Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

942 results about "Thermal bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The methods for thermal bonding include the use of a heat sealer which heats the fibers until they slightly melt together and is often used in combination with a lower melting point binder fiber.

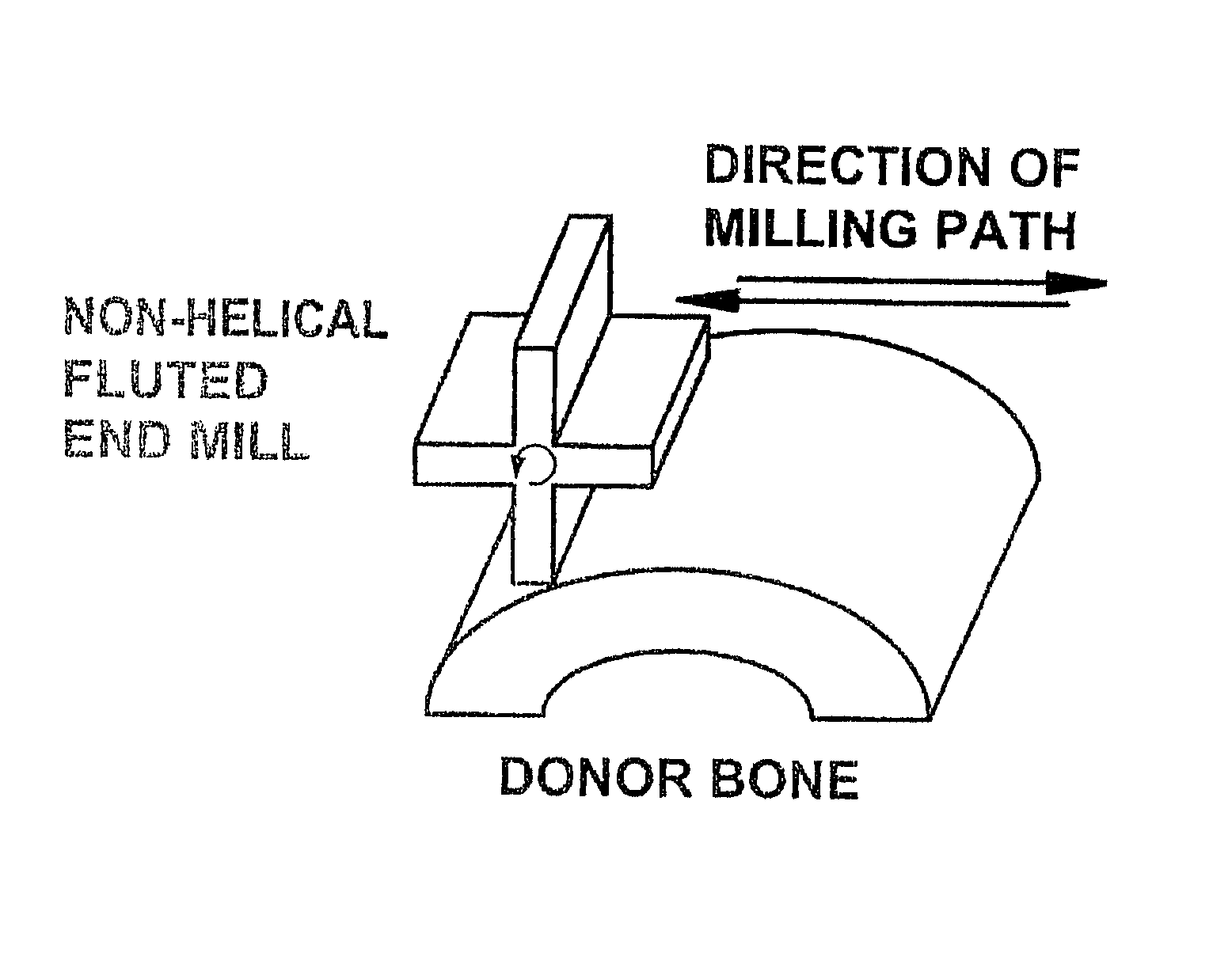

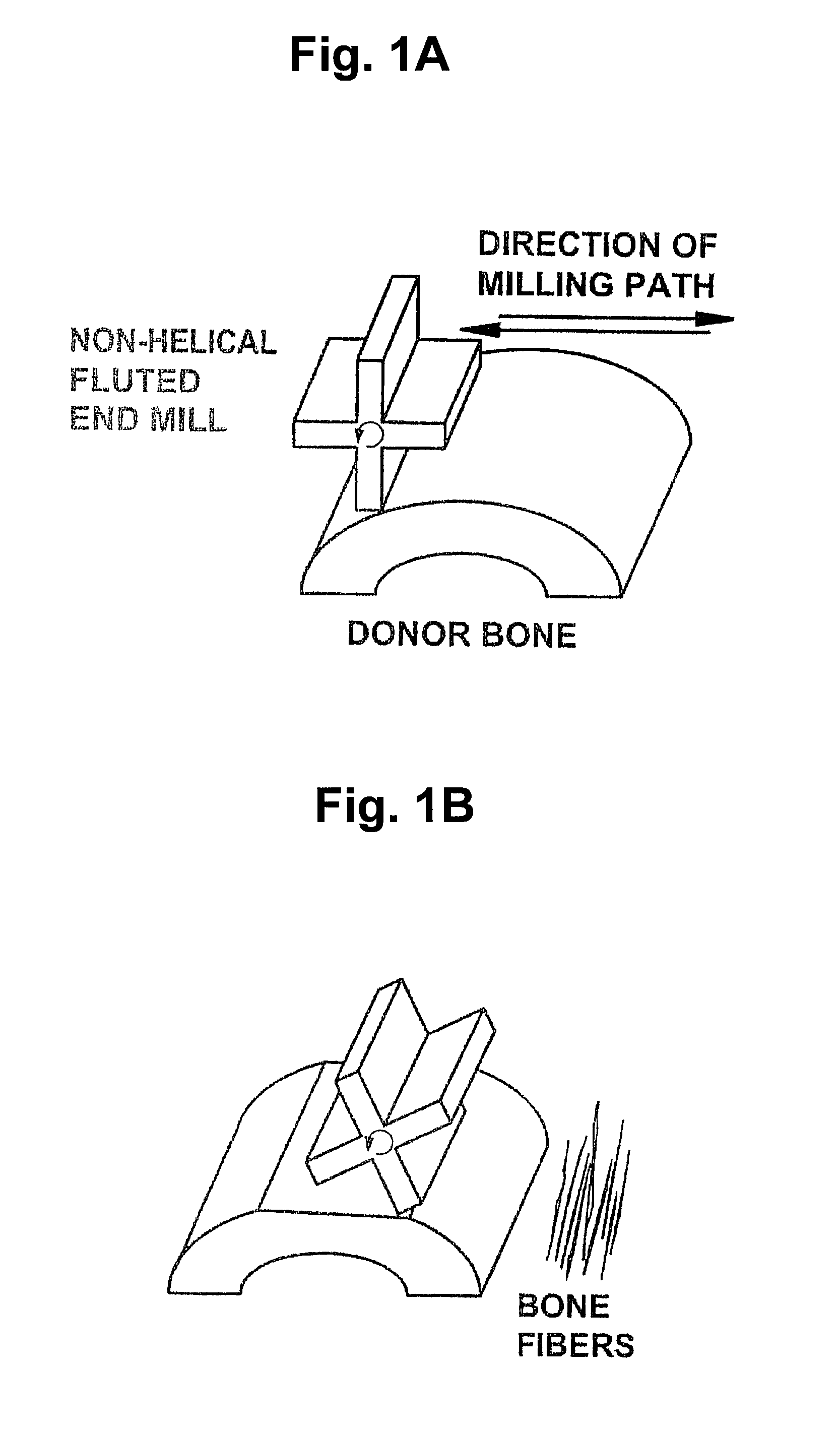

Tissue-derived mesh for orthopedic regeneration

An implant including a substantially cohesive aggregate comprising bone-derived particles. Cohesiveness is maintained by a member of mechanical interlocking, engagement of adjacent bone-derived particles with one another through engagement with a binding agent, thermal bonding, chemical bonding, or a matrix material in which the bone-derived particles are retained. The aggregate is shaped as a one-dimensional or two-dimensional body.

