Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3958 results about "Dust pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pollution caused by dust and particles, poses grave danger to children, older people and people with respiratory illnesses. What is atmospheric pollution? Dust in homes and offices consists of plant pollen, human and animal hairs, textile fibers, paper fibers, minerals from outdoor soil, human skin cells, burnt particles and many other materials.

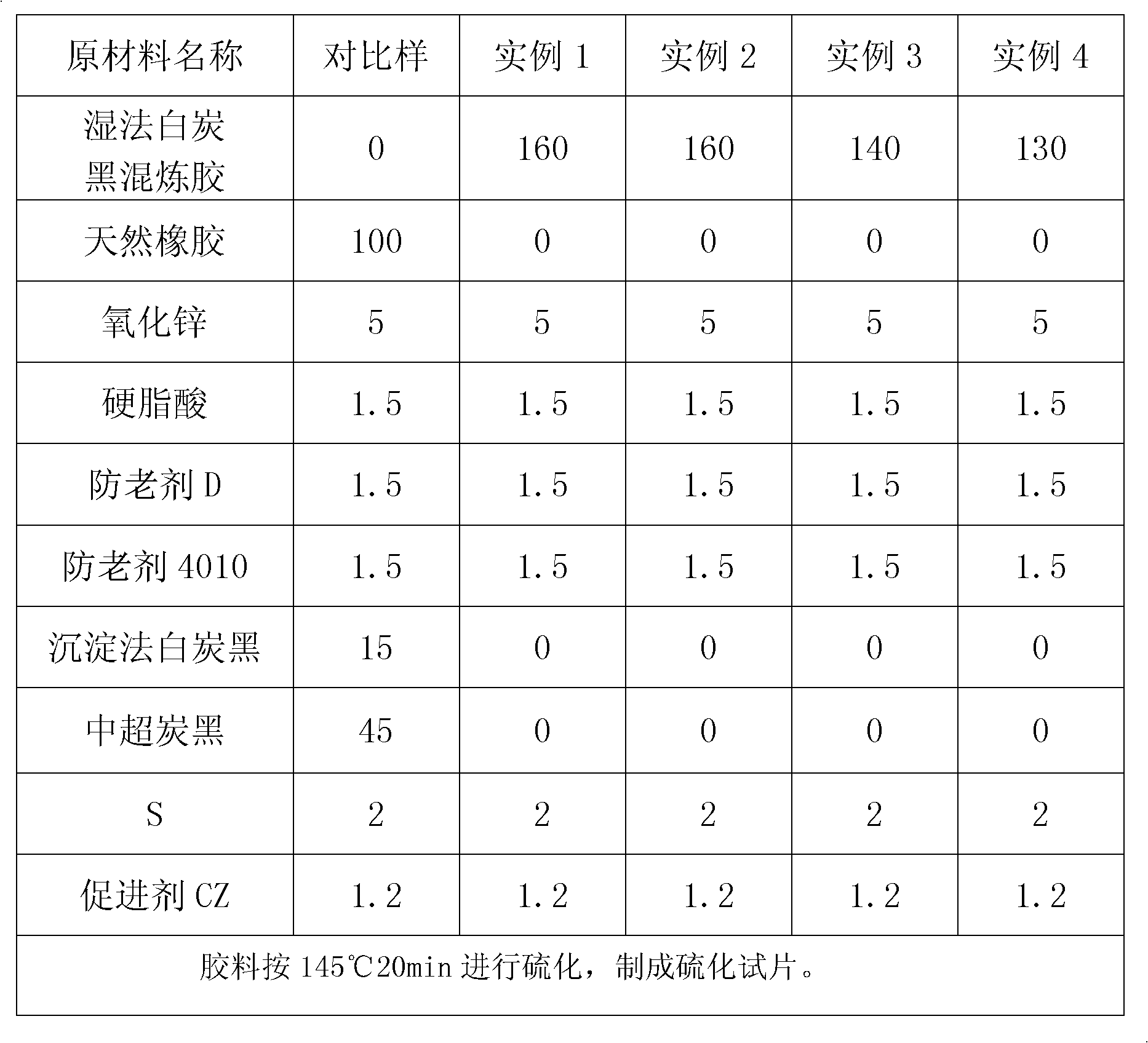

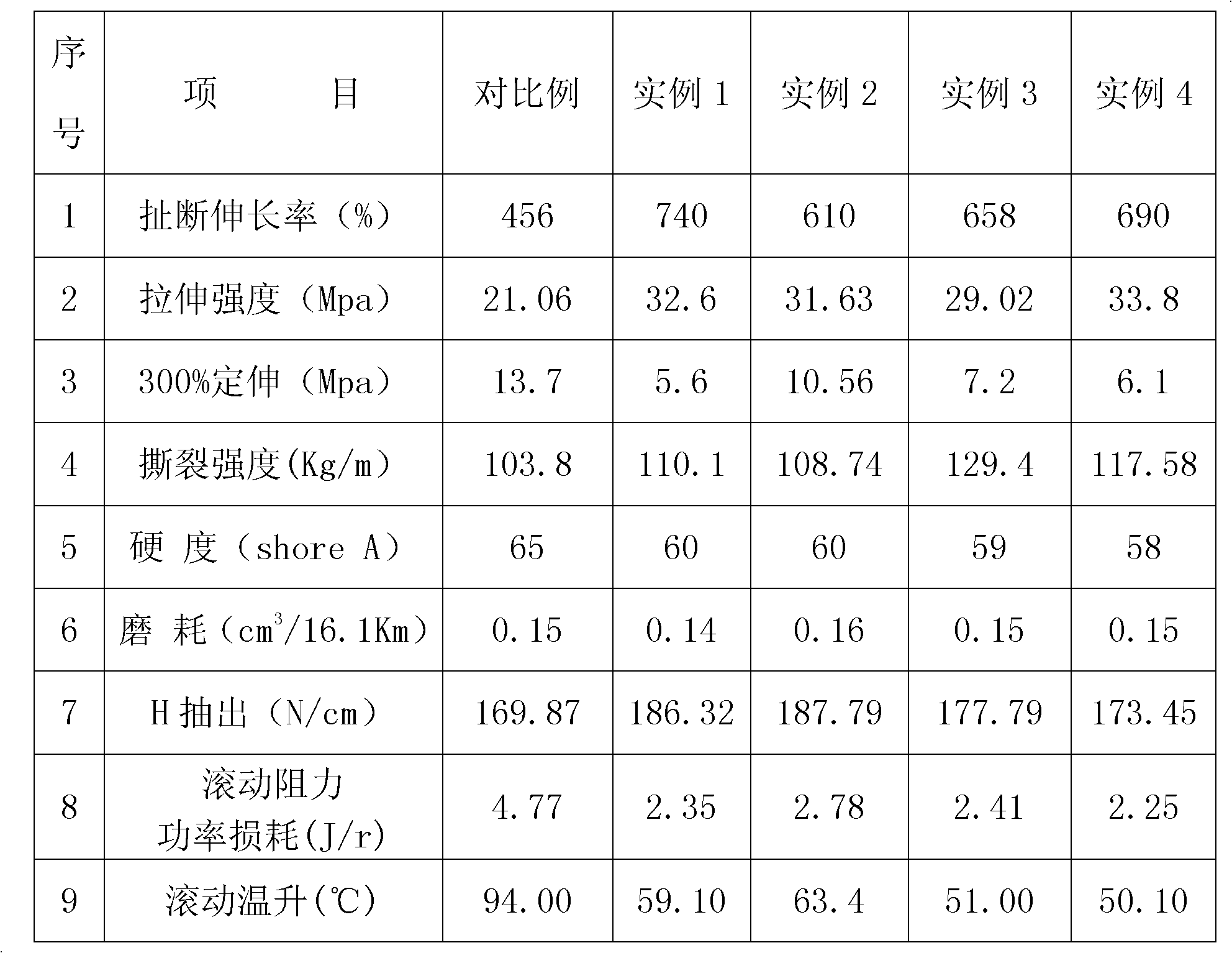

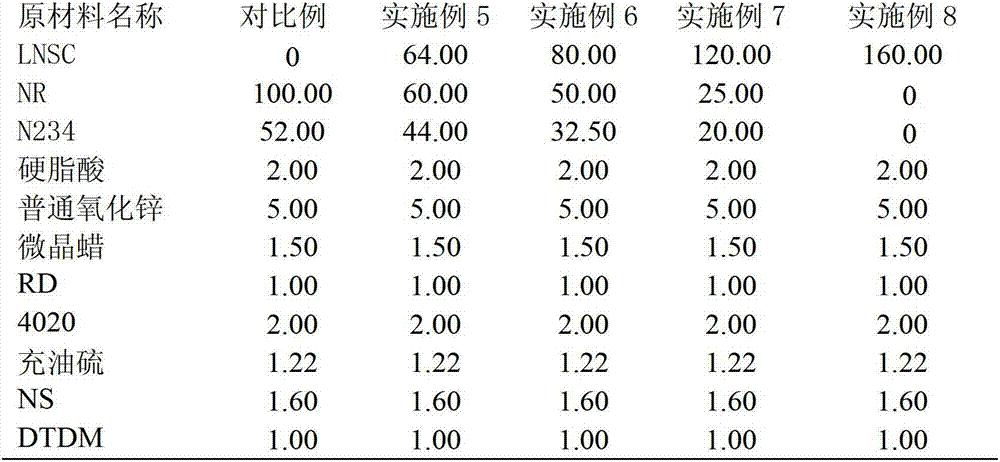

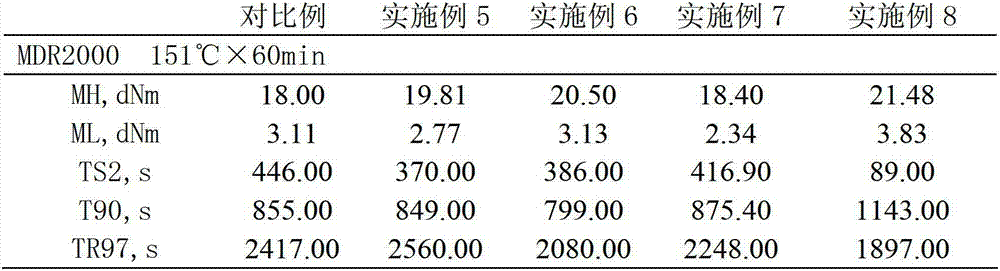

Preparation method of wet process mixed natural rubber material

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

Heavy oil hydrogenation catalyst and preparation method thereof

ActiveCN103769118AShorten drying timeAvoid pollutionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDry basisBULK ACTIVE INGREDIENT

The invention discloses a heavy oil hydrogenation catalyst and a preparation method thereof. The heavy oil hydrogenation catalyst comprises a carrier and an active ingredient; the carrier is aluminum oxide, and is prepared from pseudo-boehmite with dry basis content below 50% via moulding; the active ingredient are metals selected form family VIII, Co or Ni, and / or family VI B, Mo or W. The preparation method comprises following steps: preparation of pseudo-boehmite, preparation of the carrier, and loading of the active ingredient. The heavy oil hydrogenation catalyst is capable of maintaining high demetalization, desulphurization, and carbon residue removing activities, simplifying drying process of pseudo-boehmite preparation, avoiding dust pollution caused by moulding process, increasing production efficiency, reducing production energy consumption, and reducing catalyst cost further.

