Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13202 results about "Forming processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forming processes are particular manufacturing processes which make use of suitable stresses (like compression, tension, shear or combined stresses) which cause plastic deformation of the materials to produce required shapes. The main material used is metal due to the massive need for various products demanded by the public, nevertheless other compounds like plastic can be formed too due to a big market for plastic based products.

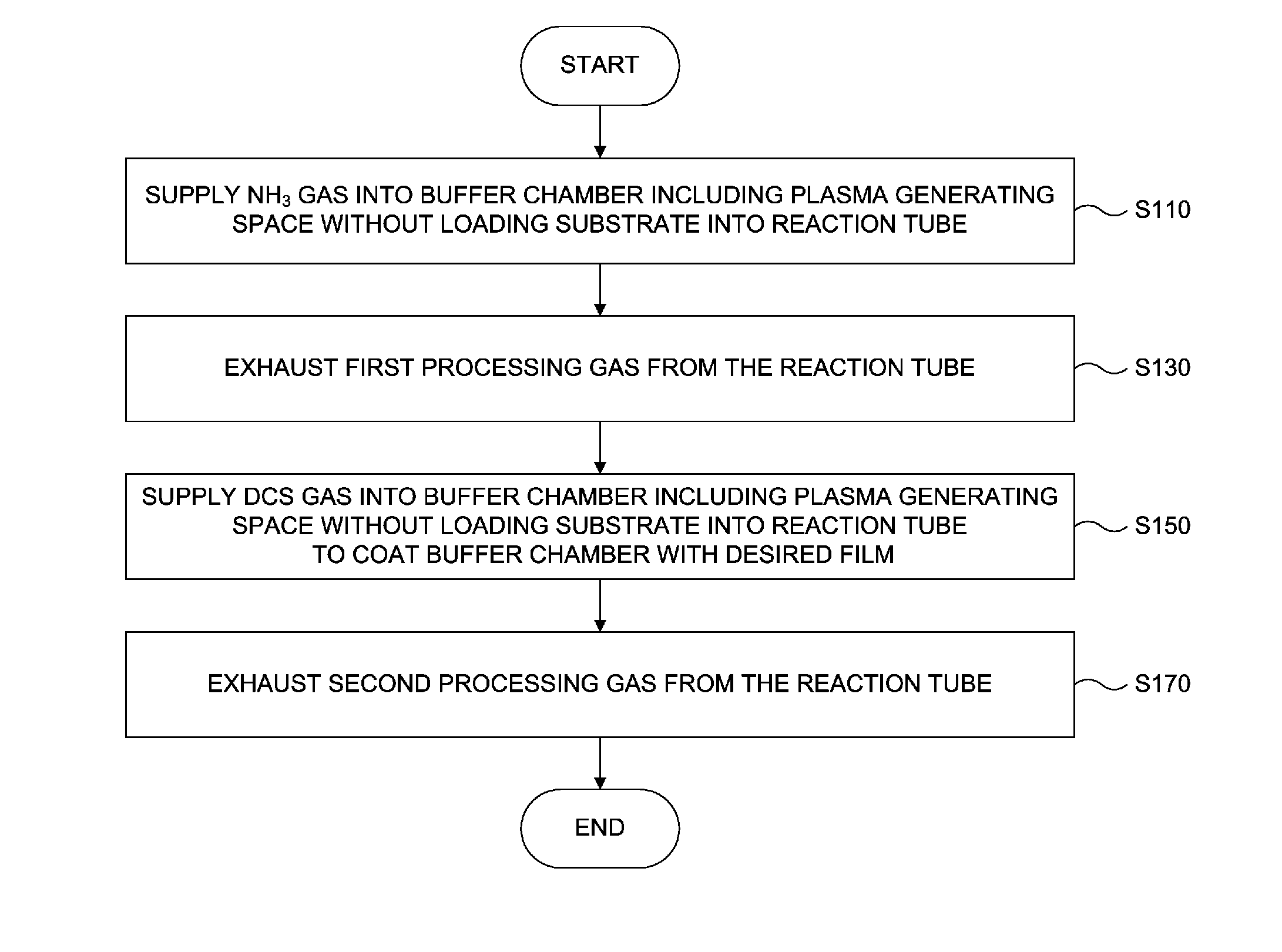

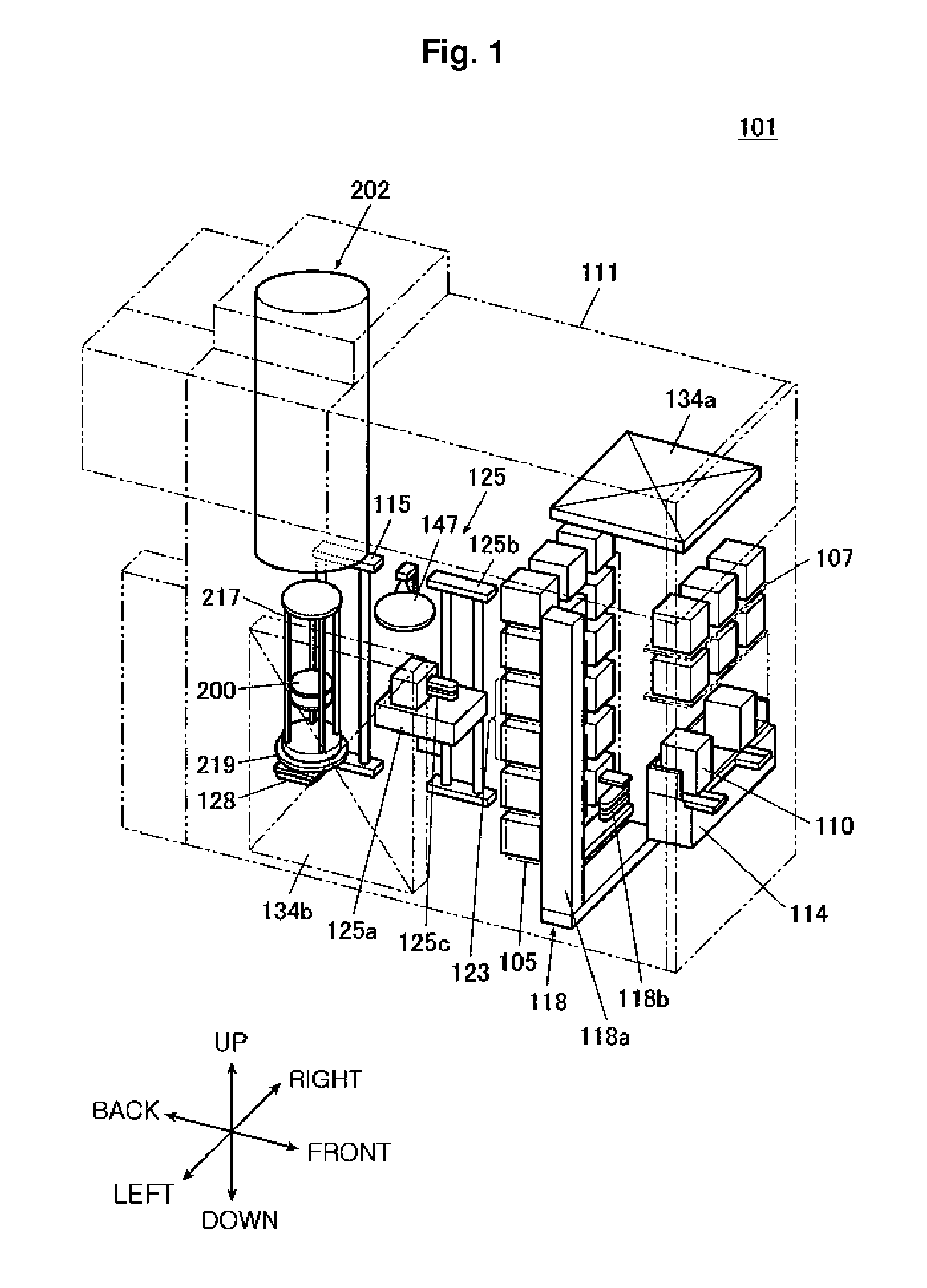

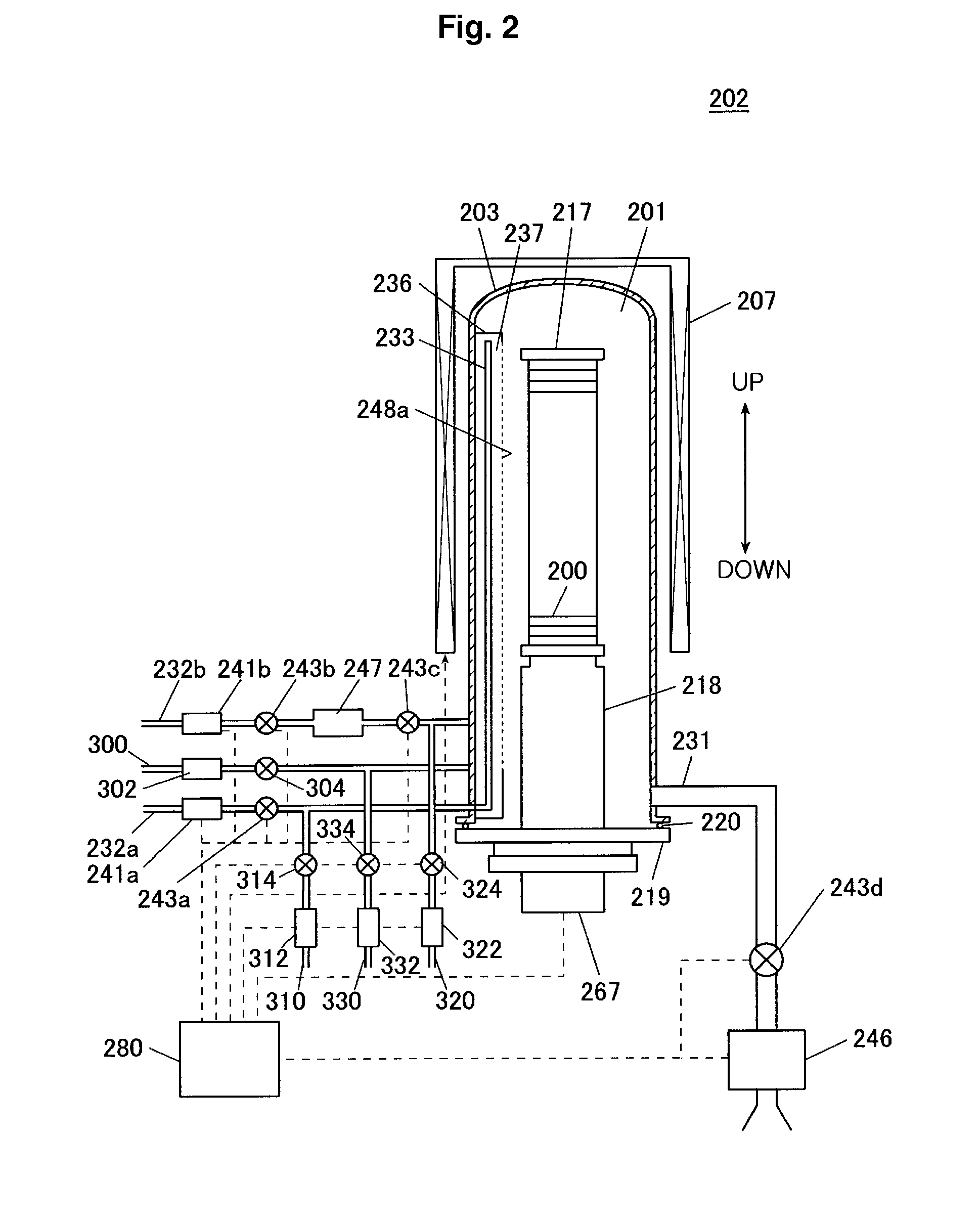

Coating method for coating reaction tube prior to film forming process

InactiveUS20120122319A1Prevent and restrainElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringContamination

Contamination of a substrate can be prevented or suppressed. A substrate processing apparatus includes a reaction tube having an inner space divided by a barrier wall into a film forming space and a plasma generating space. When a desired film is formed on a substrate placed inside the reaction tube, first and second processing gases are supplied to the reaction tube through nozzles. On the other hand, when a part of the reaction tube constituting the plasma generating space is coated with a film, second and third processing gases are supplied to the plasma generating space through the nozzle.

Owner:SHIMIZU HIRONOBU

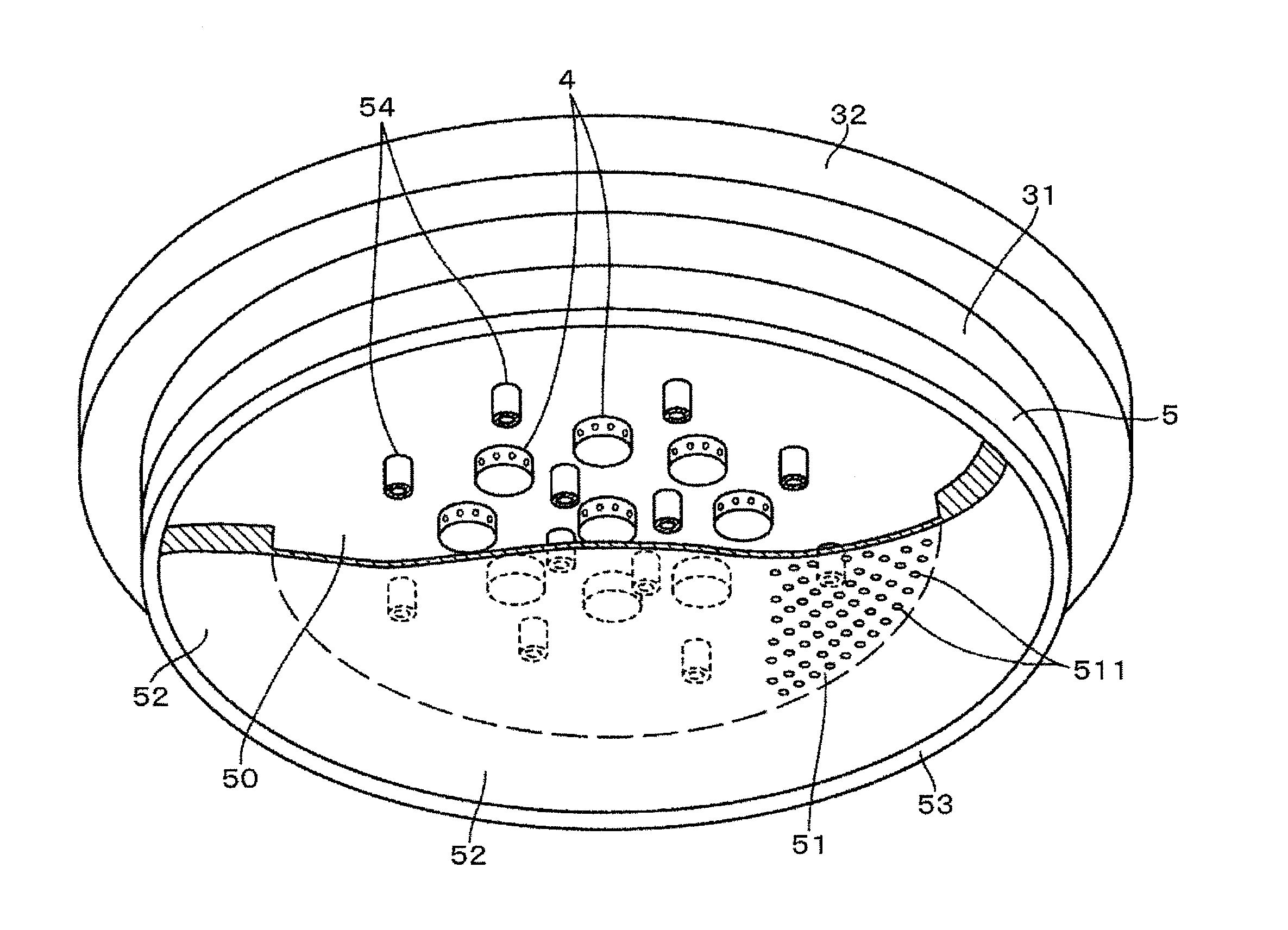

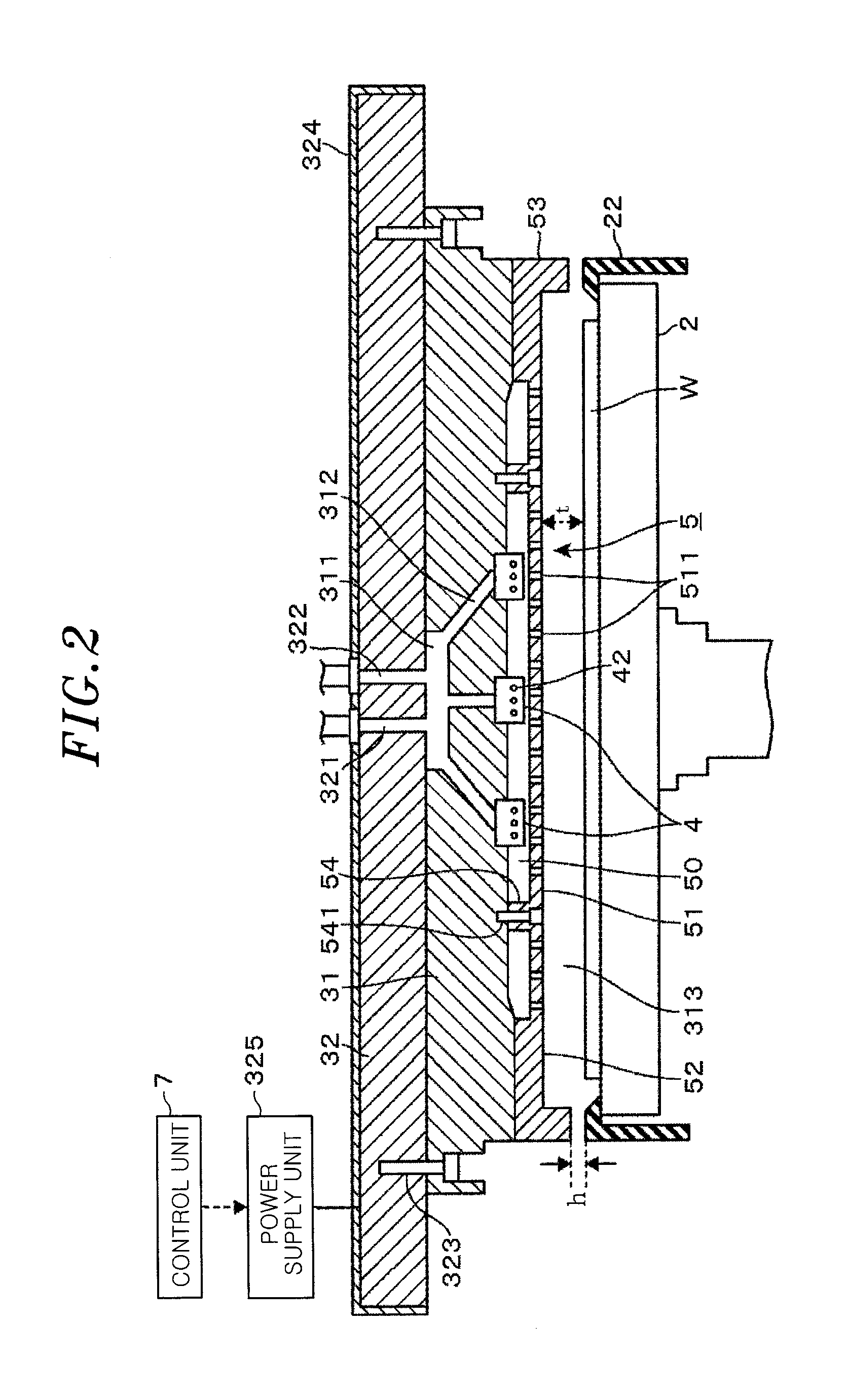

Film forming apparatus

ActiveUS20150267298A1High in-plane uniformityEfficient replacementChemical vapor deposition coatingGas supplyForming processes

A film forming apparatus for performing a film forming process by sequentially supplying a plurality of reactant gases to a substrate and supplying a replacement gas includes a mounting table configured to mount thereon a substrate, and a shower head having a flat surface facing the mounting table and a plurality of gas supply opening. An annular protrusion is provided at the shower head to form a gap between the annular protrusion and a top surface of the mounting table. A plurality of gas supply units is provided at a ceiling portion at an upper side of the shower head. Each gas supply unit has gas discharge openings formed along a circumferential direction. The diffusion space is disposed such that an outer periphery of the diffusion space is located at an inner side of an outer periphery of the substrate mounted on the mounting table in a plan view.

Owner:TOKYO ELECTRON LTD

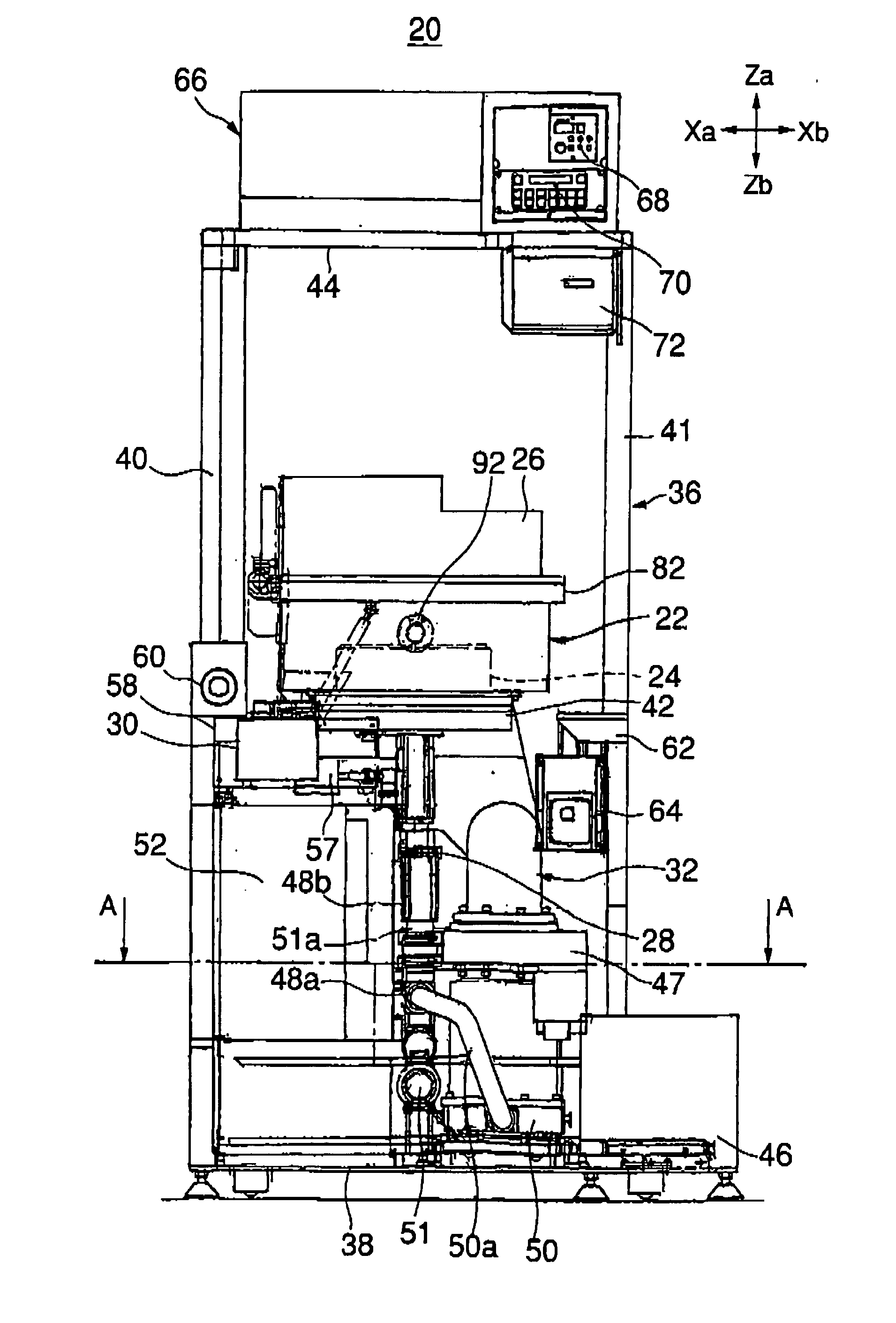

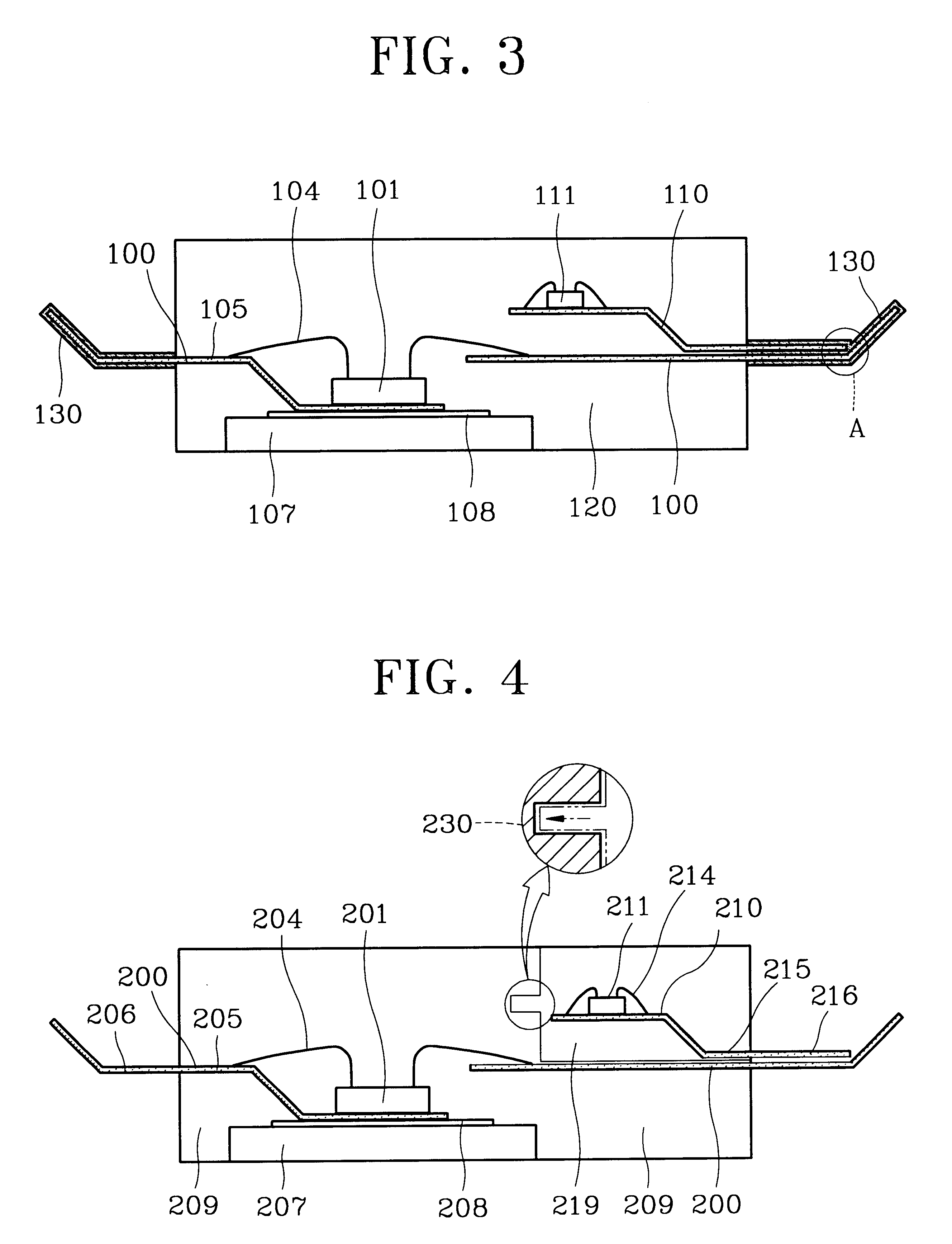

Substrate processing apparatus

InactiveUS20060057799A1Reliable formingAvoid pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingUltraviolet lightsEngineering

A substrate processing apparatus stably and efficiently conducts a film forming process on a substrate to be processed. In the substrate processing apparatus, the substrate to be processed is supported at a position facing a heater portion, and a holding member for holding the substrate is rotated, whereby the temperature distribution of the substrate is kept uniform and a warp of the substrate is suppressed. The inner wall of the processing vessel is covered with a quartz liner which is made of opaque quartz, and thus protected from ultraviolet rays emitted from an ultraviolet light source. The temperature rise of the inner wall caused by heat from the heater portion is suppressed due to the heat insulating effect of the quartz liner. Consequently, the life cycle of the processing vessel can be prolonged.

