Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17303 results about "Carbon source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A carbon source is anything that gives out carbon. For example, burning fossil fuels is a carbon source. The burning releases carbon, which joins with oxygen to become CO2.

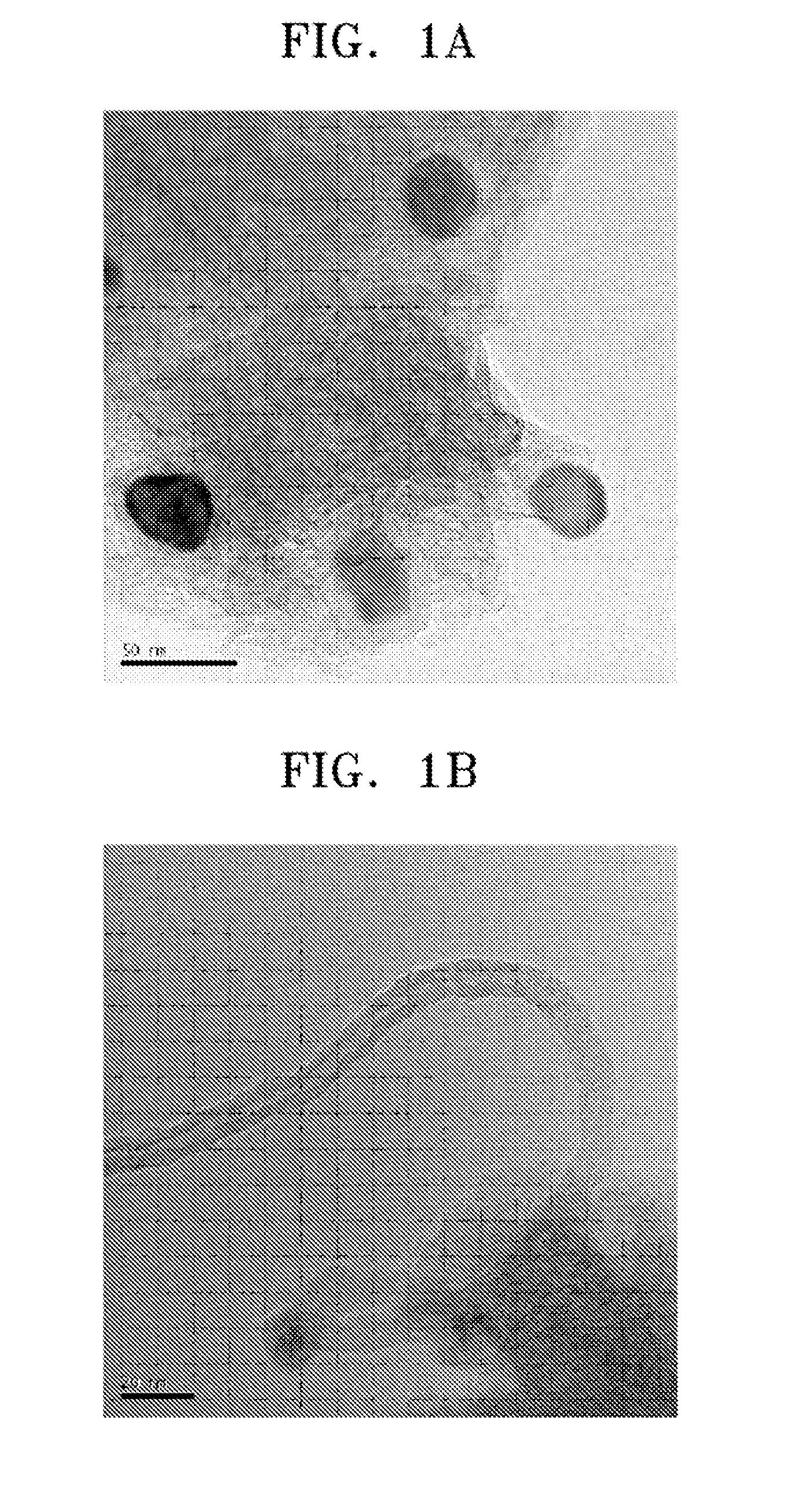

Free-standing and aligned carbon nanotubes and synthesis thereof

One or more highly-oriented, multi-walled carbon nanotubes are grown on an outer surface of a substrate initially disposed with a catalyst film or catalyst nano-dot by plasma enhanced hot filament chemical vapor deposition of a carbon source gas and a catalyst gas at temperatures between 300° C. and 3000° C. The carbon nanotubes range from 4 to 500 nm in diameter and 0.1 to 50 μm in length depending on growth conditions. Carbon nanotube density can exceed 104 nanotubes / mm2. Acetylene is used as the carbon source gas, and ammonia is used as the catalyst gas. Plasma intensity, carbon source gas to catalyst gas ratio and their flow rates, catalyst film thickness, and temperature of chemical vapor deposition affect the lengths, diameters, density, and uniformity of the carbon nanotubes. The carbon nanotubes of the present invention are useful in electrochemical applications as well as in electron emission, structural composite, material storage, and microelectrode applications.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

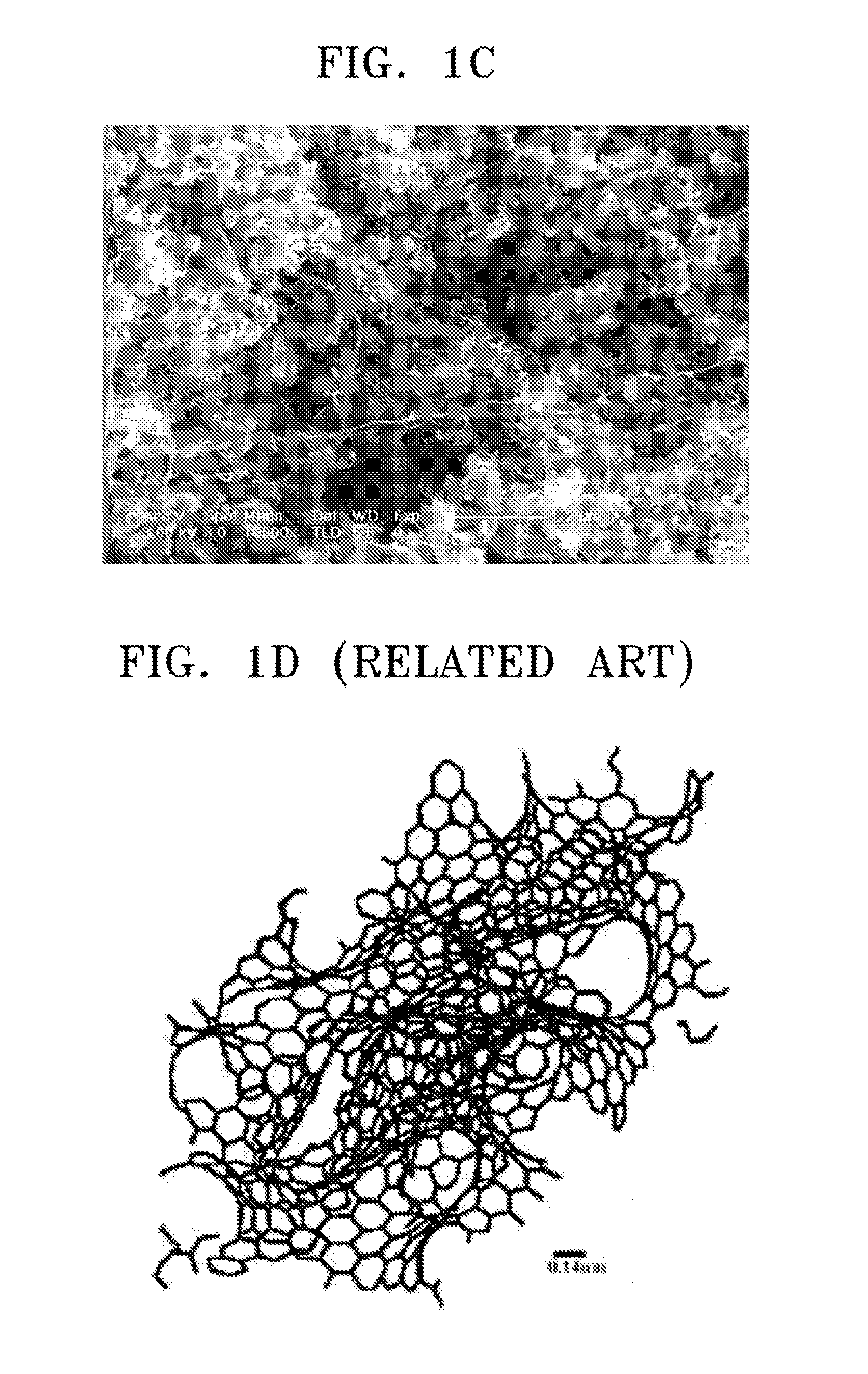

Carbon nanotube hybrid system using carbide-derived carbon, a method of making the same, an electron emitter comprising the same, and an electron emission device comprising the electron emitter

InactiveUS20080248310A1Improve uniformityLong life-timeMaterial nanotechnologyNanostructure manufactureHybrid systemHalogen

A carbon nanotube hybrid system includes: a carbide-derived carbon prepared by reacting a carbide compound and a halogen group containing gas to extract elements of the carbide compound except carbons; metals supported on the carbide-derived carbon or remaining in the carbide-derived carbon; and carbon sources from which carbon nanotubes are grown from the carbide-derived carbon. A method of preparing the carbon nanotube hybrid system includes preparing the carbide-derived carbon, extracting elements therefrom, and growing carbon nanotubes from the carbide-derived carbon. The carbon nanotube hybrid system has excellent uniformity and a long lifetime. An electron emitter having improved electron emitting properties can be inexpensively prepared using the carbon nanotube hybrid system compared to conventional carbon nanotubes. An electron emission device having excellent electron emitting properties can be prepared using the electron emitter.

Owner:SAMSUNG SDI CO LTD

Phosphorus Containing Si Epitaxial Layers in N-Type Source/Drain Junctions

ActiveUS20080182075A1Keep the pressureLayered productsSemiconductor/solid-state device manufacturingMOSFETHigh concentration

Methods for formation of epitaxial layers containing n-doped silicon are disclosed. Specific embodiments pertain to the formation and treatment of epitaxial layers in semiconductor devices, for example, Metal Oxide Semiconductor Field Effect Transistor (MOSFET) devices. In specific embodiments, the formation of the n-doped epitaxial layer involves exposing a substrate in a process chamber to deposition gases including a silicon source, a carbon source and an n-dopant source. An epitaxial layer may have considerable tensile stress which may be created in a significant amount by a high concentration of n-dopant. A layer having n-dopant may also have substitutional carbon. Phosphorus as an n-dopant with a high concentration is provided. A substrate having an epitaxial layer with a high level of n-dopant is also disclosed.

Owner:APPLIED MATERIALS INC

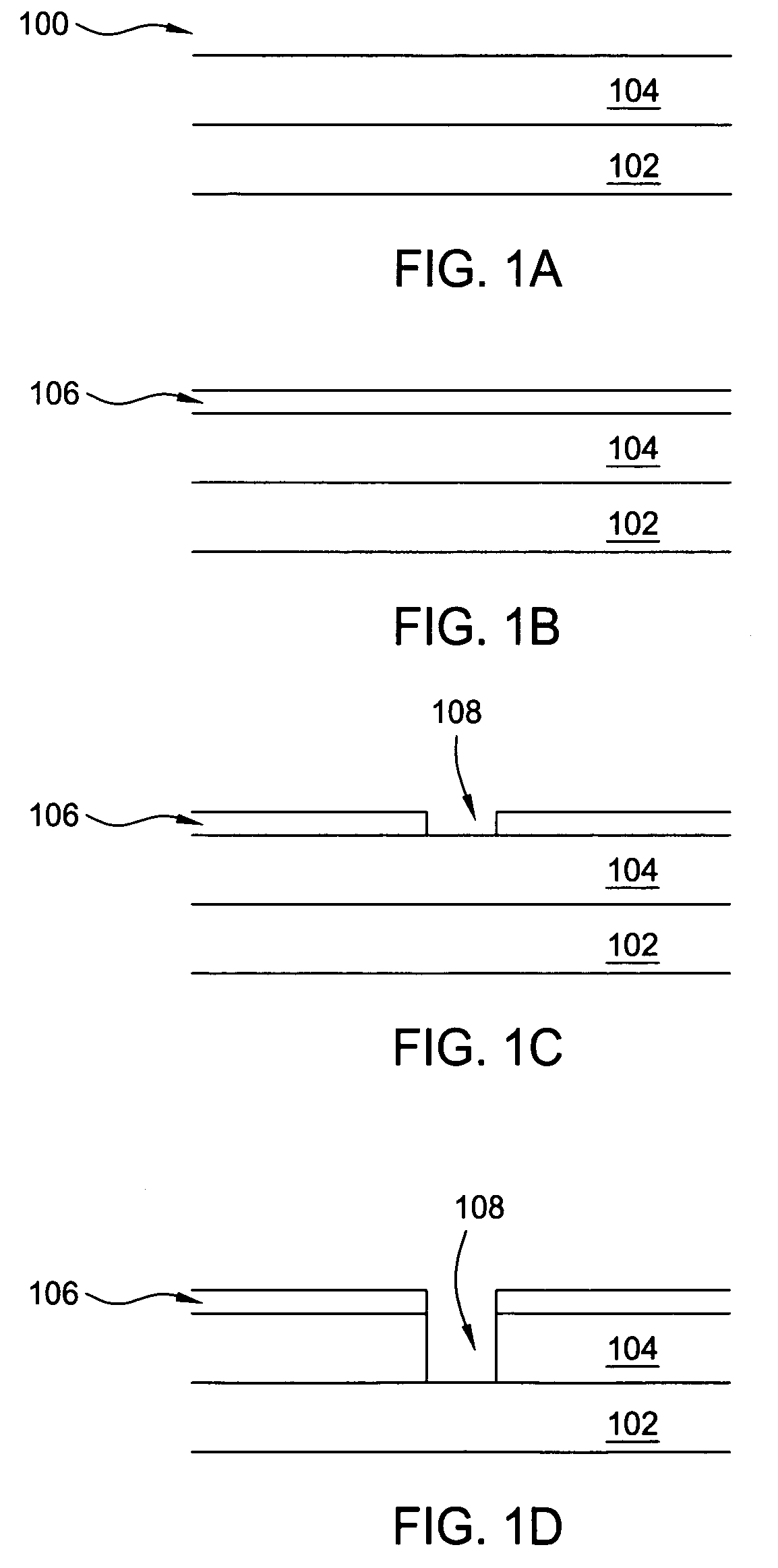

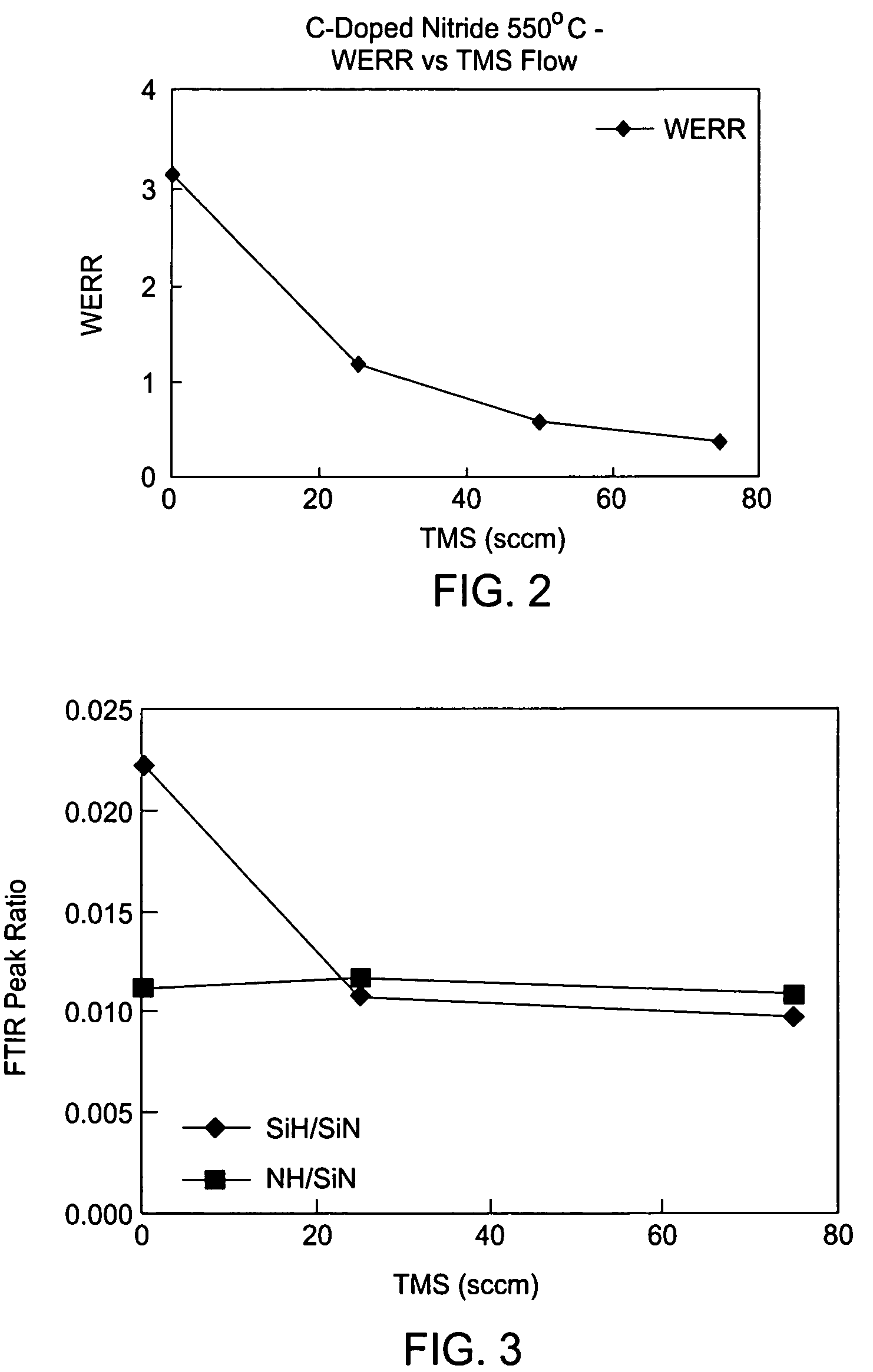

Decreasing the etch rate of silicon nitride by carbon addition

Methods for forming silicon nitride hard masks are provided. The silicon nitride hard masks include carbon-doped silicon nitride layers and undoped silicon nitride layers. Carbon-doped silicon nitride layers that are deposited from a mixture comprising a carbon source compound, a silicon source compound, and a nitrogen source in the presence of RF power are provided. Also provided are methods of UV post-treating silicon nitride layers to provide silicon nitride hard masks. The carbon-doped silicon nitride layers and UV post-treated silicon nitride layers have desirable wet etch rates and dry etch rates for hard mask layers.

