Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2805results about How to "Improve processing stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

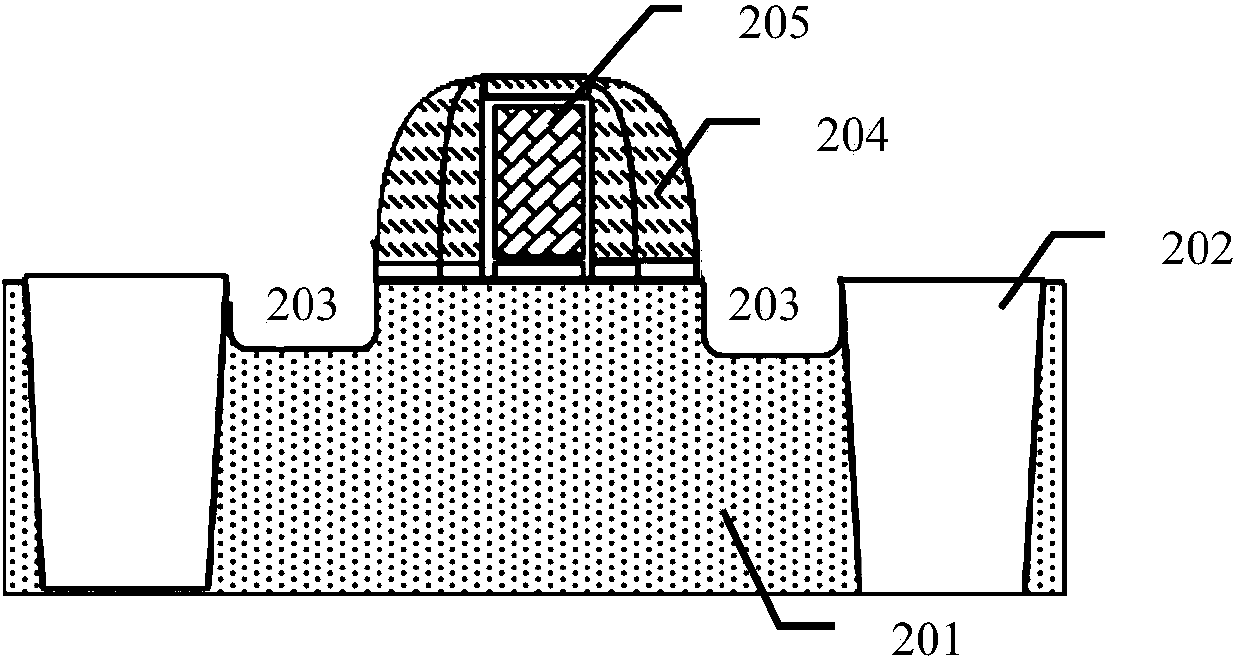

SiGe (silicon germanium) source and drain area manufacturing method

ActiveCN104201108AReduce thicknessAvoid stress relaxationSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationEngineering

The invention discloses a SiGe (silicon germanium) source and drain area manufacturing method. A multi-layer structure which comprises alternately stacked buffer layers and main body layers is formed by a method that the SiGe epitaxial growth of the buffer layer and the main body layers is alternated repeatedly and accordingly the thickness of every high Ge concentration of SiGe main body layer is effectively reduced and shared into every layer of main body layer and accordingly the stress relaxation due to the fact that thickness of every main body layer exceeds the critical thickness is avoided; the Ge content of every layer of SiGe main body layer is further improved to enable the stress of the SiGe source leakage on a channel to be increased; an SiGe process window is enlarged due to the repeated epitaxy and accordingly the process stability is enhanced and accordingly the device performance is improved; the stress can be effectively improved without increase of the process difficulty and accordingly the process is stable and controllable and the cost is low.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

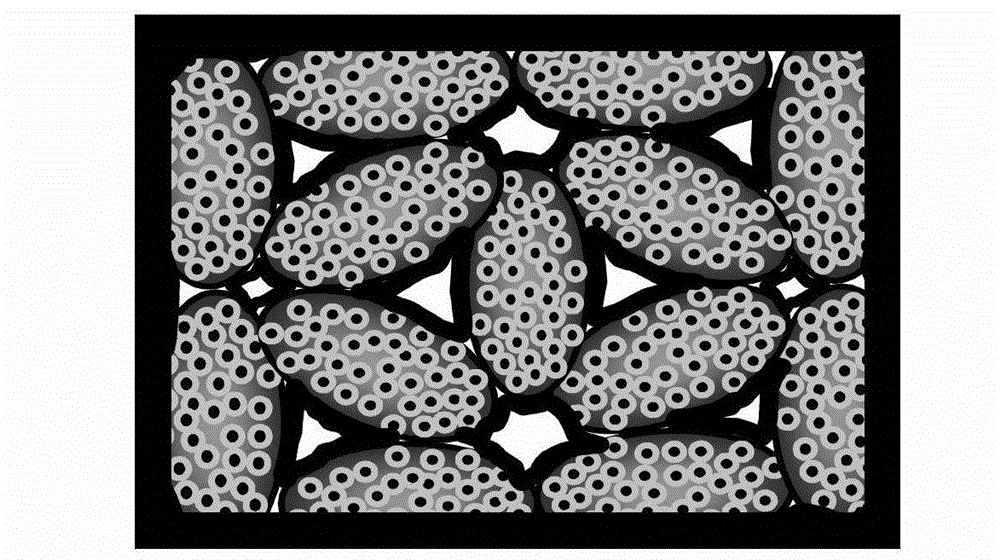

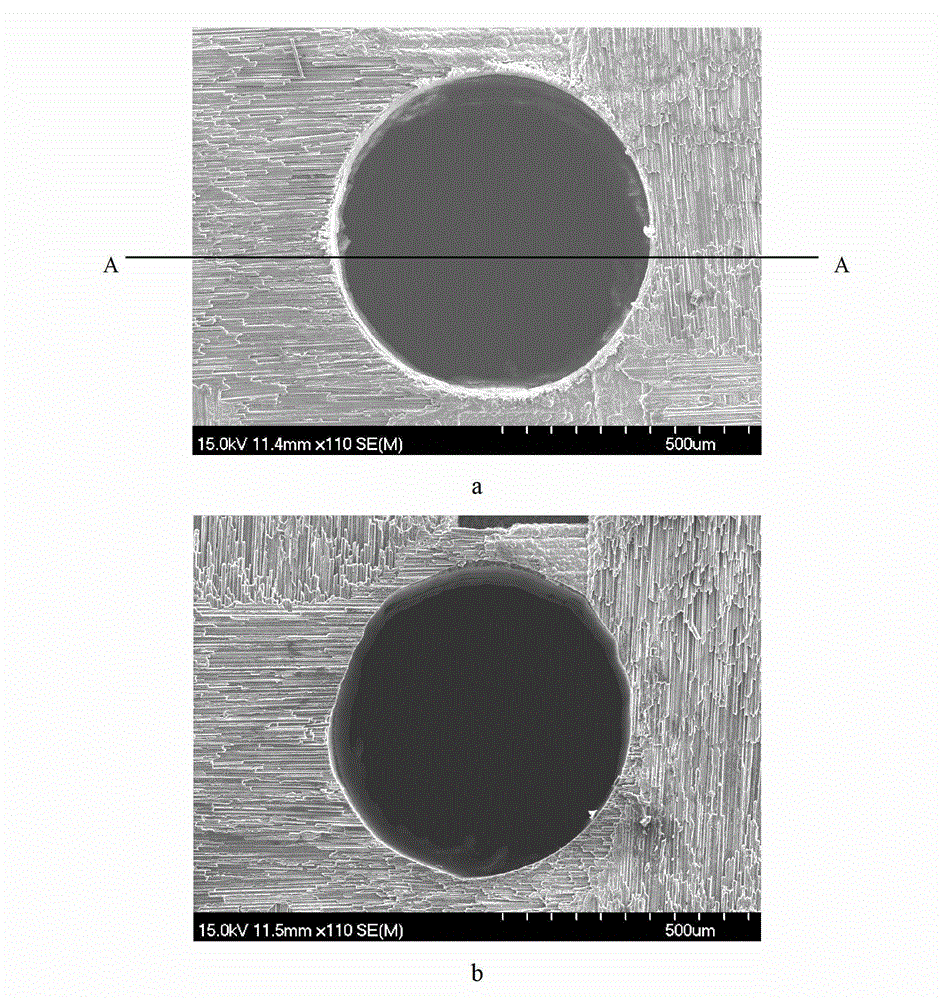

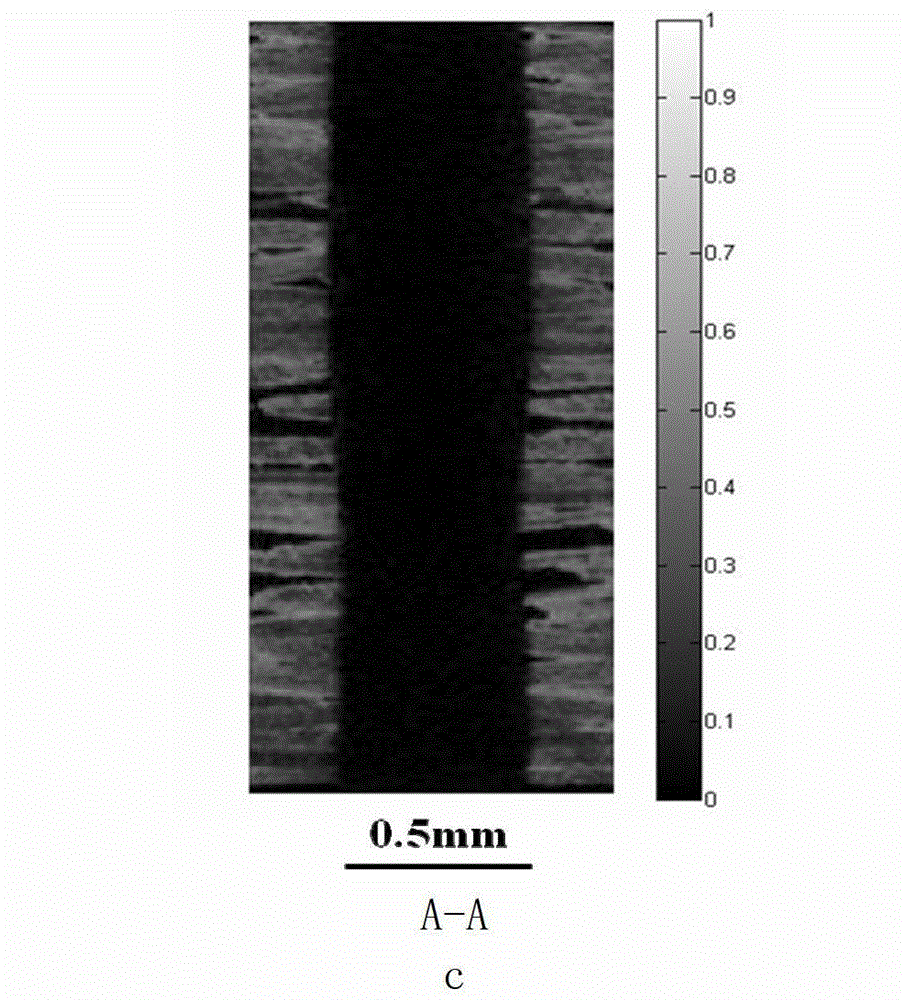

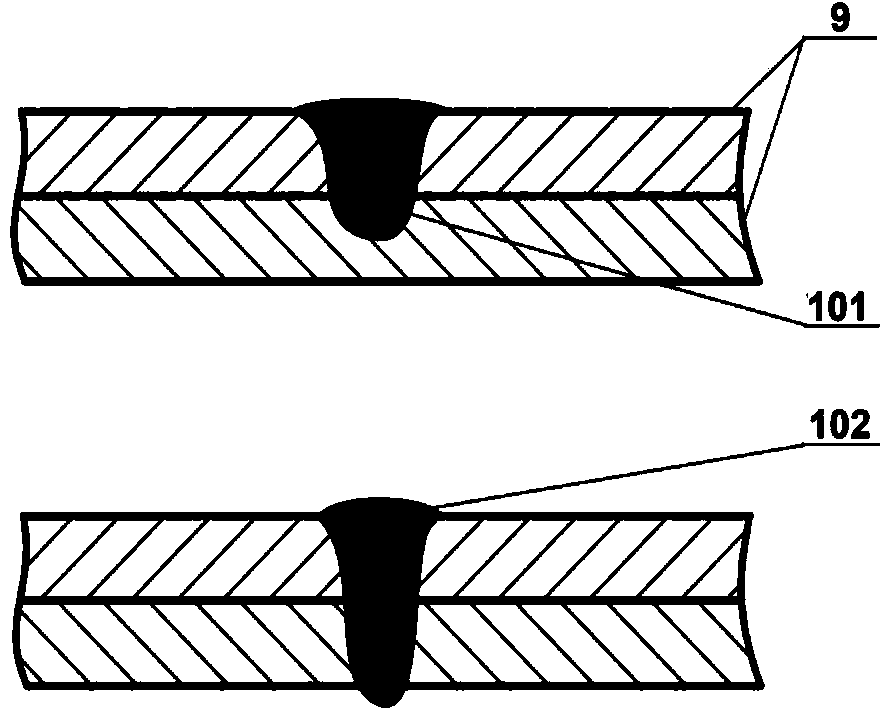

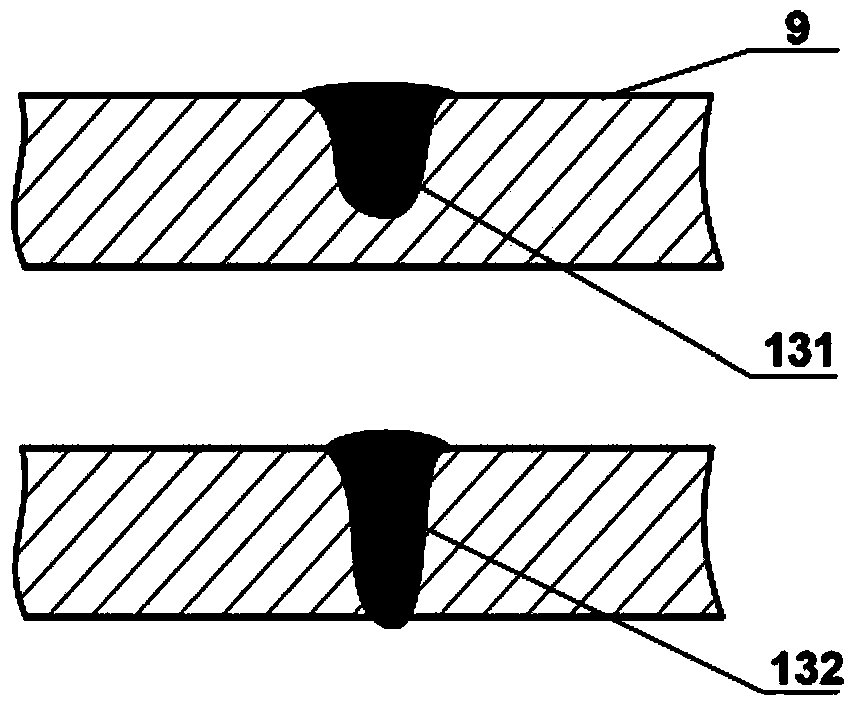

Method for hole machining with picosecond laser

ActiveCN103143841AImprove forming qualityGood processing designabilityLaser beam welding apparatusPicosecond laserOptoelectronics

A method for hole machining with picosecond laser realizes hole machining on CMC-SiC (Ceramic Matrix Composite-Silicon Carbide) material according to the characteristics of fiber composite materials and the machining feature that picosecond laser is suitable for various materials due to superhigh peak power of picosecond laser. According to the method, round holes or square holes are machined in the CMC-SiC material layer by layer in a distributed machining mode; the influence of tiny cracks can be ignored during machining; the stability is good; and the method is particularly suitable for mass repeated micro-hole machining. Layer-by-layer machining in a heliciform way is adopted when round holes are machined; and layer-by-layer machining in a linear scanning way is adopted when square holes are machined. The method has the advantages of good stability of the machining technology, strong designability, high precision and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

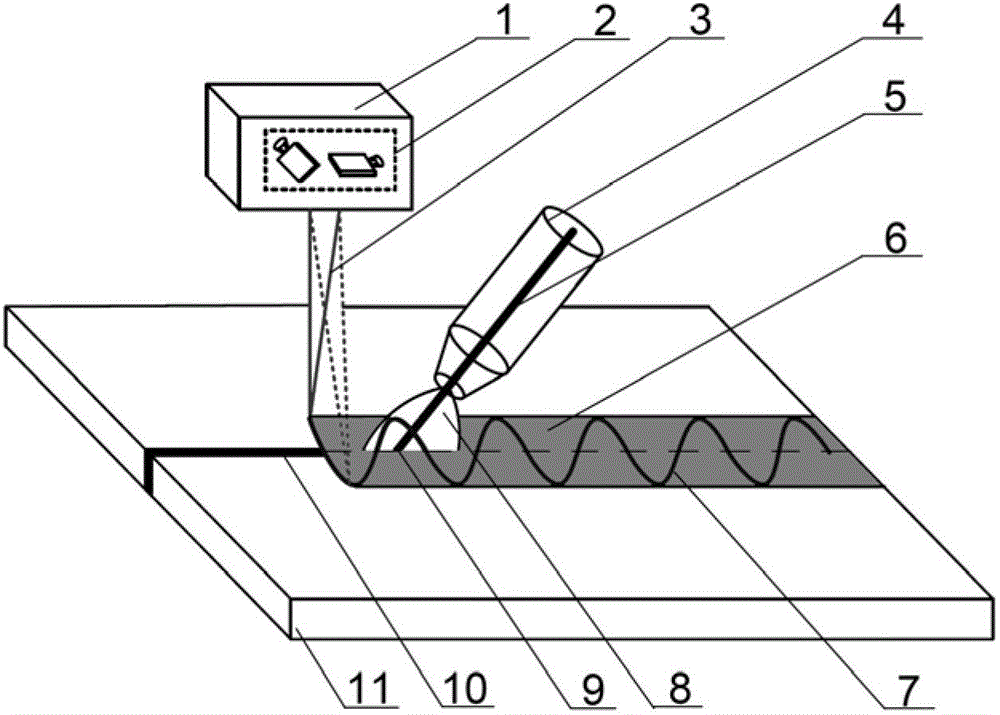

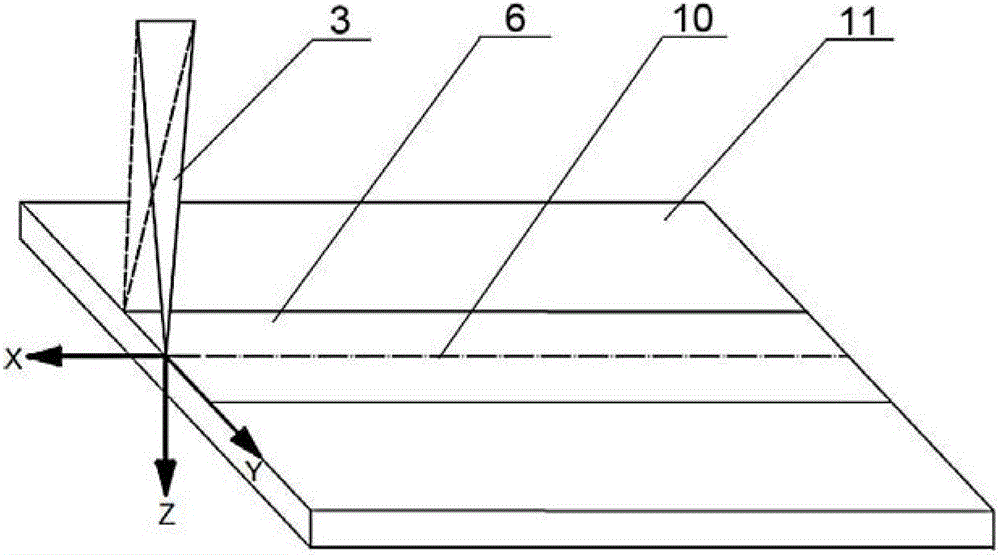

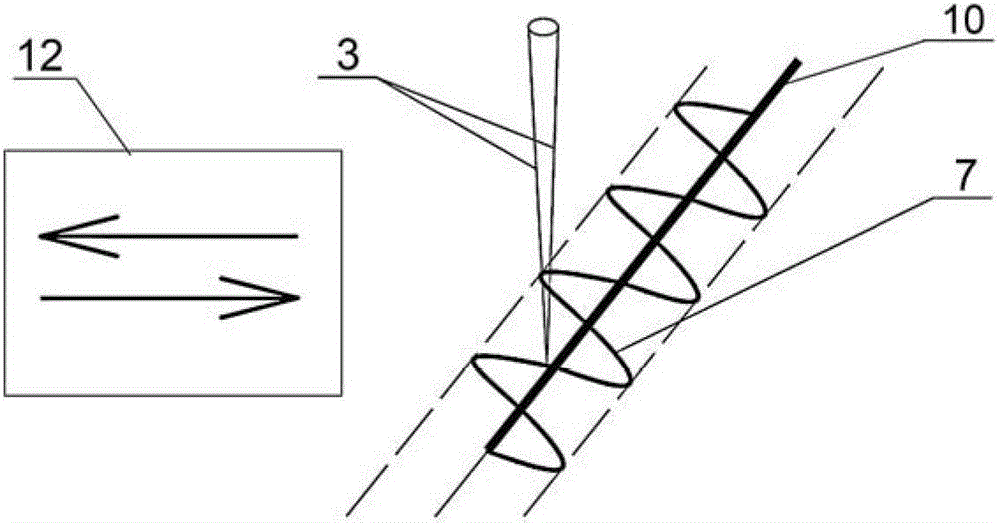

Oscillatory scanning laser beam-electric arc hybrid welding method and system

ActiveCN103056533AImprove featuresImprove welding qualityLaser beam welding apparatusPorosityLaser scanning

The invention discloses an oscillatory scanning laser beam-electric arc hybrid welding method and system. Laser beams and electric arc move together along an abutted seam in large range space, simultaneously the laser beams surround acting points of the electric arc to perform oscillatory scanning movement in a local small area, and an actual welding track is a curve formed by overlying two types of movements. As for an optimal range of laser beam oscillatory scanning displacement, the range in the direction of an X axis is minus 2mm to 3mm, the range in the direction of an Y axis is minus 5mm to 5mm, the range in the direction of a Z axis is minus 2mm to 2mm, and the oscillation frequency is in a range from 20Hz to 500Hz. According to the method and the system, an enhanced technical effect is achieved by the aid of interaction of a laser beam oscillatory scanning effect and a laser-electric arc synergistic effect, and the welding quality is improved. Compared with existing laser-electric arc hybrid welding and laser scanning welding methods and systems, the method and the system have the advantages that higher weld porosity inhibiting capability is achieved, and the weld strength is improved by 10% to 50%.

