Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3690results about "Passenger handling apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

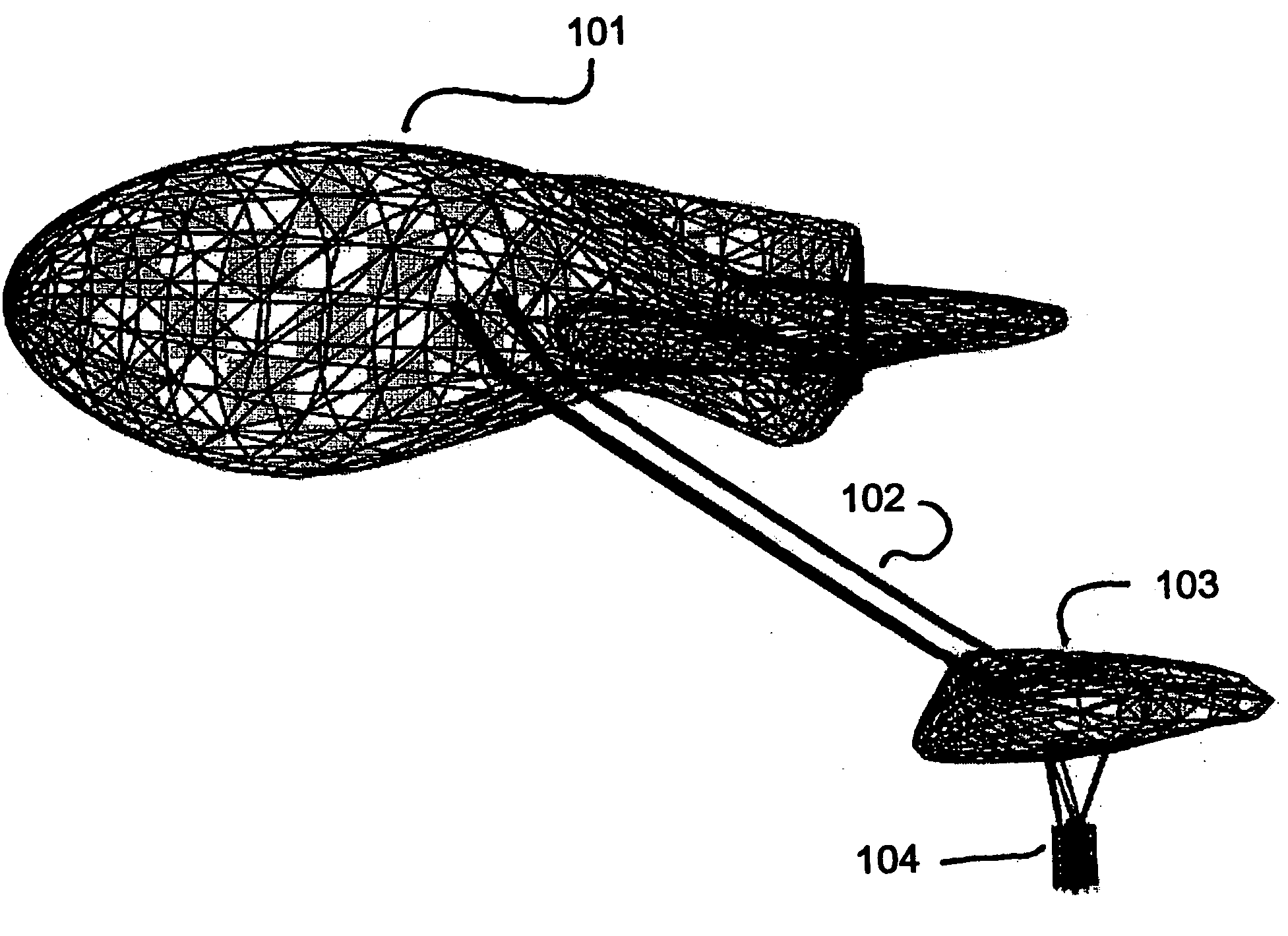

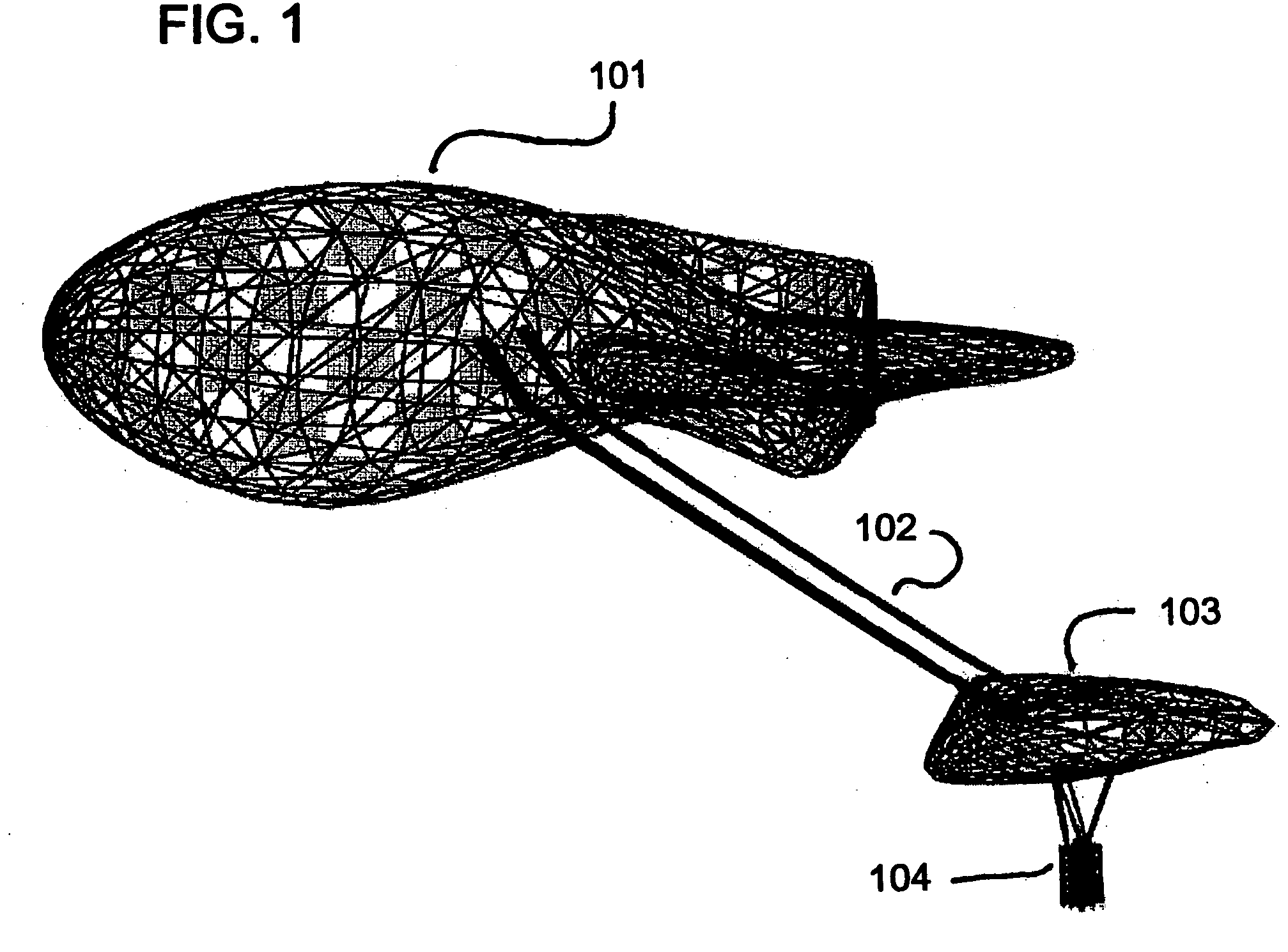

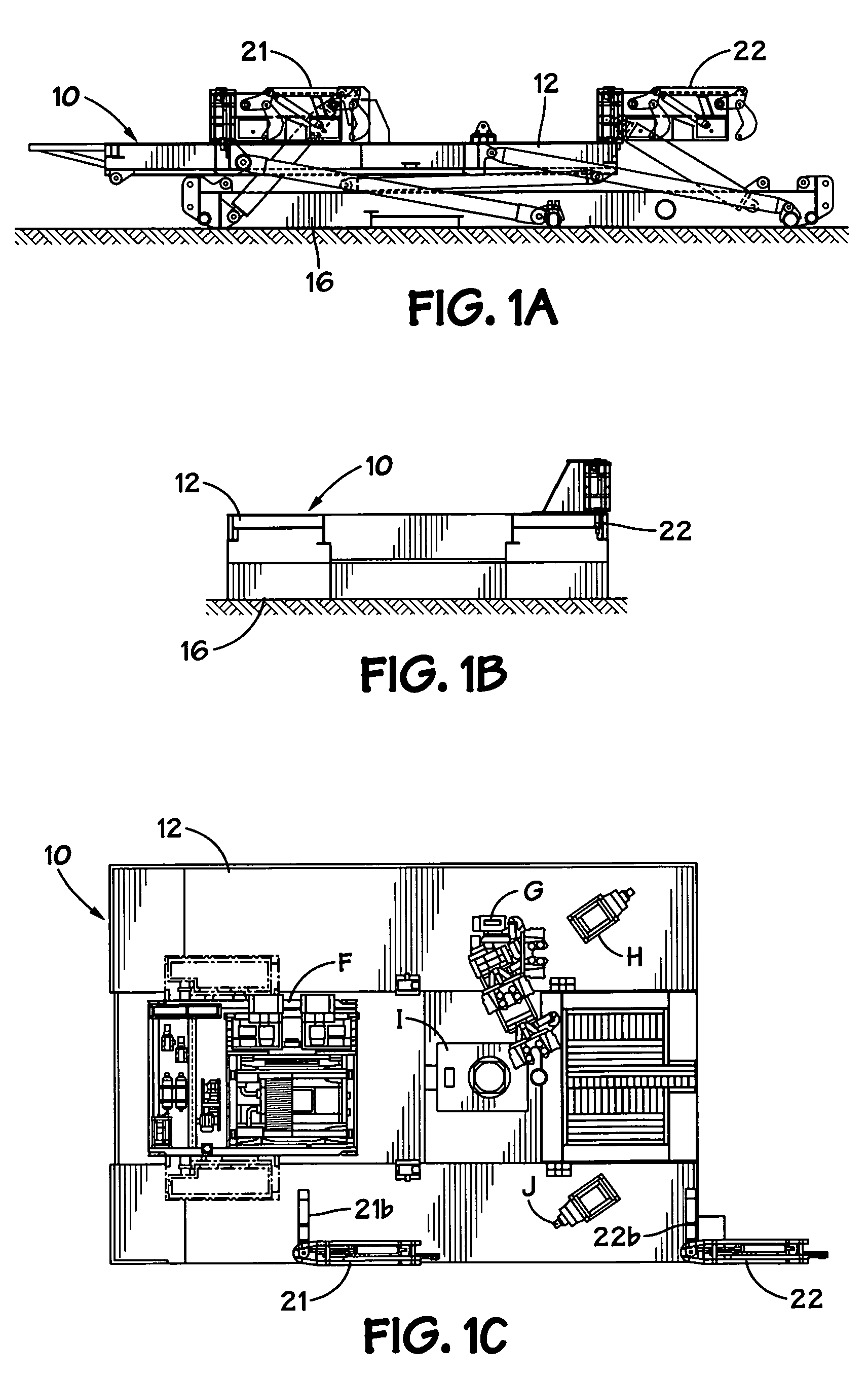

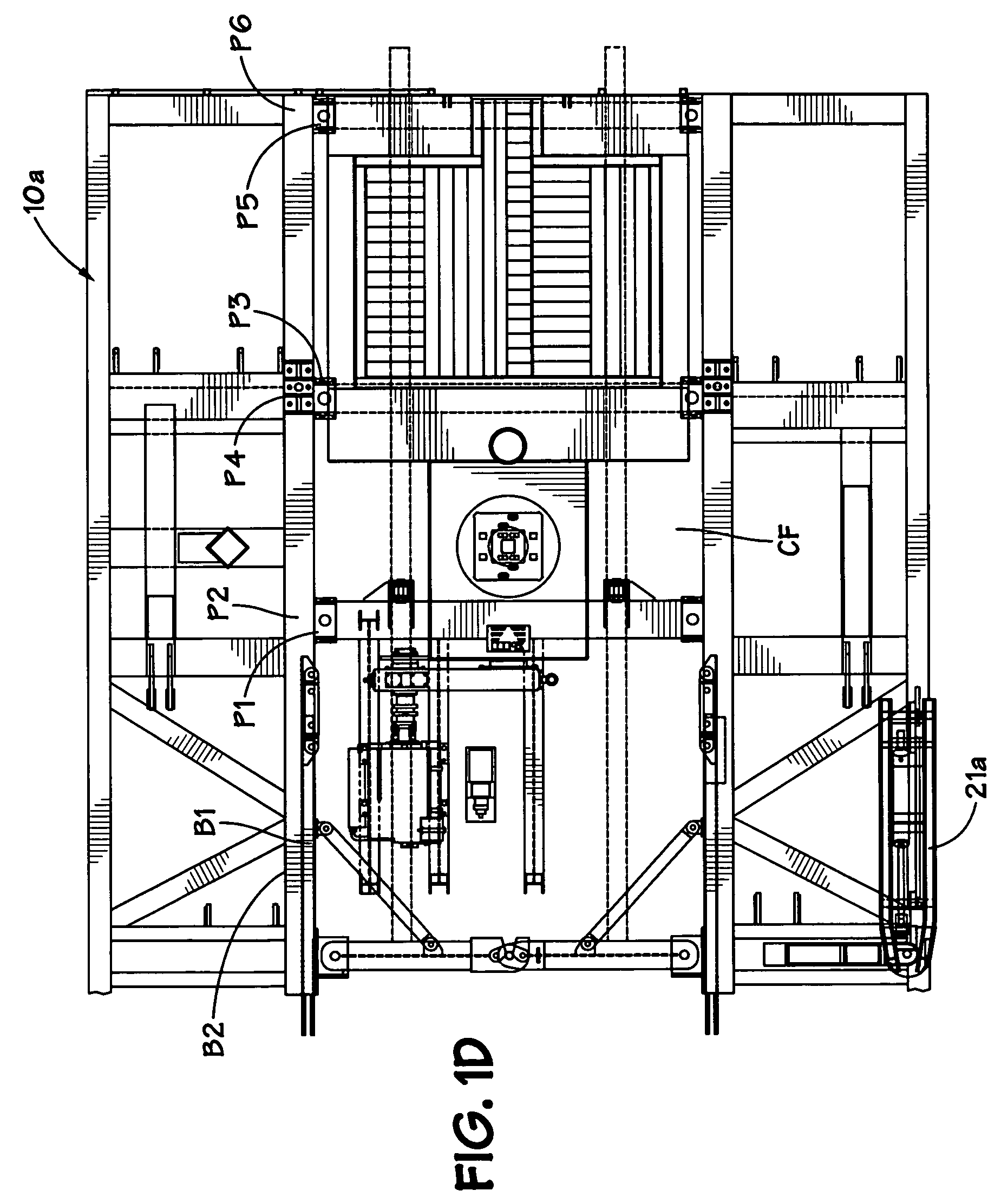

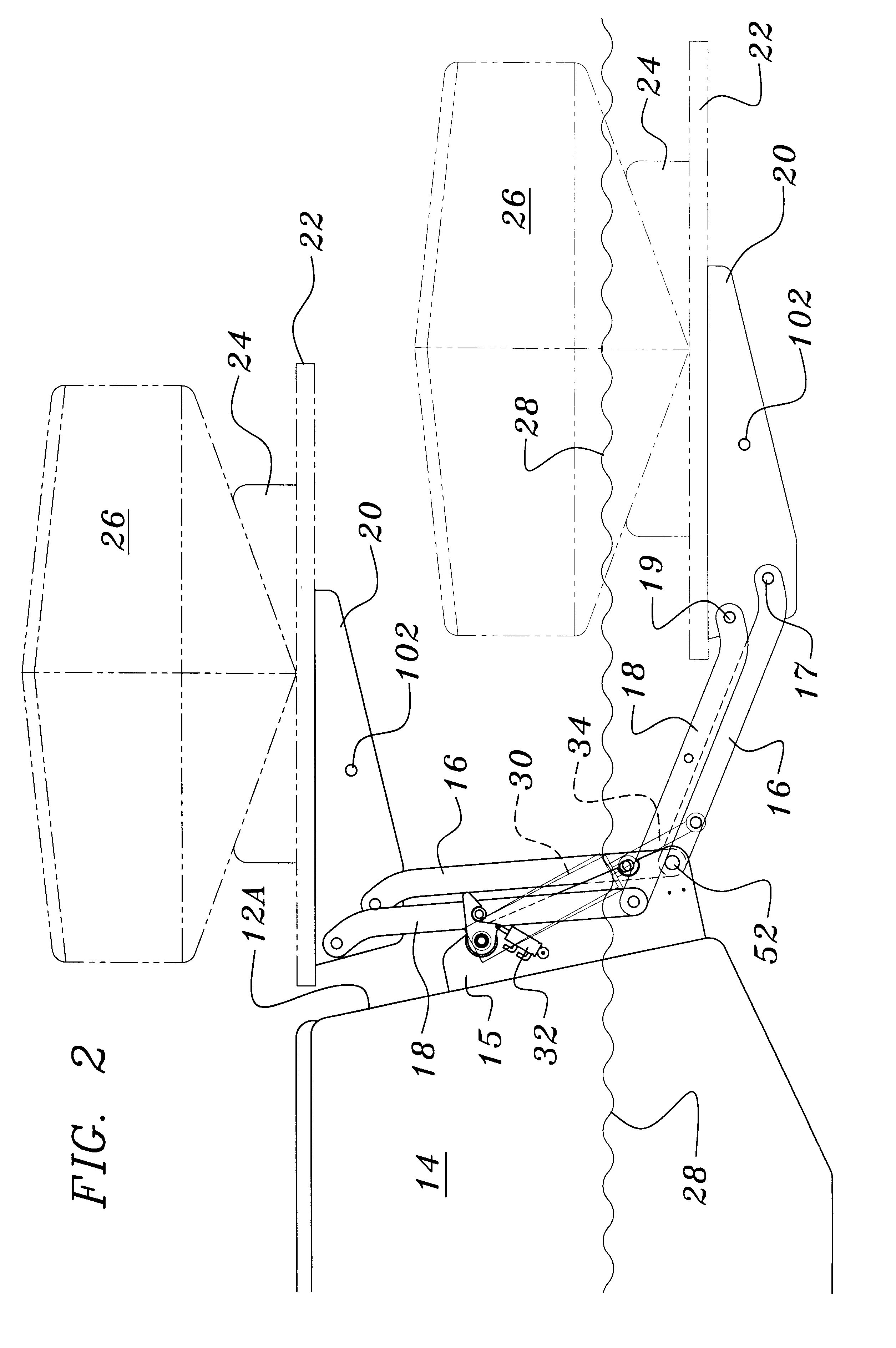

Multibody aircrane

InactiveUS20090152391A1Precise and timely point to point transferEfficient powerCargo handling apparatusPassenger handling apparatusLow speedControl line

The MULTIBODY AIRCRANE performs relative positioning, predictive control, and ballast control to achieve very heavy-lifting tasks on land or sea. Such tasks allow station keeping and precise transfer of very heavy payloads between ships underway. This scalable multibody system features three subcomponents: AIRSHIP, SKYCRANE and LOADFRAME. This semi-autonomous system combines aerodynamic (kinetic) and aerostatic (buoyancy force) lift with efficient power and propulsion. During low-speed flight, the Airship and Skycrane are decoupled but linked via a reelable Tether Control Line. Beneath the Skycrane, centered on its hull, a patented NIST (National Institute of Standards and Technology) RoboCrane (featuring a computer controlled six degrees of freedom (DoF) cabling system,) is attached, to precisely suspend and control a Loadframe, with or without payload. During subsonic forward flight, these Airship and Skycrane are coupled as a single airframe (fuselage and delta wing.)

