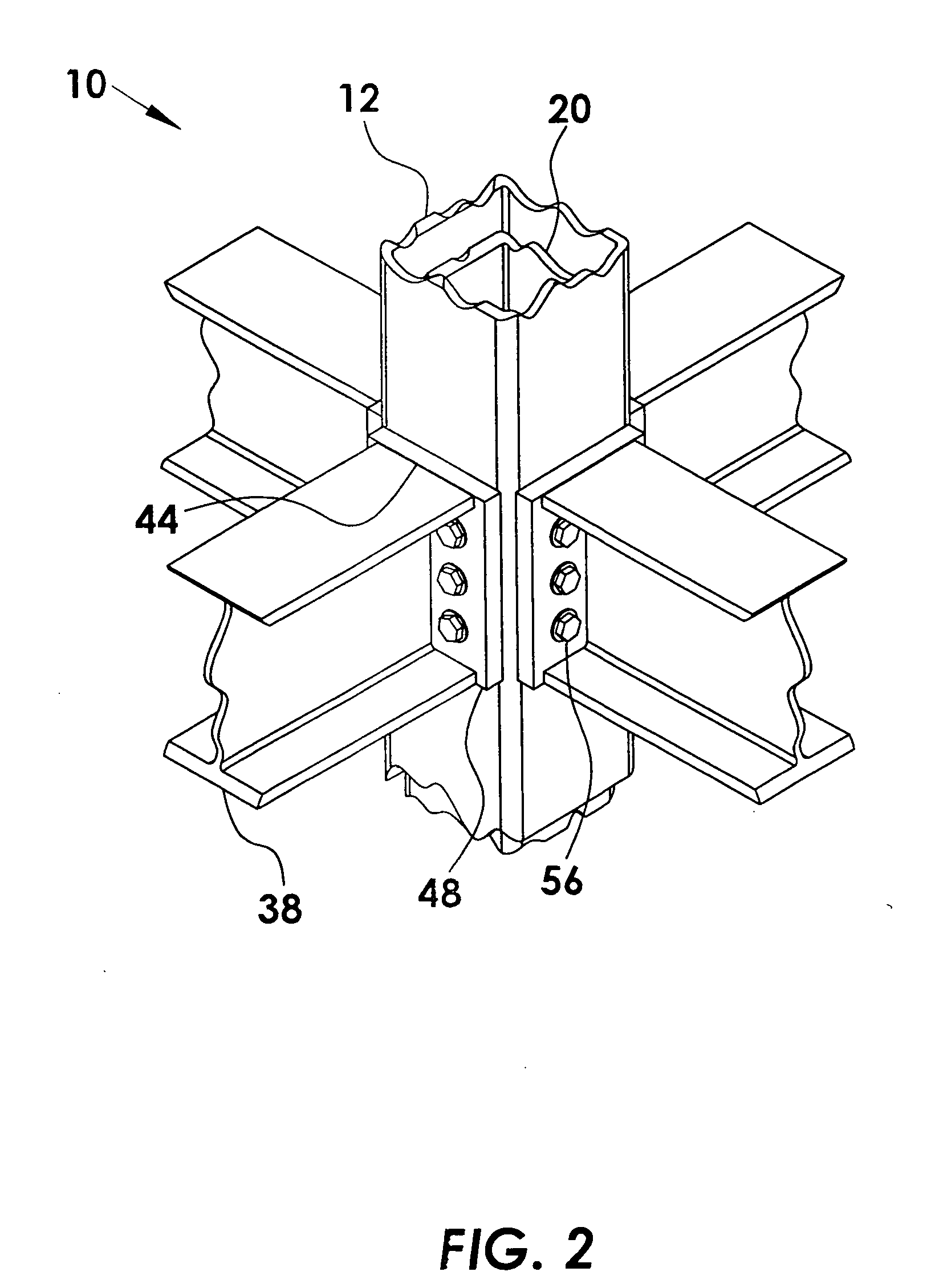

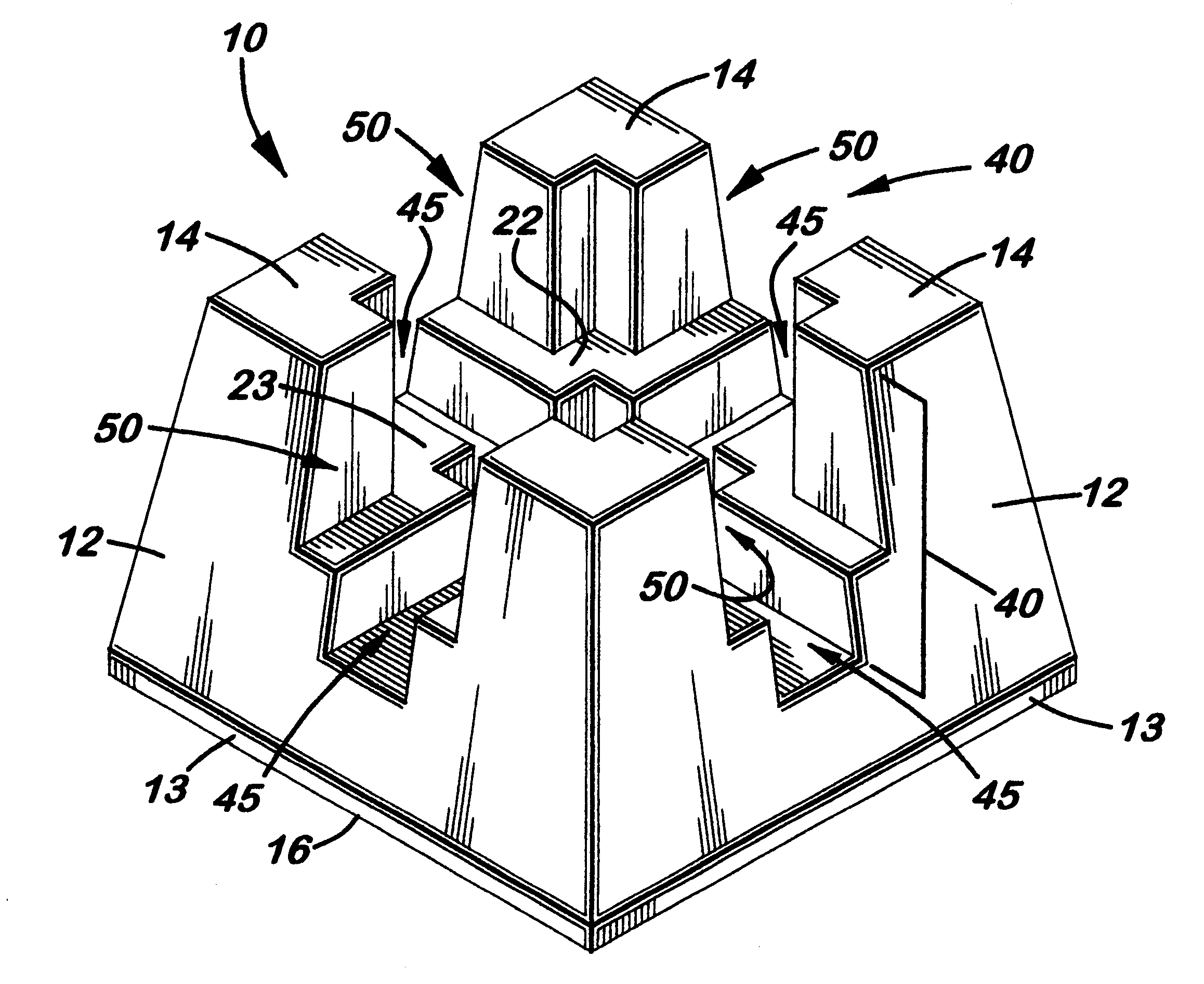

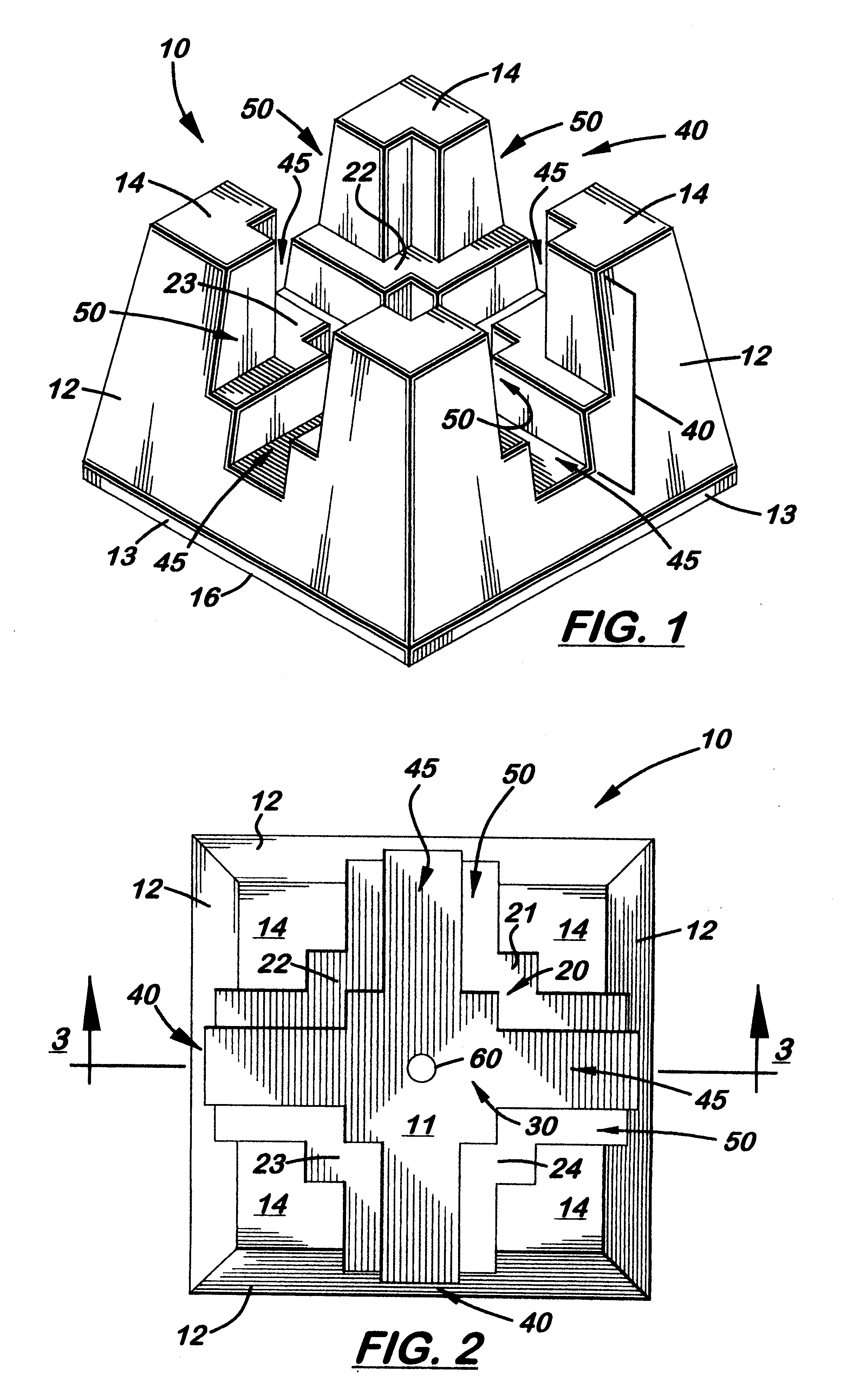

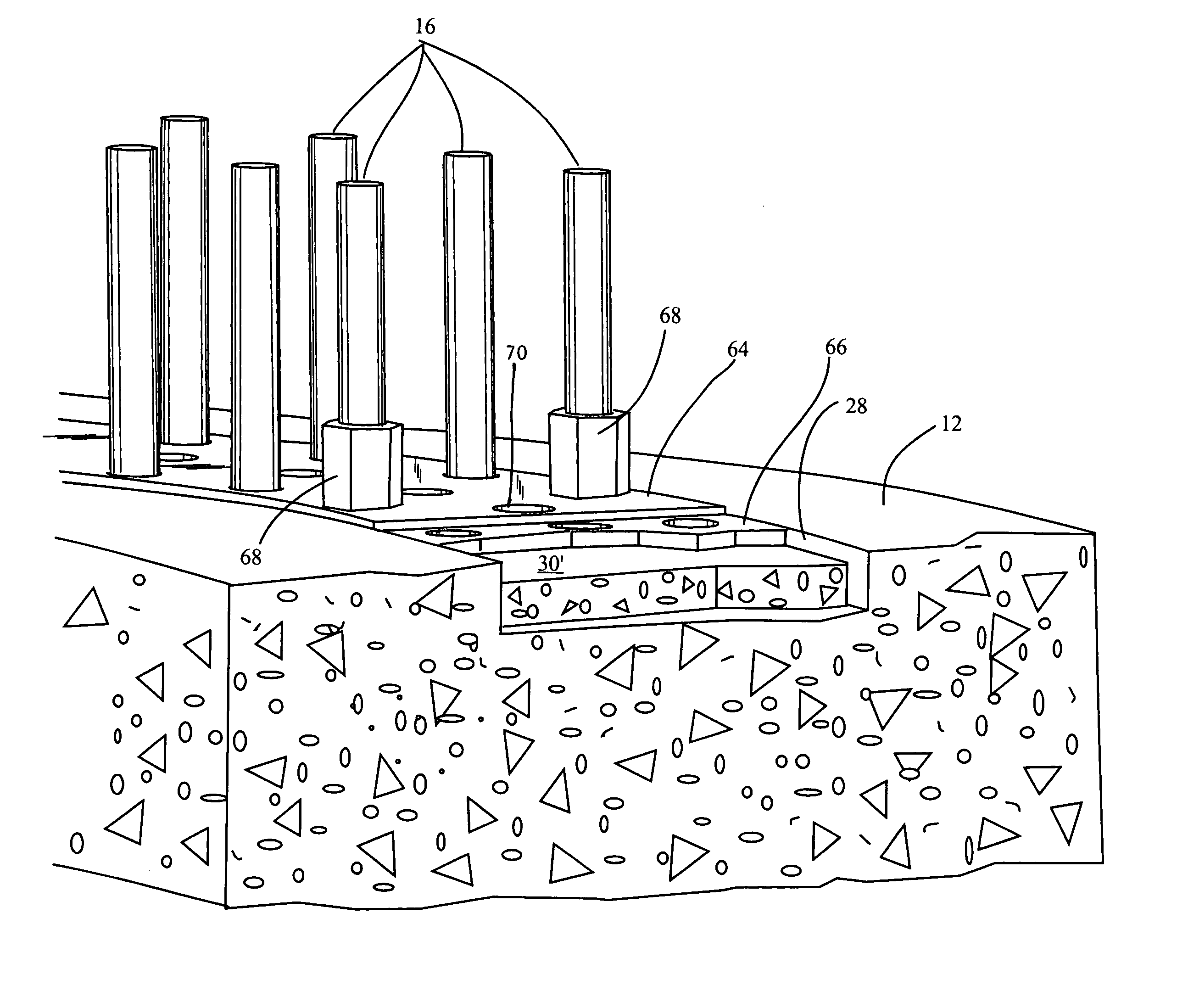

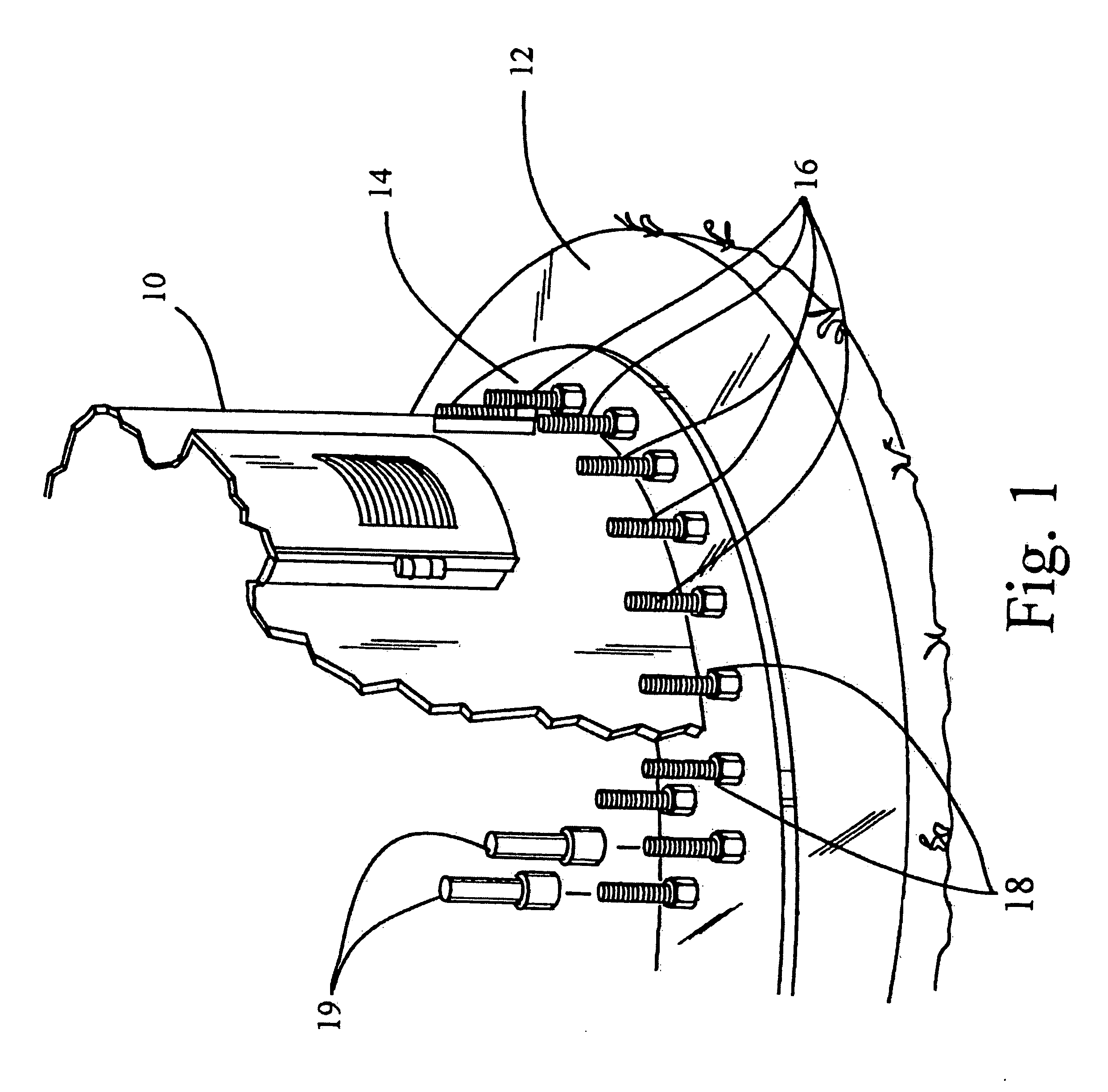

Moment-resistant building column insert system and method

InactiveUS20070209314A1Improves building column strength strengthImprove connection strengthBuilding roofsFloorsArchitectural engineeringVertical load

The invention is a novel moment-resistant building column insert system for distributing lateral and vertical loads between the column-beam and column-foundation connections. Loads are distributed between the column and beam using a column insert, nut plates and beam end plates incorporated to beam-ends. The column insert is hollow and similar cross-section shape to the building column for inserting there to. The column, column insert, nut plates and endplates have patterns of mounting holes for receiving mounting bolts tightened to nuts held by nut plates. Loads are distributed between the column and foundation using a base plate, column insert, and insert plates integrated with anchor bolts, nuts and washers in a concrete foundation. The base plate having mounting holes is incorporated to the building column bottom end to receive the plurality of anchor bolts there through for fixedly tightening as an exposed end of the column insert fits in the column.

Owner:VAUGHN WILLAIM B

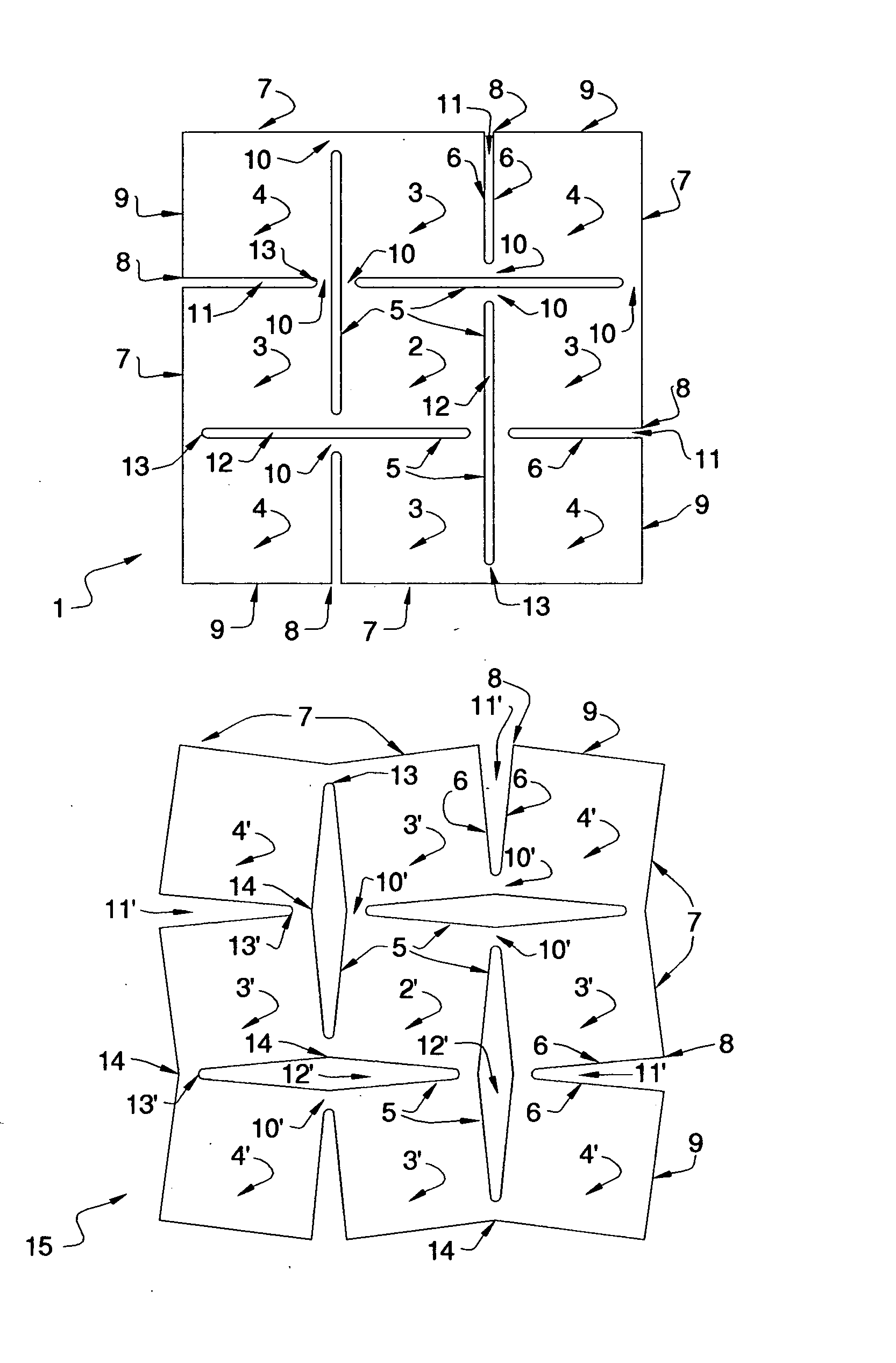

Multi-directional and variably expanded sheet material surfaces

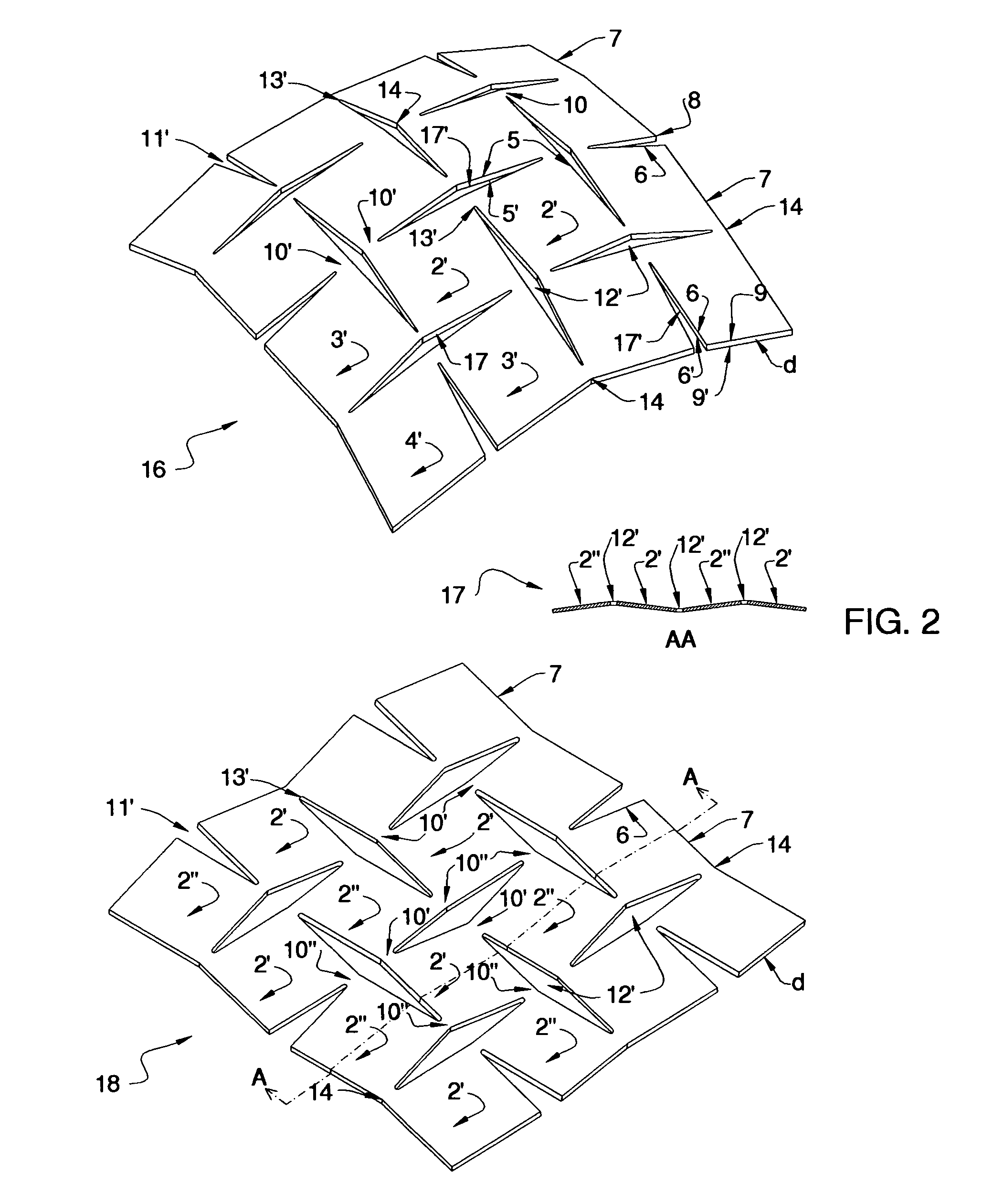

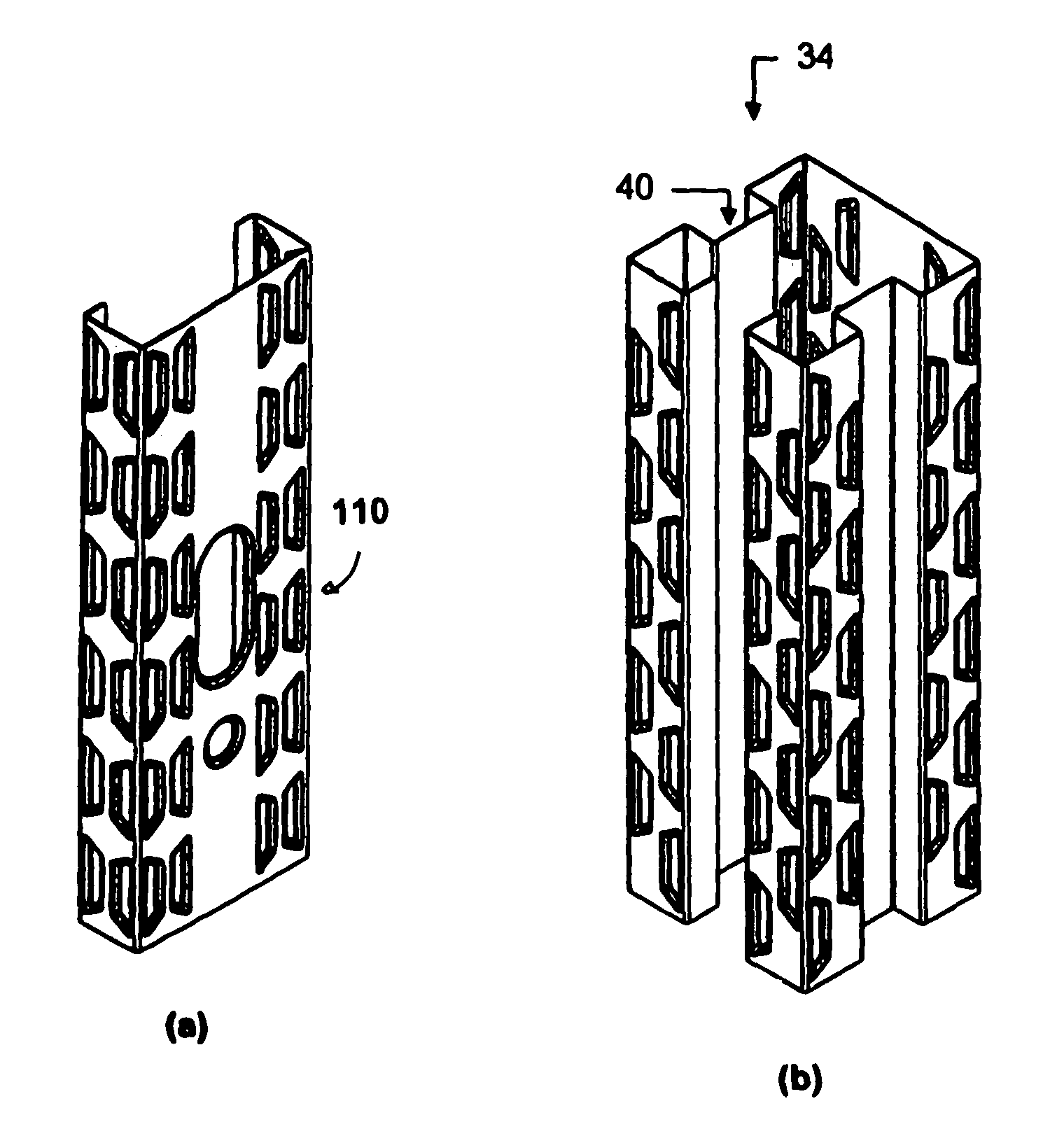

ActiveUS20070122590A1Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingNanoscopic scale

