Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Highly repeatable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

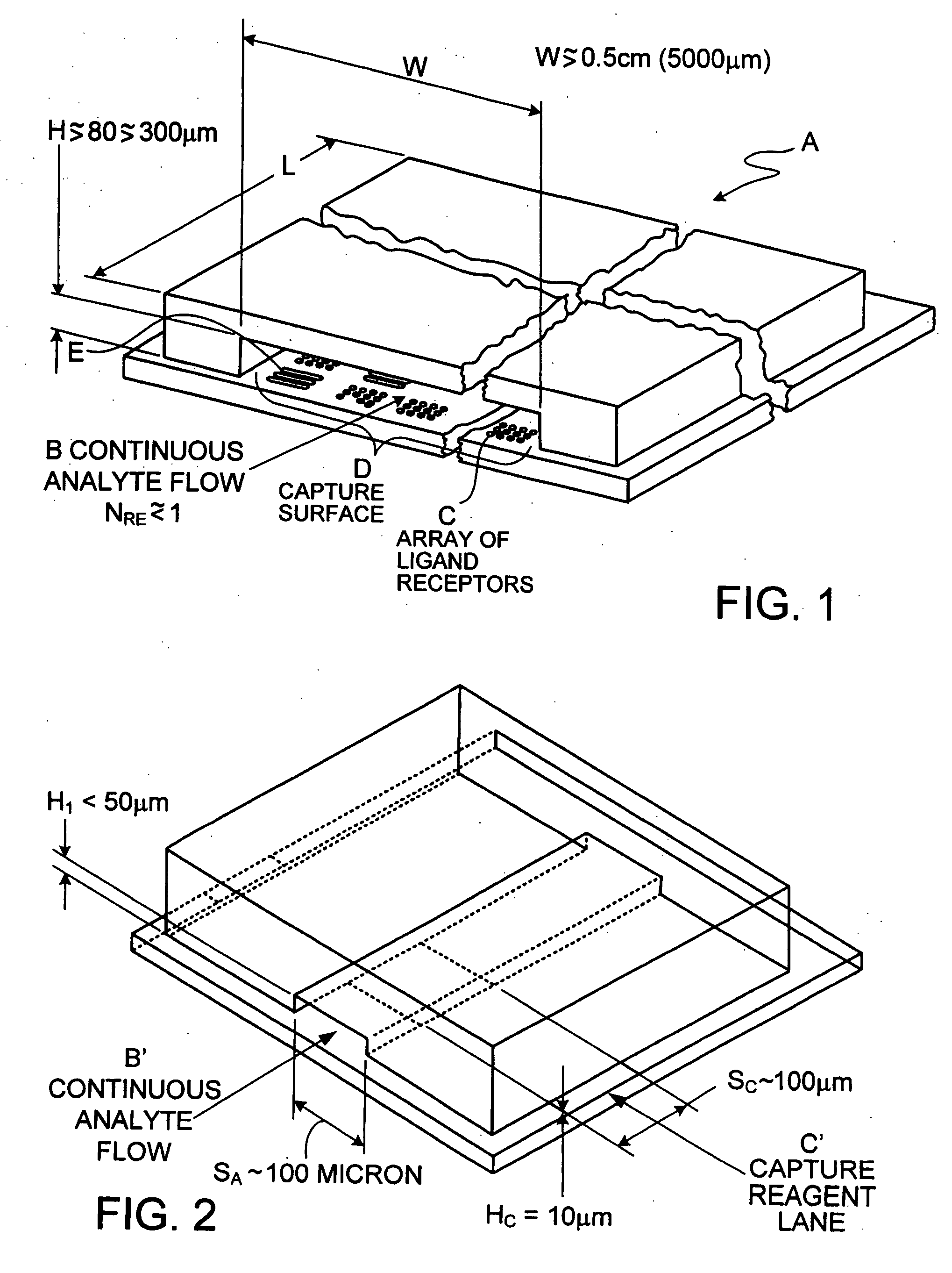

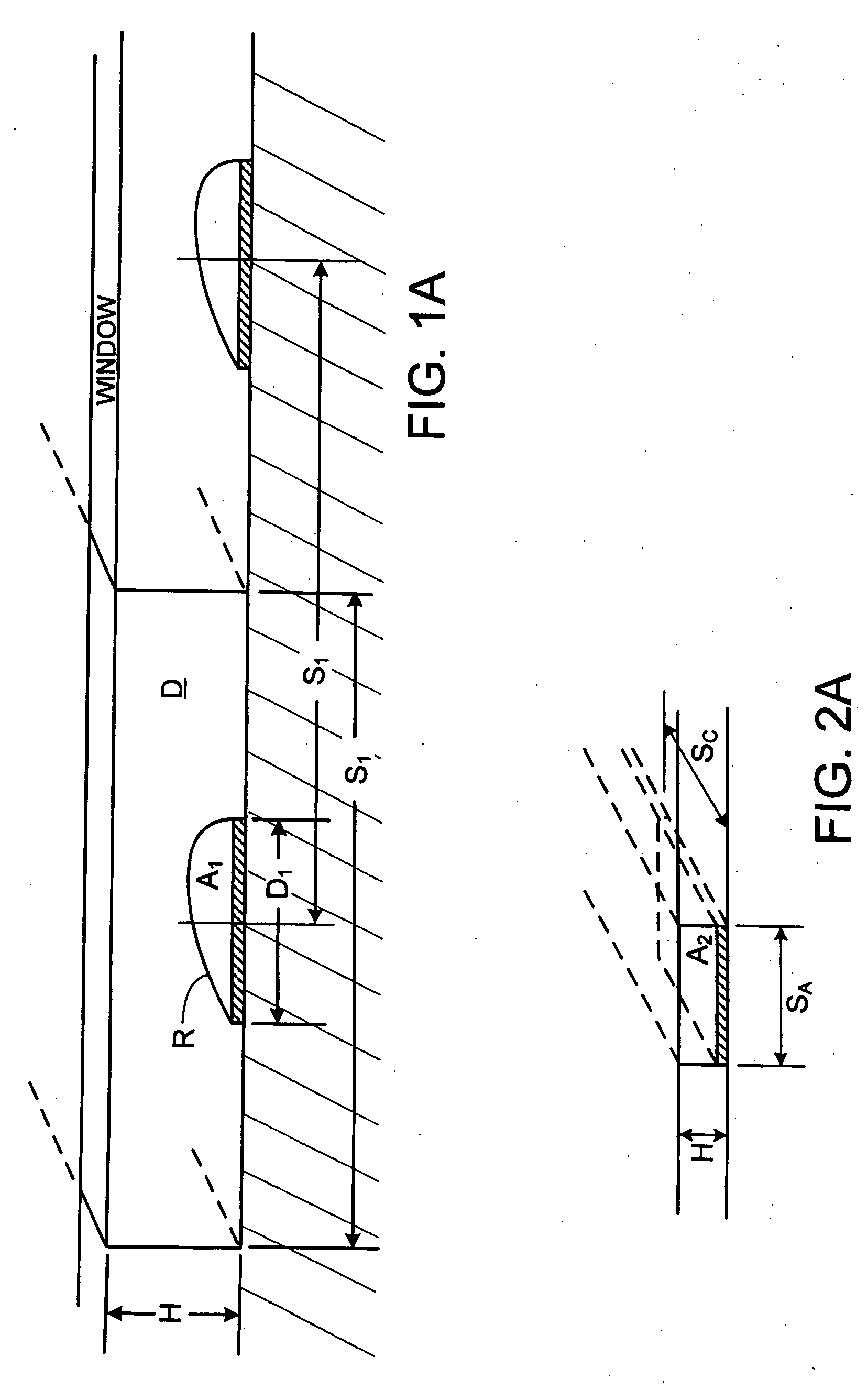

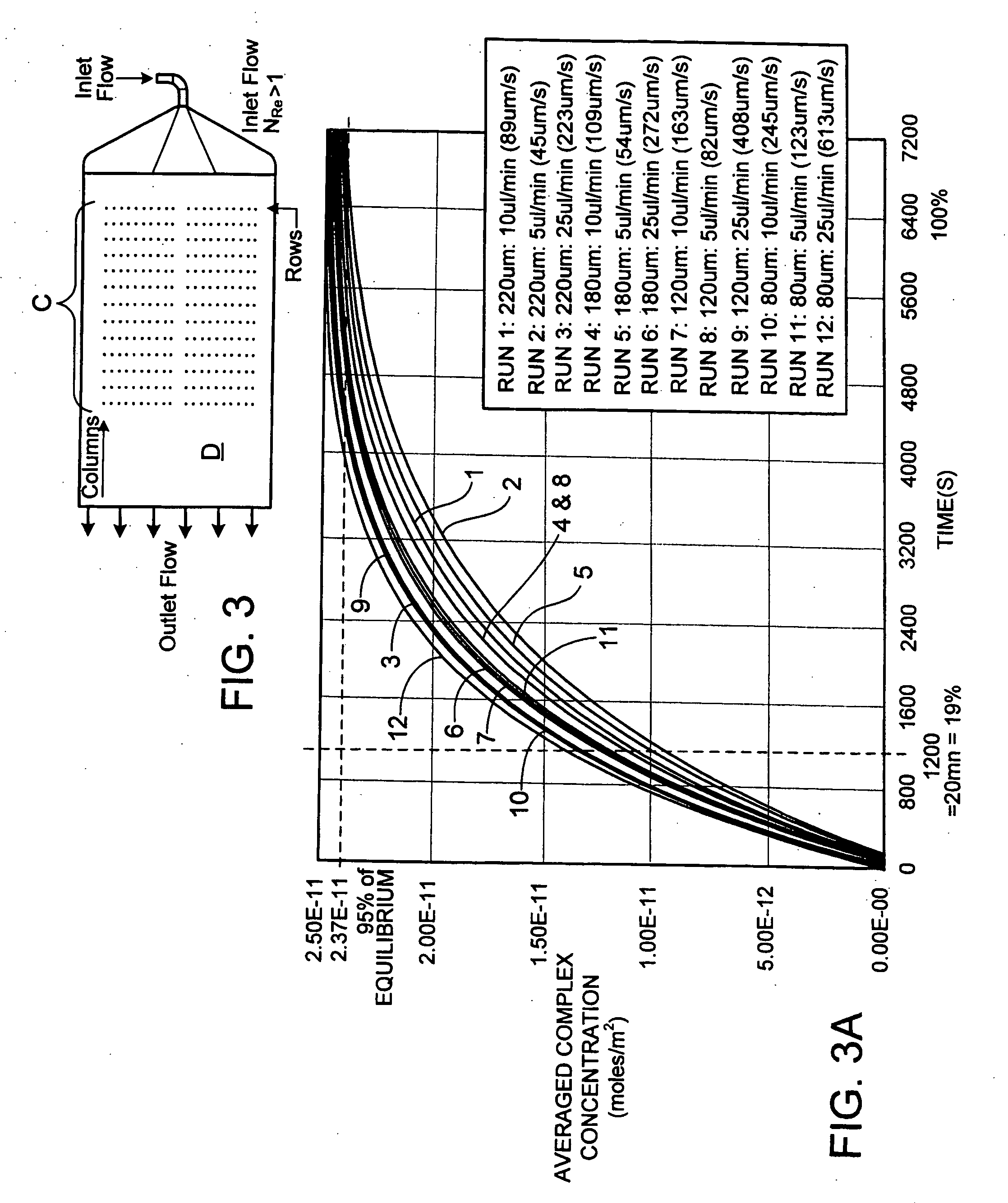

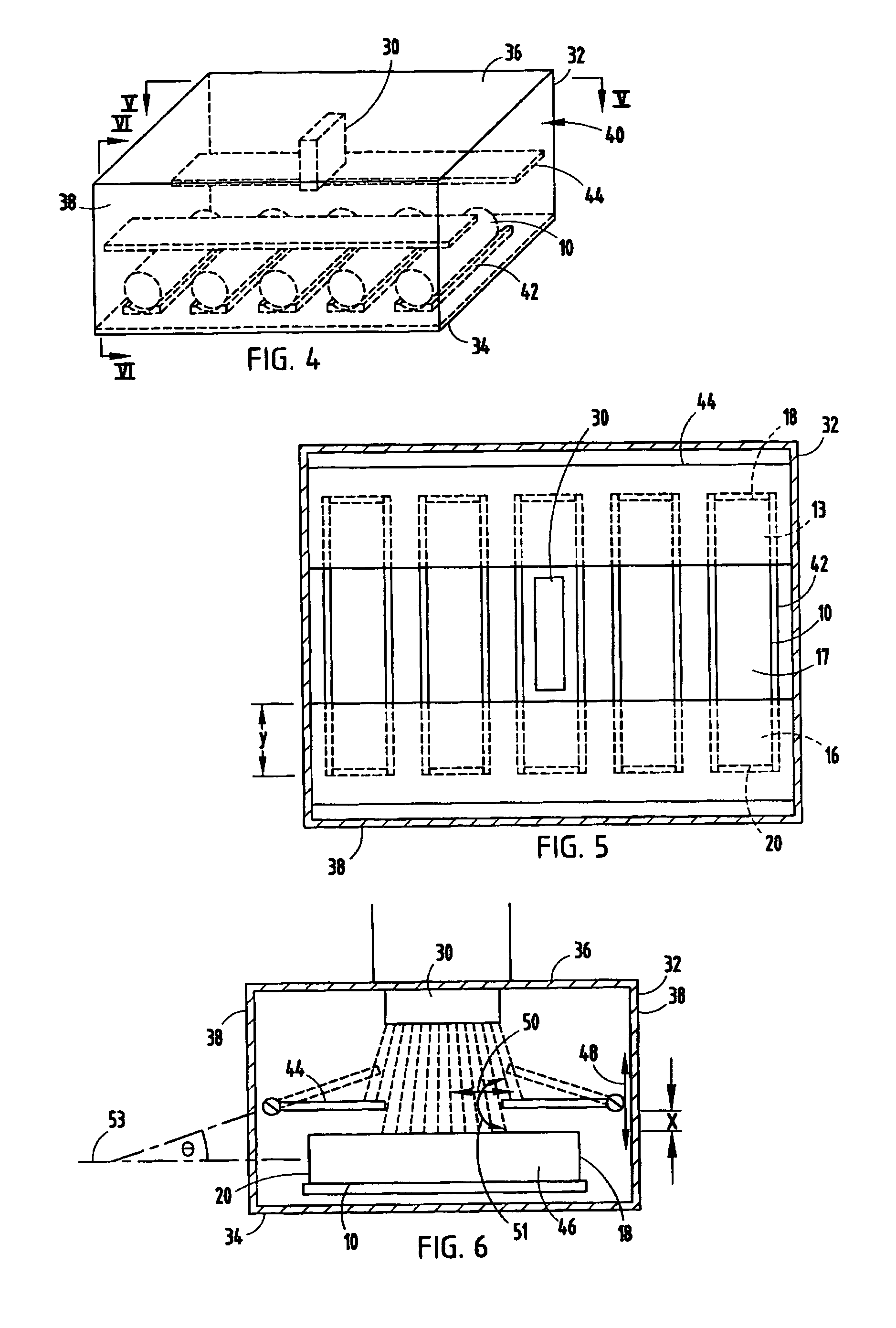

Assays based on liquid flow over arrays

InactiveUS20060275852A1Highly credible resultLow coefficient of variationBioreactor/fermenter combinationsBiological substance pretreatmentsAssayAnalyte

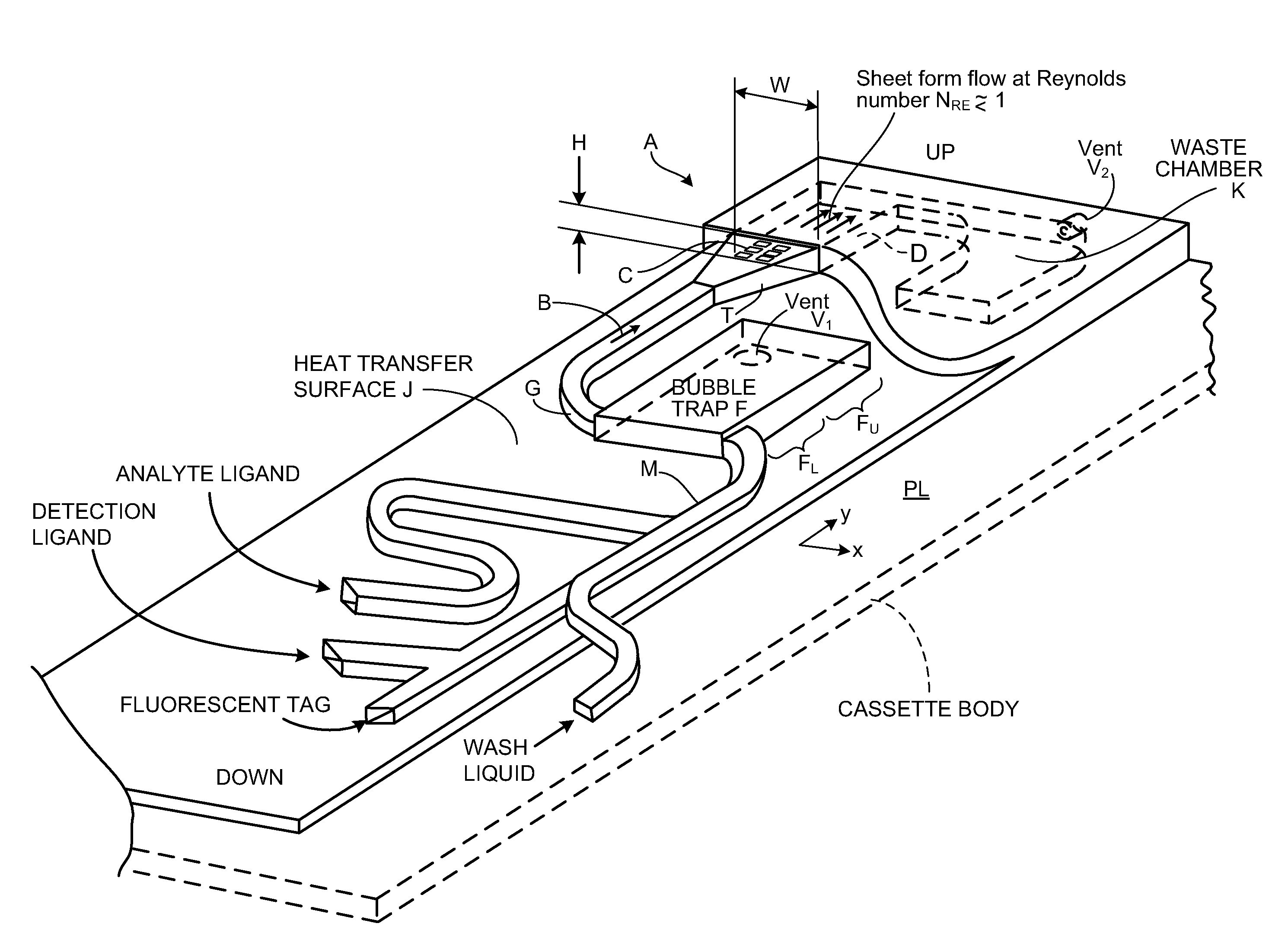

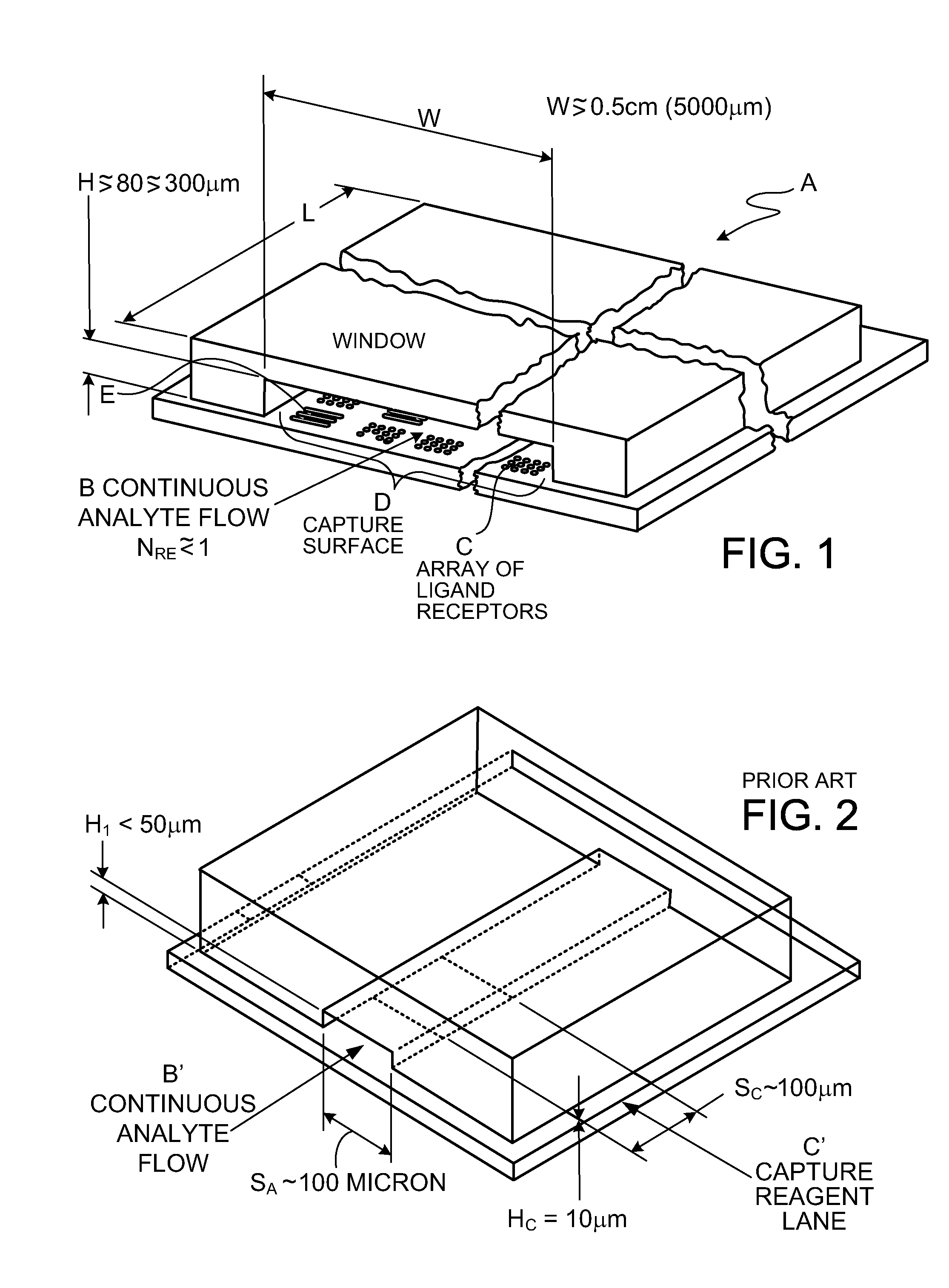

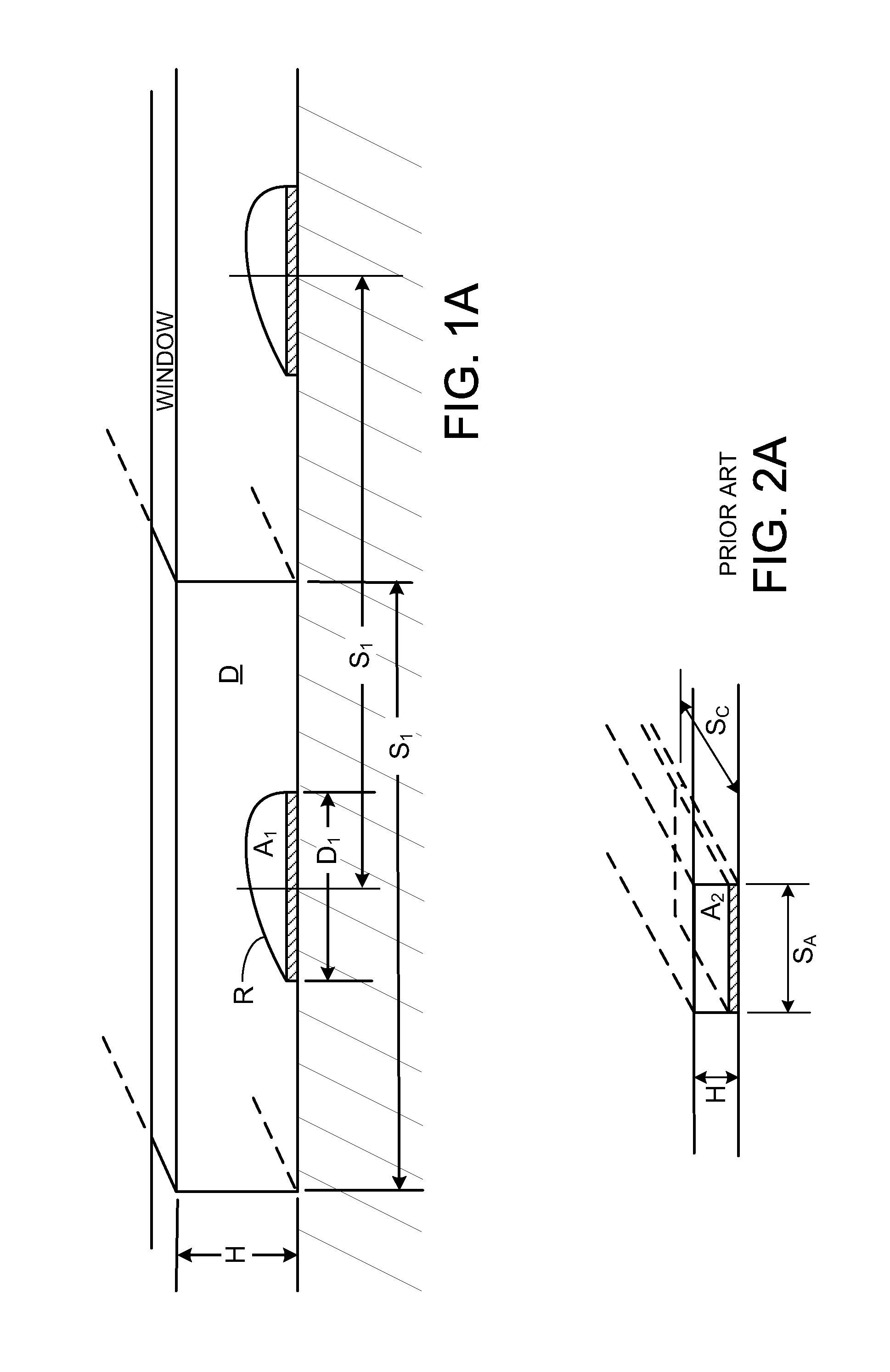

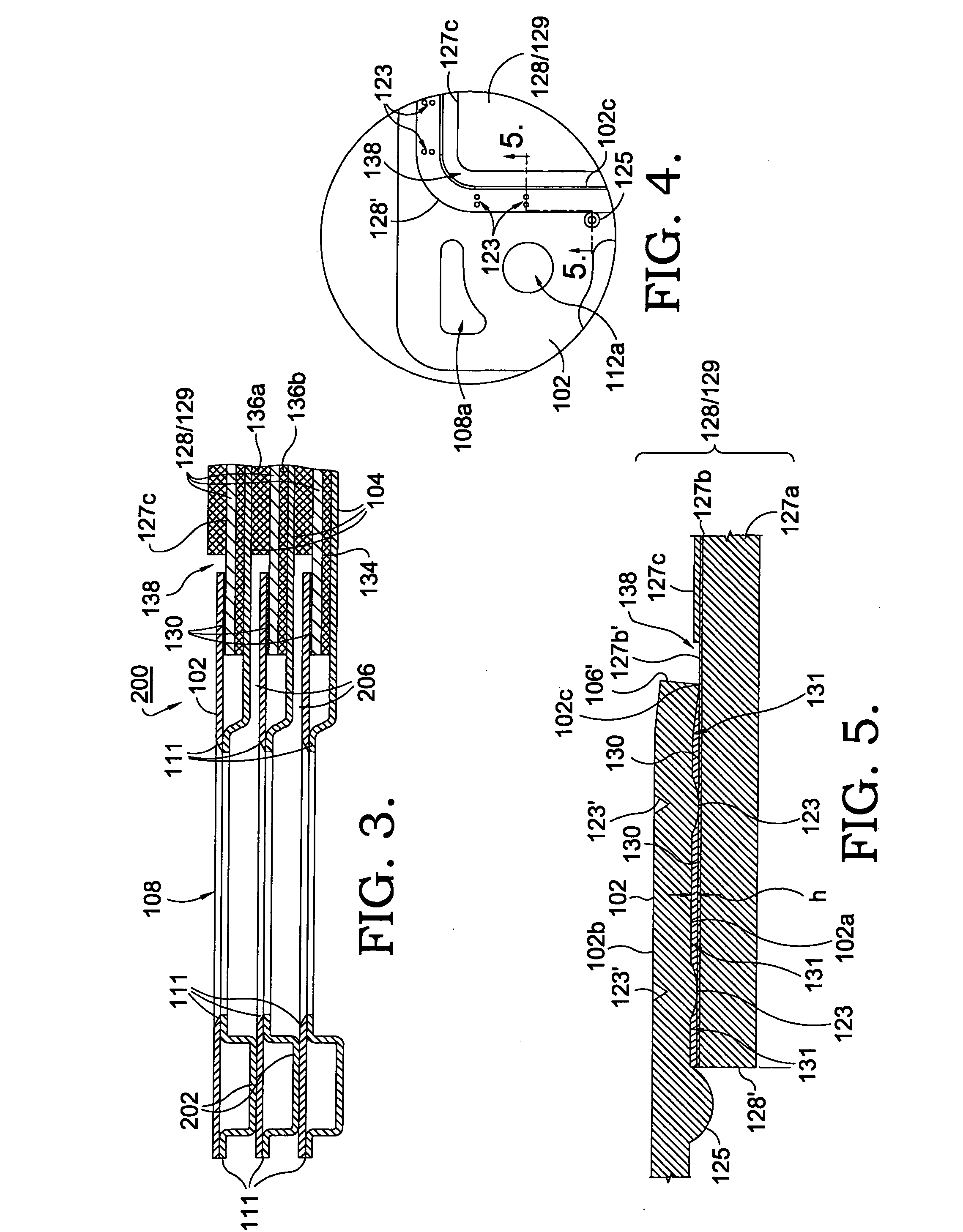

Cassette (50) performs assays, e.g. multiplexed protein biomarker assays. Wide, bubble-free, slow flows are produced from liquids stored on cassette (50), flowing over wide array (20) of ligand receptors on a capture surface. Flows of Reynolds Number less than about 1, preferably 1×10−1 to 5×10−3, are heated in region (34) preceding and including bubble removal system (128). Analyte is introduced through compressed septum (32). External actuations of displacement pumps (30, 37) and valves (137 A, B, and C) produce flows in response to flow-front optical sensors (150, 152). Elastic sheet provides pump and valve diaphragms and resilient expansion of mixing volume (131). Break-away cover portions are pistons. Heating is by conduction through cassette from external contact heater. Planar cassette body, when tilted from horizontal, enables upward flow from pumped storage (134, 135) to reaction (133) to waste (139), with buoyancy bubble removal before reaction. Reading of fluorescence is by external reader, employing calibration, control and reference features on capture surface. Extensive set of calibration features of differing intensities enables self-calibration.