Owner:APPLIED MATERIALS INC

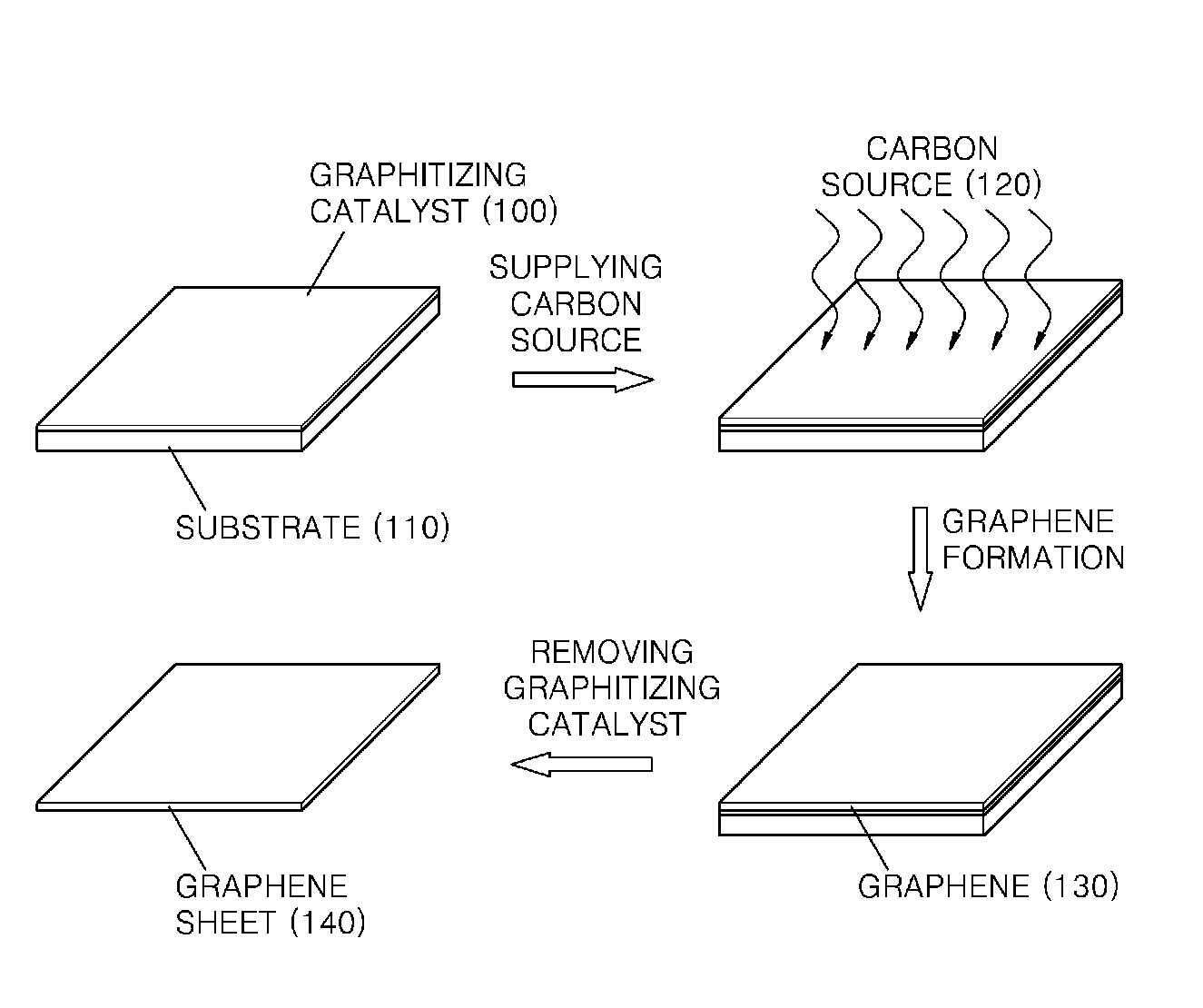

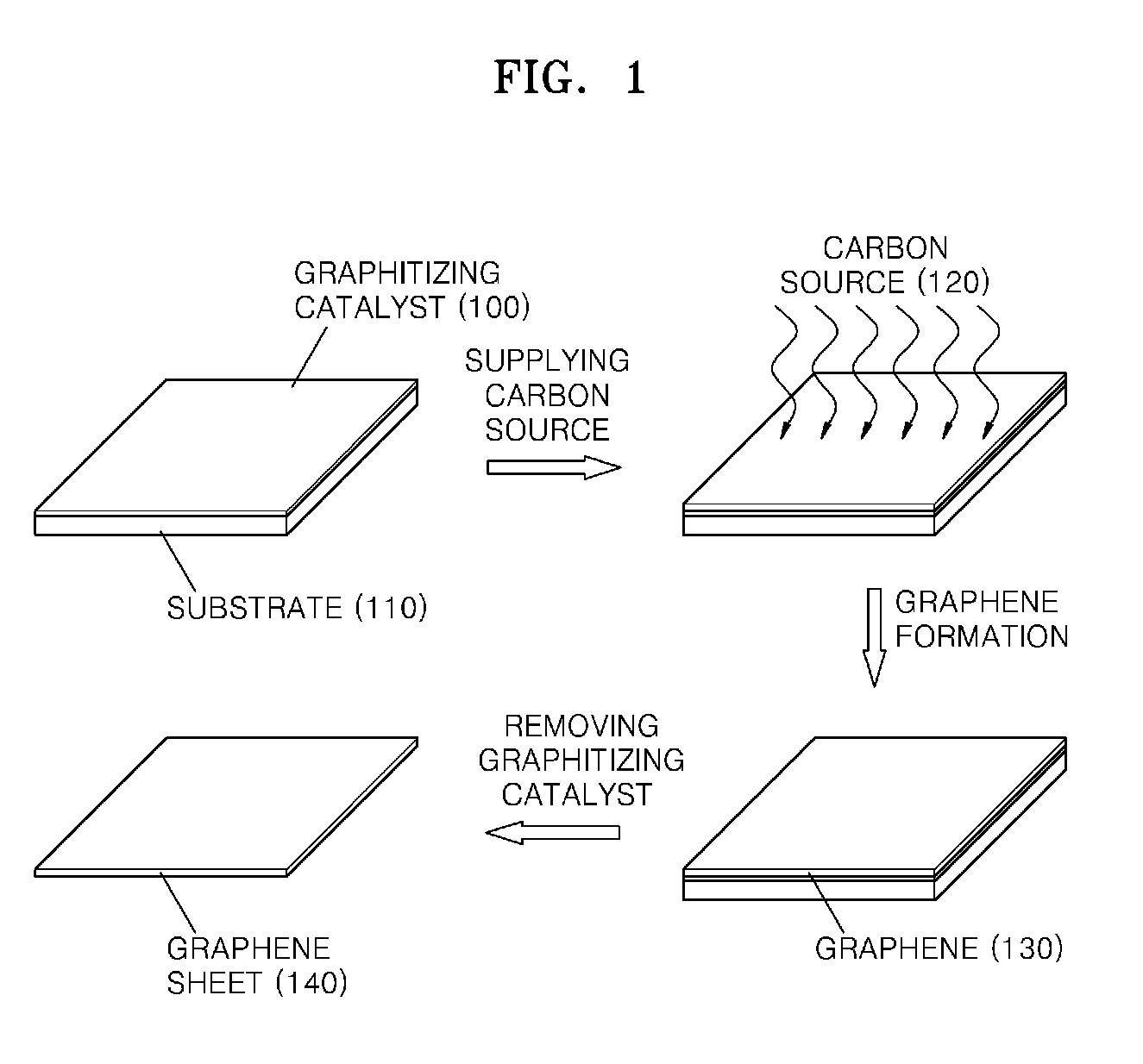

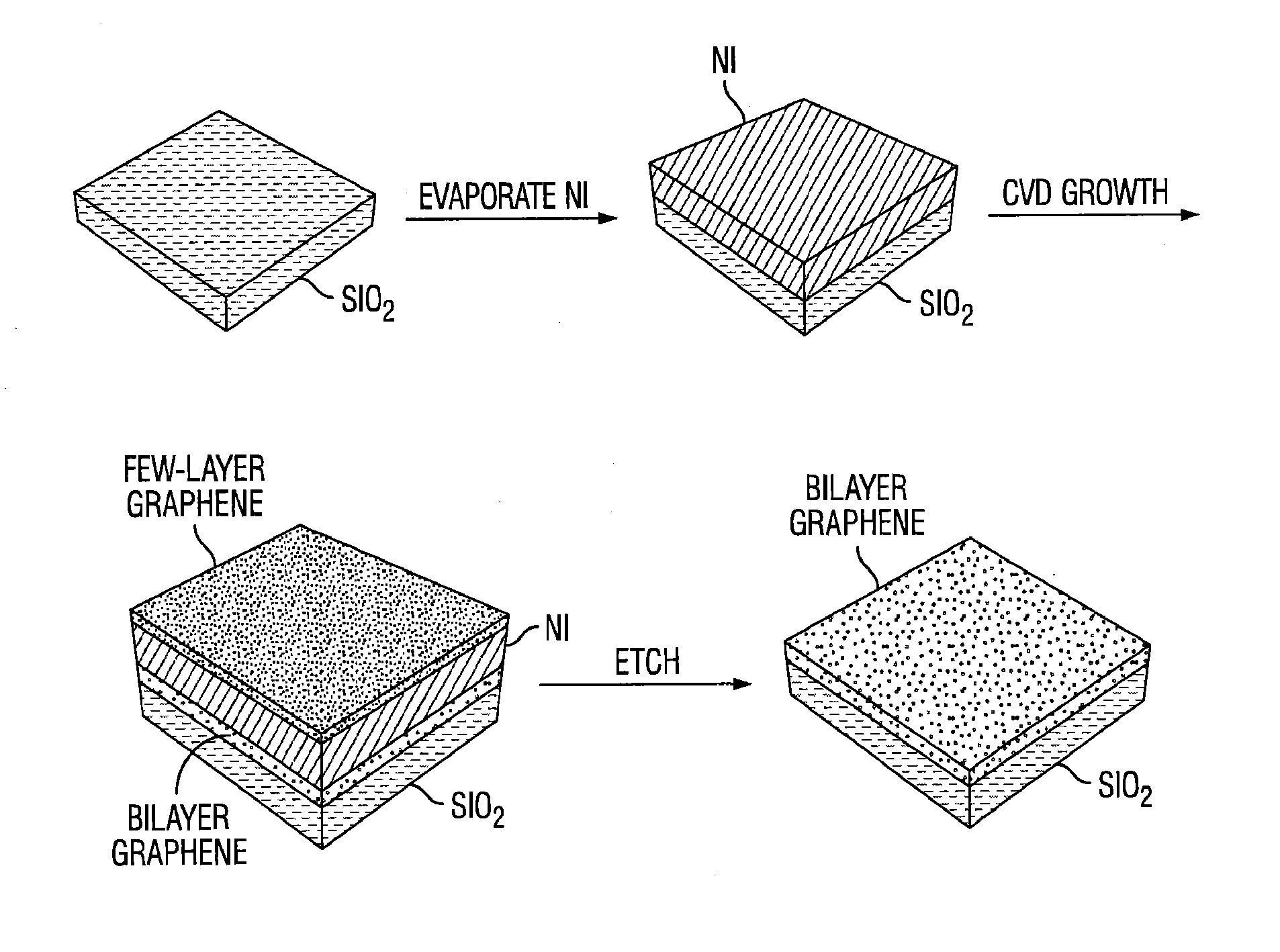

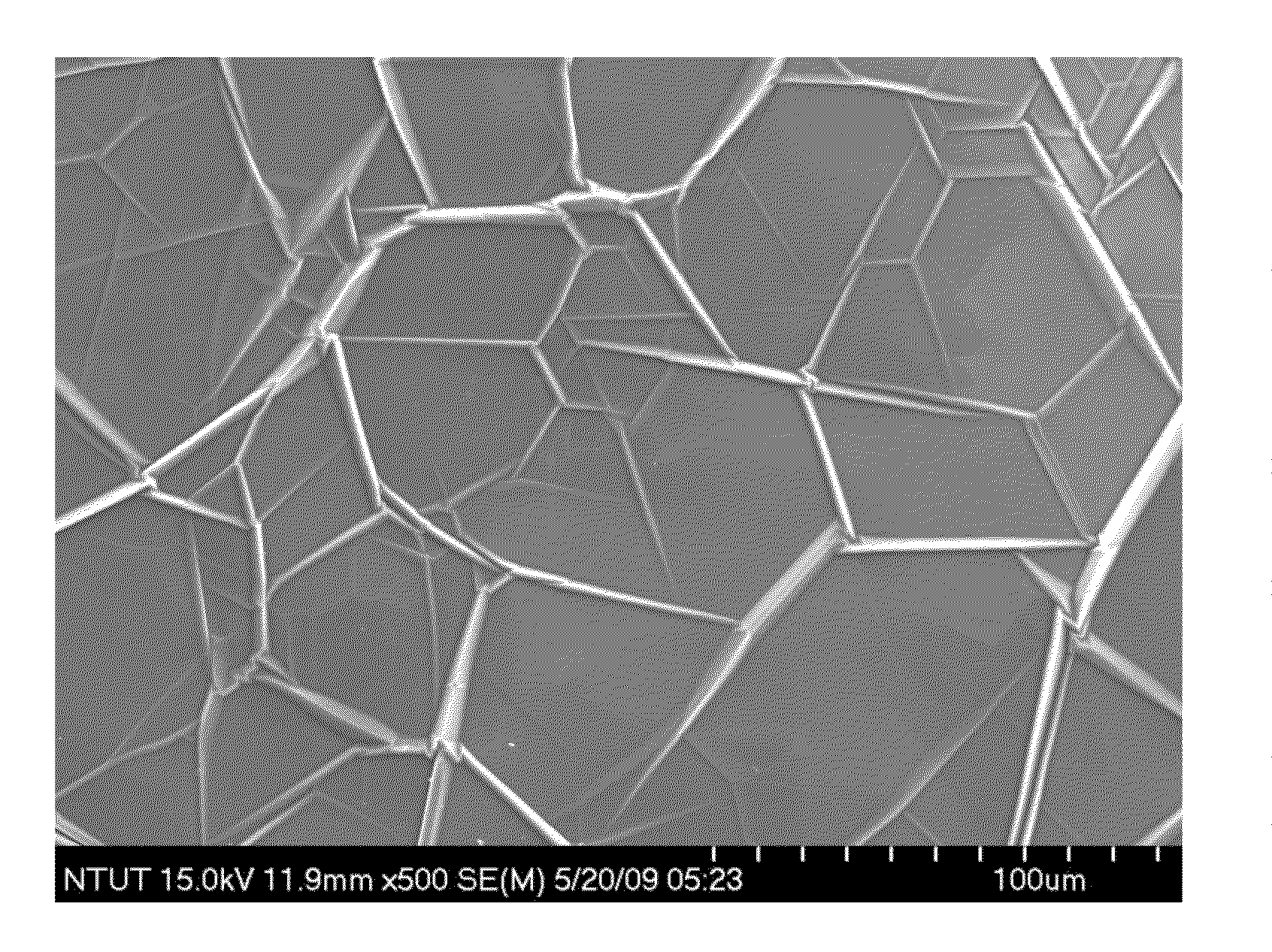

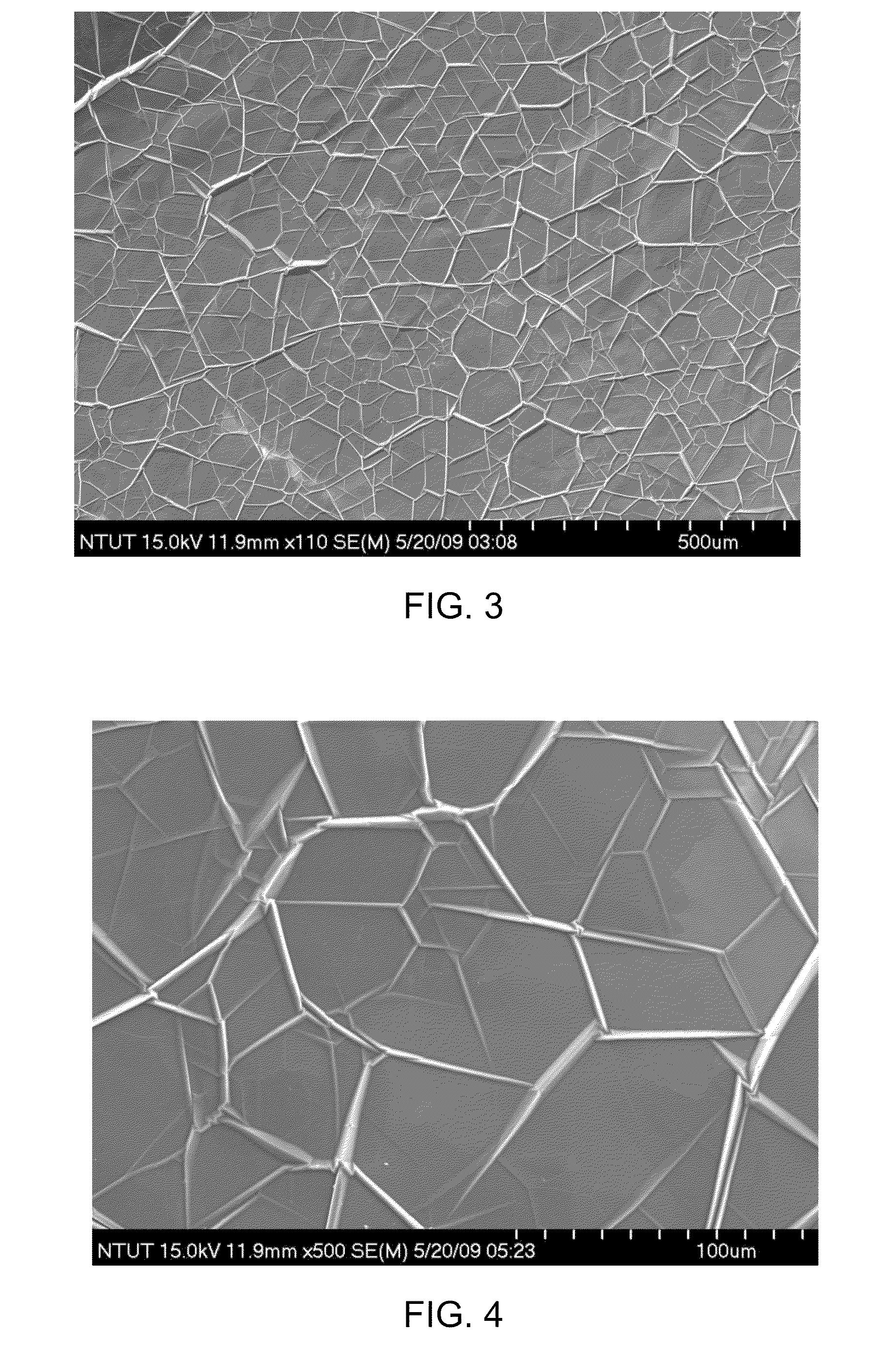

Graphene sheet and method of preparing the same

An economical method of preparing a large-sized graphene sheet having a desired thickness includes forming a film, the film comprising a graphitizing catalyst; heat-treating a gaseous carbon source in the presence of the graphitizing catalyst to form graphene; and cooling the graphene to form a graphene sheet. A graphene sheet prepared according to the disclosed method is also described.

Owner:SAMSUNG ELECTRONICS CO LTD

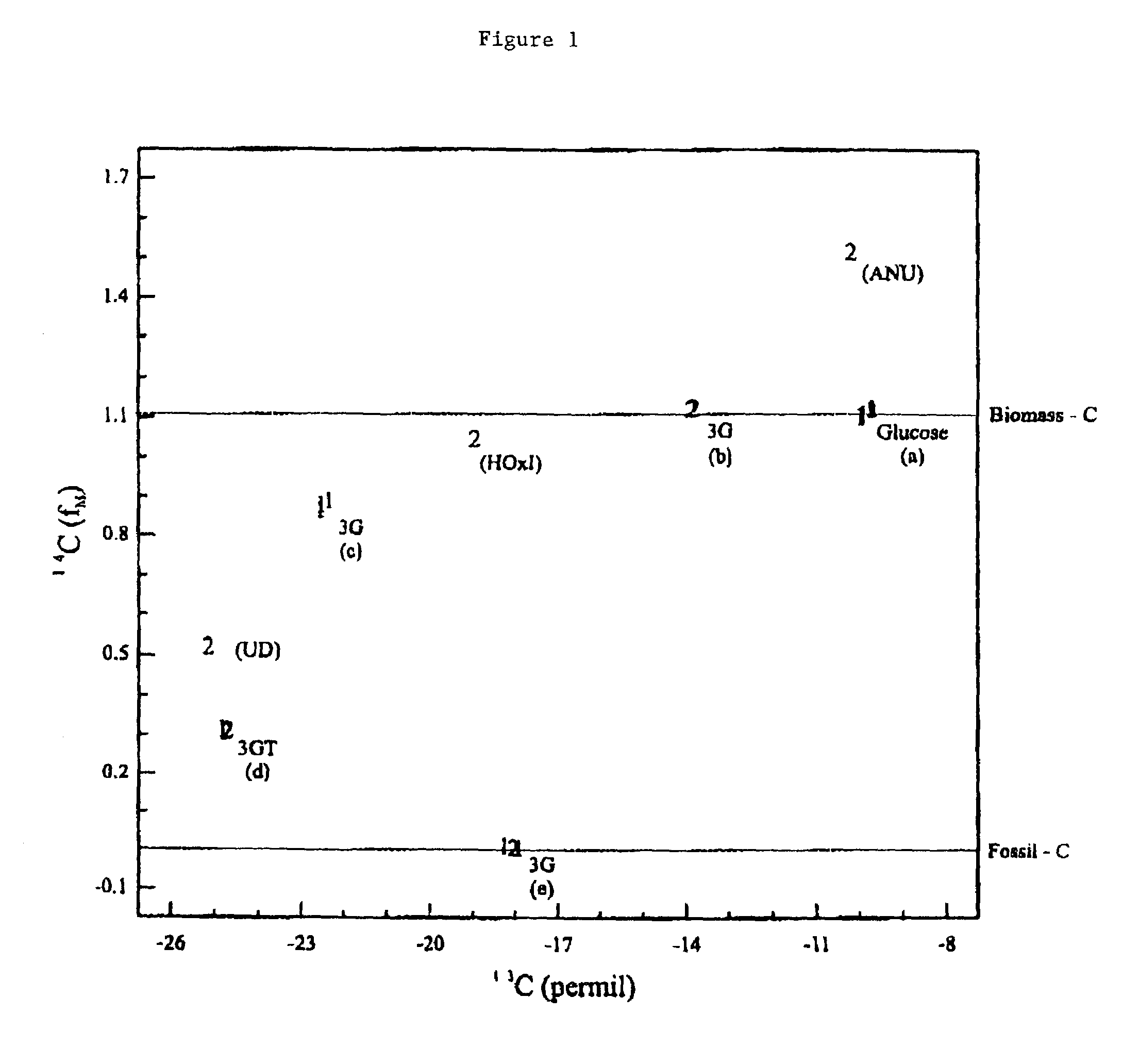

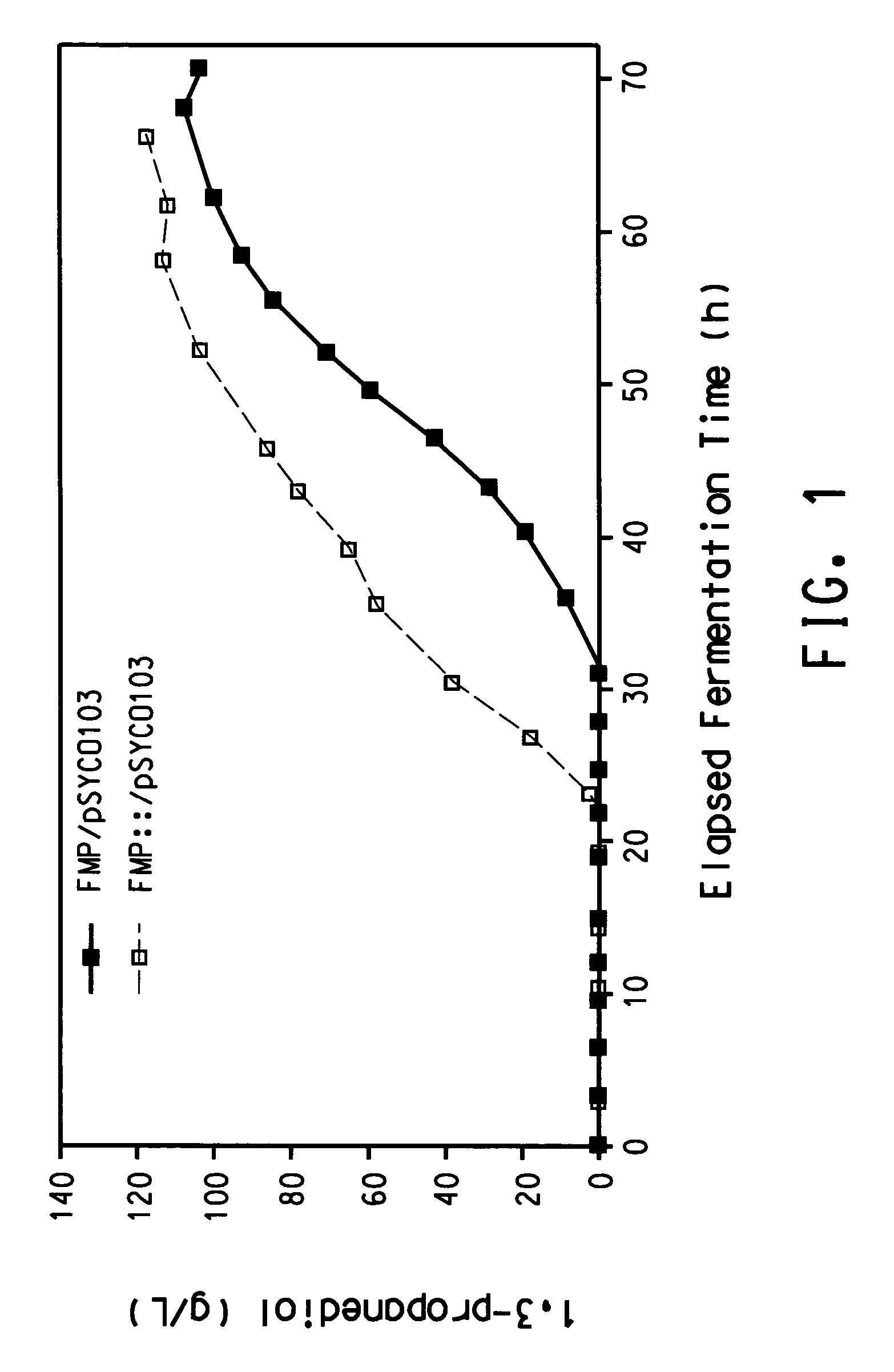

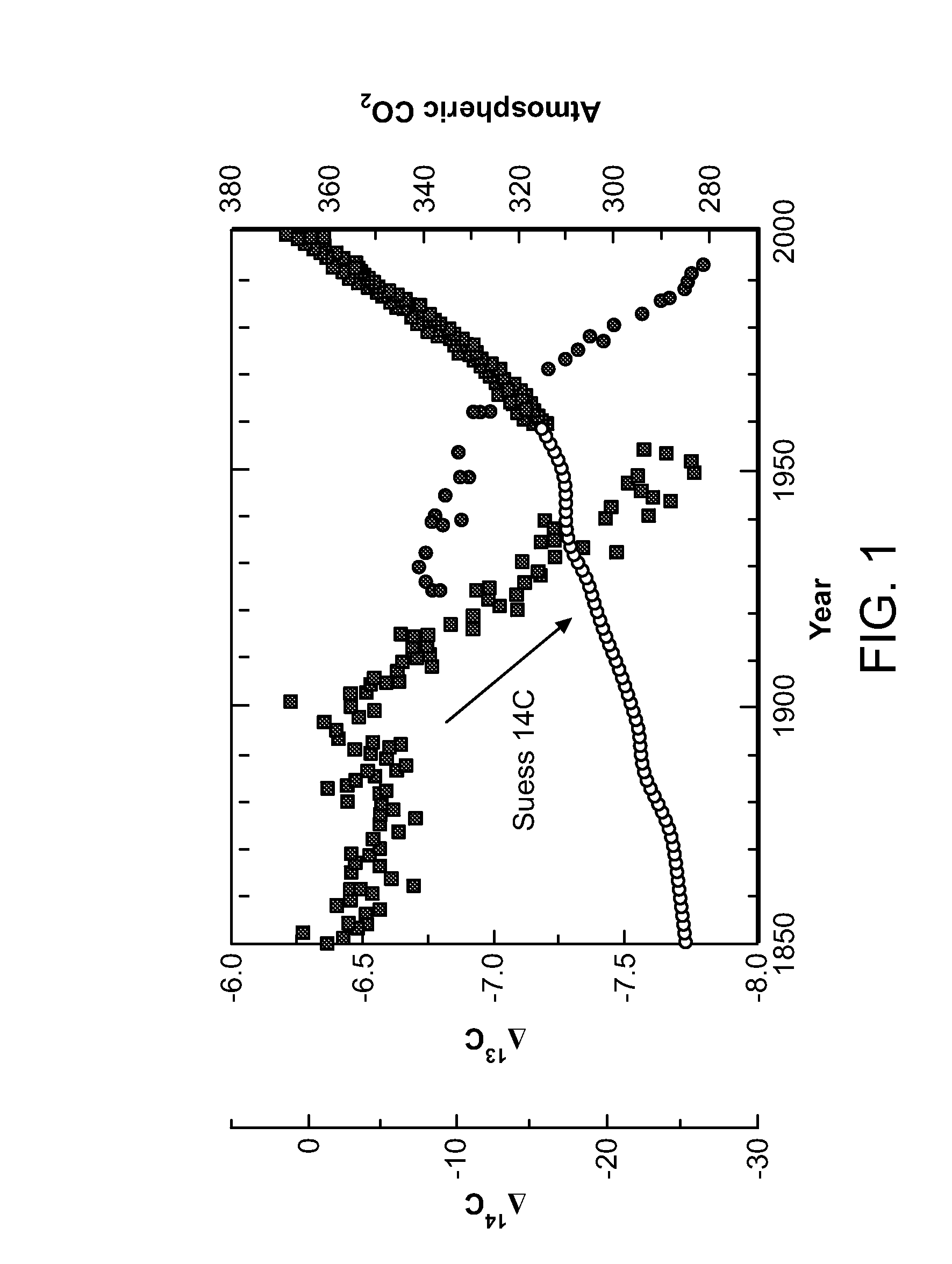

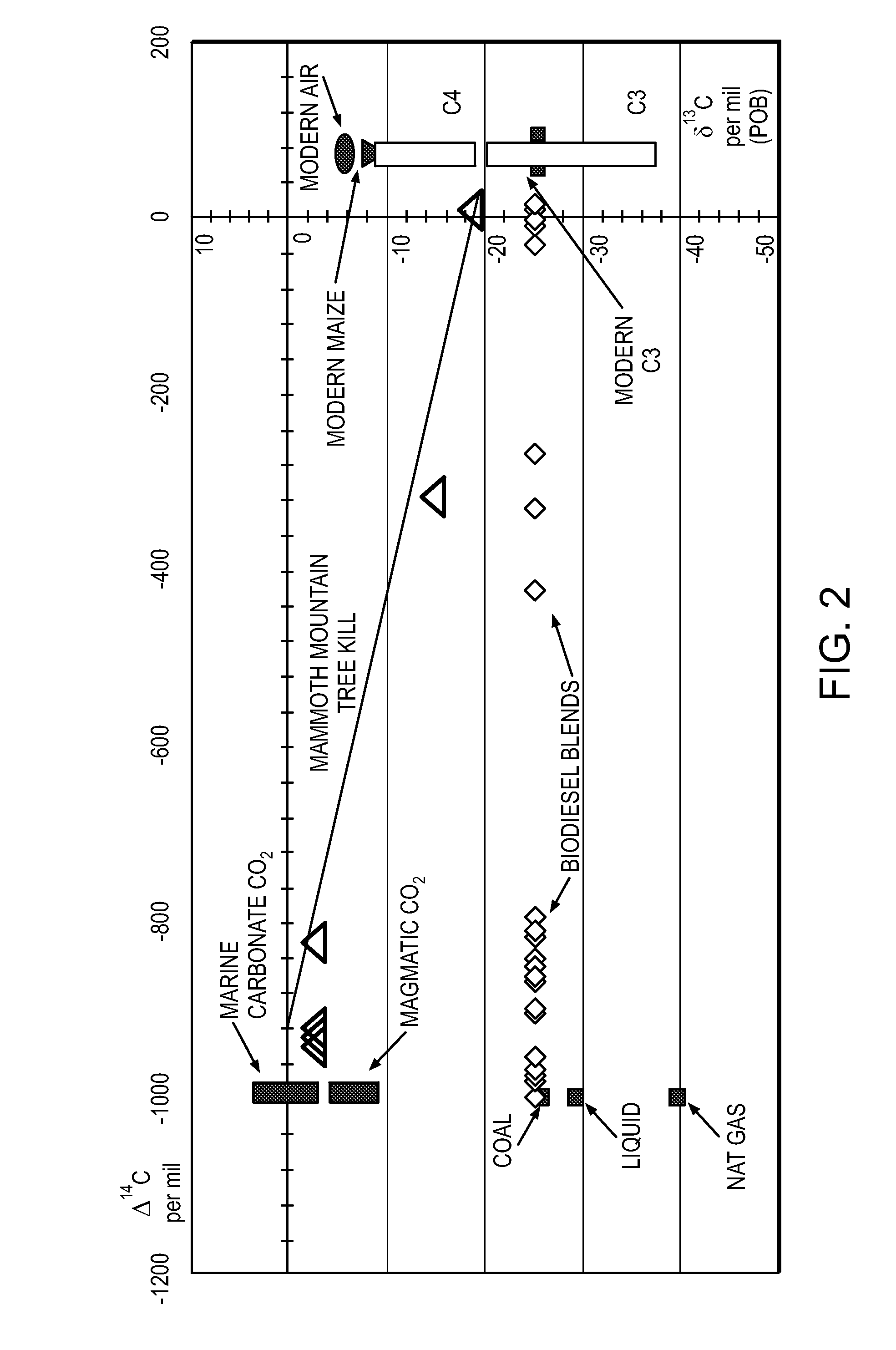

Bioconversion of a fermentable carbon source to 1,3-propanediol by a single microorganism

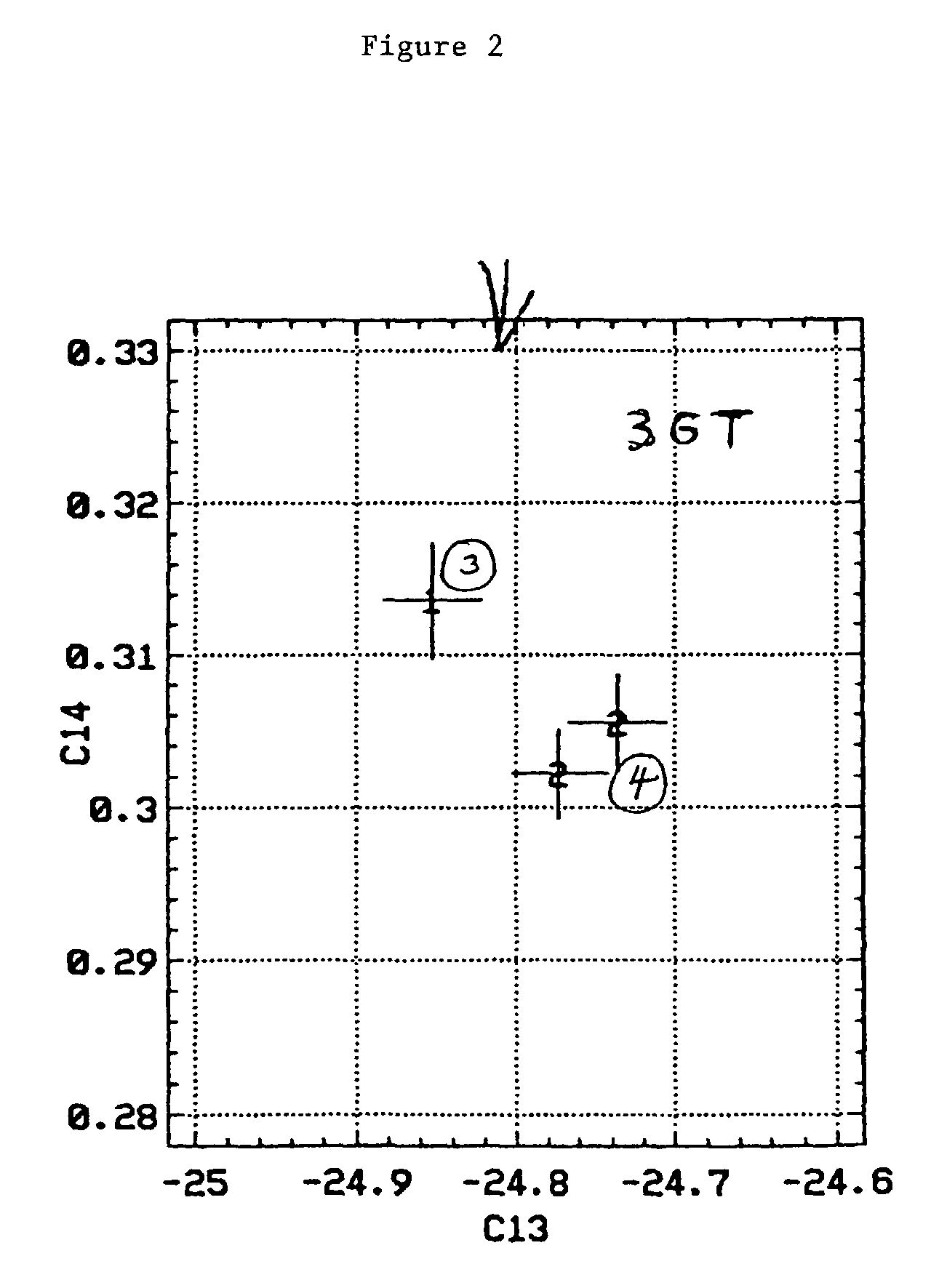

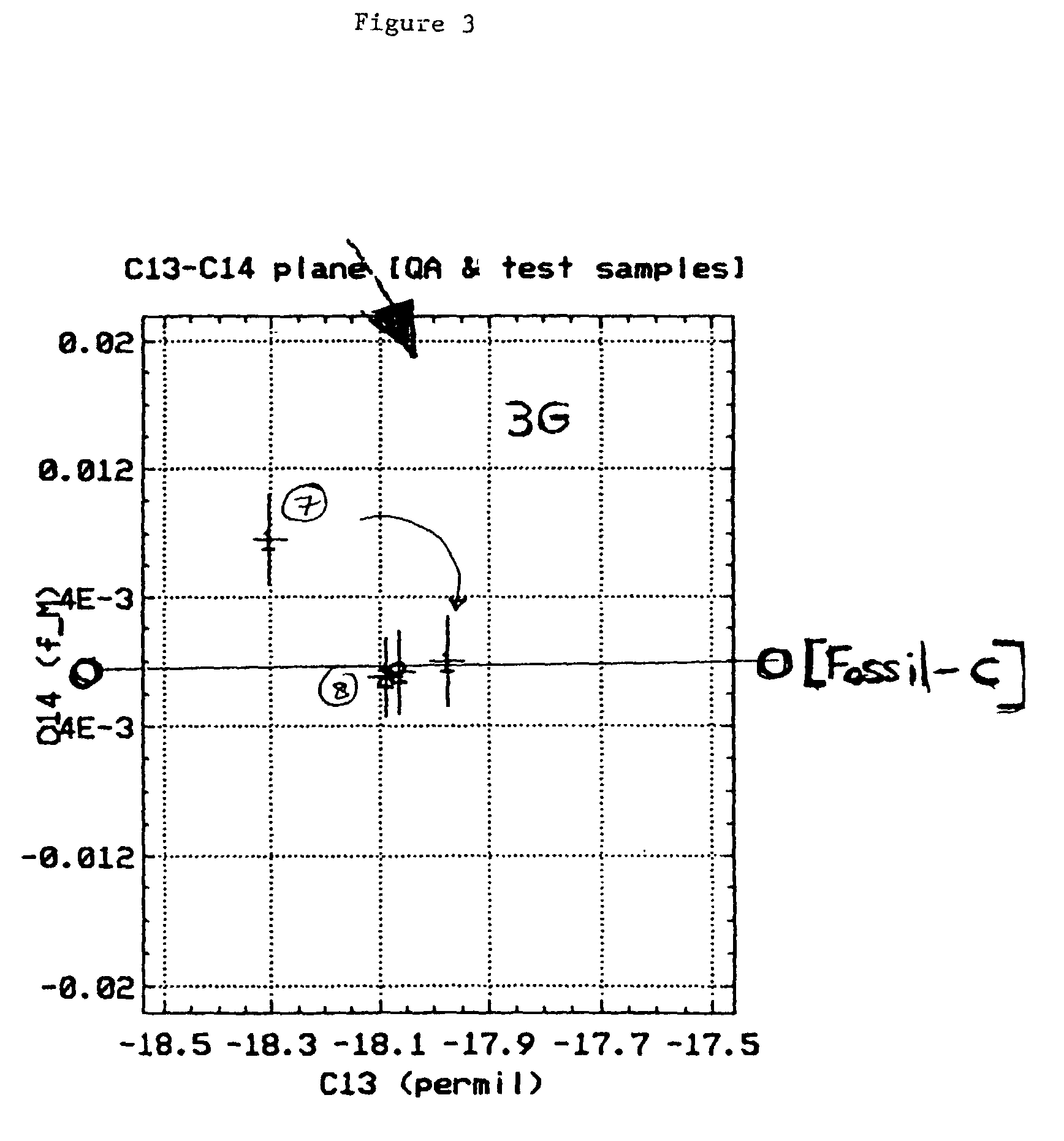

A new polypropylene terephthalate composition is provided. The polypropylene terephthalate is comprised of 1,3-propanediol and terephthalate. The 1,3-propanediol is produced by the bioconversion of a fermentatble carbon source, preferable glucose. The resulting polypropylene terephthalate is distinguished from petrochemically produced polymer on the basis of dual carbon-isotopic fingerprinting which indicates both the source and the age of the carbon.

