Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

210results about How to "Increase volume capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

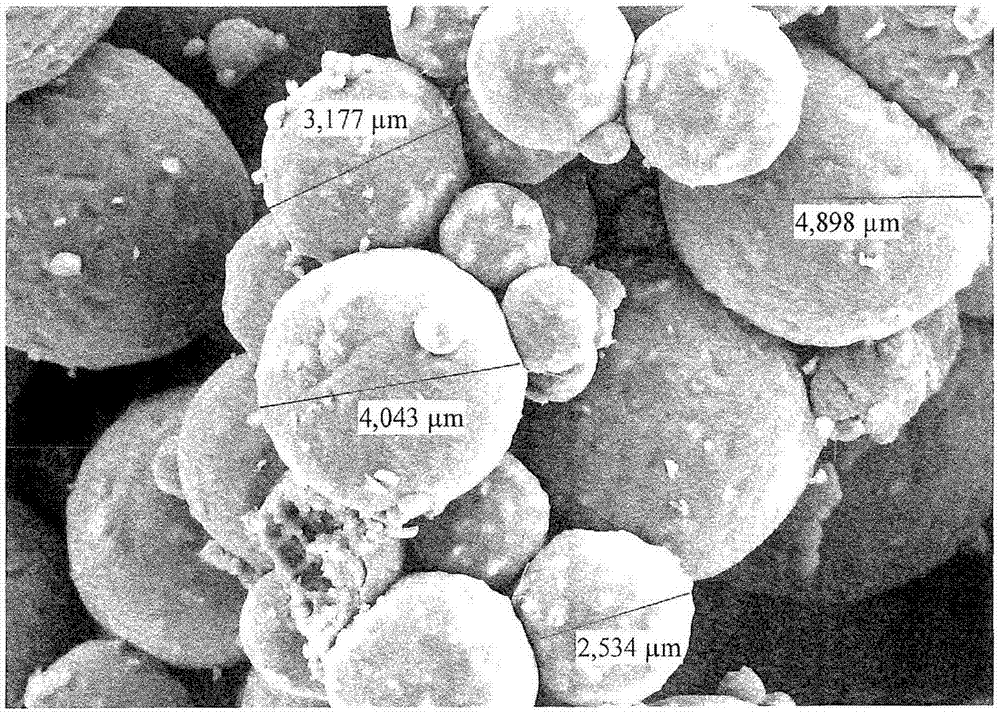

