Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

824 results about "Heptane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-Heptane is the straight-chain alkane with the chemical formula H₃C(CH₂)₅CH₃ or C₇H₁₆. When used as a test fuel component in anti-knock test engines, a 100% heptane fuel is the zero point of the octane rating scale (the 100 point is a 100% iso-octane). Octane number equates to the anti-knock qualities of a comparison mixture of heptane and isooctane which is expressed as the percentage of isooctane in heptane and is listed on pumps for gasoline (petrol) dispensed globally.

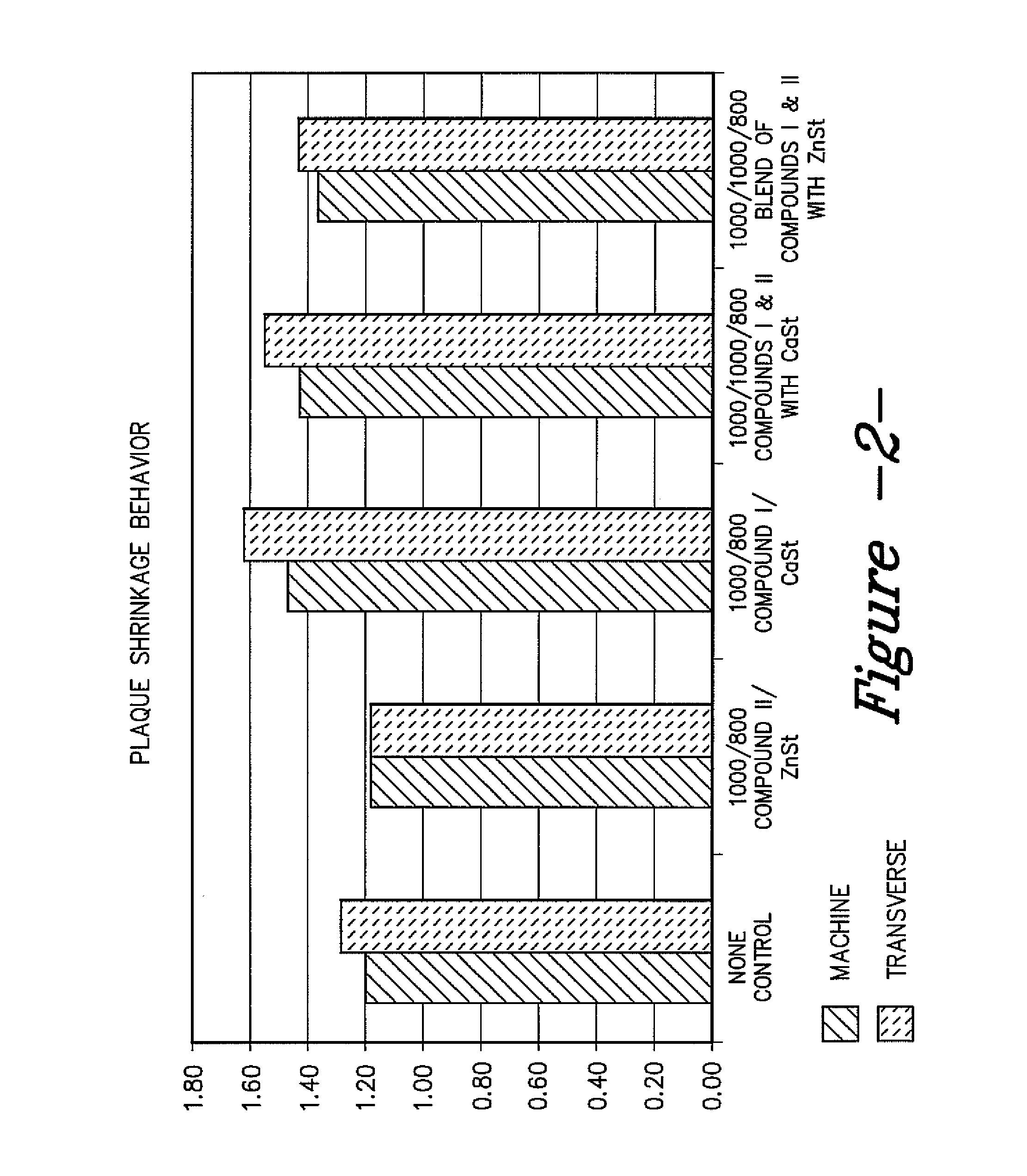

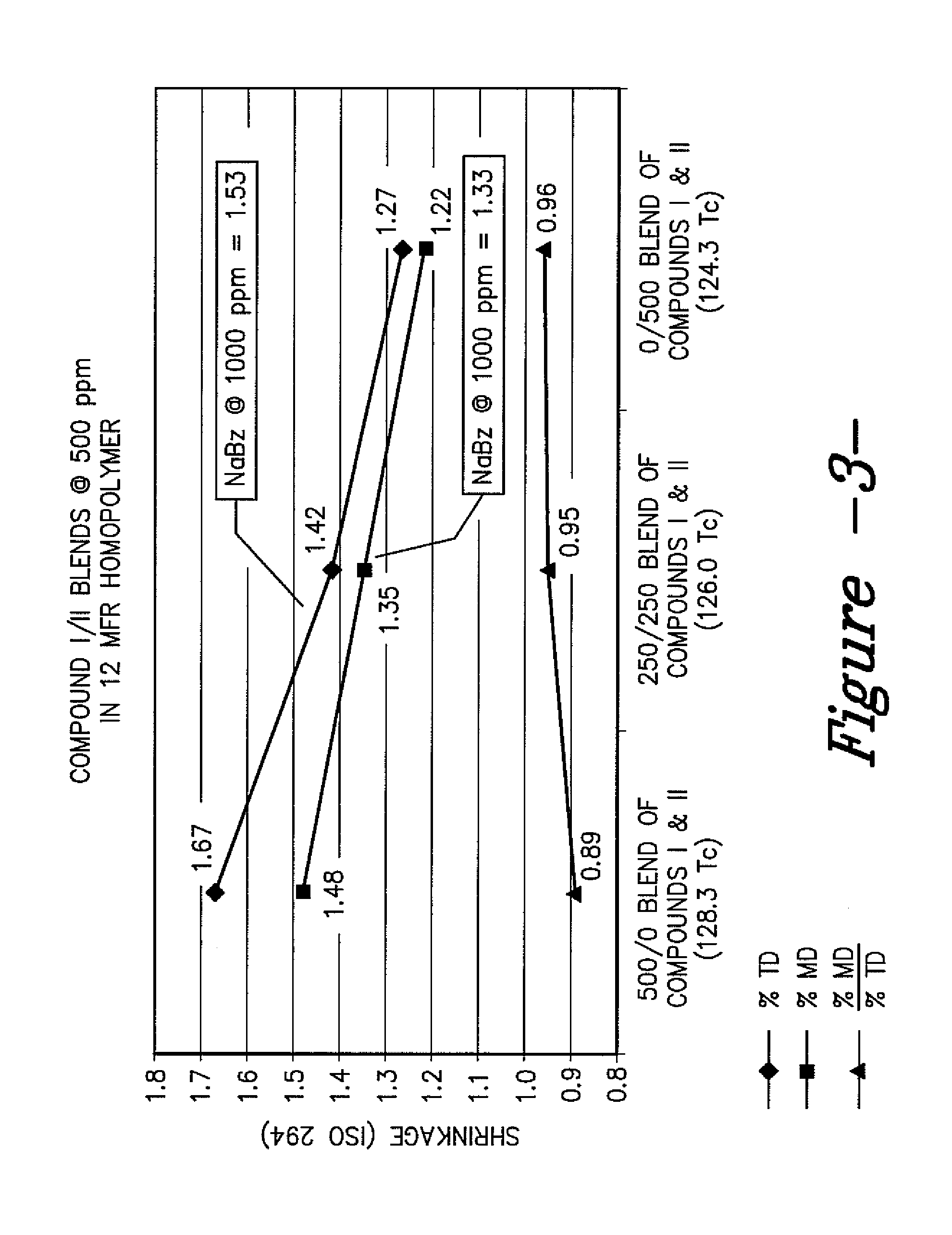

Highly nucleated thermoplastic articles

InactiveUS6534574B1Exceptional nucleation efficacyExcellent calcium stearate compatibilityOrganic active ingredientsOrganic chemistryPolyolefinCrystallization temperature

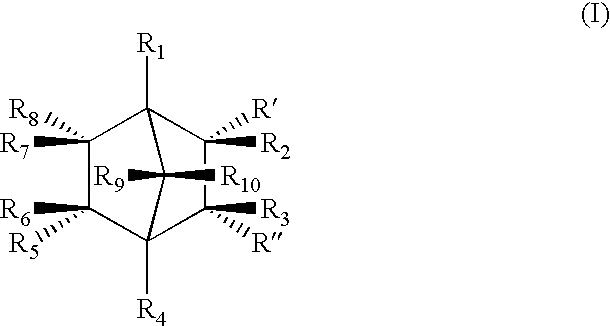

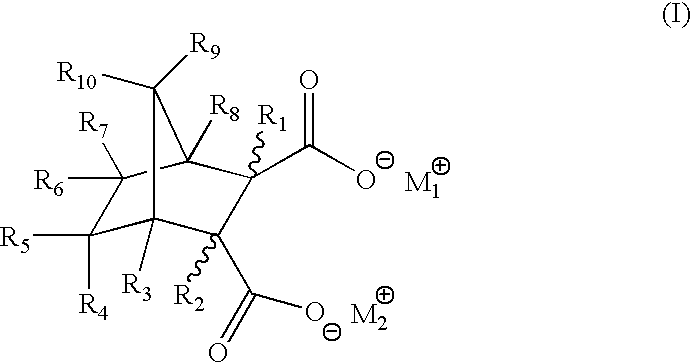

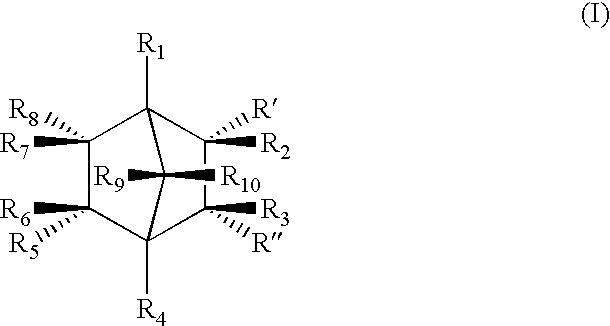

Compounds and compositions comprising specific metal salts of bicyclo[2.2.1 ]heptane dicarboxylate salts in order to provide highly desirable properties within polyolefin articles are provided. The inventive salts and derivatives thereof are useful as nucleating and / or clarifying agents for such polyolefin, provide excellent crystallization temperatures, stiffness, and calcium stearate compatibility within target polyolefin. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Polyolefin additive compositions and methods of producing polyolefin with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

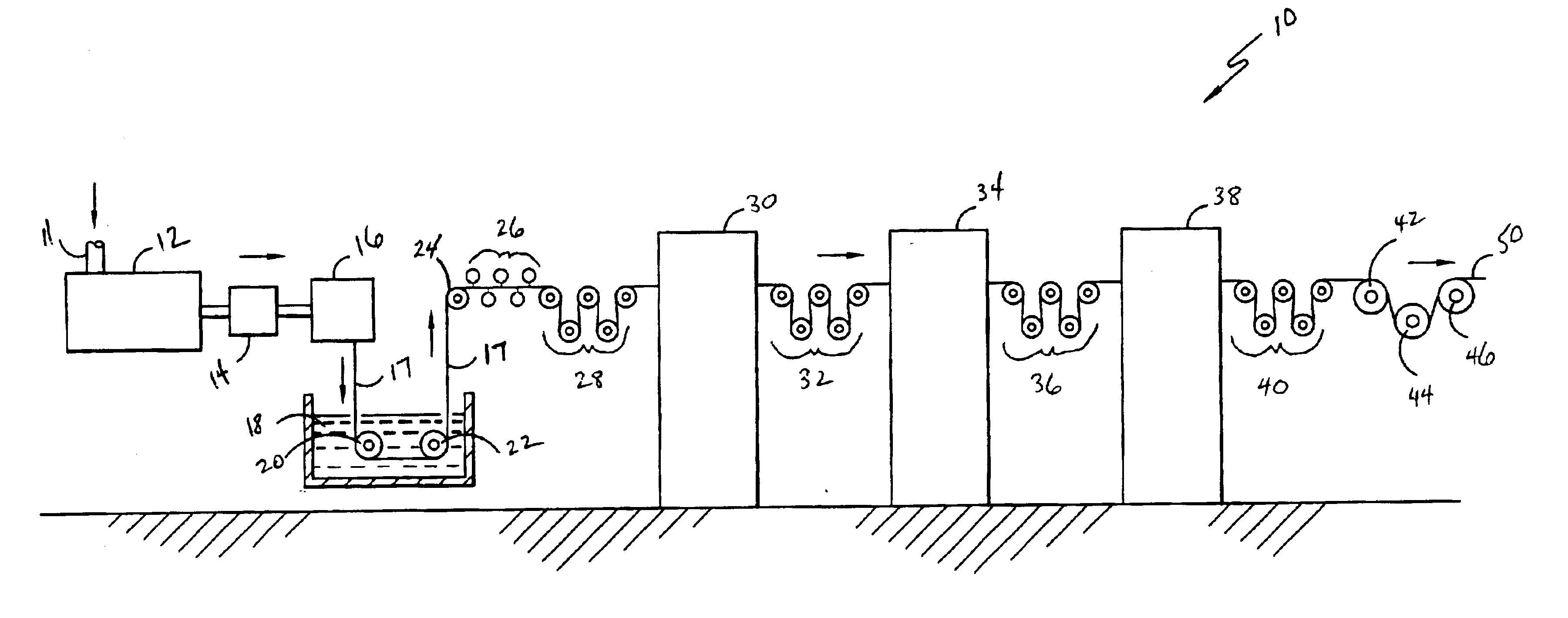

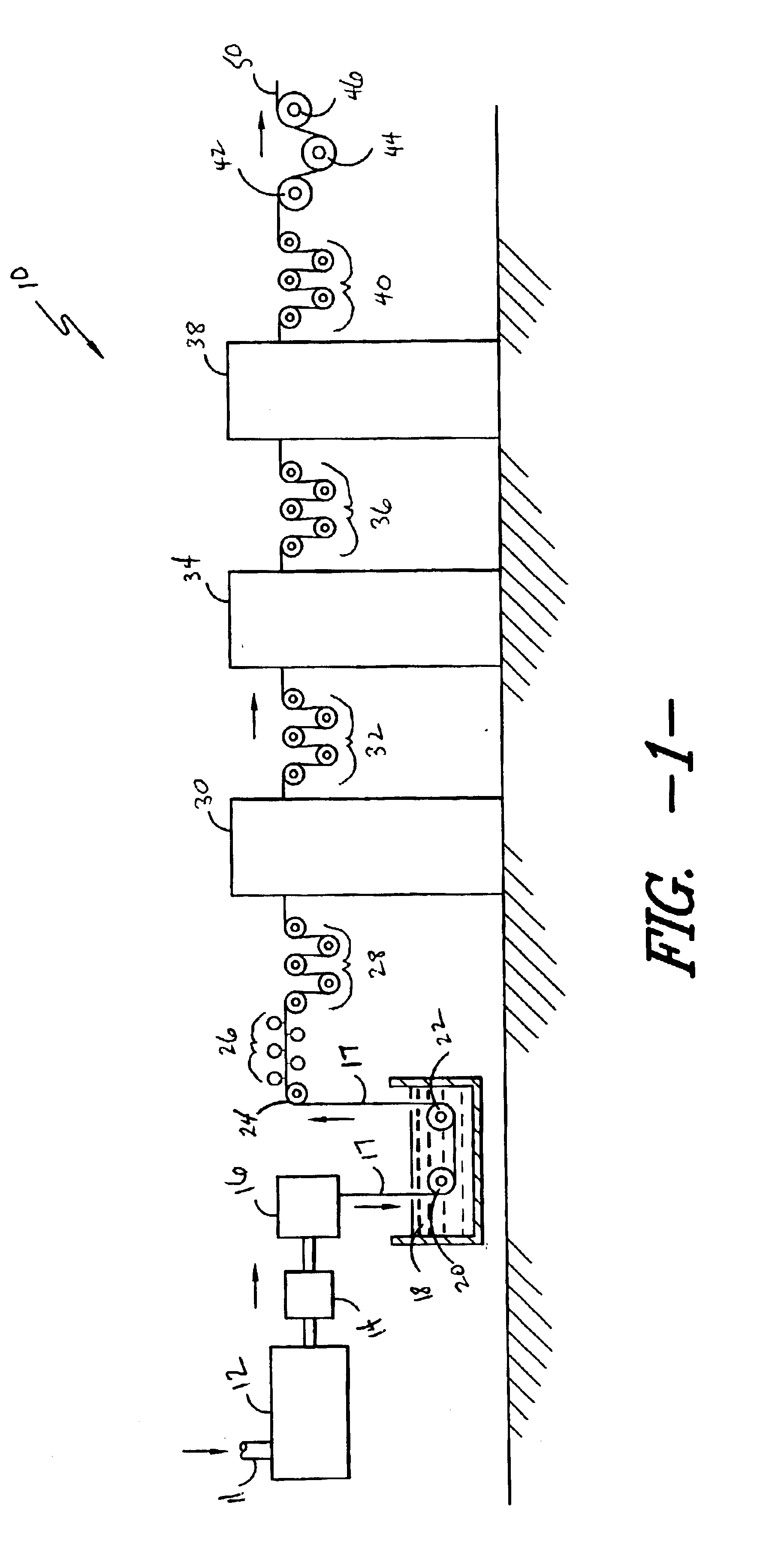

Thermoplastic monofilament fibers exhibiting low-shrink, high tenacity, and extremely high modulus levels

