Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13674results about "Servomotors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

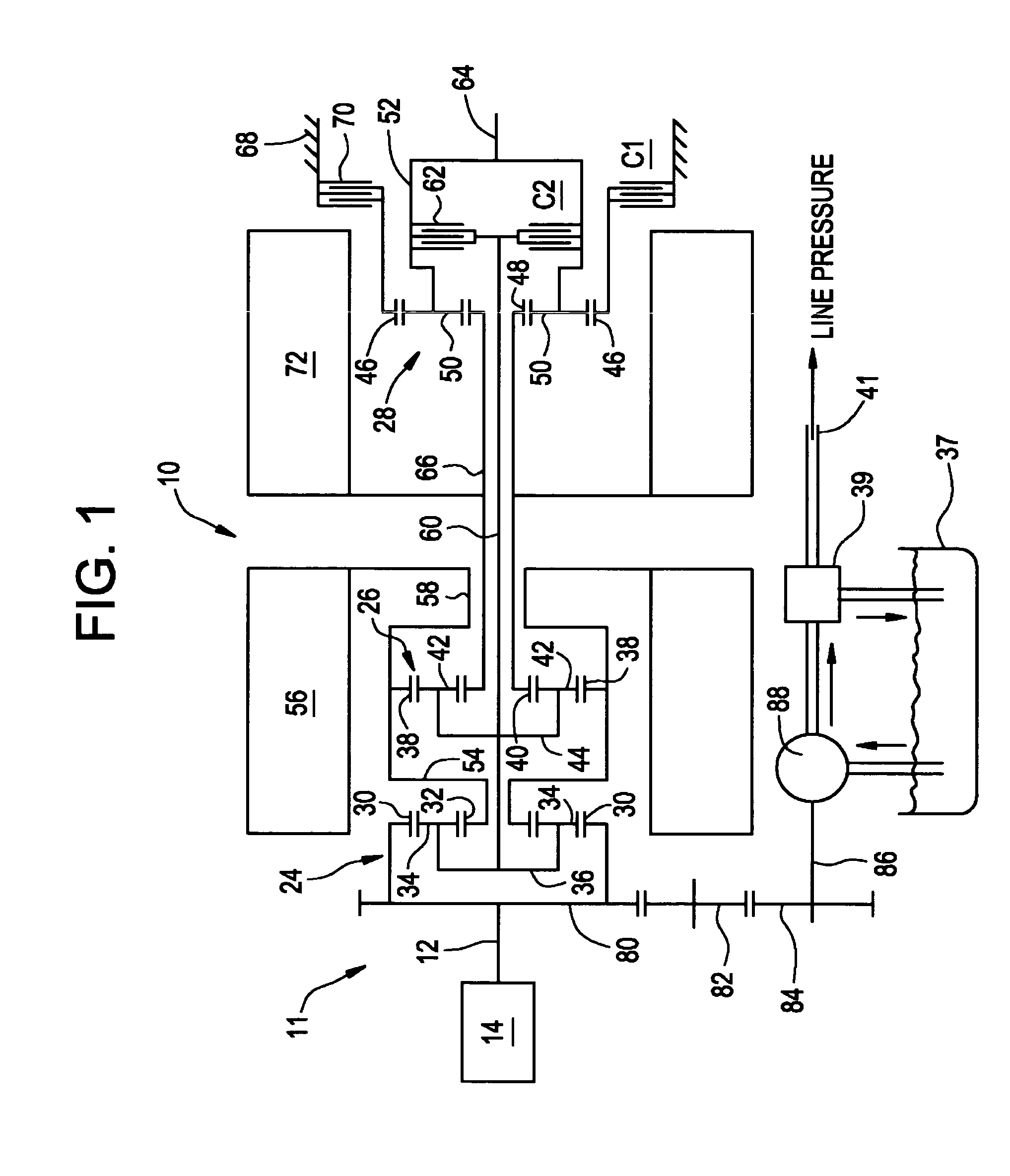

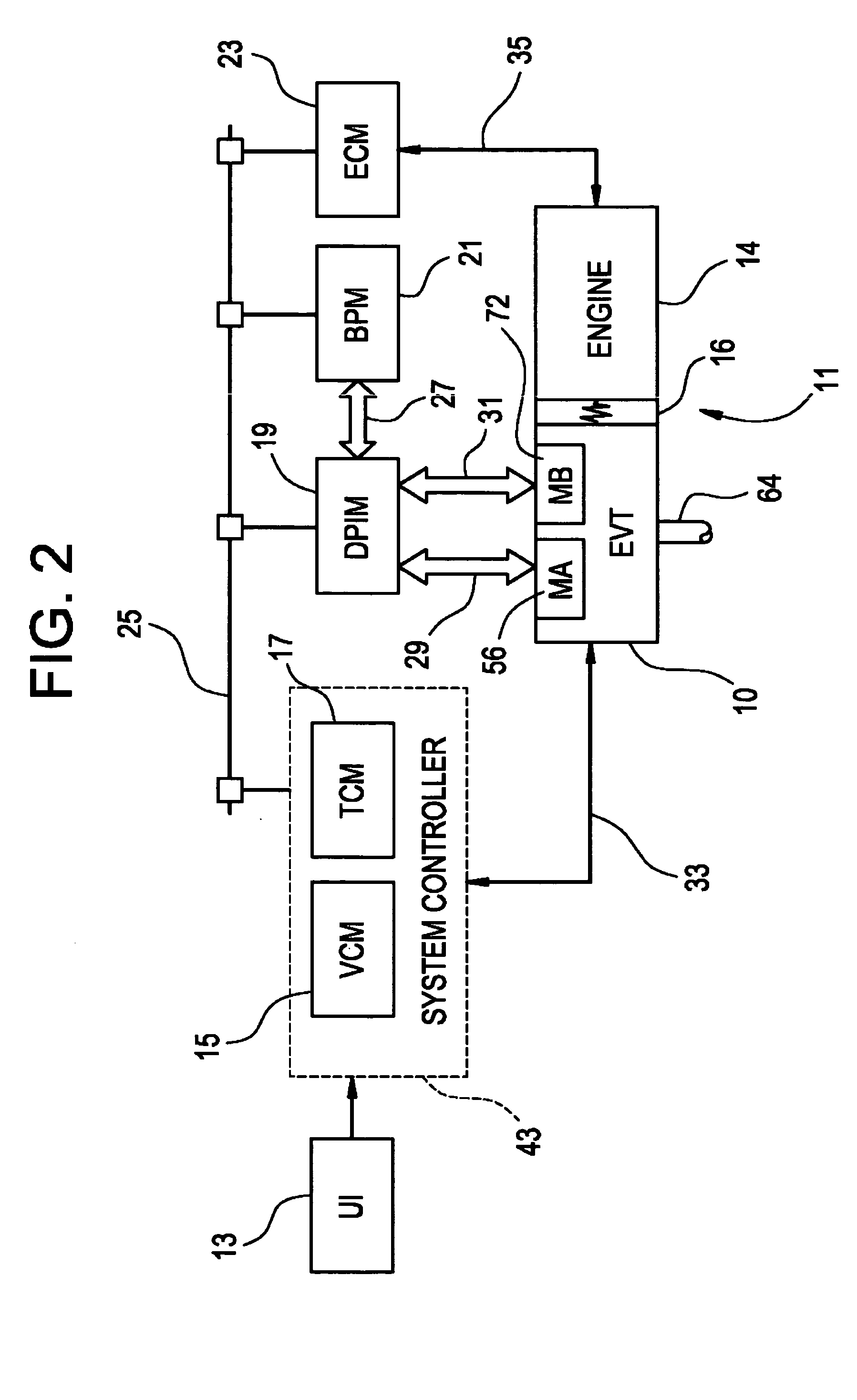

Control apparatus, method and diagnostic for hydraulic fill and drain

ActiveUS20050076958A1Improve robustnessHybrid vehiclesFluid-pressure actuator safetyControl theoryControl equipment

Hydraulic fill and drain of a clutch chamber is controlled with a blocking valve and a trim valve. The blocking valve selectively provides pressurized fluid to the trim valve which in turn selectively provides the pressurized fluid to the clutch chamber. Exhausting of the clutch chamber is effected through one of two alternate paths utilizing deactivation of one of the trim and blocking valves. Back up exhausting of the clutch chamber is effected through the other of the alternative paths. Such system allows for determination of valve failures and continued operation until such failures can be rectified.

Owner:ALLISON TRANSMISSION INC

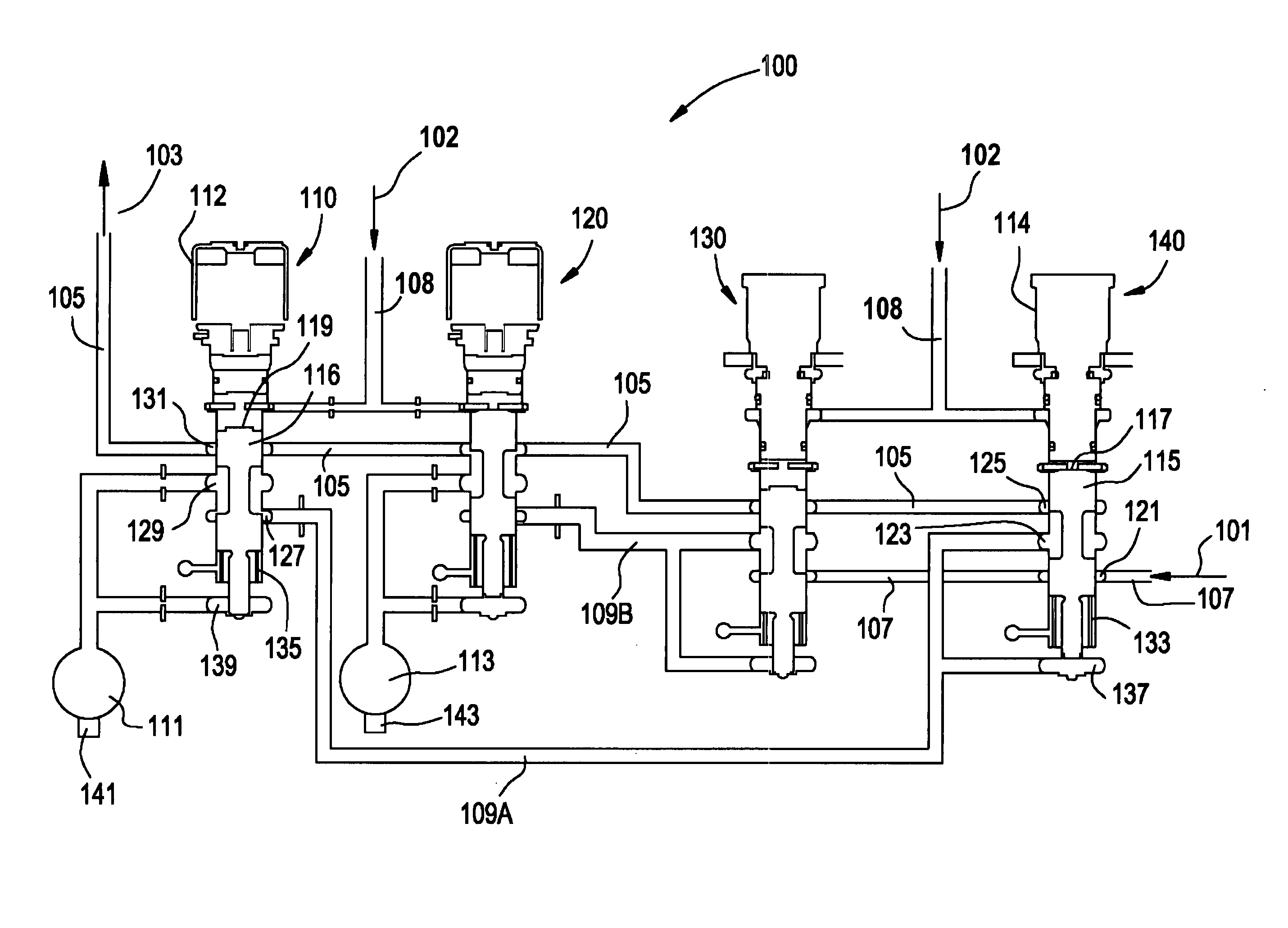

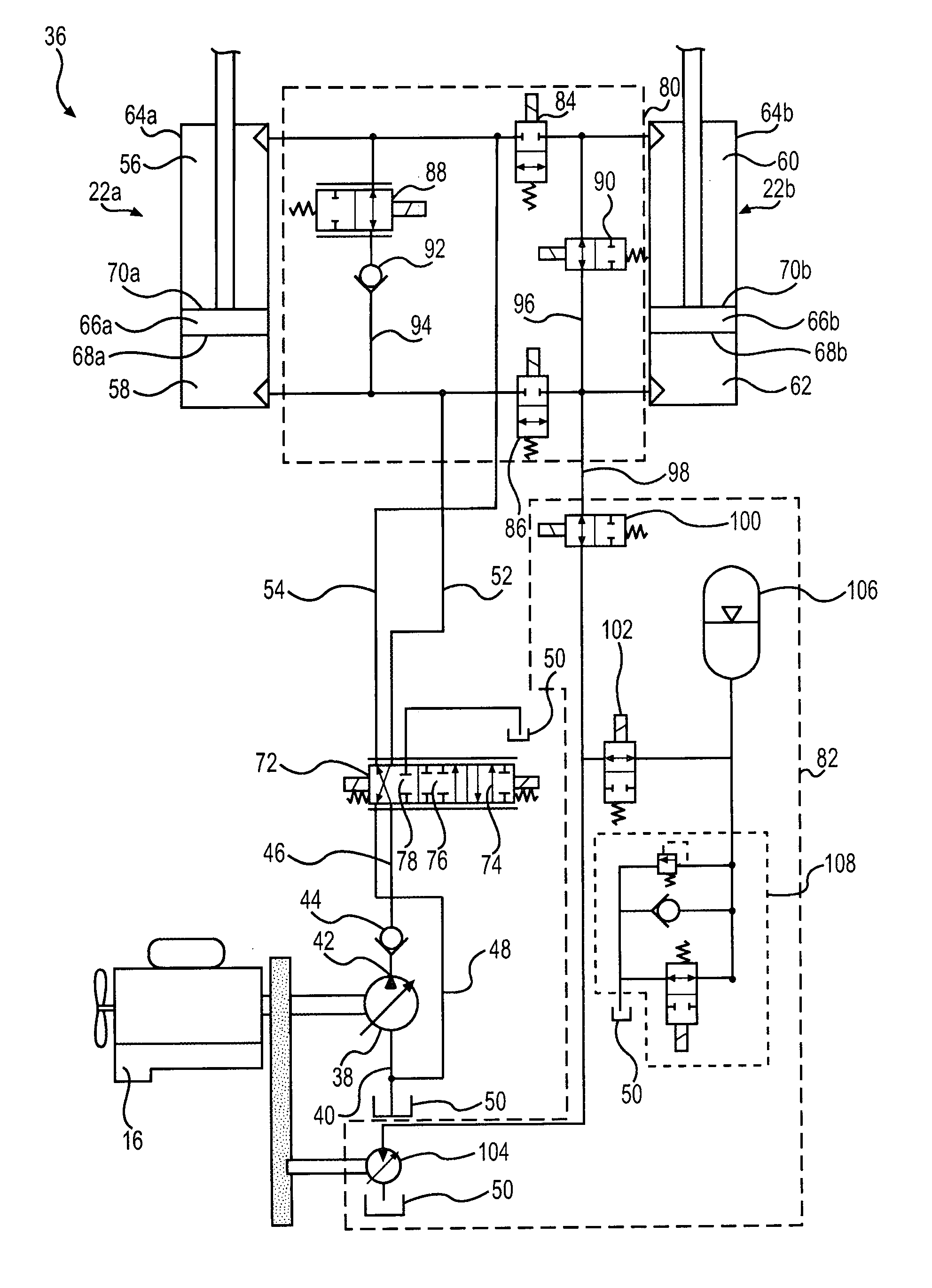

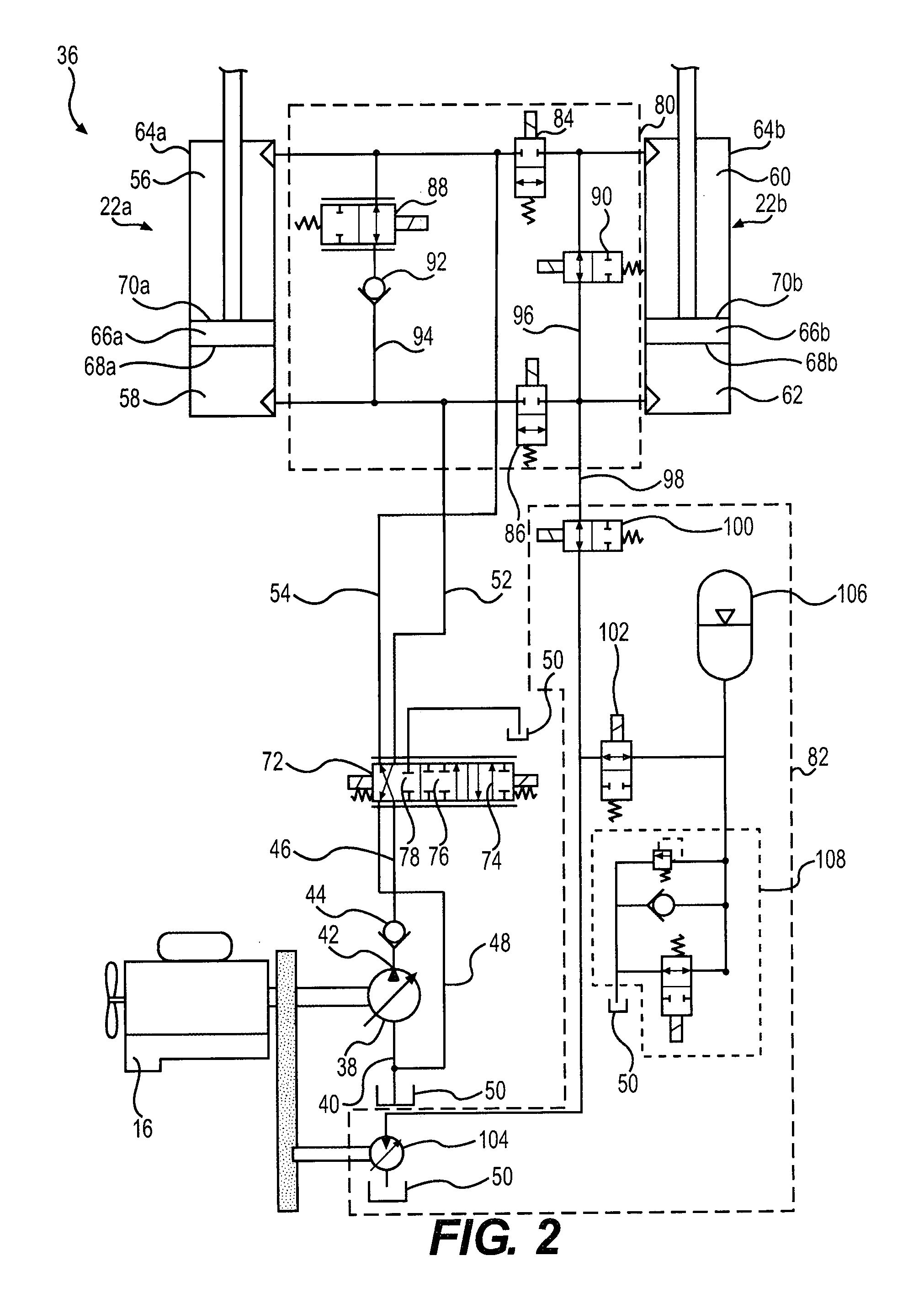

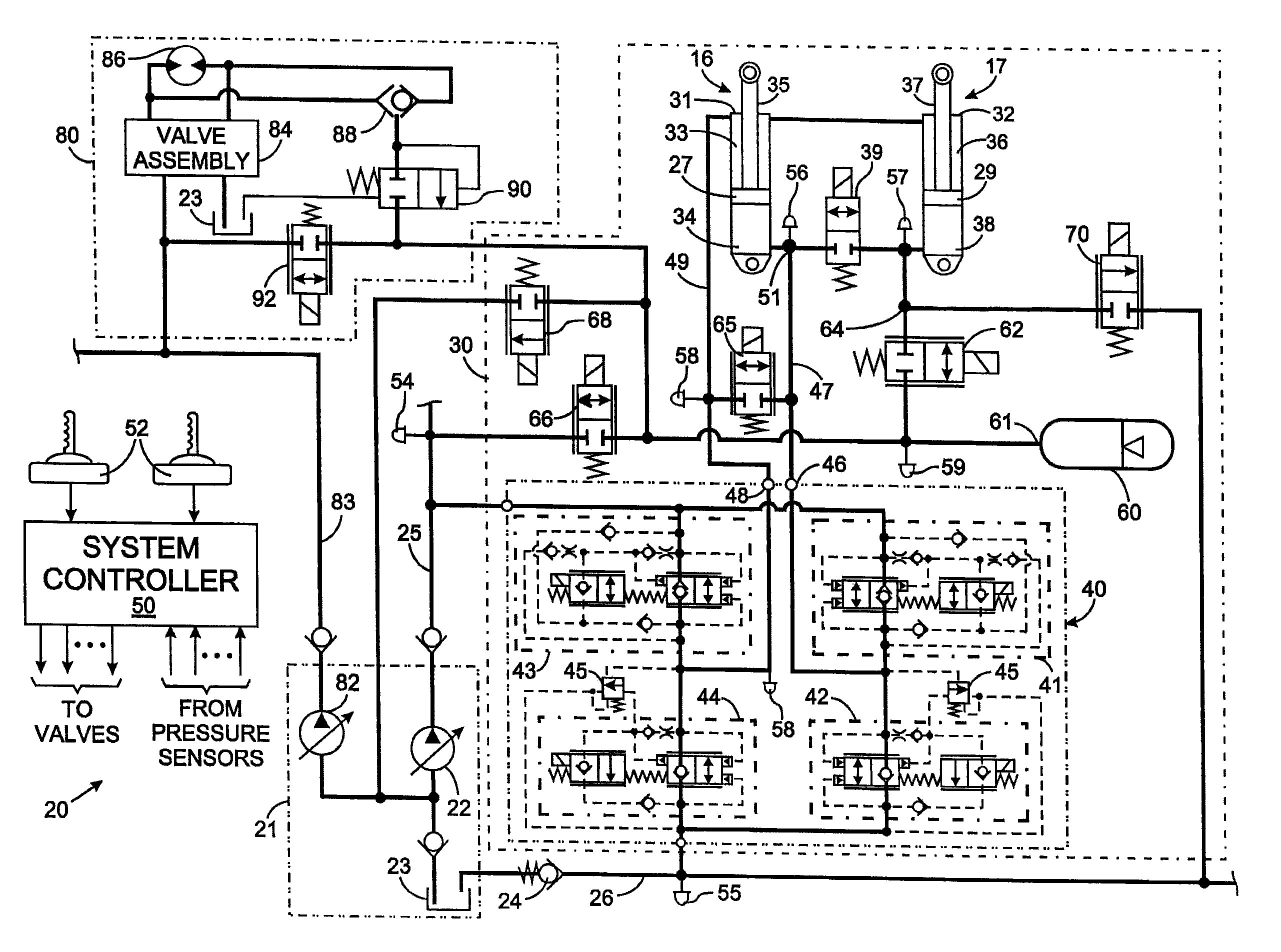

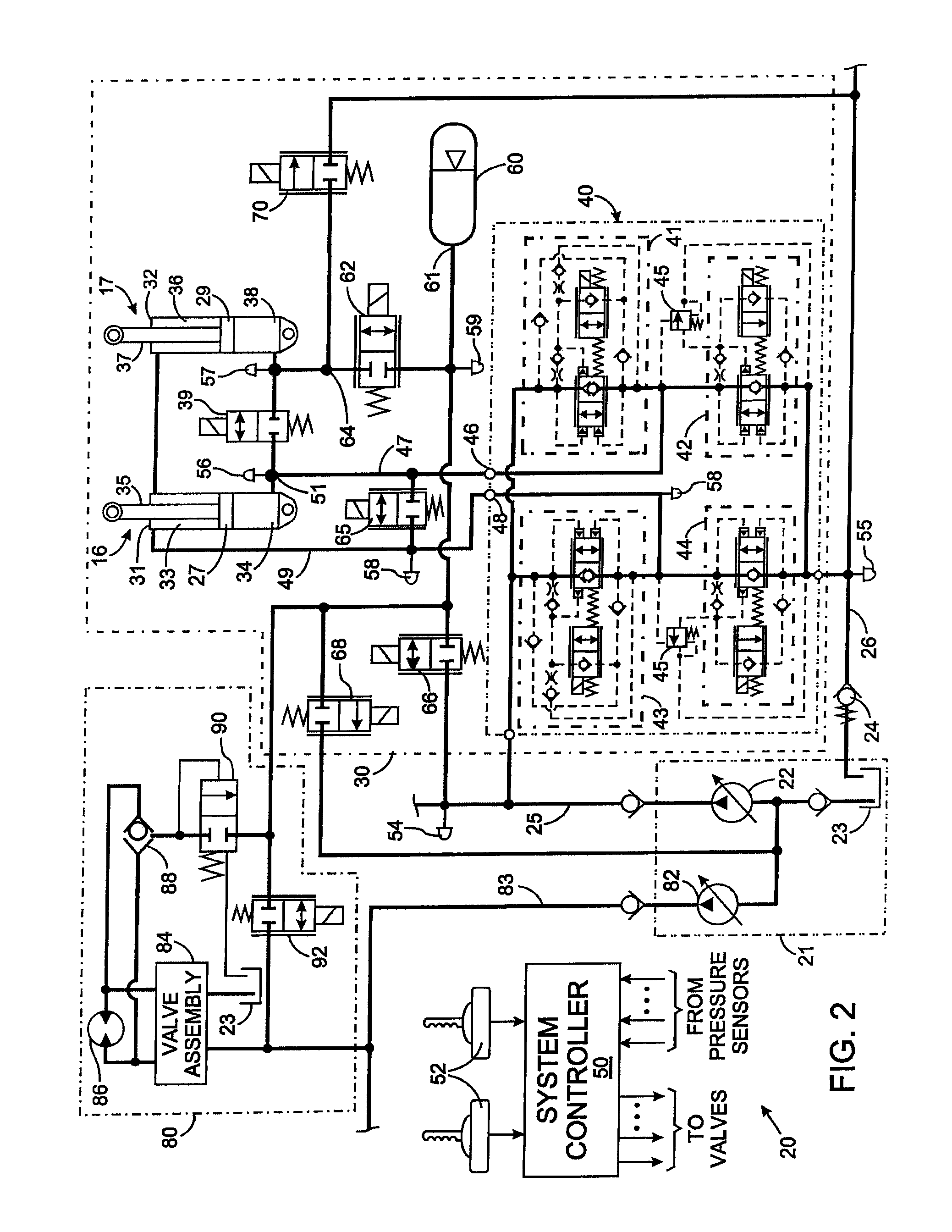

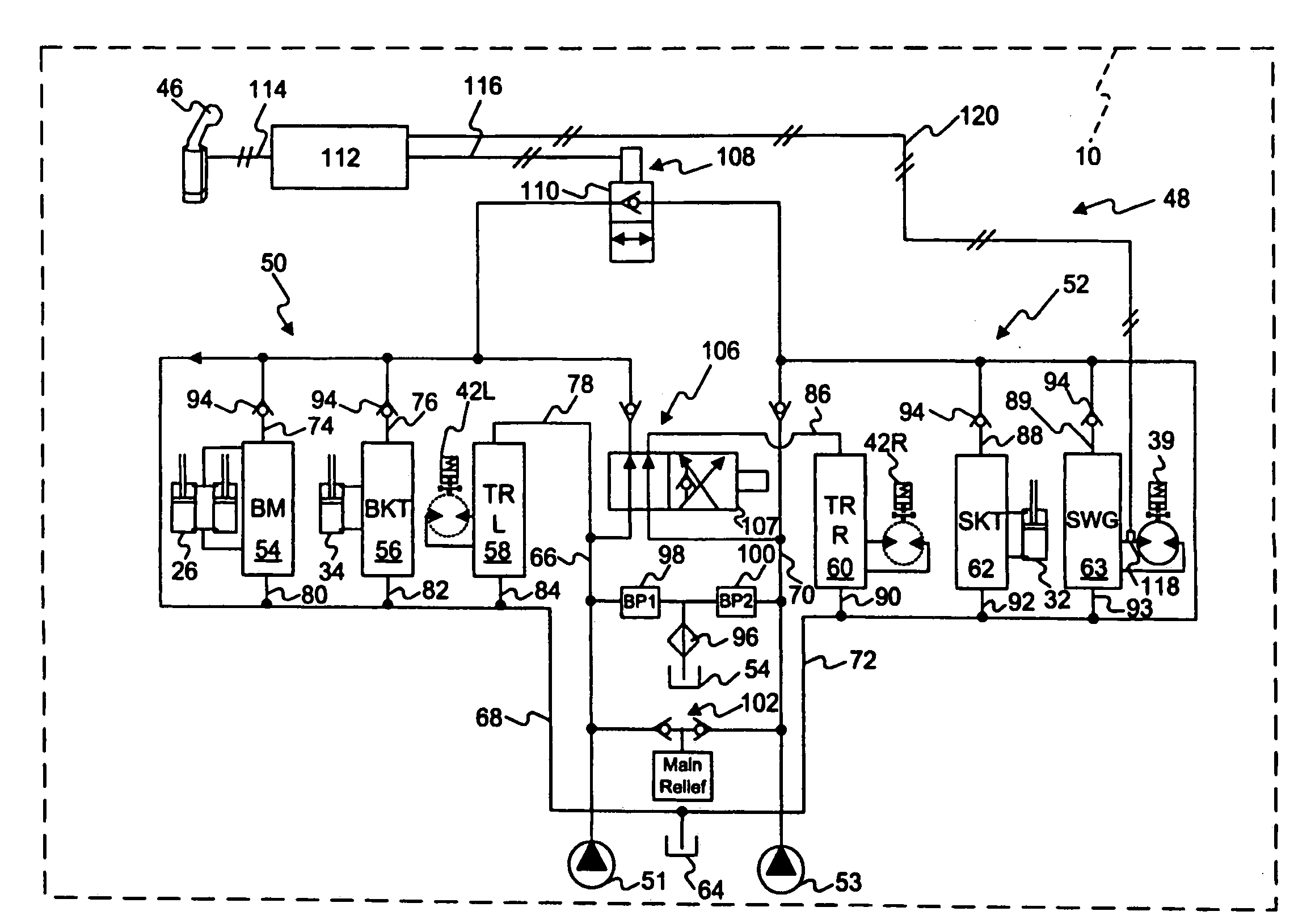

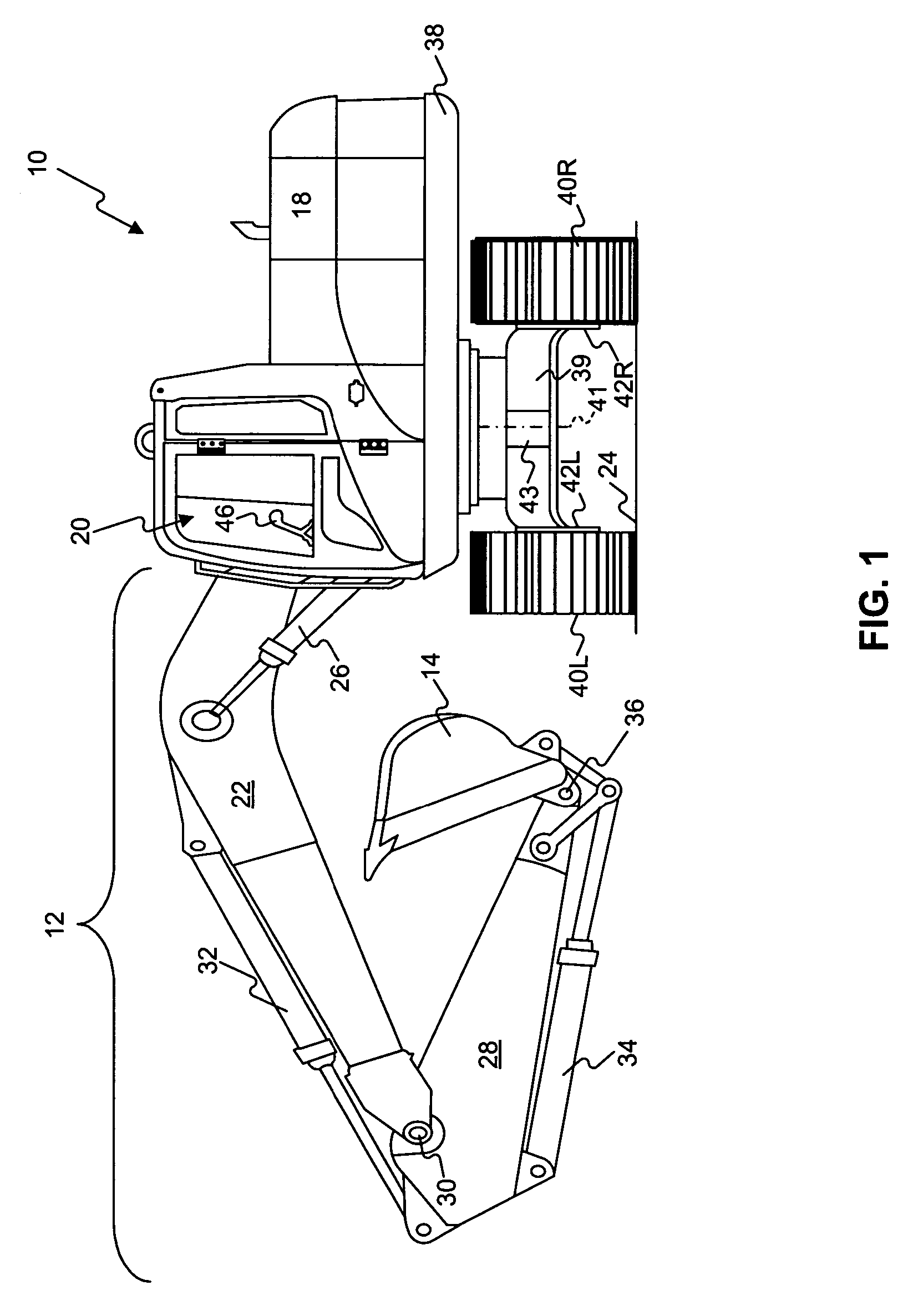

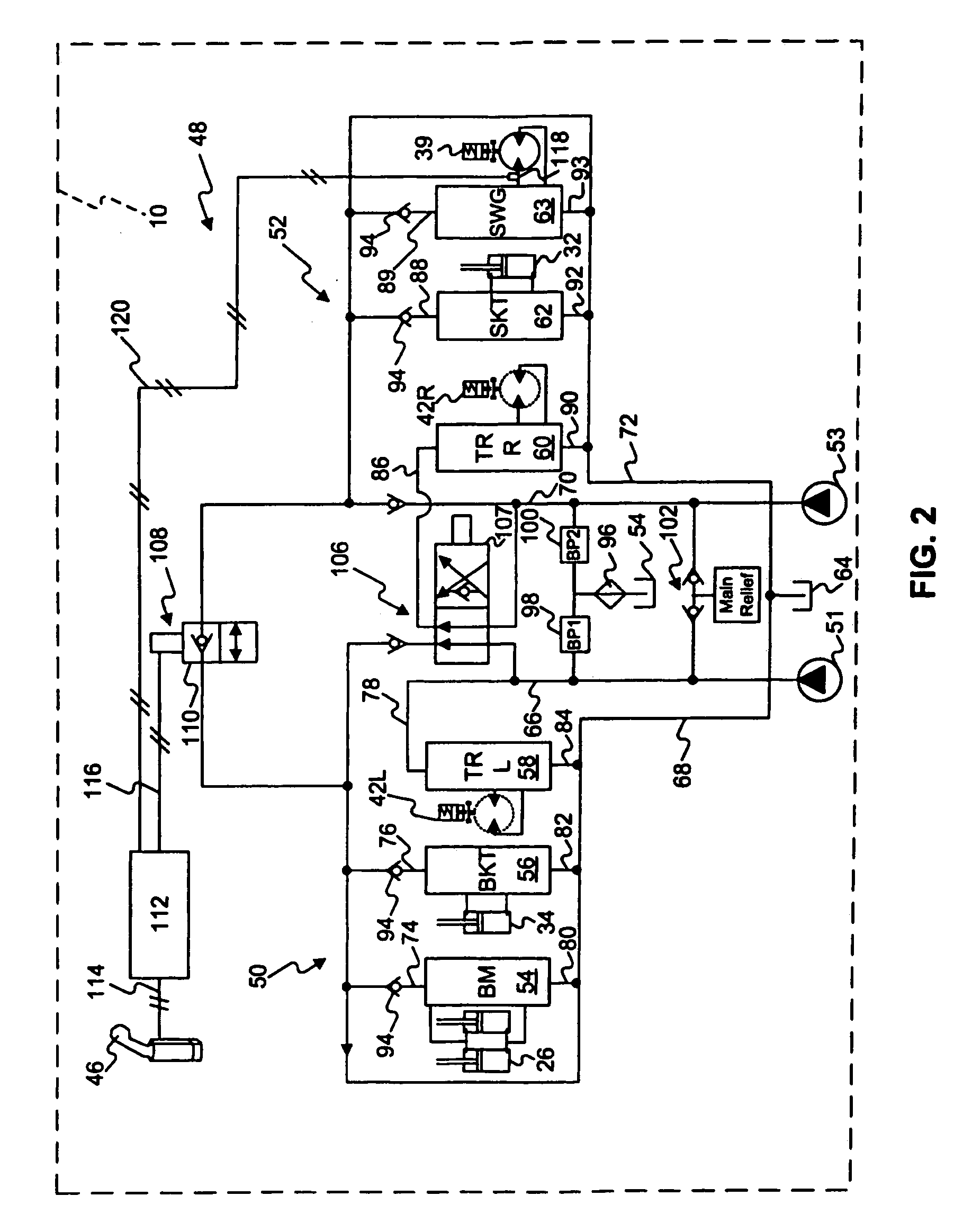

Hydraulic circuit with a return line metering valve and method of operation

A hydraulic system controls the flow of fluid to and from several functions on a machine. Each function has a valve assembly through which fluid is supplied under pressure from a source to an actuator and through which fluid returns from the actuator to a shared return line connected by a return line metering valve to the system tank. There are several regeneration modes of operation in which fluid exhausted from one port is supplied into the other port of the same actuator, which eliminates or reduces the amount of hydraulic fluid that must be supplied from the source. In some regeneration modes, input fluid for an actuator is obtained from another hydraulic function via the shared return line. In these regeneration modes an electronic controller operates the return line metering valve to restrict fluid from flowing into the tank from the shared return line, so that the fluid will be available to be supplied into an actuator port.