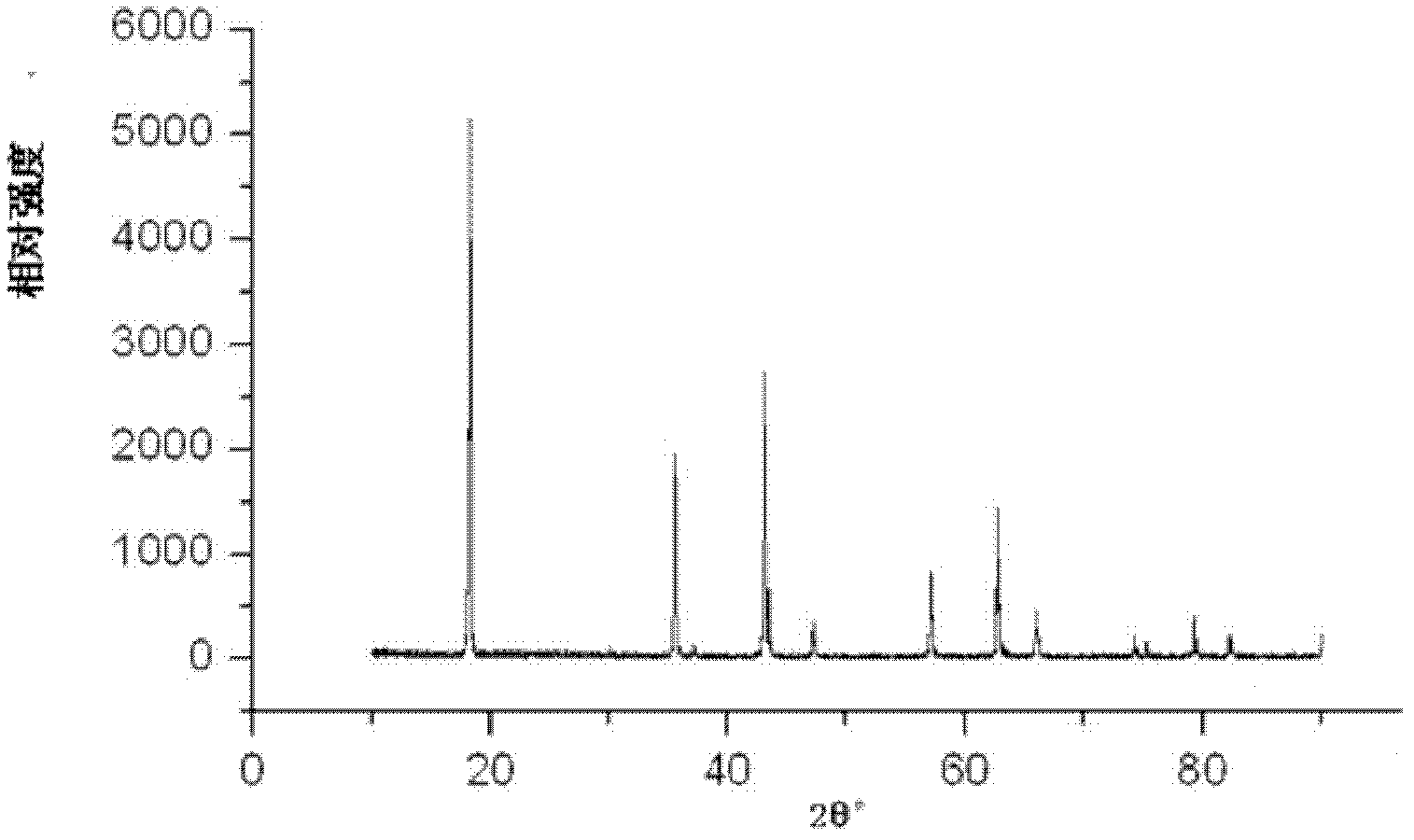

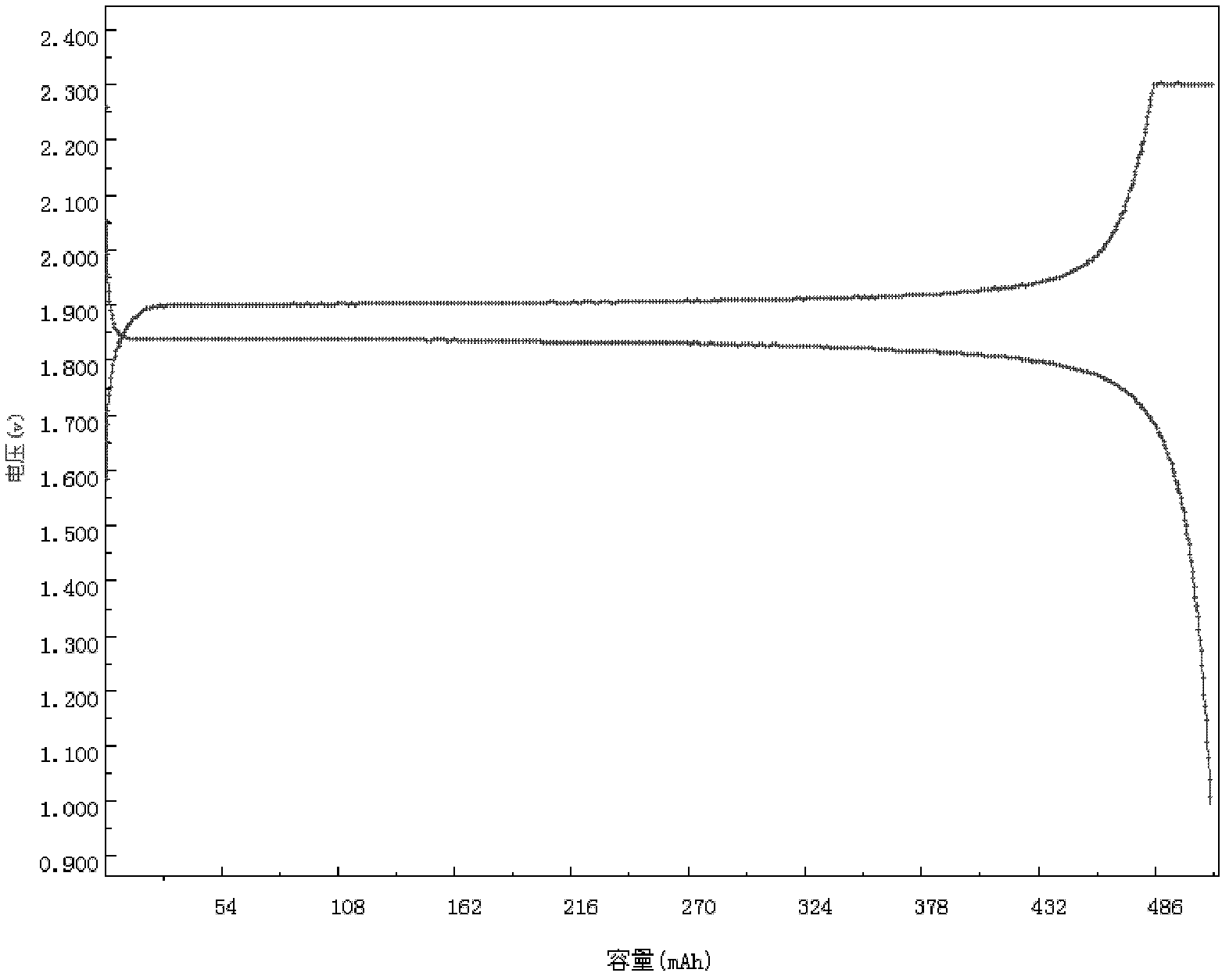

Titanium-series cathode active material and preparation method thereof, titanium-series lithium ion power battery