Owner:MCWHIRK BRUCE KIMBERLY

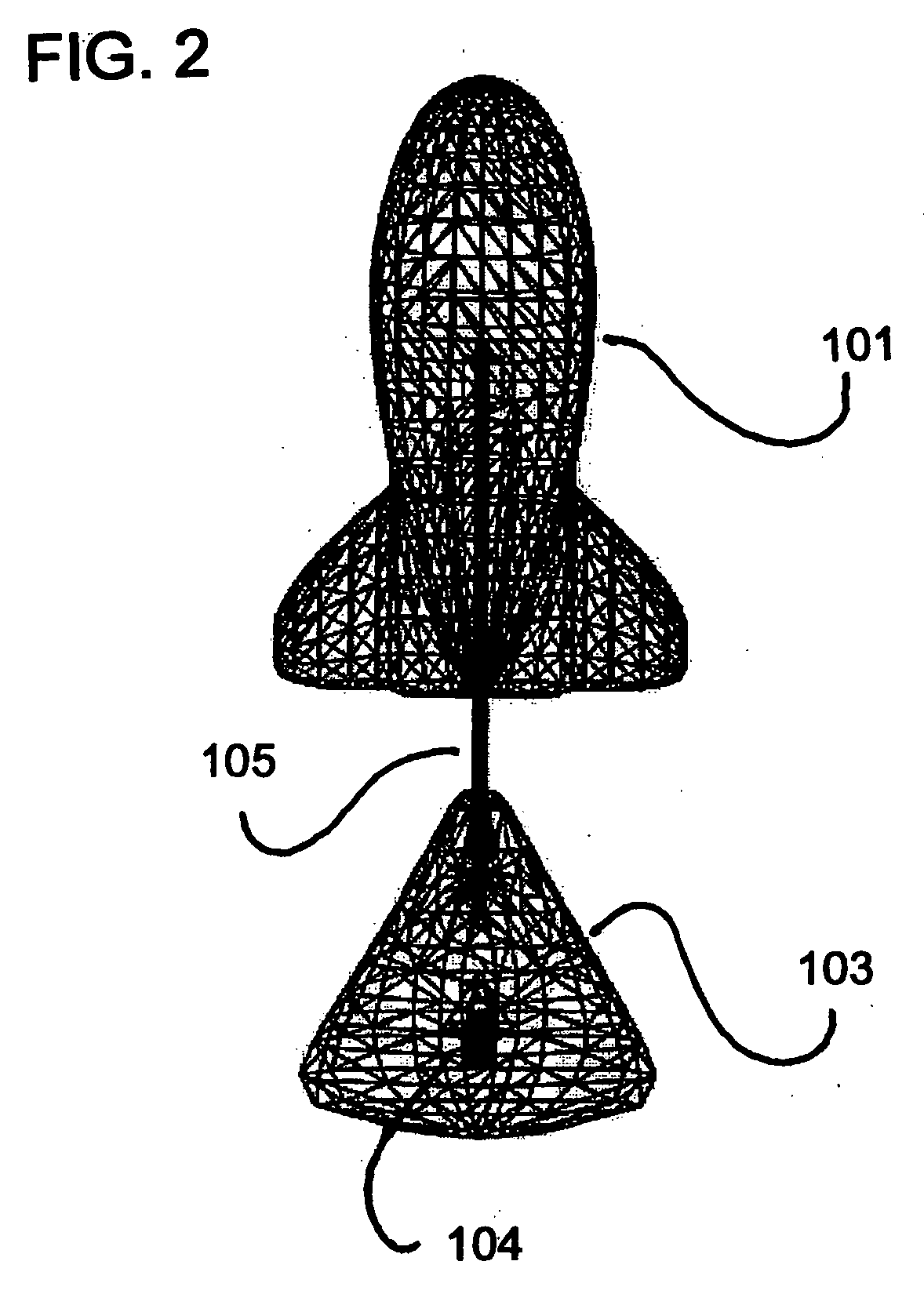

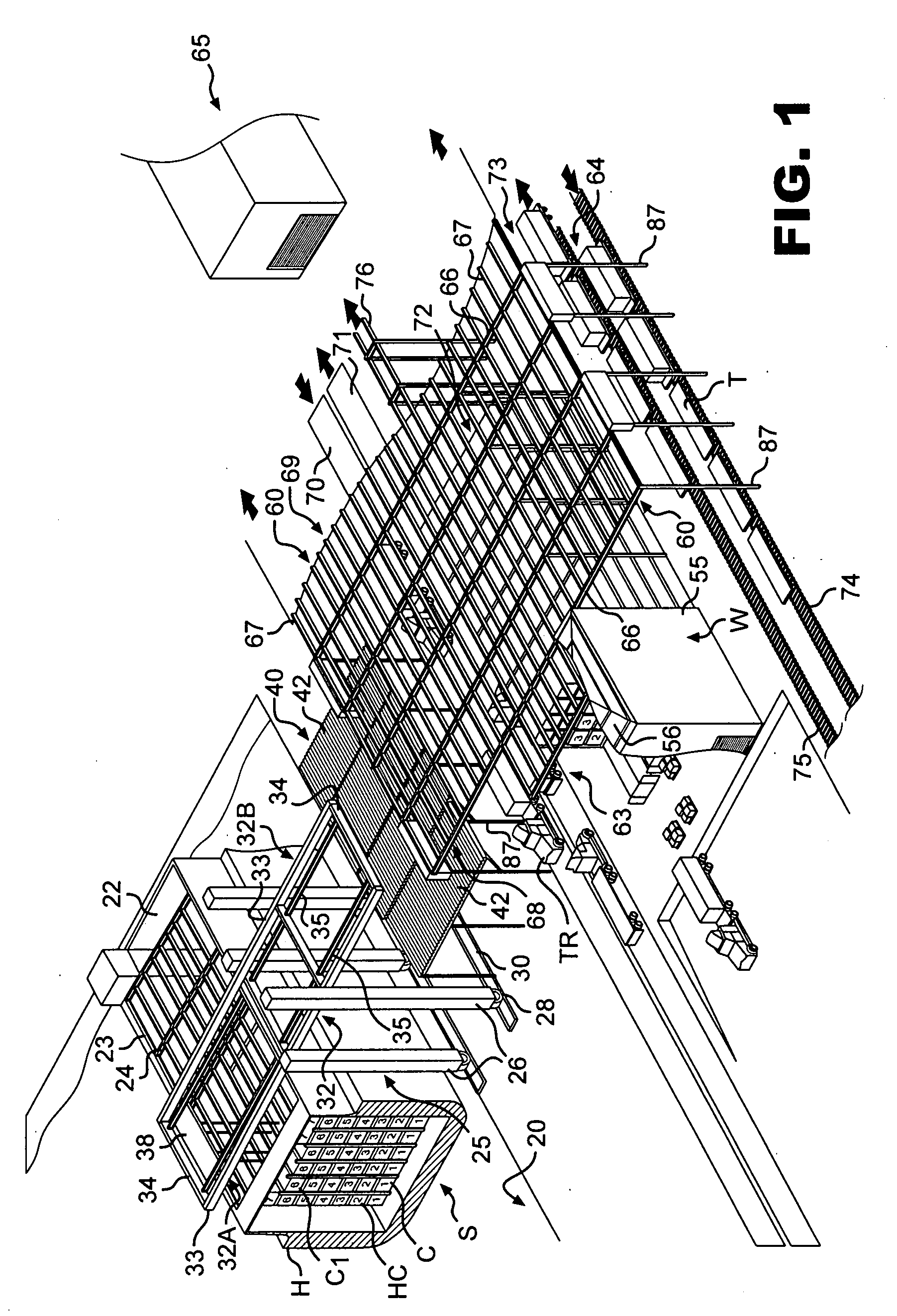

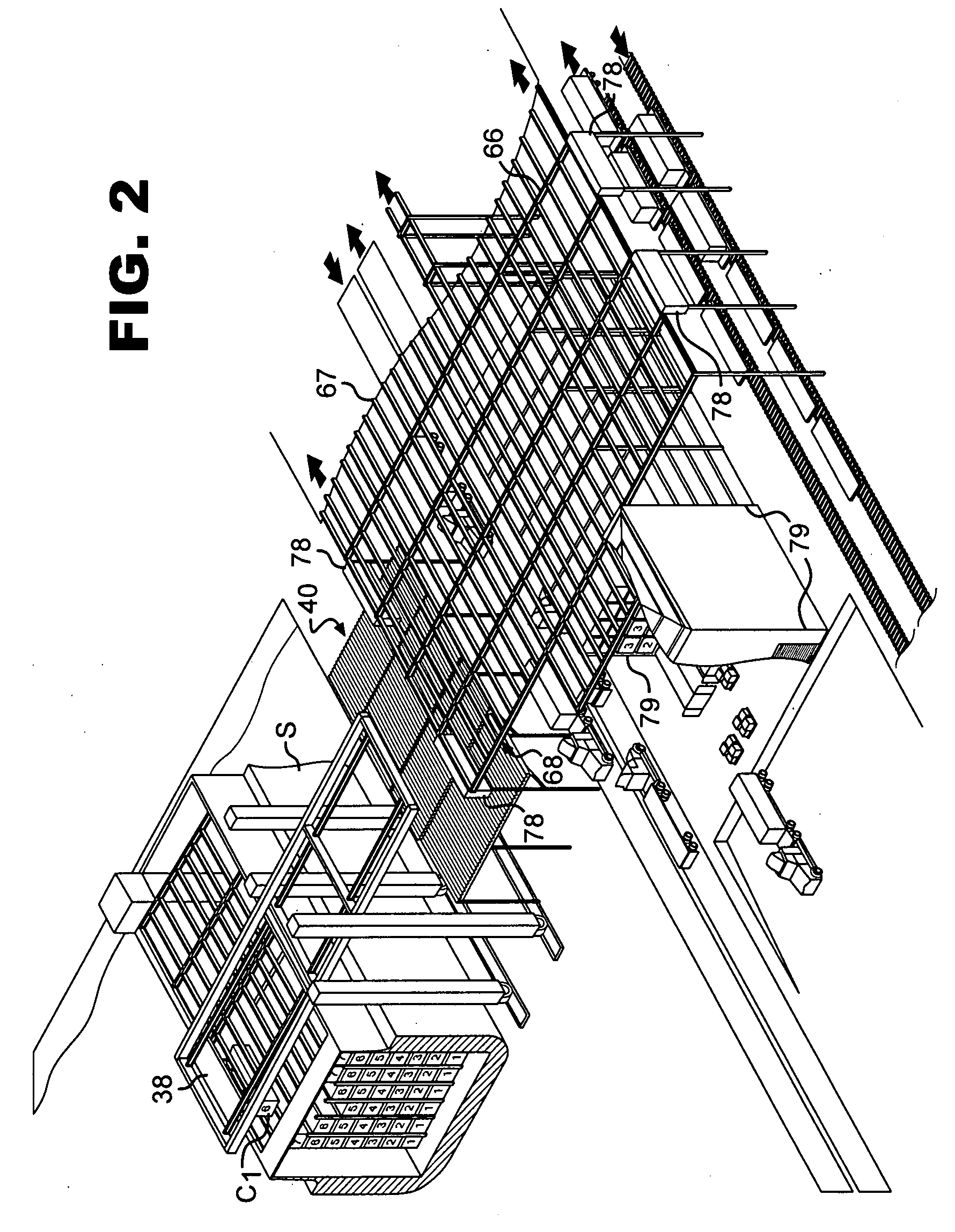

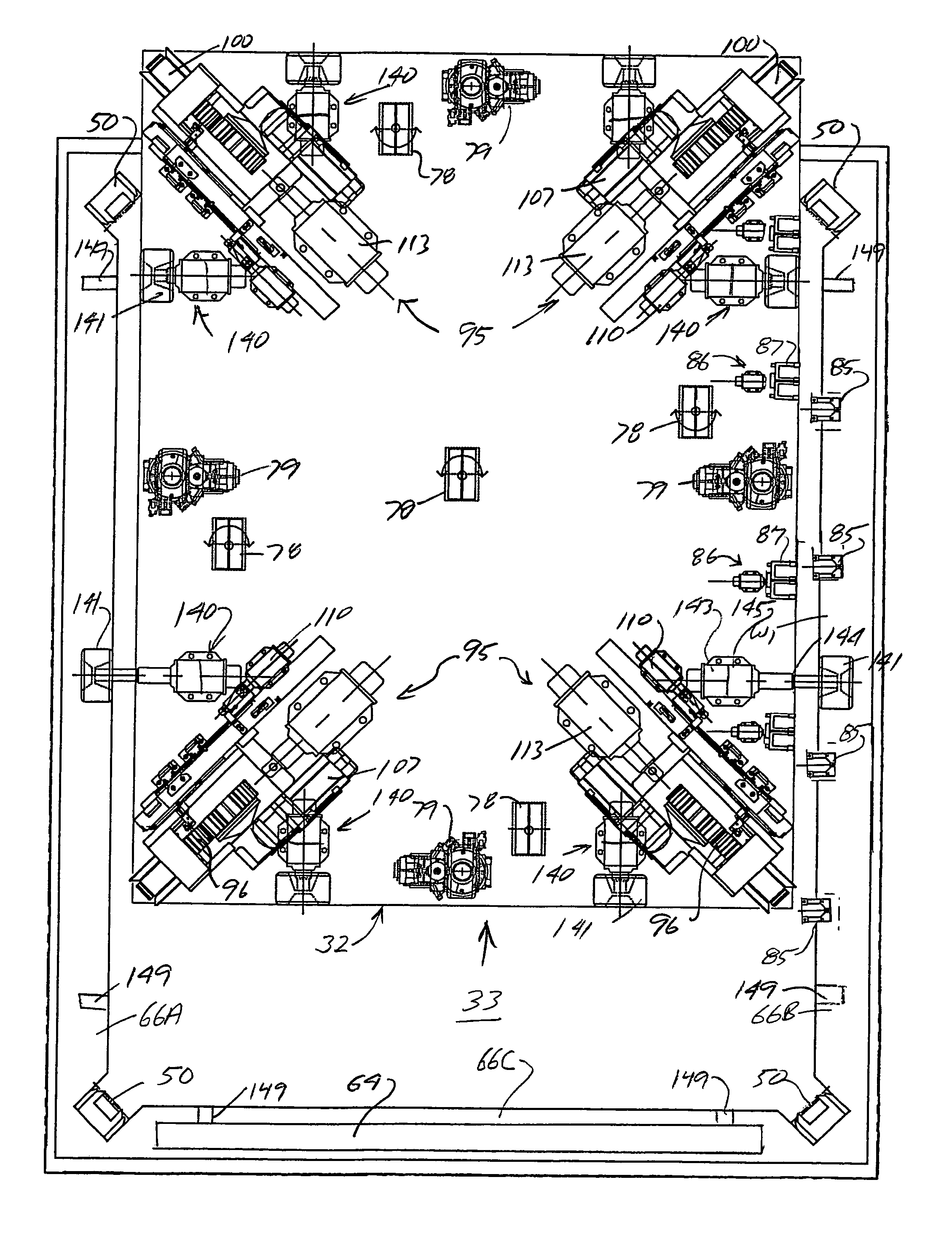

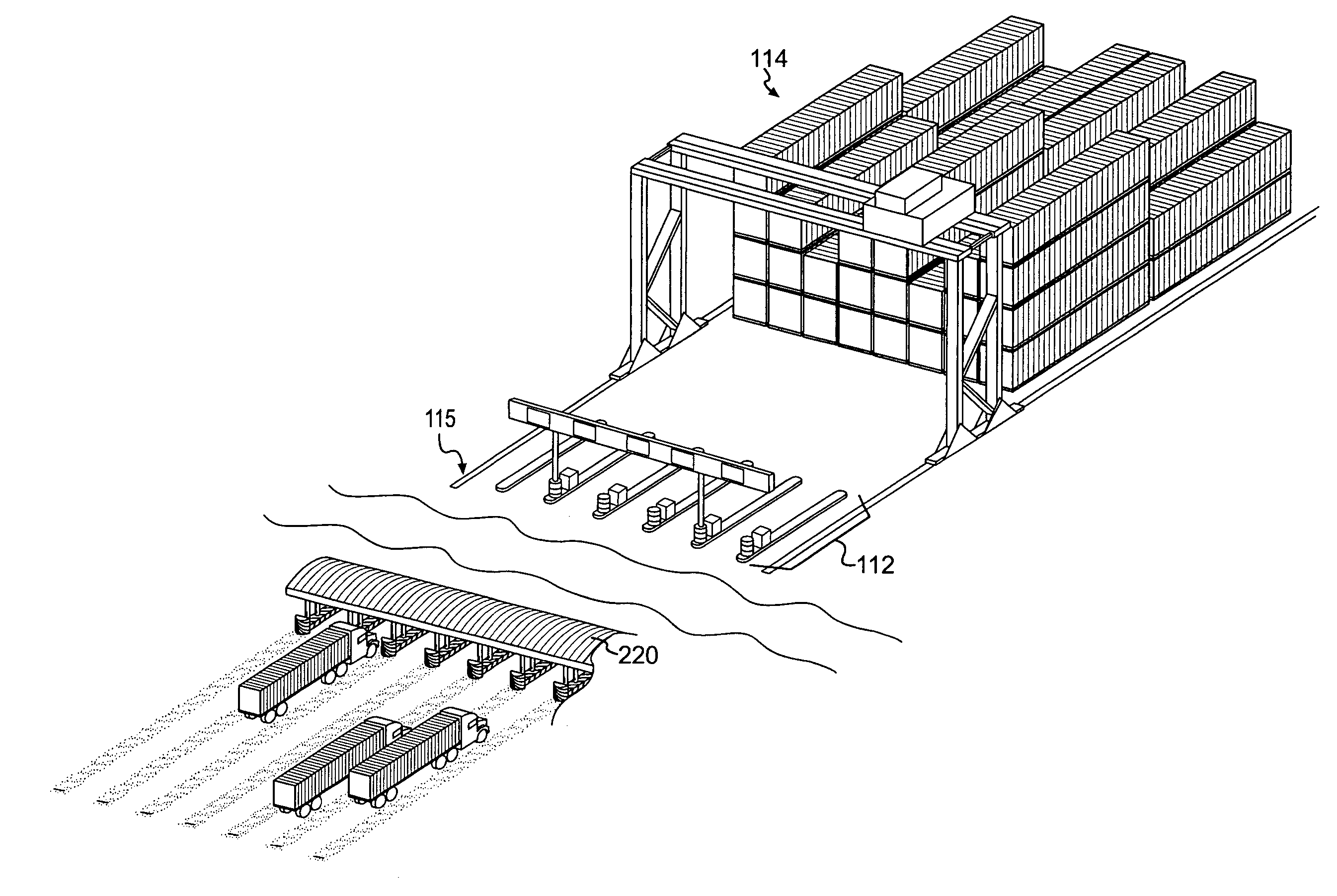

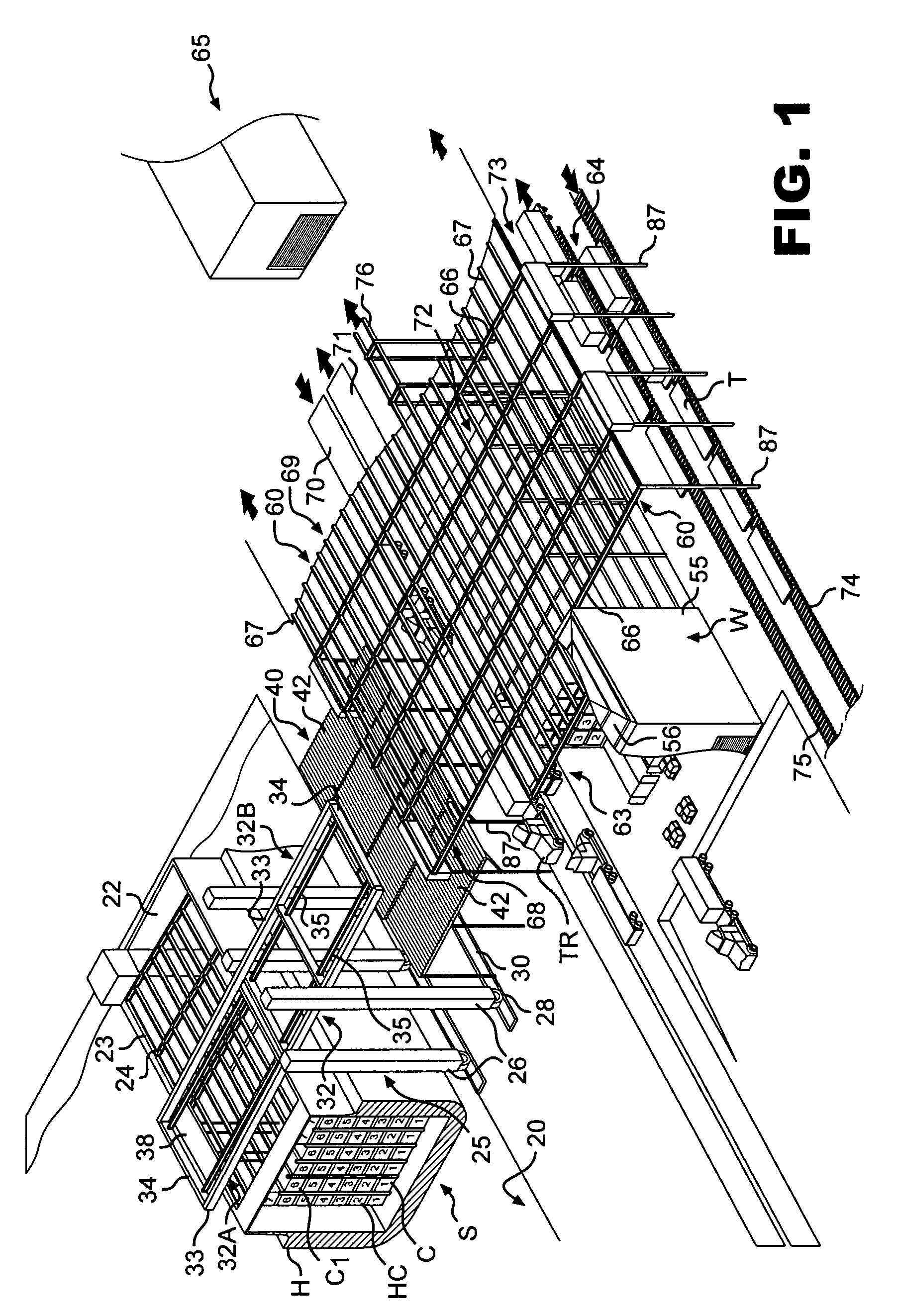

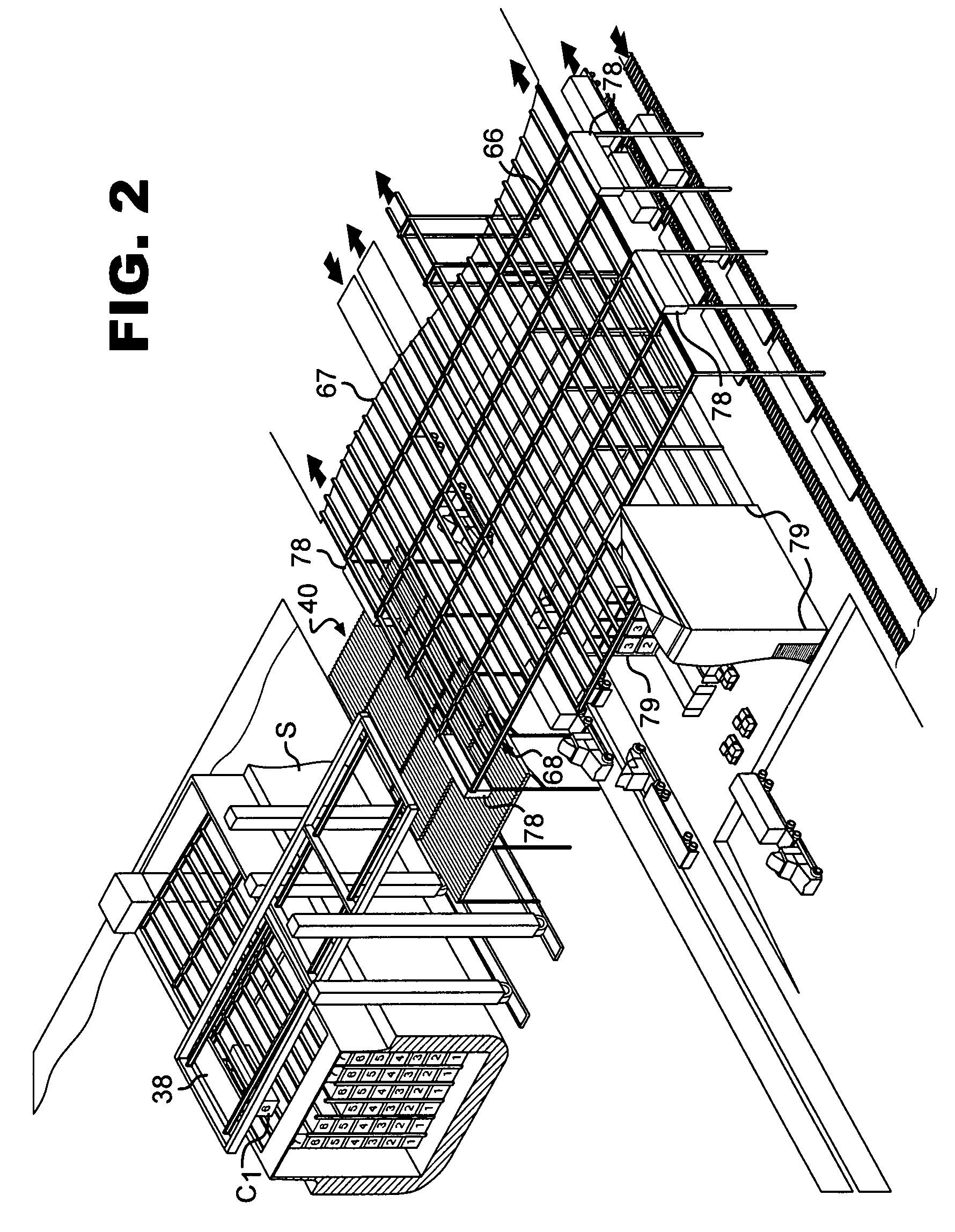

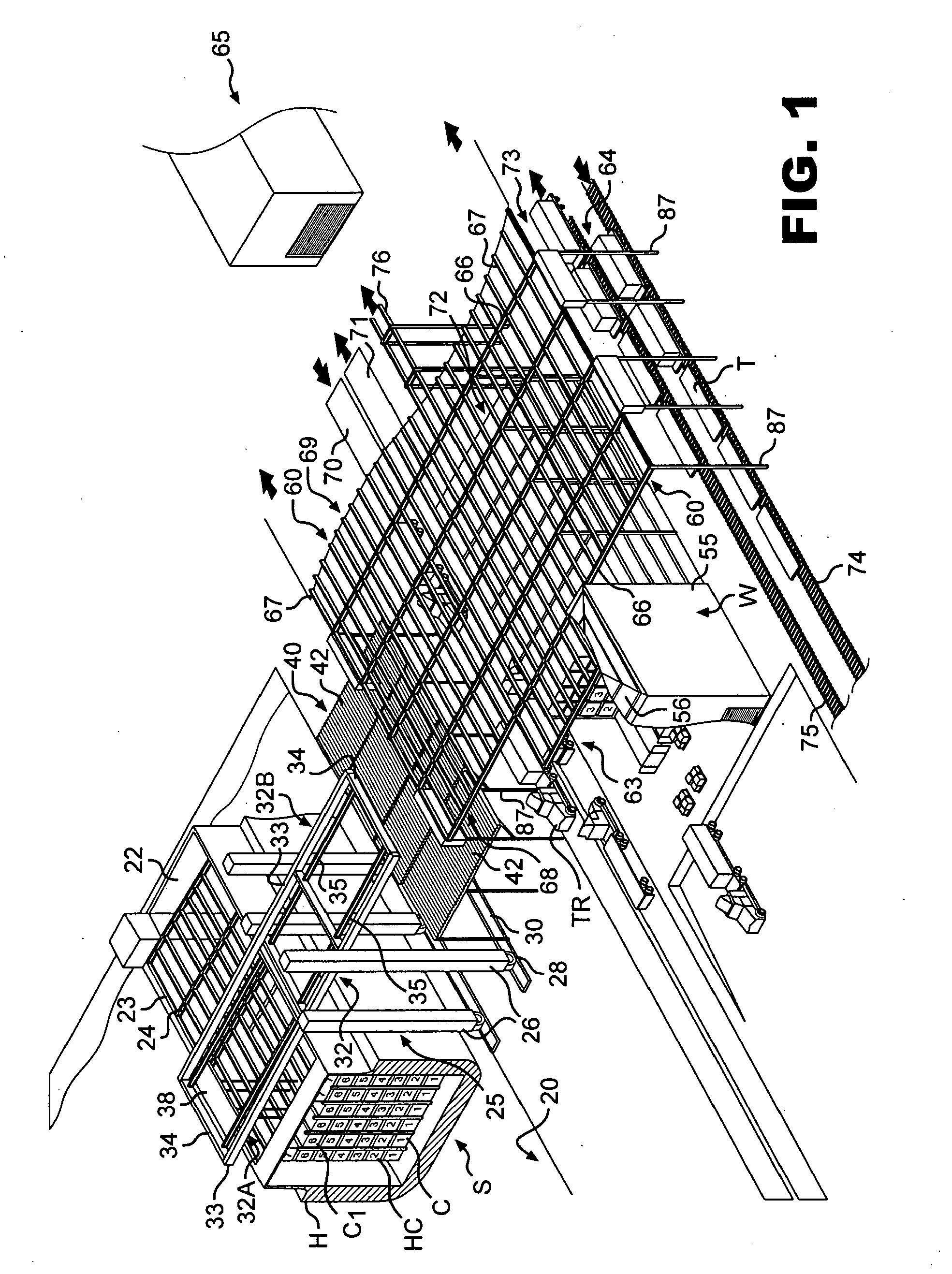

Port storage and distribution system for international shipping containers

ActiveUS20080213073A1Maximize storage spaceImprove efficiencyCargo handling apparatusPassenger handling apparatusInternational shippingDistribution system

A port storage and distribution system for facilitating the transfer and / or storage of international shipping containers between container ships and ground transport carriers wherein an overhead grid guide track structure is provide that permits overhead transfer units to selectively engage and convey containers as required between the various ships, carriers and storage area without requiring multiple transfers of containers between different handling equipment. The system provides for container scanning and is either fully automated or partially manually controlled.

Owner:GEBRR BECKER

Automated material handling system with load transfer vehicles

InactiveUS7931431B2Improve securityCargo handling apparatusPedestrian/occupant safety arrangementHandling systemMaterial handling

Owner:GEBRR BECKER

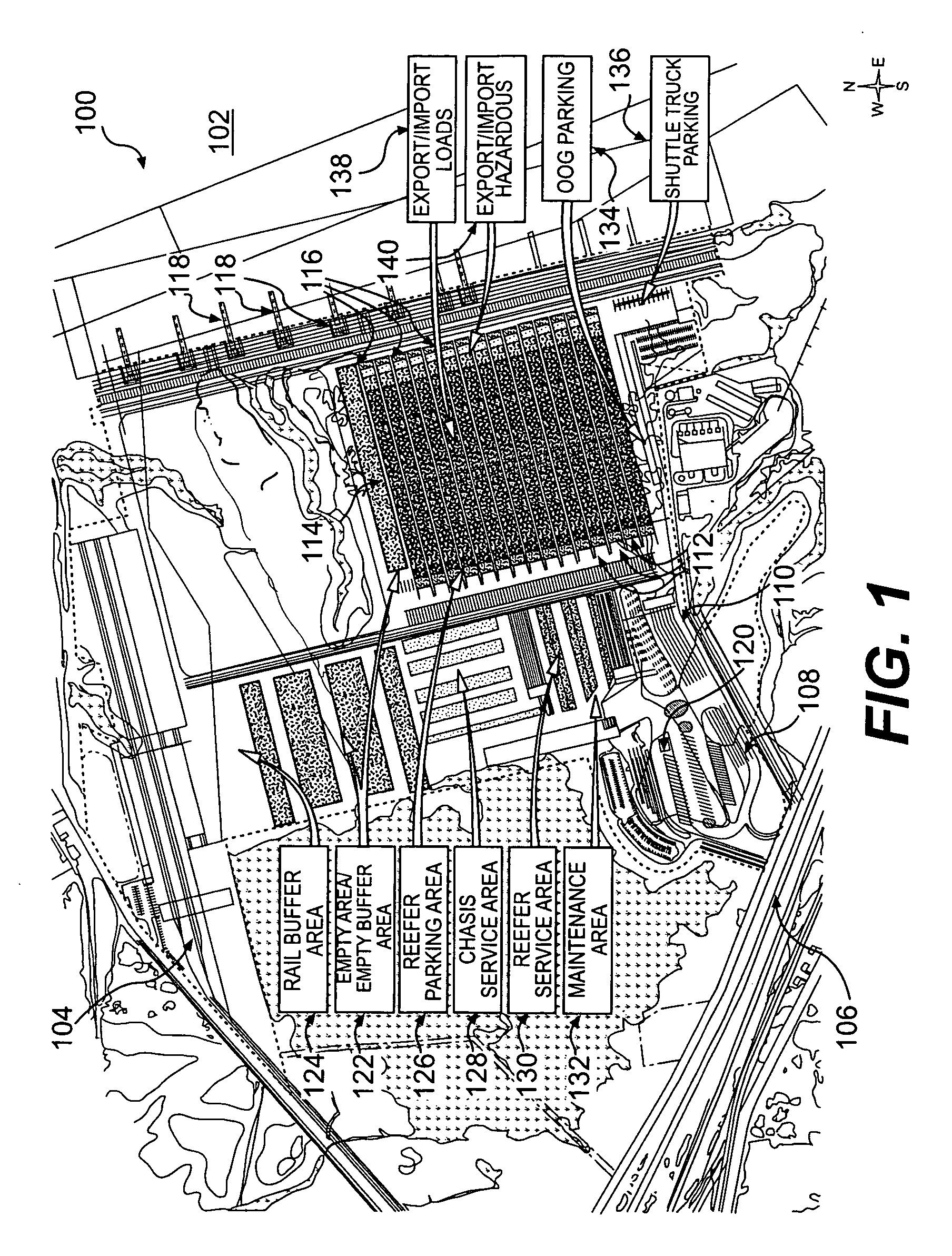

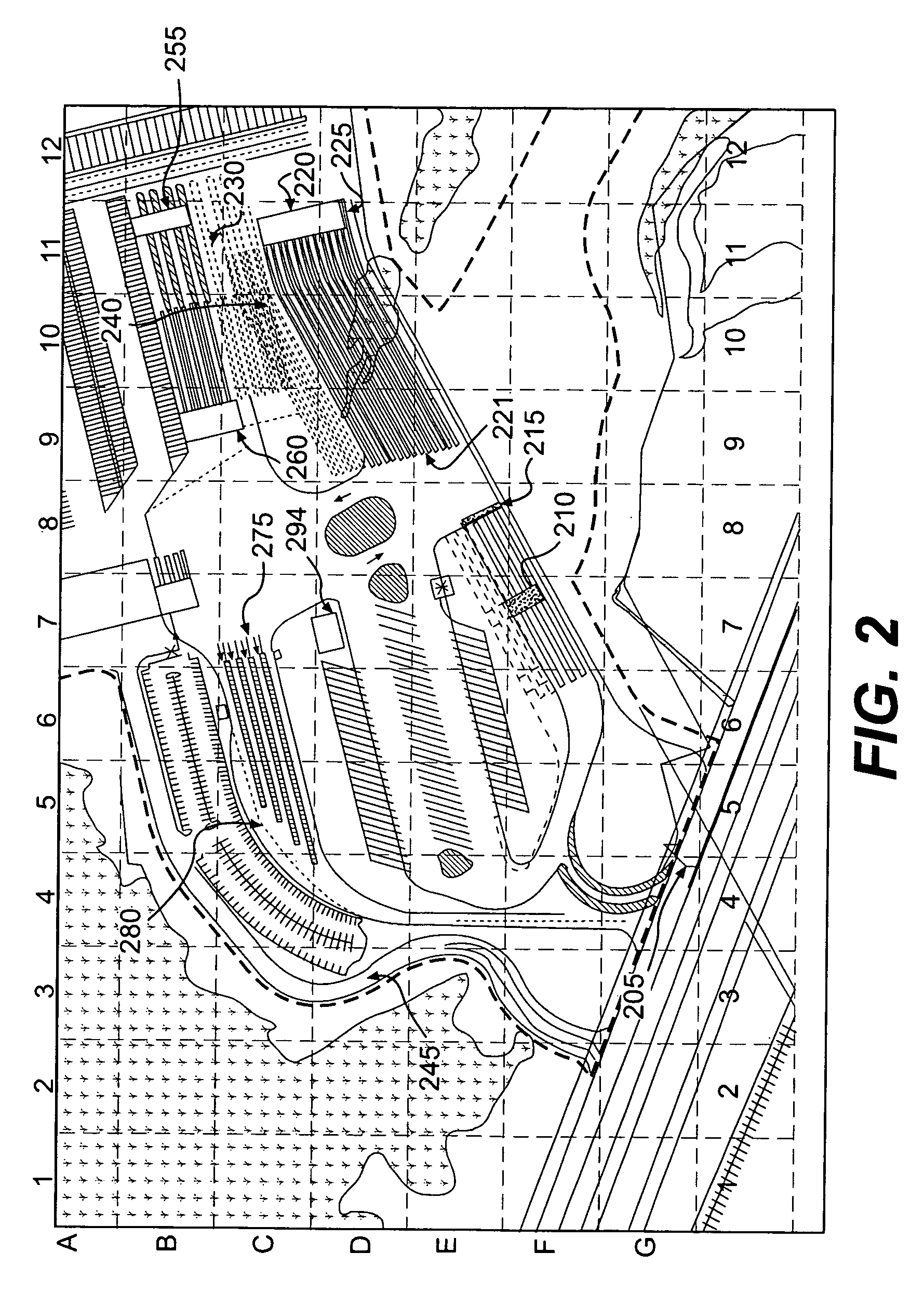

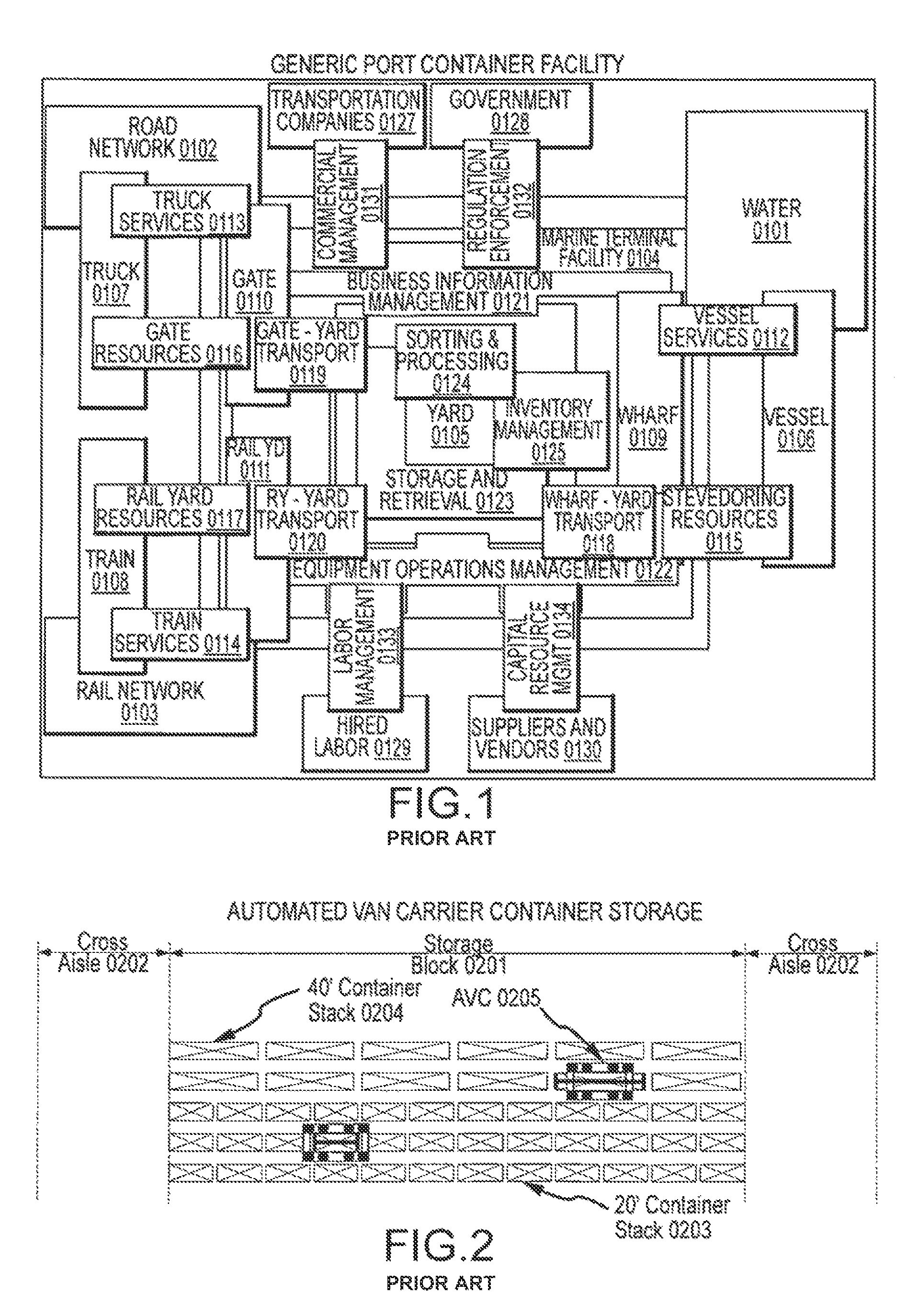

System and process for improving container flow in a port facility

ActiveUS20060251498A1Maximize effective useSimple designCargo handling apparatusDigital data processing detailsOperational systemStream flow

A system and process for improving container flow within a port facility, including improved equipment and software for controlling operation and flow of the equipment in the part facility. The system may include a port facility geographically arranged to separate land operations and water operations. Land operations such as over-the-road missions and rail missions may use landside access areas positioned at one end of a yard including rows of container stacks. Water missions such as loading / discharging a vessel may use waterside access areas positioned at the opposite end of the yard. Automated cranes linked with a terminal operating system may pick / drop / shuffle containers and / or refrigerated containers (“reefers”) within the container stacks. Shuttle trucks may be used to pick / drop containers at quayside access points and the waterside access areas. The shuttle trucks may utilize shared wheelpaths. Software systems may be used to implement various principles of the invention.

Owner:APM TERMINALS NORTH AMERICA

Port storage and distribution system for international shipping containers

ActiveUS7753637B2Maximize storage spaceImprove efficiencyCargo handling apparatusPassenger handling apparatusInternational shippingDistribution system

A port storage and distribution system for facilitating the transfer and / or storage of international shipping containers between container ships and ground transport carriers wherein an overhead grid guide track structure is provide that permits overhead transfer units to selectively engage and convey containers as required between the various ships, carriers and storage area without requiring multiple transfers of containers between different handling equipment. The system provides for container scanning and is either fully automated or partially manually controlled.

Owner:GEBRR BECKER

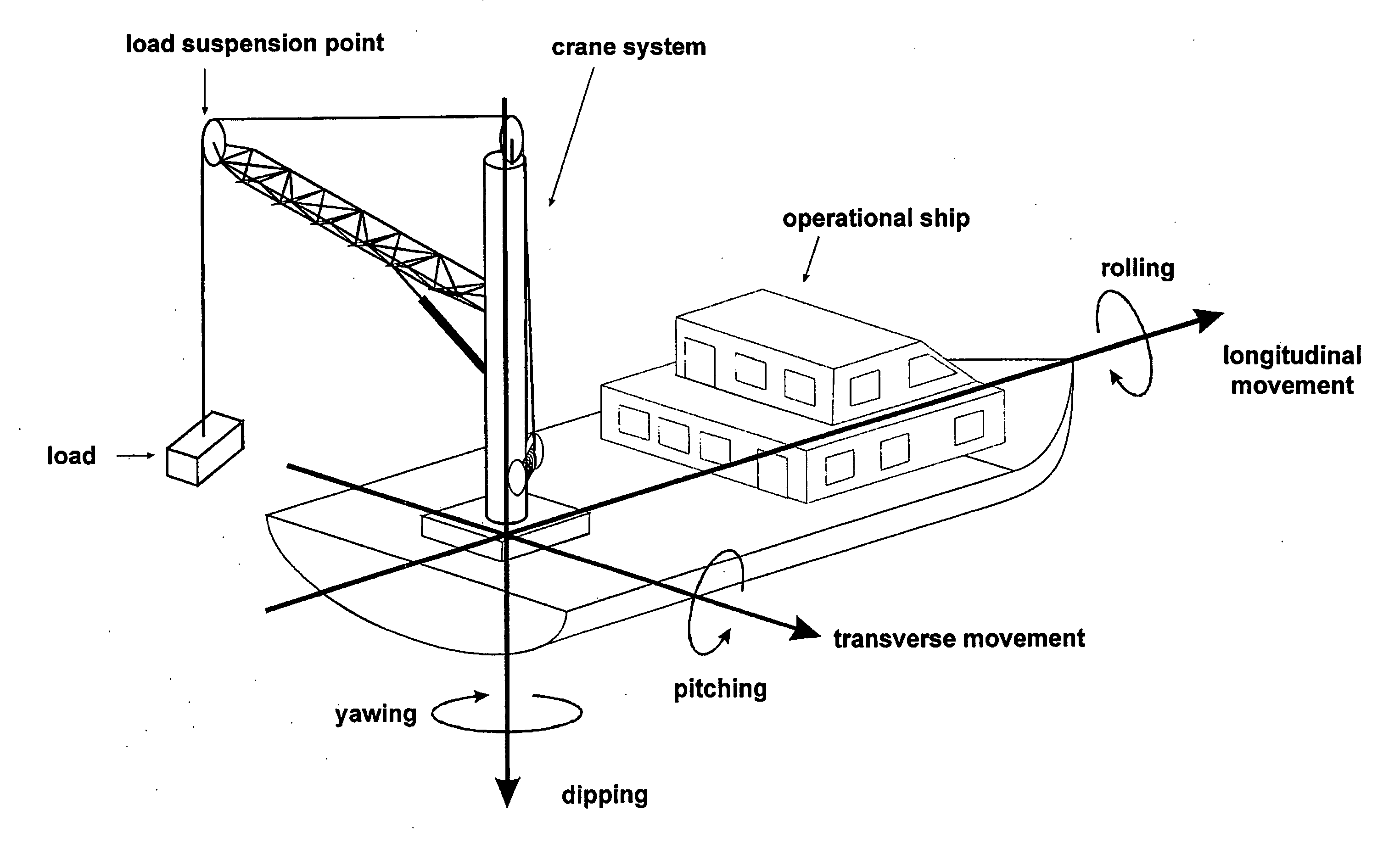

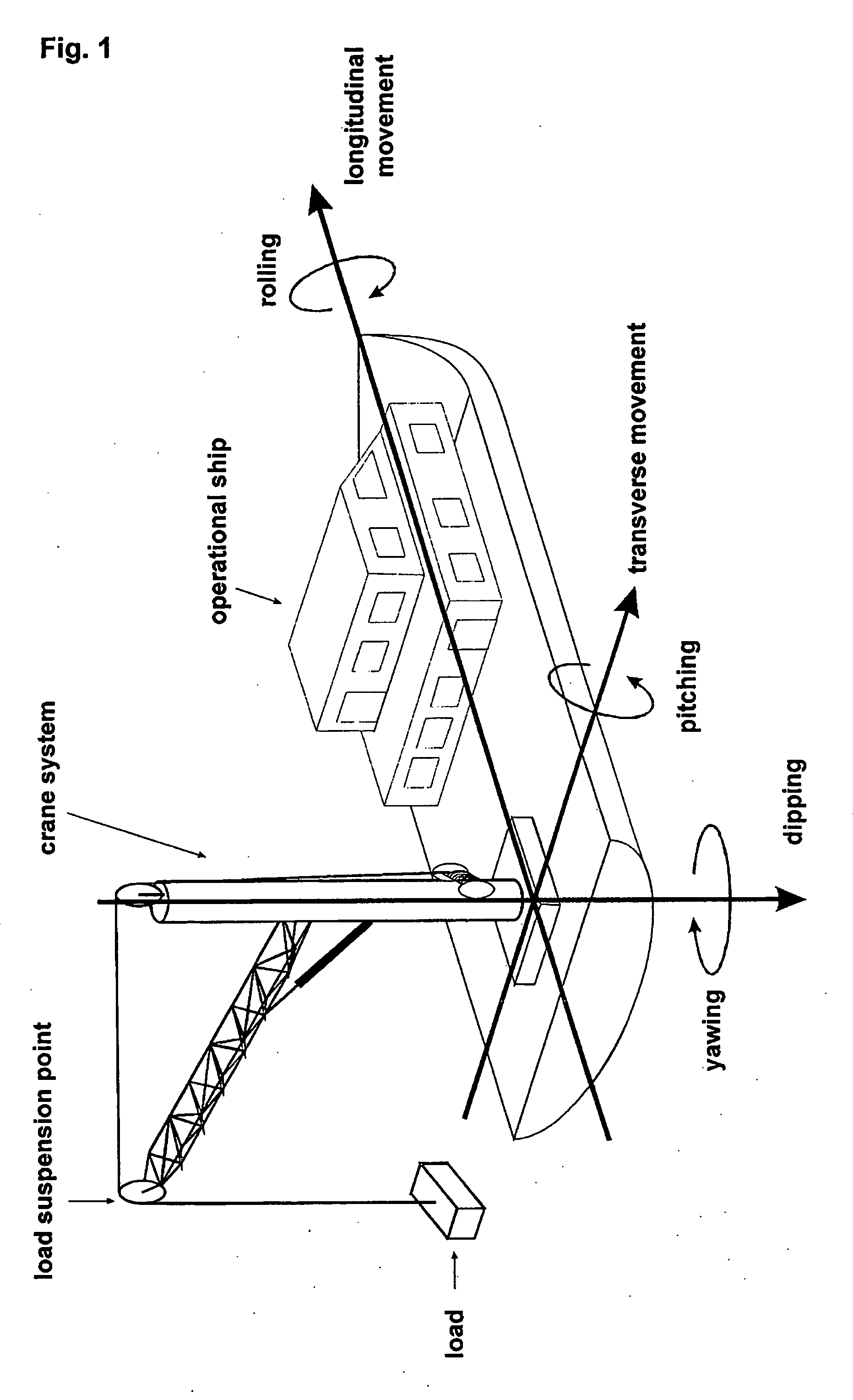

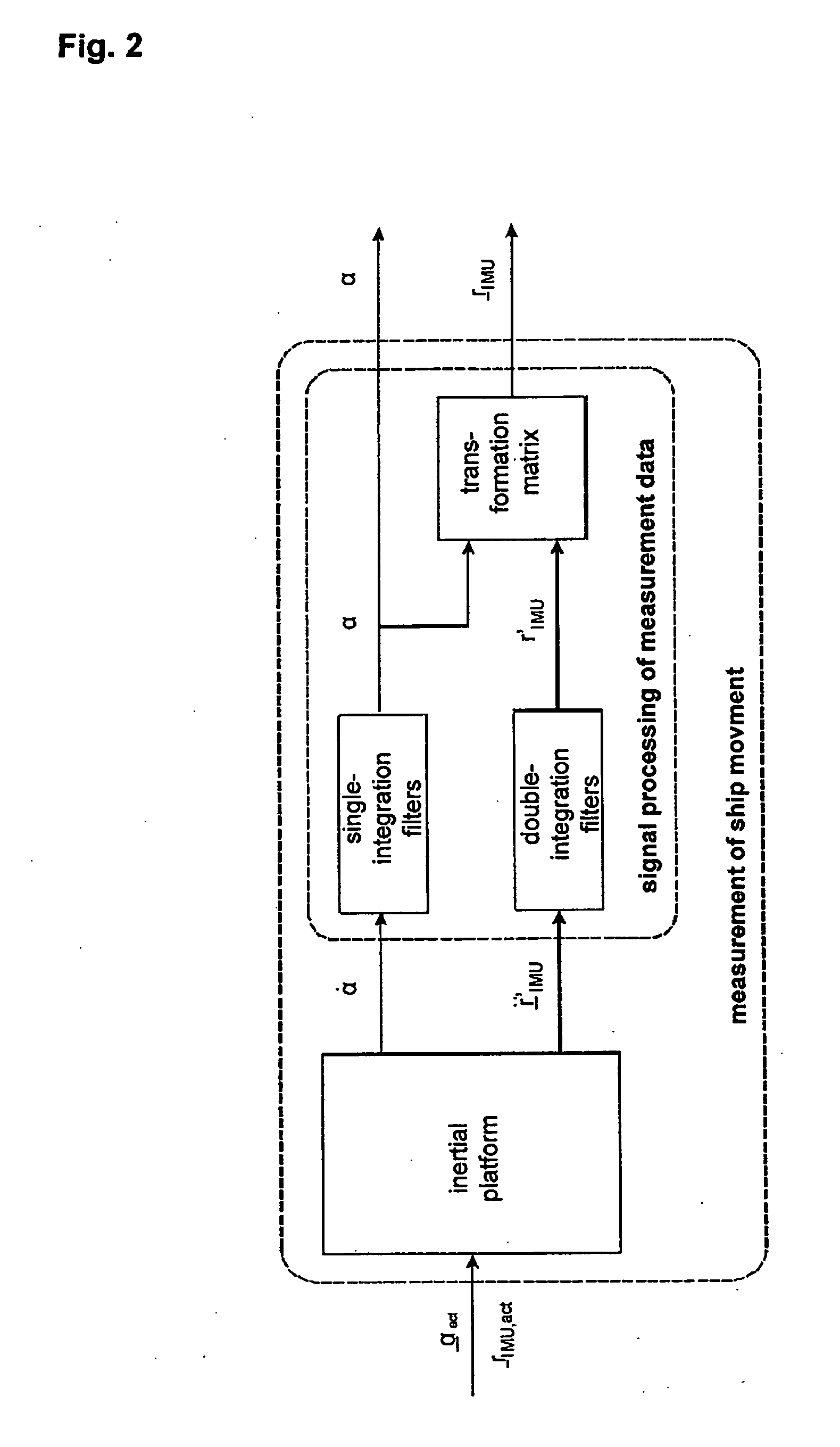

Crane control with active heave compensation

InactiveUS20100230370A1Precise positioningFlexible useCargo handling apparatusAnalogue computers for trafficDynamic modelsActive heave compensation

The present invention represents a procedure for compensating the heave movement of offshore cranes. The dynamic model of the compensation actuator (hydraulically operated winch) and the load hanging on a rope are derived. Based on this model, a path-tracking control unit is developed. To compensate the movement of the ship / watercraft caused by waves, the heave movement is defined as a time-varying disturbance and is analyzed with respect to uncoupling conditions. With a model expansion, these conditions are satisfied, and an inversion-based uncoupling control law is formulated. To stabilize the system, an observer is used for reconstructing the unknown state by means of a force measurement. Furthermore, the compensation efficiency can be improved by predicting the heave movement. There is proposed a prediction method in which no ship / watercraft models or properties are required. The simulation and measurement results validate the heave compensation method.