Owner:TOKYO ELECTRON LTD

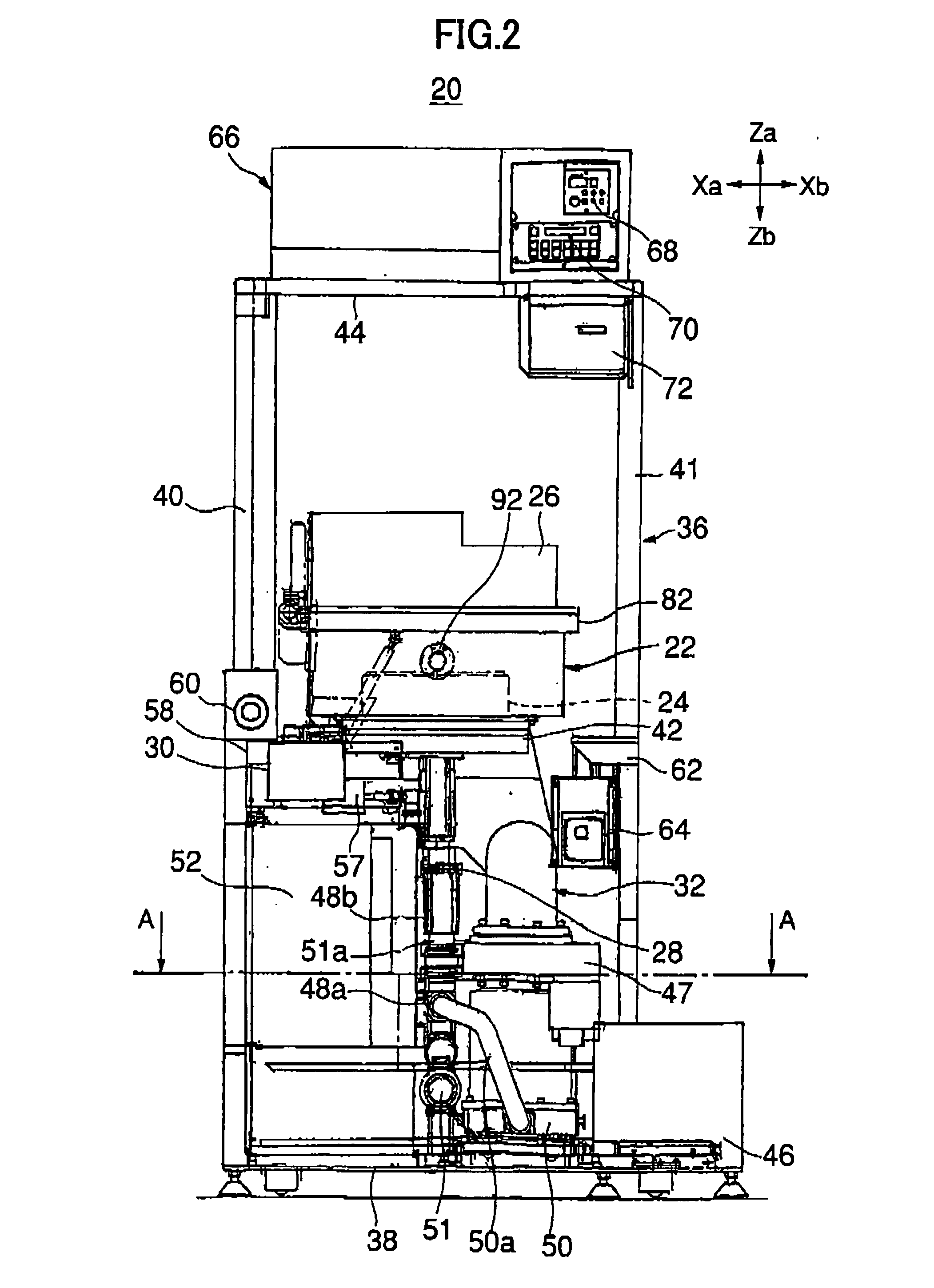

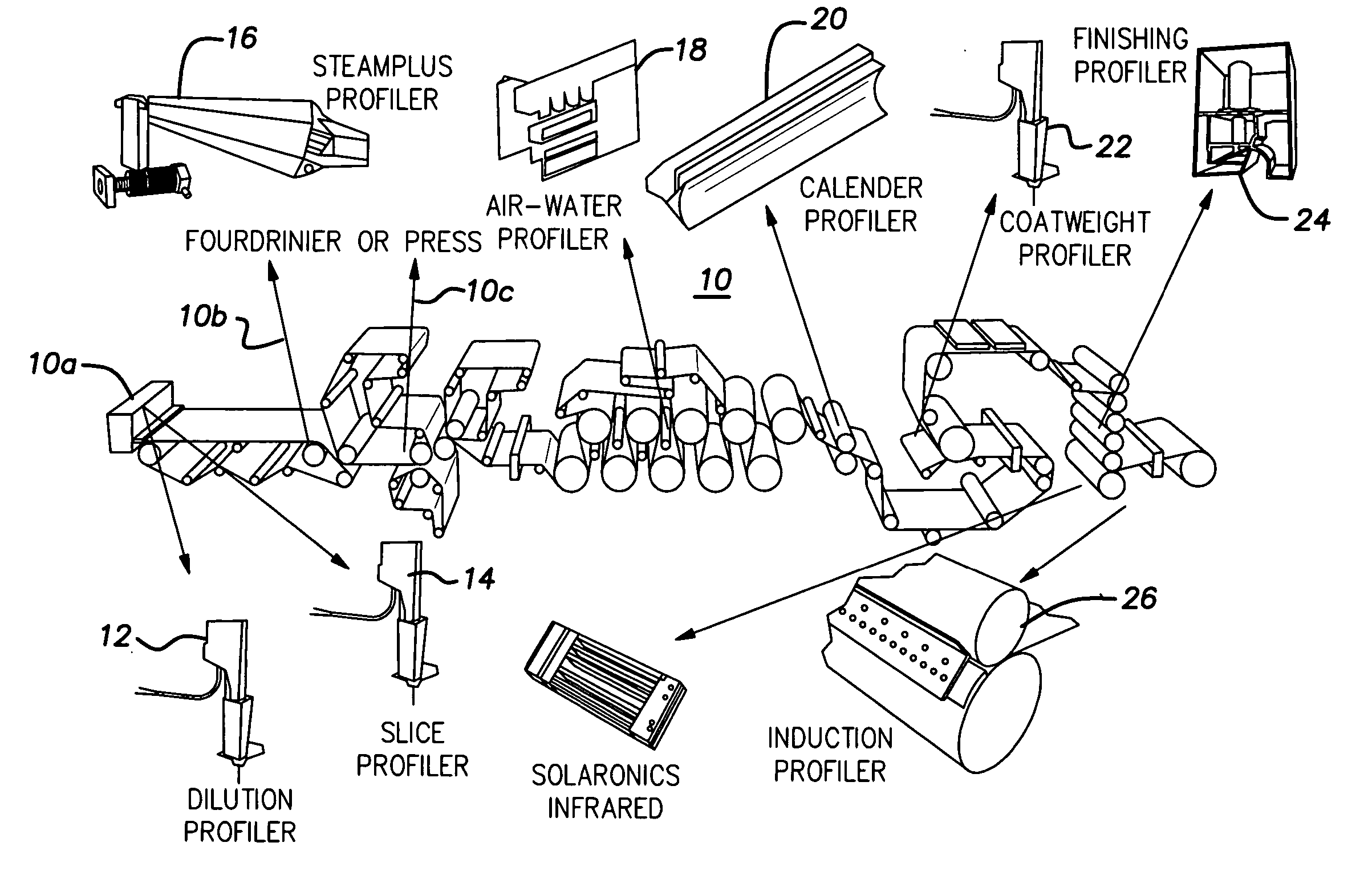

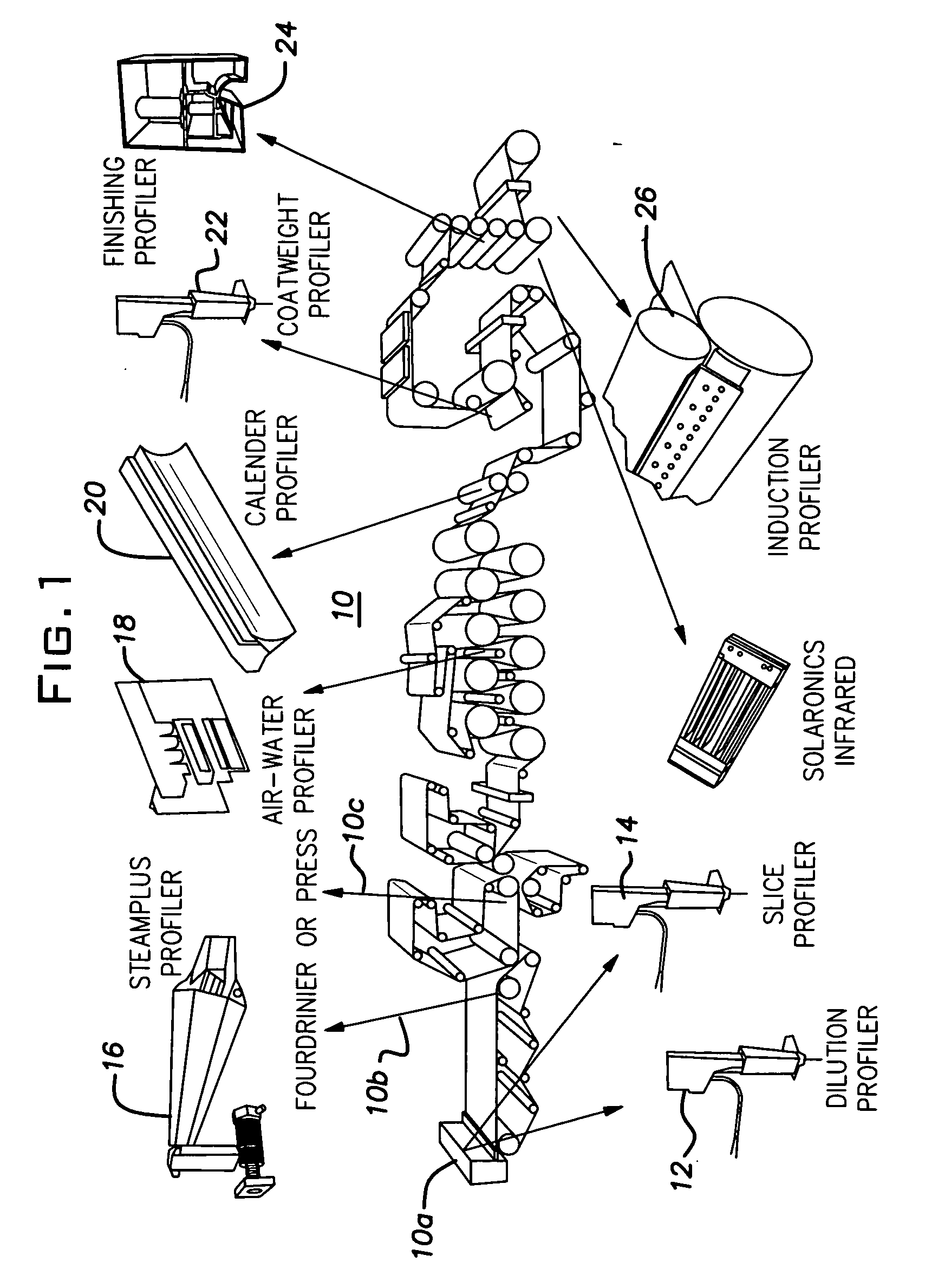

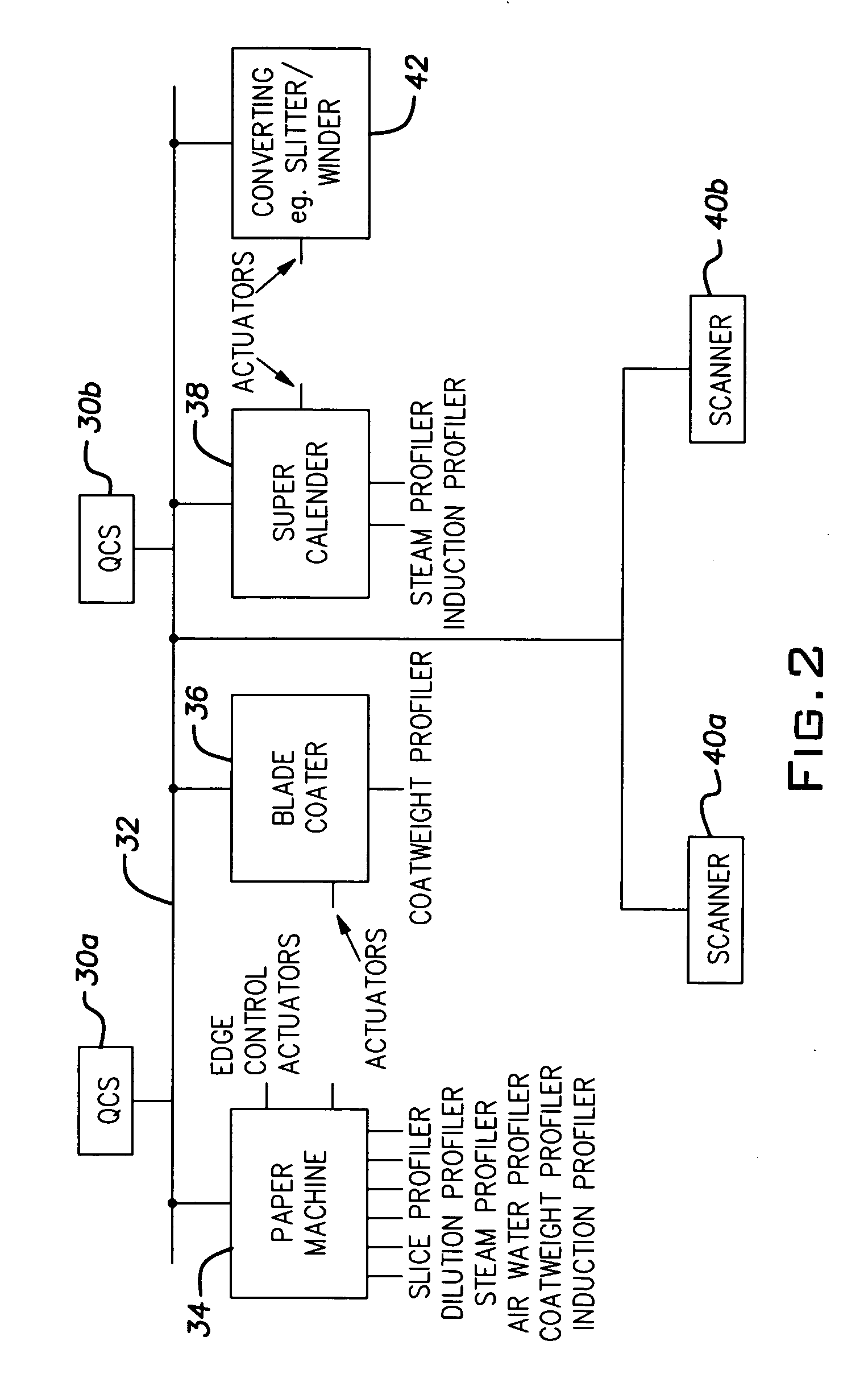

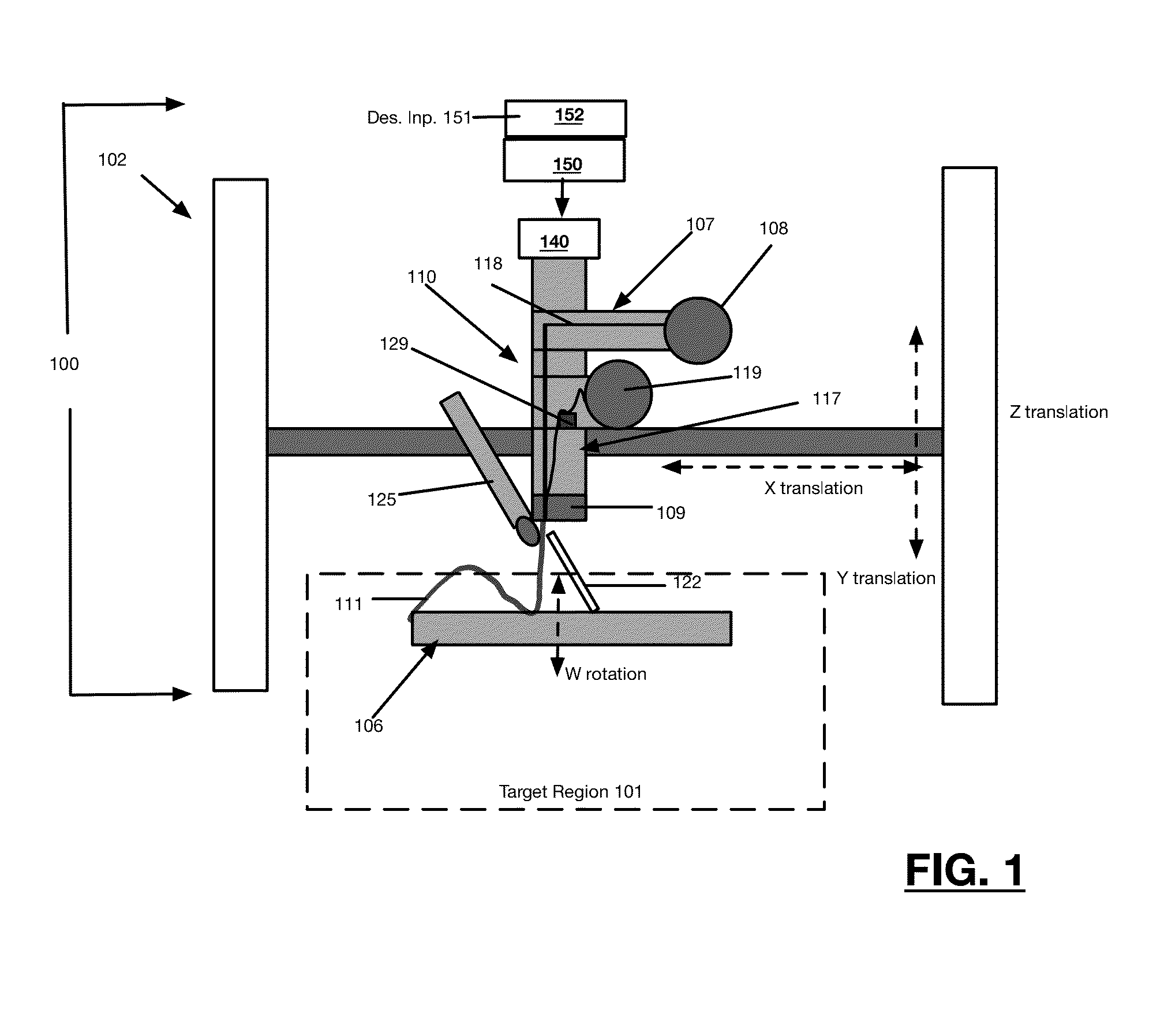

Actuator system for use in control of a sheet or web forming process

InactiveUS20060185809A1Digital differential analysersPaper-making machinesElectric power transmissionPower cable

One or more actuator driven devices on a sheet forming machine receive power and engage in bi-didrectional communications with one or more quality control systems either by having no physically connected cables to transmit the power to the actuators and no physically connected cables used for the bi-directional communications; or contactless power and communication on a power cable; or a cable connected from the power source to the actuators to provide both power and bi-directional communications; or power is provided to the actuators by a cable and the bi-directional communications are wireless.

Owner:ABB RES LTD +1

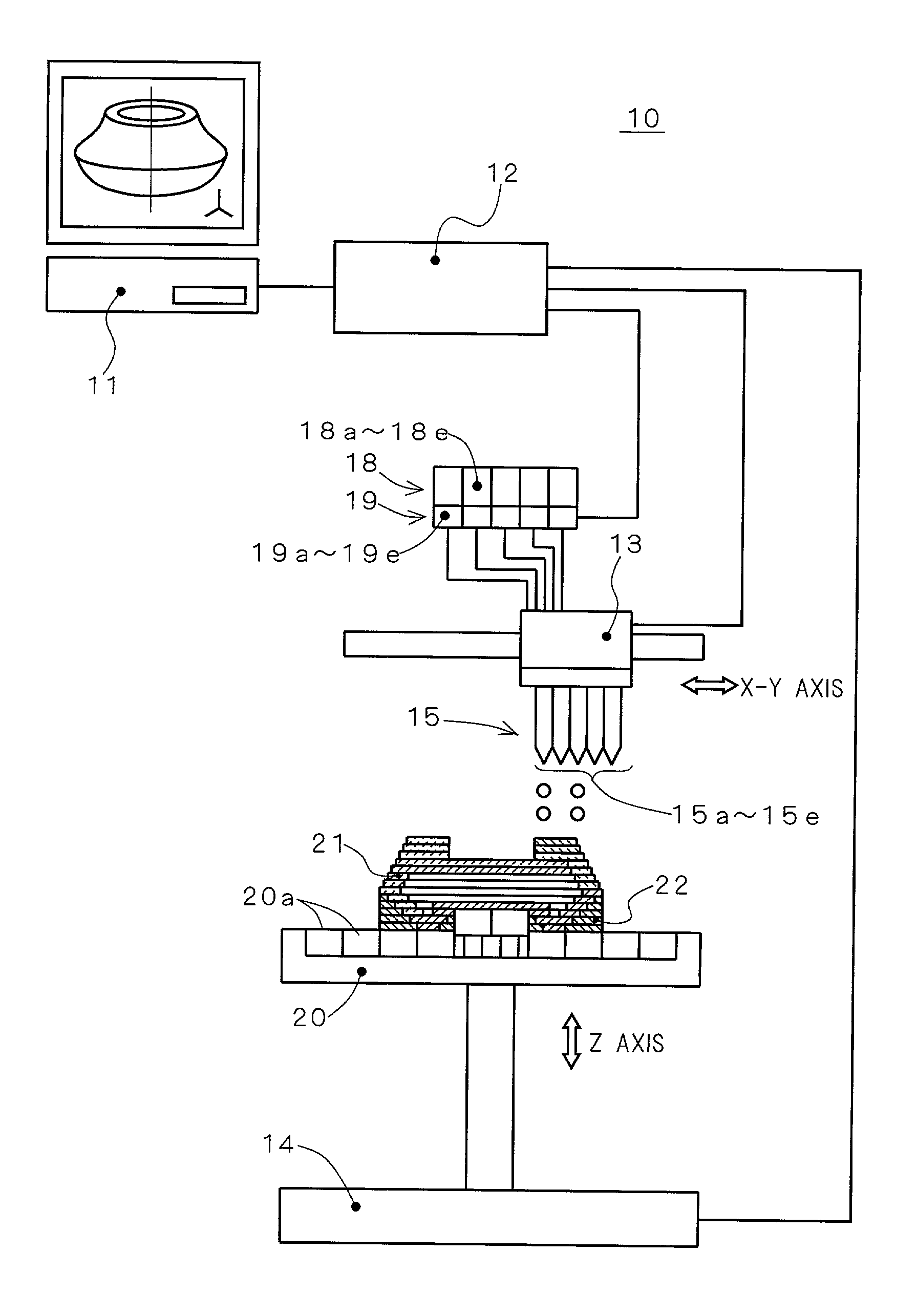

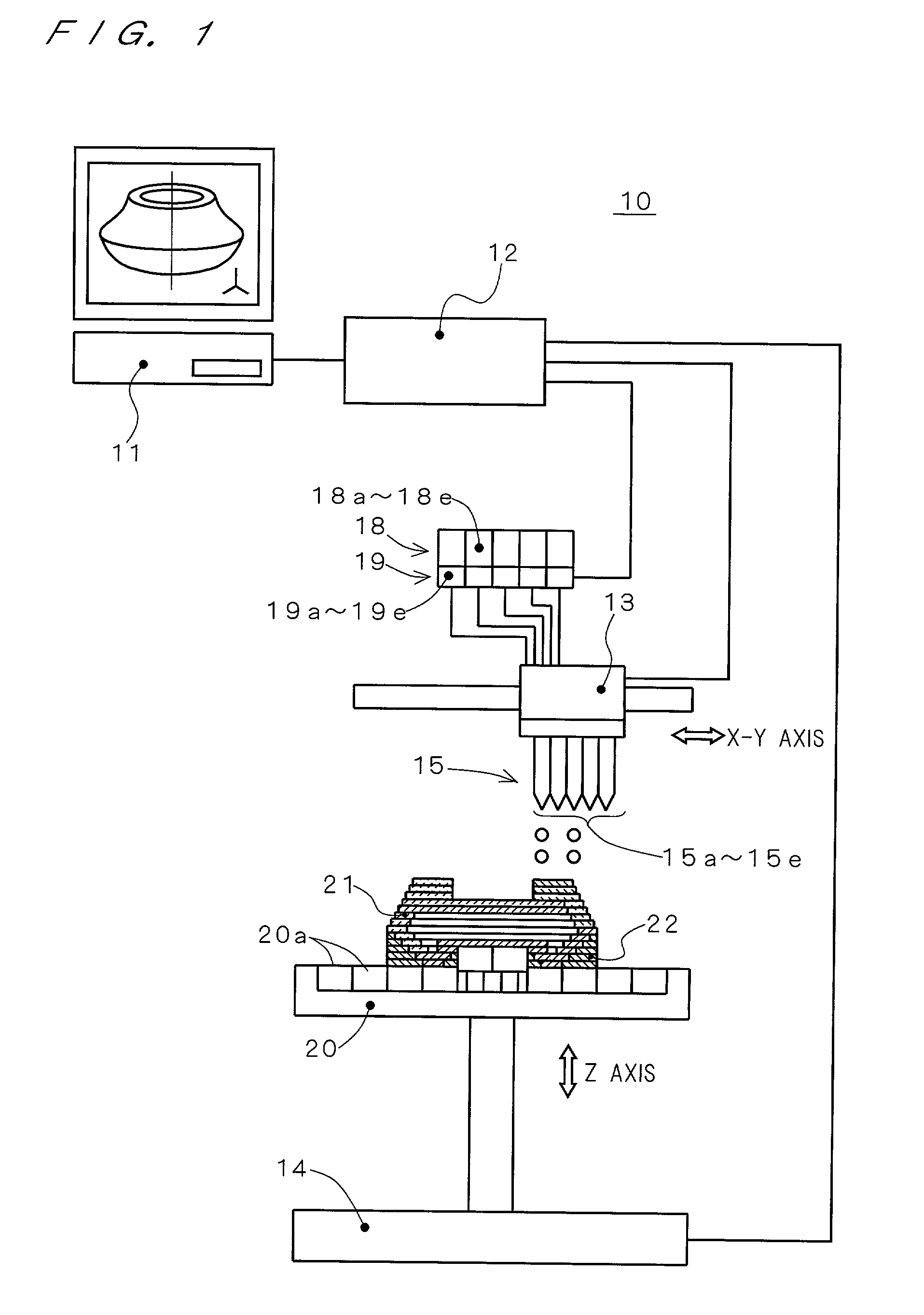

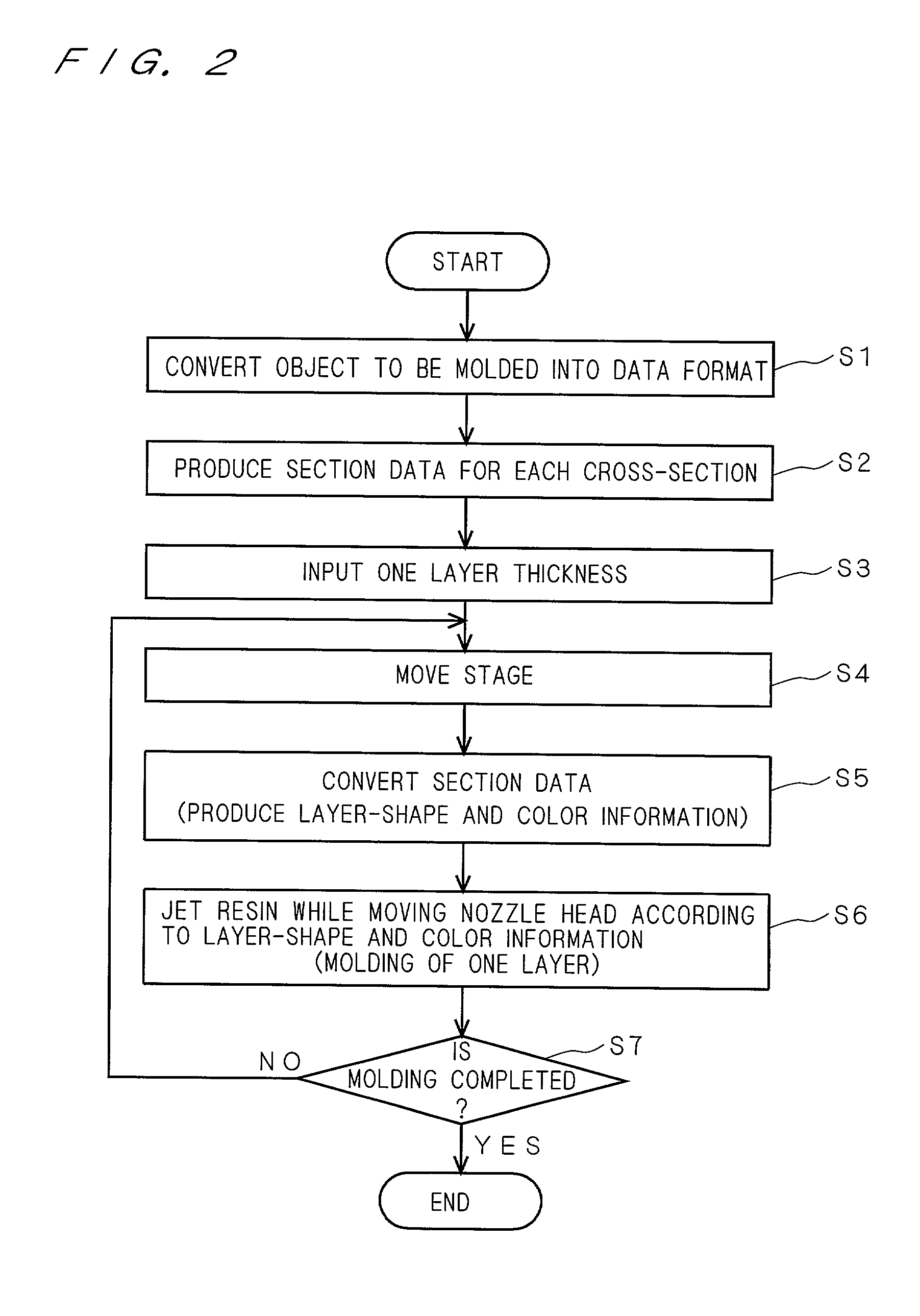

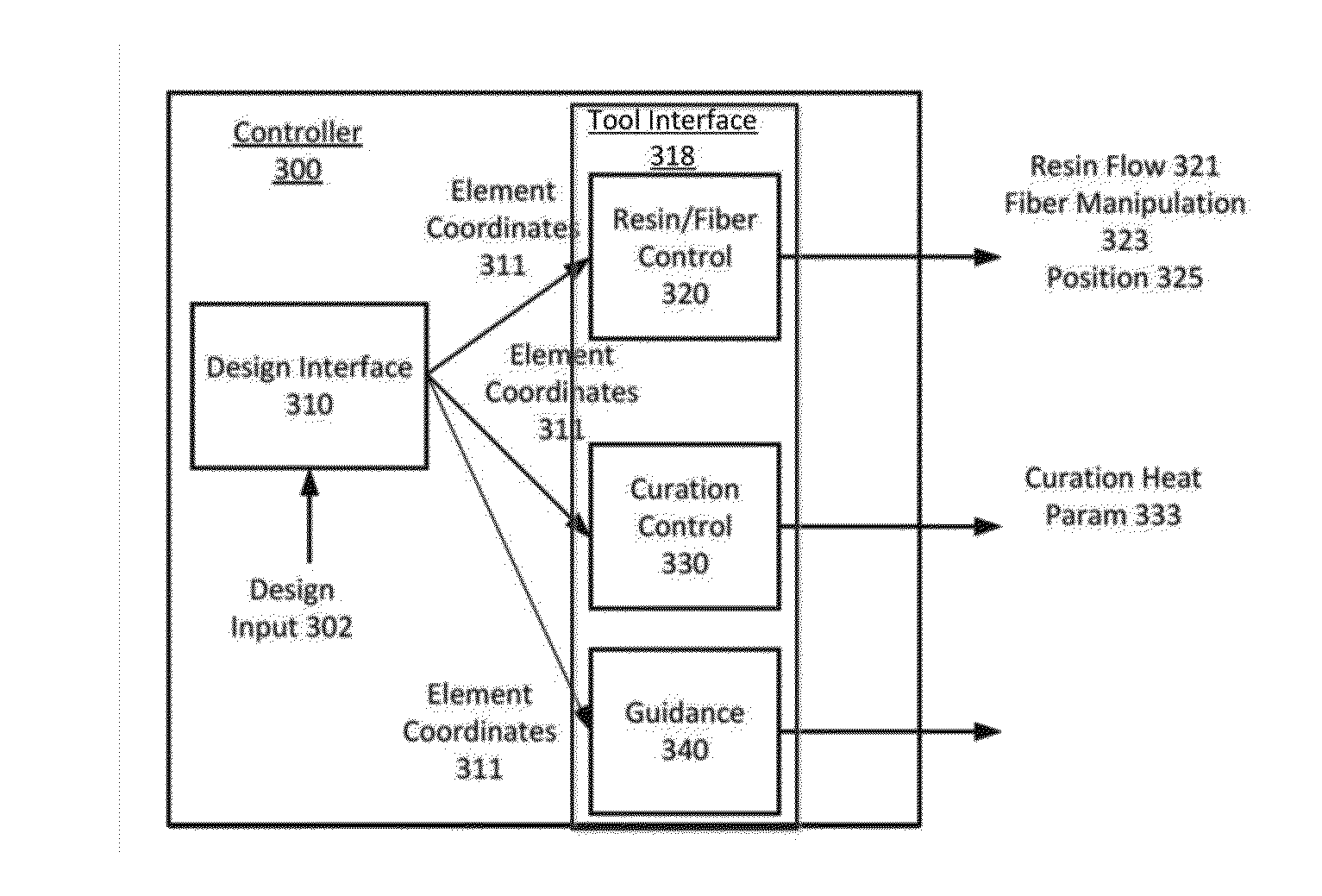

Three-dimensional object molding apparatus and method

InactiveUS20020167101A1Facilitate short-time low-cost moldingShort-time low-cost coloringConfectioneryPattern printingShell moldingColor intensity

In a 3D object molding apparatus (10), a tank (18d) holds an uncolored or white resin as a first material for use in interior molding, and tanks (18a to 18c) hold colored resins as second materials for use in surface molding. These resin materials are jetted from injection nozzles (15a to 15d) in the direction of a stage (20). A drive control unit (12) serving as control means moves a nozzle head (15) in the XY plane and controls jets of resin materials from the injection nozzles (15a to 15d). In the interior molding of a 3D molded product (21), at least the first material is jetted, while in the surface molding, at least the second materials are jetted. The injection nozzles (15a to 15c) are coloring nozzles to jet colored resins in molding color portions of the 3D molded product, and the injection nozzle (15d) is a molding nozzle to jet an uncolored molding resin in molding the other portions. The apparatus 10 provided with the coloring nozzles to jet predetermined coloring agents such as colored resins can jet coloring agents from the coloring nozzles in molding the 3D molded product, thereby achieving coloring of the 3D molded product in the molding process. Further, the use of a white resin allows representation of blight colors that are not available only with three colors (Y, M, C), thereby permitting reproduction of the color intensity and gradations in the coloring of the 3D molded product (21) in the molding process.

Owner:MINOLTA CO LTD

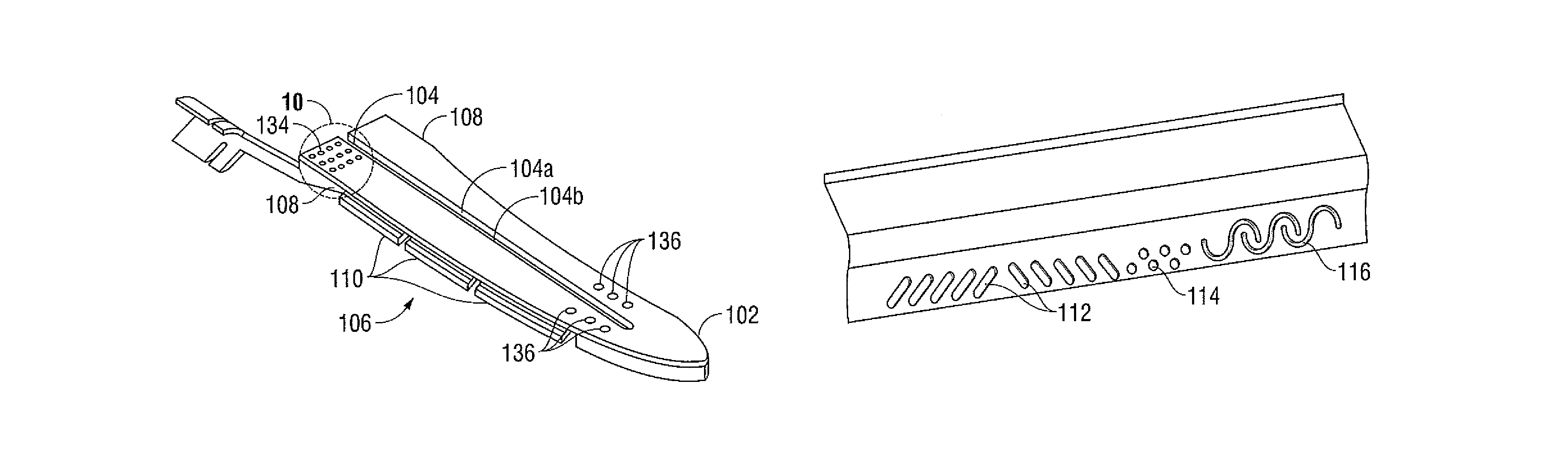

Apparatuses and methods for forming a substantially facet-free epitaxial film

InactiveUS20040175893A1Semiconductor/solid-state device manufacturingFrom chemically reactive gasesFacetMaterials science

A method of making a substantially facet-free epitaxial film is disclosed. A substrate having predetermined regions is first provided. An epitaxial film forming process gas and a carrier gas are introduced into a reactor chamber. The epitaxial film forming process gas and the carrier have a flow ratio between 1:1 and 1:200. The epitaxial film is deposited into the predetermined regions of the substrate wherein the substrate has a temperature between about 350° C. and about 900° C. when the epitaxial film is being deposited.

