Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29044results about "Loading/unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

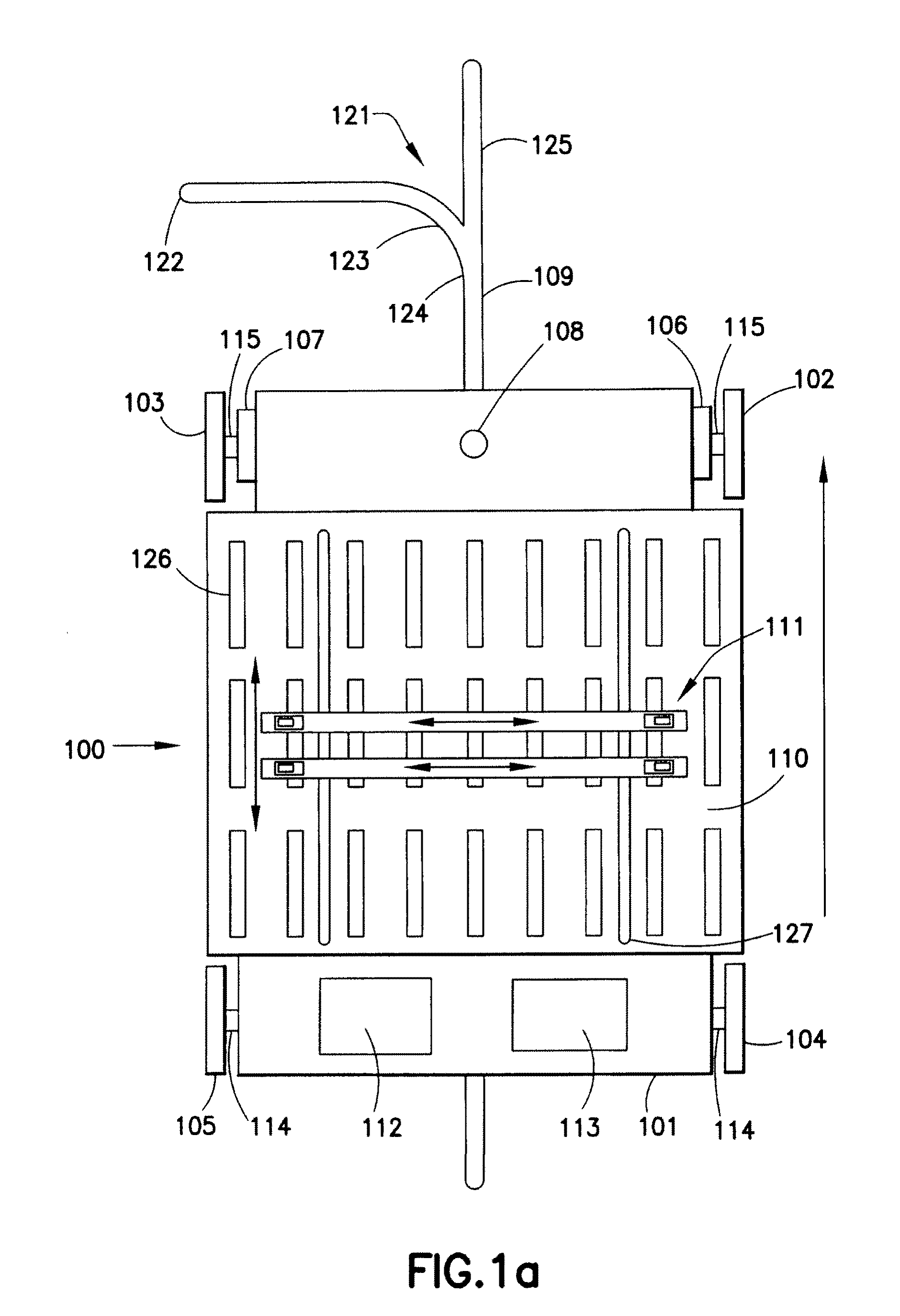

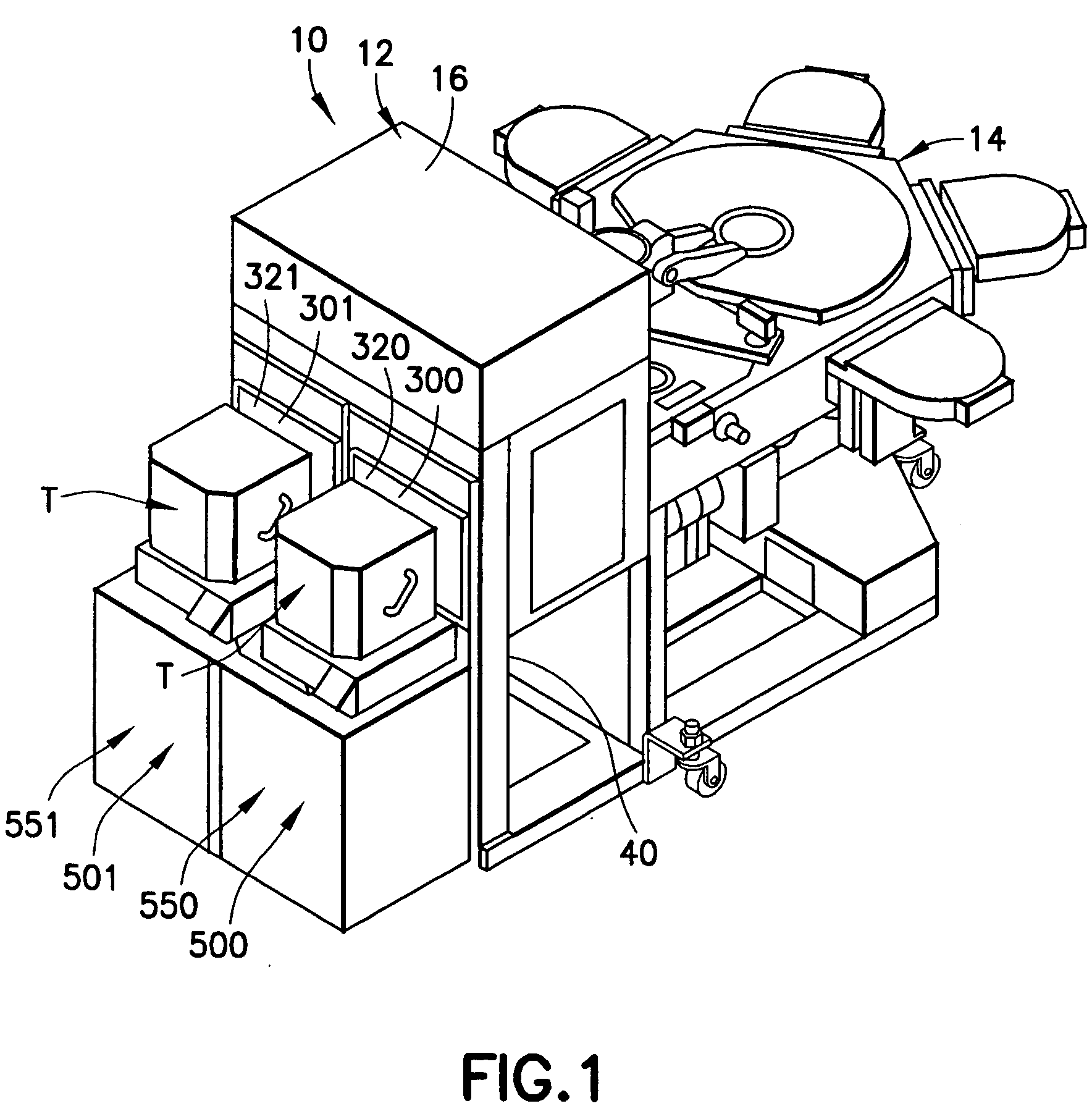

Automated battery and data delivery system

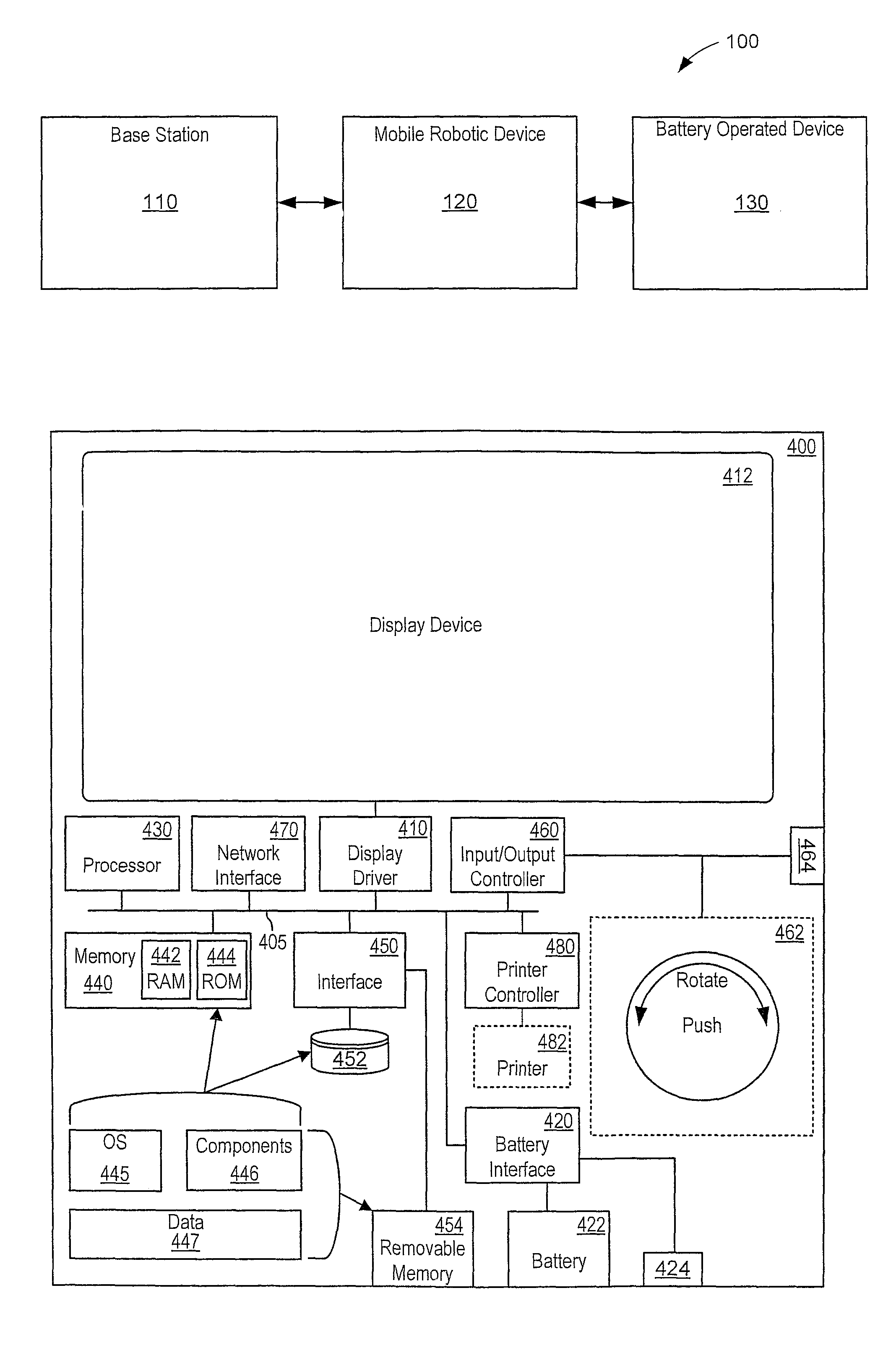

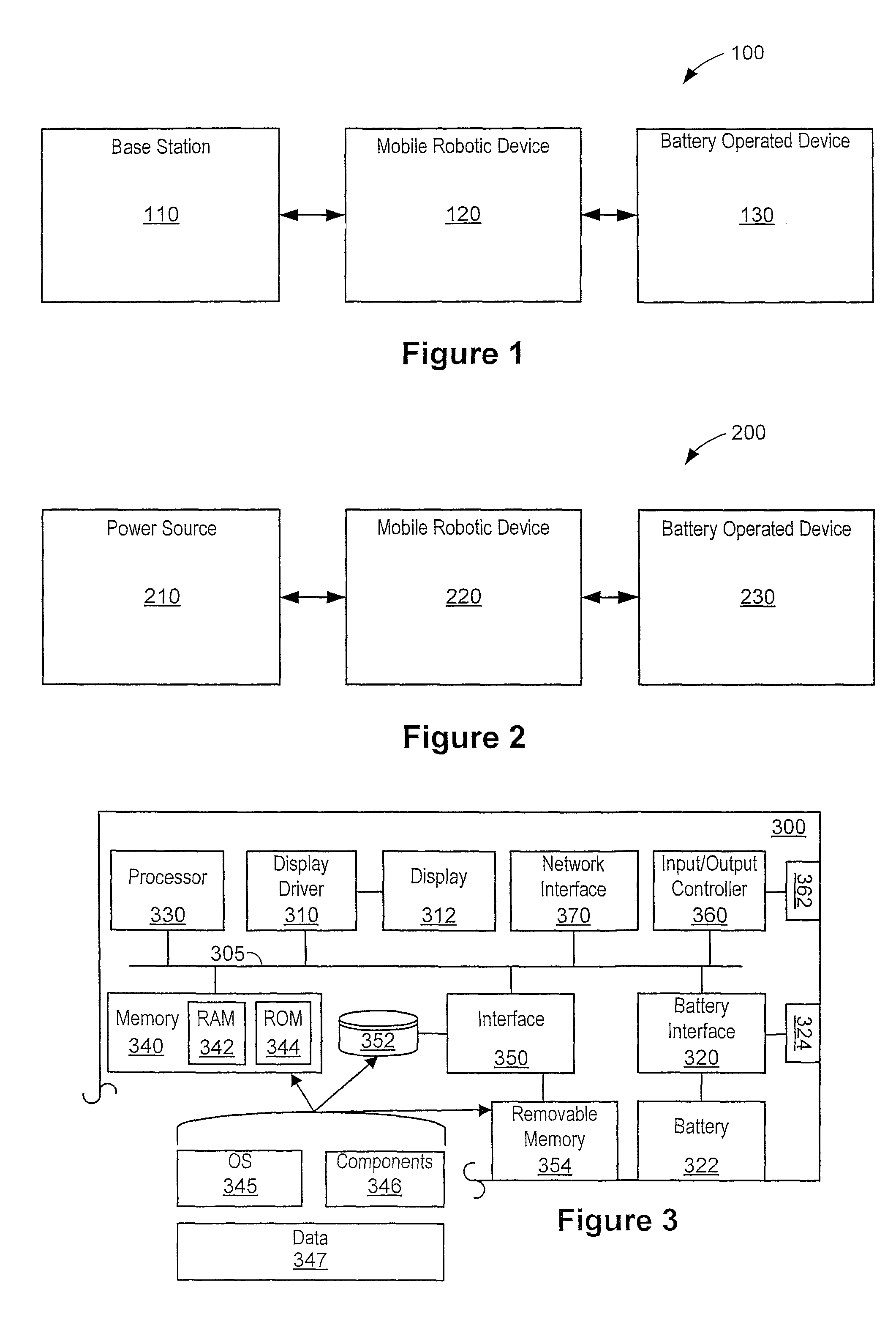

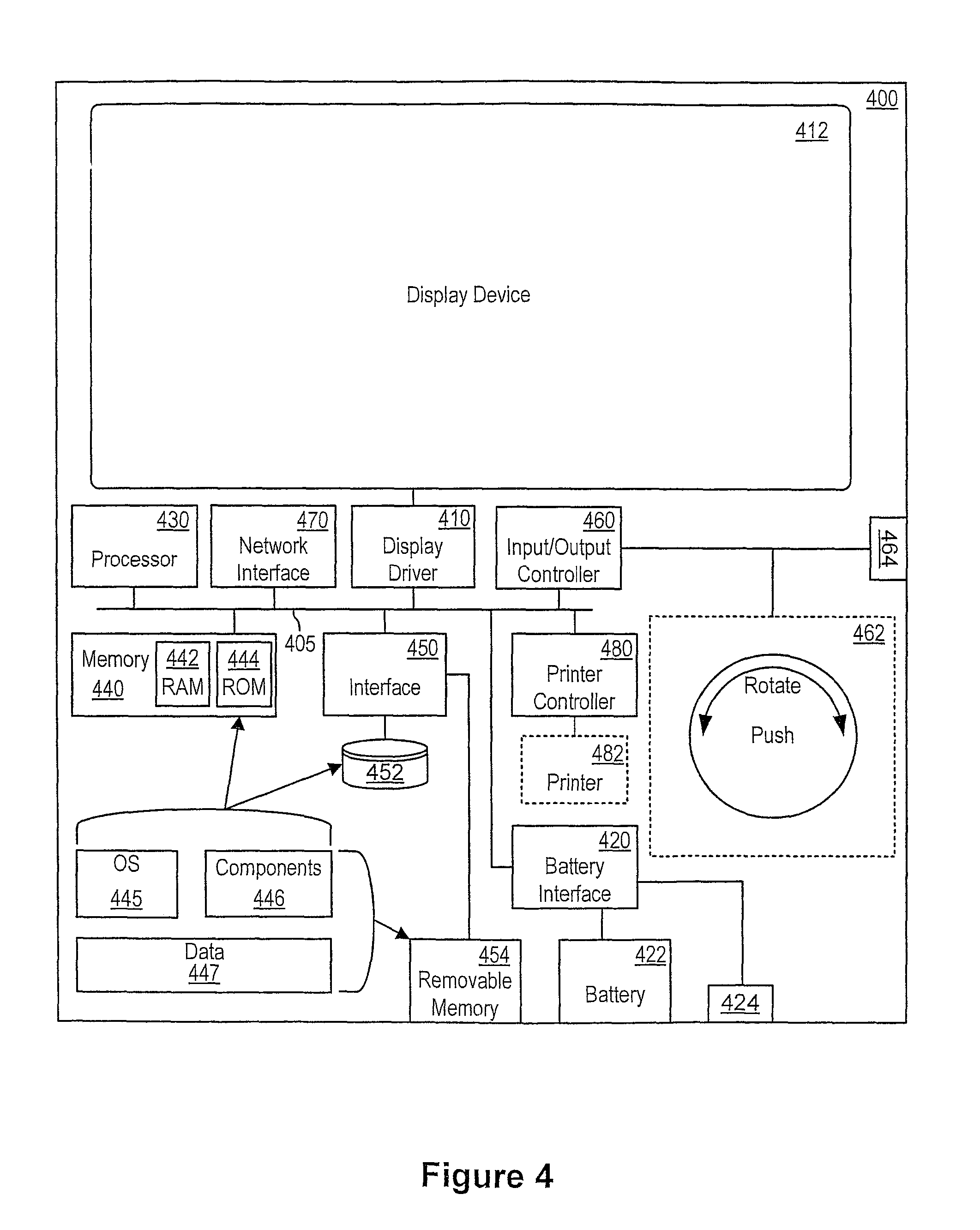

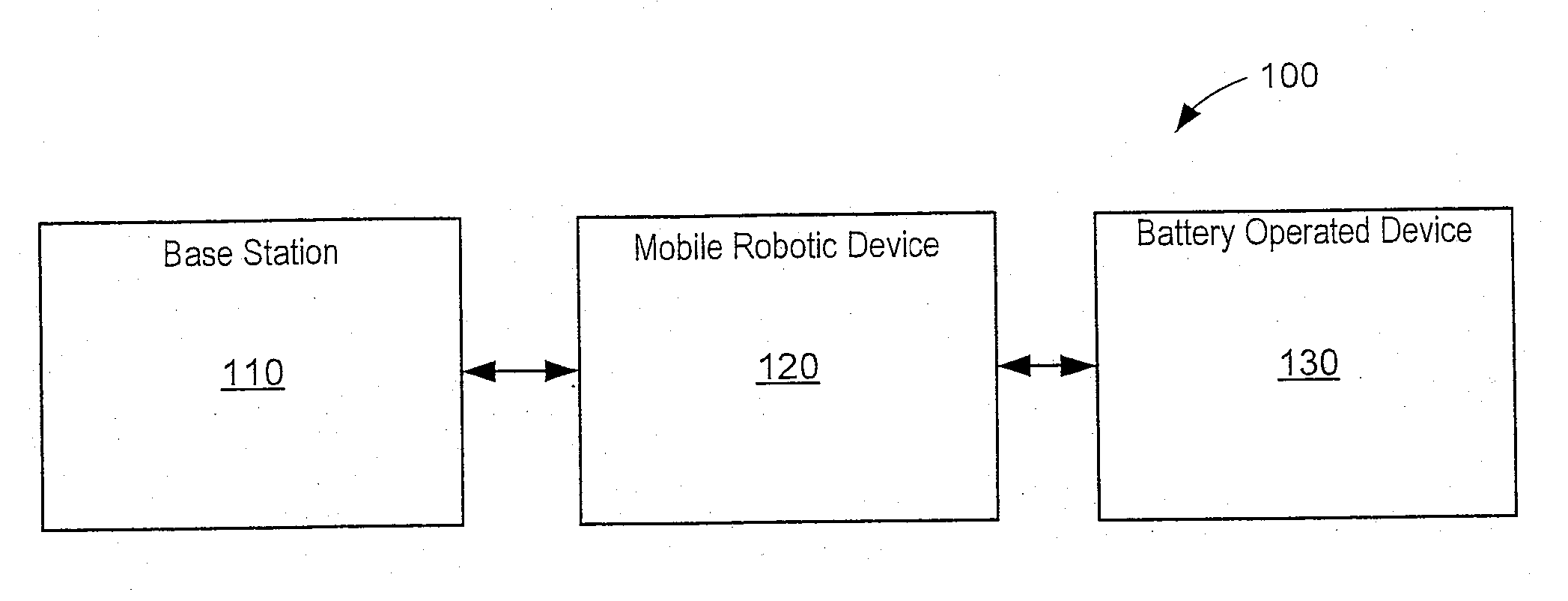

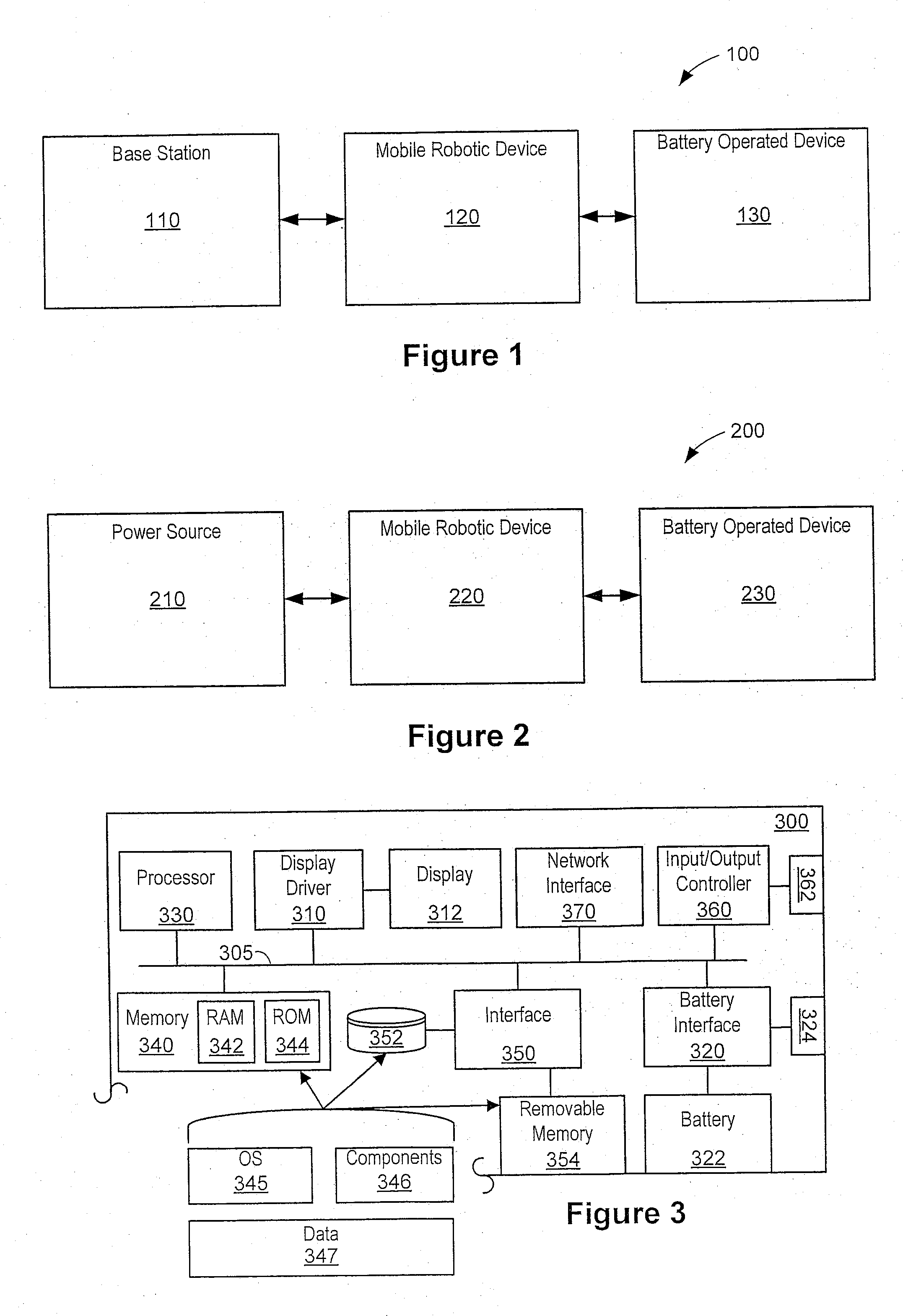

Systems and methods are provided that use a mobile robotic device to transport rechargeable batteries between a base station, which charges the batteries, and a battery operated device, such as battery powered kiosk or signage system, which uses a charged battery as a power source. After traveling to a battery operated device, the mobile robotic device removes any discharged batteries from the battery operated device and installs a charged battery. The mobile robotic device then travels to the base station and attaches the discharged battery to the base station for recharging. The mobile robotic device may be configured to perform other transfers, such as data transfers and paper transfers. In addition, the mobile robotic device may be configured to perform a photographic and spatial survey of the isles, retail shelves, and surrounding environment for various purposes, such as generating three-dimensional store models and remote viewing.