Owner:AVANTRA BIOSCI CORP

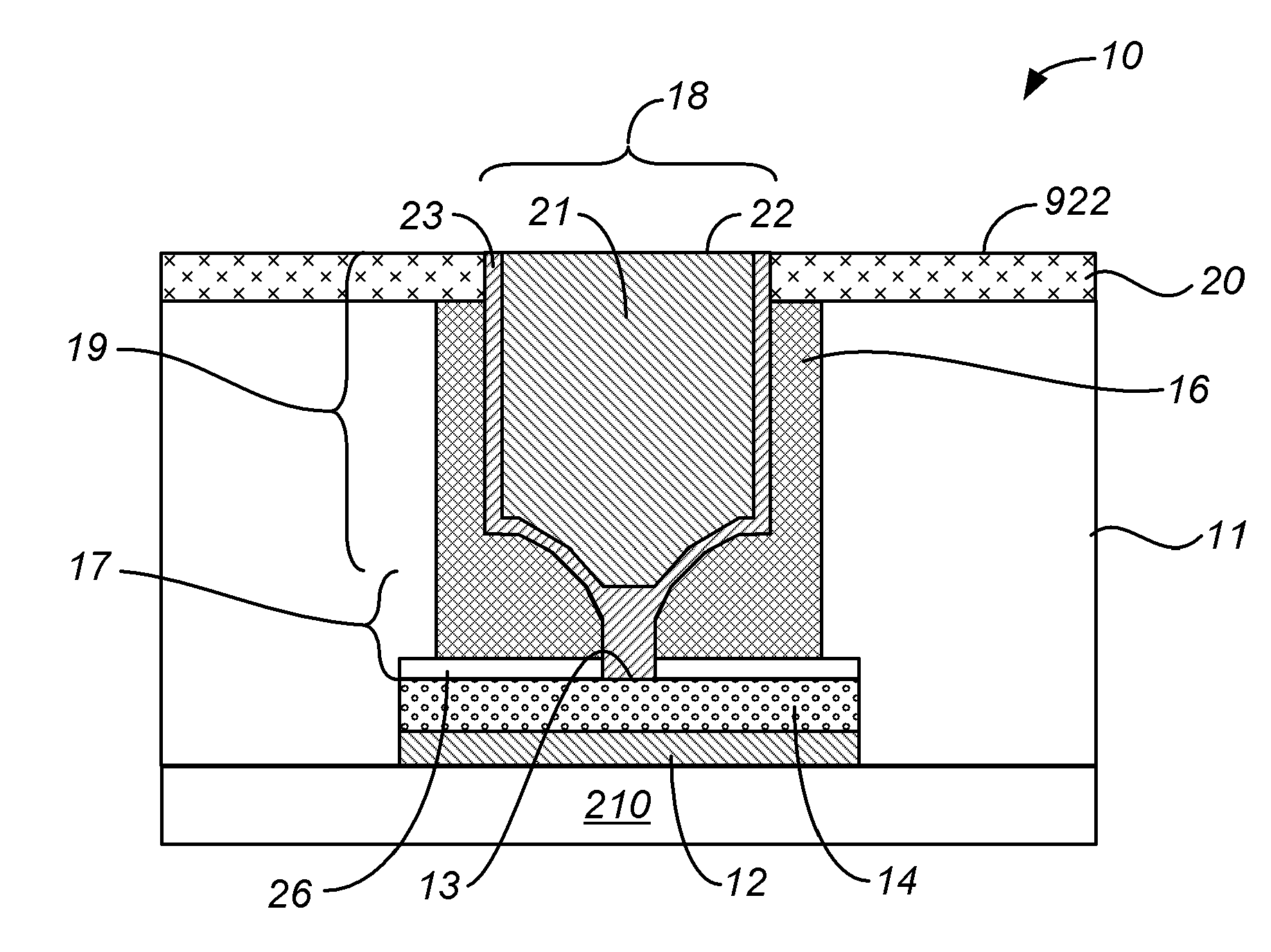

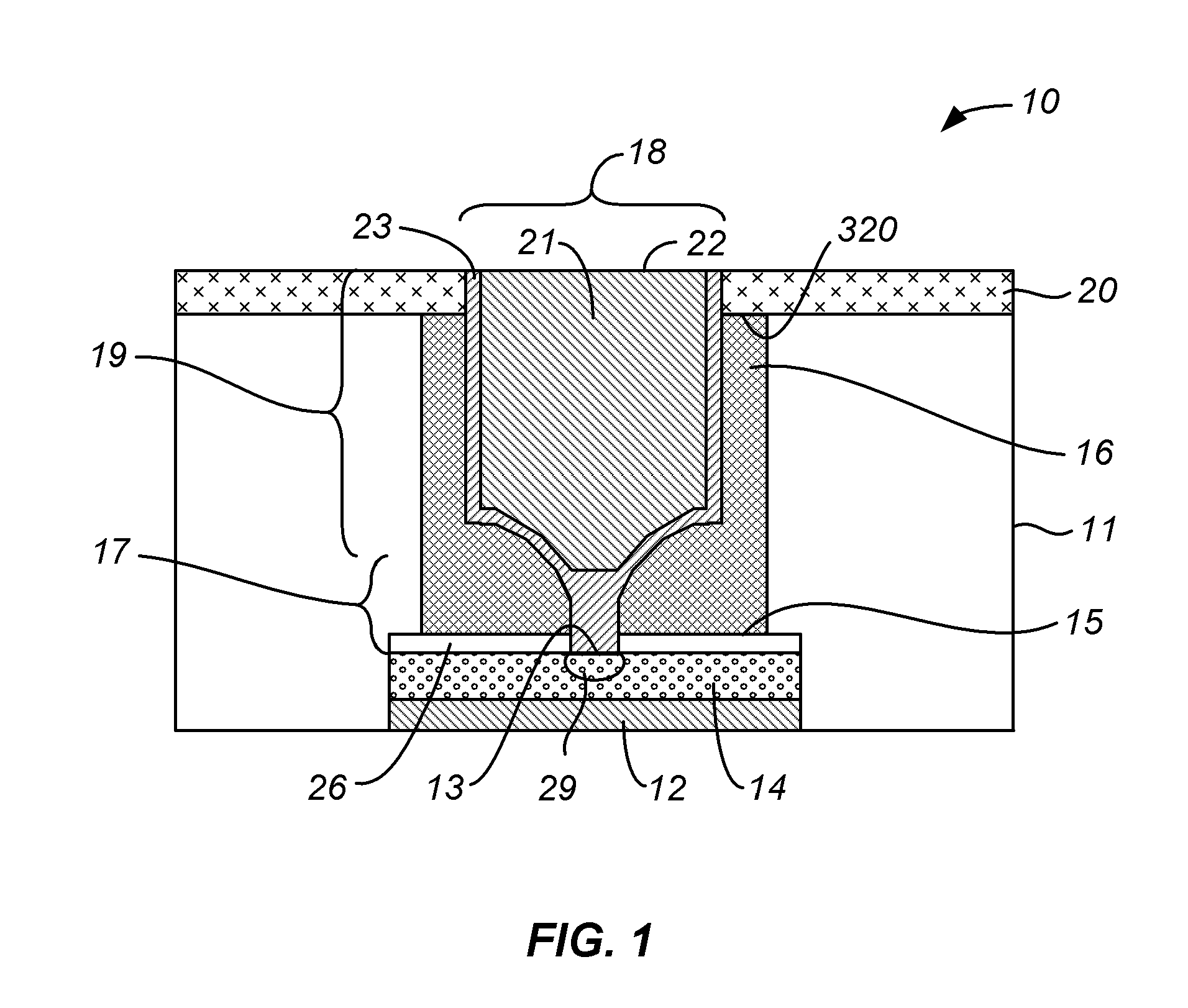

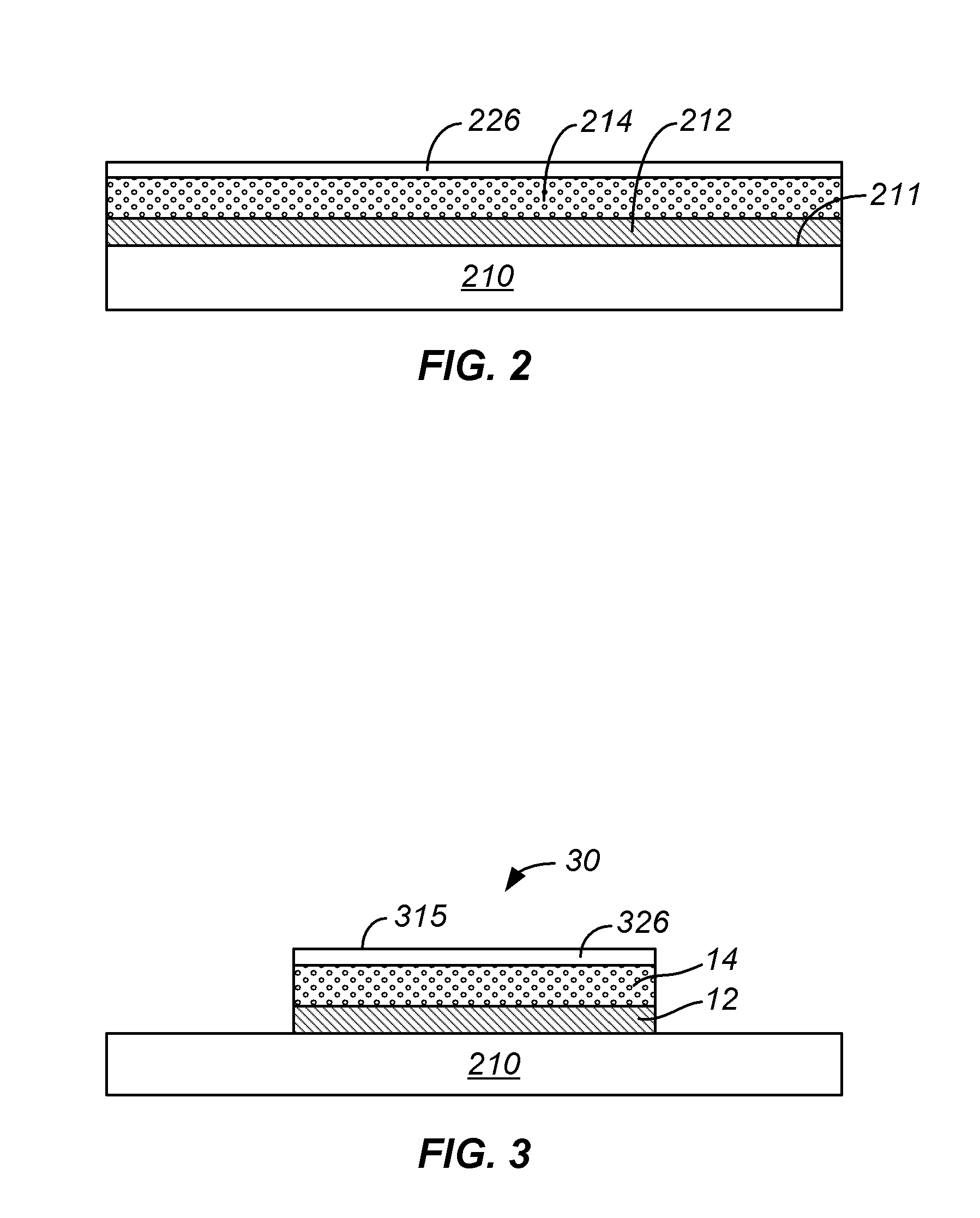

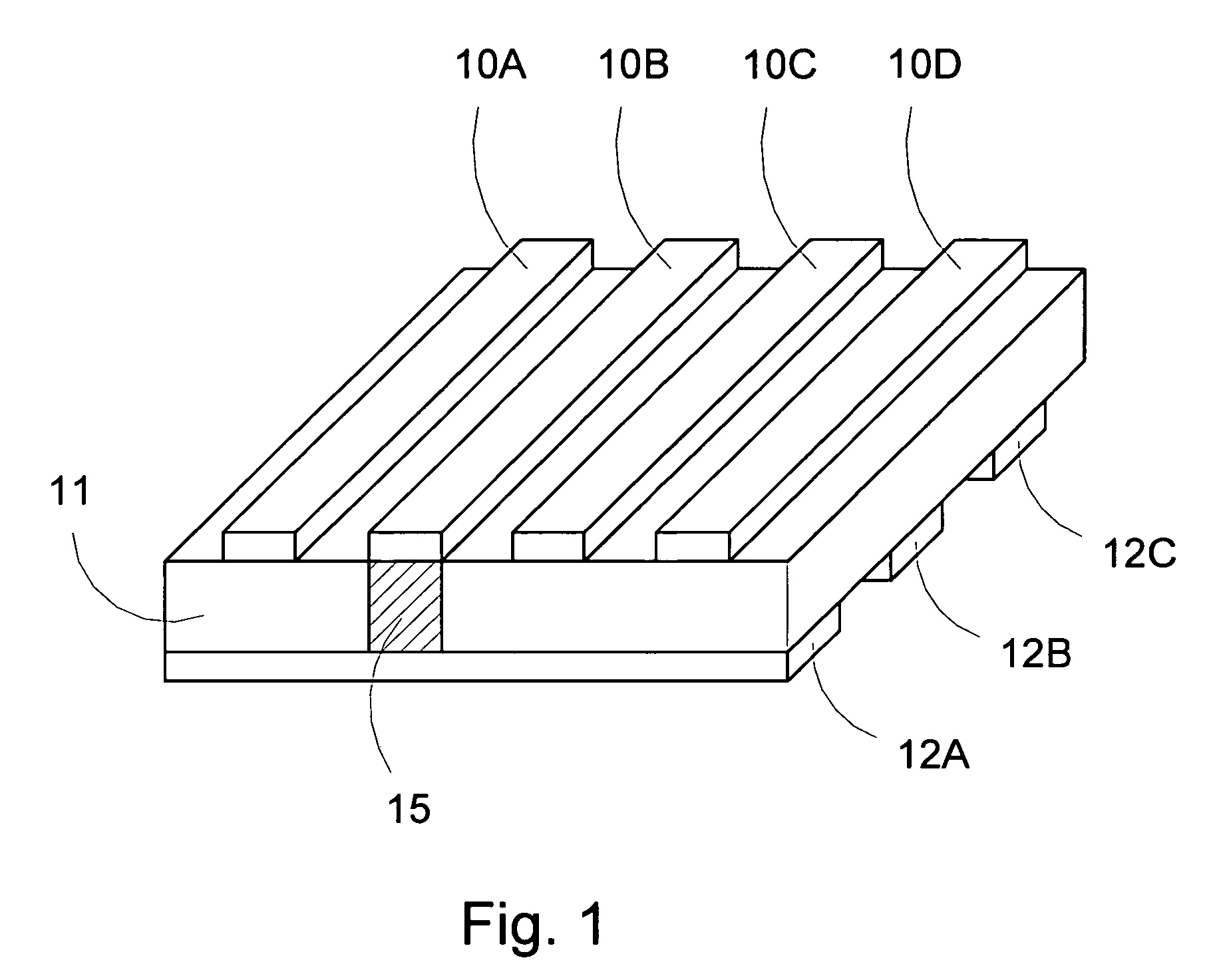

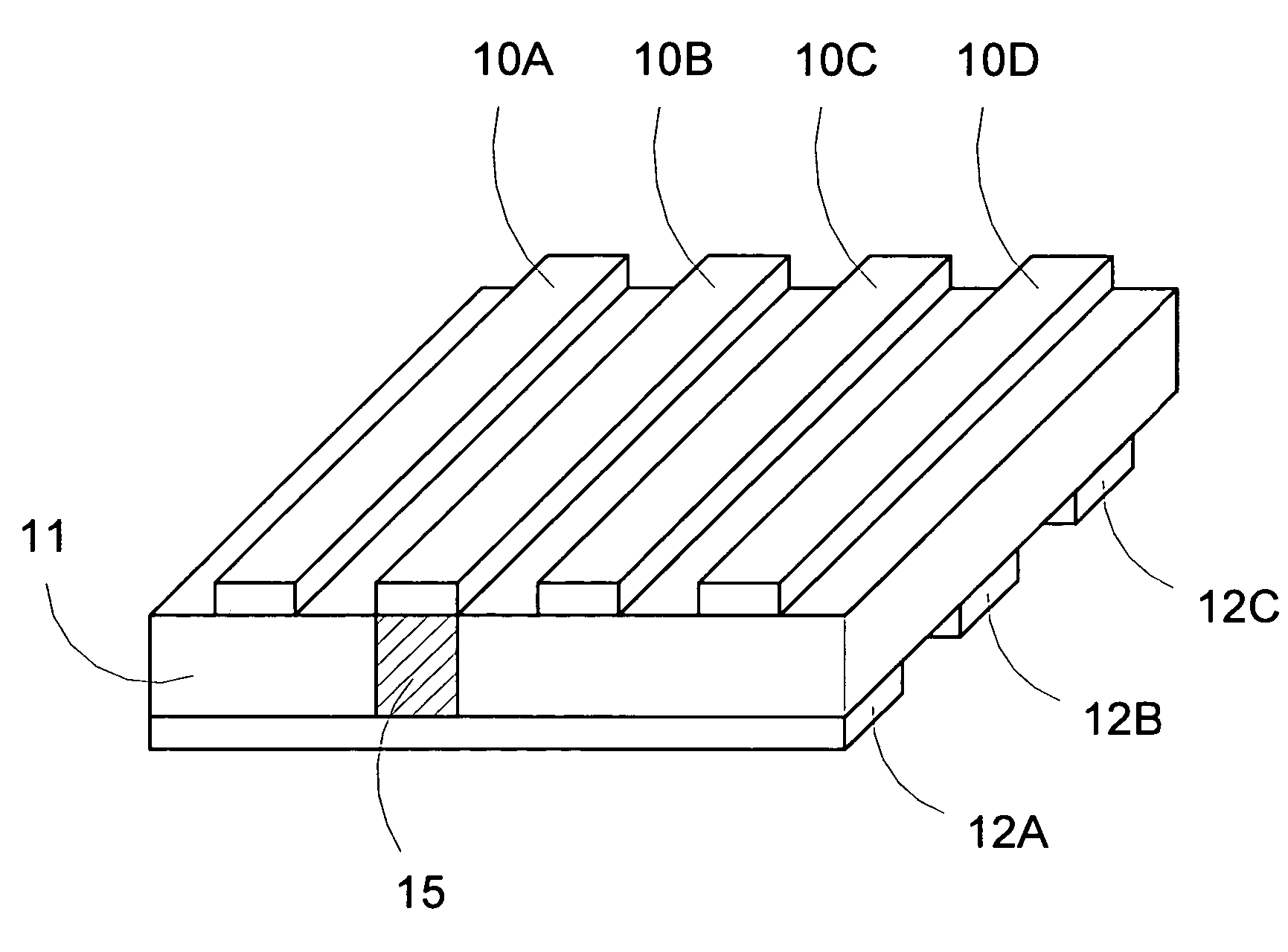

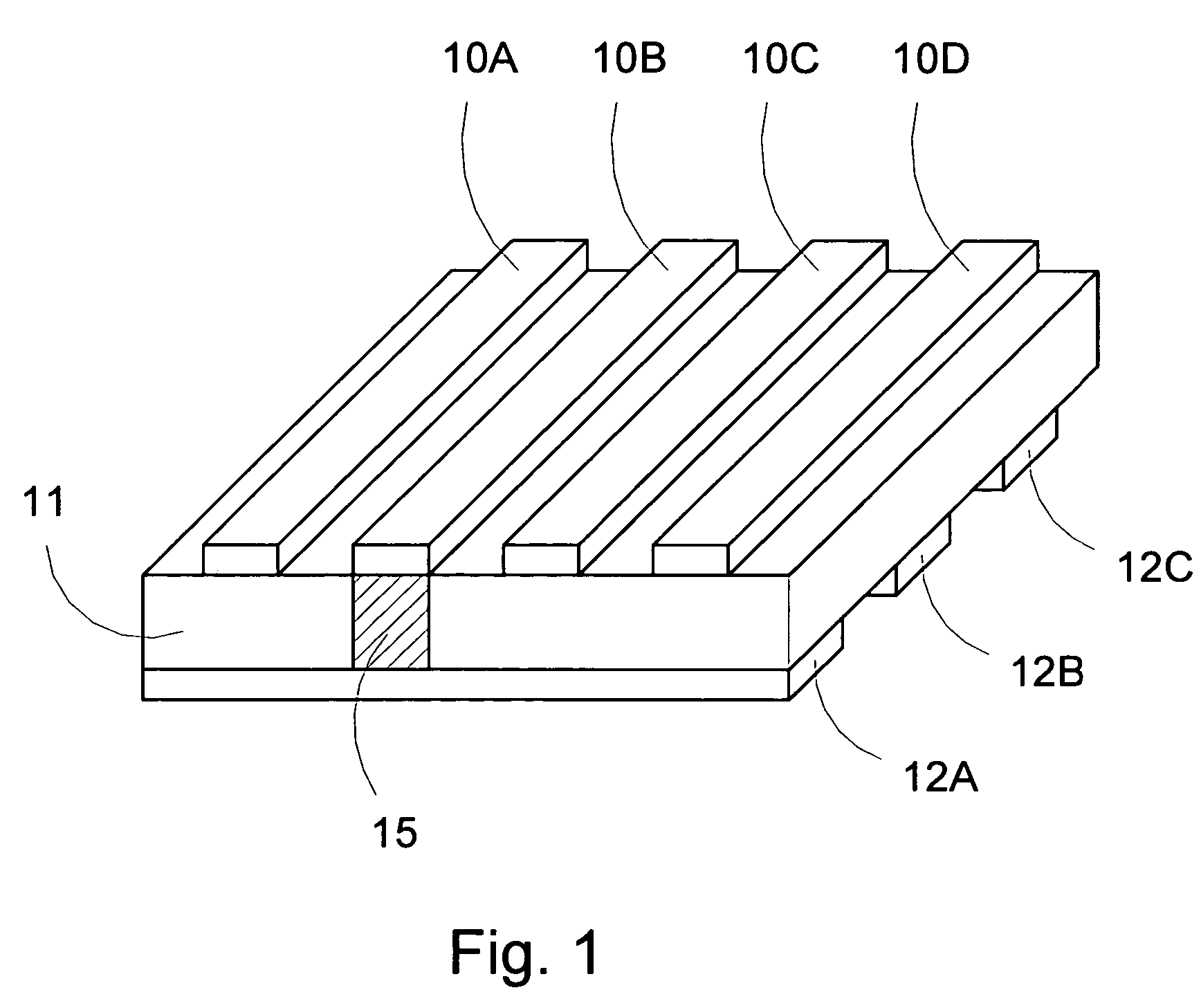

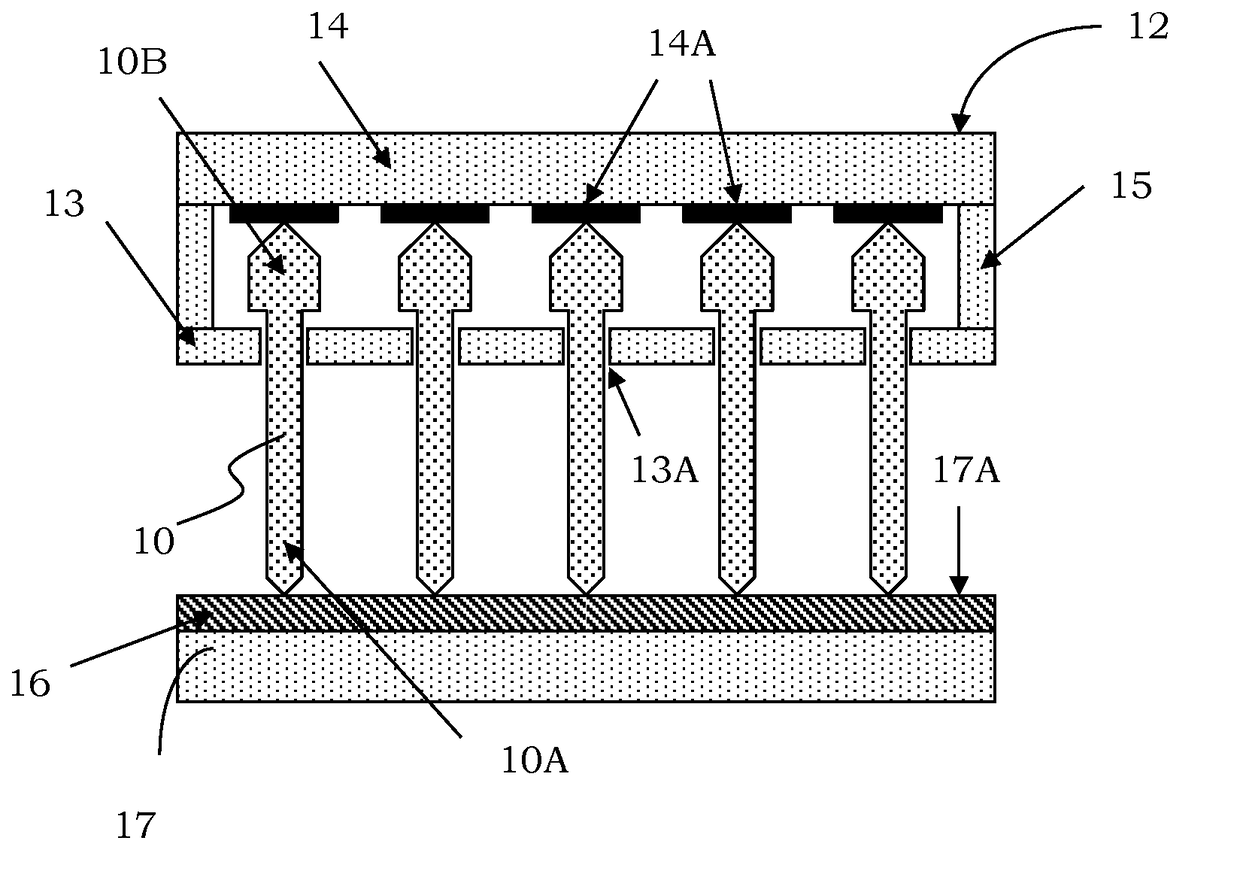

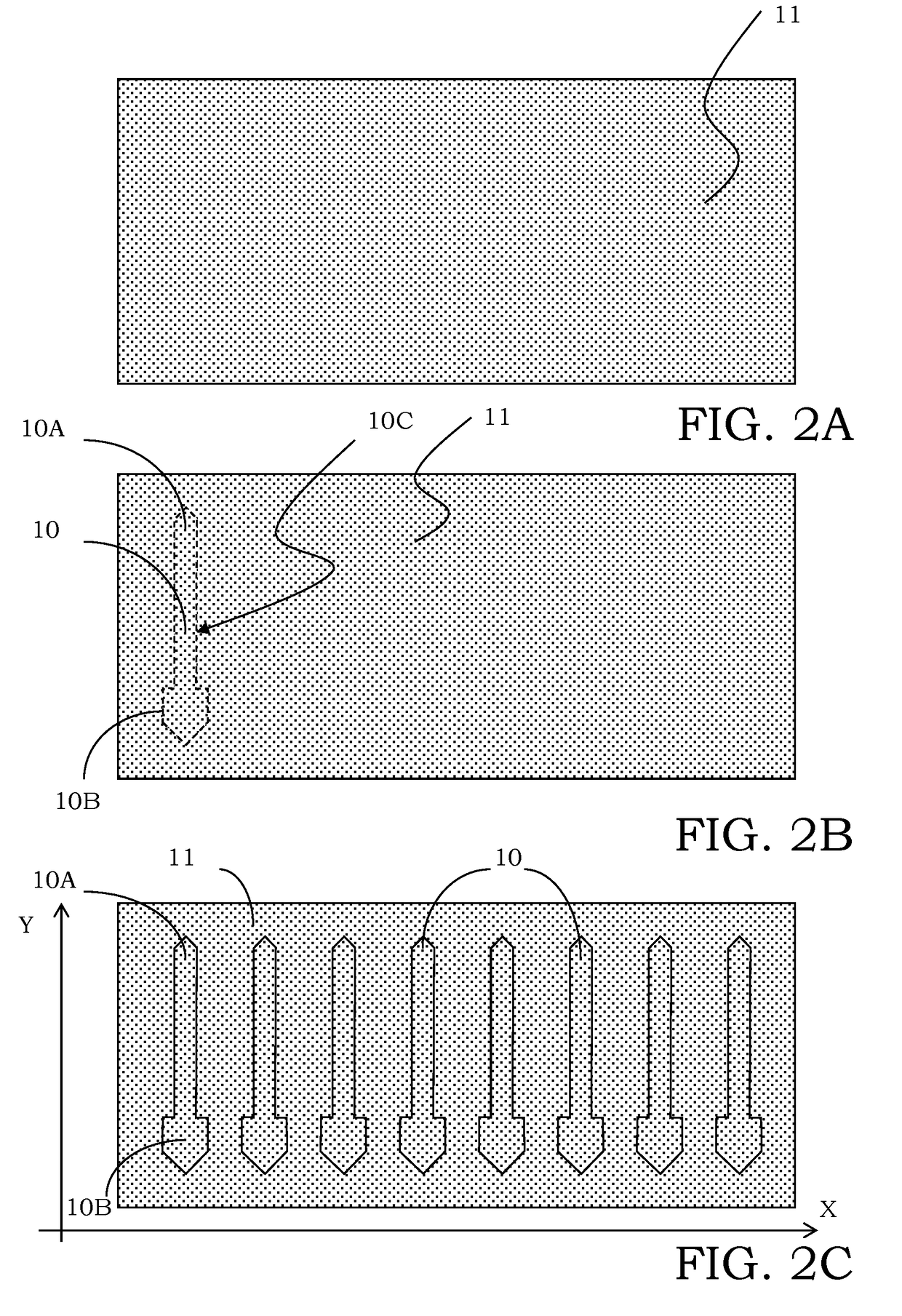

Memory device having wide area phase change element and small electrode contact area

ActiveUS7772581B2Highly repeatableEasy to controlSolid-state devicesDigital storageWide areaPhase change

A memory cell device of the type that includes a memory material switchable between electrical property states by application of energy, situated between first and second (“bottom” and “top”) electrodes has a top electrode including a larger body portion and a stem portion. The memory material is disposed as a layer over a bottom electrode layer, and a base of the stem portion of the top electrode is in electrical contact with a small area of the surface of the memory material. Methods for making the memory cell are described.

Owner:MACRONIX INT CO LTD

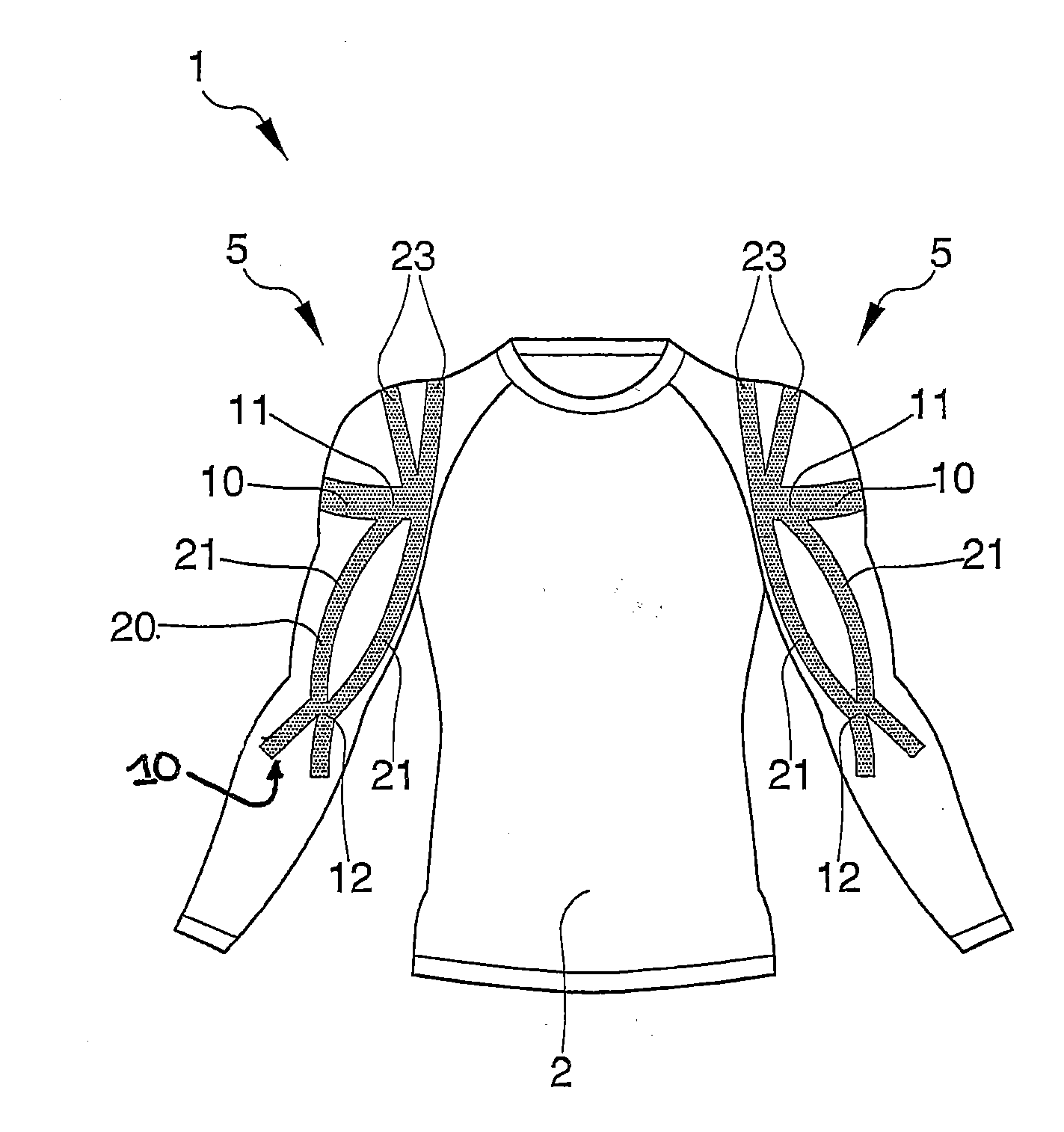

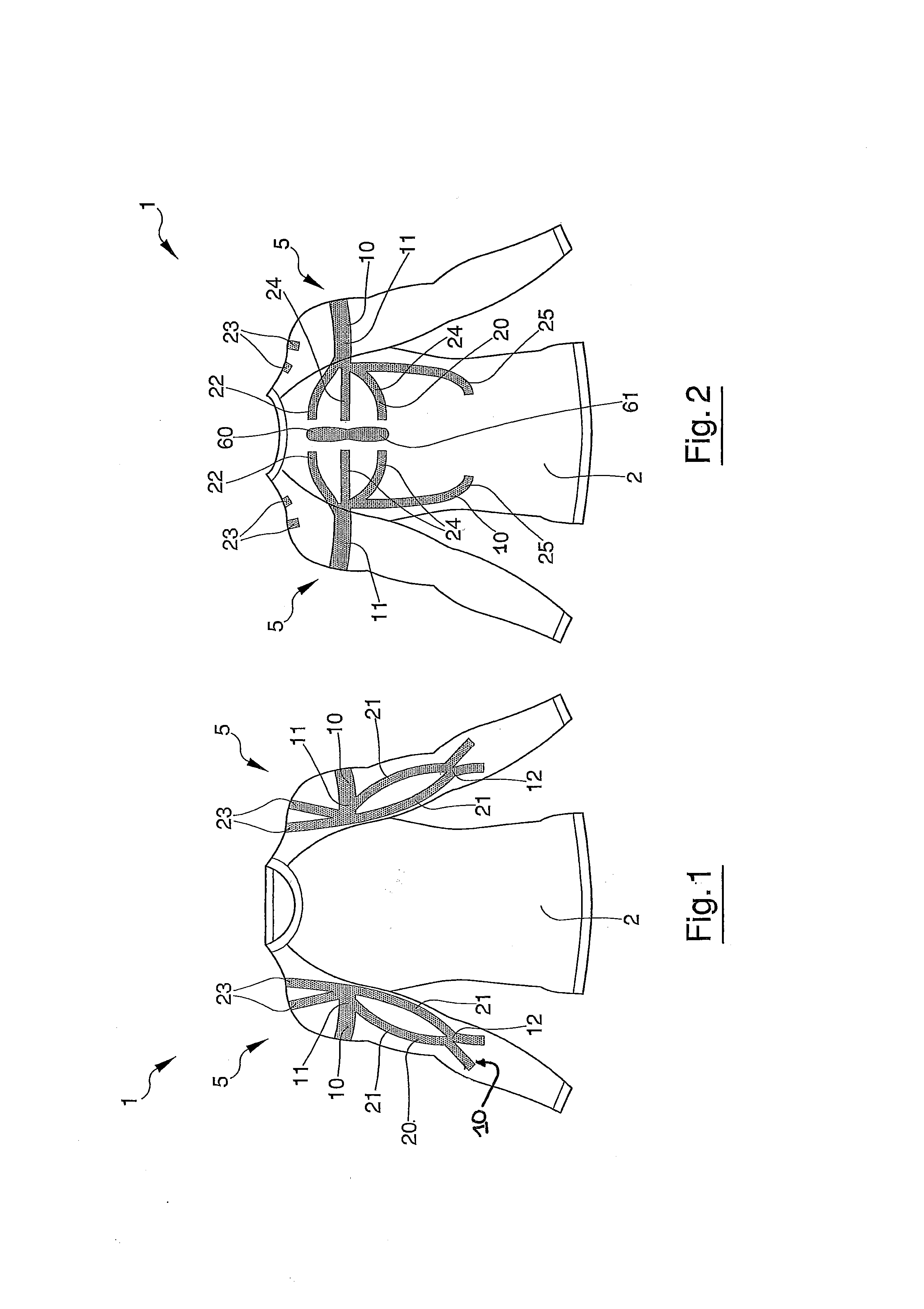

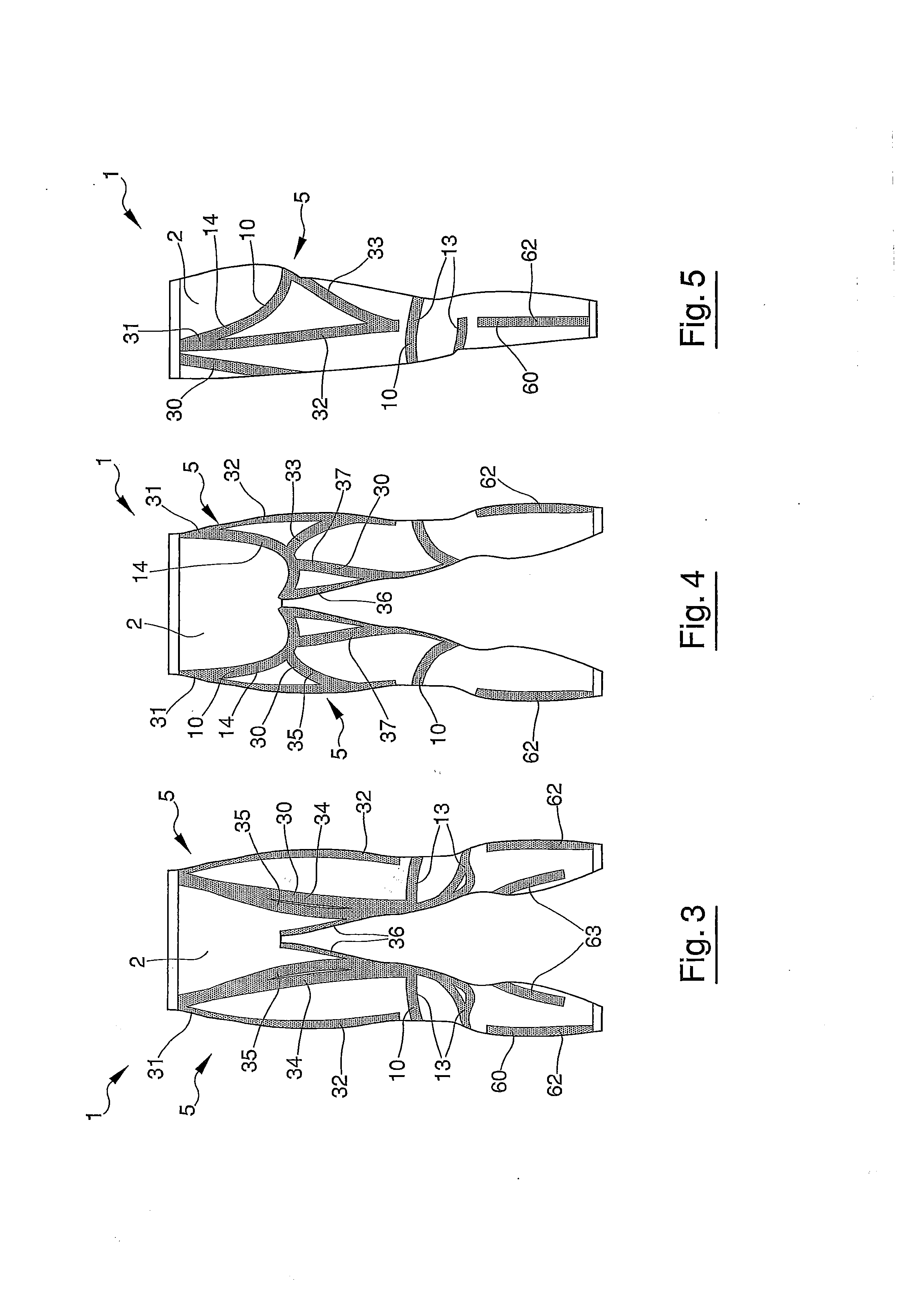

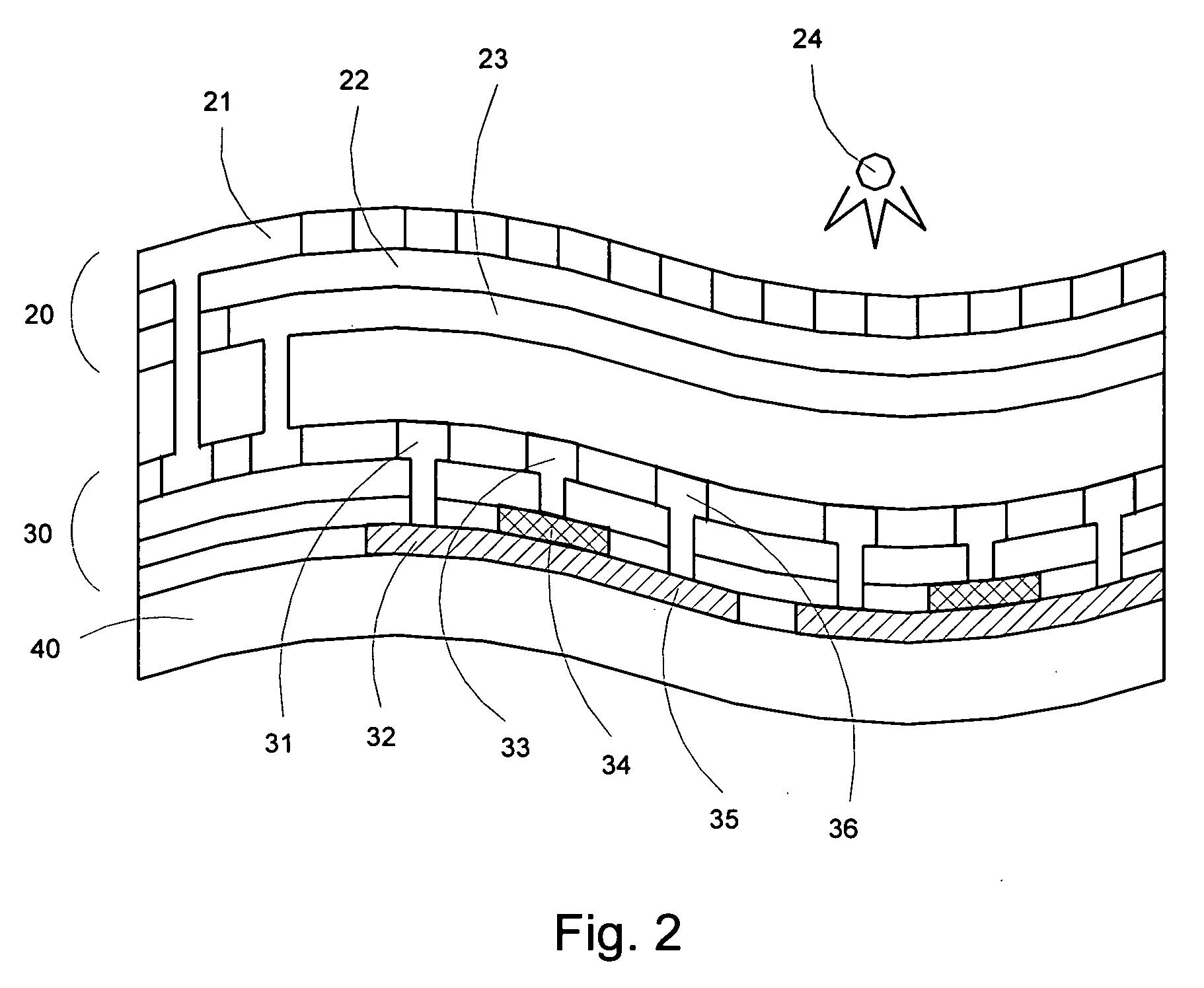

Garment for the neuro-musculo-skeletal assistance

InactiveUS20130326785A1Highly repeatableAdvantageously automatableProtective garmentSpecial outerwear garmentsEngineeringMotor activity

A garment for neuro-musculo-skeletal assistance comprising a body (2) of the garment provided with elasticity and intended to be worn by a user to adhere to a portion of the user's body and an elastic and continuous framework (5) on the body of the garment and comprising a plurality of anchoring portions (10) and a plurality of active portions (20; 30; 40; 50), each intended to coincide with respective sectors of the user's body, where the framework is structured so that, when the garment is worn by the user and the latter carries out a motor activity, the active portions deform themselves following the deformation of the respective sectors of the user's body and the anchoring portions remain substantially unchanged.