Owner:LIEBHERR WERK NENZING

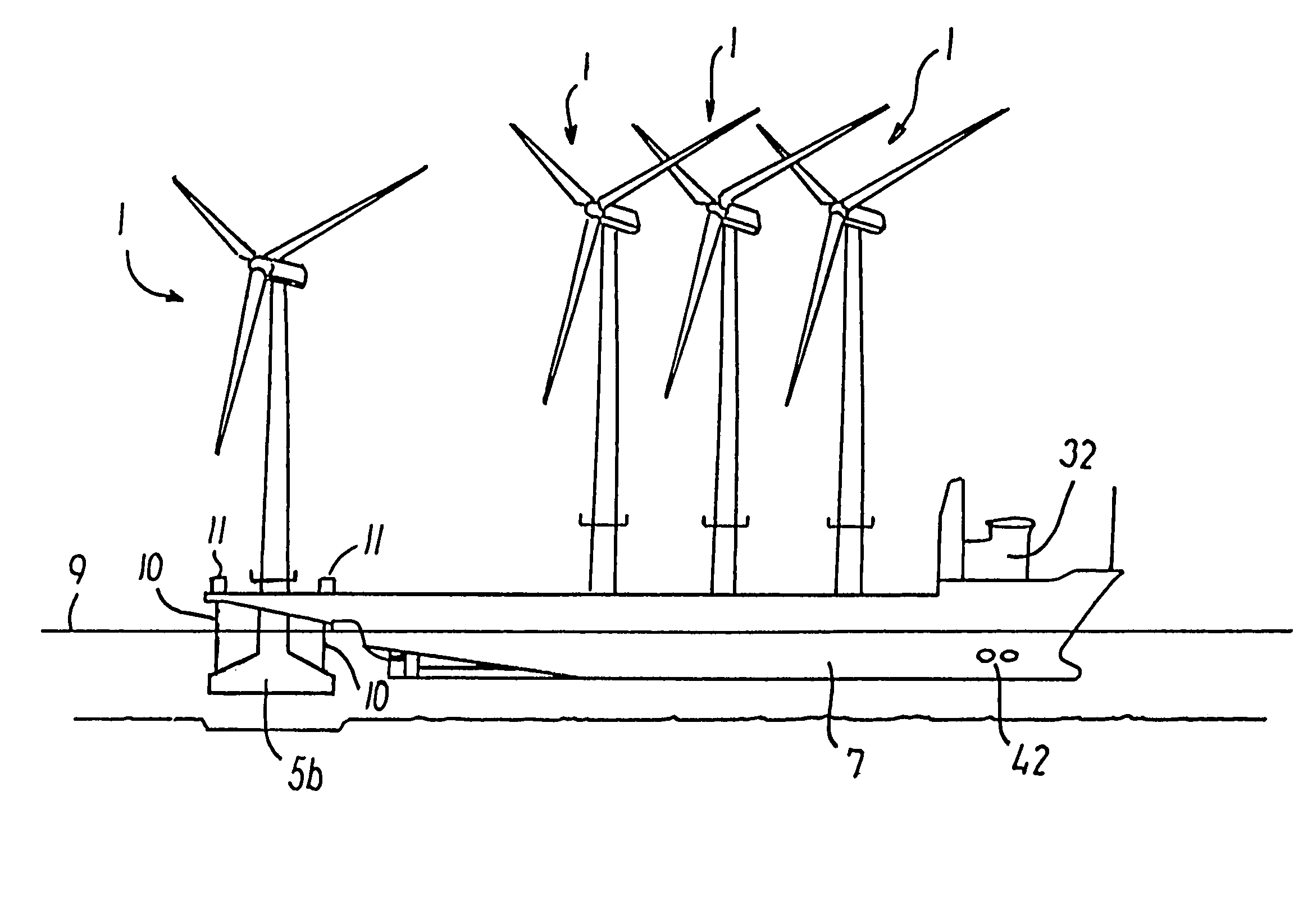

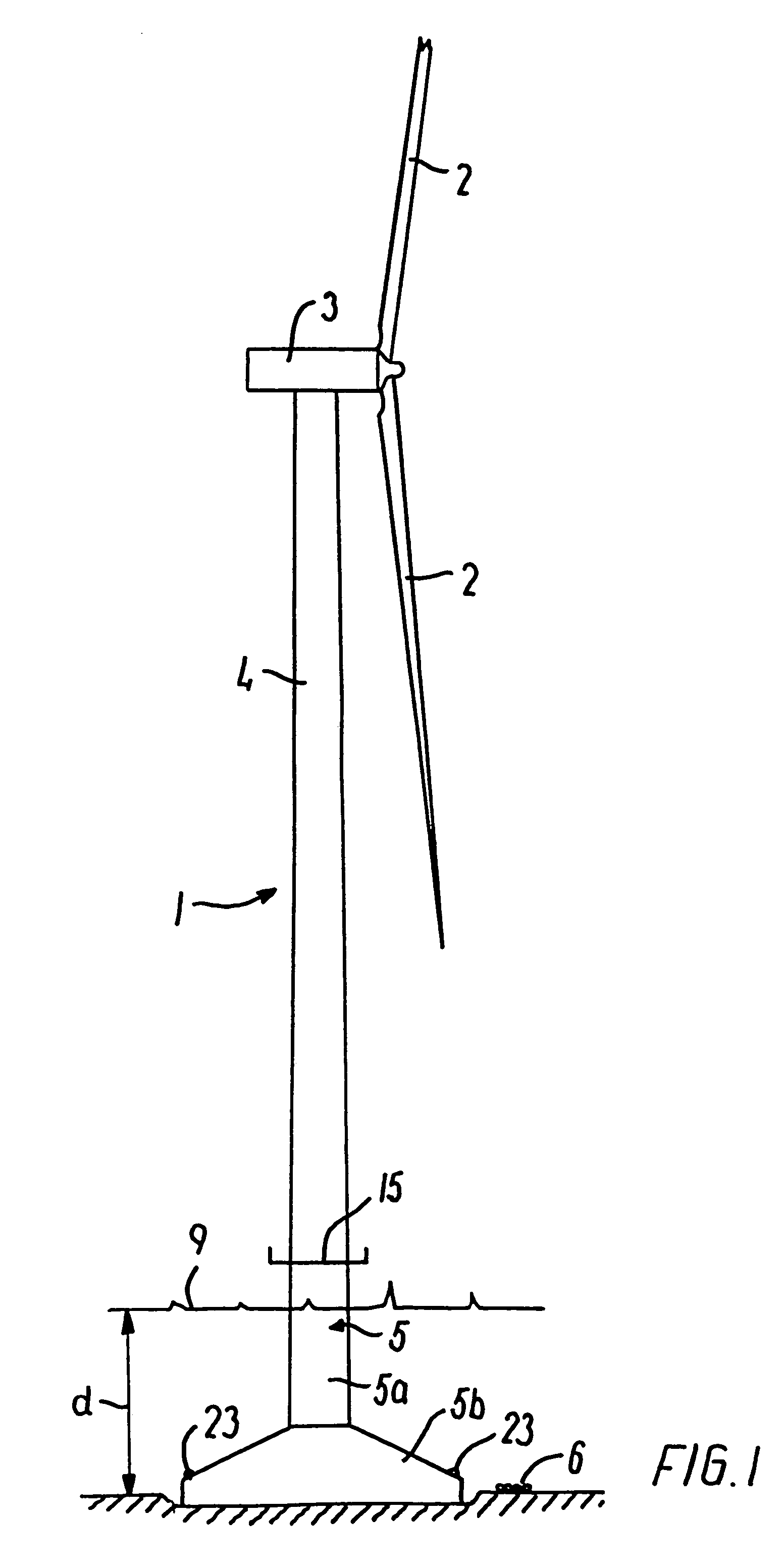

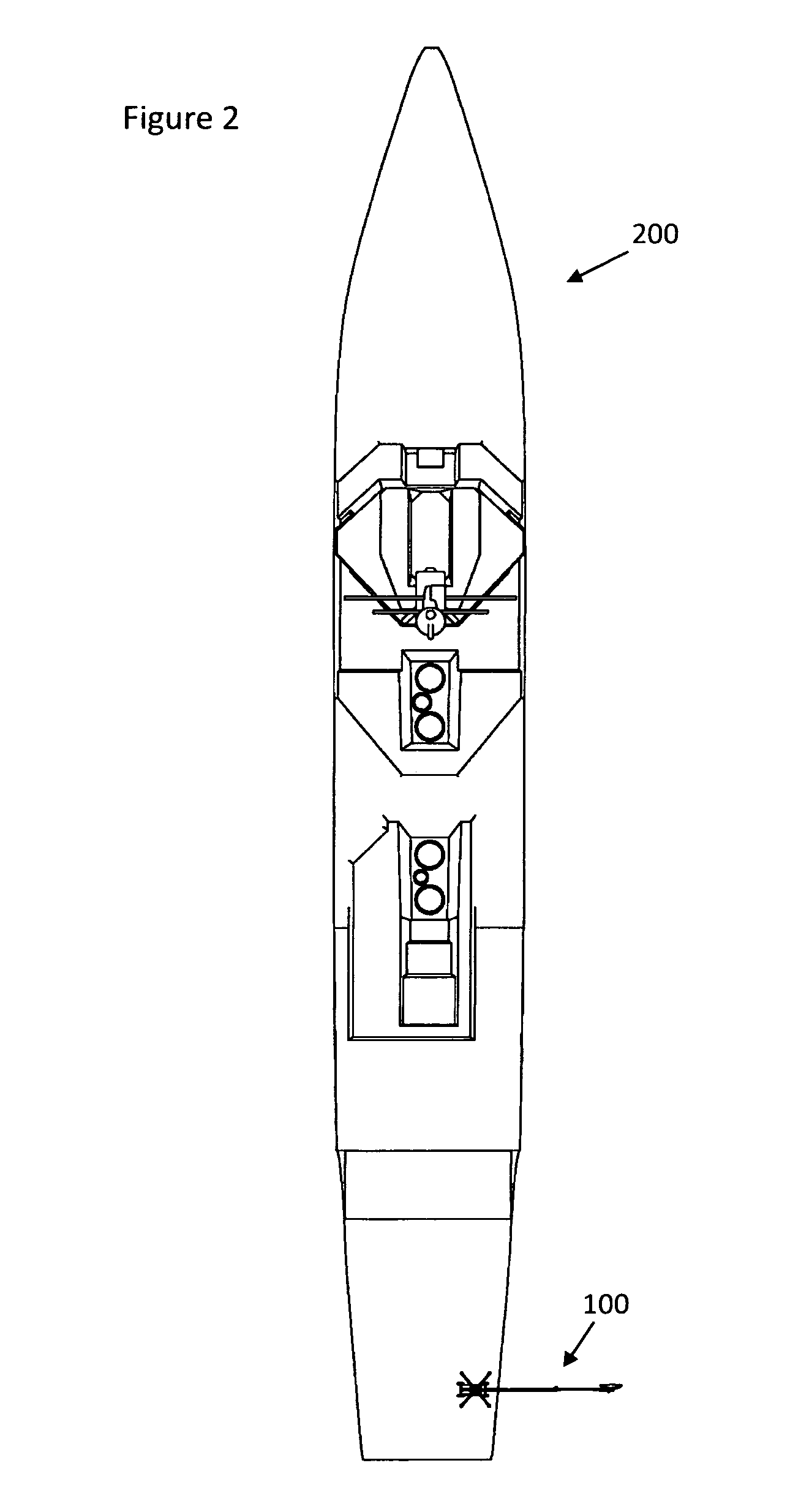

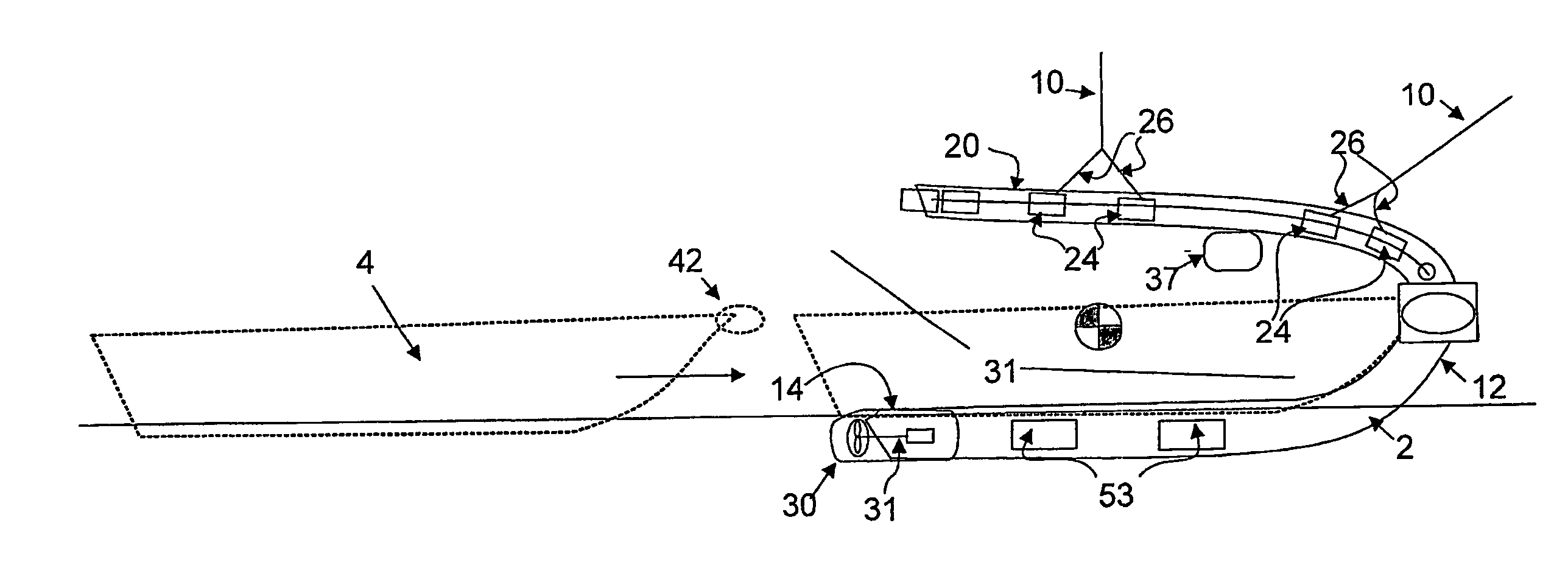

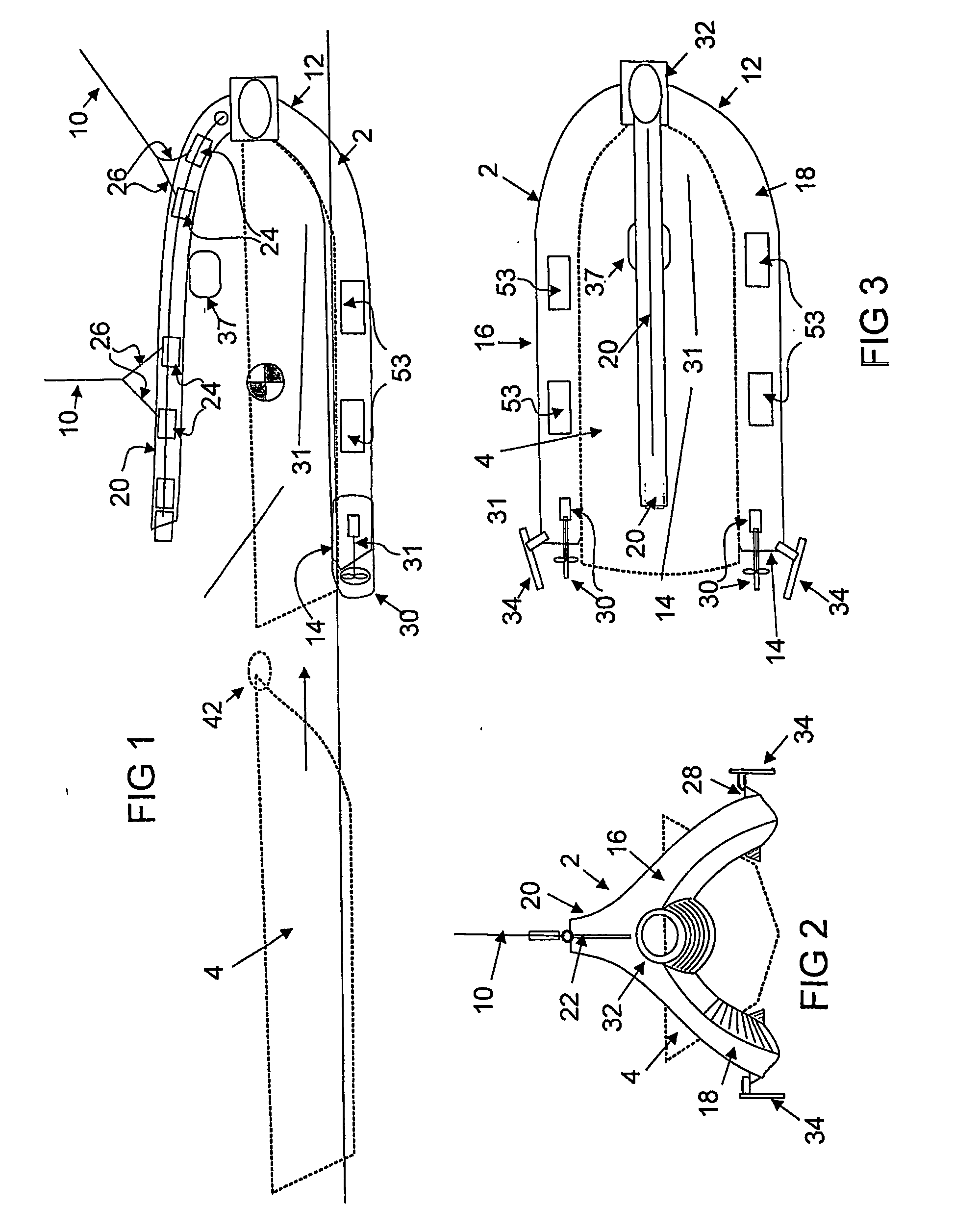

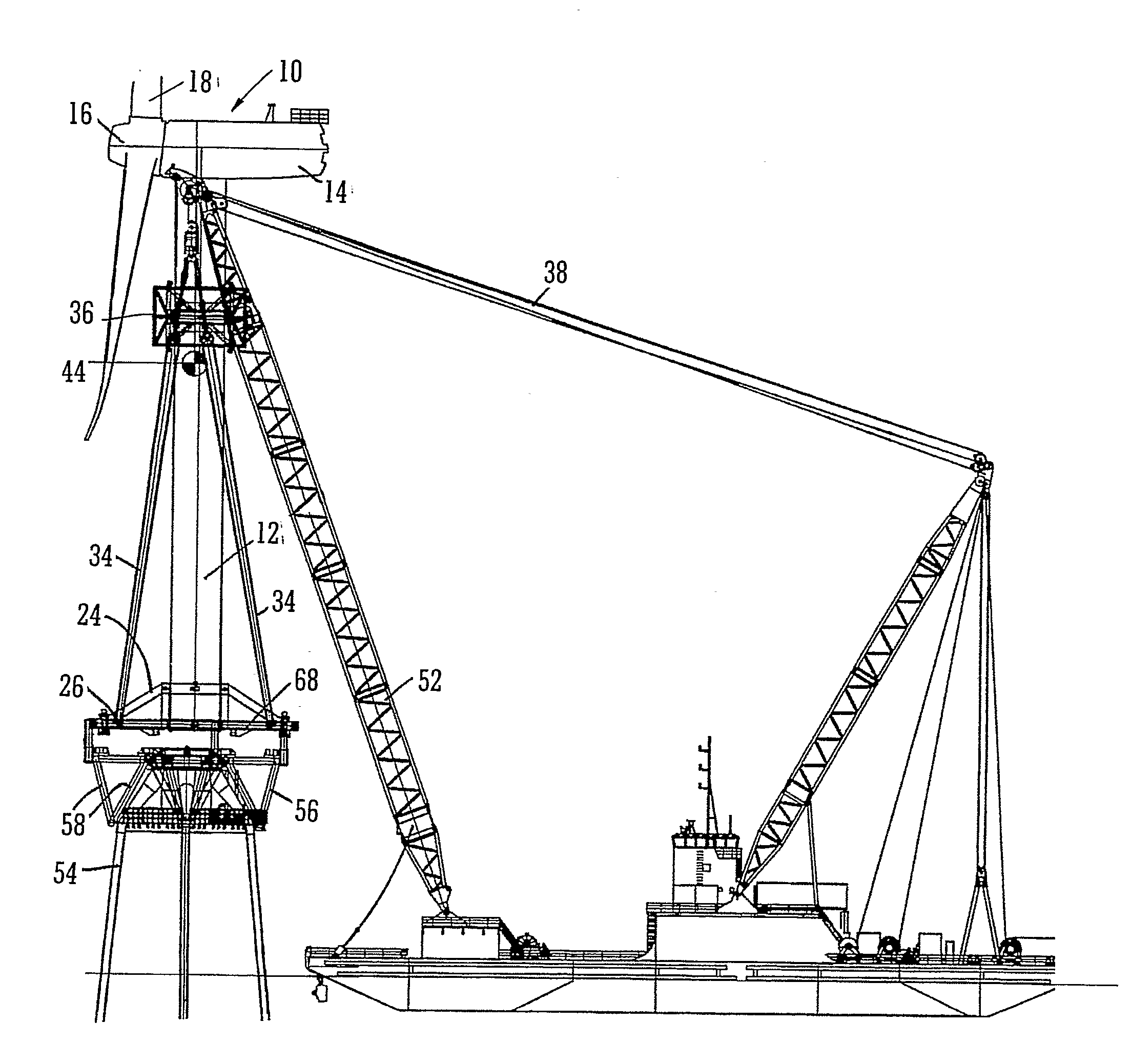

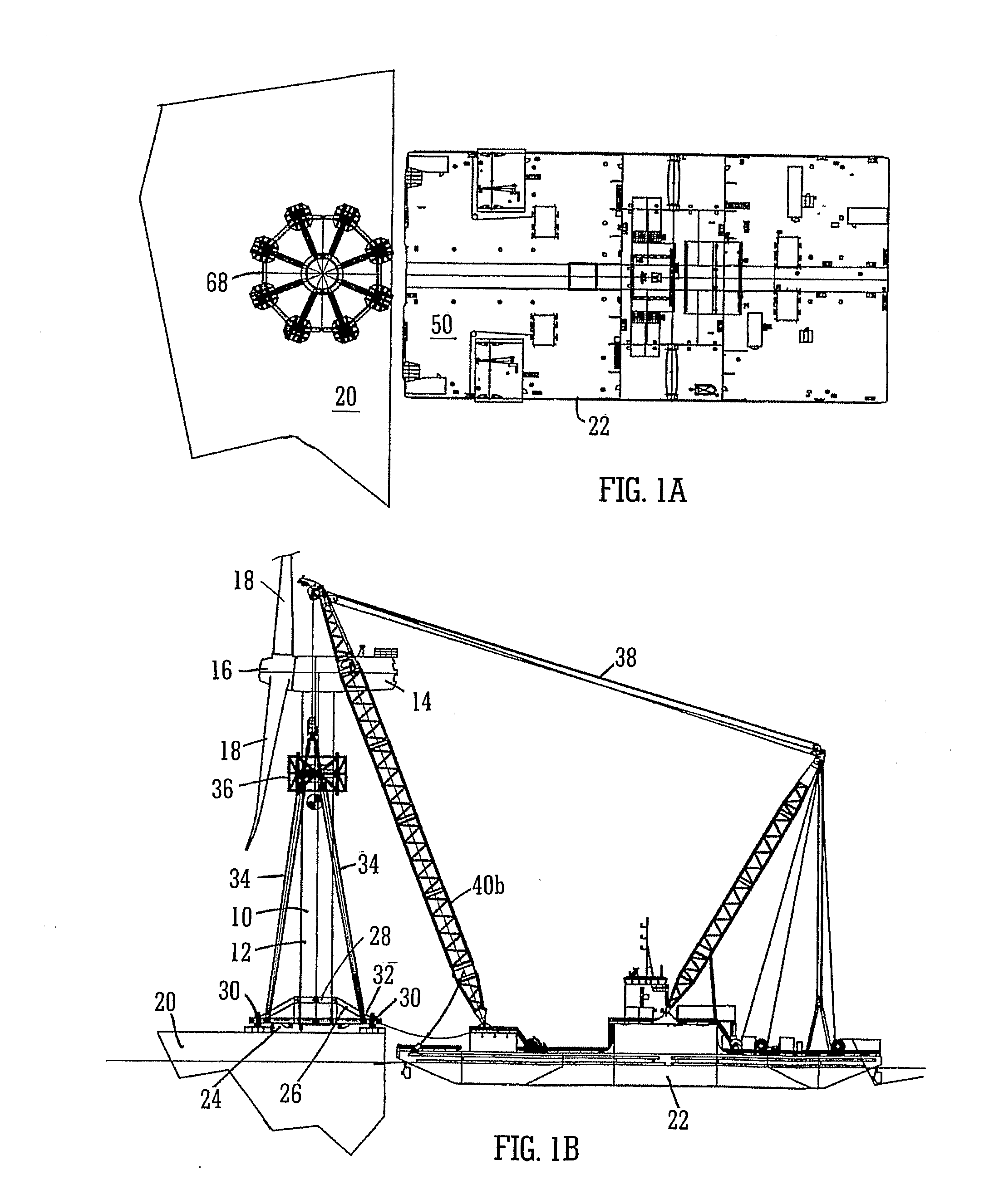

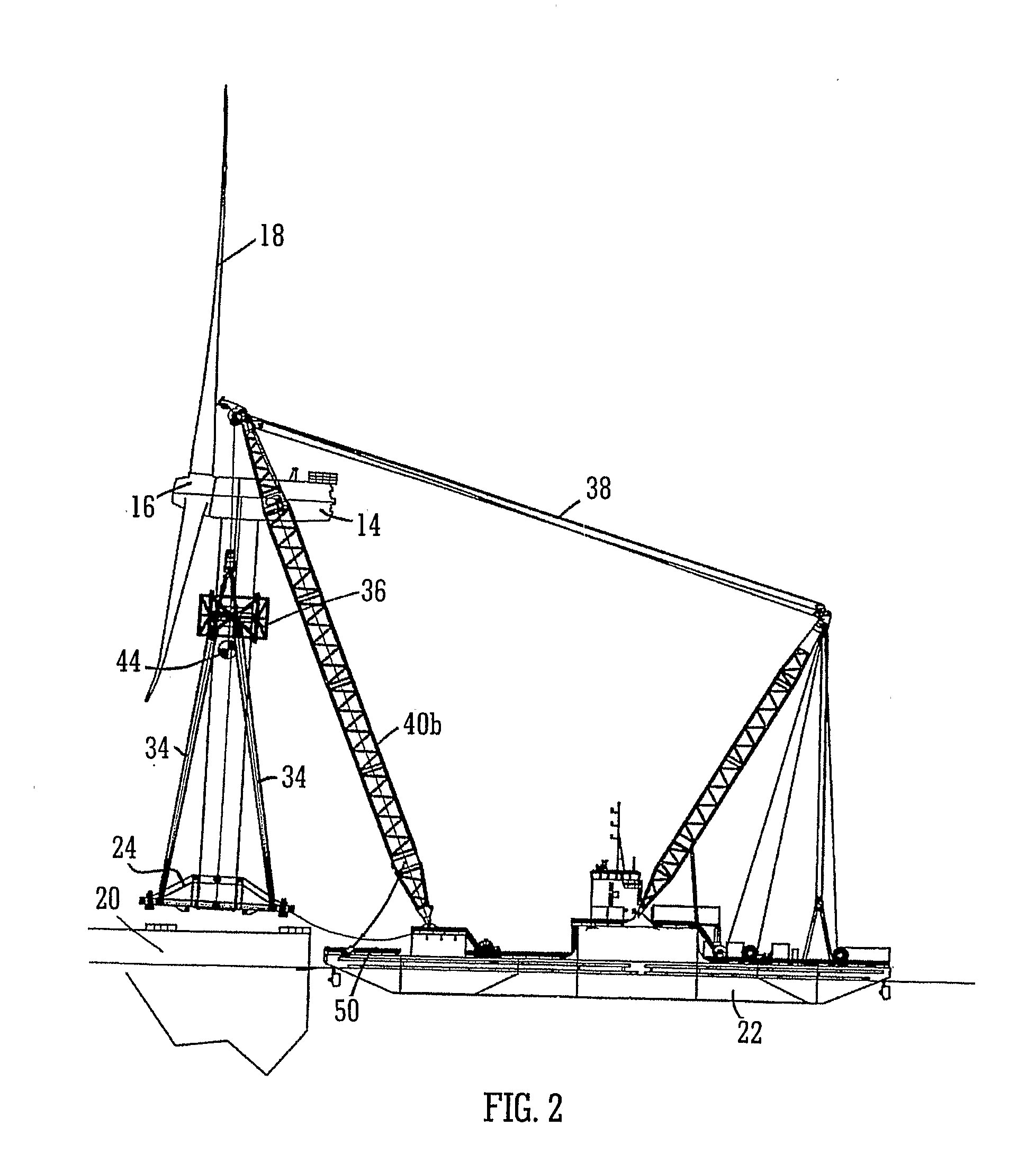

Vessel for transporting wind turbines, methods of moving a wind turbine, and a wind turbine for an off-shore wind farm

A wind turbine (1) has a base (5) divided into at least three ballast tanks (12). A vessel (7) has means for displacing the wind turbine between a loading space (25) and an unloading position (26). At its unloading position the vessel has winches (11) with at least three flexible lines (10) that can be connected with horizontally distanced lifting points (23) on the wind turbine base.

Owner:LOGIMA VSVEND ERIK HANSEN

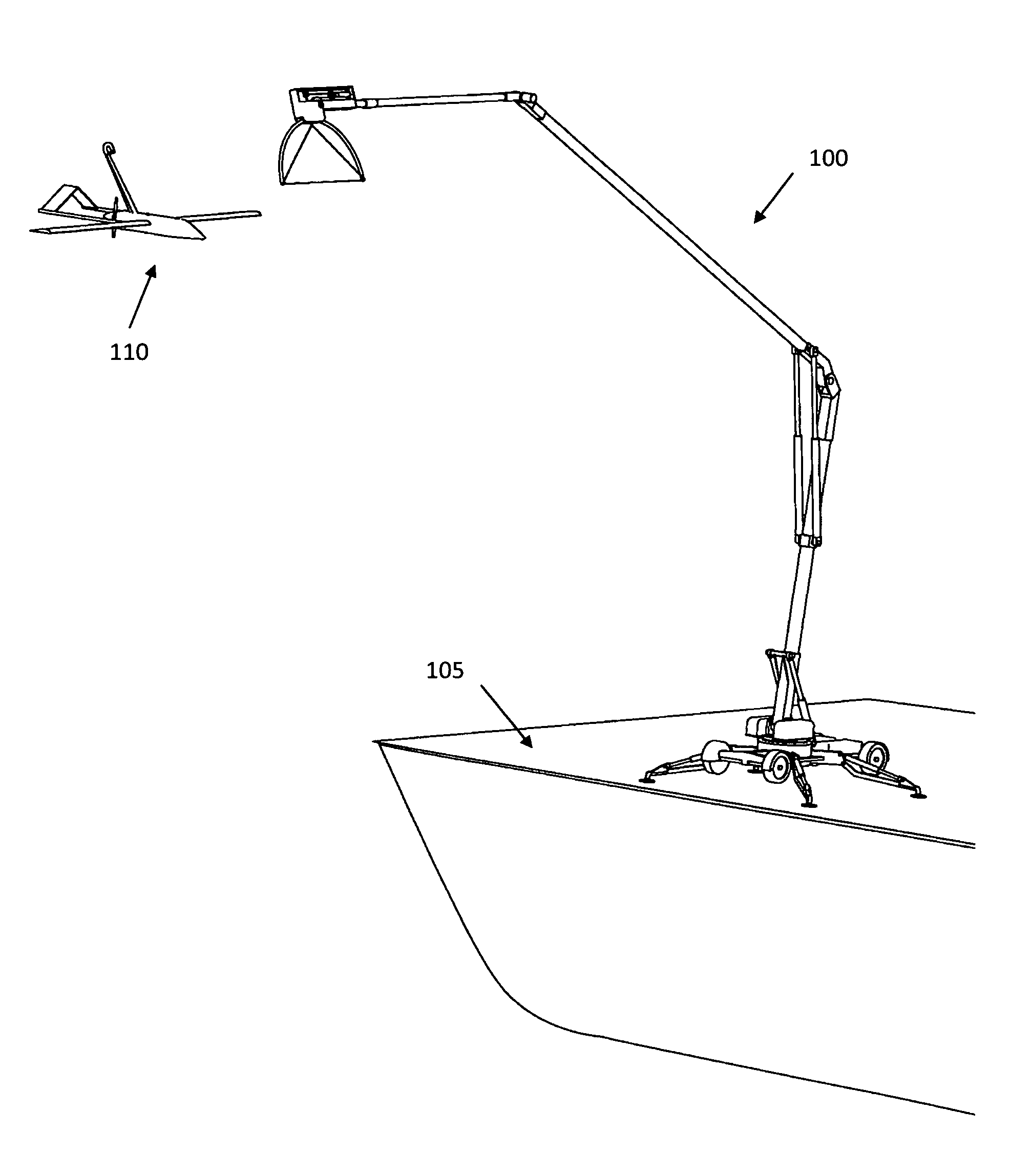

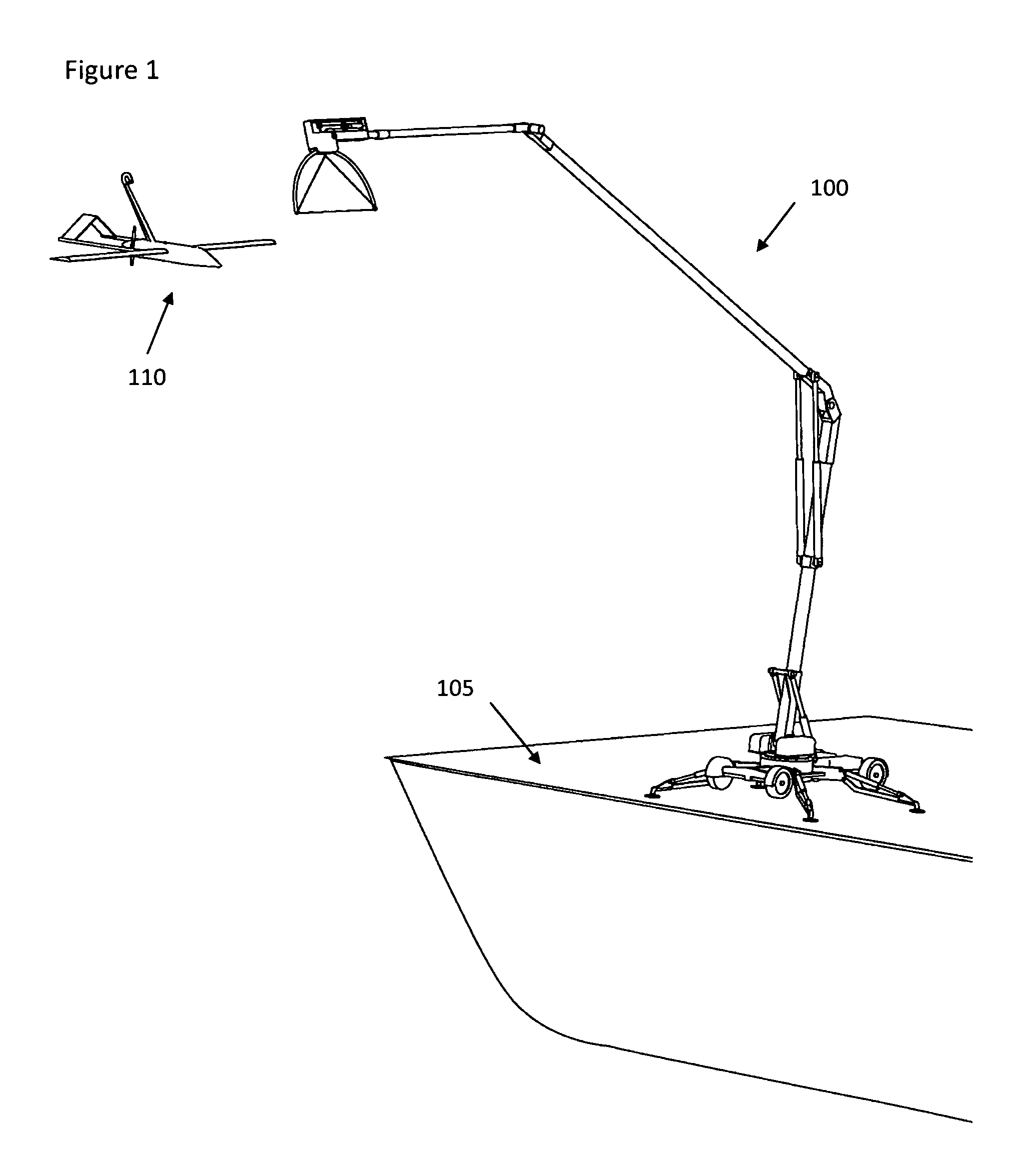

Stabilized UAV recovery system

ActiveUS8172177B2Promote recoveryIncrease probabilityCargo handling apparatusArresting gearUncrewed vehicleWinch

A stabilized UAV recovery system is disclosed. In the illustrative embodiment for UAV recovery over water, the system includes ship-based elements and UAV-based elements. The ship-based elements include a robot arm that holds a capture mechanism over the side of the ship while compensating for wave-induced ship motion. The UAV-based elements include a hook mounted to the top of the UAV fuselage. With the capture mechanism held stable from the perspective of a UAV approaching from behind or in front of the mechanism, the UAV is flown under it, snagging an arresting line with the hook. With continued forward motion of the UAV, the arresting line pulls out of a winch drum that is coupled to a brake, bringing the UAV to rest.