Owner:MACDONALD MURRAY

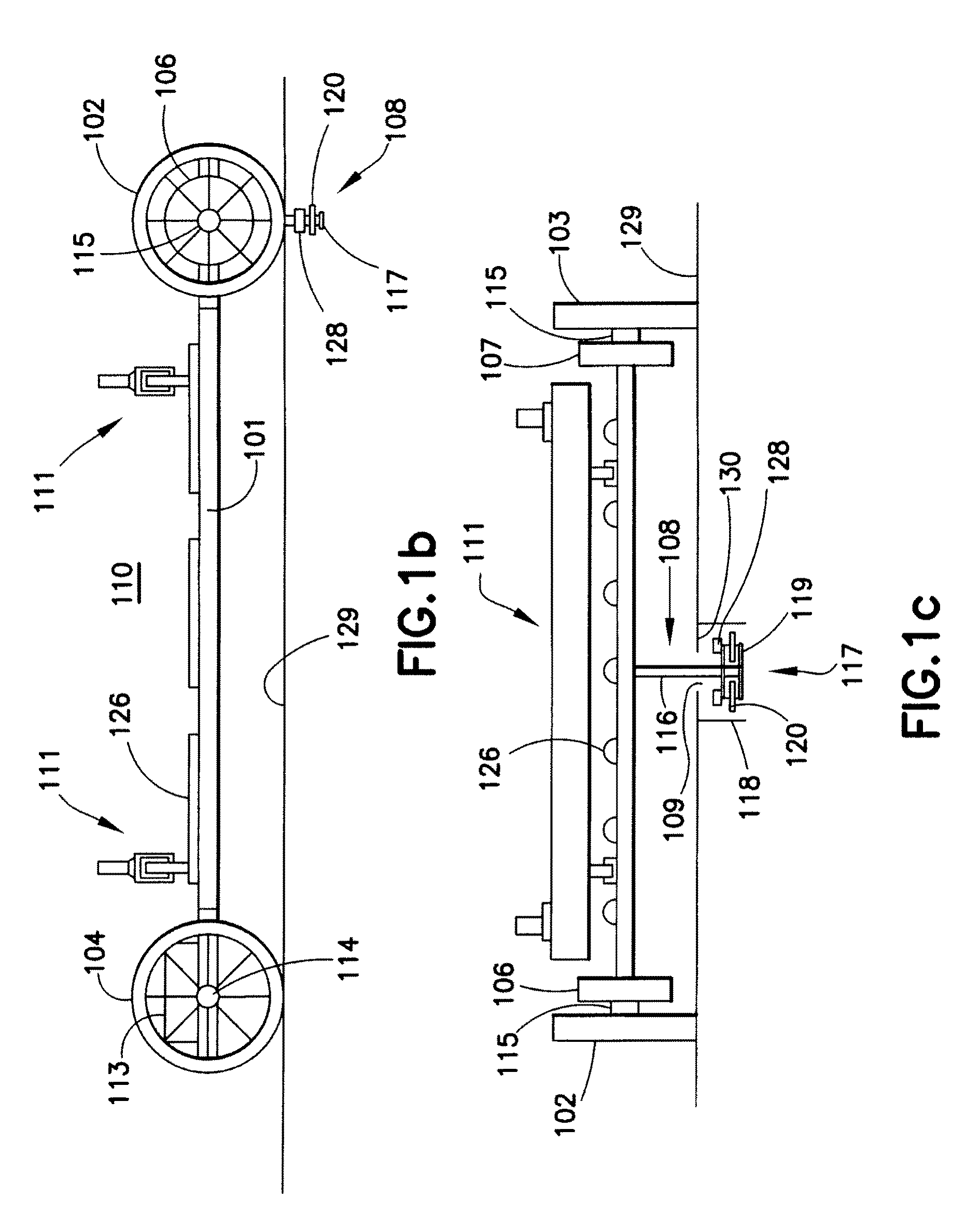

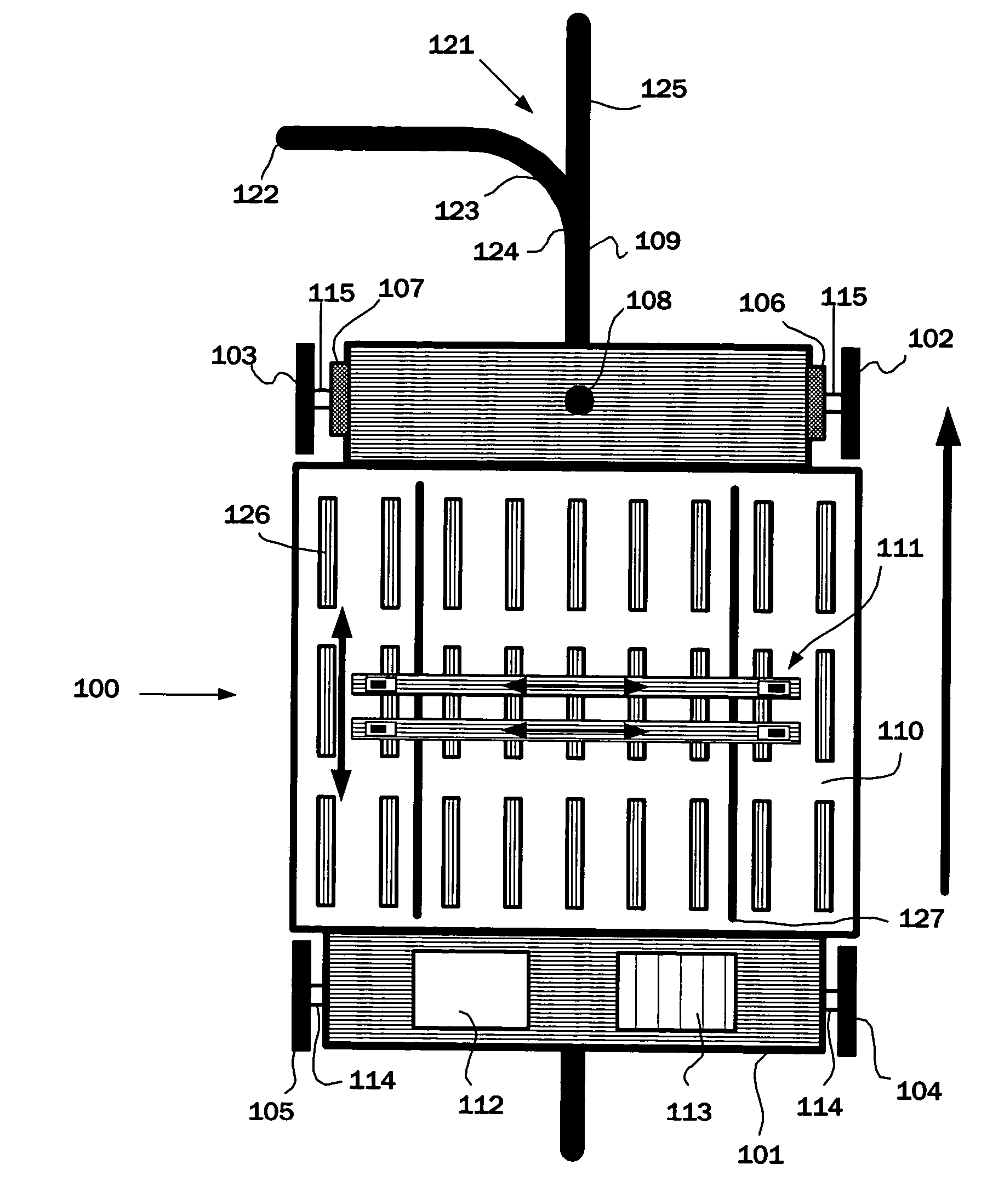

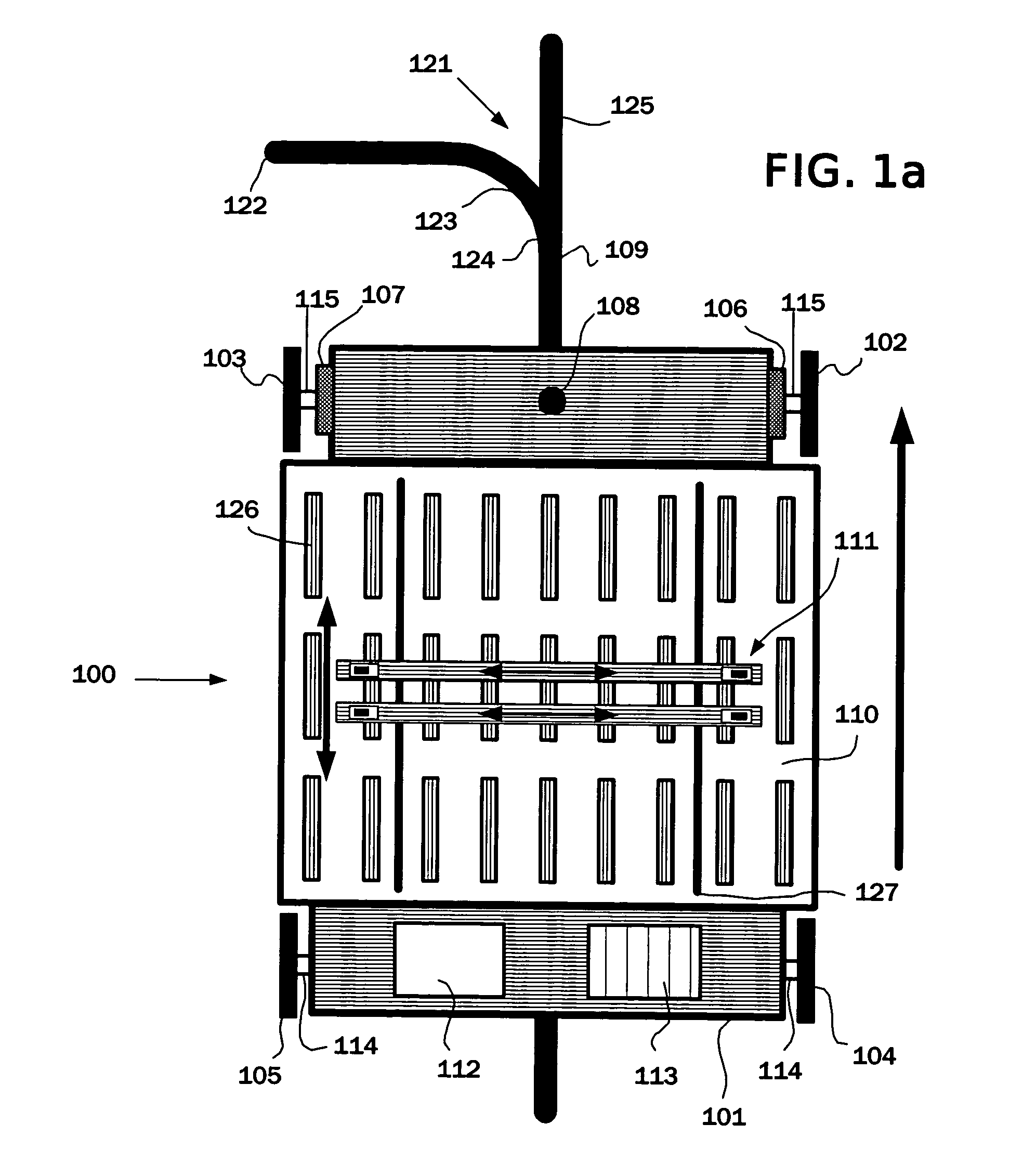

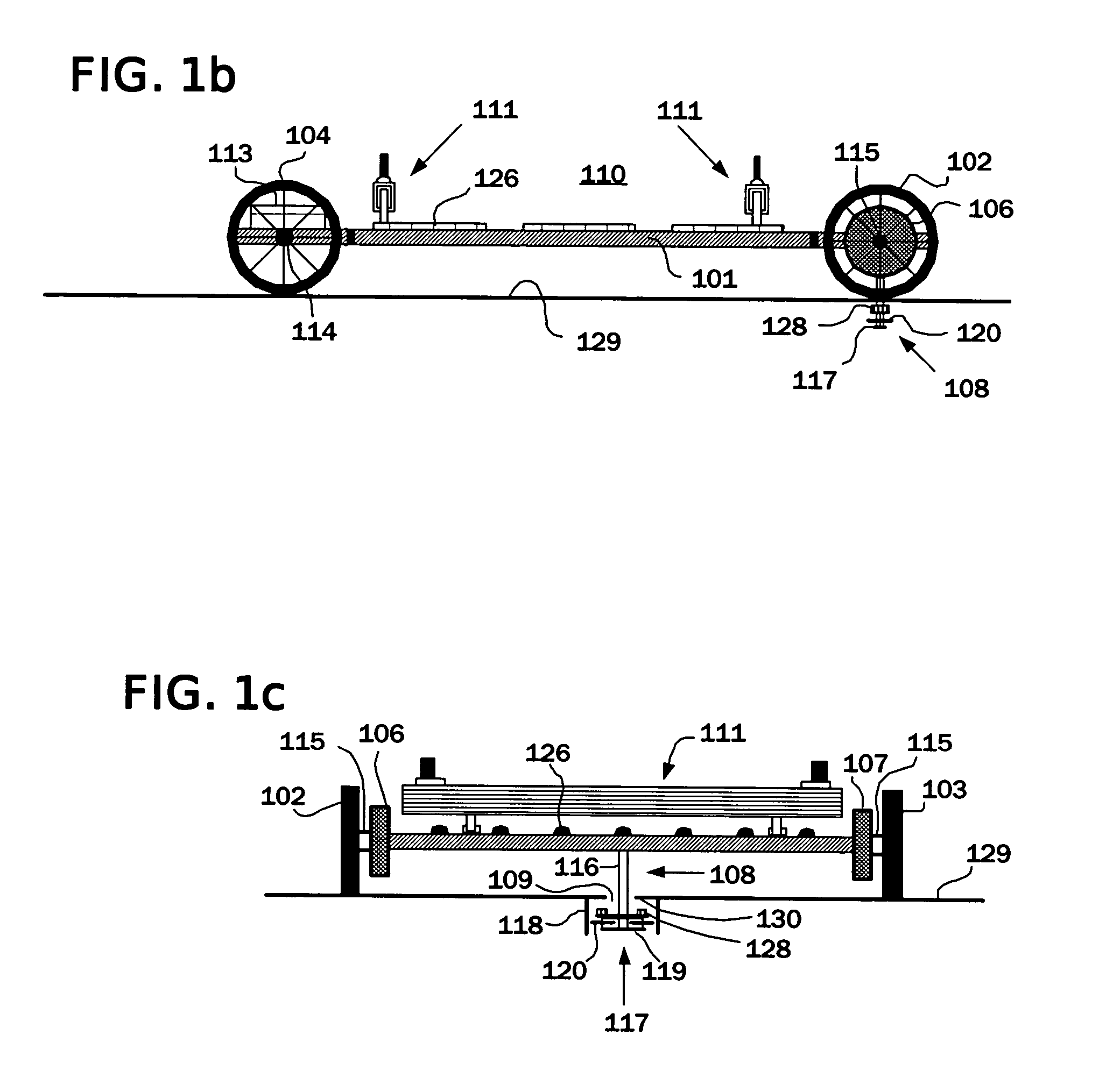

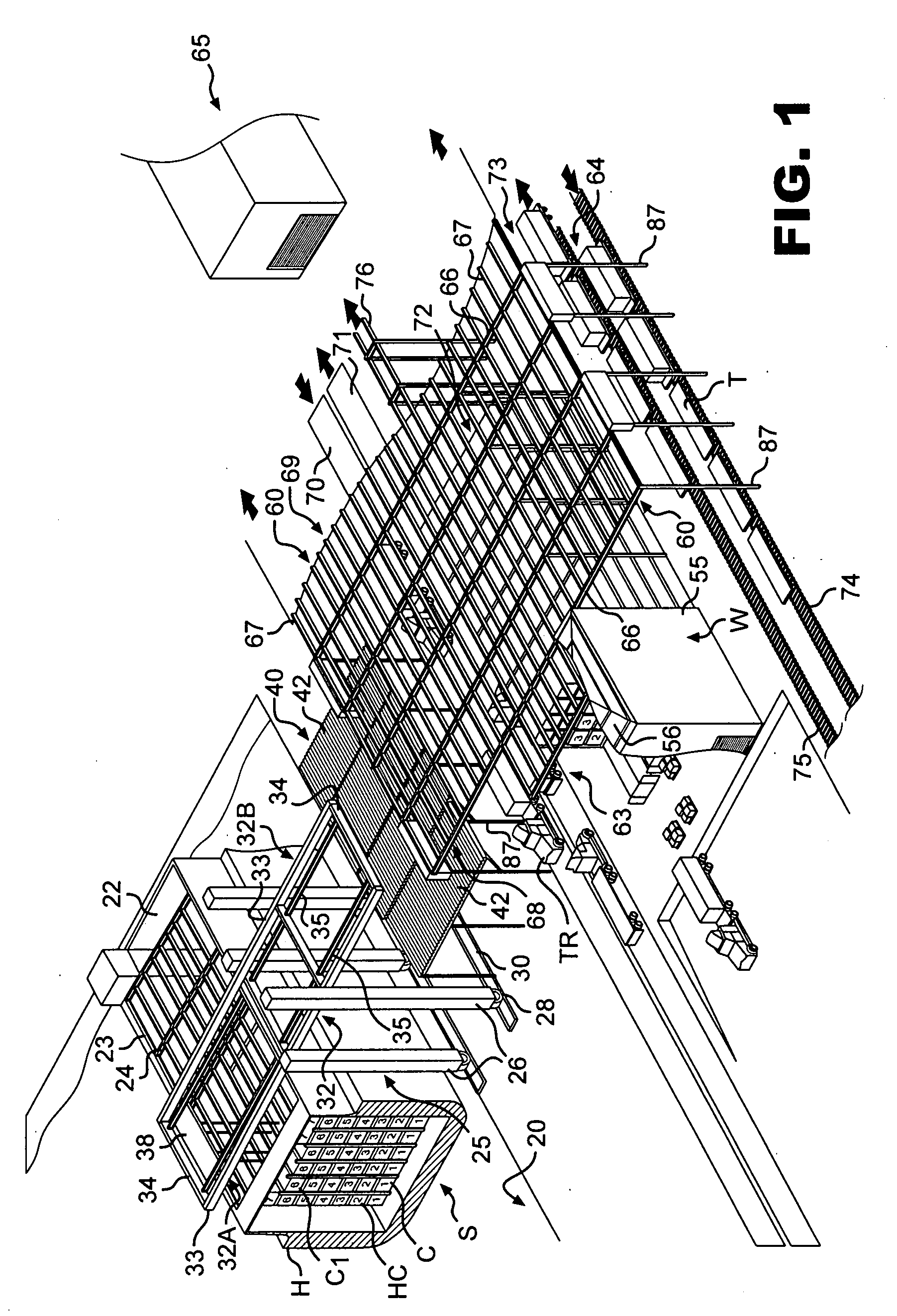

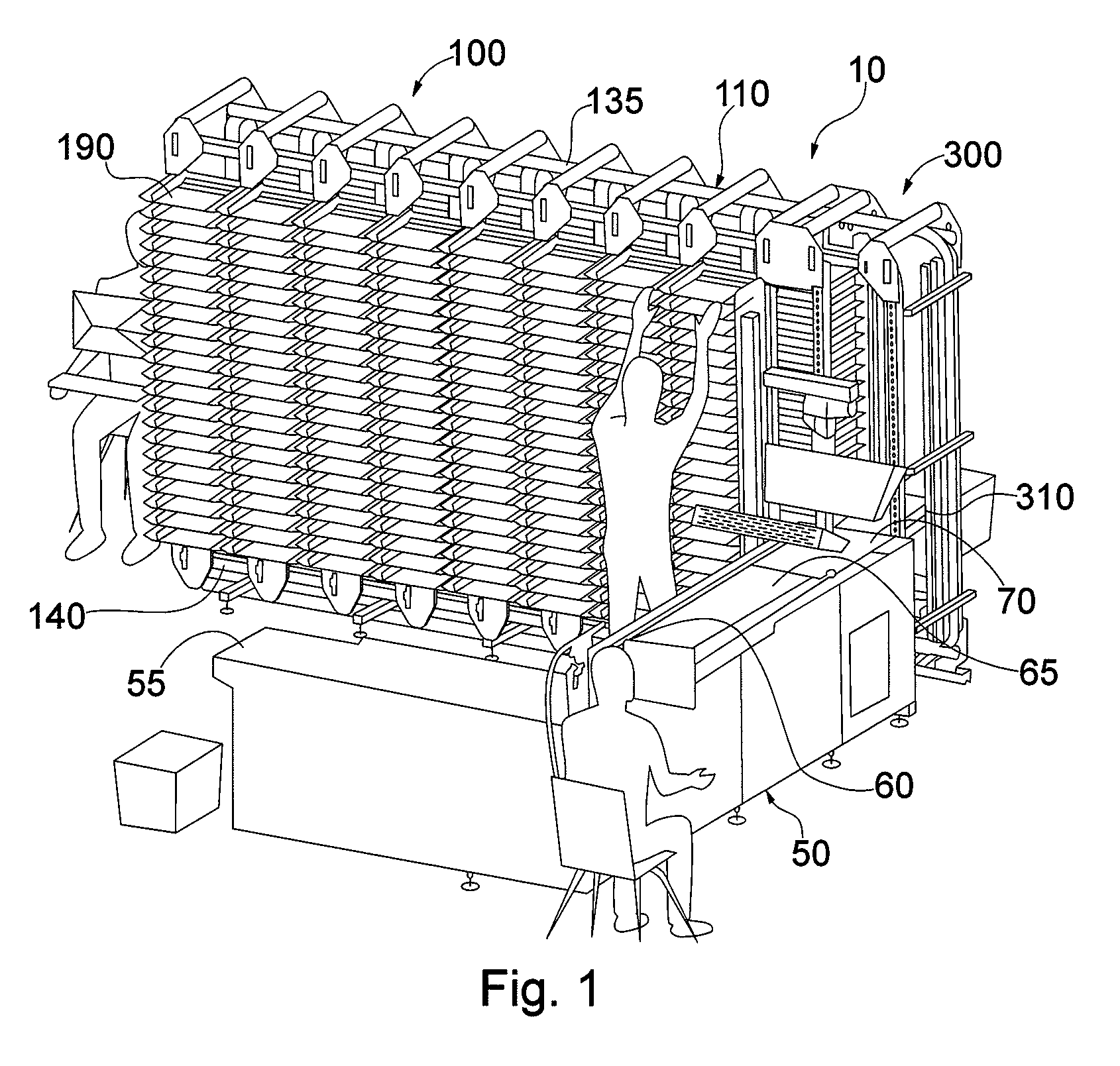

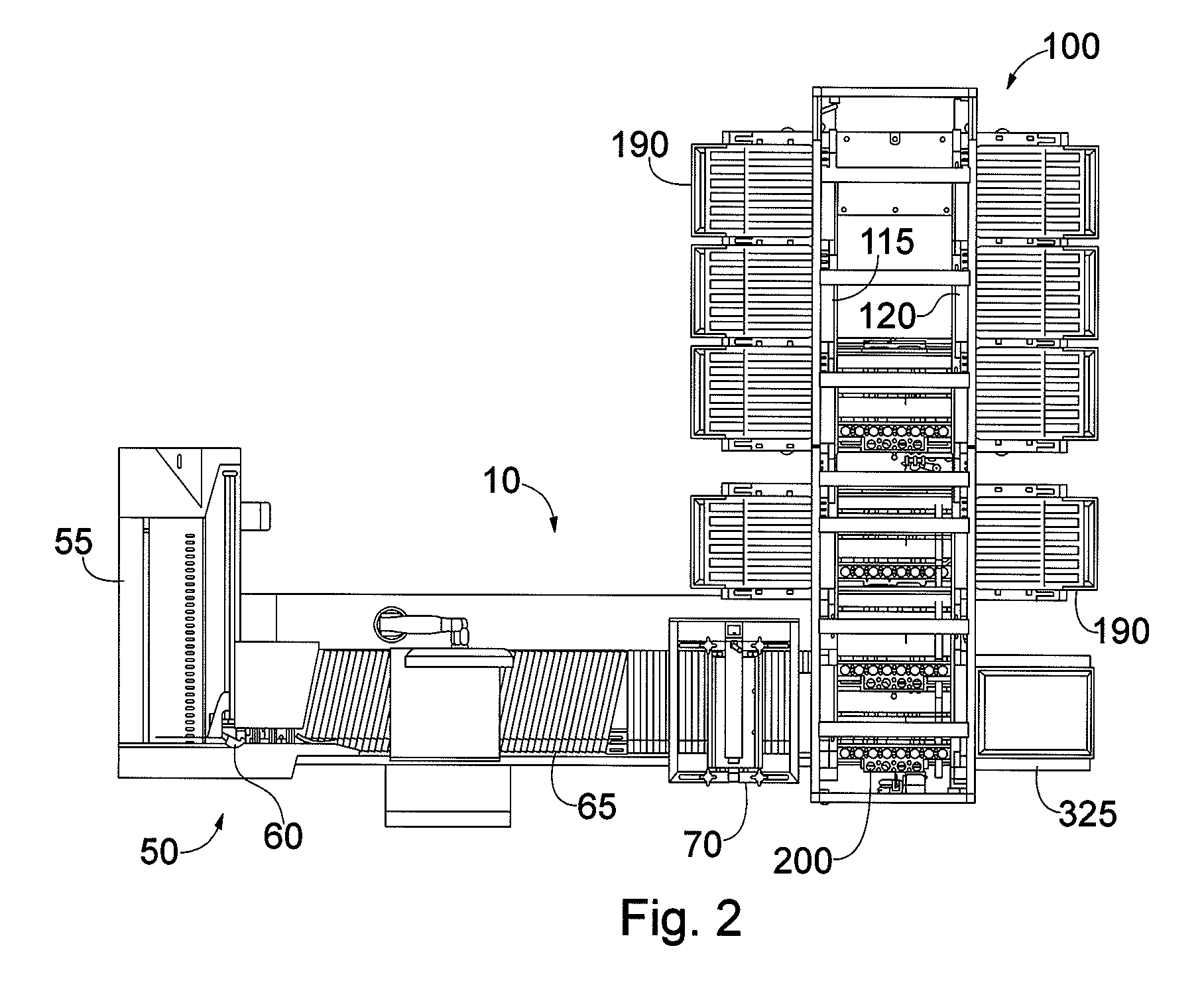

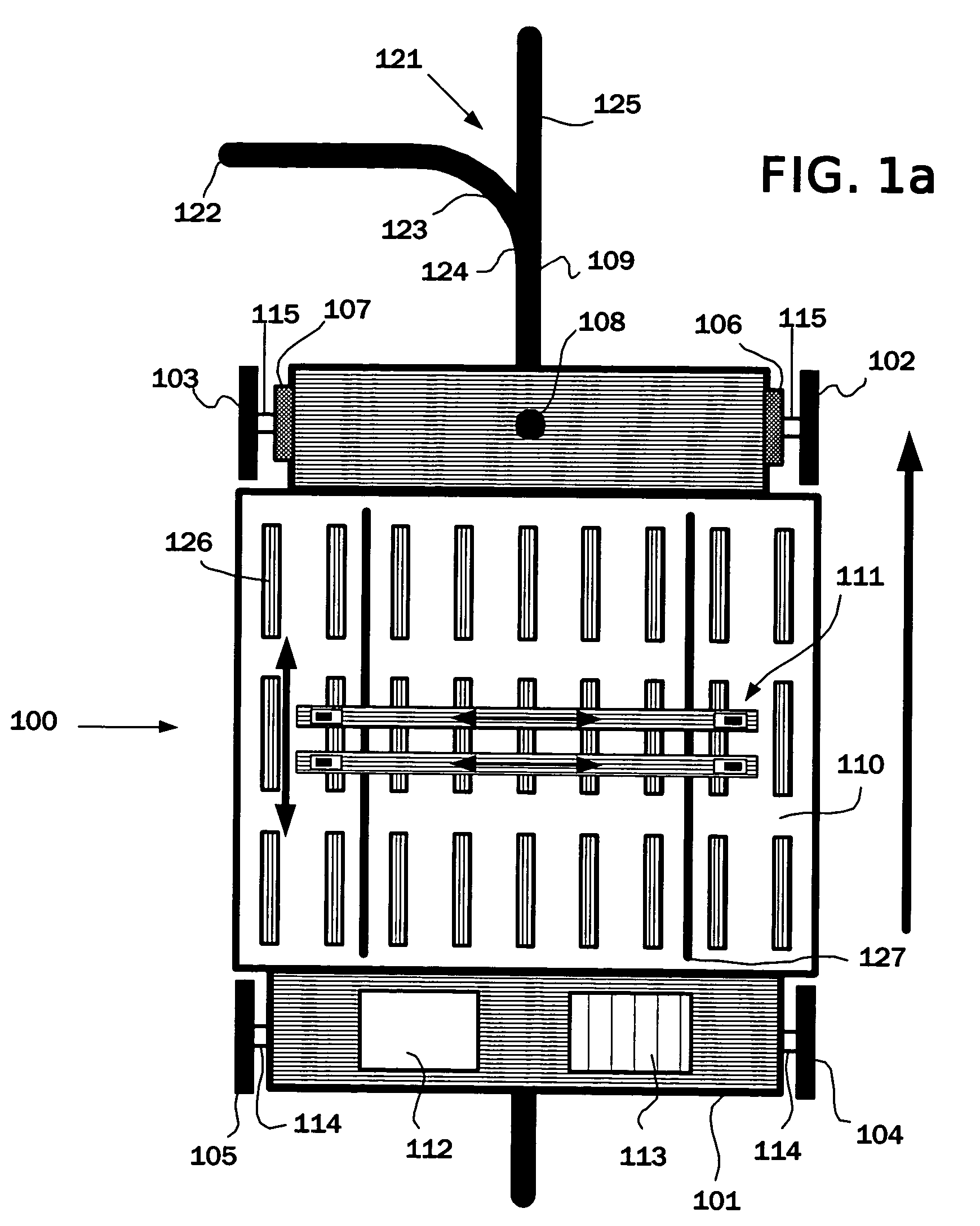

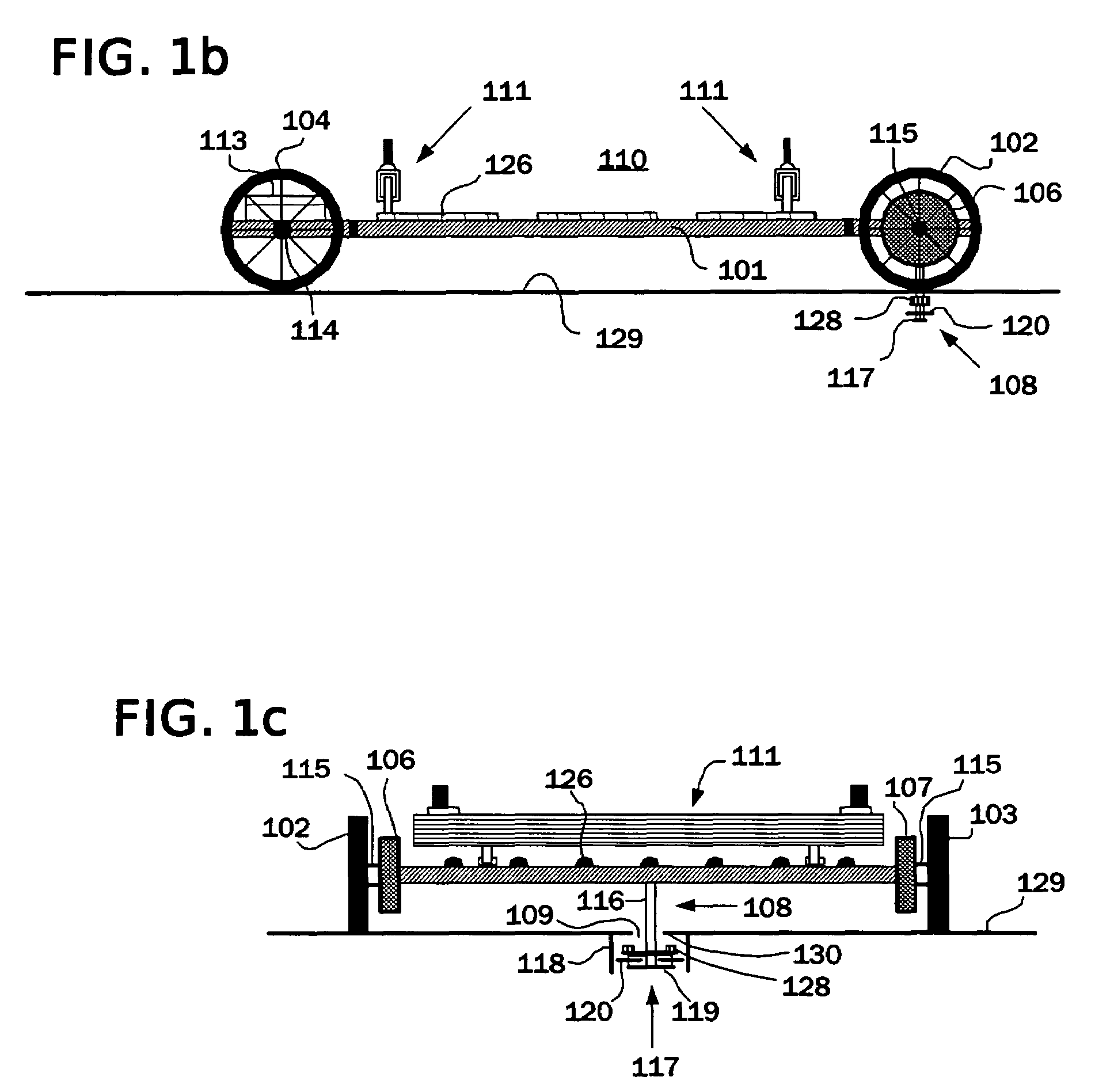

Materials-handling system using autonomous transfer and transport vehicles

ActiveUS20090074545A1High degree of automationEfficient automationDigital data processing detailsLoading/unloadingEngineeringHandling system

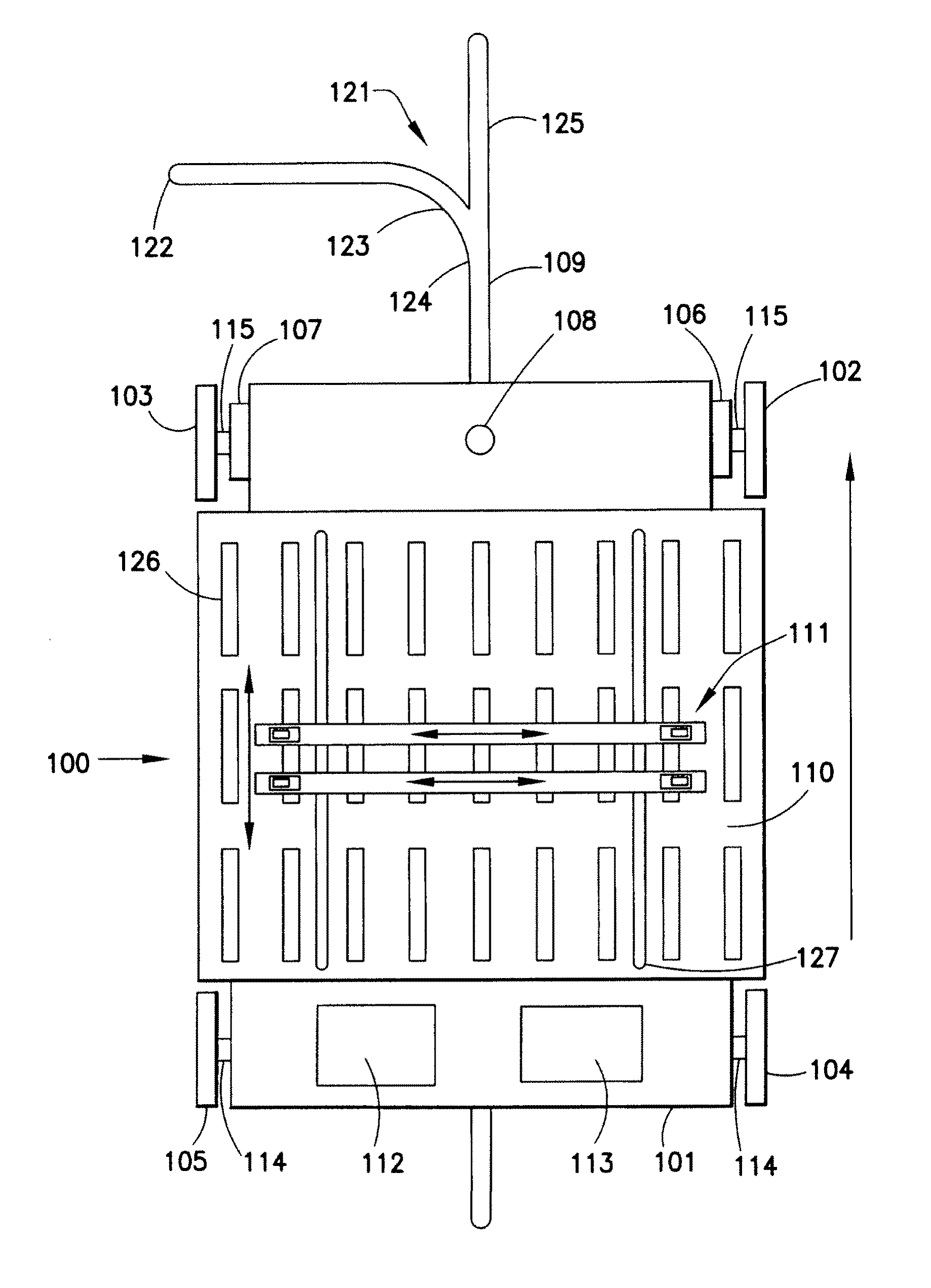

Methods and apparatus for selecting and combining packages in an outbound container by employing autonomous transfer and transport vehicles which move on a network of roadways to carry a plurality of individual cases each containing the same kind of product from a loading station and to a destination station where individual packages are combined in the outbound container. The travel of each vehicle through the roadway network is computer controlled, and each vehicle includes means for automatically loading and unloading packages from predetermined locations on the network.

Owner:SYMBOTIC LLC

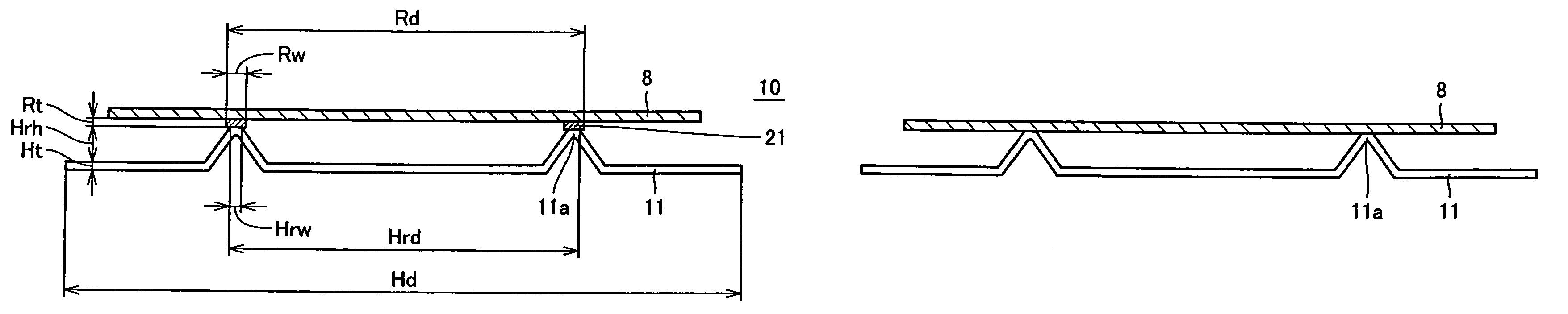

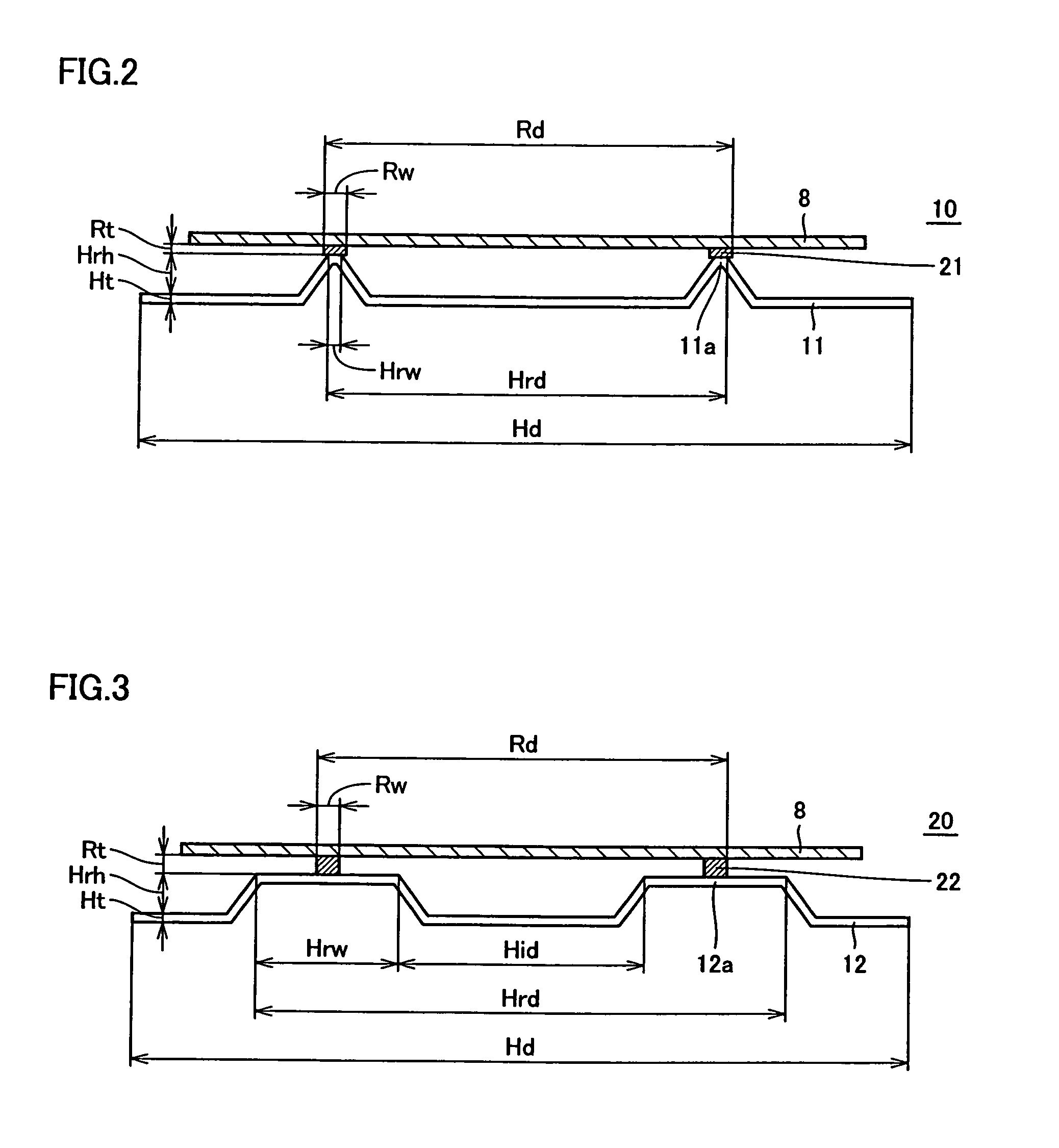

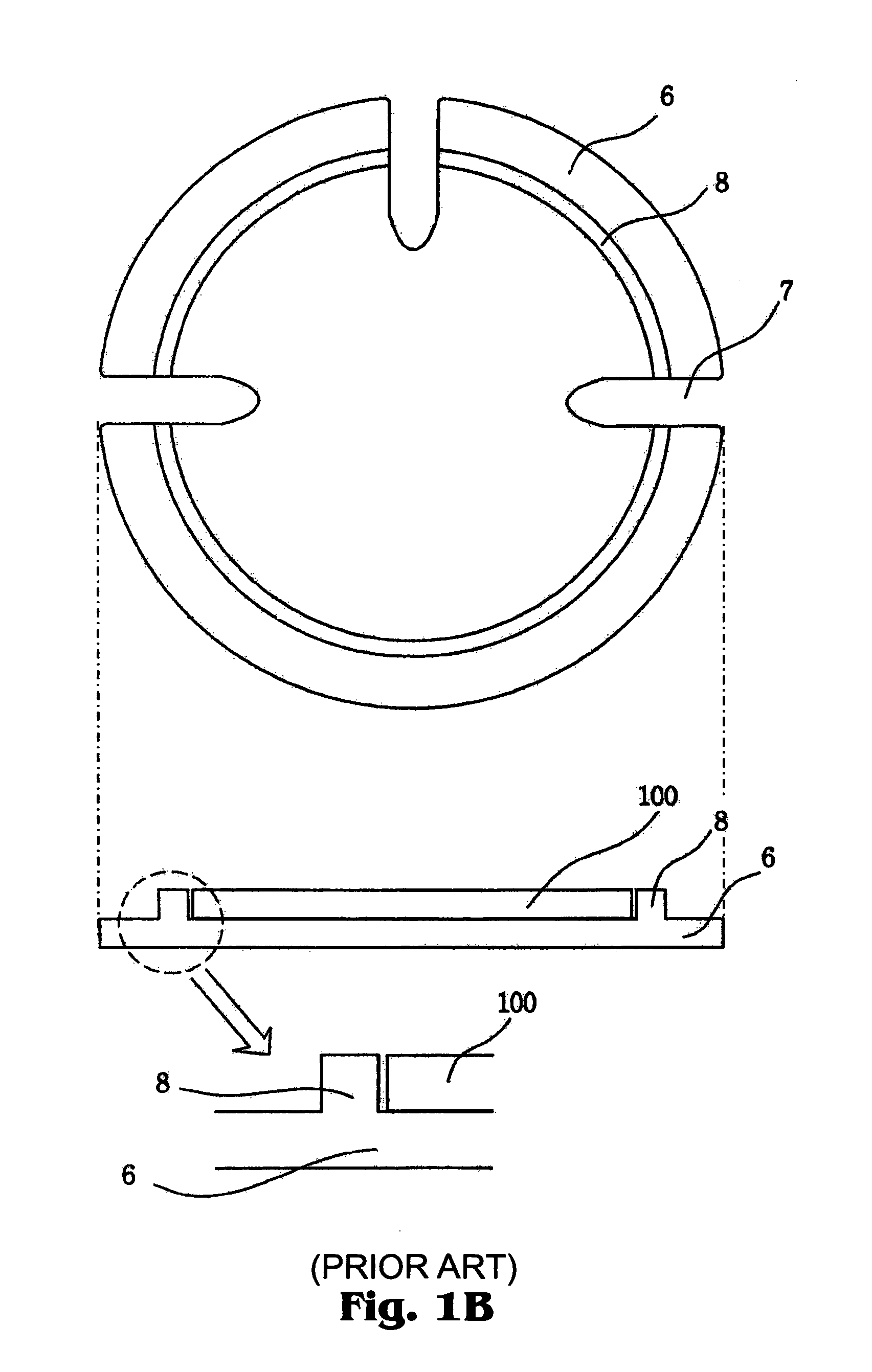

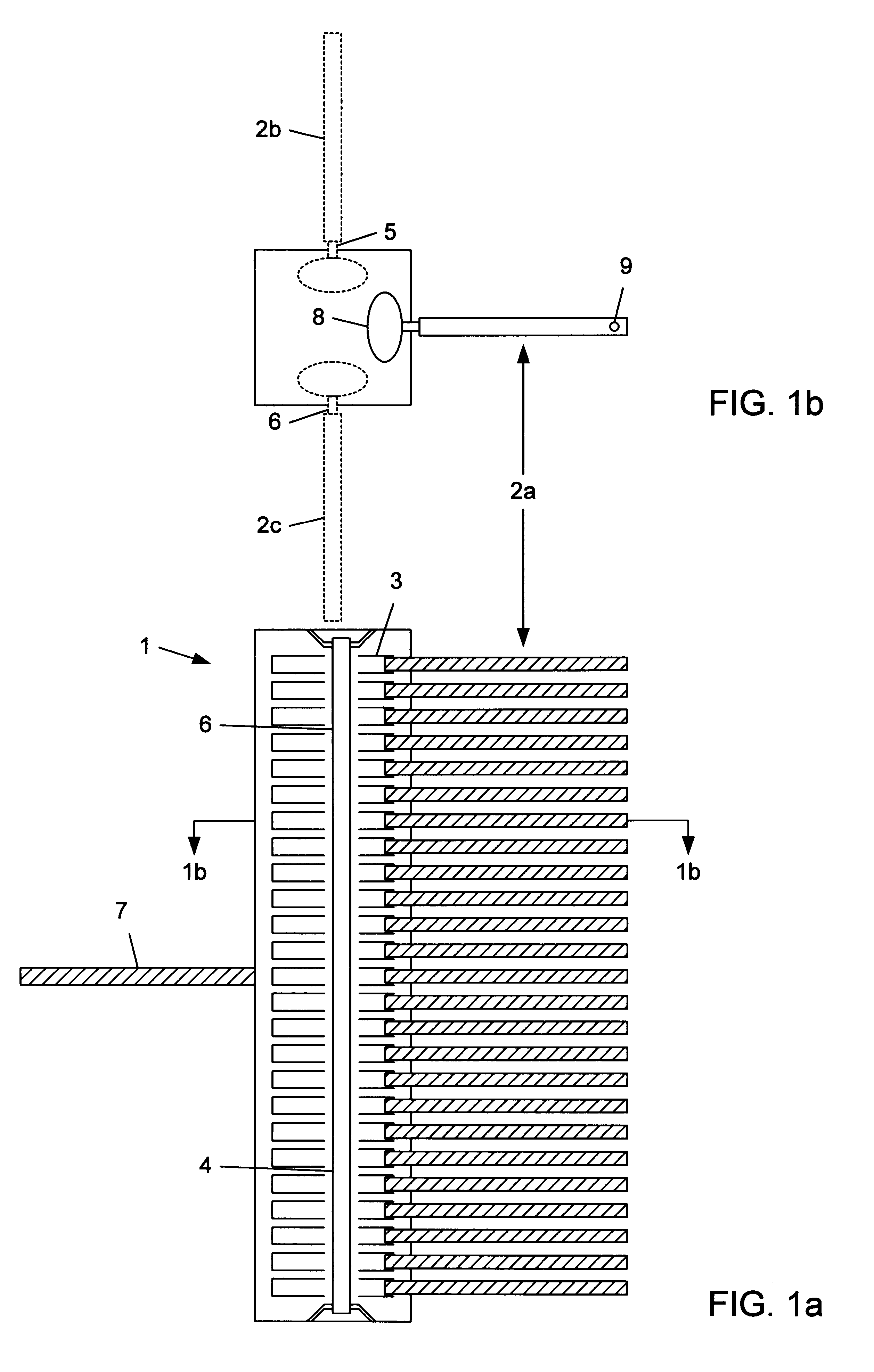

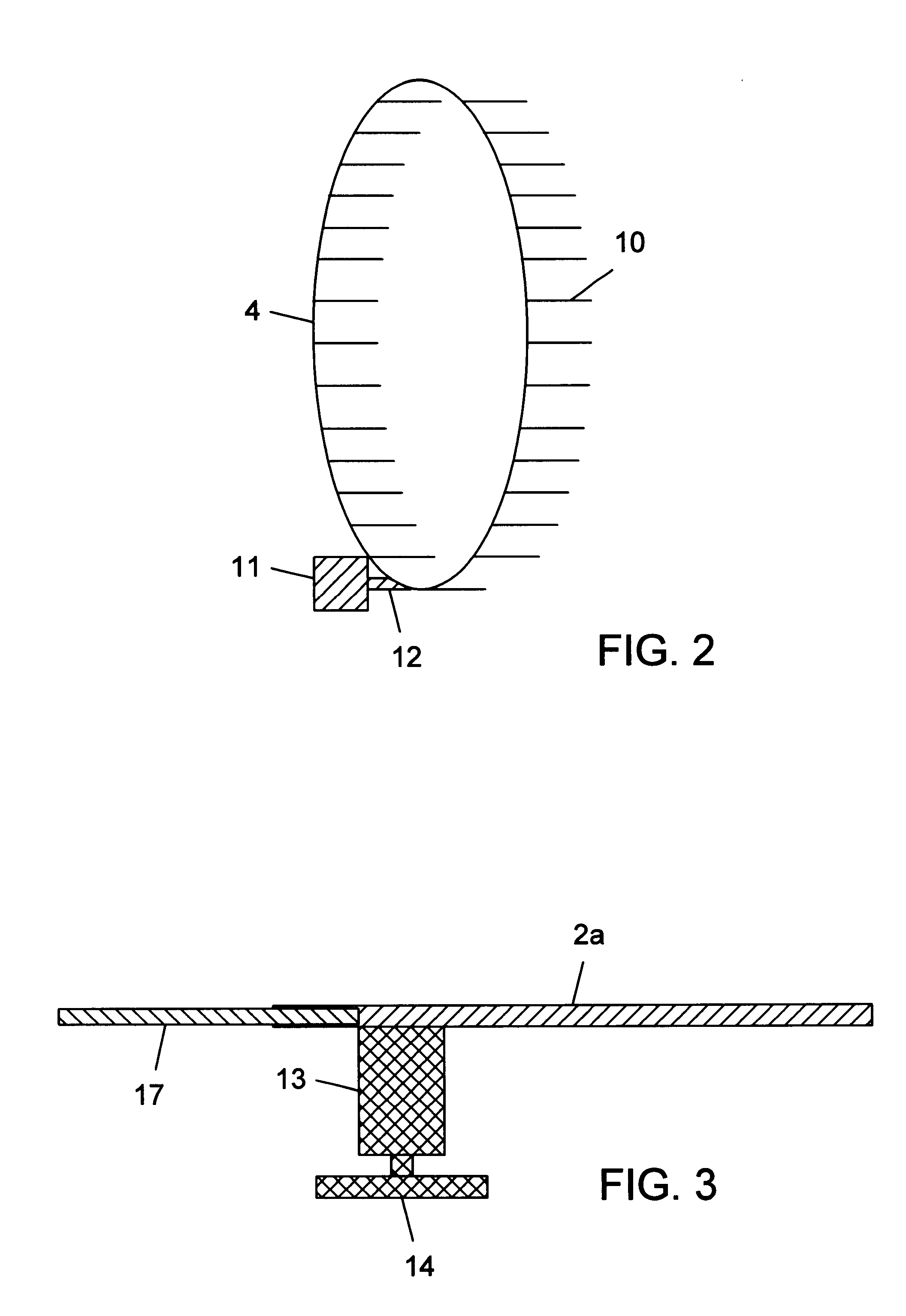

Heat treatment jig for semiconductor substrate

ActiveUS7329947B2Reduce stressSlips can be suppressed from occurringSemiconductor/solid-state device detailsCharge supportsSemiconductorSilicon