Owner:CHINA PETROLEUM & CHEM CORP +1

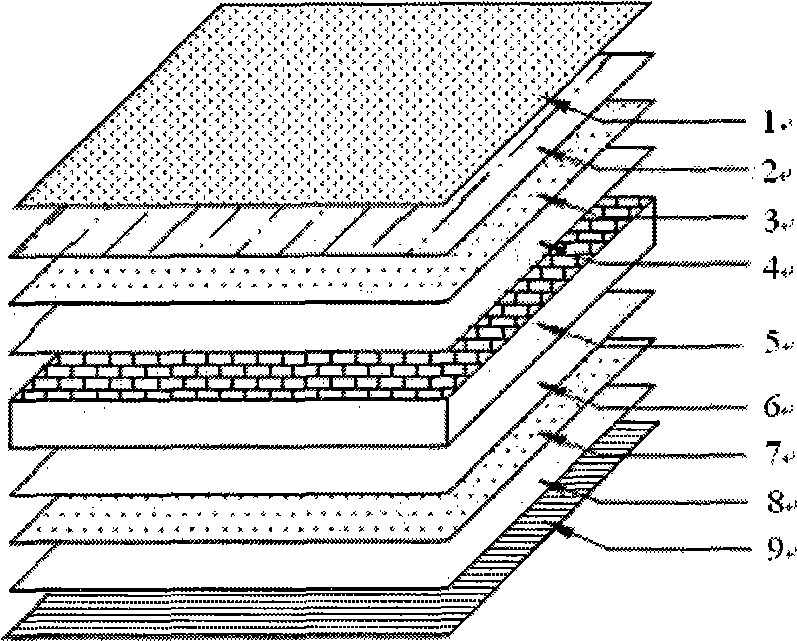

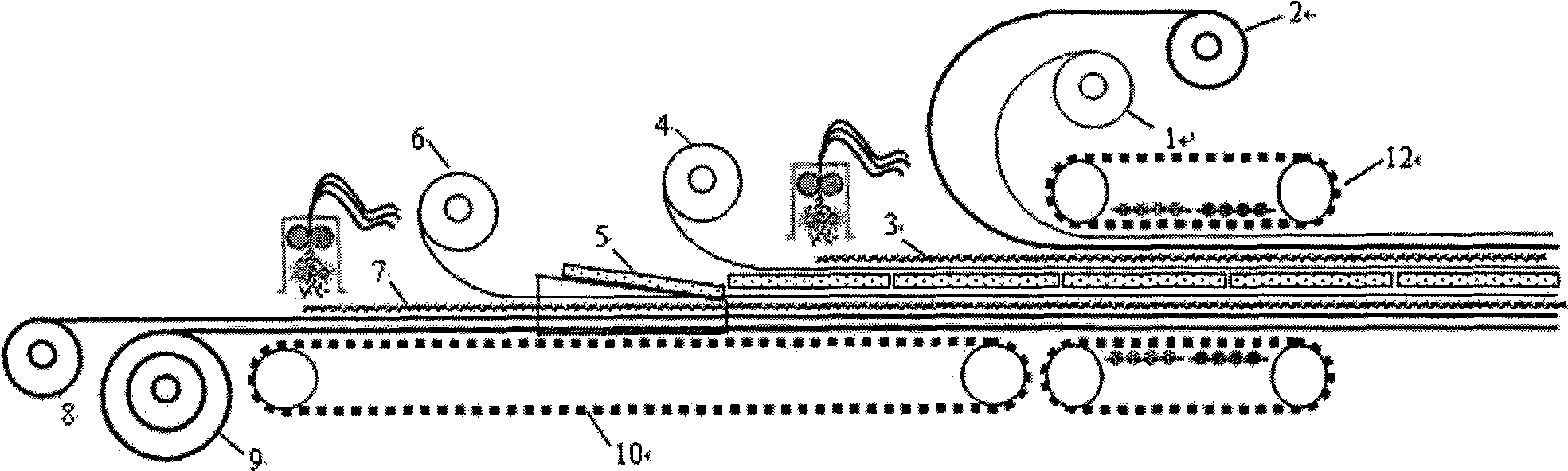

Polyurethane multilayer composite sheet for automotive headliner and processing method thereof

InactiveCN101544083ASolve pollutionAvoid product qualitySynthetic resin layered productsLaminationSurface finishGlass fiber

The invention discloses a polyurethane multilayer composite sheet for an automotive headliner, which has a non-woven fabric layer, a first reinforcing glue film layer, a first reinforcing fiber layer, a first adhesive film layer, polyurethane foam board, a second adhesive film layer, a second reinforcing fiber layer, a reinforcing glue layer and a surface finish layer from bottom to top. The production method of the polyurethane multilayer composite sheet has the characteristics that: the use of the reinforcing glue films as a substitute of hot-melt adhesive powder simplifies production process, improves production efficiency and product quality, radically solves dust pollution in a production process, and improves the working environment of workers. The polyurethane multilayer composite sheets produced by the method can be used for fiber glass-free automotive roofs, biodegradable automotive roofs, light automotive roofs, and other high-quality automotive headliners; the introduction of reinforcing fiber mats in different forms enables the method to produce breathable automobile roofs, high acoustic absorption automotive roofs, high strength automotive roofs and other functional automotive headliners; and the sheet and the method fill a gap of the automotive headliner industry in China.

Owner:陈雅君

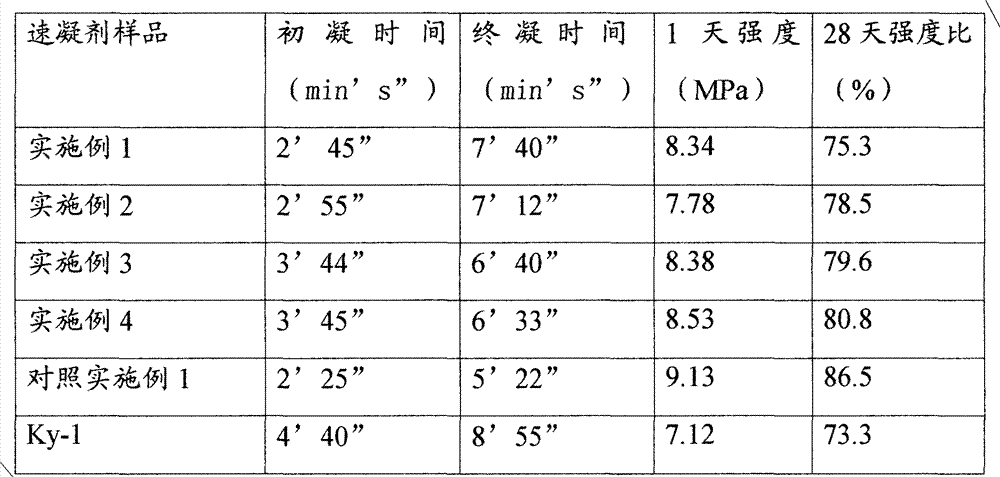

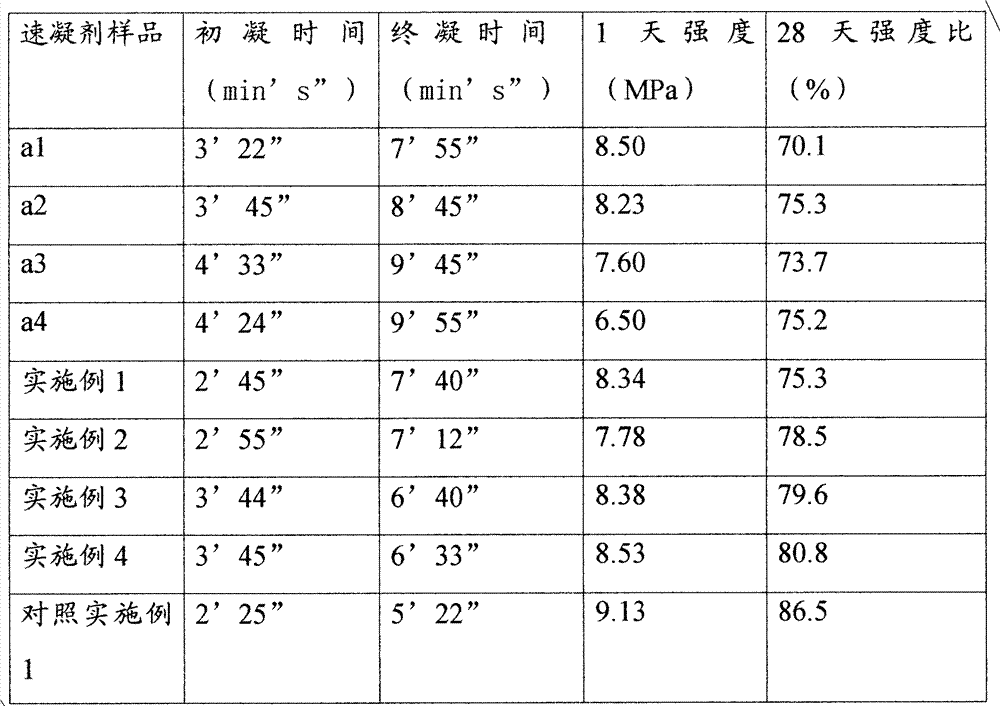

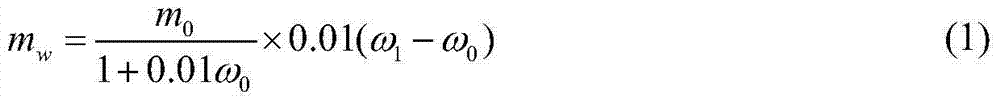

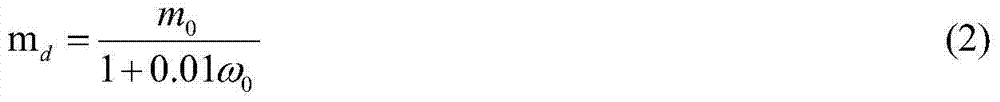

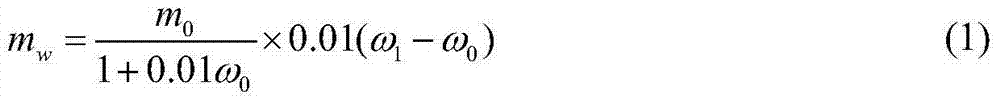

Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Owner:北京冶建特种材料有限公司 +1

Iron oxide black granular pigment and preparation method thereof

InactiveCN101691456APollution suppressionSettling fastPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersityIron oxide black

The invention belongs to the field of chemical pigments, and in particular relates to an iron oxide black granular pigment and a manufacturing method thereof. The iron oxide black granular pigment comprises a main component iron oxide black (Fe3O4) which is coated with an additive coating layer, and the main component iron oxide black is combined with the additive coating layer to form the granular pigment; and the pigment is prepared by the following steps: firstly preparing aqueous solution of an additive, and performing heating until 30 to 100 DEG C; and sending the iron oxide black into a granulator, evenly spraying the prepared aqueous solution of the additive onto powder, gradually forming small granules, and screening and drying the prepared granules with a vibrating screen to prepare a finished product. The granular pigment prepared by the method is not easy to diffuse so as to effectively prevent dust pollution, has high luster retention, good flowability and dispersity, and low cost, and is suitable to be widely applied in industry.

Owner:HANGZHOU XIAOXIANG PIGMENT CHEM

Production method for manganese sulfate by using biological cellulose and low-grade manganese ores

The invention discloses a production method for manganese sulfate by using low-grade manganese ores. According to the method, manganese sulfate with high purity can be produced by using waste low-grade manganese ores with manganese content of 10% to 20%, manganese tailing or manganese-containing solid waste residue. The method comprises the steps of preparation of raw materials, a slaking reaction, a leaching reaction, neutralization and purification of leachate, etc. According to the invention, production of manganese sulfate is not restricted by the grade of manganese ores, and low-grade manganese oxide ores with a grade greater than 10%, manganese tailing or manganese-containing solid waste residue can be fully utilized; produced manganese sulfate has high yield and high purity and is a very important industrial fundamental product; almost no external heat supply is needed, low energy consumption is achieved, production cost is low, it does not need to turn over and mix materials in the process of the reactions, the reactions are smooth, no toxic gas is generated, and no environmental pollution is produced; discharge of three wastes (waste gas, waste water and industrial residue) reaches national discharge standards for environmental protection, and there is no dust pollution in a workshop.

Owner:陈昆先 +1

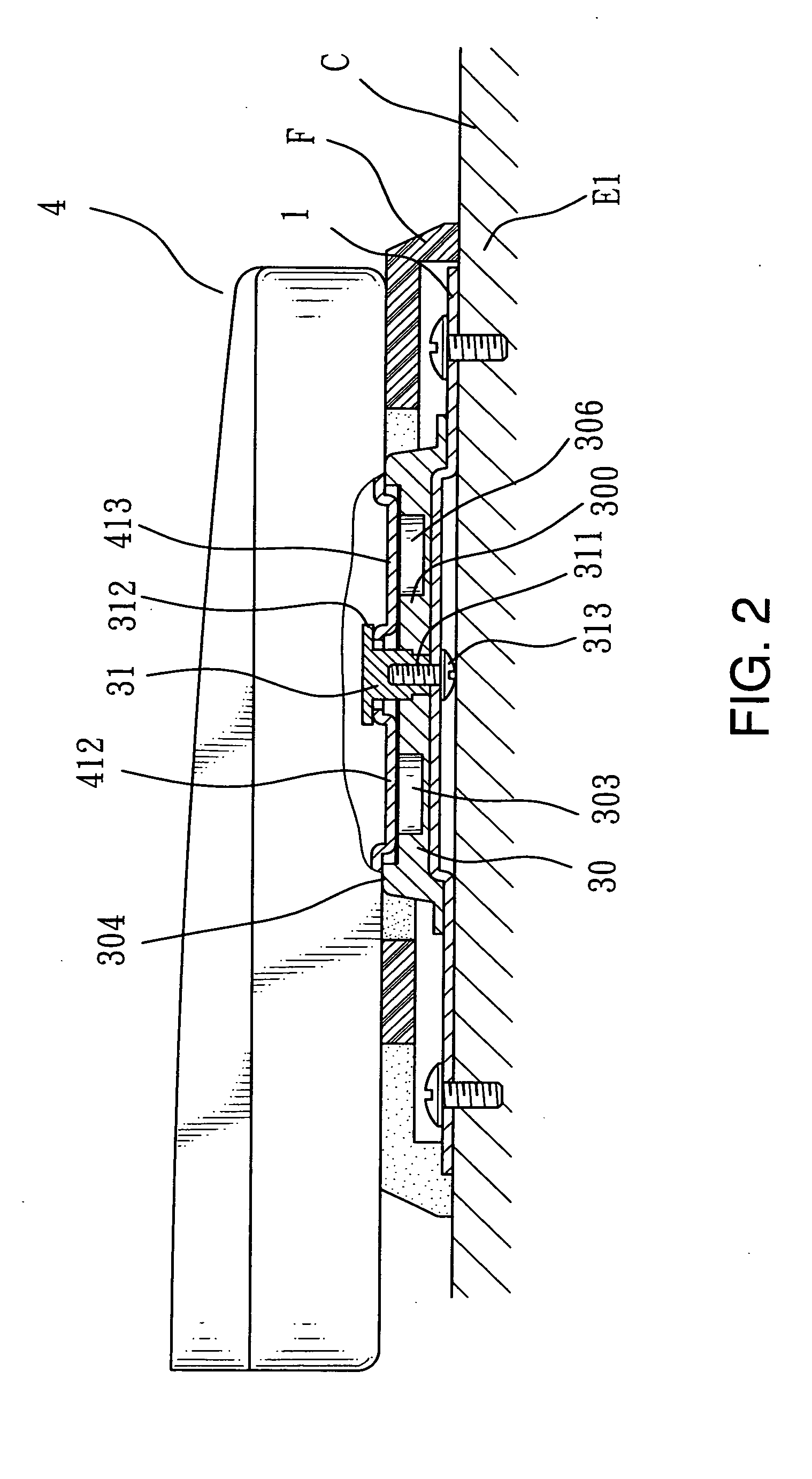

Fastening apparatus for a detachable multimedia player of cars

InactiveUS20060086873A1Easy to installEasy to removePicture framesDomestic mirrorsCouplingEngineering

A fastening apparatus for a detachable car multimedia player includes a first fastening member and a second fastening member. The first fastening member is fastened to an anchor seat and has a strut which has a wing flap extended sideward from the top end. The second fastening member is located on the bottom of the car multimedia player and has a coupling bore. The first fastening member may be coupled with the second fastening member to rapidly mount the car multimedia player and remove the car multimedia player when not in use to prevent theft and dust pollution.

