Method for preparing antifriction wear-resistant coating on metal matrix surface

A technology for metal substrates and wear-resistant coatings, applied in metal material coating processes, devices for coating liquid on surfaces, coatings, etc., can solve problems such as poor bonding force, coating damage, hard wear-resistant coatings, etc. problems, to achieve long life, prevent the accumulation of plastic deformation, and prevent the effect of eccentric seizure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] Step 1. Mix the wear-resistant powder and metal powder evenly at a mass ratio of 1:5 to obtain cladding powder. The wear-resistant powder is tungsten carbide powder, and the metal powder is nickel powder;

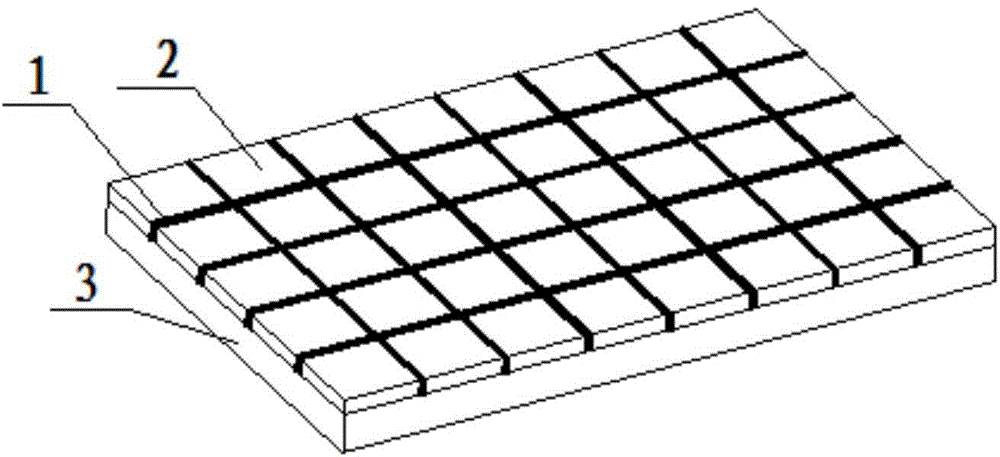

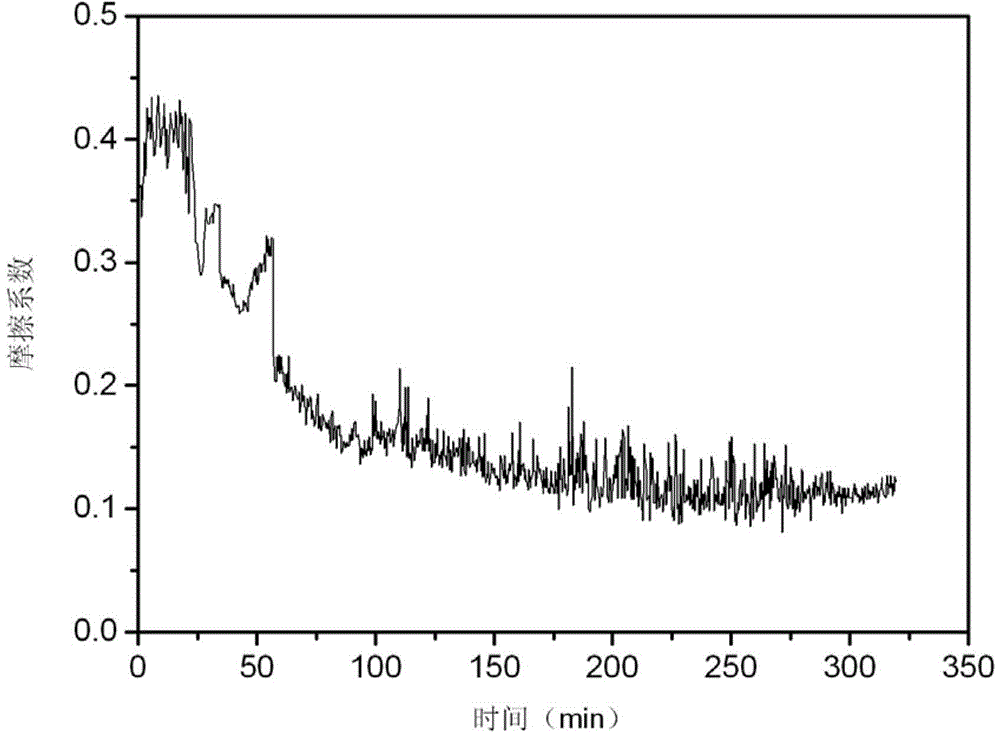

[0034] Step 2. Using the method of synchronous powder feeding, according to the preset grid-shaped scanning trajectory, under the argon protective atmosphere with a pressure of 0.01MPa, laser cladding the cladding powder described in step 1 on the surface of the metal substrate 3 , forming a plurality of cladding strips 1 that intersect horizontally and vertically, and a plurality of cladding strips 1 that intersect vertically and horizontally form a cladding skeleton with a grid structure; the laser power of the laser cladding is 6153W, and the spot diameter is 3mm. The powder feeding rate is 35g / min, and the scanning speed is 25mm / s; the metal substrate 3 is a TC4 titanium alloy substrate, the metal substrate 3...