Owner:HUSCO INT INC

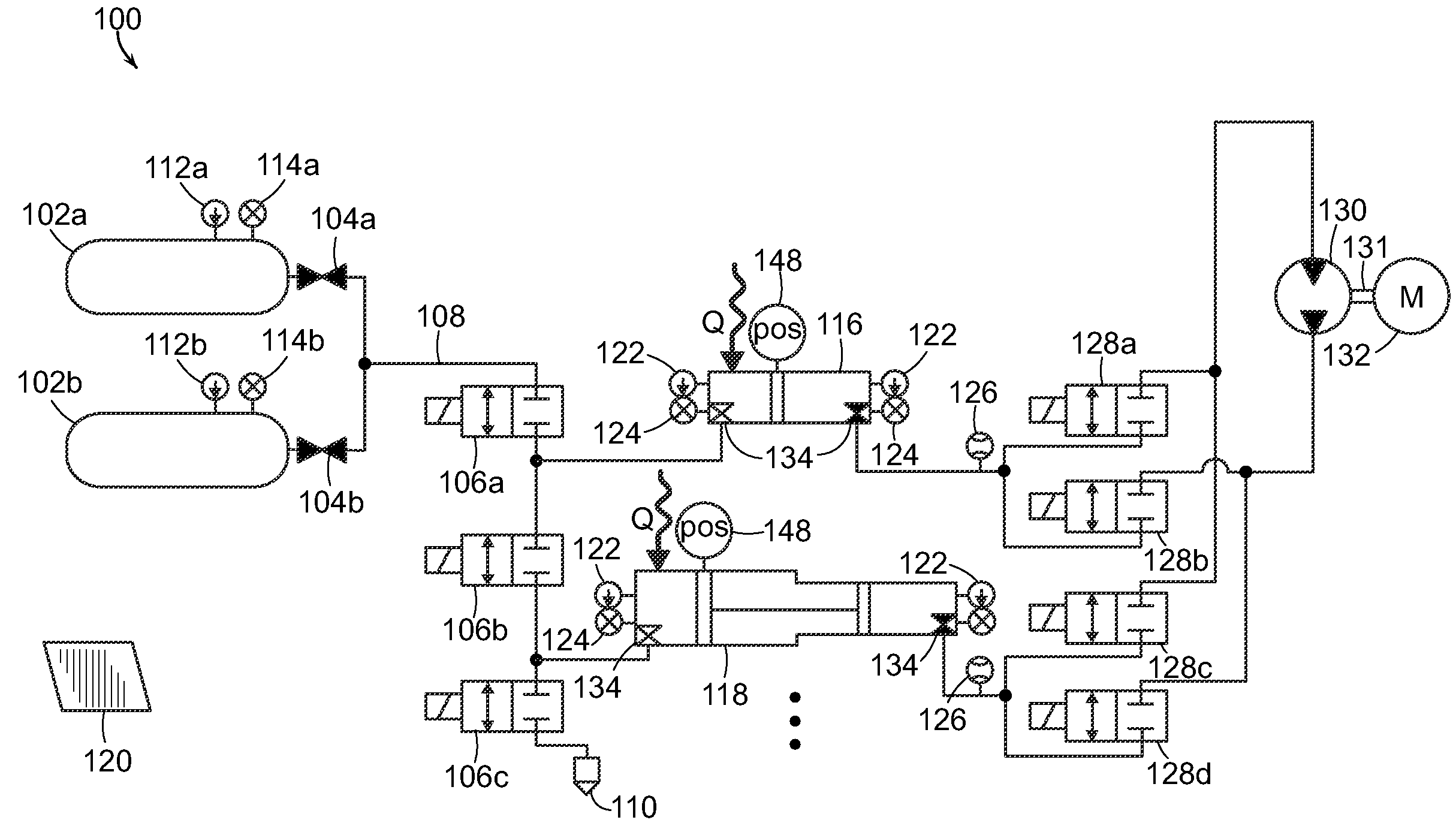

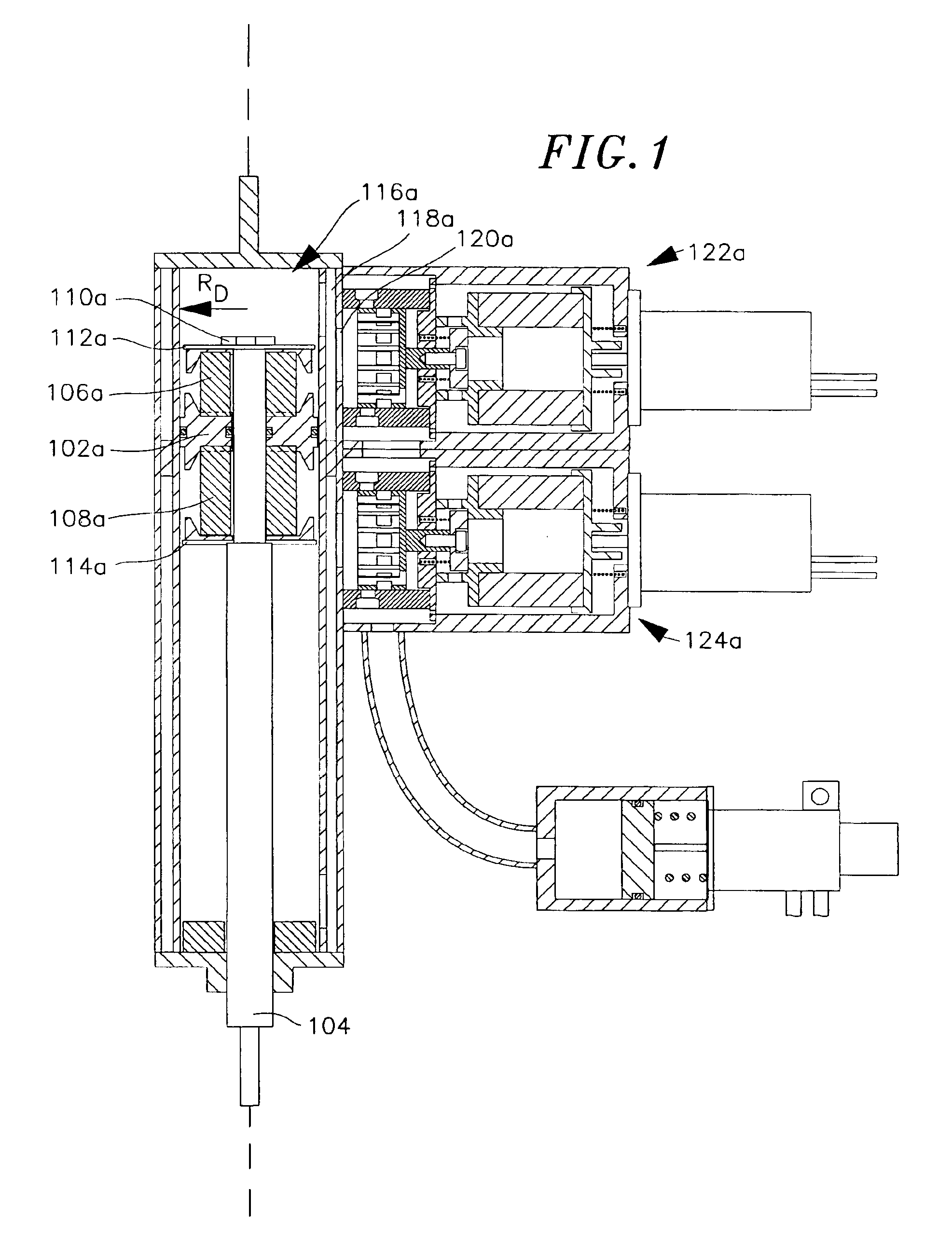

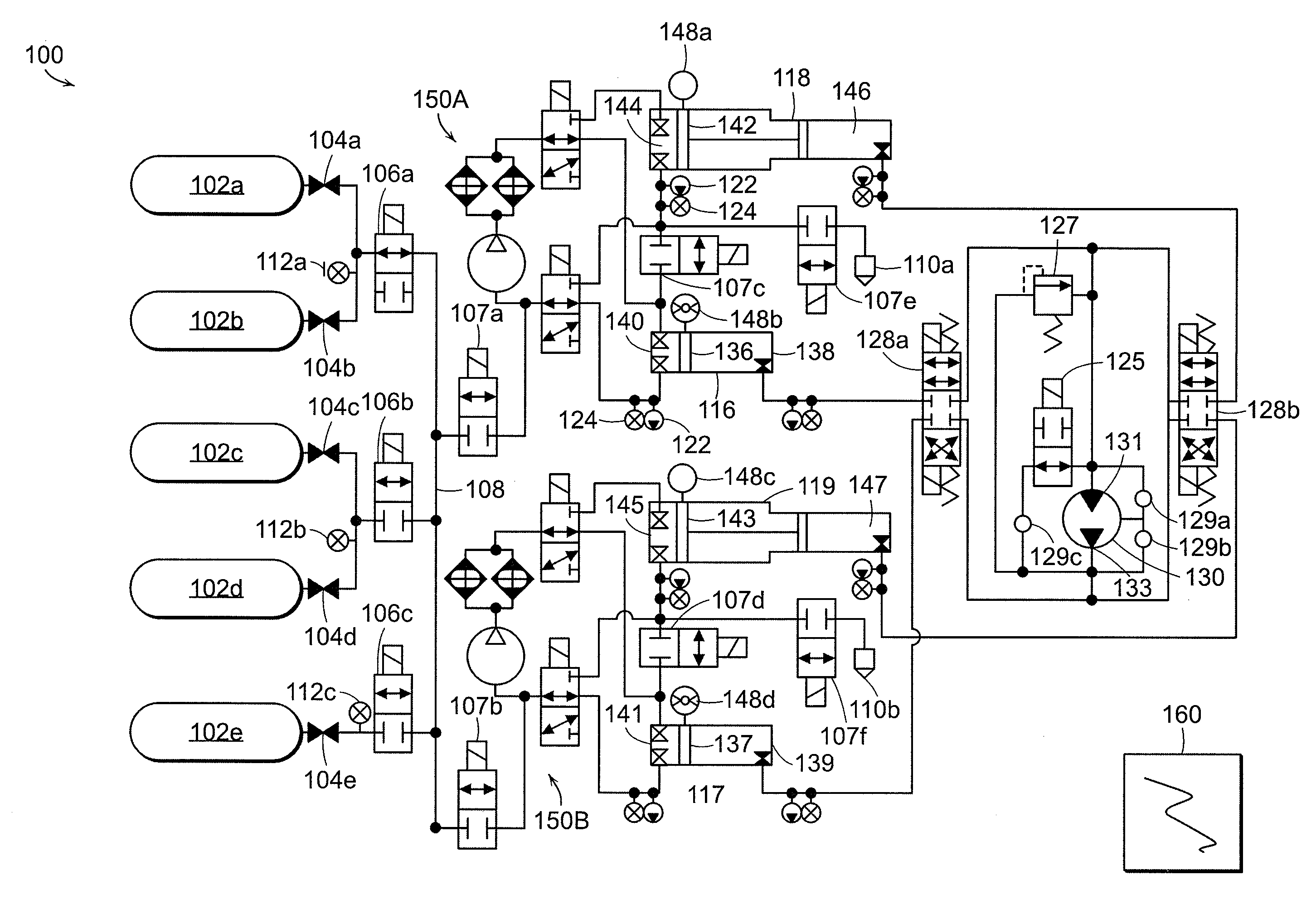

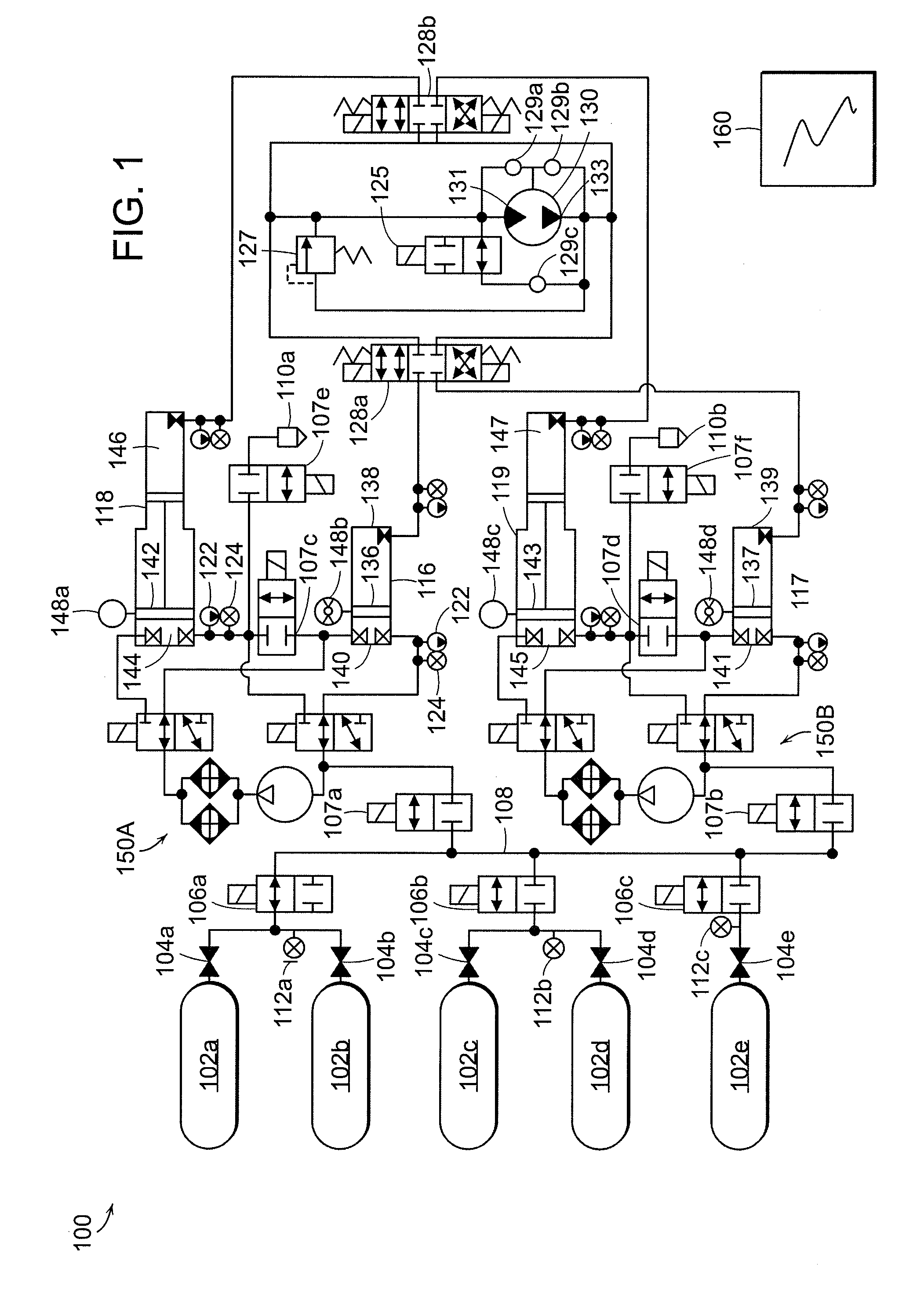

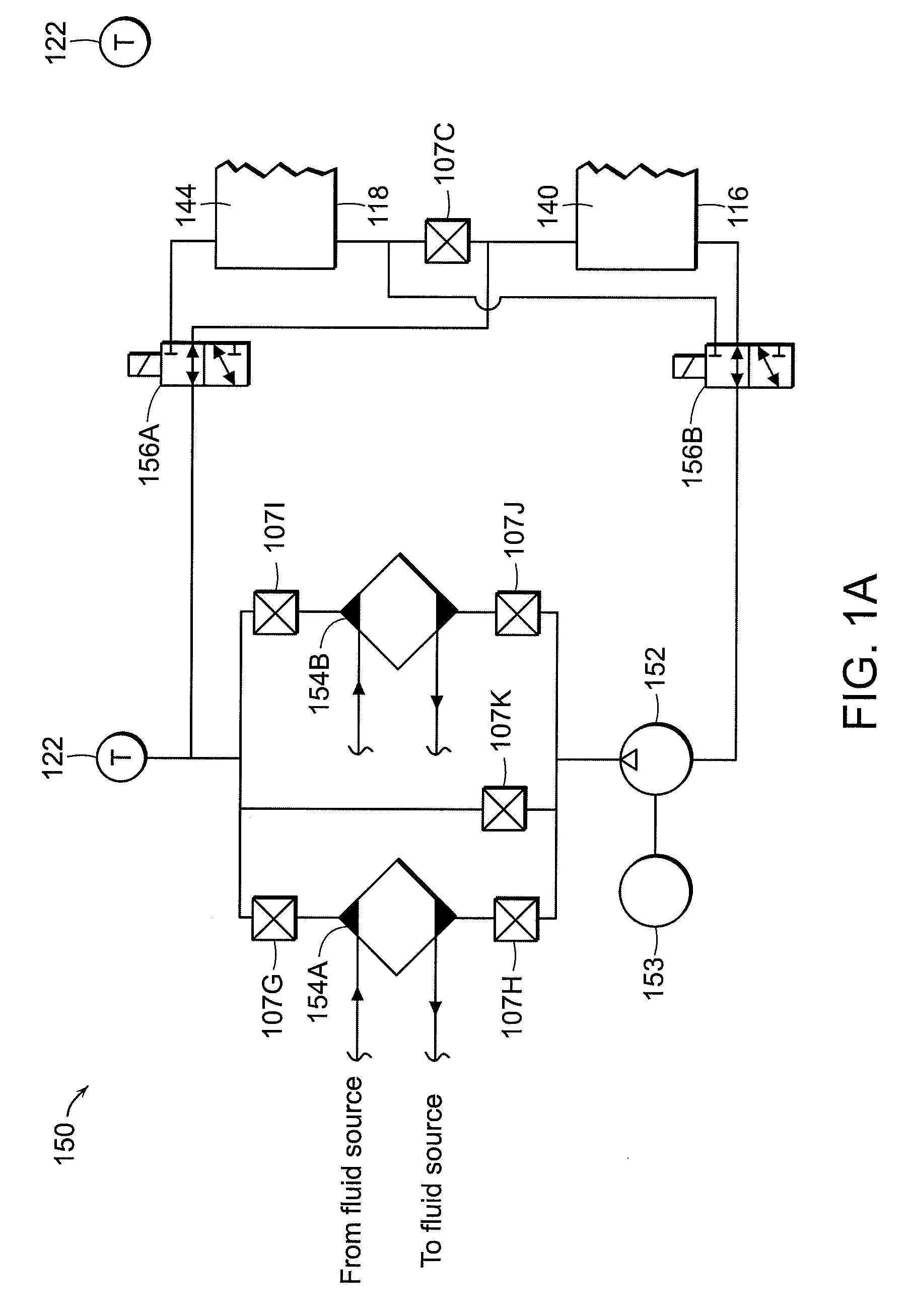

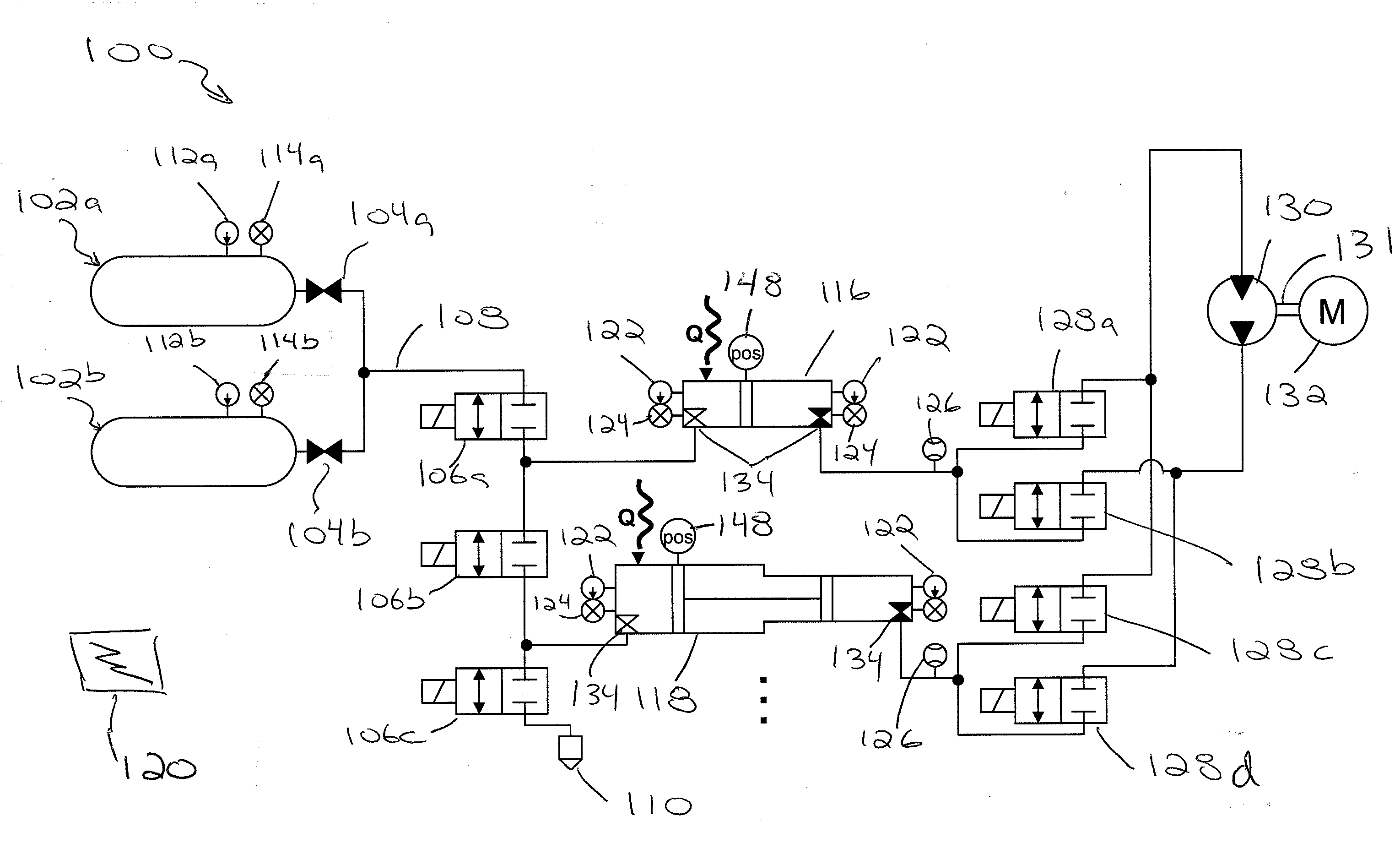

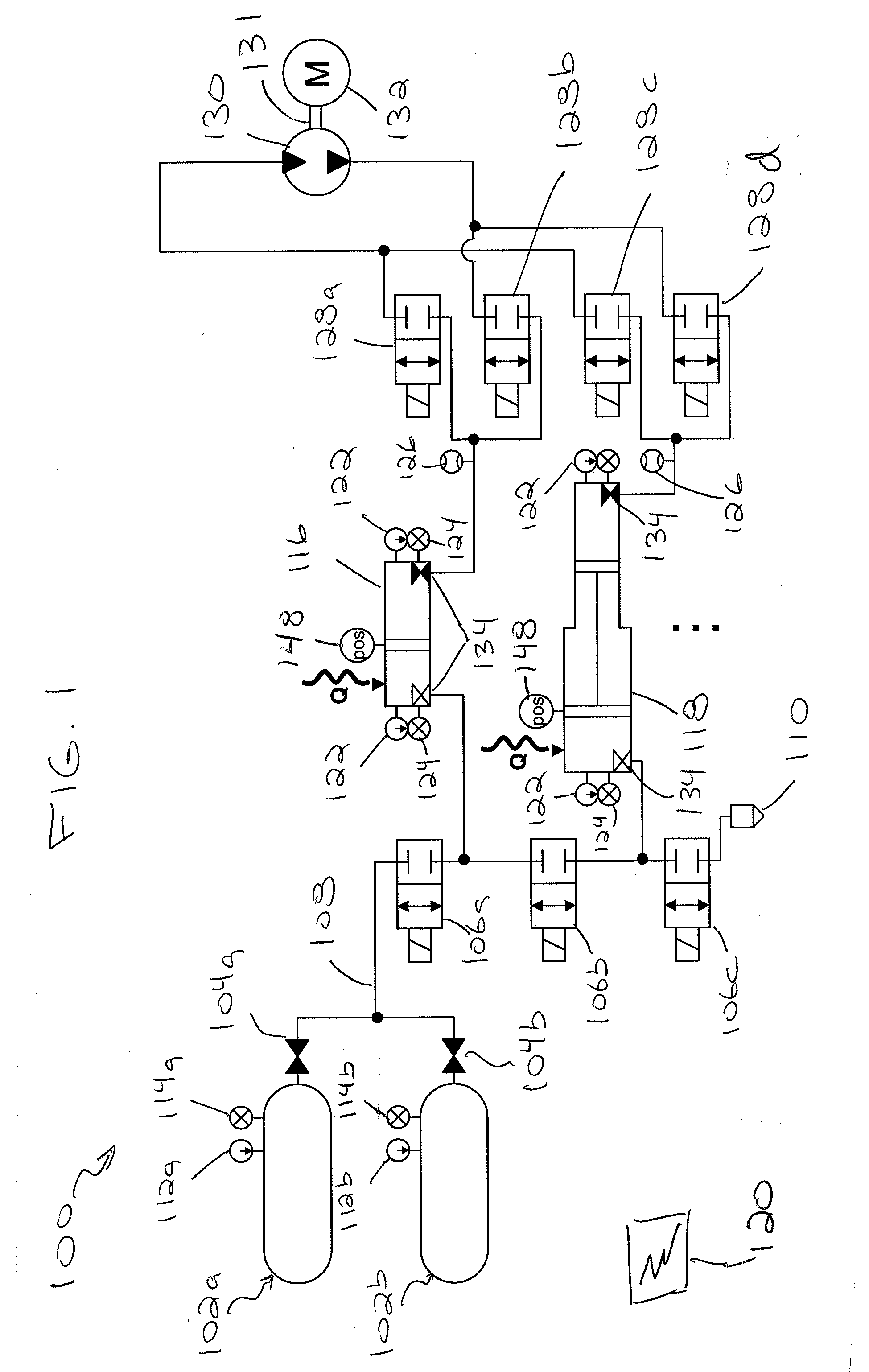

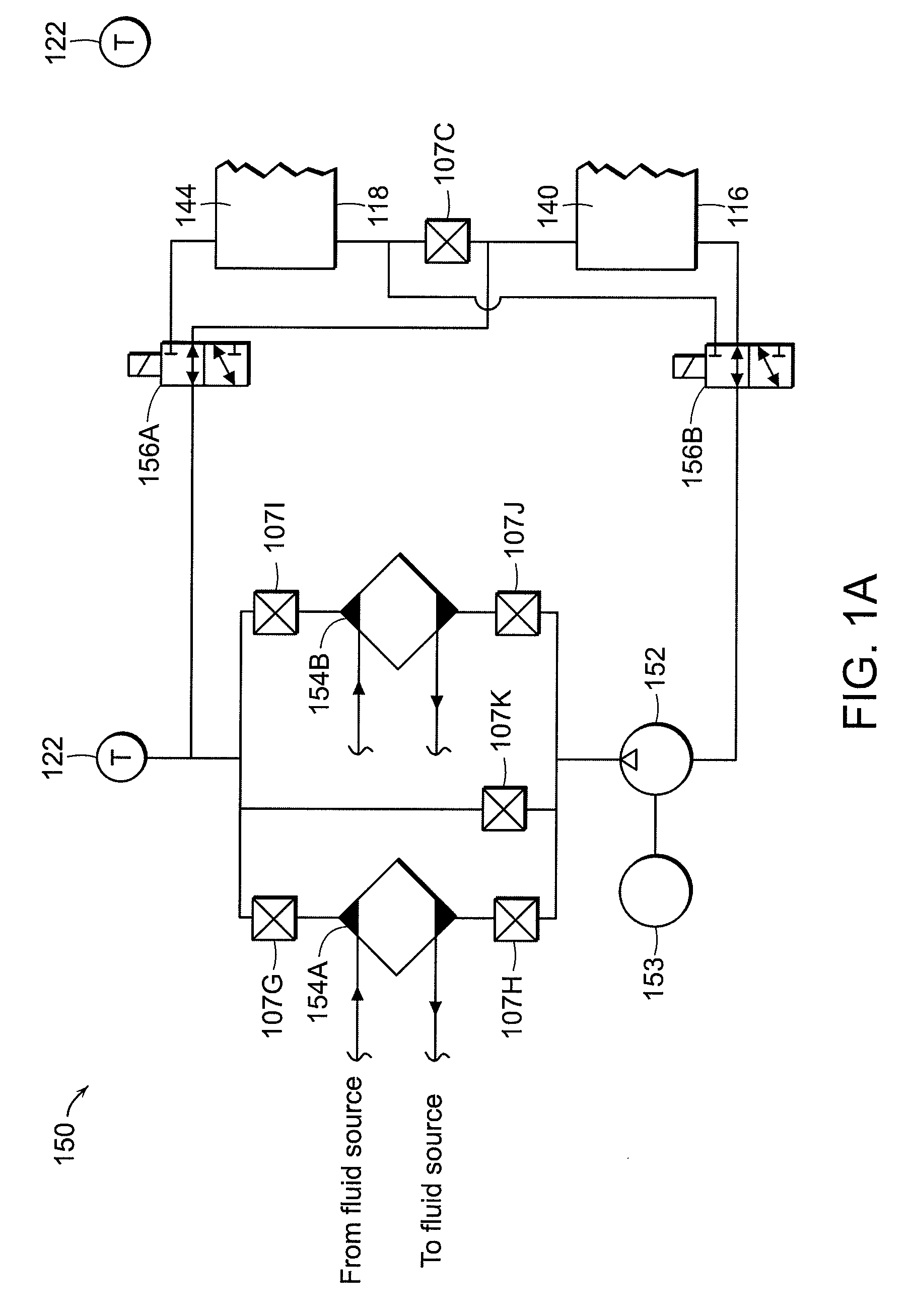

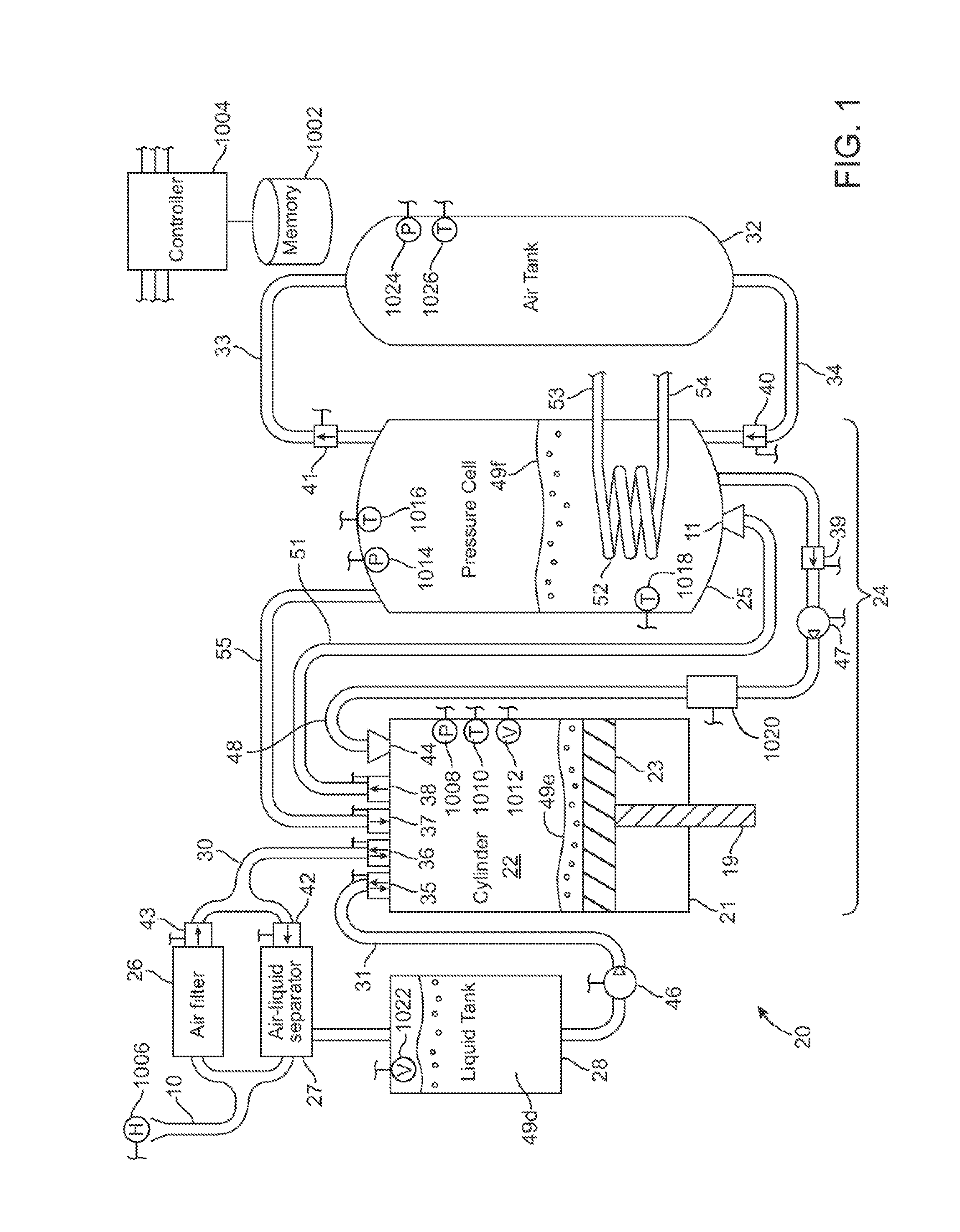

Systems and methods for energy storage and recovery using compressed gas

InactiveUS7832207B2Increase energy densityExpand/compress the gas more evenlyFluid couplingsAccumulator installationsEngineeringHigh pressure

The invention relates to methods and systems for the storage and recovery of energy using open-air hydraulic-pneumatic accumulator and intensifier arrangements that combine at least one accumulator and at least one intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits.

Owner:SUSTAINX

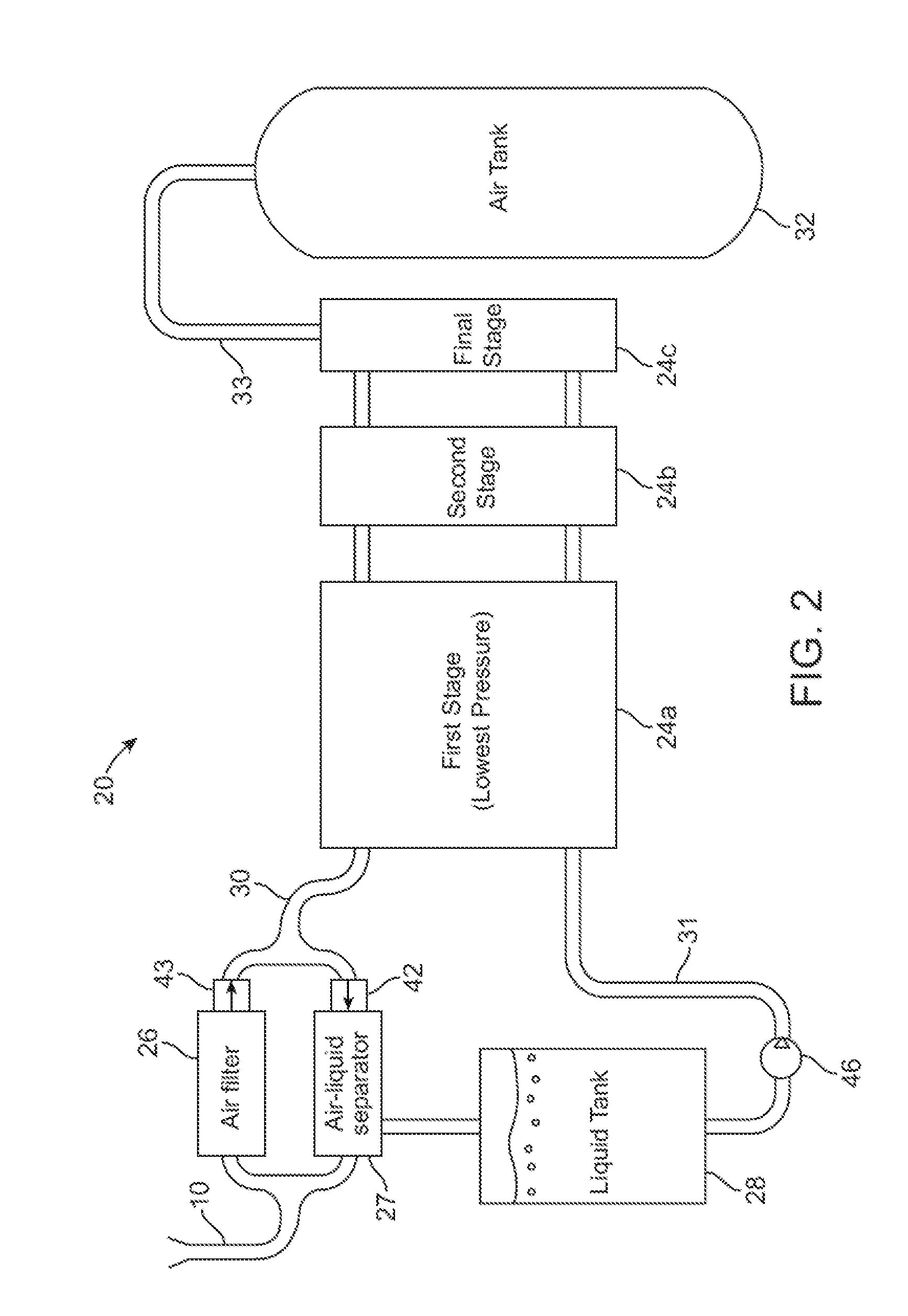

Systems and Methods for Energy Storage and Recovery Using Rapid Isothermal Gas Expansion and Compression

InactiveUS20100089063A1Increase energy densityHigh outputElectrical storage systemInternal combustion piston enginesProduct gasEngineering

The invention relates to systems and methods for rapidly and isothermally expanding and compressing gas in energy storage and recovery systems that use open-air hydraulic-pneumatic cylinder assemblies, such as an accumulator and an intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits. The systems use heat transfer subsystems in communication with at least one of the cylinder assemblies or reservoir to thermally condition the gas being expanded or compressed.