Owner:武汉飞能达激光技术有限公司

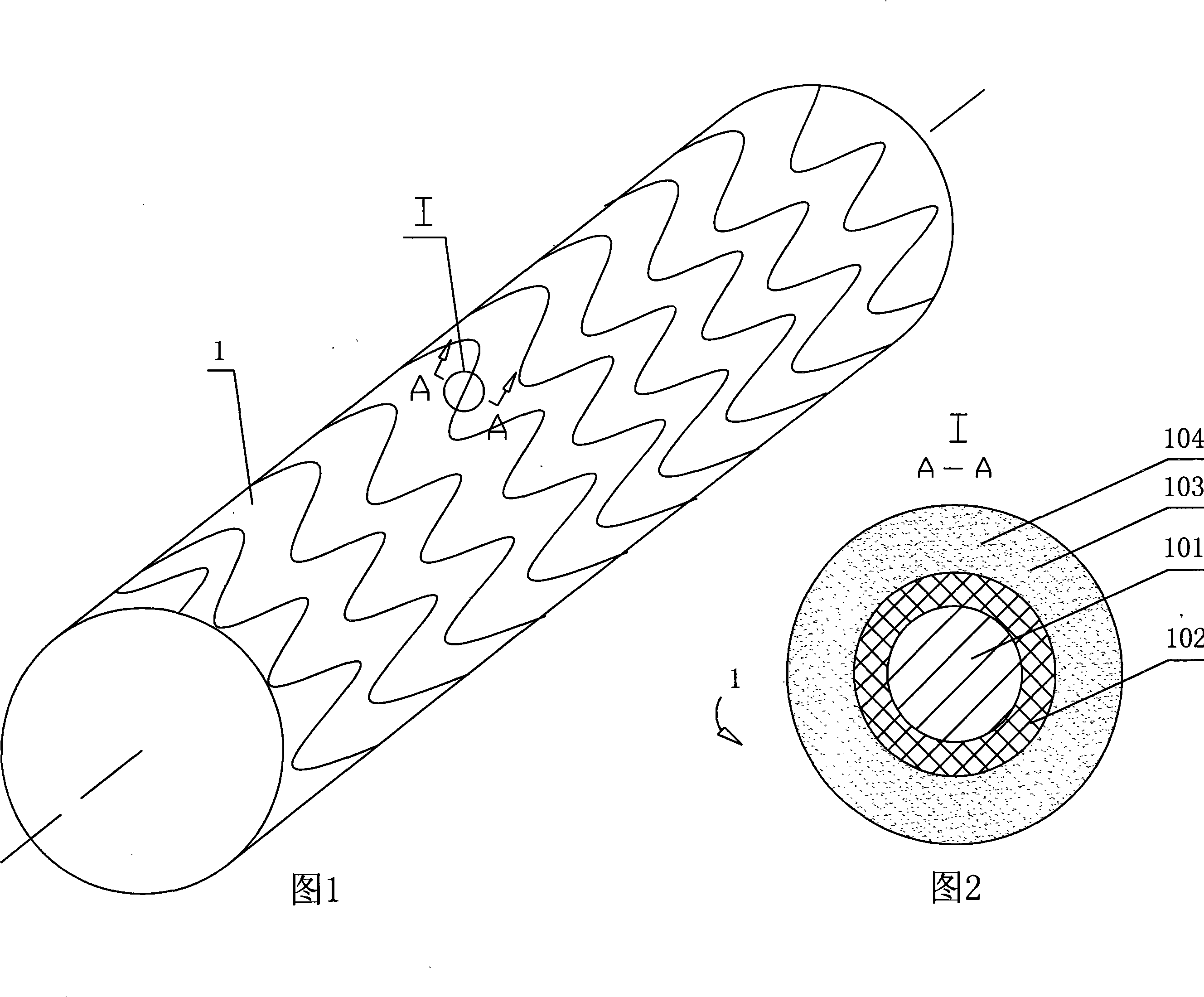

Controlled degradation magnesium alloy coating bracket and preparation thereof

InactiveCN101214396AImprove mechanical propertiesExcellent pharmacological propertiesAnodisationStentsSurface cleaningPolymer chemistry

The invention relates to a controlled degradation magnesium alloy coating stent and a preparation method. The stent body is made of medical high purity magnesium or magnesium alloy by mechanical processing or laser carving; the stent body is provided with a drug-loading coating which bears curative drug; the surface of the stent body is provided with an anti-corrosive coating; the surface of the anti-corrosive coating is provided with a degradable polymer film drug-loading coating; the preparation method includes surface cleaning, preparation of the degradable polymer film drug-loading coating, and application of curative drug; through (1)surface cleaning, (2)preparation of the degradable polymer film drug-loading coating, and (3)application of curative drug, an oxide film is formed on the surface; different drugs and dosage can be fixed by regulating the molecular weight and the thickness of the polymer layer, the drug-loading quantity is more than 30 percent, which improves the fixed stability of the drug, greatly reduces the degradation speed of the magnesium alloy and controls release of the drug, delays corrosion of the magnesium alloy, extends the service life of the stent, is safe in use, and meets the clinical requirement.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Method for purifying sesamin and sesamolin

InactiveCN101602768AHigh purityEasy to operateOrganic chemistryMetabolism disorderFiltrationSesamolin

The invention relates to a method for purifying sesamin and sesamolin in sesame oil, which comprises the steps of: separating lignanoid compounds without fat constituents from the sesame oil first; adding ether into the lignanoid compounds to precipitate the sesamin; performing the filtration; dissolving an obtained filtrate by chloroform after concentration under reduced pressure, adding petroleum ether into the mixture until white opacity appears; heating and dissolving the obtained solution; and standing the obtained solution to precipitate the sesamolin. The method for purifying the sesamin and the sesamolin has the advantages of simple operation, safety, economization, strong process stability and the like, and is particularly suitable for industrialized application; and the method can synchronously obtain high-purity sesamin and sesamolin, and achieve the aim of comprehensive utilization.

Owner:河南省农科院农副产品加工研究所

Method for preparing nitrogen-doped porous carbon nanofiber cloth

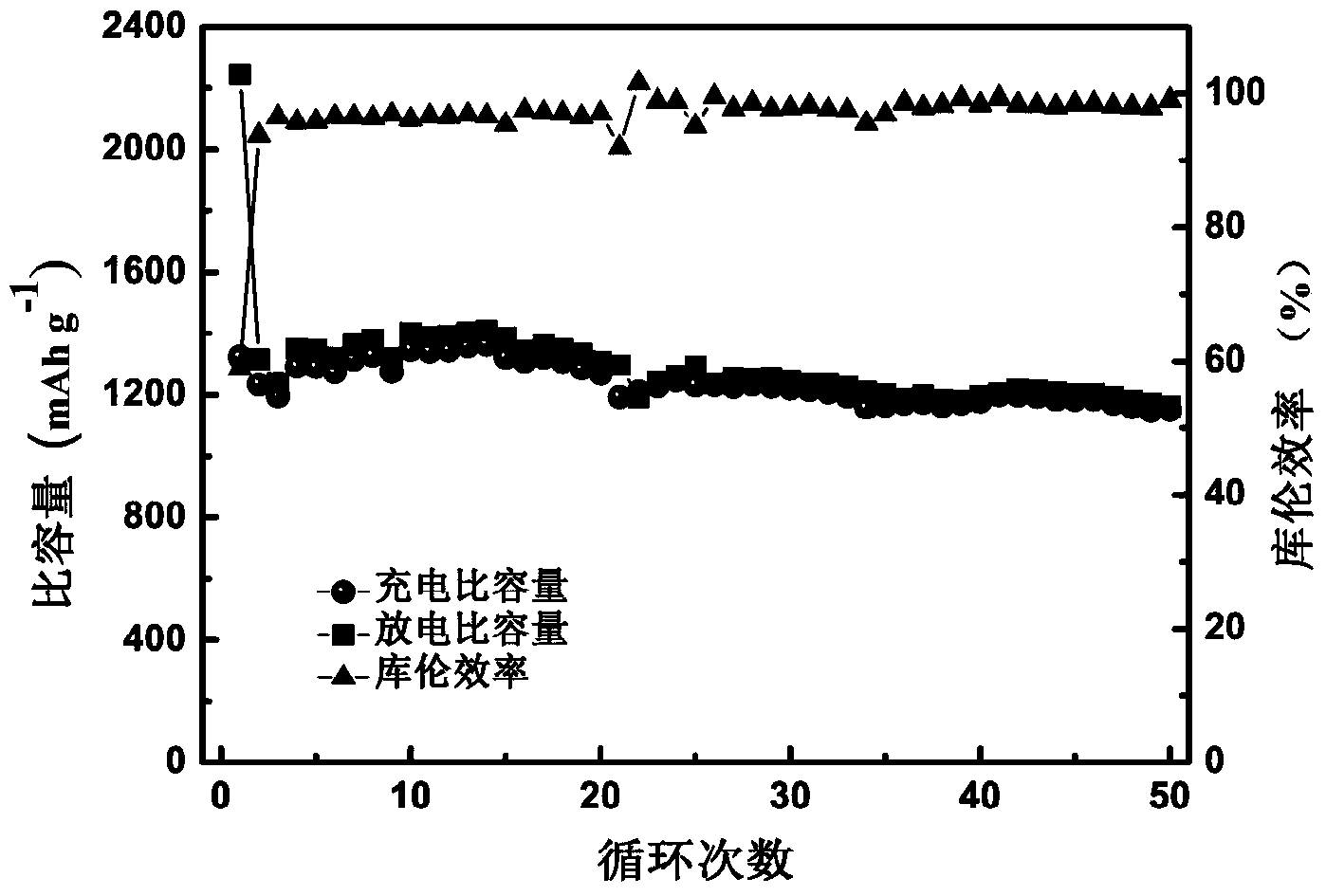

ActiveCN103855361ALow costGood spinnabilityMicroscopic fiber electrodesSecondary cellsLithium electrodeCarbon nanofiber

The invention relates to a method for preparing nitrogen-doped porous carbon nanofiber cloth. The nitrogen-doped porous carbon nanofiber cloth is prepared by adding a nitrogen-rich compound into an organic solution, electrospinning and subsequent carbonizing-activating, has a self-support structure, omits preparation steps of size mixing, coating and the like, needs no conductive agent or binder, and can be directly used as the negative electrode of a lithium ion battery. The electrochemical performance of the negative electrode material of the lithium ion battery is improved by doping nitrogen and activating and forming pores; compared with a commercial graphite lithium ion battery negative electrode material, the nitrogen doping porous carbon nanofiber cloth used as the negative electrode material of the lithium ion battery has simple steps for preparing the electrode, has higher specific capacity, good power performance and circulatory stability. The method also can be used as the electrode material of super capacitors and other novel batteries.

Owner:TSINGHUA UNIV

Powdery alloy processing material in site by movable laser smelt-coating process

A movable field processing alloy powder material for the laser melting is to reinforce the nickel-base alloy using the below elements: Cr, W, Mo, Al, Ti, Co; also it can be added with the Co, C, N, Nb, Cu, B, Si and the minim rare-earth metal which can be the Ce, Y and the Hf. The invention has the high hardness, the strength and the low melting point, high wearing resistance. It has improved the cracking resistance, moldability, the stability and the uniformity of the laser melting layer. So it can repair the high temperature alloy, the carbon steel, the structural steel and the stainless steel by the laser melting.

Owner:SHENYANG DALU LASER TECH

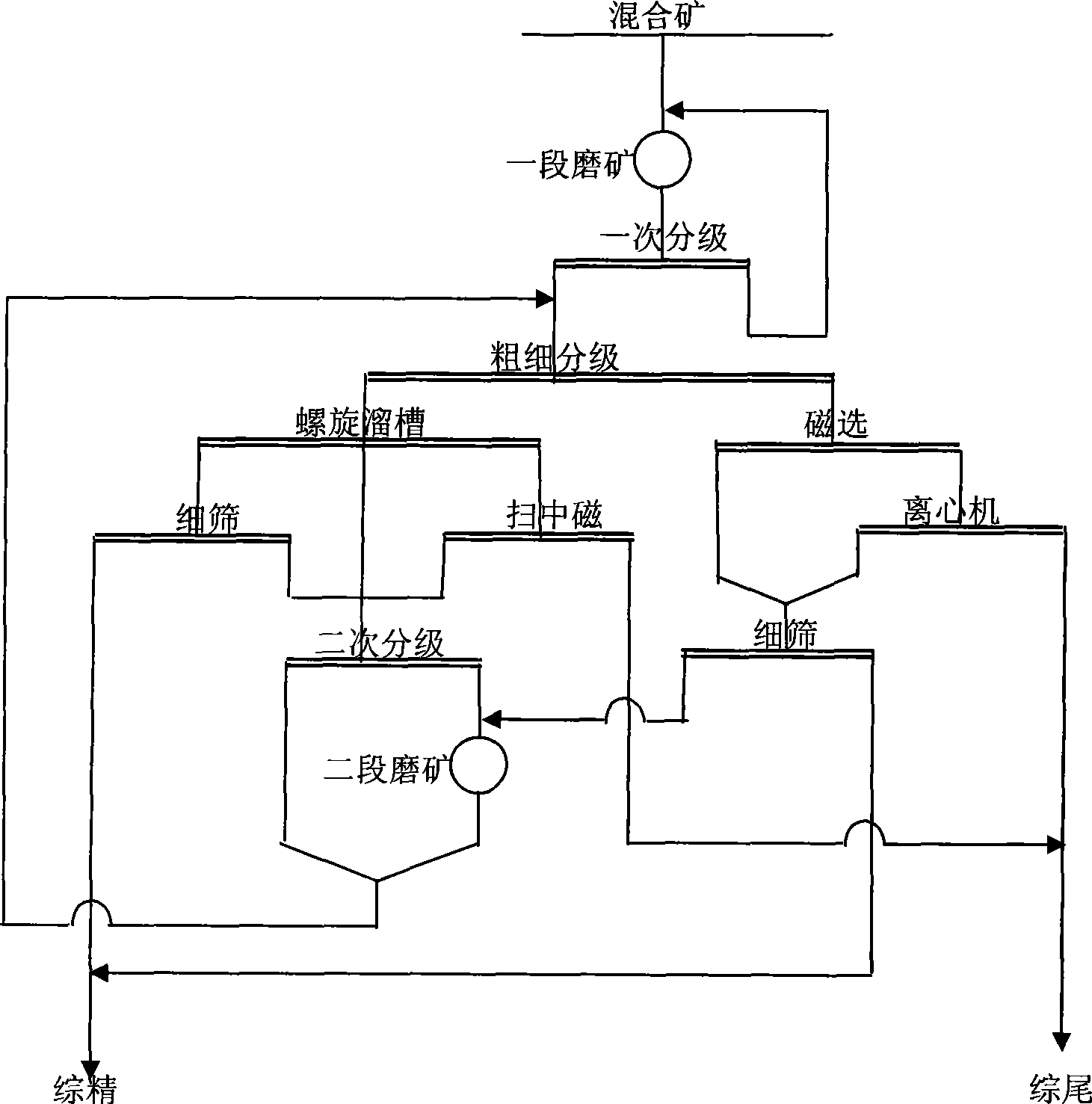

Technique for processing mixed type iron ore

ActiveCN101468330AEfficient recyclingOvercome the complex system and the shortcomings of being easily interfered by other mineralsSievingScreeningHybrid typeGravity separation

The invention discloses a process for treating mixed-type iron ore. The process comprises the following steps: raw ore is crushed and then subjected to primary grinding and primary grading which form closed circuit grinding; after primary overflow is subjected to crudeness / fineness grading and coarse grains are sorted through a gravity separation device, spiral chute concentrate is fed into a fine screen with large mesh size, and undersize products are coarse-grain concentrate; after gravity separation tailings are subjected to tailings discarding through intermediate-magnetism sweeping, intermediate-magnetism sweeping concentrate, gravity separation middlings and oversize products are merged into coarse-grain middlings; the middlings are fed into an open-circuit grinding system consisting of secondary grading and secondary grinding and reground, and then return to crudeness / fineness grading; fine grains after crudeness / fineness grading are sorted through a magnetic separation device; magnetic separation concentrate is fed into the fine screen with small mesh size, and the undersize products are fine-grain concentrate, while the oversize products are fine-grain middlings which are directly fed into two-stage grinding so as to be reground; fine-grain concentrate and the coarse-grain concentrate are merged into final concentrate; and intermediate-magnetism sweeping tailings and the magnetic separation tailings are merged into final tailings. The process has the advantages of good flow stability, easy operation and capability of effectively recovering the mixed-type ore and fully utilizing mixed-type ore resources.

Owner:鞍钢集团矿业设计研究院有限公司

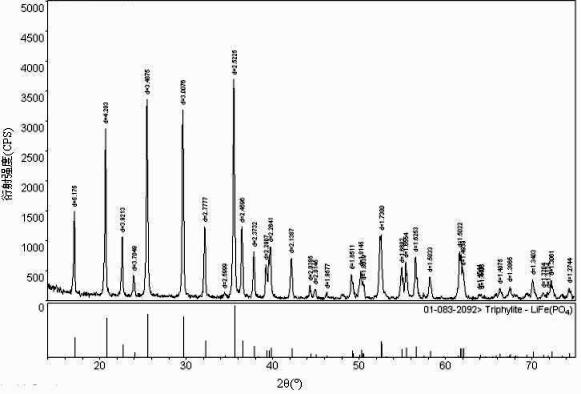

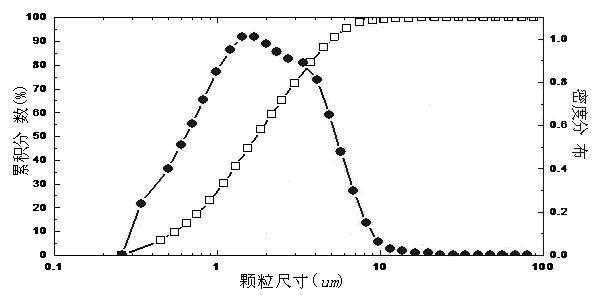

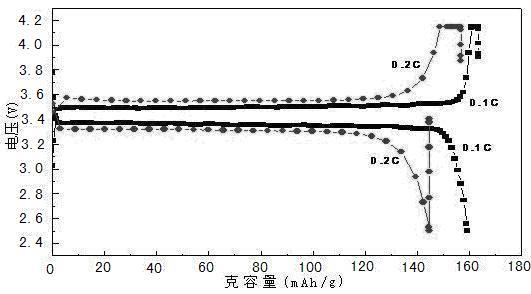

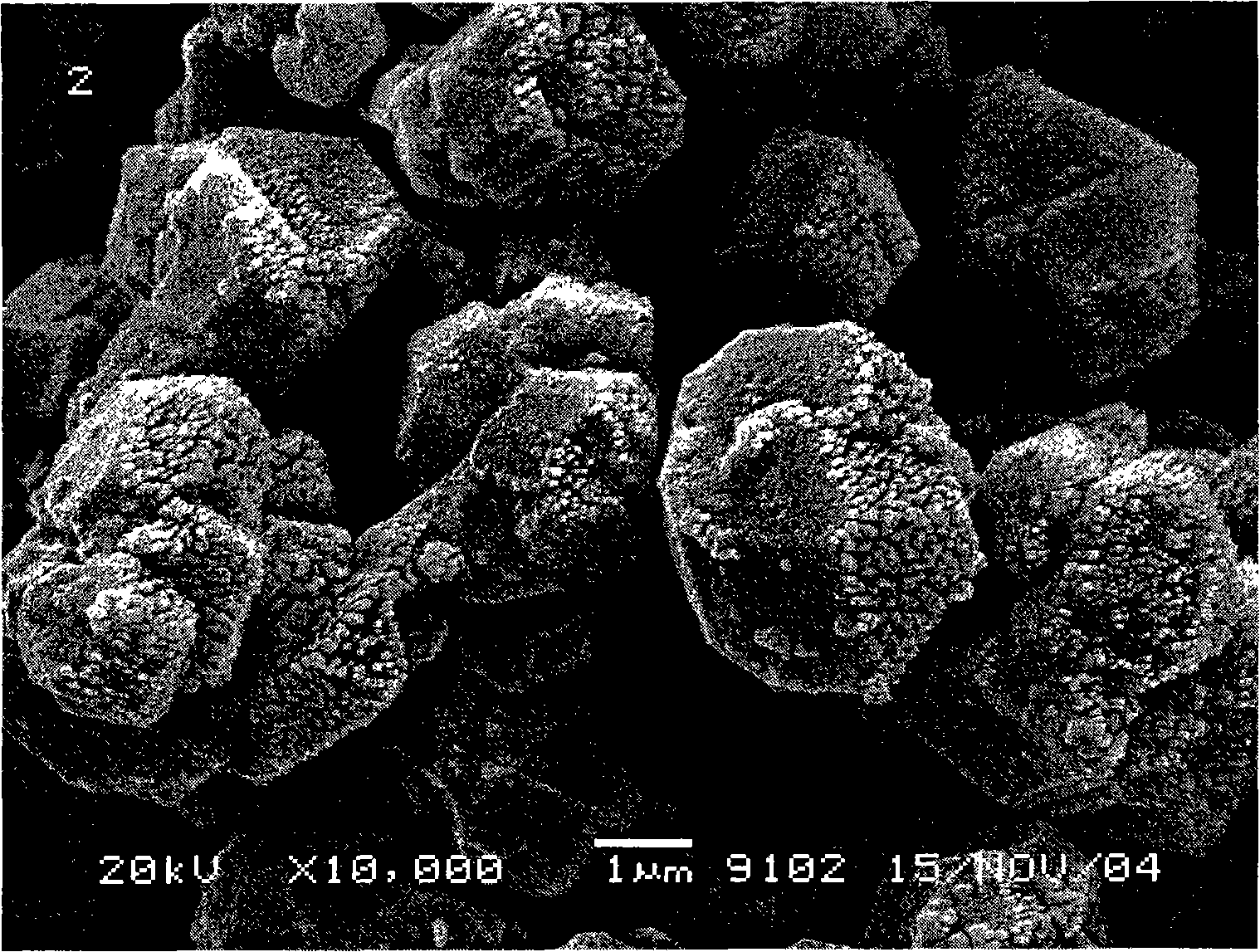

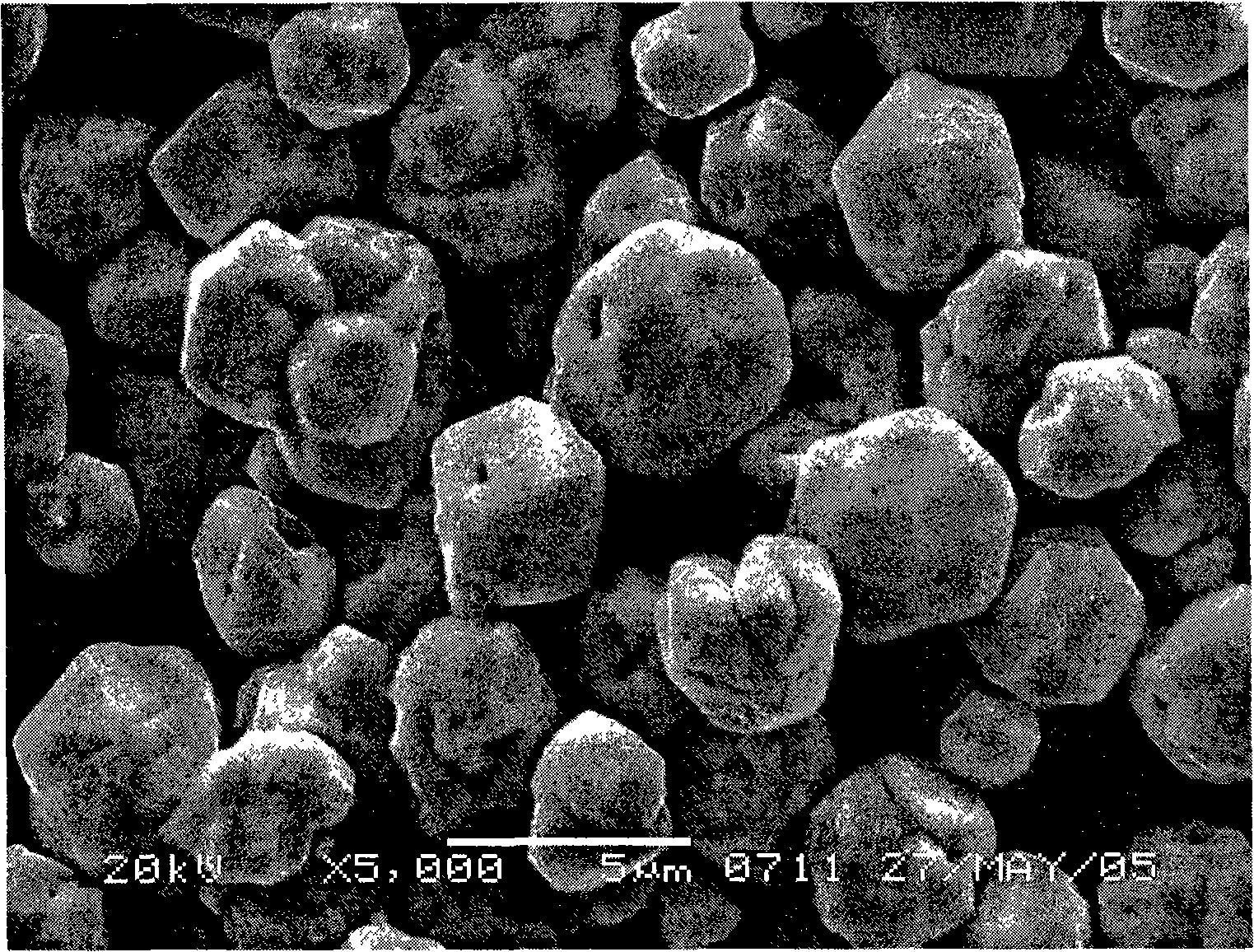

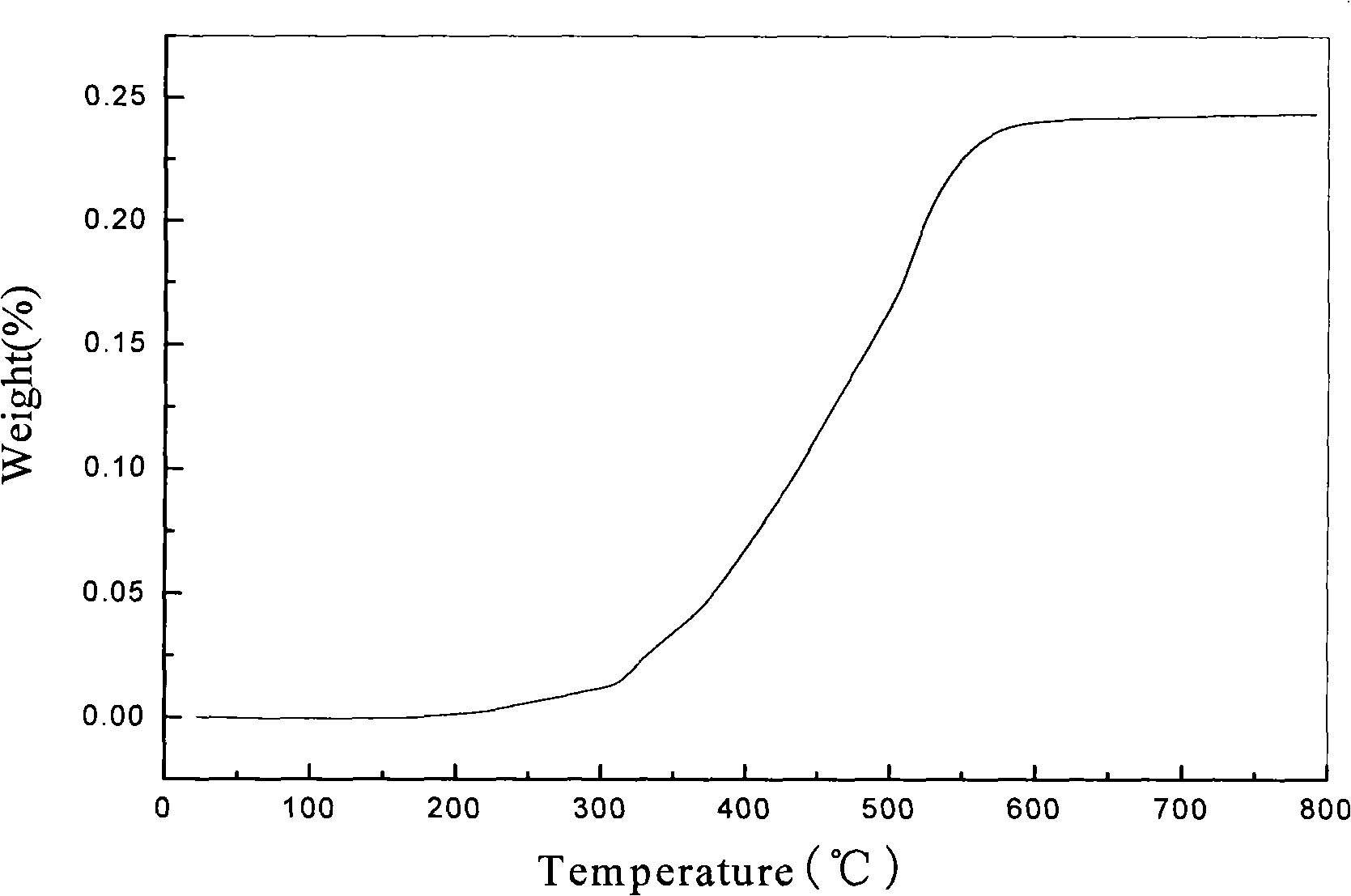

A kind of preparation method and product thereof of lithium iron phosphate material with high capacity and high compaction density

InactiveCN102275887ASolve the problem of impurityReduce manufacturing costCell electrodesPhosphorus compoundsElectrical batteryPhosphate

The invention belongs to the field of positive electrode materials for lithium ion batteries, and discloses a method for preparing lithium iron phosphate materials with high capacity and high compaction density, including (1) combining lithium source, Fe3+ source, phosphate, dopant and organic carbon source Mixing, and then spray granulation, (2) prepare calcined product, (3) mix and sand the calcined product and inorganic carbon source, and then spray dry to obtain secondary spray powder, (4) secondary spray The powder is heat-treated in vacuum or in a protective atmosphere, and sintered at a constant temperature; (5) After the above-mentioned sintered semi-finished product is passed through secondary ball milling or jet milling, a lithium iron phosphate product is obtained. The invention solves the defects of increased product cost, difficult coating and low compaction density of pole pieces caused by the use of divalent iron source, and has the characteristics of low production cost and good processability, electrical conductivity and electrochemical performance of prepared pole pieces .

