Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1531 results about "Oxide ceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

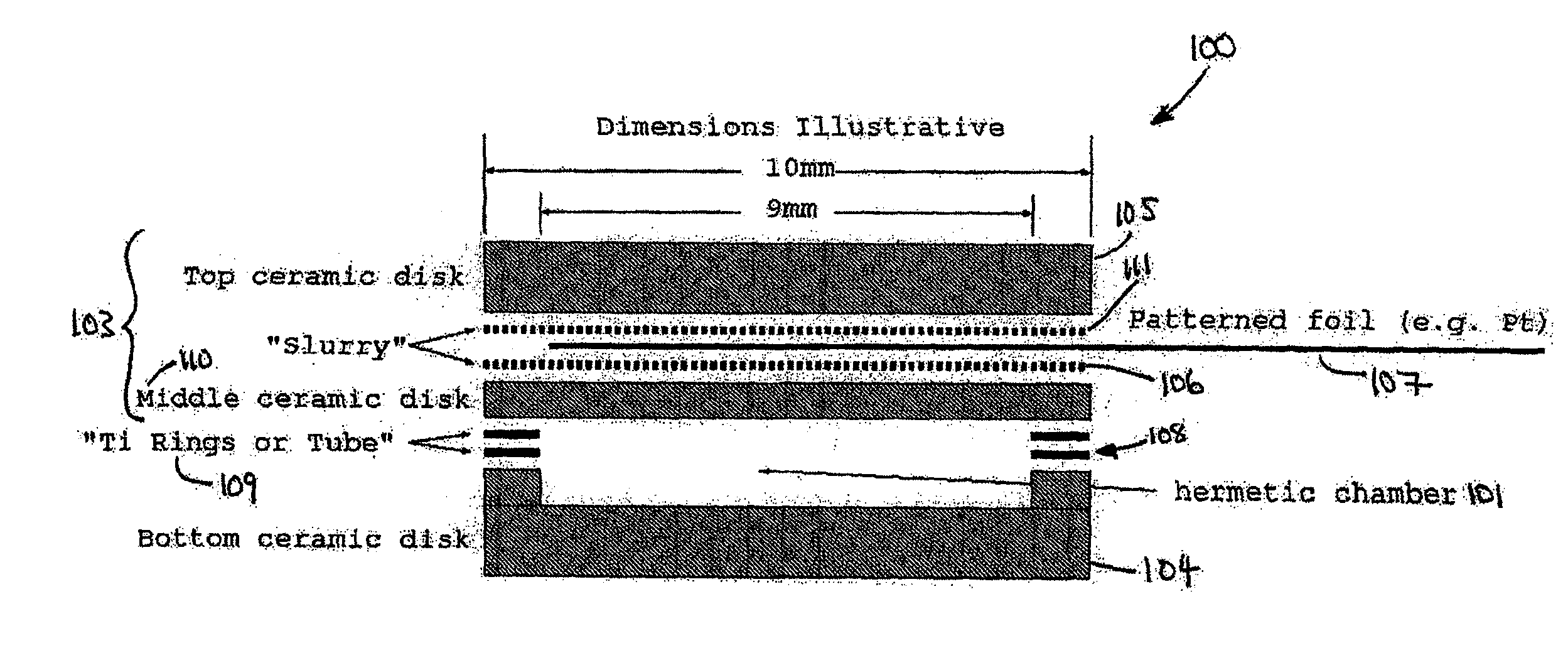

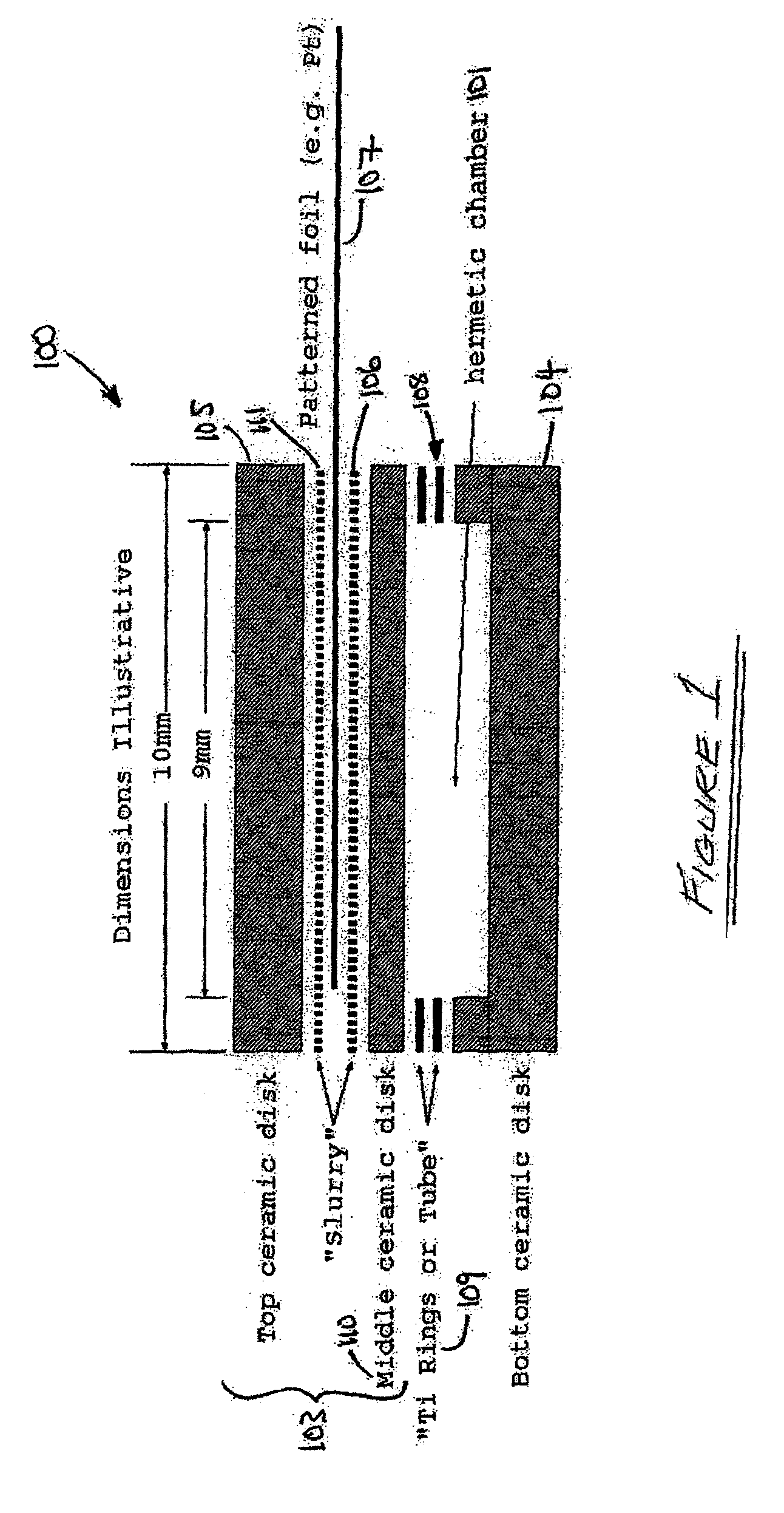

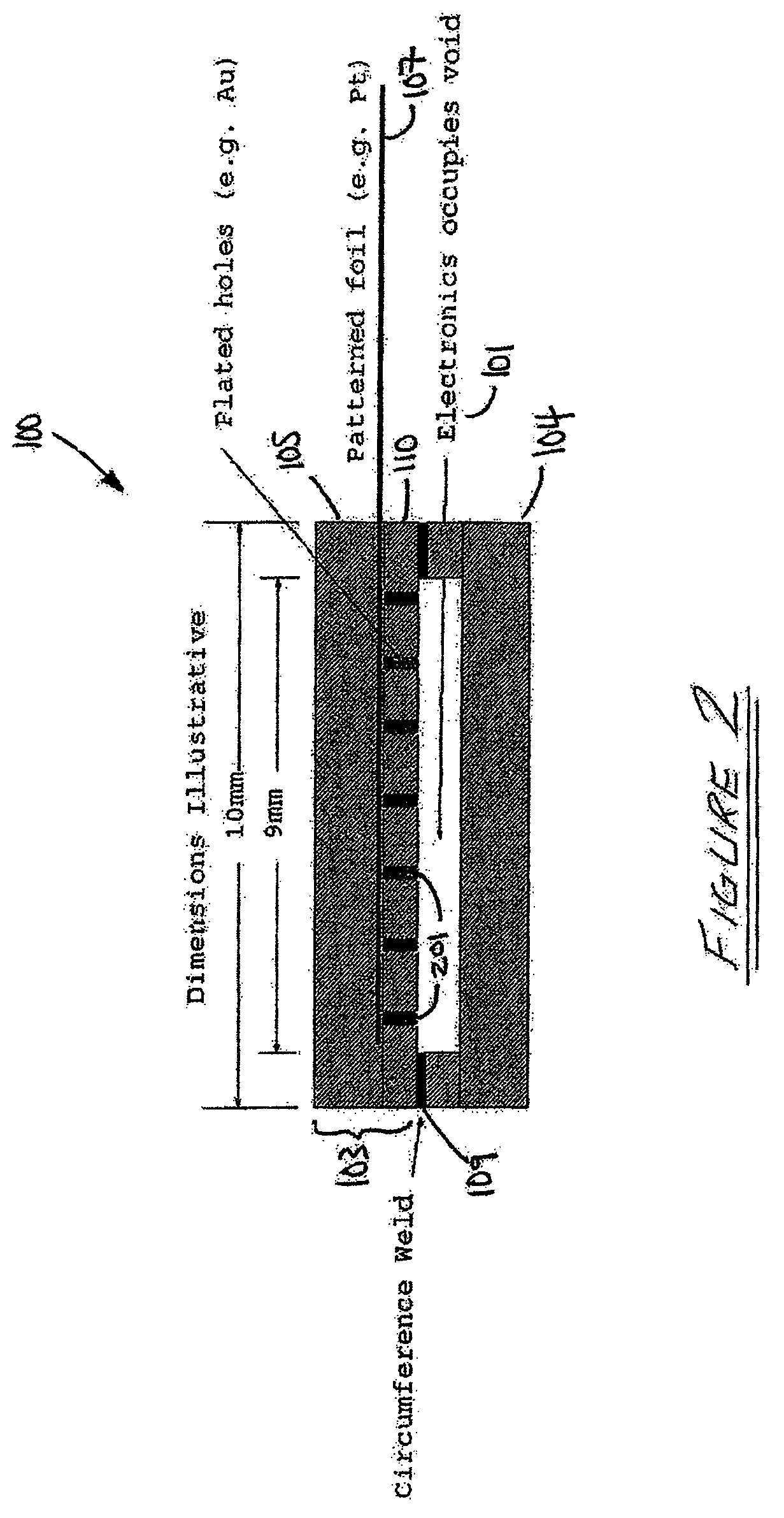

Method for fabrication of hermetic electrical conductor feedthroughs

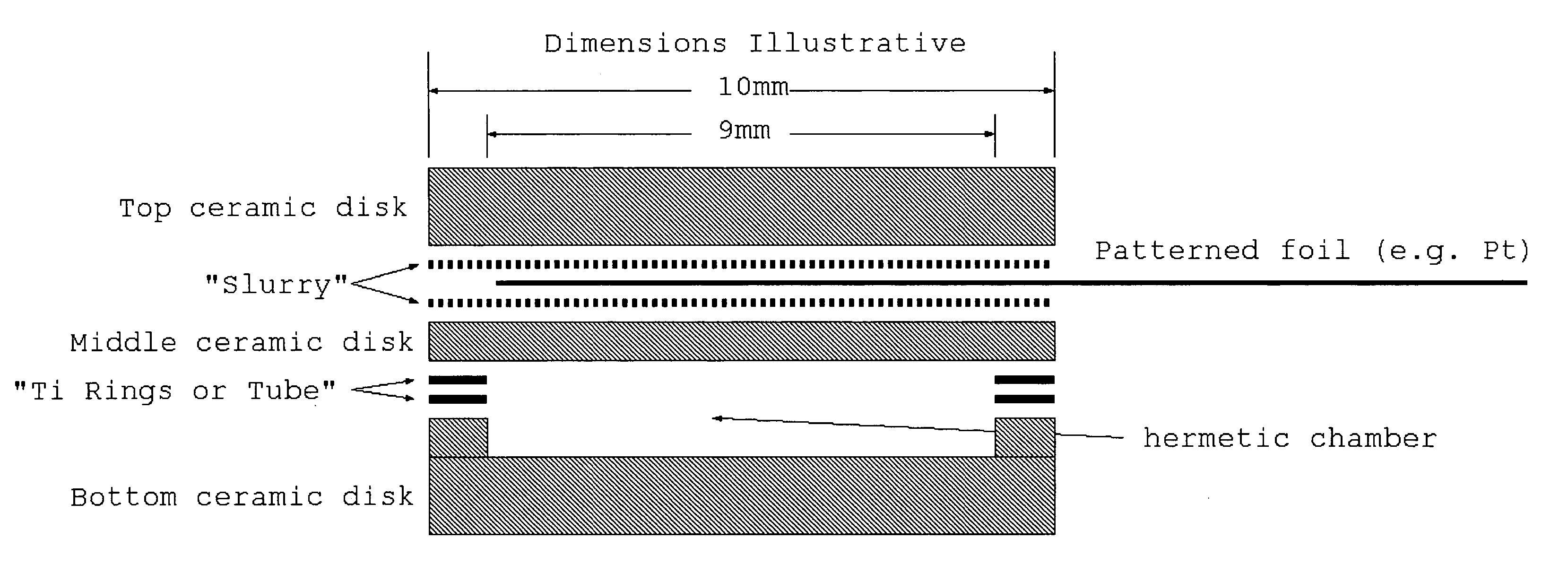

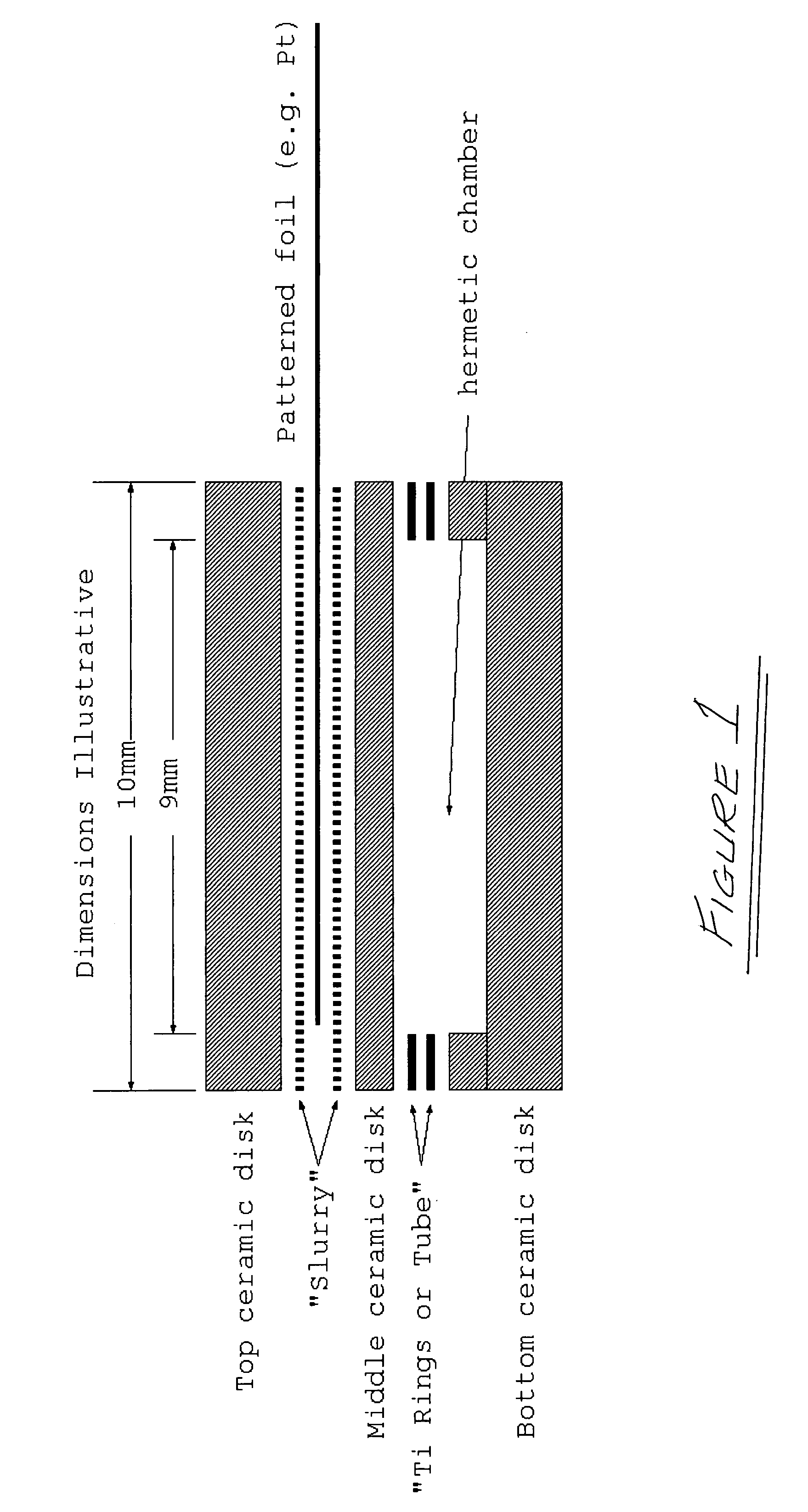

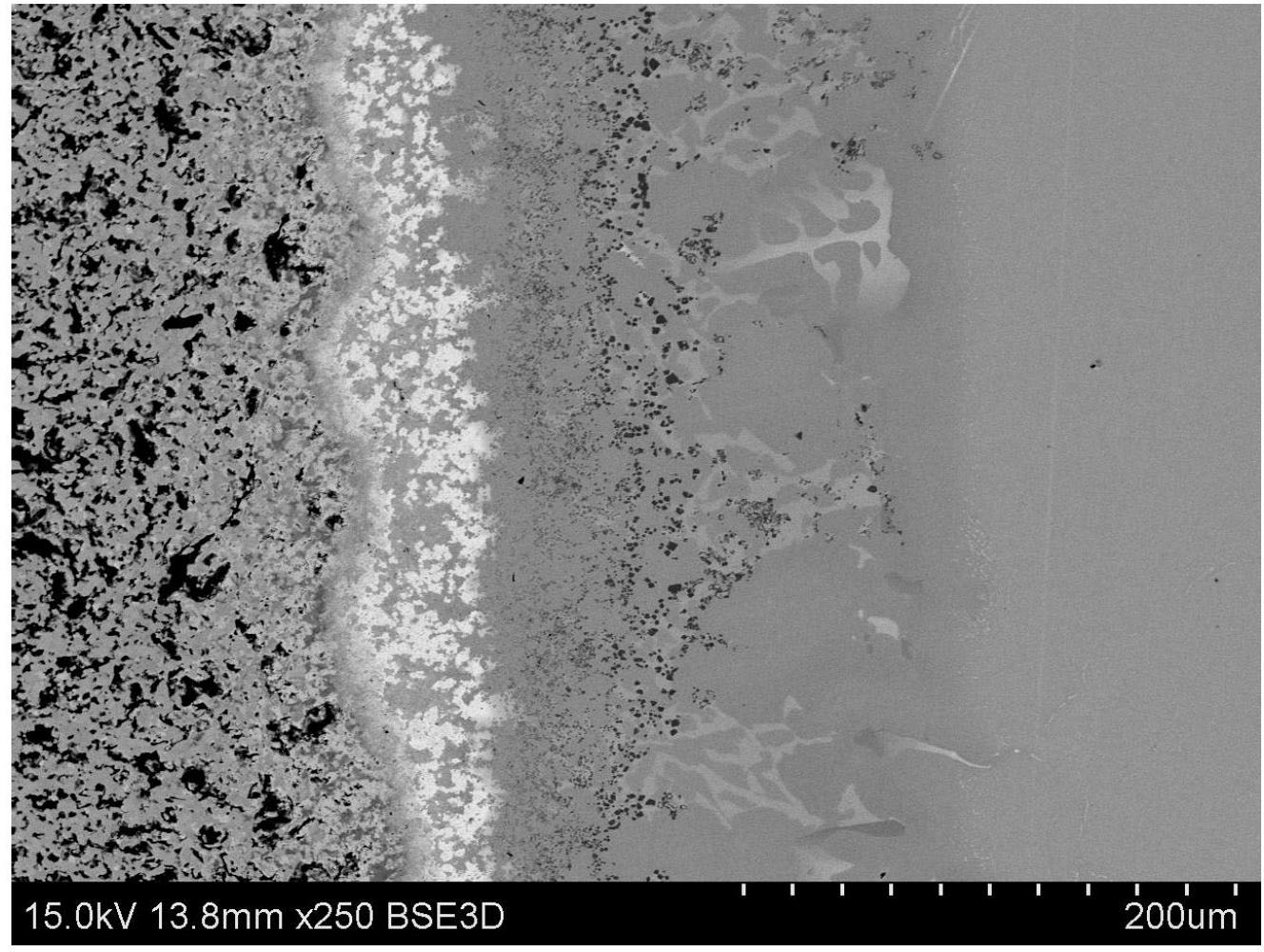

InactiveUS20070277374A1High bonding strengthComplicated in fabrication procedurePrinted circuit assemblingLine/current collector detailsOxide ceramicPlatinum

A method is disclosed for the fabrication of feedthrough devices that can transmit a single or plurality of electrical signal(s) to or from within a leak-tight (hermetic) chamber from or to the outside of said leak-tight (hermetic) chamber. The invention allows materials known to be well-tolerated within the human body such as alumina-oxide ceramic and platinum to be used as raw materials in the fabrication of body-compatible, single or multi-channel leak-tight (hermetic) feedthroughs.