InactiveUS6759124B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingThermoplasticYarn

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

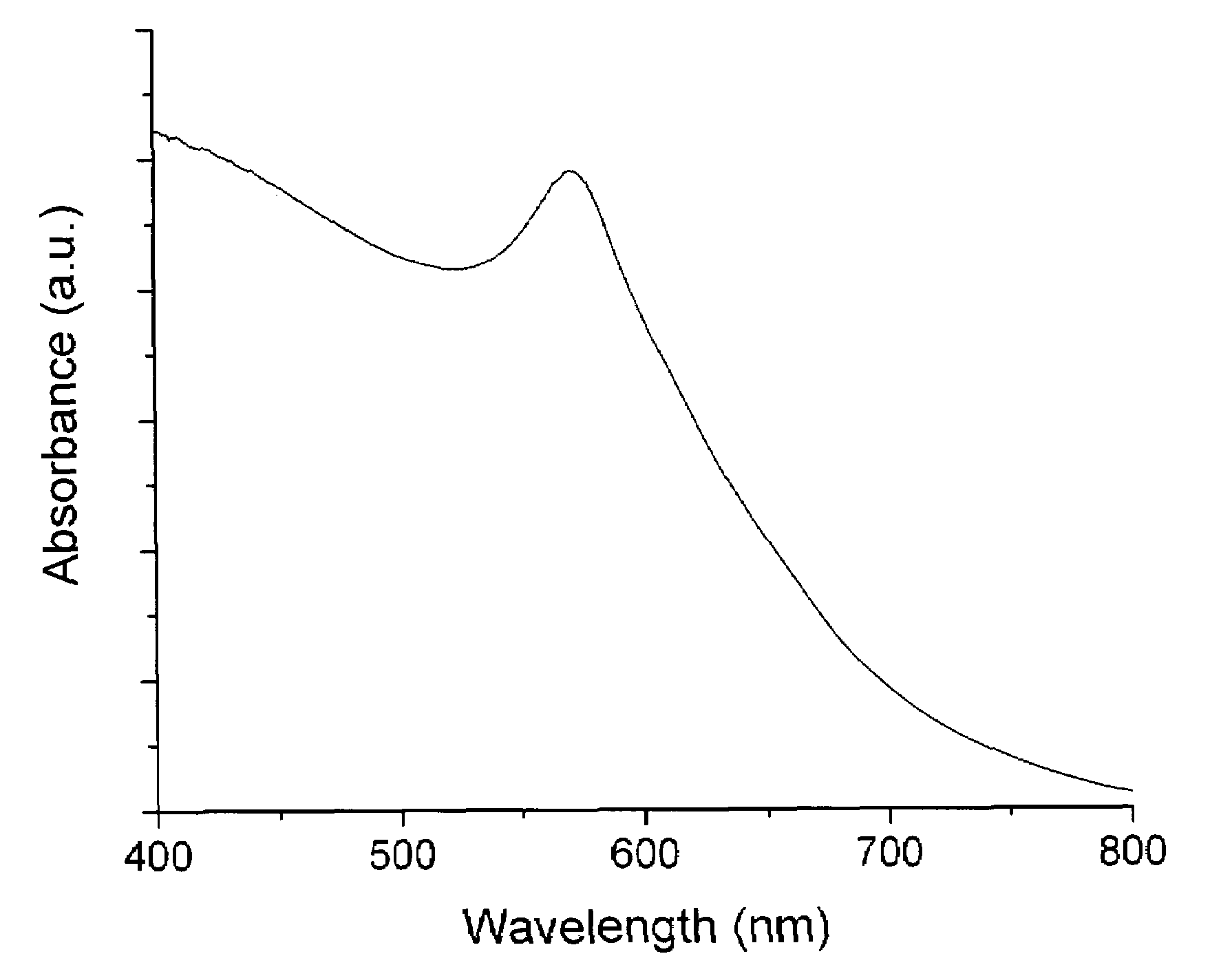

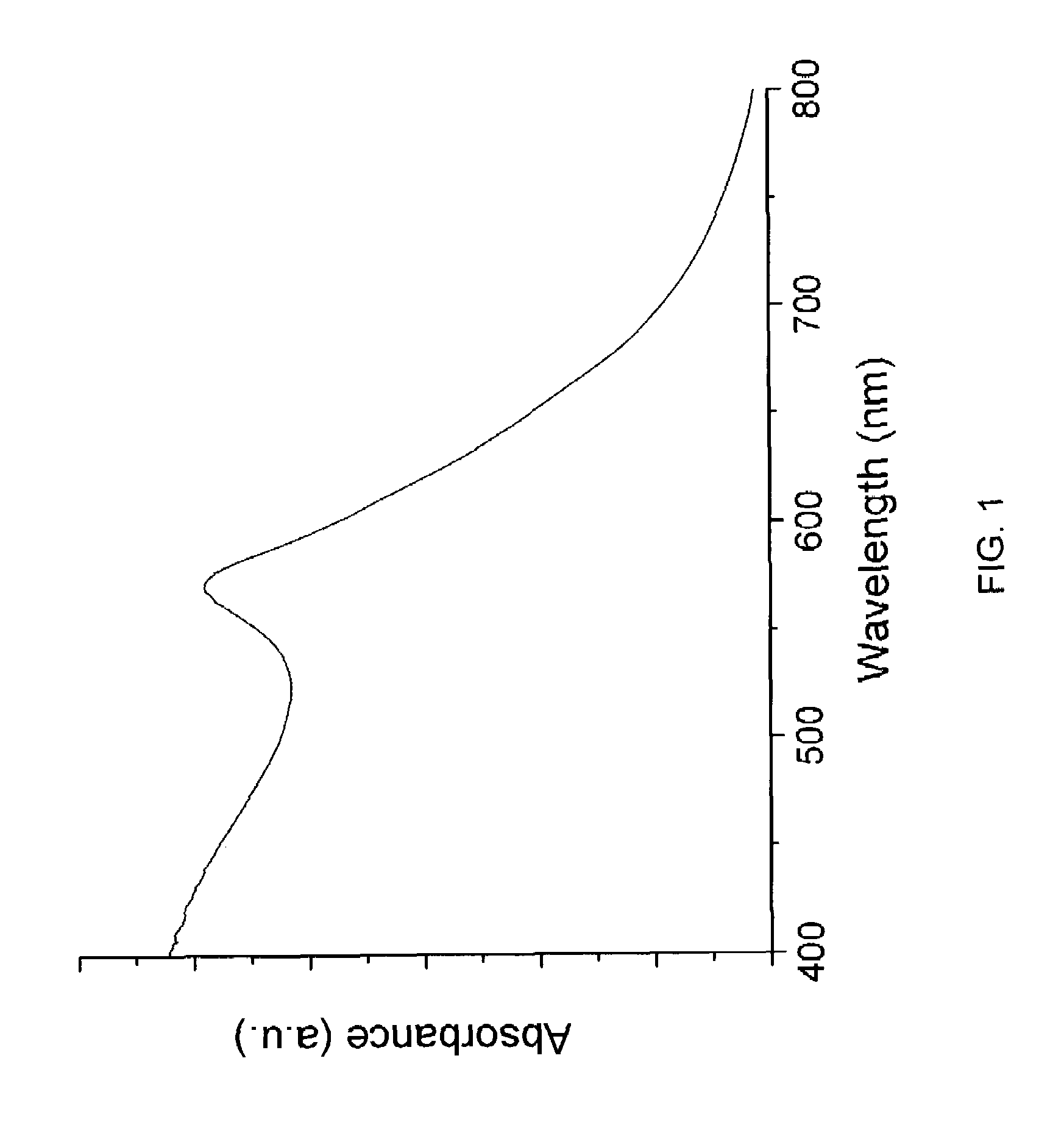

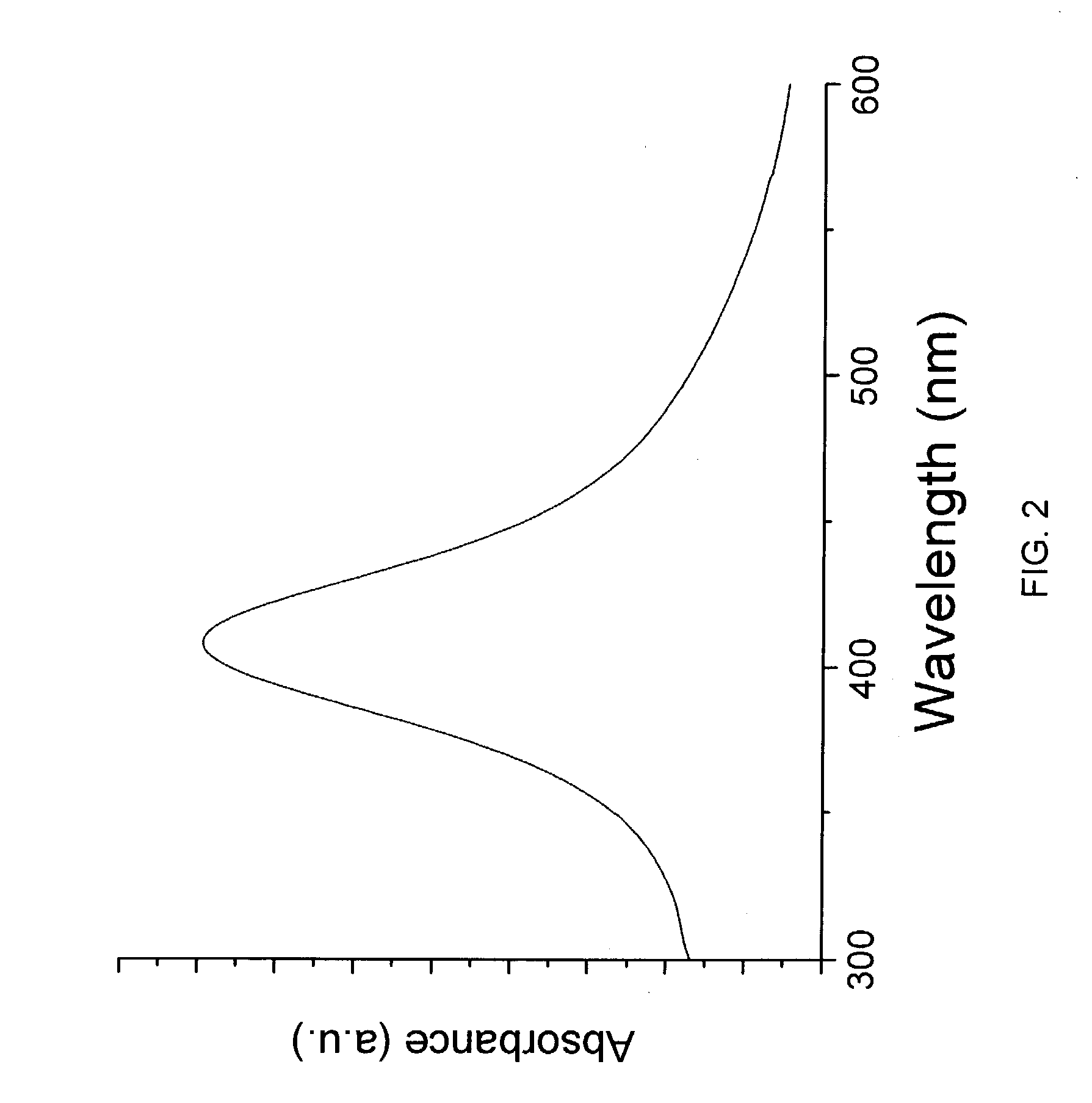

Synthesis metal nanoparticle

A method for providing an anhydrous route for the synthesis of amine capped coinage-metal (copper, silver, and gold) nanoparticles (NPs) using the coinage-metal mesityl (mesityl=C6H2(CH3)3-2,4,6) derivatives. In this method, a solution of (Cu(C6H2(CH3)3)5, (Ag(C6H2(CH3)3)4, or (Au(C6H2(CH3)3)5 is dissolved in a coordinating solvent, such as a primary, secondary, or tertiary amine; primary, secondary, or tertiary phosphine, or alkyl thiol, to produce a mesityl precursor solution. This solution is subsequently injected into an organic solvent that is heated to a temperature greater than approximately 100° C. After washing with an organic solvent, such as an alcohol (including methanol, ethanol, propanol, and higher molecular-weight alcohols), oxide free coinage NP are prepared that could be extracted with a solvent, such as an aromatic solvent (including, for example, toluene, benzene, and pyridine) or an alkane (including, for example, pentane, hexane, and heptane). Characterization by UV-Vis spectroscopy and transmission electron microscopy showed that the NPs were approximately 9.2±2.3 nm in size for Cu°, (no surface oxide present), approximately 8.5±1.1 nm Ag° spheres, and approximately 8–80 nm for Au°.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