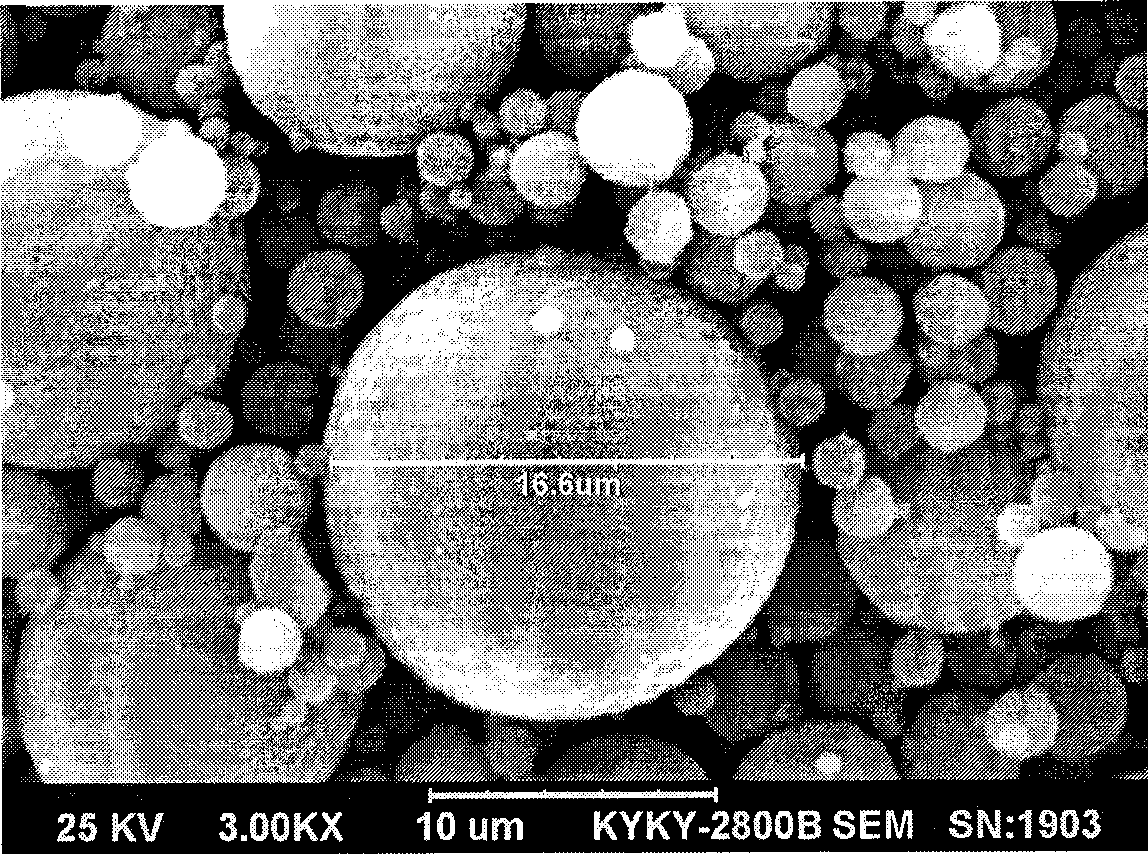

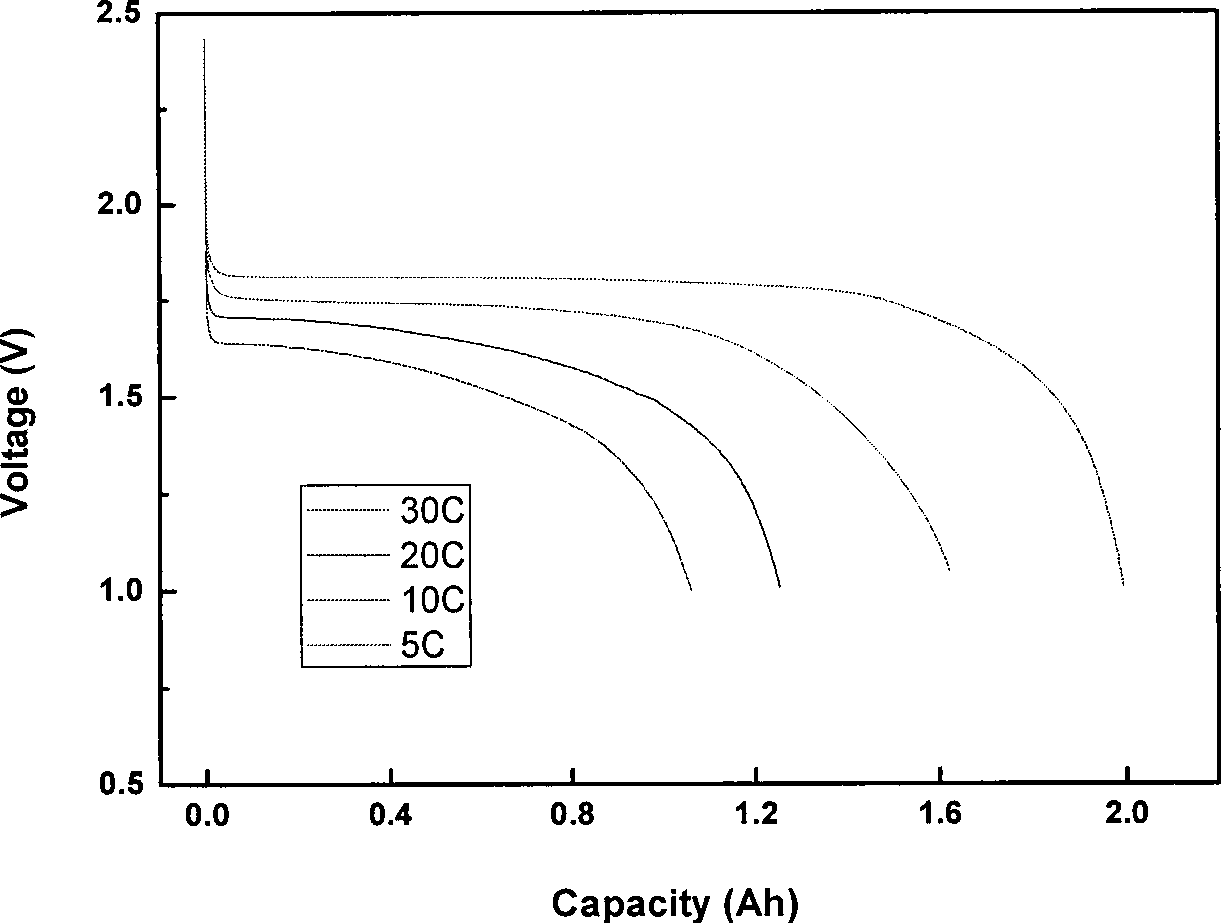

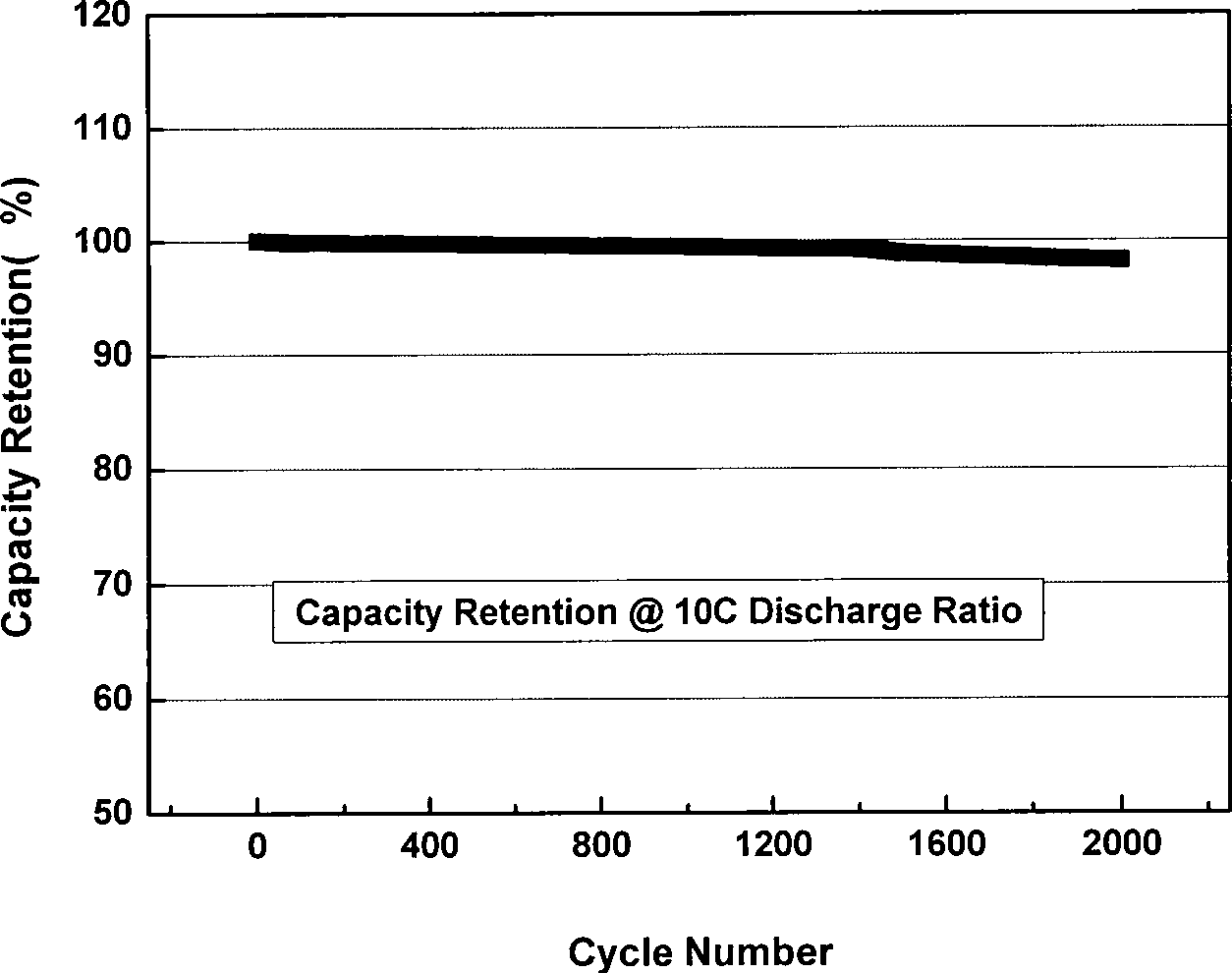

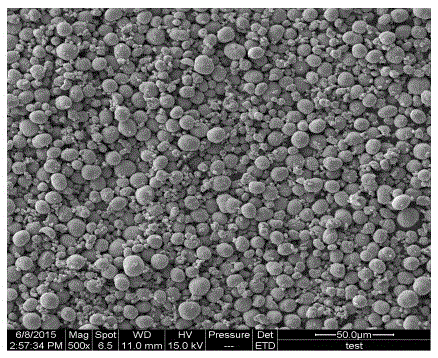

ActiveCN101373829AIncrease capacityHigh bulk densityElectrode manufacturing processesLi-accumulatorsHigh rateLithium titanate

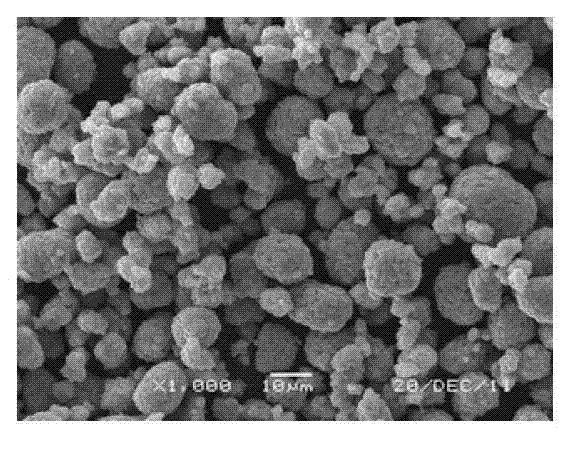

The invention discloses a titanium cathode active substance, a preparation method thereof and a titanium lithium ion power battery, and aims to solve the technical problem of enhancing the rate performance of a lithium ion power battery. The formula of the titanium cathode active substance is Li4Ti5O12 / Mx, wherein Li4Ti5O12 is spinel lithium titanate, M is a dopant such as a metal simple substance, a metal compound, a nonmetallic simple substance or a nonmetallic compound; the elements or the ions contained in the dopant enter the Li4Ti5O12 crystal lattice or are compounded with the Li4Ti5O12 crystal lattice; and the preparation method comprises the following steps: the precursor mixture of compound lithium titanate is prepared, and spray drying and heat treatment are performed. The cathode of the titanium lithium ion power battery adopts Li4Ti5O12 / Mx. Compared with the prior art, the titanium cathode active substance has the advantages of high capacity, high bulk density, high volume specific capacity, good high-rate performance, good product uniformity, good battery processability, low possibility of air bulking of the battery, and low cost.