Owner:NEWSOUTH INNOVATIONS PTY LTD

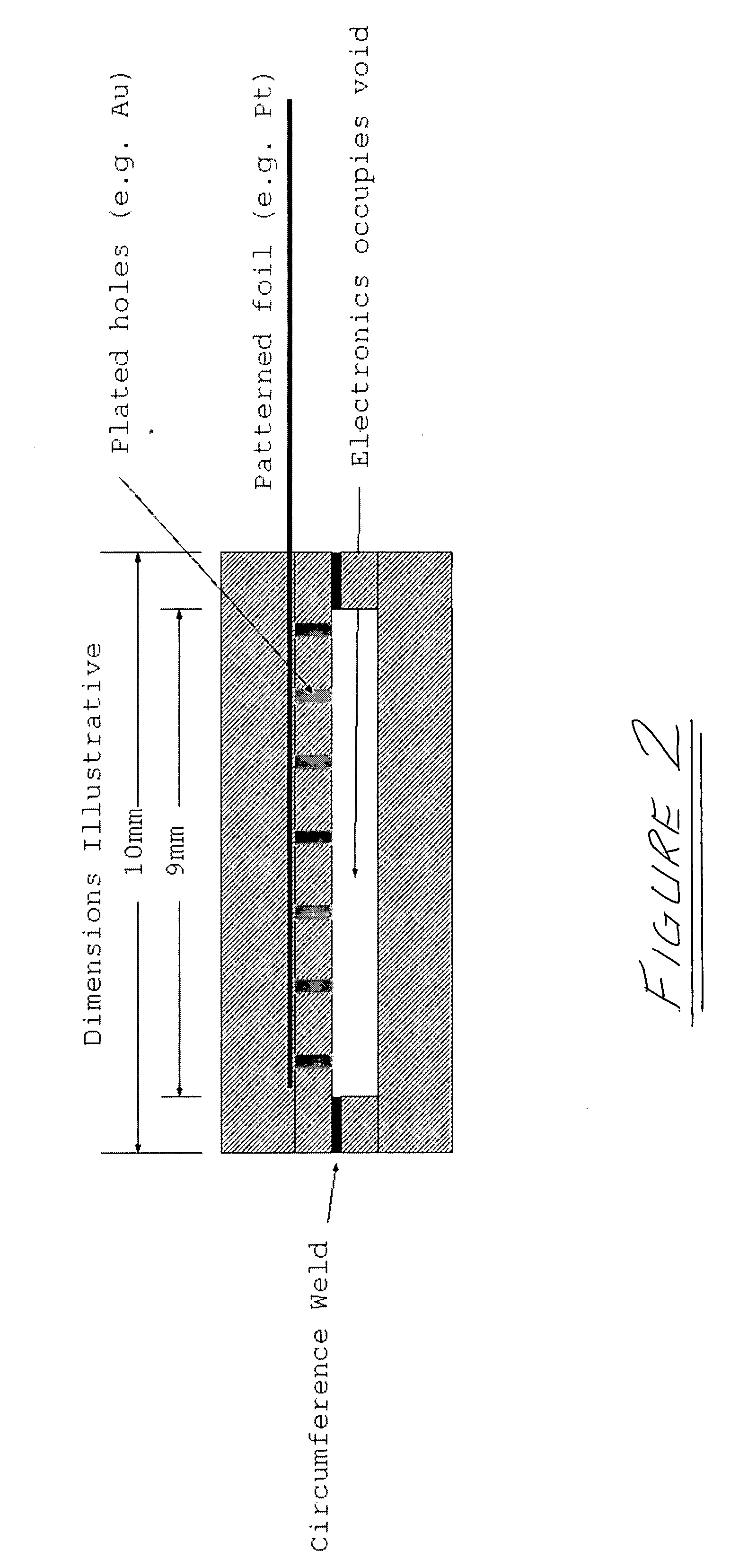

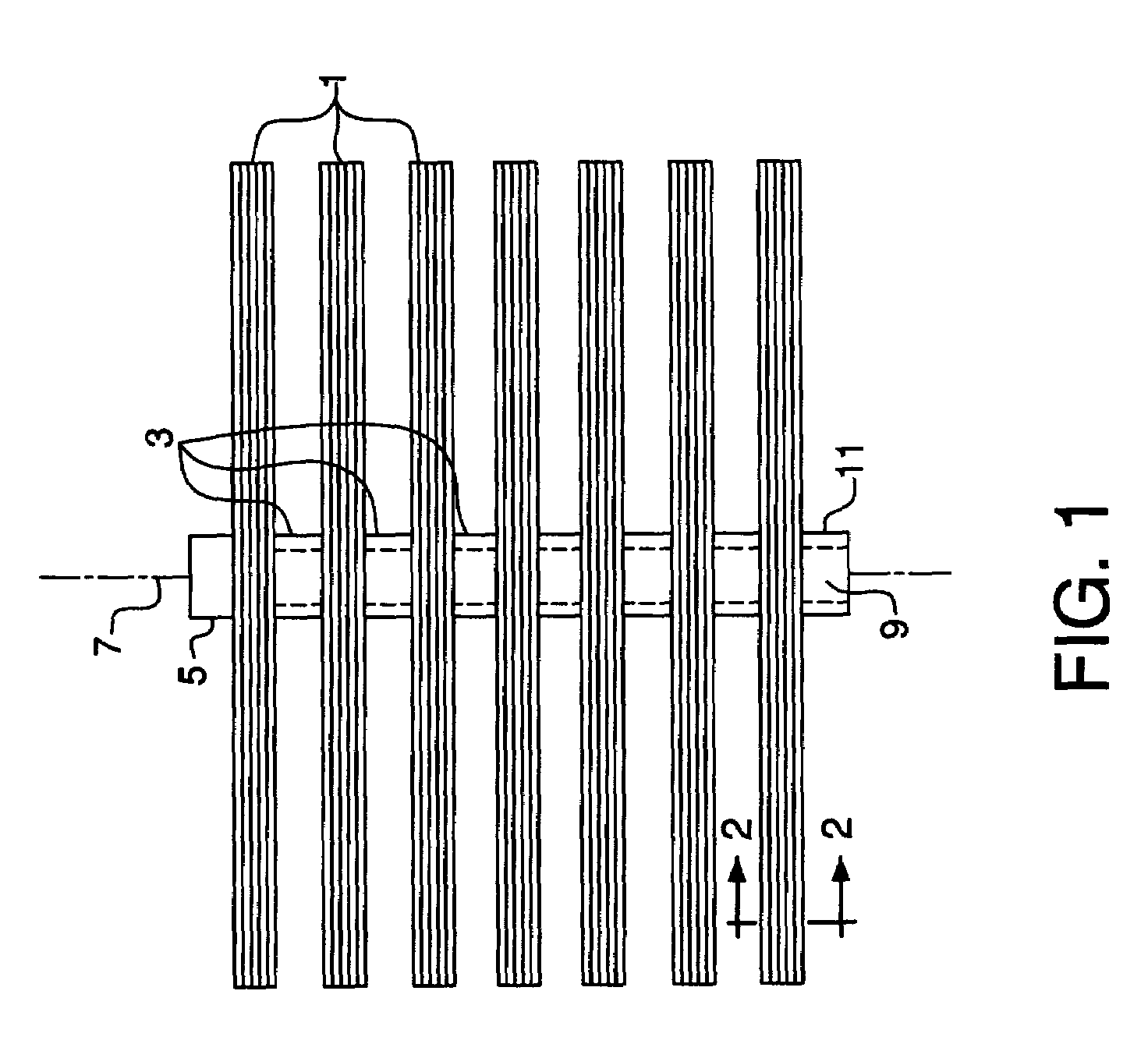

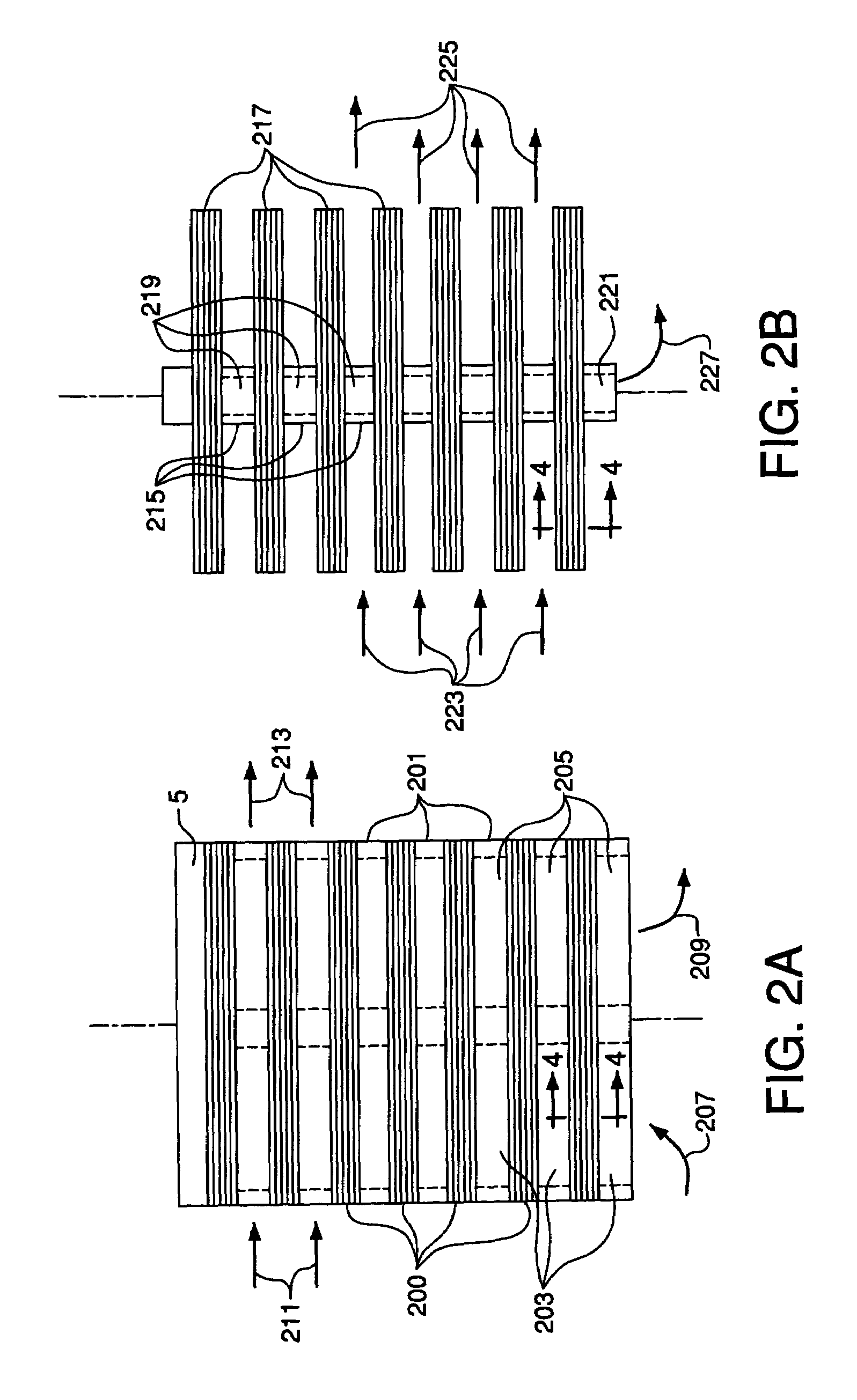

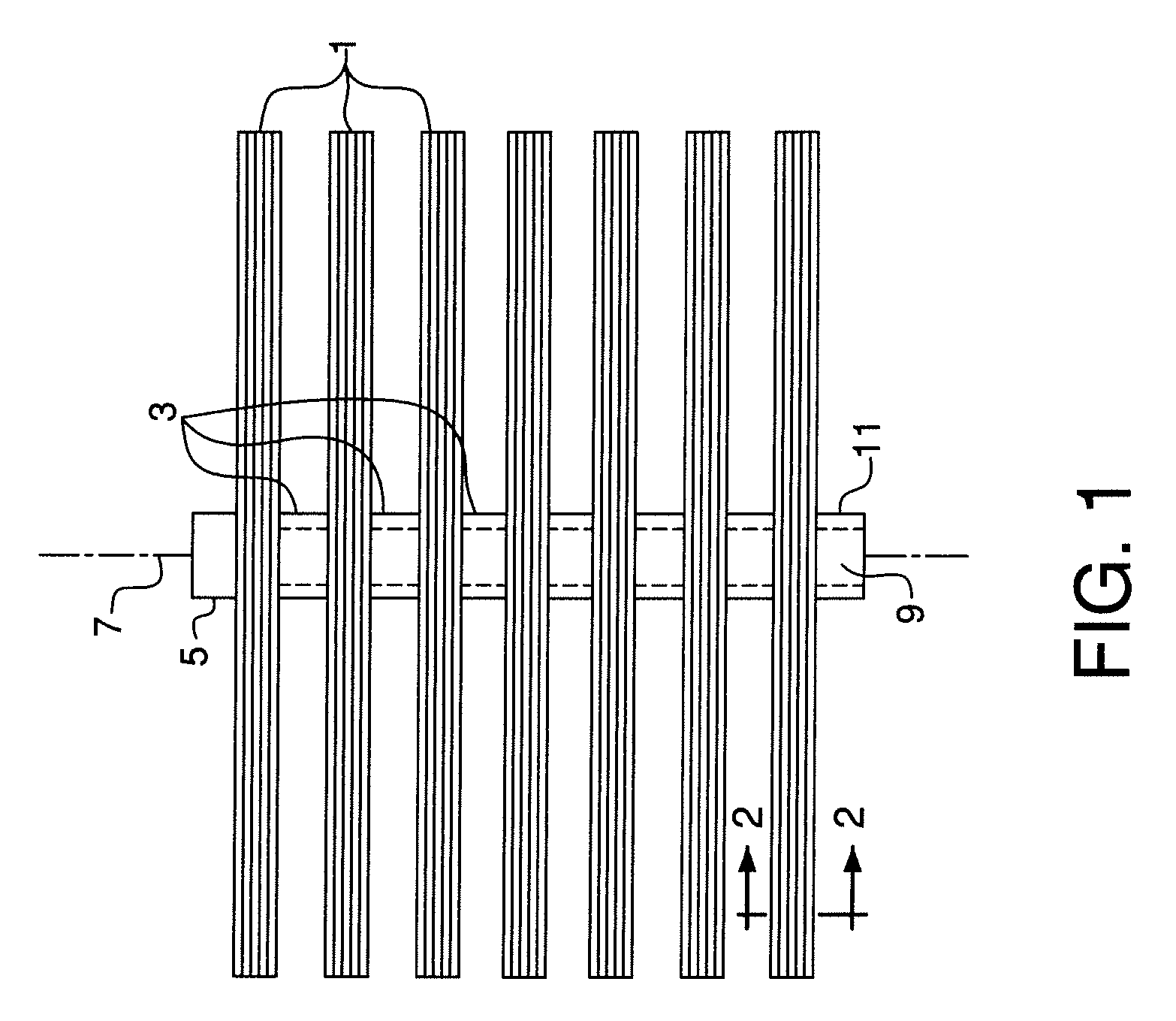

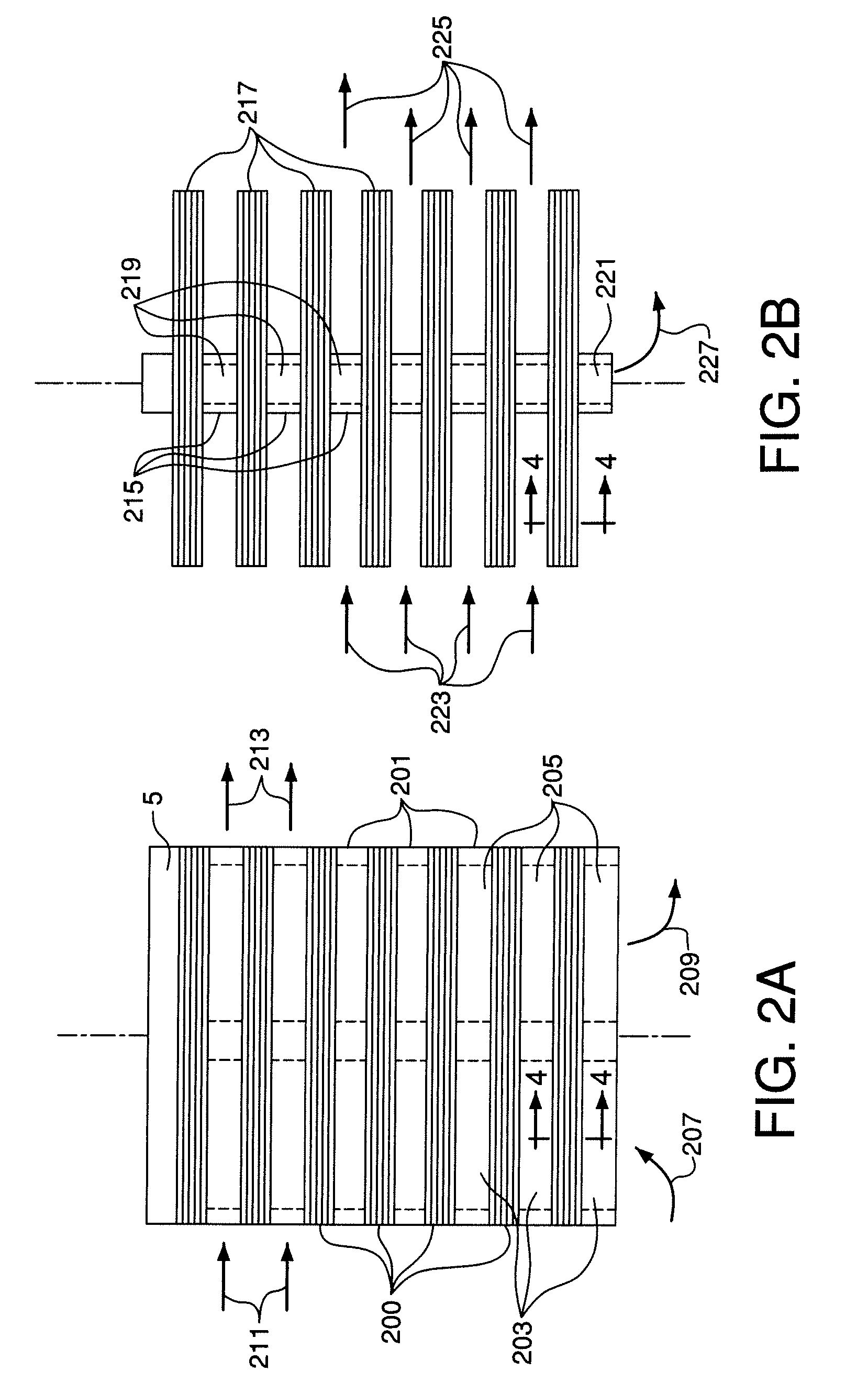

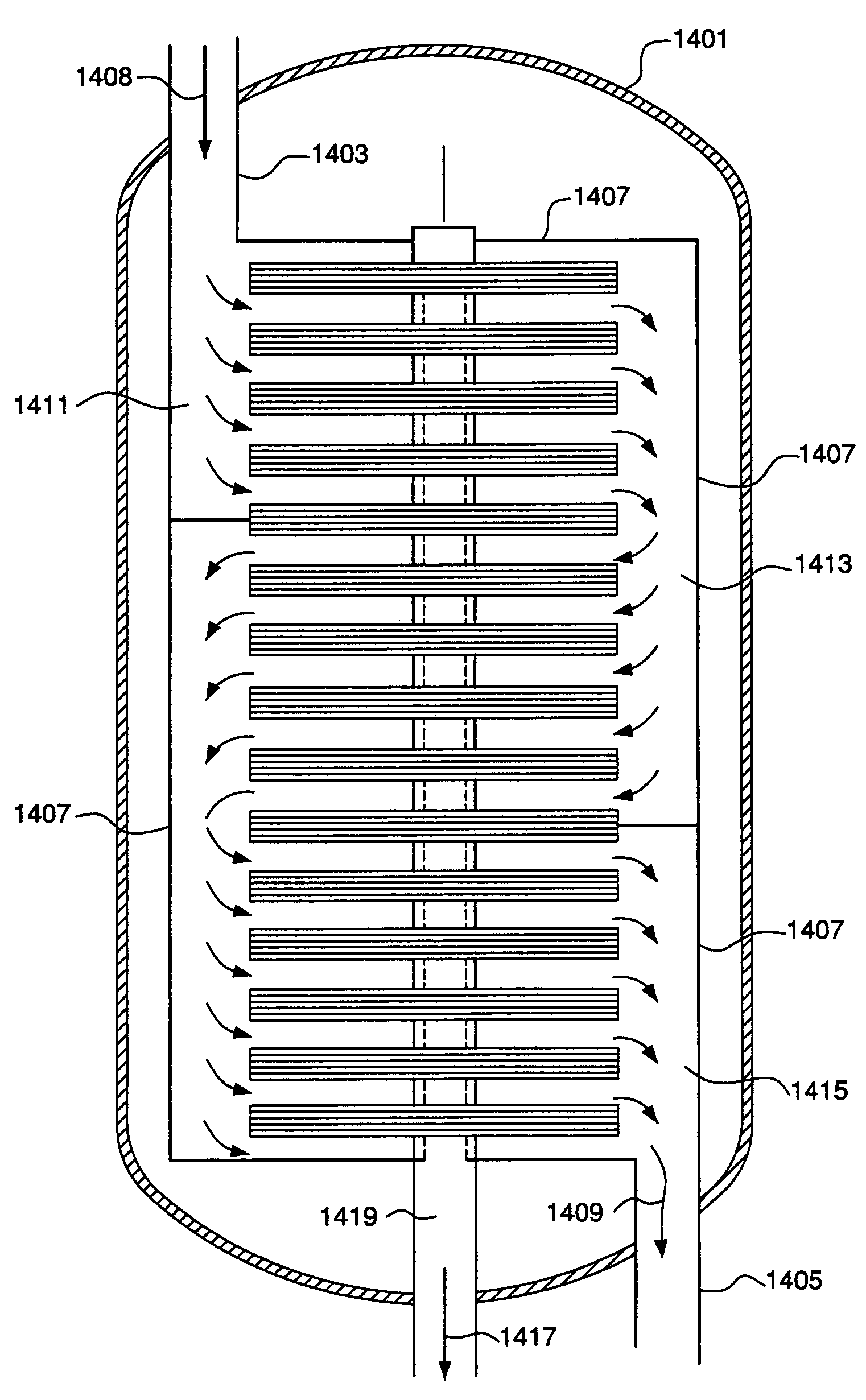

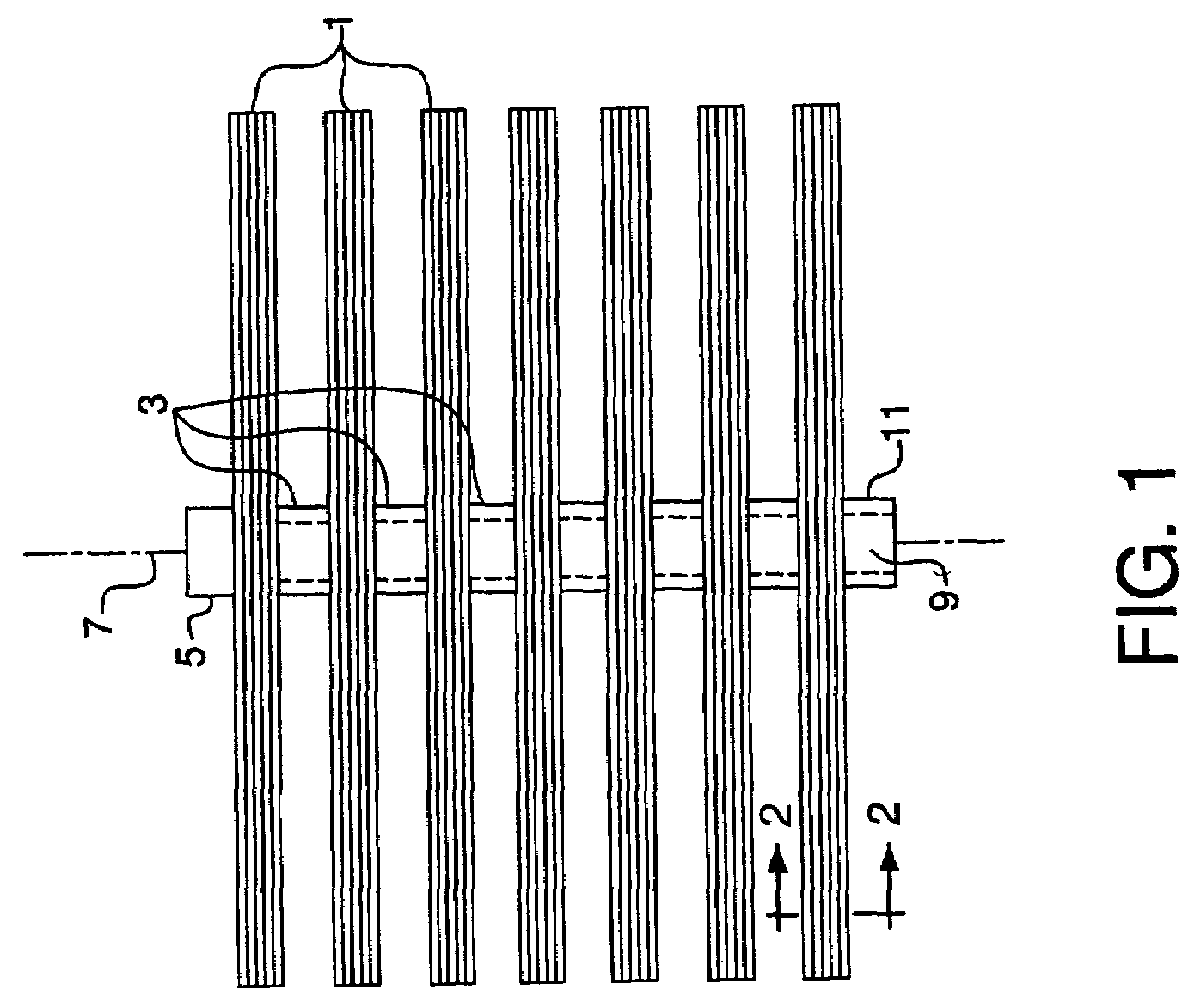

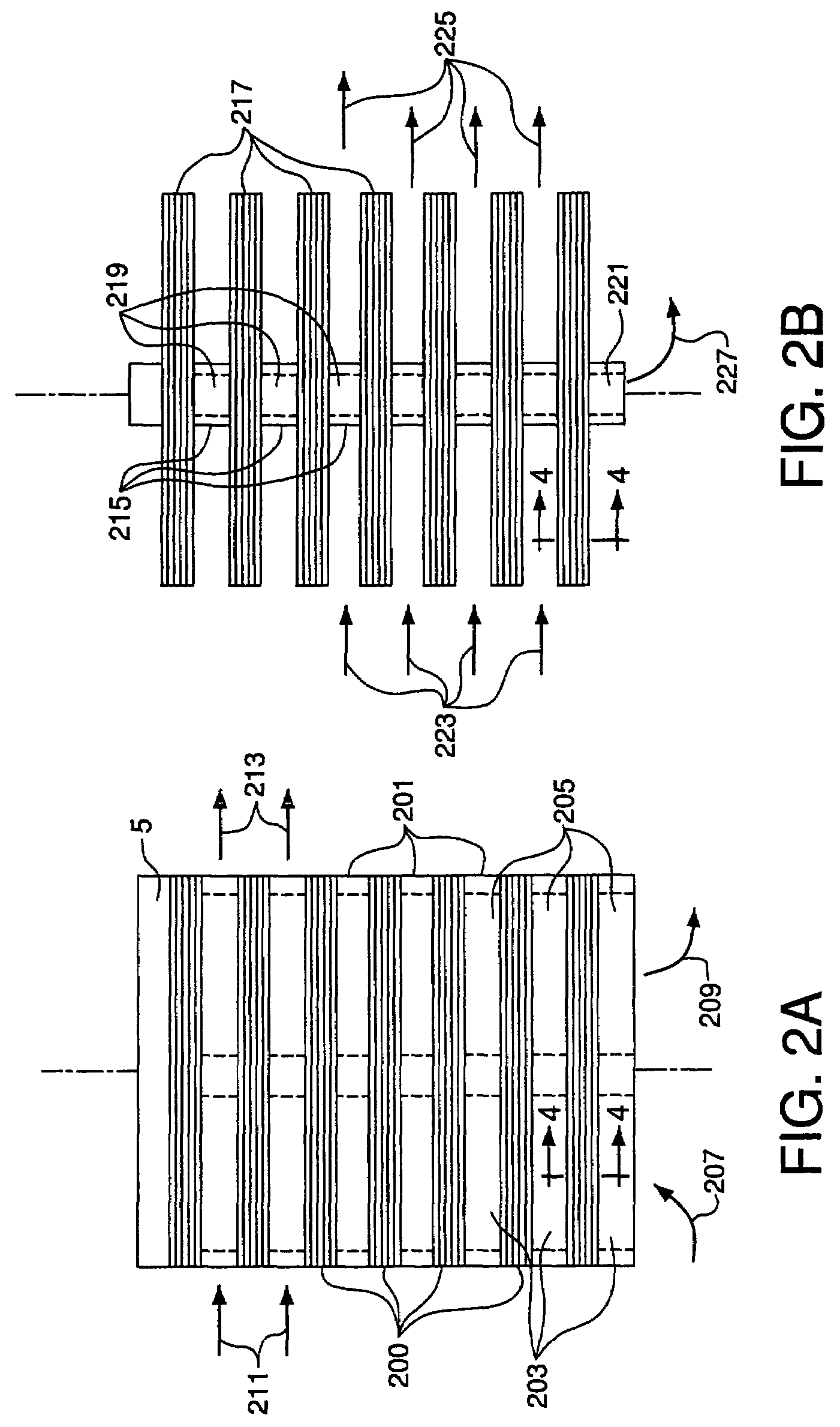

Ion transport membrane module and vessel system

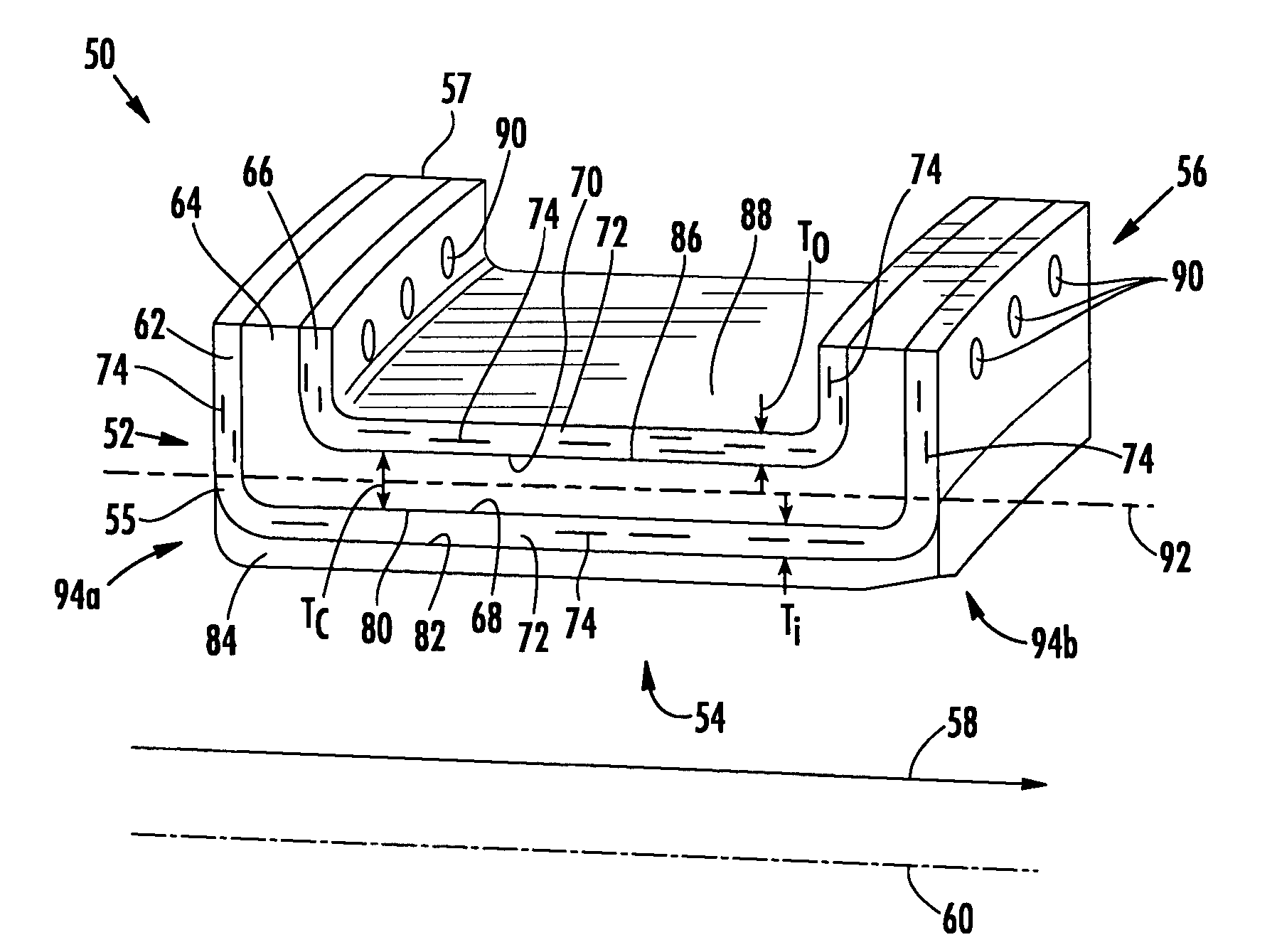

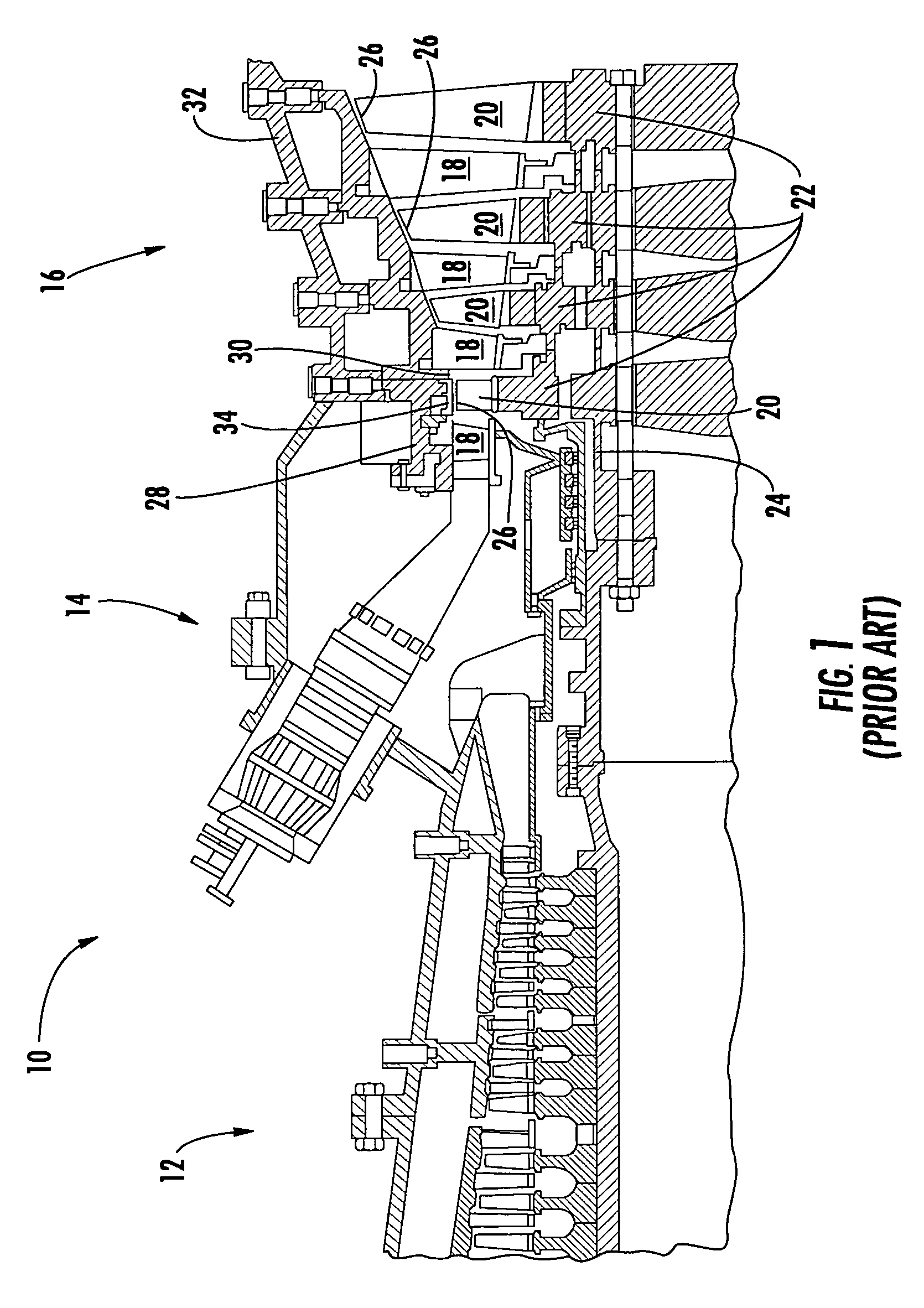

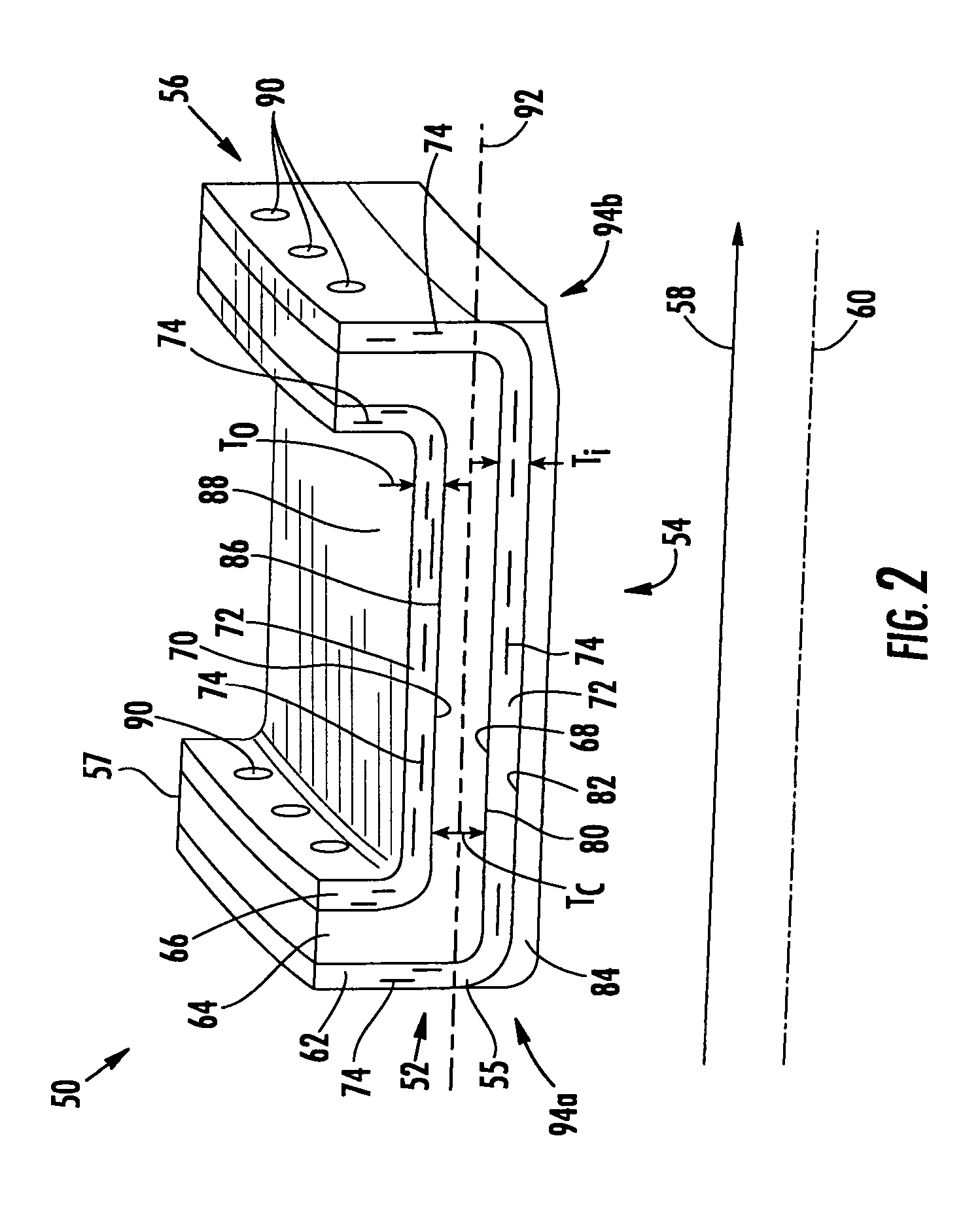

An ion transport membrane system comprising (a) a pressure vessel having an interior, an exterior, an inlet, and an outlet; (b) a plurality of planar ion transport membrane modules disposed in the interior of the pressure vessel and arranged in series, each membrane module comprising mixed metal oxide ceramic material and having an interior region and an exterior region, wherein any inlet and any outlet of the pressure vessel are in flow communication with exterior regions of the membrane modules; and (c) one or more gas manifolds in flow communication with interior regions of the membrane modules and with the exterior of the pressure vessel.The ion transport membrane system may be utilized in a gas separation device to recover oxygen from an oxygen-containing gas or as an oxidation reactor to oxidize compounds in a feed gas stream by oxygen permeated through the mixed metal oxide ceramic material of the membrane modules.

Owner:AIR PROD & CHEM INC

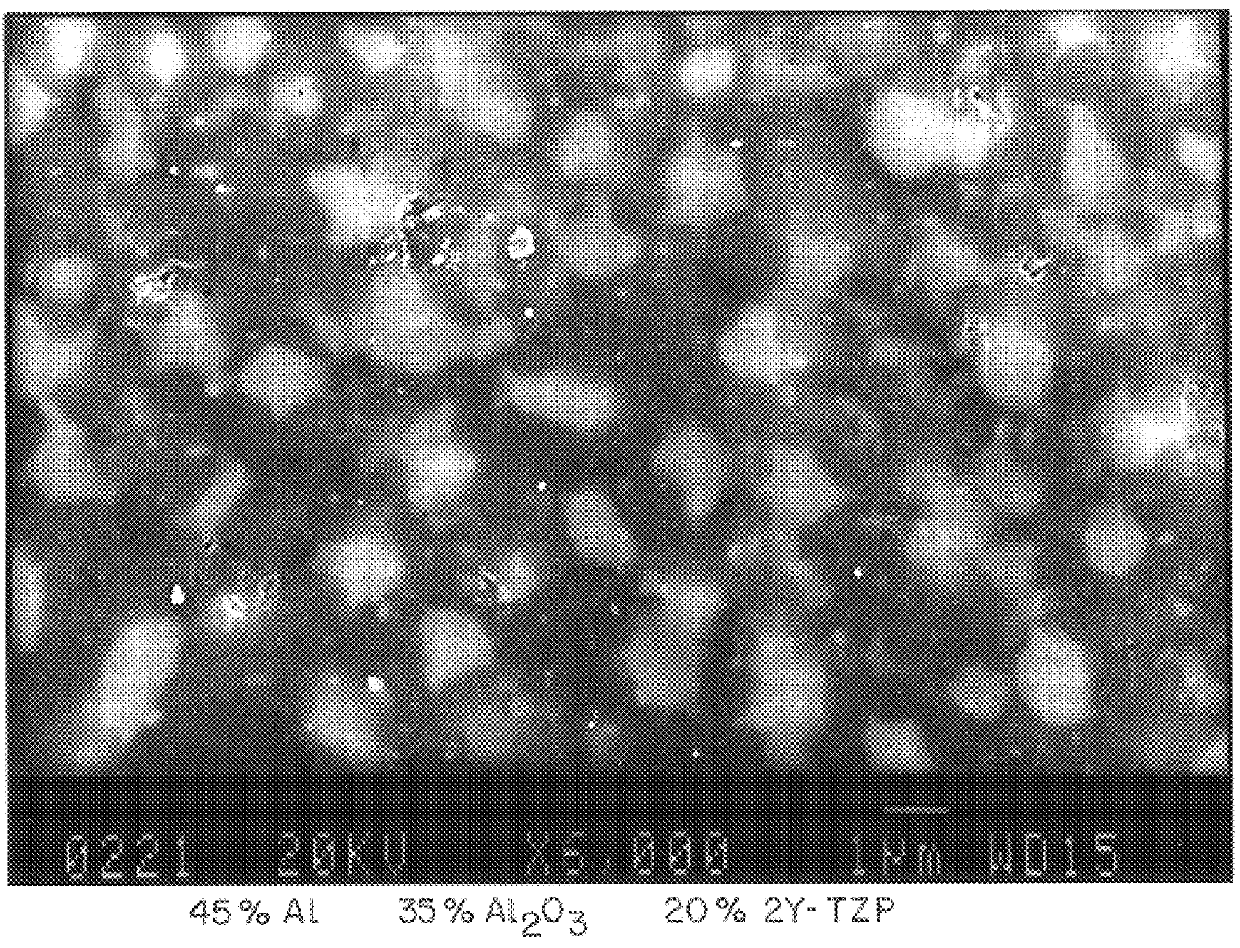

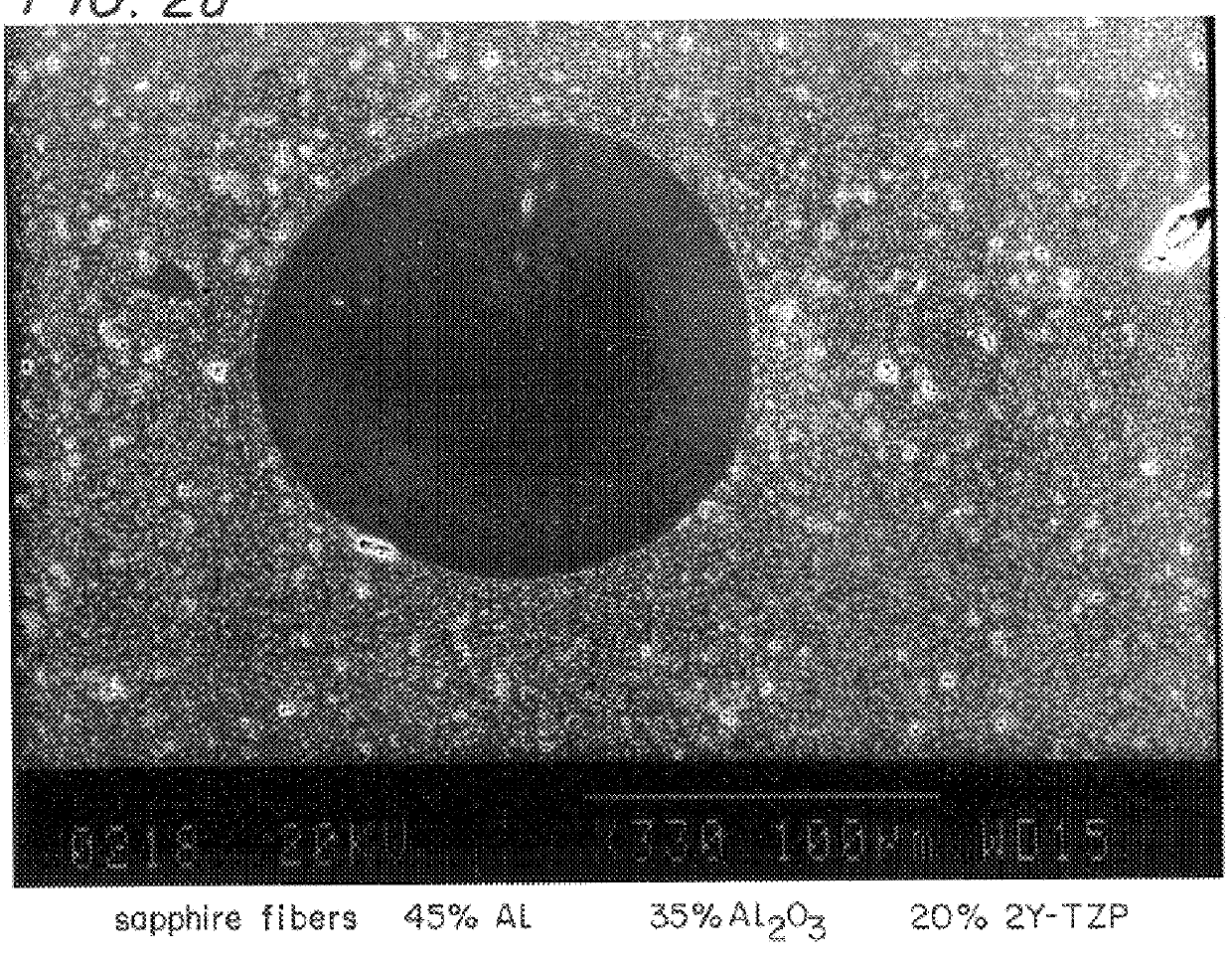

Production of an aluminide containing ceramic moulding

InactiveUS6025065AFast heatingLow heating rateSynthetic resin layered productsCeramic layered productsOxide ceramicMetal powder

PCT No. PCT / EP95 / 03347 Sec. 371 Date Nov. 19, 1997 Sec. 102(e) Date Nov. 19, 1997 PCT Filed Aug. 23, 1995 PCT Pub. No. WO96 / 20902 PCT Pub. Date Jul. 11, 1996A ceramic formed body containing a) 5 to 70 vol % of at least on intermetallic aluminide phase which additionally may contain aluminum or / and aluminum alloy, and b) 30 to 95 vol % of one or more ceramic phases which form a solid interconnecting skeleton and wherein the intermetallic phase or phases consist of predominantly interconnected areas with average sizes of 0.1 to 10 mu m, is obtained by sintering, in a non-oxidizing atmosphere, of a powder metallurgically green body which consists of a mixture of finely dispersed powder of aluminum, one or more ceramic substances and maybe further metals such that the mixture contains at least one oxide ceramic or / and metallic powder which, during sintering, reacts with aluminum thereby forming an aluminide and maybe Al2O3.

Owner:CLAUSSEN NILS

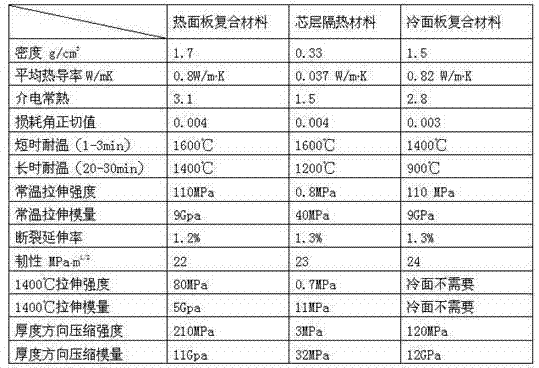

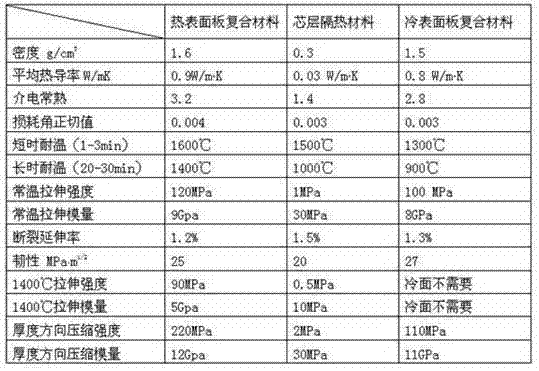