Owner:EI DU PONT DE NEMOURS & CO +1

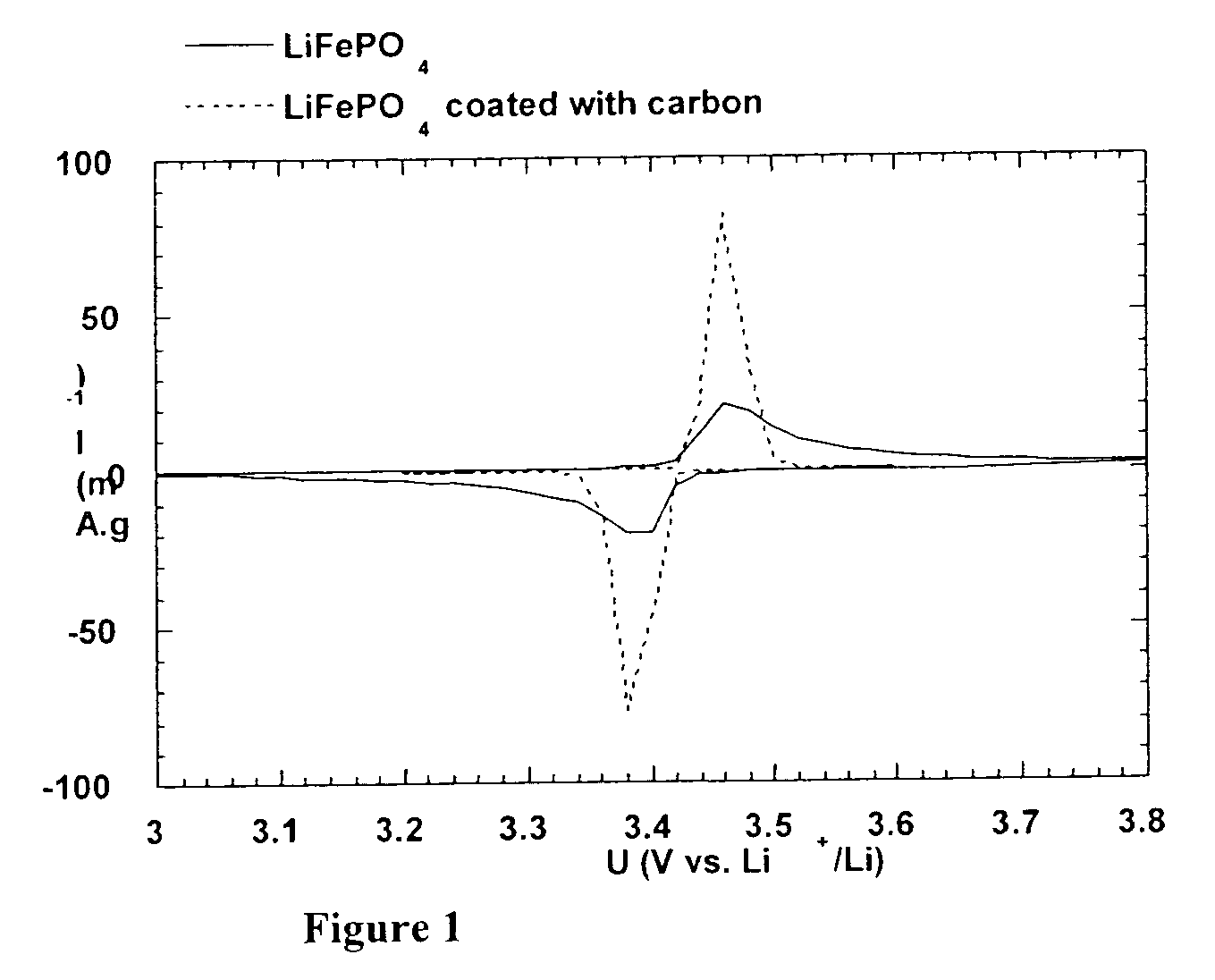

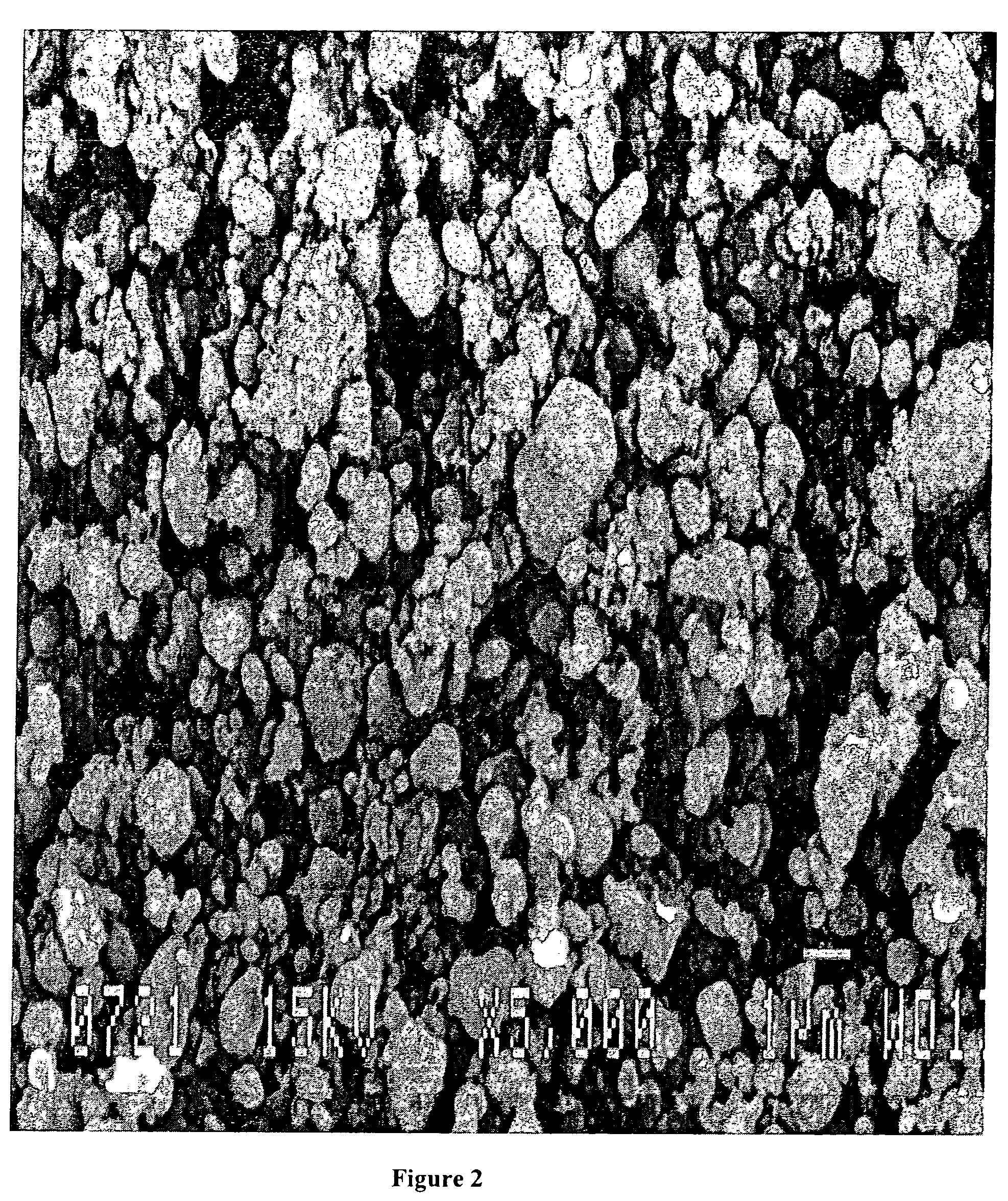

Method for synthesis of carbon-coated redox materials with controlled size

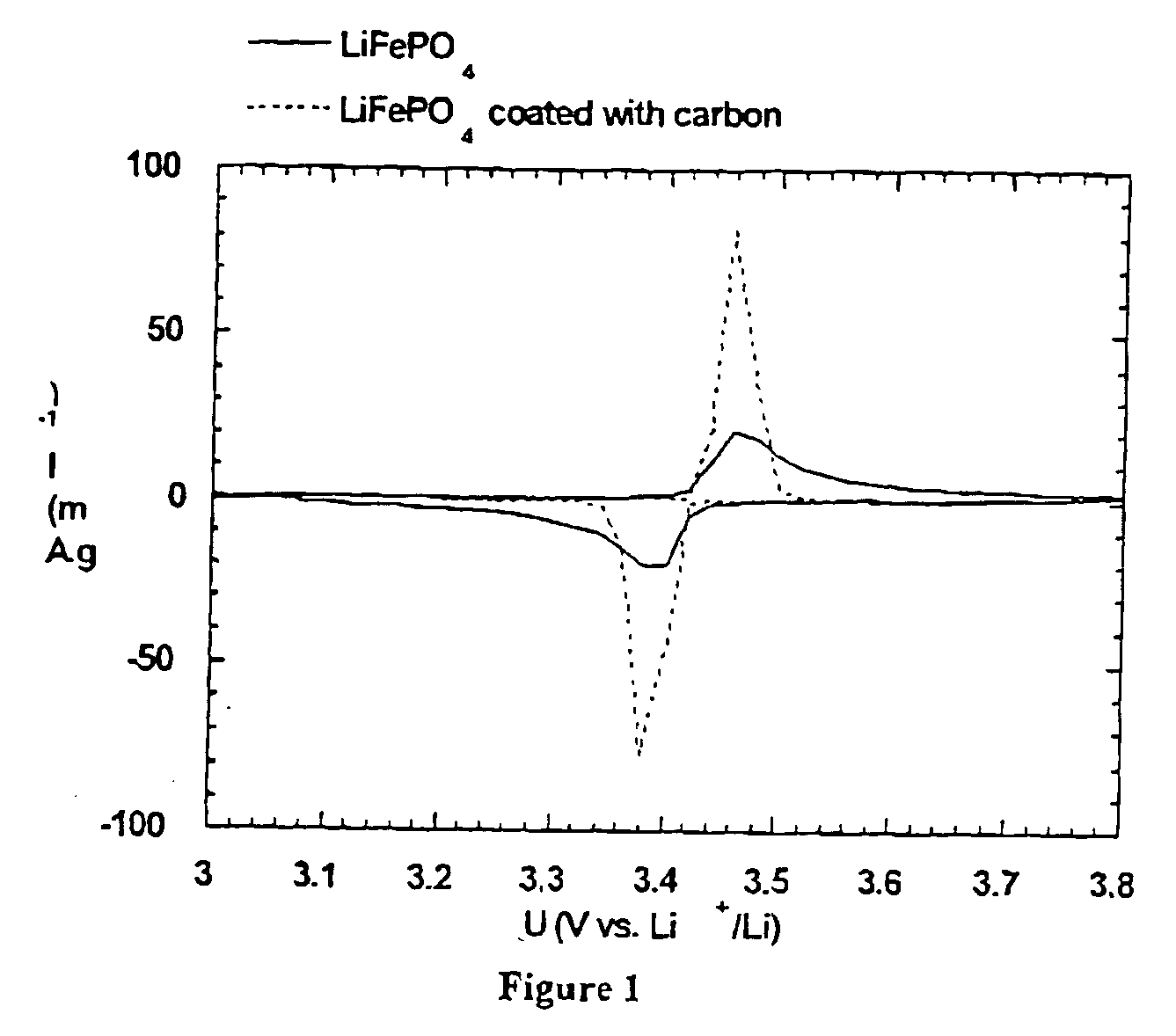

ActiveUS20040033360A1Low costReduce the numberMaterial nanotechnologyHybrid capacitorsCross-linkRedox

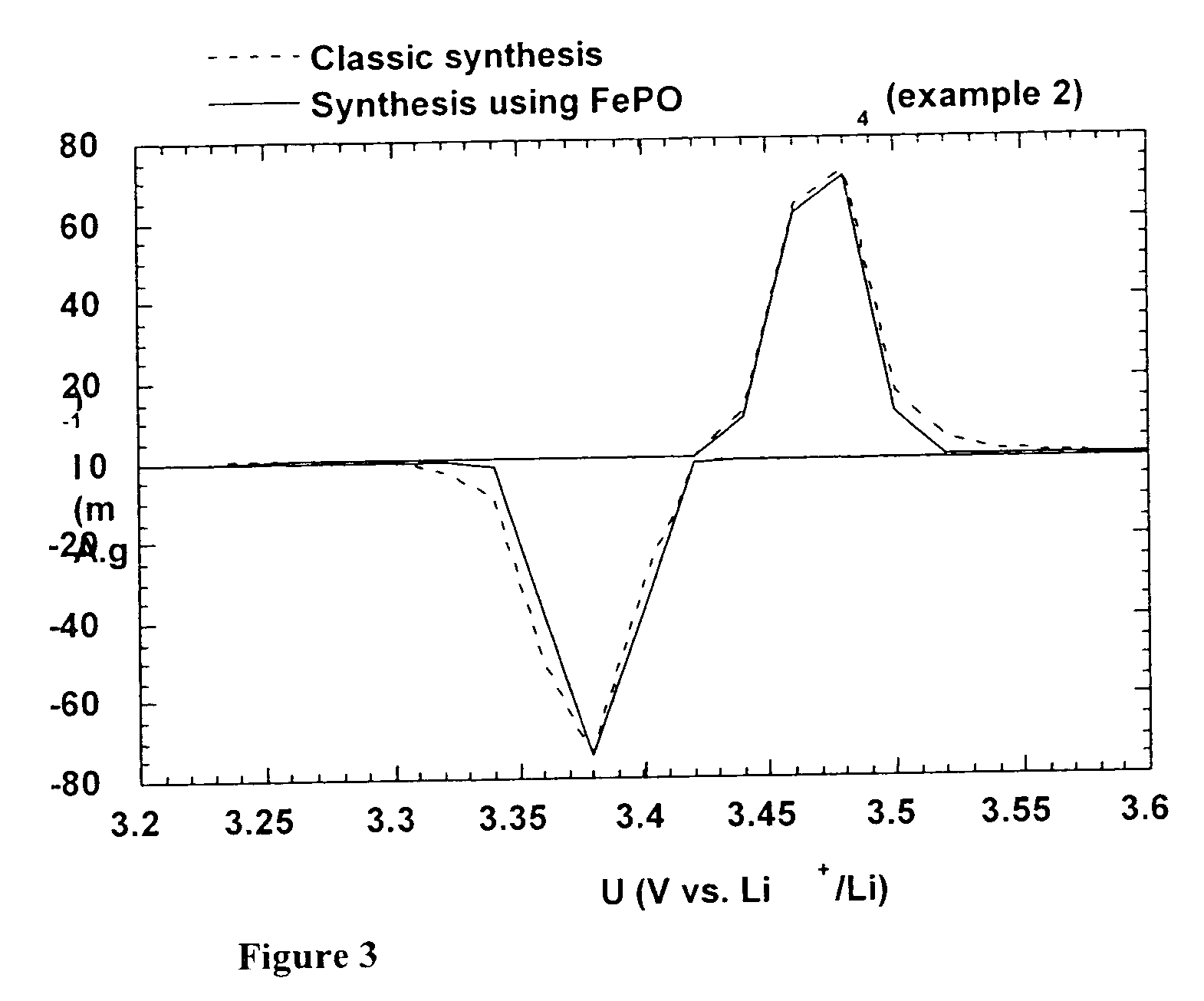

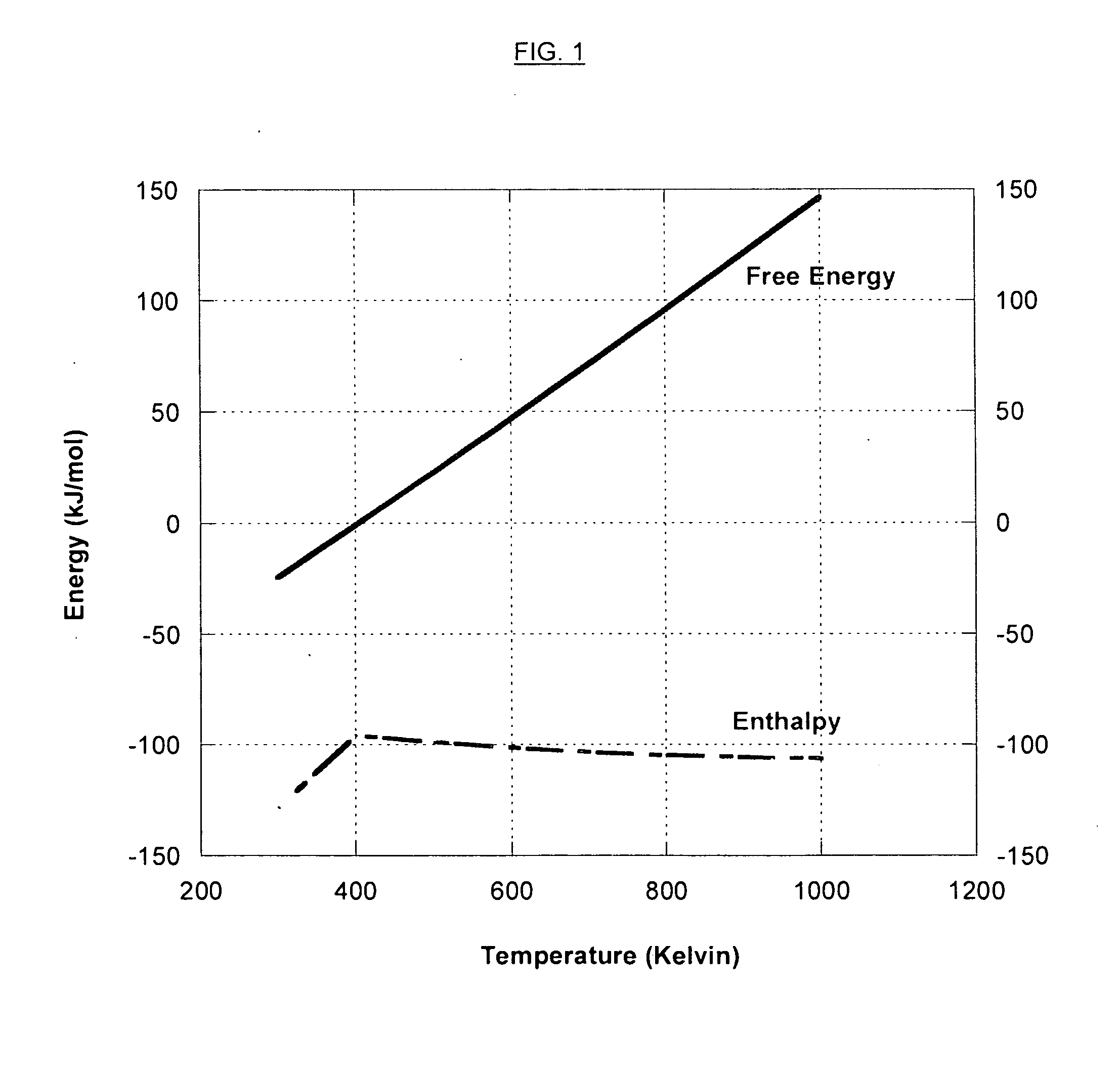

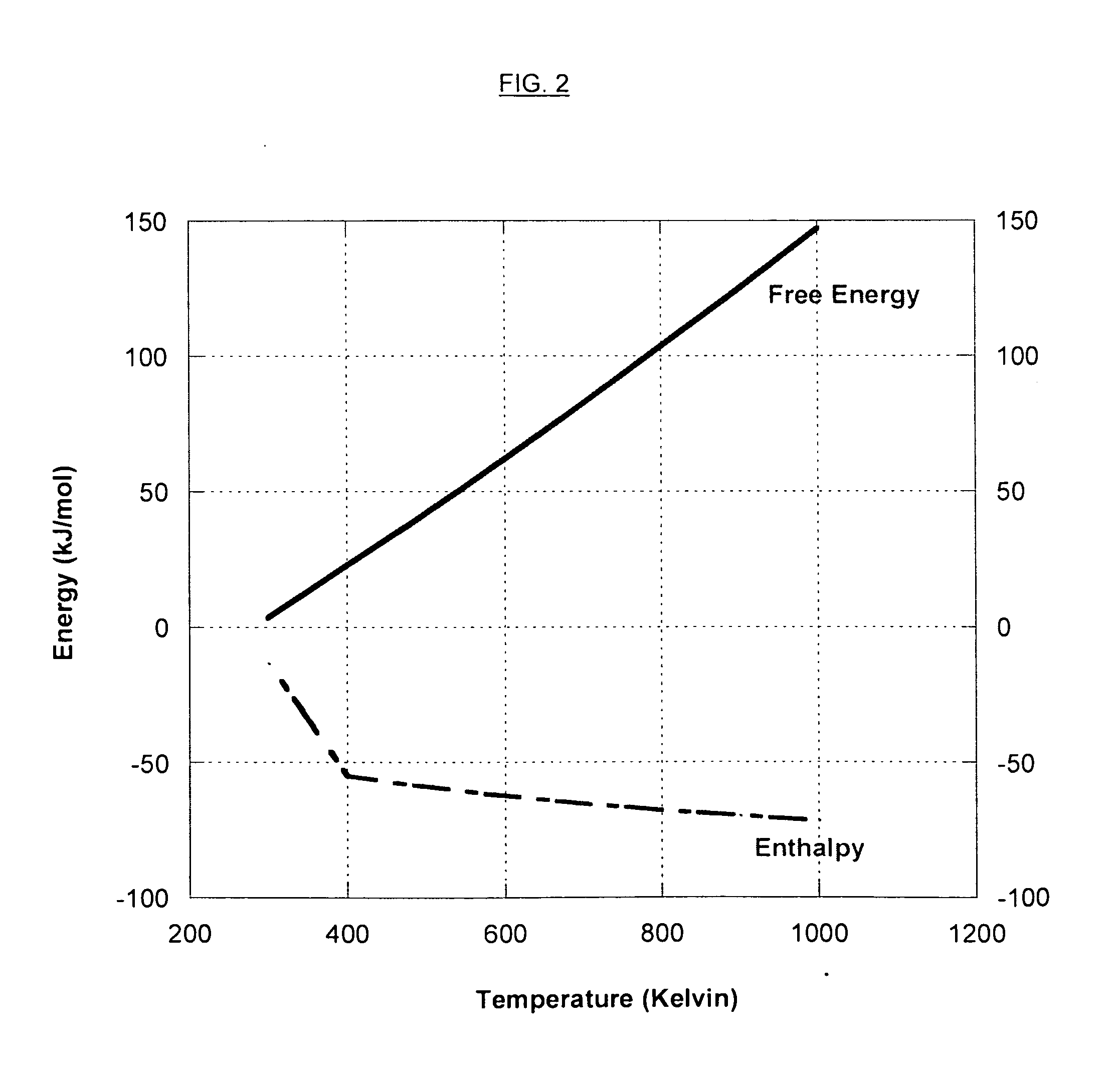

A method for the synthesis of compounds of the formula C-LixM1-yM'y(XO4)n, where C represents carbon cross-linked with the compound LixM1-yM'y(XO4)n, in which x, y and n are numbers such as 0<=x<=2, 0<=y<=0.6, and 1<=n<=1.5, M is a transition metal or a mixture of transition metals from the first period of the periodic table, M' is an element with fixed valency selected among Mg<2+>, Ca<2+>, Al<3+>, Zn<2+> or a combination of these same elements and X is chosen among S, P and Si, by bringing into equilibrium, in the required proportions, the mixture of precursors, with a gaseous atmosphere, the synthesis taking place by reaction and bringing into equilibrium, in the required proportions, the mixture of the precursors, the procedure comprising at least one pyrolysis step of the carbon source compound in such a way as to obtain a compound in which the electronic conductivity measured on a sample of powder compressed at a pressure of 3750 Kg.cm<-2 >is greater than 10<-8 >S.cm<-1>. The materials obtained have excellent electrical conductivity, as well a very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

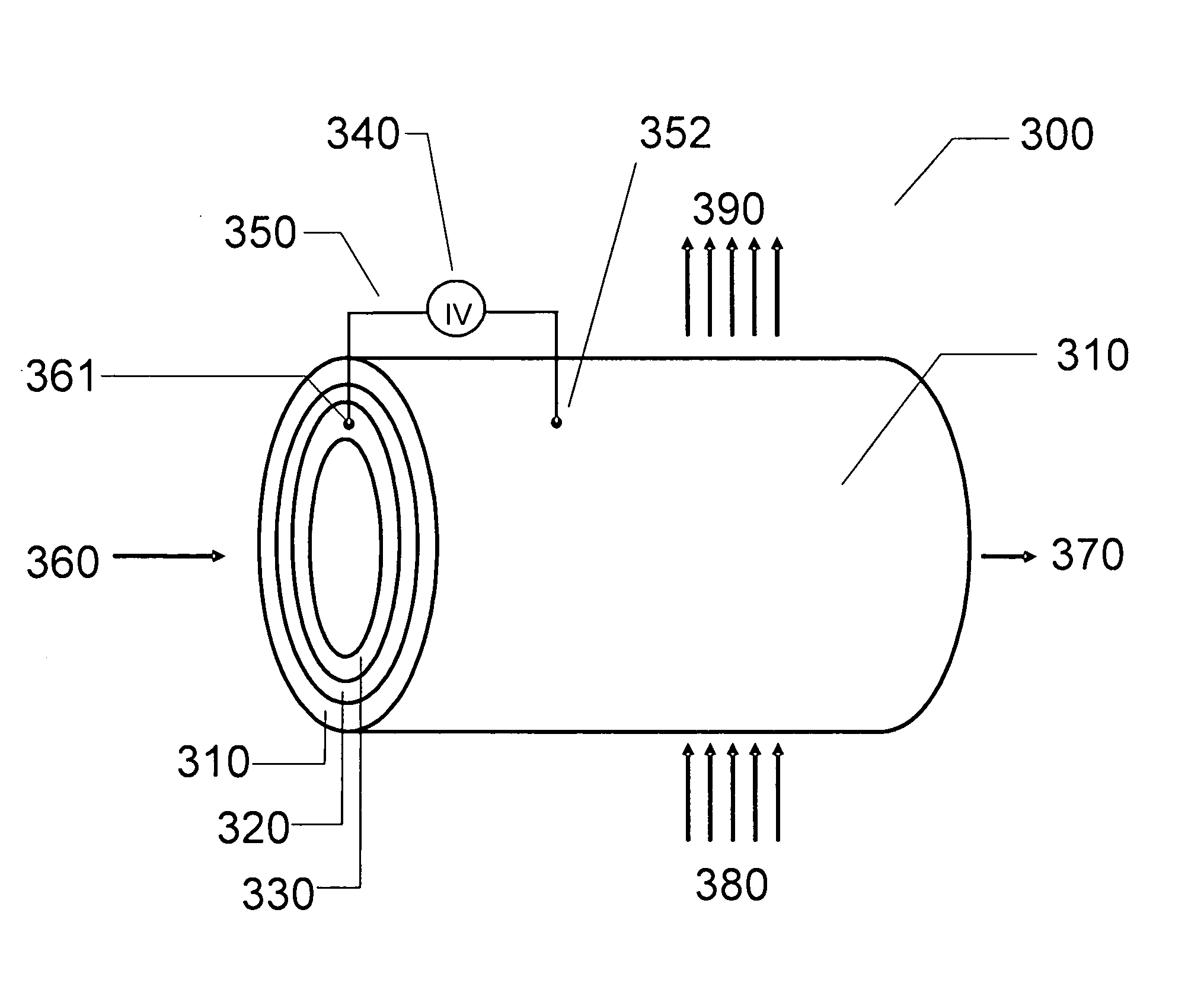

Methods and devices for the production of Hydrocarbons from Carbon and Hydrogen sources

InactiveUS20080283411A1Reduce the environmentEasy to controlPhotography auxillary processesInternal combustion piston enginesElectrolysisAtmospheric air

Devices and methods are described for converting a carbon source and a hydrogen source into hydrocarbons, such as alcohols, for alternative energy sources. The influents may comprise carbon dioxide gas and hydrogen gas or water, obtainable from the atmosphere for through methods described herein, such as plasma generation or electrolysis. One method to produce hydrocarbons comprises the use of an electrolytic device, comprising an anode, a cathode and an electrolyte. Another method comprises the use of ultrasonic energy to drive the reaction. The devices and methods and related devices and methods are useful, for example, to provide a fossil fuel alternative energy source, store renewable energy, sequester carbon dioxide from the atmosphere, counteract global warming, and store carbon dioxide in a liquid fuel.