Owner:ERREA SPORT

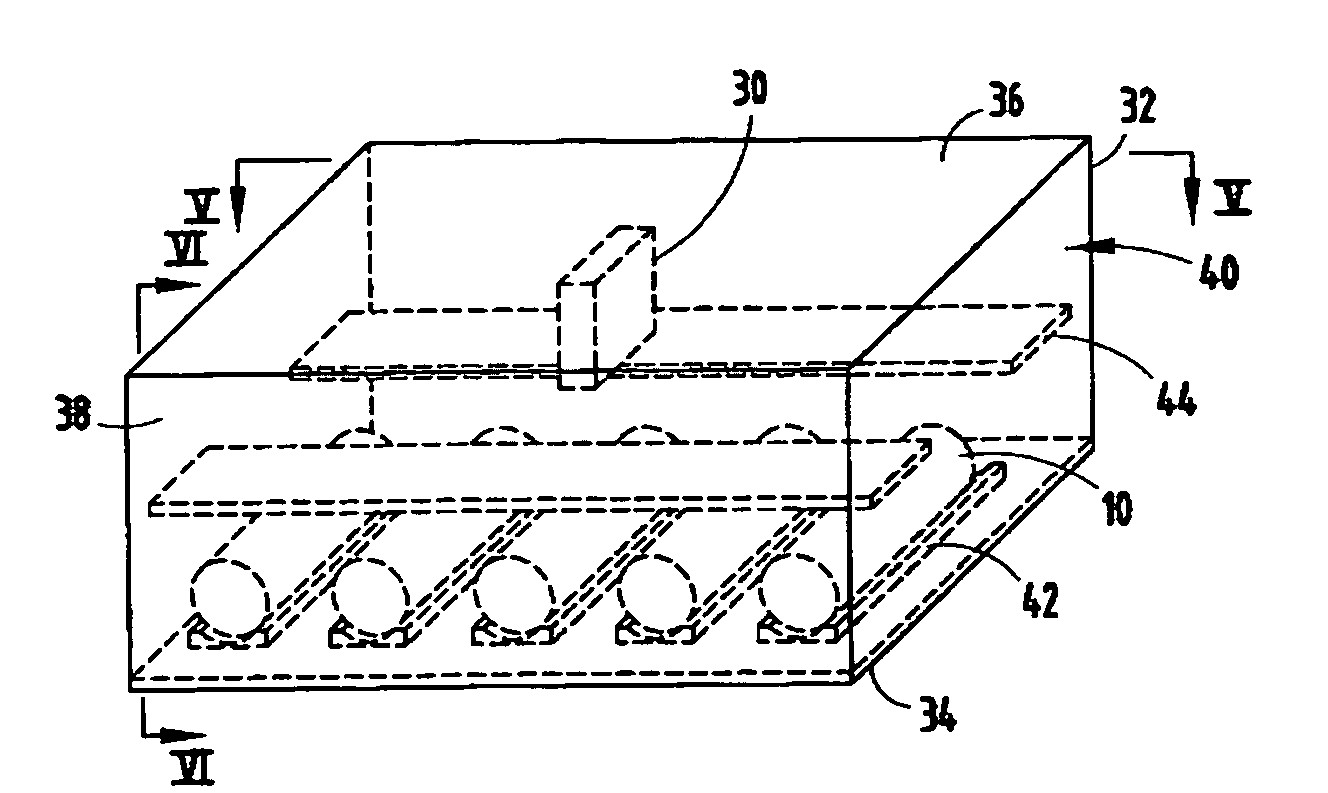

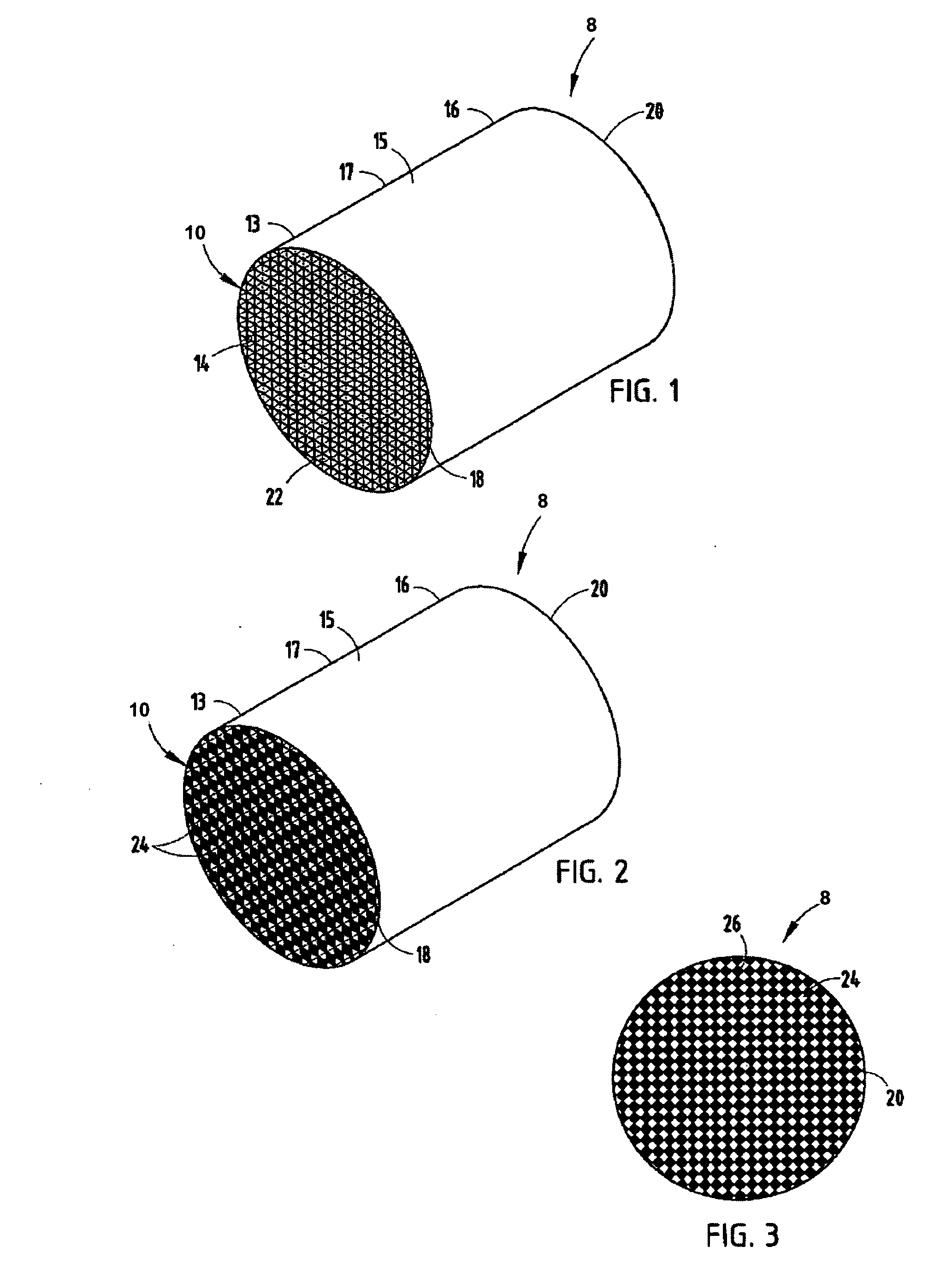

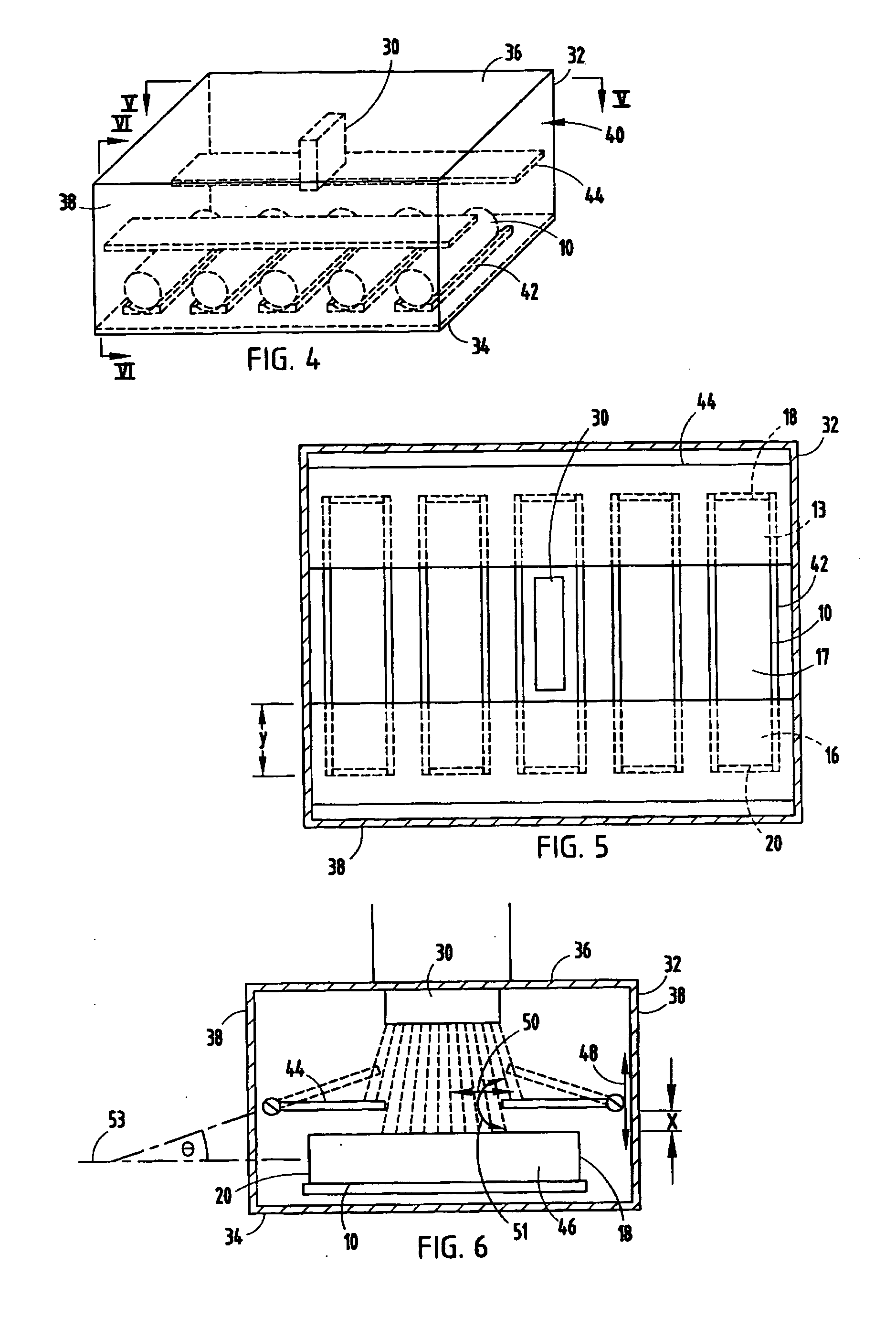

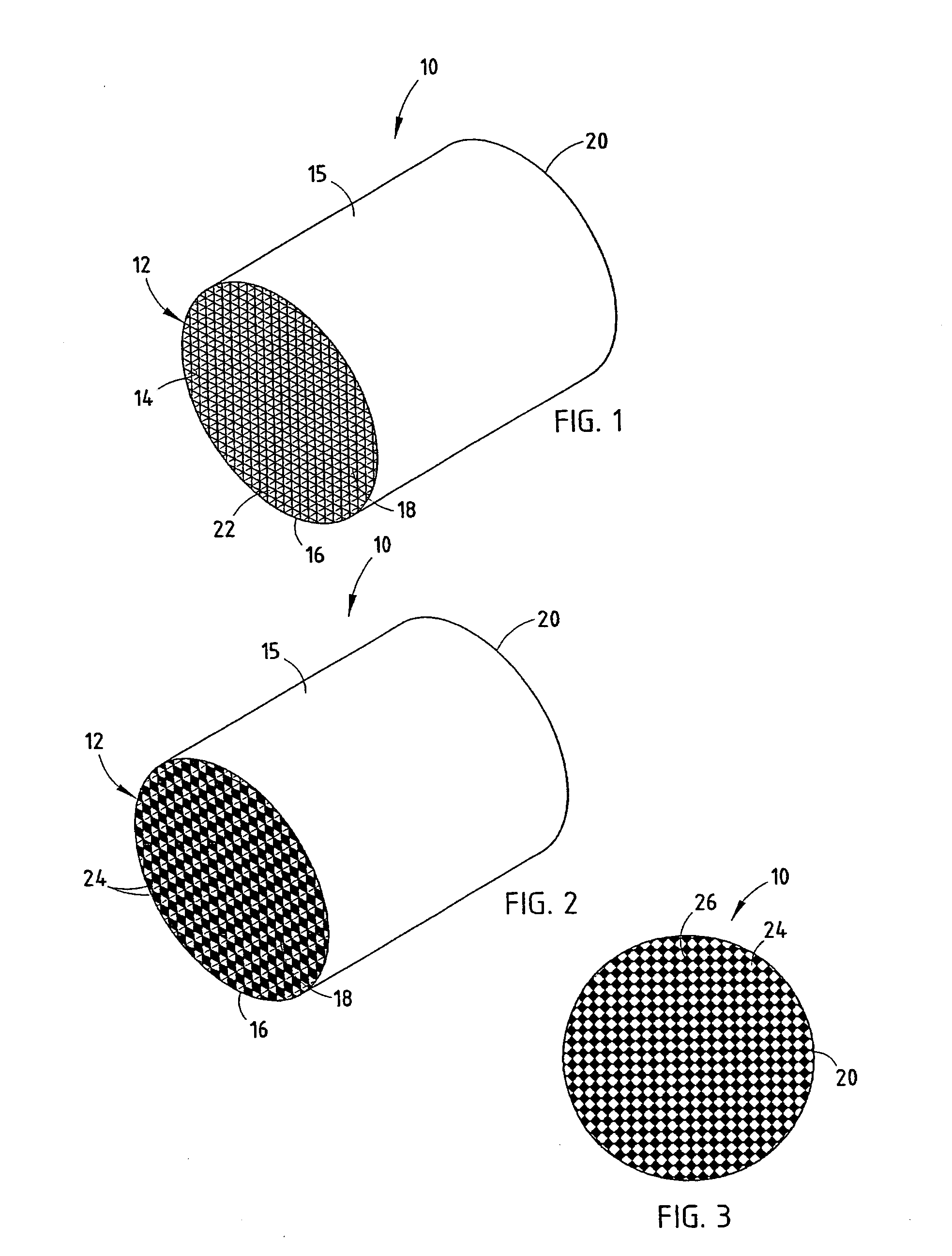

Microwave drying of ceramic structures

ActiveUS7596885B2Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

Owner:CORNING INC

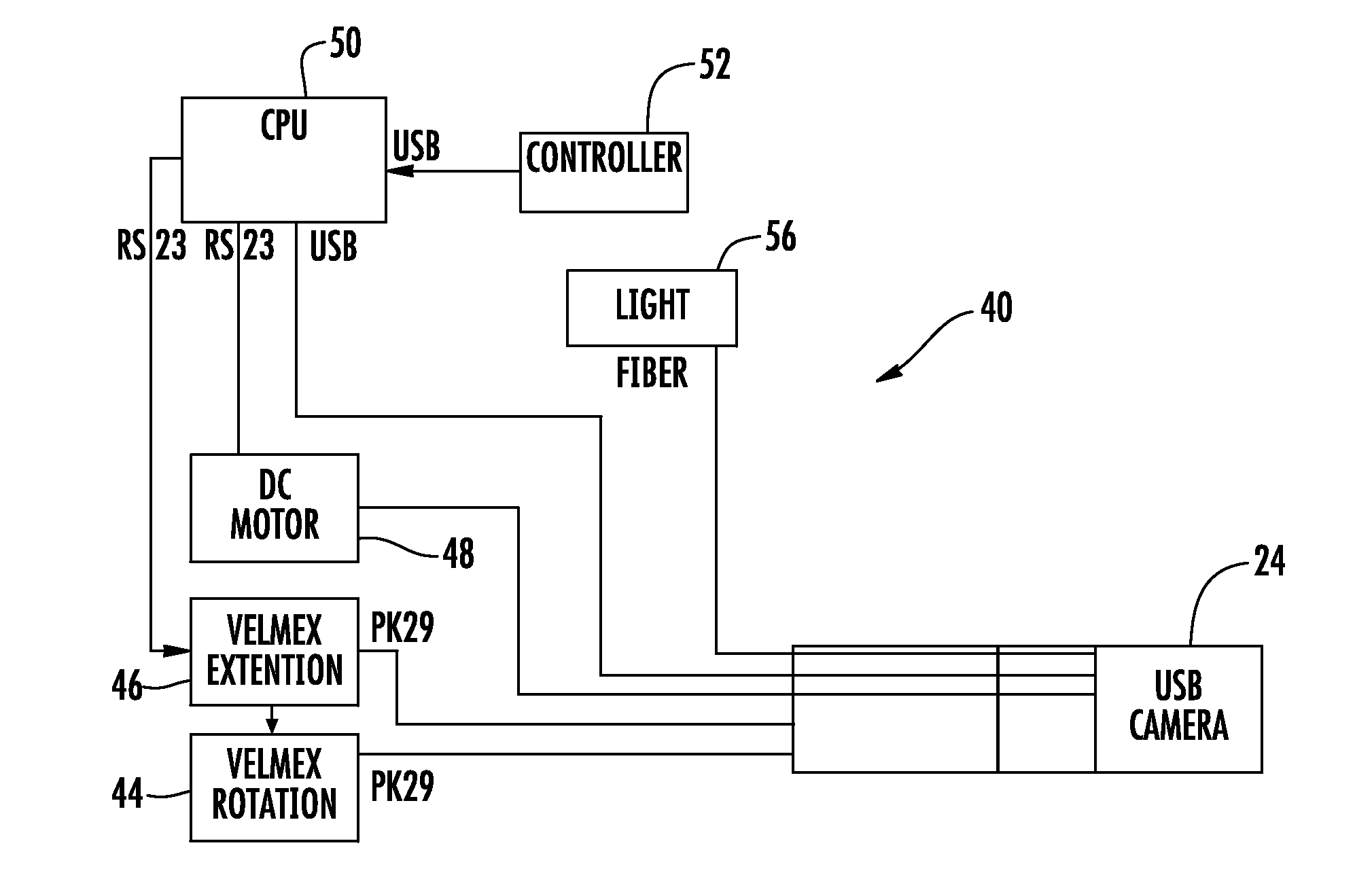

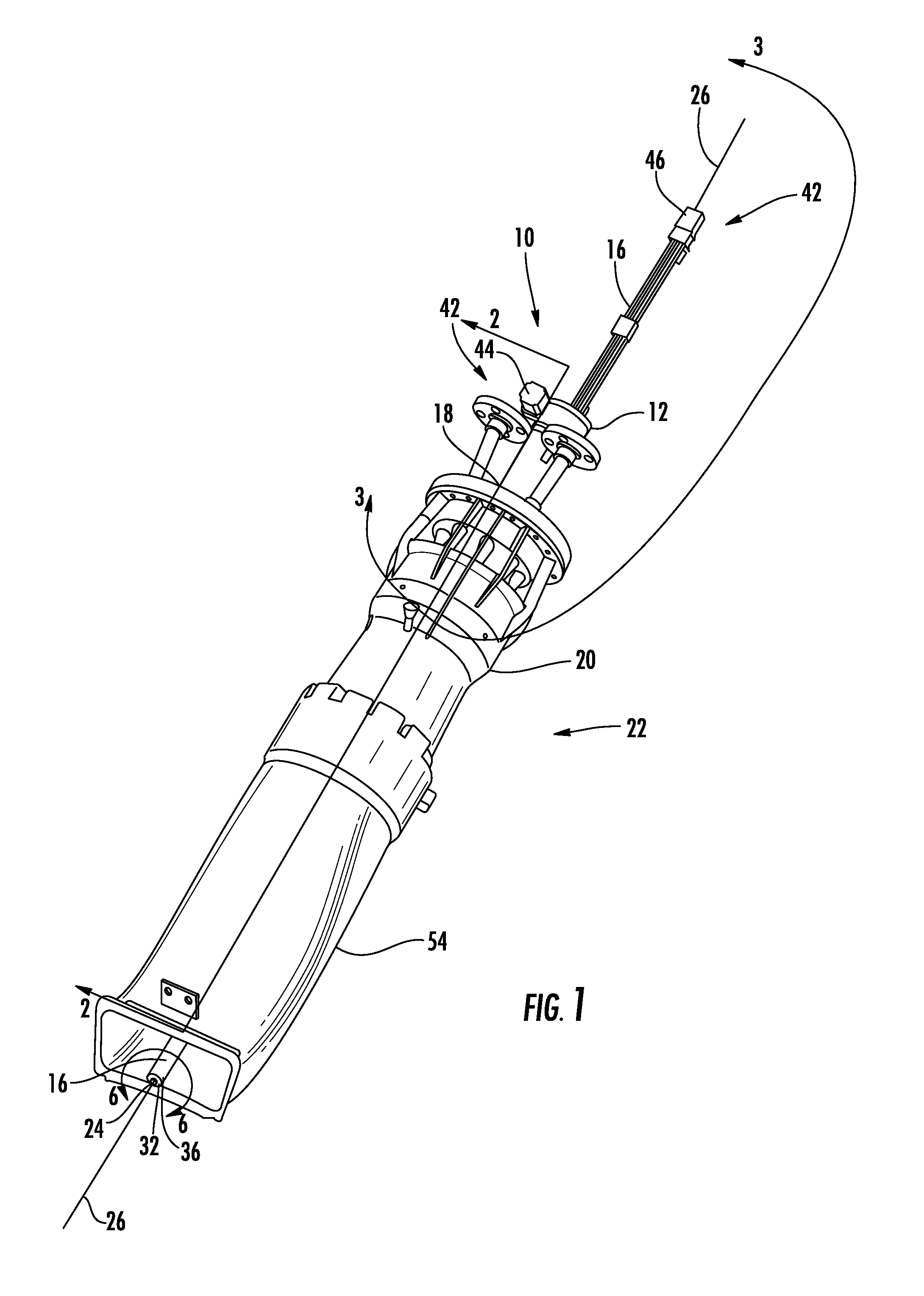

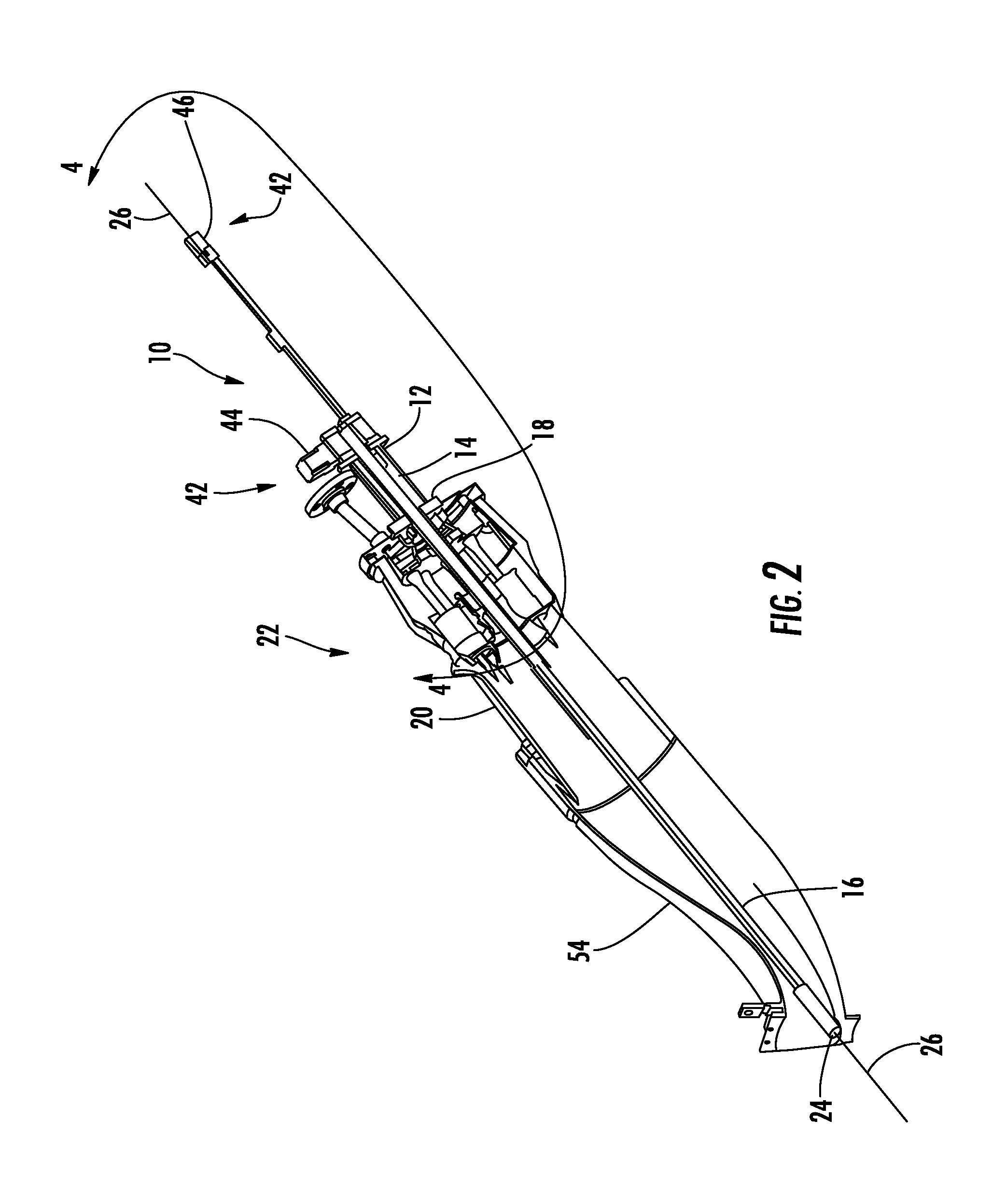

Inspection system for a combustor of a turbine engine

ActiveUS20120281084A1Highly repeatableRapid validationContinuous combustion chamberGas turbine plantsInternal cavityTroubleshooting

Owner:SIEMENS ENERGY INC

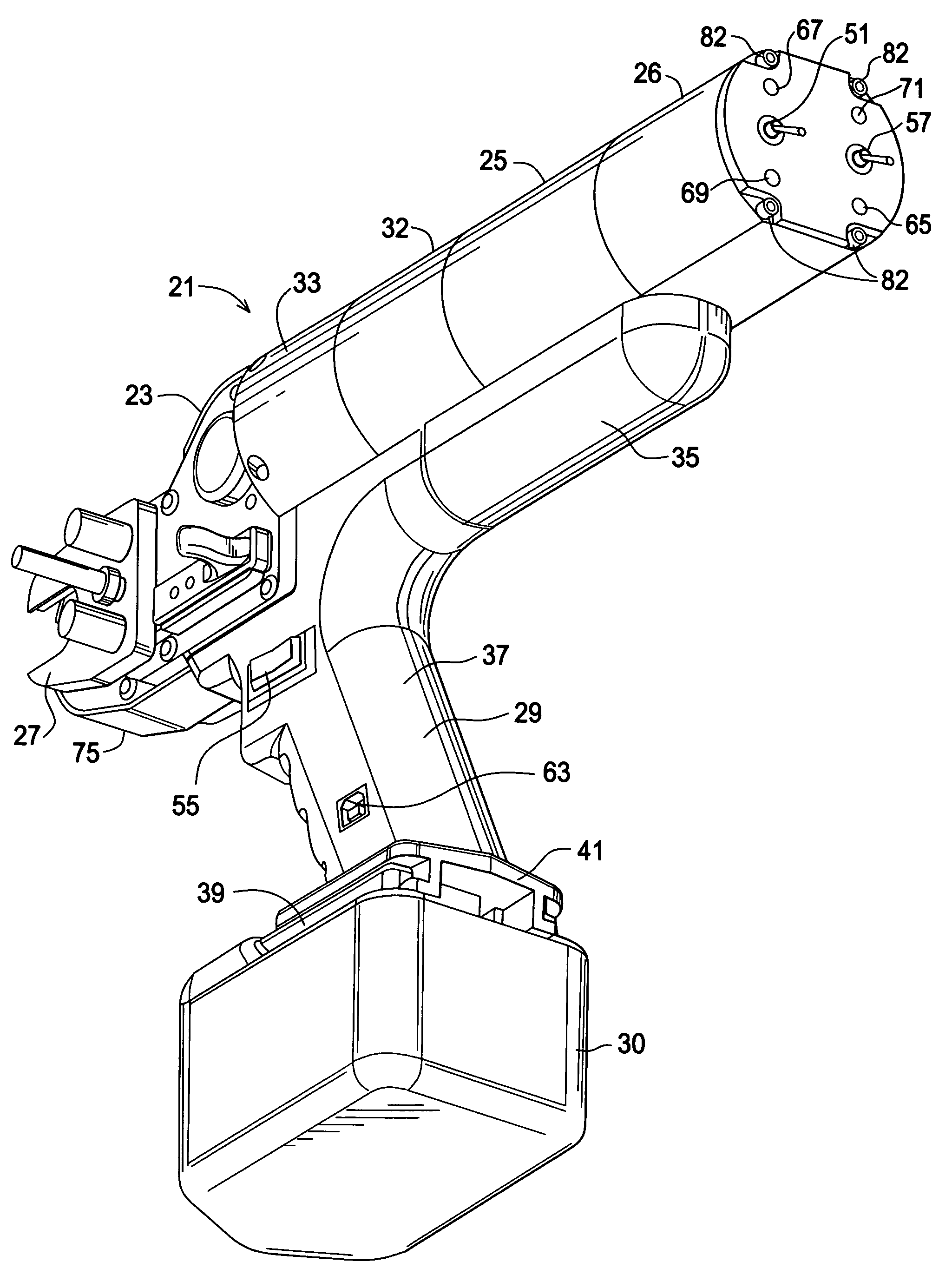

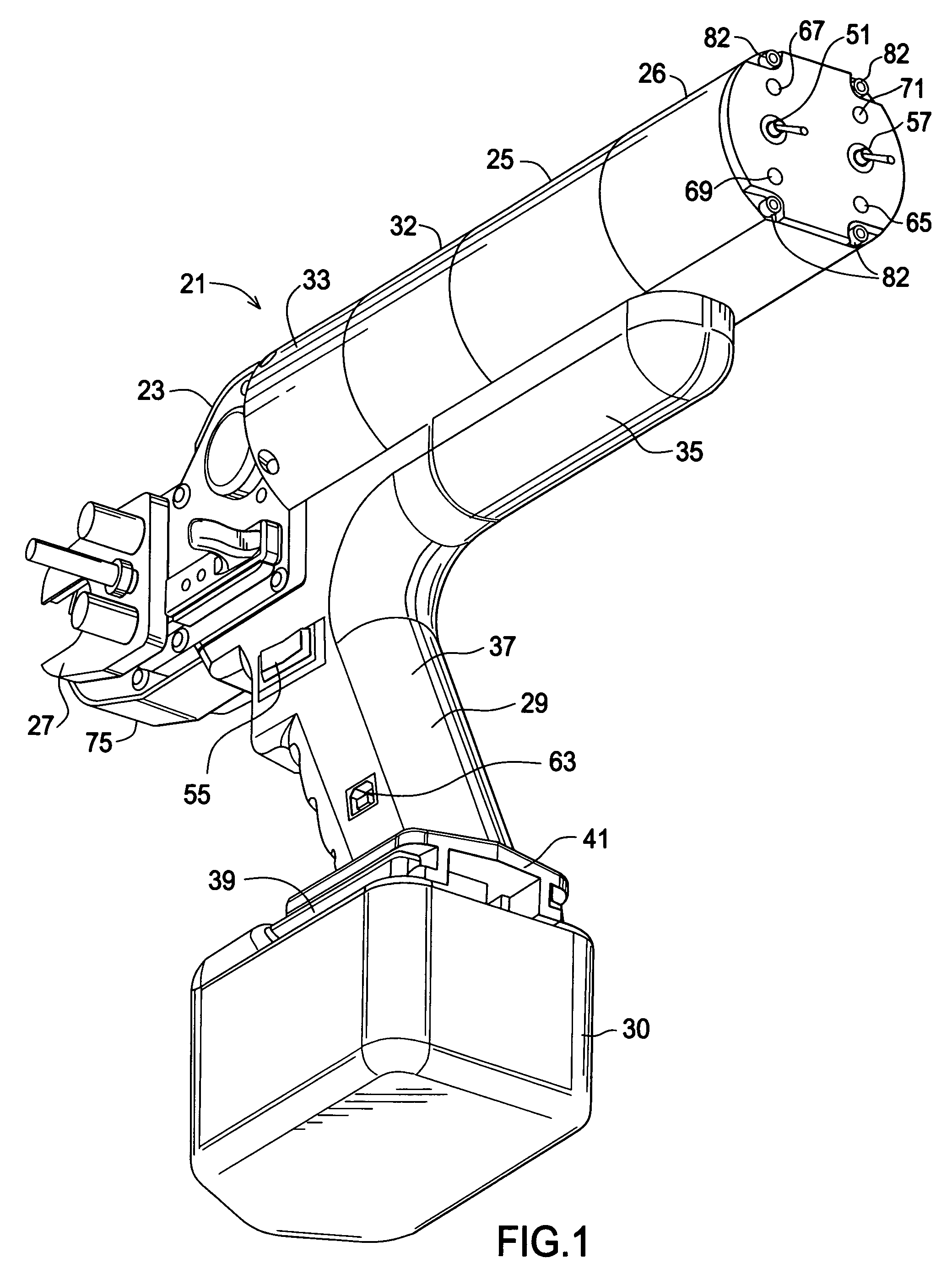

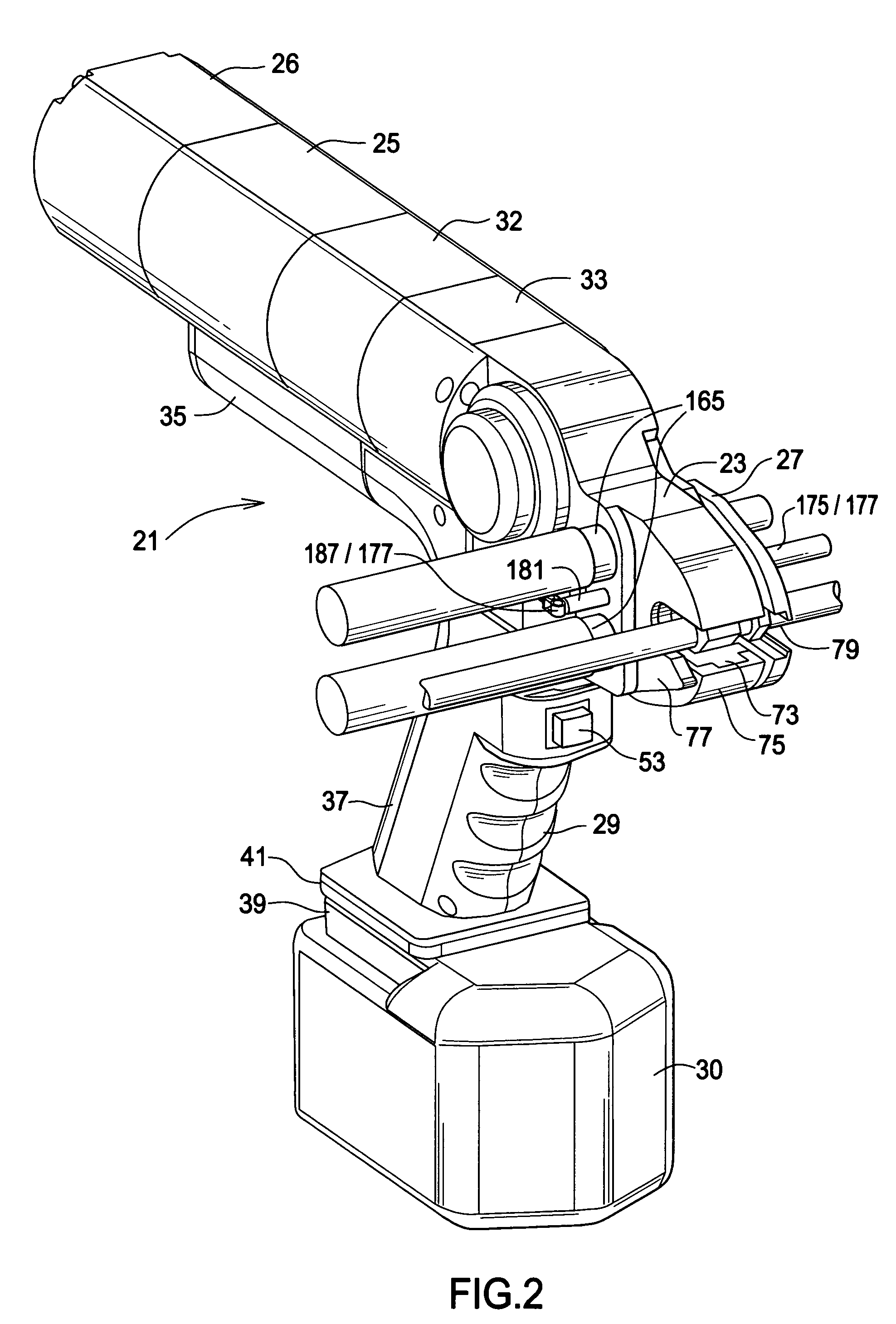

Powered driver with location specific switching

Powered drivers and methods are disclosed, the drivers including a head housing a motor driven drive transfer assembly for operating a rotatable socket engageable at a threaded connector. A reaction unit having a fitting engagement attached to rail guides is movably maintained through the head. A biasing unit is maintained at the head and is operatively associated with the rail guides of the reaction unit to bias the fitting engagement of the reaction unit toward the rotatable socket during tightening rotation of the engaged threaded connector. A probe and switch are associated with different ones of the reaction unit and the head, and are brought into operative association at selected relative locations of the reaction unit and the head during connector rotation to cause motor cessation.