Owner:SUMITOMO MITSUBISHI SILICON CORP

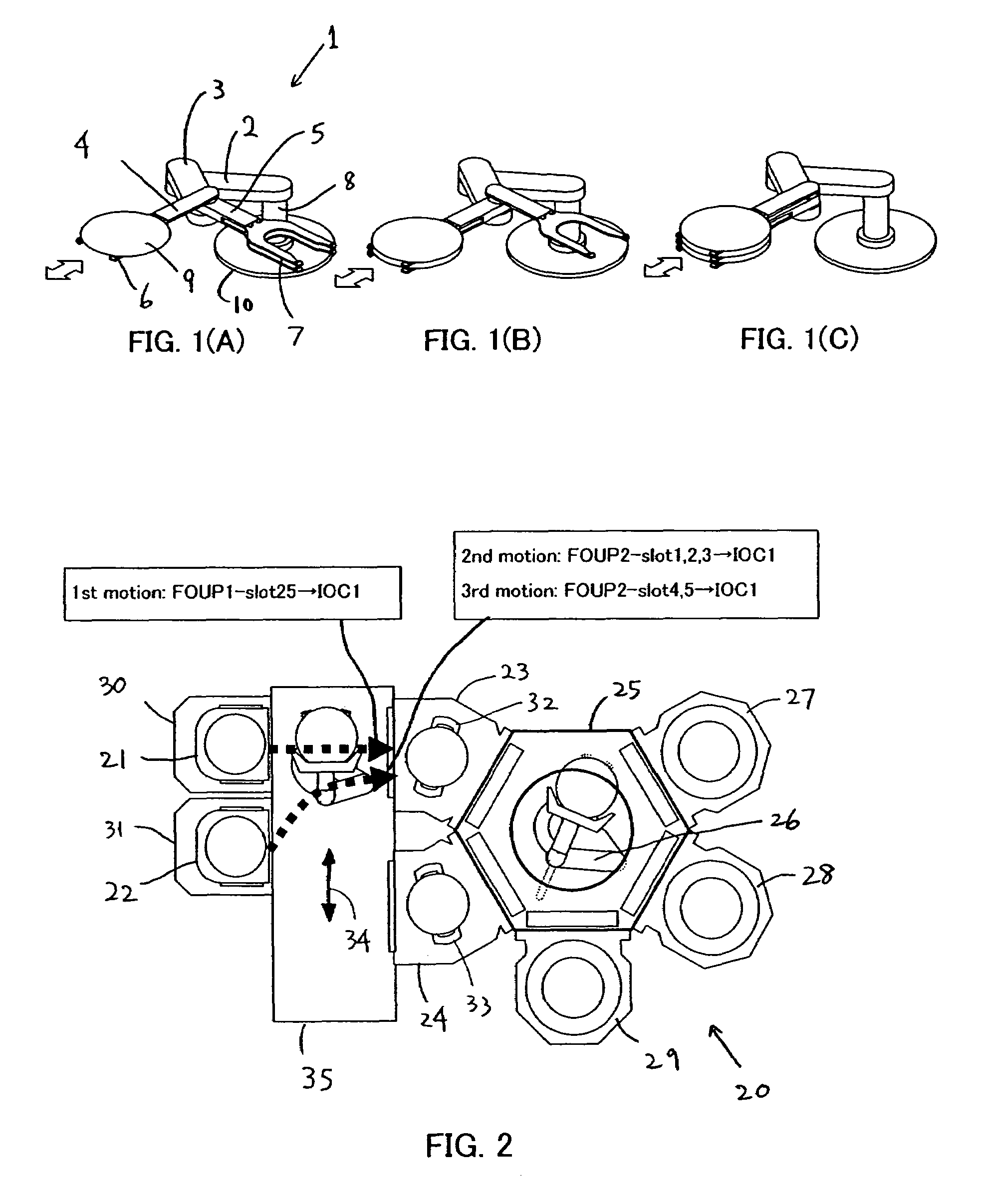

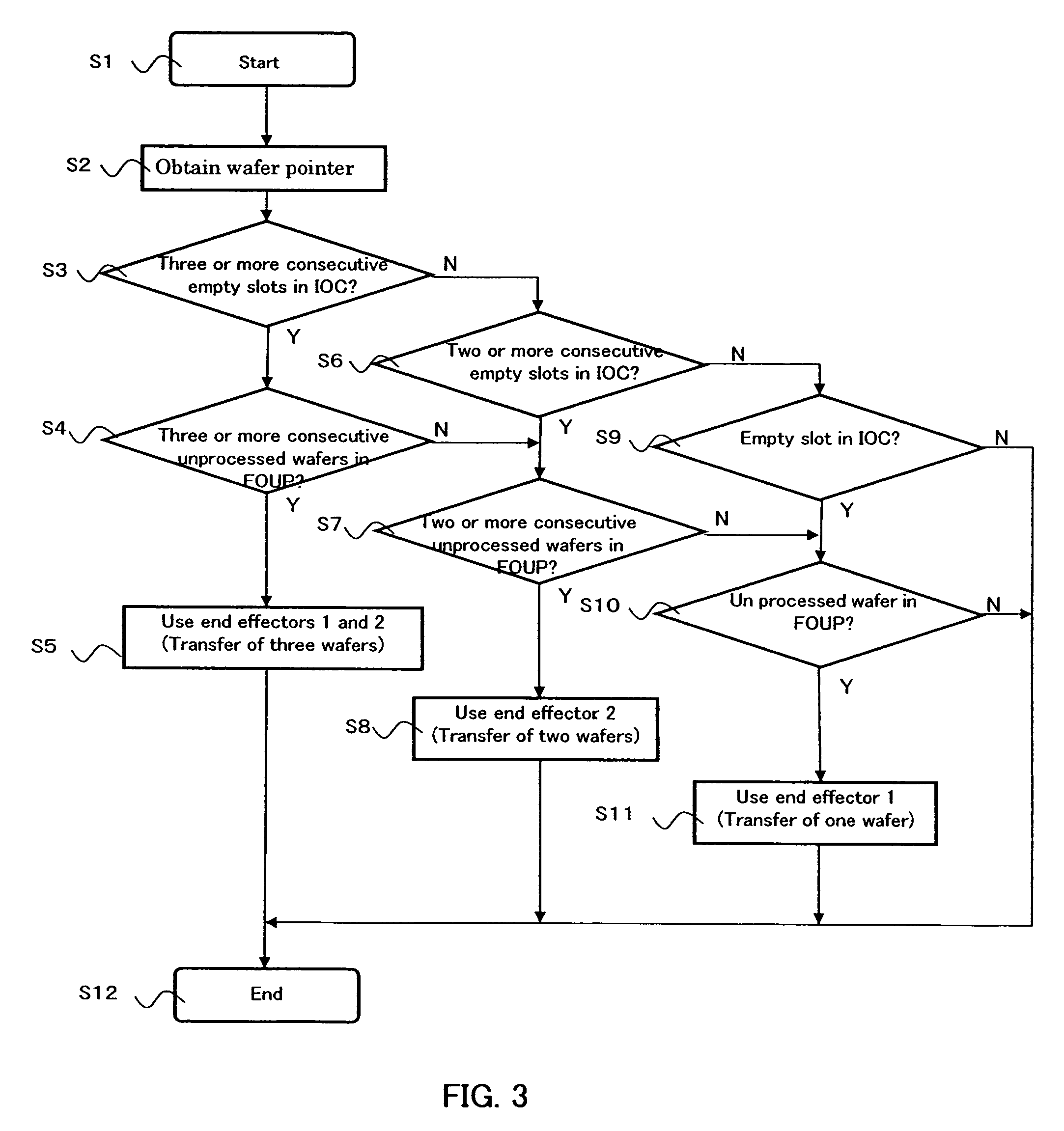

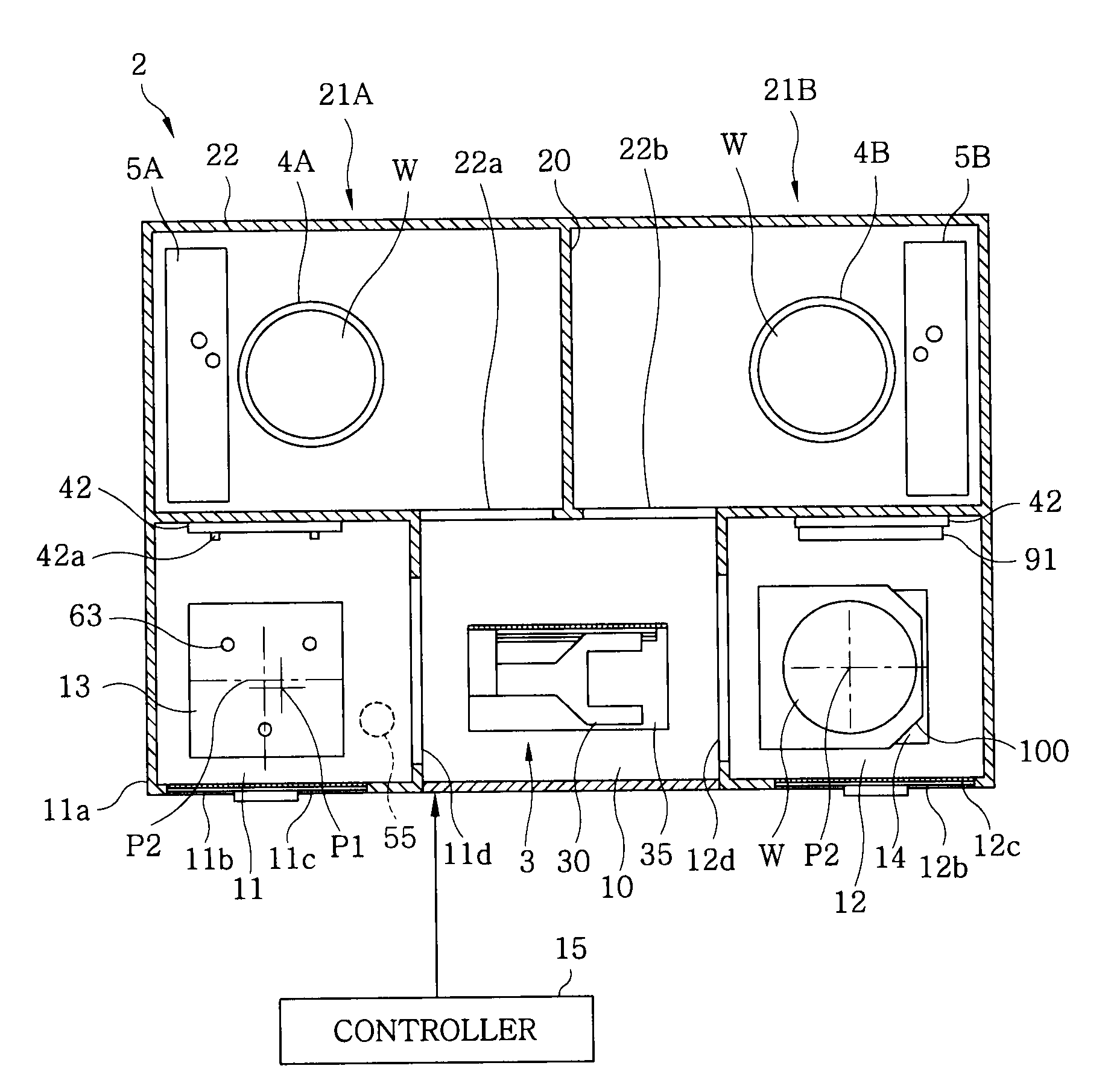

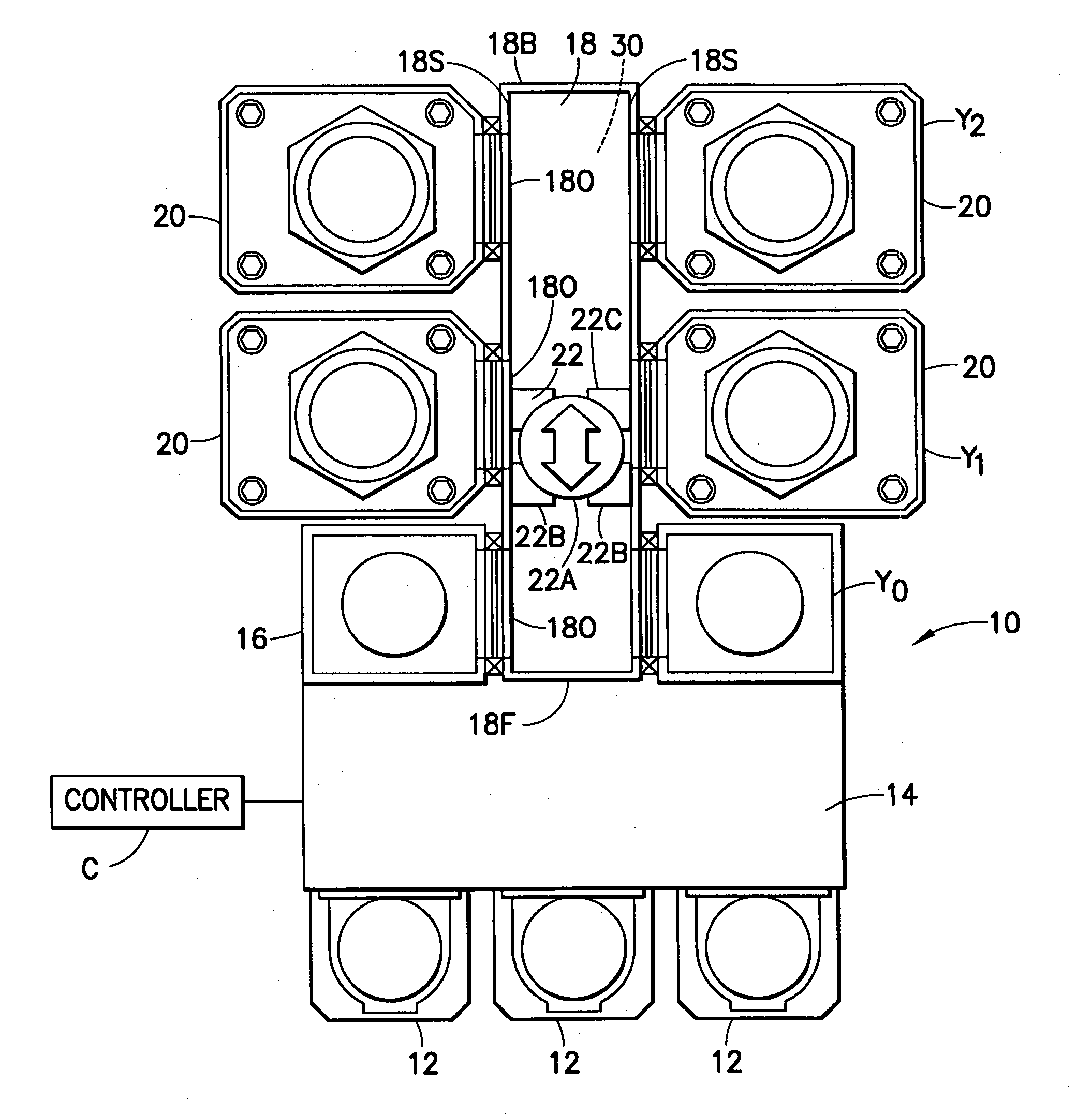

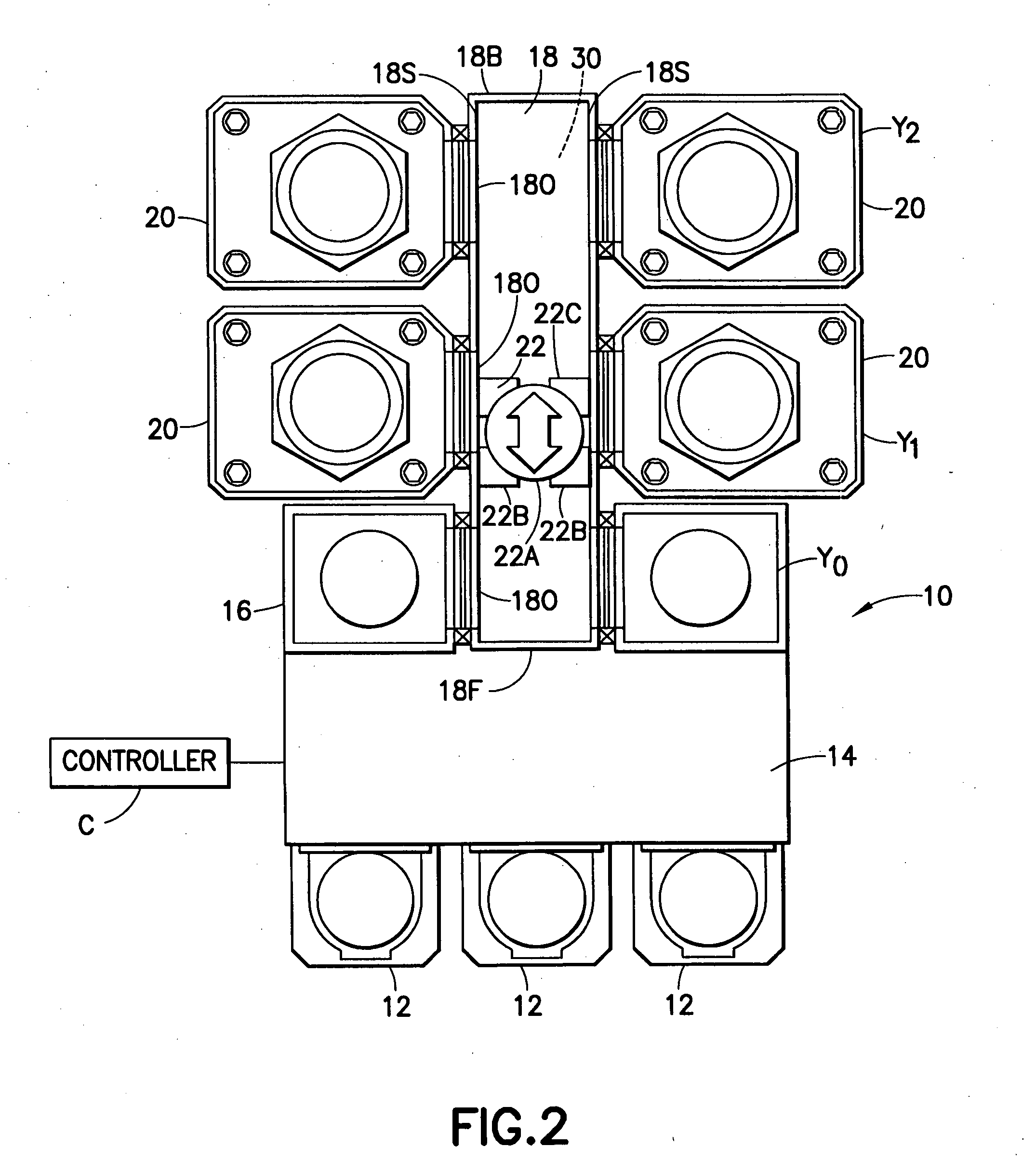

Semiconductor substrate transfer apparatus and semiconductor substrate processing apparatus equipped with the same

A semiconductor substrate transfer apparatus for transferring semiconductor substrates from a first container to a second container, includes: multiple end effectors; at least one robot arm with which the multiple end effectors are independently rotatably joined; and a controller storing software including instructions to judge which end effector or end effectors in the multiple end effectors are to be selected based on a distribution status of substrates stored in the first and second containers and to rotate the selected end effector(s) for unloading a substrate or substrates from the first container and loading the substrate or substrates to the second container.

Owner:ASM JAPAN

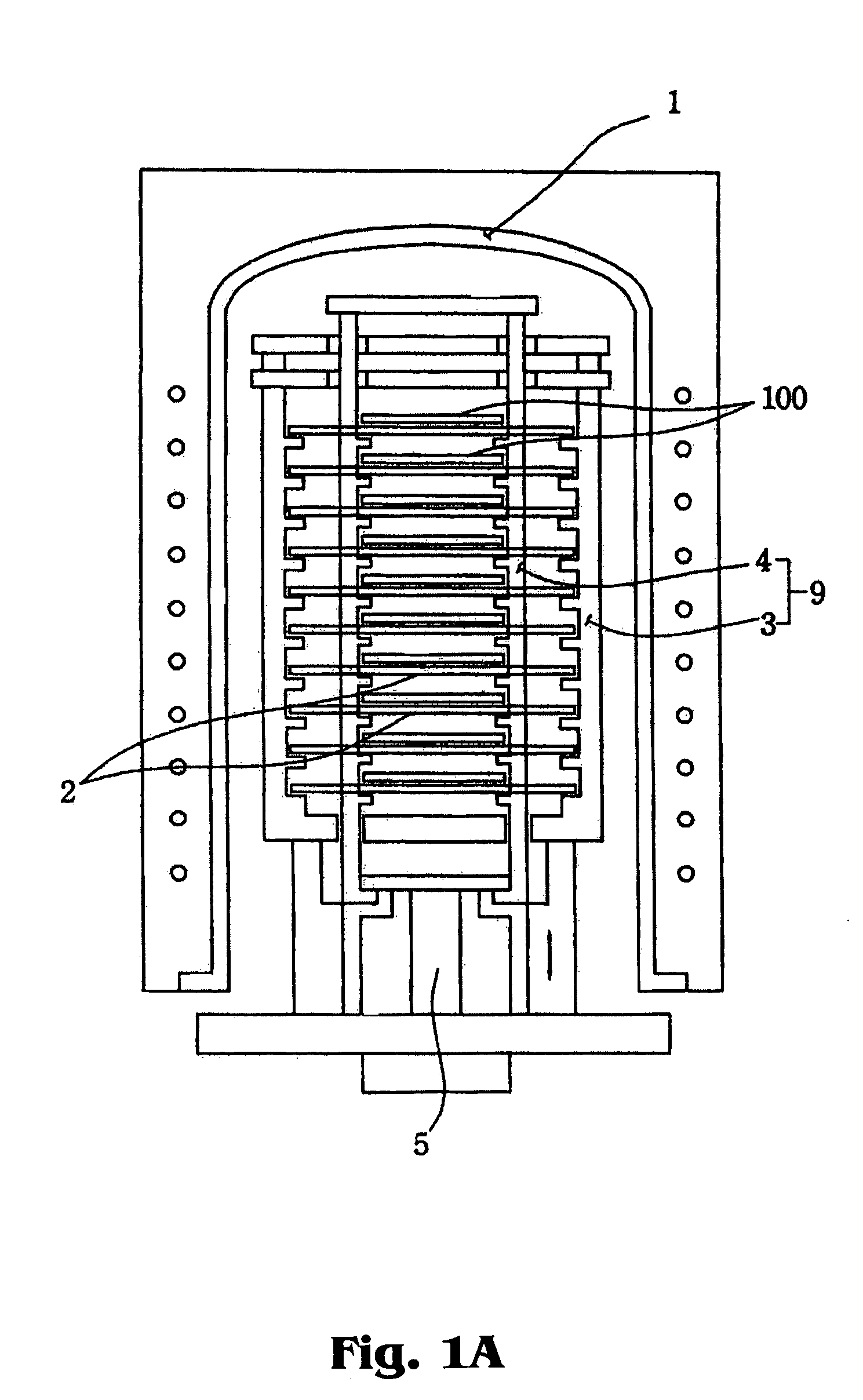

Semiconductor manufacturing system and wafer holder for semiconductor manufacturing system

InactiveUS7207763B2Improves yield and productivitySemiconductor/solid-state device manufacturingPlatesWaferingEngineering

A semiconductor manufacturing system and wafer holder for a semiconductor manufacturing system which prevents a semiconductor wafer from being exposed to a process reaction and which includes a reaction tube for providing a sealed process space and a dual boat and which prevents the backside deposition by the wafer holder. The wafer holder includes a holder body to hide the backside of the semiconductor wafer during a process in the reaction tube and a wafer lifter having a portion that can be disengaged from and coupled to the holder body so that a lower portion of the semiconductor wafer is supported by the dual boat and so that the semiconductor wafer can be lifted up from the wafer body when the semiconductor wafer is loaded and unloaded. A separation boundary between the holder body and the wafer lifter includes a gas inflow interception surface to hinder reaction gas from flowing through the separation boundary.

Owner:TERASEMICON CO LTD

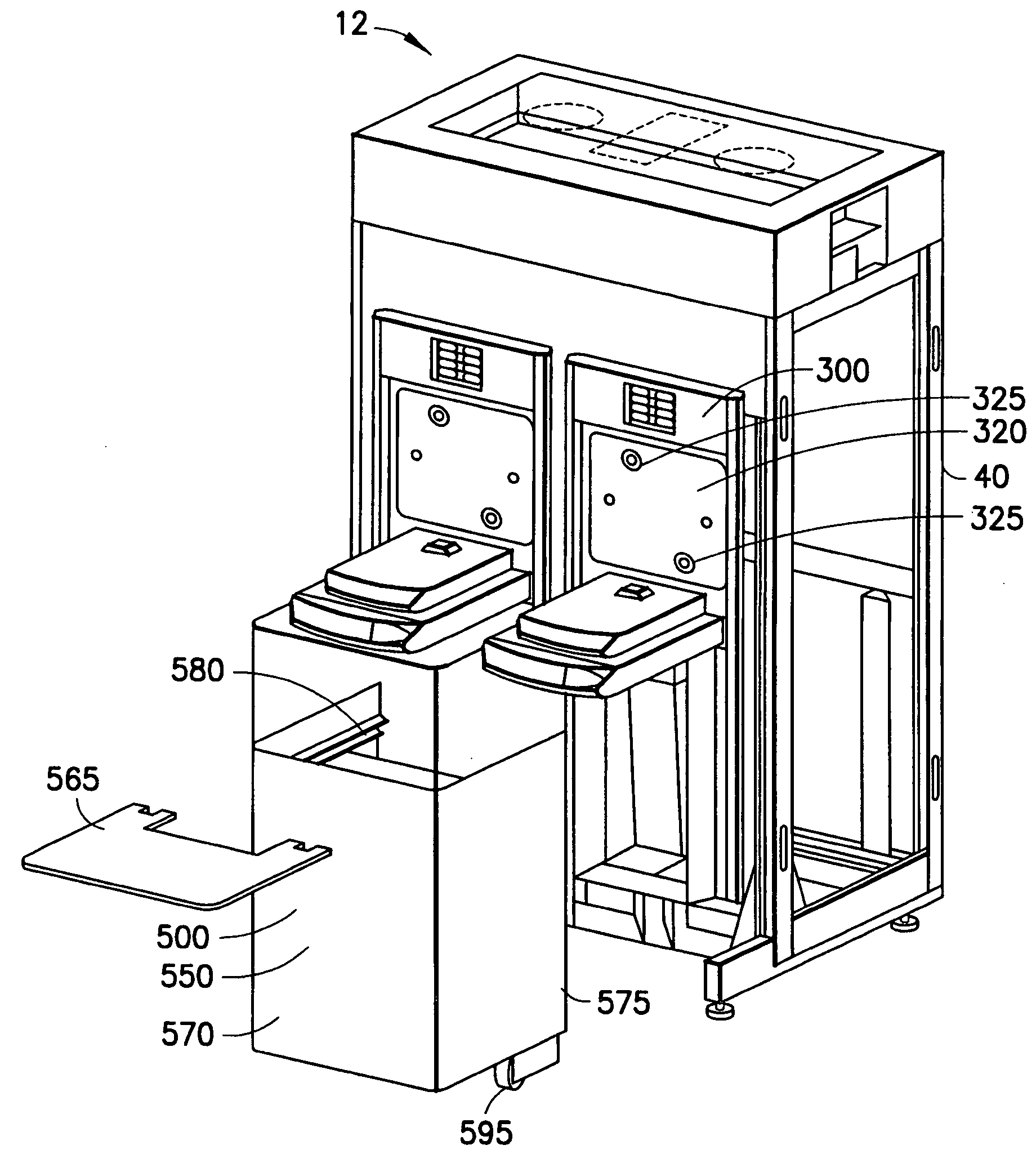

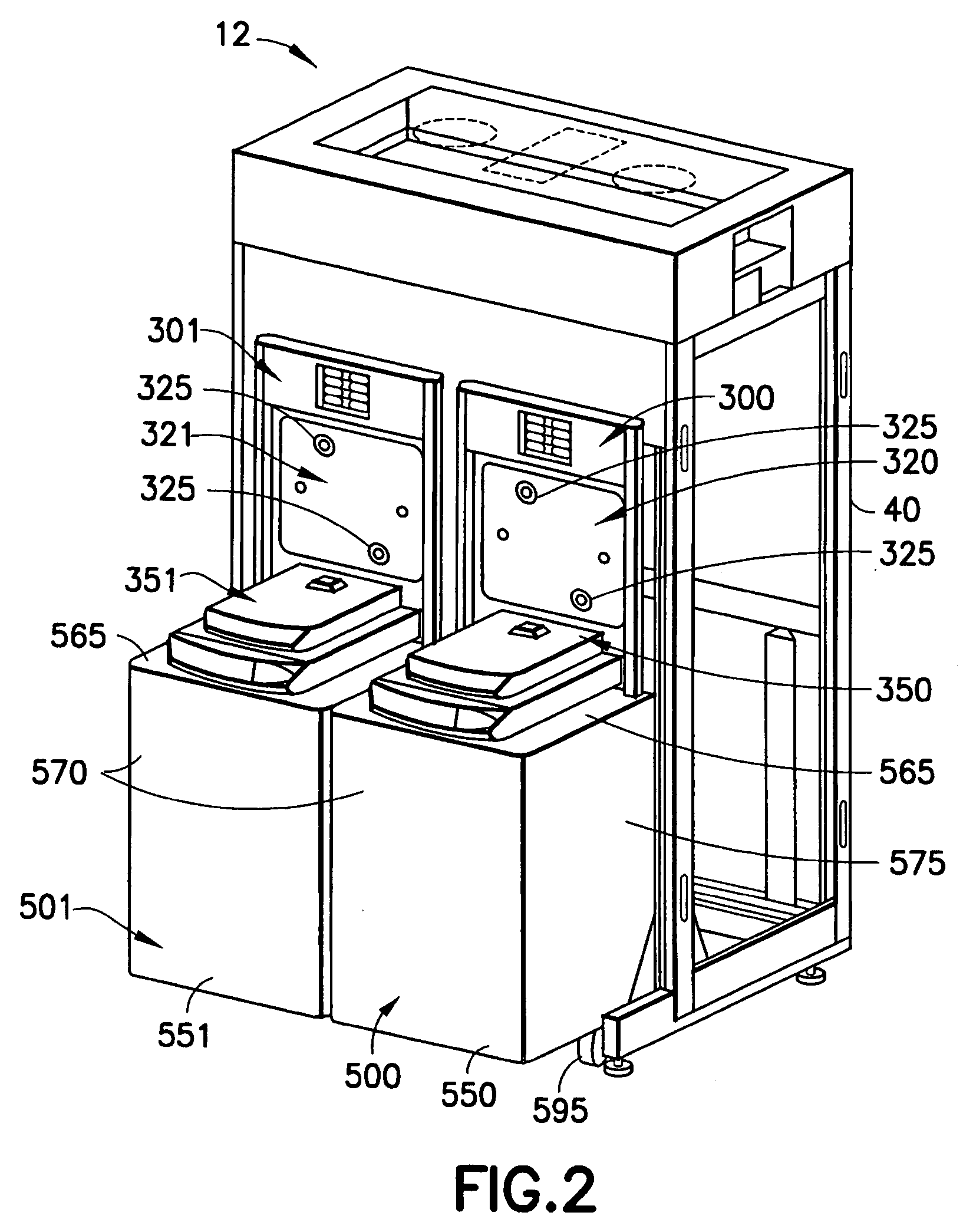

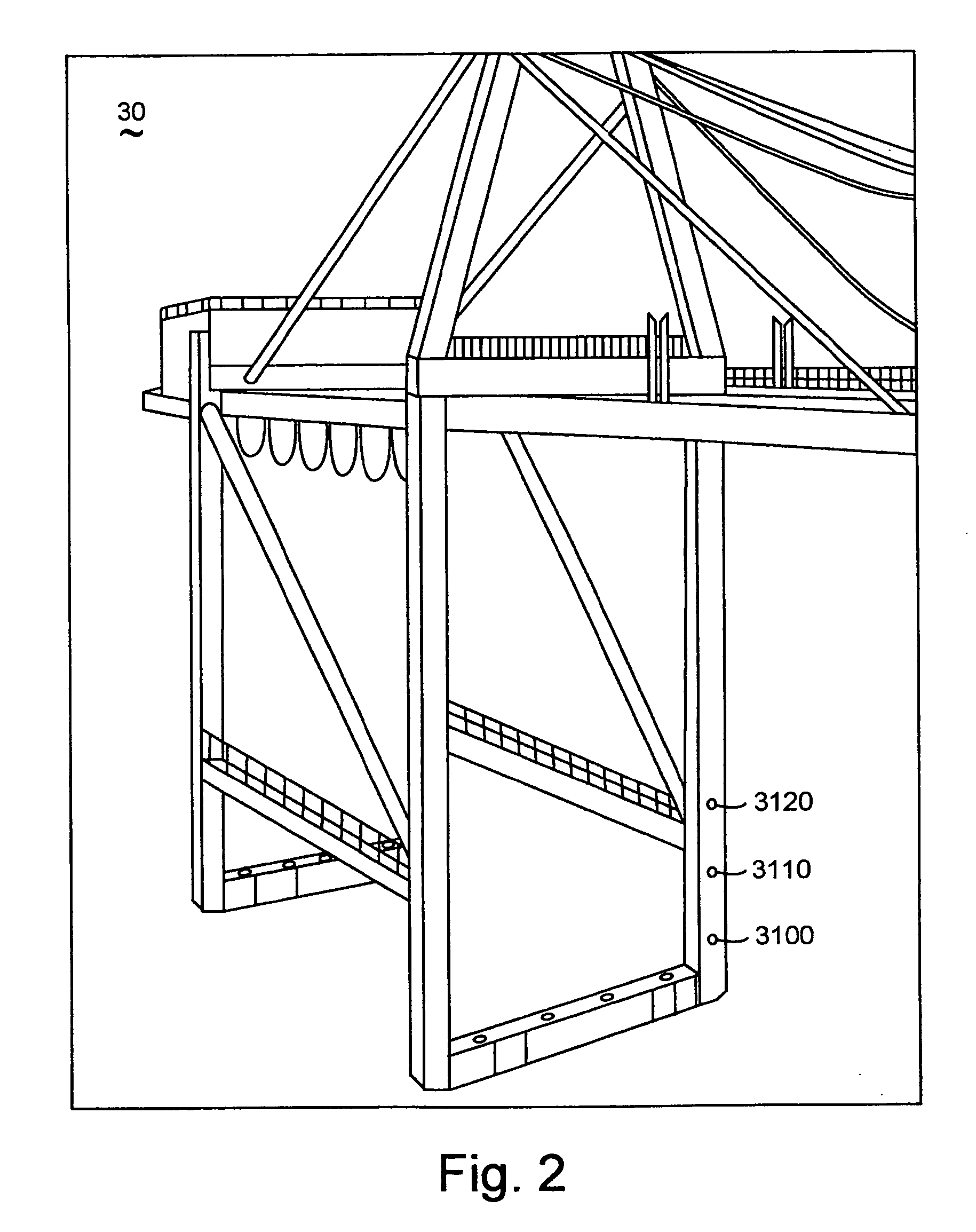

Equipment storage for substrate processing apparatus

A substrate processing apparatus has a frame and a load port connected to the frame and adapted to mate a substrate transport container to the frame. The apparatus has transportable storage that is adapted to be removably connected to the frame and fit beneath the load port. The storage may be an enclosure housing electrical, mechanical, or electromechanical devices of the substrate processing apparatus.

