Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5044 results about "Hexane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexane /ˈhɛkseɪn/ is an alkane of six carbon atoms, with the chemical formula C₆H₁₄. The term may refer to any of the five structural isomers with that formula, or to a mixture of them. In IUPAC nomenclature, however, hexane is the unbranched isomer (n-hexane); the other four isomers are named as methylated derivatives of pentane and butane. IUPAC also uses the term as the root of many compounds with a linear six-carbon backbone, such as 2-methylhexane.

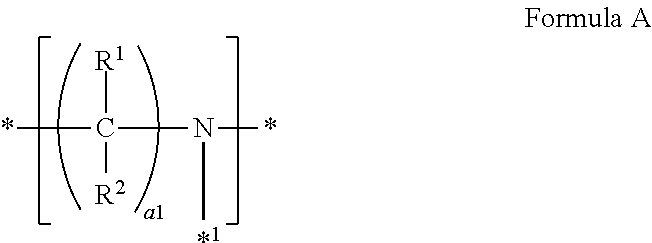

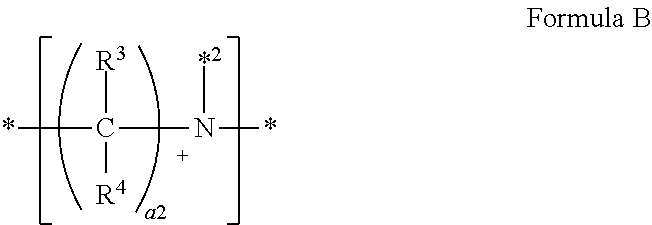

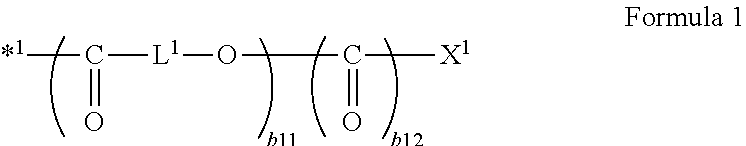

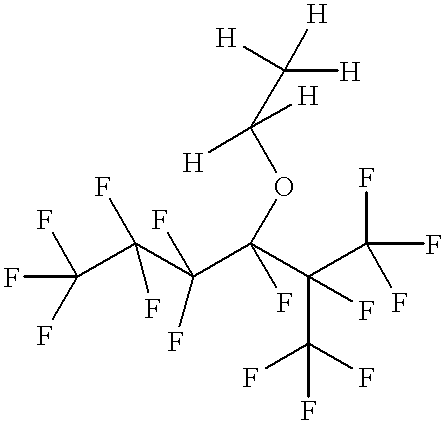

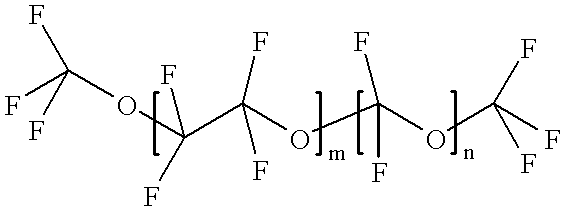

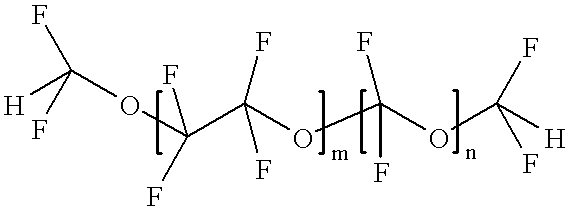

(1R,2S,5S)-N-[(1S)-3-amino-1-(cyclobutylmethyl)-2,3-dioxopropyl]-3-[(2S)-2-[[[(1,1-dimethylethyl)amino]carbonyl]amino]-3,3-dimethyl-1-oxobutyl]-6,6-dimethyl-3-azabicyclo[3.1.0]hexane-2-carboxamide as inhibitor of hepatitis C virus NS3/NS4a serine protease

The present invention discloses the compound of Formula 3 as an inhibitor of HCV protease, as well as methods for preparing the compound. In another embodiment, the invention discloses pharmaceutical compositions comprising the compound as well as methods of using them to treat disorders associated with the HCV protease.