Owner:SUSTAINX

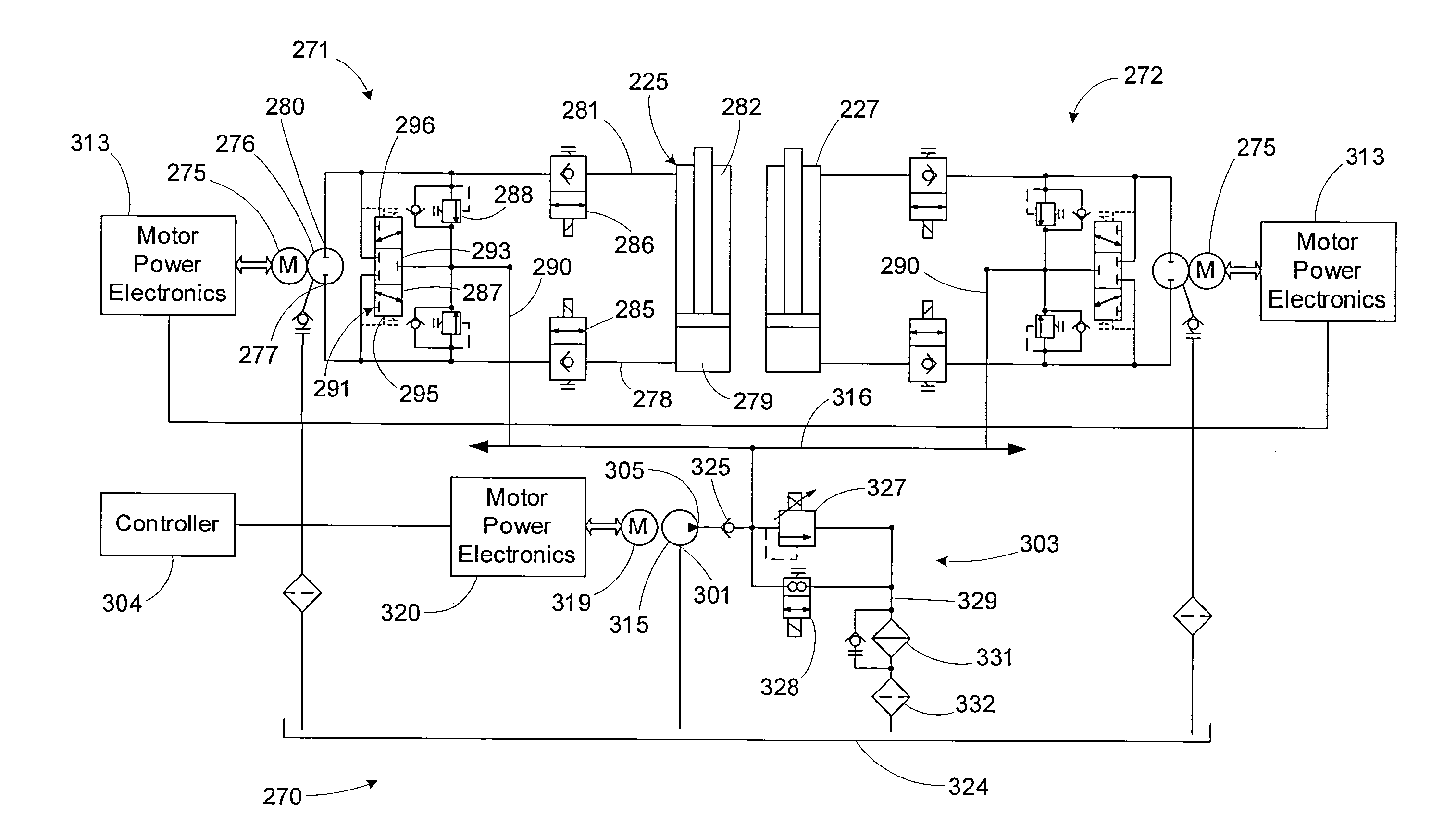

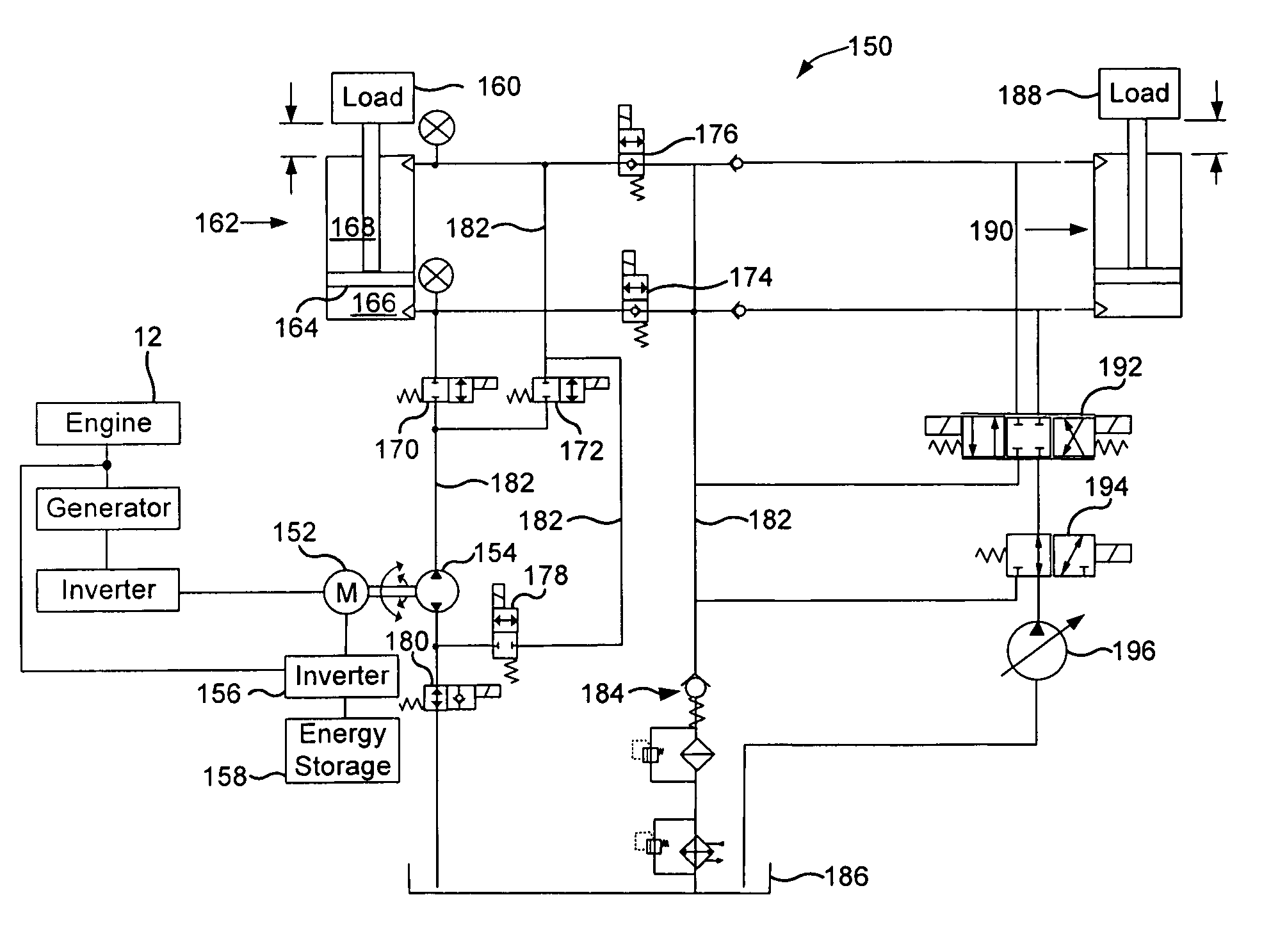

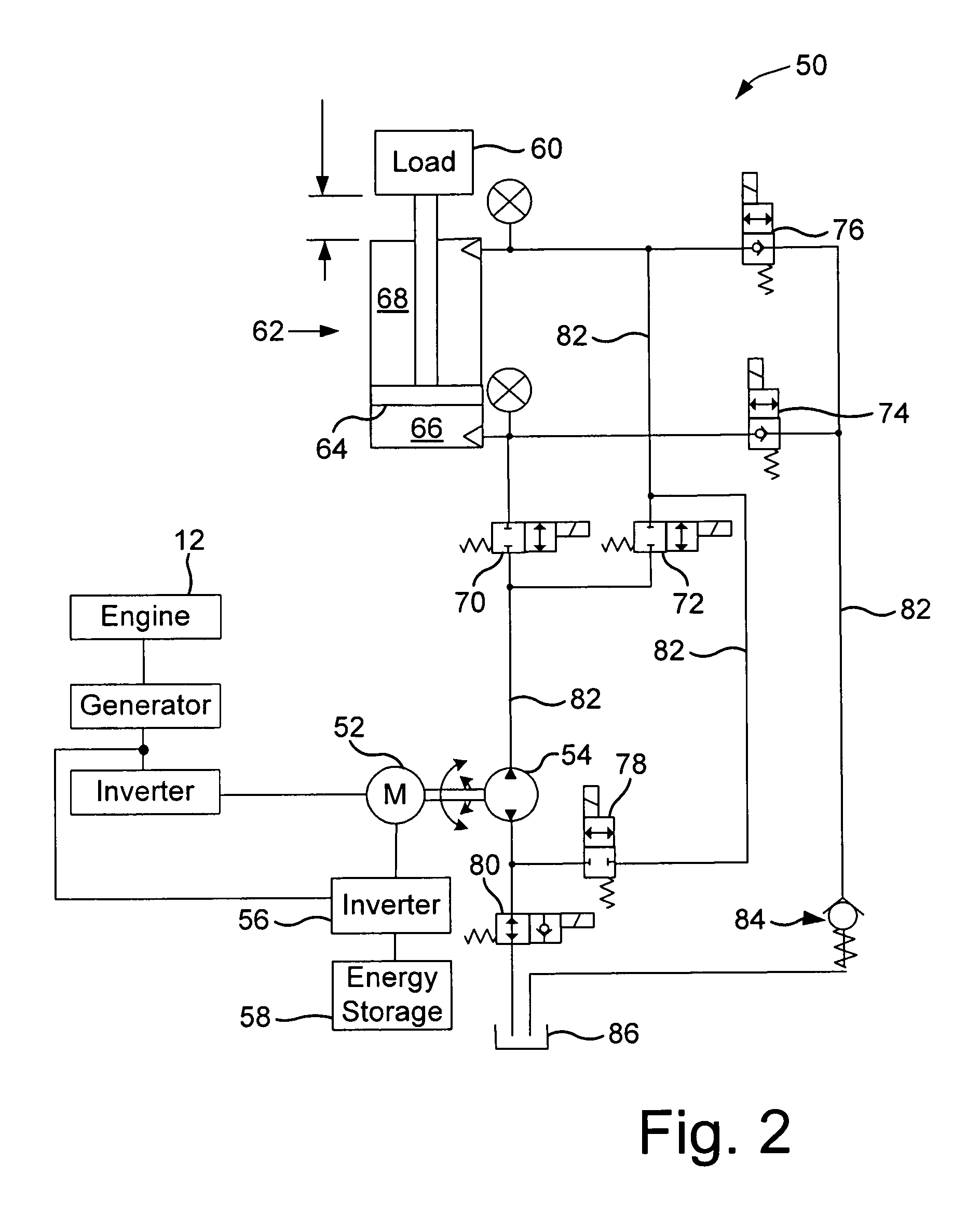

Flow management system for hydraulic work machine

A flow management system capable of providing adjustable hydraulic fluid flow or pressure at a common line to supply bidirectional pumps in electro-hydrostatic actuation systems and conditioning re-circulated hydraulic fluid. The system enables flow sharing between multiple actuation systems and minimization of energy consumption by a power-on-demand approach and / or electrical energy regeneration while eliminating the need for an accumulator. The system has particular application to electro-hydrostatic actuation systems that typically include bi-directional electric motor driven pumps and unbalanced hydraulic actuators connected within closed circuits to provide work output against external loads and reversely recover energy from externally applied loads.

Owner:PARKER INTANGIBLES LLC

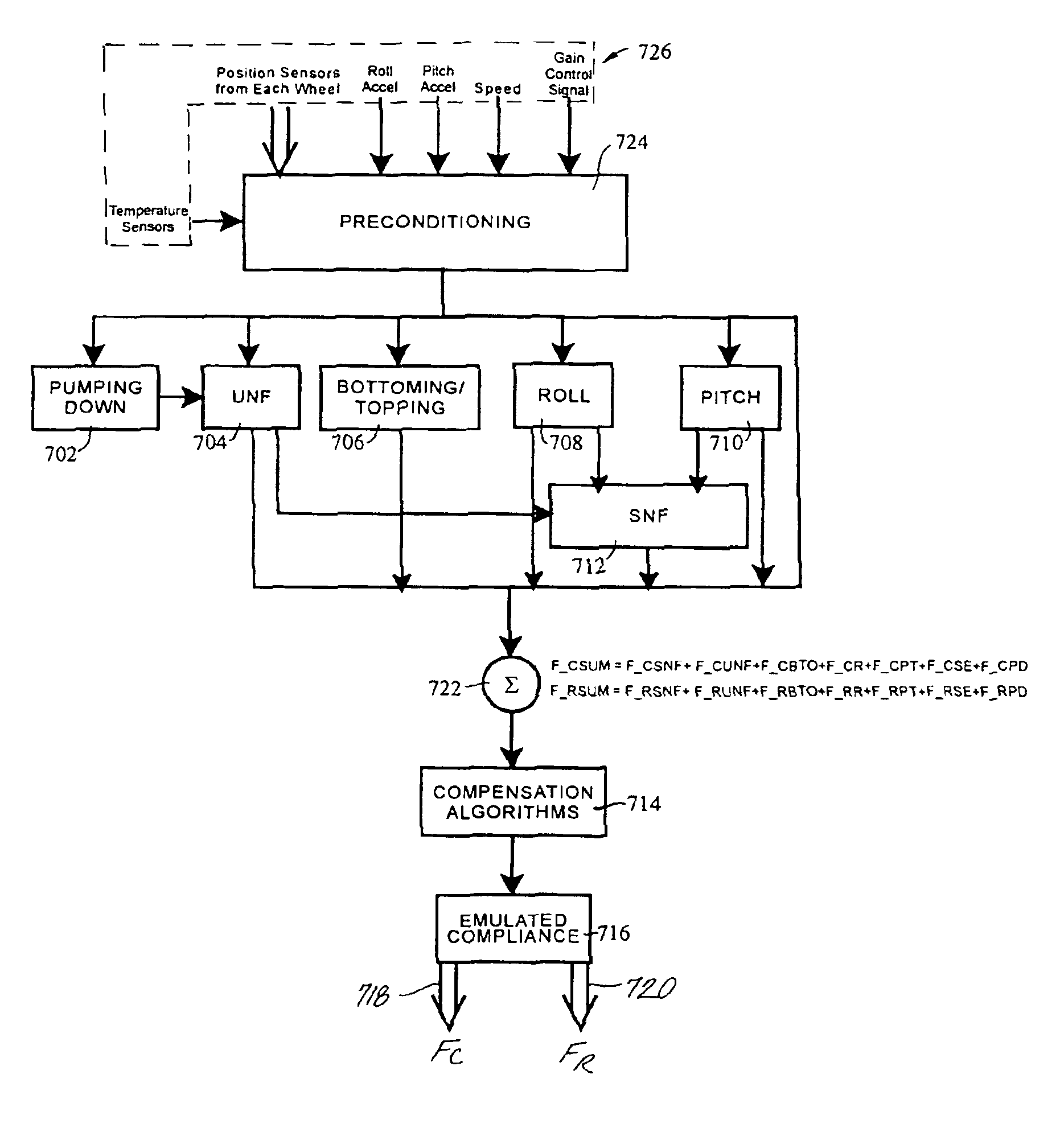

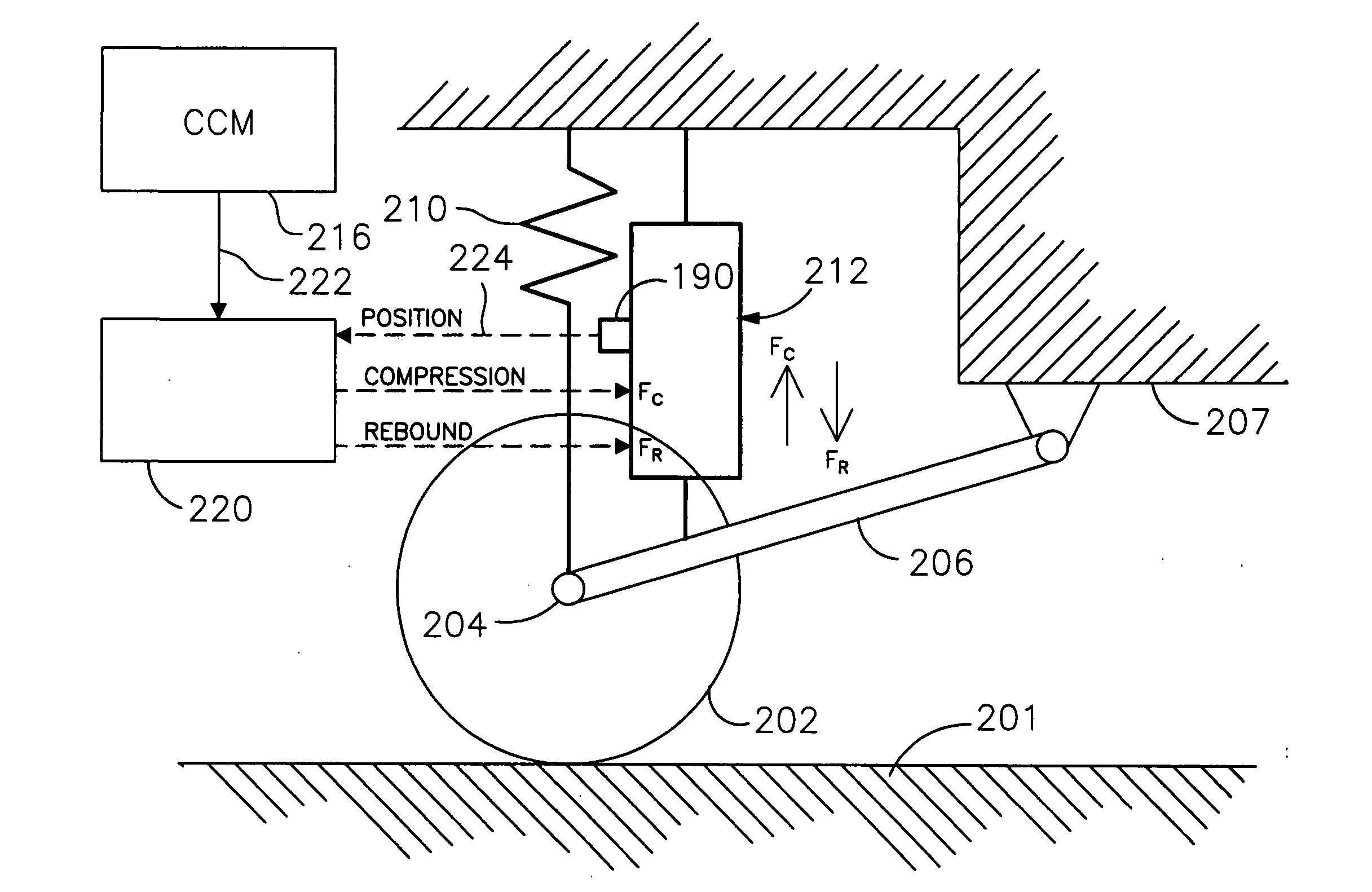

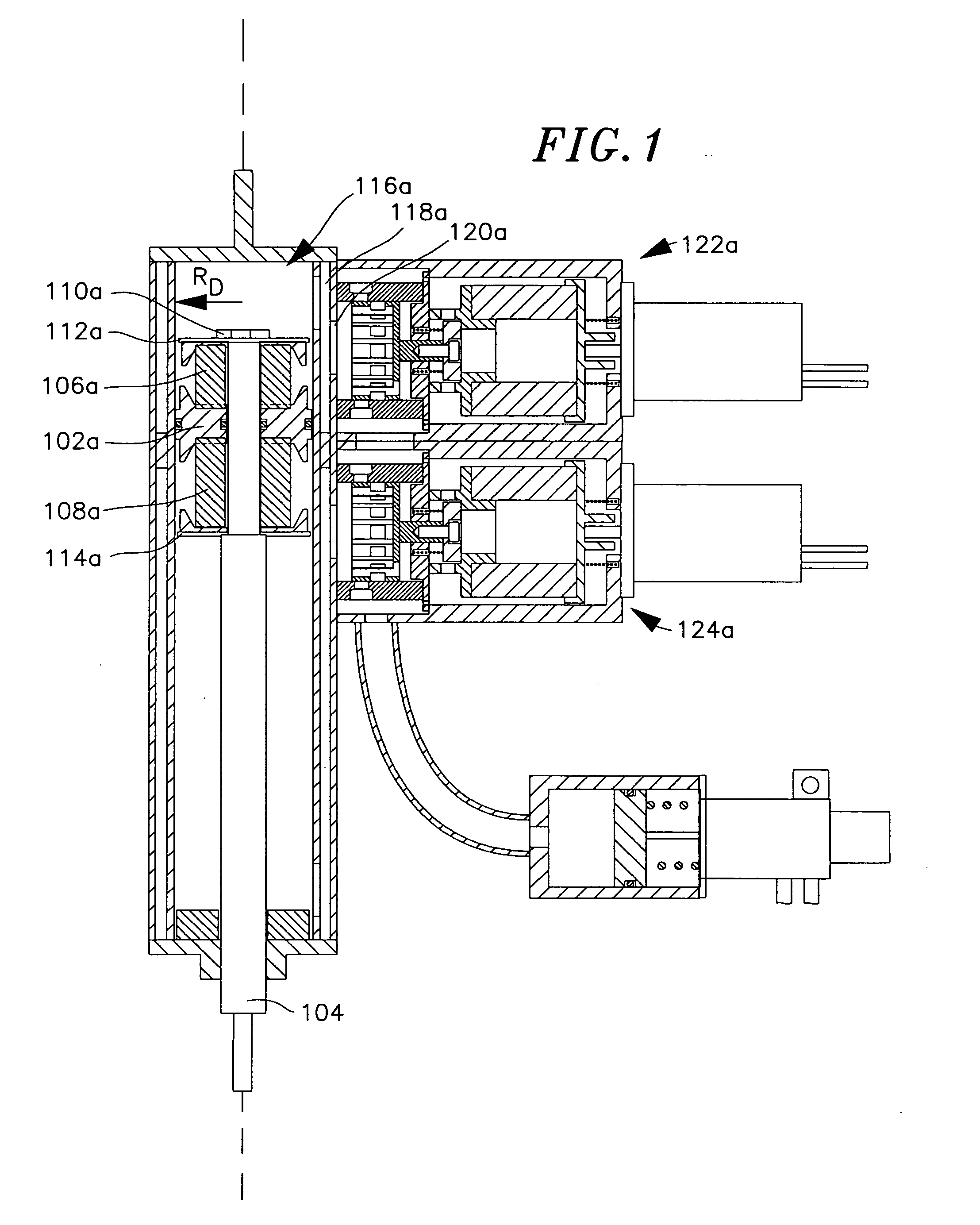

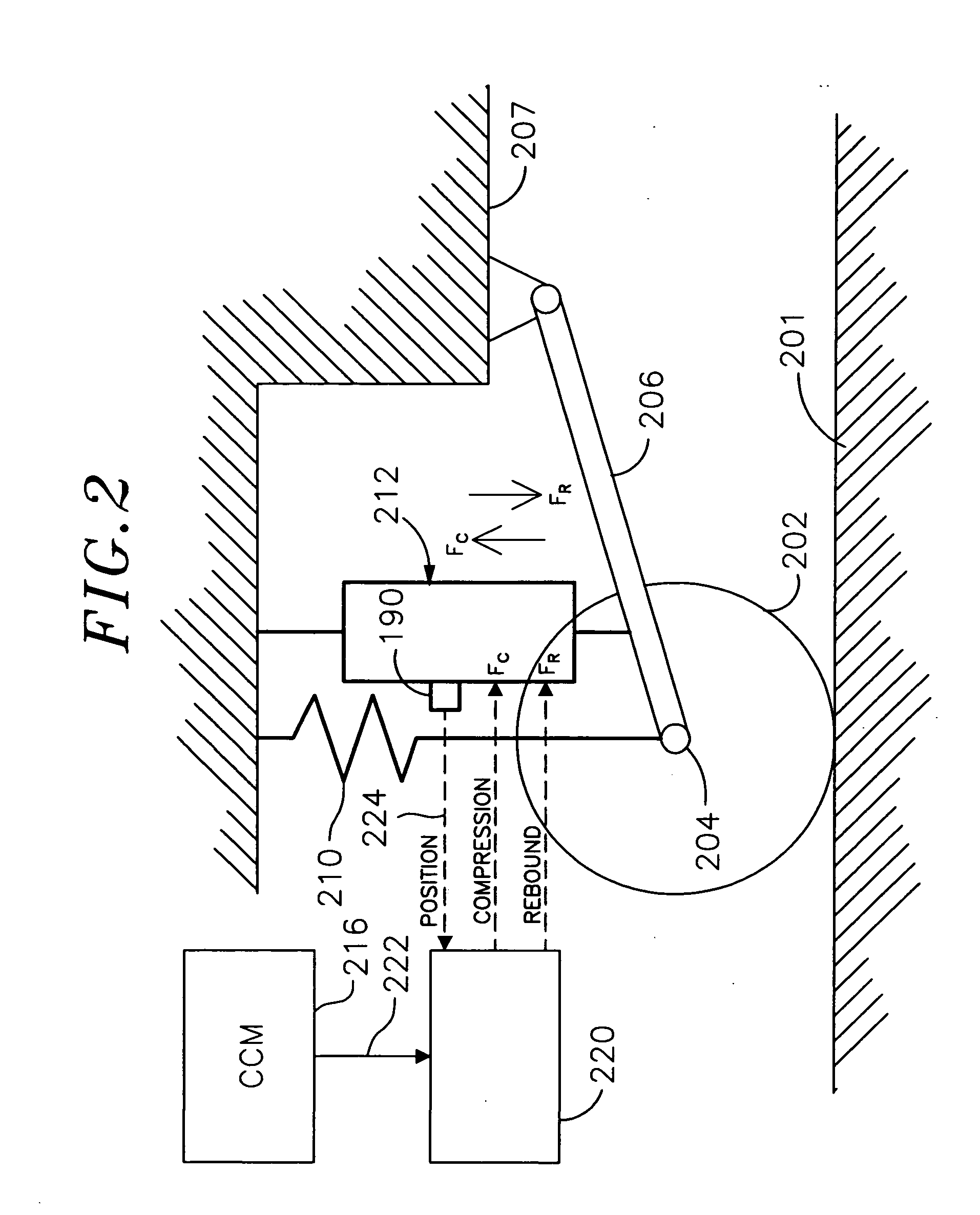

Enhanced computer optimized adaptive suspension system and method

InactiveUS7076351B2Minimizing body motionIncrease fluid pressureAuxillary drivesFunctional valve typesComputer optimizationControl signal

A system and method for controlling a damping system. The system has at least two dampers for damping between sprung and unsprung masses in the compression and rebound directions. Sensors generate signals based on position and other parameters of motion representative of the displacement between the sprung and unsprung masses. The process determines the appropriate compression and rebound forces to be applied at the wheels. A regulator responds to at least one of the independent compression and rebound control signals for adjusting, respectively, at least one of compression and rebound resisting forces of the dampers between the masses. Compliance for the dampers is emulated with software to produce the desired compliance forces. The distributed controller includes a processor that is responsive to signals representative of the position signals for forming the compression and rebound control signals for the regulator as a function of motion between the masses or a motion of a vehicle in which the dampers are located. The system has the capability of locking the suspension when parked.

Owner:WICKA JOHN D +1

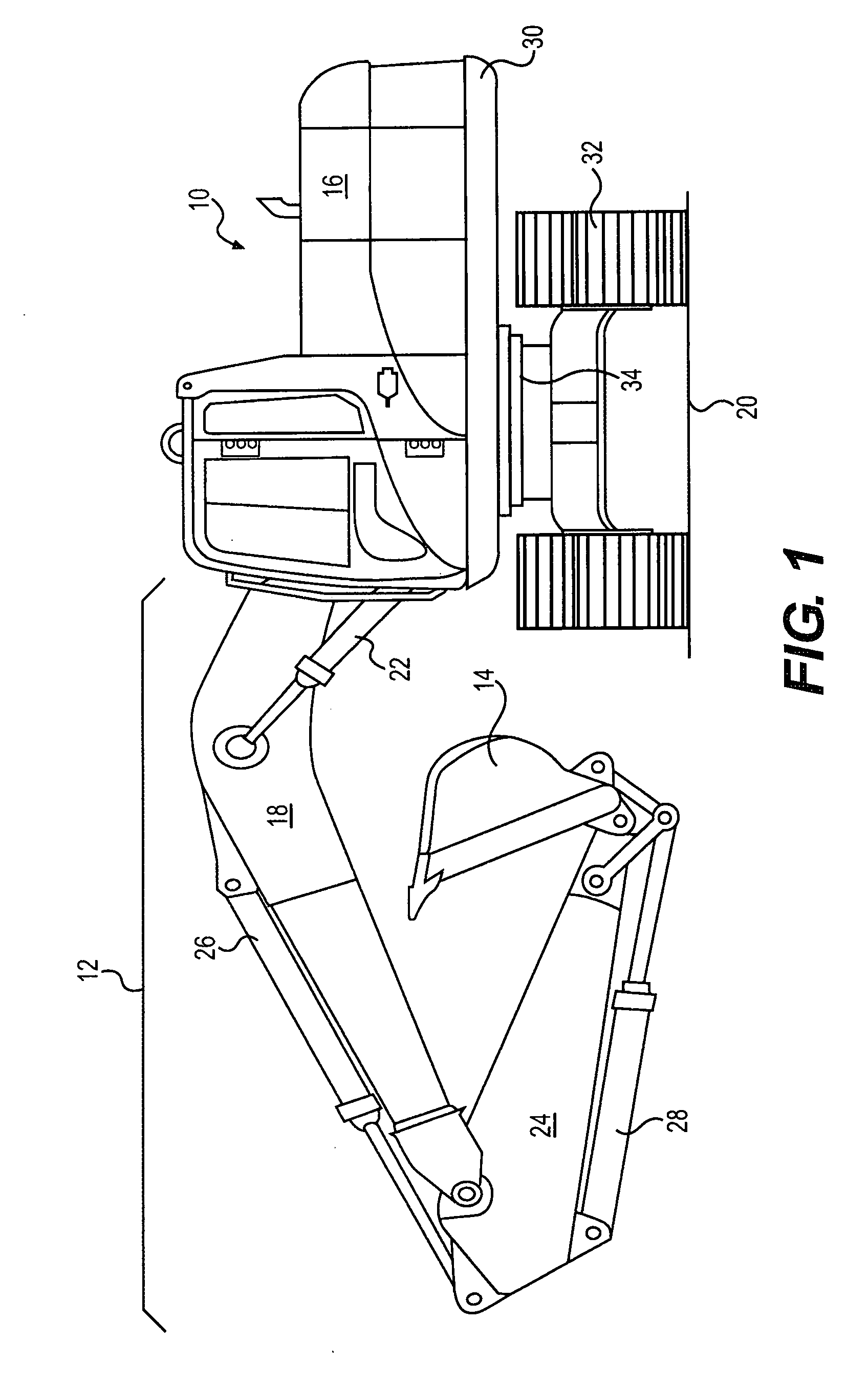

Energy recovery system

An energy recovery system for a machine is disclosed. The energy recovery system may have a pump configured to provide a flow of pressurized fluid. The energy recovery system may also have a first fluid actuator with a first chamber and a second chamber and being configured to receive the pressurized fluid, a second fluid actuator with a third chamber and a fourth chamber and being configured to receive the pressurized fluid, and a first valve fluidly connected between the pump and the first and second actuators. The energy recovery system may additionally include an isolation unit with a first selectively restrictable passageway fluidly connecting the first chamber, the third chamber, and a first outlet of the first valve, and a second selectively restrictable passageway fluidly connecting the second chamber, the fourth chamber, and a second outlet of the first valve, as well as an energy recovery unit in fluid communication with the isolation unit. The isolation unit may be configured to direct a flow of pressurized fluid from the second actuator to the energy recovery unit. The energy recovery unit may be configured to convert the flow of pressurized fluid to a first mechanical power output.

Owner:CATERPILLAR INC

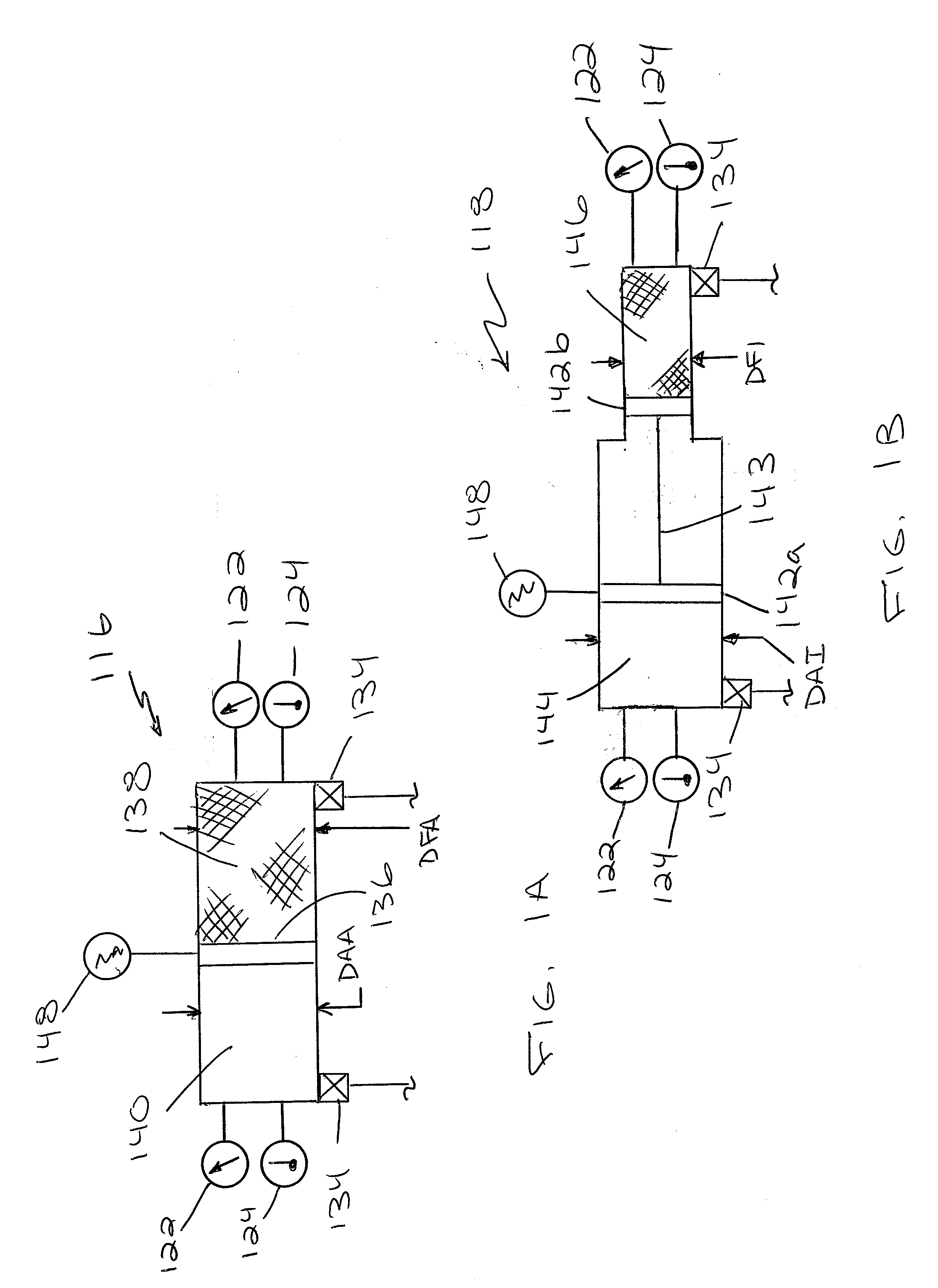

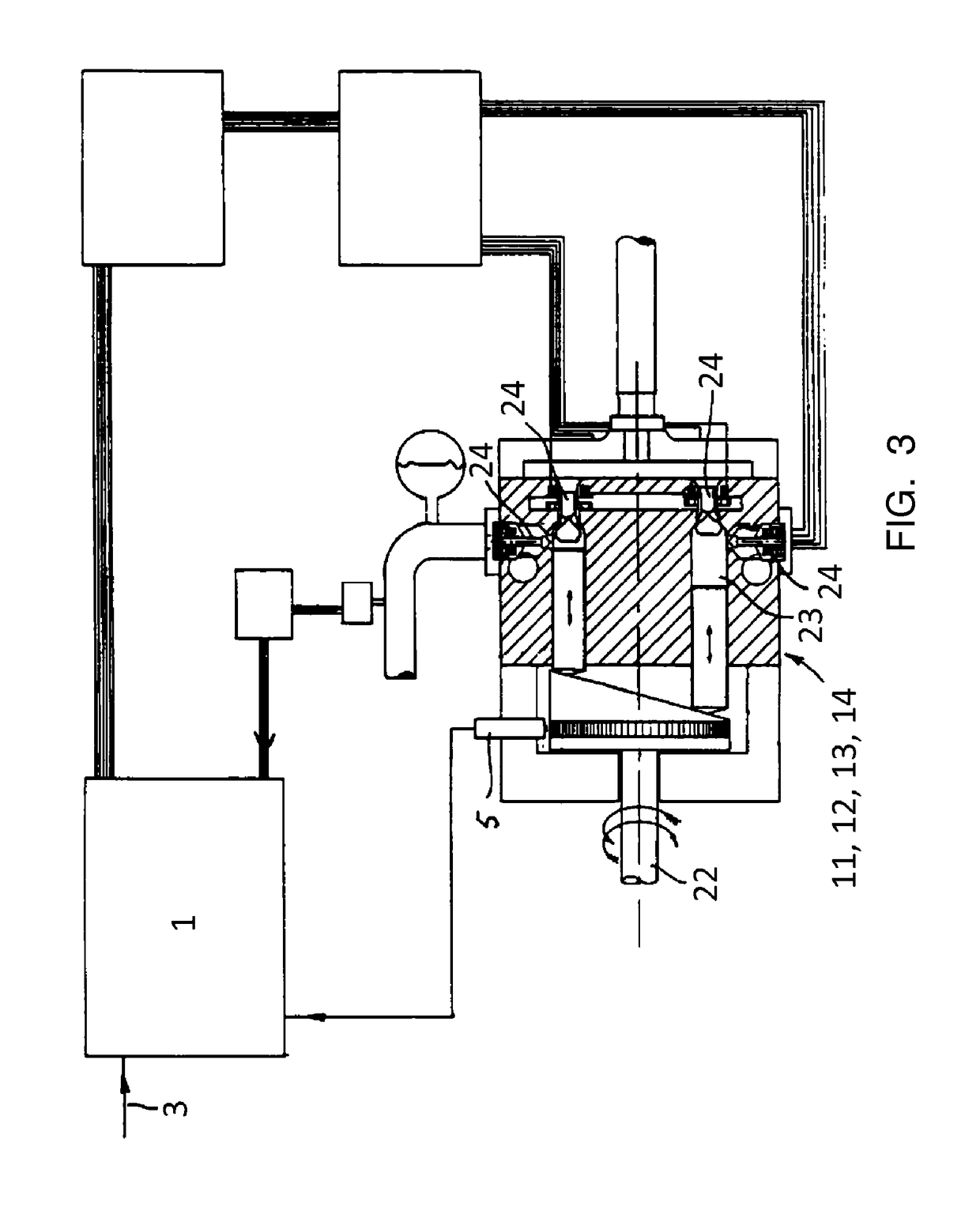

System and Method for Rapid Isothermal Gas Expansion and Compression for Energy Storage

InactiveUS20090301089A1Overcome disadvantagesInhibit migrationElectrical storage systemFluid couplingsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

Systems and Methods for Energy Storage and Recovery Using Compressed Gas

InactiveUS20090282822A1Increase energy densityExpand/compress the gas more evenlyFluid couplingsAccumulator installationsThermodynamicsGas cylinder

The invention relates to methods and systems for the storage and recovery of energy using open-air hydraulic-pneumatic accumulator and intensifier arrangements that combine at least one accumulator and at least one intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits.