Owner:BOOKS AUTOMATION US LLC

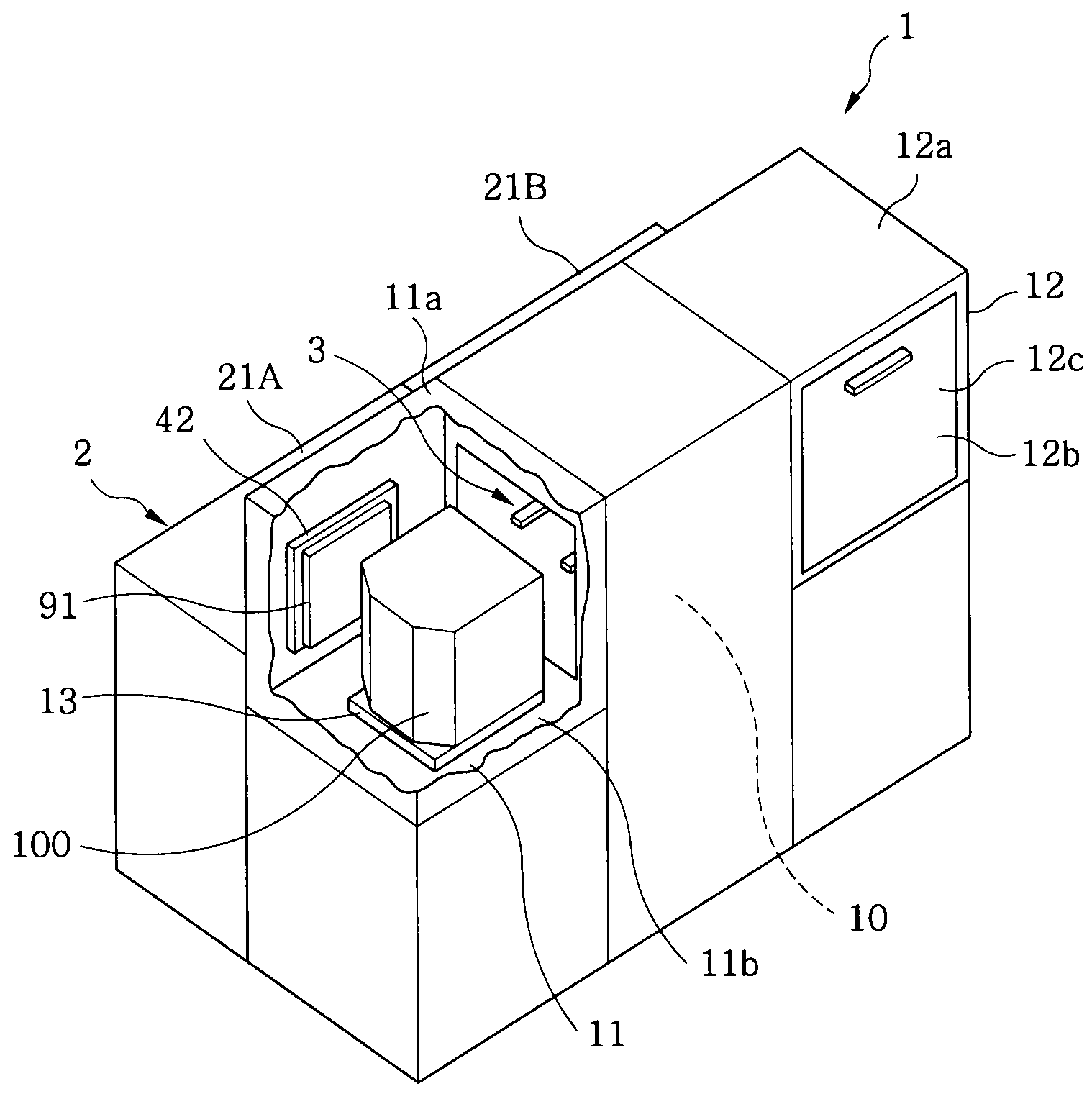

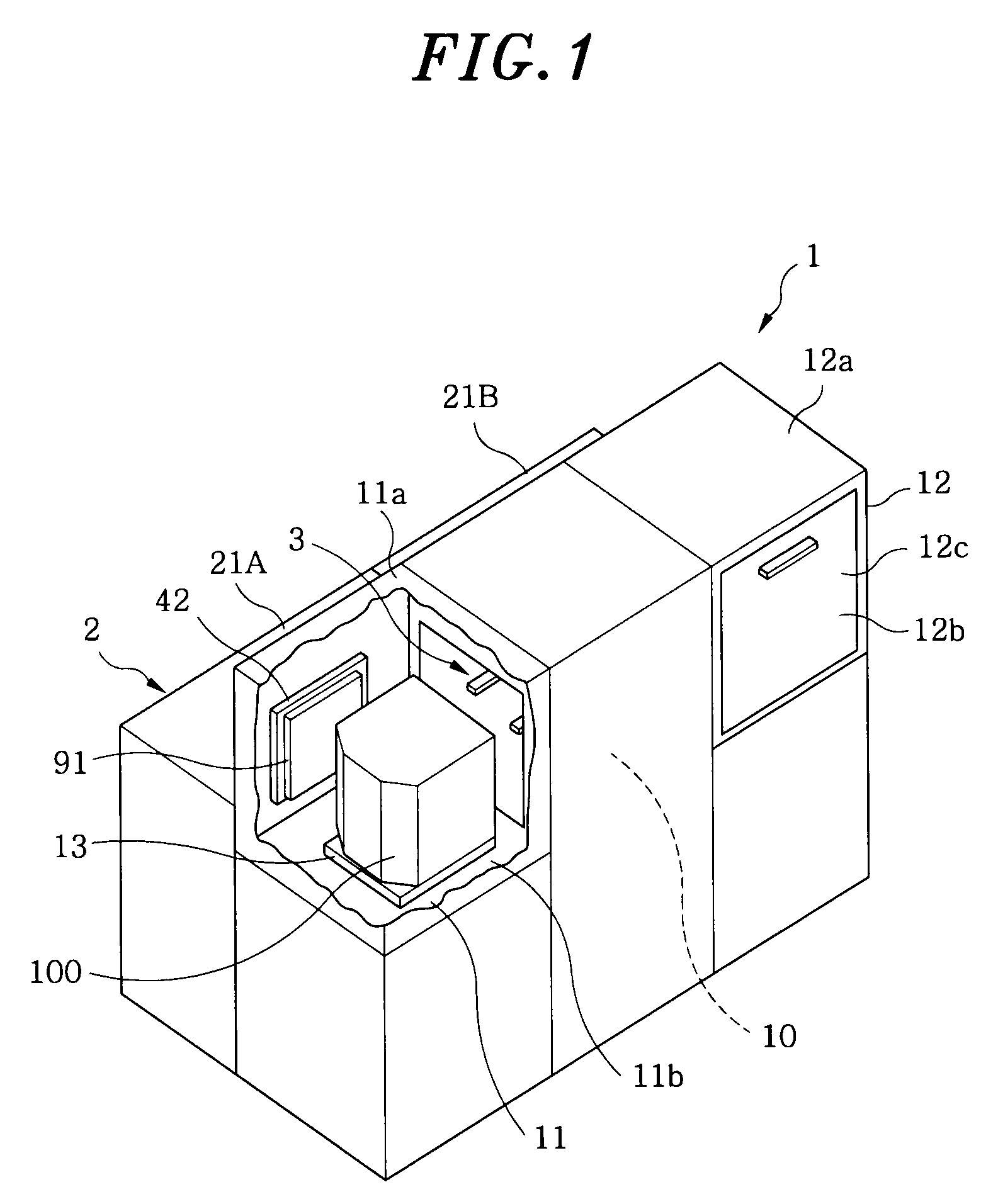

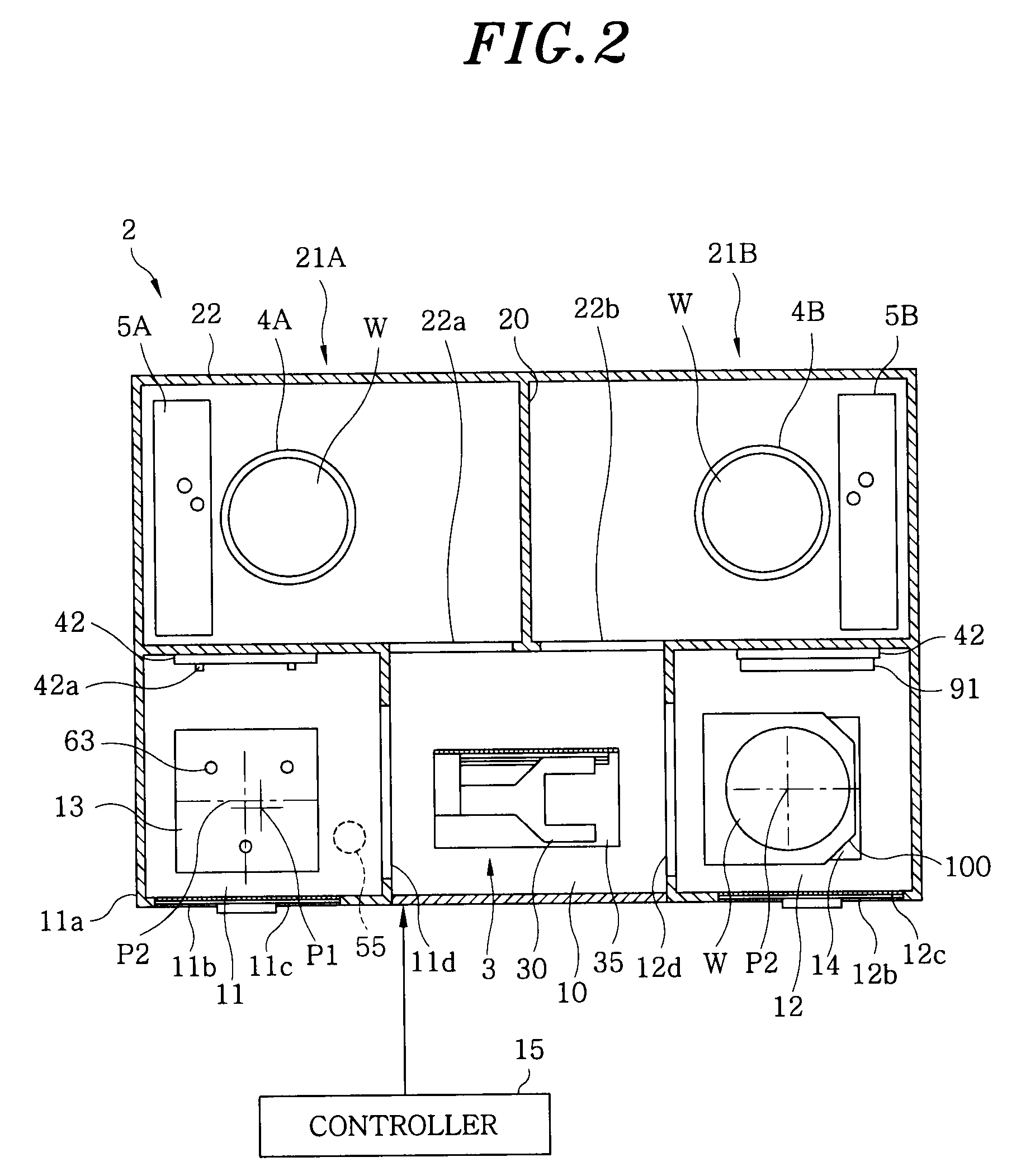

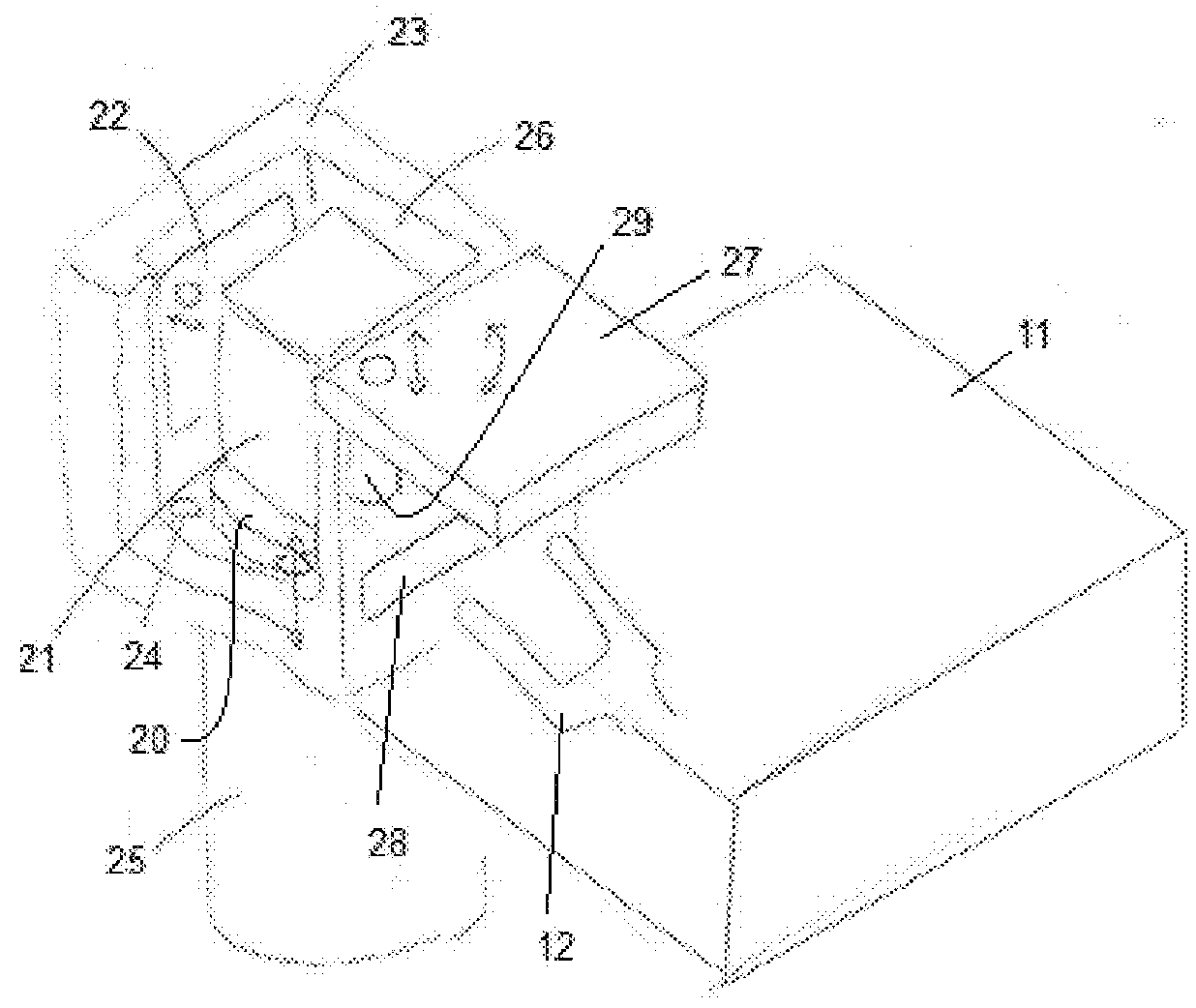

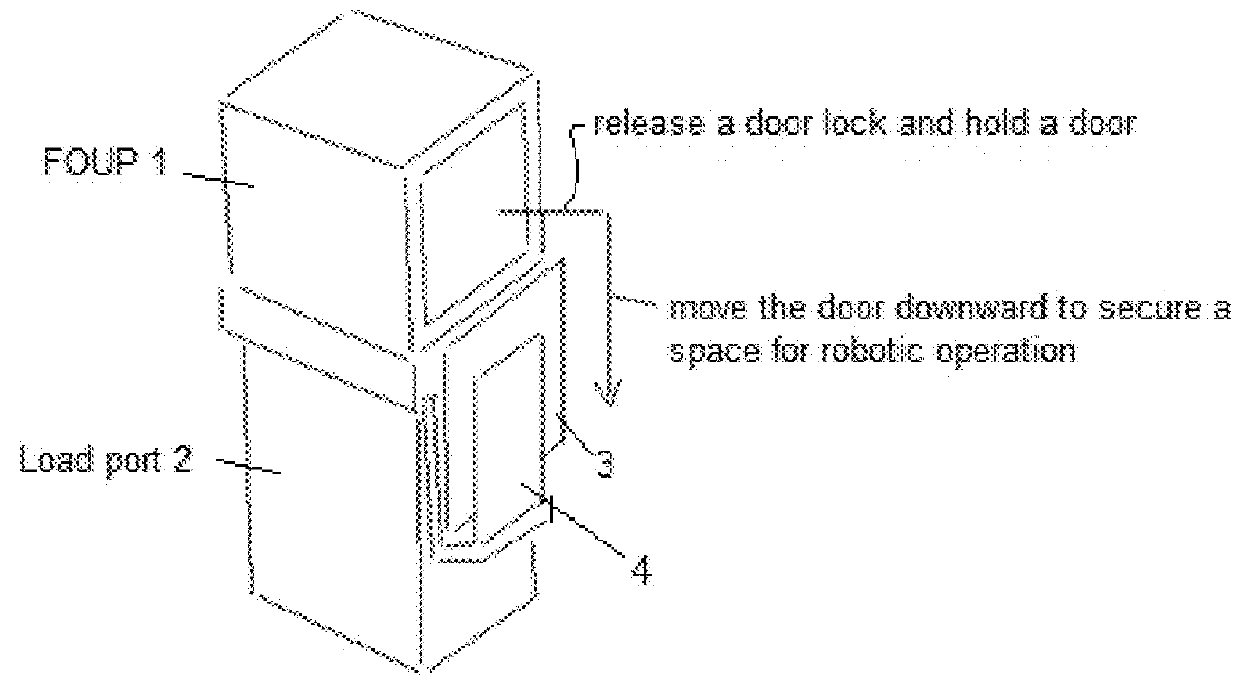

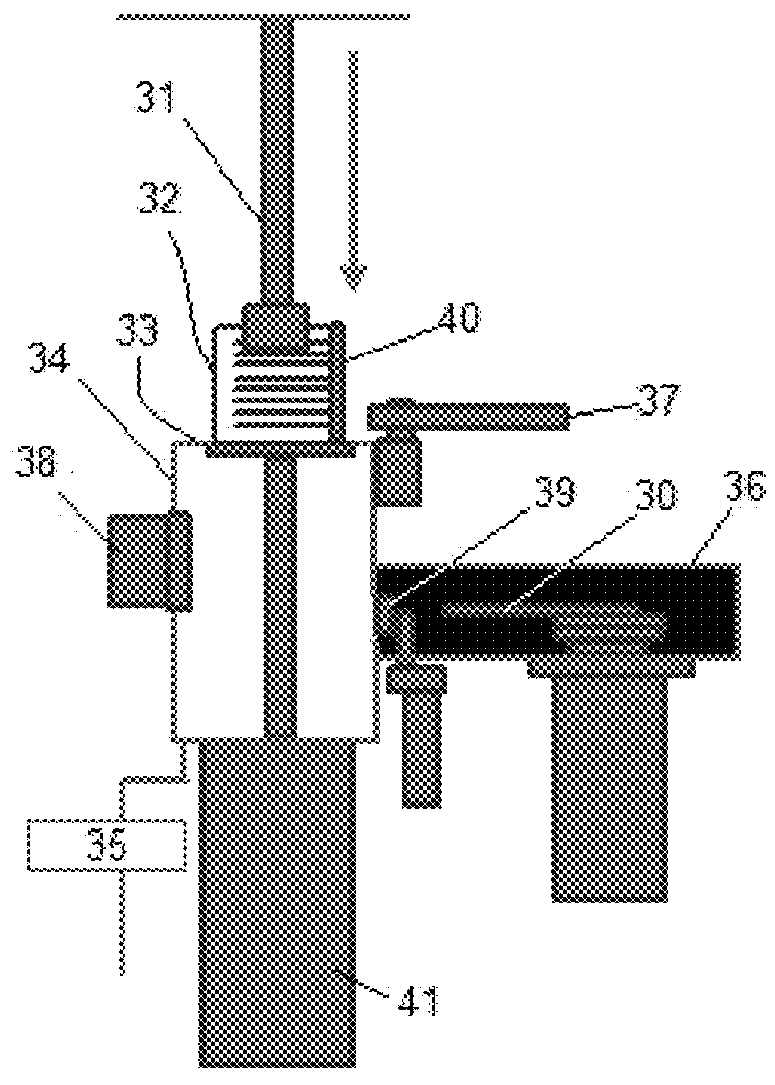

FOUP opening/closing device and probe apparatus

ActiveUS8267633B2Assure great degree of freedomEfficient comprehensive utilizationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl signalFOUP

A FOUP opening / closing device includes a housing containing a mounting table for mounting the FOUP thereon, an FOUP loading opening, and a delivery opening. The device further includes a rotator for rotating the mounting table, a door opening / closing unit to open or close the door of the FOUP and keep the door open, a mover for moving the FOUP and the door opening / closing unit in a reciprocating manner, to allow the FOUP and the door opening / closing unit to be connected to or separated from each other, and a controller to output control signals for moving the FOUP and the door opening / closing unit via operation of the mover to mount the door of the FOUP to the door opening / closing unit, separating the door from the FOUP, moving the FOUP and the door opening / closing unit away from each other, and rotating the mounting table to make the FOUP face the delivery opening.

Owner:TOKYO ELECTRON LTD

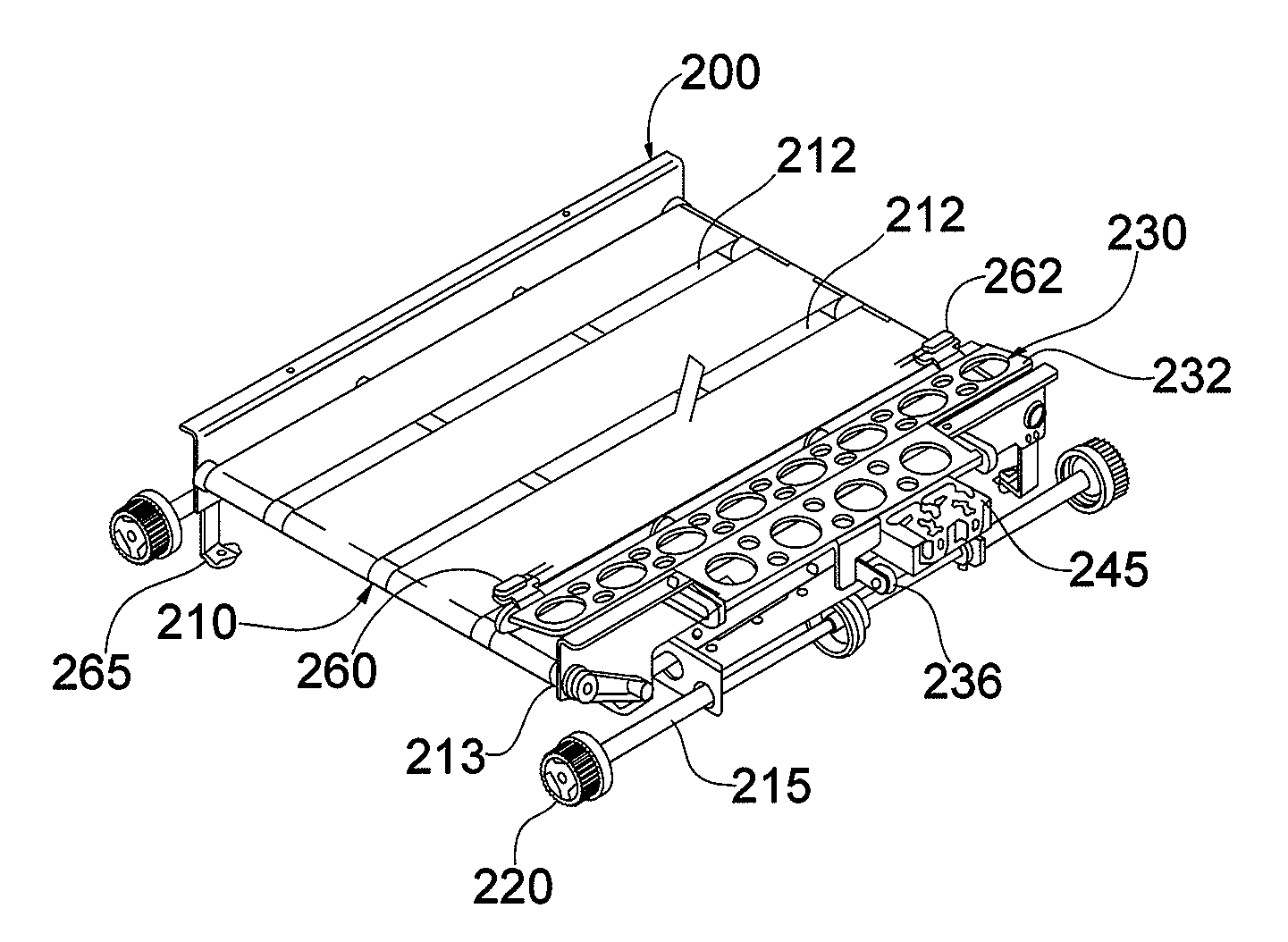

Wafer handling system

InactiveUS6981832B2Semiconductor/solid-state device manufacturingStorage devicesMagnetic tapeEngineering

A system for processing semiconductor wafers includes adaptations allowing the selective handling of cassettes for both 200-mm wafers and 300-mm wafers. The system is configured initially for handling standard 300-mm FOUP cassettes. Adaptions for handling 200-mm wafer open cassettes include a load port adapter frame for receiving such cassettes on a input / output platform; a cassette handler adapter configured for reversibly mounting on a cassette handler end effector and for receiving 200-mm open cassettes; a store adapter frame for converting 300-mm FOUP storage compartments into compartments for storing 200-mm open cassettes; and a Transhipment FOUP for holding 200-mm open cassettes upon a cassette transfer platform and bringing such cassettes into an interface with a wafer handler. The Transhipment FOUP has outer surfaces resembling a standard 300-mm FOUP cassette, but is configured to receive a 200-mm open cassette therein.

Owner:ASM INTERNATIONAL

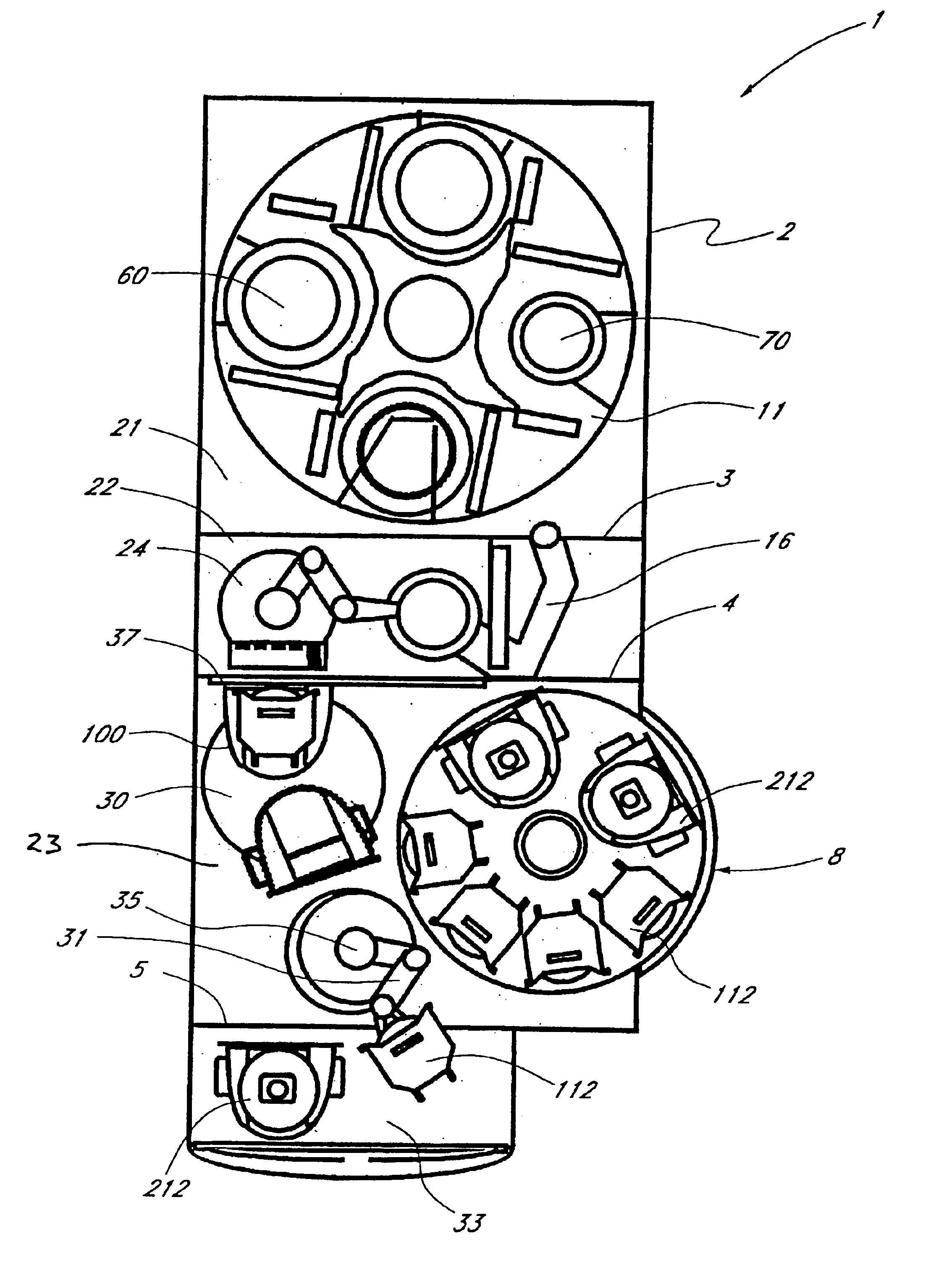

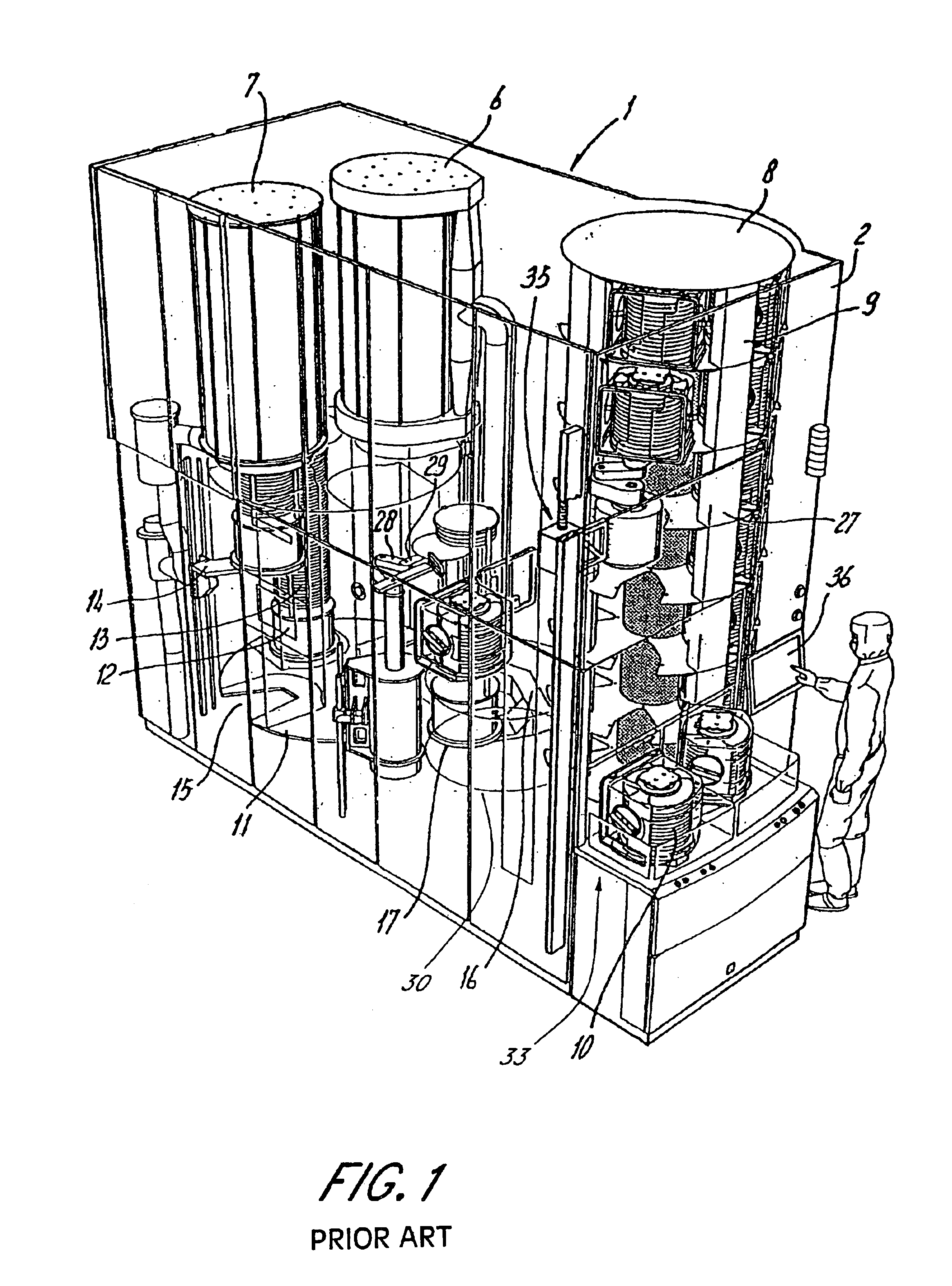

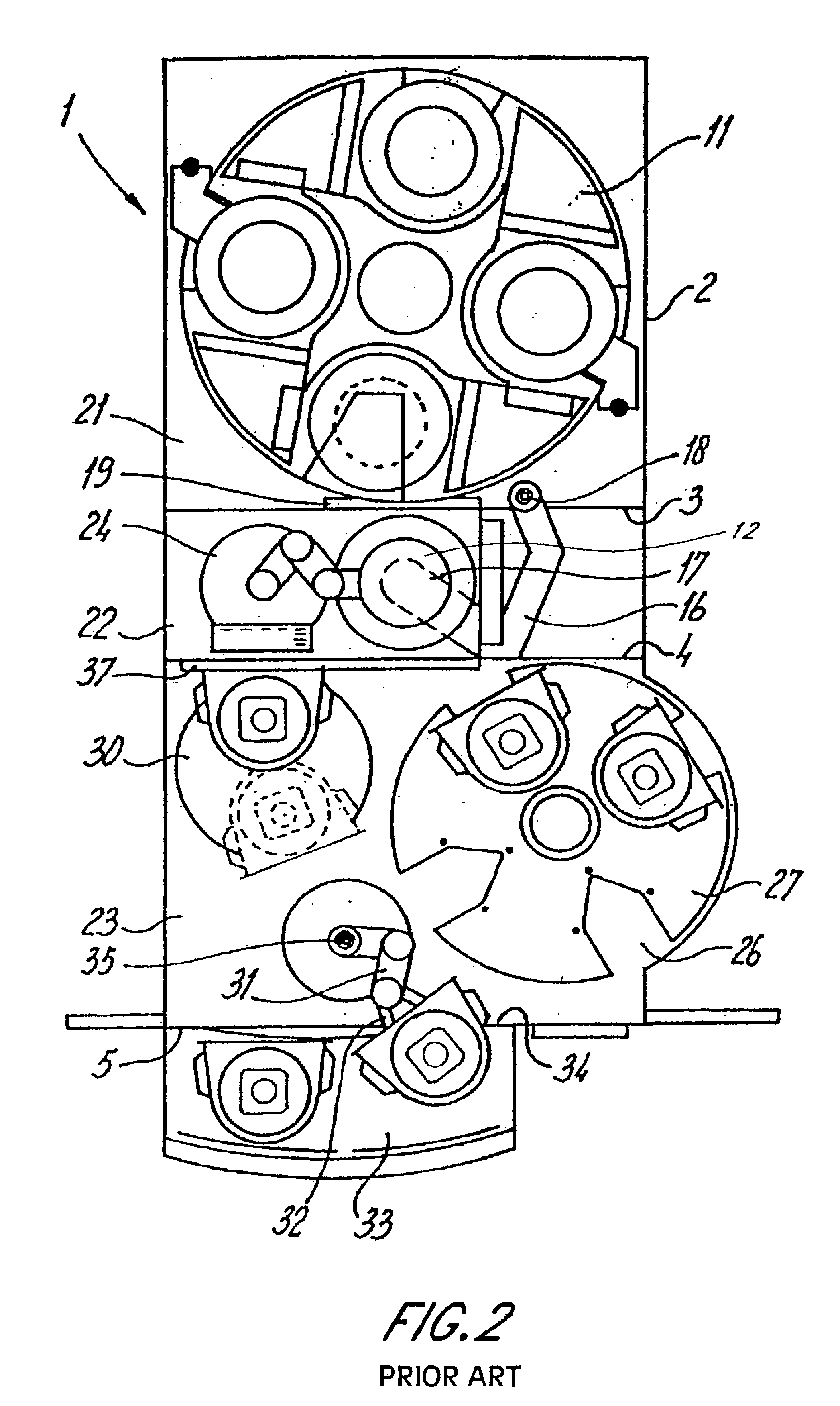

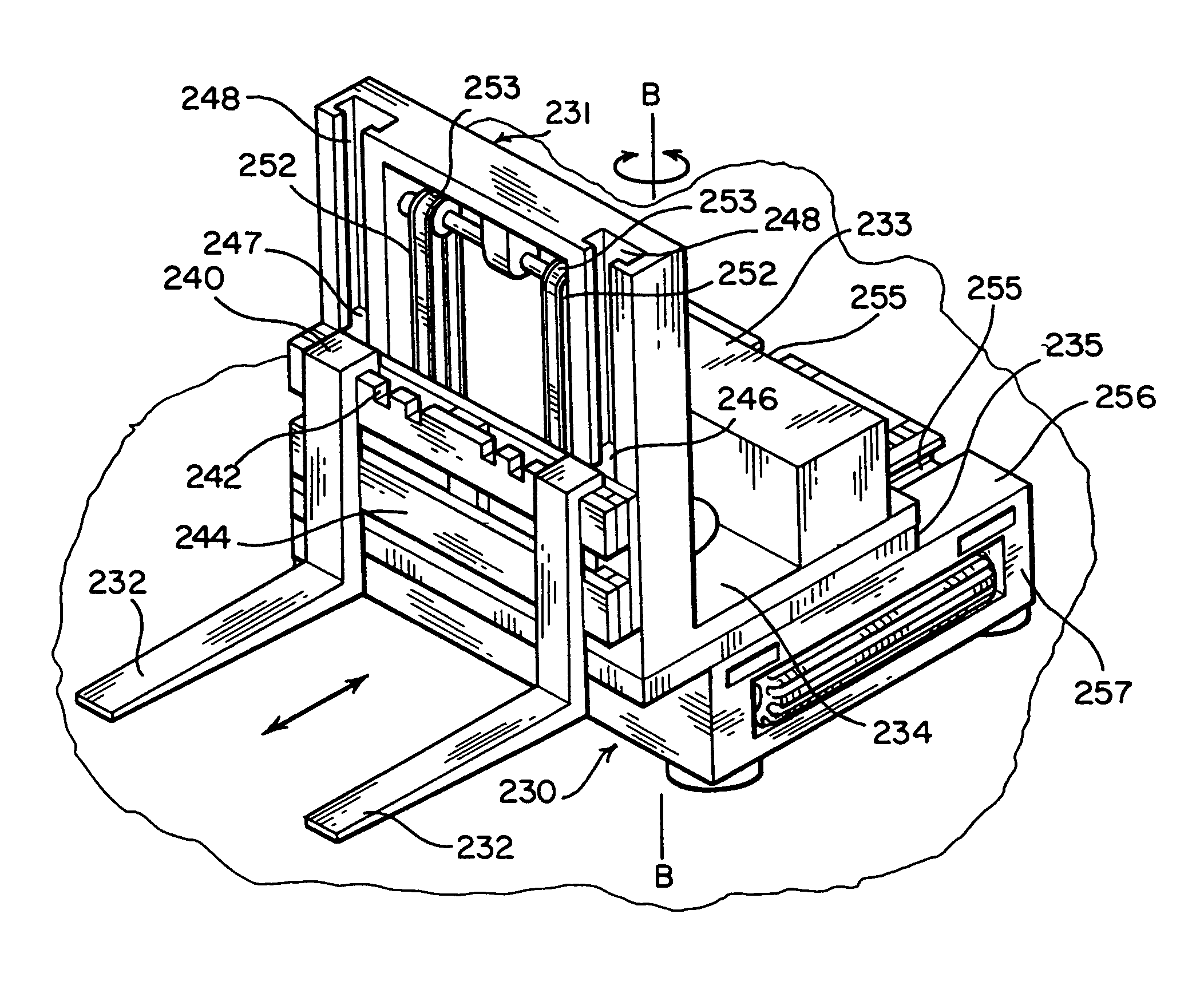

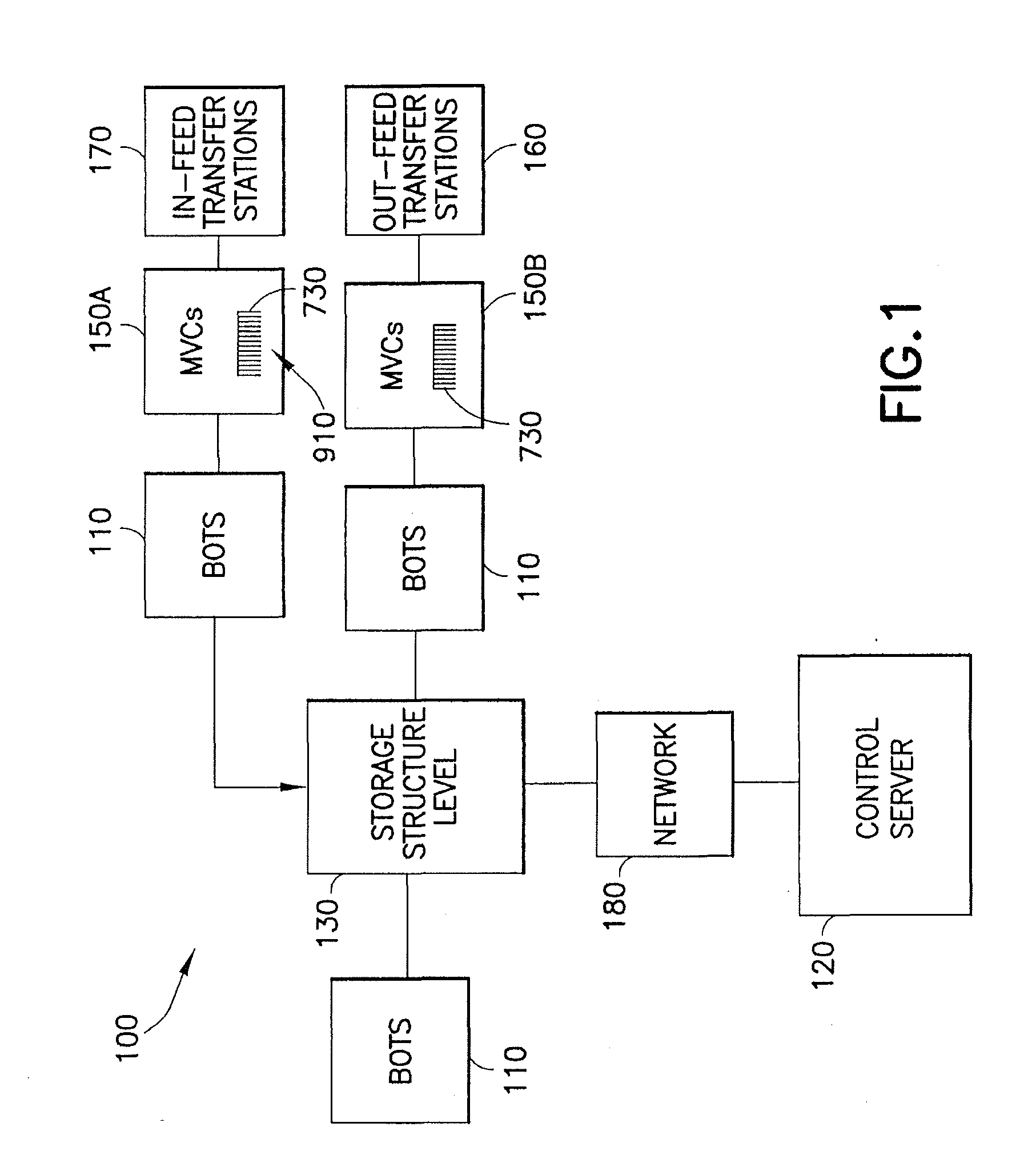

Materials-handling system using autonomous transfer and transport vehicles

Methods and apparatus for selecting and combining items in an outbound container through the use of autonomous vehicles, each of which includes means for automatically loading and unloading a payload, to perform both transfer and transport functions in moving containers of items within a workspace via a network of roadways. Under computer control, said autonomous vehicles transfer and transport case containers of item units between incoming receiving stations, intermediate storage locations, and outgoing order-assembly stations where entire containers or individual item units are combined in the outbound container.

Owner:SYMBOTIC LLC

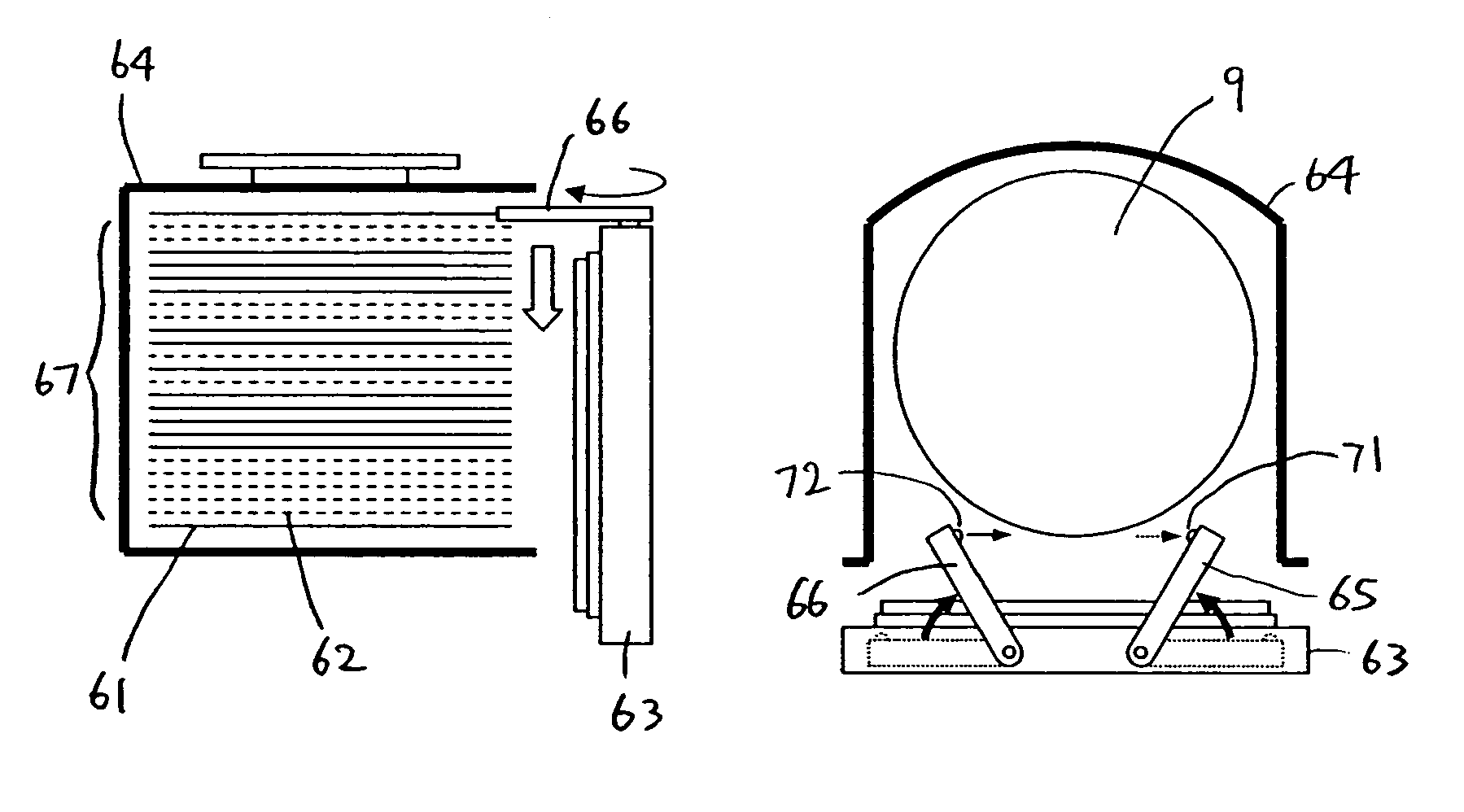

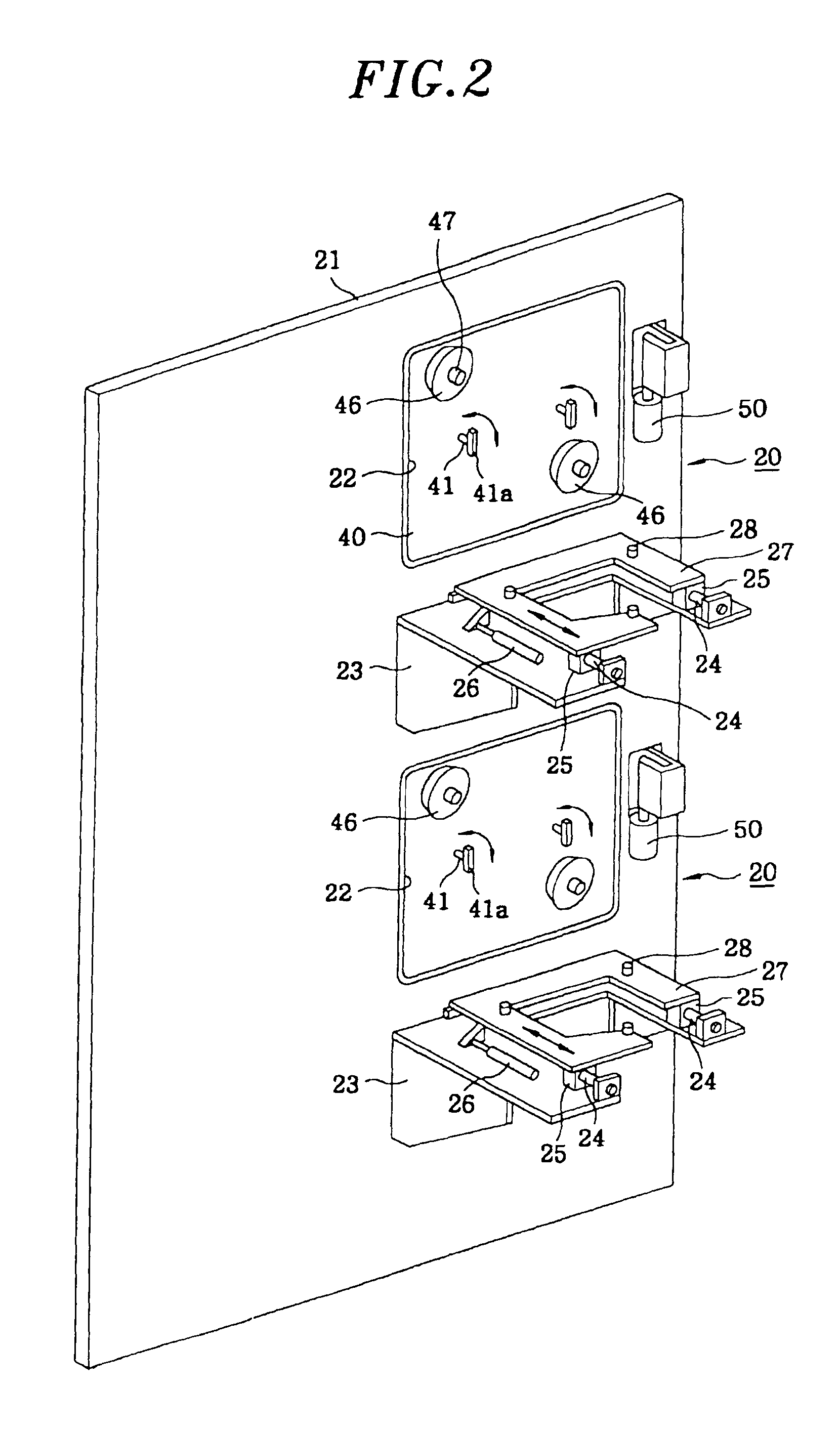

Foup opening/closing device and probe apparatus

ActiveUS20100040441A1Efficient space utilizationThe degree of freedom becomes largerSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl signalEngineering

A FOUP opening / closing device includes a housing containing a mounting table for mounting the FOUP thereon, an FOUP loading opening, and a delivery opening. The device further includes a rotator for rotating the mounting table, a door opening / closing unit to open or close the door of the FOUP and keep the door open, a mover for moving the FOUP and the door opening / closing unit in a reciprocating manner, to allow the FOUP and the door opening / closing unit to be connected to or separated from each other, and a controller to output control signals for moving the FOUP and the door opening / closing unit via operation of the mover to mount the door of the FOUP to the door opening / closing unit, separating the door from the FOUP, moving the FOUP and the door opening / closing unit away from each other, and rotating the mounting table to make the FOUP face the delivery opening.