Owner:AMERICAN POWER TOOLS

Microwave drying of ceramic structures

ActiveUS20080023886A1Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

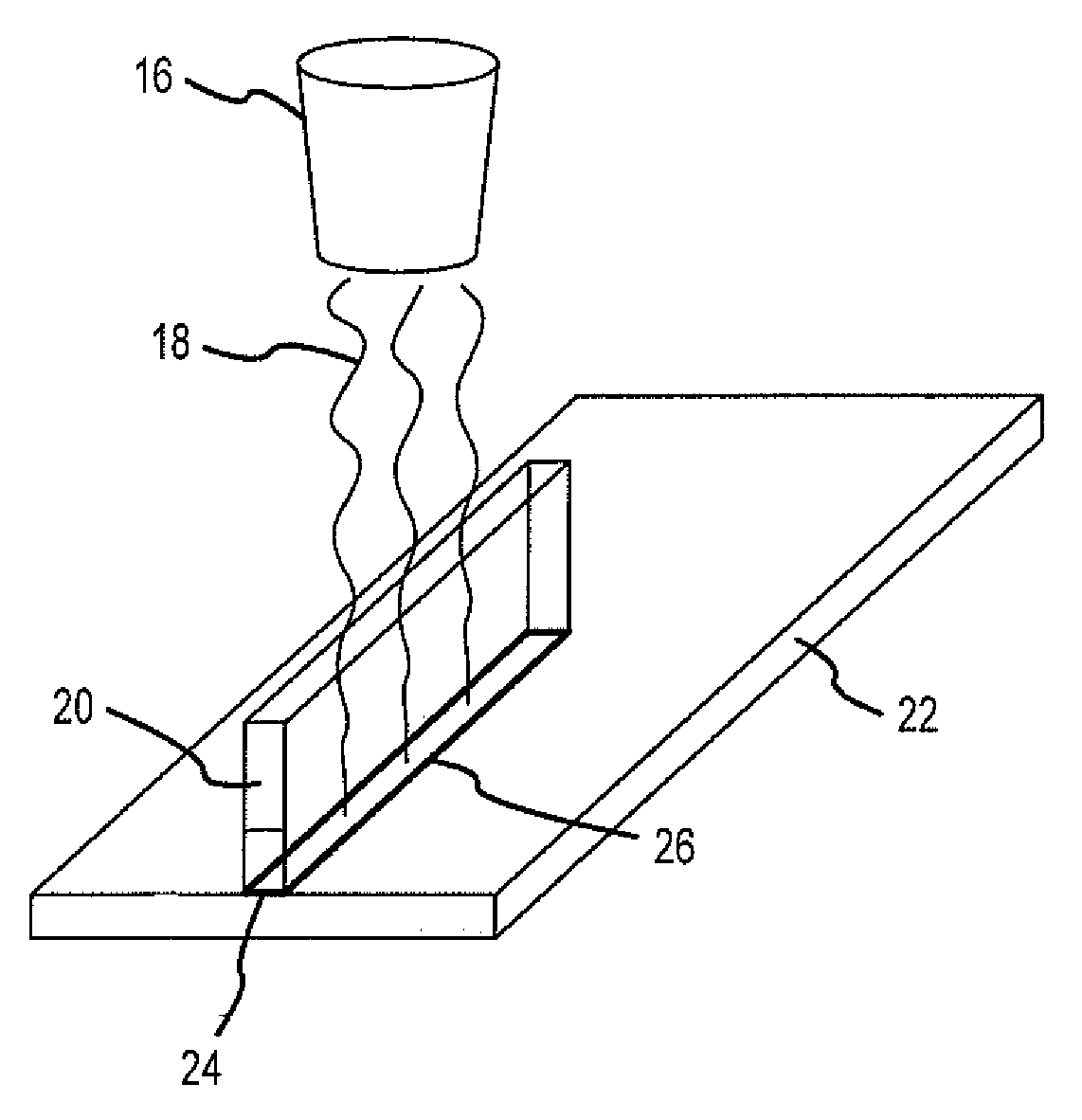

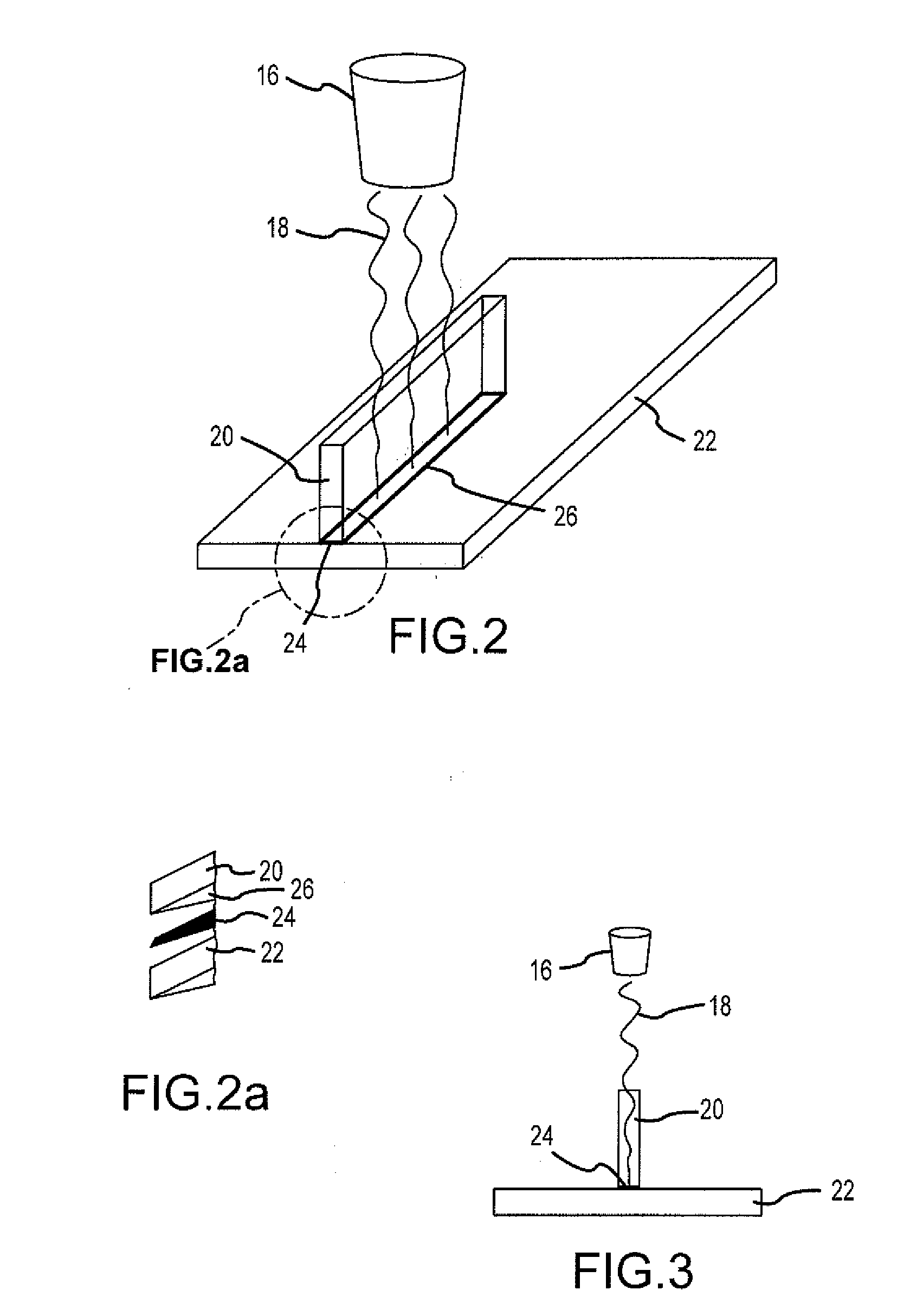

A method for drying a ceramic article comprises providing microwave radiation from a microwave generating source, providing a ceramic honeycomb structure having a middle portion and at least one end, and exposing the ceramic honeycomb structure to the microwave radiation while shielding the at least one end from directly receiving the microwave radiation, such that the radiation absorbed by the middle portion is equal to or greater than the radiation absorbed by the at least one end, and the proper drying of the entire honeycomb structure without heat-induced structural degradation is thus ensured.

Owner:CORNING INC

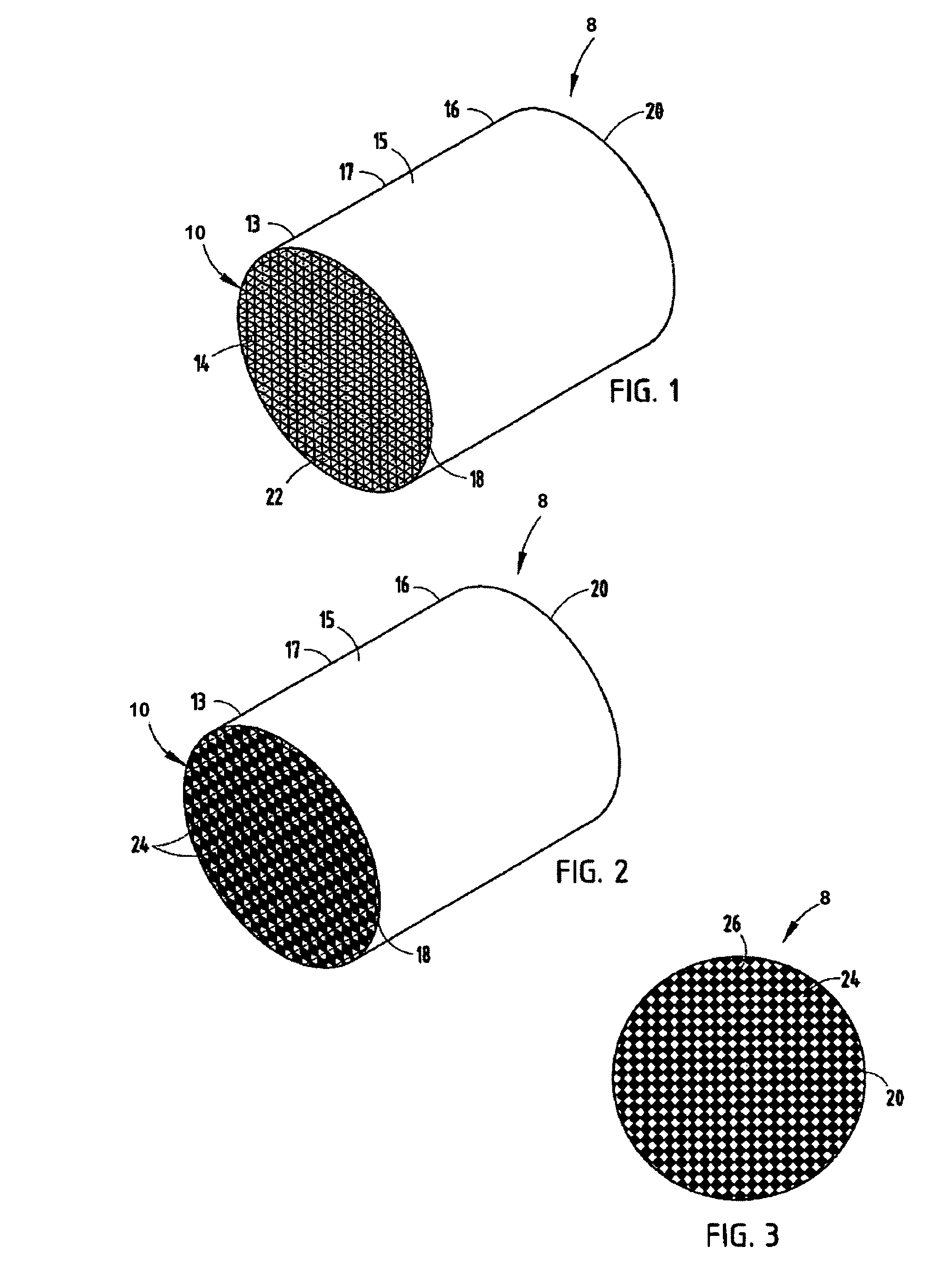

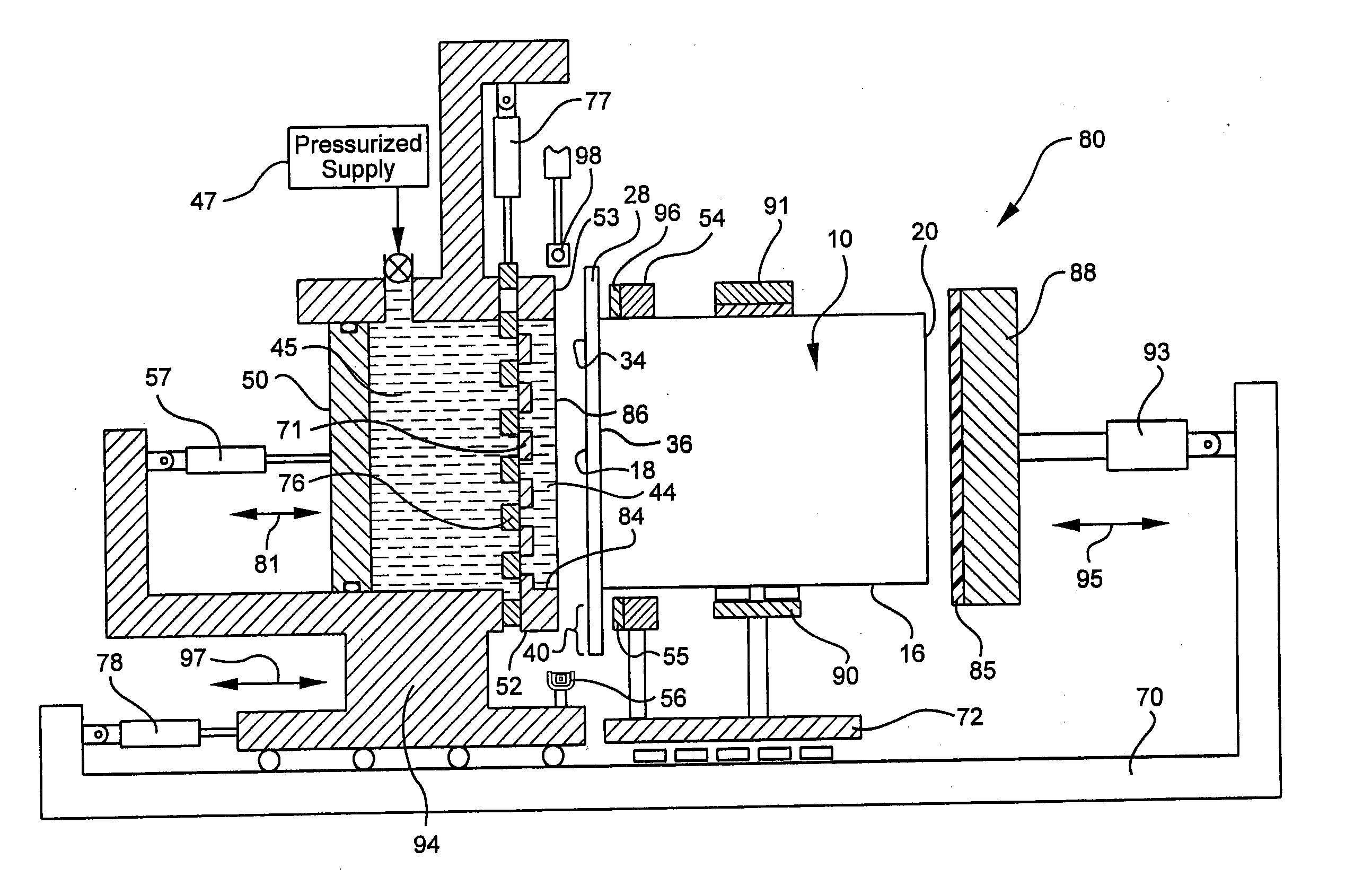

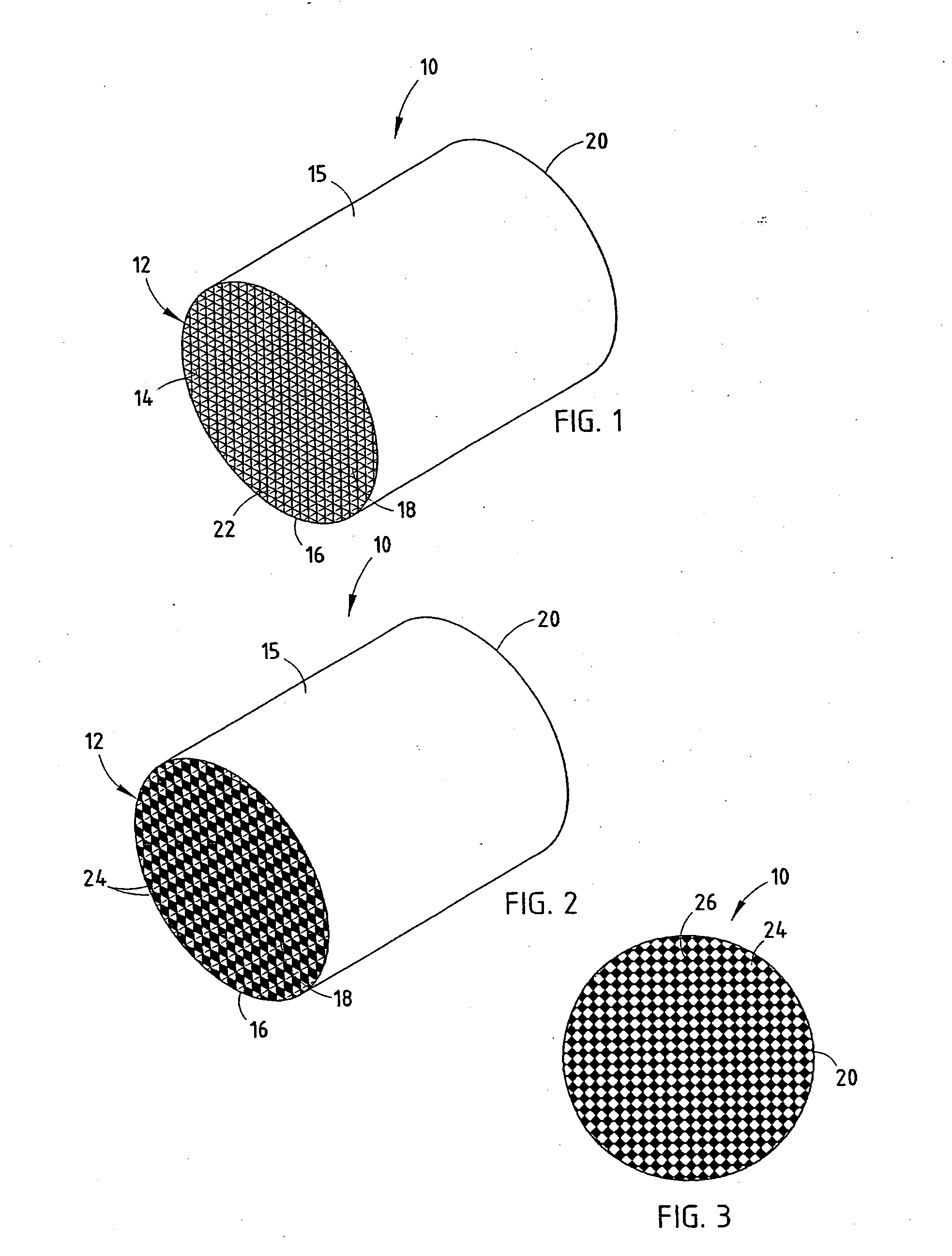

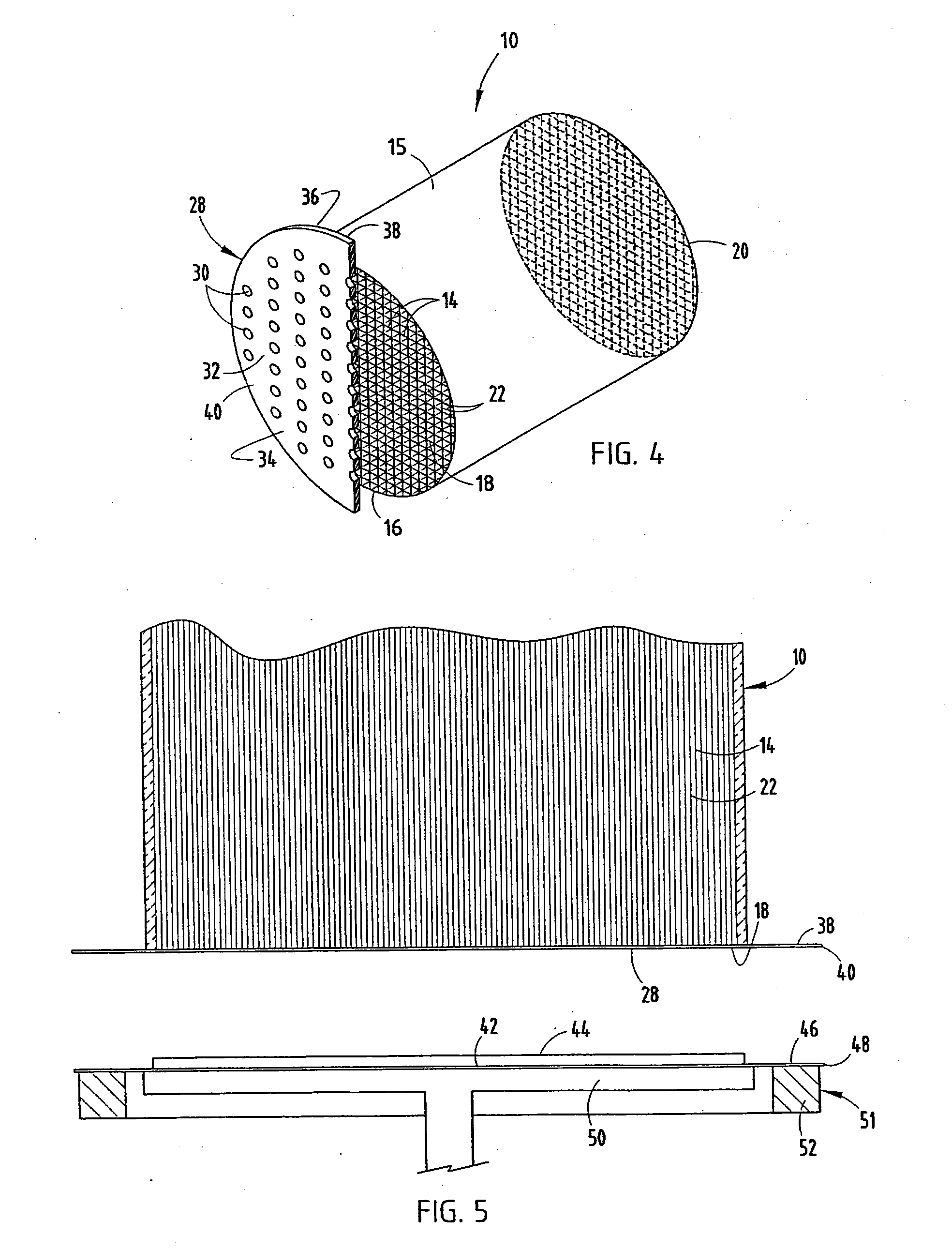

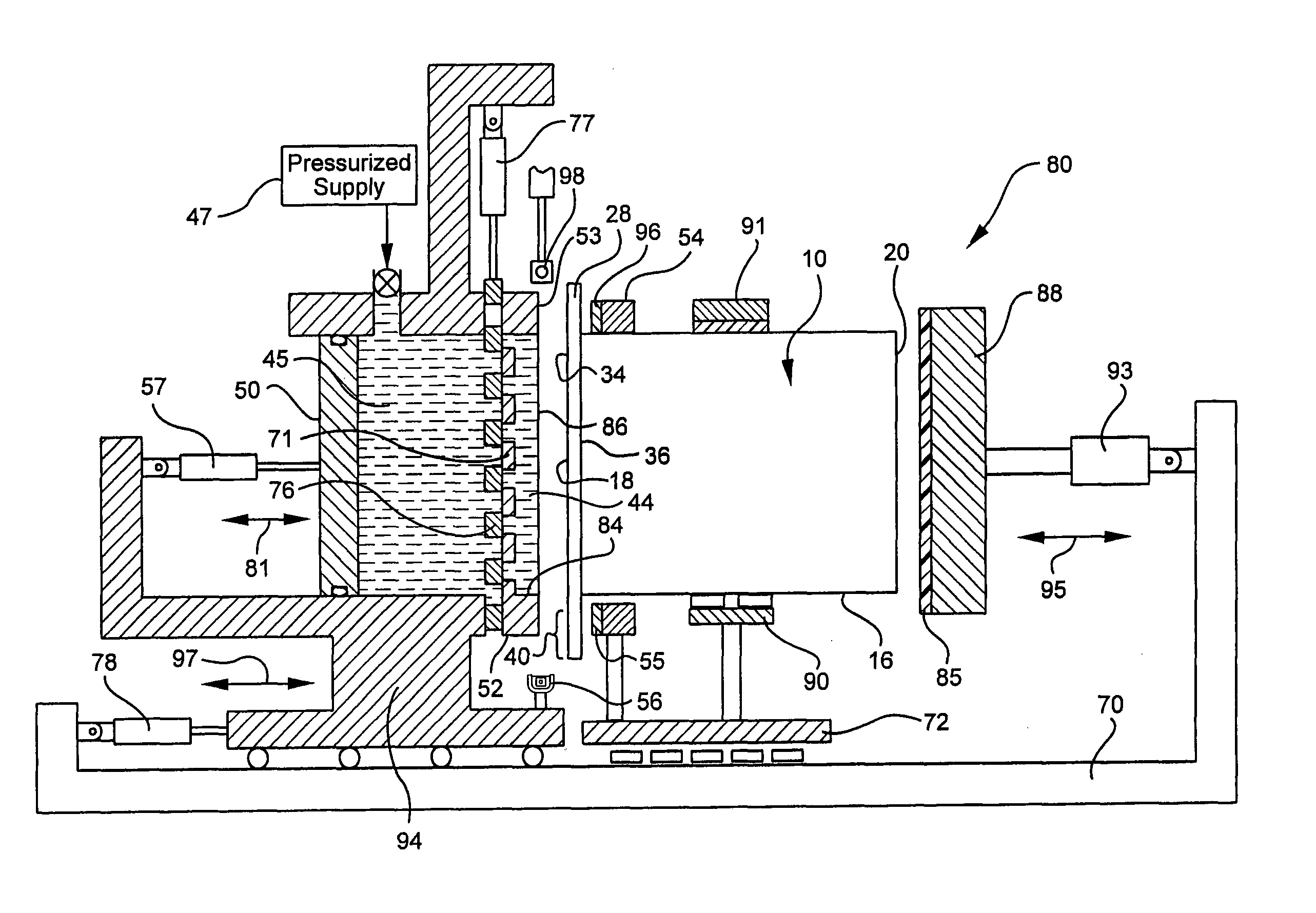

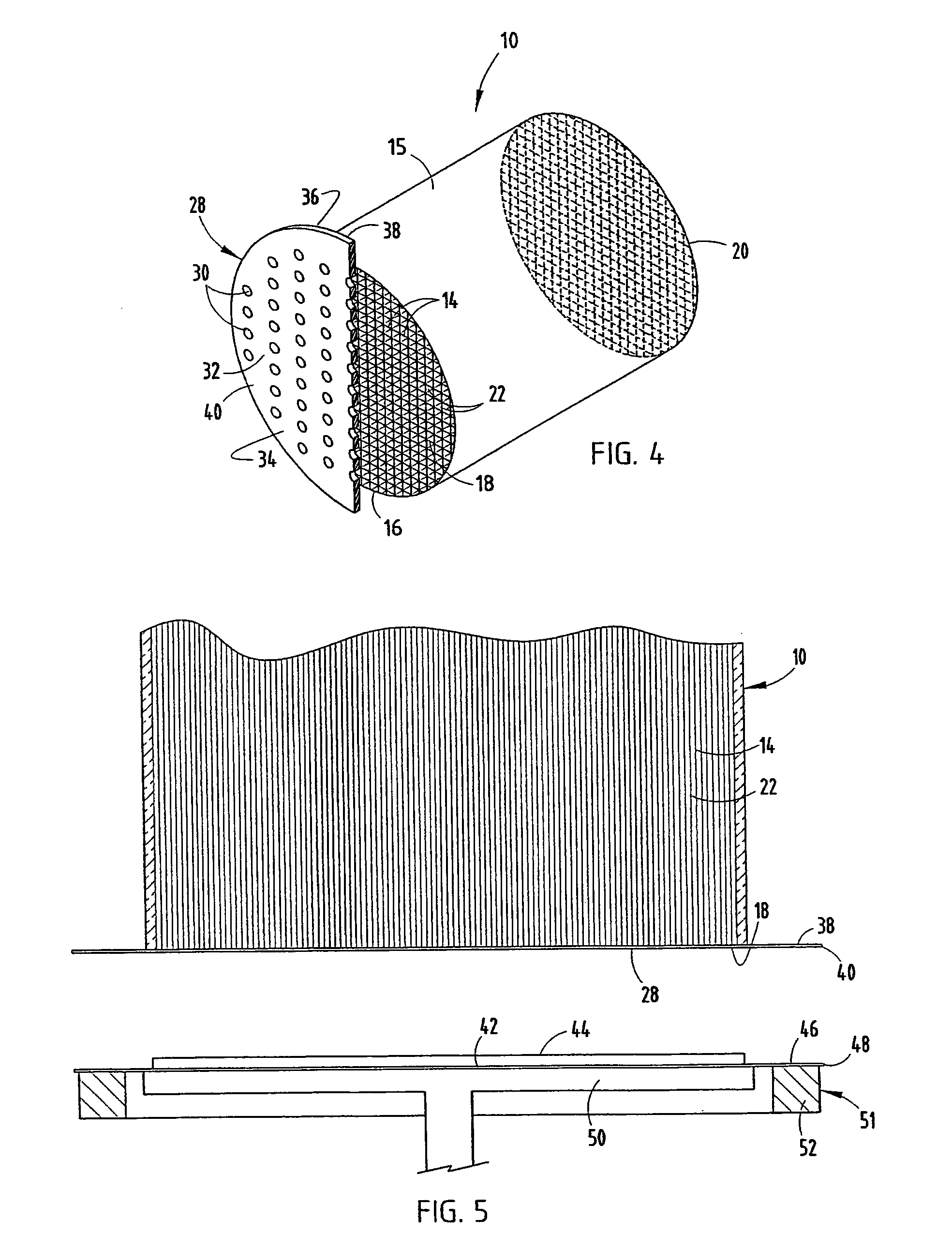

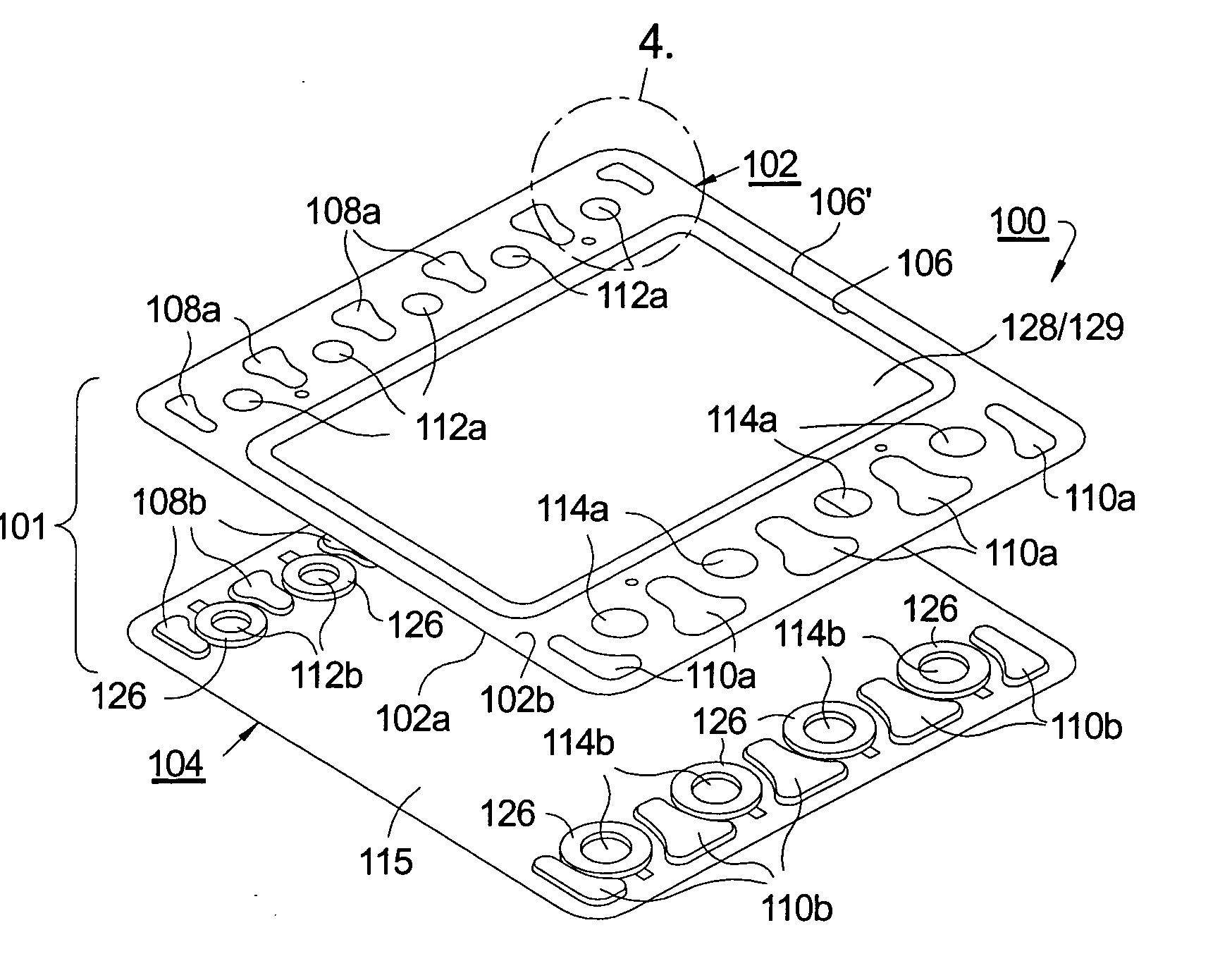

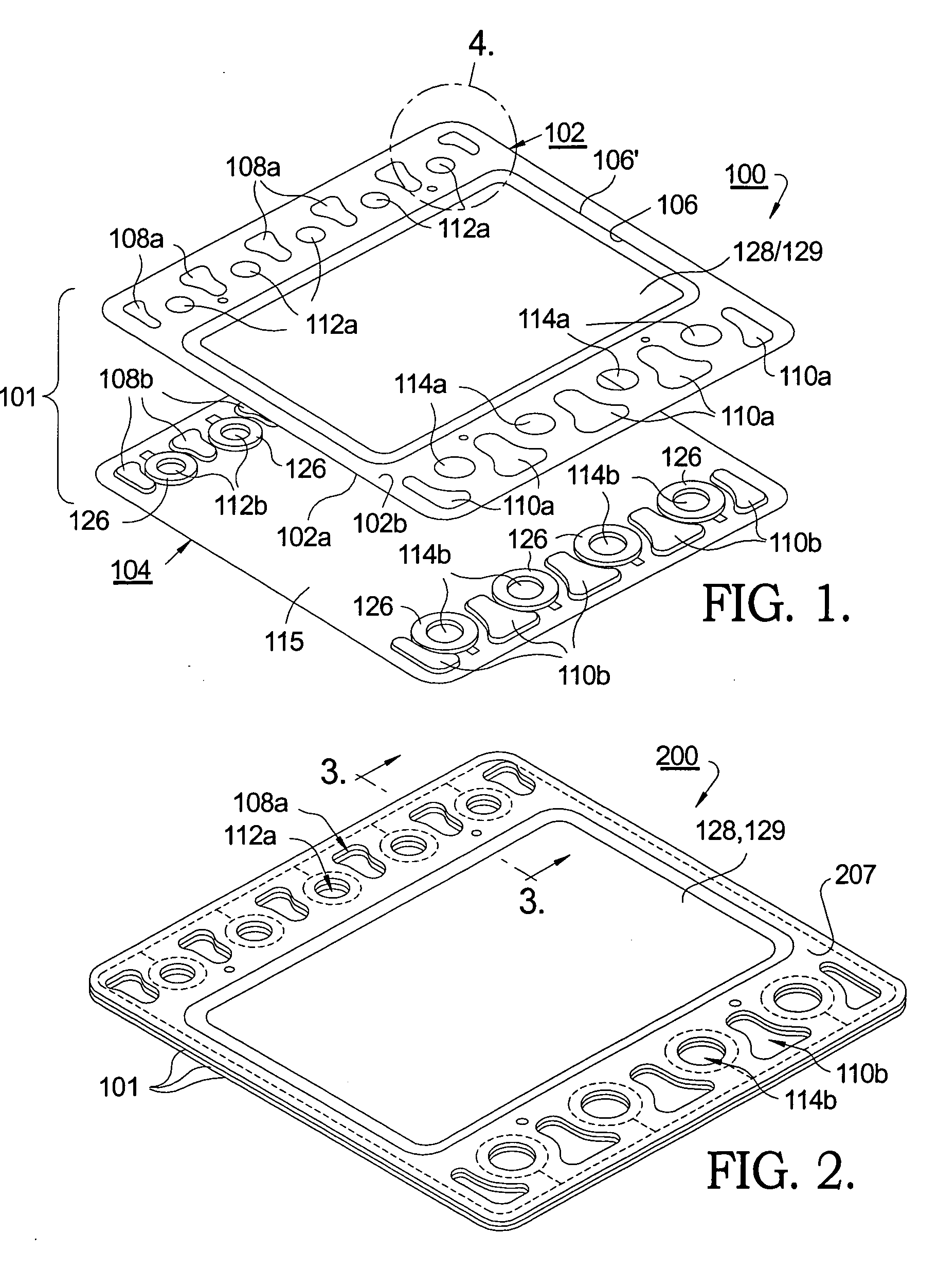

Plugging methods and apparatus for particulate filters

ActiveUS20060131782A1Eliminate overflowEfficient use ofDispersed particle filtrationLayered productsParticulatesProviding material

Methods and apparatus for plugging cells of honeycomb structures are disclosed. A first method covers the honeycomb structure's end face with a mask having a body and plurality of sized openings positioned to oppose certain cell channels, wherein the outer edge of the body extends radially outwardly from the end face. A film also extends outwardly of the end face, and a plug of material is provided upon the film. The mask and film material are sealed to one another, and a force is applied to the film forcing the material through the mask and into the cells. Also disclosed is adhering a mask to a first end face of the honeycomb structure such that the mask has an outer portion that extends radially beyond an outer edge of the honeycomb; providing a volume of plugging material; clamping the outer portion between a first clamping portion and a second clamping portion; and transferring the plugging material into the honeycomb. Also disclosed are methods and apparatus for cutting the plugging material between the mask and a pre-plugging chamber to form a substantially planar surface thereon.

Owner:CORNING INC

Assays Based on Liquid Flow Over Arrays

InactiveUS20110319279A1Reduce solubilityEasy to usePeptide librariesHeating or cooling apparatusAnalyteFluorescence

Cassette (50) performs assays, e.g. multiplexed protein biomarker assays. Wide, bubble-free, slow flows are produced from liquids stored on cassette (50), flowing over wide array (20) of ligand receptors on a capture surface. Flows of Reynolds Number less than about 1, preferably 1×10−1 to 5×10−3, are heated in region (34) preceding and including bubble removal system (128). Analyte is introduced through compressed septum (32). External actuations of displacement pumps (30, 37) and valves (137 A, B, and C) produce flows in response to flow-front optical sensors (150, 152). Elastic sheet provides pump and valve diaphragms and resilient expansion of mixing volume (131). Break-away cover portions are pistons. Heating is by conduction through cassette from external contact heater. Planar cassette body, when tilted from horizontal, enables upward flow from pumped storage (134, 135) to reaction (133) to waste (139), with buoyancy bubble removal before reaction. Reading of fluorescence is by external reader, employing calibration, control and reference features on capture surface. Extensive set of calibration features of differing intensities enables self-calibration.

Owner:COURTAGEN LIFE SCI

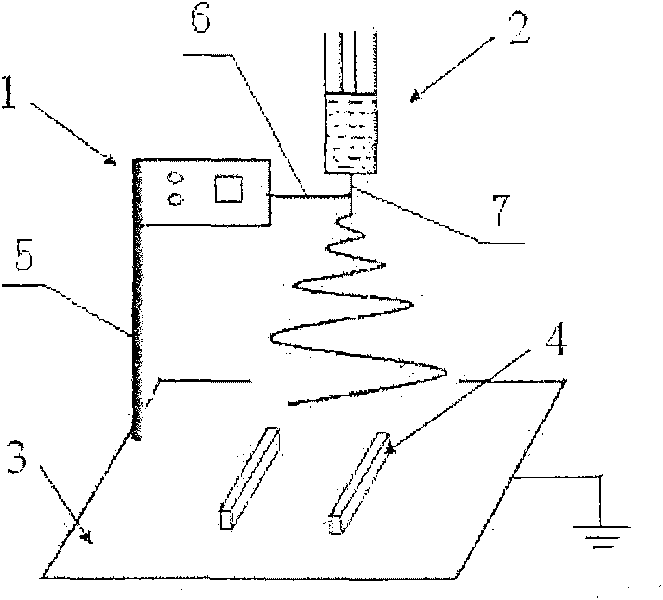

Device and method for preparing oriented polysulfonamide superfine fiber by using magnetized electrostatic spinning method

InactiveCN101724919AEasy to operateHighly repeatableArtificial thread manufacturing machinesFilament/thread formingSpinningElectrospinning

The invention relates to a device and a method for preparing an oriented polysulfonamide PSA superfine fiber by using a magnetized electrostatic spinning method. The device comprises a DC (Direct Current) high-voltage power supply, an injector, and a receiver which is obtained by arranging a pair of parallel permanent magnets on an aluminum foil receiver; two leads are respectively led from the anode and the cathode of the DC high-voltage power supply, wherein one lead is connected with the aluminum foil receiver, and the other lead is connected with a spinning nozzle of the injector. The method comprises the steps of: adding an oil-phase magnetic Fe3O4 solution to a polysulfonamide spinning solution to obtain a magnetized polysulfonamide PSA spinning solution, and processing the magnetized polysulfonamide PSA spinning solution under the action of a magnetic filed to obtain an oriented superfine fiber with the fiber diameter distribution of 100-500 nm. The method has the advantages of simple operation, high replication degree and easy popularization.