Owner:SCHERING CORP

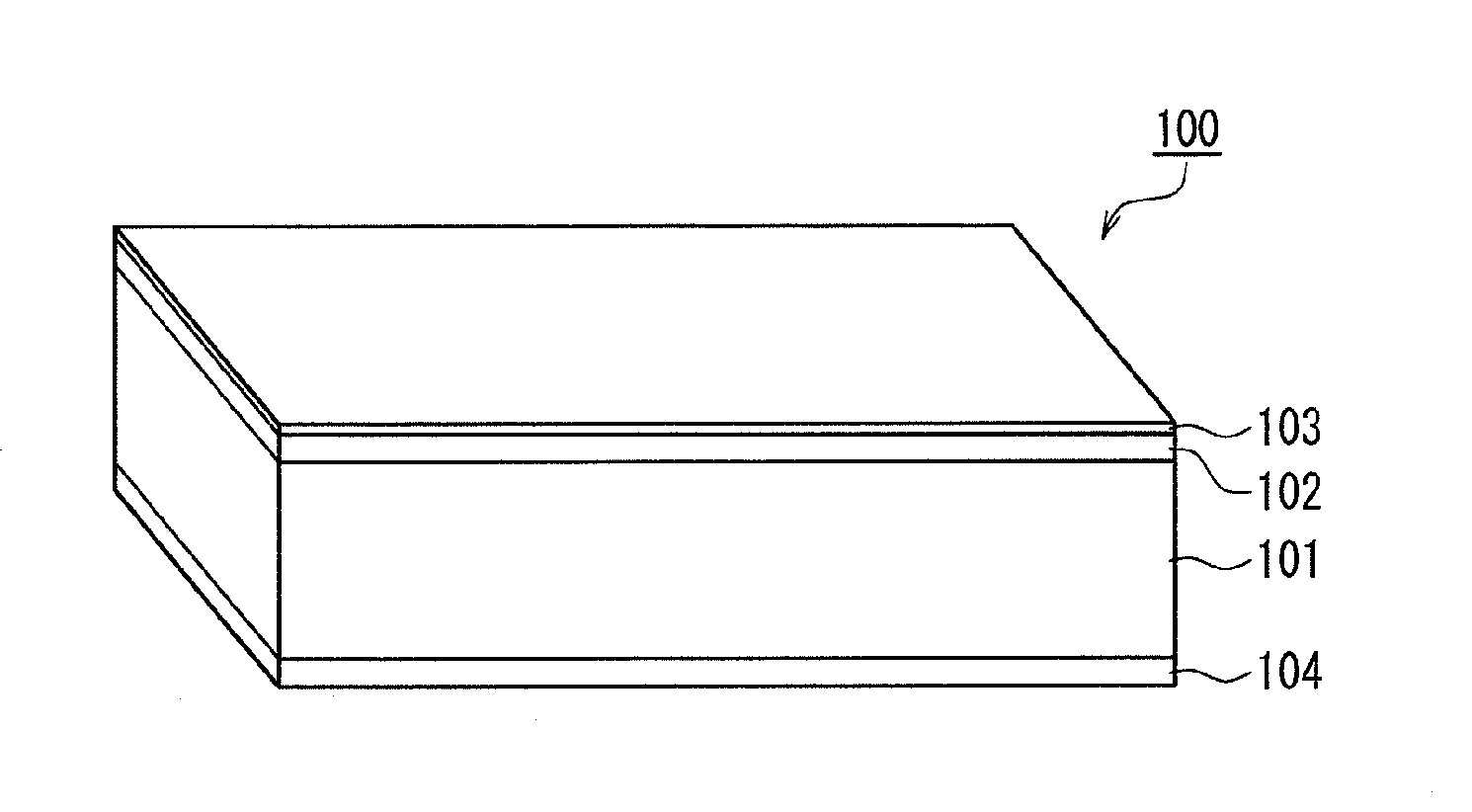

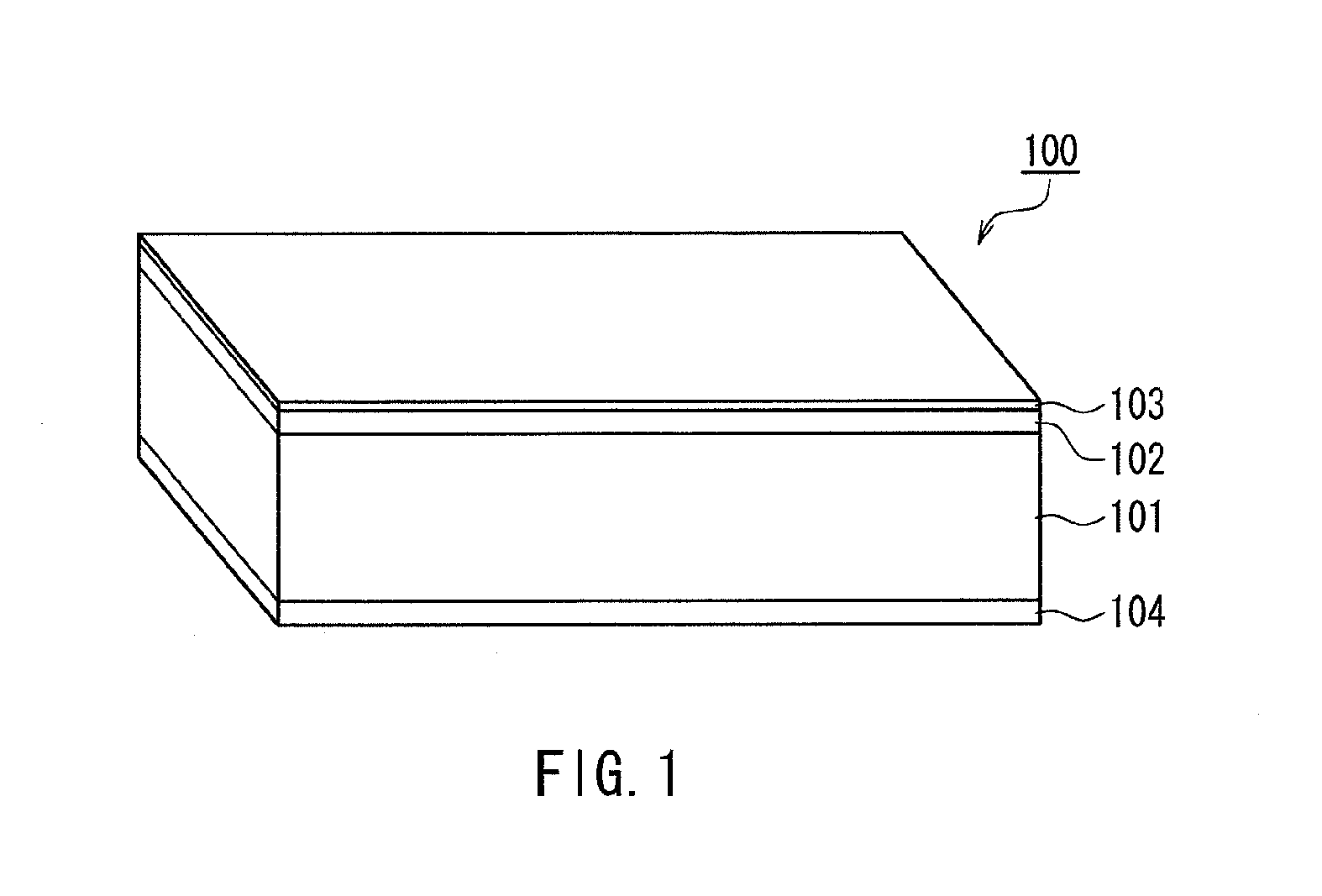

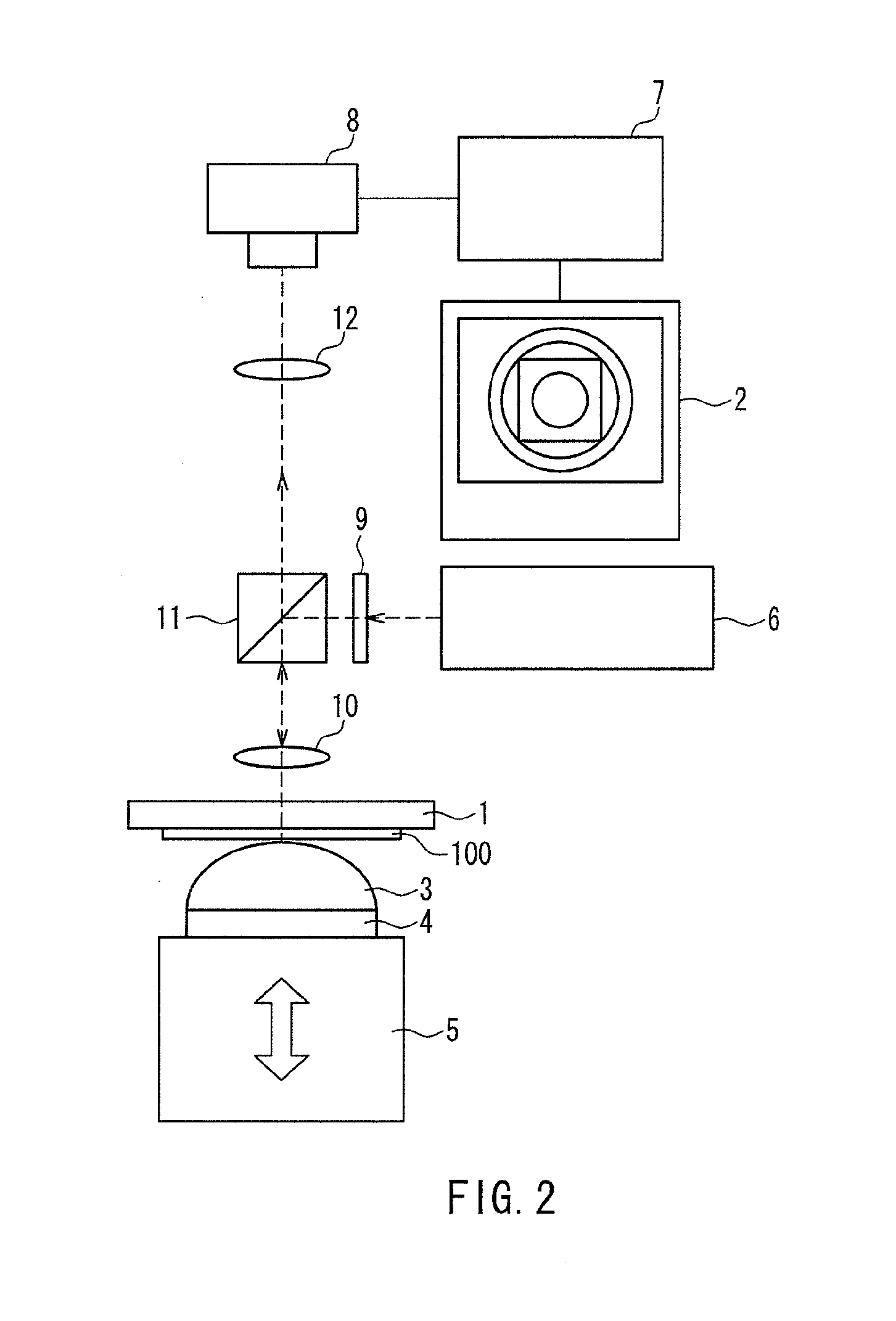

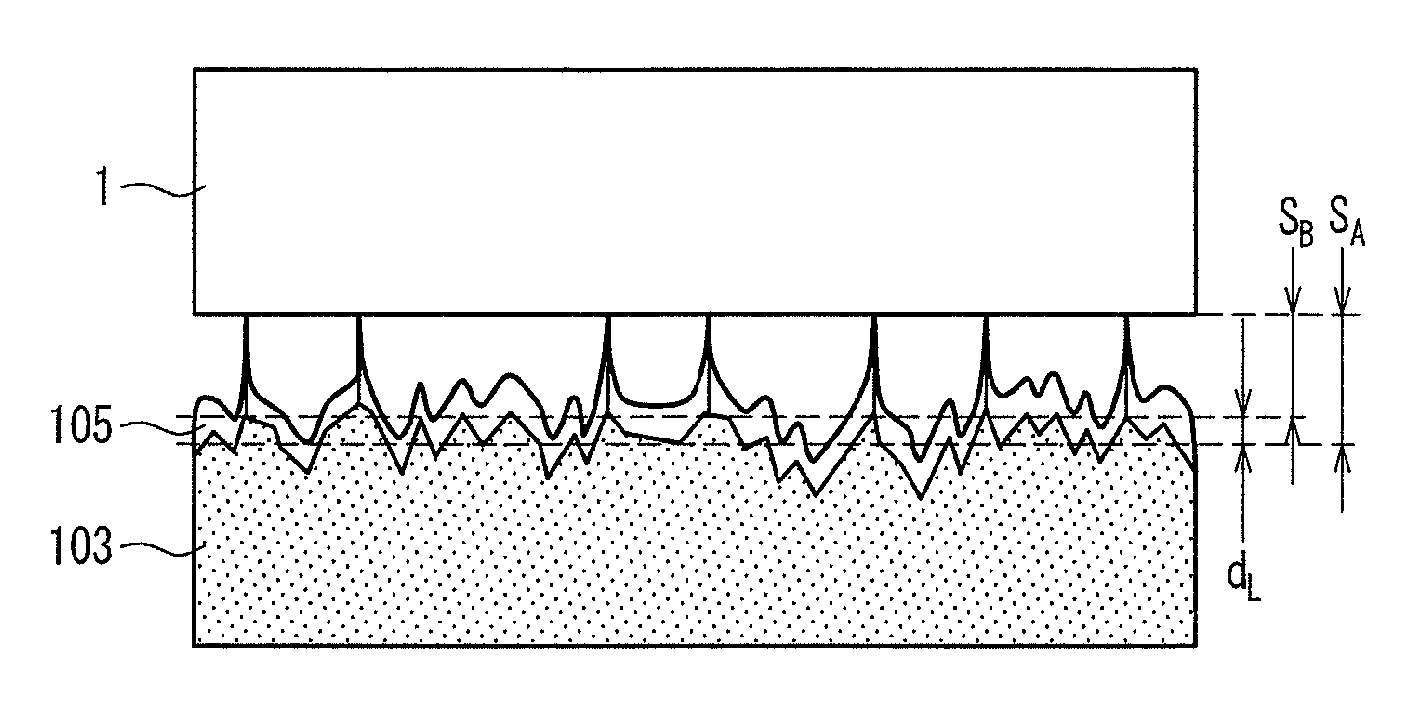

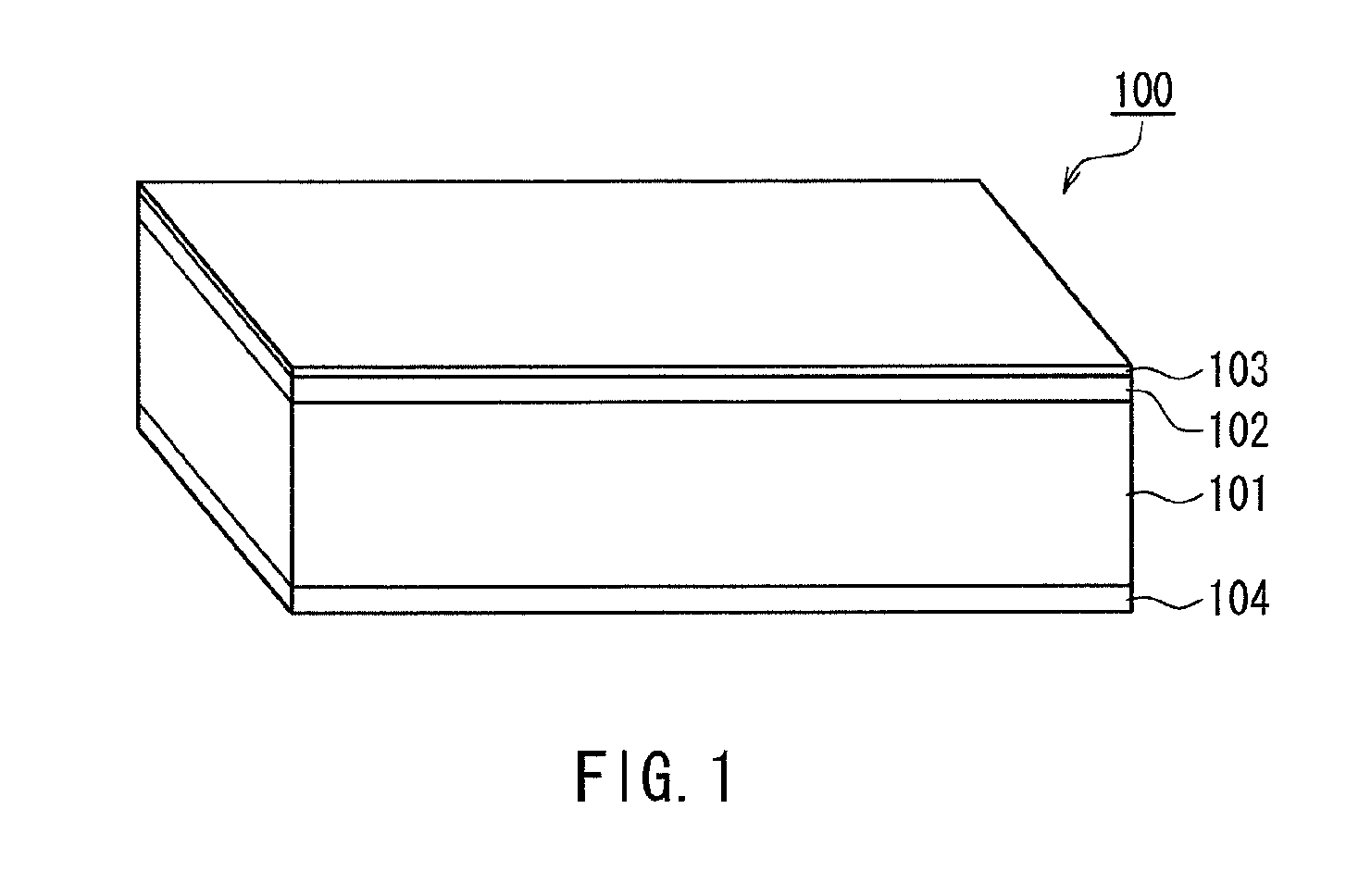

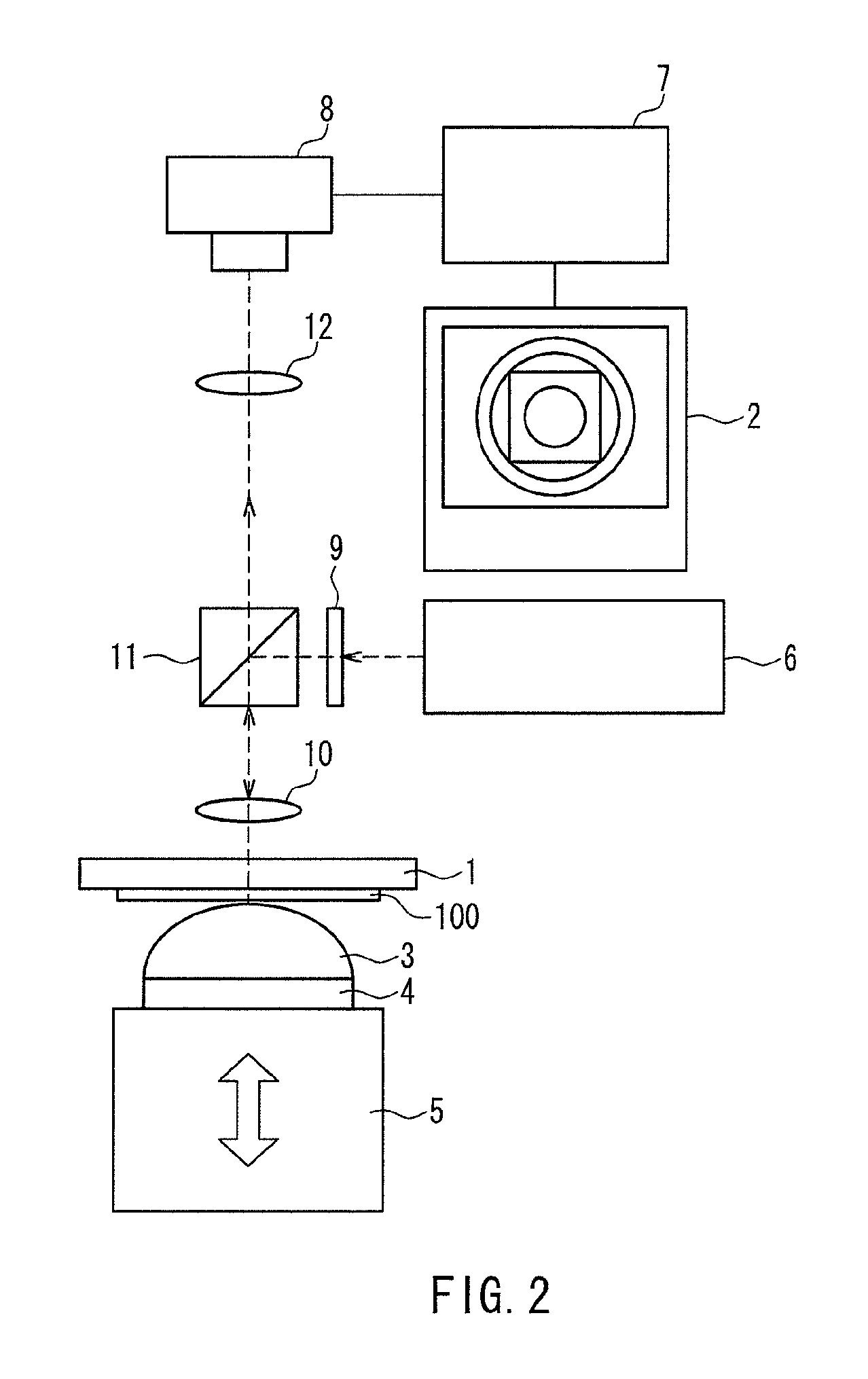

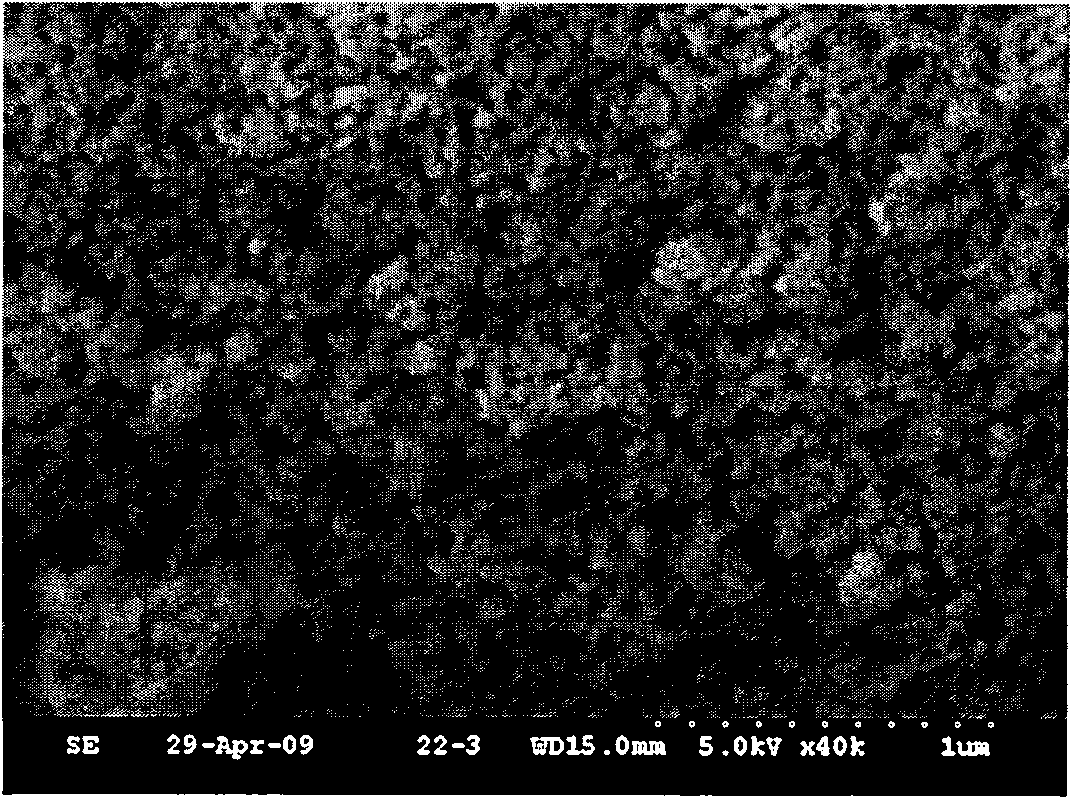

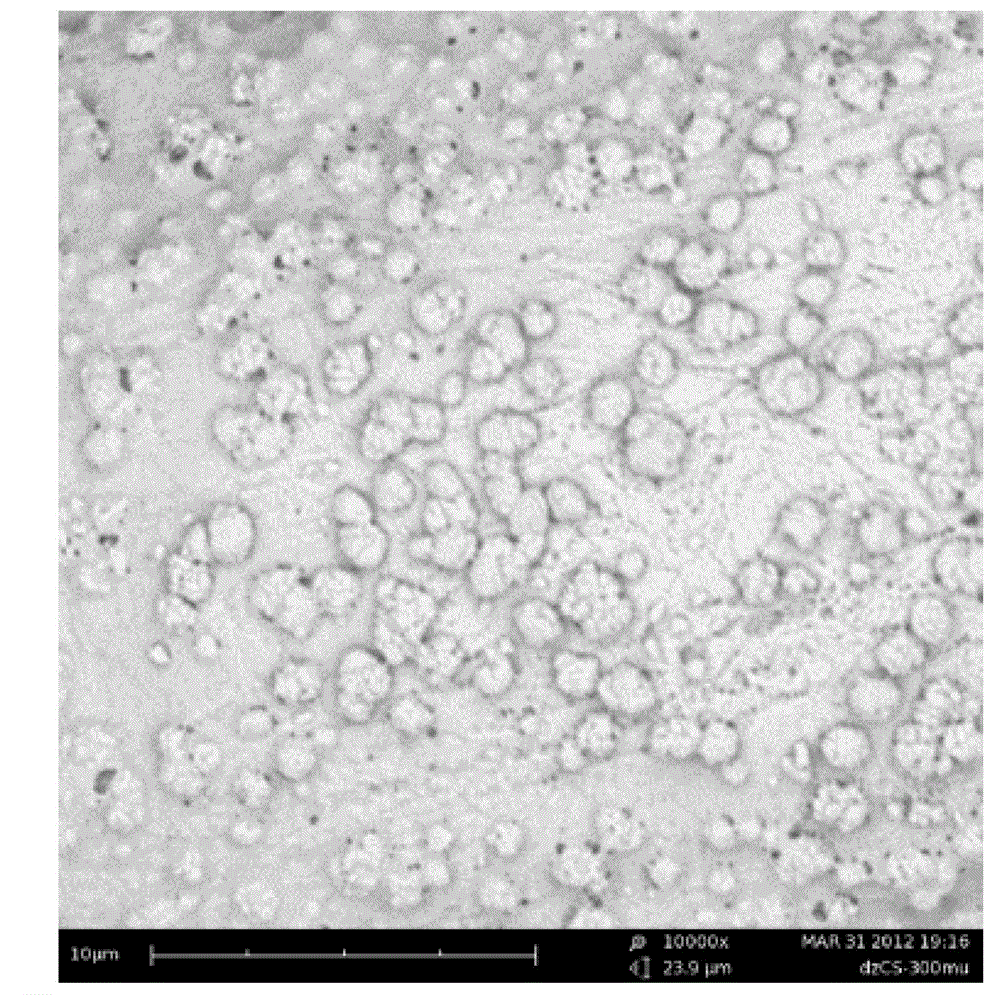

Magnetic recording medium

ActiveUS20120045664A1Superior recording/reproducing characteristicSuperior characteristic transportMaterials with ironRecord information storageNon magneticHexane

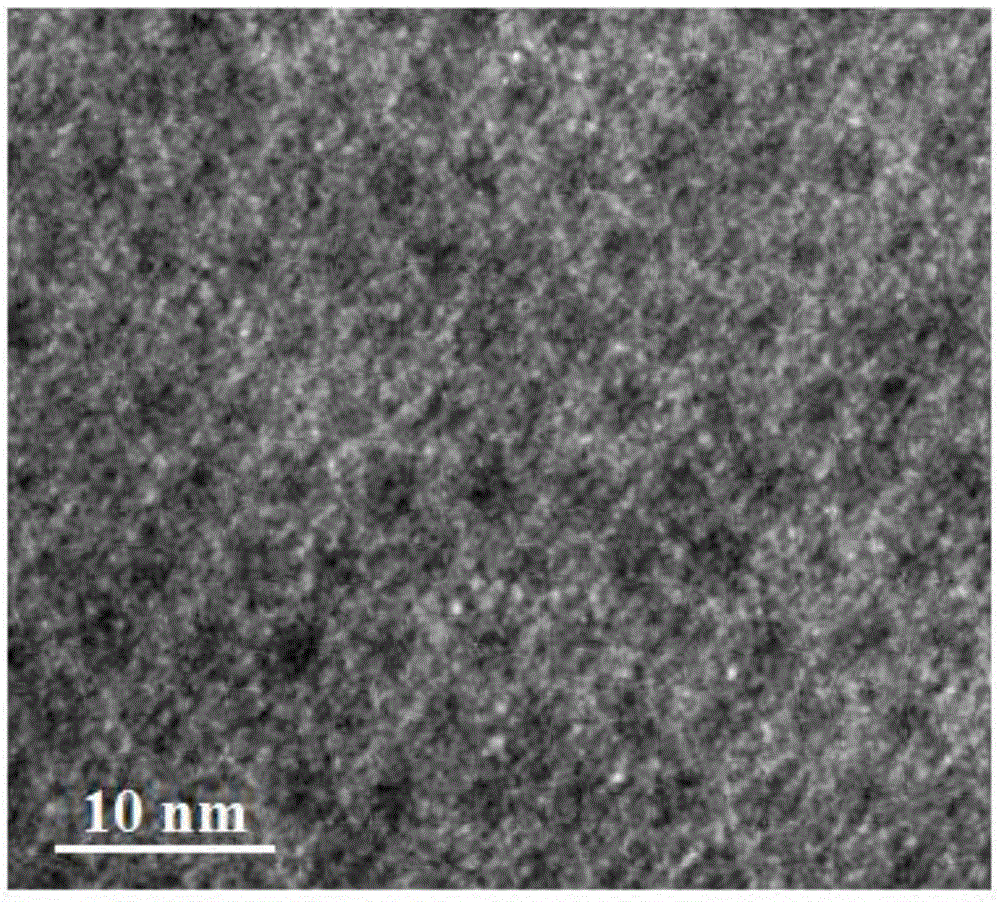

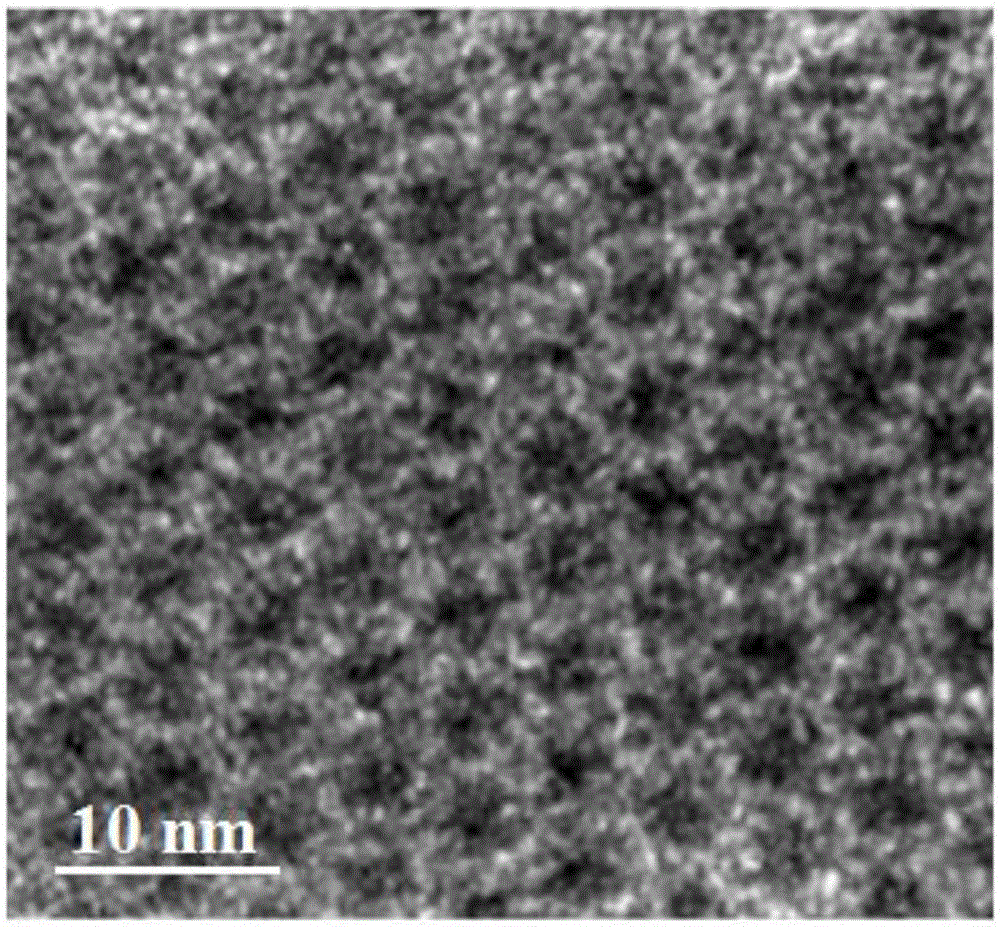

A magnetic recording medium of the present invention is a magnetic recording medium including a non-magnetic substrate; a non-magnetic layer that is formed on one of principal surfaces of the non-magnetic substrate and contains a non-magnetic powder, a binder, and a lubricant; and a magnetic layer that is formed on a principal surface of the non-magnetic layer opposite to the non-magnetic substrate and contains a magnetic powder and a binder. The magnetic powder has an average particle size between 10 inn and 35 nm inclusive. The lubricant is migratable to the magnetic layer and forms a lubricant layer on a surface of the magnetic layer when a pressure is applied to the magnetic layer. When spacing of the surface of the magnetic layer before and after washing the lubricant with n-hexane is measured with a TSA (Tape Spacing Analyzer), the value of the spacing after washing is 3 to 10 nm, and the value of the spacing before washing is 1 to 5 nm smaller than the value of the spacing after washing.

Owner:FUJIFILM CORP

Magnetic recording medium

ActiveUS9311946B2Superior recording/reproducing characteristic and transport characteristicFlat surfaceMaterials with ironRecord information storageNon magneticHexane

A magnetic recording medium of the present invention is a magnetic recording medium including a non-magnetic substrate; a non-magnetic layer that is formed on one of principal surfaces of the non-magnetic substrate and contains a non-magnetic powder, a binder, and a lubricant; and a magnetic layer that is formed on a principal surface of the non-magnetic layer opposite to the non-magnetic substrate and contains a magnetic powder and a binder. The magnetic powder has an average particle size between 10 nm and 35 nm inclusive. The lubricant is migratable to the magnetic layer and forms a lubricant layer on a surface of the magnetic layer when a pressure is applied to the magnetic layer. When spacing of the surface of the magnetic layer before and after washing the lubricant with n-hexane is measured with a TSA (Tape Spacing Analyzer), the value of the spacing after washing is 3 to 10 nm, and the value of the spacing before washing is 1 to 5 nm smaller than the value of the spacing after washing.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9959894B2Solve the lack of durabilityHigh densityTape carriersRecord information storageMedicineMagnetic tape

The magnetic tape comprises a nonmagnetic layer comprising nonmagnetic powder and binder on a nonmagnetic support, and comprises a magnetic layer comprising ferromagnetic powder and binder on the nonmagnetic layer, wherein a fatty acid ester, a fatty acid amide, and a fatty acid are contained in either one or both of the magnetic layer and the nonmagnetic layer, with the magnetic layer and nonmagnetic layer each comprising at least one selected from the group consisting of a fatty acid ester, a fatty acid amide, and a fatty acid, a quantity of fatty acid ester per unit area of the magnetic layer in extraction components extracted from a surface of the magnetic layer with n-hexane falls within a range of 1.00 mg / m2 to 10.00 mg / m2, and a weight ratio of the quantity of fatty acid ester per unit area of the magnetic layer to a combined total of a quantity of fatty acid amide and a quantity of fatty acid, quantity of fatty acid ester / (quantity of fatty acid amide+quantity of fatty acid), per unit area of the magnetic layer falls within a range of 1.00 to 3.00 in the extraction components.

Owner:FUJIFILM CORP

Hydrofluoroether as a heat-transfer fluid

InactiveUS6374907B1Good propertyCompatible electrical propertyOrganic chemistryOther chemical processesHeat transfer fluidEngineering

The present invention provides an apparatus comprising a device and a means for heat transfer comprising a hydrofluoroether heat-transfer fluid wherein the heat transfer fluid is 3-ethoxy-perfluoro(2-methylhexane). Another embodiment of the present invention is a method therefor.

