Cannabis plant isolate comprising /\9-tetrahydrocannabinol and a method for preparing such an isolate

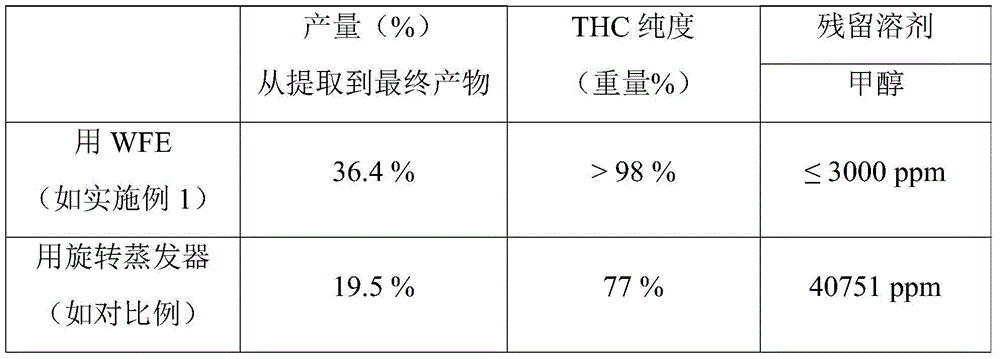

A technology for tetrahydrocannabinol and isolates, which is applied in the field of preparing cannabis plant Δ9-tetrahydrocannabinol isolates, can solve the problems of low THC yield, residue, and cumbersome methods, and achieve highly repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] The preparation method of the cannabis plant 9-tetrahydrocannabinol (THC) isolate according to the present invention is as follows.

[0093] 2 kg of cannabis flowers (ie, flowers) obtained from the hemp plant were heated to approximately 100° C. to decarboxylate the cannabinoid acids present in the cannabis flowers. The decarboxylated cannabis flower (1.8 kg) was then mixed with hexane (1 g cannabis flower per 10 ml hexane) to extract cannabinoids from said cannabis flower. The extract was isolated from the flowers and dried to dryness in a rotary evaporator. The solvent extract (about 600 g) contained about 55% THC by dry weight.

[0094] Subsequently, the dried extract was introduced into methanol (1 g of dried extract per 2 ml of methanol) and cooled to -10 °C, then filtered and centrifuged at 5000 RPM at a temperature of 6 °C (Beckman Coulter, model Avanti J-26xp )25min. Activated charcoal of p.a. grade purity was added to the obtained methanol solvent mixture at...

Embodiment 2

[0099] The preparation of tablets containing the 9-tetrahydrocannabinol (THC) isolate of the cannabis plant obtained by the method described in Example 1 is as follows.

[0100] Sucrose monolaurate (HLB=15) and cannabis plant THC isolate were heated to 120°C under nitrogen flow. The weight ratio of THC and sucrose monolaurate is 1:15. After thorough mixing, the putty-like melt was washed with CO using either of the following methods: 2 Saturation (and thus softening):

[0101] - Inject the warm melt into a preheated autoclave at 120°C and pressurize to 250 bar. The autoclave was pressurized with carbon dioxide with a plunger pump (LeWa) and heated with heating oil through a jacket. The dough was heated by CO at a supercritical rate using a Buchi(TM) magnetic stirrer. 2 Stir the melt for at least 30 min, pass it through CO 2 Saturation way to further liquefaction.

[0102] - Cool the melt to -20°C and crush for maximum surface area. For this, use -20 °C pre-cooled mortar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com