Owner:APPLIED MATERIALS INC

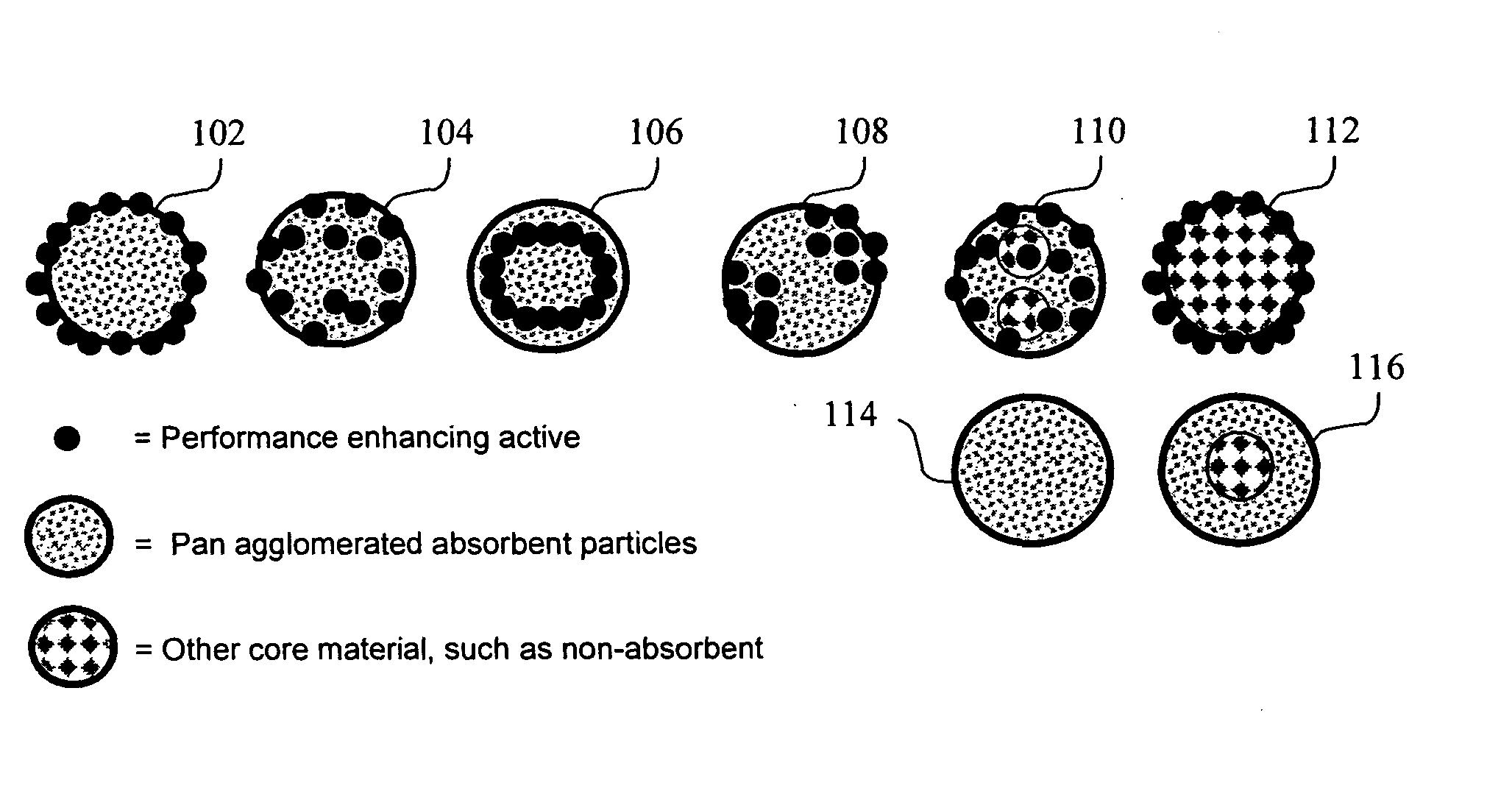

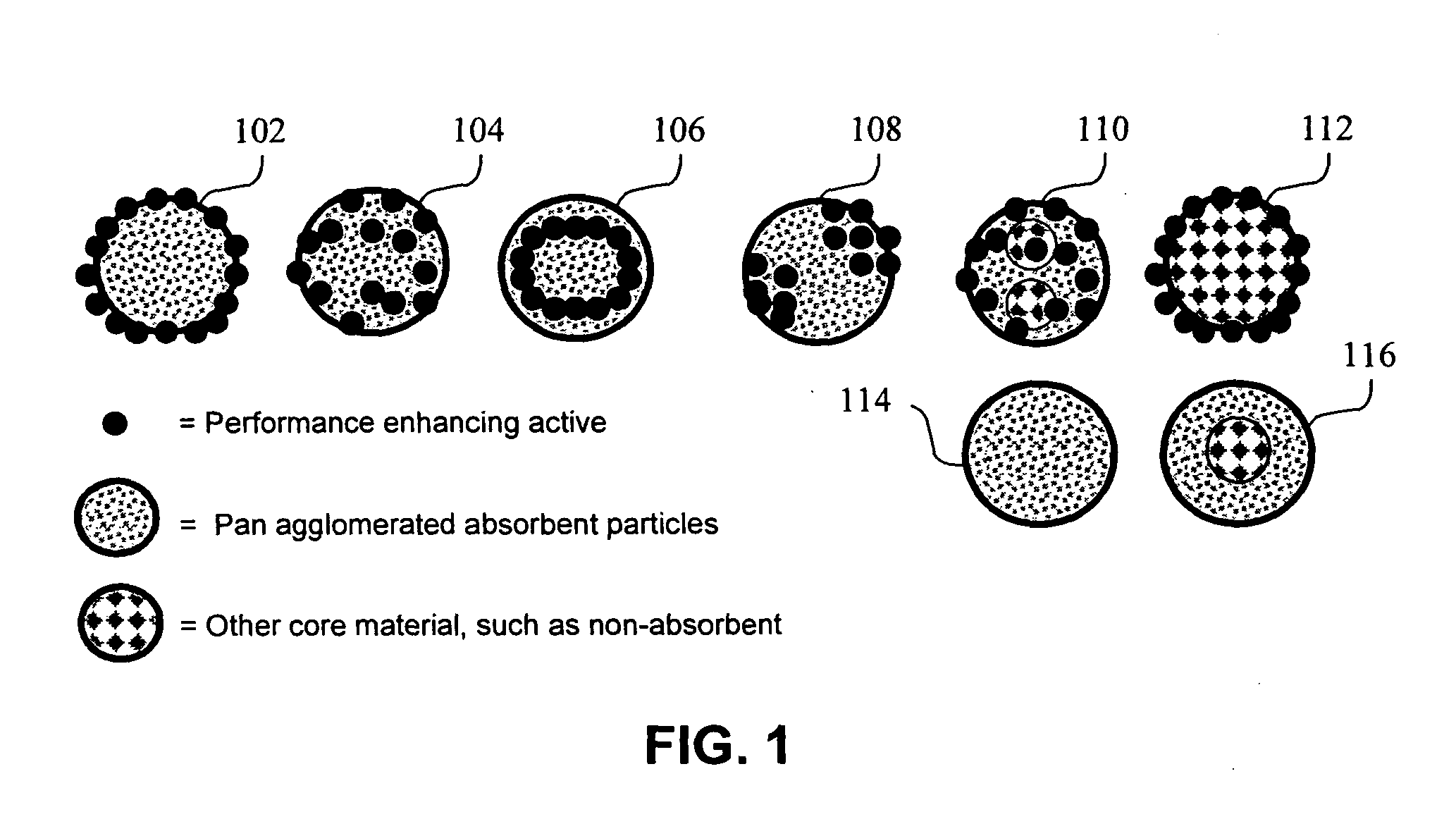

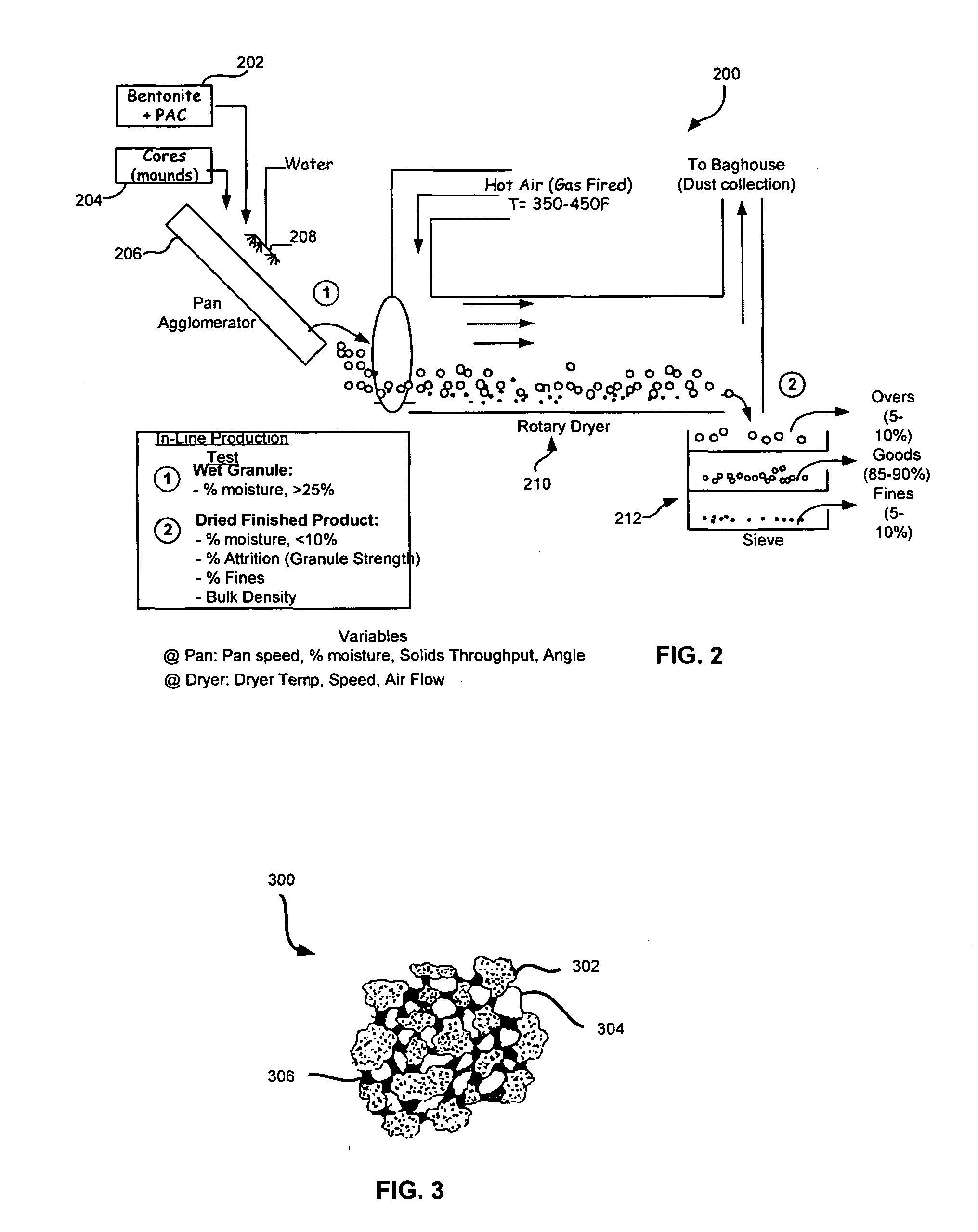

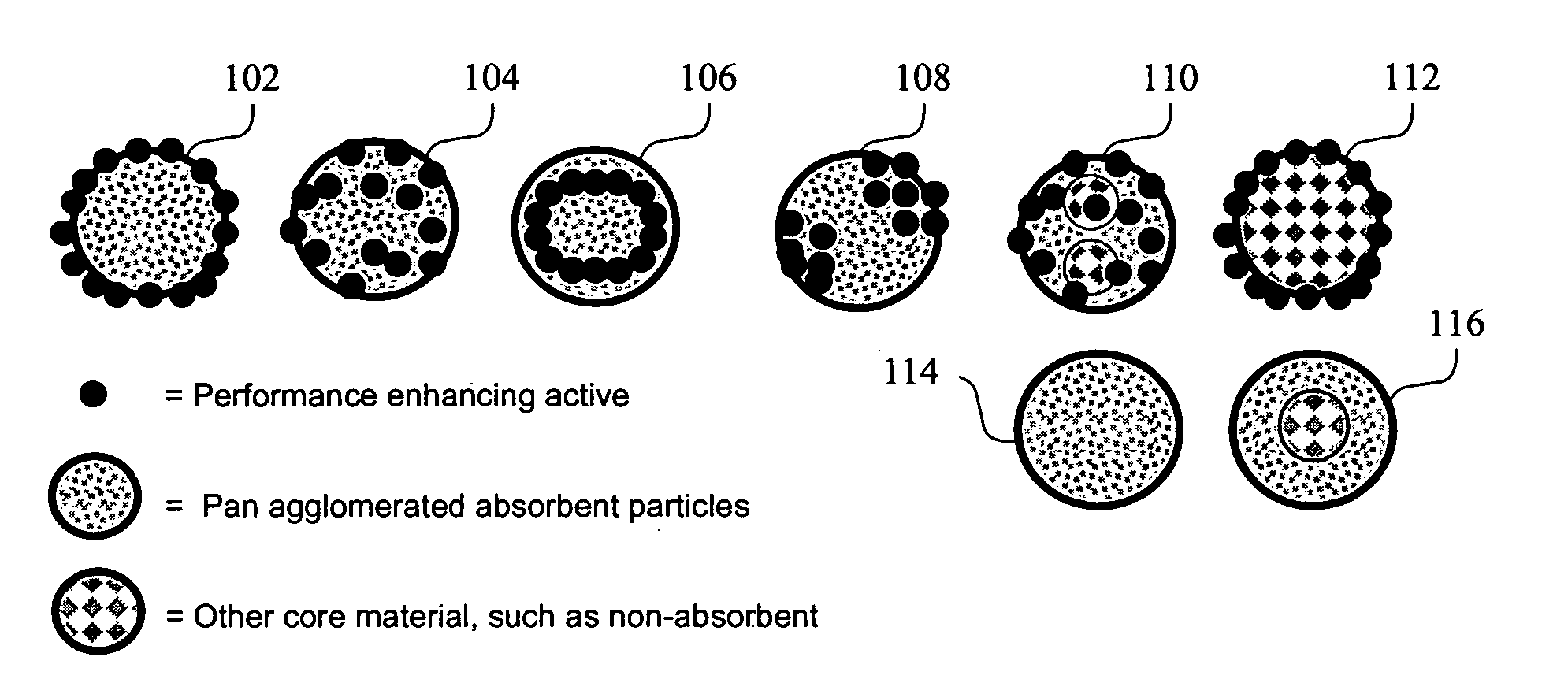

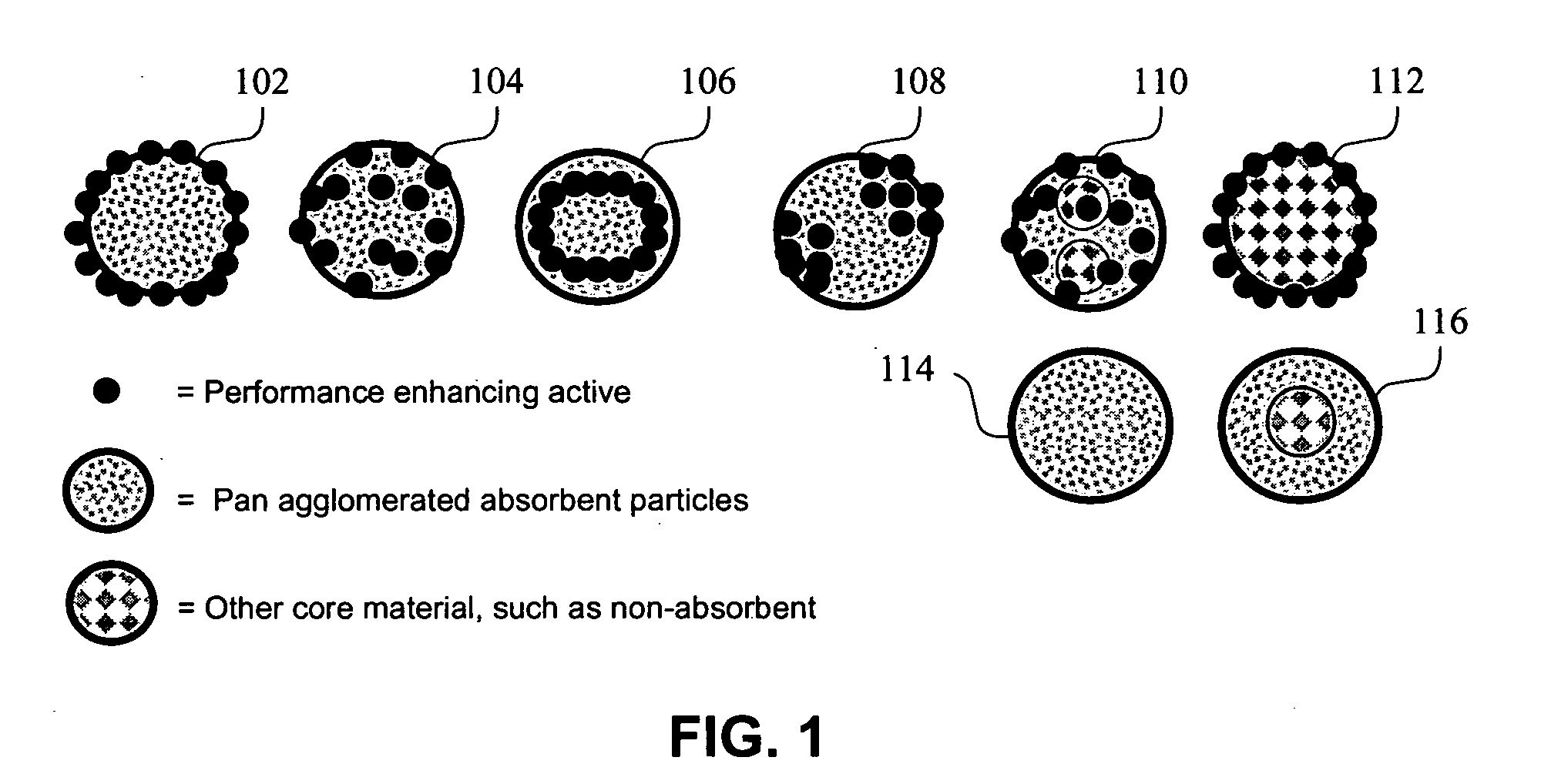

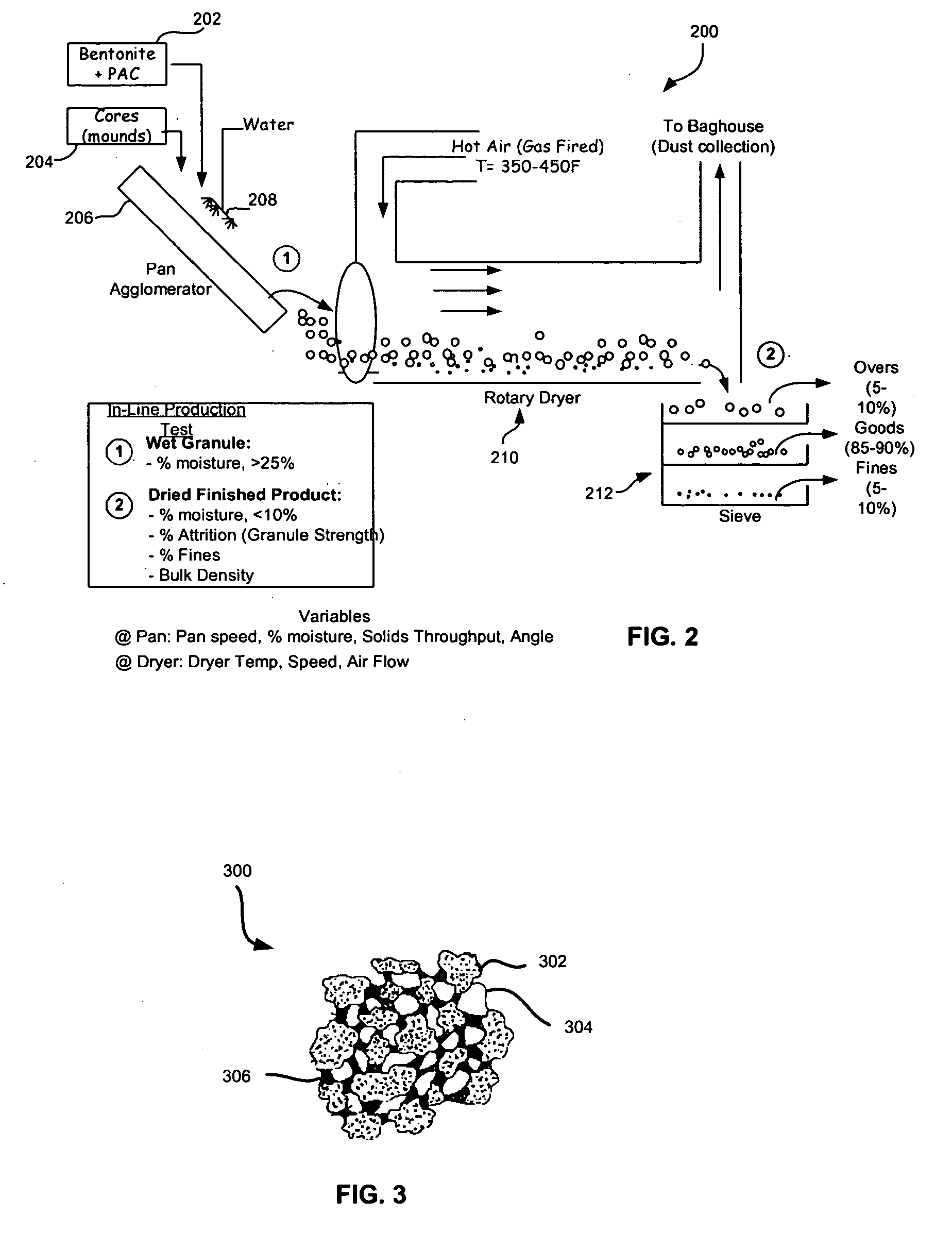

Composite absorbent particles

InactiveUS20050005869A1Low densityShorten the trackOther chemical processesAnimal housingFluidized bedEngineering

Composite particles and methods for making the same. An absorbent material is formed into a particle. An optional performance-enhancing active is coupled to the absorbent material before, during, or after the particle-forming process, homogeneously and / or in layers. Additionally, the composite absorbent particle may include a core material. Preferred methods for creating the absorbent particles include a pan agglomeration process, a high shear agglomeration process, a low shear agglomeration process, a high pressure agglomeration process, a low pressure agglomeration process, a rotary drum agglomeration process, a mix muller process, a roll press compaction process, a pin mixer process, a batch tumble blending mixer process, an extrusion process, and a fluid bed process.

Owner:THE CLOROX CO

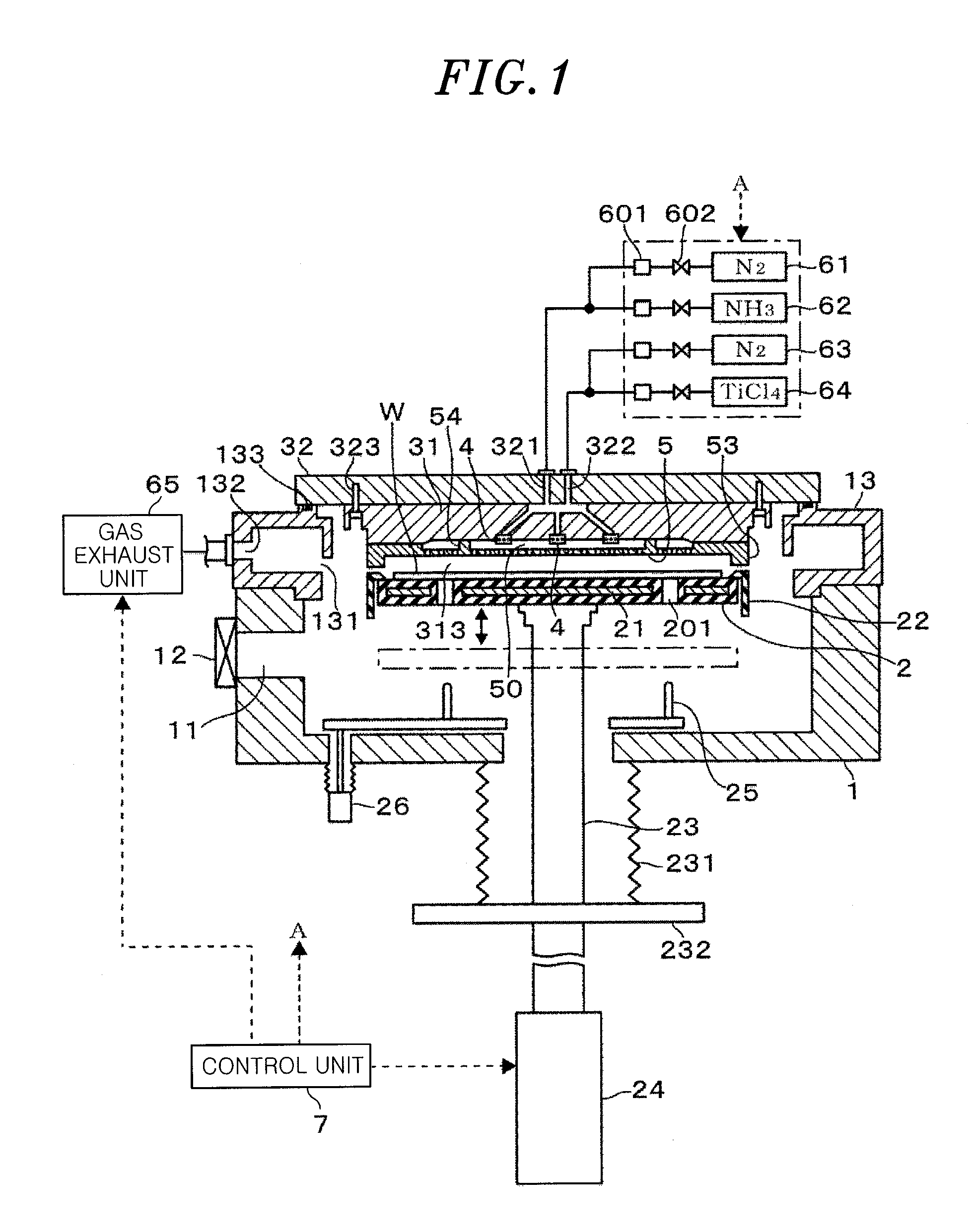

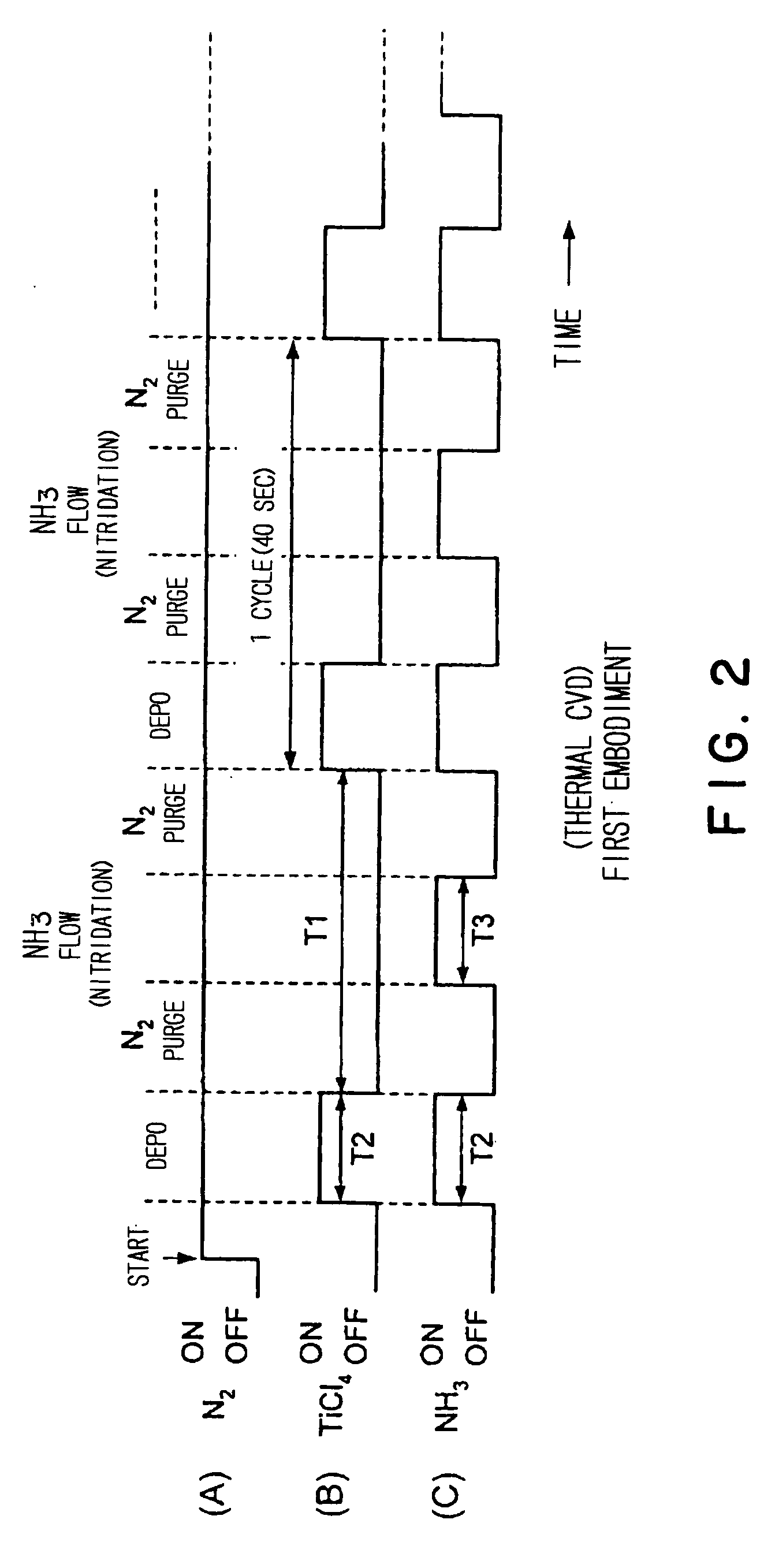

Method for forming film

InactiveUS20060193980A1Less micro crackEfficient solutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenProduct gas

The present invention relates to a method of forming a metal-nitride film onto a surface of an object to be processed in a processing container in which a vacuum can be created. The method of the invention includes: a step of continuously supplying an inert gas into a processing container set at a high film-forming temperature; and a step of intermittently supplying a metal-source gas into the processing container, during the step of continuously supplying the inert gas. During the step of intermittently supplying the metal-source gas, a nitrogen-including reduction gas is supplied into the processing container at the same time that the metal-source gas is supplied, during a supply term of the metal-source gas. The nitrogen-including reduction gas is also supplied into the processing container for a term shorter than a non-supply term of the metal-source gas, during the non-supply term of the metal-source gas. A film thickness of the metal-nitride film formed during the one supply term of the metal-source gas is not more than 60 nm. According to the invention, although the film-forming process is conducted at a relatively high temperature, a metal-nitride film can be deposited whose chlorine density is low, whose resistivity is low, and in which fewer cracks may be generated.

Owner:TOKYO ELECTRON LTD

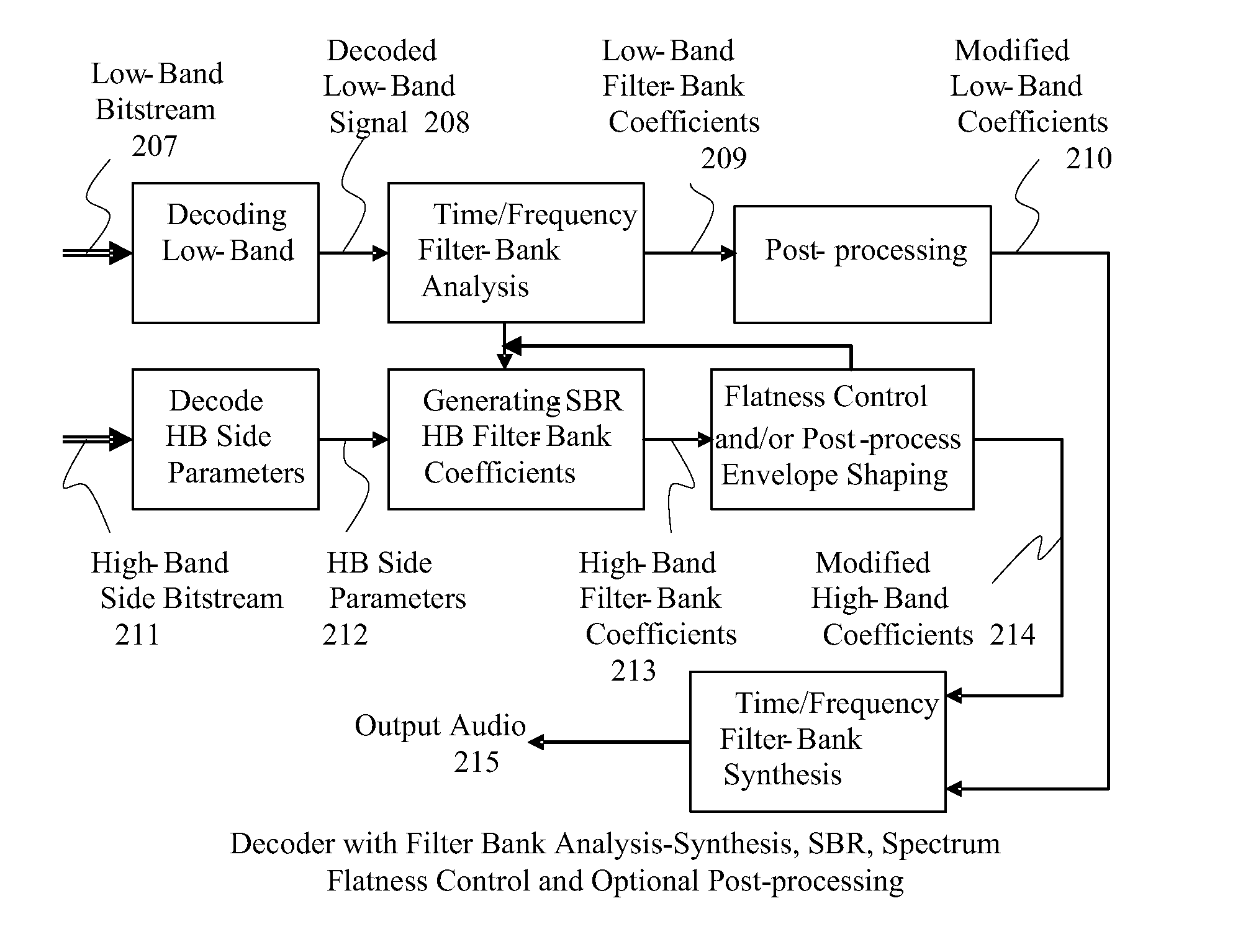

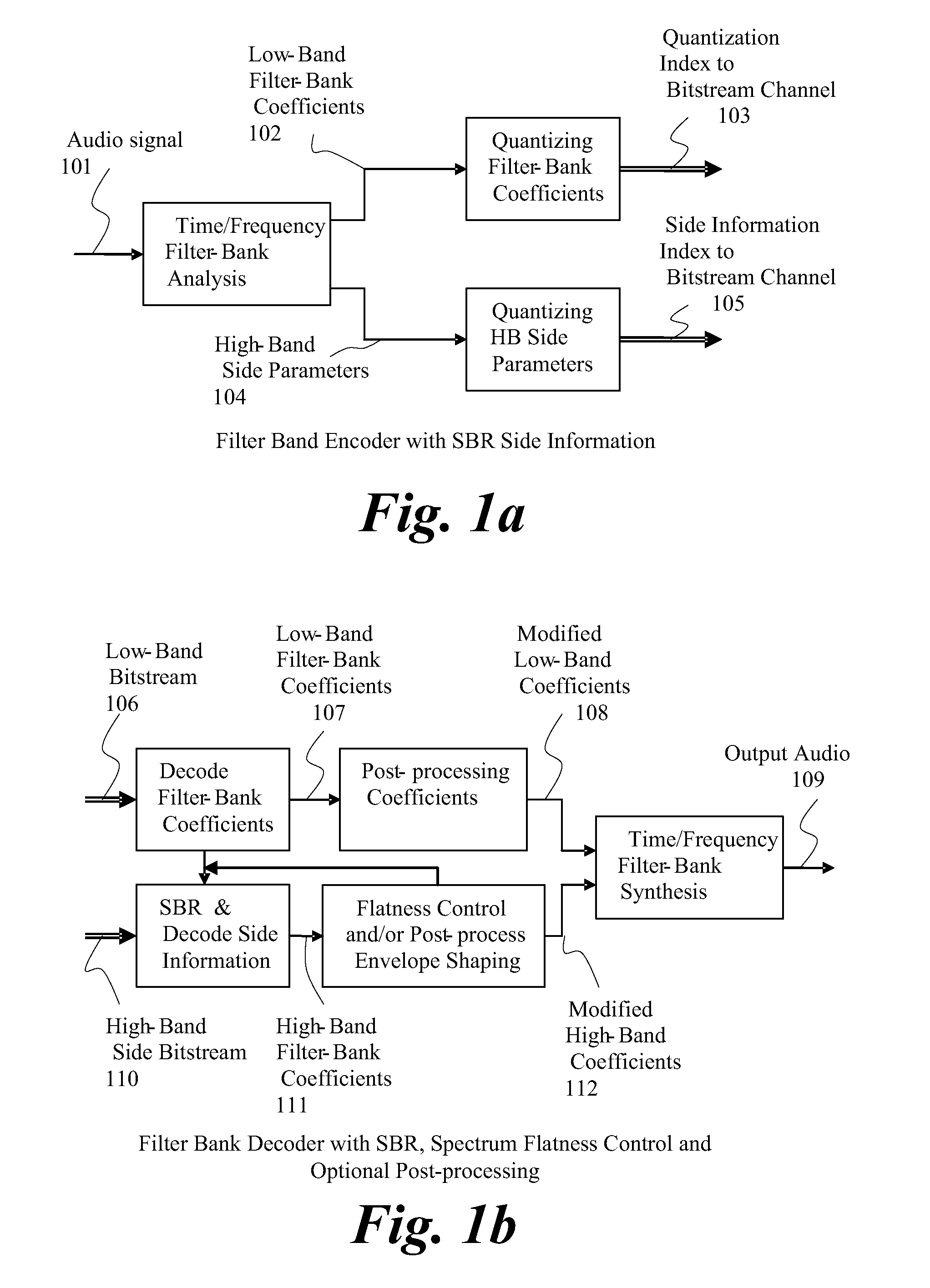

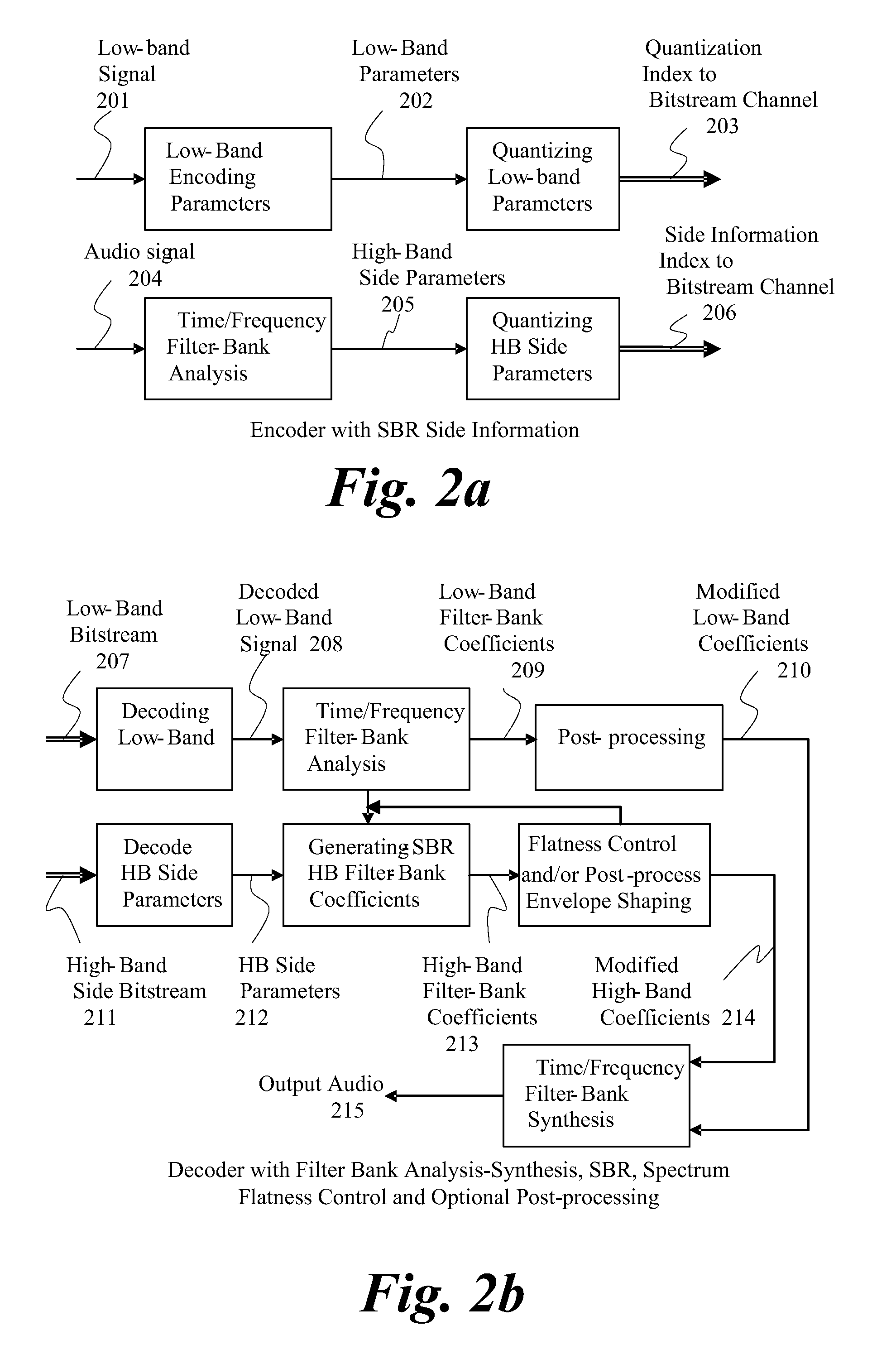

Spectrum Flatness Control for Bandwidth Extension

ActiveUS20120016667A1Improvement factorImproving spectrum flatness of high-frequencySpeech analysisFrequency spectrumBand width

In accordance with an embodiment, a method of decoding an encoded audio bitstream at a decoder includes receiving the audio bitstream, decoding a low band bitstream of the audio bitstream to get low band coefficients in a frequency domain, and copying a plurality of the low band coefficients to a high frequency band location to generate high band coefficients. The method further includes processing the high band coefficients to form processed high band coefficients. Processing includes modifying an energy envelope of the high band coefficients by multiplying modification gains to flatten or smooth the high band coefficients, and applying a received spectral envelope decoded from the received audio bitstream to the high band coefficients. The low band coefficients and the processed high band coefficients are then inverse-transformed to the time domain to obtain a time domain output signal.