Owner:3M INNOVATIVE PROPERTIES CO

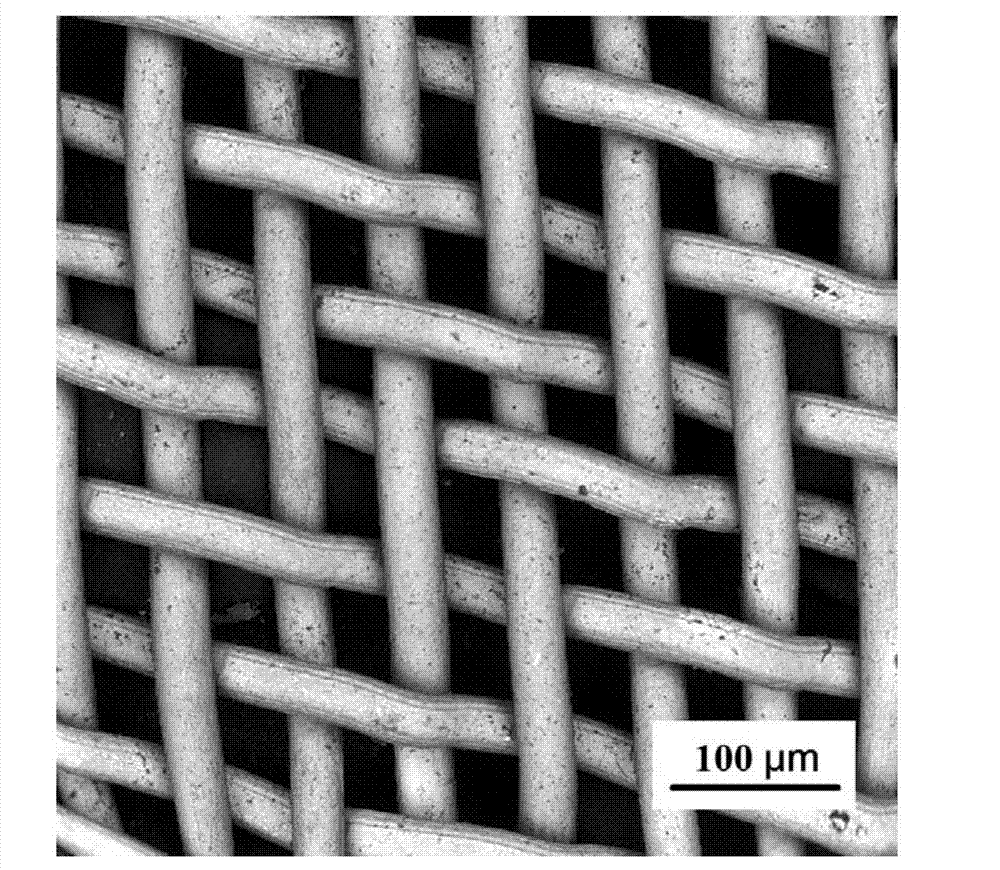

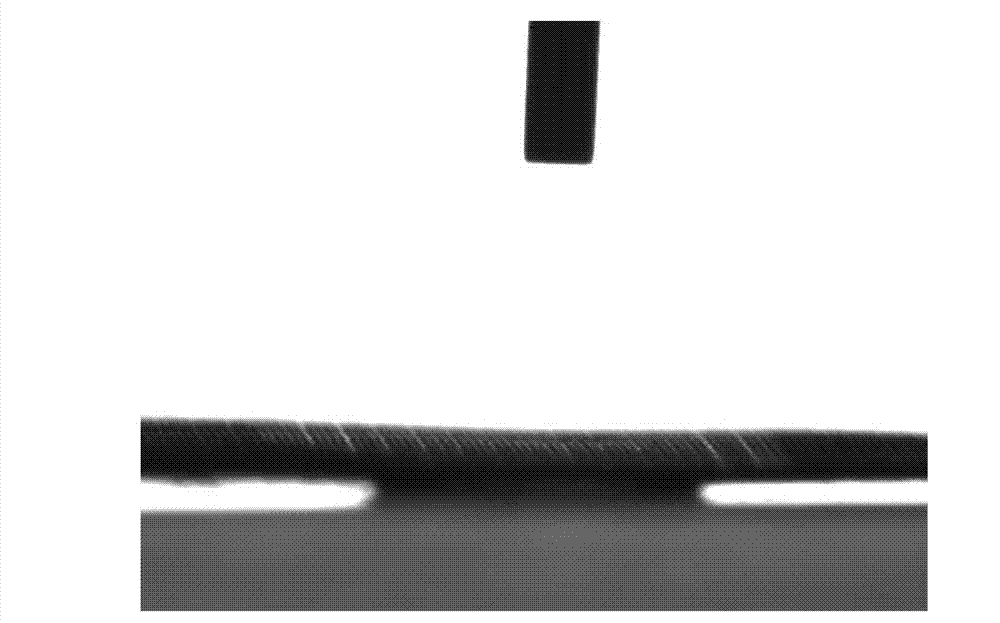

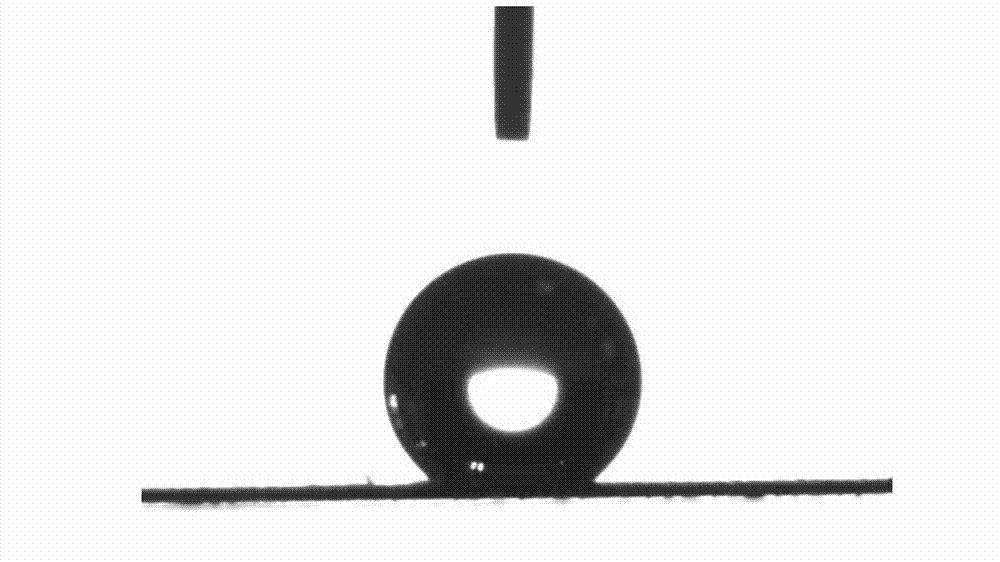

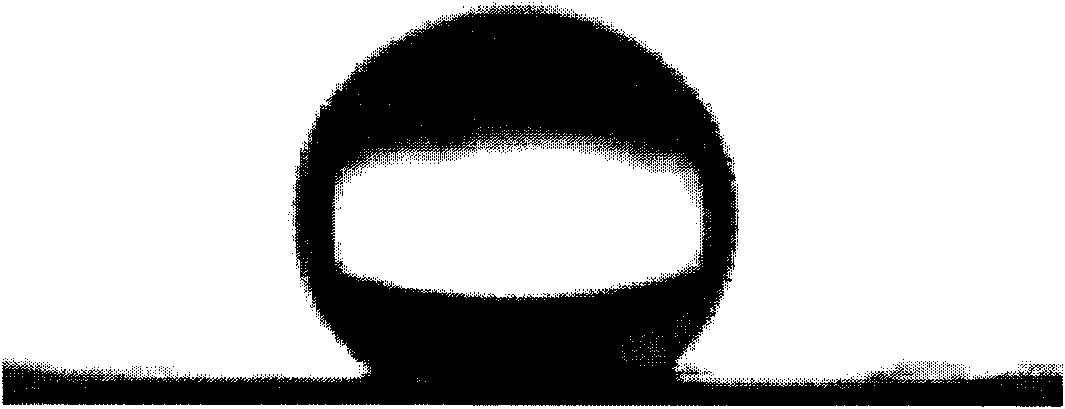

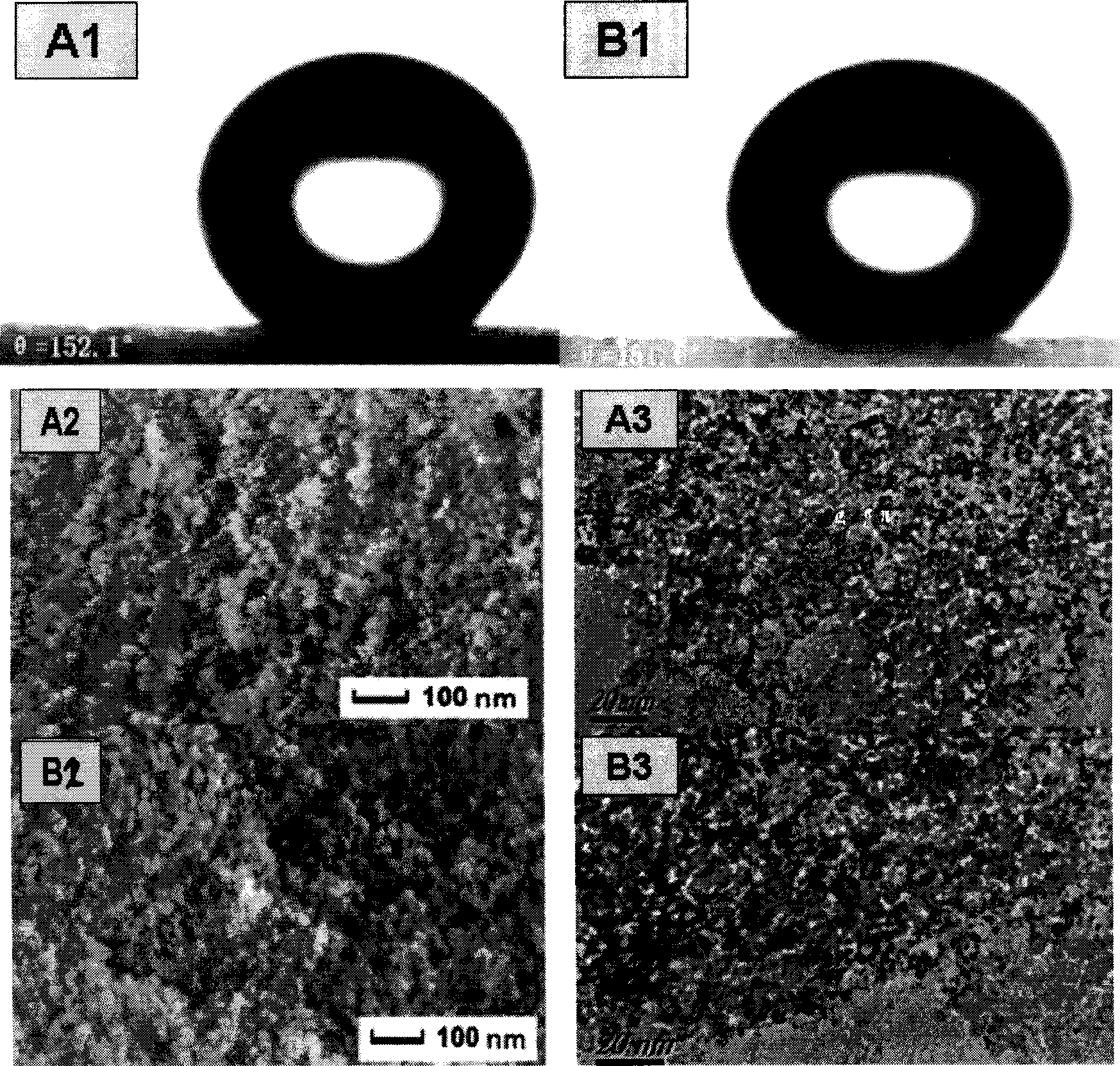

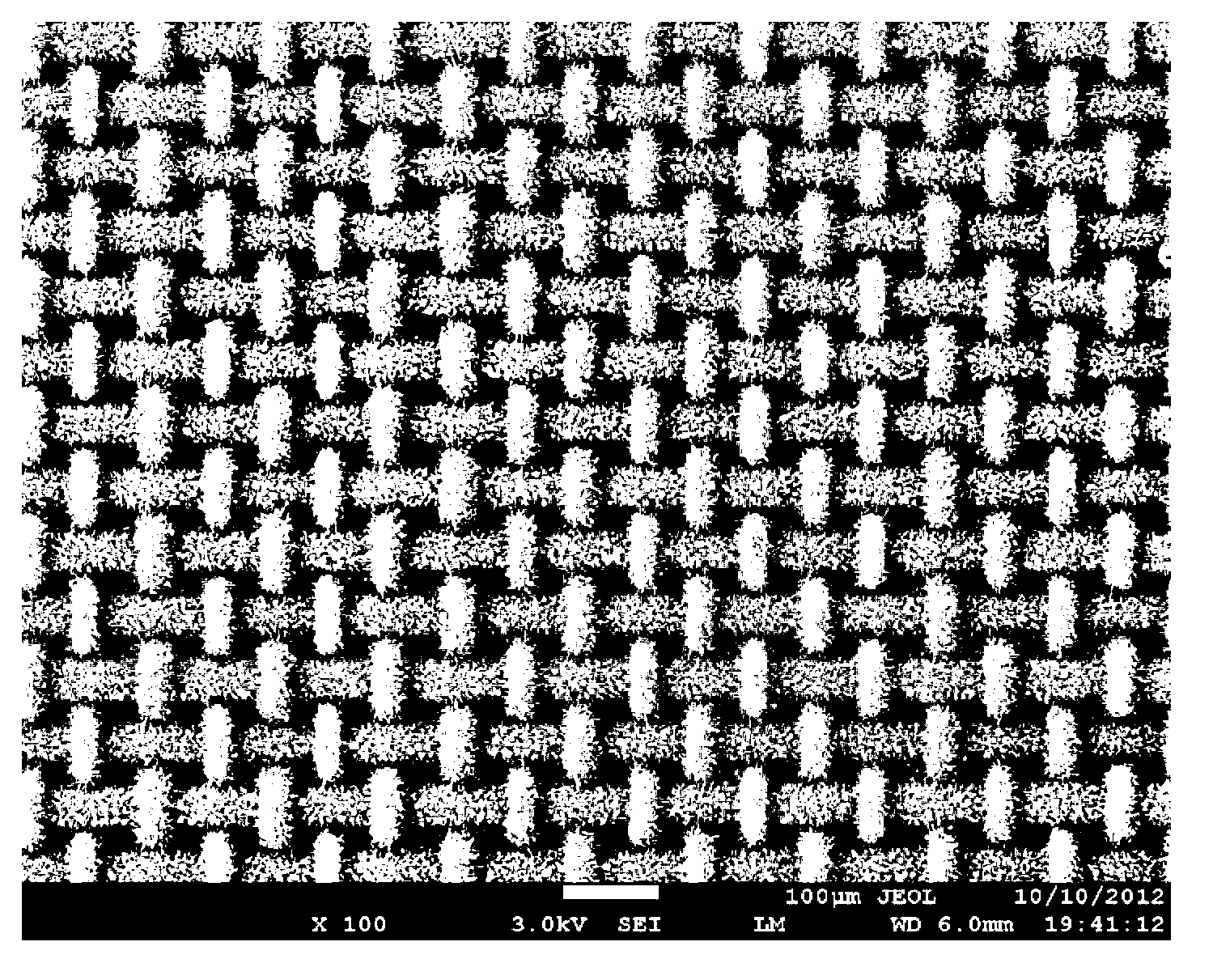

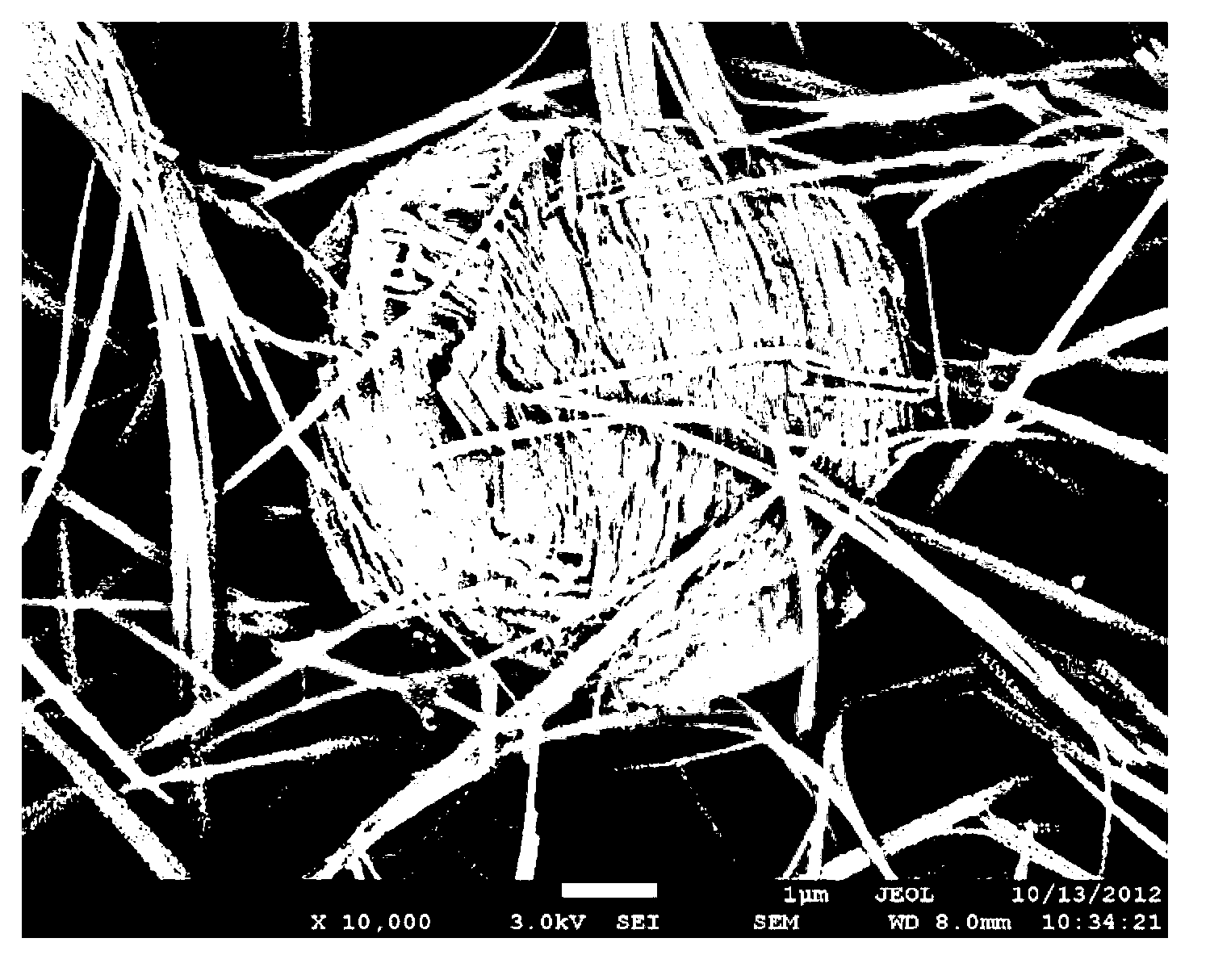

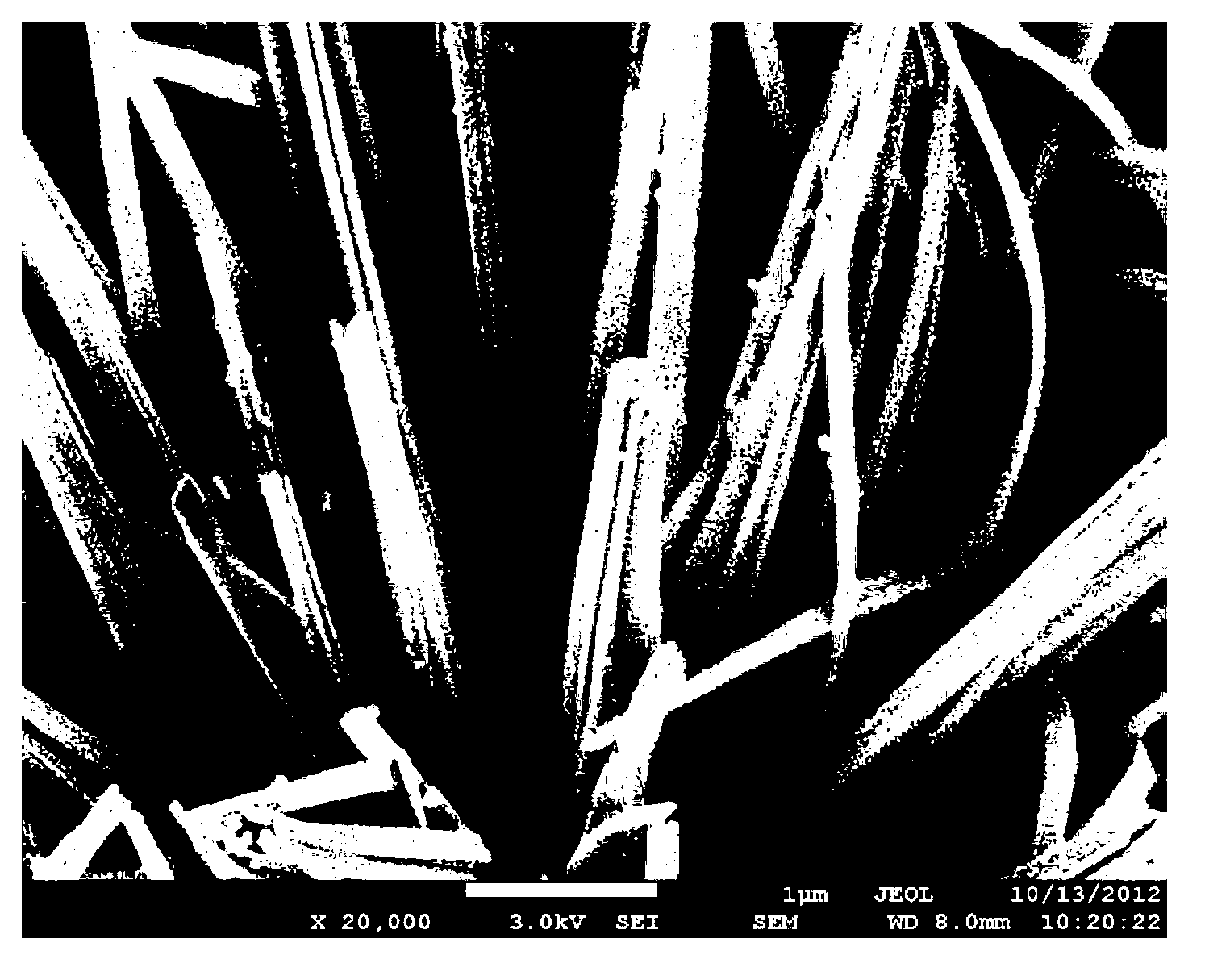

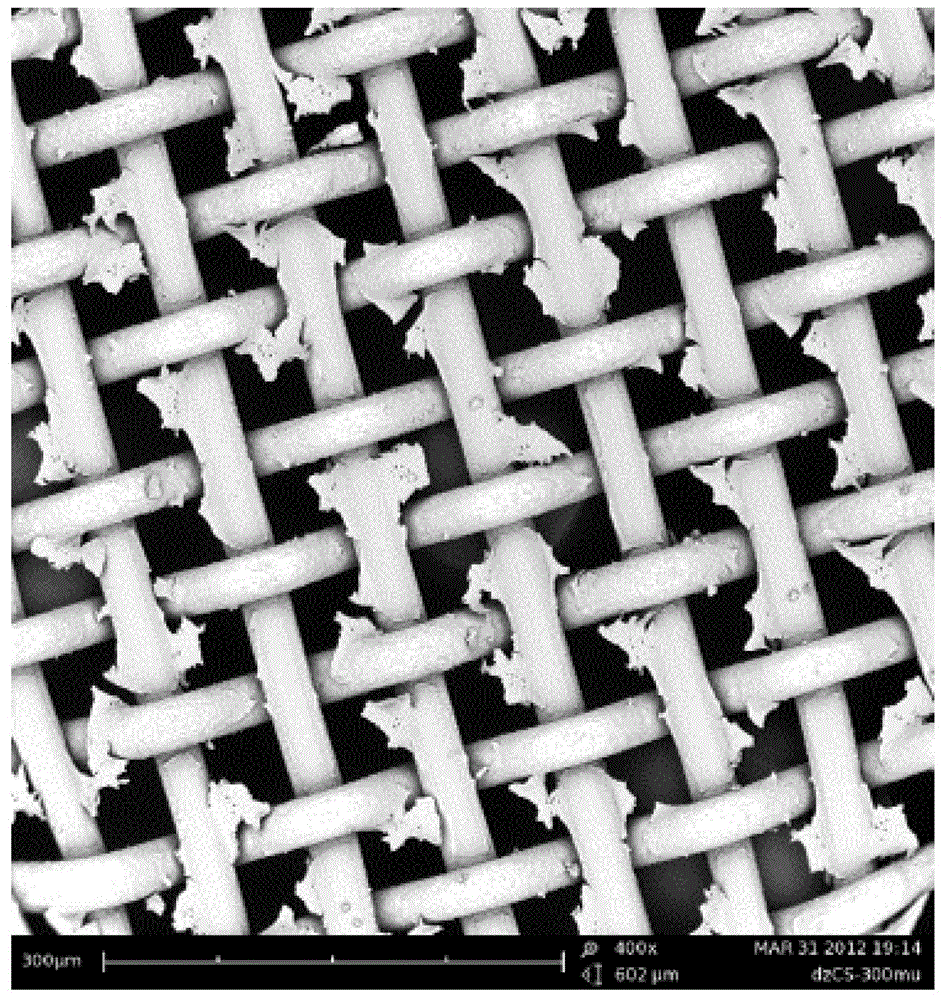

Super-hydrophobic and super-oleophylic oil-water separating mesh membrane and preparation method thereof

The invention discloses a super-hydrophobic and super-oleophylic oil-water separating mesh membrane and a preparation method thereof. The method comprises the following steps of: (1), cleaning a fabric mesh and drying the cleaned fabric mesh; (2), dissolving dopamine hydrochloride and trihytdroxy methyl-aminomethane to water to acquire a mixed solution, wherein the pH value of the mixed solution is 8.0-12.0; (3), soaking the dried fabric mesh in the mixed solution, and then getting out the soaked fabric mesh for drying; (4), dissolving mercaptan compound and sodium hydroxide in water to acquire mixed turbid liquid; (5), soaking the fabric mesh acquired in the step (3) in the mixed turbid liquid, reacting the mixture to acquire the oil-water separating mesh membrane. The oil-water separating mesh membrane disclosed by the invention has high bearing pressure to water so that oil can quickly pass, a separating effect is good, the speed is high, and the separating effect on normal hexane, petroleum ether, benzene, gasoline, diesel oil, animal and vegetable oil, crude oil and the like is good. The oil-water separating mesh membrane is non-toxic and harmless, environment-friendly, easy to clean and keep, can be reusable, and has good stability.

Owner:TSINGHUA UNIV

Process to obtain xanthophyll concentrates of high purity

An industrial process to obtain xanthophyll concentrates of high purity from plant extracts, comprising: refining the plant extracts by treating them with a diluted alkali, followed by treating them with a diluted organic or inorganic acid in order to eliminate impurities and undesirable components and obtaining a refined extract; saponifying the refined extract by means of a strongly alkali aqueous solution; treating the diluted saponified mass with a dilute organic or inorganic acid to adjust the pH to a value from 4 to 7, in order to separate a xanthophylls concentrate; and removing any remaining impurities by extracting them by means of hexane.

Owner:INDAL ORGANICA DE C V

Preparation method for hydrophobic silica aerogel

The present invention discloses a preparation method for hydrophobic silica aerogel with industrial waterglass as a raw material, which comprises the following steps: diluting the industrial waterglass with water; neutralizing with an acid to obtain hydrosol; allowing the hydrosol to stand and age for 8-48 hours at normal temperature so as to form hydrogel; replacing the water in the hydrogel with anhydrous ethanol; allowing the hydrogel to react with organosilane compounds; performing surface modification and simultaneous solvent exchange with n-hexane; suction-filtering; washing; allowing to stand at normal temperature to obtain white hydrophobic silica aerogel powder. The preparation method has simple process and low cost, and the prepared aerogel has porous network-like structure which features a low density and a high specific surface area.