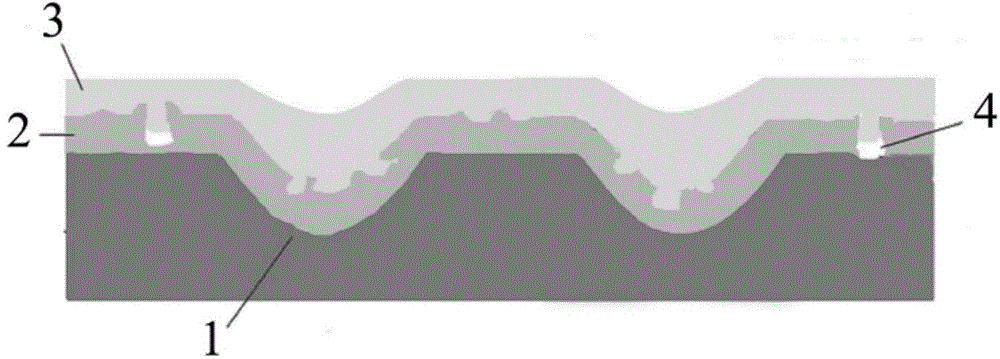

Ceramic composite material of high temperature insulation sandwich structure and method for preparing ceramic composite material

ActiveCN102642350AImprove toughnessImprove thermal conductivityLaminationLamination apparatusOxide ceramicCeramic composite

Disclosed are a ceramic composite material of a high temperature insulation sandwich structure and a method for preparing the ceramic composite material. A core layer of the composite material is an aerogel composite material layer reinforced by high temperature resistant inorganic fibers, oxide ceramic composite material surface plates reinforced by high temperature resistant inorganic fibers are compounded on the upper surface and the lower surface of the core layer, the thickness of the core layer is larger than or equal to 2mm, and the thicknesses of the upper surface plate and the lower surface plate respectively range from 0.1mm to 3.0mm. The method for preparing the ceramic composite material of the high temperature insulation sandwich structure includes the steps: (1) selecting aerogel composite materials reinforced by the high temperature resistant inorganic fibers as materials of the core layer with the thickness larger than or equal to 2mm; (2) tiling high temperature resistant inorganic fiber cloth or thin-layer fabrics on the upper surface and the lower surface of the core layer to perform needling, puncture or sewing; (3) sucking sol in a vacuum manner and gelating the sol at the temperature of 30-200 DEG C; and (4) performing heat treatment. The ceramic composite material of the high temperature insulation sandwich structure integrates the functions of heat insulation, bearing, wave penetration and the like.

Owner:NAT UNIV OF DEFENSE TECH

Composite wear-resistant antifriction coating on titanium alloy surface and preparation method thereof

InactiveCN104480511AImprove wear resistanceHigh bonding strengthSurface reaction electrolytic coatingOxide ceramicPlasma electrolytic oxidation

The invention discloses a composite wear-resistant antifriction coating on a titanium alloy surface and a preparation method thereof. The coating comprises a laser texturing surface, an oxide ceramic layer and a self-lubricating coating which are connected in sequence, wherein micropore arrays are uniformly distributed on the laser texturing surface; the oxide ceramic layer is a hard oxide ceramic coating; and the self-lubricating coating is a MoS2 coating, PTFE (polytetrafluoroethylene) coating or graphite coating. In the invention, the laser surface texturing technology is combined with the plasma electrolytic oxidation technology, and a texturing / ceramization composite coating is prepared on the titanium alloy surface which is then coated with a solid lubricant to improve the friction performance of the surface.