Owner:SUSTAINX

System and method for rapid isothermal gas expansion and compression for energy storage

InactiveUS7802426B2Overcome disadvantagesInhibit migrationElectrical storage systemServomotorsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

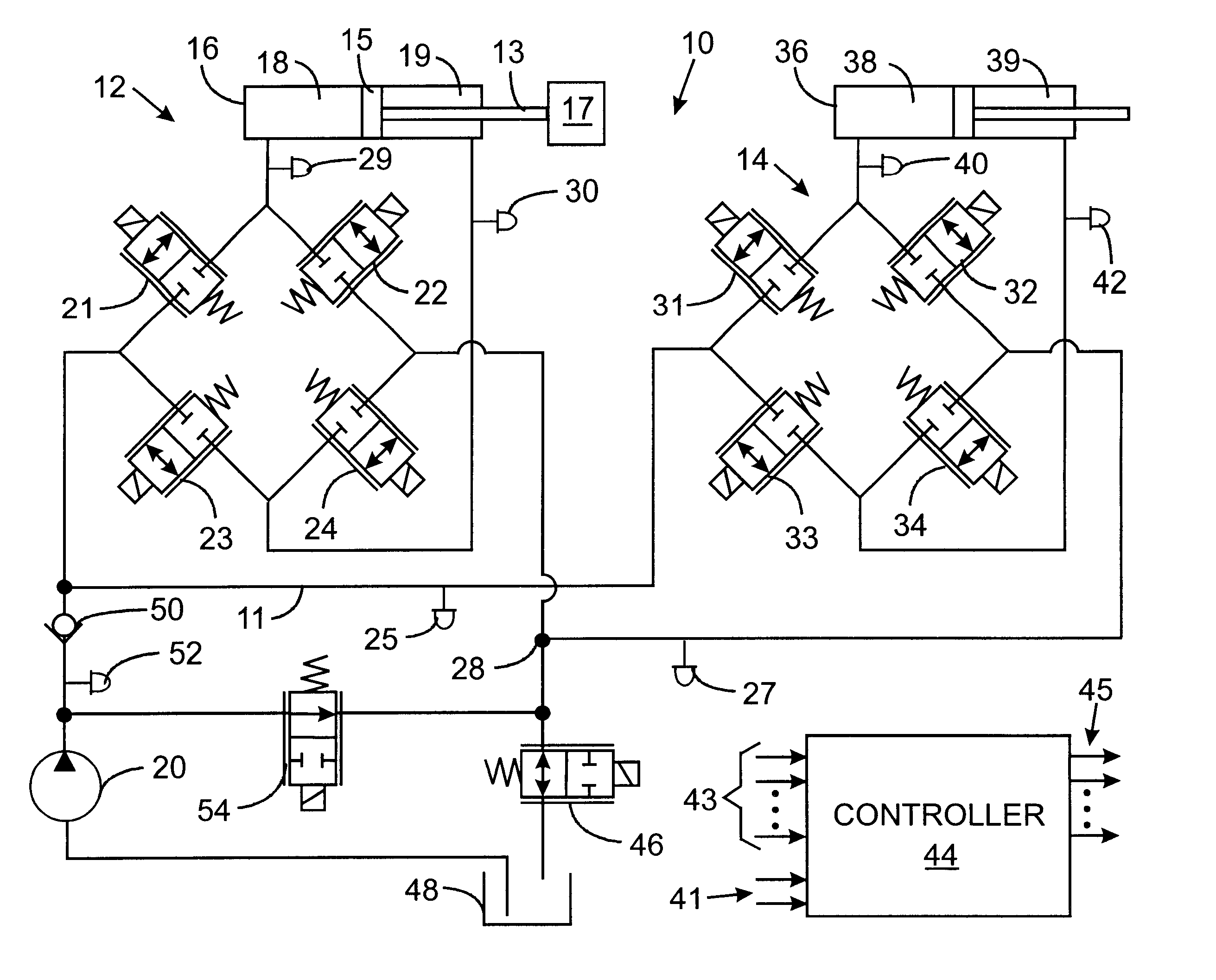

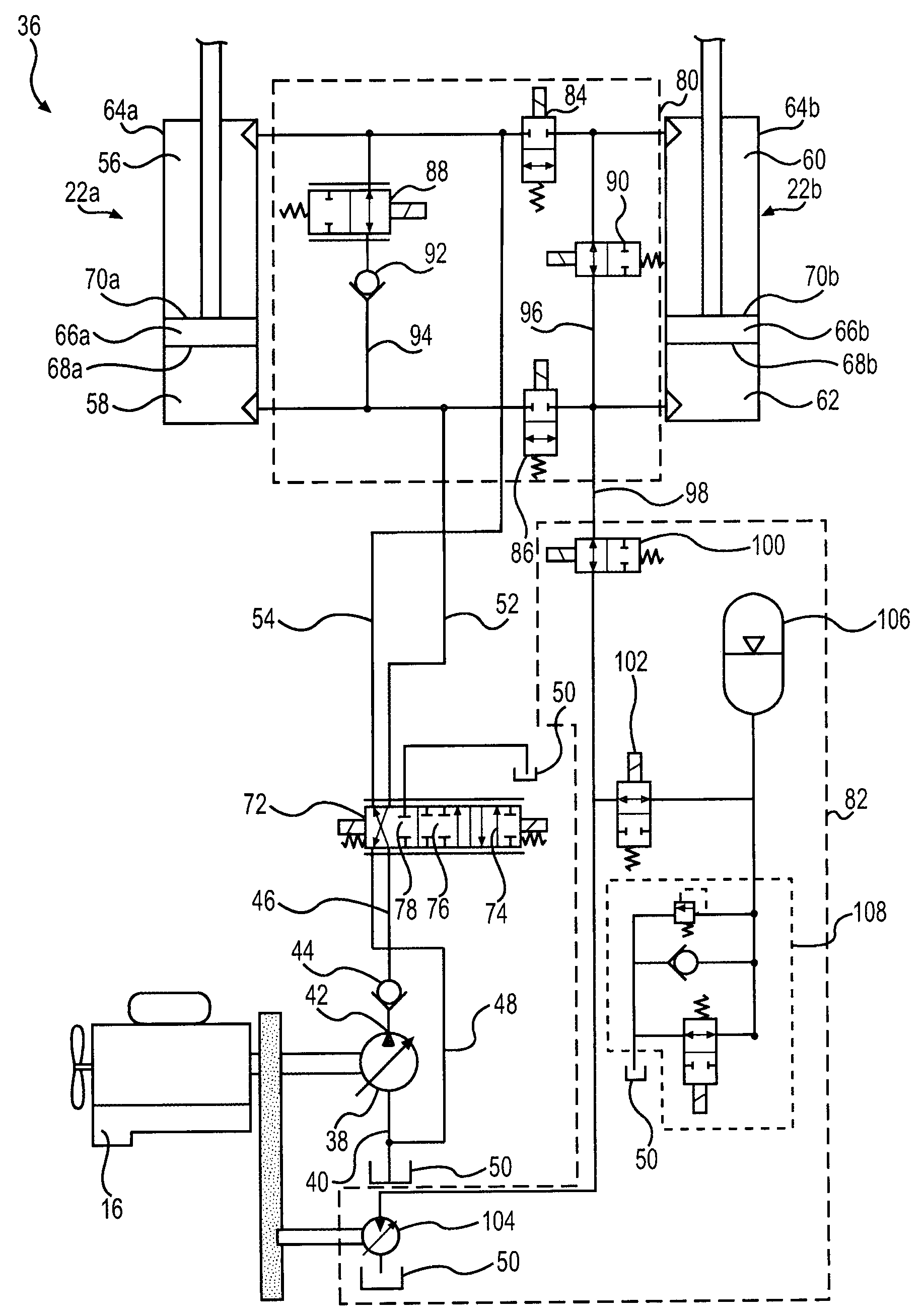

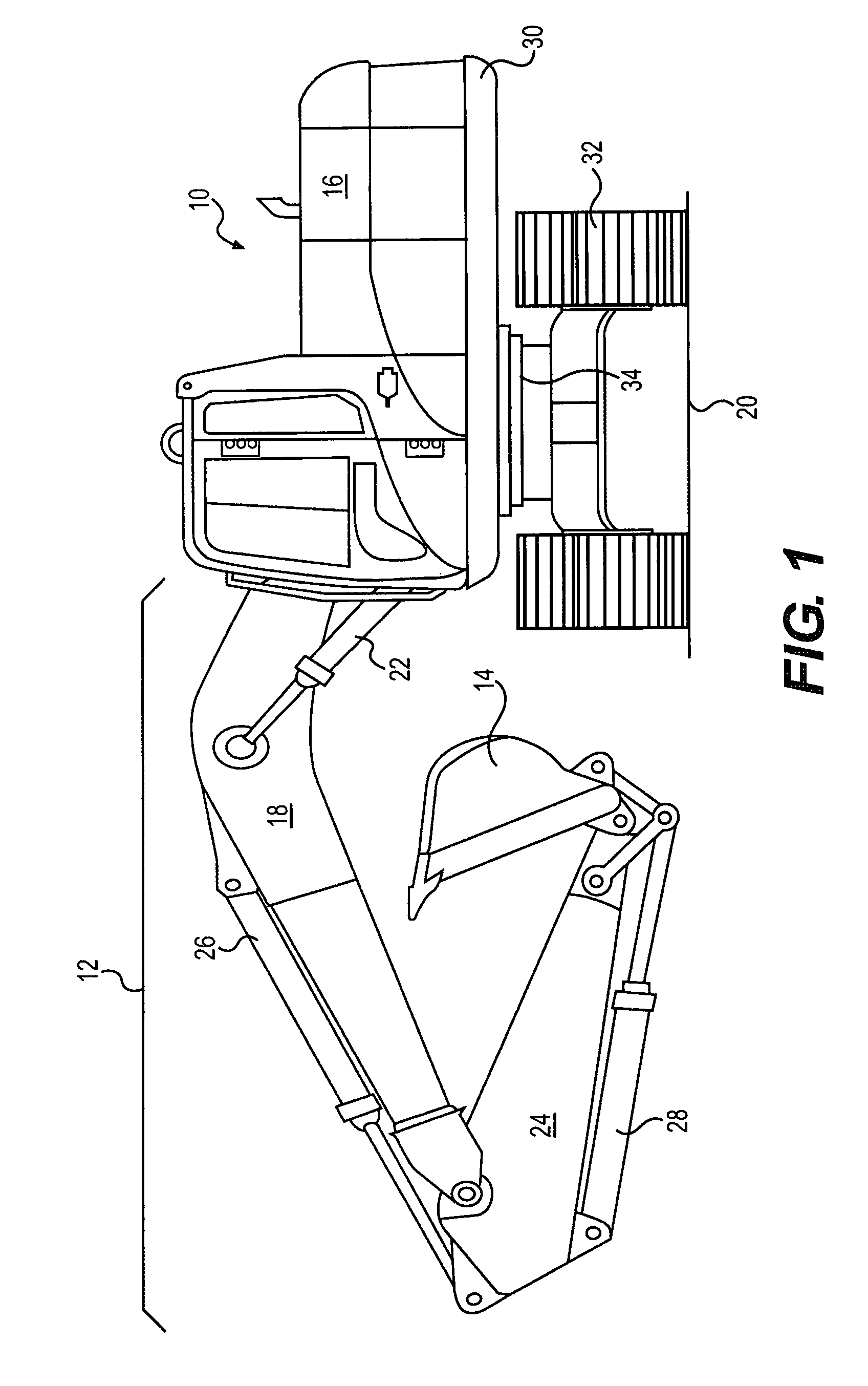

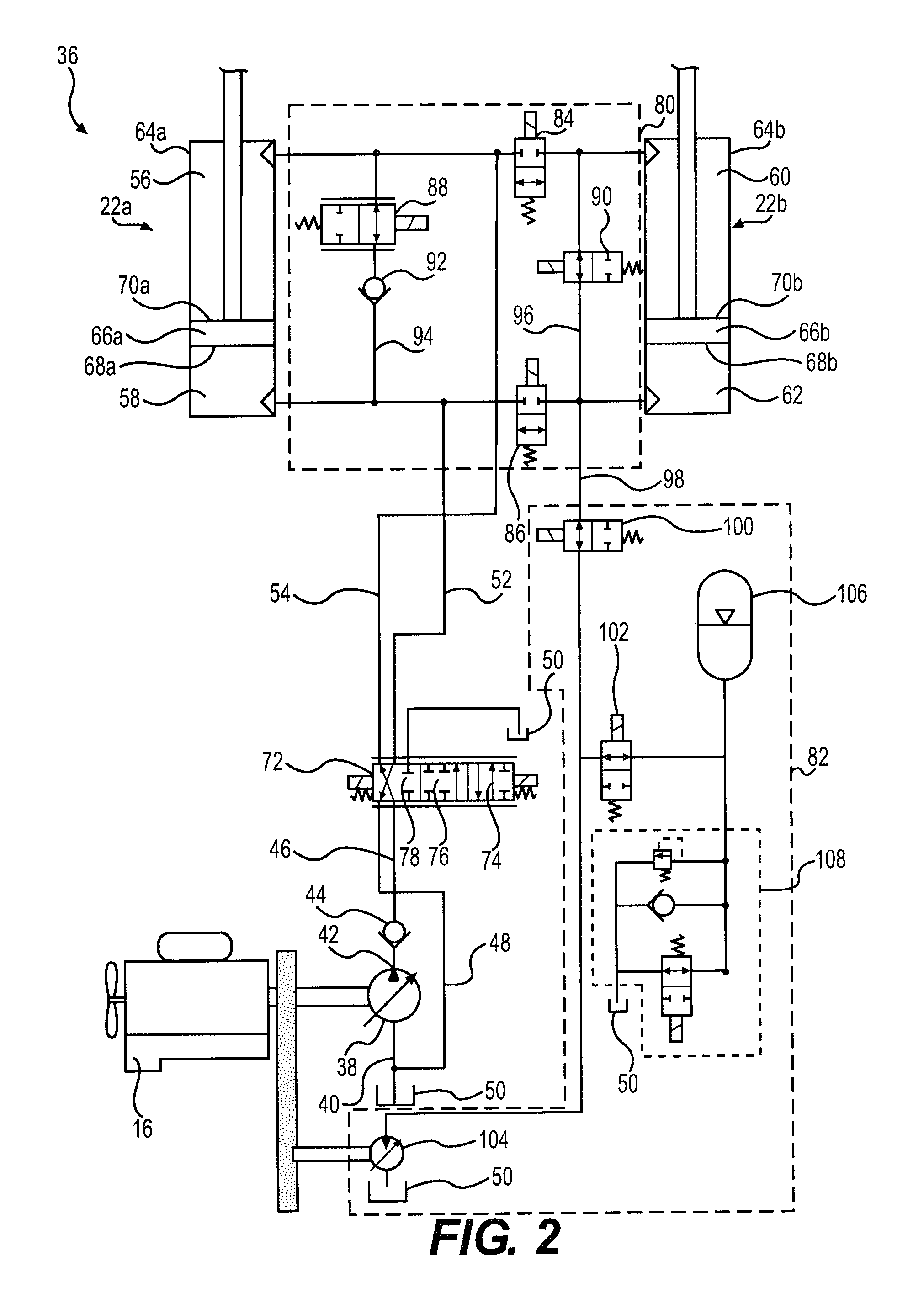

Energy recovery and reuse techniques for a hydraulic system

A hydraulic system has a valve assembly with two workports coupled to chambers of first and second cylinders which are connected mechanically in parallel to a machine component. A separation control valve is connected between first chambers of both cylinders, and a shunt control valve is connected between the workports. A recovery control valve couples an accumulator to the first chamber of the second cylinder. Opening and closing the valves in different combinations routes fluid from one or both cylinders into the accumulator where the fluid is stored under pressure, and thereafter enables stored fluid to be used to power one or both cylinders. The shunt control valve is used to route fluid exhausting from one chamber of each cylinder to the other chambers of those cylinders. Thus the hydraulic system recovers and reuses energy in various manners.

Owner:HUSCO INT INC

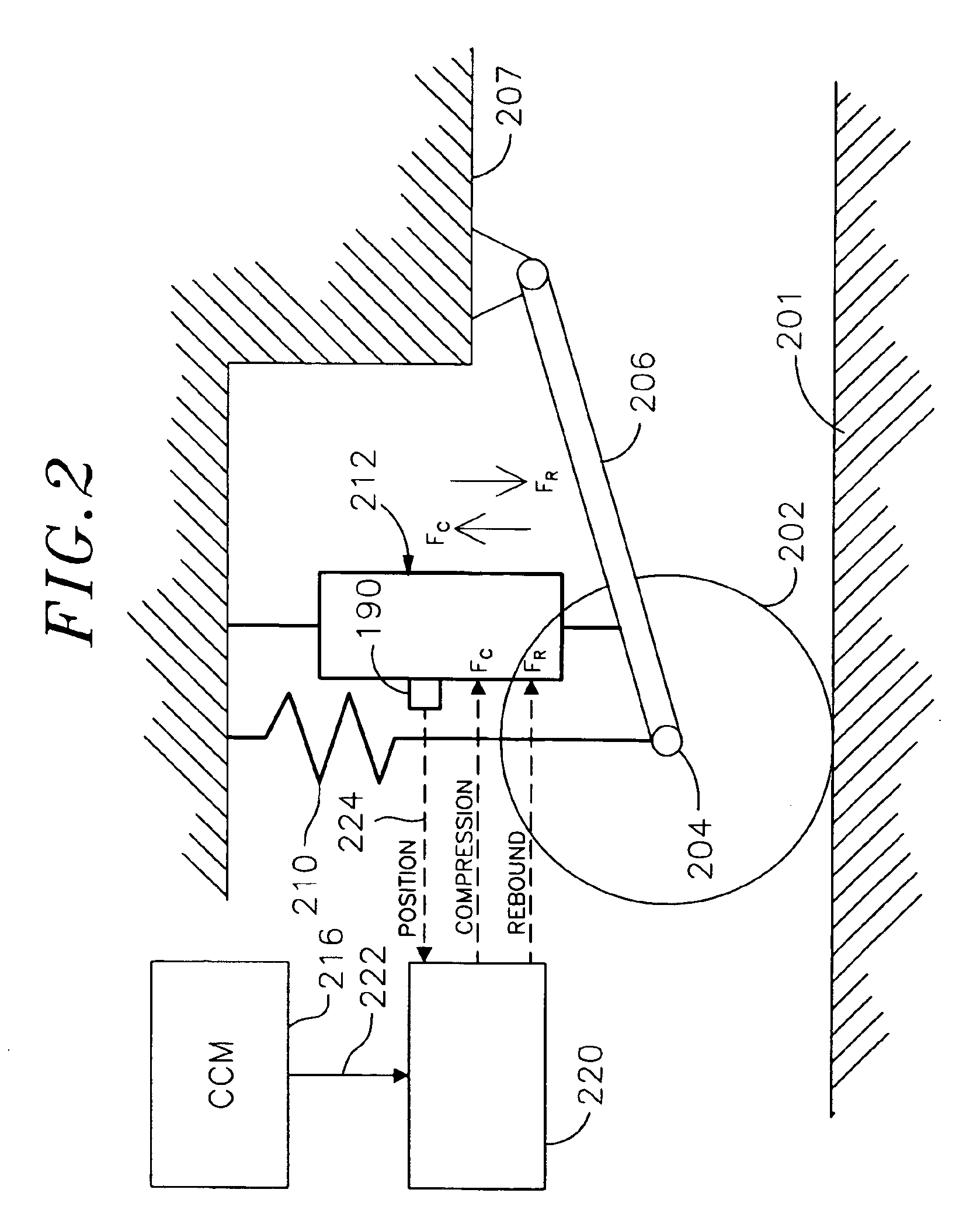

Enhanced computer optimized adaptive suspension system and method

InactiveUS20050098401A1Minimizing body motionIncrease fluid pressureOperating means/releasing devices for valvesSpringsComputer optimizationControl signal

A system and method for controlling a damping system. The system has at least two dampers for damping between sprung and unsprung masses in the compression and rebound directions. Sensors generate signals based on position and other parameters of motion representative of the displacement between the sprung and unsprung masses. The process determines the appropriate compression and rebound forces to be applied at the wheels. A regulator responds to at least one of the independent compression and rebound control signals for adjusting, respectively, at least one of compression and rebound resisting forces of the dampers between the masses. Compliance for the dampers is emulated with software to produce the desired compliance forces. The distributed controller includes a processor that is responsive to signals representative of the position signals for forming the compression and rebound control signals for the regulator as a function of motion between the masses or a motion of a vehicle in which the dampers are located. The system has the capability of locking the suspension when parked.