Owner:ADVANCED TECH & RES CORP +1

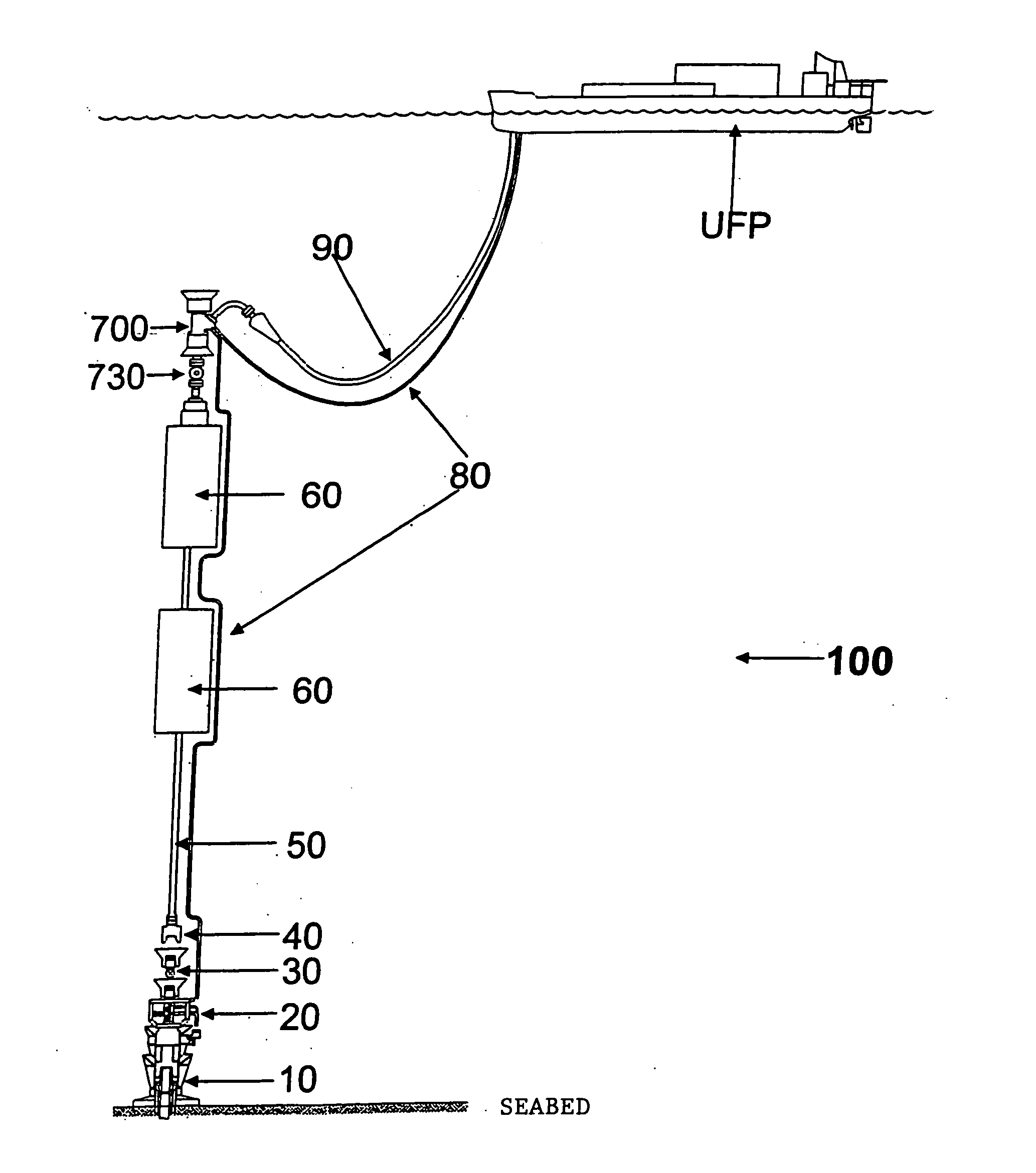

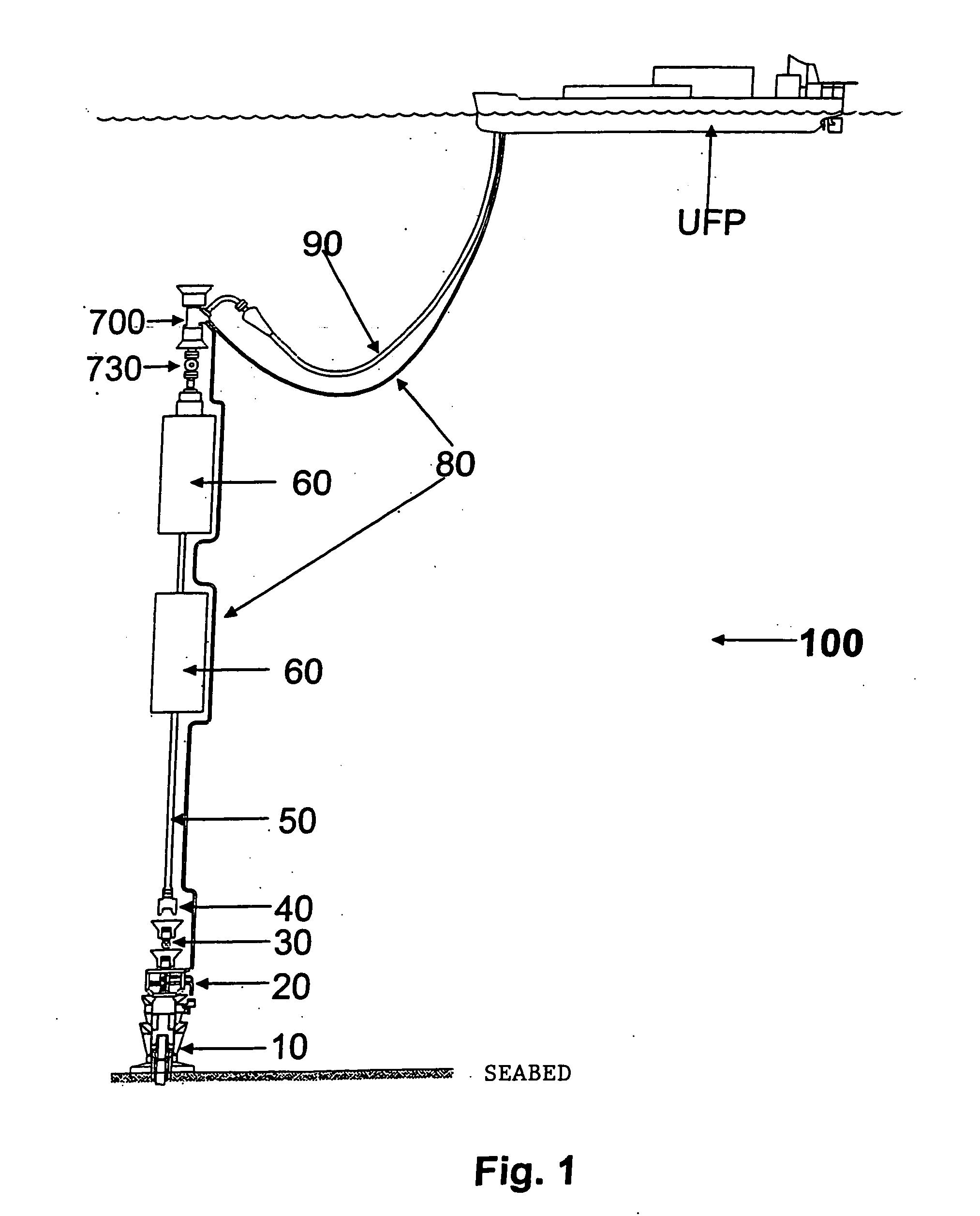

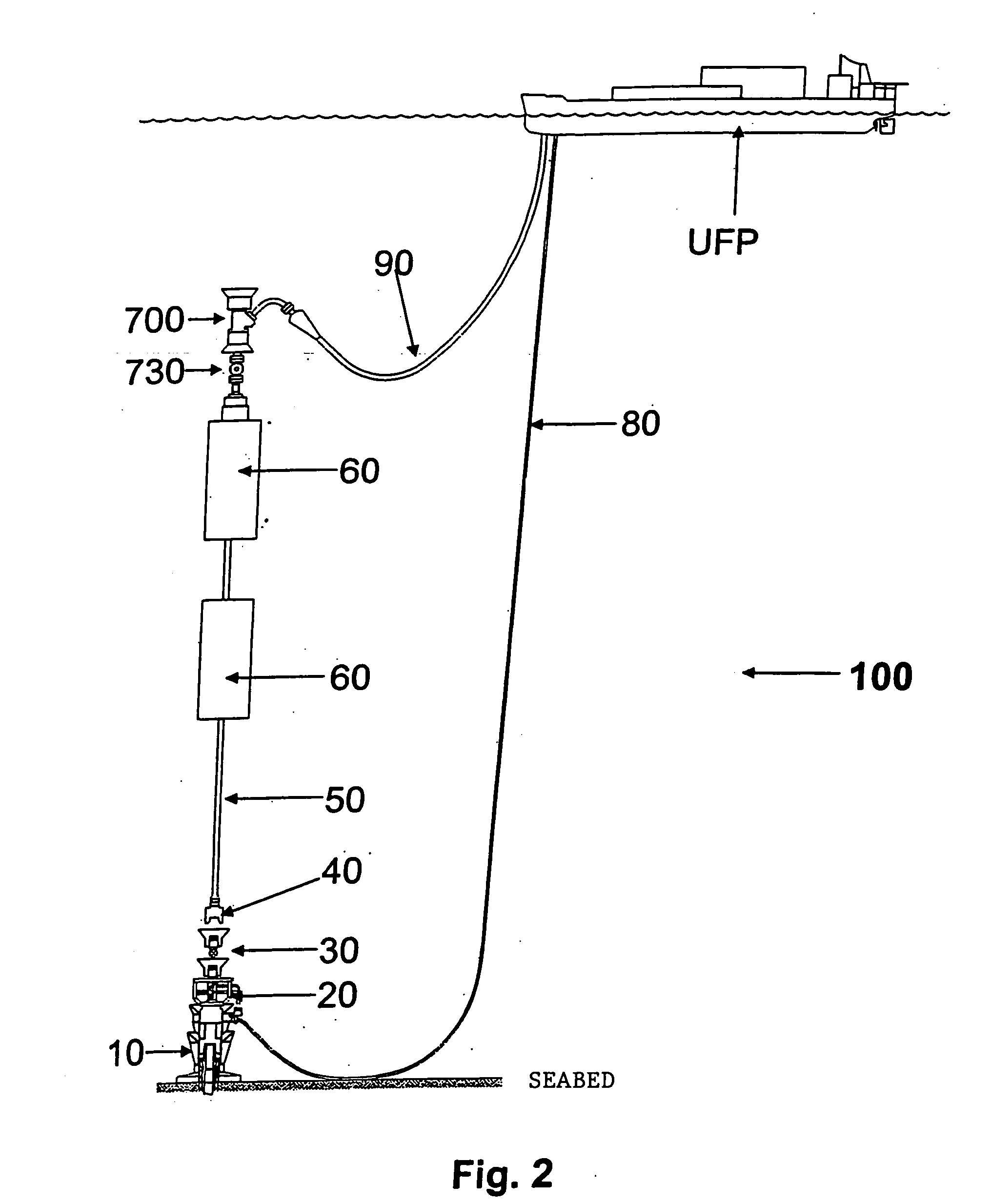

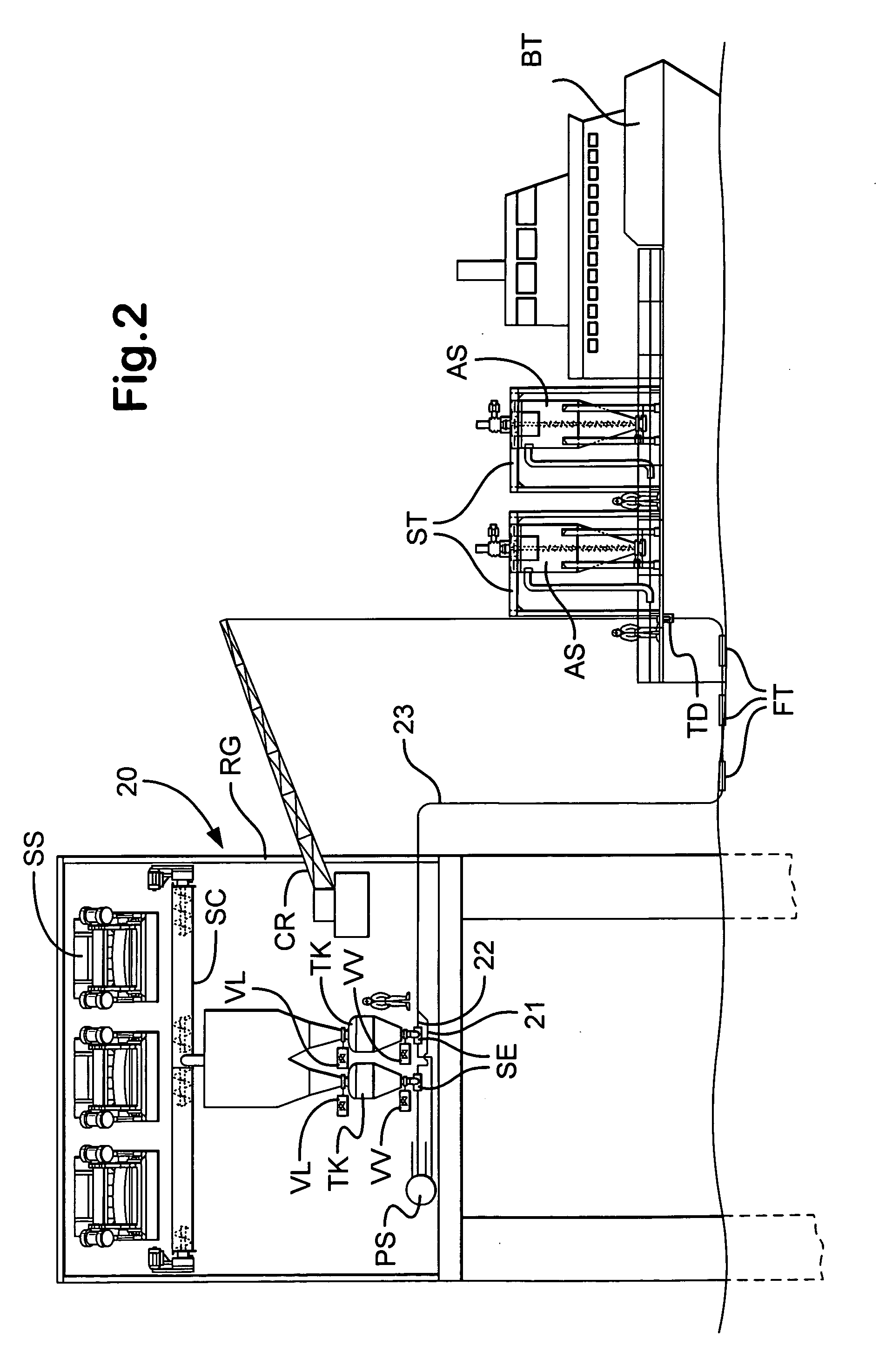

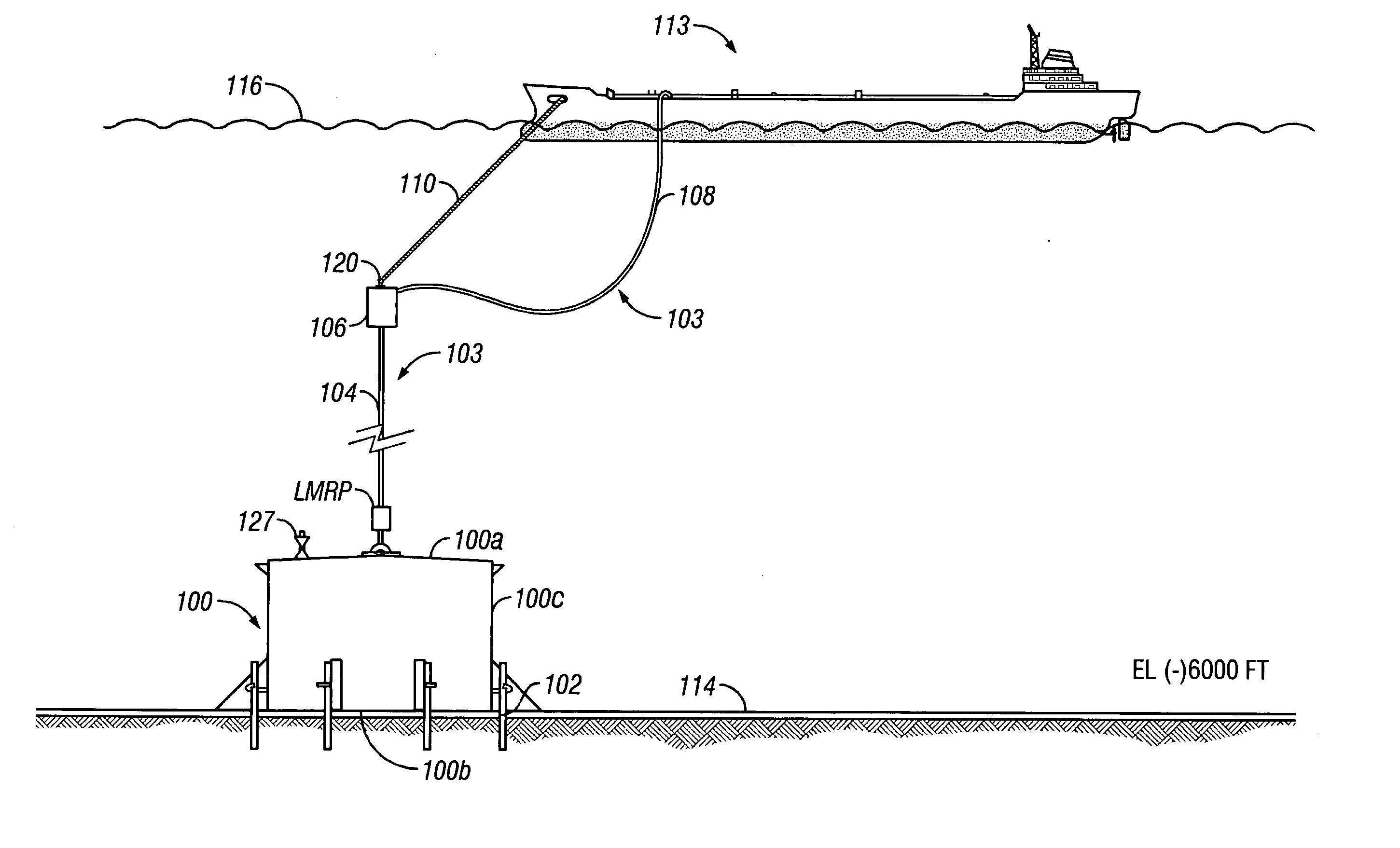

Self-supported riser system and method of installing same

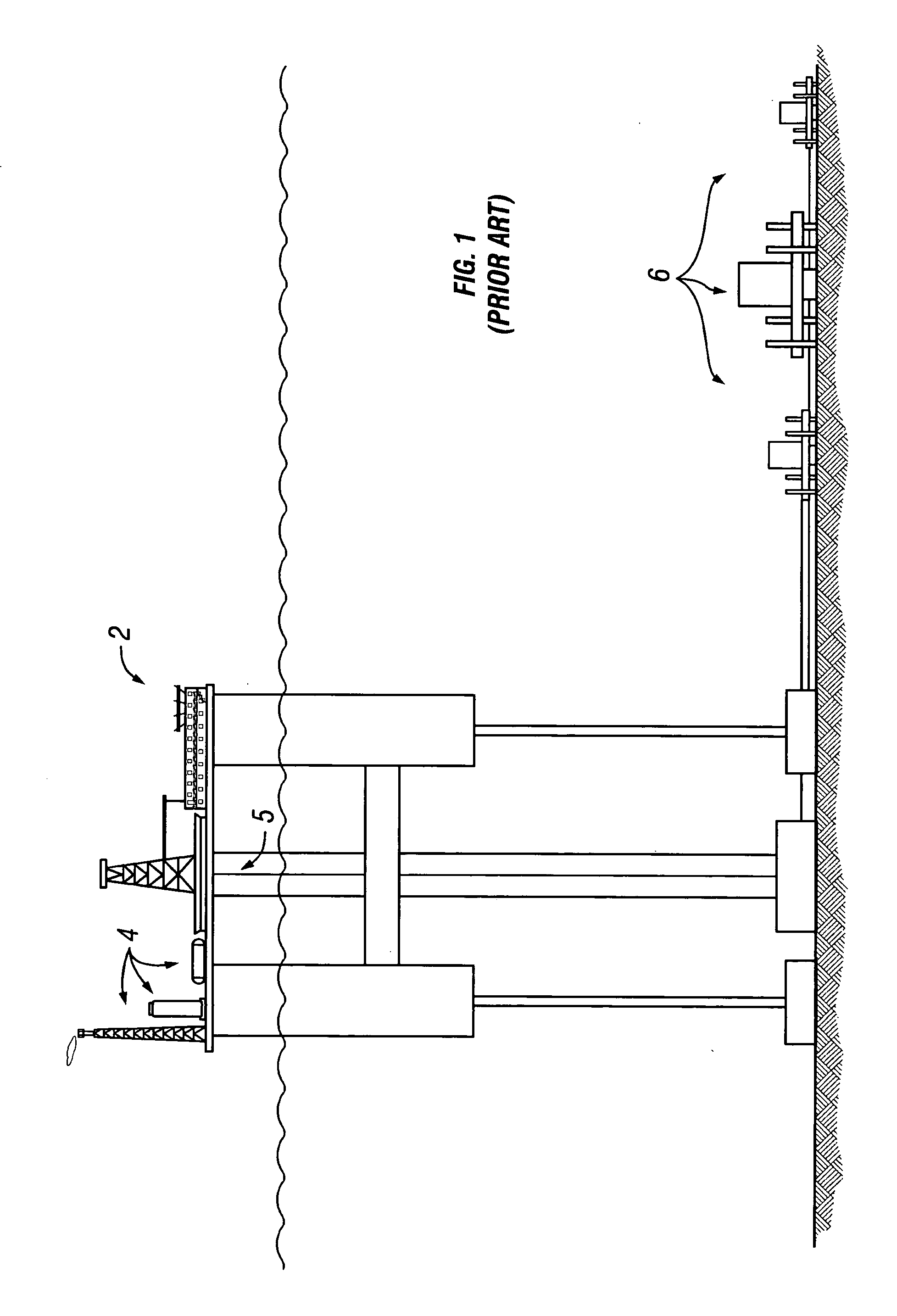

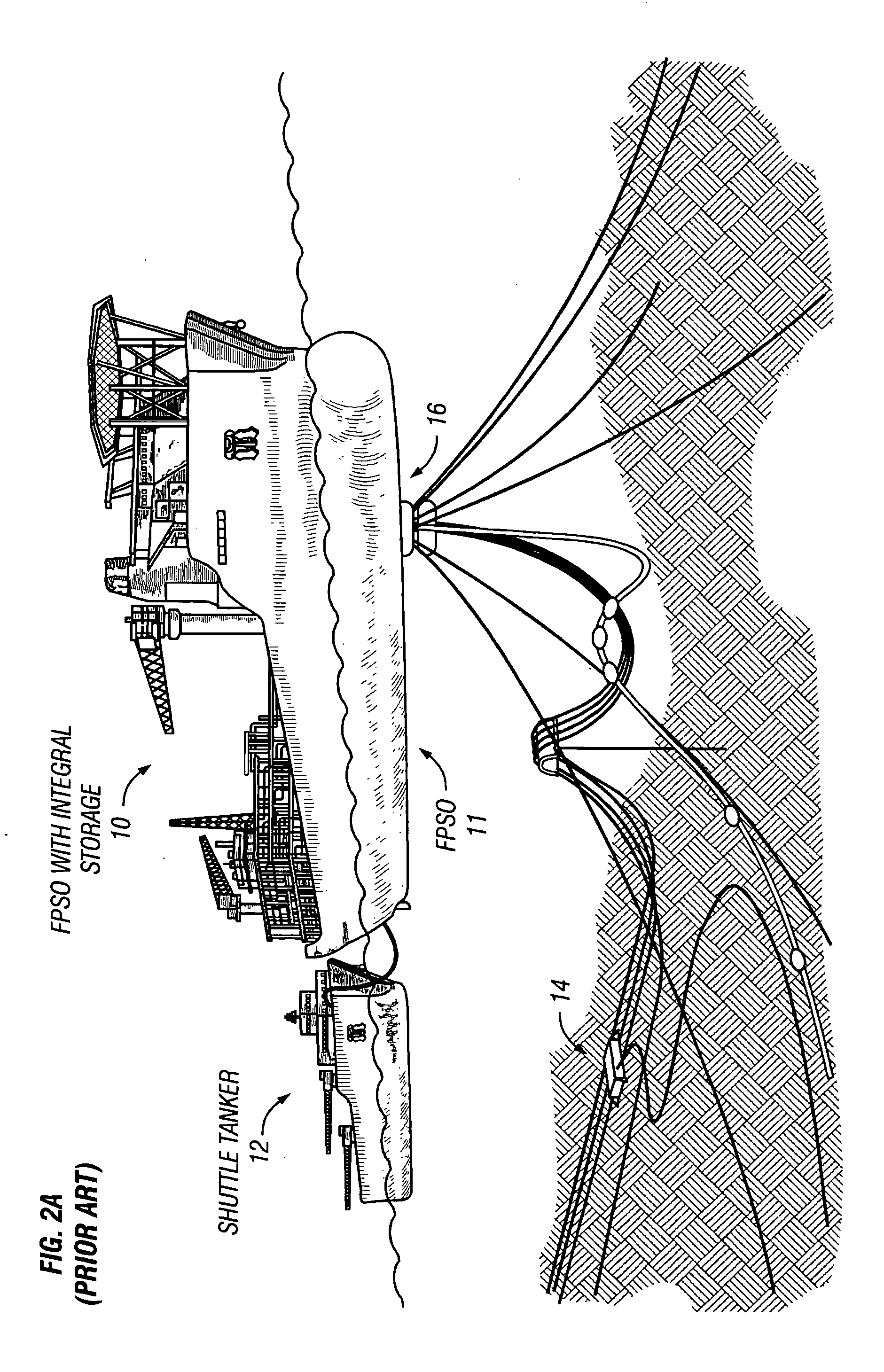

InactiveUS20070044972A1Save rig timeReducing maneuvering stepCargo handling apparatusDrilling rodsBuoyPetroleum oil

A self-supported riser system (100) for an Anticipated Production System (ASP) Test or a Long Duration Production (LDP) Test in a subsea petroleum production system, utilizing an ANM coupled to a wellhead and Floating Production Unit (FPU) is disclosed. The system includes a wellhead at the seabed, connected to an ANM (20) provided with a preventor (BOP of workover) (30). The preventor (30) is connected to a production riser (50) through a connection tool (40). The riser (50), mounted internally within a buoy assembly (60), is maintained under traction with the aid of a buoy assembly. The upper end of the riser (50) is provided with a Subsea Intervention Terminal (700), the Terminal being interlinked to the FPU by a flexible jumper (90) to carry the oil produced to the FPU. Two methods for installing the self-supported riser system (100) are also disclosed.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

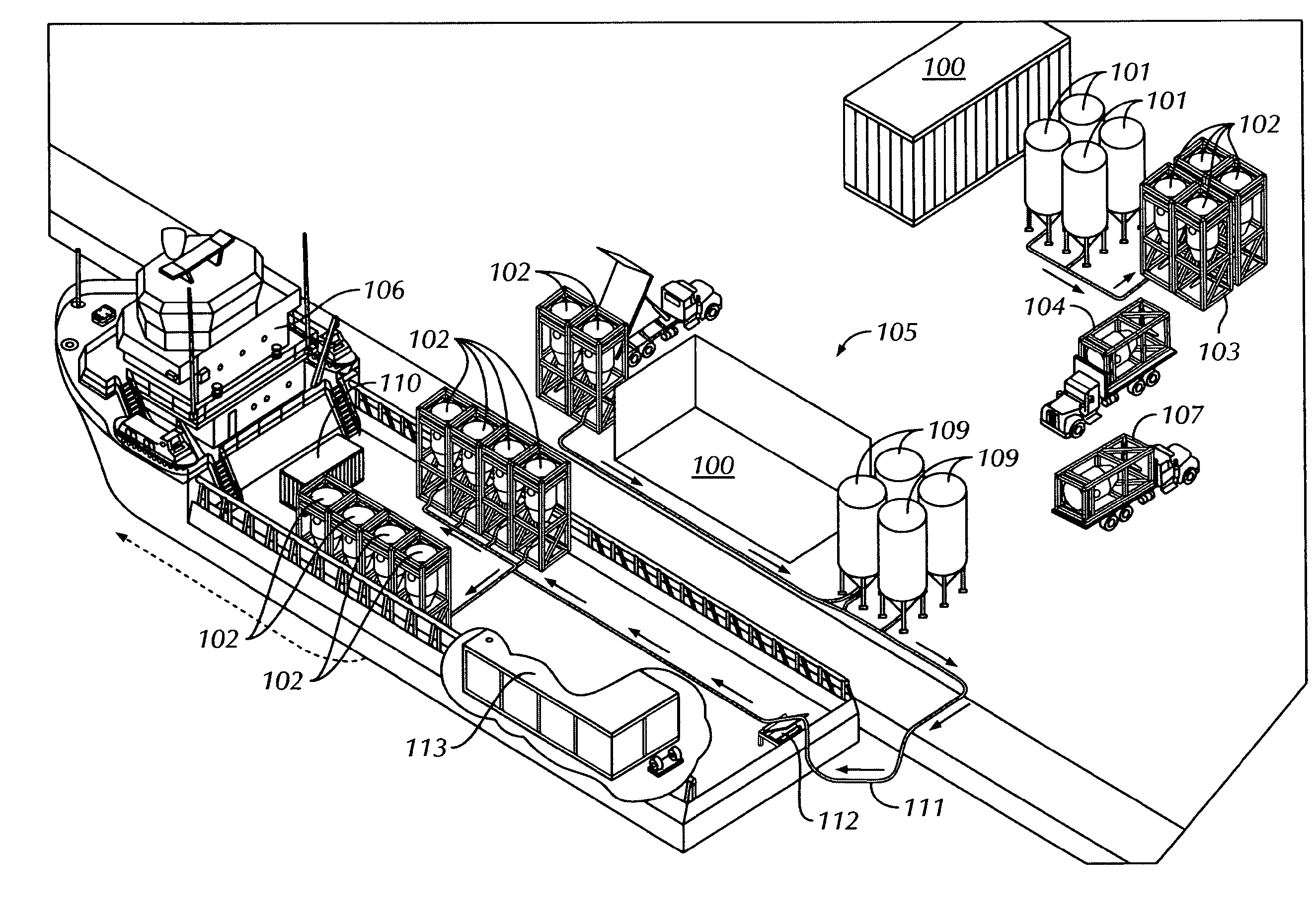

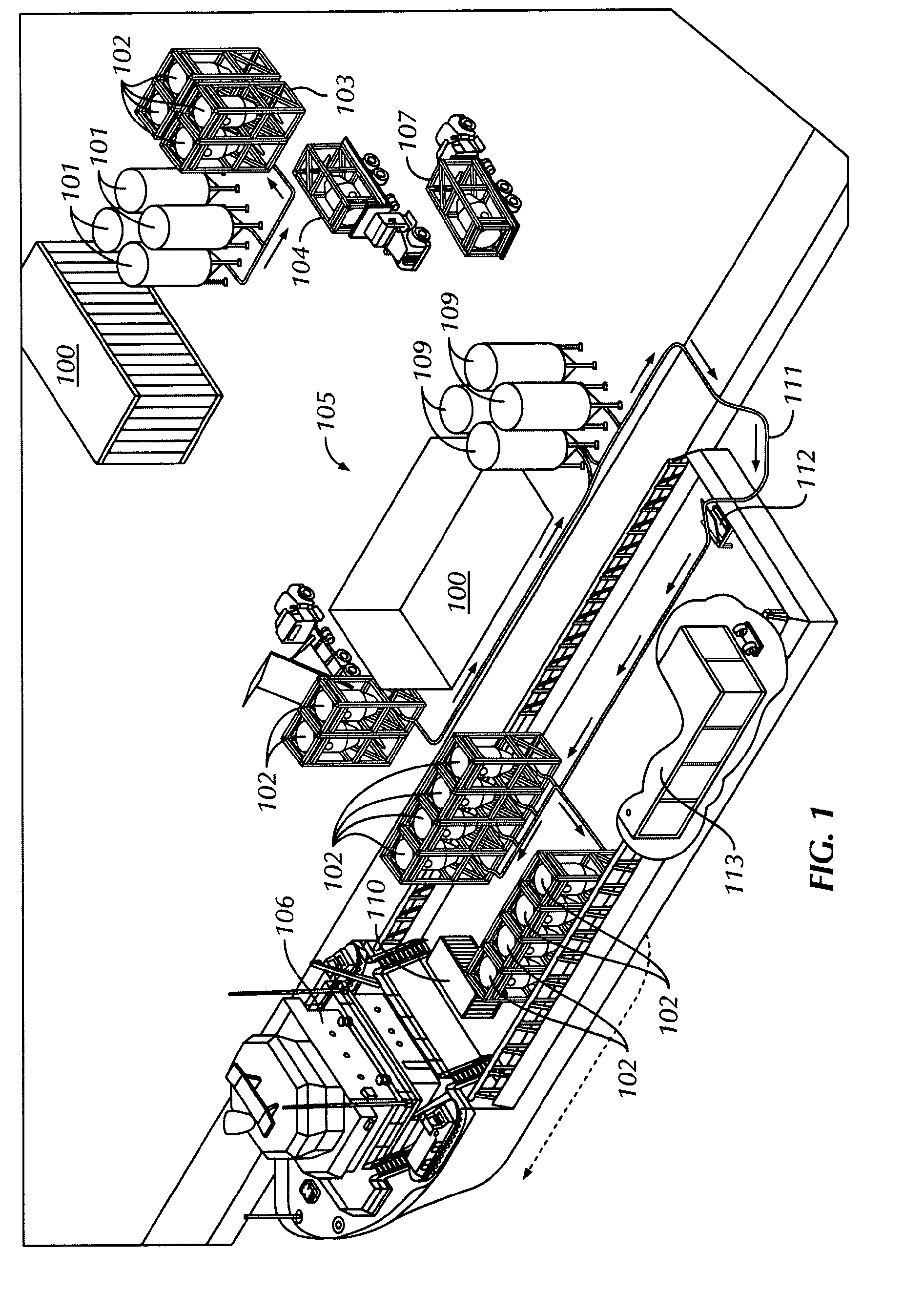

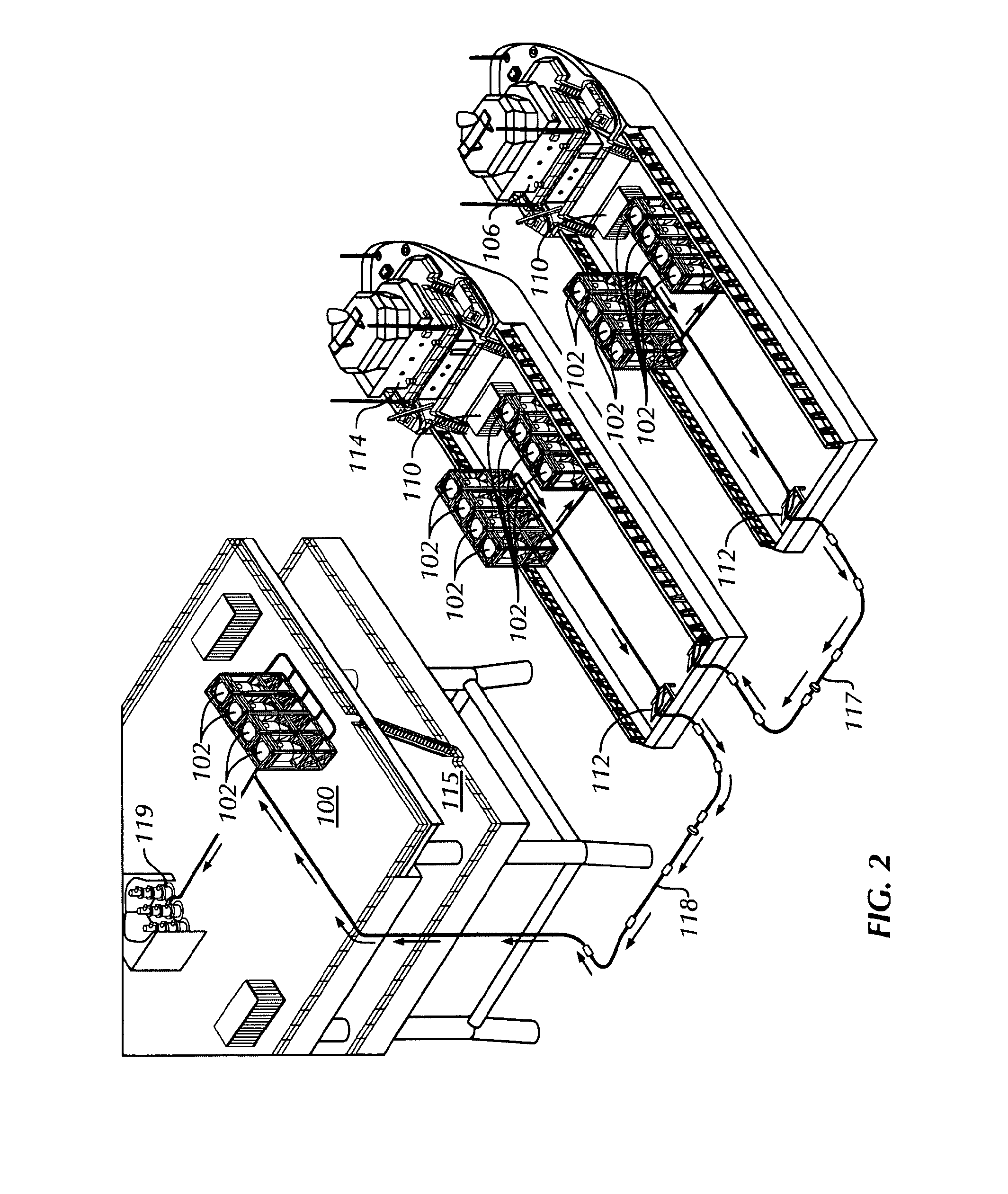

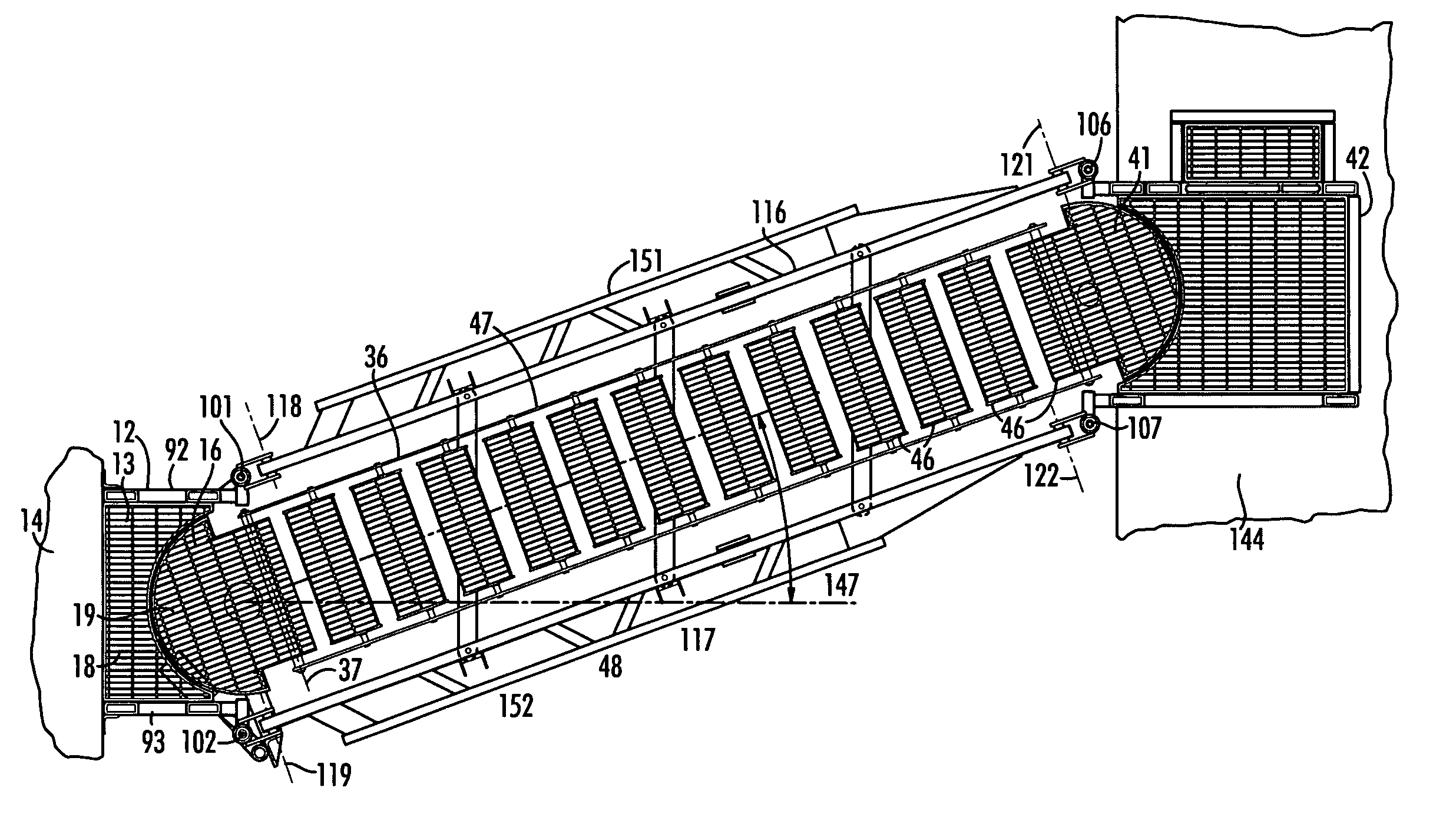

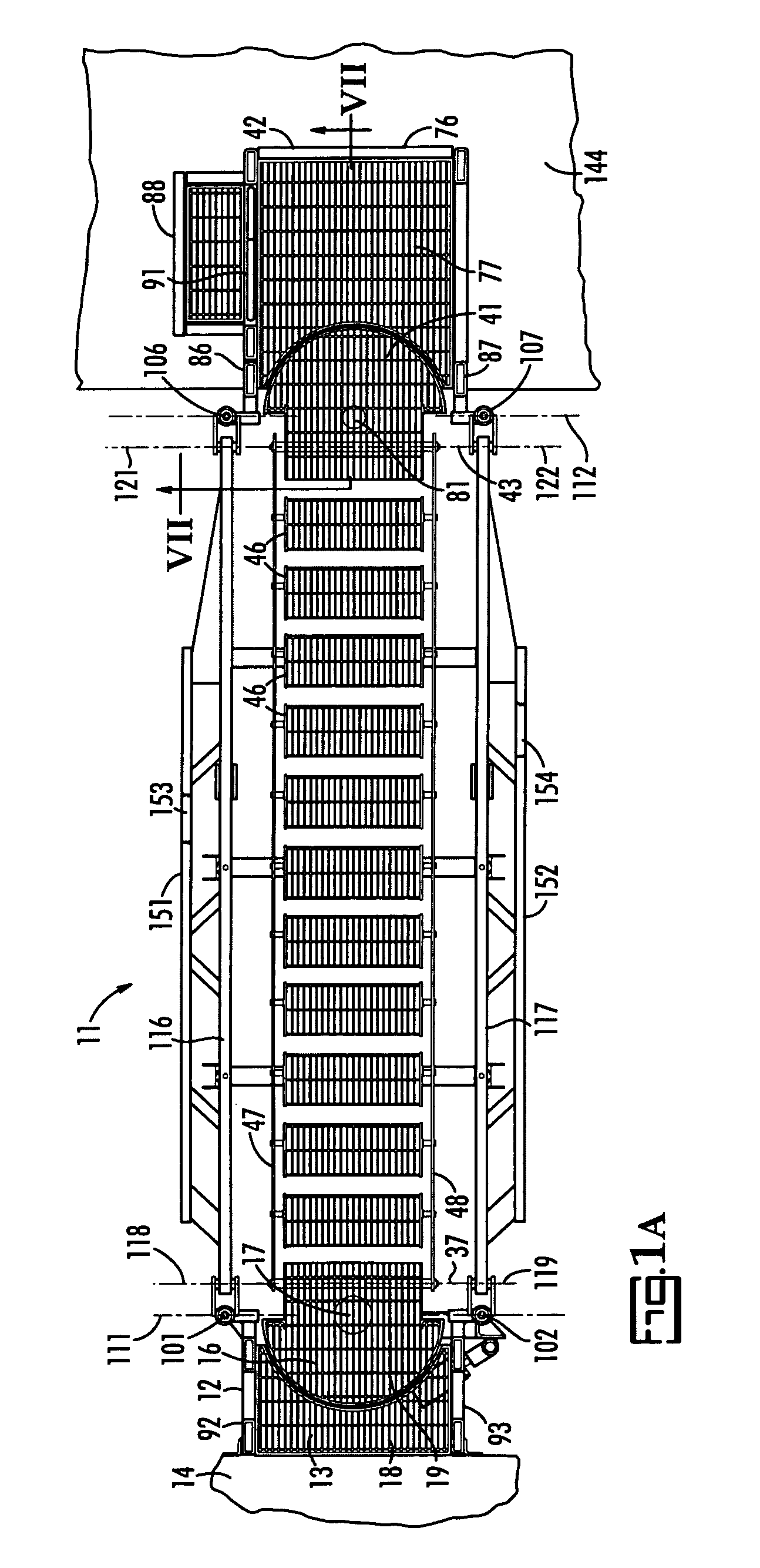

System and method for proppant transfer

A method of transferring proppant materials, wherein the method includes providing a first pressurized container (102) containing proppant materials on a first vessel (106). The method also includes connecting the first pressurized container (102) on the first vessel (106) to a second container (102) on a second vessel (114) and transferring pneumatically, proppant materials from the first pressurized container (102) on the first vessel (106) to the second container (102) on the second vessel (114). Also, a method of transferring proppant materials, the method including removing a wellbore fluid comprising excess proppant materials from a well, and screening the excess proppant materials from the wellbore fluid. The method also includes transferring the excess proppant materials to a first pressurized container (102) and transferring pneumatically, the excess proppant materials from the first pressurized container to a second pressurized container.

Owner:SHCLUMBERGER NORGE AS

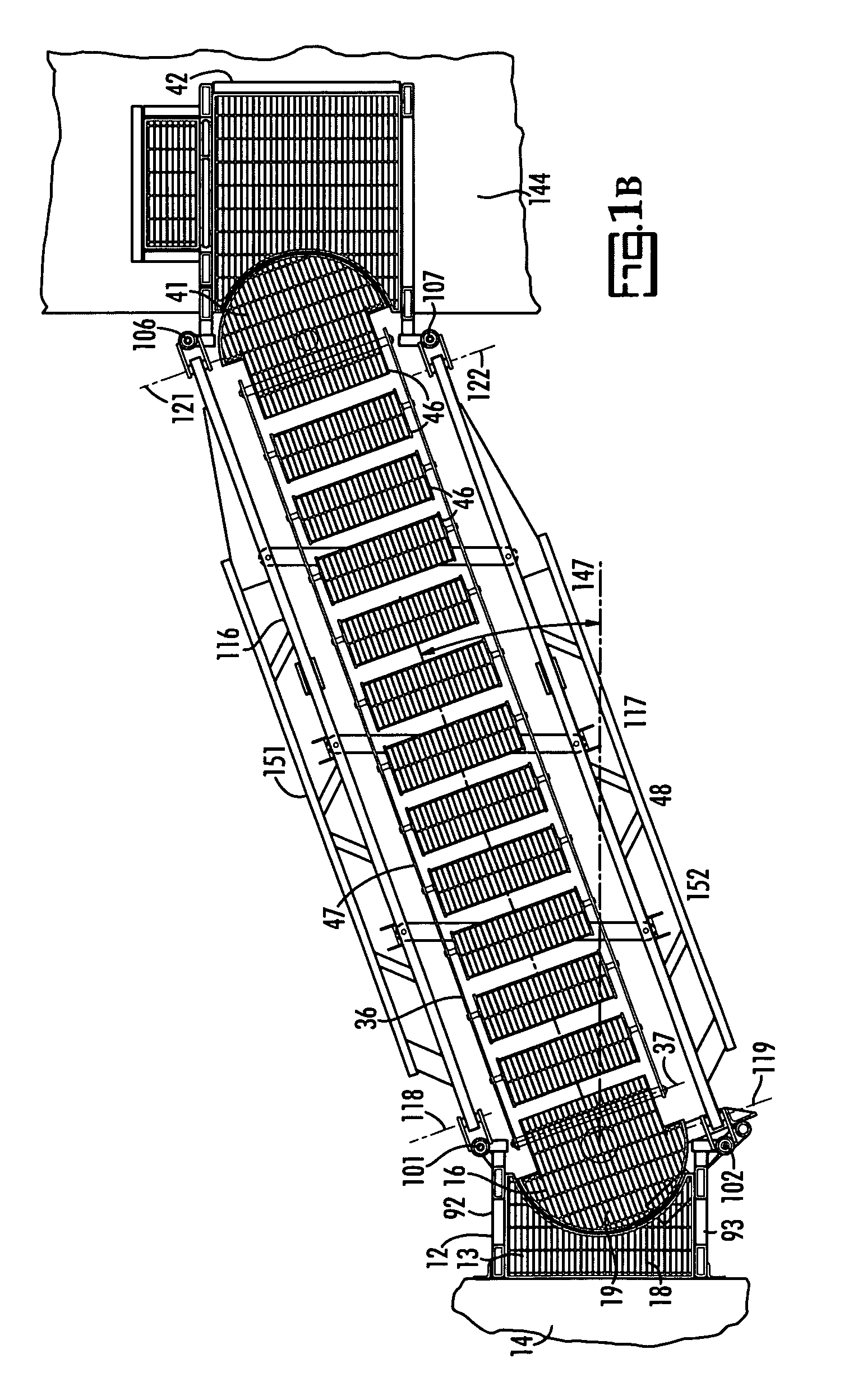

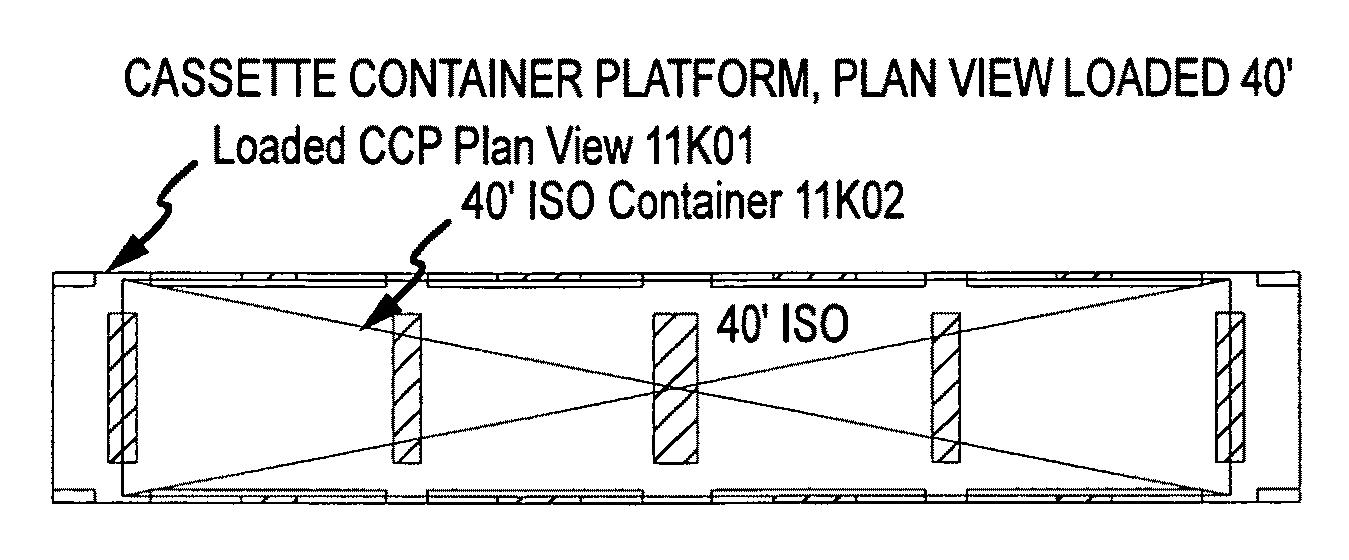

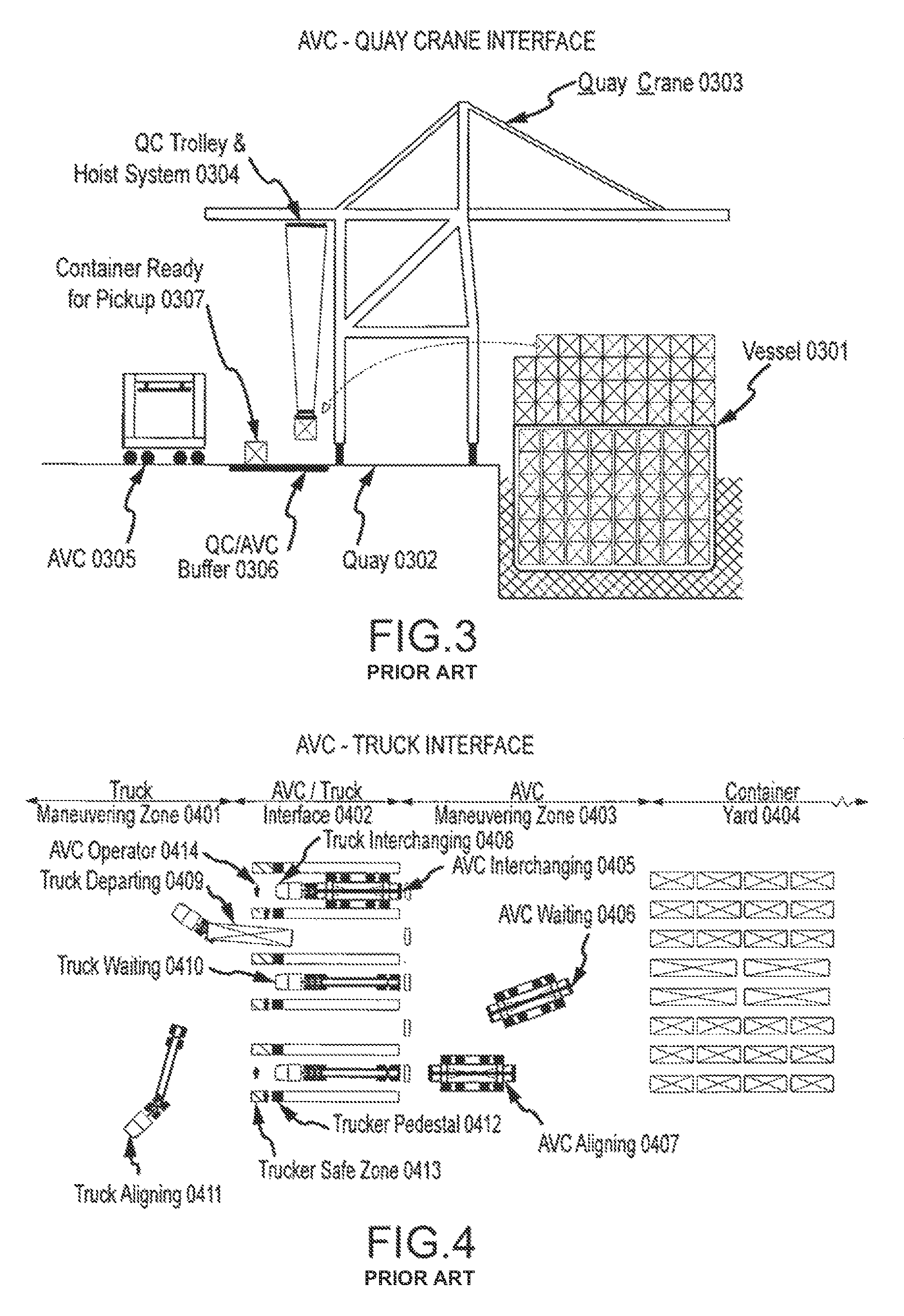

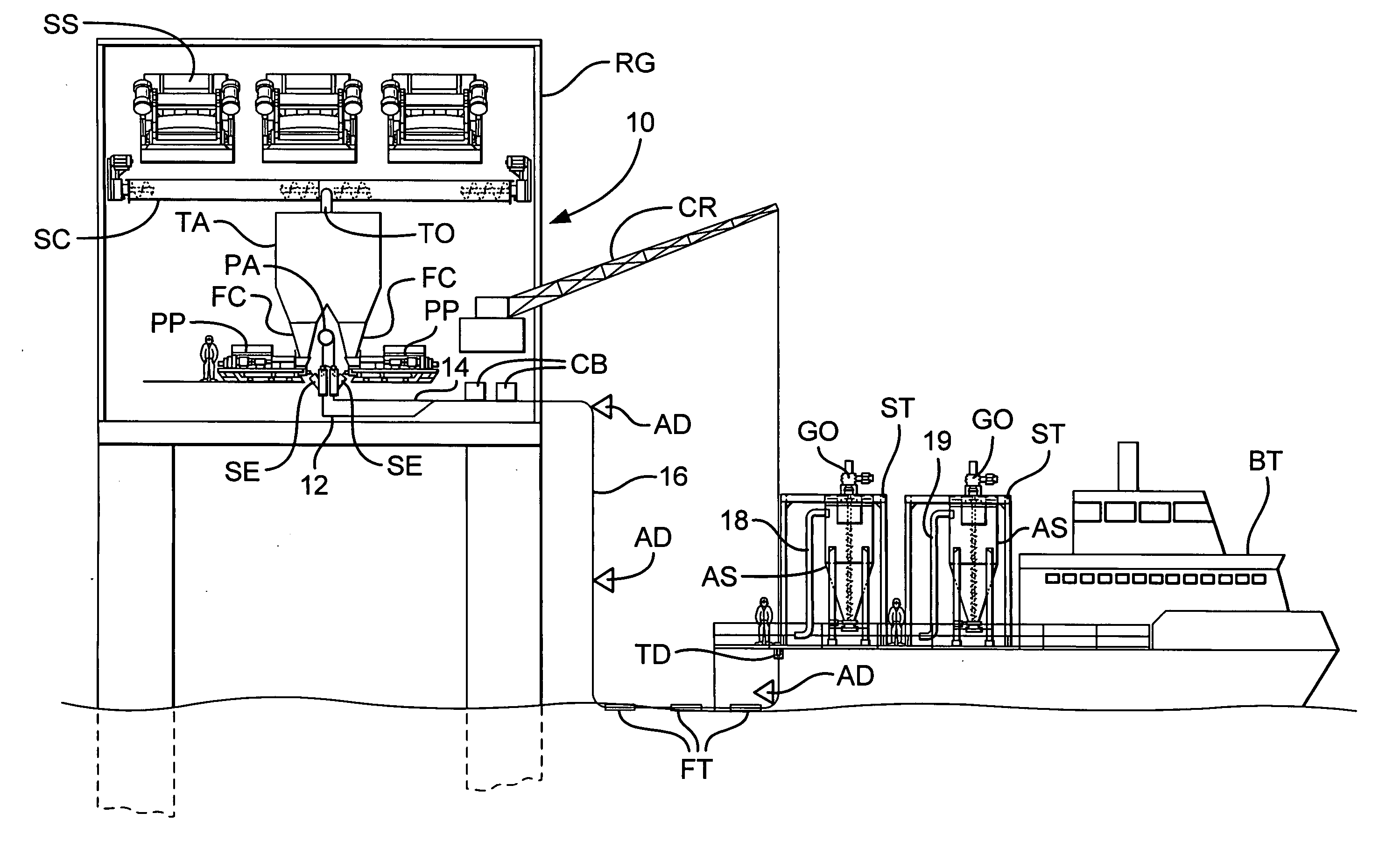

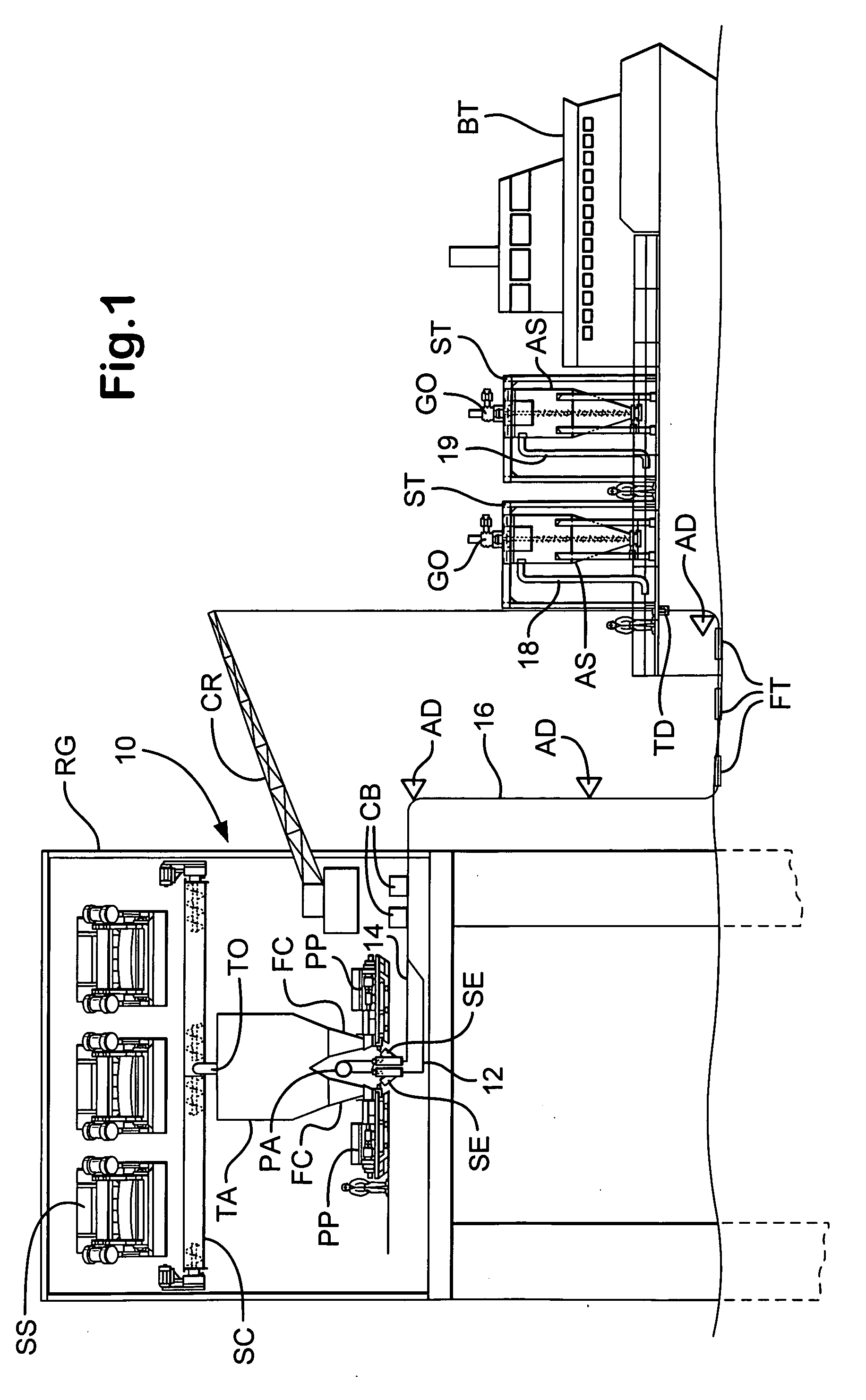

Automated marine container terminal and system

InactiveUS7972102B2Reduced footprintLow costCargo handling apparatusPassenger handling apparatusAutomated guided vehicleOverhead crane