Owner:NANJING UNIV OF SCI & TECH +1

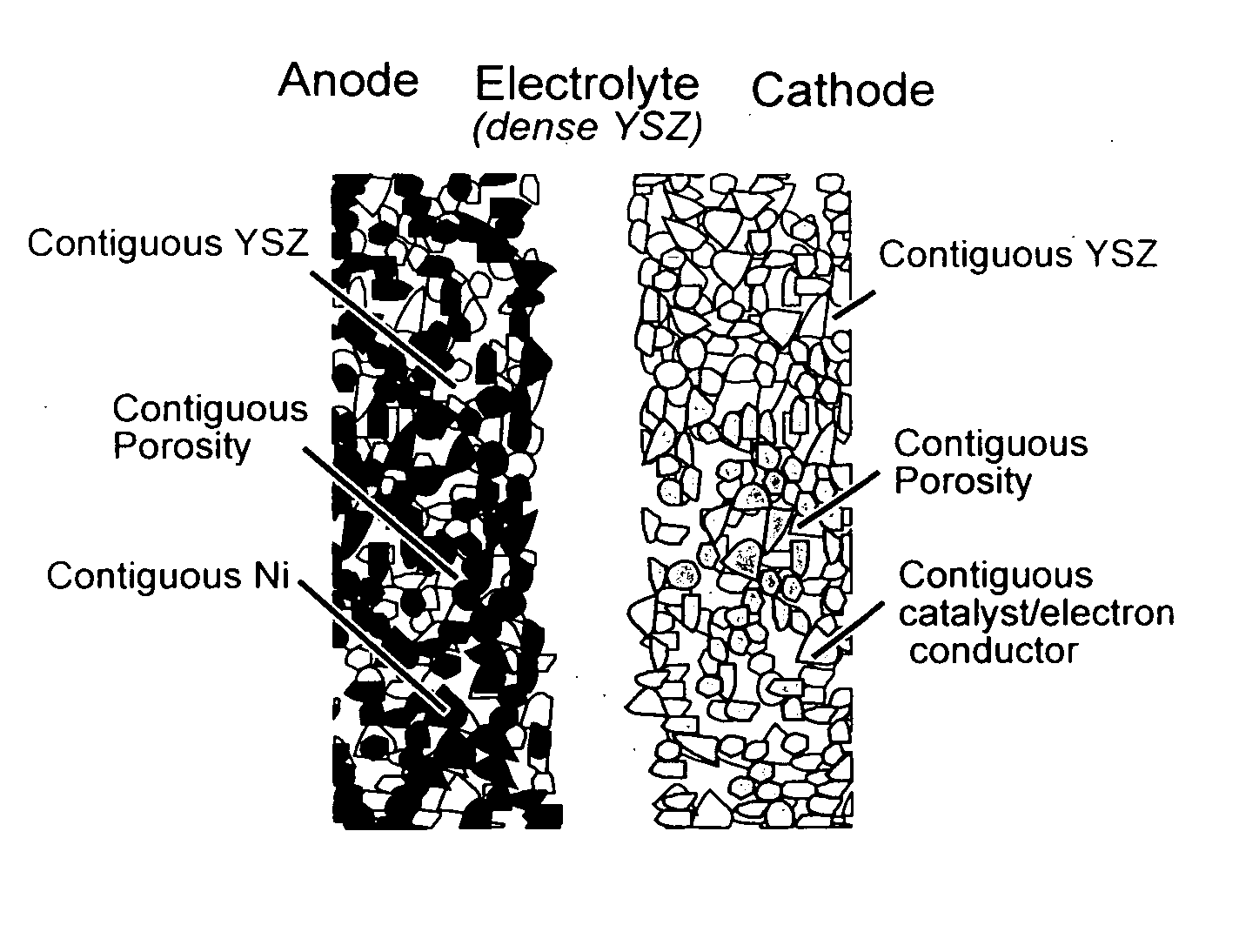

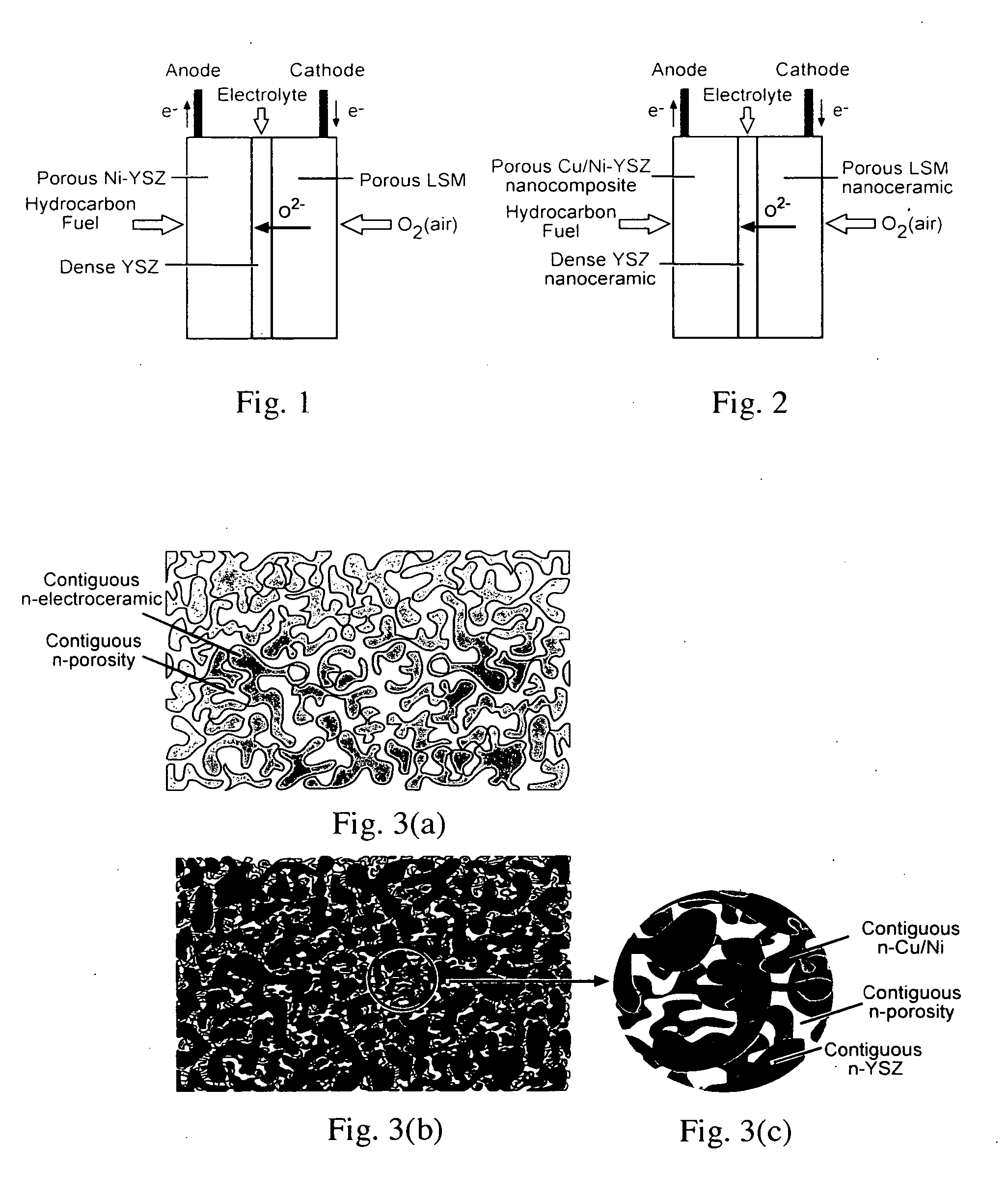

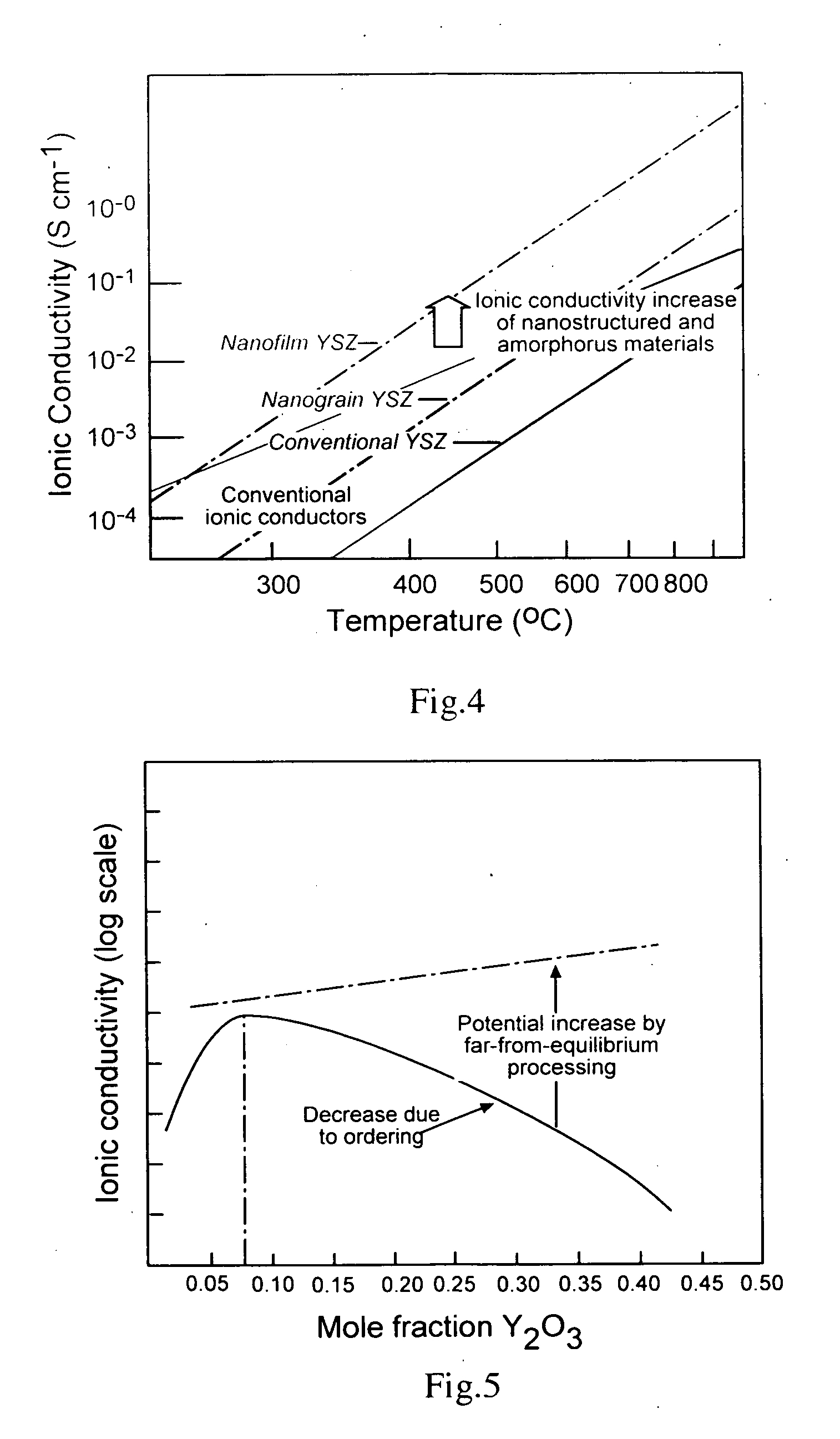

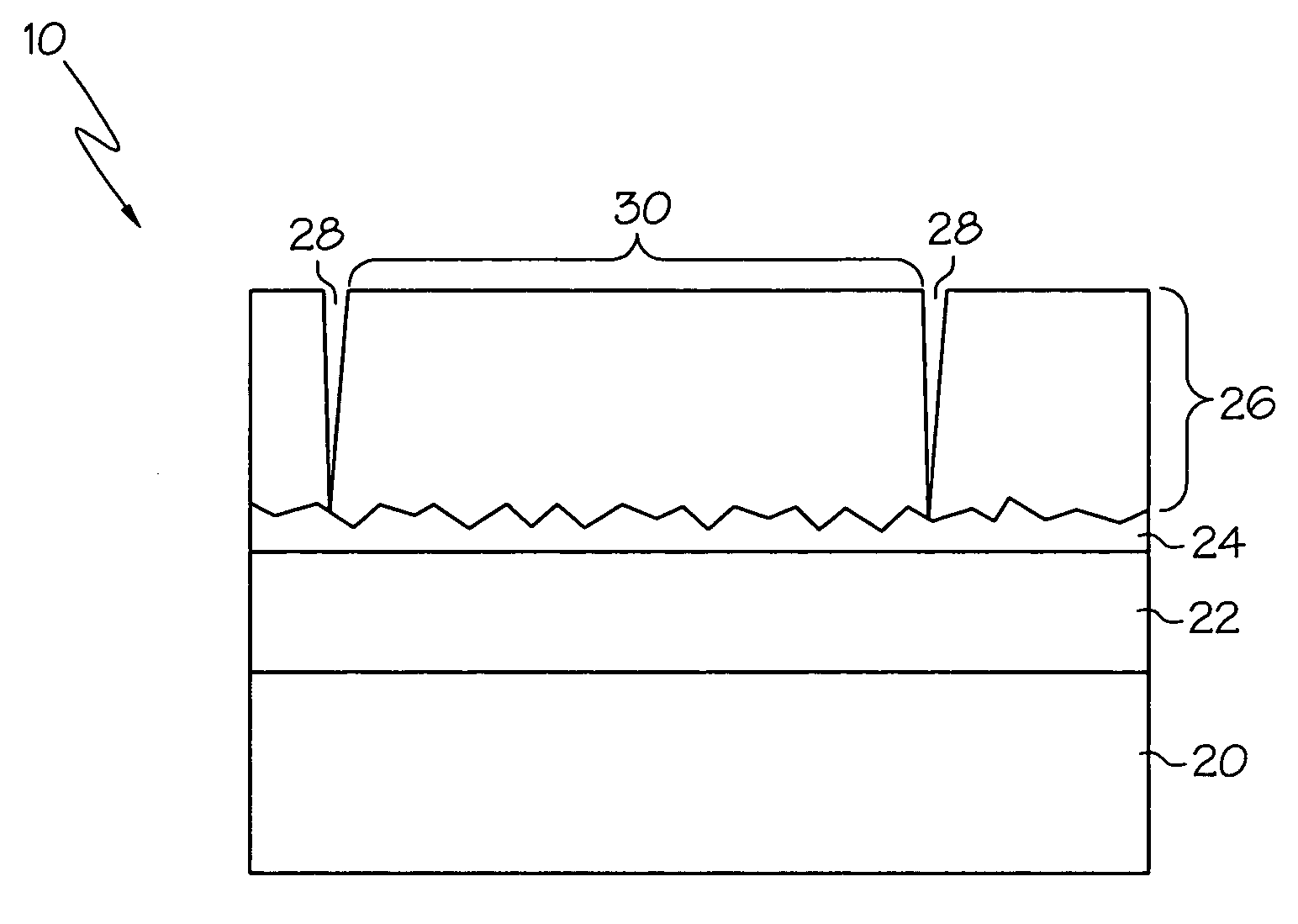

Mestastable ceramic fuel cell and method of making same

InactiveUS20050244693A1Little attentionSpeed up coolingFinal product manufactureCell electrodesSolubilityOxide ceramic

A solid oxide fuel cell has anode, cathode and electrolyte layers each formed essentially of a multi-oxide ceramic material and having a far-from-equilibrium, metastable structure selected from the group consisting of nanocrystalline, nanocomposite and amorphous. The electrolyte layer has a matrix of the ceramic material, and is impervious and serves as a fast oxygen ion conductor. The electrolyte layer has a matrix of the ceramic material and a dopant dispersed therein in an amount substantially greater than its equilibrium solubility in the ceramic matrix. The anode layer includes a continuous surface area metallic phase in which electron conduction is provided by the metallic phase and the multi-oxide ceramic matrix provides ionic conduction.

Owner:NANOCELL SYST

Method for preparing TiAl-based alloy formwork by precision-investment casting

InactiveCN101462151AFast moisture absorptionGood hygroscopicityFoundry mouldsFoundry coresWaxOxide ceramic

The invention discloses a method for preparing a shuttering for a precision investment casting TiAl-based alloy, and relates to a method for preparing an oxide ceramic shuttering. The method solves the problems of slow drying for making the shuttering, longer production period for cast and high cost during production of a TiAl-based alloy precise cast. The preparation method comprises: firstly, adopting SLS technology to prepare a fusible pattern; secondly, coating polyvinyl alcohol on the surface of bauxite and grinding the bauxite into granules; thirdly, smearing a shuttering surface layer; fourthly, smearing a shuttering back layer; fifthly, removing wax from the shuttering, and roasting the shuttering; and sixthly, casting the TiAl-based alloy in vacuum to obtain the TiAl-based alloy cast. The method only needs 13 to 15 days to obtain the TiAl-based alloy precise cast from CAD design, but the prior method at least needs 45 to 60 days, so the method saves nearly two thirds of production period, and the manufacturing cost is correspondingly lowered.

Owner:HARBIN INST OF TECH

Protective coating for oxide ceramic based composites

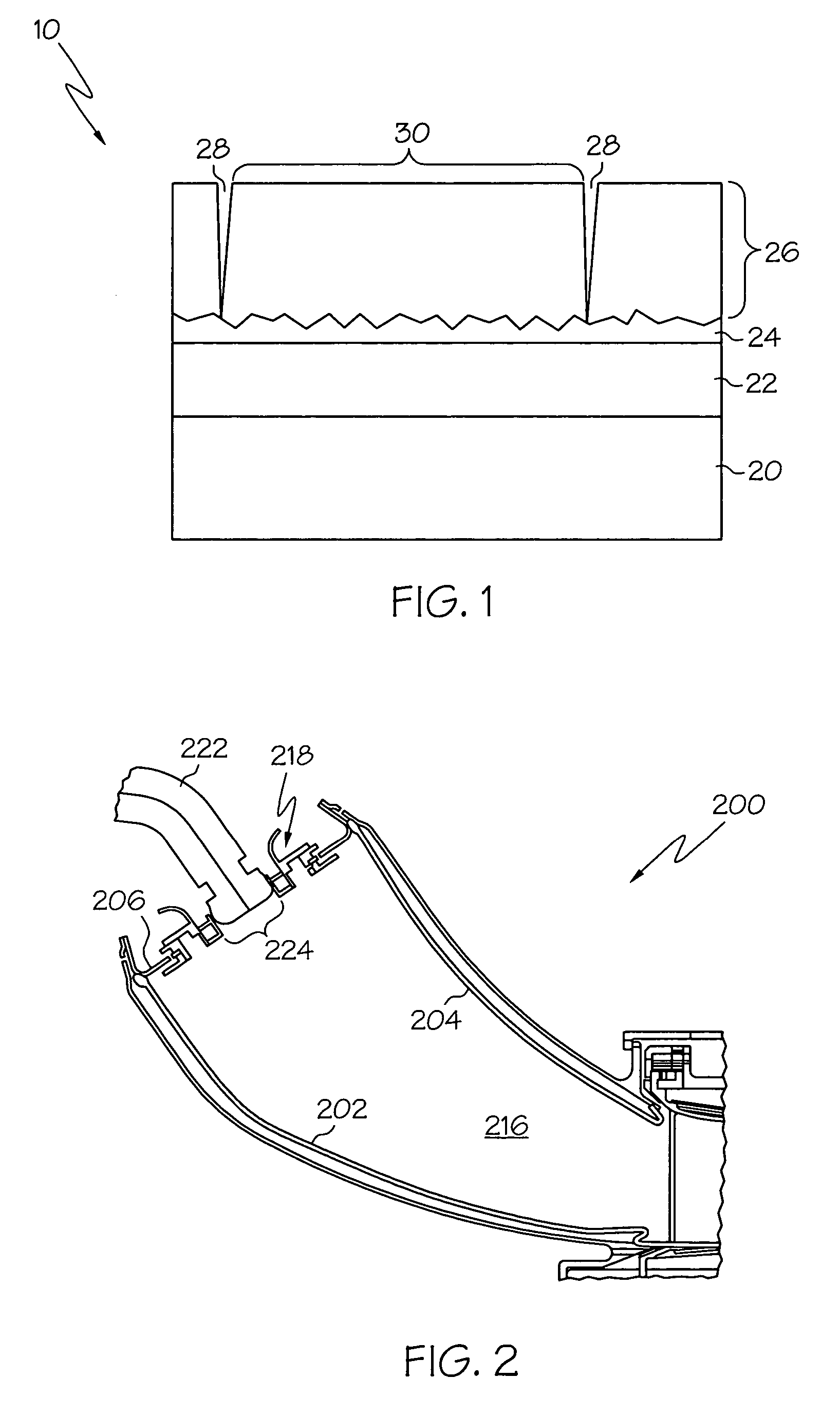

InactiveUS20060024528A1Improve accommodationGlass/slag layered productsNatural mineral layered productsOxide ceramicPorosity

A layered structure includes a substrate comprising a layer of an oxide / oxide ceramic based composite material, a first oxide layer disposed directly on the substrate and formed from a material that has no greater than about 10% porosity and is substantially impermeable by water vapor, and a second oxide layer disposed directly on the first oxide layer and having a greater porosity than the first oxide layer. Either or both the first and second oxide layers of the coating system may be deposited using a plasma spraying process, a slurry deposition process which is followed by a sintering step, or an EB-PVD process.

Owner:HONEYWELL INT INC

Silicon carbide based porous structure and method for manufacturing thereof

InactiveUS20050084717A1Easy to produceLow costFiltration separationNatural mineral layered productsCardboardOxide ceramic

A silicon carbide-based porous structure material maintaining the shape of a cardboard or sponge-like porous structure, with a great relative surface area, and a process for producing the same, is provided. To this end, a cardboard or sponge-like shaped framework of silicon carbide-based porous structure material is impregnated with a slurry comprising a resin, as a carbon source, and silicon powder, and subjected to reactive sintering in a vacuum or inert atmosphere, or in a nitrogen gas atmosphere, generating silicon carbide. At the same time pores are generated due to volume reduction reaction, thereby allows obtaining a silicon carbide-based porous structure material with a great relative surface area. Furthermore, excess carbon is removed from the fabricated silicon carbide-based porous structure material, and impregnated with a solution which becomes an oxide ceramic coating upon firing, whereby oxidization resistance is excellent and relative surface area is markedly improved.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Preparing method of low-cost oxide ceramic shell for titanium alloy precision casting

A low-cost oxide ceramic mould for the precise casting of Ti-alloy is prepared through preparing paint and wax mould of casting, immersing the wax mould in paint for 10-20 min, leveling the paint, uniformly applying the white electro-corundum powder to the paint layer of wax mould, drying, and high-pressure dewaxing.

Owner:HARBIN INST OF TECH

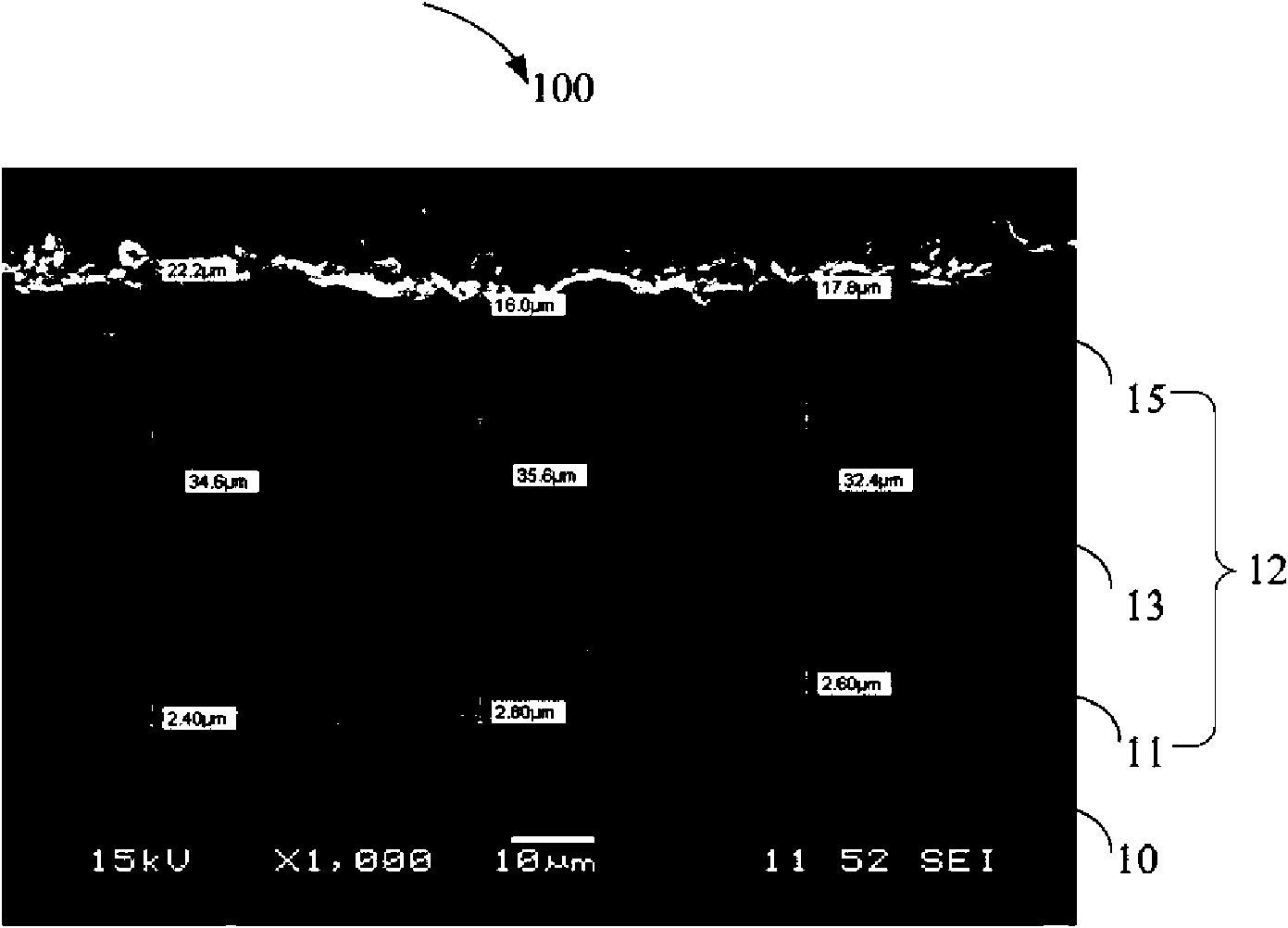

Aluminum alloy with micro-arc oxide ceramic membrane on surface and preparation method thereof

ActiveCN101608332AAvoid process problemsIncrease productivityAnodisationThin material handlingOxide ceramicPlasma electrolytic oxidation

The invention relates to an aluminum alloy which comprises an aluminum alloy matrix and a micro-arc oxide ceramic membrane formed on the surface of the matrix, wherein the ceramic membrane comprises a bottom transition layer, a middle compact layer and a surface compact layer. The preparation method of the aluminum alloy, which is used for forming the micro-arc oxide ceramic membrane without a loose layer on the surface of the aluminum alloy, comprises the following steps: putting the aluminum alloy matrix in an oxidation tank containing electrolyte; carrying out initial oxidation treatment for the aluminum alloy matrix by adopting constant current; and continuously applying oxidation treatment to the aluminum alloy matrix by adopting positive and negative bidirectional pulse voltage, wherein positive and negative voltage keeps constant after rising to the maximum value, wherein the maximum constant positive voltage is 450V-650V, the maximum constant negative voltage is 30V-200V, the width of positive and negative pulse is 1000-10000mus, the pulse interval is 300-2000mus, the continuous oxidation treatment time is 30-180min, and the treatment temperature is between 20 DEG C and 50DEG C.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