Owner:SHANGHAI UNIV

Plugging methods and apparatus for particulate filters

ActiveUS7922951B2Eliminate overflowEfficient use ofDispersed particle filtrationLayered productsParticulatesEngineering

Methods and apparatus for plugging cells of honeycomb structures are disclosed. A first method covers the honeycomb structure's end face with a mask having a body and plurality of sized openings positioned to oppose certain cell channels, wherein the outer edge of the body extends radially outwardly from the end face. A film also extends outwardly of the end face, and a plug of material is provided upon the film. The mask and film material are sealed to one another, and a force is applied to the film forcing the material through the mask and into the cells. Also disclosed is adhering a mask to a first end face of the honeycomb structure such that the mask has an outer portion that extends radially beyond an outer edge of the honeycomb; providing a volume of plugging material; clamping the outer portion between a first clamping portion and a second clamping portion; and transferring the plugging material into the honeycomb. Also disclosed are methods and apparatus for cutting the plugging material between the mask and a pre-plugging chamber to form a substantially planar surface thereon.

Owner:CORNING INC

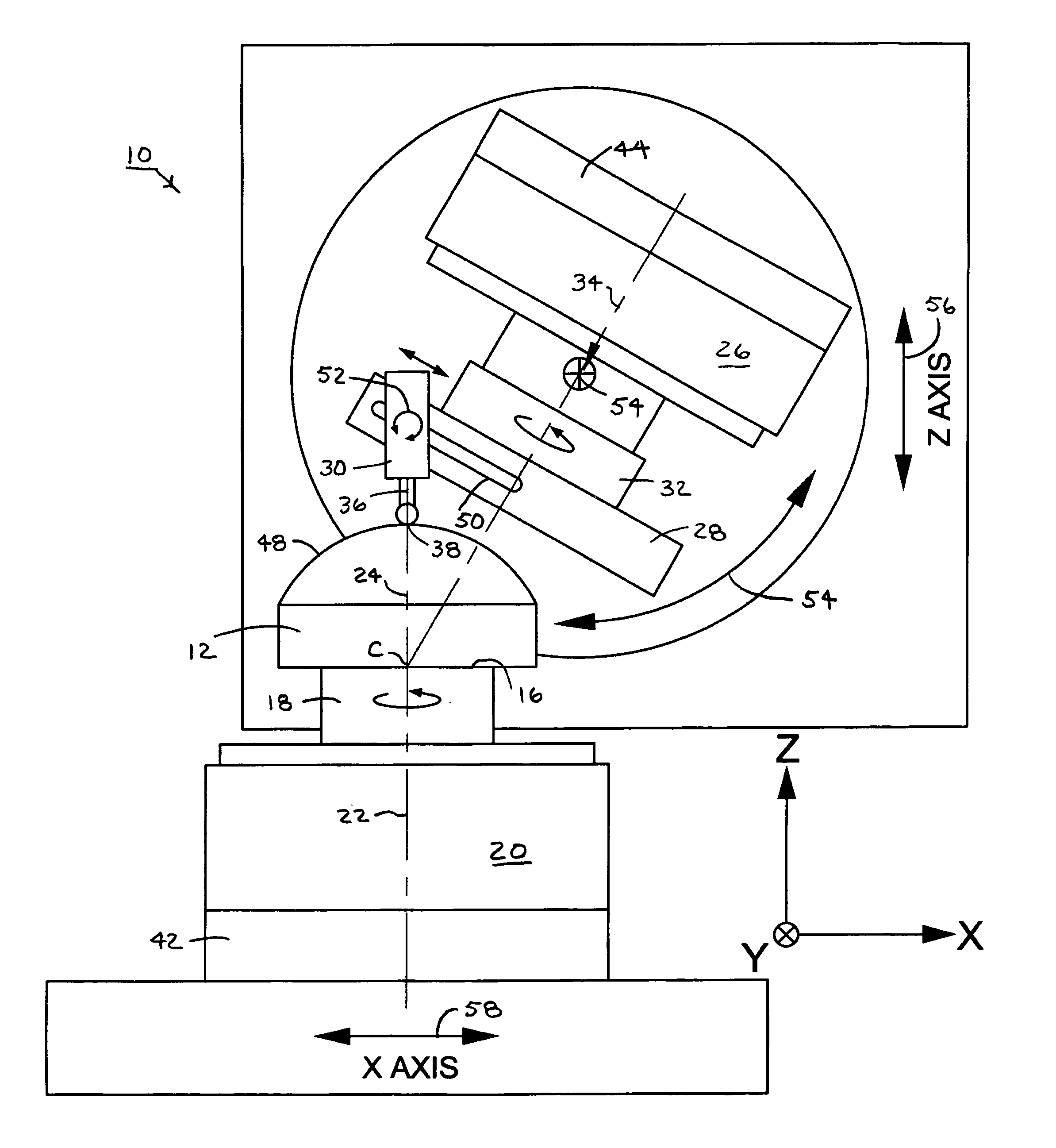

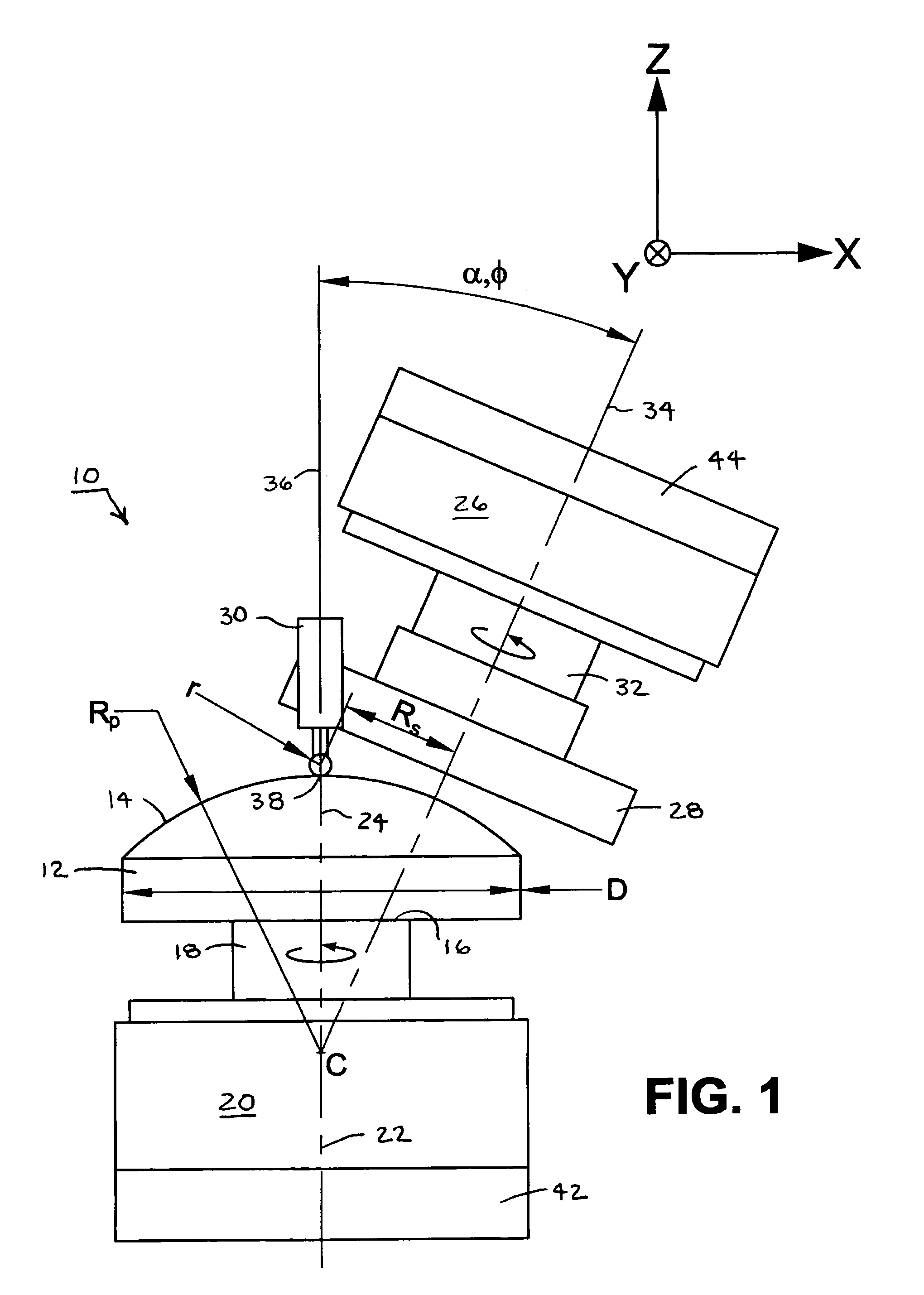

Measurement of form of spherical and near-spherical optical surfaces

InactiveUS7140119B2Improve accuracyResidual errors tendMechanical counters/curvatures measurementsUsing electrical meansOptical testOptical surface

Rotational motions between a displacement-measuring probe and an optical test surface define a spherical or near spherical datum surface against which measurements of the probe are taken. The probe has a measurement axis that is maintained substantially normal to the optical test surface during the course of measurement.

Owner:CORNING INC

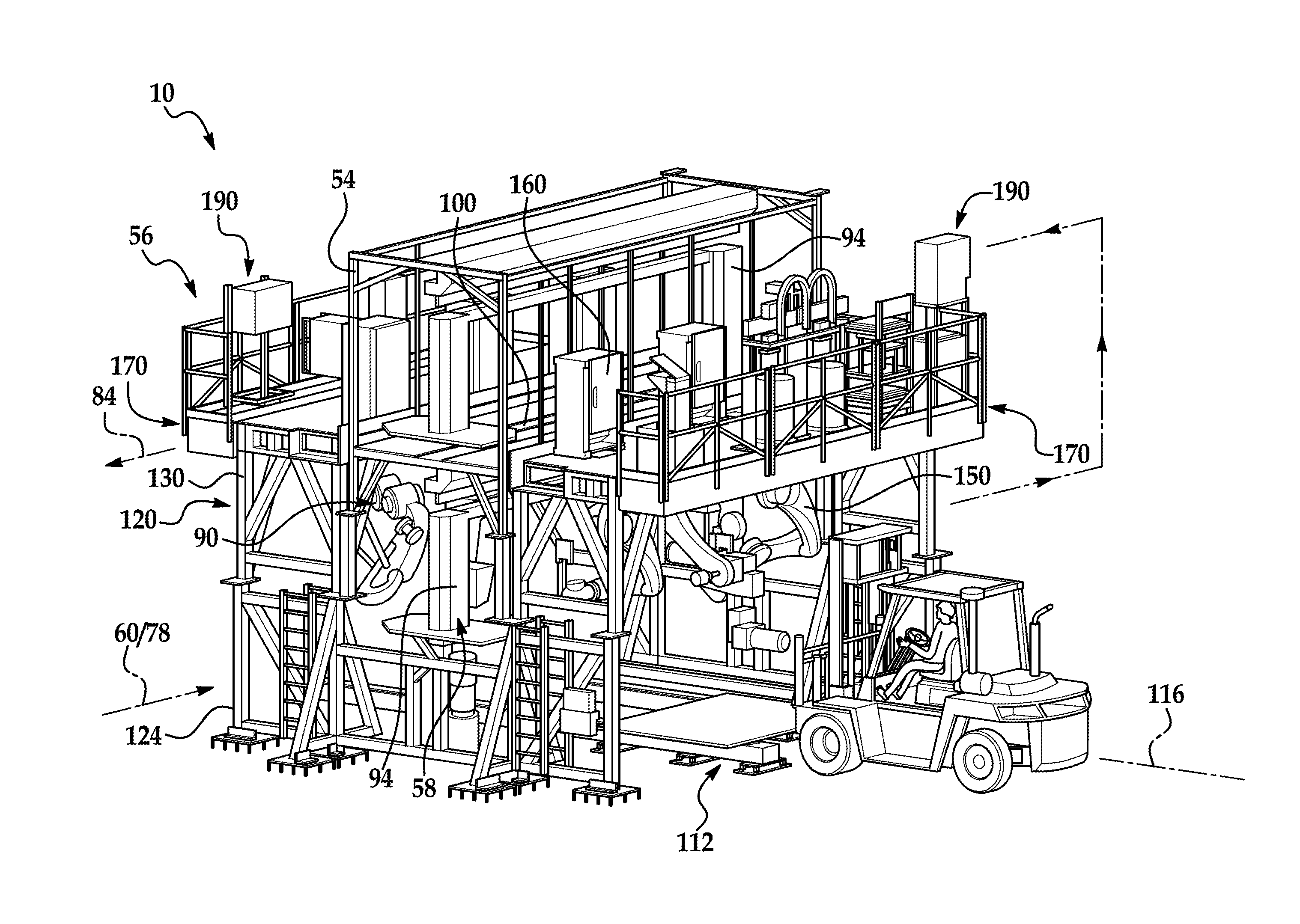

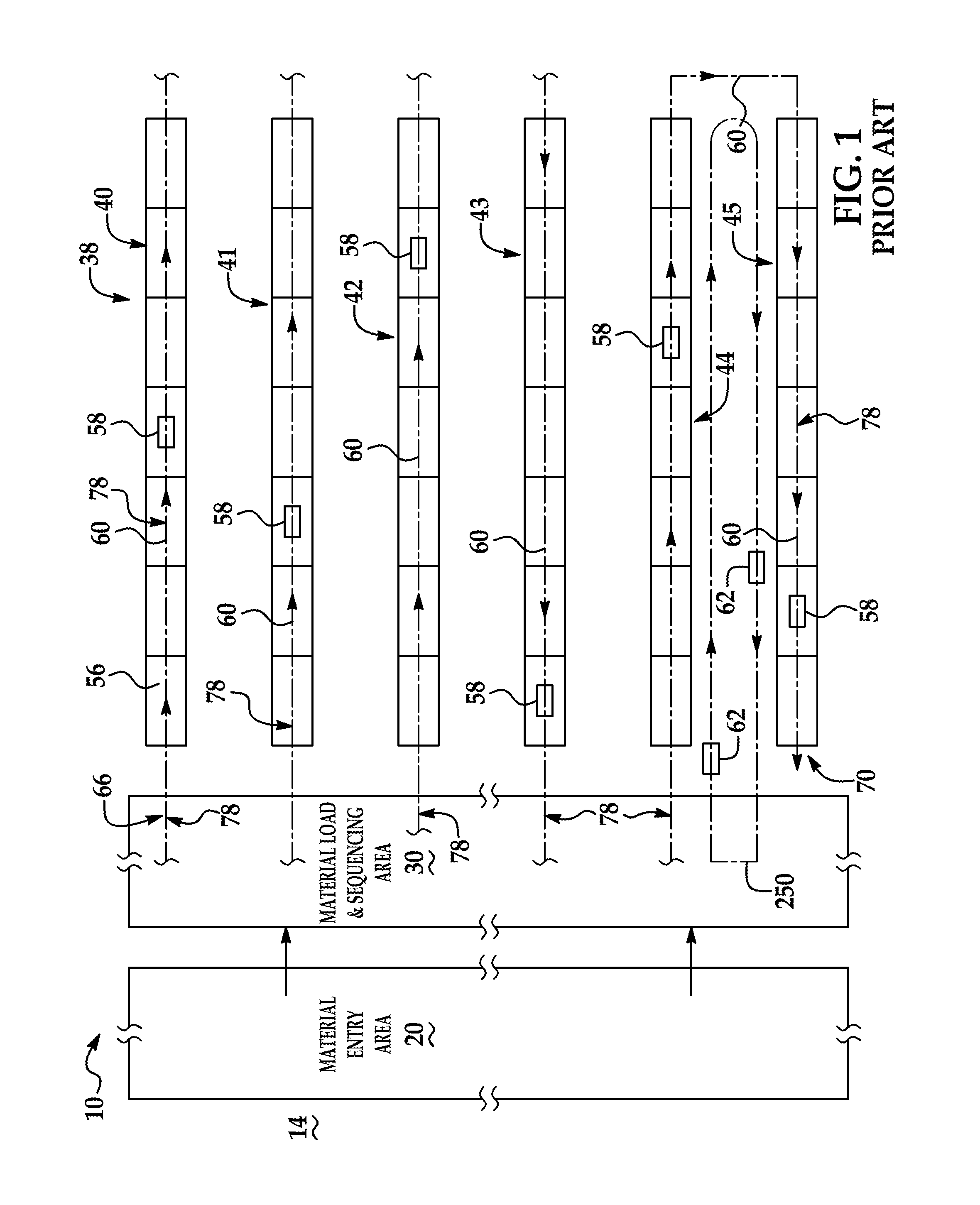

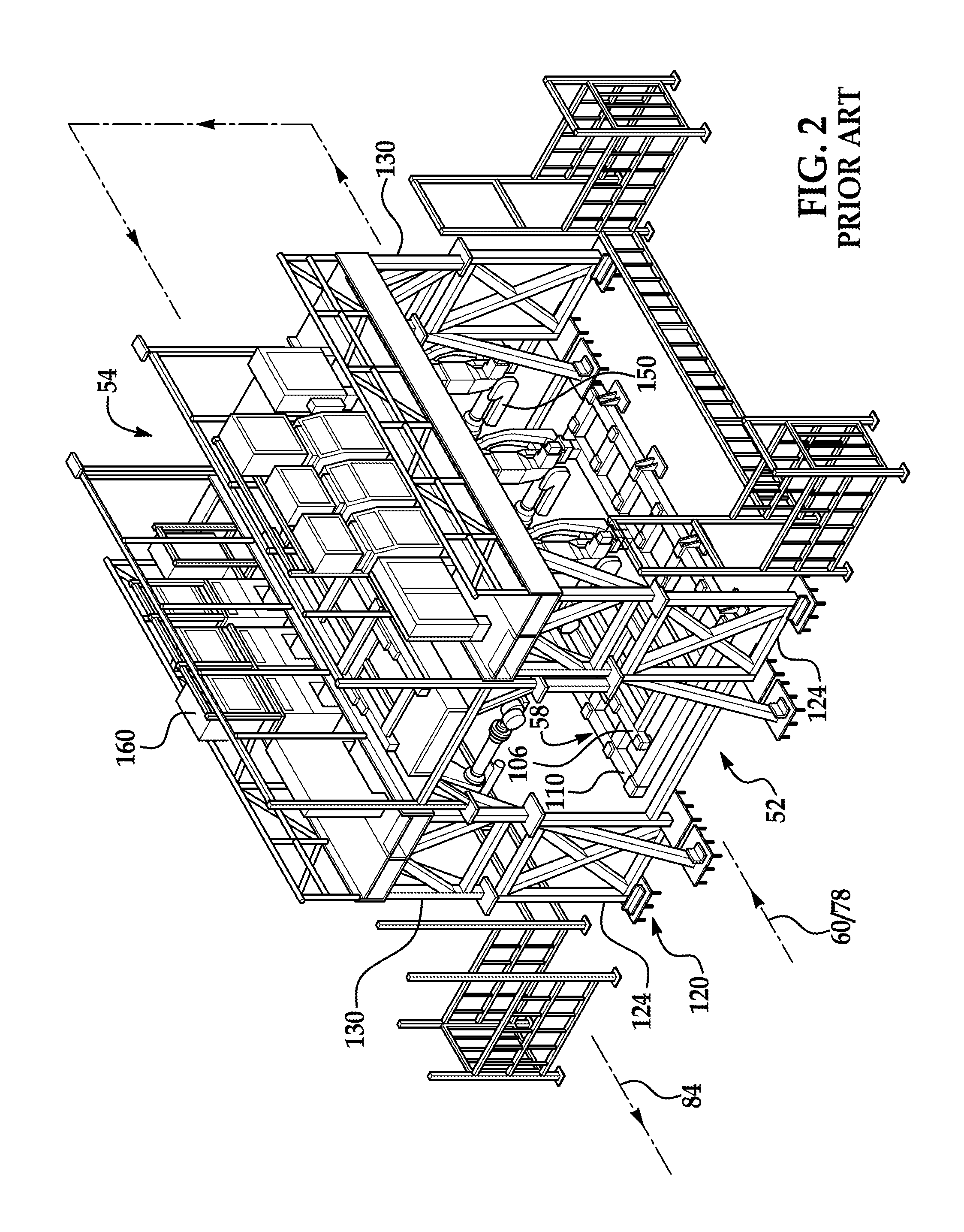

Modular vehicle assembly system and method

ActiveUS20160167724A1Simple logisticalEfficient connectionWelding/cutting auxillary devicesAssembly machinesValidation testWorking environment

A modular vehicle assembly system and methods for increased flexibility and adaptability of a high volume assembly facility which builds several vehicle models. In one example, the invention includes modular assembly equipment (AE) support pallets which are shipped to vendors for installation of selected AE equipment devices that are specific to a predetermined assembly operation and then validation tested prior to shipment. The modular AE pallets and AE devices are quickly installed and easily removable for maintenance or replacement. In other examples, modular AE support platforms and safety fencing are used to support ground level assembly operation and safer working environment.

Owner:COMAU LLC

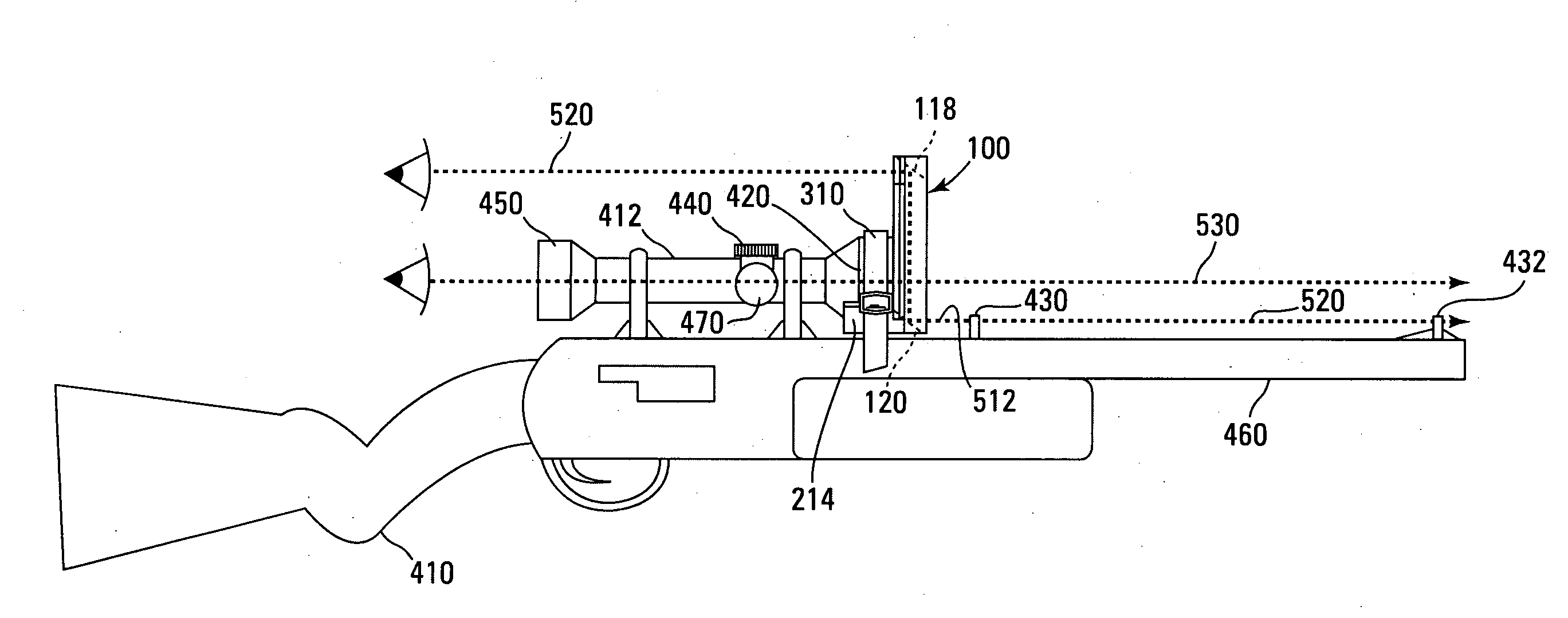

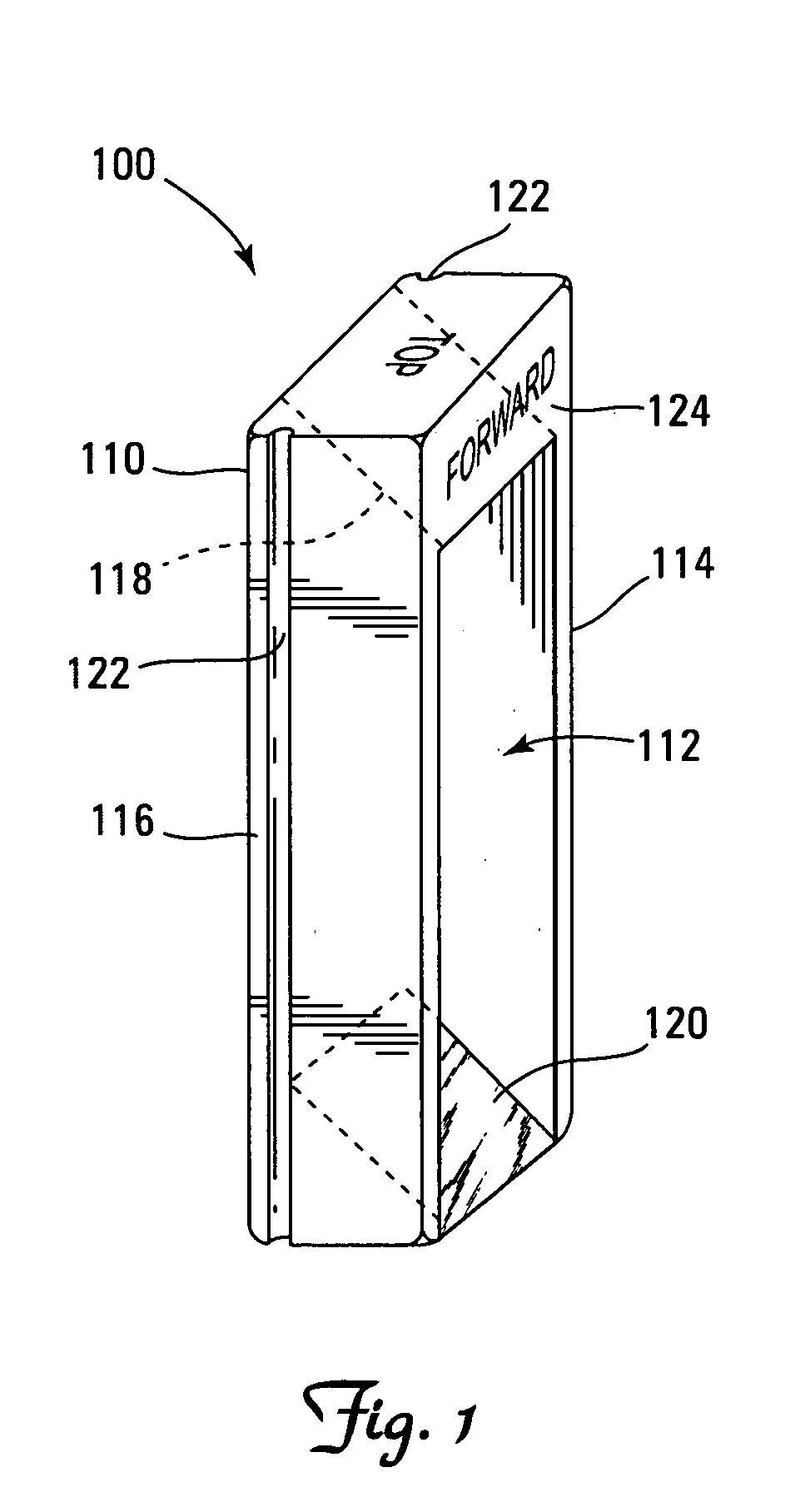

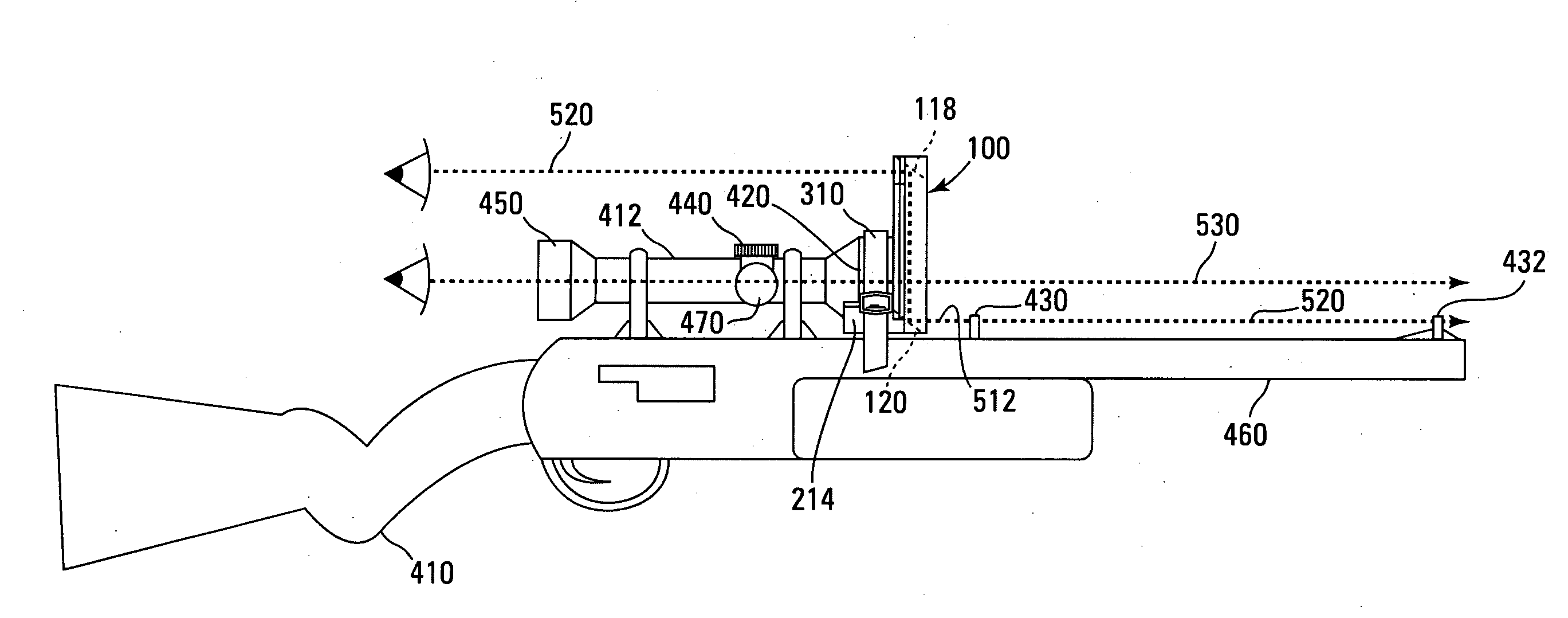

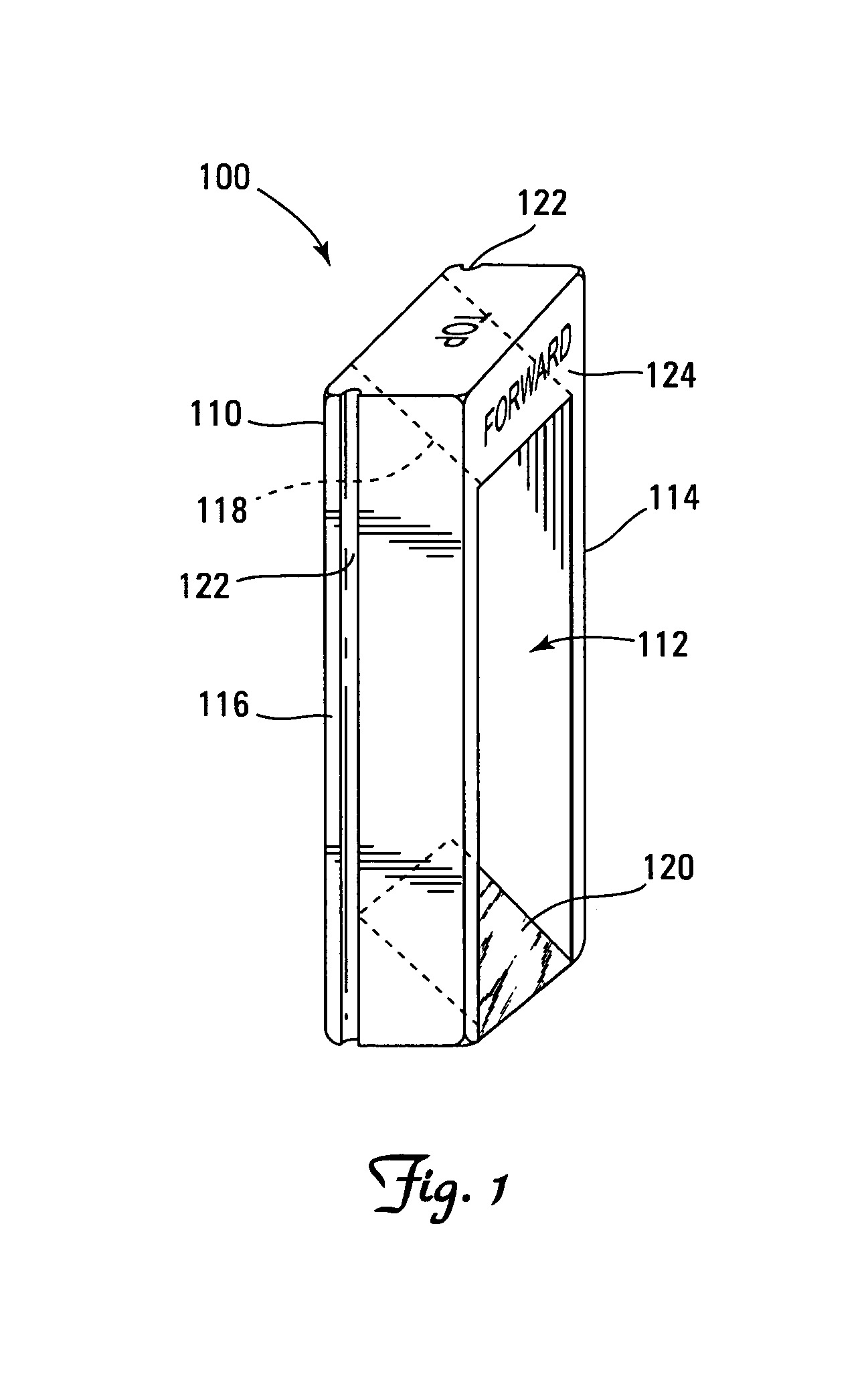

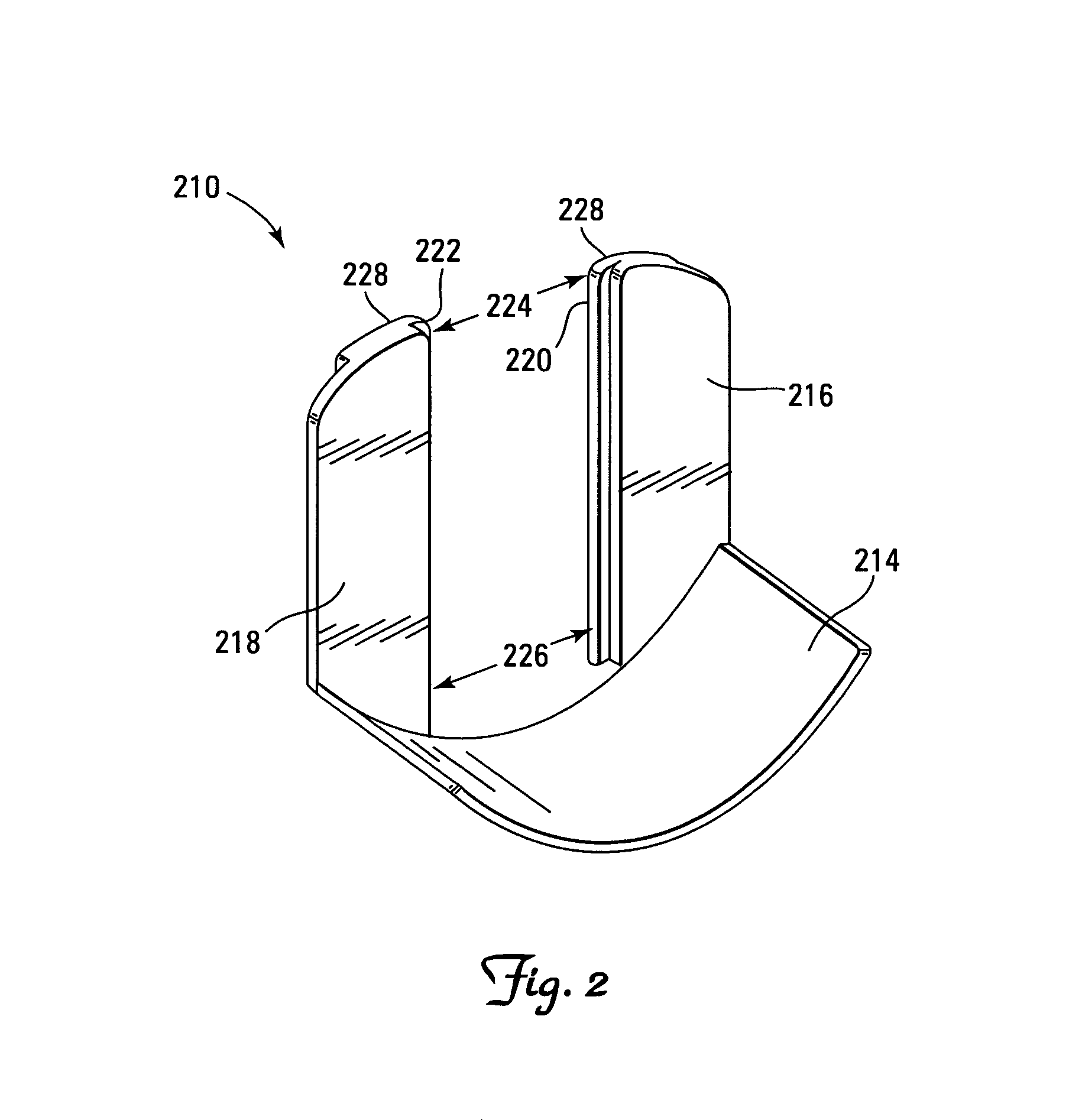

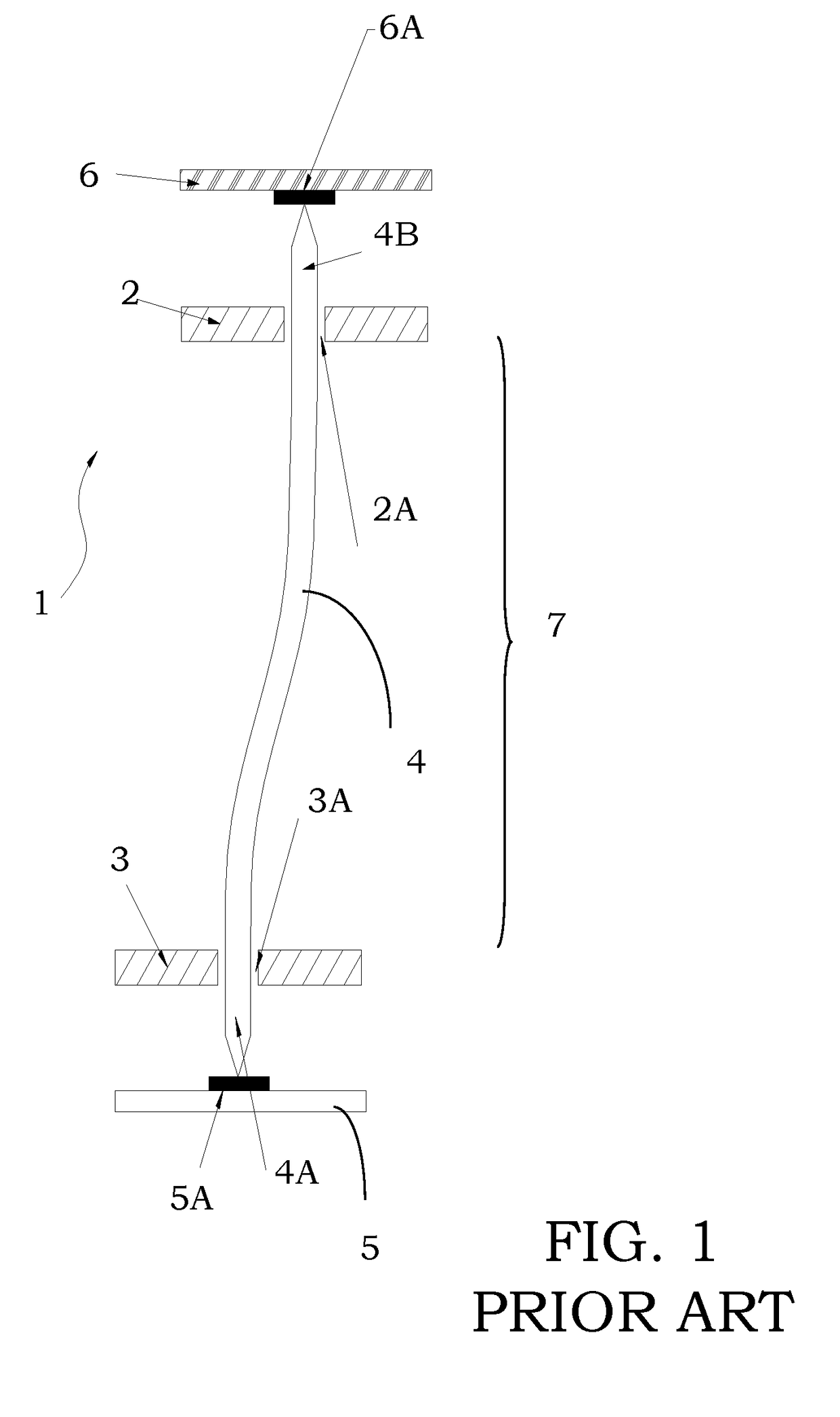

See-through periscope for sighting-in optical or open sights on a firearm

A see-through periscope for sighting-in optical sights or open sights by co-aligning one type of sighting system with the other type. The small see-through periscope is preferably used with firearms that have two conditions: (1) the rifle must be equipped with open sights, and (2) a gap must exist between the front of the optical sight and the rear open sight where the periscope can be mounted. Four unique mounts allow the periscope to be used with both magnifying or non-magnifying optical sights of different types, sizes, and shapes and open sights of different heights. The mounts position the bottom mirror at the height of the open sights and the top mirror at a point higher than the optical sight. The bottom mirror captures an image of the open sights aimed at a target and reflects that image to the top mirror, which in turn reflects the image across the top of the optical sight and into the eye of the shooter. The optical sight can still be used because the periscope mounted in front of it has no front or back panels, leaving a window for the shooter to see through the optical sight.