Owner:E LEAD ELECTRONICS

A kind of organic fiber reinforced organic airgel thermal insulation material and preparation method thereof

ActiveCN102285775AGood infrared radiation shielding effectReduce heat transfer by infrared radiationSide effectHigh intensity

The invention relates to an organic-fiber reinforced organic-aerogel heat-insulating material and a preparation method thereof, wherein the basal body of the organic-fiber reinforced organic-aerogel heat-insulating material is organic phenol-aldehyde aerogel, a reinforced body is organic pre-oxidized fibers, and the density is 0.3 to 0.6g / cm<3>. A normal-pressure semi-closed drying method is adopted for preparation. Compared with a traditional organic-foam heat-insulating material, the material disclosed by the invention has the advantages of high strength, low heat conductivity, flame retardance and the like; and compared with an inorganic-fiber reinforced inorganic oxide-aerogel composite material, the material disclosed by the invention does not have the side effects of dust pollution,harm and irritability to the skin of a human body, stimulation to a respiratory tract and the like, so that the material is environment-friendly and safe. The material disclosed by the invention is applicable to occasions with the characteristic of having a high-strength requirement on the heat-insulating material at the temperature of minus 100 to 110 DEG C and is an ideal heat-insulating material for building house-decoration industries.

Owner:NAT UNIV OF DEFENSE TECH

Heavy metal-contaminated soil solidifying agent and application method thereof

ActiveCN103833274AHigh strengthReduce risk of leachingSolid waste managementOrganic fertilisersDry weightChemical reaction

The invention discloses a heavy metal-contaminated soil solidifying agent and an application method thereof. The solidifying agent comprises the following components by mass: on the basis of the dry weight of heavy metal-contaminated soil, 10 to 15% of a binding material, 5% of biochar, 10% of vegetable fiber and 1% of a stabilizing agent. The components are added according a sequence of the stabilizing agent-the biochar-the vegetable fiber-the binding material. Addition of the chemical stabilizing agent and the biochar in the process of stabilization enables heavy metals to be absorbed and passivated and to lose mobility; preparation of heavy metal-contaminated soil slurry provides conditions for a later chemical reaction; the whole processing process is free of dust pollution and discharging of unwanted sewage. Addition of the vegetable fiber enables cracking of heavy metal-contaminated soil solidified by using a conventional solidifying agent to be effectively prevented and endurance of a solidified body to be improved. The method provided by the invention has the advantages of strong operability, low cost, extensive applicability, a high resource utilization rate, low environmental risk and easy large-scale popularization.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

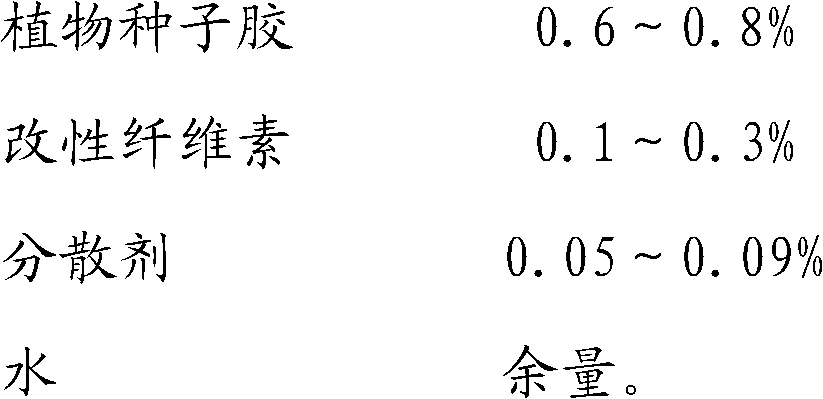

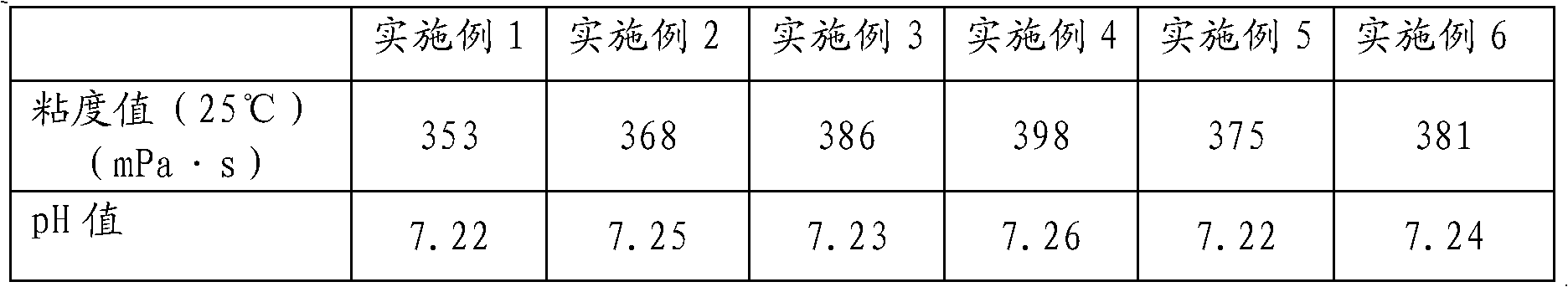

dust suppressant

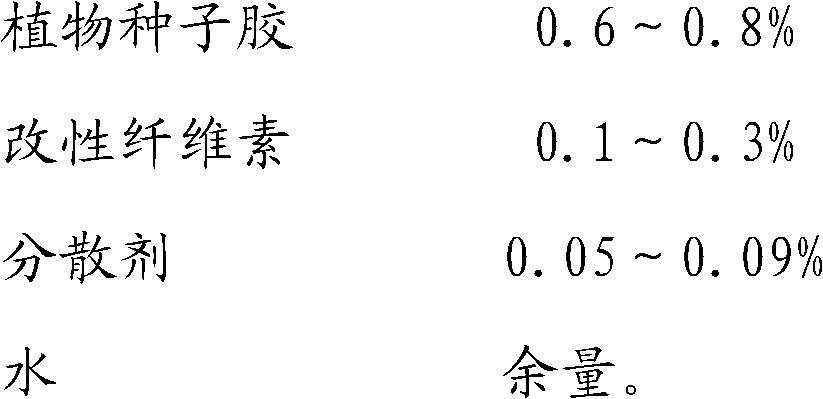

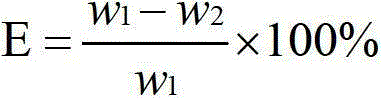

The invention discloses a dust inhibitor, which comprises the following raw material in percentage by weight: 0.6 to 0.8 percent of plant seed colloid, 0.1 to 0.3 percent of modified cellulose, 0.05 to 0.09 percent of dispersant and the balance of water. The dust inhibitor can be prepared at normal temperature in a common mixing equipment from mixed aqueous solution of plant seed colloid, modified cellulose, crosslinking agent, dispersant and reinforcing agent; and after being prepared, the dust inhibitor can be sprayed onto the surface of coal in carriages to allow the coal to form a layer of cured film on the surface, the viscosity of the film is high, the wind corrosion rate of the film is low, so that the dust pollution along railways in railway transportation of the coal and the dust loss of the coal are avoided. Besides, dust inhibition in railway coal transportation, the dust inhibitor can be used for dust inhibition on roads in mining areas, urban roads, constructions sites, stations, ports and the like so that the dust inhibitor can be used almost without being limited by fields, and the dust inhibitor can be widely used.

Owner:北京中盛益世环保科技有限公司

Ecological environment-friendly dust inhibitor

InactiveCN103184034AViscosity quick releaseIncrease viscosityOther chemical processesEcological environmentErosion rate

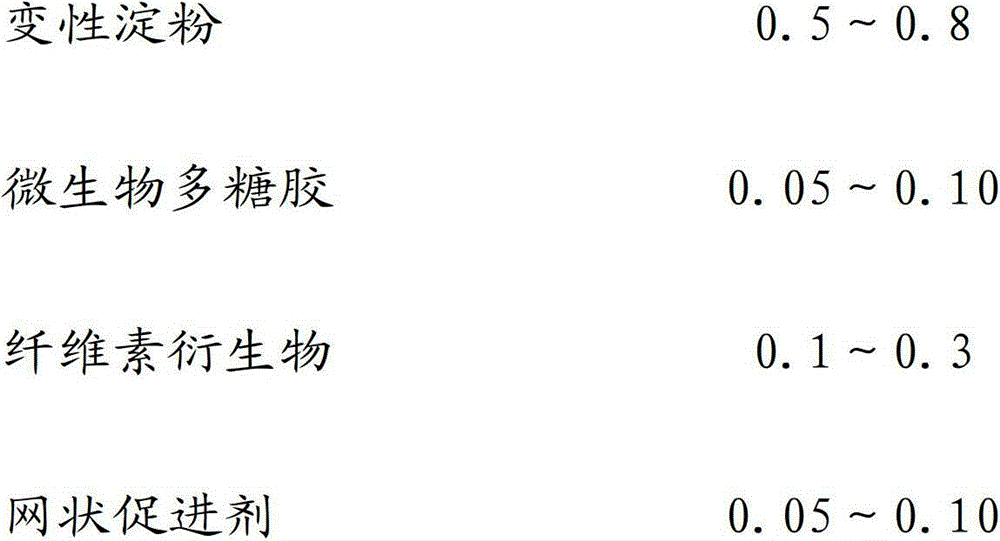

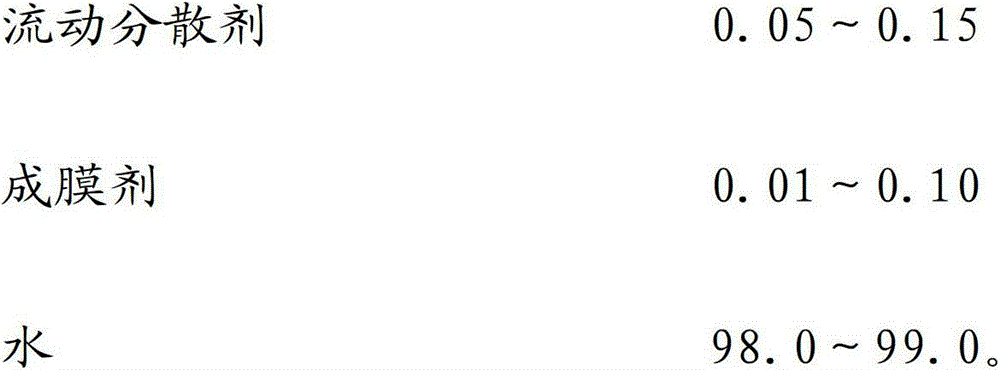

The invention provides an ecological environment-friendly dust inhibitor which comprises the following components by weight percent: 0.5-0.8% of modified starch, 0.05-0.10% of microbial polysaccharide, 0.1-0.3% of cellulose derivative, 0.05-0.10% of netty accelerant, 0.05-0.15% of flow dispersant, 0.01-0.10% of film forming agent and 98.0-99.0% of water. The dust inhibitor can enable coal or mineral powder to form a layer of curing film on the surface, is high in viscosity and low in wind erosion rate, can avoid the flowing dust pollution and the flowing dust loss of the coal or the mineral powder to the way side in the railway transportation process, and has a huge economic benefit and a social benefit of environmental protection for railway transportation and coal or mineral powder customers; and the components and a solution of the dust inhibitor do not have any toxic side effect and corrosive effect, the dust inhibitor does not cause any secondary pollution as the dust inhibitor can be quickly and biochemically degraded in the nature after the dust inhibition action period, and the soil can be properly improved.