Expandable surfaces made from sheet materials with slits distributed on the surface of sheet material where the surfaces expand by application of force along or / and across the surface of sheet material. The unexpanded surfaces are flat sheets, or closed surfaces like cylinders, spheres, tubes, or custom-designed organic shapes marked with pre-formed or post-formed slit designs. The expanded surfaces can be single units or modules which can be attached to one another through various means. The sheet materials range from hard surfaces like metals, to softer materials like papers and plastics, or pliable materials like fabrics, rubbers, synthetic surfaces or bio-surfaces. The slits are arranged in patterns ranging from periodic, non-periodic to irregular designs. The slits can be straight, bent, curved or irregularly shaped with even or uneven spacing. Slitting can be achieved by digital cutting or punching devices like laser-cutting, water-jet cutting, digital punching, automated dies, etc. or pre-formed when casting the sheet material. Force can be applied manually with tools or through the use of machines and special set-ups. Applications range from architectural surfaces, walls, ceilings, panel systems, structures and sculpture. On a smaller scale, applications include containers, packaging material, fabrics and human wear. On micro- to nano-scale, applications range from expandable surfaces for gauzes, band-aids, stent designs, skin grafts, semi-permeable membranes and micro-filters for various industries including purification of fluids and chemical substances.

Owner:LALVANI HARESH

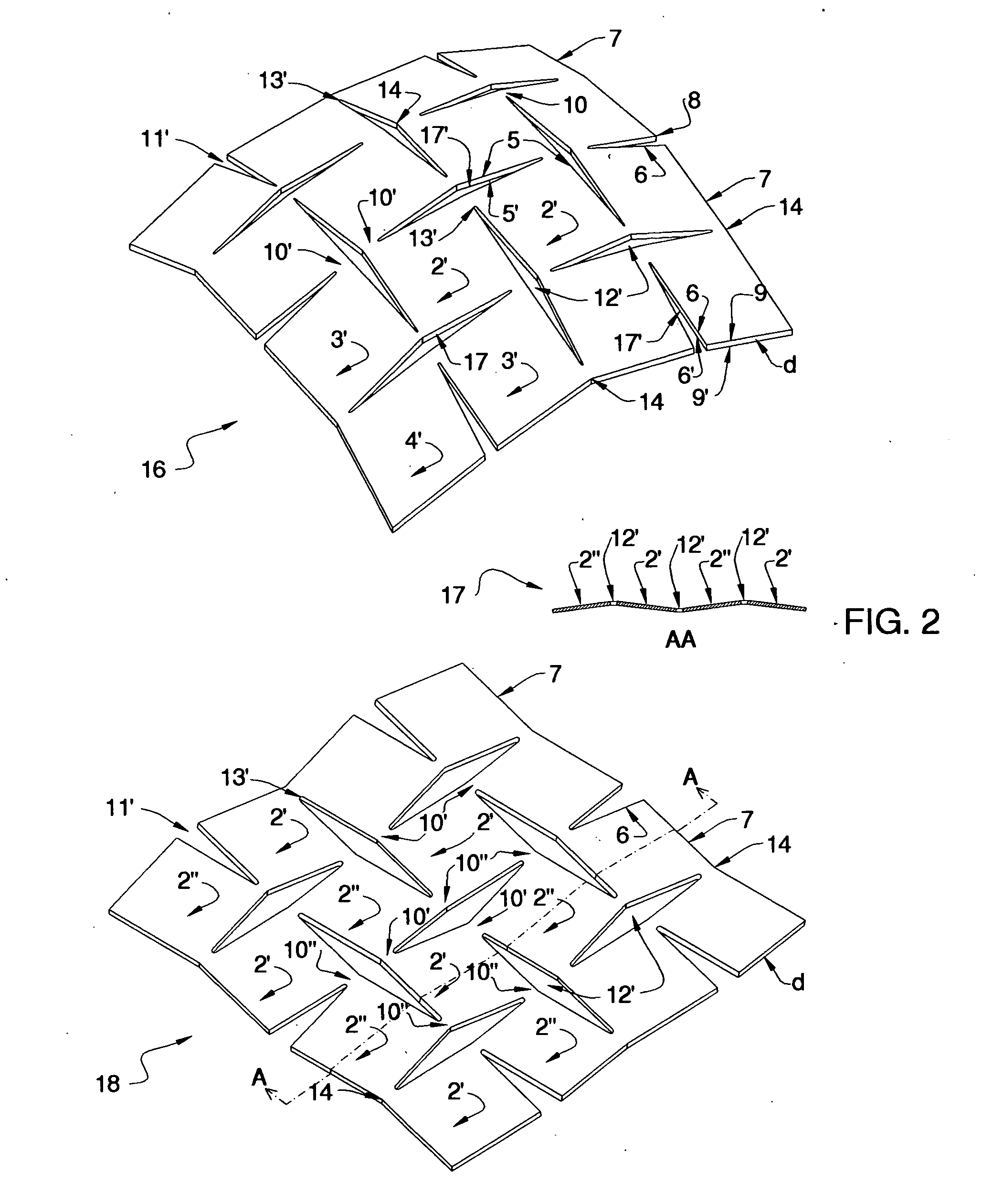

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipment to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS8627862B2Easy to installImprove installation and strength and quality and production costCovering/liningsTongue/grooves making apparatusEngineeringTongue and groove