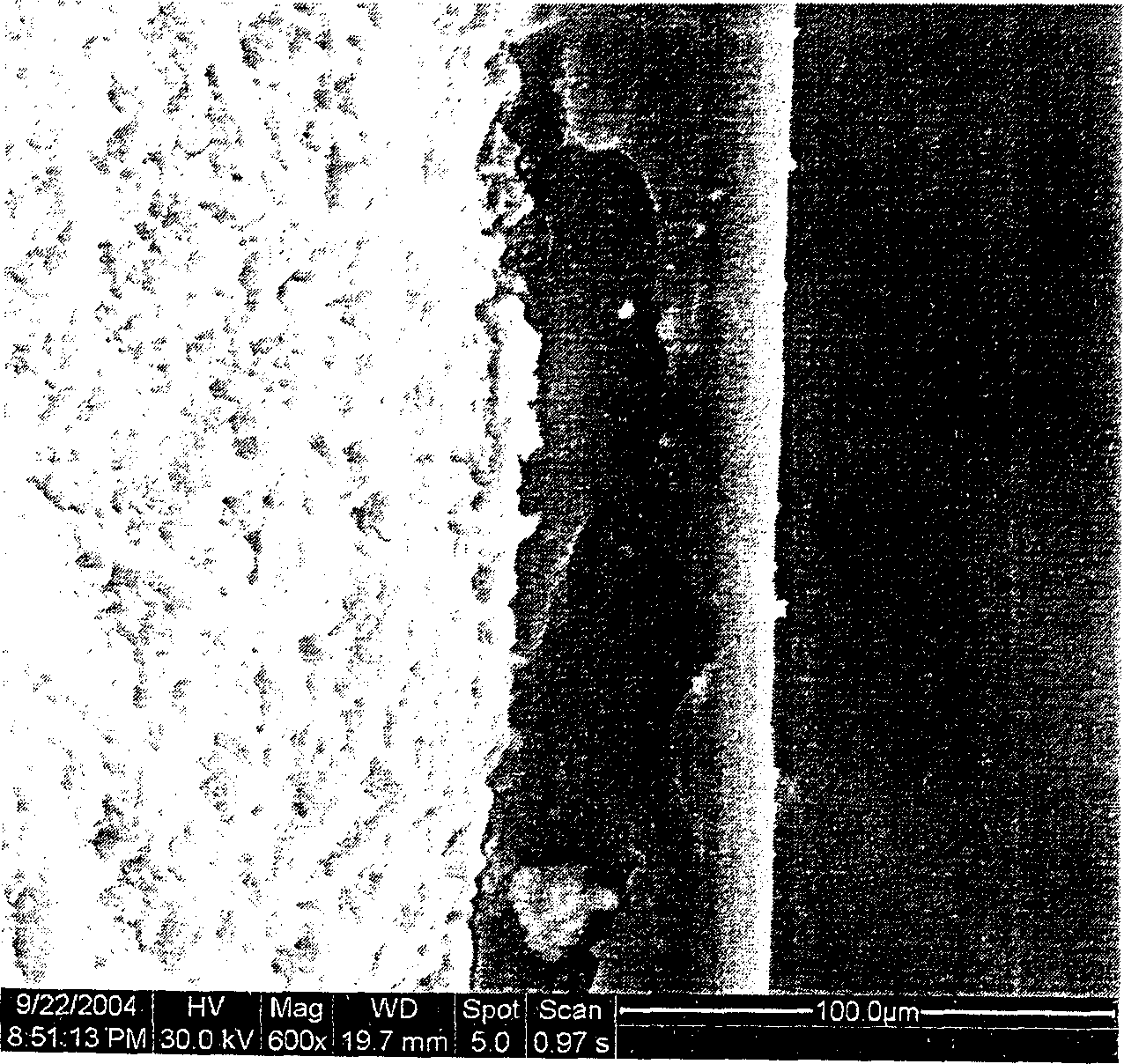

Crosslinked hyperbranched polyalcohol composite nano filter membrance and method of preparing the same

InactiveCN101254417AImprove throughputHigh retention rateSemi-permeable membranesFood additiveUltrafiltration

The invention discloses a crosslinking hyper branched polymer composite nanofiltration membrane as well as the preparation method thereof. The crosslinking hyper branched polymer composite nanofiltration membrane is prepared by taking an ultrafiltration membrane as a basement membrane and crosslinking hyper branched polymer as a selecting layer through hyper branched polymer and the interfacial polymerization of polybasic acid, polybasic acyl chloride, polybasic anhydride and polybasic amine; and the interfacial polymerization takes the mixed solution of water and ethanol as the water phase and n-hexane, n-heptane or n-octane as the organic phase. As the hyper branched polymer has the spheroidal structure, a plurality of nano-voids exist in the interior of the molecule, so as to enable the selecting layer of the crosslinking hyper branched polymer composite nanofiltration membrane to be looser, and leads the nanofiltration membrane to maintain high flux and retention rate under the lower operating pressure. The nanofiltration membrane can be used in the fields of medicament, foodstuff, environmental protection, etc. The composite nanofiltration membrane is applicable to the separation and the condensation of high valence ions, low valence ions, neutral particles, drugs, food additives, etc.