Owner:SHENZHEN UNIV

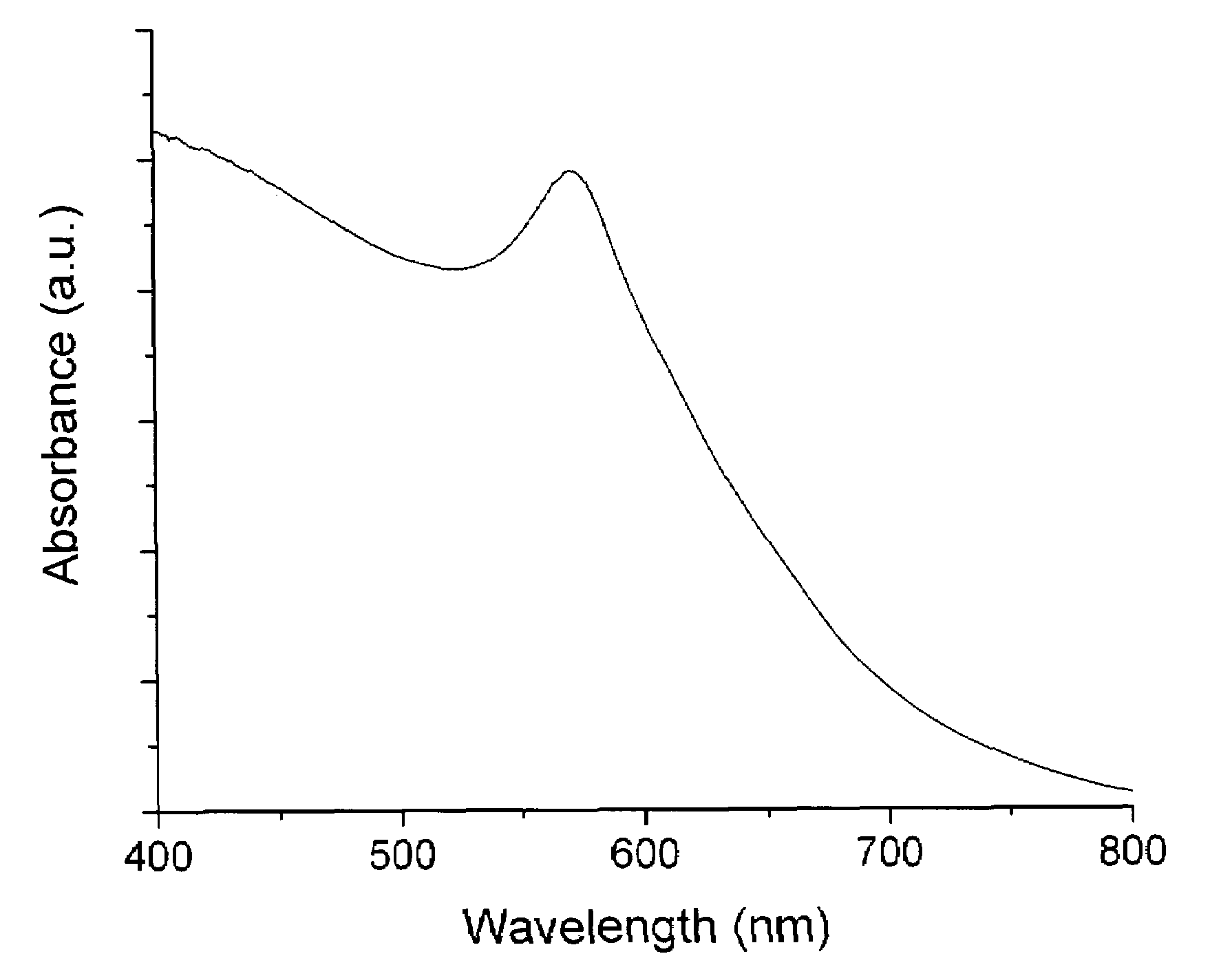

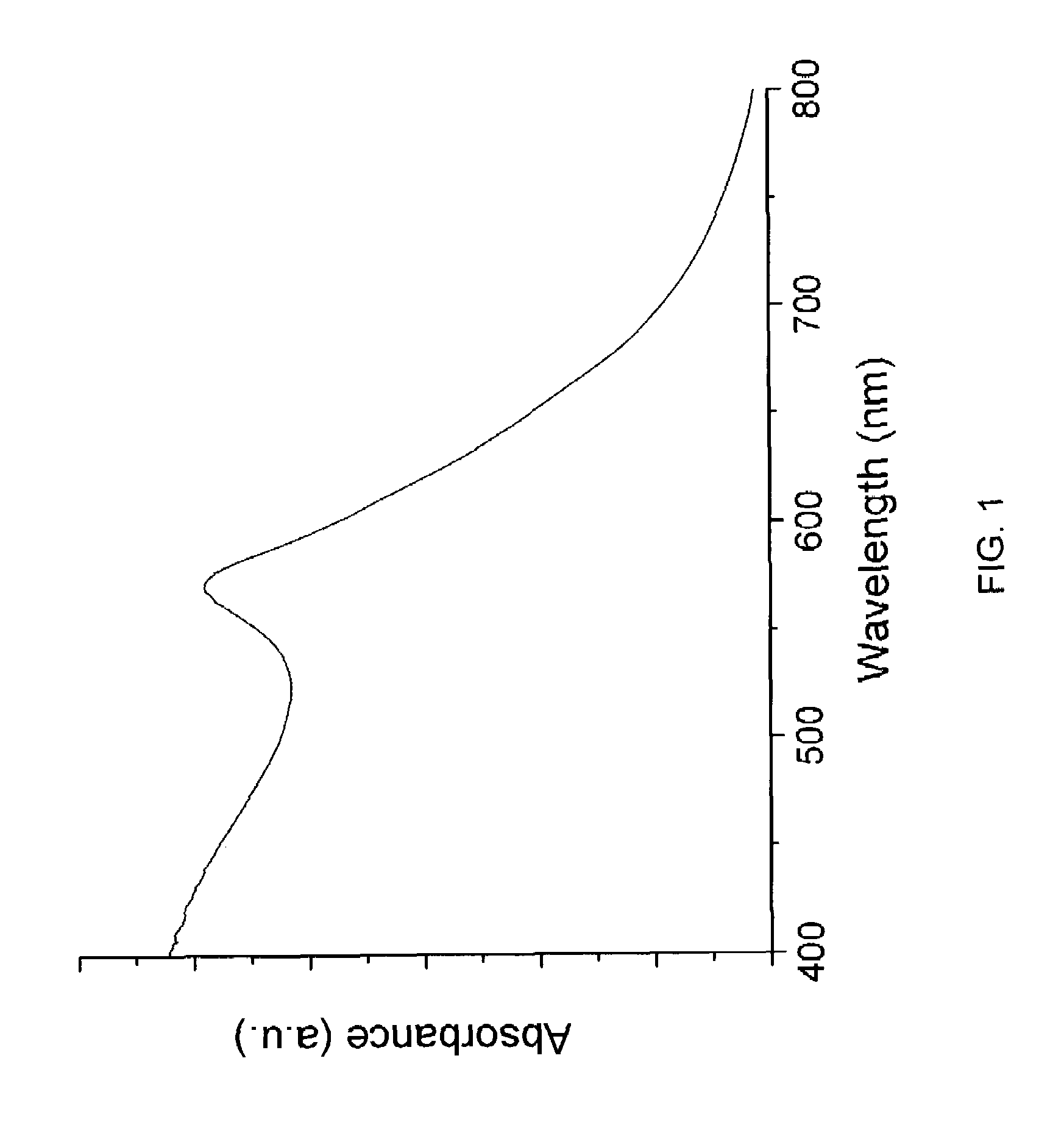

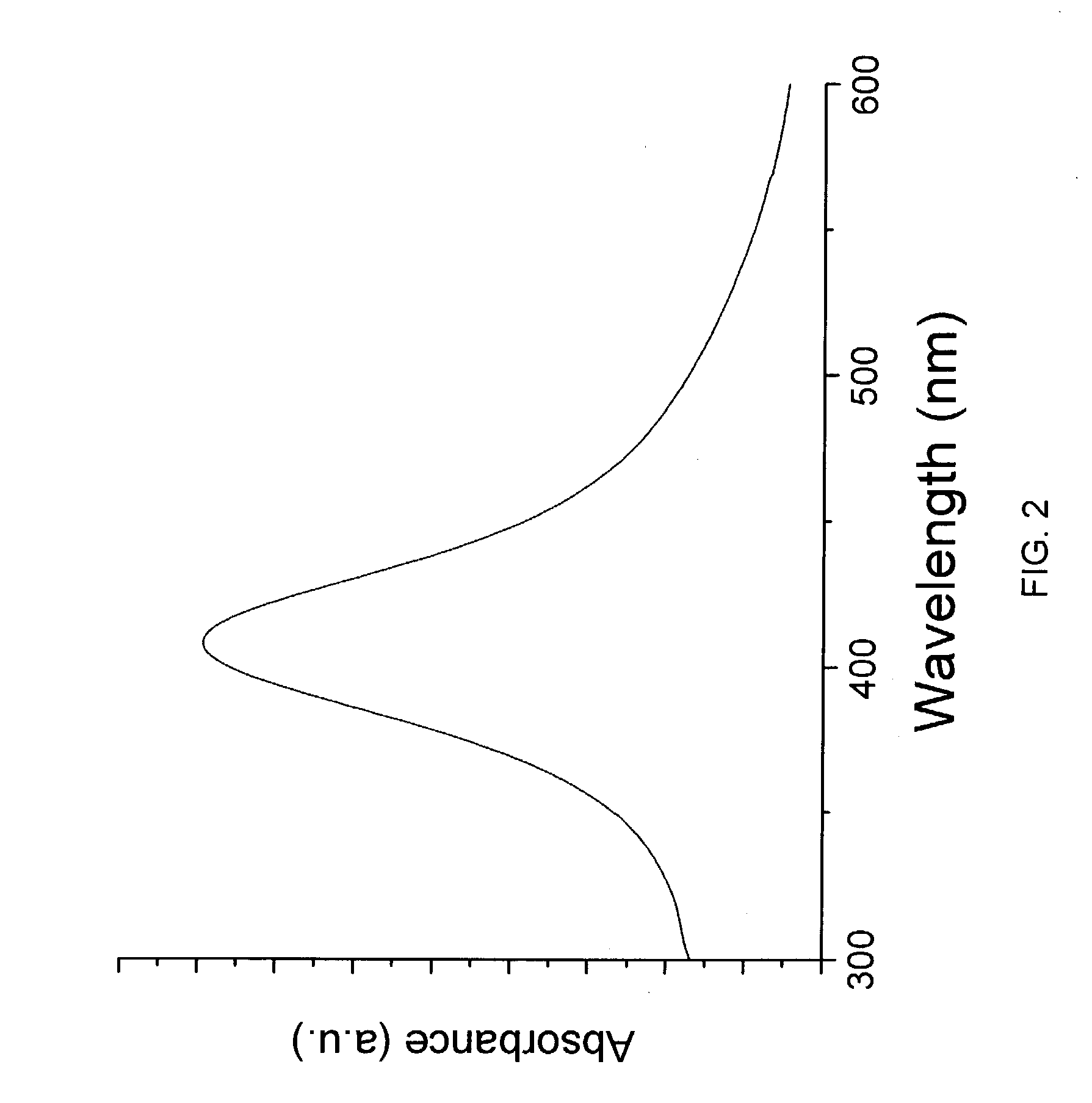

Synthesis metal nanoparticle

A method for providing an anhydrous route for the synthesis of amine capped coinage-metal (copper, silver, and gold) nanoparticles (NPs) using the coinage-metal mesityl (mesityl=C6H2(CH3)3-2,4,6) derivatives. In this method, a solution of (Cu(C6H2(CH3)3)5, (Ag(C6H2(CH3)3)4, or (Au(C6H2(CH3)3)5 is dissolved in a coordinating solvent, such as a primary, secondary, or tertiary amine; primary, secondary, or tertiary phosphine, or alkyl thiol, to produce a mesityl precursor solution. This solution is subsequently injected into an organic solvent that is heated to a temperature greater than approximately 100° C. After washing with an organic solvent, such as an alcohol (including methanol, ethanol, propanol, and higher molecular-weight alcohols), oxide free coinage NP are prepared that could be extracted with a solvent, such as an aromatic solvent (including, for example, toluene, benzene, and pyridine) or an alkane (including, for example, pentane, hexane, and heptane). Characterization by UV-Vis spectroscopy and transmission electron microscopy showed that the NPs were approximately 9.2±2.3 nm in size for Cu°, (no surface oxide present), approximately 8.5±1.1 nm Ag° spheres, and approximately 8–80 nm for Au°.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

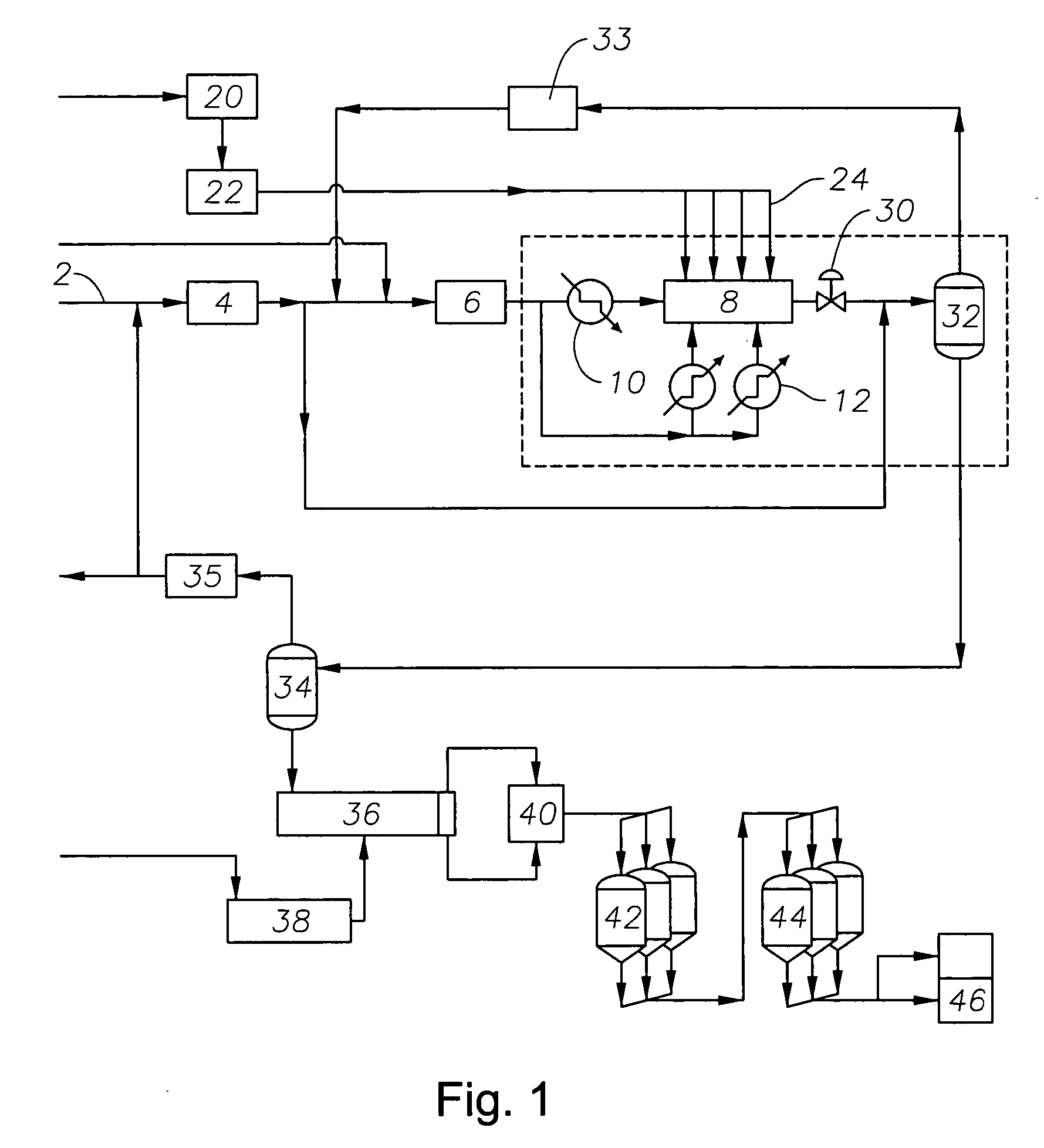

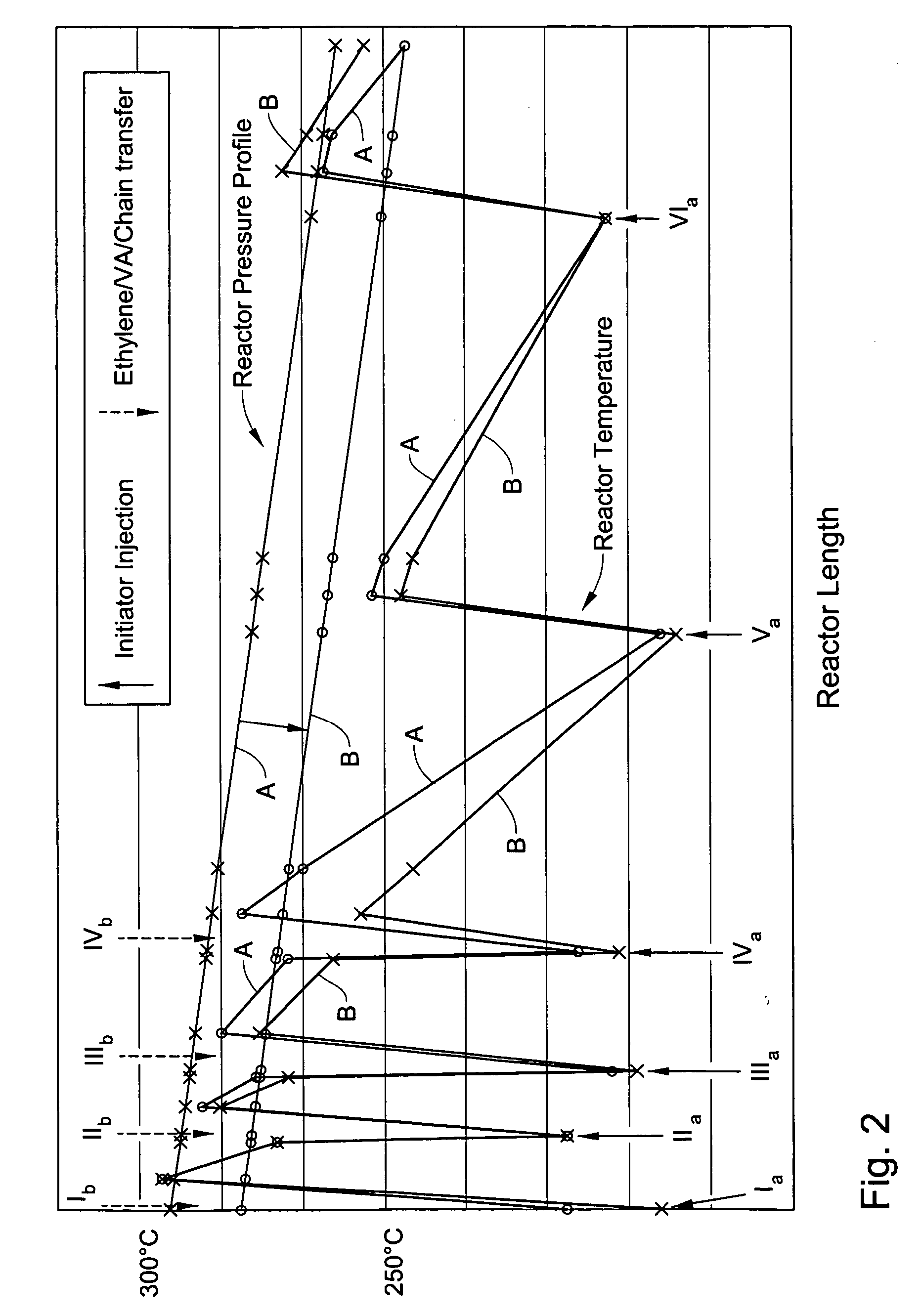

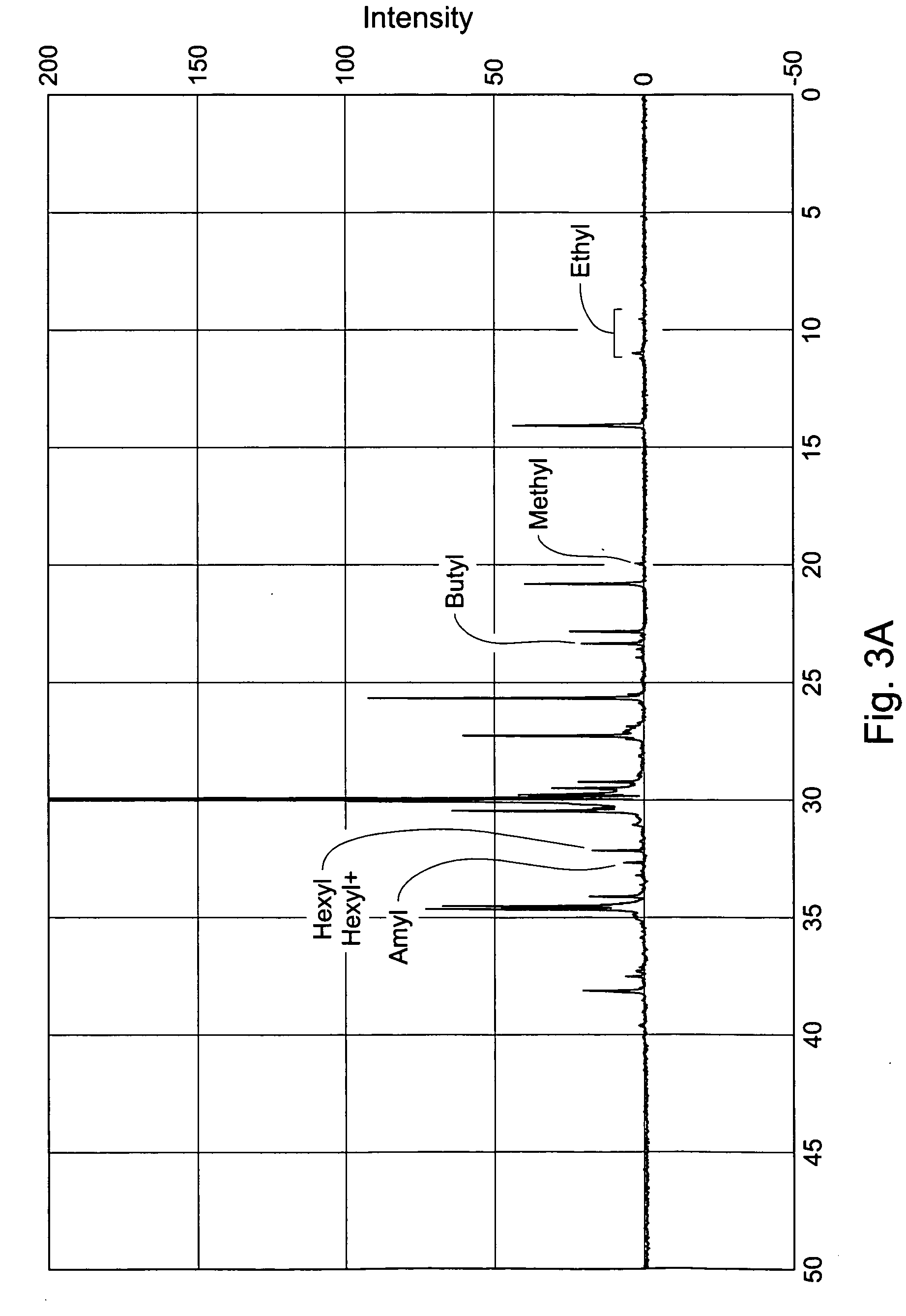

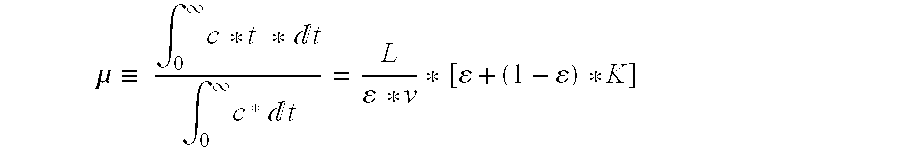

Polymers of ethylene and, optionally, copolymerizable esters, films using such polymers and stretch hood packaging processes using such films

ActiveUS20050037219A1Excellent film performanceSynthetic resin layered productsDomestic containersParticulatesMelt flow index

The invention relates to a polymer comprising units derived from ethylene, said polymer having: a) a Melt Index of from 0.05 to 20 g / 10 min as determined by ASTM-1238 Condition E; b) at least 10 per 1000 C-atoms of short chain branches, containing five carbon atoms or less, as determined by C13 NMR, and less than 3.5 mol %, of units derived from a copolymerizable ethylenically unsaturated ester, c) a density of from 0.90 to 0.94 g / cm3, preferably 0.91 to 0.935 g / cm3, especially 0.92 to 0.93 g / cm3 as determined by ASTM D1505, and d) a relaxation time as described herein of at least 10 s. Such polymers are obtainable by polymerization by free radical polymerization using a chain transfer agent that incorporates into the polymer chain such as an alpha-olefin, preferably propylene, as a chain transfer agent, preferably in a tubular reactor under circumstances to favor LCB formation in a down stream part of the tubular reactor. The polymer may be used for stretch hood film, preferably as a blown film coextruded tube comprising: a) a core of the above polymer; and b) a skin layer, on each side of the core which may be of the same or different composition, comprising at least 60 wt % of an LLDPE having density of 0.91 to 0.94 g / cm3 as determined by ASTM-D 1238 Condition E and hexane extractables less than 1.5 wt %, said skin layer containing less than 7500 ppm of anti-block particulates and said film having an elastic recovery after a 100% stretch of at least 40% and providing a normalized holding force per 100 μm thickness pre-stretch at 85% stretch after an initial stretch of 100% of at least 20 N / 50 mm at a deformation rate of less than 10% of the starting length per second.