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

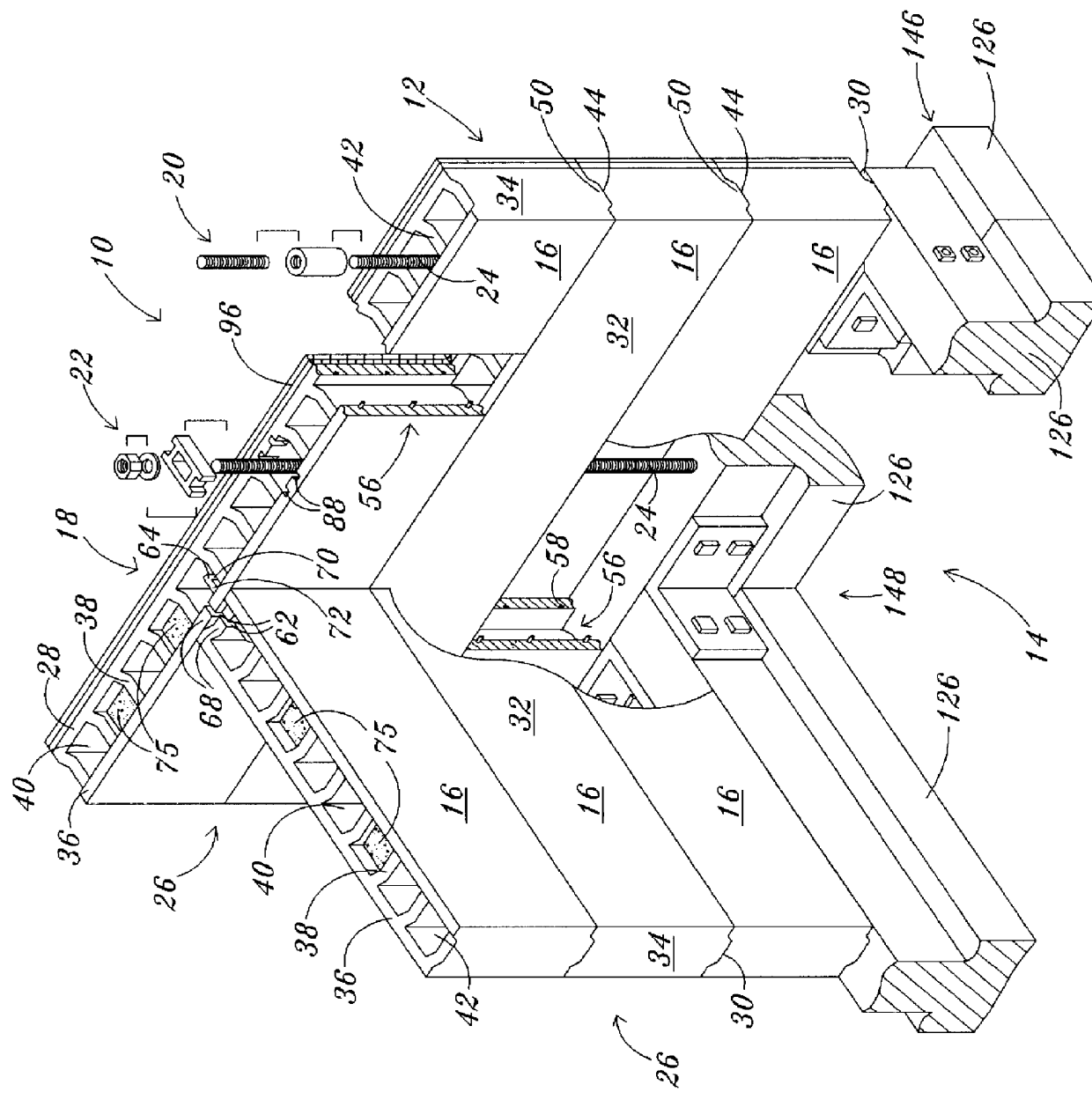

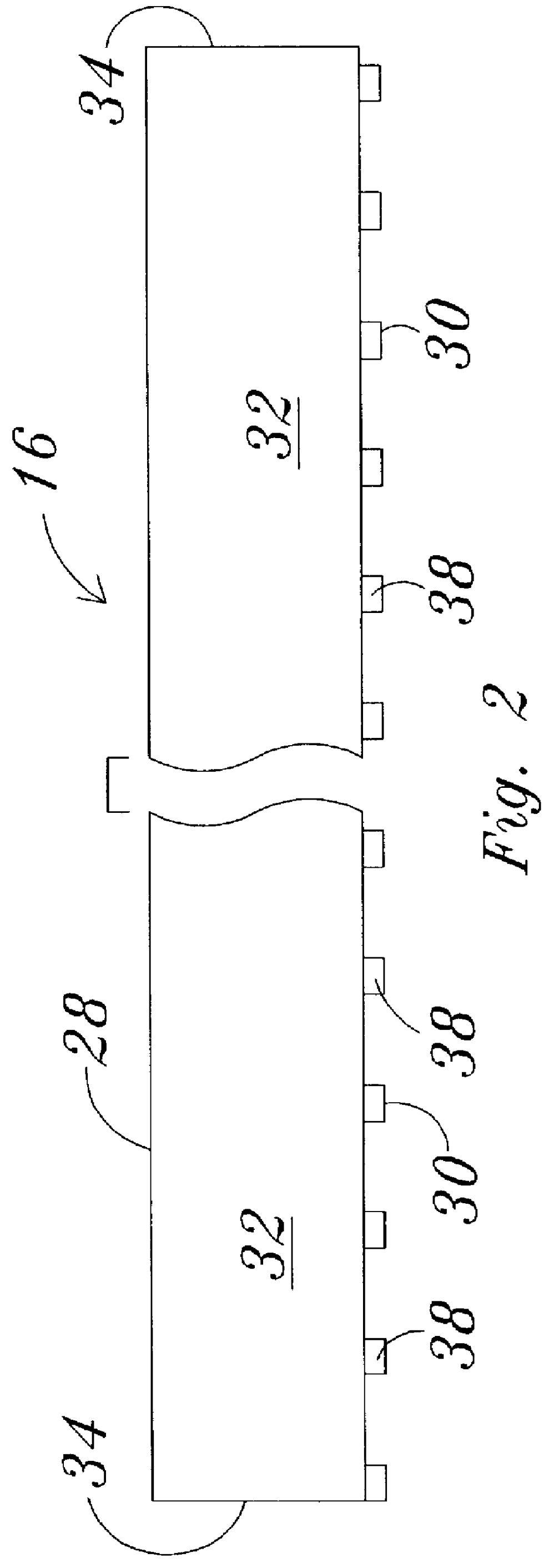

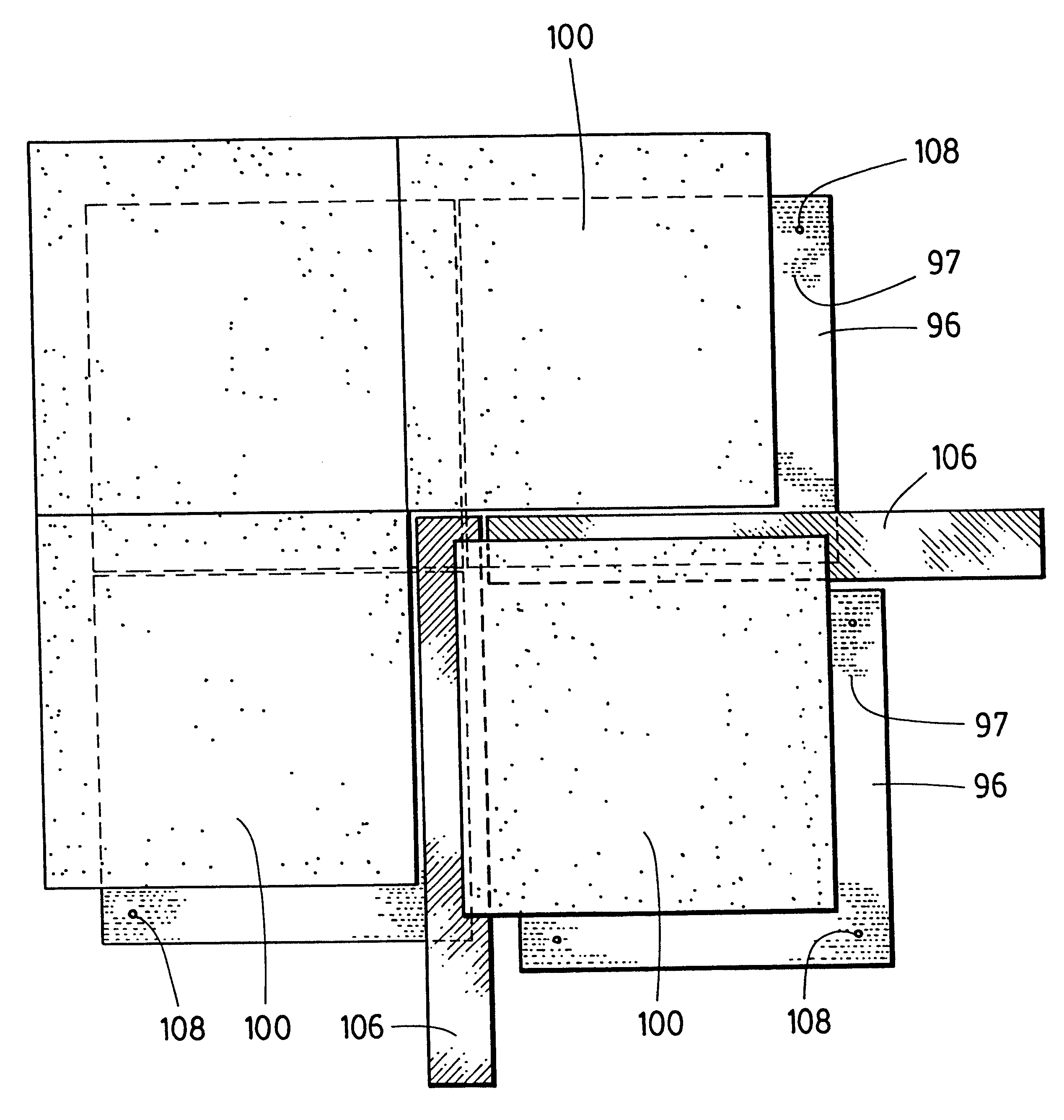

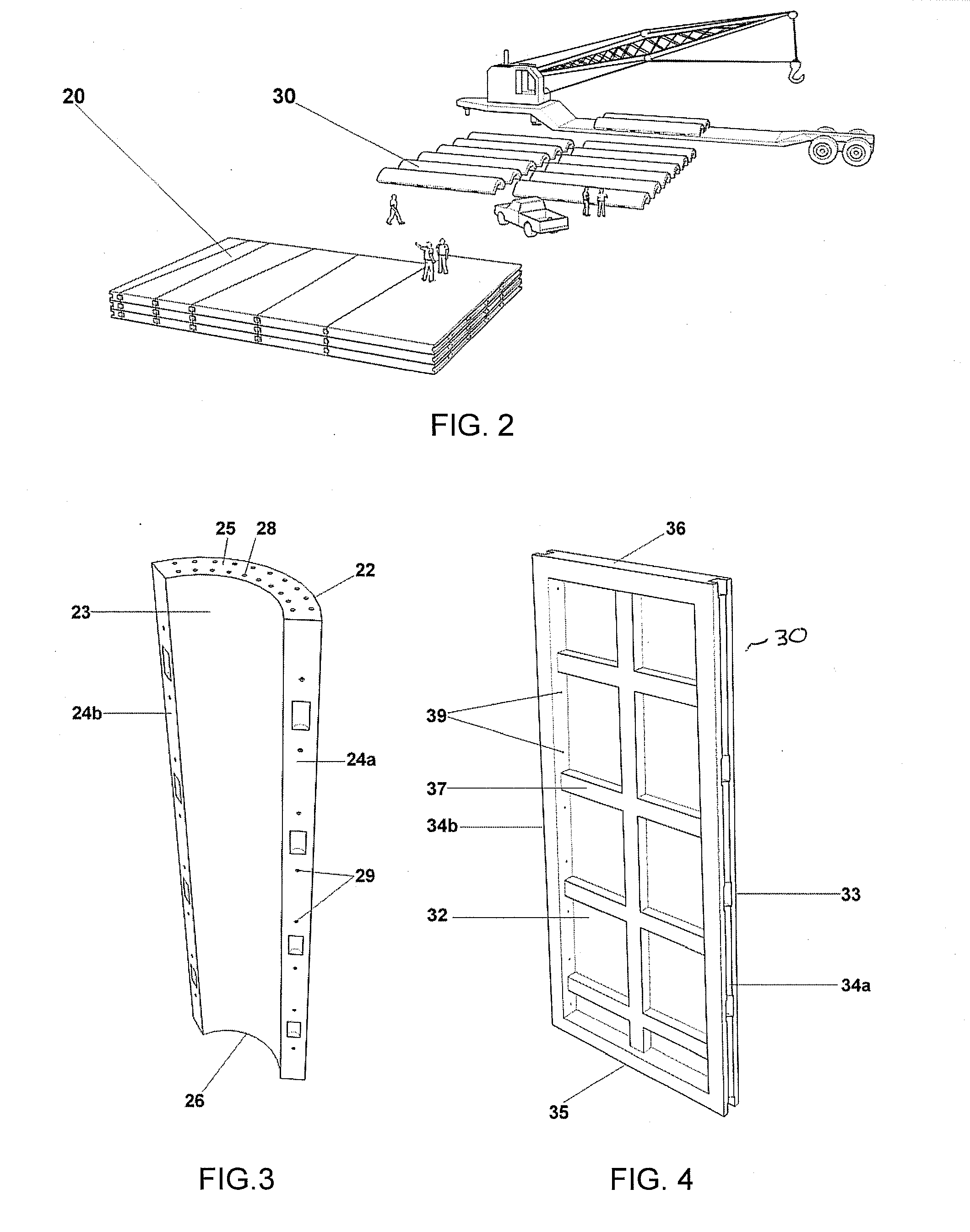

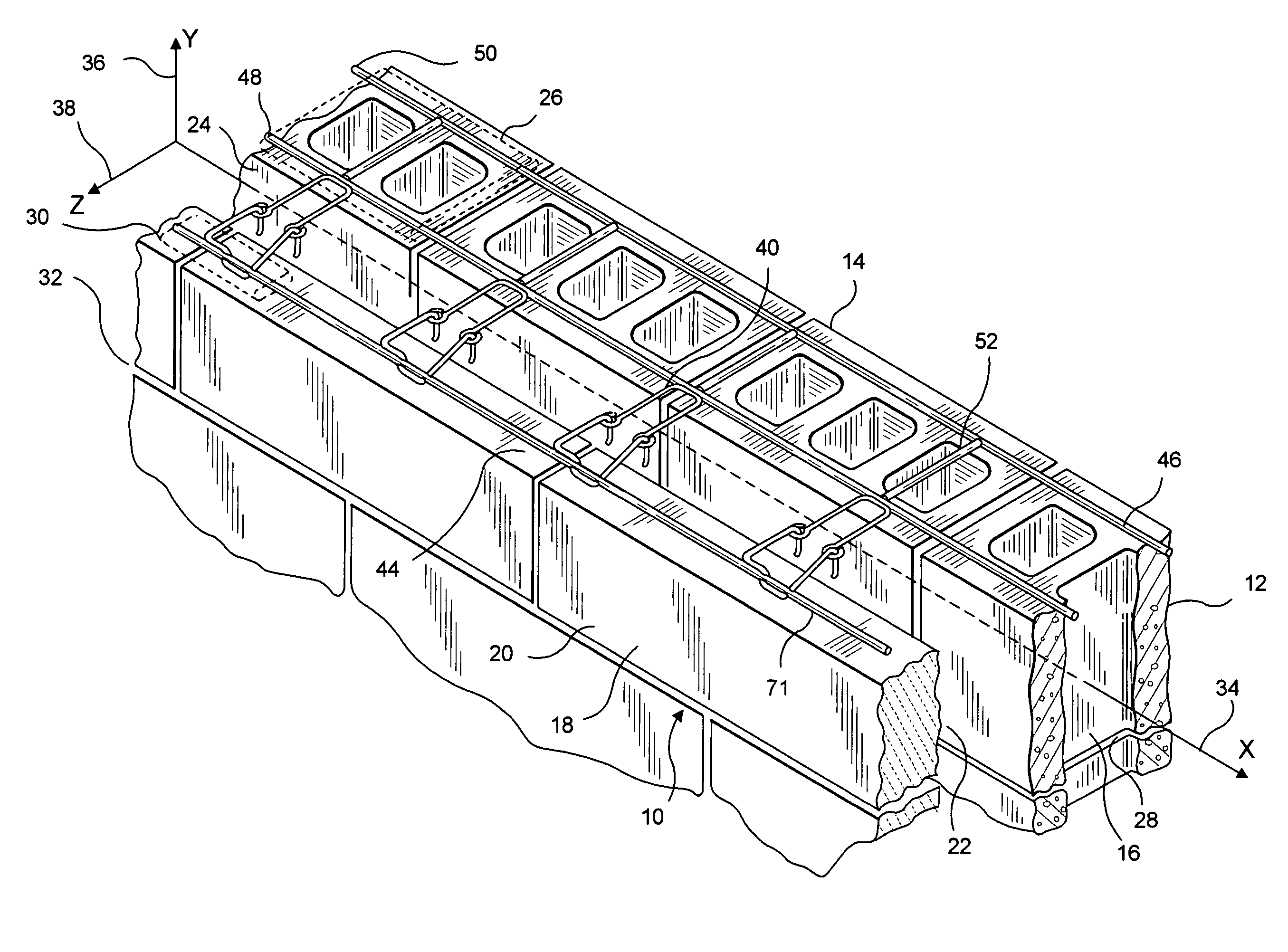

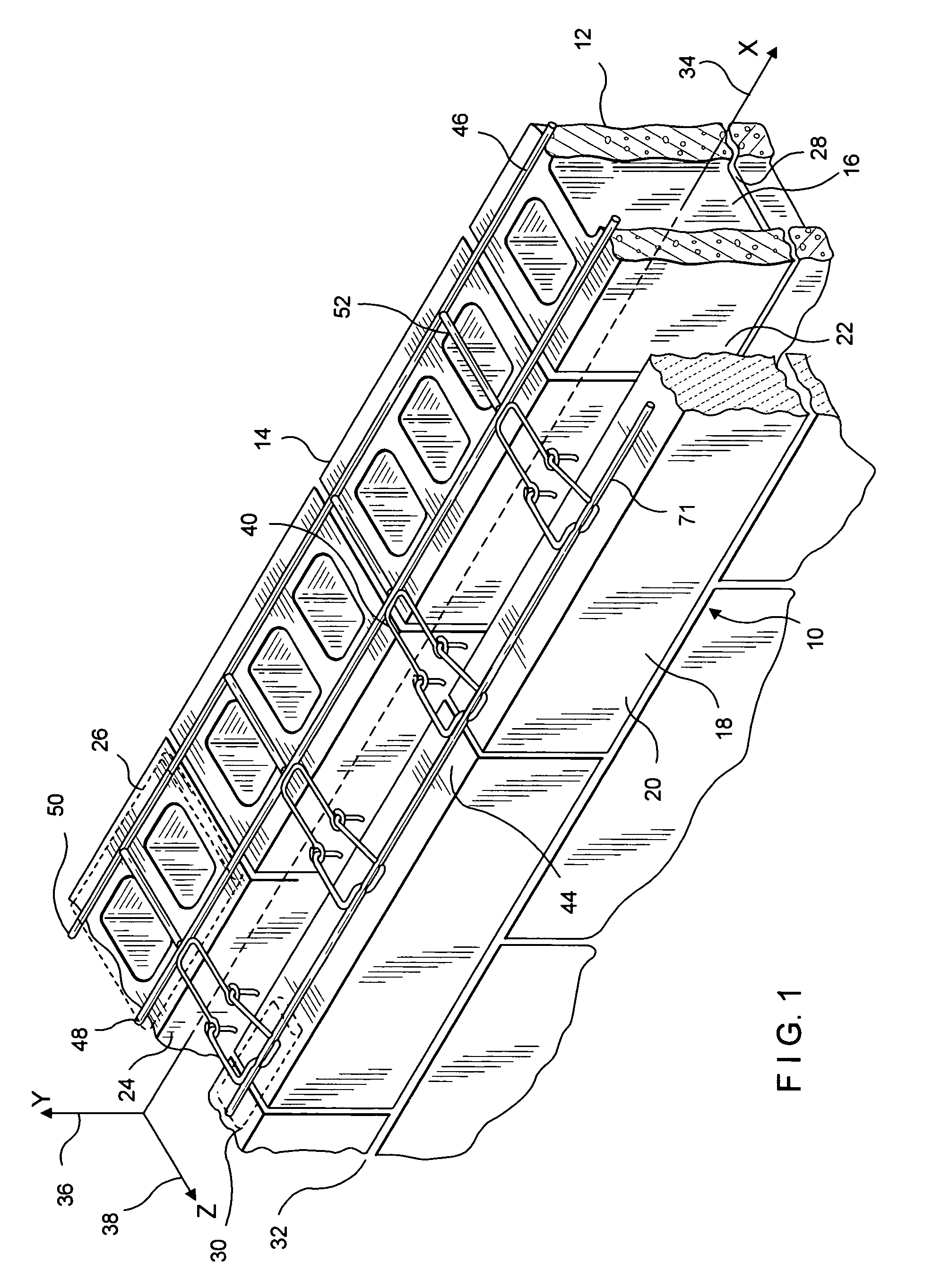

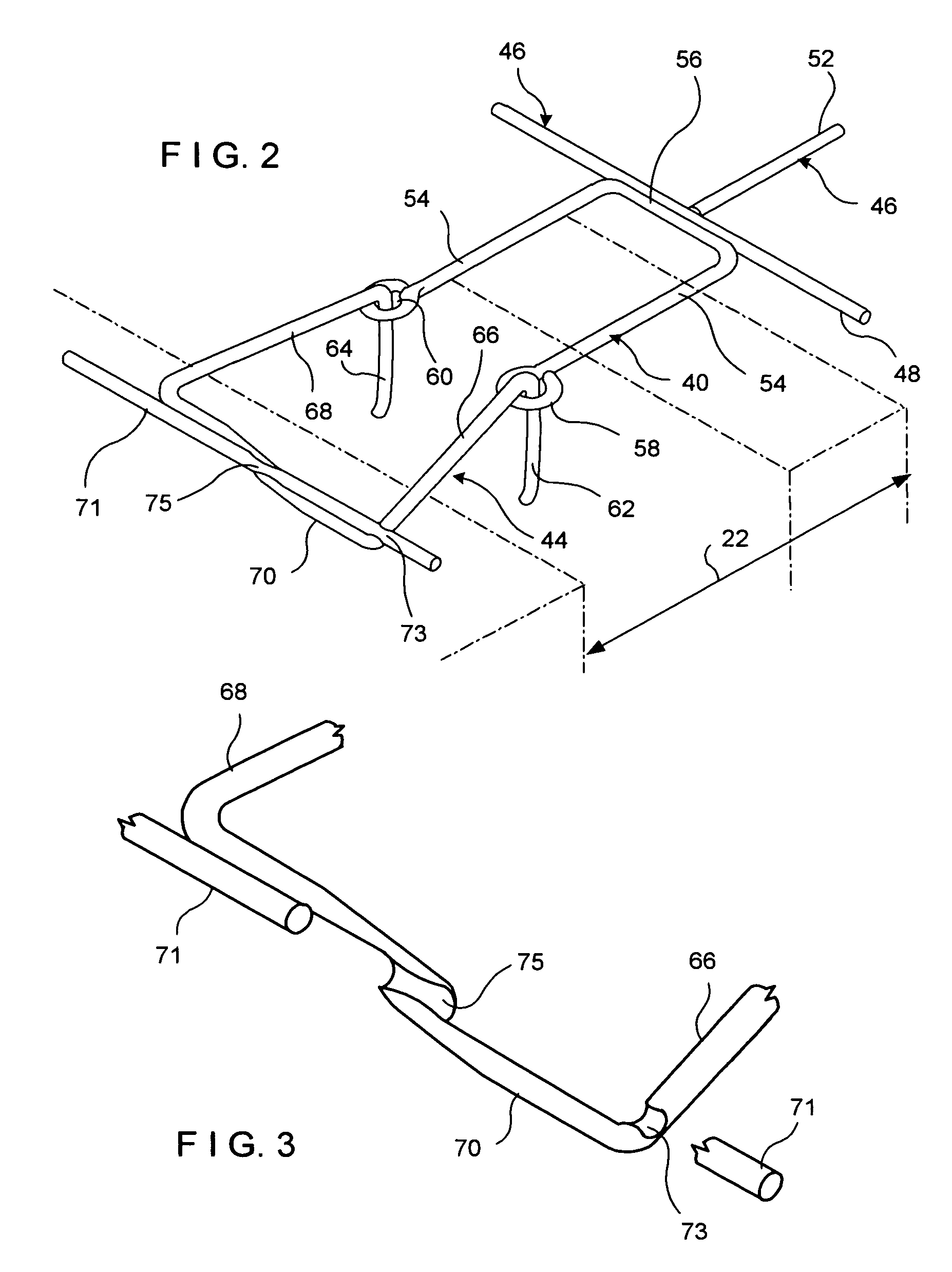

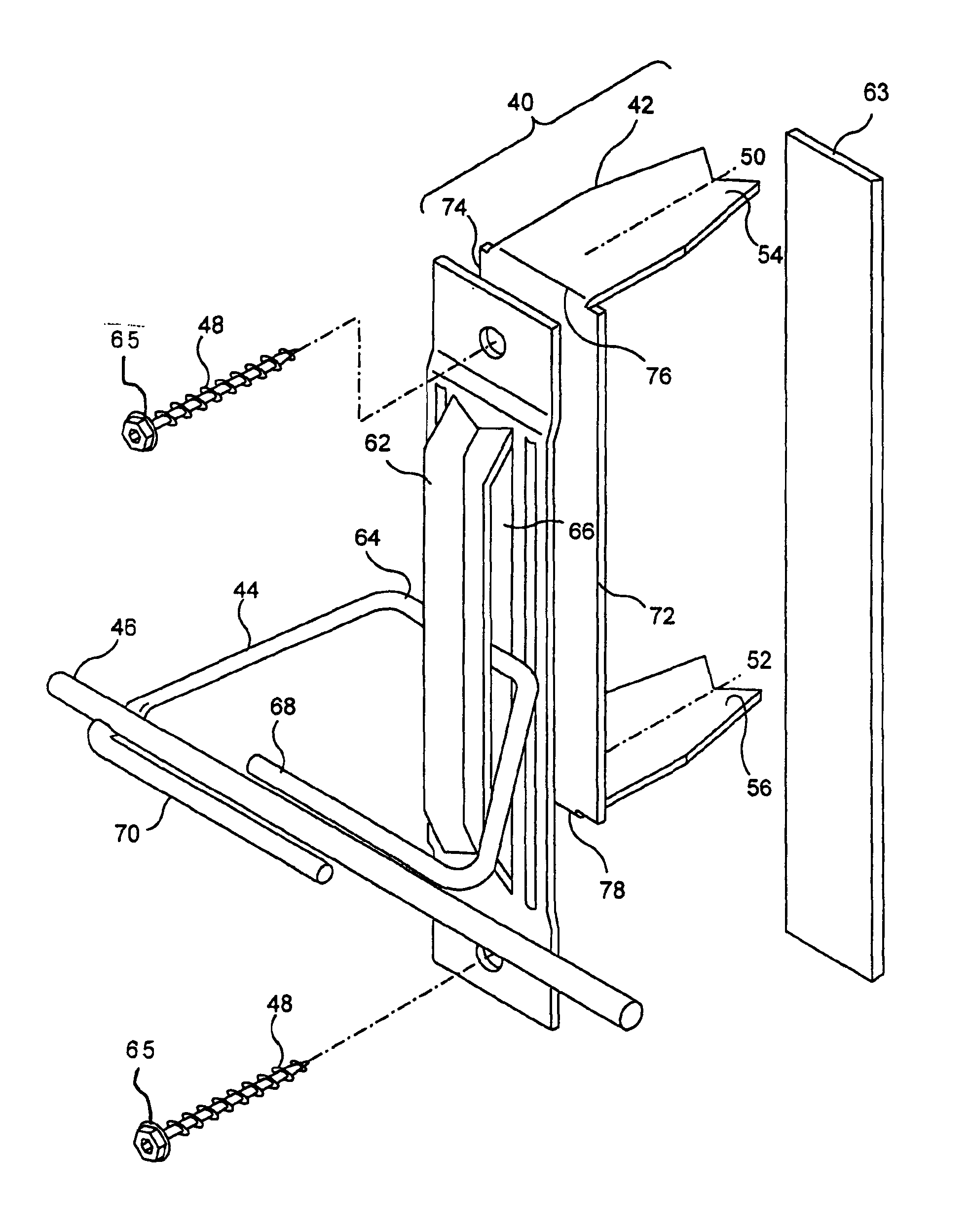

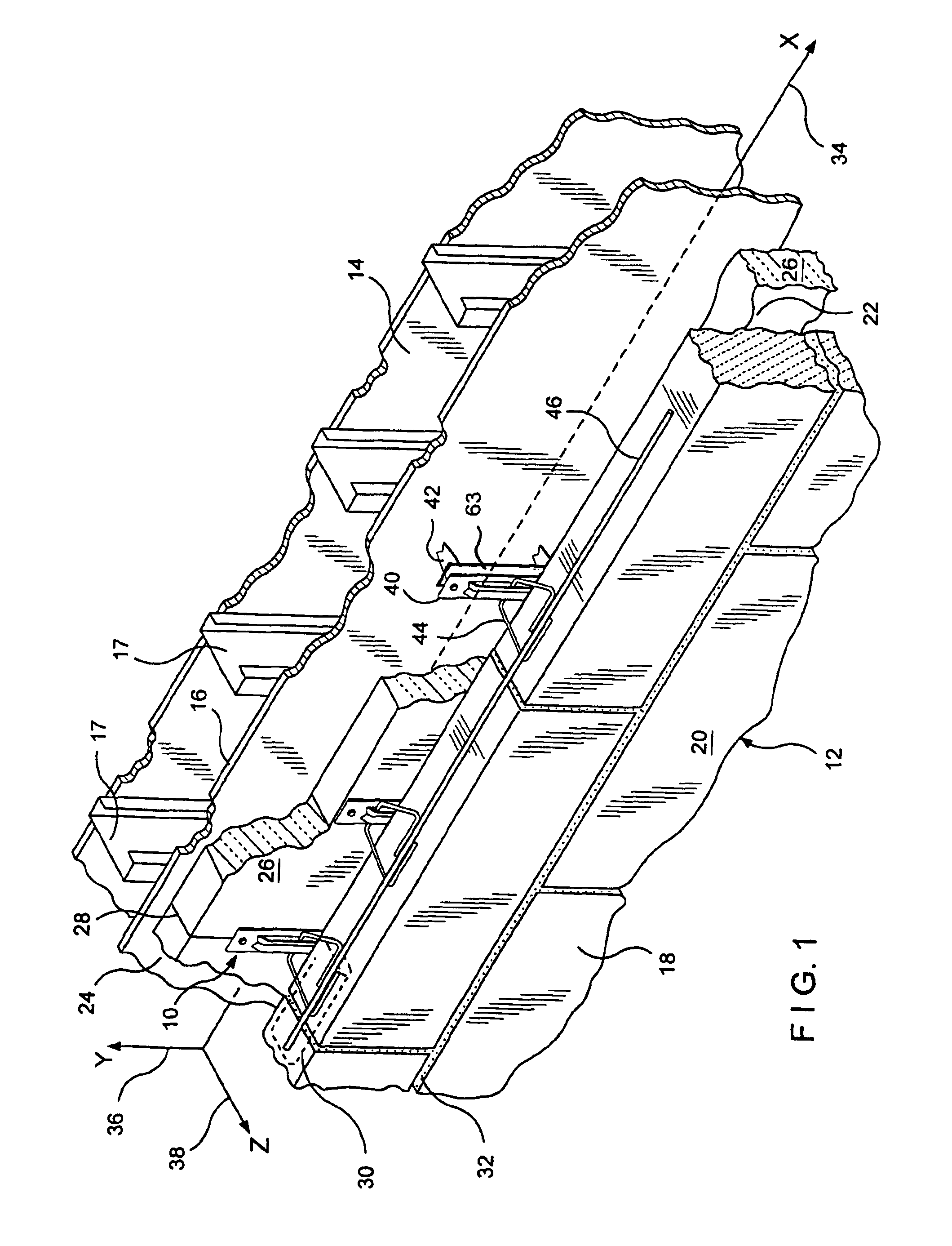

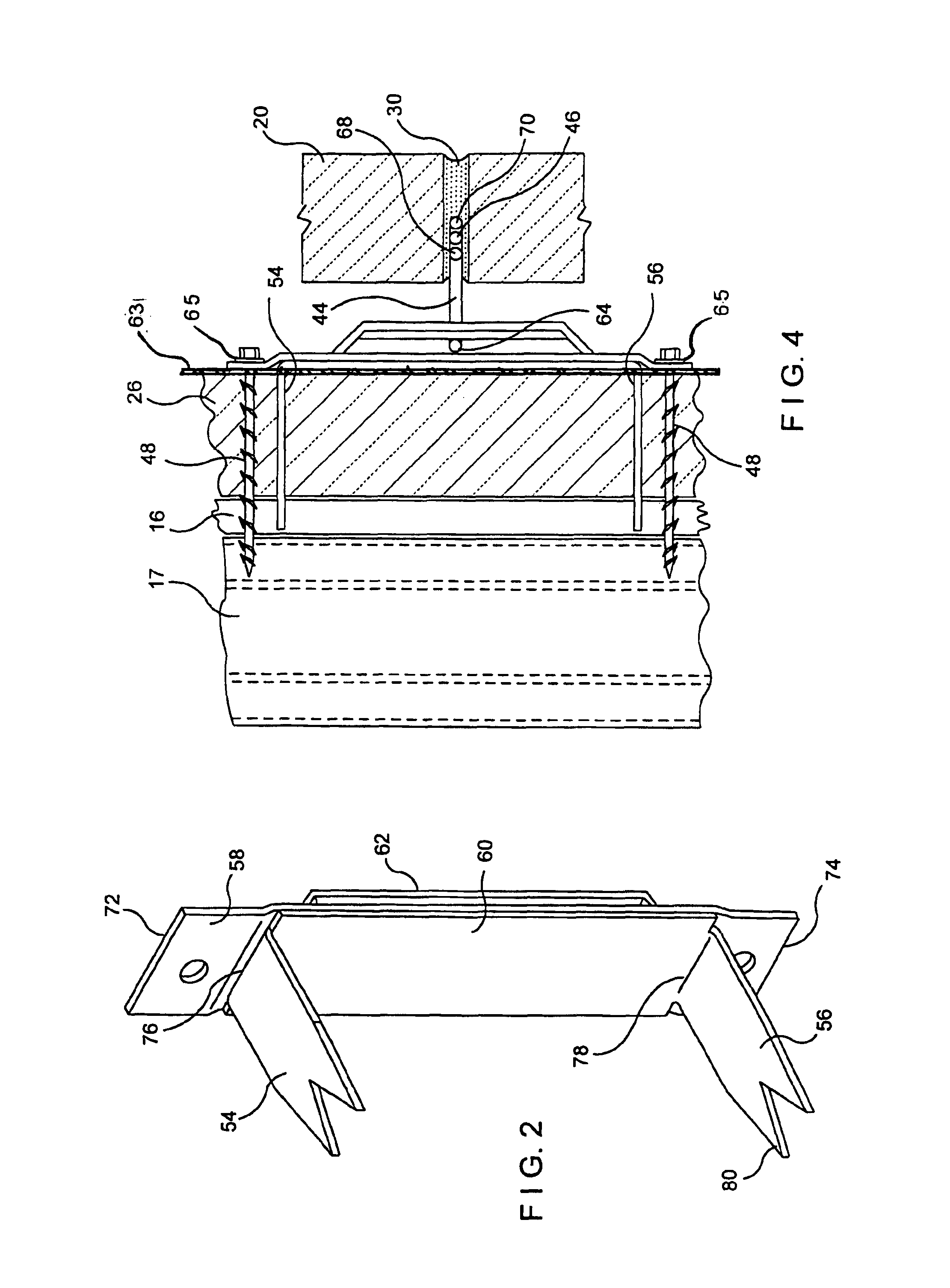

Modular precast construction block system

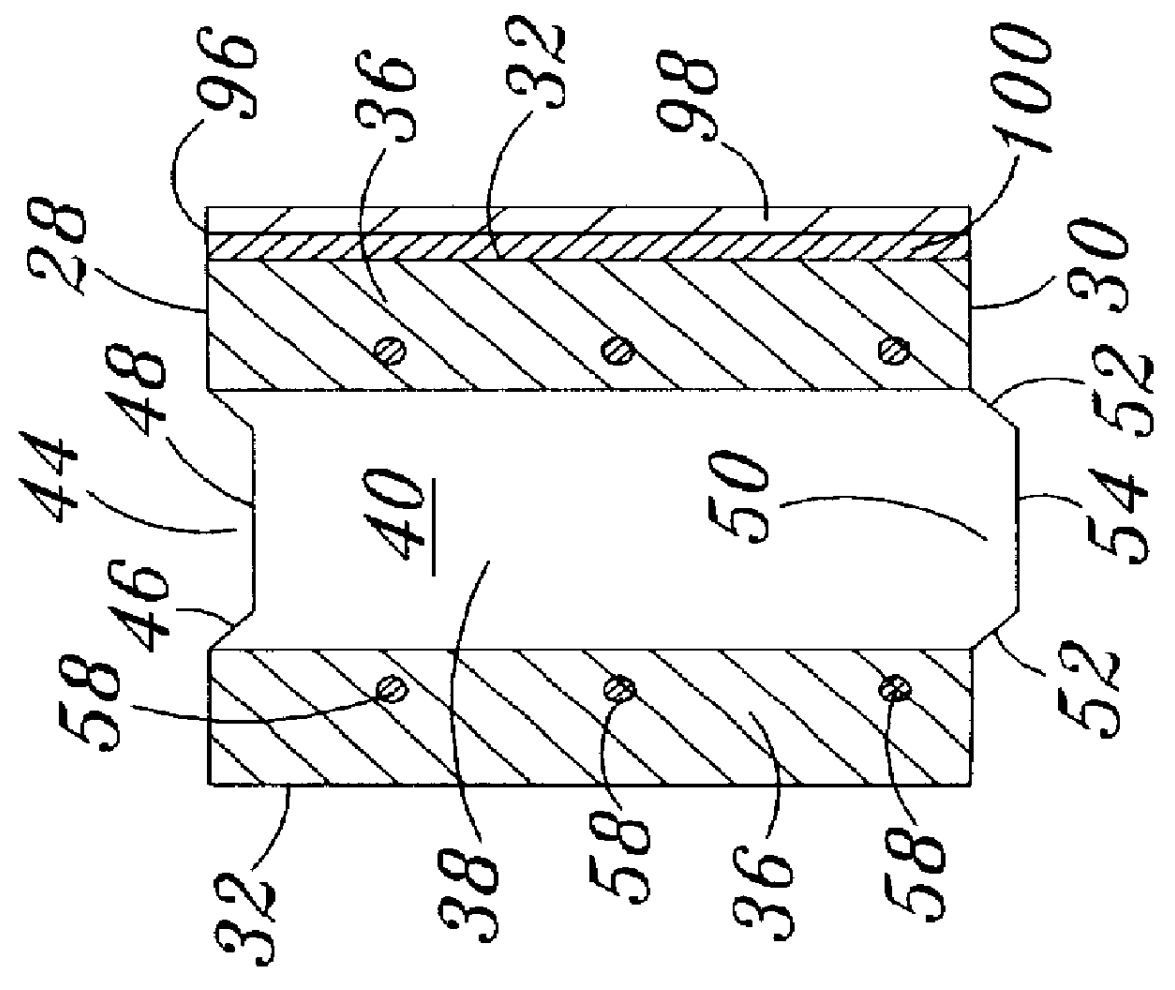

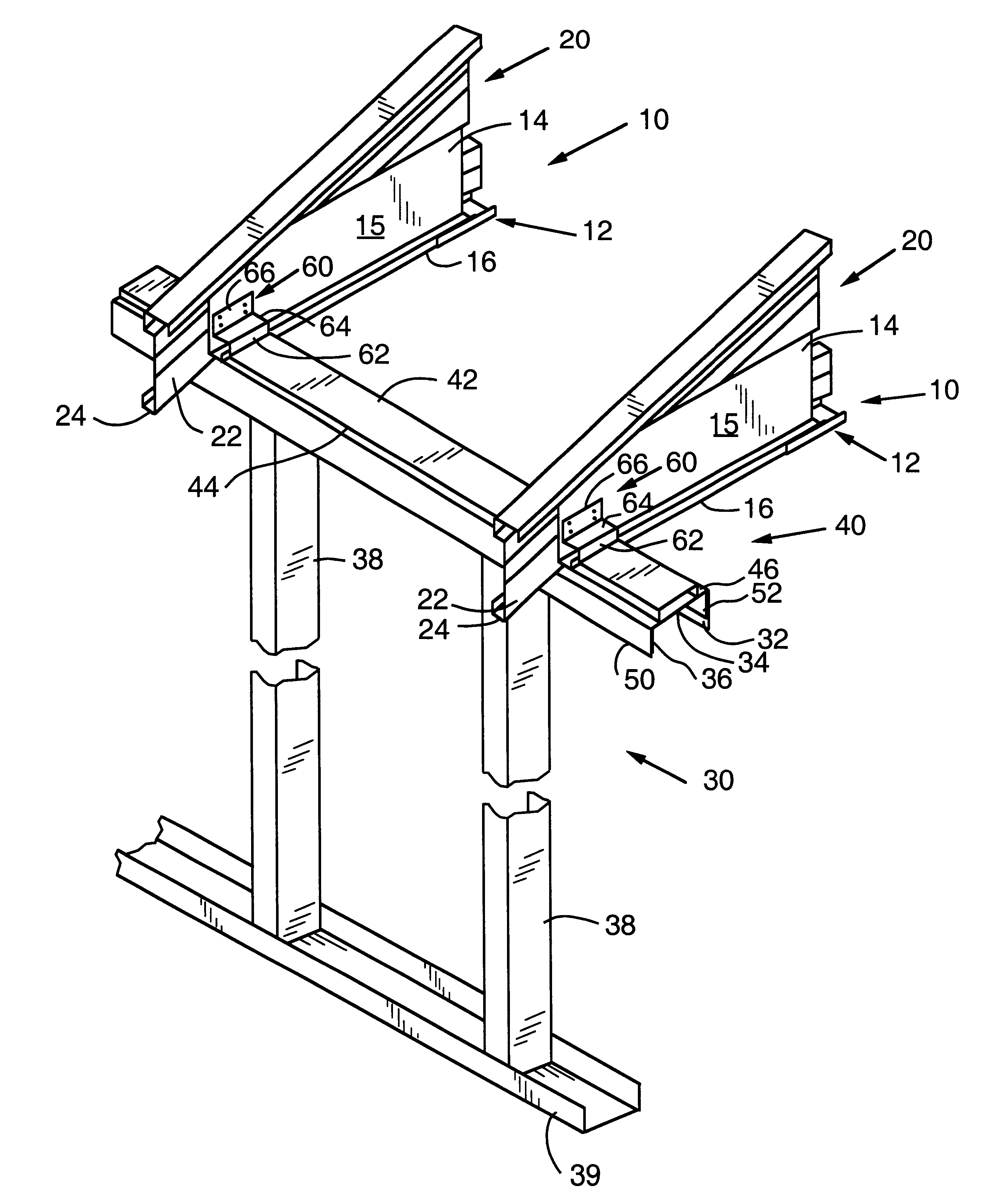

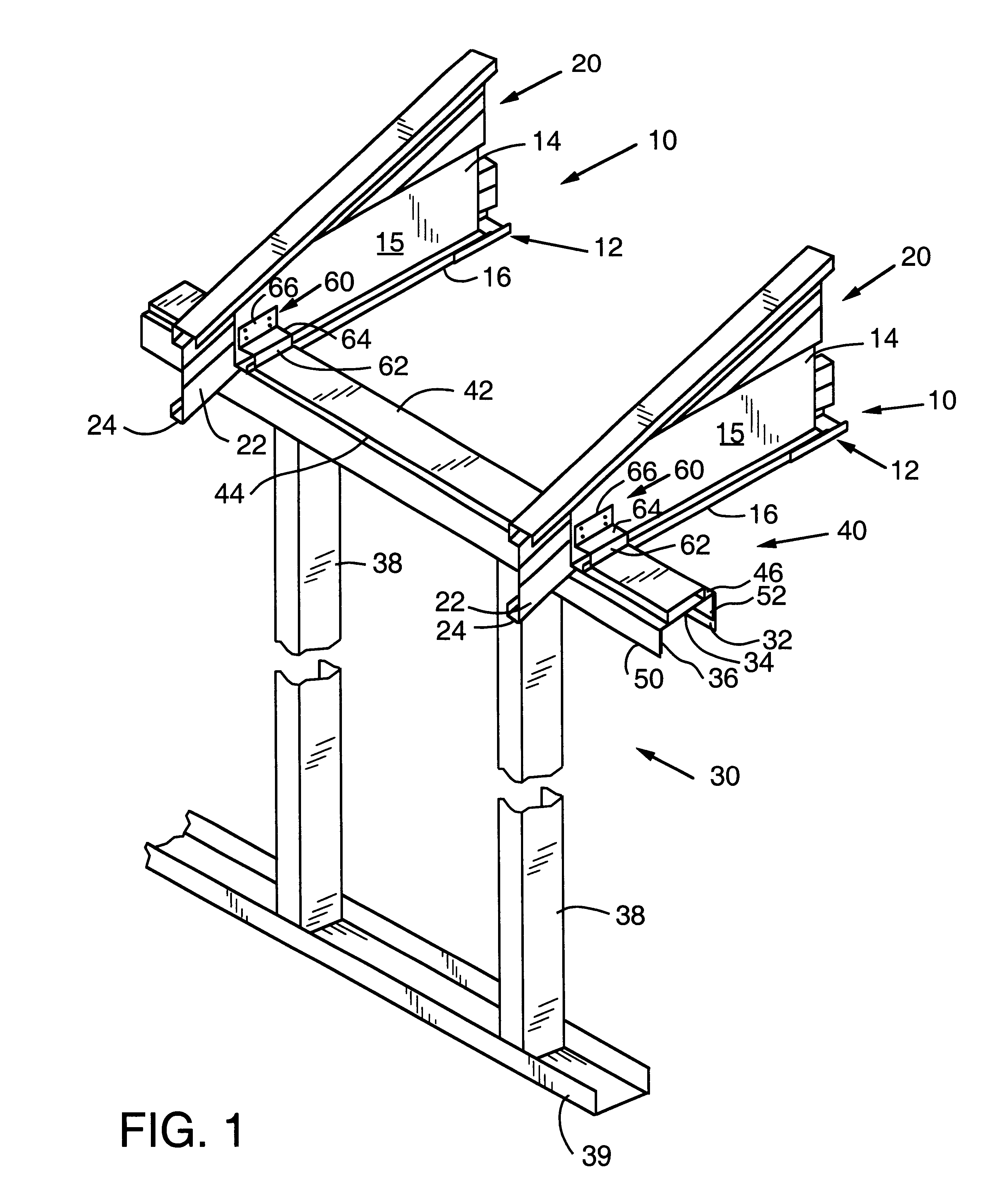

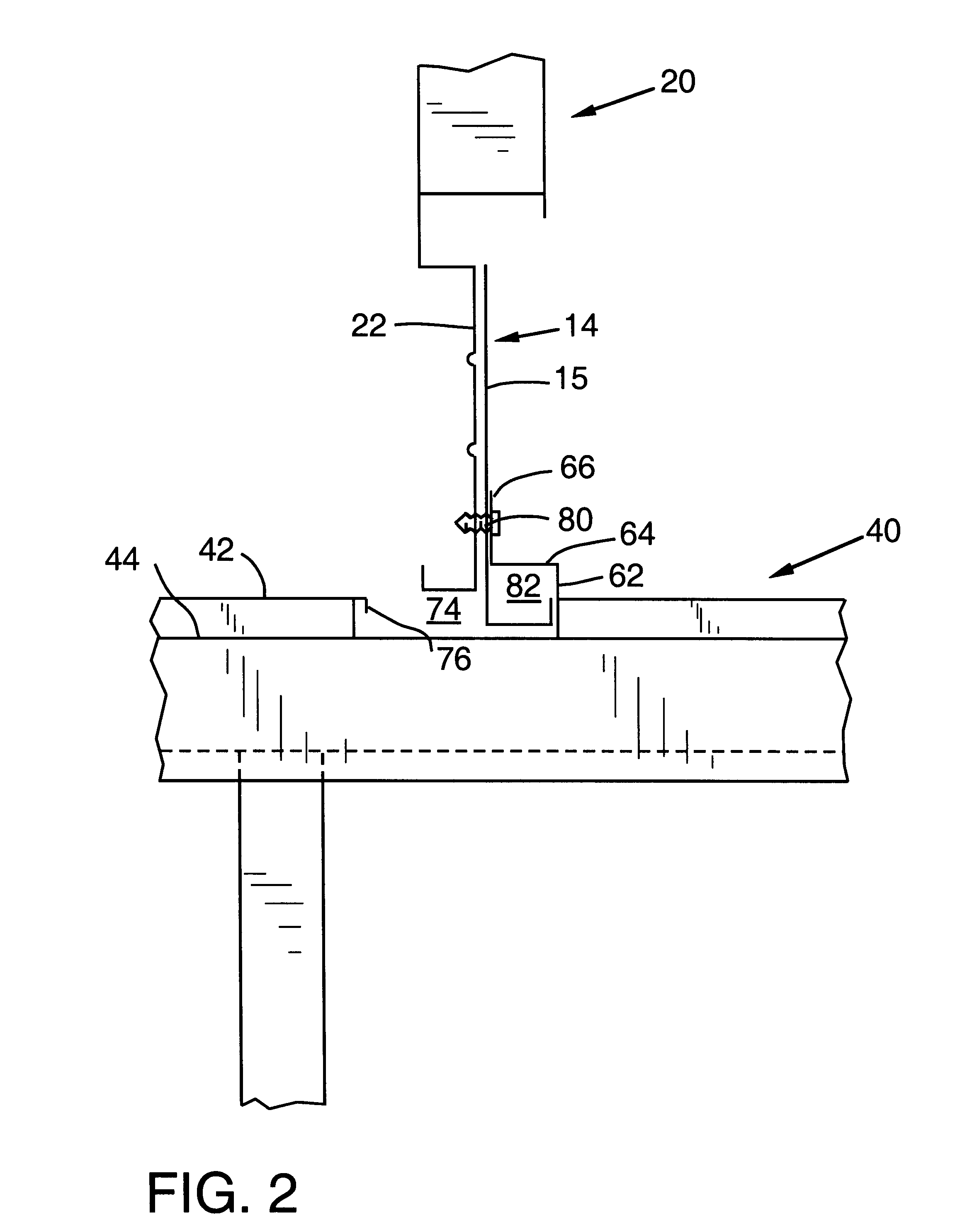

A modular precast construction block system (10) with a wall subsystem (12) and a foundation subsystem (14). The wall subsystem (12) has a number of wall units (16) having cavities (40) and prestressed tension cables (58) cast therein. The wall units (16) are vertically stacked with alignment channels (42) in the top surface (28) of one wall unit (16) receiving the key portion in the bottom surface (30) of the wall unit (16) above, to form walls (26) with vertically aligned cavities (40). Threaded wall bars (24) and extension bars (74) are threaded through the cavities with a wall tensioning assembly (22) applying downward force on the wall units (16) and providing structural strength to the wall. The foundation subsystem (14) includes a variety of precast foundation members including T footing members (126), pier members (128), grade beam members (130), and column members (132). The T footing members (126) and grade beam members (130) include complementary angled pairs for creating angled and "T" joint foundation designs.

Owner:MEGAWALL

Top plate

InactiveUS6430881B1Easy to manufactureEasy to installBuilding roofsStrutsMechanical engineeringEngineering