Embodiment 2

[0040] This embodiment includes the following steps:

[0041] Step 1, uniformly mix wear-resistant powder and metal powder at a mass ratio of 1:10 to obtain cladding powder, the wear-resistant powder is titanium carbide powder, and the metal powder is iron powder;

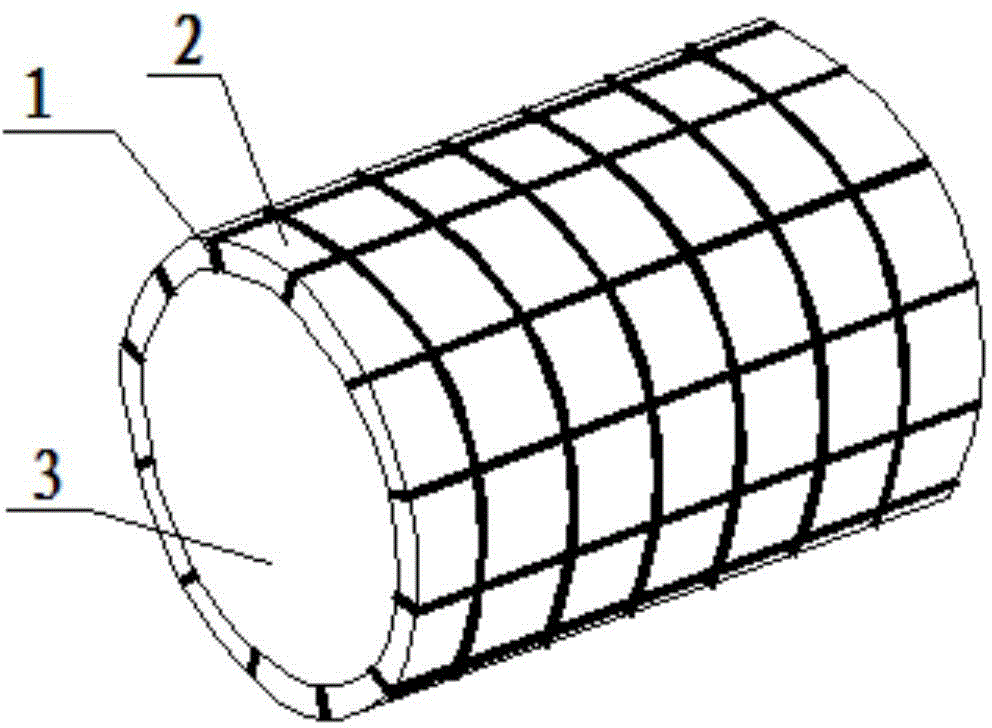

[0042] Step 2. Using the method of synchronous powder feeding, according to the preset grid-like scanning trajectory, under the argon protective atmosphere with a pressure of 0.1MPa, laser cladding the cladding powder described in step 1 on the surface of the metal substrate 3 , forming a plurality of cladding strips 1 that intersect horizontally and vertically, and a plurality of cladding strips 1 that intersect vertically and horizontally form a cladding skeleton with a grid structure; the laser power of the laser cladding is 3886W, and the spot diameter is 2mm. The powder feeding rate is 20g / min, and the scanning speed is 30mm / s; the metal base 3 is 45 # Steel substrate, the metal substrate 3 is a cylindrical s...

Embodiment 3

[0048] This embodiment includes the following steps:

[0049] Step 1, uniformly mix wear-resistant powder and metal powder at a mass ratio of 1:10 to obtain cladding powder, the wear-resistant powder is titanium carbide powder, and the metal powder is iron powder;

[0050] Step 2. Using the method of synchronous powder feeding, according to the preset grid-like scanning trajectory, under the argon protective atmosphere with a pressure of 1 MPa, laser cladding the cladding powder described in step 1 on the surface of the metal substrate 3, Form a plurality of cladding belts 1 that intersect horizontally and vertically, and form a cladding skeleton with a grid structure; the laser power of the laser cladding is 512W, and the spot diameter is 0.5mm. The powder feeding rate is 13g / min, and the scanning speed is 20mm / s; the metal base 3 is 20 # Steel substrate, the metal substrate 3 is a flat substrate, the width of the cladding strip 1 is 1.16 mm, the height of the cladding strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com