Owner:ZHEJIANG UNIV

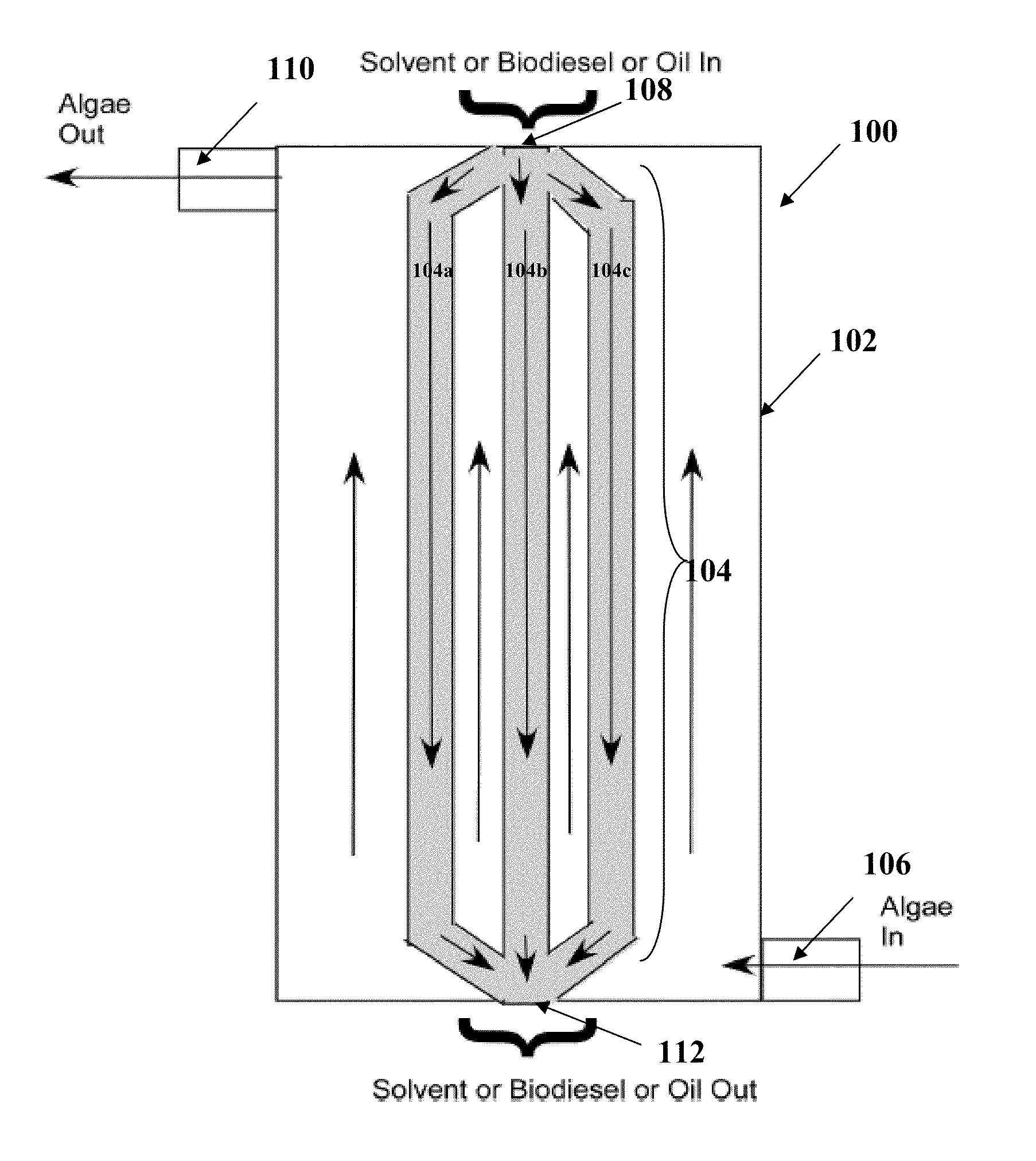

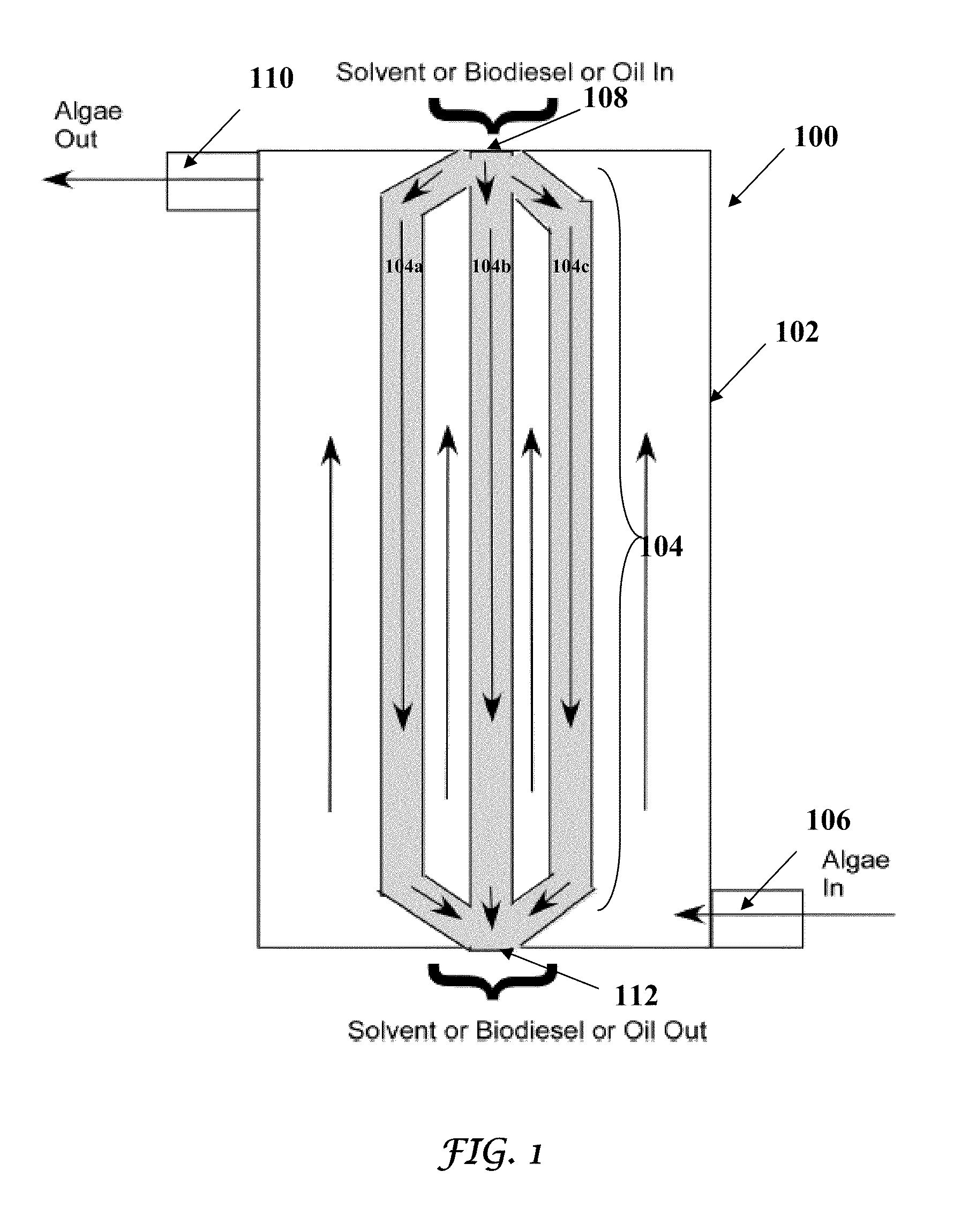

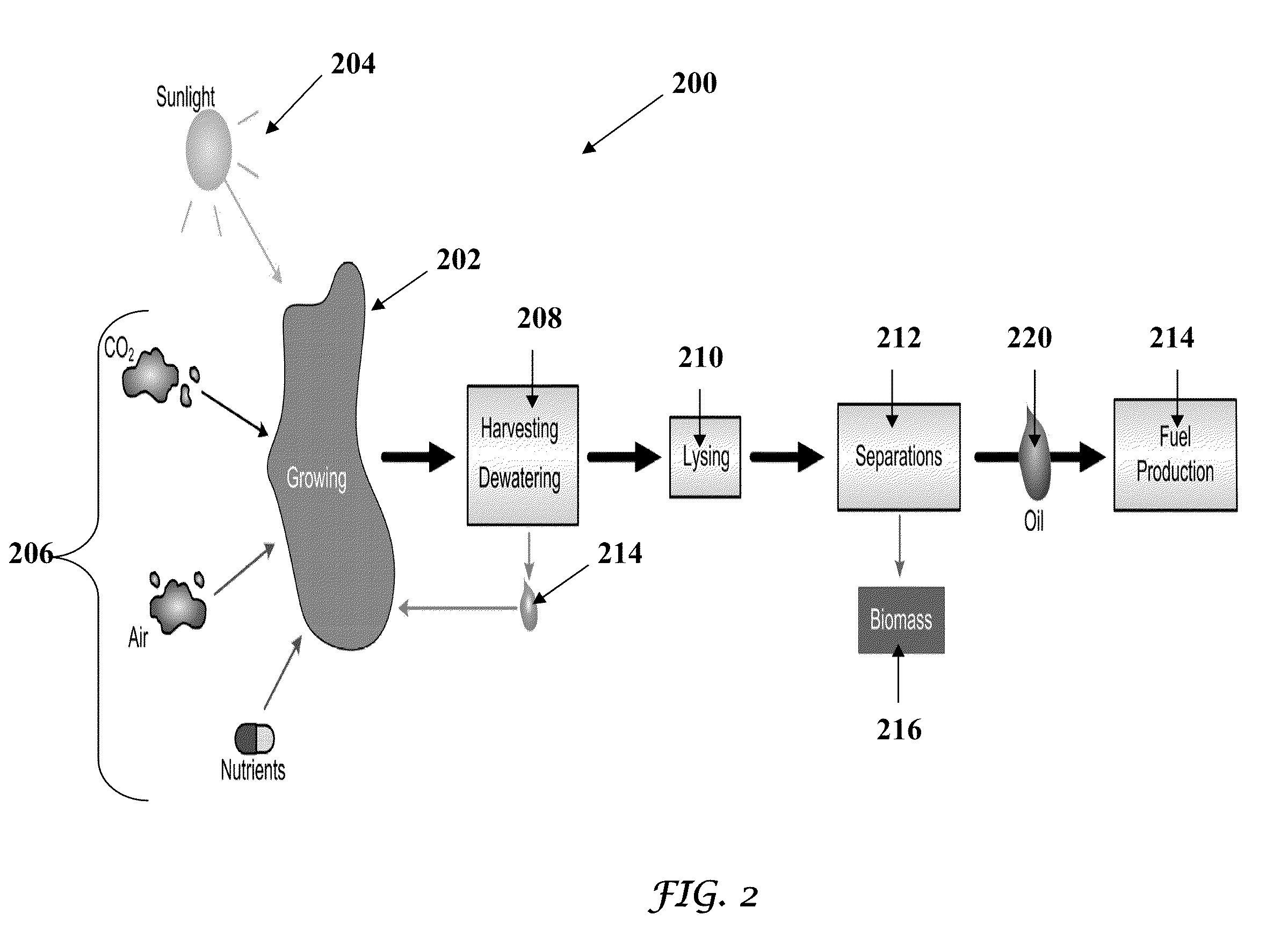

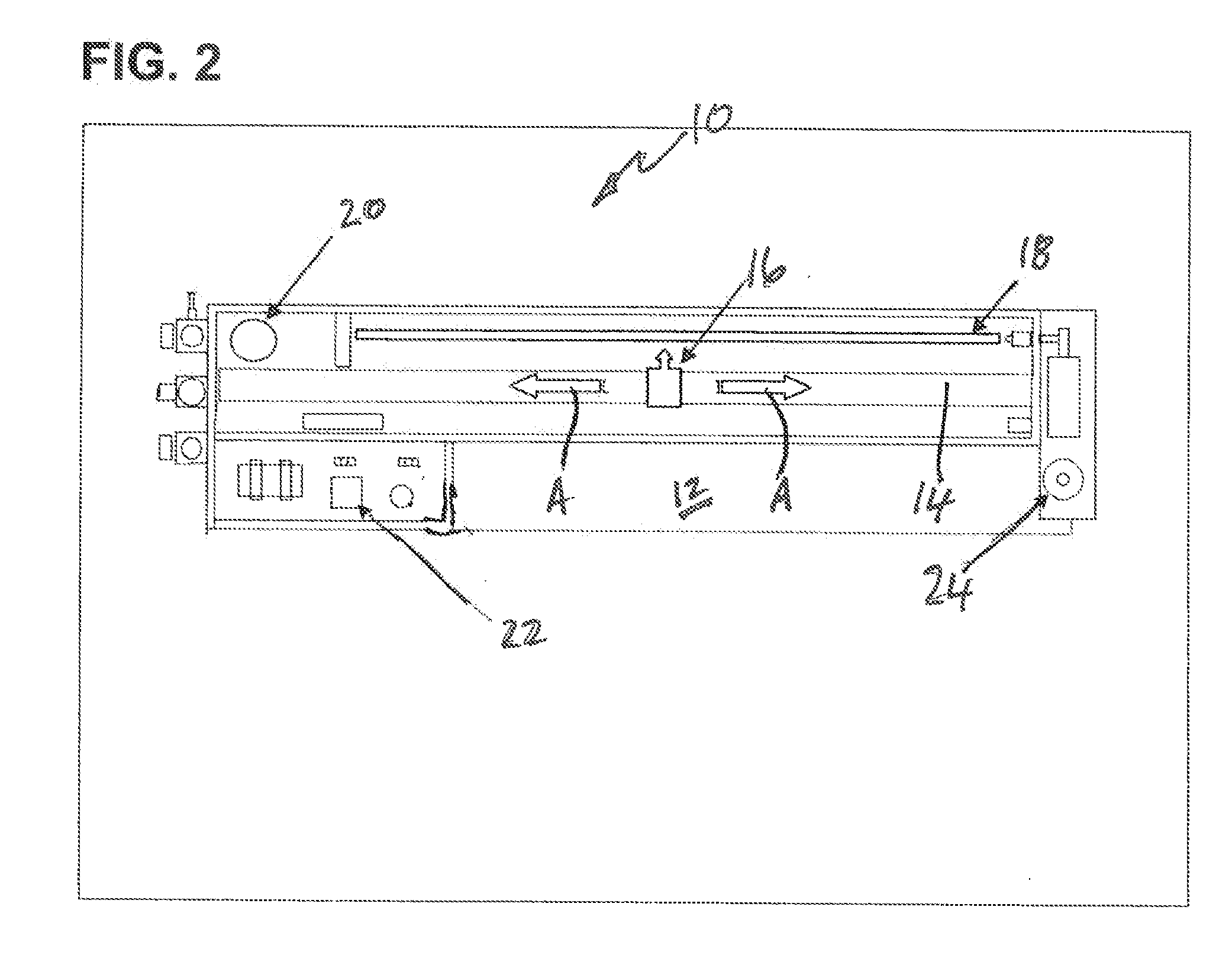

Non-Dispersive Process for Insoluble Oil Recovery From Aqueous Slurries

ActiveUS20110174734A1Efficient separationEliminate the problemFatty acid chemical modificationFatty acids production/refiningBiodieselBeta-Carotene

The development and application of a novel non-polar oil recovery process utilizing a non-dispersive solvent extraction method to coalesce and recover oil from a bio-cellular aqueous slurry is described herein. The process could apply to recovery of algal oil from a lysed algae slurry, recovery of Omega fatty acids from a bio-cellular aqueous feed, recovery of Beta-carotene from a bio-cellular aqueous feed and for the removal from produced water in oil production and similar type applications. The technique of the present invention utilizes a microporous hollow fiber (MHF) membrane contactor. The novel non-polar oil recovery process described herein can be coupled to a collecting fluid (a non-polar solvent such as heptane, a biodiesel mixture or the previously extracted oil) that is circulated through the hollow fiber membrane. In cases where the biodiesel mixture or the previously extracted oil is used the solvent recovery step (e.g. distillation) can be eliminated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

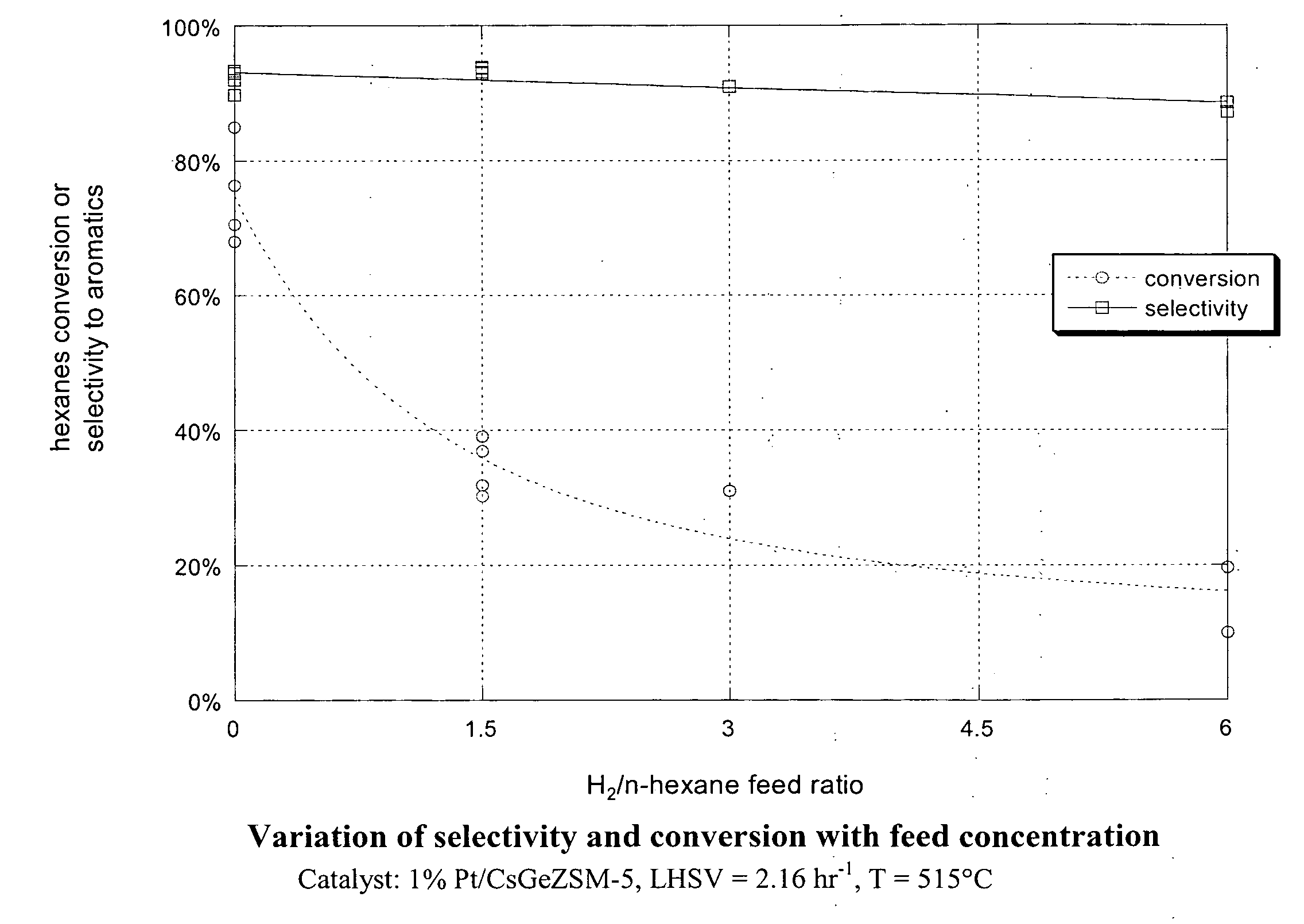

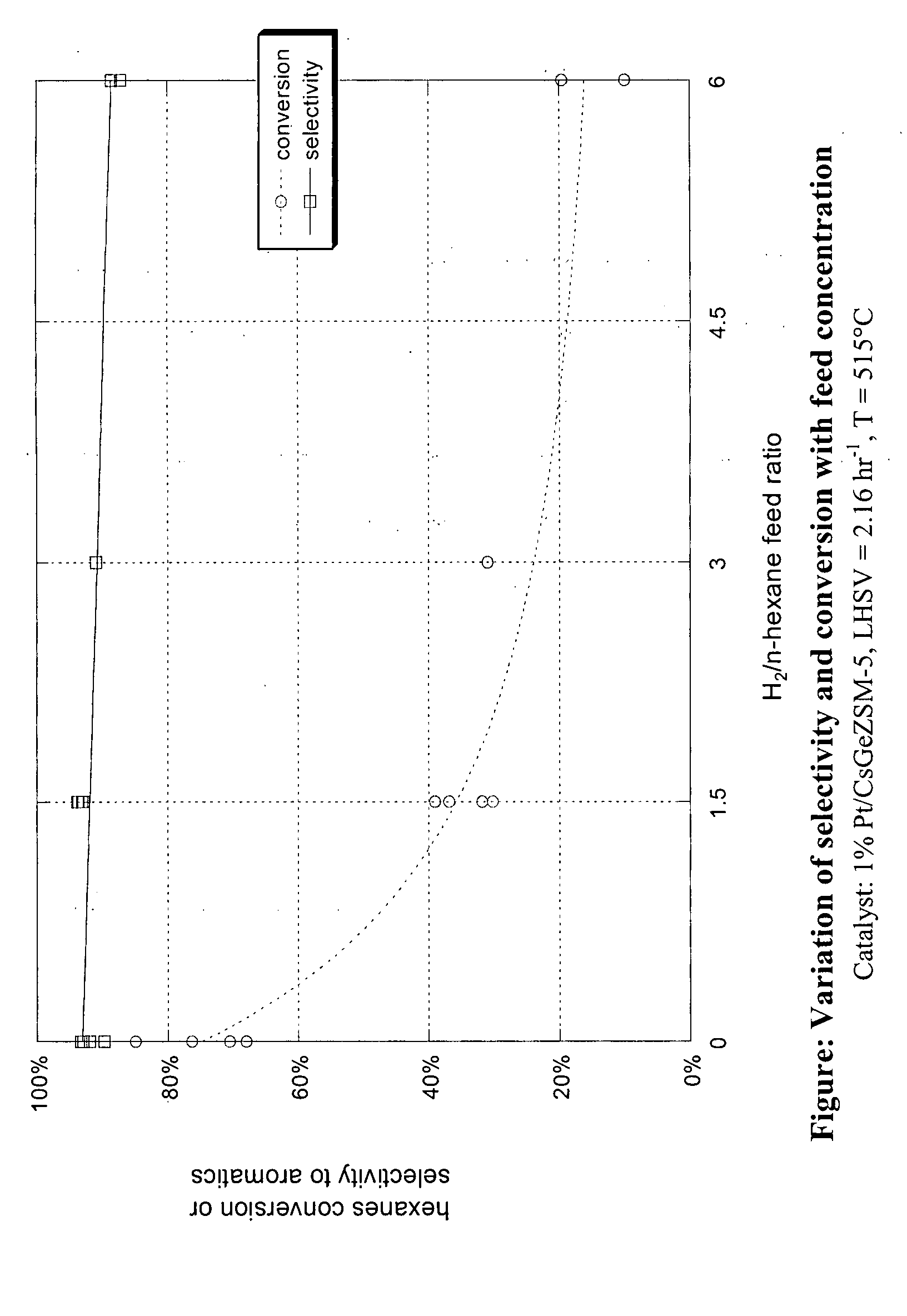

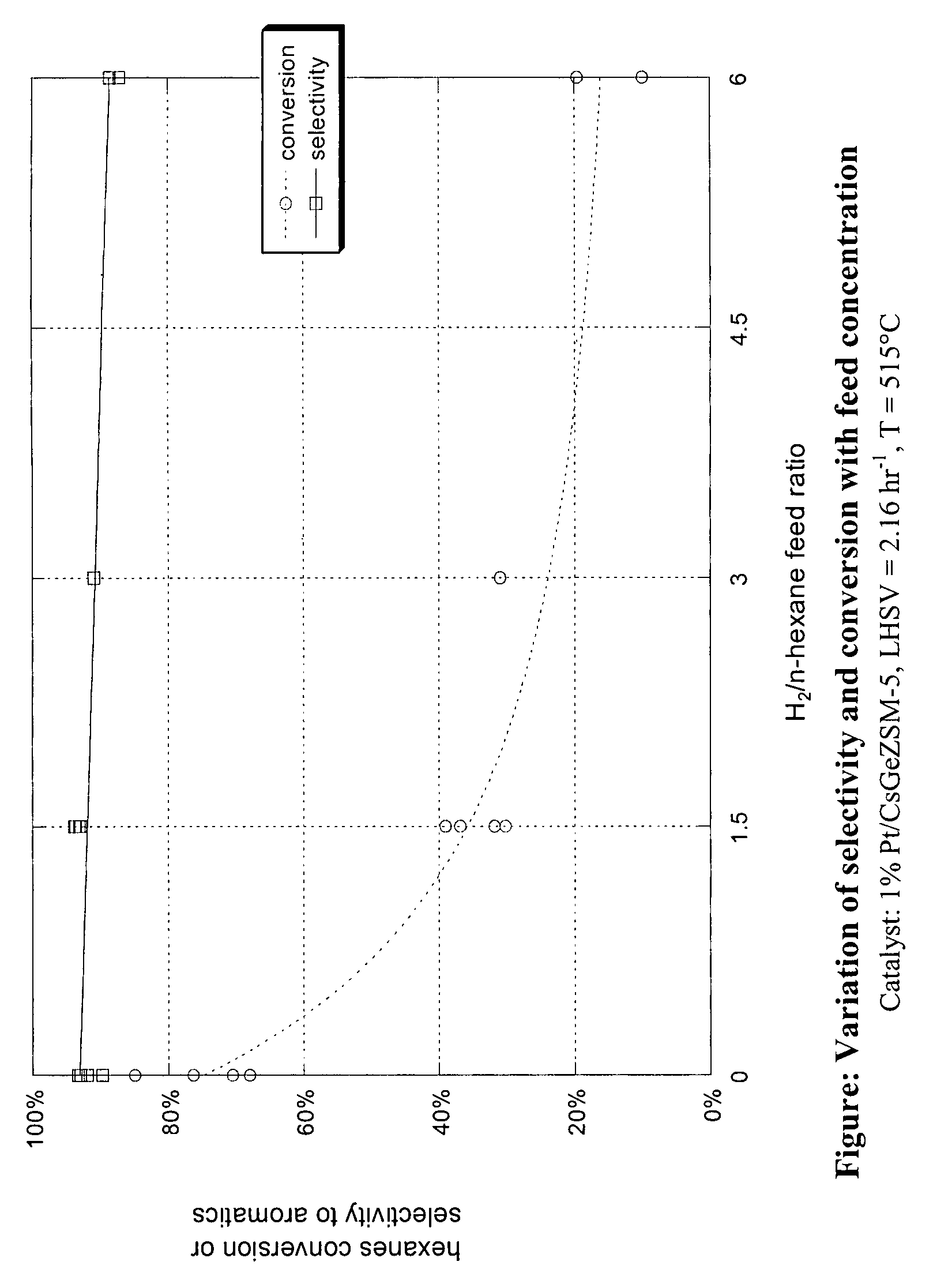

Aromatization of alkanes using a germanium-zeolite catalyst

ActiveUS20080255398A1Molecular sieve catalystsRefining to change hydrocarbon structural skeletonAlkaneAlkaline earth metal

This invention relates to a process for the aromatization of C6 to C12 alkanes, such as hexane, heptane and octane, to aromatics, such as benzene, ethyl benzene, toluene and xylenes, with a germanium-containing zeolite catalyst. The catalyst is a non-acidic aluminum-silicon-germanium zeolite on which a noble metal, such as platinum, has been deposited. The zeolite structure may be of MFI, BEA, MOR, LTL or MTT. The zeolite is made non-acidic by being base-exchanged with an alkali metal or alkaline earth metal, such as cesium, potassium, sodium, rubidium, barium, calcium, magnesium and mixtures thereof, to reduce acidity. The catalyst is sulfur tolerant and may be pretreated with a sulfur compound, i.e., sulfided. The hydrocarbon feed may contain sulfur up to 1000 ppm. The present invention could be applicable to a feedstream which is predominantly paraffinic and / or low in naphthenes. Lowering the hydrogen to hydrocarbon ratio increases conversion and aromatics selectivity.