Owner:BEIJING SUNSHINE COLORFUL TECH

Double-annular-atomizing environment-friendly dust-removing pneumatic spraying machine

InactiveCN102319648AGuaranteed trafficAchieve the effect of coverageUsing liquid separation agentLiquid spraying apparatusWater sourceEngineering

The invention discloses a double-annular-atomizing environment-friendly dust-removing pneumatic spraying machine, which belongs to the technical field of the spraying machines. The pneumatic spraying machine is technically characterized by comprising a base, wherein a spraying mechanism is arranged on the base, and a turntable is arranged on the base and connected with a horizontal rotation driving device; a bracket is arranged on the turntable; the spraying mechanism is connected with the bracket and comprises an axial flow fan, a spraying drum and a double-annular atomizer; the axial flow fan, the spraying drum and the double-annular atomizer are connected with one another in sequence; the double-annular atomizer is connected with a high-pressure water pump by a pipeline; the high-pressure water pump is connected with an external water supply source by a pipeline and connected with an electric control box by a circuit; and the horizontal rotation driving device and the axial flow fan are respectively connected with the electric control box by circuits. The invention aims at providing the double-annular-atomizing environment-friendly dust-removing pneumatic spraying machine with compact structure, long range and better covering effect; and the double-annular-atomizing environment-friendly dust-removing pneumatic spraying machine is used for removing and suppressing dusts of dust pollution caused by mining in large-sized open pit coal mines as well as disorder dust discharge pollution in coal yards and during transportation, crushing and the like.

Owner:广东风华环保设备股份有限公司

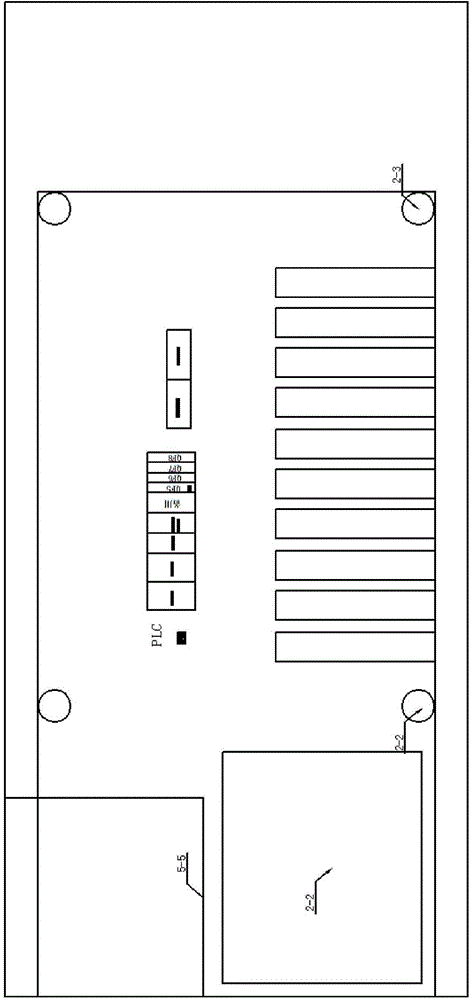

Automatic accurate weighing device for powdery material

InactiveCN101105409ANo leakageNo pollution in the processWeighing apparatus with automatic feed/dischargeMotor speedGrating

The invention discloses a powdery material accurate weighing device, which comprises a raw material tank and a weighing cup. The invention is characterized in that the feeding process is operated under vacuum, a high-level switch and a low-level switch are disposed above a vacuum intake tank, an auger conveying mechanism is disposed below the vacuum intake tank, the spiral pitch has two classes, the motor speed has two classes, a optical fiber grating pressure sensor is disposed below a weighing bunker, an automatic reverse turning bed is disposed in the weighing bunker, the signal from a material level switch and the optical fiber grating pressure sensor is transmitted to PLC, and the PLC outputs control signal to a motor of a vacuum pump, vacuum air passages and material control valves. The invention remarkably improves the weighing accuracy from above plus or minus 10 g error of the existing automatic weighing to within plus or minus 1 g error, even lower. It has the advantages of whole sealing operation under vacuum condition, no dust pollution, improved operating environment, accurate weighing, and good consistency. The invention is helpful for further improving the production quality of friction wafer product; and has high spreading and application values, and good market prospect.

Owner:李红

Composition containing water-insoluble high-activity drug and preparation method thereof