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

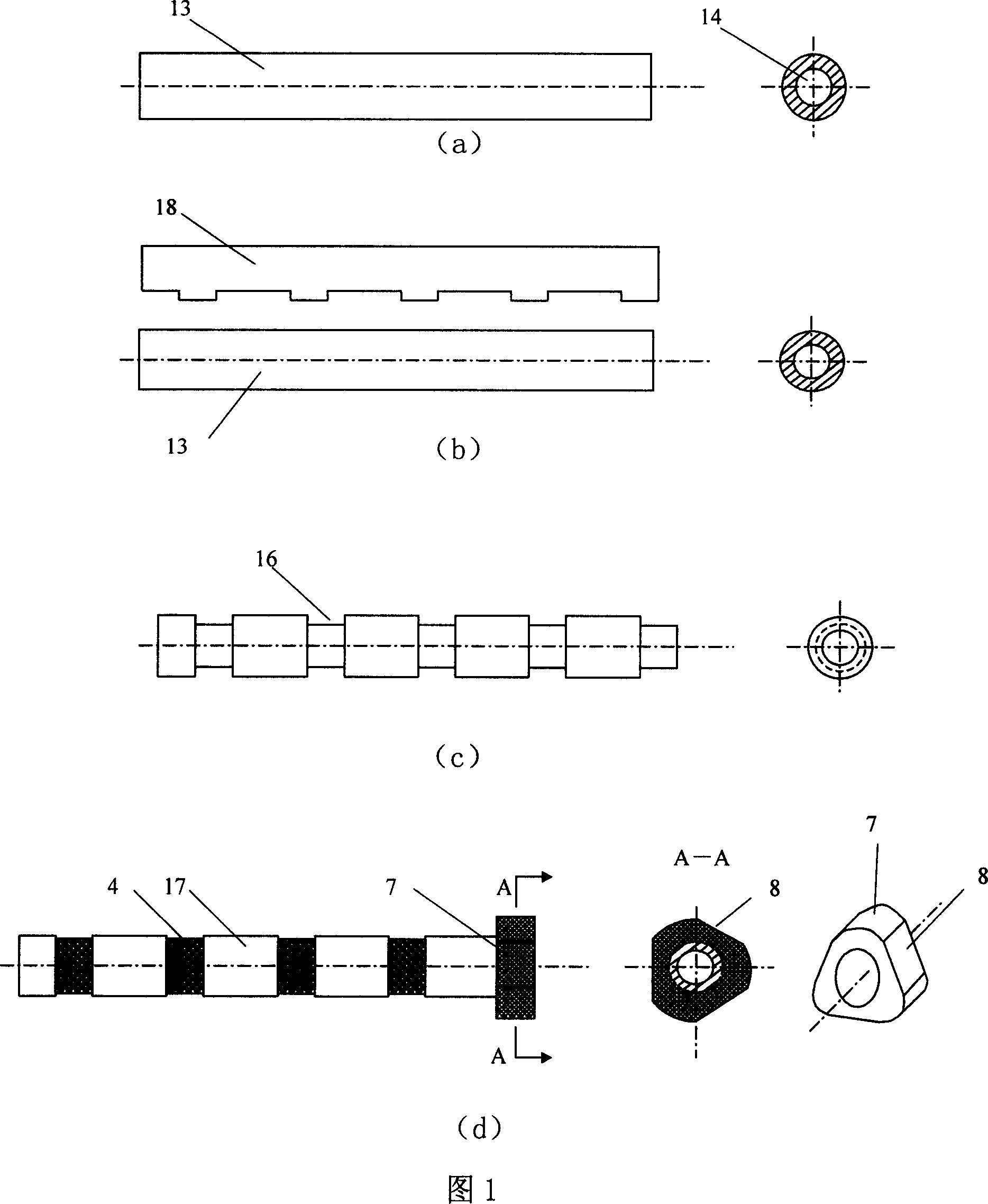

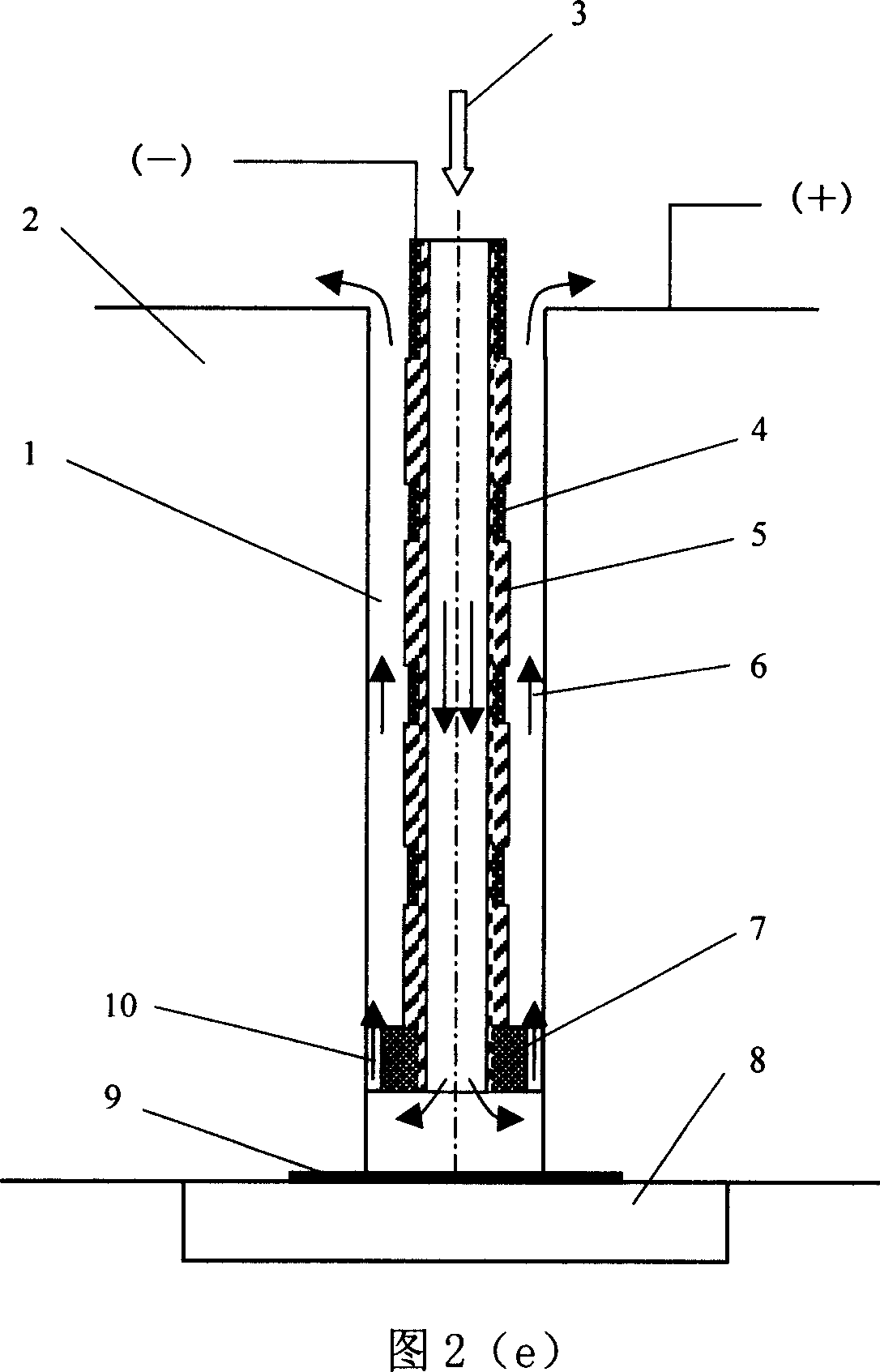

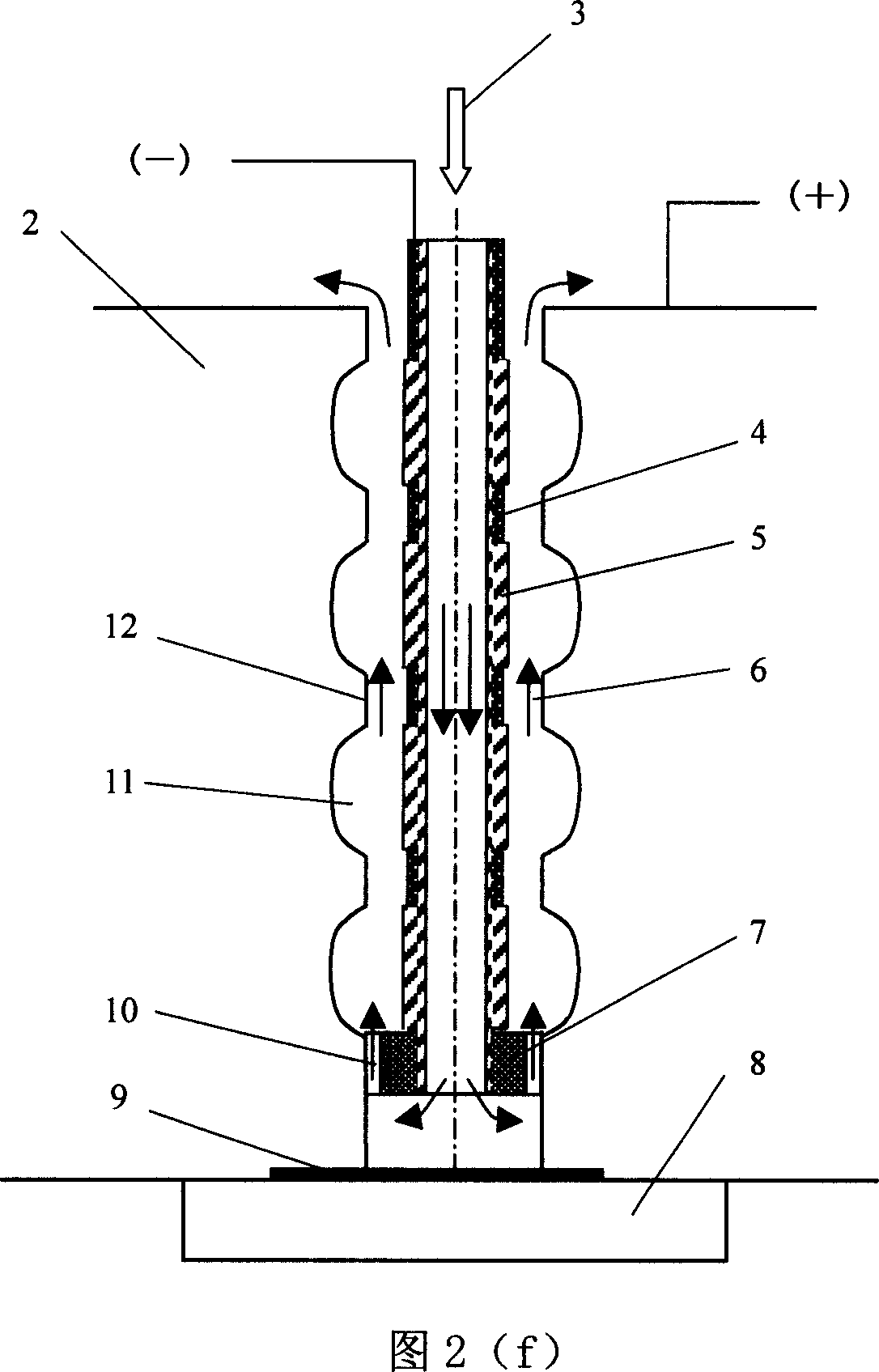

Electrolytic processing method for ribbed deep small holes and special tool cathode

InactiveCN1943951AImprove ECM EfficiencyEasy to prepareMachining electrodesElectrical-based machining electrodesMachining processSmall hole

The present invention is electrolytic processing method for ribbed deep small hole and its special tool cathode, and belongs to the field of electrolytic machining technology. The method includes the following steps: electrolytic machining one metal pipe with one reversely copied cathode to form notches in the surface of the metal pipe; coating epoxy resin glue into the notches; installing positioning rack to the end of the tool electrode to make the forming tool electrode; machining smooth hole in the workpiece; stretching the forming tool electrode into the deep smooth hole to machine the ribbed deep small hole. The present invention has simple machining of the forming tool electrode, high ribbed hole machining precision, high machining stability and other advantages.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

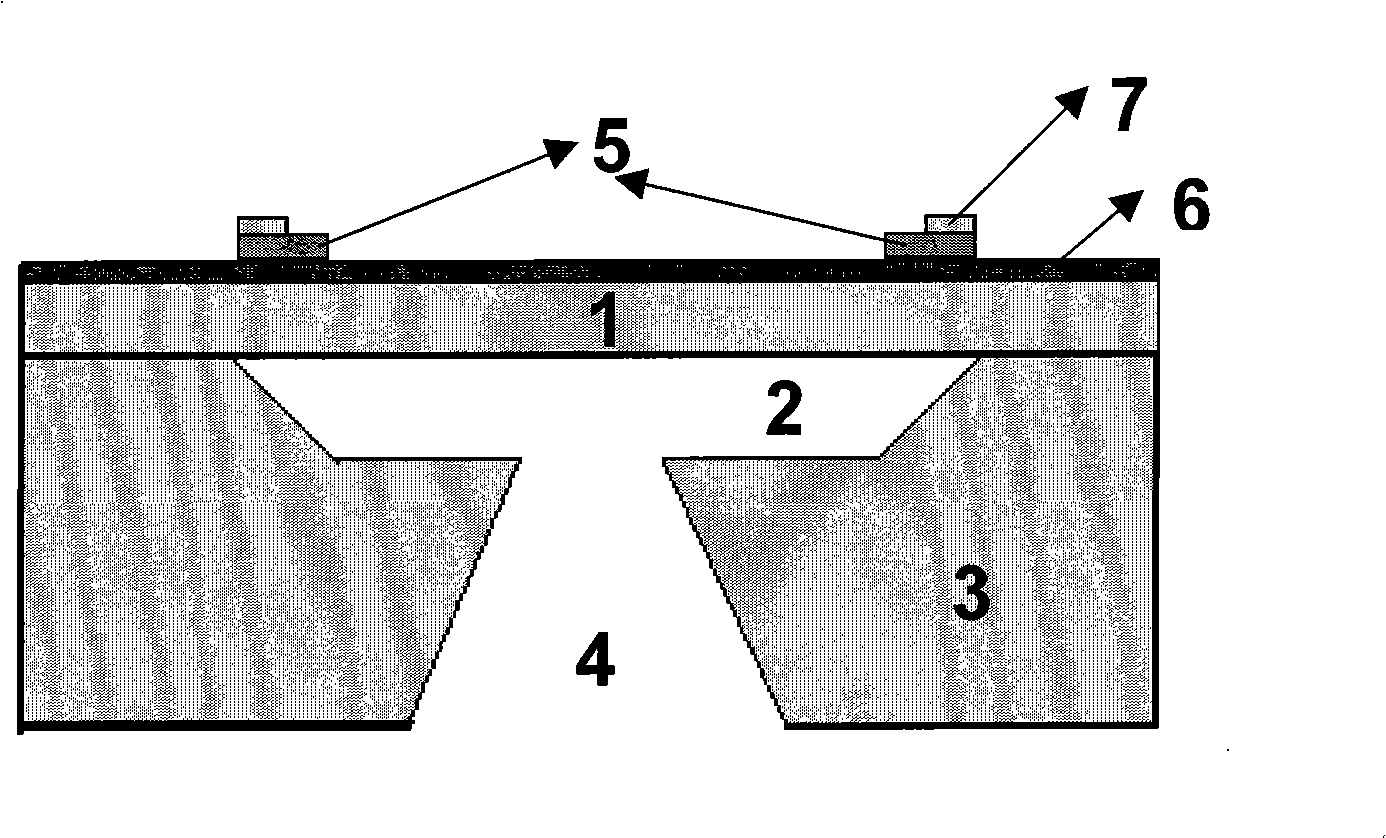

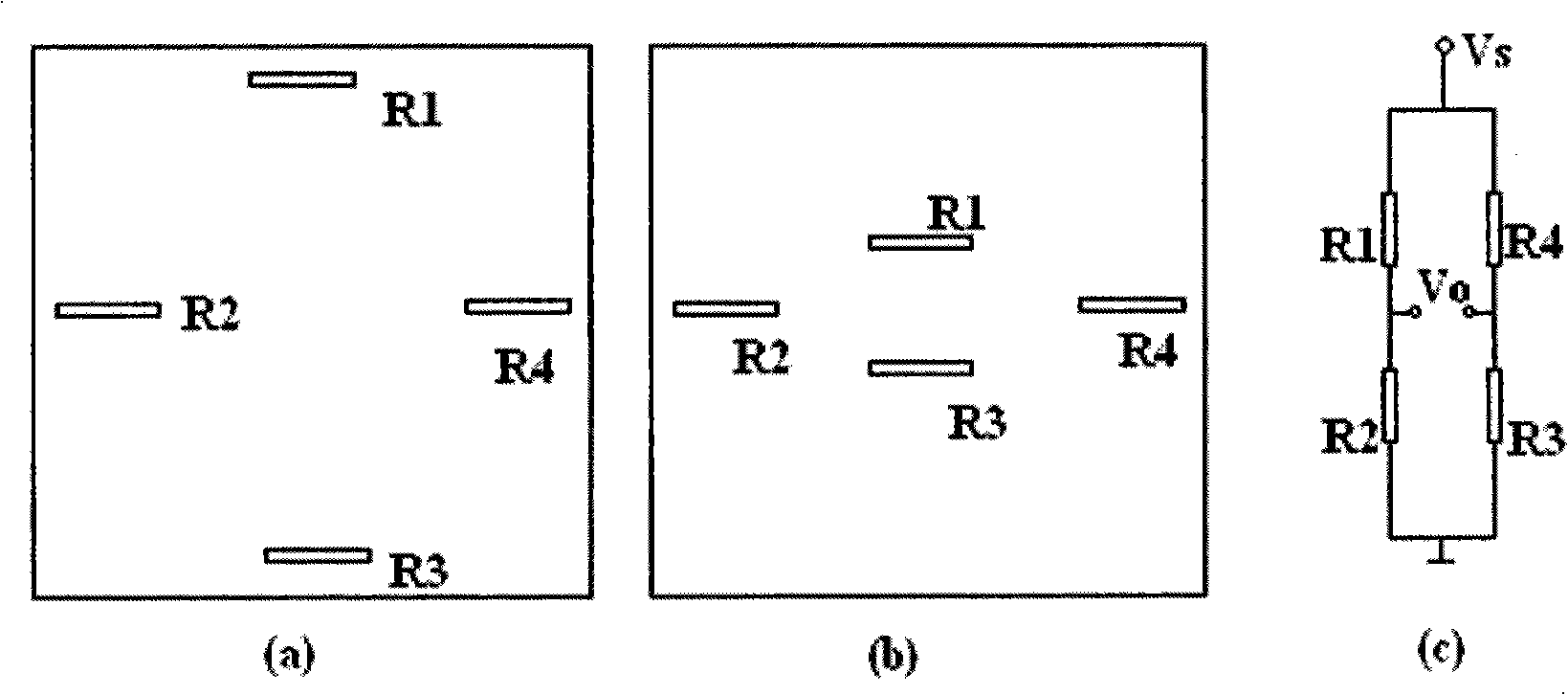

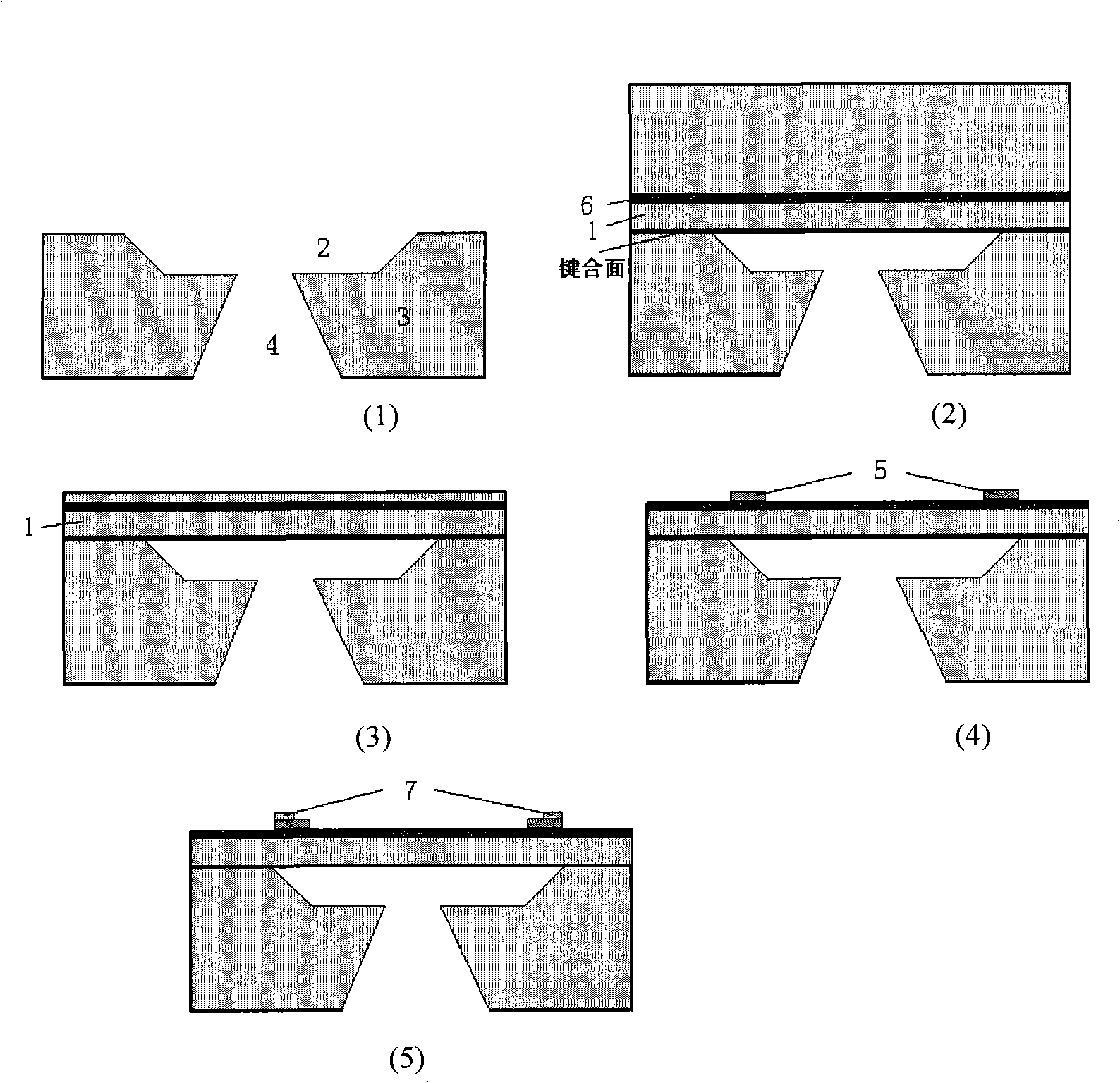

Si-Si bonding isolator upper silicon high-temperature pressure sensor chip and manufacture method