Owner:BTR NEW MATERIAL GRP CO LTD

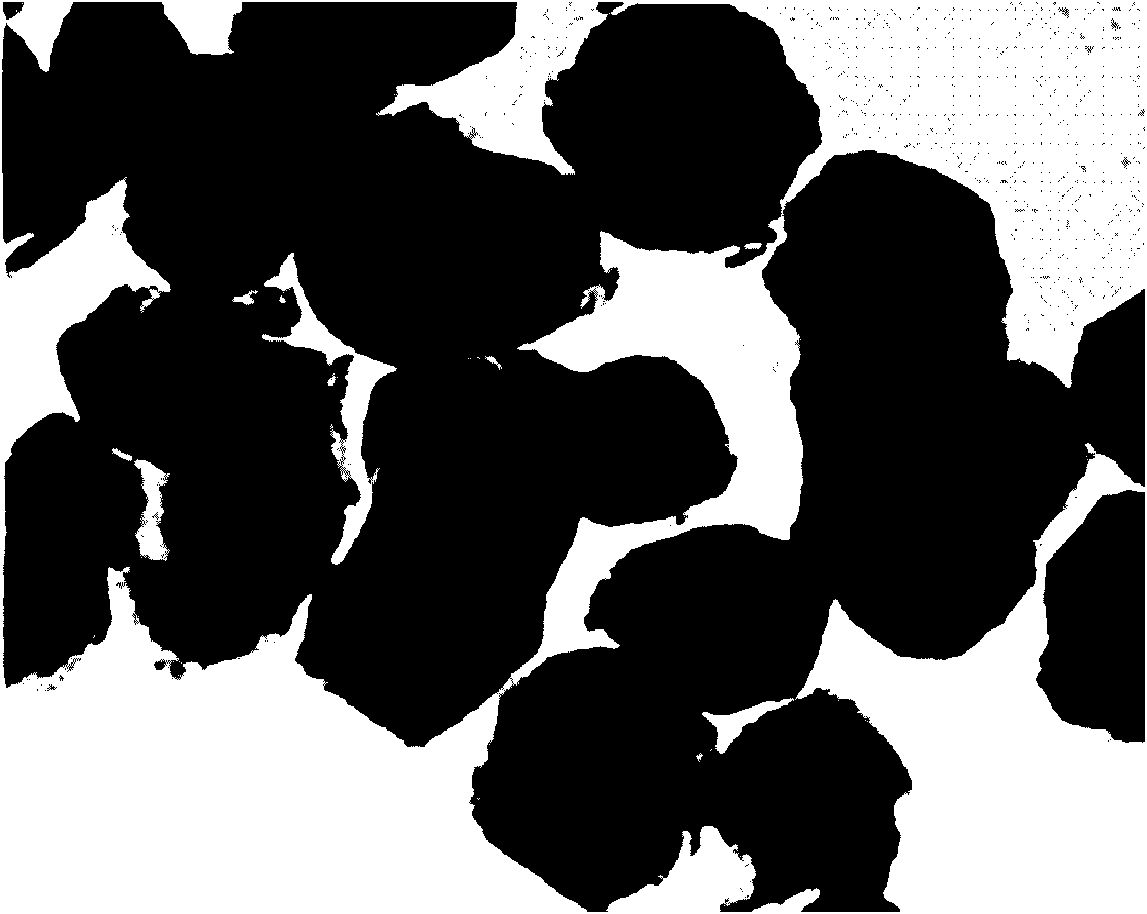

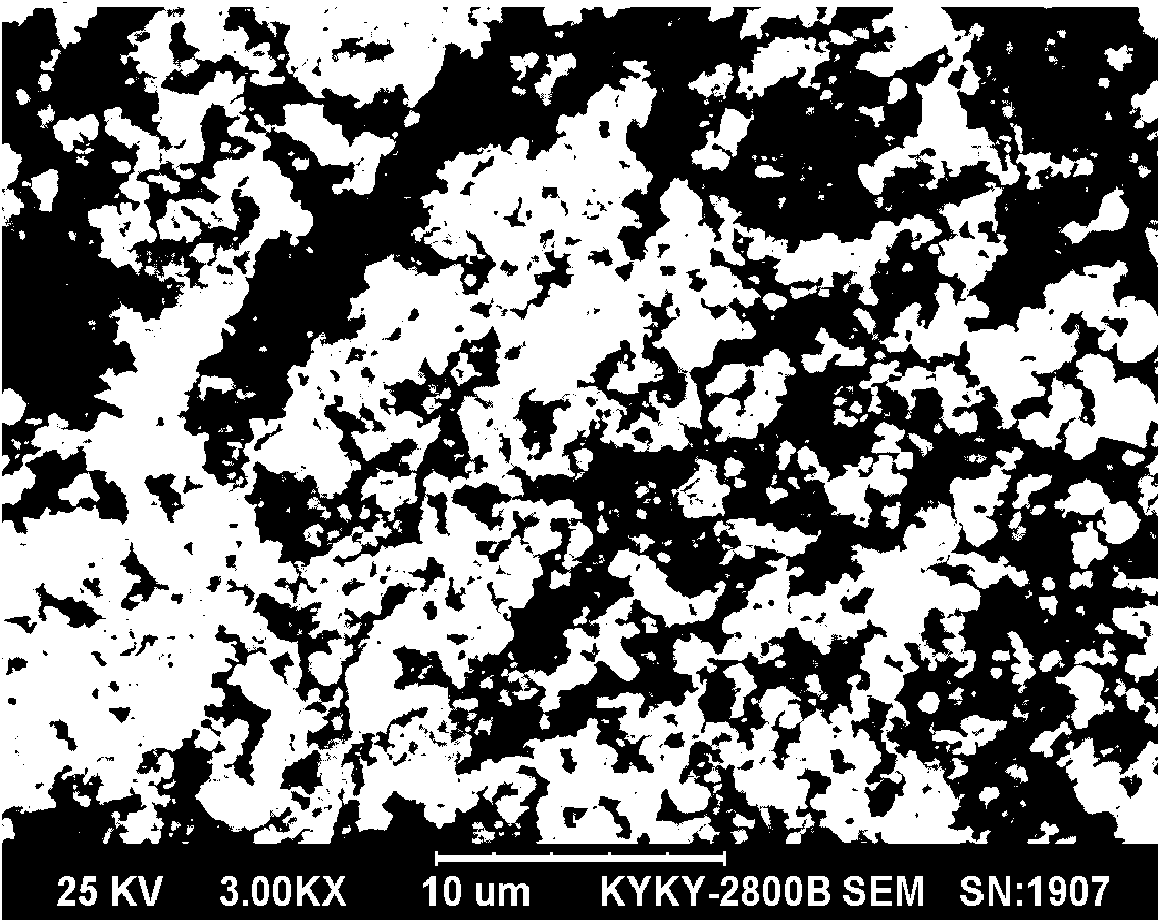

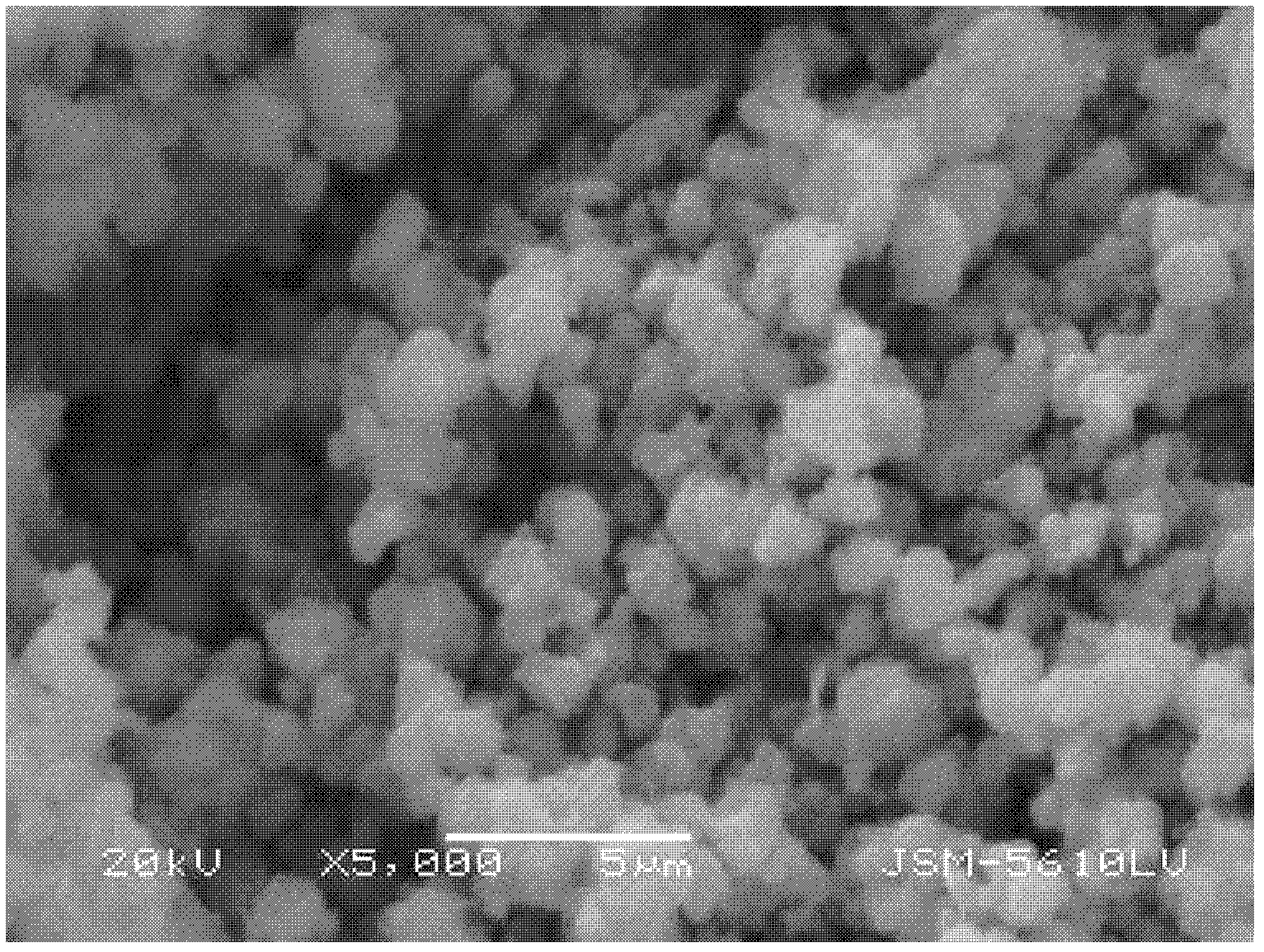

Method for preparing high-density spherical ferric lithium phosphate as anode material of lithium-ion battery

InactiveCN1635648AHigh bulk densityIncrease volume capacityElectrode manufacturing processesLithium compoundsPhosphateLithium-ion battery