Owner:MITEK HLDG INC

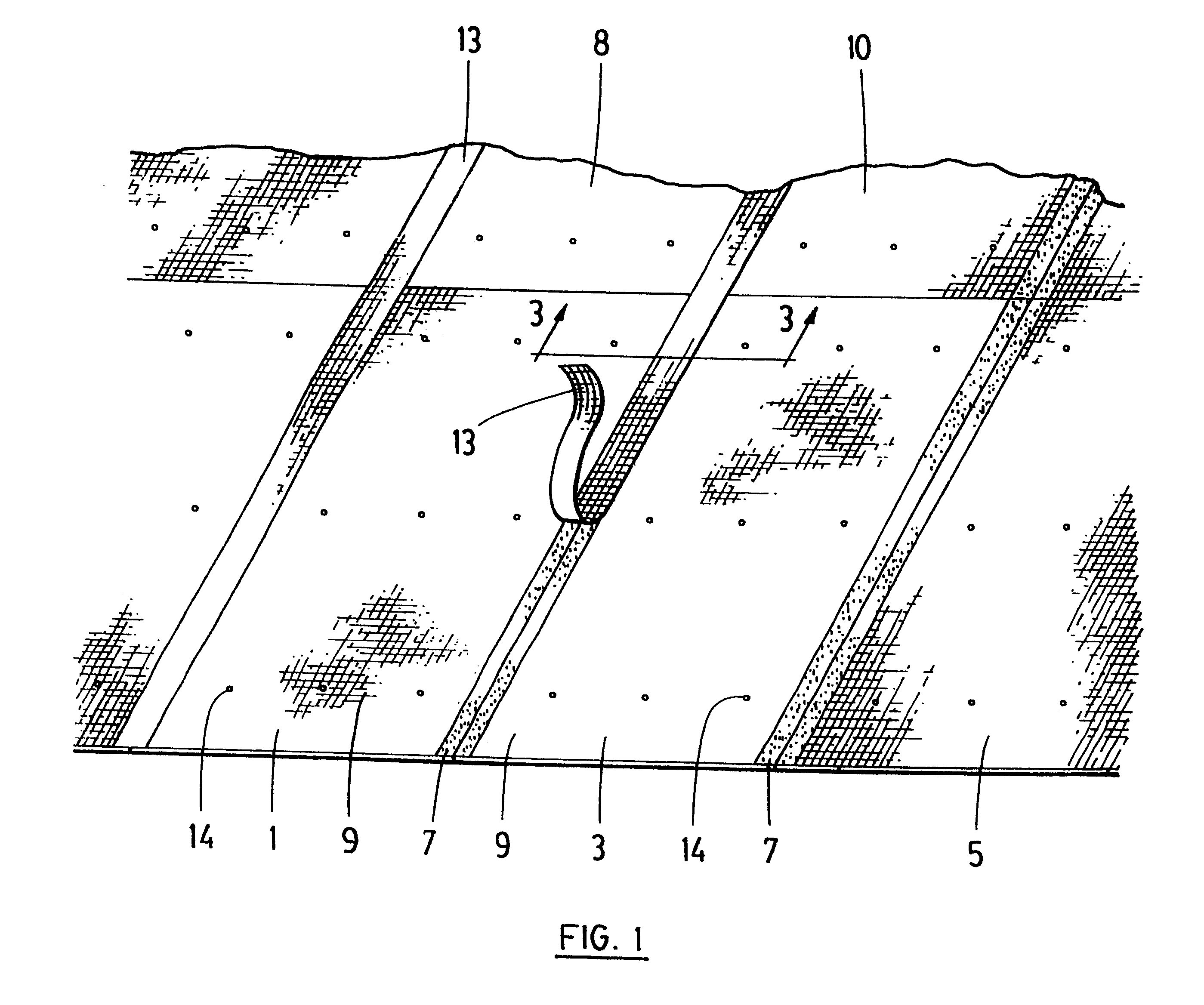

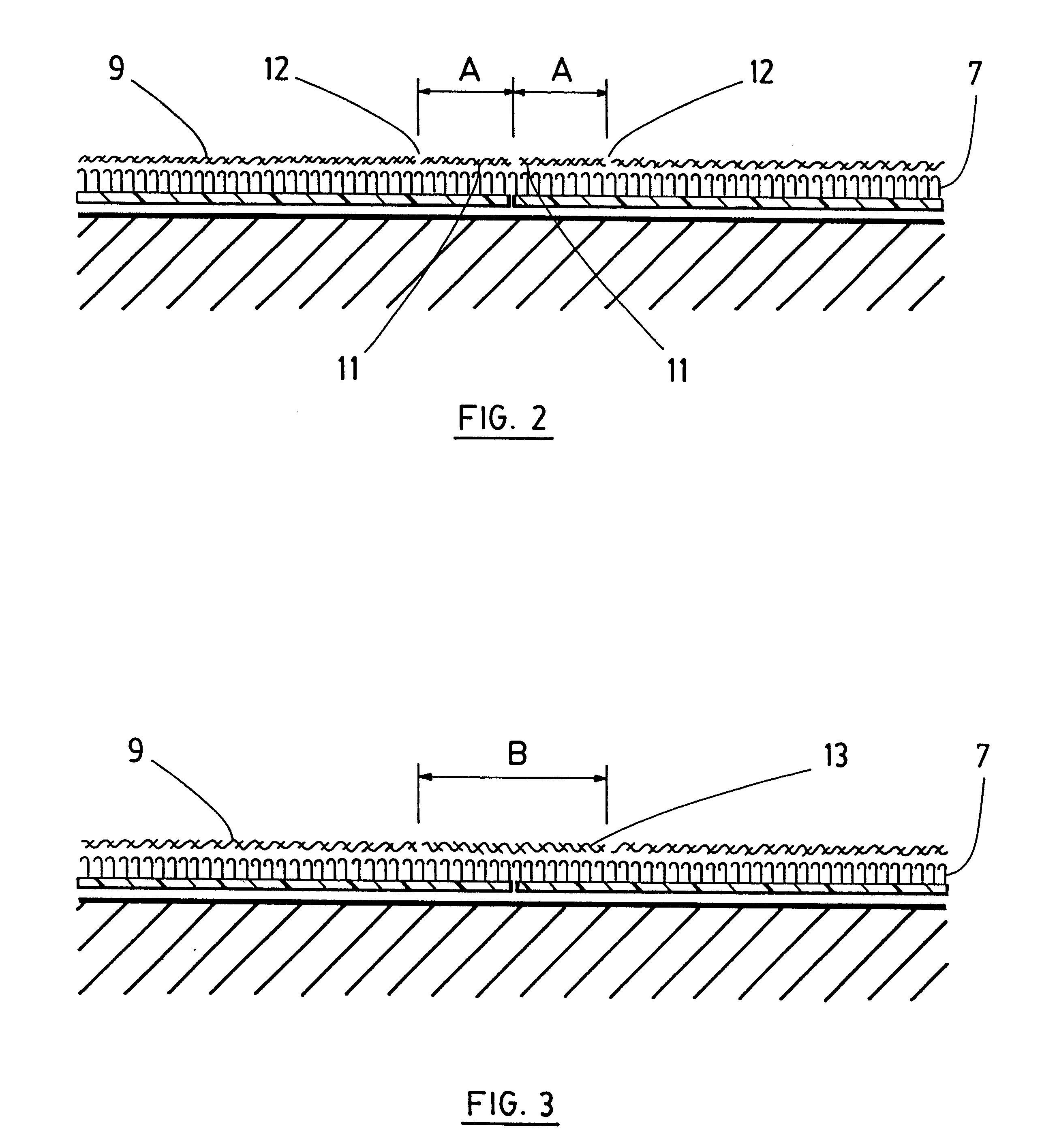

Anchor sheet and anchor sheet module

This application discloses a relatively thin flexible anchor sheet for installation under carpets or other decorative coverings and a covering module composed of a pre-attached decorative covering and anchor sheet which can be assembled by overlapping hook and loop attachment to an additional covering module to create a complete floor covering of carpet, tile, stone or other material and without substantial attachment to a floor.

Owner:TAC FAST GEORGIA

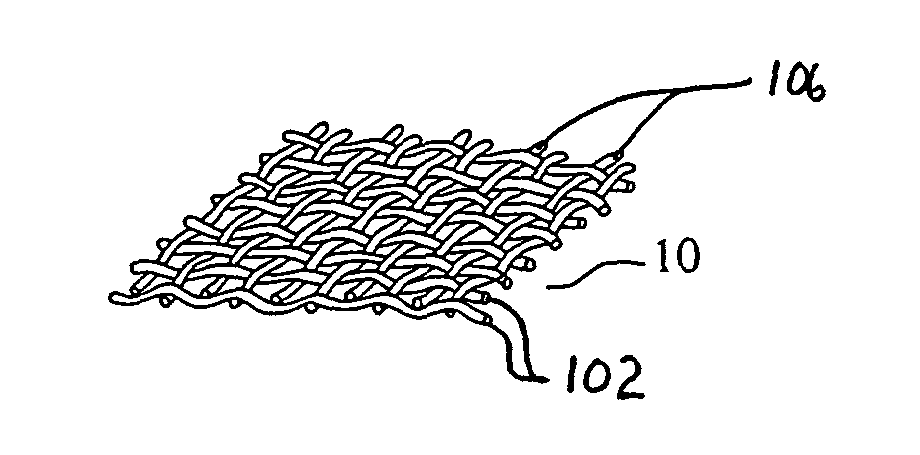

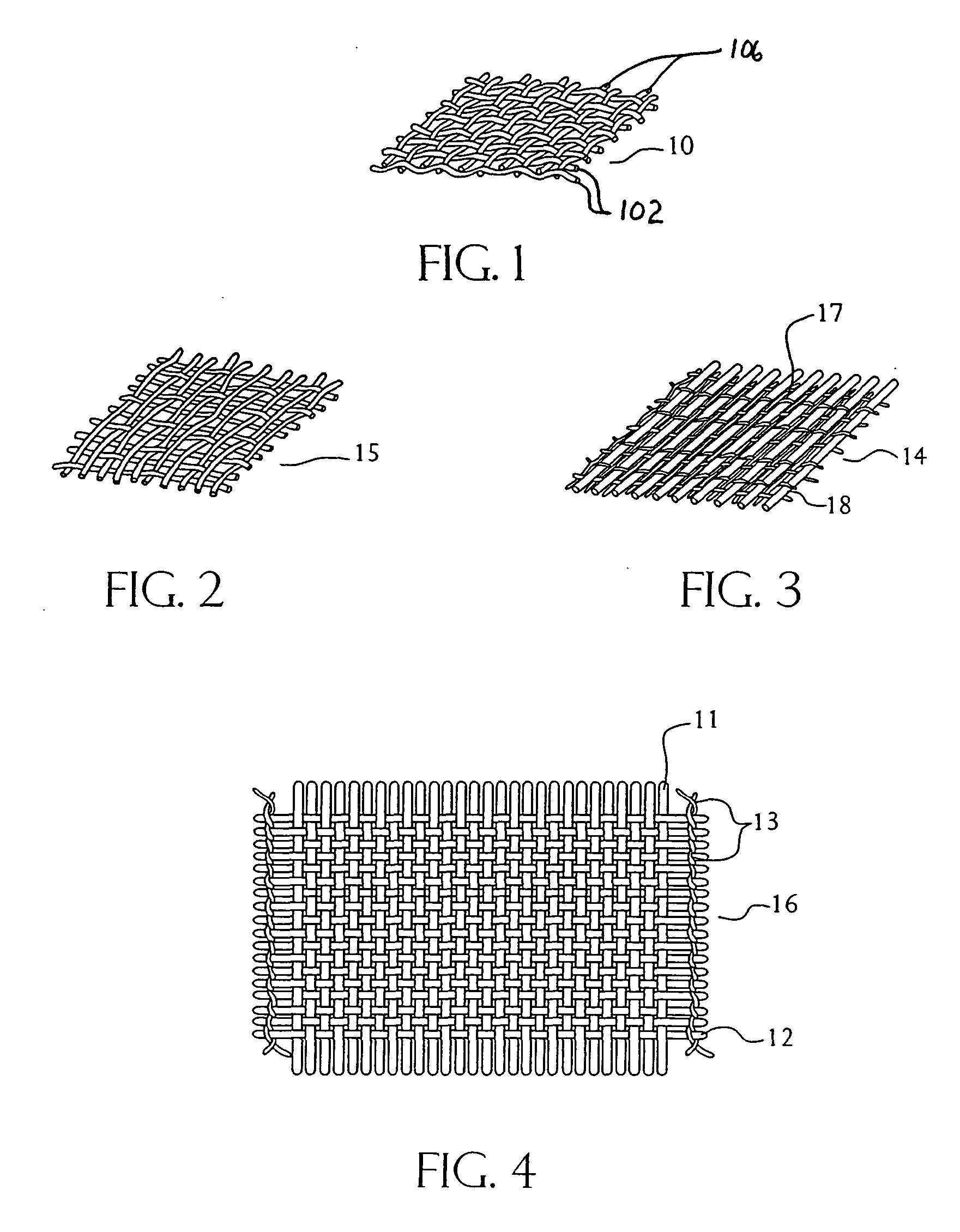

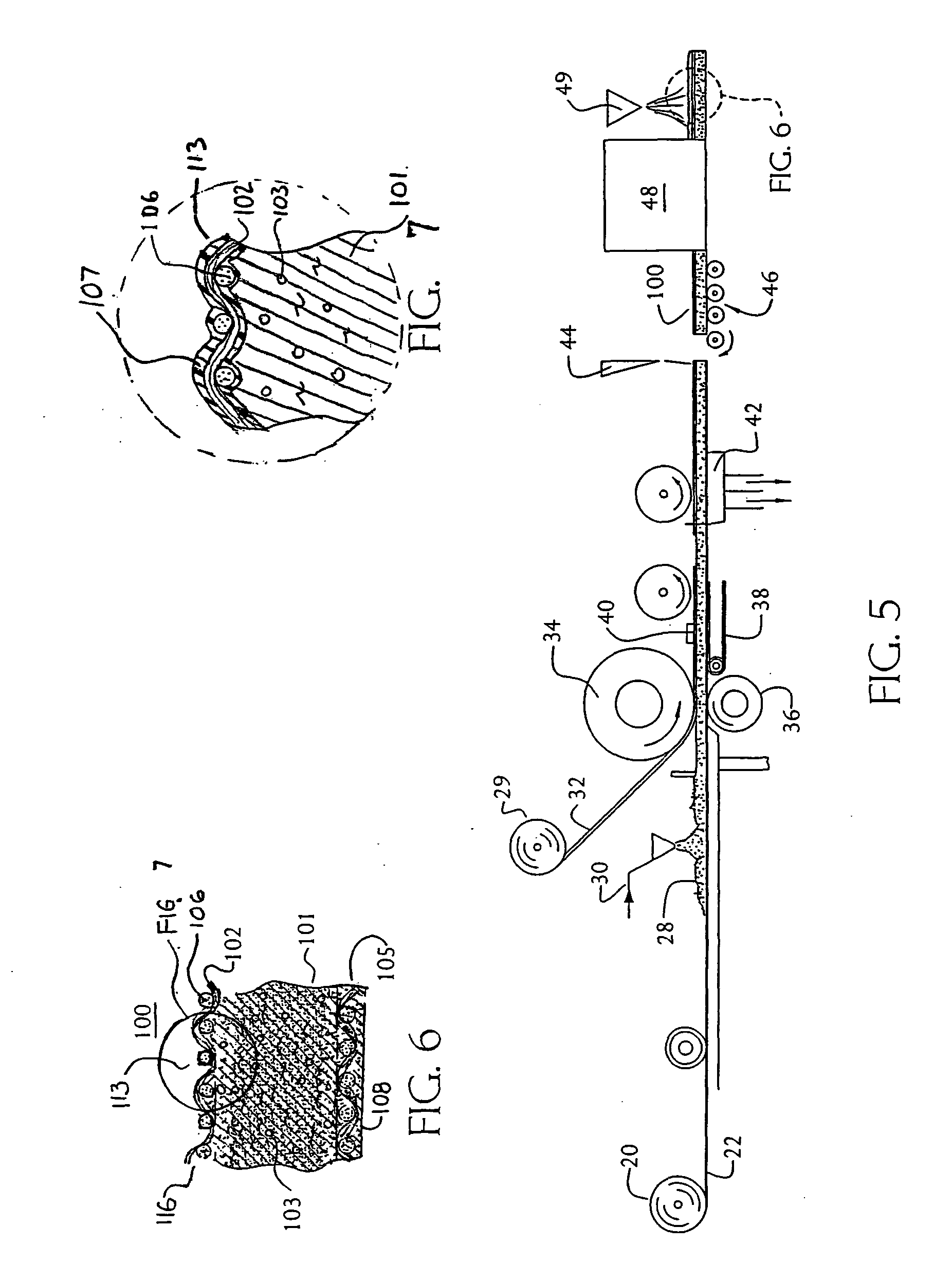

Fabric reinforcement and cementitious boards faced with same

ActiveUS20050009428A1Improve coating uniformityConvenient coatingDecorative surface effectsPretreated surfacesCement boardEngineering

Fabric and reinforcements are provided by this invention which, in a first embodiment, include a plurality of warp yarns having a first twist (turns / inch) and a plurality of weft yarns having a second twist which is greater than the first twist. A coating is applied over a substantial portion of the warp and weft yarns after they are assembled or laid together, so as to produce a weight distribution ratio of less than about 2.0:1, based upon the weight of the resinous coating of the weft yarns over the weight of the resinous coating on the warp yarns. This can be achieved, in substantial part, due to the difference in the twist ratios of the warp and weft yarns, which difference permits a more uniform coating to be applied. Further embodiments of this invention include a cementitious board and methods of making a coated fabric and cementitious board.