Owner:SAUDI BASIC IND CORP SA

Method for preparing alkane by high fatty acid ester

InactiveCN101597508ASimple preparation processLow reaction temperatureLiquid hydrocarbon mixture productionHydrocarbonsAlkaneReaction temperature

The invention discloses a method for preparing alkane by high fatty acid ester, which is characterized in that liquid-phase catalytic hydrogenation deoxidation is carried out on the high fatty acid ester to obtain the alkane. The high fatty acid ester, catalyst and solvent are added into a reactor, then hydrogen is charged into the reactor with reaction pressure at 1-10MPa and temperature at 210-320 DEG C, and the reaction time is 4-7h; the high fatty acid ester is fatty acid methyl ester containing 8-22 carbon atoms or fatty acid ethyl ester containing 8-22 carbon atoms; catalyst uses a multi-wall carbon nanotube as carrier and 2-10% of palladium in percentage by weight as active component ; the solvent is one of n-hexane, n-heptane, n-octane, dodecane, or hexadecane. In the invention, the preparation process is simple, the reaction temperature is low, the usage of solvent is less, the combustion high value of the target product is high, and the catalyst can be recycled.

Owner:ZHEJIANG UNIV

PDMS/PVDF complex film for separating organic steam and preparation method thereof

InactiveCN101229487AReduce manufacturing costSimple structureSemi-permeable membranesPolyvinylidene difluorideSolvent

The invention discloses a PDMS / PVDF composite membrane for separating organic vapor which pertains to the technical field of vapor permeation membrane separation and a preparation method thereof. The steps to prepare the composite membrane are that: polyvinylidene fluoride is firstly dissolved in a solvent to prepare a basement membrane and the basement membrane is dried, treated by a surfactant and reserved. Silicone rubber is dissolved in normal heptane to be prepared into a uniform membrane casting solution; then the filtered and defoamed membrane casting solution is coated on the treated basement membrane and PDMS / PVDF composite membrane is obtained after being cured at different temperatures. The PDMS separation layer prepared by the invention is uniformly distributed, compact and sound, and is closely combined with the PVDF. The obtained PDMS / PVDF composite membrane by preparation is applied to separating dimethylmethane / N2 system, the total flux reaches 615*10<6>cm<3>(STP) / (cm<2>s cmHg) and the separation factor is larger than 20.

Owner:中膜科技(苏州)有限公司

Nucleating agent additive compositions and methods

A blend of two different compounds may be applied together to form a nucleating agent additive composition. This additive composition is useful as an additive in thermoplastics, polyolefins and / or polymer resins. A blend of a bicyclo[2.2.1]heptane dicarboxylate salt and a dicarboxylate calcium metal salt provide useful and beneficial physical property effects in molded polymeric articles in terms of shrinkage and crystallization temperature of polymer resin compositions.

Owner:MILLIKEN & CO

Method for preparing super-high molecular weight polyacrylonitrile-base carbon fiber spinning primary fluid

InactiveCN101260172AStir wellImprove heat transfer performanceFibre chemical featuresPolymer scienceNitrogen

Owner:INST OF CHEM CHINESE ACAD OF SCI

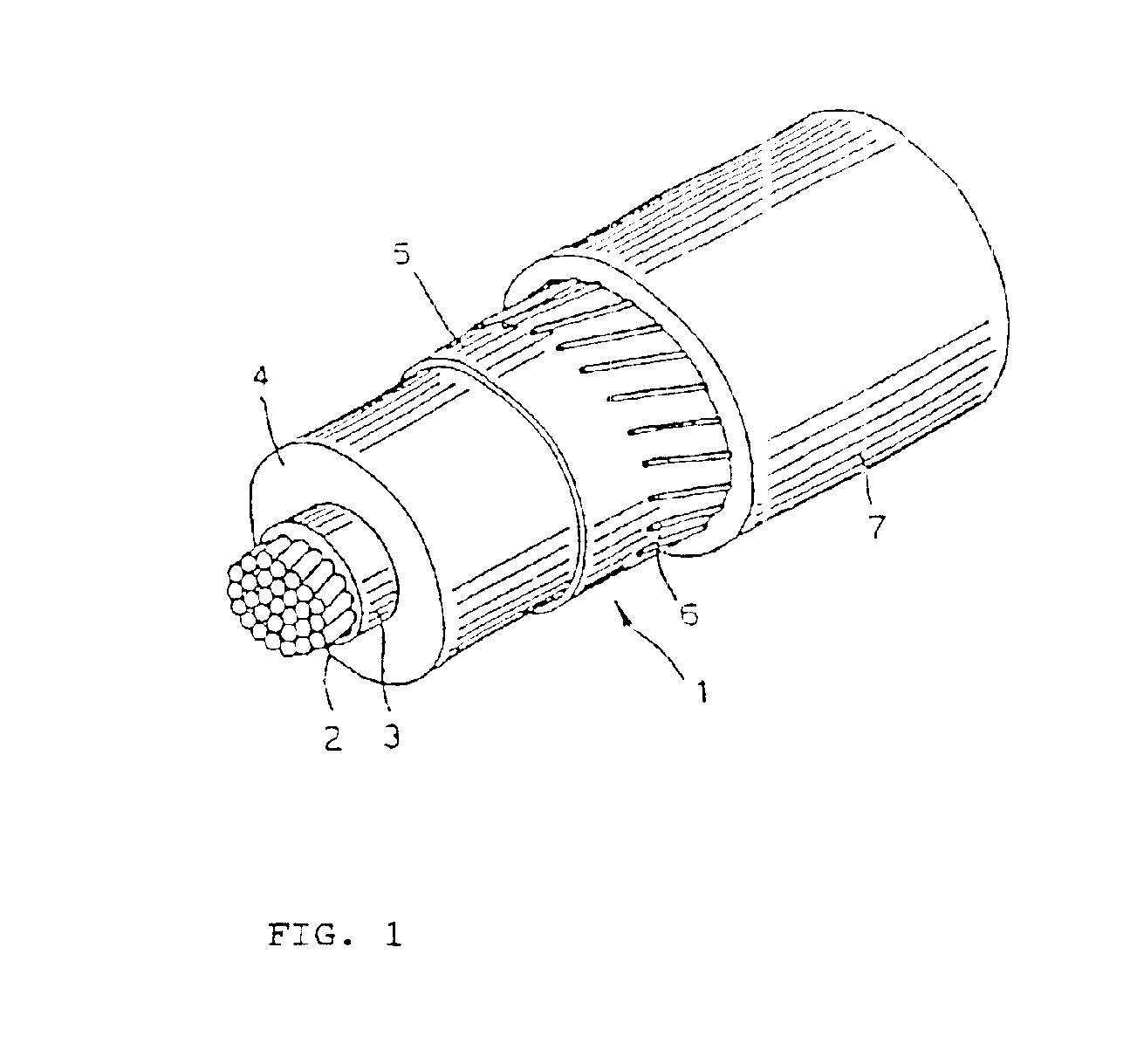

Cable with recyclable covering

InactiveUS6861143B2Improve performanceGood flexibilityPlastic/resin/waxes insulatorsSynthetic resin layered productsElectrical conductorEthylene Homopolymers

A cable includes at least one conductor and at least one covering layer. The at least one covering layer includes a thermoplastic polymer material. The polymer material includes a propylene homopolymer or a copolymer of propylene with an olefin comonomer. The olefin comonomer is ethylene, one or more α-olefins other than propylene, or ethylene and one or more α-olefins other than propylene. The homopolymer or copolymer has a melting point between 140° C. and 165° C., a melting enthalpy between 30 J / g and 80 J / g, a boiling diethyl ether soluble fraction less than or equal to 12 wt % and melting enthalpy less than or equal to 4 J / g, a boiling n-heptane soluble fraction between 15 wt % and 60 wt % and melting enthalpy between 10 J / g and 40 J / g, and a boiling n-heptane insoluble fraction between 40 wt % and 8 wt % and melting enthalpy greater than or equal to 45 J / g.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA +1

Aromatization of alkanes using a germanium-zeolite catalyst

ActiveUS7902413B2Molecular sieve catalystsRefining to change hydrocarbon structural skeletonAlkaneAlkaline earth metal

Owner:SAUDI BASIC IND CORP SA

Hexatomic-ring alkylsiloxane-phosphate natural gas pipeline corrosion-inhibition drag reducer and preparation method thereof

The invention relates to a hexatomic-ring alkylsiloxane-phosphate natural gas pipeline corrosion-inhibition drag reducer and a preparation method thereof. The preparation method comprises the following steps: reacting raw materials phosphorus pentoxide and long-chain alkyl alcohol in a mol ratio of 2:1-4:1 to generate the product mainly comprising long-chain monoalkyl phosphate (MAP); reacting long-chain alkylmethyl dimethoxysilane and the MAP product in a mol ratio of 2:1-2.5:1 to generate an alkylsiloxane-phosphate product mixture, wherein the content of the hexatomic-ring long alkylsiloxane-phosphate is 80-85 wt.%, and the content of the linear alkylsiloxane-phosphate is 15-20 wt.%; and dissolving the obtained alkylsiloxane-phosphate product mixture in n-heptane to form a 30-50 wt.% solution, thereby obtaining the hexatomic-ring alkylsiloxane-phosphate natural gas pipeline corrosion-inhibition drag reducer. The invention has the advantages of high corrosion inhibition efficiency, high drag reduction rate and long effective period.

Owner:PIPECHINA SOUTH CHINA CO

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

InactiveUS6863976B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingYarnThermoplastic

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the “rigidifying” nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred “rigidifying” compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2′-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

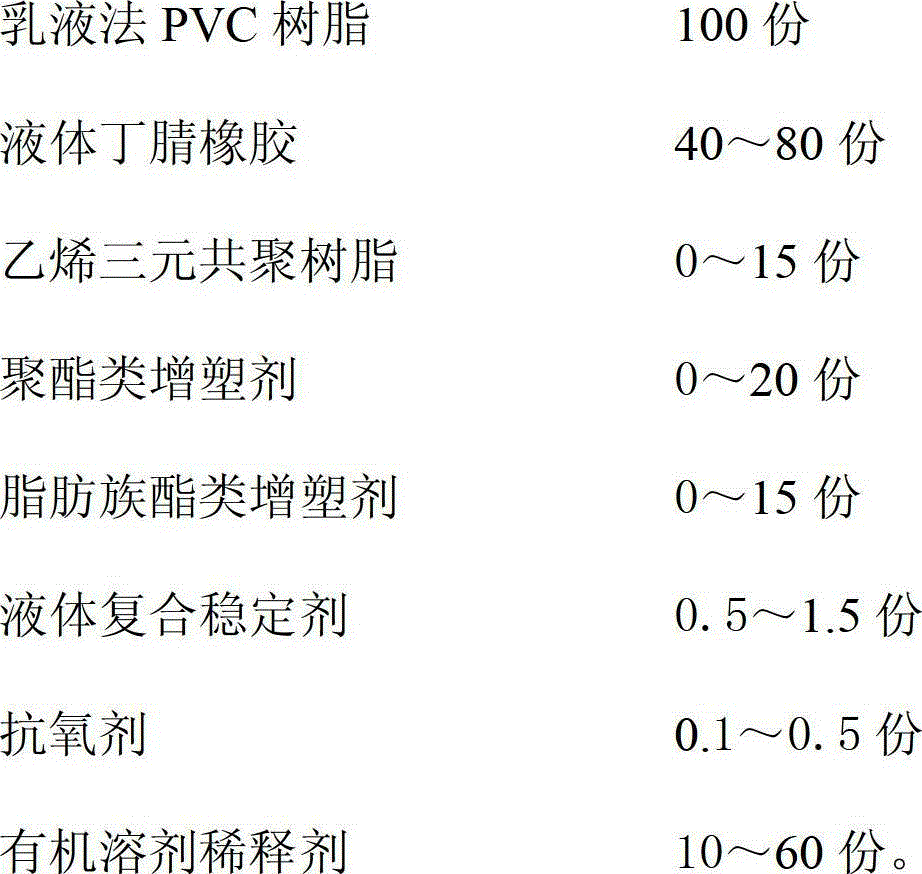

Food grade plasticizing polrvinyl chloride (PVC) glove and preparation method thereof

ActiveCN102875921AImprove processing stabilityMeet the use requirementsFlexible coversWrappersPolyesterAntioxidant

The invention discloses a food grade plasticizing polrvinyl chloride (PVC) glove and belongs to an environment-friendly food grade plasticizing PVC glove. The glove does not contain lead, cadmium and other toxic stabilizers, and phthalic acid ester plasticizer, has the advantages of high elasticity, high intensity and extremely low content of evaporation residues of n-heptane soluble substances, and can be used for the common food packaging industry, in particular contact fat type food industry with the high requirement, so that the application range of the food grade plasticizing PVC glove can be greatly widened. The food grade plasticizing PVC glove is prepared from the following raw materials in part by mass: 100 parts of emulsion method PVC resin, 40 to 80 parts of nitrile rubber liquid, 0 to 15 parts of vinyl terpolymer resin, 0 to 20 parts of polyester type plasticizer, 0 to 15 parts of aliphatic ester type plasticizer, 0.5 to 1.5 parts of compound stabilizer liquid, 0.1 to 0.5 part of antioxidant and 10 to 60 parts of organic solvent diluent.

Owner:NANJING UNIV OF TECH +1

Azeotropic compositions comprising methyl perfluoropentene ethers for cleaning applications

The present disclosure provides azeotropic and azeotrope-like compositions comprised of methylperfluoropentene ethers and at least one of methanol, ethanol, 2-propanol, hexane, heptane, trans-1,2-dichloroethylene, ethyl formate, methyl formate, HFE-7100, HFE-7200 and 1-bromopropane or combinations thereof. The present disclosure also provides for methods of use for the azeotropic and azeotrope-like compositions.