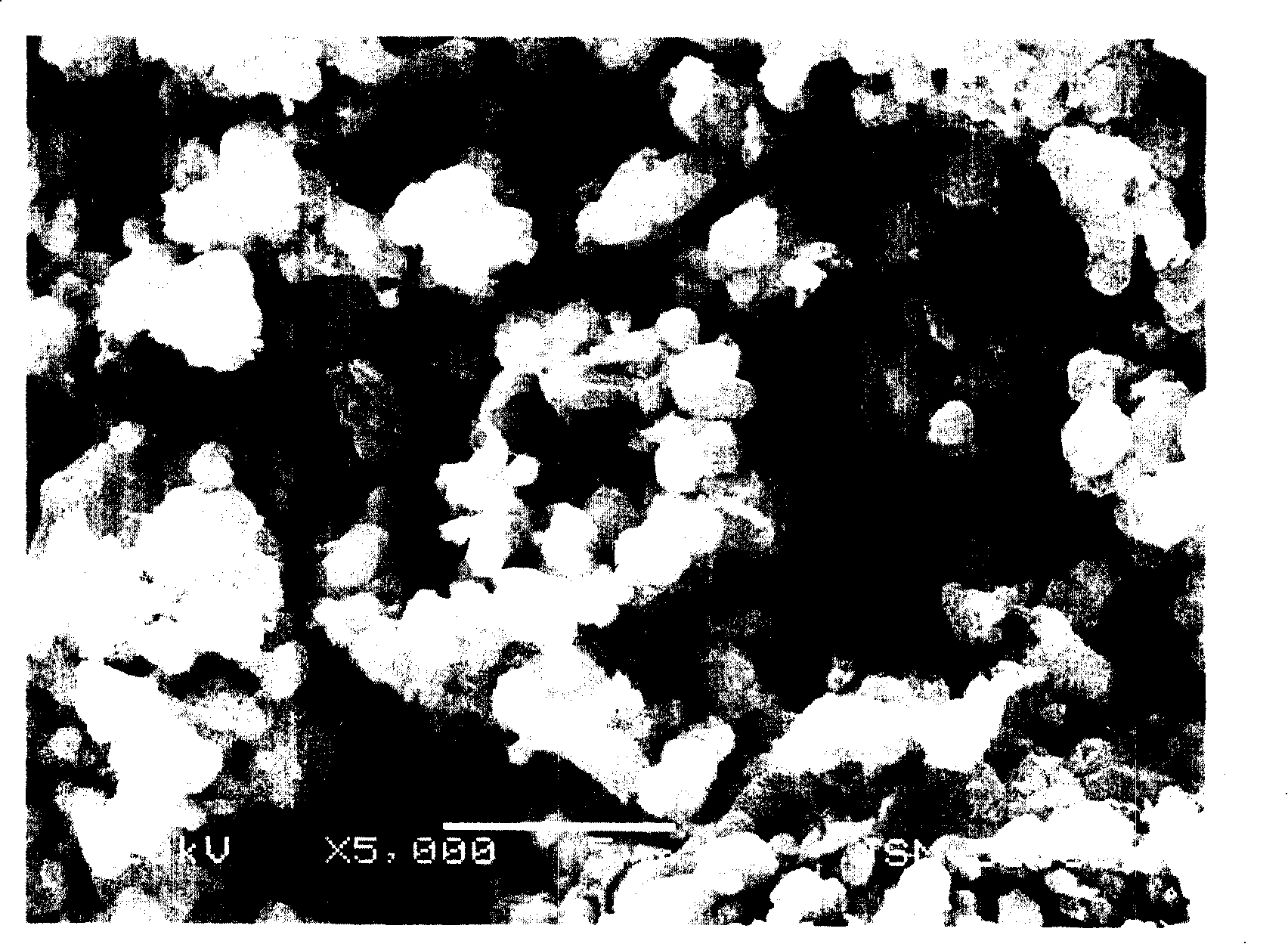

This invention discloses the method for preparing high-density spherical lithium ferric phosphate used as the positive material of lithium ion cell, which contains synthesizing the ferric iron salt aqueous solution, phosphorus source aqueous solution and alkali aqueous solution to form spherical or spheroid ferric phosphate precursor, uniformly mixed with lithium source, carbon source and doped metal compound after being washed and dried, high temperature heat treating at 600-900 degree centigrade for 8-48 hr under inertia or reducing atmosphere protection to obtain lithium ferric phosphate with mean grain size of 7-12 micrometer,2.0-2.2g / cm3 of tap density, high buck density of 140-155mAh / g first discharge ratio capacity at normal temperature, and high volume ratio capacity.

Owner:TSINGHUA UNIV

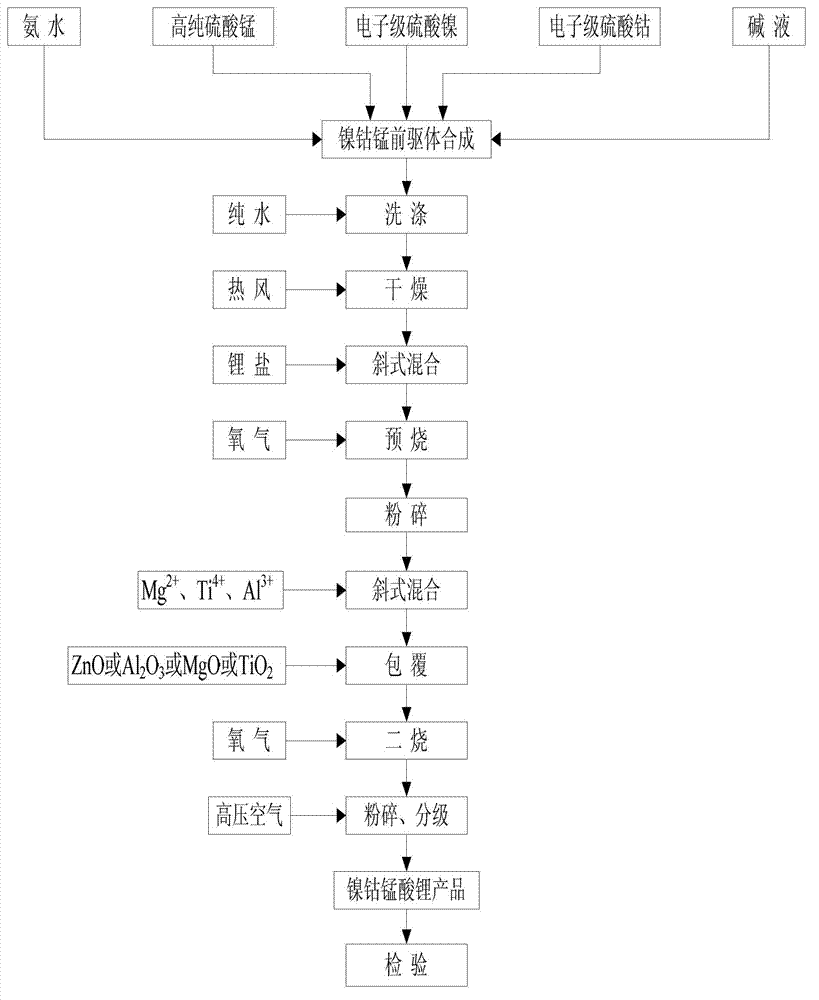

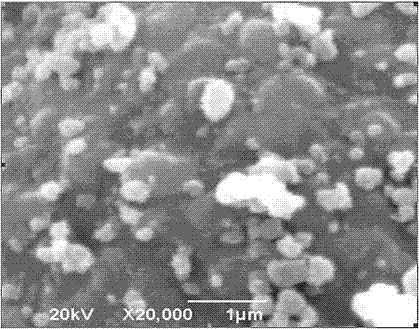

Preparation method of manganese Li-NiCoMn ternary material for lithium ion battery