Owner:SAINT GOBAIN ADFORS CANADA LTD

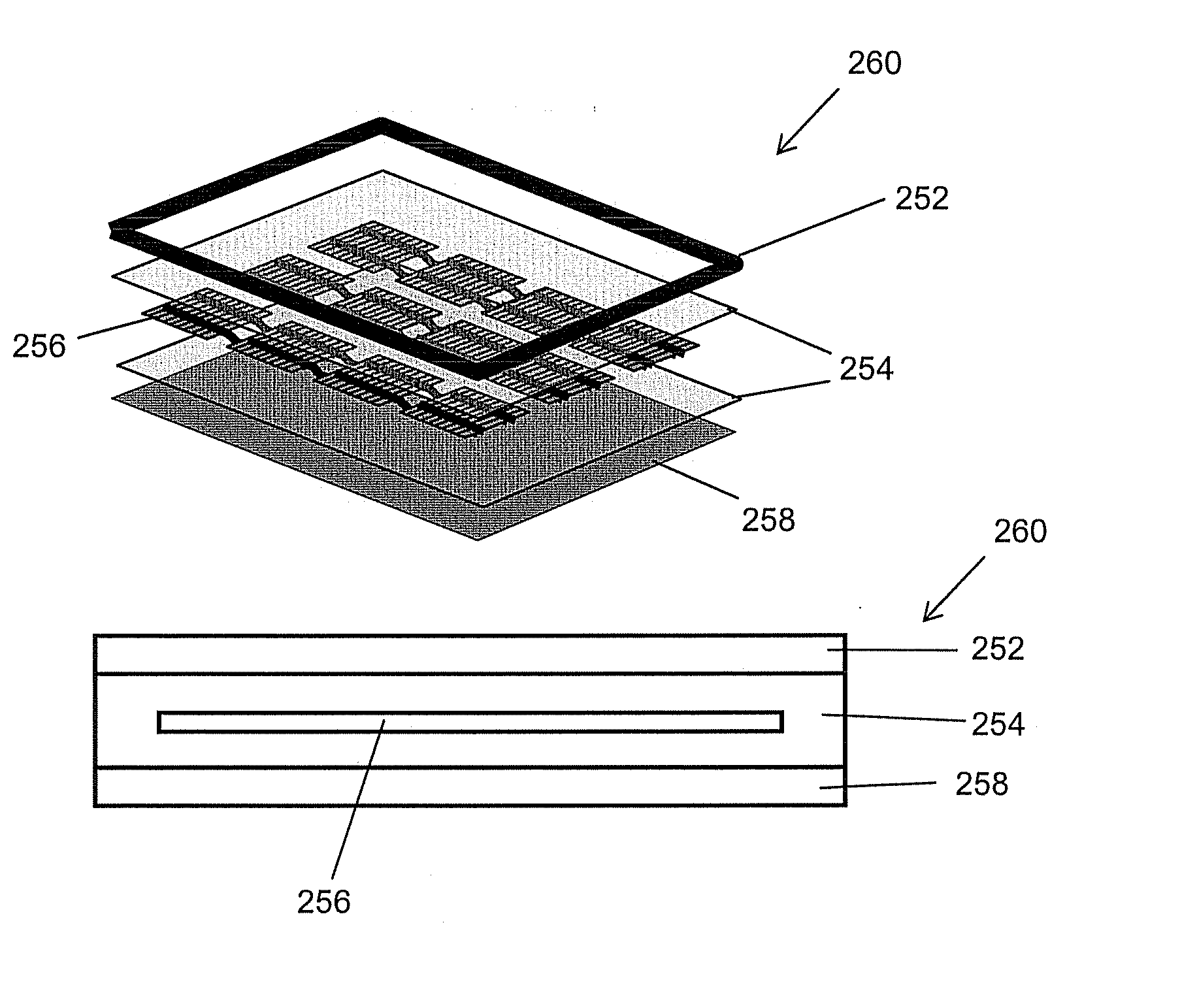

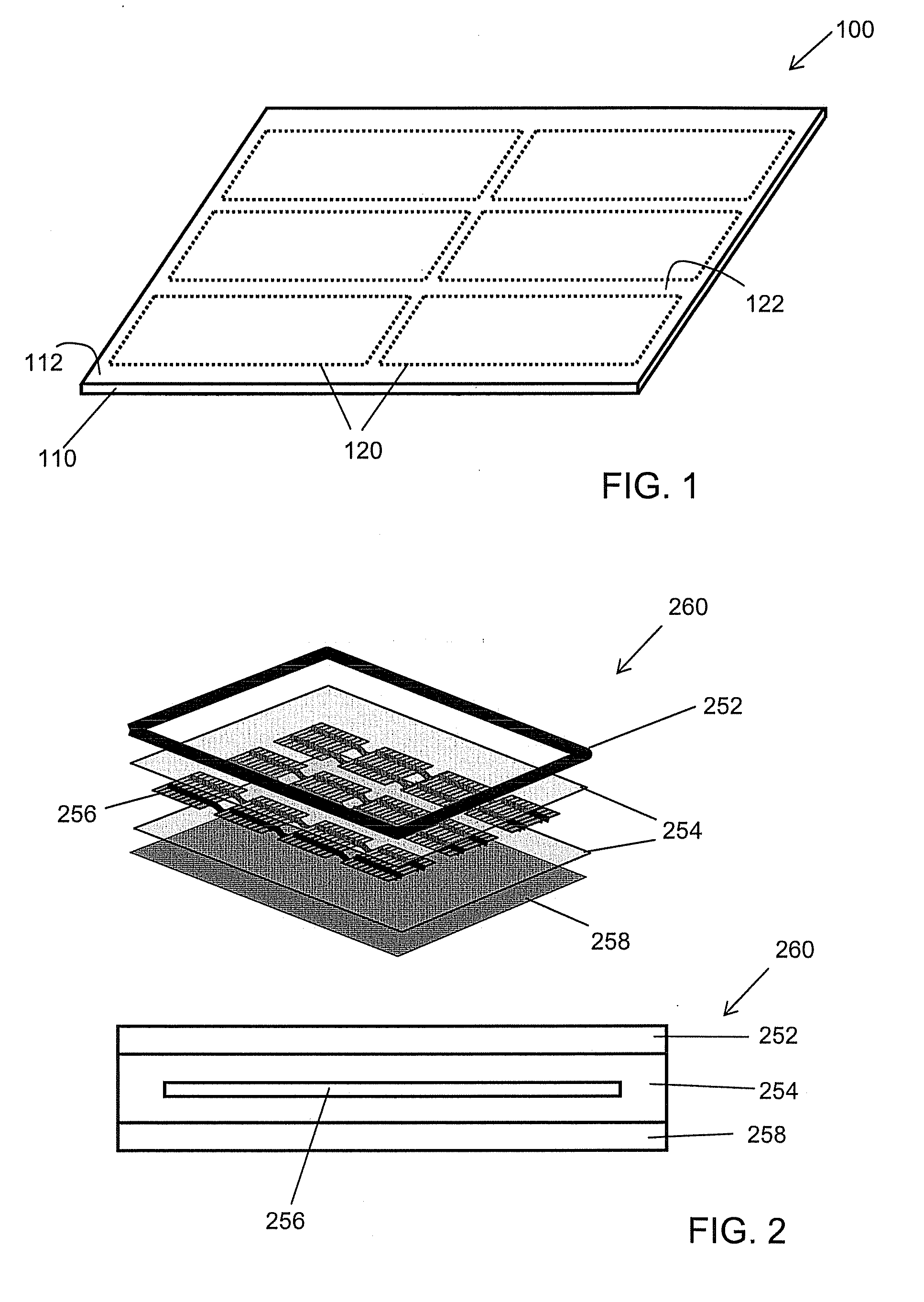

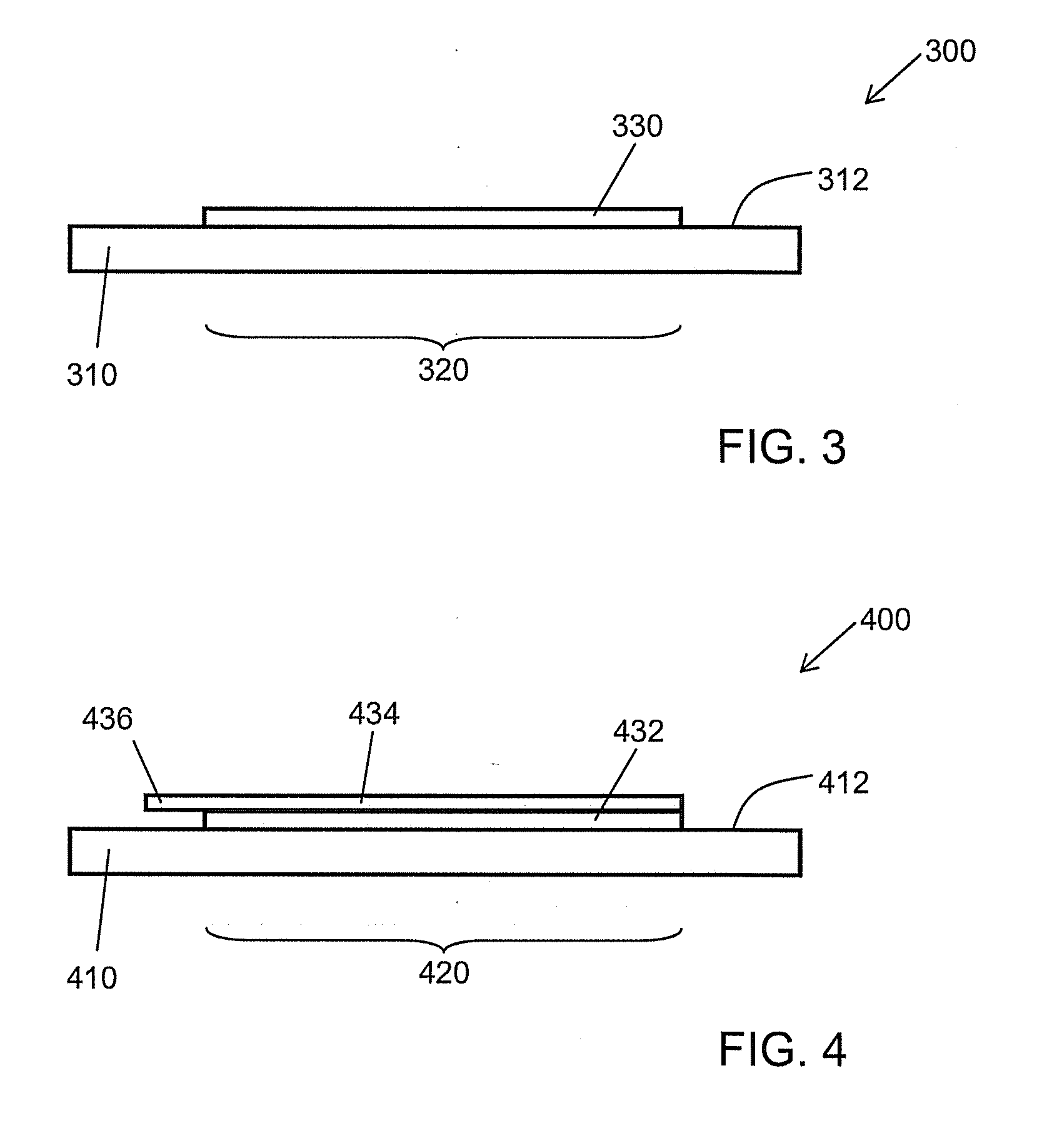

Roofing Products Having Receptor Zones and Photovoltaic Roofing Elements and Systems Using Them

InactiveUS20090159118A1Improve adhesionPhotovoltaic supportsPV power plantsPhotovoltaicsCivil engineering

The present invention relates generally to roofing products. The present invention relates more particularly to roofing products for use with photovoltaic elements, and to photovoltaic systems that include one or more photovoltaic elements is joined to a roofing substrate. In one embodiment, a roofing product includes a flexible roofing substrate having a top surface, the top surface having one or more receptor zones thereon, each receptor zone being adapted to receive one or more photovoltaic elements, each receptor zone having a different surfacing than the area of the top surface adjacent to it.

Owner:CERTAINTEED CORP

Metal strip for interlocking floorboard and a floorboard using same

InactiveUS6880305B2Not to damageUndesired joint gapCeilingsRoof covering using tiles/slatesMetal stripsMechanical engineering

Owner:VÄLINGE INNOVATION AB

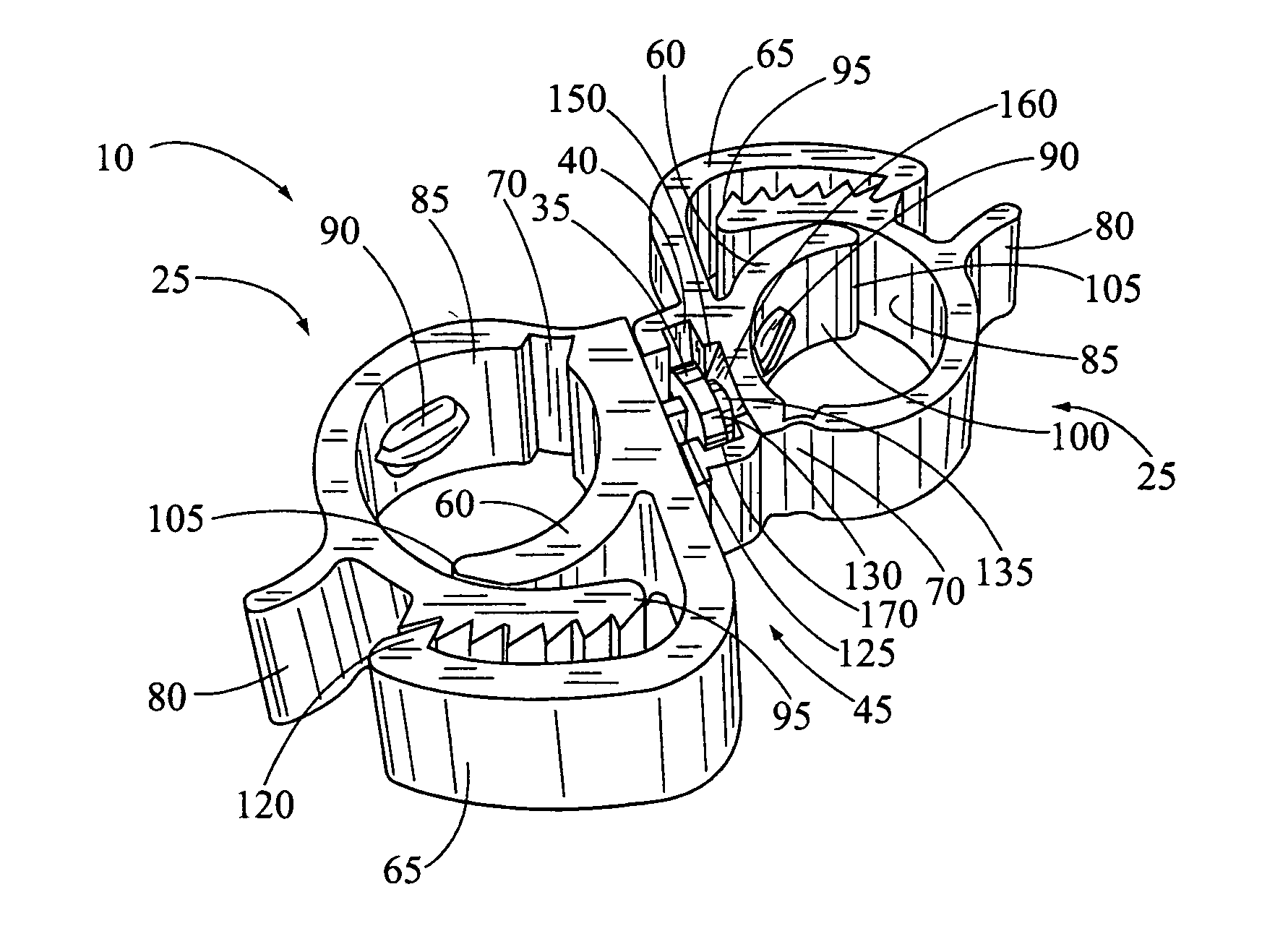

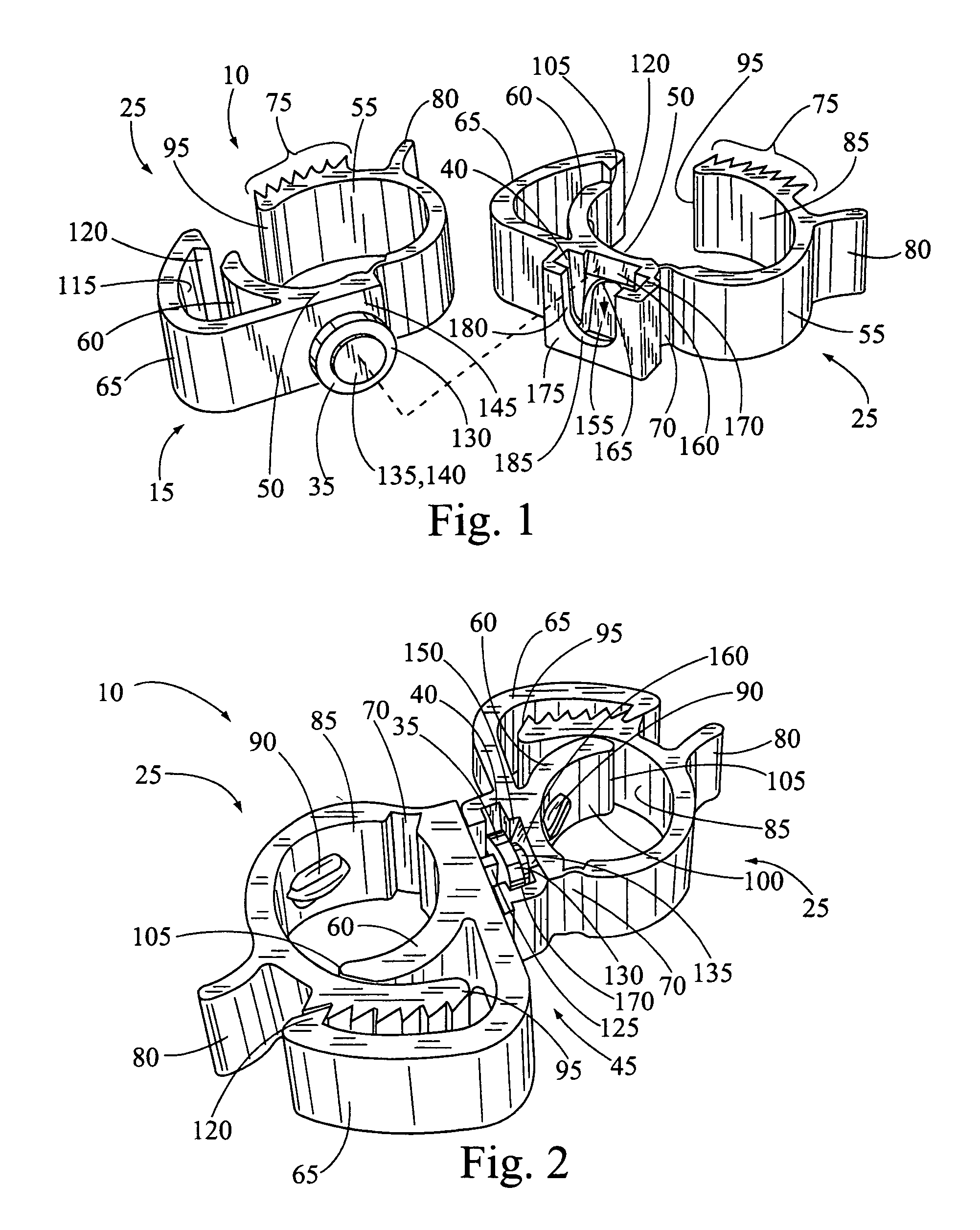

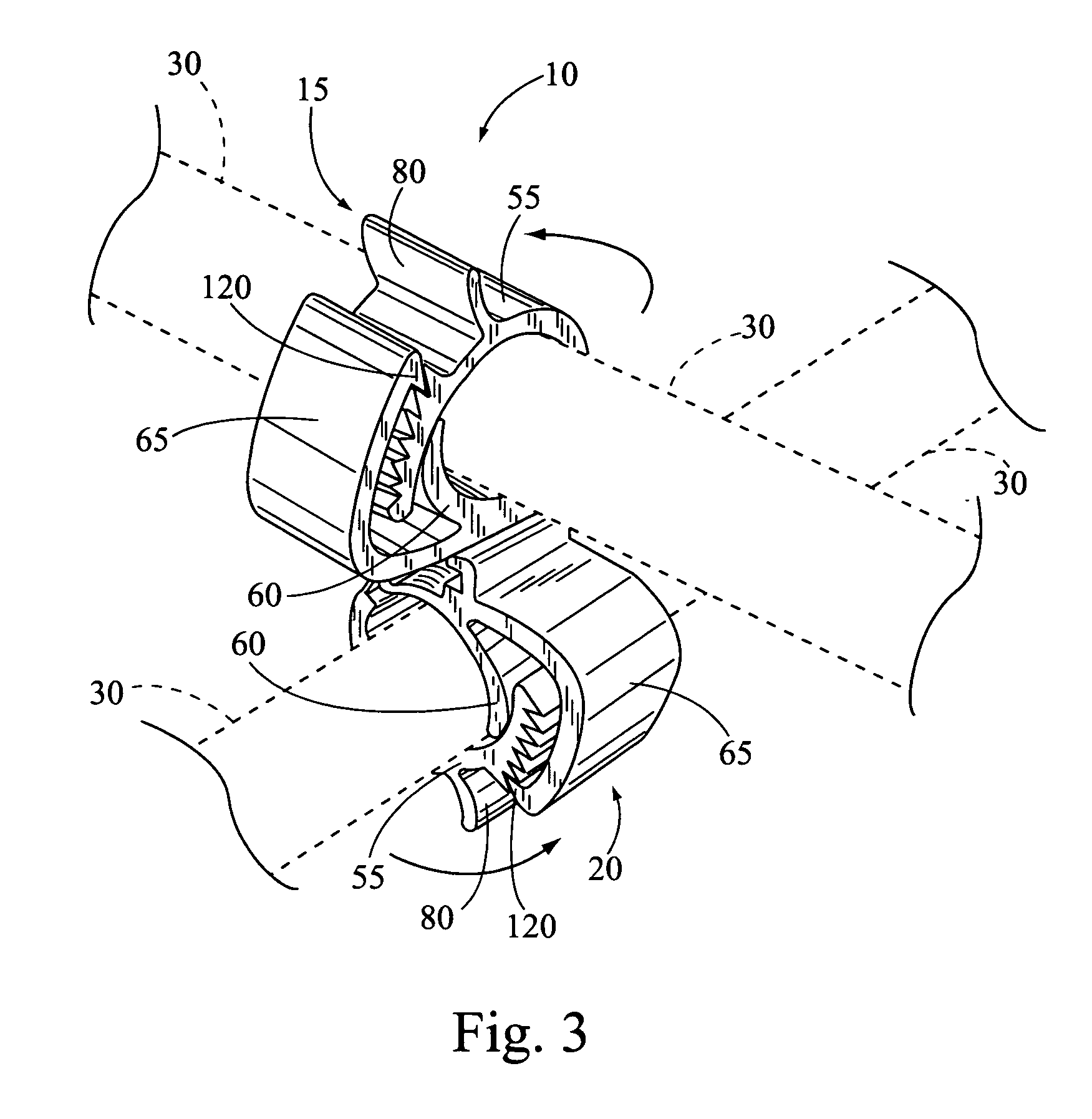

Swiveling multi-clamp fastener

A fastener for joining two pieces of rebar together in a rebar grid used to reinforce subsequently poured concrete is described. The fasteners include two clamp pieces that in certain embodiments completely wrap around a piece of rebar and are tightly secured thereto. Further, each clamp piece can swivel or rotate up to 360 degrees relative to the other clamp piece such that two rebar pieces intersecting at any angle can be coupled together.

