Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8537 results about "Pressure vessel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Pressure vessels can be dangerous, and fatal accidents have occurred in the history of their development and operation. Consequently, pressure vessel design, manufacture, and operation are regulated by engineering authorities backed by legislation. For these reasons, the definition of a pressure vessel varies from country to country.

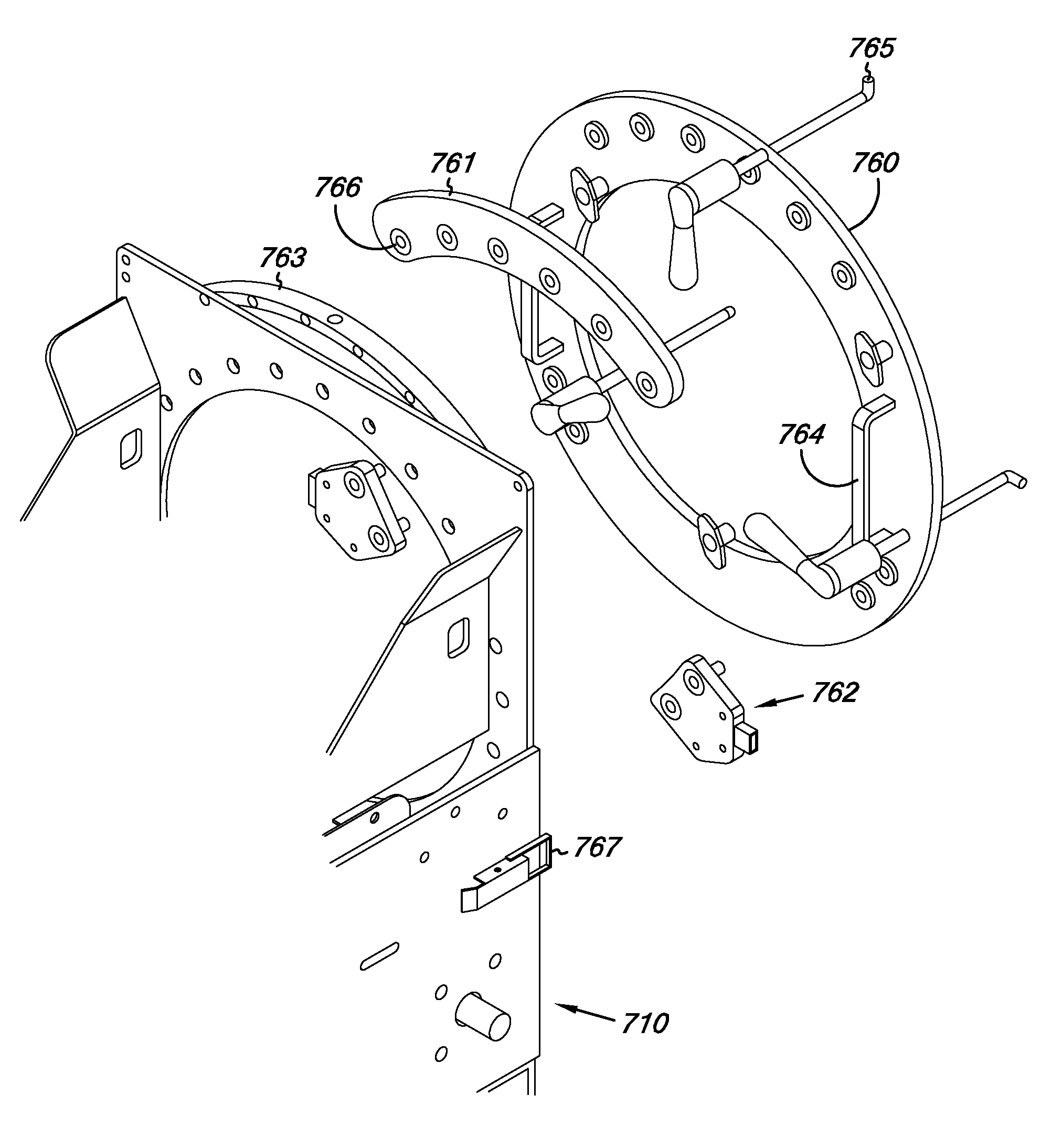

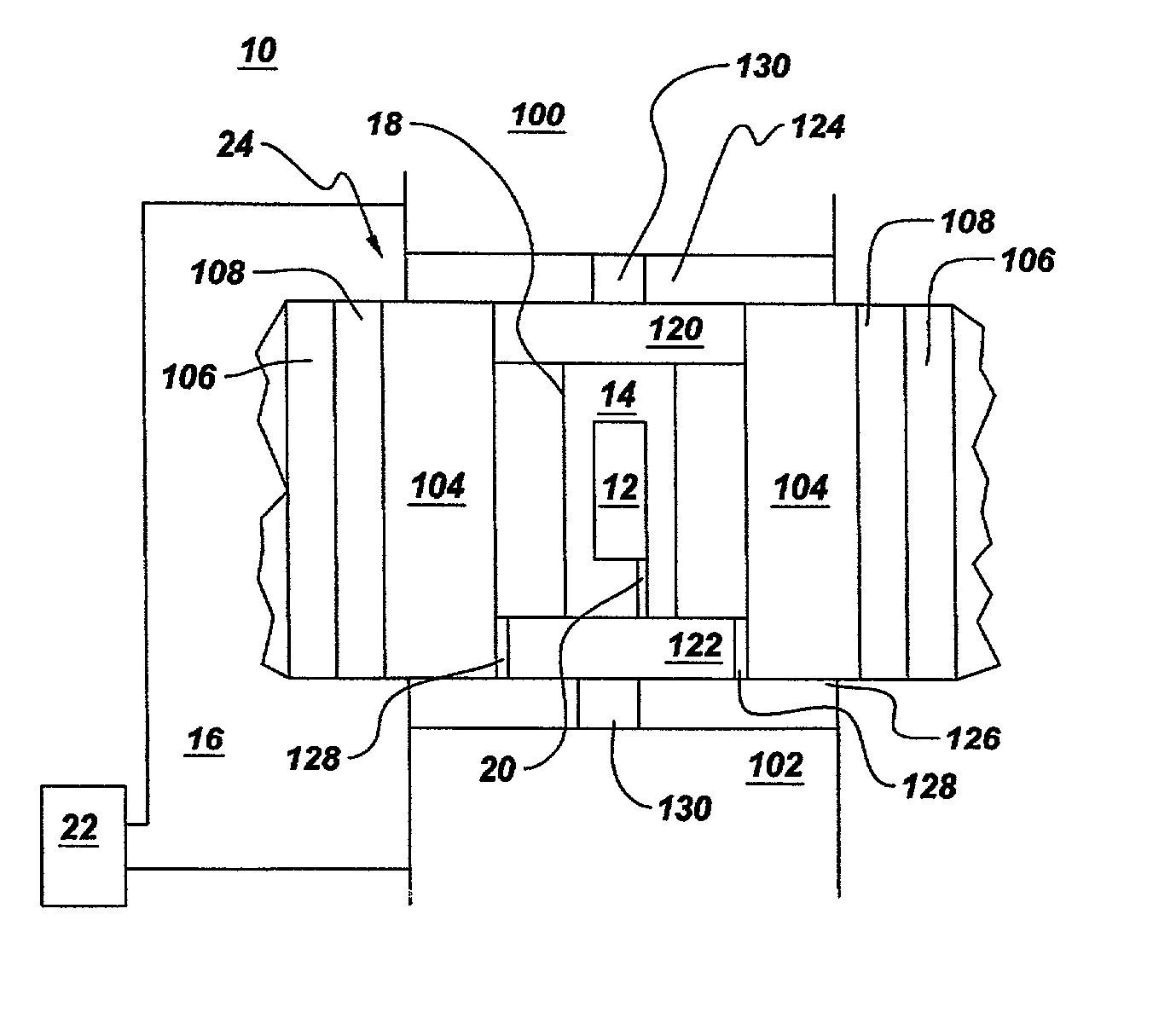

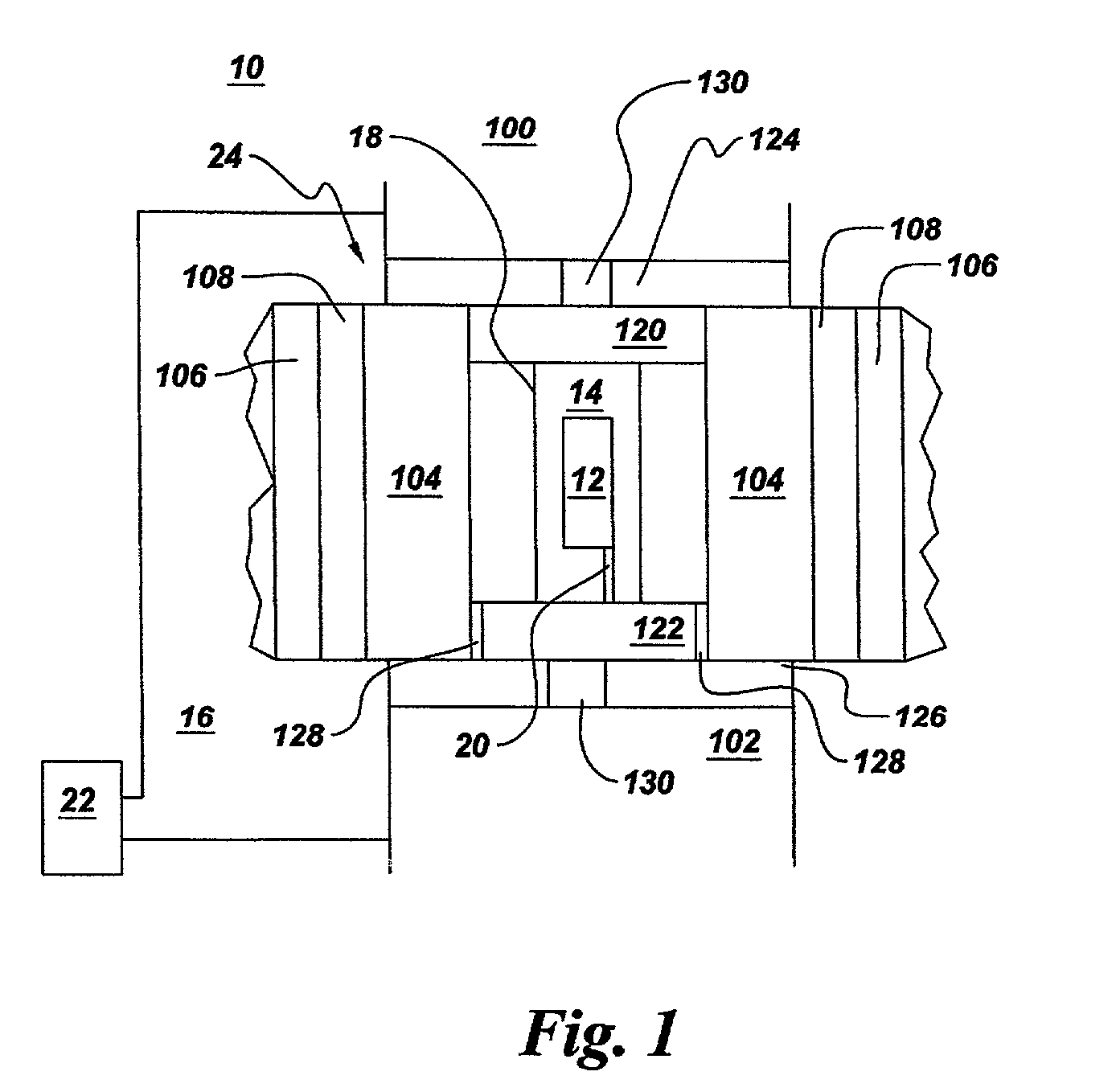

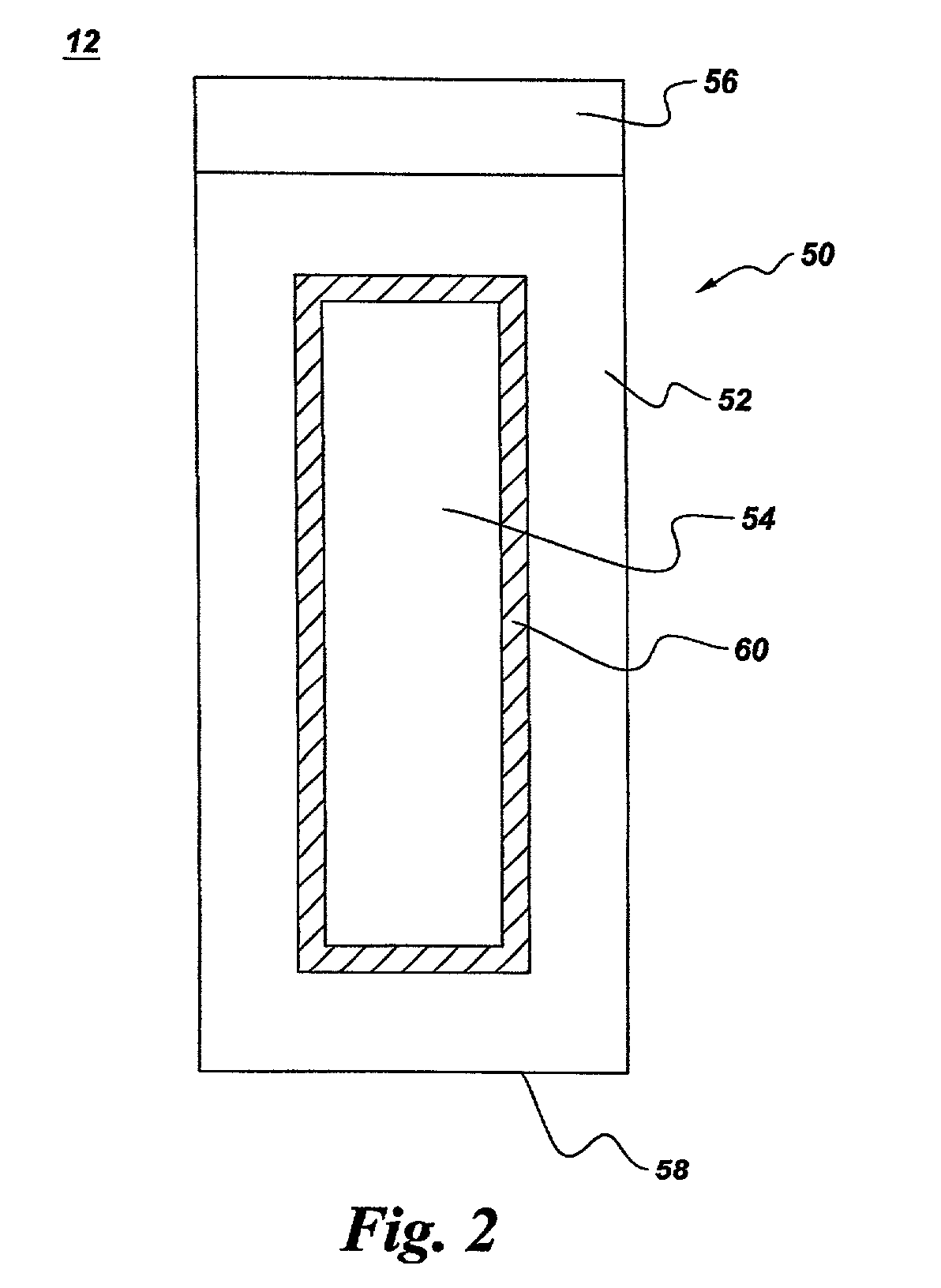

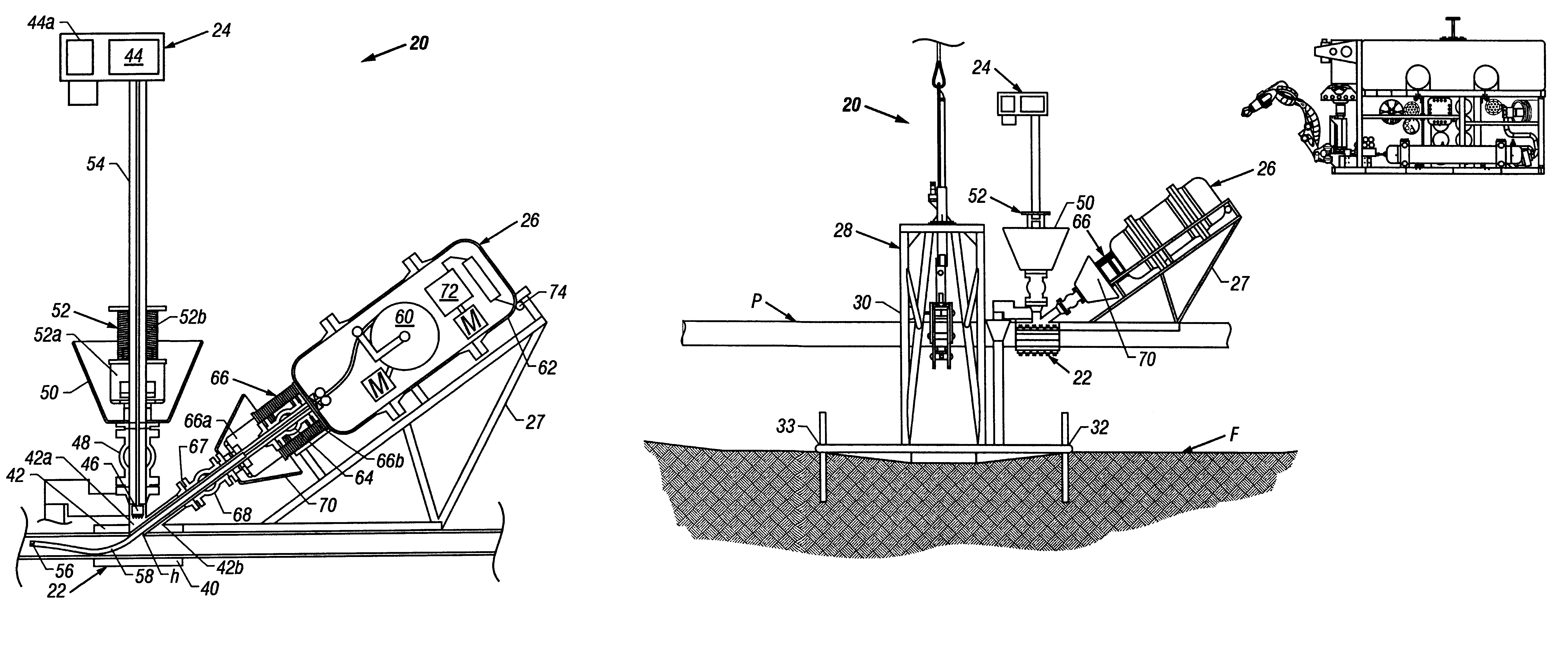

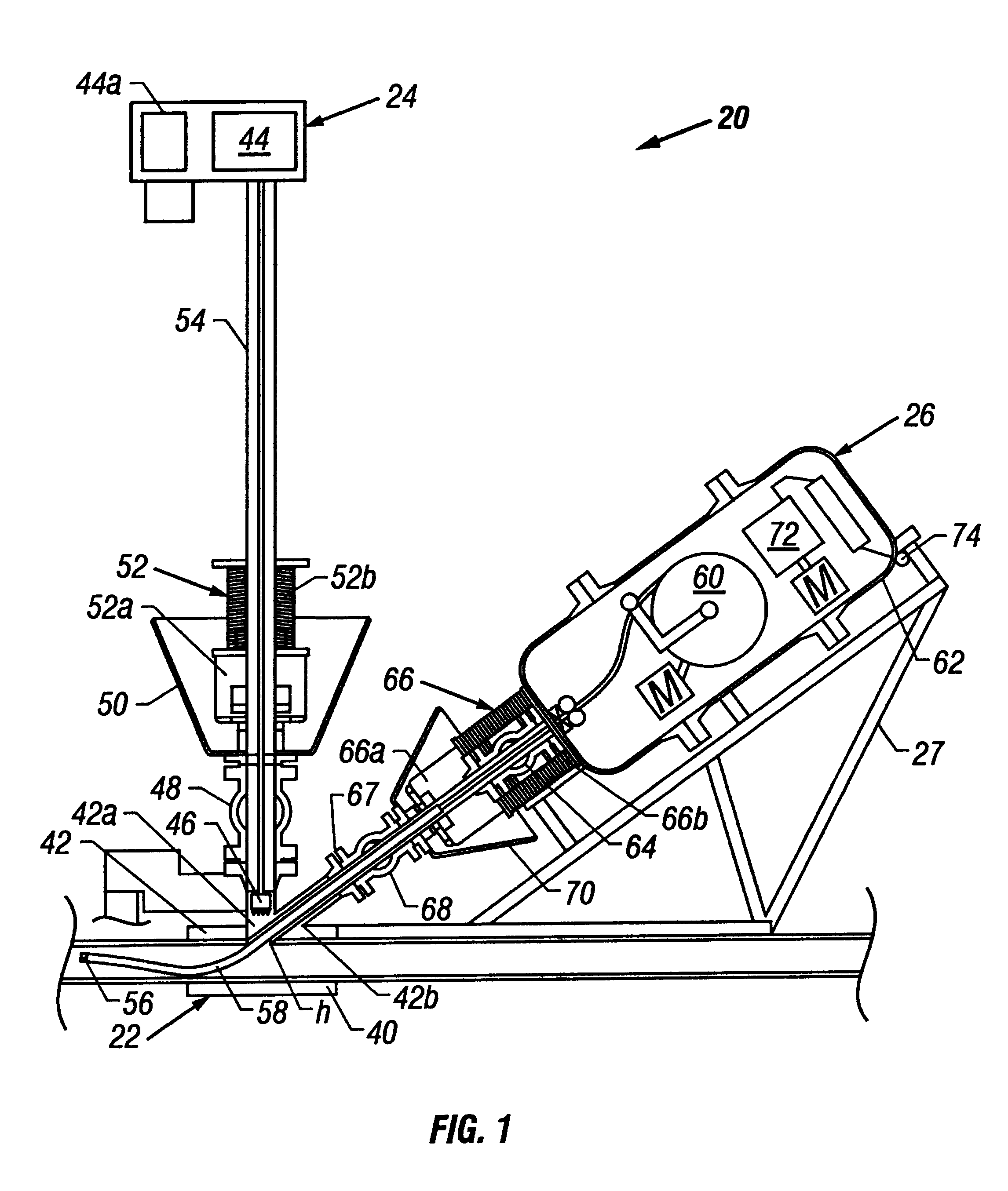

Element loading mechanism and method

A loader for moving a filter element between loaded and unloaded positions with respect to a pressure vessel is provided. The loader includes a connection section associated with a loader section. The connection section is operative to be secured in coaxial alignment with the pressure vessel. The loader section is operative to receive a filter element and move the filter element between the loaded and unloaded positions. The loader section includes a cradle assembly for supporting a filter element and a carriage assembly operative to engage the filter element and move it between the loaded and unloaded positions.

Owner:HALLAN MATTHEW J +3

Reagent supply vessel for chemical vapor deposition

InactiveUS6077356AEasy constructionLiquid transferring devicesLiquid dispensingSemiconductor materialsGas phase

A liquid reagent dispensing assembly, comprising a gas-pressurizable vessel including a floor, and an interior volume bounded by interior wall and floor surfaces. A dip-tube liquid discharge conduit is employed for discharging liquid from the gas-pressurized vessel. The vessel is provided with a liquid level sensor for sensing liquid reagent level in the vessel interior volume. The floor of the vessel has a cavity therein extending downwardly from the surface of the floor, and the lower end of the dip tube is positioned in the cavity. The dispensing assembly of the invention may usefully be employed for dispensing of reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices, and achieves a high level of withdrawal of the reagent liquid from the vessel.

Owner:ENTEGRIS INC

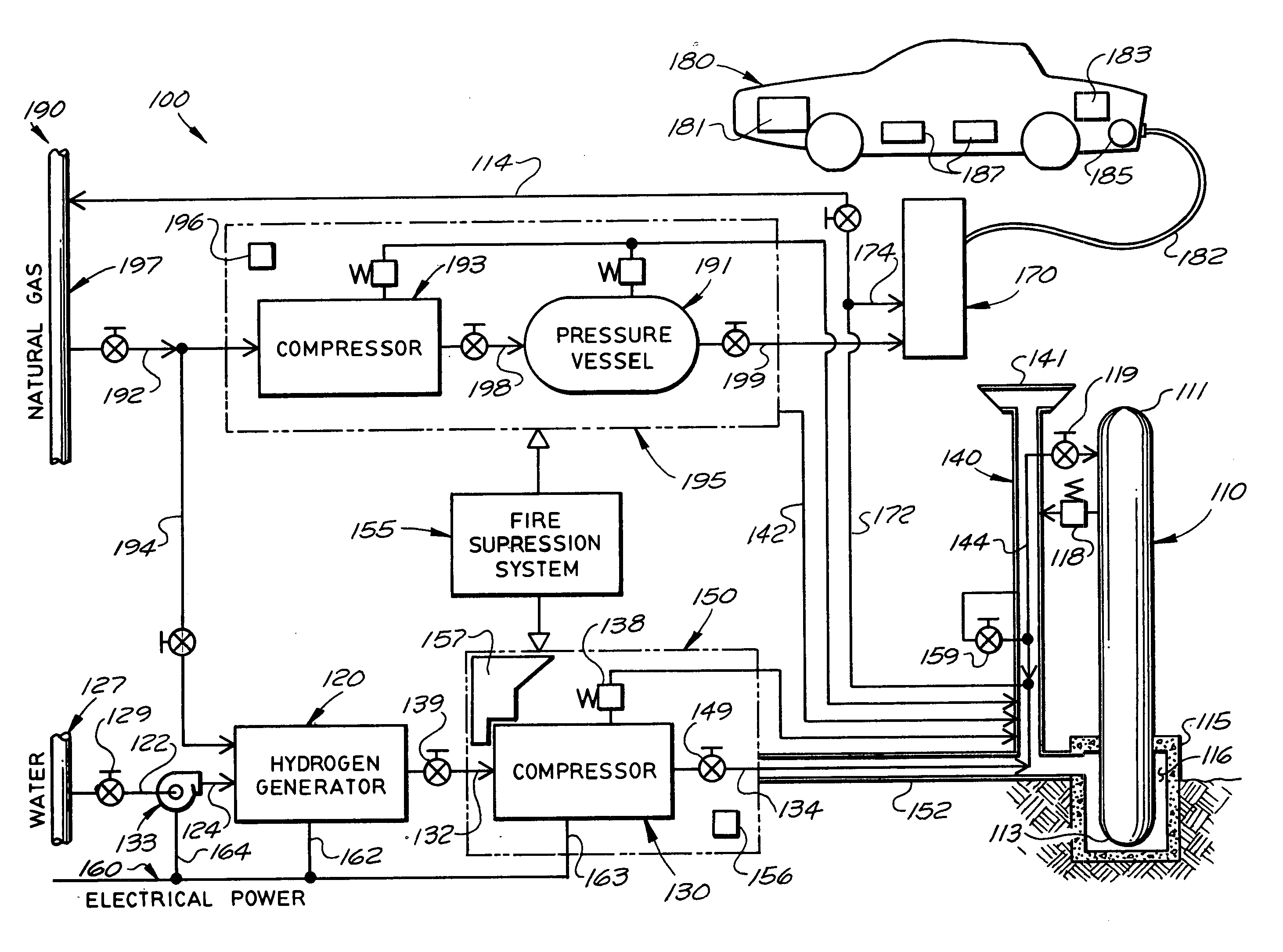

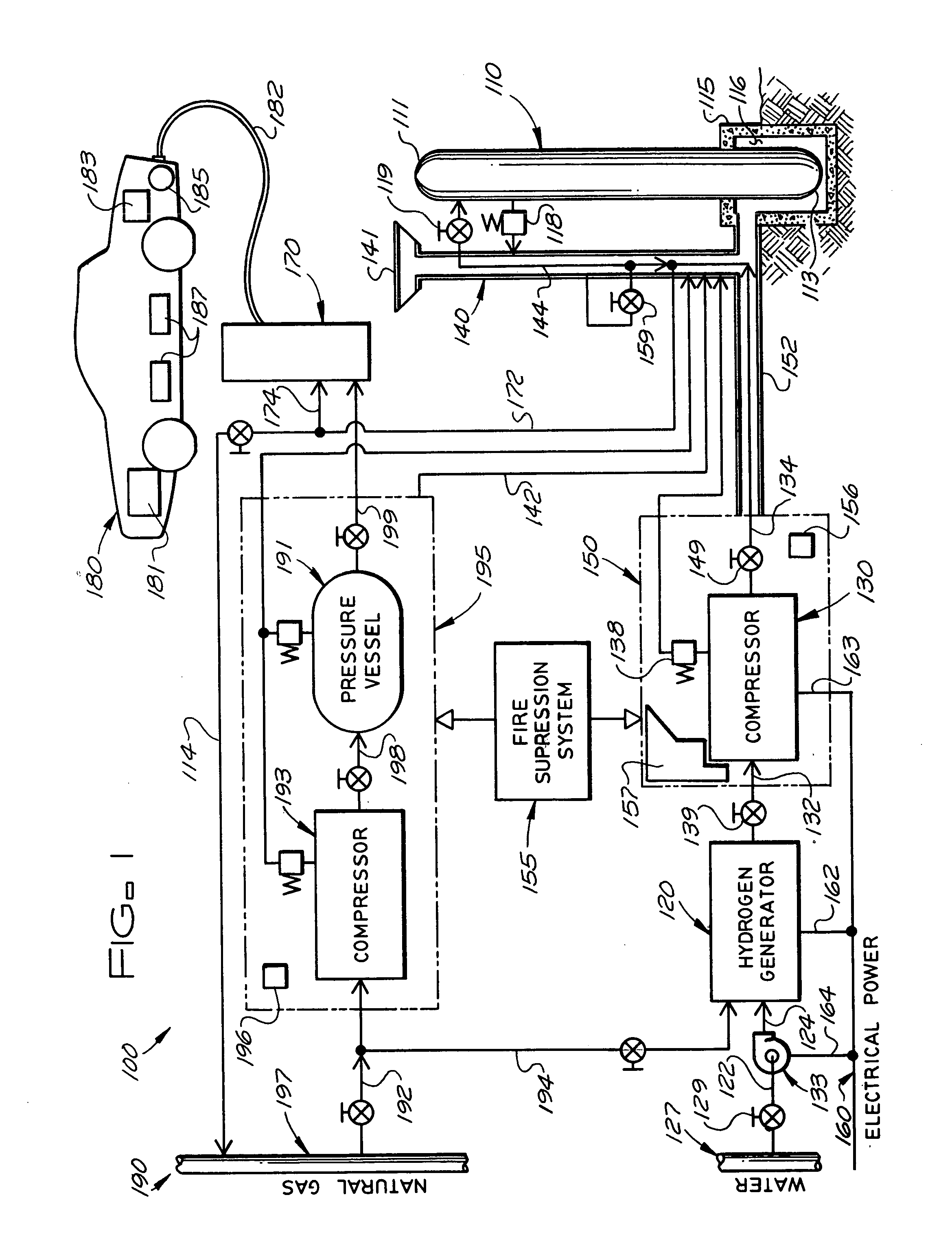

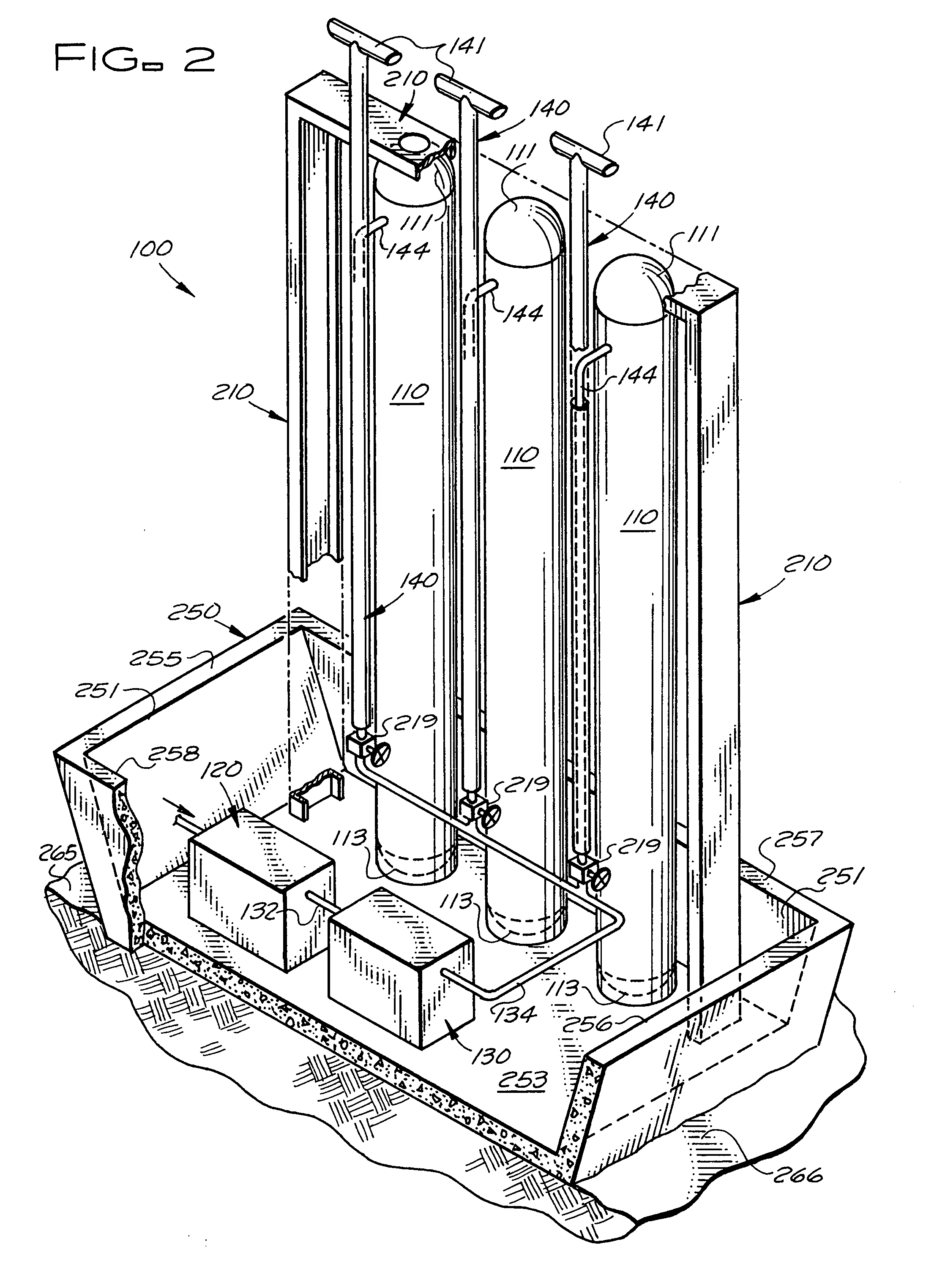

Hydrogen handling or dispensing system

InactiveUS20050000802A1Avoid burnsCheap manufacturingLiquid fillingGas handling applicationsHydrogenHuman life

Systems for handling and / or dispensing hydrogen or a mixture of fuels containing hydrogen gas including refueling stations for hydrogen-powered vehicles. Pure hydrogen or various mixtures ratios of hydrogen and CNG may be dispensed. Hydrogen handling equipment may include a hydrogen generator, a pressurizing apparatus or compressor, pressure vessels, piping, valves, vent pipes, and / or a dispenser. Substantially vertical orientation of pressure vessels may reduce the amount of land required and facilitate installation in urban environments. Pressurization may take place before hydrogen generation to reduce the power required for pressurization. Safety features include enclosures and surrounding walls that lean away from the equipment. Any leaking hydrogen, fires, or explosions may be contained and / or directed upward, protecting human life and property. Systems may be shop assembled and certified.