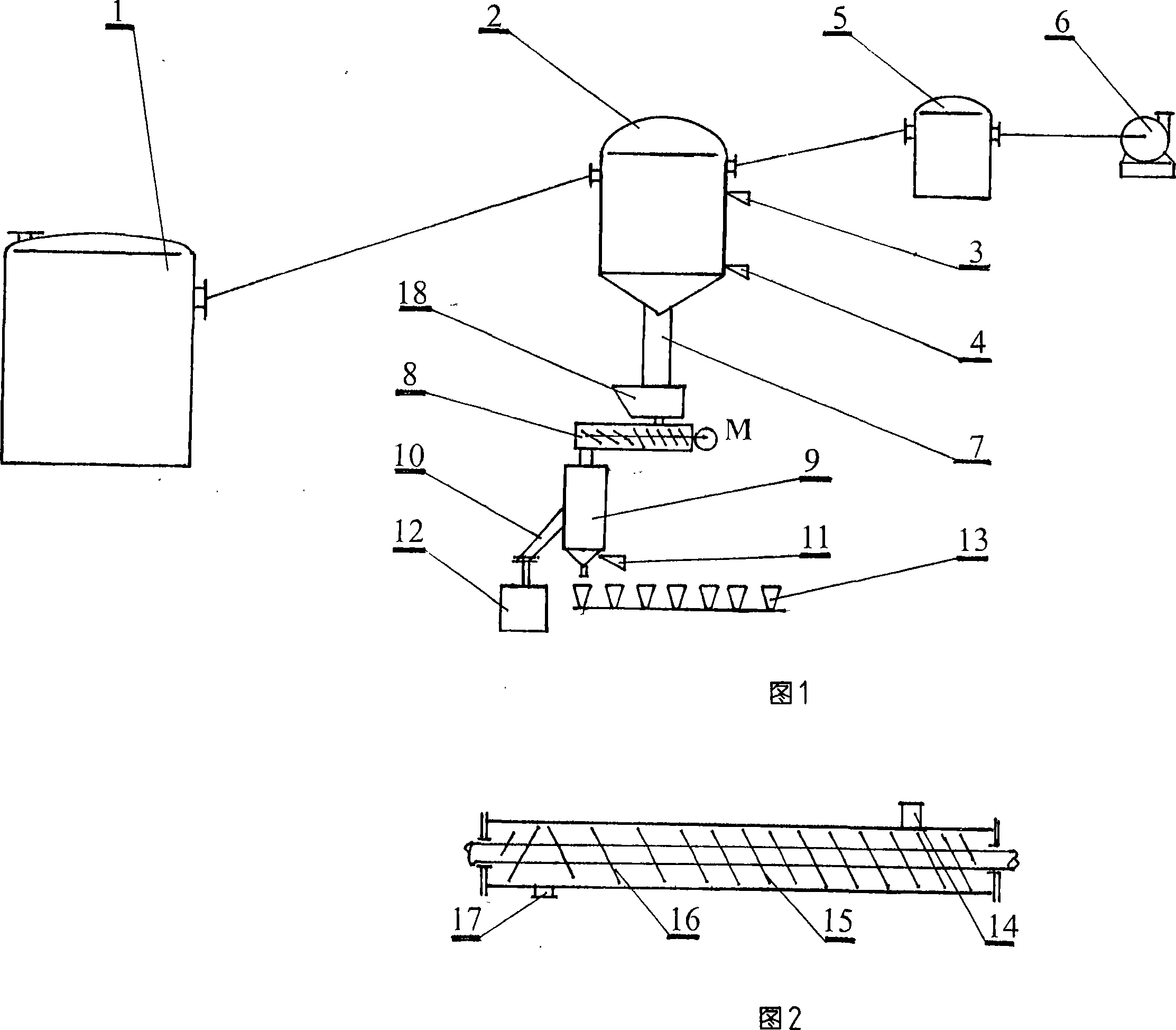

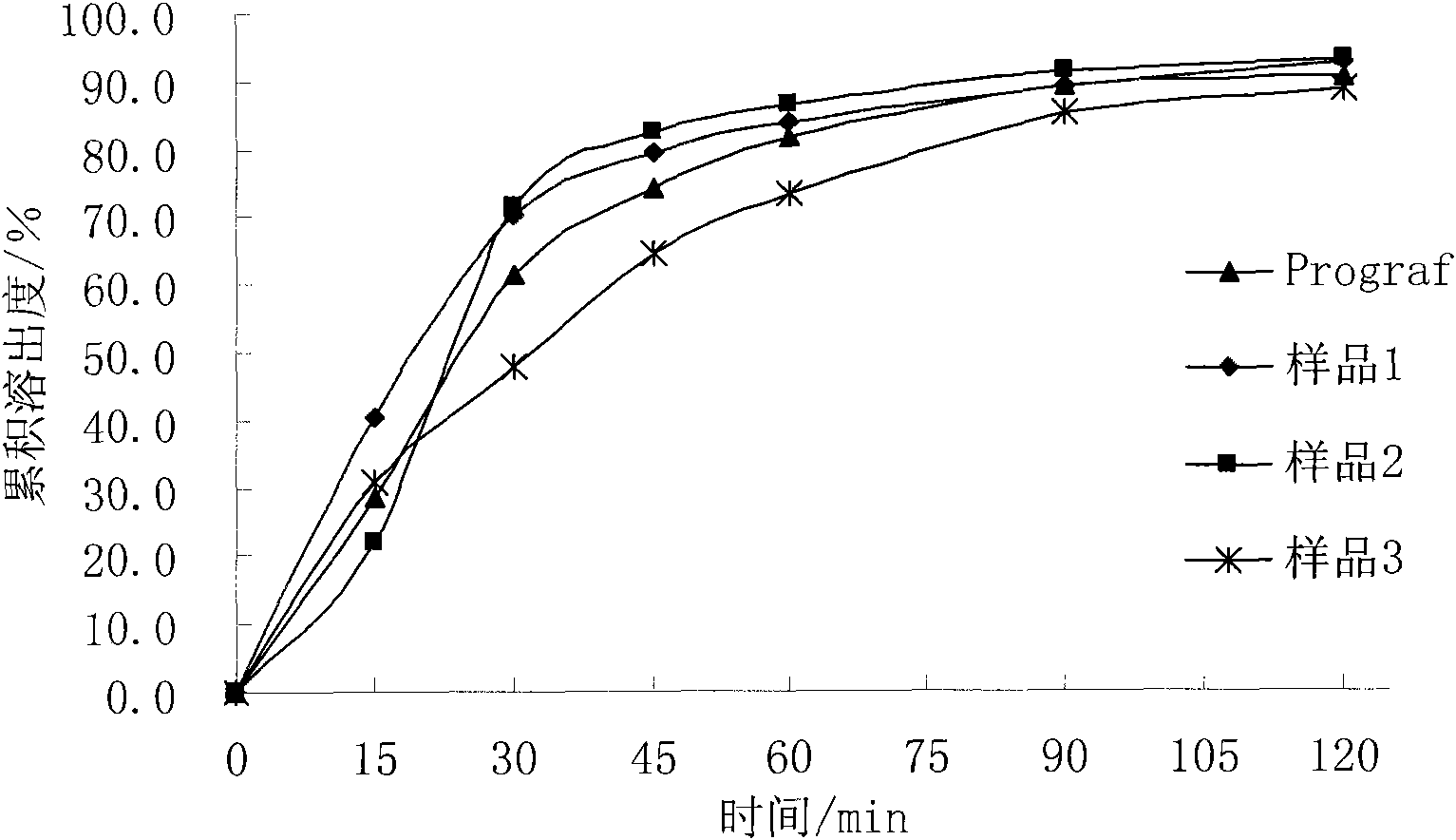

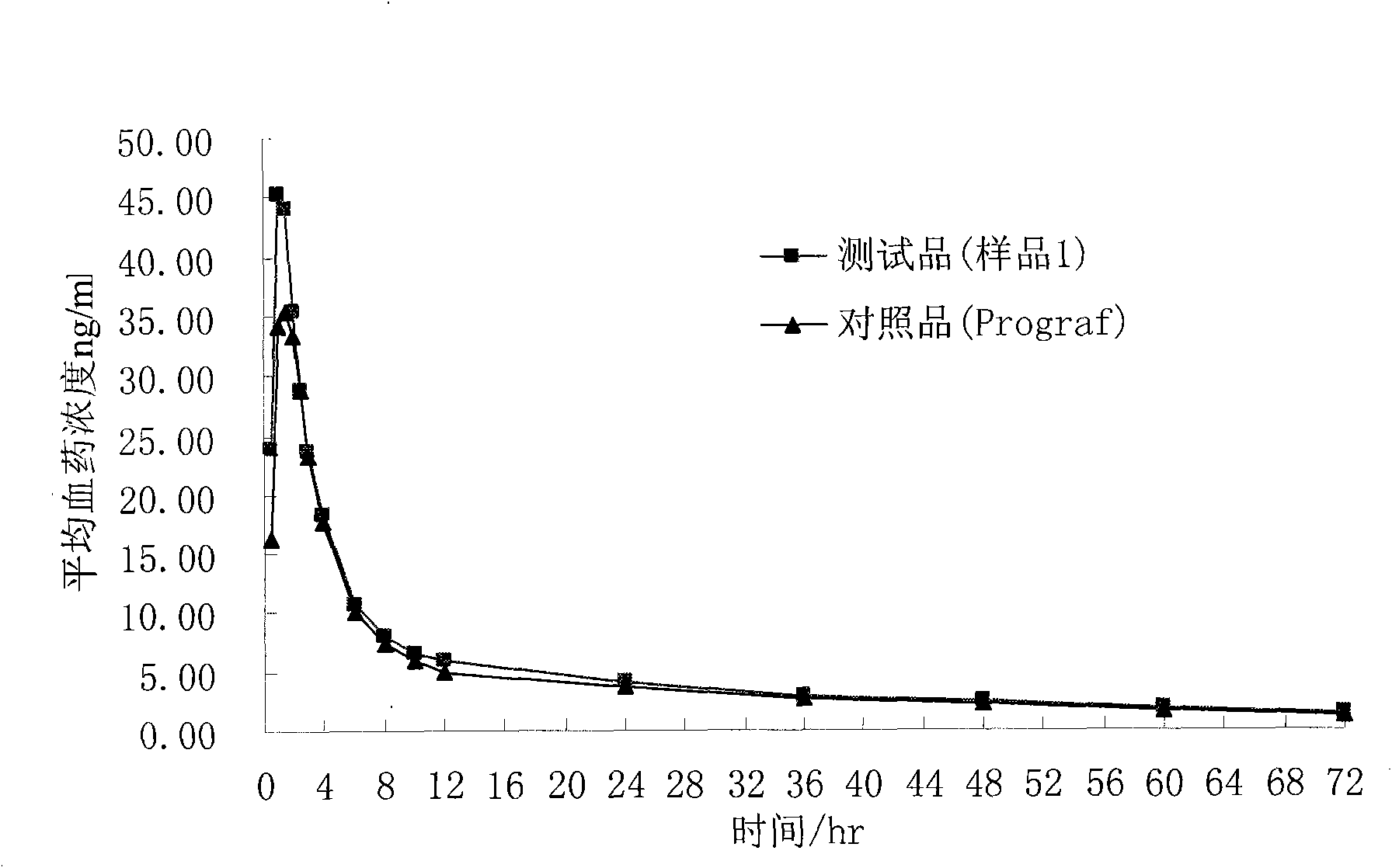

ActiveCN101537184ASolving DissolutionSolve the two major problems of dustOrganic active ingredientsPowder deliveryOrganic solventWater insoluble

The invention discloses a composition containing a water-insoluble high-activity drug and a preparation method thereof. The water-insoluble high-activity drug is dissolved in an organic solvent containing a solid dispersion carrier, evenly sprayed on the surface of filler or blank pellets by adopting a fluidized bed and dried. The invention realizes the one-step completion of preparing the solid dispersion of the water-insoluble high-activity drug, pelleting and drying, has simple and convenient process, and no dust pollution, and effectively avoids the adverse influence of the high-activity drug on the health of production staff. The granules prepared by the method has even granularity, and good liquidity and compression formability, and can be further prepared into oral solid preparation. The composition prepared by the method has good drug dissolvability, and high oral absorption and bioavailability.

Owner:HANGZHOU ZHONGMEI HUADONG PHARMA +1

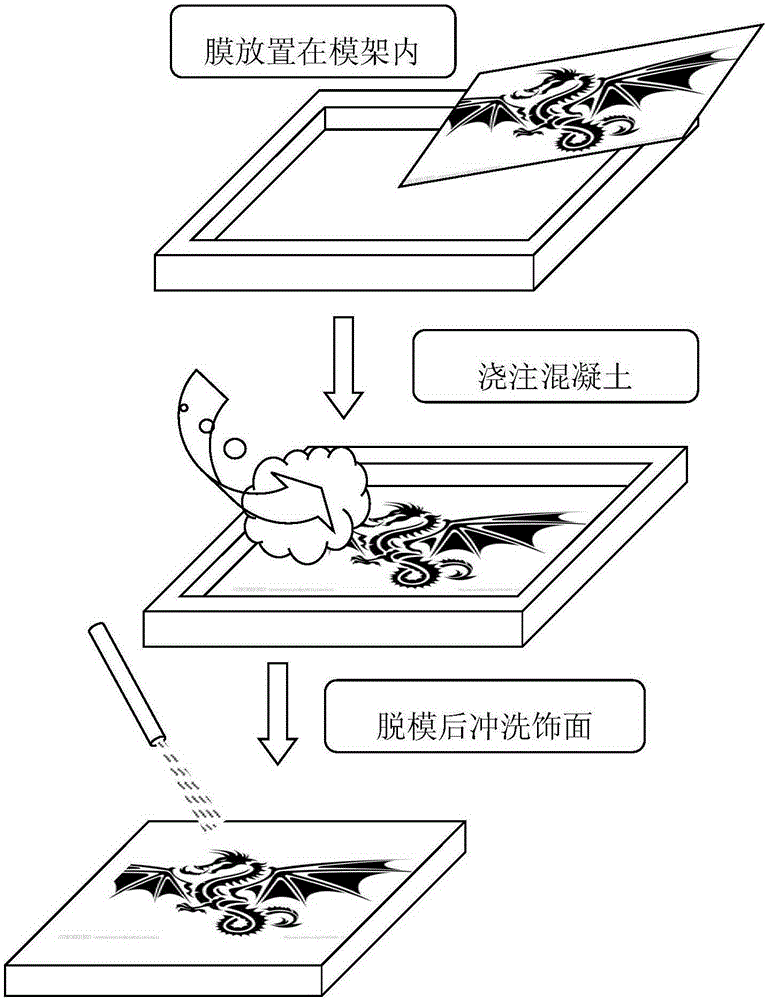

Artistic transfer print film for making concrete veneer through set-retarding and eroding

The invention relates to an artistic transfer print film for making a concrete veneer through set-retarding and eroding. The art transfer print film comprises a base film and a set-retarder coating, wherein the set-retarder coating is attached to the surface of the base film, the surface area of the set-retarder coating is smaller than that of the base film, and set-retarders coat a pattern region of the base film in a film structure. The artistic transfer print film for making the concrete veneer through set-retarding and eroding is laid at the bottom of a mold, concrete is poured, after concrete members are demolded, washing is performed with water for erosion so as to obtain designed patterns, and a decoration surface of comparison and convex-concave changes of aggregate exposing pattern veneers and plain concrete base surfaces is formed on the concrete surface. The technology is simple, clear and convenient, the connecting surface of a plain concrete base surface and an aggregate exposing pattern is clear and delicate, the construction period is short, the production cost is low, and the transfer print efficiency is high; the transfer print film is economic and environmentally friendly, good in durability and suitable for high-pressure cleaning; and abundant and exquisite design patterns are achieved, and decoration effects are clear and artistic. Compared with a conventional technology, the transfer print film does not have any harm to other positions of the concrete, and besides, dust pollution can be eliminated.

Owner:RECKLI

Method for preparing nano calcium carbonate quantum dot through microemulsion system

InactiveCN103570051BRich sourcesLow priceCalcium/strontium/barium carbonatesMaterial nanotechnologySolventRaw material

A method for a nano calcium carbonate quantum dot through a microemulsion system belongs to the technical field of nanometer materials. According to the method, a non-aqueous toluene / emulsifier / co-emulsifier microemulsion system is firstly prepared, then a calcium chloride microemulsion and a sodium carbonate microemulsion are respectively prepared in a microemulsion area, then the sodium carbonate microemulsion is slowly added into the calcium chloride microemulsion and reacts to finally obtain a nano calcium carbonate quantum dot microemulsion. The nano calcium carbonate prepared through the method provided by the invention has the characteristics such as small grain size and uniformity. The nano calcium carbonate quantum dot, as a modified intermediate, can be directly used in a special occasion with methylbenzene as a solvent, so as to reduce the dust pollution of the environment. According to the method, the reaction condition is mild, the equipment is simple and easy to operate, and meanwhile, the chosen main materials are rich in source and low in cost, so that the method is easy in promotion and application.

Owner:HENAN ANALYSIS TESTING CENT

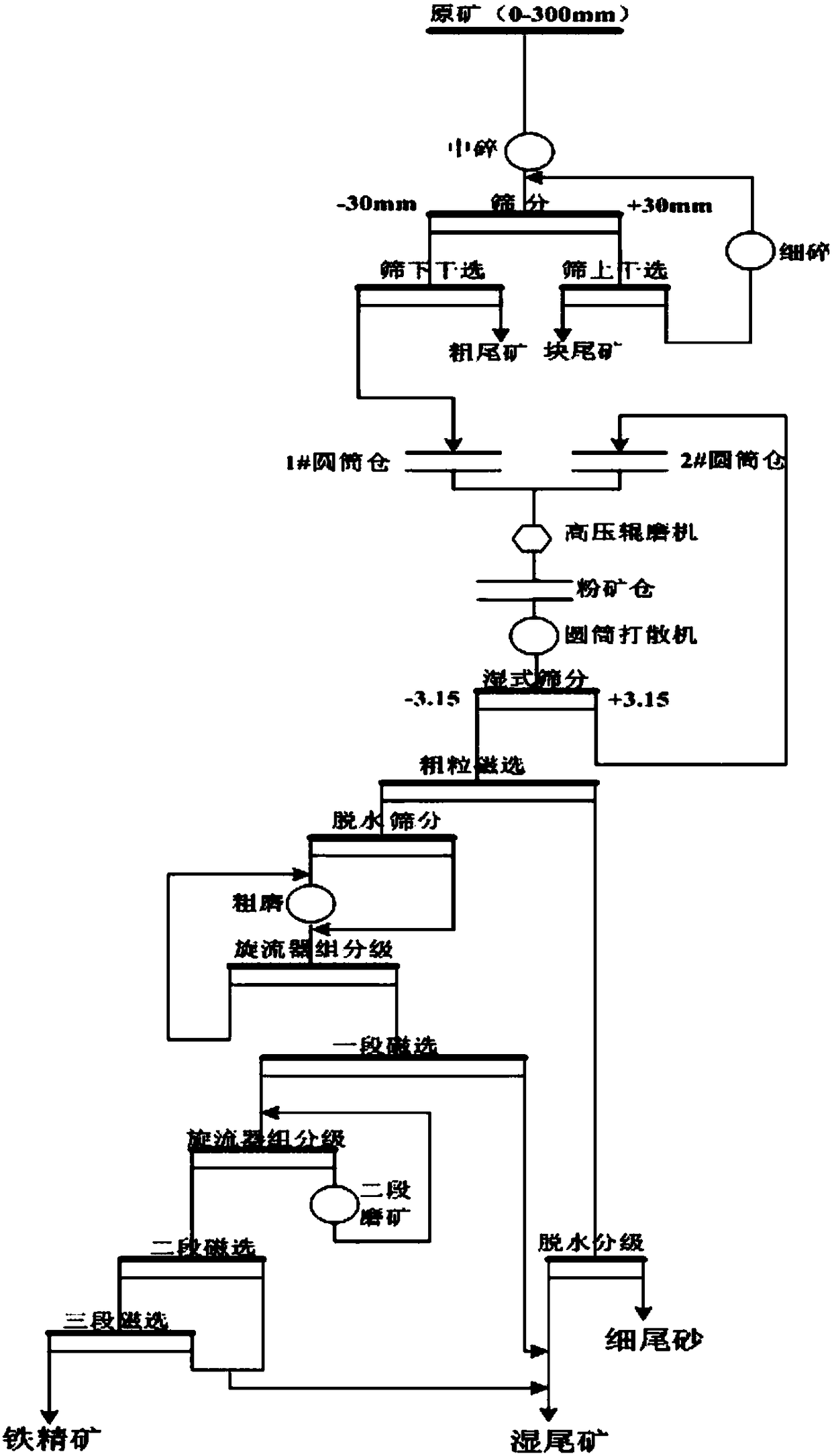

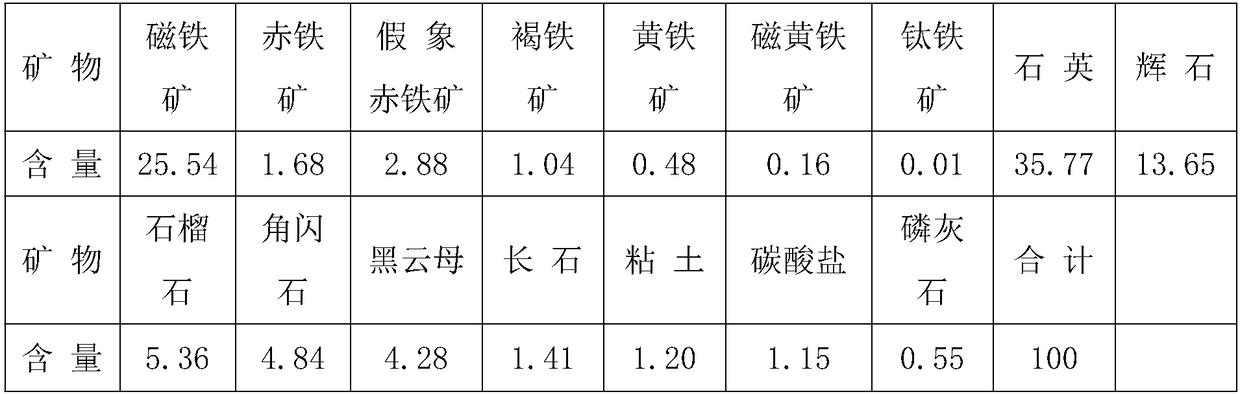

Iron improvement and silicon reduction beneficiation method of high ferrosilite and lean magnet iron ore

ActiveCN108246490AEasy to transportReasonable layoutMagnetic separationWet separationHigh pressureMaterials science

The invention discloses an iron improvement and silicon reduction beneficiation method of high ferrosilite and lean magnet iron ore, the method comprises the following processes of crushing-screening,fine crushing, dry-type preconcentration tailings discardinghigh-pressure roller milling, coarse particle magnetic separation, and coarse particle magnetic separation concentrate rough grinding-low intensity magnetic separation, wherein coarse crushing is arranged underground, medium and fine crushing are arranged on the ground, the placement is reasonable and orderly, reducing of occupied spaceis facilitated, and transporting and lifting of ore from the downhole is convenient. The dry-type preconcentration tailings discarding is carried out on sieve residue and through product after intermediate crushing and fine crushing, mixed barren rock is thrown out, throwing out is carried out and rough gangue and block gangue used as building products are recovered in advance, the iron grade of follow-up separating operations is recovered and improved, the ore content given to the follow-up operations is greatly reduced, " receiving early and losing early" is realized. The feeding grain sizeof high-pressure roller milling is up to 30mm, a precedent is broken, characteristics of low energy consumption and high processing capacity of a high-pressure roller milling machine is fully played,a product stock heap is not arranged in design, and occupied space and dust pollution are reduced.