InactiveCN101266176AIncrease flexibilityReduce residual stressTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPhysicsBuried oxide

The invention relates to a high-temperature press sensor of silicon-silicon-bonded-based silicon on an insulator (SOI) and a producing method, belonging to the field of sensor chip, characterized in that a shallow slot and a gas vent on a support silicon substrate are all formed through anisotropic etch; suitable depth of the shallow slot can be obtained by controlling etching time so as to accomplish over-voltage protection for the device; the support silicon substrate is bonded with an inverted SOI chip; a piezoresistor is produced on the top layer of silicon after reducing and polishing the back of the SOI chip. The device can operate normally at high temperature using SOI buried oxide layer for isolation of sensitive component and elastic component.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

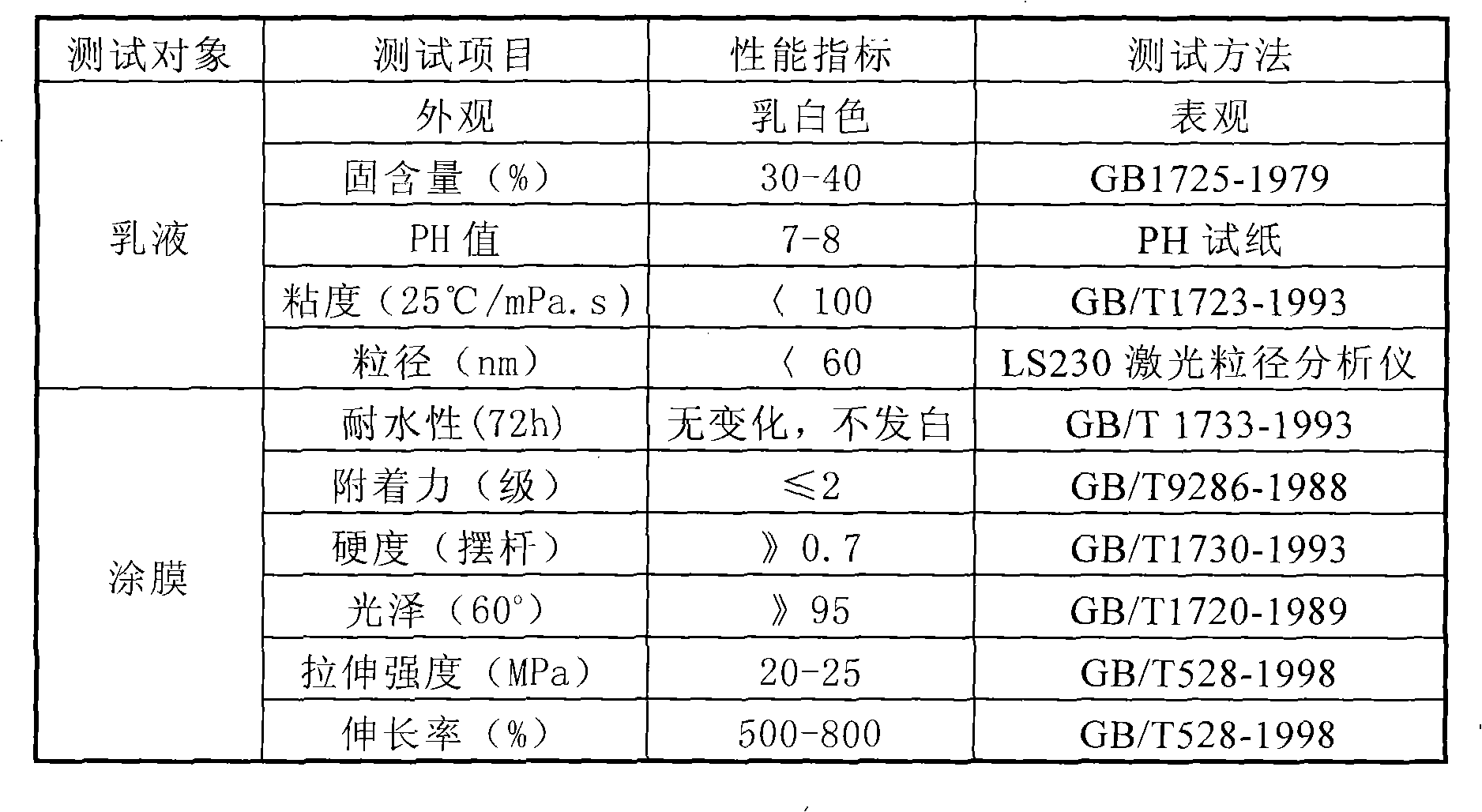

Waterborne polyurethane-polyacrylate emulsion and preparation method thereof

The invention relates to aqueous polyurethane-polyacrylate emulsion and a preparation method thereof. In the preparation method of the aqueous polyurethane-polyacrylate emulsion, vinyl monomers containing reactive groups react with an excess of polyisocyanate under the controlled conditions of a minute amount of a polymerization inhibitor and low temperature to produce partially single terminated vinyl isocyanate; the partially single terminated vinyl isocyanate reacts with a polyhydric alcohol polymer to produce a prepolymer; small amounts of acrylate monomers are added as a thinner; an neutralizer and a small molecule chain extendor are added; the product is dispersed into de-ionized water after reaction; an initiator and remaining acrylate monomers are added, thus getting the stable aqueous polyurethane-polyacrylate emulsion after polymerization. The aqueous polyurethane-polyacrylate emulsion has the characteristics of being free of organic solvent, being friendly to the environment, small and uniform particle size, excellent mechanical property of emulsion film coating, high resistivity against water, high solvent resistance, high hardness and adhesion.

Owner:中国科学院嘉兴应用化学工程中心

Laser cladding Co-based alloy powder for conductor roll

InactiveCN101187022ASolve repair problemsImprove performanceMetallic material coating processesChemical compositionAlloy substrate

Provided is cobalt-based alloy powder for laser cladding electricity conducting roller, the weight percentages of the chemical components of the material are that Cr is 24-30%, W is 6-10%, Mo is 3-6%, Ni takes 6-12%, Fe holds 2-10%, Mn is 0.5-2%, Si holds 0.2-2%, V is 0.1-0.6%, B takes 0.3-1.5%, C holds 0.5-2.5%, Y2O3 is 0-0.5%, Hf takes 0-0.5%, La2O3 holds 0-0.5%, Ce is 0-0.5%, and the rest is Co. The invention has the advantages that with multiple strengthened methods, the alloy substrate is strengthened and the crystal boundary quality is improved, which enables the alloy to achieve perfect combination property, thereby achieving medium rigidity and relatively high intensity of the alloy, simultaneously forming self-fluxing alloy and reducing alloy melting point, and increasing properties of oxidation resistance, abrasion resistance, corrosion resistance, and certain electricity conduction.

Owner:SHENYANG DALU LASER TECH

High-strength invar alloy and its alloy wire rod production method

ActiveCN1743490AReasonable designHigh strengthFurnace typesMetal rolling arrangementsInvar alloyWire rod

A high intensity invariable steel and a production method for it's wire rod characterizes in taking Fe-36Ni alloy as the base added with W, V and C in the following weight percentage: C 0.15 to 0.40, Si is not greater than 0.60, Mn is not greater than 0.8, p is not greater than 0.025, S is not greater than 0.02, Ni: 34.0 to 42.0, co is not greater than 3.5, Cr is not greater than 0.5, Cu is not greater than 0.2, W: 1.5 to 5.0, v 0.3 to 1.2, Mo is not greater than 0.5, the rest is Fe and unavoidable impurities, W.V is greater than 1.5, c=0.9-1.3(0.033w+0.2V). The production method includes: 1, processing the steel ingot into rods then to wire rods (phi=10 to 15mm) 2, applying special twice cold processing deformation and hot process, the twice cold-draw deformations are 20-70%, 55 to 95% then they are hot processed under 450-750 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD +1

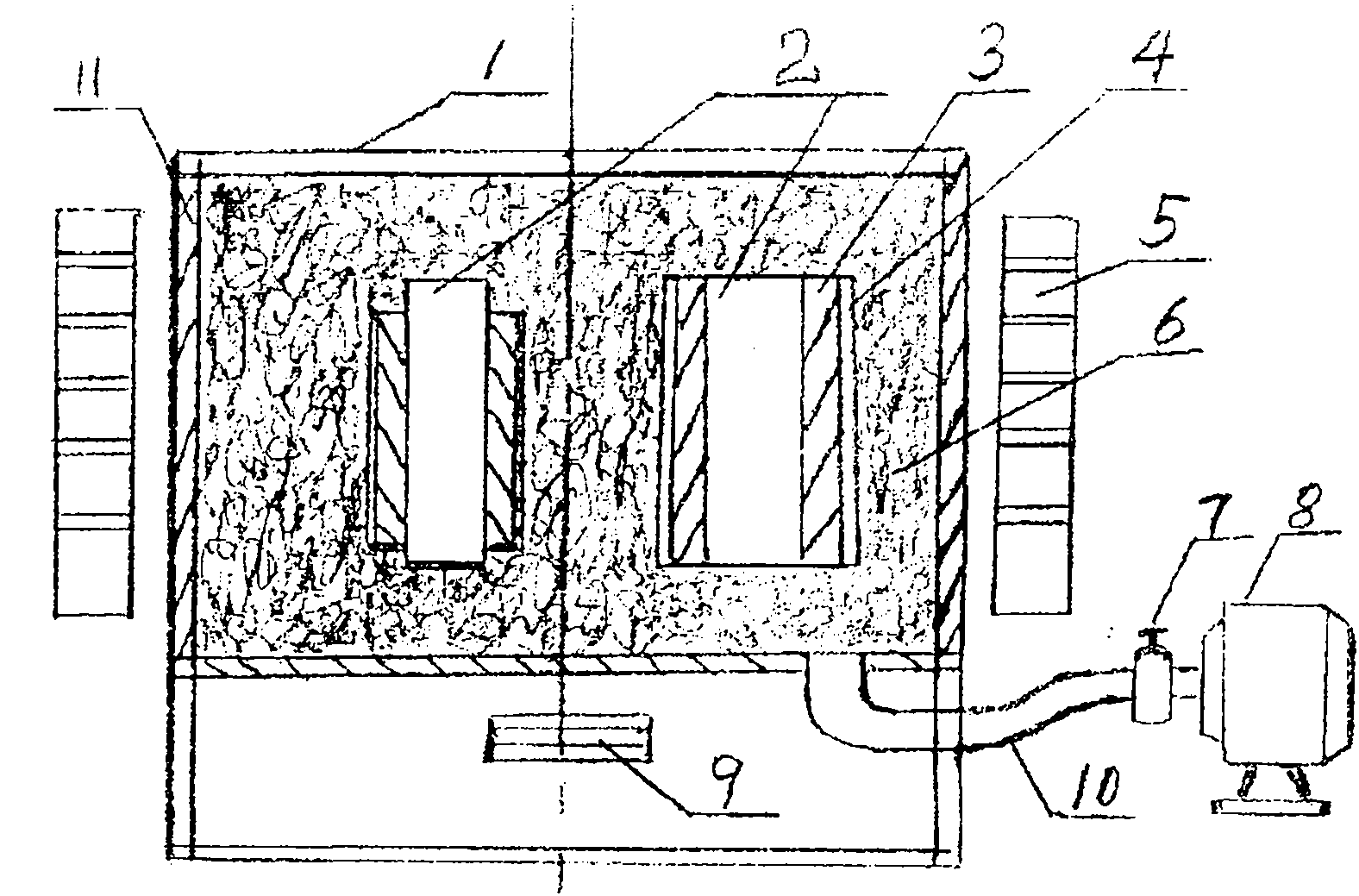

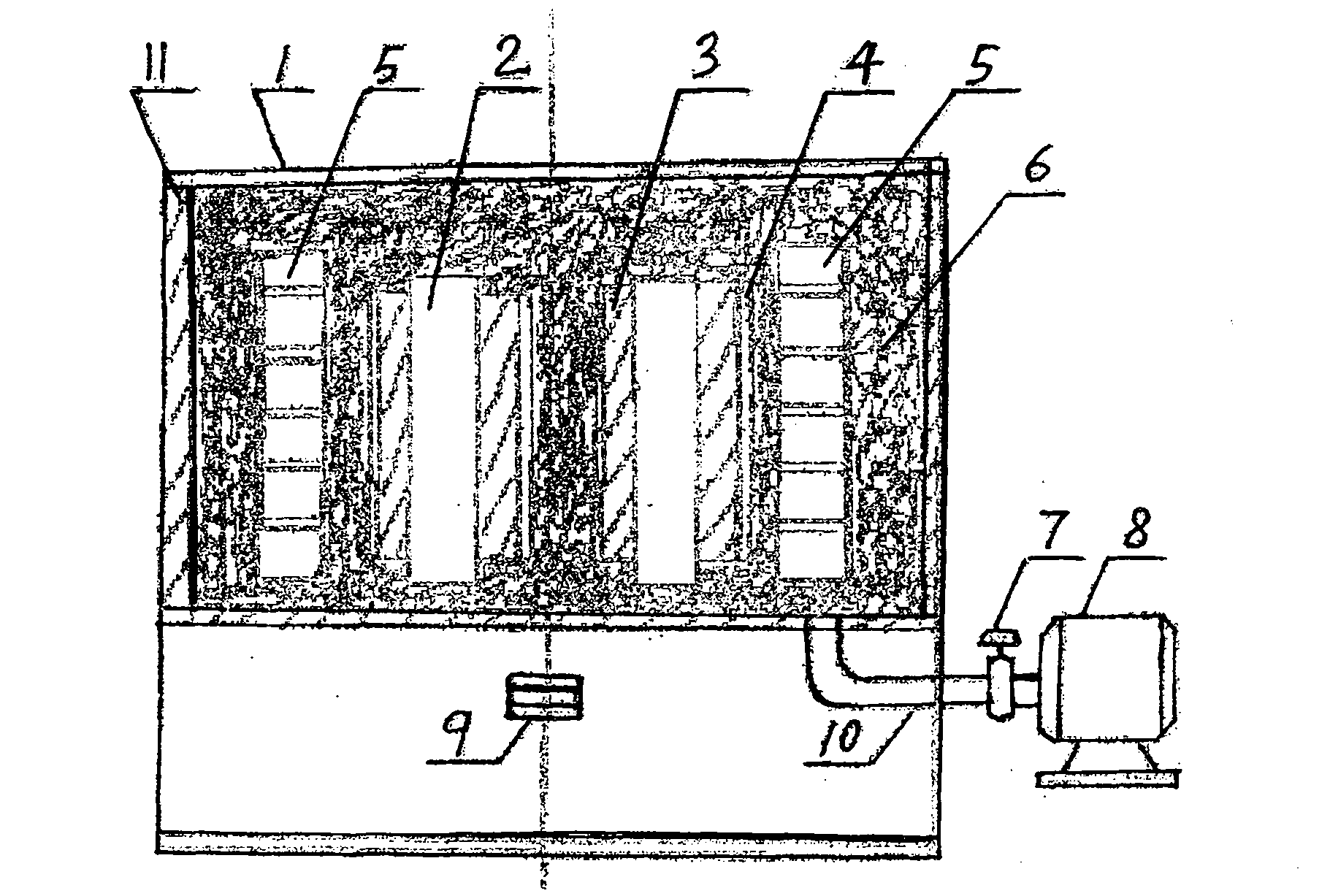

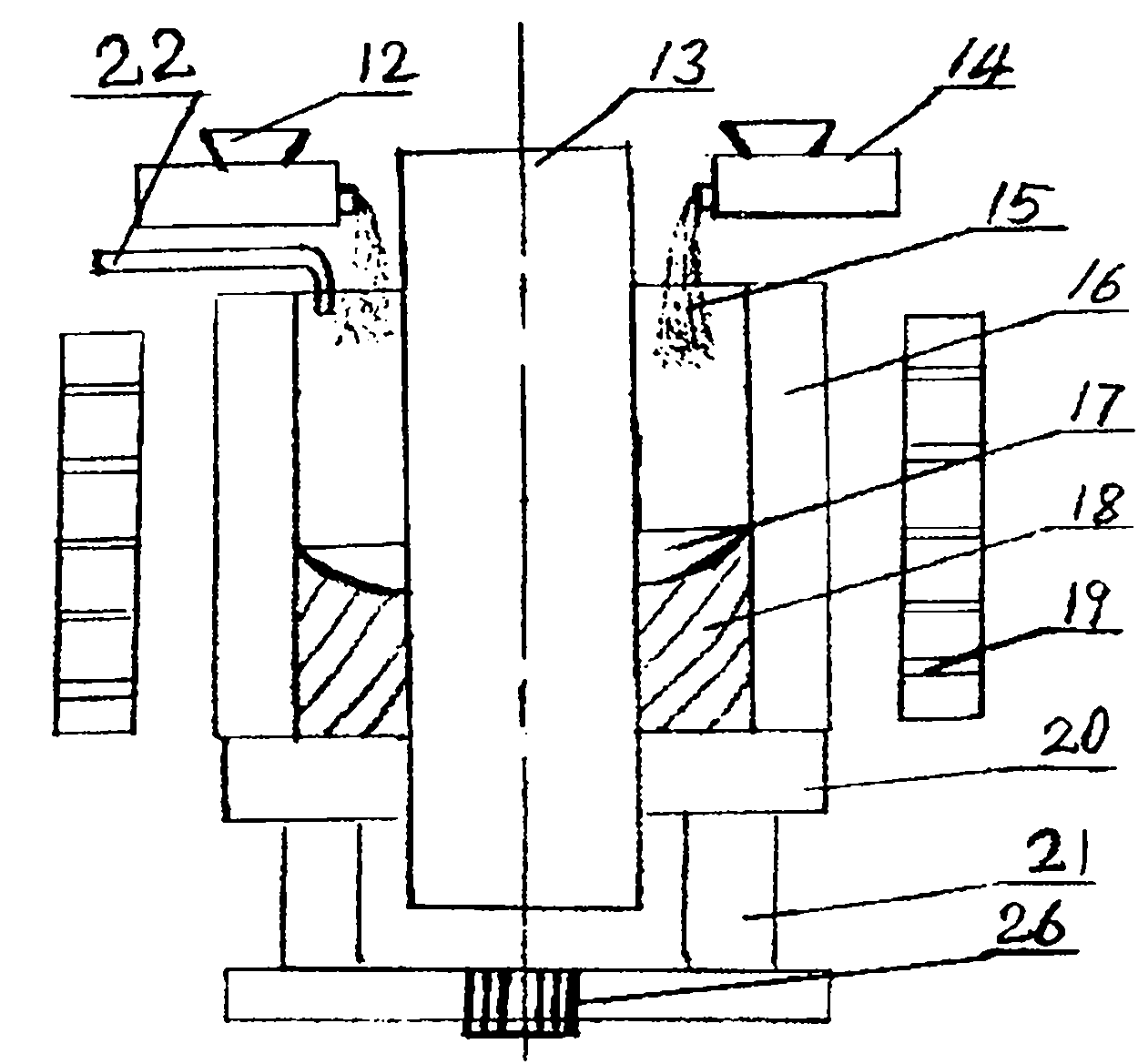

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

Halogen-free flame-proof static resistant polycarbonate composition and method for producing the same

The invention discloses a halogen-free flame retardant antistatic polycarbonate composition and a preparation method thereof. The composition comprises the components based on parts by weight: 50-70 parts of polycarbonate, 5-20 parts of polymer which can form a third phase, 8-15 parts of impact modifier, 3-15 parts of phosphonium flame retardant, 0.2 part of fluoro-polyolefine additive, 1-10 parts of conducting material and 0.1-1 part of other accessory ingredient. When in operation, the polymer which can form the third phase, the phosphonium flame retardant, the conducting material and other accessory ingredient are firstly melted and extruded by a double screw extruder to prepare intermediate composition; after being melted and extruded by the double screw extruder, the intermediate composition, the polycarbonate, the impact modifier and the fluoro-polyolefine additive are pelleted and then dried. The composition prepared by the invention does not contain chlorine and bromine, has excellent antistatic property, flame retardance, impact resistance and formability and needs a little conductive filler.