Owner:JIFFY CLIP

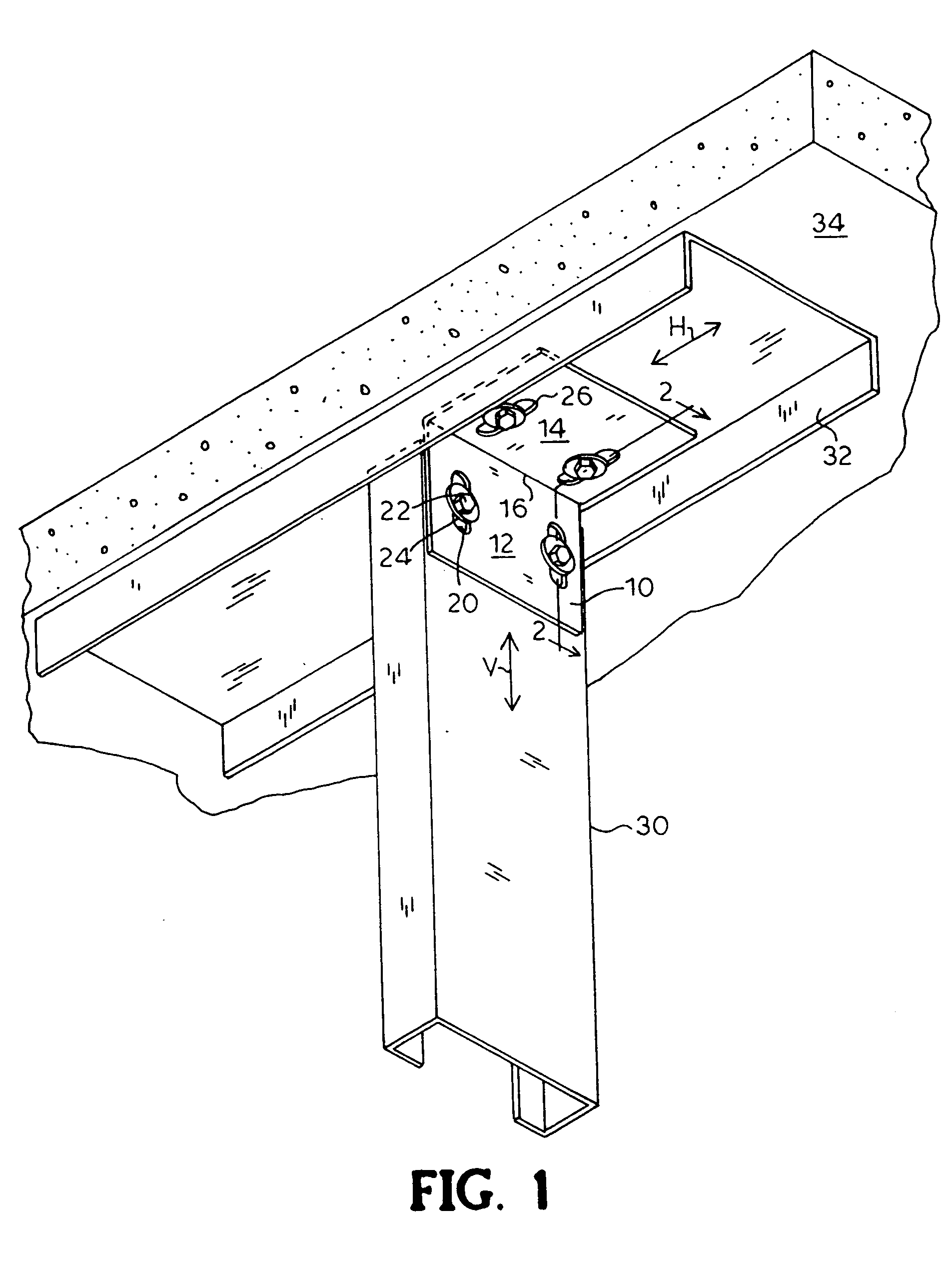

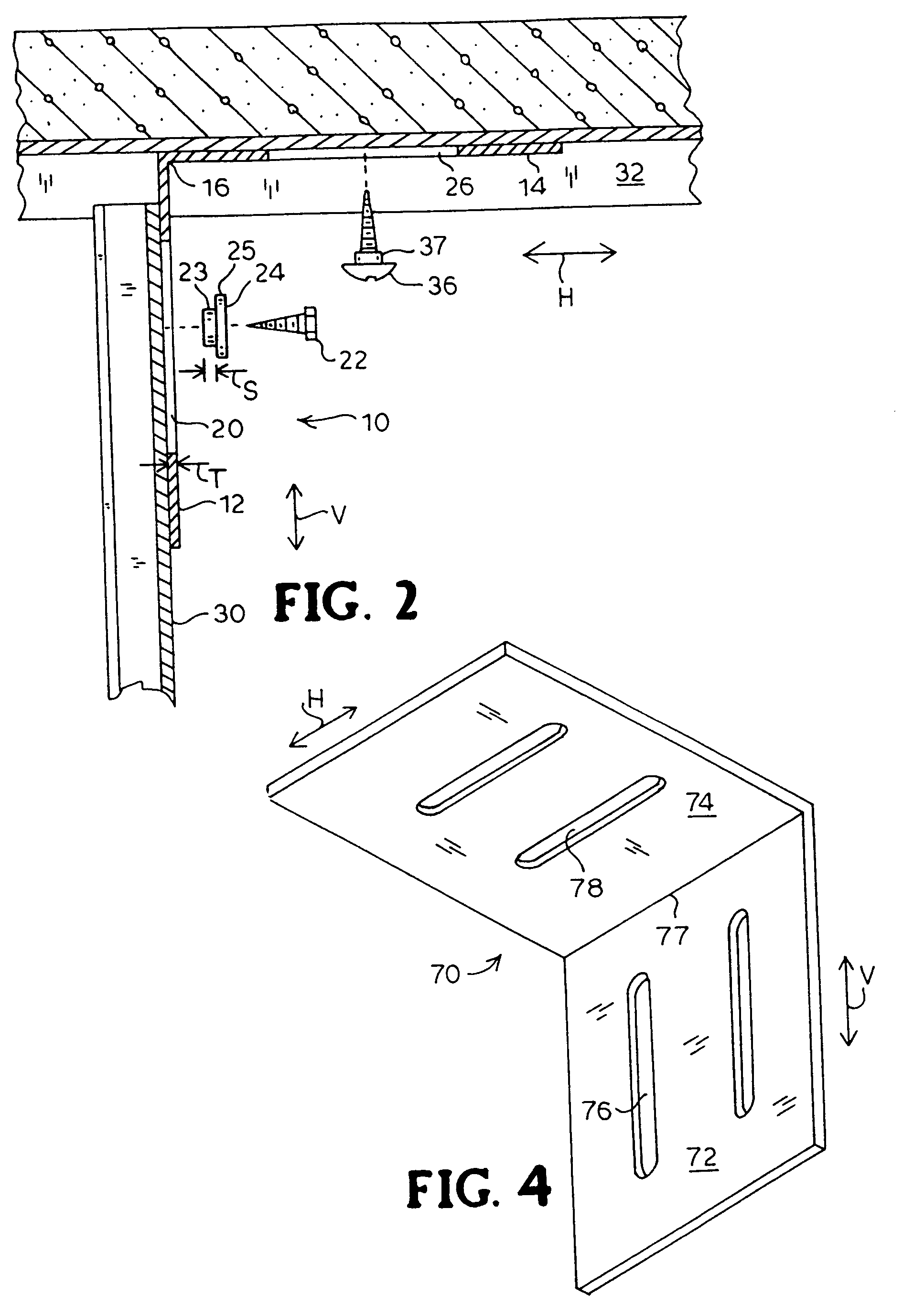

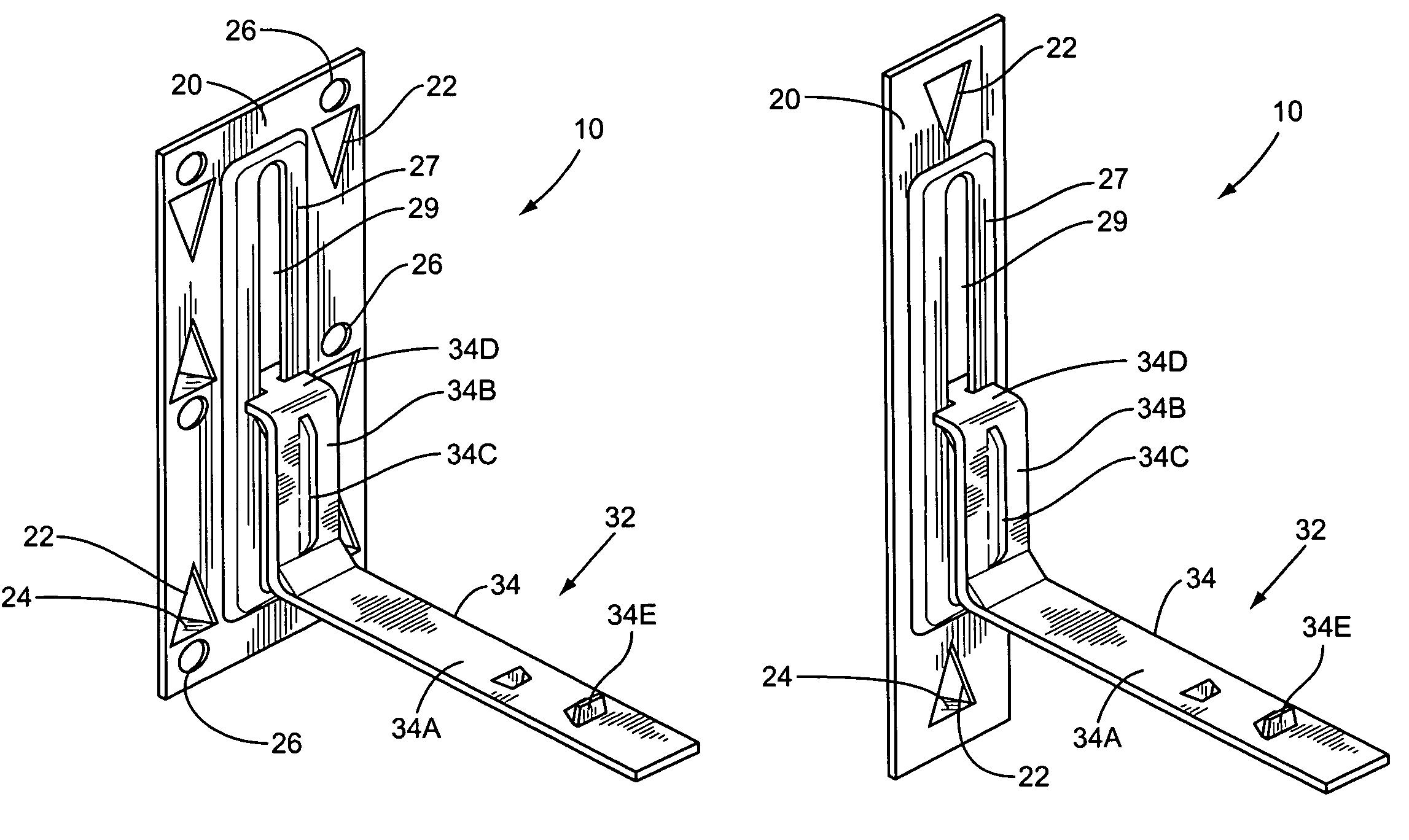

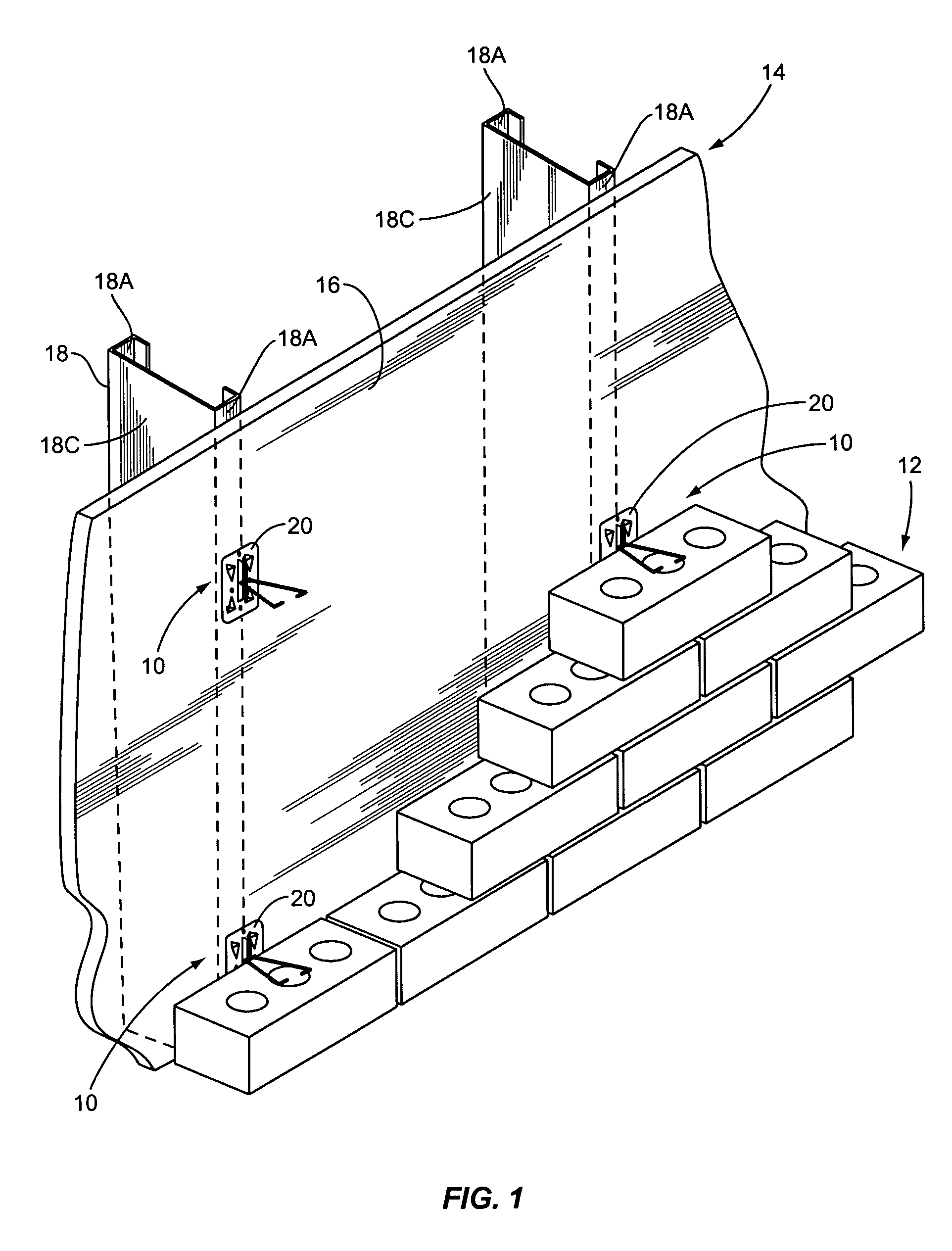

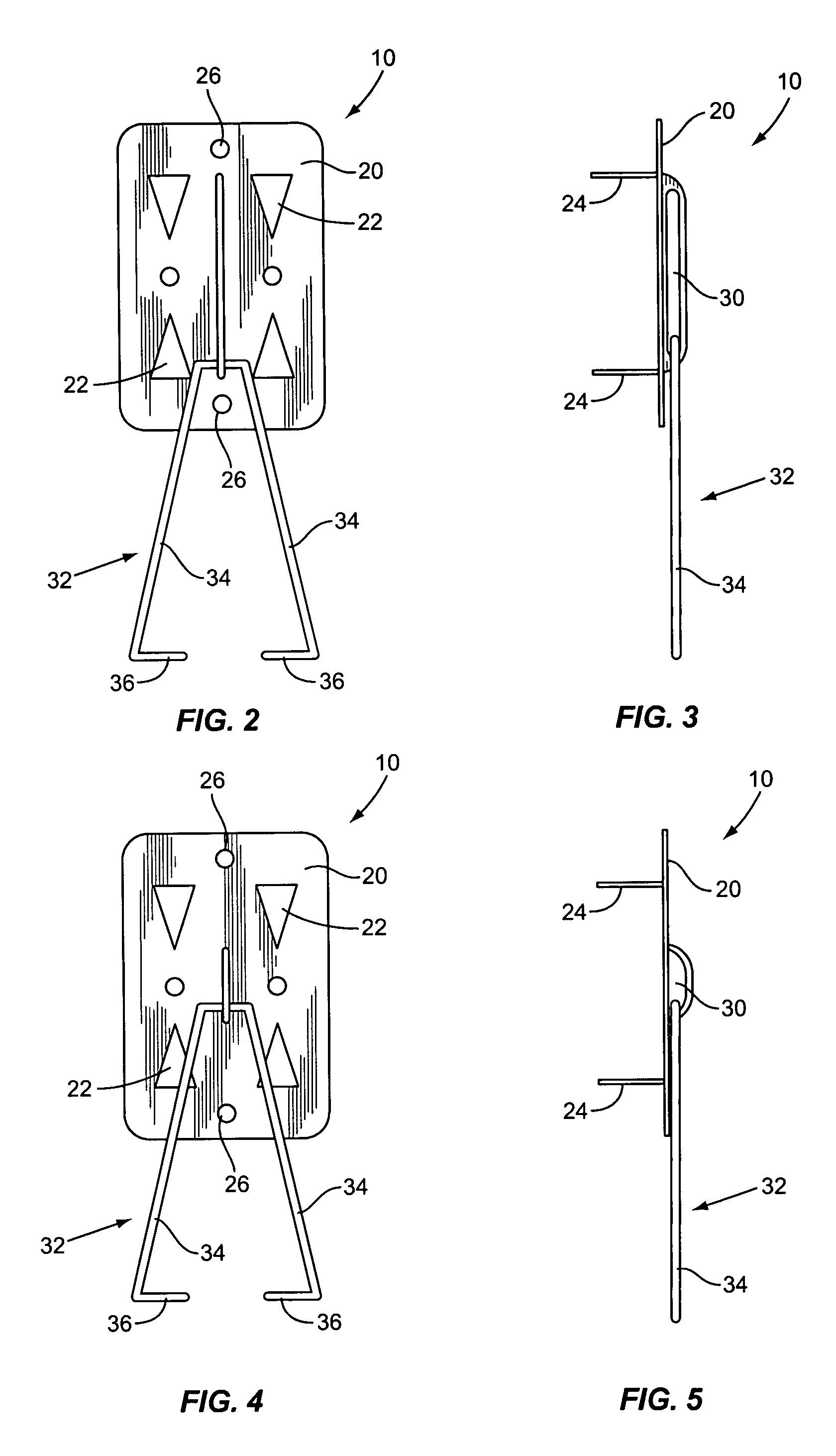

Brick tie

A brick tie for interconnecting a brick wall with a back-up wall comprised of a plurality of spaced apart studs and a wall board secured to the studs wherein each stud includes a pair of opposed side flanges and a web formed between the flanges. The brick tie includes a plate having a series of spikes projecting from a backside. The spikes are adapted to be pushed into and through a portion of the wallboard so as to at least partially support the plate on the wallboard. Further, the plate is positioned on the wallboard such that it aligns with one side flange of a stud. Further, the brick tie includes a series of fasteners that are extended through the plate, through the wallboard and into the side flange of the stud. A loop or tie holder is secured or formed on the front of the plate. A tie is at least partially confined in the loop and the loop is of such a size that the tie can be vertically adjusted within the loop when the plate is secured to the wallboard. When the brick tie is secured to the back-up wall, the tie projects outwardly from the plate and extends between two layers of brick or block so as to anchor or secure the brick or block wall to the back-up wall.