Owner:WARSAW ORTHOPEDIC INC

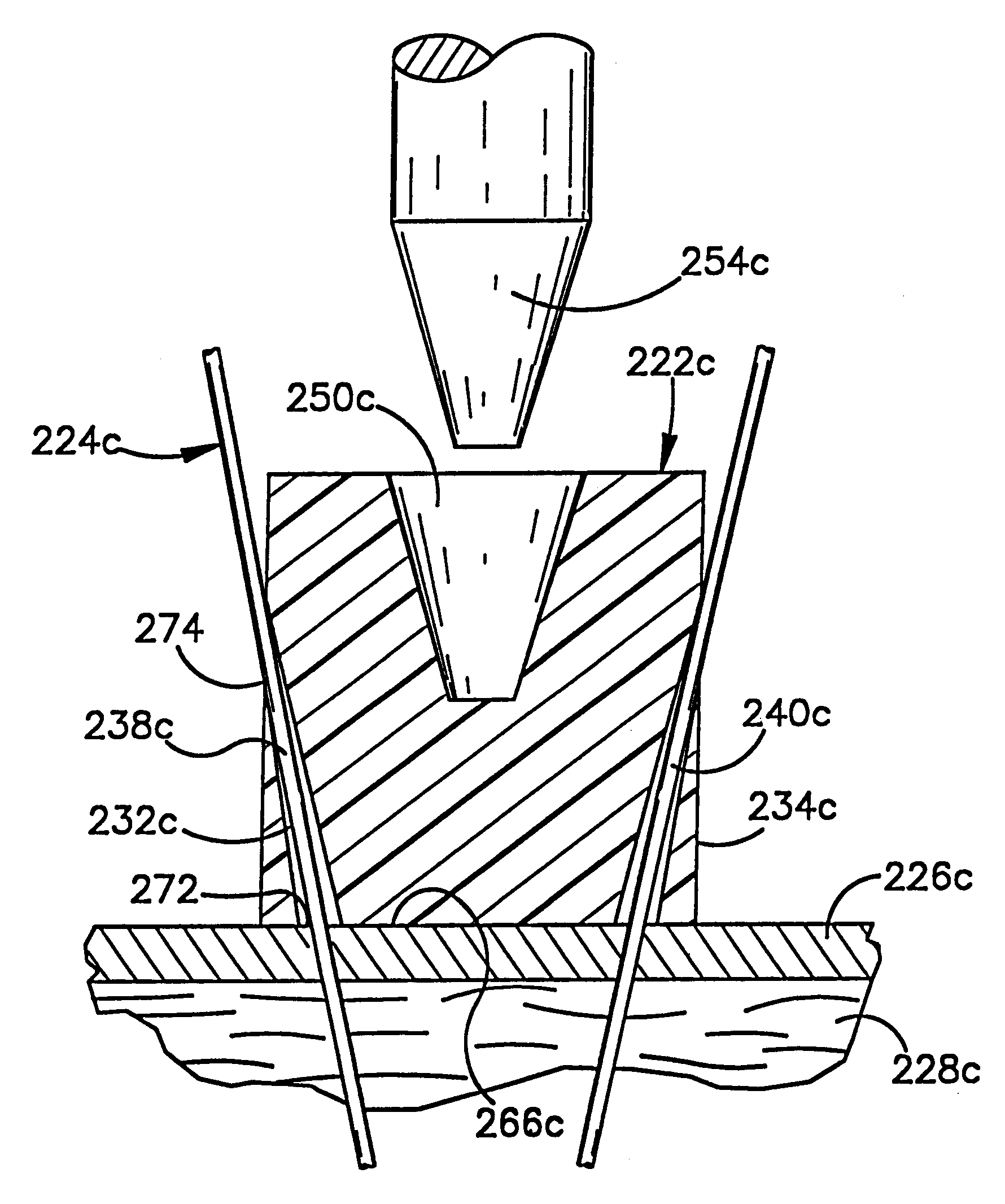

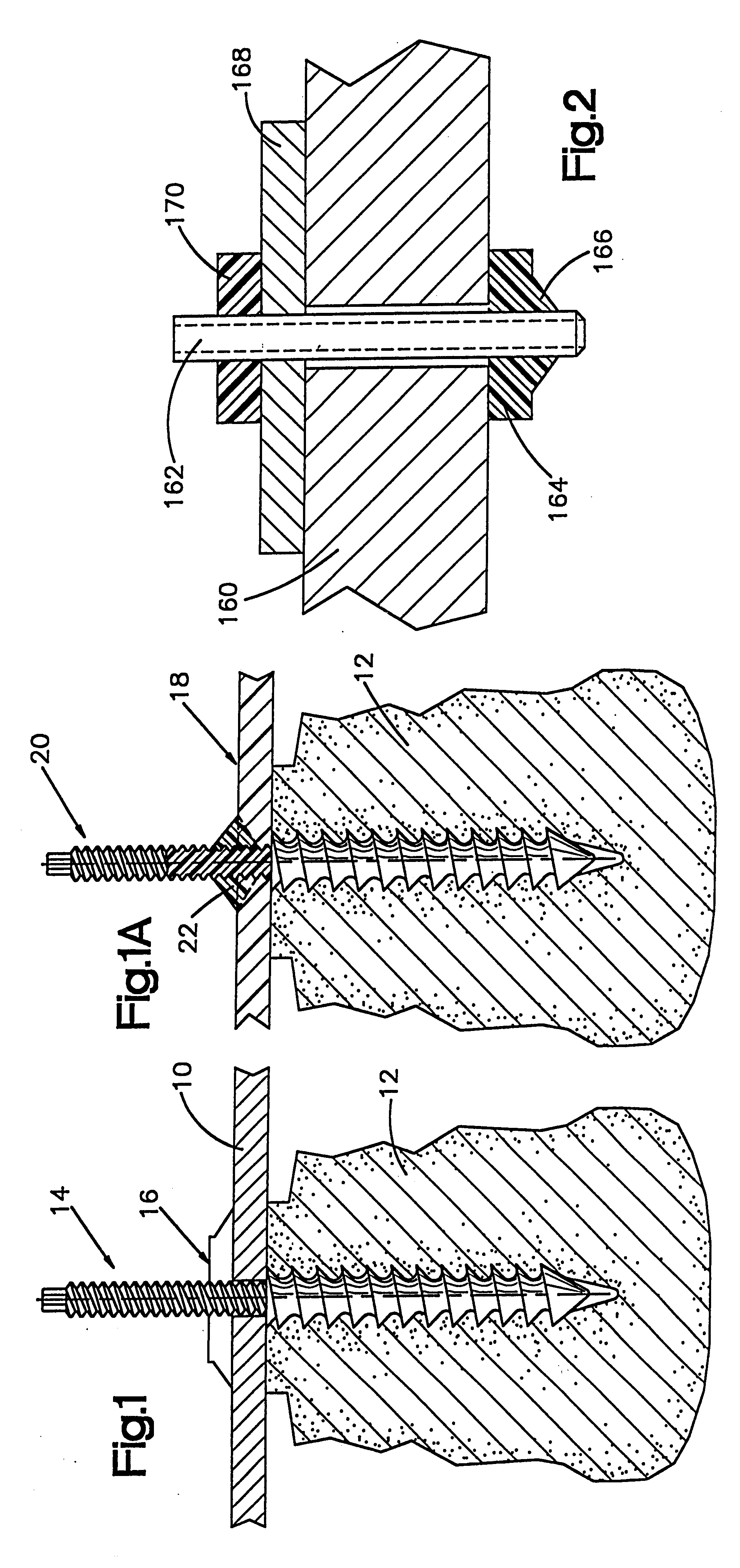

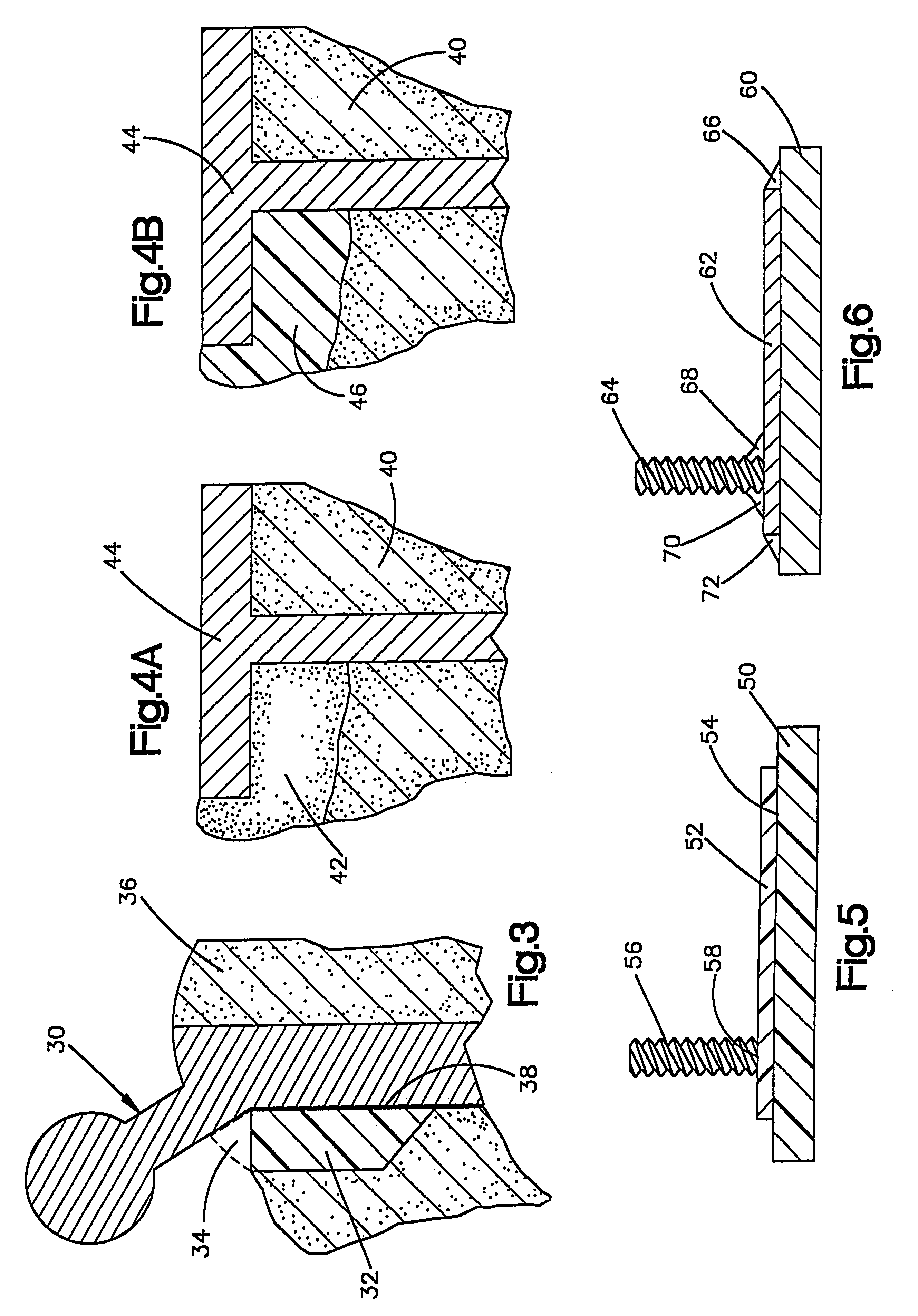

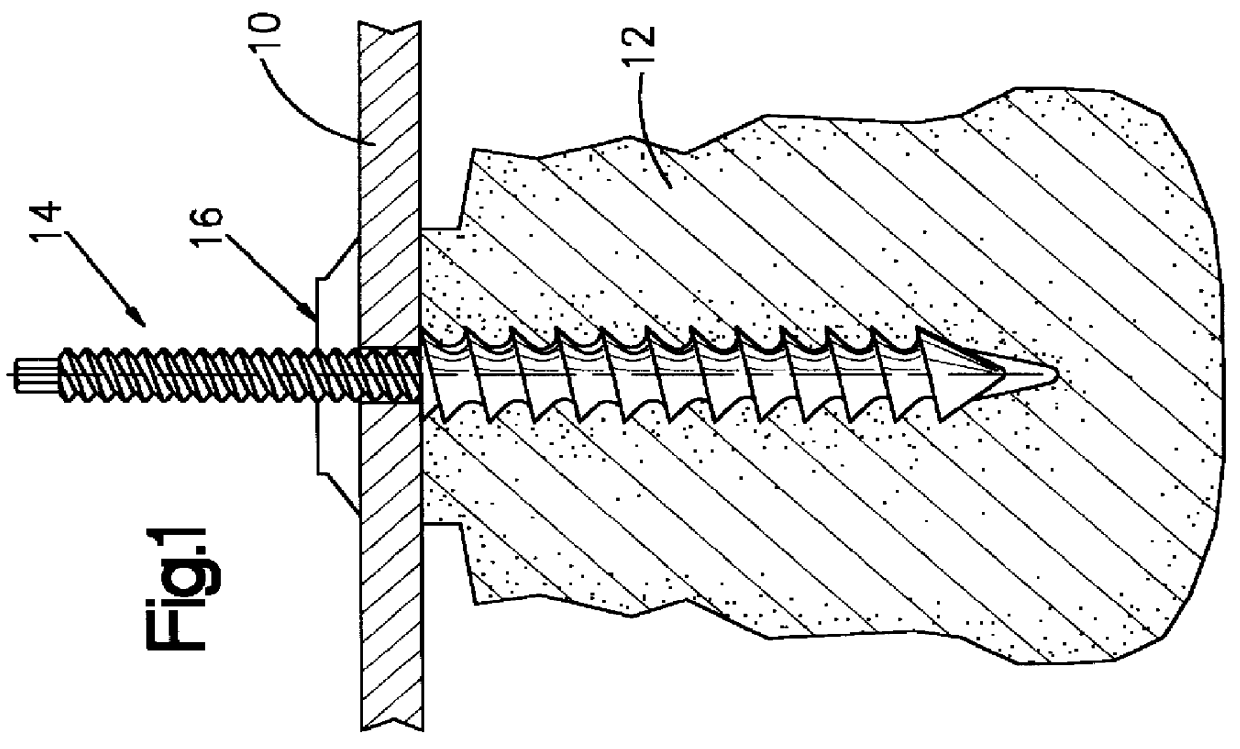

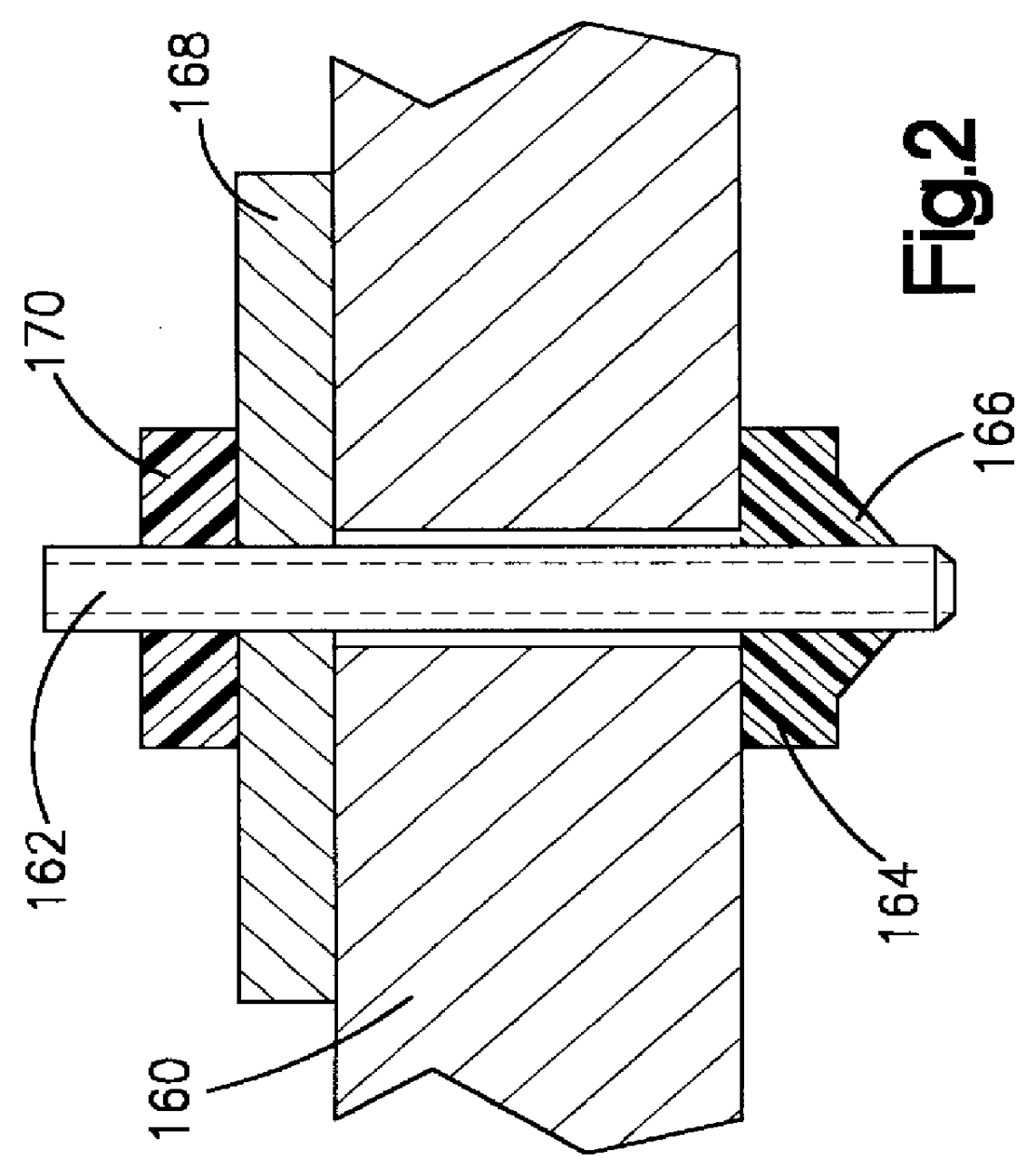

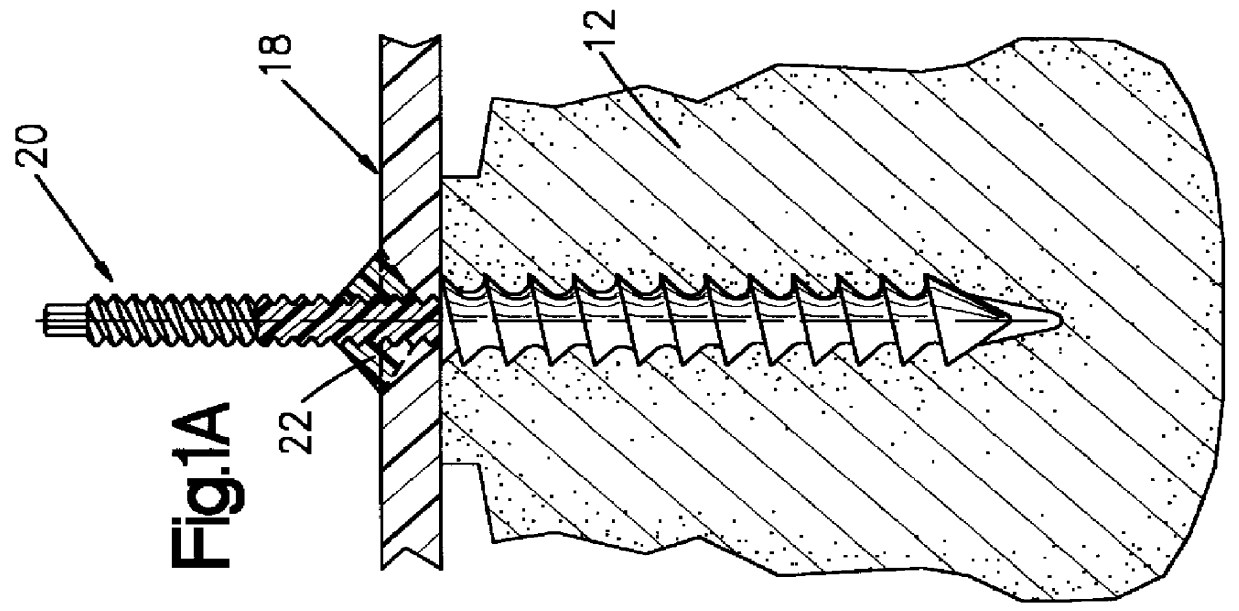

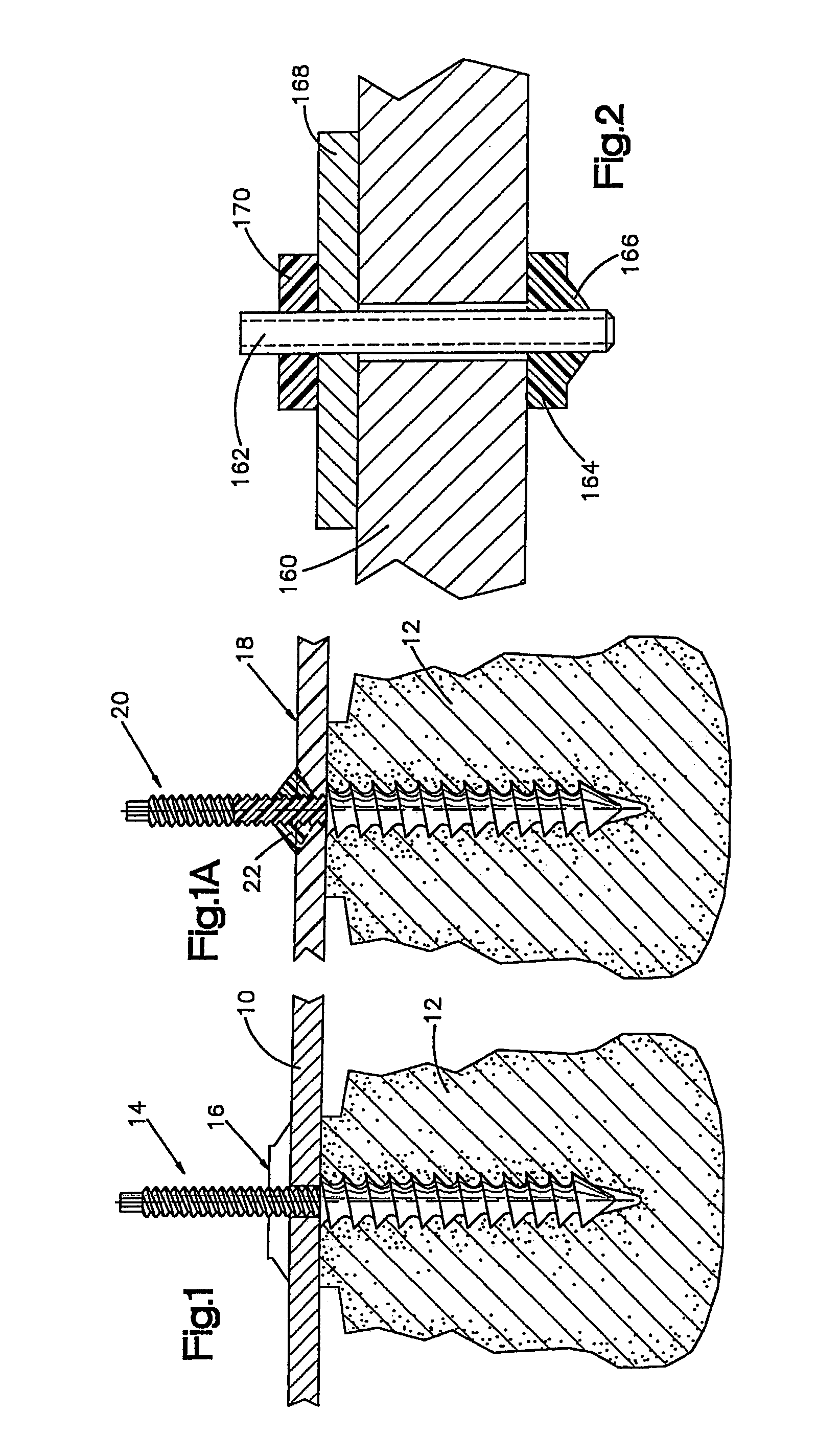

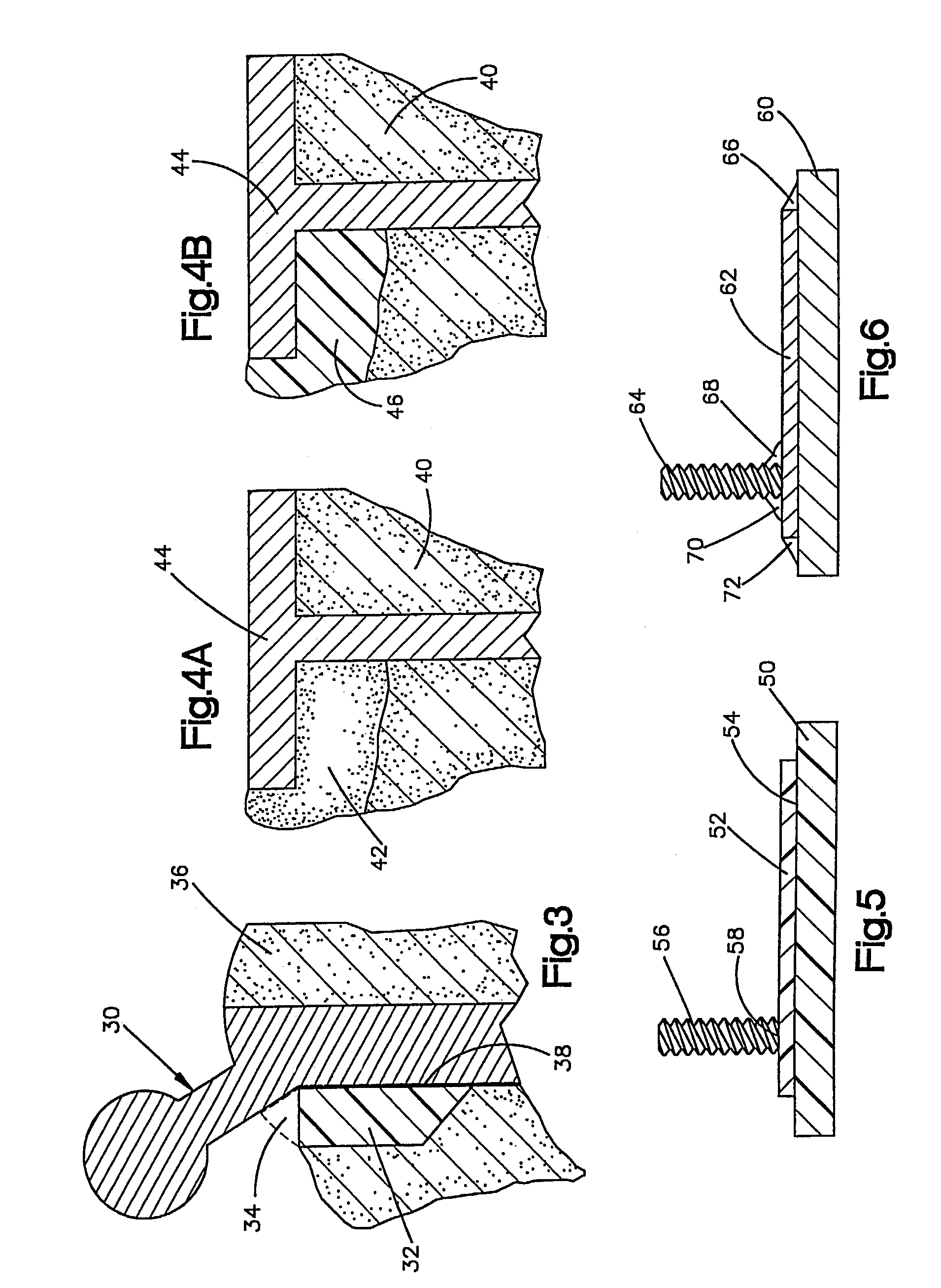

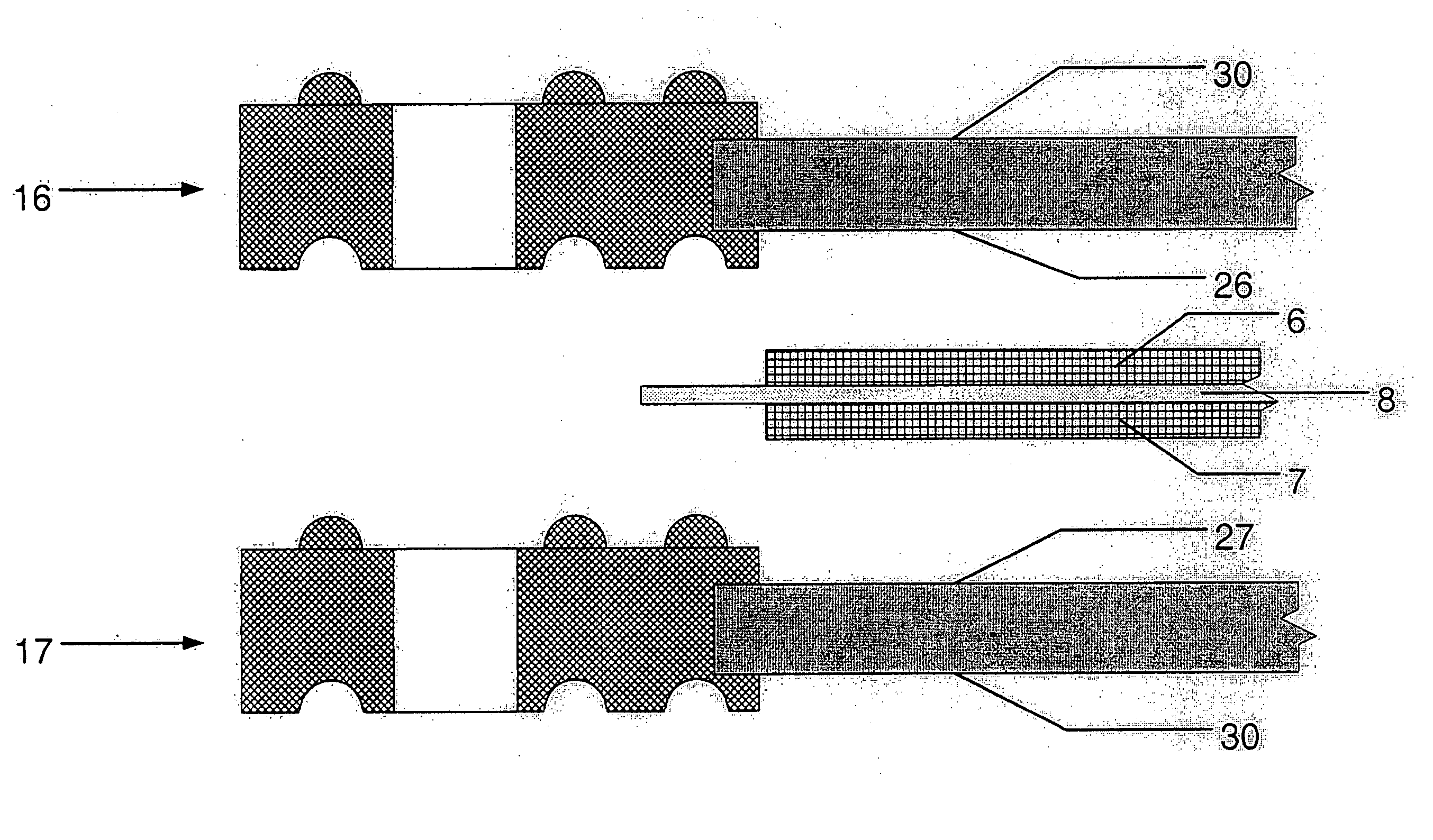

Surgical devices assembled using heat bondable materials

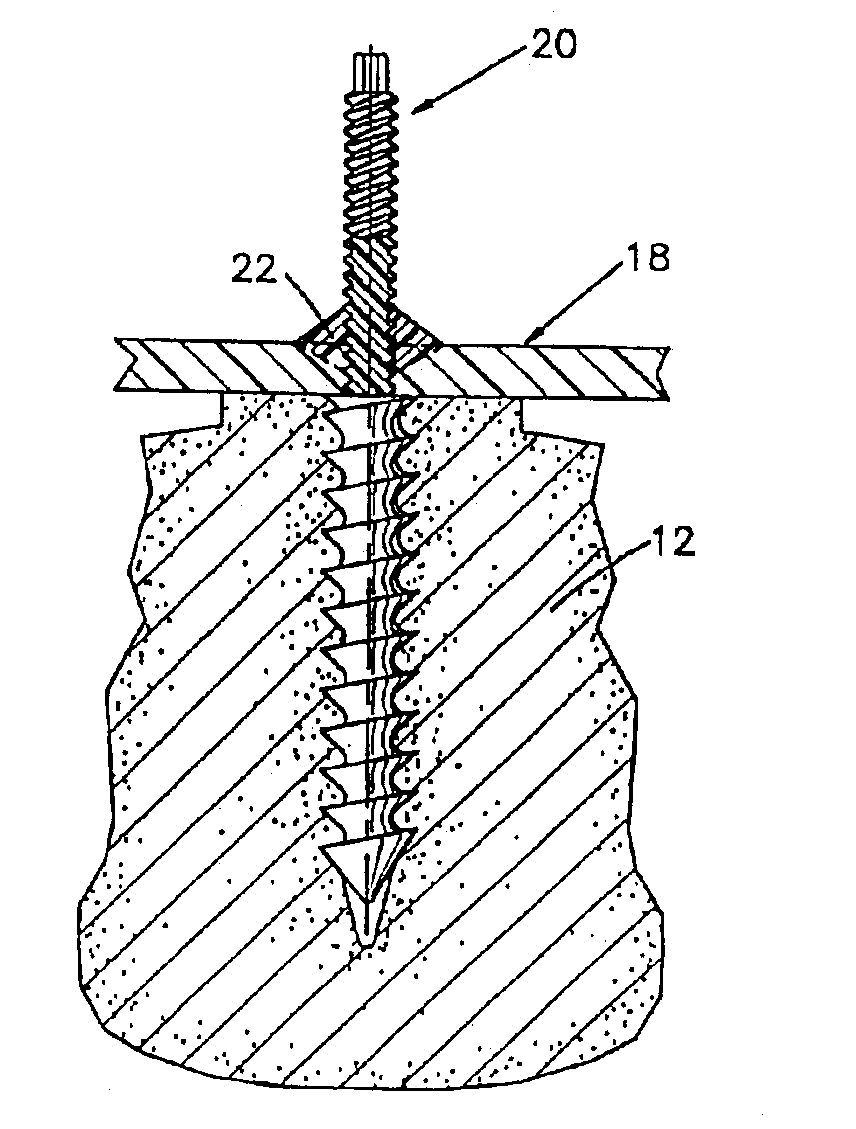

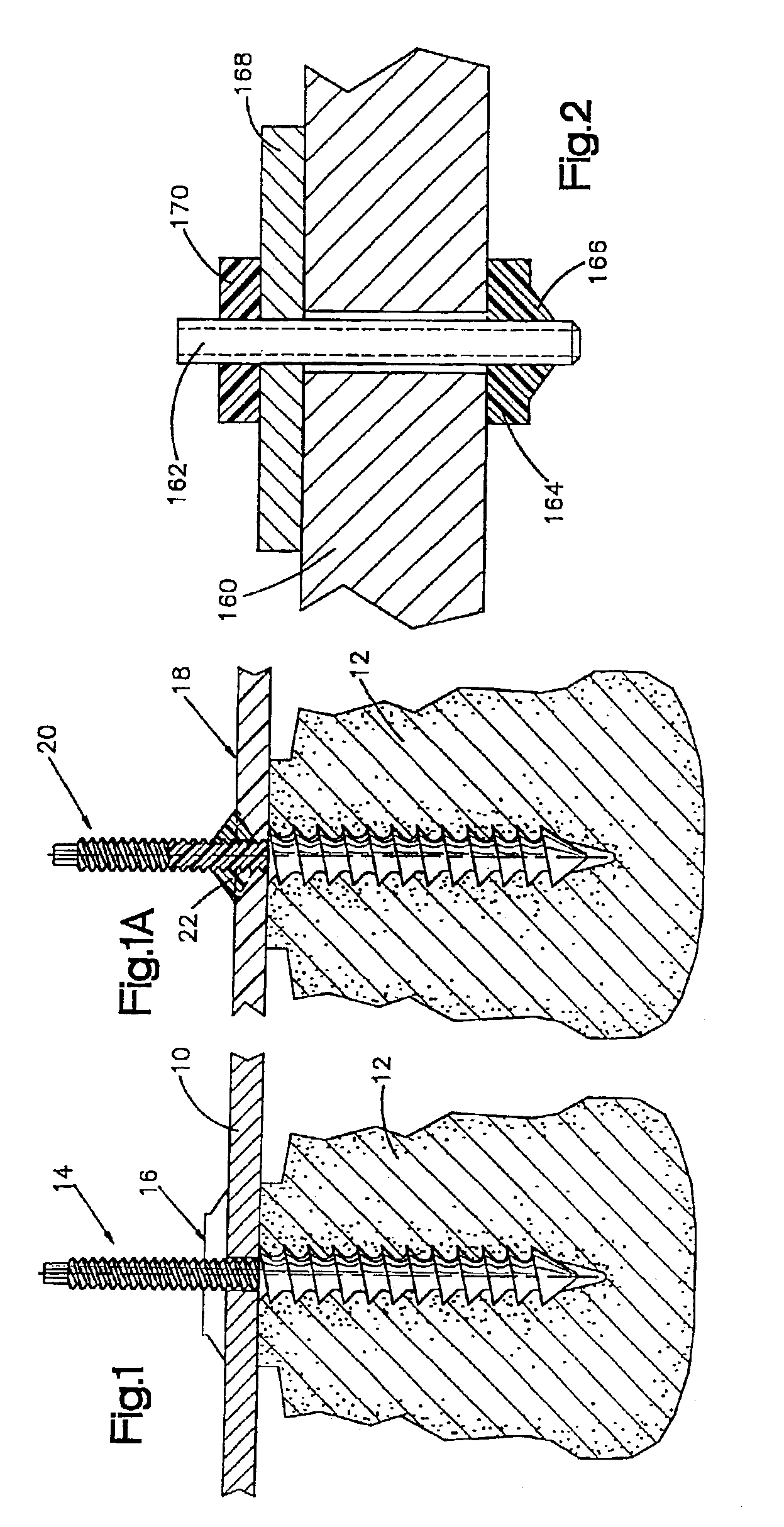

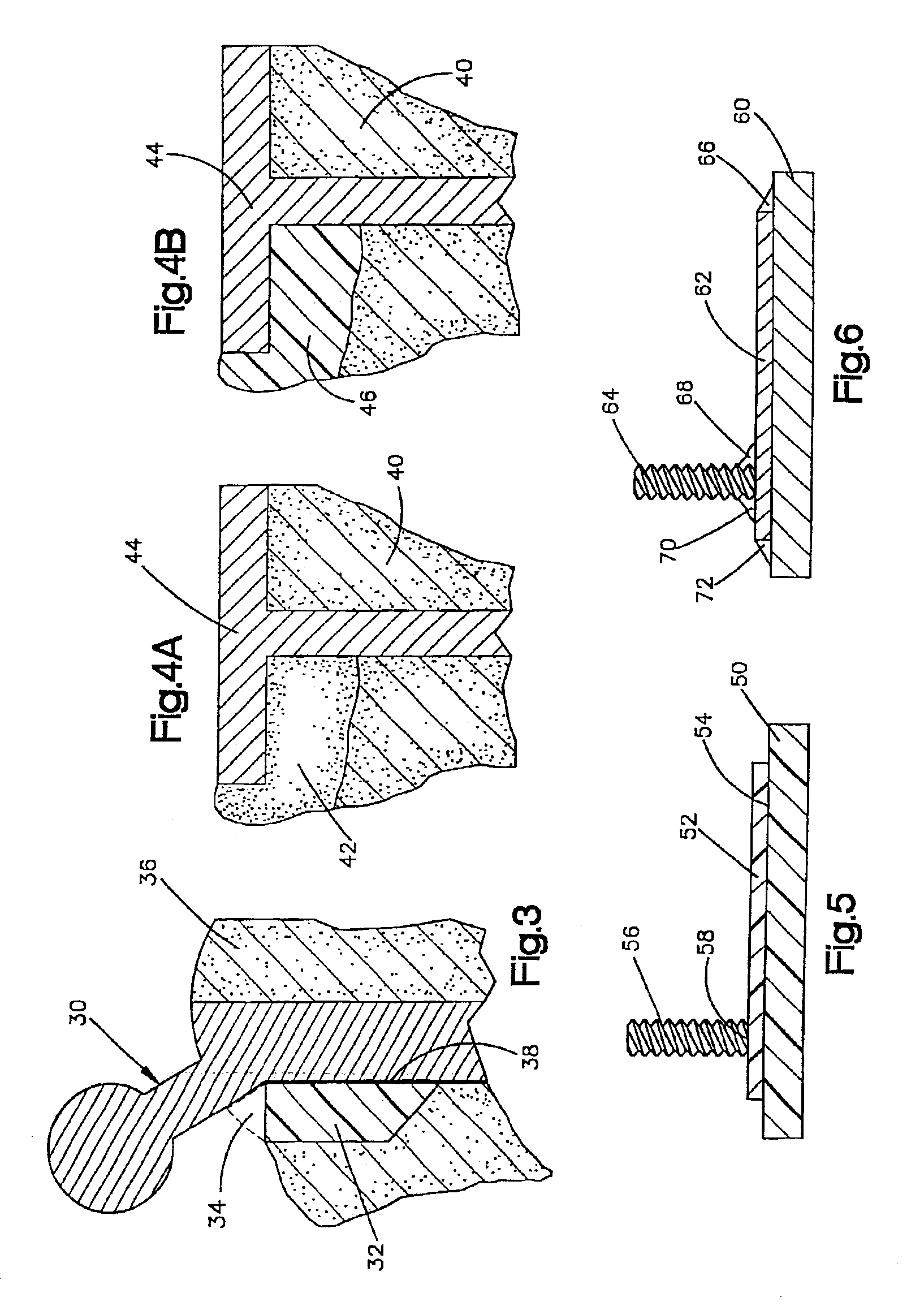

Surgical devices such as implants or suture fastenings are assembled from a plurality of discrete components, one of which components includes a heat bondable plastic material for bonding the components together. At least two components are bonded to each other by the applying heat to the heat bondable plastic material of one component. The heat bondable plastic material is preferably a polymeric or composite material suitable for surgical applications and implantation in humans, and may be a biodegradable material. A laser may be used as the heat source. The present invention is advantageously embodied in heat bonded fastenings for sutures or K-wires, in which a variety of different suture anchors are usable, including expandable distal suture anchors. Other embodiments include a metal bone plate which is held to bone by a metal bone screw and a nut of bondable material bonded to the plate to secure the connection; a piece of bondable material bonded to a metal prosthesis to custom fit the prosthesis; and a surgical implant custom formed by bonding together a plurality of discrete elements one or more of which is bondable.

Owner:P TECH +1

Surgical devices assembled using heat bondable materials

Surgical devices such as implants or suture fastenings are assembled from a plurality of discrete components, one of which components includes a heat bondable plastic material for bonding the components together. At least two components are bonded to each other by the applying heat to the heat bondable plastic material of one component. The heat bondable plastic material is preferably a polymeric or composite material suitable for surgical applications and implantation in humans, and may be a biodegradable material. A laser may be used as the heat source. The present invention is advantageously embodied in heat bonded fastenings for sutures or K-wires, in which a variety of different suture anchors are usable, including expandable distal suture anchors. Other embodiments include a metal bone plate which is held to bone by a metal bone screw and a nut of bondable material bonded to the plate to secure the connection; a piece of bondable material bonded to a metal prosthesis to custom fit the prosthesis; and a surgical implant custom formed by bonding together a plurality of discrete elements one or more of which is bondable.

Owner:P TECH +1

Surgical devices having a biodegradable material with a therapeutic agent

Surgical devices such as implants or suture fastenings are assembled from a plurality of discrete components, one of which components includes a heat bondable plastic material for bonding the components together. At least two components are bonded to each other by the applying heat to the heat bondable plastic material of one component. The heat bondable plastic material is preferably a polymeric or composite material suitable for surgical applications and implantation in humans, and may be a biodegradable material. A laser may be used as the heat source. The present invention is advantageously embodied in heat bonded fastenings for sutures or K-wires, in which a variety of different suture anchors are usable, including expandable distal suture anchors. Other embodiments include a metal bone plate which is held to bone by a metal bone screw and a nut of bondable material bonded to the plate to secure the connection; a piece of bondable material bonded to a metal prosthesis to custom fit the prosthesis; and a surgical implant custom formed by bonding together a plurality of discrete elements one or more of which is bondable.

Owner:P TECH +1

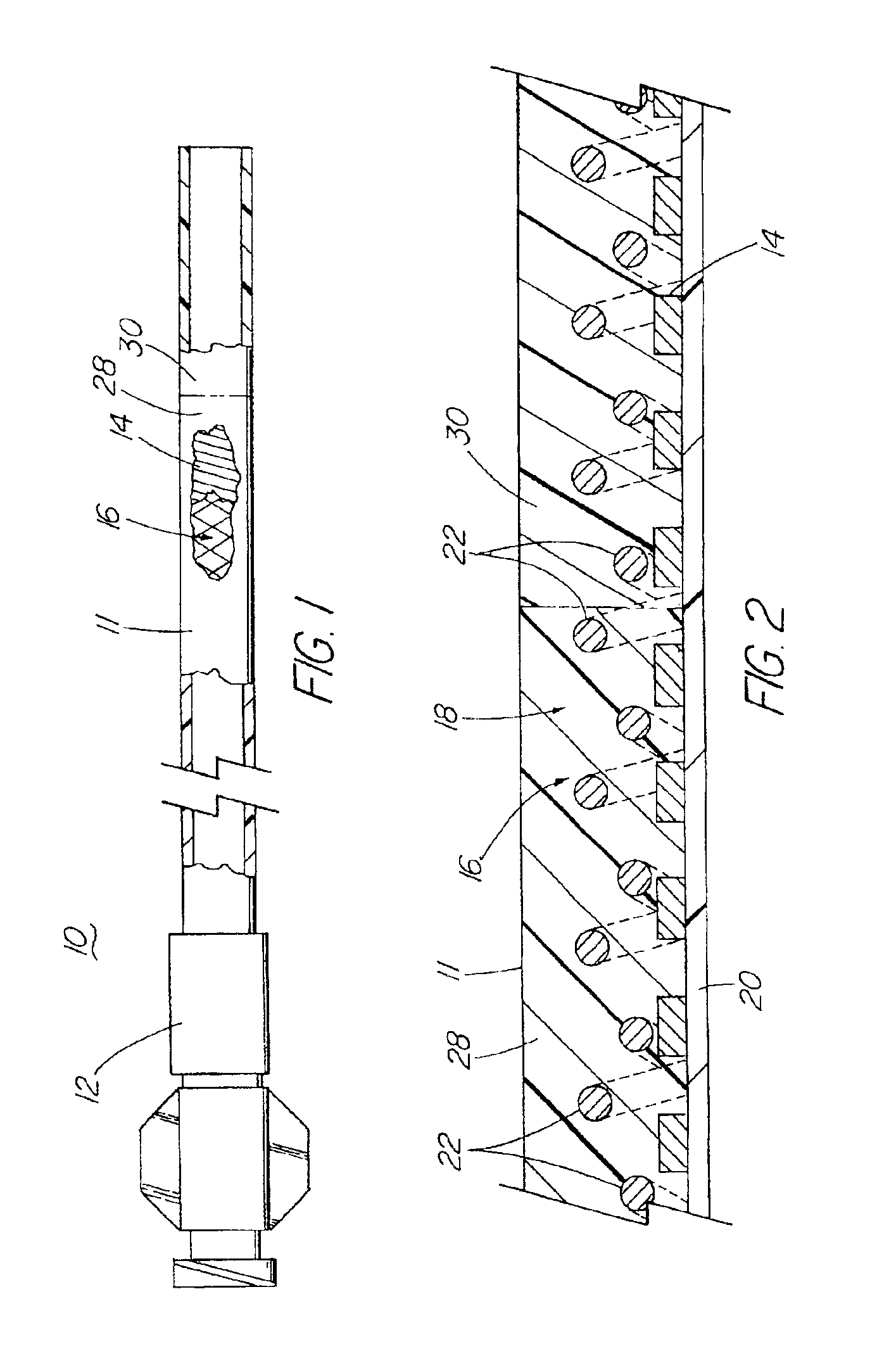

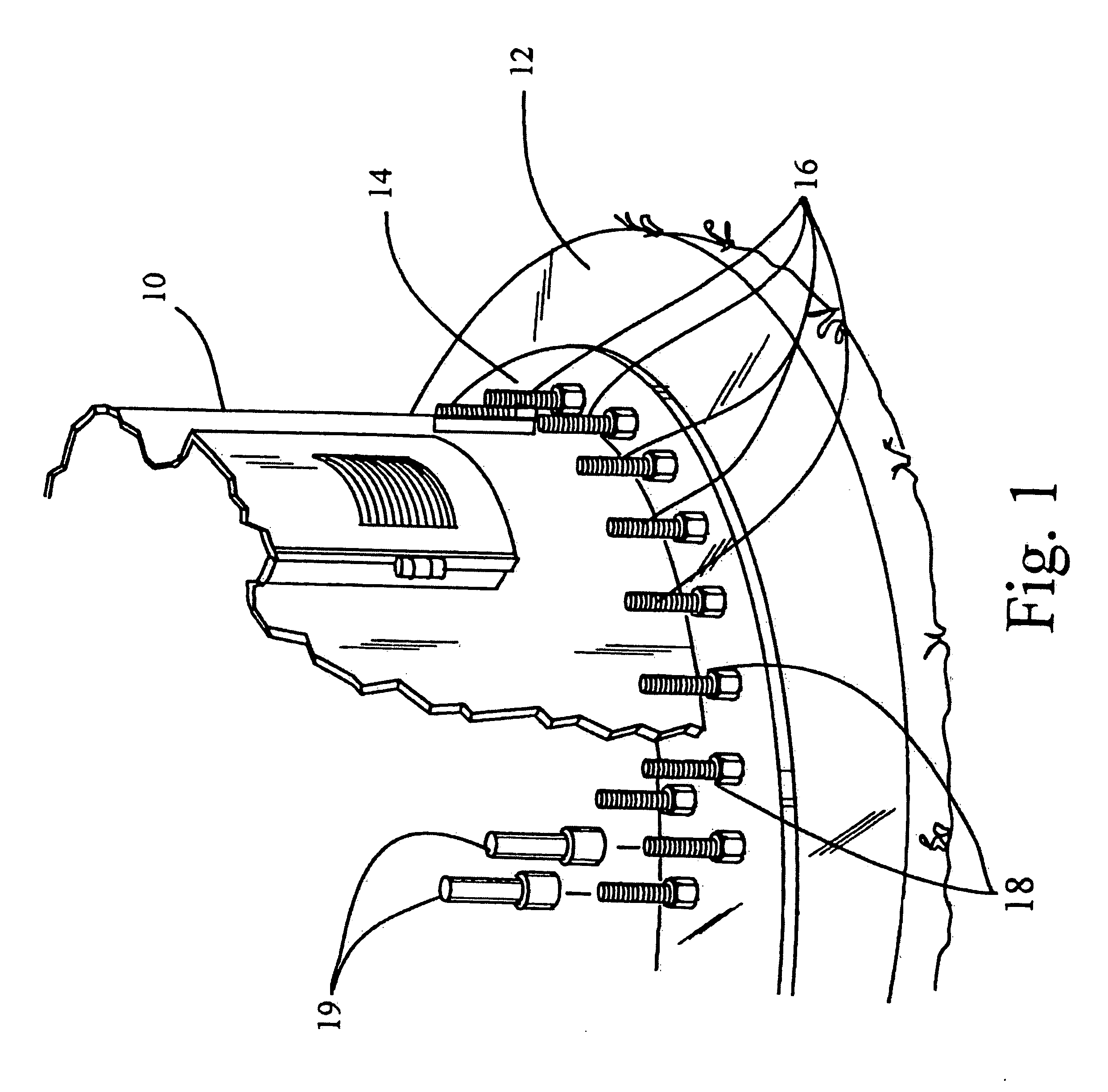

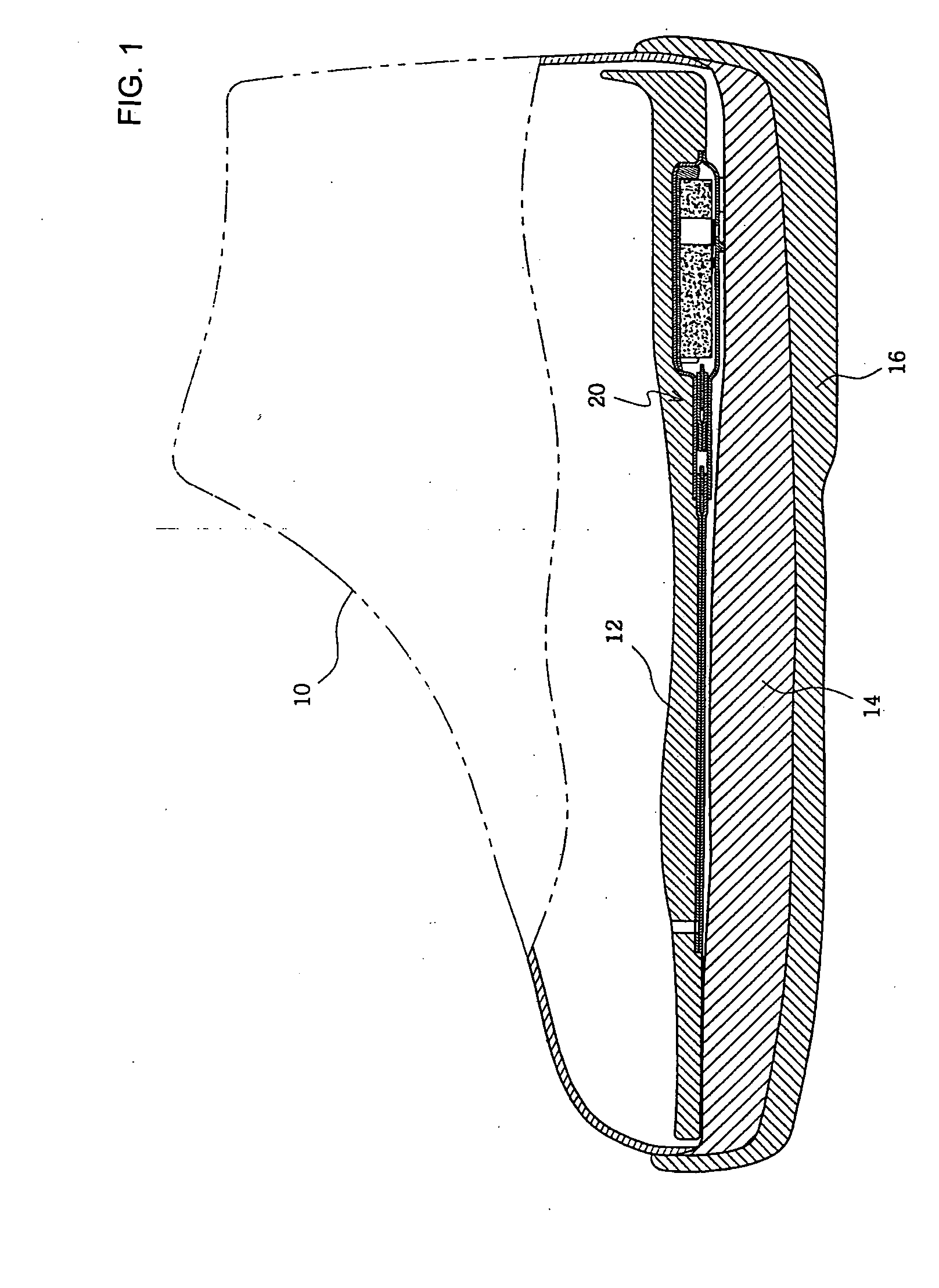

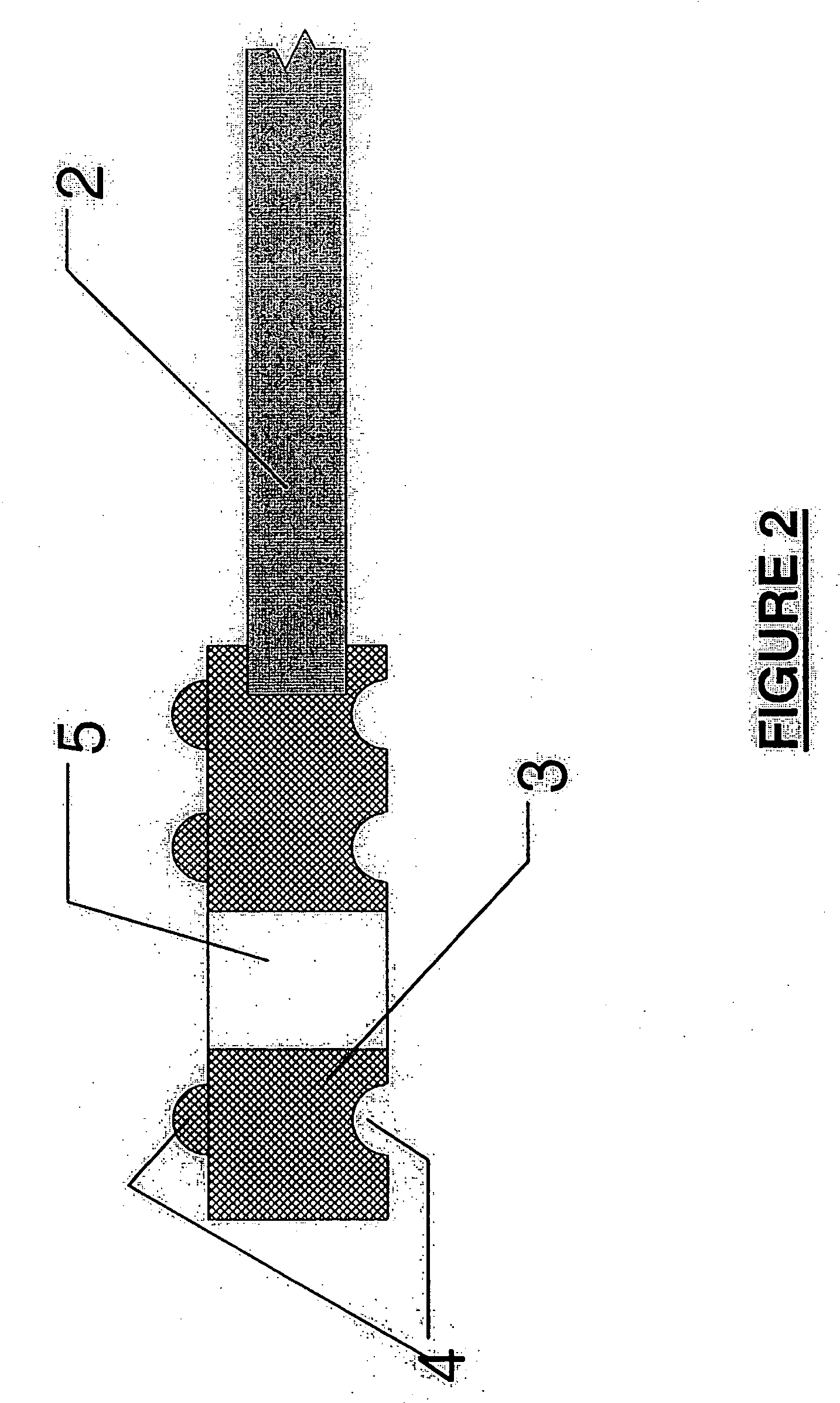

Medical device including tube having a braid and an expanded coil

A medical device (10) including a tube (11) having a highly uniform and repeatable inner and outer diameter, the tube (11) possessing good trackability, pushability and torquability, and the tube (11) being highly resistant to collapse, necking or kinking during use. The tube (11) first includes a metal coil (14) in a stressed, radially expanded condition, the metal coil (14) preferably being formed as a flat wire. The tube (11) also includes a metal braid (16) extending over at least part of the coil (14). The tube (11) further includes a polymeric bonding layer (18) positioned over and contacting at least the coil (14). The polymeric layer (18) is preferably heat-shrinkable shrinkable tubing made of one or more of nylon or polyurethane. The tube (11) optionally includes an inner liner (20) beneath and in contact with at least part of the coil (14), the liner (20) preferably being composed of PTFE. The polymeric layer (18) maintains the coil (14) in its stressed, radially expanded condition, for example, by adhesion to the coil (14) (such as by thermal bonding to it).