Owner:SOUTH CHINA UNIV OF TECH

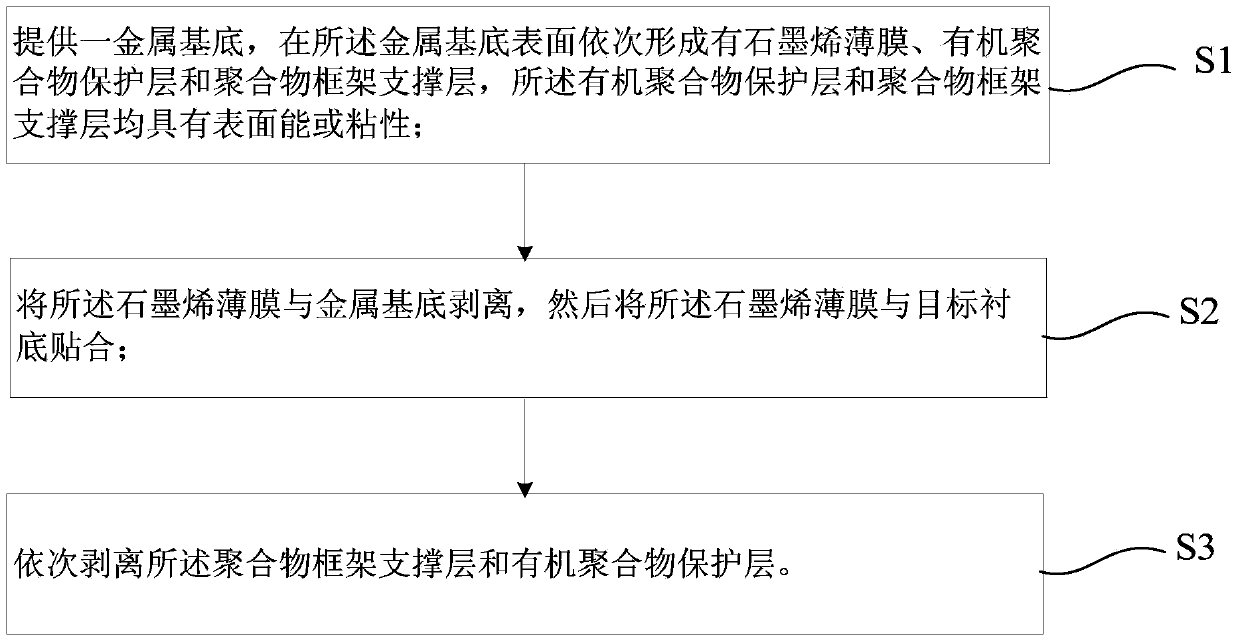

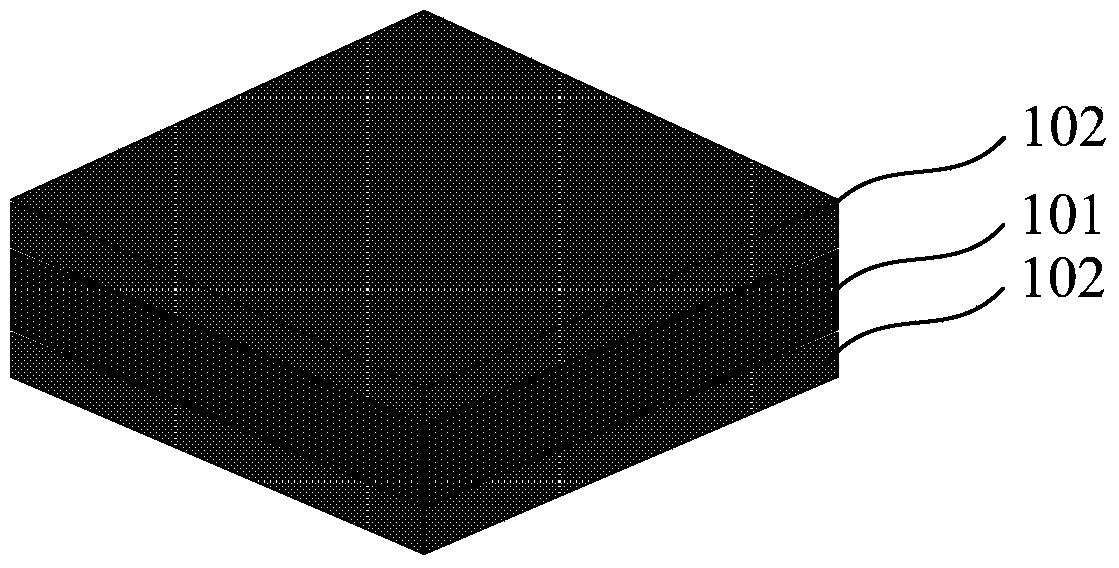

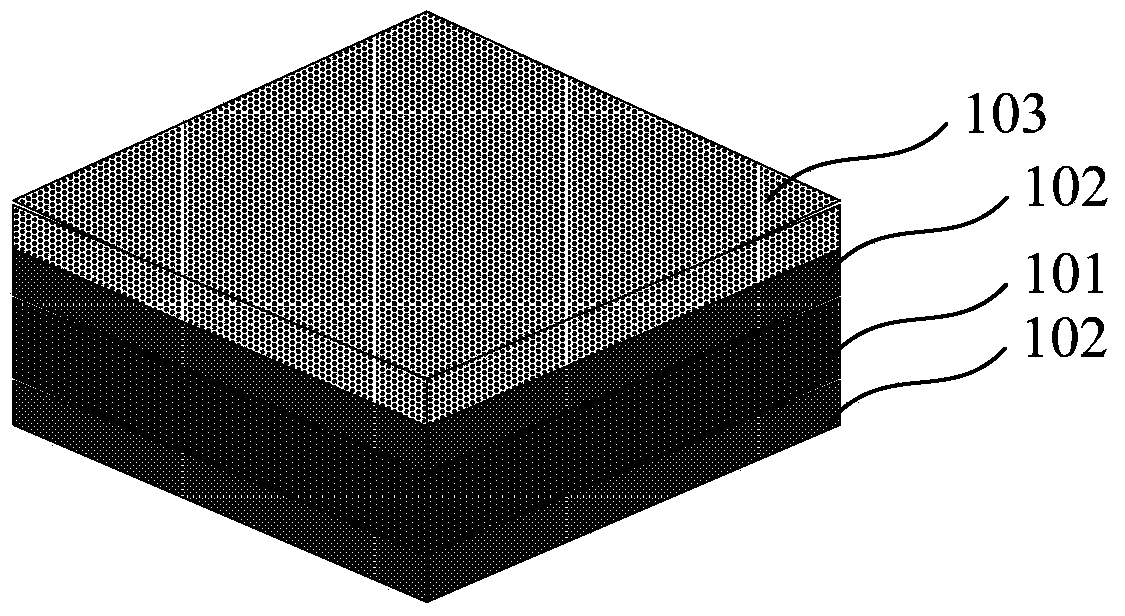

Transfer method of graphene film

The invention provides a transfer method of a graphene film, which at least comprises the following steps: providing a metal substrate, and sequentially forming a graphene film, an organic polymer protective layer and a polymer frame support layer on the metal substrate surface, wherein the organic polymer protective layer and polymer frame support layer respectively have surface energy or viscosity; peeling the graphene film from the metal substrate, and attaching the graphene film to a target substrate; and finally, sequentially peeling the polymer frame support layer and organic polymer protective layer. By utilizing the proper surface energy or proper viscosity of the organic polymer protective layer and polymer frame support layer, the organic polymer protective layer and polymer frame support layer can be directly attached without any adhesive, and can be peeled without damage after transfer, thereby simplifying and stabilizing the technique and ensuring the complete transfer of the graphene film and the reutilization of the metal substrate.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

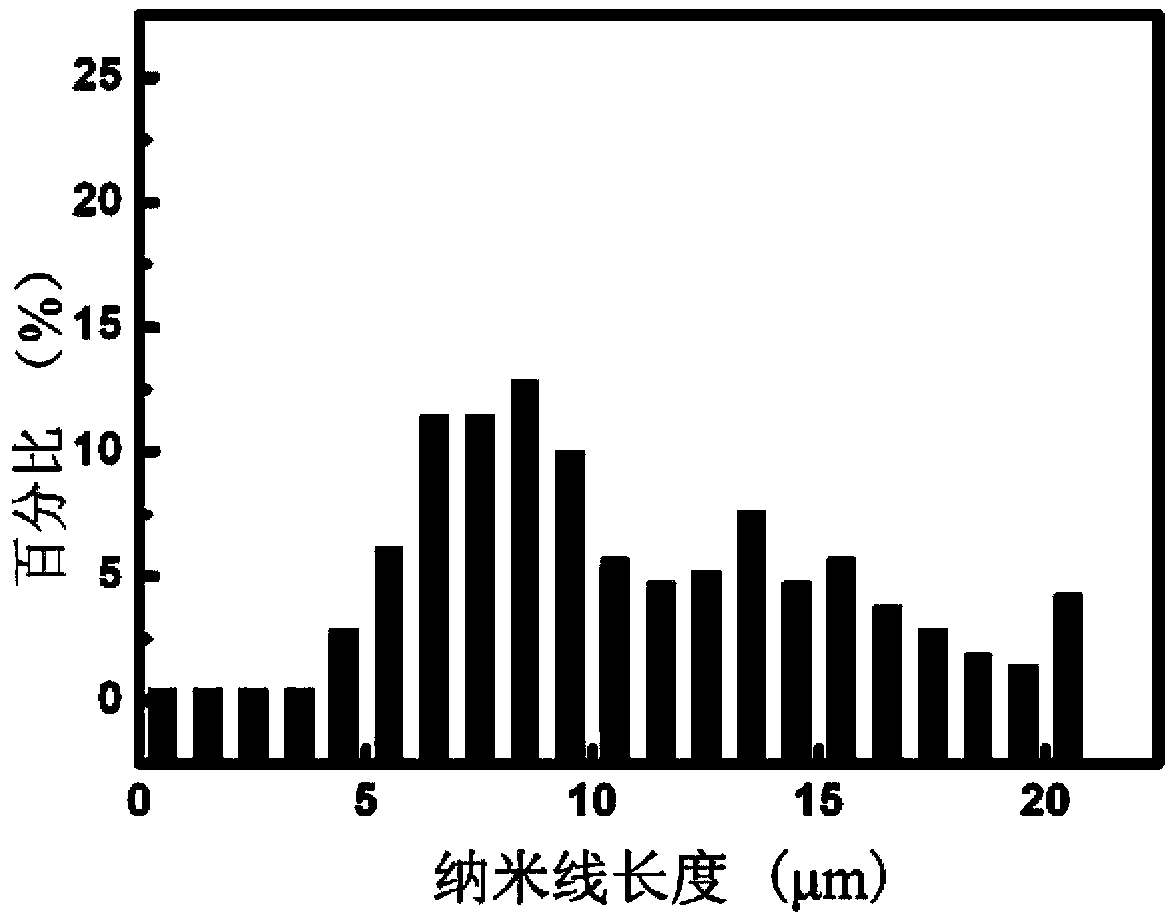

Preparation method and application of silver nanowire with high length-width ratio

ActiveCN103357889AGrowth inhibitionPrompt generation and lengthConductive layers on insulating-supportsMetal/alloy conductorsWidth ratioElectrically conductive

The invention discloses a method for compositing a silver nanowire with a high length-width ratio, that is, through a one-time addition of silver salt to carry out reduction reaction, the silver nanowire with the average length of more than 52 micrometers and the average length-width ratio of more than 400 can be acquired. The method does not need to accurately control the adding velocity of reactant, the composited silver nanowire is good in dispersity and high in uniformity, compared with the traditional polyhydric alcohol method, the average length-width ratio of the silver nanowire is improved by more than 5 times, through the preparation of a flexible transparent conductive film on a transparent flexible plastic substrate, the visible light penetration rate is more than 90 %, and the square resistance is lower than 10 Omega / square. Compared with the traditional polyhydric alcohol method, the method provided by the invention is simple in technology control and high in repeatability, and is in favor of the batch production of the silver nanowire with the high length-width ratio.