Owner:EXXONMOBIL CHEM PAT INC

Elimination of trans-unsaturated fatty acid compounds by selective adsorption with zeolites

InactiveUS6229032B1Low yieldLow costFatty oils/acids recovery from wasteFatty acid hydrogenationPartial hydrogenationDouble bond

A novel process for the selective elimination of fatty acid compounds containing carbon-carbon double bonds in trans configuration from a substrate containing cis- and trans-isomers of said fatty acid compounds, by selective adsorption by a microporous zeolite material is disclosed. The pore size and shape of usable zeolite materials enable differentiation between cis- and trans-isomers of unsaturated fatty acid chains. The zeolite materials used have a selectivity ratio alphatrans / cis higher than 1.00; this ratio is defined based on the elution properties of cis and trans double bond containing fatty acid methylesters dissolved in n-hexane during a column chromatography experiment with the zeolite material as the stationary phase and n-hexane as the mobile phase. Besides selective adsorption of trans-unsaturated fatty acid compounds, simultaneous or subsequent total or partial hydrogenation of the double bonds in said compounds can be carried out while using the same or similar zeolite material, containing finely dispersed catalytic active metals. The majority of these catalytic active sites must be inside the pores.

Owner:K U LEUVEN RES & DEV

Method for preparing low density silica aerogel under normal pressure

InactiveCN103435055AShorten the production cycleIncrease productivitySilicaEnergy inputTrimethylsilyl chlorideSilicic acid

The present invention discloses a method for preparing low density silica aerogel under normal pressure. The method comprises: mixing tetraethoxysilane, water and ethanol according to a volume ratio of 1:0.5-19:1-29, adding an acid to adjust the pH value to 3-4, carrying out catalysis hydrolysis, adding an alkali to adjust the pH value to 6-6.5, carrying out catalysis gelating for 8-10 min to obtain a wet gel, aging the wet gel for 6-36 h at a room temperature, adding n-hexane to carry out solvent replacement for 6-36 h, immersing in a trimethylchlorosilane and n-hexane mixed solution to carry out hydrophobic modification for 12-15 h, adopting a n-hexane washing solution to remove the modification solution, placing into a muffle furnace to heat to a temperature of 30-250 DEG C, drying, and finally cooling to a room temperature to obtain the silica aerogel. Test results show that the density of the SiO2 aerogel is 50-80 kg / m<3> and is significantly lower than the density of the SiO2 aerogel prepared under the normal pressure dry condition in most of the public reports.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing hydrophobic SiO2 aerogel

The invention relates to a method for preparing lyophobic SiO2 aerogel, belonging to the technical field of new material preparation. The method comprises the steps: tetraethyl orthosilicate, absolute ethyl alcohol and oxalic acid solution are firstly mixed in a container for sealing, and then the mixed solution is put into water bath, hydrolyzed under agitation and added with ammonia dropwise; when gel is formed, the absolute ethyl alcohol is added into the gel for exchanging the water in the gel; n-hexane is used for exchanging ethanol in the gel; wet gel which is processed by solvent exchange and aging is dipped into the mixed solution of modifying agent and n-hexane for surface modification, then the n-hexane is added for exchanging the unreacted modifying agent; finally, a test tube is sealed by a aluminum foil provided with a needle hole and is placed into an oven for classified drying under normal pressure, so that the modified SiO2 aerogel is obtained. The SiO2 aerogel prepared by the method has the advantages of high porosity, large specific surface area, good hydrophobic property, etc. The method has the advantages of mild reaction condition, easy control of the reaction as well as simple and convenient process flow.

Owner:YANGZHOU TIANCHEN FINE CHEM +1

Super-hydrophilic and underwater super-oleophobic oil-water separation mesh membrane having, and its preparation method

The invention discloses a super-hydrophilic and underwater super-oleophobic oil-water separation mesh membrane, and its preparation method. The method comprises the following steps: 1, cleaning a copper mesh, and airing; 2, dissolving an alkaline medium and an oxidant in water, and uniformly stirring to obtain a mixed solution; and 3, dipping the aired copper mesh in the mixed solution, and carrying out an oxidation reaction to obtain the oil-water separation mesh membrane. The oil-water separation mesh membrane has the advantages of easily available raw material, low cost, simple equipment and making technology, realization of large-scale preparation, large water flux, fast water-water separation speed, good oil-water separation effect, suitableness for the treatment of sewage containing a large amount of water, very good separation effect on n-hexane, petroleum ether, dichloroethane, benzene, gasoline, diesel oil, kerosene, machine oil, crude oil, animal and plant oil, and the like, easy cleaning, repeatable use, and good stability.

Owner:TSINGHUA UNIV

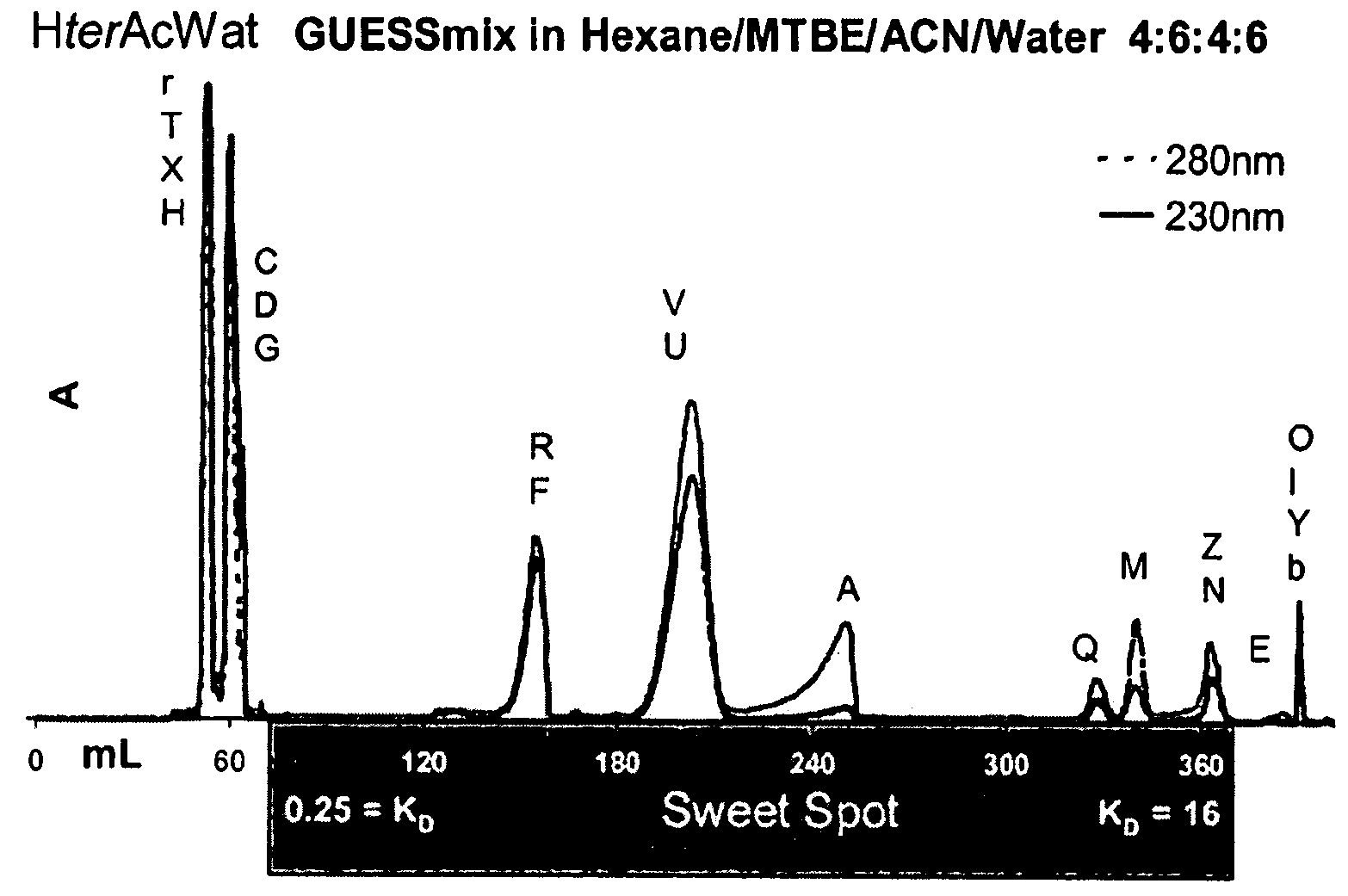

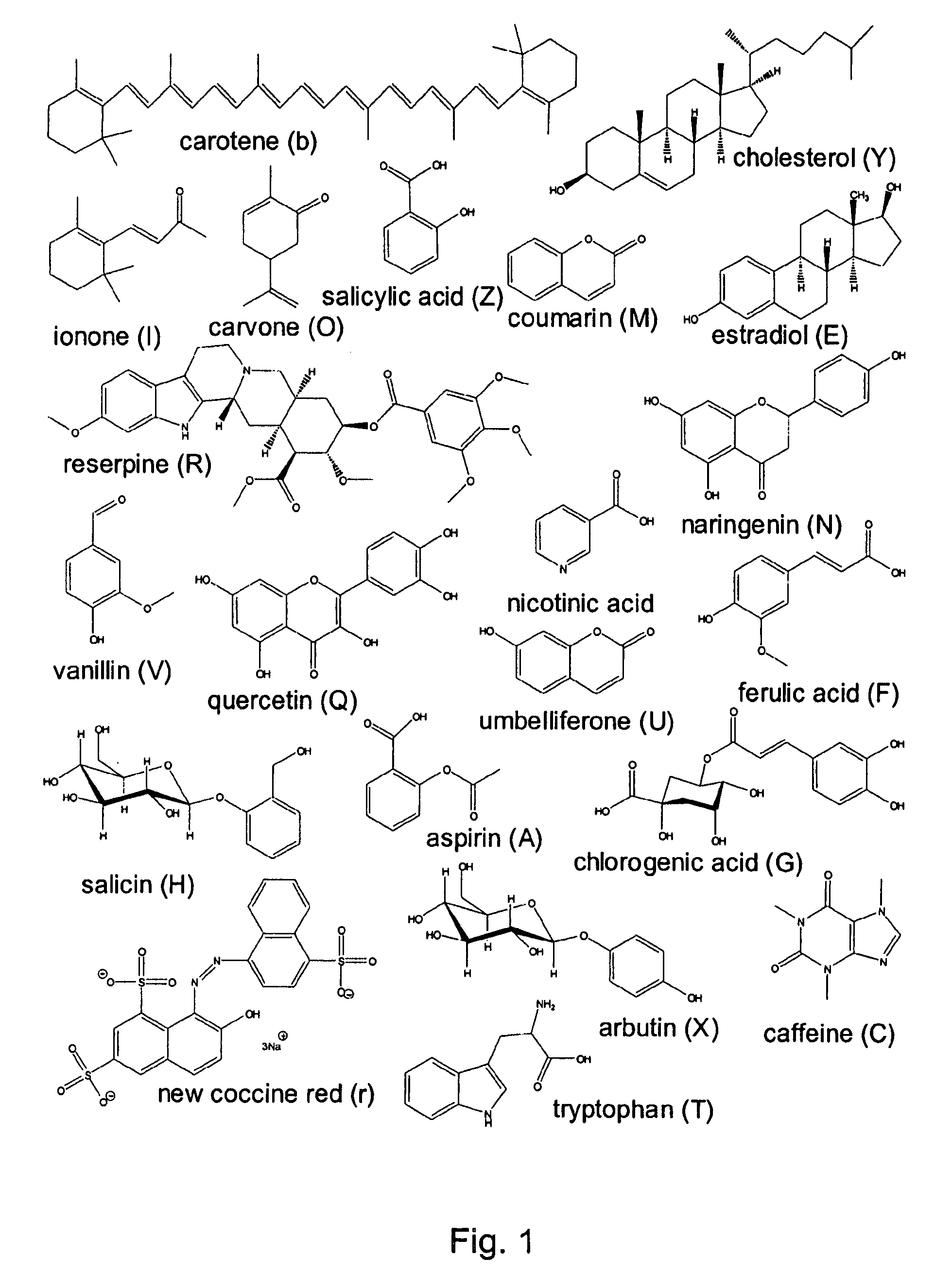

Selection and rational development of solvent systems in counter-current chromatograph

ActiveUS20080127720A1Easy to separateComponent separationMaterial analysis by electric/magnetic meansNatural productSystems analysis

Application of a reference mixture of natural products for systematic analysis and comparison of the properties of biphasic solvent systems in counter-current / partition chromatography. Because the reference mixture is comprised of compounds with varying polarities, functional groups, and structural features it provides a rational method for mapping the optimal resolution polarity range of a particular solvent system. The mapping of optimal resolution polarity ranges of solvent systems provided for the description of the overall optimal resolution polarity range of a solvent system family, comprised of the same solvents in different proportions. By comparing the reference mixture performance in the individual members of a solvent system family, the solvent system that best functions as the representative of, or portal to, the solvent system families is determined. Use of the reference mixture also afforded a method to compare the overall optimal resolution polarity ranges of solvent system families. Based on performance of reference mixture chromatograms, the CCC properties of solvent systems, can be compared and their CCC potential examined. The methods of the invention employing the reference mixture provides was used to identify a quaternary solvent system, hexane / t-butylmethylether / acetonitrile / water (HterAcWat), which was found to be useful for CCC of mixtures containing natural products.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Crosslinked hyperbranched polyalcohol composite nano filter membrance and method of preparing the same

InactiveCN101254417AImprove throughputHigh retention rateSemi-permeable membranesFood additiveUltrafiltration

The invention discloses a crosslinking hyper branched polymer composite nanofiltration membrane as well as the preparation method thereof. The crosslinking hyper branched polymer composite nanofiltration membrane is prepared by taking an ultrafiltration membrane as a basement membrane and crosslinking hyper branched polymer as a selecting layer through hyper branched polymer and the interfacial polymerization of polybasic acid, polybasic acyl chloride, polybasic anhydride and polybasic amine; and the interfacial polymerization takes the mixed solution of water and ethanol as the water phase and n-hexane, n-heptane or n-octane as the organic phase. As the hyper branched polymer has the spheroidal structure, a plurality of nano-voids exist in the interior of the molecule, so as to enable the selecting layer of the crosslinking hyper branched polymer composite nanofiltration membrane to be looser, and leads the nanofiltration membrane to maintain high flux and retention rate under the lower operating pressure. The nanofiltration membrane can be used in the fields of medicament, foodstuff, environmental protection, etc. The composite nanofiltration membrane is applicable to the separation and the condensation of high valence ions, low valence ions, neutral particles, drugs, food additives, etc.

Owner:ZHEJIANG UNIV

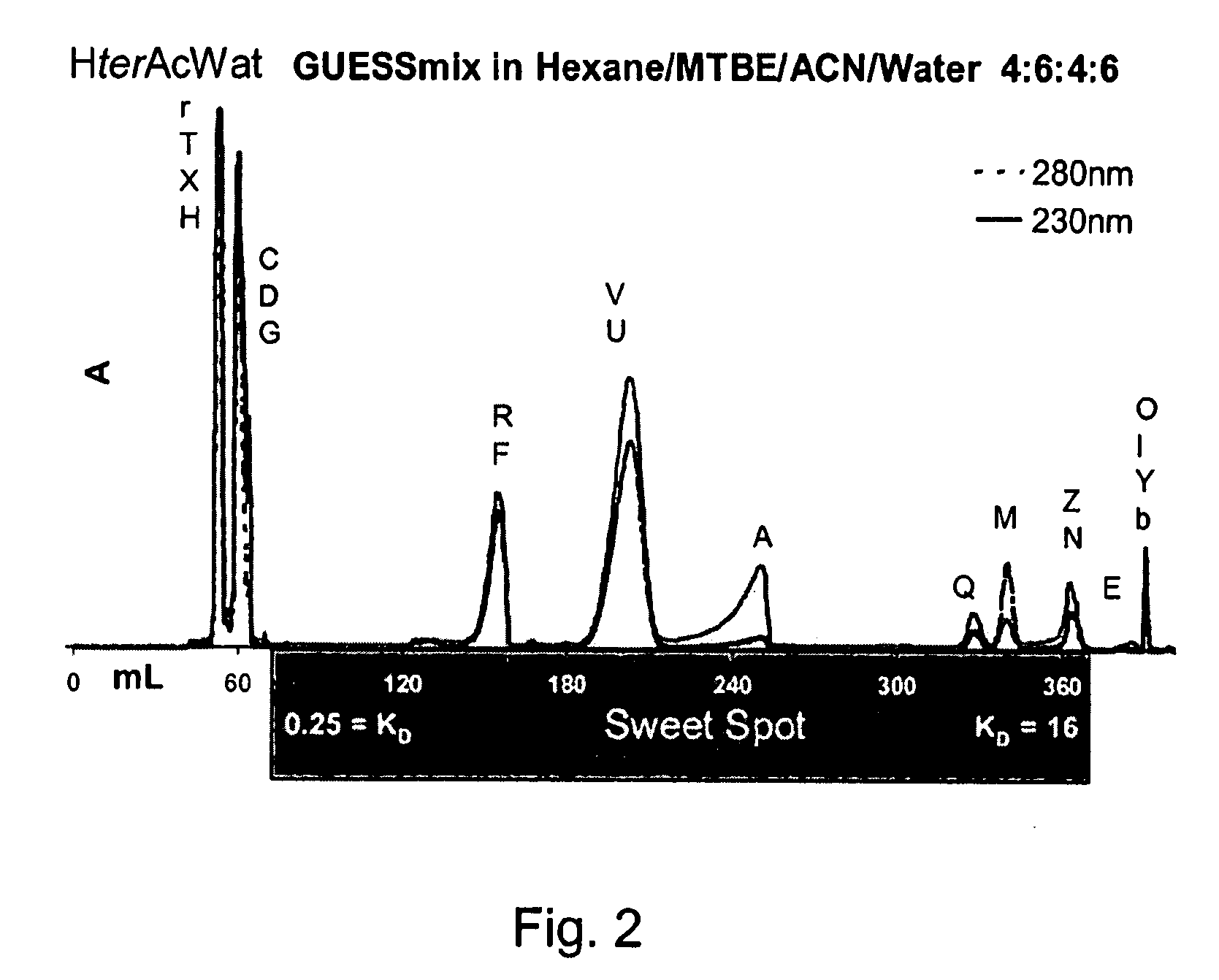

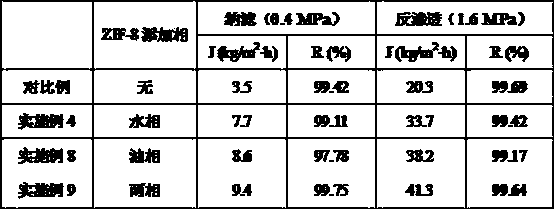

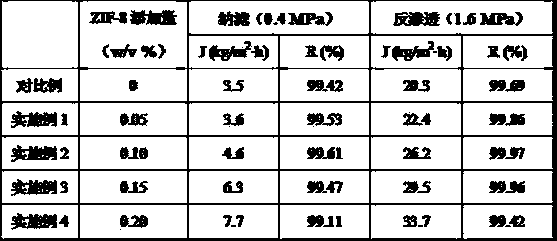

Preparation method of aromatic polyamide film modified by ZIF-8 type metal-organic framework material

InactiveCN104209021AIncrease fluid channelFacilitate water permeation membraneSemi-permeable membranesPolymer scienceMetal-organic framework

The invention discloses a preparation method of an aromatic polyamide film modified by a ZIF-8 type metal-organic framework material. A ZIF-8 filling polyamide composite film is prepared on an ultrafiltration bottom film by an interfacial polymerization method, wherein nano-grade ZIF-8 particles are added into an m-phenylenediamine aqueous solution and / or a trimesoyl hexane solution; a polyamide ultrathin skin layer, to which ZIF-8 is added, is formed through interfacial polymerization. The preparation method has the advantages that by the use of a ZIF-8 nano-grade aperture and a three-dimensional multi-hole structure, the selectivity or the permeability of the aromatic polyamide film is improved; the prepared ZIF-8 filling polyamide composite film can serve as a nanofiltration or reverse osmosis film for removing organic matters from the aqueous solution; when the adding ratio of an organic phase or water phase solution, to which ZIF-8 is added, is 0.05-0.15% (w / v), the performance of the film is the highest, and the permeation flux and the retention rate can be increased at the same time; furthermore, the nanofiltration or reverse osmosis performance of the two-phase adding film is higher than that of a single-phase adding film.