Owner:EI DU PONT DE NEMOURS & CO

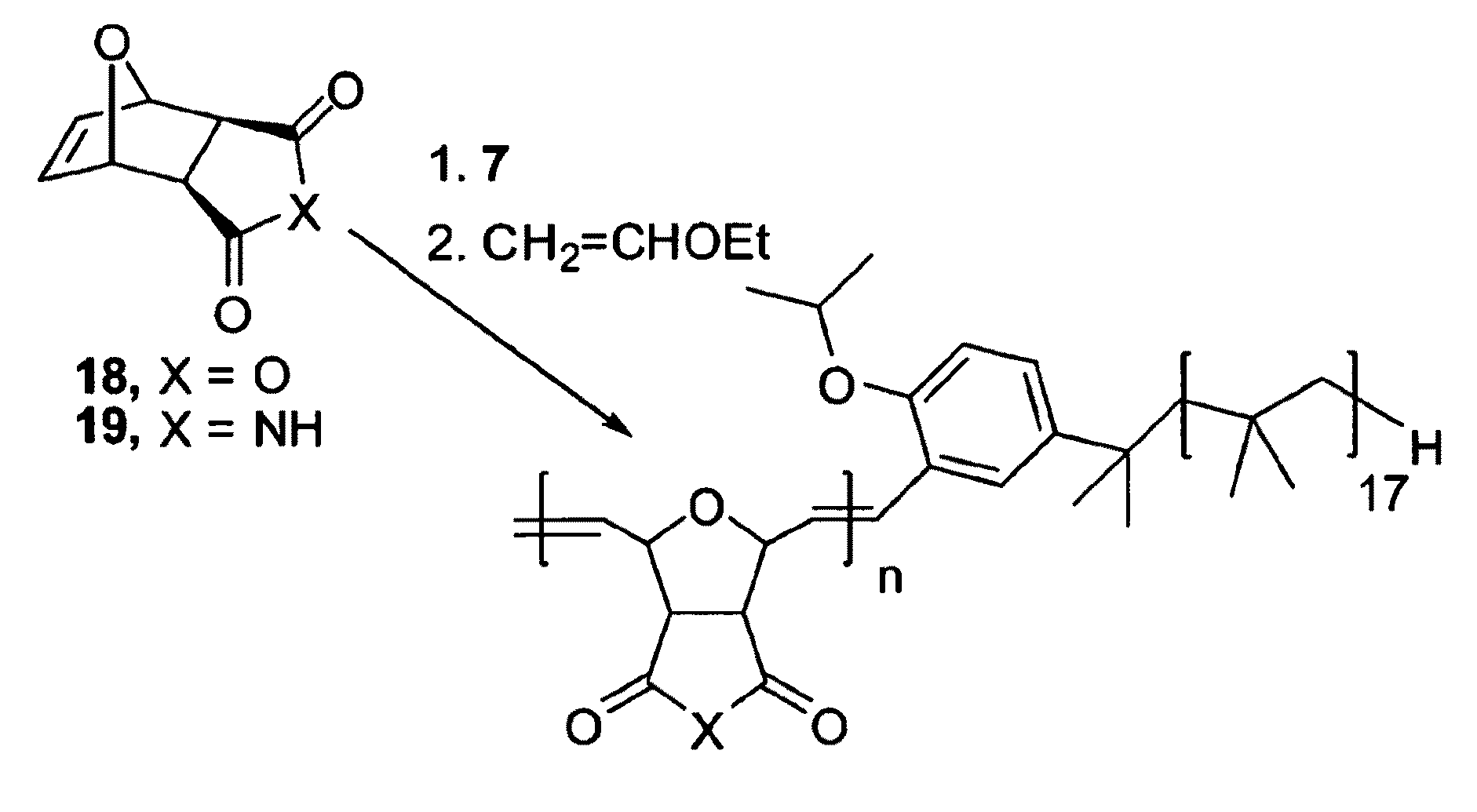

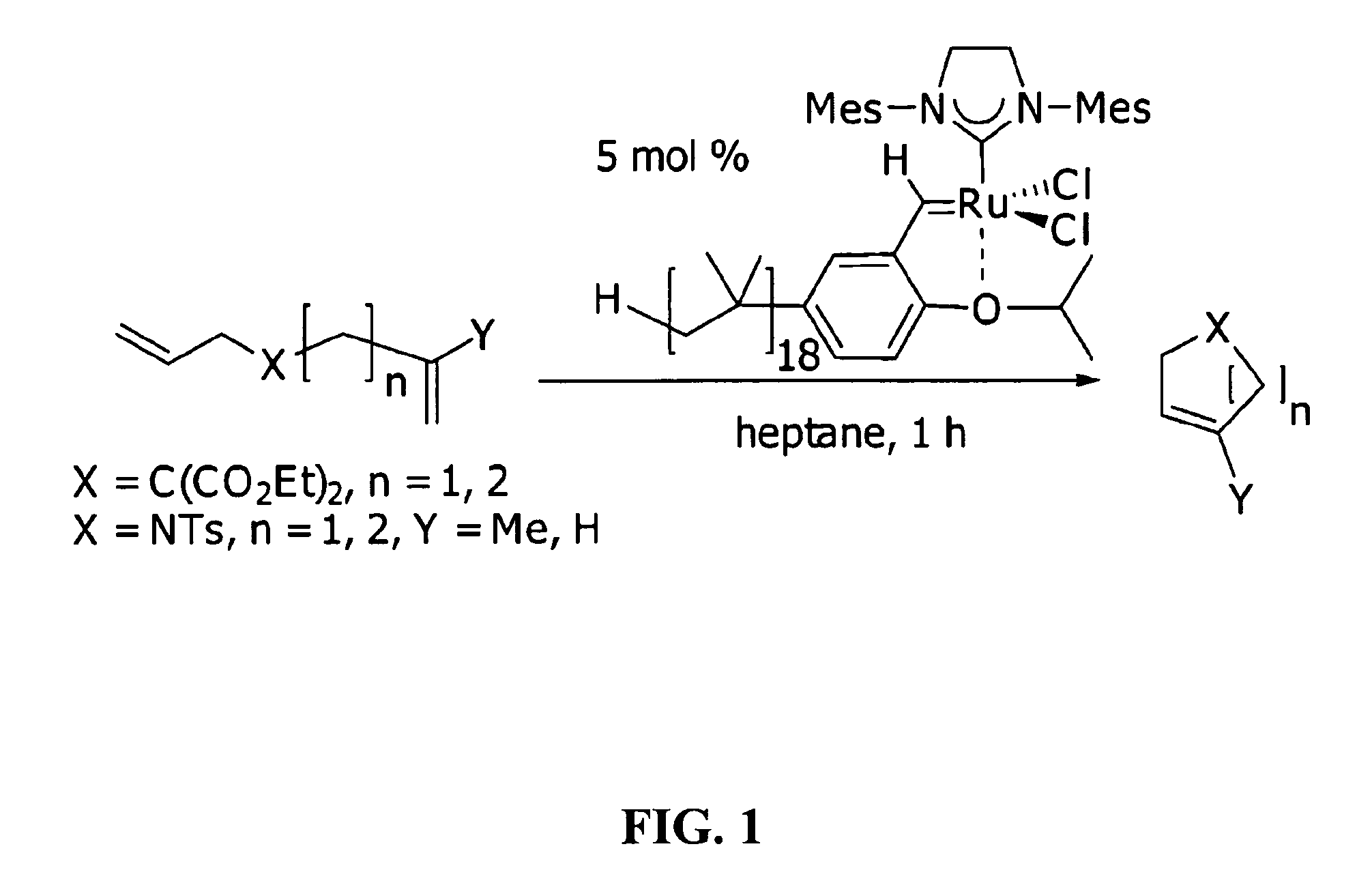

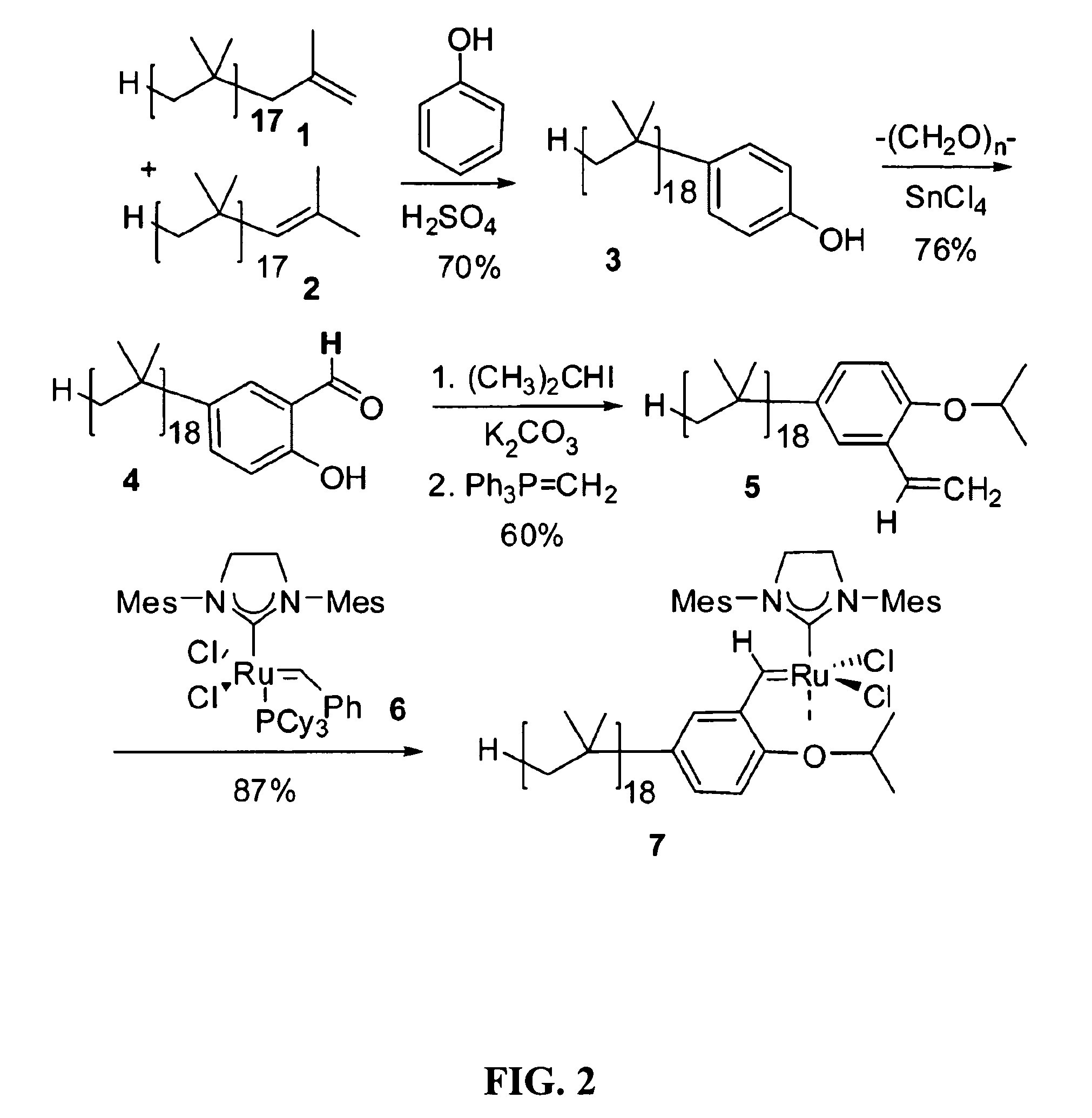

Nonpolar phase-soluble methathesis catalysts

InactiveUS20090203860A1Less solubleLittle and solubilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolubilityOligomer

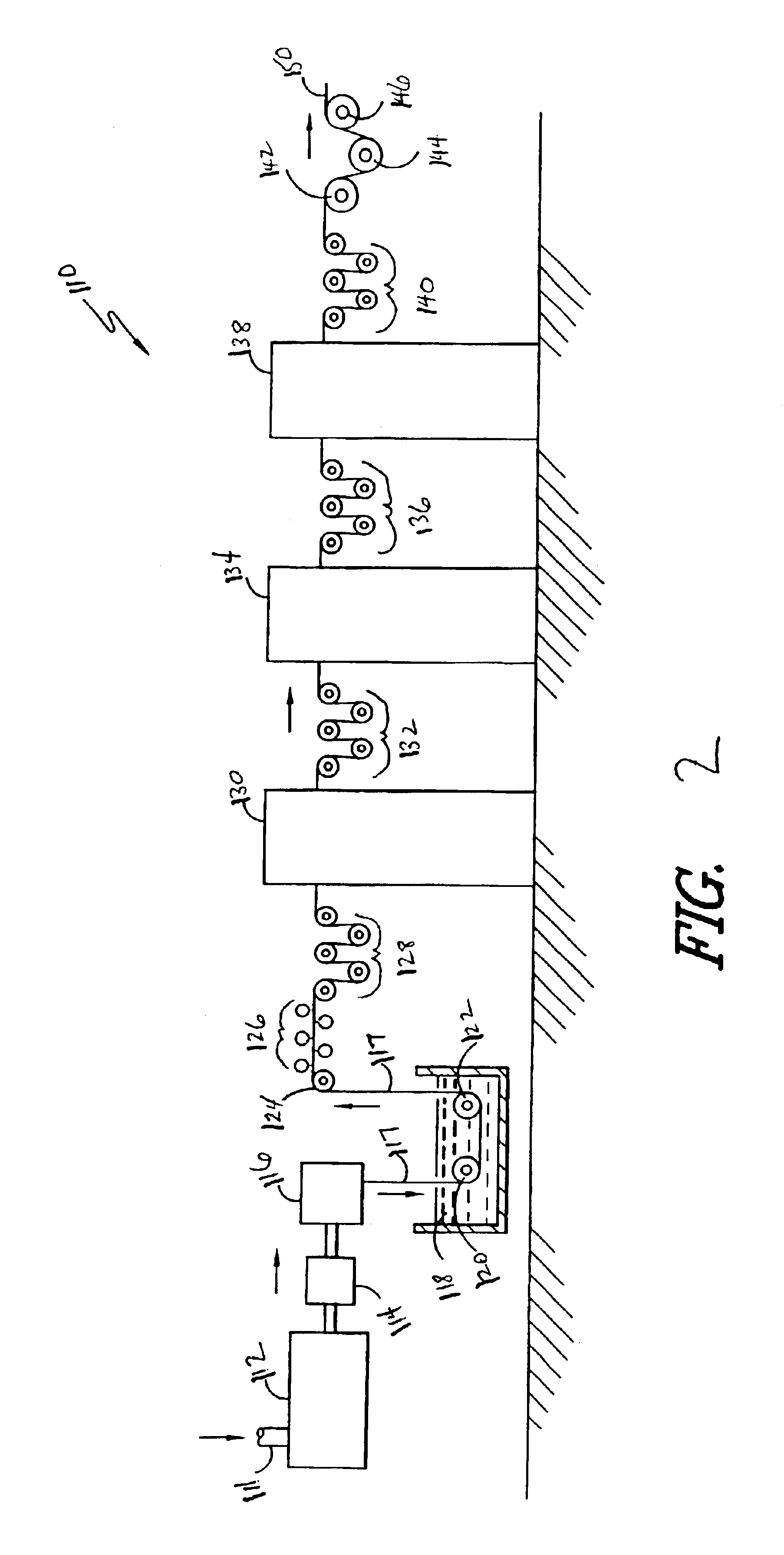

One embodiment of the invention provides polyisobutylene (PIB) oligomers that are end-functionalized with ruthenium (Ru) catalysts. Such nonpolar catalysts can be dissolved in nonpolar solvents such as heptane, or any other nonpolar solvent that is otherwise not latently biphasic (i.e., if two or more solvent components are present, they remain miscible with each other throughout the entire reaction process, from the addition of substrate through to the removal of product). Substrate that is dissolved in the nonpolar solvent with the catalyst is converted into product. The lower solubility of the product in the nonpolar solvent renders it easily removable, either by extraction with a more polar solvent or by applying physical means in cases where the product precipitates from the nonpolar solvent. In this manner the catalysts are recycled; since the catalysts remain in the nonpolar solvent, a new reaction can be initiated simply by dissolving fresh substrate into the nonpolar solvent.