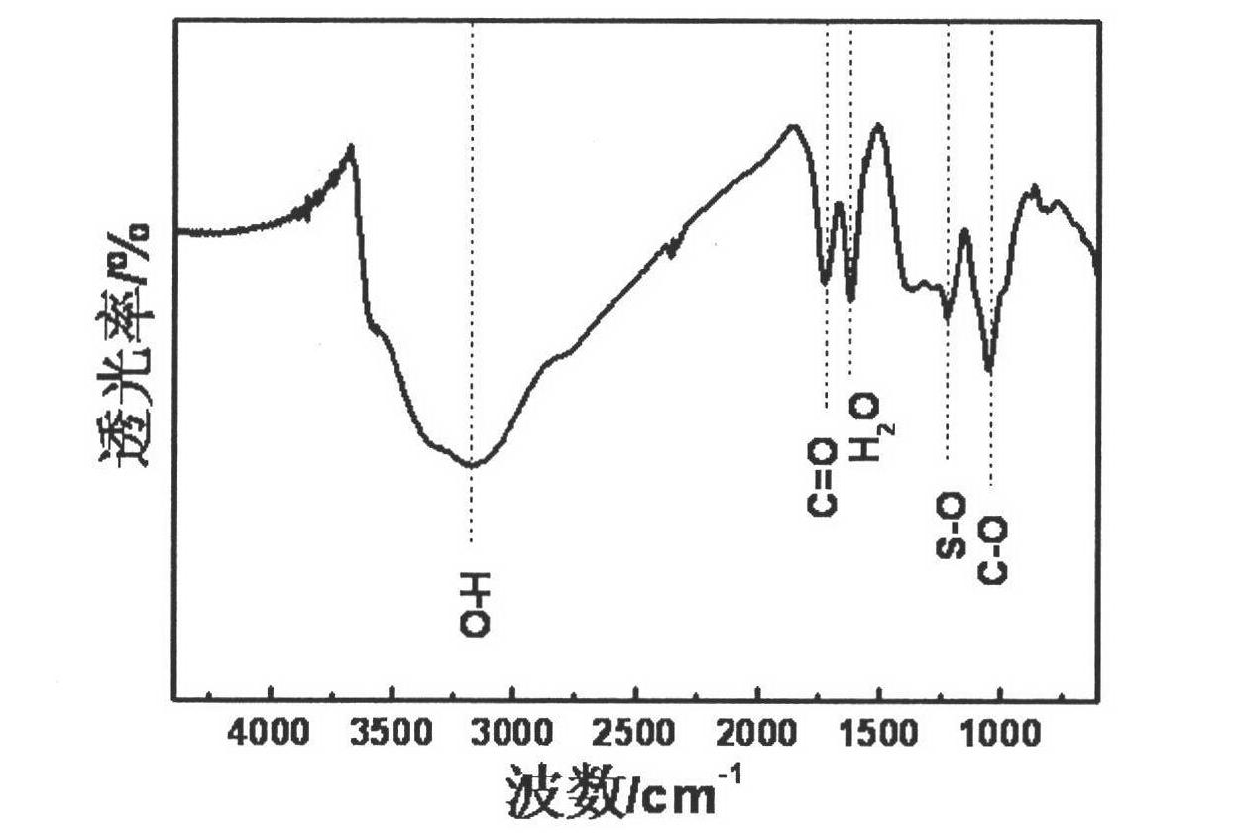

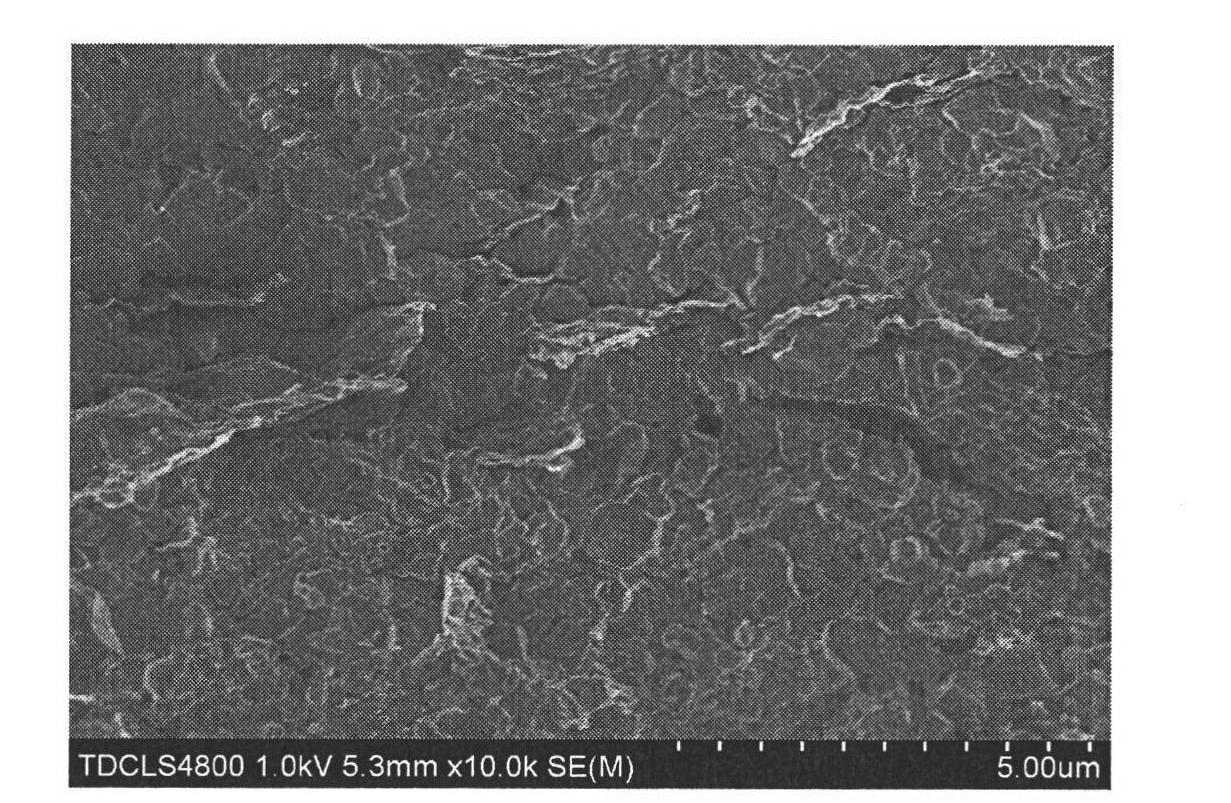

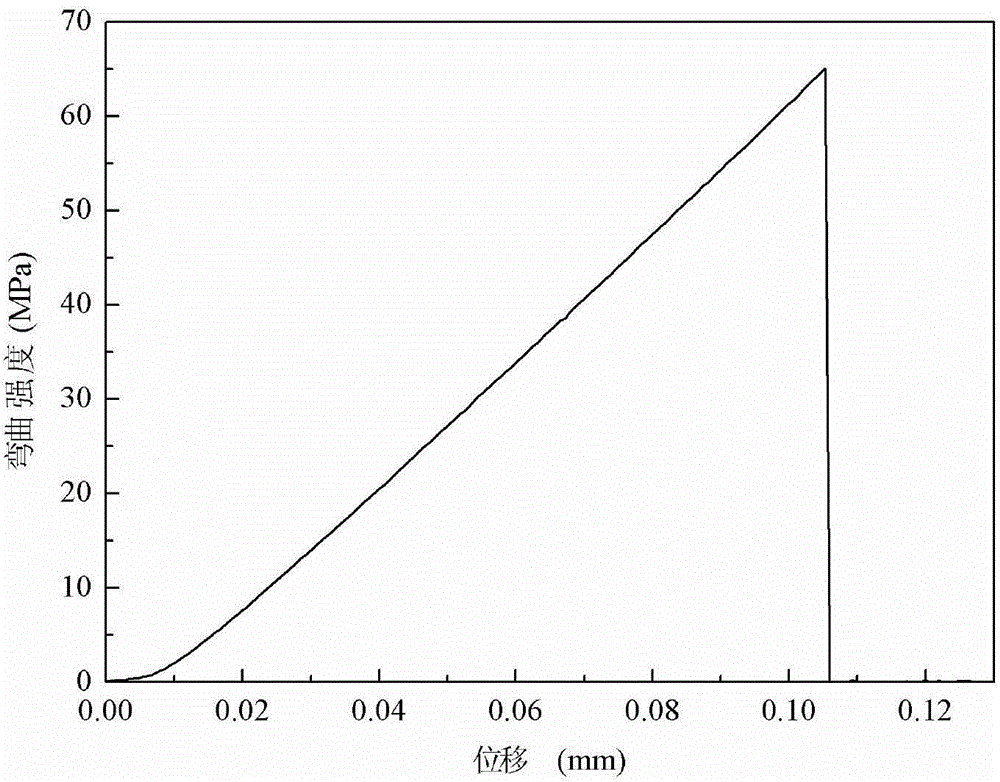

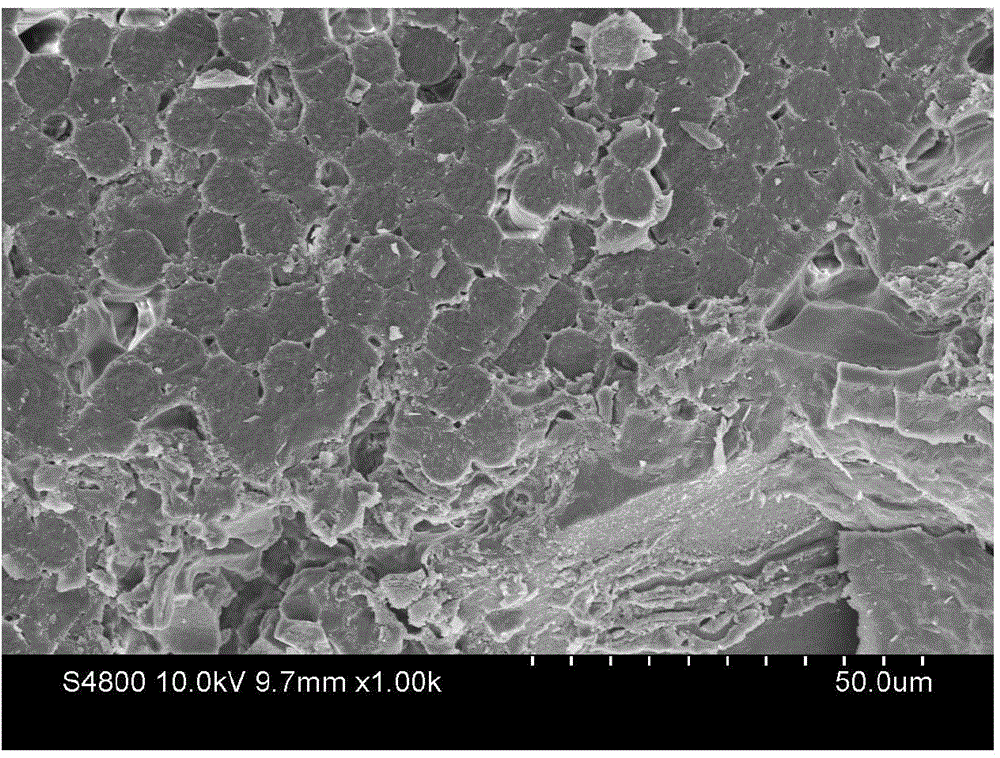

Graphene and oxide ceramic composite material and preparation method

The invention relates to a graphene and oxide ceramic composite material and a preparation method. Graphite oxide is used as a graphene precursor, the graphite oxide is mixed with zirconium oxide ceramic powder according to a certain proportion, and the mixture is molded and sintered so as to form the graphene and oxide ceramic composite material. The graphene and oxide ceramic composite material has a nanometer composite structure with network connections, nanometer layered graphene is uniformly distributed on a ceramic matrix to form the nanometer composite structure, the nanometer composite structure is conductive to strengthening of strength of the ceramic and endows the ceramic with the functional characteristics of semiconductor, electric conduction, heat conduction, electrochemistry, and the like, and the composite material can be used for developing sensors, electromagnetic shielding, electric heating devices, heat conduction materials, energy-storage electrodes, and the like and is used for the fields of aerospace, electronics, chemical engineering and energy sources. The graphene and oxide ceramic composite material is formed by one step in the sintering process, does not need the processes of functionalizing, mixing and the like, is simple in preparation process and is suitable for large-scale production.