Owner:CENT SOUTH UNIV

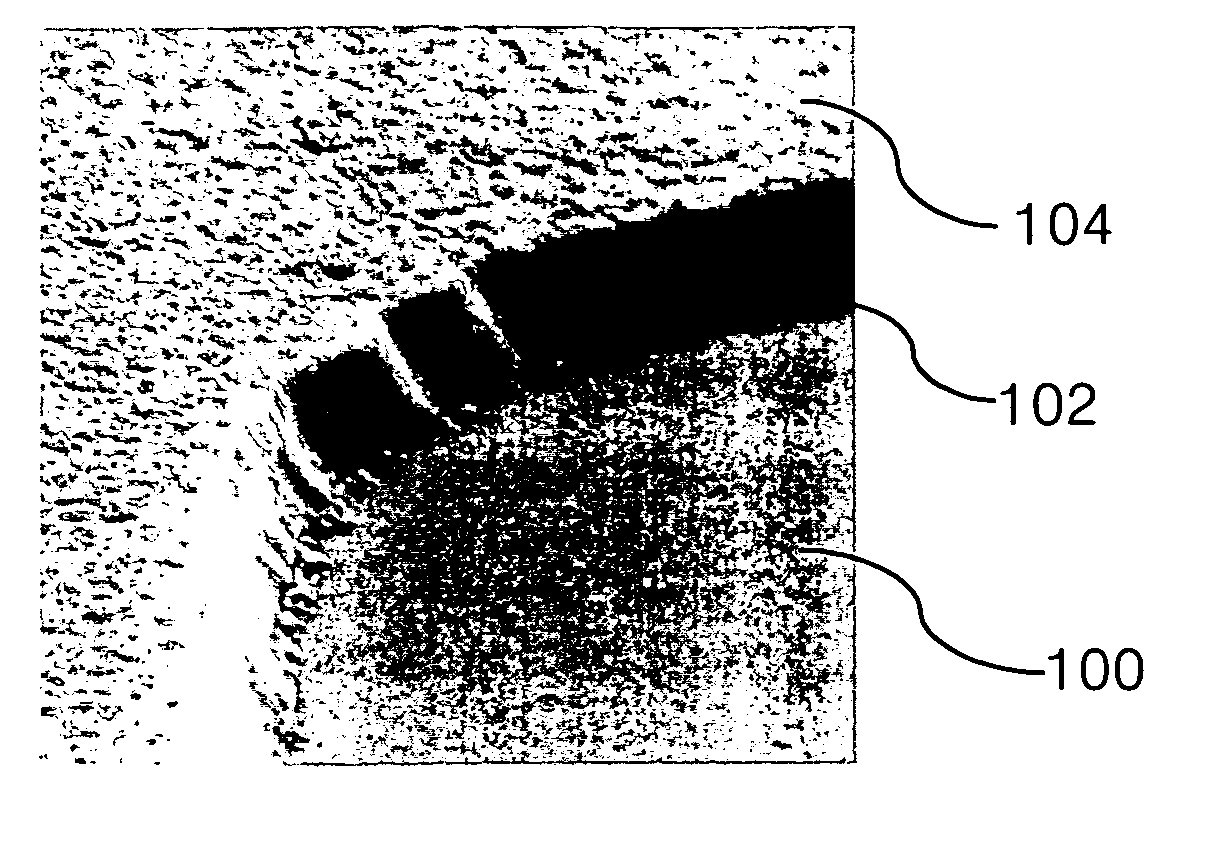

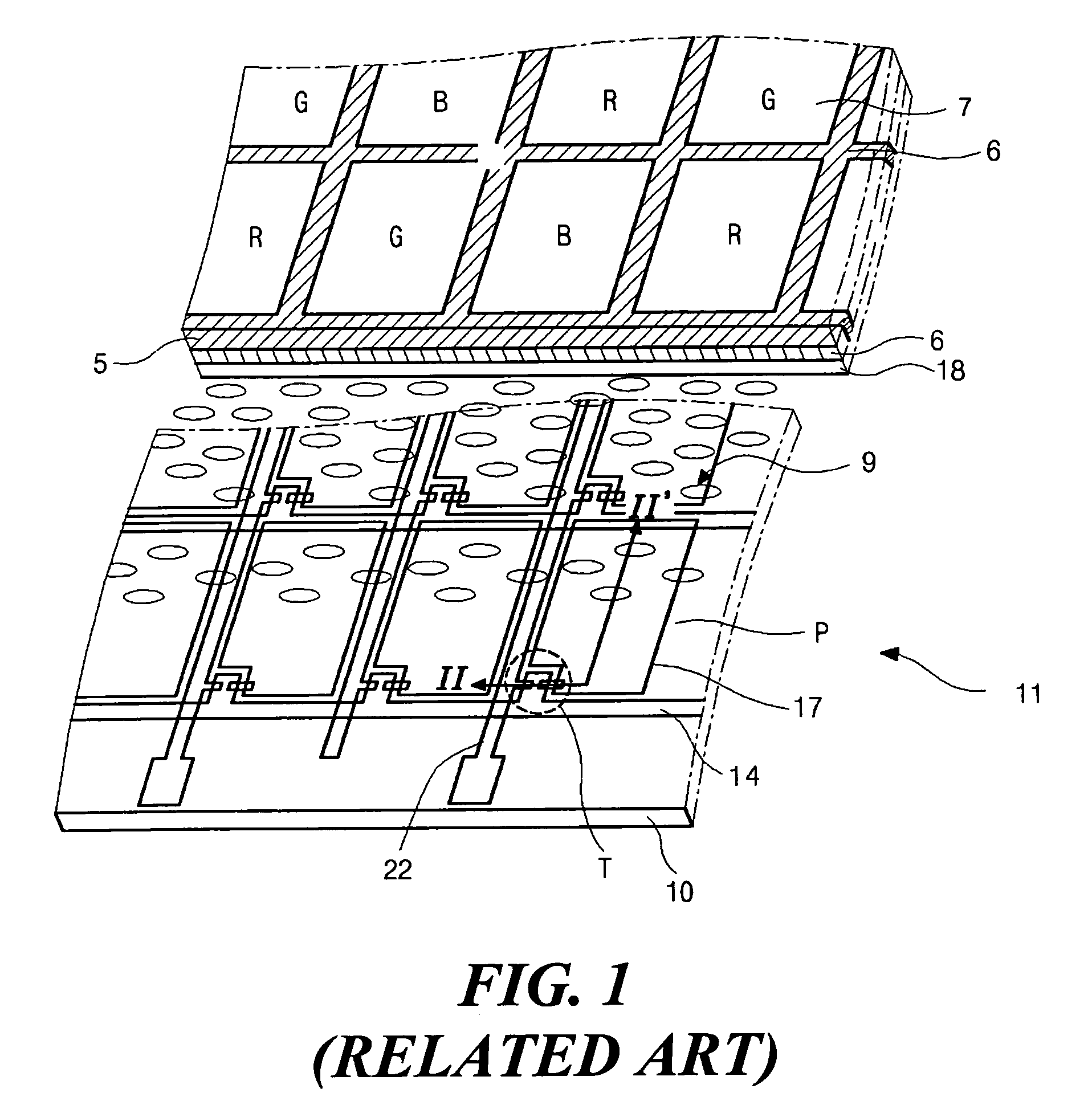

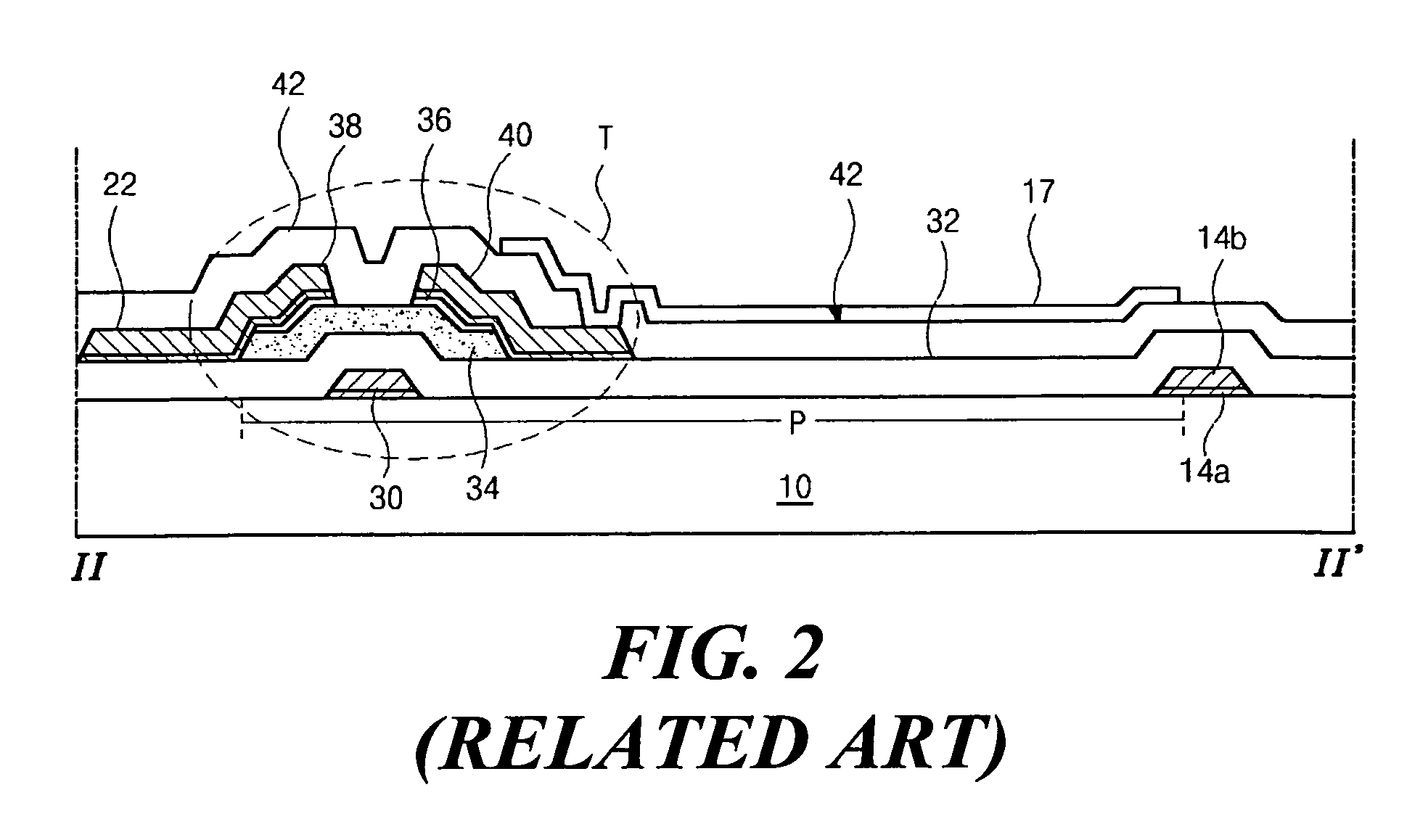

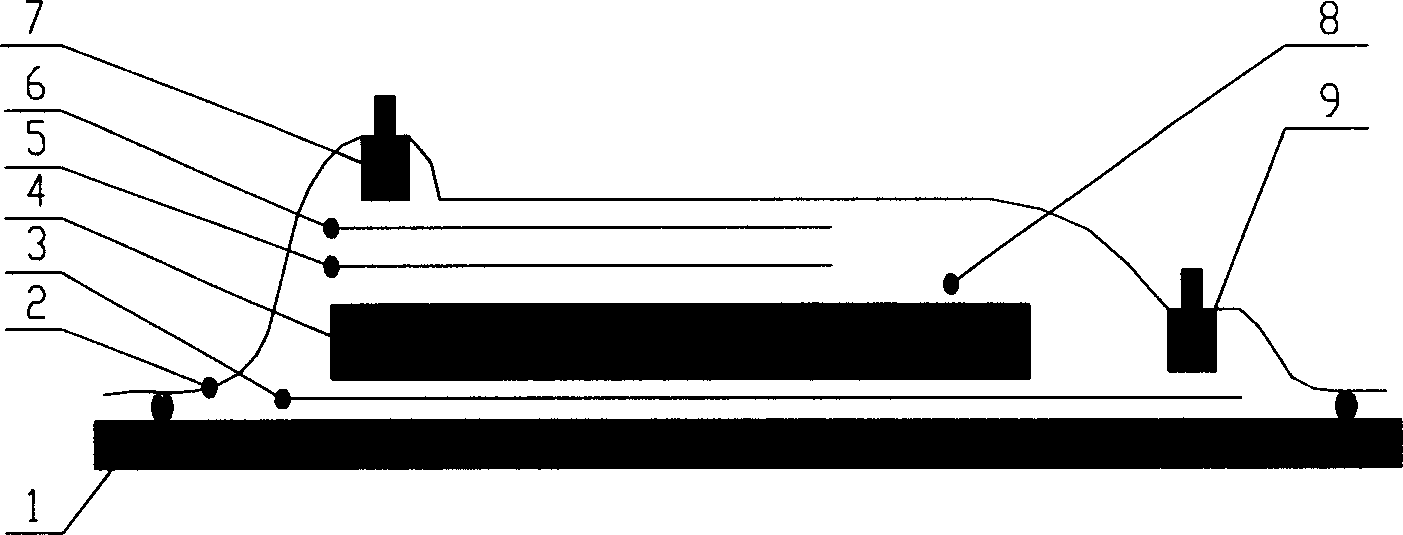

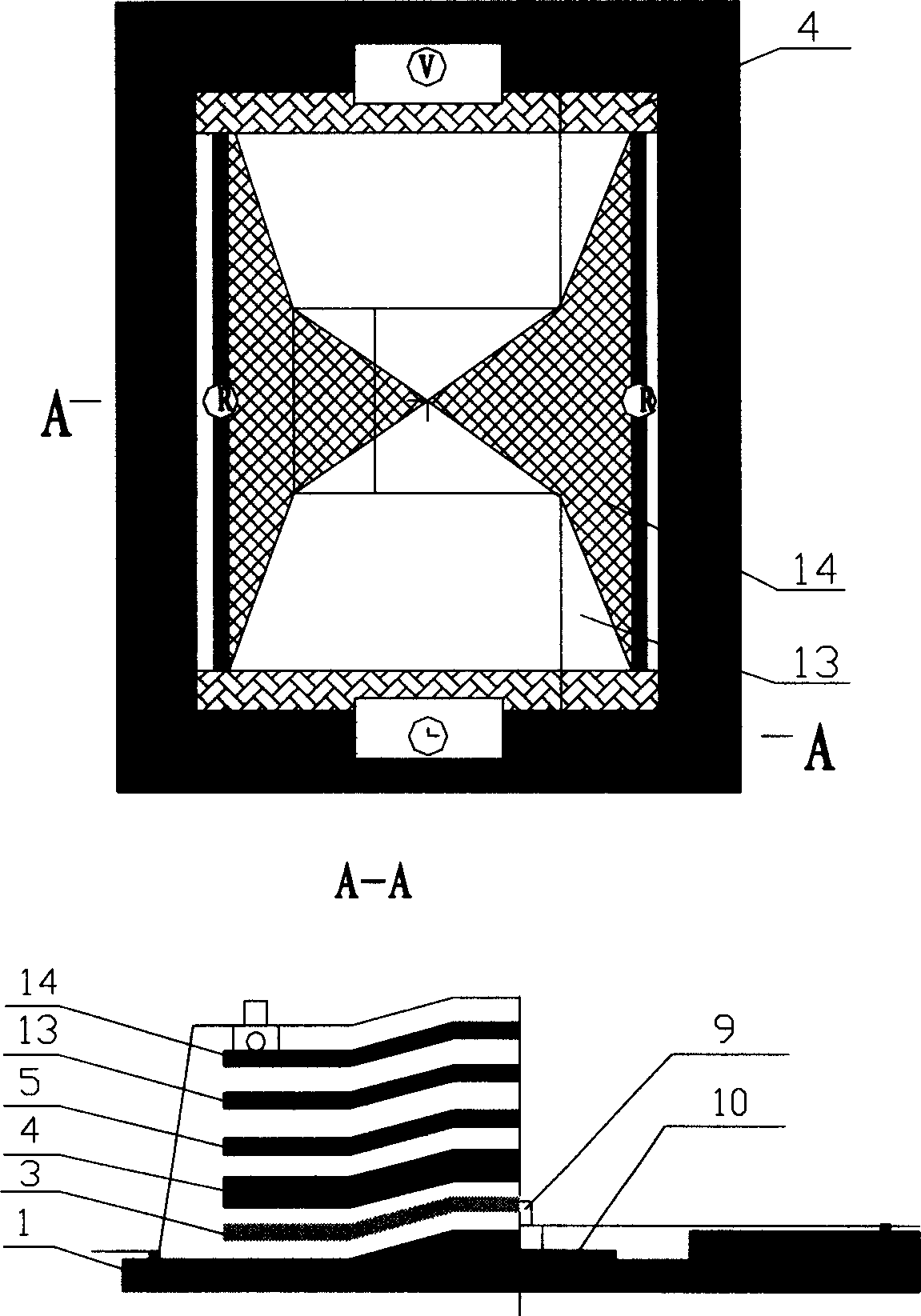

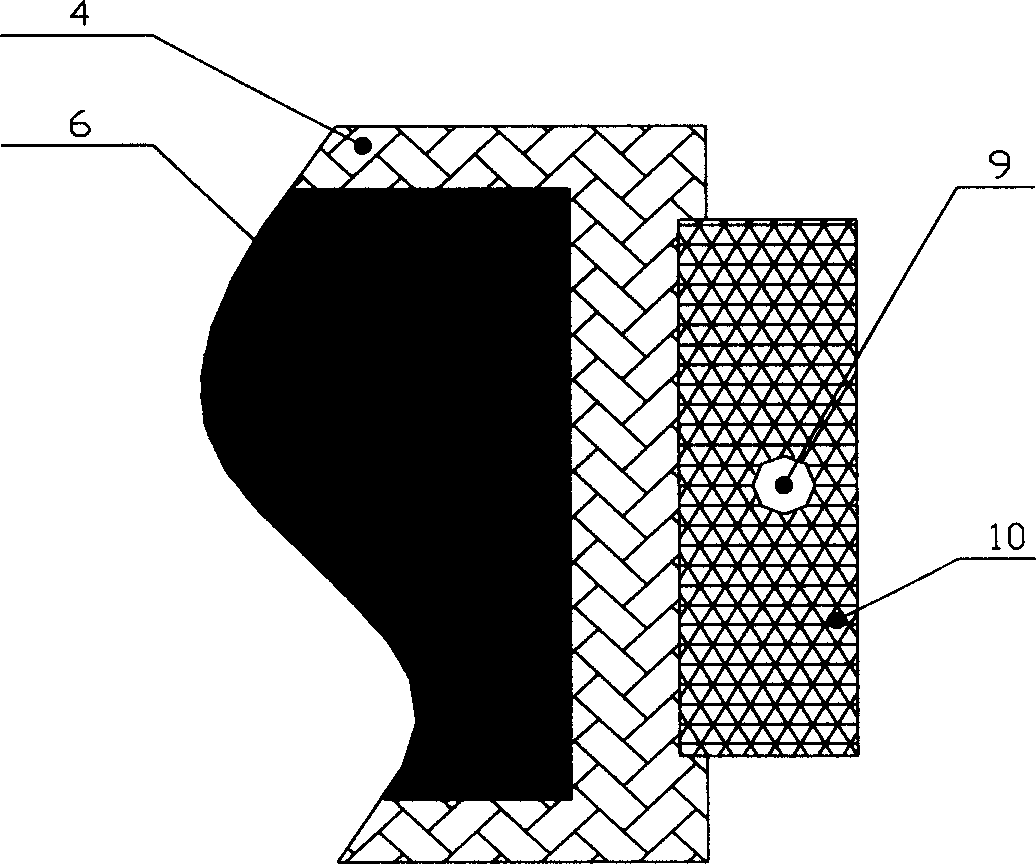

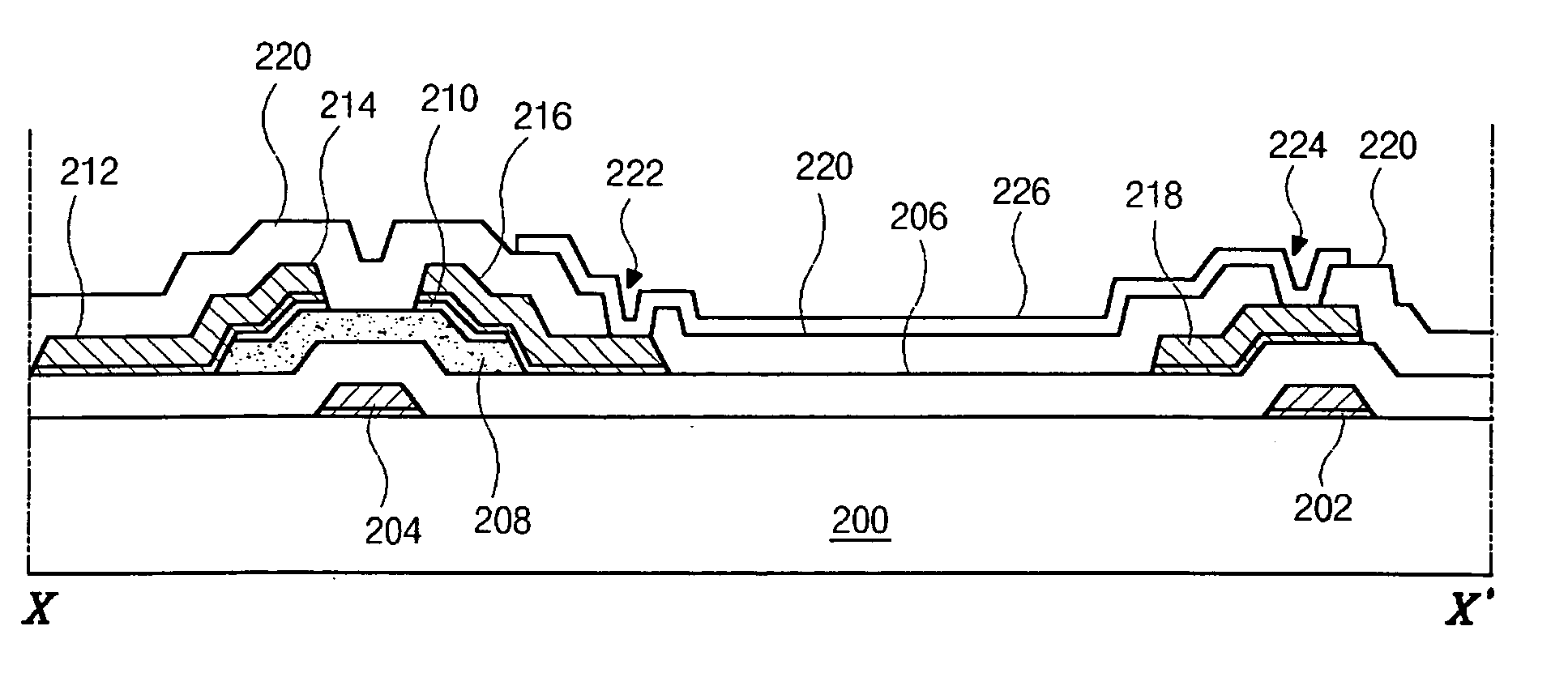

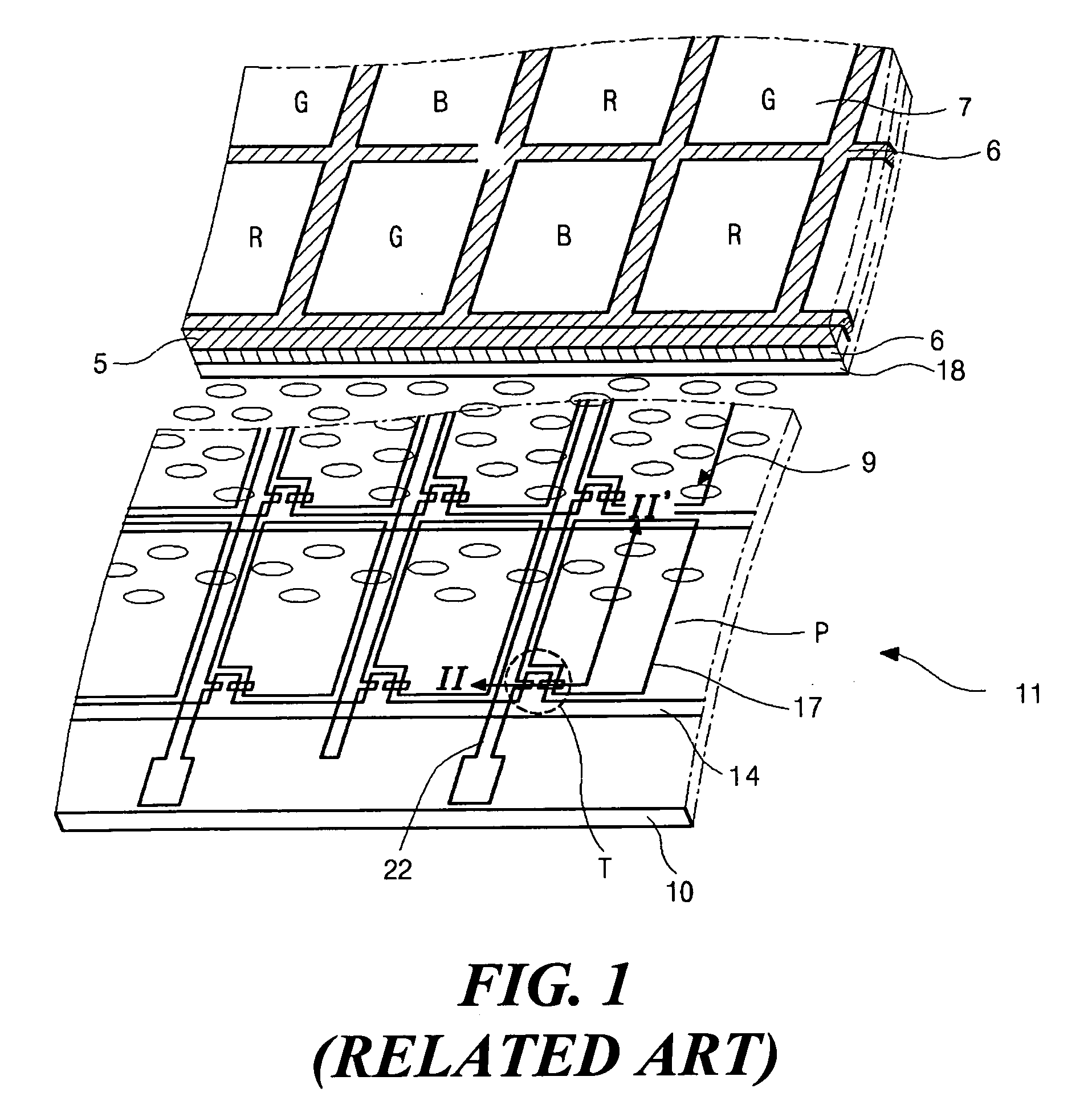

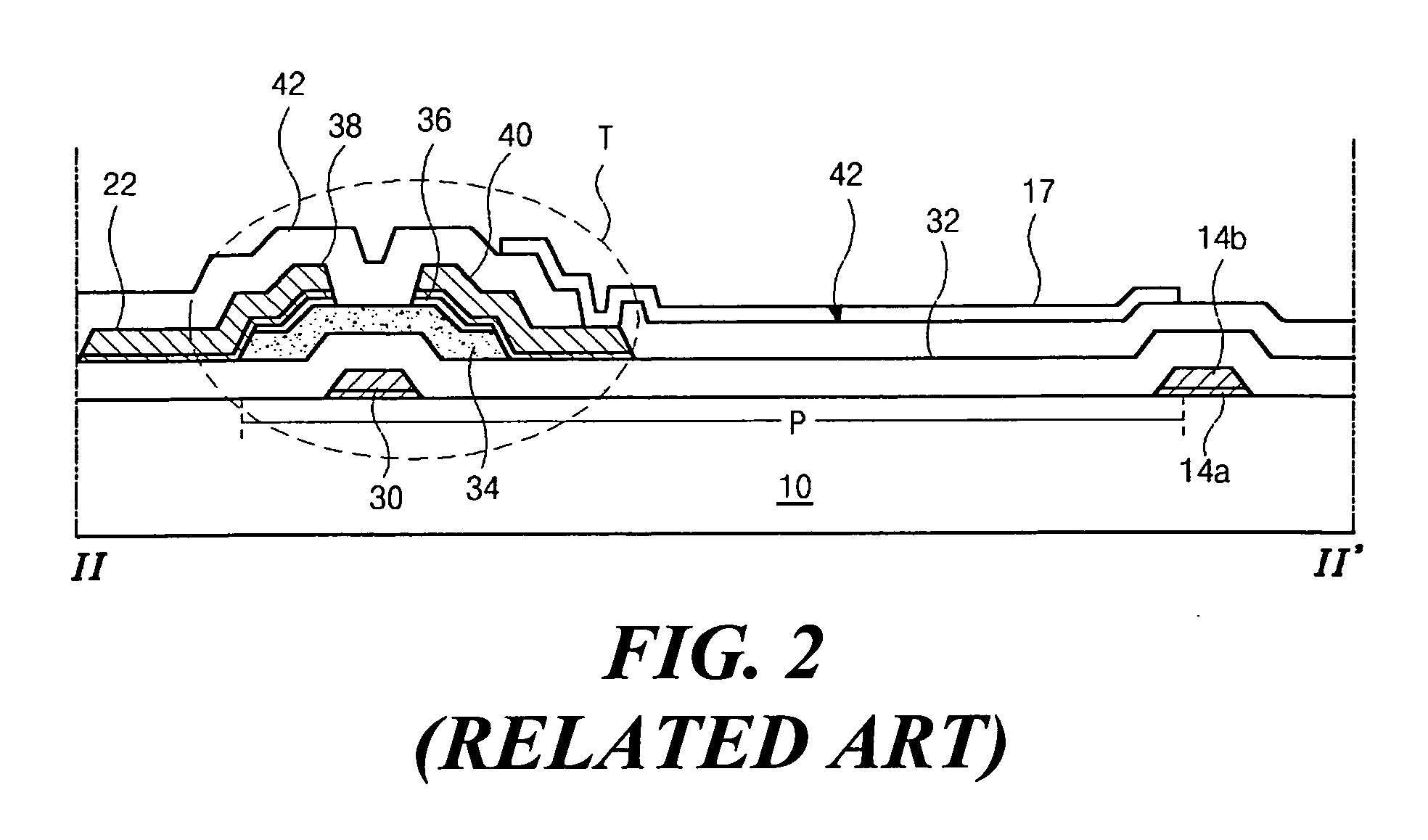

Array substrate having double-layered metal patterns and method of fabricating the same

ActiveUS7061565B2Improve processing stabilityImprove manufacturing yieldTransistorSemiconductor/solid-state device detailsInsulation layerLiquid-crystal display

An array substrate having double-layered metal patterns for use in a liquid crystal display device and a manufacturing method thereof are disclosed in the present invention. The array substrate includes a gate electrode and a gate line each having a molybdenum alloy (Mo-alloy) layer and a copper (Cu) layer configured sequentially on a substrate; a gate insulation layer on the substrate to cover the gate electrode and the gate line; an active layer arranged on the gate insulation layer in a portion over the gate electrode; an ohmic contact layer on the active layer; a data line on the gate insulation layer, the data line crossing the gate line and defining a pixel region; source and drain electrodes on the ohmic contact layer, the source electrode extending from the data line, and the drain electrode spaced apart from the source electrode; a passivation layer on the gate insulation layer covering the data line and the source and drain electrode, the passivation layer having a drain contact hole exposing a portion of the drain electrode; and a pixel electrode configured on the passivation layer in the pixel region, the pixel electrode electrically contacting the drain electrode through the drain contact hole.

Owner:LG DISPLAY CO LTD

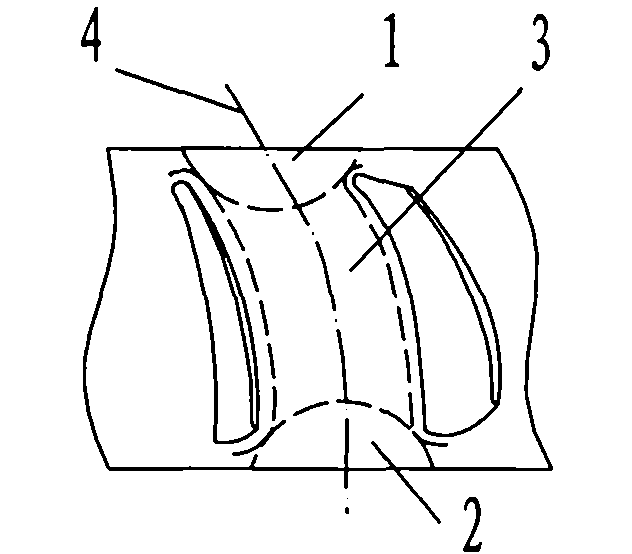

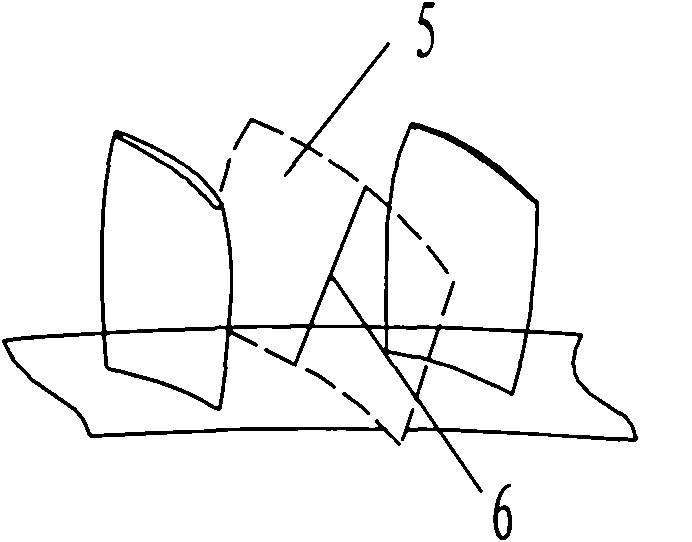

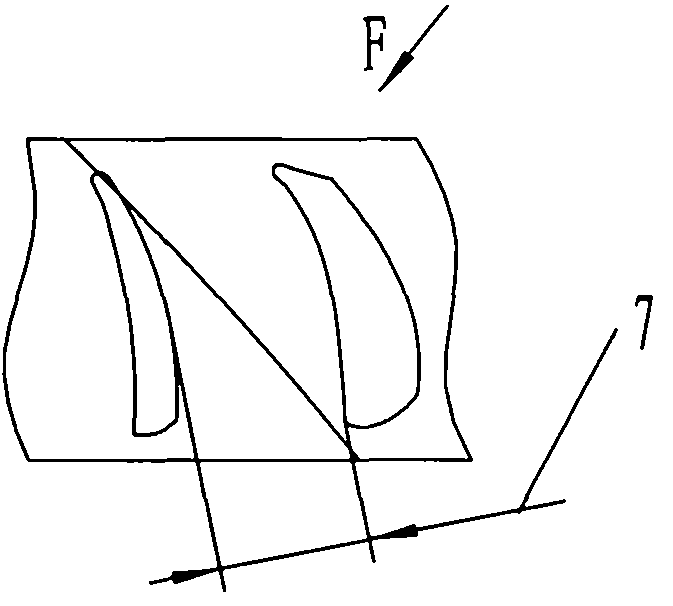

Method for composite machining of blisk flow passage

InactiveCN101966604AImprove rigidityImprove processing stabilityMilling equipment detailsNumerical controlBoundary contour

The invention belongs to the technical field of aircraft engines, and discloses a method for the composite machining of a blisk flow passage. The method is a numerical control machining method of selecting the adaptive machining strategy based on regional characteristics. The method comprises the following steps of: (1) dividing a machining region; and (2) selecting the adaptive numerical control machining strategy based on the regional characteristics. In the method, a rough slotting numerical control machining method of combining milling, drilling milling and slotting milling of a cycloid is adopted, so that a medial cambered surface is approximate to a curved surface of a blade profile, and the boundary contour and the optimal cutter-axis vector of a rough machining region in a channel are determined. The method has the advantages that the machining method of region division and cutting-in changing enhances the rigidity and machining stability of blades; a process method of combining the milling and slotting milling of the cycloid improves the durability of cutters and the removal rate of materials; and the vibration phenomenon in the rough machining process is prevented effectively, the cutting force is reduced, the movement space of the cutters is expanded farthest, and the machining efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

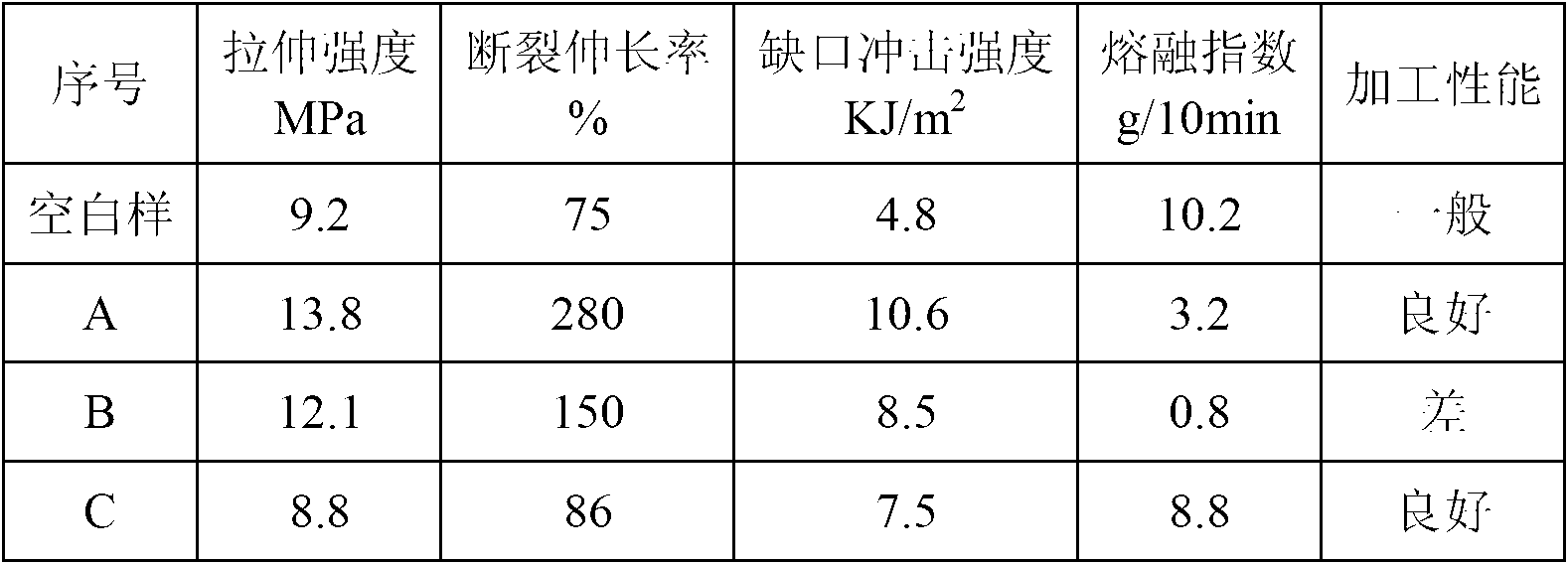

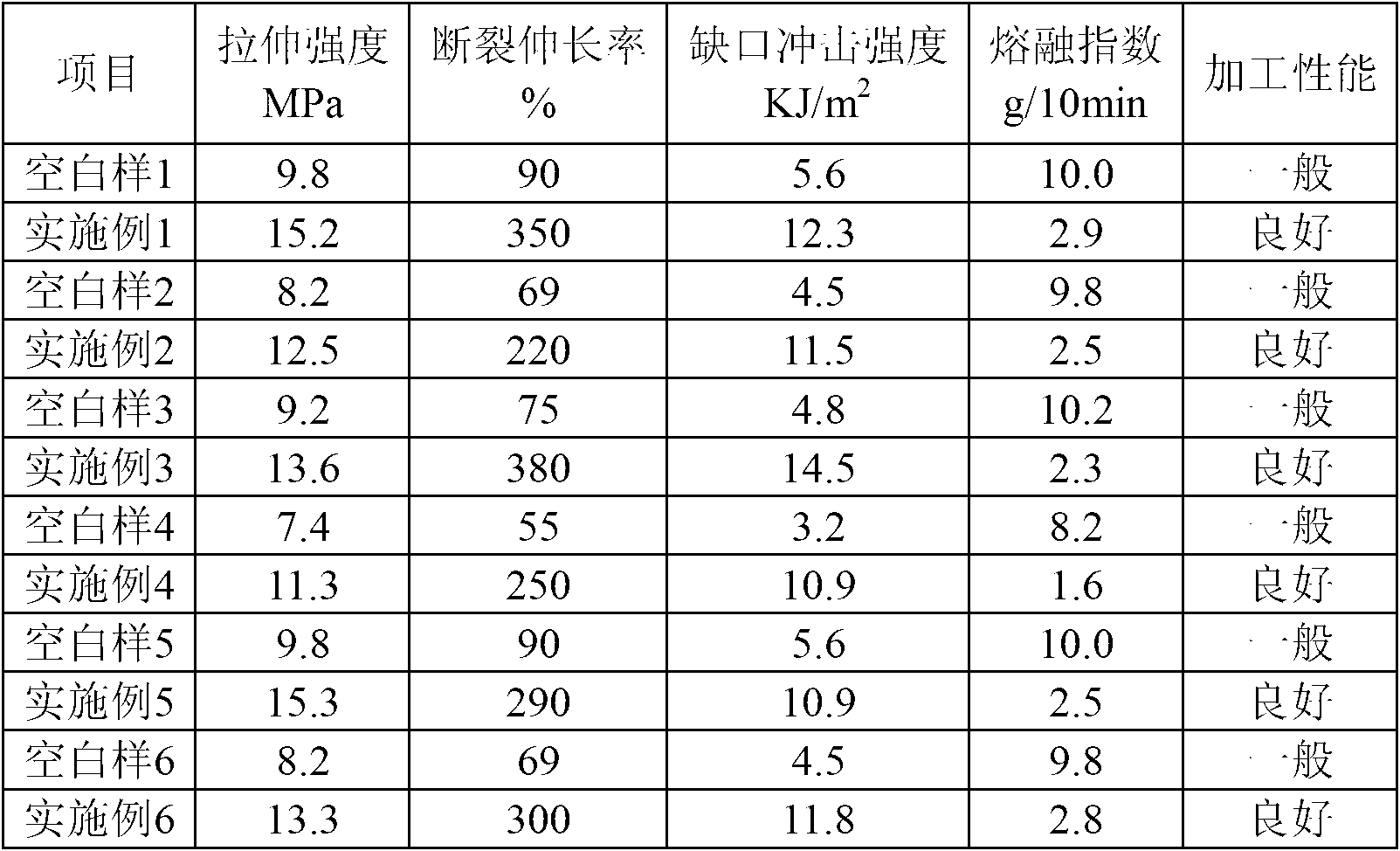

Enhanced toughening recycled polyethylene material and preparation method thereof

The invention relates to an enhanced toughening recycled polyethylene material. The enhanced toughening recycled polyethylene material is characterized by comprising, by mass, recycled polyethylene 100 parts, crosslinking masterbatch 1part to 5 parts, flexibilizer 0part to 3 parts, antioxygen 0.2 part to 1.5 parts, and processing agent 0.1 part to 0.5 part, wherein the crosslinking masterbatch is ethylene-vinyl acetate copolymer with a substrate as ethylene, a cross-linking agent is dicumyl peroxide and the like, an assistant cross-linking agent is melamine three allyl ester and the like, on the basis of total mass of the crosslinking masterbatch, by mass, a base body is 95%-98%, the cross-linking agent is 2%-5%, and the assistant cross-linking agent is 0%-2%. The tensile strength of the enhanced toughening recycled polyethylene material is 11.3-15.3MPa, the rupture elongation ratio is 220%-380%, the notch impact strength is 10.9-14.5KJ / m2, the melt index is 1.6g-2.9g / 10min, and the processability is good. The invention further discloses and a preparation method of the enhanced toughening recycled polyethylene material.