Owner:ARIZONA PUBLIC SERVICE

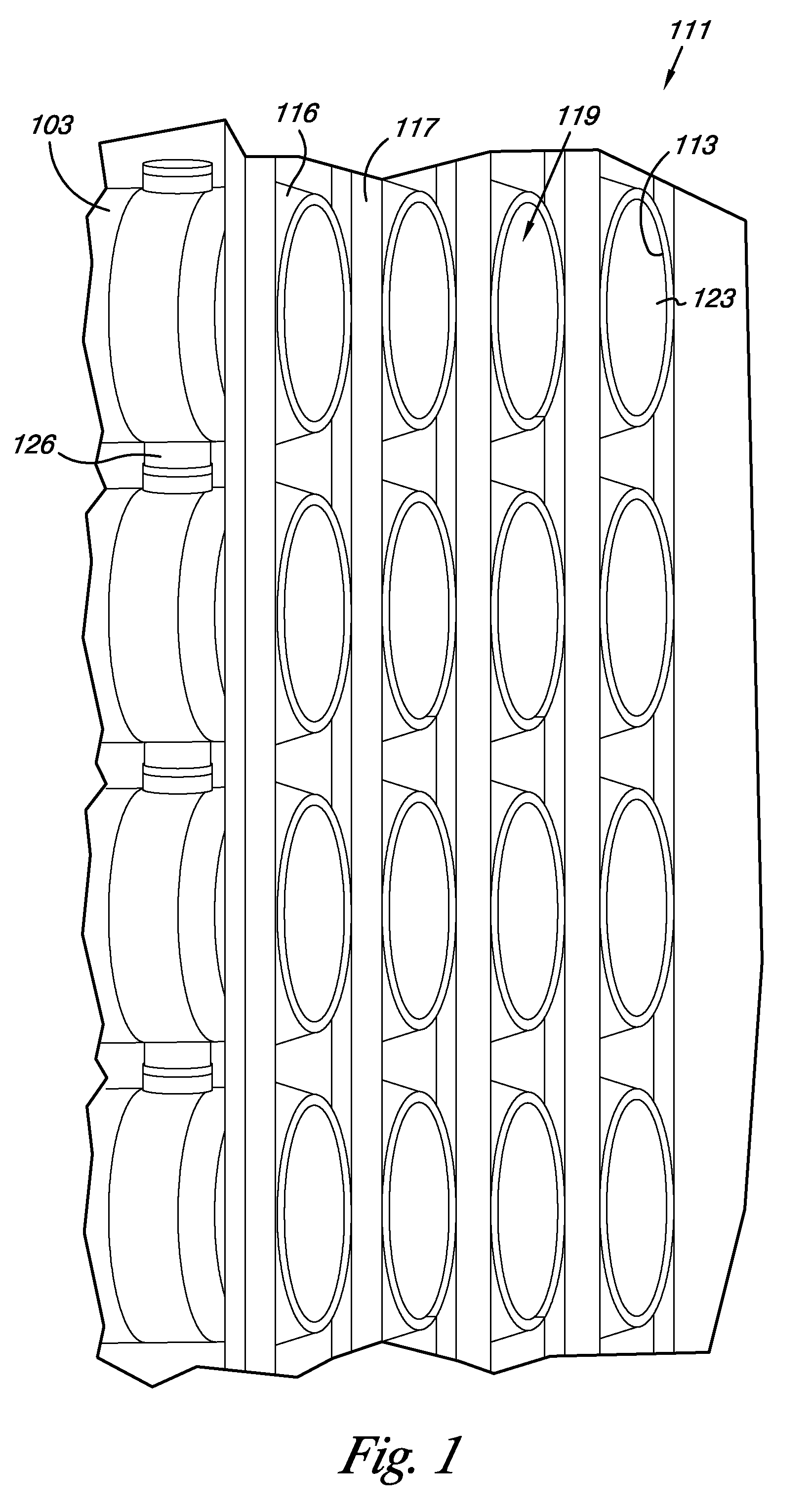

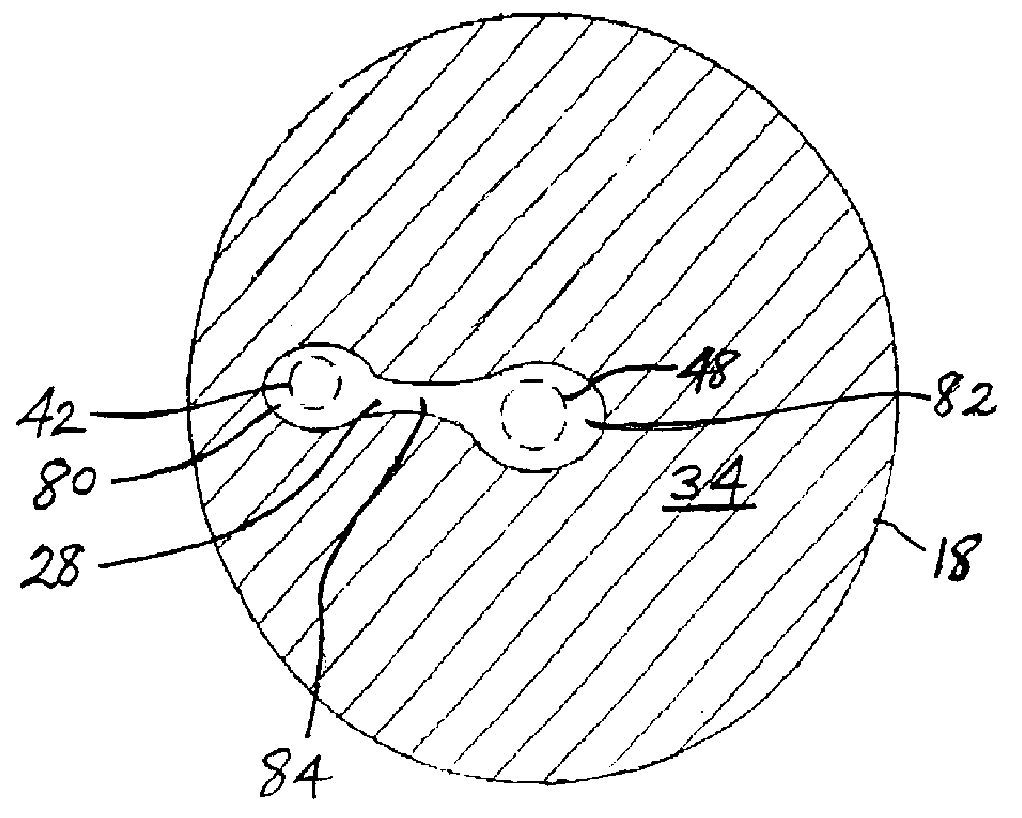

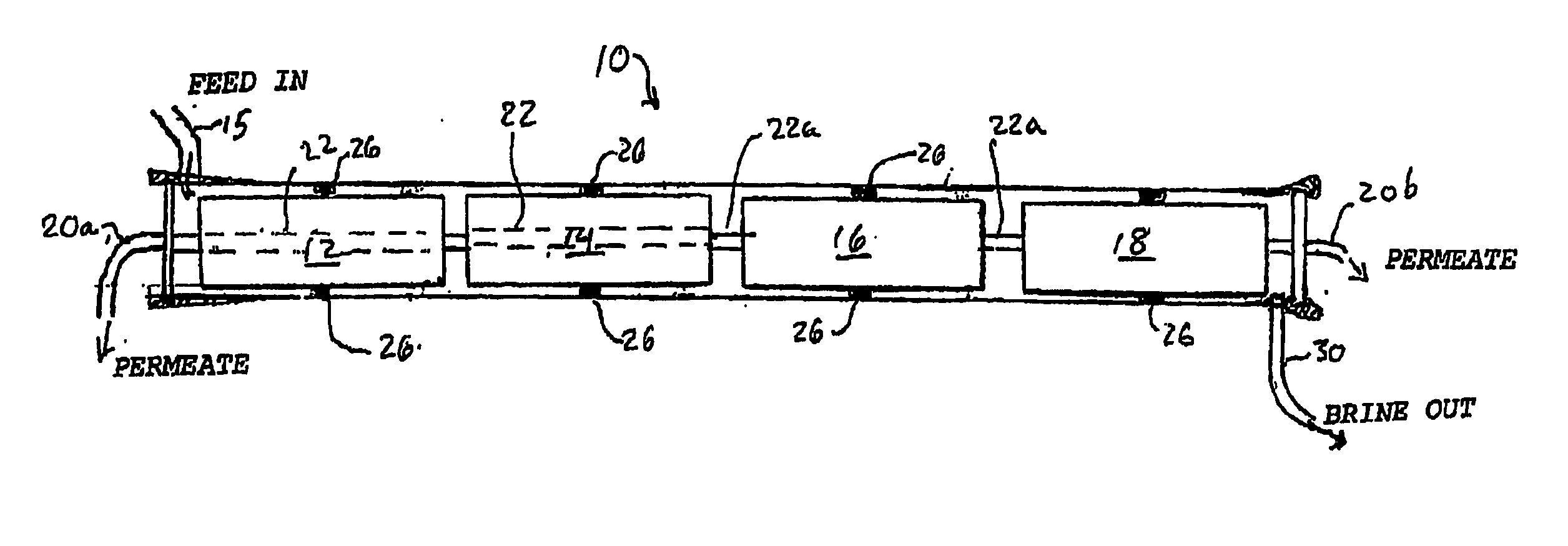

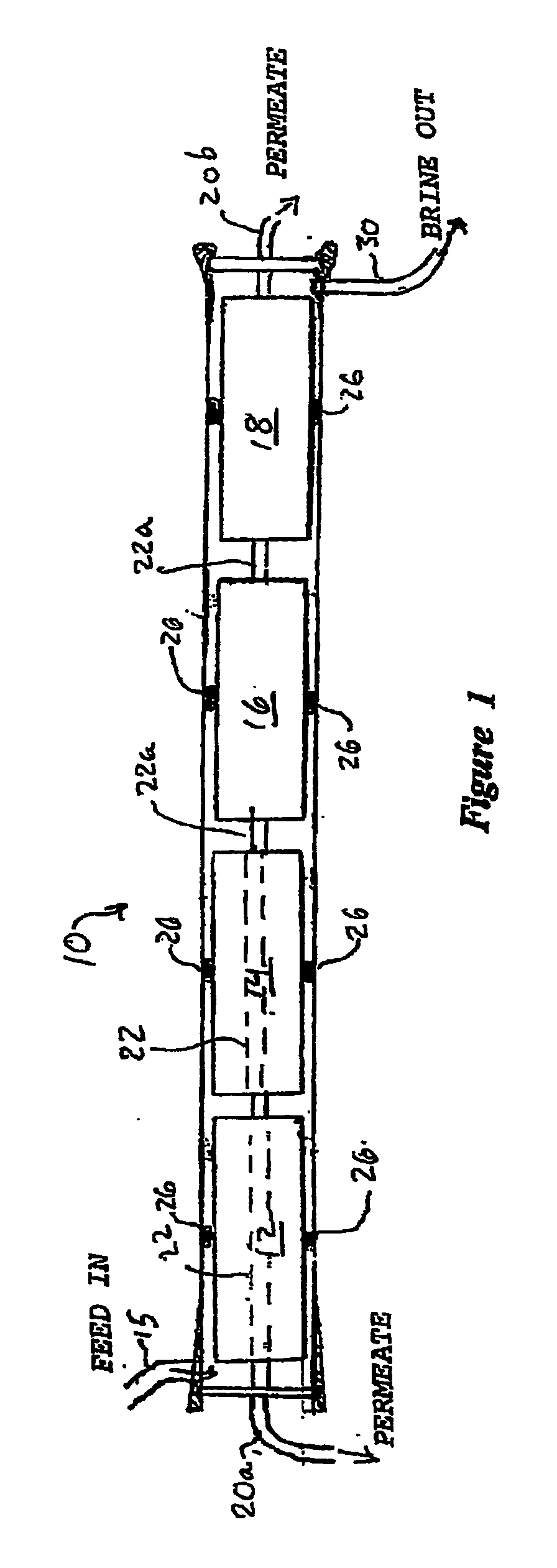

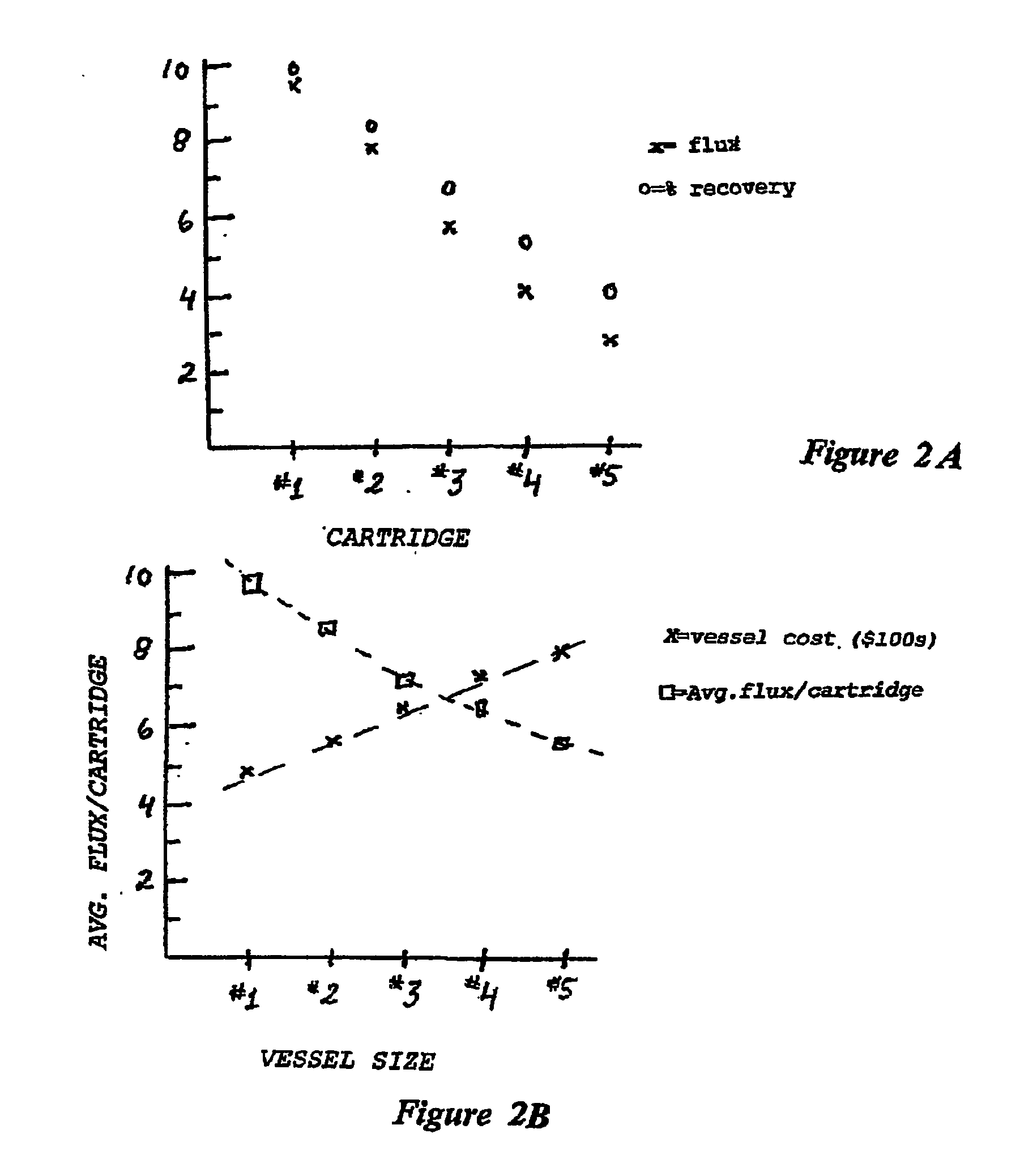

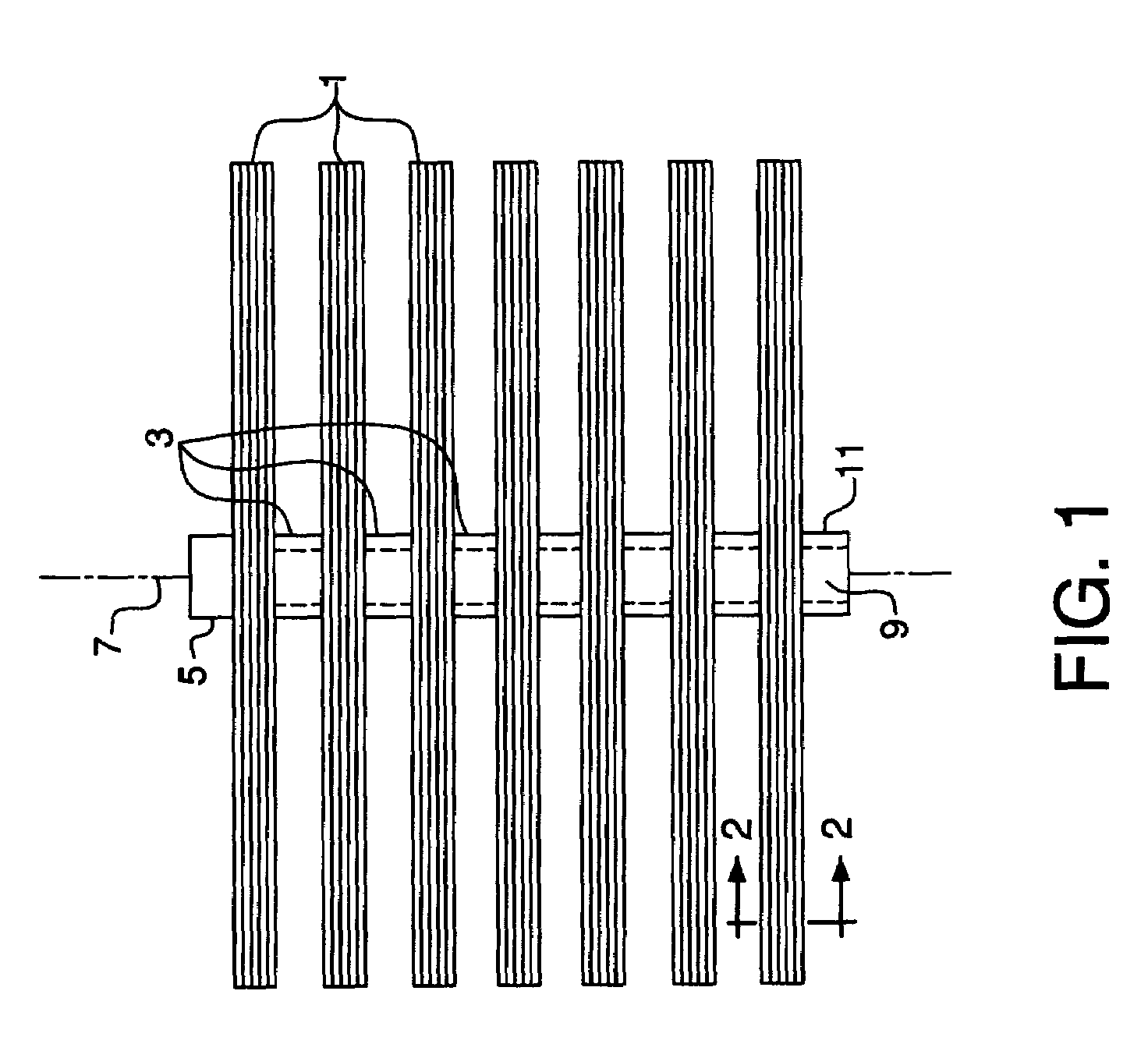

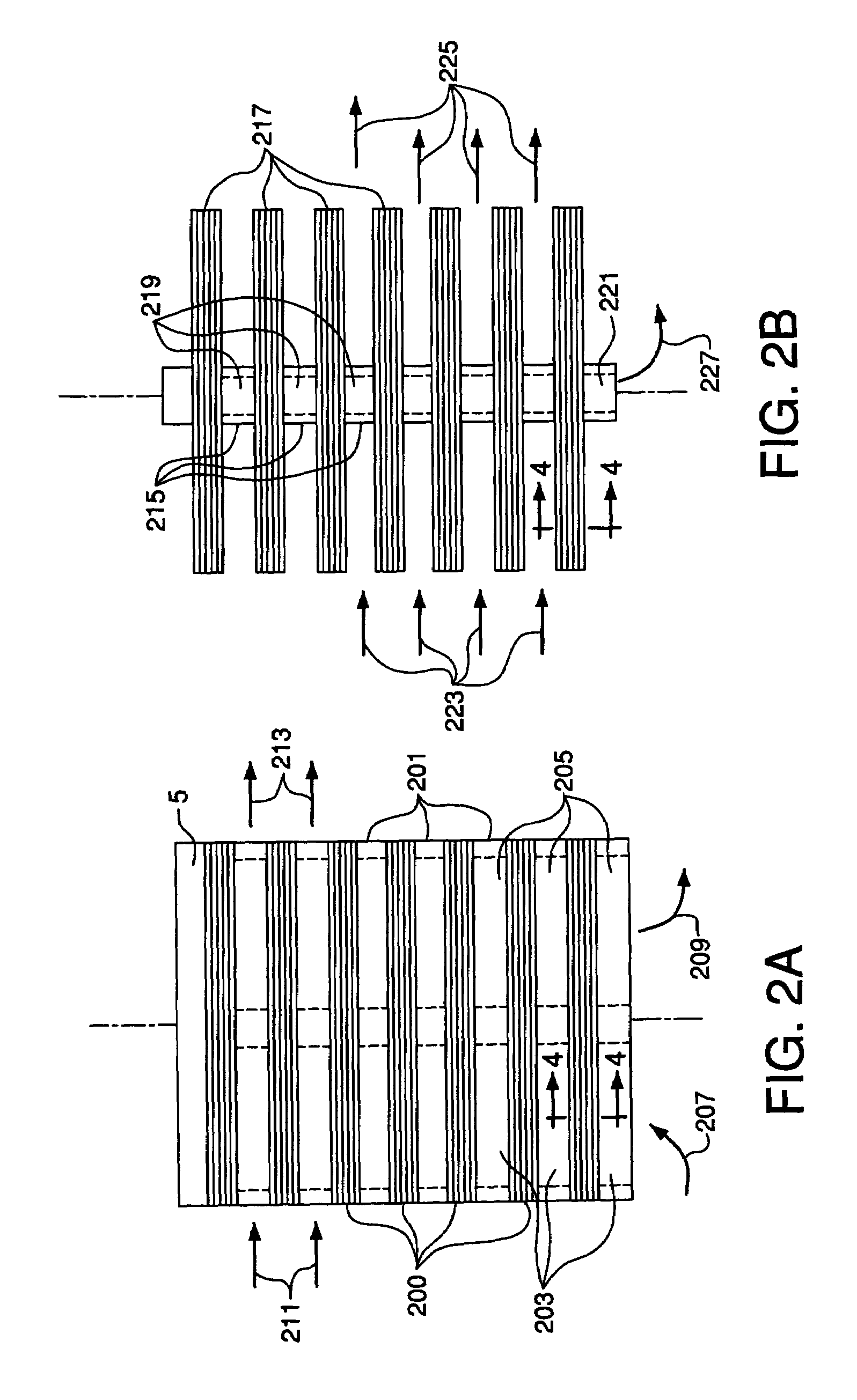

Branched flow filtraction and system

InactiveUS20050029192A1Improve operationImprove performanceMembranesWater/sewage treatment bu osmosis/dialysisReverse osmosisCross-flow filtration

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

Pressure vessel

InactiveUS20030140845A1Prevent escapeAvoid creatingFrom gel statePolycrystalline material growthTemperature controlPressure transmission

A pressure vessel for processing at least one material in a supercritical fluid. The pressure vessel includes a self-pressurizing capsule for containing at least one material and the supercritical fluid in a substantially air-free environment, a pressure transmission medium surrounding the capsule for maintaining an outer pressure on the capsule, at least one heating element insertable in the pressure transmission medium such that the heating element surrounds the capsule, a temperature measurement means for measuring a temperature of the capsule, a temperature controller for controlling the temperature and providing power to the heating element, a restraint to contain and hold in place the capsule, the pressure transmission medium, and the heating element, and at least one seal between the restraint and the pressure transmission medium for preventing escape of the pressure transmission medium. Methods of using the pressure vessel, processing a material at high temperature and high pressure in the presence of a supercritical fluid within the capsule are also described.

Owner:SORAA

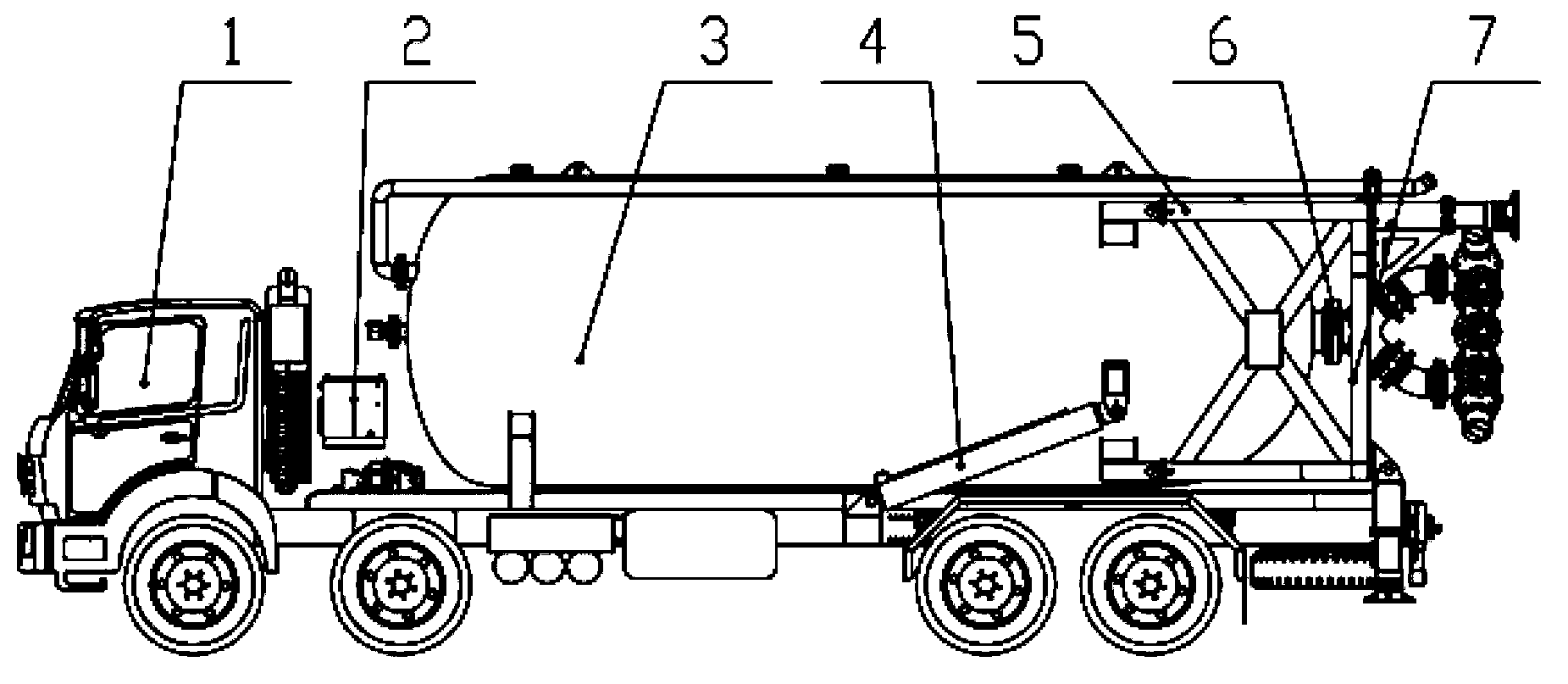

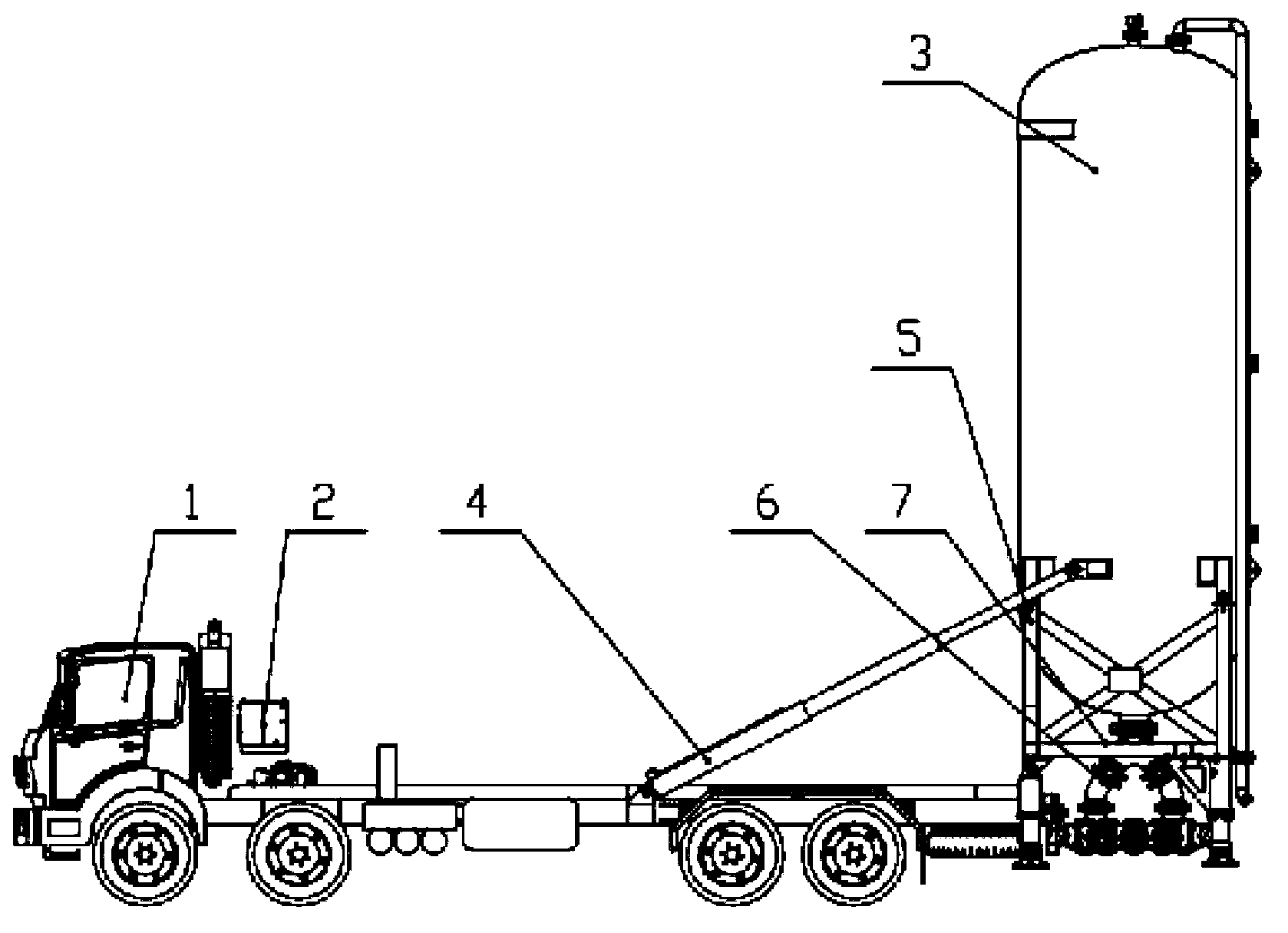

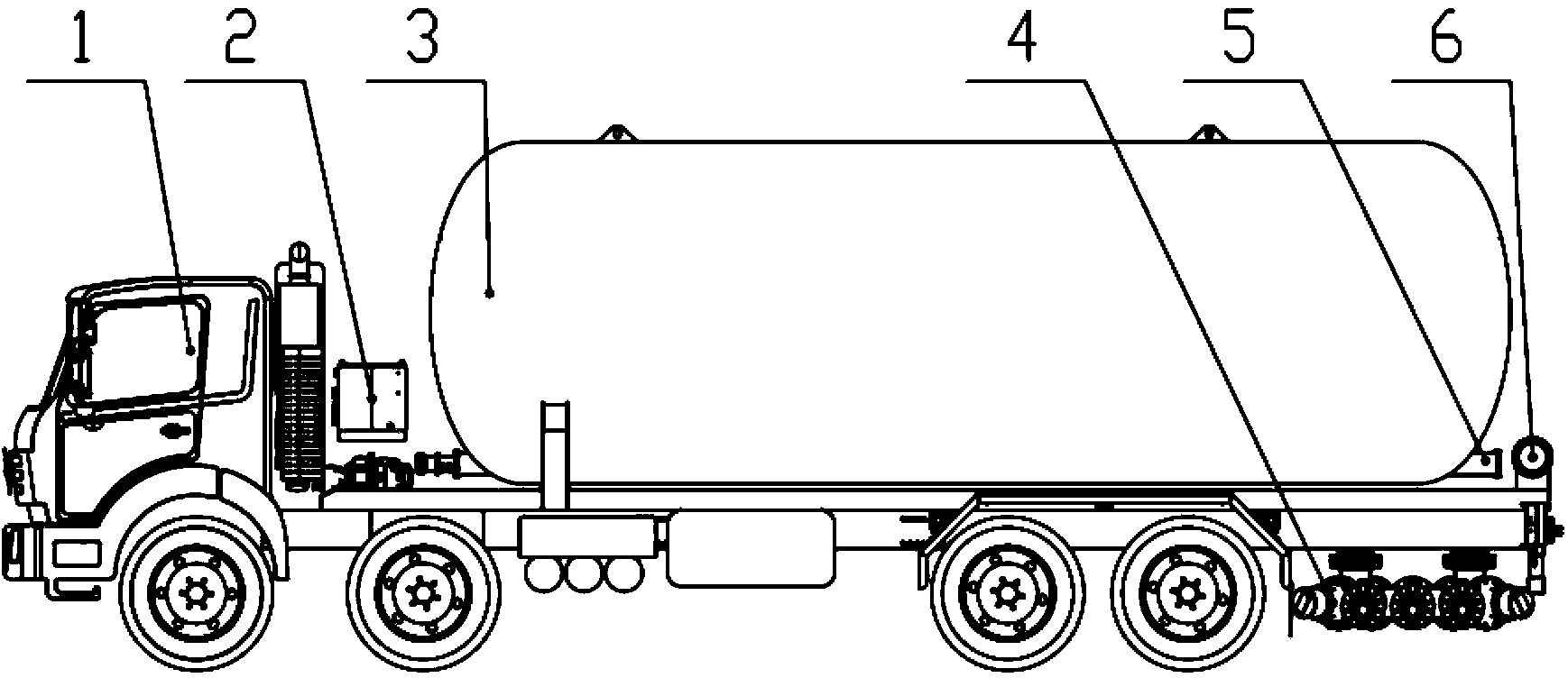

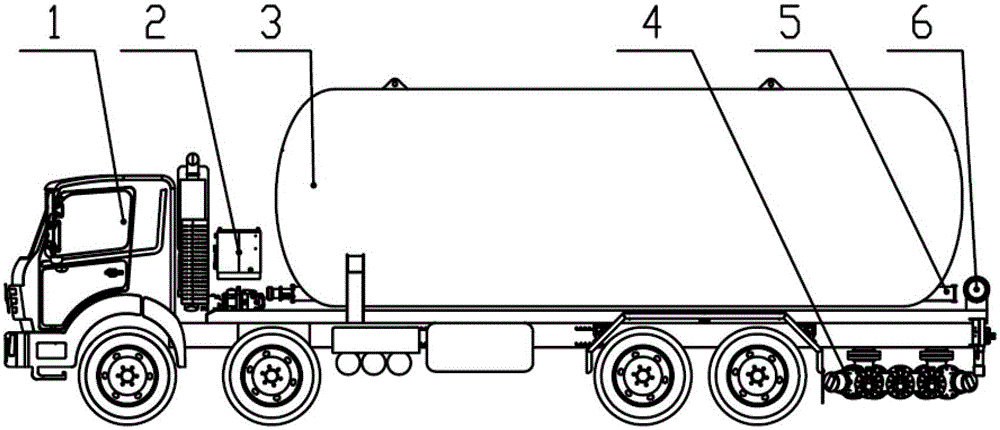

Fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid-liquid mixing device, and the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