Owner:TIANJIN UNIV

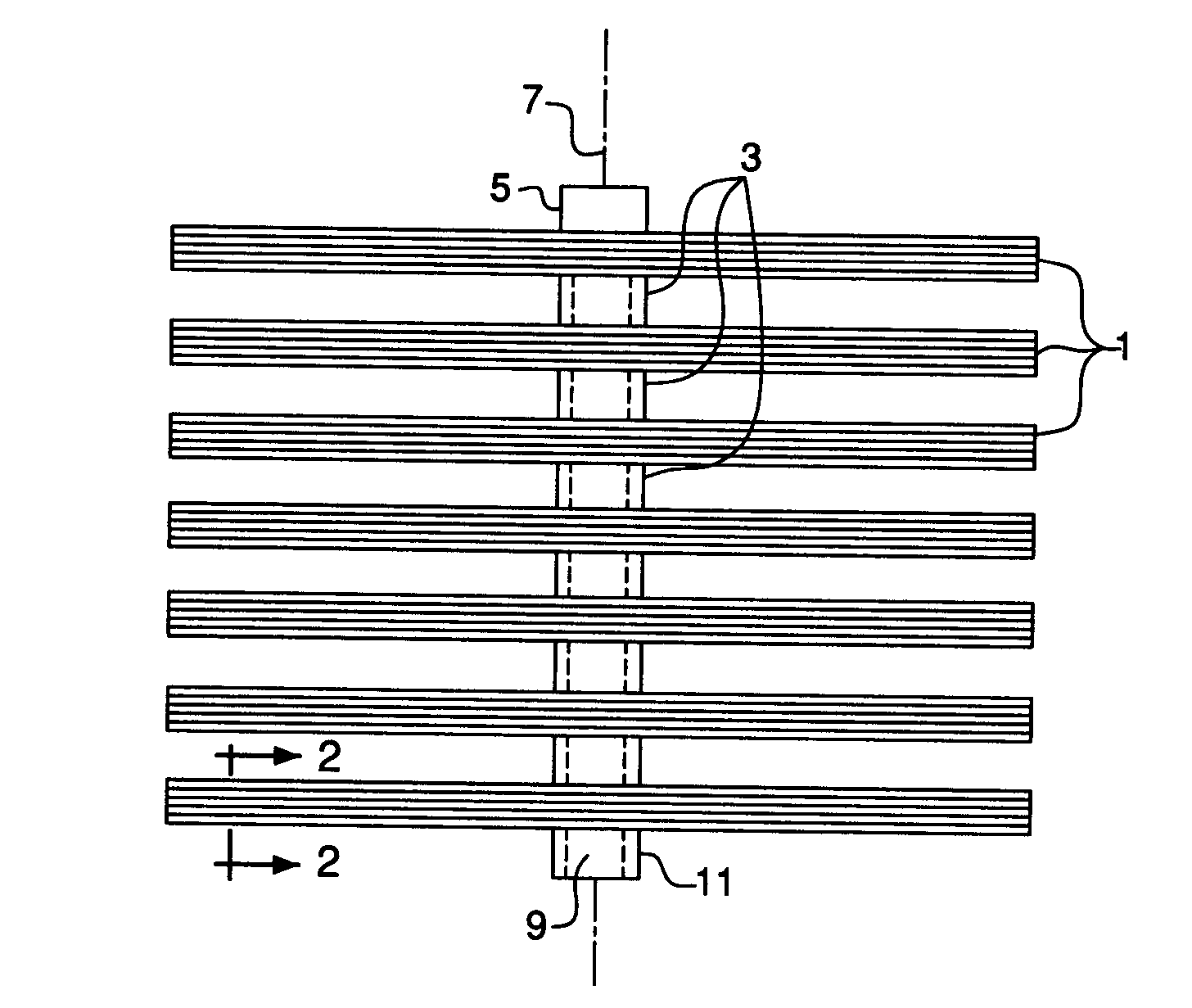

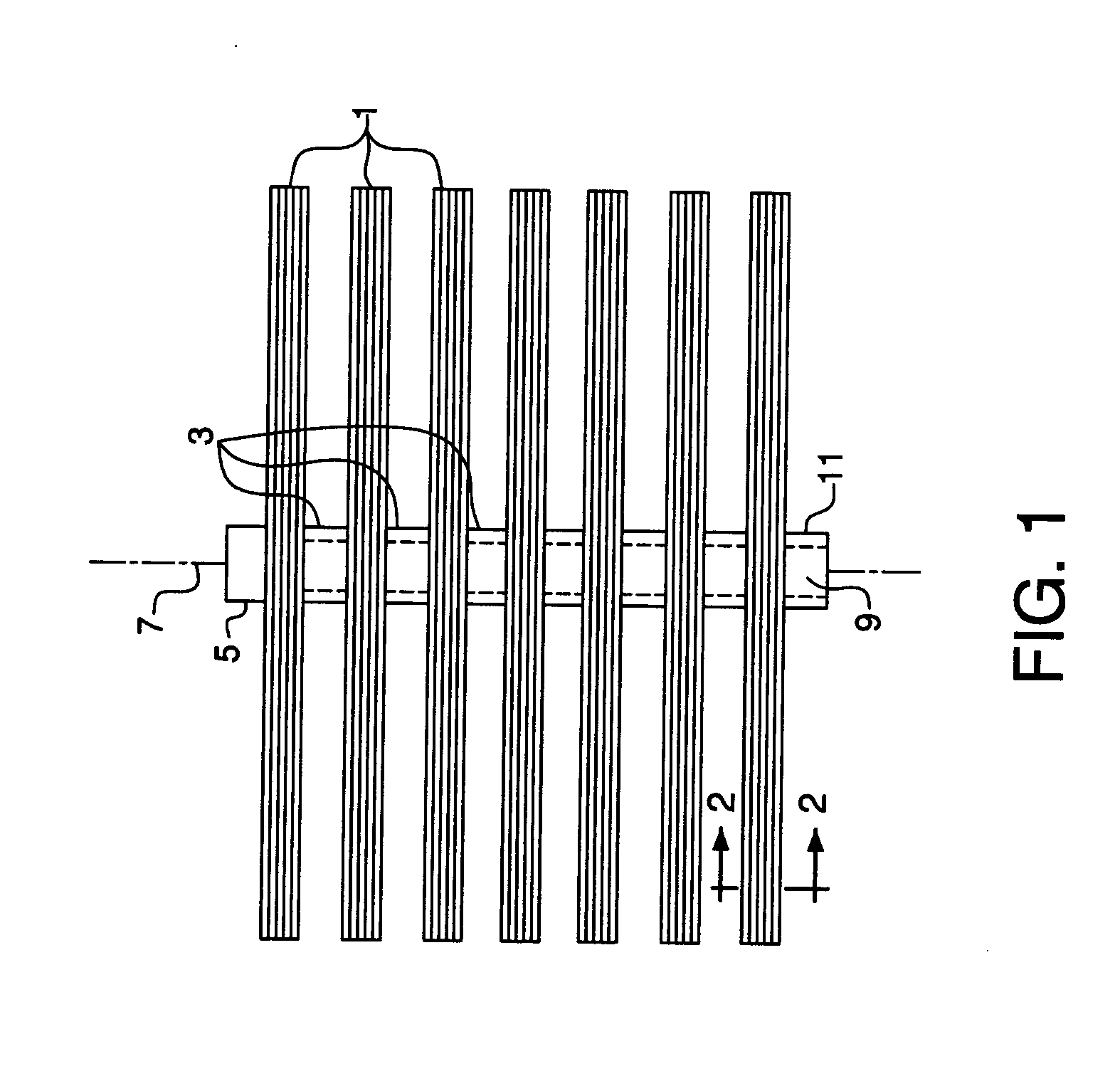

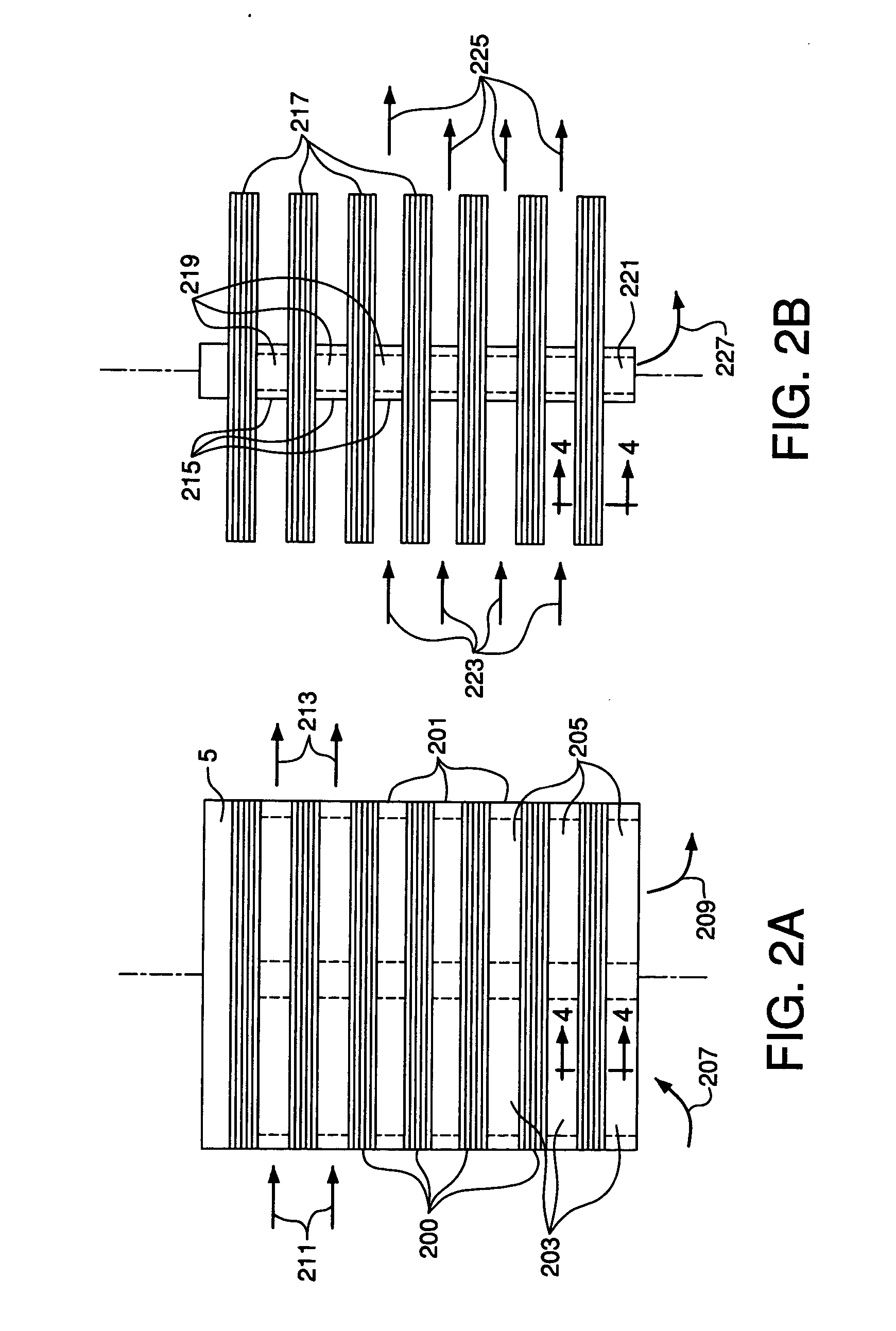

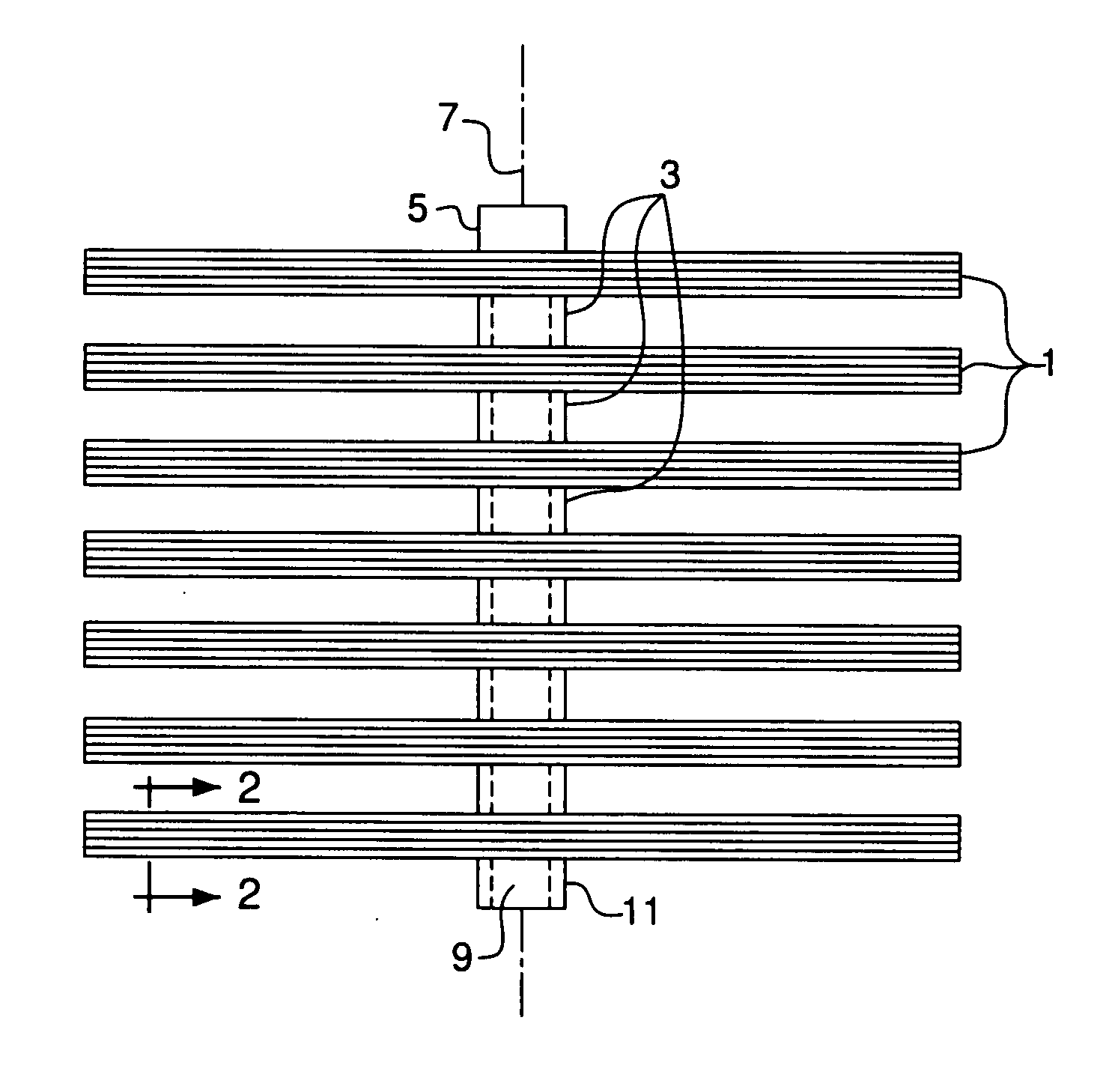

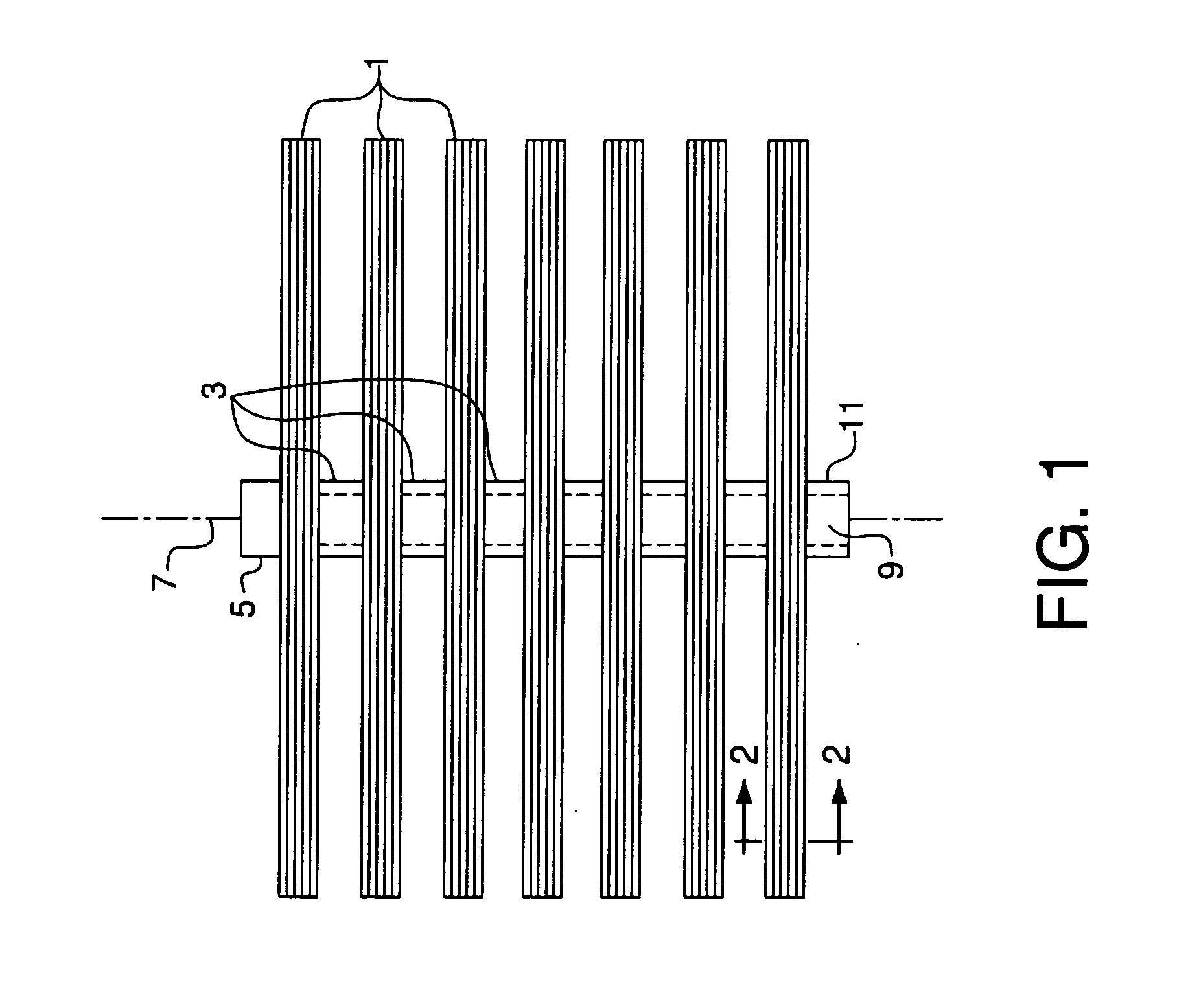

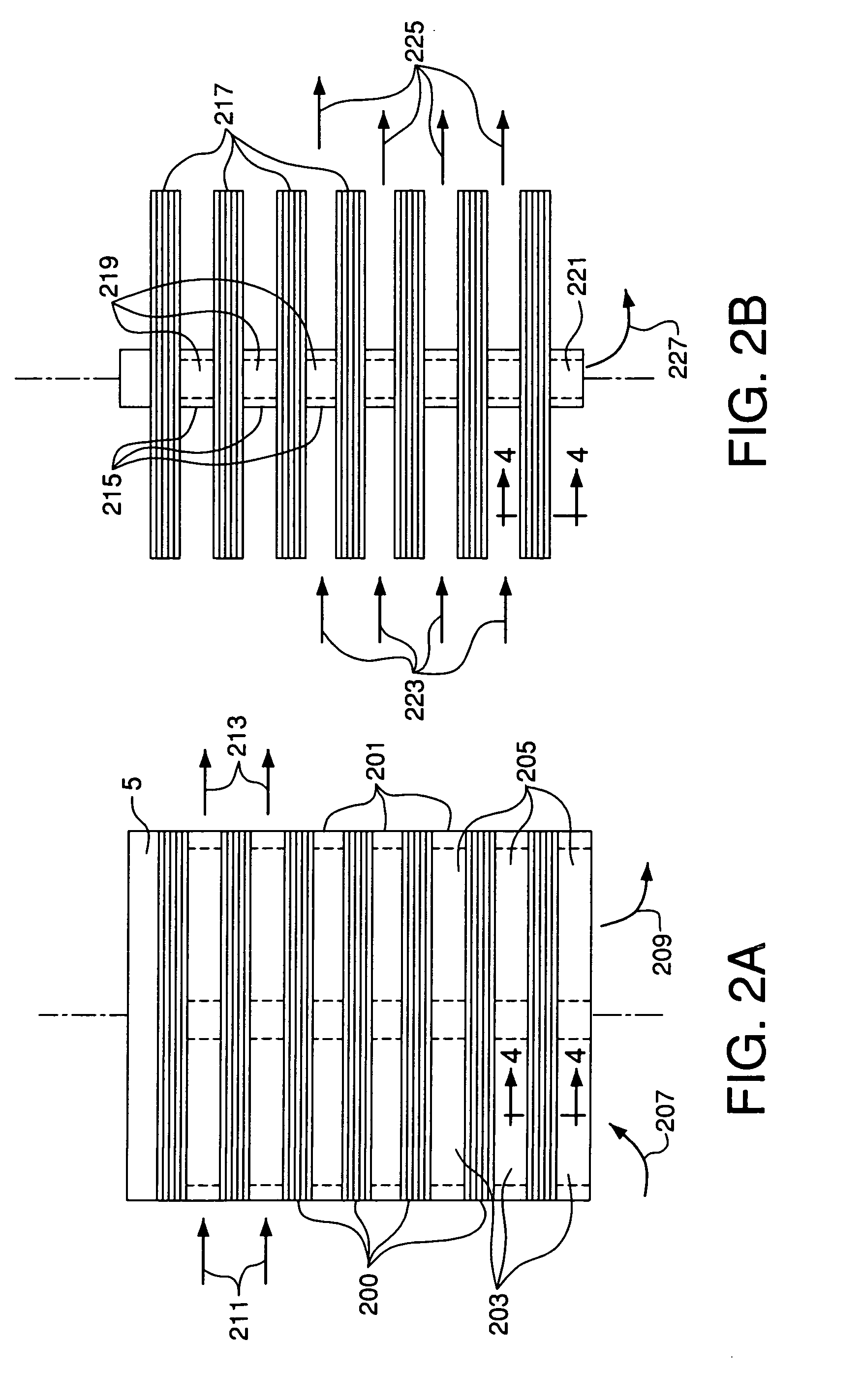

Ion transport membrane module and vessel system

An ion transport membrane system comprising (a) a pressure vessel having an interior, an exterior, an inlet, and an outlet; (b) a plurality of planar ion transport membrane modules disposed in the interior of the pressure vessel and arranged in series, each membrane module comprising mixed metal oxide ceramic material and having an interior region and an exterior region, wherein any inlet and any outlet of the pressure vessel are in flow communication with exterior regions of the membrane modules; and (c) one or more gas manifolds in flow communication with interior regions of the membrane modules and with the exterior of the pressure vessel. The ion transport membrane system may be utilized in a gas separation device to recover oxygen from an oxygen-containing gas or as an oxidation reactor to oxidize compounds in a feed gas stream by oxygen permeated through the mixed metal oxide ceramic material of the membrane modules.

Owner:AIR PROD & CHEM INC

Multi-layer ring seal

Aspects of the invention are directed to a multi-layer ring seal segment that can incorporate a plurality of material systems. The ring seal segment can include an inner layer, a central layer and an outer layer. The inner layer can be attached to one side of the central layer, and the outer layer can be attached to an opposite side of the central layer. The inner and outer layers can be made of a ceramic matrix composite, such as a hybrid oxide ceramic matrix composite or an oxide-oxide ceramic matrix composite. The central layer can be made of a material that has high shear strength relative to the inner and outer layers. The ring seal segment according to aspects of the invention can take advantage of the benefits of the different materials so as to better withstand the operational loads of the turbine.

Owner:SIEMENS ENERGY INC

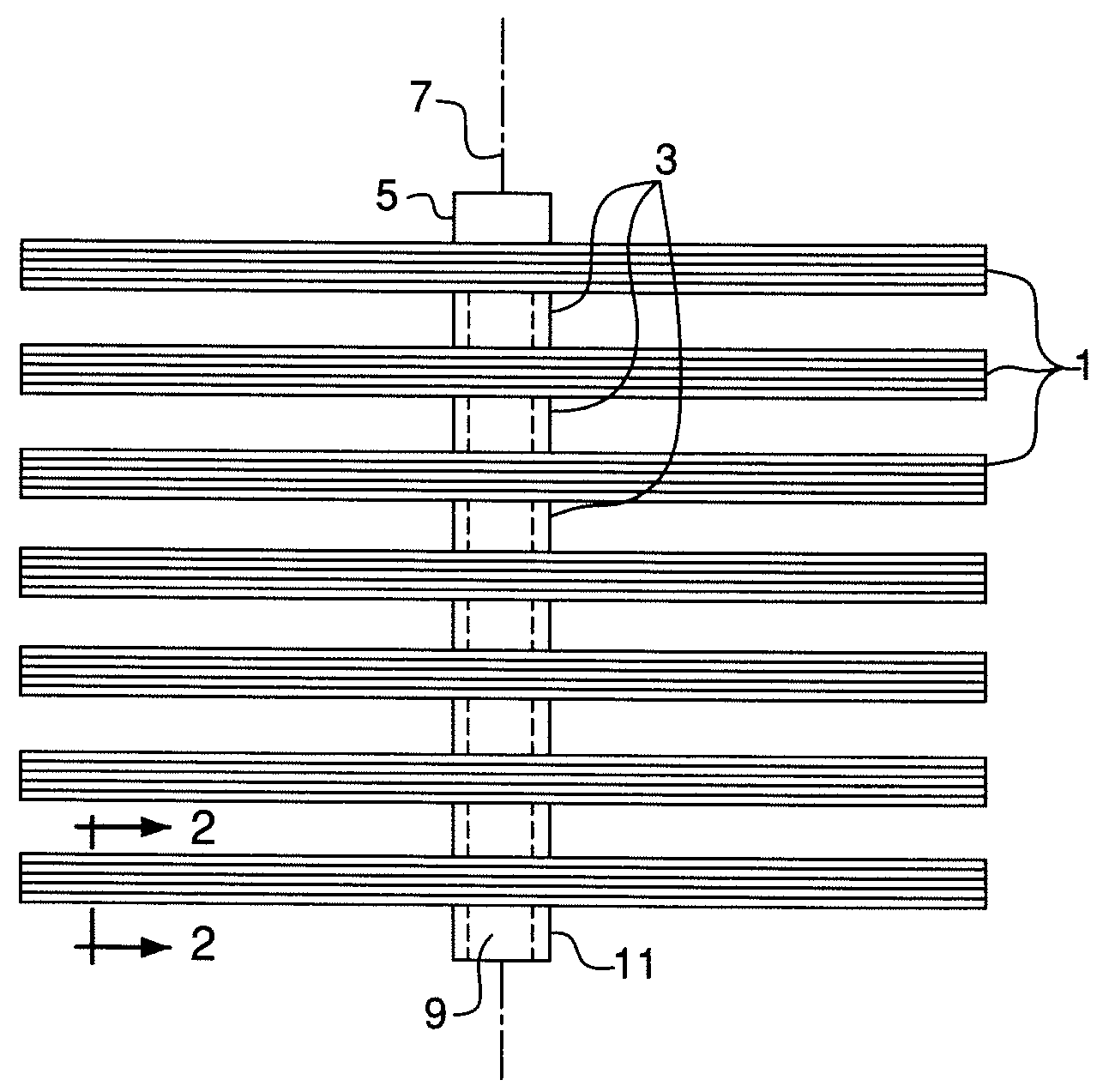

Liners For Ion Transport Membrane Systems

Ion transport membrane system comprising (a) a pressure vessel comprising an interior, an exterior, an inlet, an inlet conduit, an outlet, and an outlet conduit; (b) a plurality of planar ion transport membrane modules disposed in the interior of the pressure vessel and arranged in series, each membrane module comprising mixed metal oxide ceramic material and having an interior region and an exterior region, wherein the inlet and the outlet of the pressure vessel are in flow communication with exterior regions of the membrane modules; (c) a gas manifold having an interior surface wherein the gas manifold is in flow communication with the interior region of each of the planar ion transport membrane modules and with the exterior of the pressure vessel; and(d) a liner disposed within any of the inlet conduit, the outlet conduit, and the interior surface of the gas manifold.

Owner:AIR PROD & CHEM INC

Ion transport membrane module and vessel system with directed internal gas flow

An ion transport membrane system comprising (a) a pressure vessel having an interior, an inlet adapted to introduce gas into the interior of the vessel, an outlet adapted to withdraw gas from the interior of the vessel, and an axis; (b) a plurality of planar ion transport membrane modules disposed in the interior of the pressure vessel and arranged in series, each membrane module comprising mixed metal oxide ceramic material and having an interior region and an exterior region; and (c) one or more gas flow control partitions disposed in the interior of the pressure vessel and adapted to change a direction of gas flow within the vessel.