Owner:TOKYO ELECTRON LTD

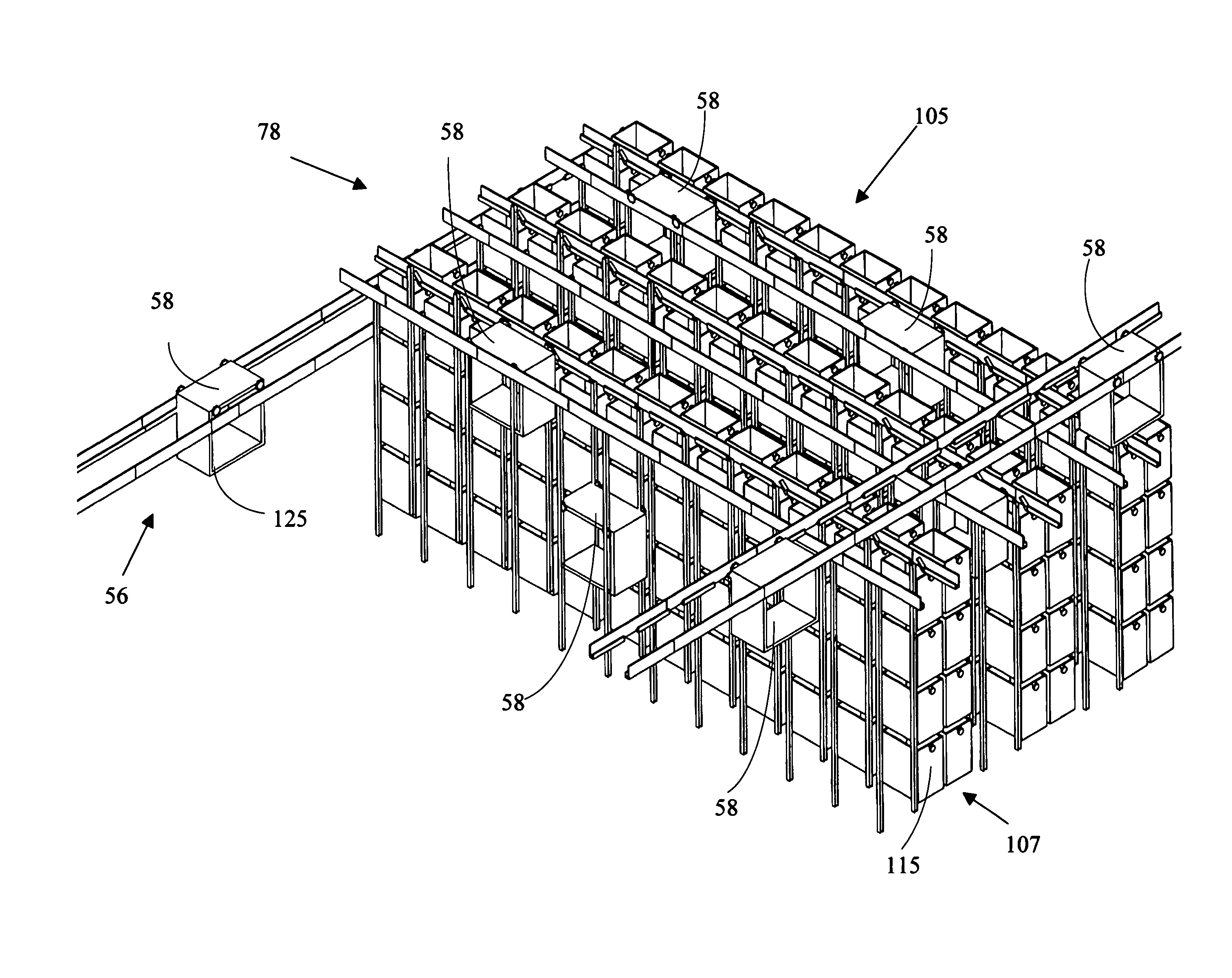

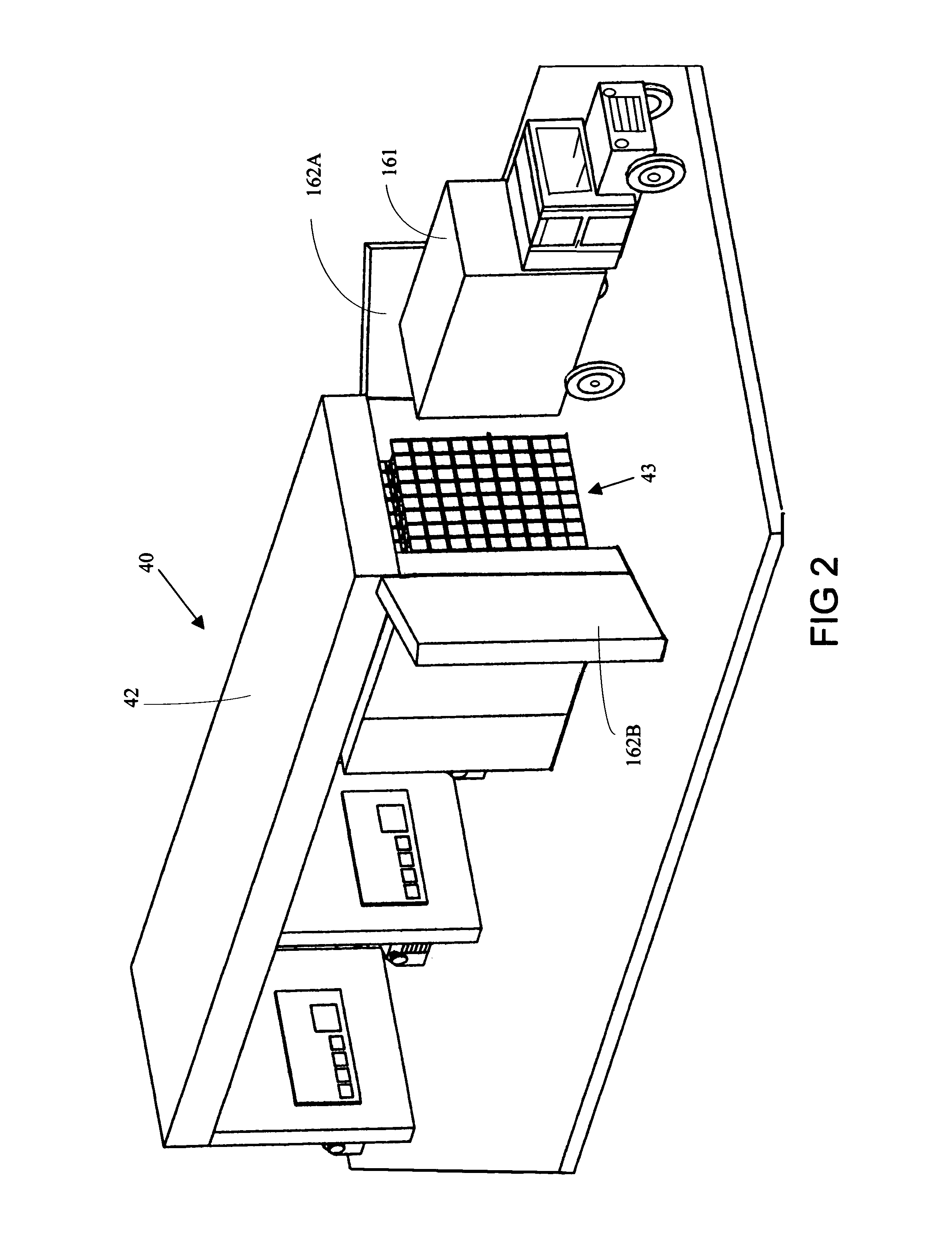

Automated 3-dimensional multitasking, stocking, storage, and distribution system

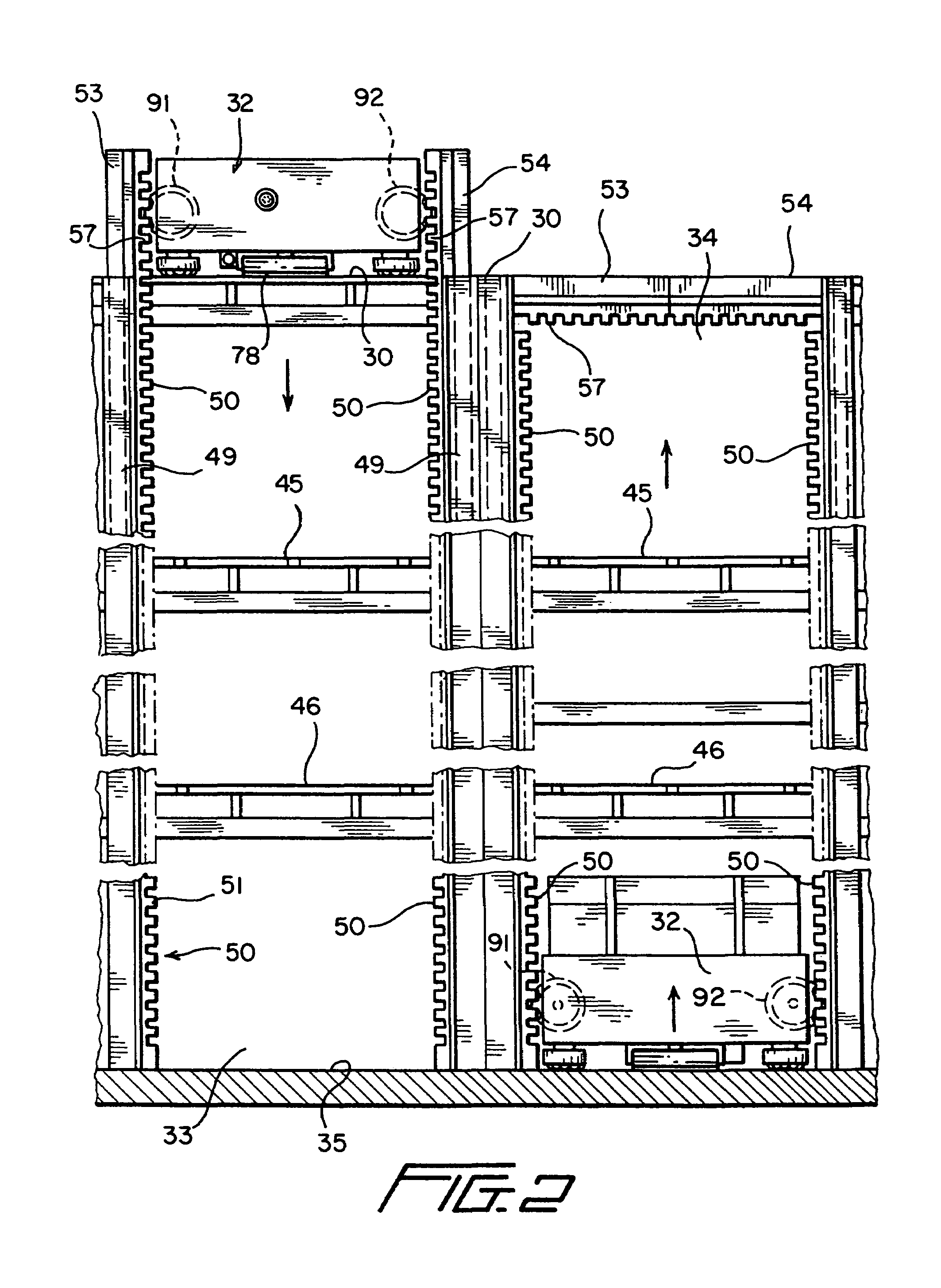

An automated storage and retrieval system wherein electrically driven, computer-controlled carriages (58) can navigate a system of rails (78) in three-dimensions. Multiple carriages (58) can independently operate at the same time to accomplish a task faster or to work on several different tasks at the same time. The rails (78) have a system of trap doors (95) that allow a carriage (58) to use a single reversible motor (67) to navigate the rails (78) in three-dimensions. With the carriage (58) in positioned in font of a bin position, the carriage mounted manipulating device (125) can move bins (115) to and from the racks (107) from either side with a single reversible motor (131). The rails (78) are electrified to provide power for the drive (67) and manipulator motors (131). A main computer (146) maintains the inventory, handles transactions and assigns tasks to the computer-controlled carriages (58). The system can be scaled to handle different types of items and can be configured to fit in the space available.

Owner:KING RODNEY JOE

Substrate processing apparatus

Substrate processing apparatus having a chamber, a generally linear array of process modules, a substrate transport, and a drive system. The chamber is capable of being isolated from the outside atmosphere. Each process module of the array is communicably connected to the chamber to allow a substrate to be transferred between the chamber and process module. The substrate transport is located in and is movably supported from the chamber. The transport is capable of moving along a linear path defined by the chamber for transporting the substrate between process modules. The drive system is connected to the chamber for driving and moving the transport along the linear path. The chamber comprises a selectable number of chamber modules serially abutted to defined the chamber. Each module has an integral portion of the drive system.

Owner:BOOKS AUTOMATION US LLC

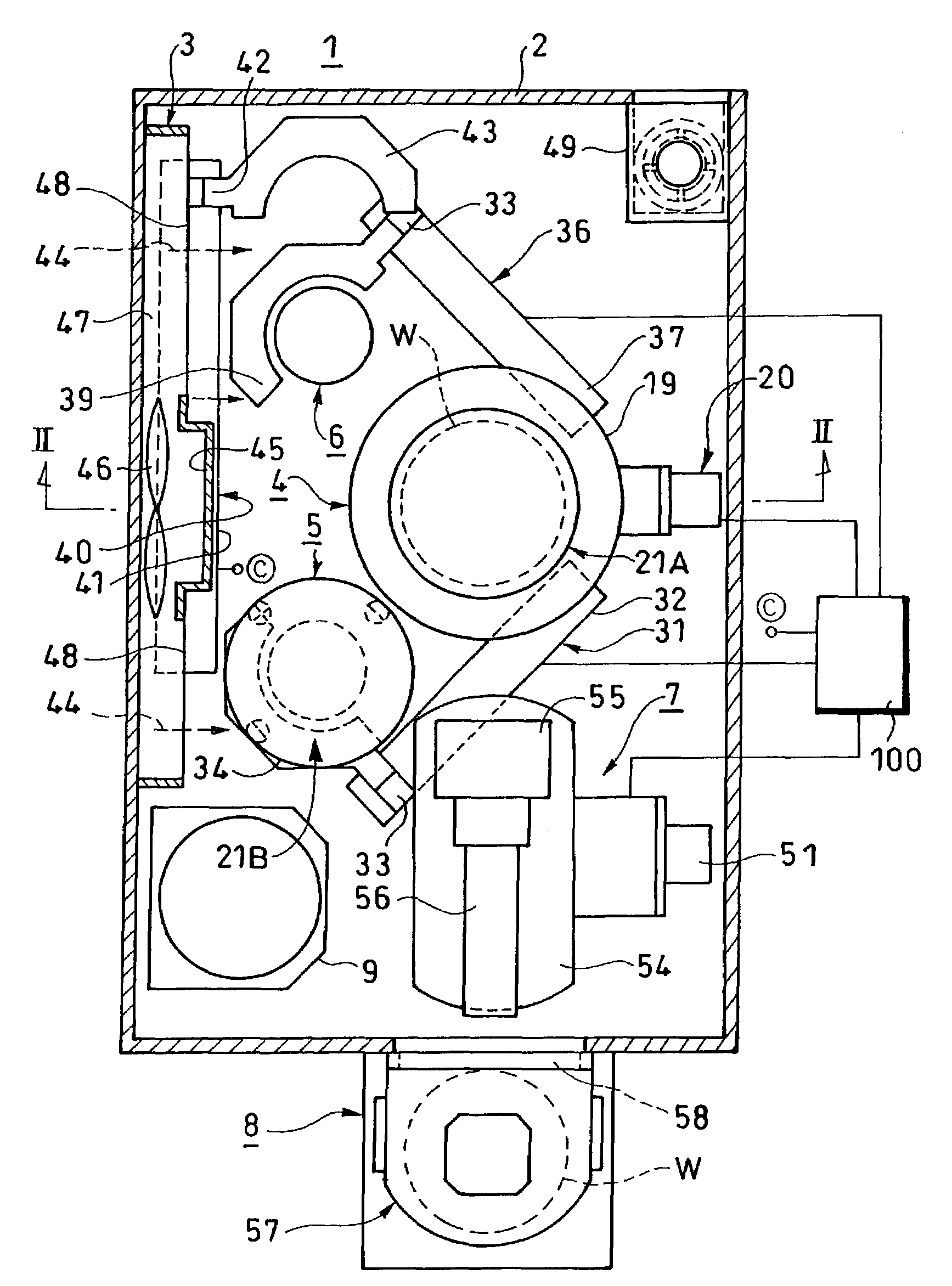

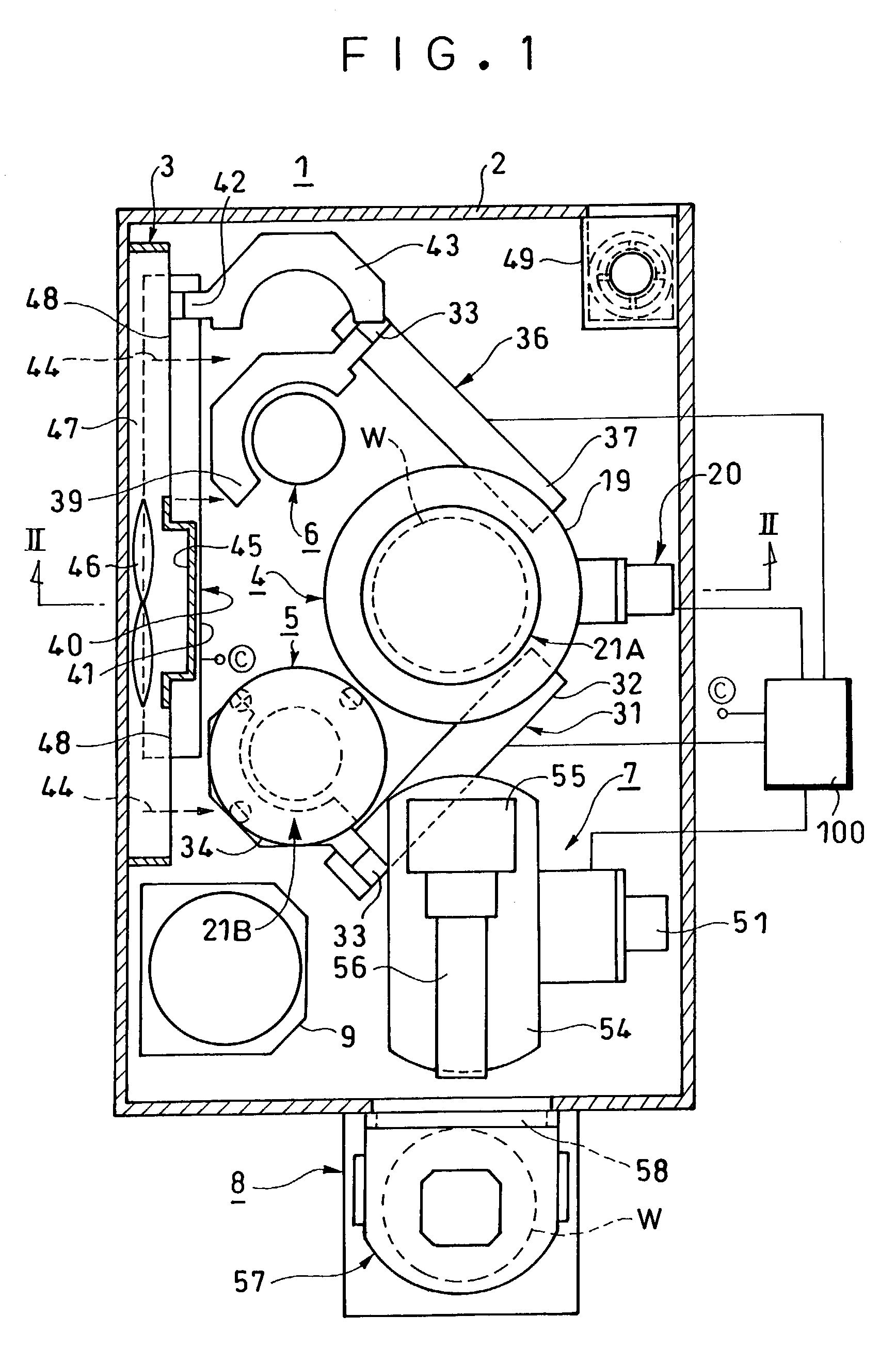

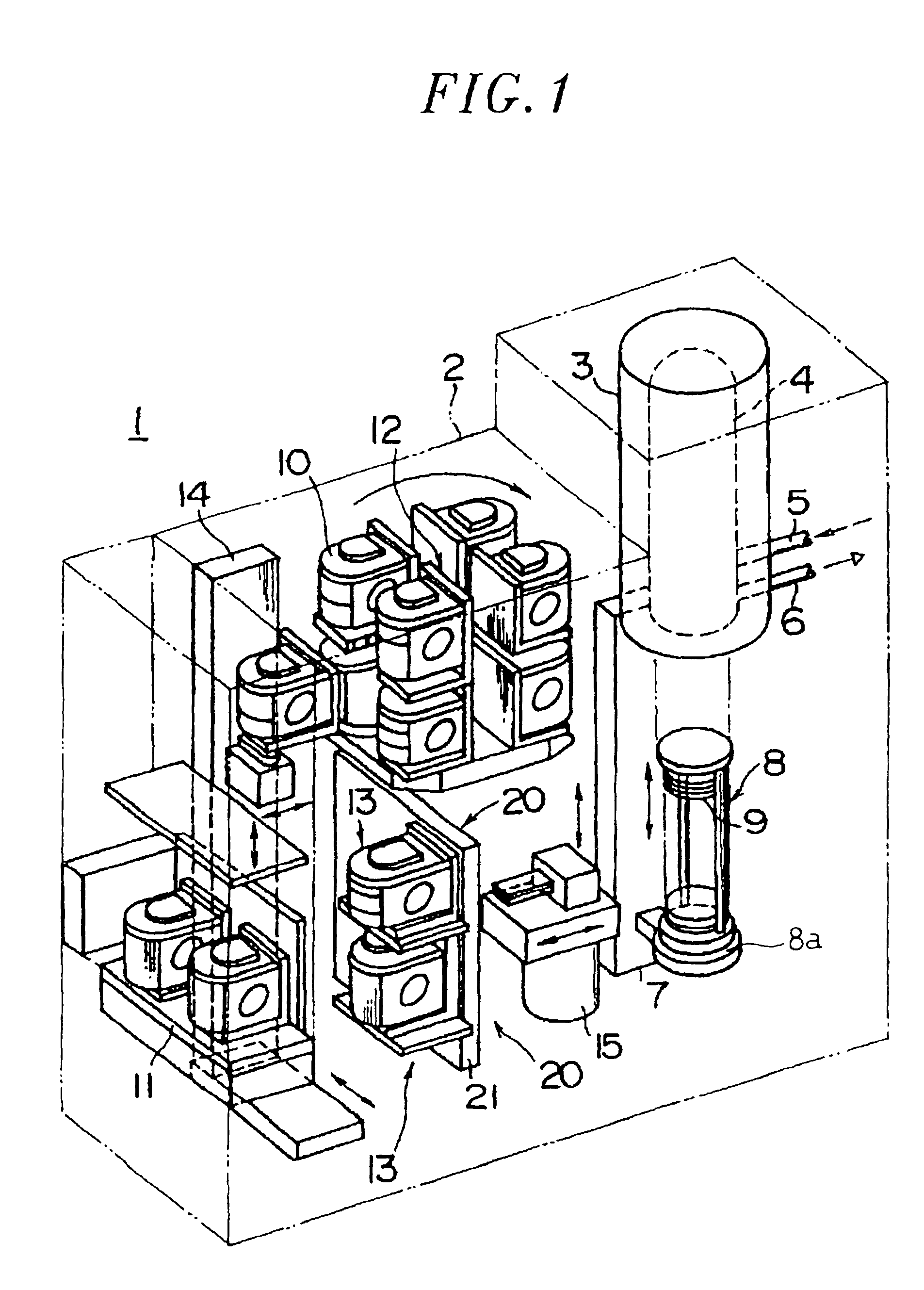

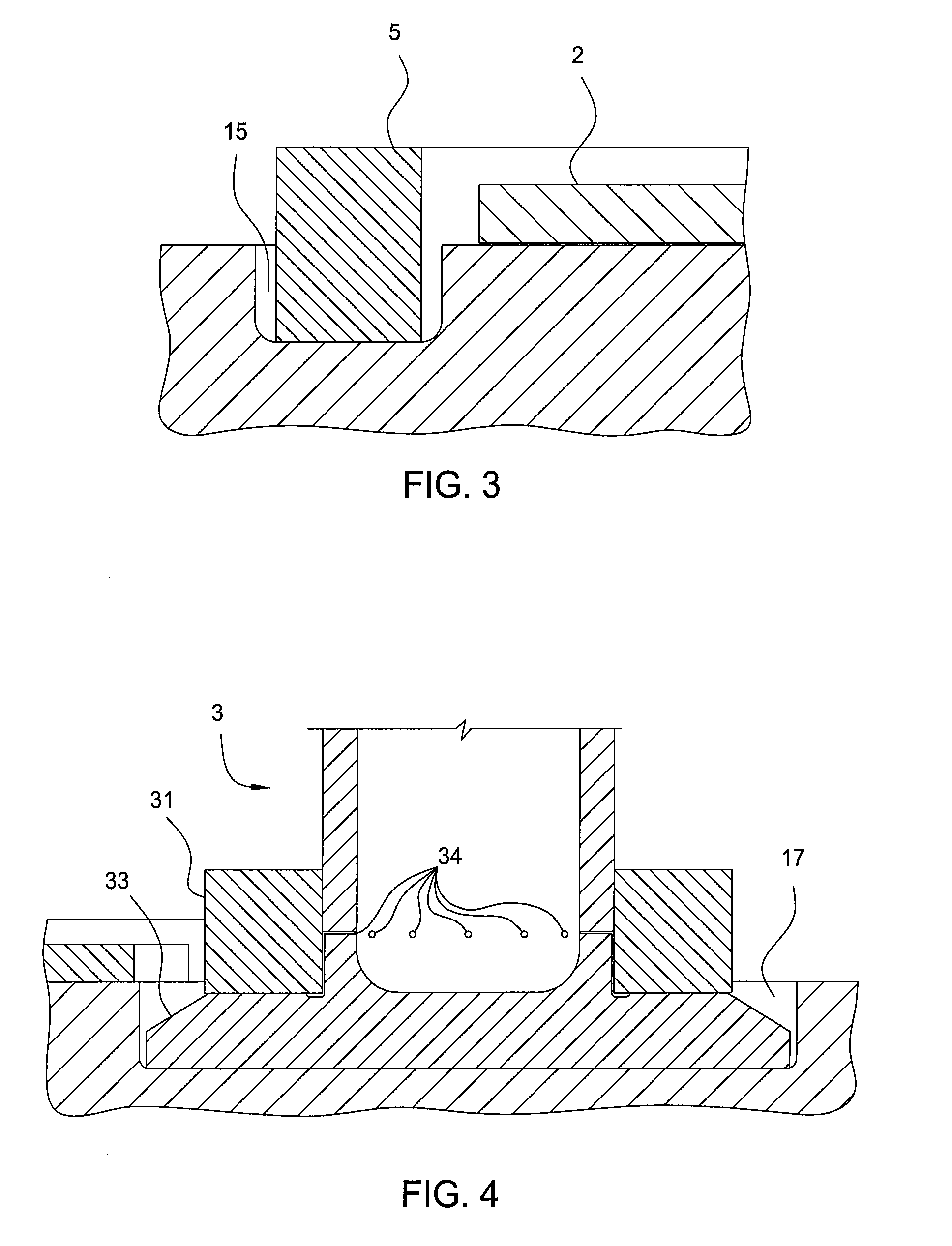

Semiconductor device producing apparatus and producing method of semiconductor device

InactiveUS7198447B2Reduce standby timeAvoid it happening againSemiconductor/solid-state device manufacturingArticle unpackingEngineeringTransfer mechanism

A semiconductor device producing apparatus is disclosed. The apparatus includes a carrier-holding stage for placing a carrier; first, second and third stages each for holding first and second boats one at a time, each boat holding one or more substrates; a boat transfer mechanism for transferring the boats among the first, second and third stages; and a substrate transfer mechanism for transferring the substrate(s) from the carrier to the boat held by the first stage. A controller controls the first stage, the boat transfer mechanism and the substrate transfer mechanism so that the boat transfer mechanism transfers one of the boats from the second stage to the first stage, the substrate transfer mechanism then transfers the substrate(s) from the carrier to the boat held by the first stage, and the first stage then moves the boat into the processing chamber for processing.

Owner:KOKUSA ELECTRIC CO LTD

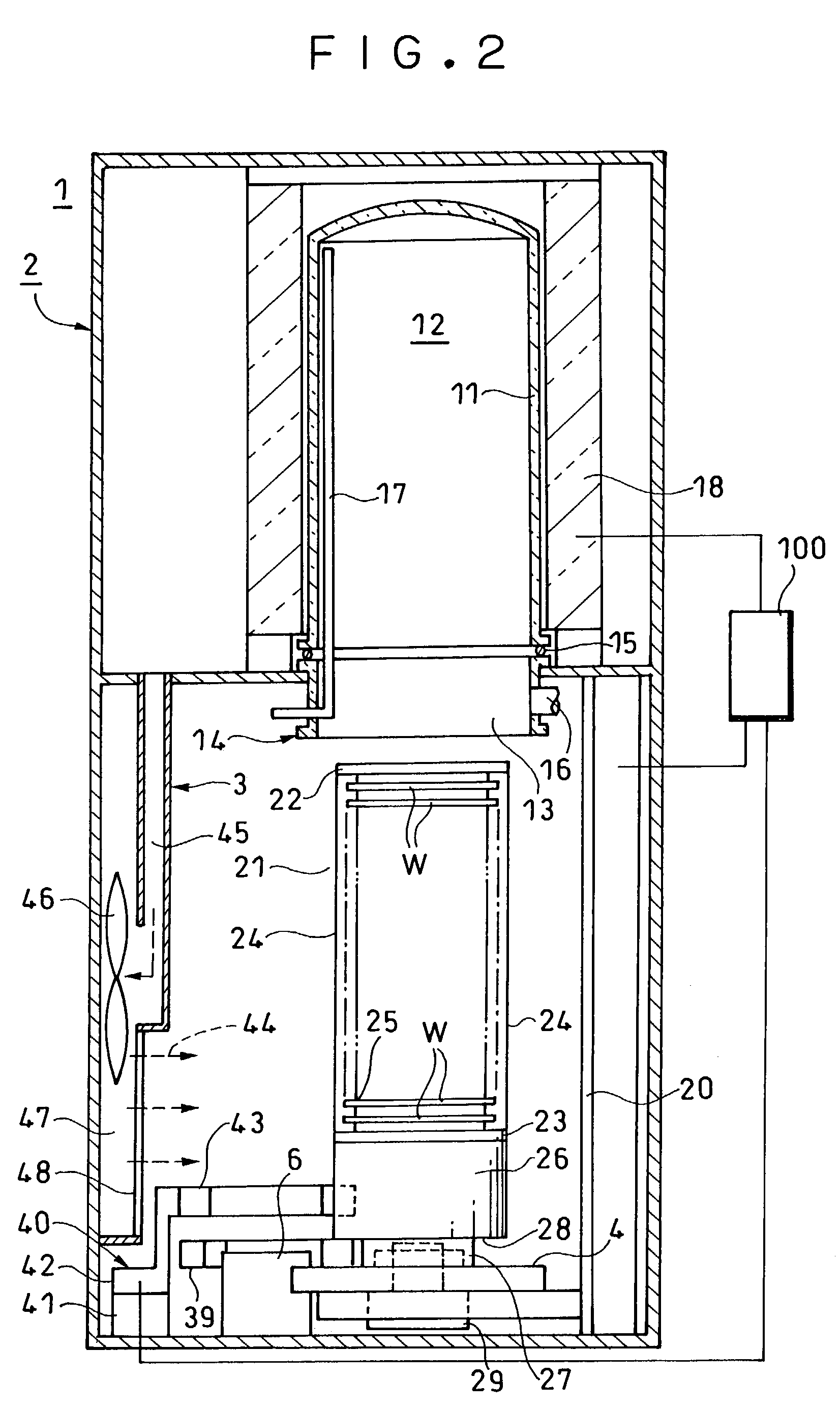

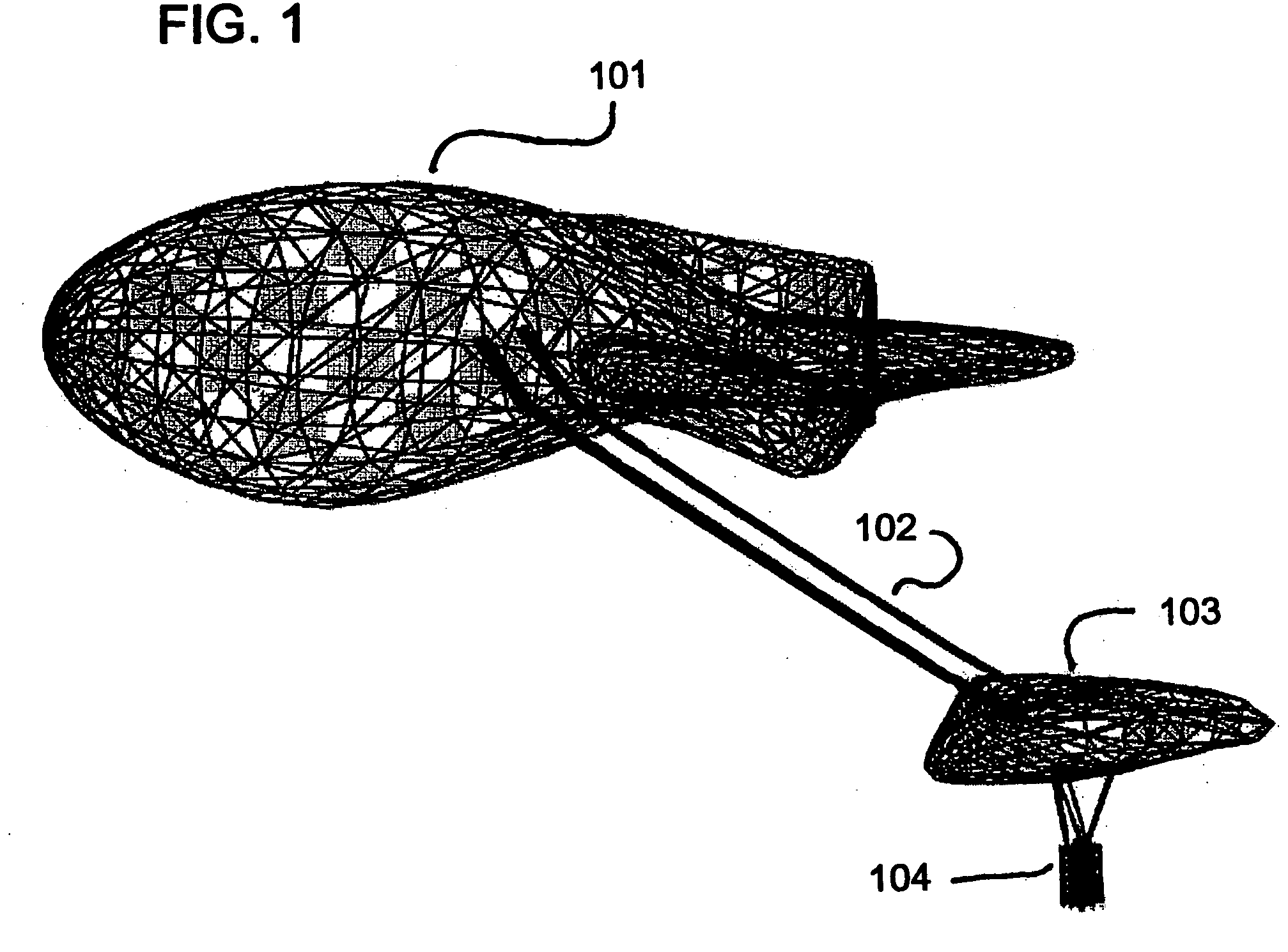

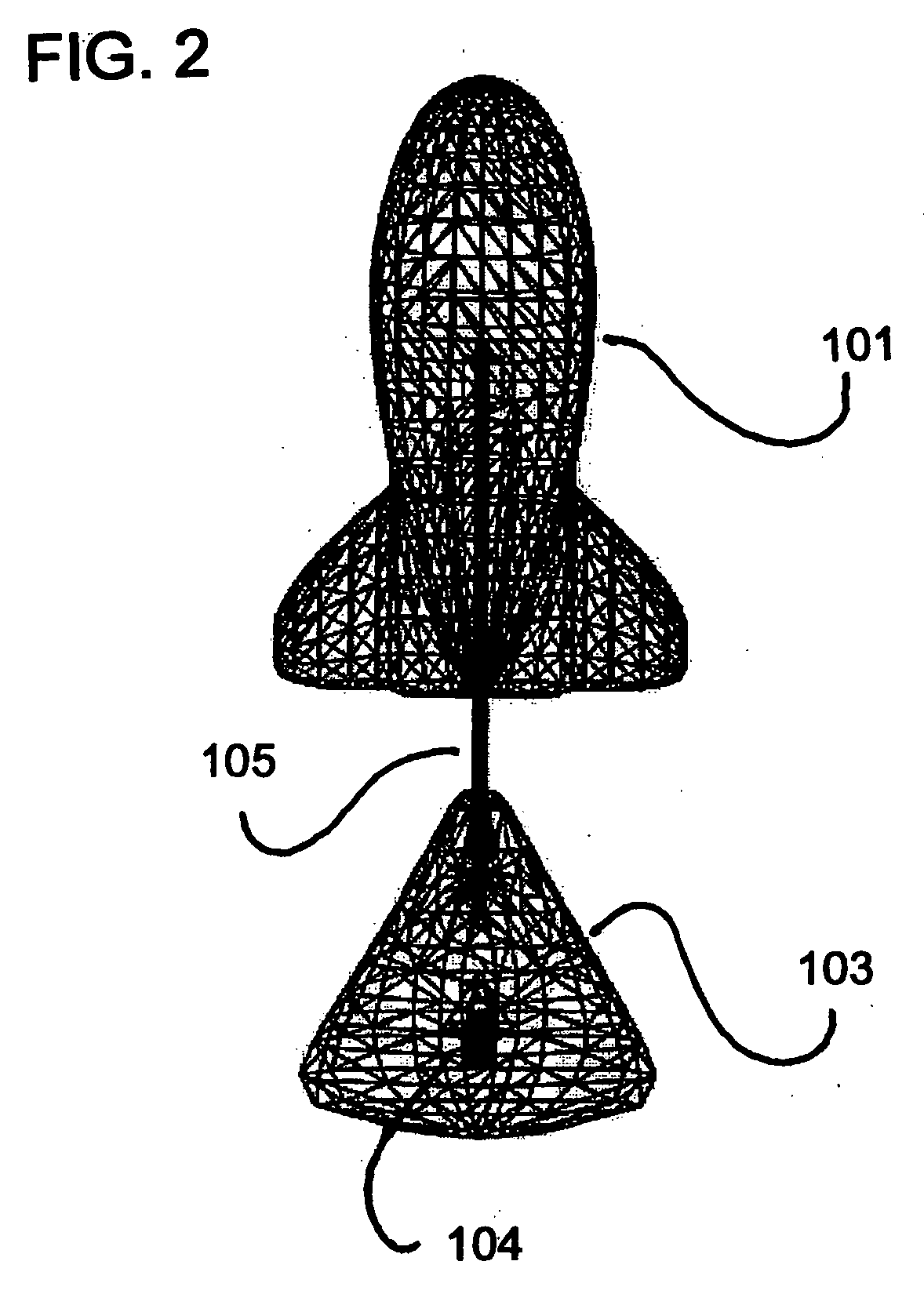

Multibody aircrane

InactiveUS20090152391A1Precise and timely point to point transferEfficient powerCargo handling apparatusPassenger handling apparatusLow speedControl line

The MULTIBODY AIRCRANE performs relative positioning, predictive control, and ballast control to achieve very heavy-lifting tasks on land or sea. Such tasks allow station keeping and precise transfer of very heavy payloads between ships underway. This scalable multibody system features three subcomponents: AIRSHIP, SKYCRANE and LOADFRAME. This semi-autonomous system combines aerodynamic (kinetic) and aerostatic (buoyancy force) lift with efficient power and propulsion. During low-speed flight, the Airship and Skycrane are decoupled but linked via a reelable Tether Control Line. Beneath the Skycrane, centered on its hull, a patented NIST (National Institute of Standards and Technology) RoboCrane (featuring a computer controlled six degrees of freedom (DoF) cabling system,) is attached, to precisely suspend and control a Loadframe, with or without payload. During subsonic forward flight, these Airship and Skycrane are coupled as a single airframe (fuselage and delta wing.)