Owner:GREAT NORTHERN TECH

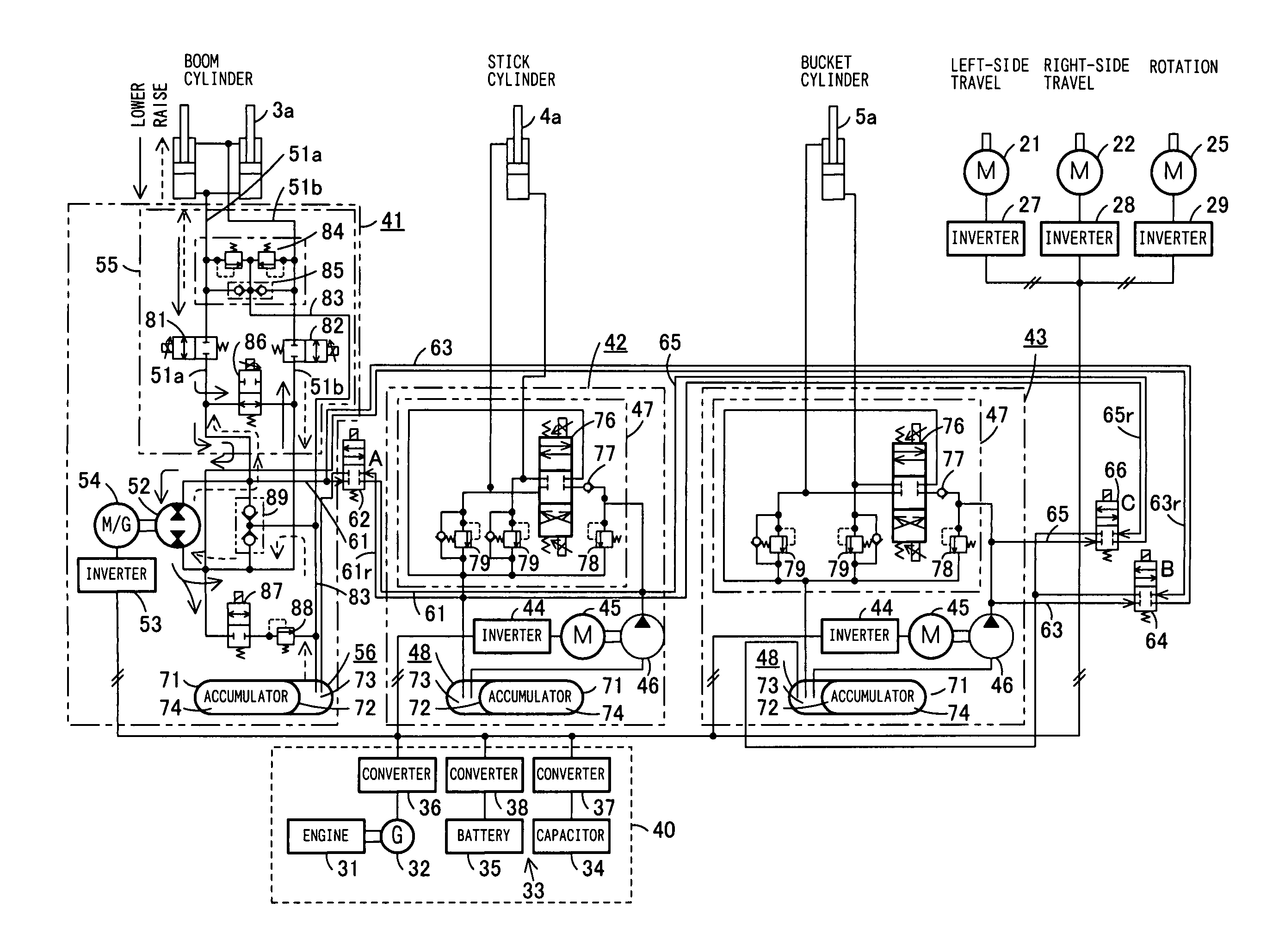

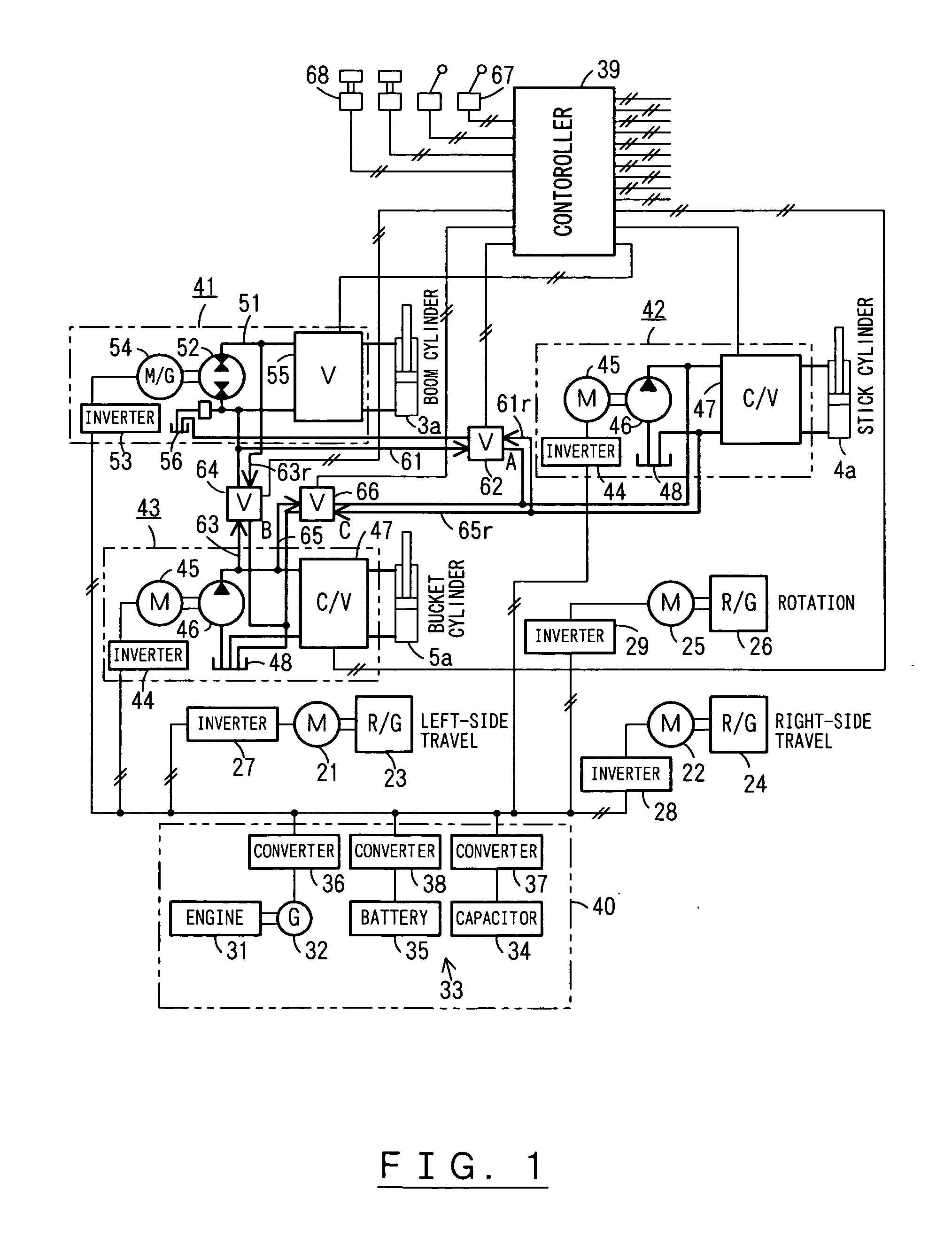

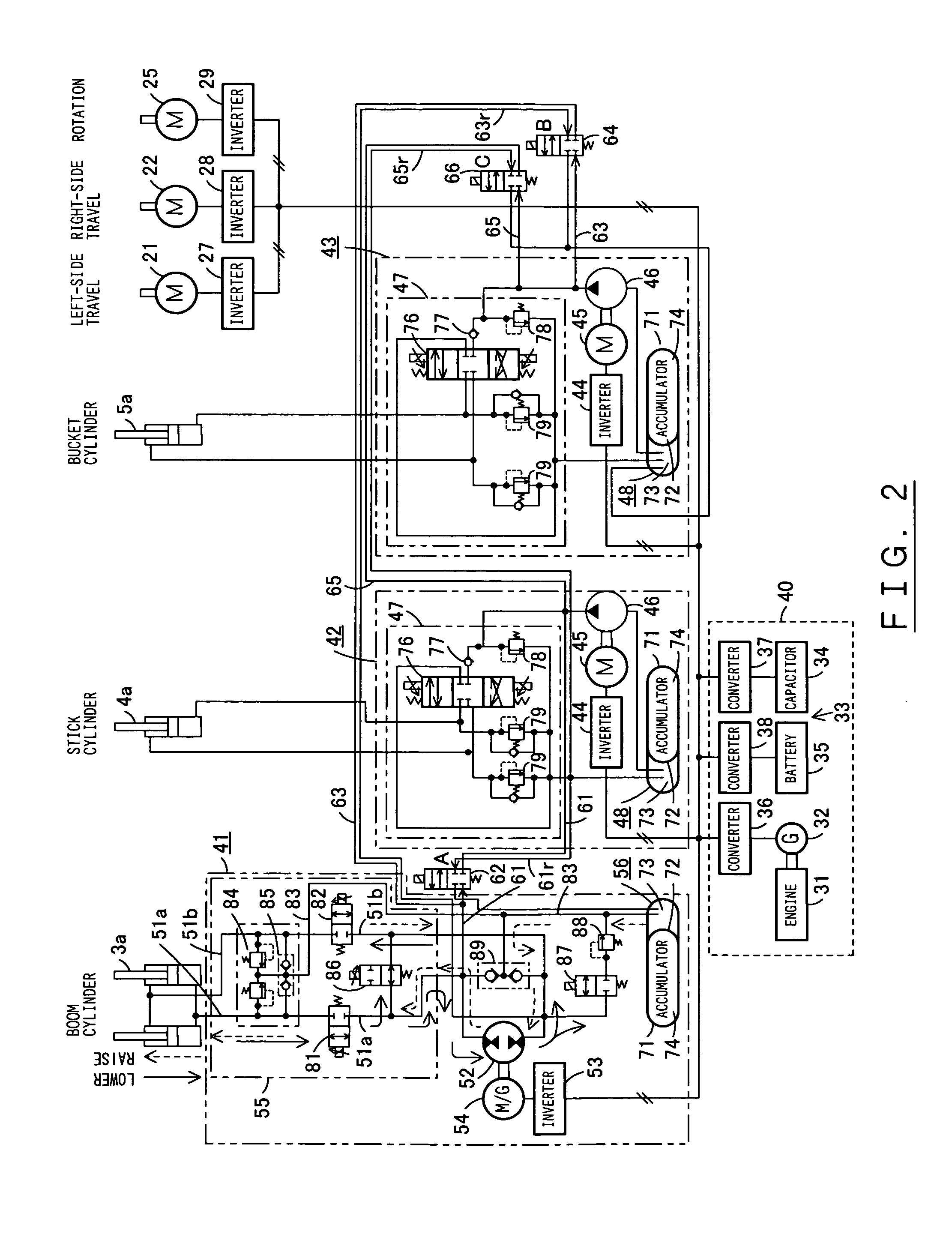

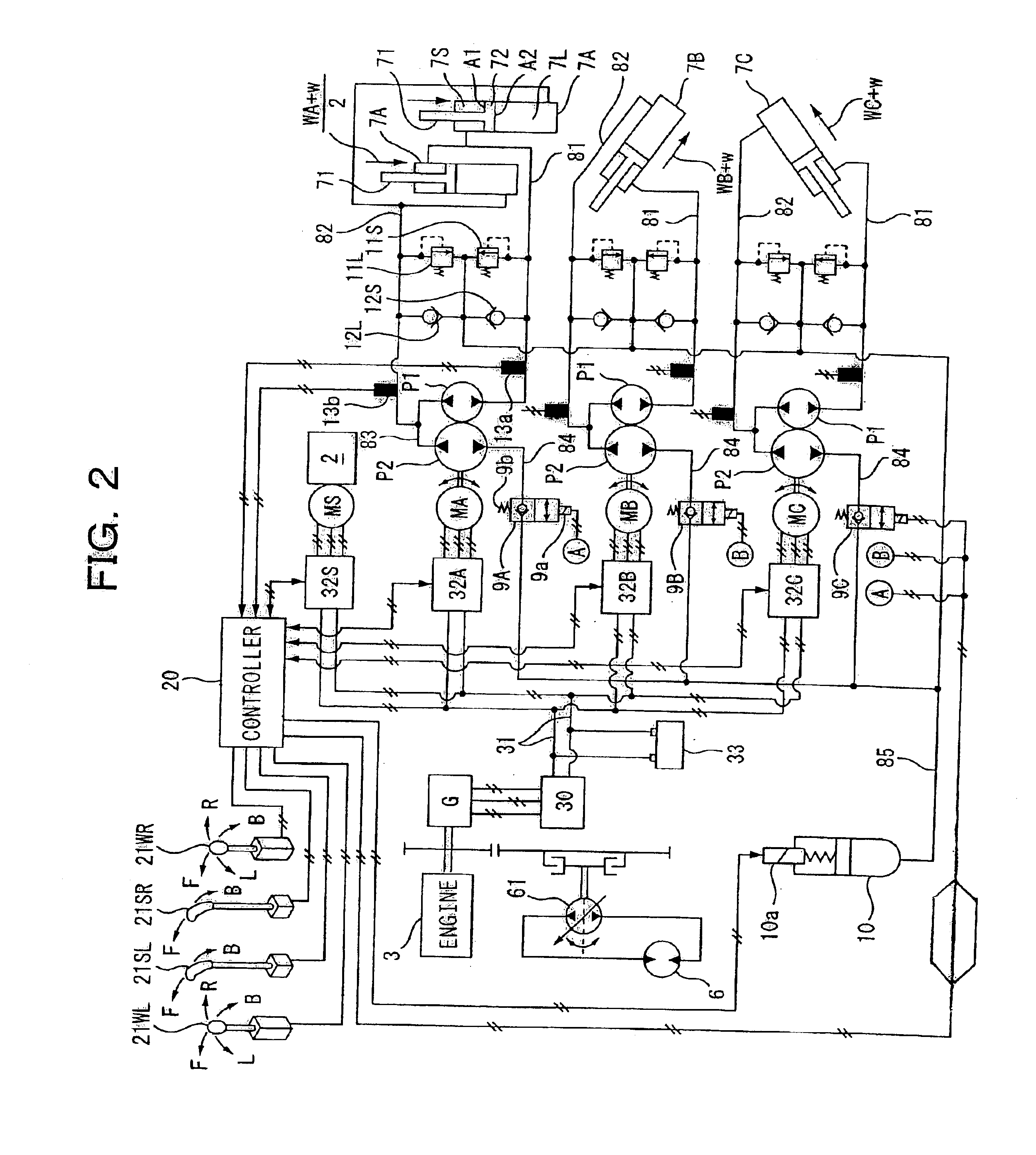

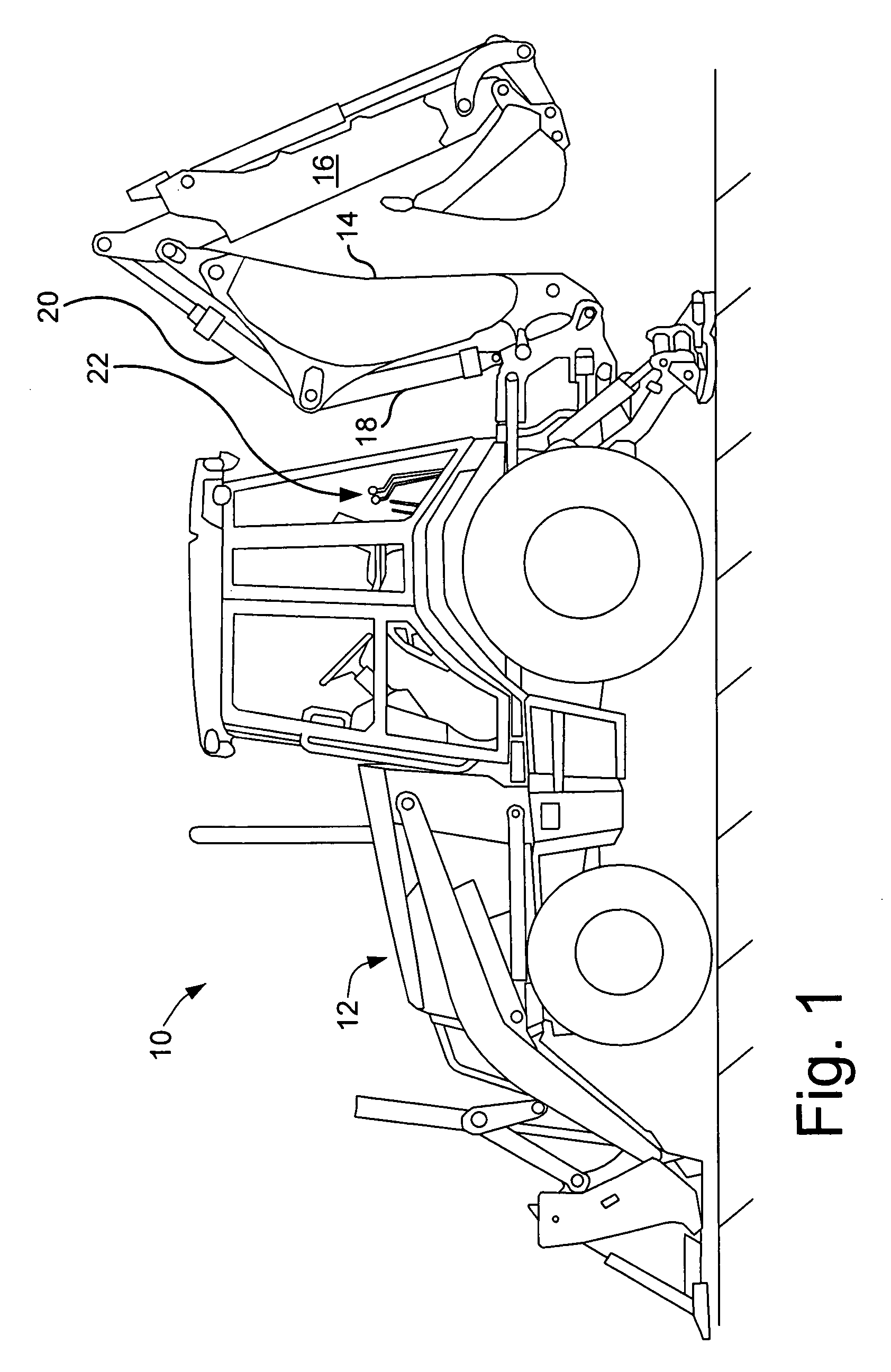

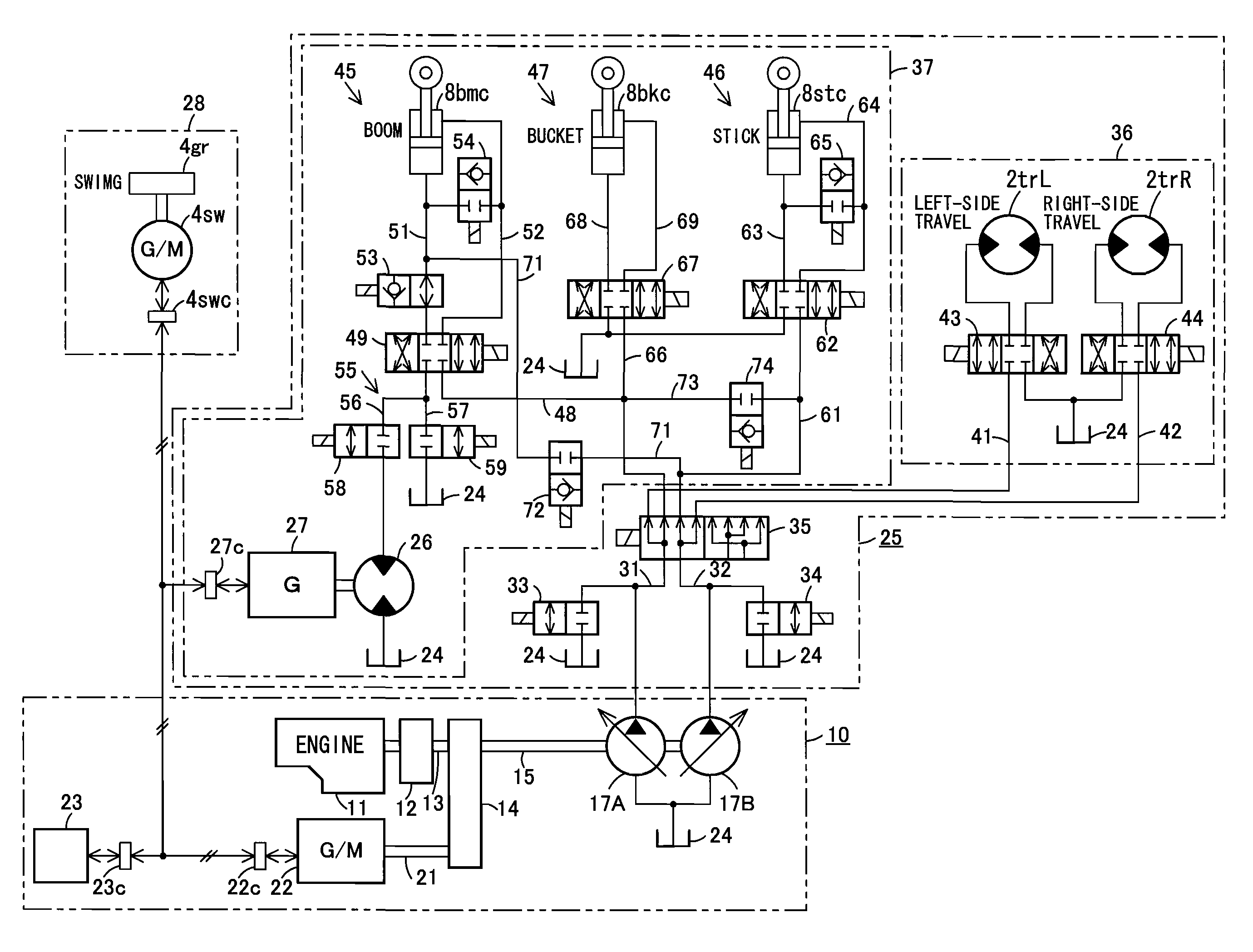

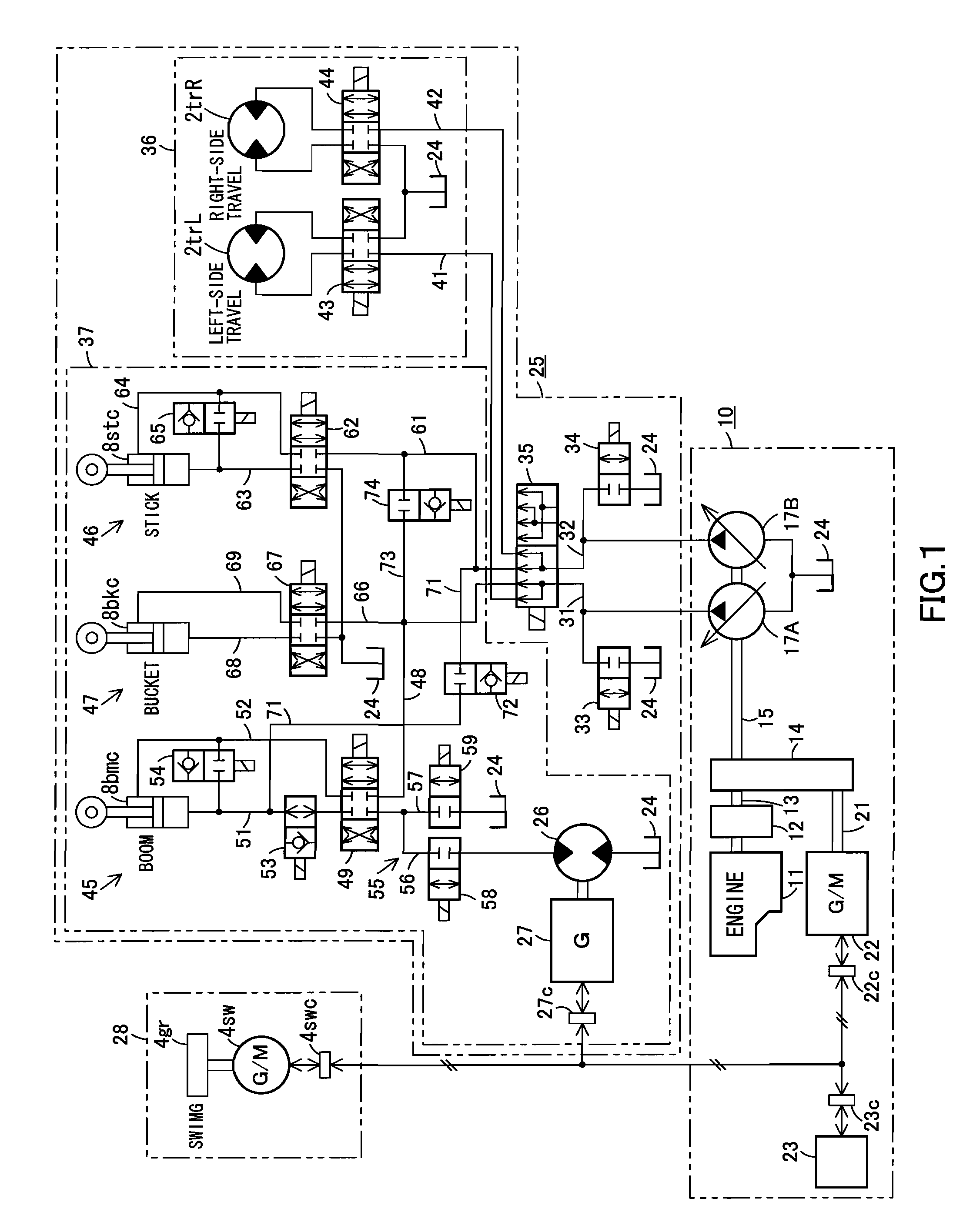

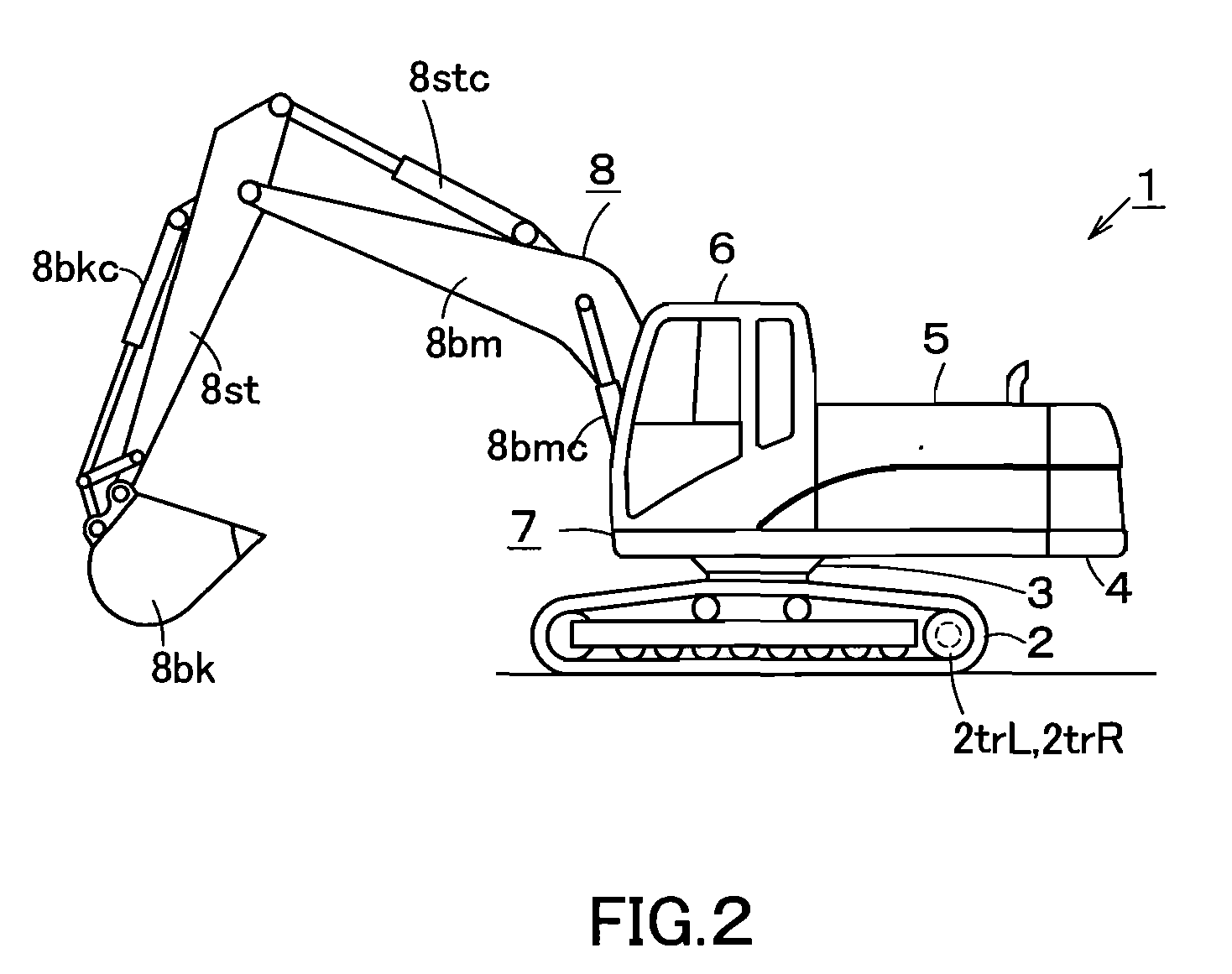

Working machine driving unit

InactiveUS20050246082A1ShortfallEfficient sharingAnalogue computers for trafficServomotorsWork unitActuator

A driving device of a work machine includes a power generator adapted to be driven by an engine, and a power storage device for storing the electric power generated by the power generator. Electric motors and a motor generator, both adapted to be operated by electric power supplied from either one or both of the power generator and the power storage device respectively drive pumps and a pump motor. Supporting circuits for feeding supporting hydraulic oil are provided between a plurality of driving circuits that drive a plurality of hydraulic actuators of a working unit by oil hydraulics generated by the pumps and the pump motor. By enabling the plurality of driving circuits to effectively share excess energy, the invention makes possible a compact construction of a driving device of a work machine.

Owner:SHIN CATERPILLAR MITSUBISHI LTD CORP

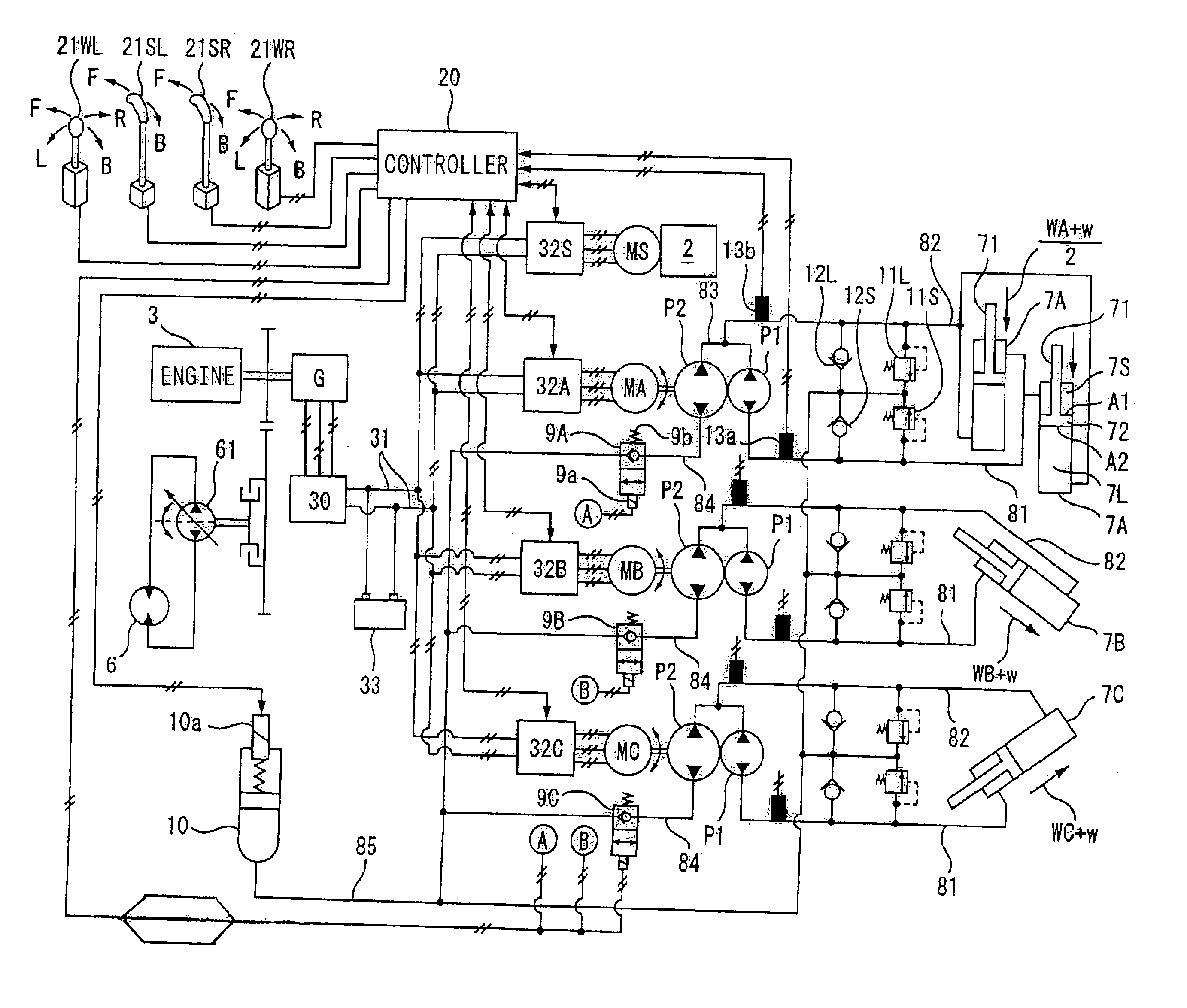

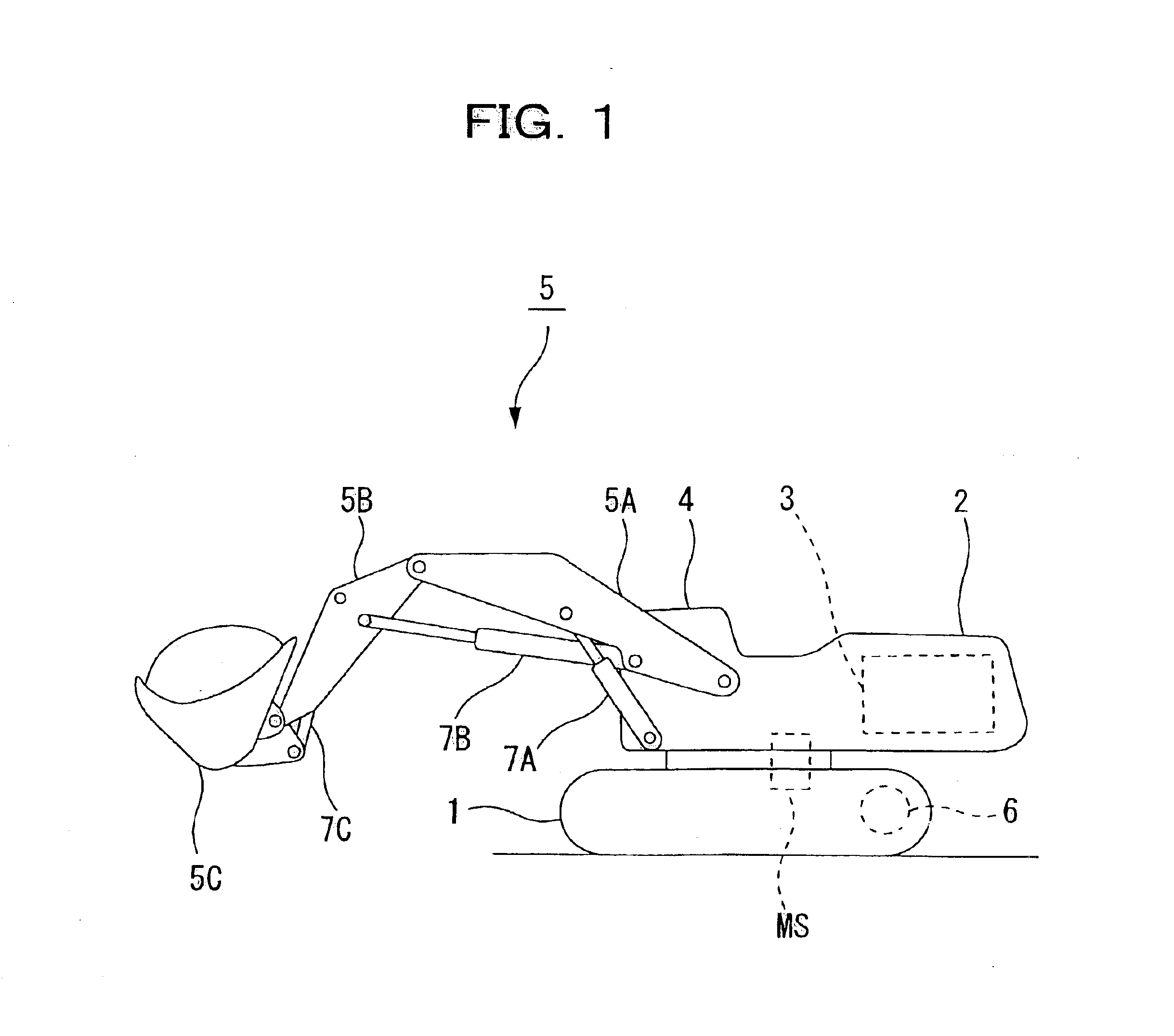

Hybrid machine with hydraulic drive device

A hybrid machine with a hydraulic drive device having hydraulic actuators allowed to operate against and by external loads is provided. To this end, the hybrid machine comprises hydraulic cylinders (7), first hydraulic pumps (P1) connected, with closed circuits, to head side pressure receiving chambers (7S) and bottom side pressure receiving chambers (7L) of the hydraulic cylinders (7), and second hydraulic pumps (P2) connected, with open circuits, to the bottom side pressure receiving chambers (7L) and an external oil chamber (10), wherein the first and second hydraulic pumps (P1, P2) are connected to electric motors (M) so as to be driven.

Owner:KOMATSU LTD

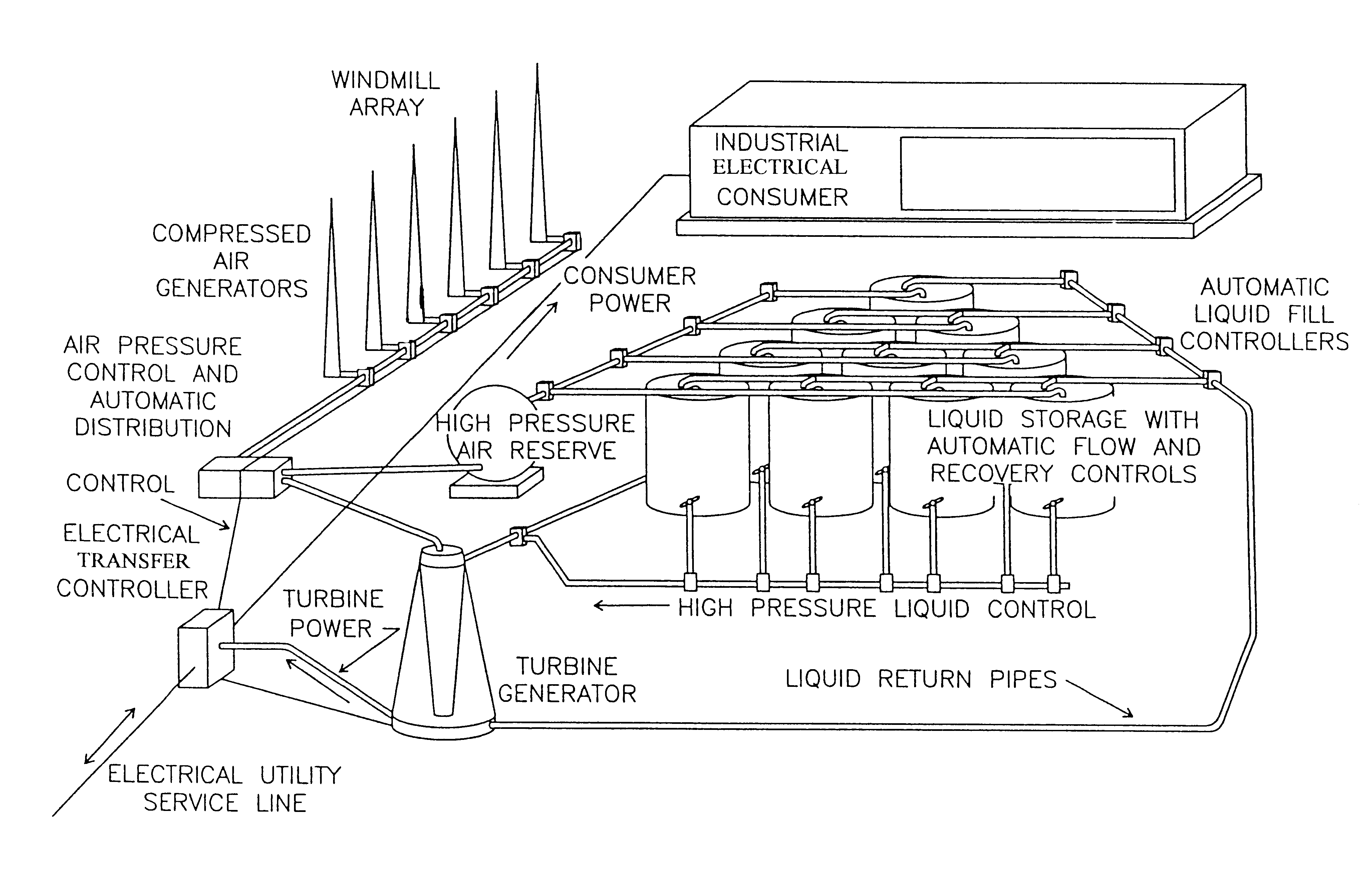

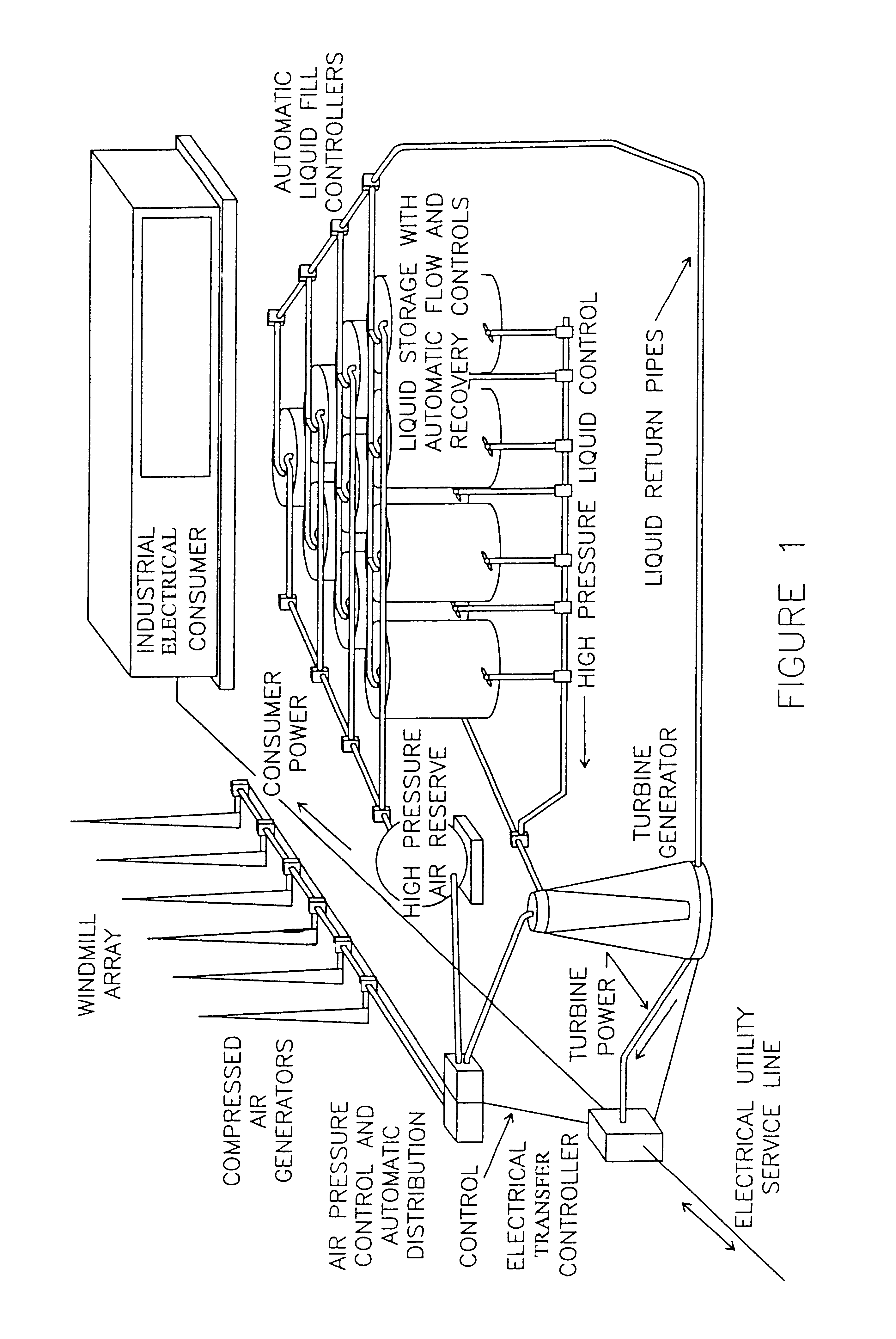

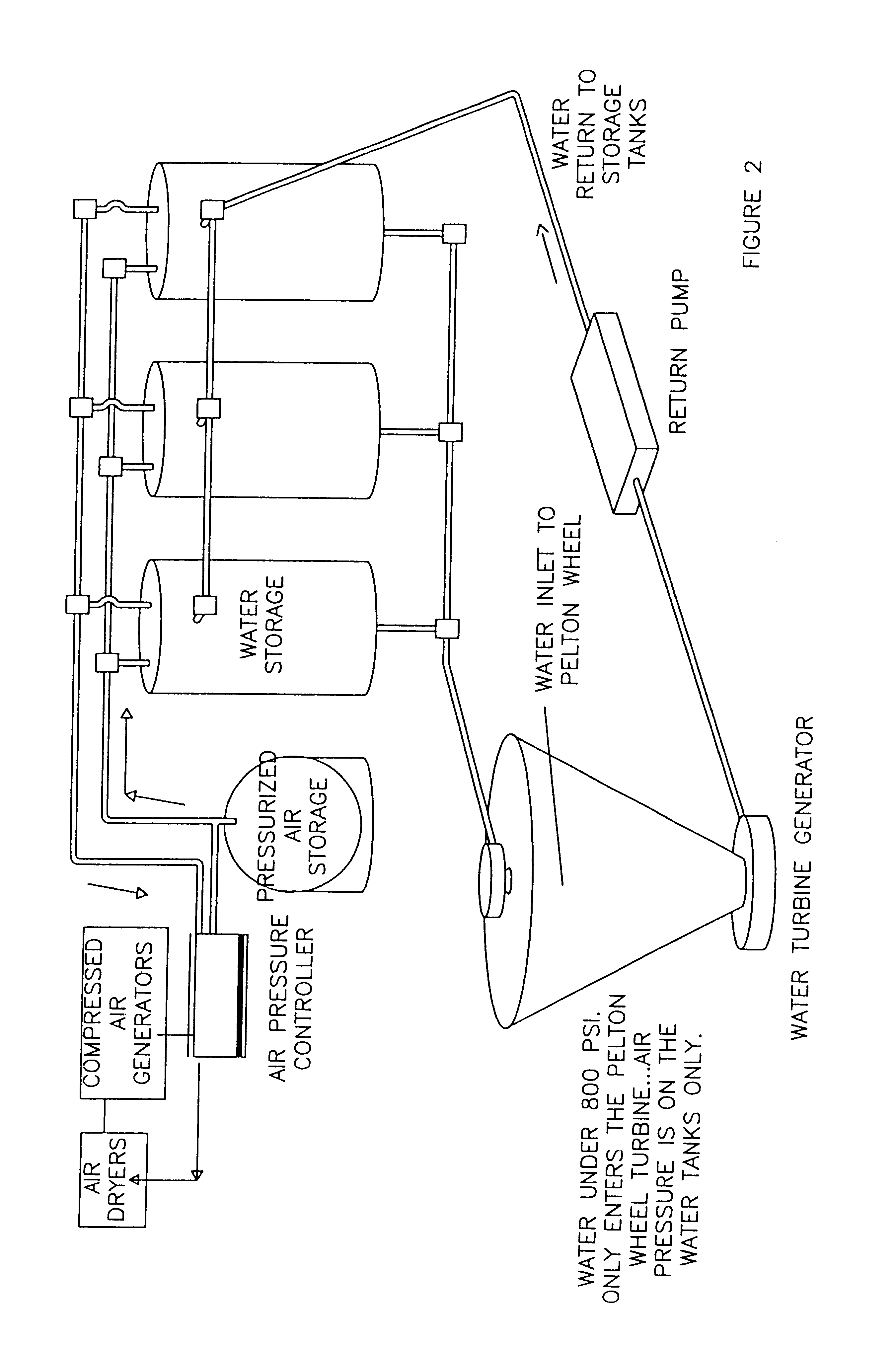

Wind powered hydroelectric power plant and method of operation thereof

A hydroelectric power plant uses a plurality of windmills connected to compressed air generators to produce pressurized air. Pressurized air is used to drive water through a turbine to produce electrical power. The water is recycled and the power plant includes reserve pressurized air tanks to allow the plant to continue to operate when the wind levels are not sufficient to produce high pressure air. The power plant is designed to be operated on a continuous basis based on wind power. When the wind subsides and the reserve capacity has been exhausted, electricity can be drawn from the local utility supplier. When excess power is generated by the power plant, electricity from the power plant can be added to the grid of the local electricity supplier.