A storage area is accessed by automated guided vehicles which receive and unload containerized loads. On the waterside, loads are exchanged between the vehicles and ships using quay cranes. On the ground transportation side, loads are exchanged between the vehicles and truck or rail carriers using semi automated or automated remote-controlled bridge cranes. Within the storage area, loads are exchanged between the vehicles and the storage facilities using automated stacking cranes. The vehicles are adapted to receive a cassette storage platform which in turn receives standard ISO containers. The vehicles also are adapted to receive one or more alternative platforms including a coning platform for workers to manage container coning, a reefer access and maintenance platform, and a worker transport platform.

Owner:MARINE TERMINALS CORP

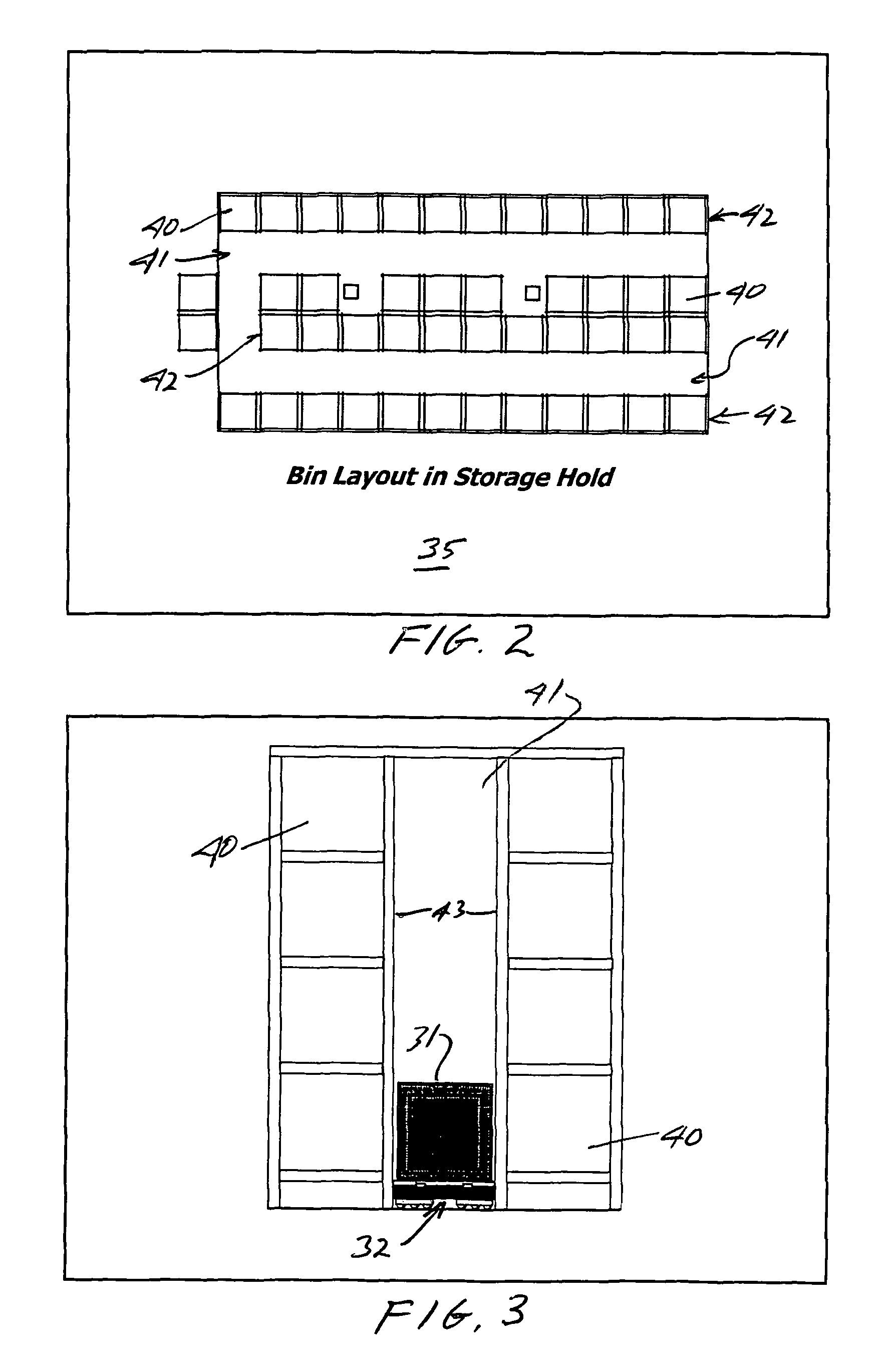

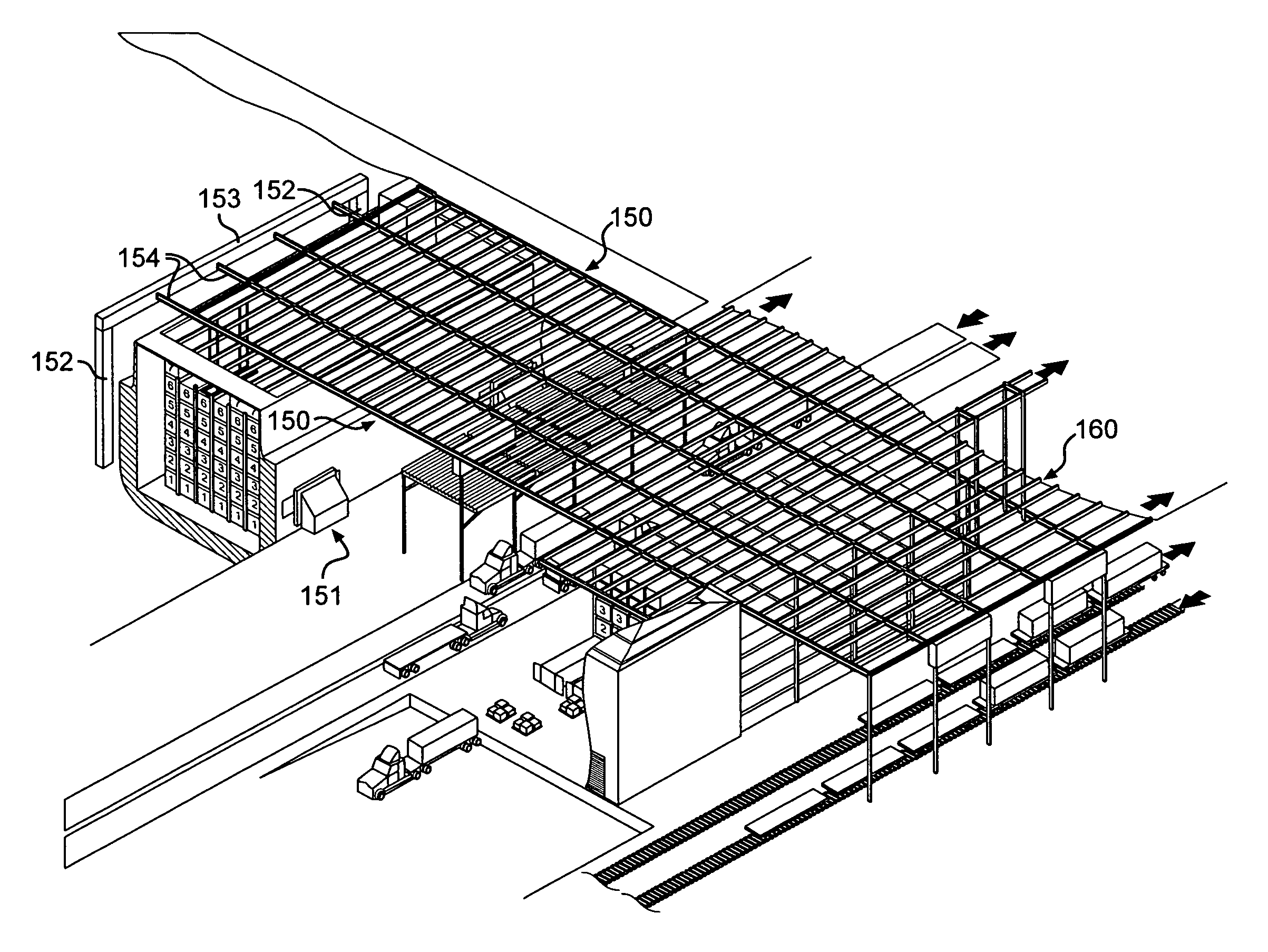

Port storage and distribution system for international shipping containers

ActiveUS20110027059A1Maximize storage spaceImprove efficiencyCargo handling apparatusPassenger handling apparatusInternational shippingDistribution system

A port storage and distribution system for facilitating the transfer and / or storage of international shipping containers between container ships and ground transport carriers wherein an overhead grid guide track structure is provide that permits overhead transfer units to selectively engage and convey containers as required between the various ships, carriers and storage area without requiring multiple transfers of containers between different handling equipment. The system provides for container scanning and is either fully automated or partially manually controlled.

Owner:BEC COMPANIES INC

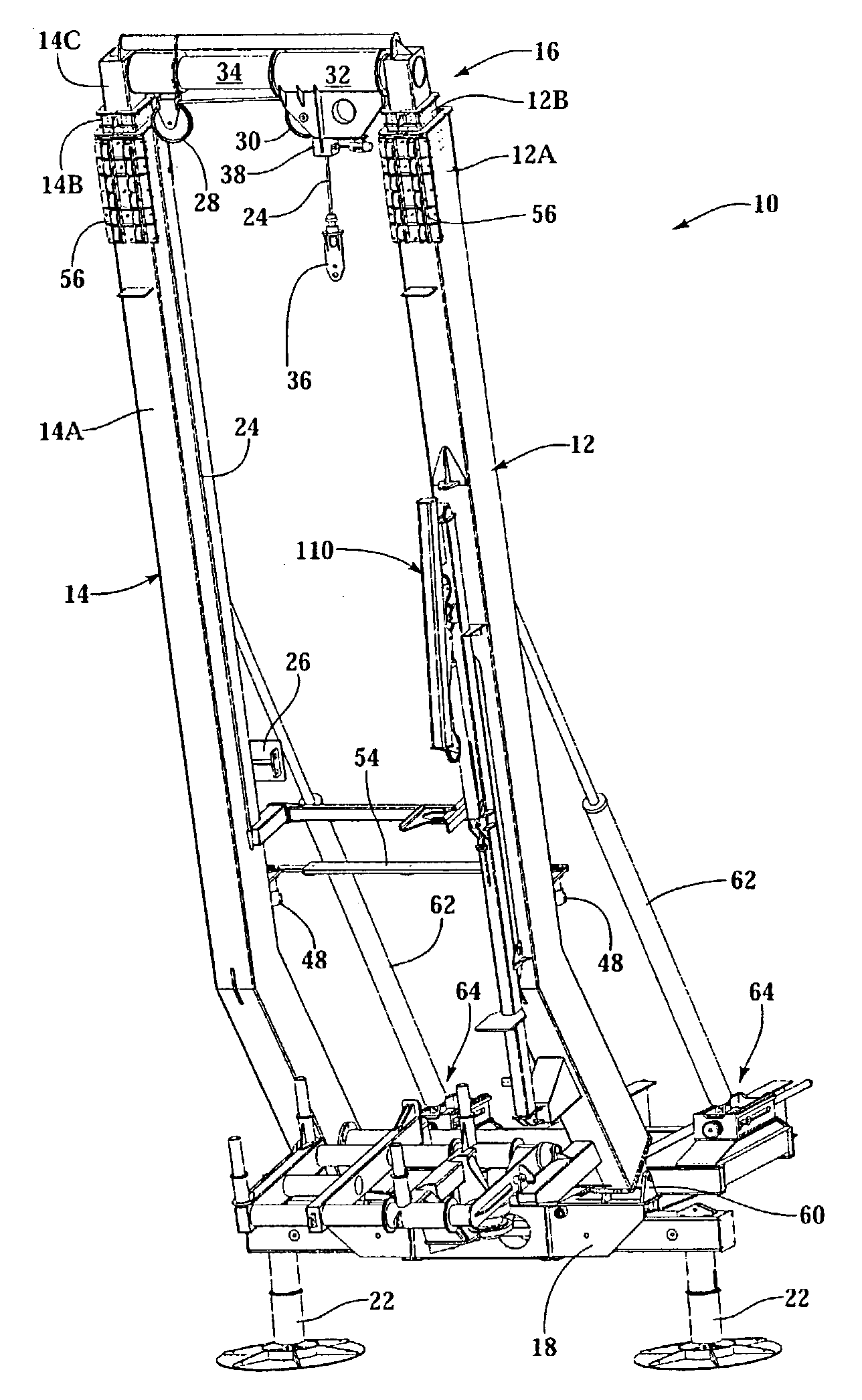

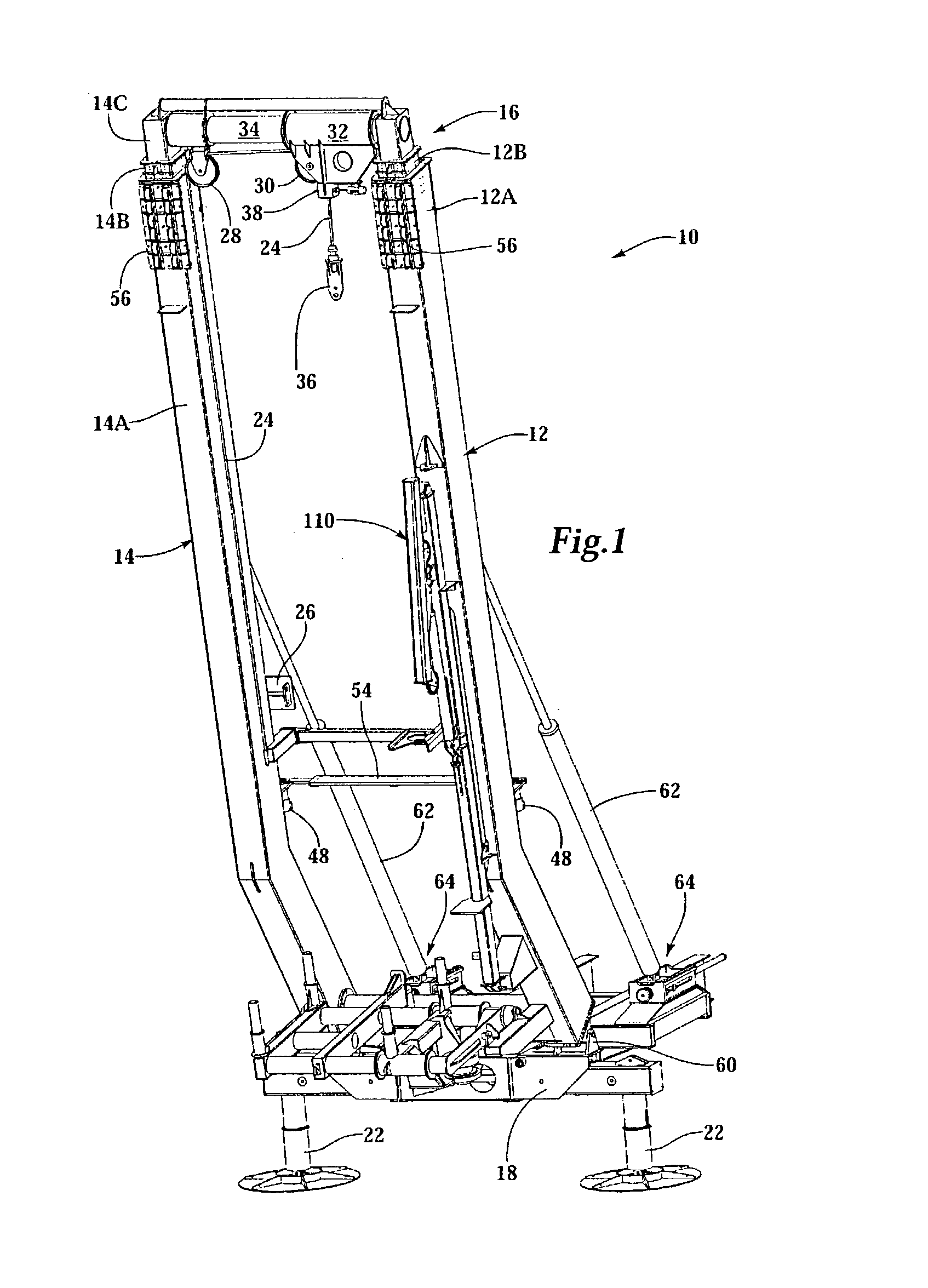

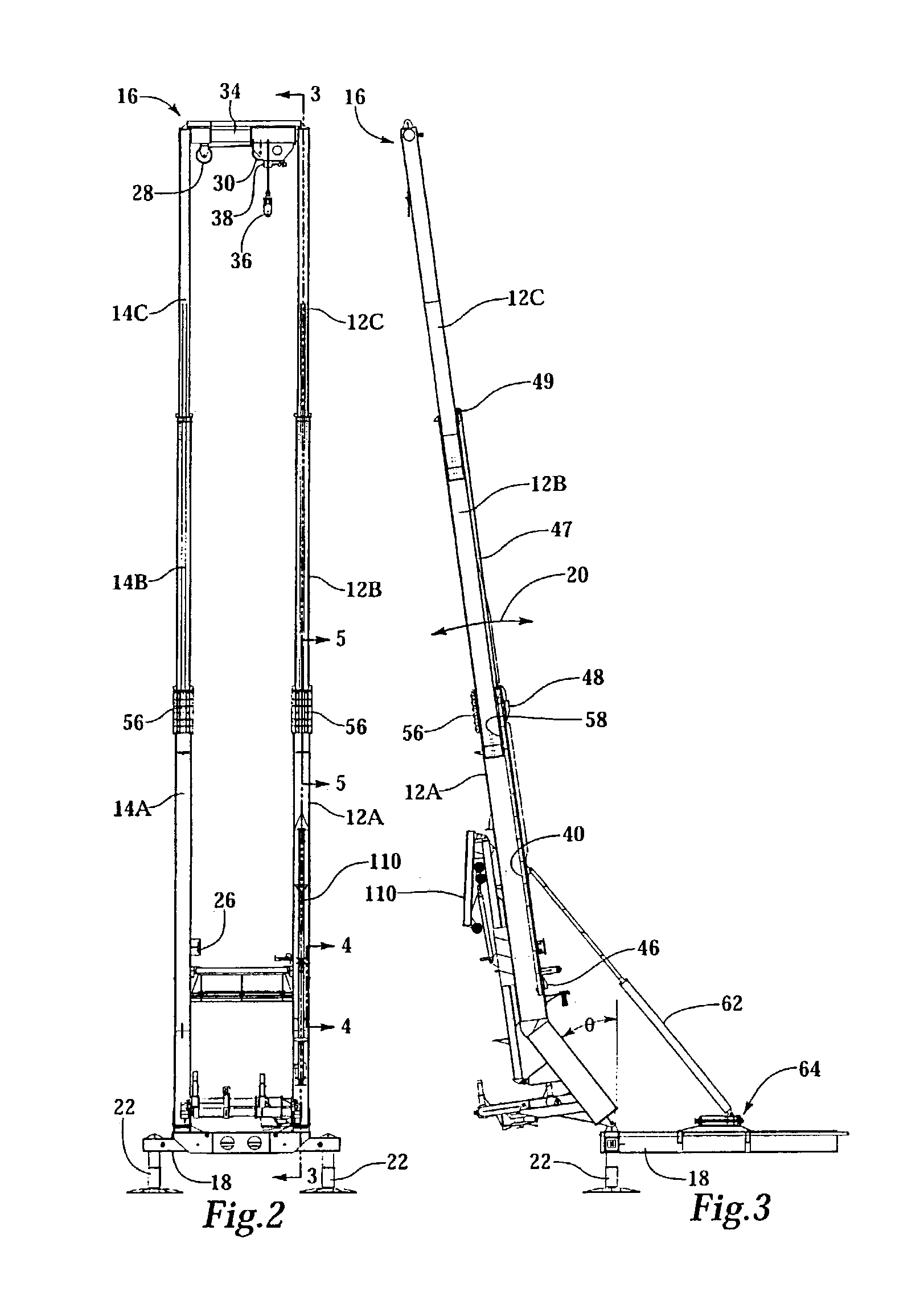

Mast for handling a coiled tubing injector

A mast for lifting and suspending over a wellhead a coiled tubing injector and blow out preventer is pivotally mounted on a rear portion of a truck. The mast has two side-by-side telescoping legs that extend and retract synchronously. When in a retracted position, the blow out preventer and coiled tubing injector are attached to the mast, between the legs, and legs of the mast extended to lift the equipment.

Owner:VARCO I P INC

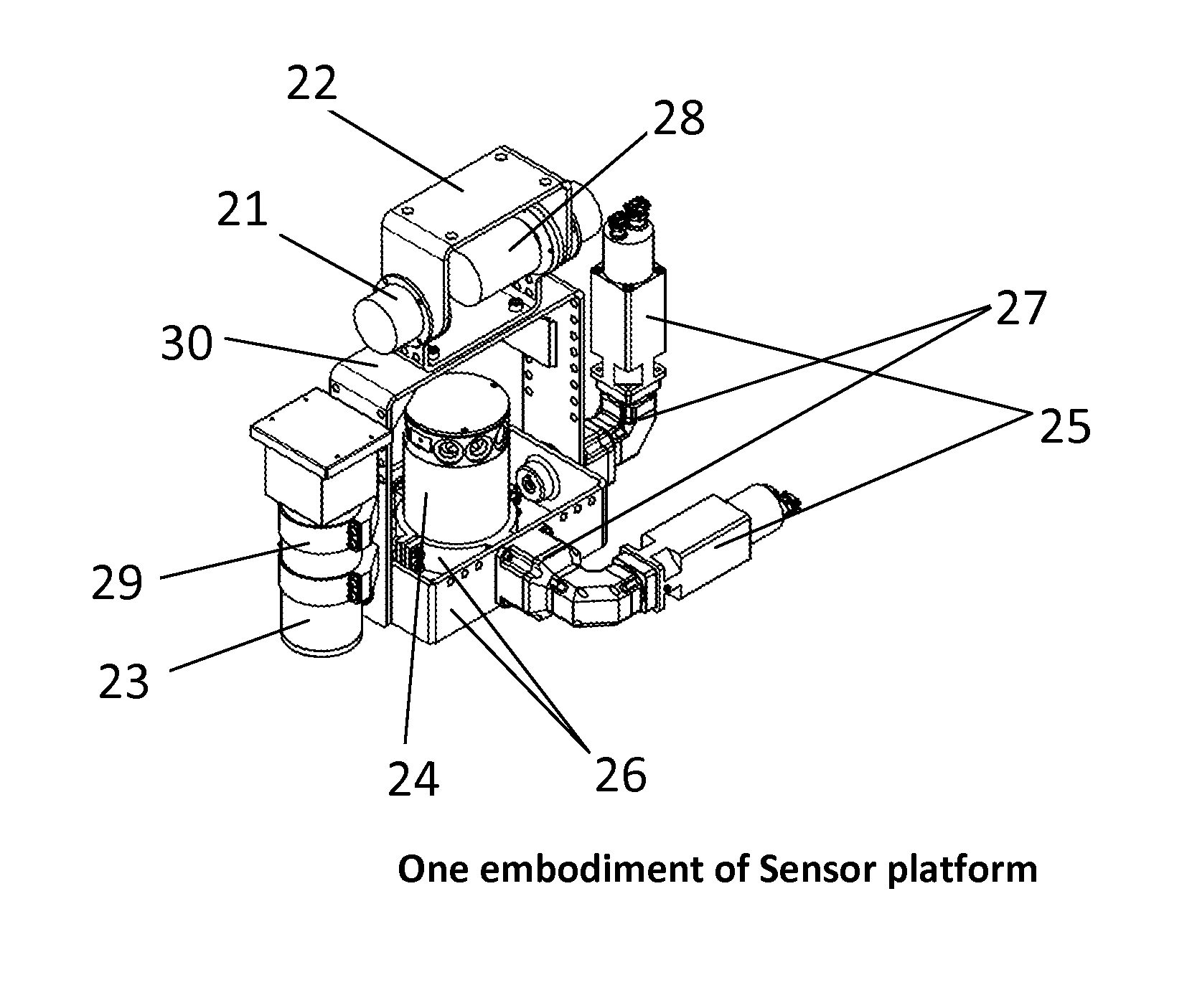

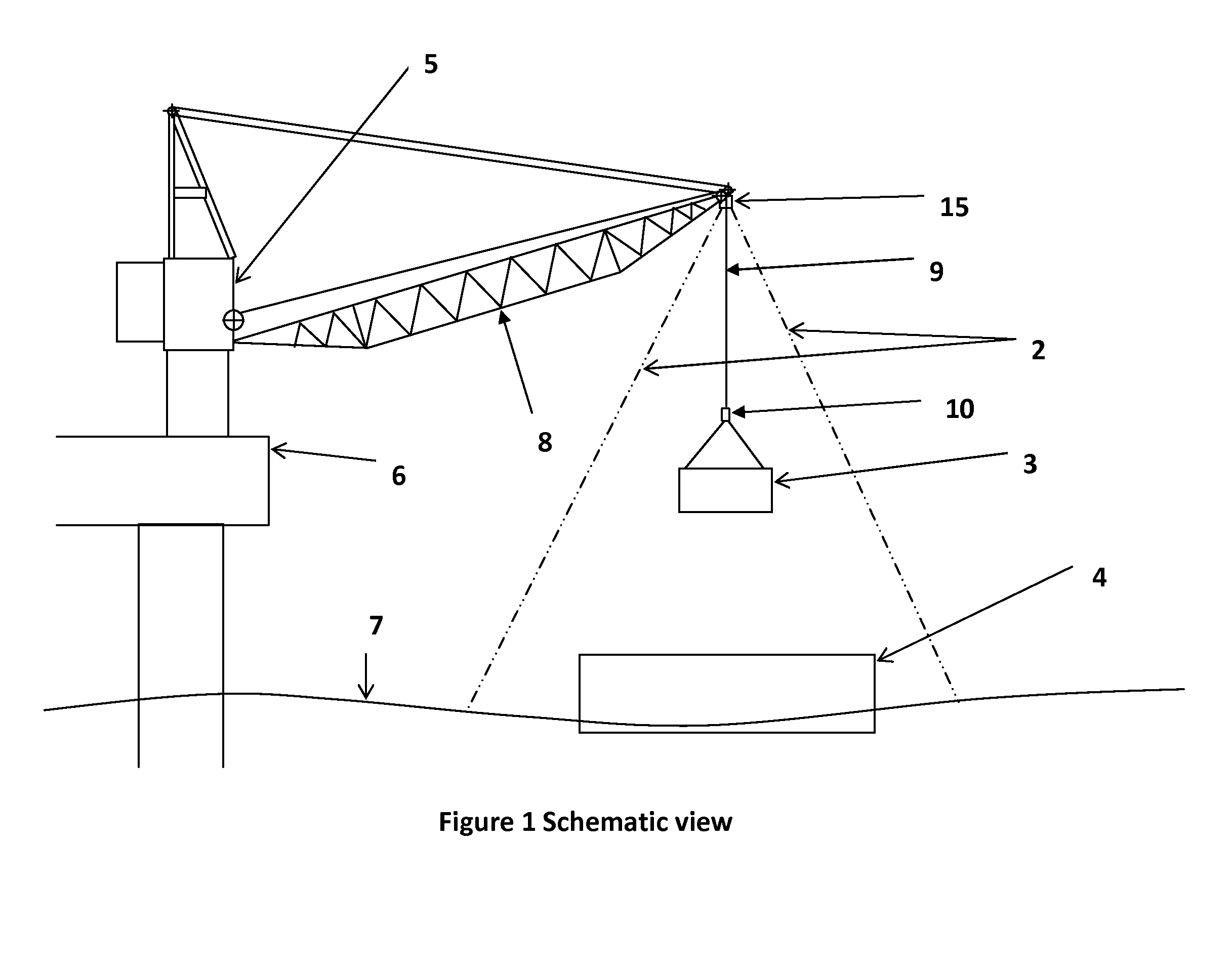

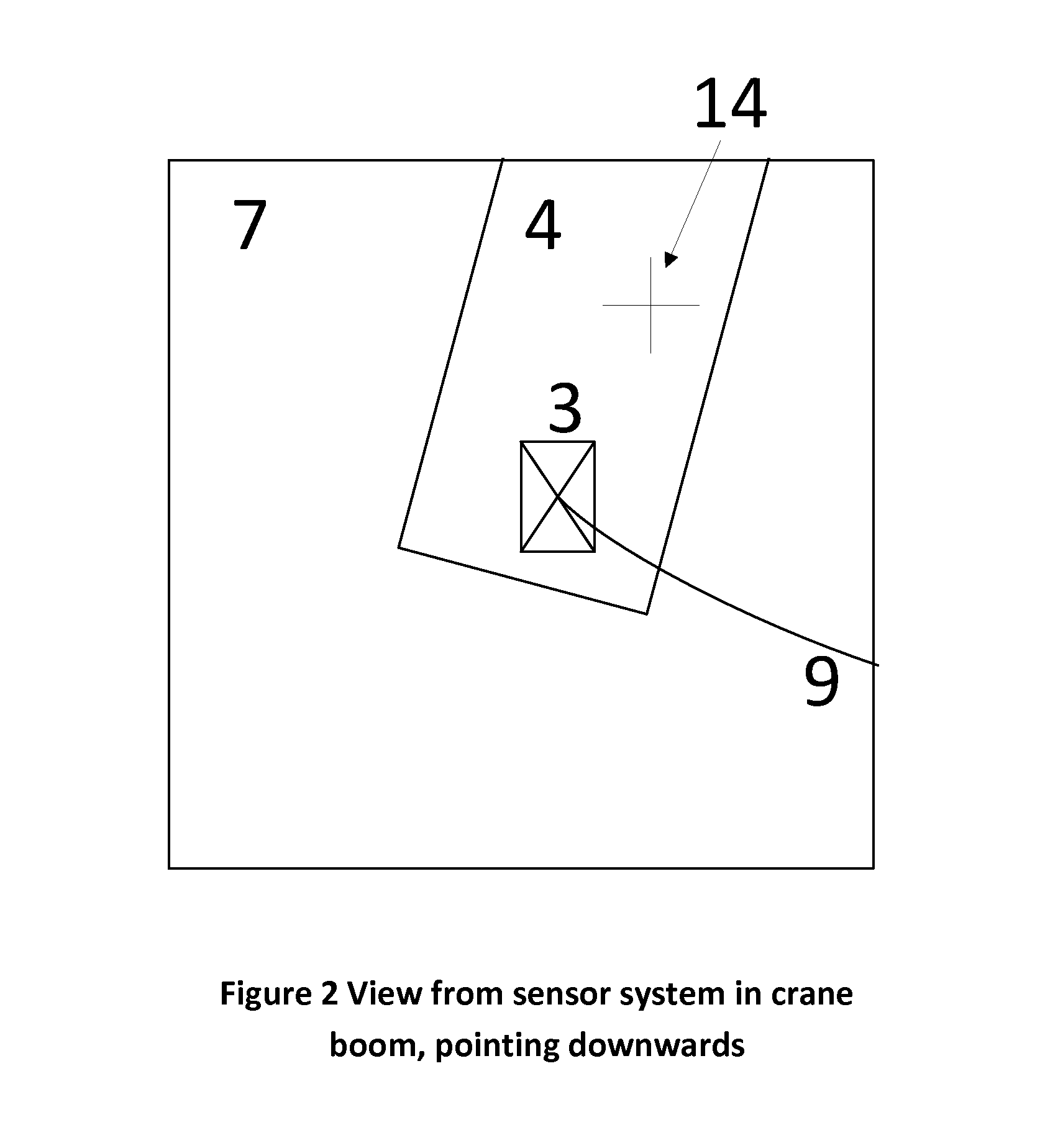

System, Device And Method For Tracking Position And Orientation Of Vehicle, Loading Device And Cargo In Loading Device Operations

ActiveUS20140107971A1Cargo handling apparatusDigital computer detailsSensor systemAutomotive engineering

The present invention generally relates to a system, device and a method for loading and / or unloading a cargo to and / or from a second vehicle where a loading device is mounted on a first vehicle. More specifically, the present invention relates to a method and a device for a sensor system (with sensor platform deployed at the crane tip) used for heave compensation and 3D positioning of cargo and second vehicle during loading and unloading process of cargo to / from a ship where a crane is mounted on an oil rig.

Owner:OPTIELEVATOR

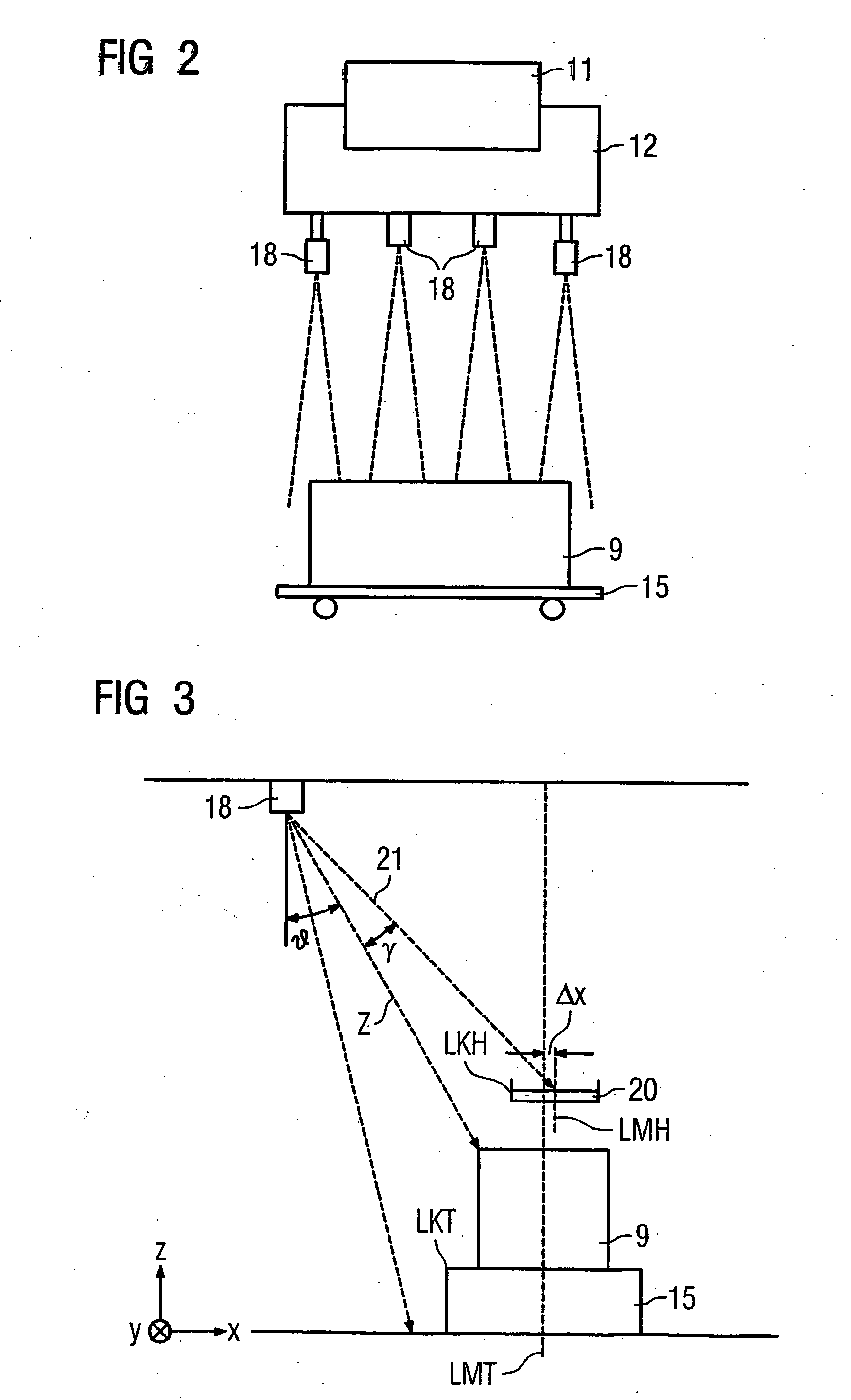

Crane apparatus equipped with container security scanning system

InactiveUS6845873B1Improve reliabilityCargo handling apparatusBase supporting structuresEngineeringNeutron

Crane apparatus is equipped with a container security scanning system for scanning containers for radioactive material, such as neutron or gamma ray emissions. The crane apparatus has a crane for unloading containers from a marine vessel and placing the containers on a deck located at the portal girder level of the crane and for transferring the containers from the deck to another location. The container security scanning system comprises one or more scanning units disposed on the deck, each scanning unit having one or more scanning platforms for supporting a container such that a bottom of the container is vertically spaced from the deck. A scanning device is movable beneath the container in a space between the underside of the scanning platforms and the deck for scanning the container to detect whether radioactive material is present. Existing cranes can be retrofitted with the container security scanning system, and newly manufactured cranes can be upgraded to include such a system.