Process for the production of particles or powders

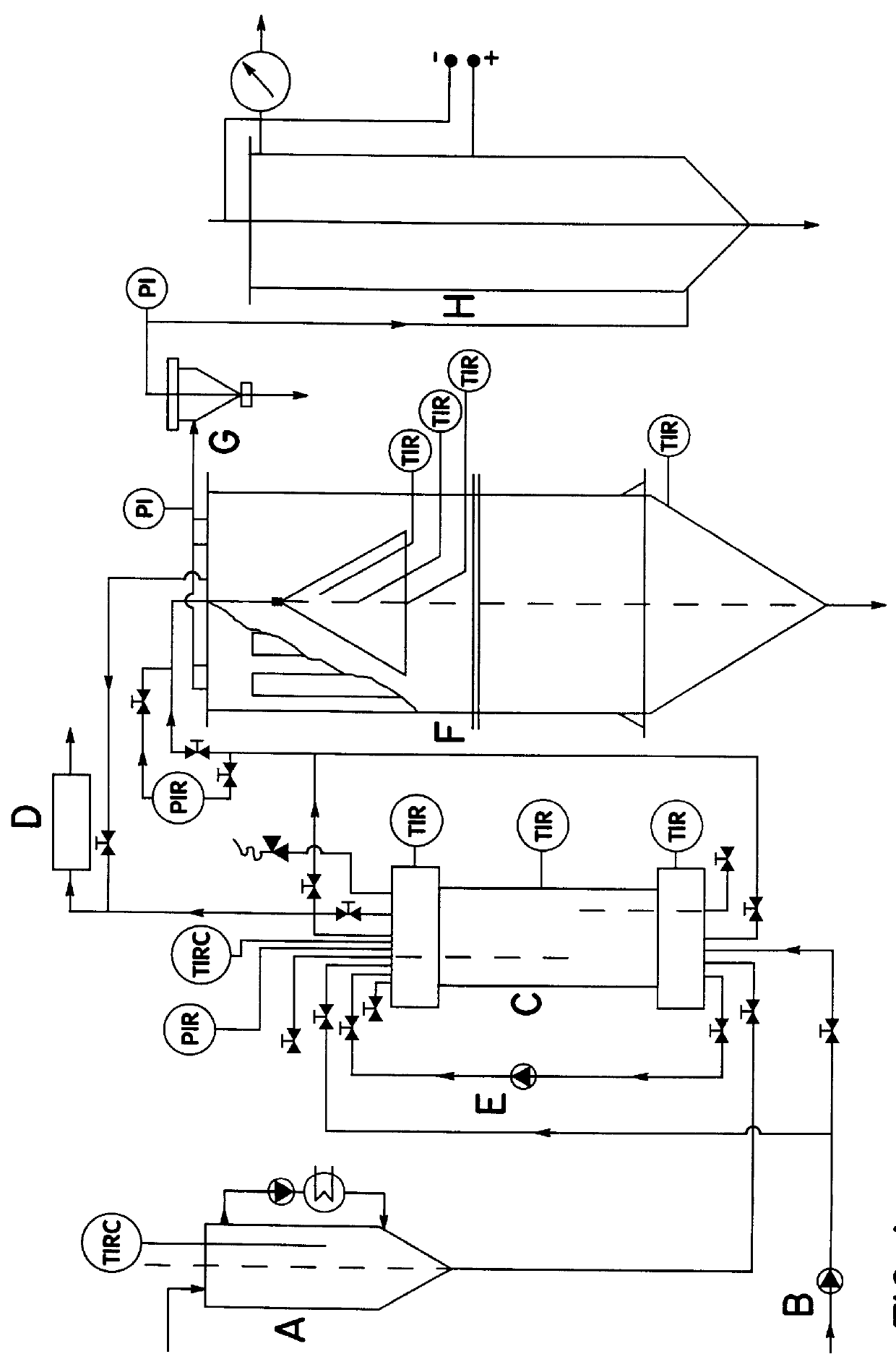

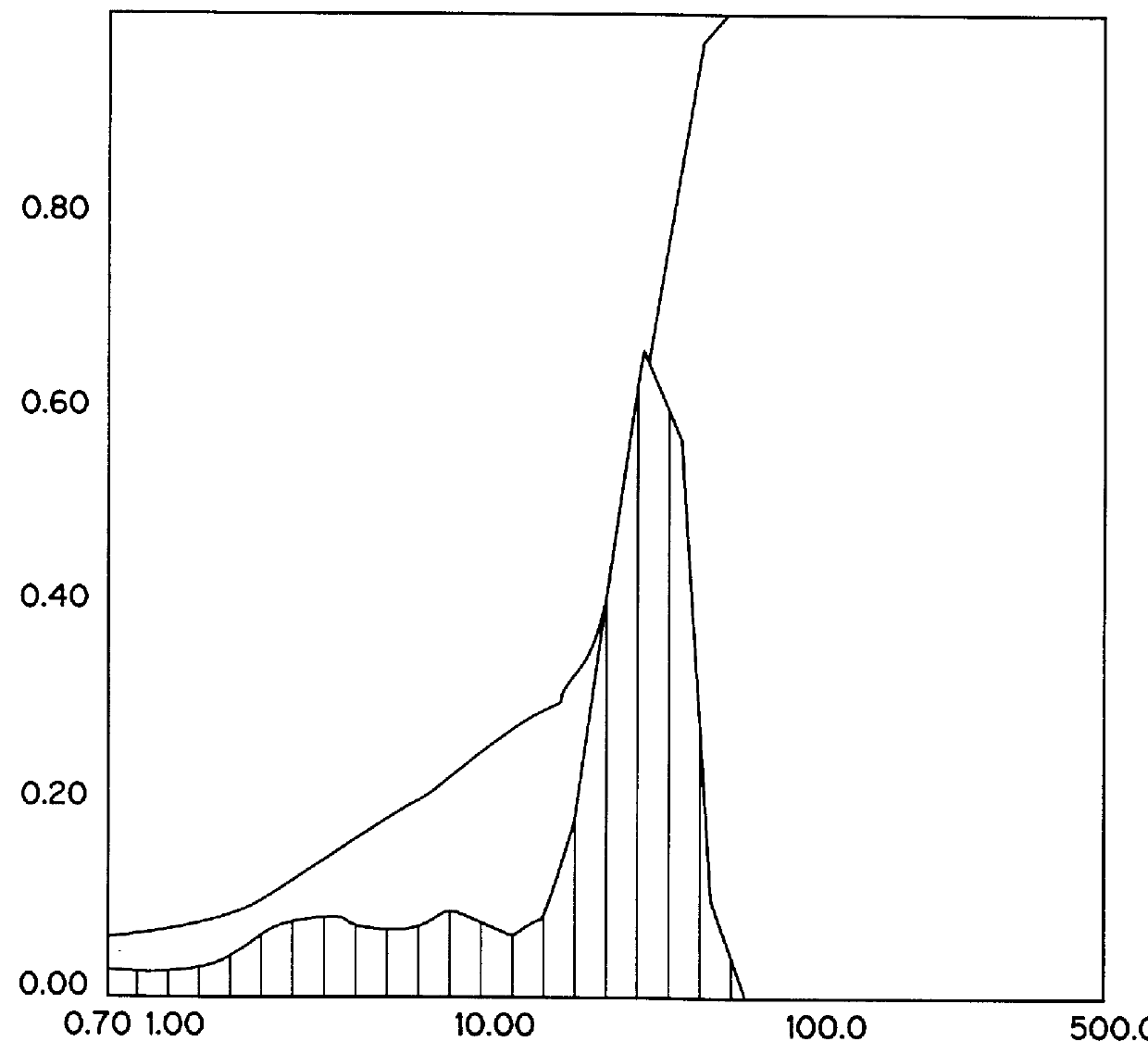

In a novel process for the production of particles or powders, a substance or mixture of substances to be treated is provided in a pressure vessel. A highly compressible fluid is dissolved under pressure in the substance or mixture of substances provided until a solution containing 5% to 90% by weight of said highly compressible fluid has formed. The melting point of said highly compressible fluid is at least around 40 K lower than the melting point of the substance or mixture of substances to be treated. The solution obtained by dissolving said highly compressible fluid in the substance or mixture of substances provided is adjusted to a temperature of up to around 50 K above or below the melting point under atmospheric pressure of the substance or mixture of substances to be treated and is then rapidly decompressed by means of a decompression device in such a way that the temperature falls, downstream of the decompression device, below the solidification point of the substance or mixture of substances to be treated and essentially all of the highly compressible fluid turns gaseous, whereby particles of the substance or mixture of substances provided form. Subsequently, the particles which have formed are removed from the stream of decompressed highly compressible fluid.

Owner:WEIDNER ECKHARD +2

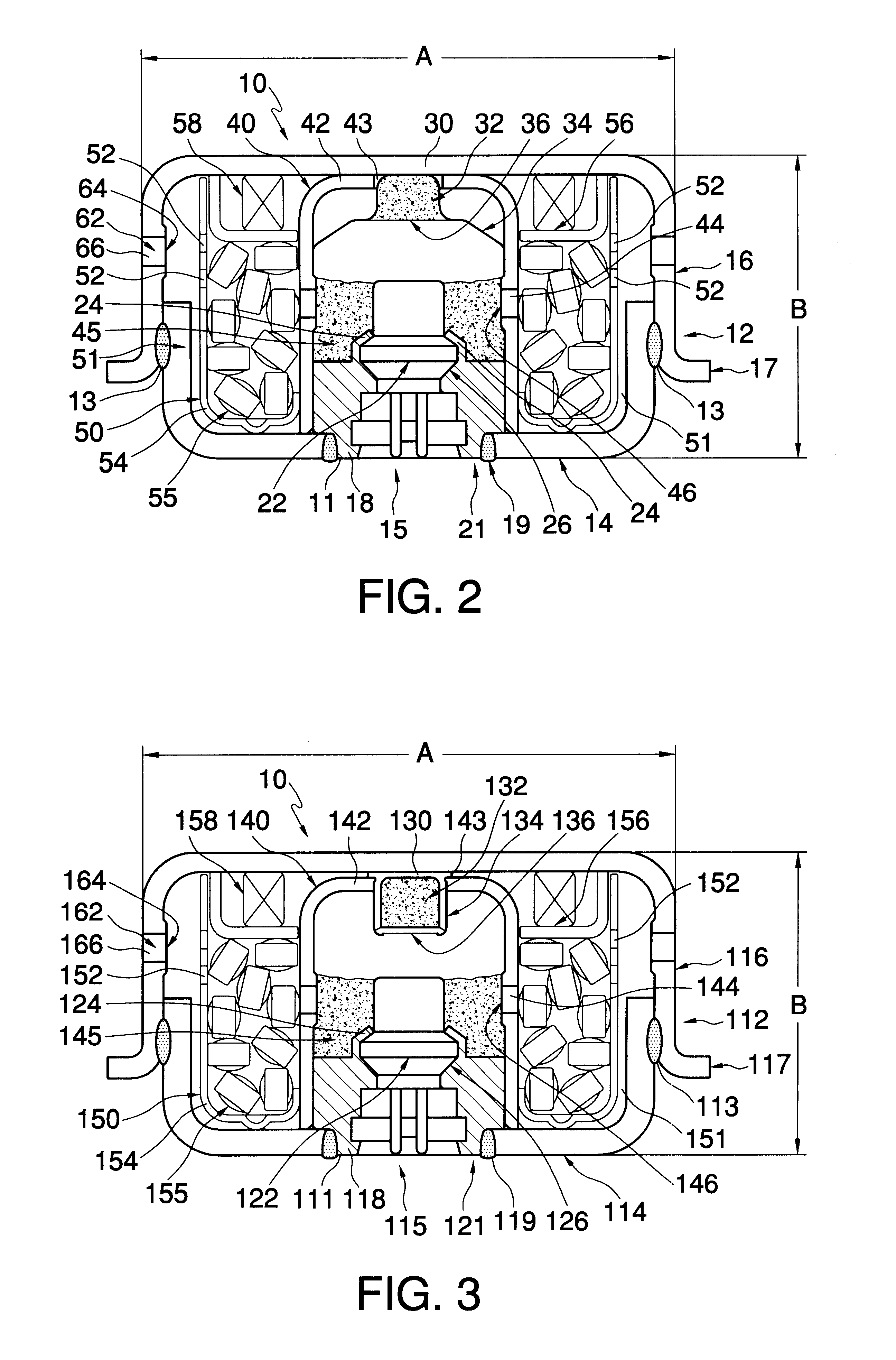

Dual stage inflator

InactiveUS6474684B1Reduced weight and sizeFew constraintsPedestrian/occupant safety arrangementIgnitorsDual stageEngineering

A non-hybrid pyrotechnic filterless inflator, i.e., gas generator, for an automotive passive restraint air bag having a generally discoidally-shaped pressure vessel having a diameter that preferably is greater than or about equal to its height formed of a cup-shaped closure cap and a base member and having at least one exhaust nozzle for directing gaseous products out of the inflator and into the air bag. The pressure vessel contains two separated and independently initiated initiator assemblies. By initiating either one or both initiator assemblies, the inflator can generate a modulated gas output between a first minimum output level and a second maximum output level in response to passenger and driver conditions.

Owner:TALLEY DEFENSE SYST

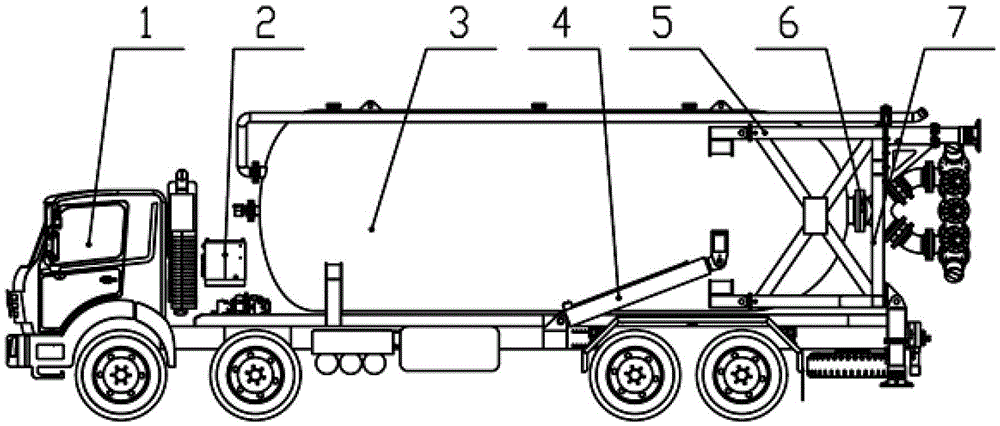

Fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid conveying device and a solid-liquid mixing device communicated with the solid conveying device, wherein the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid output by the solid conveying device, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

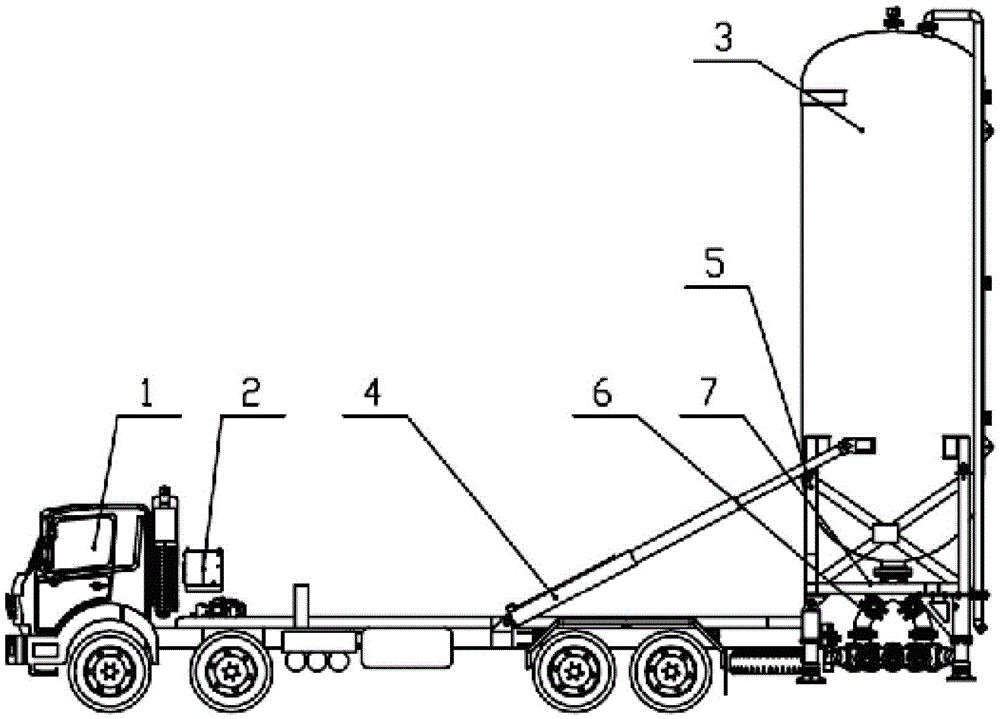

A fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid-liquid mixing device, and the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

A fracturing sand mixing device

The invention provides a fracturing sand mixing device used for mixing fracturing fluid. The fracturing sand mixing device comprises a solid conveying device and a solid-liquid mixing device communicated with the solid conveying device, wherein the solid-liquid mixing device is a pressure container. The solid-liquid mixing device comprises a solid lead-in port capable of leading in solid particles of the fracturing fluid output by the solid conveying device, a base fluid lead-in port for leading in base fluid of the fracturing fluid, a mixing inner cavity for accommodating the solid particles and the base fluid and a solid-liquid lead-out port for leading out the fracturing fluid formed by mixing. Substances such as carbon dioxide or petroleum gas which are in a gas state under normal temperature can be kept in a liquid state by high pressure through the fracturing sand mixing device and are mixed with the solid particles to form the fracturing fluid, and the goal of preparing the fracturing fluid with liquid carbon dioxide or liquefied petroleum gas (propane) serving as the base fluid is achieved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

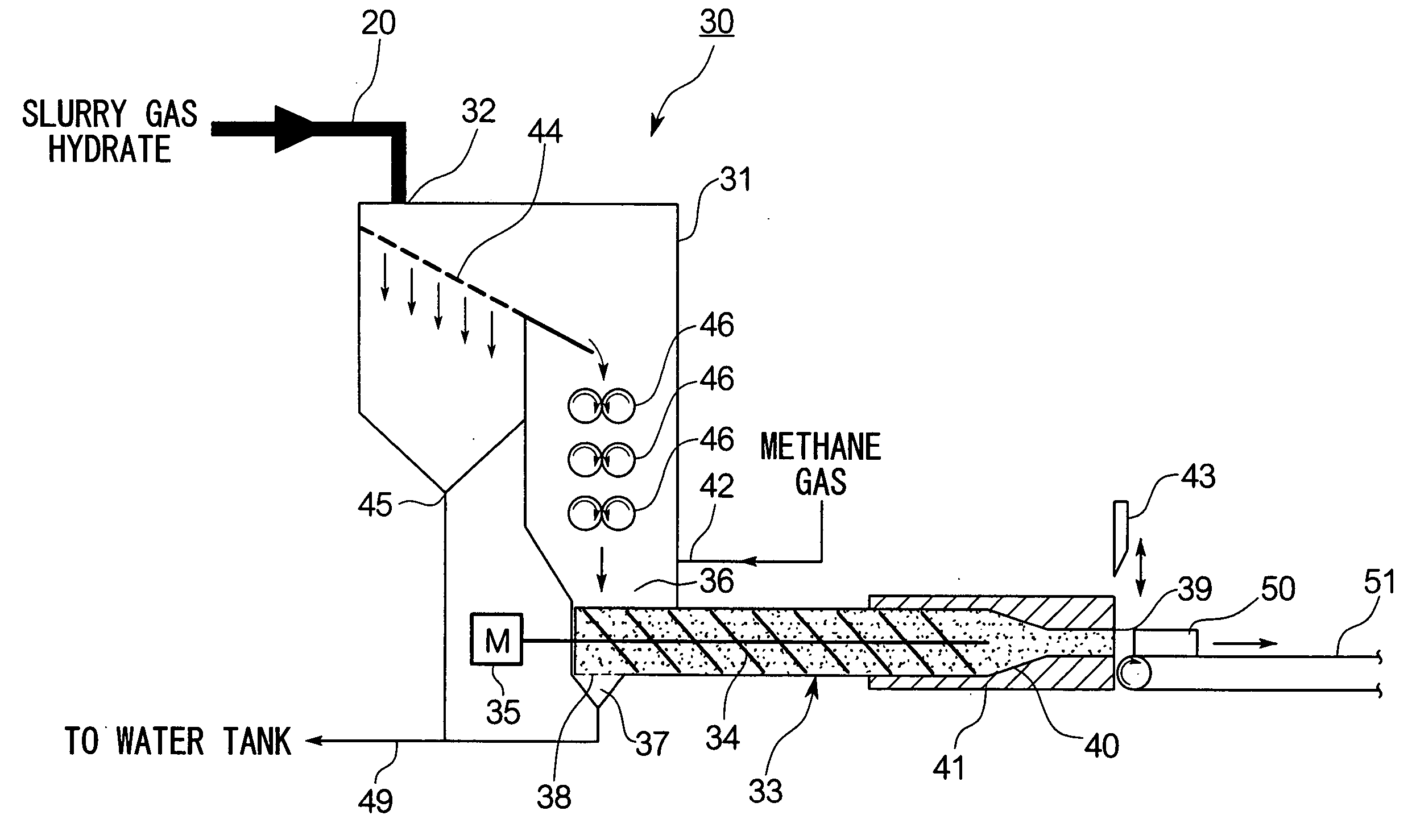

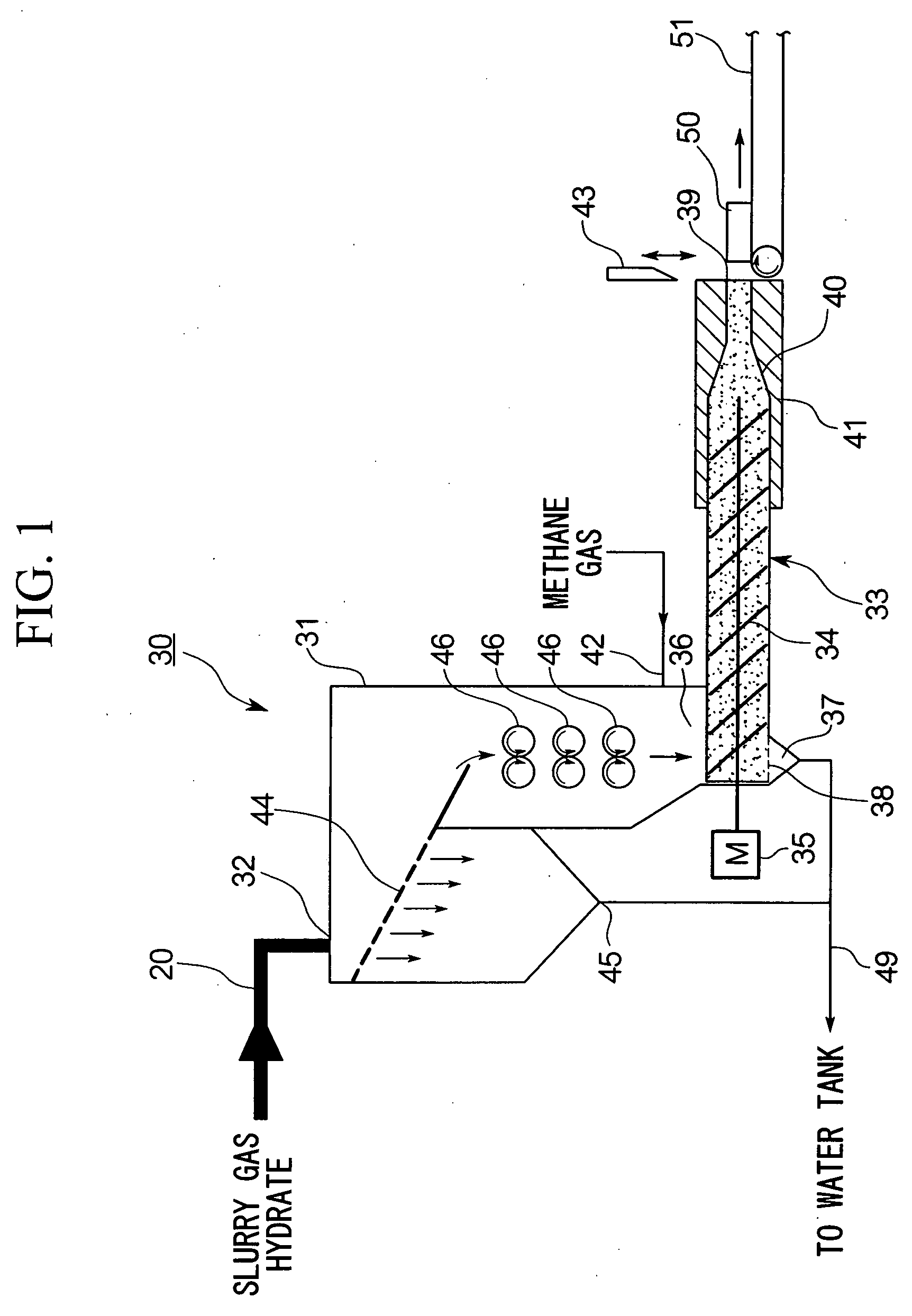

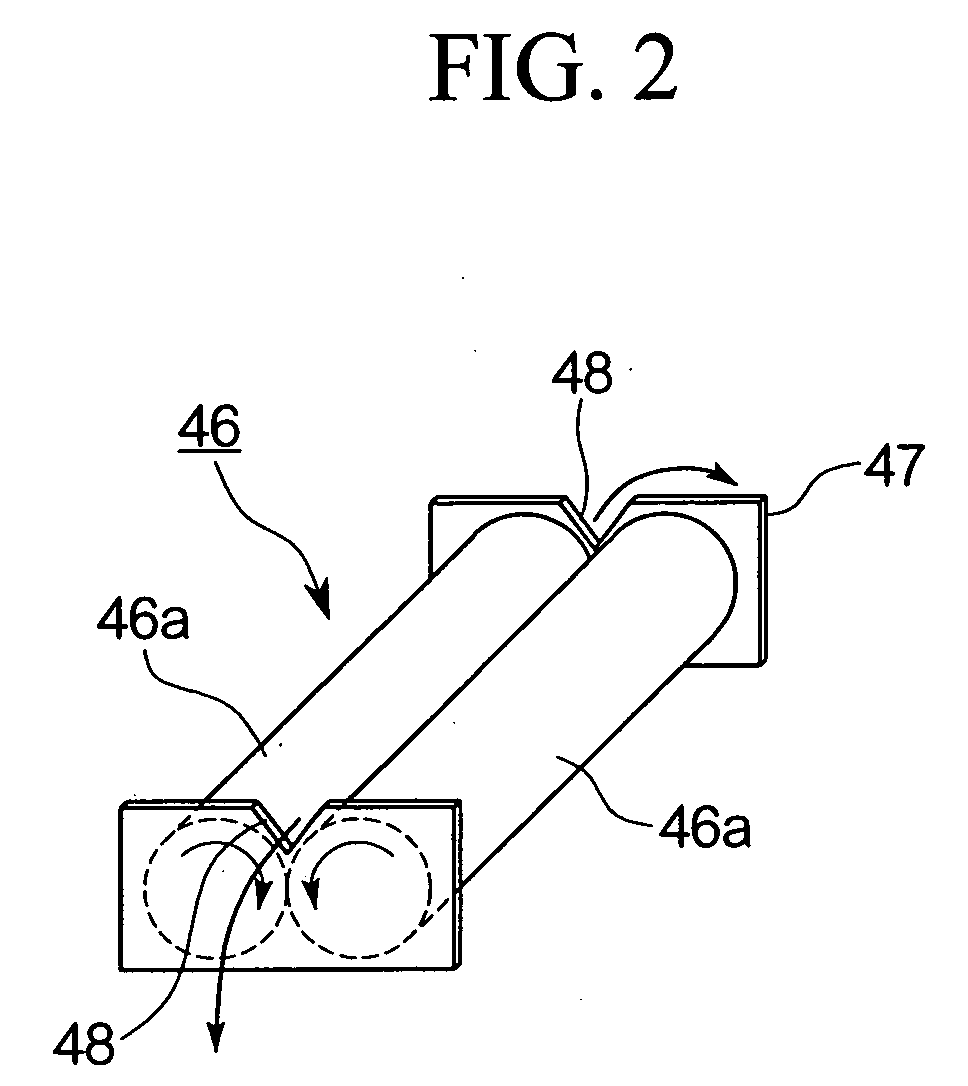

Gas hydrate production device and gas hydrate dehydrating device

InactiveUS20050107648A1Easy to implementSmall sizeOrganic chemistryDrying solid materials without heatAmbient pressureSlurry

The invention relates to a gas hydrate dewatering cooling and outputting apparatus which dewaters and solidifies gas hydrate slurry and takes out the solidified gas hydrate under ambient pressure. The apparatus comprises an output apparatus body 31 having a supply port 32 for the gas hydrate slurry on an upper part of a pressure vessel, a screw extruder 33 provided at a lower part inside the output apparatus body 31 and having a drain 37 and an outlet sealing device, and a cooling device 41 which cools the vicinity of the outlet 39 of the screw extruder 33. According to such a construction, slurry gas hydrate can be efficiently and continuously dewatered, cooled and solidified, and gas hydrate powder can be consolidated into blocks and taken out to the atmosphere.