Owner:安徽马钢张庄矿业有限责任公司

Method for cleaning green tealeaves

InactiveCN103071639AAvoid pollutionSolve pollutionPre-extraction tea treatmentDrying solid materials without heatPesticide residueDust pollution

The invention discloses a method for cleaning green tealeaves. The method comprises: 1, an impregnation step of adding 18 to 22 grams of organophosphate-degrading enzyme into every 500 to 600 liters of water, pouring 40 to 50 kilograms of tealeaves, impregnating the tealeaves for 0.5 to 1.5 hours, washing the tealeaves, and collecting the tealeaves in a bucket; 2, a spin-drying step of placing the tealeaves into spin-drying equipment for spin-drying; 3, an air-drying step of air-drying the spin-dried tealeaves by using high-speed air-drying equipment; 4, an airing step of spreading the air-dried tealeaves in a thin layer on a shelf for airing; and 5, a step of subsequently processing the aired tealeaves by using a fixation process. The problems of pesticide residues on the surfaces of the tealeaves, dust pollution, heavy metal pollution, harm of remaining ozone to a human body during ozone washing and incapability of decomposing most of pesticides by pure fresh water washing are solved by impregnation, washing and dehydration.

Owner:QINGDAO HAIXIN TEA CO LTD

Coal dust suppression agent and method of preparing the same

InactiveCN101508884ALow costEasy to operateOther chemical processesLoading/unloadingCarboxymethyl celluloseSocial benefits

The invention relates to a coal dust suppression agent and a preparation method thereof. The coal dust suppression agent comprises 0.5-1.5wt% of sodium carboxymethyl cellulose, 0.5-1.5wt% of sodium carboxy nethyl, 0.1-0.3wt% of glycerol and 96.7-98.9wt% of water. The coal dust suppression agent can be mixed at normal temperature without needing any other warming-up devices; after being mixed at the normal temperature, the coal dust suppression agent is sprayed or coated on the coal of carriage, so that a solidifying layer is formed on the coal, and dust pollution along the line and dust loss of the coal when in the railway transport can be avoided. Furthermore, the coal dust suppression agent does not cause environmental pollution, and has great economic benefit for railway transport and coal customer as well as social benefit for environmental protection. The method of the invention is simple in operation, low in cost and good in dust suppression effect.

Owner:BEIJING UNIV OF CHEM TECH

Nano antibacterial powdered paint and its micro-suspension one-step preparation therefor

InactiveCN1844270ALittle pollutionEasy reunionAntifouling/underwater paintsPaints with biocidesUltrasonic dispersionOrganic polymer

The invention relates to a manufacturing domain of nanopowder composite, especially to a nano antibacterial powder coating and one-step manufacturing method of microsuspension. The nano antibacterial powder coating consists of water, mixture monomer, pigment, surface processing agent, nanometre-sized inorganic antiseptic particle and auxiliary agent. The method comprises dispersing components such as water and suspending disperser by ultra-audio wave, then performing dispersion by high-shear emulsifier to prepare the predispersion; afterwards, adding the other components into polymerization kettle according to priority, after agitation and heating, adding the said predispersion at one time, reacting at a constant temperature, then cooling, discharge, centrifugally dewatering and drying to obtain the product. The invention solves the problems that the nanoparticles are easy to aggregate inside the organic polymer existed in present technology and the manufacturing engineering of the traditional powder coating is difficult, and has advantages that the process flow is short, the equipment investment is low, and can save working hours and energy resource, is of no dust pollution, the prepared powder coating particles is of regular shape, and has better levelling property in application.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

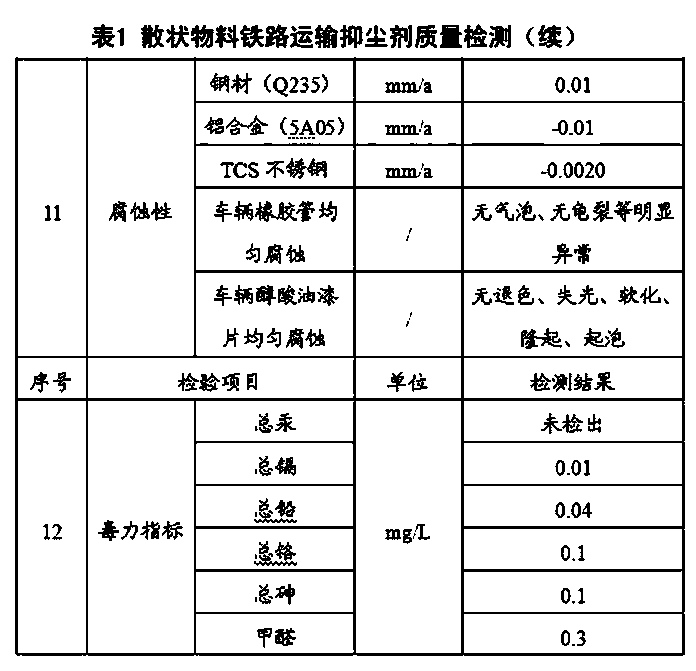

Dust inhibiting agent used during railway transportation process of powdered materials and preparation method thereof

The invention relates to a dust inhibiting agent used during the railway transportation process of powdered materials and a preparation method thereof, the dust inhibiting agent comprises the following raw materials: polyvinyl alcohol, starch, polyacrylamide, carboxymethyl cellulose, natural plant glue, a surfactant, an antifreeze auxiliary agent, and a bacteriostatic agent. The dust inhibiting agent provided by the invention can inhibit the dust pollution brought by railway transportation of powdered materials, especially inhibits the PM 2.5, is capable of solving the antifreeze problem when using the dust inhibiting agent in winter, and achieves the goals of safety and environment-friendliness.

Owner:北京安平联合环保科技有限公司

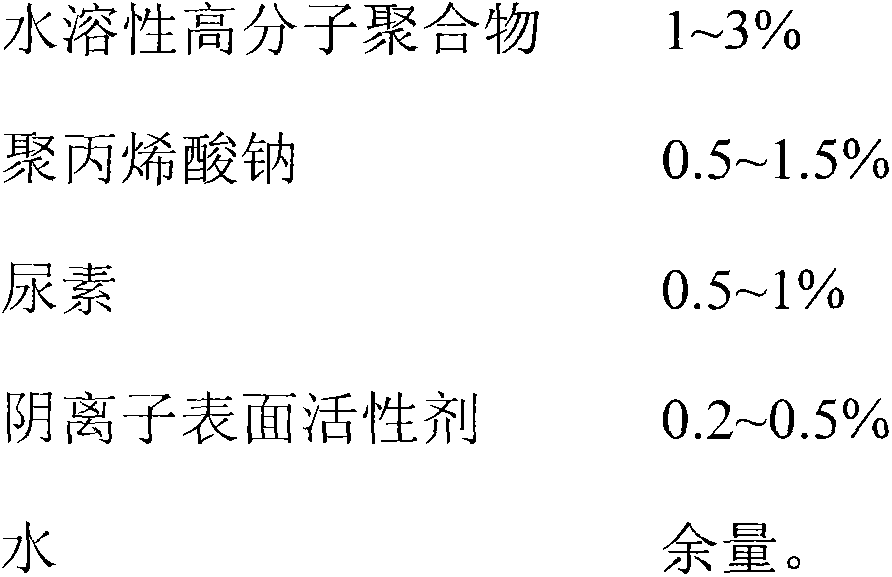

Road surface dust suppressant and preparation method thereof

InactiveCN103965834ASolve pollutionSolve the problem of rolling dustOther chemical processesRoad surfaceDust emission

The present invention discloses a road surface dust suppressant and a preparation method thereof, wherein the road surface dust suppressant comprises 1-3% of a water-soluble macromolecule polymer, 0.5-1.5% of sodium polyacrylate, 0.5-1% of urea, 0.2-0.5% of an anionic surfactant, and the balance of water. According to the present invention, the road surface dust suppressant can be applied in road dust suppression, earth work dust emission treatment in mine exploitation, mine field road transportation and municipal construction, and other fields so as to effectively solve the problem of dust pollution, ensure transportation safety and health safety of motorcyclists and staffs around, reduce the maintenance cost of the transportation equipment, increase the service life of the equipment, and especially solve the problem of rolling dust emission of the heavy duty transportation tool.

Owner:RIZHAO K GREEN ENVIRONMENTAL SCI & TECH

Halogen-free flame-retardant polypropylene master batch

The invention relates to a halogen-free flame-retardant polypropylene master batch. The halogen-free flame-retardant polypropylene master batch comprises the following components in percentage by weight: 20 to 40 percent of polypropylene pellets, 40 to 60 percent of ammonium polyphosphate, 0.5 to 3.0 percent of flame-retardant synergist, 6 to 25 percent of halogen-free charring agent, and 5 to 15 percent of compatibilizer. A method for preparing the halogen-free flame-retardant polypropylene master batch comprises the following steps of: weighing raw materials according to the weight proportion, drying, and extruding and granulating by a co-rotating or counter-rotating twin-screw extruder, wherein the rotating speed of a screw is 70 to 200rpm; and the temperature is 160 to 230 DEG C. The disadvantages that the atactic polypropylene (APP) is independently added, so flame-retardant efficiency is low, the mechanical properties of matrixes are greatly influenced, great inconvenience is brought to the drying treatment of the raw materials, dust pollution is caused and the like are overcome. The invention has the advantages that: the flame-retardant synergistic effect can be well realized among components of the master batch, mixing and drying processes of the raw materials in the production process are simplified, and the production efficiency is improved; the dust in the production process is reduced, and the production environment is improved; and a flame-retardant polypropylene material prepared from the master batch has a good flame-retardant effect and excellent mechanical properties.