Owner:CHATTEY NIGEL

Drill cuttings conveyance systems and methods

ActiveUS20060102390A1Low densityEasy accessCargo handling apparatusDispersed particle separationPressure senseDrill cuttings

Vessels, system and methods for conveying drilling cuttings material, which, in certain aspects, include a system for conveying material from a vessel, the system having a vessel for receiving material to be conveyed, a first conduit for conveying air, a second conduit for receiving air from the first conduit and for conveying air into the vessel, a metering screw for receiving material from the vessel and for moving the material from the vessel, a discharge line for receiving the material from the metering screw, the discharge line having an exit end, pressure sensor apparatus for sensing pressure in the discharge line, and control apparatus for automatically controlling the metering screw in response to a pressure sensed by the pressure sensor apparatus.

Owner:VARCO I P INC

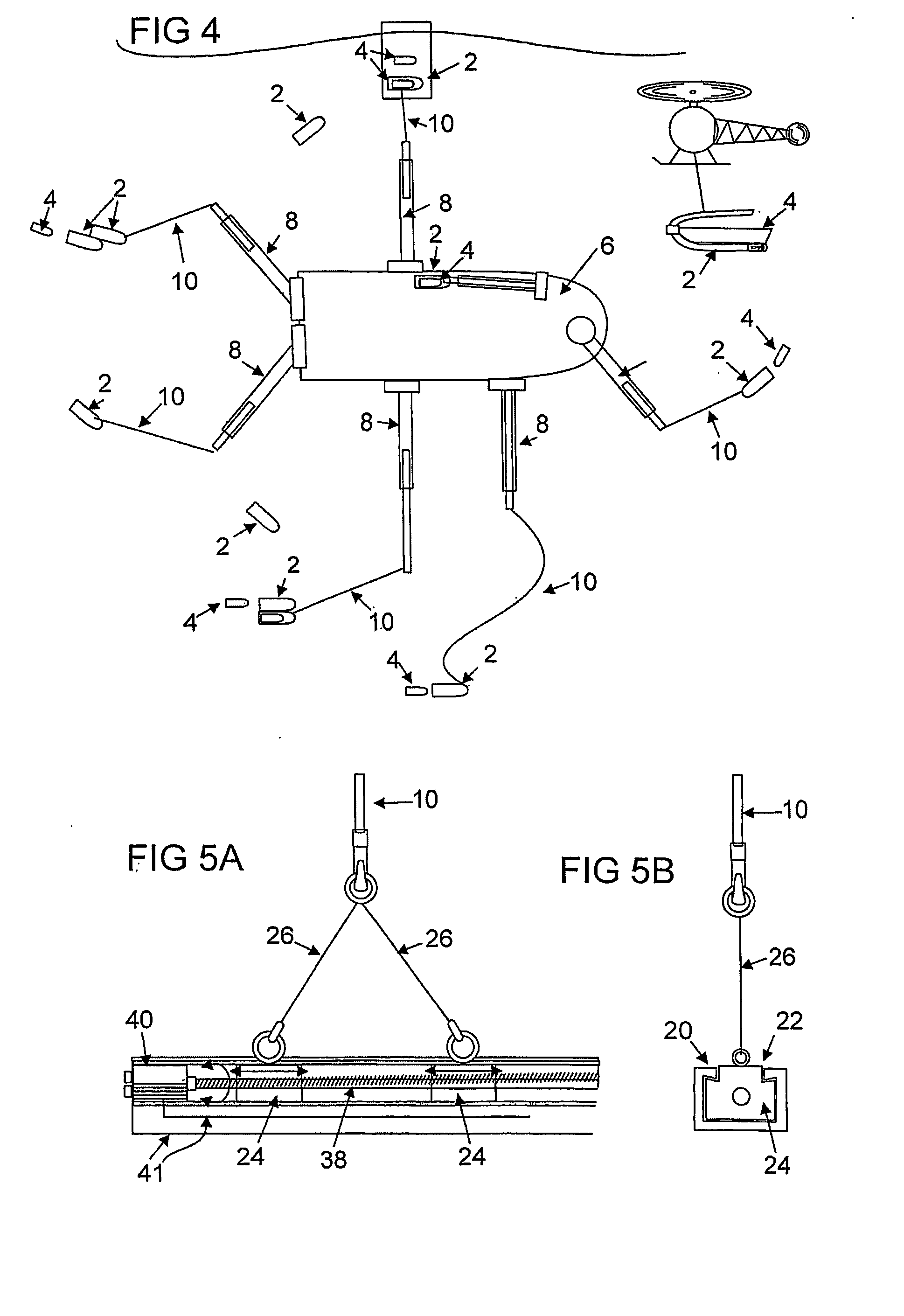

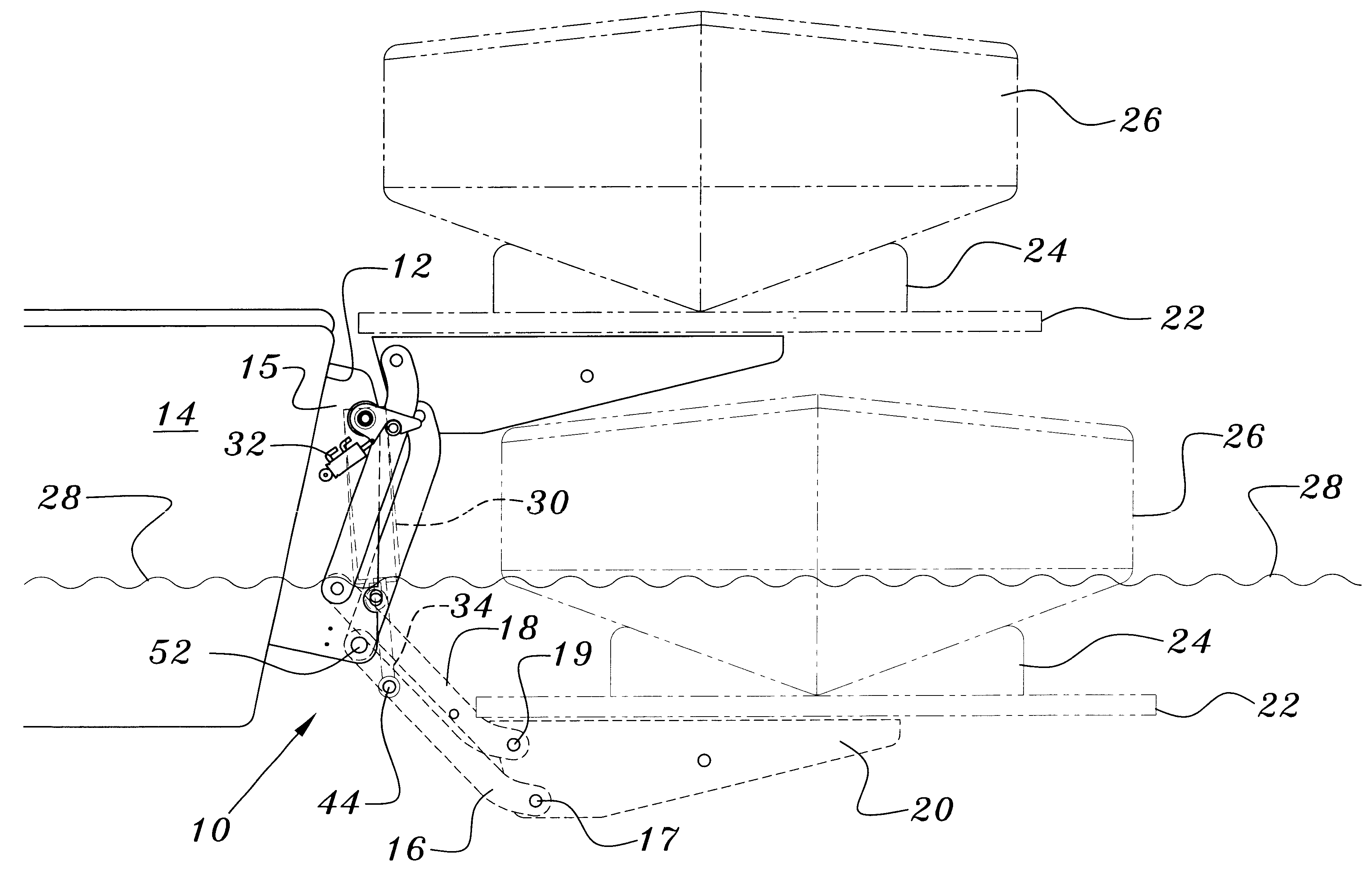

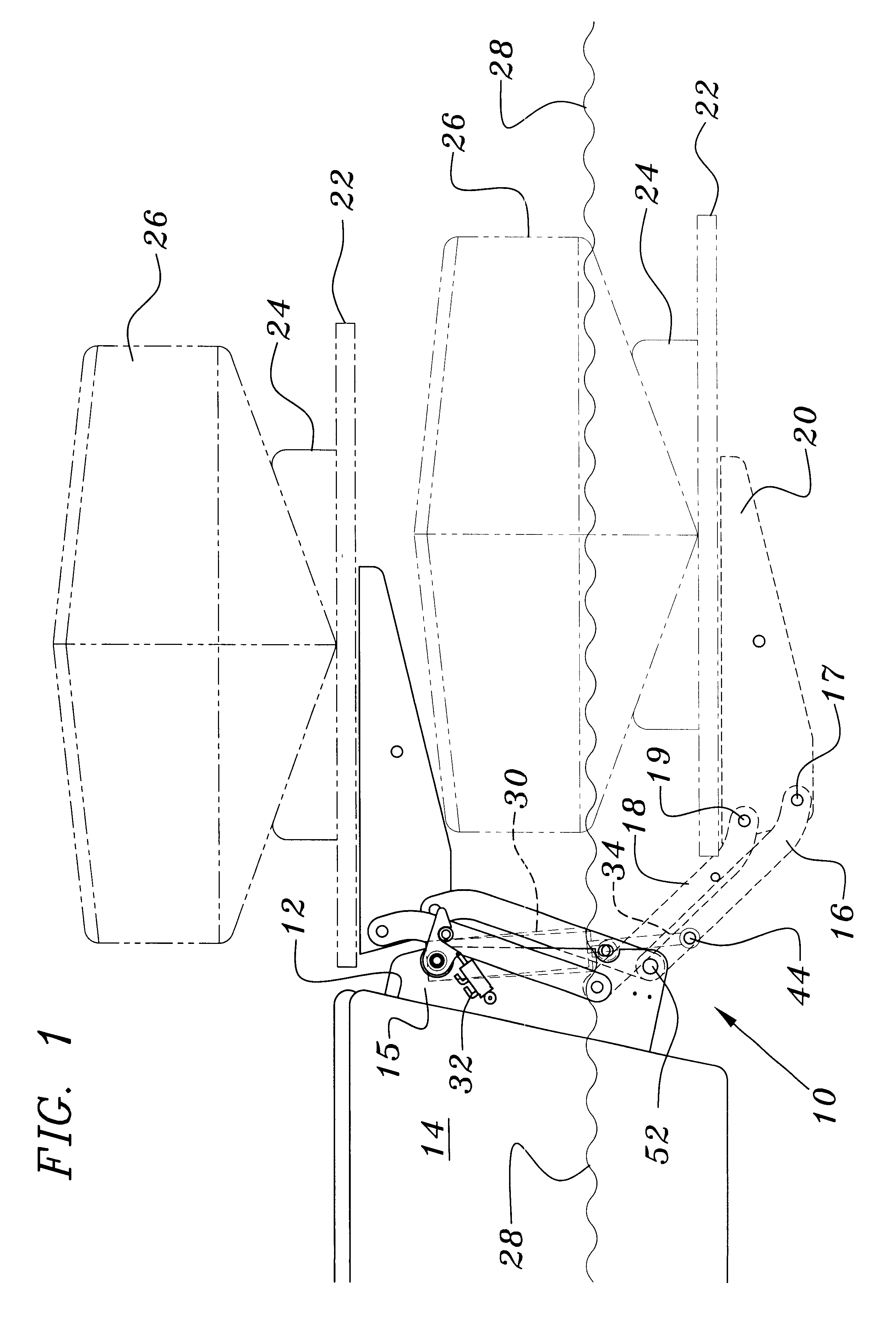

Marine payload handling craft and system

InactiveUS20060191457A1Easy to carryMinimizing motionsTowing/pushing equipmentCargo handling apparatusMarine engineeringOrbit

A marine handling craft and system is intended for use in deploying, inspecting and receiving vessels and payloads to and from locations on, under, over or near water and wet soils in potentially turbulent aquatic or atmospheric conditions. The marine handling craft may operate as a robot, or deployed from a crane or boom on a mother ship or other platform or helicopter so that it can transport and mate and dock at various locations, such as supply ships or autonomous marine vessels, at a stand off distance to limit potential harm to valuable assets. A sliding fastener and track are included on the marine handling craft so that it can be tethered and lifted by a single line or cable, and so can be manipulated by a single crane or helicopter. The utility of the handling craft is not limited to the transport of payloads and it may function as a stand-alone vessel for various remote sensing purposes. Smart communication between the marine handling craft and other vessels or other nodes in a distributed computer network facilitates simultaneous, hierarchical and multi-tasking control of the craft and permits verification and inspection of payloads, which might otherwise cause damage when proximate to more valuable assets.