Owner:MAYERLE RONALD T

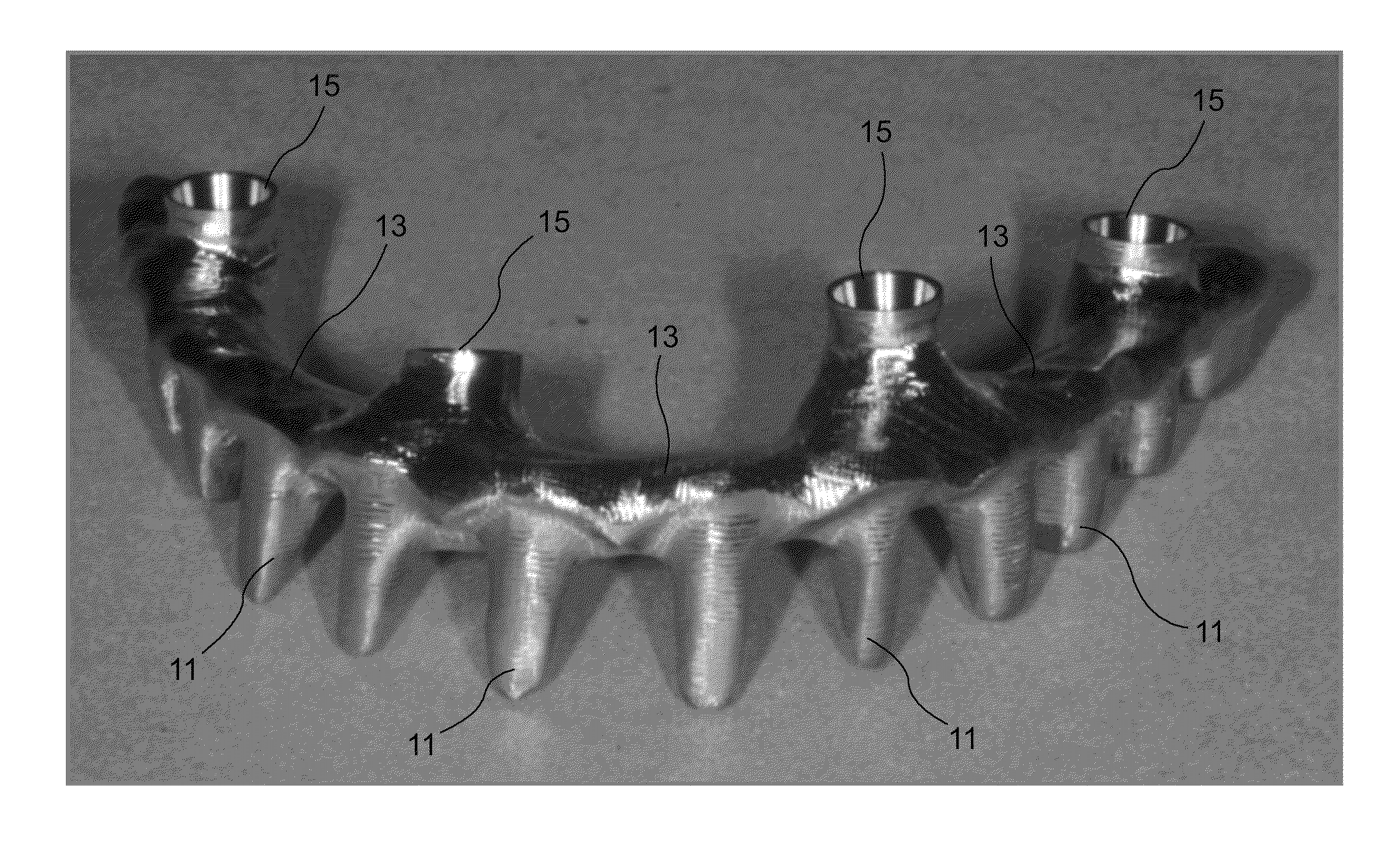

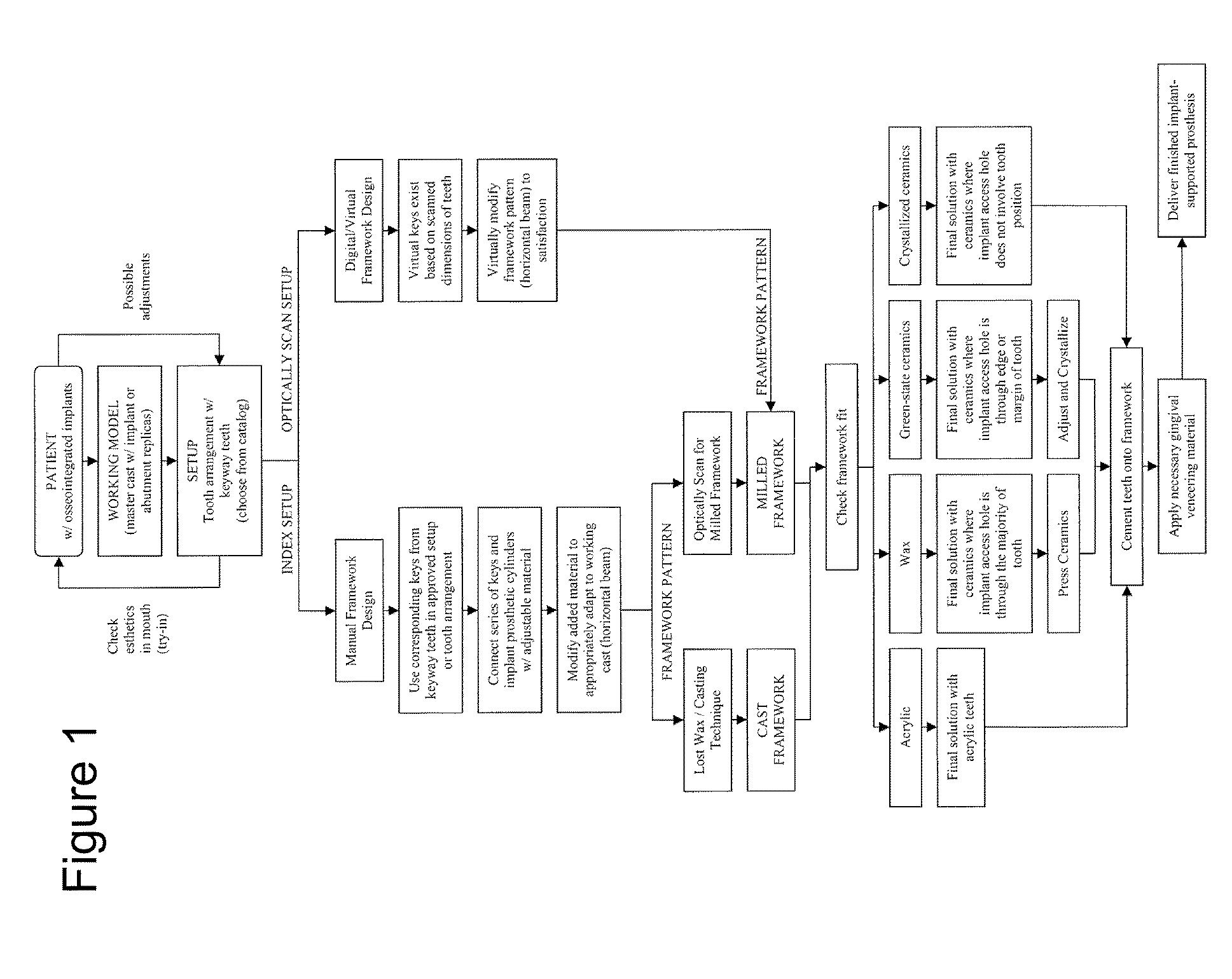

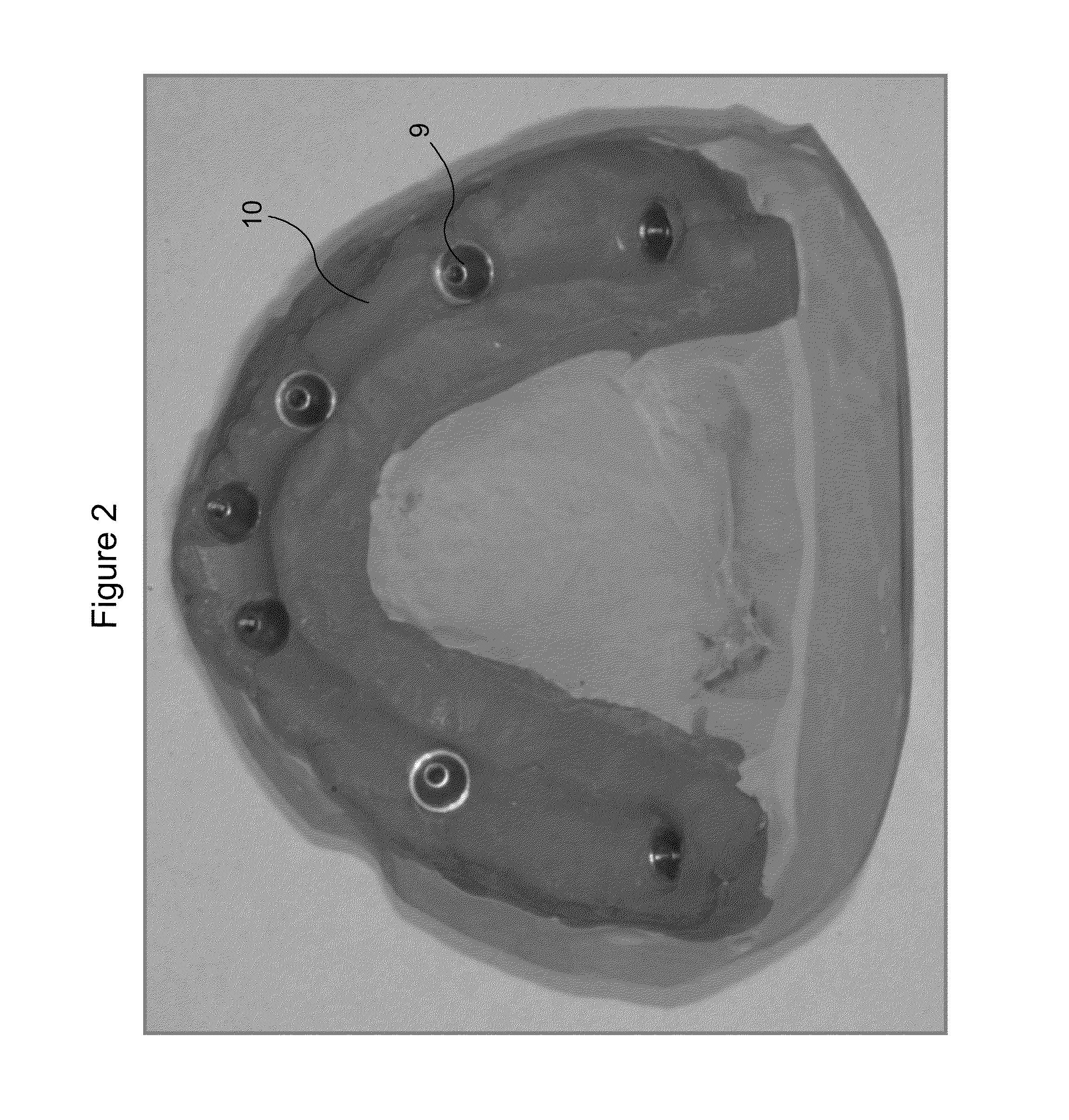

Dental prosthesis and method of its production utilizing standardized framework keys and matching premanufactured teeth

ActiveUS8875398B2Rapid and precisely accurate methodHighly repeatableDental implantsFastening prosthesisDenturesMethods of production

A system including a method and associated structures creates efficiencies in the manufacture of prosthetic tooth support frameworks. Pre-manufactured teeth with matching internal keys are used in the setup of a patient prototype. Each key includes a shaft, a cervical platform, a retention knob and preferably at least one channel for the expulsion of excess adhesive fluid. The cervical platforms are shaped to provide intimate contact with a base of their respective tooth. The same tooth / key pairs are then used to make a framework pattern from the setup positioning. The pattern can be cast or scanned for direct machining to produce the finished framework.

Owner:GLOBAL DENTAL SCI

Thin film non volatile memory device scalable to small sizes

InactiveUS20060151616A1Highly repeatableHighly stableNanoinformaticsDigital storageThin-film memoryEngineering

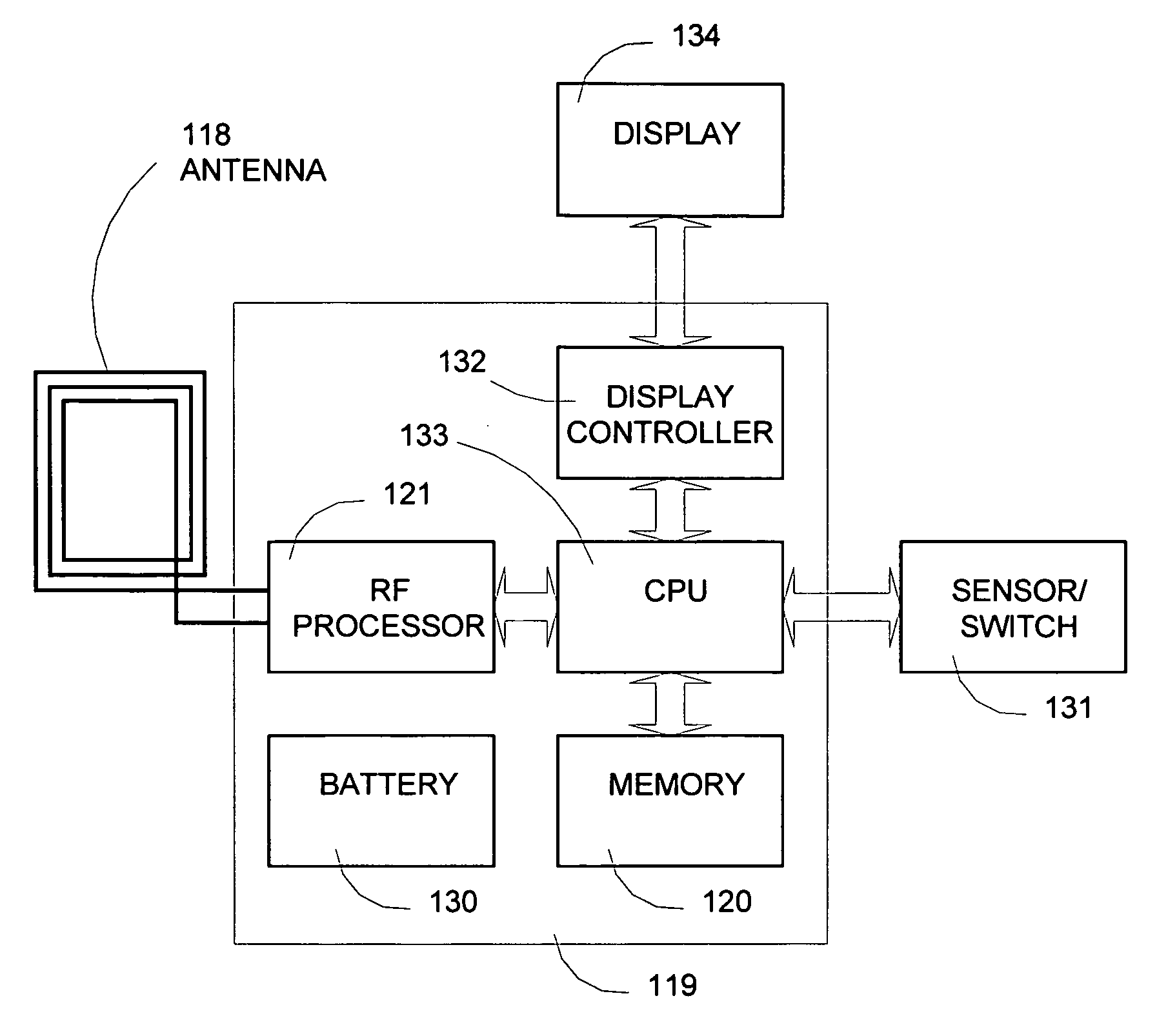

A thin film non volatile memory scalable to small sizes and its fabrication process are disclosed. The thin film memory comprises a thin film transistor control circuitry fabricated on a flexible substrate, together with an optoelectronic cross bar memory comprising a photoconducting material. The thin film non volatile memory can be used in RFID communication tag with the control circuitry further comprises wireless communication circuitry such as an antenna, a receiver, and a transmitter.

Owner:TERECIRCUITS CORP

Quantitative phantomless calibration of computed tomography scans

ActiveUS20140376701A1Improve consistencyEasily implemented clinicallyMedical automated diagnosisTomographySpinal columnComputed tomography

An apparatus, method, and computer program product for calibrating a CT scan without the use of an external calibration phantom, to enable quantitative assessment of internal body tissues and organs and additionally for any application that would benefit from a calibration of the scan attenuation data, such as viewing CT images in a consistent fashion. Embodiments are described with applications to quantitative assessment of bone density in the spine and hip, mineral content in blood vessels, hepatic-fat content in the liver, and gray-to-white matter ratio in the brain. The primary advantages of the method are that it does not require the use of an external calibration phantom, it is robust across different CT machines and scanner settings, and it is also highly precise, lending itself to a high degree of automation.

Owner:O N DIAGNOSTICS

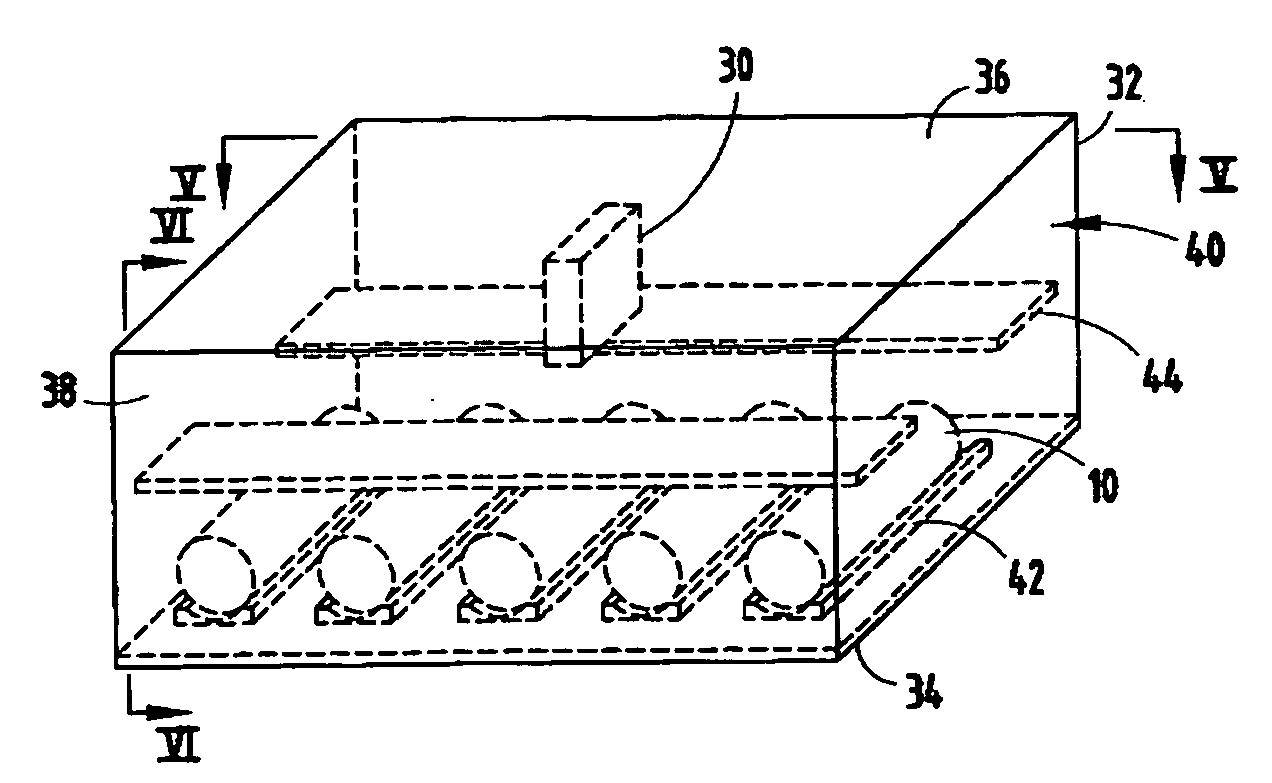

SOFC assembly joint spacing

ActiveUS20060147782A1Reduce manufacturing costReduce and eliminate joint spacingFuel cells groupingFinal product manufactureJoint spacingCHEEK DIMPLES

A textured surface is formed on at least one of a fuel cell mounting plate or fuel cell subassembly to define a joint spacing between these two components. In a preferred embodiment, the textured surface comprises a plurality of dimples coined or otherwise formed in the metal mounting plate. The joint spacing improves the manufacturing and assembly process of the fuel cell cassettes through precise application and control of the brazing process which improves the braze joint strength while reducing material cost.

Owner:APTIV TECH LTD

See-through periscope for sighting-in optical or open sights on a firearm

A see-through periscope for sighting-in optical sights or open sights by co-aligning one type of sighting system with the other type. The small see-through periscope is preferably used with firearms that have two conditions: (1) the rifle must be equipped with open sights, and (2) a gap must exist between the front of the optical sight and the rear open sight where the periscope can be mounted. Four unique mounts allow the periscope to be used with both magnifying or non-magnifying optical sights of different types, sizes, and shapes and open sights of different heights. The mounts position the bottom mirror at the height of the open sights and the top mirror at a point higher than the optical sight. The bottom mirror captures an image of the open sights aimed at a target and reflects that image to the top mirror, which in turn reflects the image across the top of the optical sight and into the eye of the shooter. The optical sight can still be used because the periscope mounted in front of it has no front or back panels, leaving a window for the shooter to see through the optical sight.

Owner:MAYERLE RONALD T

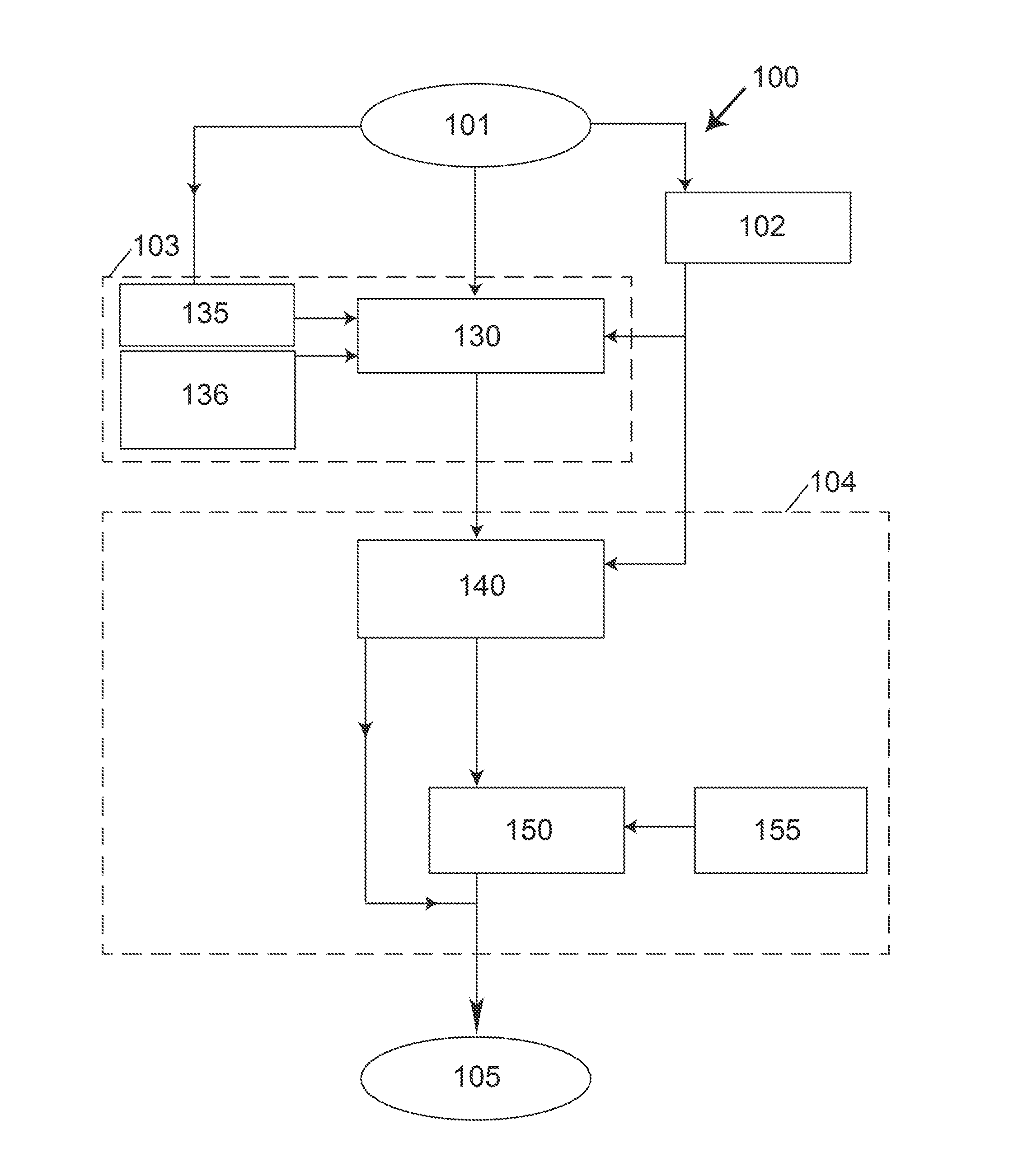

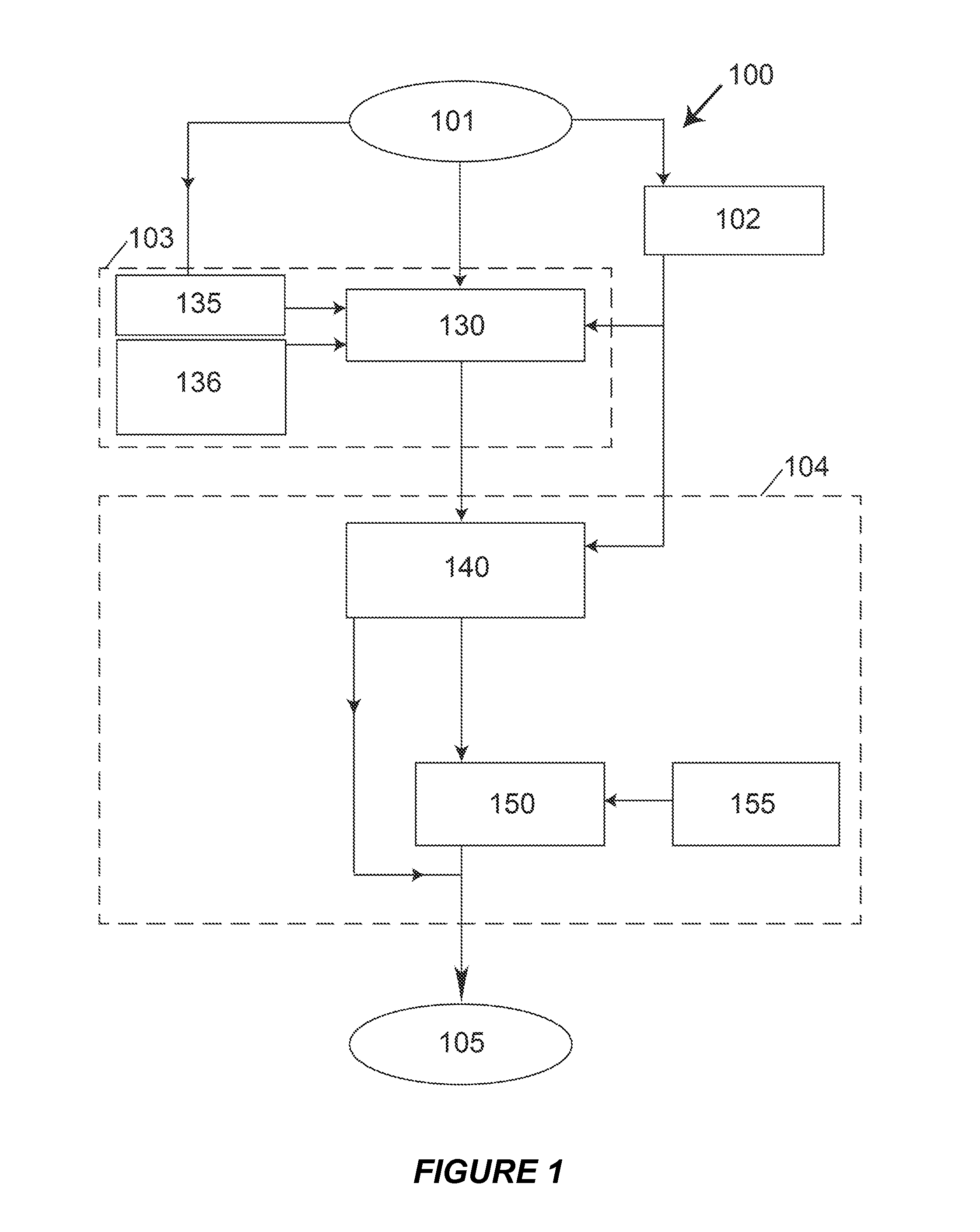

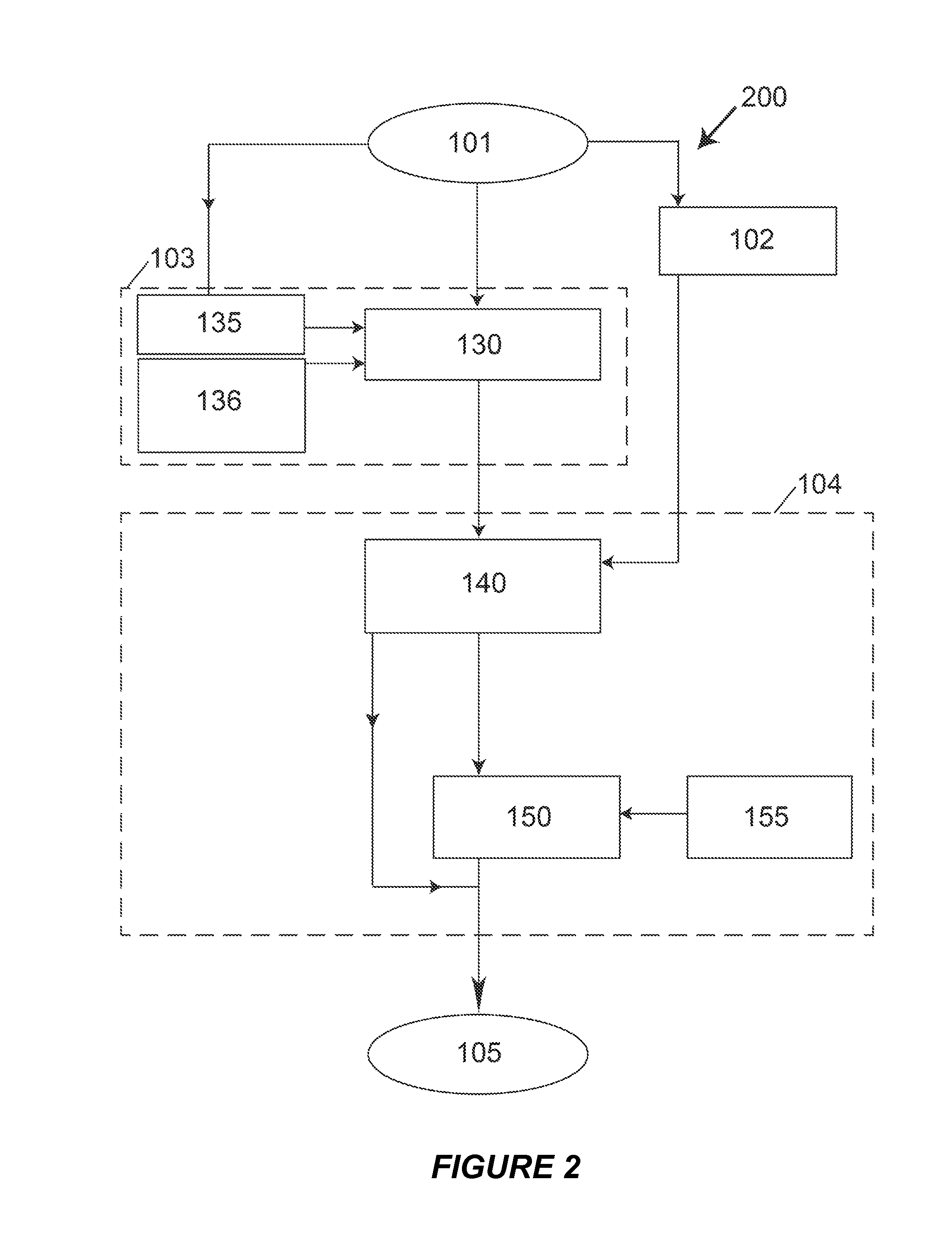

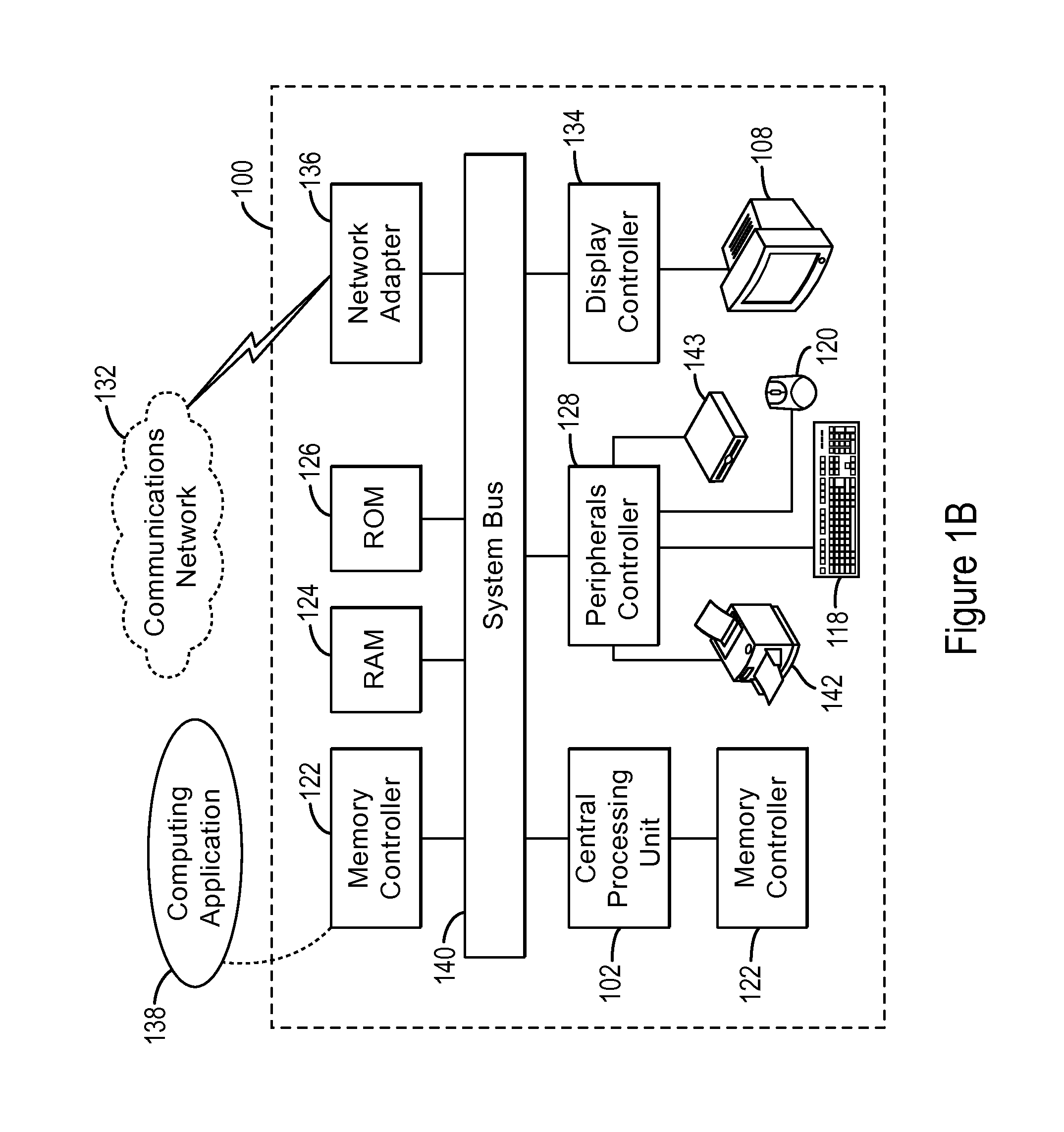

Systems and methods for assessment of fluid intelligence

InactiveUS20130323704A1Highly repeatableAccurate comparisonElectrical appliancesMechanical appliancesAlgorithmAnimation

A computing device determines a matrix reasoning assessment (MRA) to assess fluid intelligence of a user operating a client computer / device. The MRA includes a matrix having designs in design spaces, where the designs form one or more patterns. The matrix has one or more design spaces in the matrix that are missing a design. Examples of a design include, without limitation, a number, a letter, a symbol. a shape, a picture, an image, a photograph, an icon, an animation, a video, audio, or any other symbol, character, or representation that can be used in a pattern. In one embodiment, the computing device transmits the matrix to the client device. The user responds with a design for the “empty” design space (i.e., the design space previously missing a design) and the computing device receives this design selection.