Owner:NEW WORLD GENERATION

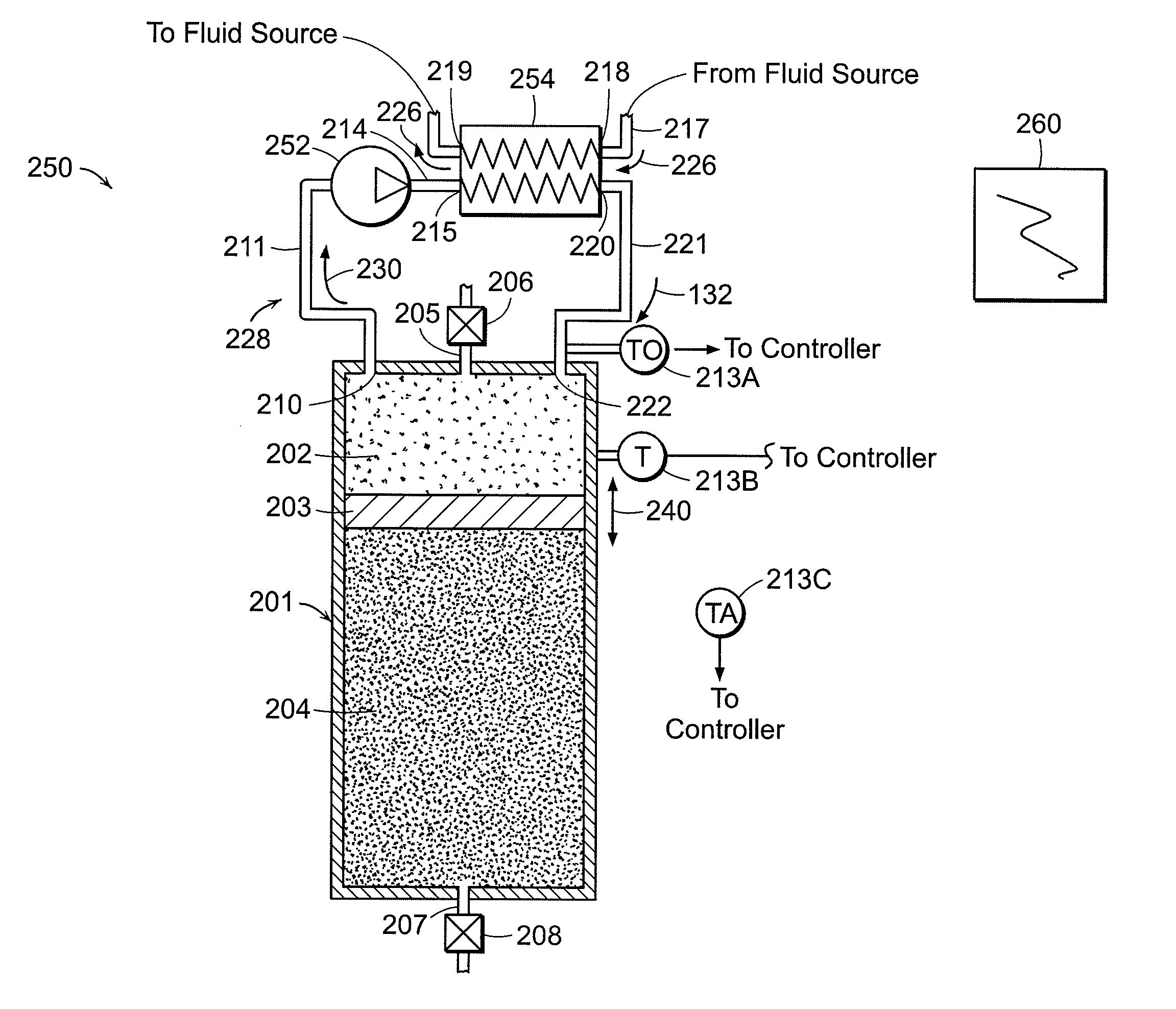

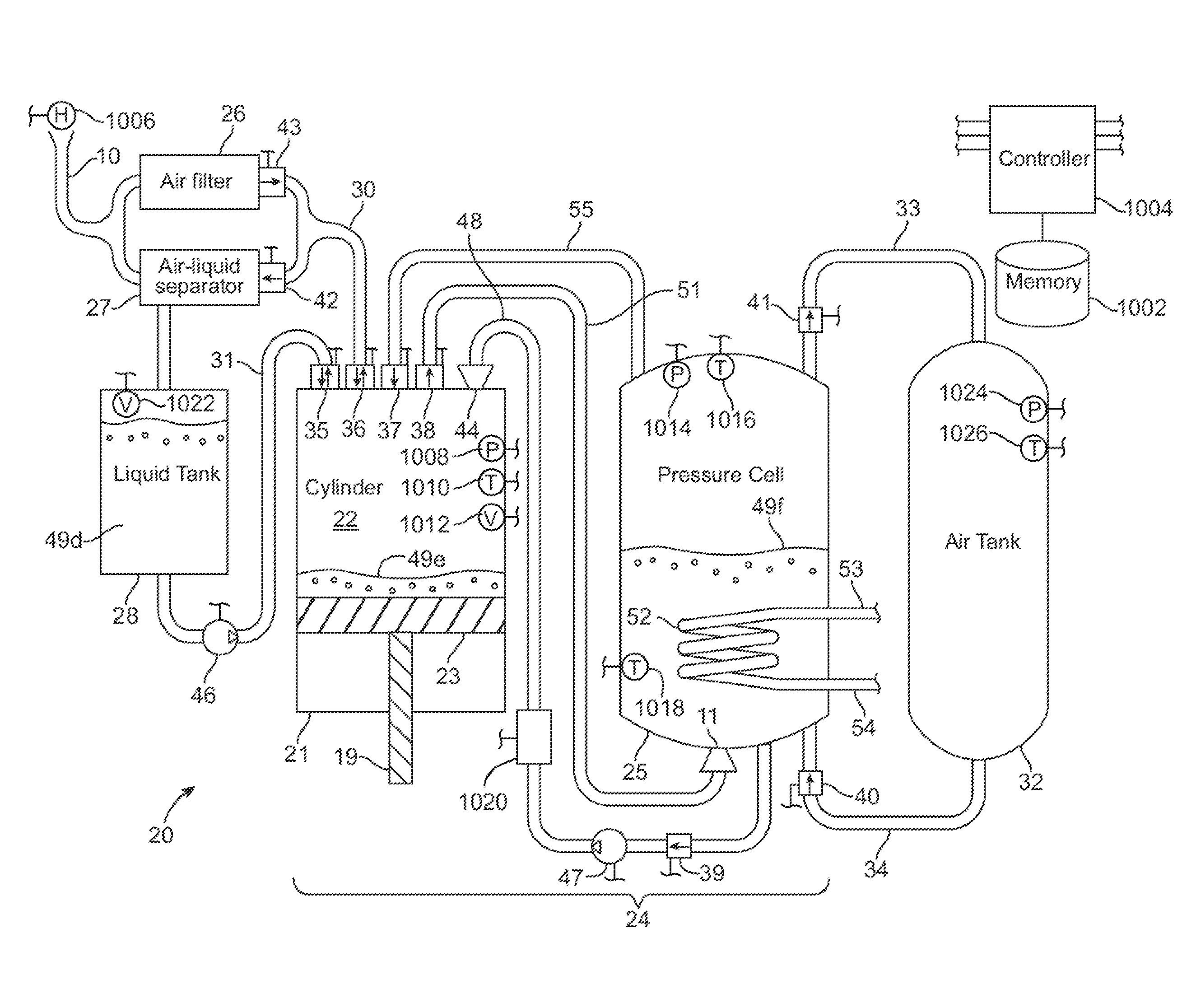

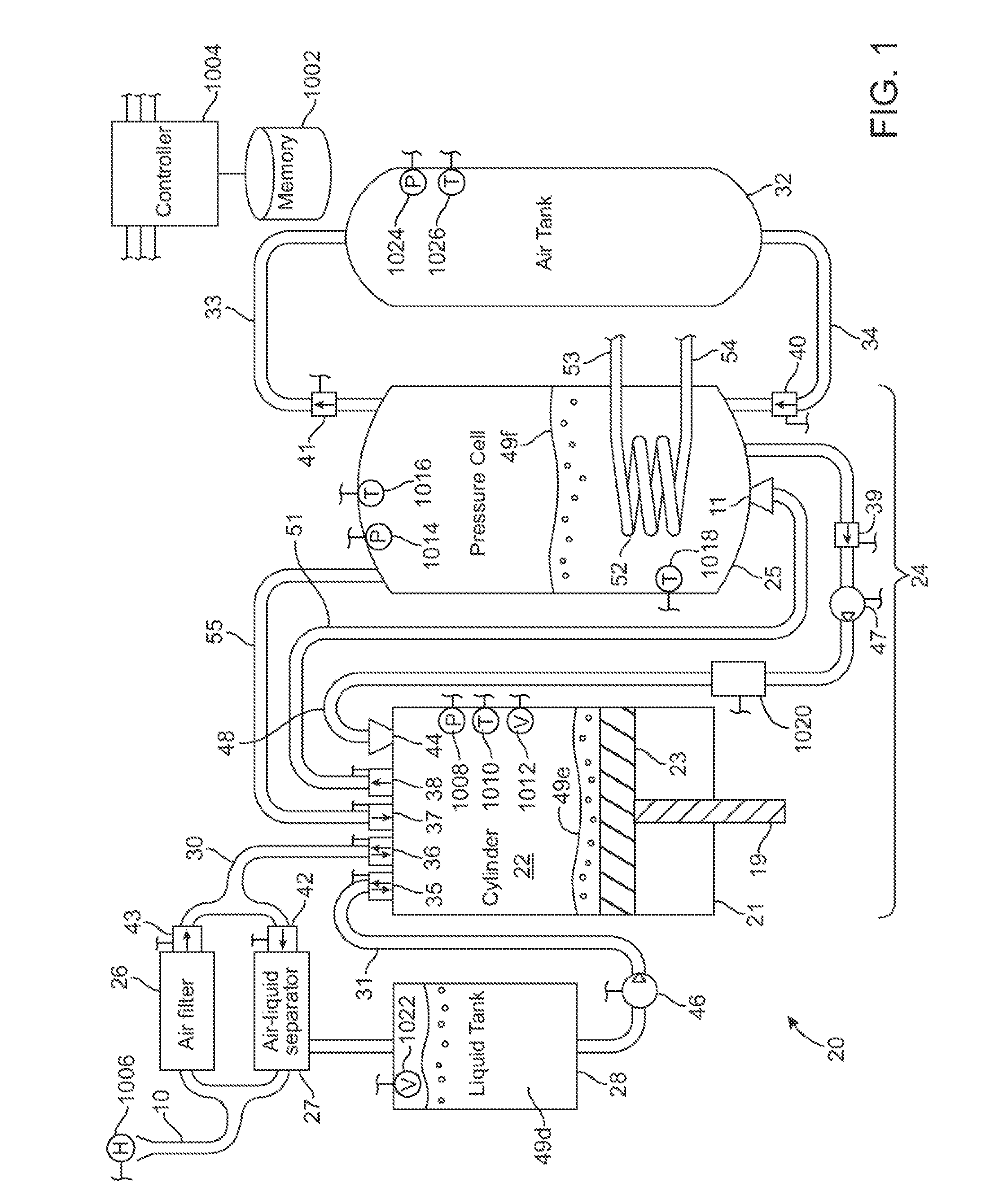

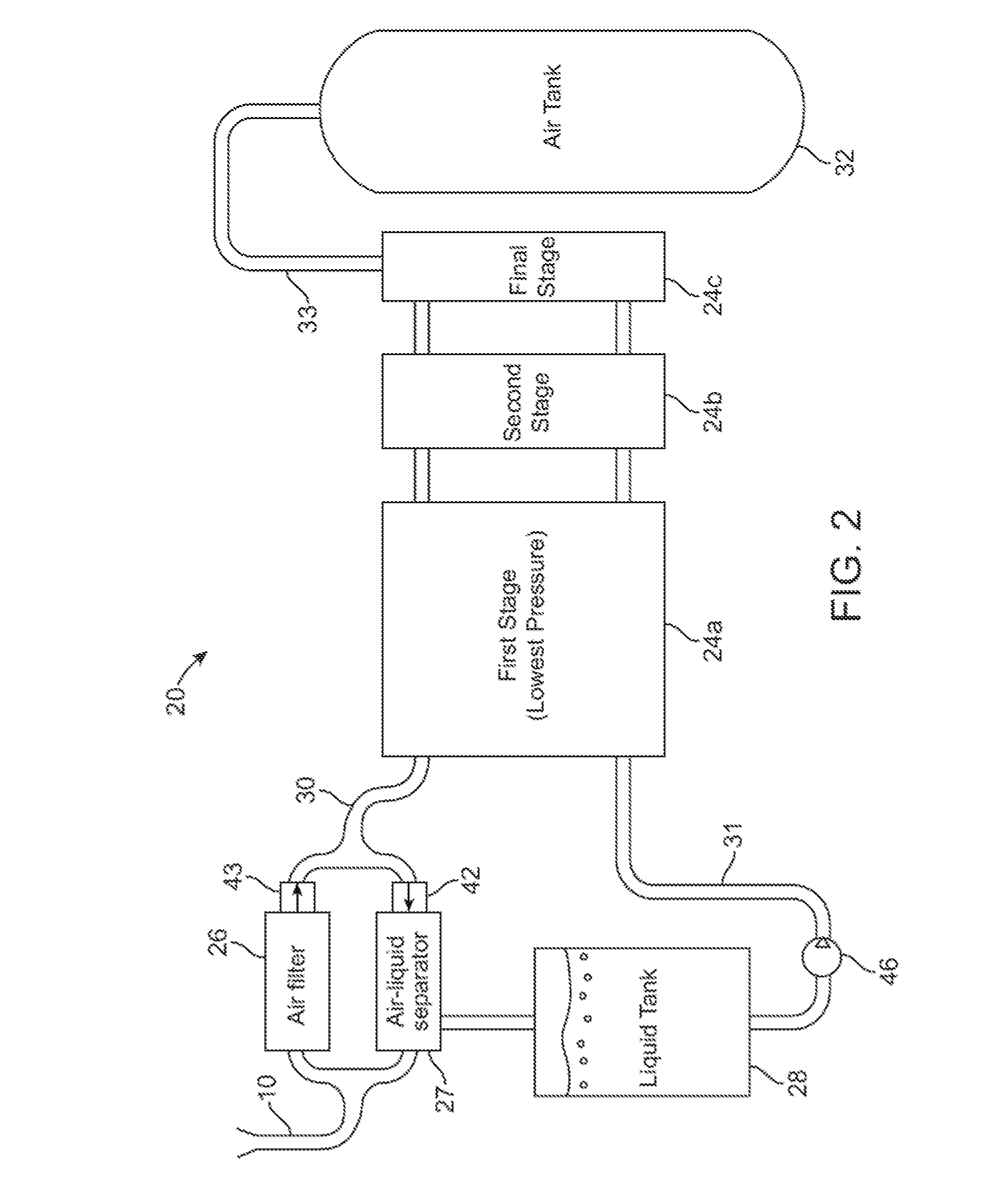

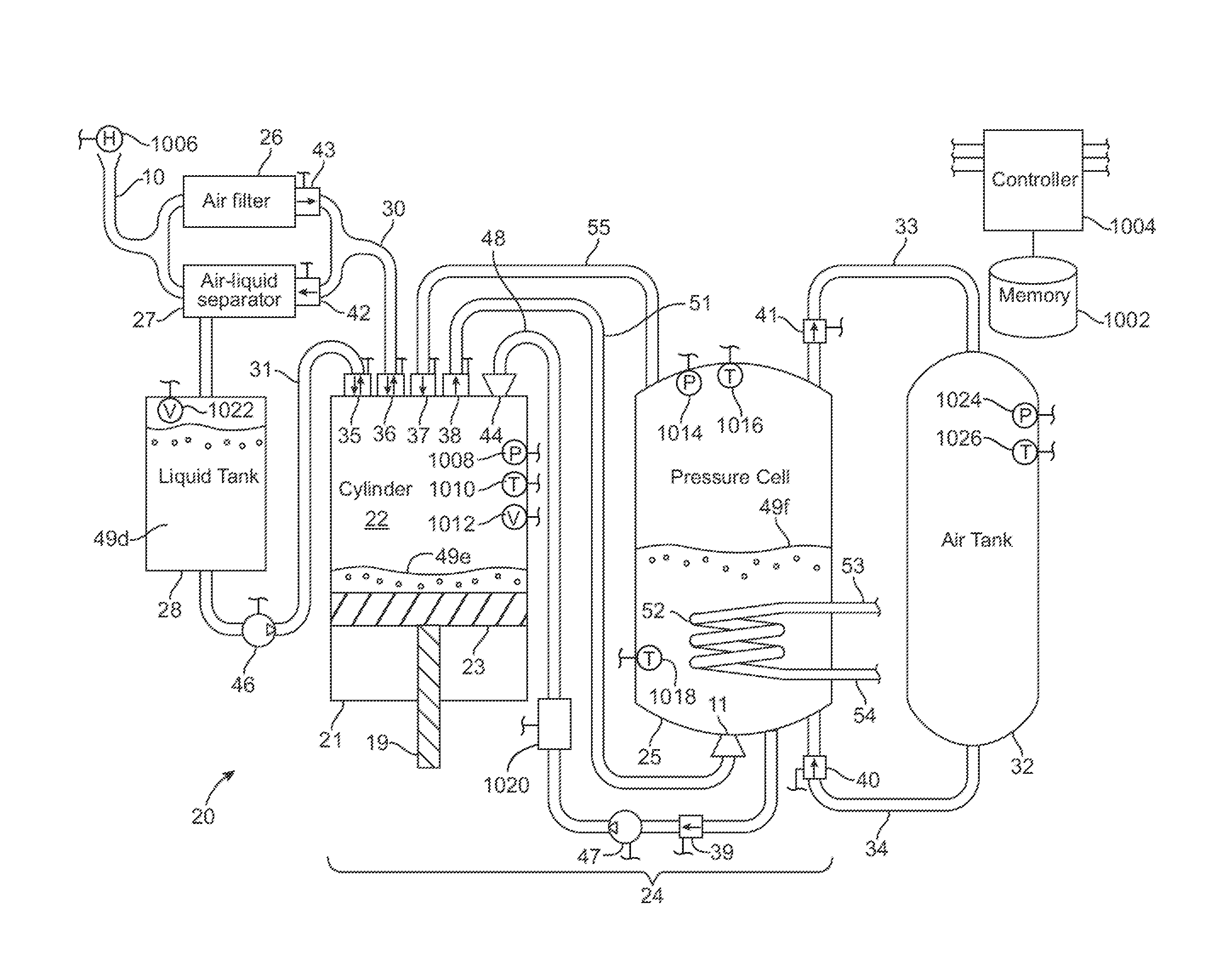

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326062A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

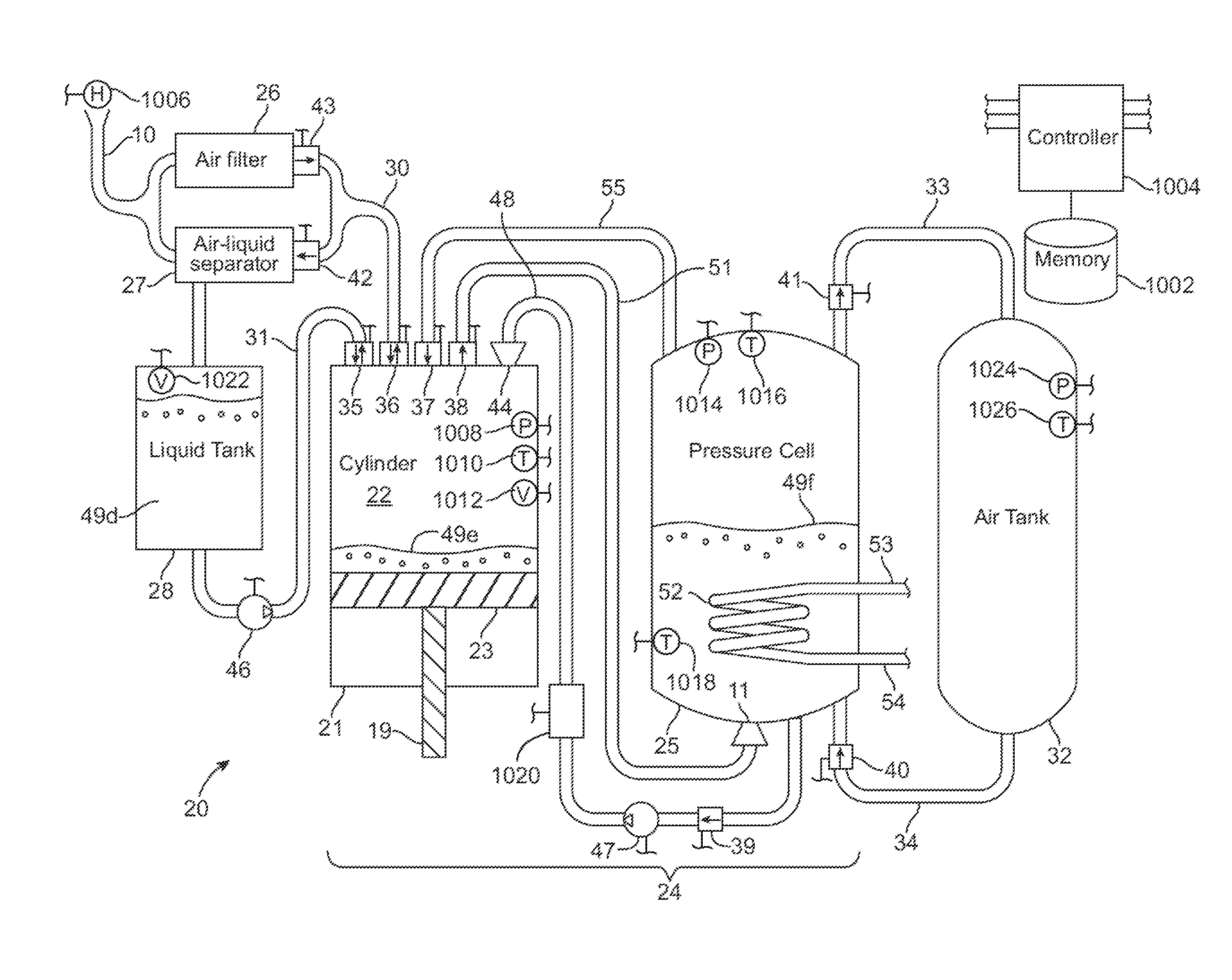

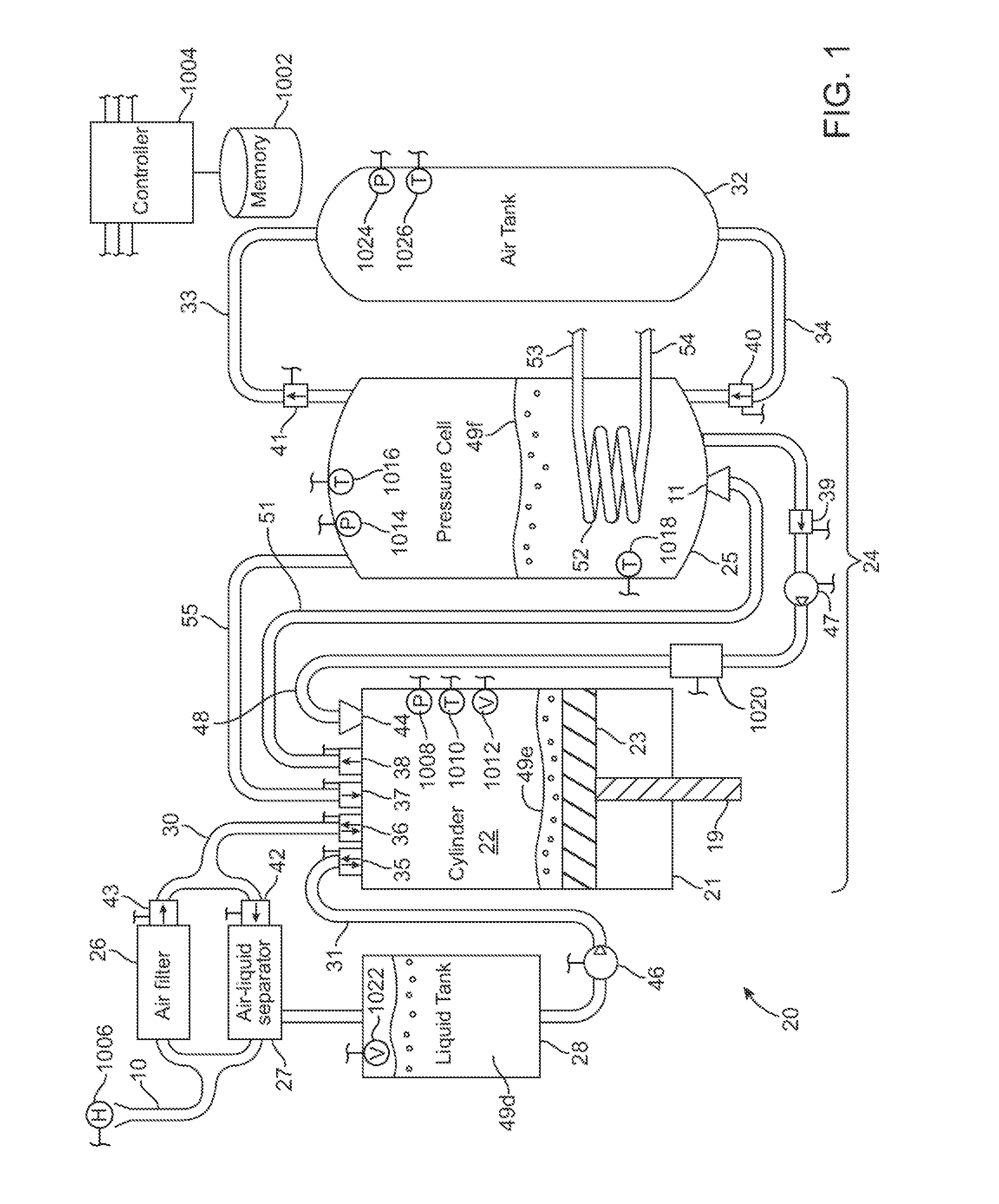

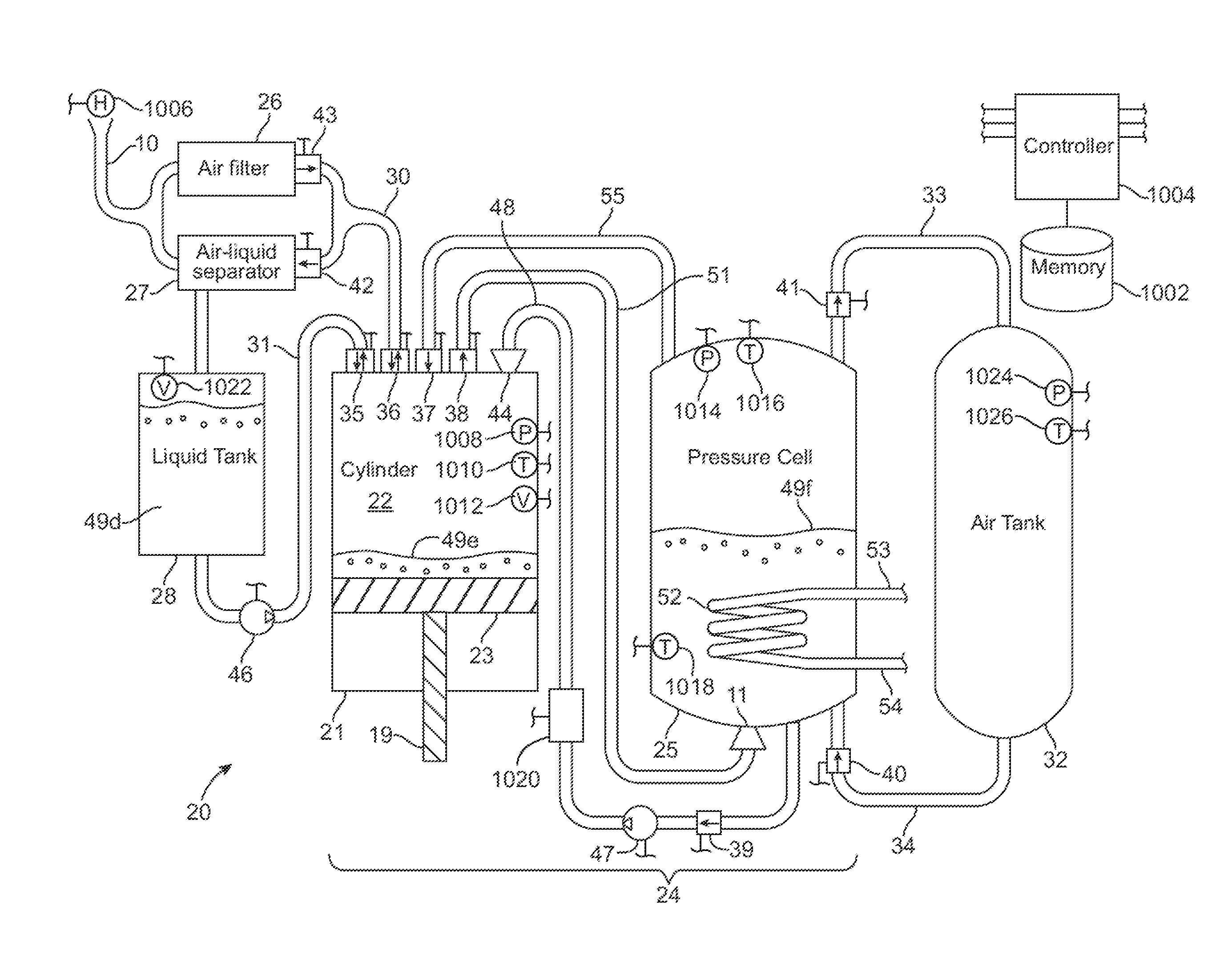

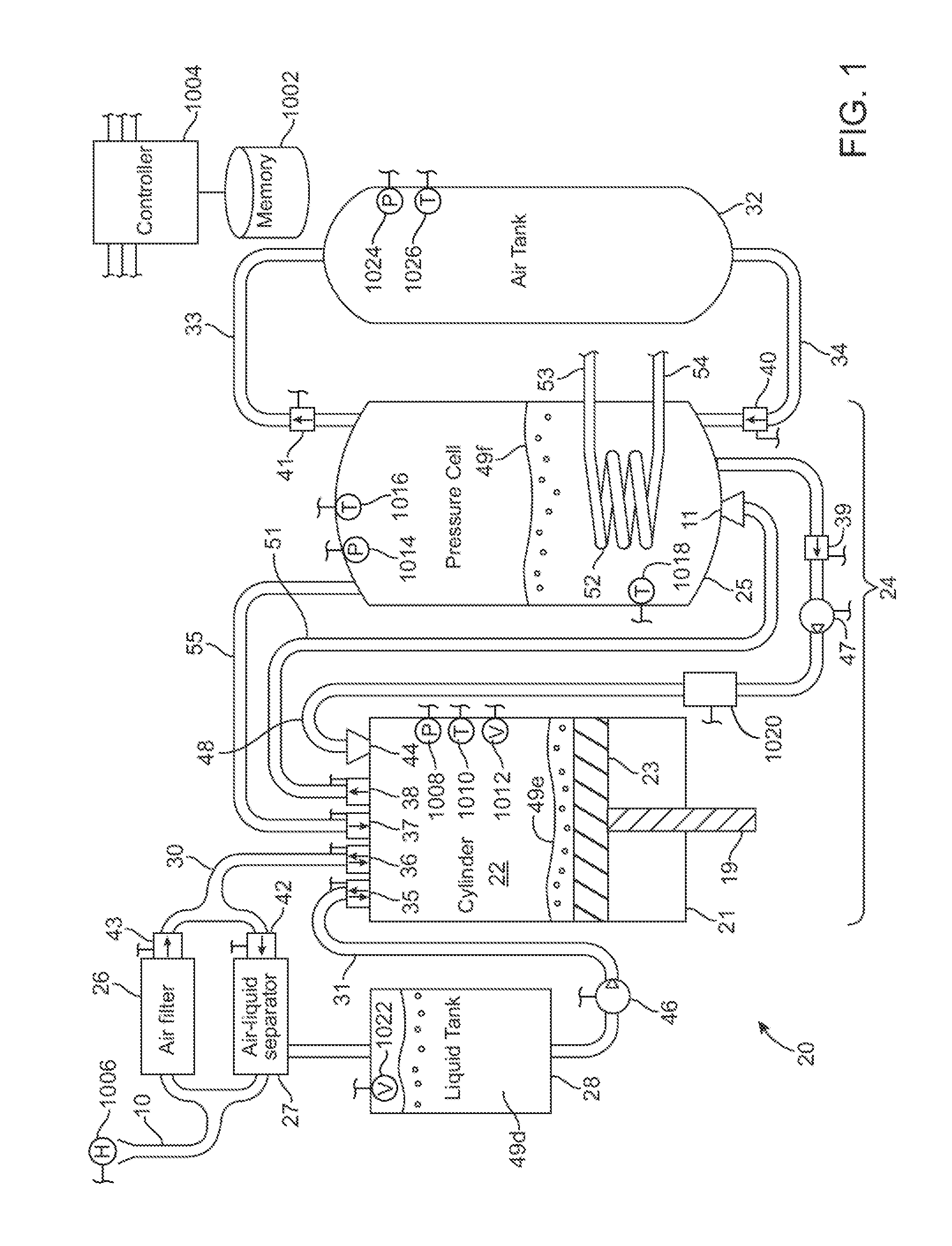

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

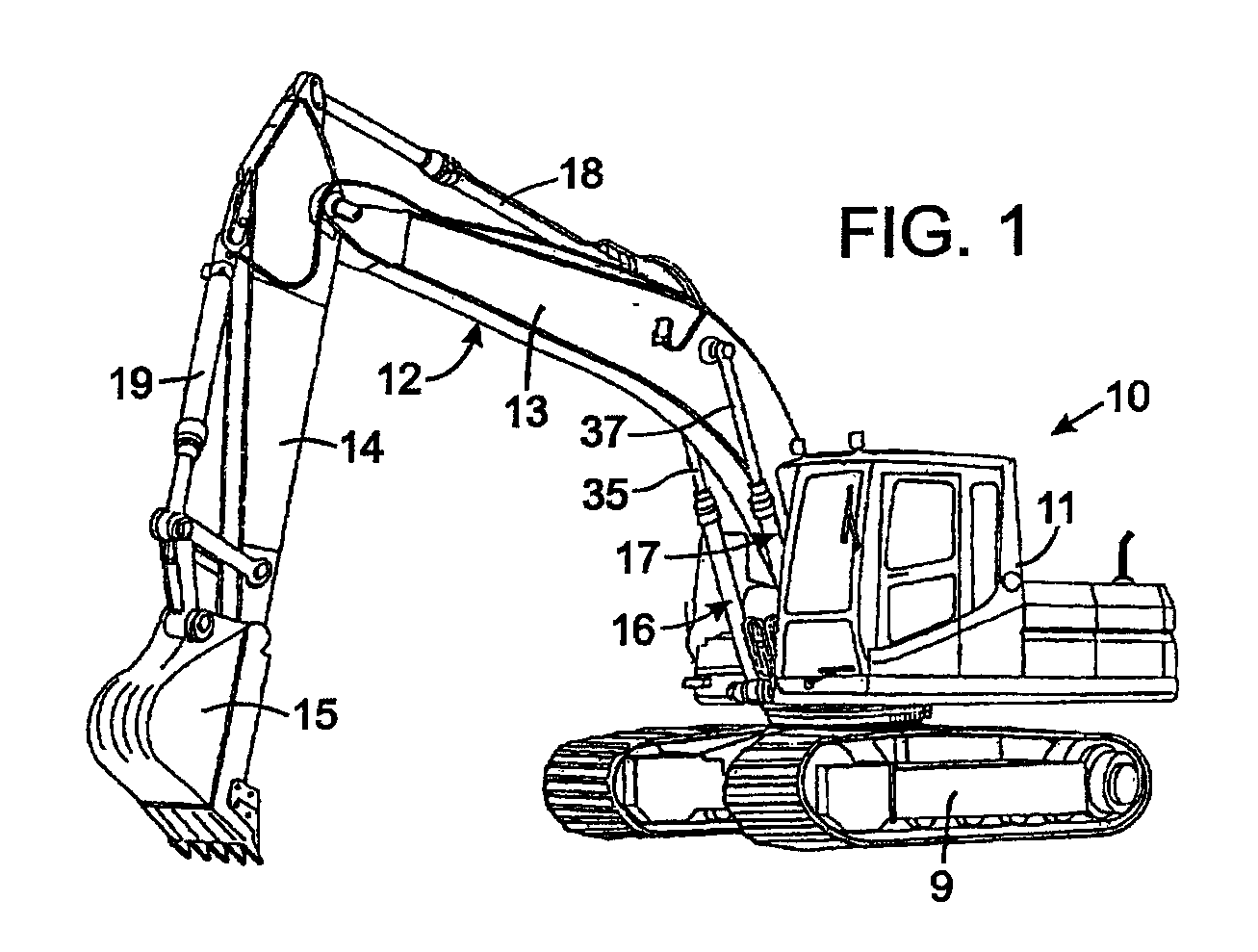

Method and device for attenuating the motion of hydraulic cylinders of mobile work machinery

InactiveUS7318292B2Good conditionServomotorsSoil-shifting machines/dredgersHydraulic cylinderEngineering

The present invention relates to a method for attenuating the motion of hydraulic cylinders of mobile work machinery, in particular of hydraulic excavators, in which prior to the hydraulic cylinder reaching one of the limits of travel, its motion speed is reduced, and the hydraulic cylinder is moved to the respective limit of travel at reduced speed; wherein for the purpose of reducing the speed, the inflow to, and / or the outflow from, the hydraulic cylinder are / is throttled by a flow control device. According to the invention, the method is characterized by, prior to the respective limit of travel being reached, the motion speed of the hydraulic cylinder is registered, and the point in time when throttling commences is changed depending on the registered motion speed. Furthermore, the present invention relates to a device for attenuating the motion of hydraulic cylinders of mobile work machinery, in particular of hydraulic excavators, a position registering device for registering a preliminary limit position of the hydraulic cylinder, a control device for throttling the inflow and / or outflow of the hydraulic cylinder, and a control device for controlling the flow control device when the preliminary limit position is reached. According the invention, the device has a speed registering device for registering the motion speed of the hydraulic cylinder when the preliminary limit position is reached, and the control device has a delay device for delaying driving the flow control device, depending on the recorded motion speed.

Owner:LIEBHERR FRANCE

Electro-hydraulic actuator system

The system includes a hydraulic powered actuator. A pump system having first and second hydraulic lines is coupled to the first and second ports, respectively and is capable of providing hydraulic fluid to either the first and second lines. First and second pressure sensors are coupled to the first and second lines, respectively. A third line is coupled between the first and second lines and includes first and second valves mounted in series therein. Preferably, the first and second valves are capable of latching in the open position. A reservoir is coupled to the third line between the first and second valves. A shut off valve is included for cutting off the flow from the reservoir.

Owner:NORTHROP GRUMMAN SYST CORP

Hydraulic system

A ground engaging vehicle including a movable member, a hydraulically driven actuator, a hydraulic pump, a plurality of valves and at least one hydraulic conduit. The hydraulically driven actuator is coupled to the movable member and the actuator has a first chamber and a second chamber. The plurality of non-proportional valves include a first valve, a second valve, a third valve and a fourth valve. The at least one hydraulic conduit couples the pump with the first valve and the second valve. The first valve is in direct fluid communication with the first chamber. The second valve is in direct fluid communication with the second chamber. The third valve is in direct fluid communication with the first chamber and the fourth valve is in direct fluid communication with the second chamber. The first valve and the second valve each include an open position and a closed position.

Owner:DEERE & CO

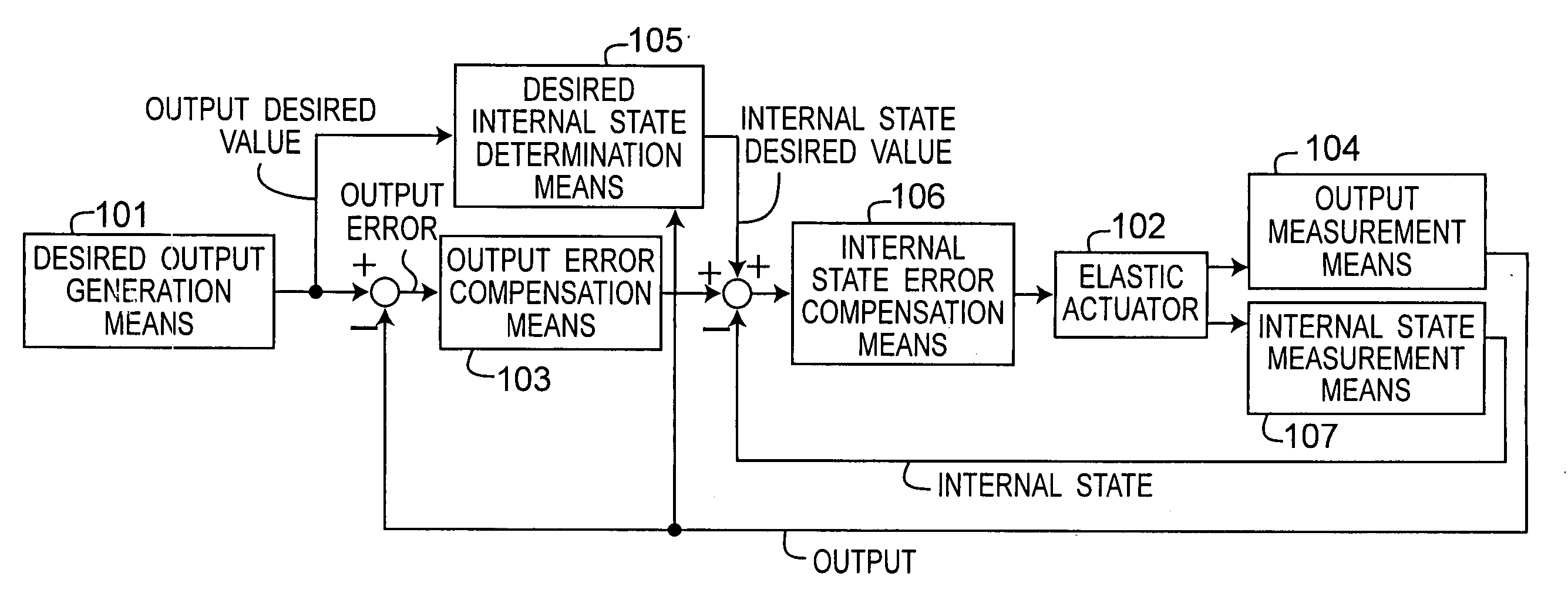

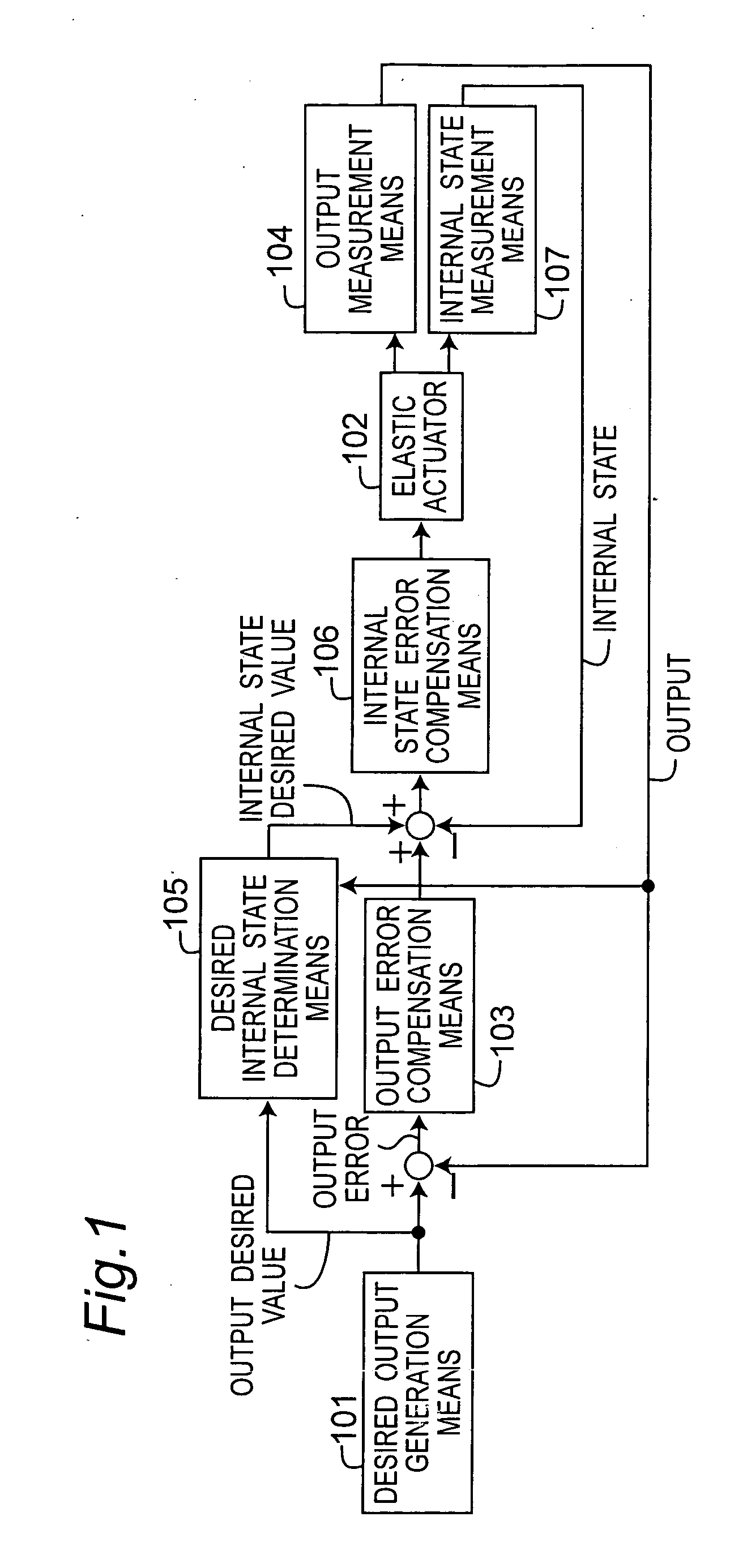

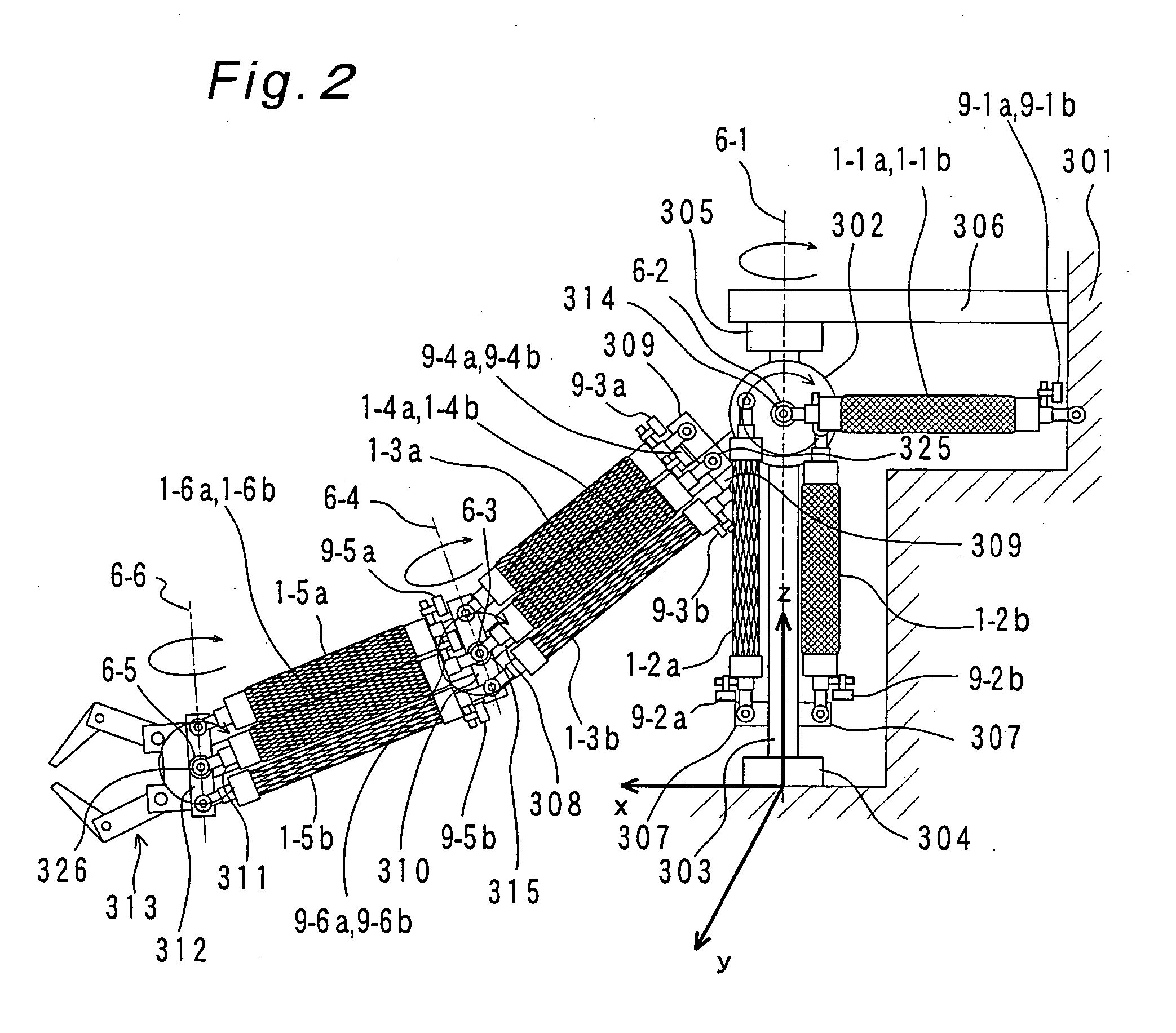

Apparatus and method for controlling elastic actuator

ActiveUS20060207419A1Rapid responseLow steady-state deviationProgramme-controlled manipulatorLiquid surface applicatorsInternal pressureMeasurement device

An internal pressure of a hydropneumatic drive actuator is measured by a pressure measurement device, a displacement amount of a movable mechanism is measured, a desired value and a measurement value of the displacement are inputted so that a position error is compensated by a position error compensation device, a desired value of a pressure difference of the actuator to which antagonistic driving is performed by the desired value is calculated by a desired pressure difference calculation device, outputs from the position error compensation device, the desired pressure difference calculation device, and the pressure measurement device are inputted, and a pressure difference error is compensated by pressure difference error compensation device.