Owner:HUAWEI TECH CO LTD

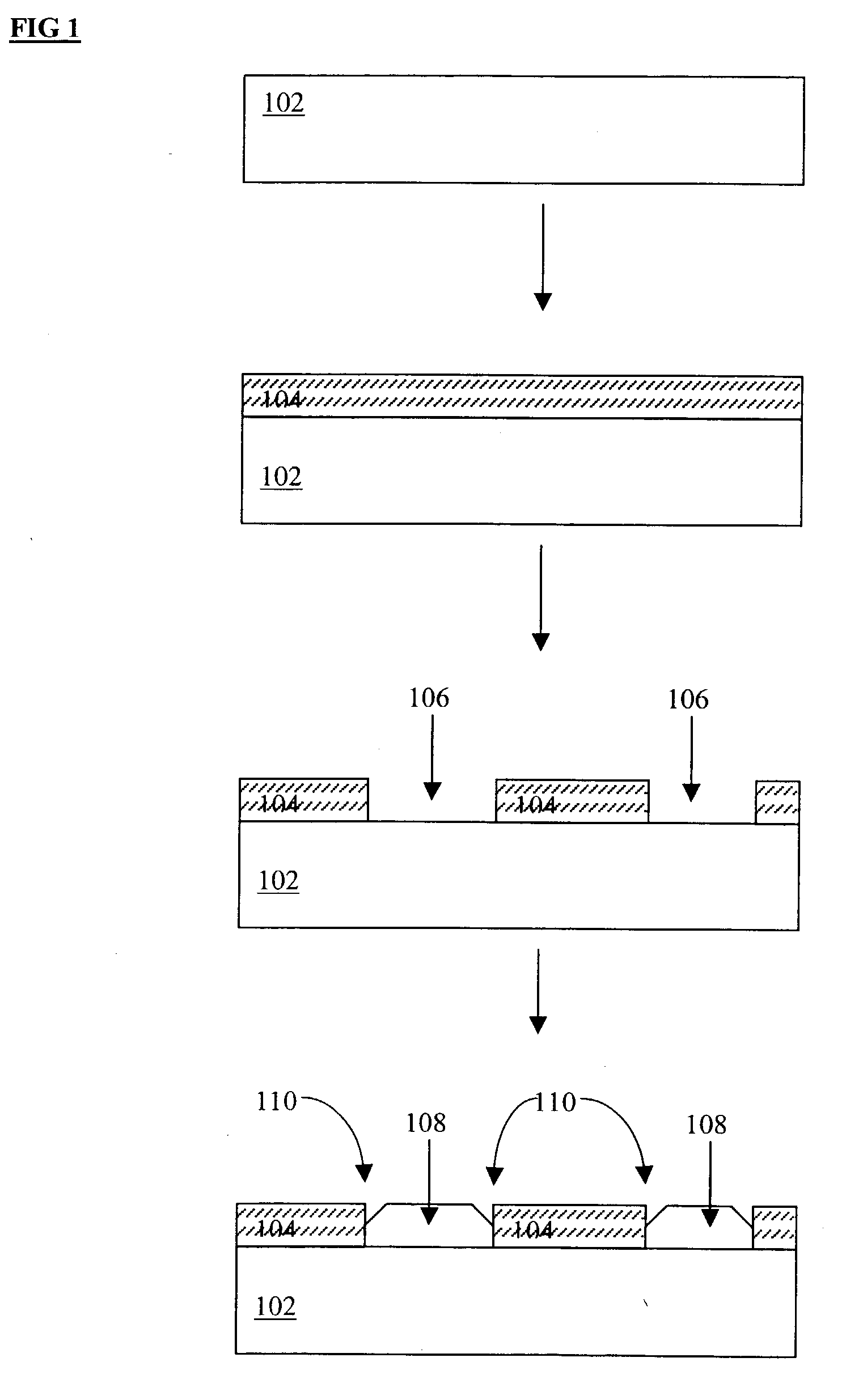

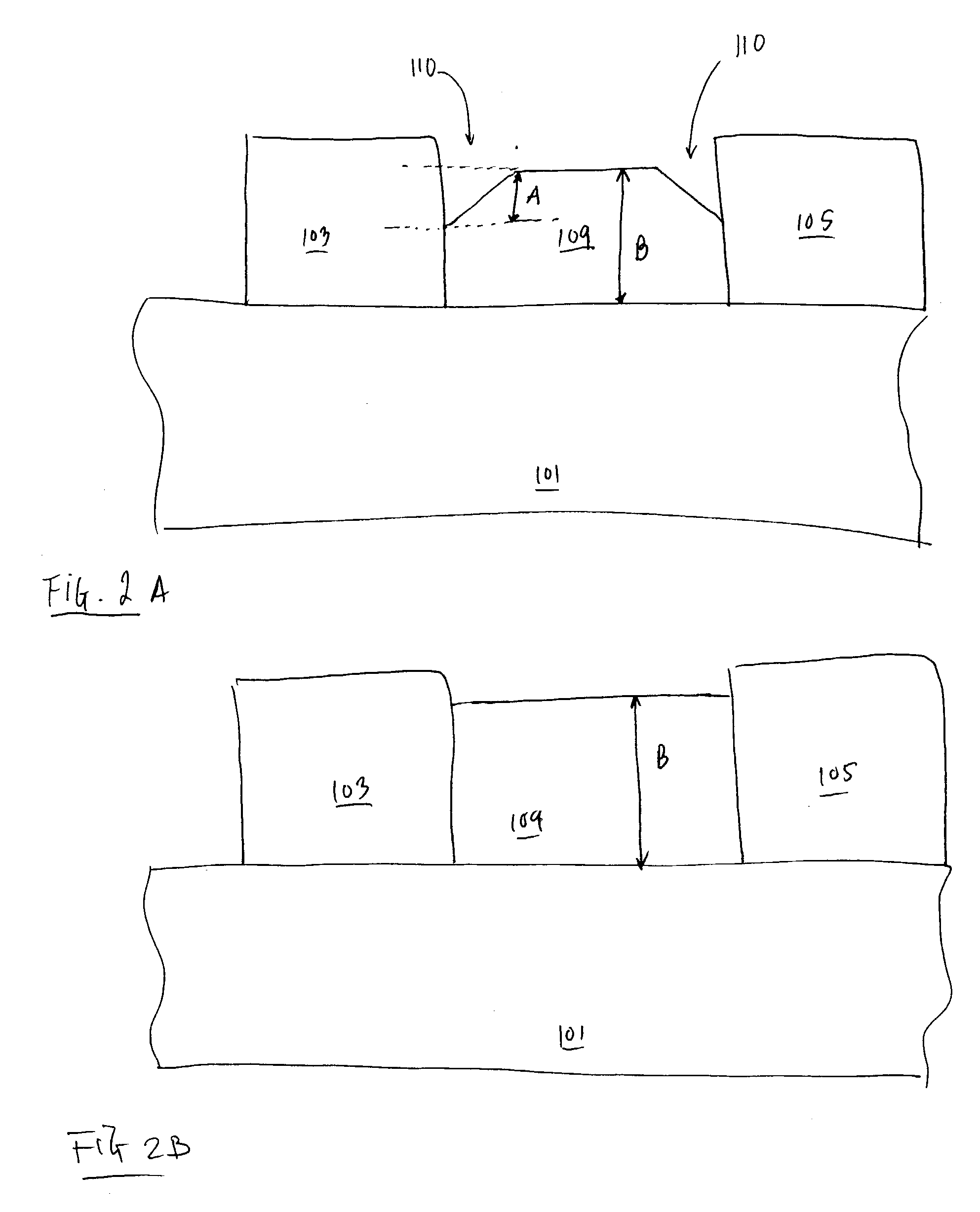

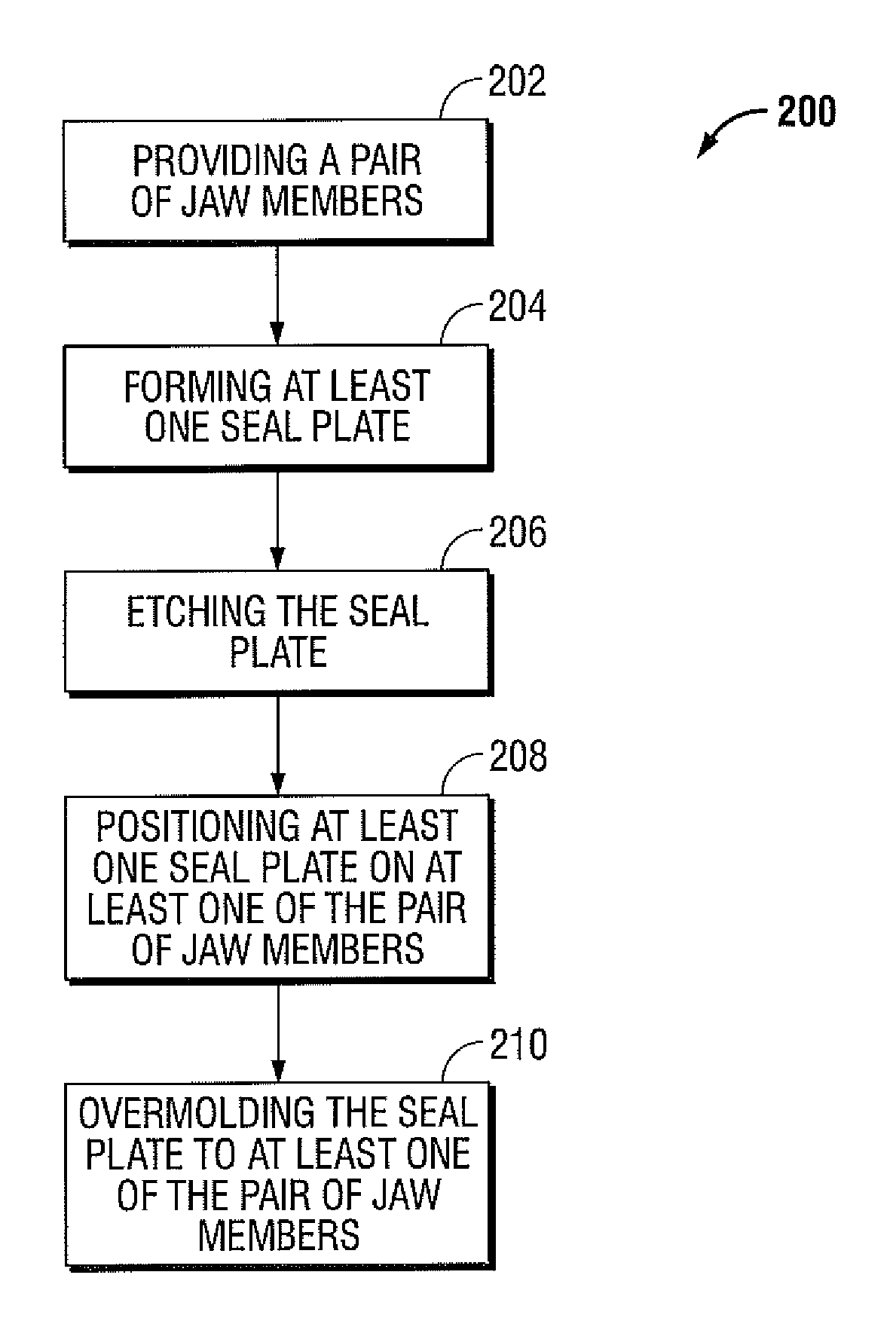

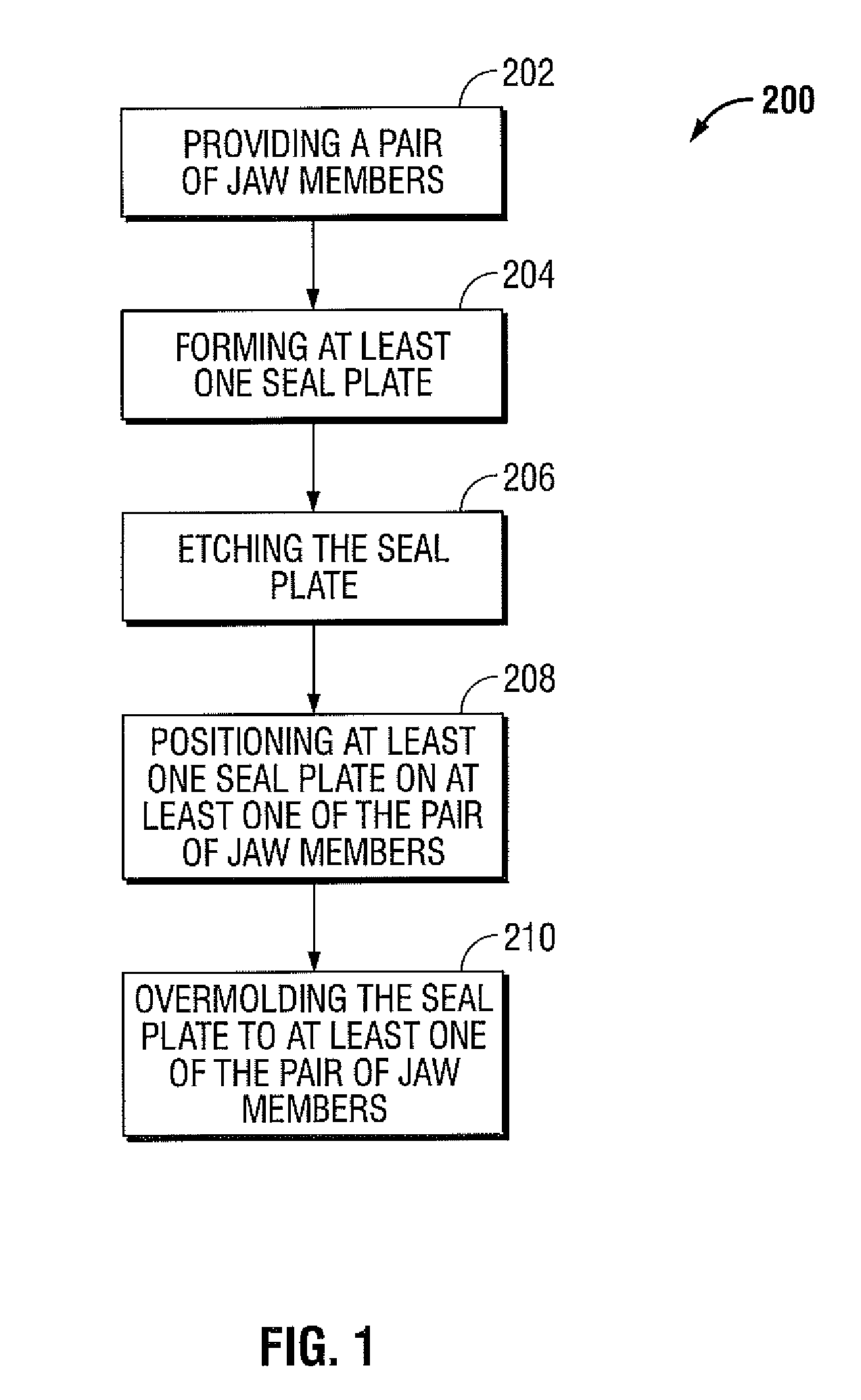

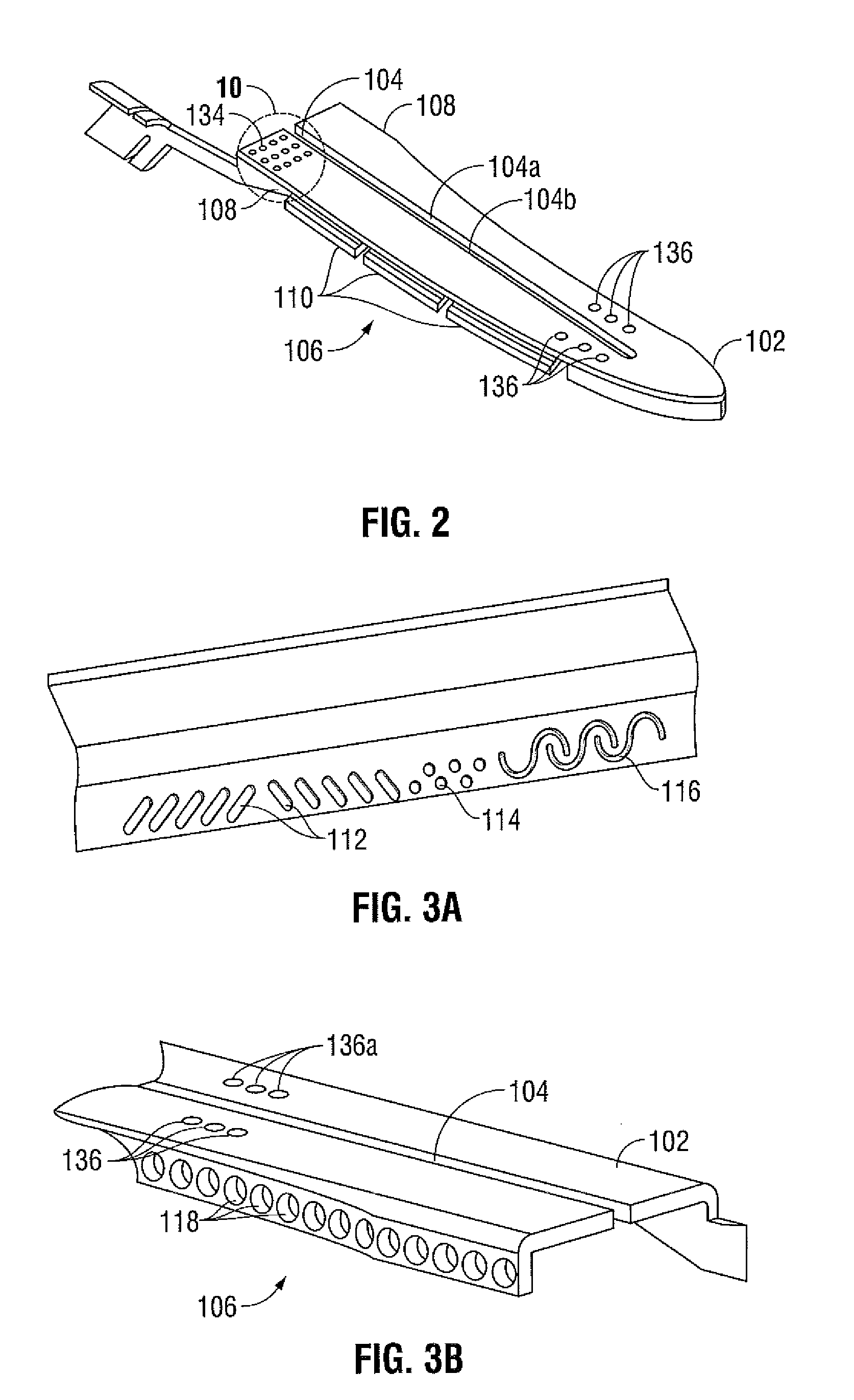

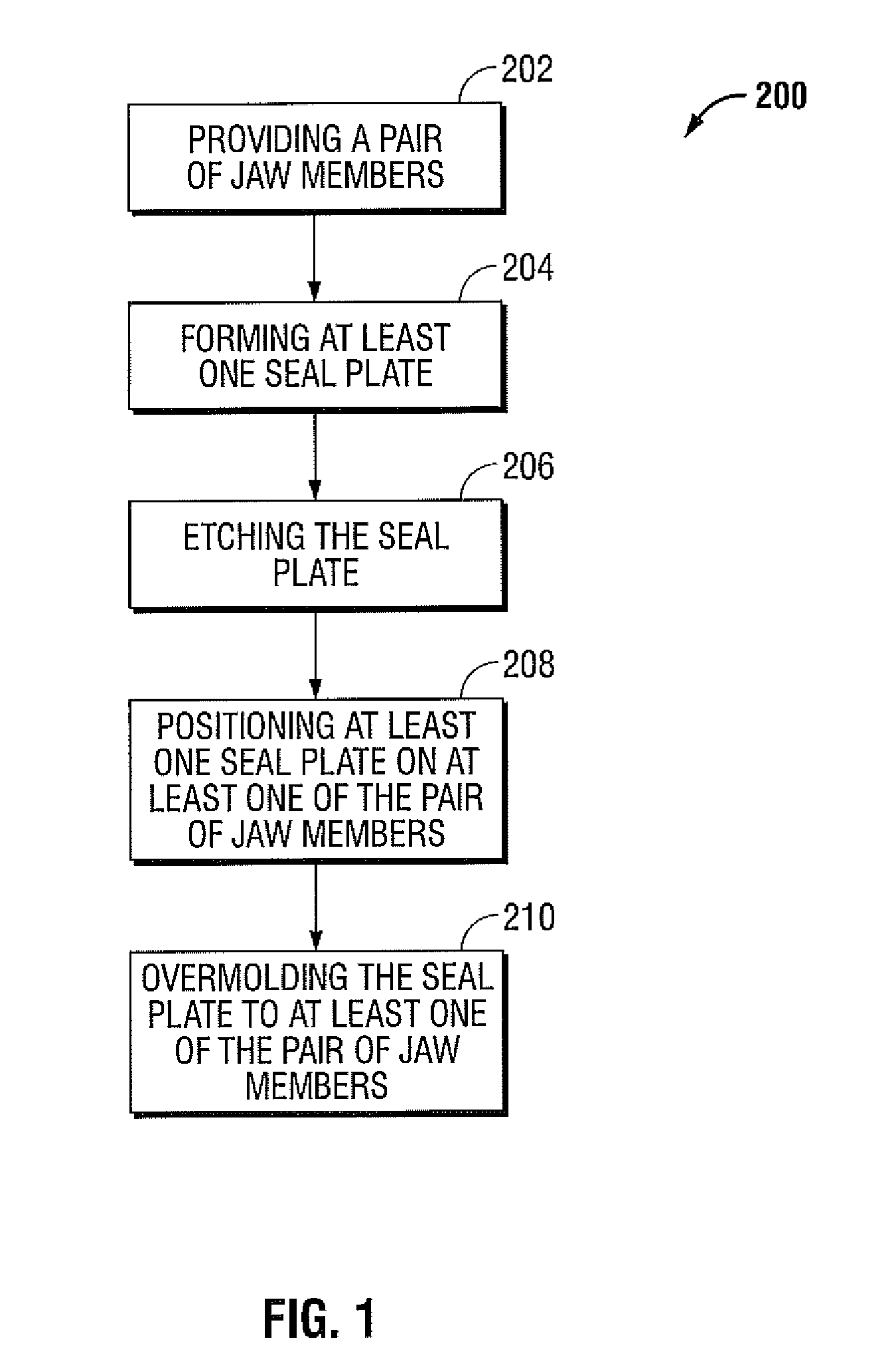

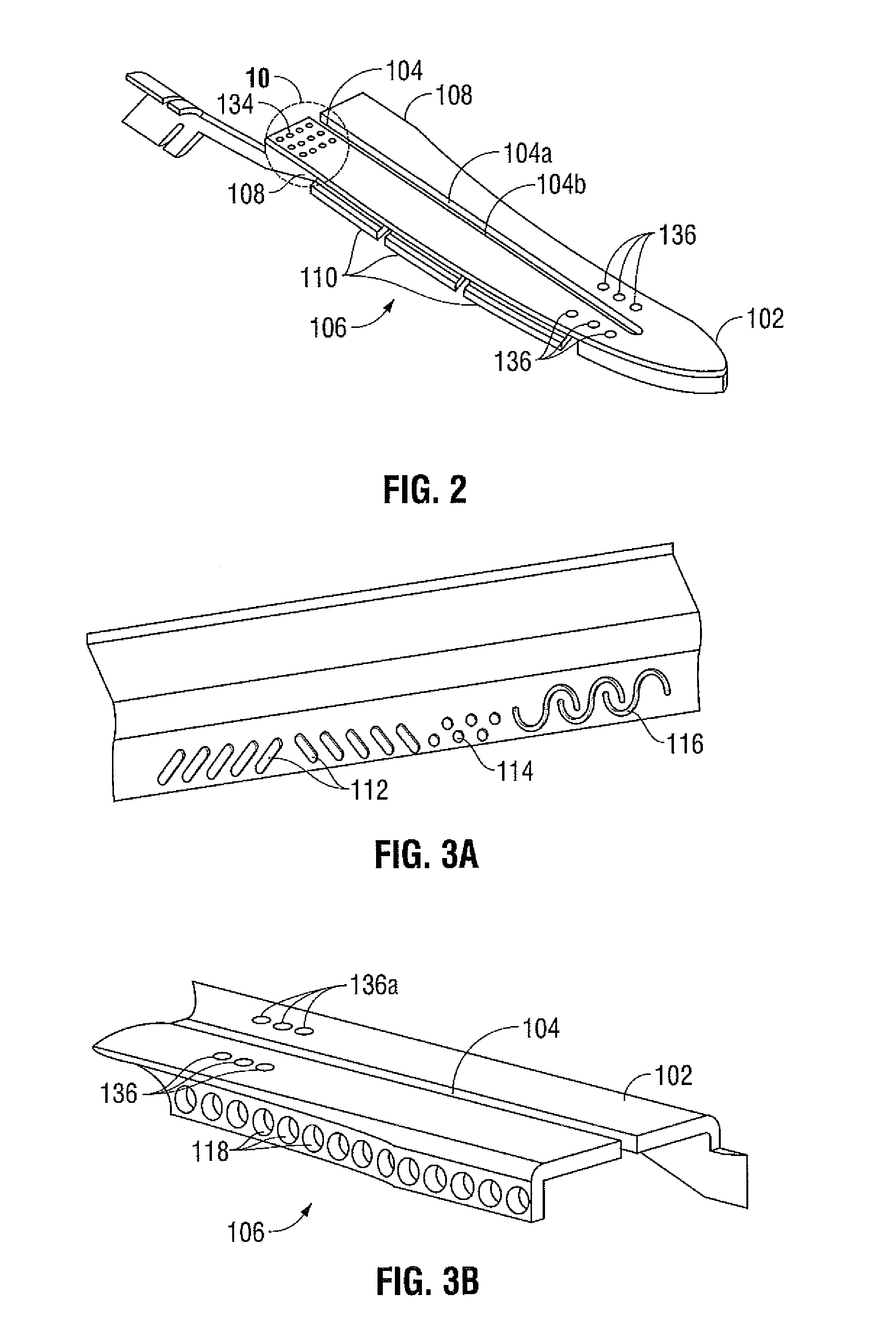

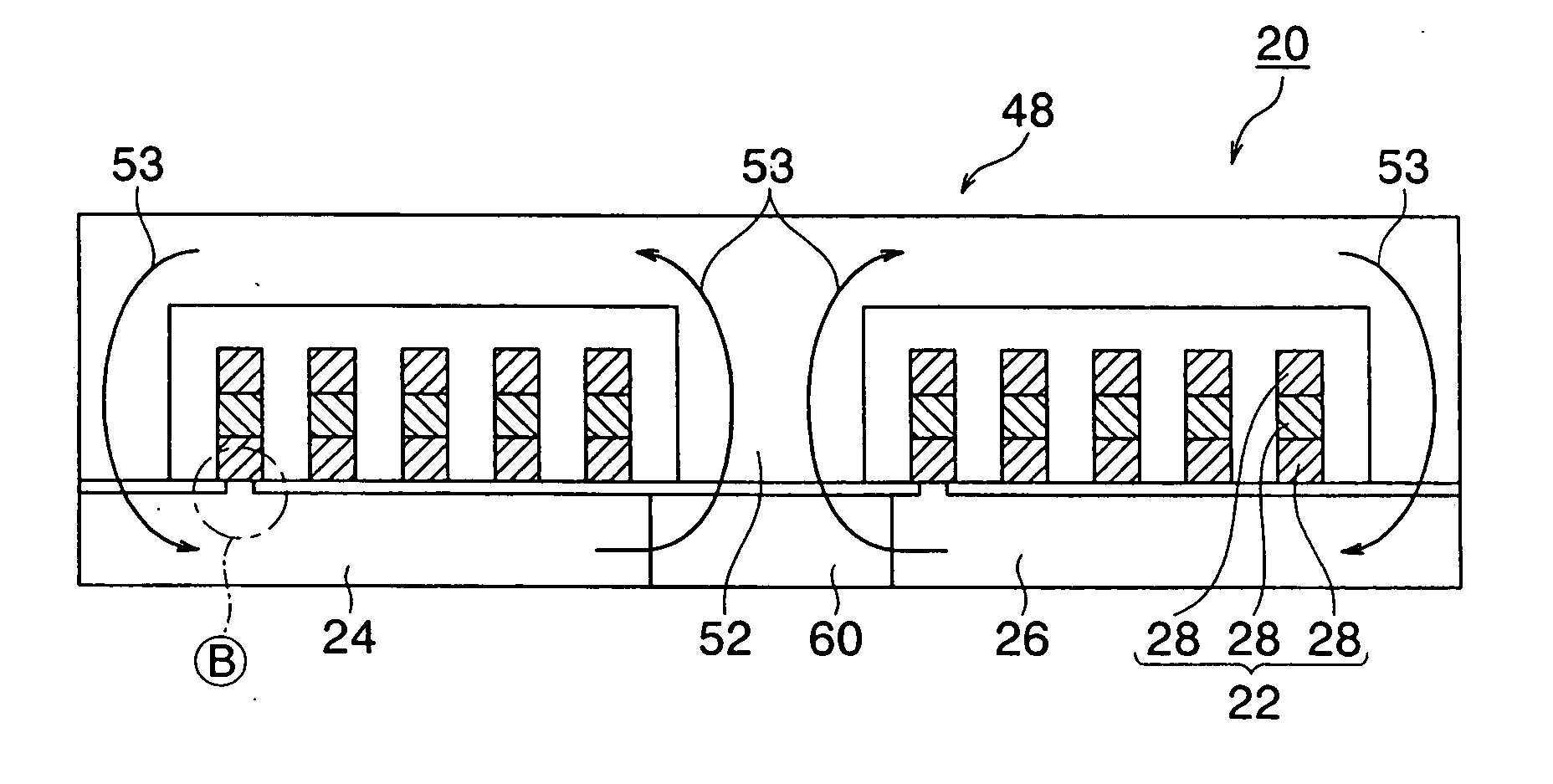

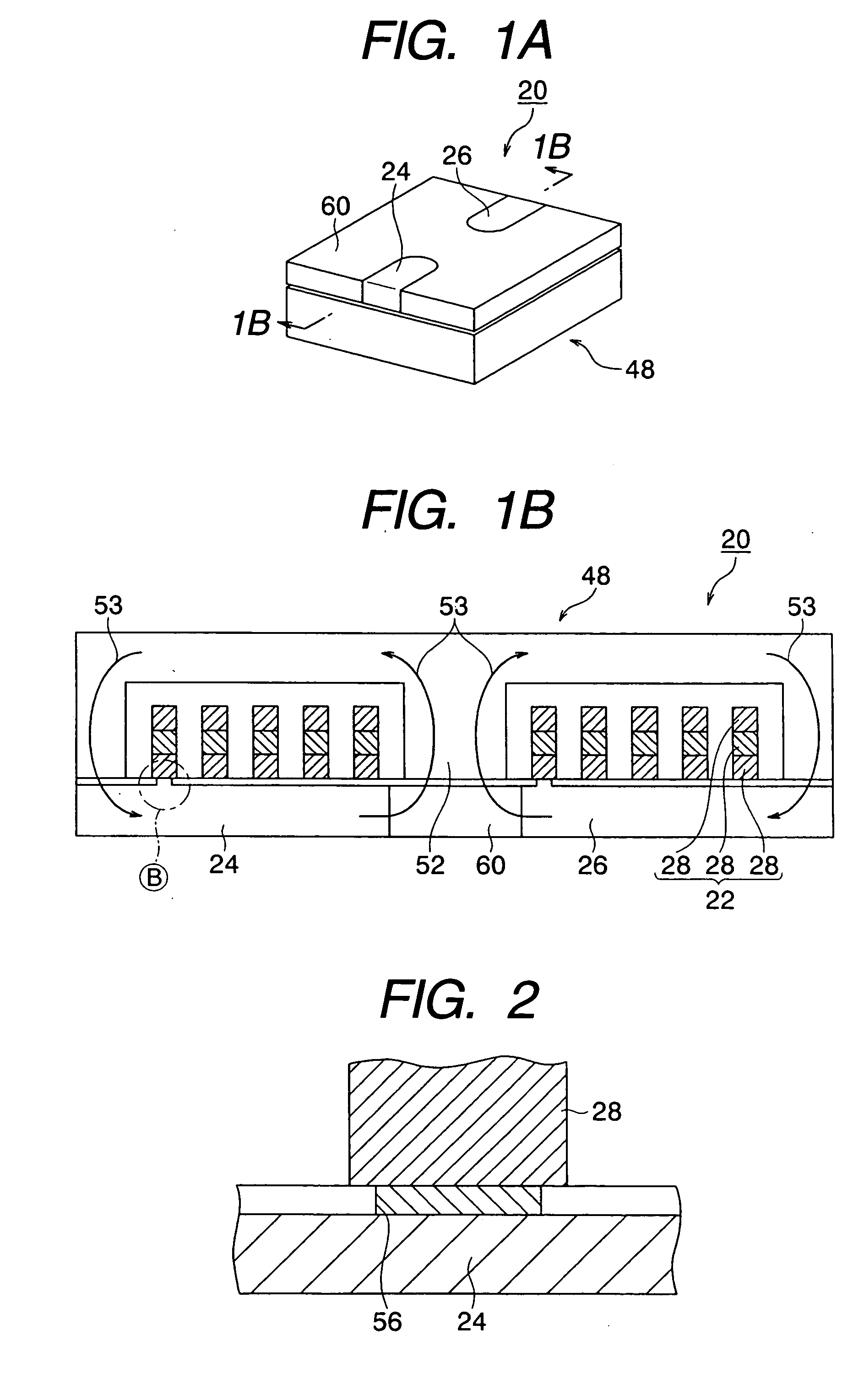

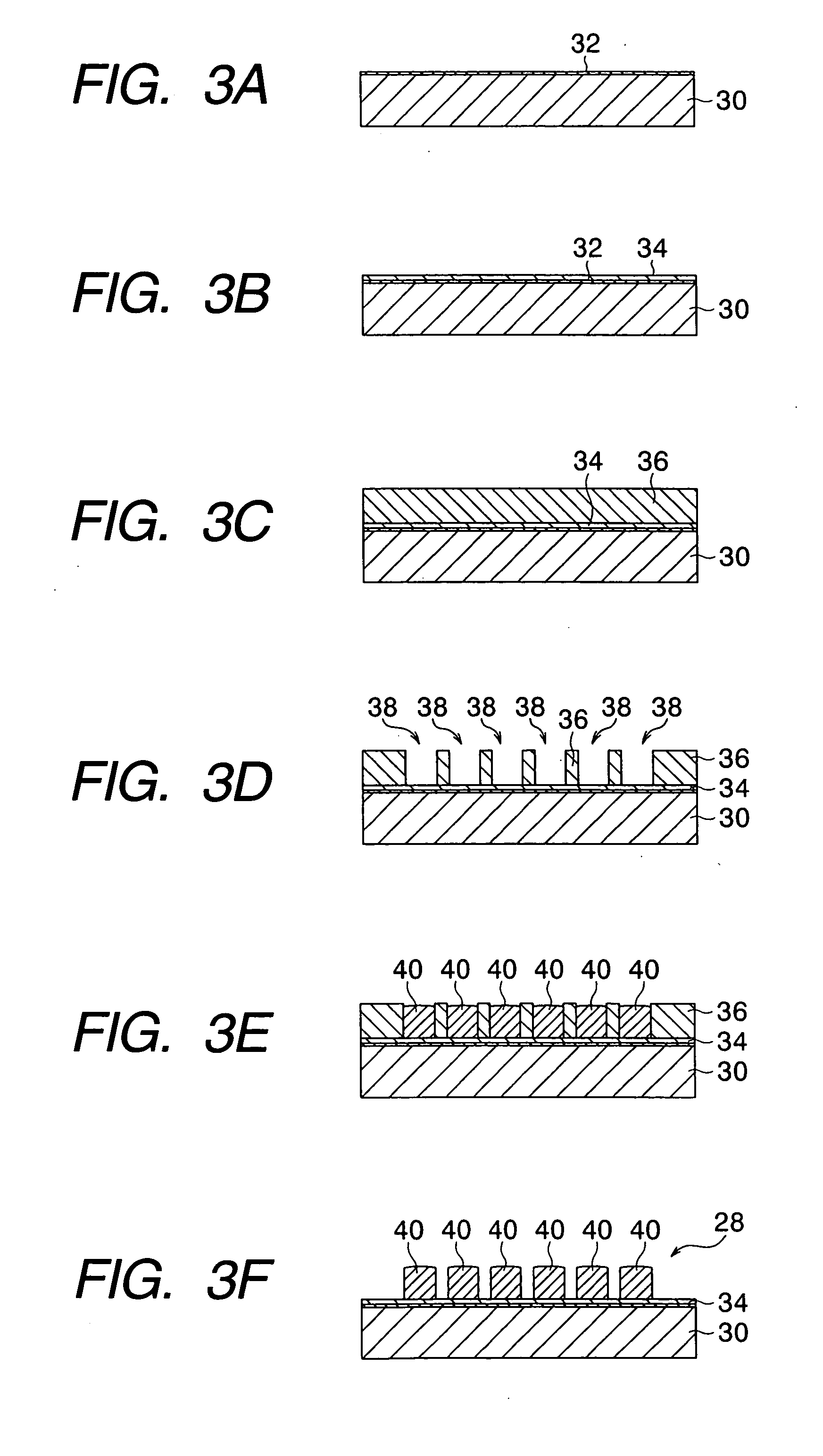

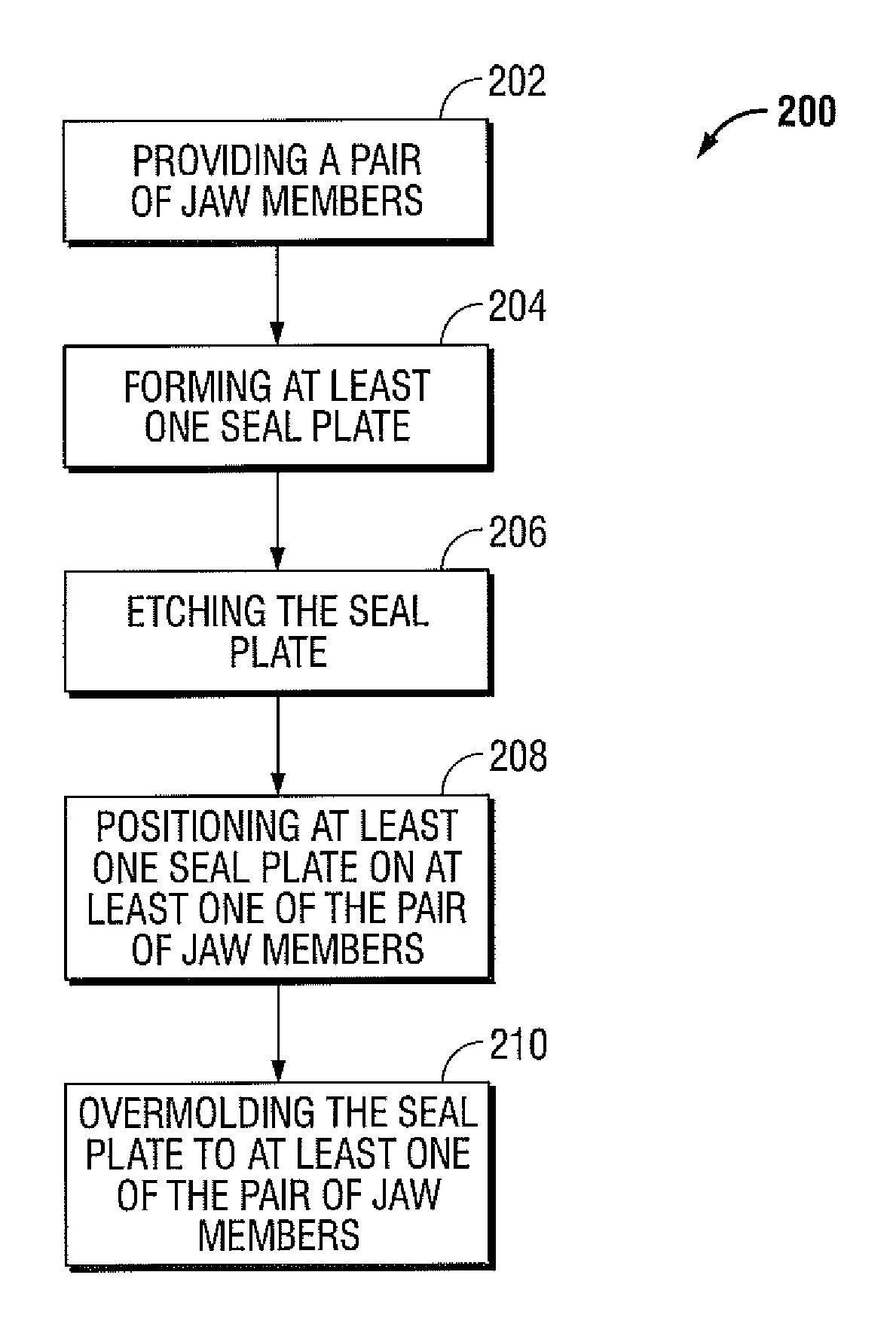

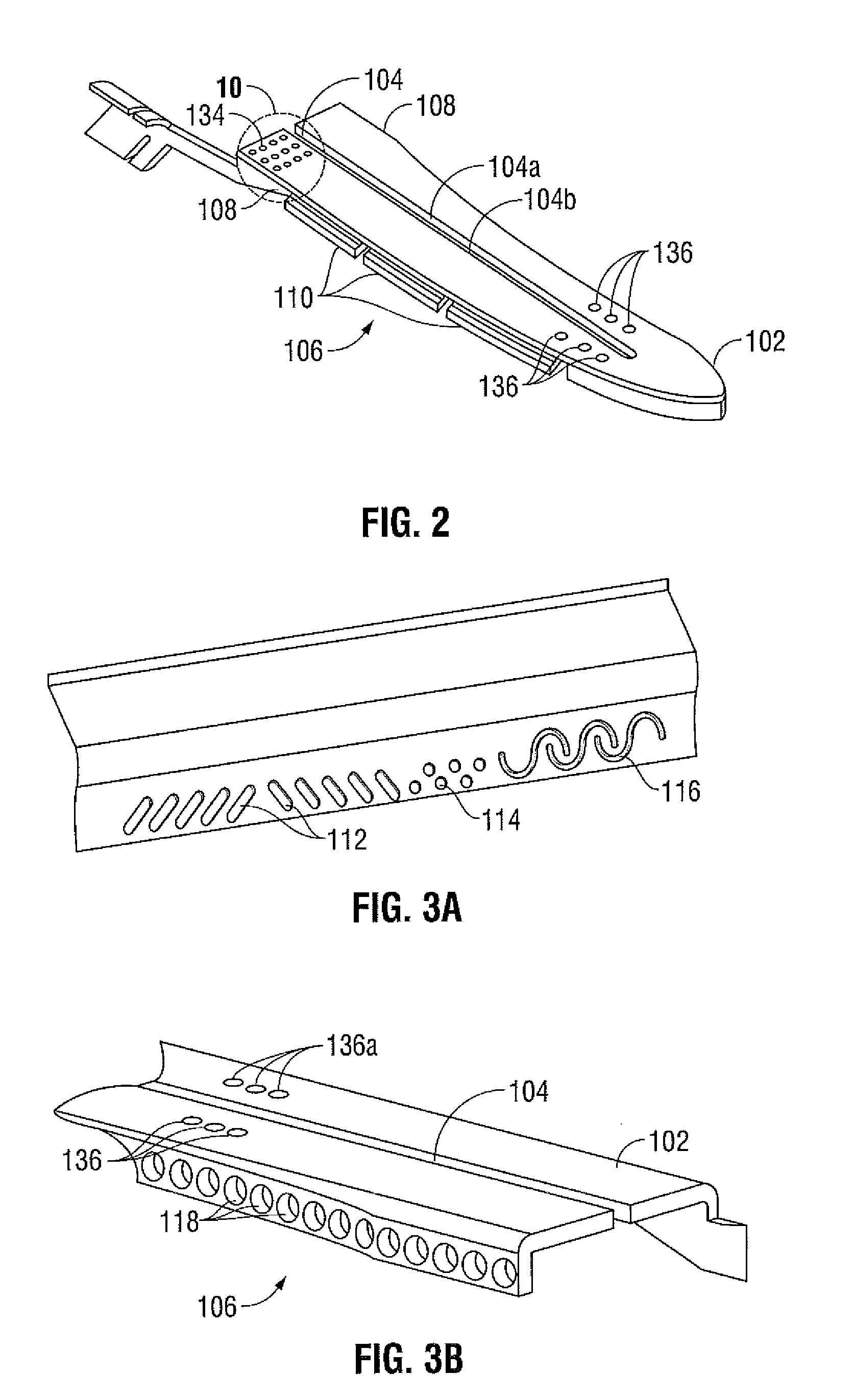

Method for manufacturing electrosurgical seal plates

ActiveUS8112871B2Avoid flowMeet the height limit requirementsContact member manufacturingLamination ancillary operationsEngineeringActuator

A method of manufacture for an end effector assembly is provided. The method includes providing a pair of jaw members. A step of the method includes forming one or more seal plates positionable on one of the pair of jaw members. Etching a dam along a side of the one or more seal plates is a step of the method, wherein the etched dam inhibits the flow of a plastic on the one or more seal plate such that a height of the plastic with respect to the at least one seal plate during an overmolding process may be controlled. The method includes positioning the one or more seal plates on the one of the pair of jaw members; and overmolding the seal plate to one or more of the pair of jaw members.

Owner:TYCO HEALTHCARE GRP LP

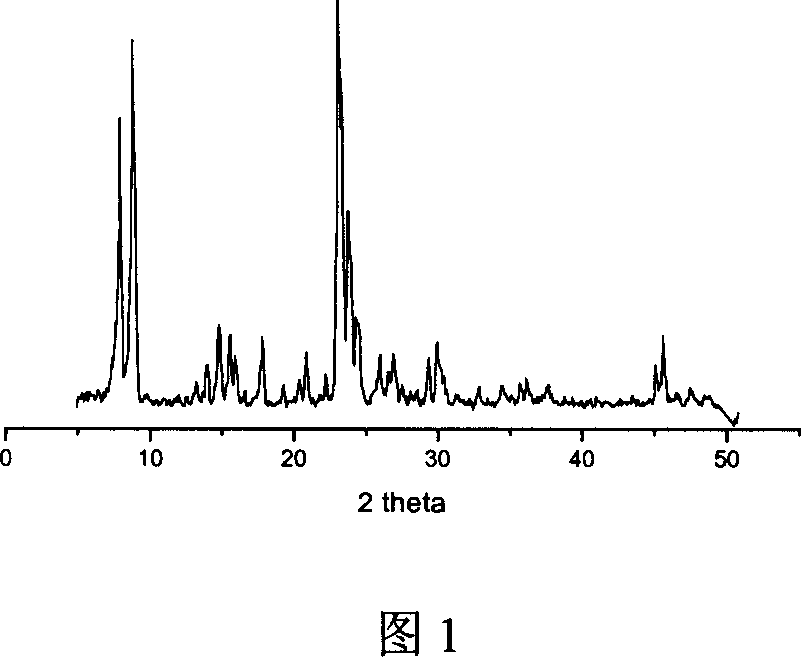

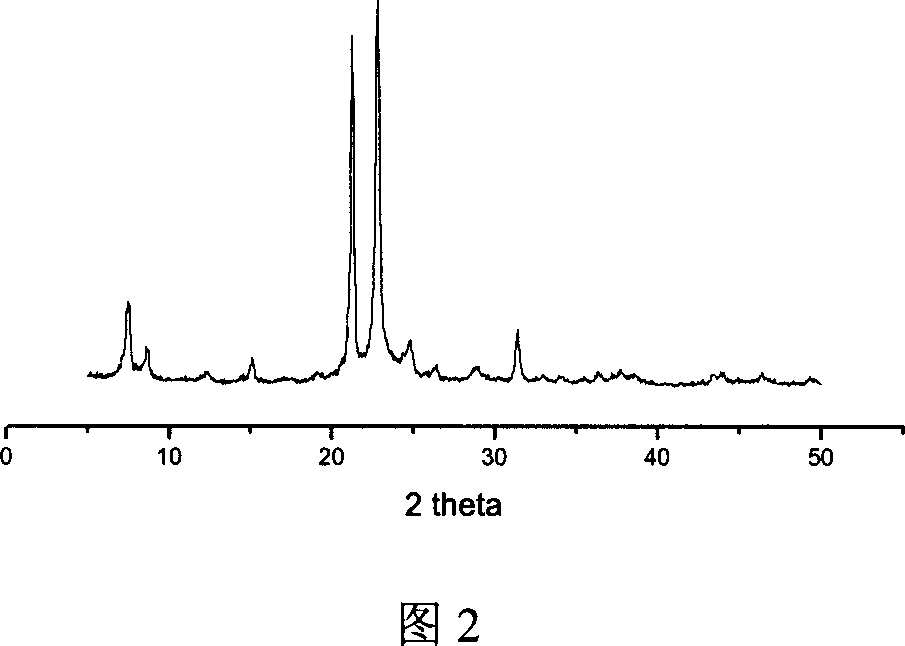

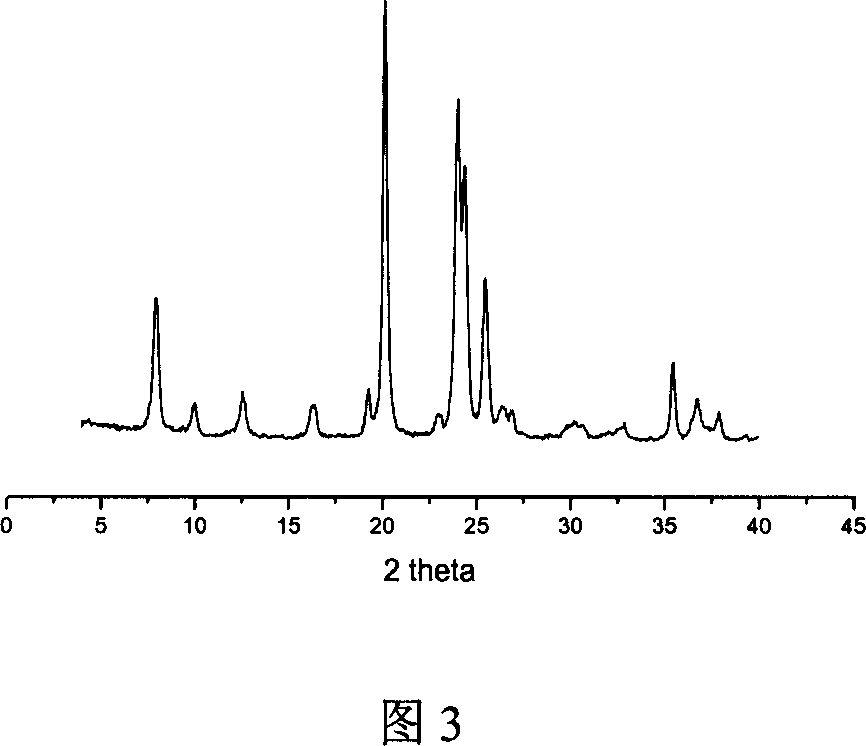

Preparation method of ZSM-type molecular sieve without binding agent

ActiveCN1927714ATemplate index highHigh crystallinityPentasil aluminosilicate zeoliteMolecular sieveEffective surface area

The present invention relates to preparation process of adhesive-free ZSM type molecular sieve, and aims at solving the problem of adding adhesive causing decrease in effective surface area and limited diffusion. Technologically, the present invention is that adhesive silica in 5-50 wt% and ZSM type molecular sieve powder are made to form mixture, and the mixture is hydrothermally converted inside water solution or steam containing organic amine halide and alkyl diamine into integrated ZSM type molecular sieve. The process of the present invention may be used in the industrial preparation of ZSM type molecular sieve catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