Owner:MITSUBISHI HEAVY IND LTD

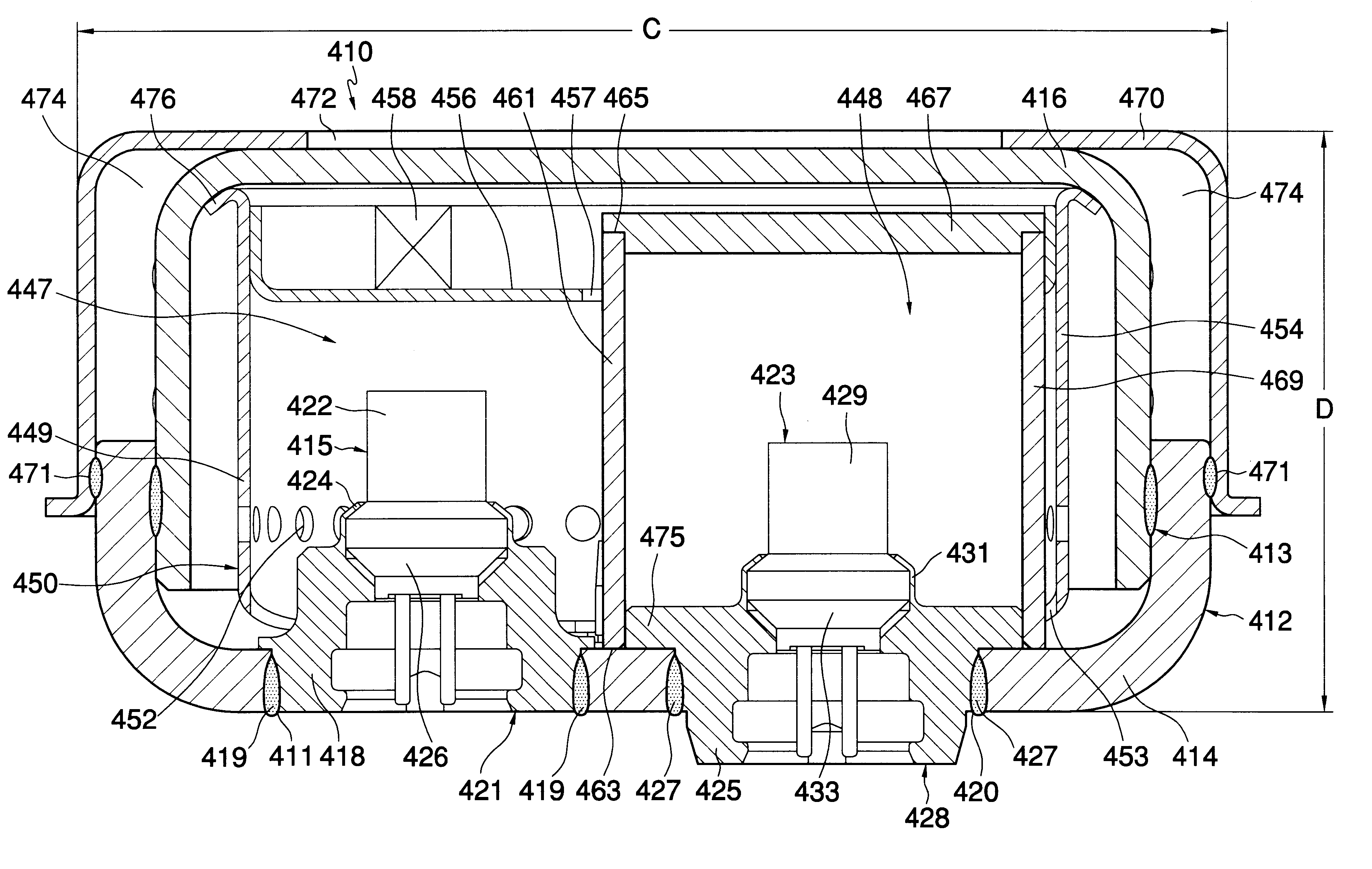

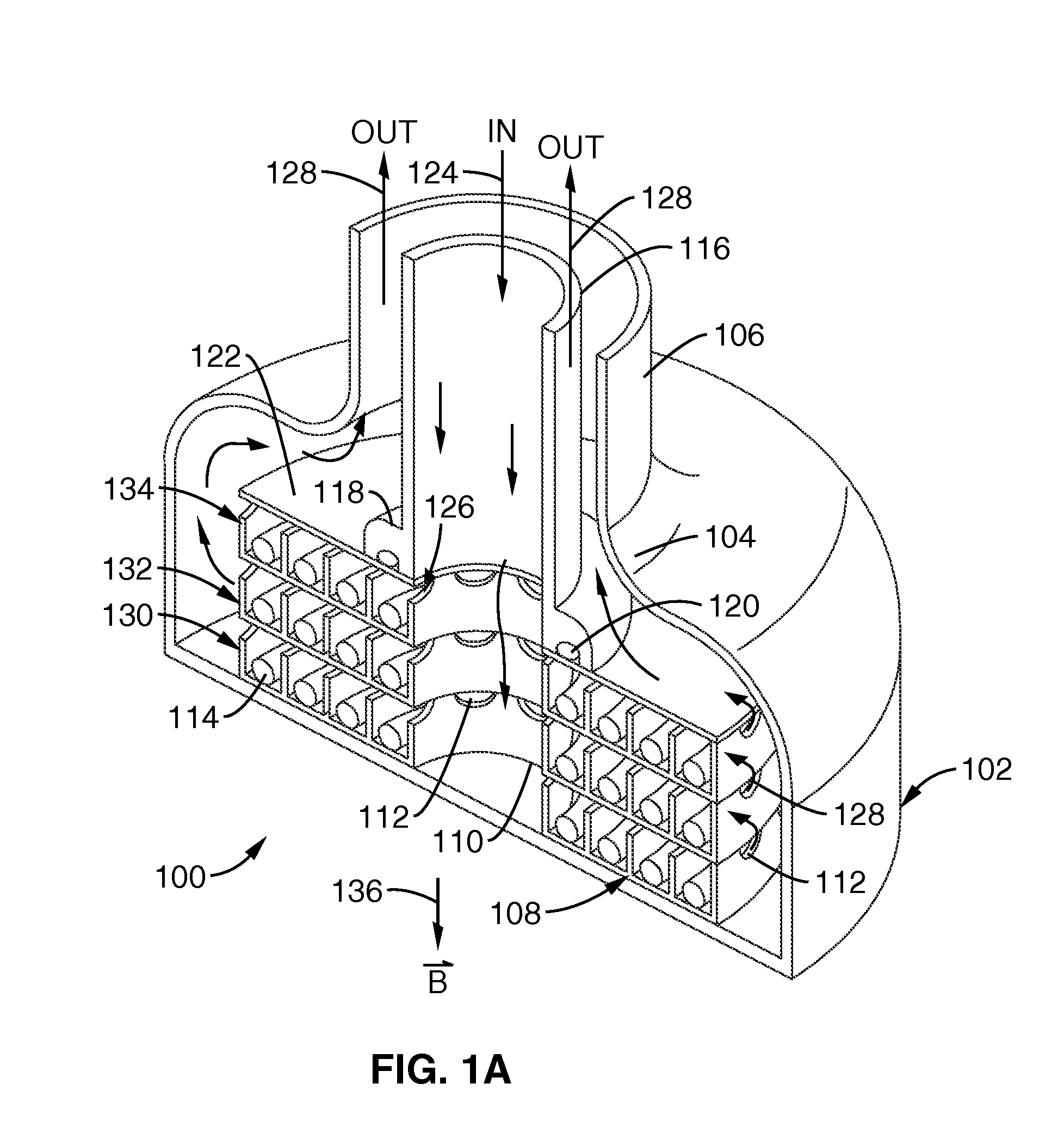

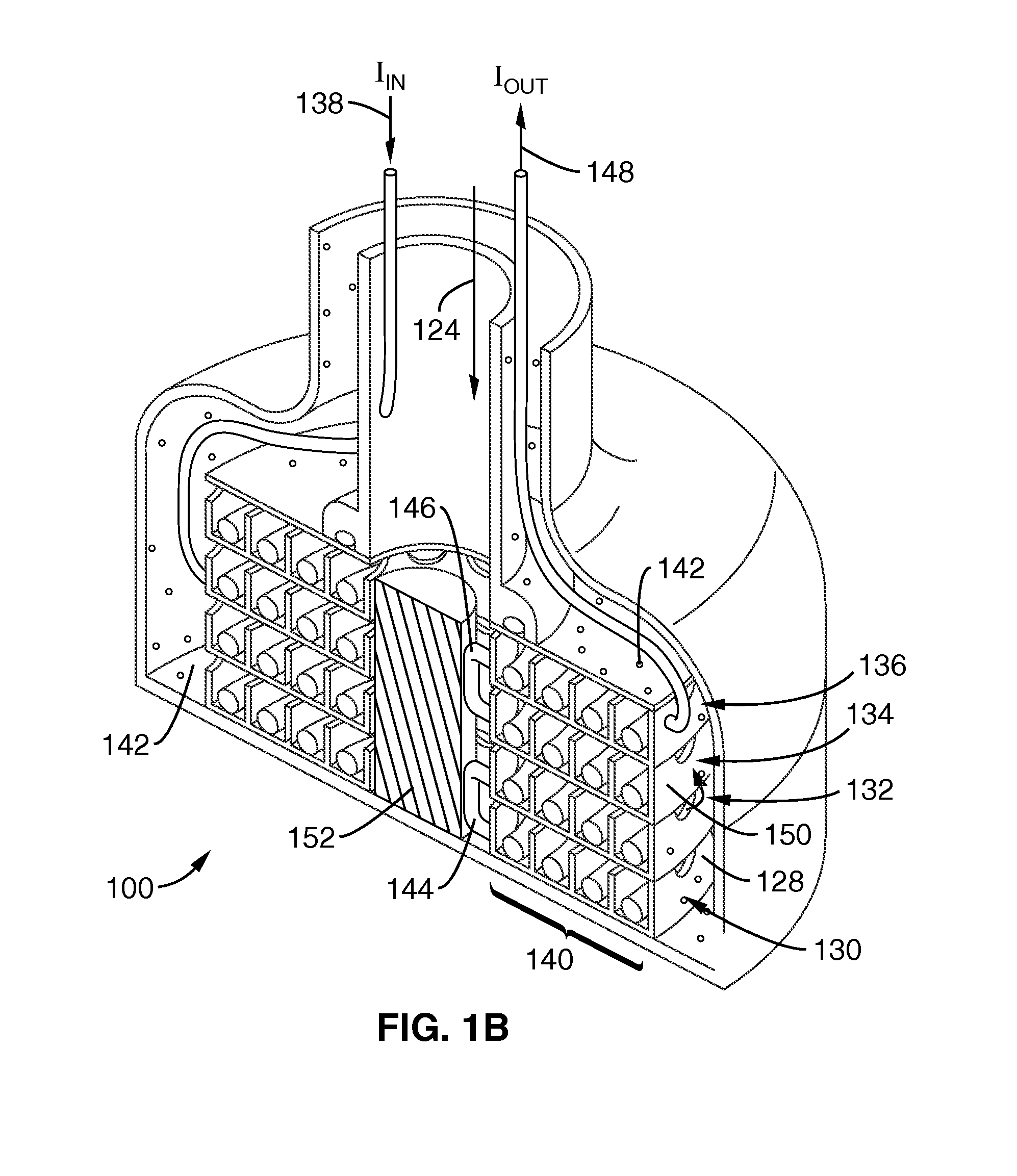

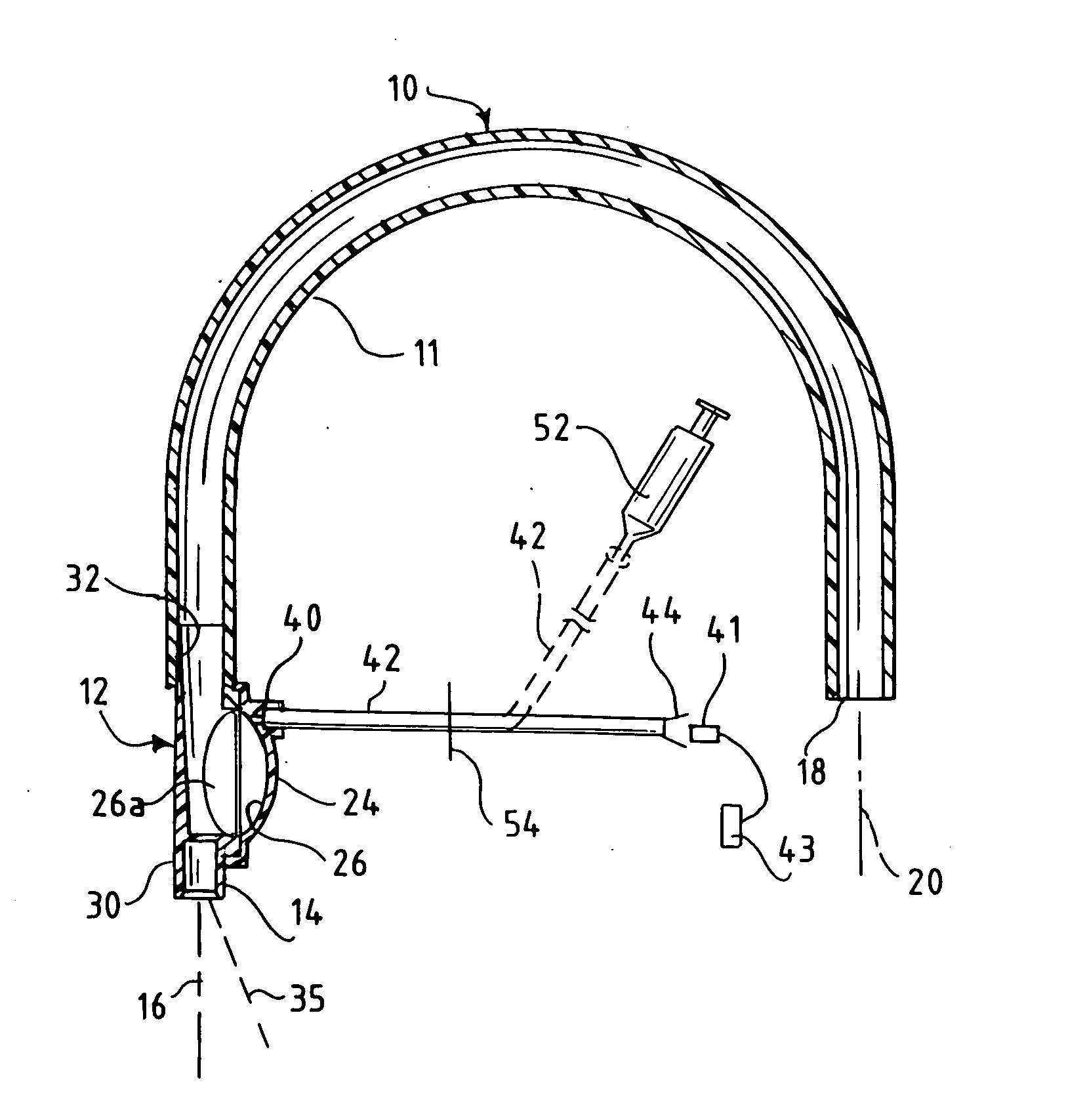

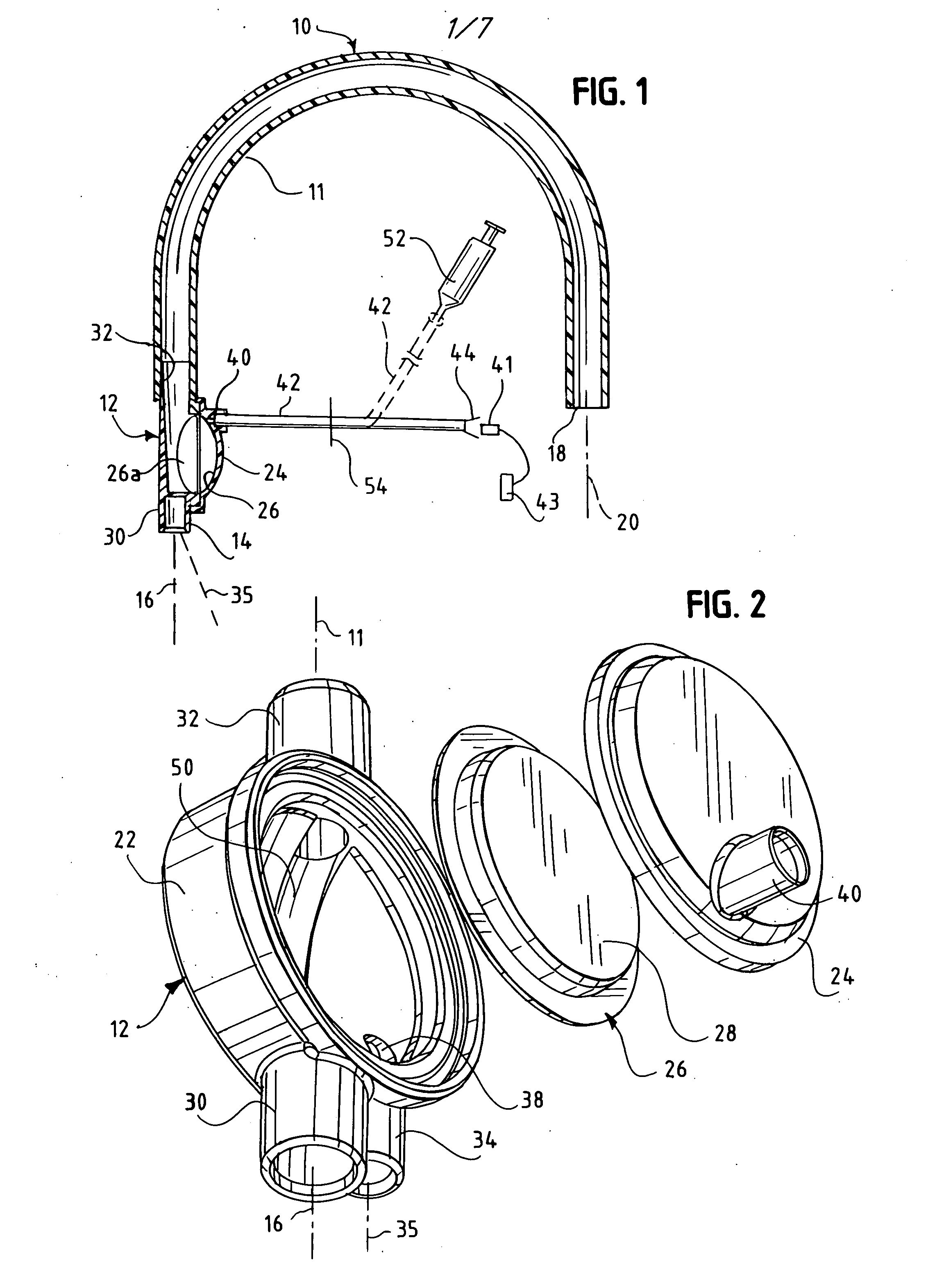

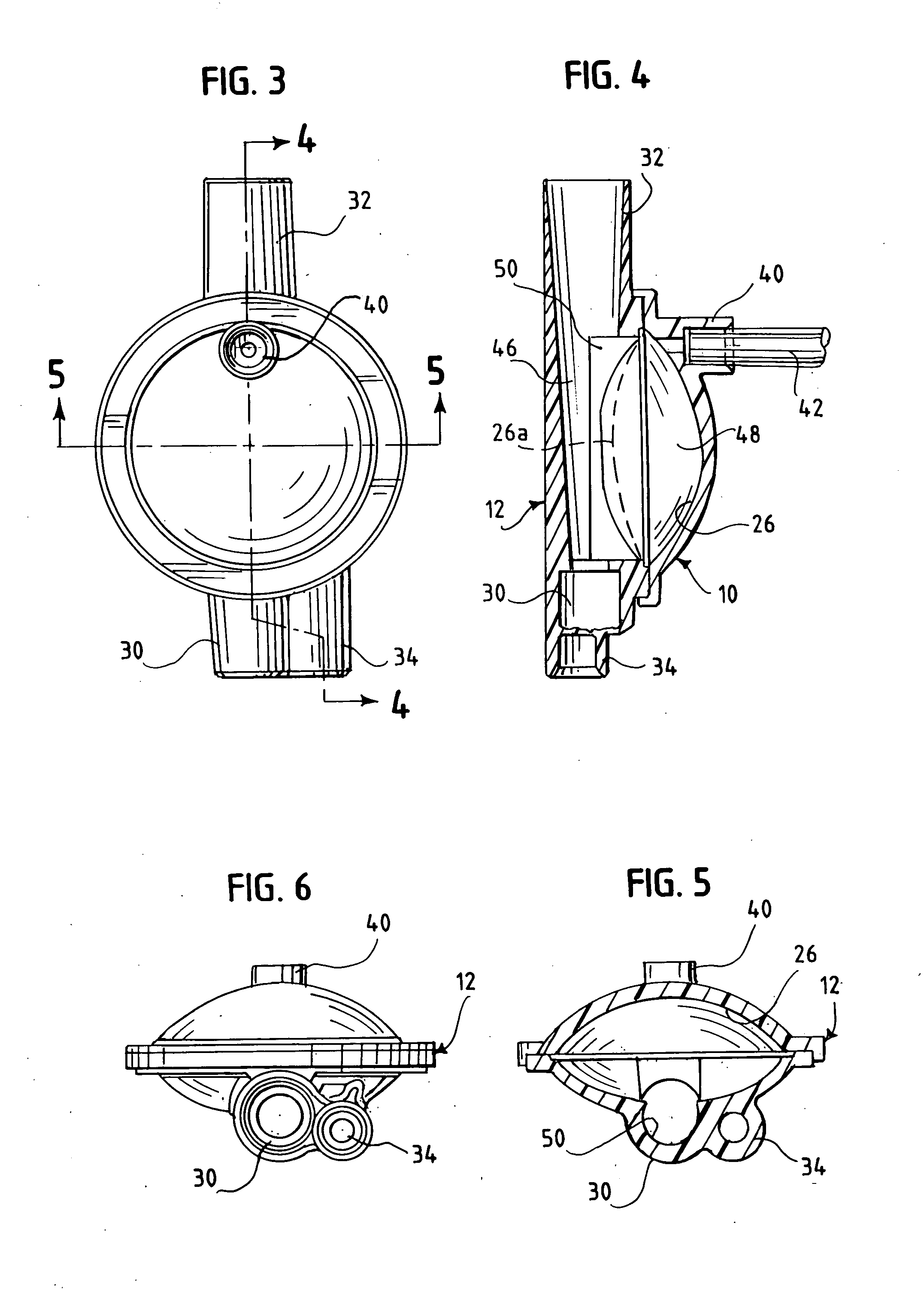

Apparatus and method for transcranial and nerve magnetic stimulation

InactiveUS20090108969A1Avoid lostElectromagnets without armaturesTransformers/inductances coolingNeuronal stimulationLitz wire

An electromagnet coil comprising Litz wire windings and power leads without break or interruption is cooled by a perfluorinated liquid by sensible and phase change heat transfer in a closed system. The electromagnet coil may be housed in a pentagonal or hexagonal pressure vessel to allow high packing densities in an array or helmet configuration. The helmet is then lowered over a human cranium for transcranial electromagnetic stimulation. The Litz wire windings reduce the power and voltages required for operation, yet allow production of over 2 T of accurately directed magnetic pulses for direct nerve or neuron stimulation. The perfluorinated liquid maintains the temperature of the helmet to less than 35-40° C., ensuring a comfortable temperature device for a human test subject. A utility cable connects the helmet to an external cooling unit and an external power supply.

Owner:LOS ALAMOS NATIONAL SECURITY

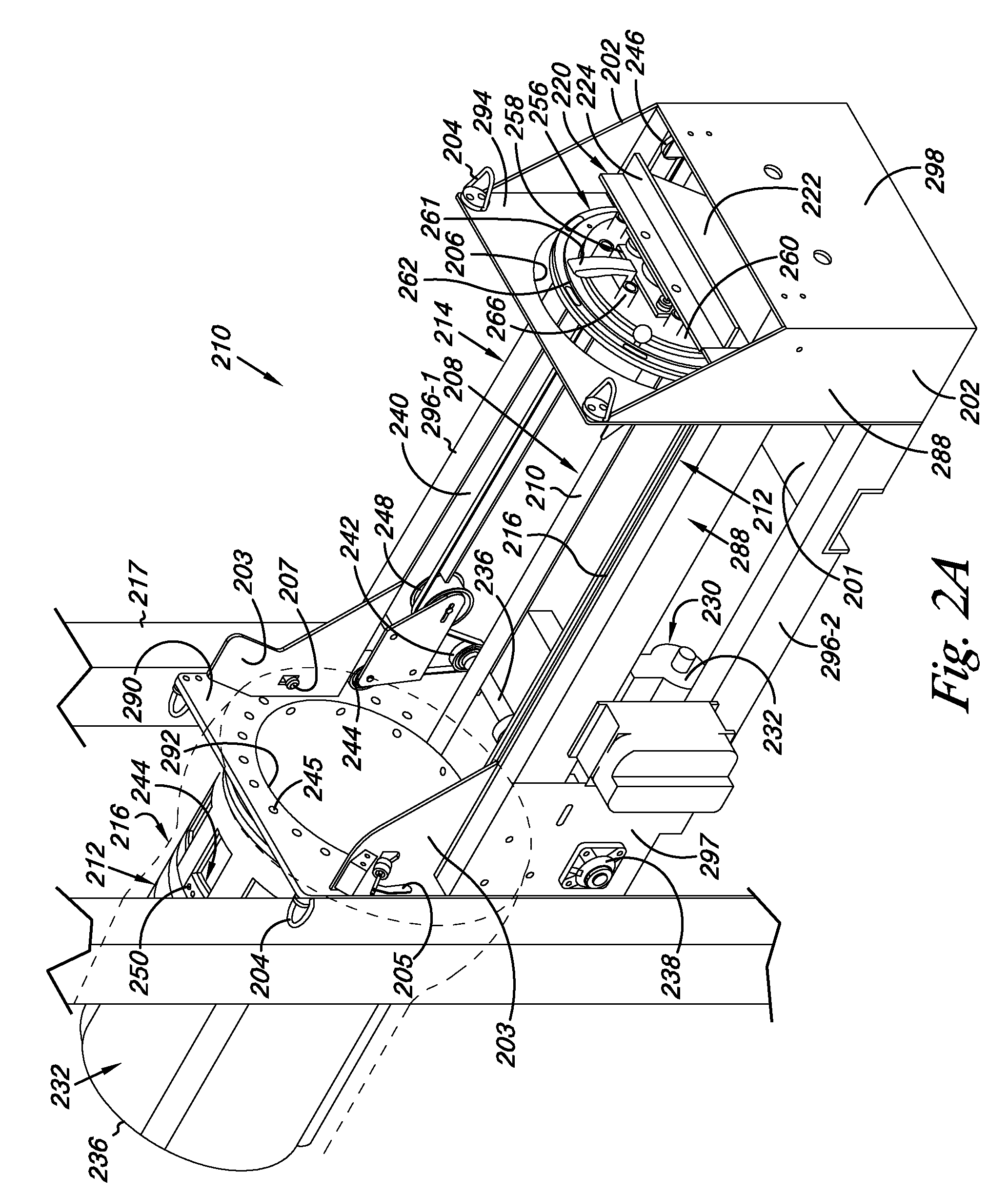

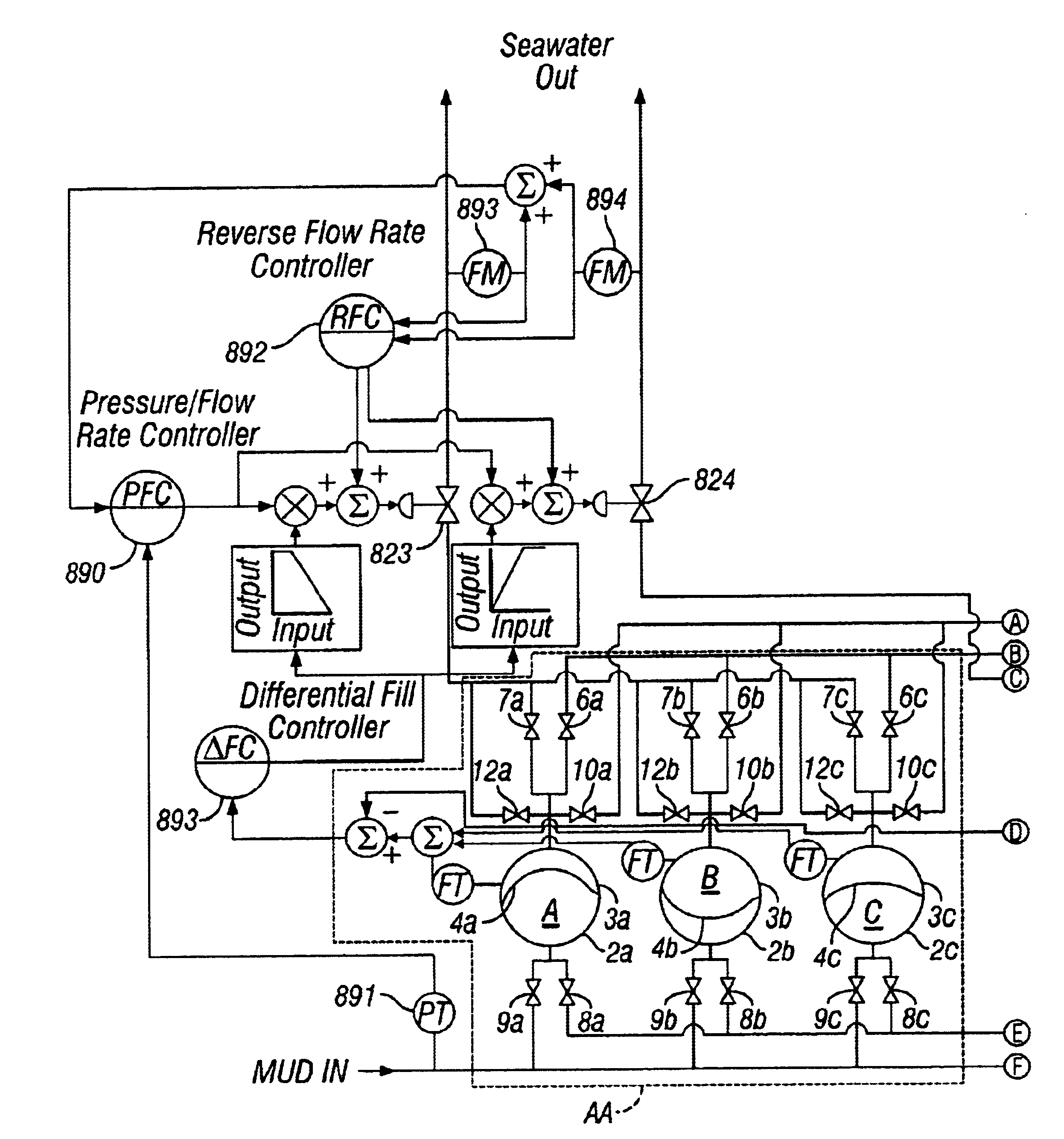

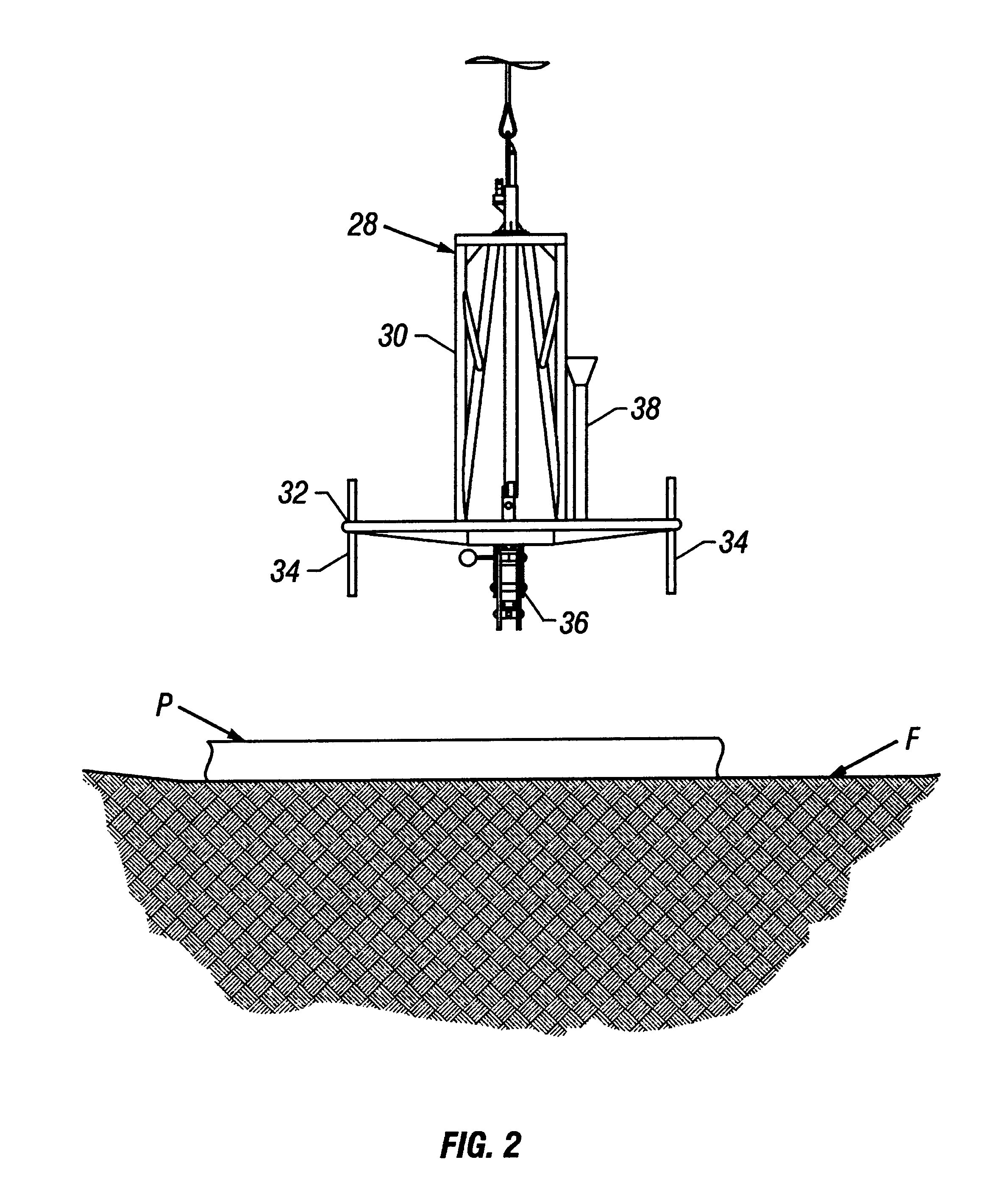

Subsea mud pump and control system

A sub-sea mud pump system includes a plurality of pump units, and each pumping unit includes a plurality of pumping elements. Each pumping element includes a pressure vessel with a first and a second chamber, a separating member between the first and second chambers, a measurement device adapted to measure the volume of at least one of the first and second chambers, a hydraulic inlet control valve and a hydraulic outlet control valve coupled to the first chamber, a mud suction valve and a mud discharge valve coupled to the second chamber. The first chamber is hydraulically coupled to receive and discharge a hydraulic fluid, and the second chamber is hydraulically coupled to receive and discharge a drilling fluid. The separating member is adapted to move within its the pressure vessel in response to a pressure differential between the first and second chambers. The pump system also includes a hydraulic control unit adapted to control the plurality of pump units.