Owner:COOK MEDICAL TECH LLC

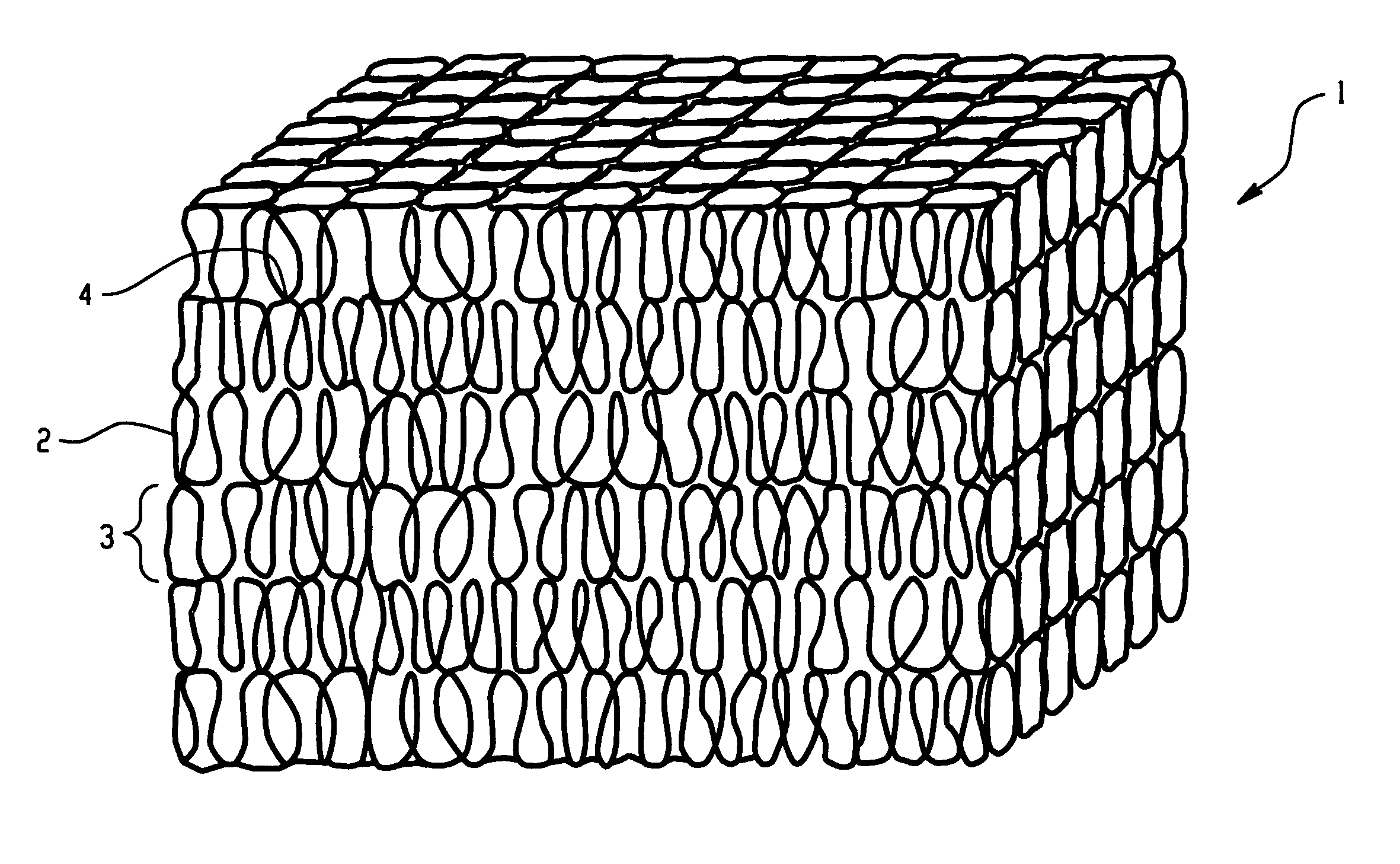

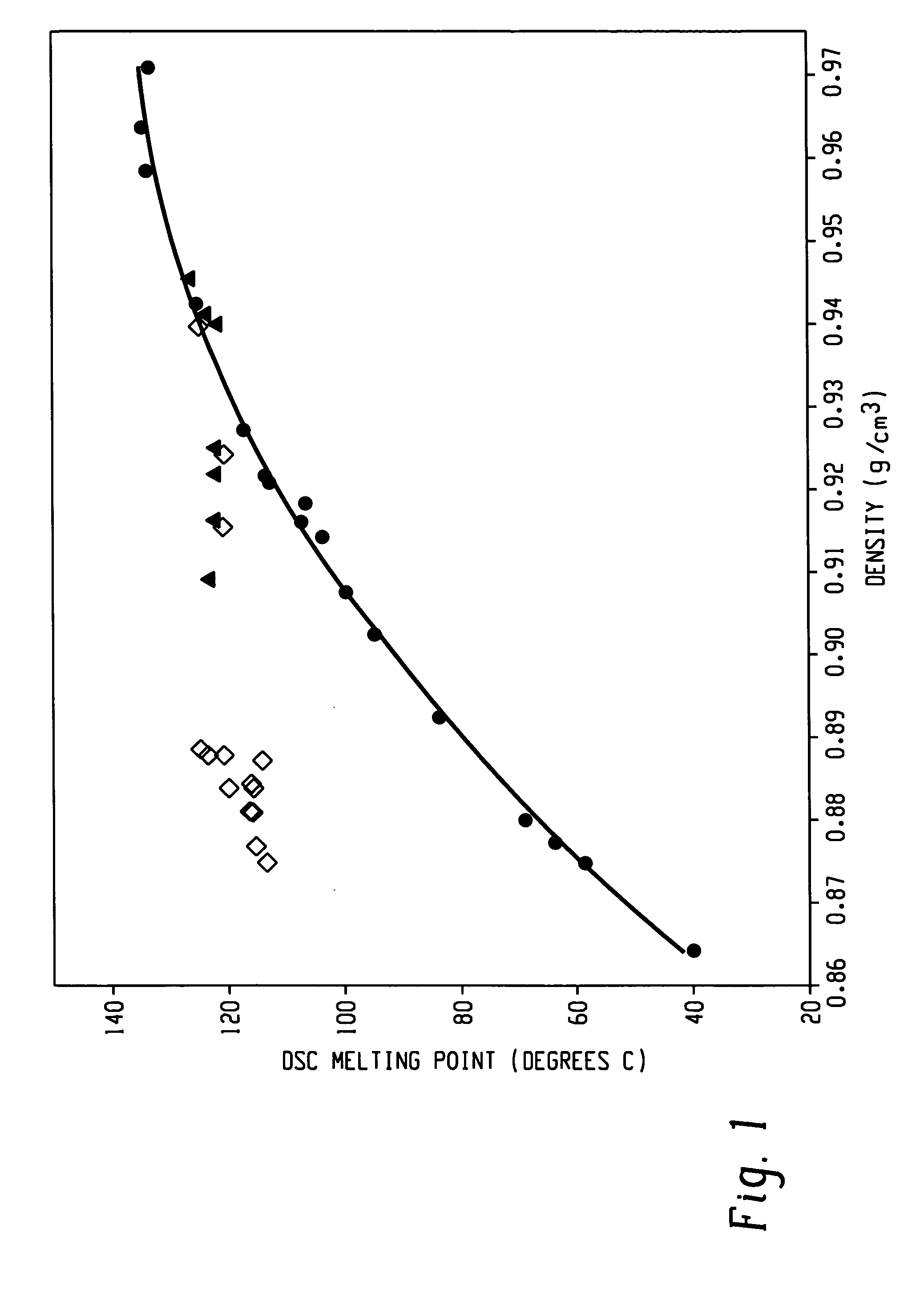

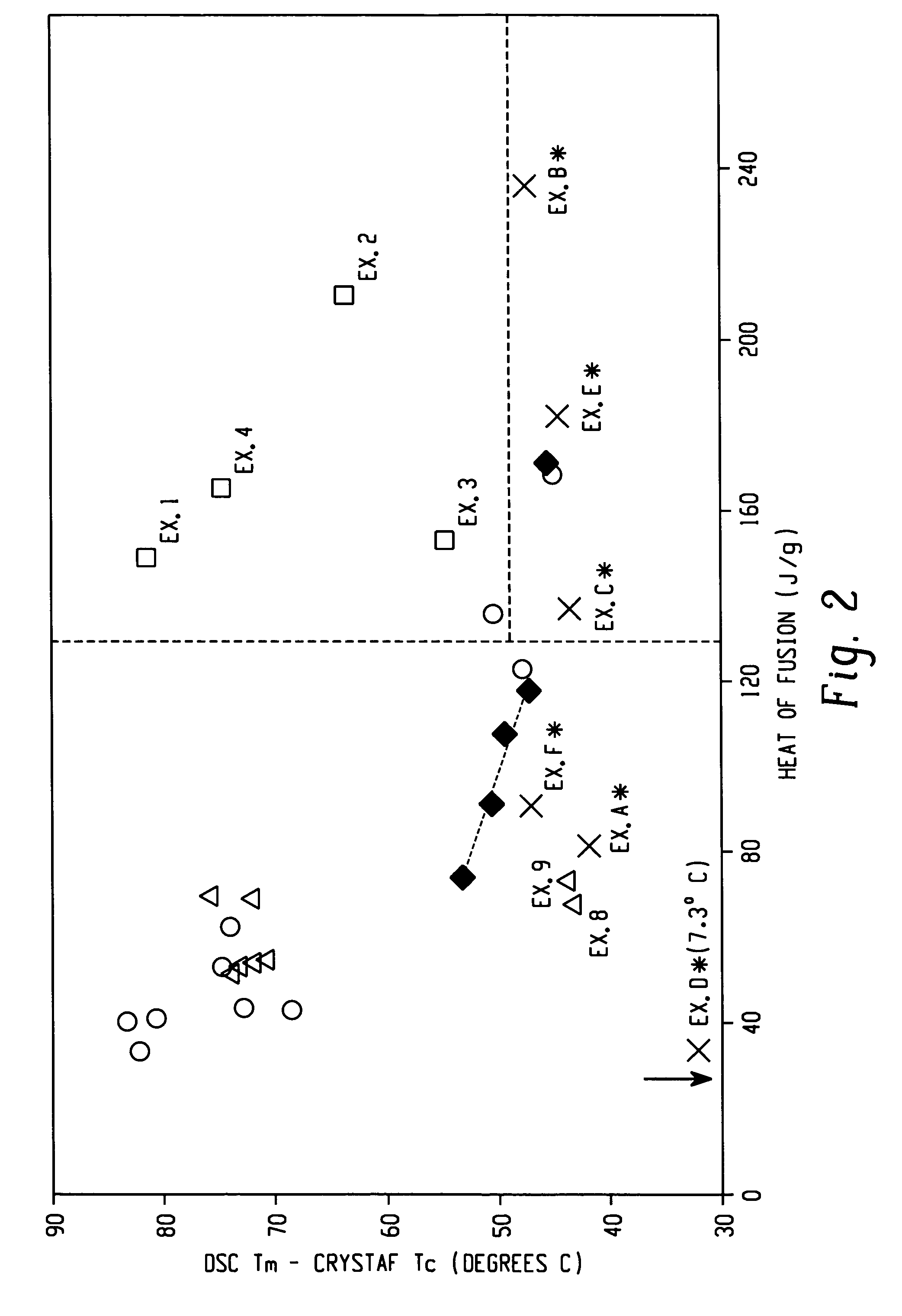

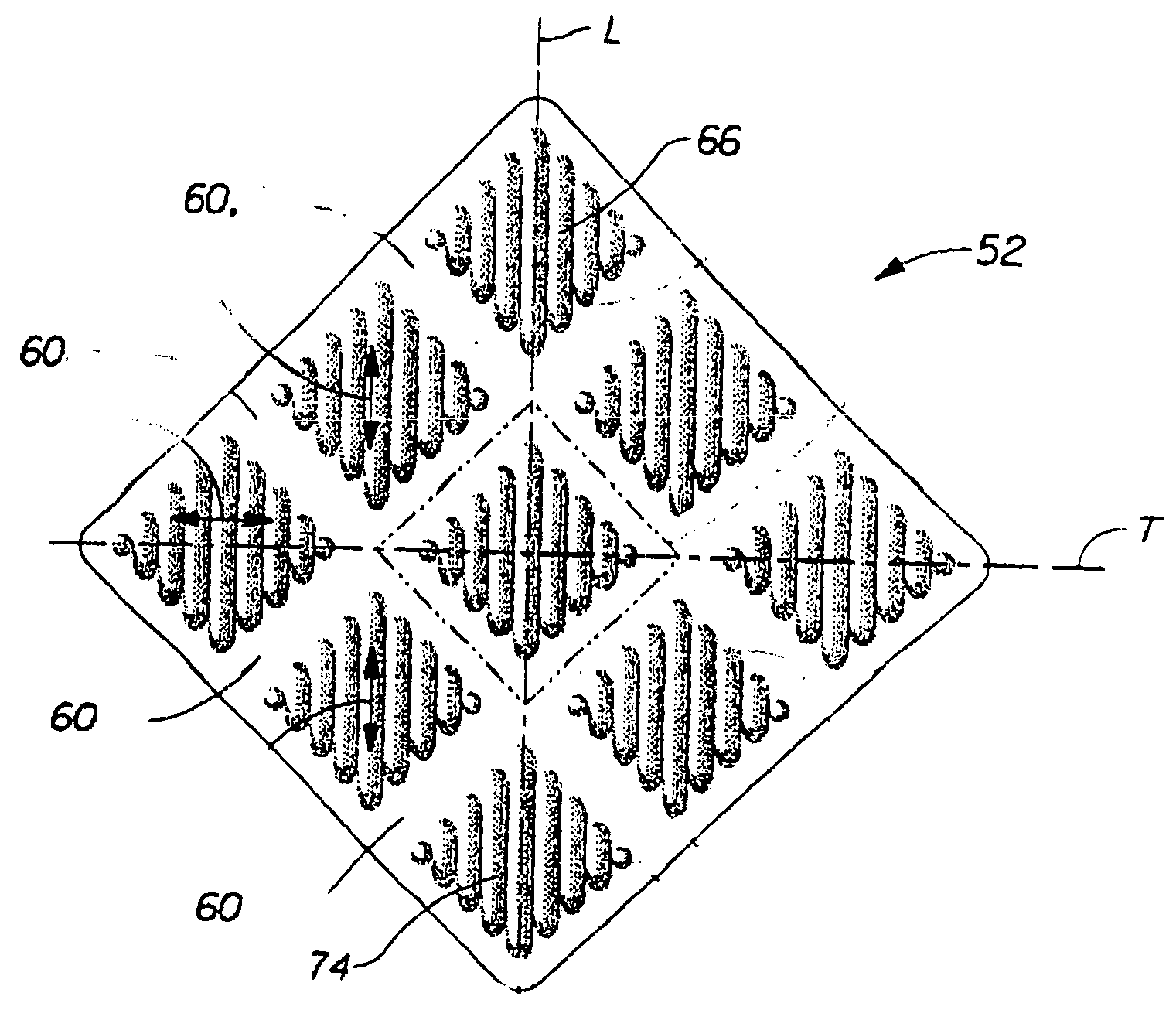

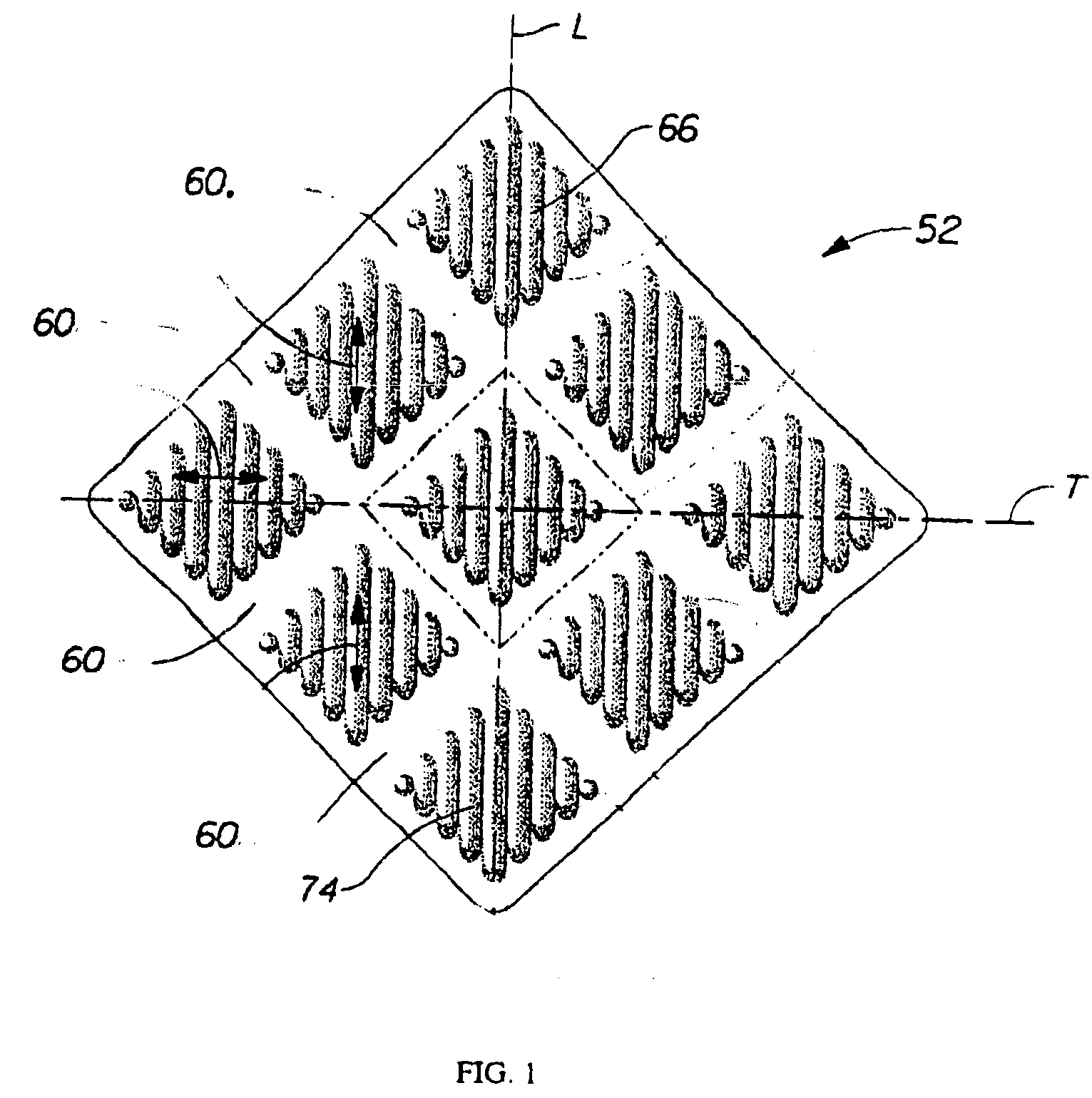

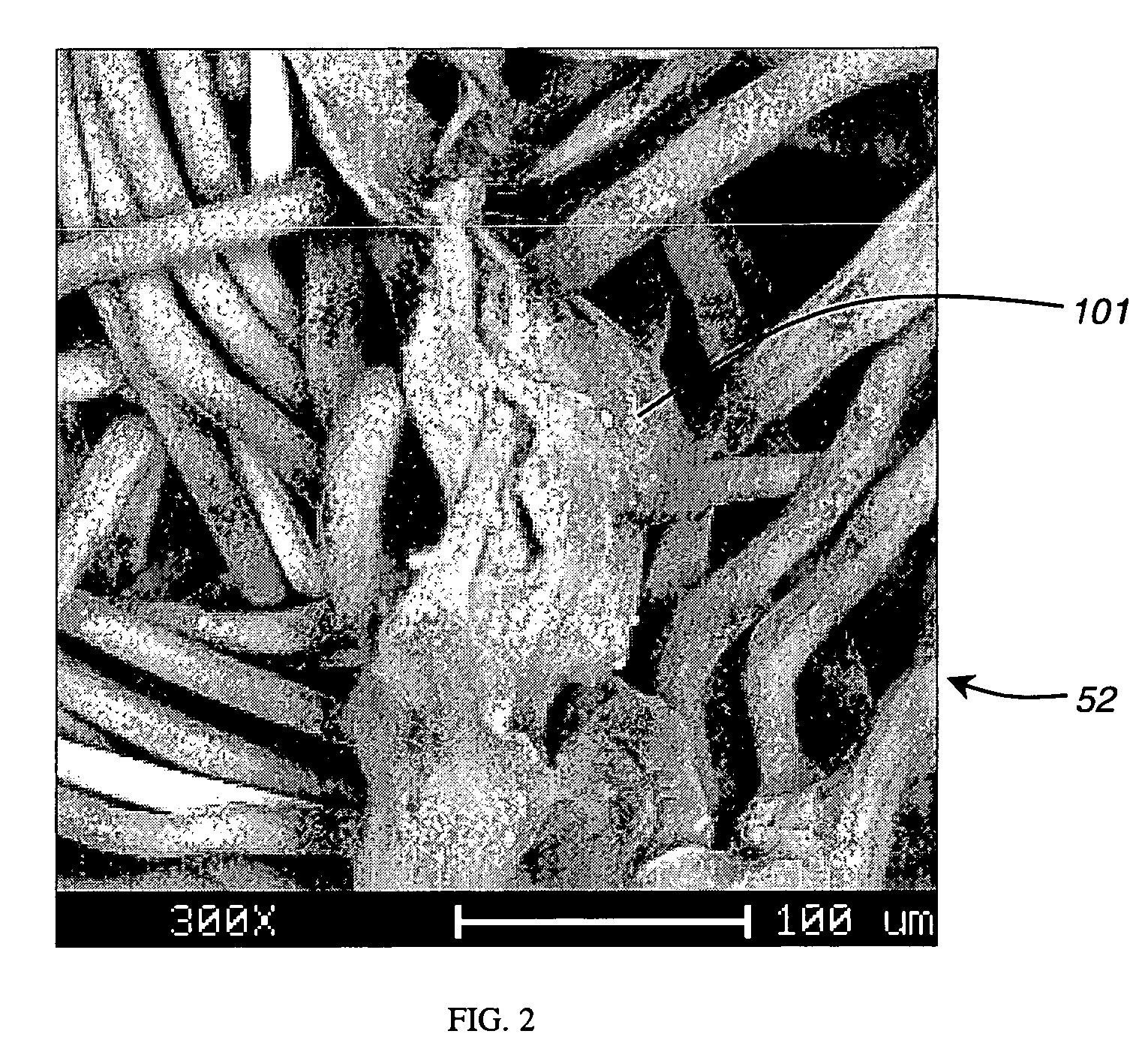

Three dimensional random looped structures made from interpolymers of ethylene/alpha-olefins and uses thereof

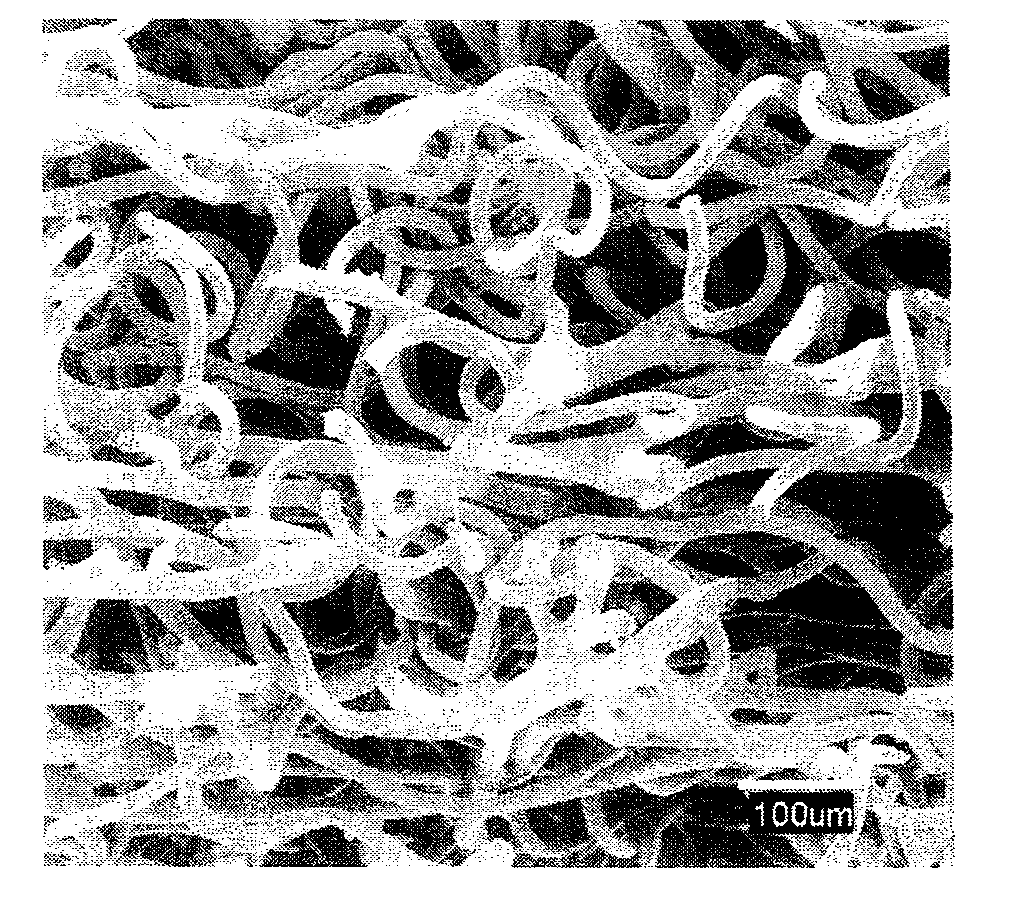

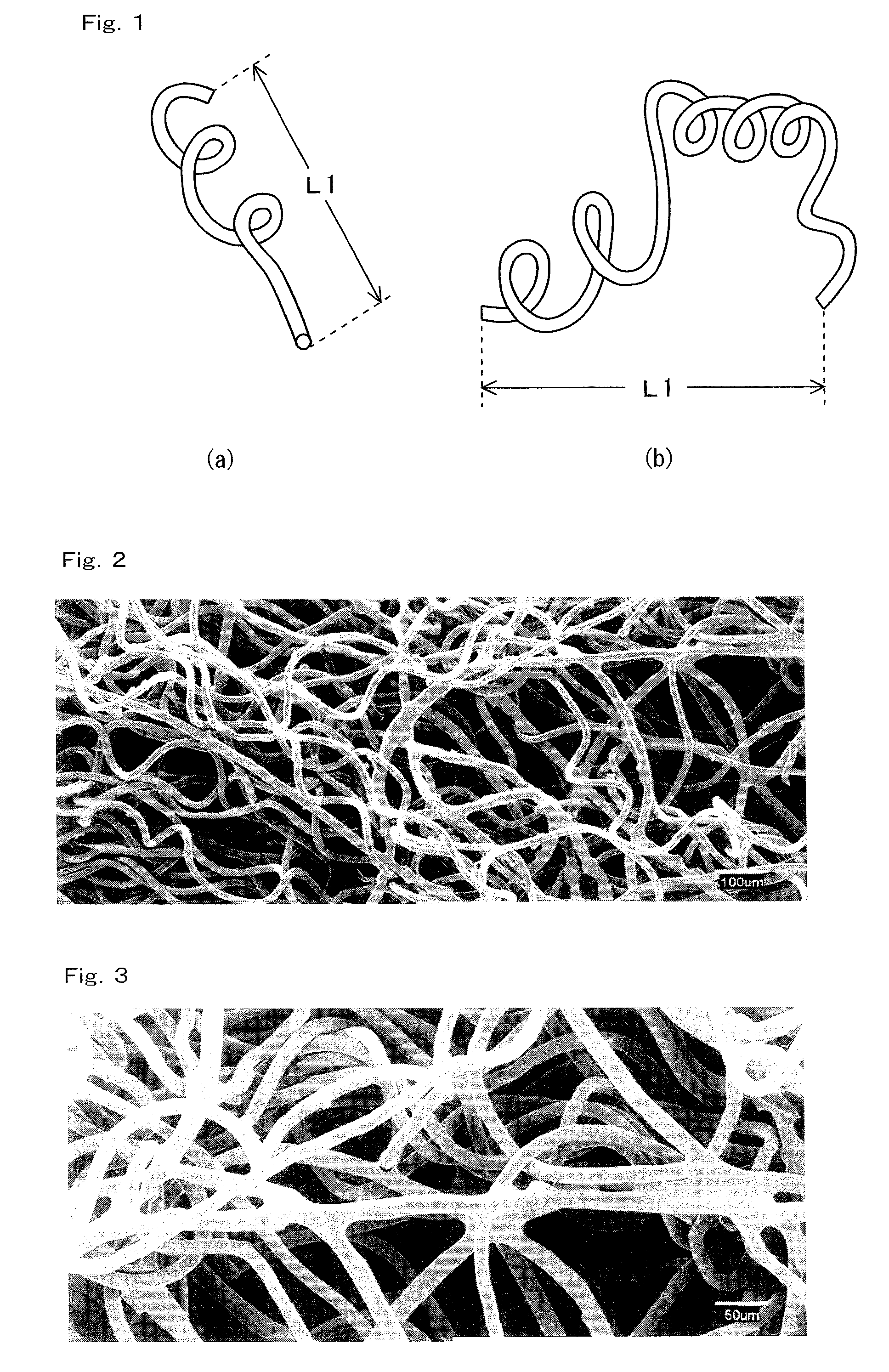

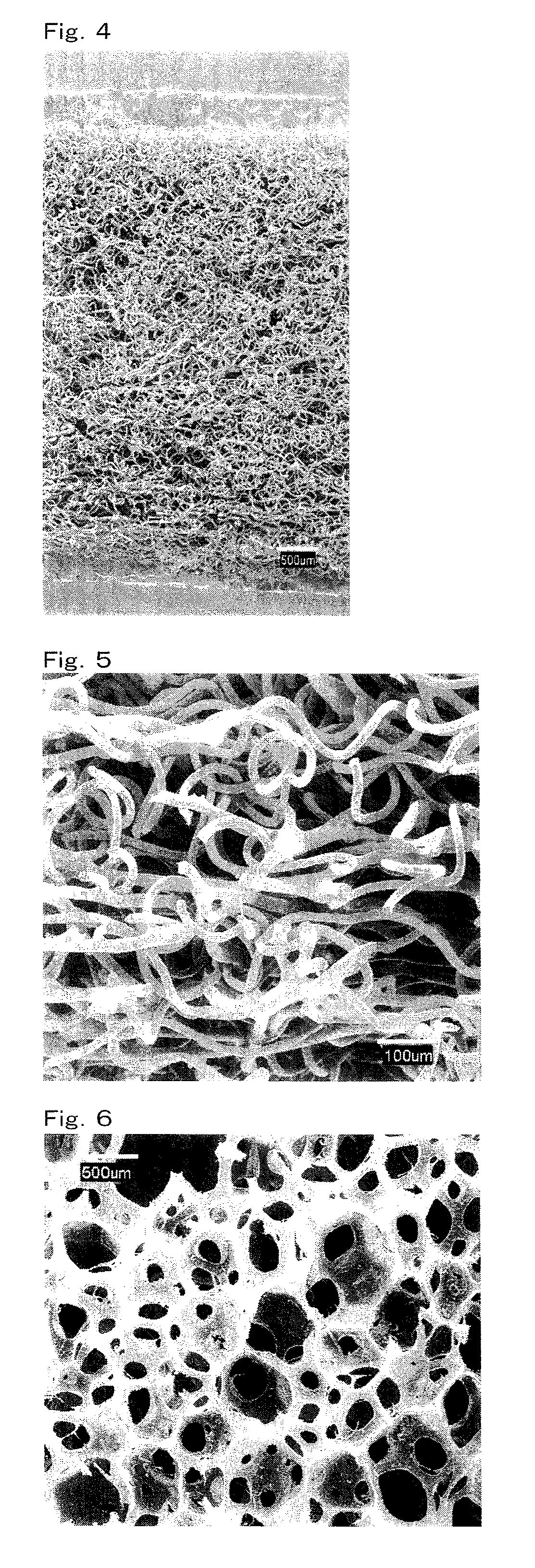

Cushioning net structures comprise random loops, such as three-dimensional random loops, bonded with one another, wherein the loops are formed by allowing continuous fibers, made of ethylene / α-olefin interpolymers, to bend to come in contact with one another in a molten state and to be heat-bonded at most contact points. The structures provided herein have desirable heat resistance, durability and cushioning property. The cushioning structures are used in furniture, vehicle seats etc.

Owner:DOW GLOBAL TECH LLC

Nonwovens having reduced poisson ratio

InactiveUS20050142331A1Reduces Poisson ratioNegative Poisson ratioNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringNonwoven fabric