Owner:THE STEEL NETWORK

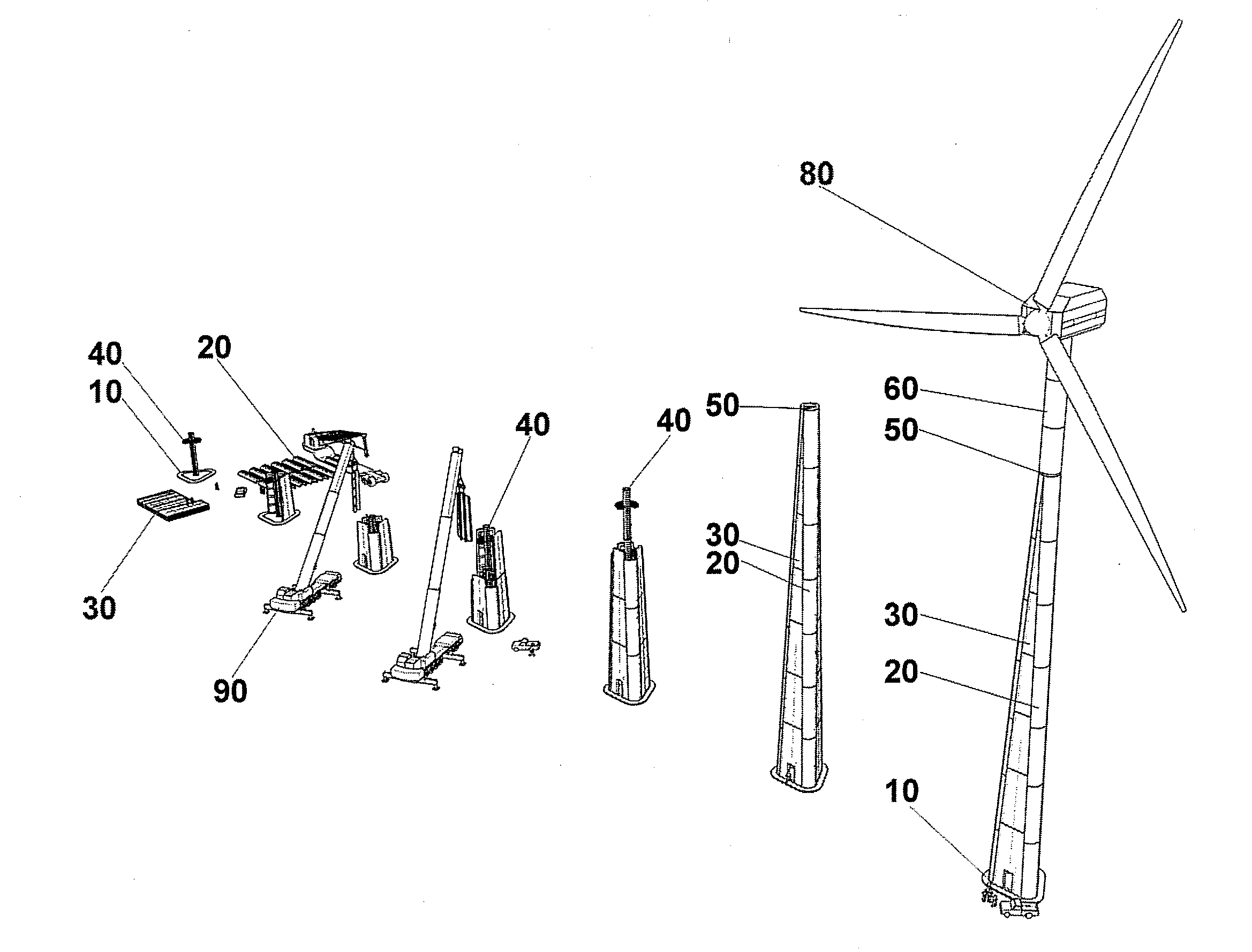

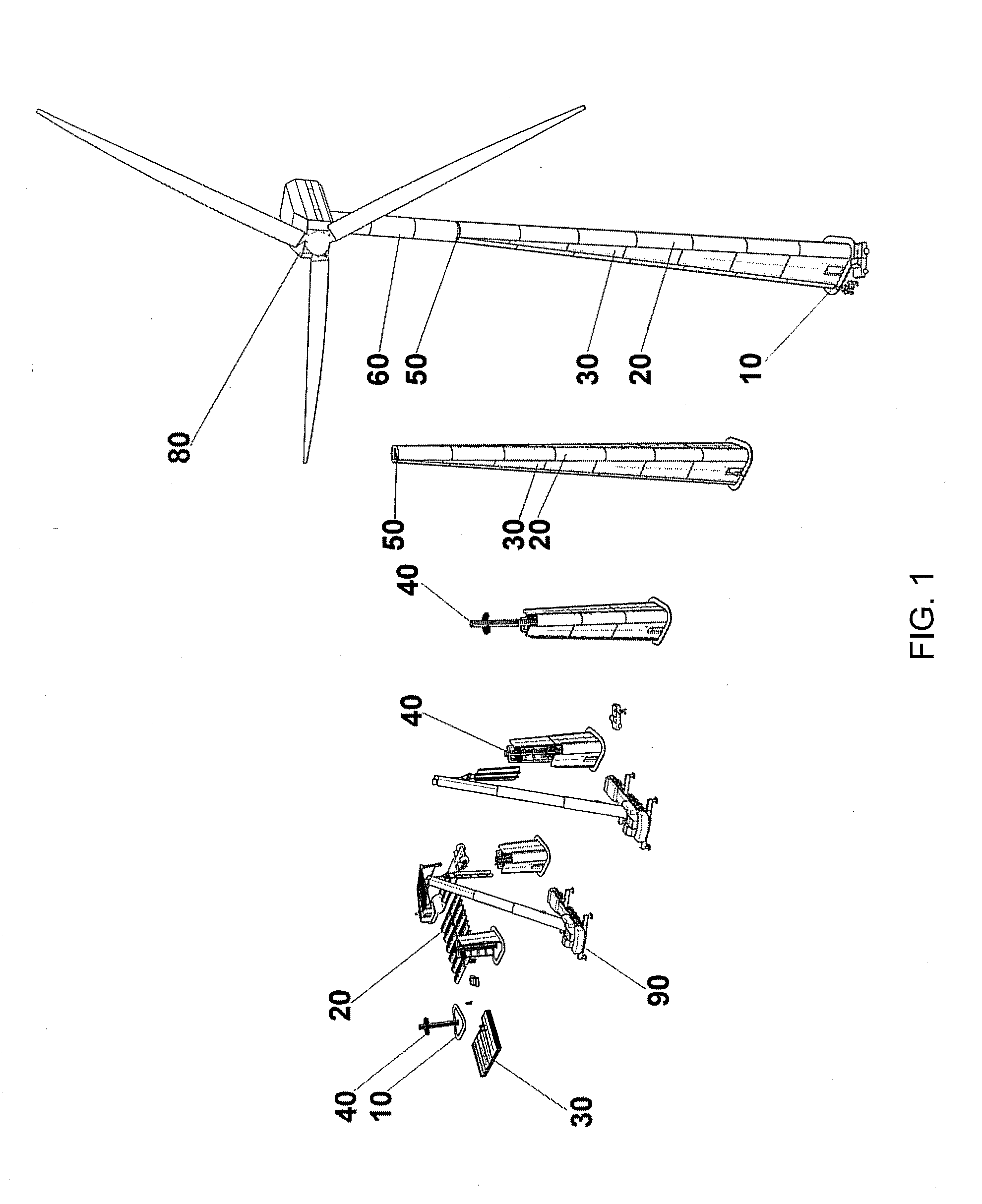

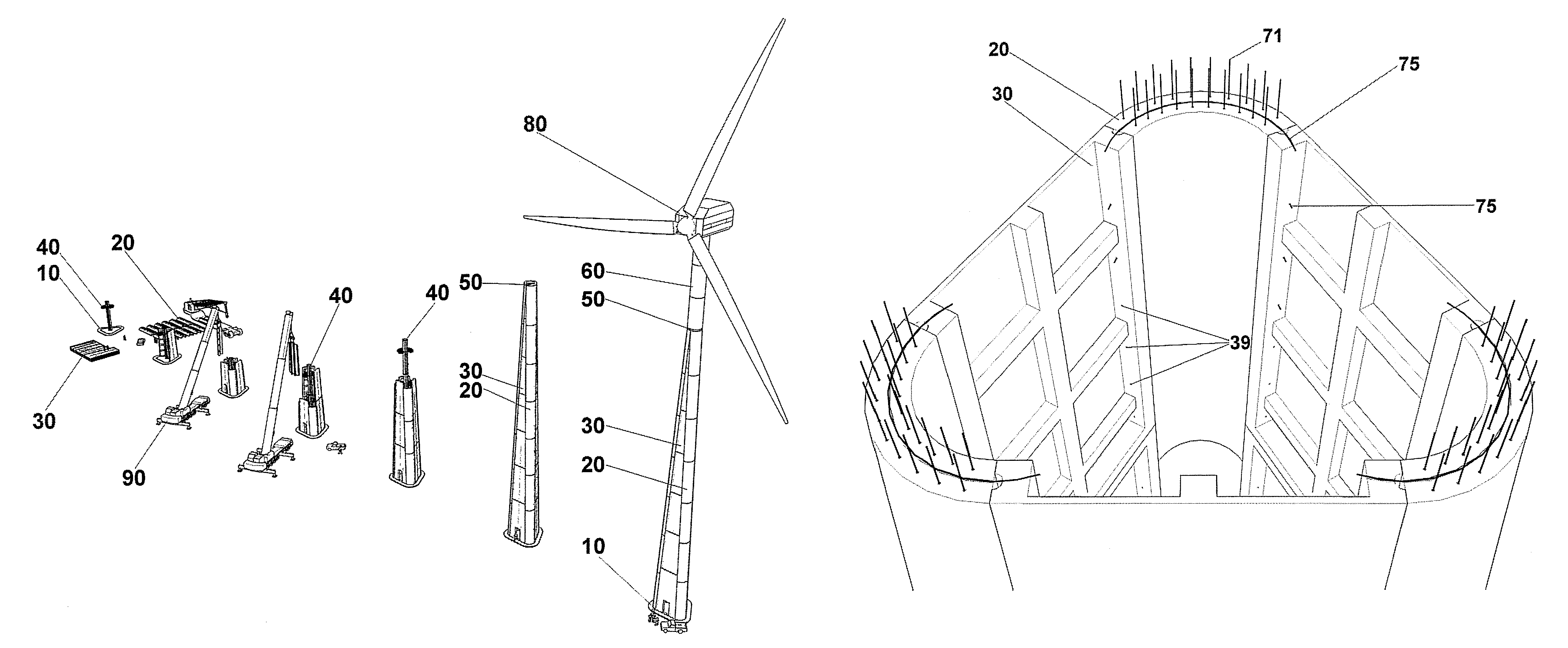

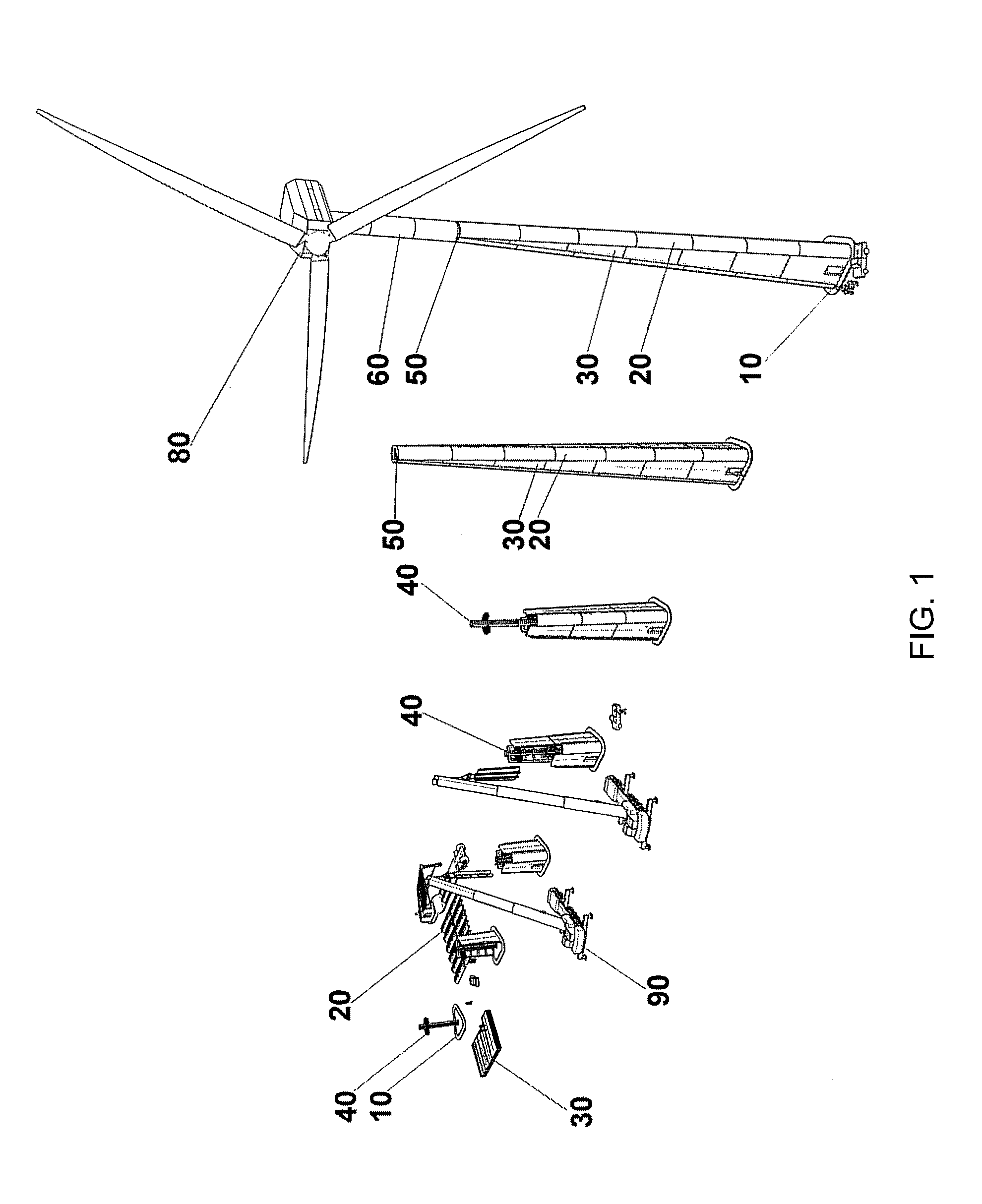

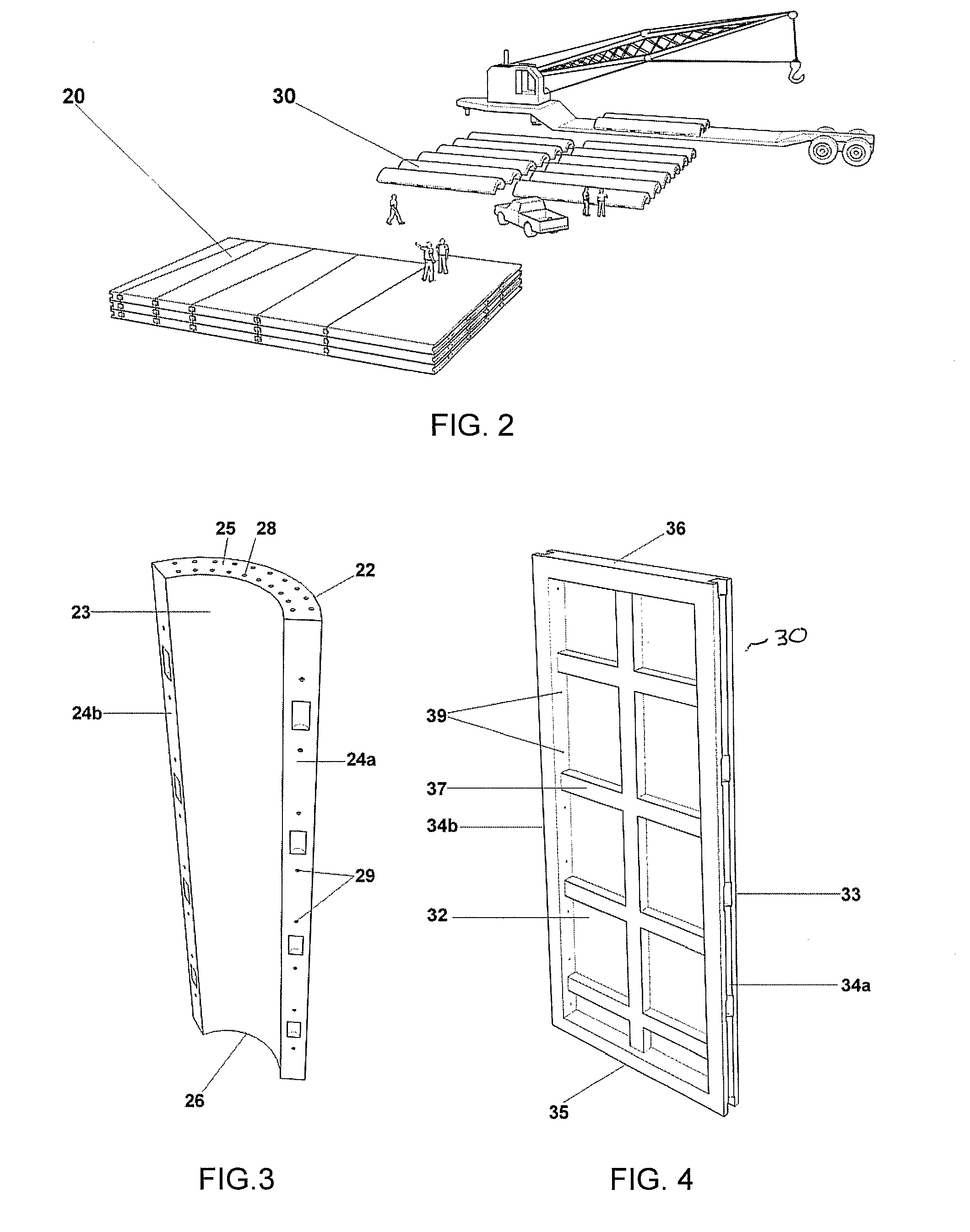

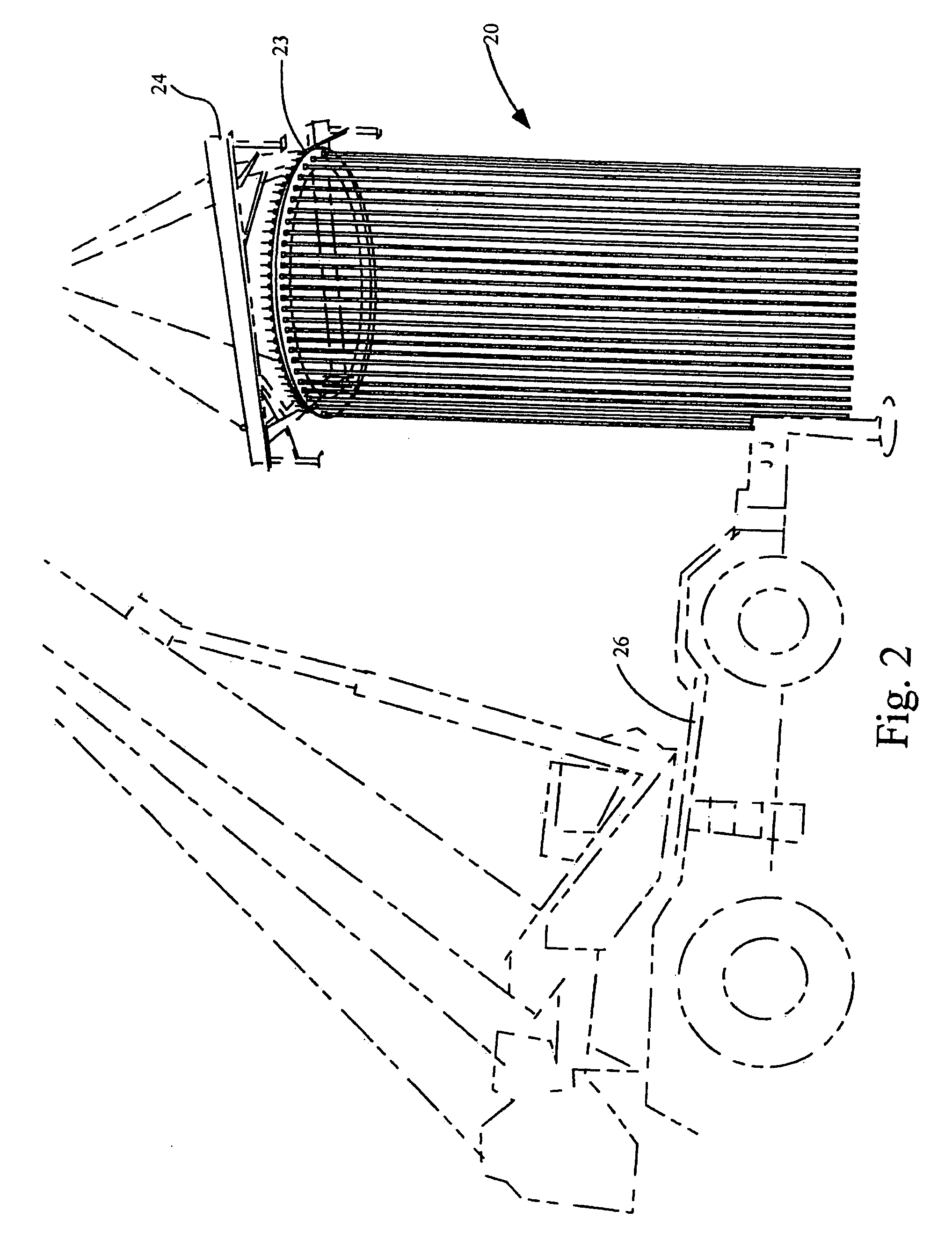

Pre-stressed concrete tower for wind power generators

InactiveUS20090031639A1Simplifying erectionSimplifying fabricationFinal product manufactureWind motor assemblyPre stressPre stressing

A pre-stressed segmented concrete tower for wind power generators is described, and a method for its fabrication, wherein in a pyramidal structure is formed by prefabricated segments, the structure comprising three rounded walls formed with circular segments, and three flat walls, formed with flat segments between the circular walls. One standard curved mold is used for the circular walls, and the flat walls are fabricated horizontally, over templates.

Owner:CORTINA INNOVATIONS DE C V

Tornado and hurricane roof tie

InactiveUS6837019B2Easily damagedBetter resist any upward liftBuilding roofsRoof covering using slabs/sheetsRafterFastener

Owner:COLLIE ANTHONY D

Insulated concrete form and method of using same

InactiveUS20130074432A1Retain heatEasy and inexpensive attachmentCeilingsConstruction materialInsulating concrete formFlange

Owner:CIUPERCA ROMEO ILARIAN

Pre-stressed concrete tower for wind power generators

InactiveUS7739843B2Simplifying erectionSimplifying fabricationFinal product manufactureWind motor assemblyPre stressPre stressing

A pre-stressed segmented concrete tower for wind power generators is described, and a method for its fabrication, wherein in a pyramidal structure is formed by prefabricated segments, the structure comprising three rounded walls formed with semi-circular segments, and three flat walls, formed with flat segments between the semi-circular walls. One standard curved mold is used for the semi-circular walls, and the flat walls are fabricated horizontally, over templates.

Owner:CORTINA INNOVATIONS DE C V

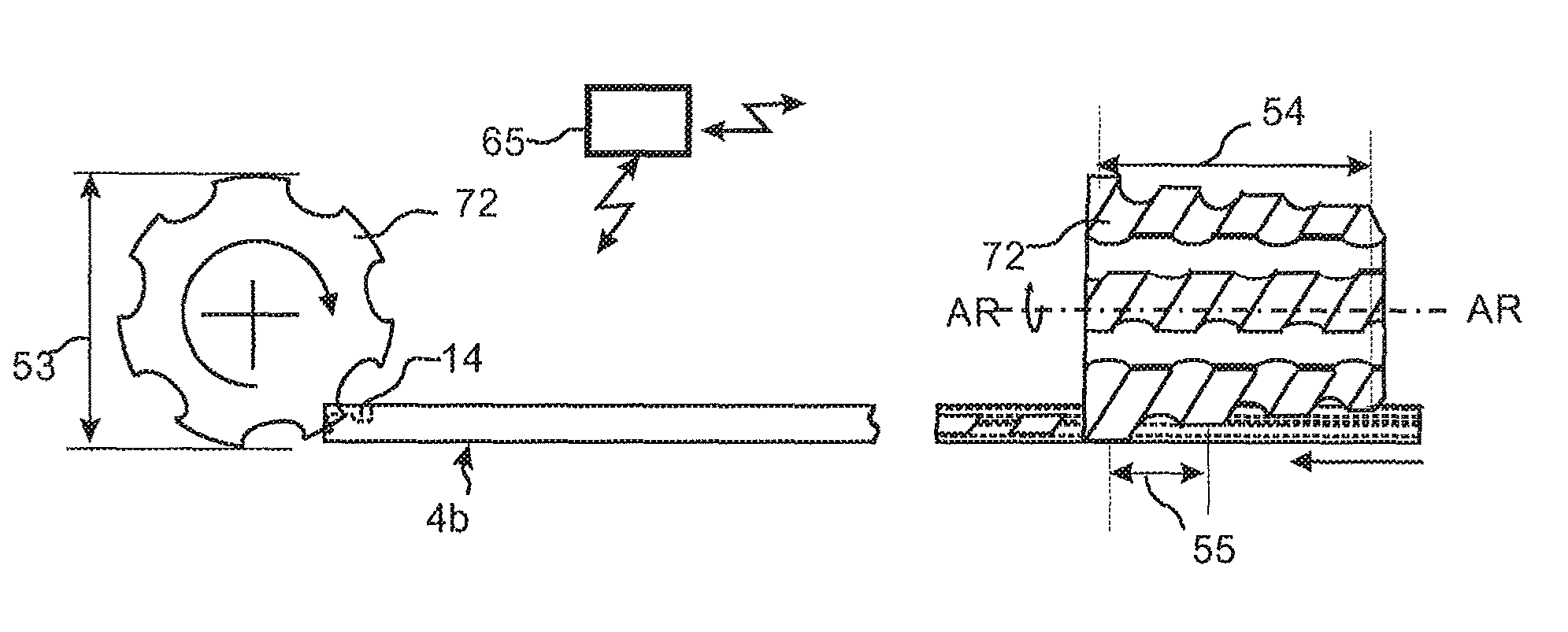

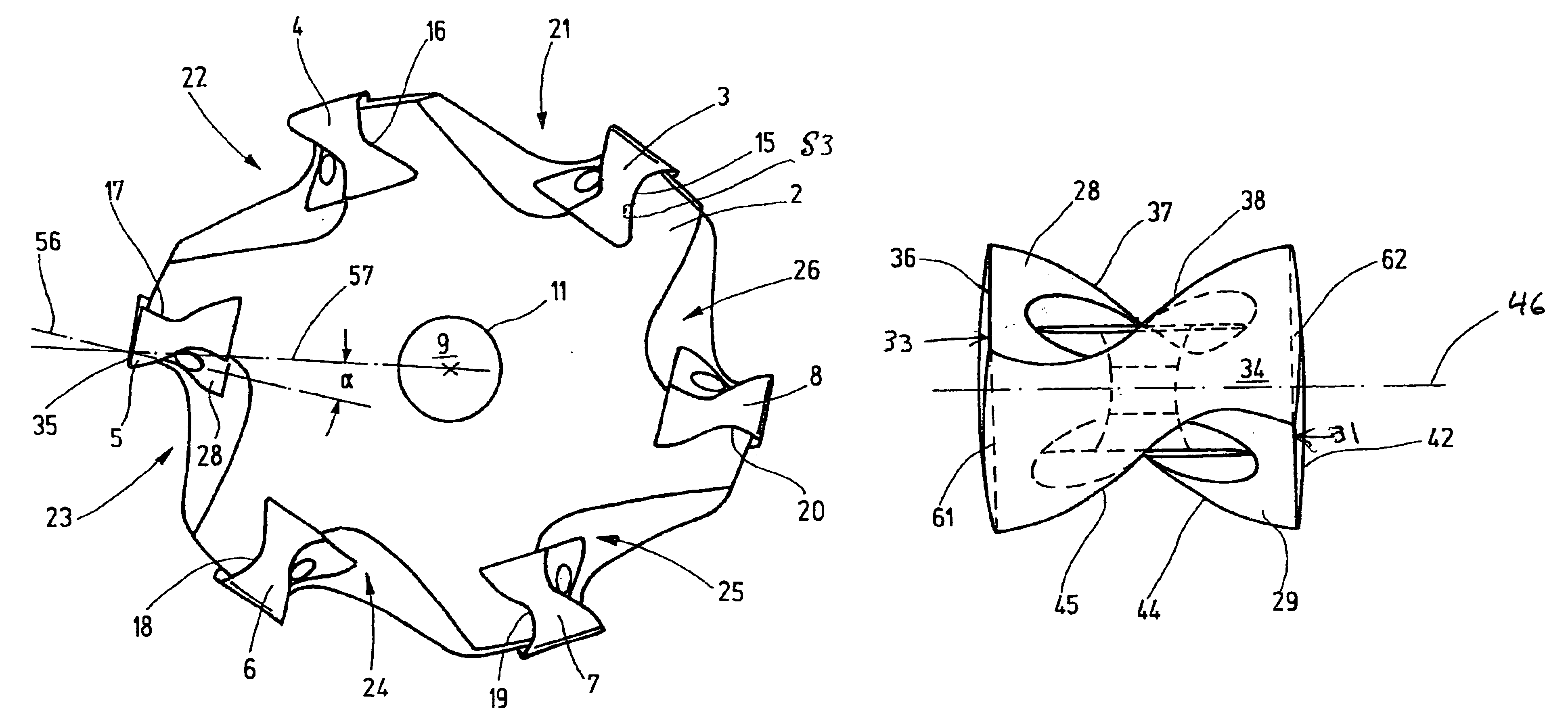

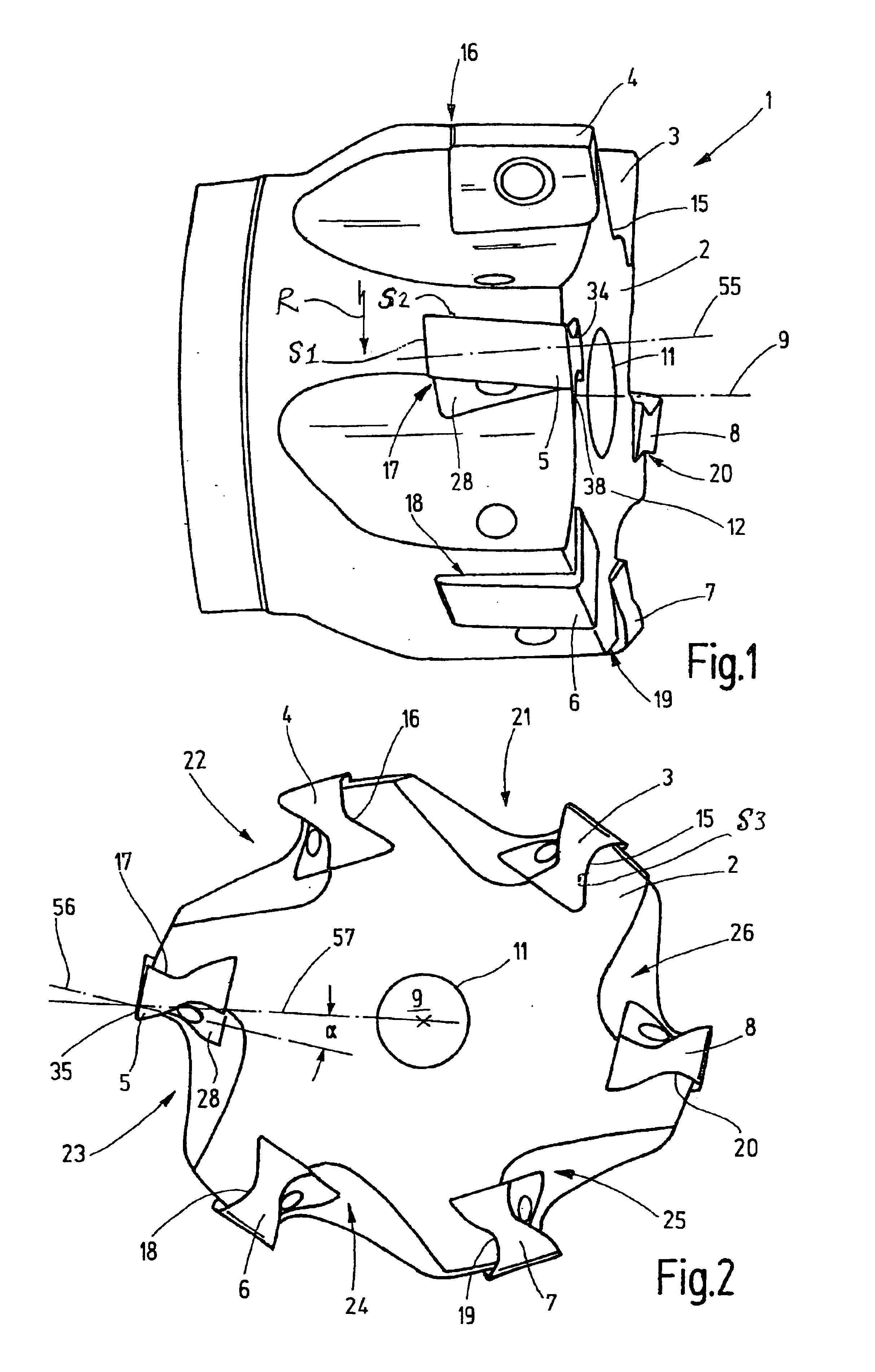

Cutter insert and milling tool

ActiveUS6921233B2Easy to useEasy to manufactureMilling cuttersTurning toolsEngineeringMechanical engineering

A cutter insert for milling tools includes a base body having a base surface, a top surface, and four side surfaces. The four side surfaces, together with each of the base surface and the top surface, define respective cutting edges. The base body is twisted about each of two perpendicular, coplanar axes of the base body. Each side surface has two opposite corner edges that are offset from one another in a direction parallel to a center axis of the base body.

Owner:WALTER AG

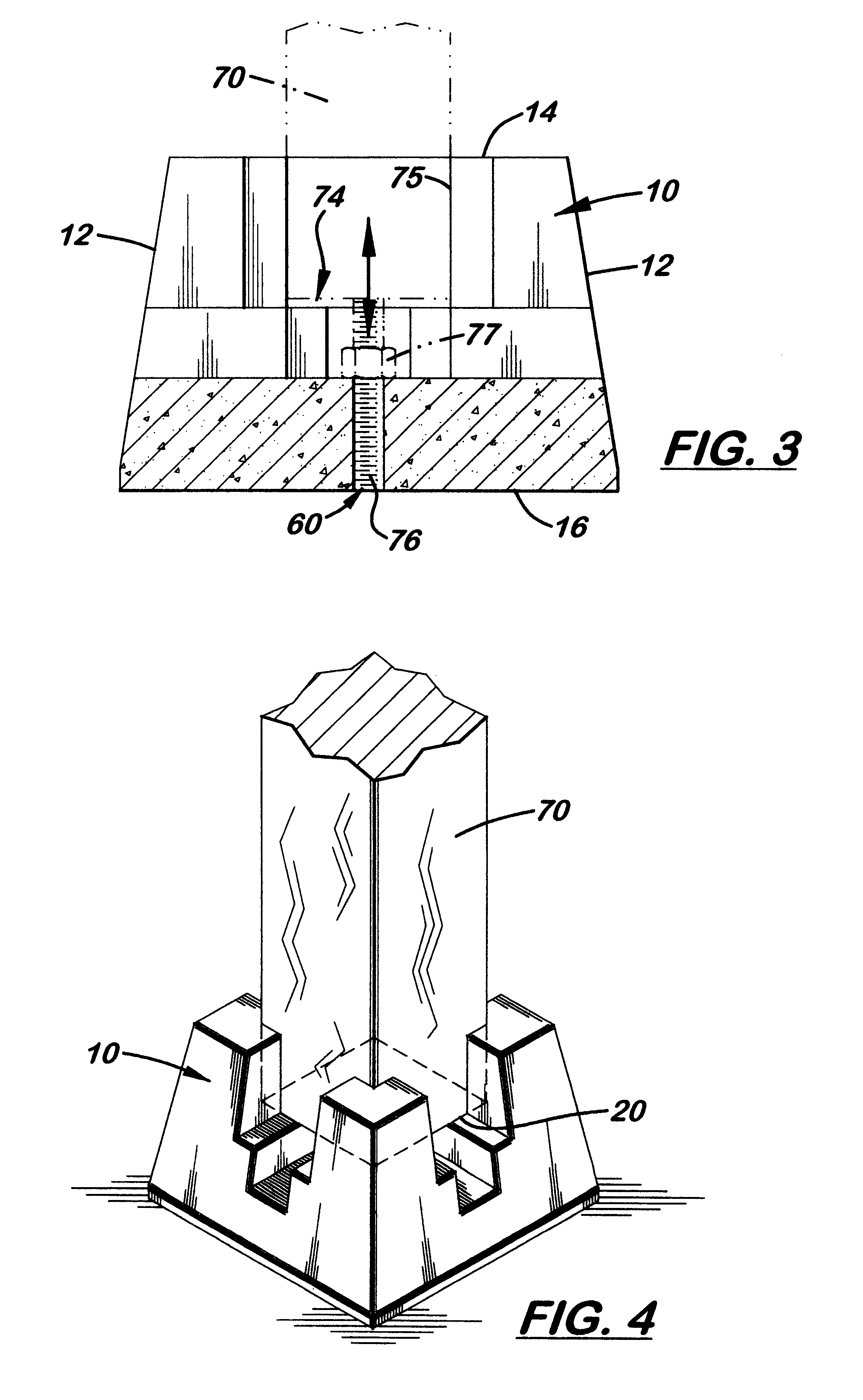

Universal pier block

A universal block made of concrete designed to be used with different size posts and beams. The pier block is a conical, six-sided structure and includes two concentrically aligned, post-receiving voids designed to receive the ends of a (4x4) or (6x6) inch post. The (6x6) inch void is positioned above the (4x4) inch void. Formed horizontally on the top surface of the pier block are two transversely aligned beam-receiving slots. Each beam-receiving slot includes a narrow and a wide slot longitudinally aligned. The wide slot is positioned above the narrow slot. A vertically aligned drain hole is formed through the pier block from the bottom surface of the (4x4) inch void to the bottom of the pier block, which allows water to drain from the post-receiving voids.

Owner:TRIPLETT DAVID

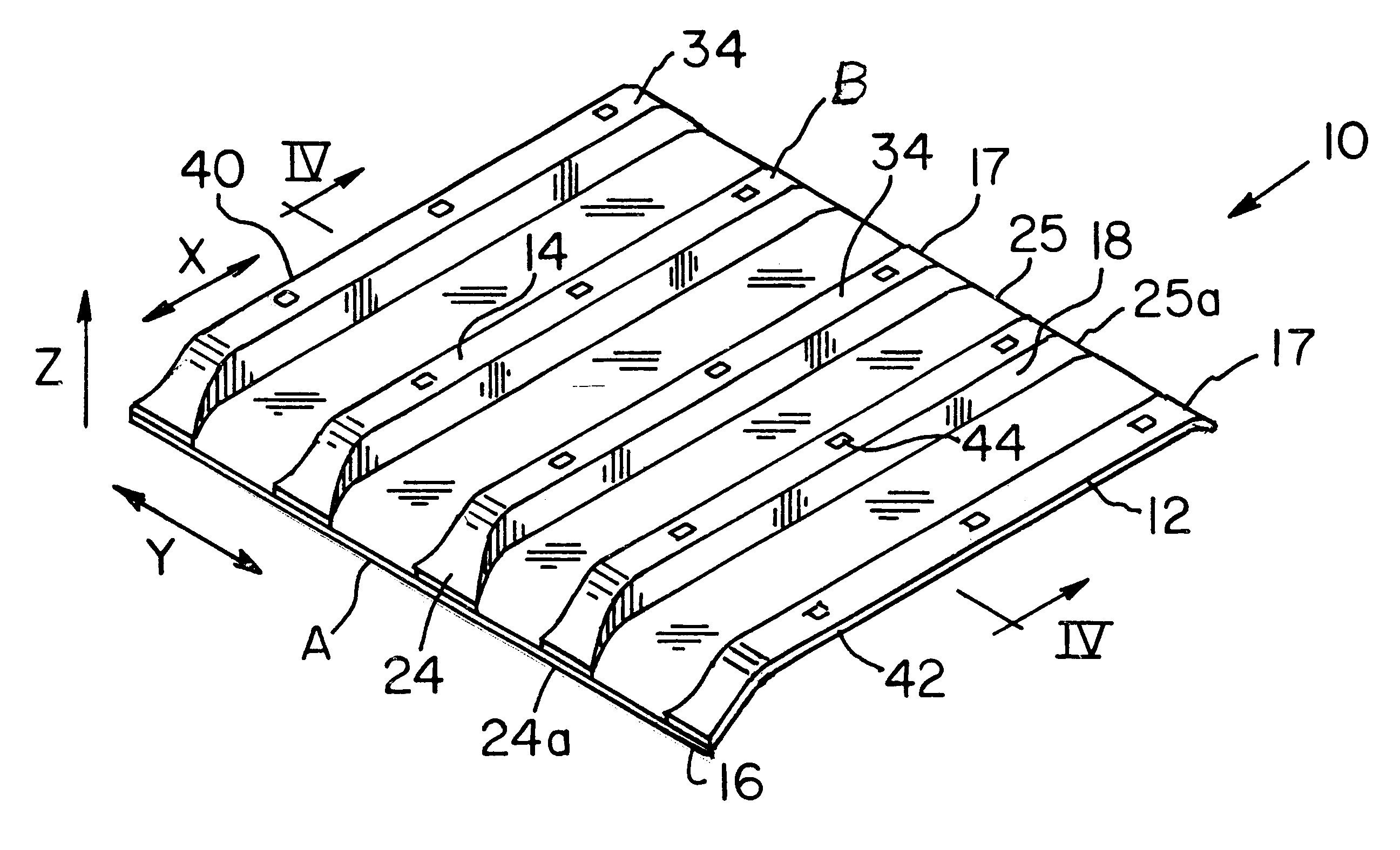

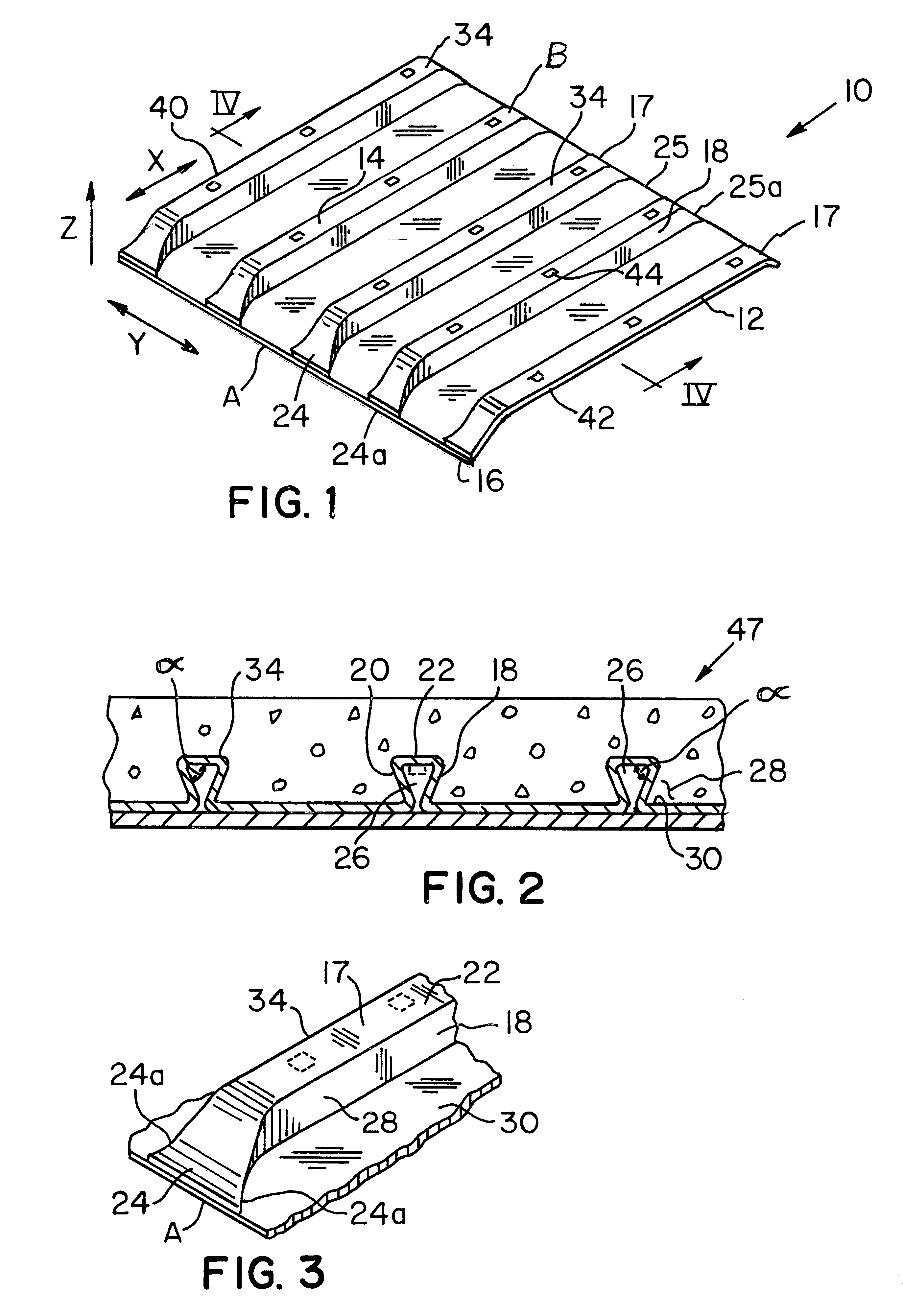

Composite deck

InactiveUS6357191B1Improve the quality of sound insulationImproved rodent and insect controlBuilding roofsCeilingsComposite slabMechanical engineering

A ribbed metal plate for a composite slab that includes a substantially planar plate having an upper surface and a lower surface and a plurality of laterally-spaced, longitudinally-extending ribs that have a keystone profile and wherein the sidewalls are angled toward each other. Ends of the ribs are integrally formed. The rib plate is secured to bearing walls in a structure and concrete is poured on the ribs to form a composite deck. The ends of the ribs extend in the lateral direction to form a composite structure retarding movement of cured concrete in a longitudinal direction. The ribbed plate can also be used in composite beams.