Owner:PRINCIPLE ENERGY SOLUTIONS

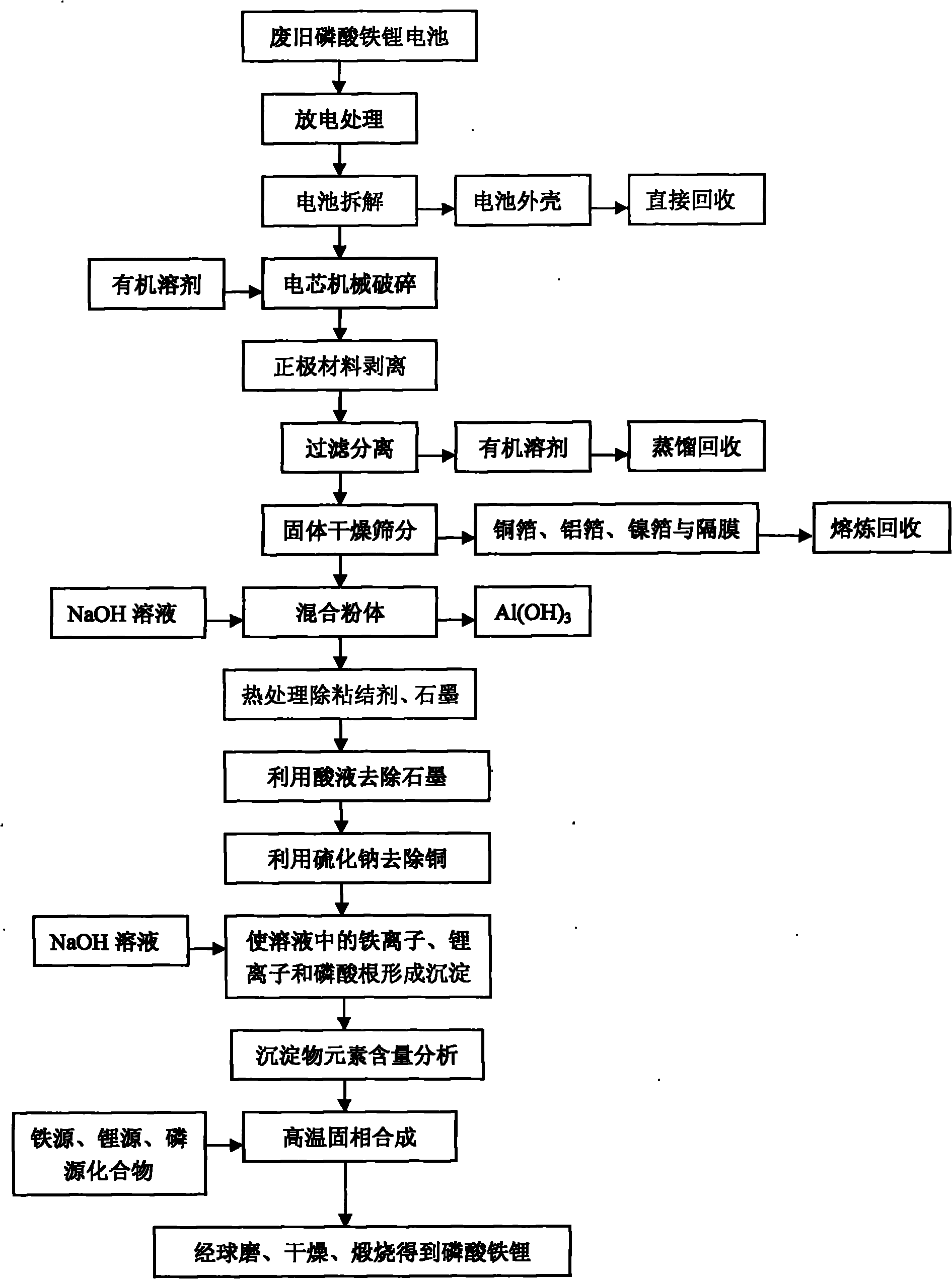

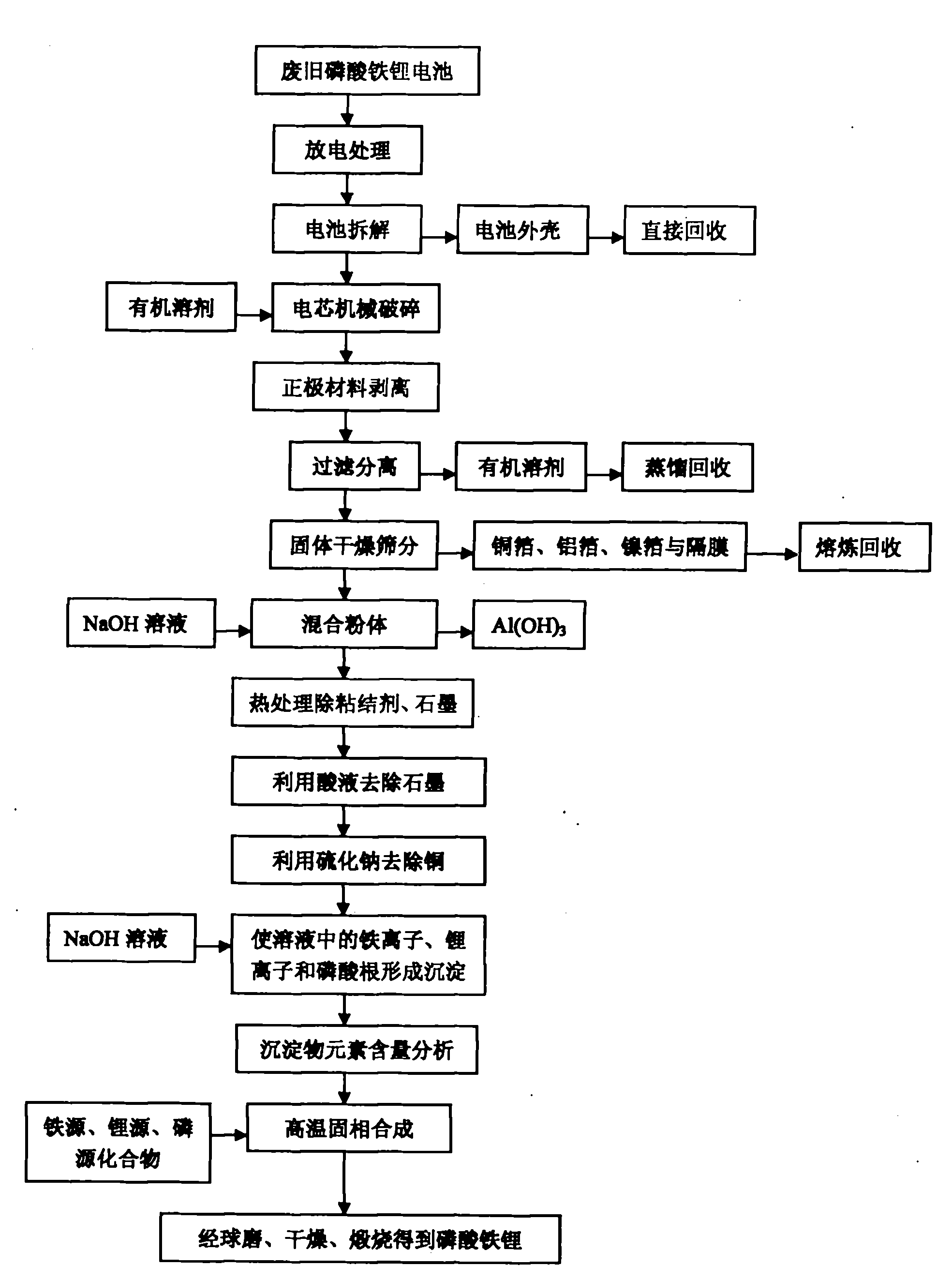

Comprehensive recovering method of waste lithium iron phosphate battery

InactiveCN101847763AImprove performanceLow priceWaste accumulators reclaimingProcess efficiency improvementAdhesiveCalcination

The invention provides a comprehensive recovering method of waste lithium iron phosphate batteries, which has simple and reasonable process, low recovering cost and high added value. The method comprises the following steps: utilizing an organic solvent to dissolve an adhesive on battery cell fragments, and realizing the separation of lithium iron phosphate material and clean aluminum and copper foils through screening, wherein the aluminum and copper foils are recovered by smelting; utilizing a NaOH solution to remove residual aluminum foil scraps in the lithium iron phosphate material, and removing graphite and remaining adhesive by heat treatment; after dissolving the lithium iron phosphate with acid, utilizing sodium sulphide to remove copper ions, and utilizing the NaOH solution or ammonia solution to allow iron, lithium and phosphorus ions in the solution to generate sediments; adding iron source, lithium source or phosphorus source compounds to adjust the molar ratio of iron, lithium and phosphorus; and finally adding a carbon source, and obtaining a lithium iron phosphate cathode material through ball milling and calcination in inert atmosphere. After the treatment of the steps, the recovery rate of valuable metals in the batteries is more than 95%, and the comprehensive recovery rate of the lithium iron phosphate cathode material is more than 90%.

Owner:CHERY AUTOMOBILE CO LTD

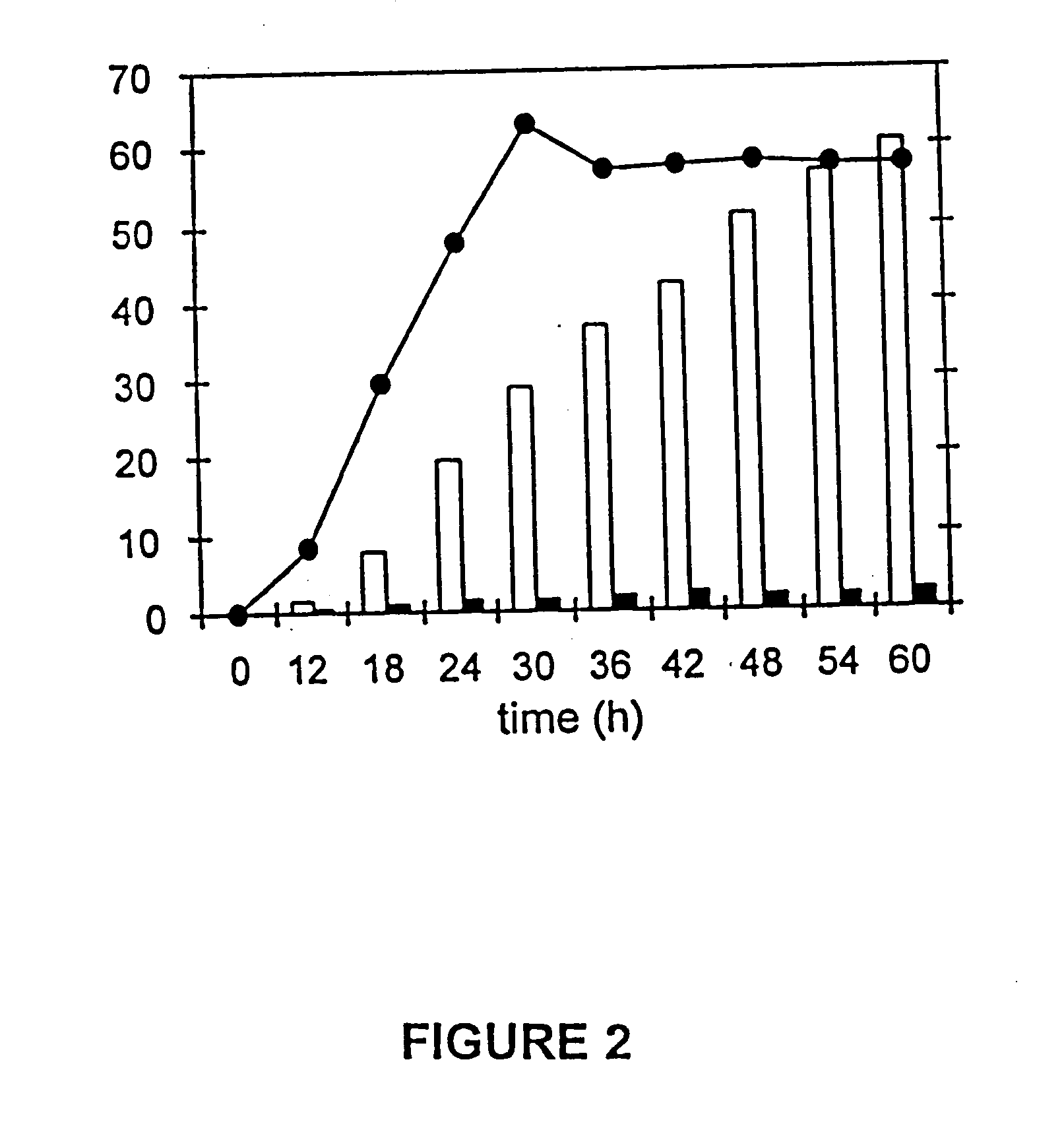

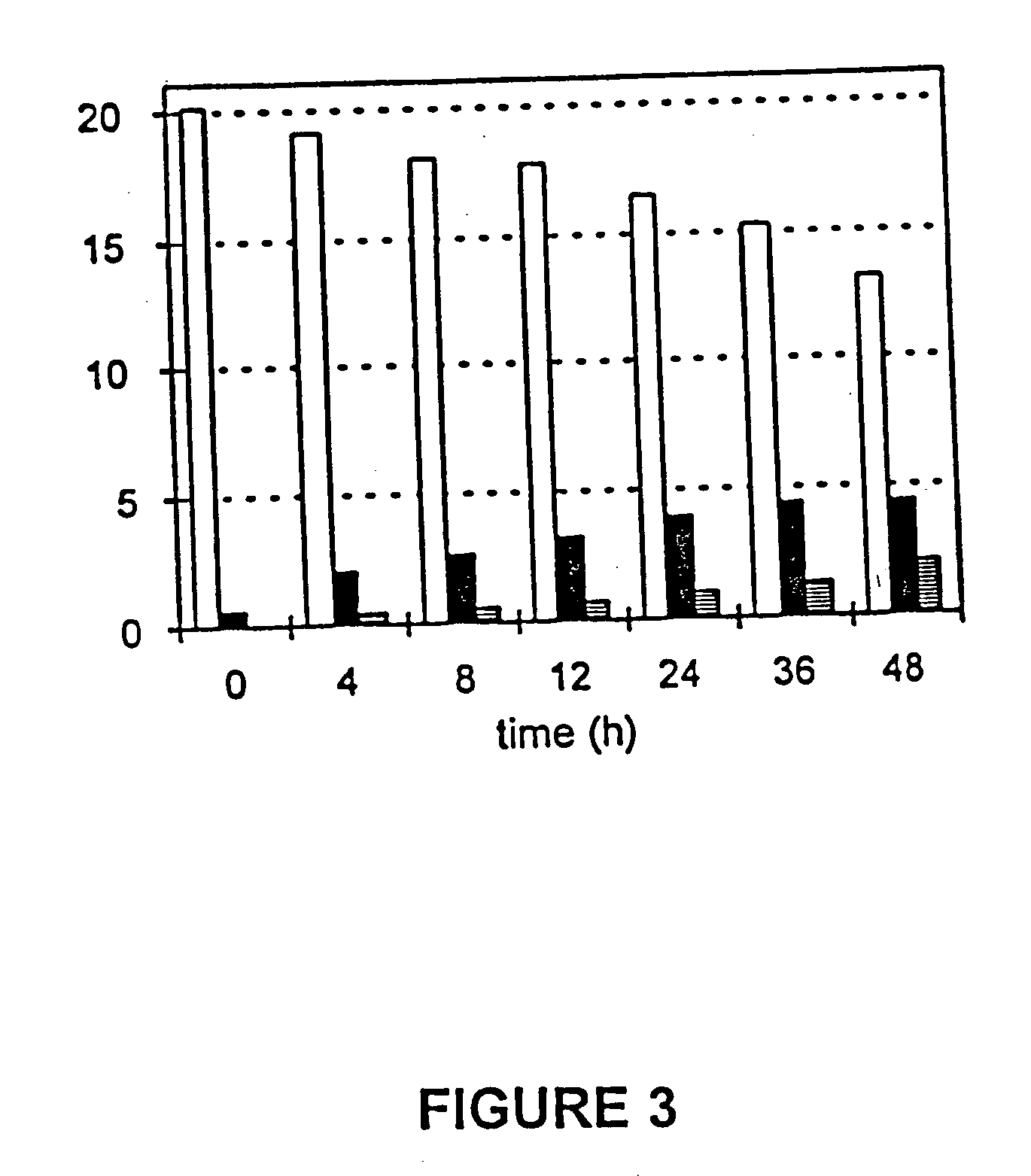

Process for the biological production of 1,3-propanediol with high yield

The present invention provides a microorganism useful for biologically producing 1,3-propanediol from a fermentable carbon source at higher yield than was previously known. The complexity of the cofactor requirements necessitates the use of a whole cell catalyst for an industrial process that utilizes this reaction sequence to produce 1,3-propanediol. The invention provides a microorganism with disruptions in specified genes and alterations in the expression levels of specified genes that is useful in a higher yielding process to produce 1,3-propanediol.

Owner:NUTRITION & BIOSCIENCES USA 4 INC +1

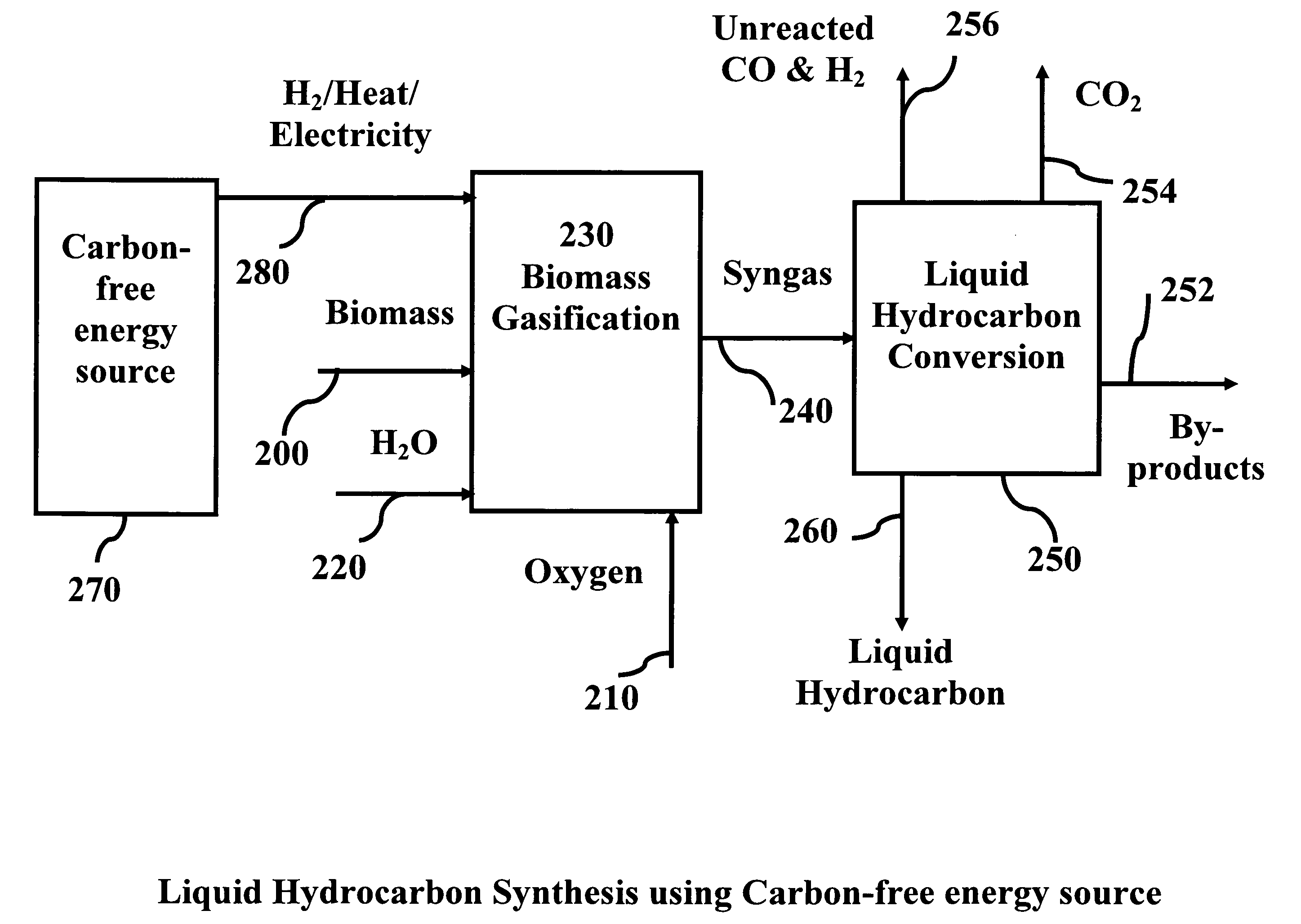

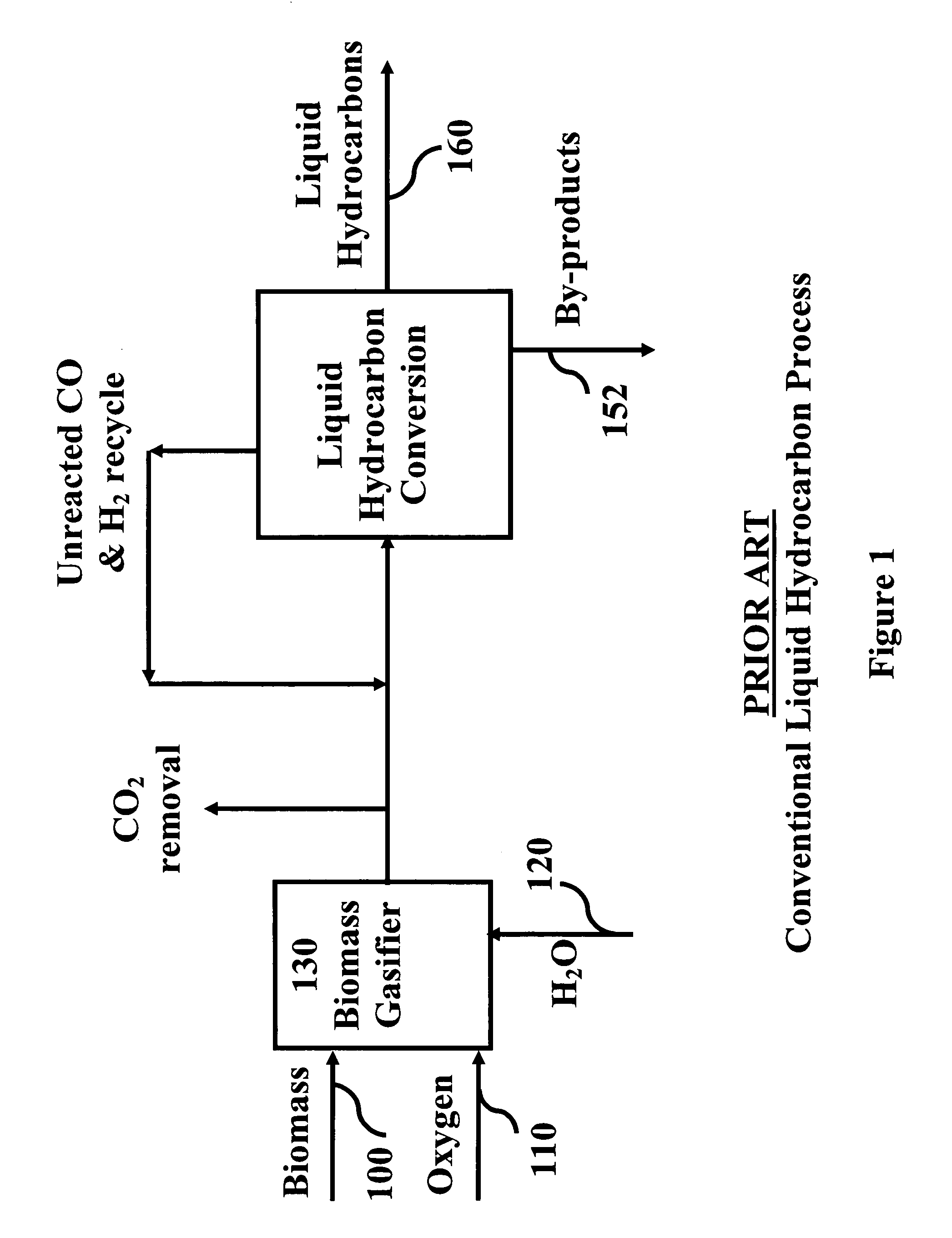

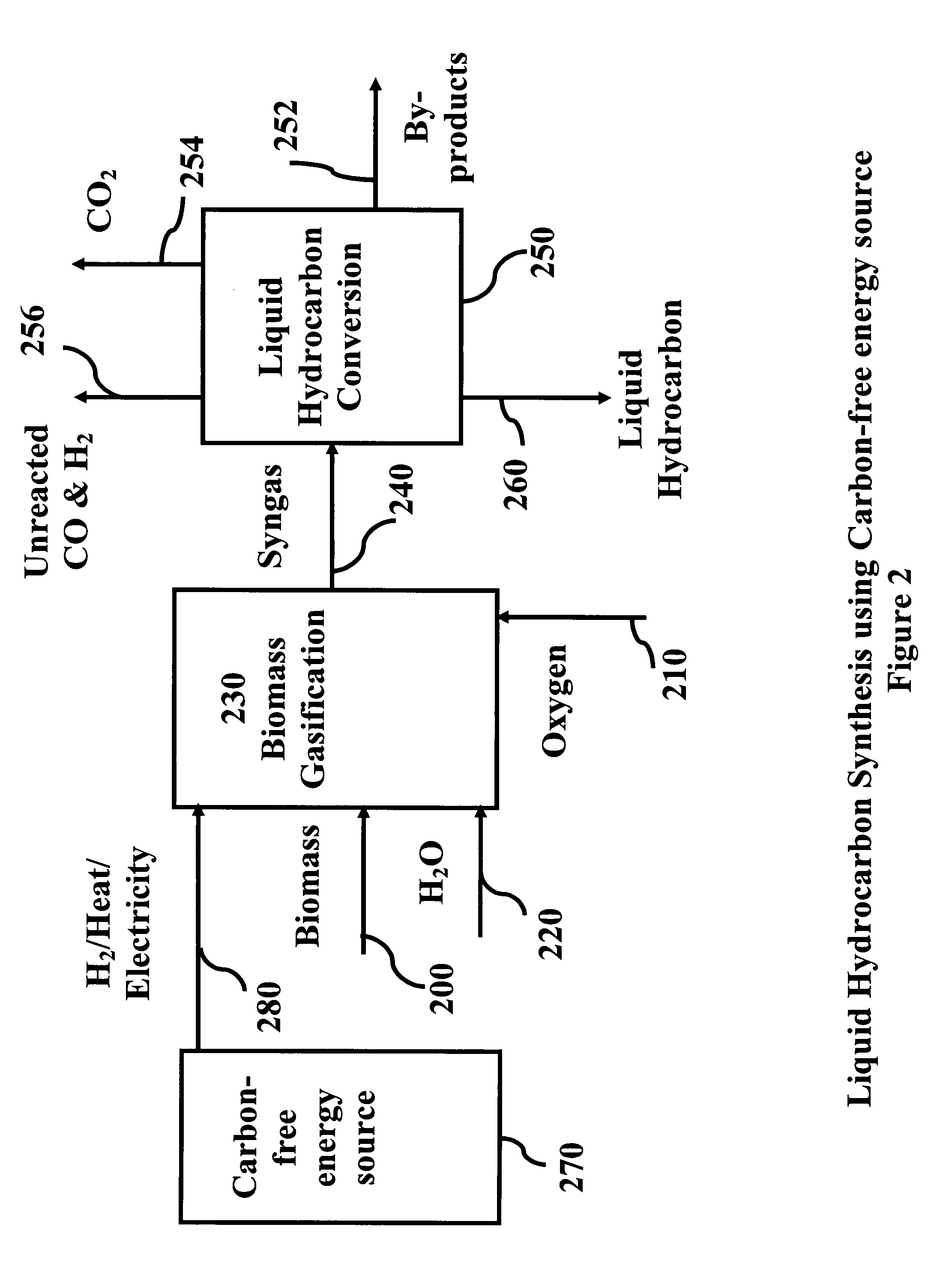

System and process for producing synthetic liquid hydrocarbon

ActiveUS20080115415A1Improve carbon efficiencyReduce area requirementsMuffle furnacesCarbon compoundsOxygenElectrolysis of water

Production of synthetic liquid hydrocarbon fuel from carbon containing moieties such as biomass, coal, methane, naphtha as a carbon source and hydrogen from a carbon-free energy source is disclosed. The biomass can be fed to a gasifier along with hydrogen, oxygen, steam and recycled carbon dioxide. The synthesis gas from the gasifier exhaust is sent to a liquid hydrocarbon conversion reactor to form liquid hydrocarbon molecules. Unreacted CO & H2 can be recycled to the gasifier along with CO2 from the liquid hydrocarbon conversion reactor system. Hydrogen can be obtained from electrolysis of water, thermo-chemical cycles or directly by using energy from carbon-free energy sources.

Owner:PURDUE RES FOUND INC

Method for producing carbon coated nano stage lithium iron phosphate by precipitation

InactiveCN101393982AAvoid synthetic stepsEasy to controlElectrode manufacturing processesIron saltsPhosphate

The invention discloses a precipitation method for preparing nanometer level iron phosphate lithium coated with carbon. The method comprises the following steps: firstly, weighing iron salt, deionized water and a compound of metallic elements; after the stirring and the mixing are performed, adding a phosphorous compound and citric acid diluted with water to the mixture; after the stirring is performed again, adding a precipitation agent to the mixture and controlling to the neutrality; stirring to react in a container, and after the static placement, respectively adding the deionized water, a carbon source and lithium salt to mix uniformly after the precipitate is filtered and washed; stirring again to react, and drying the water at 30 to 160 DEG C and warming up at the heating rate under the protection of non-oxidized gas after a product is crashed; baking at a constant temperature of 450 to 850 DEG C, cooling down to a room temperature at a cooling rate or with a stove, and finally obtaining the nanometer level ferric phosphate lithium coated with the carbon after crashing is performed. The precipitation method has the advantage that the raw material cost and the processing cost are low because bivalent iron is taken as the raw material. The iron phosphate lithium prepared by using the process has the characteristics of good physical processing performance and good electrochemistry performance, and is suitable for industrialized production.