Owner:CHANGZHOU HIGH TECH RES INST OF NANJING UNIV

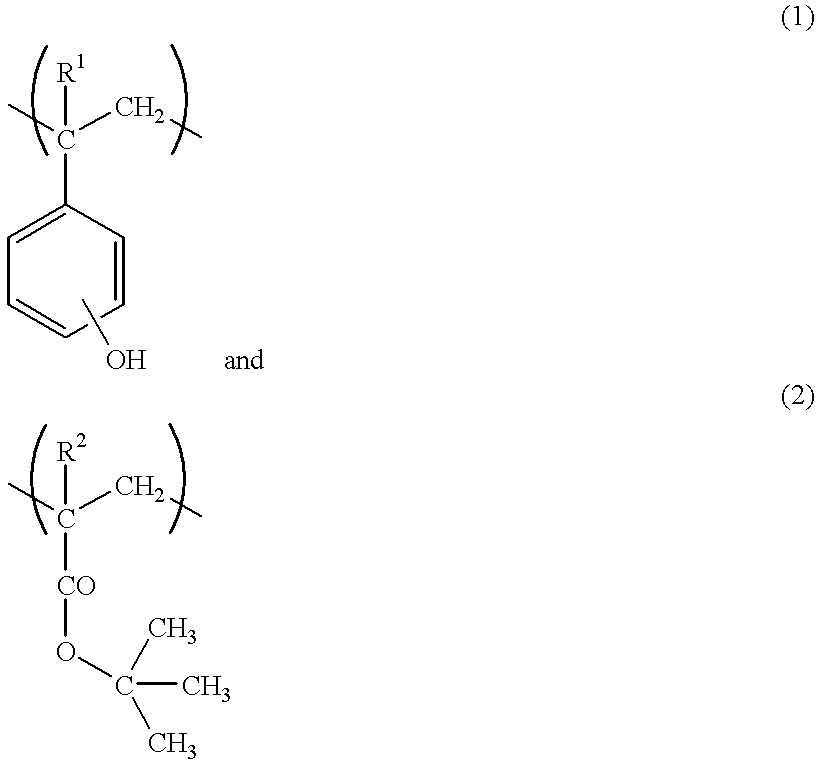

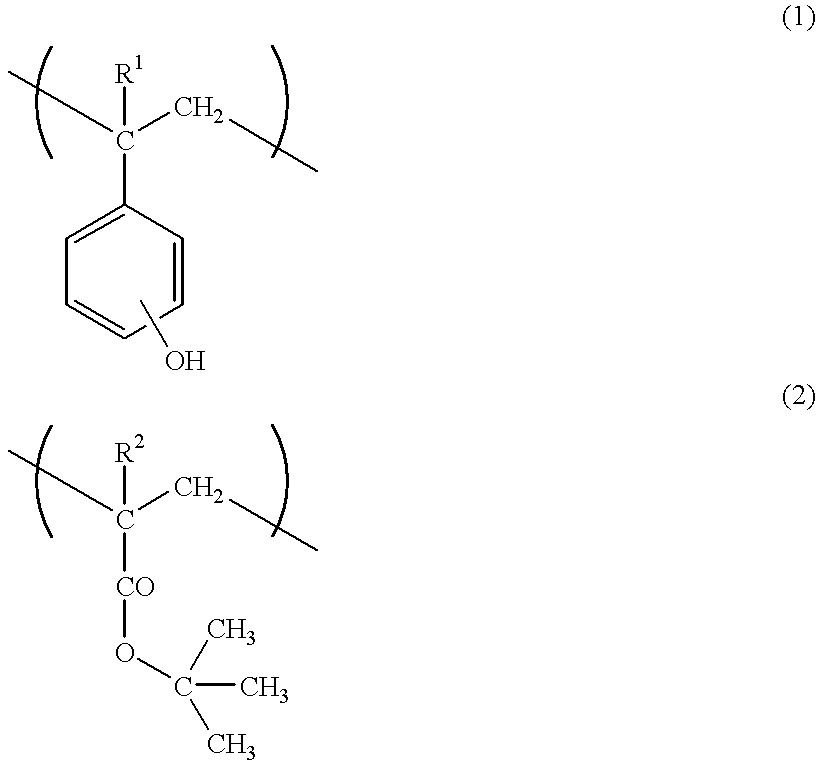

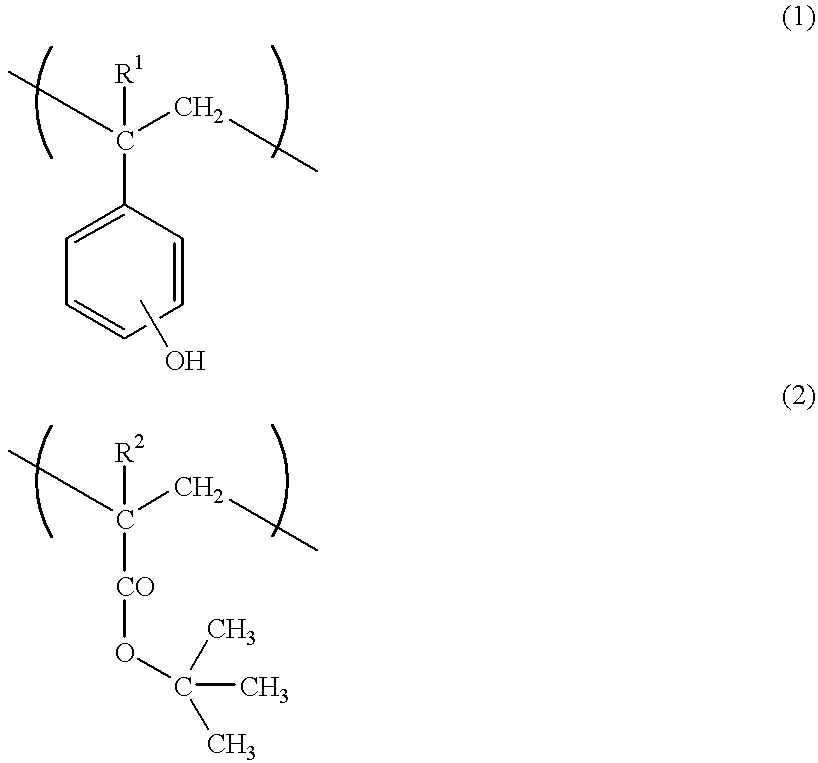

Radiation sensitive resin composition

InactiveUSRE37179E1Improve accuracyIncrease resistanceRadiation applicationsSemiconductor/solid-state device manufacturingPolymer dissolutionPolymer science

A radiation sensitive resin composition which comprises (A) a polymer which becomes alkali-soluble in the presence of an acid and (B) a radiation sensitive acid generator which generates an acid upon irradiation with a radiation, said polymer (A) comprising two recurring units represented by the general formulas (1) and (2) and a recurring unit which acts to reduce the solubility of the polymer is an alkali developer after the irradiation:wherein R1 represents a hydrogen atom or a methyl group and R2 represents a hydrogen atom or a methyl group. Said composition provides a chemically amplified positive resist which can give a fine pattern with a good pattern shape, and said resist is freed from volume shrinkage, peeling failure and adhesive failure, is excellent in dry etching resistance and effectively reacts with various radiations to give a good pattern shape which is excellent in photolithographic process stability, said pattern shape having no thinned portion at the upper part.

Owner:JSR CORPORATIOON

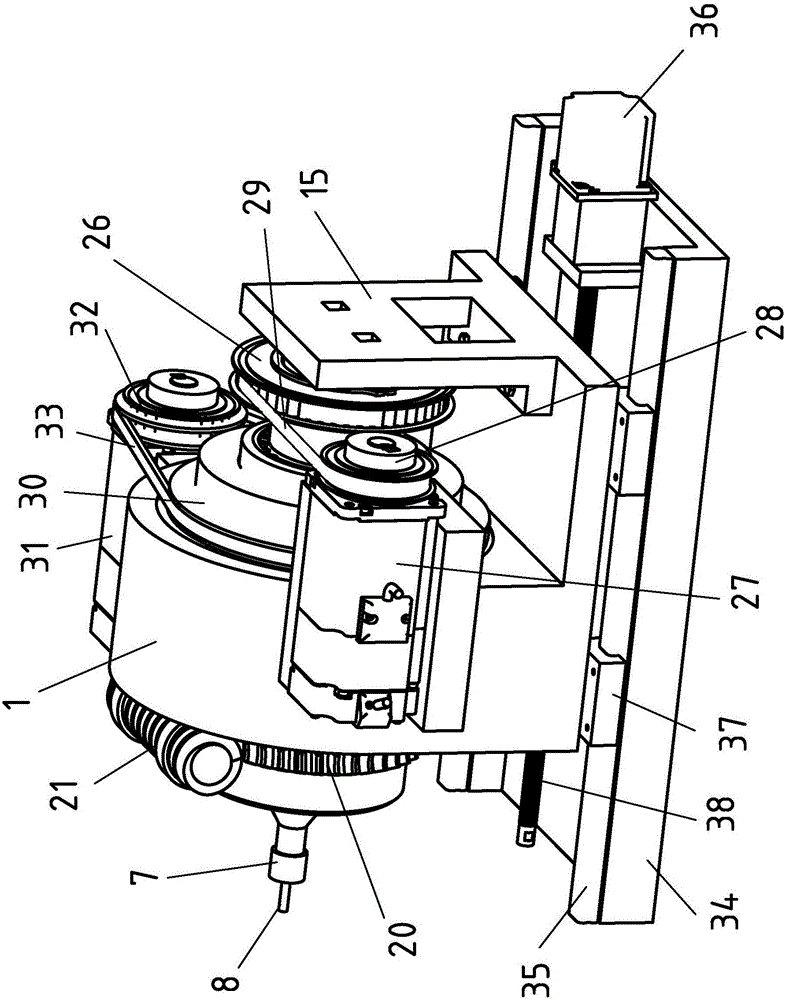

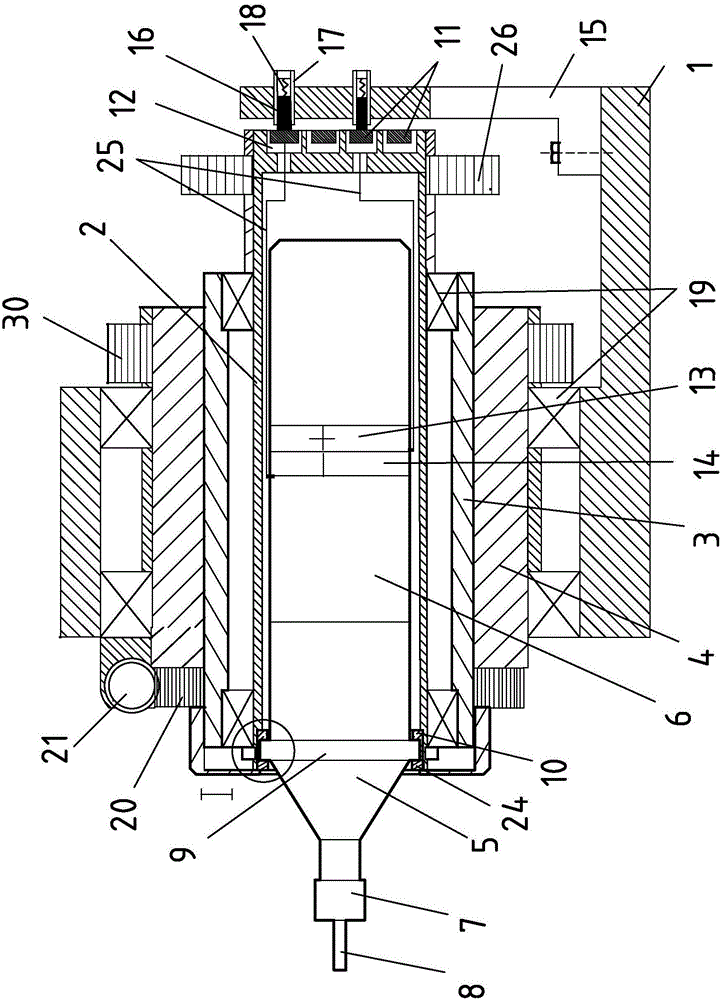

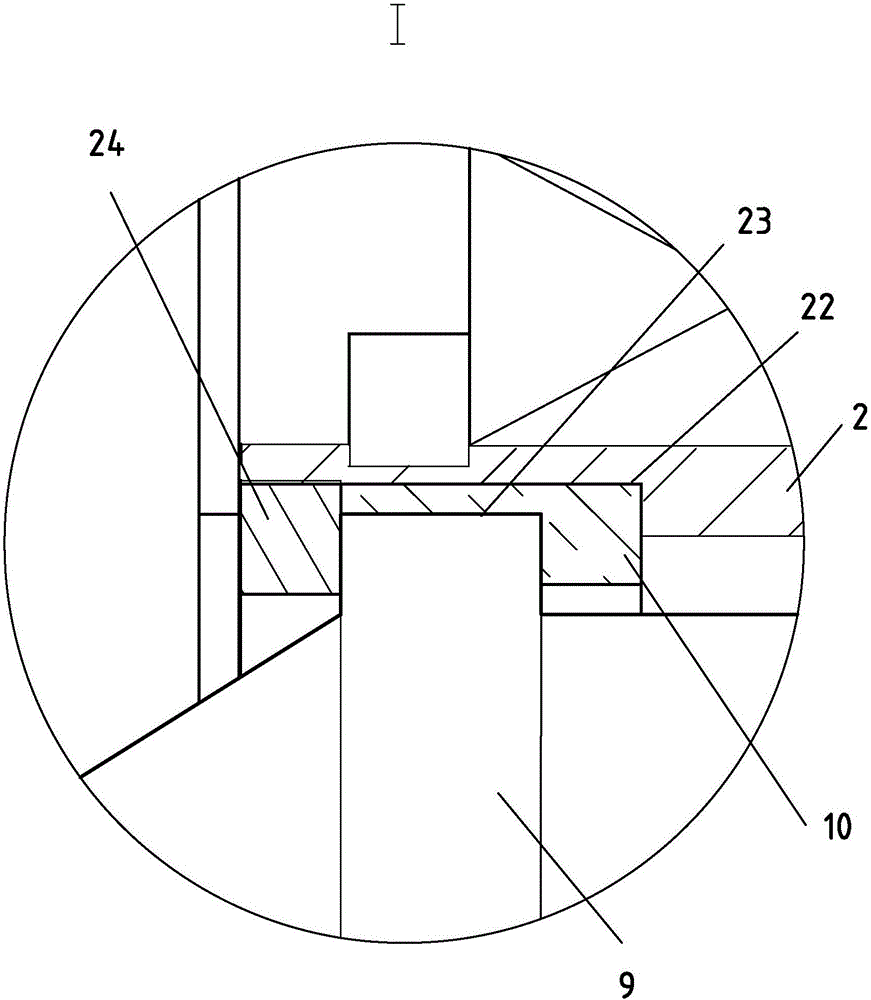

Ultrasonic helical hole milling device and machining method

ActiveCN106077774AImprove hole qualityReduce cutting forceRevolution surface grinding machinesMilling equipment detailsMilling cutterTransducer

The invention discloses an ultrasonic helical hole milling device which comprises a spindle support, an ultrasonic sleeve, an inner eccentric sleeve, an outer eccentric sleeve, an amplitude-change pole and a transducer located in the ultrasonic sleeve. The amplitude-change pole is connected with a hole forming tool through a spring chuck, and the hole forming tool is a milling cutter or a grinding wheel. The amplitude-change pole is connected with the transducer through an annular flange which is connected with the inner wall of the ultrasonic sleeve through an annular force sensor used for measuring axial and radial force borne by the annular flange. The ultrasonic helical hole milling device further comprises a helical hole-milling rotation driving device connected with the ultrasonic sleeve, a helical hole-milling revolution driving device connected with the outer eccentric sleeve and a feeding system for driving the spindle support to conduct feeding along the axis of the amplitude-change pole. The invention further discloses a machining method for conducting ultrasonic helical hole milling through the ultrasonic helical hole milling device. The ultrasonic helical hole milling device and the machining method have the advantages that the hole forming quality is high, hole forming quality consistency is good, and machining stability is good.

Owner:DALIAN UNIV OF TECH

Composite material vacuum auxiliary forming process

The present invention relates to the basic technological process the same as traditional vacuum auxiliary forming process. The present invention has the obvious features that resin baffling area is set in the edges of prefabricated part to lower the resin flow rate and form perfect soaking of resin to the prefabricated part; that air exhaust passage is set in the air exhaust system to form the 'line type' air exhaust structure for fast exhaust of air inside the vacuum bag; and that resin medium guiding laminated and spread structure is applied to control the flow state of resin effectively. The said technological process can raise the reliability and product quality of complicated product, and has low supplementary material consumption.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