Owner:PANASONIC CORP

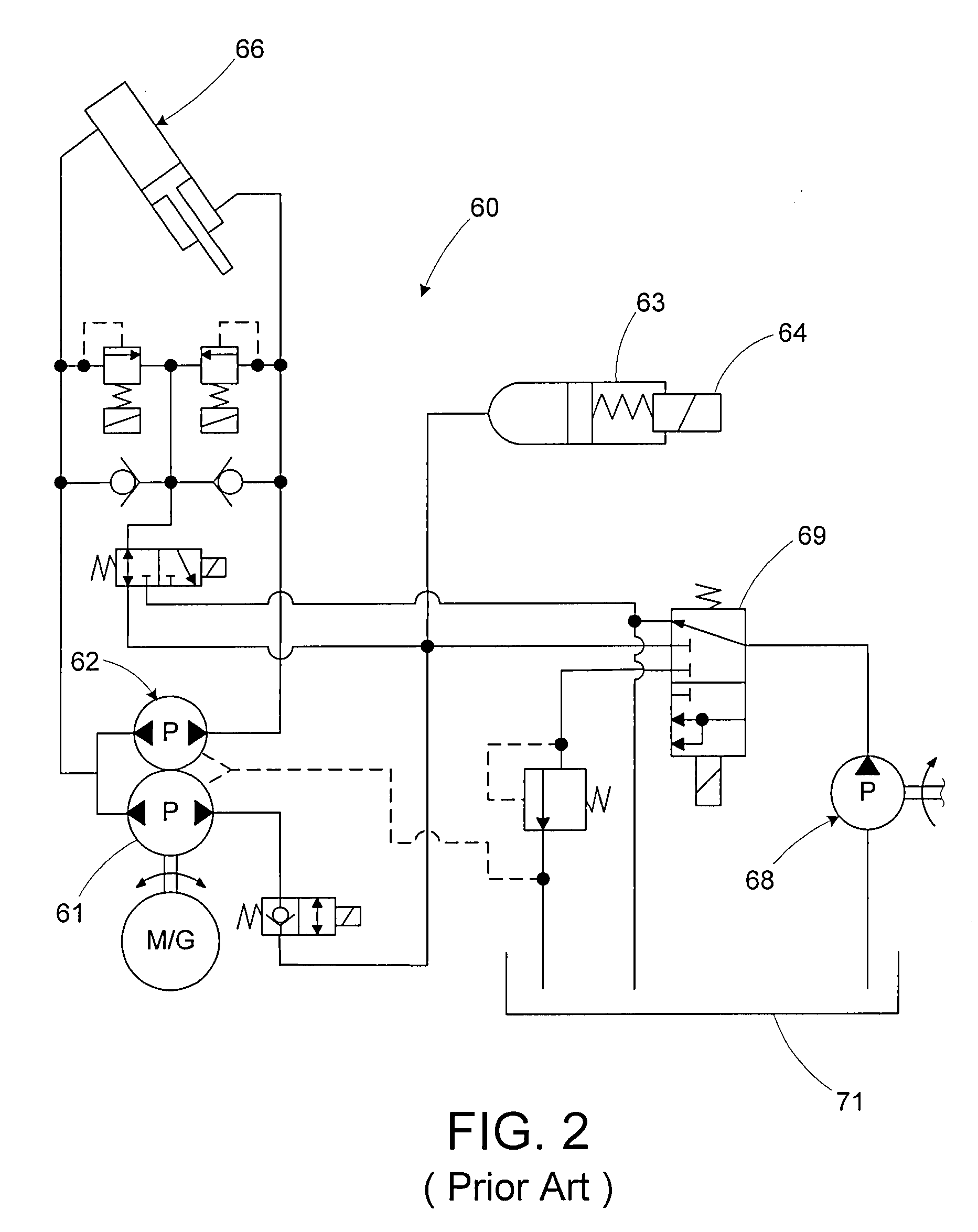

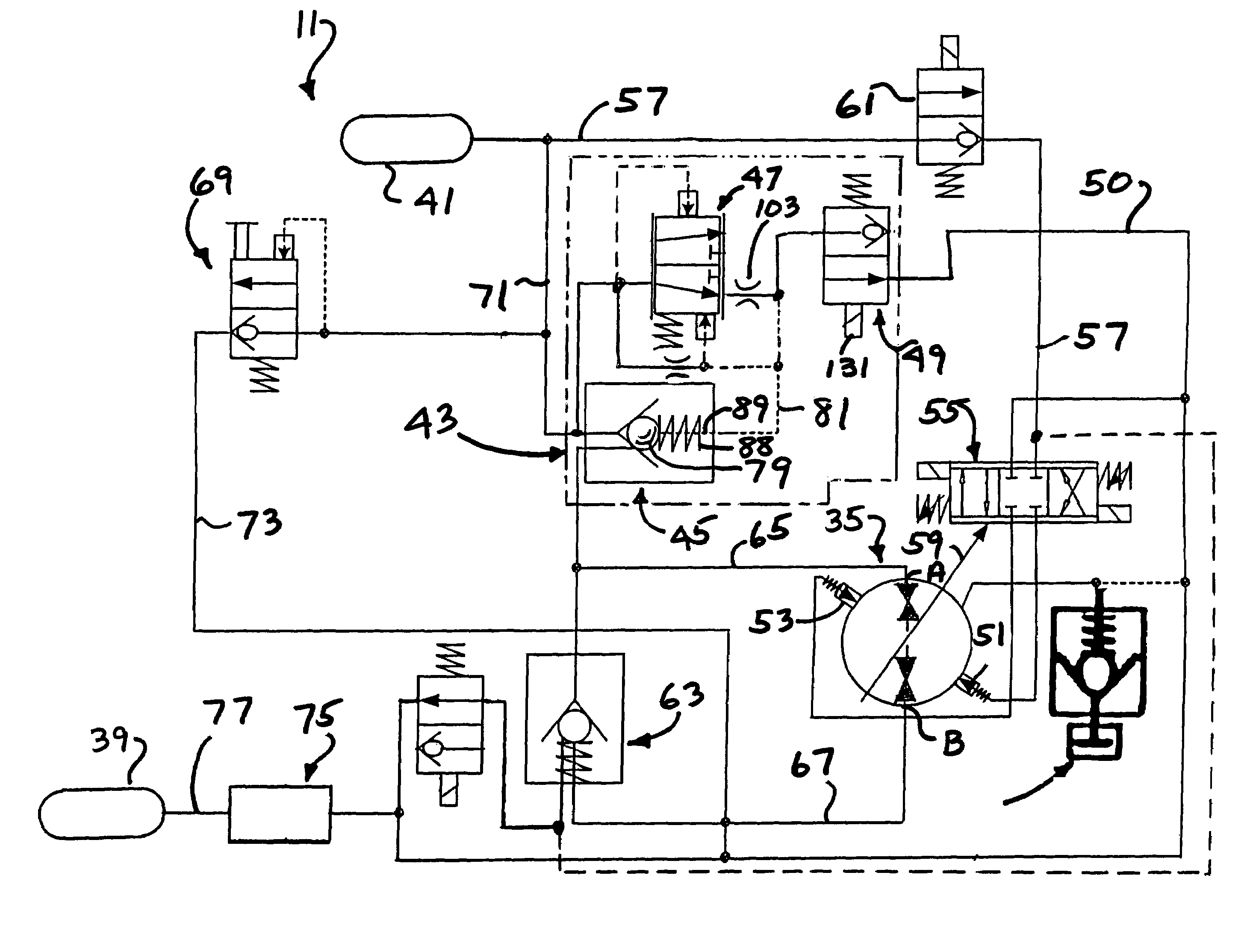

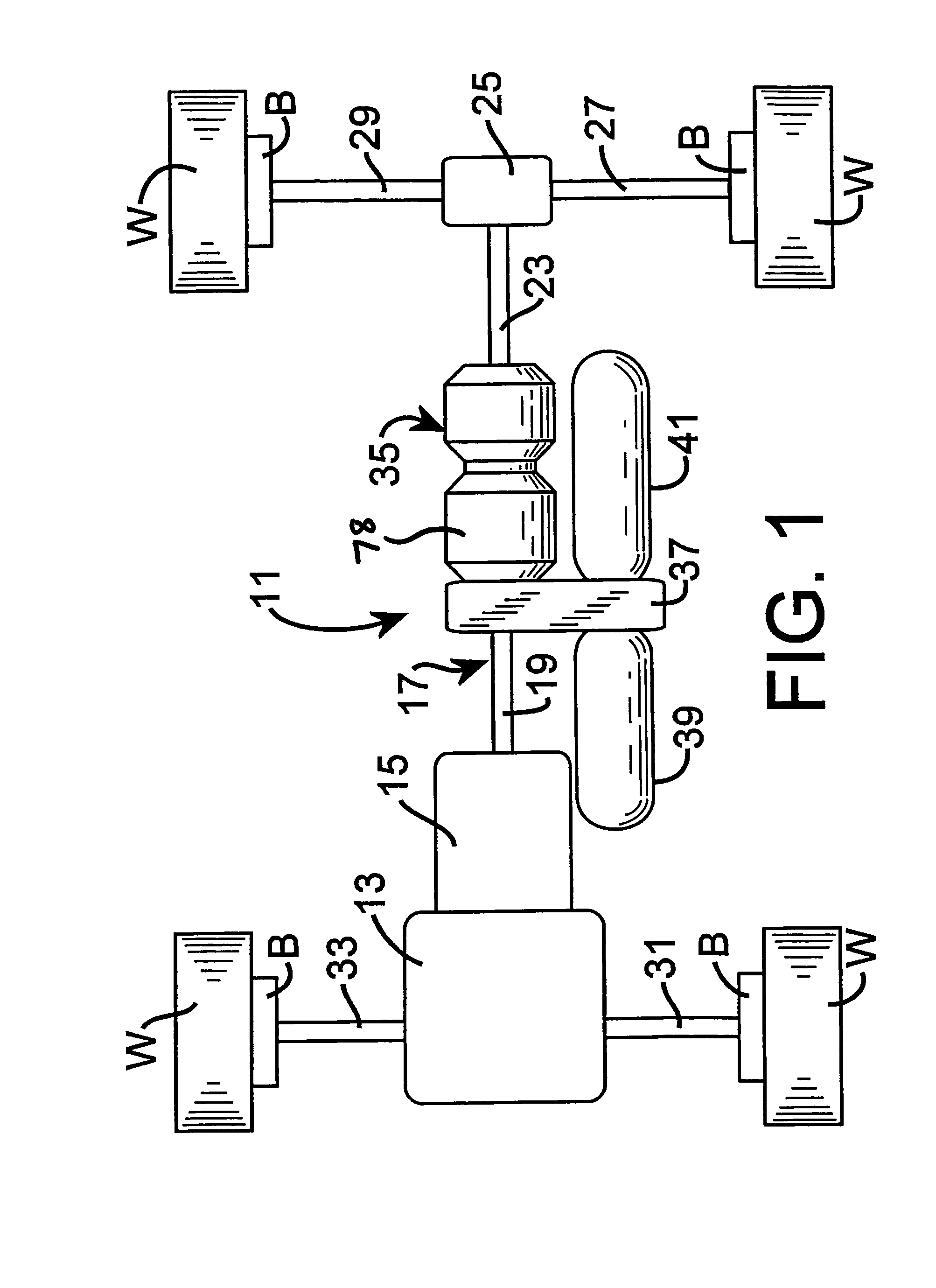

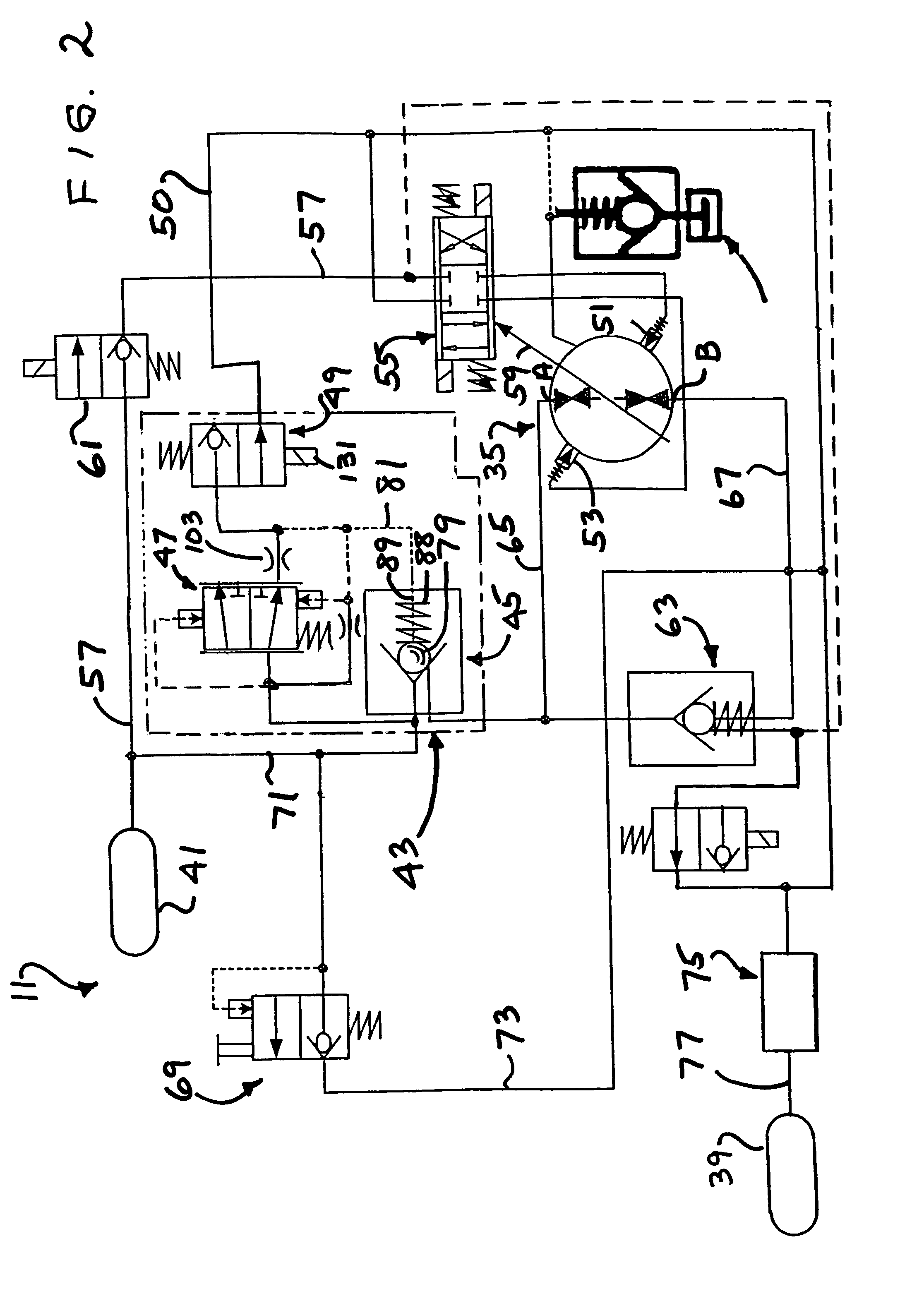

Hydraulic drive system and improved control valve assembly therefor

InactiveUS6971232B2Fast response timeSmall pressure dropBraking element arrangementsServomotor componentsEngineeringHigh pressure

A control valve assembly (43) for use in a system in which a pump-motor unit (35) can either receive drive torque from a drive-line (17) or transmit torque thereto. The system includes a high pressure accumulator (41) and the control valve assembly is disposed between the pump-motor unit and the accumulator, and includes a mode valve (45) normally biased closed by pressure in a control cavity (89), the fluid pressure in which is controlled by a pilot valve assembly (49) in response to an electrical signal (133). A step-orifice valve (47) associated with the mode valve poppet member (79) provides a relatively larger orifice (115) into the control cavity (89) when pressure therein is high, and a relatively smaller orifice (119) into the control cavity when pressure therein is low, i.e., when the pilot valve assembly (49) is open. Thus, a large volume of flow can occur from the accumulator to the unit (35) in a motoring mode, with a relatively low pressure drop, while the poppet member is able to have softer, relatively longer opening time, but a relatively faster closing time.

Owner:EATON CORP

Energy recovery system

Owner:CATERPILLAR INC

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326069A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

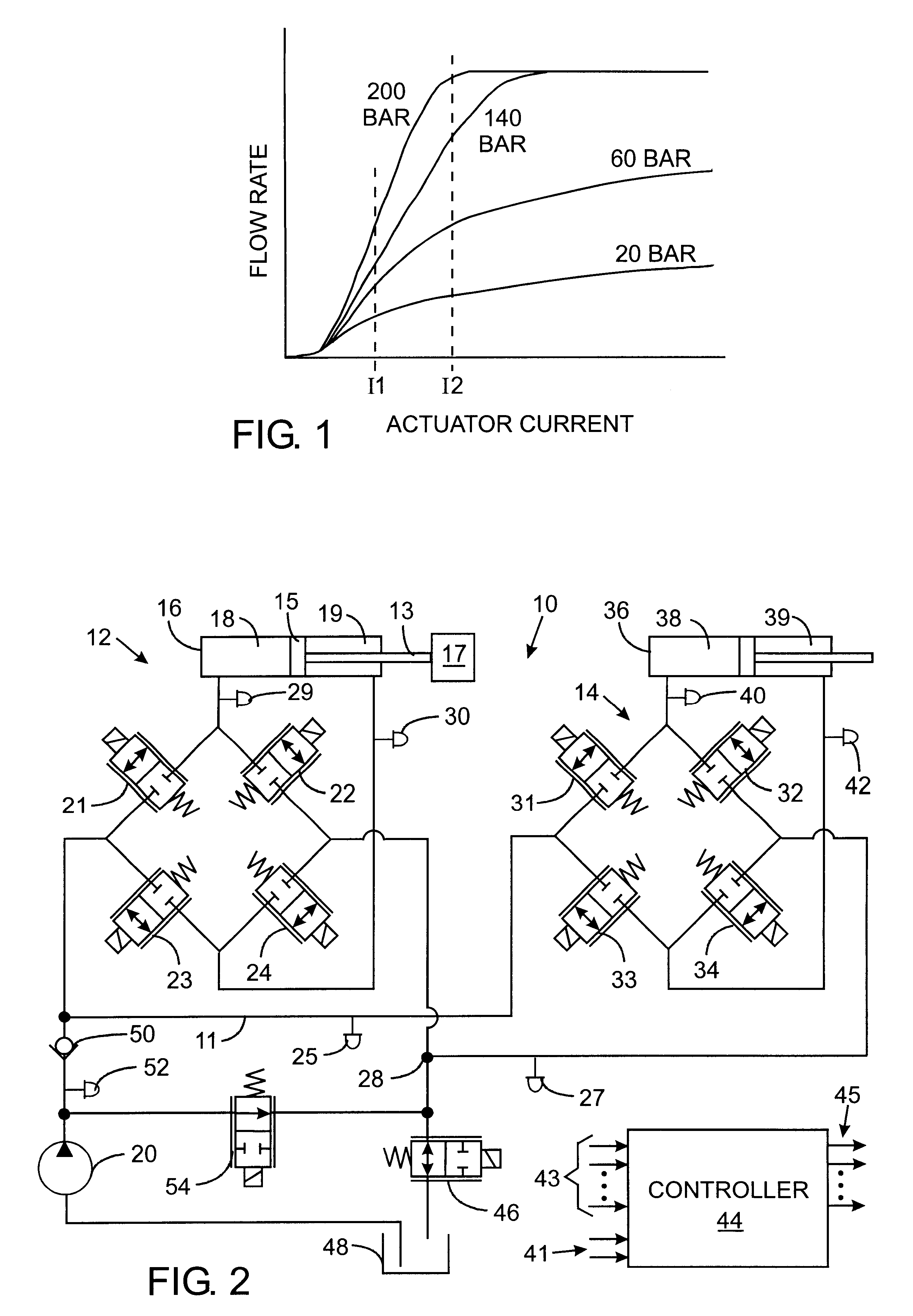

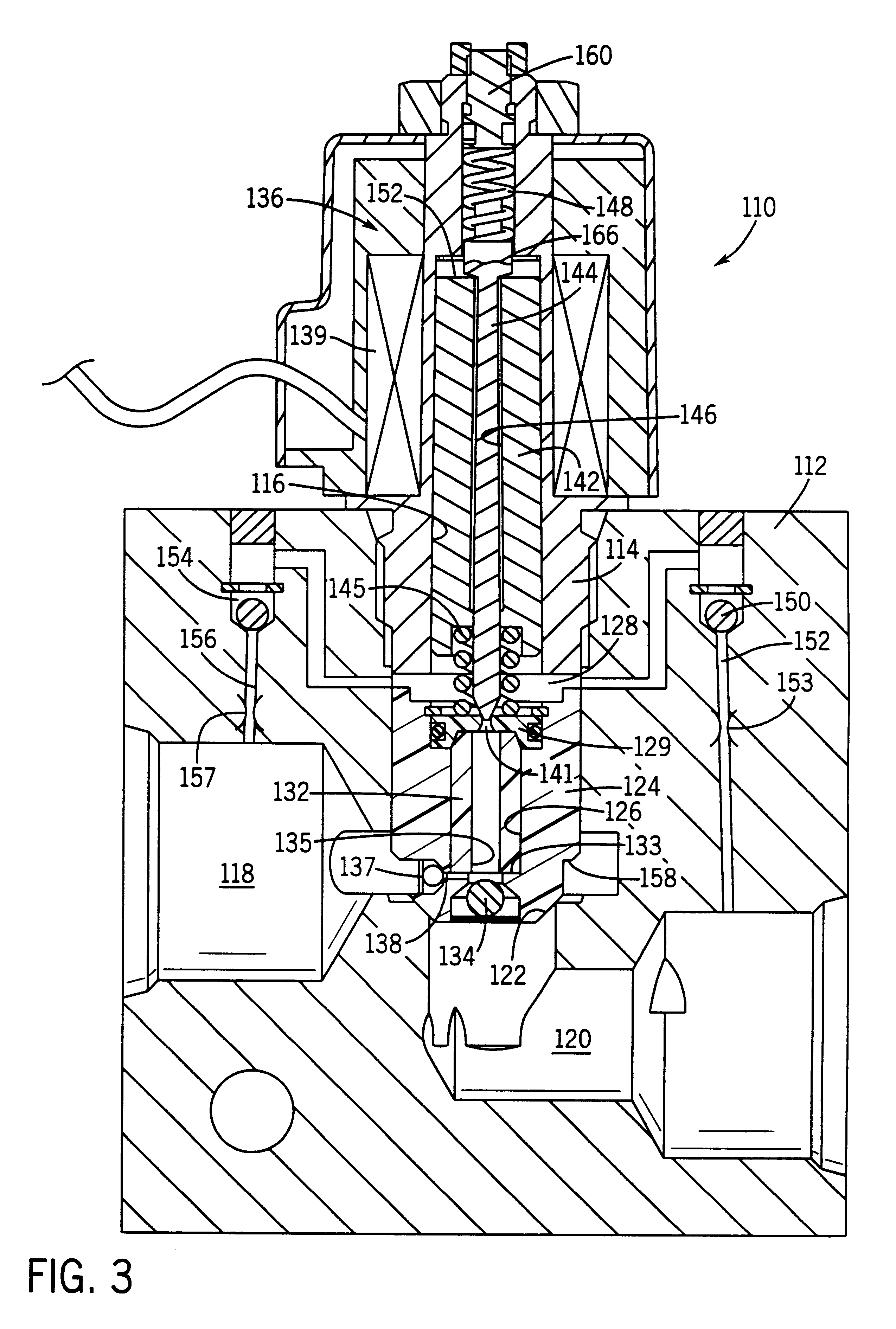

Multi-actuator pressure-based flow control system

A hydraulic control system for a work machine is disclosed. The hydraulic control system has a fluid actuator, a supply of pressurized fluid, and a control valve movable to selectively pass pressurized fluid to the fluid actuator. The hydraulic control system also has a sensor configured to sense the pressure of the pressurized fluid passed to the fluid actuator and a controller in communication with the control valve and the sensor. The controller is configured to receive an input indicative of a desired velocity of the fluid actuator and to determine a fluid flow rate corresponding to the desired velocity. The controller is also configured to determine a ratio of the sensed pressure to a stall pressure of the supply and to scale down the determined flow rate an amount based on the determined ratio. The controller is further configured to move the control valve an amount corresponding to the scaled down flow rate.

Owner:CATEPILLAR SARL +2

Hydraulic circuit, energy recovery device, and hydraulic circuit for work machine

InactiveUS20090288408A1Increase speedImprove work efficiencyFluid couplingsServomotor componentsSolenoid valveHydraulic circuit

A hydraulic circuit that enables smooth absorption of the energy of a return fluid from a hydraulic actuator by means of an energy recovery motor. A return fluid passage to which the fluid discharged from a boom cylinder is branched is provided at the tank passage side of a solenoid valve of a boom control circuit. The return fluid passage comprises two return passages, which are provided with a flow rate ratio control valve for controlling a ratio of fluid that branches off into the return passages. The flow rate ratio control valve is comprised of a solenoid valve disposed in the return passage, which is provided with an energy recovery motor, and a solenoid valve disposed in the return passage, which branches off the upstream side of the solenoid valve.

Owner:CATEPILLAR SARL

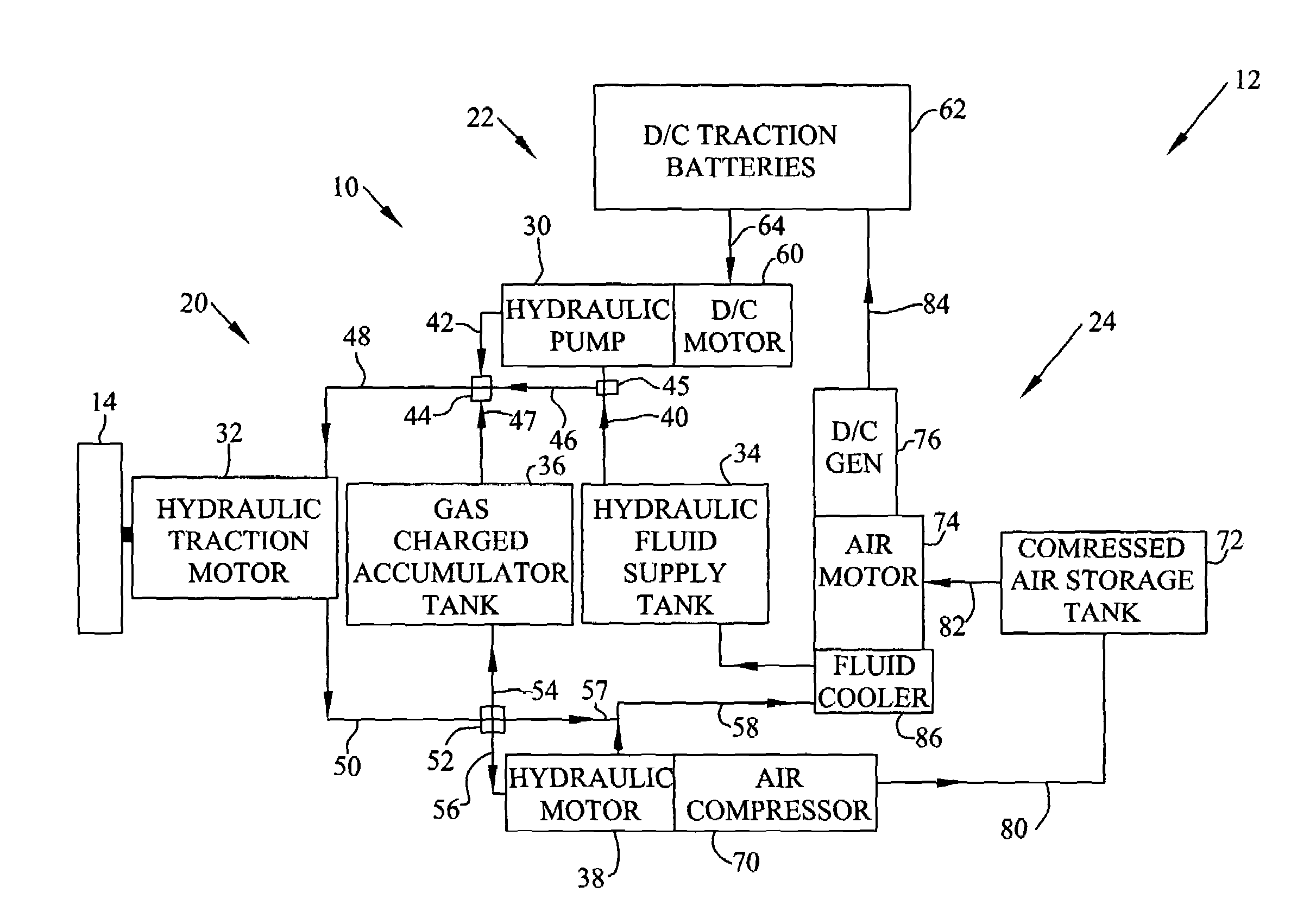

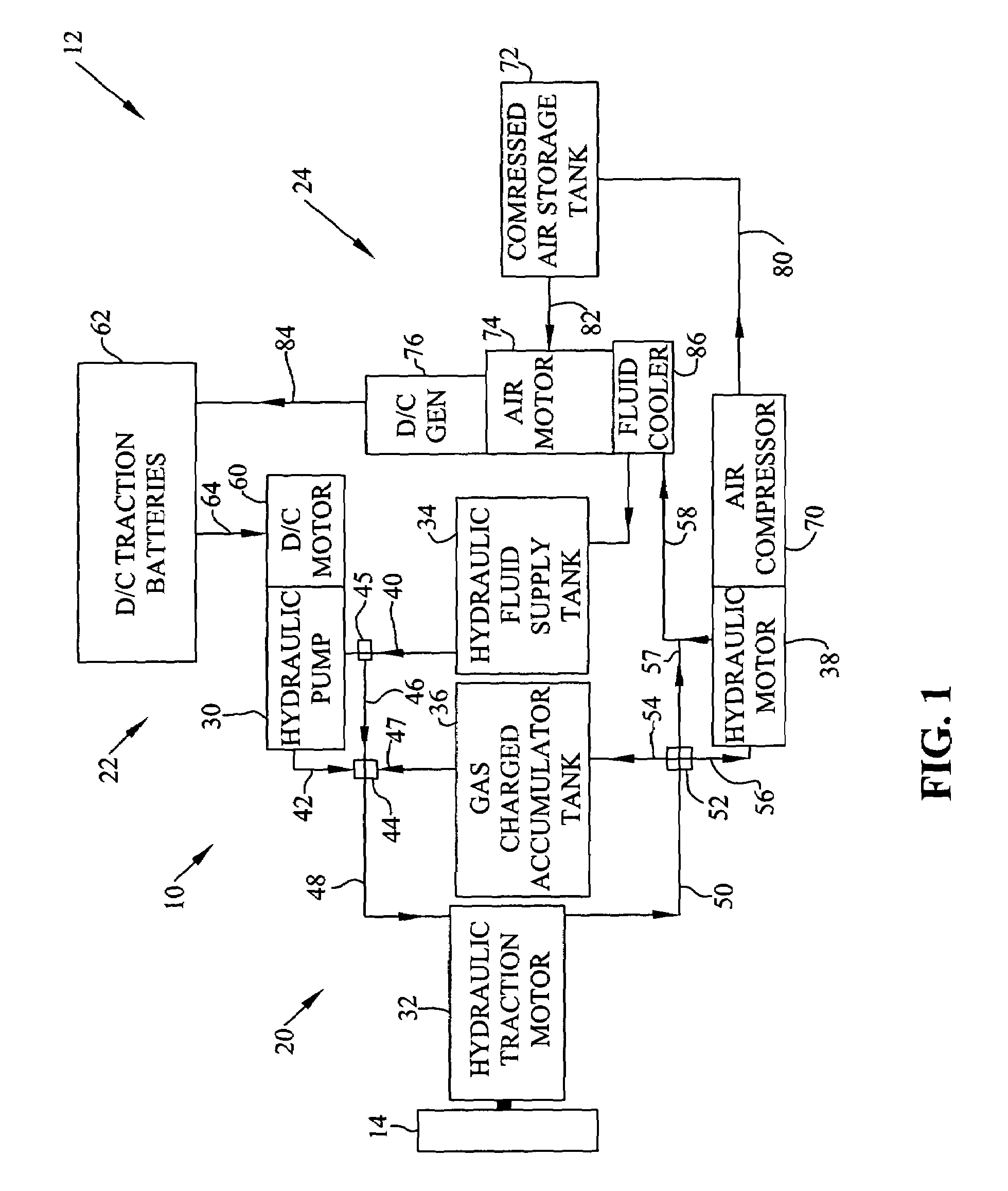

Vehicle system to recapture kinetic energy

A fluid drive system that can be used to drive a vehicle and has energy regeneration and storage capabilities. The fluid drive system includes an electrical energy supply source mounted on the vehicle, at least one electrical motor electrically connected to the electrical supply source, and a hydraulic pump driven that may be of the variable displacement type by the electrical motor. The fluid drive system may also include a low pressure hydraulic fluid supply tank supplying fluid to the hydraulic pump, at least one pneumatically charged accumulator tank for storing pressurized hydraulic fluid, a combination hydraulic motor and pump that may also be of the variable displacement type being alternately driven by the hydraulic pump and the pneumatically charged accumulator tank; and an electrical regeneration system for regenerating the electrical energy supply. The electrical regeneration system may be powered by hydraulic fluid from the combination electrical motor and pump. The combination hydraulic motor and pump propels the vehicle during acceleration and speed maintaining operations and may also serves as a braking mechanism during deceleration of the vehicle. The combination hydraulic motor and pump may also pump hydraulic fluid into the pneumatically charged accumulator tank during at least a portion of the time that the vehicle is decelerating. The combination hydraulic motor and pump may further pump hydraulic fluid for powering the electrical regeneration system when the pneumatically charged accumulator tank is fully pressurized. The electrical regeneration system also has the ability to recharge the electrical energy supply while the vehicle is stopped using stored recovered kinetic energy.