Owner:KIMBERLY-CLARK WORLDWIDE INC

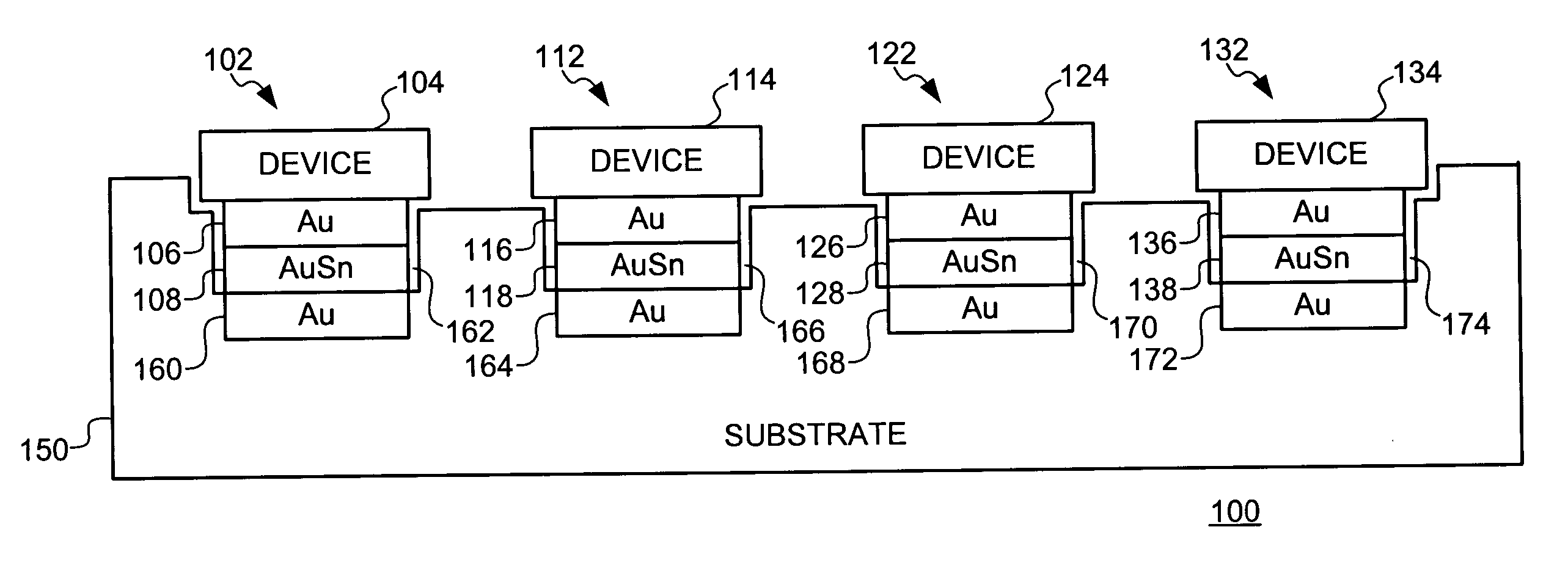

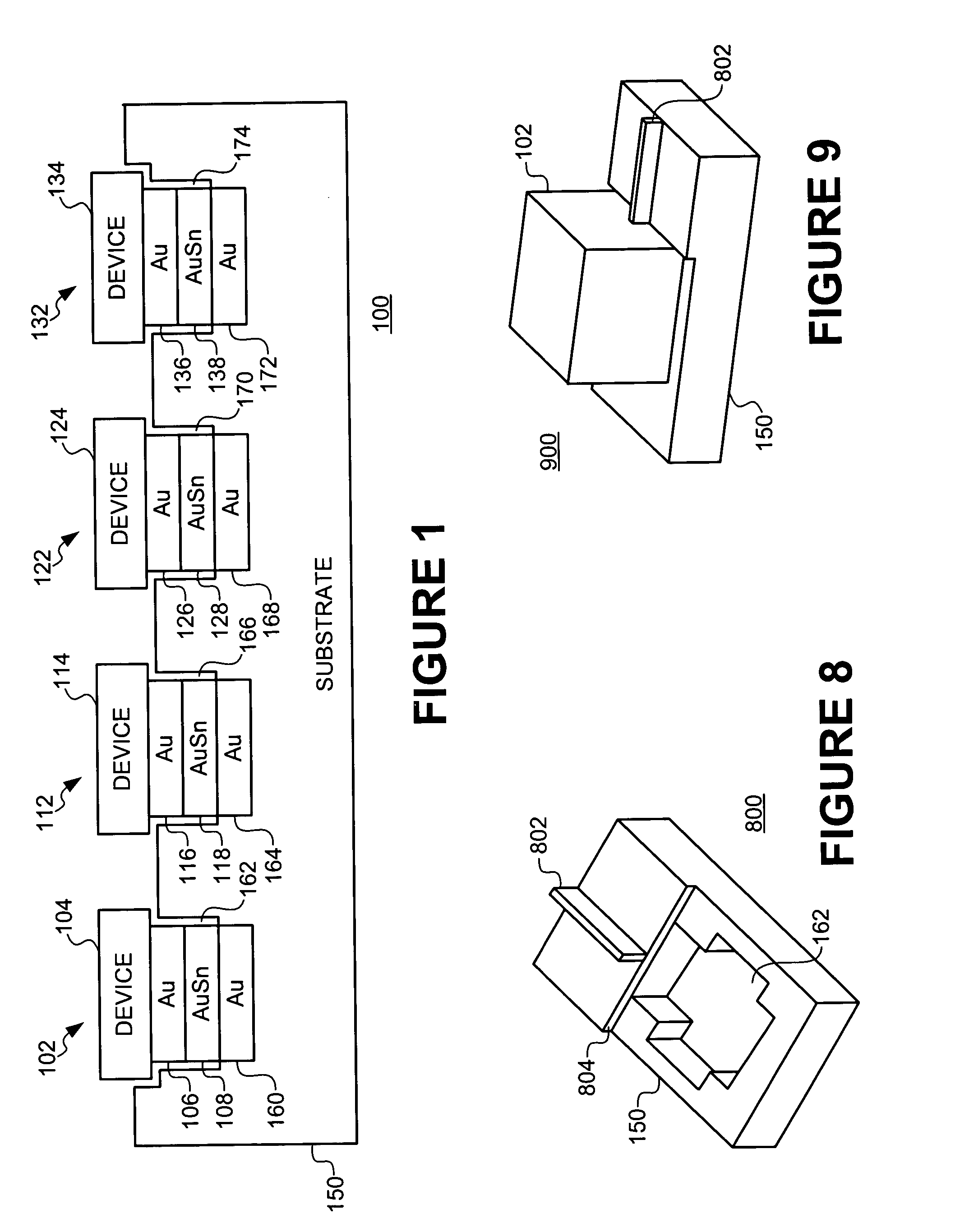

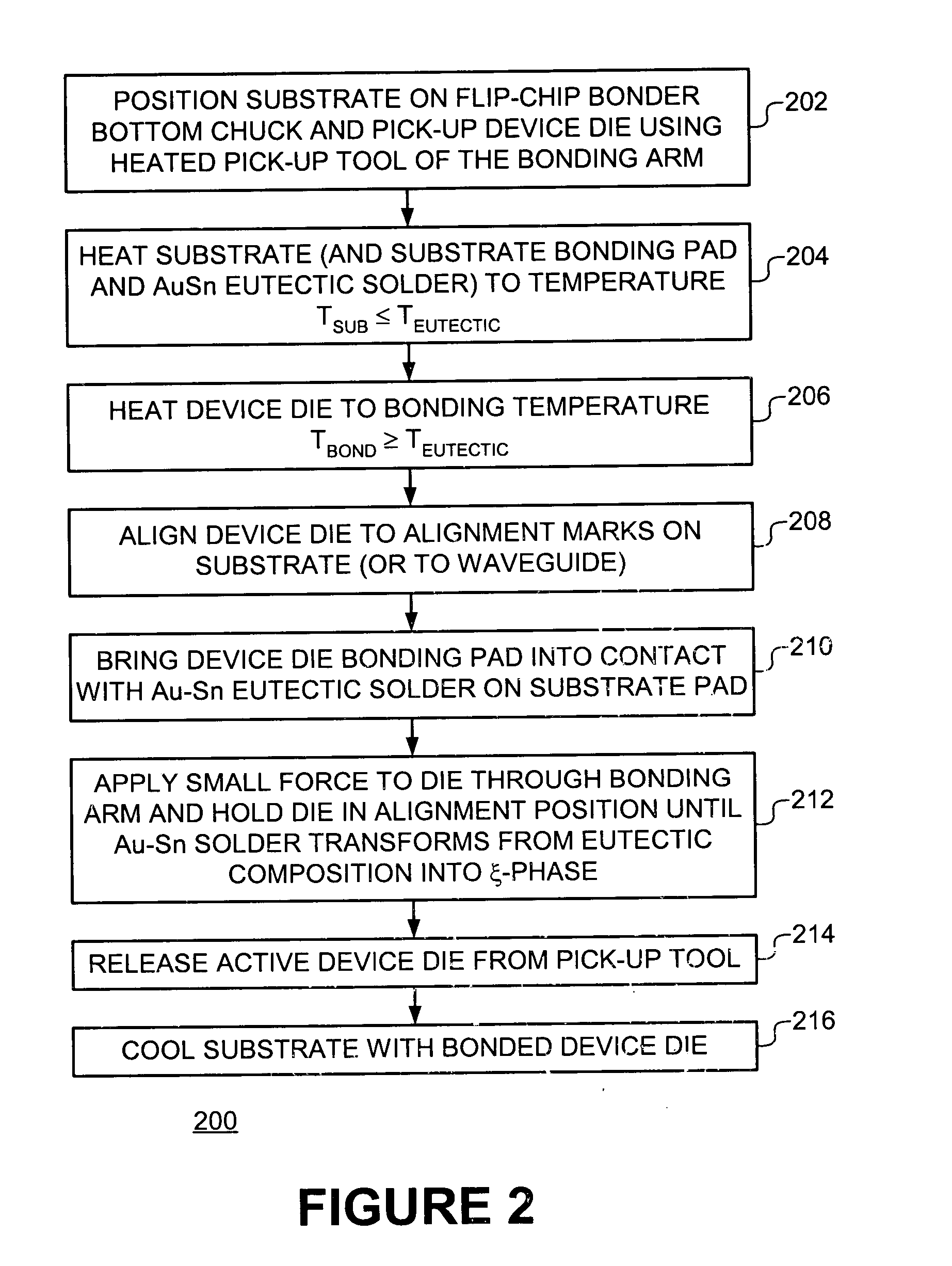

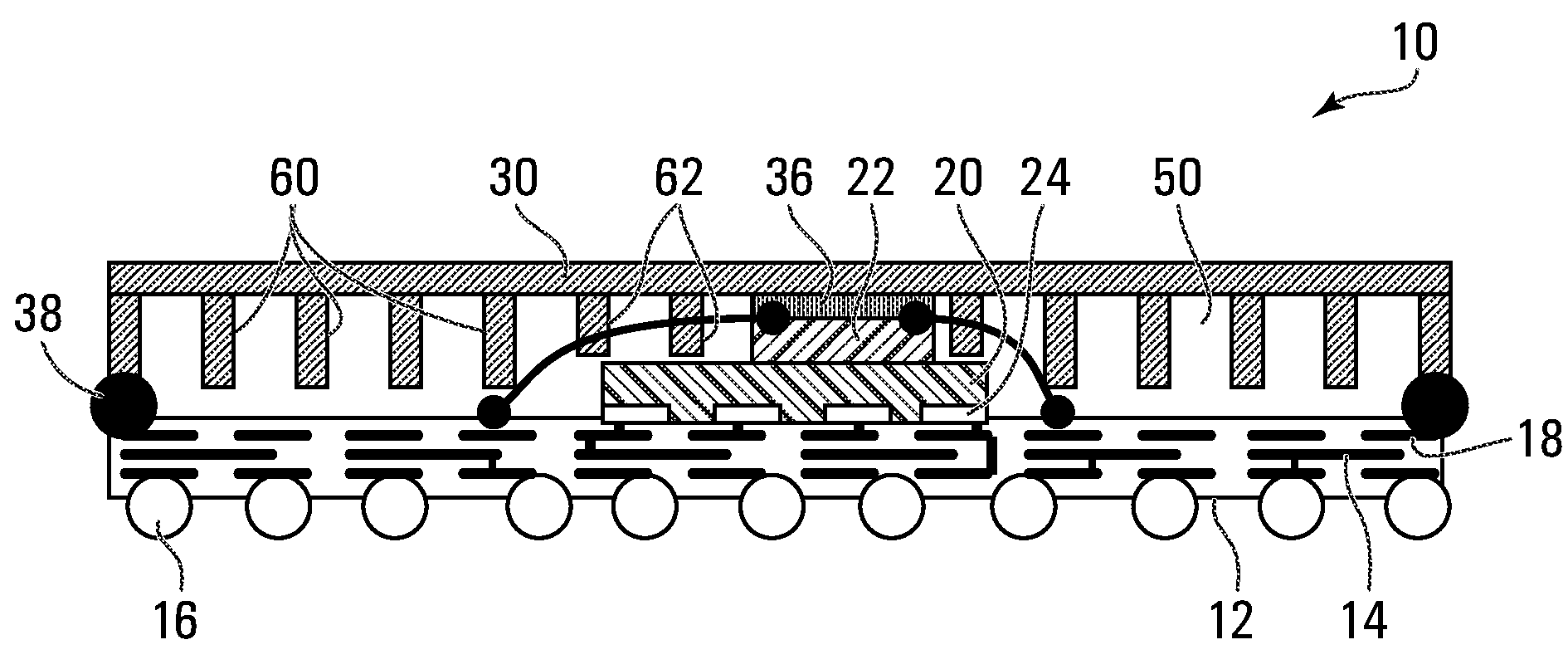

Packaging of multiple active optical devices

InactiveUS20040029304A1Printed circuit assemblingSemiconductor/solid-state device manufacturingEngineeringElectron

A cost effective method is provided for assembly of hybrid optoelectronic circuits requiring flip-chip bonding of multiple active optoelectronic devices onto common substrate or optical bench platform with fine pitch and high accuracy "after-bonding" alignment to the alignment features on substrate and / or to other elements of the hybrid circuit. A Flip-Chip Bonder equipped with high precision Bonding Arm and optical and mechanical system, heated substrate chuck and heated pick-up tool may be used both for alignment and thermal bonding of active component dies to corresponding bonding pads on the common substrate using gold-tin (Au-Sn) solder disposed between die bonding pad and the corresponding substrate bonding pad. During bonding of the first die, tin (Sn) diffuses from a eutectic composition of gold-tin (Au-Sn) solder to (gold (Au) on) the die-bonding pad and / or (gold (Au) on) the substrate bonding-pad resulting in transformation of the Au-Sn eutectic composition to a zeta-phase composition having much higher melting temperature as compared to that of a eutectic composition. As bonding of one or more subsequent dies is performed at temperatures equal to or slightly higher than the melting temperature of a eutectic composition and significantly lower than the melting temperature of a zeta-phase composition, the gold-tin (Au-Sn) solder at the bond of previously attached die does not melt and, consequently, the alignment is not compromised.

Owner:INTEL CORP

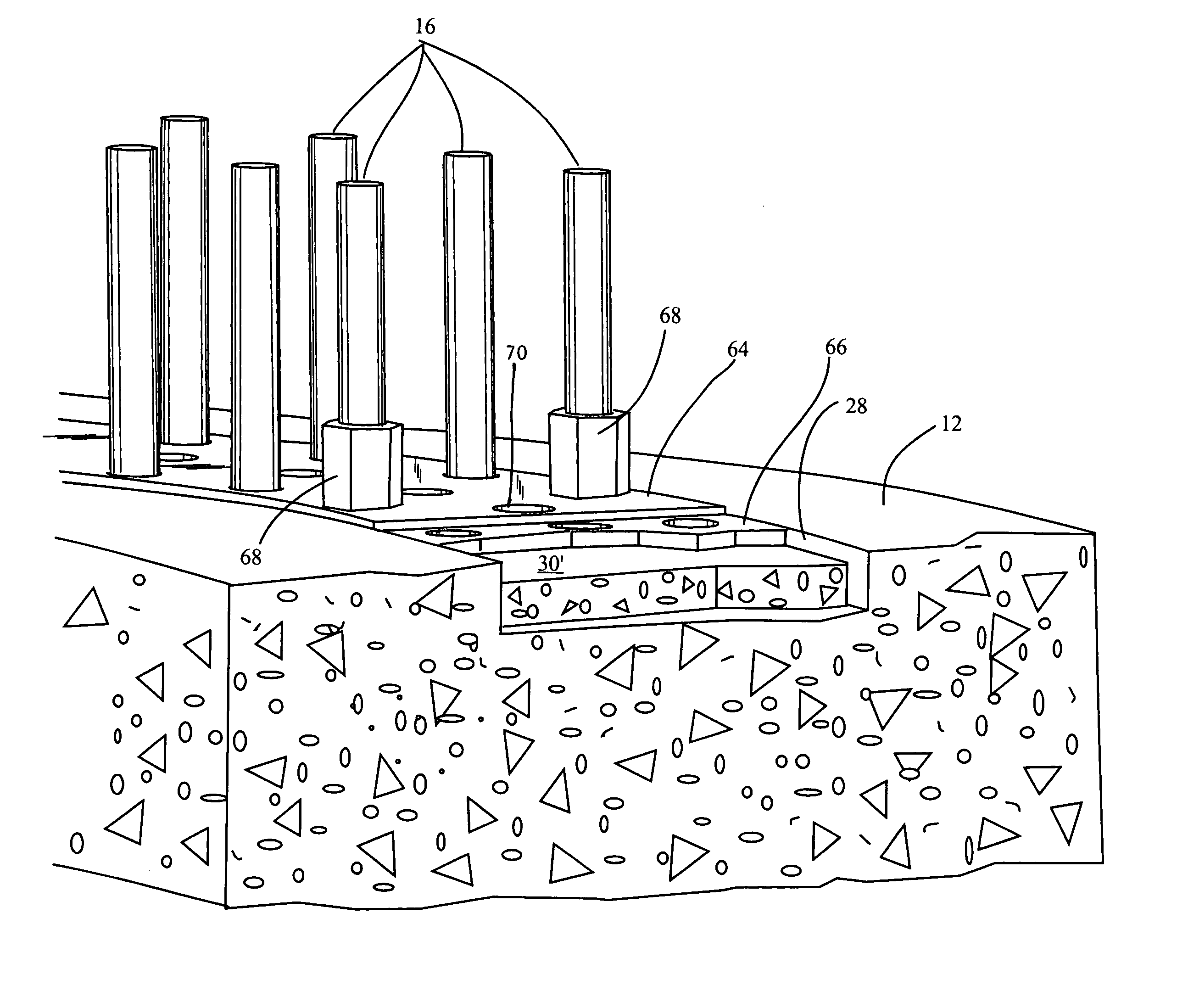

Wind turbine installation comprising an apparatus for protection of anchor bolts and method of installation

InactiveUS20090044482A1Preventing greatly limiting axial migrationAvoid stickingBuilding repairsWind motor supports/mountsEngineeringTower

An apparatus for use in providing a level grout surface for placement of a wind turbine tower flange, the apparatus comprising a template member levelly suspended on the anchor bolts above the grout trough, wherein the template member comprises a surface to which grout will not adhere. The template member can comprise an upper layer and a lower grout engagement layer, wherein the grout engagement layer comprises a surface to which grout will not adhere. The upper layer can comprise a metallic layer, and the lower layer can comprise a plastic layer, wherein the upper layer and the lower layer are bonded together. The lower layer can comprise polypropylene. The means of bonding are selected from the group consisting of mechanical bonding, thermal bonding and chemical bonding. The grout can comprise an epoxy grout. The template member can be suspended through the use of magnetic nuts or the use of a rotating sleeve. The template member can comprise a plurality of sections, and can comprise a circular form.

Owner:TOOMAN NORMAN L

Nonwoven wipe with resilient wet thickness

InactiveUS20040137200A1Without increasing dry basis weightWood working apparatusCleaning machinesWet wipeEngineering

Nonwoven substrates suitable for use as wet wipes are disclosed. The nonwoven substrates comprise at least one first region and at least one second region. The second region comprises reinforced protruding elements. In a preferred embodiment, the second region of the nonwoven substrate is reinforced by means of thermal bonding during the creation of the protruding elements of the second region. A liquid can be added to the nonwoven substrate prior to packaging or prior to use to make wet wipes. The reinforced second regions of the nonwoven substrates of the present invention make it possible to retain thickness of the wipe when wet without increasing the dry basis.

Owner:THE PROCTER & GAMBLE COMPANY

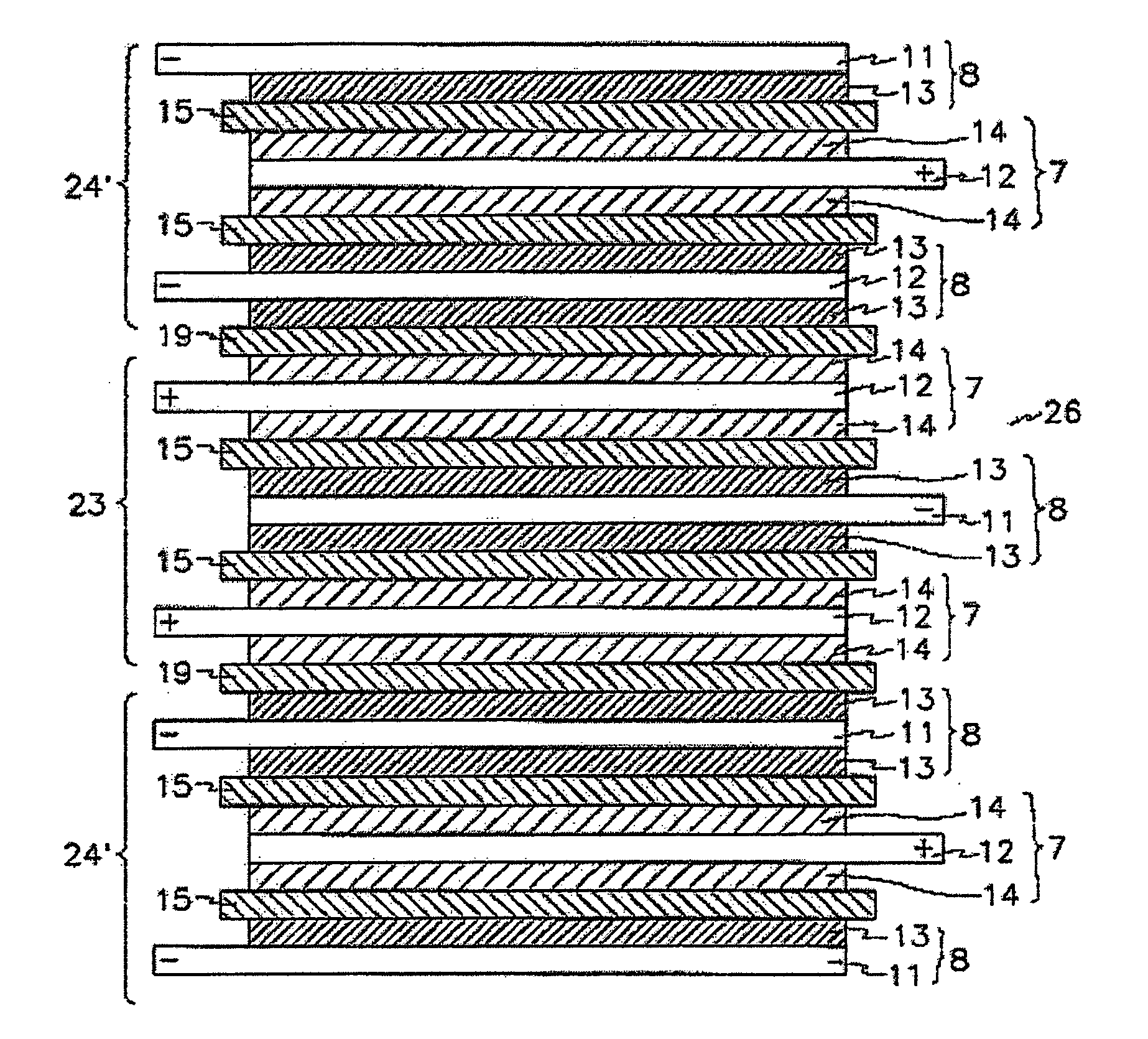

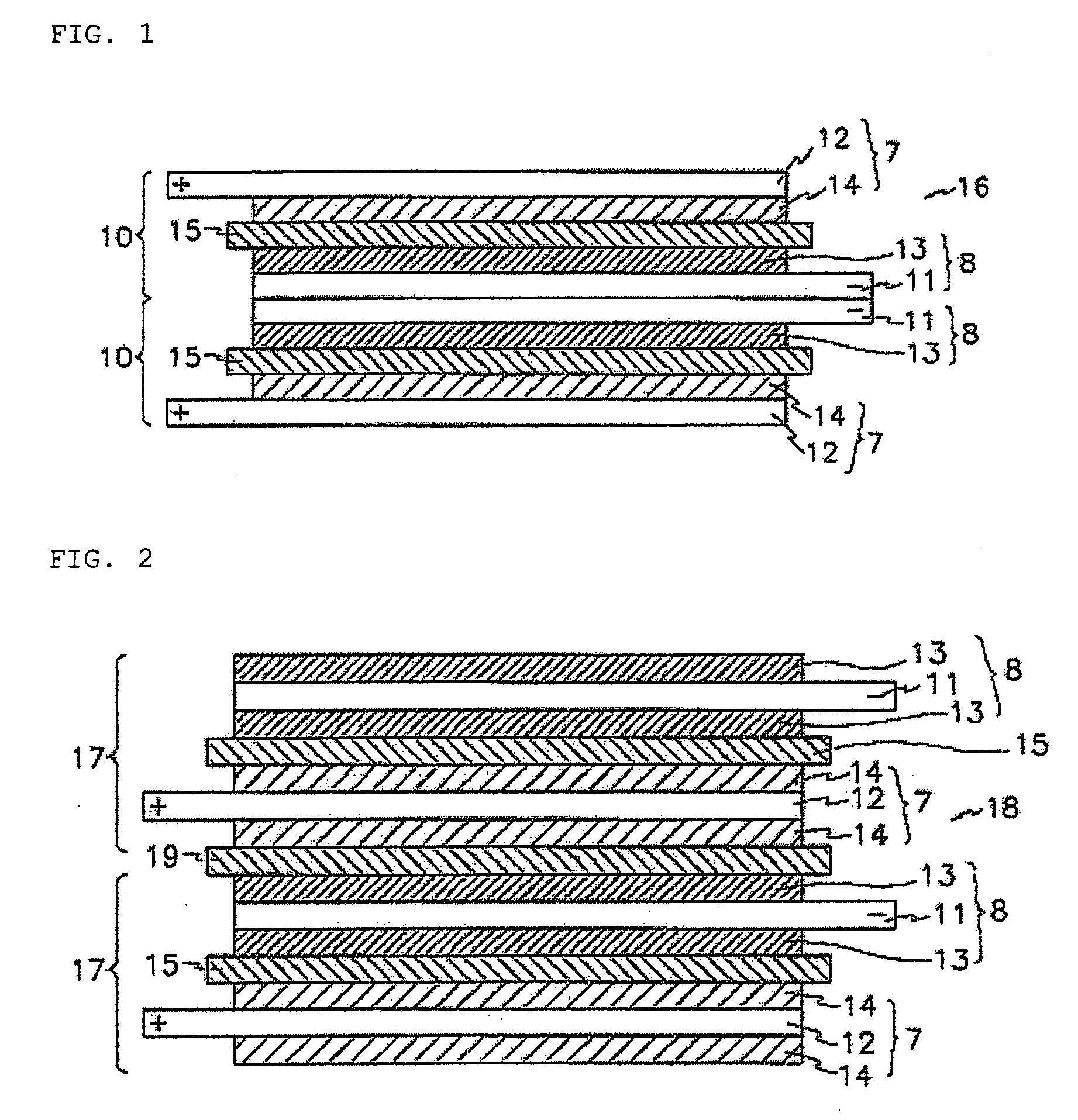

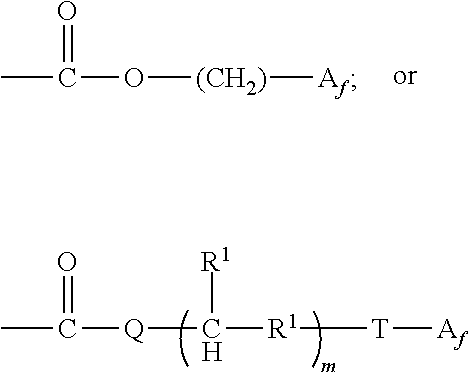

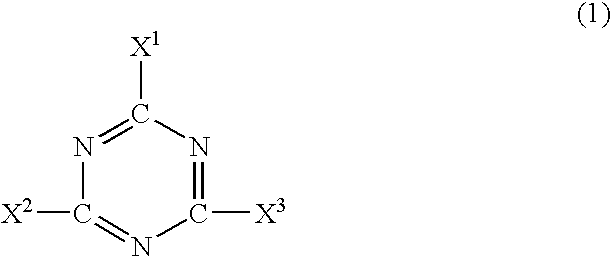

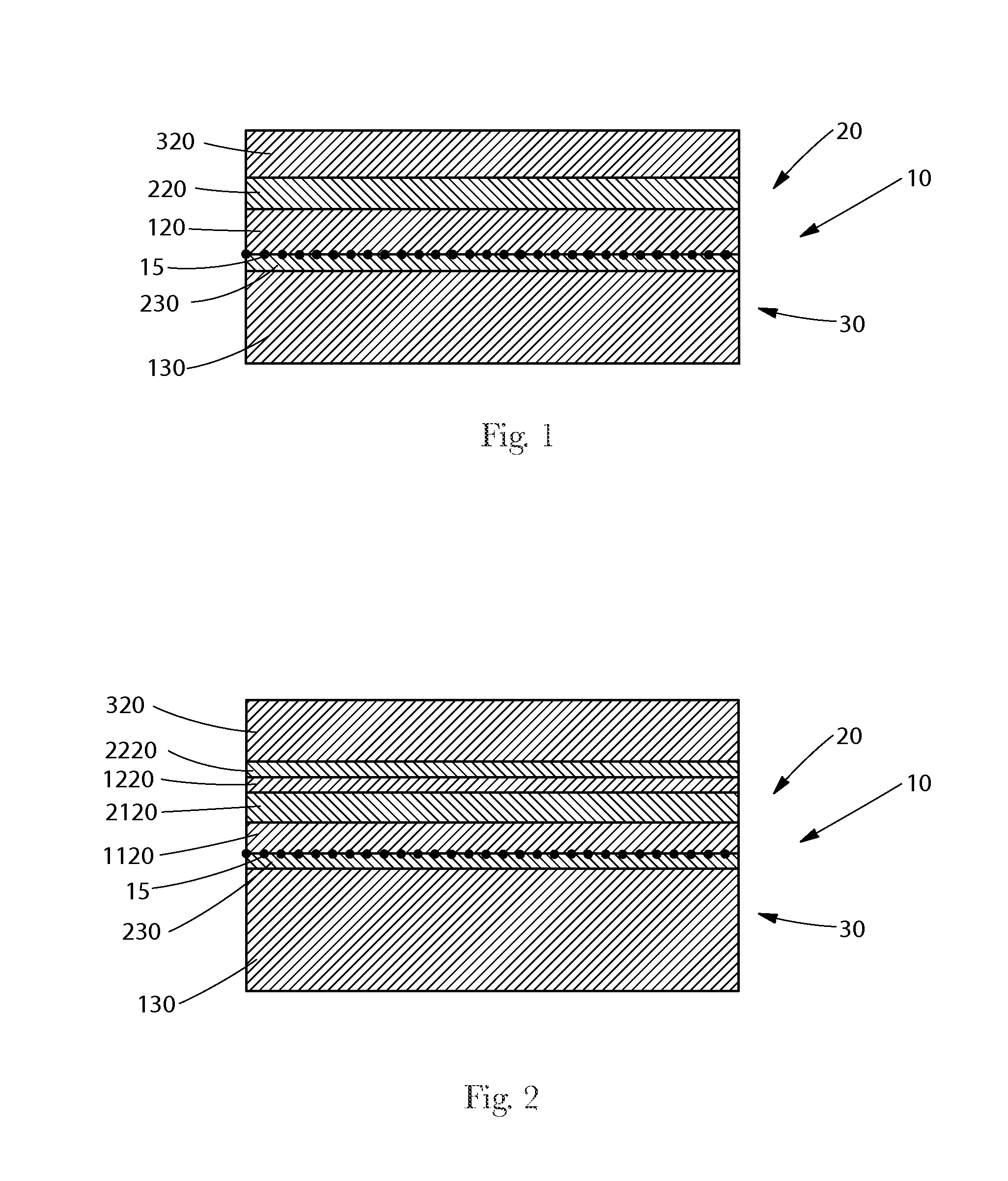

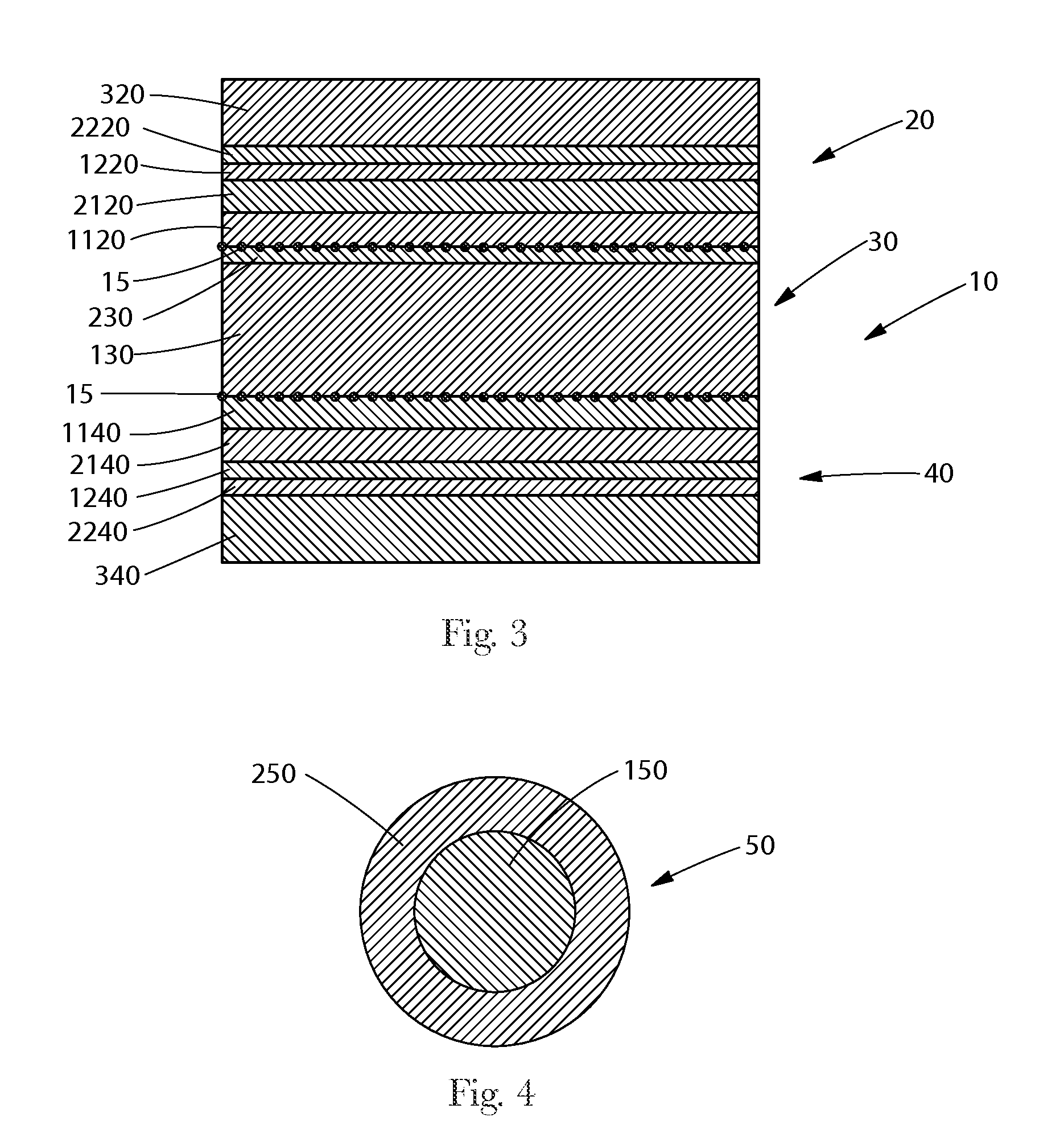

Polymer binder for electrochemical device comprising multiply stacked electrochemical cells

ActiveUS20060275661A1Increase in bulk energy densityHighly-integratedLarge-sized flat cells/batteriesFinal product manufactureMethacrylateMeth-

Disclosed is an electrochemical device, which comprises: (A) a binder comprising polymer particles obtained from the polymerization of: (a) 20-70 parts by weight of a (meth)acrylic acid ester monomer; (b) 20-60 parts by weight of a vinyl monomer; and (c) 0.01-30 parts by weight of an unsaturated carboxylic acid monomer, based on 100 parts by weight of a binder polymer; and (B) electrochemical cells stacked multiply by using the binder, wherein the binder allows electrode active material particles in an electrode to be fixed and interconnected among themselves and between the electrode active material and a collector, and the electrode and a separator that is in contact with the electrode are bonded to each other by way of hot fusion. The binder is also disclosed. The binder has excellent adhesion and thermal bonding characteristics, and thus is useful for an electrochemical device comprising multiply stacked electrochemical cells, and can improve the overall quality of a battery.

Owner:LG CHEM LTD

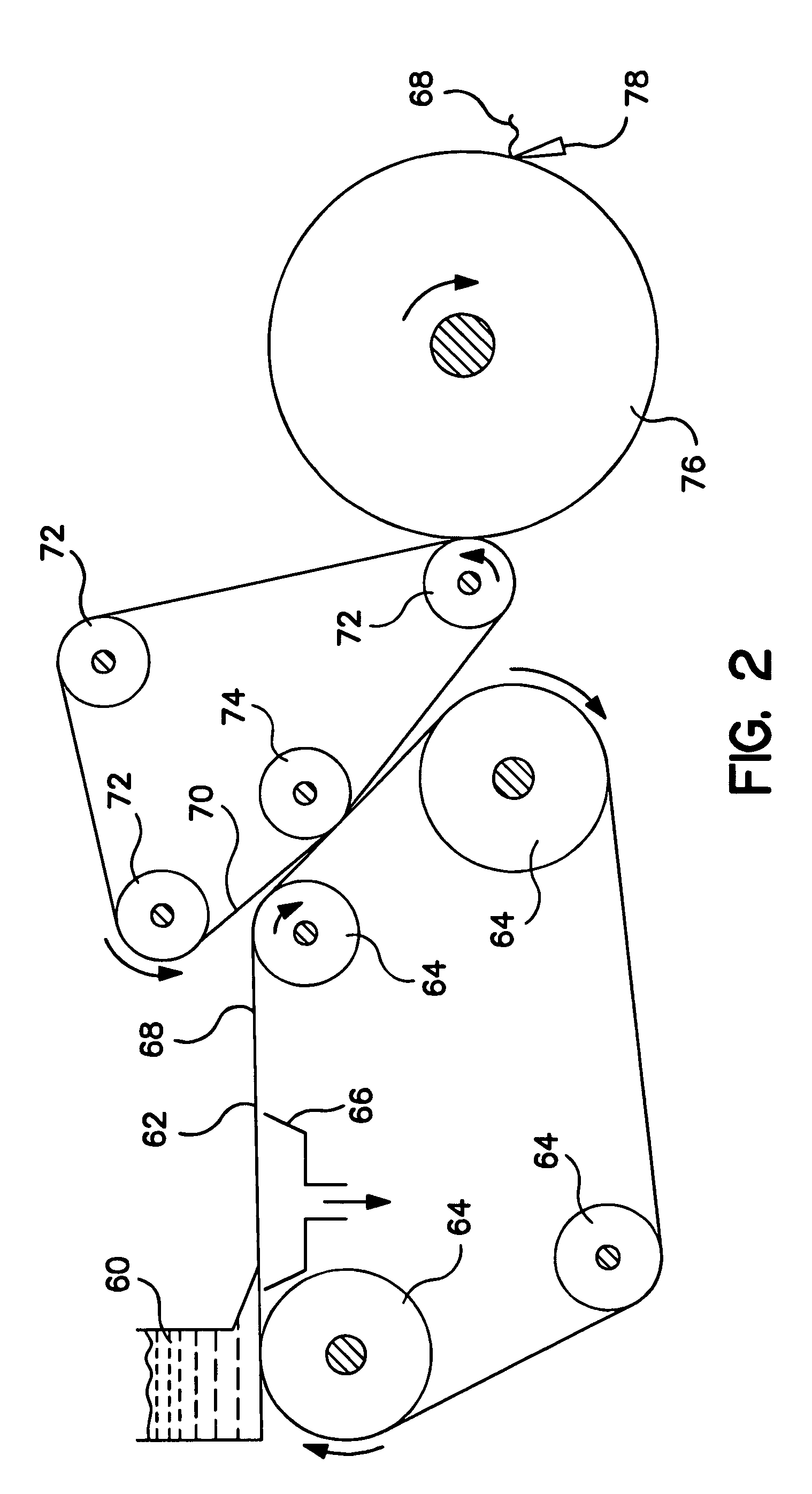

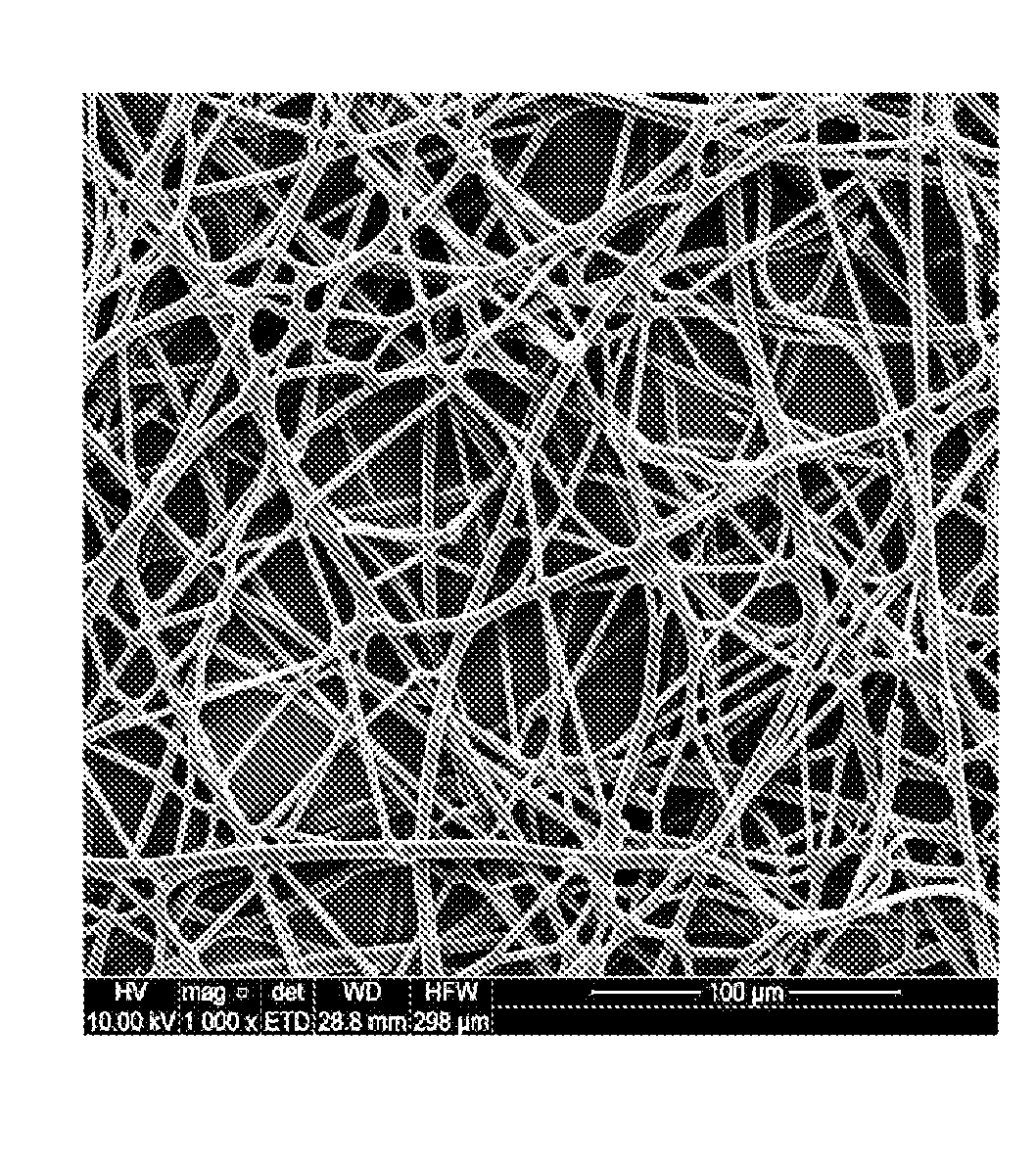

Hydroentangled nonwoven material

ActiveUS20050112980A1Improved textile feelingReduced twosidednessWoven fabricsWood layered productsPolyesterPolymer science

An improved hydroentangled well integrated composite nonwoven material, including a mixture of continuous filaments, synthetic staple fibres, and natural fibres which has a reduced twosidedness and an improved textile feeling. The synthetic staple fibres should have a length of 3 to 7 mm, and preferably there should be no thermal bondings between the filaments. The method of producing such a nonwoven material is also disclosed. The nonwoven includes a mixture of 10-50 w-% continuous filaments preferably chosen from polypropylene, polyesters and polylactides, 5-50 w-% synthetic staple fibres chosen from polyethylene, polypropylene, polyesters, polyamides, polylactides, rayon, and lyocell, and 20-85 w-% natural fibres, preferably pulp.