Owner:ADVANCED MARITIME SUPPORT TECH

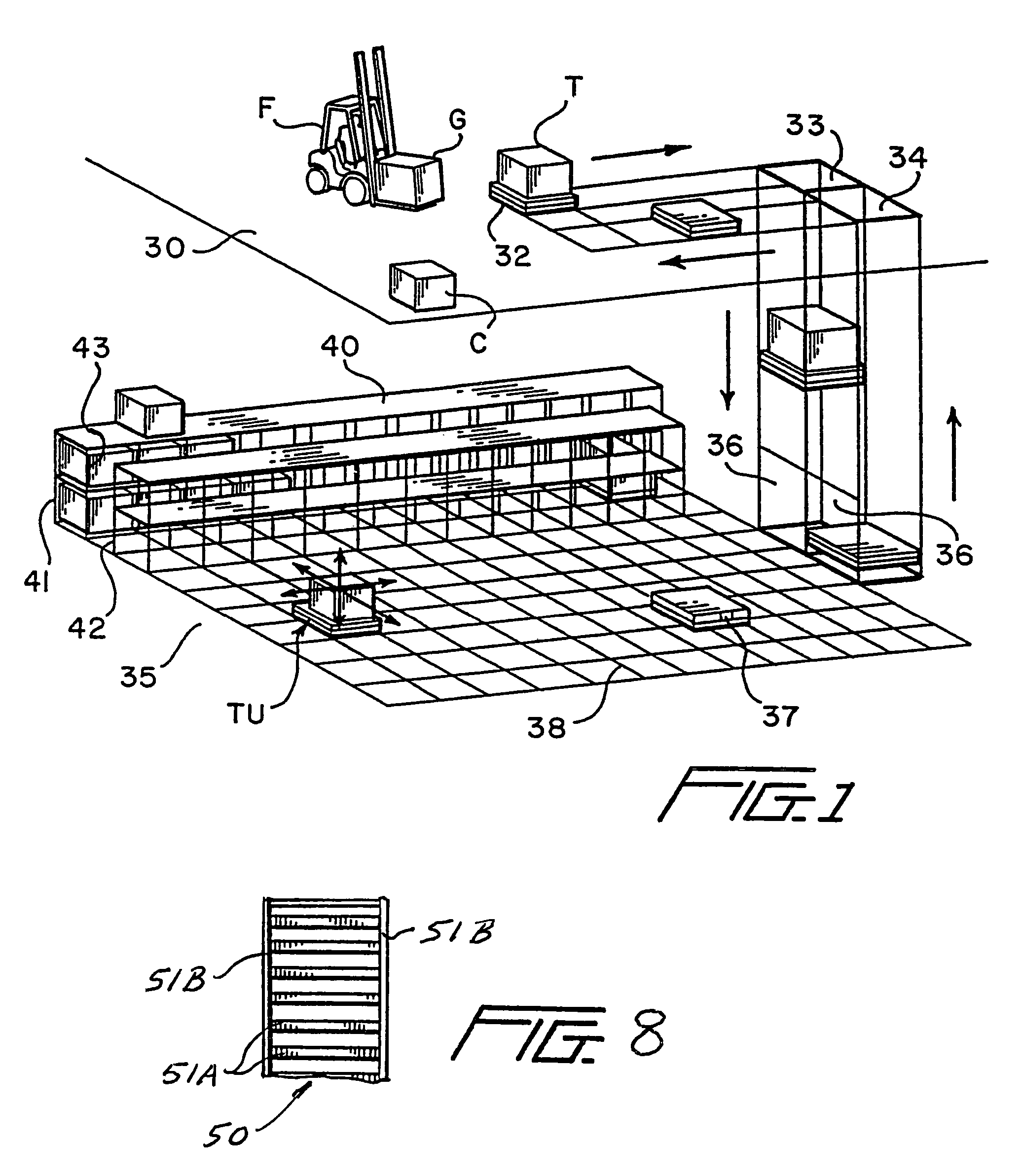

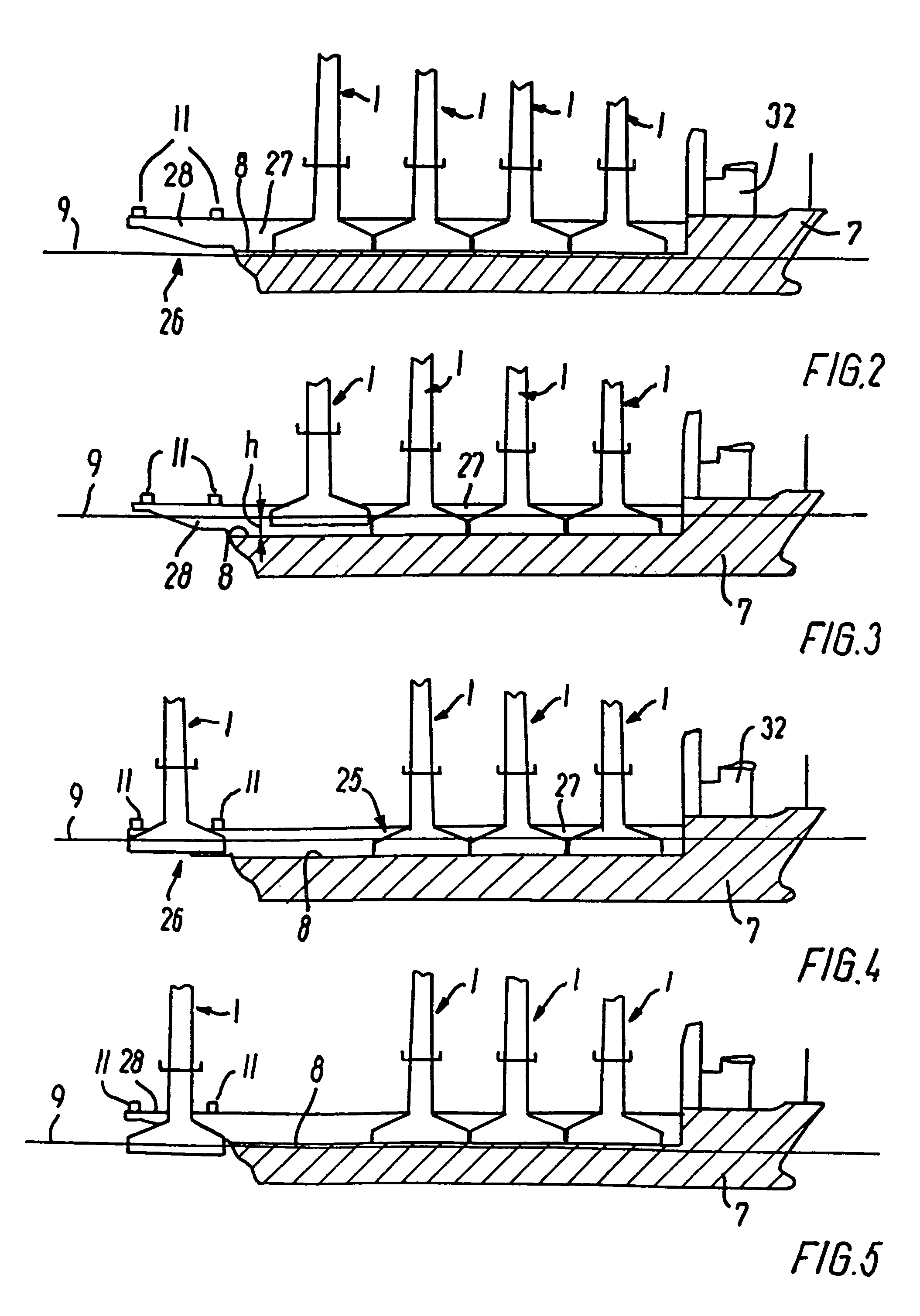

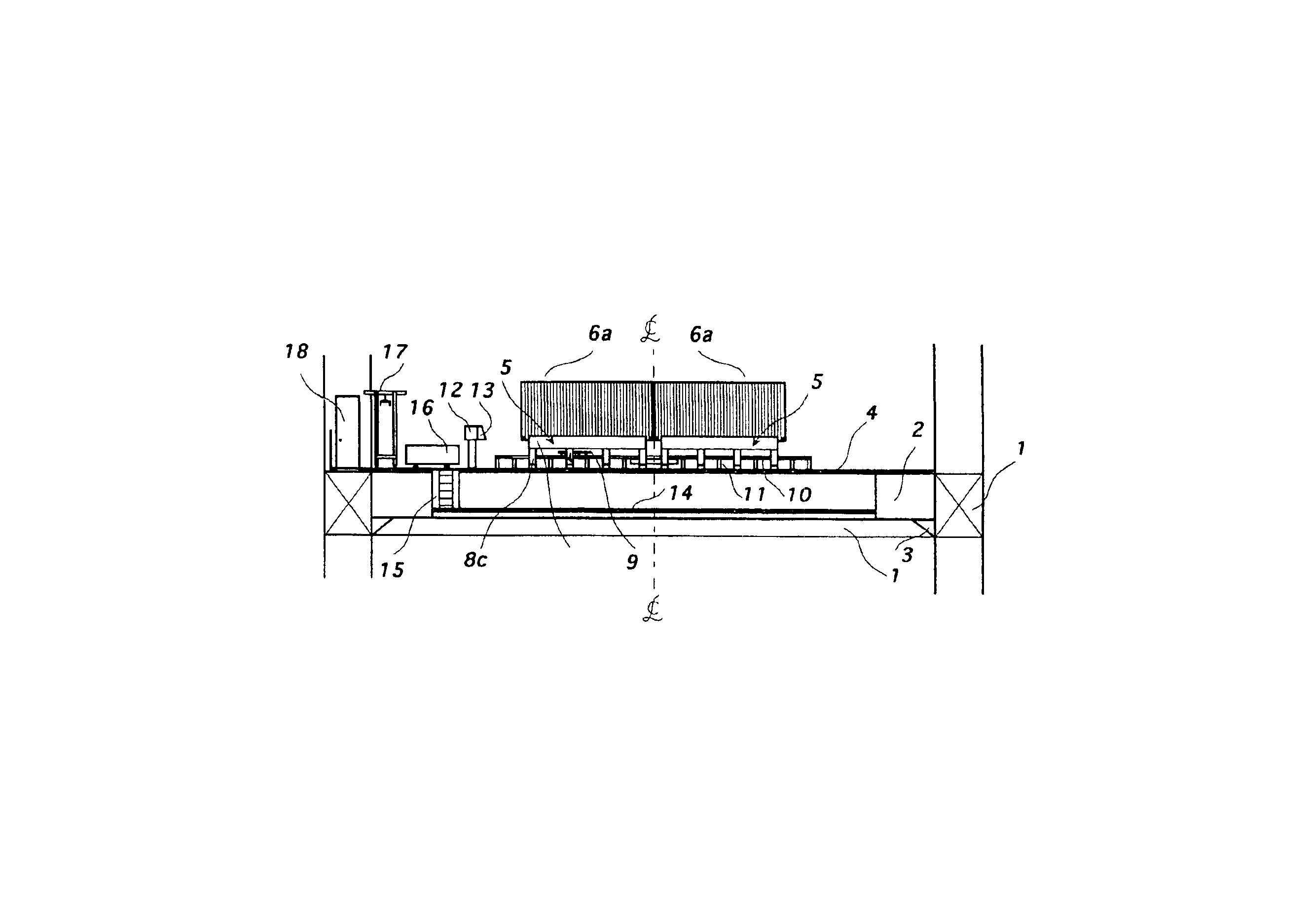

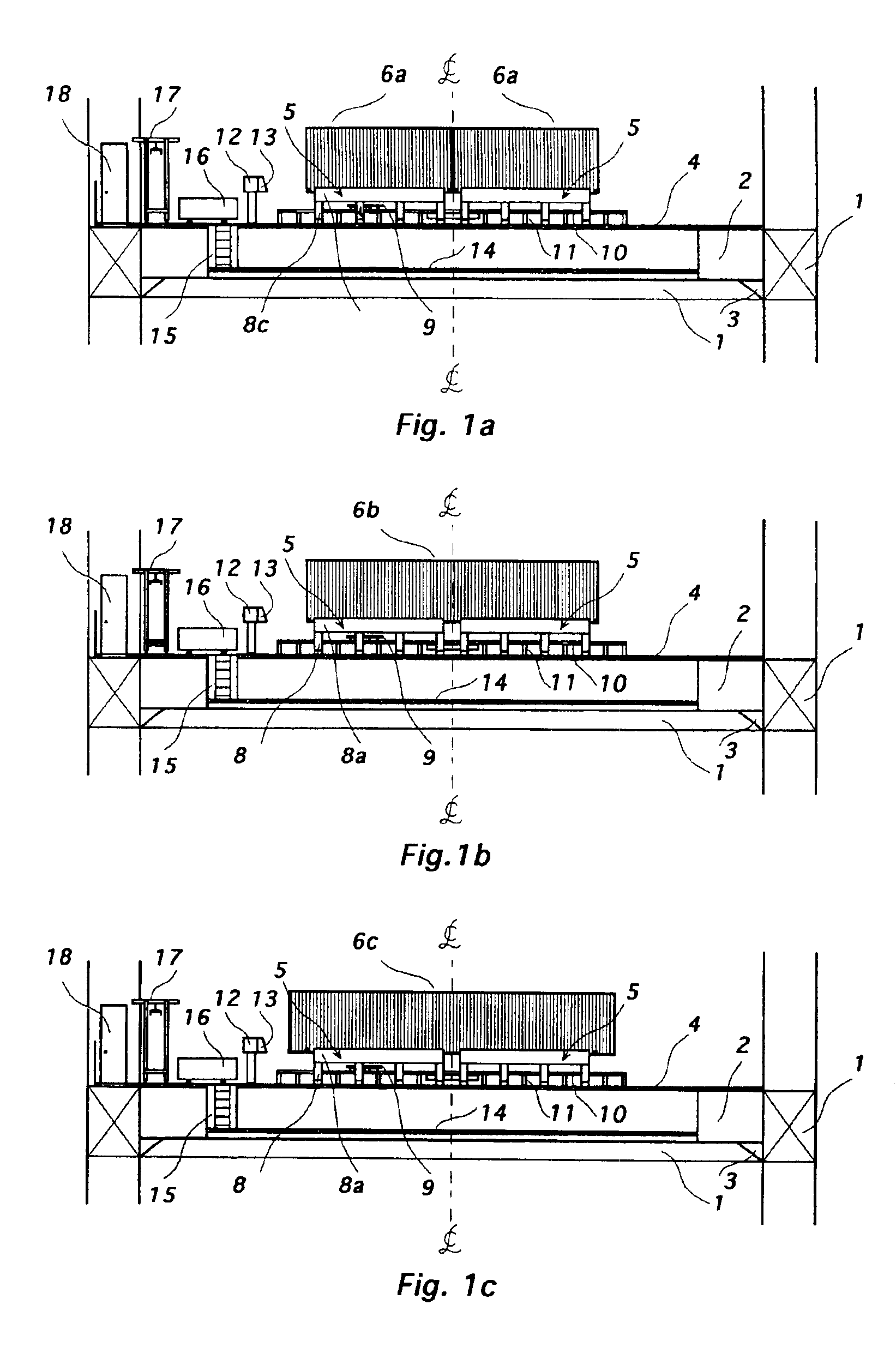

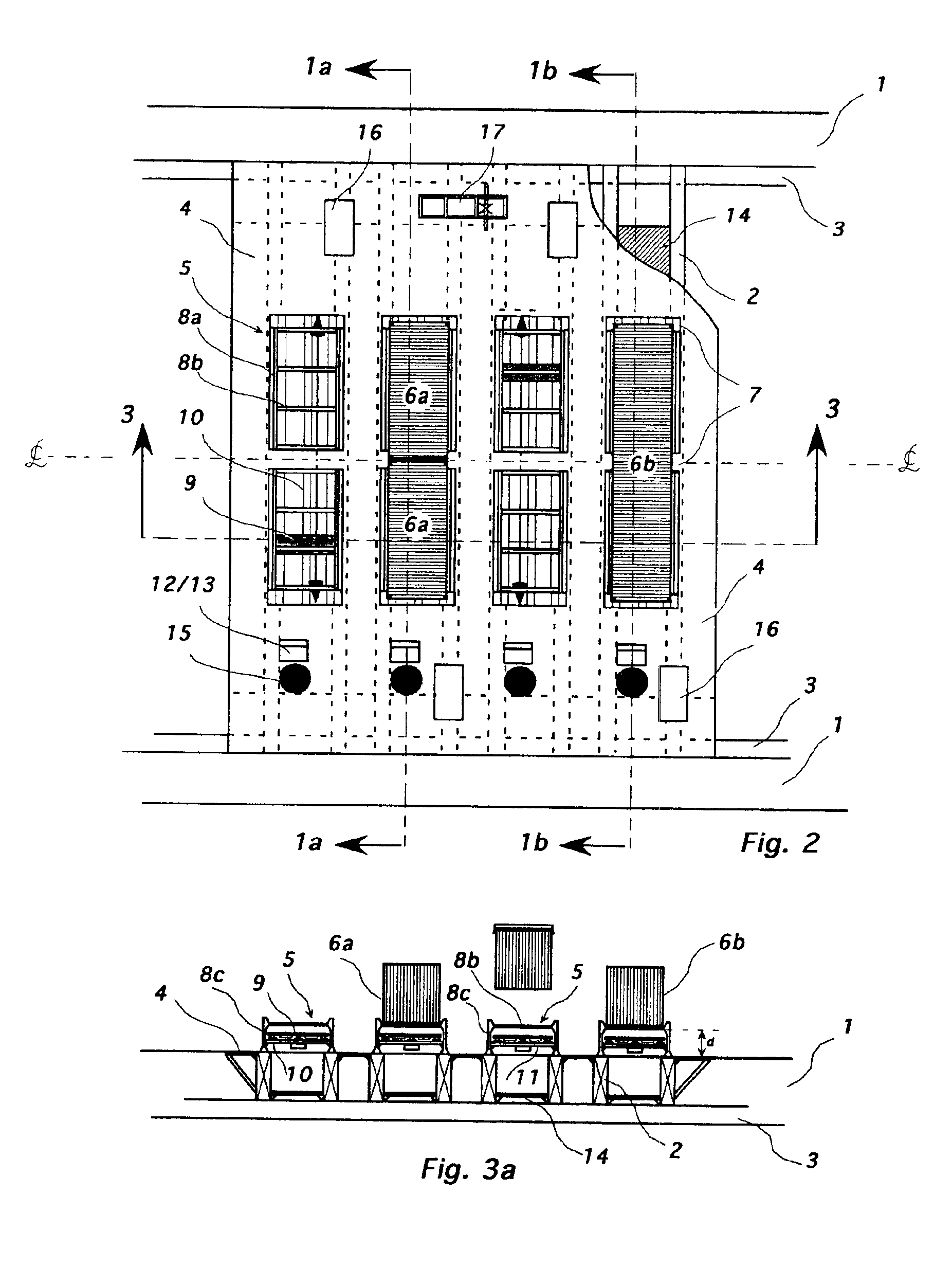

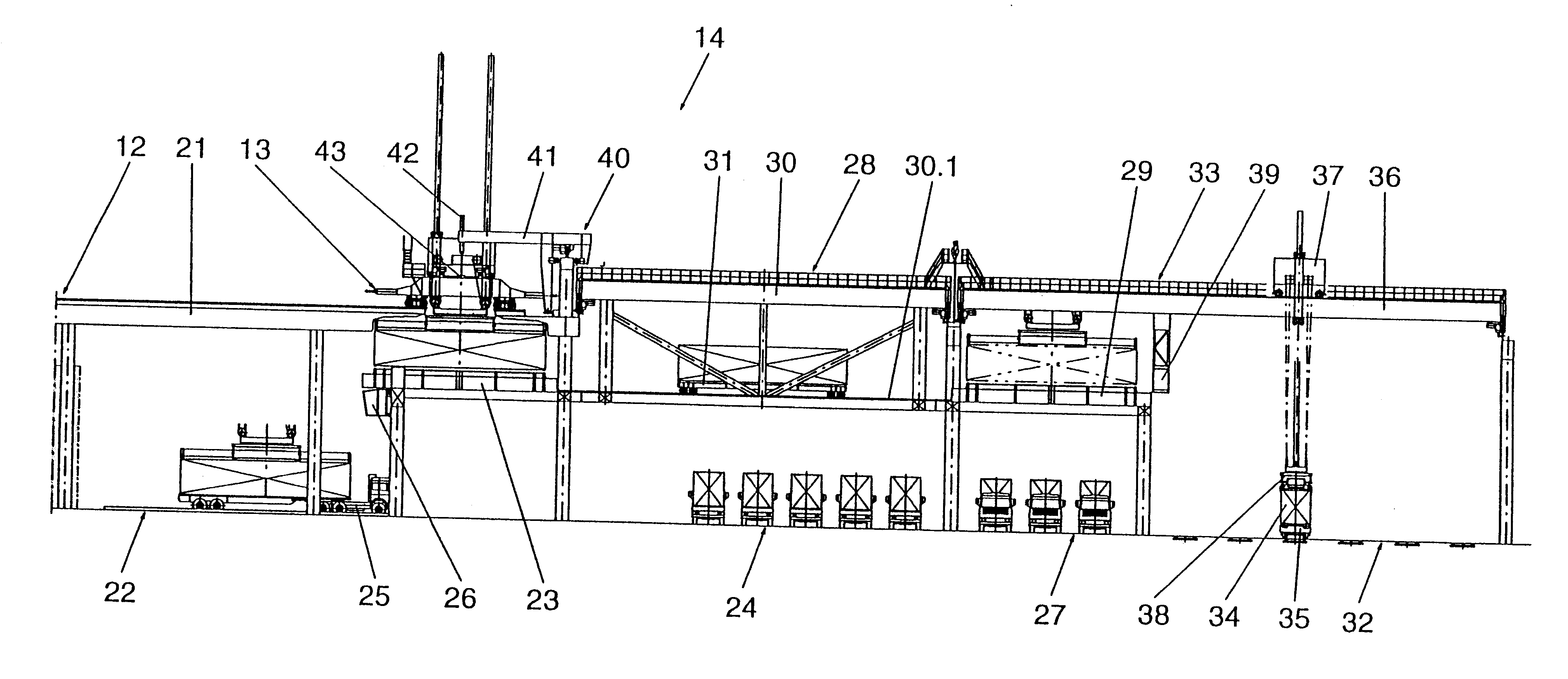

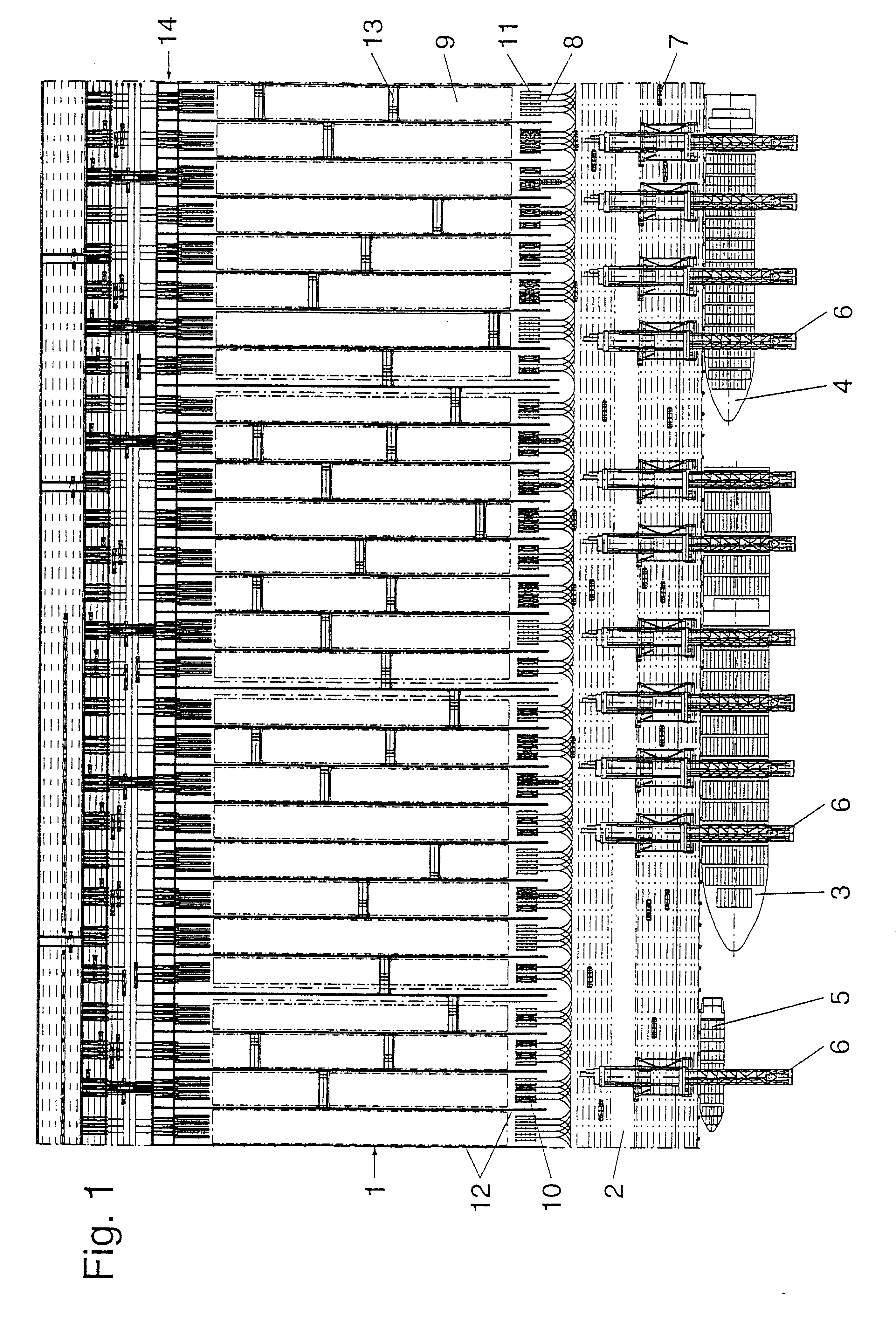

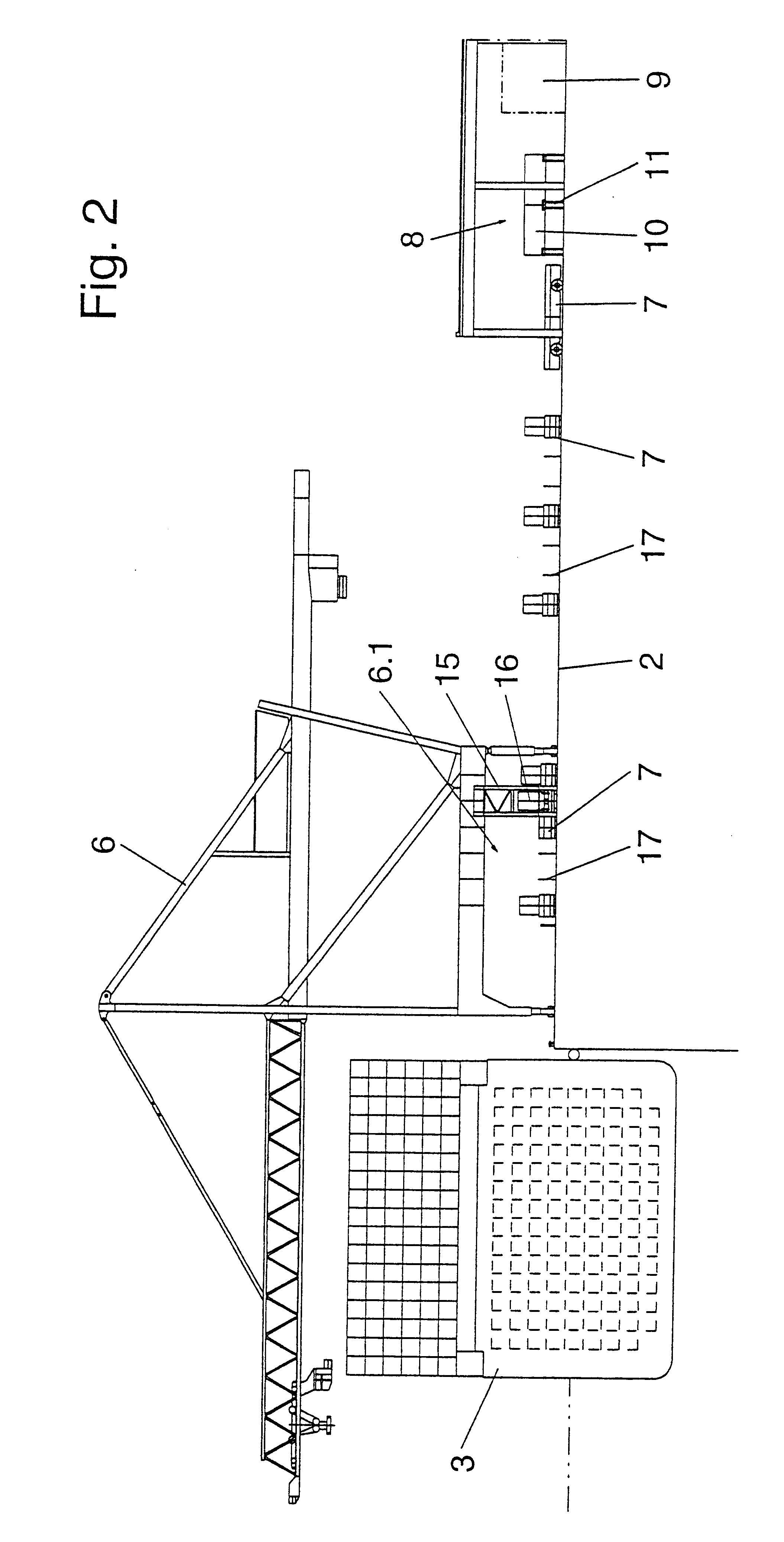

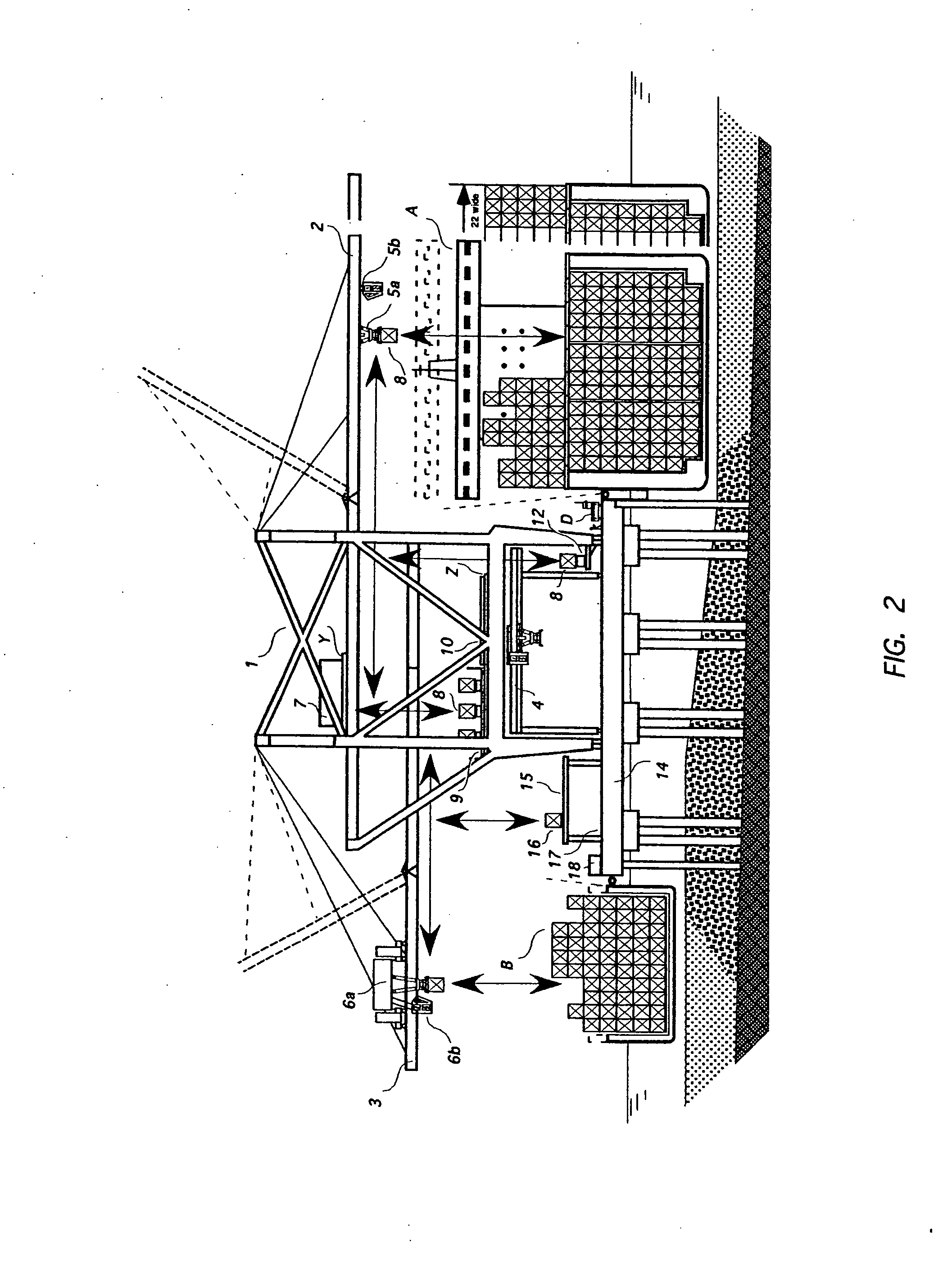

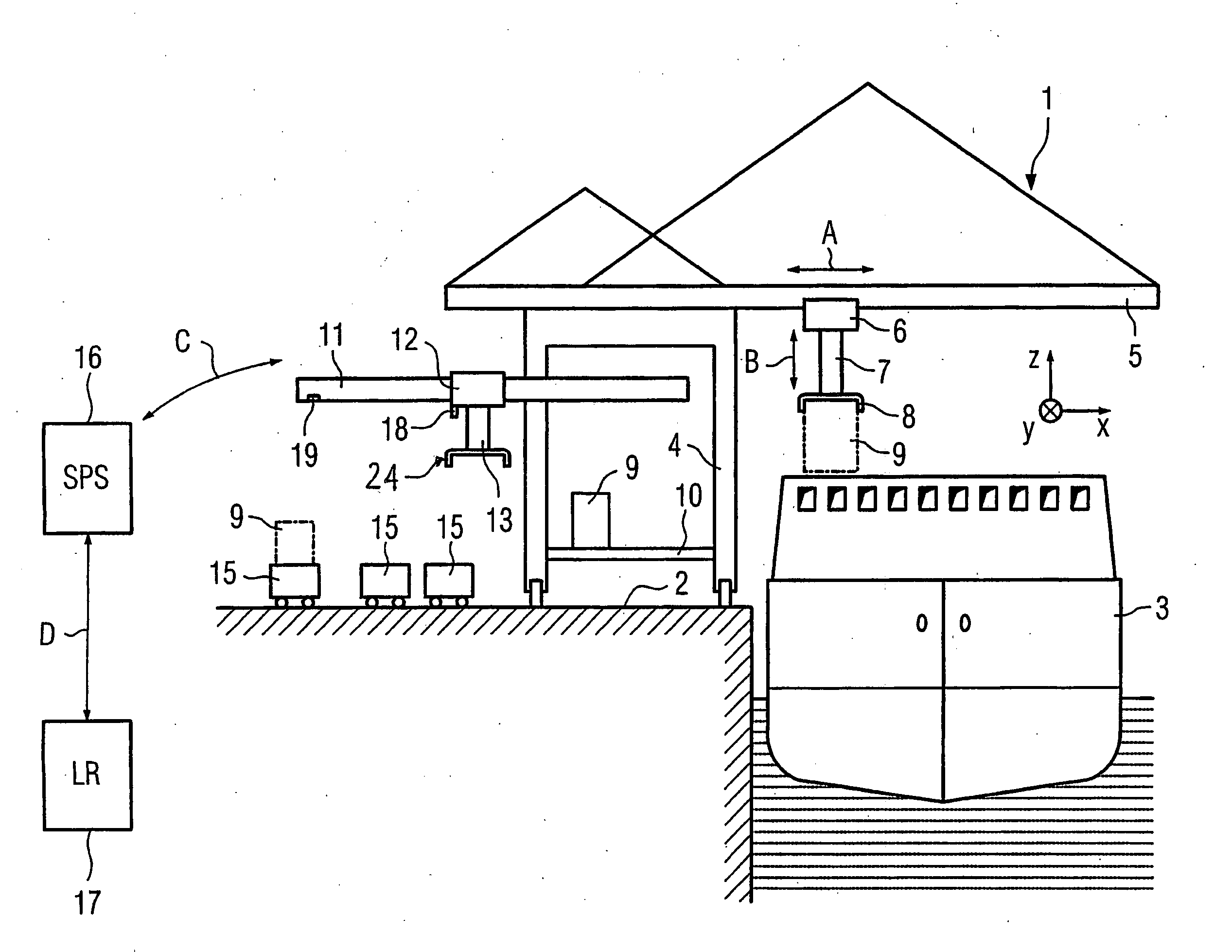

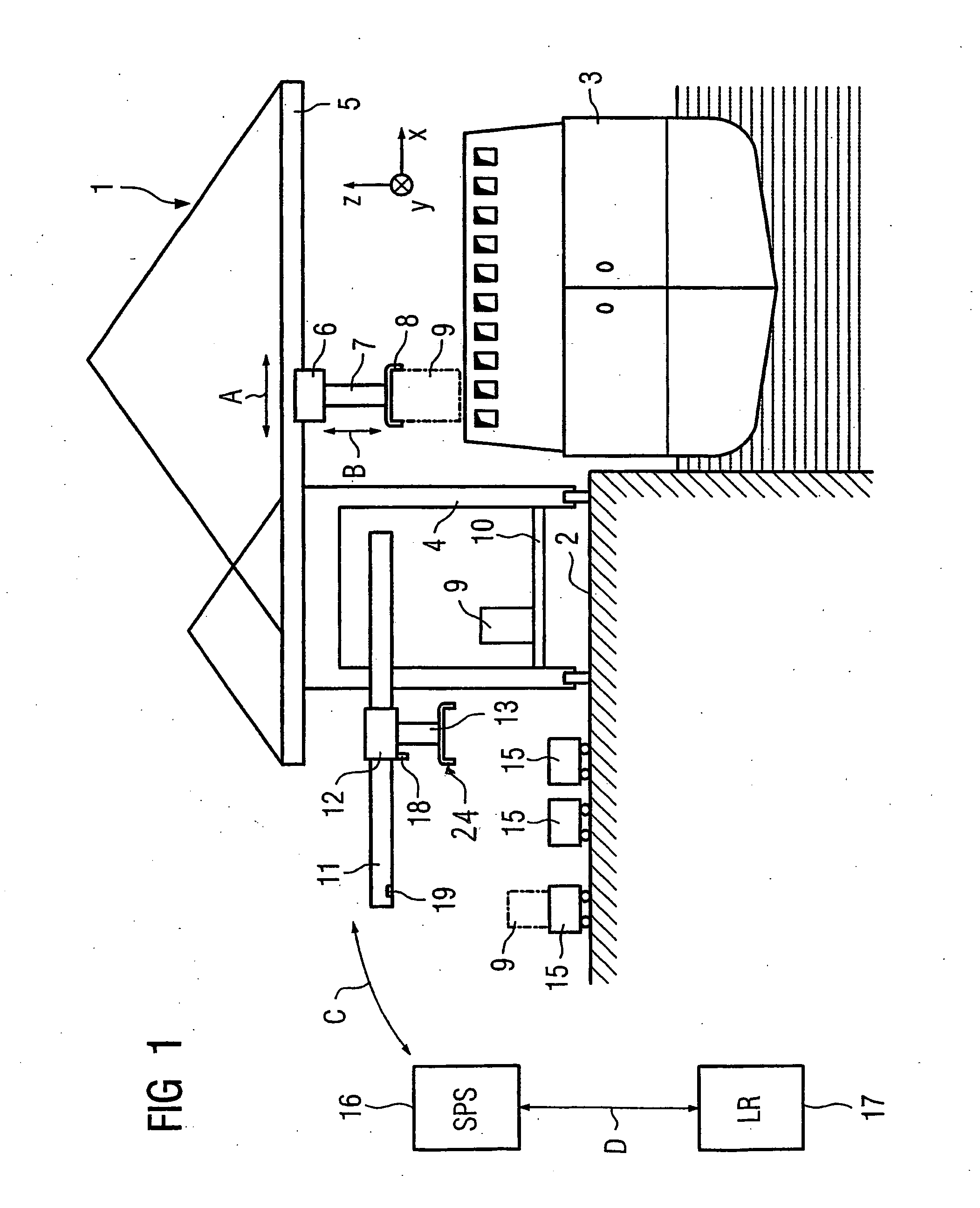

Loading and unloading installation for general cargo, especially for ISO containers

InactiveUS6698990B1Reduce spendingEasy to observeCargo handling apparatusPassenger handling apparatusWaste managementGround level

A transfer installation for piece goods, in particular for ISO containers, including a warehouse having individual linear storage modules, and including at least one loading installation which can be displaced transversely to the storage modules and is intended for land-going means of transport, between which a storage and retrieval unit assigned to each storage module operates. The loading installation includes at least two ground-level leading stations for means of transport, to each of which is assigned one intermediate buffer store which is arranged on the second level, located above the means of transport, and has at least one storage location from which the respective means of transport can be manually loaded / unloaded by means of an associated loading crane. The intermediate buffer stores are connected to one another via a transfer transporter and one of the intermediate buffer stores is connected to the warehouse via the storage and retrieval unit.

Owner:TEREX MHPS

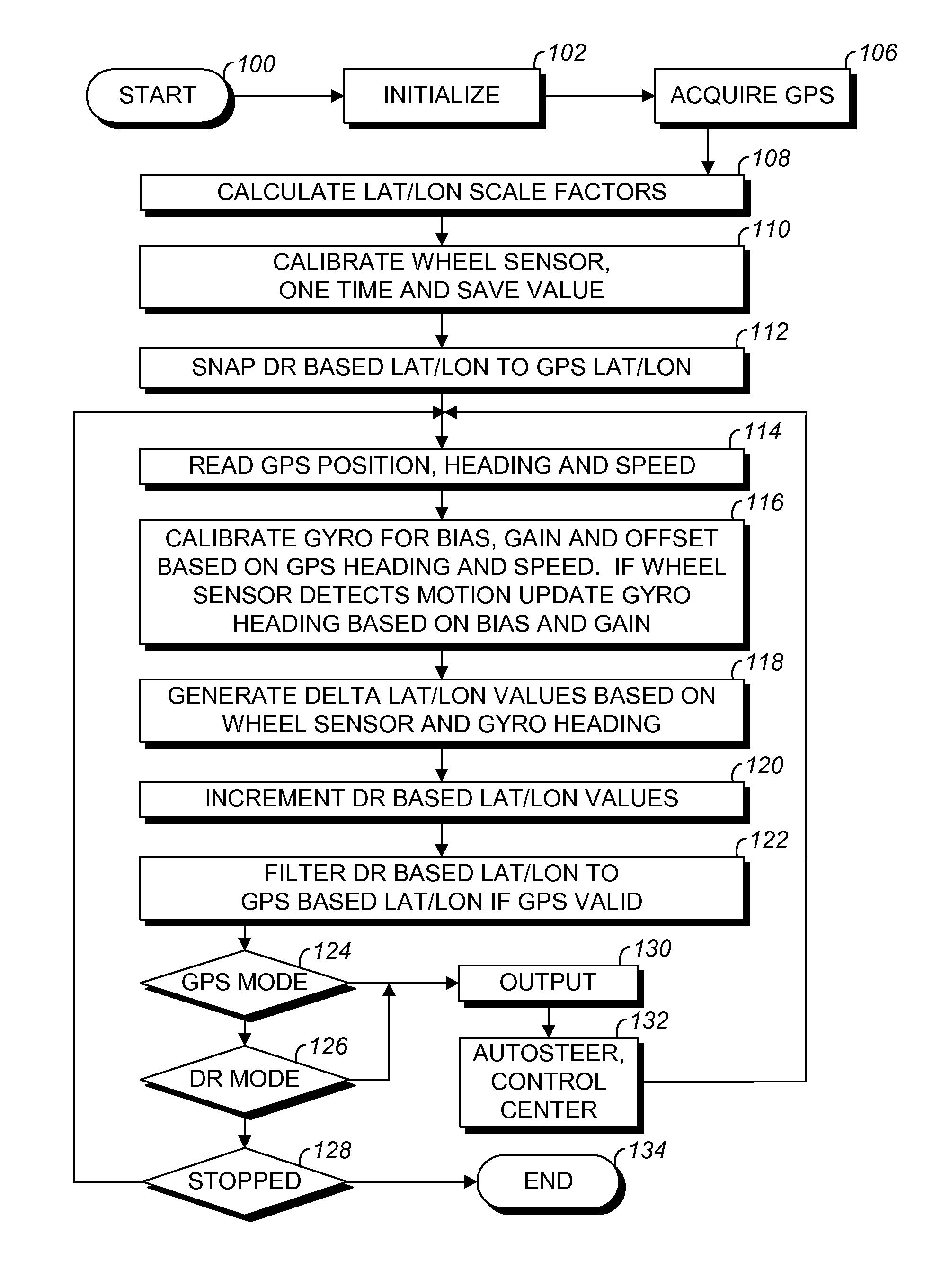

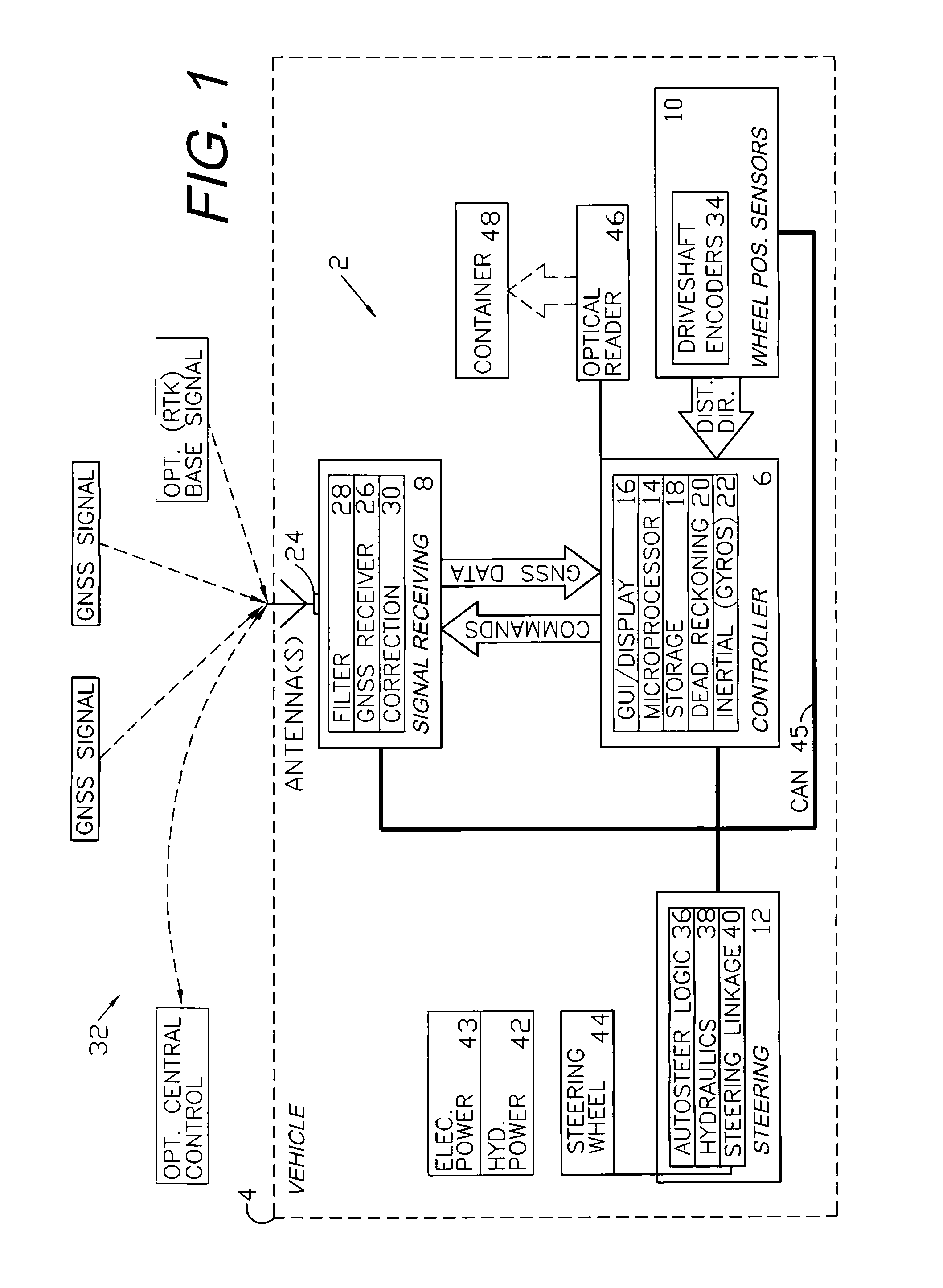

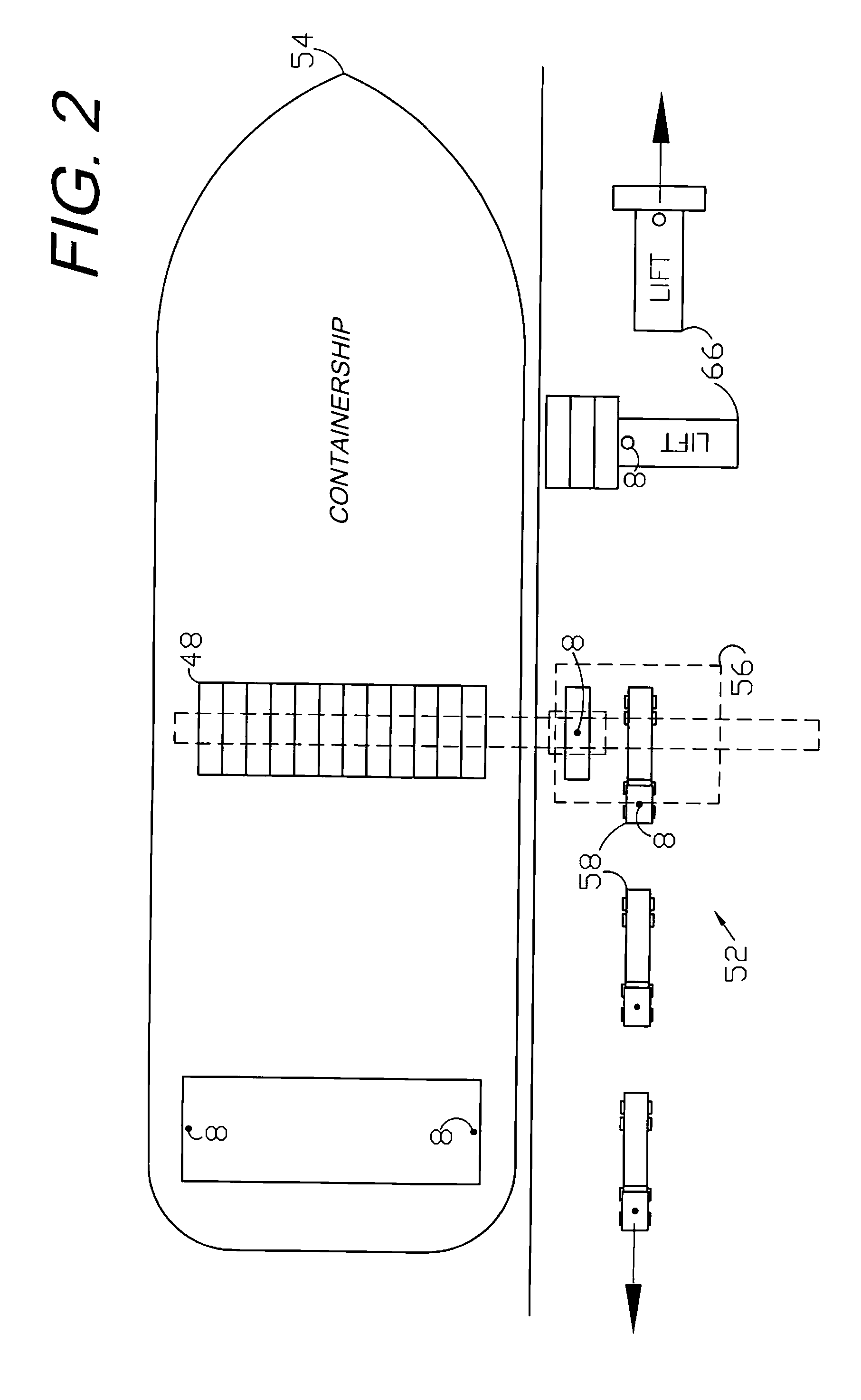

Integrated dead reckoning and gnss/ins positioning

InactiveUS20100161179A1Steering initiationsDigital data processing detailsLogistics managementControl system

An integrated dead reckoning (DR) and GNSS / INS control system and method are provided for guiding, navigating and controlling vehicles and equipment. A controller generally prioritizes GNSS navigation when satellite signals are available. Upon signal interruption, DR guidance can be integrated with INS to continue autosteering and other automated functions. Exemplary applications include logistics operations where ships, cranes and stacked containers can block satellite signals.

Owner:AGJUNCTION

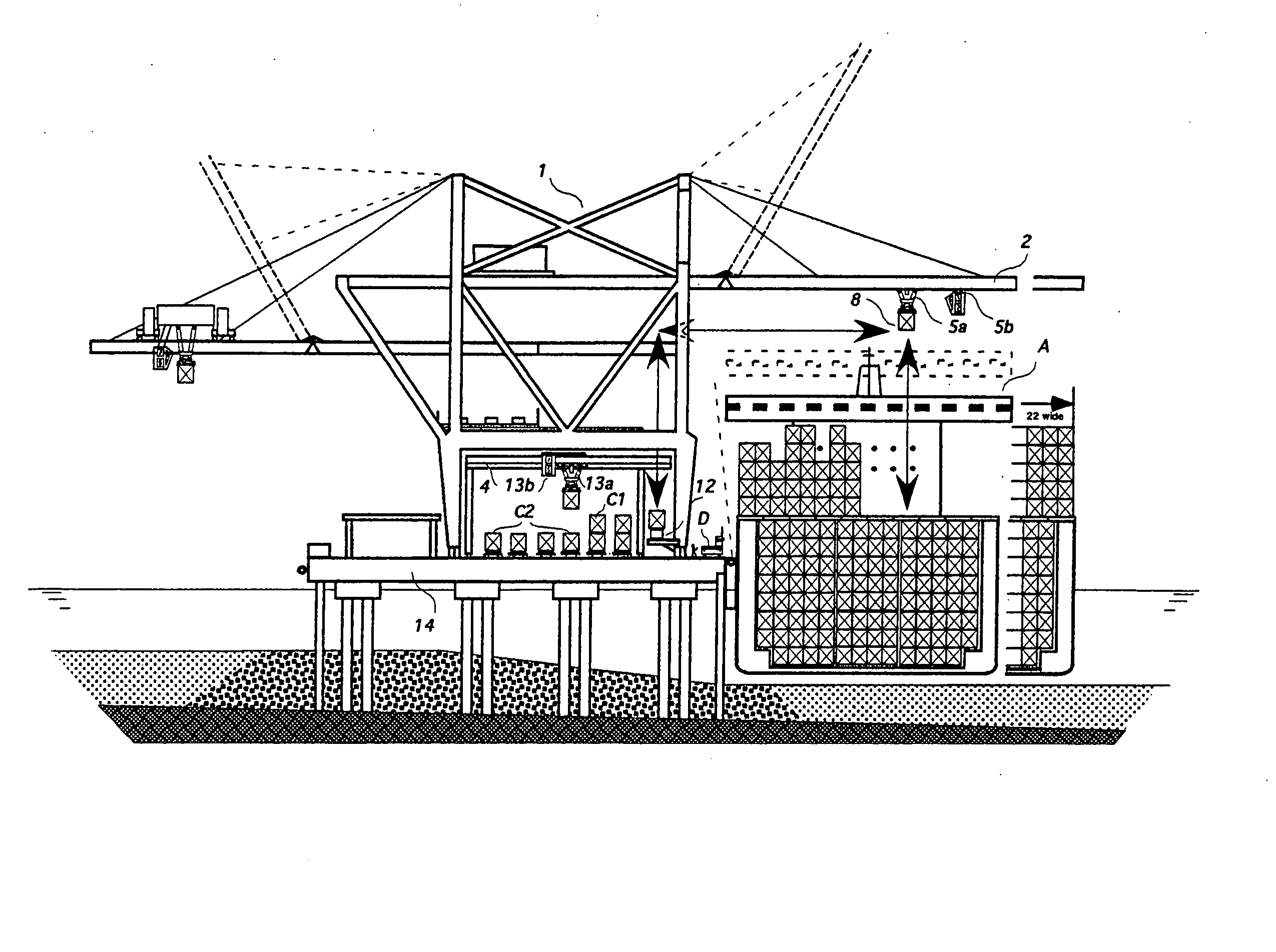

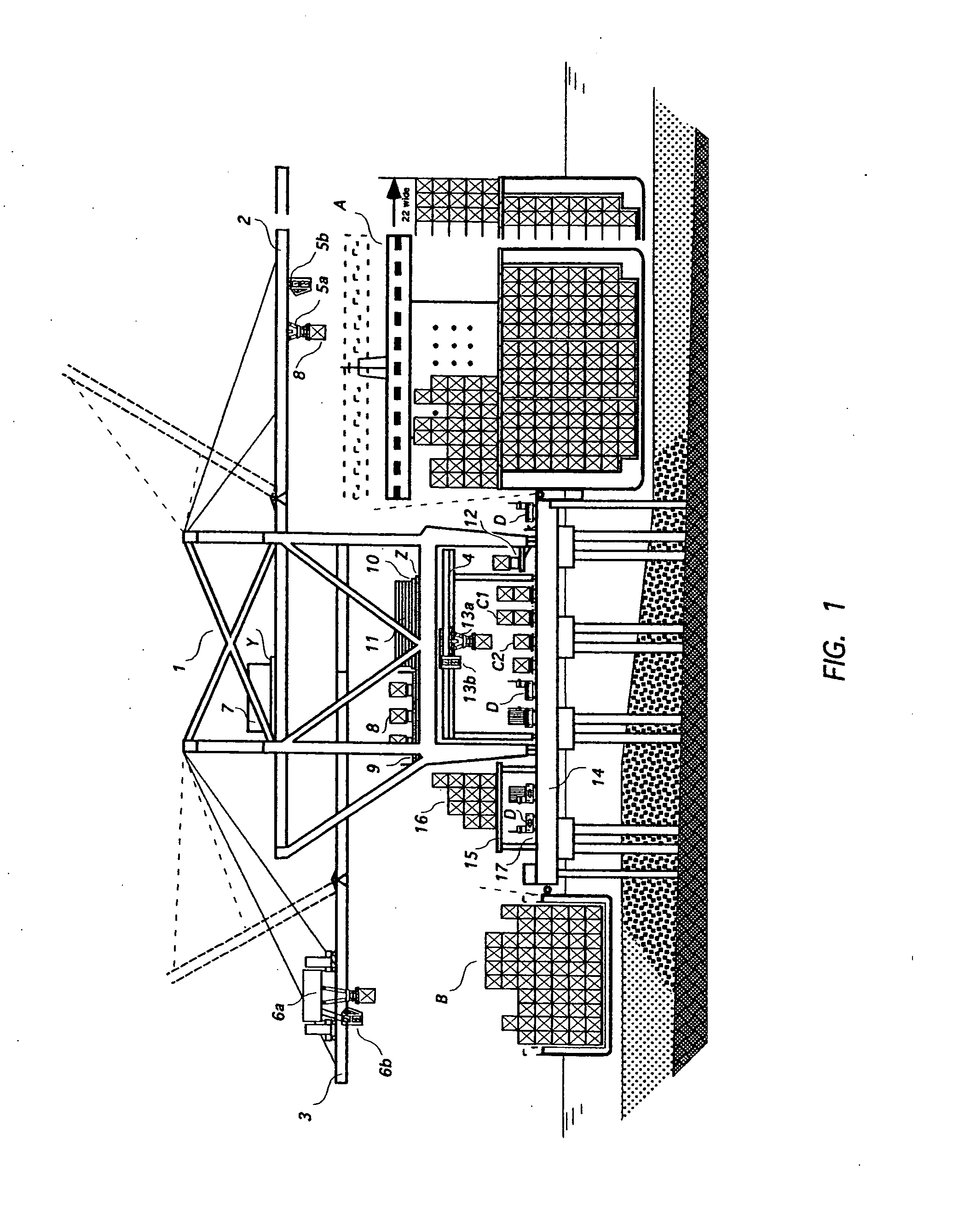

Container crane apparatus and method for container security screening during direct transshipment between transportation modes

InactiveUS20080219804A1Save a lot of costCargo handling apparatusBase supporting structuresContainer craneGround vehicles

A crane apparatus installed on a pier, wharf, bulkhead wharf or other foundation directly transships containers from a vessel moored alongside the foundation to another transportation mode without ground placement of the containers. The crane apparatus includes a parent crane displaceable along the foundation for unloading containers from the vessel and placing them on a first platform of the parent crane, and a sibling crane displaceable along the foundation independently of displacement of the parent crane for loading containers from the first platform directly onto over-the-ground vehicles or onto another vessel moored alongside the foundation. The parent crane has a first trolley-hoist-spreader movable along an outreach boom for unloading containers from the vessel and placing them on either the first platform or a second platform of the parent crane, and a second trolley-hoist-spreader movable along a backreach boom for loading containers from the second platform onto another vessel or onto over-the-ground vehicles. A container security scanning system may be provided on the second platform for scanning the containers while on the second platform to determine whether one or more preselected chemical, biological, explosive or nuclear materials are present in the containers.

Owner:CHATTEY NIGEL

Installation Of Offshore Structures

A method and system for transporting an offshore structure such as a wind turbine generator includes a supporting frame in which the offshore structure is assembled on land in an upright configuration. The frame is used for lifting the structure onto a transport vessel, on which it is retained in the upright configuration. At its location of use, the offshore structure is transferred to a pre-prepared foundation. The foundation is provided with a frame which cooperates with the supporting frame. The supporting frame includes a plurality of legs having hydraulically controlled feet. The frame of the foundation includes an equal number of supporting formations on which the feet ultimately rest. The feet are moveable in response to the hydraulic control along a nominally vertical line of action and provide a damping arrangement for the mounting of the offshore structure.

Owner:IHC IQIP HLDG BV

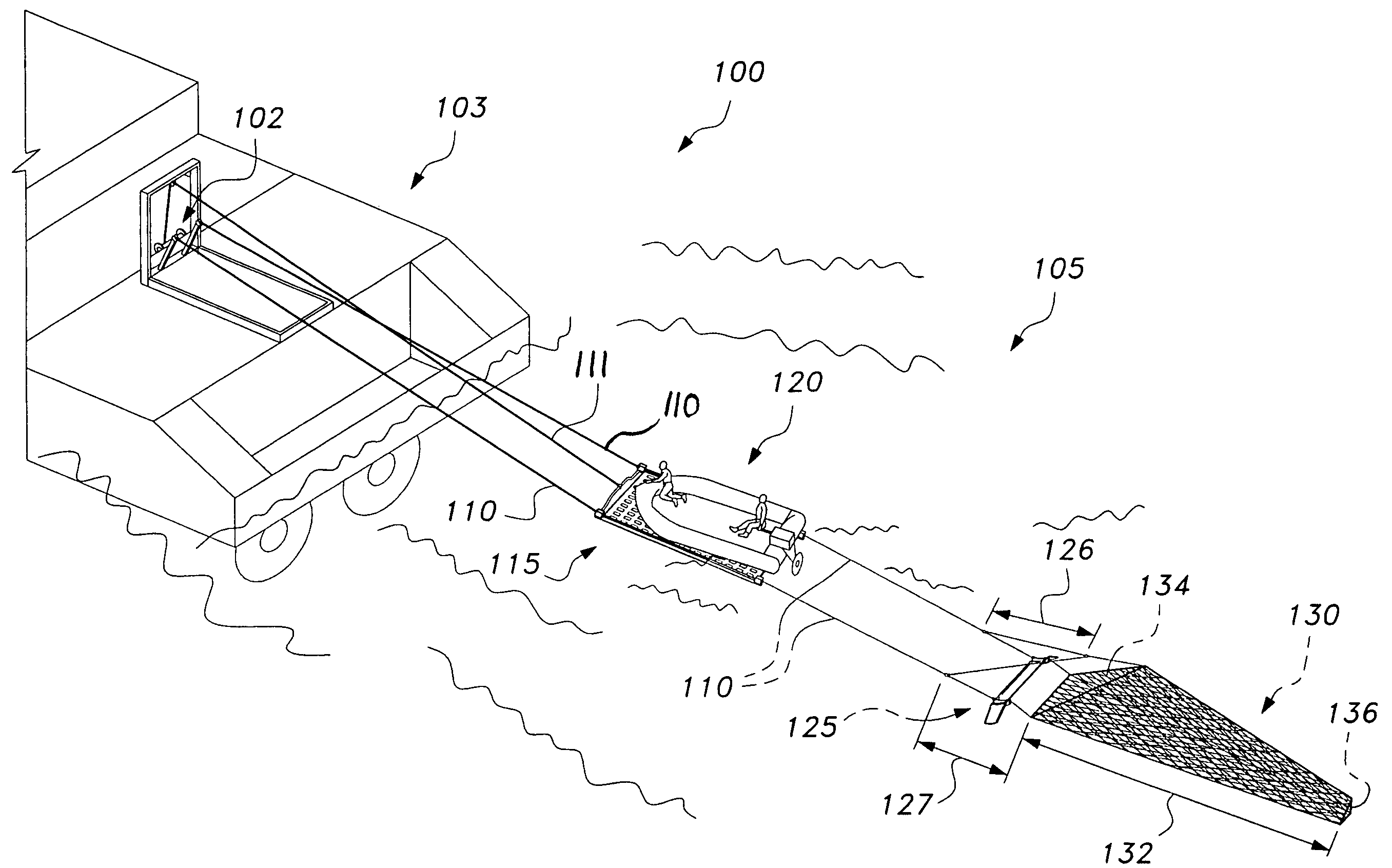

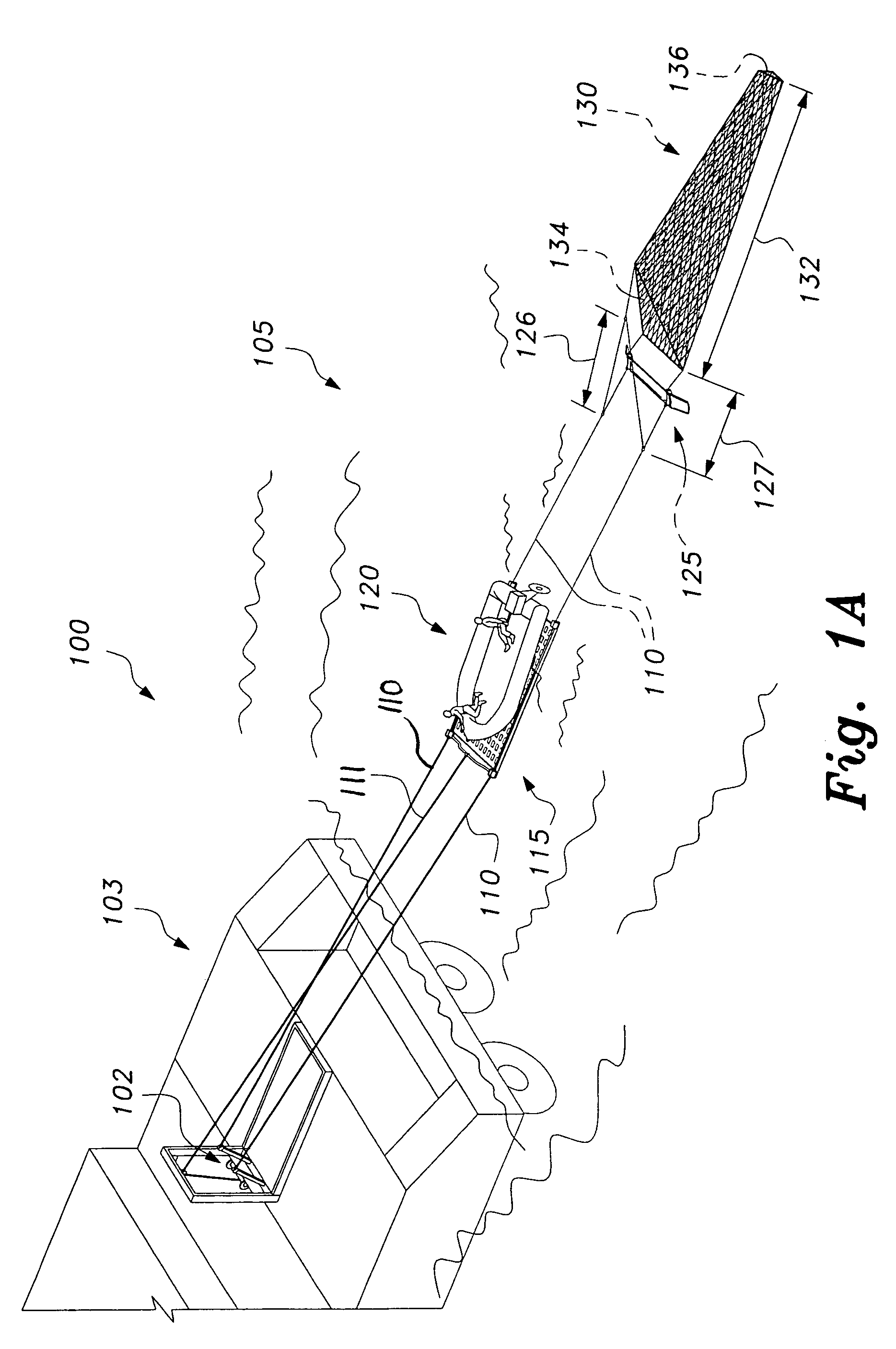

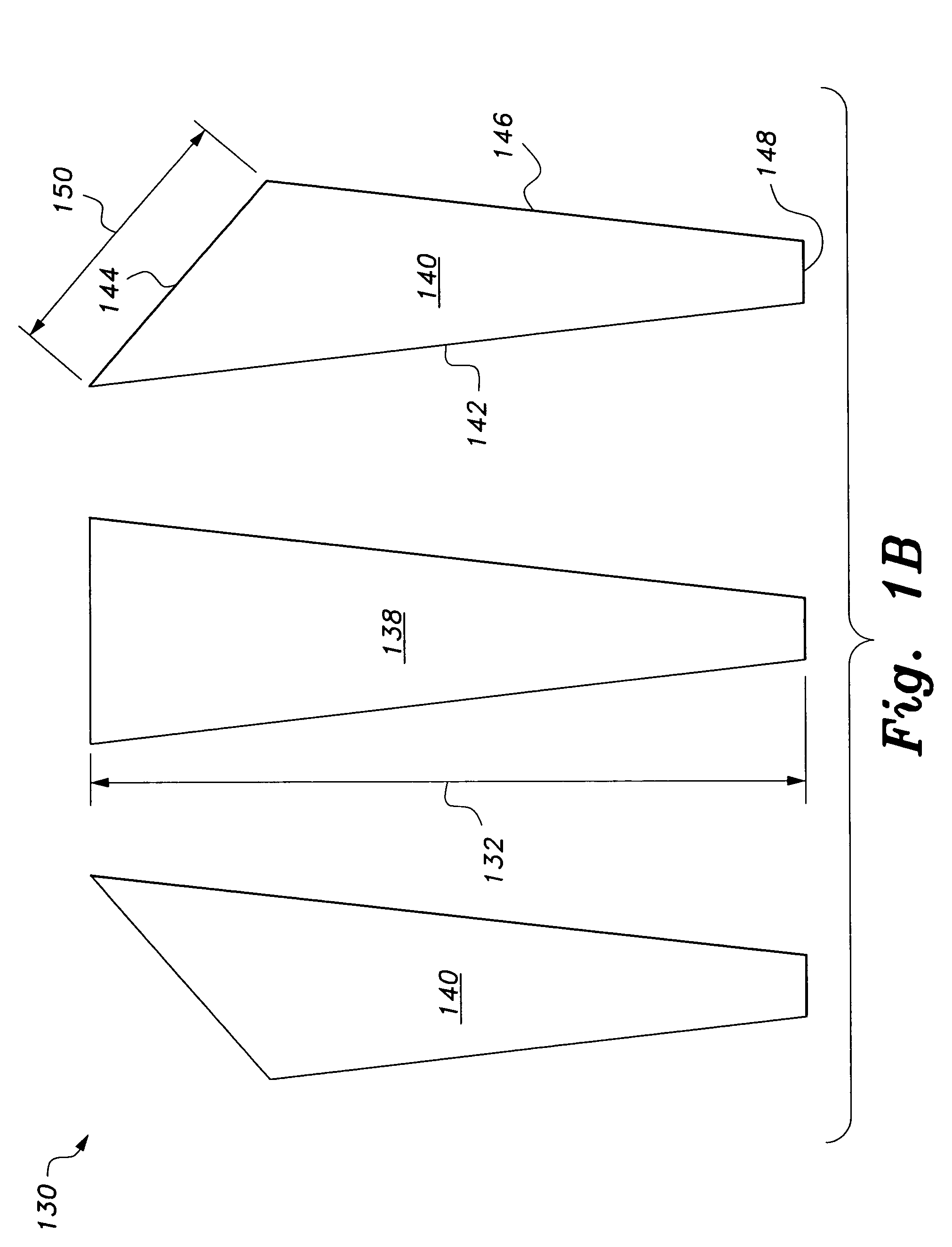

Launch and recovery system

The launch and recovery system provides a dive wing and drogue assembly that is towed behind a ship by cables. The dive wing imparts a downward thrust to the drogue, so that the drogue is towed underwater, placing tension on the cables. The cables become stiff due to the speed of the ship and the weight and depth of the dive wing and drogue assembly, so that the cables take on the character of rails. The boat or watercraft to be launched is placed on a sling carriage that is slidably mounted on the cables, so that the sling slides down the cables, launching the watercraft in the stable wake of the ship. The watercraft is recovered by tying a winch cable or line to the watercraft, winching the watercraft back onto the sling, and winching the sling back onto the fantail of the ship.