Owner:MCWHIRK BRUCE KIMBERLY

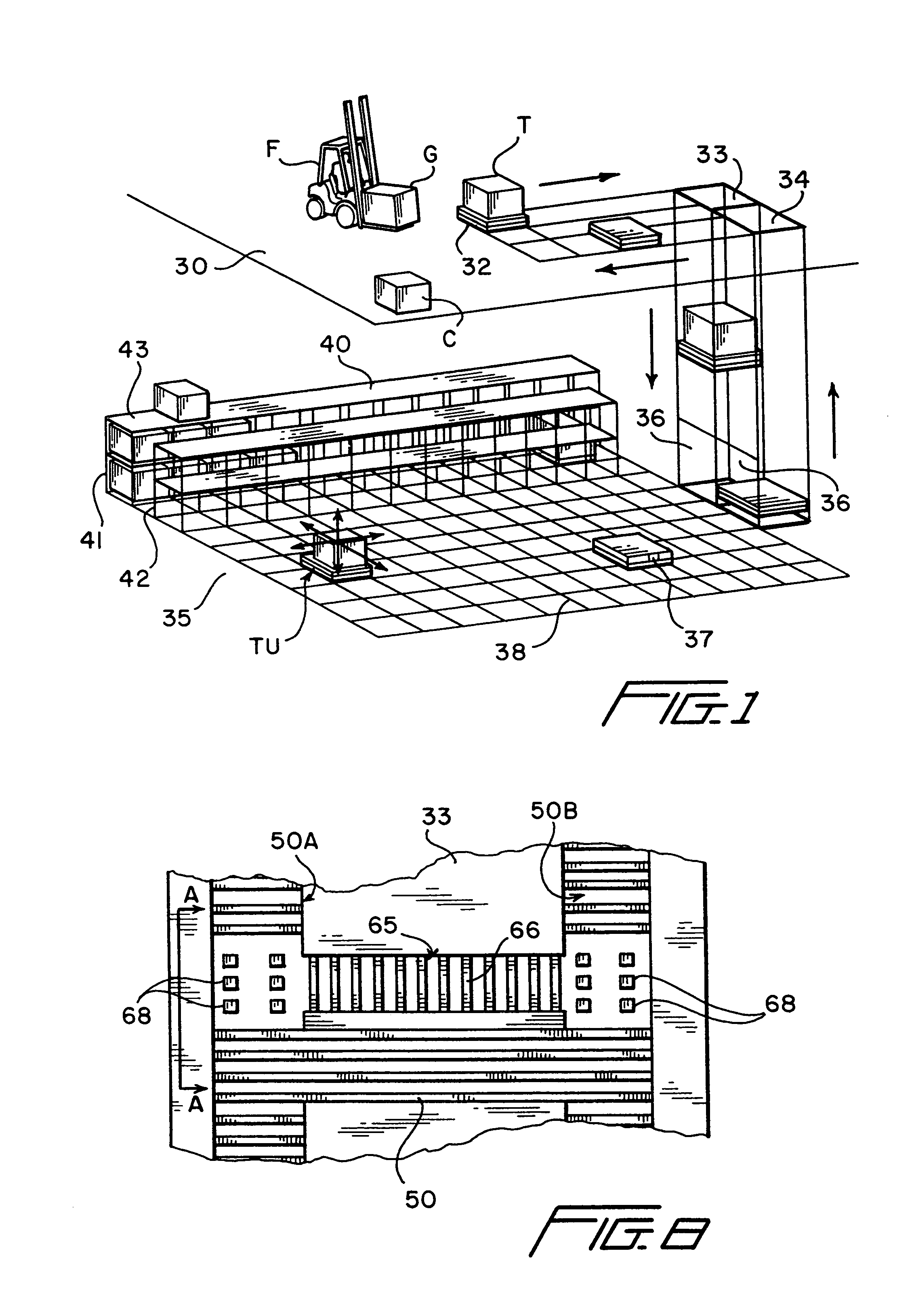

Automated material handling system with motorized transfer vehicles

InactiveUS7101139B1Improve securityProvide energyAutomatic initiationsLoad accommodationMaterial handlingTreatment system

A material handling system for use in storing and moving goods within multi-level storage warehouses, ocean going vessels and the like wherein storage areas are provided on at least one of the levels and wherein goods are automatically transferred to and from the storage areas and between the various levels by self-propelled load transfer vehicles. The load transfer vehicles move across the surface of the various levels and deliver are also movable within open vertical trunks between the levels to thereby move goods to any desired area.

Owner:GEBRR BECKER

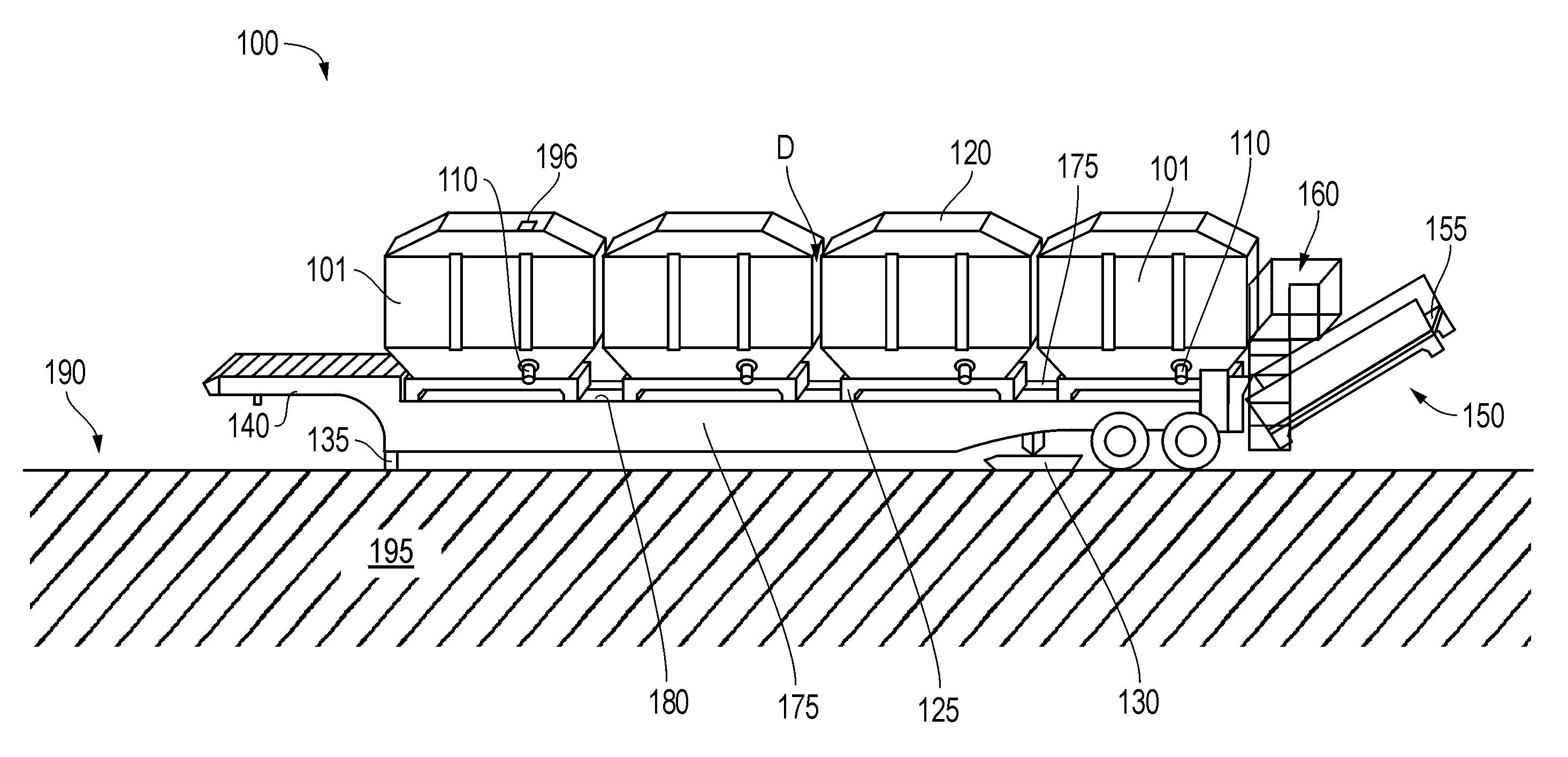

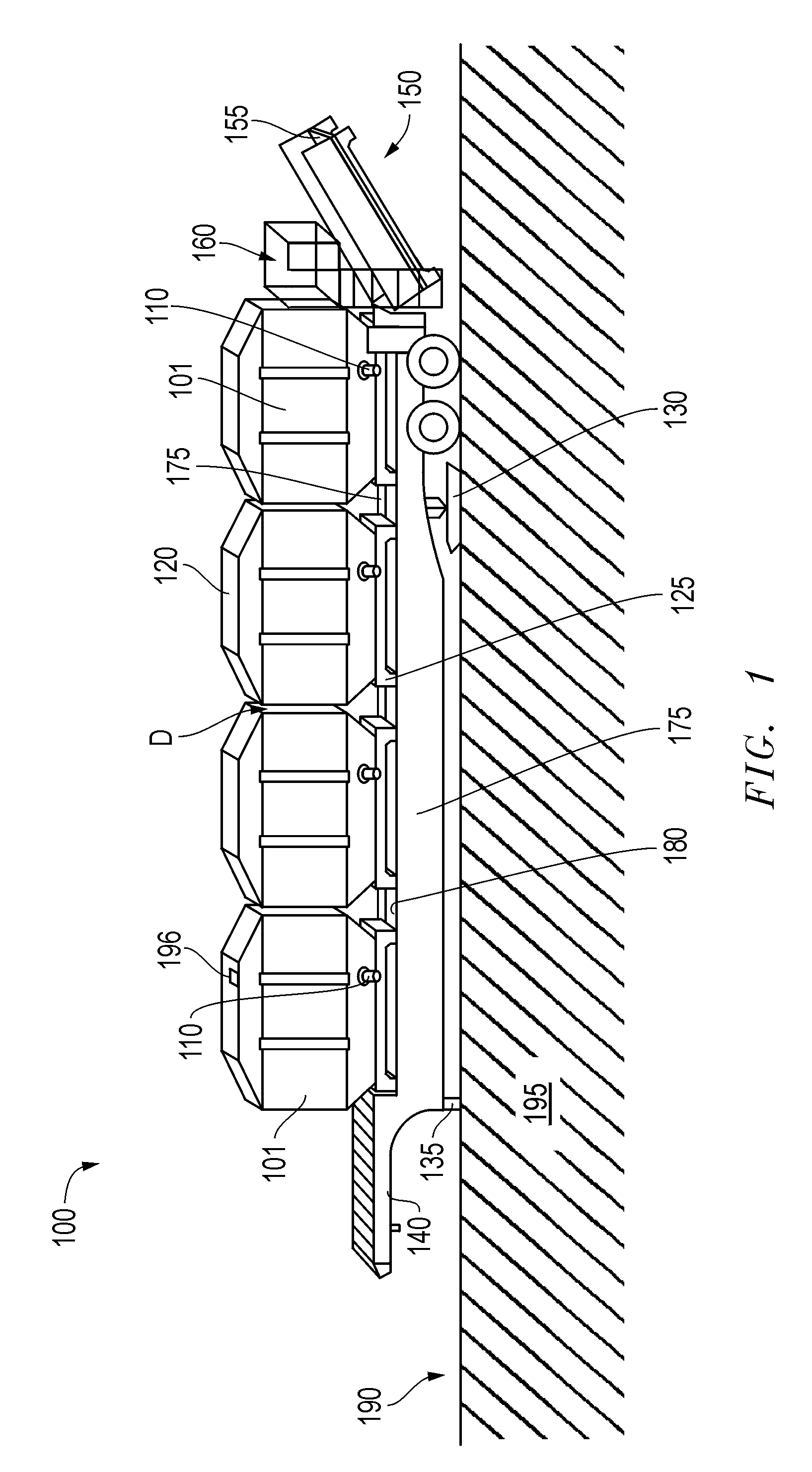

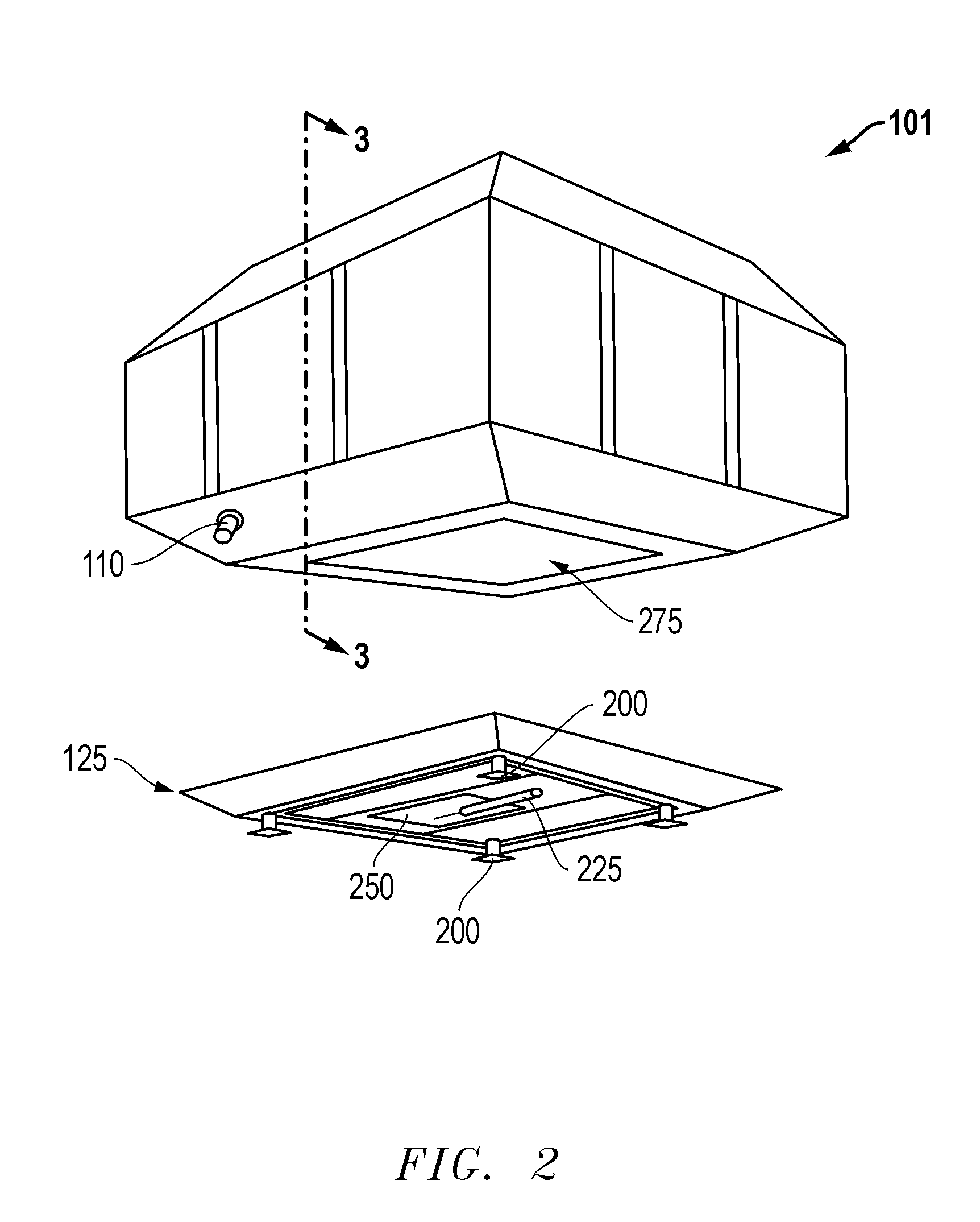

Aggregate Delivery Unit

A delivery unit for providing aggregate to a worksite, such as a wellsite location. The unit may include a mobile chassis for accommodating a plurality of modular containers which in turn house the aggregate. As such, a weight measurement device may be located between each container and the chassis so as to monitor aggregate levels within each container over time. The units may be particularly well suited for monitoring and controlling aggregate delivery during a fracturing operation at an oilfield. The modular containers may be of an interchangeable nature. Furthermore, a preferably wireless control device may be provided for monitoring and directing aggregate delivery from a relatively remote location.

Owner:SCHLUMBERGER TECH CORP

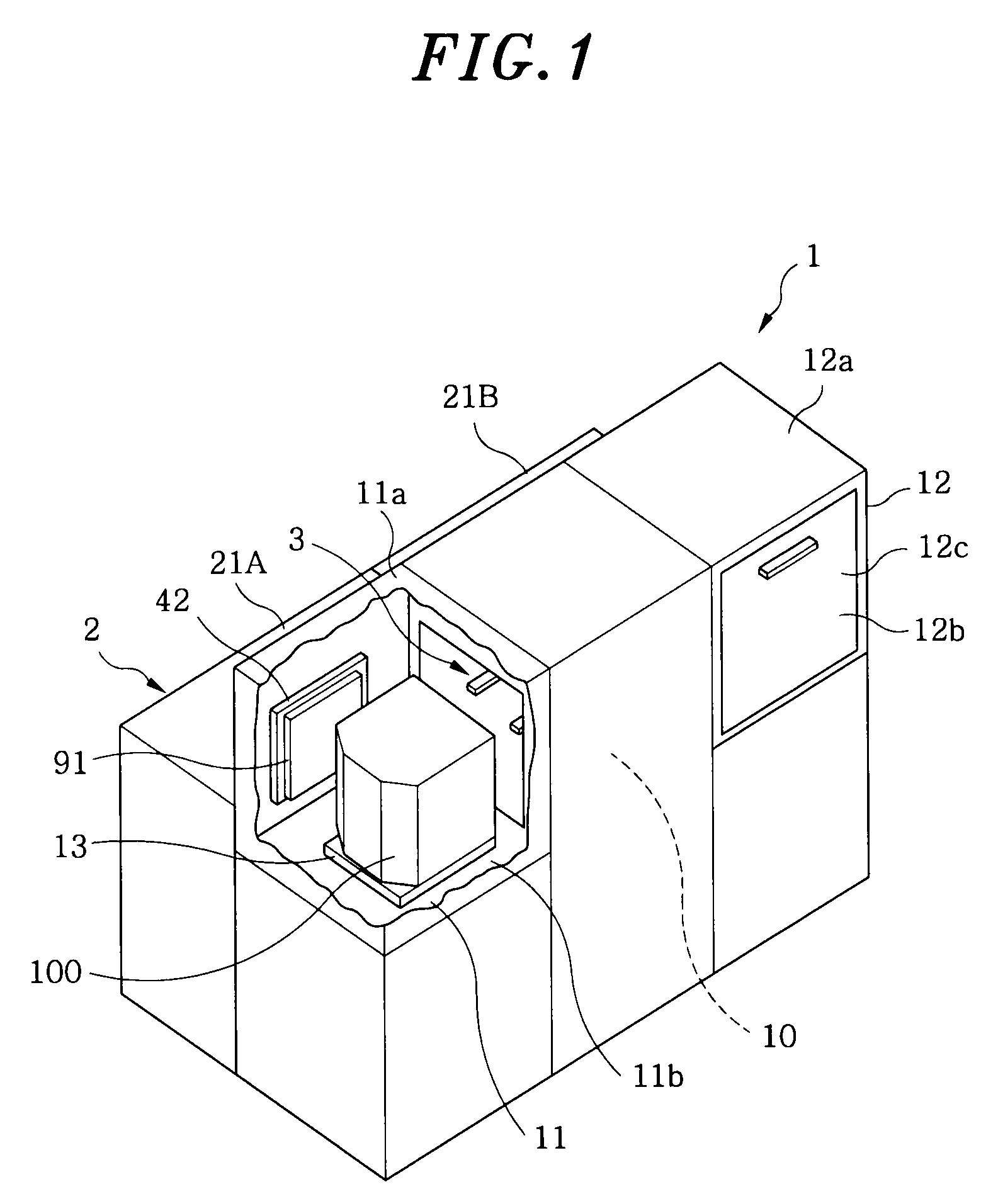

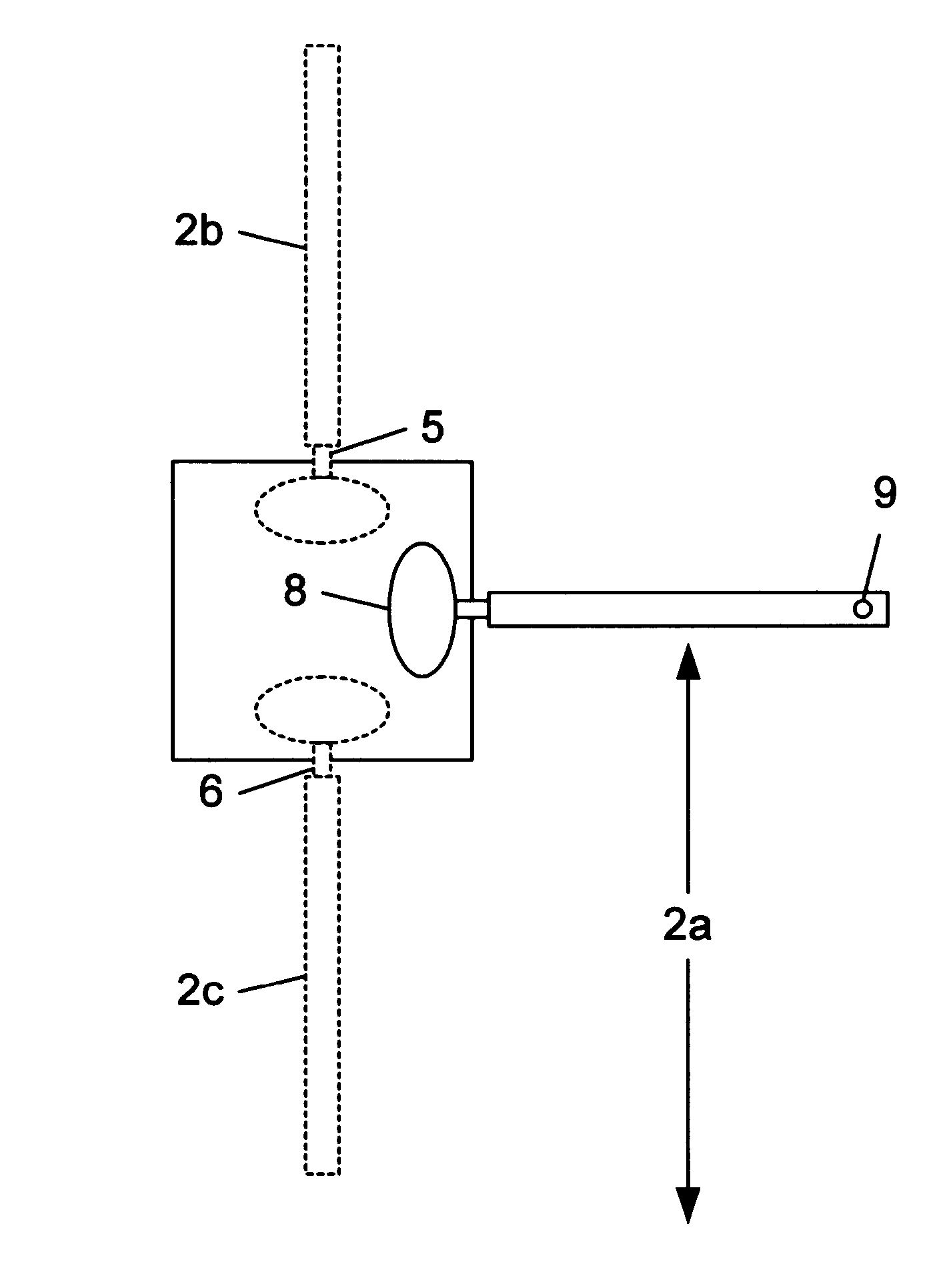

Apparatus And Method For Transporting Wafers Between Wafer Carrier And Process Tool Under Vacuum

ActiveUS20160035596A1Efficient solutionReduction in inner volumeSemiconductor/solid-state device manufacturingLoading/unloadingEngineeringElectrical and Electronics engineering

An integrated transport device for a wafer carrier includes: an evacuatable chamber for accommodating therein a wafer carrier having a front opening with a cover; a rotatable platform for placing the wafer carrier thereon in the chamber; and an opening / closing device for opening and closing the cover of the wafer carrier placed on the platform at a first position, wherein the platform rotates to set the wafer carrier at the first position and a second position for transporting a wafer to a wafer-handling chamber.

Owner:ASM IP HLDG BV

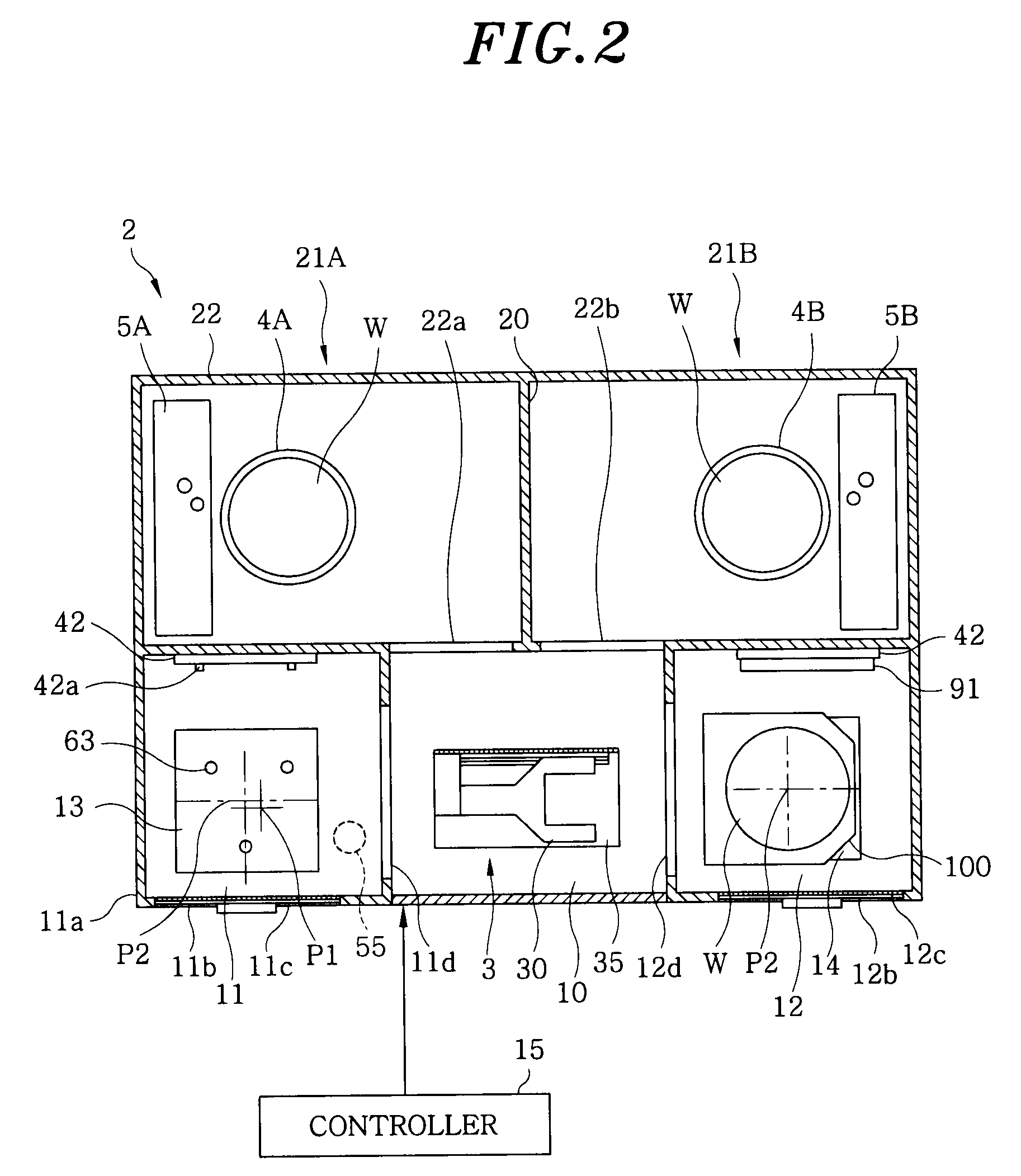

Dual loading port semiconductor processing equipment

InactiveUSRE43023E1Improve throughputDrying gas arrangementsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A substrate processing equipment comprises two pod supporting stages and two independently operable pod door openers. Each pod supporting stage is capable of placing thereon a pod for containing substrates therein. Each pod door openers having means for permitting access to the substrates inside the pod placed on a corresponding pod supporting stage.

Owner:KOKUSA ELECTRIC CO LTD

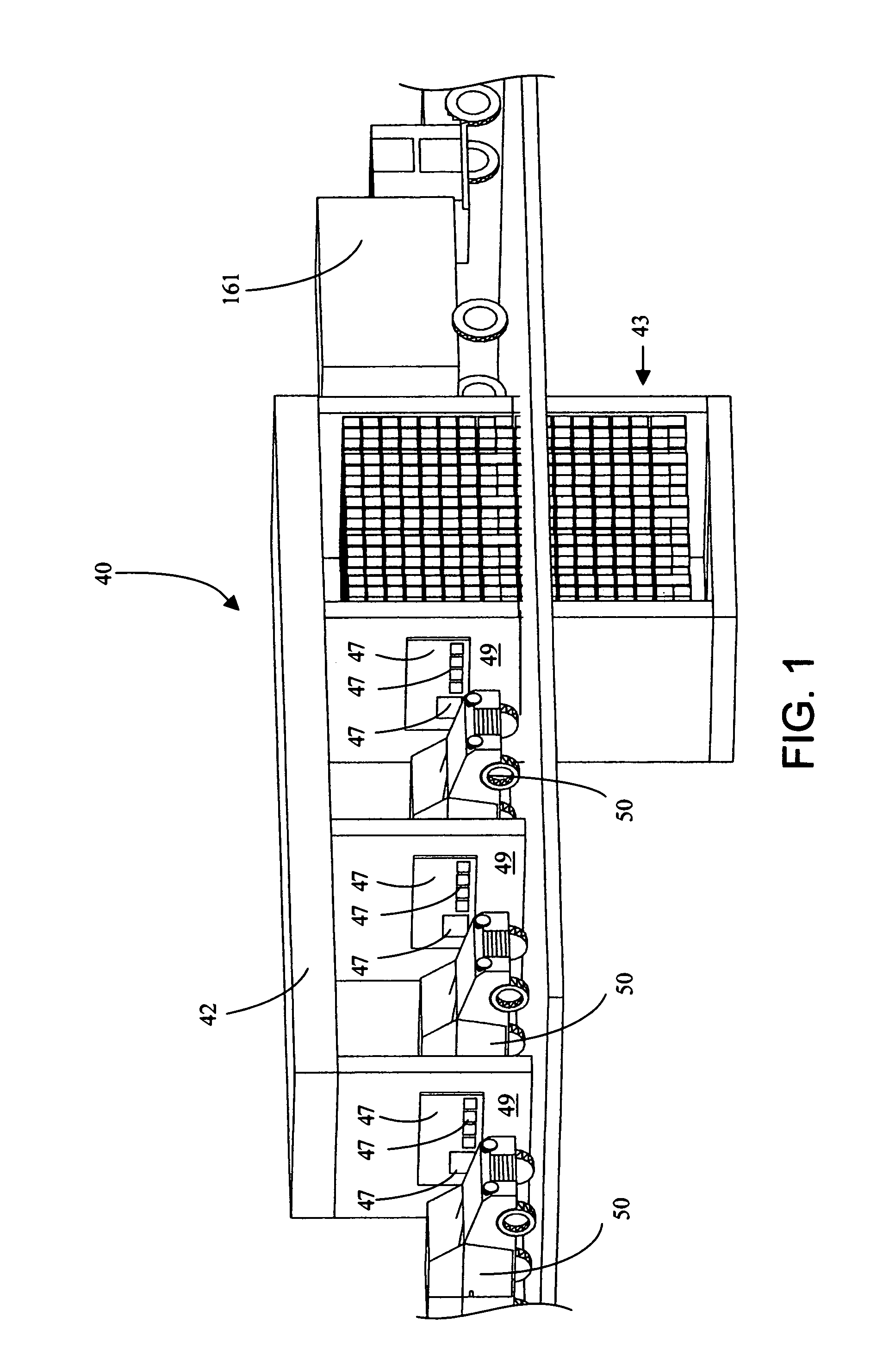

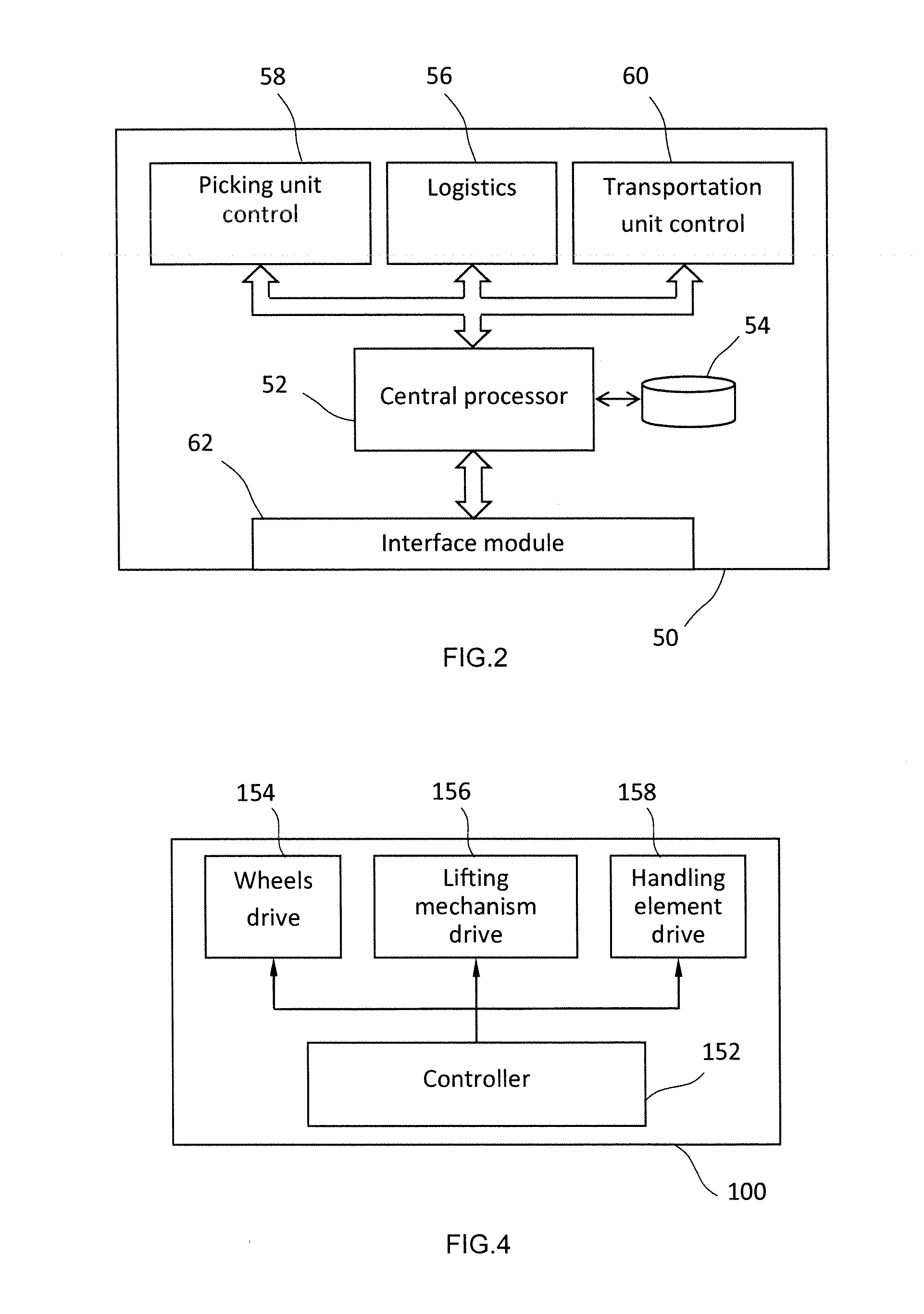

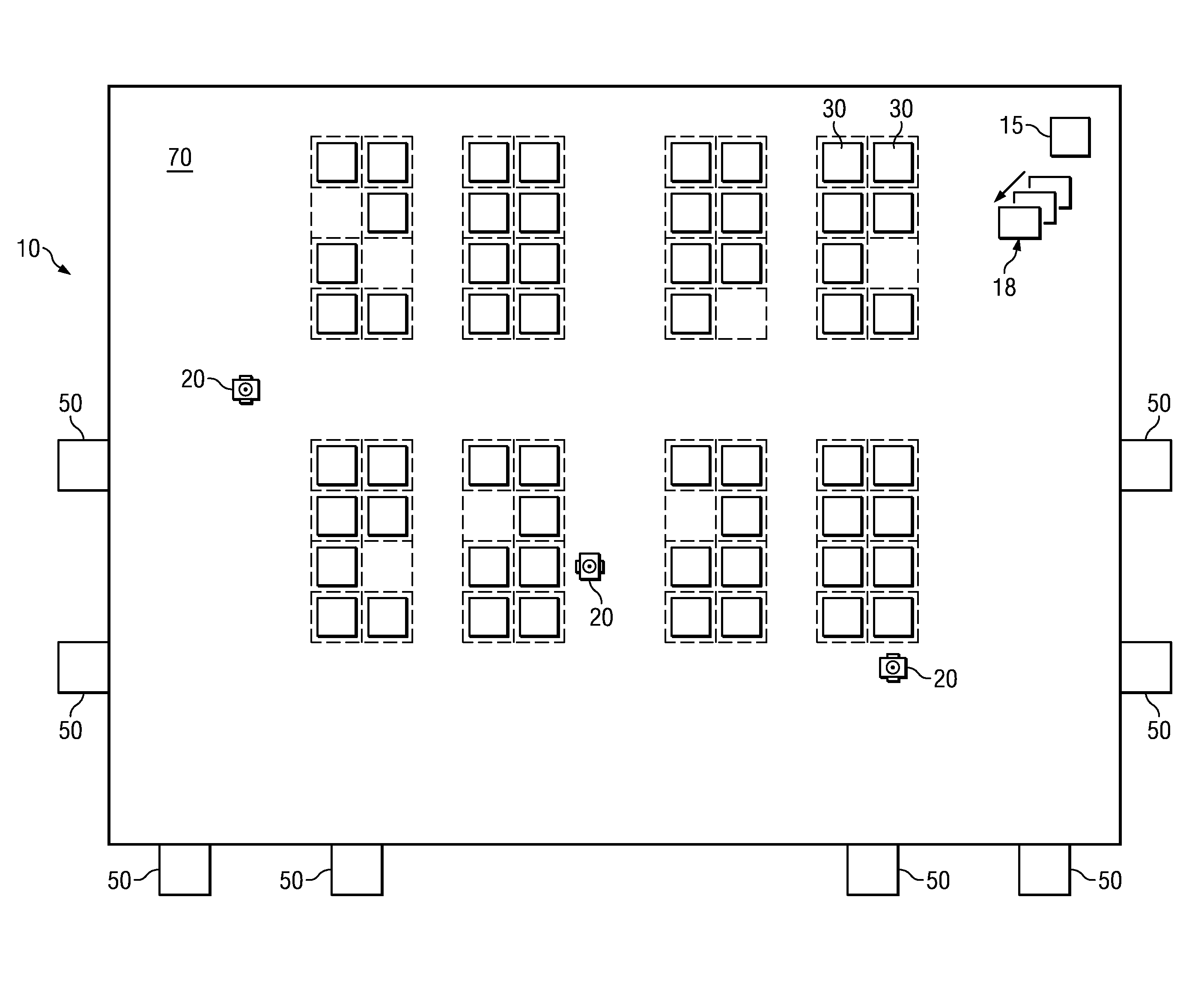

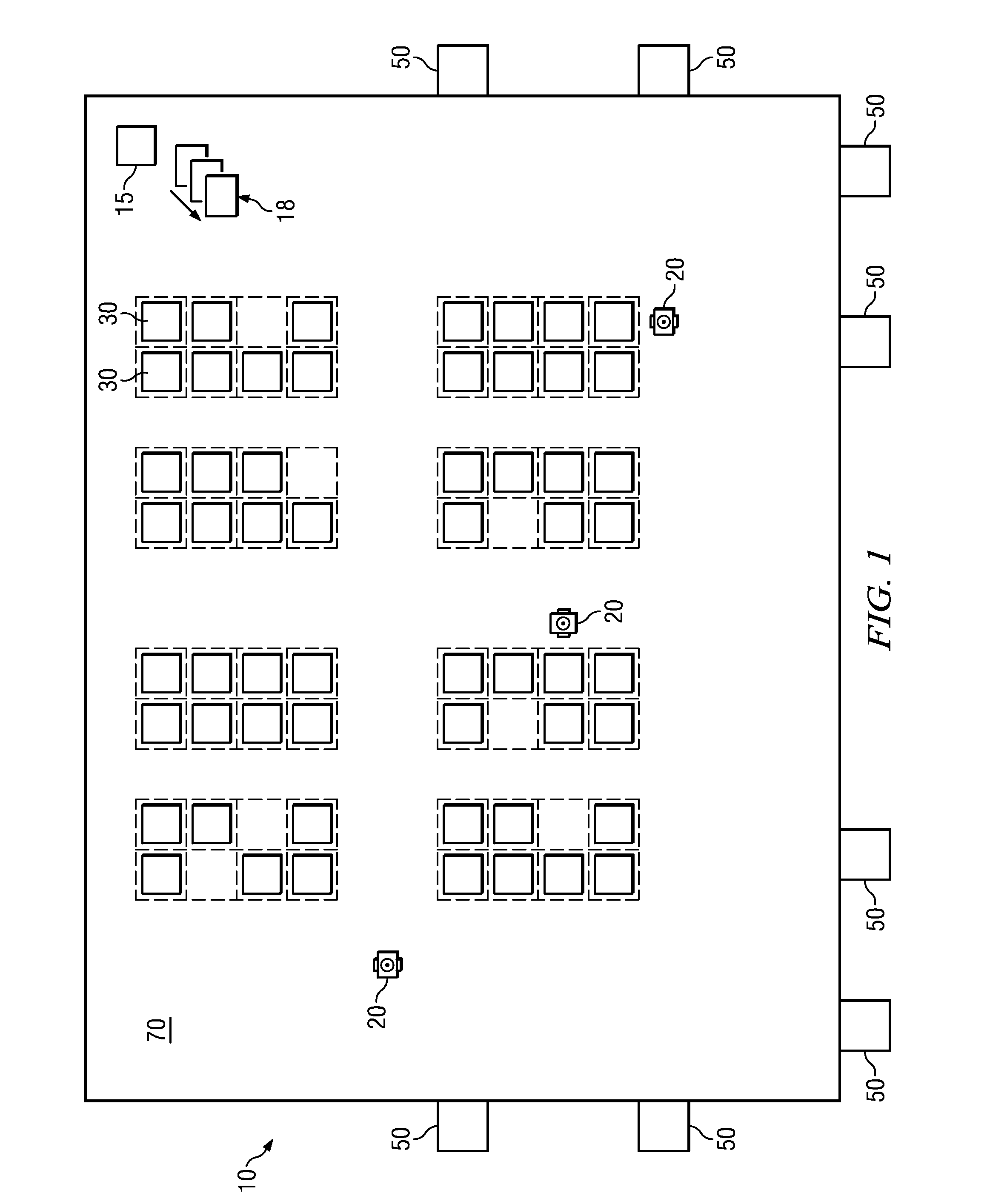

Automatic order picking system and method in retail facility

InactiveUS20150098775A1Reduce order picking timeShorter picking timeConveyorsLifting devicesTransport engineering

An order picking system includes a storage system for storing containers arranged in multiple rows at various horizontal levels with respect to ground, the containers including source containers with goods stored in the storage system and reception containers to be filled with the ordered goods. At least one mobile picking unit may be moved in a horizontal direction along an upper level of the storage system, the picking unit is configured for taking ordered goods from the source containers arranged at the upper level and placing the ordered goods into the reception containers for delivery to the customers. At least one transportation unit may be moved along a lower level of the storage system arranged lower than the upper level. The transportation unit is configured for taking the containers from levels of the storage system lower than the upper level, and delivering the containers to the upper level.