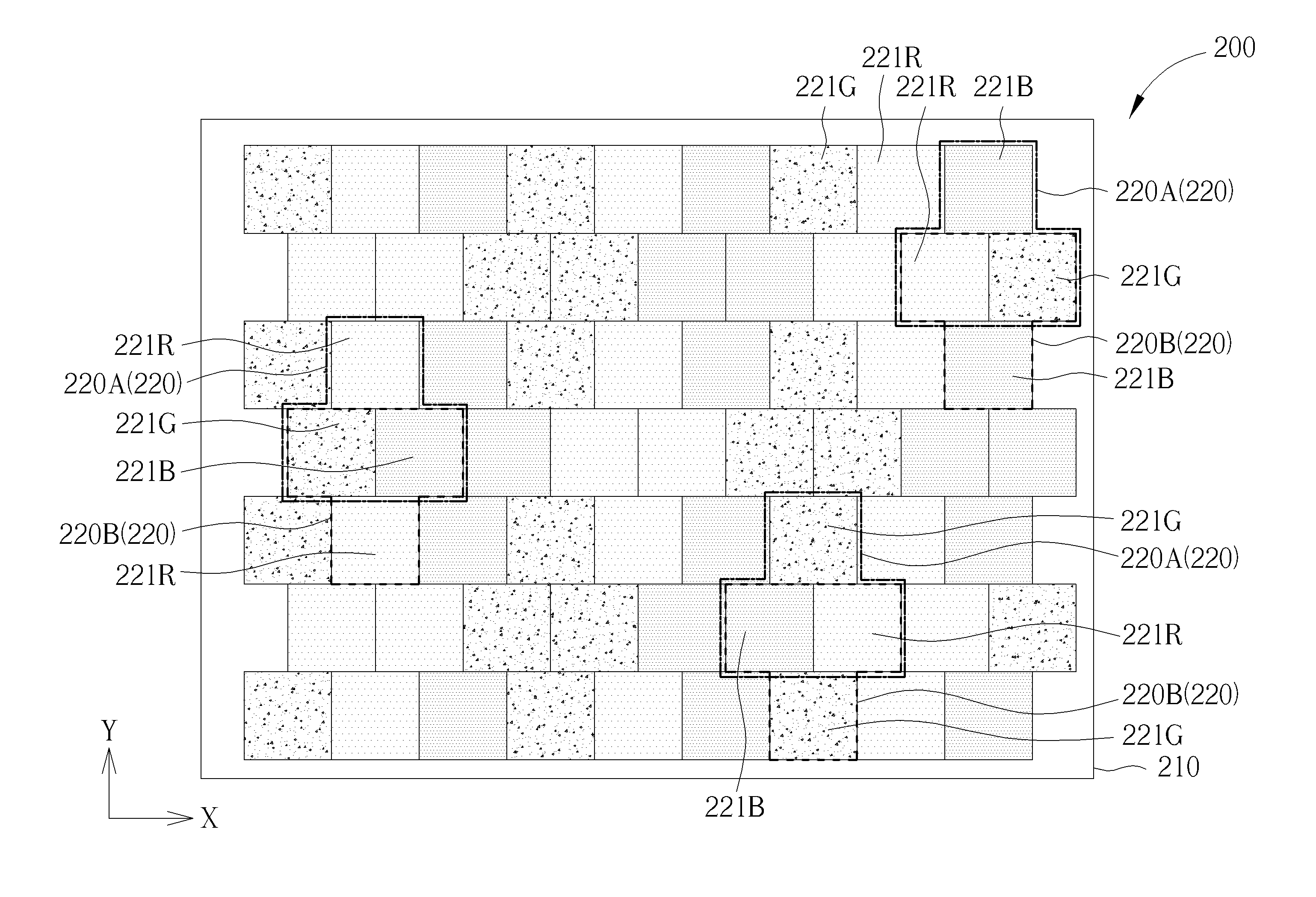

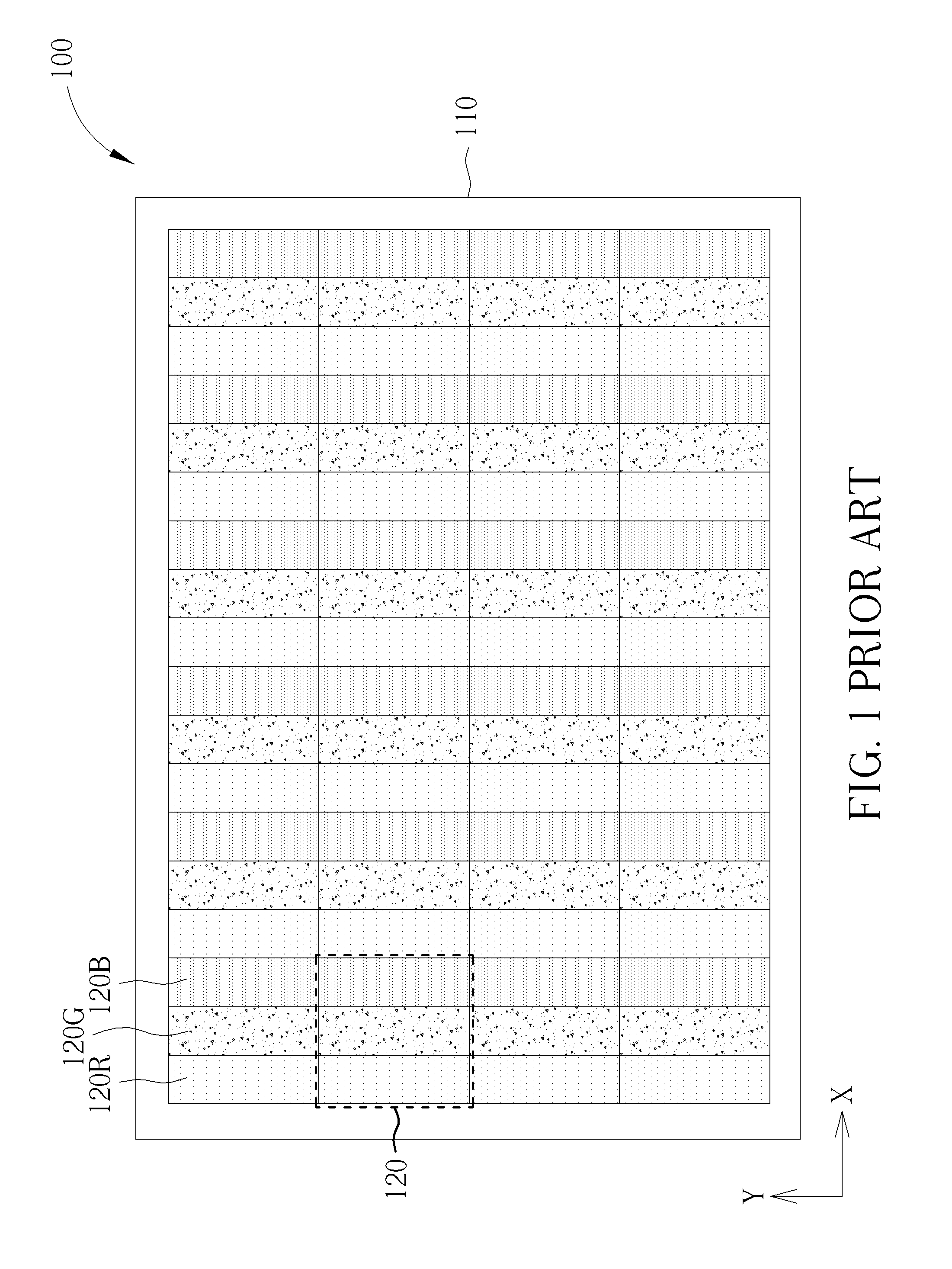

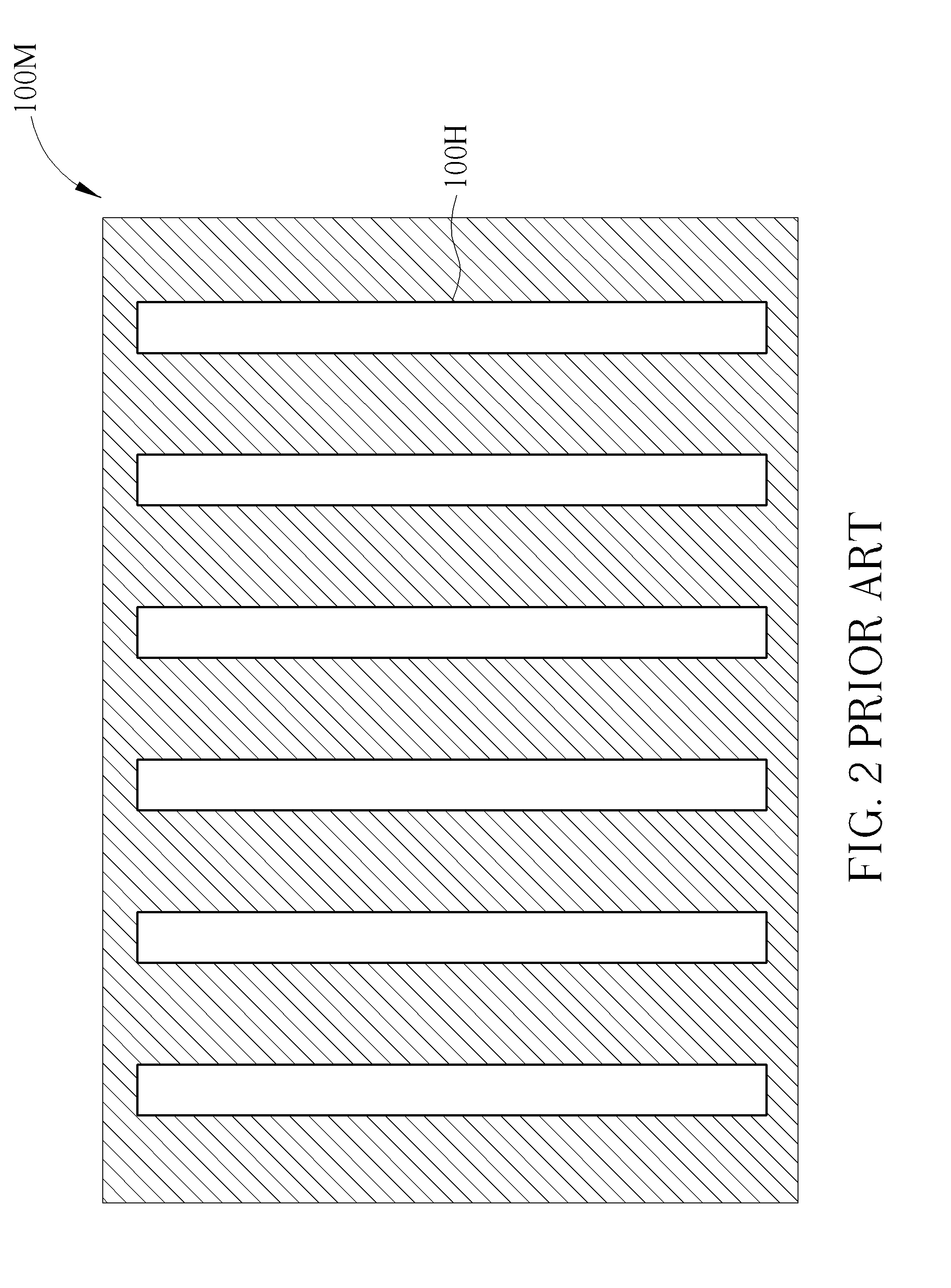

Pixel structure of organic light emitting display device

InactiveUS8896200B2Solve high precisionImprove processing stabilityDischarge tube luminescnet screensLighting support devicesComputer graphics (images)Display device

A pixel structure of an organic light emitting display device includes a substrate and a plurality of display pixel units disposed on the substrate. Each of the display pixel units includes a first sub-pixel, a second sub-pixel and a third sub-pixel disposed adjacently to one another. The first sub-pixel in each of the display pixel units is disposed adjacently to three first sub-pixels respectively disposed in three adjacent display pixel units to form a first pixel unit. The second sub-pixel in each of the display pixel units is disposed adjacently to three second sub-pixels respectively disposed in three adjacent display pixel units to form a second pixel unit. The third sub-pixel in each of the display pixel units is disposed adjacently to three third sub-pixels respectively disposed in three adjacent display pixel units to form a third pixel unit.

Owner:CHUNGHWA PICTURE TUBES LTD

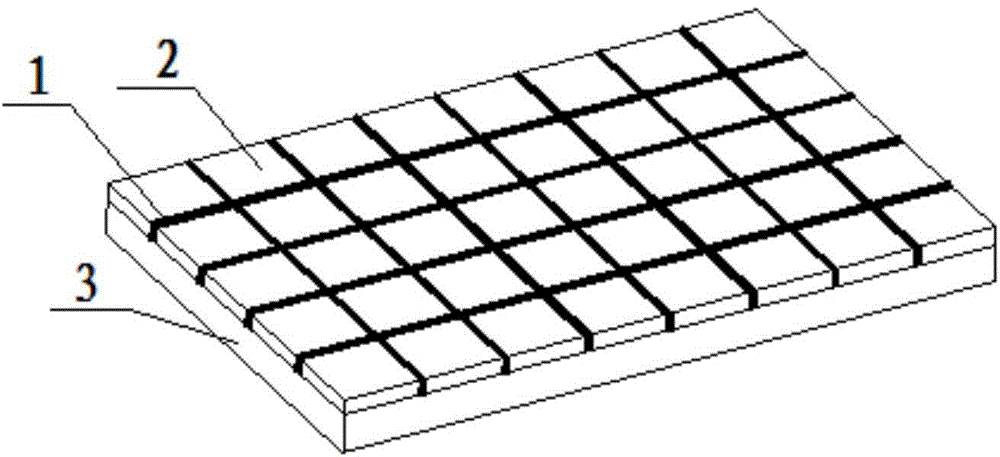

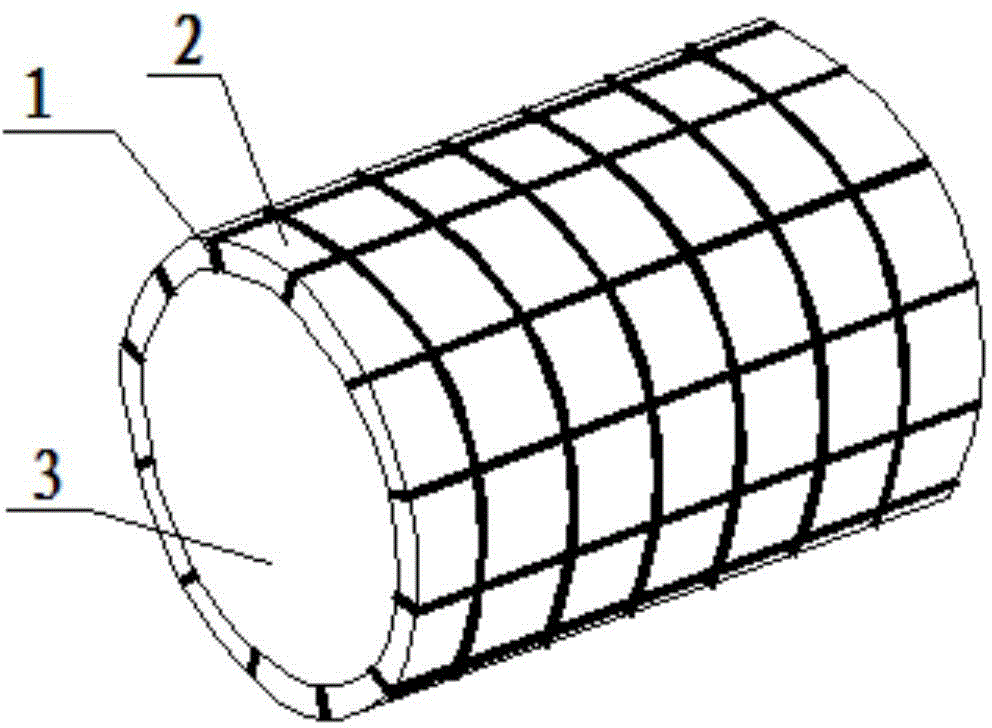

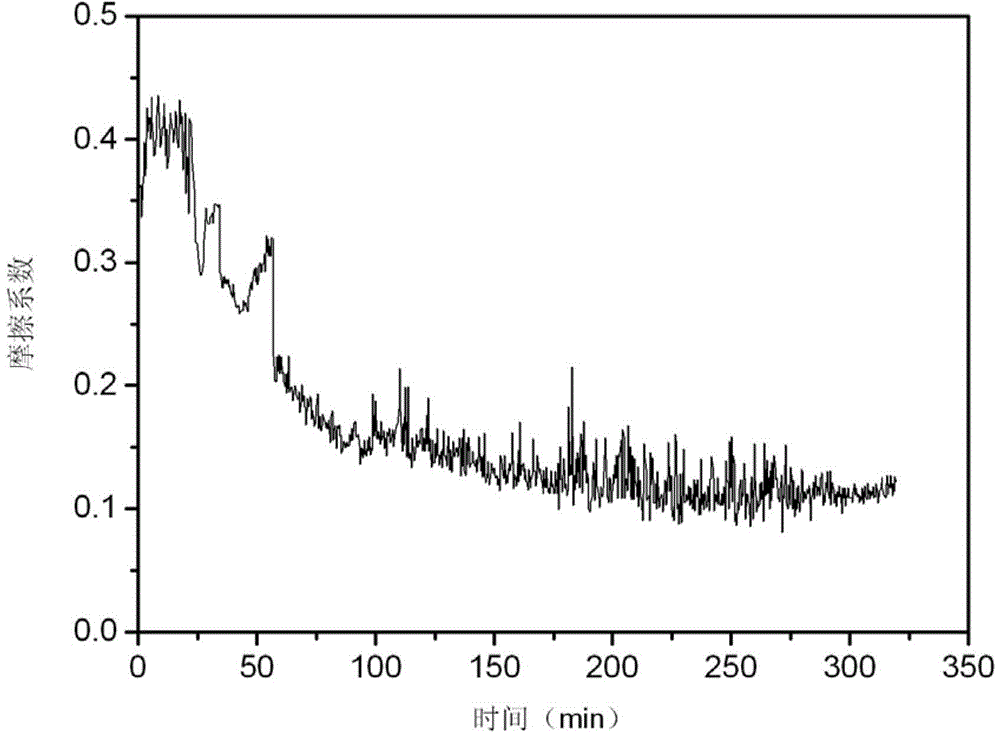

Method for preparing antifriction wear-resistant coating on metal matrix surface

ActiveCN104962909APrevents the accumulation of plastic deformationHigh hardness valueLiquid surface applicatorsMolten spray coatingWear resistantHardness

The invention discloses a method for preparing an antifriction wear-resistant coating on a metal matrix surface. The method comprises the following steps: (I) uniformly mixing wear-resistant powder with metal powder to obtain cladding powder; (II) performing laser cladding on the metal matrix surface by use of the cladding powder to form multiple cladding belts in horizontal-longitudinal crossing, wherein the cladding belts in horizontal-longitudinal crossing form a cladding skeleton of a mesh structure; and (III) filling the metal matrix surface with a lubricating phase, and polishing to obtain the antifriction wear-resistant coating on the metal matrix surface. According to the method disclosed by the invention, the cladding skeleton prepared on the metal matrix surface through the laser cladding process has a remarkably high hardness value; the cladding skeleton can realize a load dispersing function in a wear process to effectively prevent accumulation of plastic deformation on the metal matrix surface; and meanwhile, the mesh structure of the cladding skeleton realizes a support effect on the follow-up film forming process of the lubricating phase.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

Surface modification method of copper powder for conductive paste

The invention provides a method for decorating the surface of copper powder used in conductive paste, which relates to the processing of metal powder, in particular to the characteristic improvement and the coating of the metal powder. The method is characterized in that: the copper powder is dispersed into a water solution that contains a dispersing agent, an organic mixed acid is added, and the mixture is stirred and mixed for 30 to 90 min; a reductant is added, temperature is increased to 50 to 90 DEG C and heat preservation reaction occurs for 60 to 120 min; a coating agent is added for carrying out the heat preservation reaction for 60 to 150 min; then liquid-solid separation, washing and vacuum drying are carried out to finish the method. The adding amount of additional substances is as follows: the copper powder : the dispersing agent : the organic mixed acid : the reductant : the coating agent is equal to 1 : 0.05 to 0.25 : 0.05 to 0.5 : 0.1 to 1 : 0.05 to 0.5, and the ratio of liquid to solid is 4 to 8 : 1. The antioxidant capability of the copper powder is improved by the two processes of recrystallization and organic coating, thereby solving the problem of the serious oxidation of copper during the sintering process of the paste and greatly improving the stability of the conductive paste due to the existence of an organic-inorganic interface.

Owner:CENT SOUTH UNIV +1

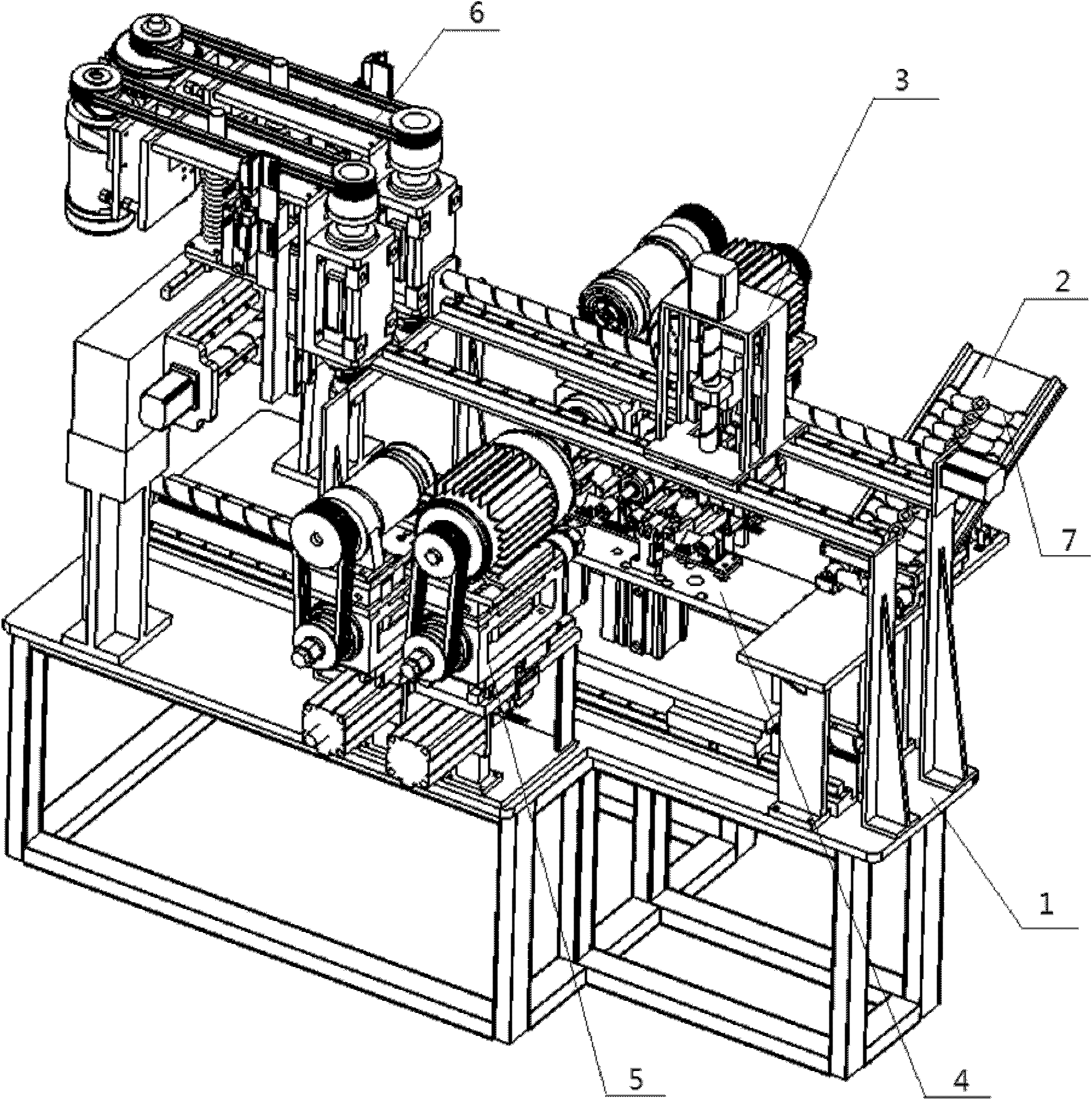

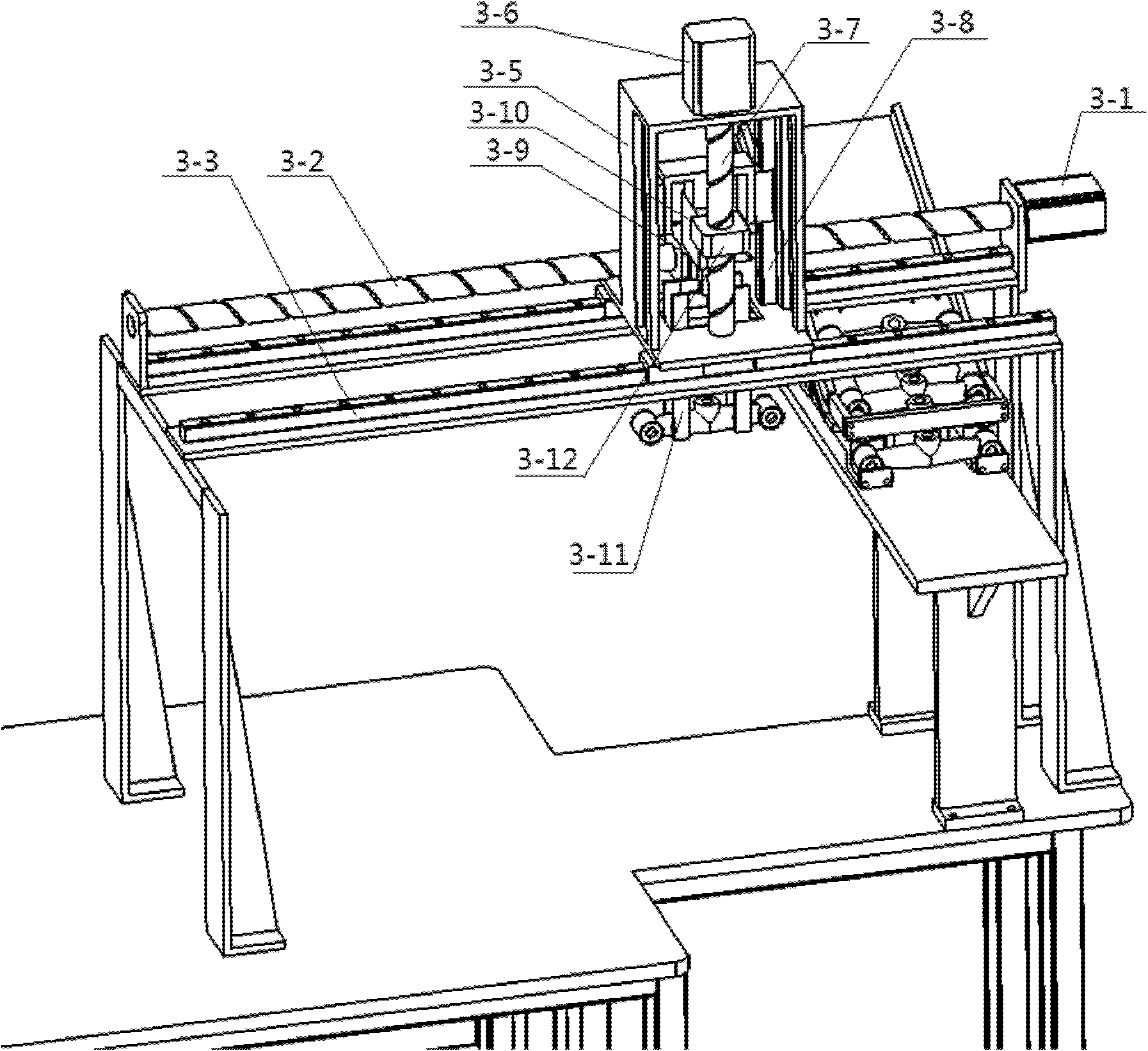

Reconfigurable special combined machine tool

InactiveCN102303242AImprove processing efficiencyImprove processing qualityFeeding apparatusOther manufacturing equipments/toolsFixed frameManipulator

The invention discloses a reconfigurable special combined machine tool which comprises a stand, a feeding module, a loading and unloading manipulator, a workpiece horizontal feeding module and sampling port unitized machining power heads, wherein the feeding module is arranged at one end of the stand, the loading and unloading manipulator is arranged at the upper ends of the feeding module and the workpiece horizontal feeding module, the workpiece horizontal feeding module comprises a workpiece horizontal feeding working platform, a workpiece clamping device and a clamp combination, two ends of the workpiece horizontal feeding module are respectively provided with the sampling port unitized machining power heads, the other end of the stand is provided with a top hole unitized machining power head, the top hole unitized machining power head comprises a drilling machining power head, a tapping machining power head, a power head main drive device, a power head vertical feeding device, a first power head fixing frame, a second power head fixing frame and a power head transverse driving device, and input shafts of the drilling machining power head and the tapping machining power head are in transmission connection with the power head main drive device. The reconfigurable special combined machine tool has the advantages of high machining efficiency, high machining precision and larger machining flexibility.

Owner:ZHEJIANG UNIV

Array substrate having double-layered metal patterns and method of fabricating the same

ActiveUS20050018097A1Improve processing stabilityImprove manufacturing yieldTransistorSemiconductor/solid-state device detailsInsulation layerLiquid-crystal display

An array substrate having double-layered metal patterns for use in a liquid crystal display device and a manufacturing method thereof are disclosed in the present invention. The array substrate includes a gate electrode and a gate line each having a molybdenum alloy (Mo-alloy) layer and a copper (Cu) layer configured sequentially on a substrate; a gate insulation layer on the substrate to cover the gate electrode and the gate line; an active layer arranged on the gate insulation layer in a portion over the gate electrode; an ohmic contact layer on the active layer; a data line on the gate insulation layer, the data line crossing the gate line and defining a pixel region; source and drain electrodes on the ohmic contact layer, the source electrode extending from the data line, and the drain electrode spaced apart from the source electrode; a passivation layer on the gate insulation layer covering the data line and the source and drain electrode, the passivation layer having a drain contact hole exposing a portion of the drain electrode; and a pixel electrode configured on the passivation layer in the pixel region, the pixel electrode electrically contacting the drain electrode through the drain contact hole.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com