Owner:AIR PROD & CHEM INC +1

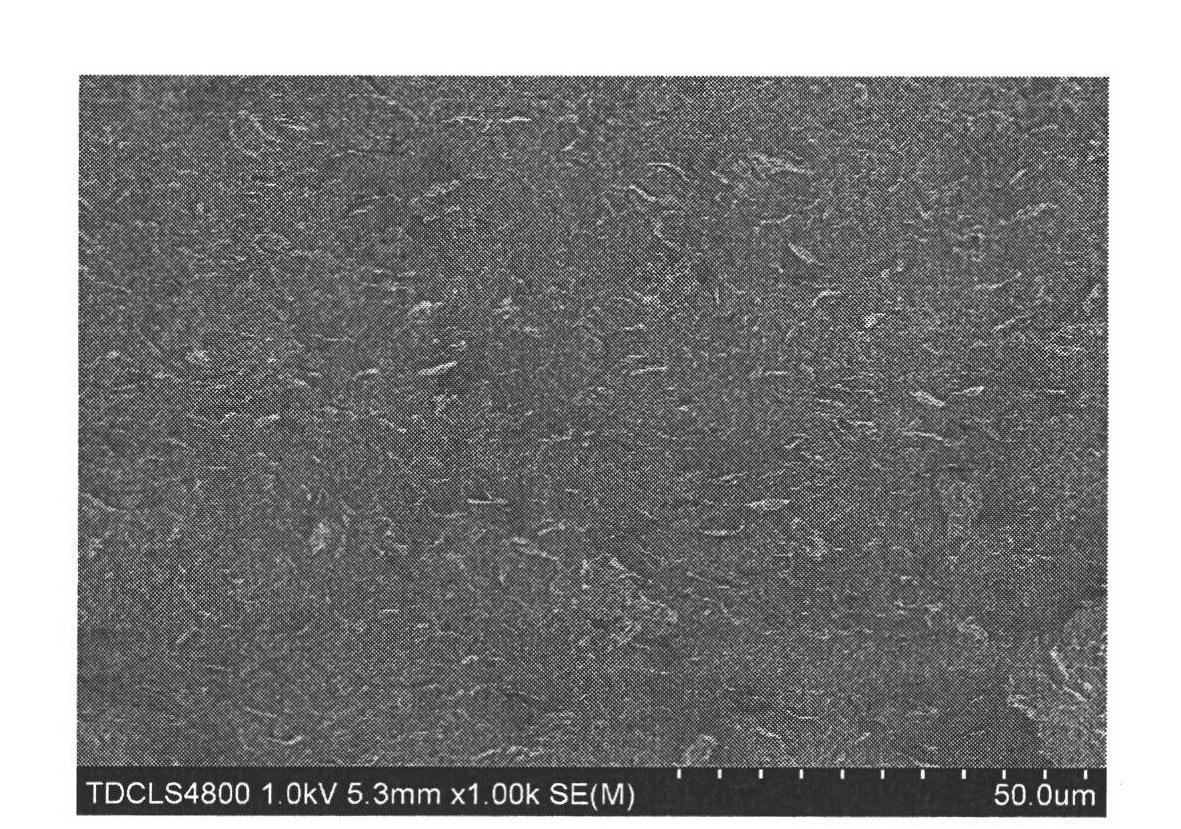

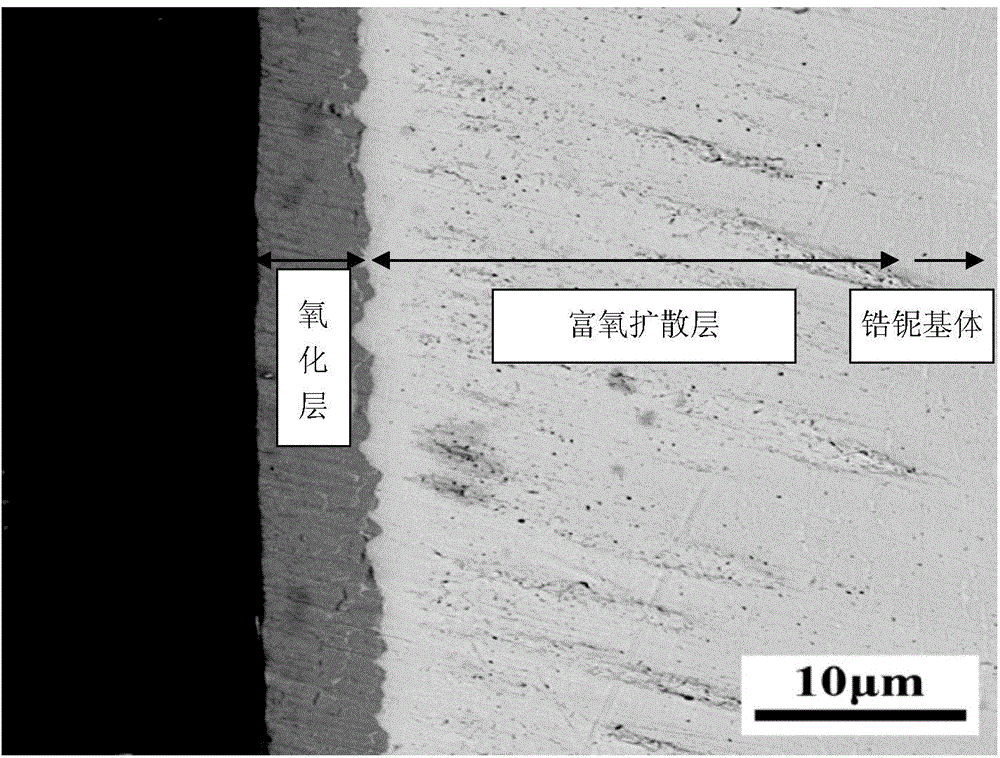

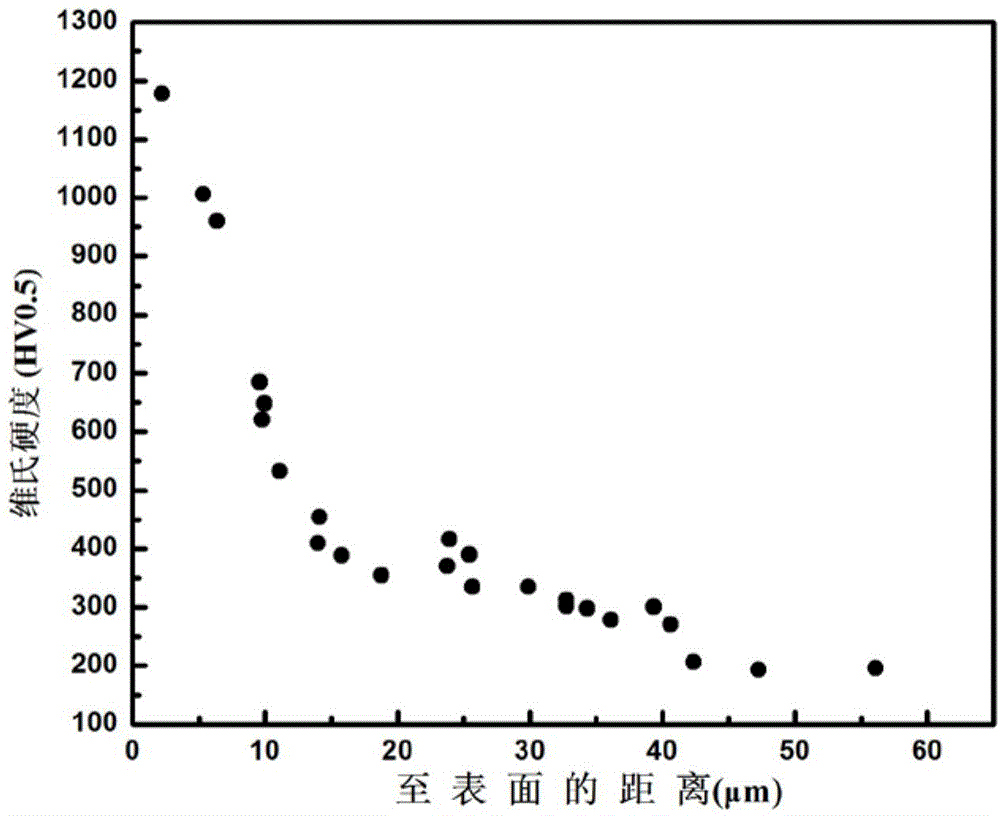

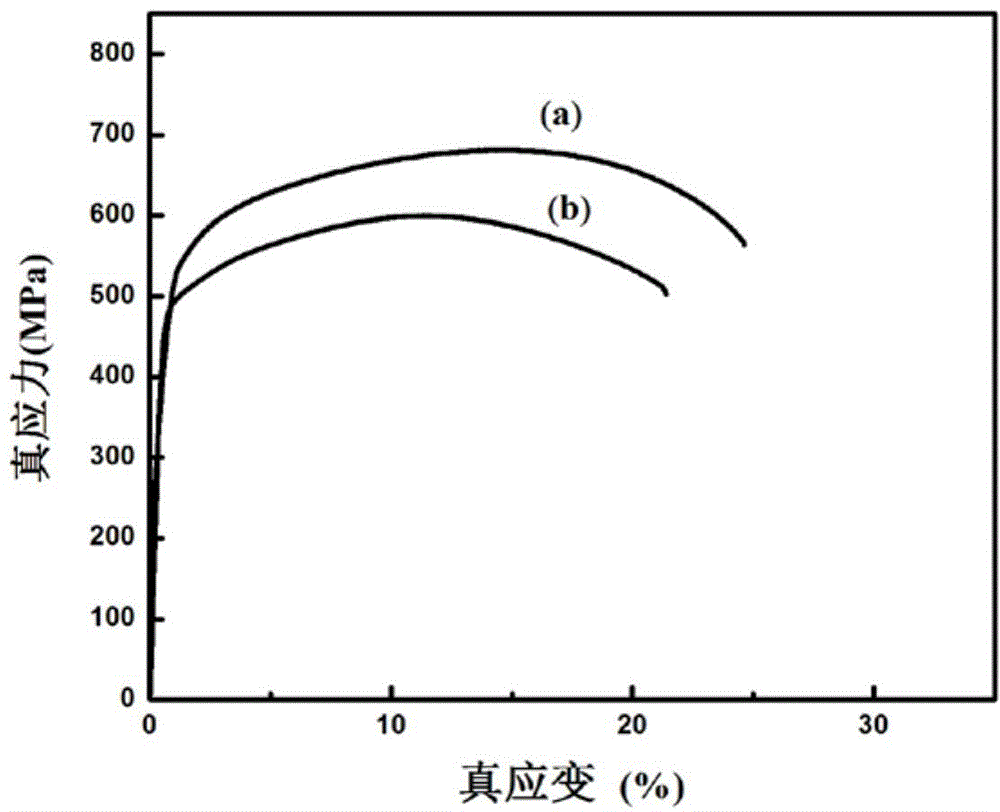

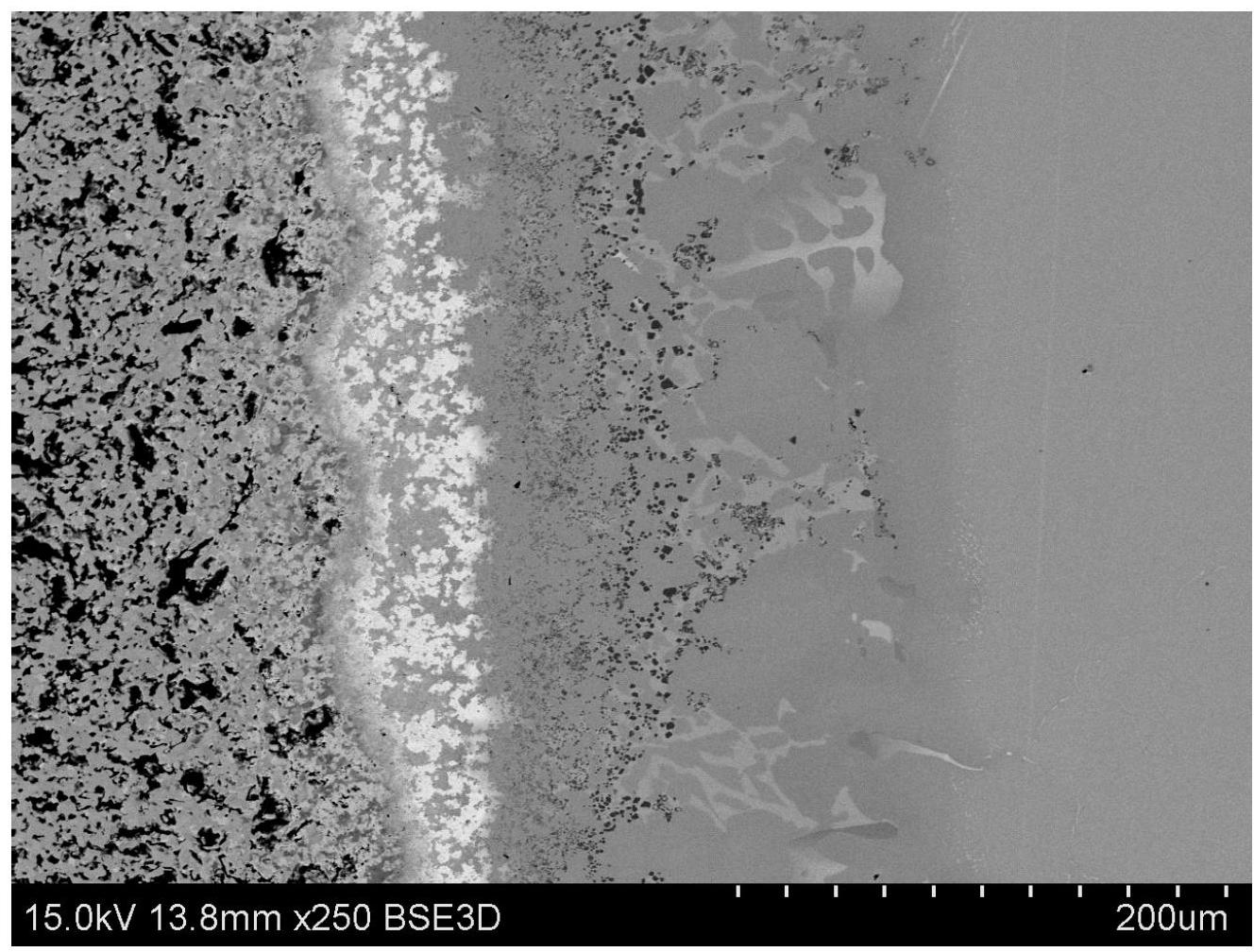

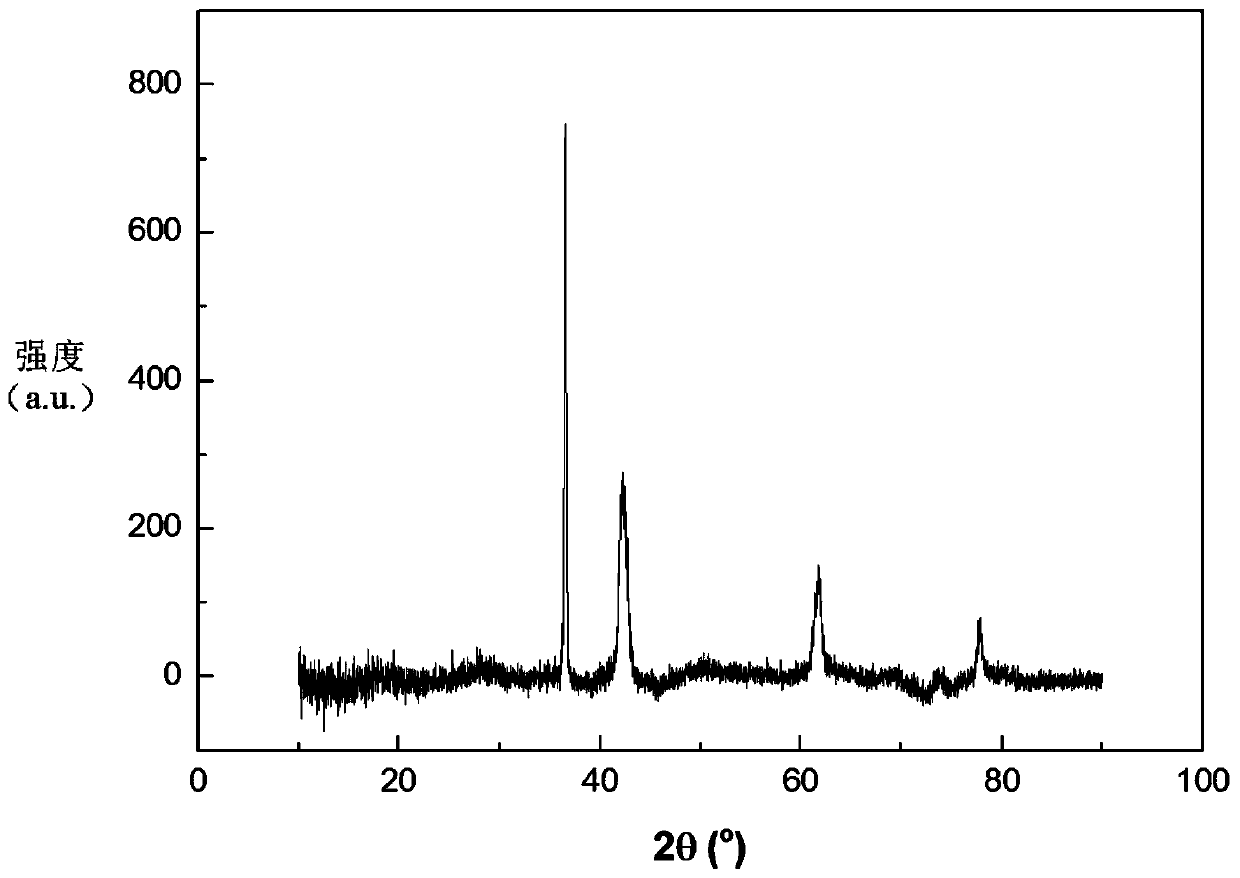

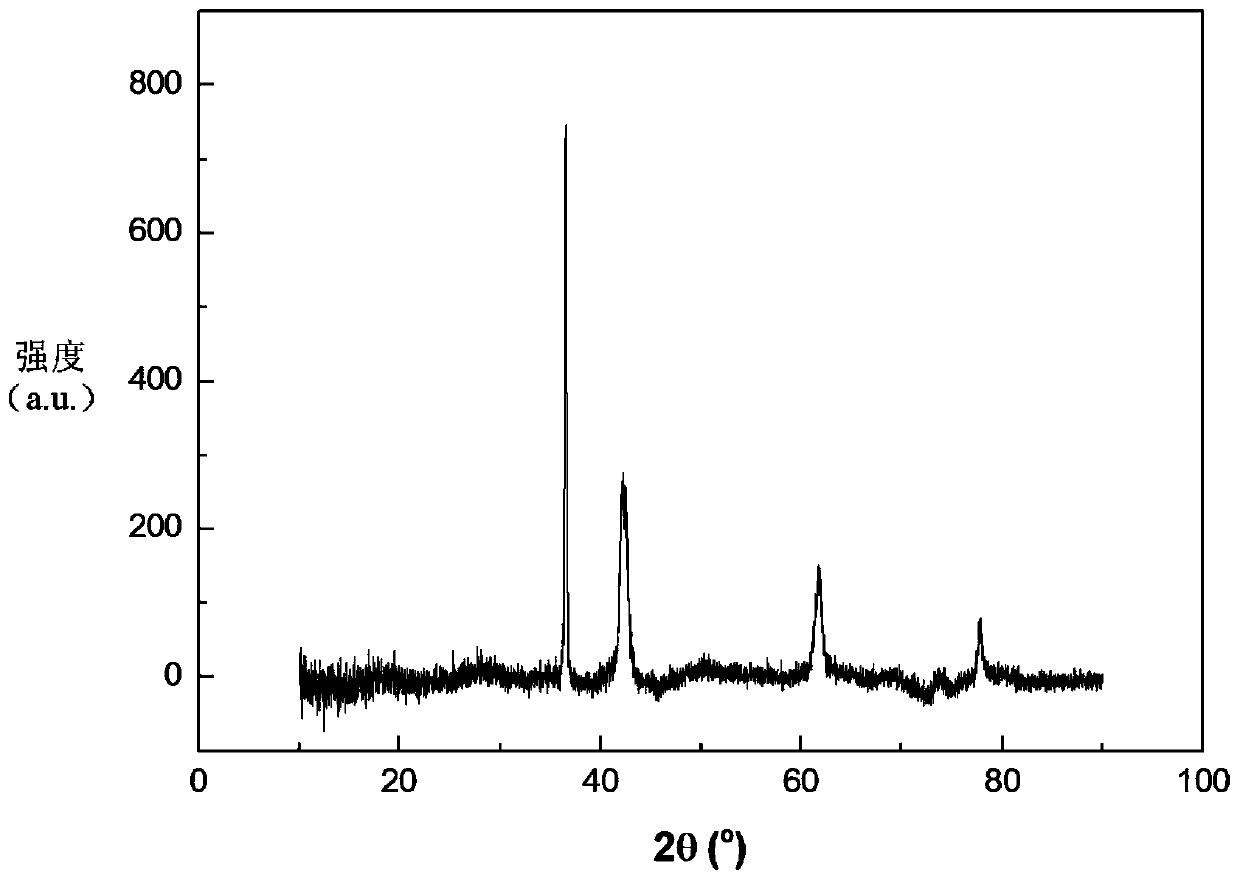

High-wear-resistance and high-tenacity medical zirconium alloy and preparation method and application thereof

The invention belongs to the technical field of high-performance medical alloy materials and particularly relates to a medical zirconium alloy high in surface wear resistance and integral tenacity and a preparation method and application thereof. The surface of the medical zirconium alloy is provided with a micron-level thick oxide ceramic layer is mainly composed of nonoclinic-system zirconia and a small amount of tetragonal-system zirconia; the matrix of the medical zirconium alloy is zirconium alloy, which is specifically composed of, by weight percentage, 76.5-100 wt.% of Zr, 0-19 wt.% of Nb, 0-4.5 wt.% of Hf and inevitable trace impurities as balance; an oxygen-enriched transition layer is arranged between the oxide ceramic layer and the matrix alloy, namely, oxygen is dissolved inside the matrix to form zirconium-oxygen solid solution. The high-wear-resistance and high-tenacity medical zirconium alloy combines the plastic deformation technology and the high-temperature oxidation technology and greatly improves the surface hardness, the wear resistance and the alloy strength, thereby having a broad application prospect in biomedicine, particularly in the aspect of biomedical implants.

Owner:SOUTH CHINA UNIV OF TECH

Ion transport membrane module and vessel system

An ion transport membrane system comprising (a) a pressure vessel having an interior, an exterior, an inlet, and an outlet; (b) a plurality of planar ion transport membrane modules disposed in the interior of the pressure vessel and arranged in series, each membrane module comprising mixed metal oxide ceramic material and having an interior region and an exterior region, wherein any inlet and any outlet of the pressure vessel are in flow communication with exterior regions of the membrane modules; and (c) one or more gas manifolds in flow communication with interior regions of the membrane modules and with the exterior of the pressure vessel. The ion transport membrane system may be utilized in a gas separation device to recover oxygen from an oxygen-containing gas or as an oxidation reactor to oxidize compounds in a feed gas stream by oxygen permeated through the mixed metal oxide ceramic material of the membrane modules.

Owner:AIR PROD & CHEM INC

High-entropy brazing filler metal for brazing non-oxide ceramics and non-oxide ceramic composite material and preparation method of brazing filler metal

ActiveCN102689109AImprove performanceGood compatibilityWelding/cutting media/materialsSoldering mediaNon oxide ceramicsCeramic composite

The invention relates to a high-entropy brazing filler metal and a preparation method thereof, and particularly relates to a high-entropy brazing filler metal for brazing non-oxide ceramics and the composite material of the non-oxide ceramics and the preparation method of the brazing filler metal, aiming to solve the problem that the brazing filler metal at the joint of the non-oxide ceramics and the ceramic composite material which are soldered together is unreliable in performance at a temperature higher than 500 DEG C in the prior art. The brazing filler metal comprises the following components in parts by weight: 18 to 24 parts of Ni, 14.3 to 19 parts of Cr, 16.8 to 22.5 parts of Co, 15.9 to 21 parts of Fe, 10.1 to 13.5 parts of Cu, and 0 to 24.9 parts of Ti or TiH2. The preparation method comprises the following steps of: carrying out vacuum melting on the weighed components at the temperature of 1200 to 1800 DEG C, performing linear cutting and carrying out foiling or composite tabletting on the components, so as to obtain the brazing filler metal; or the preparation method comprises the following steps of: carrying out ball-milling on the components in a ball material mass ratio of (12-16):1, and then tabletting and cleaning the components to obtain the brazing filler metal. The strength of the alloy joint obtained by using the method reaches 35 to 71 MPa, and the strength retention of the alloy joint at a high temperature of 800 DEG C exceeds 67%.

Owner:HARBIN INST OF TECH

Method for preparing porous implant through gelcasting 3D printing and electroreduction

ActiveCN106421904AAchieve forming controlConvenient treatmentPharmaceutical delivery mechanismCoatingsOxide ceramicElectrolysis

The invention discloses a method for preparing a porous implant through gelcasting 3D printing and electroreduction. The preparation method comprises steps as follows: according to the human body features of a to-be-implanted part, a personalized gradient porous implant negative-type mold adopting a microstructure is designed by the aid of a medical image data reverse solution model; a gradient porous implant negative-type resin mold is prepared through photo-curing forming equipment; metal oxide ceramic slurry is injected into the negative-type resin mold through a gel injection mold and sintered at the high temperature, and a metal oxide ceramic porous scaffold is obtained; a primary porous metal implant is produced through molten salt in-situ reduction; a metal coating is deposited on the surface of the primary porous metal implant with a chemical vapor deposition method. The defects that implants with complex shapes, precise sizes and uncontrollable microstructures cannot be produced with a traditional porous implant preparation method are overcome, structure nanosizing can be realized, and a new way for preparing the porous implant is expected to be developed.

Owner:XI AN JIAOTONG UNIV

Method for fabrication of hermetic electrical conductor feedthroughs

InactiveUS7818876B2Improve bindingImprove air tightnessPrinted circuit assemblingLine/current collector detailsOxide ceramicElectrical conductor

A method is disclosed for the fabrication of feedthrough devices that can transmit a single or plurality of electrical signal(s) to or from within a leak-tight (hermetic) chamber from or to the outside of said leak-tight (hermetic) chamber. The invention allows materials known to be well-tolerated within the human body such as alumina-oxide ceramic and platinum to be used as raw materials in the fabrication of body-compatible, single or multi-channel leak-tight (hermetic) feedthroughs.

Owner:NEWSOUTH INNOVATIONS PTY LTD

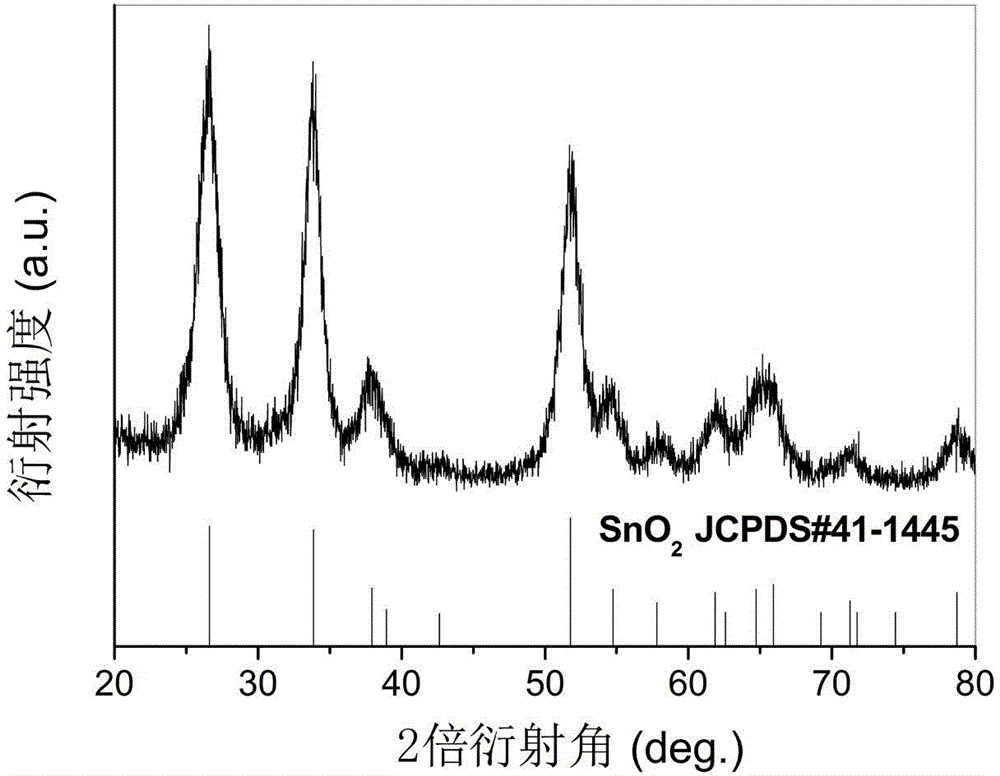

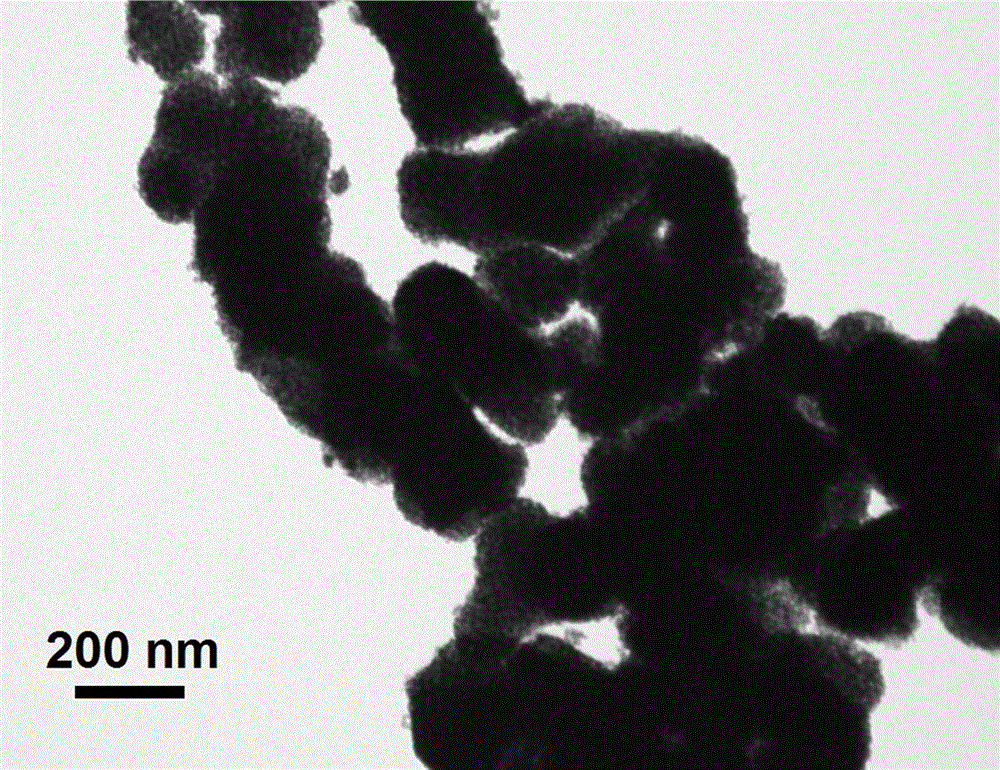

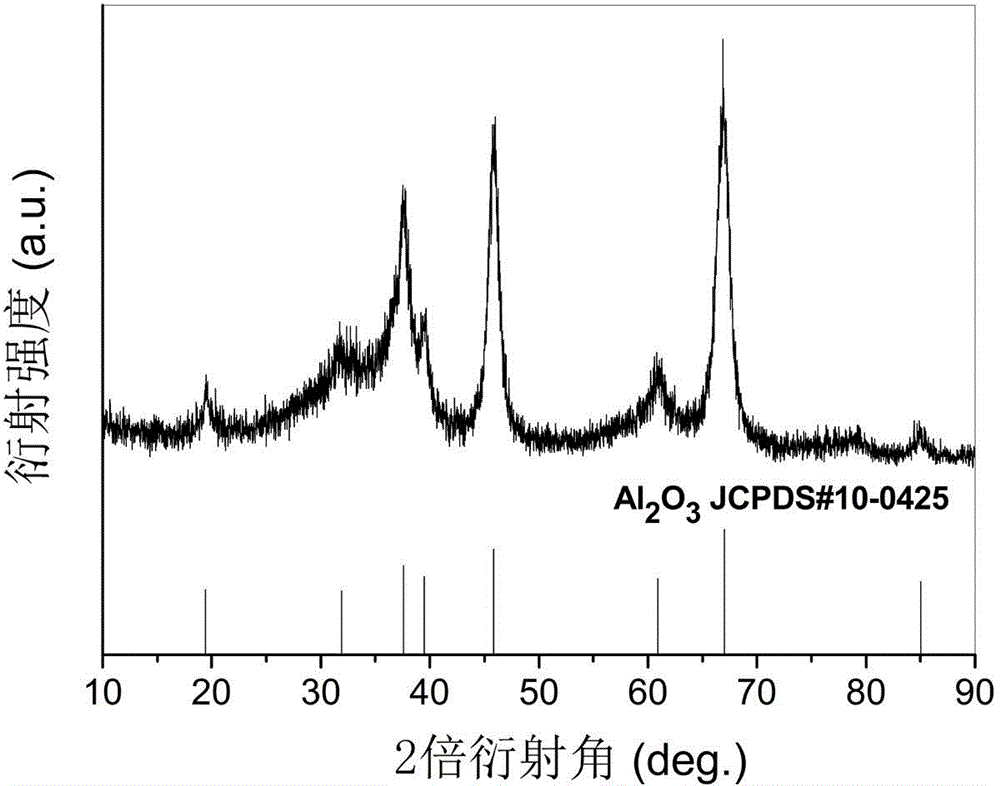

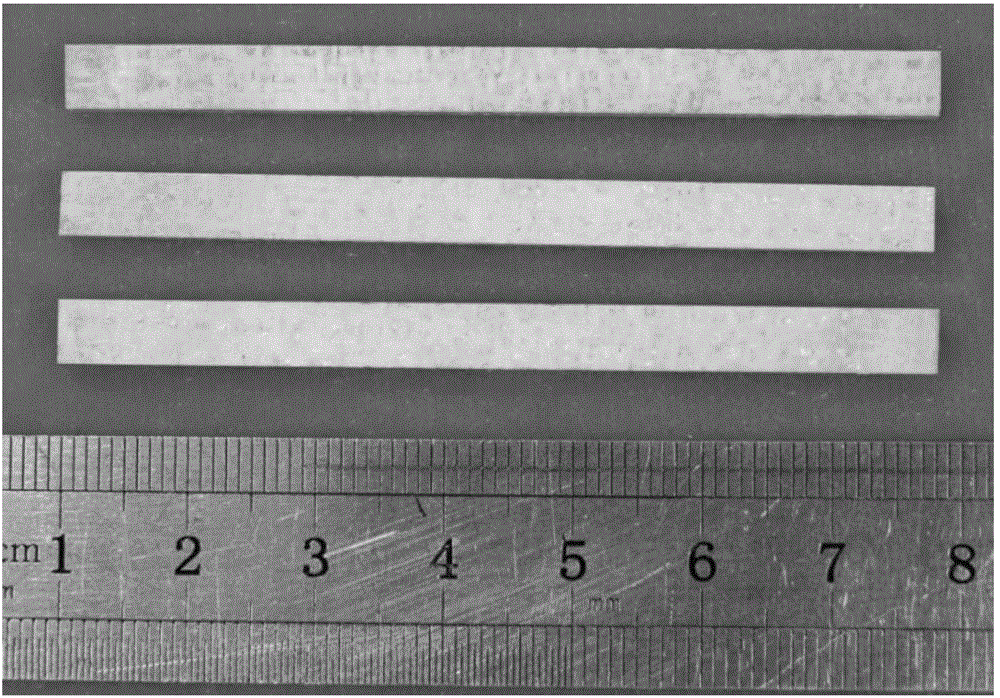

Tin oxide alumina-based low-concentration acetone gas sensor and preparation method thereof

InactiveCN104820068ALow detection limitResponse recovery time is shortMaterial analysisOxide ceramicPhysical chemistry

The invention relates to a preparation method of a low-concentration acetone gas sensor, and belongs to the technical field of preparation processes of metal oxide semiconductor gas sensors. The gas sensor is mainly characterized in that double layers of nanometer sensitive materials with porous structures are coated on the surface of an aluminum oxide ceramic pipe, an inner substrate material is Pt doped nanometer porous SnO2, and an outer sensitizing material is nanometer porous Al2O3. After a gas-sensitive element coating the Pt doped porous SnO2 substrate material is roasted for 2 hours at the temperature of 500 DEG C, the porous Al2O3 sensitizing material is uniformly coated on the outer surface of the gas-sensitive element, and the gas-sensitive element is welded according to a thick-film semiconductor gas-sensitive element manufacturing process after dried at the indoor temperature (comprises a platinum wire and a nickel-cadmium heating wire in a cavity of a ceramic pipe), aged and packaged to make the low-concentration acetone gas sensor. The made sensor has the advantages of low detection limit, fast response and recovery, fine stability and the like for acetone gas.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