Owner:HYDRIL USA MANUFACTURING LLC

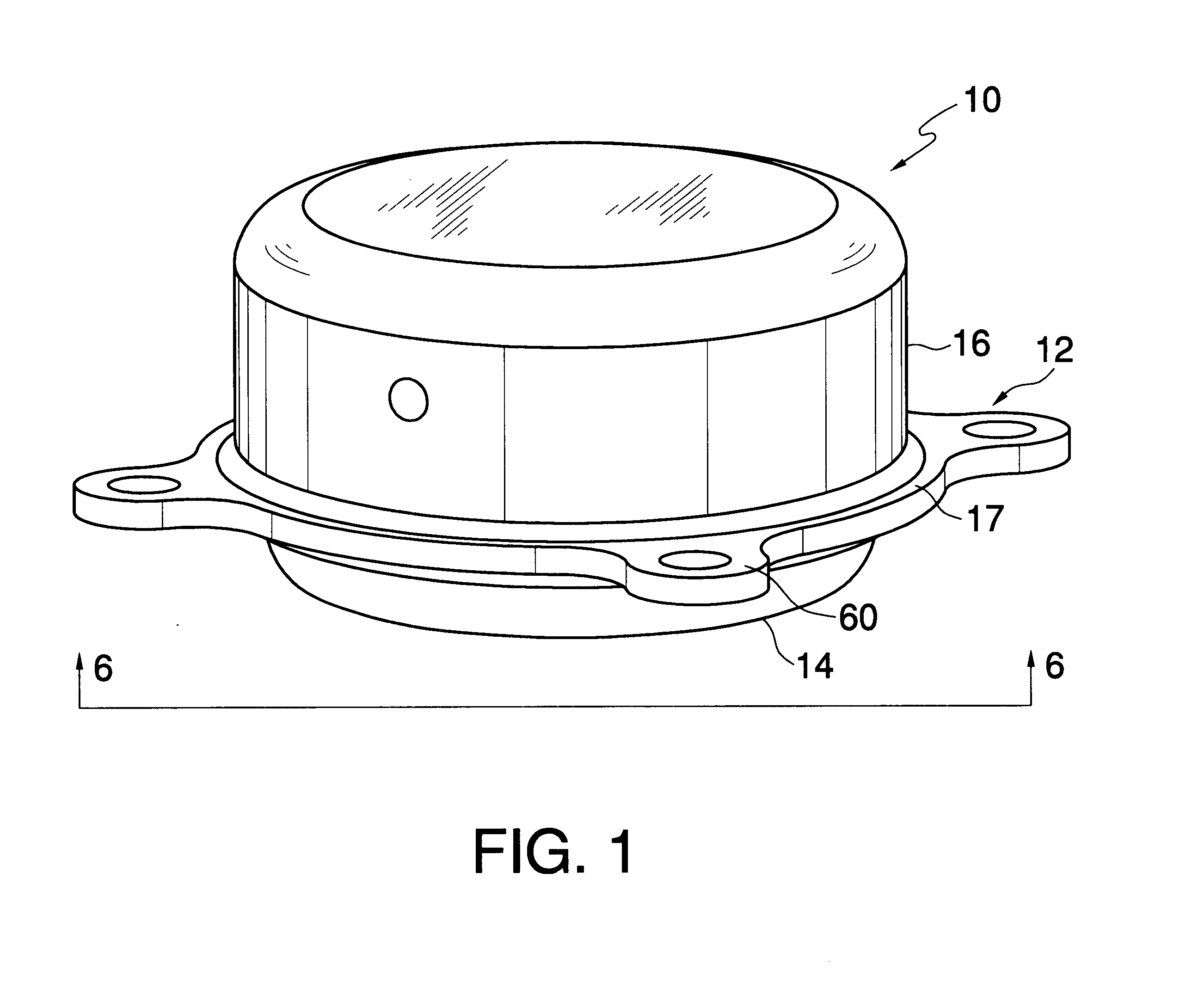

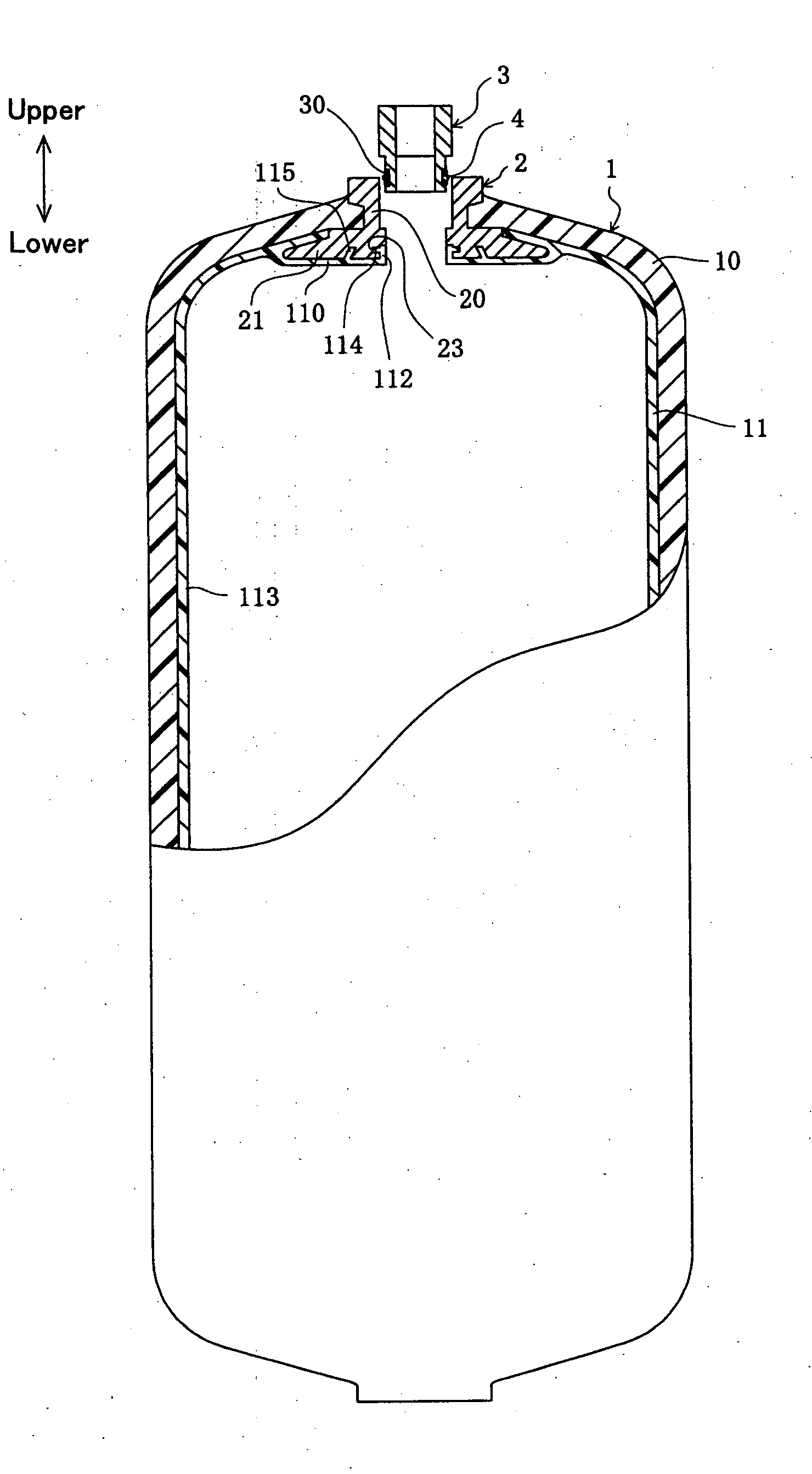

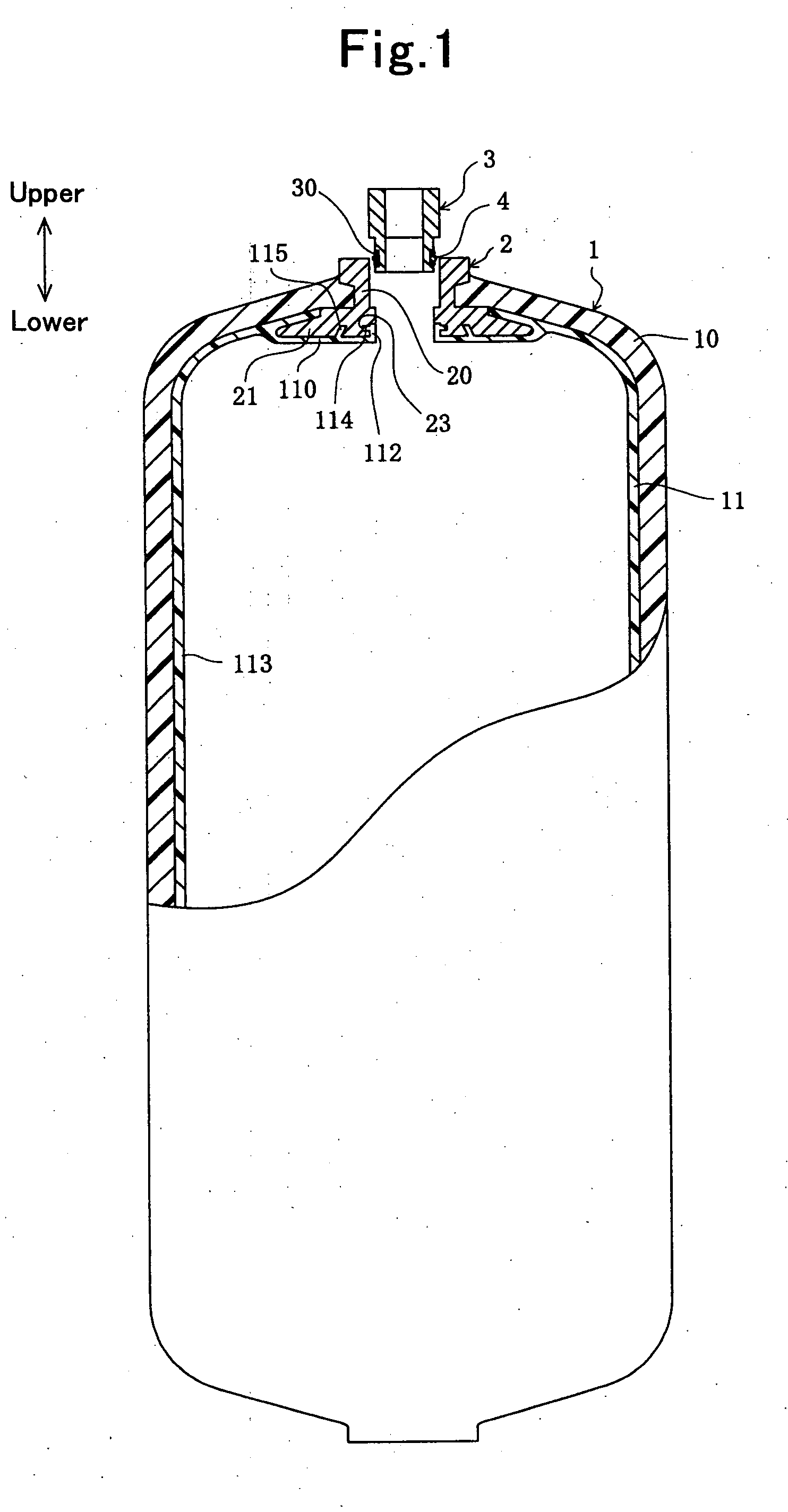

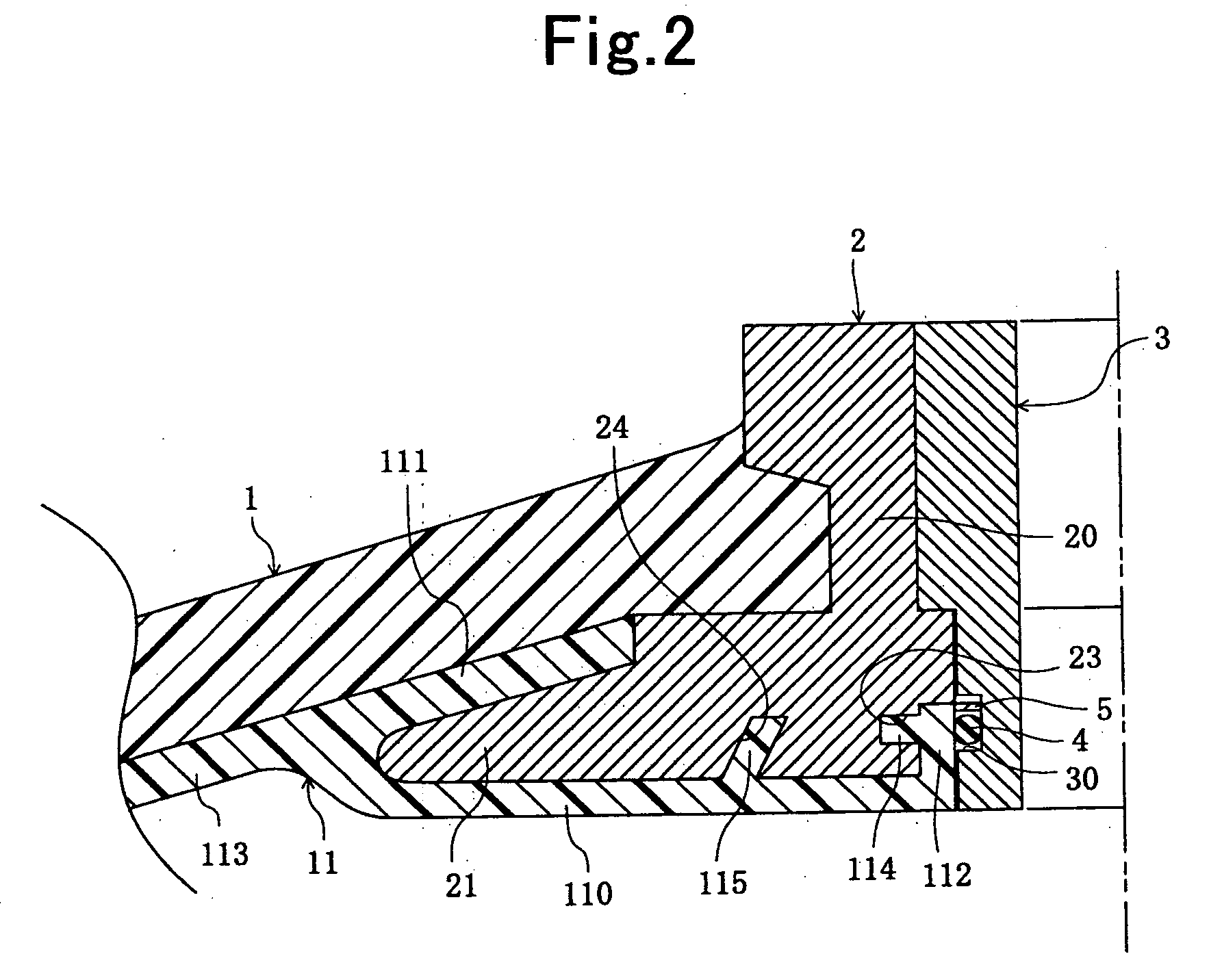

Pressure vessel

A pressure vessel capable of securely sealing a mouth ring with a liner portion, and being manufactured at low costs. A boss seal part 112 is provided in a liner portion 11 of the pressure vessel, and an inner peripheral surface of a boss part 20 of a mouth ring 2 is covered with the boss seal part 112. A boss-side collar part 114 is provided in the boss seal part 112 so as to project outwardly, and a sealing member 4 composed of a resilient body is disposed in a space between an inner peripheral surface of the boss seal part 112 and an outer peripheral surface of the valve 3.

Owner:TOYODA GOSEI CO LTD +1

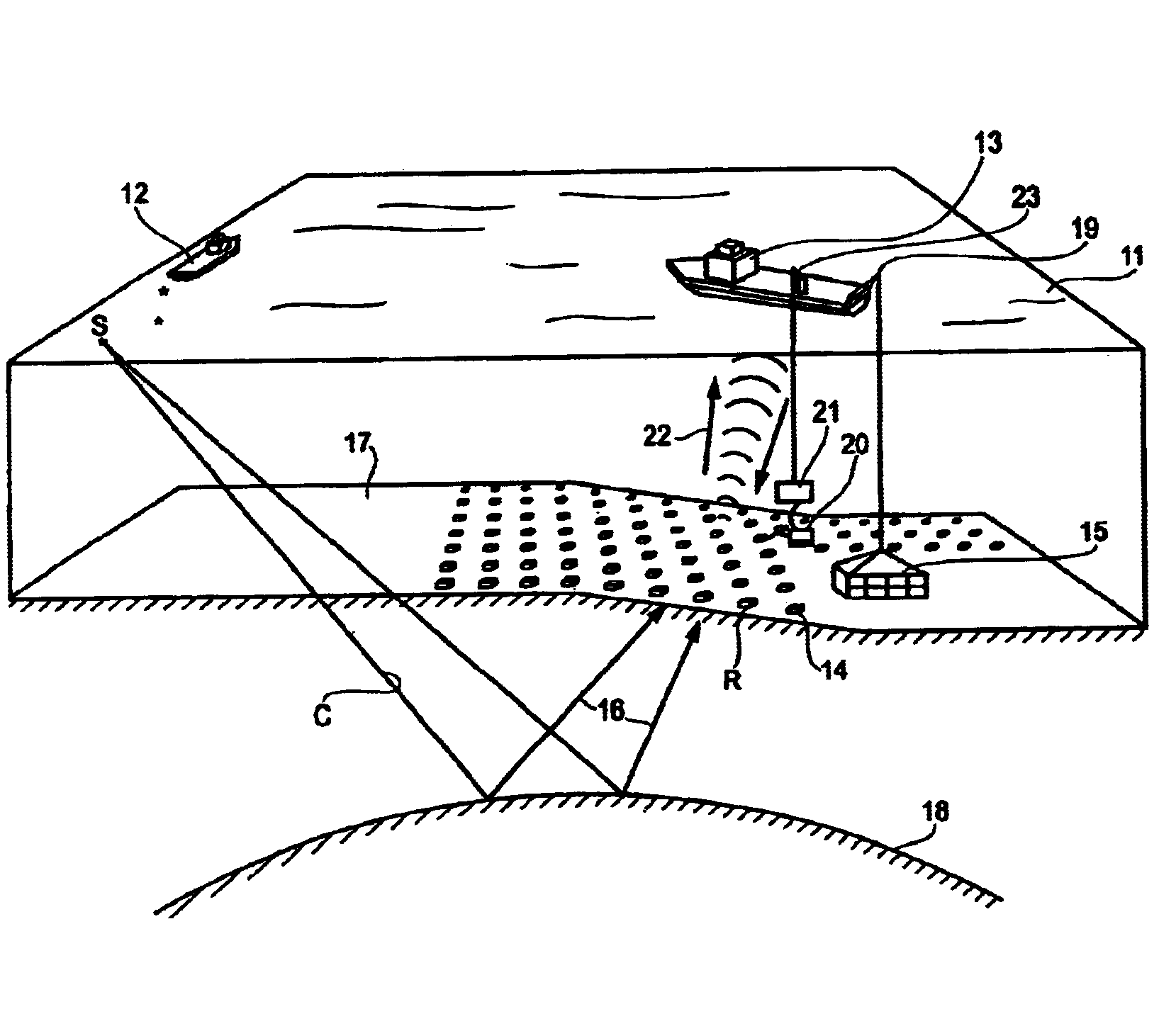

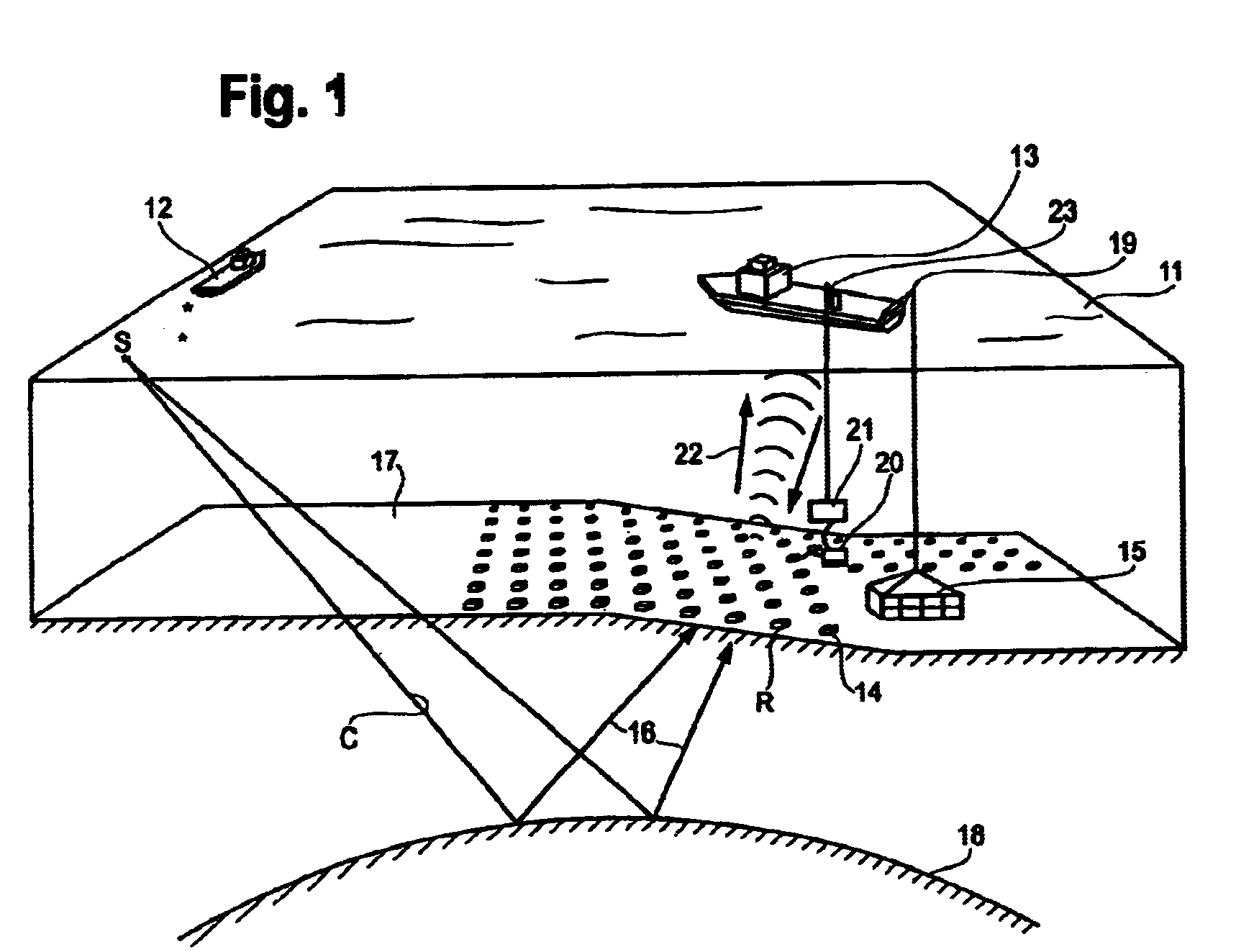

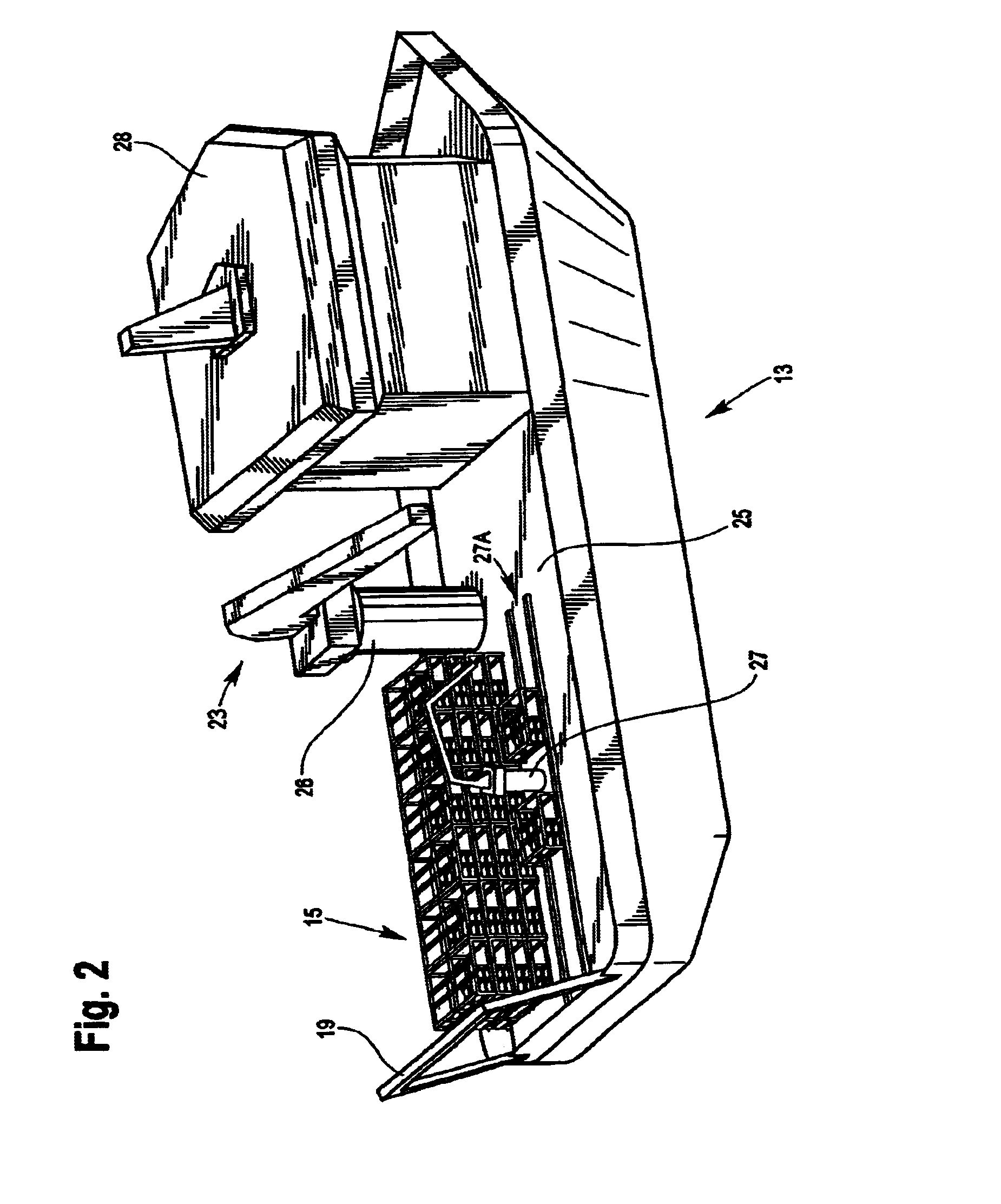

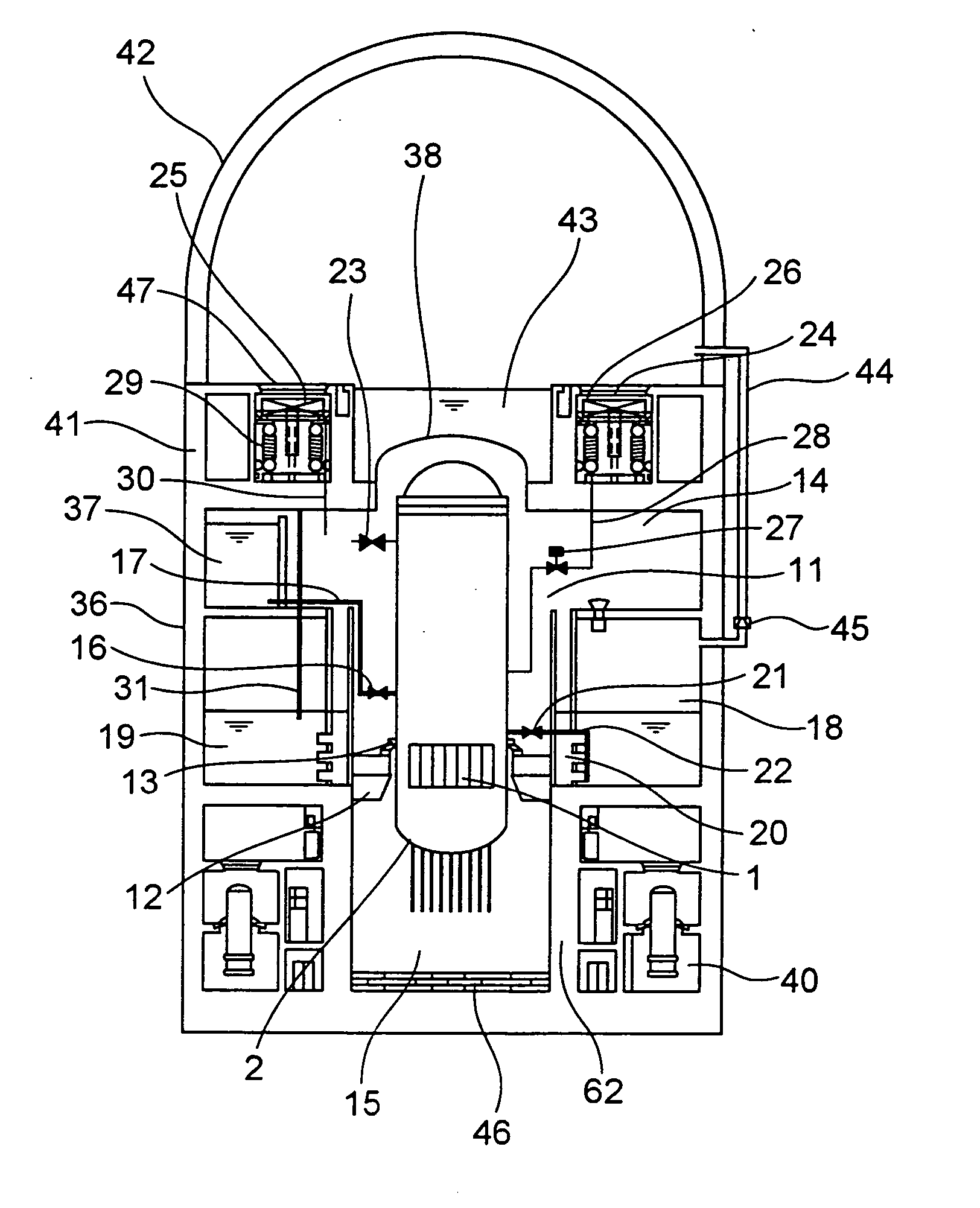

Geophysical method and apparatus

ActiveUS6975560B2Deploying seismic receivers on the seabed much quickerRapid deploymentSonic/ultrasonic/infrasonic transmissionSeismology for water-covered areasGeophoneSeismic survey

A method and apparatus is disclosed for performing a seismic survey below the surface of a body of water and on the seabed. In one embodiment, a plurality of seismic data receivers are removably loaded in a carrier located above the surface of the water and the carrier is lowered into the water and placed at a depth relatively close to the seabed. Each of the receivers has a memory for recording the vibrations of the seabed and has a switch for activating the memory. A ROV is used to unload the receivers from the carrier and to deposit each receiver on the seabed and along a survey line. In one embodiment, the receivers comprise a frame, a pressure vessel for housing the memory and remotely activated controls, and a geophone that is separately planted into the seabed at a relatively short distance from the frame.

Owner:BP CORP NORTH AMERICA INC

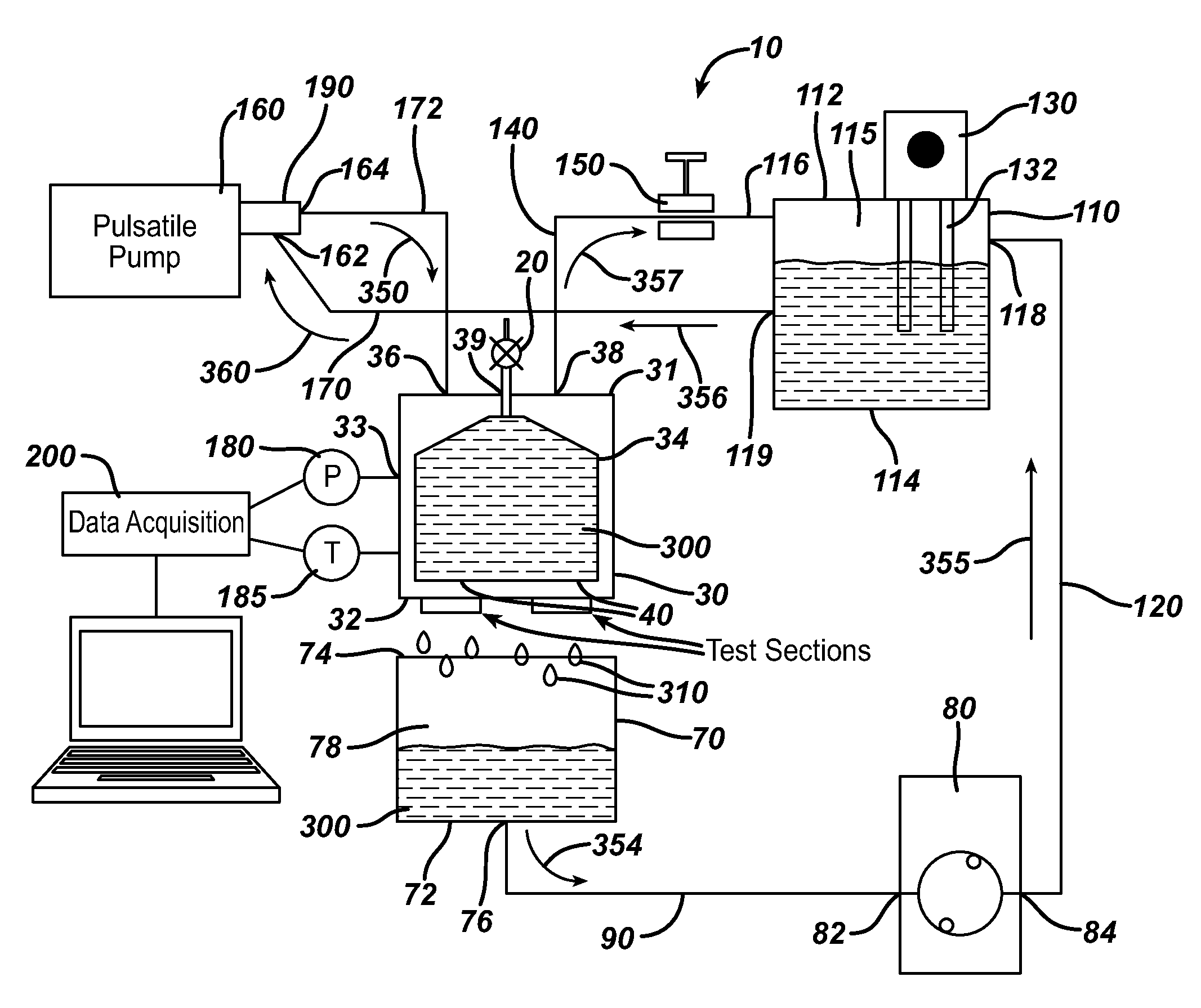

Paravalvular leak test apparatus and method

An apparatus and method for measuring paravalvular leakage from a prosthetic heart valve in vitro. The apparatus has a pulse chamber pressure vessel and a pulsatile pump. The sewing ring of a prosthetic heart valve is mounted to a mounting member which is affixed to the pressure chamber, and paravalvular leakage from the heart valve is collected and measured.