Owner:YANGZHOU UNIV

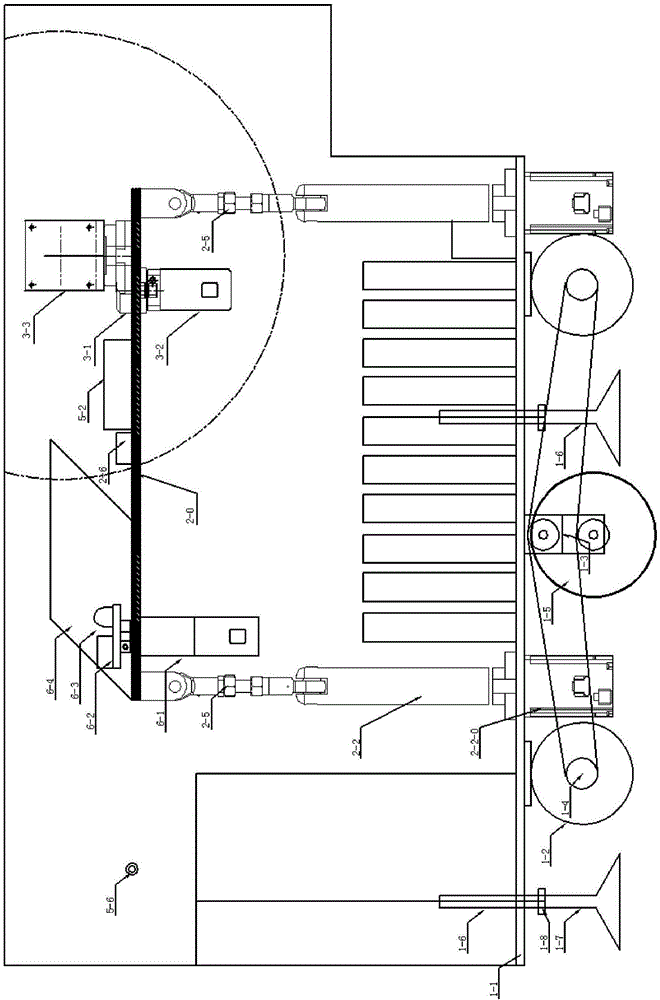

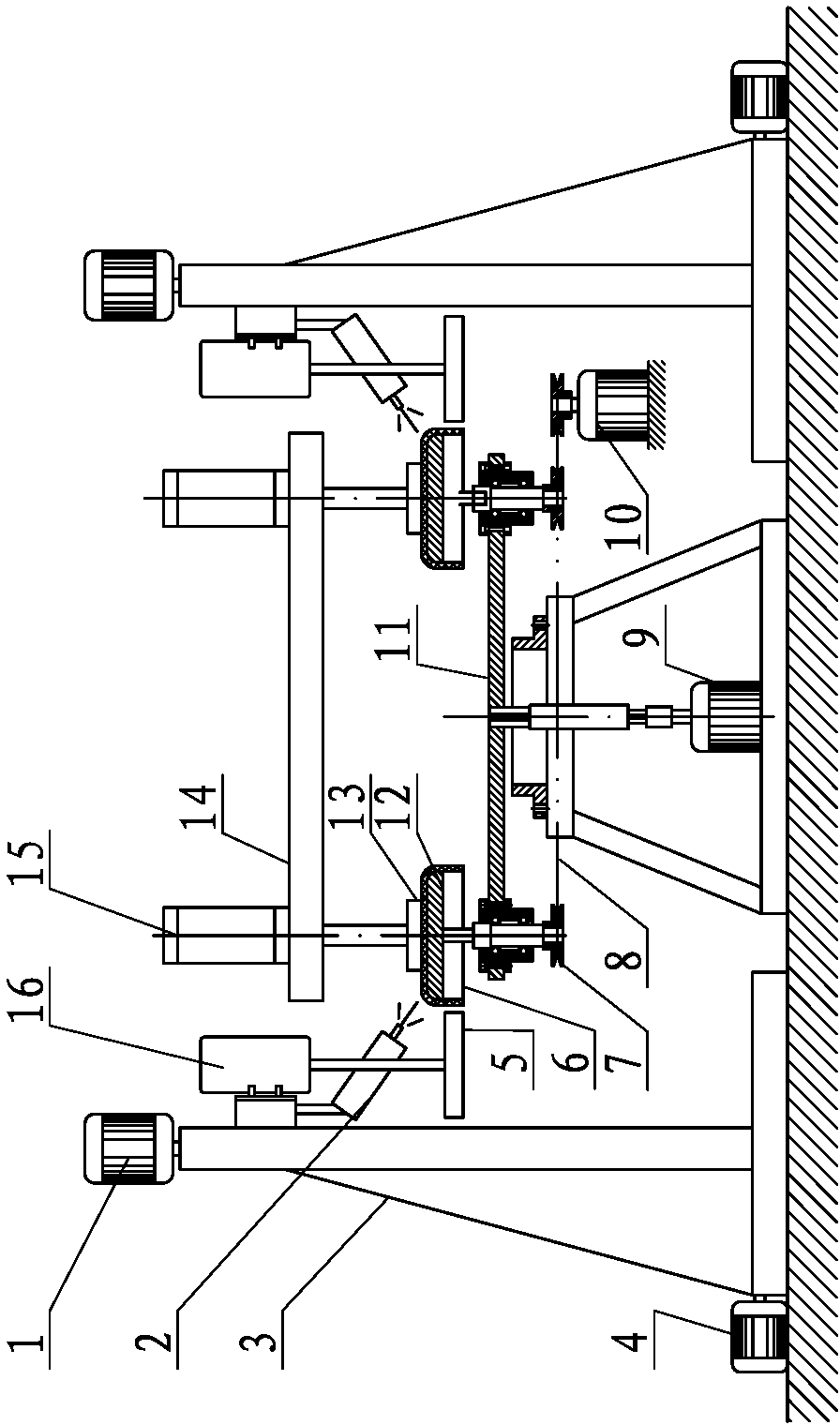

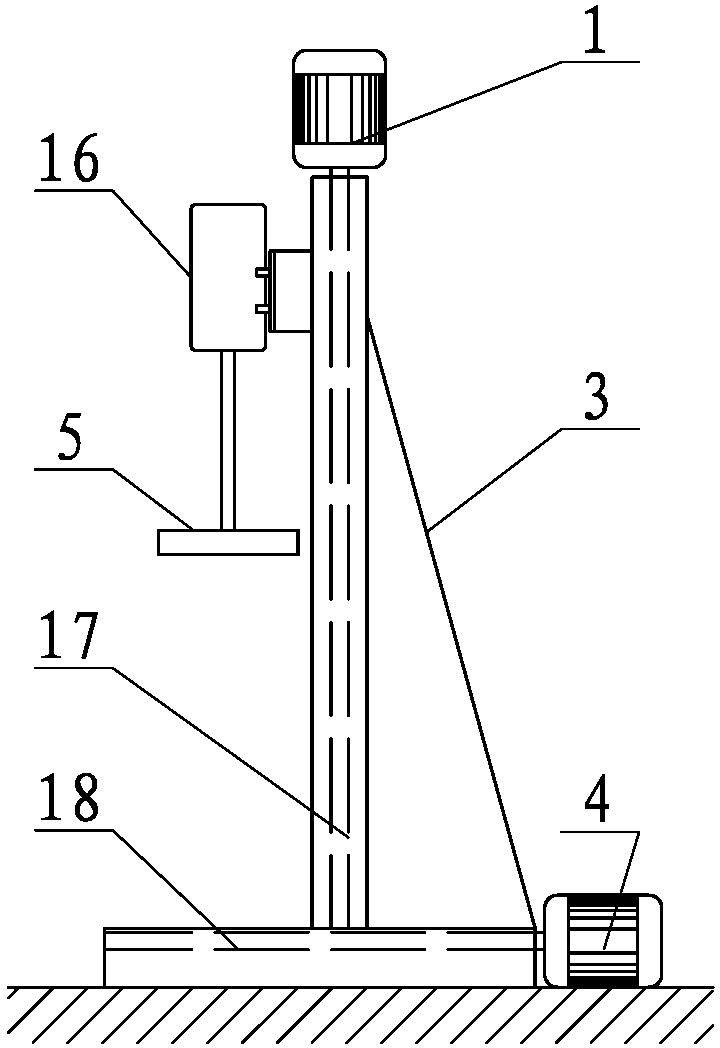

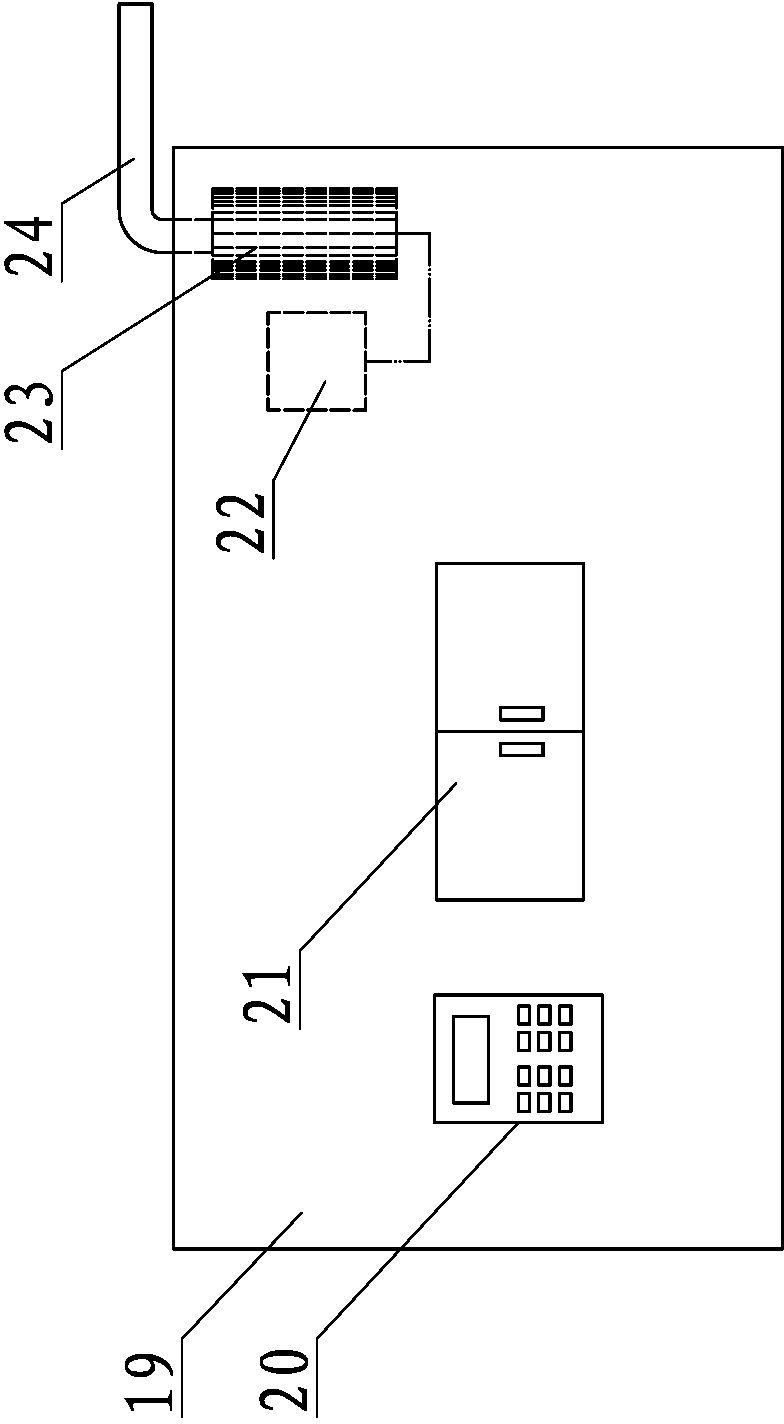

Fully automatic wall surface and shed surface spray coating grinding device

InactiveCN104563458AImprove adaptabilityImprove toleranceBuilding constructionsPlane surface grinding machinesSpray coatingFully automatic

The invention discloses a fully automatic wall surface and shed surface spray coating grinding device, which comprises a moving mechanism, a bearing installing platform and an automatic moving arm, and is characterized in that the moving mechanism adopts a manual moving mechanism or an automatic moving mechanism, a fixing plate of the bearing installing platform is arranged on a regulating bearing or a ball head of the moving mechanism, the regulating bearing or the ball head is connected onto a regulating foot driven by an electric cylinder, the electric cylinder is connected onto the bottom plate of the moving mechanism, the bottom plate is moved by the moving mechanism, the automatic moving arm is arranged on the bearing installing platform, and a spray coating device, a grasping mechanism or an anti-collision grinding dust sucking mechanism is arranged on the front end of the automatic moving arm. The fully automatic wall surface and shed surface spray coating grinding device has the advantages that the flexible splicing layout can be realized according to the room area, wall surface and shed surface coating, trowelling and whole surface flattening and putty grinding dust collection work can be simultaneously completed according to different requirements, and the problems of dust pollution and high work intensity of operators can be thoroughly solved.

Owner:董旺建

Drilling device for hardware machining

InactiveCN105798696AAffect processing efficiencyEfficient purificationCombination devicesLarge fixed membersEngineeringMachining

The invention discloses a drilling device for hardware machining. The drilling device comprises a device body, a vertical plate is arranged on one side of the top of the device body and sleeved with a support plate in a connected manner, a drilling machine is arranged at the top of the support plate, a movable block connected to the vertical plate in a sleeving manner is arranged on the front face of the support plate, and a working table is arranged at the position, corresponding to the drilling machine, of the top of the device body; a hardware original piece is arranged at the top of the working table; and a draught fan and a dust removal purification plant are arranged in an inner cavity of the device body. By means of the drilling device, hardware chippings generated when hardware is machined can be collected and then treated, and the problem that when machining is carried out for a long time, dust pollution occurs in a working space due to the fact that the chippings are too many is solved; and meanwhile, as the purification effect of the dust removal purification plant can be used for effectively purifying the chippings of the hardware, the quality of air in the working space can be improved, the health of an operator is facilitated, and influences of too-low quality of the air in the working space on the hardware machining efficiency are avoided.

Owner:CHANGZHOU JINHAIJI MACHINERY MFG

Dustproof fine ore-smashing device

InactiveCN107649233AEfficient collection and recyclingAvoid pollutionDirt cleaningGrain treatmentsCycloneEngineering

The invention discloses a dust-proof ore fine crushing device, which comprises a shell and a cyclone dust collector; the top of the shell is provided with a top plate, and a symmetrical dust suction pipe is arranged on the top plate, and a dust collection cover is connected above the dust suction pipe. The dust collection hood is connected with a dust pipeline, and the dust pipeline is connected with a cyclone dust collector; a fixed crushing roller is arranged inside the housing, and a mobile crushing roller device is arranged above the fixed crushing roller. The invention is equipped with an axial flow fan and a cyclone dust collector to efficiently collect and recycle the dust generated in the crushing process, and is also equipped with a hinged plate to prevent the dust from leaking and polluting the environment; the invention is equipped with a mobile crushing roller device, through Adjust the distance between the crushing rollers to adapt to ores of different particle sizes, and has good adaptability; the present invention is equipped with crushing rollers, crushing blades, crushing hammers and grinding cones to perform multi-stage crushing of ores, improve crushing efficiency, and ensure crushing Effect.