Owner:BEIJING FORESTRY UNIVERSITY

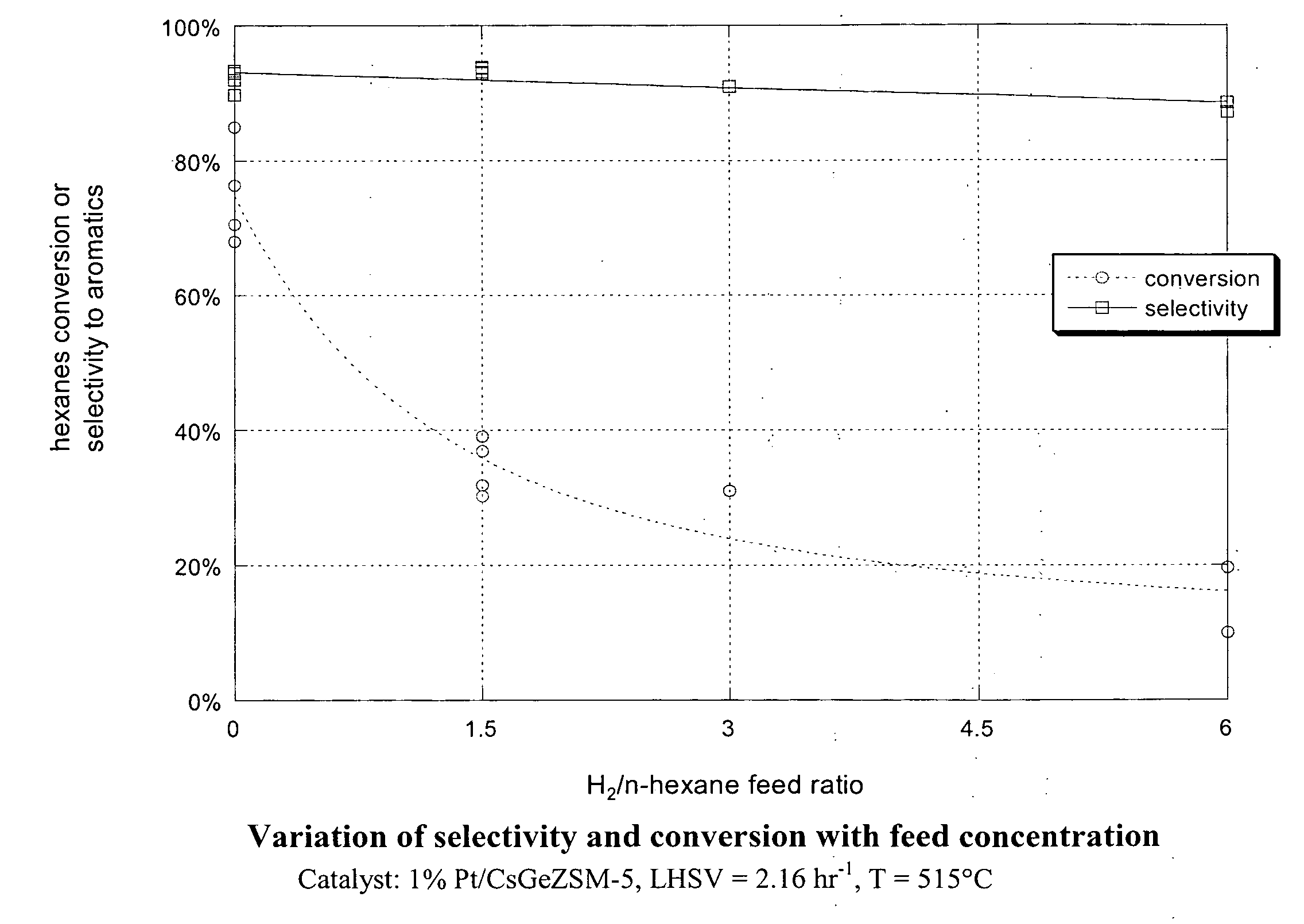

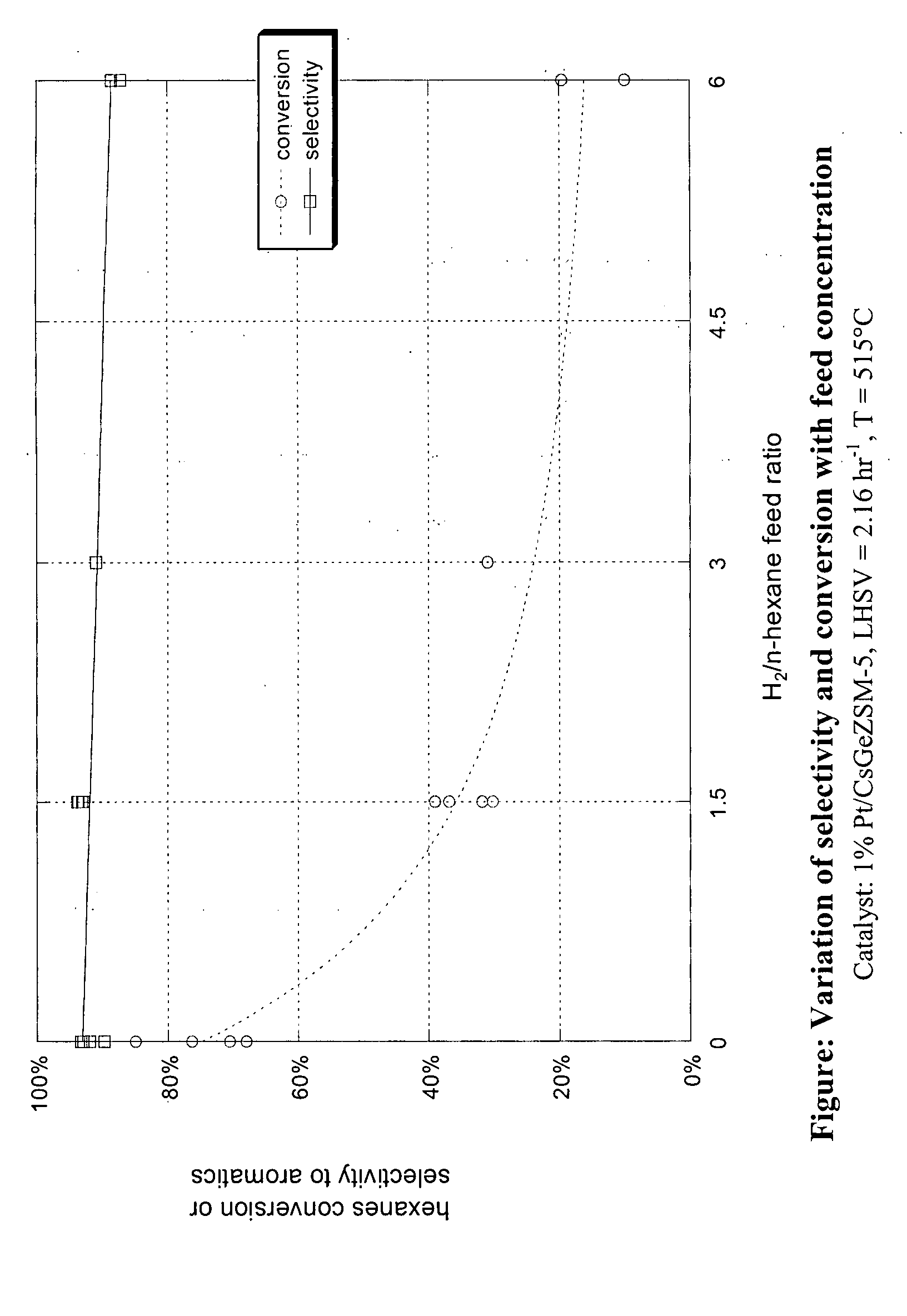

Aromatization of alkanes using a germanium-zeolite catalyst

ActiveUS20080255398A1Molecular sieve catalystsRefining to change hydrocarbon structural skeletonAlkaneAlkaline earth metal

This invention relates to a process for the aromatization of C6 to C12 alkanes, such as hexane, heptane and octane, to aromatics, such as benzene, ethyl benzene, toluene and xylenes, with a germanium-containing zeolite catalyst. The catalyst is a non-acidic aluminum-silicon-germanium zeolite on which a noble metal, such as platinum, has been deposited. The zeolite structure may be of MFI, BEA, MOR, LTL or MTT. The zeolite is made non-acidic by being base-exchanged with an alkali metal or alkaline earth metal, such as cesium, potassium, sodium, rubidium, barium, calcium, magnesium and mixtures thereof, to reduce acidity. The catalyst is sulfur tolerant and may be pretreated with a sulfur compound, i.e., sulfided. The hydrocarbon feed may contain sulfur up to 1000 ppm. The present invention could be applicable to a feedstream which is predominantly paraffinic and / or low in naphthenes. Lowering the hydrogen to hydrocarbon ratio increases conversion and aromatics selectivity.

Owner:SAUDI BASIC IND CORP SA

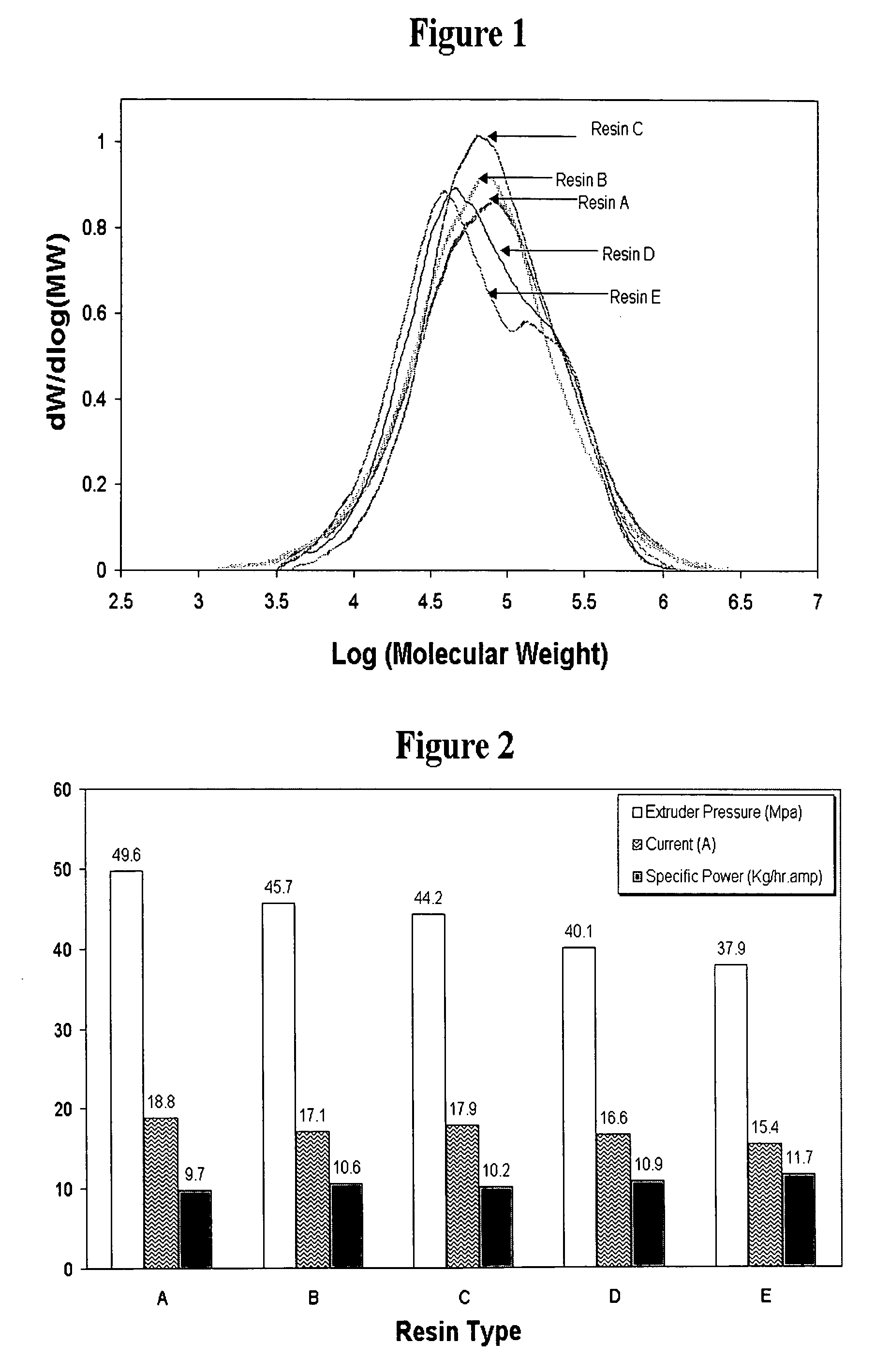

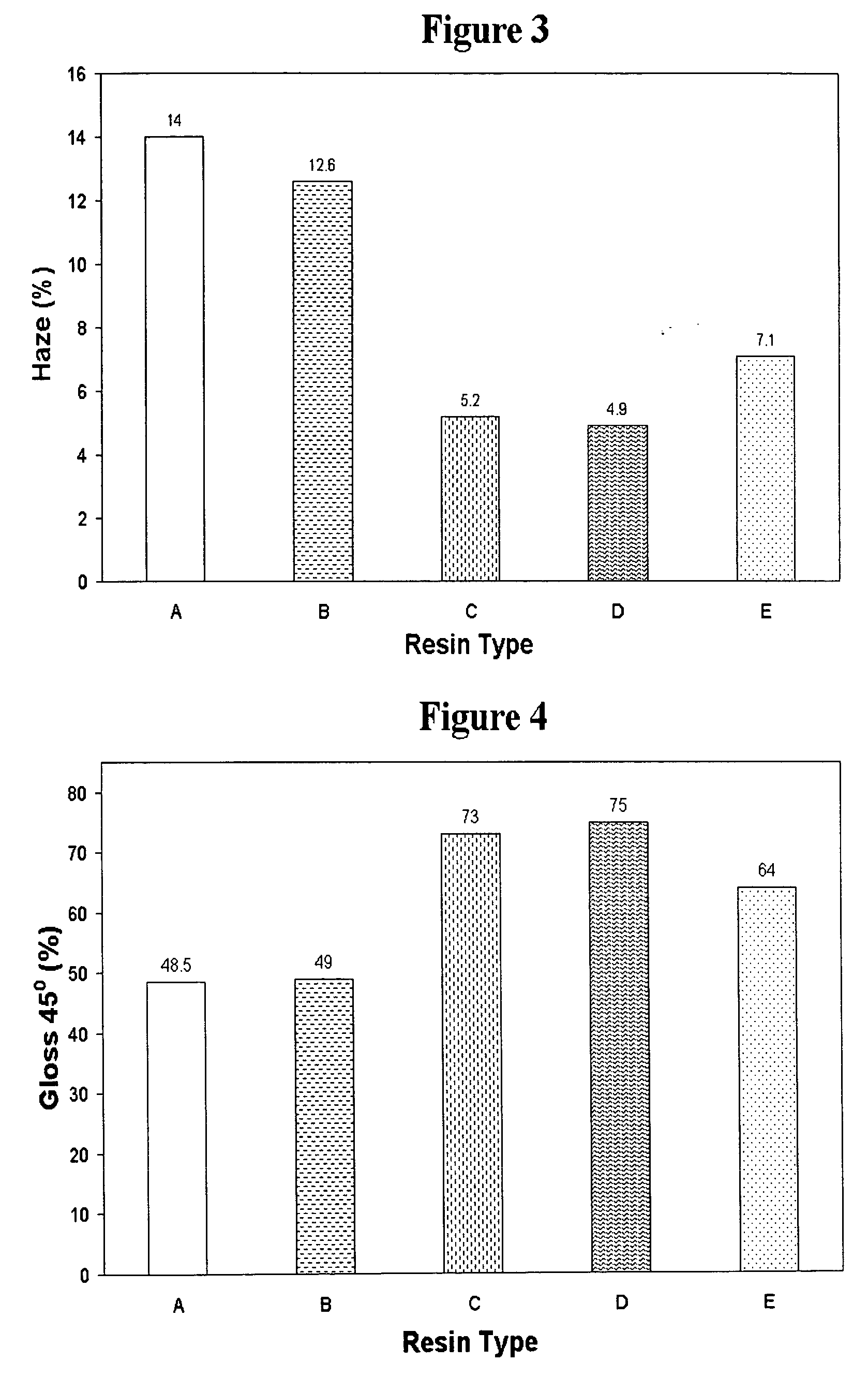

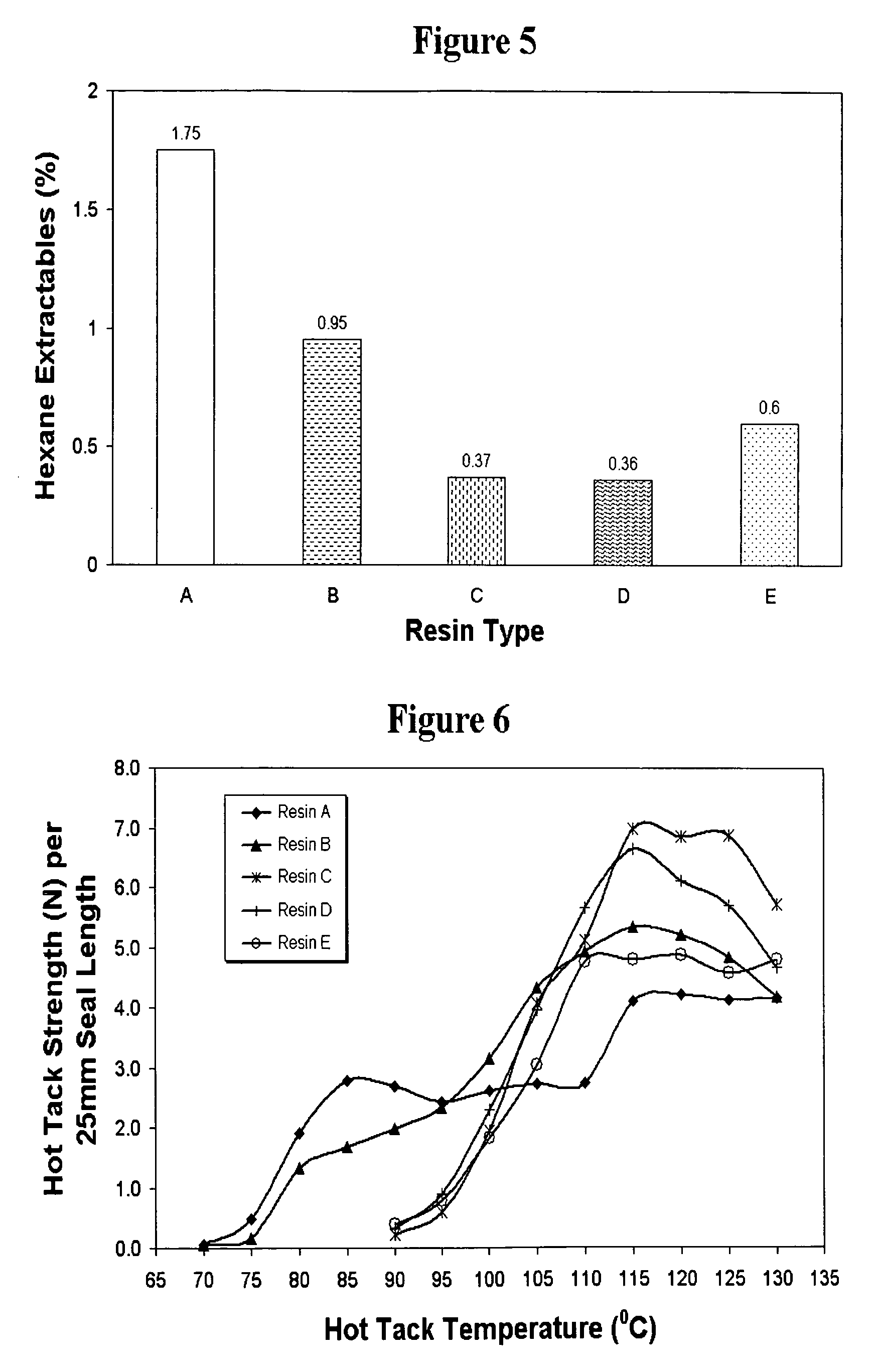

Dual reactor polyethylene resins for electronic packaging-films, tapes, bags and pouches

InactiveUS20060247373A1Good optical performanceHeat sealabilityLinear low-density polyethylenePolymer science

Owner:NOVA CHEM (INT) SA

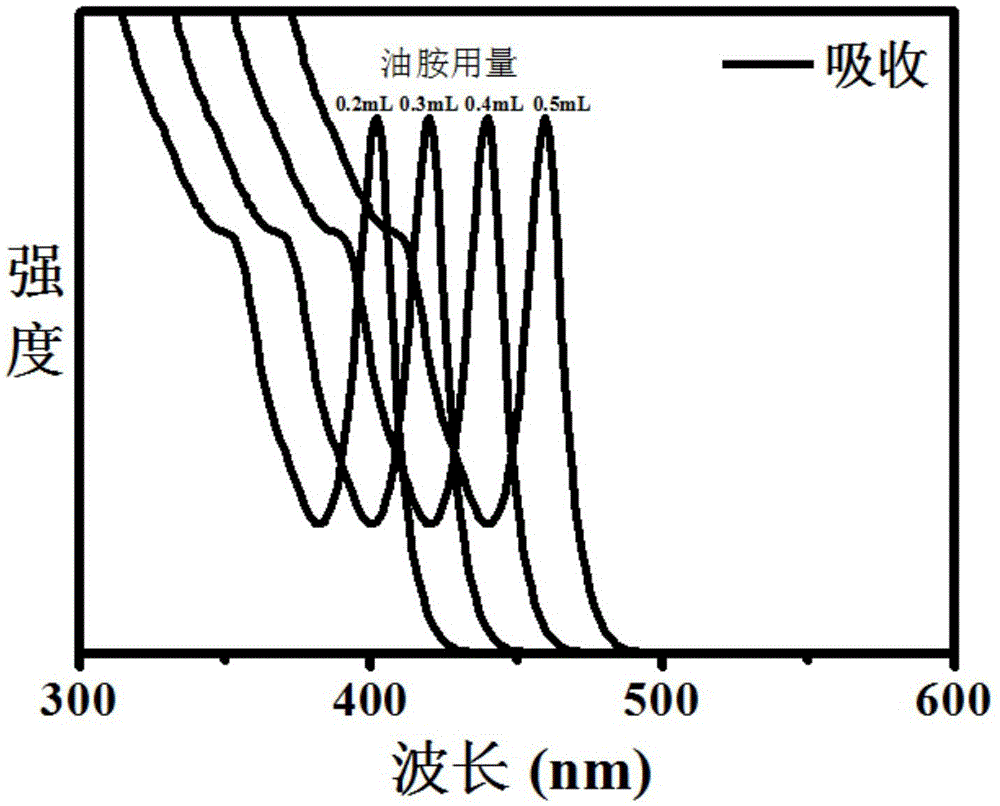

Single-size CsPbX3 perovskite nanocrystalline preparation method

InactiveCN105523581AEasy to adjust sizeEasy to operateLead compounds preparationLead halidesCarboxylic saltLead chloride

The invention belongs to the technical field of preparation of semiconductor nanomaterials and discloses a single-size CsPbX3 perovskite nanocrystalline preparation method. The method includes: adding cesium carboxylate solution into N2 protected lead bromide solution to realize reaction for obtaining single-size CsPbBr3 perovskite nanocrystalline; scattering the single-size CsPbX3 perovskite nanocrystalline into normal hexane, and gradually adding lead chloride solution or lead iodide solution drop by drop to realize reaction for obtaining single-size CsPbBr3 perovskite nanocrystalline. The single-size CsPbX3 perovskite nanocrystalline preparation method has the advantages of simplicity in operation, easiness in size adjustment of products, component controllability and the like.