Owner:ETHICON INC

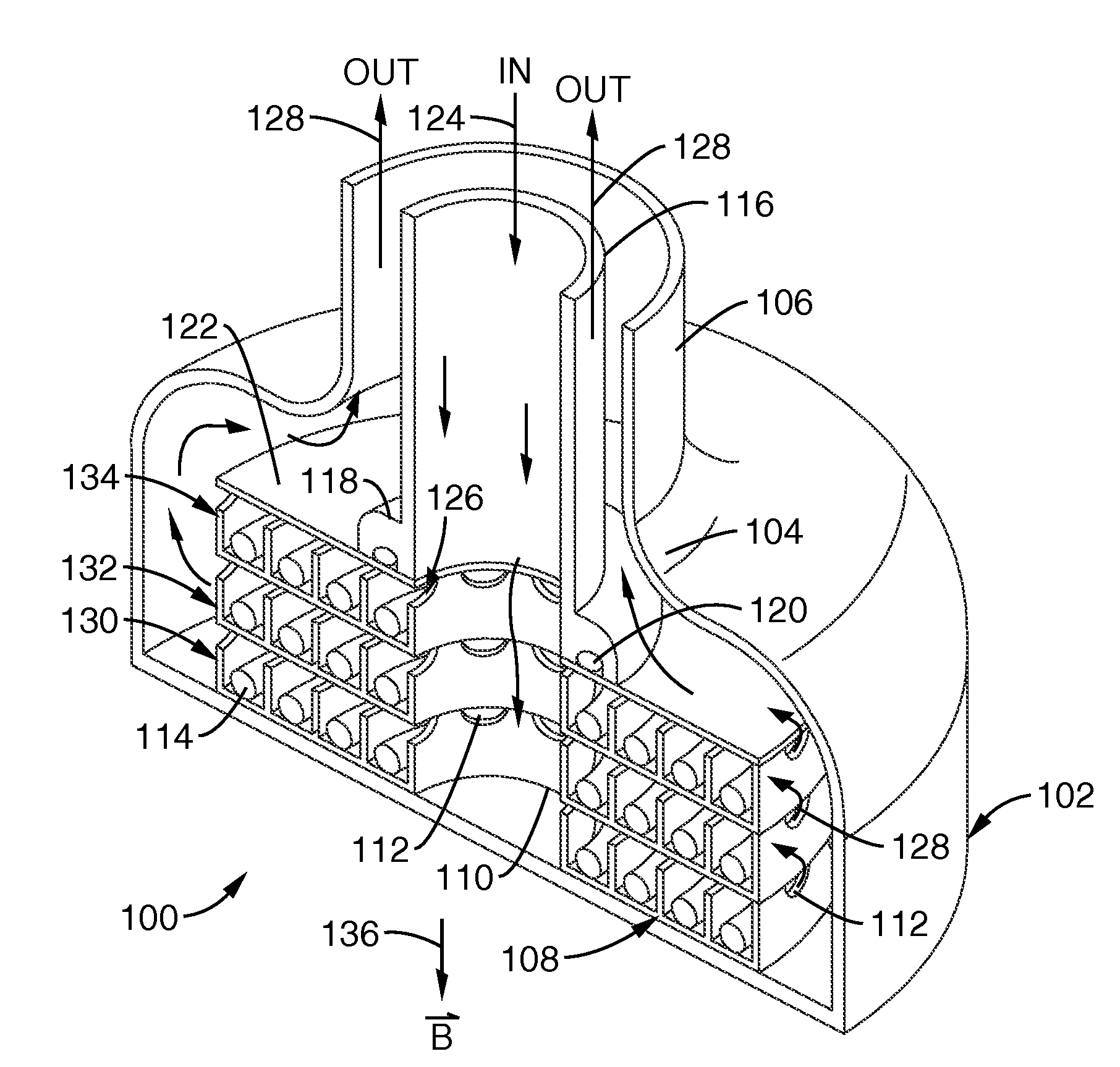

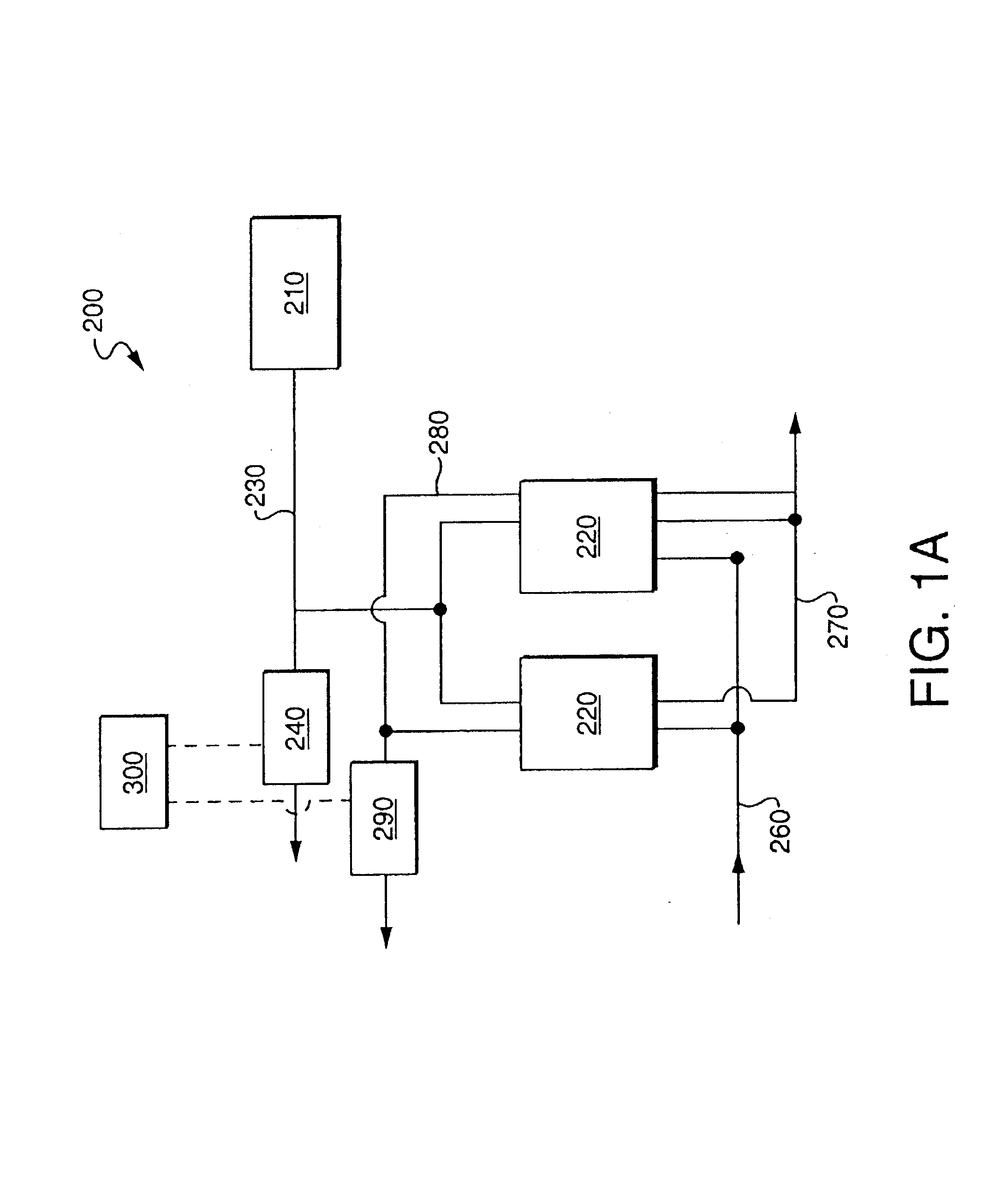

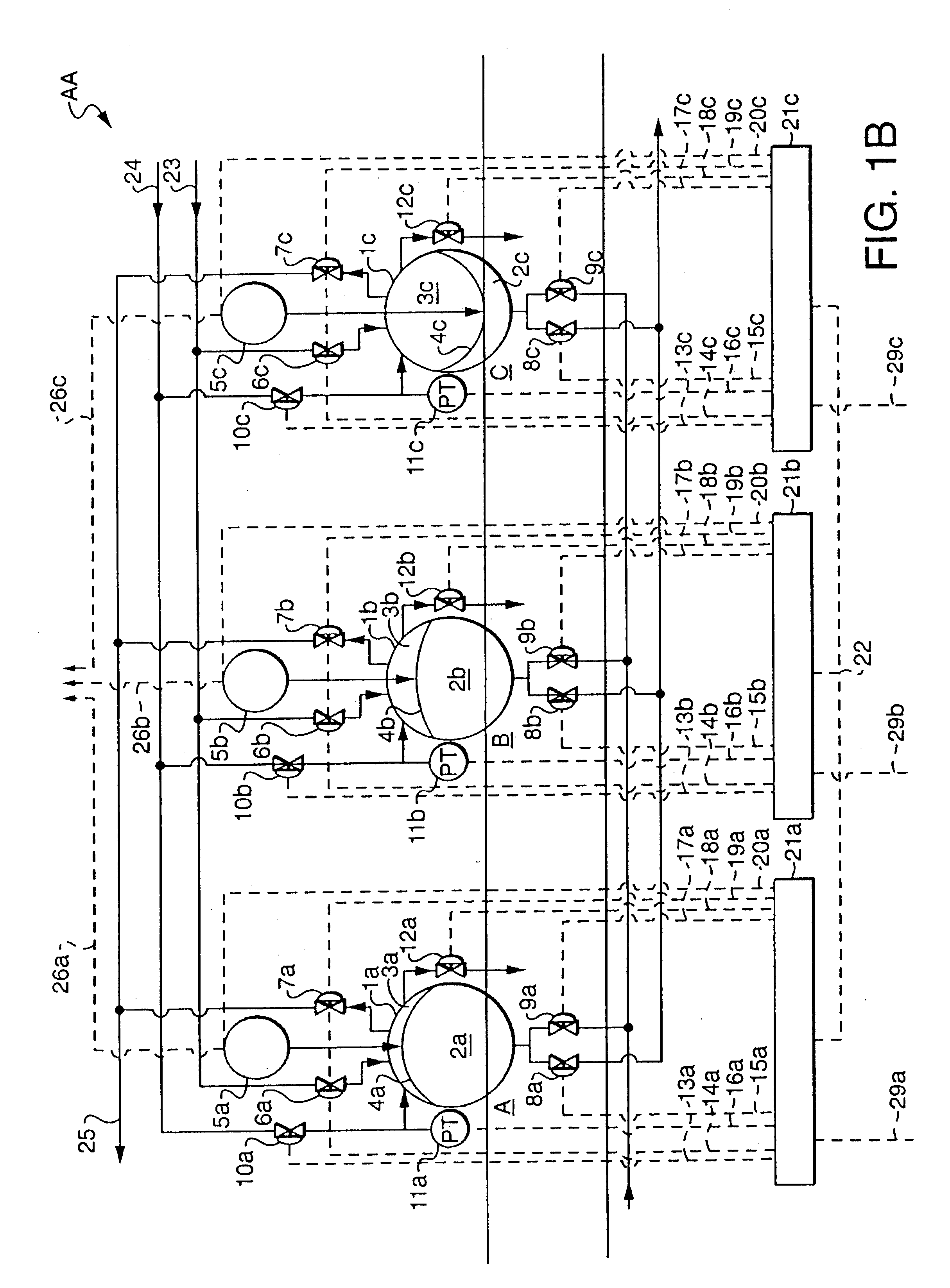

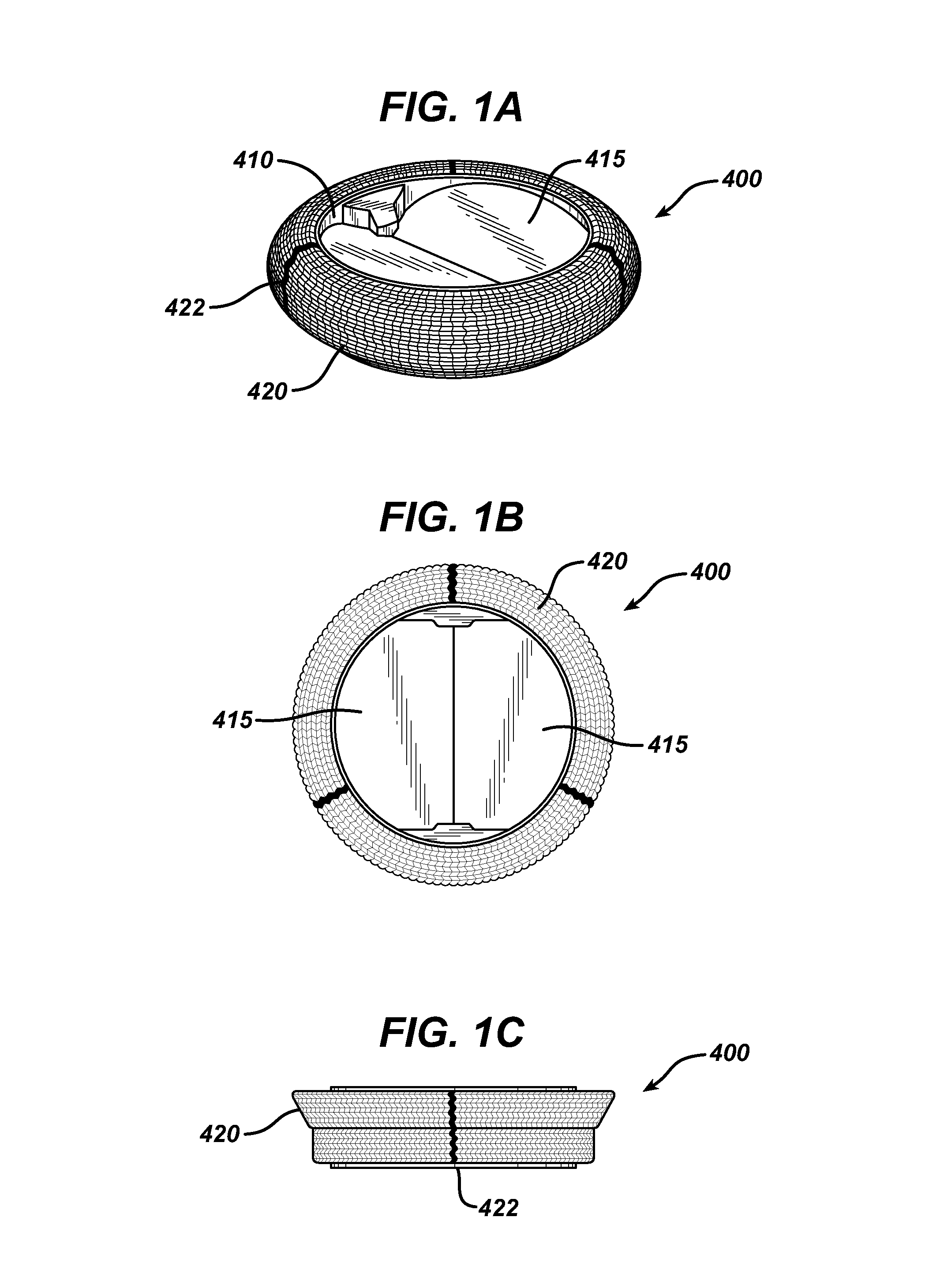

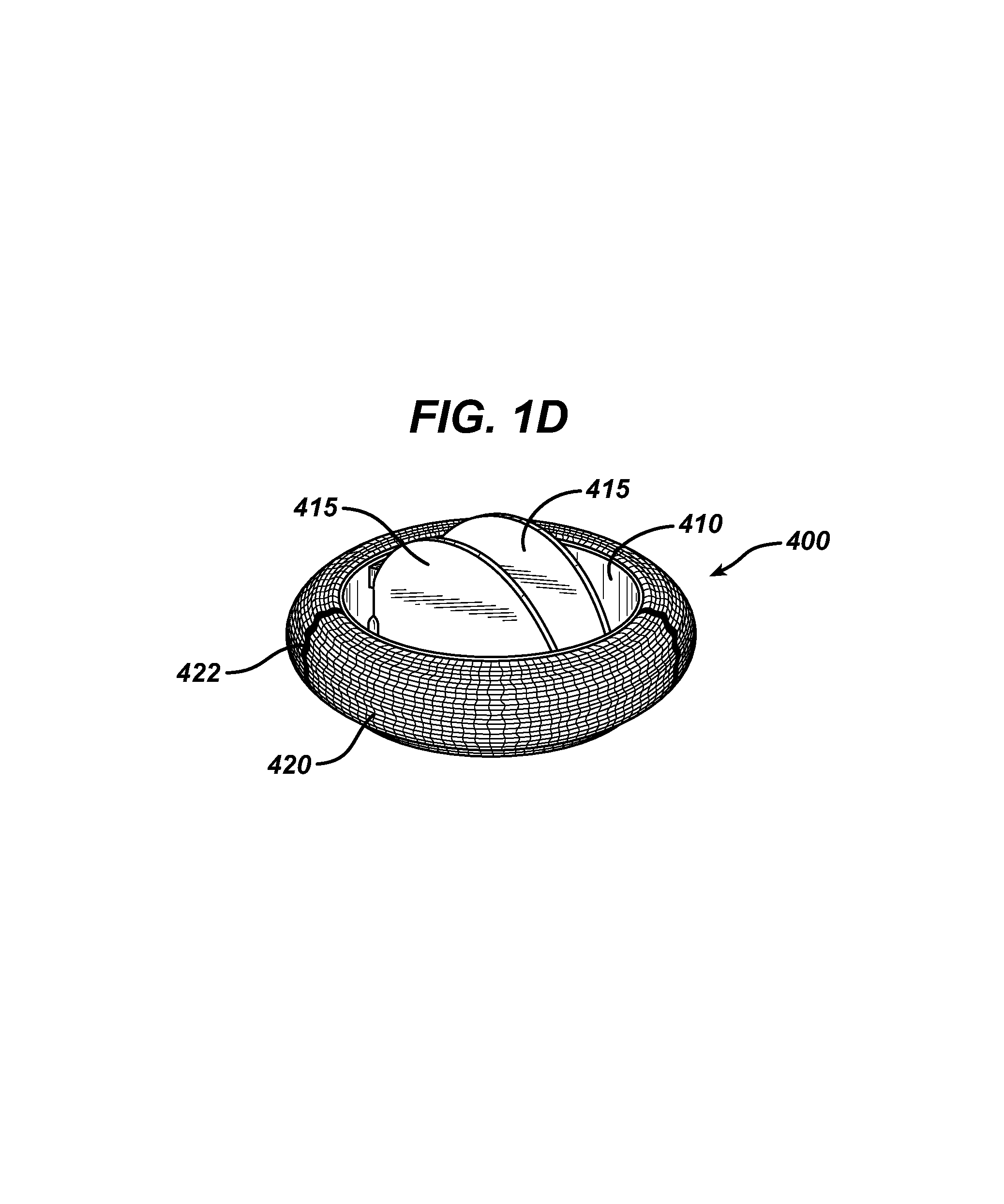

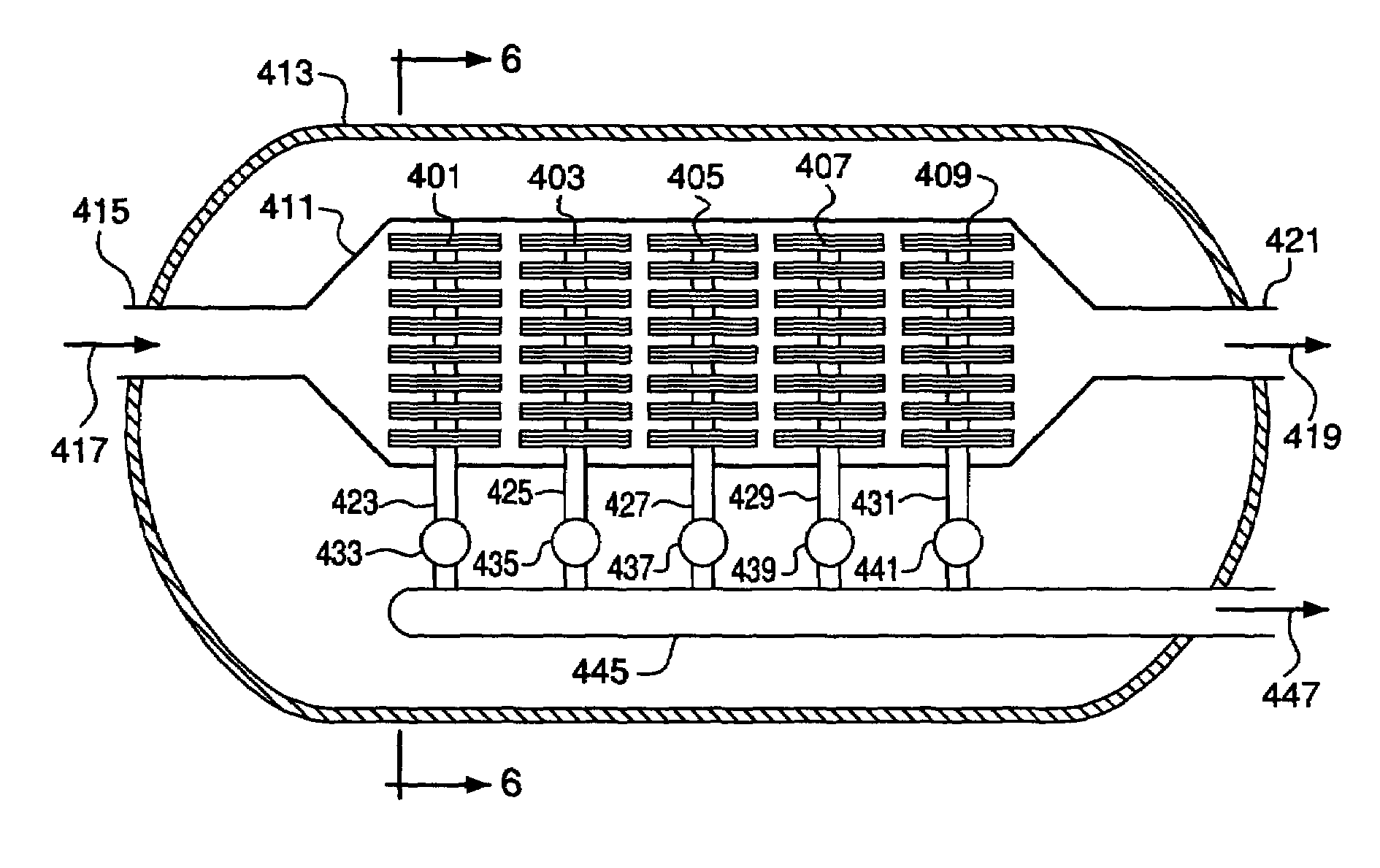

Ion transport membrane module and vessel system

An ion transport membrane system comprising (a) a pressure vessel having an interior, an exterior, an inlet, and an outlet; (b) a plurality of planar ion transport membrane modules disposed in the interior of the pressure vessel and arranged in series, each membrane module comprising mixed metal oxide ceramic material and having an interior region and an exterior region, wherein any inlet and any outlet of the pressure vessel are in flow communication with exterior regions of the membrane modules; and (c) one or more gas manifolds in flow communication with interior regions of the membrane modules and with the exterior of the pressure vessel.The ion transport membrane system may be utilized in a gas separation device to recover oxygen from an oxygen-containing gas or as an oxidation reactor to oxidize compounds in a feed gas stream by oxygen permeated through the mixed metal oxide ceramic material of the membrane modules.

Owner:AIR PROD & CHEM INC

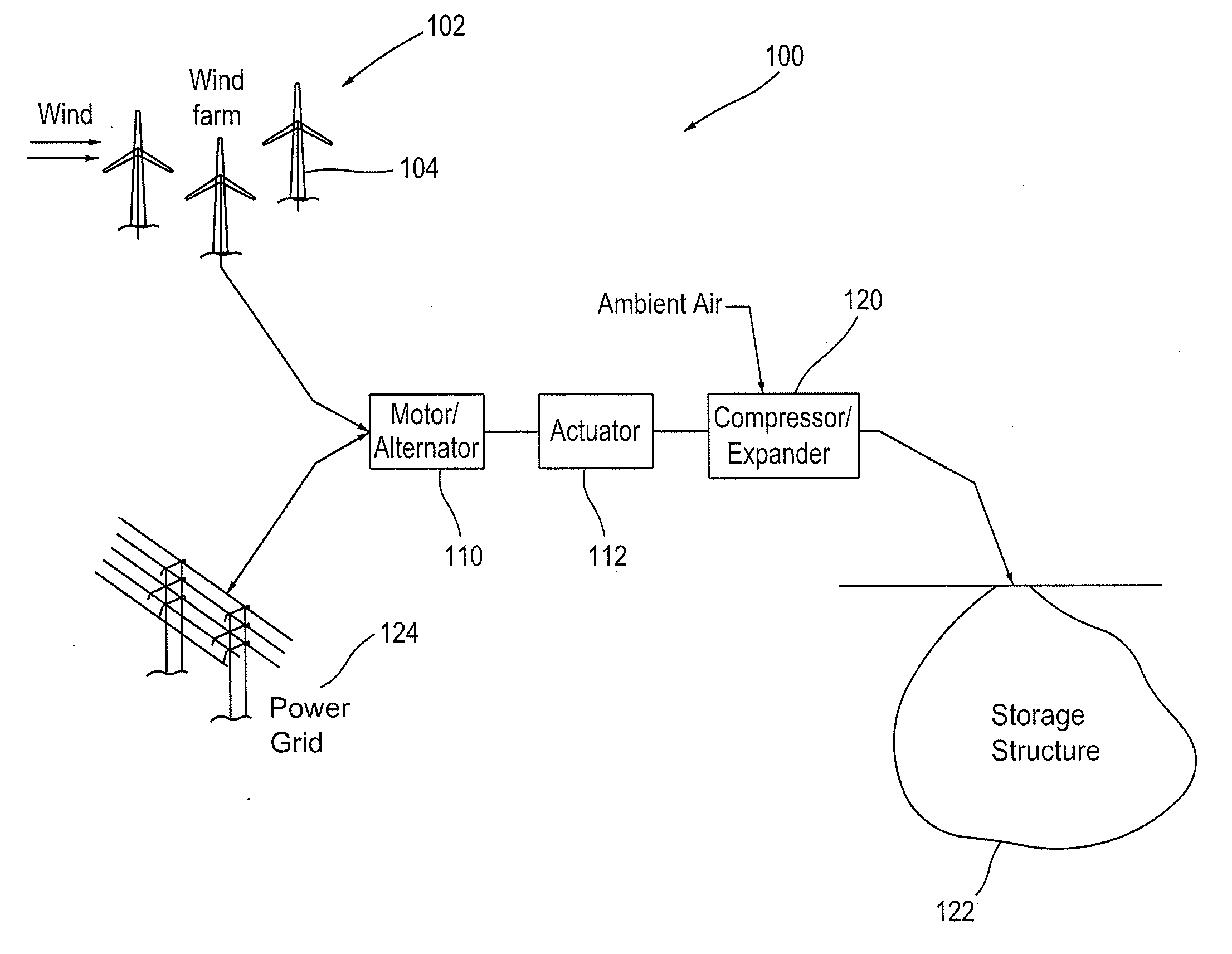

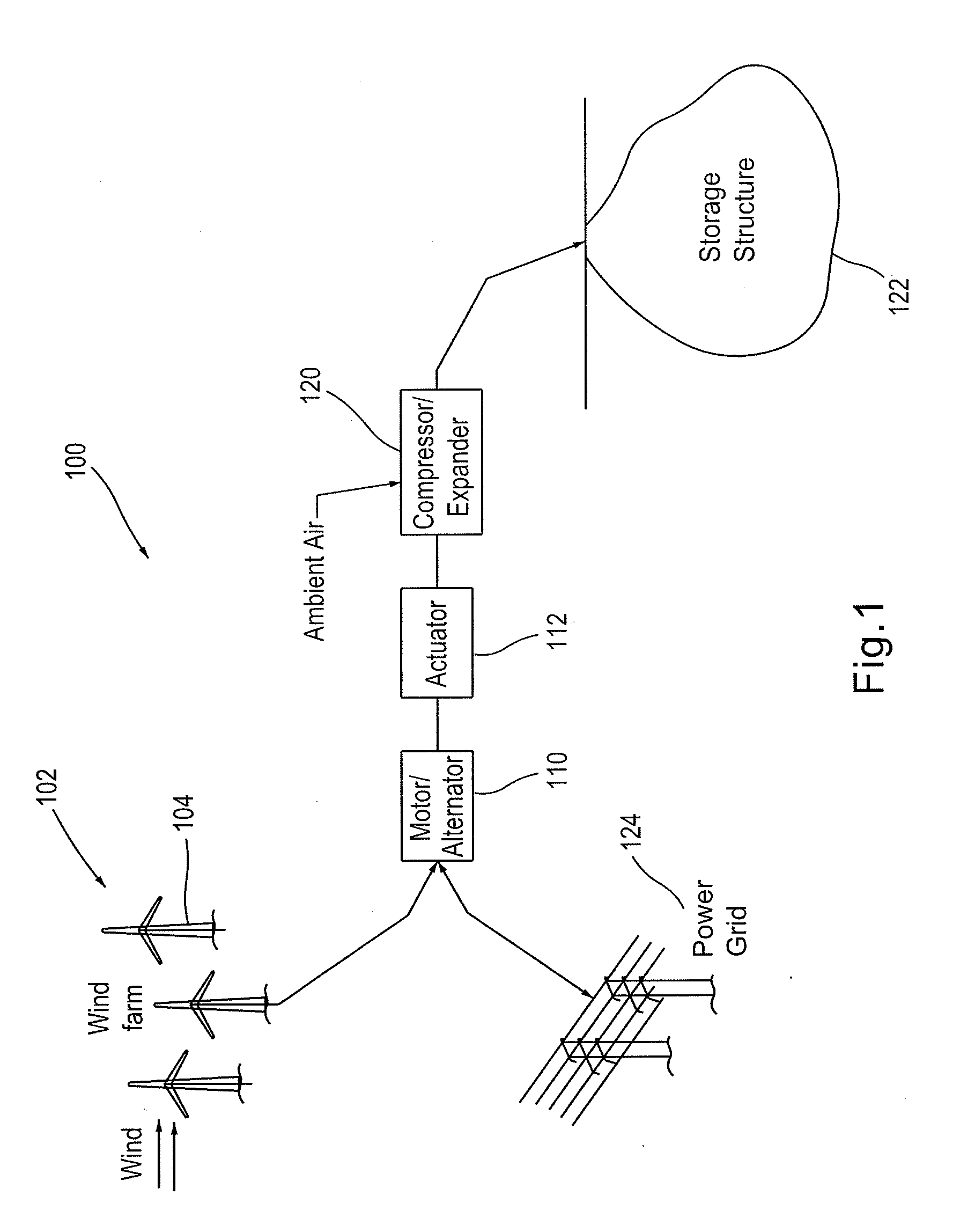

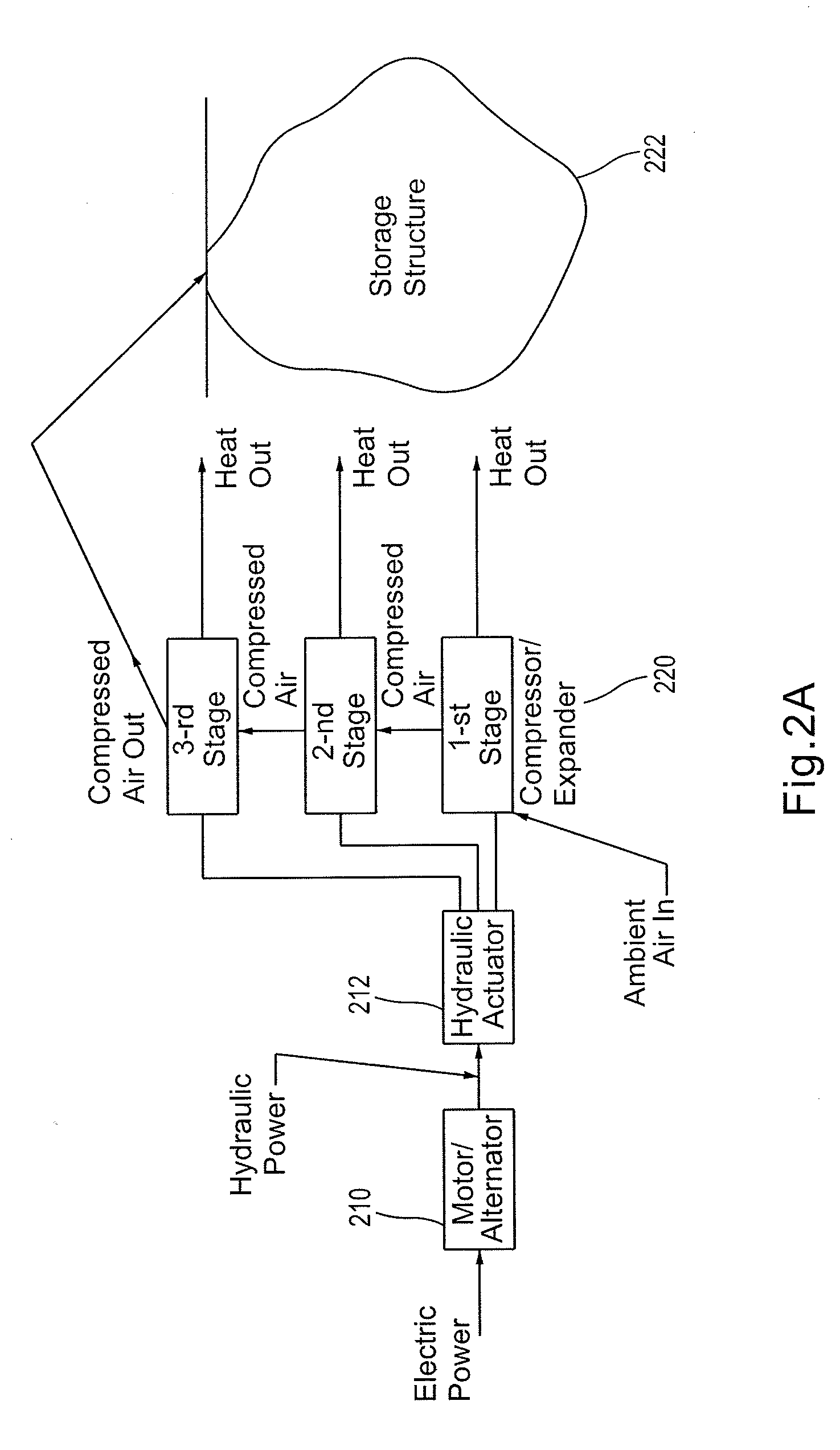

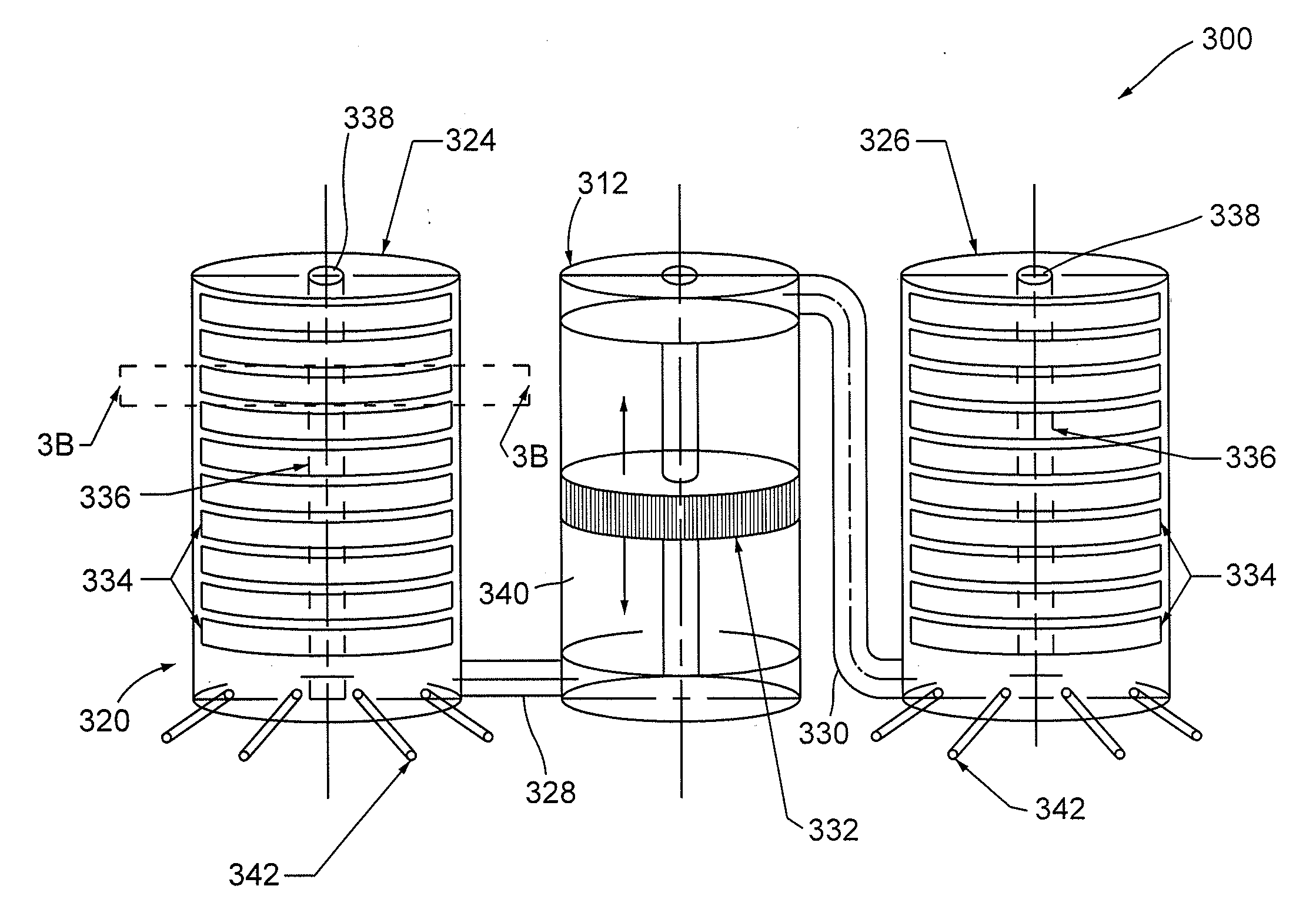

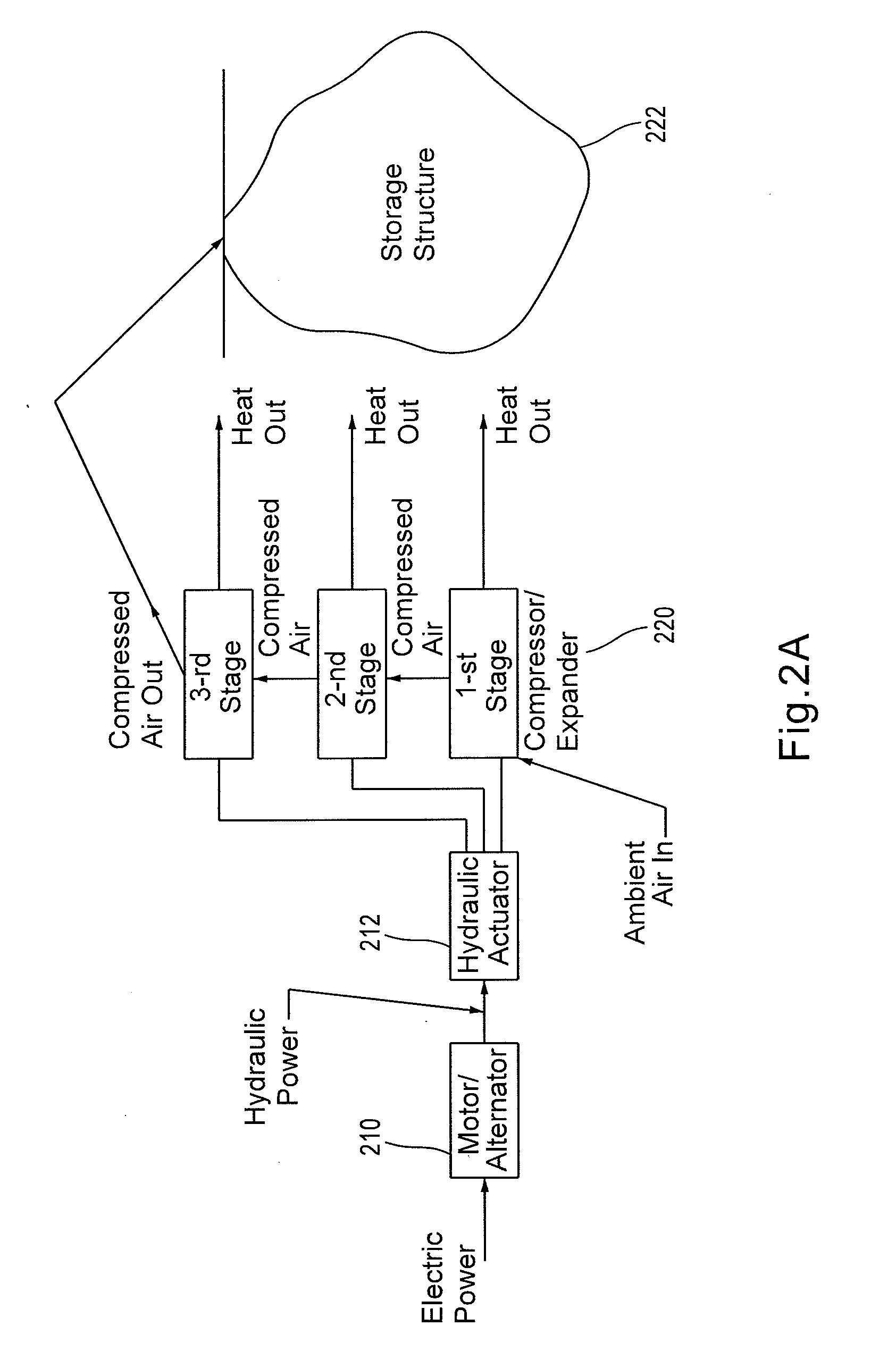

Compressor and/or Expander Device

InactiveUS20110062166A1Fluid couplingsWind energy with garvitational potential energyEngineeringActuator

Systems and methods for operating a hydraulically actuated device / system are described herein. For example, systems and methods for the compression and / or expansion of gas can include at least one pressure vessel defining an interior region for retaining at least one of a volume of liquid or a volume of gas and an actuator coupled to and in fluid communication with the pressure vessel. The actuator can have a first mode of operation in which a volume of liquid disposed within the pressure vessel is moved to compress and move gas out of the pressure vessel. The actuator can have a second mode of operation in which a volume of liquid disposed within the pressure vessel is moved by an expanding gas entering the pressure vessel. The system can further include a heat transfer device configured to transfer heat to or from the at least one of a volume of liquid or a volume of gas retained by the pressure vessel.