Owner:EPIC METALS

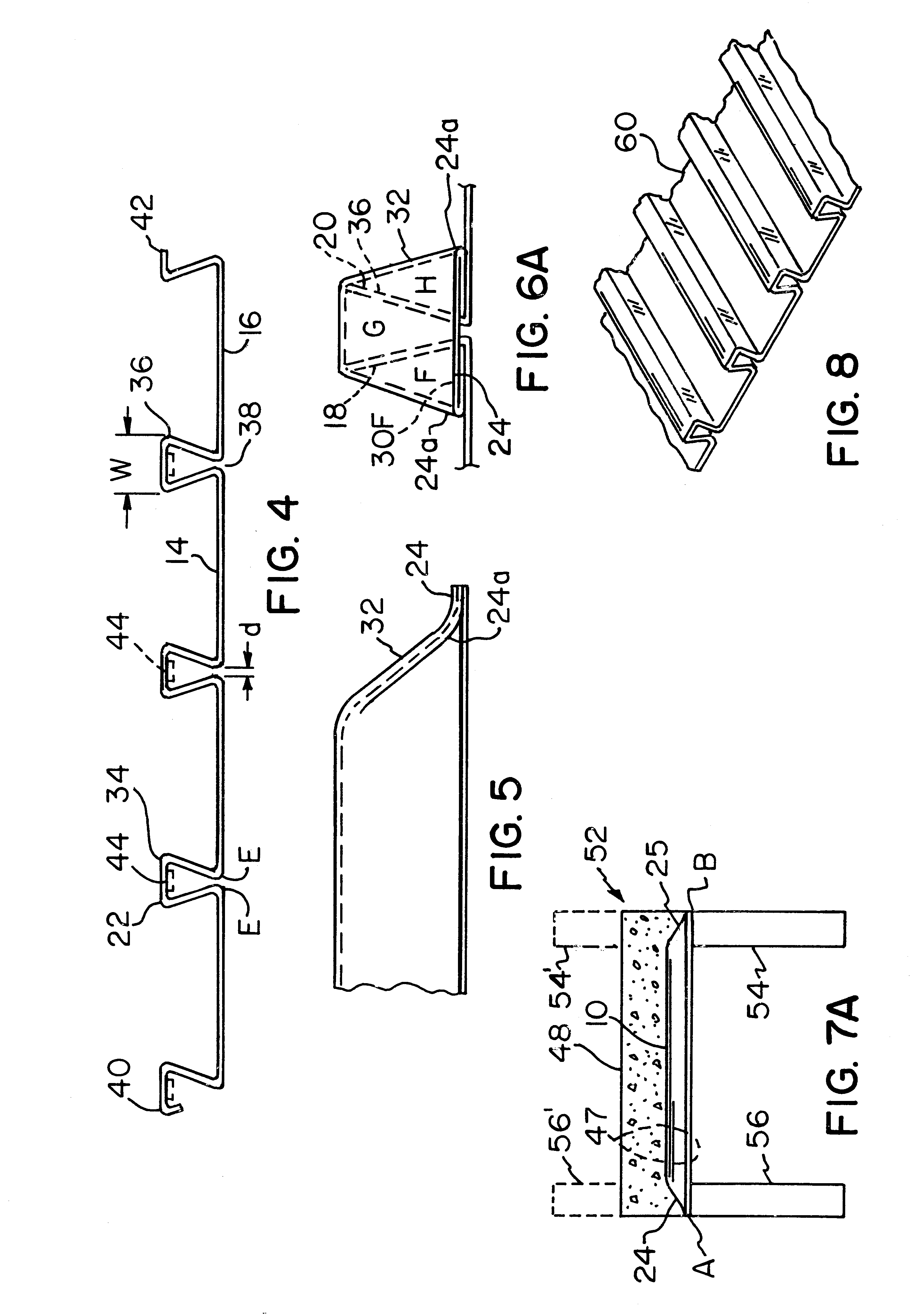

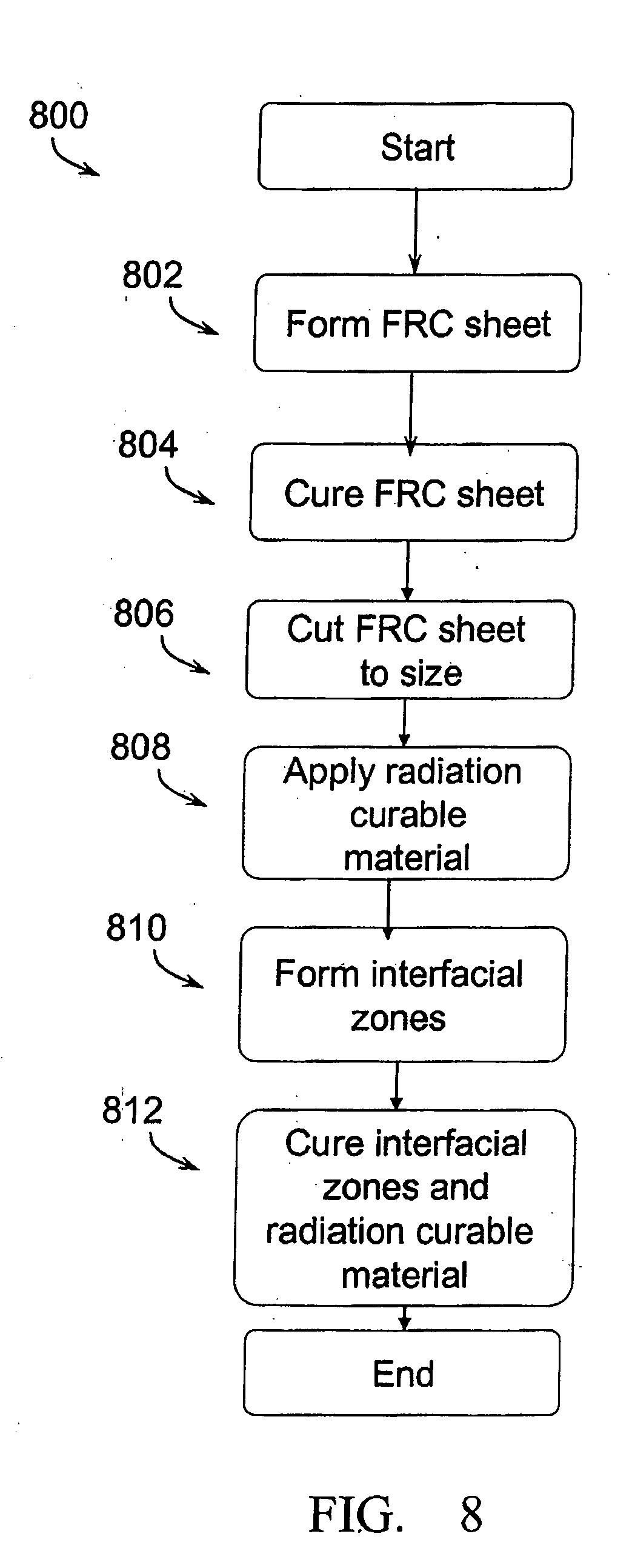

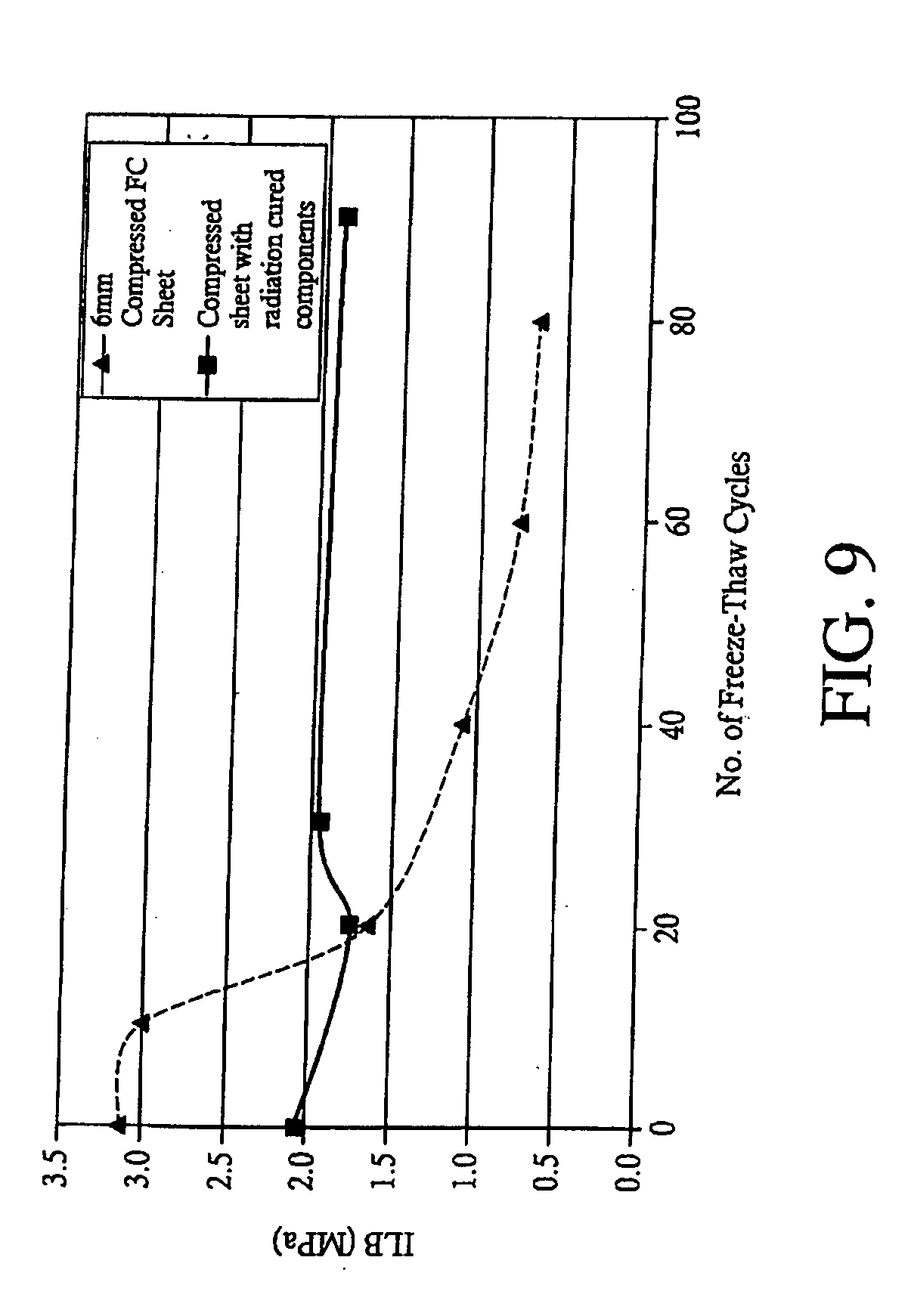

Composite fiber cement article with radiation curable component

ActiveUS20050208285A1Increased durabilityImprove adhesionConstruction materialSolid waste managementFibre cementRadiation

A composite building article is configured with one or more subsurface interfacial zones provided to improve the durability of the article. Each subsurface interfacial zone is made of a matrix of fiber cement and radiation curable material. The radiation curable material forms an interlocking network with the fiber cement to provide a interfacial zone against ingress of environmental agents that can degrade the article. The number, configuration and distribution of the subsurface interfacial zones can vary dependent on the desired characteristics of the final product. The subsurface interfacial zones also improves the adhesion between exterior coatings and the substrate as the interfacial zones can be integrally formed with the substrate as well as exterior coating layer.

Owner:JAMES HARDIE TECH LTD

Wind turbine installation comprising an apparatus for protection of anchor bolts and method of installation

InactiveUS20090044482A1Preventing greatly limiting axial migrationAvoid stickingBuilding repairsWind motor supports/mountsEngineeringTower

An apparatus for use in providing a level grout surface for placement of a wind turbine tower flange, the apparatus comprising a template member levelly suspended on the anchor bolts above the grout trough, wherein the template member comprises a surface to which grout will not adhere. The template member can comprise an upper layer and a lower grout engagement layer, wherein the grout engagement layer comprises a surface to which grout will not adhere. The upper layer can comprise a metallic layer, and the lower layer can comprise a plastic layer, wherein the upper layer and the lower layer are bonded together. The lower layer can comprise polypropylene. The means of bonding are selected from the group consisting of mechanical bonding, thermal bonding and chemical bonding. The grout can comprise an epoxy grout. The template member can be suspended through the use of magnetic nuts or the use of a rotating sleeve. The template member can comprise a plurality of sections, and can comprise a circular form.

Owner:TOOMAN NORMAN L

Tornado and hurricane roof tie

InactiveUS6931813B2Easily damagedResist upward liftBuilding roofsBuilding reinforcementsUltimate tensile strengthRafter

A building roof tie for attaching roof trusses and rafters to wood top plates in building structures, such roof tie having a sheet metal body with risers and a bridge for overlapping a rafter and flaps for wrapping on the sides of the top plate. A generally triangular shaped reinforcing wing provides strength and stability, and can also provide additional hold-down strength, allowing the roof tie to be manufactured from different weights of steel. Turnbuckles attached to the bridge provide additional hold-down strength against increased uplift forces. The roof ties are pitched to conform to a variety of framing applications. A plurality of apertures is formed in the roof tie to provide openings for fasteners for connecting the tie to the wood top plate and rafter.

Owner:COLLIE ANTHONY D

Snap-in wire tie

ActiveUS7325366B1Reduce manufacturing costLower unit costConstruction materialFloorsEngineeringCavity wall

A seismic construction system for a cavity wall is disclosed. The system is shown in three exemplary applications—a masonry backup wall with ladder- or truss-type reinforcement cooperating with a snap-in wire tie; a masonry backup wall with ladder- or truss-type reinforcement with a high-span wall anchor cooperating with a low-profile, snap-in wire tie; and a drywall backup wall with internal insulation, a sheetmetal wall anchor, and snap-in wire ties. The snap-in wire ties accommodate a continuous reinforcing wire for the outer wythe, which reinforcing wire snaps into the wire housings therefor with a predetermined force. With the interconnected wall and veneer anchors and the respective reinforcing elements a seismic construct is formed.

Owner:HOHMANN & BARNARD INC

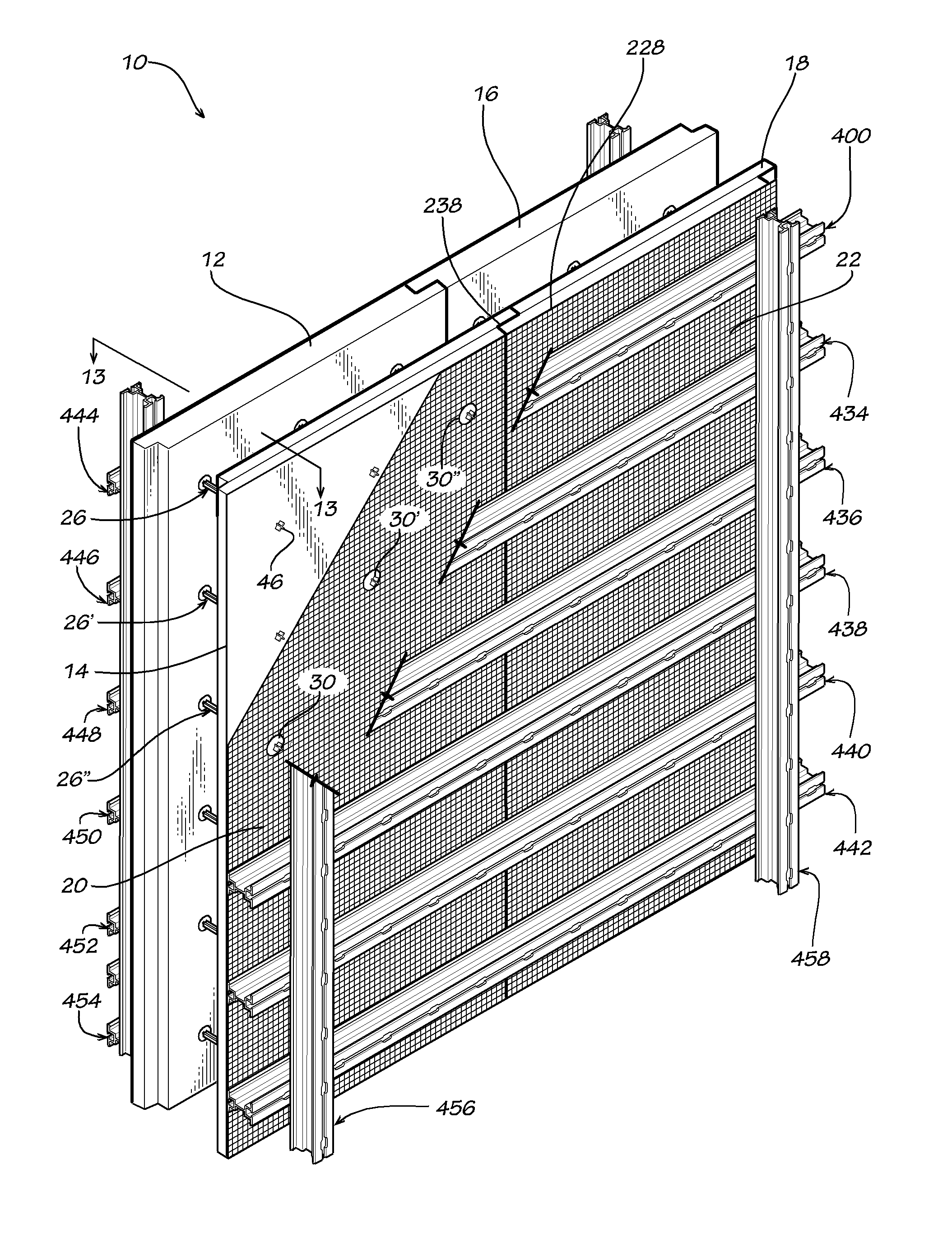

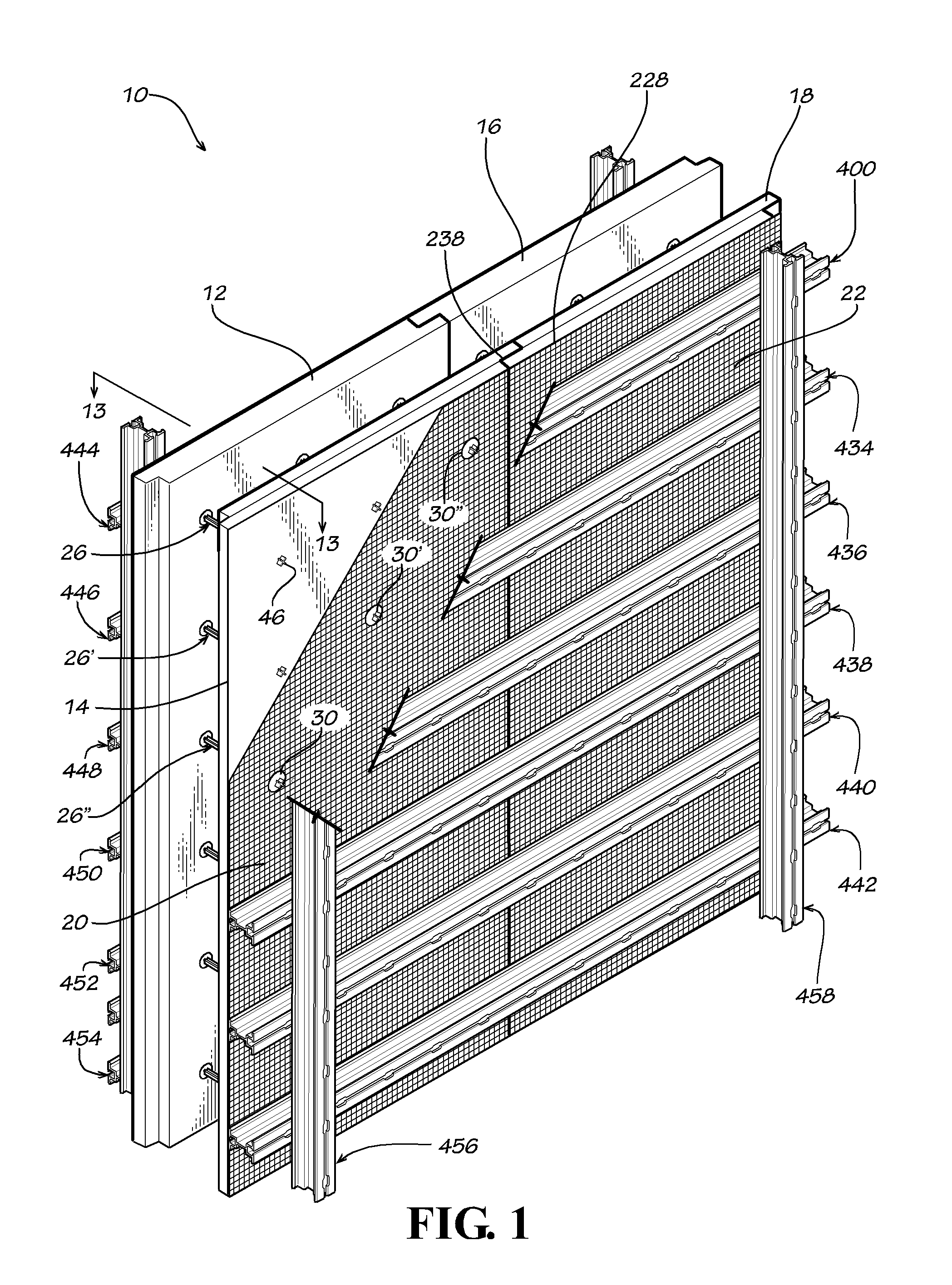

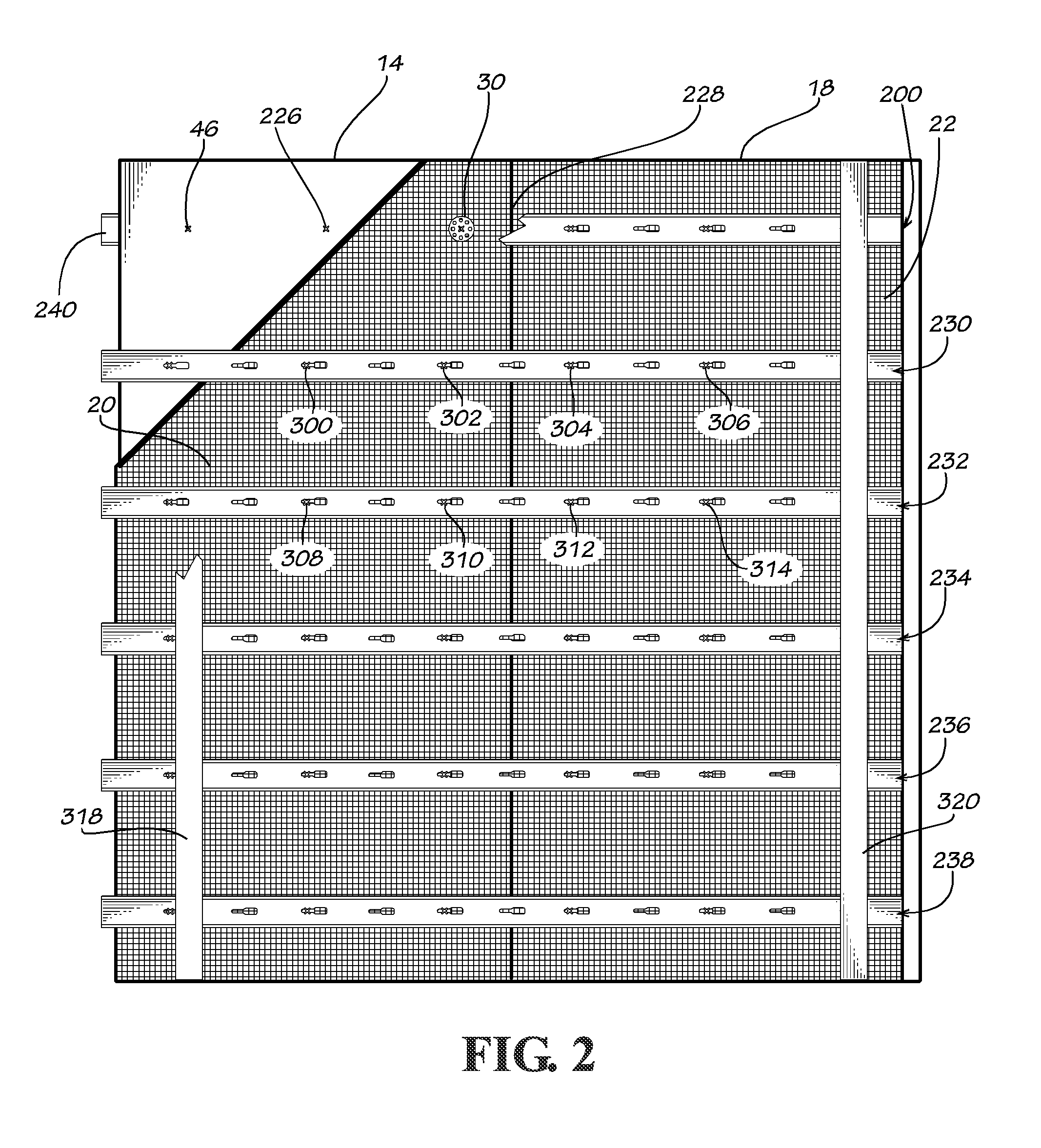

Wall anchor constructs and surface-mounted anchoring systems utilizing the same

Wall anchor constructs and anchoring systems employing the same are disclosed. Each anchor is a sheetmetal construct utilizable with various wire formative veneer ties. In the wall anchor structures, the junctures of the legs and the base of the wall anchor are located inboard from the periphery of the wall anchor base. With the surfaces of the leg base and the anchor base coplanar, the leg insertion point is, upon installation, sealed thereby. This sealing precludes penetration of air, Moisture, and water vapor into the wall structure. Various embodiments showing wall anchor configurations with suitable veneer ties are provided.

Owner:HOHMANN & BARNARD INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com