Owner:SEIPLE RONALD L

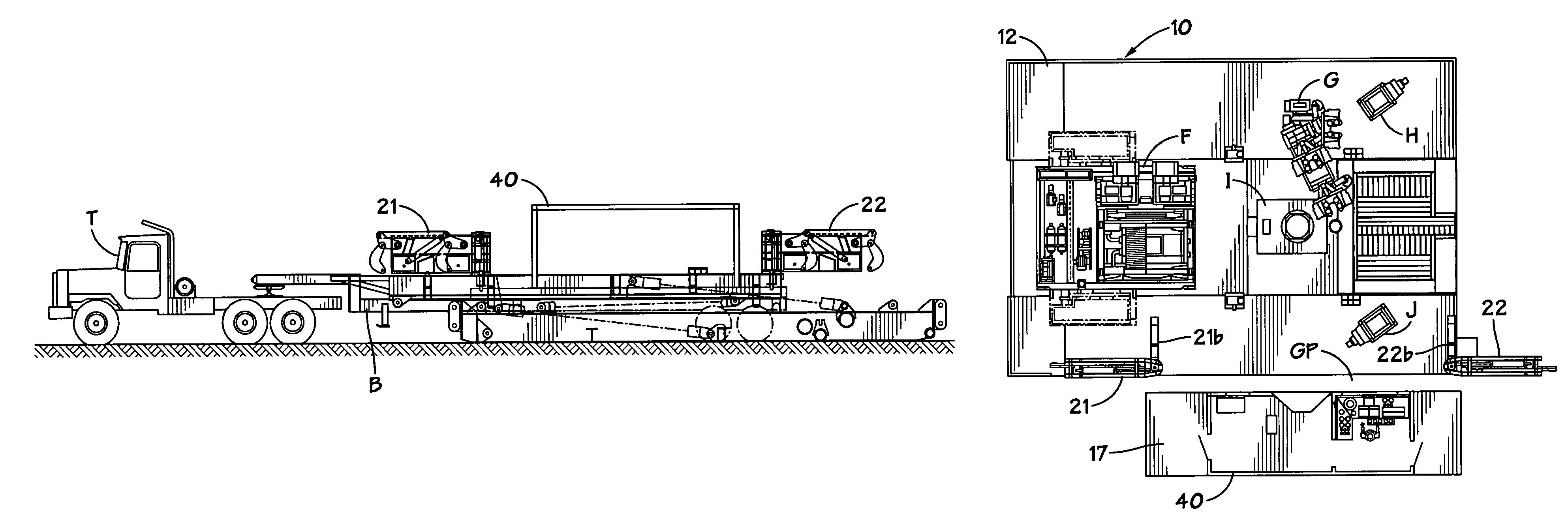

Drilling rig structure installation and methods

Owner:NAT OILWELL VARCO LP

Hydraulic lift for small watercraft mounted to a boat transom

A transom bracket enclosing a hydraulic power cylinder is mounted to the transom of a watercraft. An actuation rod of the power cylinder moves multiple lift arms connected to a platform bracket supporting a platform for supporting a small auxiliary watercraft. Electrical or manual operation of the power cylinder causes the platform bracket to move in a vertical direction either upwards out of the water or downwards into the water. A lock mechanism operated by a lock cylinder locks the lift apparatus in place when not in operation. Grooves on sides of the transom bracket and transversely extended pins connecting the linkage arms provide a downward stop to movement of the lift apparatus.

Owner:GENERAL HYDRAULIC SOLUTIONS

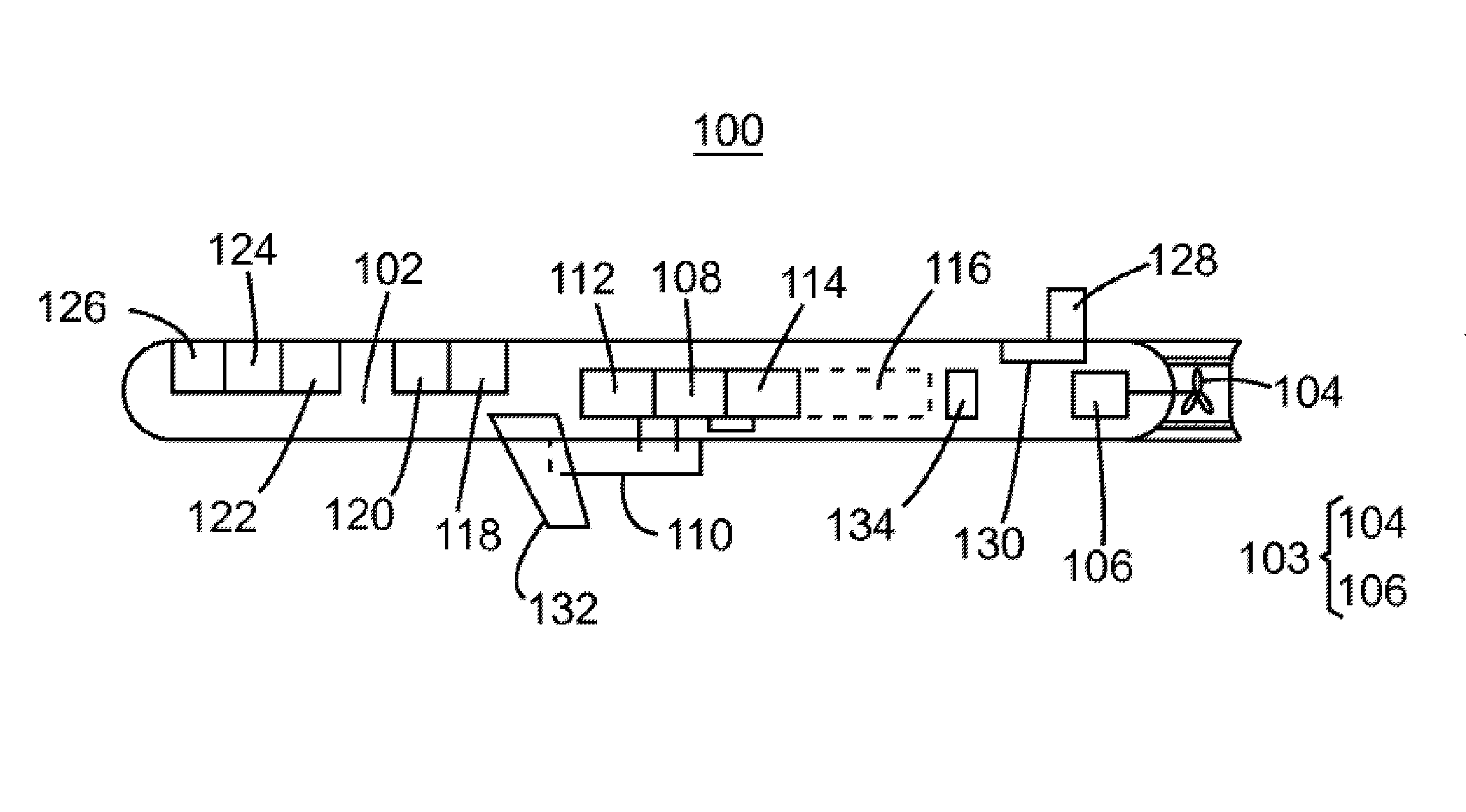

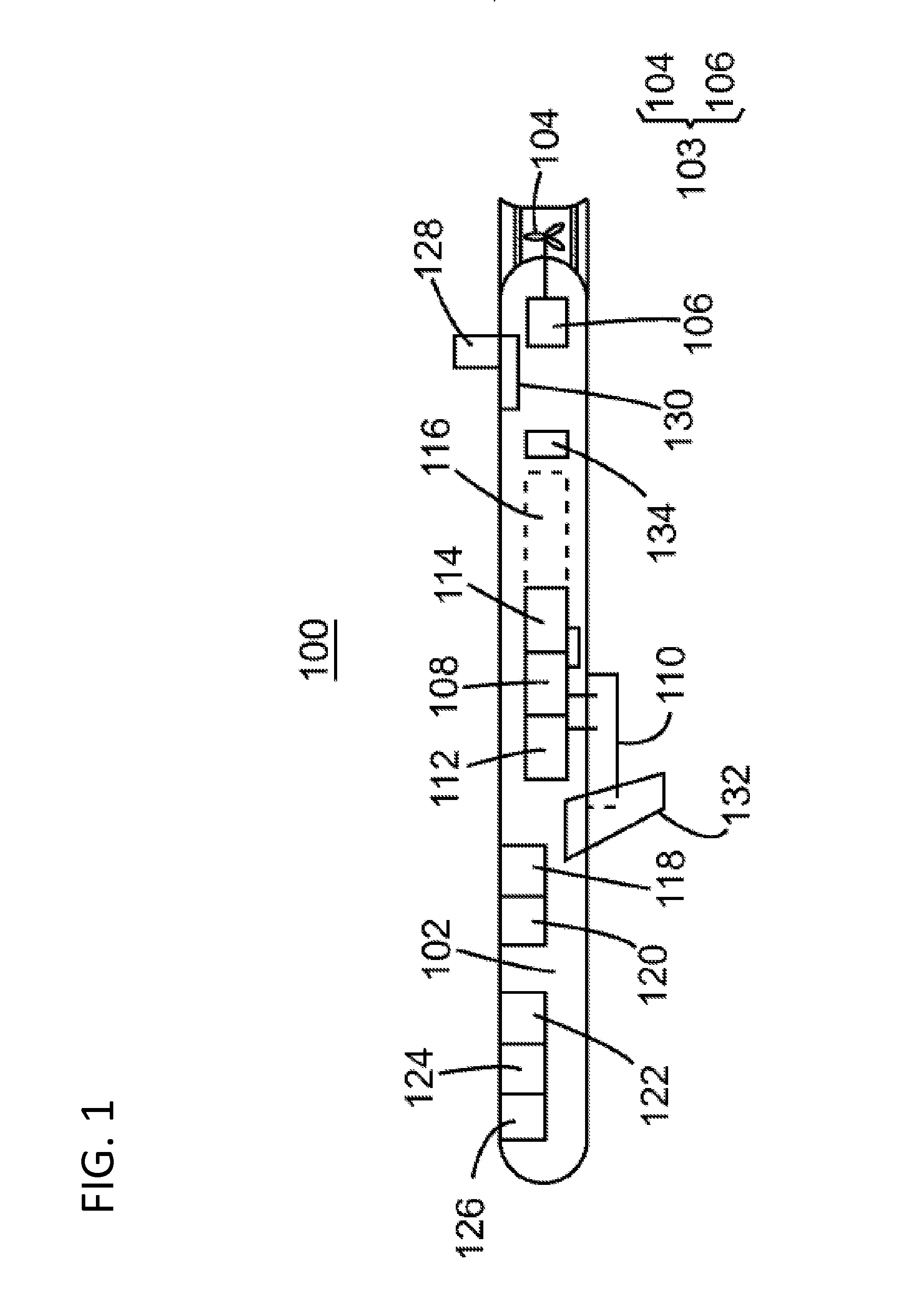

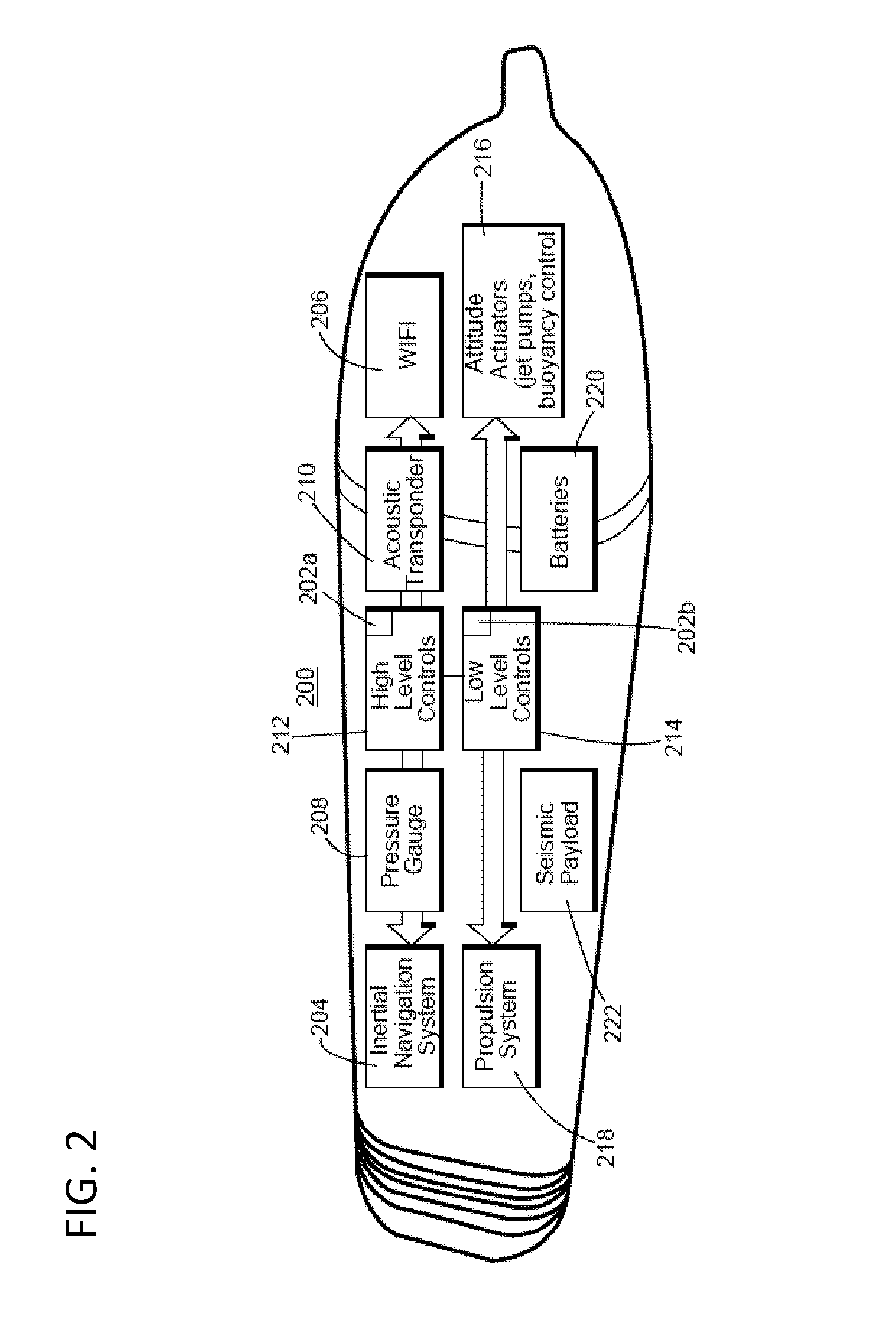

Deployment and retrieval of seismic autonomous underwater vehicles

ActiveUS20160121983A1Cargo handling apparatusPassenger handling apparatusOcean bottomRemotely operated vehicle

Apparatuses, systems, and methods for the deployment of a plurality of autonomous underwater seismic vehicles (AUVs) on or near the seabed based on acoustic communications with an underwater vehicle, such as a remotely operated vehicle. In an embodiment, the underwater vehicle is lowered from a surface vessel along with a subsea station with a plurality of AUVs. The AUVs are configured to acoustically communicate with the underwater vehicle or a second surface vessel for deployment and retrieval operations. The underwater vehicle and / or second surface vessel is configured to instruct the AUVs to leave the subsea station or underwater vehicle and to travel to their intended seabed destination. The underwater vehicle and / or second surface vessel is also configured to selectively instruct the AUVs to leave the seabed and return to a seabed location and / or a subsea station for retrieval.

Owner:SEABED GEOSOLUTIONS

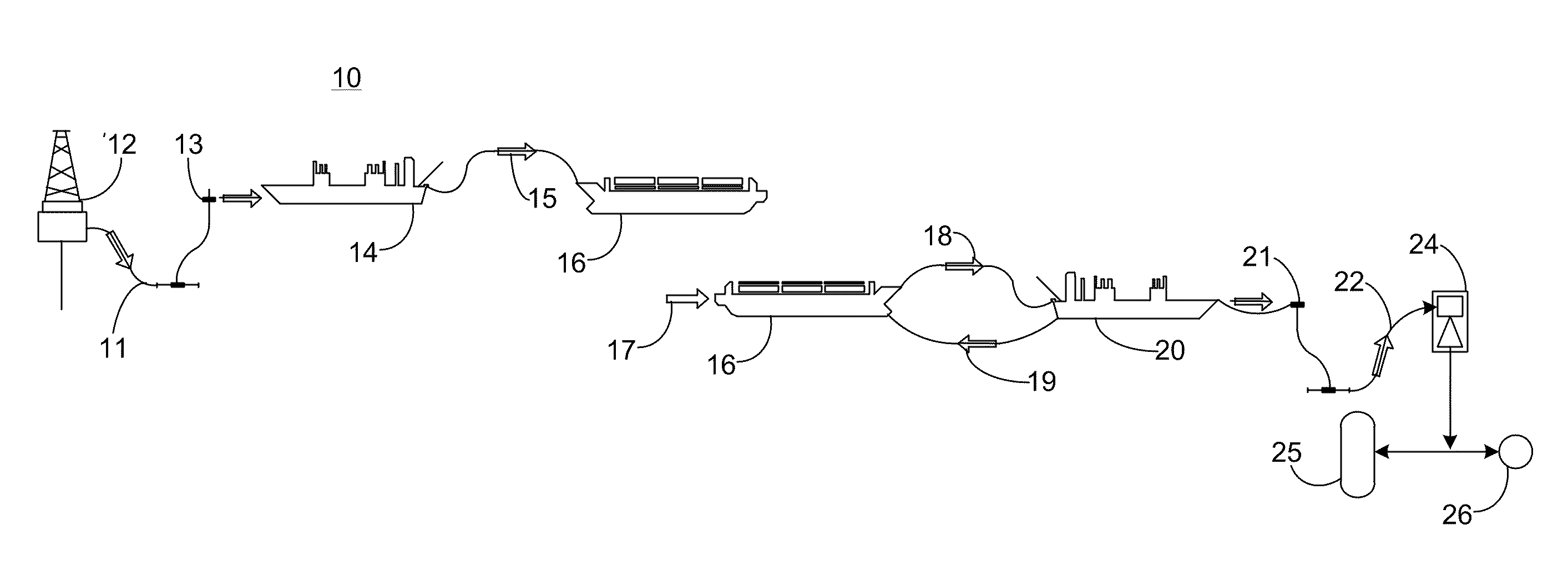

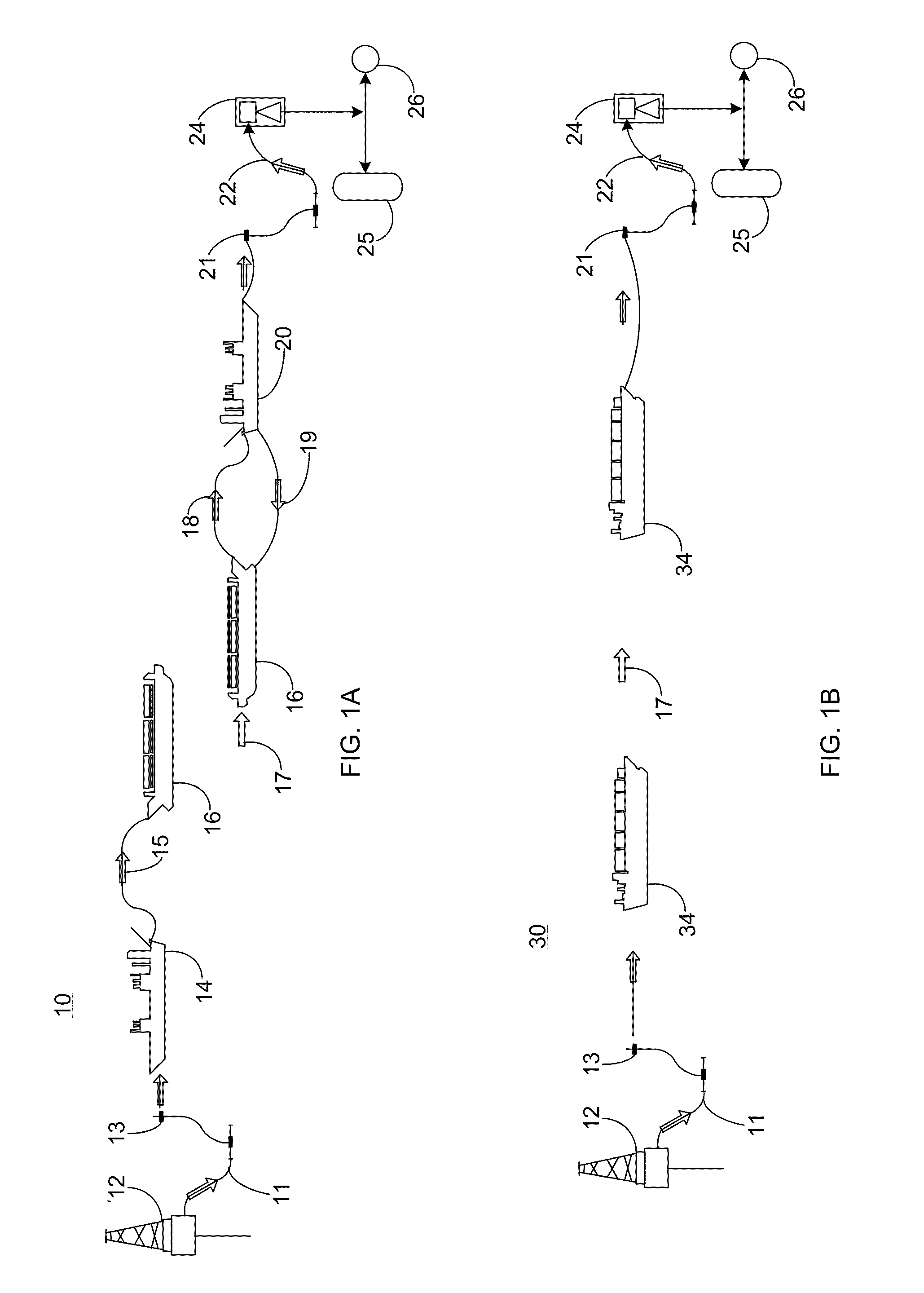

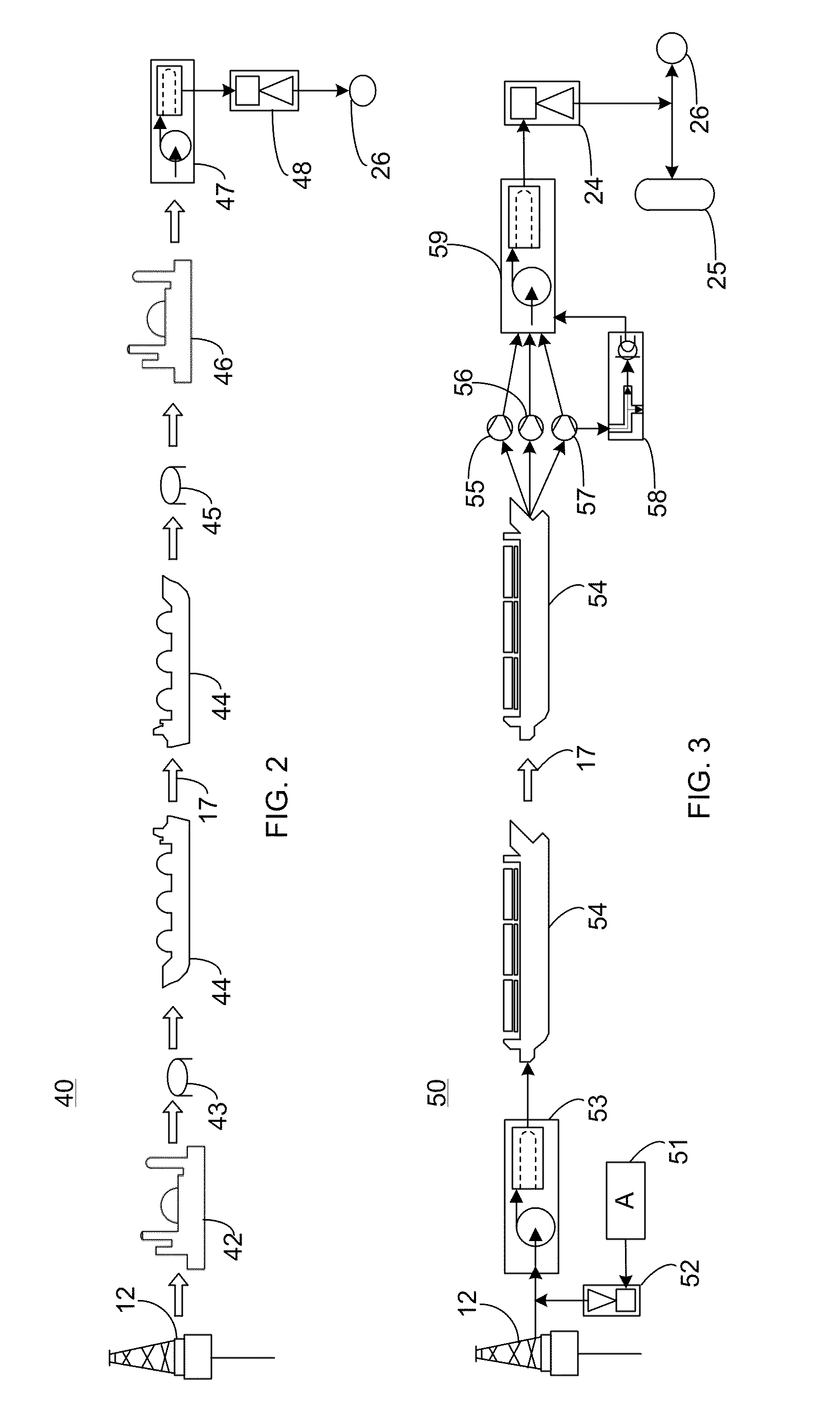

Comprehensive system for the storage and transportation of natural gas in a light hydrocarbon liquid medium

ActiveUS20100000252A1Rapid economic developmentRaise the ratioSolidificationLiquefactionProcess systemsLiquid medium

This invention provides a means of loading, processing and conditioning raw production gas, production of CGL, storage, transport, and delivery of pipeline quality natural gas or fractionated products to market. The CGL transport vessel utilizes a pipe based containment system to hold more densely packed constituents of natural gas held within a light hydrocarbon solvent than it is possible to attain for natural gas alone under such conditions. The containment system is supported by process systems for loading and transporting the natural gas as a liquid and unloading the CGL from the containment system and then offloading it in the gaseous state. The system can also be utilized for the selective storage and transport of NGLs to provide a total service package for the movement of natural gas and associated gas production. The mode of storage is suited for both marine and land transportation and configured in modular form to suit a particular application and / or scale of operation.

Owner:SEAONE HLDG

Infrastructure-independent deepwater oil field development concept

A method for developing a sub-sea hydrocarbons field includes sub-sea wells, sub-sea oil / gas separation, storing the degassed oil in a storage tank located or the seabed, liquefying natural gas aboard a vessel using liquid nitrogen aboard the vessel to obtain liquefied natural gas, transporting the liquefied natural gas to an onshore terminal, re-gasifying the liquefied natural gas, and obtaining a new batch of liquid nitrogen using energy recovered from the re-gasifying the liquefied natural gas.

Owner:CONOCOPHILLIPS CO

Container crane, and method of determining and correcting a misalignment between a load-carrying frame and a transport vehicle

ActiveUS20050281644A1Large enough scanning areaEnough recording areaDigital data processing detailsArticle unpackingContainer craneEngineering

A container crane includes a movable trolley and a load-carrying frame pendantly connected to the trolley and comprised of a spreader and a head block, for transfer of a container from or to a transport vehicle. Plural optical detectors are mounted on the trolley for identifying longitudinal and transversal edges of the head block or spreader and the transport vehicle. Operatively connected to the detectors is a processing device for determining a spatial position of the edges and calculating a position of longitudinal and transversal center lines of the head block or spreader and the transport vehicle and their spatial positions in relation to one another. In this way a possible offset of the center lines of the head block or spreader with regard to those of the transport vehicle in longitudinal and transversal directions as well as a rotation angle of the center lines can be determined, whereby a detected offset or rotation angle is compensated by displacing the spreader relative to the head block.

Owner:SIEMENS AG

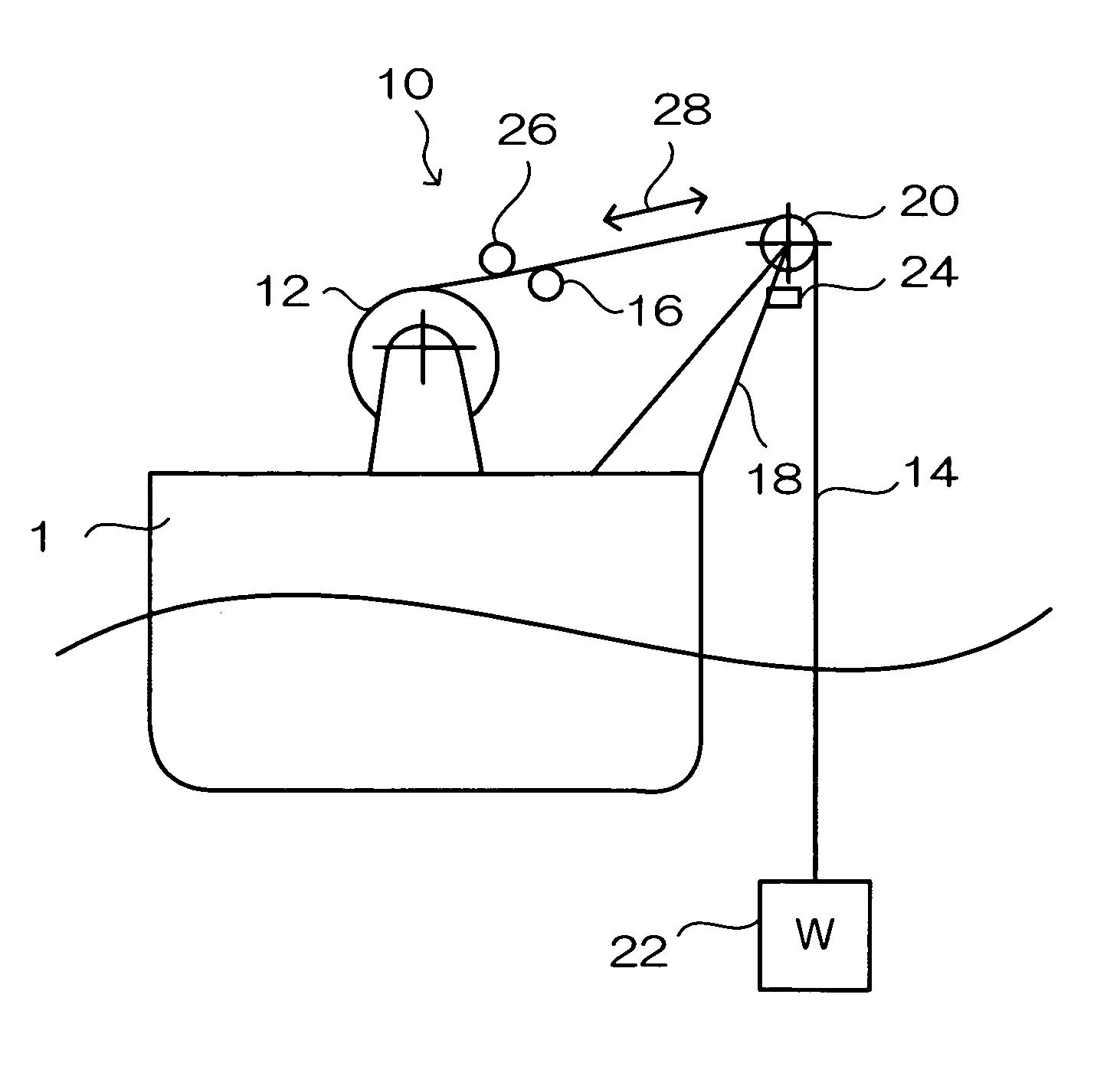

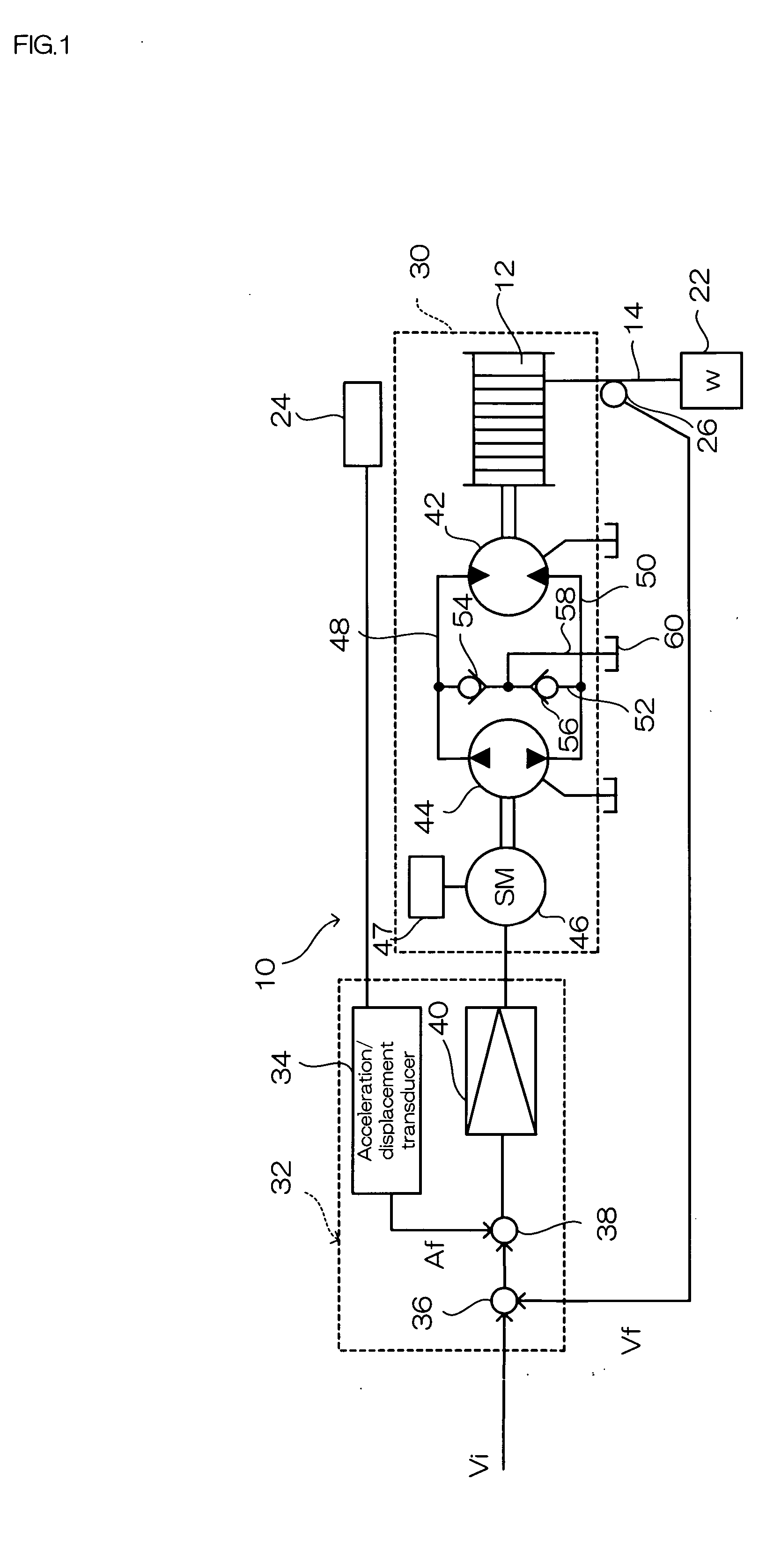

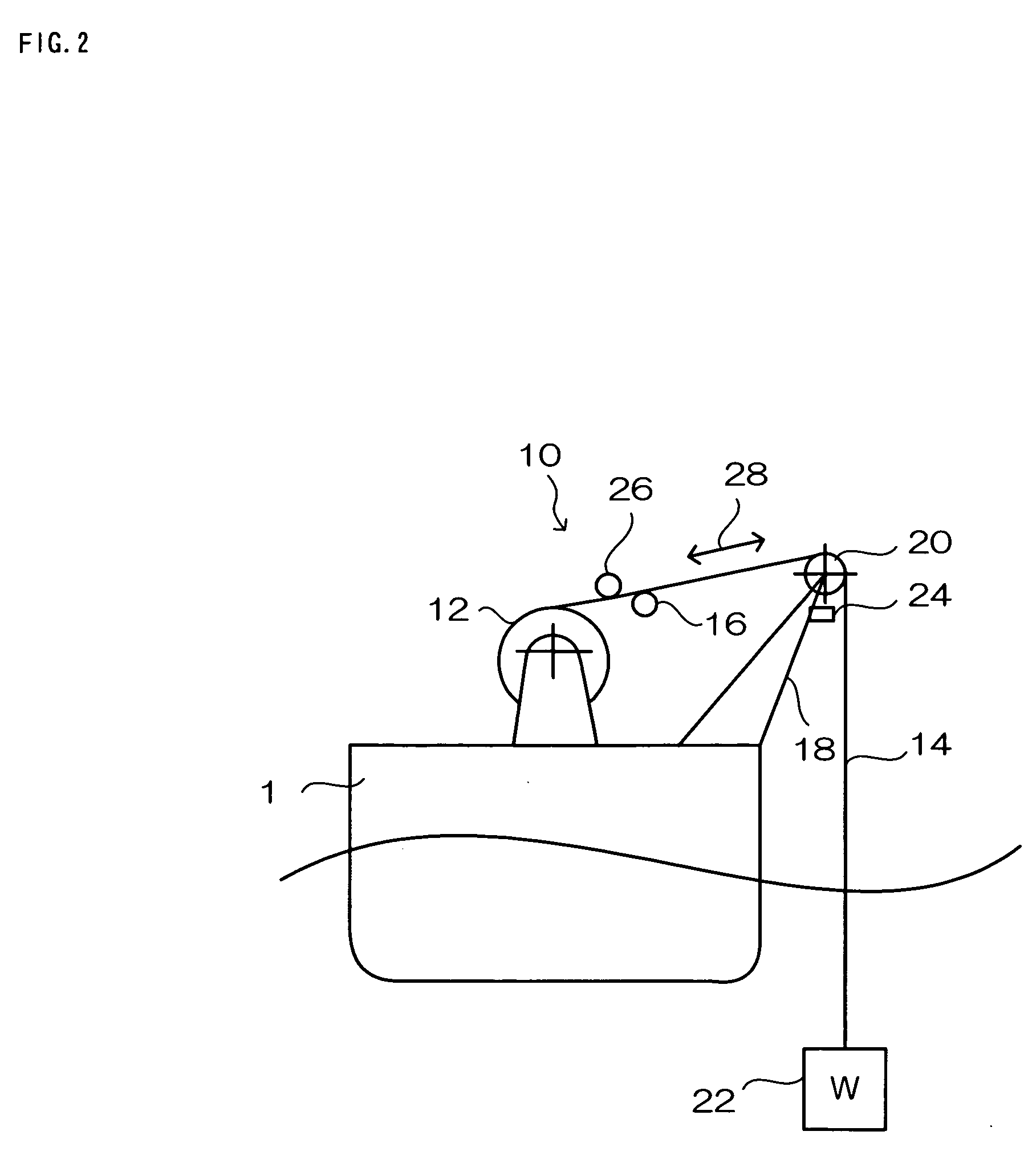

Hoisting device with vertical motion compensation function

InactiveUS20050242332A1High precisionConsumption energy can be savedCargo handling apparatusServomotorsControl signalTransducer

A hoisting device can be small-sized and energy can be saved. A hoisting device 10 according to the present invention has a hoist 30 and a control unit 32. The hoist 30 rotates a drum 12 having a wire 14 wound thereon by an oil pressure motor 42 rotatable in normal and reverse directions. To the oil pressure motor 42, operating oil is supplied from an oil pressure pump 44. The oil pressure pump 44 is a two-way discharge fixed capacity type, and rotated by a servomotor 46. An acceleration / displacement transducer 34 in the control unit 32 finds a moving direction and a moving speed of a wire hanging point in the vertical direction from an output signal of an acceleration sensor 24. The control unit 32 outputs a drive control signal of the servomotor 46 according to a paying-out speed or a rolling-up speed of the wire 14 offsetting the vertical motion of the wire hanging point caused by the heaving of a hull based on a speed instruction Vi of the paying-out or rolling-up speed of the wire, a detected signal of the acceleration sensor 24 and a detected signal of a wire speed sensor 26.

Owner:MITSUI ENG & SHIPBUILD CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com