Owner:ESSITY HYGIENE & HEALTH AB

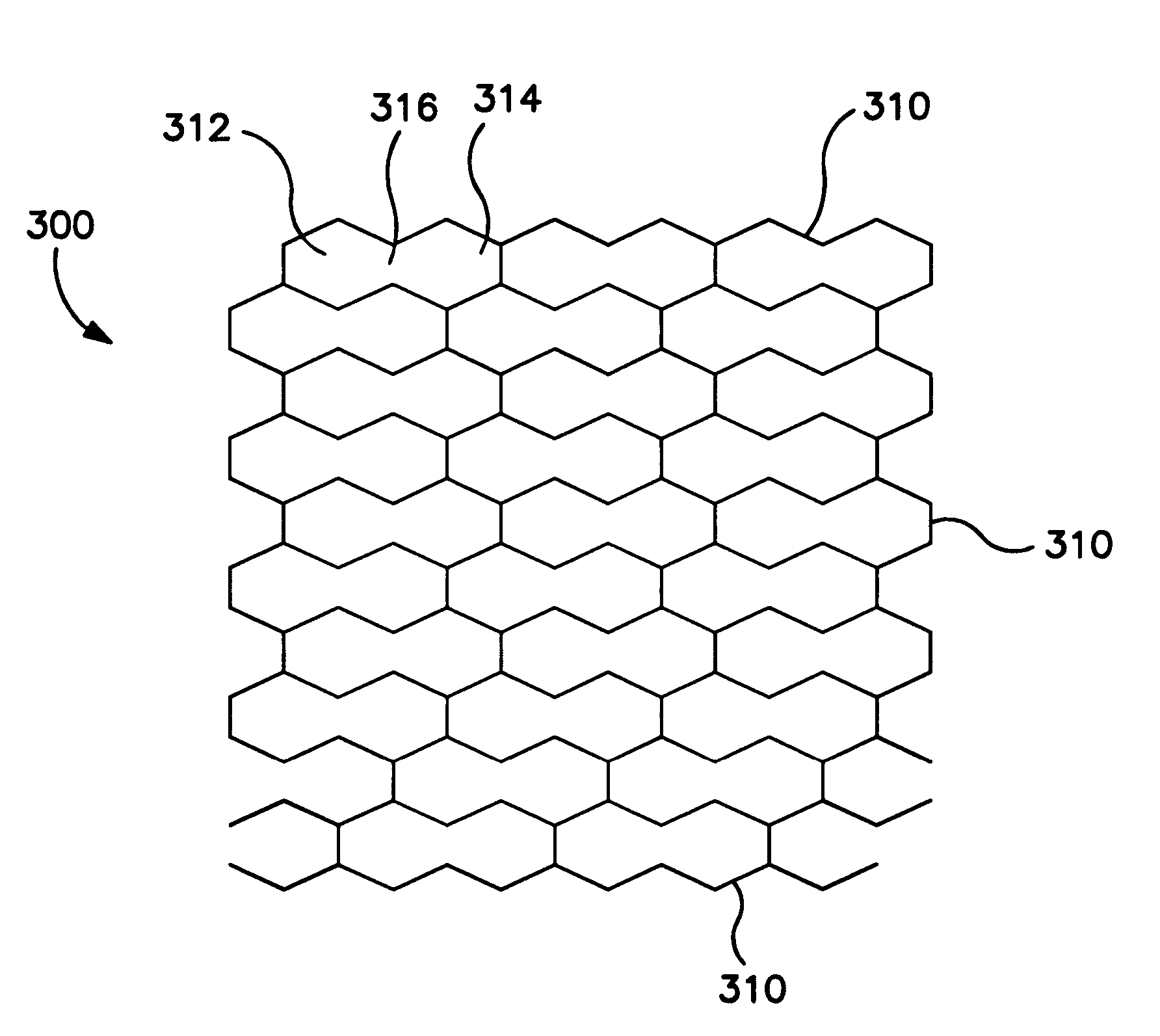

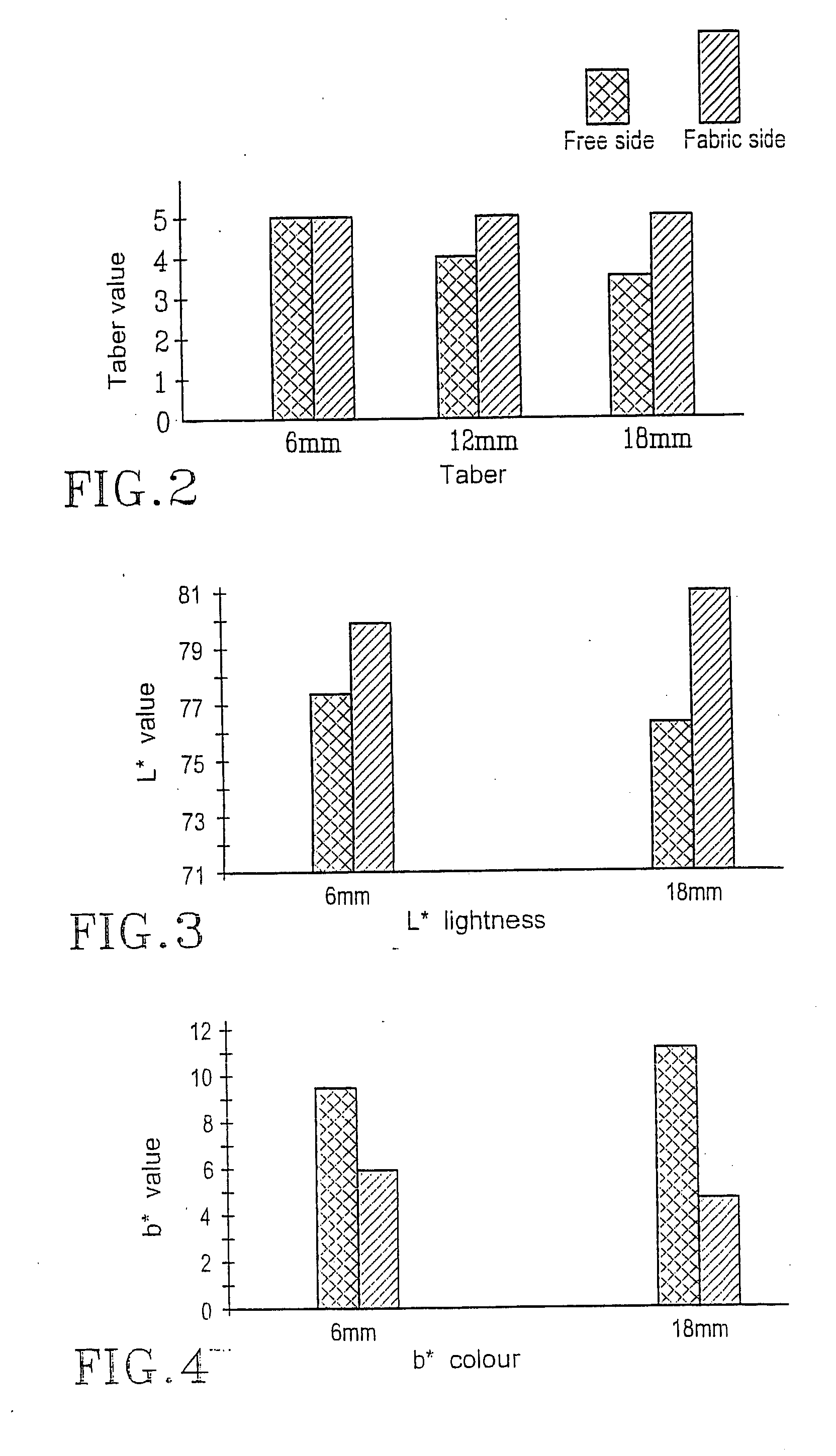

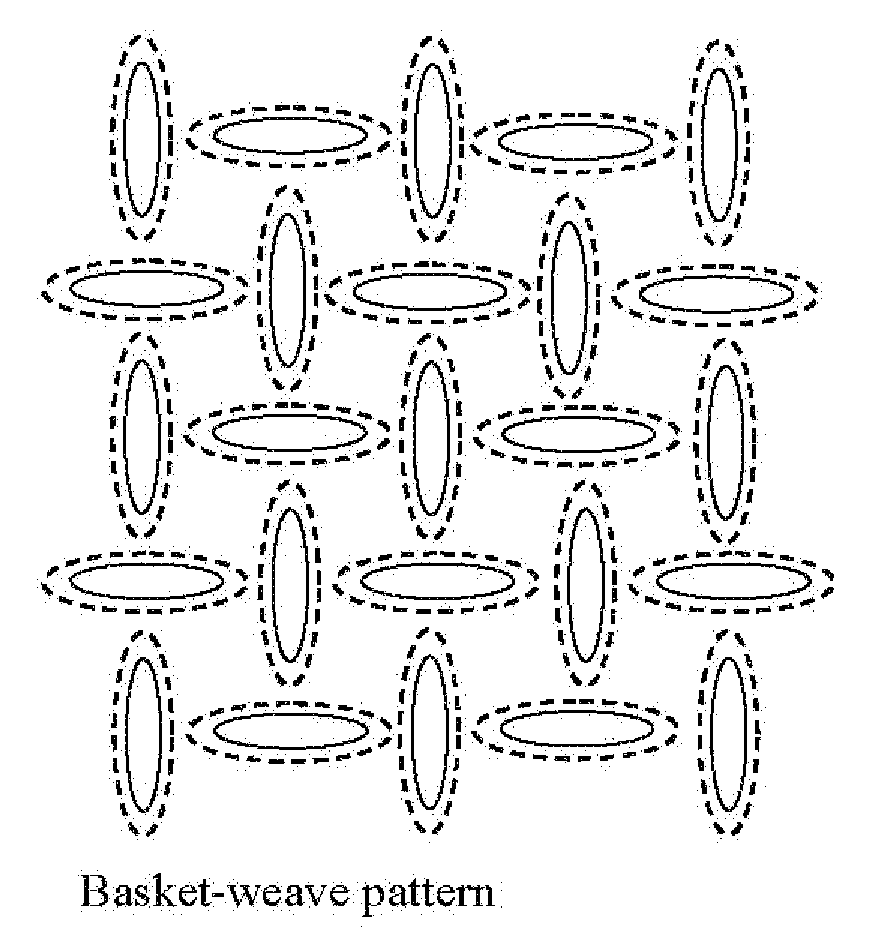

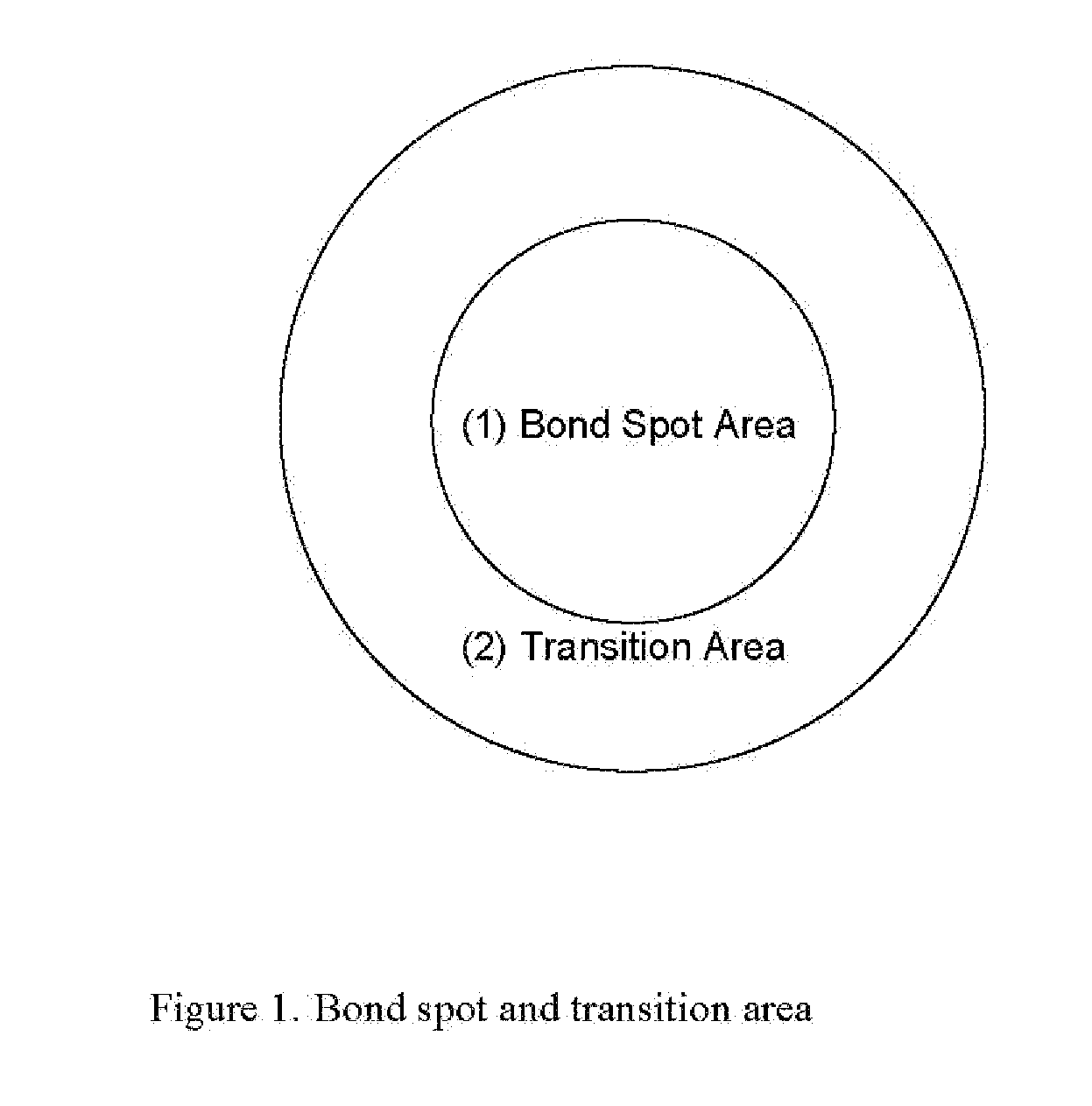

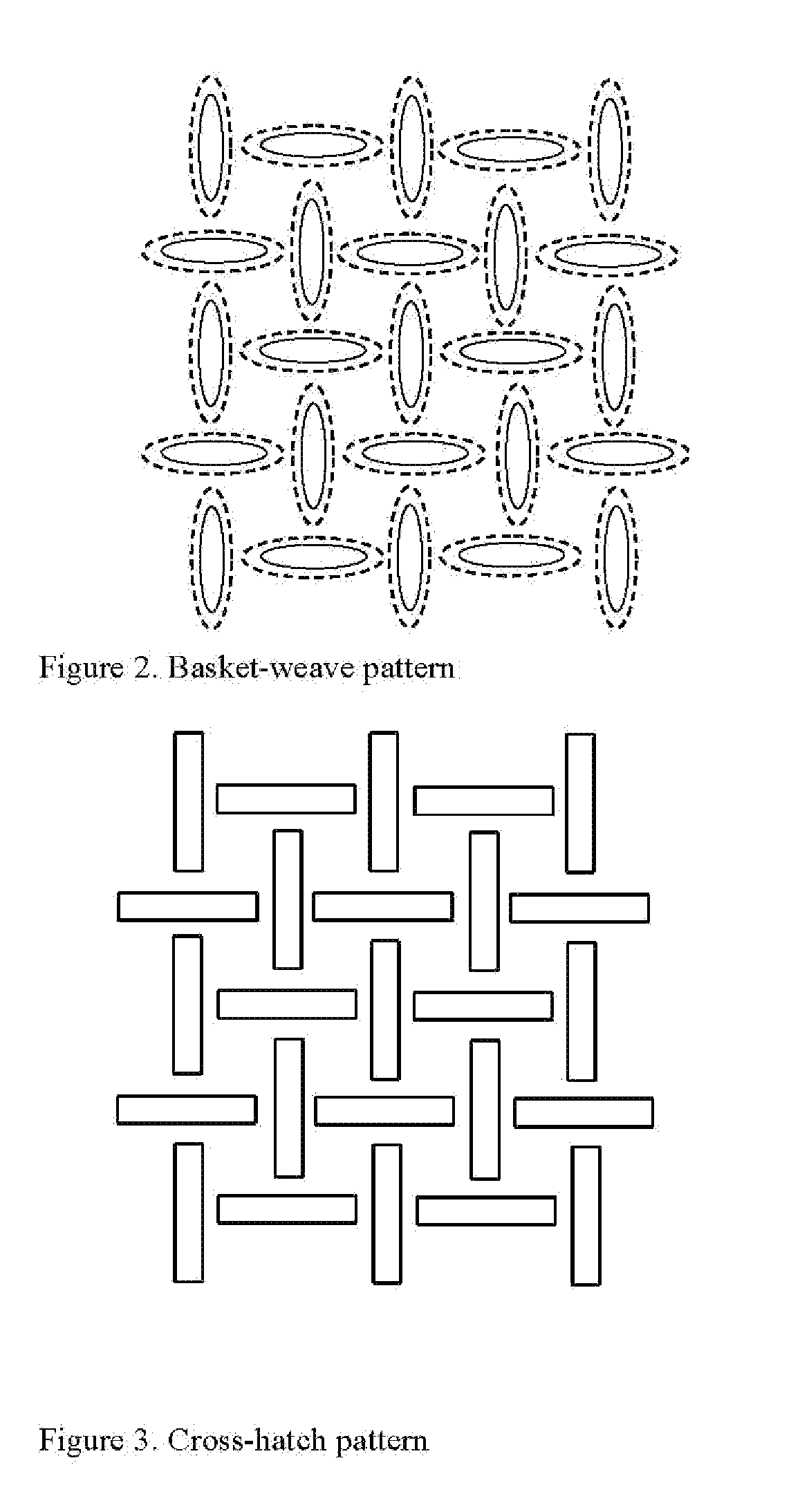

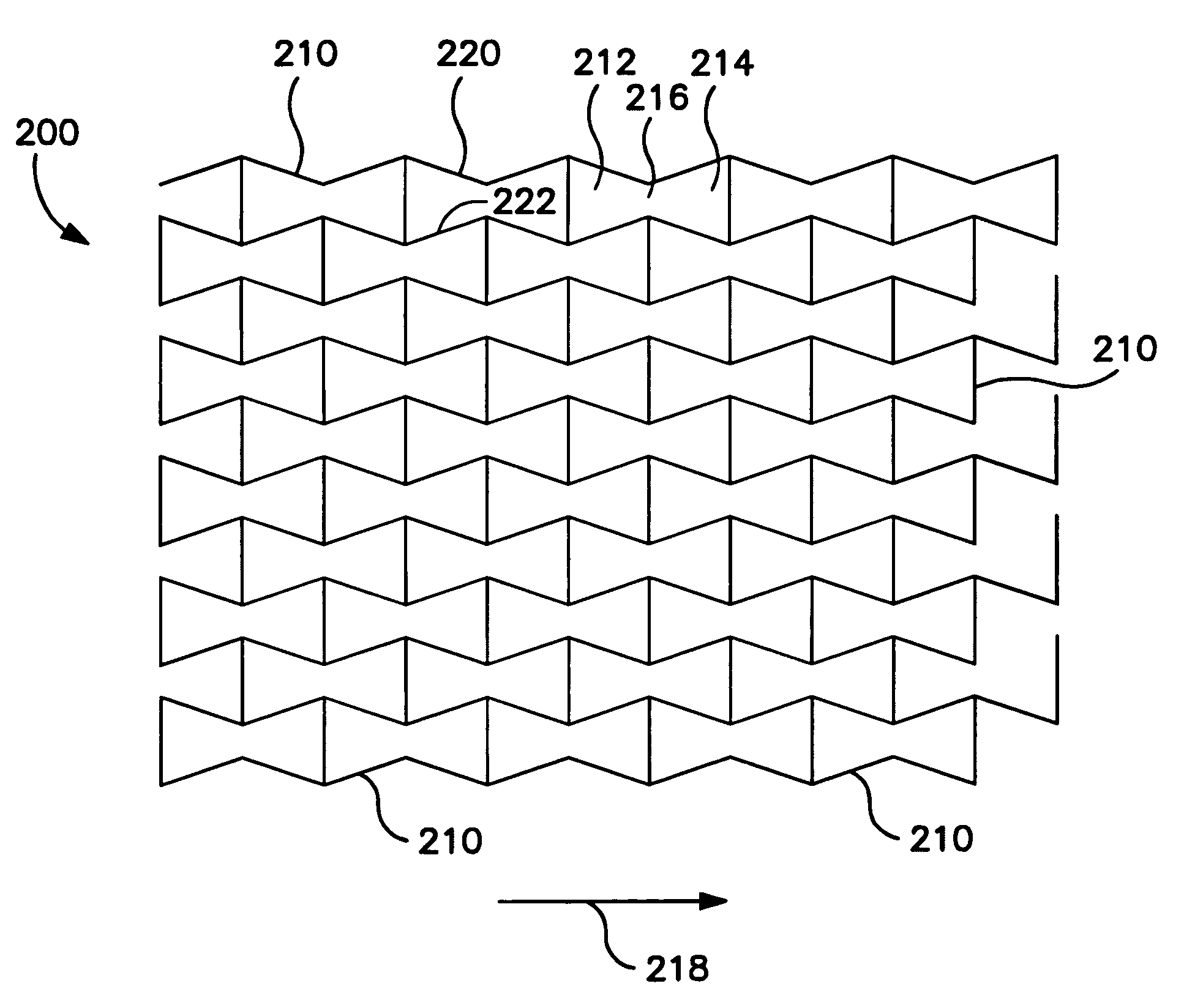

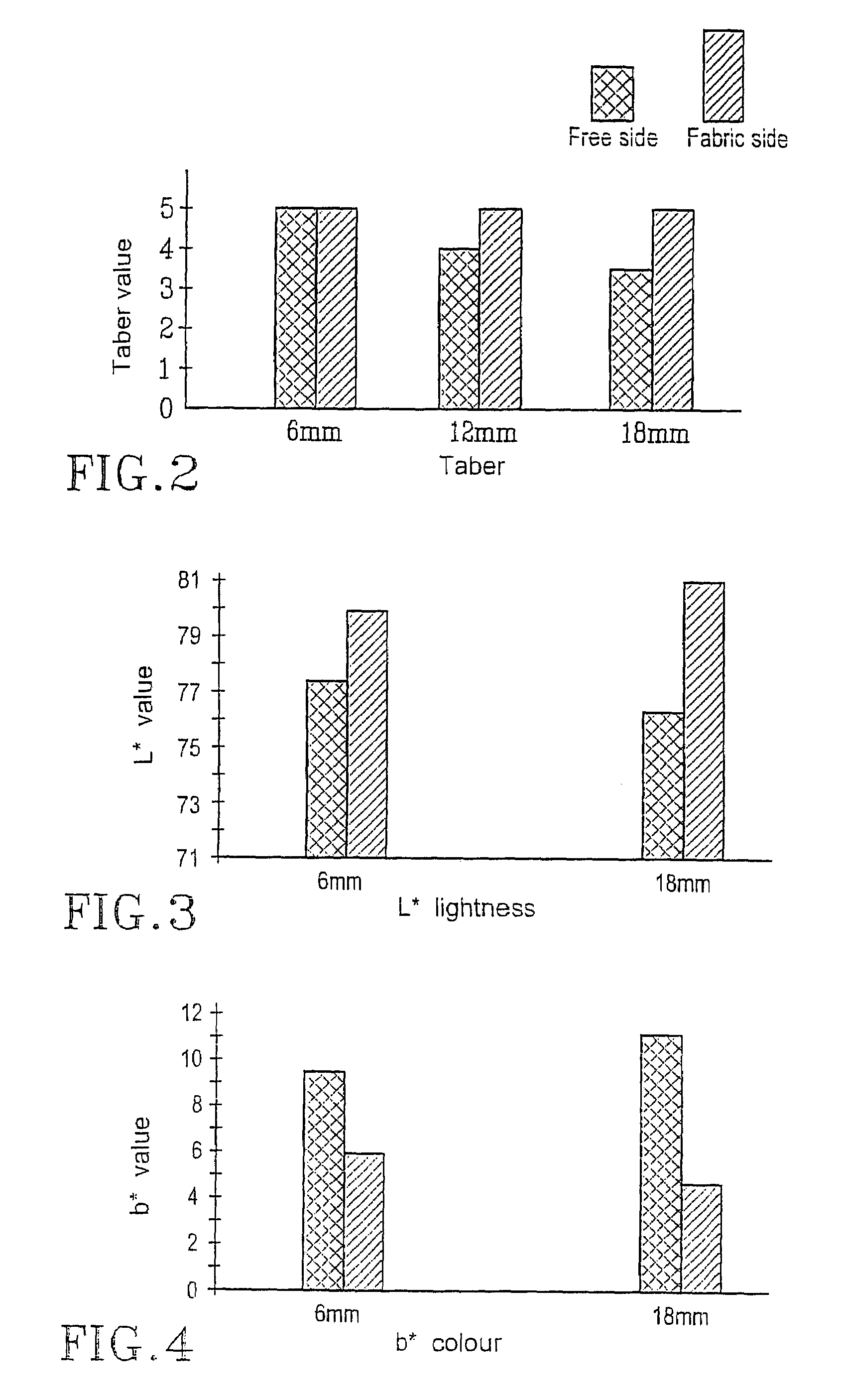

Nonwoven bonding patterns producing fabrics with improved abrasion resistance and softness

ActiveUS20080268194A1Excellent abrasion resistanceHigh strengthStampsWrappersEngineeringNonwoven fabric

A thermal bonding pattern for nonwoven fabric possessing improved abrasion resistance while retaining softness, comprising a basket-weave pattern or other pattern having a transition area (2) equal to at least 10% of bonding spot area (1) in FIG. 1, more preferably a transition area (2) equal to at least 50% of bonding spot area (1), and most preferably a transition area (2) equal to at least 100% of bonding spot area.

Owner:A AHLSTROM CORP

Nonwovens having reduced Poisson ratio

InactiveUS7252870B2Reduces Poisson ratioNegative Poisson ratioNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringThermal bonding

Nonwoven materials having a pattern incorporated into the materials are disclosed. The nonwoven materials may be, for instance, tissue webs, meltspun webs such as meltblown webs or spunbond webs, bonded carded webs, hydroentangled webs, and the like. The pattern may be incorporated into the webs using various techniques. For instance, the pattern may be formed into the web by topically applying a bonding material. In an alternative embodiment, the pattern may be formed according to a thermal bonding process. The pattern contains individual cells that include two spaced apart expanded regions separated by a constricted region. By incorporating the pattern into the web, a material is produced having a relatively low Poisson ratio.

Owner:KIMBERLY-CLARK WORLDWIDE INC

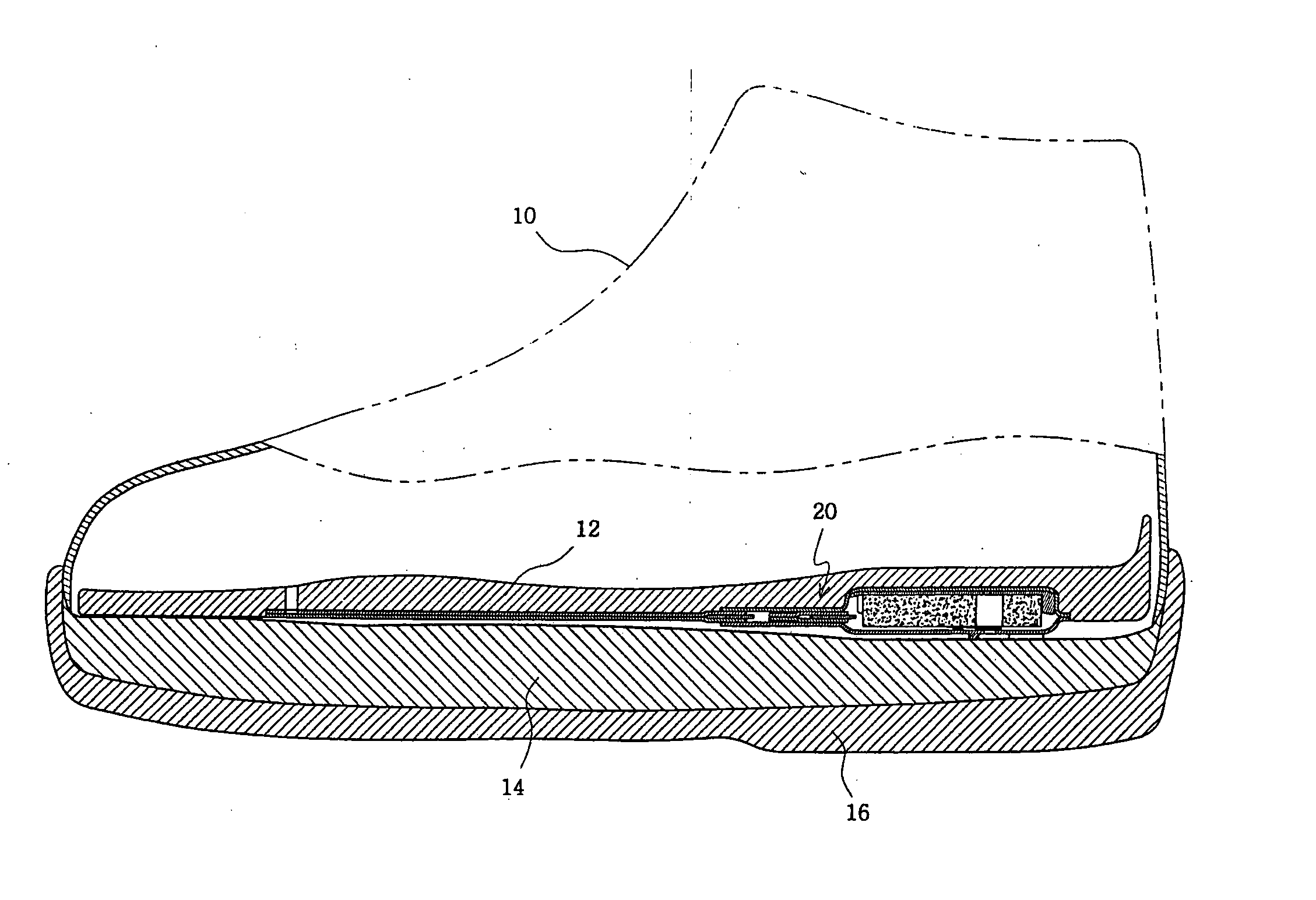

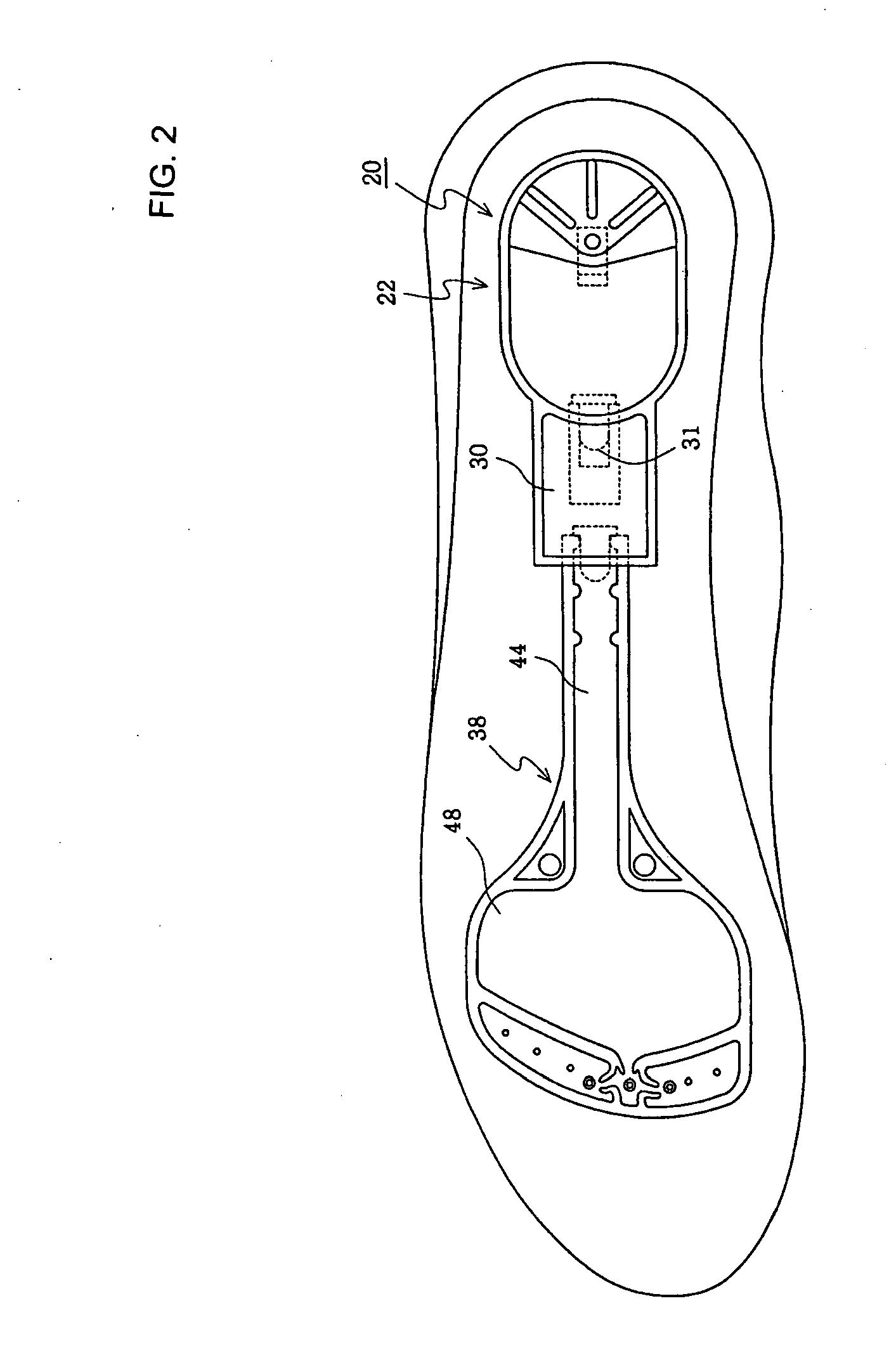

Shoe with cushion and ventilation device

Provided is a shoe with a cushion and ventilation device. The cushion and ventilation device includes an air pump having an air discharge tube provided at its one side, and an air tube having a connection pipe connecting to the air discharge tube of the air pump, and an air chamber, wherein the air pump is provided by placing an upper sheet having a cavity on a lower sheet having an intake hole, and thermally bonding circumference surfaces of the upper and lower sheets using microwave, and wherein the upper and lower sheets further comprise a sponge having contraction and restoring forces therein.