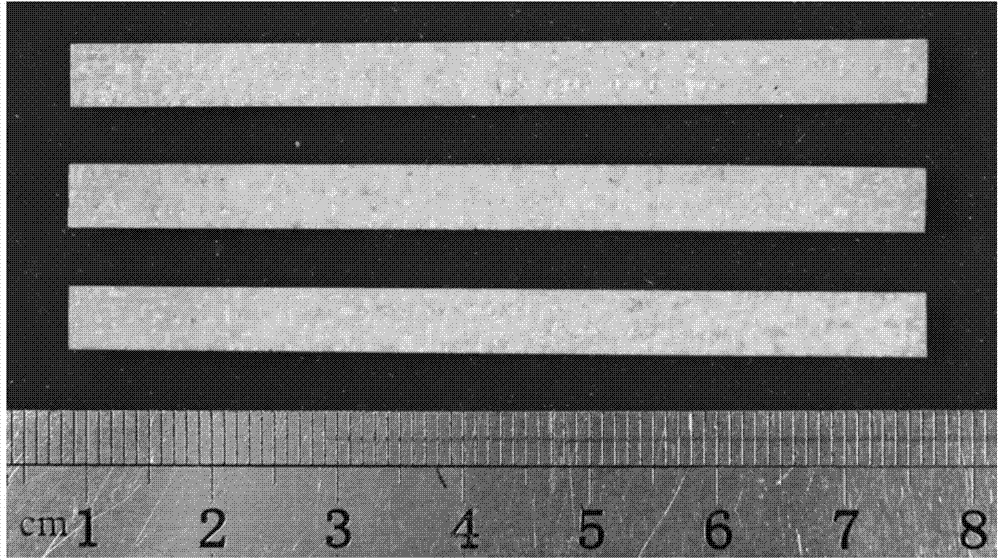

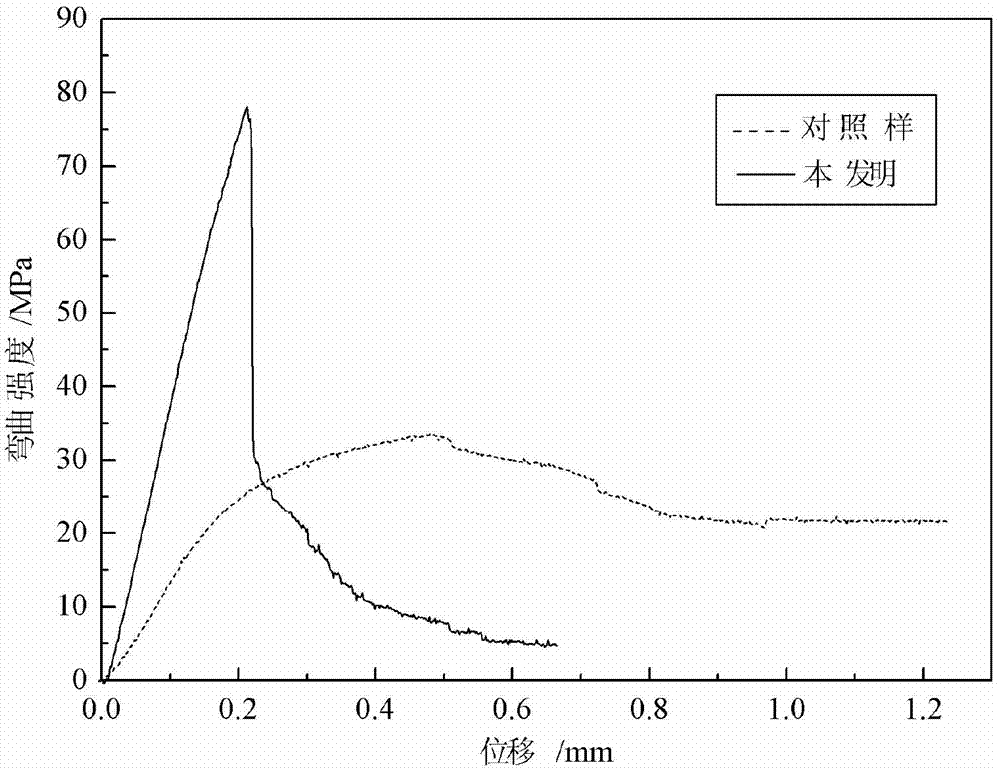

Aluminum silicate fiber reinforced oxide ceramic and preparation method thereof

The invention relates to aluminum silicate fiber reinforced oxide ceramic. The aluminum silicate fiber reinforced oxide ceramic adopts one or a mixture of more of mullite, aluminum silicate, aluminum oxide and silicon oxide as a ceramic substrate and adopts aluminum silicate fiber as a reinforcing phase. The preparation method comprises the steps: carrying out heat treatment for an aluminum silicate fiber fabric, and removing adhesive on the surface of the fiber; taking oxide sol as a precursor, vacuum impregnating the pretreated aluminum silicate fiber fabric, then carrying out the gelatination, carrying out high-temperature ceramization, and completing primary compacting process; repeating the steps for at least ten times, so as to prepare the aluminum silicate fiber reinforced oxide ceramic. The product is excellent in mechanical property and antioxidant property and has the advantages of short preparation period, low cost, capability of realizing near-net shape and the like.

Owner:NAT UNIV OF DEFENSE TECH

Three-dimensional alumina fiber fabric reinforced oxide ceramic and preparation method thereof

The invention discloses three-dimensional alumina fiber fabric reinforced oxide ceramic. Al2O3, SiO2 and SiOC ceramics are used as a substrate, a three-dimensional alumina fiber fabric is used as a reinforcing body, alumina and silicon dioxide in the substrate are introduced by a sol-gel process, and the SiOC ceramic is obtained by high-temperature cracking of polysiloxane. The preparation method of the three-dimensional alumina fiber fabric reinforced oxide ceramic comprises the following steps: performing vacuum soaking, gelating and high-temperature ceramic treatment on oxide sol serving as a precursor, and repeating for multiple times to obtain an alumina fiber reinforced oxide blank body; soaking the blank body in vacuum by using a polysiloxane-ethanol solution as a precursor, and performing crosslinking and high-temperature ceramic treatment to complete a densifying process; and repeating the steps for multiple times to obtain the oxide ceramic blank body, and oxidizing to prepare the three-dimensional alumina fiber fabric reinforced oxide ceramic. The three-dimensional alumina fiber fabric reinforced oxide ceramic has the advantages of high bending strength, high modulus, good interlaminar shear strength and the like.

Owner:NAT UNIV OF DEFENSE TECH

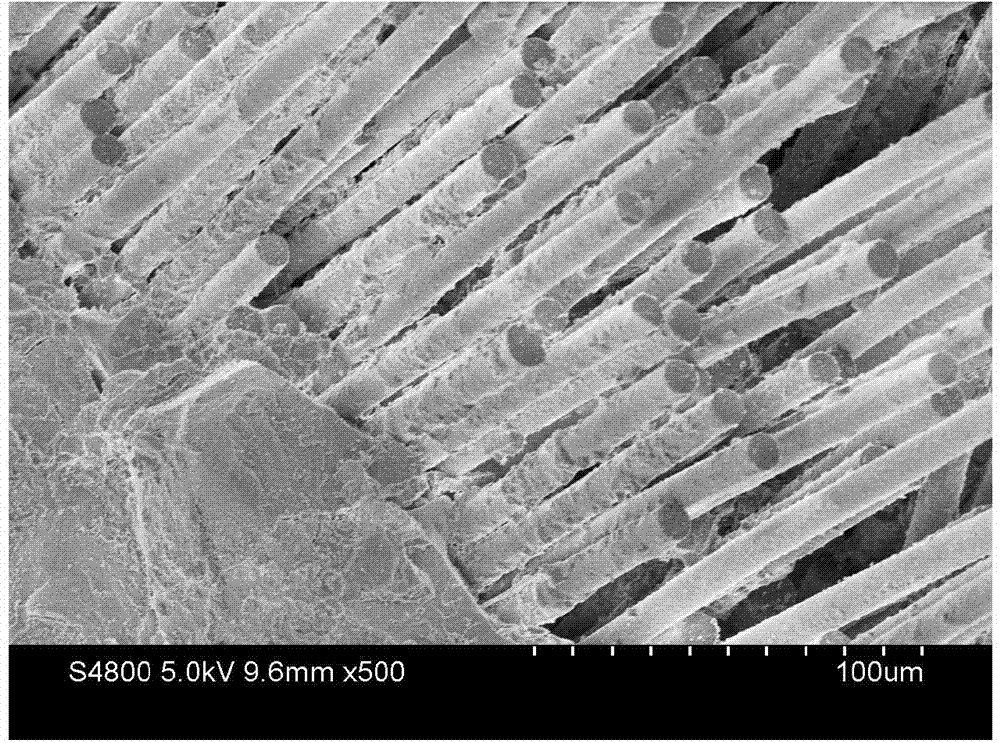

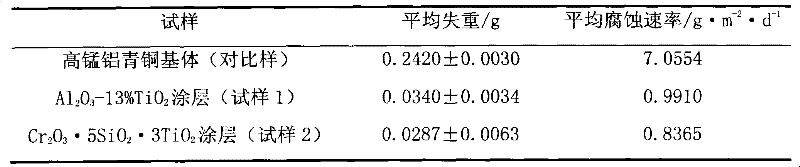

Method for preventing corrosion and marine creature fouling on ship propeller

InactiveCN102336256ASolve corrosiveSolve the defacementVessel cleaningMolten spray coatingOxide ceramicThermal spraying

The invention relates to a method for preventing corrosion and marine creature fouling on a ship propeller. Cathode protection, a ceramic insulating coating and a metallic antifouling coating are organically combined in the method. The method comprises the following steps of: removing scales on the surface of the copper alloy propeller, obtaining a uniform and rough surface, and spraying a metallic adhesive coating by adopting a thermal spraying method; preparing a metallic oxide ceramic insulating coating on the surface of the adhesive coating by adopting the thermal spraying method, wherein the ceramic insulating coating comprises single-component oxides such as Al2O3, Cr2O3 and the like and multi-component composite powder of TiO2 or SiO2 with low melting point; preparing the metallic antifouling coating on the ceramic insulating coating, wherein the metallic antifouling coating is made of pure copper or copper alloy with antifouling function; and meanwhile, performing cathode protection on the propeller. The ceramic and the metallic coating adopted in the method have higher bonding force and longer protection life, the current requirement of the ship cathode protection is reduced, the corrosion and marine creature fouling problems of the ship propeller can be simultaneously solved, and the ceramic and the metallic coating have obvious corrosion resistance and antifouling effect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

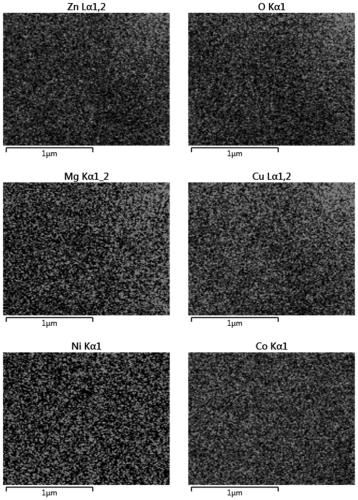

Preparation method of high-entropy oxide ceramic

The invention discloses a preparation method of high-entropy oxide ceramic. The method comprises the following steps that 1, according to metal atom mole ratio being 1:1:1:1 or 1:1:1:1:1, four or fiveor less kinds of metal oxide powder are weighed; the oxide powder includes MgO, ZnO, NiO, CuO, CaO, CoO, ZrO2, CeO2, Al2O3, Gd2O3, La2O3, Er2O3, Y2O3, Fe2O3, Co3O4 and CaCO3; 2, powder weighed in step 1 is subjected to ball milling, drying and granulation; 3, granulated powder is pressed and molded to form a green body; 4, the green body obtained in step 3 is subjected to thermal treatment; 5, the green body obtained after thermal treatment in step 4 is heated to the preset temperature, an electric field of the preset electric field intensity is applied to a sample, after flash-burning appears, a power source is converted from the constant voltage state to the constant current state, the temperature is kept constant for 1-60 min under the preset current density, and then quenching is performed to obtain the needed high-entropy oxide ceramic. The flash-burning is adopted for preparing the high-entropy oxide ceramic, the sintering temperature is remarkably lowered, and the sintering time is remarkably shortened.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method of magnesium oxide foam ceramic filter for filtering magnesium and magnesium alloy melt

InactiveCN101785944BHigh strengthImprove adhesionFiltration separationProcess efficiency improvementOxide ceramicWater based

The invention provides a magnesium oxide ceramic foam filter for filtering a magnesium and magnesium alloy melt and a preparation method thereof, relating to the field of metallurgy. The process is as follows: a polyurethane foam template is soaked in sodium hydroxide solution (10%) for 30 minutes under the temperature of 50 DEG C and is then washed by water and dried; electric-melting magnesium oxide, magnesium fluoride and water are mixed in a ball-milling manner according to the mass ratio so as to obtain water-based dispersion slurry; the polyurethane foam template is soaked in the slurry, and bisque is obtained through repeated slurry dipping and centrifugal slurry throwing; the bisque is put into an oven; finally, the dried bisque is put into a high-temperature furnace, is heated to 1,200 to 1,300 DEG C at the speed of 1 to 3 DEG C / min, is heat-preserved for 2 hours, and is then naturally cooled in a furnace body. An obtained product of the invention has good chemical stability in the magnesium and the magnesium alloy melt, does not pollute the magnesium and the magnesium alloy melt, has good functions of absorbing and filtering nonmetallic inclusions in the magnesium and the magnesium alloy melt, and is suitable for filtering as well as purifying the magnesium and the magnesium alloy melt.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Thin, fine grained and fully dense glass-ceramic seal for sofc stack

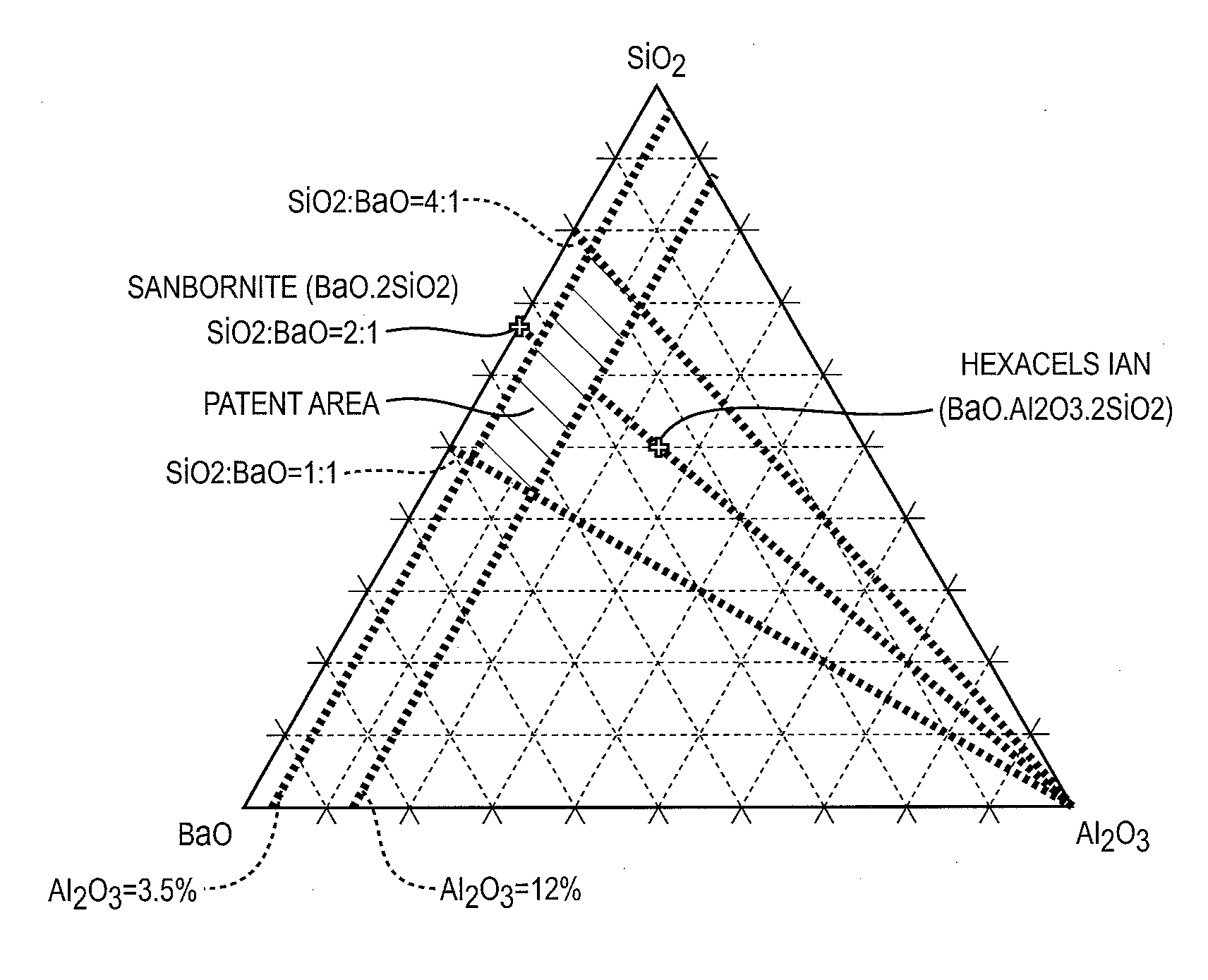

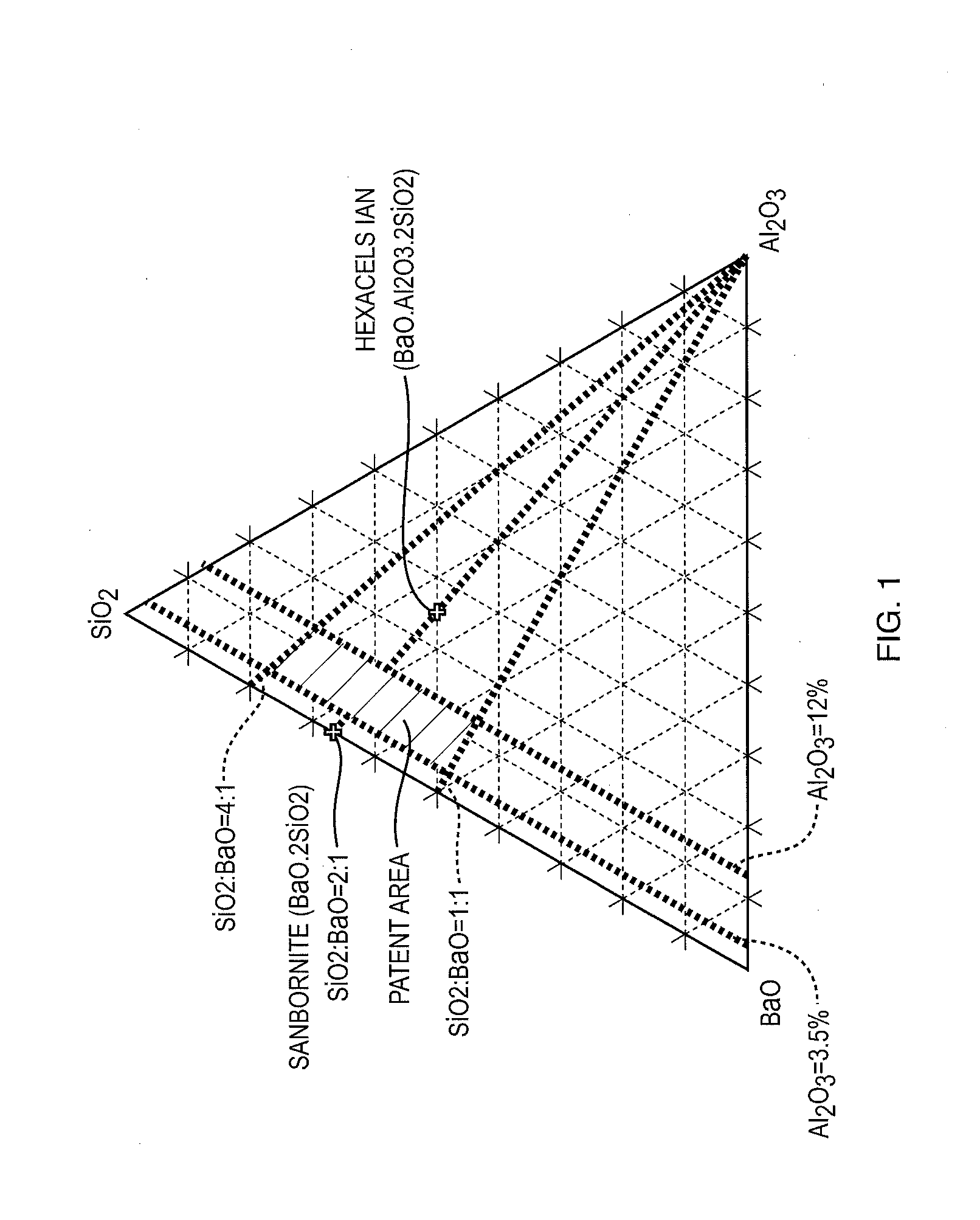

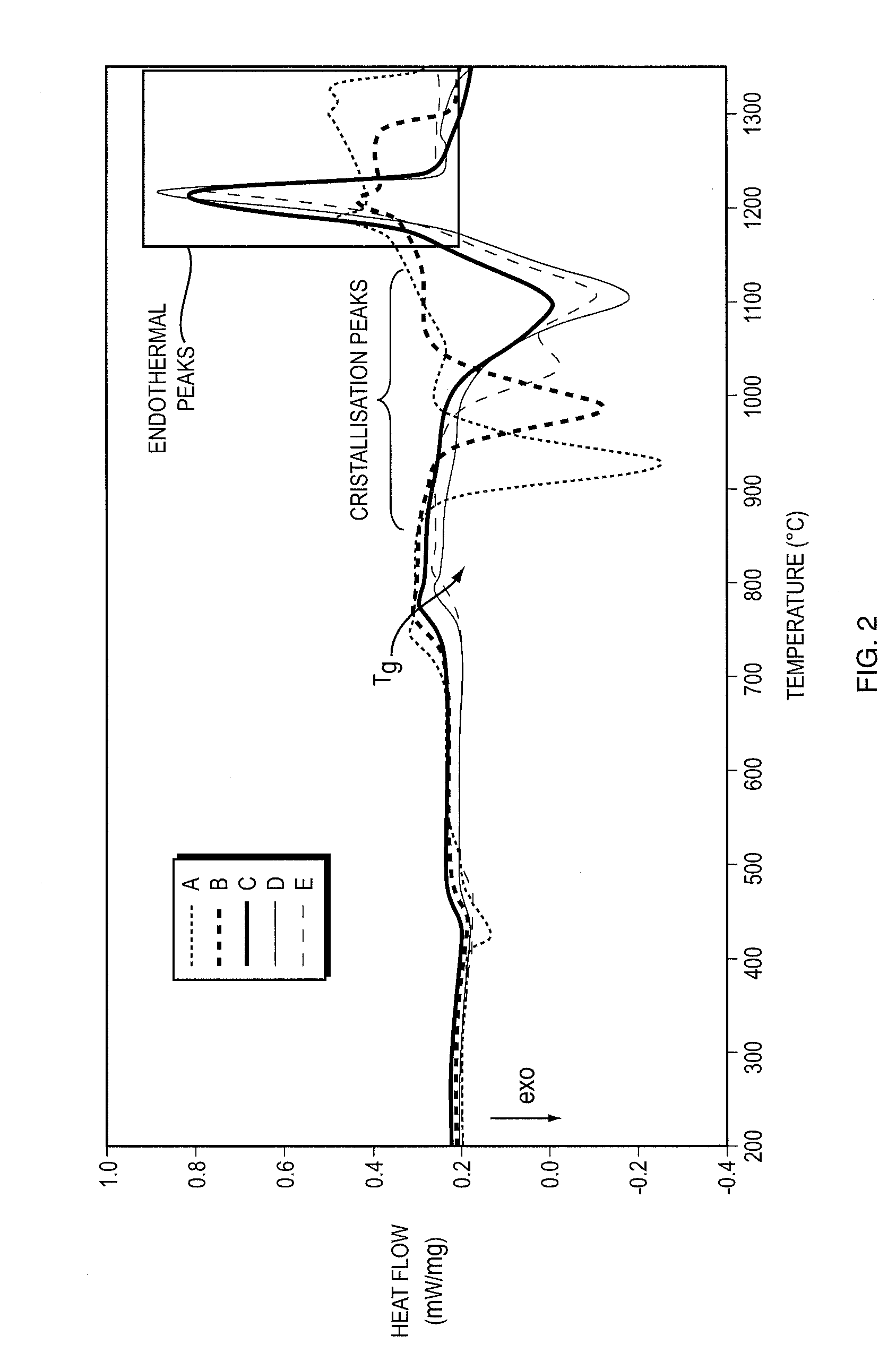

InactiveUS20110200909A1Reduce sealReduce volatilityFuel cells groupingOther chemical processesOxide ceramicStrontium titanate

A solid oxide ceramic includes a substrate defining a surface, the substrate including at least one material selected from the group consisting of yttria-stabilized zirconia (YSZ), lanthanum strontium titanate (LST), lanthanum strontium manganite (LSM), and nickel oxide-YSZ composite. The solid oxide ceramic further includes a seal coating at least a portion of the surface, the seal including a Sanbornite (BaO.2SiO2) crystal phase, a Hexacelsian (BaO.Al2O3.2SiO2) crystal phase, and a residual glass phase, wherein the seal has a coefficient of thermal expansion equal to or less than that of the substrate at said surface. The glass composition can have a difference between a glass crystallization temperature and a glass transition temperature in a range of between about 200° C. and about 400° C. at a heating rate of about 20° C. / min.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Wear resistant ceramic composite coatings and process for production thereof

InactiveCN101248144AMolten spray coatingEfficient propulsion technologiesOxide ceramicNon oxide ceramics

Owner:STANDARD AERO SAN ANTONIO

Preparation method for oxide fiber-reinforced oxide porous ceramic matrix composite

InactiveCN108892522AGuaranteed mechanical propertiesPromote sinteringCeramicwareOxide ceramicLap joint

The invention relates to a preparation method for an oxide fiber-reinforced oxide porous ceramic matrix composite. The method comprises the following steps: firstly, mixing an oxide ceramic precursorsolution, ceramic powder and sintering aid powder, thus obtaining ceramic slurry; brushing the slurry on an oxide fiber fabric surface, thus obtaining an oxide fiber prepreg; paving the prepreg, hot-pressing and sintering, thus obtaining a continuous fiber reinforced porous ceramic matrix composite. According to the preparation method, in order to prepare a porous matrix, the ceramic powder and the sintering aid powder with different grain sizes and sintering properties are mixed with the oxide ceramic precursor solution so as to obtain the slurry; when the porous matrix is formed, a frameworkof the porous matrix is formed by the large-size and hardly sintered ceramic powder; a continuous phase of the porous matrix is formed by the small-size and easily sintered ceramic powder; a bridgingfiber lap joint is formed between the framework of the porous matrix and the continuous phase of the porous matrix by the sintering aid powder; the sintering of the matrix is accelerated and the mechanical property of the porous matrix is guaranteed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com