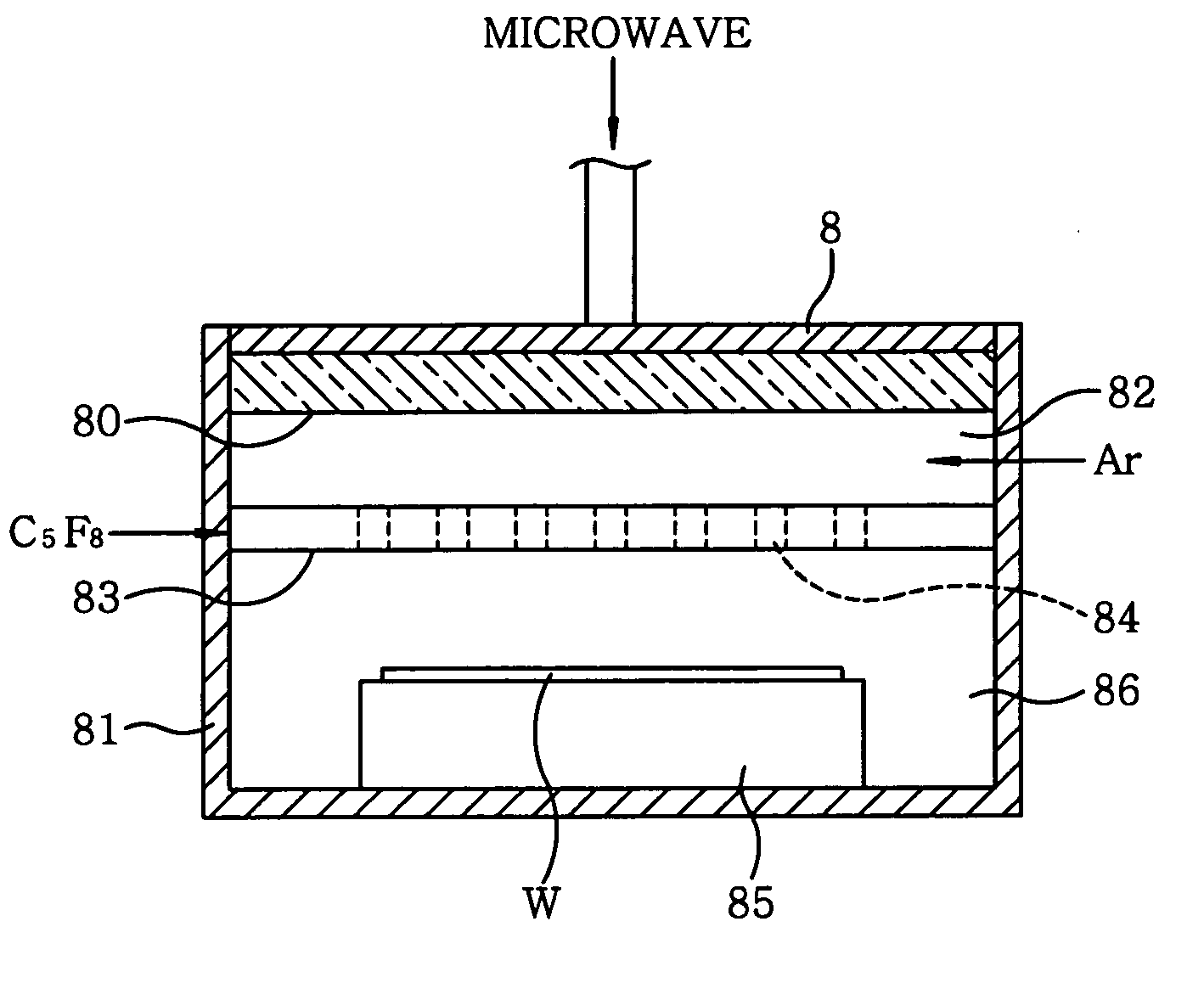

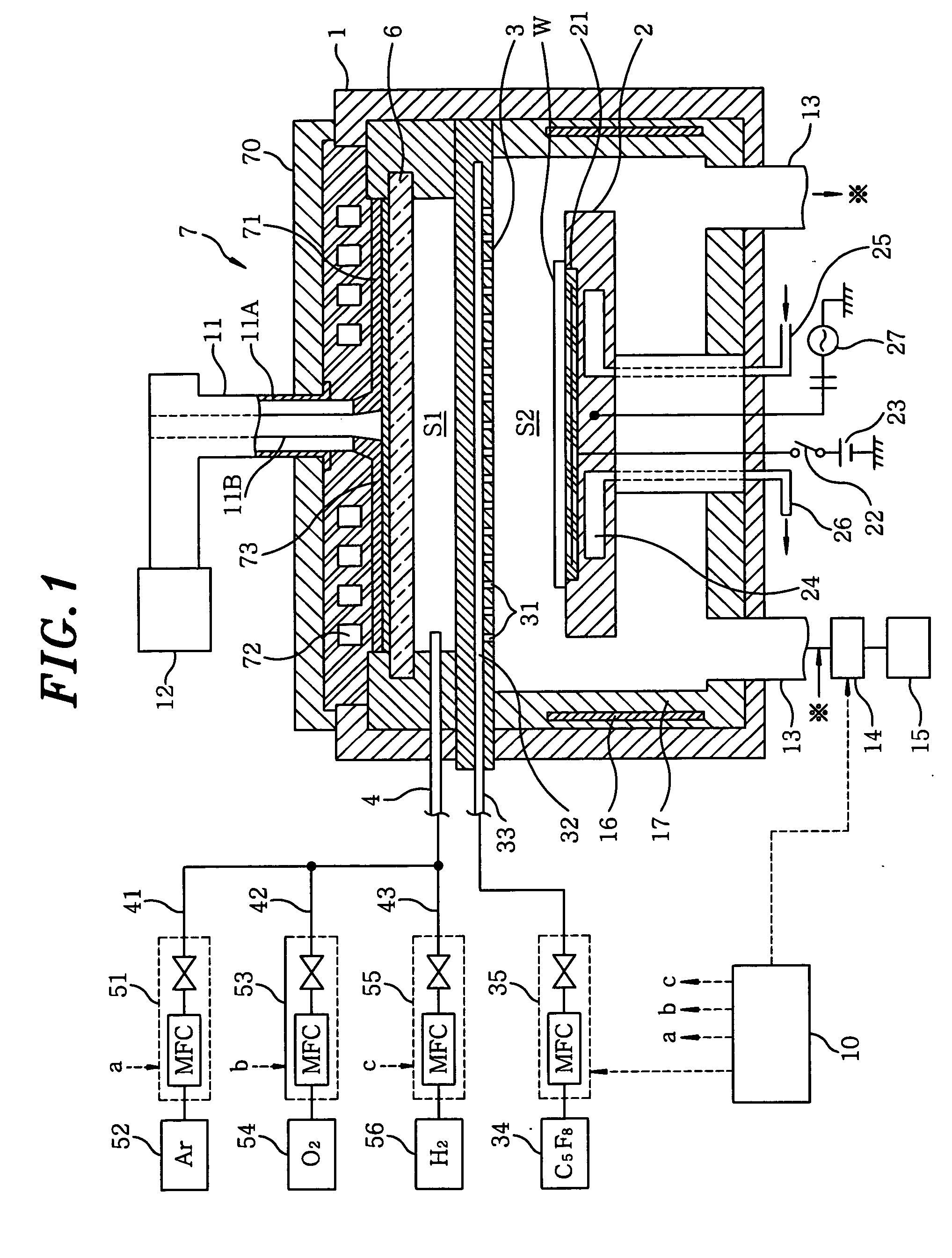

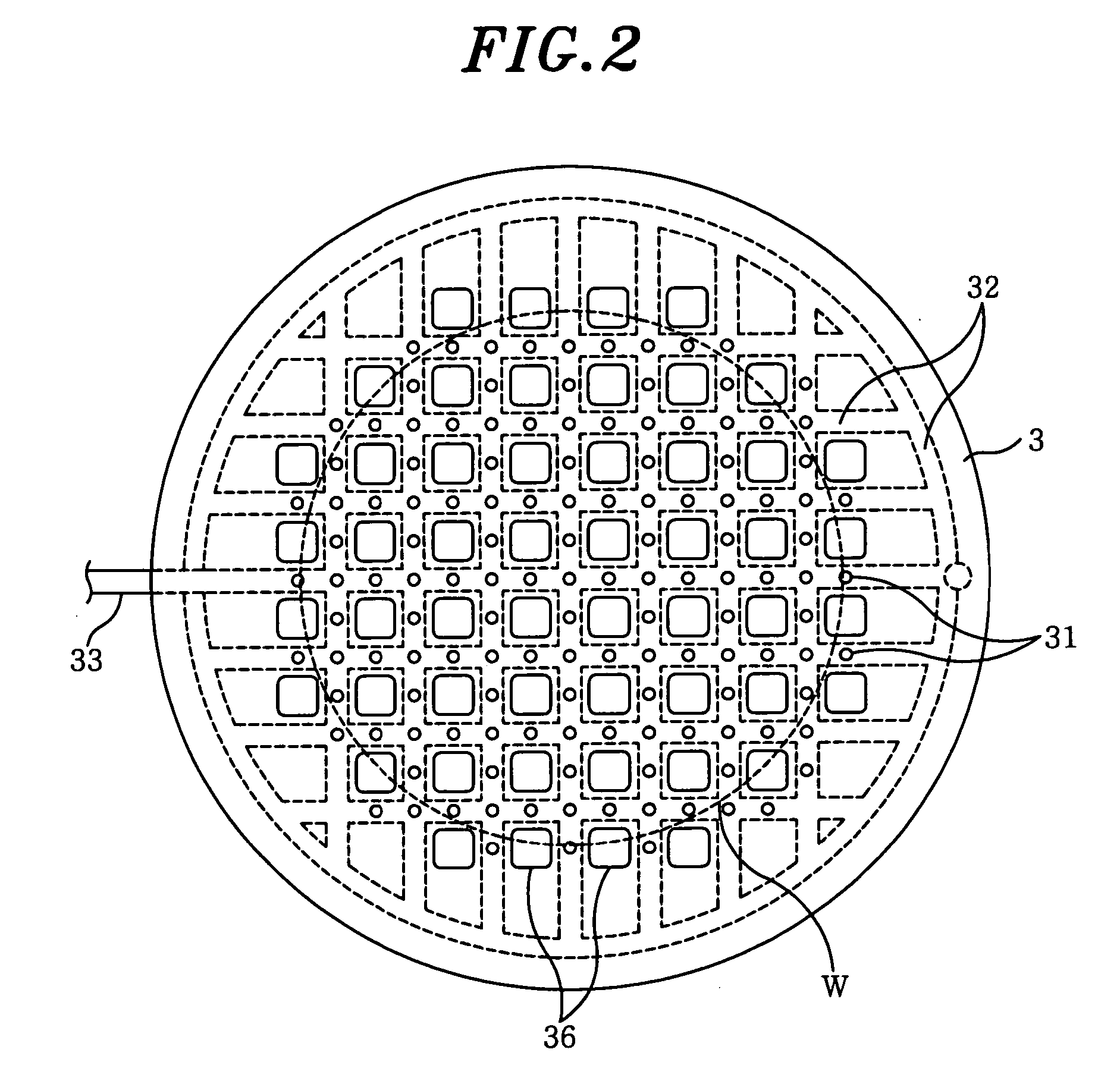

Plasma processing method and plasma processing apparatus

InactiveUS20070077737A1High densityLow electron temperatureElectric discharge tubesSemiconductor/solid-state device manufacturingCarbon filmEngineering

A microwave is radiated into a processing chamber (1) from a planar antenna member of an antenna (7) through a dielectric plate (6). With this, a C5F8 gas supplied into the processing chamber (1) from a gas supply member (3) is changed (activated) into a plasma so as to form a fluorine-containing carbon film of a certain thickness on a semiconductor wafer (W). Each time a film forming process of forming a film on one wafer is carried out, a cleaning process and a pre-coating process are carried out. In the cleaning process, the inside of the processing chamber is cleaned with a plasma of an oxygen gas and a hydrogen gas. In the pre-coating process, the C5F8 gas is changed into a plasma, and a pre-coat film of fluorine-containing carbon thinner than the fluorine-containing carbon film formed in the film forming process is formed.

Owner:TOKYO ELECTRON LTD

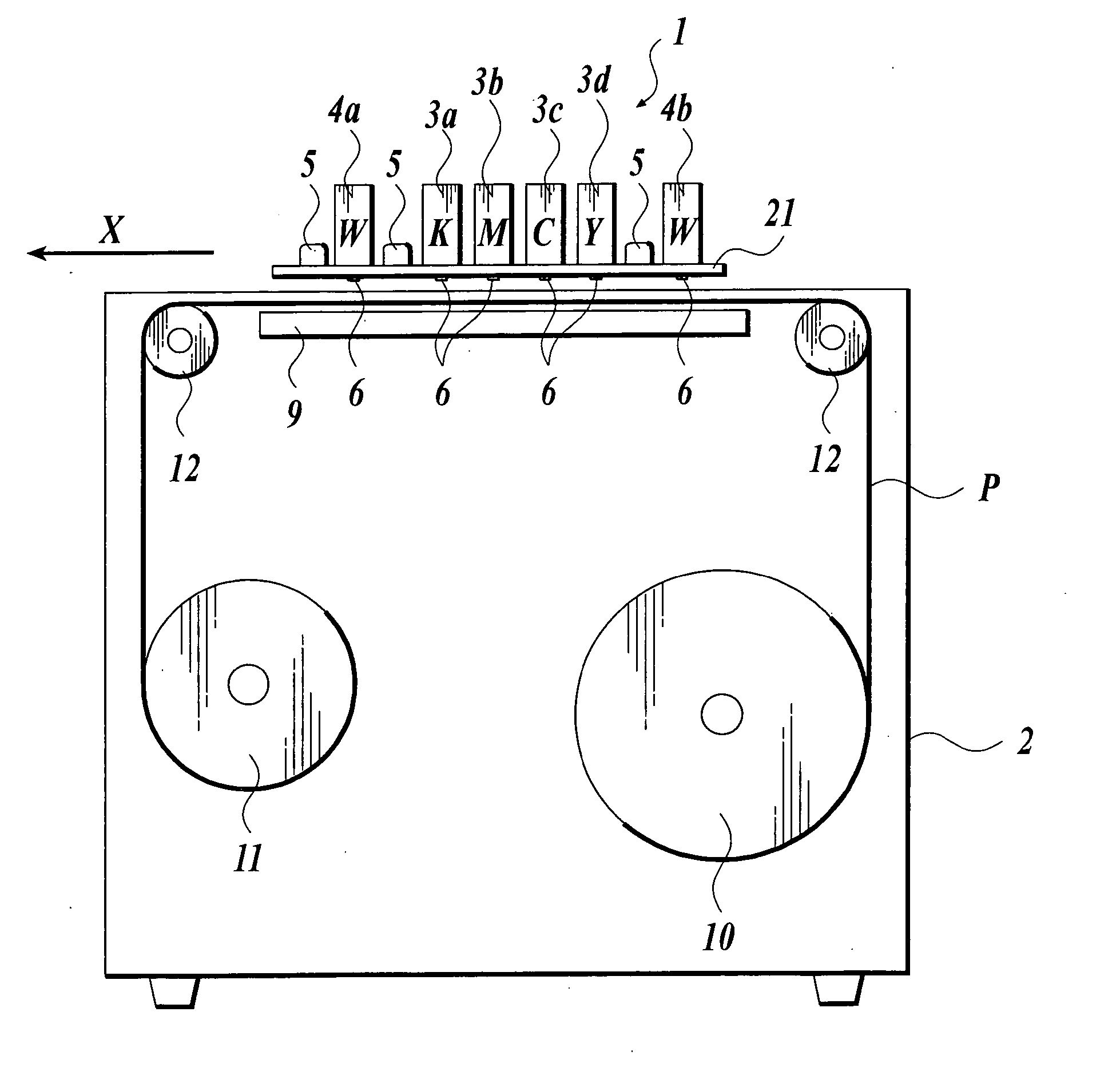

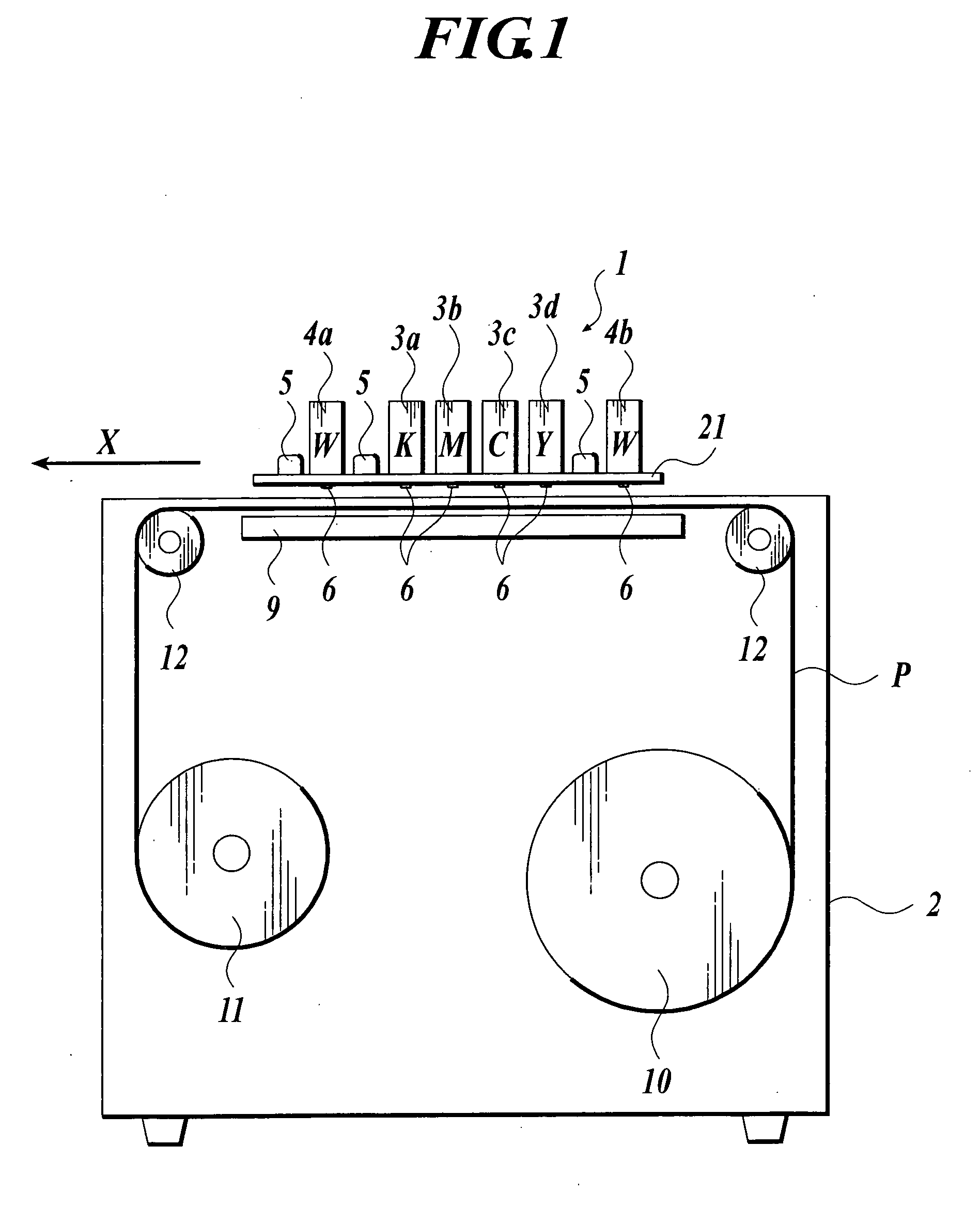

Image recording device

An image recording device has: a first recording head which discharges a first ink for a first image forming process; a second recording head which discharges a second ink for a second image forming process; a curing section which cures an ink on a recording medium; and a controller which controls the curing section to cure the first ink on the recording medium, and controls the second recording head to start discharging the second ink after a conversion of the first ink on the recording medium becomes not less than 30%.