Owner:GENERAL COMPRESSION

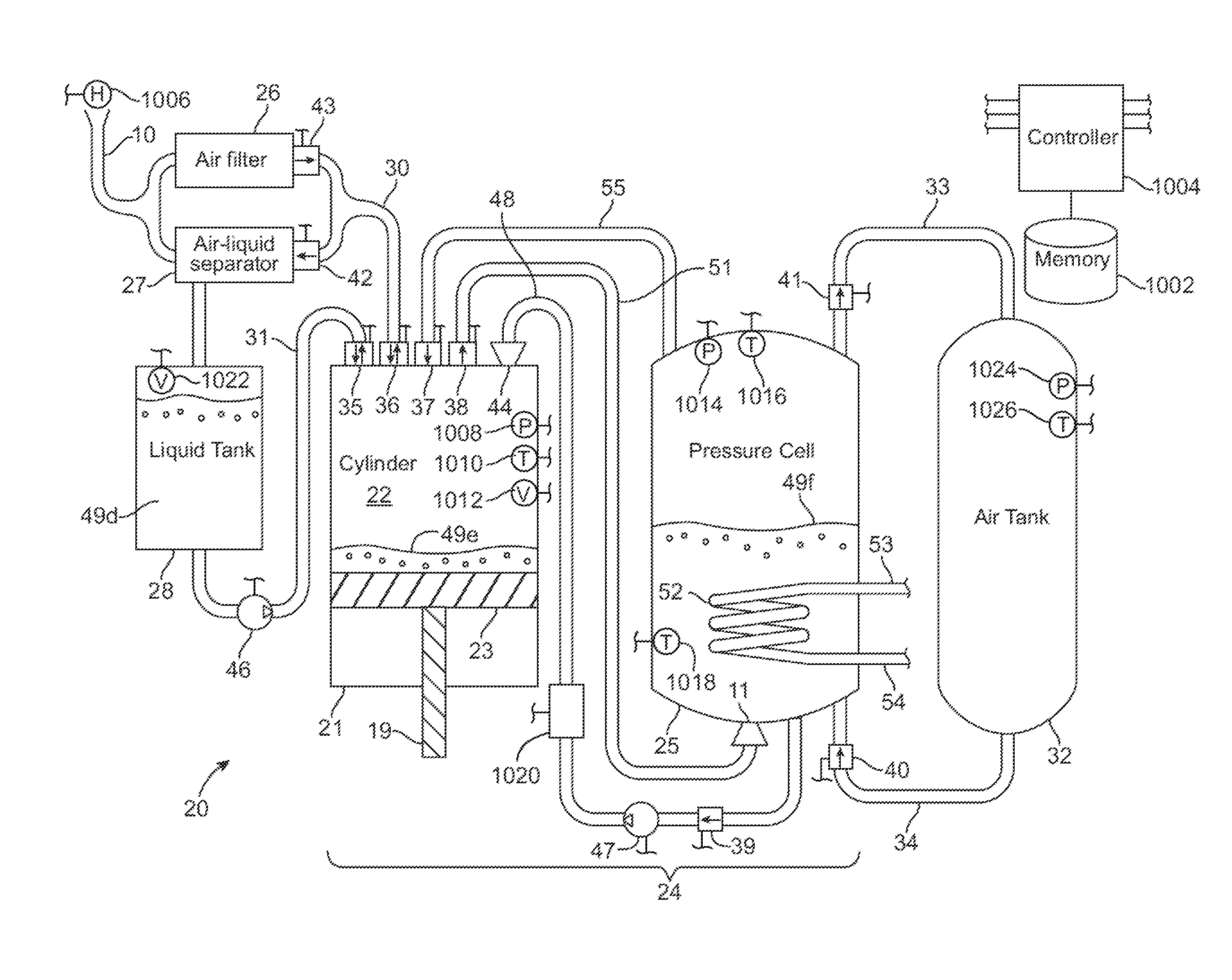

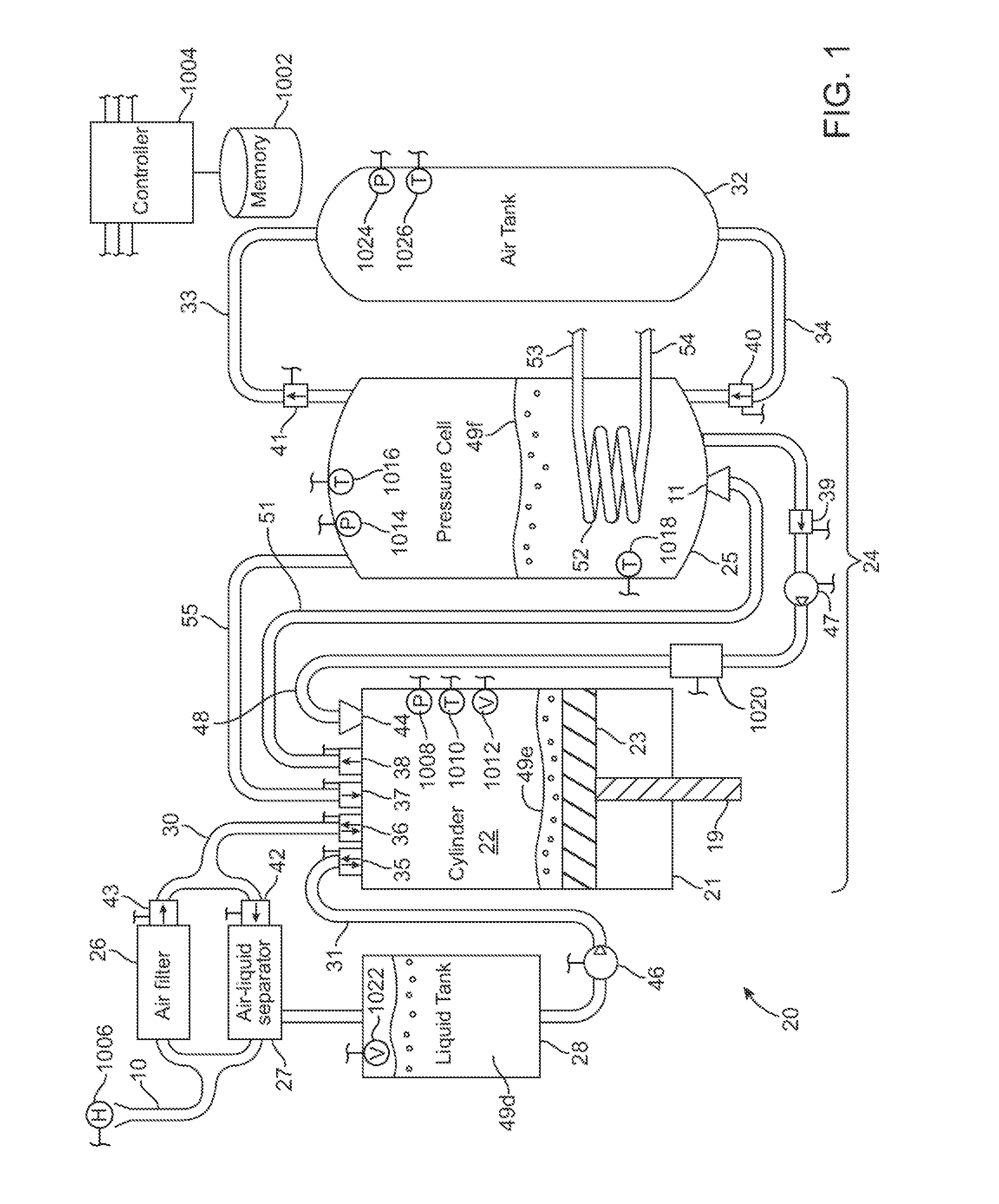

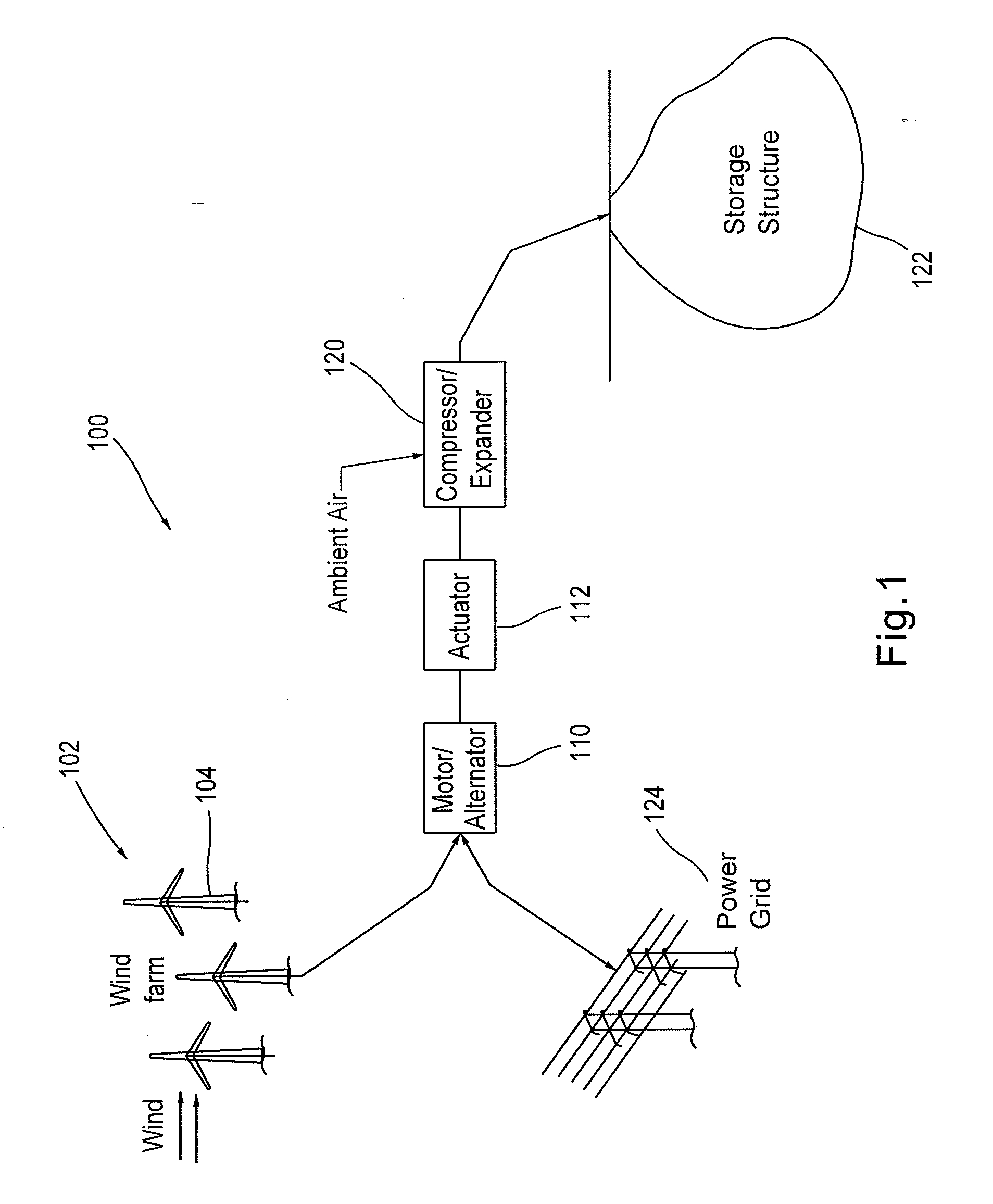

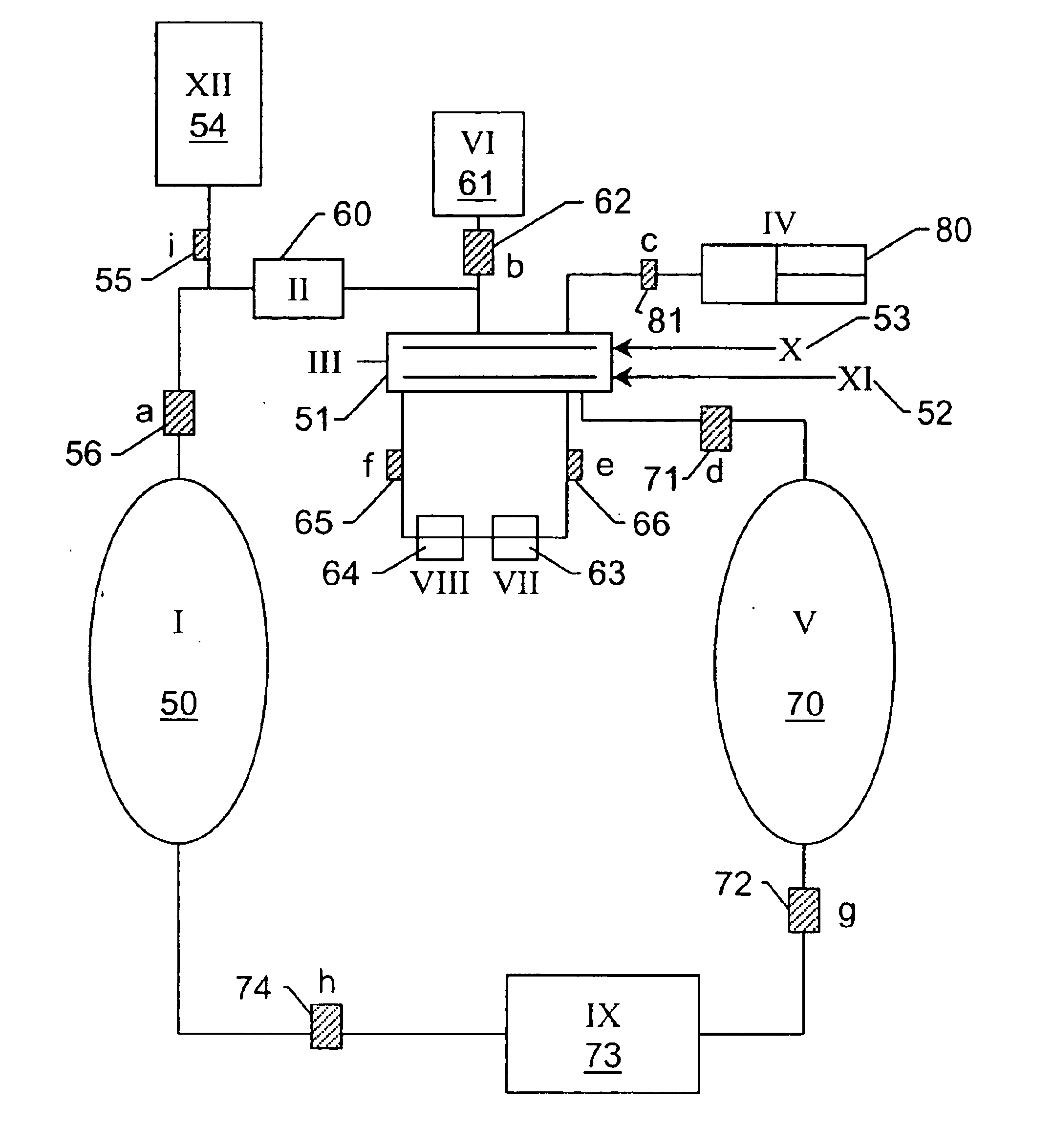

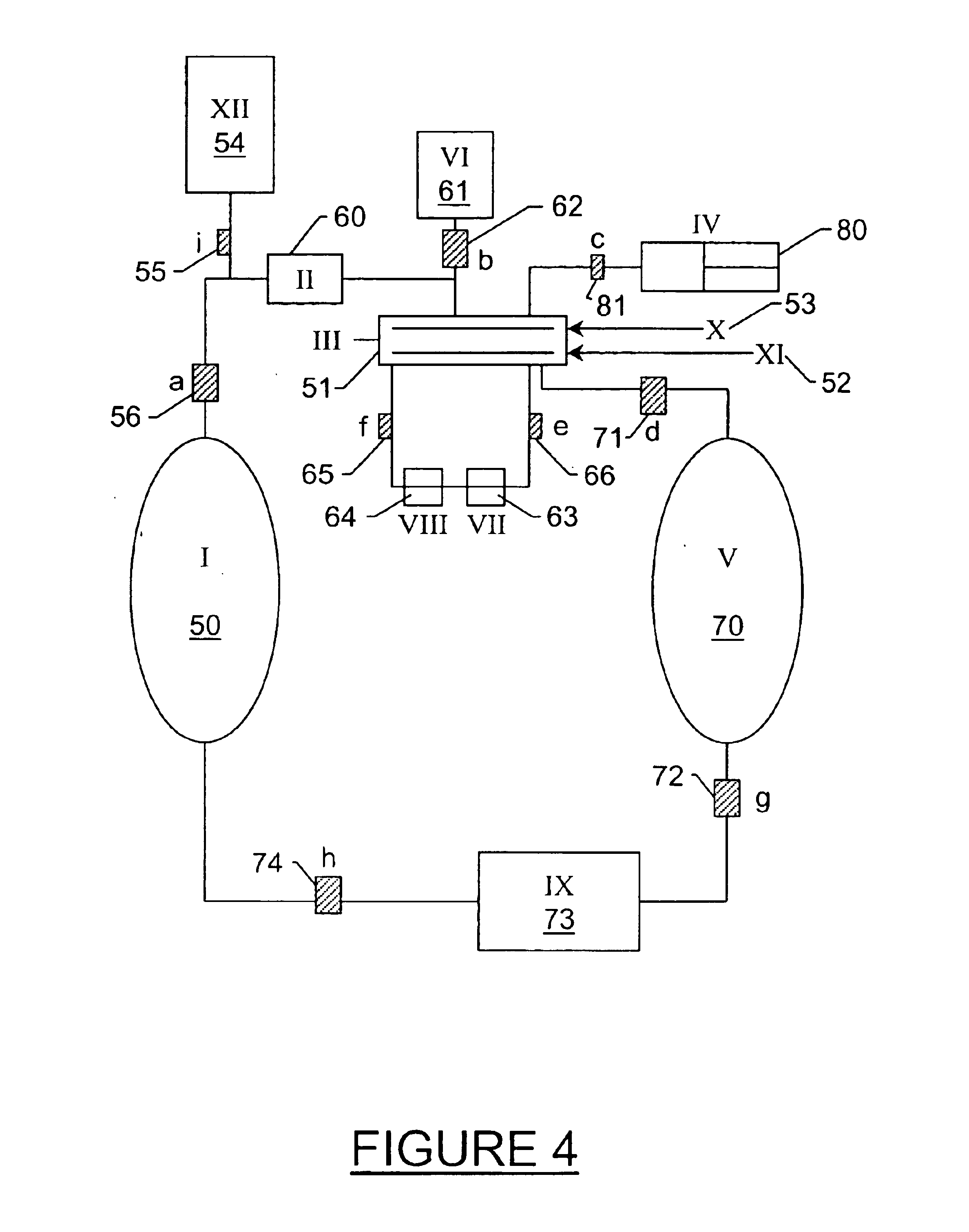

Compressed air energy storage system utilizing two-phase flow to facilitate heat exchange

InactiveUS20100326062A1Facilitate heat exchangeImprove efficiencyElectrical storage systemServomotor componentsThermal energy storageEngineering

A compressed-air energy storage system according to embodiments of the present invention comprises a reversible mechanism to compress and expand air, one or more compressed air storage tanks, a control system, one or more heat exchangers, and, in certain embodiments of the invention, a motor-generator. The reversible air compressor-expander uses mechanical power to compress air (when it is acting as a compressor) and converts the energy stored in compressed air to mechanical power (when it is acting as an expander). In certain embodiments, the compressor-expander comprises one or more stages, each stage consisting of pressure vessel (the “pressure cell”) partially filled with water or other liquid. In some embodiments, the pressure vessel communicates with one or more cylinder devices to exchange air and liquid with the cylinder chamber(s) thereof. Suitable valving allows air to enter and leave the pressure cell and cylinder device, if present, under electronic control.

Owner:LIGHTSAIL ENERGY

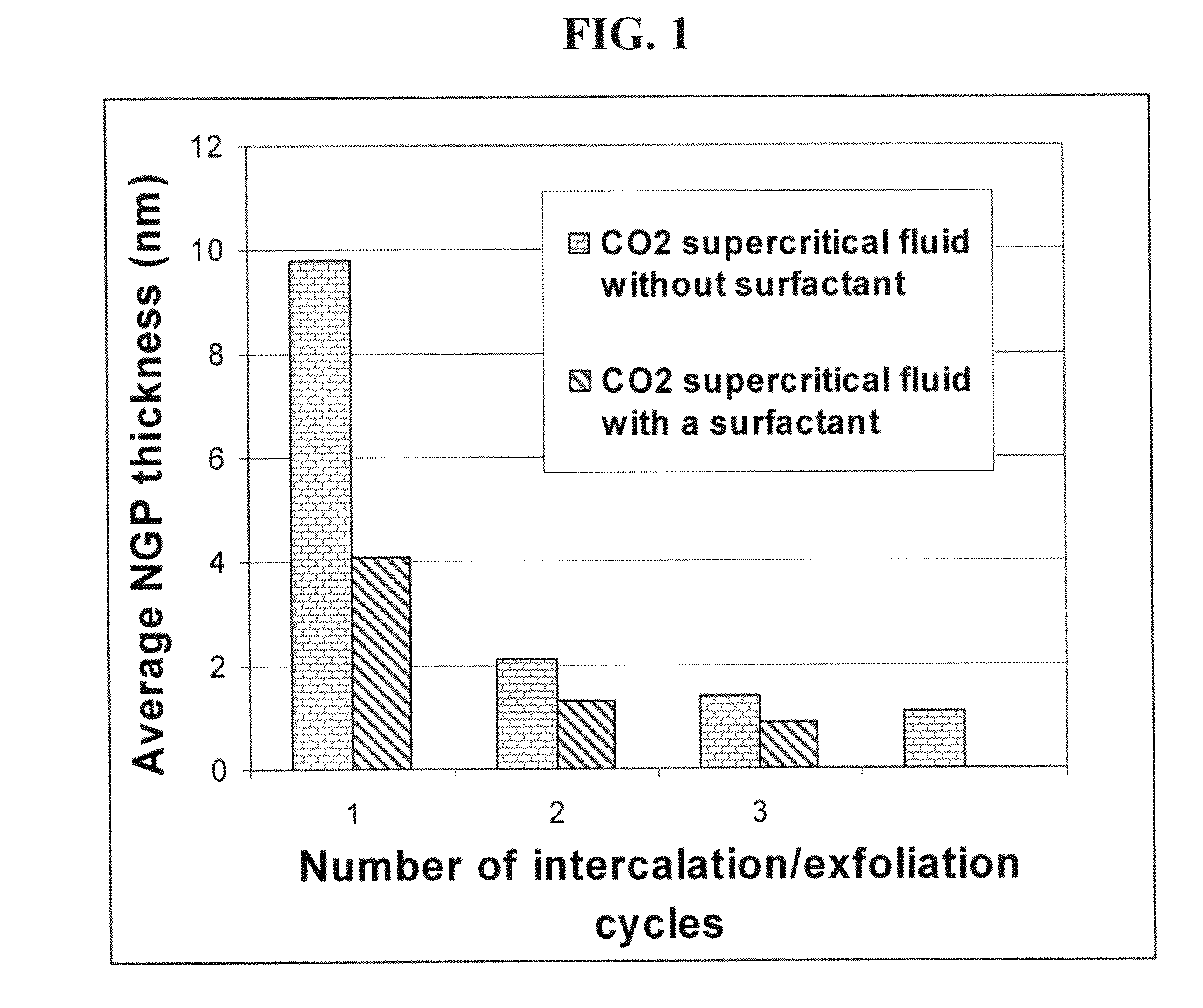

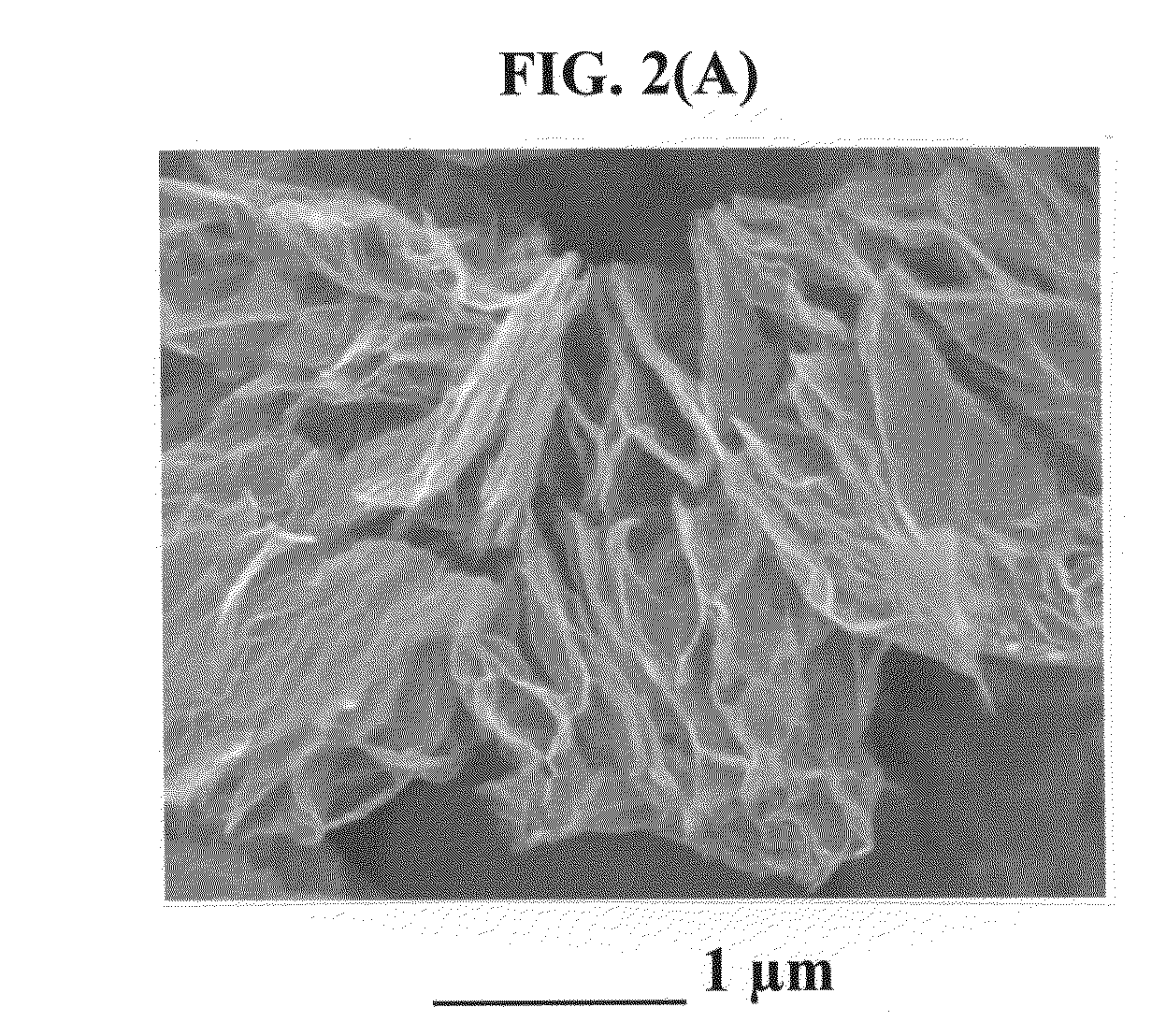

Supercritical fluid process for producing nano graphene platelets

ActiveUS20100044646A1Improve conductivityPigmenting treatmentNon-metal conductorsDisplay deviceSolar cell

The present invention provides a process for producing pristine or non-oxidized nano graphene platelets (NGPs) that are highly conductive. The process comprises: (i) subjecting a graphitic material to a supercritical fluid at a first temperature and a first pressure for a first period of time in a pressure vessel and then (ii) rapidly depressurizing the fluid at a fluid release rate sufficient for effecting exfoliation of the graphitic material to obtain the NGP material. Conductive NGPs can be used as a conductive additive in transparent electrodes for solar cells or flat panel displays (e.g., to replace expensive indium-tin oxide), battery and supercapacitor electrodes, and nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

Compressor and/or Expander Device

InactiveUS20110061836A1Wind energy with garvitational potential energyEnergy storageEngineeringActuator

Systems and methods for operating a hydraulically actuated device / system are described herein. For example, systems and methods for the compression and / or expansion of gas can include at least one pressure vessel defining an interior region for retaining at least one of a volume of liquid or a volume of gas and an actuator coupled to and in fluid communication with the pressure vessel. The actuator can have a first mode of operation in which a volume of liquid disposed within the pressure vessel is moved to compress and move gas out of the pressure vessel. The actuator can have a second mode of operation in which a volume of liquid disposed within the pressure vessel is moved by an expanding gas entering the pressure vessel. The system can further include a heat transfer device configured to transfer heat to or from the at least one of a volume of liquid or a volume of gas retained by the pressure vessel.

Owner:GENERAL COMPRESSION

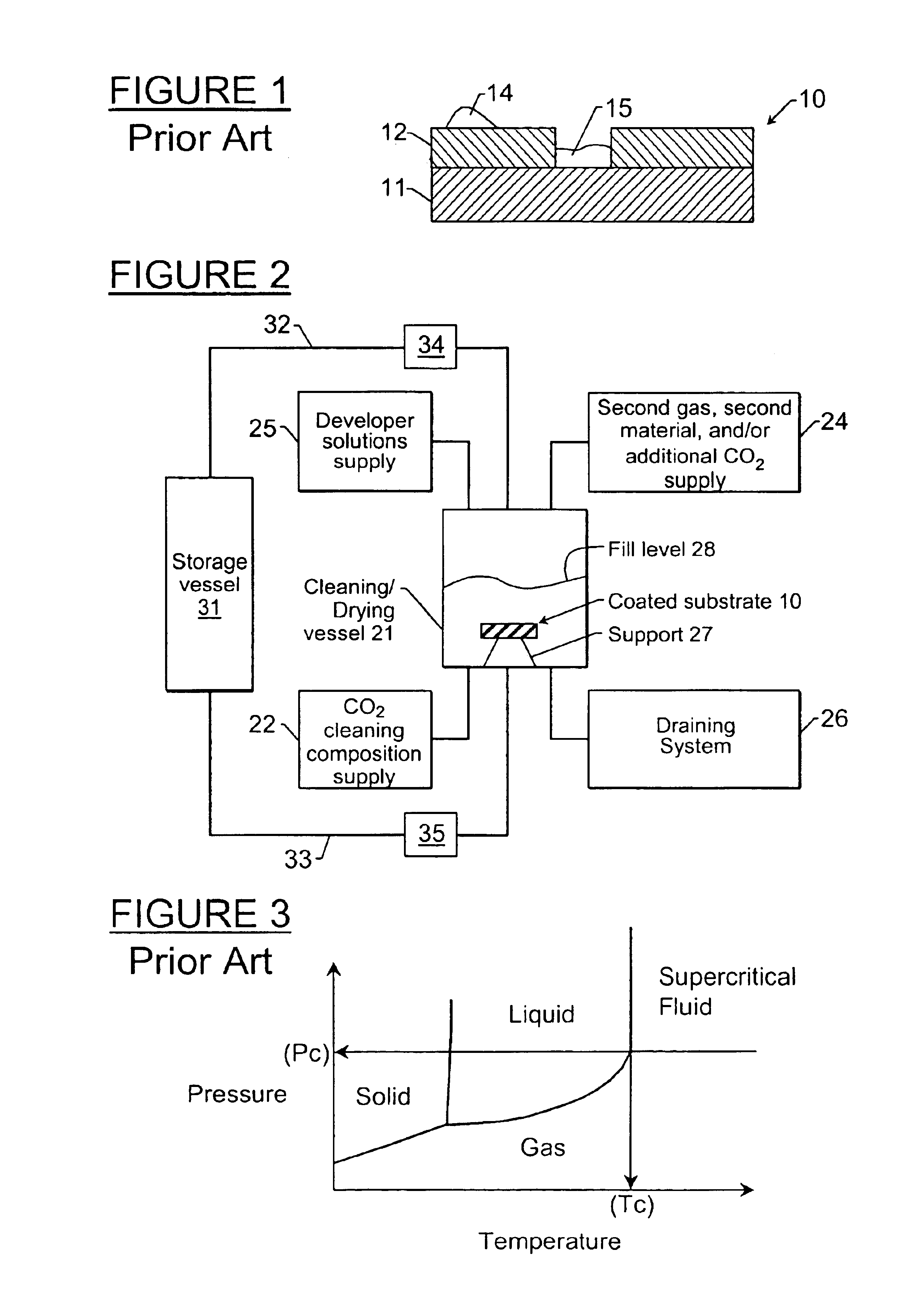

Methods for transferring supercritical fluids in microelectronic and other industrial processes

InactiveUS6905555B2Decorative surface effectsSemiconductor/solid-state device manufacturingVolumetric Mass DensityPressure vessel

A method of displacing a supercritical fluid from a pressure vessel (e.g., in a microelectronic manufacturing process), with the steps of: providing an enclosed pressure vessel containing a first supercritical fluid (said supercritical fluid preferably comprising carbon dioxide); adding a second fluid (typically also a supercritical fluid) to said vessel, with said second fluid being added at a pressure greater than the pressure of the first supercritical fluid, and with said second fluid having a density less than that of the first supercritical fluid; forming an interface between the first supercritical fluid and the second fluid; and displacing at least a portion of the first supercritical fluid from the vessel with the pressure of the second, preferably fluid while maintaining the interface therebetween.

Owner:MICELL TECH INC

Hot tap fluid blaster apparatus and method of using same

A apparatus and method of using the apparatus for removing a blockage in a subsea pipeline without retrieval of the pipeline to the surface. The apparatus components include a hot tap saddle, a drill assembly, a fluid blaster assembly and a support frame. The hot tap saddle component has a first portion and a second portion, with the first and second portions being configured to clampingly engage in a sealing relationship to the subsea pipeline. The first portion of the saddle includes a first and second opening with the first opening extending generally upwardly and configured for connecting to a drill assembly and the second opening being positioned generally at an angle to the first opening and configured for connecting to a fluid blaster assembly. The fluid blaster assembly including a nozzle, a hose and a high pressure pump with the fluid blaster assembly being contained within a pressure vessel. The fluid blaster assembly is configured for mounting to the second opening of the hot tap saddle component. The support frame assembly is configured for gripping and supporting the subsea pipeline on the sea floor while the fluid blaster assembly operates to remove a blockage in the subsea pipeline with the pipeline being under pressure and without severing the pipeline.