Owner:南京海泰纳米材料有限公司

Graphene foam with three dimensional fully connected network and macroscopic quantity preparation method thereof

The invention relates to a graphene-based novel material and a chemical vapor deposition preparation technology thereof, in particular to graphene foam with a three dimensional fully connected network and a macroscopic quantity preparation method thereof. The method is suitable for a mass preparation of the graphene foam with high qualities. Three dimensional connected graphene can grow by catalytic cracking of carbon source gases on the surface of a three dimensional porous metal through the chemical vapor deposition technology, and a porous foam-shaped graphene three dimensional macroscopic body can be obtained after a porous metal base is removed by dissolving subsequently. According to the graphene foam with the three dimensional fully connected network and the macroscopic quantity preparation method thereof, a simple template replication method is used for preparing the three dimensional connected graphene macroscopic body, and the method has the advantages that the operation is simple and convenient, the rate of production is high, and the adjustment and control of the structure are easy. The graphene foam forms the fully connected network in a seamless connection mode, has a low density, a high porosity and specific surface area and excellent capabilities of charge conduction and heat conduction and establishes a foundation for applications of graphene in fields of electric conduction, thermally conductive composite materials, electromagnetic shielding, wave absorbing, catalysis, sensing and energy storage materials and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

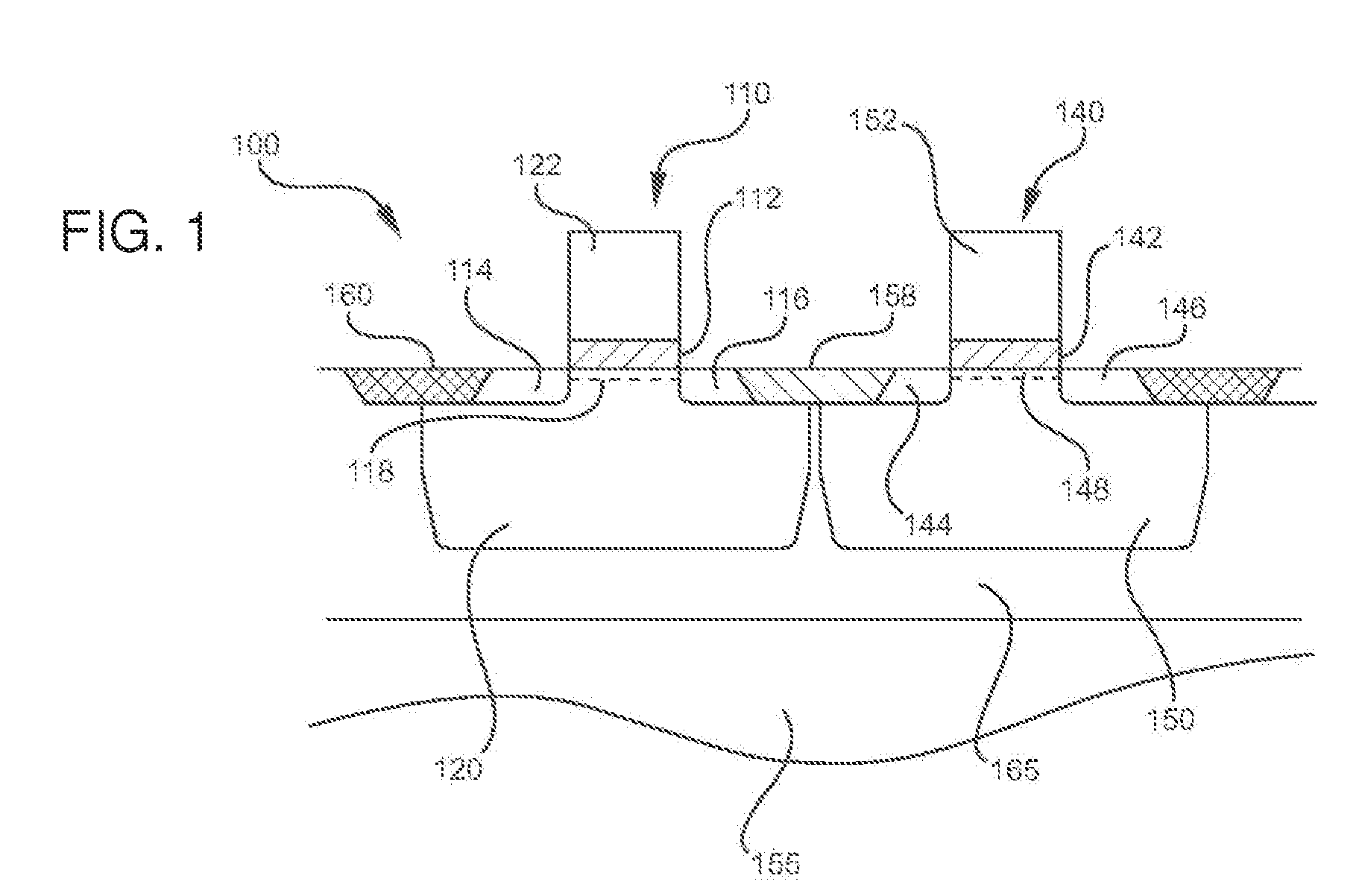

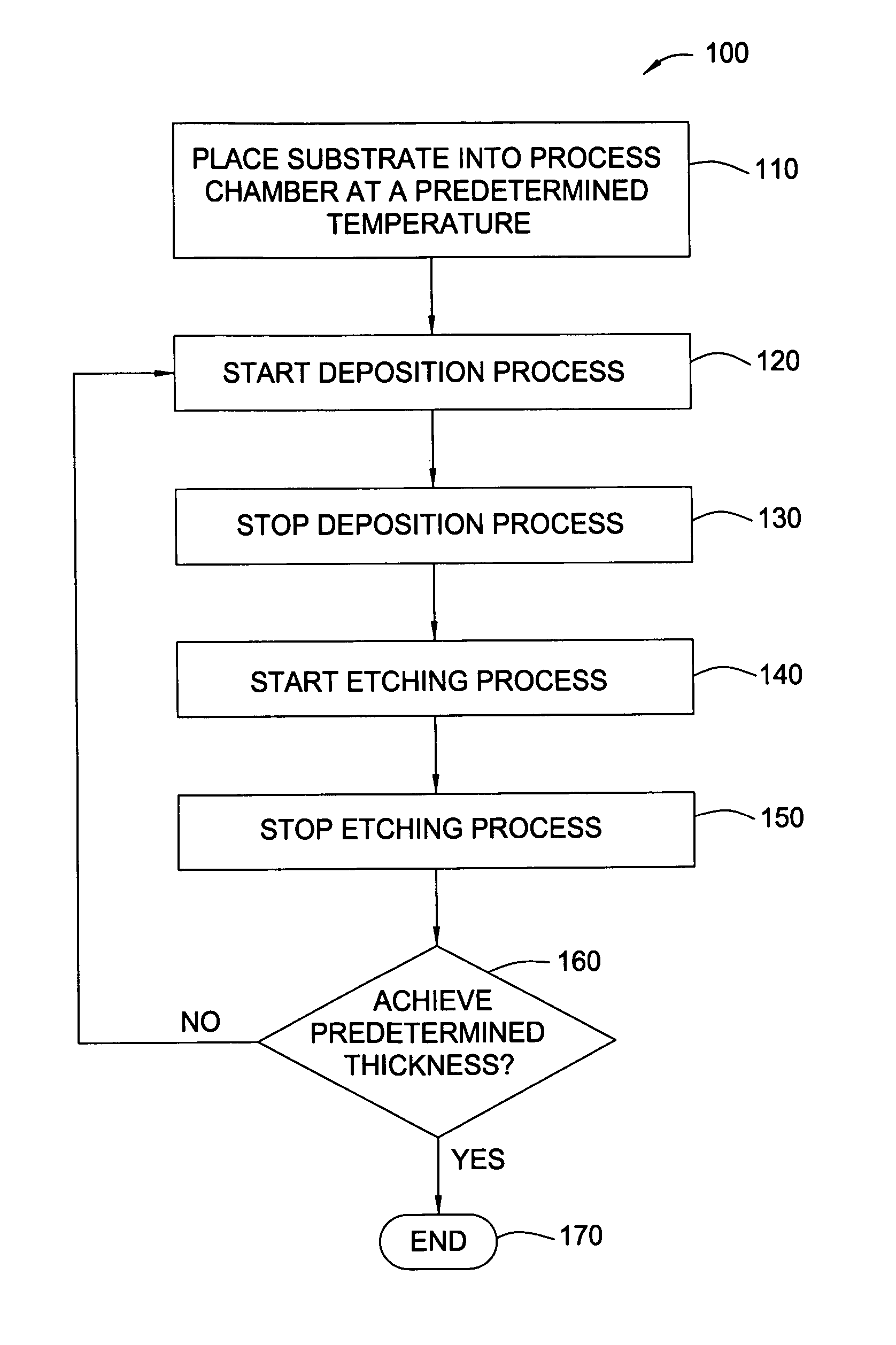

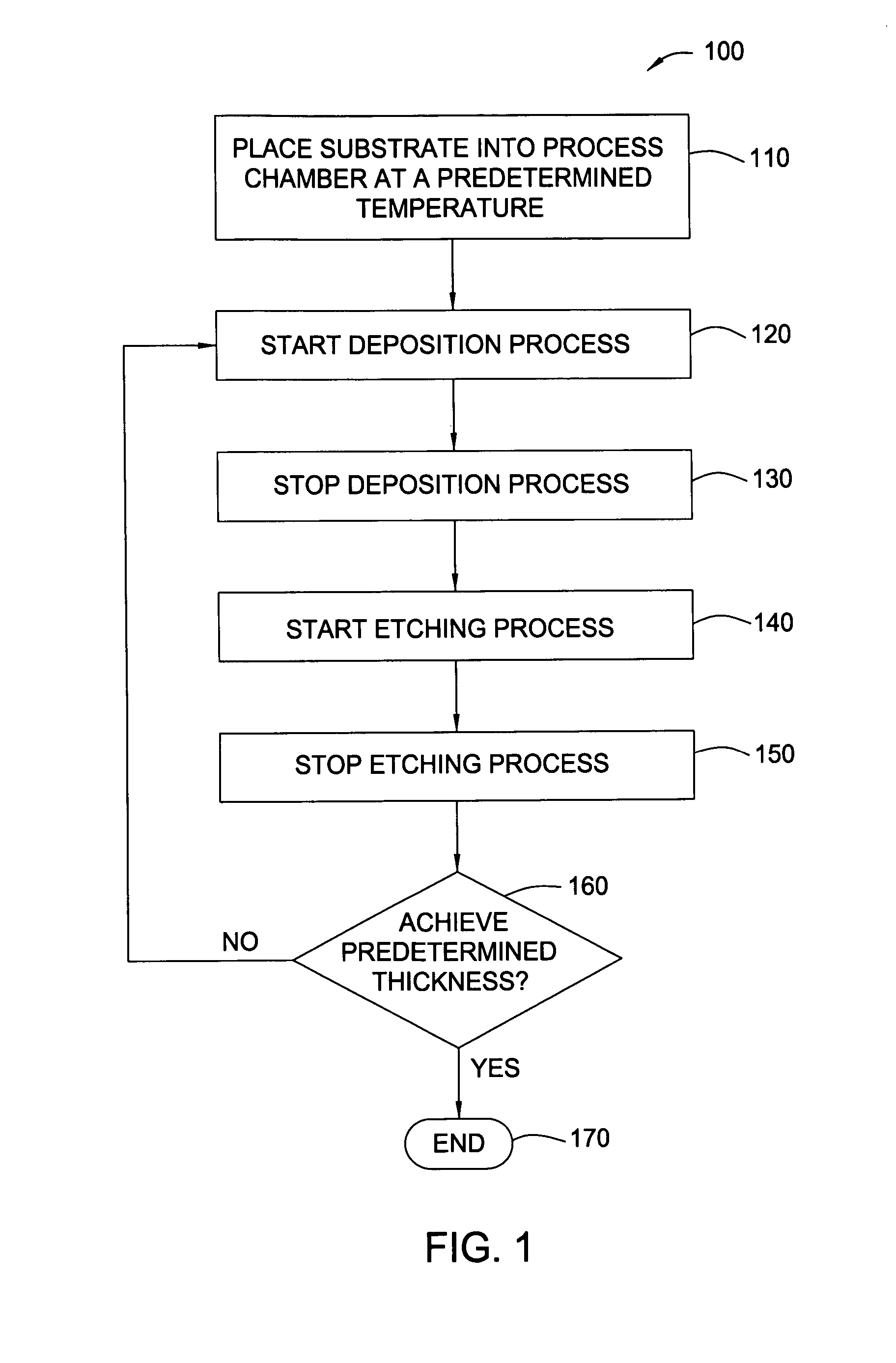

Selective epitaxy process with alternating gas supply

ActiveUS20060115934A1Semiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalGas supply

In one example, a method of epitaxially forming a silicon-containing material on a substrate surface is presented which includes positioning a substrate into a process chamber. The substrate has a monocrystalline surface and at least a second surface, such as an amorphous surface and / or a polycrystalline surface. The substrate is exposed to a deposition gas to deposit an epitaxial layer on the monocrystalline surface and a polycrystalline layer on the second surface. The deposition gas preferably contains a silicon source and at least a second elemental source, such as a germanium source, a carbon source and / or combinations thereof. Thereafter, the method further provides exposing the substrate to an etchant gas to etch the polycrystalline layer and the epitaxial layer in a manner such that the polycrystalline layer is etched at a faster rate than the epitaxial layer. The method may further include a deposition cycle that includes repeating the exposure of the substrate to the deposition and etchant gases to form a silicon-containing material with a predetermined thickness.

Owner:APPLIED MATERIALS INC

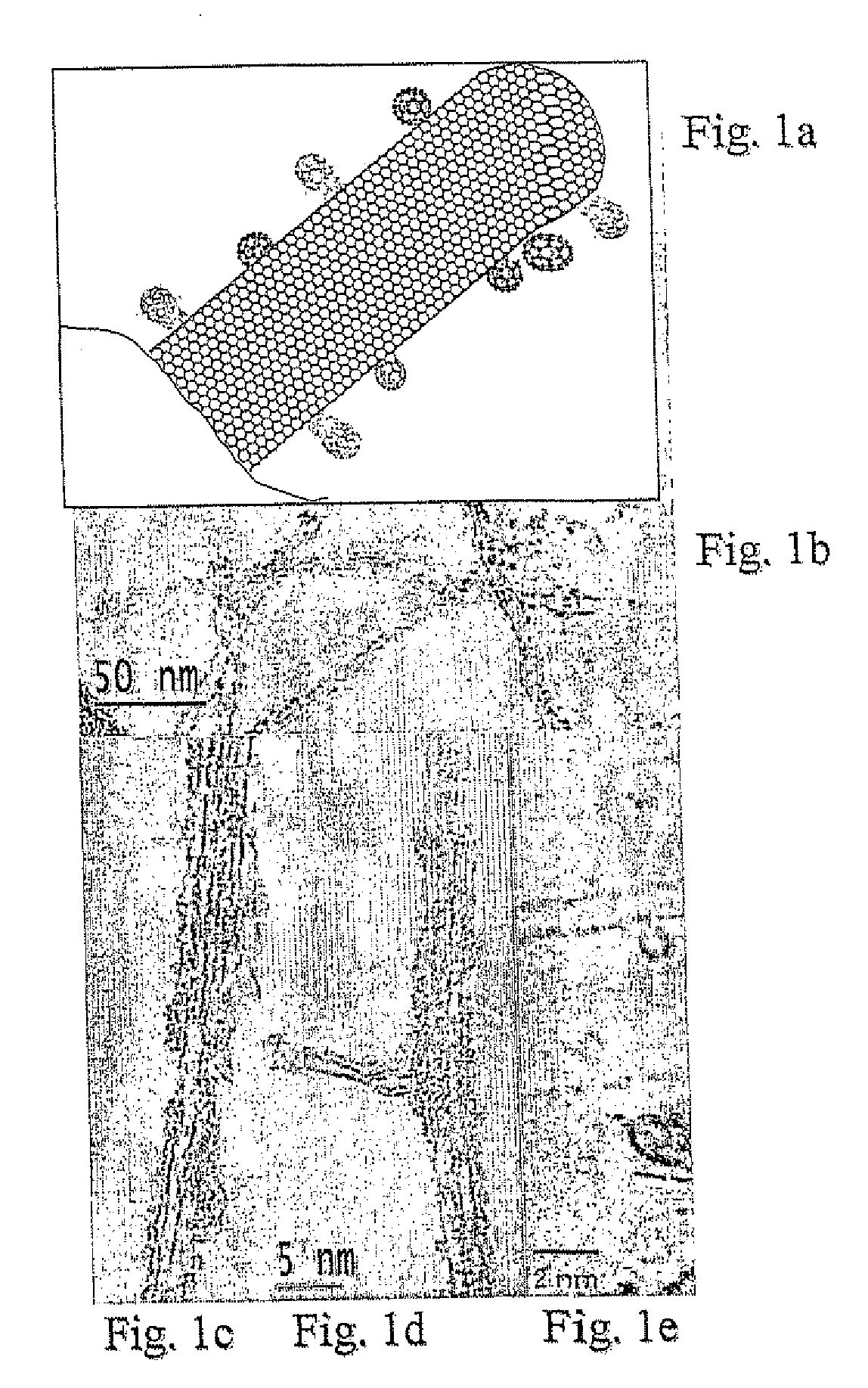

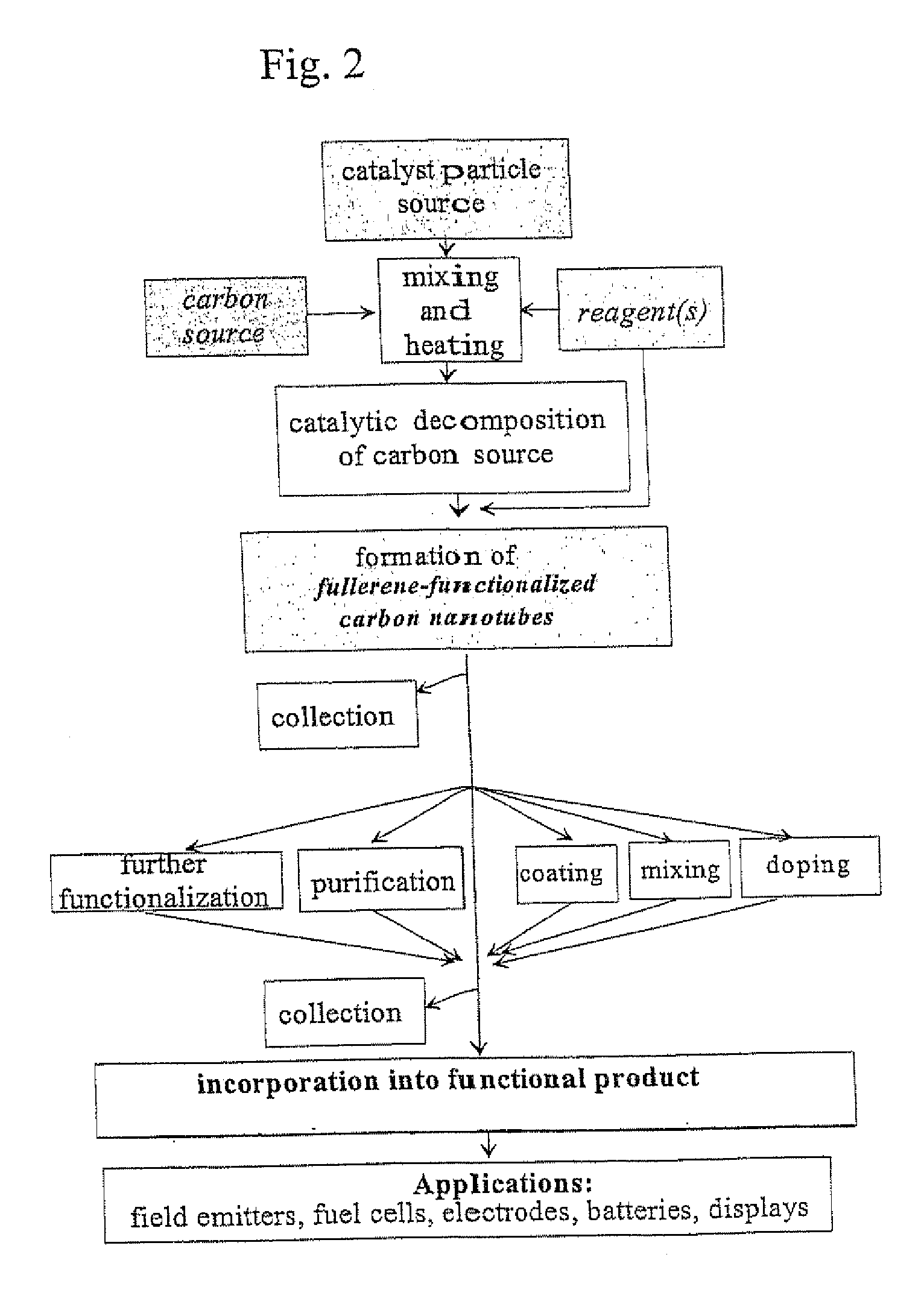

Carbon nanotubes functionalized with fullerenes

InactiveUS20090226704A1Enhancement in cold electron field emissionImprove mechanical propertiesSpecific nanostructure formationMaterial nanotechnologyC60 fullereneNanotube

The present invention relates to covalently bonded fullerene-functionalized carbon nanotubes (CBFFCNTs), a method and an apparatus for their production and to their end products. CBFFCNTs are carbon nanotubes with one or more fullerenes or fullerene based molecules covalently bonded to the nanotube surface. They are obtained by bringing one or more catalyst particles, carbon sources and reagents together in a reactor.

Owner:CANATU OY

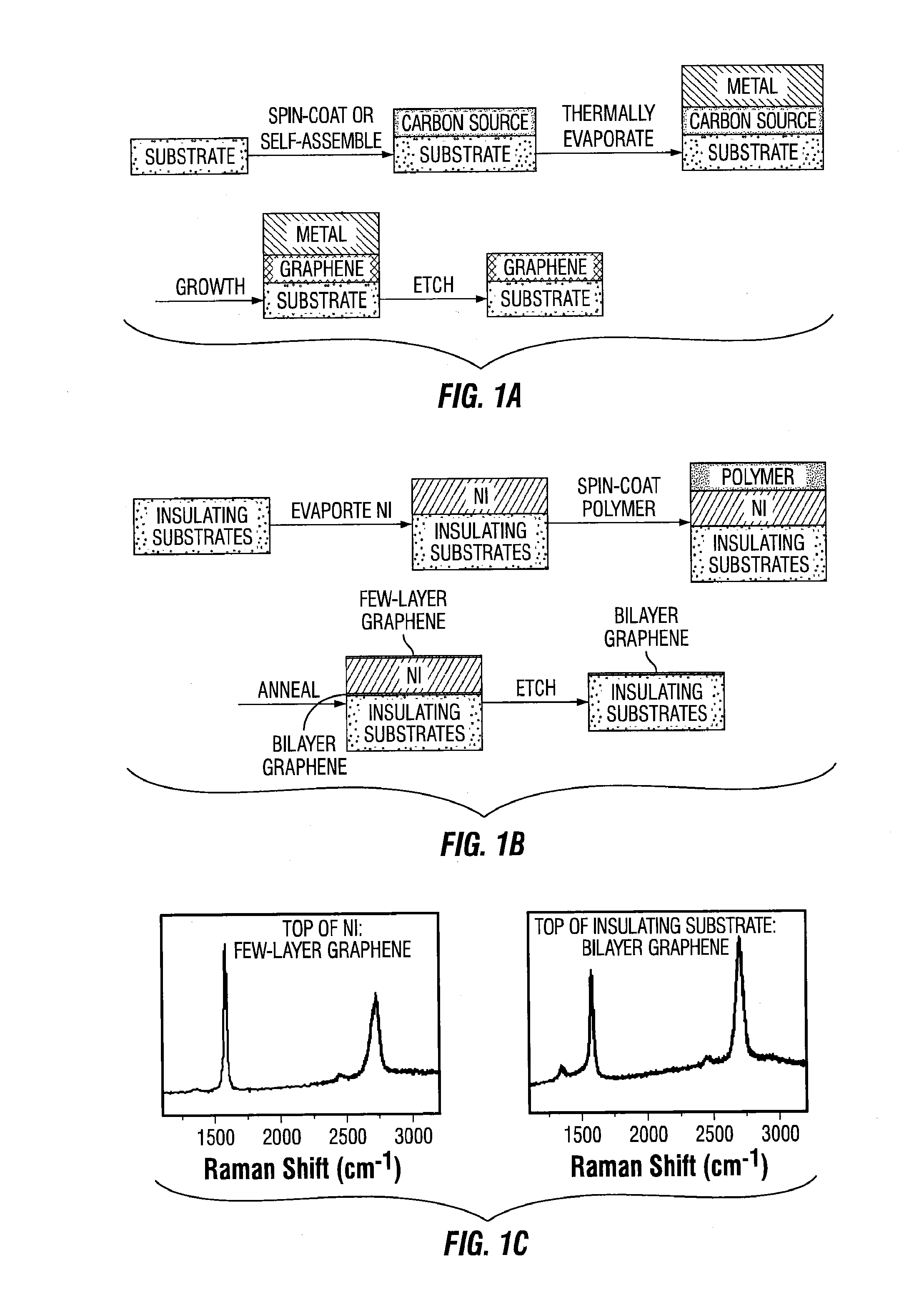

Direct growth of graphene films on non-catalyst surfaces

The present invention provides methods of forming graphene films on various non-catalyst surfaces by applying a carbon source and a catalyst to the surface and initiating graphene film formation. In some embodiments, graphene film formation may be initiated by induction heating. In some embodiments, the carbon source is applied to the non-catalyst surface before the catalyst is applied to the surface. In other embodiments, the catalyst is applied to the non-catalyst surface before the carbon source is applied to the surface. In further embodiments, the catalyst and the carbon source are applied to the non-catalyst surface at the same time. Further embodiments of the present invention may also include a step of separating the catalyst from the formed graphene film, such as by acid etching.