Owner:JILIN UNIV

(-)-1-(3,4-Dichlorophenyl)-3-azabicyclo[3.1.0]hexane, compositions thereof, and uses as a dopamine-reuptake

InactiveUS6569887B2Inhibiting dopamine reuptakeInhibiting dopamine uptakeBiocidePowder deliveryDiseaseAttention deficits

Owner:DOV PHARMA

Underwater super-oleophobic oil-water separation mesh membrane and preparation method thereof

InactiveCN102716676AFast separationEasy to separateSemi-permeable membranesPolymer scienceVegetable oil

The invention discloses an underwater super-oleophobic oil-water separation mesh membrane and a preparation method thereof. The oil-water separation mesh membrane is prepared by coating a micron-thickness chitosan-based polymer coating layer on the mesh wire of a fabric mesh with 100-400 meshes. The oil-water separation mesh membrane is provided with micrometer-scale meshes and the chitosan-based polymer coating layer is provided with protruding structures with a nanoscale width. The preparation method of the oil-water separation mesh membrane comprises the following steps of: (1) cleaning and drying the fabric mesh; (2) dissolving a chitosan-based polymer in acid solution and stirring evenly to obtain mixed solution; (3) immersing the cleaned and dried fabric mesh in the mixed solution, taking out and drying the fabric mesh; and (4) immersing the fabric mesh obtained by the step (3) in alkaline solution, taking out and drying the fabric mesh to obtain the oil-water separation mesh membrane. The oil-water separation mesh membrane provided by the invention has the advantages of large water flux, high oil-water separation speed and good oil-water separation effect, is applicable to treatment of sewage with high oil content, and has good separation effect on normal hexane, petroleum ether, dichloroethane, benzene, animal and vegetable oils and the like.

Owner:TSINGHUA UNIV

Method for preparing alkane by high fatty acid ester

InactiveCN101597508ASimple preparation processLow reaction temperatureLiquid hydrocarbon mixture productionHydrocarbonsAlkaneReaction temperature

The invention discloses a method for preparing alkane by high fatty acid ester, which is characterized in that liquid-phase catalytic hydrogenation deoxidation is carried out on the high fatty acid ester to obtain the alkane. The high fatty acid ester, catalyst and solvent are added into a reactor, then hydrogen is charged into the reactor with reaction pressure at 1-10MPa and temperature at 210-320 DEG C, and the reaction time is 4-7h; the high fatty acid ester is fatty acid methyl ester containing 8-22 carbon atoms or fatty acid ethyl ester containing 8-22 carbon atoms; catalyst uses a multi-wall carbon nanotube as carrier and 2-10% of palladium in percentage by weight as active component ; the solvent is one of n-hexane, n-heptane, n-octane, dodecane, or hexadecane. In the invention, the preparation process is simple, the reaction temperature is low, the usage of solvent is less, the combustion high value of the target product is high, and the catalyst can be recycled.

Owner:ZHEJIANG UNIV

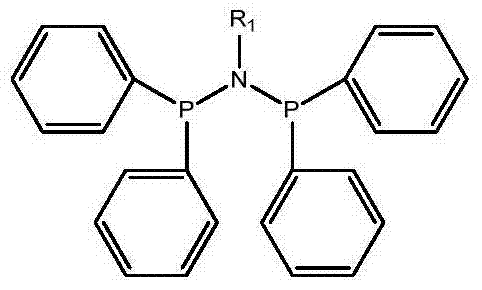

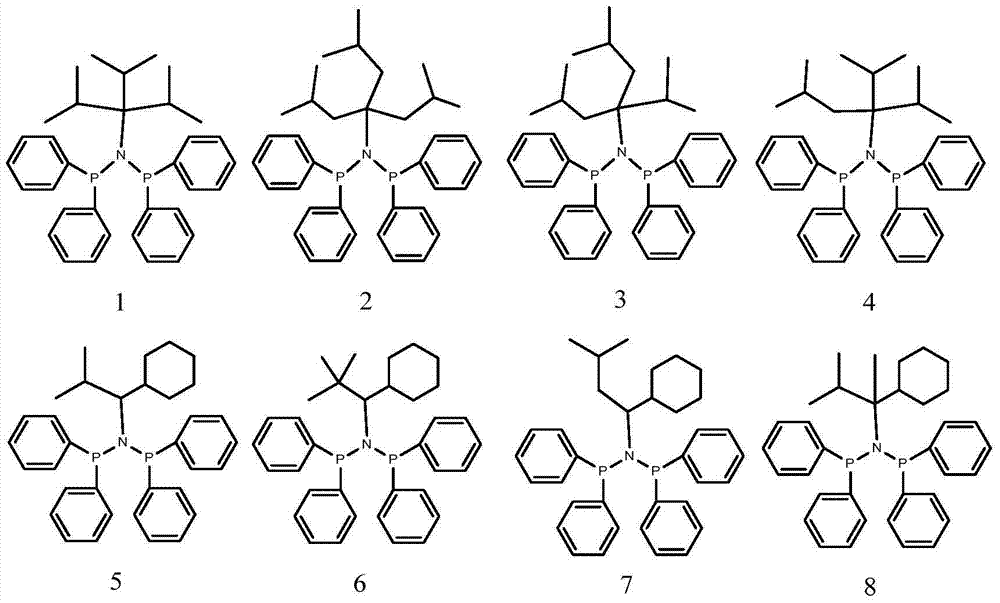

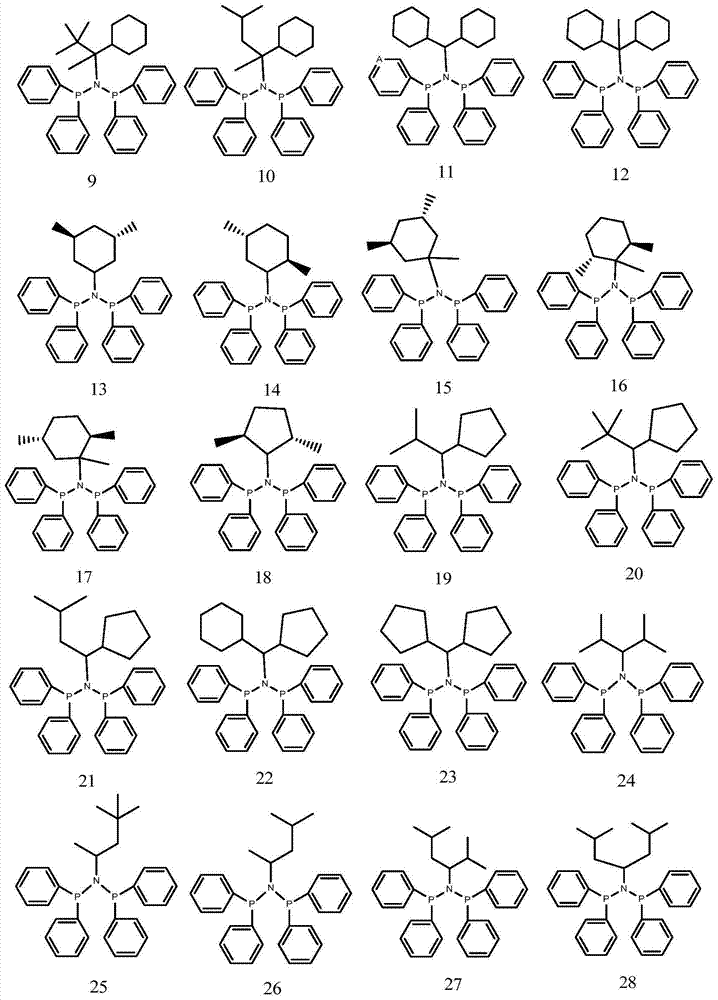

High-selectivity catalyst system used in trimerization and tetramerization of ethylene and use method thereof

ActiveCN104511311AIncreased co-selectivityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsChromium Compounds1-Octene

The invention provides a high-selectivity catalyst system used in trimerization and tetramerization of ethylene and a use method thereof. The catalyst system includes three components: (1) a chromium compound, (2) a ligand, of which a general structure formula is (Ph2)P-N(R1)-P(Ph2), wherein R1 is a synthetic phenyl group, alkyl group or cycloalkyl group; and (3) an activating agent or a co-catalyst. According to the catalyst system, a conventional PNP chromium-series catalyst is improved so that a co-selectivity of 1-hexane and 1-octylene is increased, wax-like products are reduced and a high activity is maintained.

Owner:EAST CHINA UNIV OF SCI & TECH

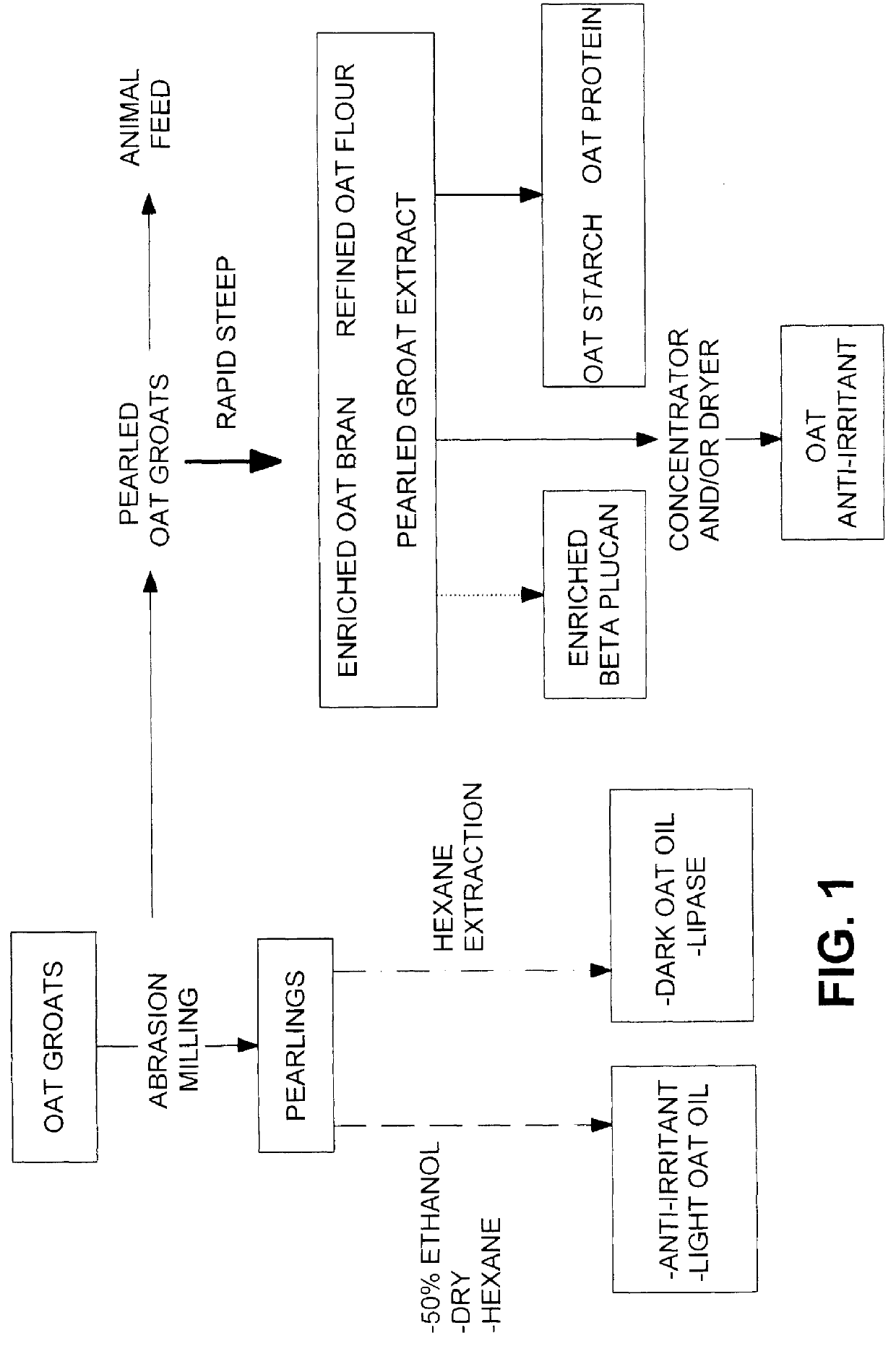

Methods for processing oat groats and products thereof

InactiveUS6113908AEffective alcohol concentrationHandling characteristics of the process mass are not negatively affectedCosmetic preparationsBiocideBeta-glucanAqueous medium

Methods of treating dehulled or hull-less oat, i.e. oat groats, to produce oat pearlings, oat flour and oat bran products are described. Oat groats are abrasion milled to remove up to 15% by weight and produce pearled oat groats and pearlings. The pearlings are extracted sequentially with aqueous ethanol and hexane to produce an anti-irritant and a light oat oil, or with hexane to produce a dark oat oil and lipase. The pearled oat groats are steeped in an aqueous medium for up to 4 hours and then macerated to produce an enriched oat bran, from which an enriched beta glucan may be extracted; a refined oat flour, from which oat starch and oat protein may be extracted; and a pearled oat groat extract from which further products, such as an oat anti-irritant can be recovered.

Owner:AGRI & AGRI FOOD

Azeotrope-like compositions comprising trans-1-chloro-3,3,3-trifluoropropene

ActiveUS20100102273A1Other chemical processesNon-surface-active detergent compositionsZeotropic mixtureMedicinal chemistry

An azeotrope-like mixture consisting essentially of chlorotrifluoropropene and at least one component selected from the group consisting of pentane, hexane, methanol, and trans-1,2-dichloroethene.

Owner:HONEYWELL INT INC

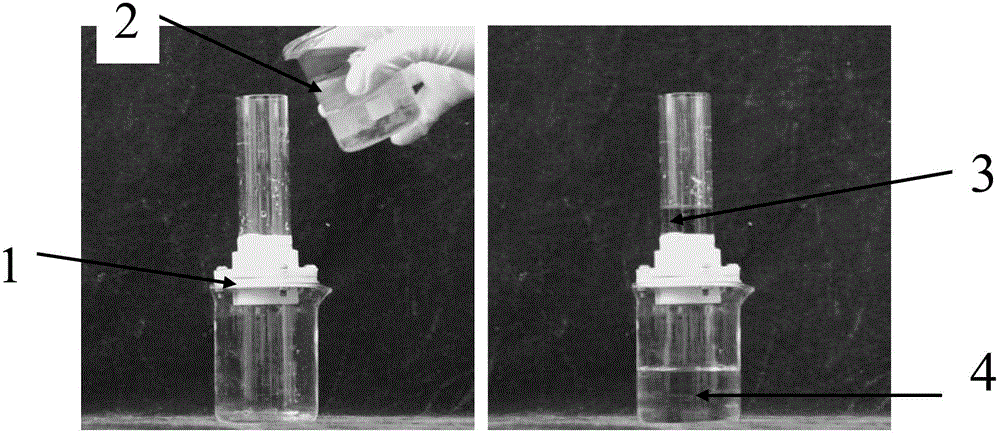

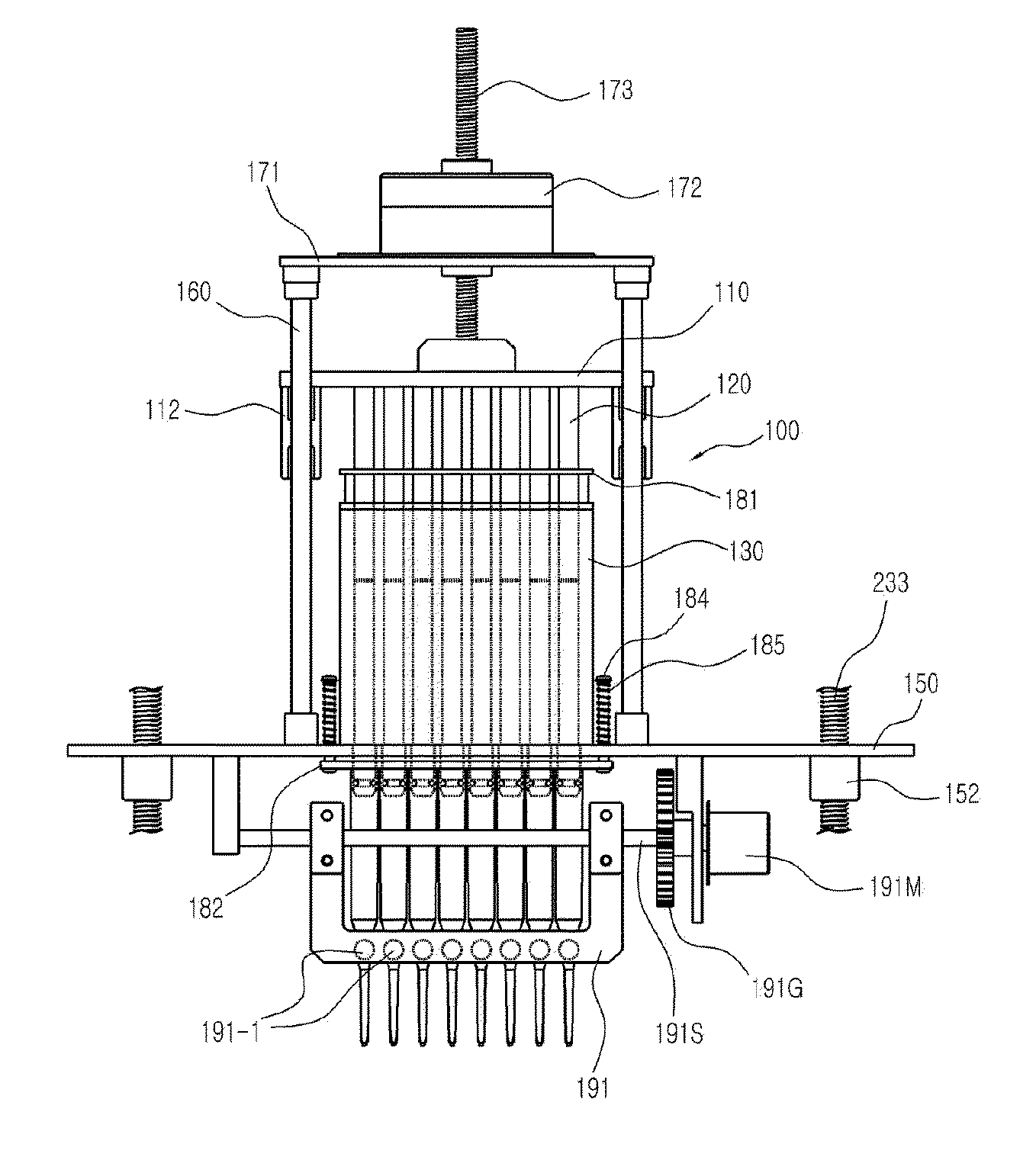

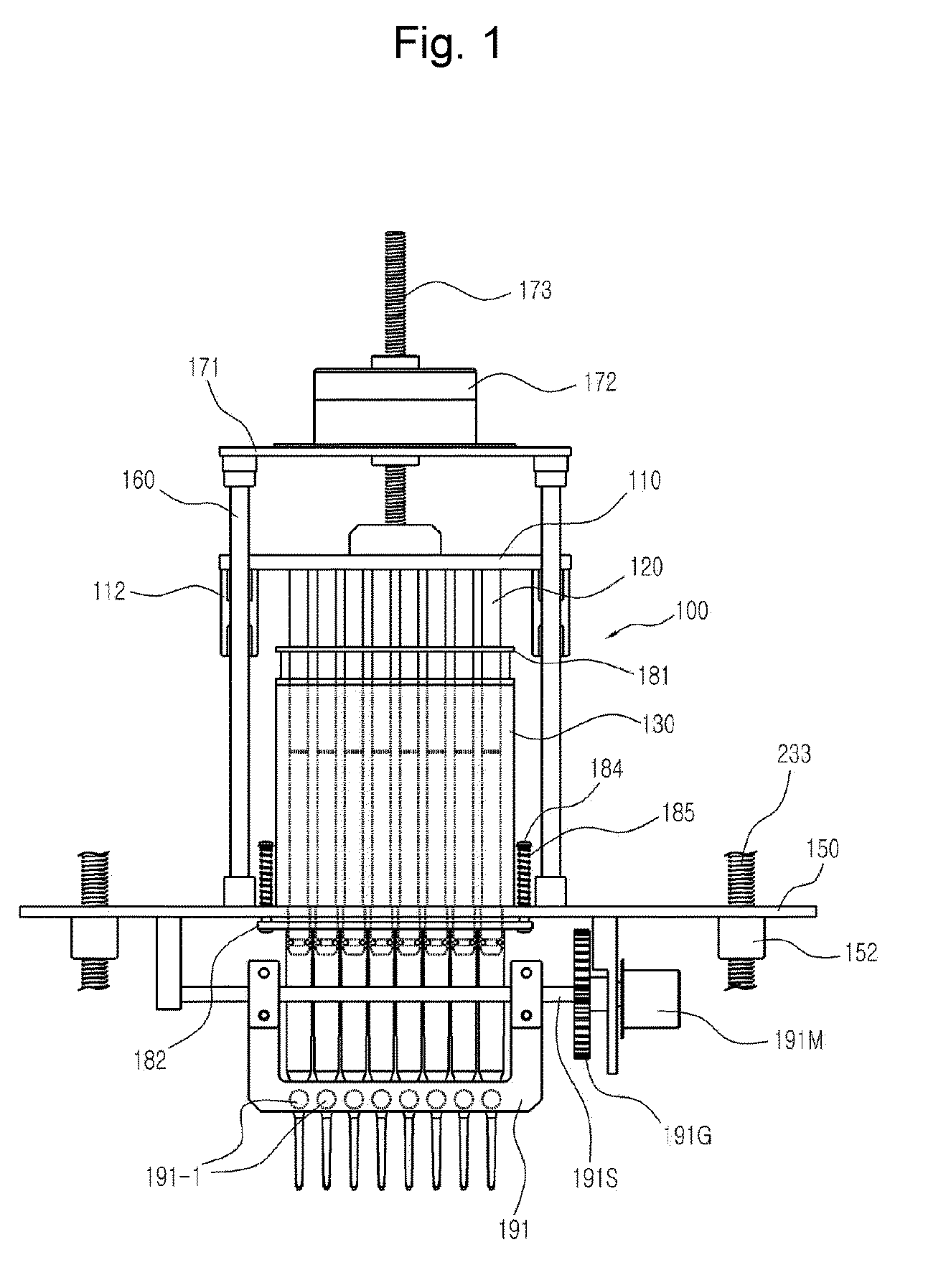

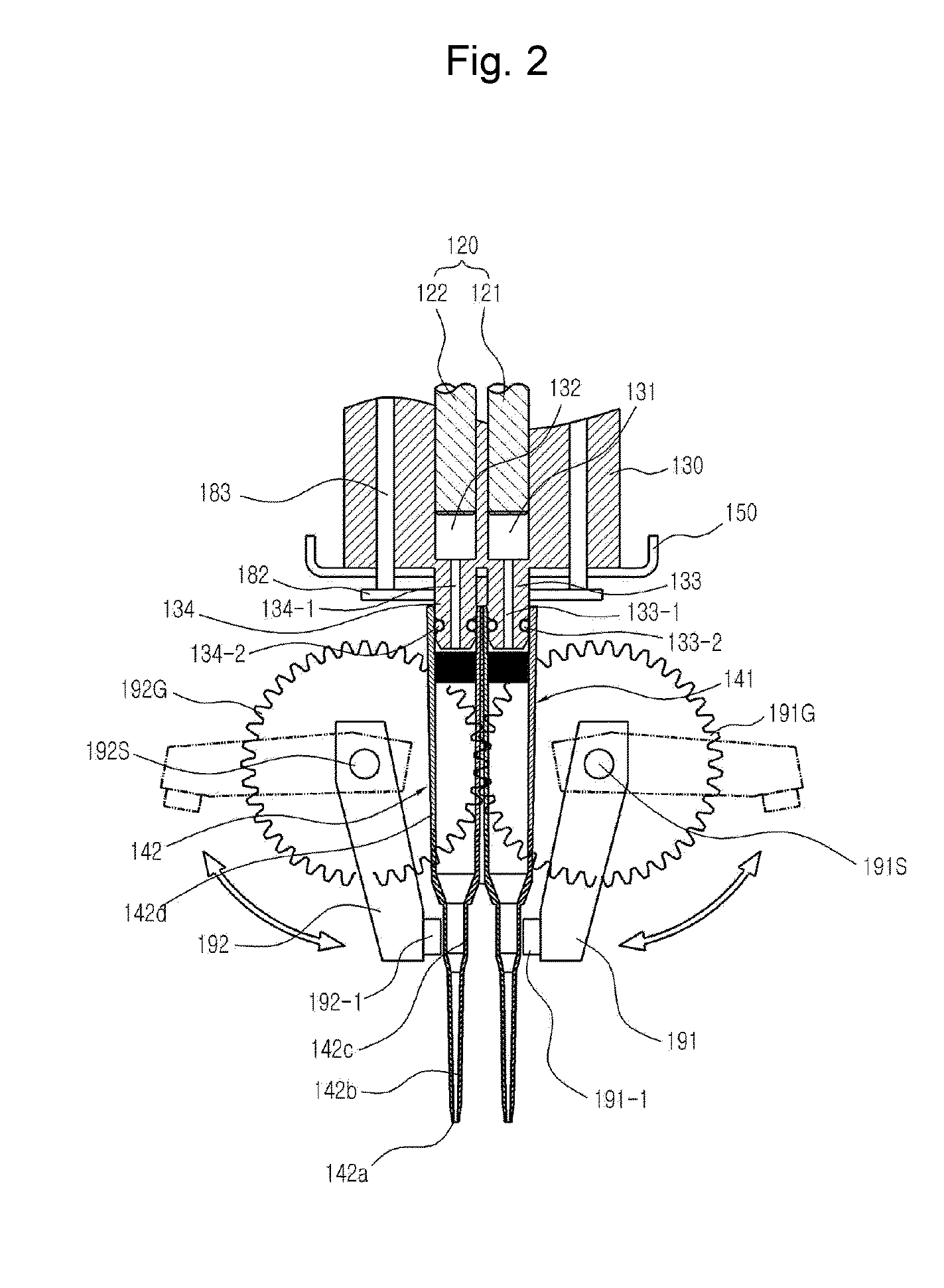

Automatic refining apparatus, multi-well plate kit and method for extracting hexane from biological samples

InactiveUS20110009608A1Done simply and quicklyFast refiningSugar derivativesWater/sewage treatment by magnetic/electric fieldsBioinformaticsHexane

The present invention relates to an automatic refining apparatus for separating target materials from a plurality of biological sample solutions by using magnetic particles to which the magnetic particles are to be reversibly coupled, and to a multi-well plate kit for use in the automatic refining apparatus. Further, the present invention relates to a method for extracting nucleic acids from biological samples by using the above-described automatic refining apparatus. The present invention can be used in the automatic separation of nucleic acid, protein, and the like from biological samples.