Owner:KONICA MINOLTA INC

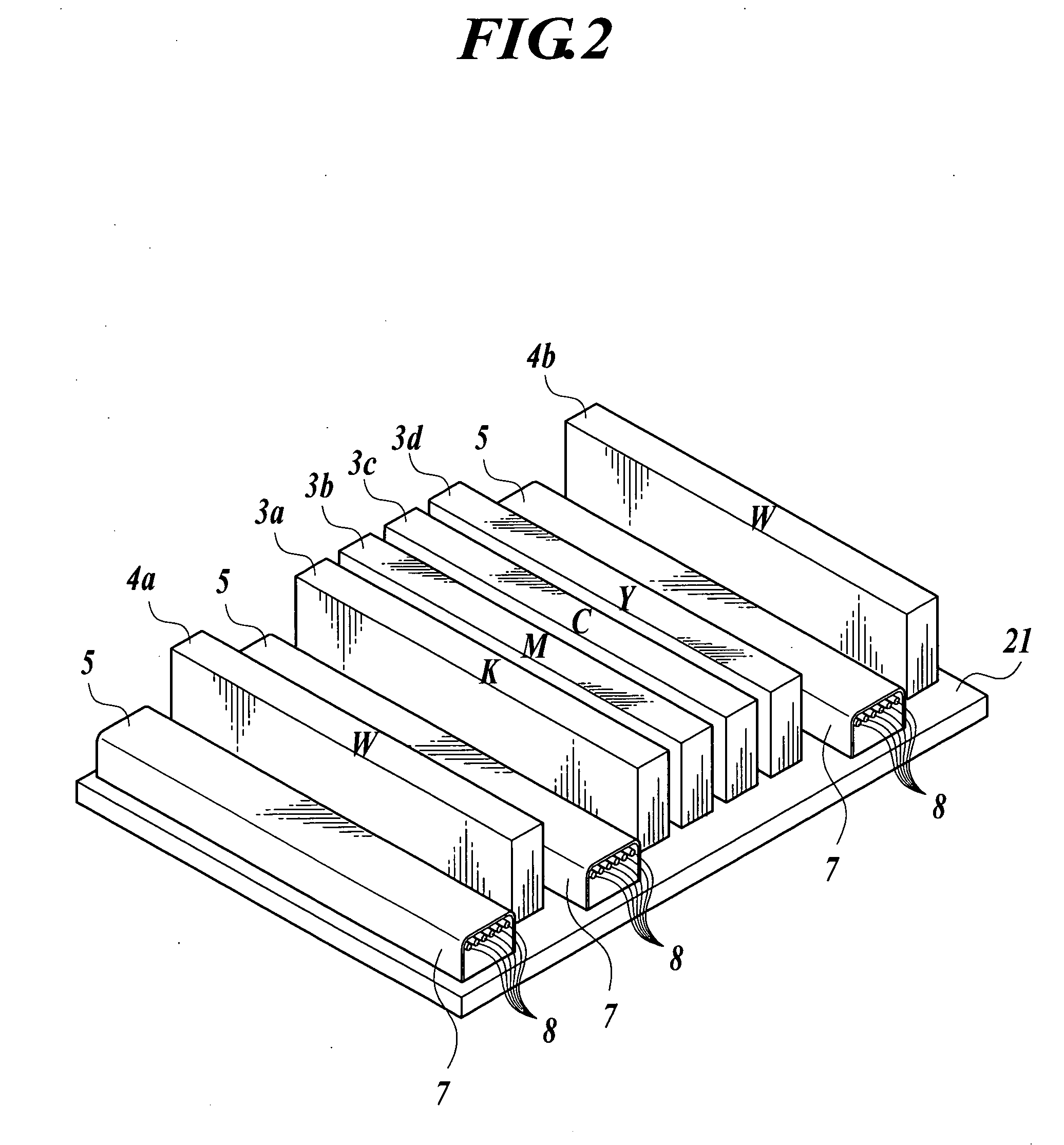

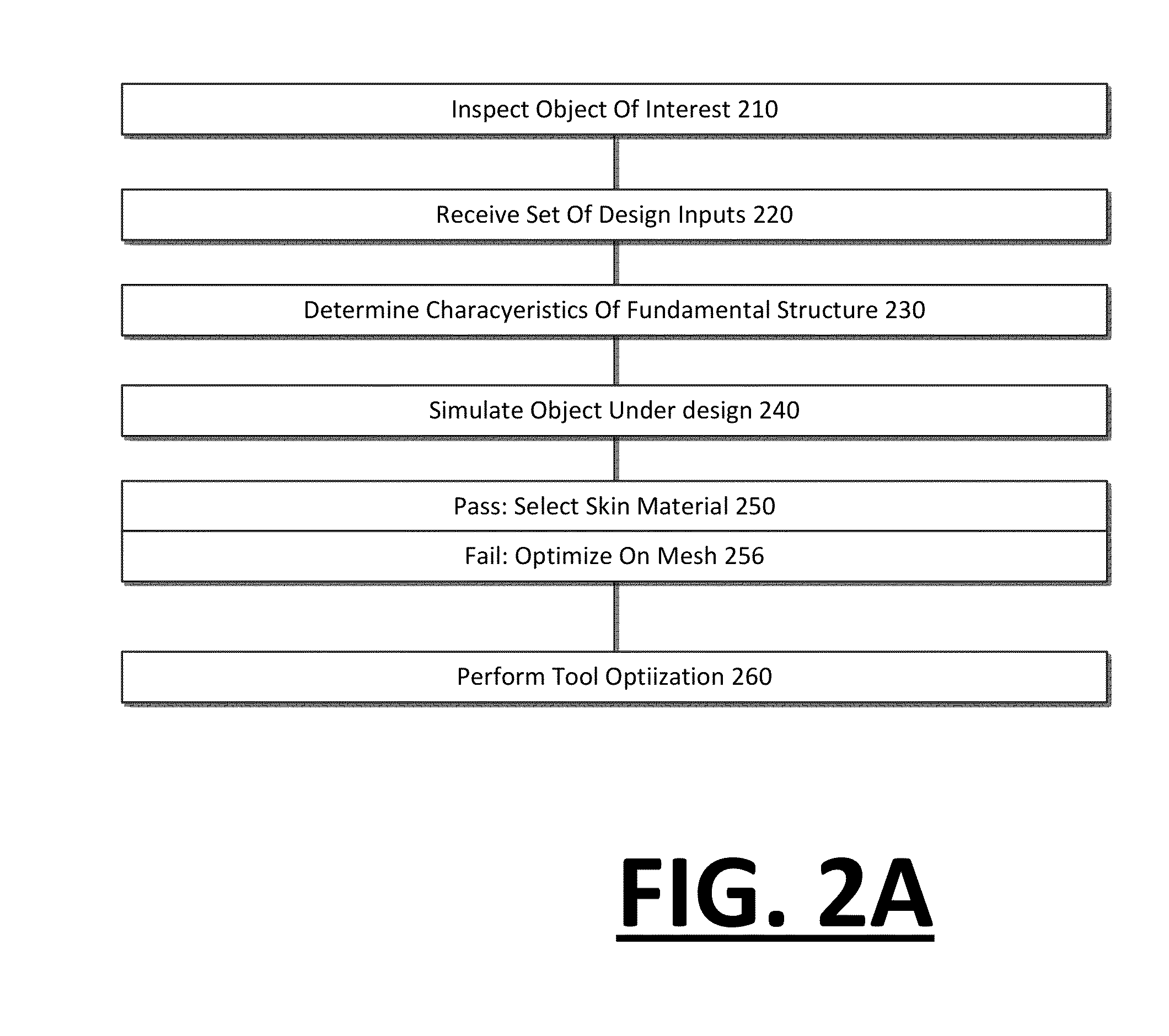

Automated design, simulation, and shape forming process for creating structural elements and designed objects

InactiveUS20160243762A1Additive manufacturing with liquidsPrinted circuit manufactureEngineeringStructuring element

A three-dimensional printer, system and method is provided for individually creating three-dimensional structural elements (individually termed fundamental structures) which are sequentially positioned into formation of a shaped object.

Owner:FLEMING ROBERT J

Heavy oil hydrogenation catalyst and preparation method thereof

ActiveCN103769118AShorten drying timeAvoid pollutionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDry basisBULK ACTIVE INGREDIENT

The invention discloses a heavy oil hydrogenation catalyst and a preparation method thereof. The heavy oil hydrogenation catalyst comprises a carrier and an active ingredient; the carrier is aluminum oxide, and is prepared from pseudo-boehmite with dry basis content below 50% via moulding; the active ingredient are metals selected form family VIII, Co or Ni, and / or family VI B, Mo or W. The preparation method comprises following steps: preparation of pseudo-boehmite, preparation of the carrier, and loading of the active ingredient. The heavy oil hydrogenation catalyst is capable of maintaining high demetalization, desulphurization, and carbon residue removing activities, simplifying drying process of pseudo-boehmite preparation, avoiding dust pollution caused by moulding process, increasing production efficiency, reducing production energy consumption, and reducing catalyst cost further.

Owner:CHINA PETROLEUM & CHEM CORP +1

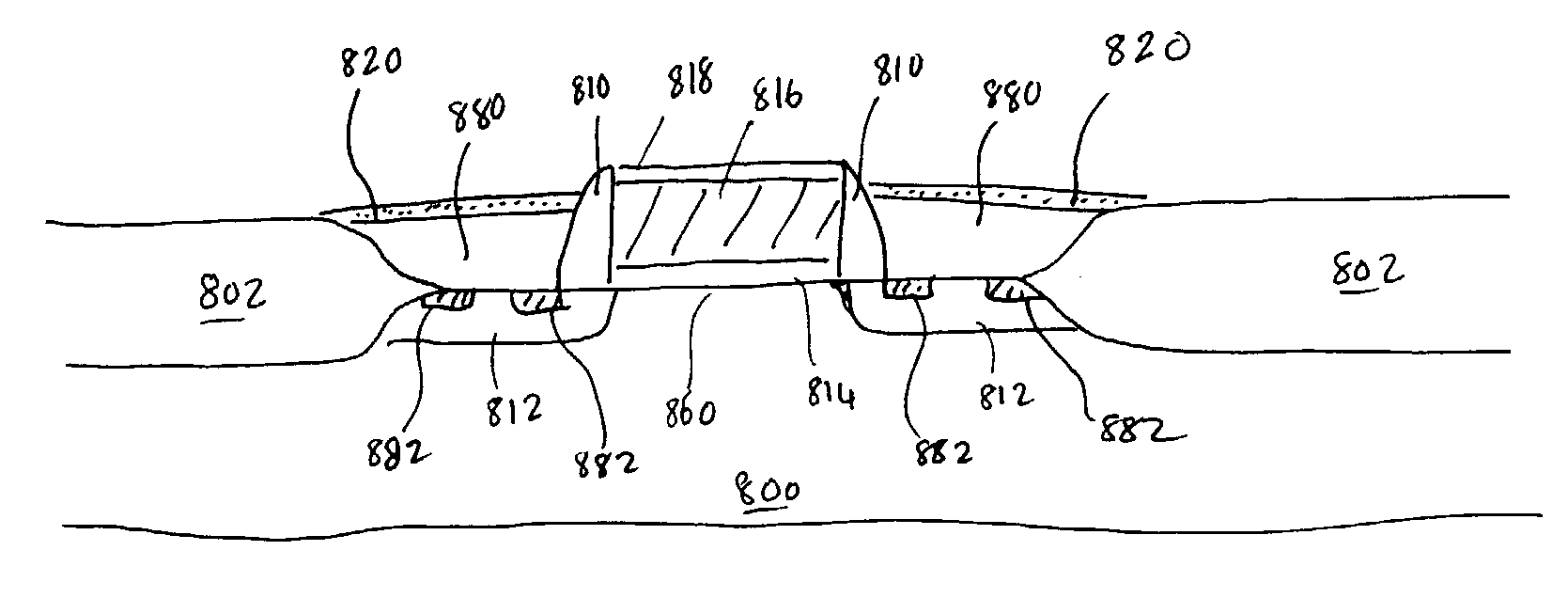

Method and system for manufacturing electrosurgical seal plates

ActiveUS8266783B2Avoid flowMeet the height limit requirementsPrinted circuit assemblingLine/current collector detailsEngineeringActuator

A method of manufacture for an end effector assembly is provided. The method includes providing a pair of jaw members. A step of the method includes forming one or more seal plates positionable on one of the pair of jaw members. Etching a dam along a side of the one or more seal plates is a step of the method, wherein the etched dam inhibits the flow of a plastic on the one or more seal plate such that a height of the plastic with respect to the at least one seal plate during an overmolding process may be controlled. The method includes positioning the one or more seal plates on the one of the pair of jaw members; and overmolding the seal plate to one or more of the pair of jaw members.

Owner:TYCO HEALTHCARE GRP LP

Shape forming process and application thereof for creating structural elements and designed objects

Owner:FLEMING ROBERT J

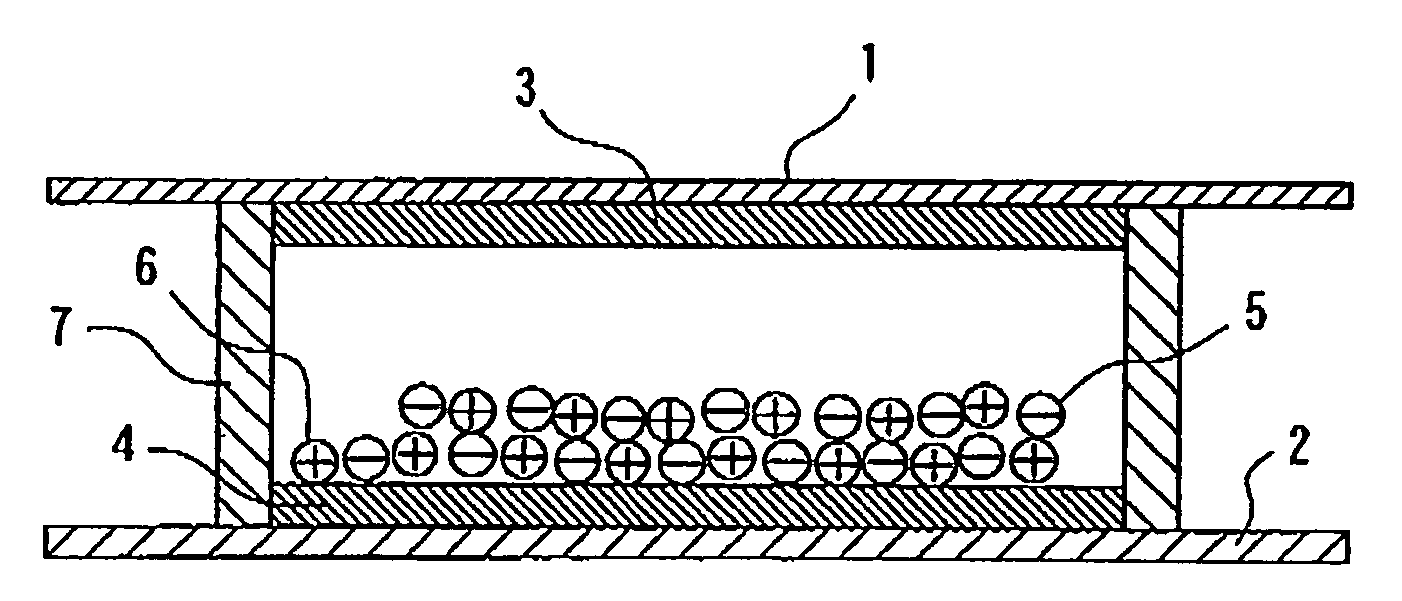

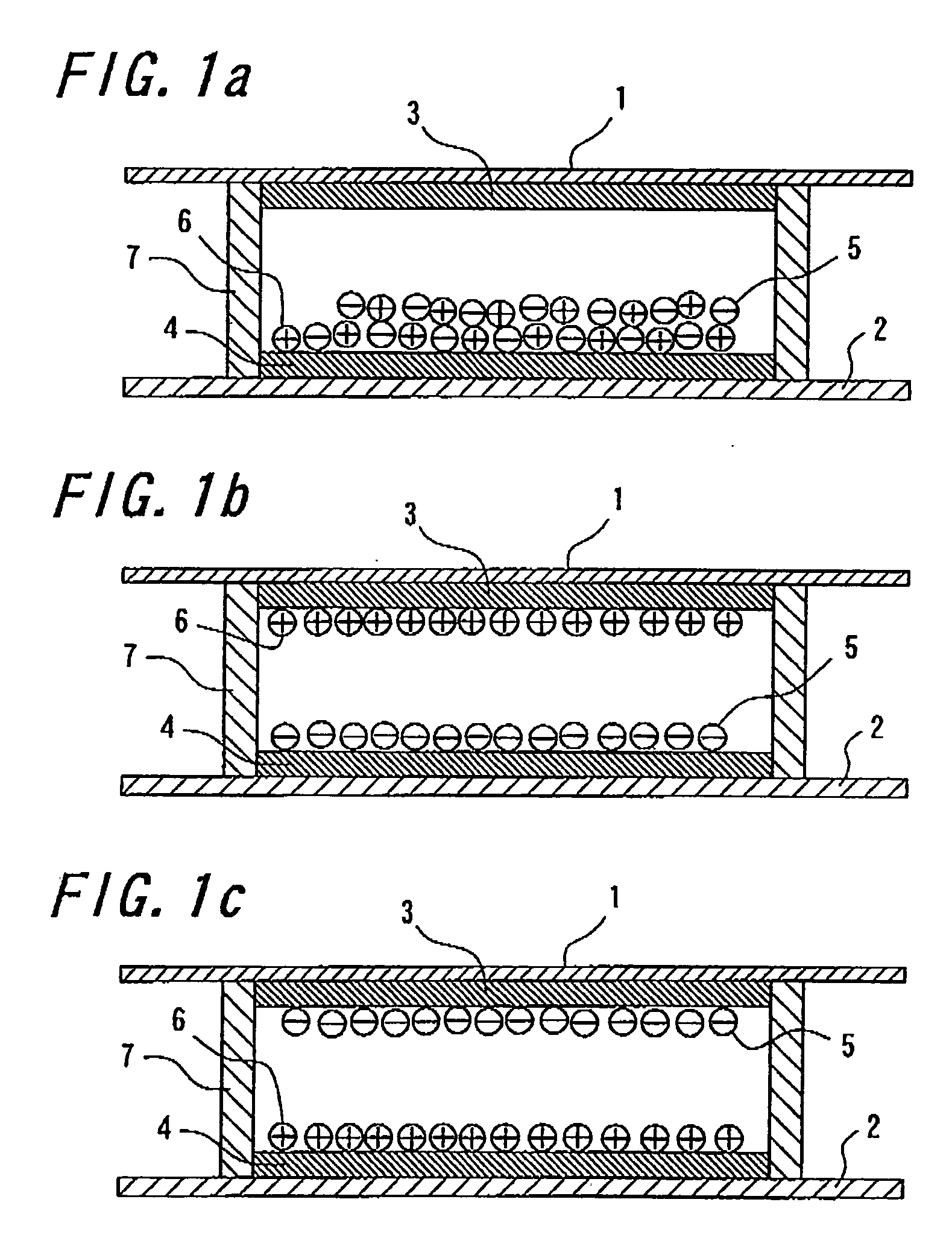

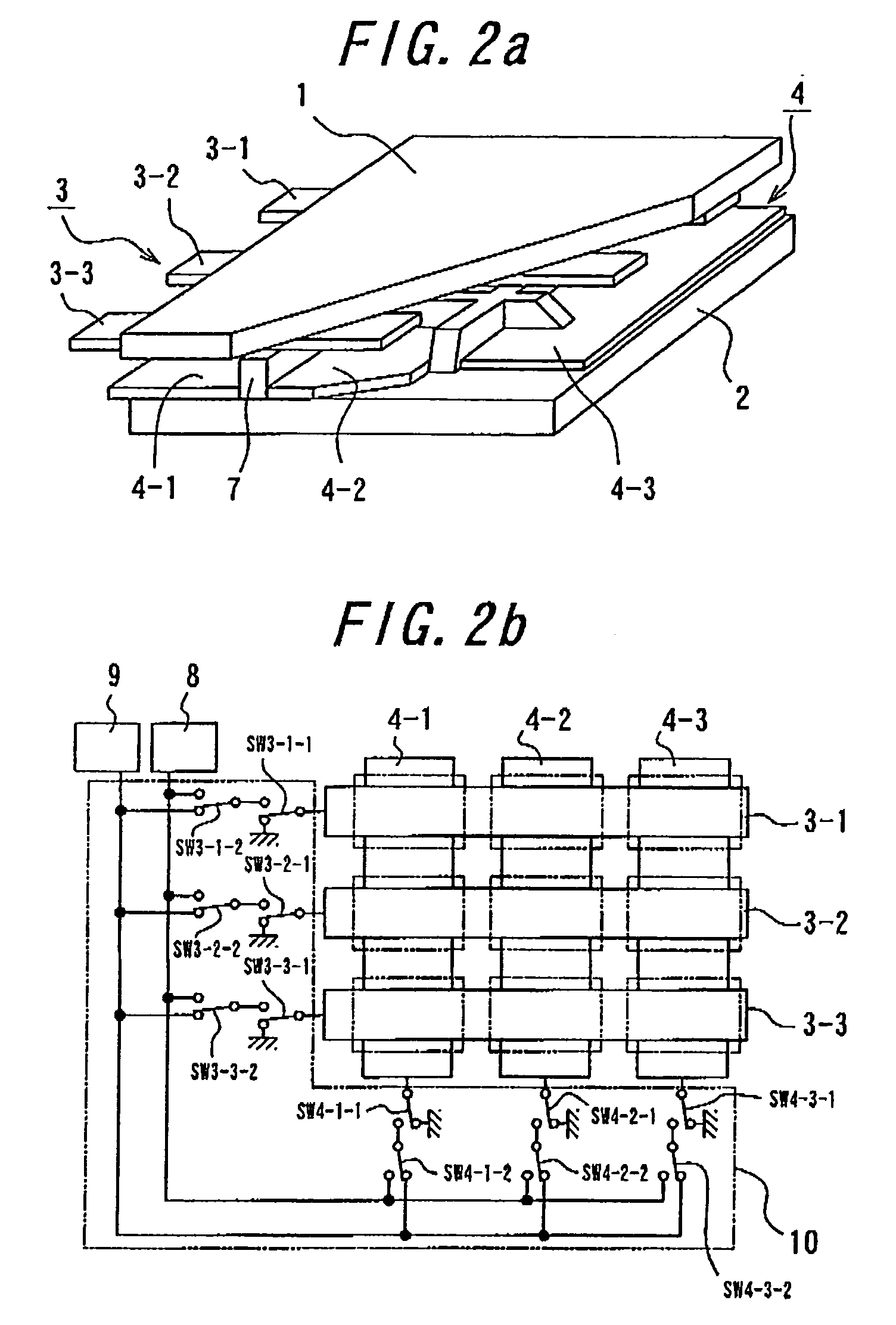

Image display unit

InactiveUS20060238488A1Rapid responseEasy constructionStatic indicating devicesNon-linear opticsImage formationComputer science

Each embodiment relates to an image display device which comprises an image display panel, in which two or more groups of particles having different colors and different charge characteristics are sealed between two substrates, at least one of two substrates being transparent, and, in which the particles, to which an electrostatic field produced by a pair of electrodes provided on one or both substrates is applied, are made to fly and move so as to display an image. Among them, in the first aspect of the invention, an image forming process for forming the image by applying an electric field pattern between the electrodes, the electric field pattern serving to fly particles A to the substrate at an image display side; and an image forming process for forming the image by applying an inversion (negative) electric field pattern with respect to the electric field pattern, the inversion electric field pattern serving to fly particles B having different colors and different charge characteristics with respect to those of the particles A to the substrate at an image display side; so that an image deleting process prior to forming the image to be displayed is eliminated.

Owner:BRIDGESTONE CORP

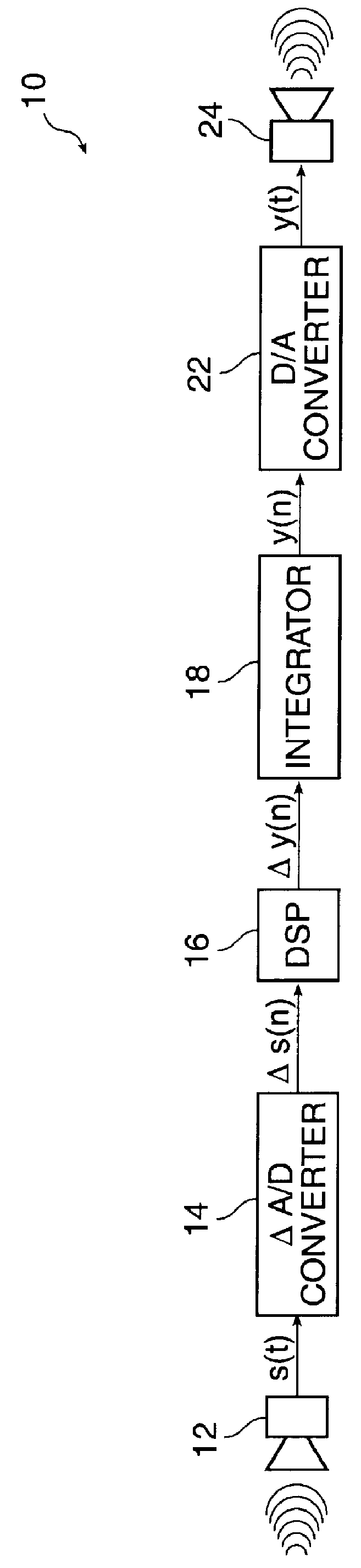

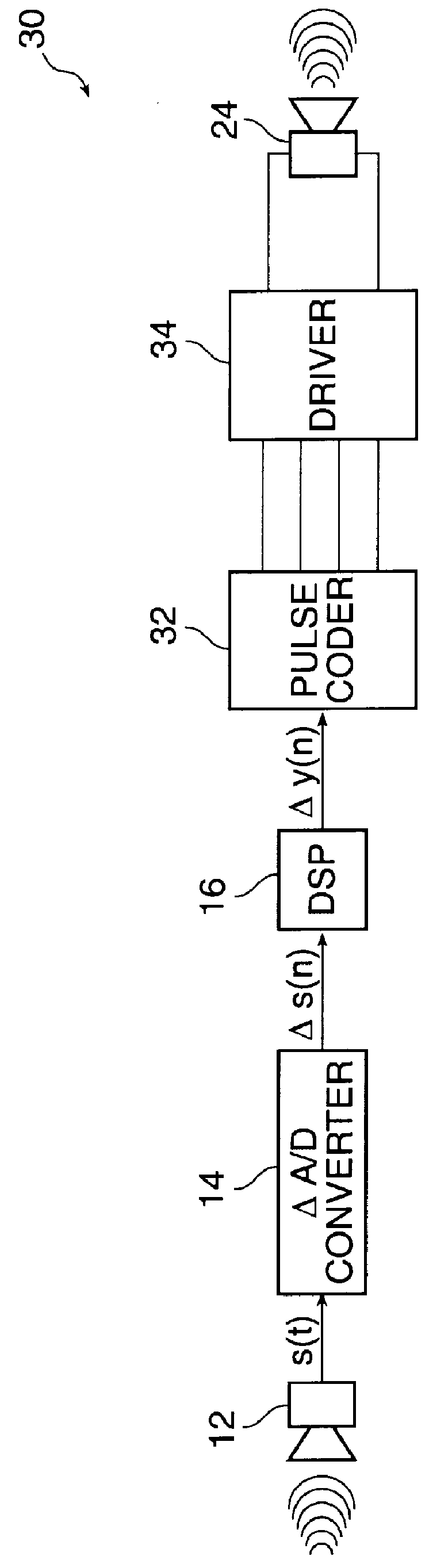

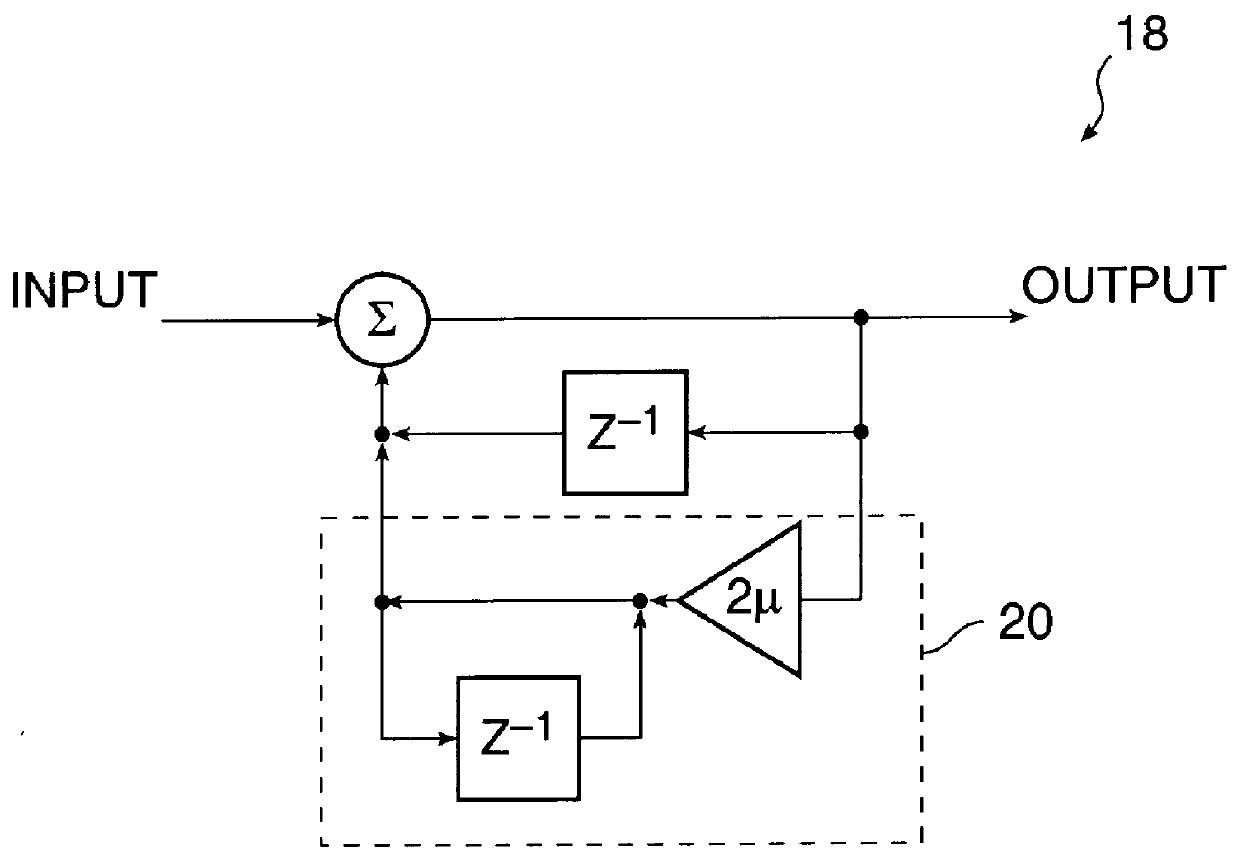

Digital hearing aid using differential signal representations

InactiveUS6044162AMinimize number of bitDeaf-aid setsDigital signal processingDifferential signaling

A hearing compensation system comprises an input transducer for converting acoustical information at an input thereof to electrical signals at an output thereof, a differential analog-to-digital converter sampling the electrical signals output from the input transducer at an input thereof and outputting differential signal samples at an output thereof, a digital signal processing circuit having an input connected to the output of the differential analog-to-digital converter and operating on the differential signal samples to form processed differential signal samples at an output thereof, and an output transducer for converting electrical signals at an input thereof to acoustical information at an output thereof, the processed differential signal samples coupled to the input of the output transducer.

Owner:SONIC INNOVATIONS

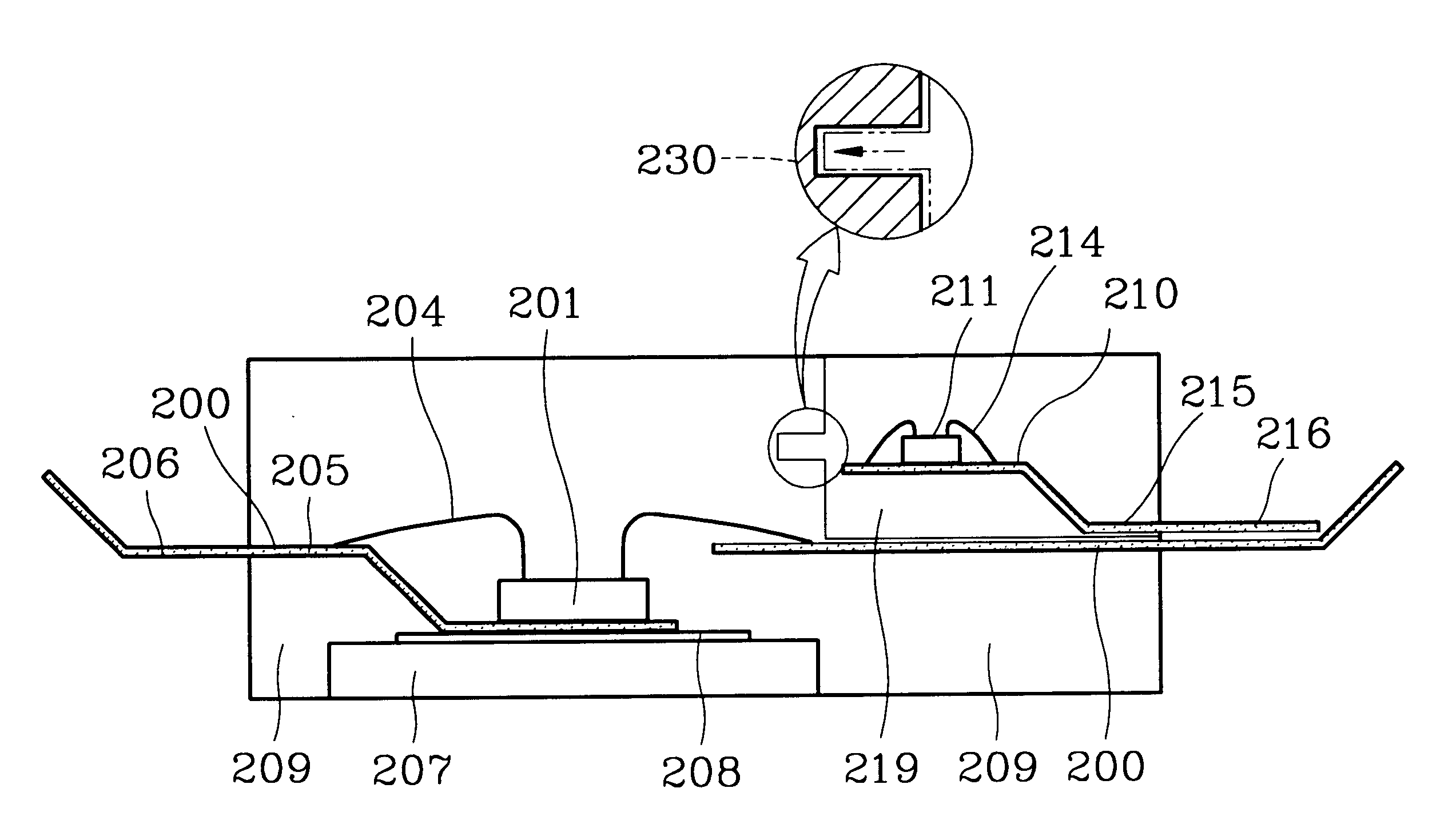

Stacked intelligent power module package

InactiveUS6574107B2Improve propertiesImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectricitySemiconductor package

A stacked intelligent power module package is provided. The intelligent power module package of the present invention includes a power unit including a heat sink and a control unit which is separately manufactured from the power unit and is subsequently stacked on the power unit. The power unit and the control unit of the intelligent power module package are stacked in two different ways including stacking two wire-bonded leadframes of the power unit and the control unit and stacking two separate semiconductor packages of the power unit and the control unit by using locking means formed in each of the semiconductor packages after a trimming / forming process and an electrical property test are finished.

Owner:SEMICON COMPONENTS IND LLC

Composite absorbent particles

InactiveUS20050005870A1Low densityShorten the trackAnimal housingOther apparatusFluidized bedEngineering

Composite particles and methods for making the same. An absorbent material is formed into a particle. An optional performance-enhancing active is coupled to the absorbent material before, during, or after the particle-forming process, homogeneously and / or in layers. Additionally, the composite absorbent particle may include a core material. Preferred methods for creating the absorbent particles include a pan agglomeration process, a high shear agglomeration process, a low shear agglomeration process, a high pressure agglomeration process, a low pressure agglomeration process, a rotary drum agglomeration process, a mix muller process, a roll press compaction process, a pin mixer process, a batch tumble blending mixer process, an extrusion process, and a fluid bed process.

Owner:THE CLOROX CO

High-temperature thermal-insulation anticorrosive nano coating and its preparing method

InactiveCN1709988AImprove Radiation PerformanceGood heat insulationAlkali metal silicate coatingsPolymer scienceThermal insulation

The invention discloses a kind of new industry dope. It comprises such materials as 95 - 105 weight shares of Component A, and 1 - 3 weight shares of Component B; thereinto, Component A is made from following weight percents of materials: cementing agent 30-60%, pigment 12 - 30%, filling agent 10 - 30%, auxiliary agent 0.1 - 5%, compound nanometer dispersing agent 5 - 15% and solvent 10 - 25%; Component B is comprised of catalyzed membrane forming agent - nanometer Sb2O3 and mixed organic solvent carriers. The invention firstly brings nanometer Sb2O3 into high temperature heat preservation dope as catalyzer in dope membrane forming process. The dope of the invention has following advantages: it has high temperature heat preservation and heavy anticorrosion performances, and the coat has good acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:孙启明

High density inductor and method for producing same

InactiveUS20040164835A1Reduce core sizeAccurate shapeTransformers/inductances coils/windings/connectionsSolid-state devicesHigh densityInductor

A method for producing a high density inductor includes the steps of forming a coil having a spiral shape, sealing the coil in the interior of a core member, and forming a terminal electrode for allowing electric conduction to said coil on the outside of said core member. In this method, the coil is formed by repeating a process of forming a wire layer by means of a thin film forming process and a process of forming an additional wire layer on top of the wire layer by means of the thin film forming process to pile up the wire layers. With this production method, it is possible to form a coil with a high aspect ratio. In addition, the inductor is designed in such a way that the core member envelopes only the coil. With that design, it is possible to make the inductor compact.

Owner:TDK CORPARATION

Vegetable capsule of starch composition and preparation method

InactiveCN1687203AWide variety of sourcesNo pollution in the processPharmaceutical delivery mechanismFood preparationPreservativePlasticizer

The present invention relates to a starch composite plant capsule and its preparation method. Said method includes the following steps: uniformly mixing starch or starch composite, dispersing it in distilled water, heating for 15-60 min, at 60-95 deg.c to make starch be fully gelatinated, then adding plasticizer, gel, surfactant, opacifier, edible color matter, preservative, ant-oxidant and enhancer, fully and uniformly mixing them, then decompressing and defoaming, and adopting conventional capsule-forming process to make the obtained colloid liquid into the invented starch composite plant hollow capsule, and its capsule-forming temperature is 40-95 deg.C.