Owner:ATOOL TRADING LTD

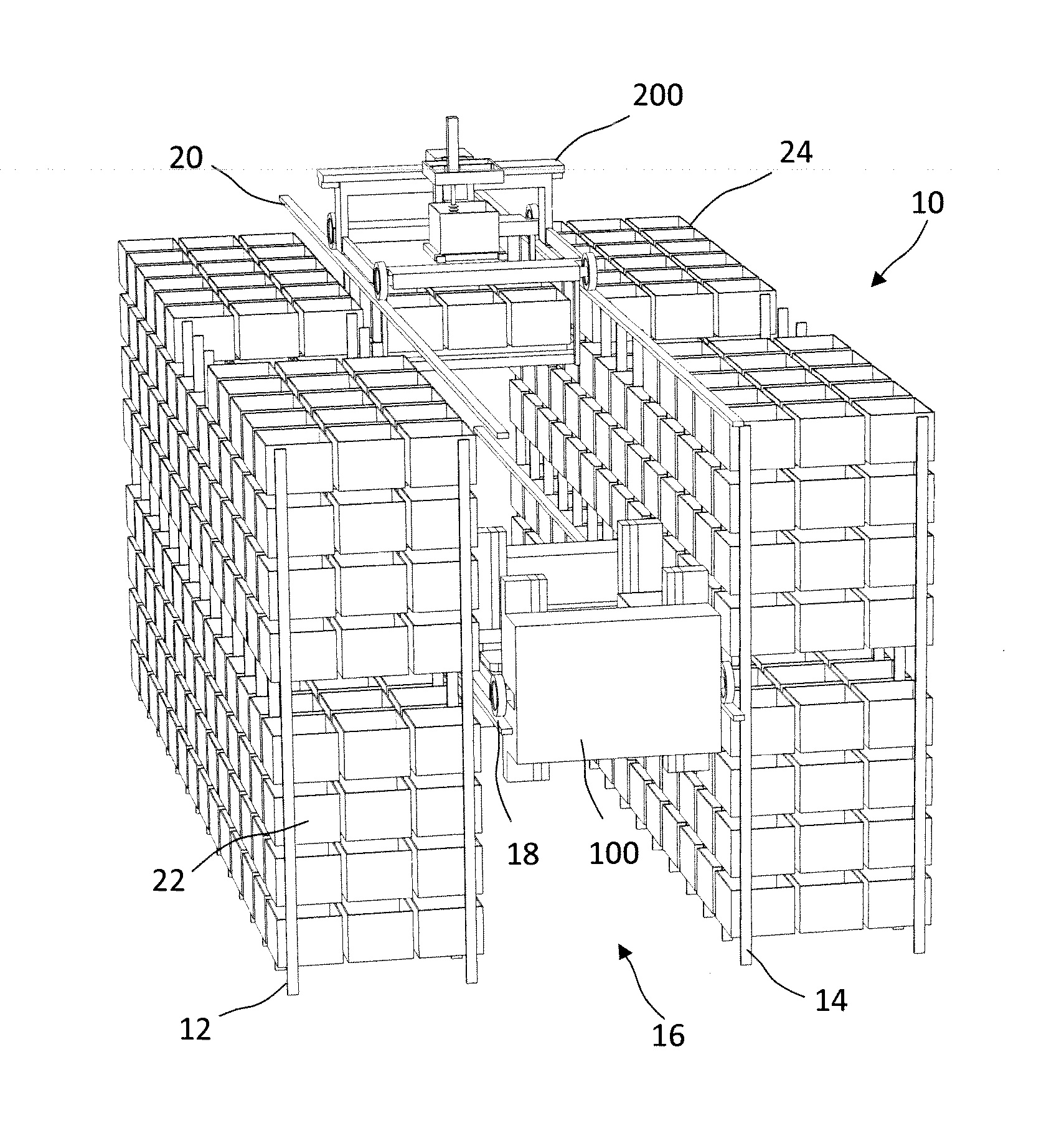

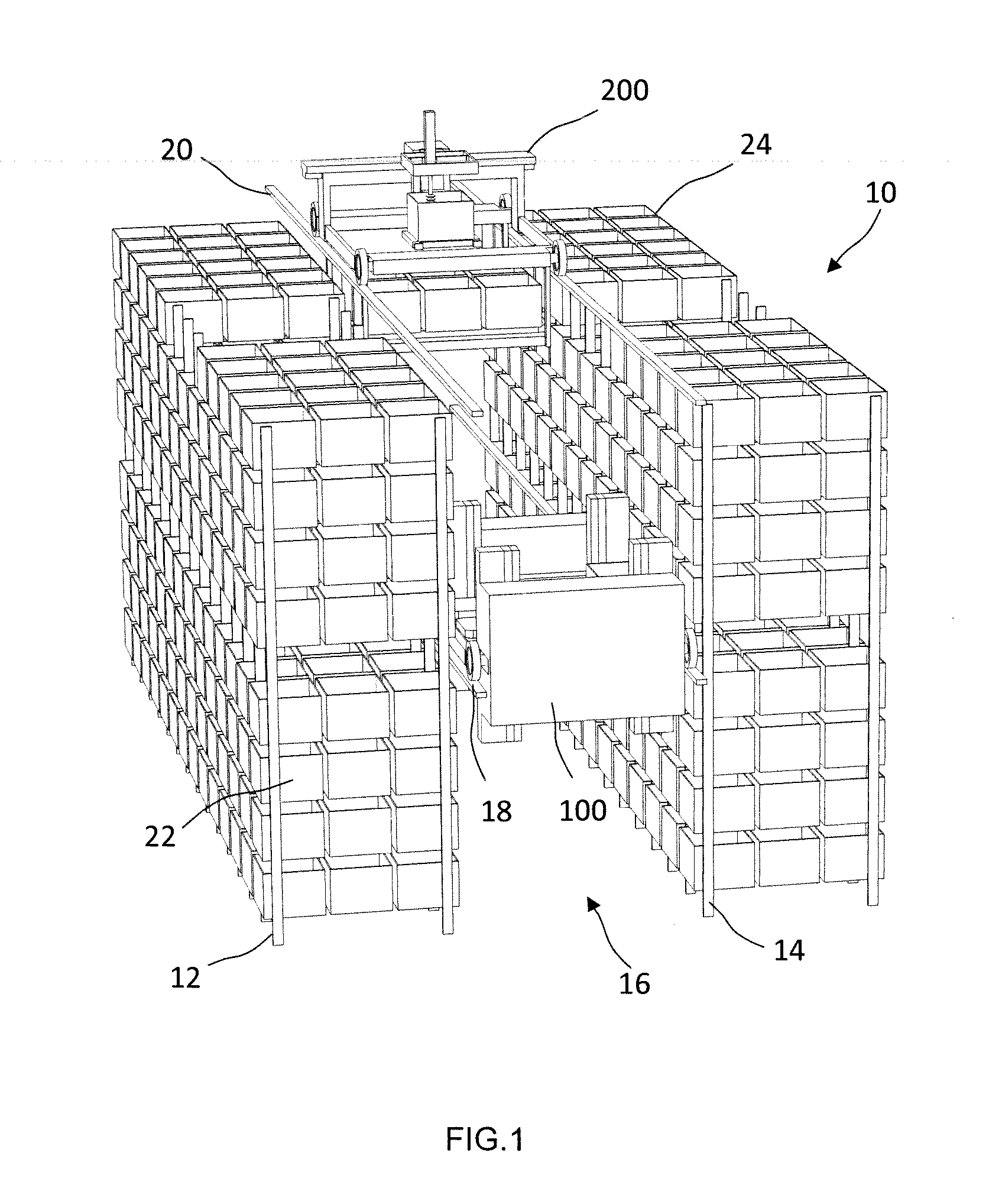

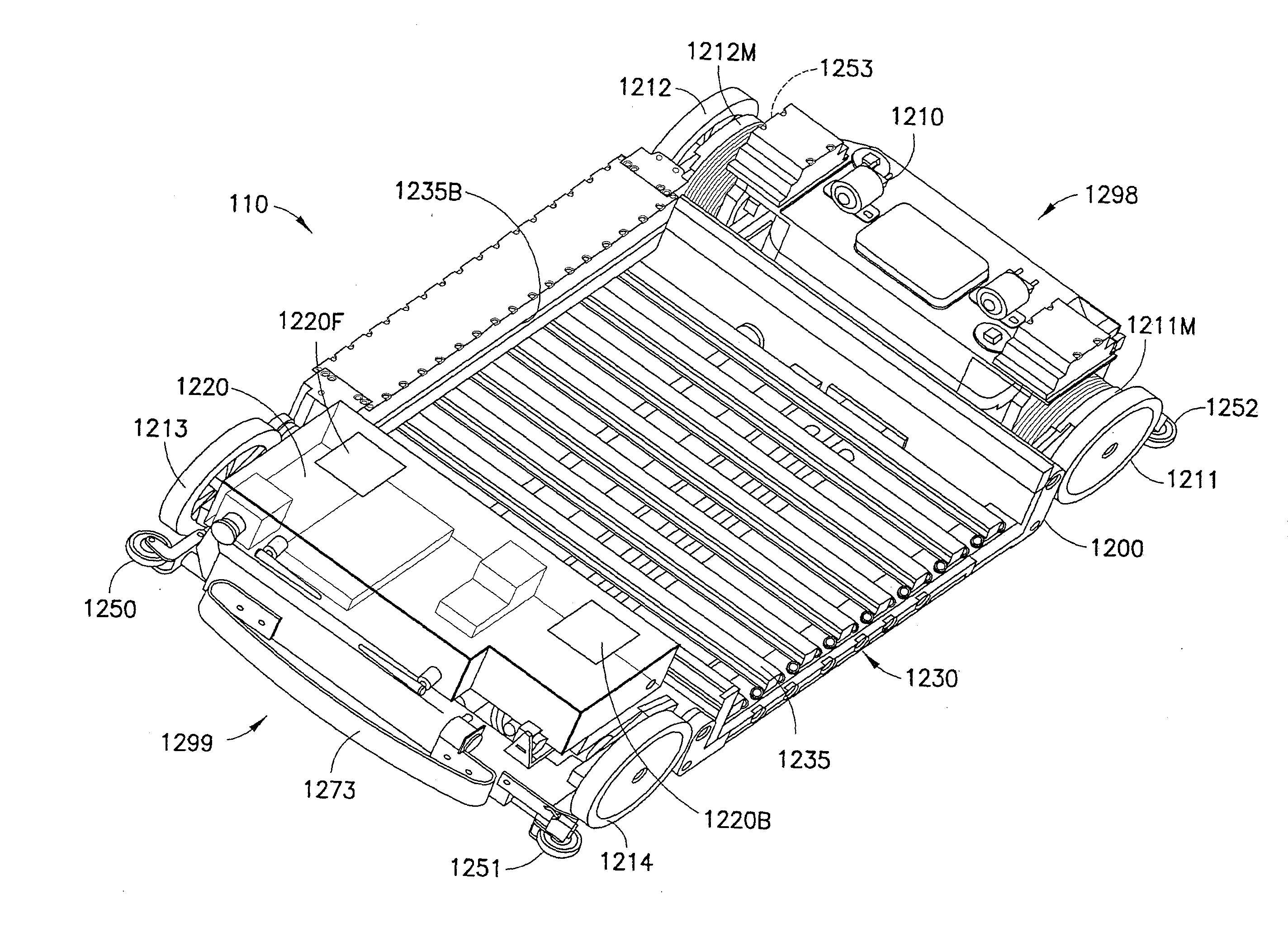

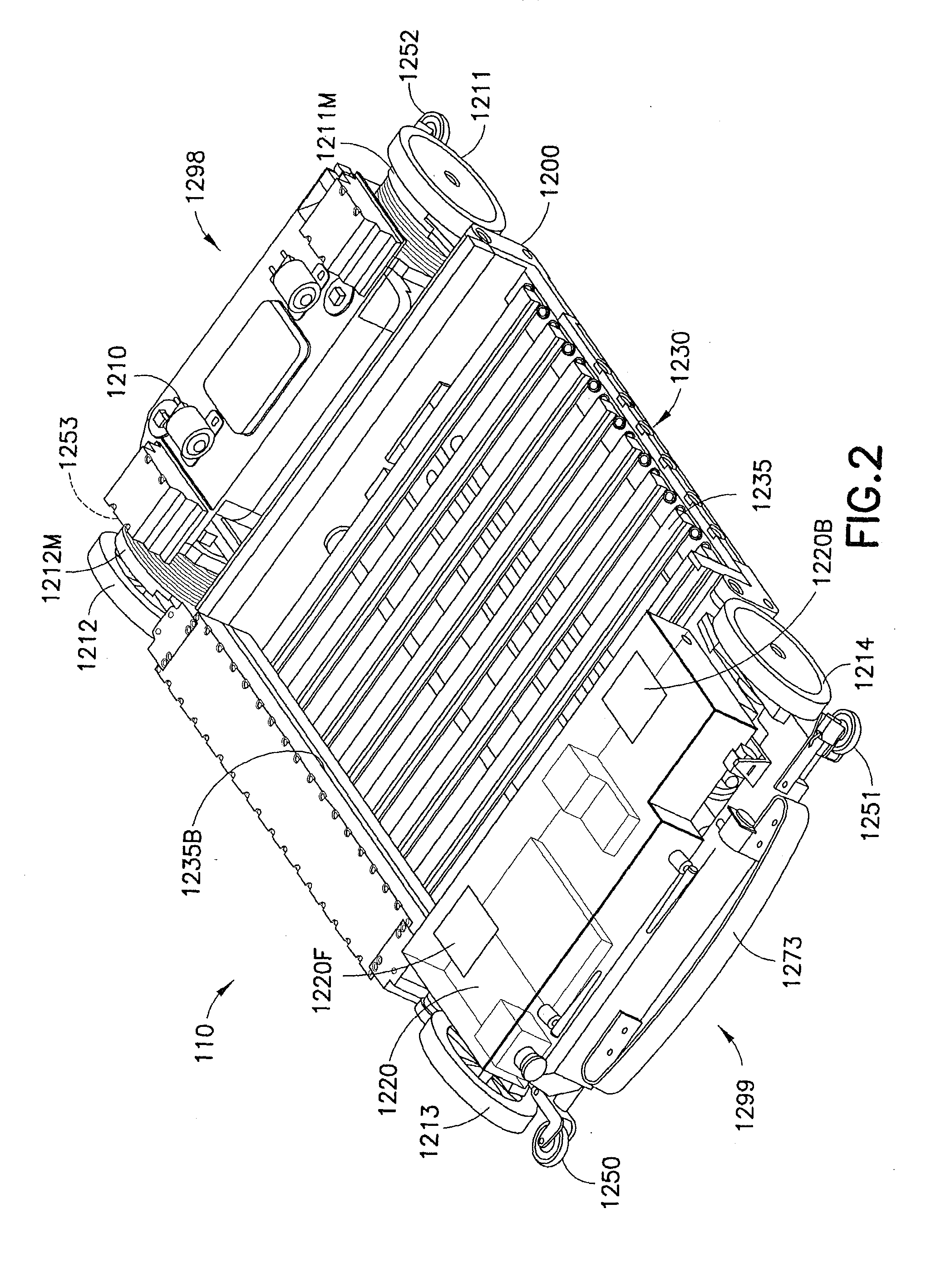

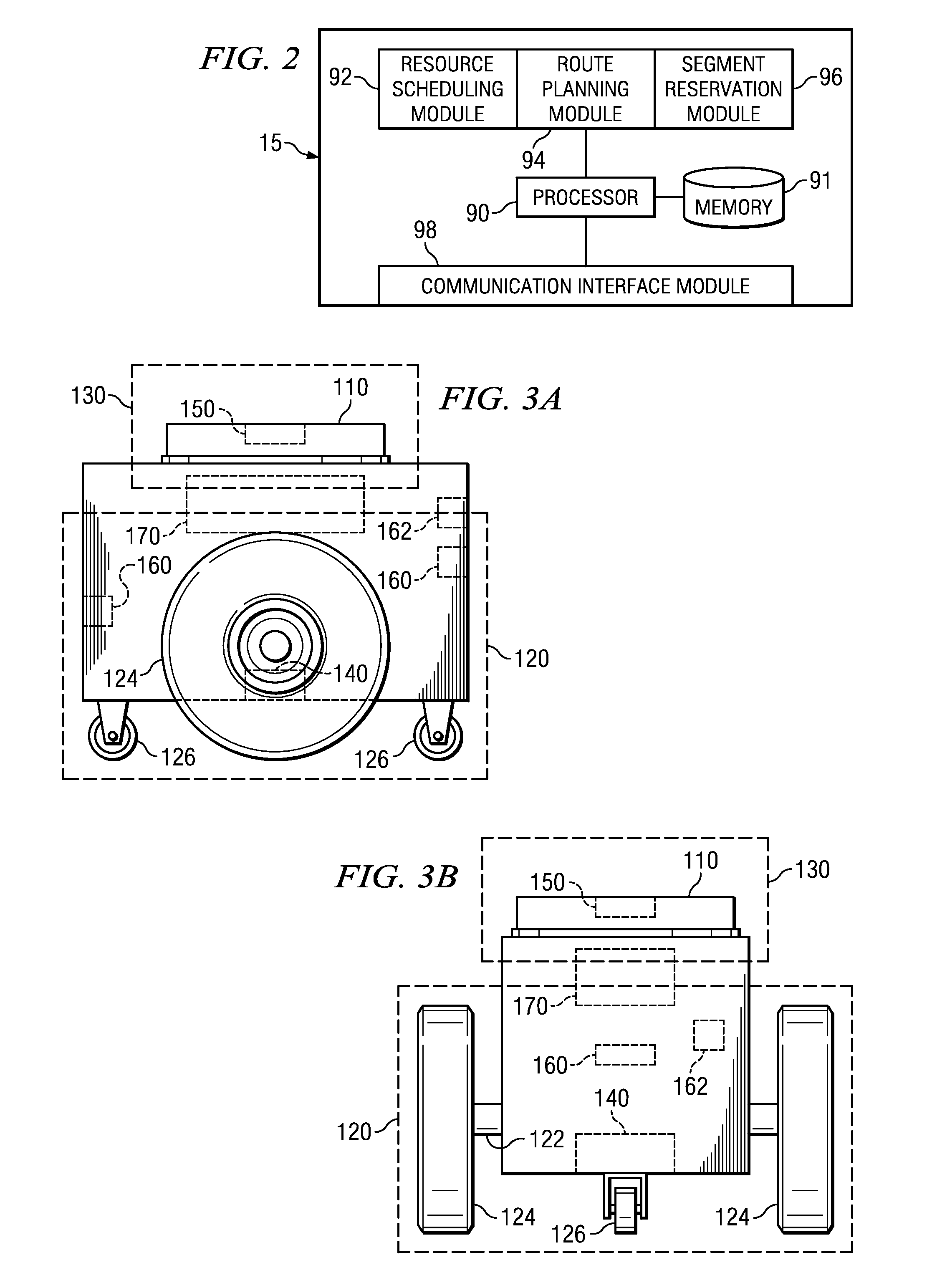

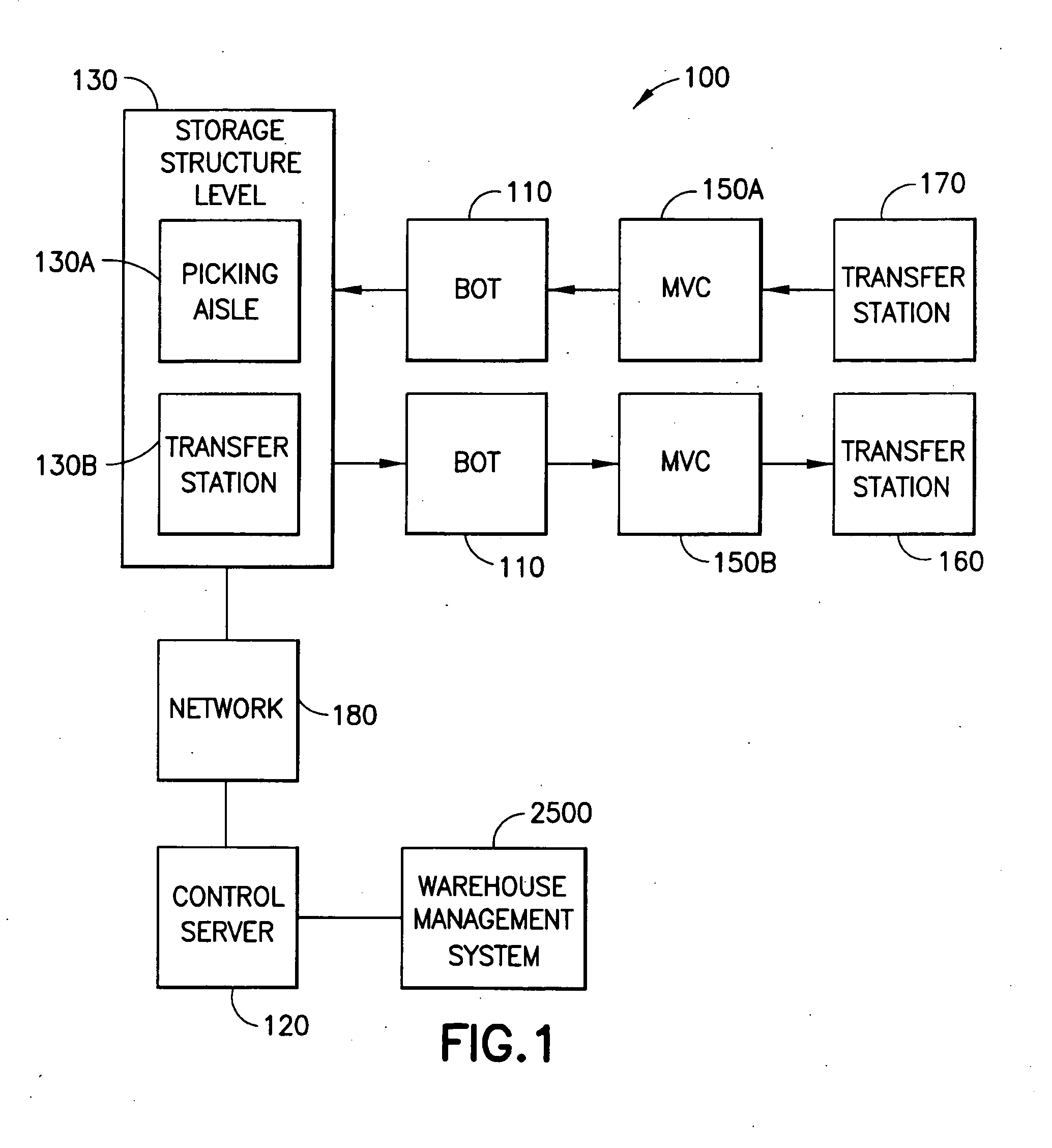

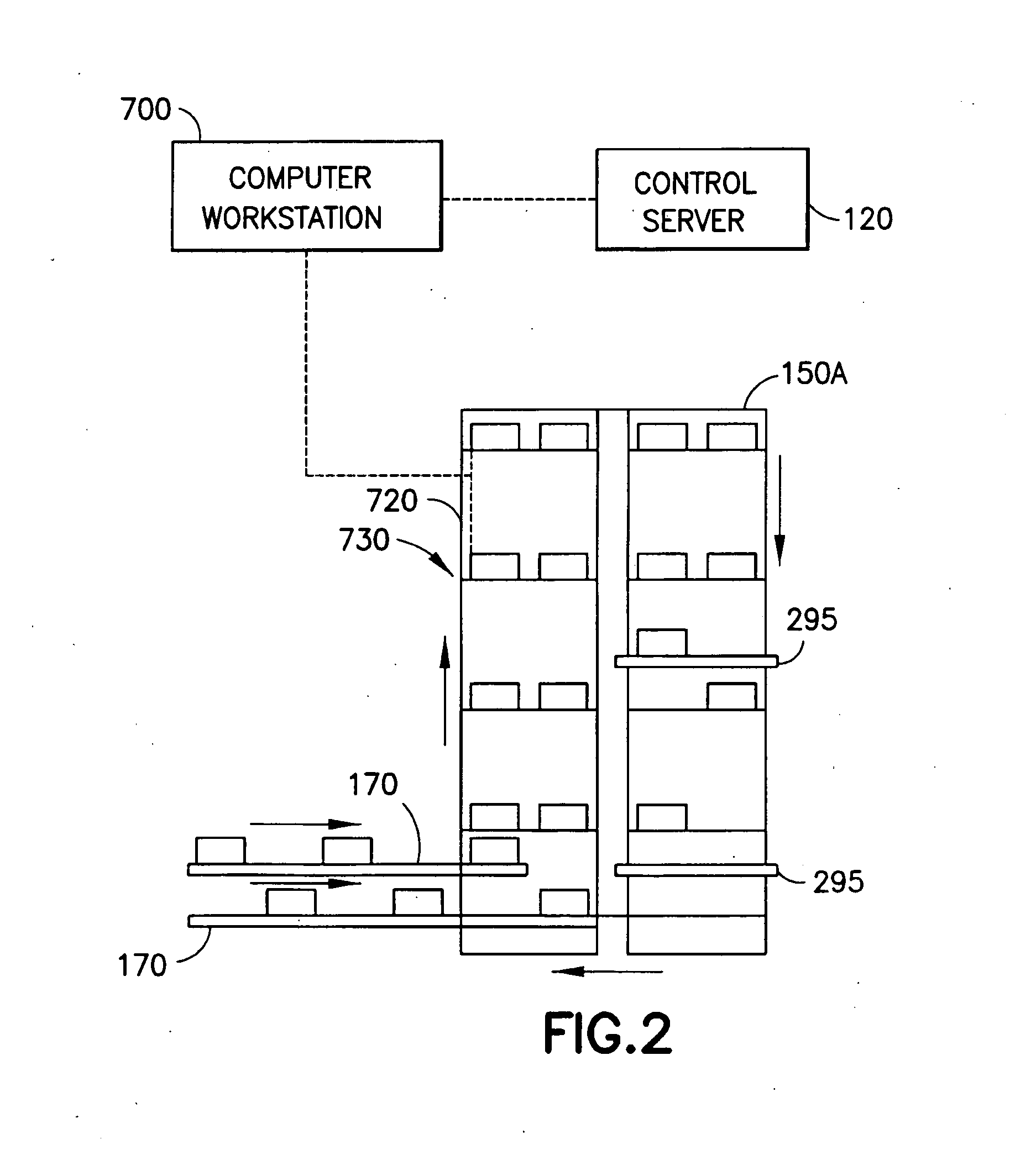

Autonomous transports for storage and retrieval systems

An autonomous transport vehicle for transferring case units to and from predefined storage areas in an automated case unit storage system, the automated case unit storage system including an array of multilevel storage racks with picking aisles passing therebetween and at least one multilevel vertical conveyor having movable shelves, the autonomous transport vehicle including a frame configured to traverse the picking aisles and a transfer deck connecting the picking aisles to the at least one multilevel vertical conveyor for transferring case units between the predefined storage areas and the at least one multilevel vertical conveyor, and a controller connected to the frame, the controller being configured to effect movement of the autonomous transport vehicle through the picking aisles for accessing each storage area within a respective level of the array of multilevel storage racks and each shelf of the at least one multilevel vertical conveyor.

Owner:SYMBOTIC LLC

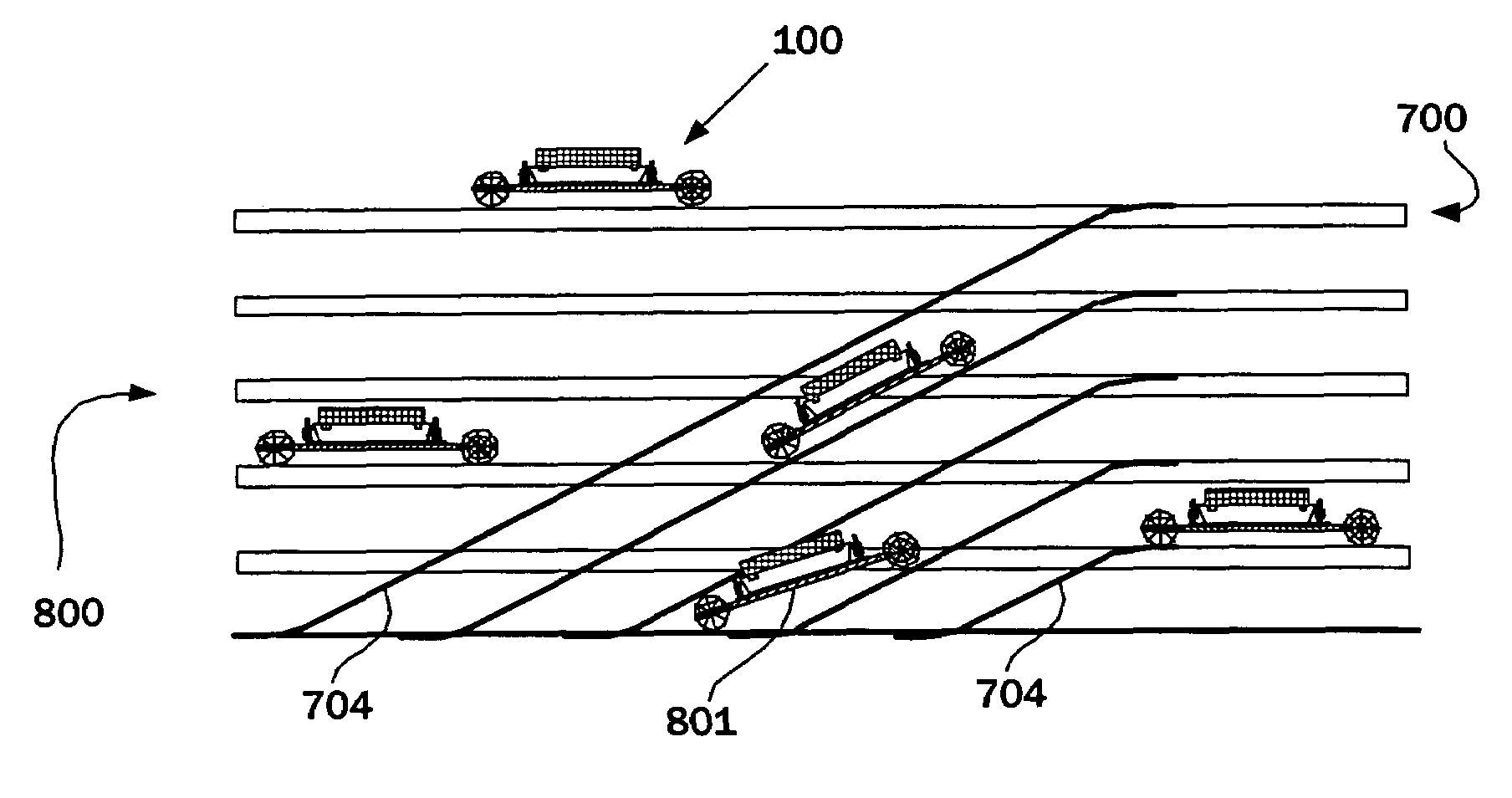

Materials-handling system using autonomous transfer and transport vehicles

ActiveUS7991505B2High degree of automationEfficient automationDigital data processing detailsLoading/unloadingEngineeringHandling system

Methods and apparatus for selecting and combining packages in an outbound container by employing autonomous transfer and transport vehicles which move on a network of roadways to carry a plurality of individual cases each containing the same kind of product from a loading station and to a destination station where individual packages are combined in the outbound container. The travel of each vehicle through the roadway network is computer controlled, and each vehicle includes means for automatically loading and unloading packages from predetermined locations on the network.

Owner:SYMBOTIC LLC

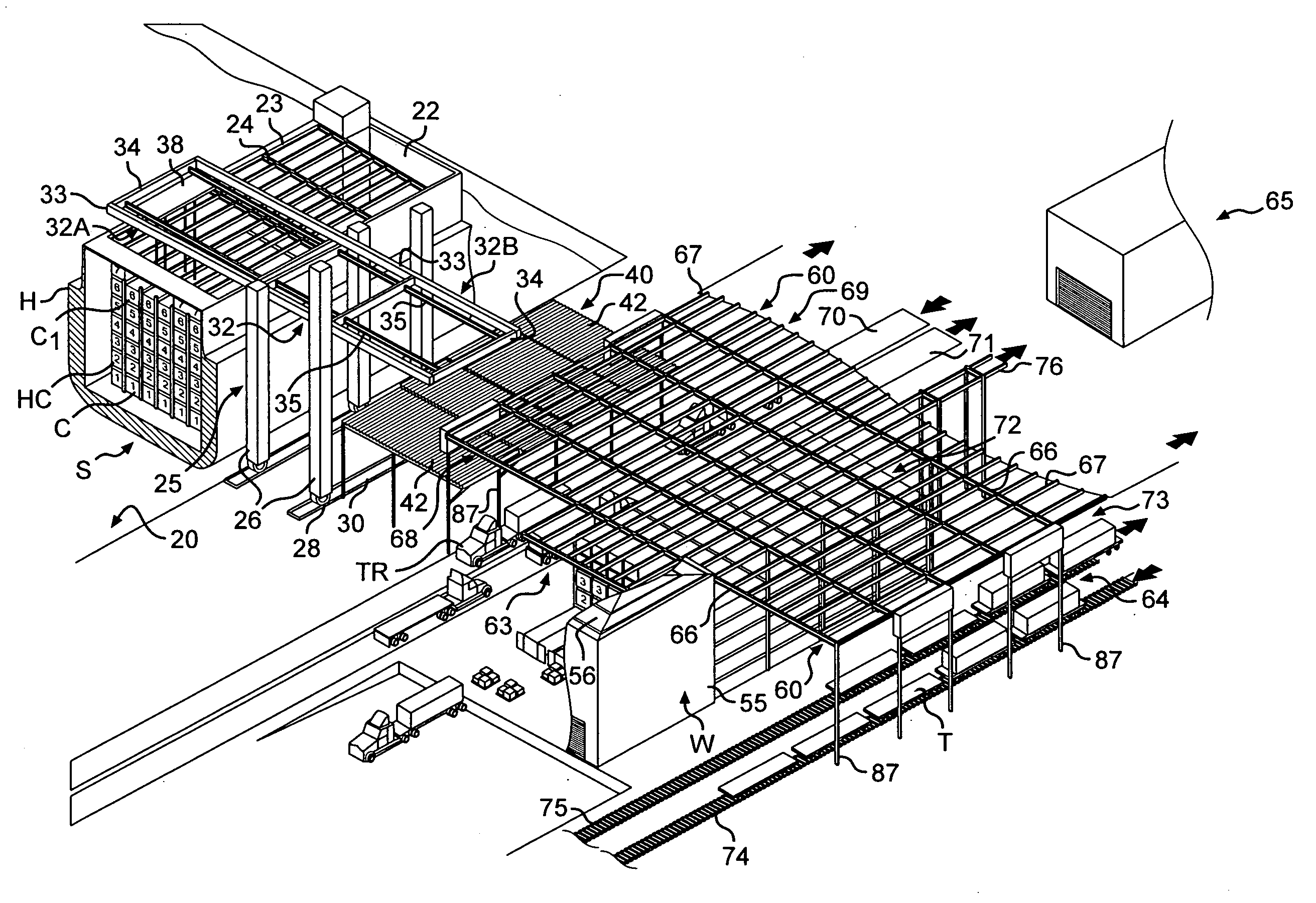

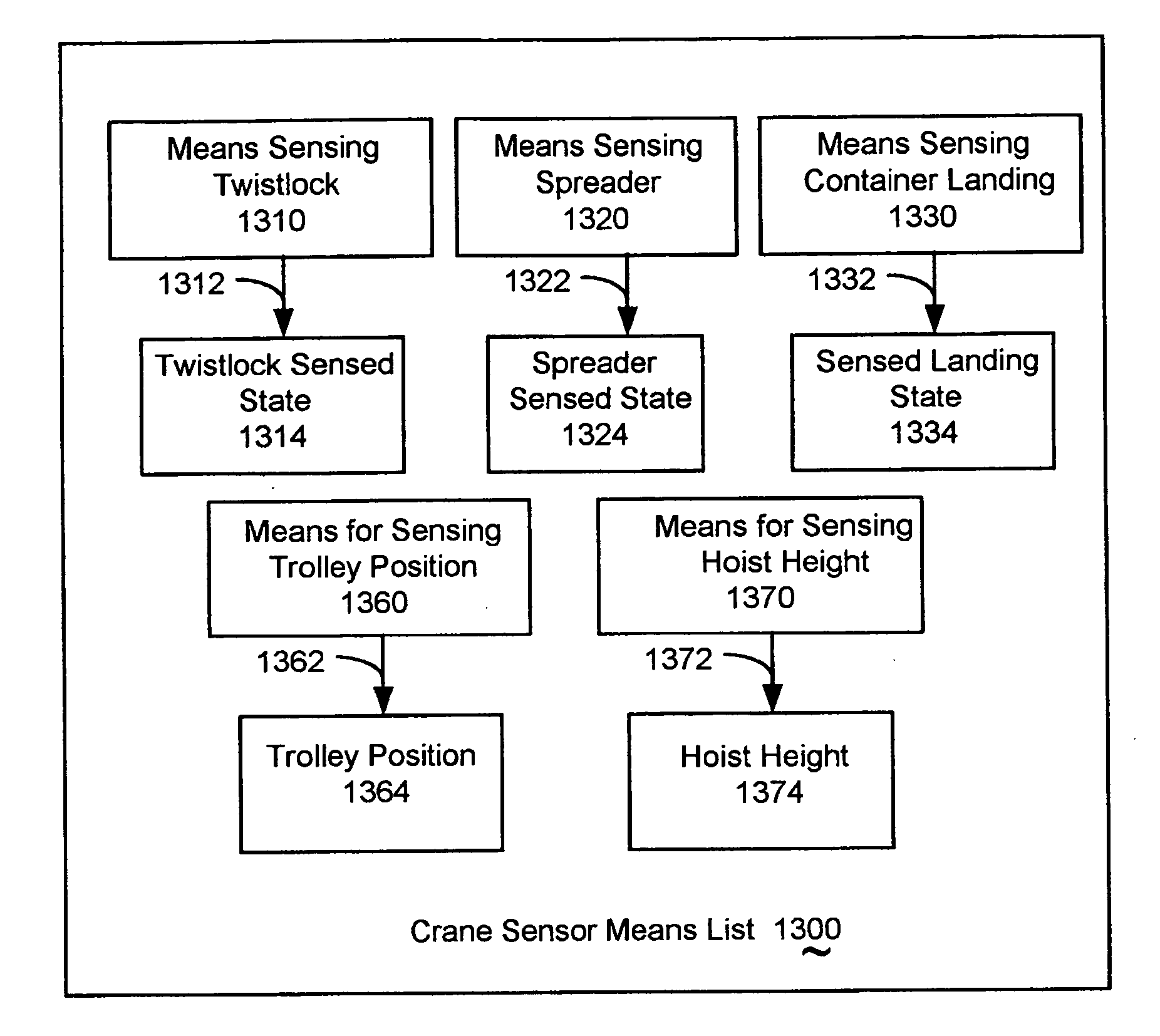

Port storage and distribution system for international shipping containers

ActiveUS20080213073A1Maximize storage spaceImprove efficiencyCargo handling apparatusPassenger handling apparatusInternational shippingDistribution system

A port storage and distribution system for facilitating the transfer and / or storage of international shipping containers between container ships and ground transport carriers wherein an overhead grid guide track structure is provide that permits overhead transfer units to selectively engage and convey containers as required between the various ships, carriers and storage area without requiring multiple transfers of containers between different handling equipment. The system provides for container scanning and is either fully automated or partially manually controlled.

Owner:GEBRR BECKER

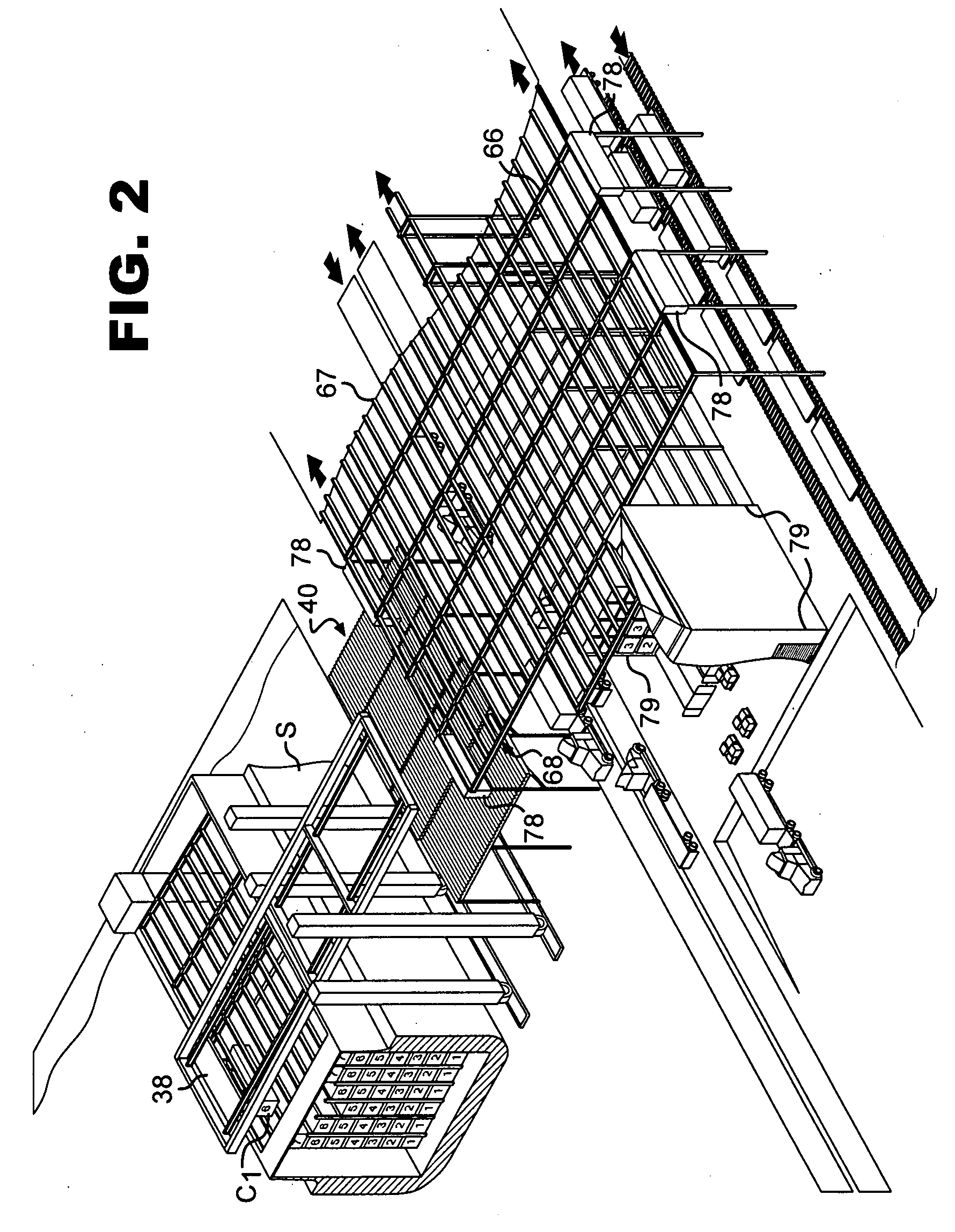

Method and apparatus for making status reporting devices for container handlers

ActiveUS20050256608A1Improve reliabilityDigital data processing detailsRoad vehicles traffic controlEngineeringComputer access

A mechanism and method for making status reporting devices for container handlers, including: providing a micro-controller module, and installing a program system into memory accessed by a computer directing the micro-controller module. The micro-controller module communicatively couples with means for wirelessly communicating and for sensing a state of the container handler. Means for wirelessly communicating may include means for wirelessly determining container handler location. The micro-controller module may be communicatively coupled to a separate means for determining location. An apparatus making the devices may include a second program system directing the invention's method through a second computer, which may control an assembly device in creating the micro-controller, coupled with the means for sensing and for wirelessly communicating.