Owner:RICE UNIV

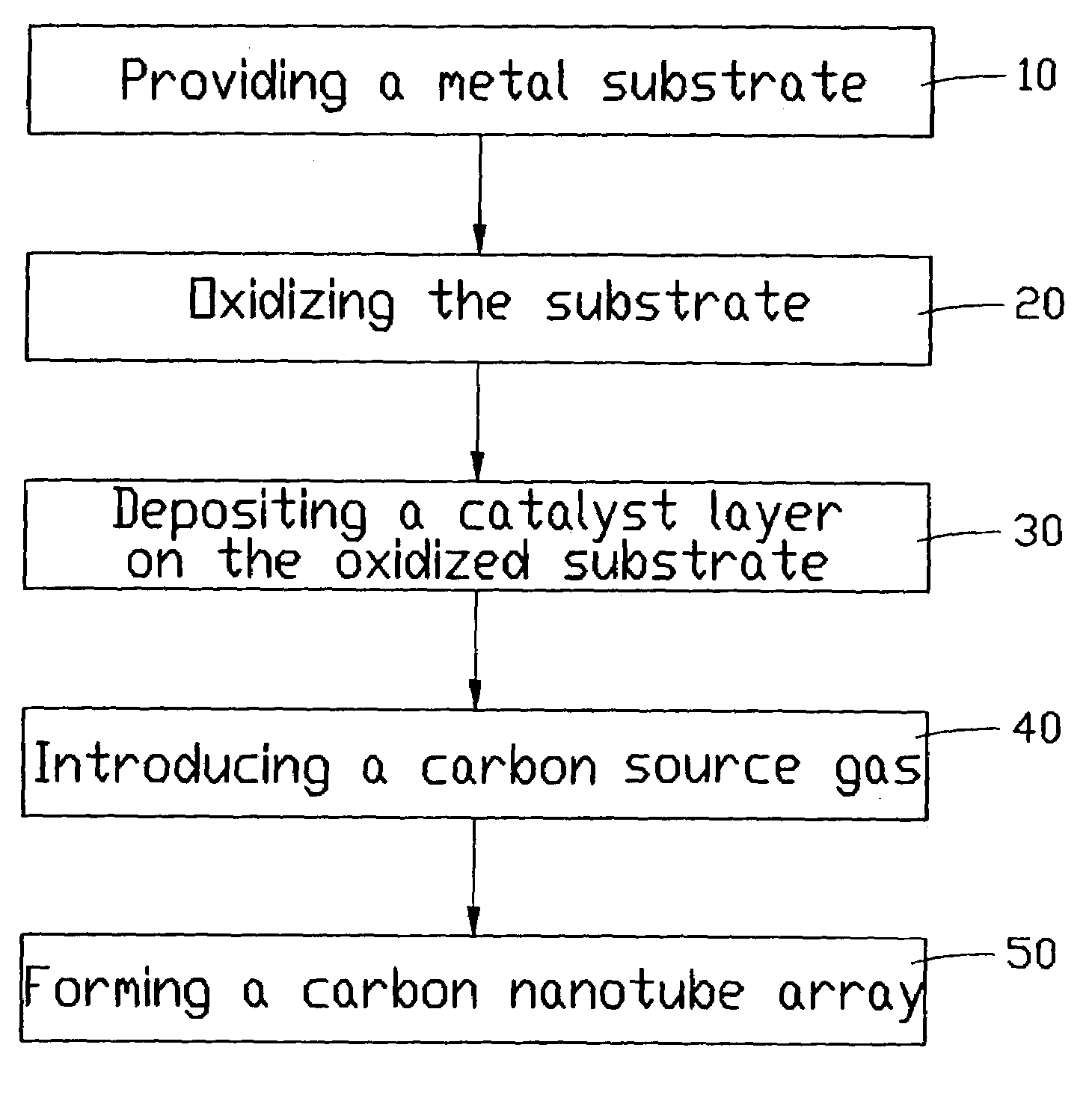

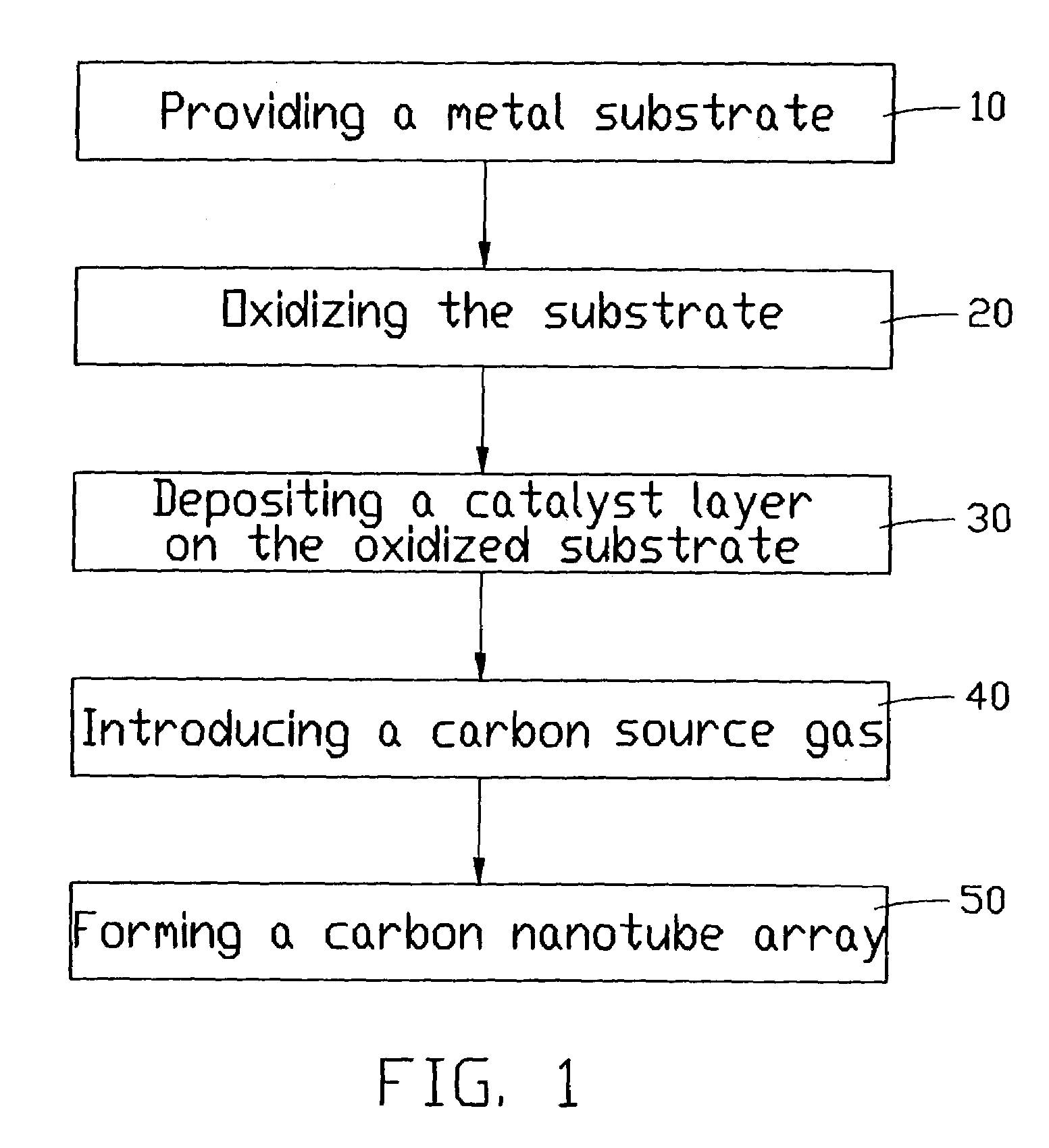

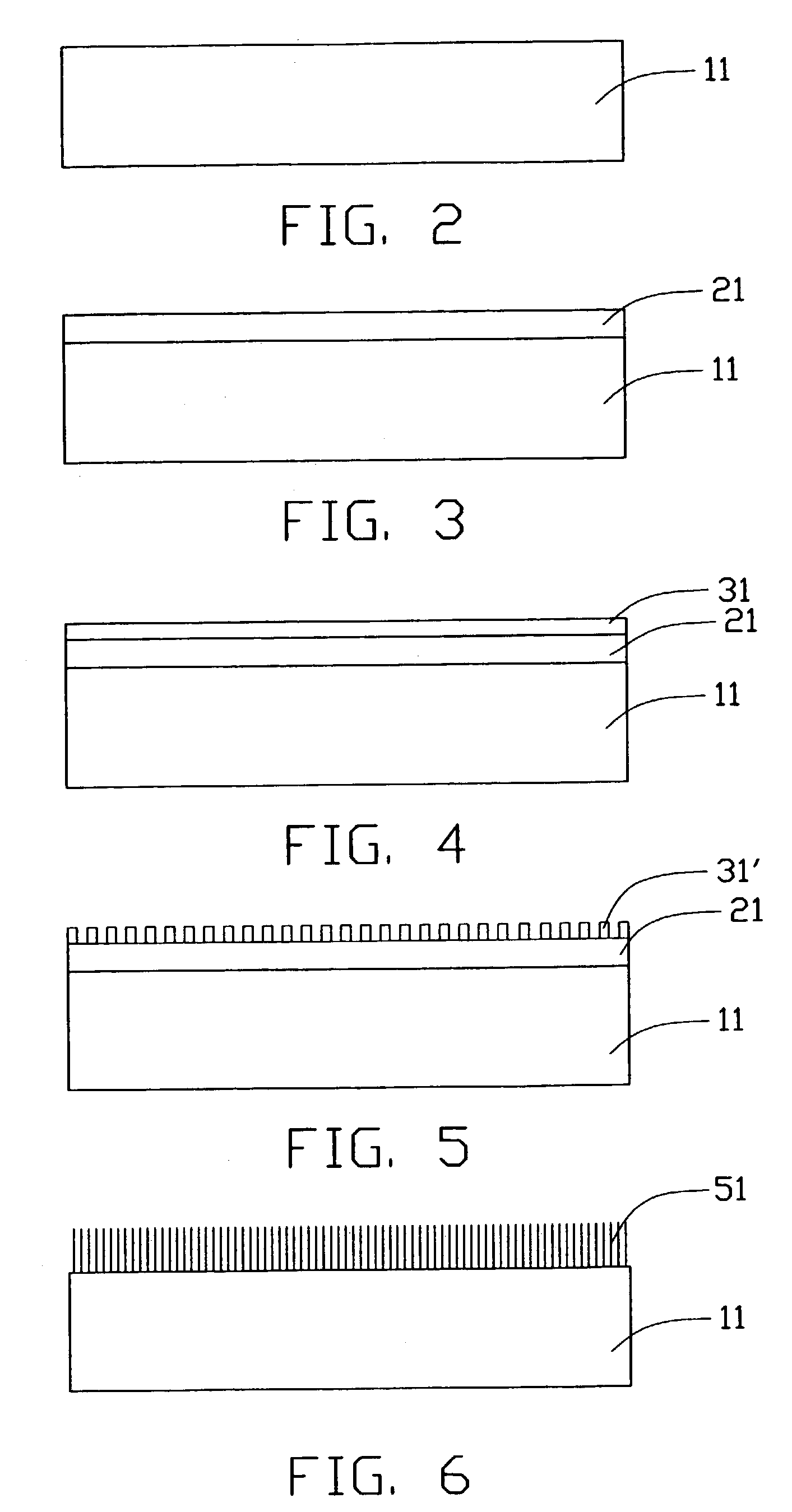

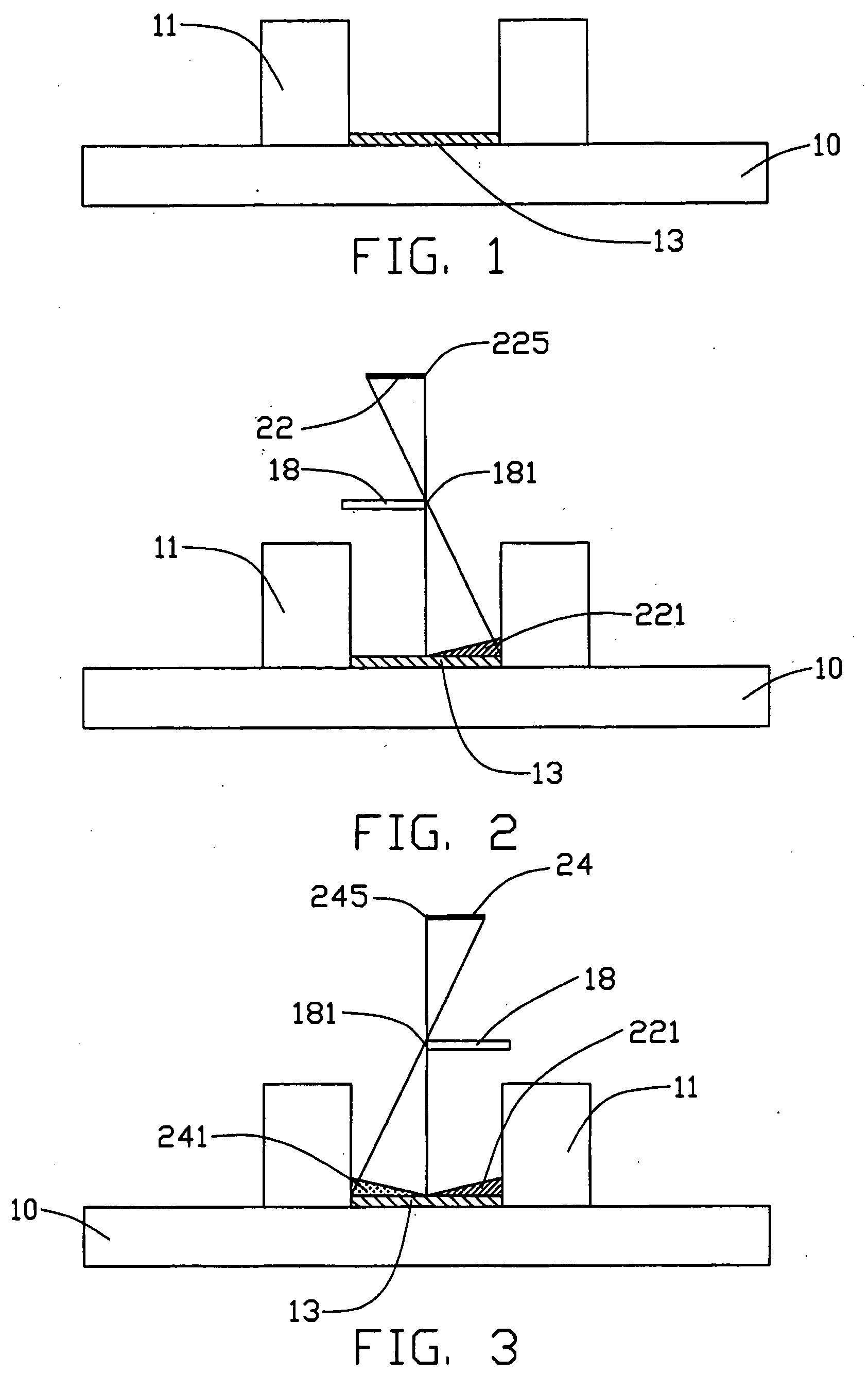

Carbon nanotube array and method for forming same

ActiveUS7160532B2Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceCarbon nanotube

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

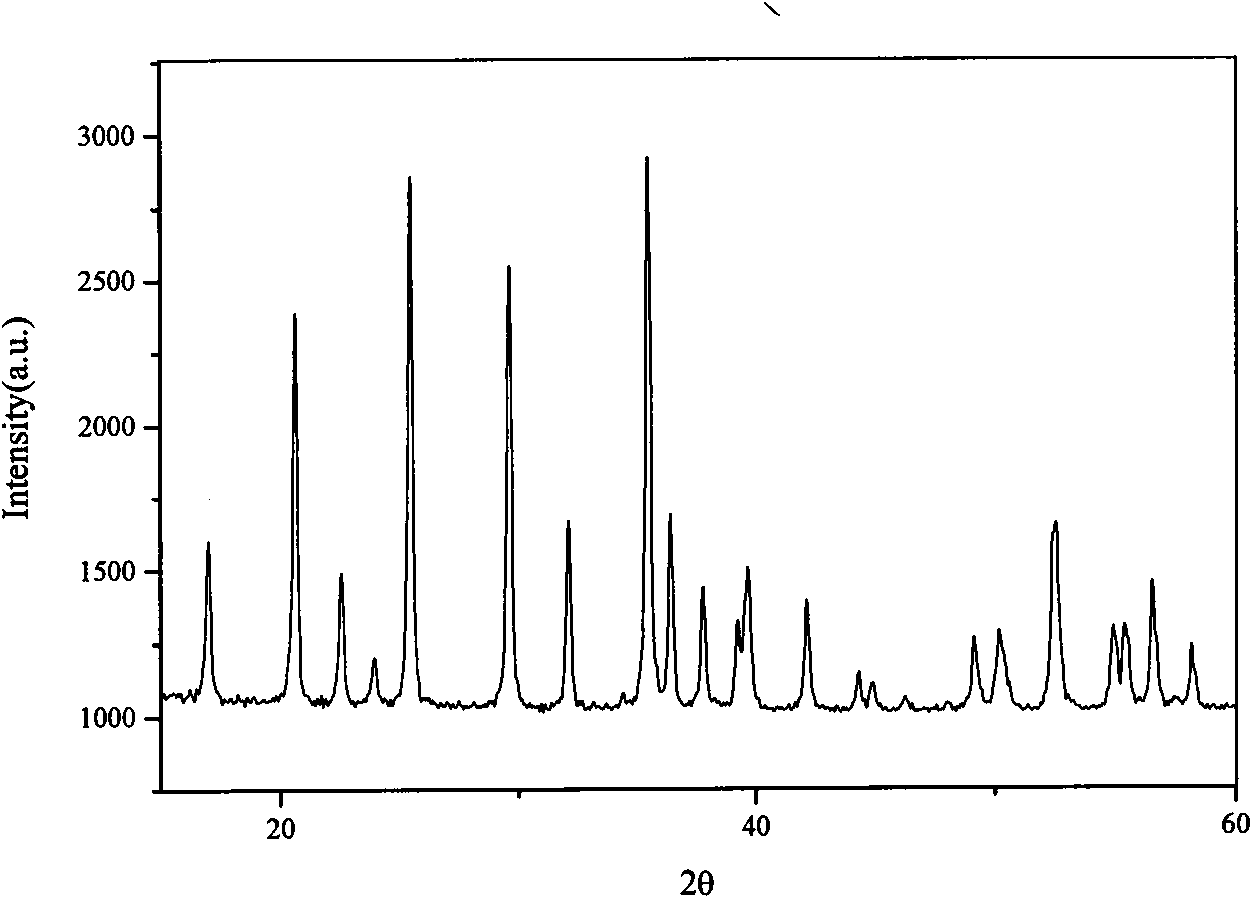

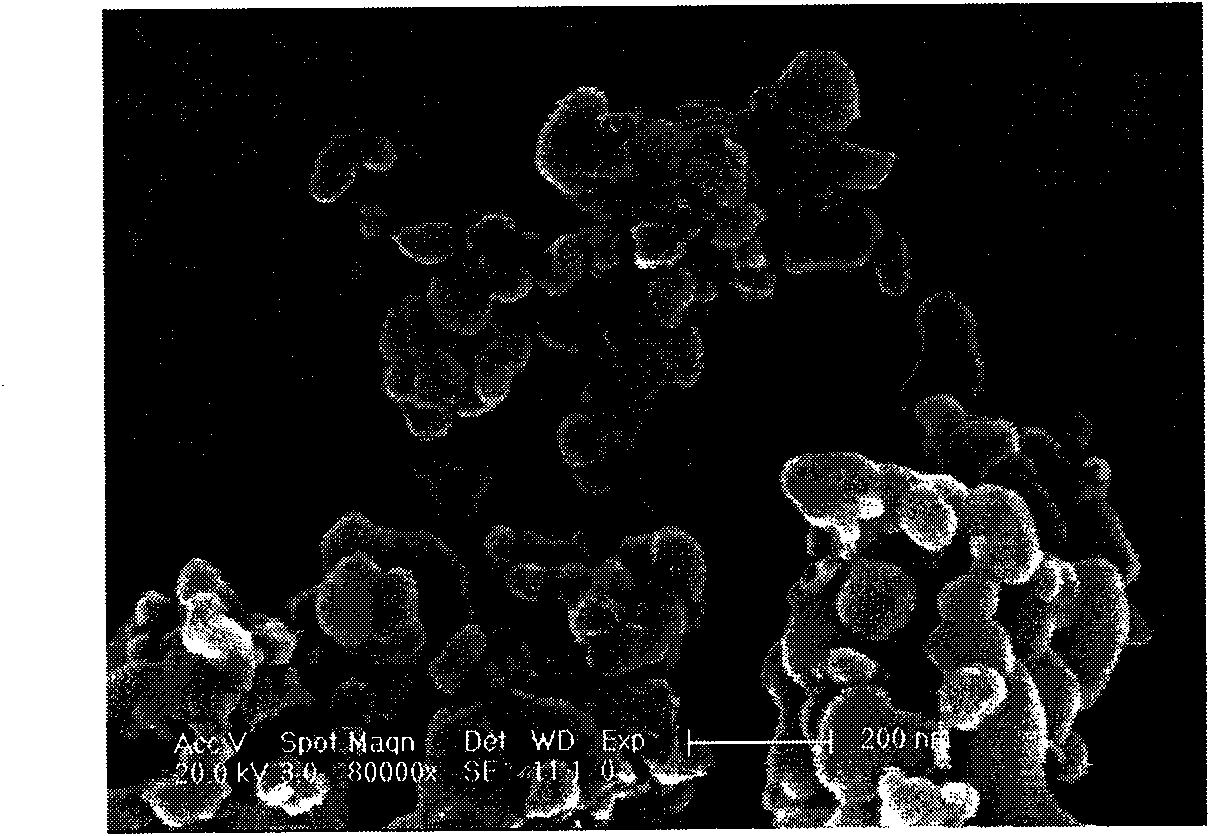

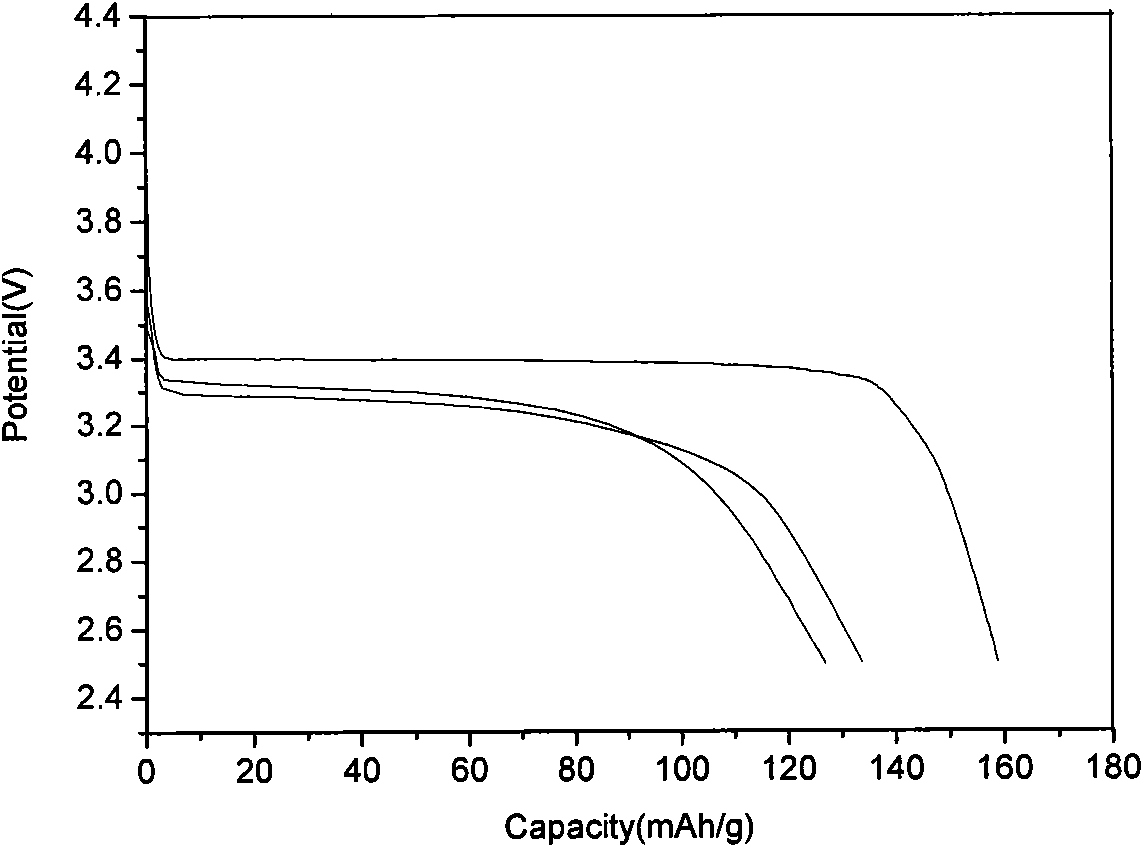

Method for preparing nanometer ferrous phosphate lithium /carbon composite material

InactiveCN101582498ARich sourcesLow priceElectrode manufacturing processesCapacitanceCarbon composites

The invention belongs to energy materials, particularly relating to a method for preparing nanometer ferrous phosphate lithium / carbon composite material. In the invention, ferrous source, lithium source, phosphorus source are mixed with a small quantity of doped metal salt and organic macromolecular polymer carbon source according to certain ratio followed by the steps of ball milling, parching and calcining. High temperature sintering is carried out on the above mixture in the atmosphere of non-oxidation gas to obtain nanometer lithium iron phosphate LiMxFe(1-x)PO4 / C coated with carbon and LiFe(1-x)NxPO4 / C material, and the particle sizes of which are remarkably reduced and are less than 100nm. When the material is applied to battery assemble, 0.2C multiplying power discharge capacity can reach above 160mAh / g at room temperature, 1C multiplying power discharge capacity can be 140-155mAh / g, and 5C multiplying power discharge capacity is 130-150mAh / g. the initial capacity is 120-140mAh / g under the large multiplying power of 10C, and remains more than 90% through thousands of cycles, demonstrating good multiplying power and cycle properties. The invention features low cost, simple production process and fine safety. The prepared nanometer ferrous phosphate lithium / carbon composite material can be widely applied into manufacturing of convenient and fast equipment, electric vehicles and the like.

Owner:NORTHEAST NORMAL UNIVERSITY

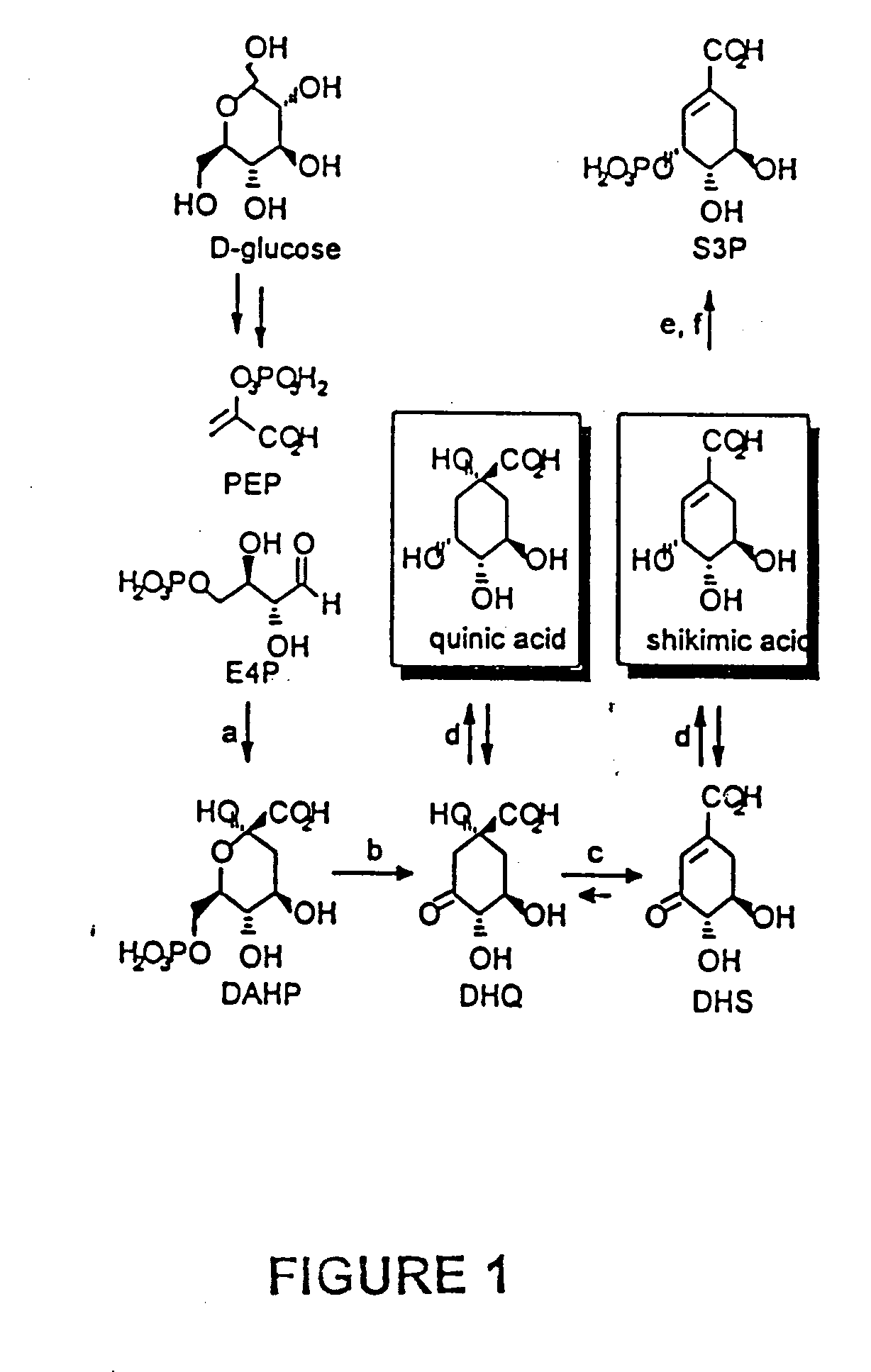

Biocatalytic synthesis of quinic acid and conversion to hydroquinone

A bioengineered synthesis scheme for the production of quinic acid from a carbon source is provided. Methods of producing quinic acid from a carbon source based on the synthesis scheme as well as conversion of quinic acid to hydroquinone are also provided.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