Owner:TIANJIN UNIV

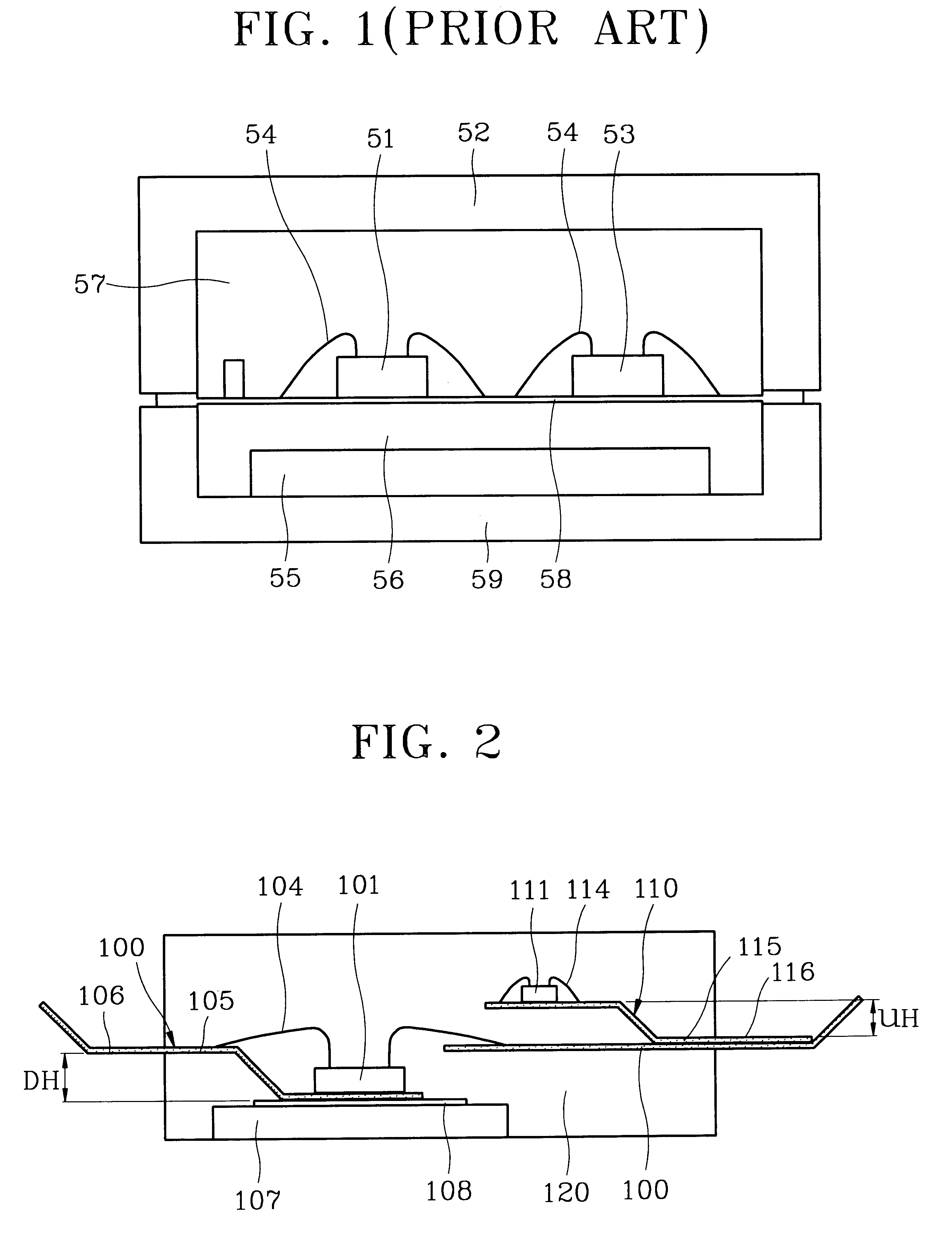

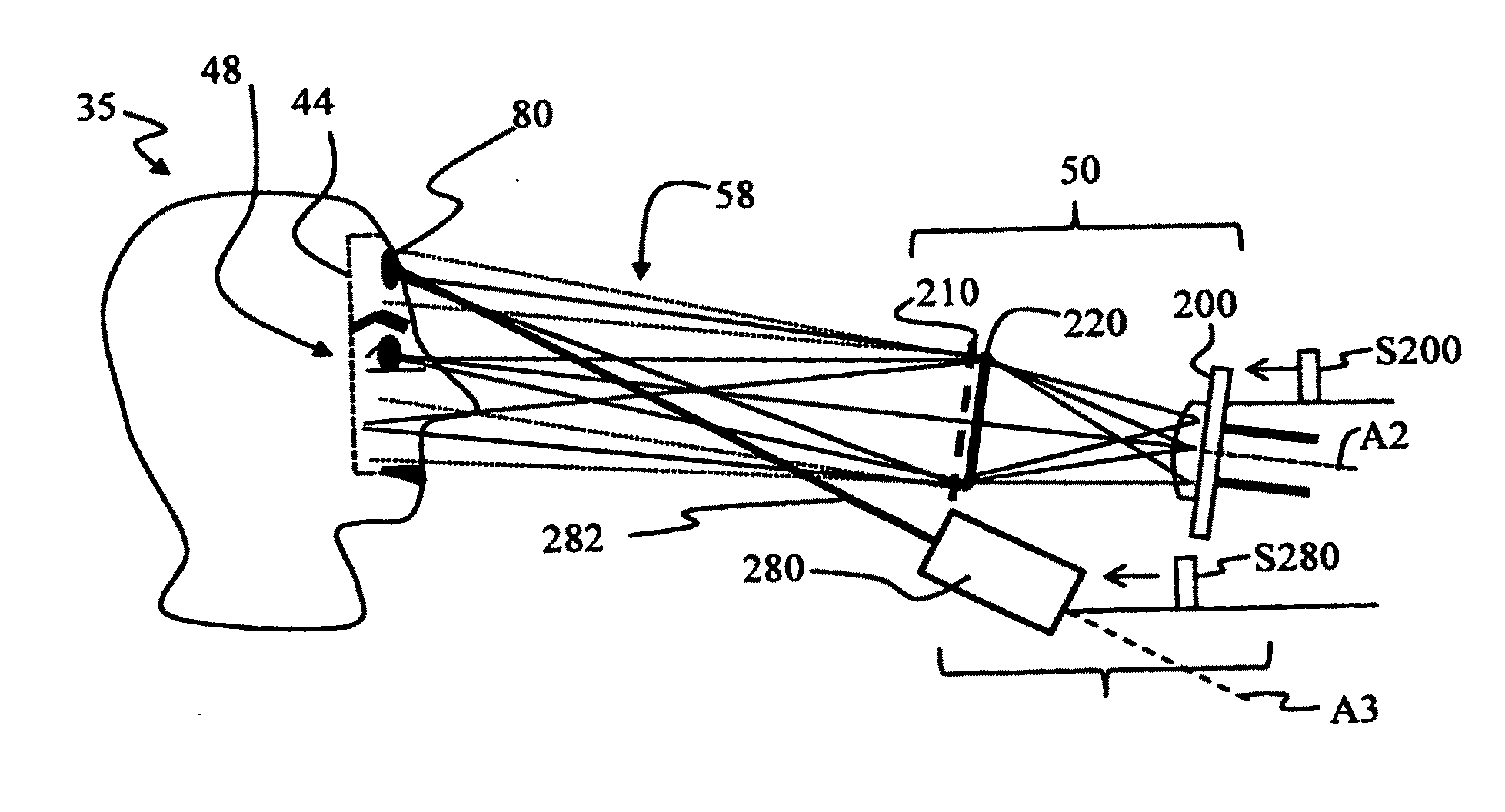

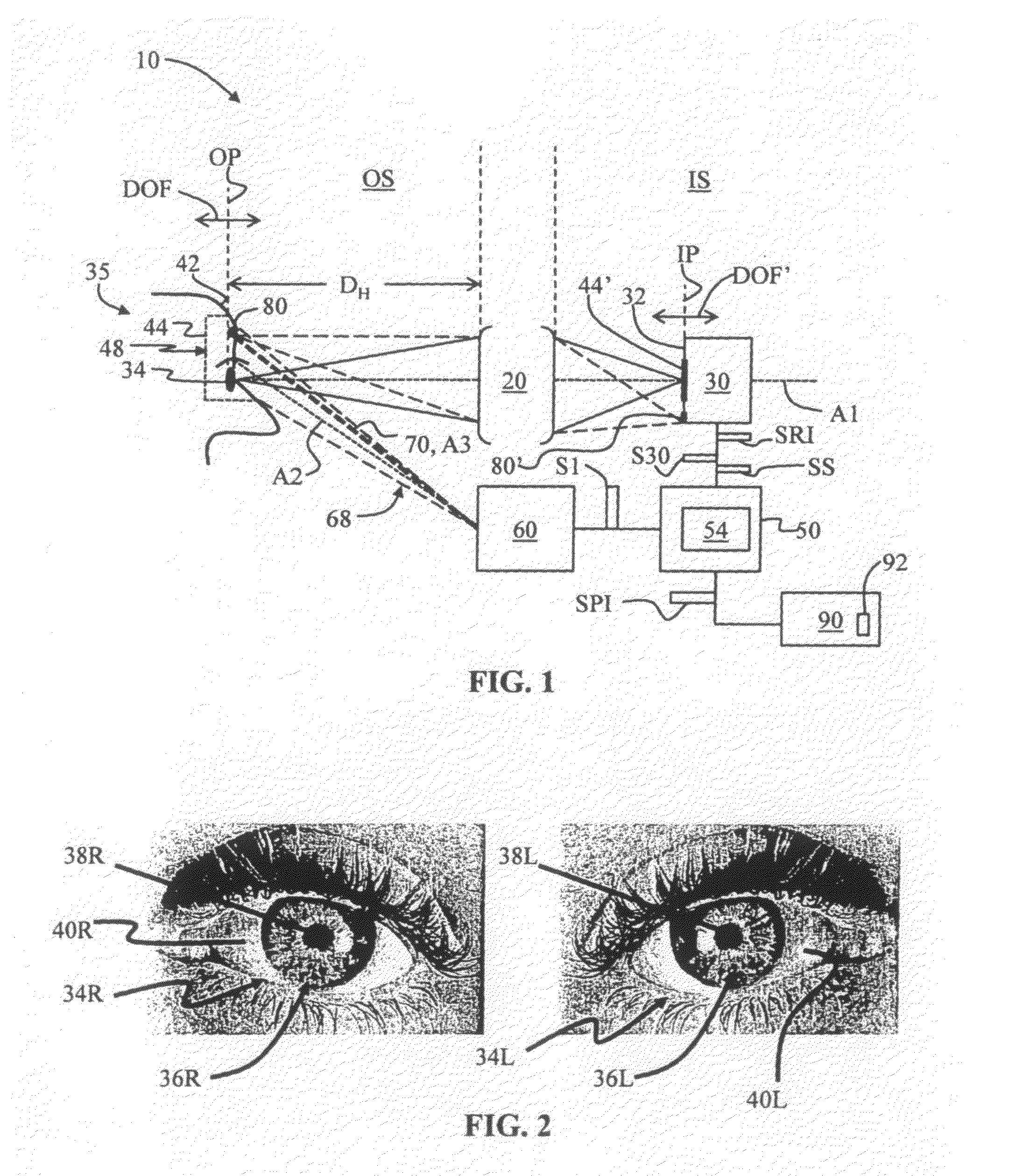

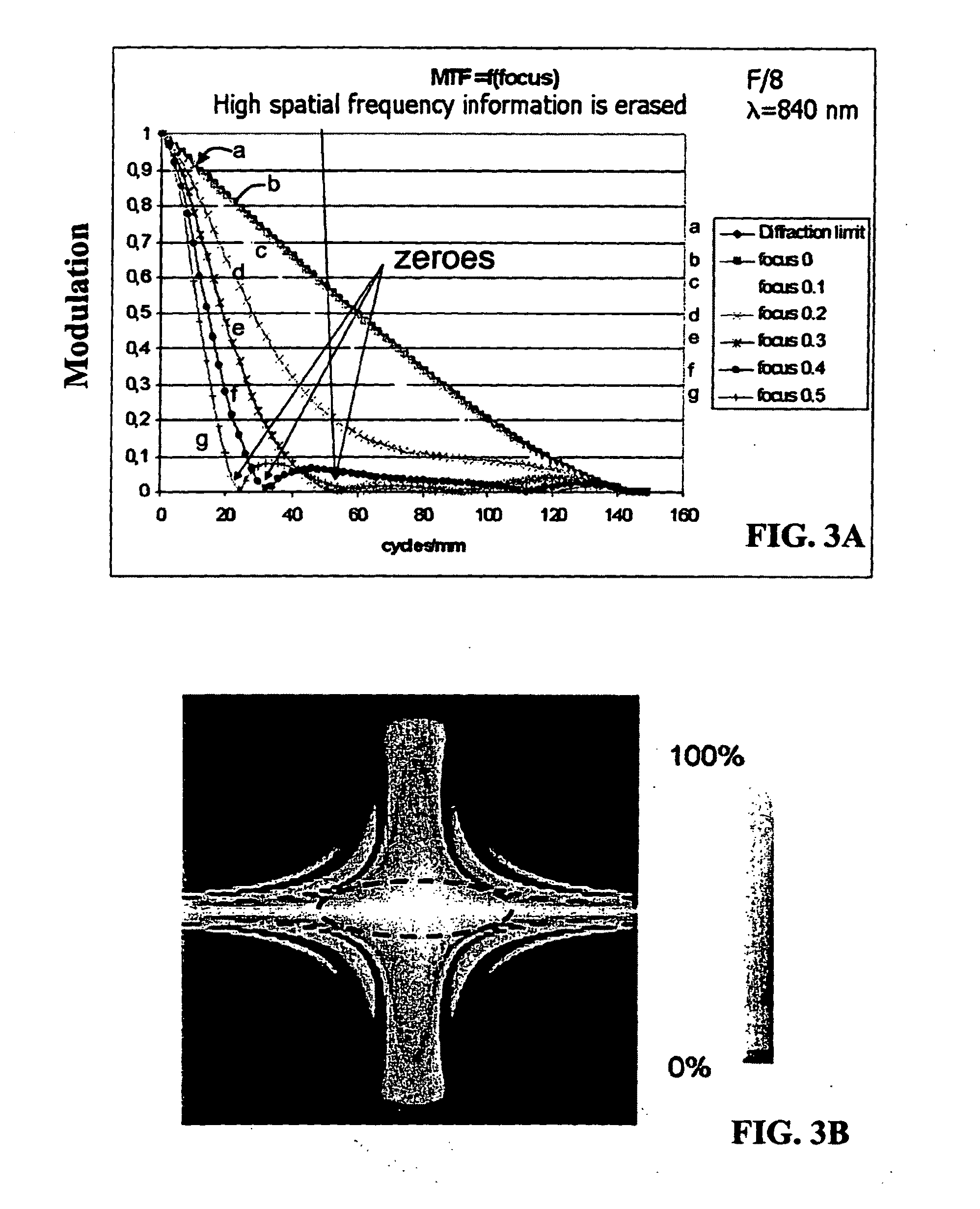

Large depth-of-field imaging system and iris recogniton system

InactiveUS20100110275A1High transfer functionTelevision system detailsImage analysisDepth of fieldDigital image processing

(A2) An extended depth of field (DOF) imaging system (10) is disclosed that has a corresponding extended depth of focus (DOF′) by virtue of its optical system (20) having a select amount of spherical aberration. The imaging system has an image processing unit (54) adapted to process the raw images and perform contrast enhancement to form processed images. The image processing includes restoring the defocused modulation transfer functions (MTFs) using a gain function (G) and the amount of defocus. The imaging system can include an illumination system (60) that illuminates the object being imaged to establish a distance (DH) between the optical system and the object, where distance DH is used in the restoring of the MTF. An iris-recognition (I-R) system based on the enhanced DOF imaging system is also disclosed.; Optical system embodiments for use in the DOF imaging system that can provide select amounts of spherical aberration—and thus select increases in DOF—without increasing the adverse impact of other aberrations on image formation are also disclosed.

Owner:GLOBAL BIONIC OPTICS PTY LTD

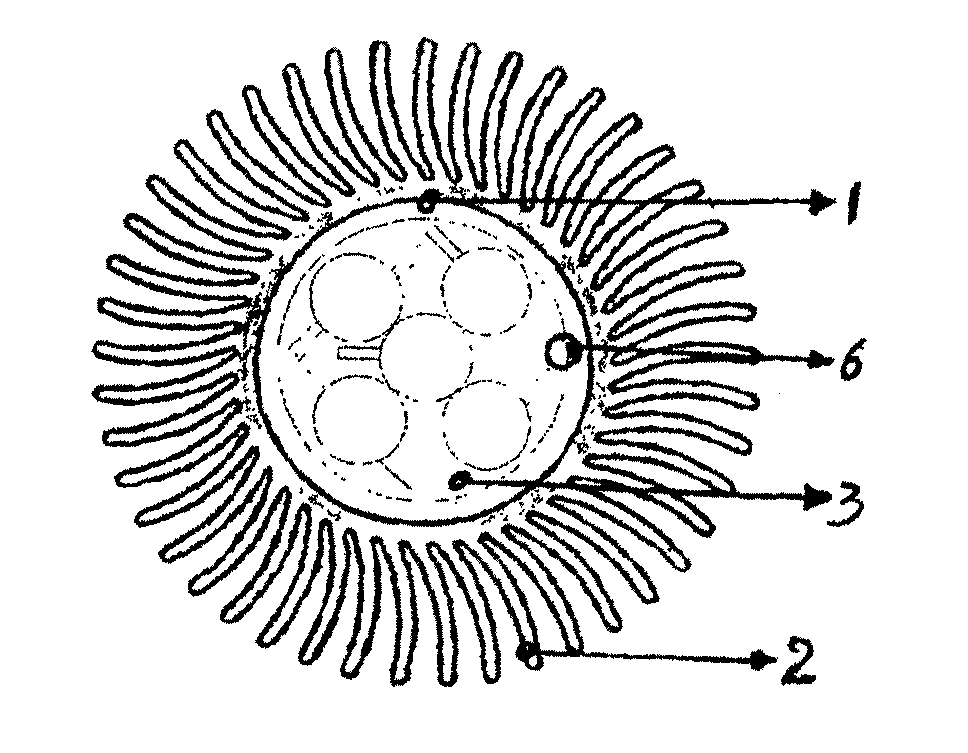

Built-in Heat Diffusion Lamp Body for LED Lamp

InactiveUS20090016063A1Simple materialSimple structurePoint-like light sourceElectric circuit arrangementsDiffusionInterference fit

A built in beat diffusion lamp body for LED lamp was invented. The purpose of the invention is to solve the difficulties of poor heat conduction and diffusion caused by the small heat diffusion surface of the material of a conventional LED lamp. The lamp body is made of a set of heat diffusion vanes encircling the heat diffusion complex. The vanes and heat diffusion complex are made from Aluminum alloy in a single process of extrusion moulding. The transverse section of the heat diffusion body is volute shaped. The bottom of the heat diffusion complex is fixed to an aluminum board or an aluminum circuit: board by interference fit. The heat generated by the LED elements can be absorbed and diffused by the board, the heat diffusion complex and the surrounding diffusion element. The outward appearance of the heat diffusion lamp body may be shaped into cup, ladder, or cylinder likeness to satisfy the application requirement. The advantages of current invention are: efficient heat absorption, conduction, and diffusion, low cost for manufacturing, and aesthetic appearance.