Owner:HKI SYST & SERVICE

System and Method for Maneuvering a Mobile Drive Unit

InactiveUS20130302132A1Disadvantages and reduced eliminatedInventory reduced eliminatedLifting devicesLogisticsEngineeringMechanical engineering

Owner:AMAZON TECH INC

Method and apparatus for sorting items

A method and apparatus are provided for sorting items to a plurality of sort destinations. The items are loaded onto one of a plurality of independently controlled delivery vehicles. The delivery vehicles follow a track that guides the delivery vehicles to the sort destinations, which are positioned along the track. Once at the appropriate sort destination, the delivery vehicle ejects the item to the sort destination and returns to receive another item to be delivered.

Owner:OPEX

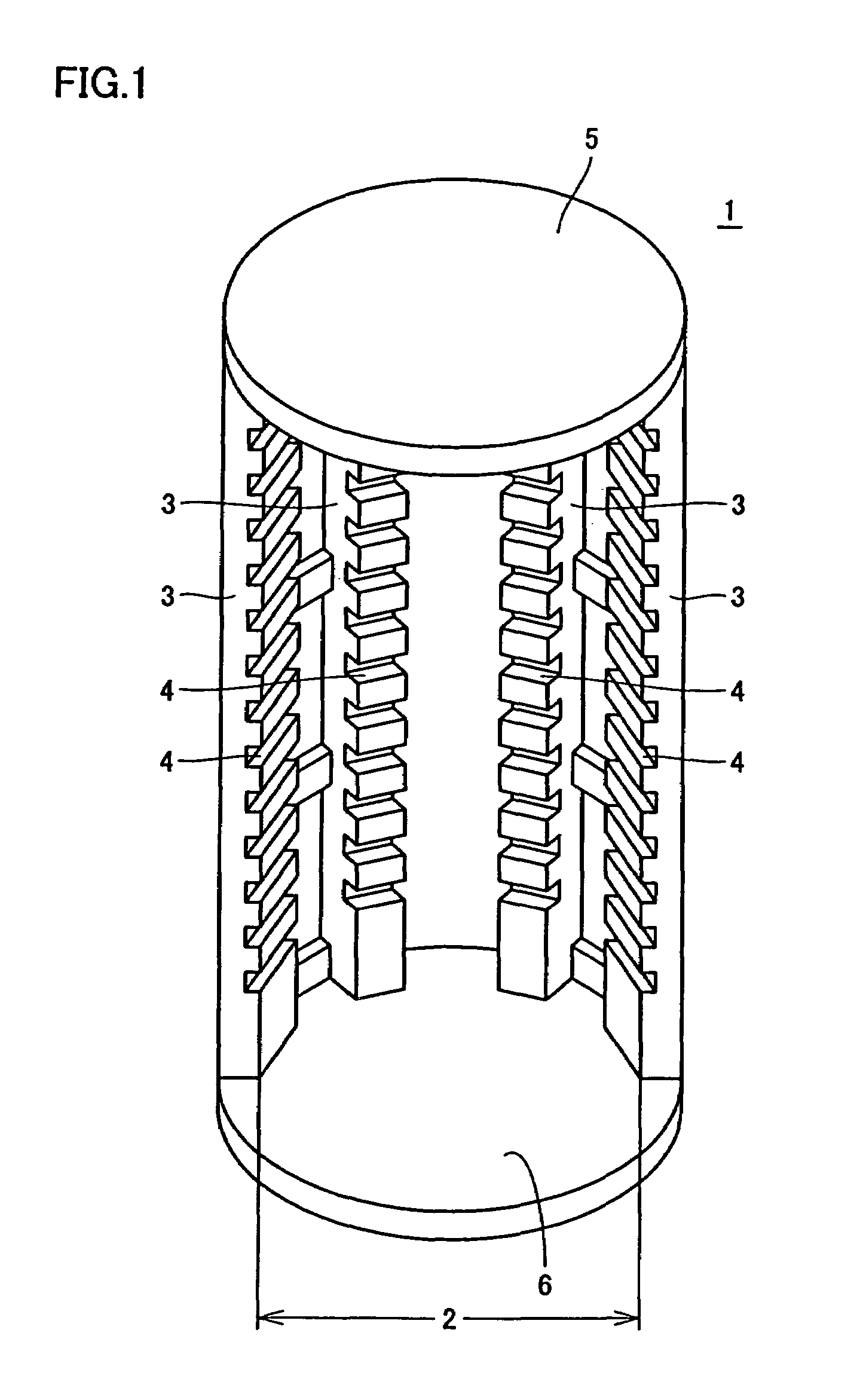

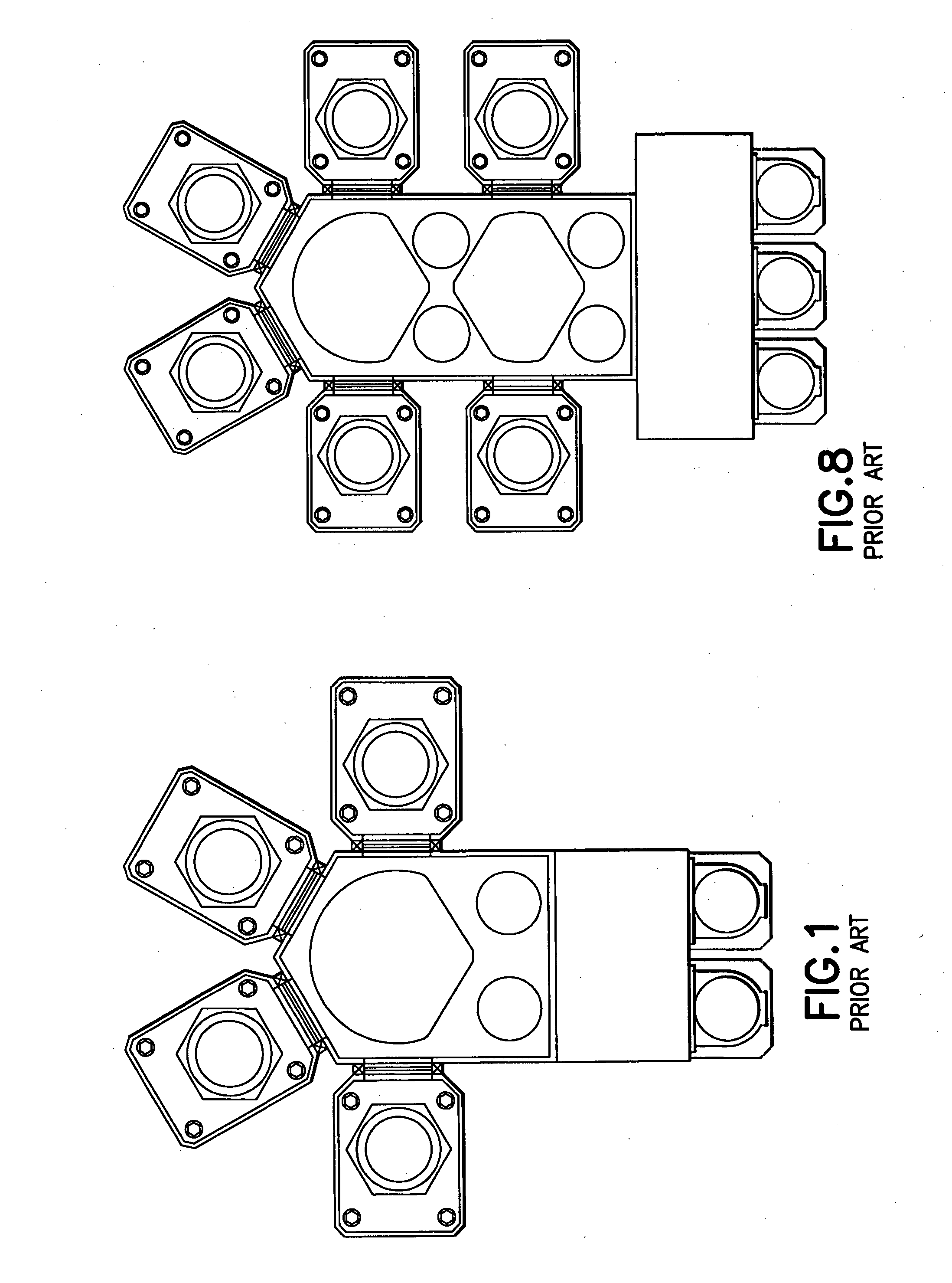

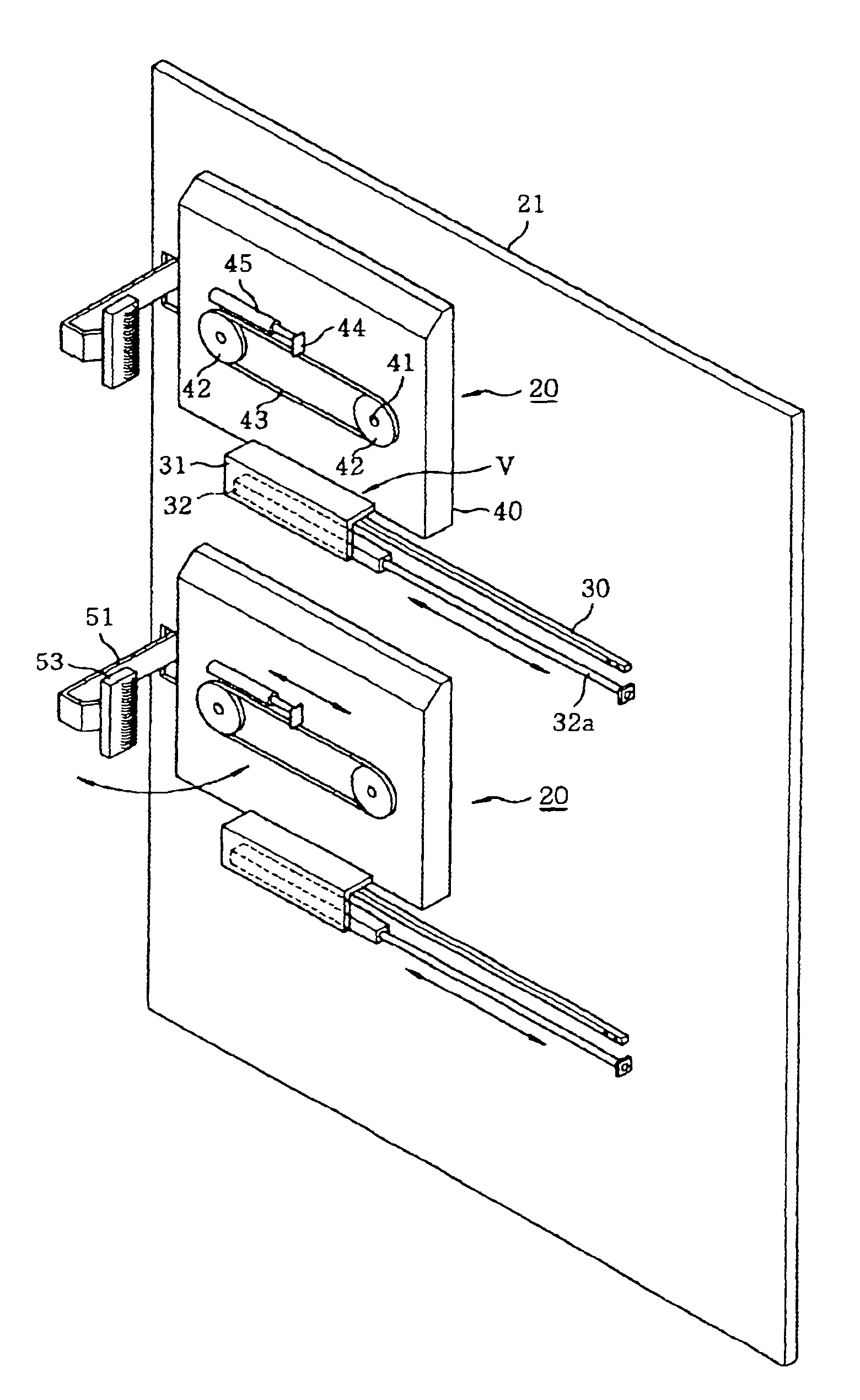

System for sorting multiple semiconductor wafers

InactiveUS6213708B1Semiconductor/solid-state device manufacturingArticle unpackingRobotic armEngineering

A wafer sorting system is provided. The wafer sorter system is used to simultaneously sort multiple semiconductor wafers of a cassette. The wafer sorter system includes multiple arms which extend from a tower. These arms are at different vertical locations along the tower. The wafer sorter system also comprises a robotic arm which may move the tower to a position where the arms contact wafers. These wafers are in different vertical slots of a cassette. Further included in the wafer sorter system is a belt which may rotate to move arms vertically through slots of the tower. Wafers may become attached to arms by applying a vacuum suction to each arm. The arms having wafers may be rotated to the belt in a clockwise or counterclockwise direction about a portion of the tower via a slot in the tower. The arms may then be attached to the belt. After the belt moves the arms to new levels of the tower, the arms may then be rotated back to their original positions. The rearranged wafers may then be placed in their original cassette, in several different cassettes, or in one different cassette via turning off the vacuum suction.

Owner:ADVANCED MICRO DEVICES INC

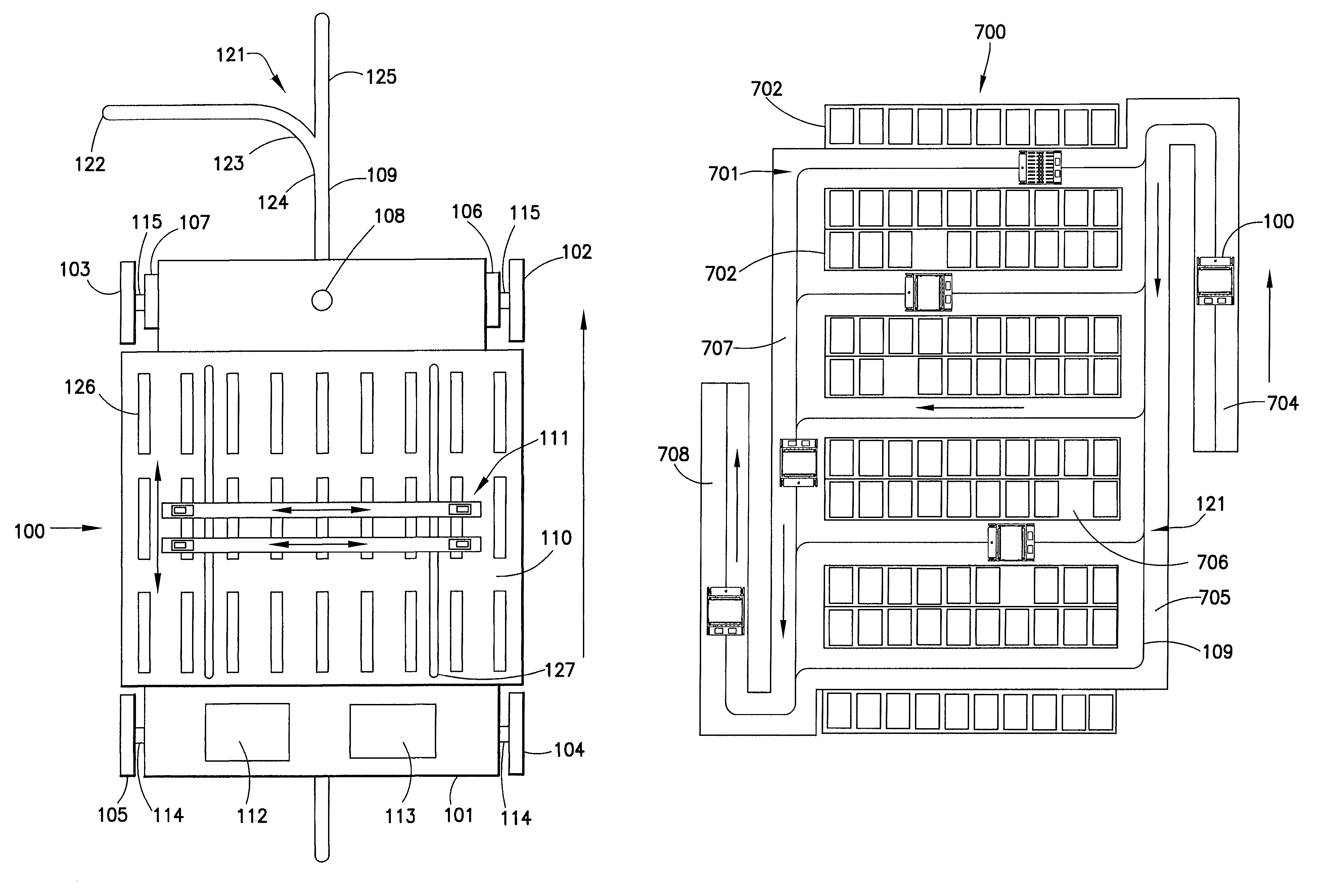

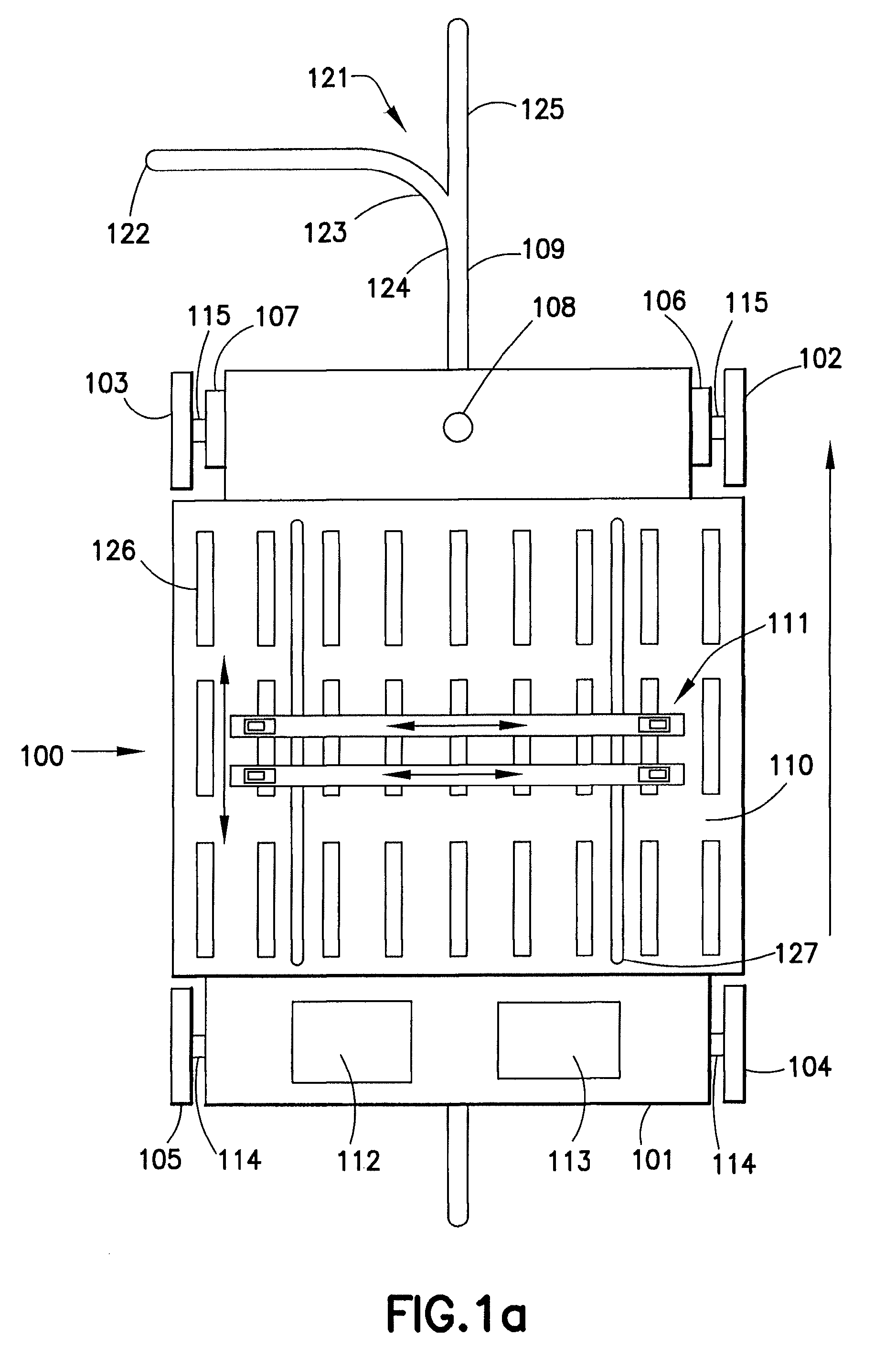

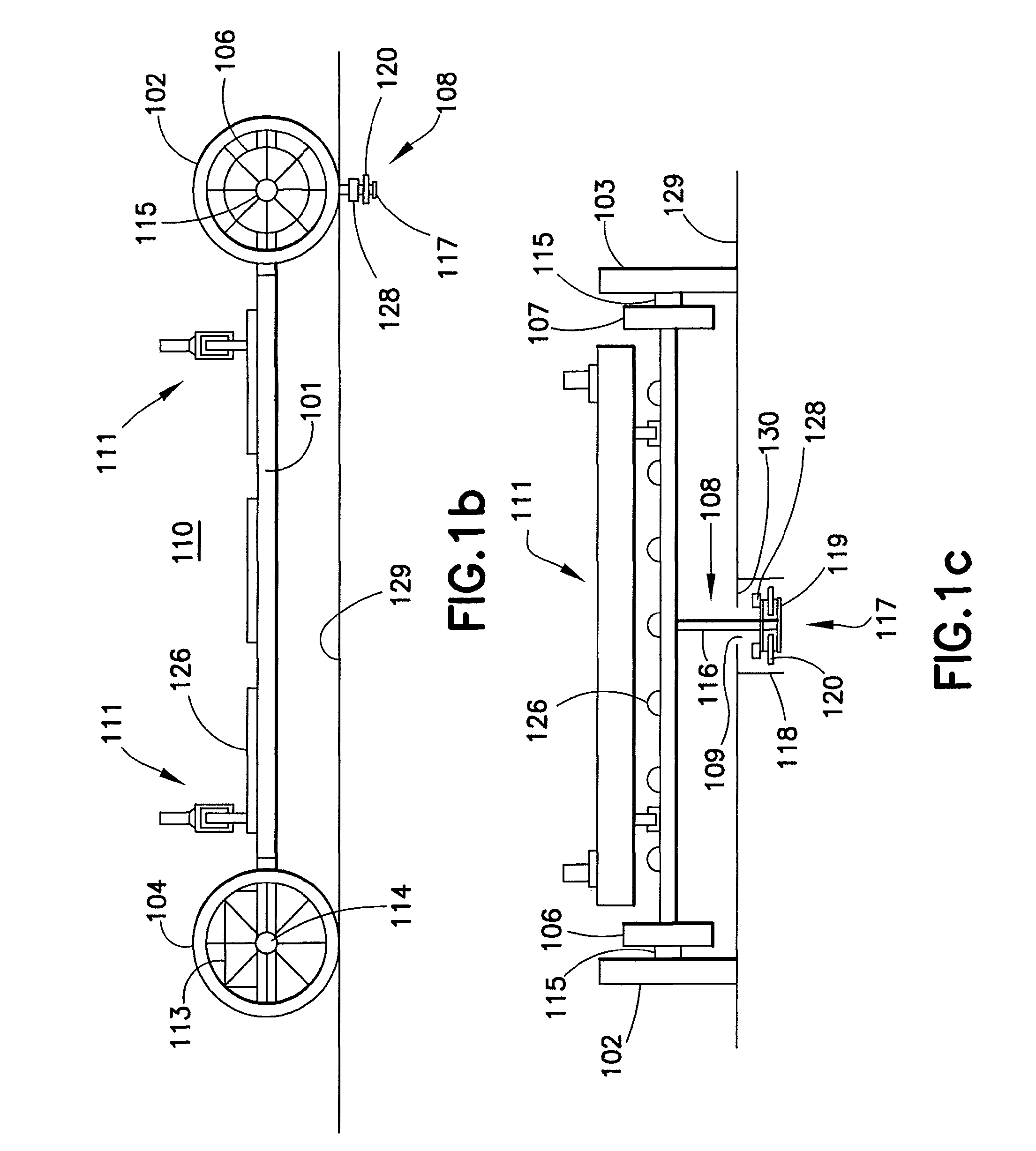

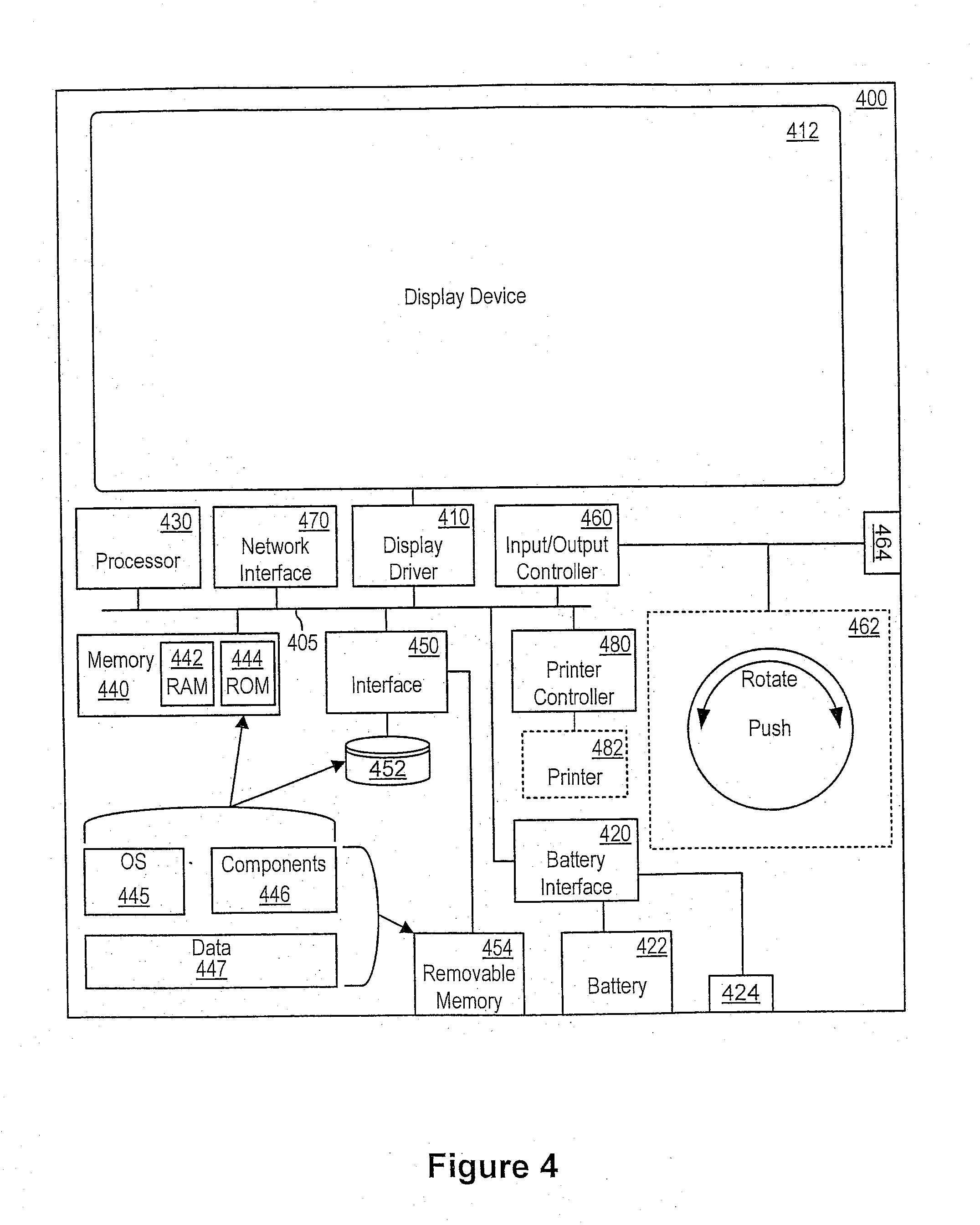

Automated battery and data delivery system

Systems and methods are provided that use a mobile robotic device (120, 220, 800) to transport rechargeable batteries (322, 422, 530, 570, 610, 722) between a base station (110, 600, 700), which charges the batteries, and a battery operated device (130, 230, 300, 400, 500, 550), such as battery powered kiosk (400) or signage system (300), which uses a charged battery as a power source. After traveling to a battery operated device, the mobile robotic device removes any discharged batteries from the battery operated device and installs a charged battery. The mobile robotic device then travels to the base station and attaches the discharged battery to the base station for recharging. The mobile robotic device may be configured to perform other transfers, such as data transfers and paper transfers. In addition, the mobile robotic device may be configured to perform a photographic and spatial survey of the isles, retail shelves, and surrounding environment for various purposes, such as generating three-dimensional store models and remote viewing.

Owner:MACDONALD MURRAY

Materials-handling system using autonomous transfer and transport vehicles

Methods and apparatus for selecting and combining items in an outbound container through the use of autonomous vehicles, each of which includes means for automatically loading and unloading a payload, to perform both transfer and transport functions in moving containers of items within a workspace via a network of roadways. Under computer control, said autonomous vehicles transfer and transport case containers of item units between incoming receiving stations, intermediate storage locations, and outgoing order-assembly stations where entire containers or individual item units are combined in the outbound container.

Owner:SYMBOTIC LLC

Warehousing scalable storage structure

A storage and retrieval system is provided and includes a transfer deck having a longitudinal axis, a first storage section and a second storage section. The first storage section and second storage section are located on opposite sides of the transfer deck and are substantially symmetrically opposed to one another about the longitudinal axis, where each of the first and second storage sections includes storage aisles that are in communication with the transfer deck.

Owner:SYMBOTIC LLC

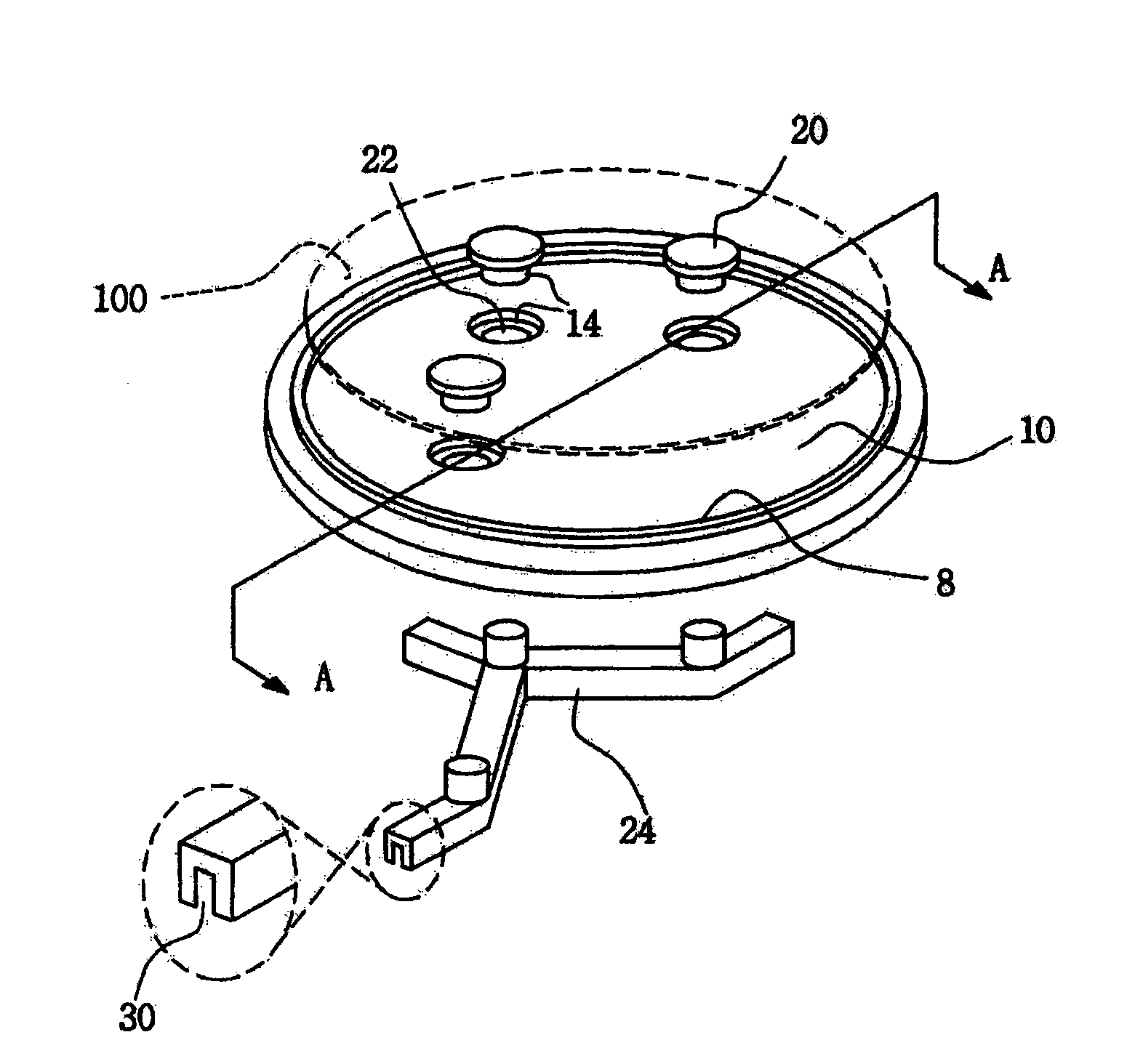

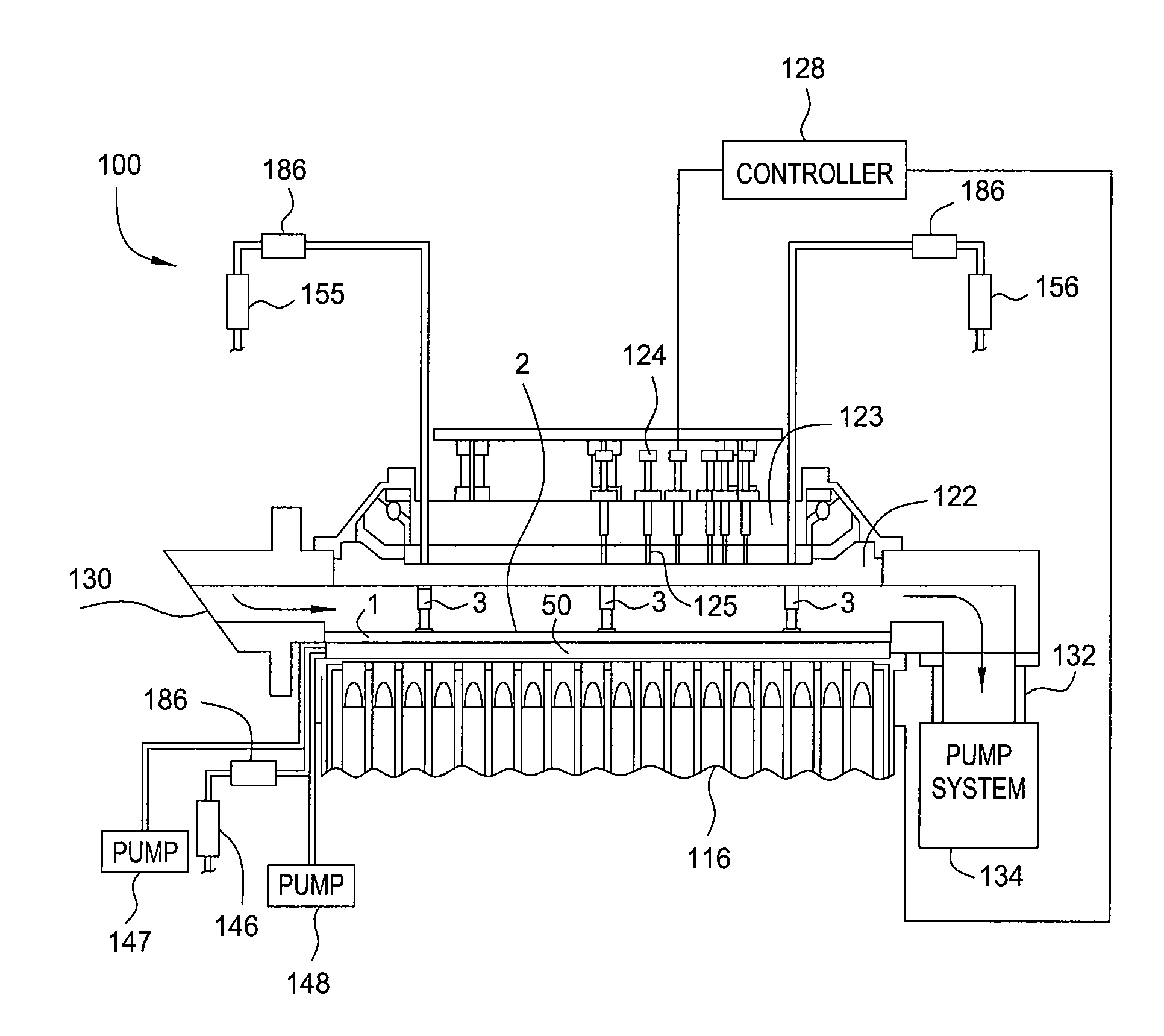

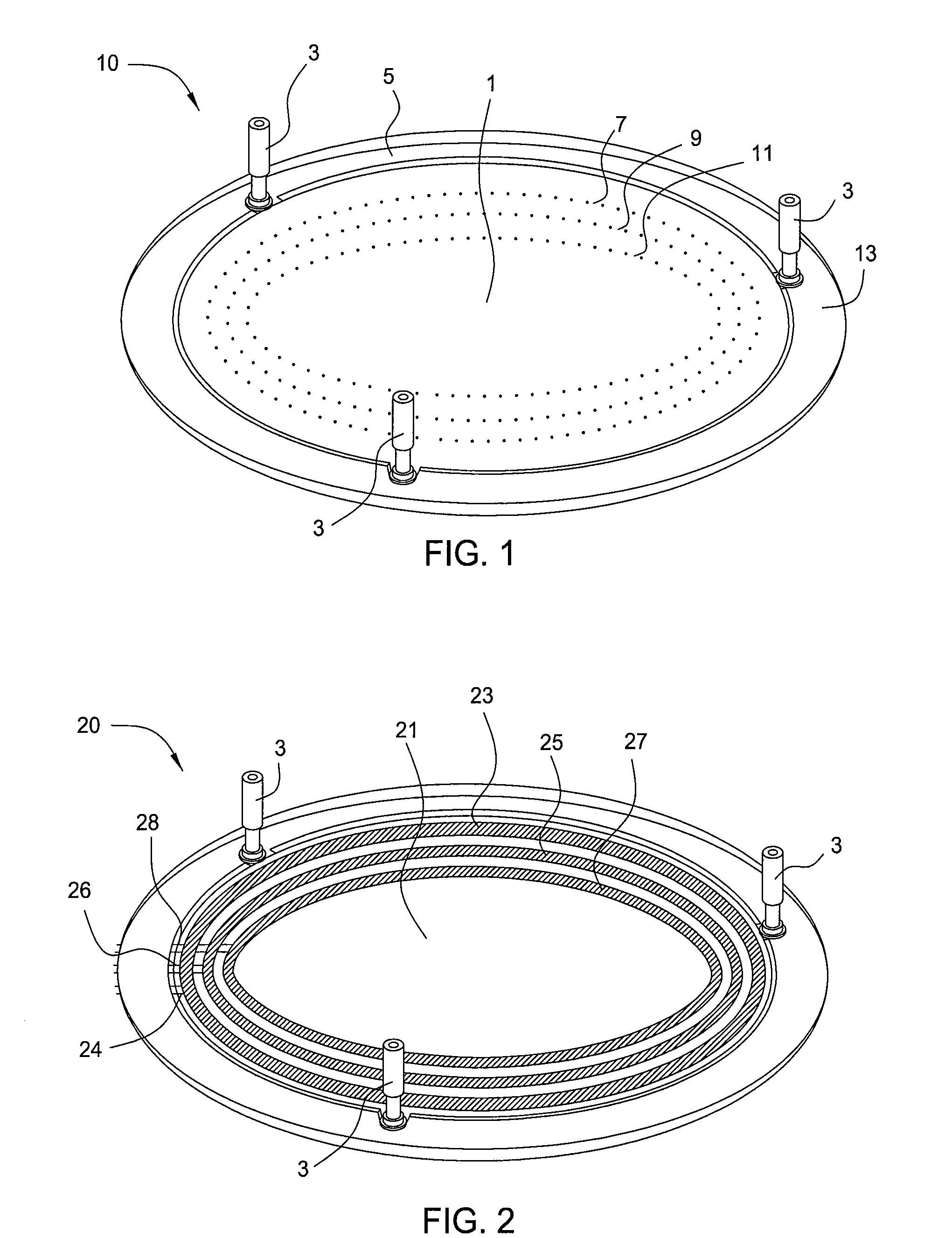

Apparatus and method for supporting, positioning and rotating a substrate in a processing chamber

ActiveUS20080276864A1Increase pressureReduce stressLiquid surface applicatorsSemiconductor/solid-state device manufacturingAir bearingThin layer

An apparatus and method for supporting, positioning and rotating a substrate are provided. In one embodiment, a support assembly for supporting a substrate includes an upper base plate and a lower base plate. The substrate is floated on a thin layer of air over the upper base plate. A positioning assembly includes a plurality of air bearing edge rollers or air flow pockets used to position the substrate in a desired orientation inside above the upper base plate. A plurality of slanted apertures or air flow pockets are configured in the upper base plate for flowing gas therethrough to rotate the substrate to ensure uniform heating during processing.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com