Owner:SAIPEM AMERICA

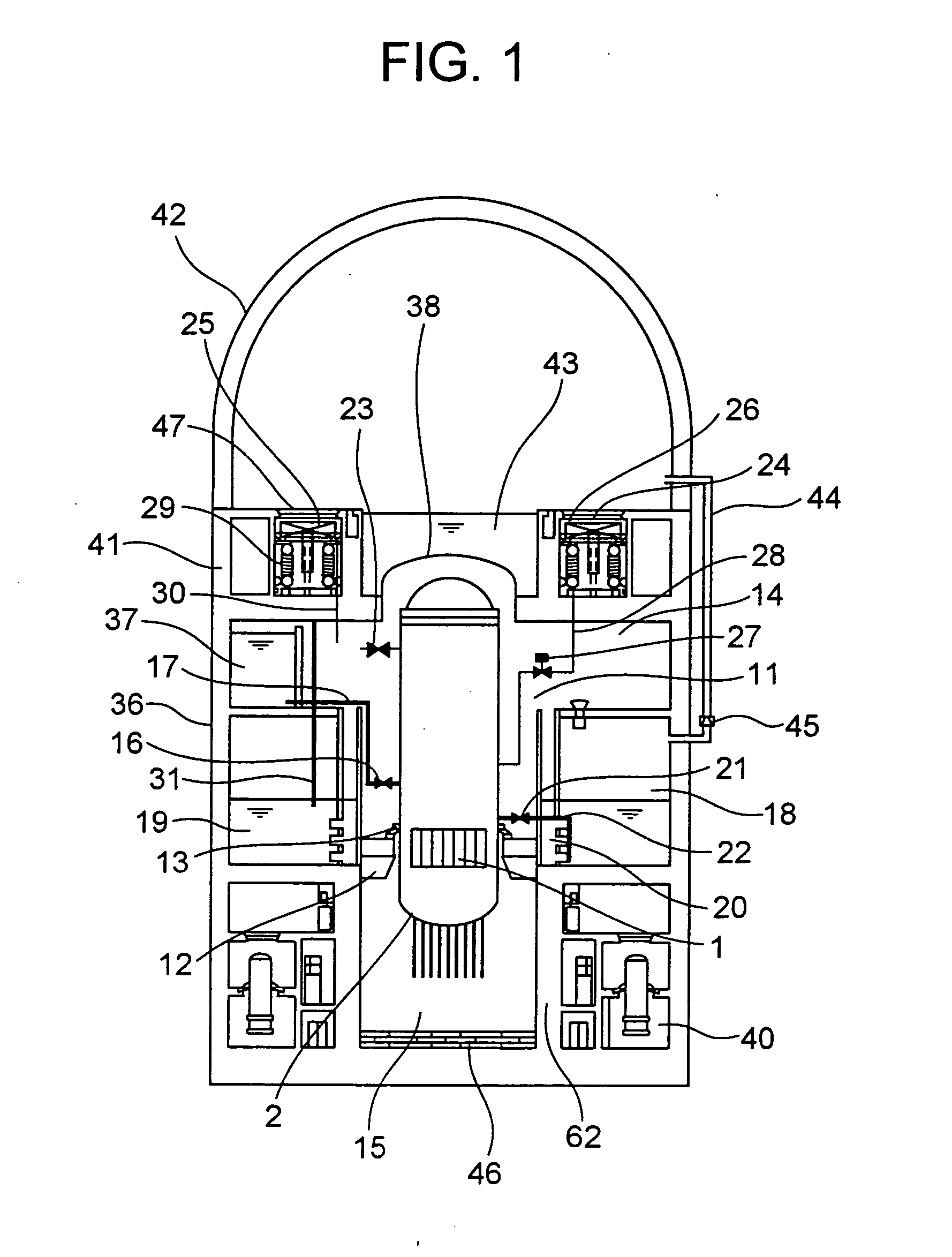

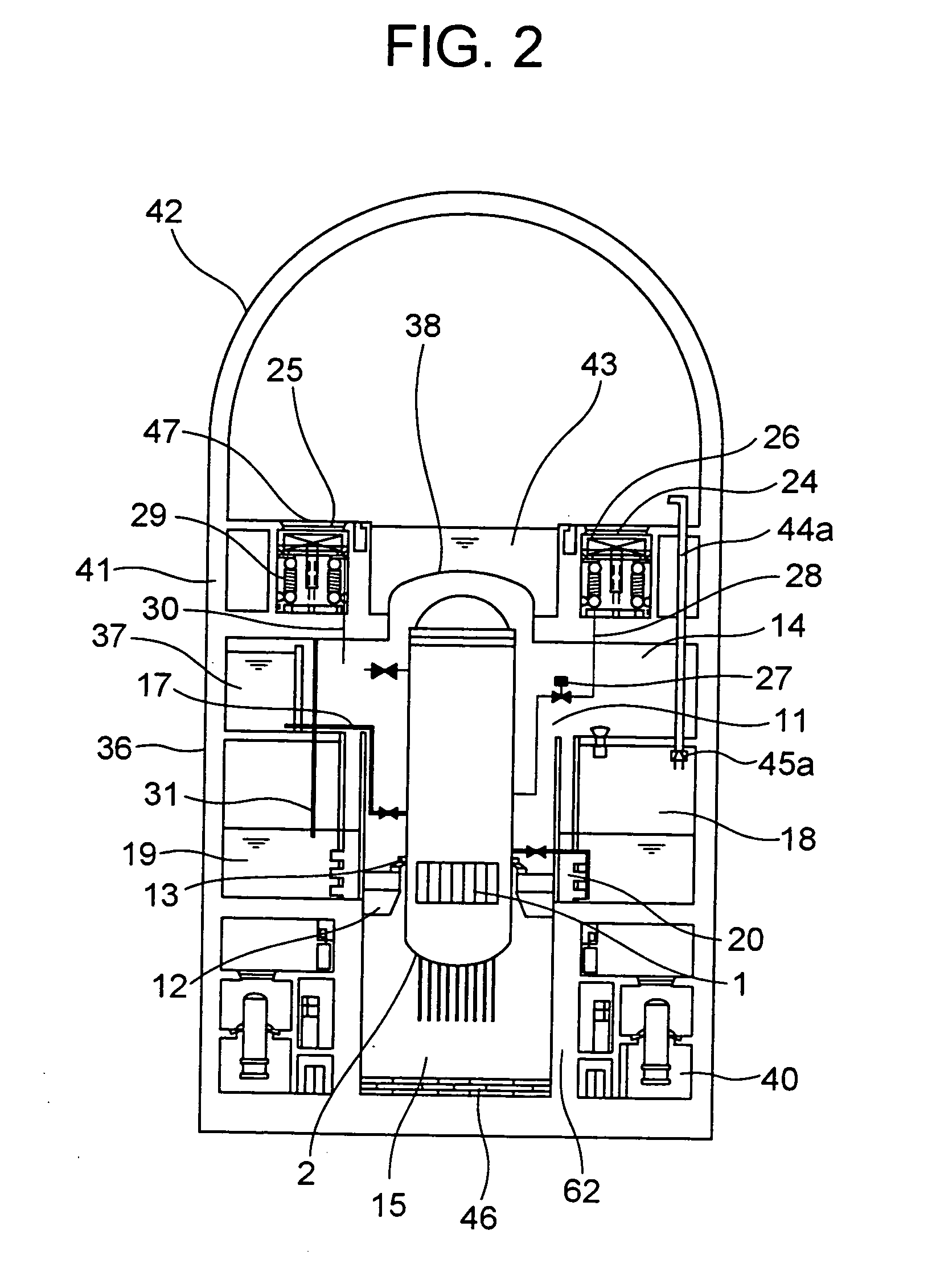

Reactor containment vessel and boiling water reactor power plant

ActiveUS20070092053A1Nuclear energy generationNuclear engineering problemsPower stationReactor pressure vessel

A containment vessel includes a primary containment vessel containing a reactor pressure vessel, an upper secondary containment vessel arranged above the primary containment vessel, and a gas-phase vent pipe linking the primary containment vessel and the upper secondary containment vessel by way of an isolation and connection switching system. The gas-phase vent pipe may be arranged either inside or outside the primary containment vessel and the upper secondary containment vessel. Alternatively, it may be embedded in the wall. An igniter may be arranged in the upper secondary containment vessel. The air in the upper secondary containment vessel may be replaced by nitrogen. A gravity-driven flooding system pool may be arranged in the upper secondary containment vessel and cooling water may be led from the inside of the pool to the inside of the primary containment vessel.

Owner:KK TOSHIBA

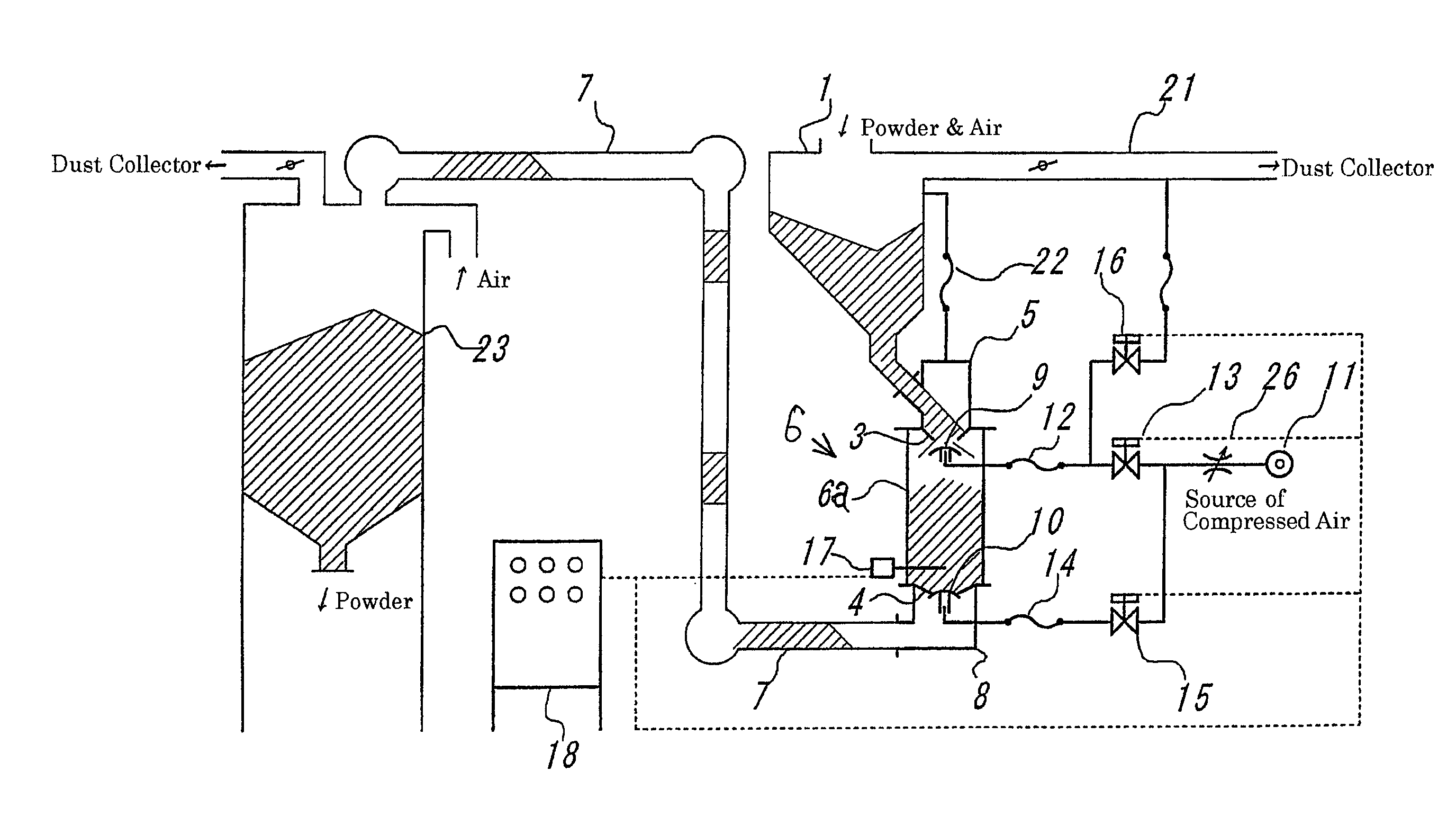

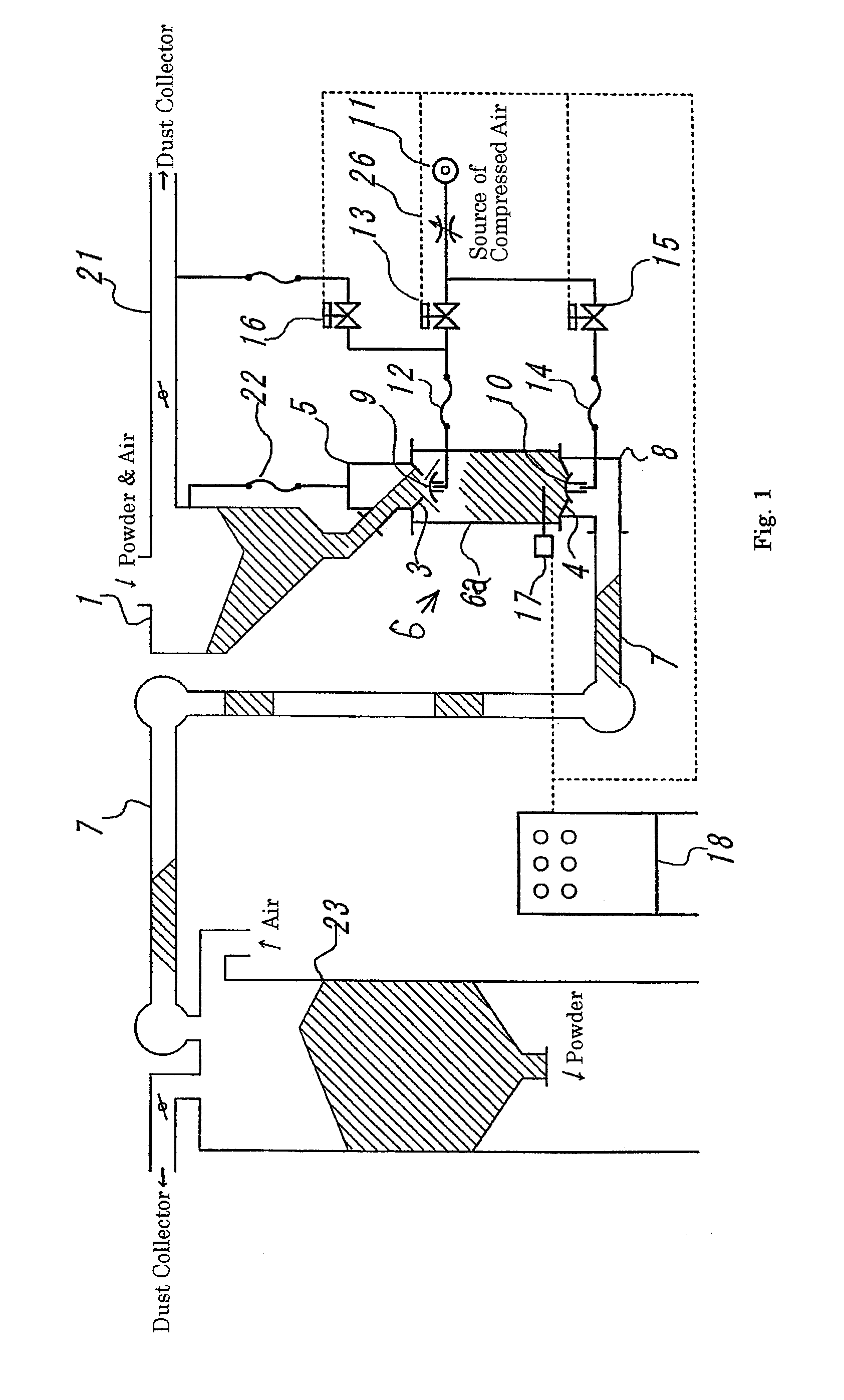

Pressure tank, an device for feeding powder to a conveying pipe, and its feeding method, and method for determining feeding intervals of powder to the conveying pipe

A pressure tank having a simple structure to intermittently feed powder to a conveying pipe, and a method for determining the intervals for feeding the powder to the conveying pipe. The pressure tank includes a tank body used as a structure of a pressure vessel having a receiving port at its upper portion and a discharging port at its lower portion, a first check valve disposed just under the receiving port so that it can freely move up and down, and so that it can close the receiving port by its upward movement that is caused by means of compressed air, and a second check valve disposed just under the discharging port so that it can freely move up and down, and so that it can close the discharging port by its upward movement that is caused by means of compressed air. To determine the intervals for feeding the powder to the conveying pipe, the apparatus is controlled based on measurements of the pressure loss or of the time that is required for feeding the powder to the conveying pipe, so that the pressure loss of the compressed air in the conveying pipe corresponds to the pressure of the compressed air supplied to the conveying pipe.

Owner:SINTOKOGIO LTD

Gas generants comprising transition metal nitrite complexes

InactiveUS6077371AMetal azide explosive compositionsAlkali metal salt explosive compositionsNitriteHydrazine compound

High nitrogen gas generant compositions, useful for inflating passenger restraint gas inflator bags, comprise a nitrogen rich coordination compound selected from coordination complexes comprised of anionic nitro and nitrito ligands coordinated with a transitional metal template, and nonmetallic or nonmetallic / metallic cations. The gas generant compositions generate relatively more gas and less solids, and are safer than known gas generant compositions. Certain gas generant compositions ignite at lower autoignition temperatures thereby facilitating the use of an aluminum or light weight metal pressure vessel. Other gas generants self-deflagrate eliminating the need for other constituents in the composition. Novel methods for the synthesis of nonmetal derivative coordination complexes, guanidine and hydrazine for example, are also presented.

Owner:AUTOMOTIVE SYST LAB +1

Diaphragm pressure pod for medical fluids

ActiveUS20070179422A1Volume maximizationEliminate volumeDialysis systemsMedical devicesMedicineMedical treatment

A tubular medical fluid flow set comprises a pressure sensing chamber connected in flow-through relation to fluid flow tubing of the set. The pressure sensing chamber defines a movable, flexible, impermeable diaphragm dividing the chamber into two separate compartments. The fluid flow tubing communicates with one of the compartments and is isolated from the other of the compartments. A port is carried on the chamber, the port having a seal therein, and communicating with the other of the compartments. Thus, the other of the compartments is hermetically sealed until the port is opened for connection with a pressure measuring device, to keep the flexible diaphragm in a desired, initial position prior to opening of the seal.

Owner:B BRAUN MEDICAL

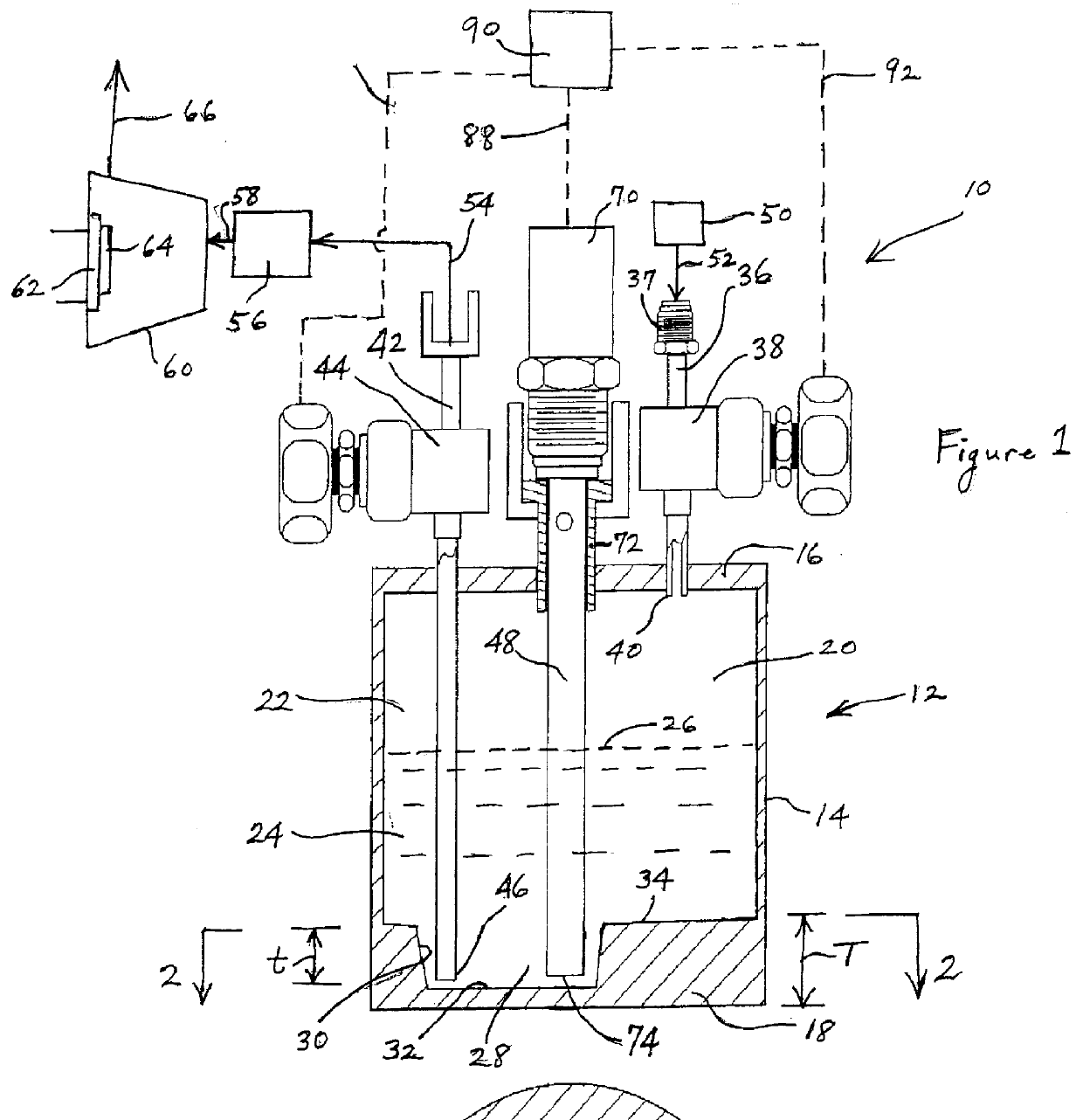

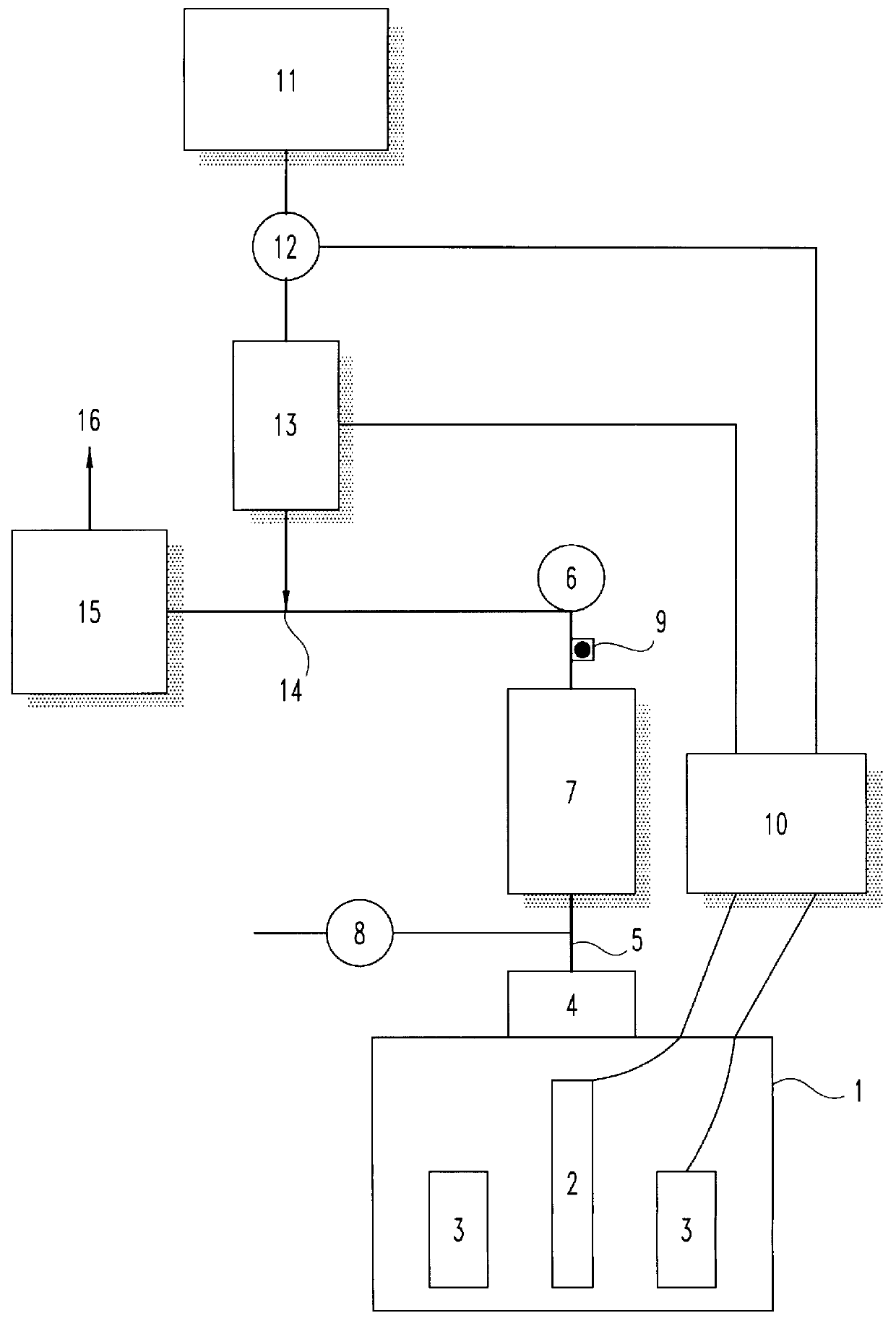

Method and apparatus for constant composition delivery of hydride gases for semiconductor processing

InactiveUS6080297AMaintain consistencyCellsPolycrystalline material growthConstant compositionProduct gas

The present invention provides an electrochemical system and process for the production of very high purity hydride gases and the feed product streams including these hydride gases at constant composition over extended periods of time. The processes and apparatuses of the invention can employ a lined pressure vessel (1) within which resides an electrochemical cell including cathode (2) and anode (3) material. The hydride gas produced within the vessel exits through port (4) to a manifold which contains automatic valve (8) to allow exit of the hydride gas. The hydride gas passes through one or more filters (7). The gas finally exits the manifold through a pressure regulator (6) to the point where it is utilized in semiconductor fabrication. A source of gas (11) for mixing with the hydride gas is also included.

Owner:VERSUM MATERIALS US LLC +1

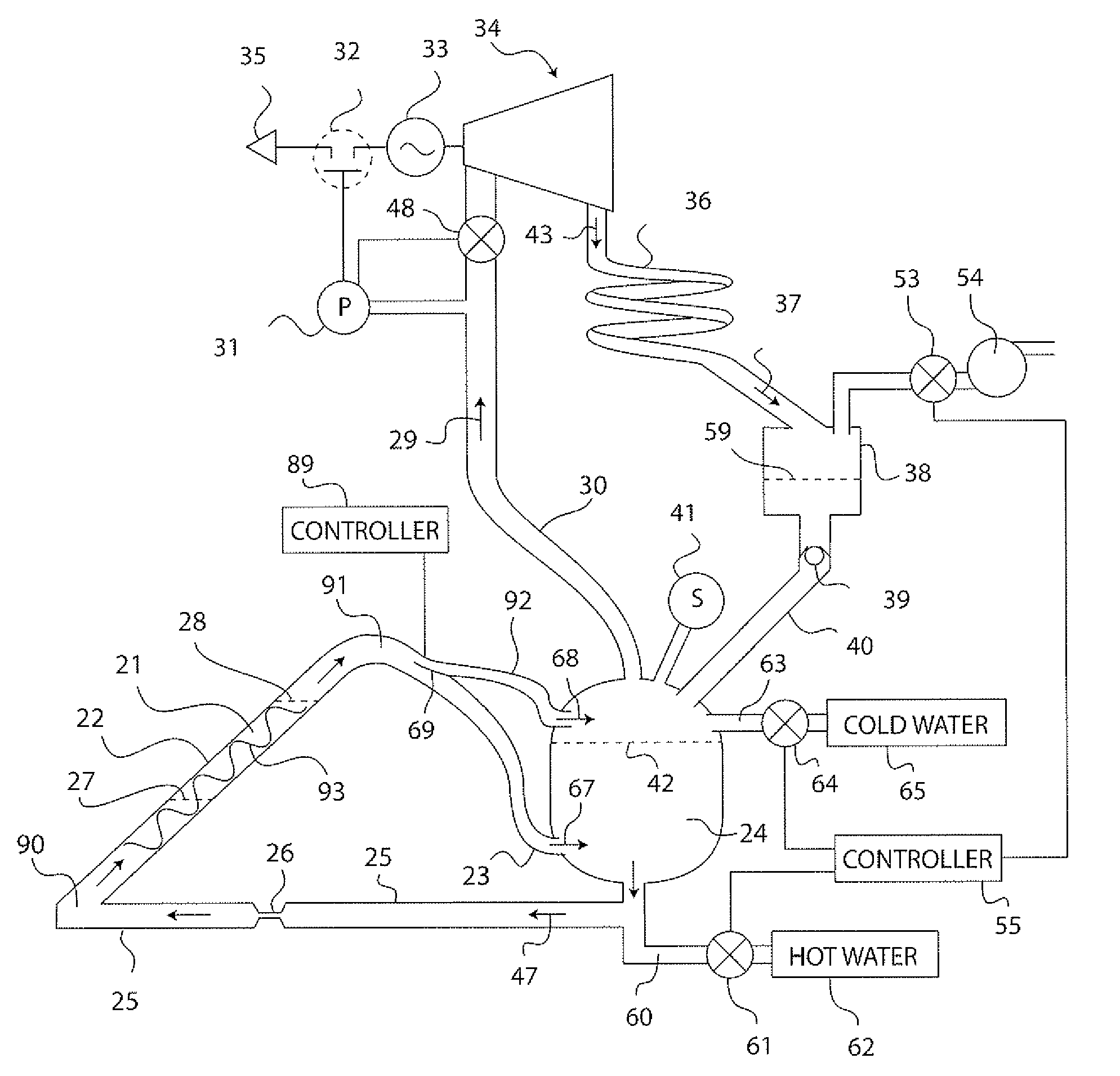

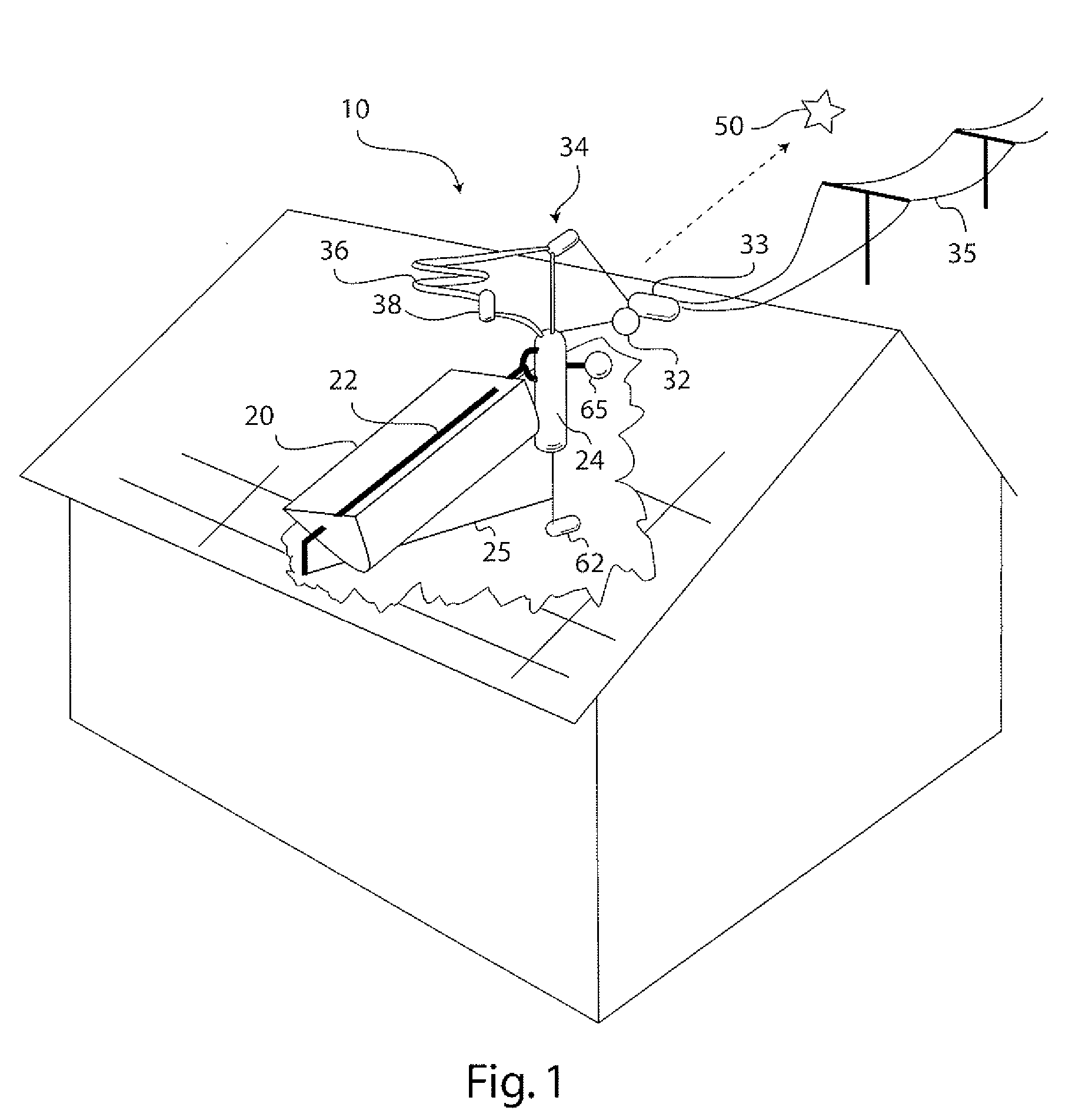

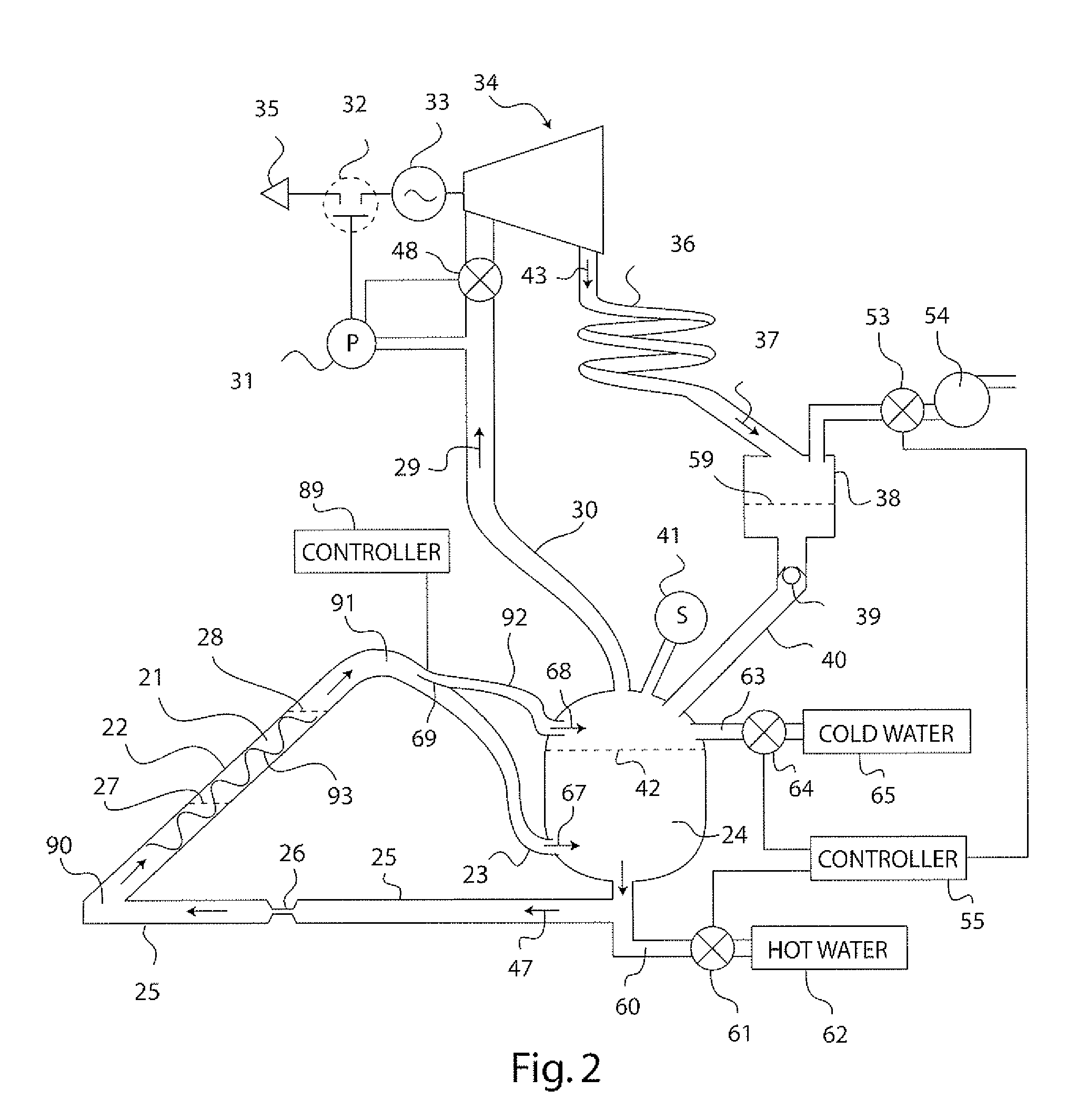

Solar Thermal Power System

InactiveUS20090199557A1Simple efficiencyTechnology being suitableAuxillary drivesSteam separation arrangementsThermal energy storageEngineering

A solar thermal power generator includes an inclined elongated boiler tube positioned in the focus of a solar concentrator for generating steam from water. The boiler tube is connected at one end to receive water from a pressure vessel as well as connected at an opposite end to return steam back to the vessel in a fluidic circuit arrangement that stores energy in the form of heated water in the pressure vessel. An expander, condenser, and reservoir are also connected in series to respectively produce work using the steam passed either directly (above a water line in the vessel) or indirectly (below a water line in the vessel) through the pressure vessel, condense the expanded steam, and collect the condensed water. The reservoir also supplies the collected water back to the pressure vessel at the end of a diurnal cycle when the vessel is sufficiently depressurized, so that the system is reset to repeat the cycle the following day. The circuital arrangement of the boiler tube and the pressure vessel operates to dampen flow instabilities in the boiler tube, damp out the effects of solar transients, and provide thermal energy storage which enables time shifting of power generation to better align with the higher demand for energy during peak energy usage periods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com