Owner:TEXAS A&M UNIVERSITY

Method for preparing micron SiO2 gas gel small ball

The present invention relates to the process of preparing micron level SiO2 aerogel ball as the stuffing of chromatographic column for separating biological macromolecule. The process includes the following steps: preparing alcohol sol of SiO2 via mixing silicon gel and nitric acid in the volume ratio of 1 to 0.5-20, and adding anhydrous ethanol; mixing n-heptane, span-80, Tween-85 and n-butanol in certain volume proportion through stirring to obtain oil phase; adding the sol of SiO2 into the oil phase in certain volume ratio to form W / O emulsion; stirring, adding concentrated ammonia water to alkaline for depositing gel, further stirring, and liquid-solid separation to obtain SiO2 gel microballoon; washing with acetone and drying to obtain micron level SiO2 aerogel ball. The process has normal pressure, easy control, low cost, and other advantages.

Owner:TONGJI UNIV

Povidone-iodine antibacterial material and its production

ActiveCN101073325AWith embedding effectImprove antibacterial durabilityBiocideLavatory sanitoryFreeze-dryingDistillation

The invention is concerned with the preparation method for new povidone iodine anit-bacterium dressing that uses the carboxymethyl chitosan to fix. The graft of the carboxymethyl chitosan (Polyacrylates - copolymer - N - vinylpyrrolidone) dissolves in water and processes complexation with iodine, reduces pressure and distillation to wipe off the solvent and part of un-reactive iodine, uses normal heptanes to marinate and wash the produce in order to wipe off the un-reactive iodine, processes freeze drying and crushing to get the new povidone iodine anit-bacterium dressing that uses the carboxymethyl chitosan to fix: t he graft of the carboxymethyl chitosan (Polyacrylates - copolymer - N - vinylpyrrolidone).

Owner:陈煜 +1

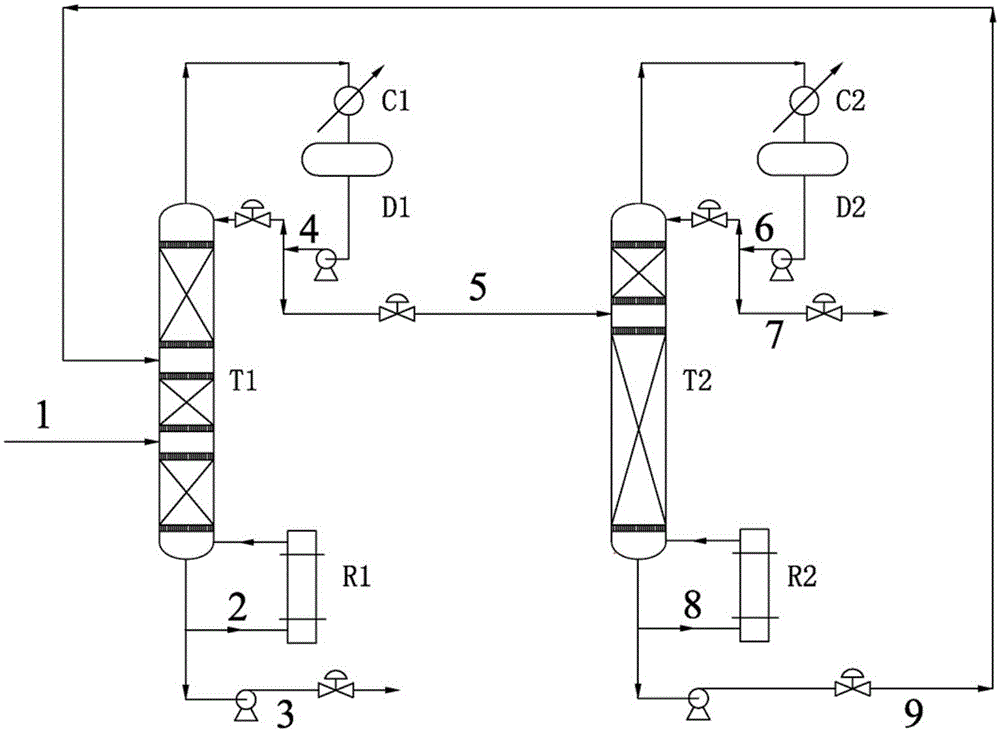

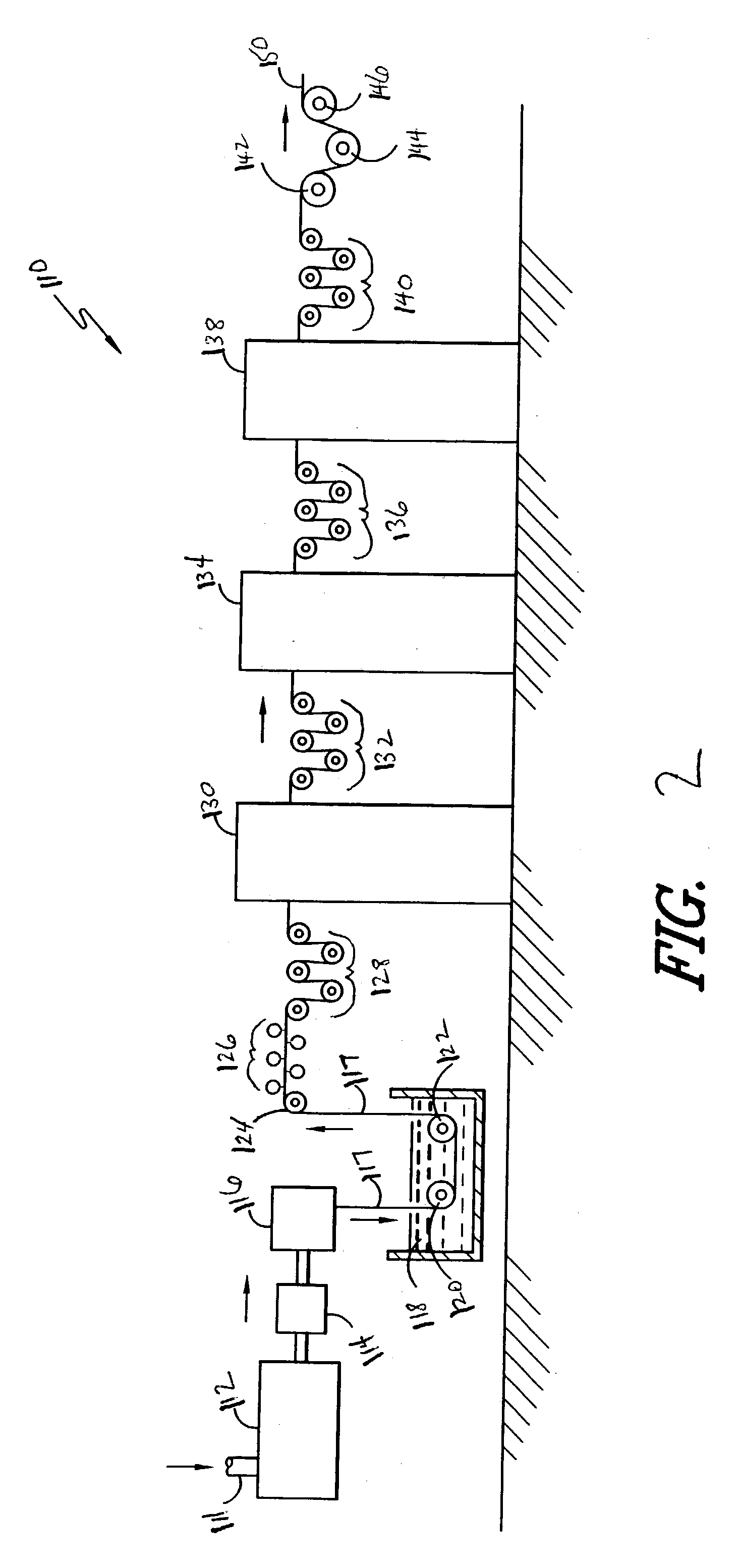

Method for separating isobutyl alcohol and normal heptanes azeotropic system by using pressure swing distillation

ActiveCN105001056AHigh purityLow investment costOrganic compound preparationChemical industryIsobutyl alcoholReboiler

The invention relates to a method for separating an isobutyl alcohol and normal heptanes azeotropic system by using pressure swing distillation and a device applicable to the method. The device mainly comprises an atmospheric tower T1, a pressurized tower T2, a condenser C1, a condenser C2, a reflux drum D1, a reflux drum D2, a reboiler R1 and a reboiler R2, wherein the reboiler R1 and the reboiler R2 are respectively connected at the bottoms of the atmospheric tower T1 and the pressurized tower T2, the condenser C1 and the reflux drum D1 are sequentially connected at the top of the atmospheric tower T1, the condenser C2 and the reflux drum D2 are sequentially connected at the top of the pressurized tower T2. The separation steps are as follows: a fresh material first enters into the atmospheric tower T1, an isobutyl alcohol product is extracted at the bottom of the tower, after being condensed through the condenser C1, and collected through the reflux drum D1, part of overhead vapor is back flowed, part of the extract enters into the pressurized tower T2 for a secondary rectification, a normal heptanes product is extracted at the top of the pressurized tower T2, and the material flow at the bottom of the tower cycles to the atmospheric tower T1. The method provided by the invention solves the difficult separation problem that the azeotropic behaviors of the system respectively show up a lowest feature and a highest feature along with the raising pressure, and has the advantages of low energy consumption and high product recovery rate.

Owner:QINGDAO UNIV OF SCI & TECH

Chemically modified hyaluronic acid or salts thereof, and a process for producing thereof

InactiveUS6673919B2Reduce weightHigh viscositySugar derivativesSugar derivatives preparationChlorideChloroform

This invention relates to a chemically modified hyaluronic acid and salts thereof, which are obtained by O-acylating, alkoxylating or crosslinking a complex consisting of hyaluronic acid or a salt thereof and a cationic compound in a nonaqueous solvent, and a process for the production thereof. The nonaqueous solvent used in the invention is preferably one or more solvents selected from the group consisting of chloroform, toluene, methylene chloride and heptane.

Owner:JNC CORP +1

Organic and inorganic composite hydrophobic film and its preparing process

ActiveCN1724127AEasy to prepareThe requirements for inorganic support are not highSemi-permeable membranesAlcoholAqueous solution

A composite organic-inorganic hydrophobic membrane for separating alcohol or other organic substances from aqueous solution is composed of inorganic ceramic substrate and organic polydimethyl siloxane layer. Its preparing process includes such steps as dissolving polydimethl siloxane in n-heptane, adding ethy / silicate, ultrasonic dispersing, dripping tin dibutyl bilaurate in it, stirring, de-foaming, coating it one said substrate, solidifying while cross linking, thermal drying, immersing in acetone for 30 min, and thermal drying.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

Method of extracting rare earth from apatite

InactiveCN1514029AImprove stabilityHigh extraction rateRare earth metal compoundsProcess efficiency improvementApatiteKerosene

A process for extracting RE from the RE contained phosphorite is disclosed, which features that its immersing liquid is nitric acid, its salting-out agent is ammonium (or sodium) nitrate, its extractant is dimethylheptyl methylphosphonate (P350) or 2-ethylhexyl phosphonate-bis(2-ethylhexyl) ester (P502), its diluent is n-heptane or kerosene, its washing liquid is the solution of sodium (or ammonium) nitrate, its backextractant is the solution of nitric acid or hydrochloric acid, and its preciptant is oxalic acid. Its advantage is high purity (more than 95%) and high output rate (more than 98%) of RE.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