Owner:BIONEER

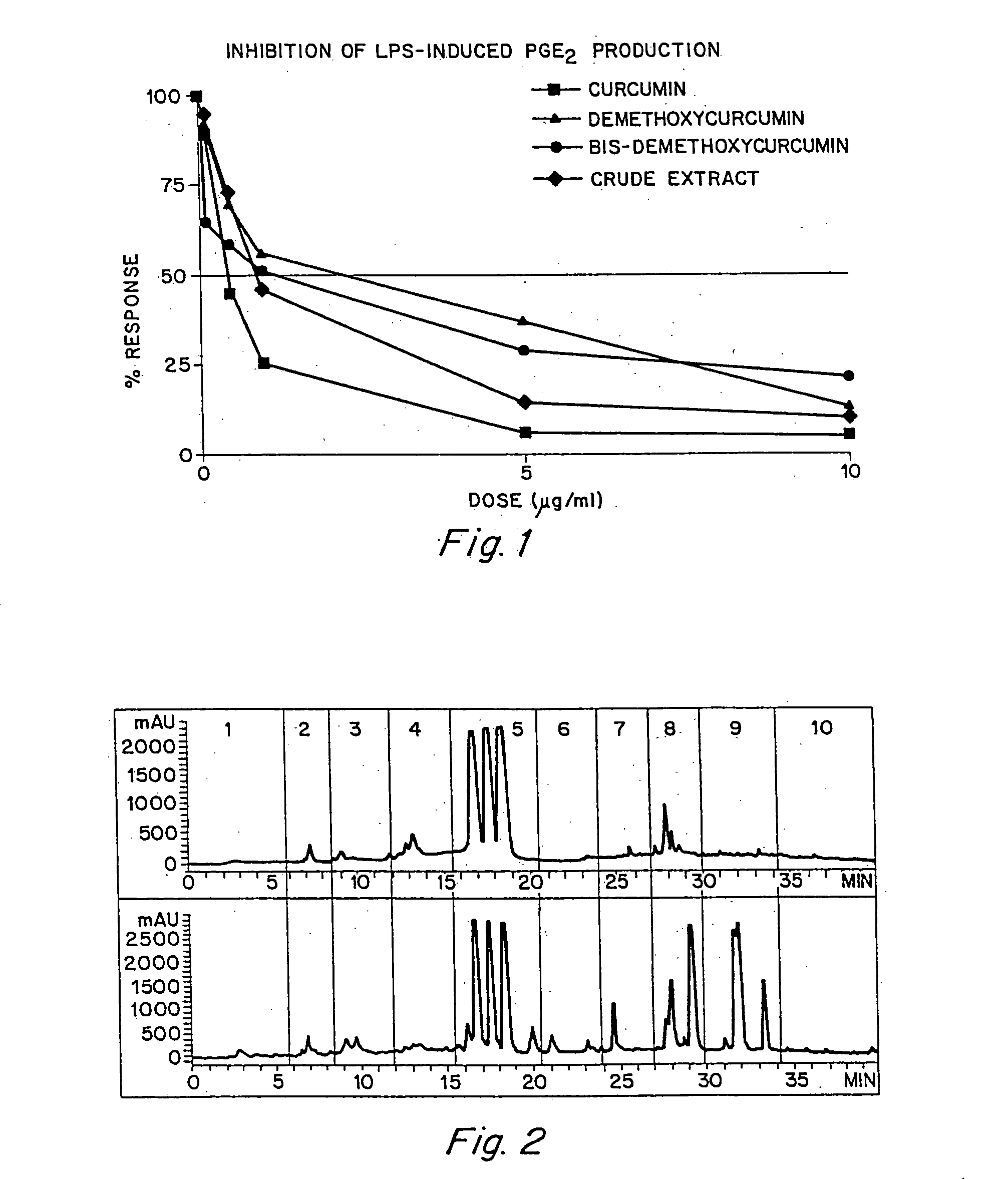

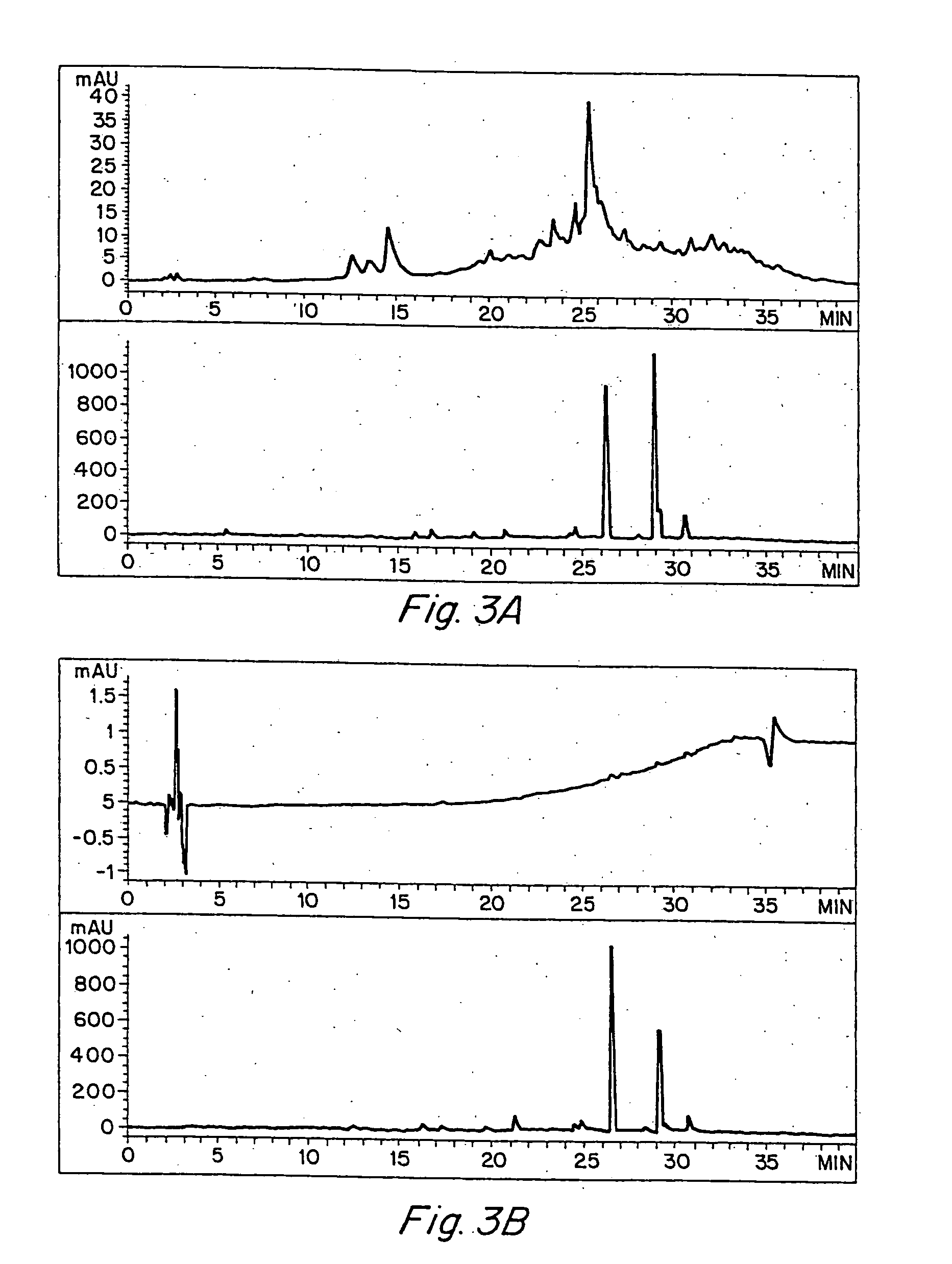

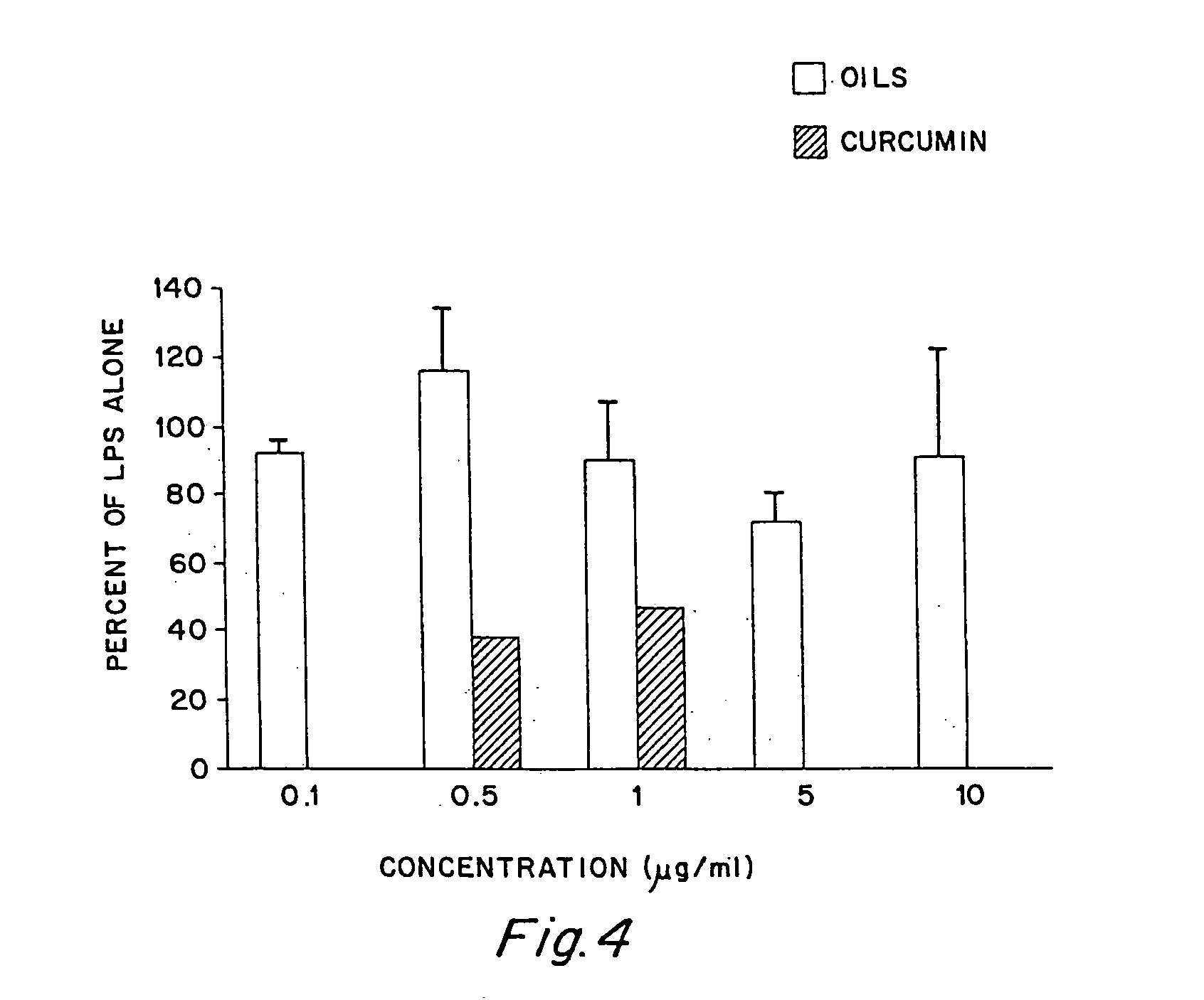

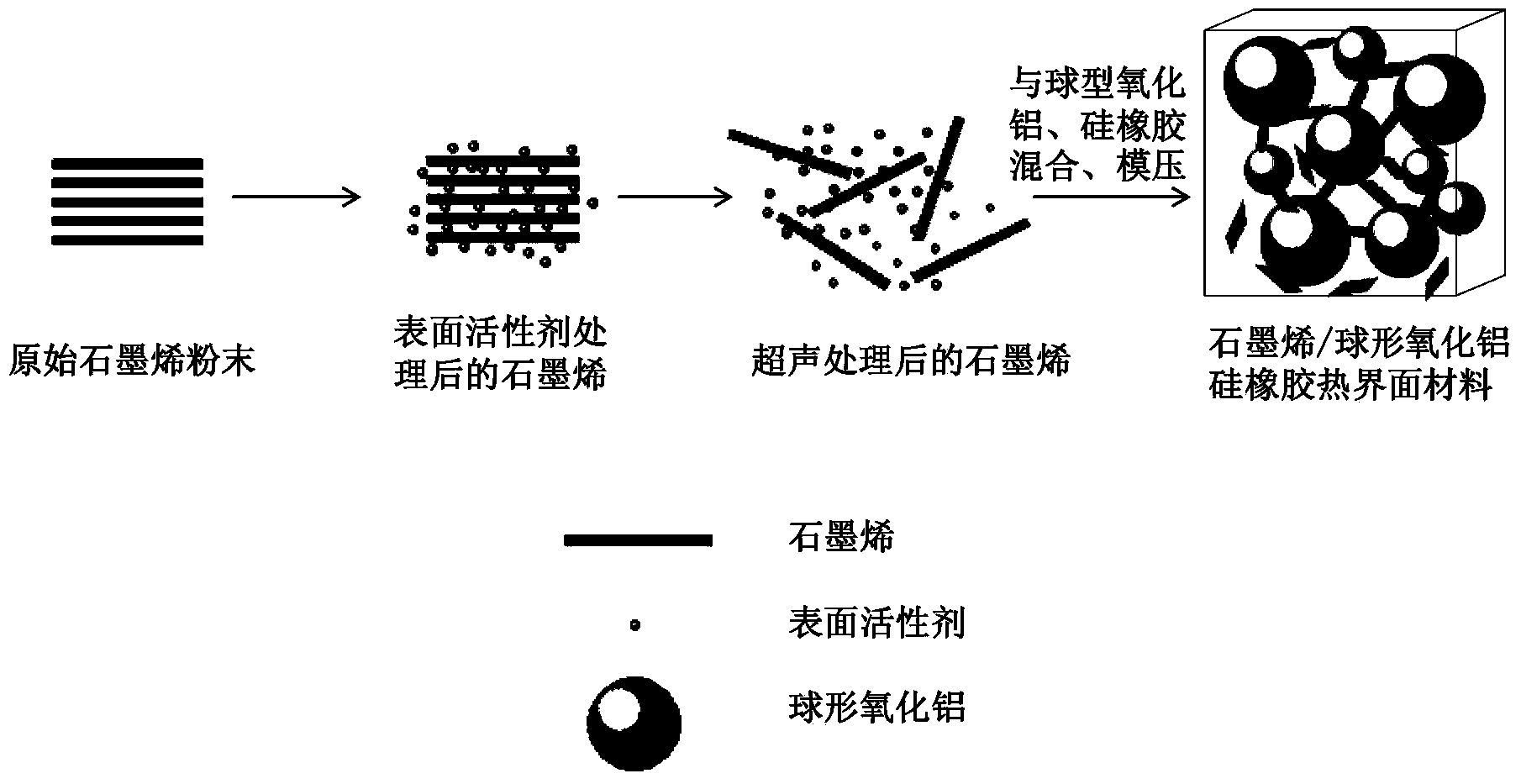

Anti-inflammatory activity of a specific turmeric extract

Disclosed herein are mixtures of turmeric extract oils. One mixture of turmeric oils is the hexane soluble fraction obtained by dissolving turmeric powder in hexane to form a hexane mixture, filtering the hexane mixture and evaporating the hexane from the turmeric oil mixture. A more refined turmeric oil combination is the oil left after the turmeric oil mixture is dissolved in hexane, placed on a silica gel / hexane chromatography column, and eluted with hexane into fractions that were then evaporated, thereby leaving the refined turmeric oil combination. Also disclosed are methods for treating inflammation, arthritis and rheumatoid arthritis and a pharmaceutical dosage form of the refined turmeric oil combination.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Heat-conducting electric insulation silicon rubber thermal interface material and preparation method thereof

The invention discloses a heat-conducting electric insulation silicon rubber thermal interface material and a preparation method thereof and belongs to the technical field of rubber nanocomposite materials. The preparation method comprises the following steps: treating graphene by employing a surfactant, ultrasonically dispersing the graphene into a relatively thin and uniform nano sheet structure, compounding the graphene with spherical aluminum oxide, adding compounded packing into raw silicon rubber dissolved by normal hexane for uniformly mixing, drying, adding a cross-linking agent, a catalyst and a polymerization inhibitor, vulcanizing and performing compression molding to obtain the heat-conducting electric insulation silicon rubber thermal interface material. The graphene is subjected to the surface treatment and is ultrasonically dispersed into a relatively thin sheet structure, and the formation of a heat-conducting network is promoted; moreover, due to the addition of a small amount of treated graphene, the heat-conducting performance can be greatly improved, the influence on the hardness of a composite material is small, and the composite material can reach an insulating level by controlling the amount of the graphene, so that the heat-conducting electric insulation silicon rubber thermal interface material can be applied to electronic products.

Owner:BEIJING UNIV OF CHEM TECH +1

Two-step decolorization method for phospholipid

ActiveCN102517148AReduce dosageReduce the degree of oxidationSolid sorbent liquid separationFatty-oils/fats refiningAcid valuePhospholipid

The invention provides a two-step decolorization method for phospholipid. The method comprises the following steps of: dissolving the phospholipid by using n-hexane as a solvent, adding a proper amount of hydrogen peroxide into the mixed phospholipid for oxidation and decolorization, and removing most pigment; and performing vacuum heating to remove un-reacted hydrogen peroxide and solvent, adding n-hexane to dissolve the phospholipid in a certain ratio, adding chromatography silica gel in a certain ratio, reacting with stirring, adsorbing peroxide, impurities and partial pigment in the phospholipid, filtering, desolventizing, and thus obtaining decolorized phospholipid. By adopting two-step decolorization, on the premise that the decolorization effect is ensured, the consumption of the hydrogen peroxide is reduced by over 30 percent, and the oxidation degree of the phospholipid in the decolorization process is effectively reduced; and by the adsorption effect of the silica gel, the acid value and the peroxide value of the phospholipid are further reduced, the transparency of the phospholipid is improved, and the quality of the product is effectively improved.

Owner:SHANDONG BOHI INDUSTRY CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![(1R,2S,5S)-N-[(1S)-3-amino-1-(cyclobutylmethyl)-2,3-dioxopropyl]-3-[(2S)-2-[[[(1,1-dimethylethyl)amino]carbonyl]amino]-3,3-dimethyl-1-oxobutyl]-6,6-dimethyl-3-azabicyclo[3.1.0]hexane-2-carboxamide as inhibitor of hepatitis C virus NS3/NS4a serine protease (1R,2S,5S)-N-[(1S)-3-amino-1-(cyclobutylmethyl)-2,3-dioxopropyl]-3-[(2S)-2-[[[(1,1-dimethylethyl)amino]carbonyl]amino]-3,3-dimethyl-1-oxobutyl]-6,6-dimethyl-3-azabicyclo[3.1.0]hexane-2-carboxamide as inhibitor of hepatitis C virus NS3/NS4a serine protease](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/68ff82f9-3880-45b4-9833-0144a15a0351/US20050249702A1-20051110-C00001.png)

![(1R,2S,5S)-N-[(1S)-3-amino-1-(cyclobutylmethyl)-2,3-dioxopropyl]-3-[(2S)-2-[[[(1,1-dimethylethyl)amino]carbonyl]amino]-3,3-dimethyl-1-oxobutyl]-6,6-dimethyl-3-azabicyclo[3.1.0]hexane-2-carboxamide as inhibitor of hepatitis C virus NS3/NS4a serine protease (1R,2S,5S)-N-[(1S)-3-amino-1-(cyclobutylmethyl)-2,3-dioxopropyl]-3-[(2S)-2-[[[(1,1-dimethylethyl)amino]carbonyl]amino]-3,3-dimethyl-1-oxobutyl]-6,6-dimethyl-3-azabicyclo[3.1.0]hexane-2-carboxamide as inhibitor of hepatitis C virus NS3/NS4a serine protease](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/68ff82f9-3880-45b4-9833-0144a15a0351/US20050249702A1-20051110-C00002.png)

![(1R,2S,5S)-N-[(1S)-3-amino-1-(cyclobutylmethyl)-2,3-dioxopropyl]-3-[(2S)-2-[[[(1,1-dimethylethyl)amino]carbonyl]amino]-3,3-dimethyl-1-oxobutyl]-6,6-dimethyl-3-azabicyclo[3.1.0]hexane-2-carboxamide as inhibitor of hepatitis C virus NS3/NS4a serine protease (1R,2S,5S)-N-[(1S)-3-amino-1-(cyclobutylmethyl)-2,3-dioxopropyl]-3-[(2S)-2-[[[(1,1-dimethylethyl)amino]carbonyl]amino]-3,3-dimethyl-1-oxobutyl]-6,6-dimethyl-3-azabicyclo[3.1.0]hexane-2-carboxamide as inhibitor of hepatitis C virus NS3/NS4a serine protease](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/68ff82f9-3880-45b4-9833-0144a15a0351/US20050249702A1-20051110-C00003.png)