Owner:COMMON TECH DEV CO LTD

Preparation method for liquid phase stirring and mixing of white carbon black and natural rubber

ActiveCN102775654APreserve the status quoKeep strongSpecial tyresRolling resistance optimizationHysteresisBrute force

The invention relates to the production field of tire rubber sizing materials, in particular to a method for mixing liquid state white carbon black and liquid state natural rubber in a liquid phase. The preparation method for liquid phase stirring and mixing of the white carbon black and the natural rubber comprises the steps of (1) preparing slurry; (2) mixing; (3) solidifying, dehydrating, washing and stoving. The method adopts liquid-liquid high speed stirring and mixing to effectively preserve original states of natural rubber macromoleculars, effectively preserves brute force of the natural rubber and substantially promotes brute force and abrasive resistance of mixed glue. Brute force of sizing materials mixed by using the method is substantially promoted, and themogenesis and hysteresis loss are obviously reduced. The mixed glue produced by the method can be singly used and can also be blended with the natural rubber, rubber polymer, natural rubber carbon black rubber master batch and rubber polymer carbon black rubber master batch according to certain proportion. According to the method, the liquid state white carbon black and the liquid state natural rubber are mixed directly, the process is simple, the land occupation is small, the equipment investment is low, and dust pollution does not exist in a production process.

Owner:ZHONGCE RUBBER GRP CO LTD

Novel crushing device for building

InactiveCN106000602AAvoid or reduce pollutionSufficient and effective crushing and processing operationsUsing liquid separation agentGrain treatmentsEngineeringDust pollution

The invention relates to a novel crushing device for a building. The novel crushing device comprises a support frame and a shell, wherein a feeding hole is formed in the top of the left side of the shell; a motor is arranged at the top end of the shell; the output shaft end of the motor is connected with a rotating shaft on which stirring rods are distributed; tapered bulges are distributed at the upper part of the inner side wall of the shell; a left crushing roller, a right crushing roller and a mesh screen are sequentially arranged below the rotating shaft; the right end of the mesh screen is hinged with the inner side wall of the shell; a partition plate is arranged below the mesh screen; the left end of the mesh screen is connected with the partition plate through a spring; the mesh screen is provided with a vibrating motor; partition plate through holes are distributed in the partition plate, and the upper surface of the mesh screen is covered by a filter screen; a first discharging hole is formed in the left side of the shell located above the mesh screen, and a second discharging hole is formed in the right side of the shell located above the partition plate; a water outlet in the bottom of the left side of the shell; a water inlet and a spray head are arranged at the top end of the shell; and a water purifying tank is arranged at the right side of the shell and is connected to the spray head through a water inlet hose. Due to the adoption of the structure, the crushing operation can be more effectively performed, and dust pollution can also be avoided or relieved.

Owner:成都聚立汇信科技有限公司

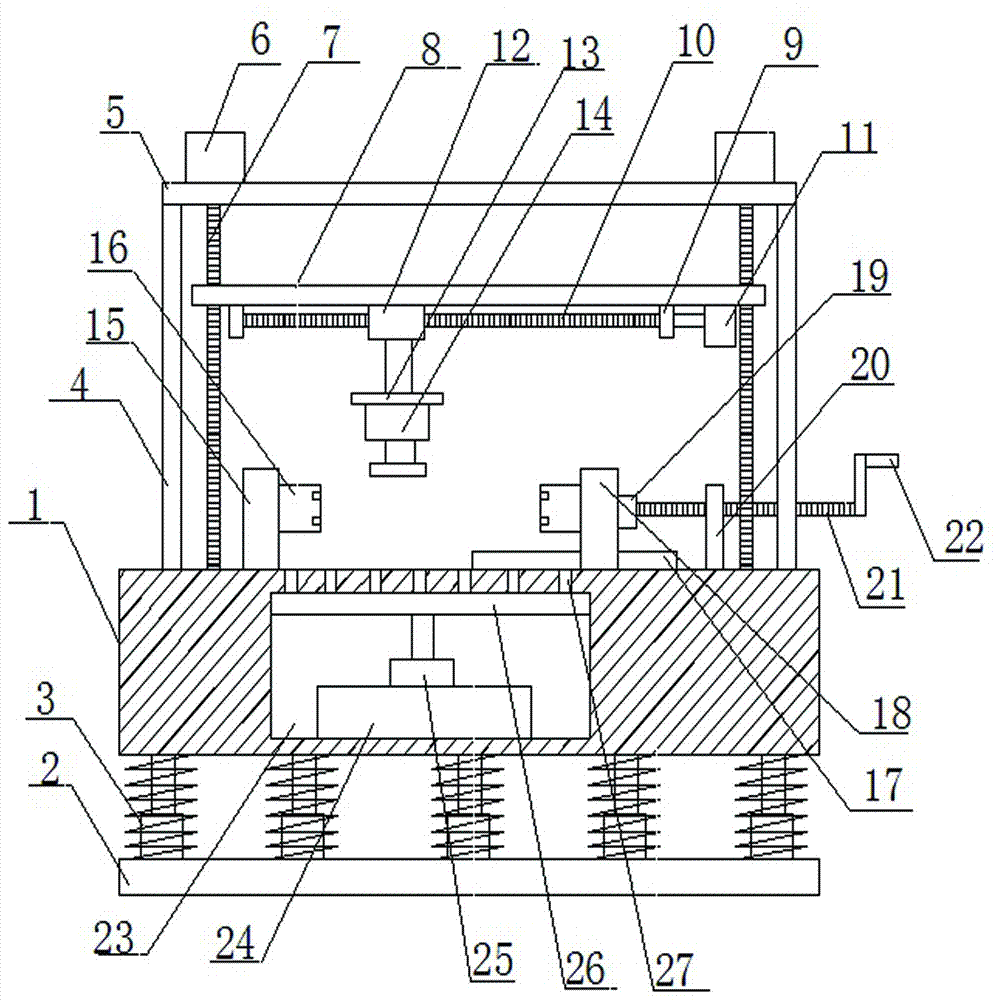

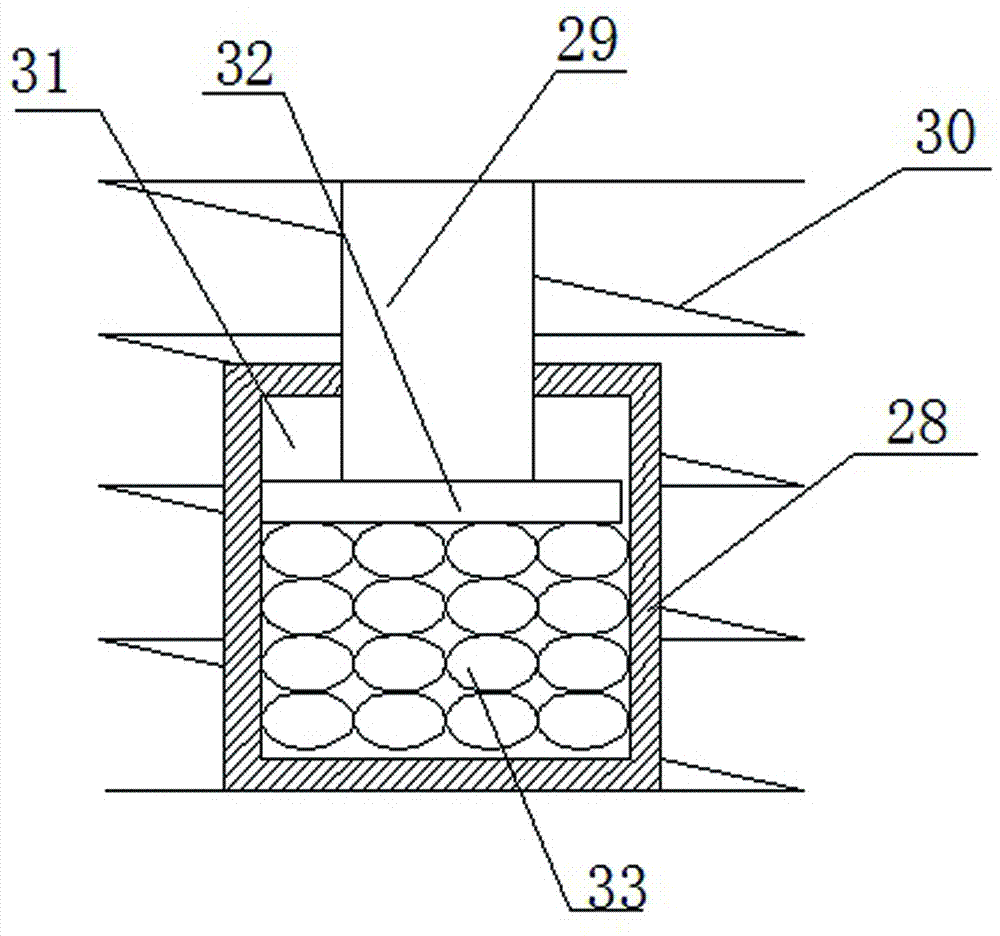

Derusting device for outer surface of pipeline

InactiveCN107243817AReduce pollutionProtect your healthGrinding carriagesGrinding drivesEngineeringThreaded rod

The invention discloses a rust removal device for the outer surface of a pipeline, which comprises a workbench and a base, a number of shock absorbing devices are arranged between the workbench and the base, a pillar is arranged on the upper side of the workbench, and a mounting plate is arranged on the upper end of the pillar. The upper side of the plate is left and right symmetrically provided with a first motor, the output end of the first motor is provided with a first threaded rod, the first threaded rod is threadedly connected with a support plate, and the lower side of the support plate is provided with a mounting seat symmetrically left and right, A second threaded rod is arranged between the two installation seats, a second motor for driving the second threaded rod is installed on the right end of the lower side of the support plate, a slider is threaded on the second threaded rod, and the upper left part of the workbench is set There is a fixed table, the right side of the fixed table is provided with a fixed block, the upper right part of the workbench is provided with a slide rail, the slide rail is provided with a sliding table, and the left side of the slide table is provided with a fixed block. The invention has the advantages of simple structure, convenient use, reduced use cost, good shock absorption effect and reduced dust pollution.

Owner:何秋英

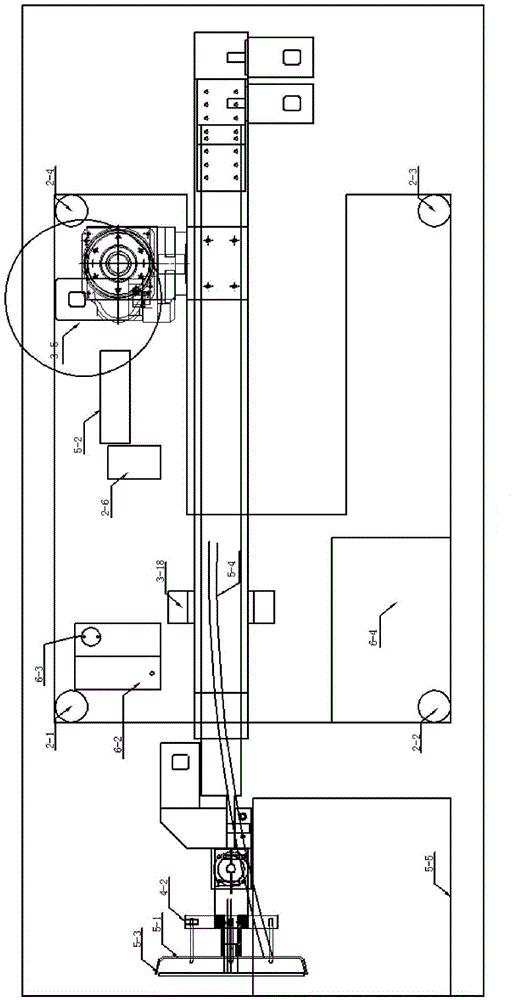

Automatic stainless pan polishing equipment

InactiveCN103273410ANo pollutionNo harmPolishing machinesGrinding work supportsElectrical controlEngineering

The invention belongs to the technical field of polishing and particularly relates to automatic stainless pan polishing equipment. The automatic stainless pan polishing equipment is characterized in that the equipment comprises an electrical control device, a workbench, fixing clamps, supports and polishing devices, the fixing clamps are mounted on the workbench through a rotating device, the workbench is connected with a workbench motor and driven by the same to rotate, the polishing devices are mounted on the supports through a moving device, and the electrical control device is connected with and controls the polishing devices, the rotating device, the workbench motor and the moving device. The automatic stainless pan polishing equipment is reasonable in structural design and high in working efficiency, polished products are shining, dust pollution and damages to human bodies cannot be caused in the process of operating, labor intensity of workers is reduced, production cost is lowered, and a brand-new automatic polisher equipment capable of replacing manpower is provided.

Owner:冯会民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com