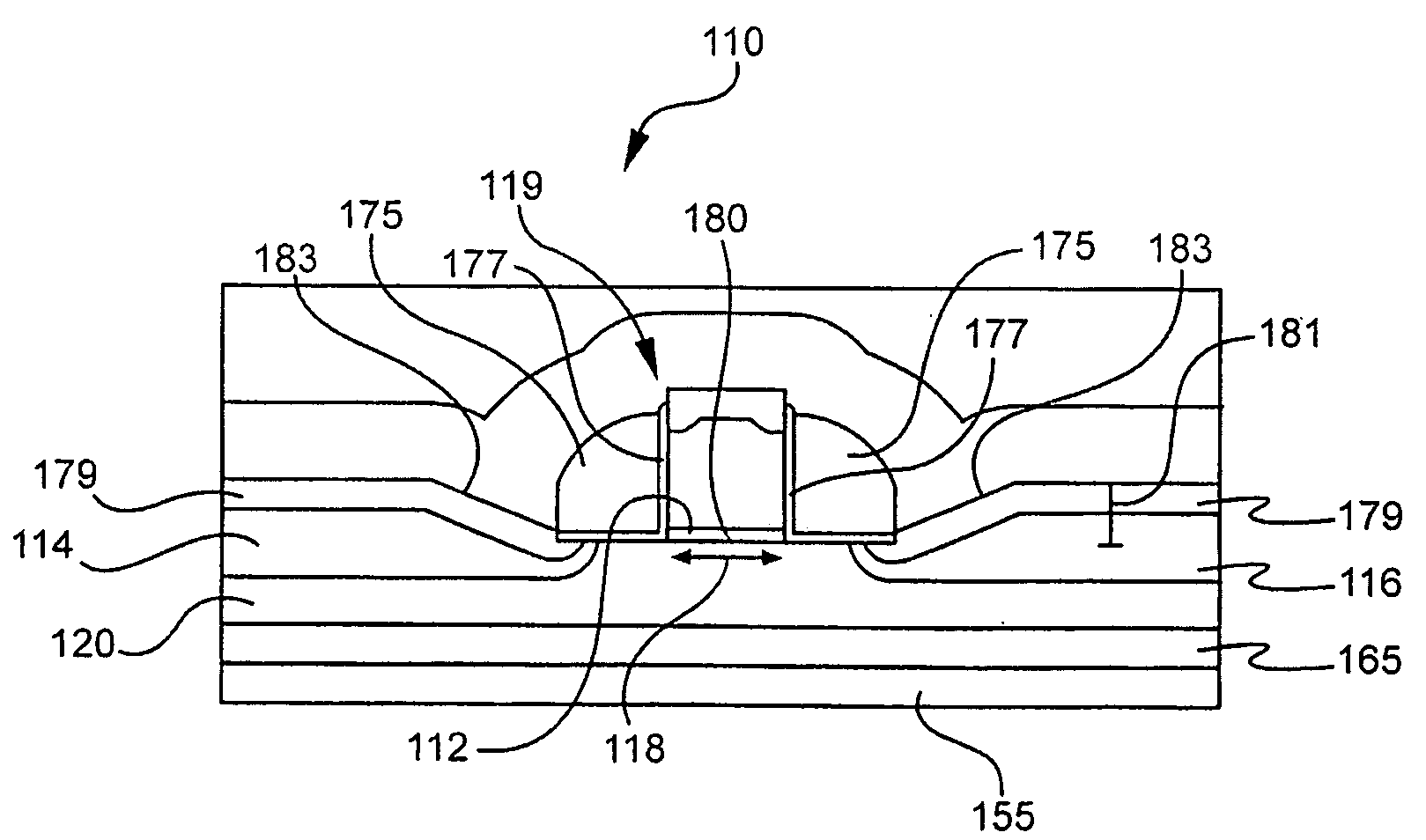

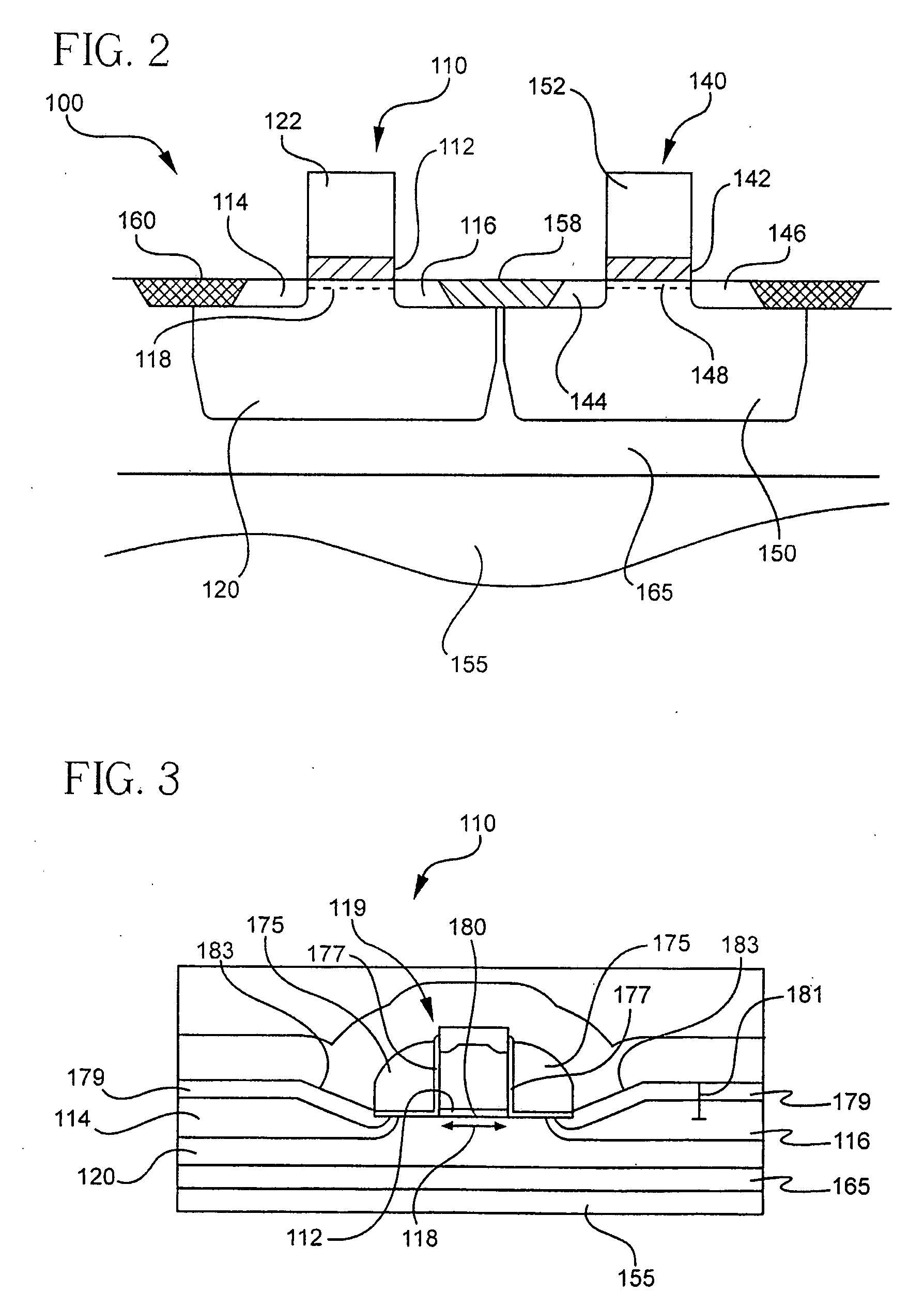

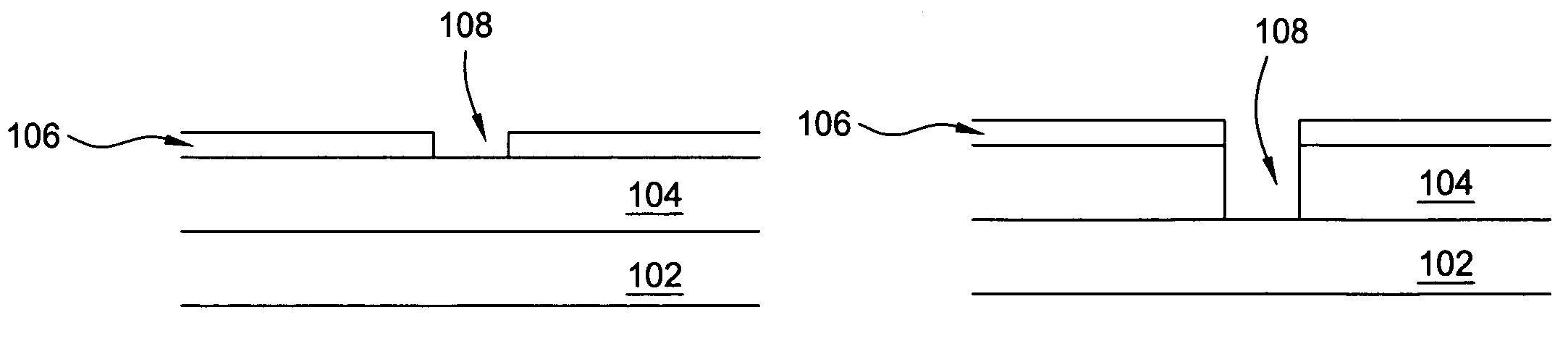

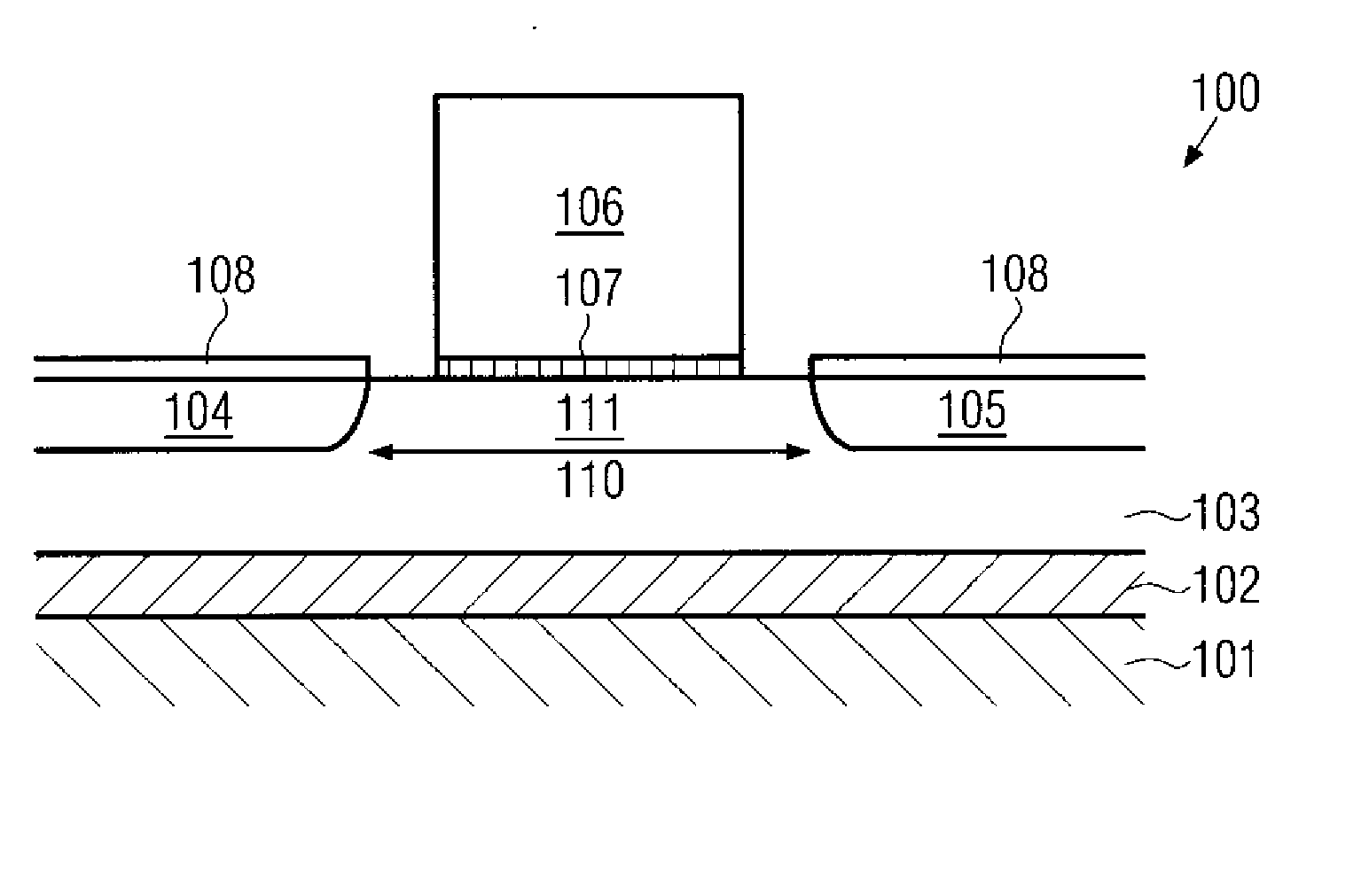

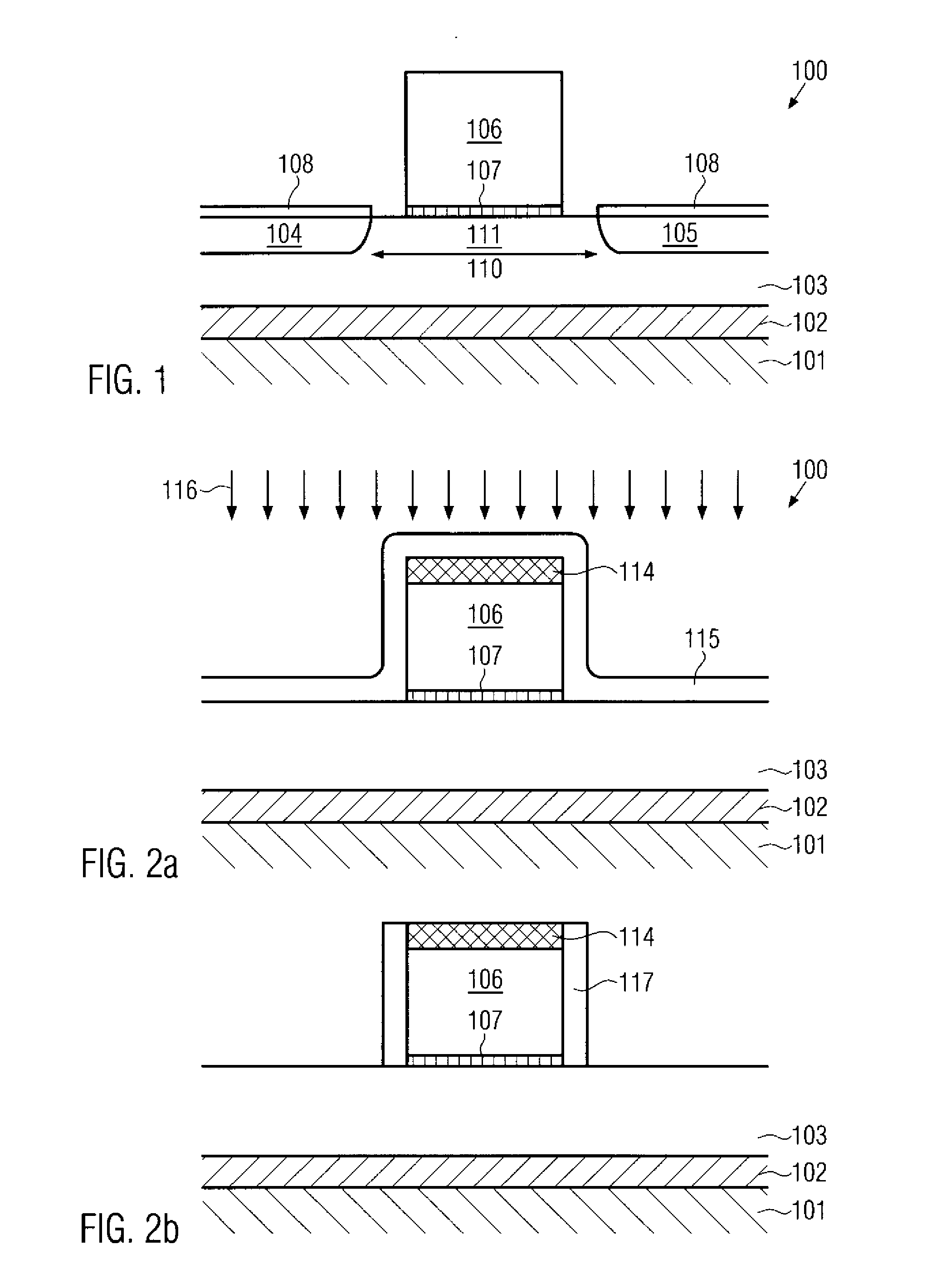

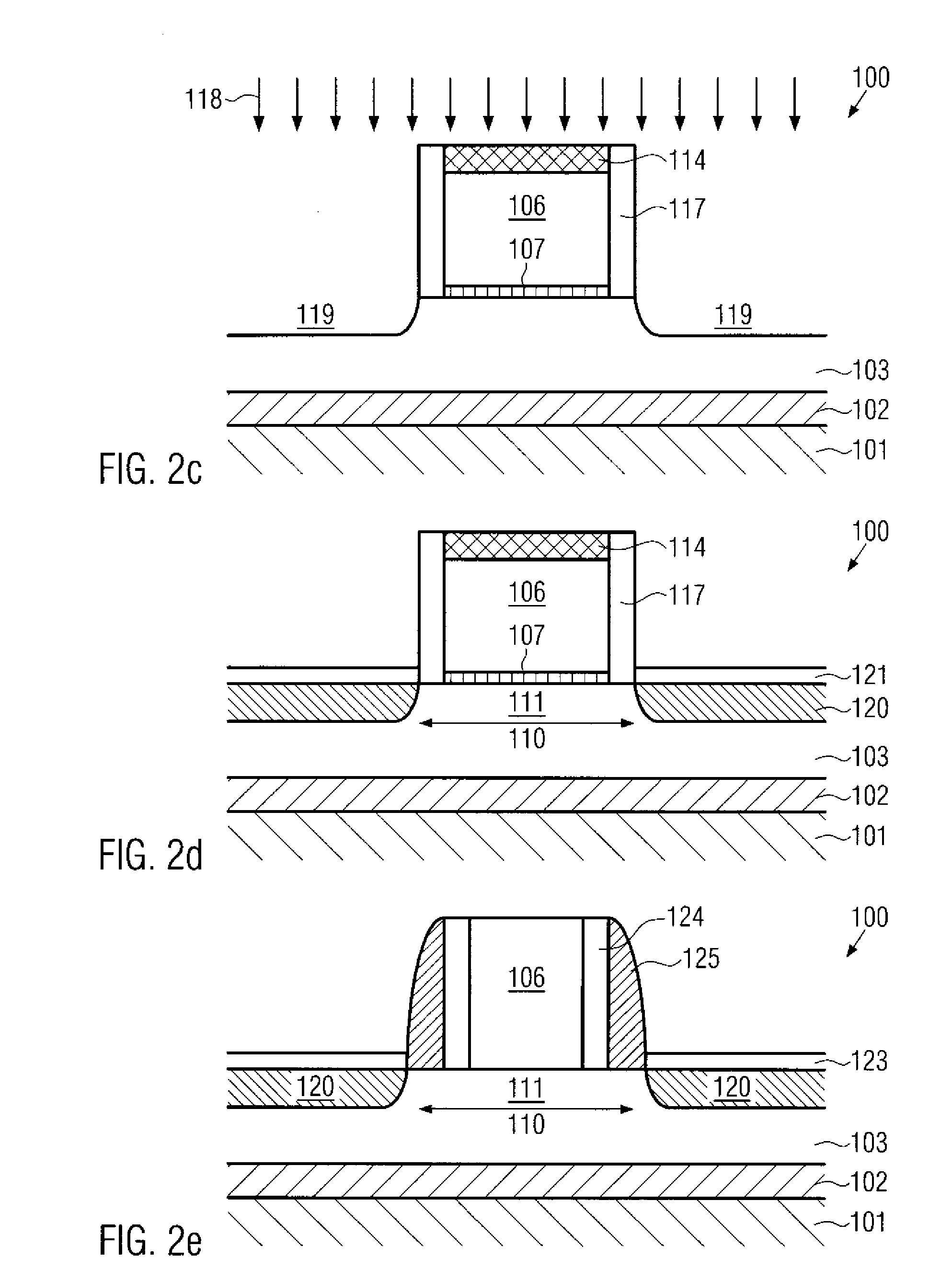

Formation of silicided surfaces for silicon/carbon source/drain regions

Formation of a silicide layer on the source / drain regions of a field effect transistor with a channel under tensile strain is disclosed. The strain is originated by the silicon / carbon source / drain regions which are grown by CVD deposition. In order to form the silicide layer, a silicon cap layer is deposited in situ by CVD. The silicon cap layer is then employed to form a silicide layer made of a silicon / cobalt compound. This method allows the formation of a silicide cobalt layer in silicon / carbon source / drain regions, which was until the present time not possible.

Owner:GLOBALFOUNDRIES INC

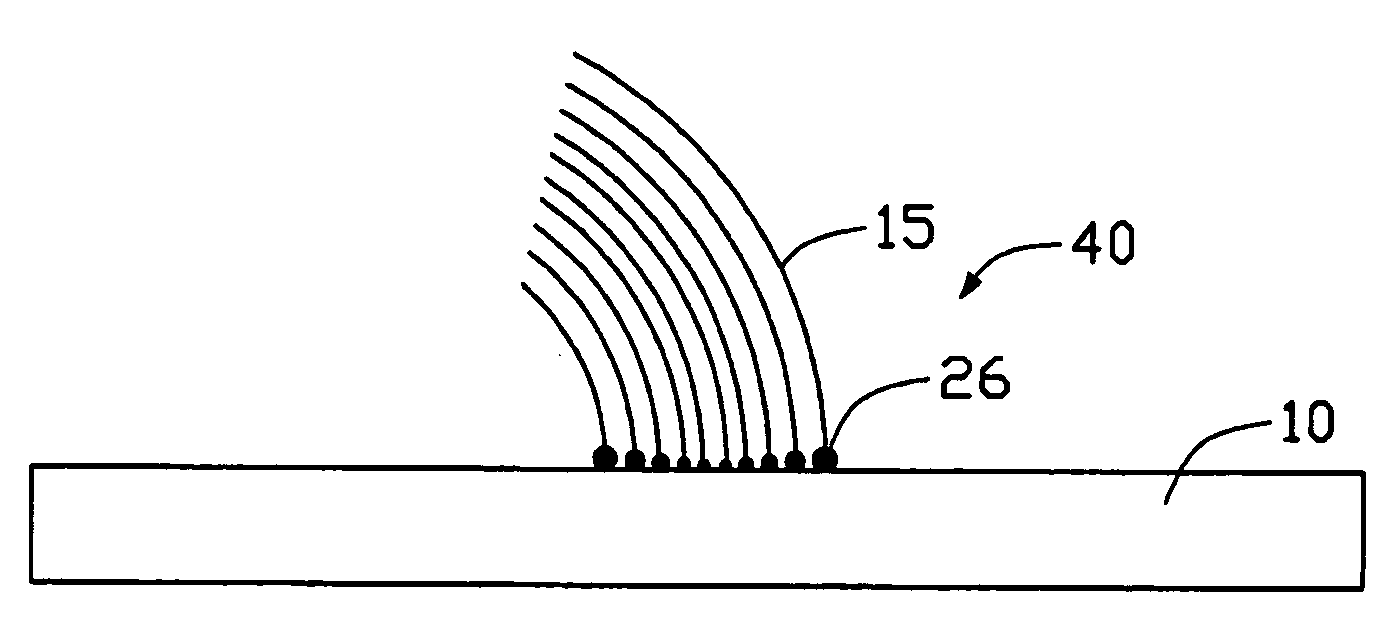

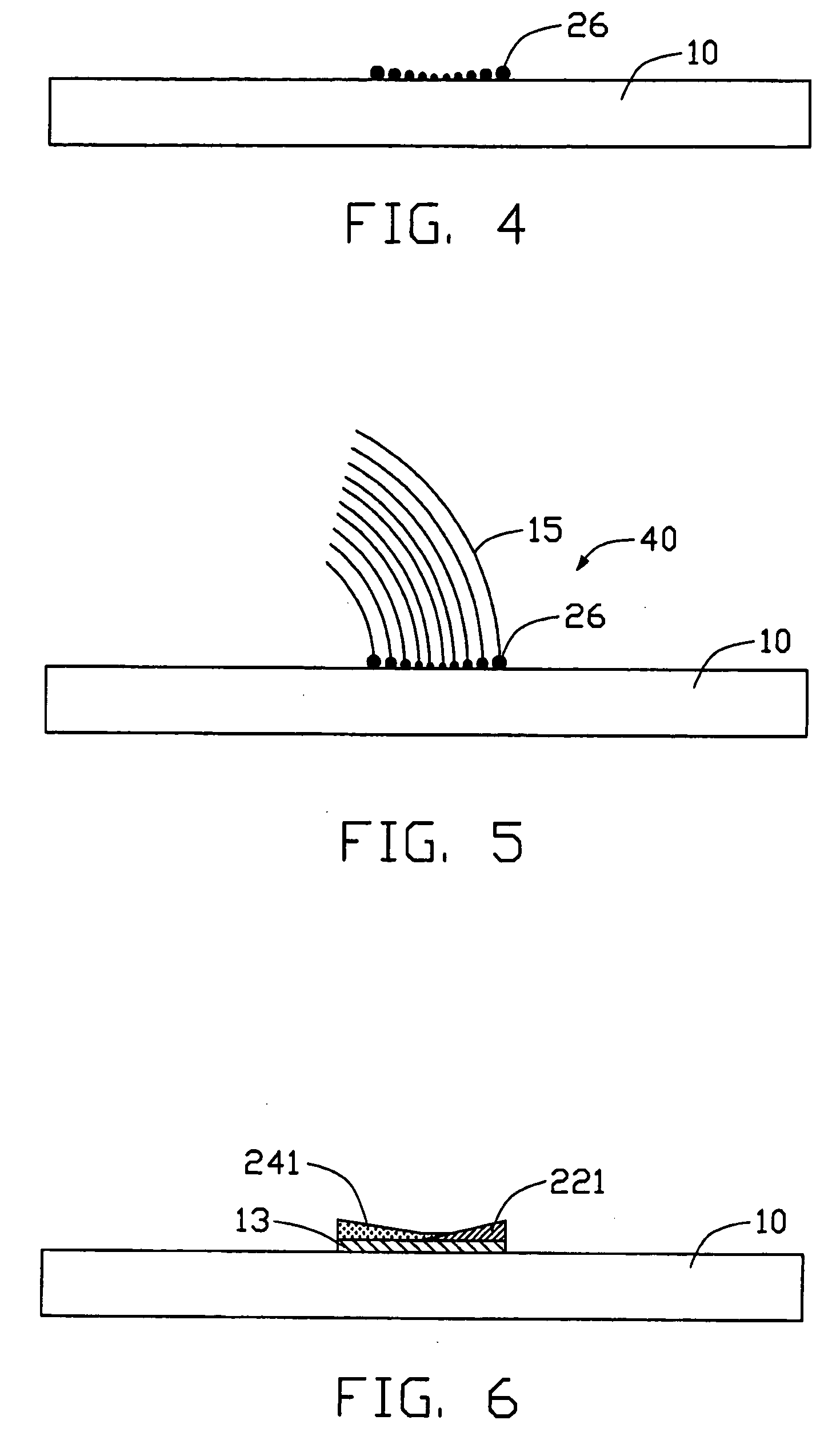

Carbon annotate-based device and method for making carbon nanotube based device

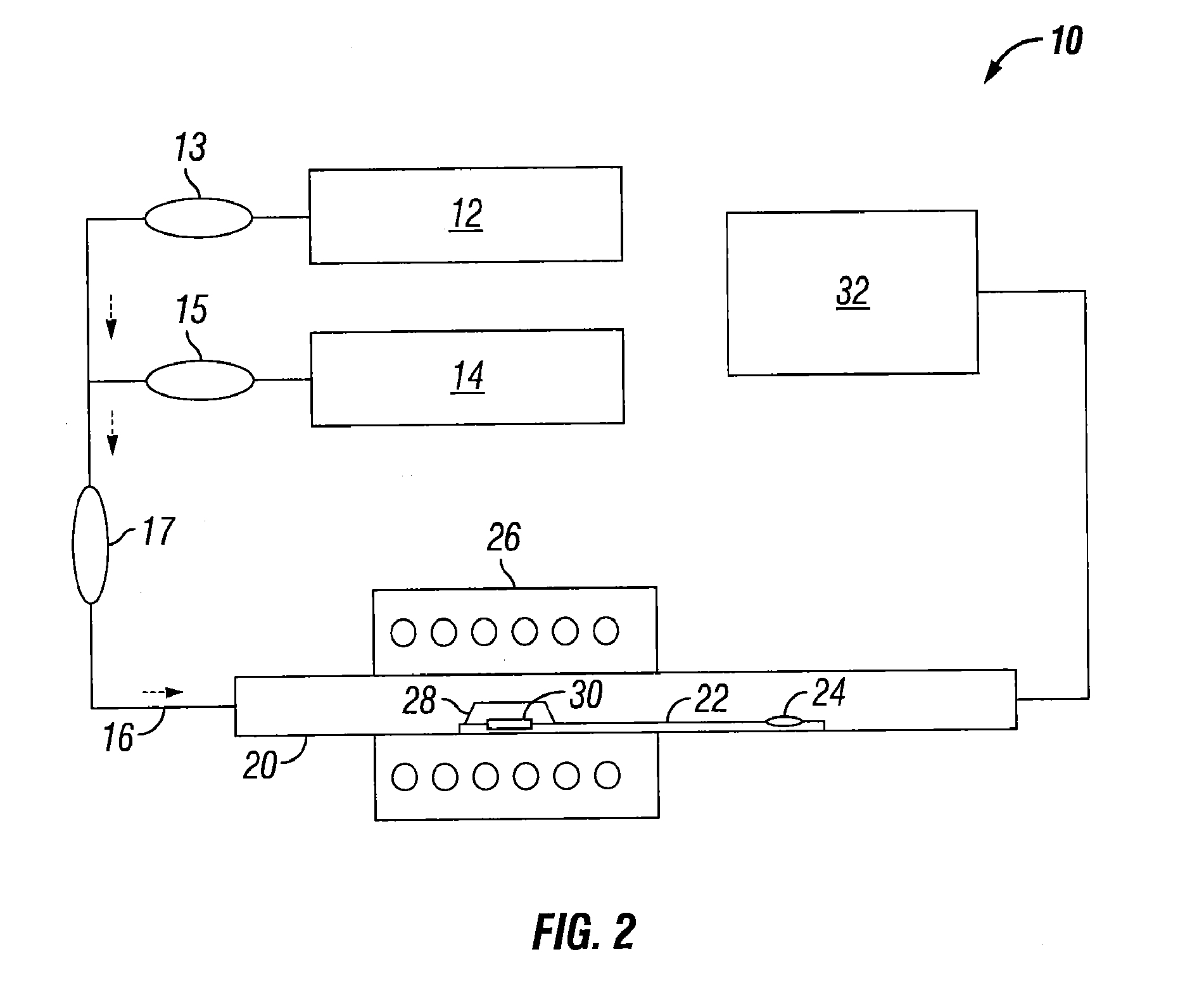

ActiveUS20040136896A1Easy to controlWide applicationMaterial nanotechnologyLayered productsGas phaseAlloy

A carbon nanotube-based device (40) includes a substrate (10), a number of alloyed, nano-sized catalytic particles (26) formed on the substrate, and an array of aligned carbon nanotubes (15) extending from the alloyed, nano-sized catalytic particles. The nanotube array bends in an arcuate configuation. A method for making the carbon nanotube-based device includes the steps of: providing a substrate; depositing a catalyst layer on the substrate; depositing two different layers of catalyst-doped materials on different areas of the catalyst layer for accelerating or decelerating the rate of synthesis of the aligned carbon nanotube array; annealing the catalyst and the catalyst-doped materials in an oxygen-containing gas at a low temperature; introducing a carbon source gas; and forming an array of aligned carbon nanotubes extending from the alloyed, nano-sized catalytic particles using a chemical vapor deposition method.

Owner:TSINGHUA UNIV +1

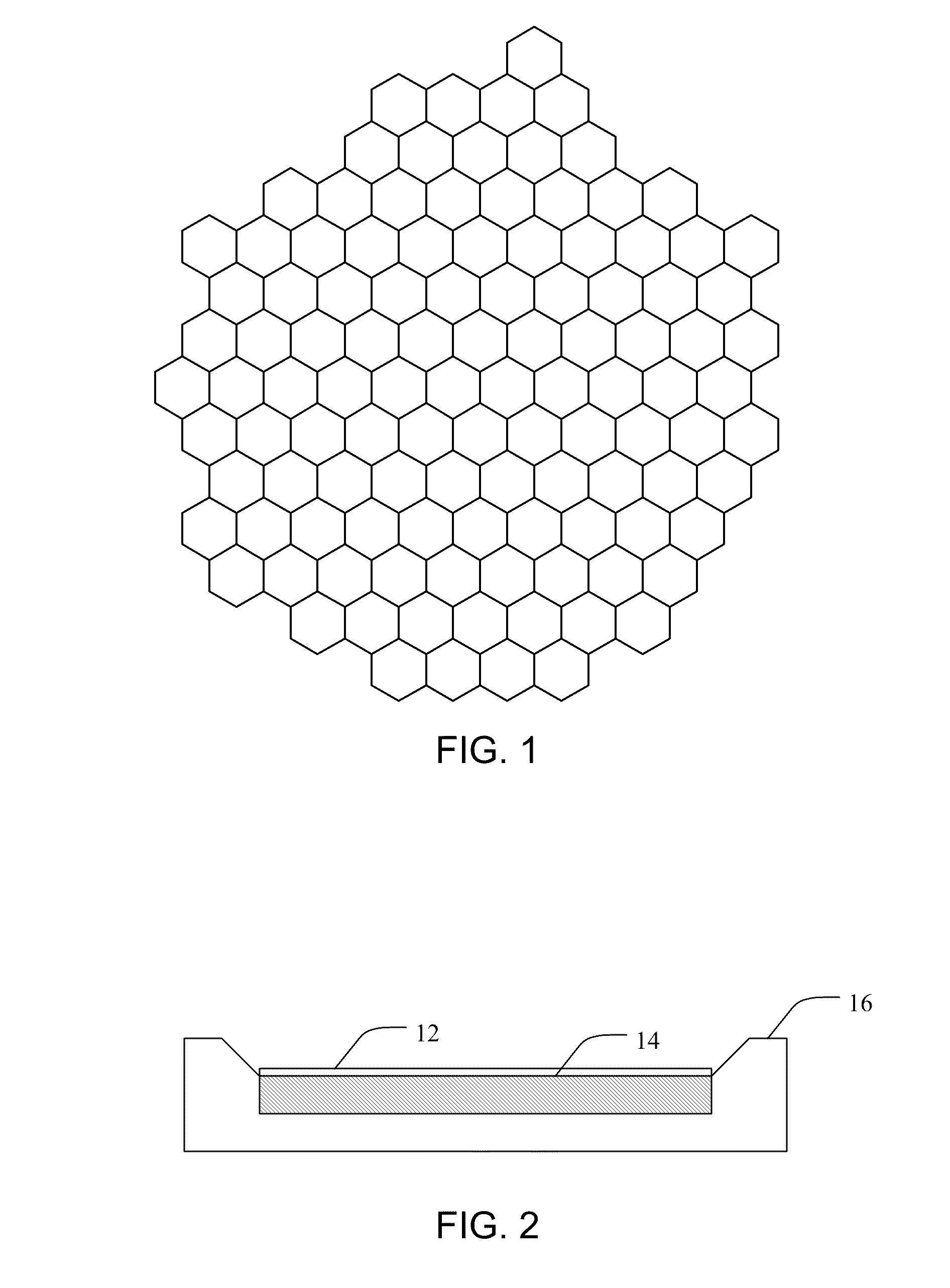

Graphene and Hexagonal Boron Nitride Planes and Associated Methods

InactiveUS20100055464A1Material nanotechnologyNitrogen compoundsHexagonal boron nitrideBoron nitride

Graphene layers, hexagonal boron nitride layers, as well as other materials made of primarily sp2 bonded atoms and associated methods are disclosed. In one aspect, for example, a method of forming a graphene layer is provided. Such a method may include mixing a carbon source with a horizontally oriented molten solvent, precipitating the carbon source from the molten solvent to form a graphite layer across the molten solvent, and separating the graphite layer into a plurality of graphene layers.