Owner:PARKER I L L C +1

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326068A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326064A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

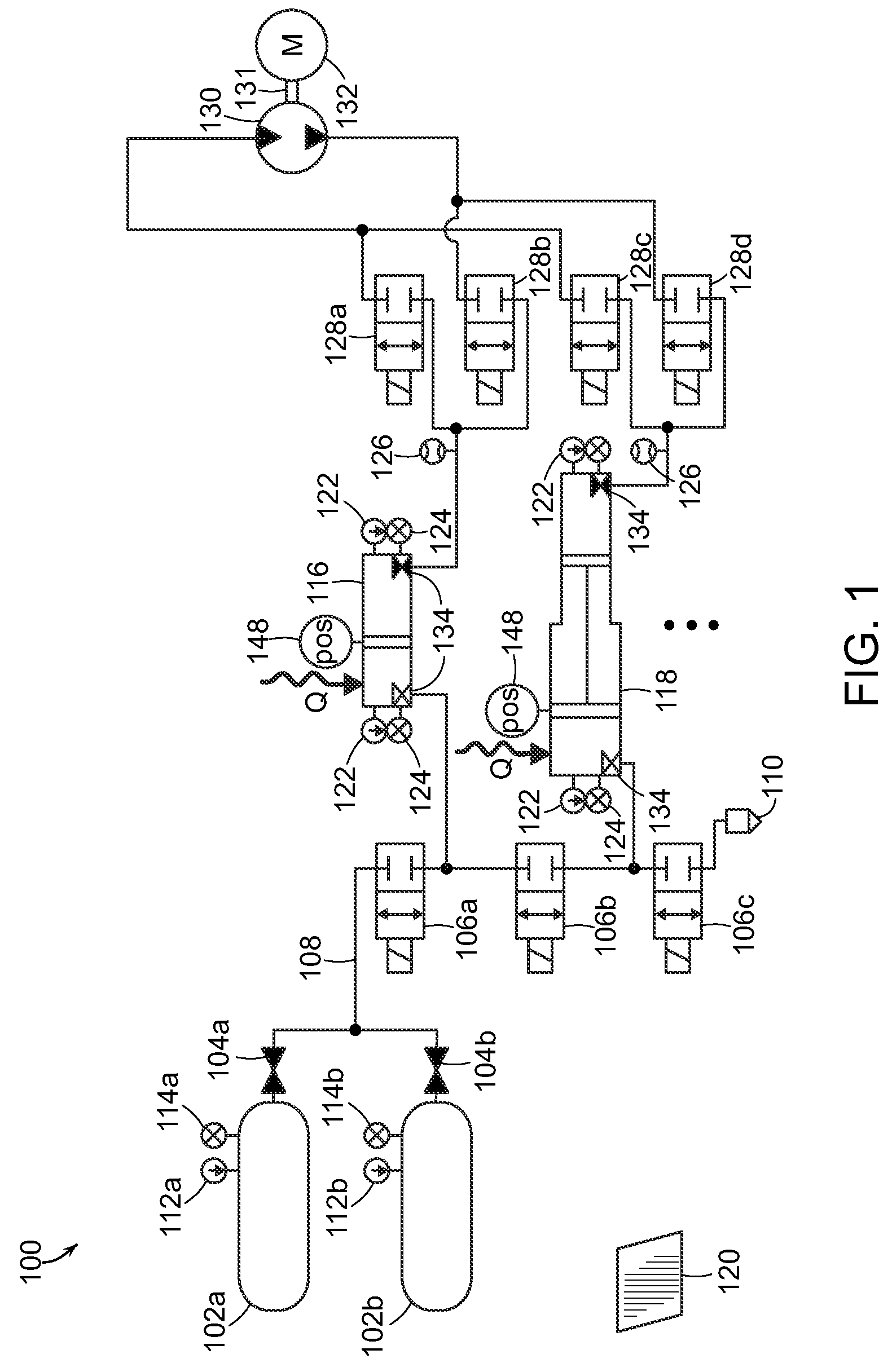

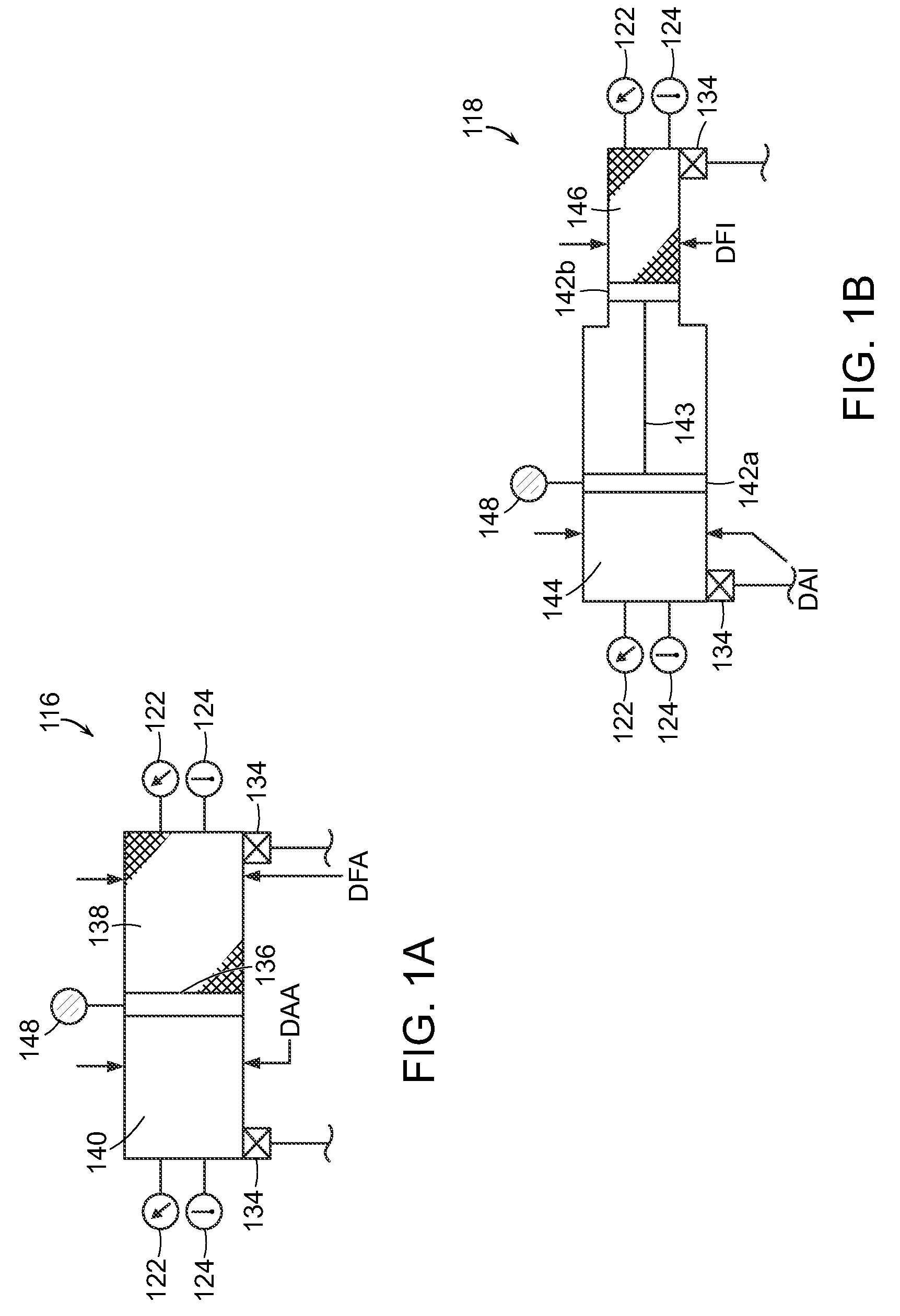

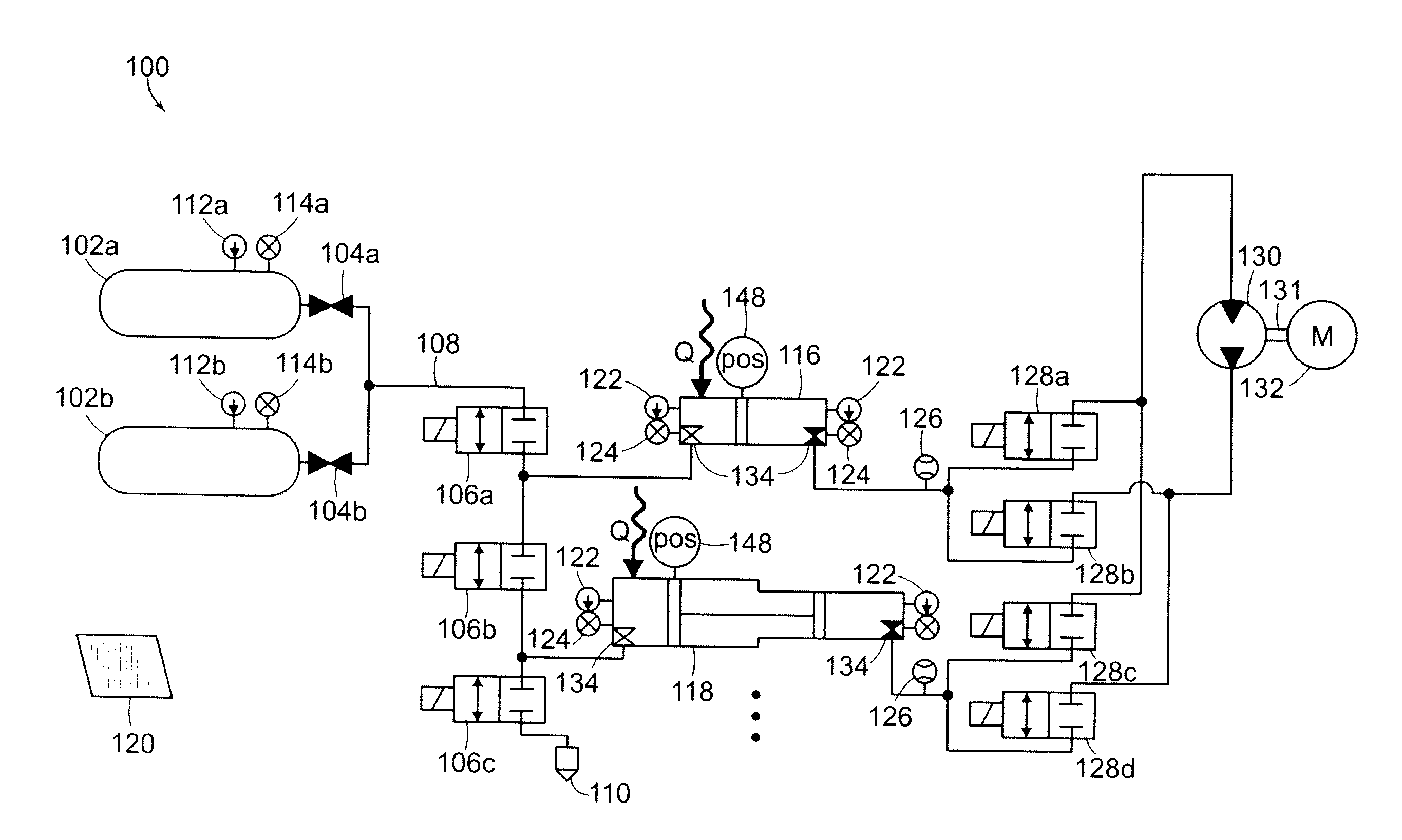

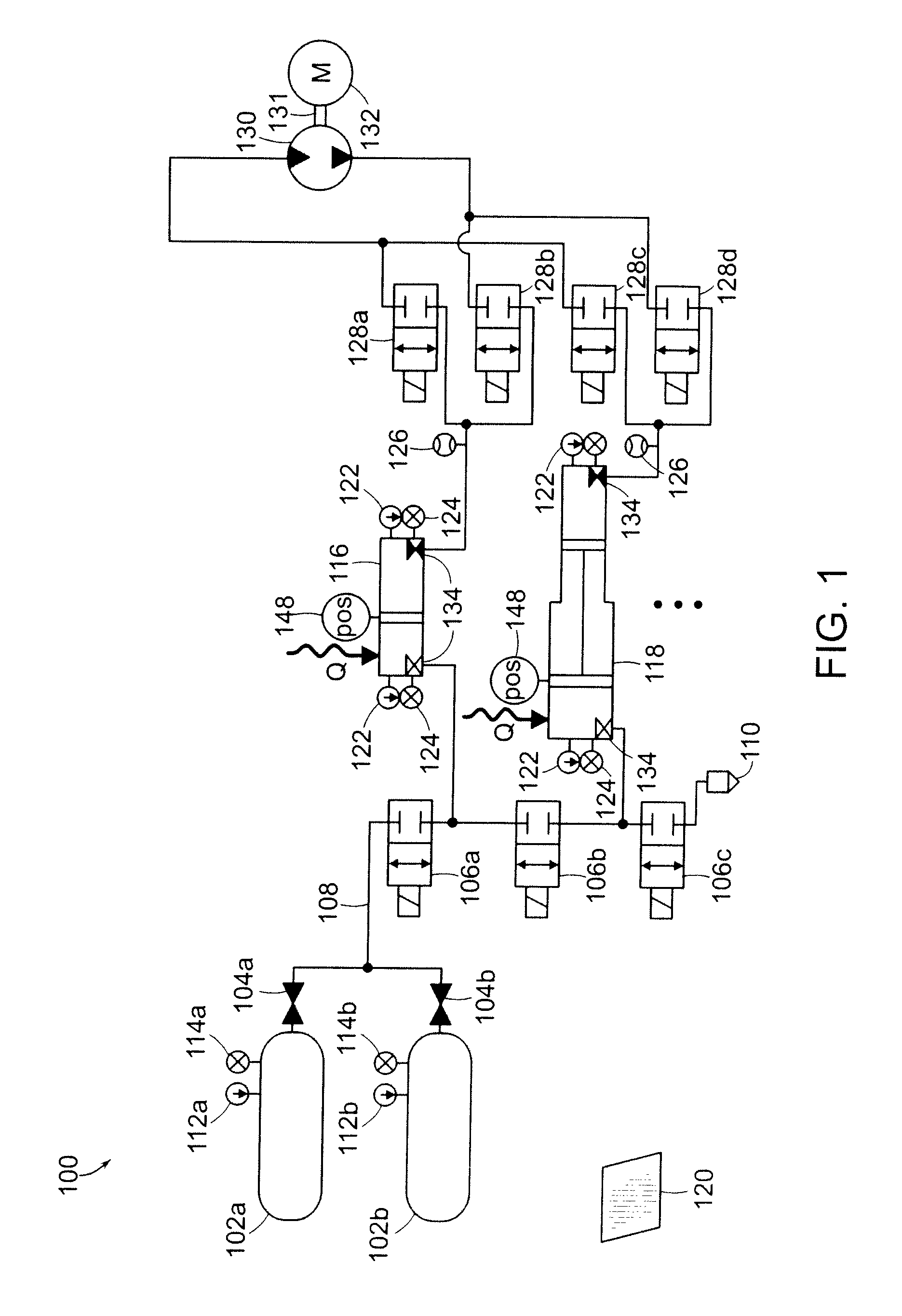

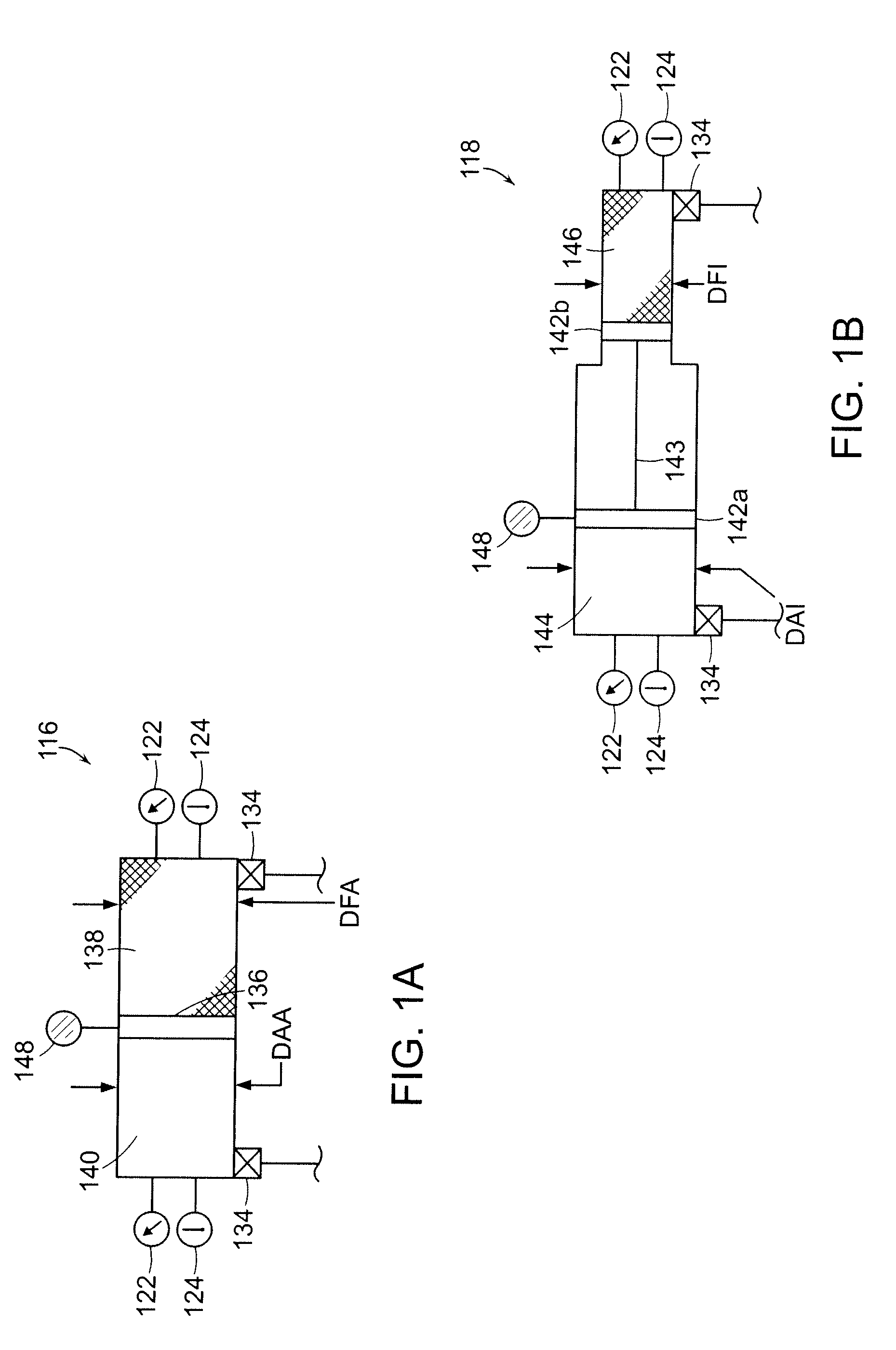

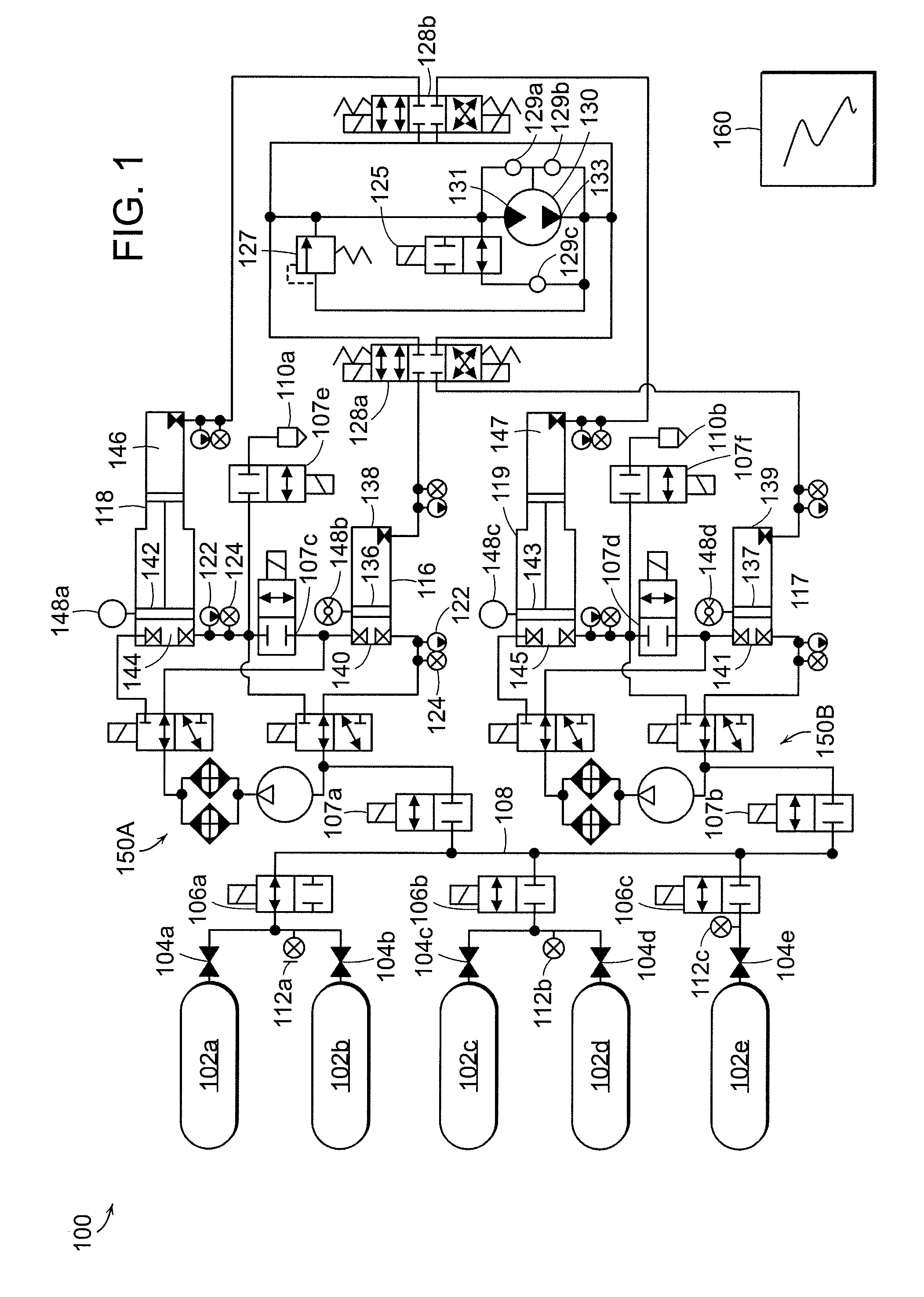

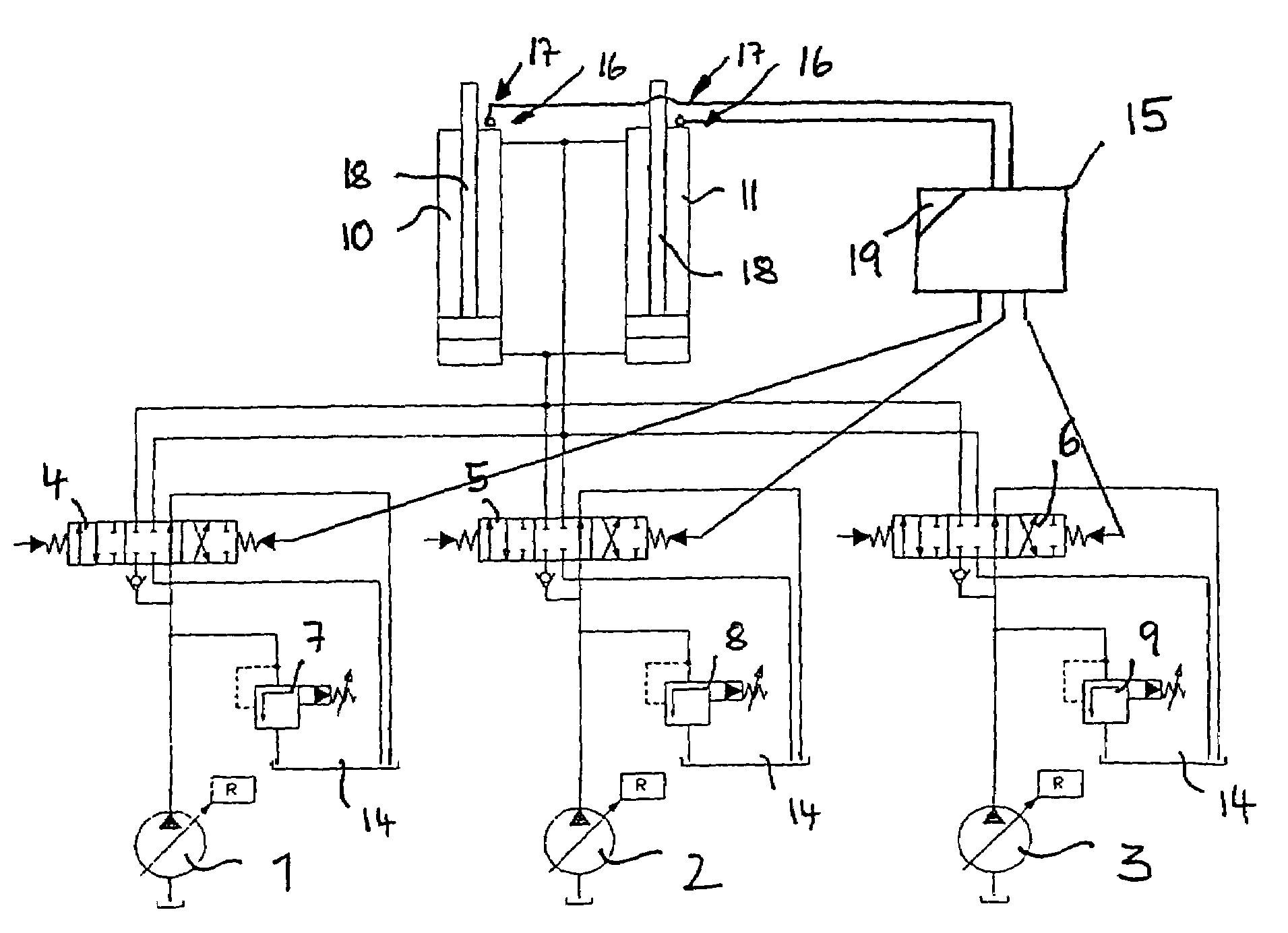

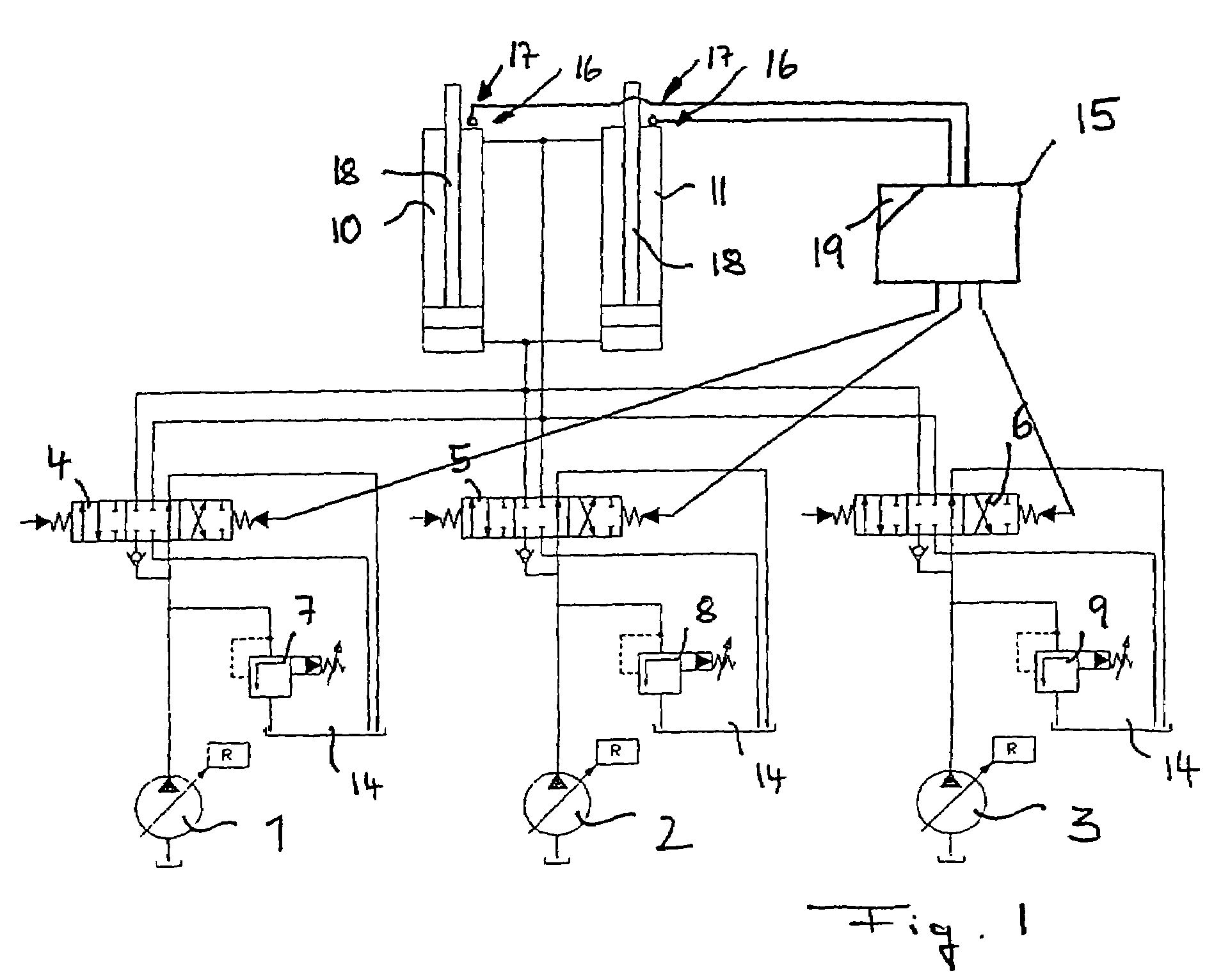

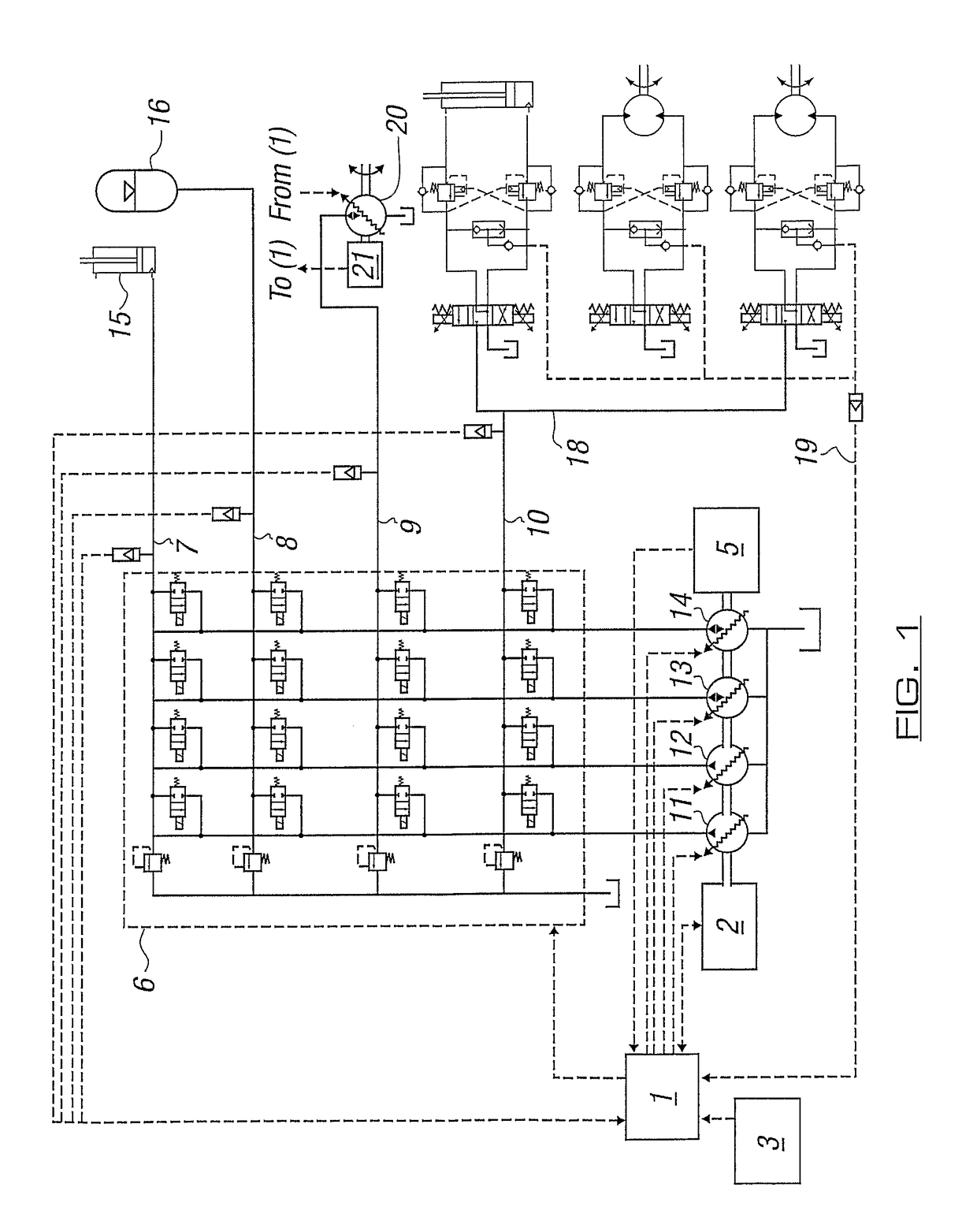

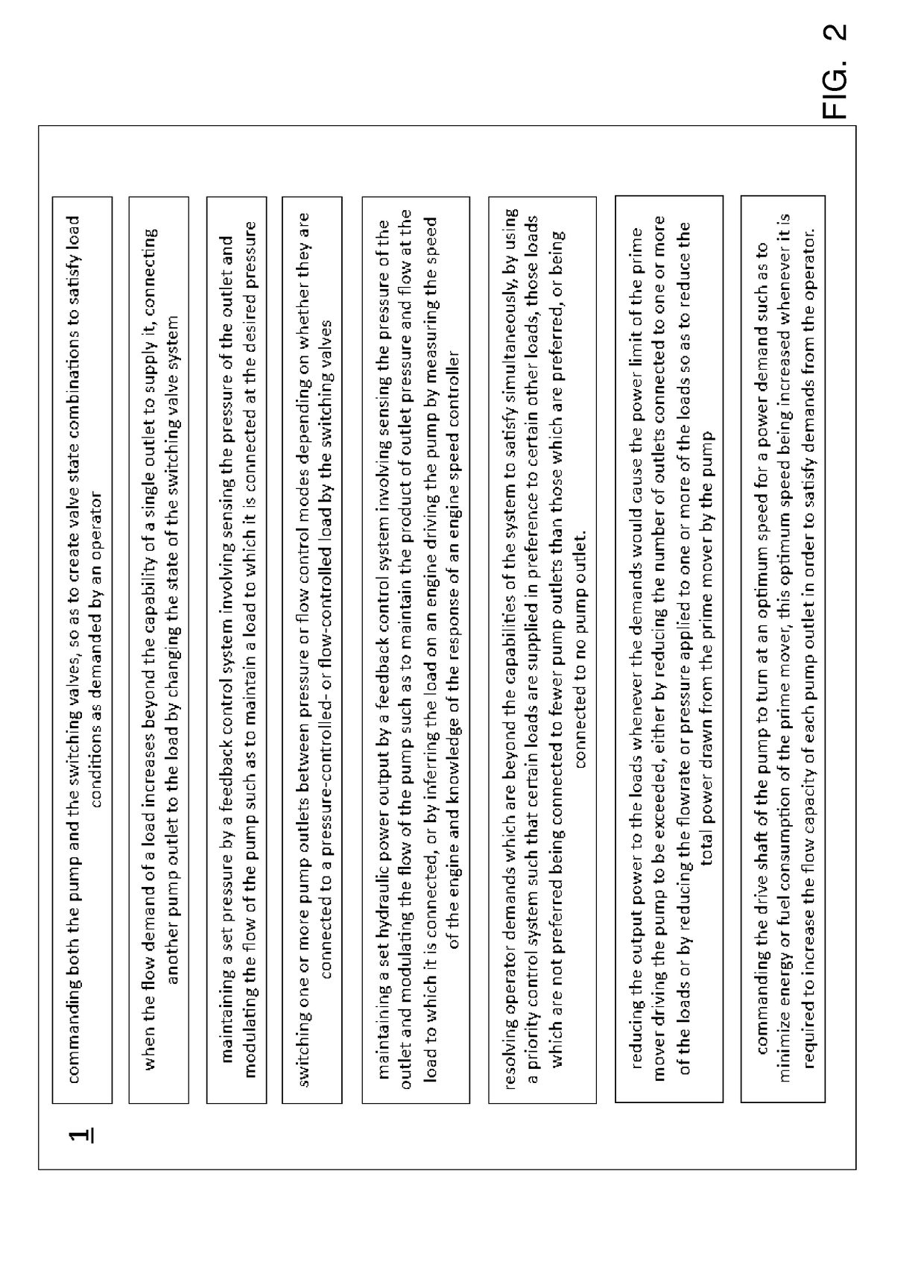

Fluid power distribution and control system

ActiveUS10161423B2Improve energy efficiencyQuick switchFluid couplingsServomotorsControl systemSystem configuration

A fluid power system comprises a pump with multiple independently variable outlets (11, 12, 13, 14), each of which is capable of delivering fluid in individually controllable volume units and a plurality of hydraulic loads (15, 16, 18, 20). A system of switching valves is configured to create fluid connections between the pump outlets and the loads. A control system commands both the pump and the switching valves, so as to create valve state combinations to satisfy load conditions as demanded by an operator. The number of pump outlets (11, 12, 13, 14) connected to one or more of the loads (15, 16, 18, 20) is changeable to satisfy the flow required of the load due to the operator demand, each pump outlet being commanded to produce a flow depending on the status of other outlets connected a load to which the outlet is connected and the operator demand for that load.

Owner:DANFOSS PAUER SOLYUSHENS APS

Induced symbiotic osmosis [iso] for salinity power generation

ActiveUS20110044824A1Reduce excessive wasteMaximizing membrane efficiencyFlexible member pumpsServomotorsHigh concentrationConcentration ratio

A method and apparatus for renewable power generation utilizes the chemical potential dissimilarity between solutions of differing ionic formulations. A train is formed by a sequentially ordered set of a plurality of cells in which each successive cell is related to the preceding cell. Each cell has pumping means and hydro-power generation turbine means to form a closed hydraulic loop configured for specified volumetric and flow capacity. Adjacent cells share semipermeable membranes. Each cell is charged with a brine of specified ionizable inorganic salt quantity and type with the brine being cycled in a controlled concentration-pressure loop, with each of the cells operating at progressively increasing concentration and osmotic pressure ratio. A continuous and constant flow rate of substantially salt-free permeate flux is maintained across each cell, the flux being osmotically induced from low salt concentration water being fed at the first cell in the train and exiting at the last cell along with the discarded high concentration water brine. The salt-free permeate flux is continuously induced, in symbiotic mode, through the shared membranes, driven by the chemical influence of concentration potential field bounded by water of low to no salt concentration on one end of the train and by brine of high salt concentration on the other end of the train with sufficient concentration difference to provide driving force for said plurality of cells, while maintaining adequate concentration difference between adjacent cells to enhance osmosis function, as well as defining a concentration ratio within each cell to ensure a net positive power generation.

Owner:KELADA MAHER ISAAC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Induced symbiotic osmosis [iso] for salinity power generation Induced symbiotic osmosis [iso] for salinity power generation](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/b4b27964-7dda-4348-9317-116c9790f6a1/US20110044824A1-20110224-D00000.png)

![Induced symbiotic osmosis [iso] for salinity power generation Induced symbiotic osmosis [iso] for salinity power generation](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/b4b27964-7dda-4348-9317-116c9790f6a1/US20110044824A1-20110224-D00001.png)

![Induced symbiotic osmosis [iso] for salinity power generation Induced symbiotic osmosis [iso] for salinity power generation](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/b4b27964-7dda-4348-9317-116c9790f6a1/US20110044824A1-20110224-D00002.png)