Owner:CHO JONG SOO +1

Hydroentangled nonwoven material

An improved hydroentangled well integrated composite nonwoven material, including a mixture of continuous filaments, synthetic staple fibers, and natural fibers which has a reduced twosidedness and an improved textile feeling. The synthetic staple fibers should have a length of 3 to 7 mm, and preferably there should be no thermal bondings between the filaments. The method of producing such a nonwoven material is also disclosed. The nonwoven includes a mixture of 10-50 w-% continuous filaments preferably chosen from polypropylene, polyesters and polylactides, 5-50 w-% synthetic staple fibers chosen from polyethylene, polypropylene, polyesters, polyamides, polylactides, rayon, and lyocell, and 20-85 w-% natural fibers, preferably pulp.

Owner:ESSITY HYGIENE & HEALTH AB

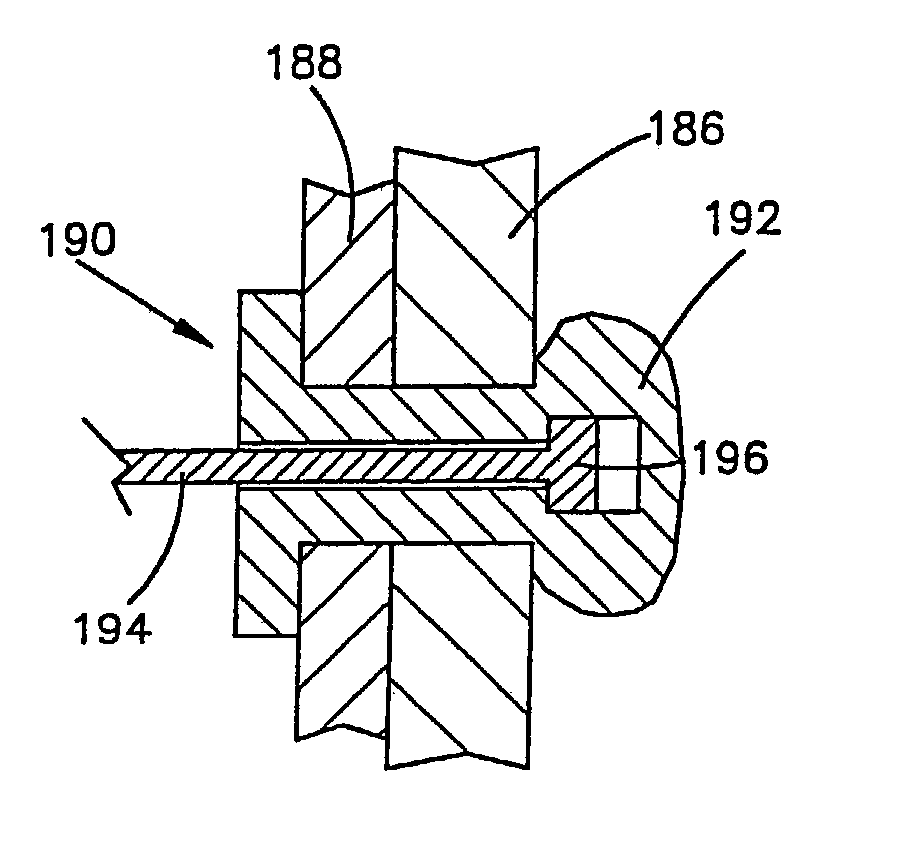

Composite surgical devices

Surgical devices such as implants or suture fastenings are assembled from a plurality of discrete components, one of which components includes a heat bondable plastic material for bonding the components together. At least two components are bonded to each other by the applying heat to the heat bondable plastic material of one component. The heat bondable plastic material is preferably a polymeric or composite material suitable for surgical applications and implantation in humans, and may be a biodegradable material. A laser may be used as the heat source. The present invention is advantageously embodied in heat bonded fastenings for sutures or K-wires, in which a variety of different suture anchors are usable, including expandable distal suture anchors. Other embodiments include a metal bone plate which is held to bone by a metal bone screw and a nut of bondable material bonded to the plate to secure the connection; a piece of bondable material bonded to a metal prosthesis to custom fit the prosthesis; and a surgical implant custom formed by bonding together a plurality of discrete elements one or more of which is bondable.

Owner:P TECH +1

High temperature treated media

ActiveUS20120234748A1Reduce and eliminate in filtrationImprove filtering effectNon-fibrous pulp additionNatural cellulose pulp/paperParticulatesFiber

A thermally bonded filtration media that can be used in high temperature conditions in the absence of any loss of fiber through thermal effects or mechanical impact on the fiber components is disclosed. The filter media can be manufactured and used in a filter unit or structure, can be placed in a stream of removable fluid, and can remove a particulate load from the mobile stream at an increased temperature range. The combination of bi-component fiber, other filter media fiber, and other filtration additives provides an improved filtration media having unique properties in high temperature, high performance applications.

Owner:DONALDSON CO INC

Fuel cell metallic separator

The invention provides a fuel cell metallic separator, wherein the metallic plate's edges include a resin portion comprising the communication ports. The resin portion around the communication ports is shaped so as to be capable of interlocking with a fuel cell stack component adjacently located in a fuel cell system. The invention also provides a resin portion capable of press fitting or thermal bonding with adjacent a fuel cell stack components.

Owner:CELLCENTRIC GMBH & CO KG +1

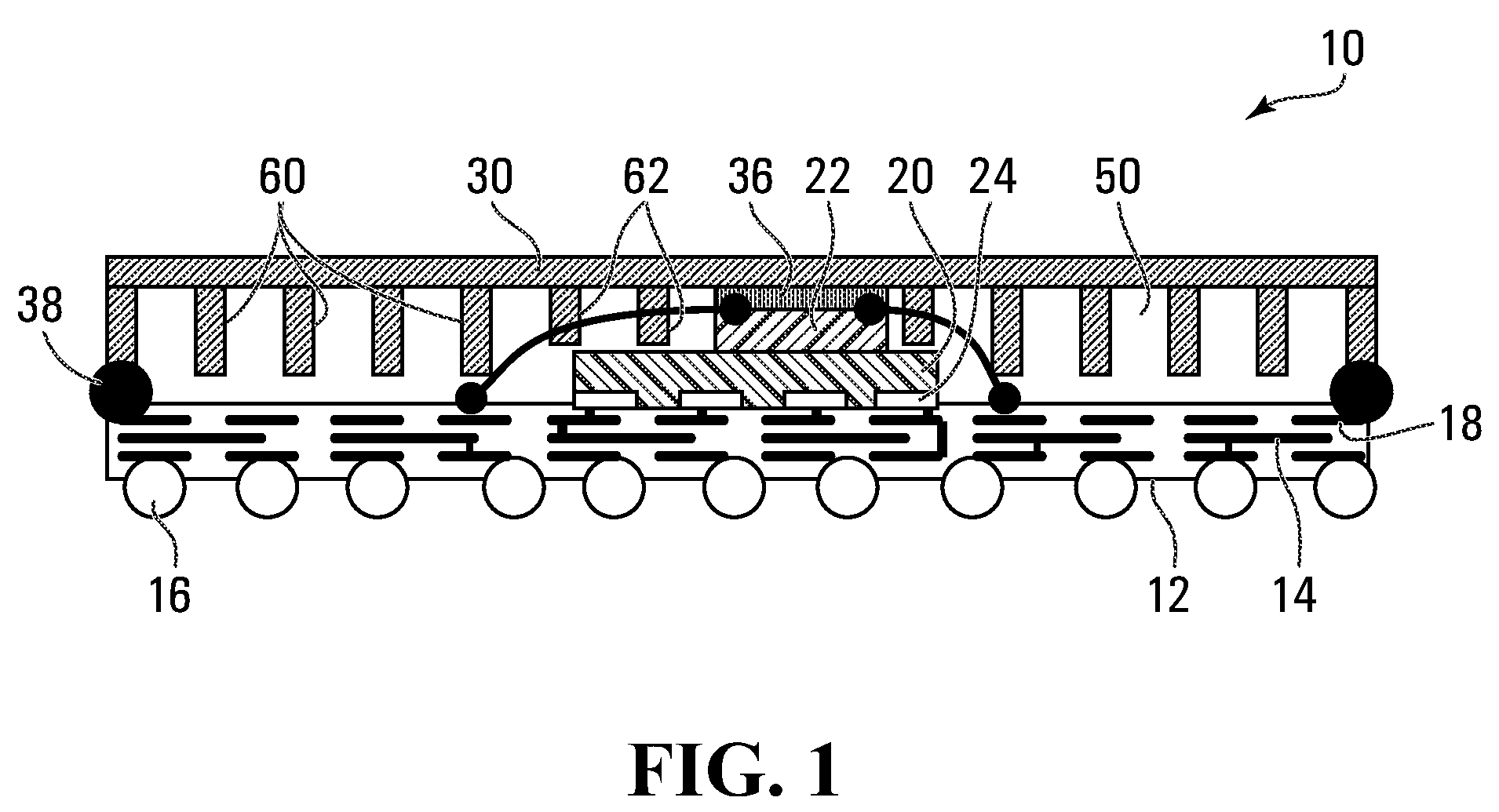

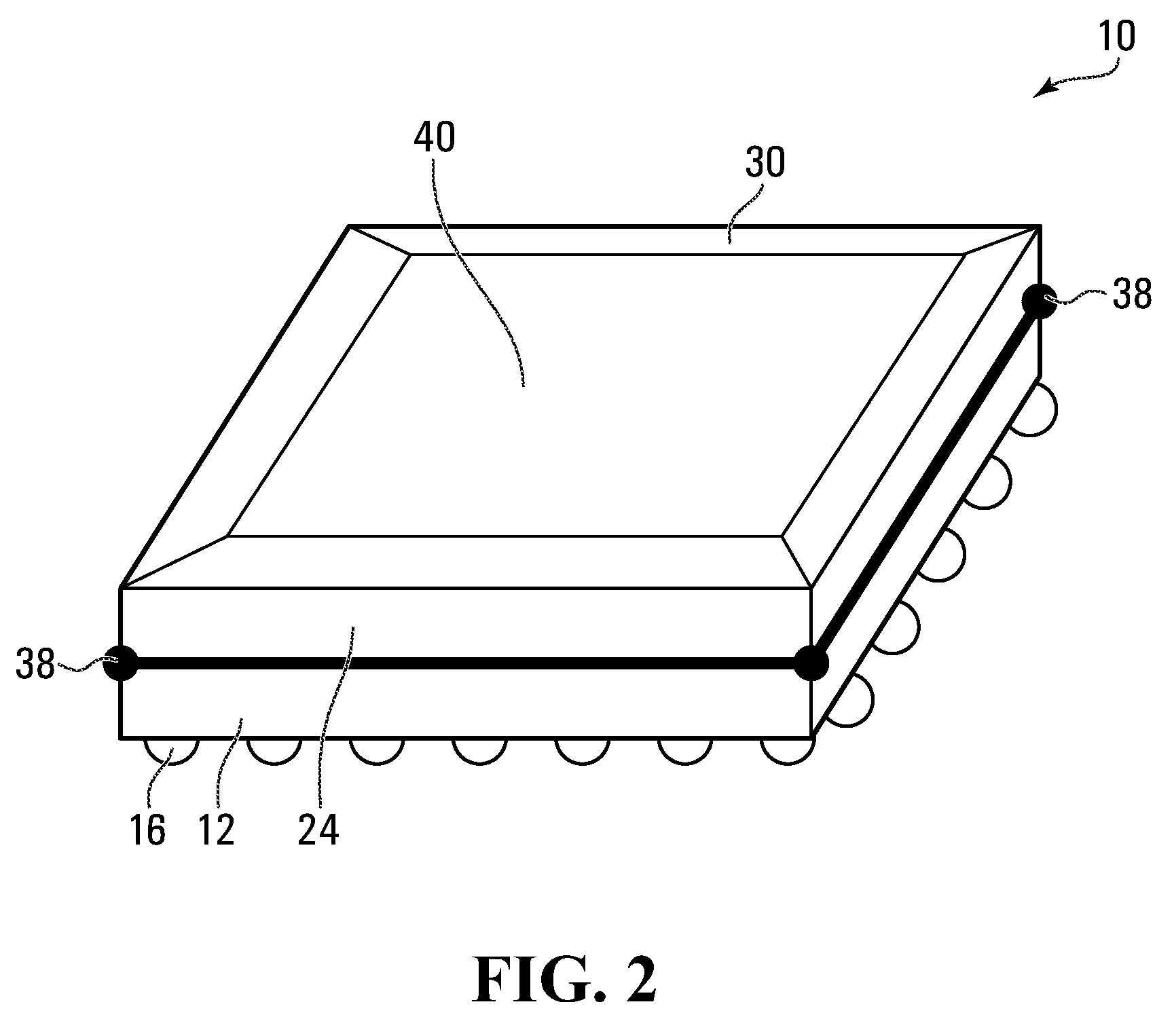

Multi-die semiconductor package with heat spreader

ActiveUS20100230805A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductor packageLiquid metal

A semiconductor device includes first and second stacked semiconductor dies on a substrate. A lid having a plurality of fins extending downwardly into the cavity is mounted on the substrate to encapsulate the semiconductor dies. At least some of the fins are longer than other ones of said fins. The lid is attached to the substrate, with the longer fins extending downwardly above a region of the substrate not occupied by the first die. The shorter fins extend downwardly above a region of said first die not covered by said second die. A thermal interface material fills the remainder of the cavity and is in thermal communication with both dies, the substrate and the fins. The lid may be molded from metal. The lid may be bonded to the topmost die, using a thermal bonding material that may be liquid metal, or the like.

Owner:ATI TECH INC

Wet-lay flame barrier

InactiveUS20060068675A1Increase speedExtension of timeDomestic upholsteryLayered productsFiberGlass fiber

Nonwoven wet-lay flame barrier of the invention comprises a blend of water dispersible fibers, that are inherently fire resistant and nonshrinking to direct flame, along with water dispersible fibers extruded from polymers made with halogenated monomers and optionally including fiberglass and wood pulp, being together thermally bonded with a binder resin in a wet-lay manufacturing process to provide a relatively thin, but dense, durable flame barrier with excellent tensile, and durability properties in the end use application. The wet-lay flame barrier of this invention also allows for the manufacture of open flame resistant composite articles, while also permitting the continued use of conventional non-flame retardant dress cover fabrics, conventional non-flame retardant fiberfills and conventional non-flame retardant polyurethane foams.

Owner:HANDERMANN ALAN C +3

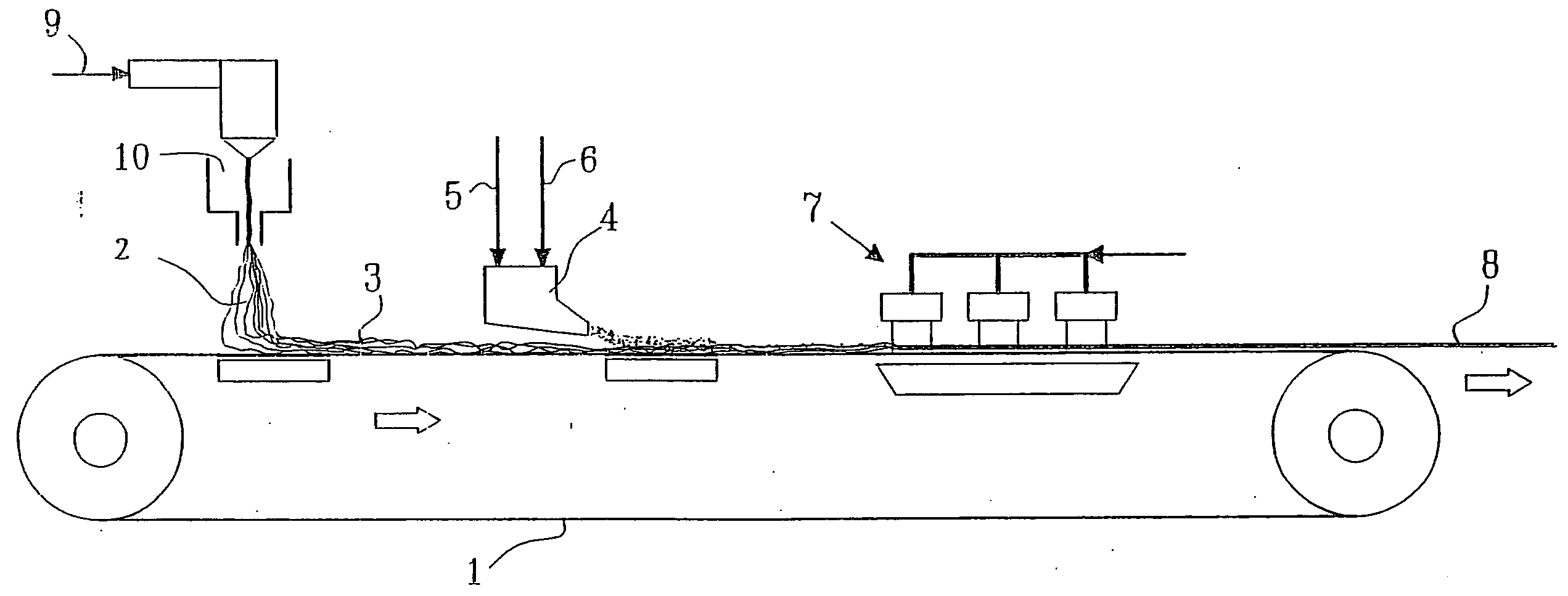

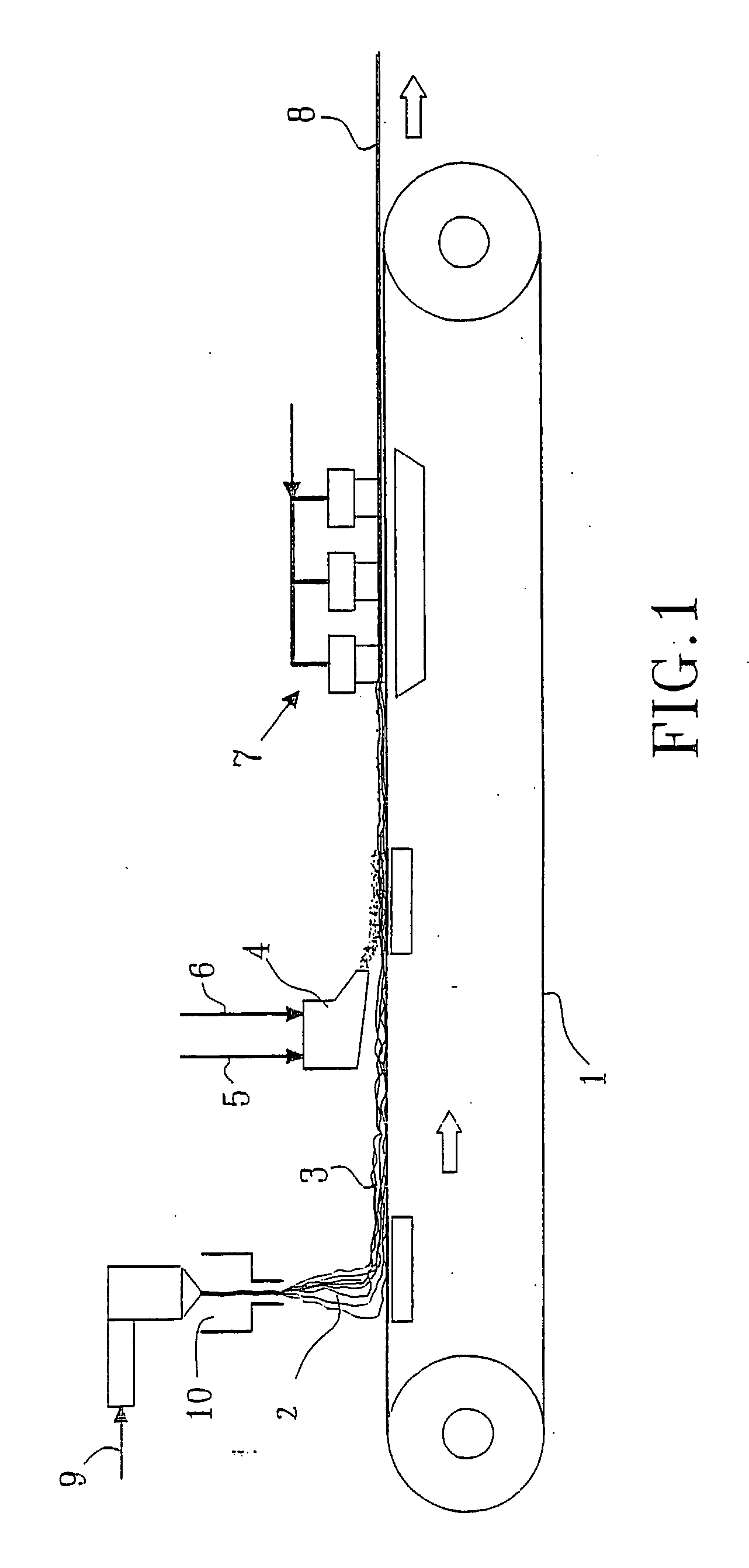

Nonwoven fabric air filter for internal combustion engine

A thin and uniform nonwoven fabric air filter for an internal combustion engine with a pleated form which comprises an air-laid nonwoven fabric obtained by forming a plurality of layers mainly composed of polyester-based binder fibers having a fiber length of 1 to 10 mm by an air-laid nonwoven fabric production process and performing heat adhesion, wherein an upper layer side (fluid inflow side) comprises large fibers, a lower layer side (fluid outflow side) comprises fine fibers, a final fluid outflow side comprises 100% of the polyester-based binder fibers, the basis weight (METSUKE) is from 100 to 350 g / m2, the apparent density is from 0.04 g / cm3 to 0.3 g / cm3, and the dry-heat shrinkage factor after 300 hours at 100° C. is 3% or less. The air filter induces no environmental pollution, is high in dust collection efficiency, and has long life.