Owner:SUNG CHIEN MIN

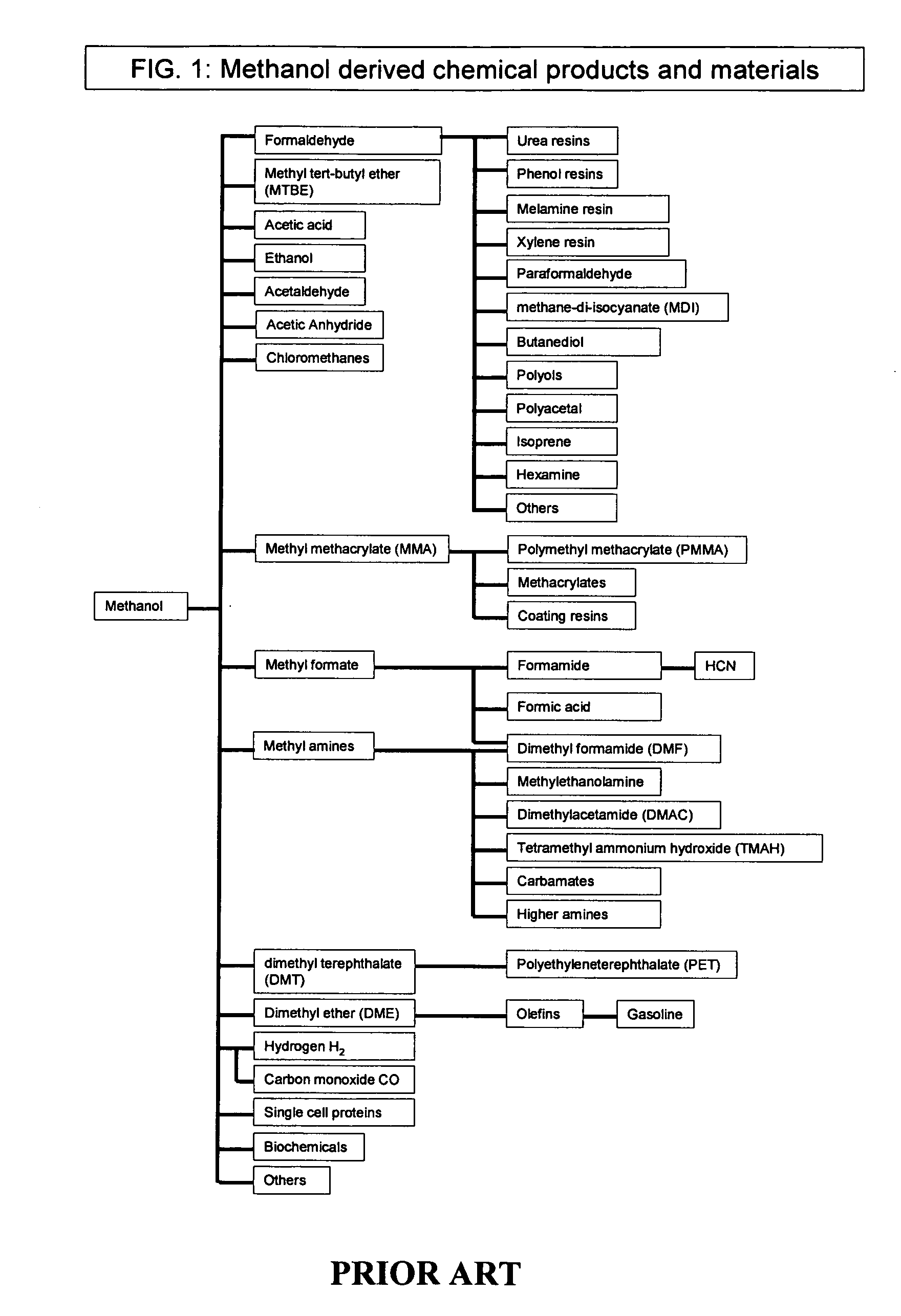

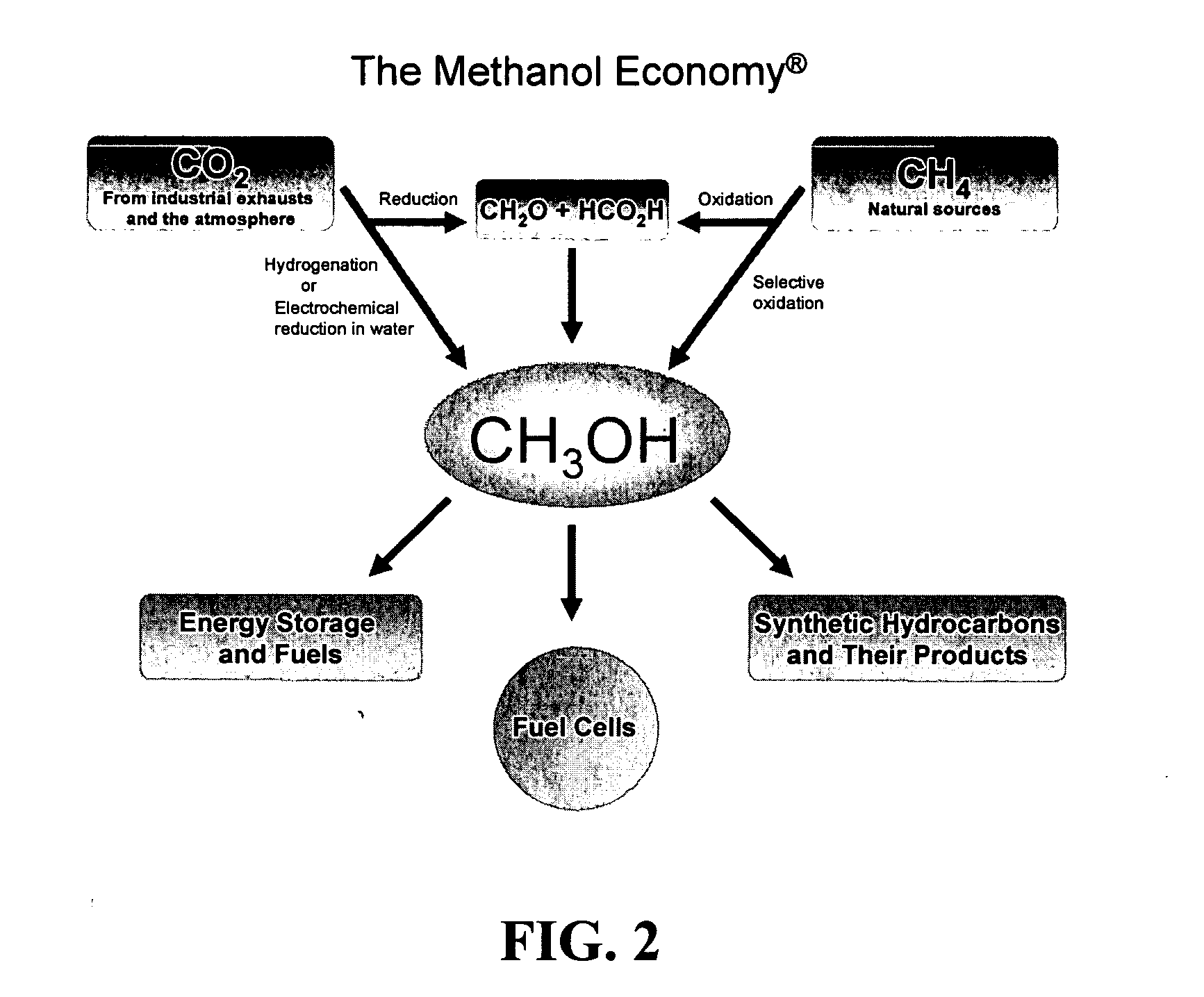

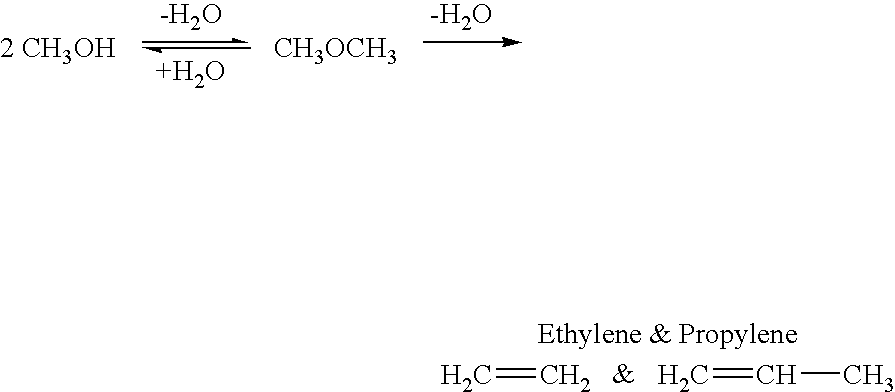

Efficient and selective conversion of carbon dioxide to methanol, dimethyl ether and derived products

ActiveUS20060235091A1Minimize or eliminate the disadvantages or dangers inherentElectrolysis componentsCarbon compoundsHydrogenFlue gas

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning powerplants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by electrochemical reduction produces formic acid acid and some formaldehyde and methanol mixtures. The formic acid can be used as source of carbon as well as hydrogen to produce methanol, dimethyl ether and other products.

Owner:UNIV OF SOUTHERN CALIFORNIA

Recycling treatment method of waste and old lithium iron phosphate battery anode materials

InactiveCN102208706ANo pollution in the processEasy to operateSolid waste disposalWaste accumulators reclaimingLithium iron phosphateHigh energy

The invention discloses a recycling treatment method of waste and old lithium iron phosphate battery anode materials, which comprises the following steps of: firstly, scattering waste and old lithium iron phosphate batteries and stripping and collecting anode materials in the waste batteries; heating the collected anode materials at high temperature and removing carbon and an adhesion agent to obtain solid powder; adding a lithium source compound and a carbon source into the solid mixture; ball-milling the mixture through a high-energy wet method; and finally, charging the ball-milled powder into a non-oxide atmosphere and roasting at high temperature to obtain the qualified lithium iron phosphate anode materials. The recycling method disclosed by the invention has the advantages of simple process, convenience for operation and high recovery rate.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for preparing single-layer graphene

The invention discloses a method for preparing single-layer graphene. The method comprises the following steps of: 1) preparing an alloy substrate; and 2) in the hydrogen and inert atmosphere, catalyzing to grow graphene on the surface of the alloy substrate obtained in the step 1) by a chemical vapor deposition method, thereby finishing the preparation of the single-layer graphene. The method makes use of the characteristics of two or more alloy metals in the alloy substrate, realizes control on the decomposition, diffusion and precipitation processes of a carbon source, simply and efficiently restrains the precipitation process of carbon dissolved in the metal substrate to enable the graphene to be capable of growing in a surface catalytic manner to obtain the single-layer graphene withuniform layer distribution, and is suitable for industrial production and particularly for the controllable preparation of single-layer or few-layer graphene.

Owner:PEKING UNIV

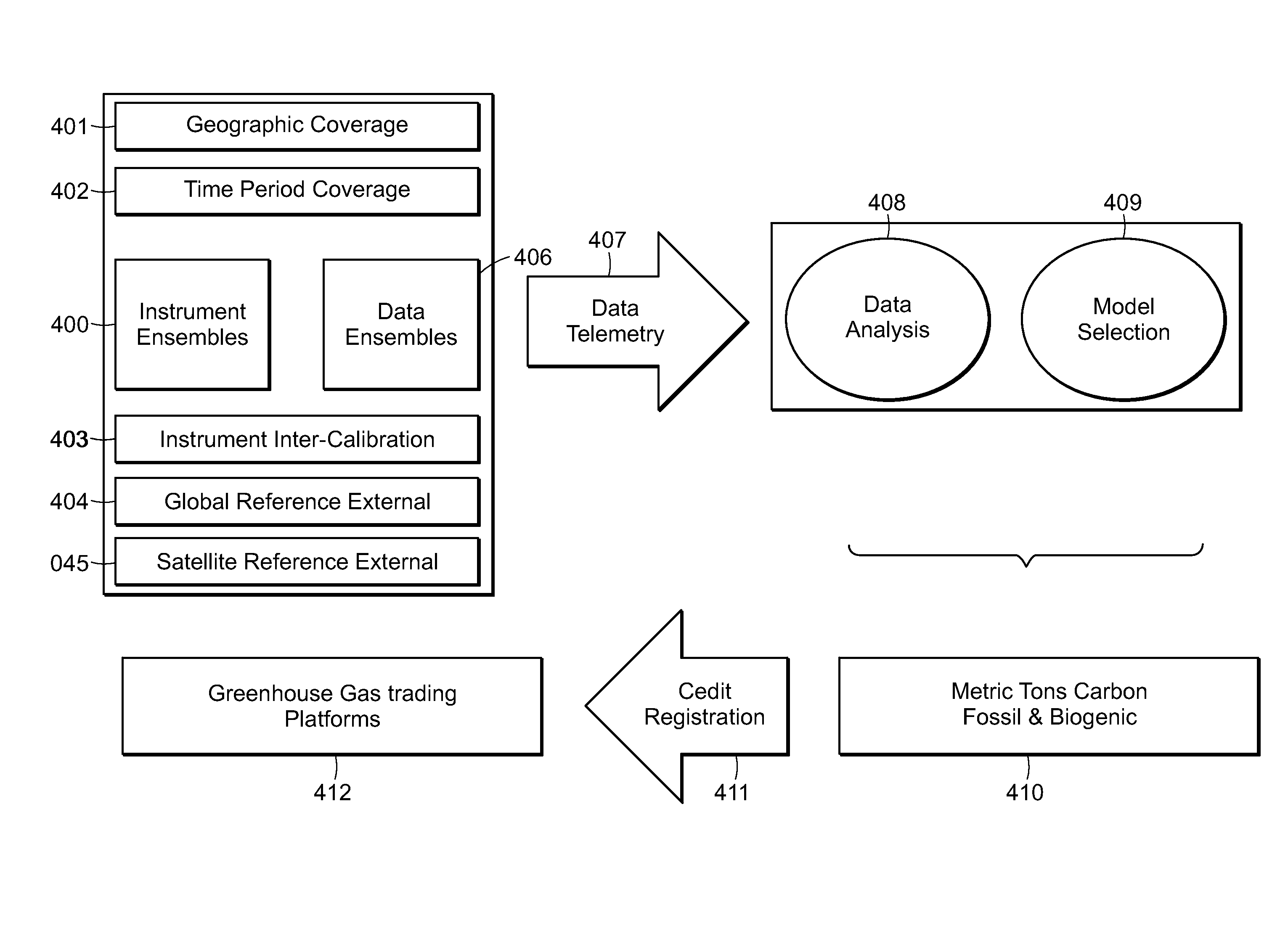

System of systems for monitoring greenhouse gas fluxes

ActiveUS20100198736A1High precisionReduce uncertaintySustainable waste treatmentCarbon compoundsNatural sourceGreenhouse gas flux

A system of systems to monitor data for carbon flux, for example, at scales capable of managing regional net carbon flux and pricing carbon financial instruments is disclosed. The system of systems can monitor carbon flux in forests, soils, agricultural areas, body of waters, flue gases, and the like. The system includes a means to identify and quantify sources of carbon based on simultaneous measurement of isotopologues of carbon dioxide, for example, industrial, agricultural or natural sources, offering integration of same in time and space. Carbon standards are employed at multiple scales to ensure harmonization of data and carbon financial instruments.

Owner:PLANETARY EMISSIONS MANAGEMENT

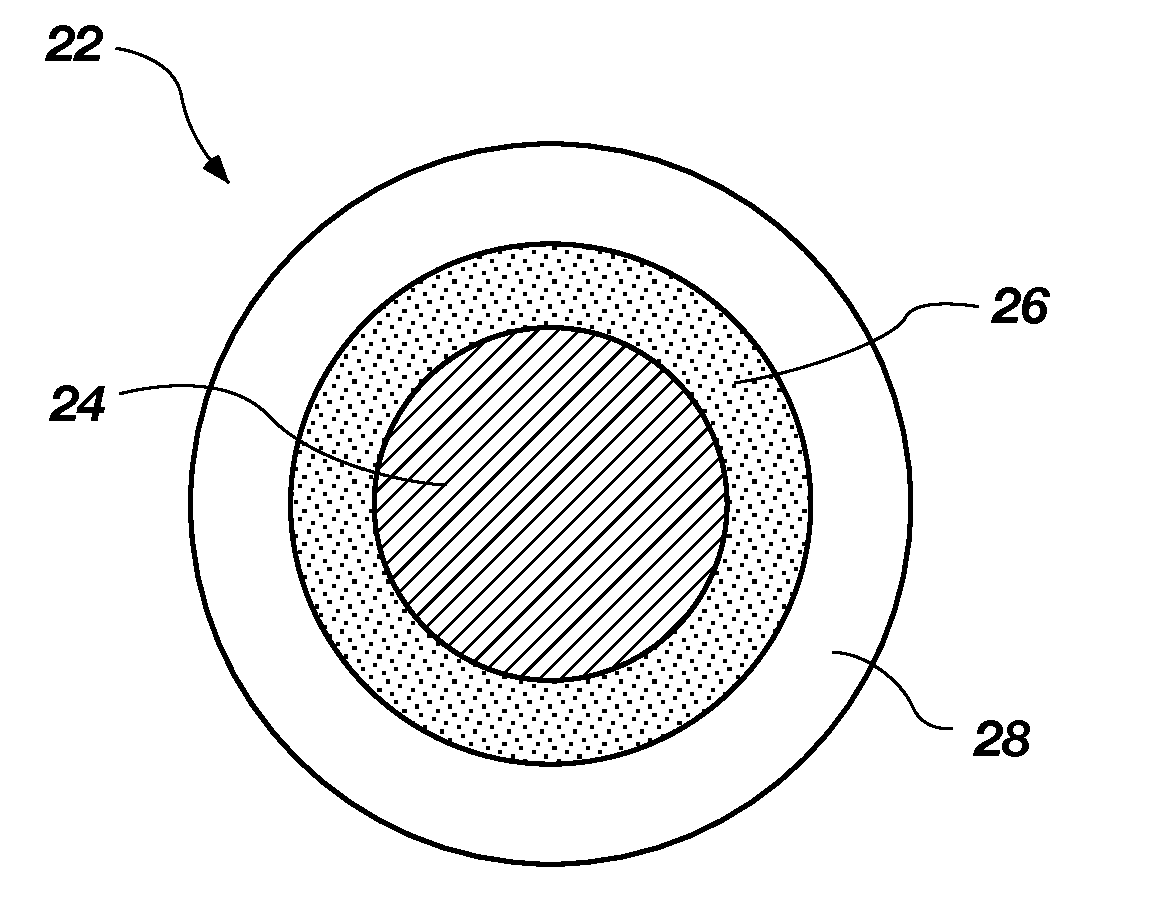

Synthesis method for carbon material based on lixm1-ym'(xo4)n

InactiveUS20040086445A1Improve performanceLow costHybrid capacitorsElectrolytic capacitorsElectrical conductorSynthesis methods

Method of synthesis for a material made of particles having a core and a coating and / or being connected to each other by carbon cross-linking, the core of these particles containing at least one compound of formula LixM1-yM'y(XO4)n, in which x,y and n are numbers such as 0<=x<=2, 0<=y<=0.6 and 1<=n<=1.5, M is a transition metal, M' is an element with fixed valency, and the synthesis is carried out by reaction and bringing into equilibrium the mixture of precursors, with a reducing gaseous atmosphere, in such a way as to bring the transition metal or metals to the desired valency level, the synthesis being carried out in the presence of a source of carbon called carbon conductor, which is subjected to pyrolysis. The materials obtained have excellent electrical conductivity as well as very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

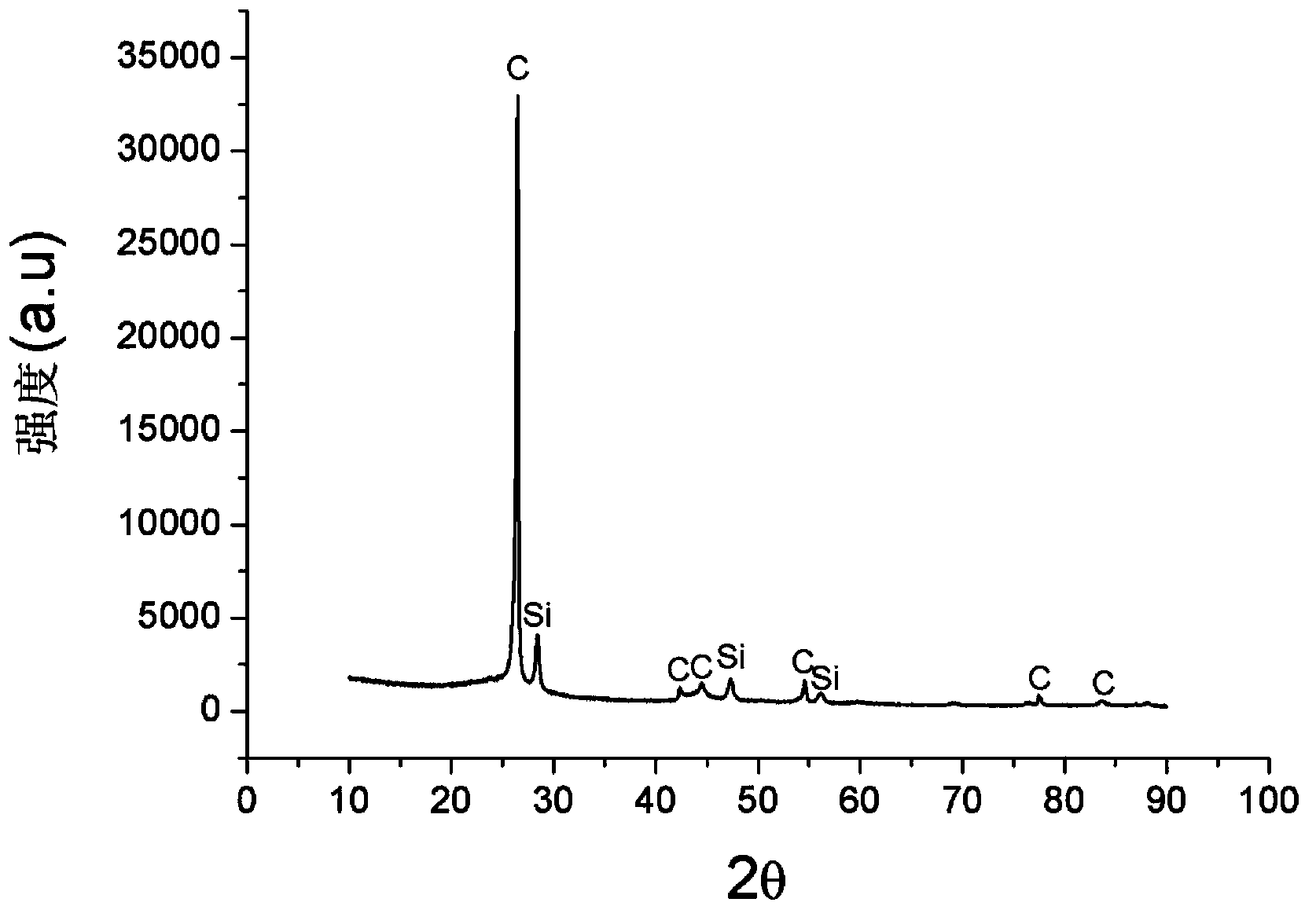

Lithium ion battery silicon-carbon anode material and preparation method thereof

ActiveCN103367727APromote circulationHigh specific capacityCell electrodesSecondary cellsLithium-ion batteryRetention ratio

The invention relates to a lithium ion battery silicon-carbon anode material which comprises nanometer silicon, graphite polymer and organic matter pyrolysis carbon, wherein the graphite polymer is formed by granular graphite; the nanometer silicon is embedded and clamped among gaps of the granular graphite or attached on the surface of the granular graphite; nanometer silicon / graphite polymer is covered by the organic matter pyrolysis carbon. A preparation method of the lithium ion battery silicon-carbon anode material comprises the steps of: mixing the nanometer silicon, a dispersing agent, a bonding agent and the granular graphite in an organic solvent, and drying to obtain composite nanometer silicon / graphite polymer; adding the obtained composite nanometer silicon / graphite polymer into the dispersion liquid of a carbon source precursor, mixing and drying; and carrying out heat treatment on material to obtain the lithium ion battery silicon-carbon anode material. The prepared silicon-carbon material has high specific capacity, high first time efficiency and excellent cycle performance, the capacity is larger than 450mAh / g, the first time efficiency is more than 85%, and the capacity retention ratio is more than 97% after circulation is carried out for 60 times.

Owner:BTR NEW MATERIAL GRP CO LTD

Method for preparing high-density spherical ferric lithium phosphate as anode material of lithium-ion battery

InactiveCN1635648AHigh bulk densityIncrease volume capacityElectrode manufacturing processesLithium compoundsPhosphateLithium-ion battery

This invention discloses the method for preparing high-density spherical lithium ferric phosphate used as the positive material of lithium ion cell, which contains synthesizing the ferric iron salt aqueous solution, phosphorus source aqueous solution and alkali aqueous solution to form spherical or spheroid ferric phosphate precursor, uniformly mixed with lithium source, carbon source and doped metal compound after being washed and dried, high temperature heat treating at 600-900 degree centigrade for 8-48 hr under inertia or reducing atmosphere protection to obtain lithium ferric phosphate with mean grain size of 7-12 micrometer,2.0-2.2g / cm3 of tap density, high buck density of 140-155mAh / g first discharge ratio capacity at normal temperature, and high volume ratio capacity.

Owner:TSINGHUA UNIV

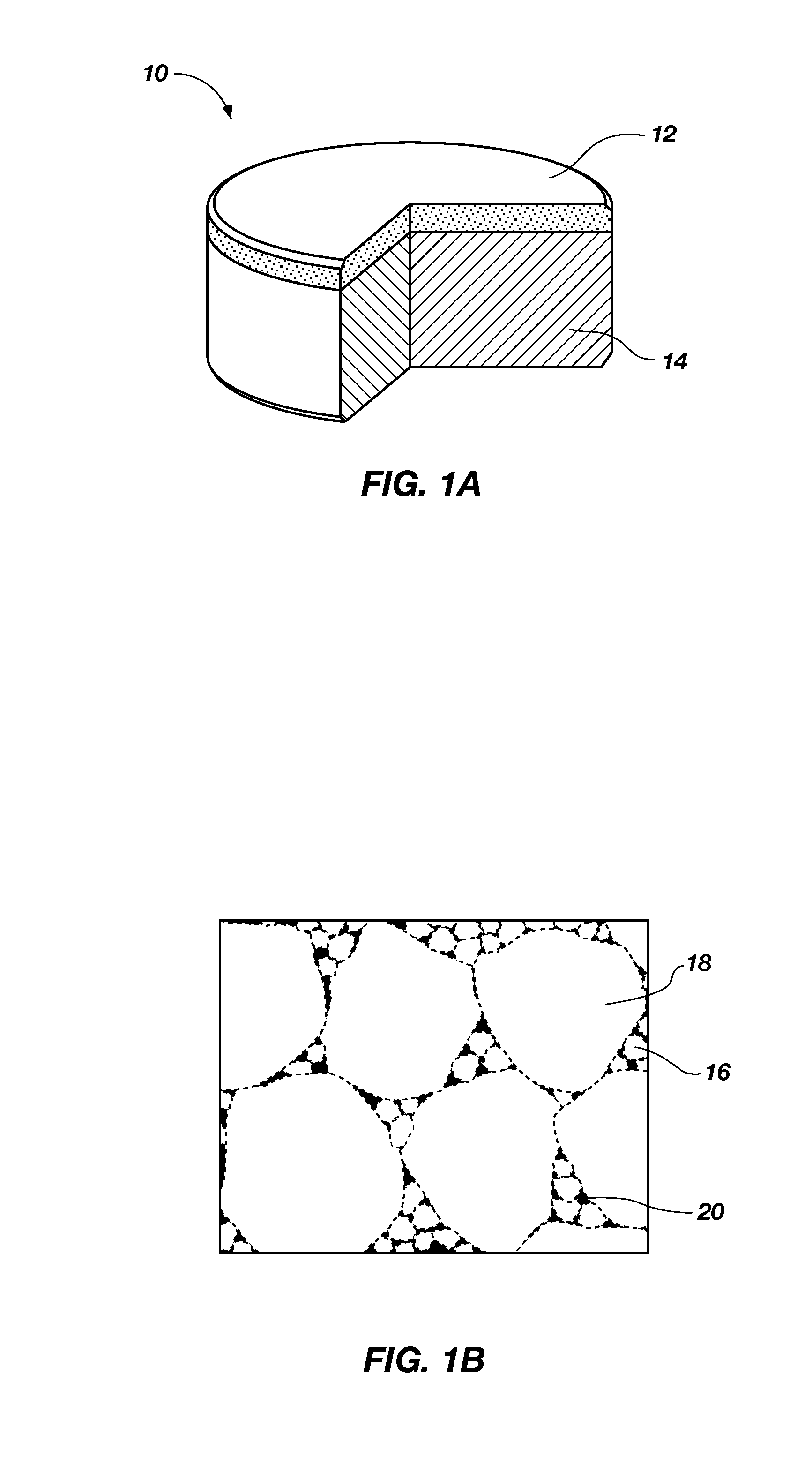

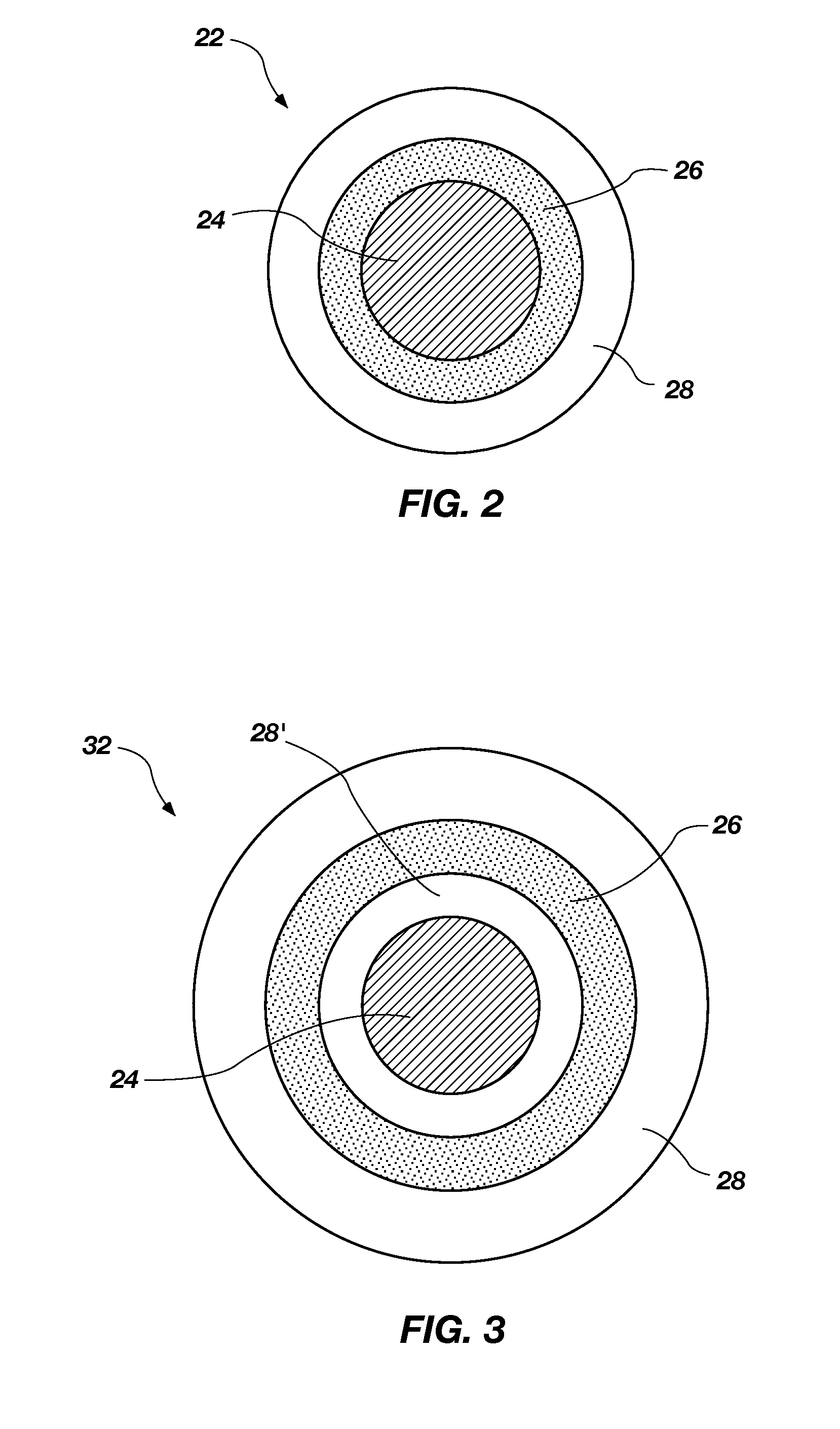

Polycrystalline compacts including in-situ nucleated grains, earth-boring tools including such compacts, and methods of forming such compacts and tools

Polycrystalline compacts include hard polycrystalline materials comprising in situ nucleated smaller grains of hard material interspersed and inter-bonded with larger grains of hard material. The average size of the larger grains may be at least about 250 times greater than the average size of the in situ nucleated smaller grains. Methods of forming polycrystalline compacts include nucleating and catalyzing the formation of smaller grains of hard material in the presence of larger grains of hard material, and catalyzing the formation of inter-granular bonds between the grains of hard material. For example, nucleation particles may be mixed with larger diamond grains, a carbon source, and a catalyst. The mixture may be subjected to high temperature and high pressure to form in smaller diamond grains using the nucleation particles, the carbon source, and the catalyst, and to catalyze formation of diamond-to-diamond bonds between the smaller and larger diamond grains.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com