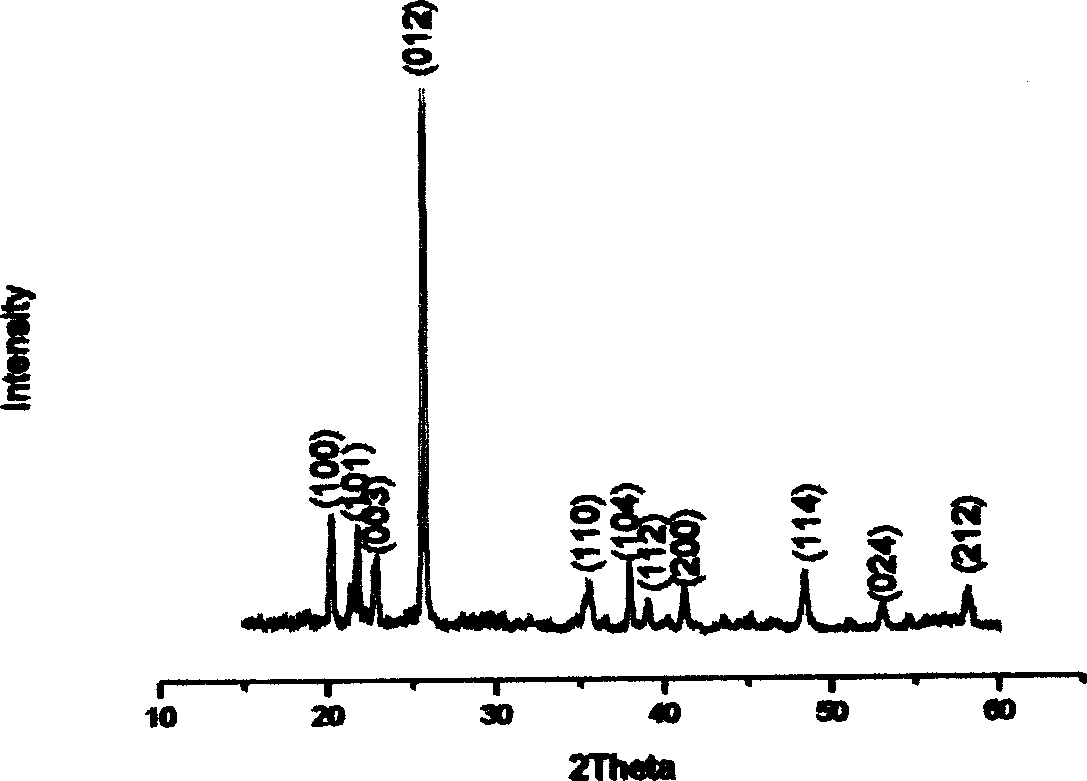

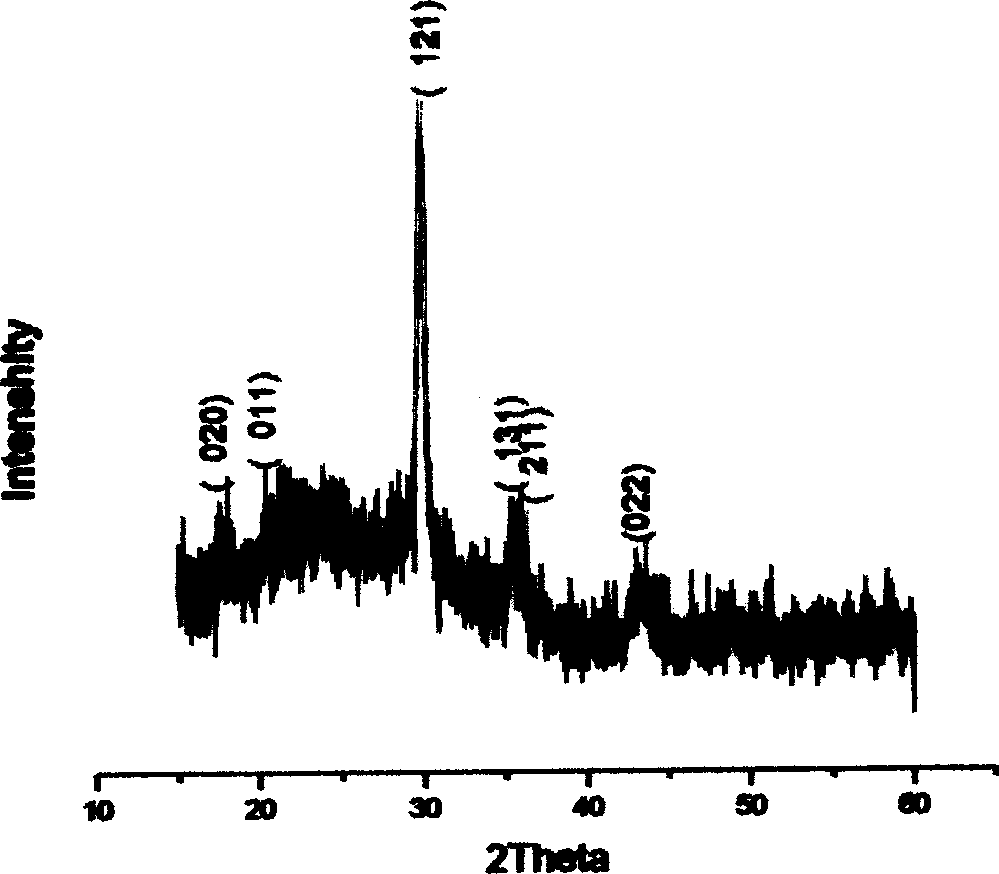

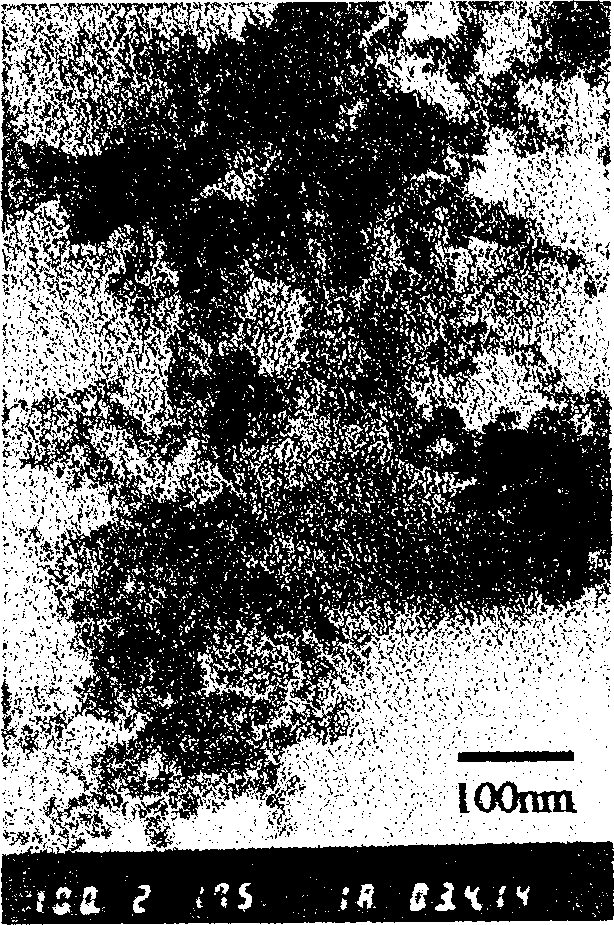

Reversed phase lithium inserting process of preparing polycrystal LiFePO4 nano powder material

InactiveCN1469499APromote generationNo precipitation reactionAlkaline accumulatorsActive material electrodesN-ButanolNanoscopic scale

The present invention is reversed phase lithium inserting process of preparing polycrystal nano LiFePO4 powder material. Mixed surfactant ST of Span-80 and Tween-80 is added slowly into n-heptane, and mixed water solution of FeCl3 and glacial acetic acid and n-butanol are added to reversed phase microemulsion of FeCl3; the mixed solution of NH4H2PO4 and anhydrous glacial acetic acid and the microreactor of the microemulsion is utilized to prepare deposited nano size FePO4 grains; and LiI is inserted to obtain nano LiFePO4 powder finally. The present invention has the advantages of low synthesis temperature, and small size, great specific surface area and high activity of the synthesized material. The LiFePO4 powder material is suitable for use in producing lithium ion cell.

Owner:TSINGHUA UNIV

Method of preparing exo-dicyclopentadiene from endo-dicyclopentadiene or cyclopentadiene

InactiveCN1907927ALiquid phase reaction conditions are mildHigh yieldHydrocarbon by isomerisationBENZYL ALCOHOL/WATERHeptane

The invention discloses a preparation method for exo-dicyclopentadiene from bridge-type dicyclopentadiene or cyclopentadiene, belonging to the exo-dicyclopentadiene preparation technology. The method includes preparing a solution composed of bridge-type dicyclopentadiene or cyclopentadiene, and benzene, or toluene, or benzyl alcohol, or decalin, or cyclohexane, or heptane, or hexane at a certain quality ratio, adding p-tert-butylcatechol, or 2, 5-di-tert-butylhydroquinone, or 2,6-di-tertbutyl-4-methylphenol, or hydroquinone, or 2-methyl-1,4-dihydroxybenzene, or o-hydroquinone inhibitor and carrying out reaction at a certain temperature and pressure, distilling and separating to obtain the exo-dicyclopentadiene. The invention has the advantages of one-step synthesis without catalyst, mild reaction conditions and high yield, and is suitable for industrial production.

Owner:TIANJIN UNIV

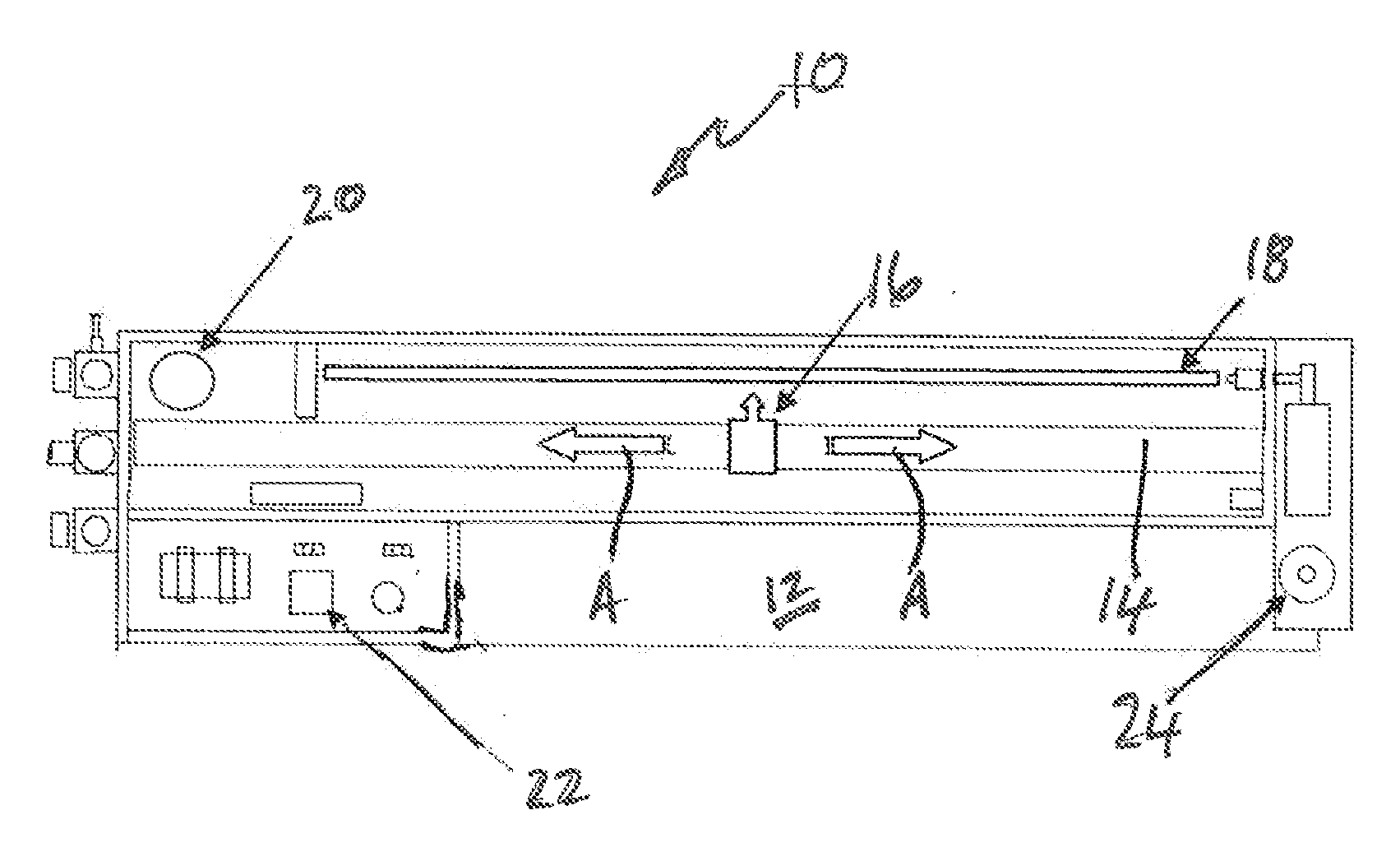

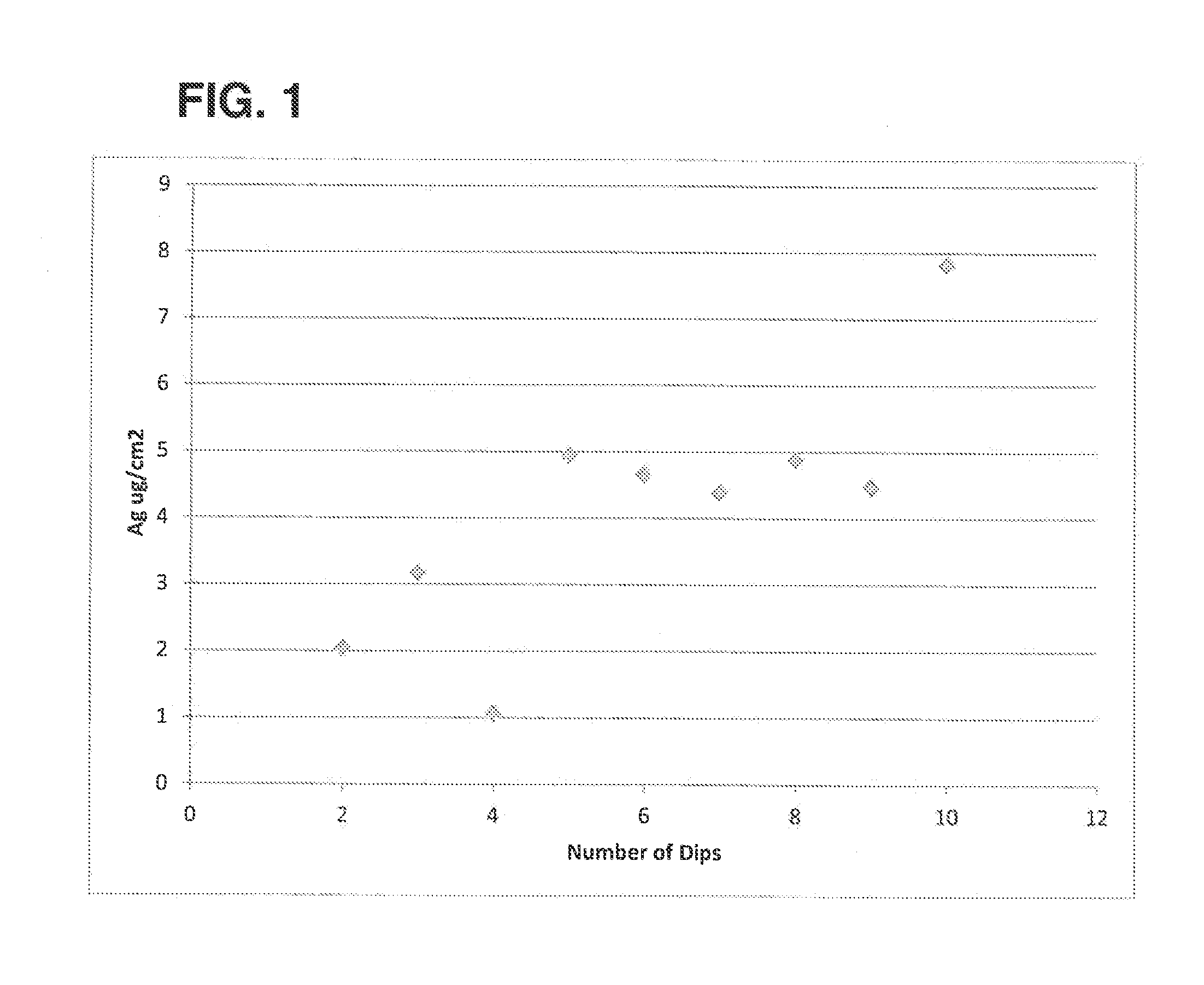

Method of Selectively Applying an Antimicrobial Coating to a Medical Device or Device Material

A process for depositing nanoparticles on a surface. The process includes the steps of: providing a sol including a volatile non-aqueous liquid and nanoparticles suspended in the non-aqueous liquid; processing the sol to form a plurality of droplets; depositing the plurality of droplets on a surface; and evaporating the non-aqueous liquid from the surface leaving a residue of nanoparticles. The liquid can be selected from heptane, chloroform toluene, and hexane and mixtures thereof and the nanoparticles are desirably silver nanoparticles. The plurality of droplets may be formed by a spray process. The surface may be selected from a particular area, region, portion, or dimension of a medical device, device material, packaging material or combinations thereof. The residue of nanoparticles desirably provides antimicrobial properties.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Bacillus adhaerens and its use in preparing health food having thrombolysis property

InactiveCN1464046AHigh activityStrong thrombolytic effectBacteriaBacteria material medical ingredientsAcid-fastSolubility

Bacilliis natto NLSSc with the preservation number CGMCC No. 0724 is Gram staining positive, non-acid fast, straight or near straight, (0.6-0.8)x(1.5-2.0) micron sized and aerobic; has mesial and un-swelled spore with the spore number inside one sporange cell not more than one, meso diamino heptane diacid and glycin contained in the cell wall, no characteristic saccharum and peripheral flagellum; and can be grown well in five kinds of natural organic culture medium and can form relatively thick mycoderm and butter fat colored colony with smooth edge in soybean cake powder culture medium. Bacilliis natto can be cultured in culture medium with nitrogen source to obtain thrombus dissolving matter natto kinase and the cultured matter may be extracted to obtain powdered matter as the additive for thrombolytic health food.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Residual solvent extraction method and microparticles produced thereby

InactiveUS20060099271A1Decrease in levelReduce residue levelsOrganic active ingredientsPowder deliveryMicroparticleHeptane

Methods for preparing microparticles having reduced residual solvent levels. Microparticles are contacted with a non-aqueous washing system to reduce the level of residual solvent in the microparticles. Preferred non-aqueous washing systems include 100% ethanol and a blend of ethanol and heptane. A solvent blend of a hardening solvent and a washing solvent can be used to harden and wash microparticles in a single step, thereby eliminating the need for a post-hardening wash step.

Owner:ALKERMES PHARMA IRELAND LTD

Aluminum electroplating solution

InactiveUS20130168258A1Accelerated precipitationImprove film thickness uniformitySolubilityAluminum metal

Owner:HITACHI LTD

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com