Owner:LUMOS LABS

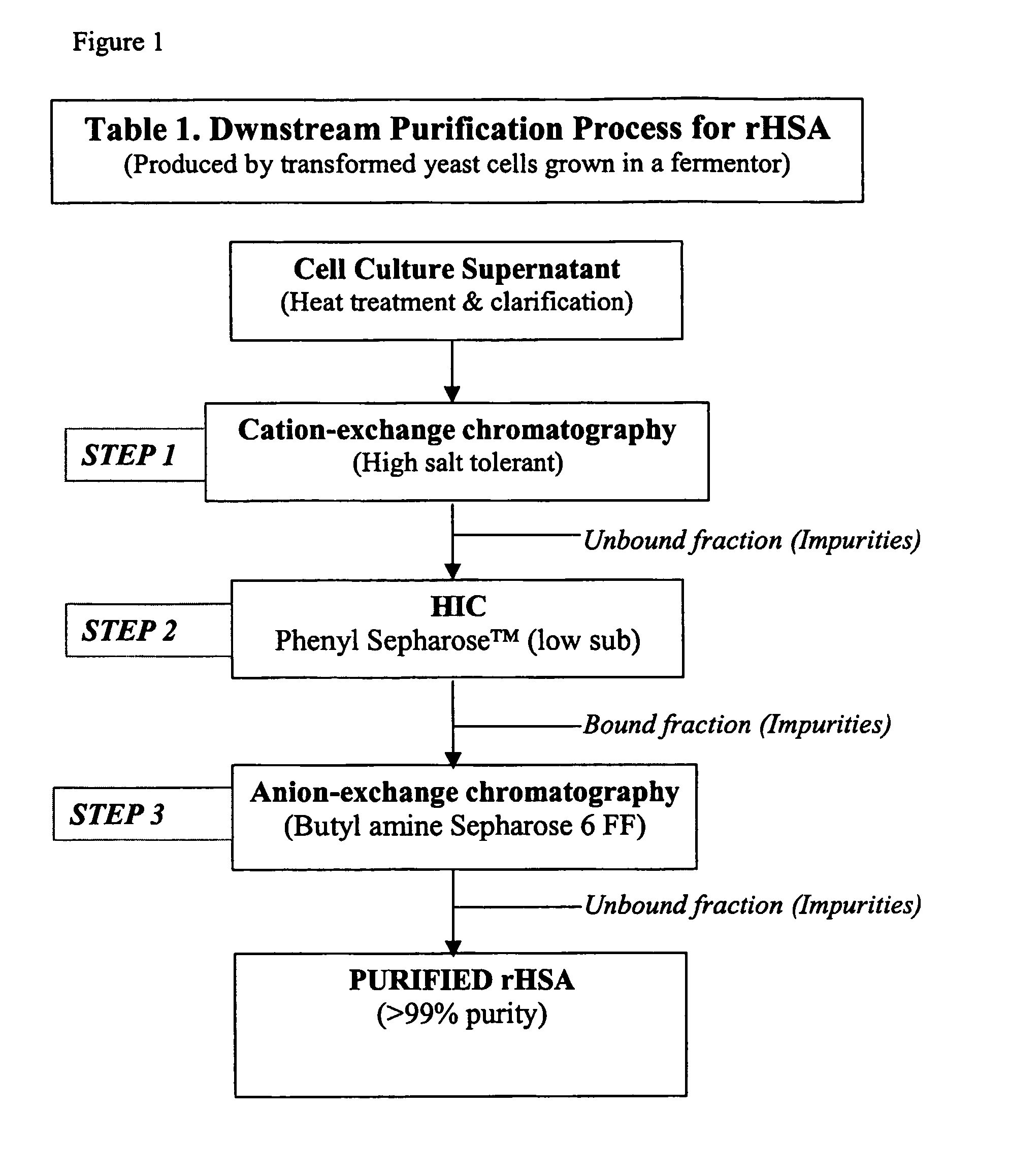

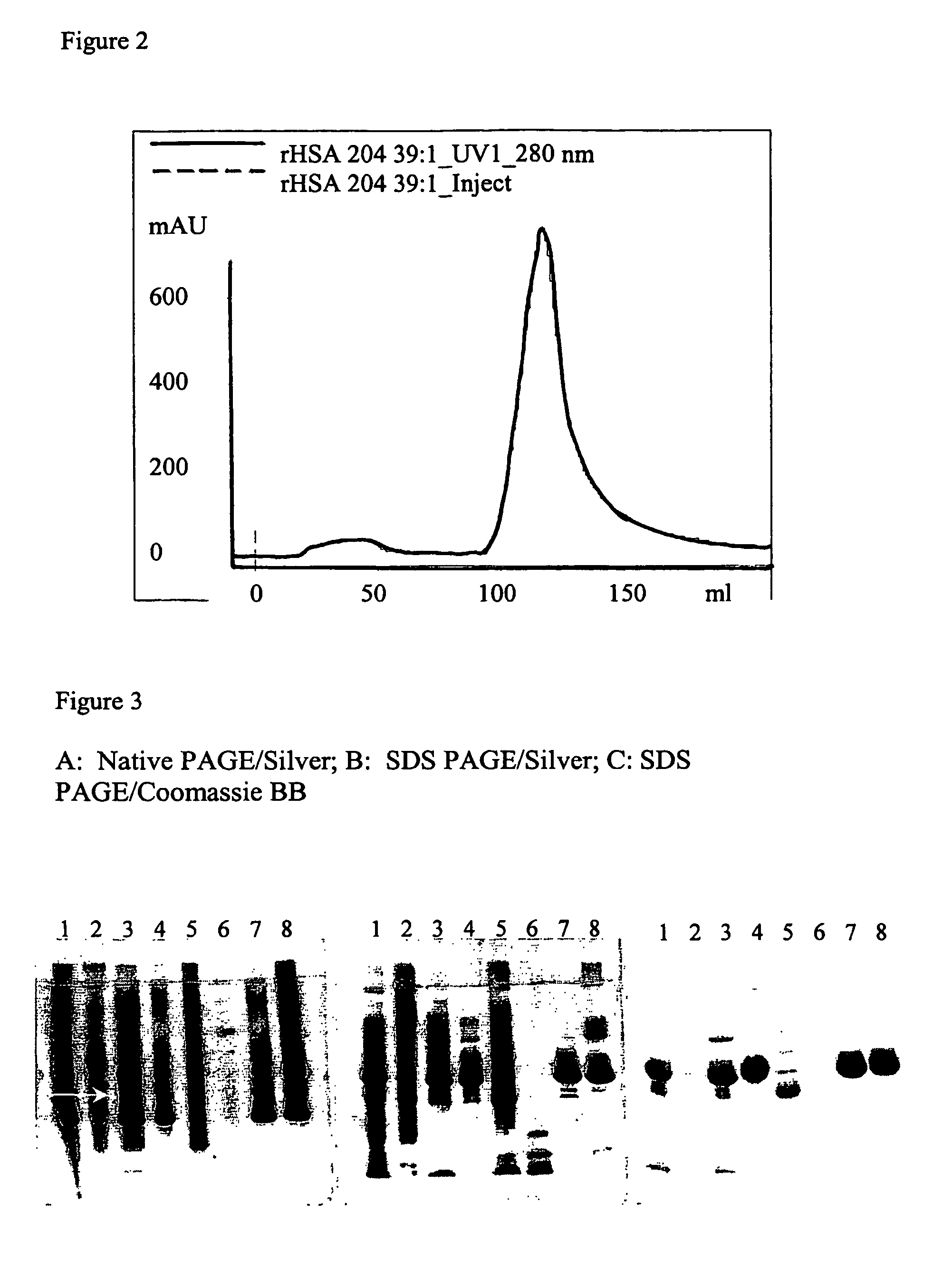

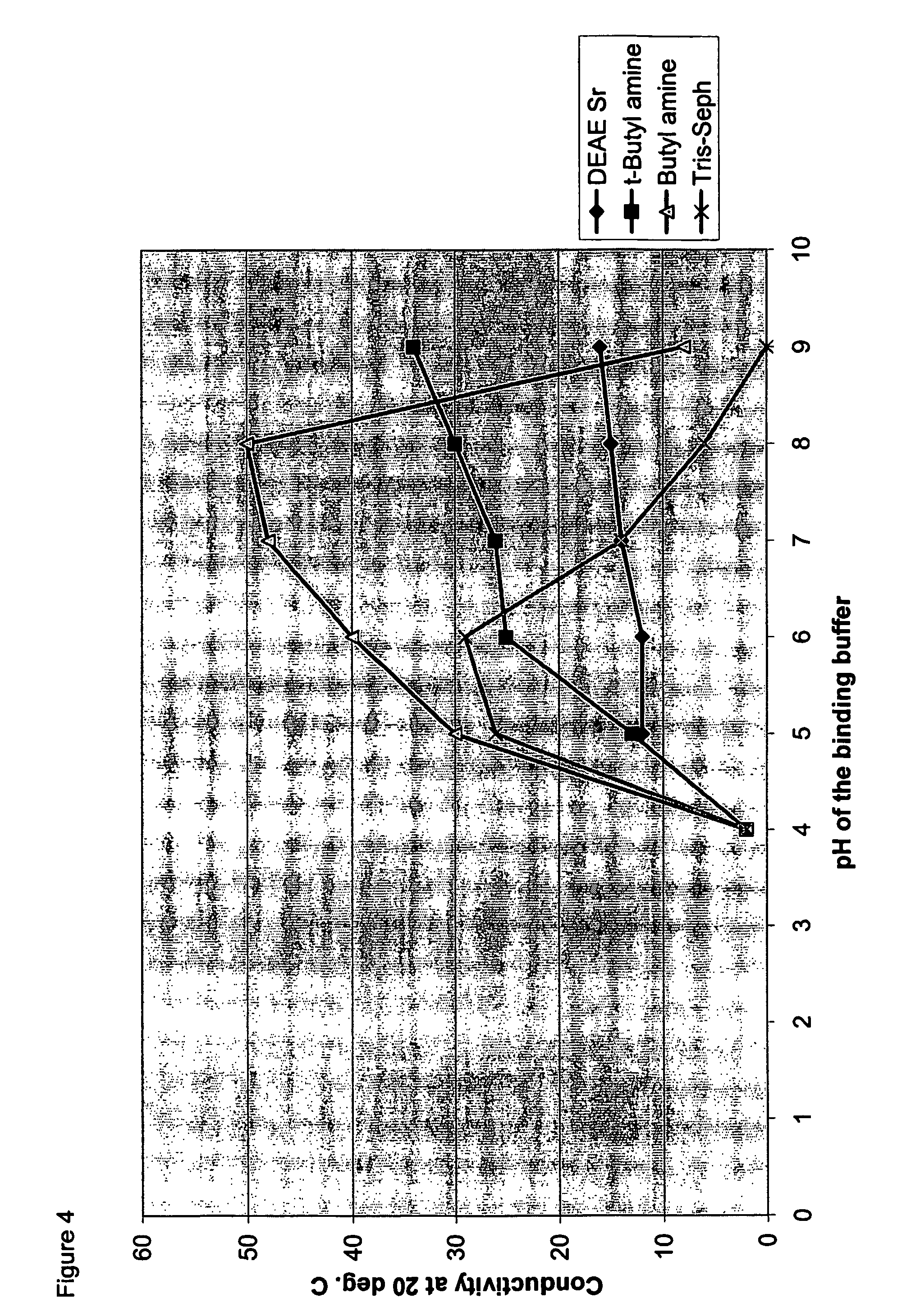

Method, use and kit for separating albumin from contaminants in a liquid

InactiveUS7351801B2Highly repeatableEasy to useSerum immunoglobulinsSerum albuminIon exchangeAlbumin

The present invention is a method of separating recombinant human serum albumin (rHSA) from low molecular weight contaminants in a liquid, which method comprises the steps of: (a) providing a separation medium, which includes anion-exchanging ligands coupled to a base matrix; and (b) contacting the liquid with the separation medium to adsorb the rHSA to the ligands. In one embodiment, the functional groups of the ligands are weak anion-exchanging groups, preferably secondary amines, and the density of ligands on the base matrix is relatively high.

Owner:GE HEALTHCARE BIO SCI CORP

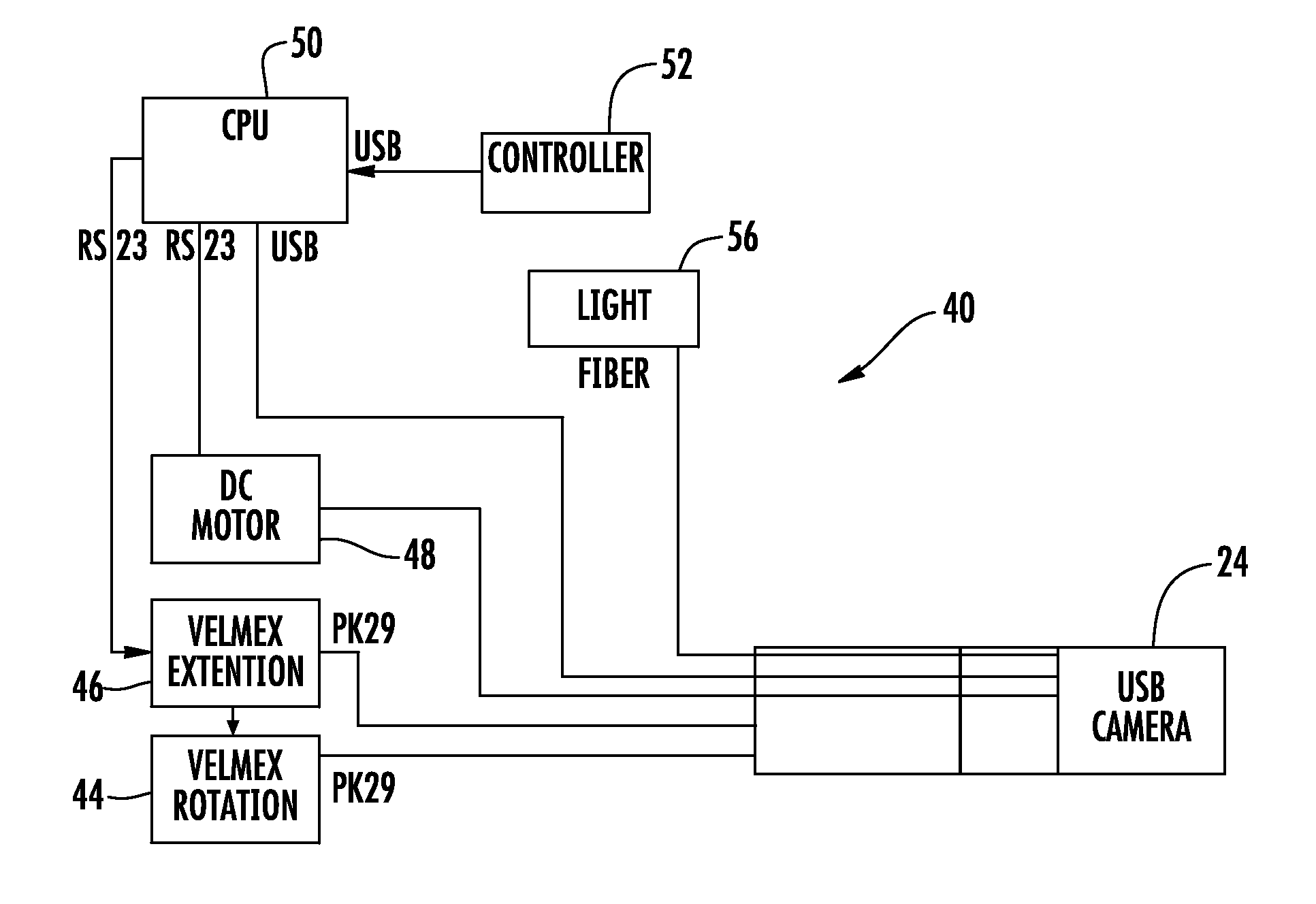

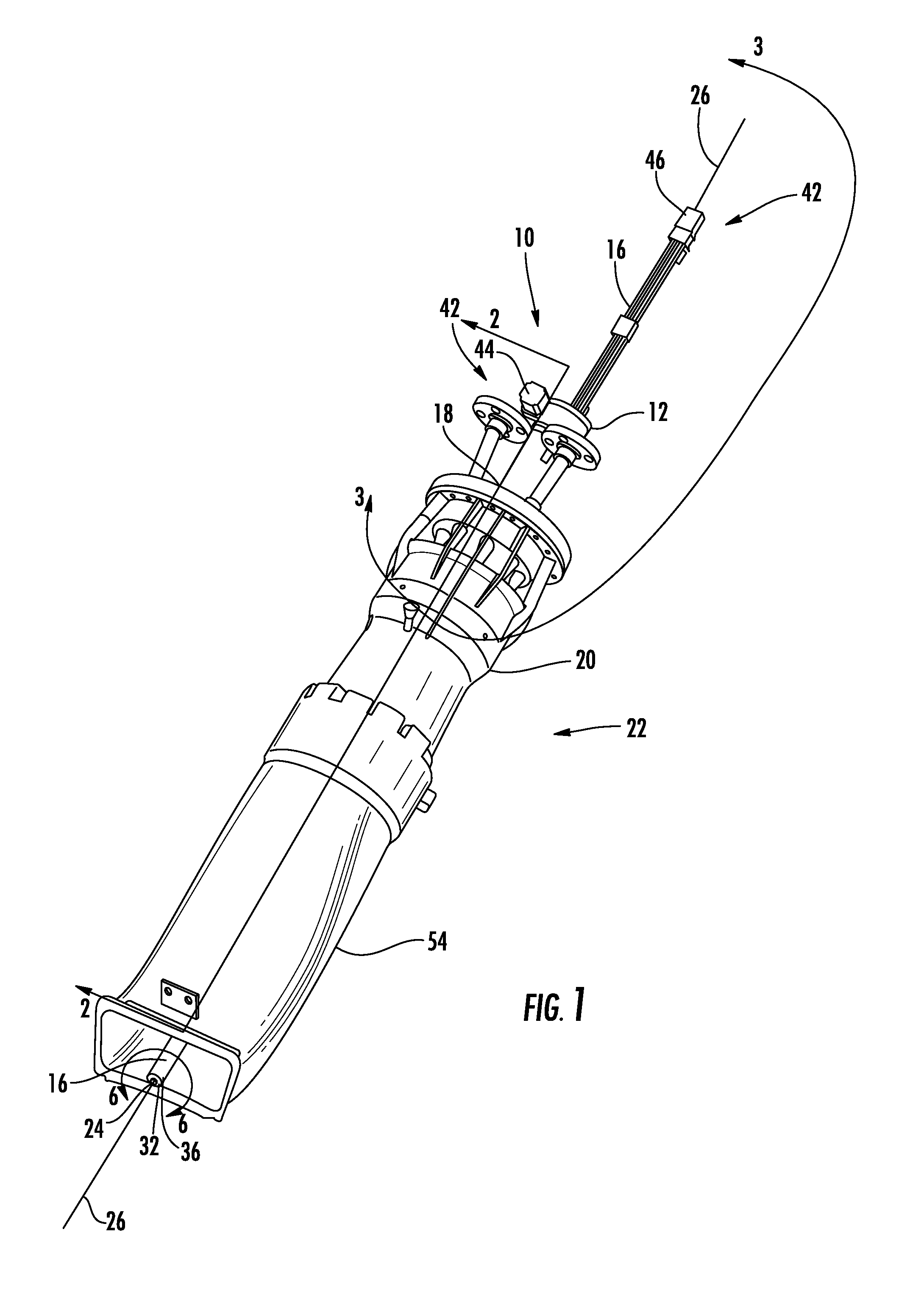

Inspection system for a combustor of a turbine engine

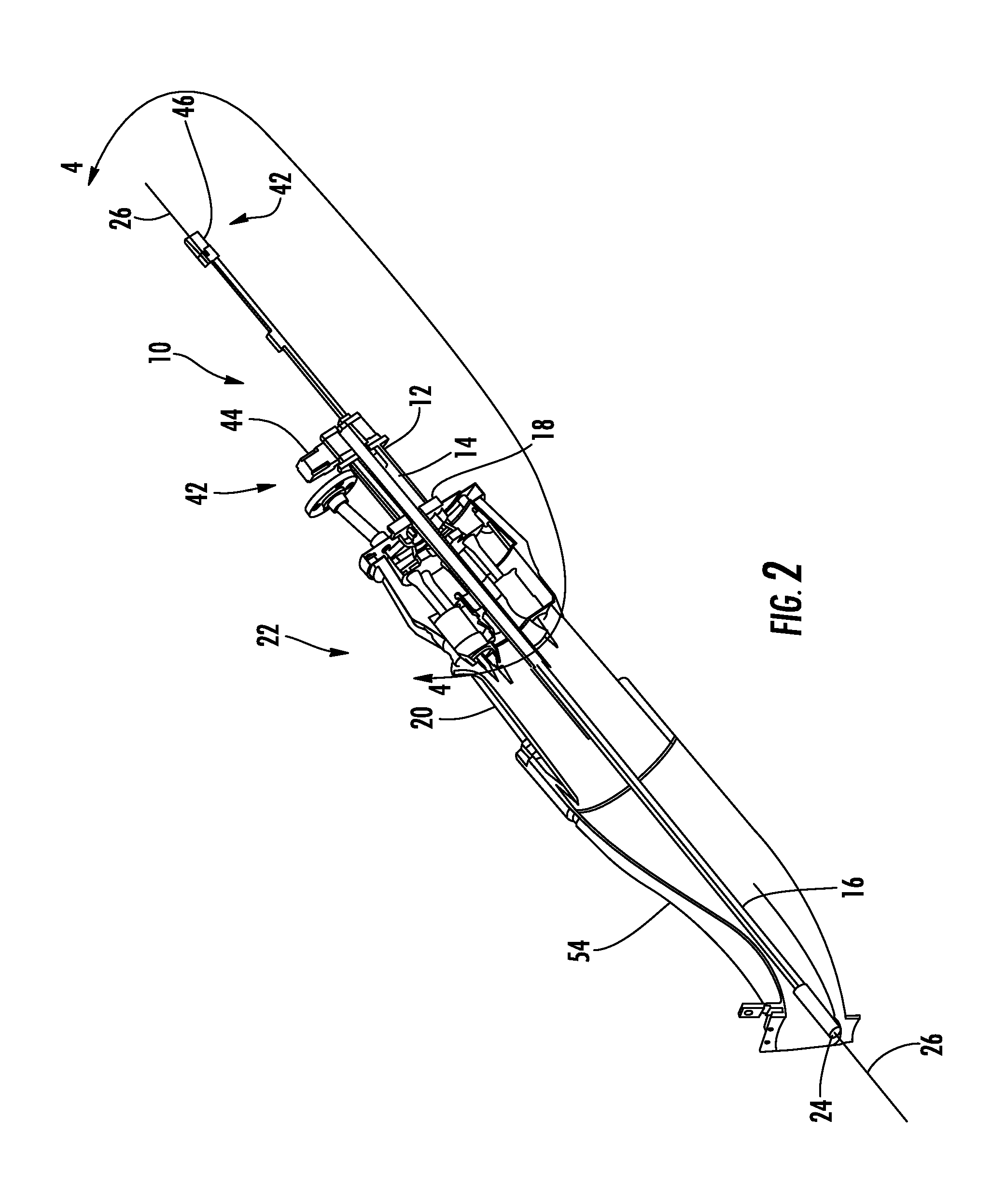

ActiveUS8786848B2Highly repeatableQuick verificationContinuous combustion chamberMaterial analysis by optical meansCombustorThree degrees of freedom

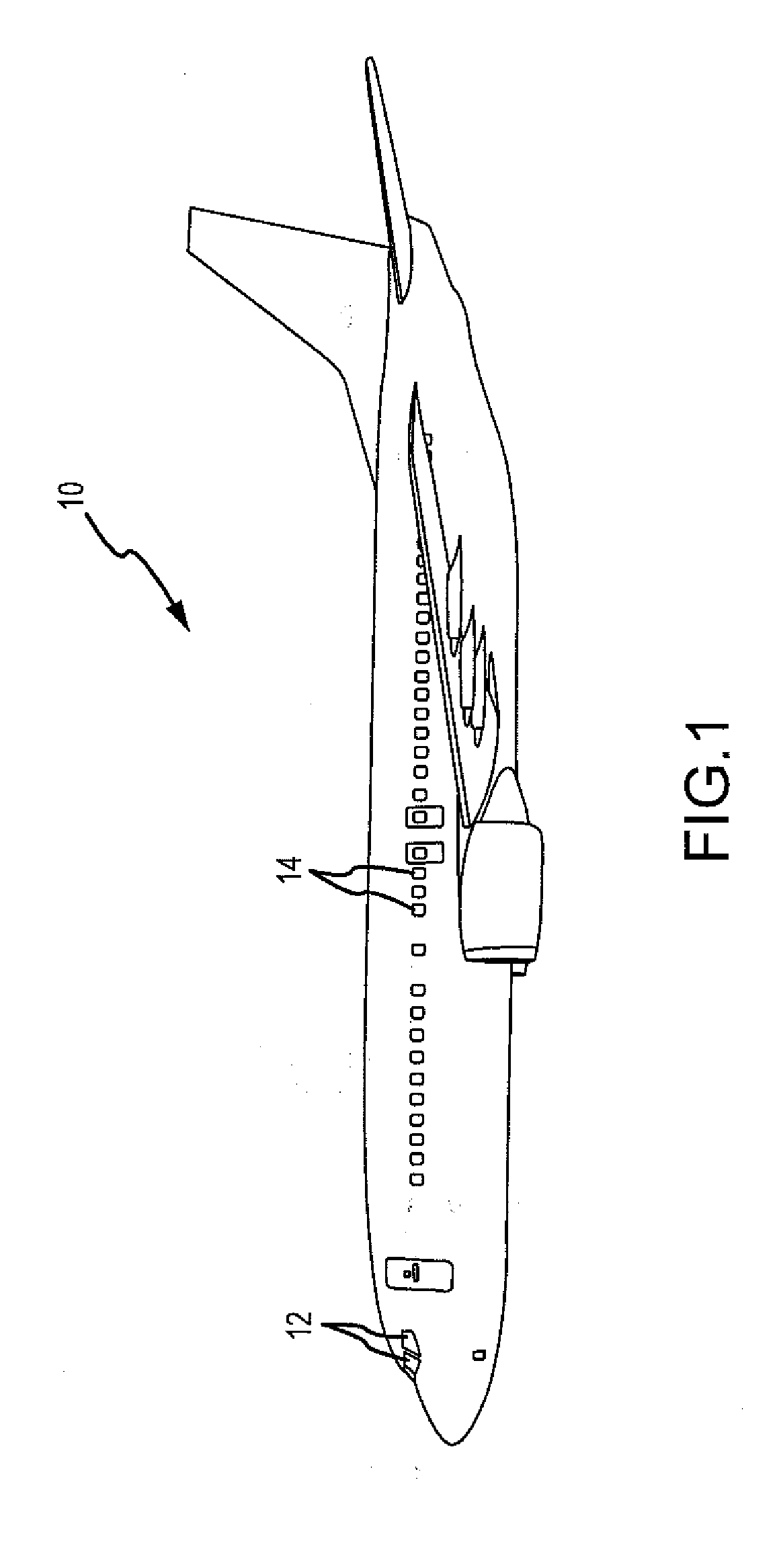

An inspection system formed at least from an inspection system housing including at least one internal chamber that supports an extendible camera support shaft extending distally through a pilot nozzle port into a combustor of a gas turbine engine is disclosed. The inspection system may include a camera capable of capturing high quality images together with position coordinates. Thus, the inspection system enables images in a combustor of a gas turbine engine to be captured and recaptured at a subsequent outage so that the images may be analyzed and compared for preventive maintenance, troubleshooting, and the like. The inspection system may include three degrees of freedom for the camera mounted on the extendible camera support shaft.

Owner:SIEMENS ENERGY INC

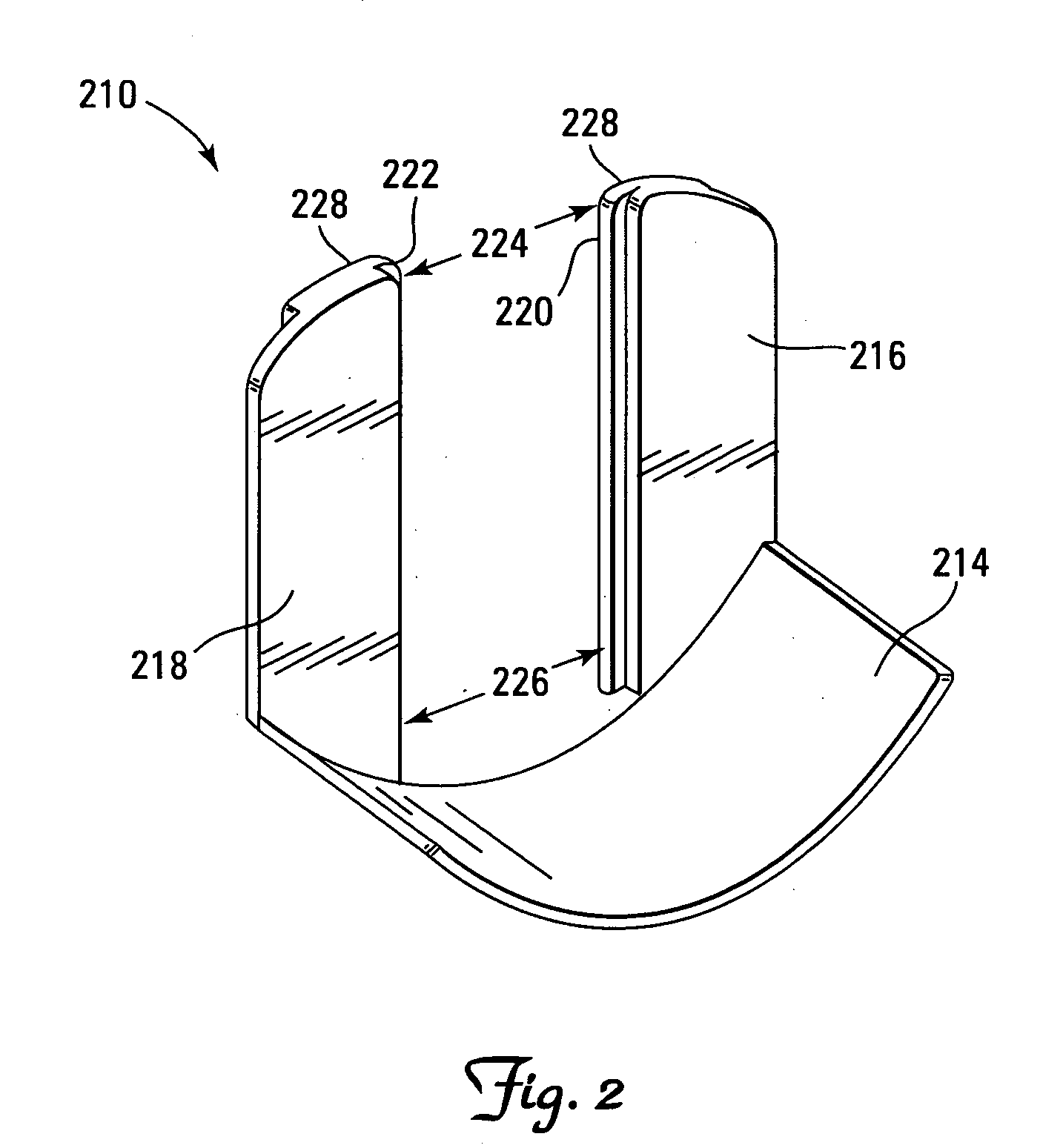

Method of making a transparency

InactiveUS20090258233A1Strong jointHighly repeatable and consistentLamination ancillary operationsLayered product treatmentThermoplasticNear infrared absorption

A method of making a transparency is provided, the method comprising the steps of: layering at least two pieces of transparent thermoplastic, wherein a portion of at least one of the pieces of transparent thermoplastic is treated with a near infrared absorbing material; and, fusing the layered pieces of transparent thermoplastic together using a heat source to form an optically transparent and undistorted transparency. There is also provided a transparency comprising at least two layers of transparent thermoplastic, wherein the layers of transparent thermoplastic have been fused together using a heat source, such that the transparency is optically transparent and undistorted.

Owner:THE BOEING CO

Method to fabricate a thin film non volatile memory device scalable to small sizes

InactiveUS20060152960A1Highly repeatableHighly stableSolid-state devicesDigital storageThin-film memoryControl circuit

A thin film non volatile memory scalable to small sizes and its fabrication process are disclosed. The thin film memory comprises a thin film transistor control circuitry fabricated on a flexible substrate, together with an optoelectronic cross bar memory comprising a photoconducting material. The thin film non volatile memory can be used in RFID communication tag with the control circuitry further comprises wireless communication circuitry such as an antenna, a receiver, and a transmitter.