Owner:AMBIC +1

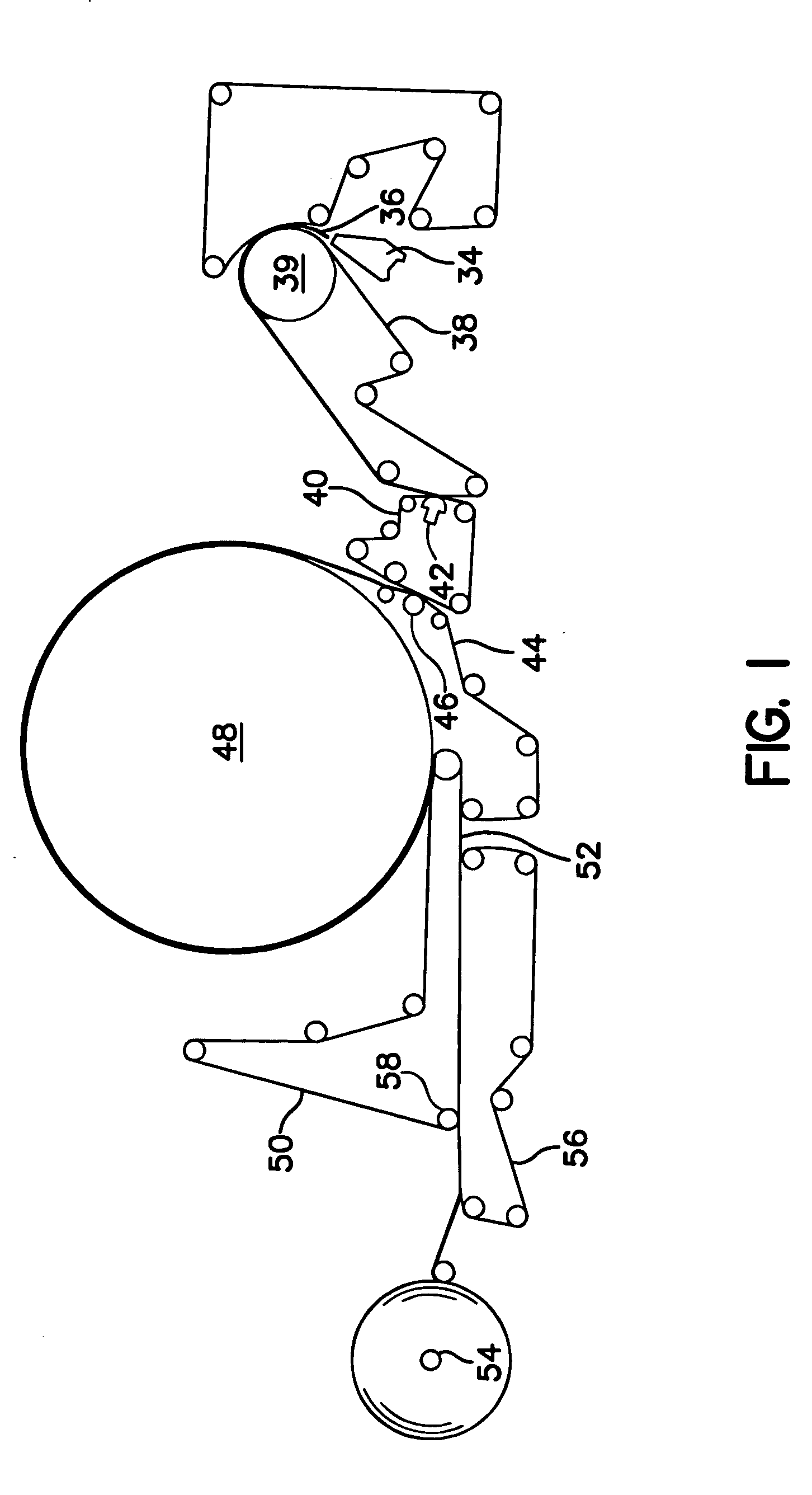

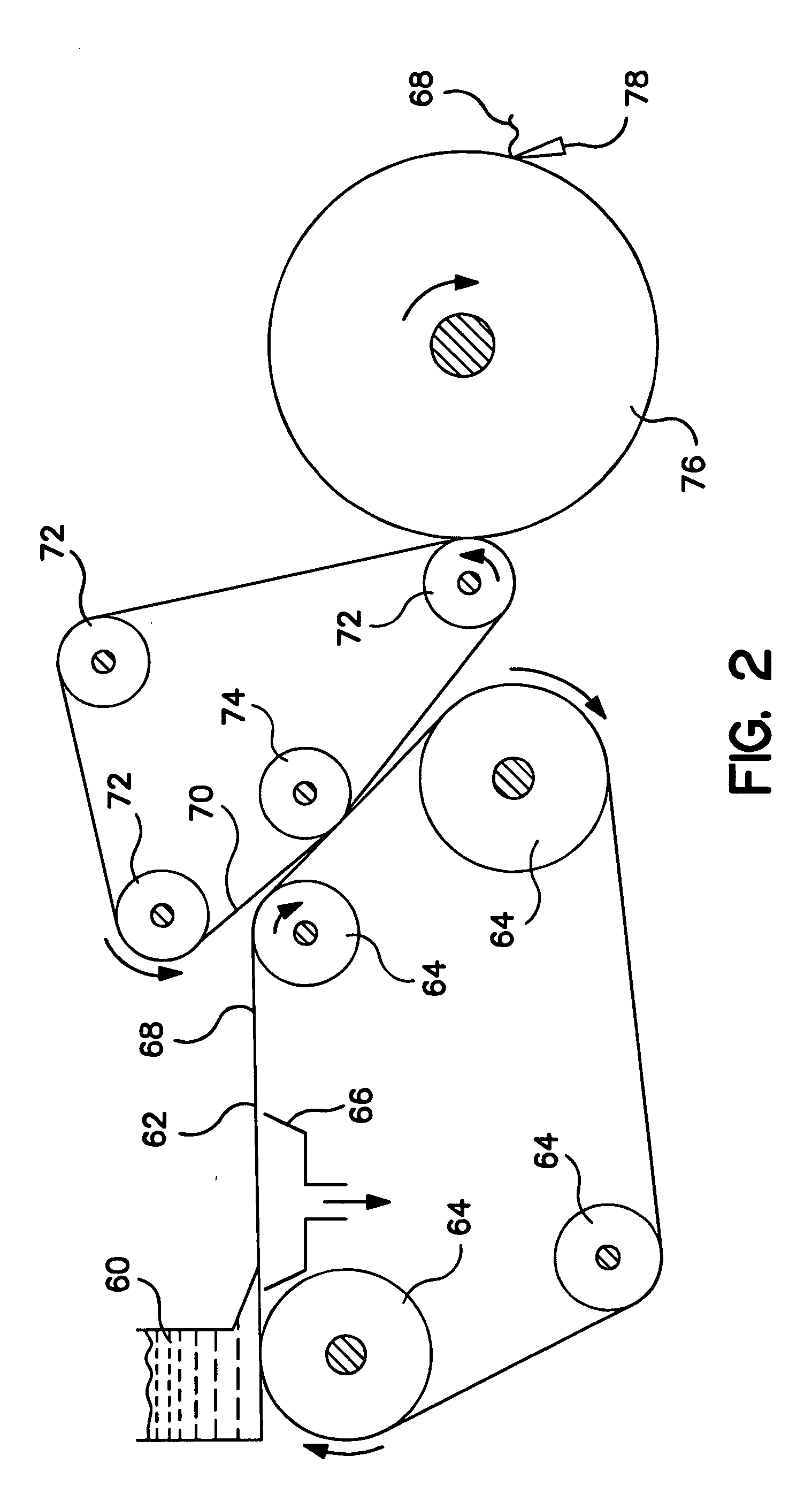

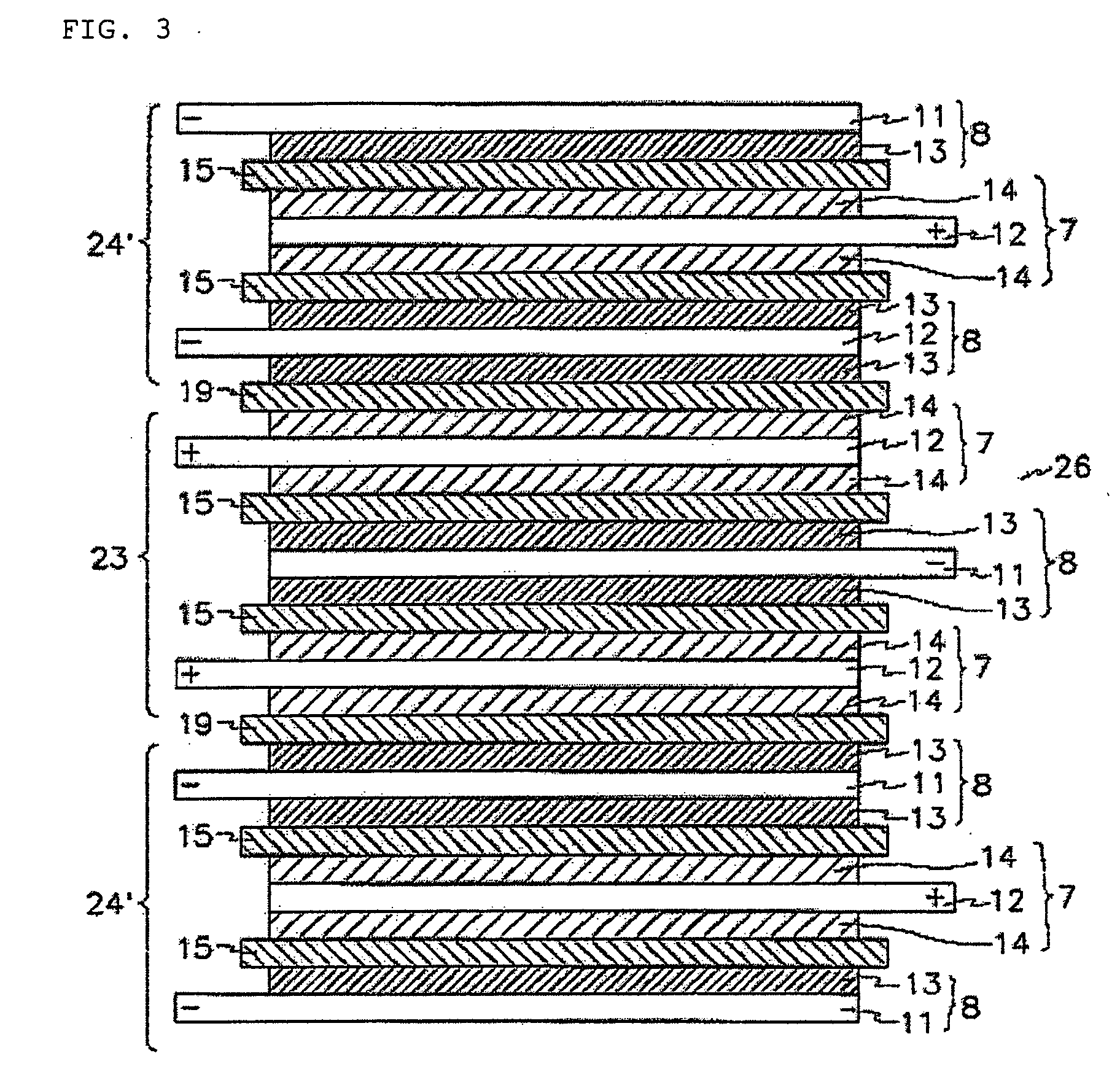

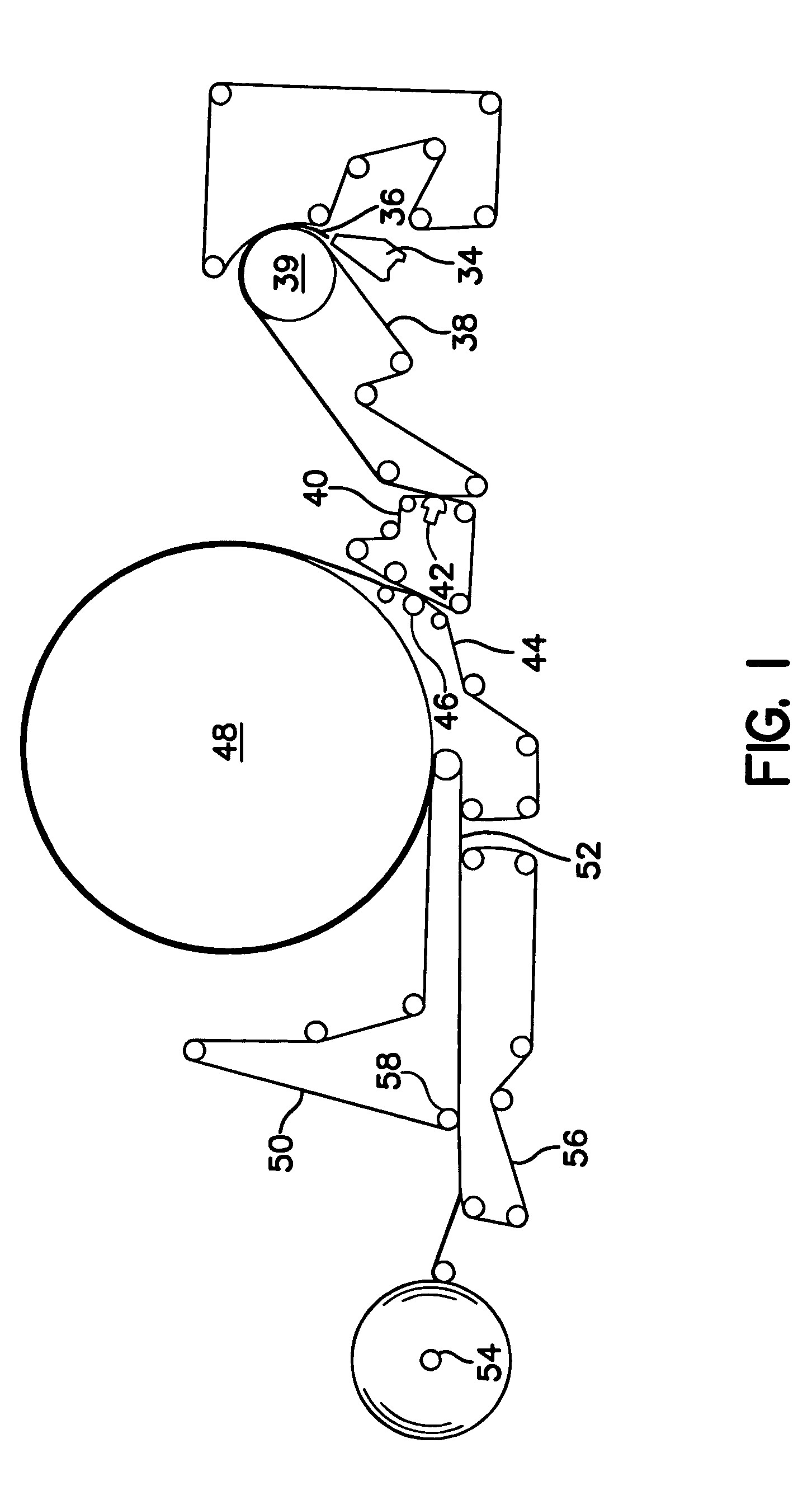

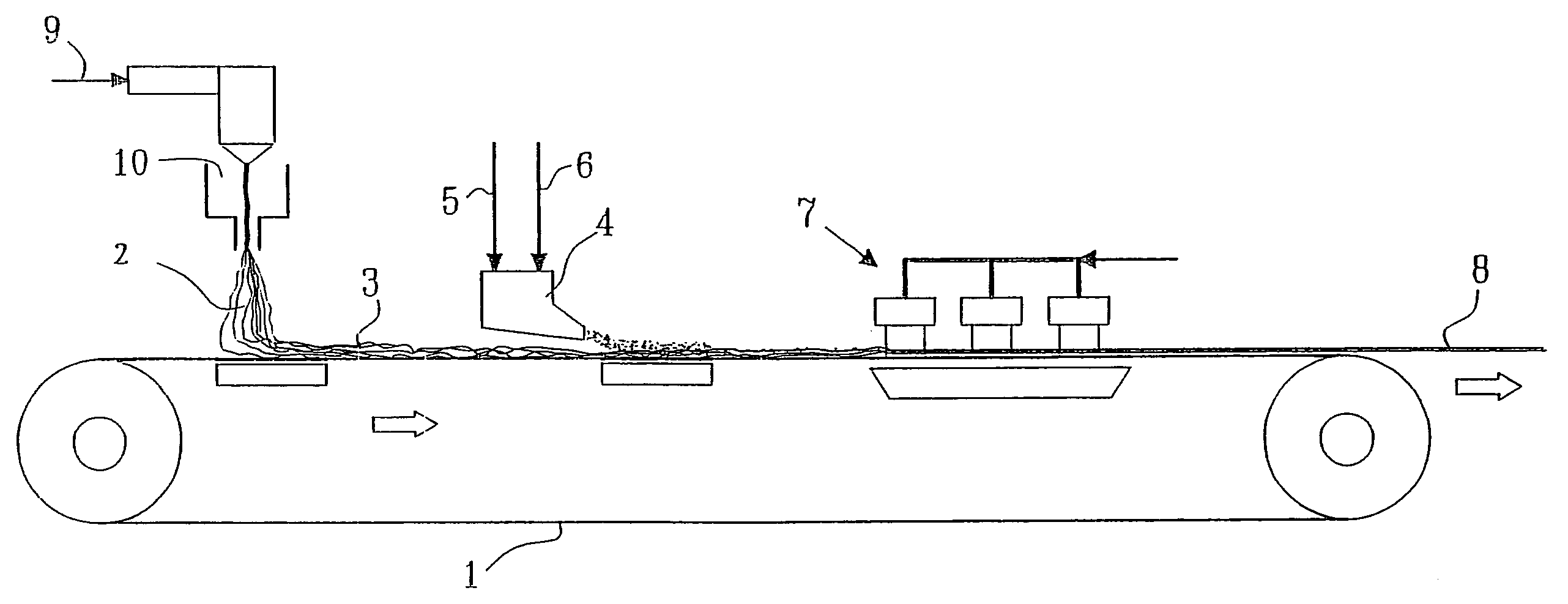

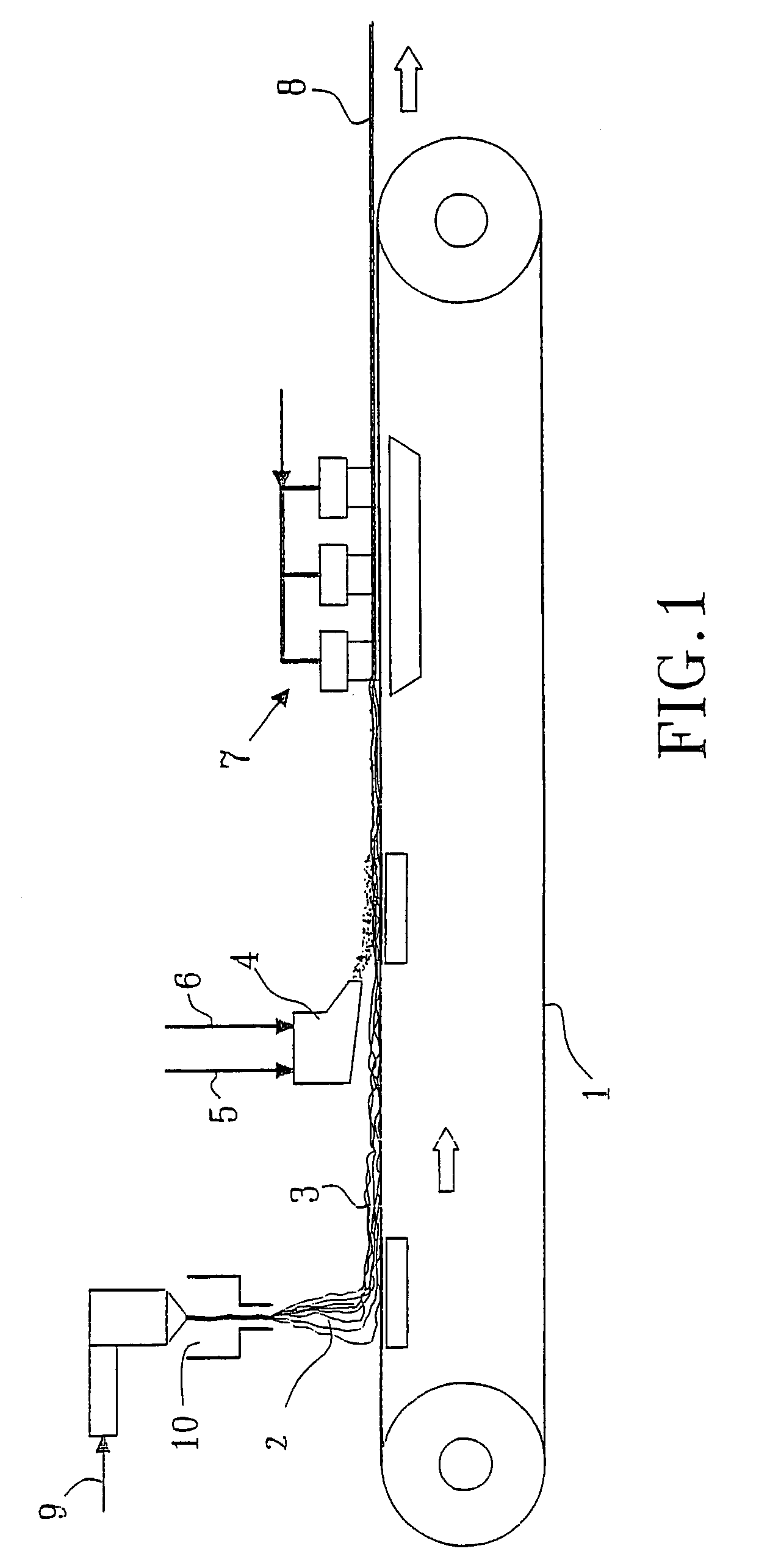

Process for producing resonant tag

InactiveUS6618939B2Easy to manufactureStable resonant characteristicWave amplification devicesElectrical connection printed elementsMetal foilAdhesive

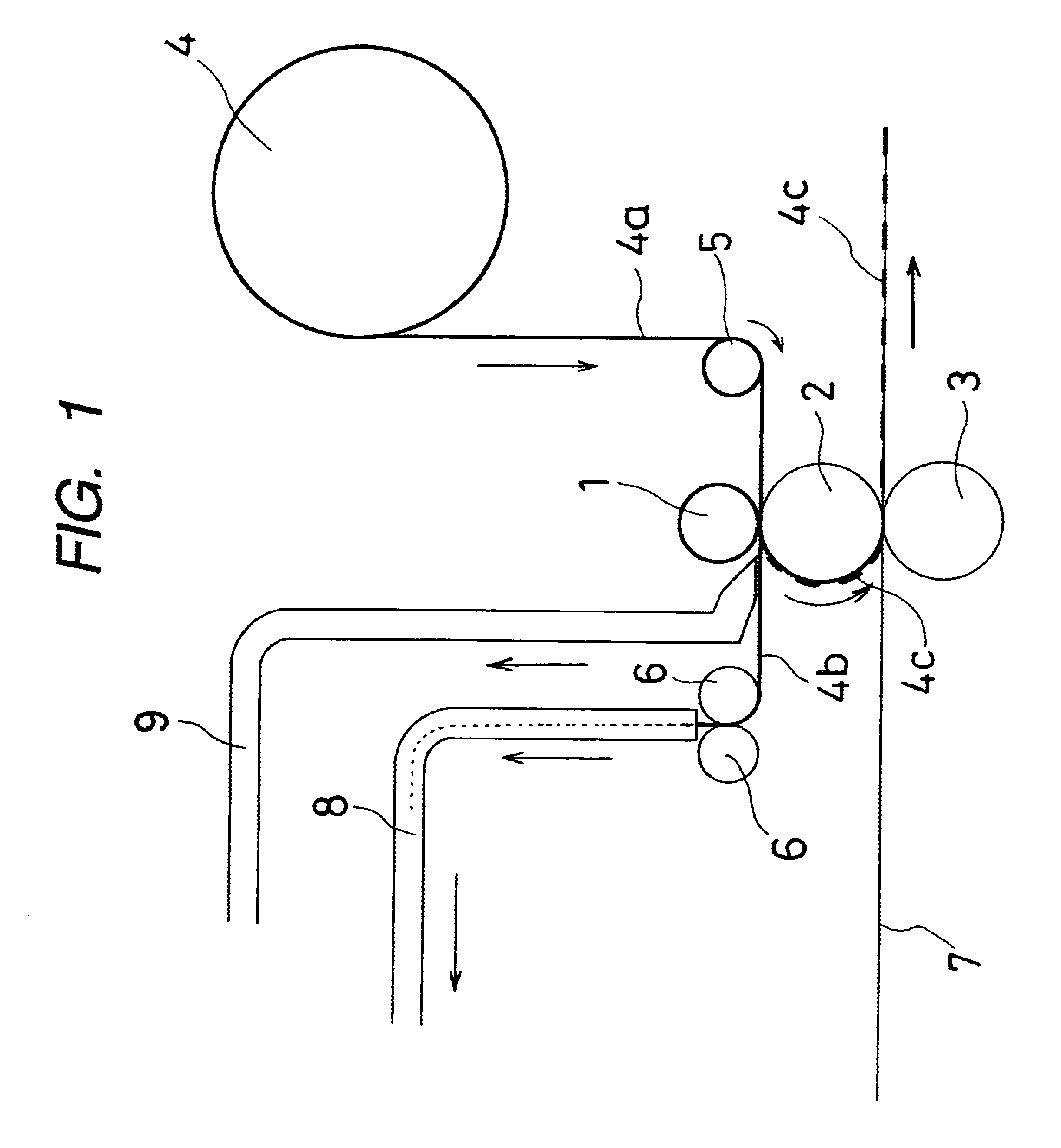

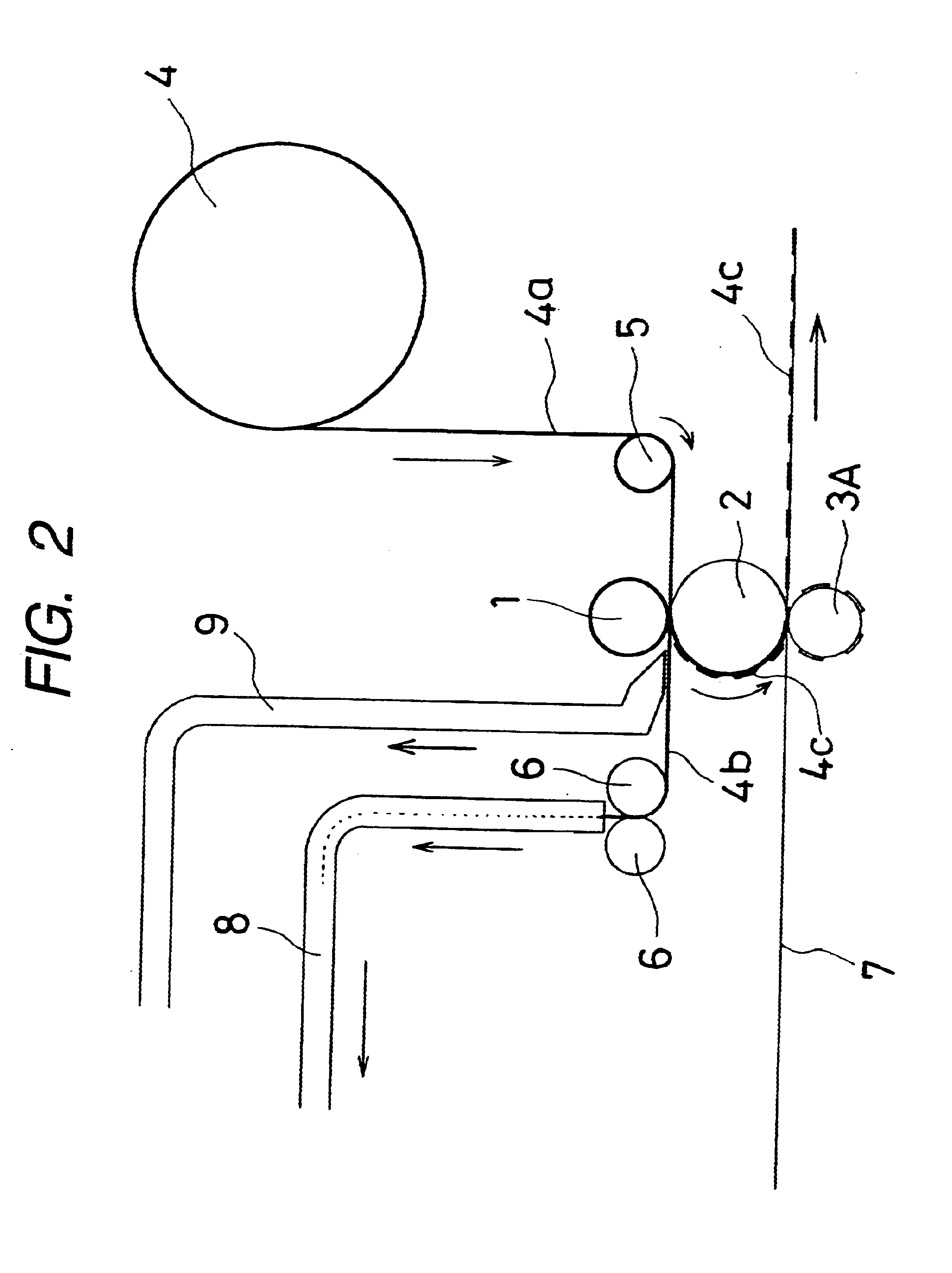

A process for producing a resonant tag, wherein a metal foil having a thermal adhesion adhesive applied to at least one face thereof is stamped out into a circuit-like shape and is adhered to a base sheet, the process comprising: stamping out the metal foil into a predetermined shaped metal foil portion (4c) while being passed through a die roll (1) having thereon a stamping blade with a predetermined shape and a transfer roll (2) in contact with the die roll (1) which functions also as a die back-up roll; holding this metal foil portion obtained by the stamping-out operation onto the surface of the transfer roll by suction holes formed in the transfer roll; and thermally adhering the stamped metal foil portion to the base sheet (7) in contact with the transfer roll (2) at its another face by an adhesive roll (3) in contact with the transfer roll through the base sheet. The present invention has such advantages as no damage to the base sheet since the stamping-out operation for the metal foil and the thermal adhesion operation thereof to the base sheet are carried out in separate positions, and no requirement of carrier sheet because the resultant metal foil portion obtained by the stamping-out operation is sucked and held onto the surface of the transfer roll.

Owner:NOVATRON ELECTRONICS HANGZHOU

Paper and nonwoven articles comprising synthetic microfiber binders

InactiveUS20140311695A1Inorganic fibres/flakesNon-fibrous pulp additionPolymer scienceMelting temperature

A process of making a paper or nonwoven article is provide. The process comprising:a) providing a fiber furnish comprising a plurality of fibers and a plurality of binder microfibers, wherein the binder microfibers comprise a water non-dispersible, synthetic polymer; wherein the binder microfibers have a length of less than 25 millimeters and a fineness of less than 0.5 d / f; and wherein the binder microfibers have a melting temperature that is less than the melting temperature of the fibers;b) routing the fiber furnish to a wet-laid nonwoven process to produce at least one wet-laid nonwoven web layer;c) removing water from the wet-laid nonwoven web layer; andd) thermally bonding the wet-laid nonwoven web layer after step (c); wherein the thermal bonding is conducted at a temperature such that the surfaces of the binder microfibers at least partially melt without causing the fibers to melt thereby bonding the binder microfibers to the fibers to produce the paper or nonwoven article.

Owner:EASTMAN CHEM CO

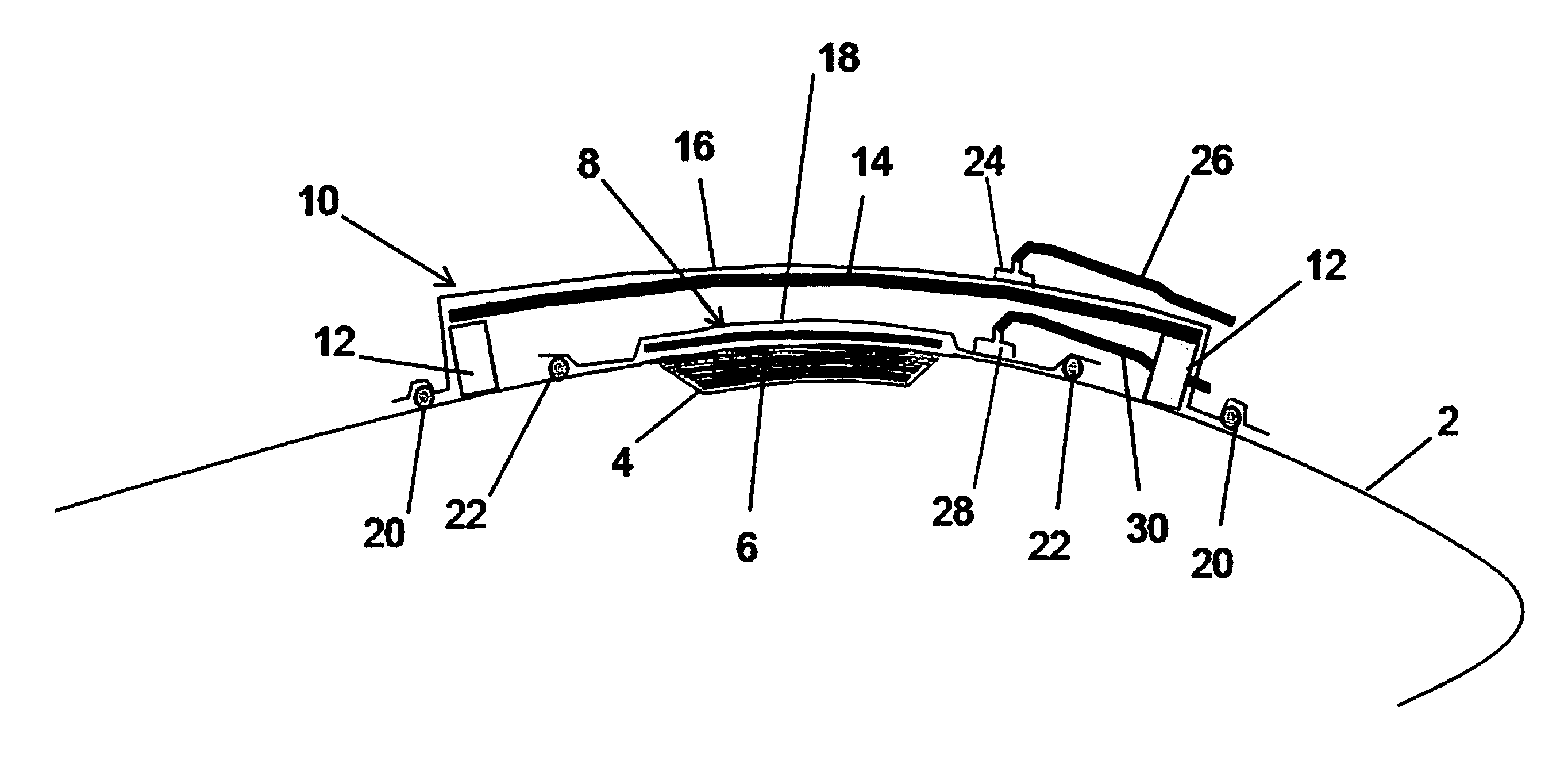

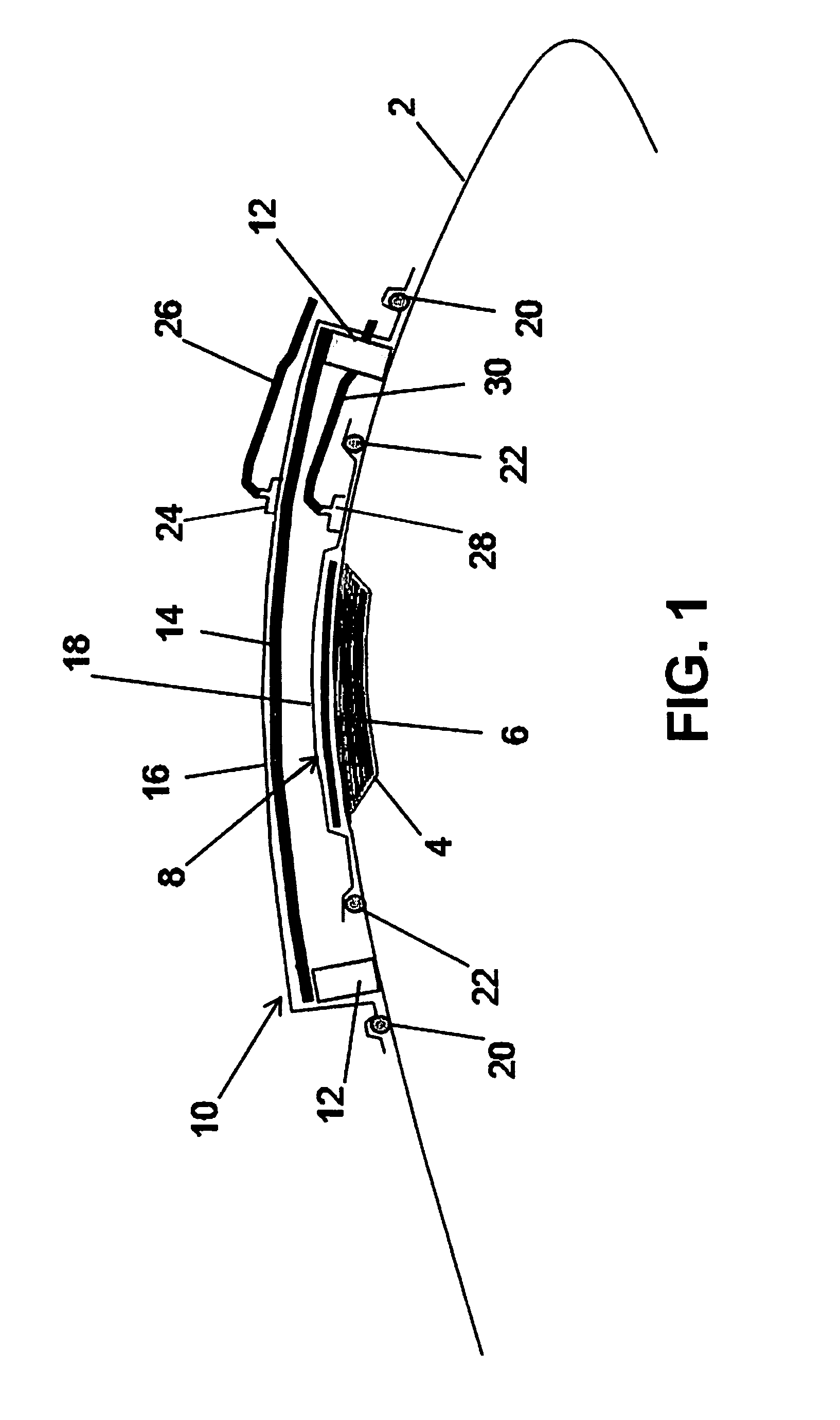

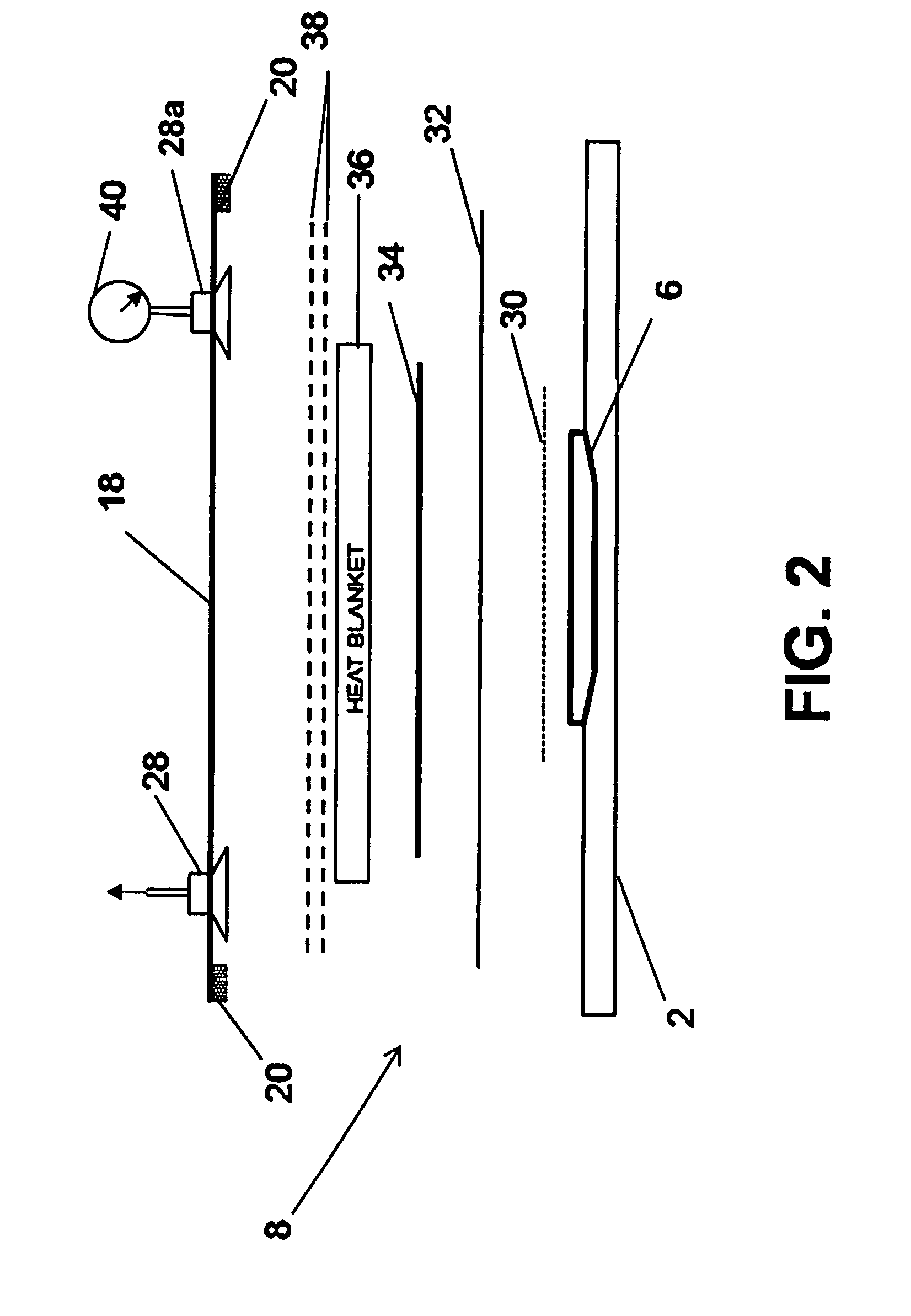

Systems and Methods for On-Aircraft Composite Repair Using Double Vacuum Debulking

InactiveUS20120080135A1Eliminate processingIncrease probabilityLaminationLamination apparatusThermal bondingAirplane

An in-situ double vacuum debulk (DVD) composite repair system designed to produce partially or fully cured autoclave-quality hot-bond composite repairs on contoured structures. The system provides vacuum pressure for hot bond repairs to be performed on flat and contoured structures using one set-up capable of debulking (partially curing) and then fully curing composite repairs on composite and metallic aircraft structures. The use of in-situ DVD also eliminates handling of the patch / adhesive when transferring from an off-aircraft DVD chamber to the repair site on the aircraft. This can increase the probability of successful repairs because the possibility of contaminating and misaligning the adhesive and repair patch are eliminated.