Owner:HU KAI

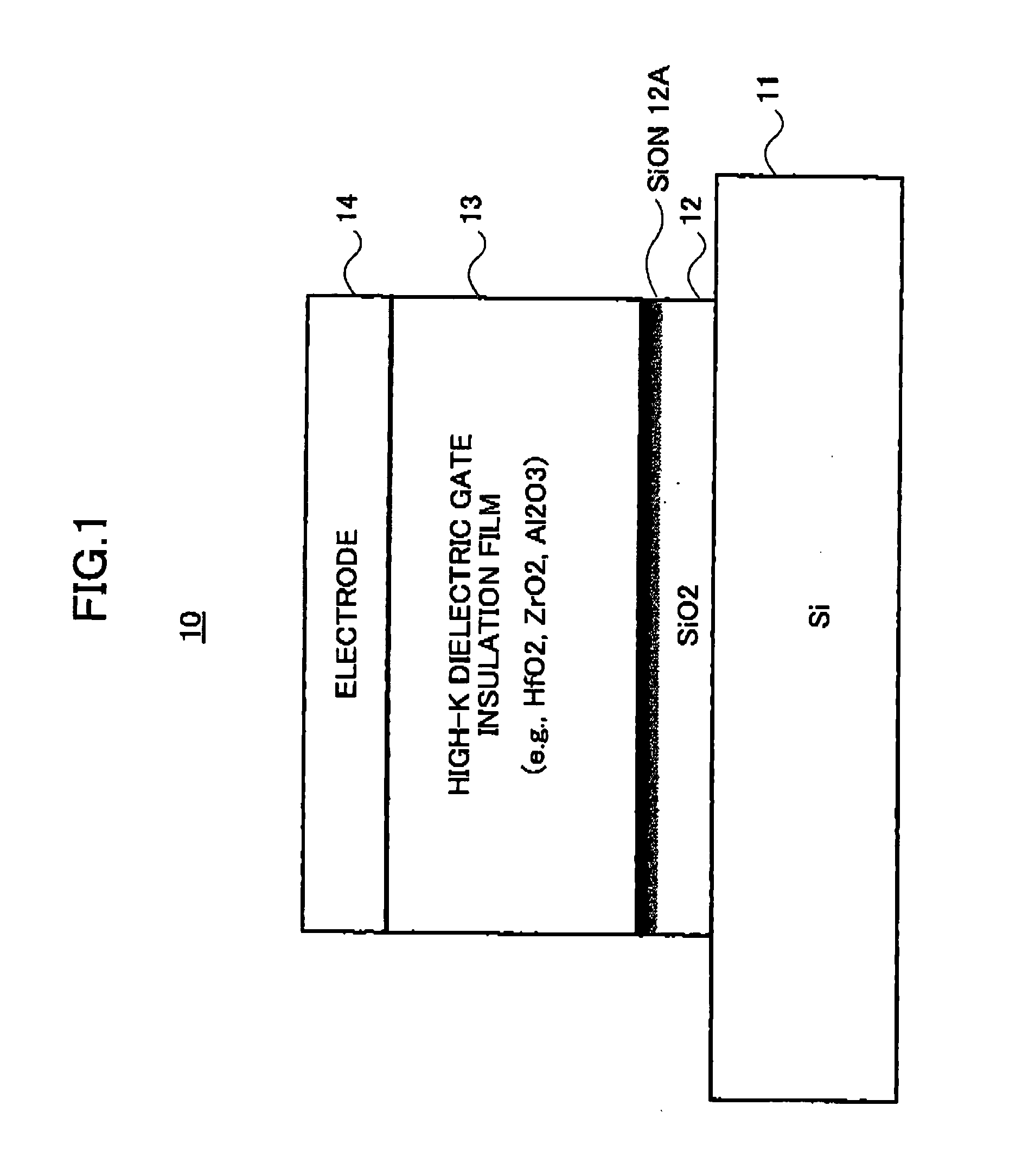

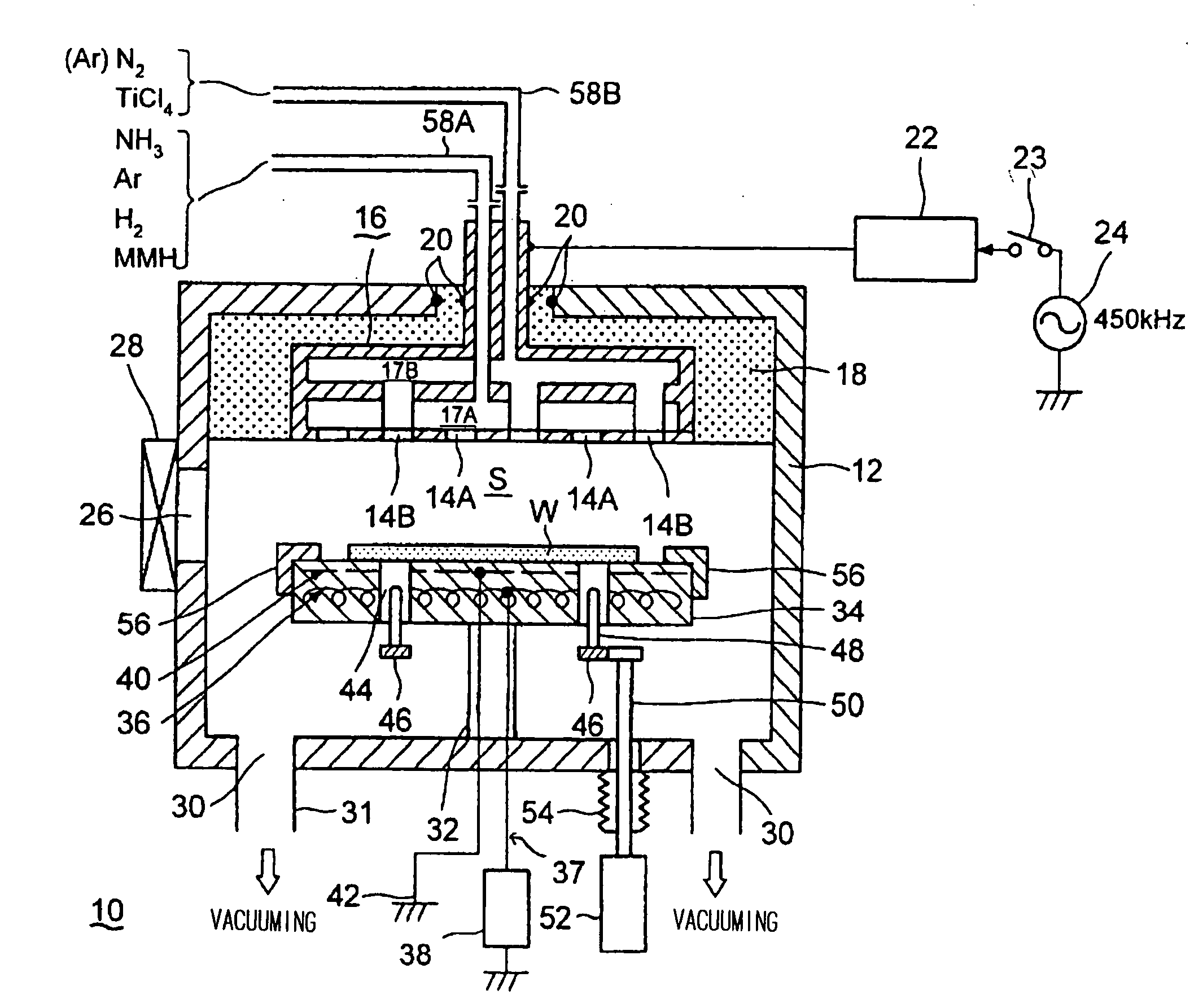

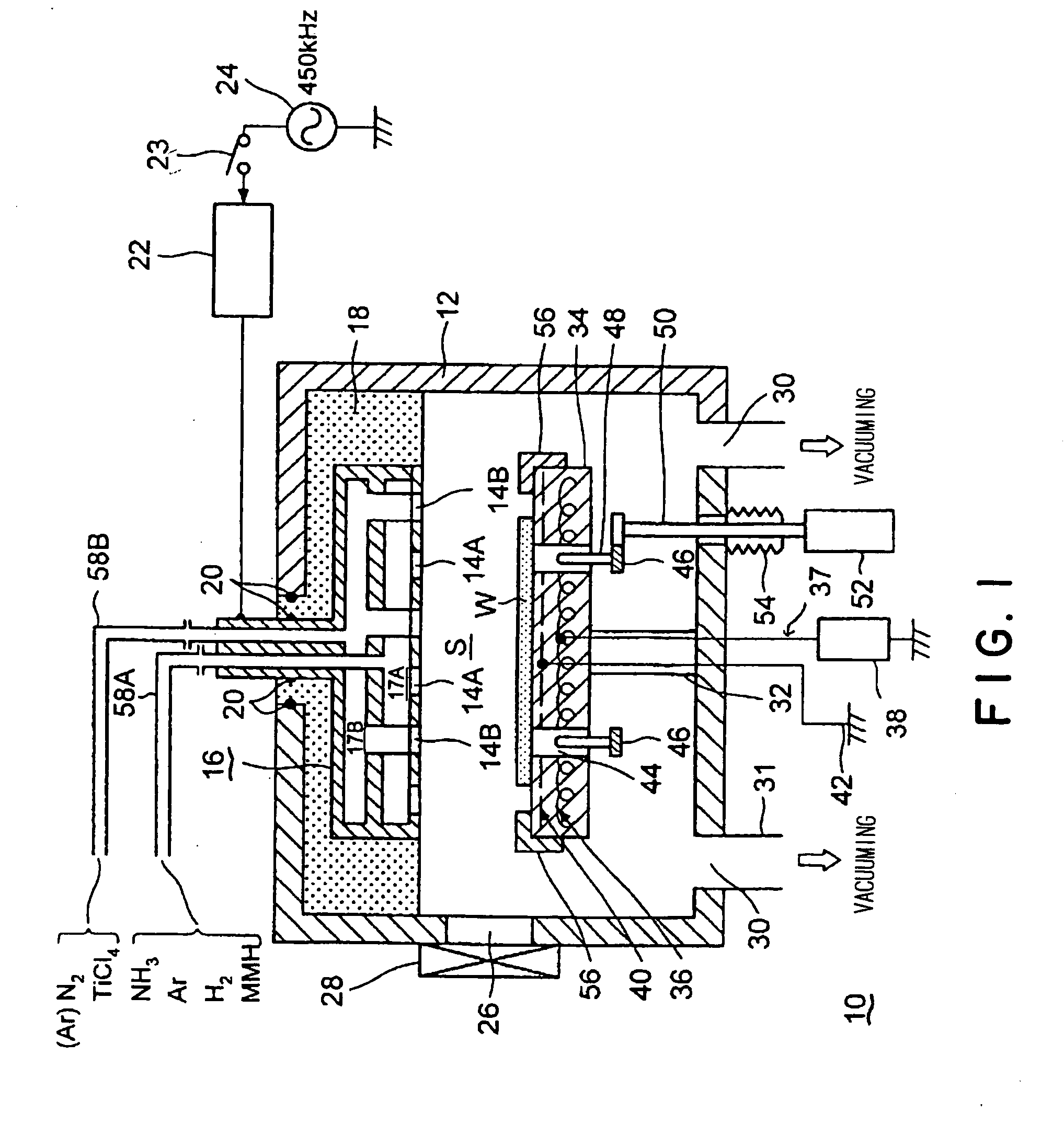

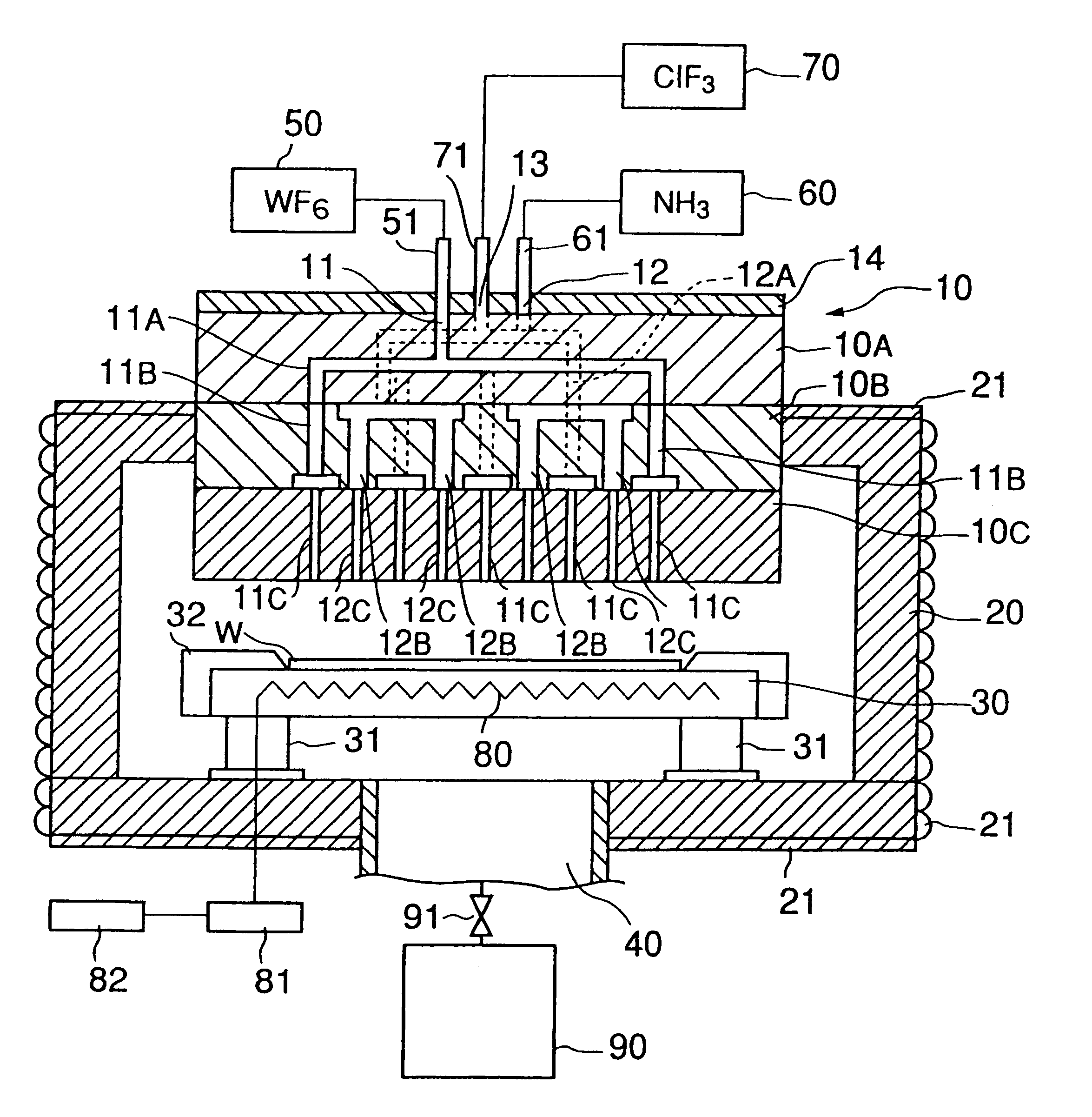

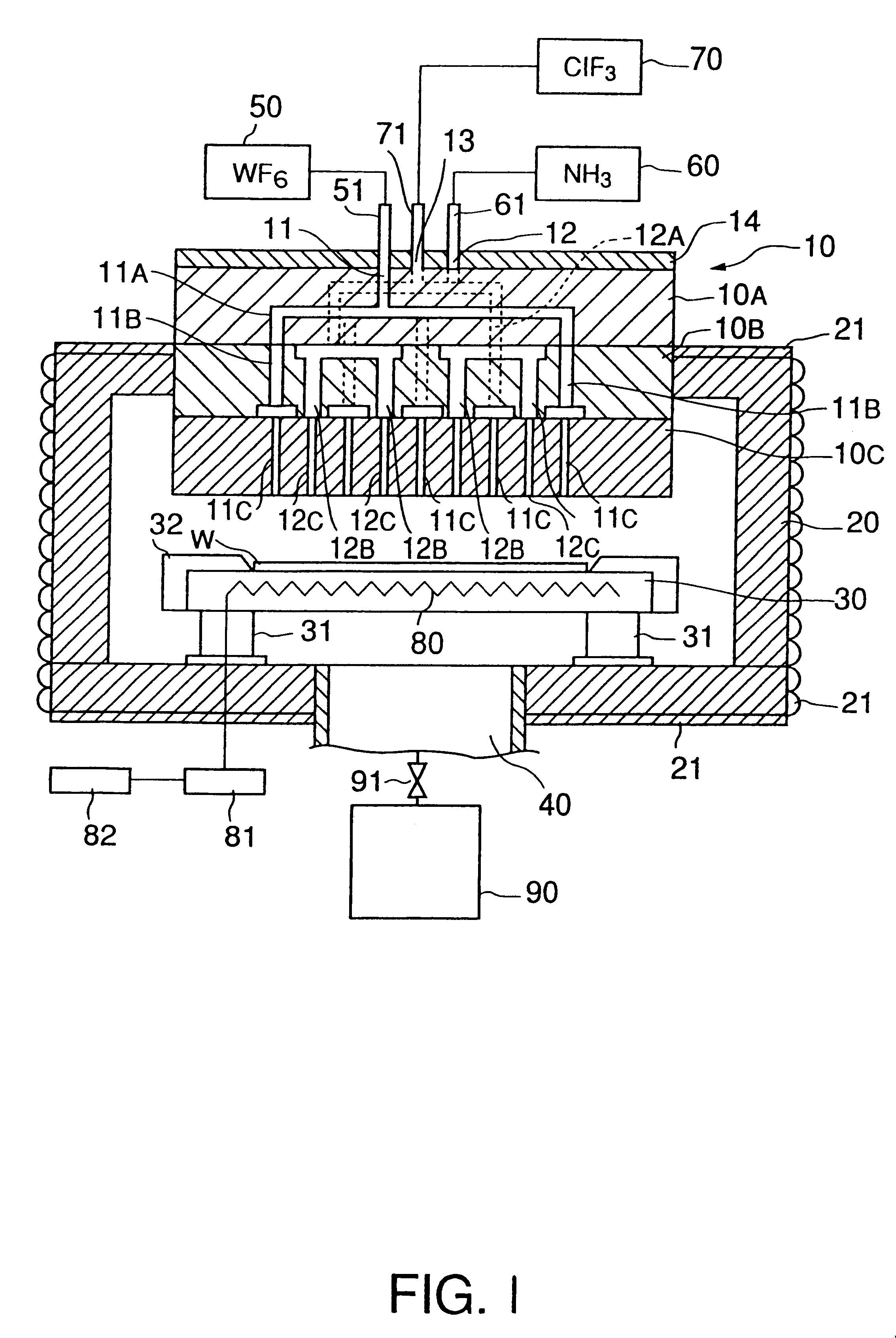

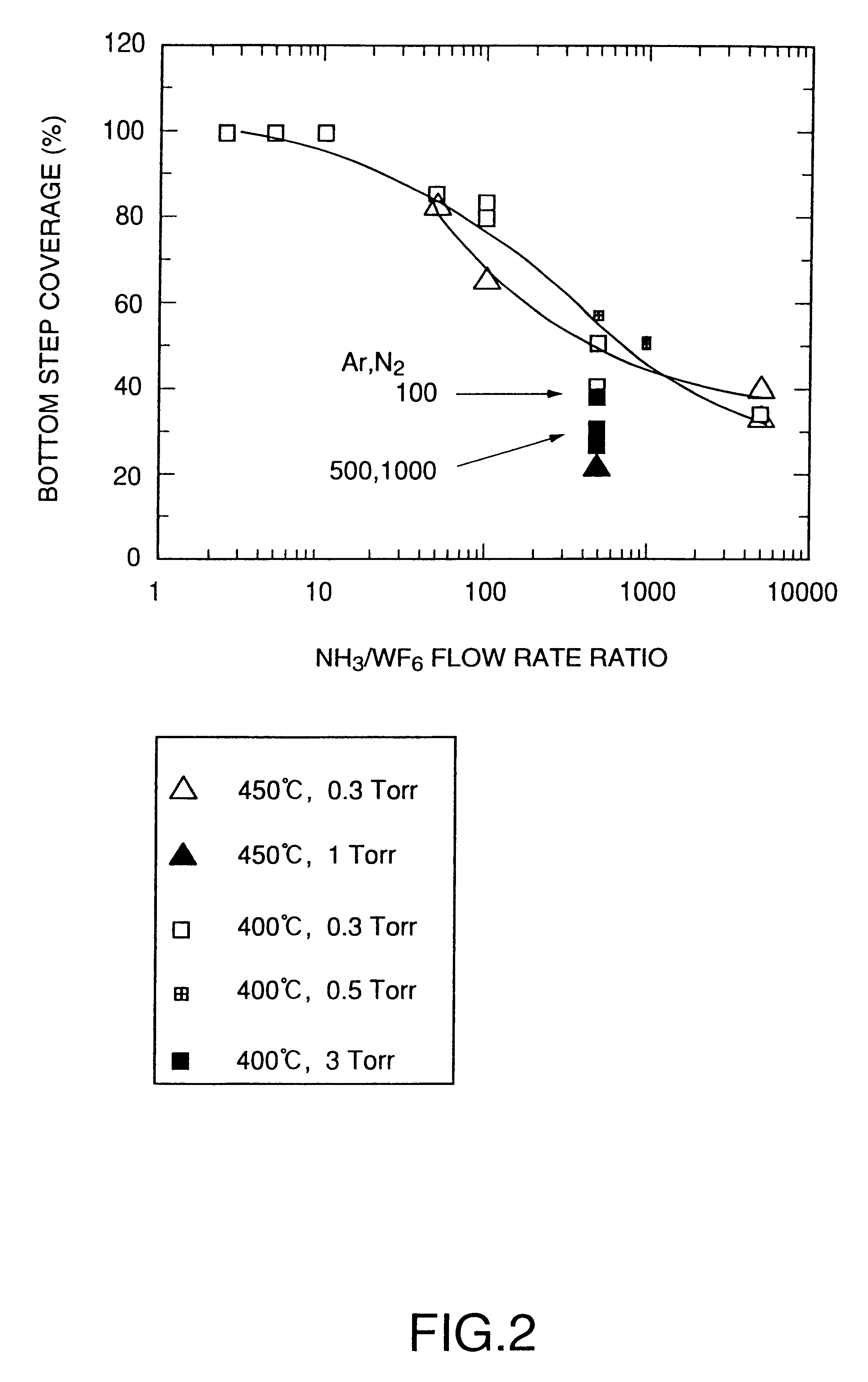

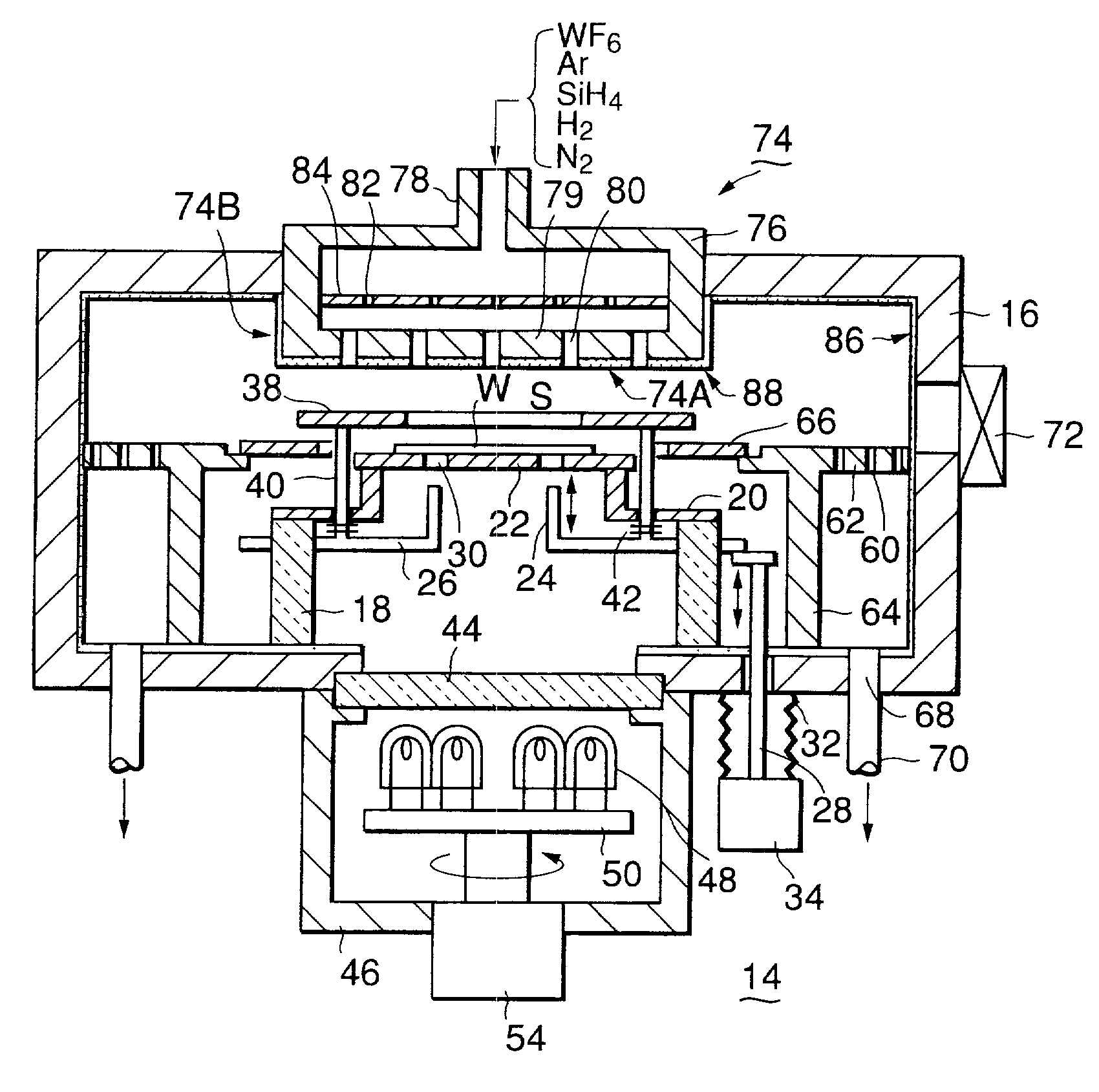

Semiconductor device fabricating method and system for carrying out the same

InactiveUS6399484B1Reduced form requirementsAvoid depositionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTungsten nitrideNitrogen

A semiconductor device fabricating method includes a preparatory process that brings a first source gas containing tungsten atoms into contact with a workpiece and that does not bring a second source gas containing nitrogen atoms into contact with the workpiece, and a film forming process that forms a tungsten nitride film on the workpiece by using the first and the second source gases so as to fabricate a semiconductor device. The semiconductor device fabricating method is capable of preventing the tungsten nitride film from peeling off from a layer underlying the same when the tungsten nitride film is subjected to heat treatment.

Owner:TOKYO ELECTRON LTD

Method and System for Manufacturing Electrosurgical Seal Plates

ActiveUS20110073246A1Avoid flowMeet the height limit requirementsContact member manufacturingLamination ancillary operationsEngineeringActuator

A method of manufacture for an end effector assembly is provided. The method includes providing a pair of jaw members. A step of the method includes forming one or more seal plates positionable on one of the pair of jaw members. Etching a dam along a side of the one or more seal plates is a step of the method, wherein the etched dam inhibits the flow of a plastic on the one or more seal plate such that a height of the plastic with respect to the at least one seal plate during an overmolding process may be controlled. The method includes positioning the one or more seal plates on the one of the pair of jaw members; and overmolding the seal plate to one or more of the pair of jaw members.

Owner:TYCO HEALTHCARE GRP LP

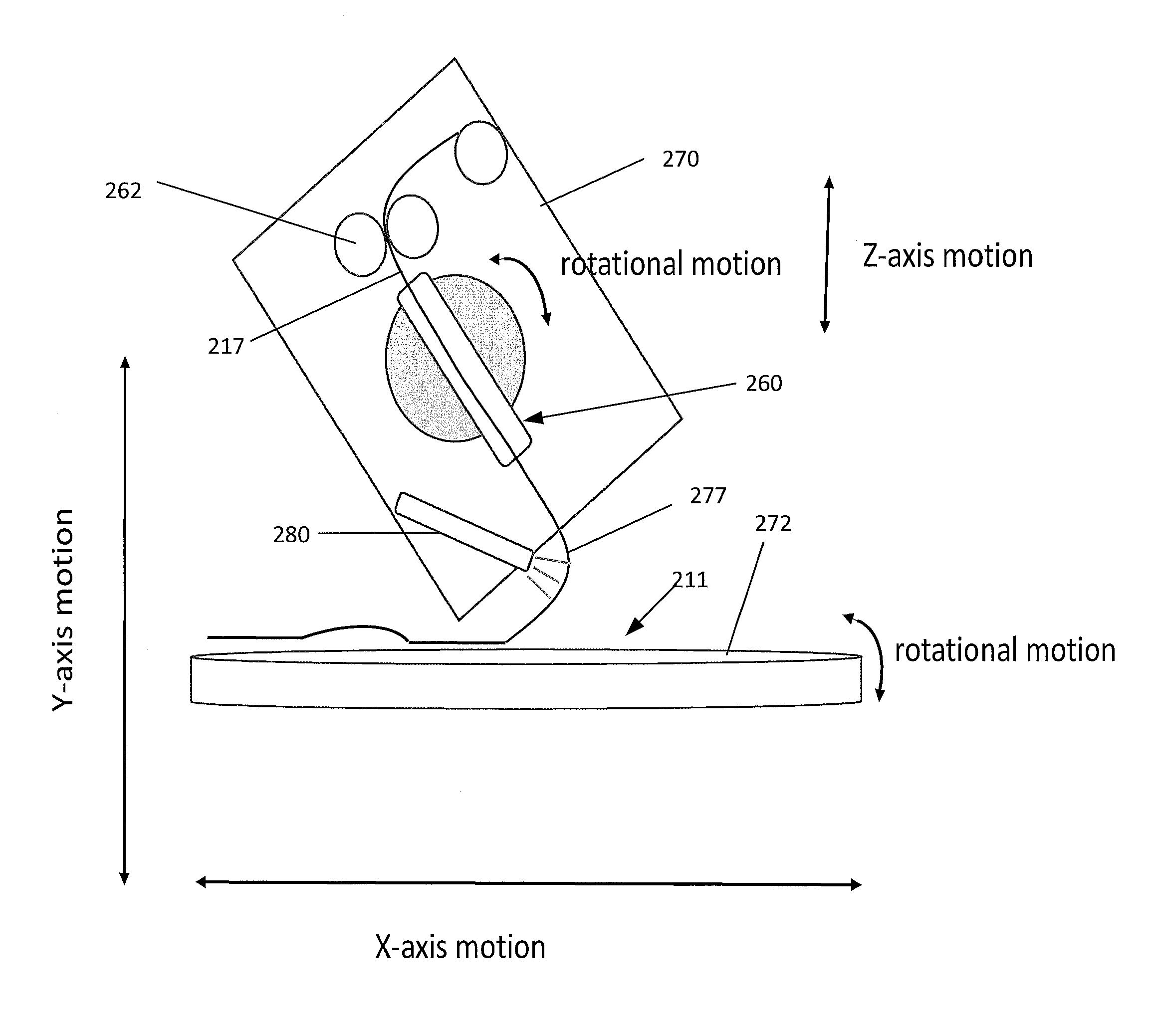

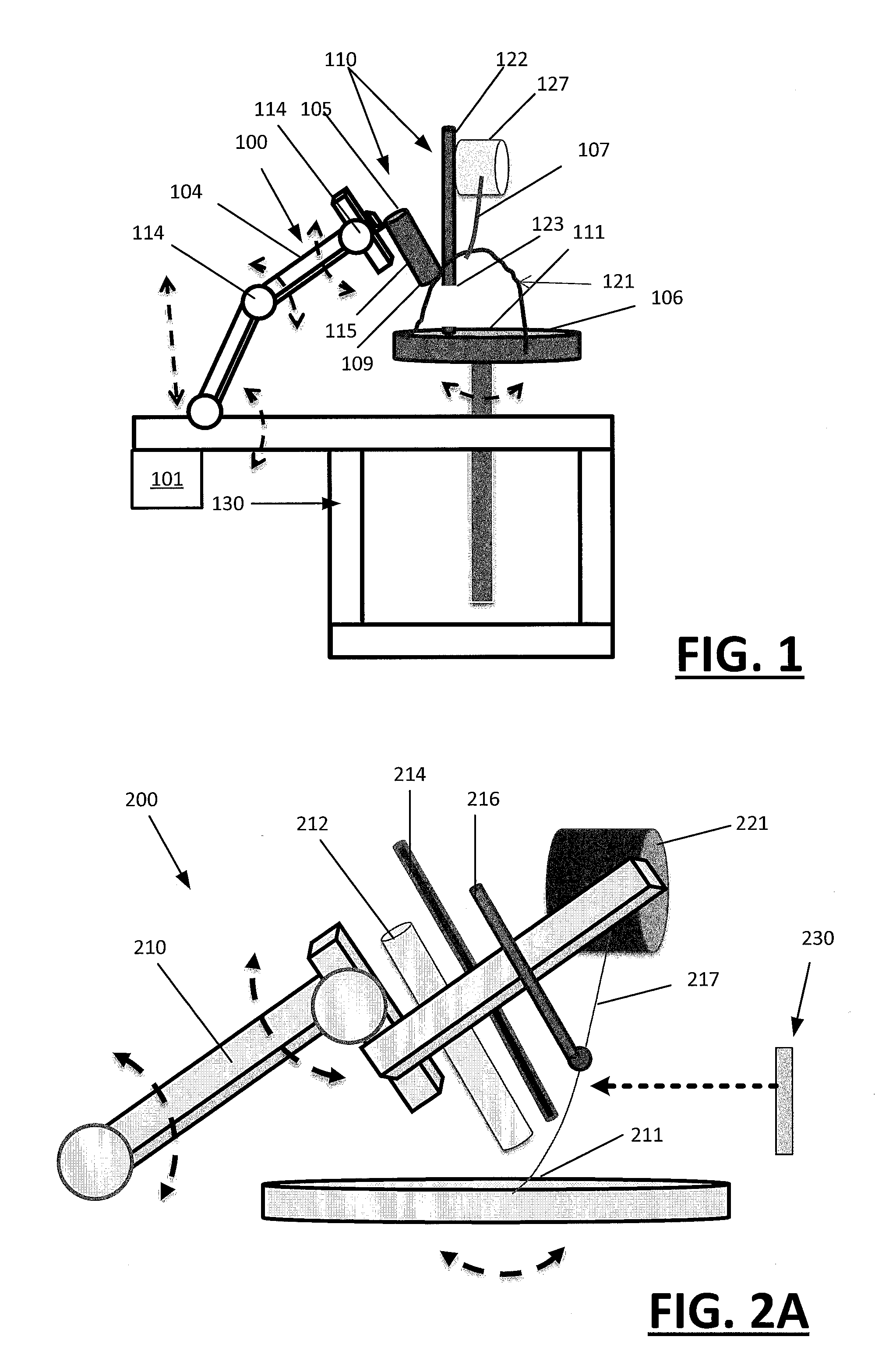

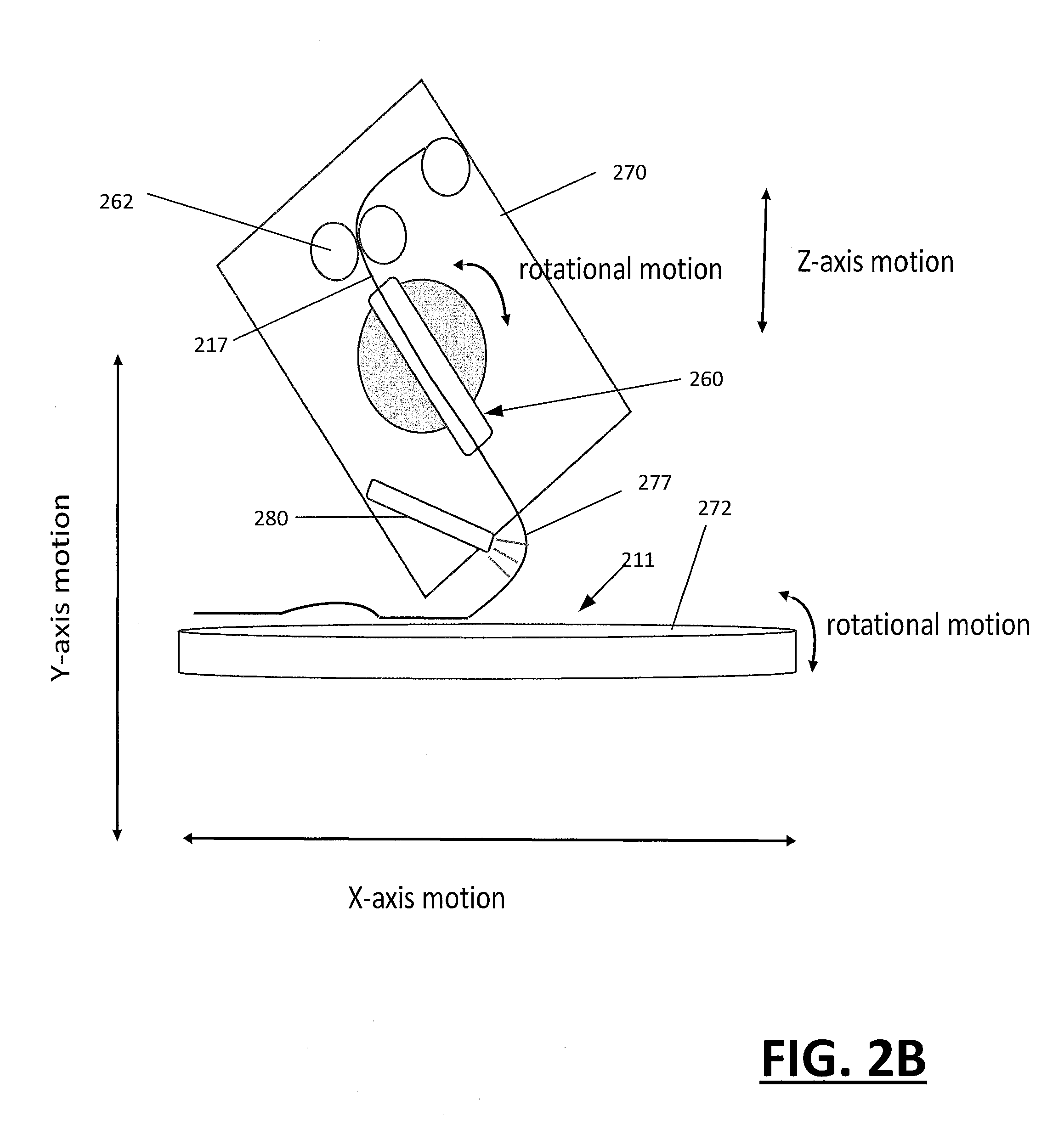

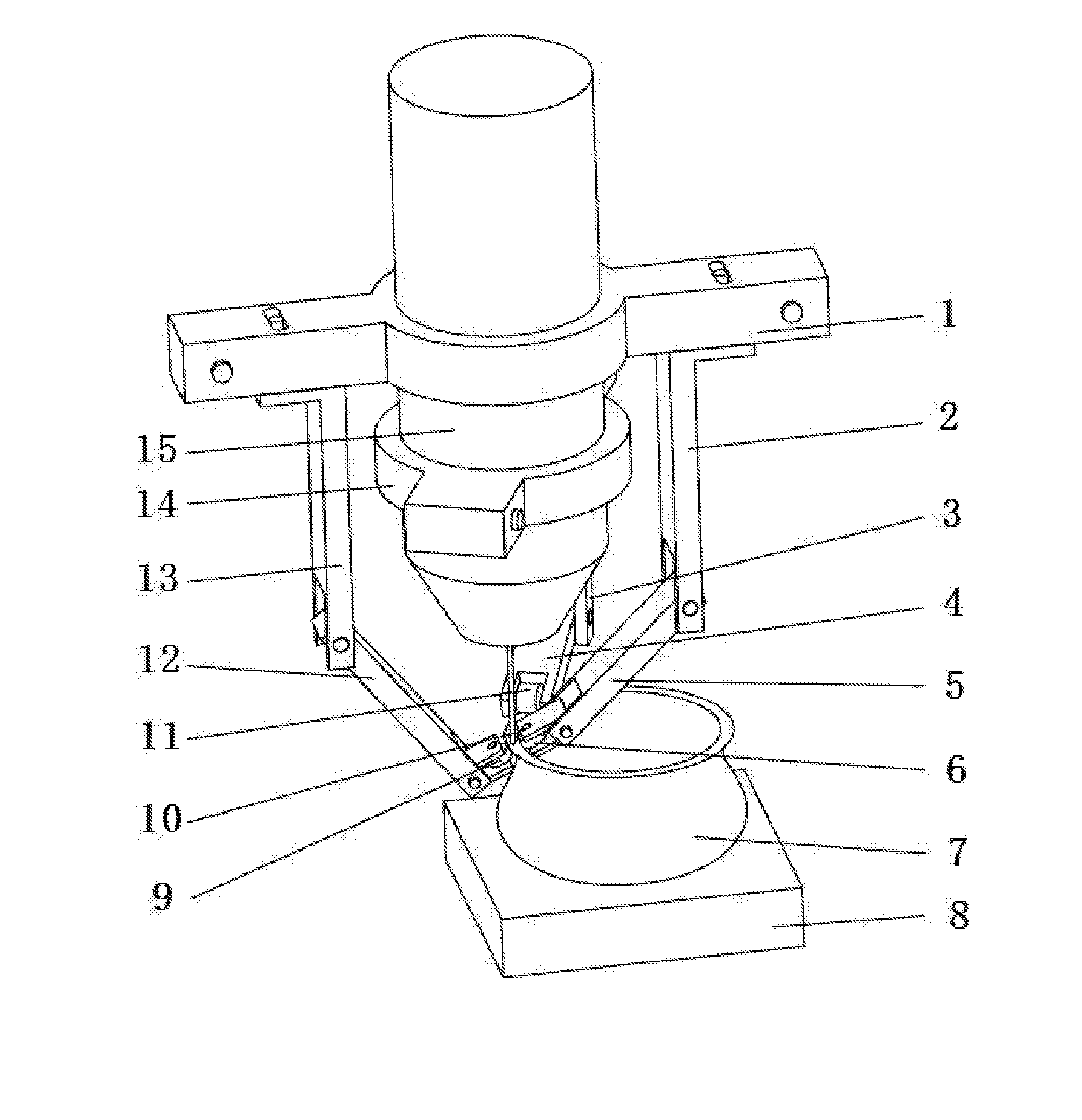

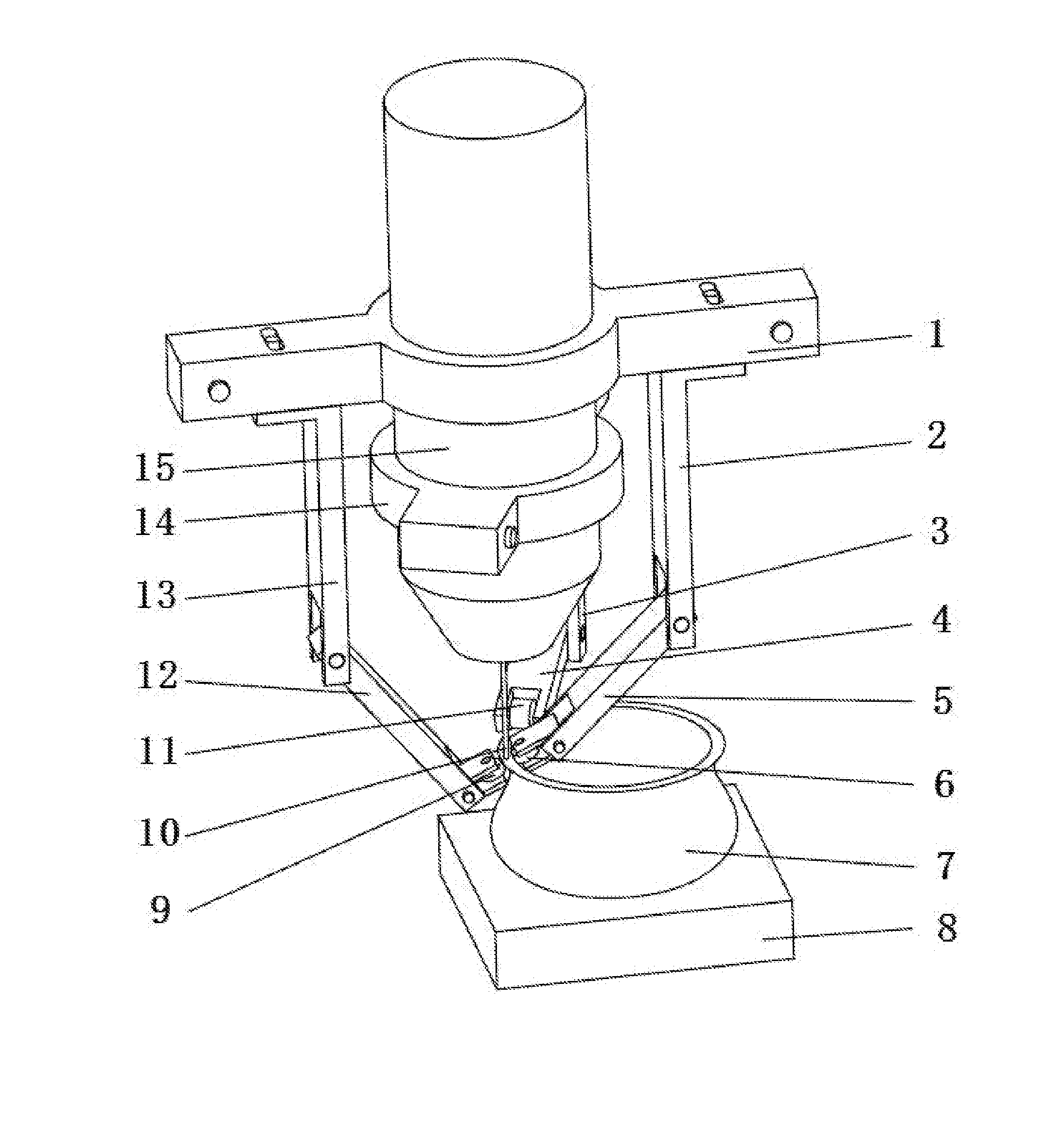

Method for manufacturing metal parts and molds and micro-roller used therefor

ActiveUS20130197683A1Formability of complexImprove accuracyArc welding apparatusAdditive manufacturing with liquidsNumerical controlWire rod

A method for manufacturing parts and molds by: 1) slicing a three-dimensional CAD model of a part or mold; 2) planning a modeling path according to slicing data of the three-dimensional CAD model, whereby generating numerical control codes for modeling processing; and 3) performing fused deposition modeling of powders or wire material of metal, intermetallic compounds, ceramic and composite functional gradient materials by layer using a welding gun on a substrate layer via a numerical control gas shielded welding beam or laser beam according to a track specified by the numerical control code for each layer. A micro-roller or a micro-extrusion unit is installed at a contact area between melted and softened areas. The micro-roller or the micro-extrusion unit synchronously moves along with fused deposition area, which results in compressing and processing of the fused deposition area during the fused deposition modeling.

Owner:HUAZHONG UNIV OF SCI & TECH

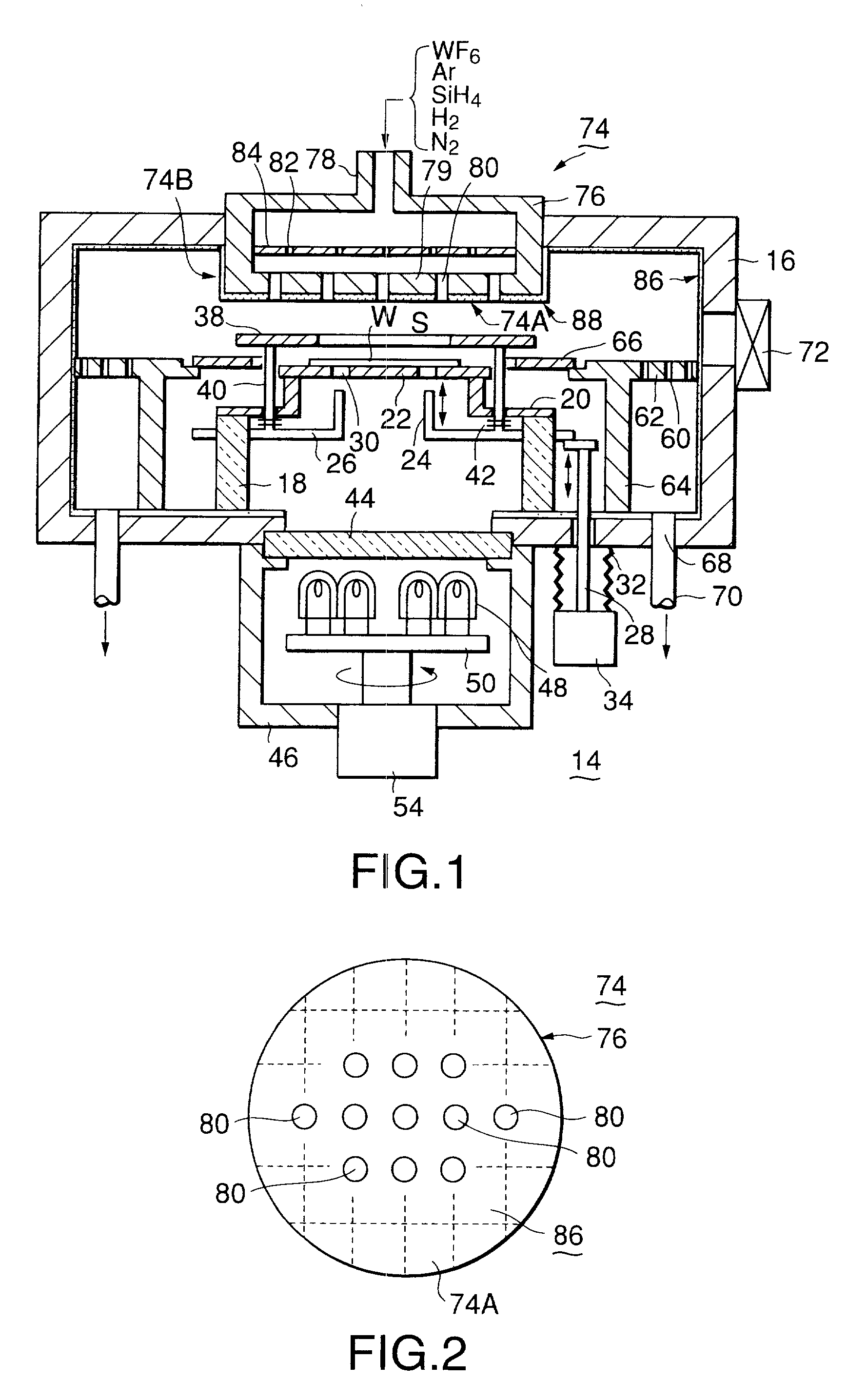

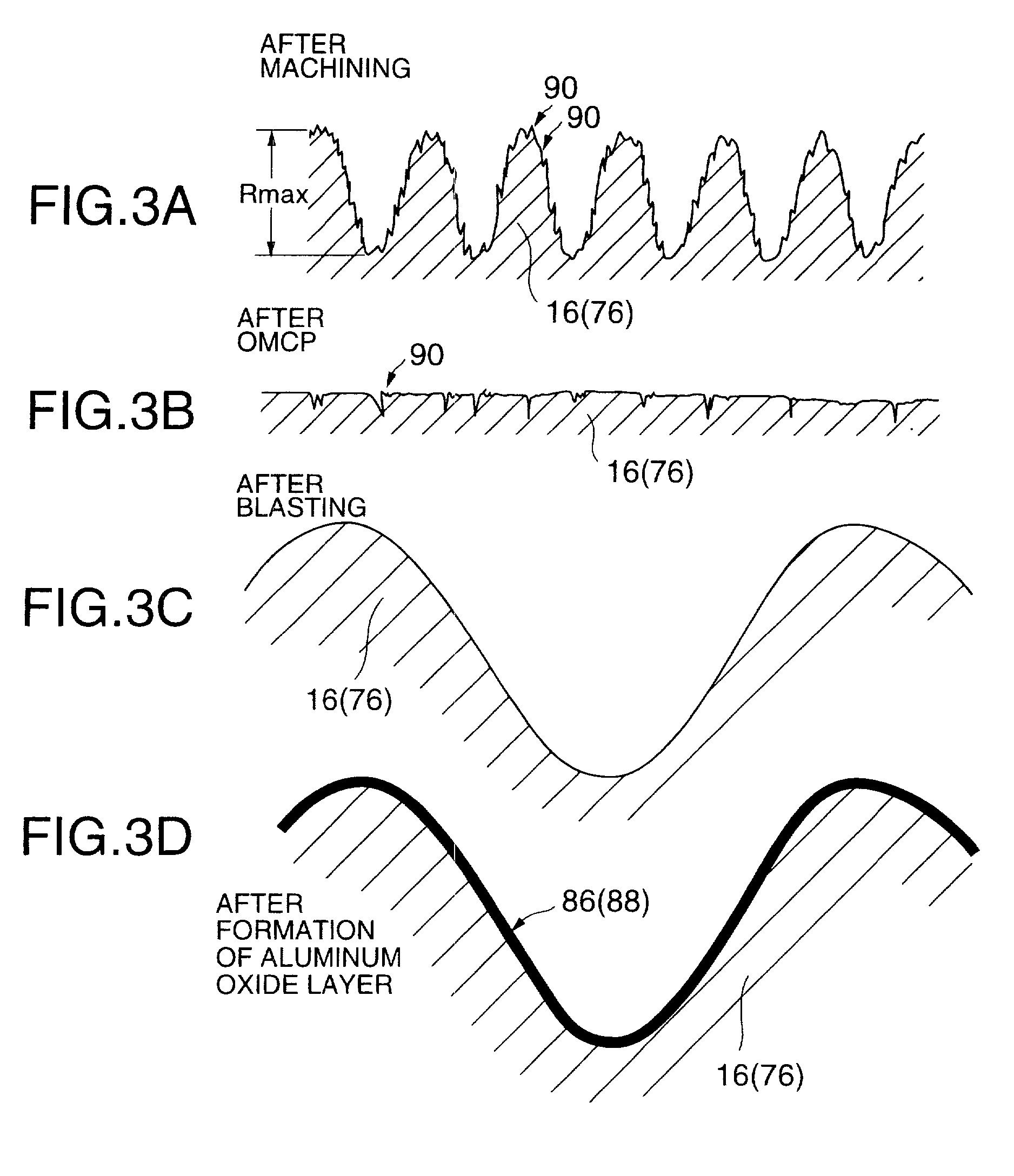

Method of manufacturing a processing apparatus

InactiveUS20030010446A1Improve throughputSuppress production of particleDecorative surface effectsPretreated surfacesSusceptorEngineering

A wafer processing apparatus (14) has a wafer processing vessel (16). A wafer is mounted on a susceptor (22) included in the wafer processing apparatus. Process gases are supplied to the wafer through a shower head (74) disposed in an upper region within the processing vessel to carry out a predetermined process for processing the wafer. The surfaces of aluminum members (16, 74) employed in the wafer processing apparatus are subjected to an organic mechanical chemical polishing process, a blasting process and an aluminum oxide film forming process in that order. It is difficult for unnecessary films to adhere to the thus treated surfaces and it is difficult for unnecessary films deposited on the thus treated surfaces to come off the surfaces. Consequently, intervals between cleaning operations can be extended and production of particles can be suppressed.

Owner:RENESAS ELECTRONICS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com