Owner:TERECIRCUITS CORP

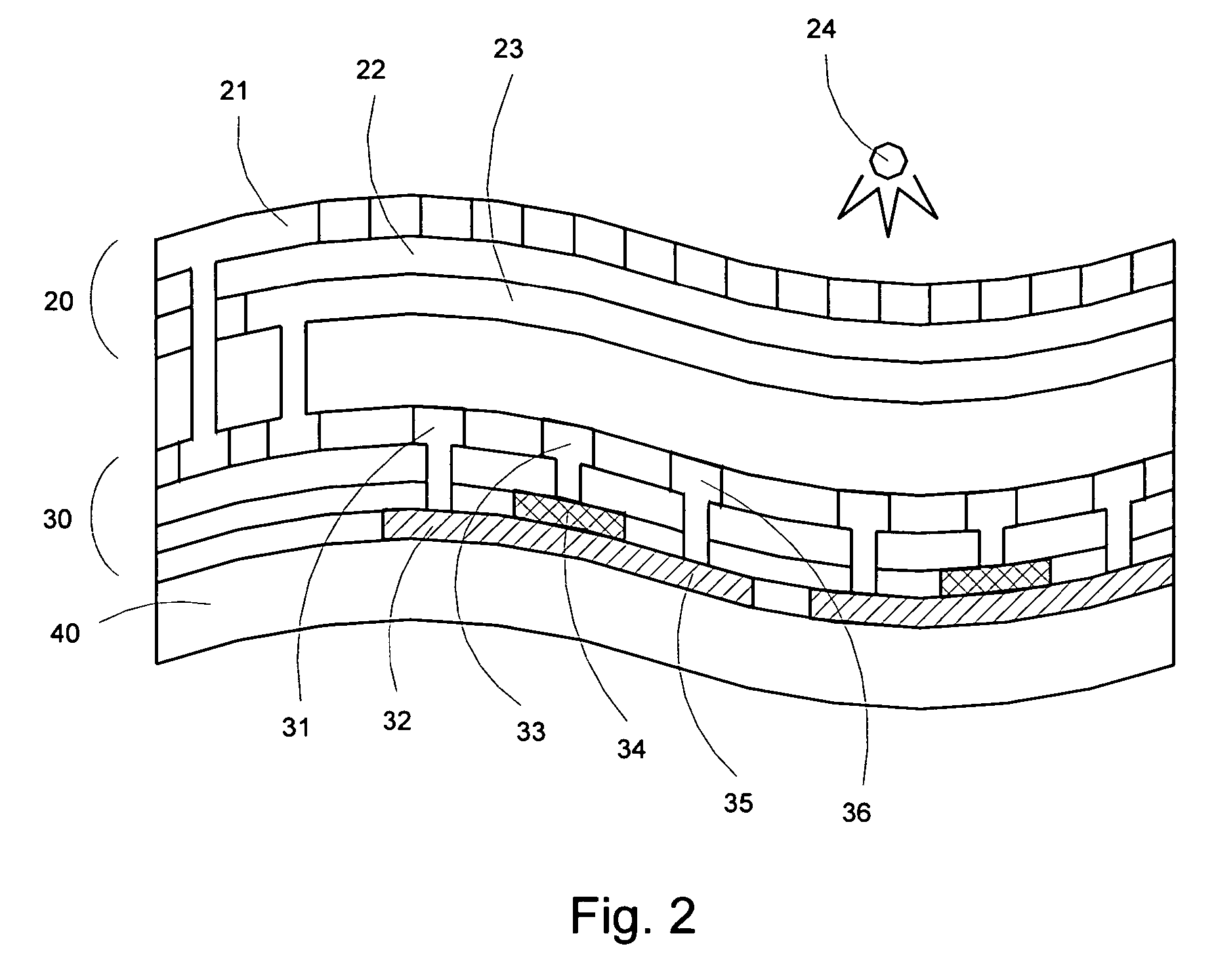

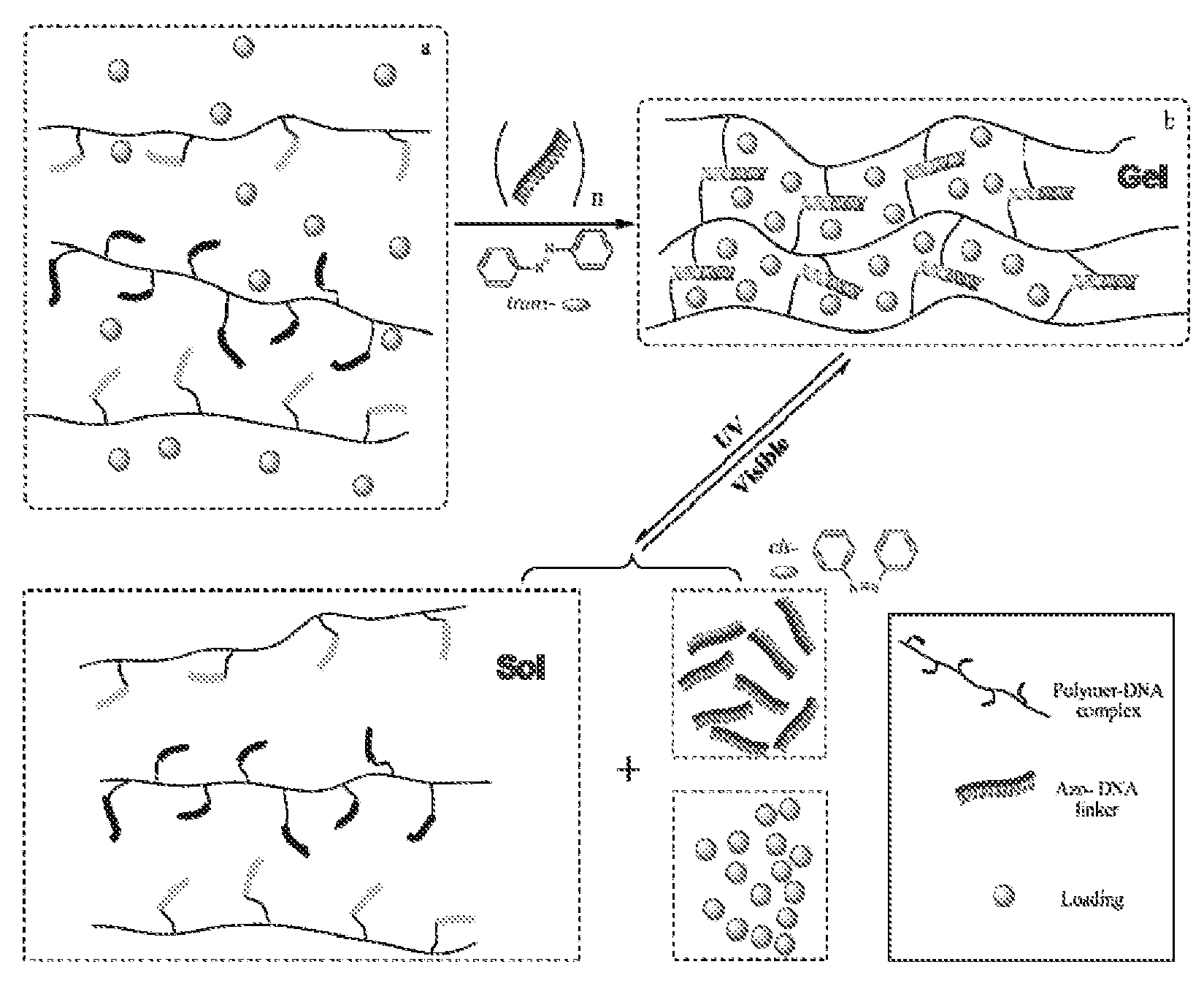

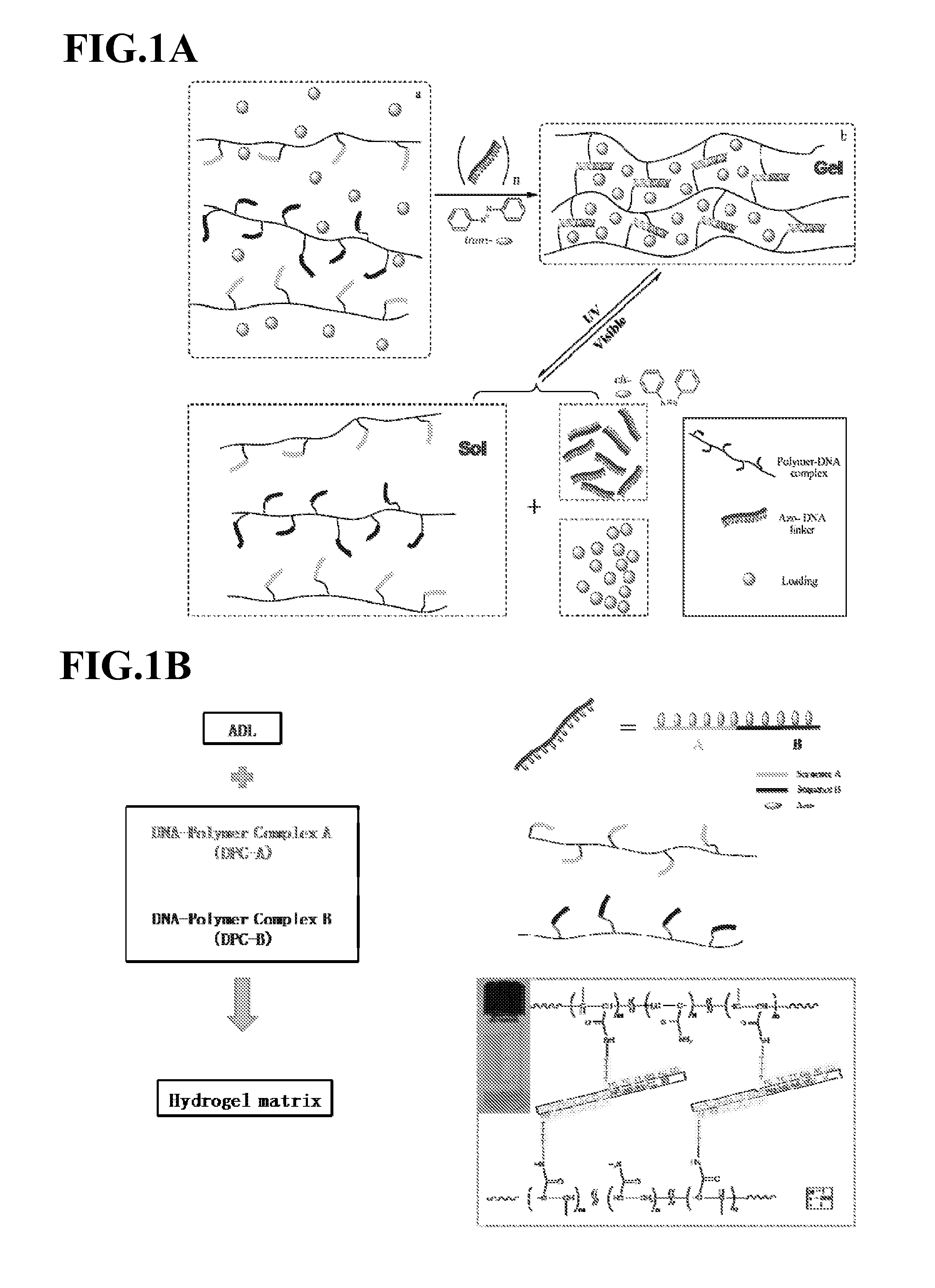

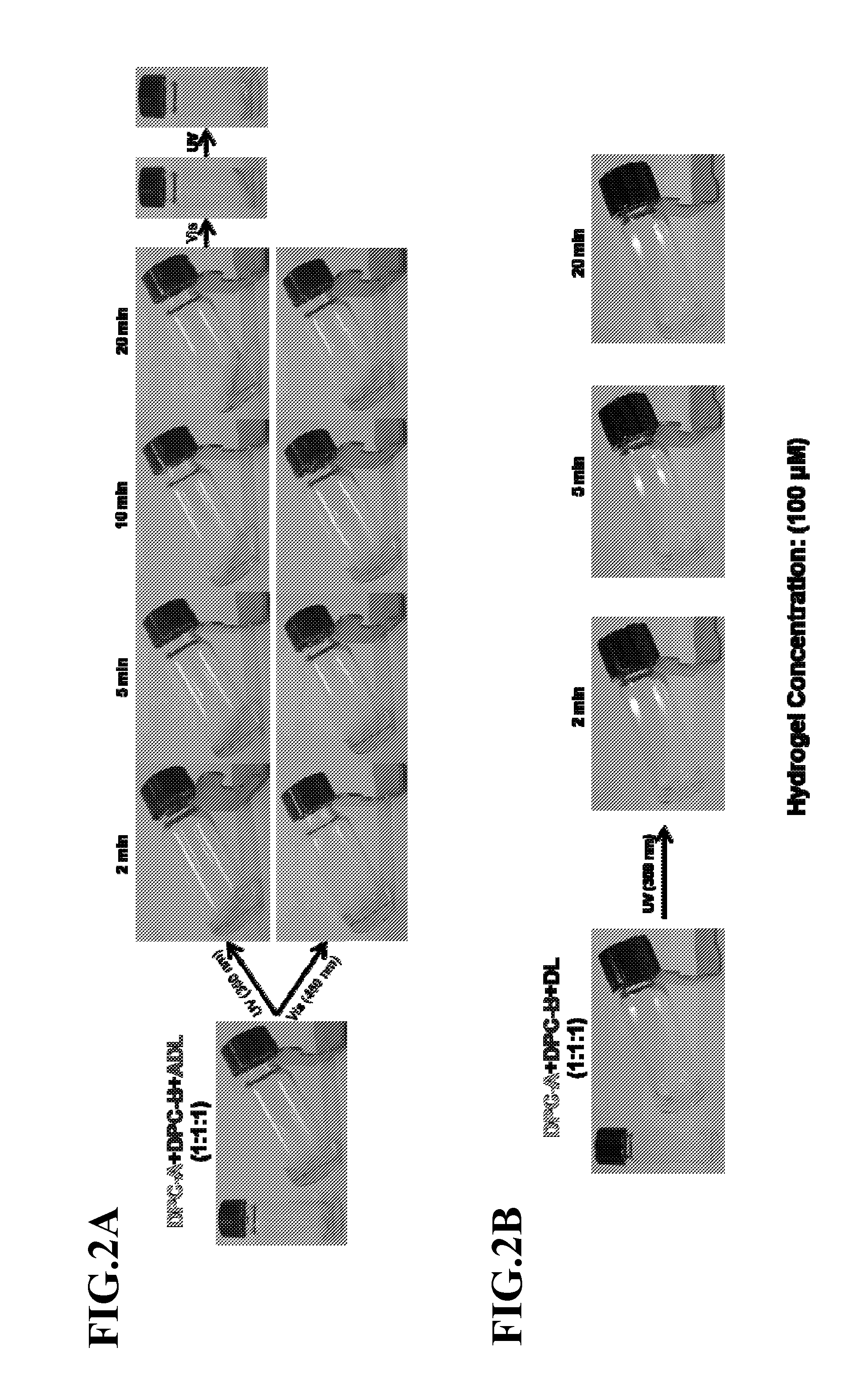

Photoregulated Reversible Hydrogels for Delivery and Releasing of Drugs and Other Therapeutical Reagents

InactiveUS20120228520A1Improve spatial resolutionFaster and deep penetrationOintment deliveryPharmaceutical non-active ingredientsCross-linkIsomerization

A novel hydrogel delivery systems useful for encapsulating and releasing pharmaceuticals or chemicals is disclosed where water soluble polymers containing crosslinker repeating units that associate or dissociate with complementary crosslinking repeating units or separate linkers to reversibly crosslink the hydrogel. In an exemplary embodiment, a DNA crosslinked hydrogel displays photoreversibility. An exemplary hydrogel delivery system comprises DNA polymer conjugates, wherein complementary DNA sequences are crosslinked with polymer chains and hybridization of the DNA sequences is controlled by photoresponsive moieties. Such hydrogels can be used to release drug molecules and / or other therapeutic reagents. The exemplary hydrogel employs photosensitive azobenzene moieties that are incorporated into the DNA crosslinker units. The azobenzene moieties respond to different wavelengths of light so that the state of azobenzene isomerization is induced by the proportion of visible and UV light irradiated. The isomer state of the azobenzene dictates whether the complementary DNA sequences hybridize to cross link the DNA polymer conjugates. Thus, irradiation of light (visible or UV) can transform the hydrogel network between a sol and any of multiple gel states to regulate the degree of crosslinking between complementary DNA sequences and, therefore, provide a profile of release of a hydrogel encapsulated pharmaceutical or other chemical.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

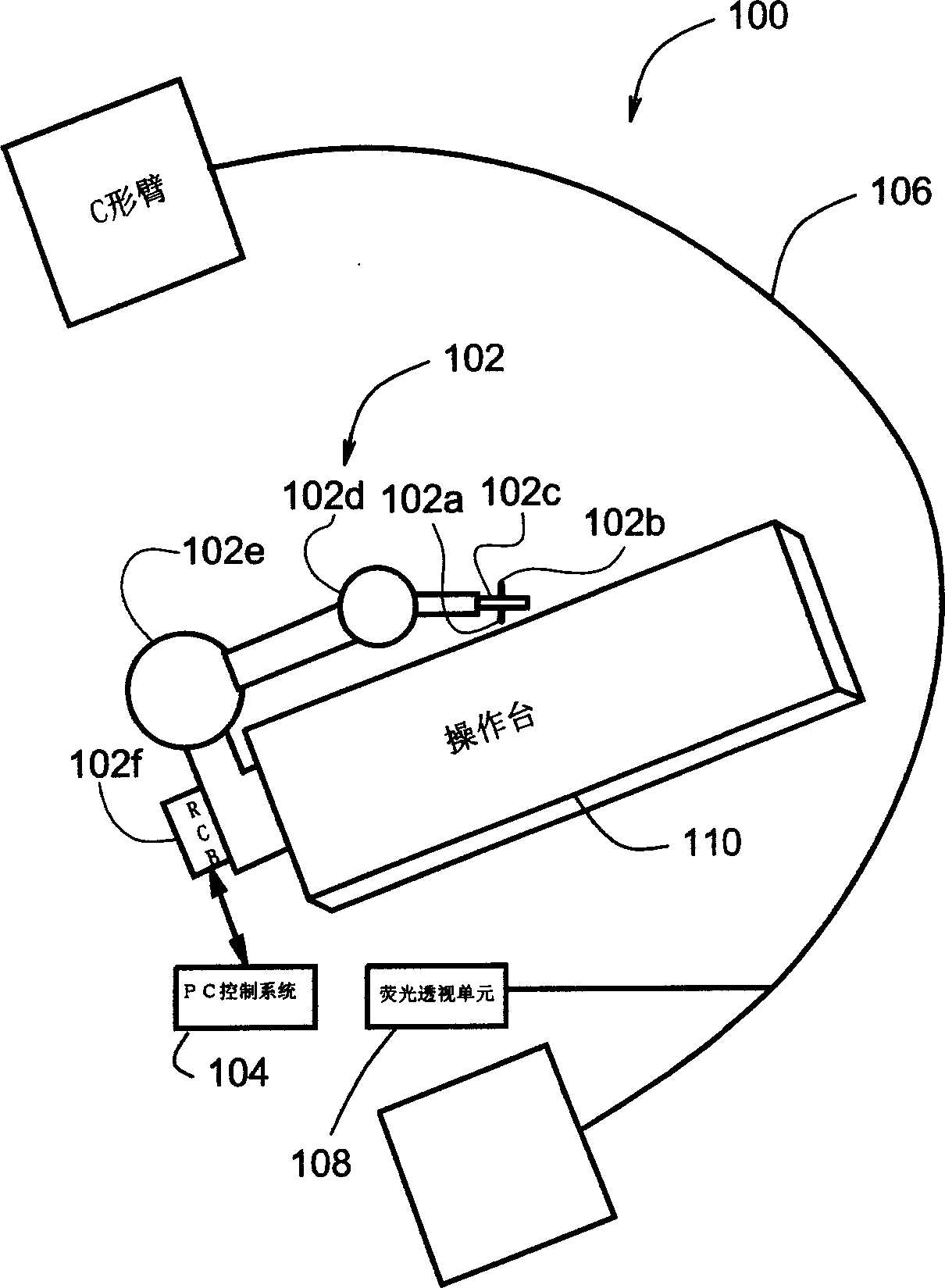

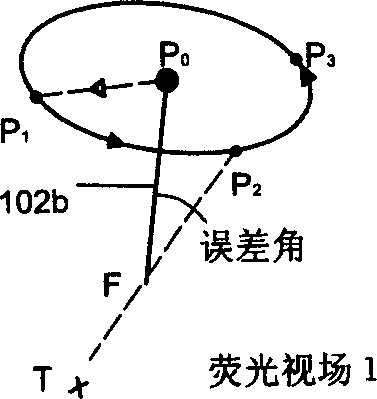

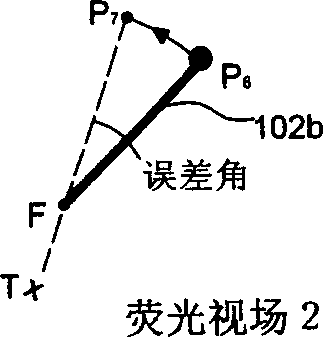

System and method for robot targeting under fluoroscopy based on image servoing

InactiveCN1612711ARealize 3D calibrationGood precisionSurgical navigation systemsDiagnostic recording/measuringData controlRobotics

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

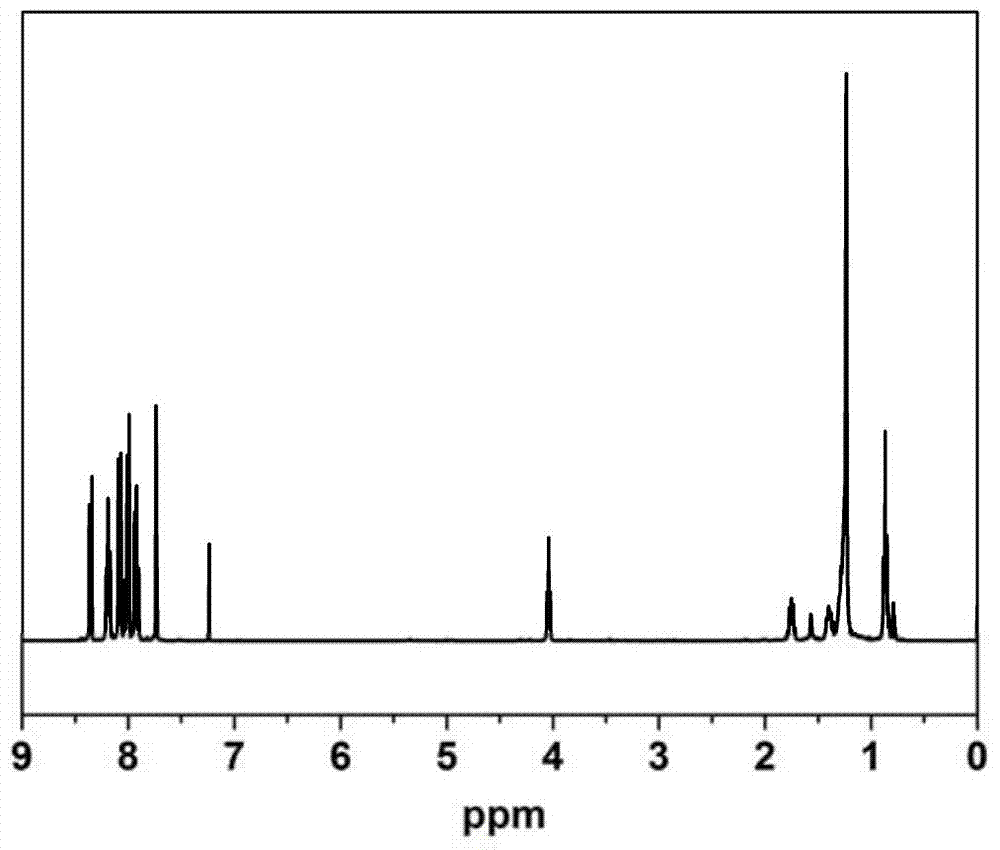

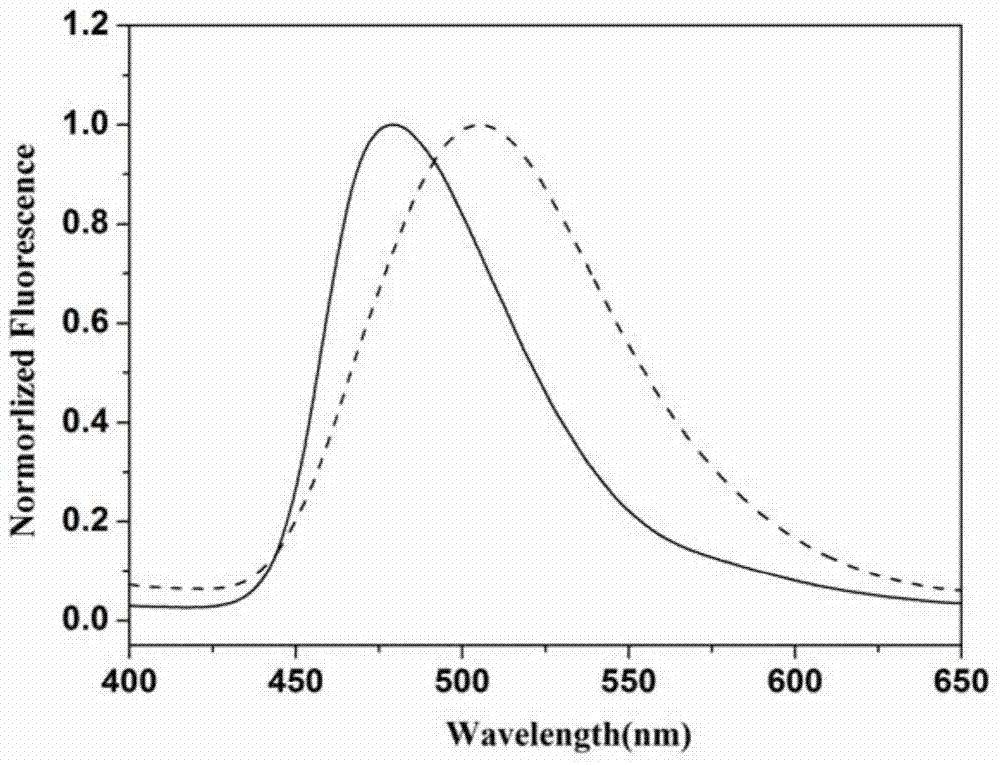

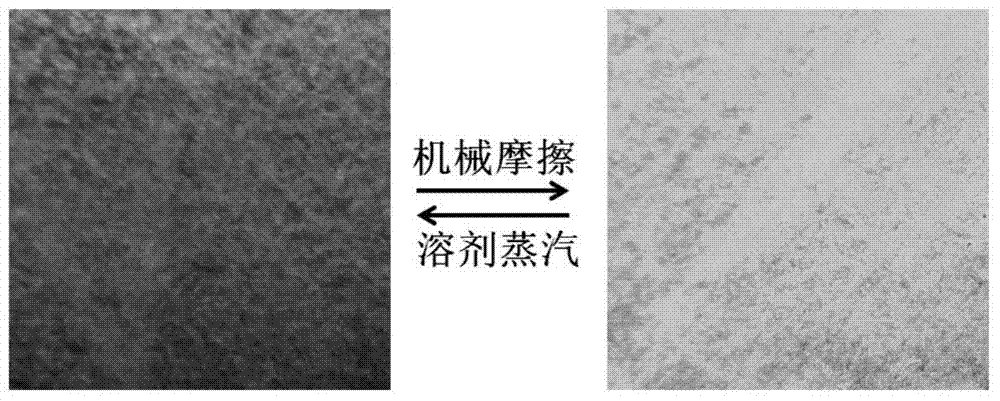

Bis-pyrene type compound with piezochromic property and preparation method and application thereof

ActiveCN103922915AGood suppression of fluorescent color change propertiesChange intensityNon-fibrous pulp additionSpecial paperChemical compoundFluorescence

The invention discloses a bis-pyrene type compound with piezochromic property and a preparation method and application thereof. The compound has the structure as shown in general formula (I), and the preparation is completed by four-step conventional reactions, namely etherification reaction, hydrolysis reaction, chloroformylation reaction and Friedel-Crafts acylation reaction. The bis-pyrene type compound disclosed by the invention can be used for preparing a thin film in a spin-coating way, and the thin film has piezochromic luminescent property with high repeatability, high contrast and high sensitivity and can be used for information storage.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

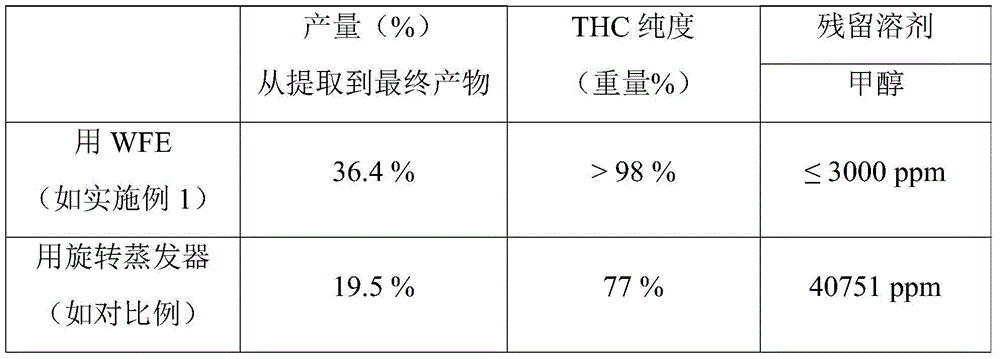

Cannabis plant isolate comprising /\9-tetrahydrocannabinol and a method for preparing such an isolate

InactiveCN104619318AGood yieldHighly repeatableNervous disorderOrganic chemistrySolventΔ9-tetrahydrocannabinol

The present invention relates to a method for preparing a Cannabis plant Δ9-tetrahydrocannabinol isolate from a crude solvent extract of Cannabis plant material. The invention relates further to a Cannabis plant THC isolate comprising Δ9-tetrahydrocannabinol, Cannabinol (CBN) and / or Cannabidiol (CBD) and to a pharmaceutical composition comprising the Cannabis plant THC isolate.

Owner:ECHO PHARM BV (NL)

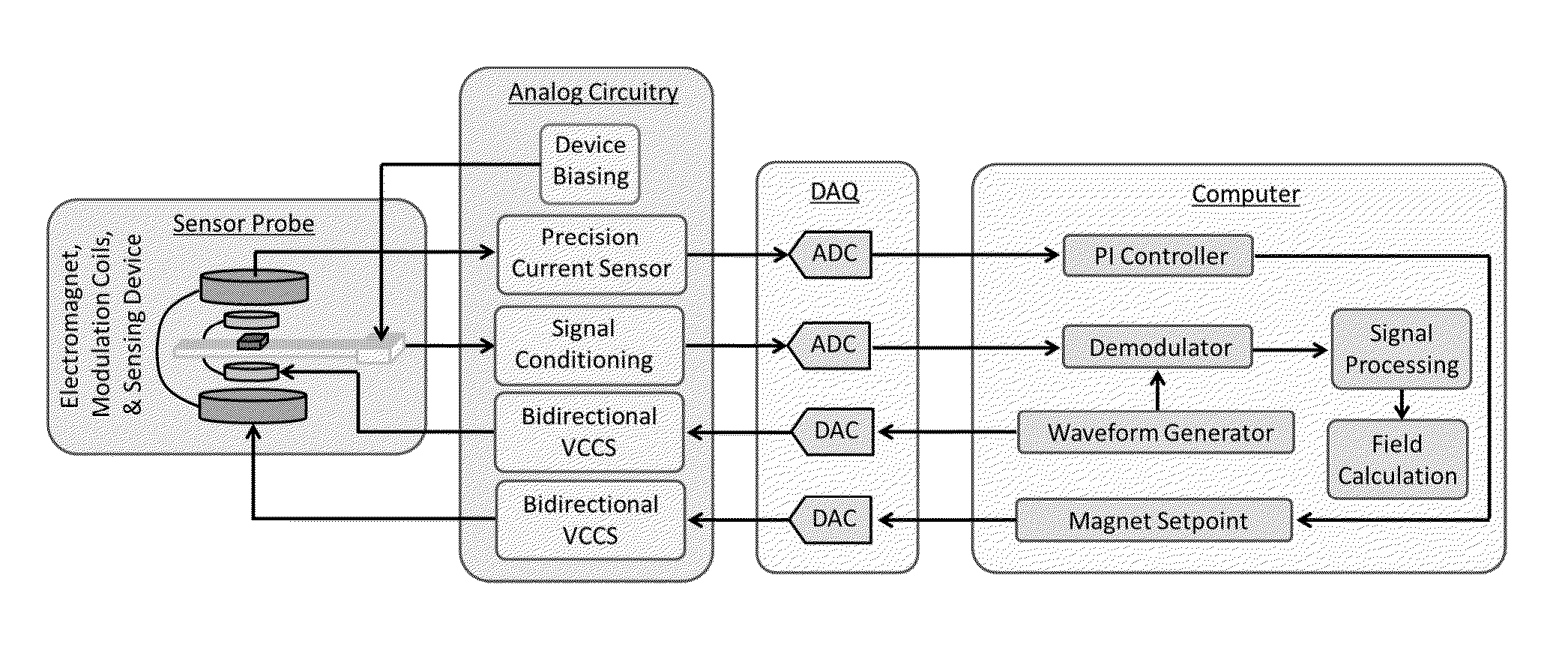

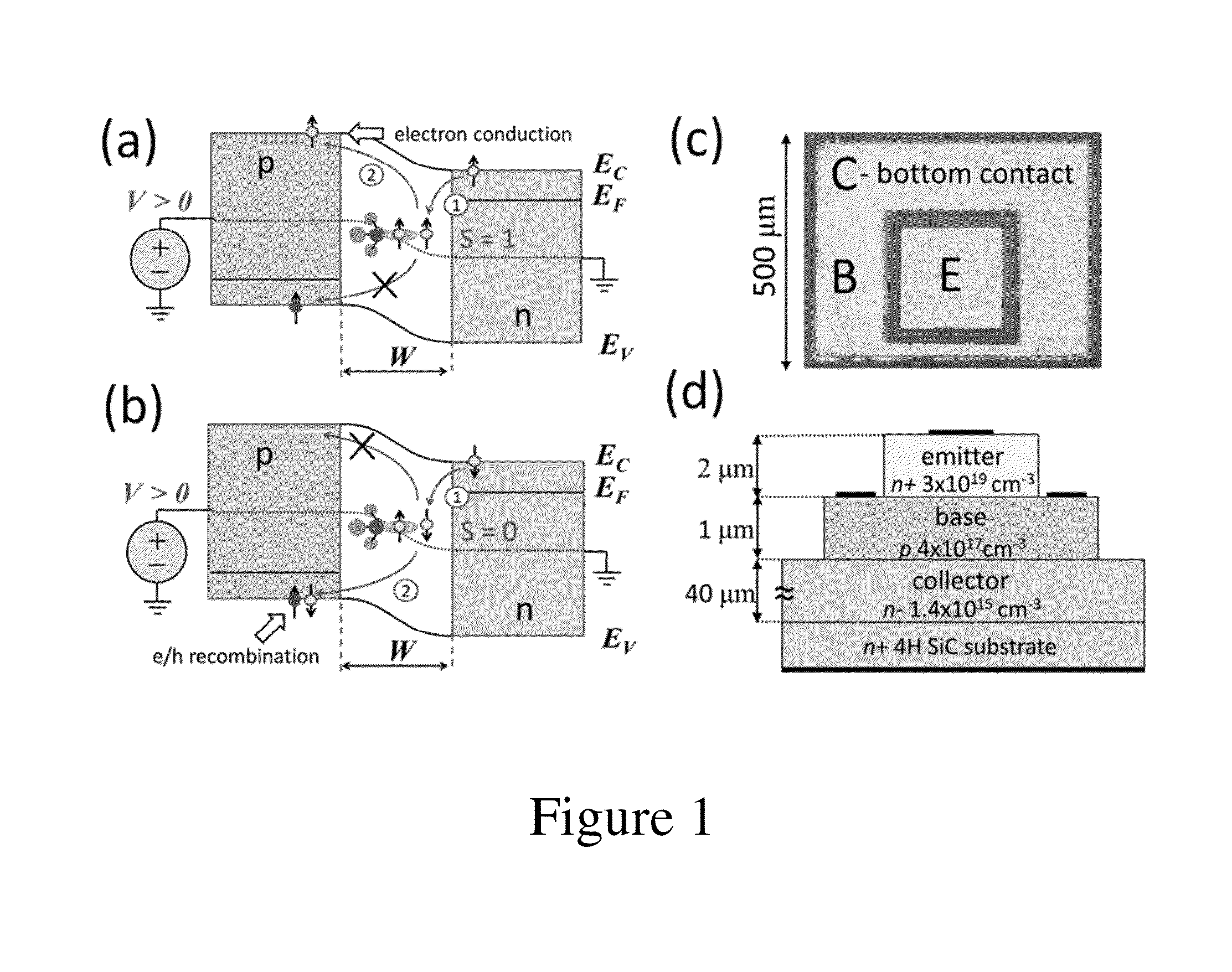

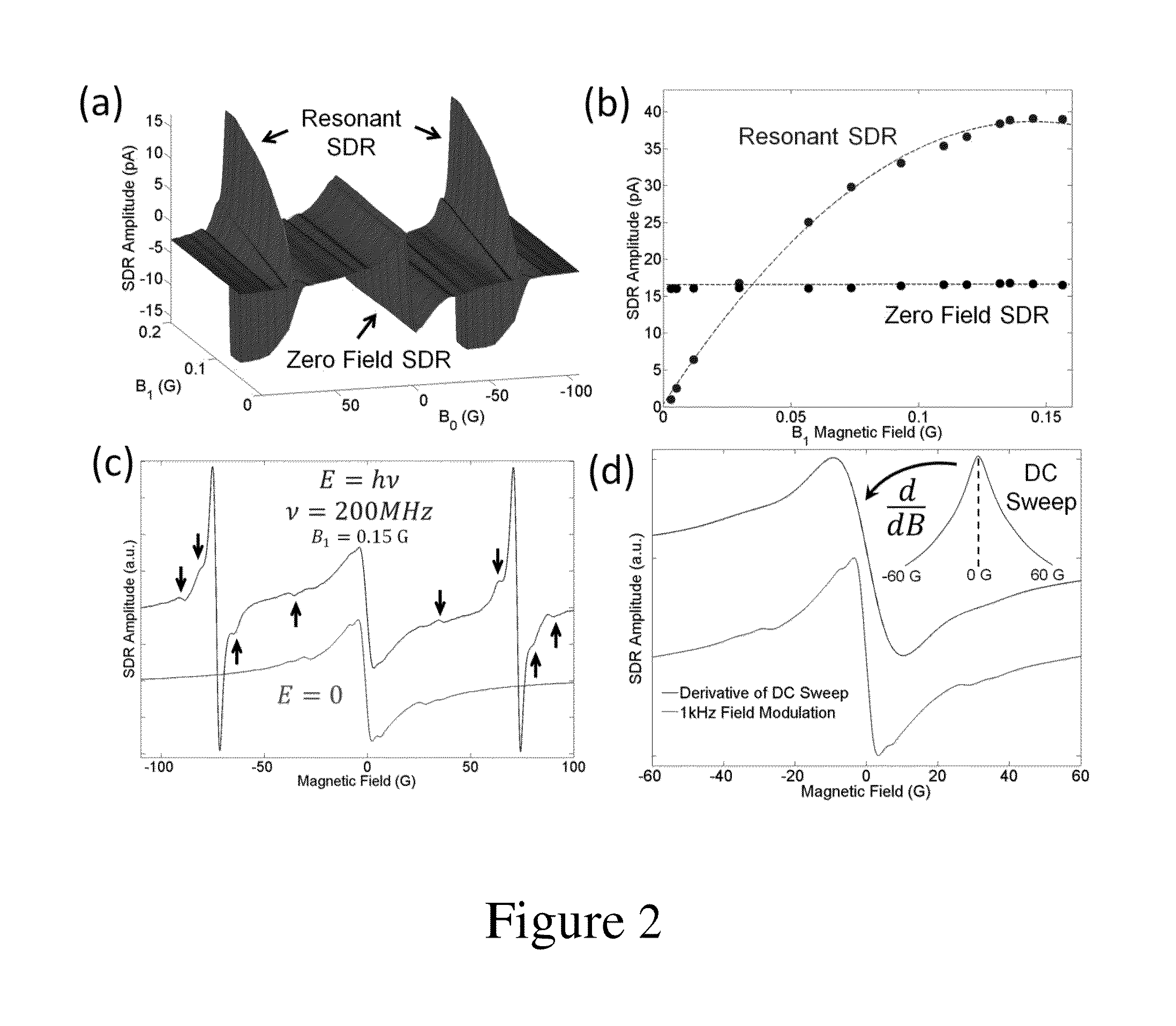

Zero- & Low-Field Transport Detection System

ActiveUS20140247048A1Improve analytical performanceSignificant to useAnalysis using electron paramagnetic resonanaceElectric/magnetic detectionElectromagnetic fieldAudio frequency

A sensing apparatus for detecting and determining the magnitude of a static magnetic field has a first set of coils capable of producing a sweeping, quasi static, magnetic field when driven by a direct current and a second set of coils, for magnetic field modulation, positioned between the first set of coils capable of producing a low-frequency (audio), oscillating magnetic field when driven by an oscillating current. The magnetic fields induce a current through the semiconductor device which sampled to identify changes as a function of sweeping, quasi static magnetic field. To create an apparatus for detecting and identifying atomic scale defects in fully processed devices, a radio frequency circuit with a resonant component is added which provides an oscillating electromagnetic field in a direction perpendicular to that of the static magnetic field produced by the first set of coils.

Owner:PENN STATE RES FOUND

Manufacturing method of contact probes for a testing head

ActiveUS20170307656A1Simple and reliable processHighly repeatableDecorative surface effectsElectrical measurement instrument detailsLaser cuttingBiomedical engineering

A manufacturing method of contact probes for a testing head comprises the steps of:—providing a substrate made of a conductive material; and—defining at least one contact probe by laser cutting the substrate. The method further includes at least one post-processing fine definition step of at least one end portion of the contact probe, that follows the step of defining the contact probe by laser cutting, the end portion being a portion including a contact tip or a contact head of the contact probe. The fine definition step does not involve a laser processing and includes geometrically defining the end portion of the contact probe with at least a substantially micrometric precision.

Owner:TECHNOPROBE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com