Owner:THE BOEING CO

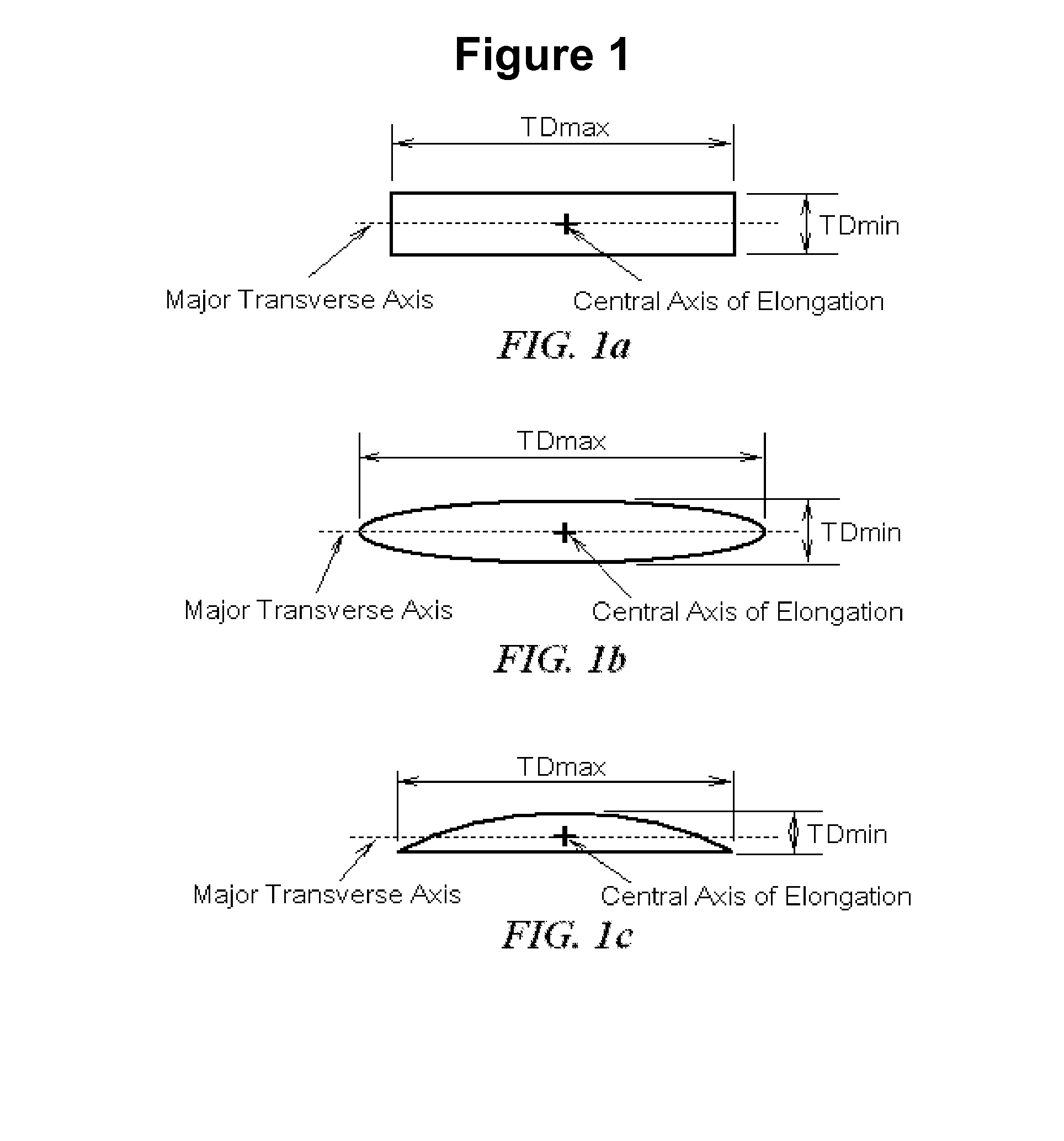

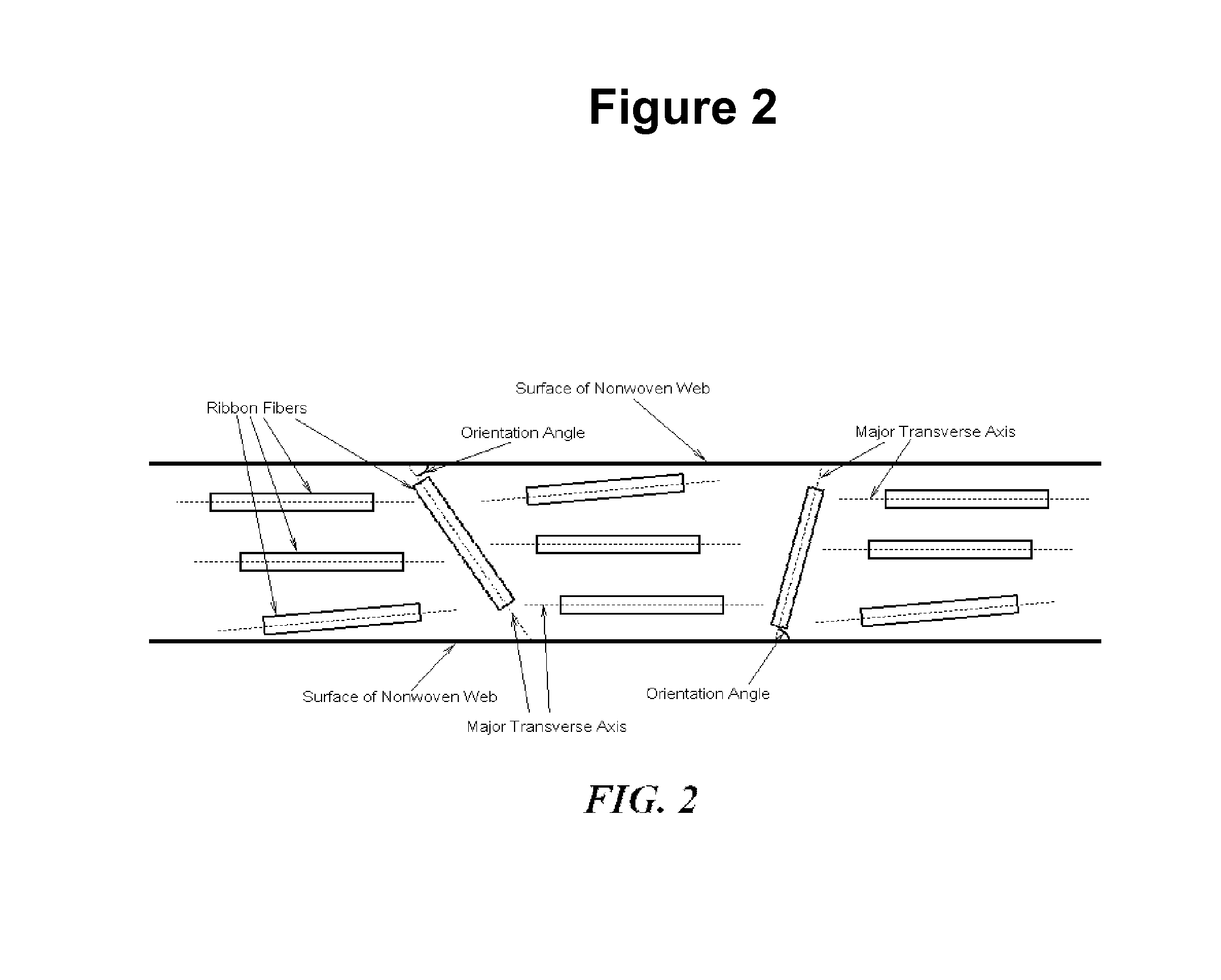

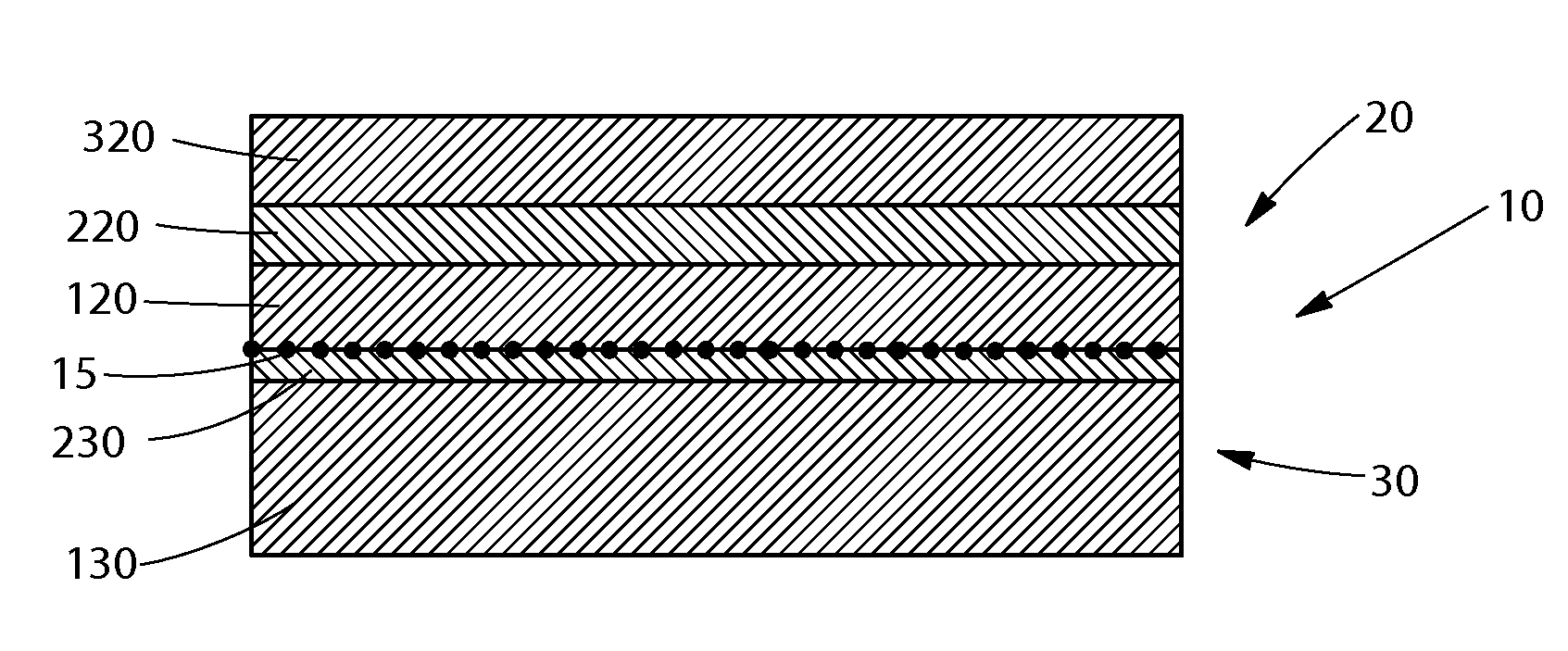

Stretchable Laminates of Nonwoven Web(s) and Elastic Film

A stretchable laminate, a process of making a stretchable laminate and a disposable absorbent article that includes a stretchable laminate are disclosed. The stretchable laminate includes a nonwoven web and a web of elastomeric material. The nonwoven web includes two layers of spunbond multi-component fibers and one layer of meltblown fibers. The multi-component fibers include a first polymer and a second polymer having different melt temperatures. Thermo-bonds are formed at least partially through the nonwoven web. Some of the thermo-bonds can be elongated in the cross-machine direction of the nonwoven web.

Owner:THE PROCTER & GAMBLE COMPANY

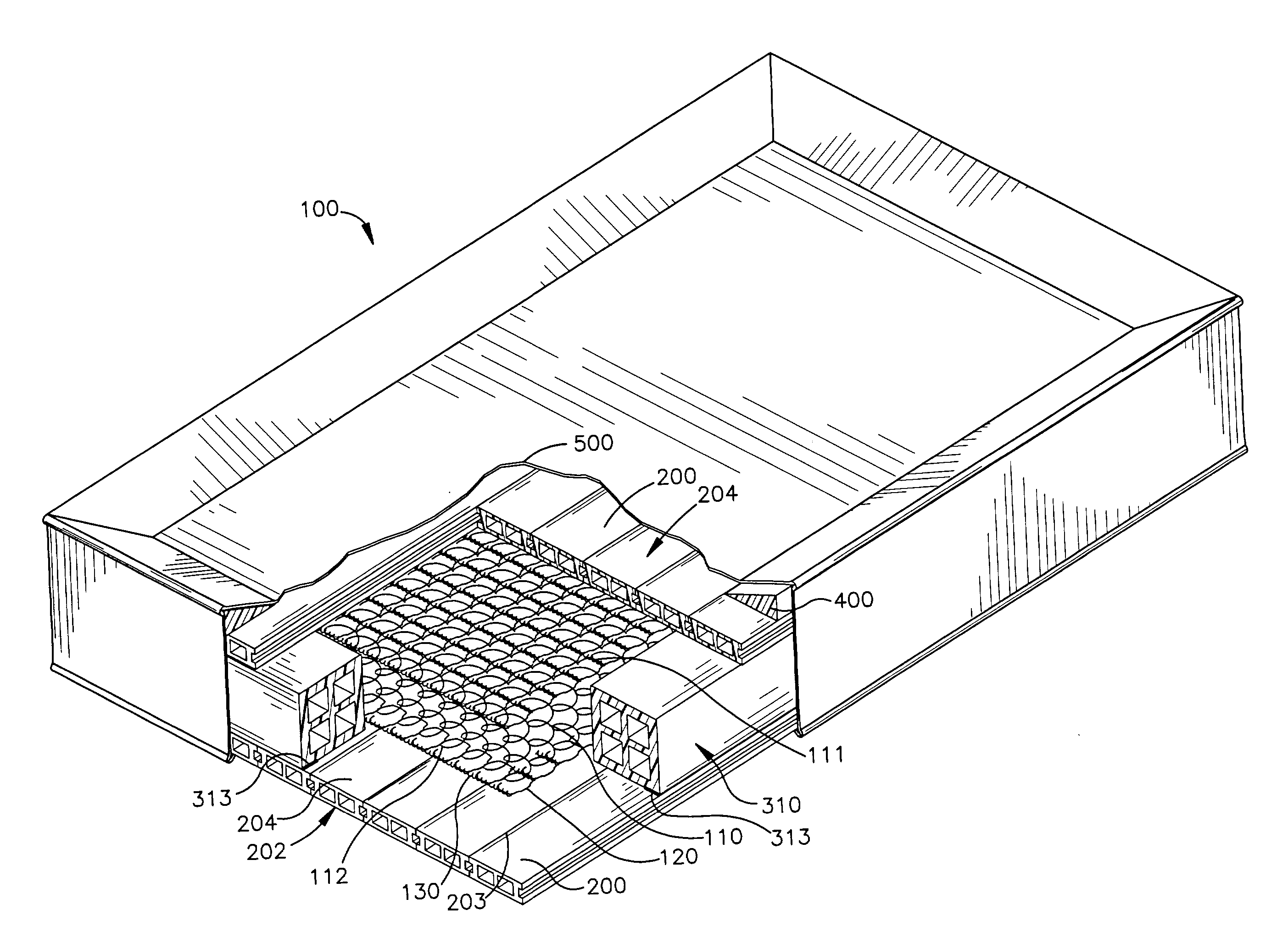

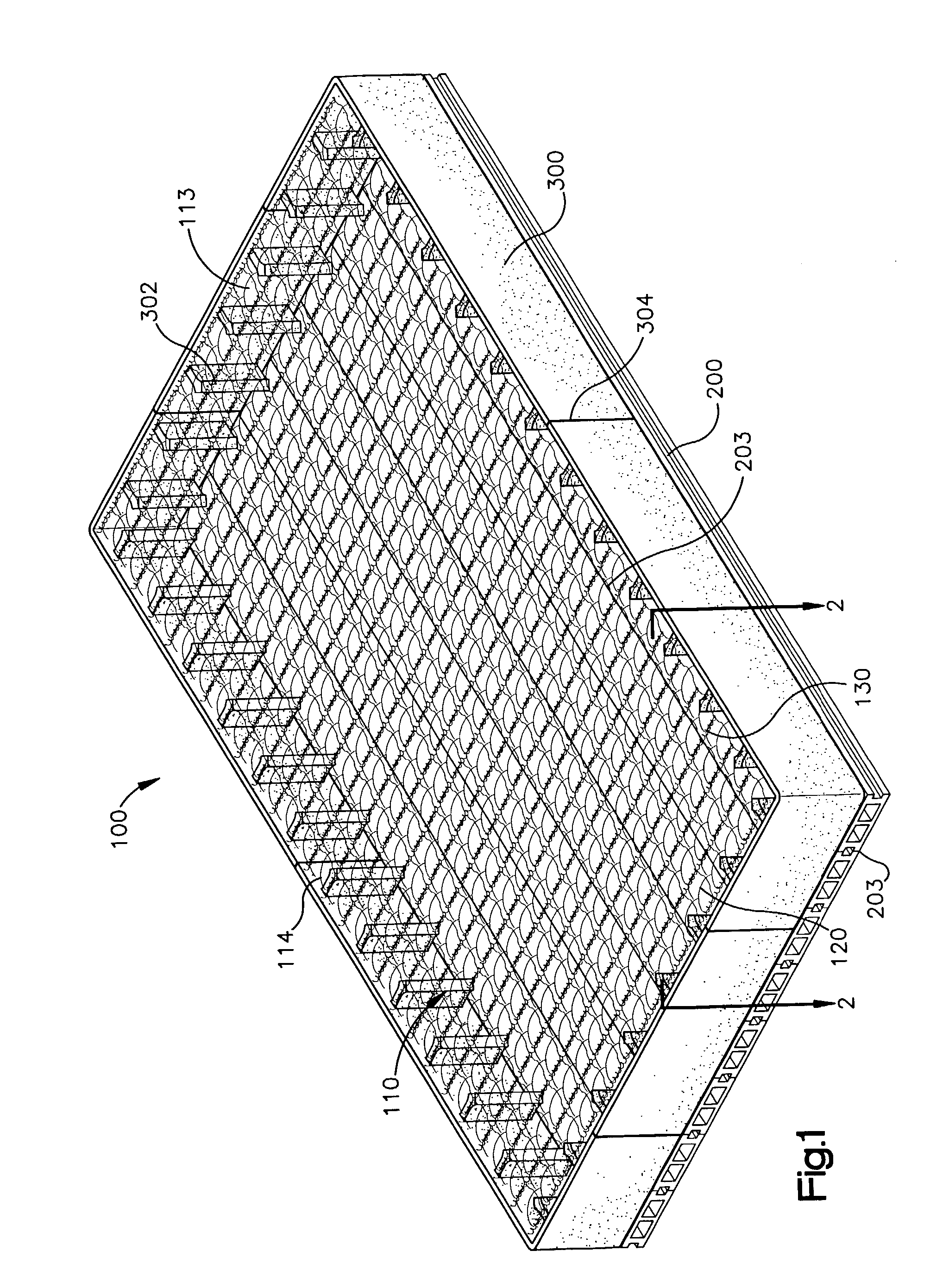

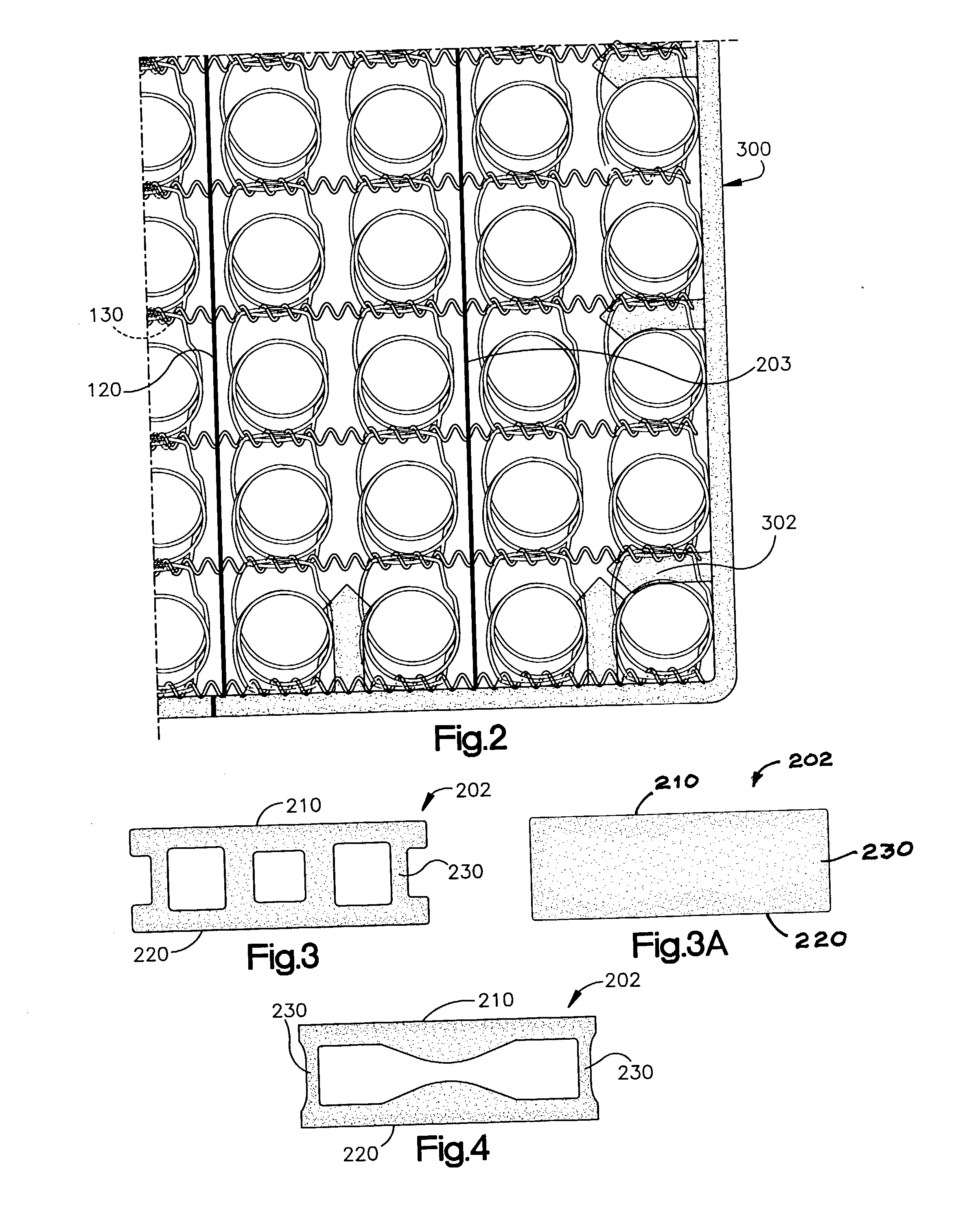

Unitized thermoplastic foam structures

InactiveUS20040187217A1Good supportLimit lateral deflectionStuffed mattressesSpring mattressesThermal bondingWelding

Three-dimensional unitized thermoplastic foam structures are made by thermoplastic welding of different foam components. The unitized foam structures may include a planar base to which other foam components are welded to project from the base and provide a flexible three-dimensional structure. The thermal bonding or welding of the thermoplastic foam components creates a unitized structure which is both flexible and load bearing. For mattress and seating applications, the welded foam structures may be combined with an innerspring, and certain of the foam components of the structure may mechanically engage parts of the innerspring. The preferred foam deck has first and second panels interconnected by one or more webs. One or more foam decks may be employed. Other foam components may be attached to the foam decks or other components. The unitized foam structures can be employed as single or double-sided mattresses, seating structures or other flexible support structures.

Owner:SEALY TECH LLC

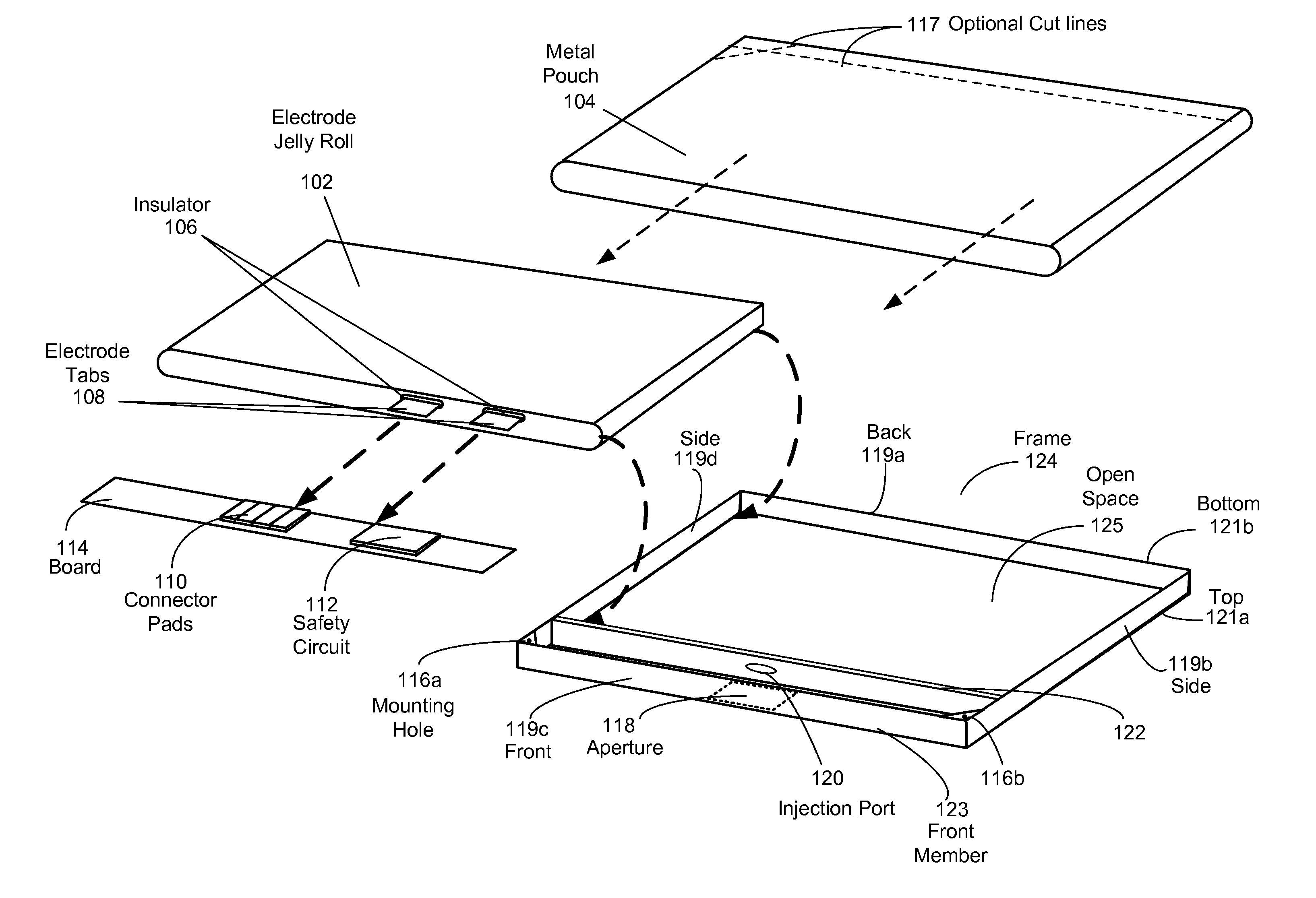

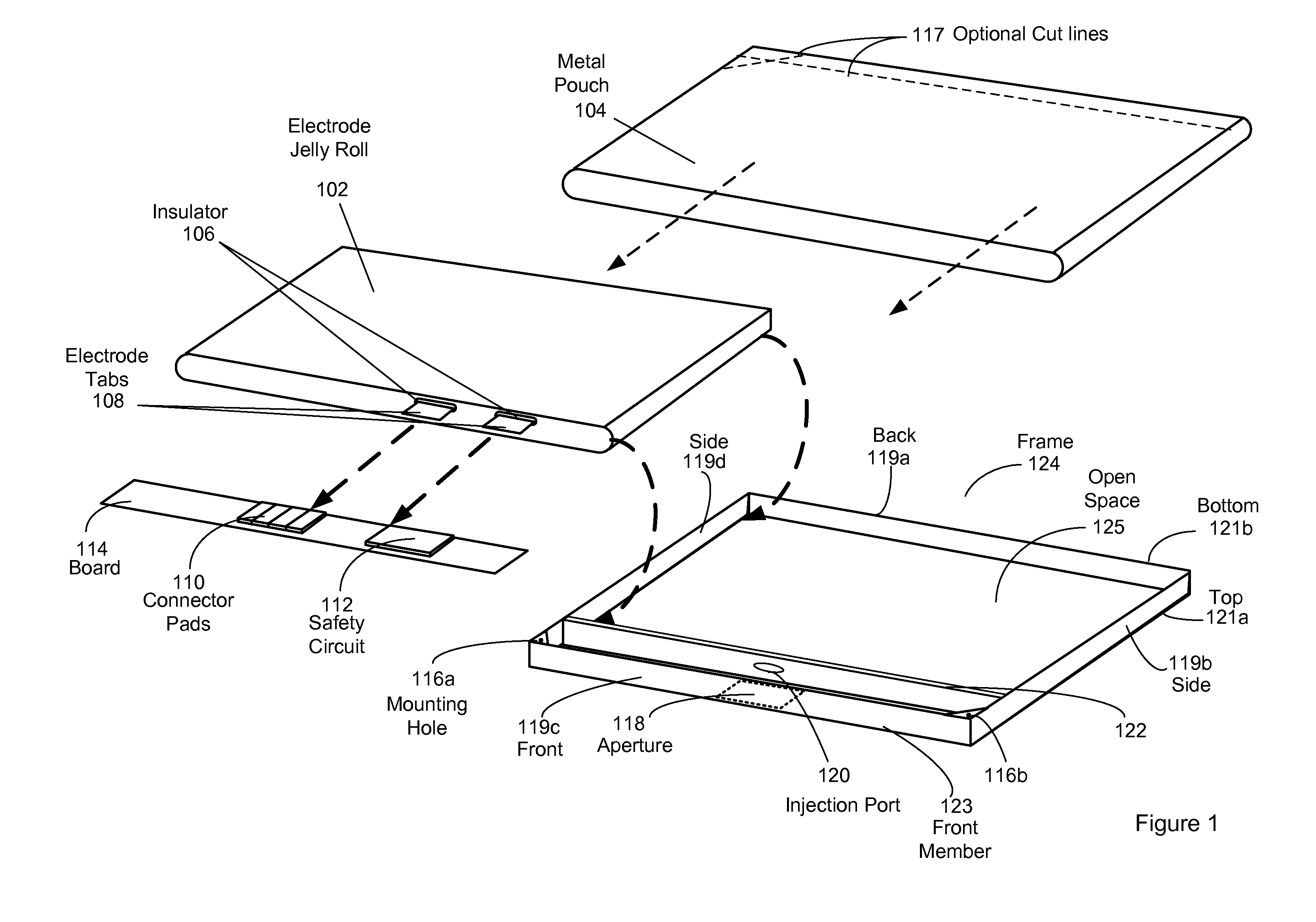

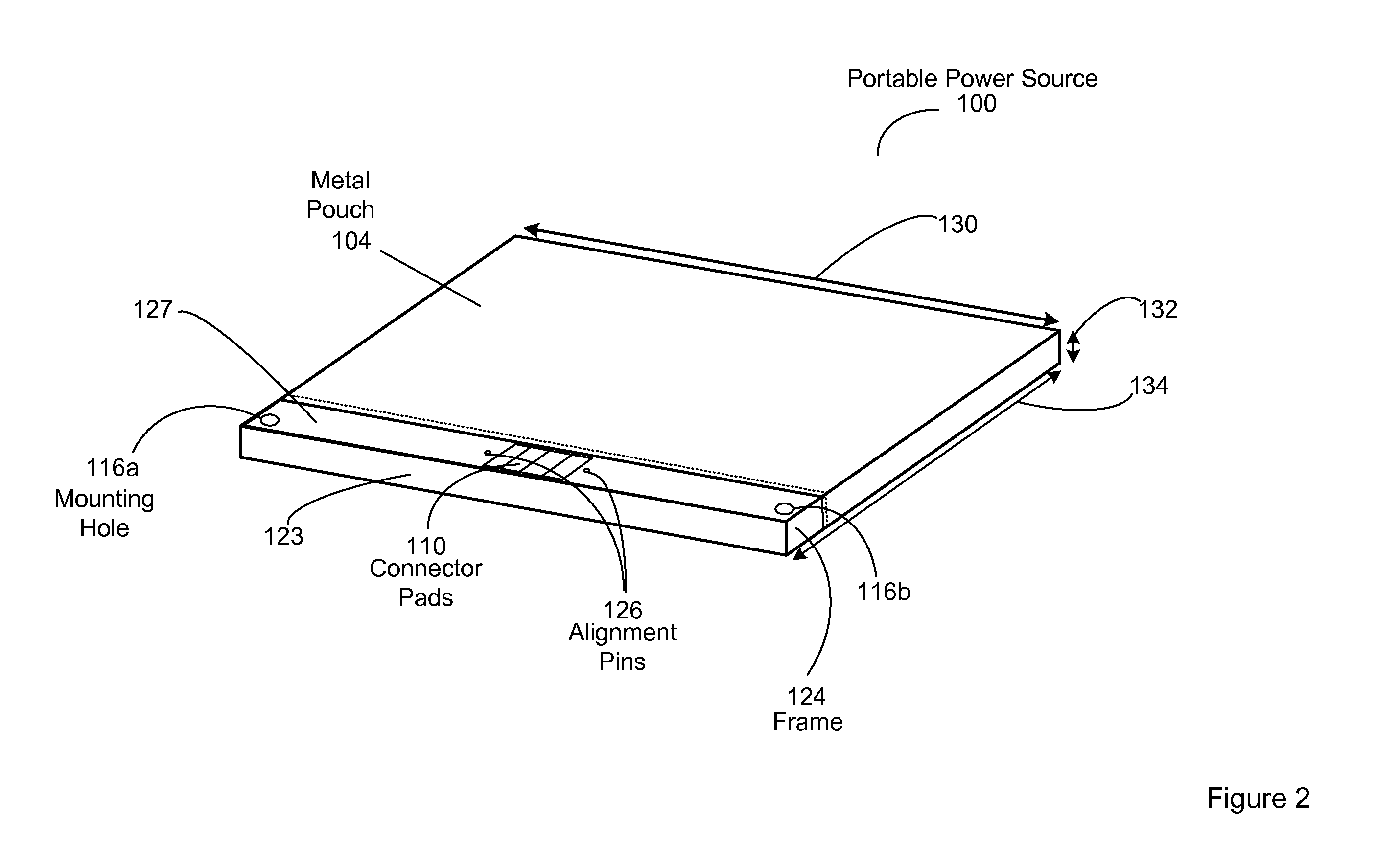

Integrated frame battery cell

ActiveUS20110210954A1Prevent leakageRapid assimilationLamination ancillary operationsFinal product manufactureMetal foilPortable power

An electrolyte containment structure for an electrode jelly roll and electrolyte in a portable power source is described. The electrolyte containment structure comprises metal foil, such as metal foil sleeve, coupled to and partially surrounding a rigid frame. The rigid frame can protect the electrode jelly roll edges from crush events. To prevent shorts, the metal foil can be coated in plastic, which can insulate the metal foil from the electrode jelly roll. Further, the plastic can serve as a bonding and sealing agent. For instance, the metal foil can be coupled to the rigid frame using a thermal bonding method involving melting of the plastic. The rigid frame can provide a platform for connector pads and safety circuitry associated with the portable power source. The connector pads and safety circuitry can be assembled as modular components, which can simplify the assembly process The containment structure provides features associated with a pouch cell battery design, such as a light-weight metal foil pouch, but can be utilized in a portable computing device without being enclosed in a hard casing traditionally associated with pouch cell battery designs.

Owner:APPLE INC

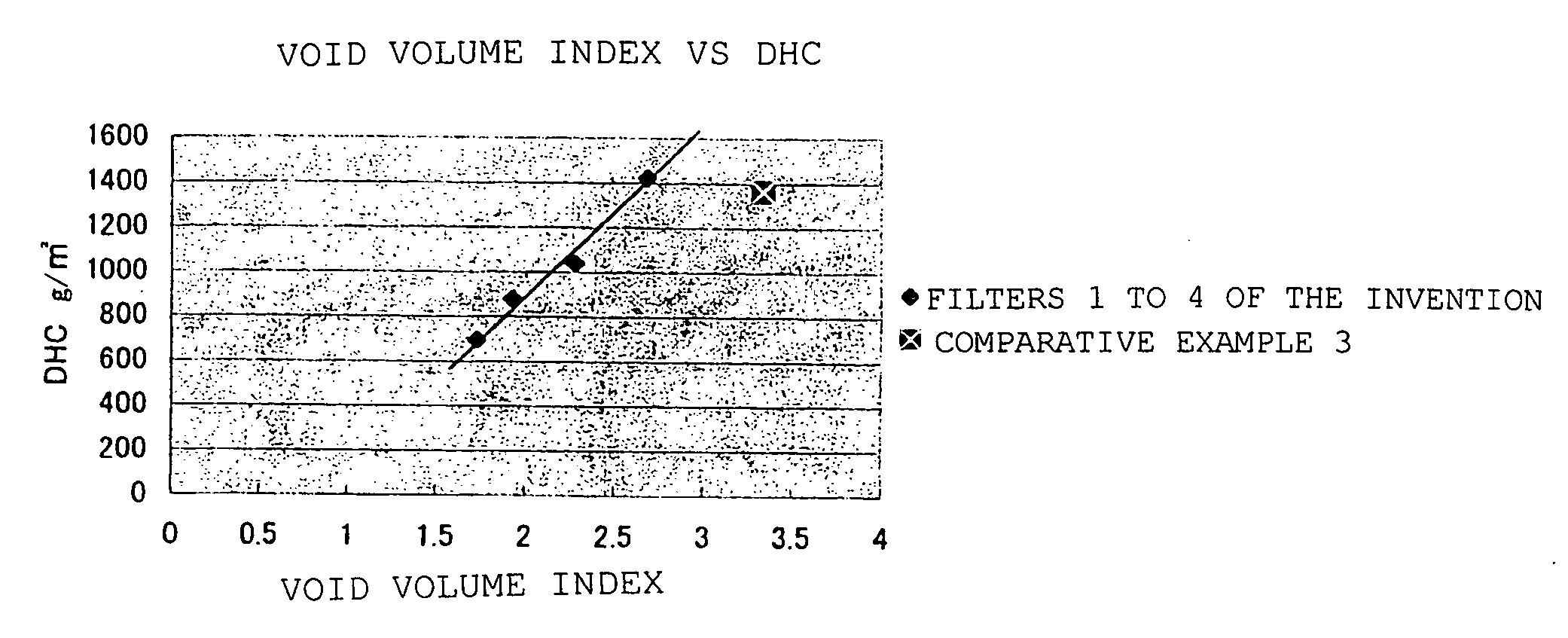

Filter medium and structure

Thermoplastic bicomponent binder fiber can be combined with other media, fibers and other filtration components to form a thermally bonded filtration media. The filtration media can be used in filter units, such as breather caps. Such filter units can be placed in the stream of a mobile fluid and can remove a particulate and / or fluid mist load from the mobile stream. The unique combination of media fiber, bicomponent binder fiber and other filtration additives and components provide a filtration media having unique properties in filtration applications.

Owner:DONALDSON CO INC

Buffer substrate and use thereof

ActiveUS20100203788A1Improve breathabilityImprove buffering effectInsolesLaminationFiberPolymer science

In a nonwoven fiber assembly which comprises a fiber comprising a thermal adhesive fiber under moisture and in which the fiber are entangled with each other, the fibers are bonded at contacting points of the fibers by melting the thermal adhesive fiber under moisture to distribute the bonded points approximately uniformly, thereby obtaining a buffer substrate. The buffer substrate may further comprises a conjugated fiber comprising a plurality of resins which are different in thermal shrinkage and form a phase separation structure, and the conjugated fibers may have an approximately uniform crimps having an average curvature radius of 20 to 200 μm and are entangled with the fibers constituting the nonwoven fiber assembly. The buffer substrate can be obtained by a method comprising the steps of: forming a web from the fiber comprising the thermal adhesive fiber under moisture; and subjecting the obtained fiber web to a heat and moisture treatment with a high-temperature water vapor to melt the thermal adhesive fiber under moisture for bonding the fibers. The buffer substrate has a high air-permeability, an excellent cushion property and softness.

Owner:KURARAY CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com