InactiveCN103117380AImprove high temperature performanceHigh densityCell electrodesPhysical chemistryManganese

The invention relates to a preparation method of a manganese Li-NiCoMn ternary material for a lithium ion battery. The chemical formula of the manganese Li-NiCoMn ternary material is LiNixMnyCo(1-x-y)O2, wherein x is equal to 0.1 to 0.5, y is equal to 0.1 to 0.6, and 1-x-y is more than or equal to 0. According to the manganese Li-NiCoMn ternary material for the lithium ion battery, prepared by the method, the volume ratio capacity of a final product is increased by improving the density of a NiCoMn ternary precursor material, the high-temperature performance of the Li-NiCoMn is improved through composite cladding, and the problems that the Li-NiCoMn is poor in high-temperature cycle performance and poor in storage performance can be solved. Advantages such as high compaction density, large specific volume, good cycle performance, stability in quality, low cost, simplicity in preparation process and easiness for realizing industrialization can be realized.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

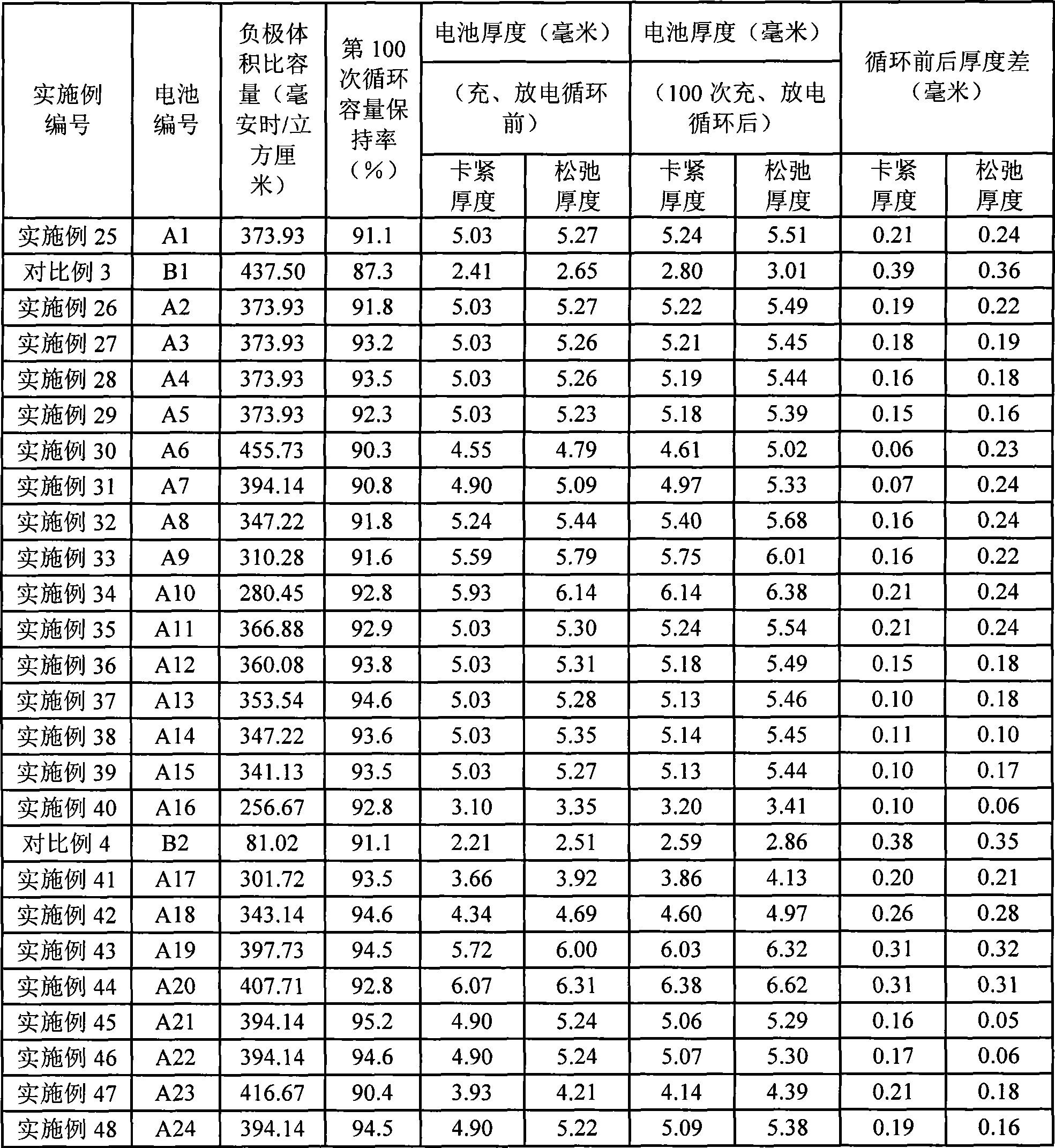

Negative electrode material used for lithium battery and preparation method and application thereof

ActiveCN103474632AStable structureImprove performanceMaterial nanotechnologyCell electrodesPorosityMicro nano

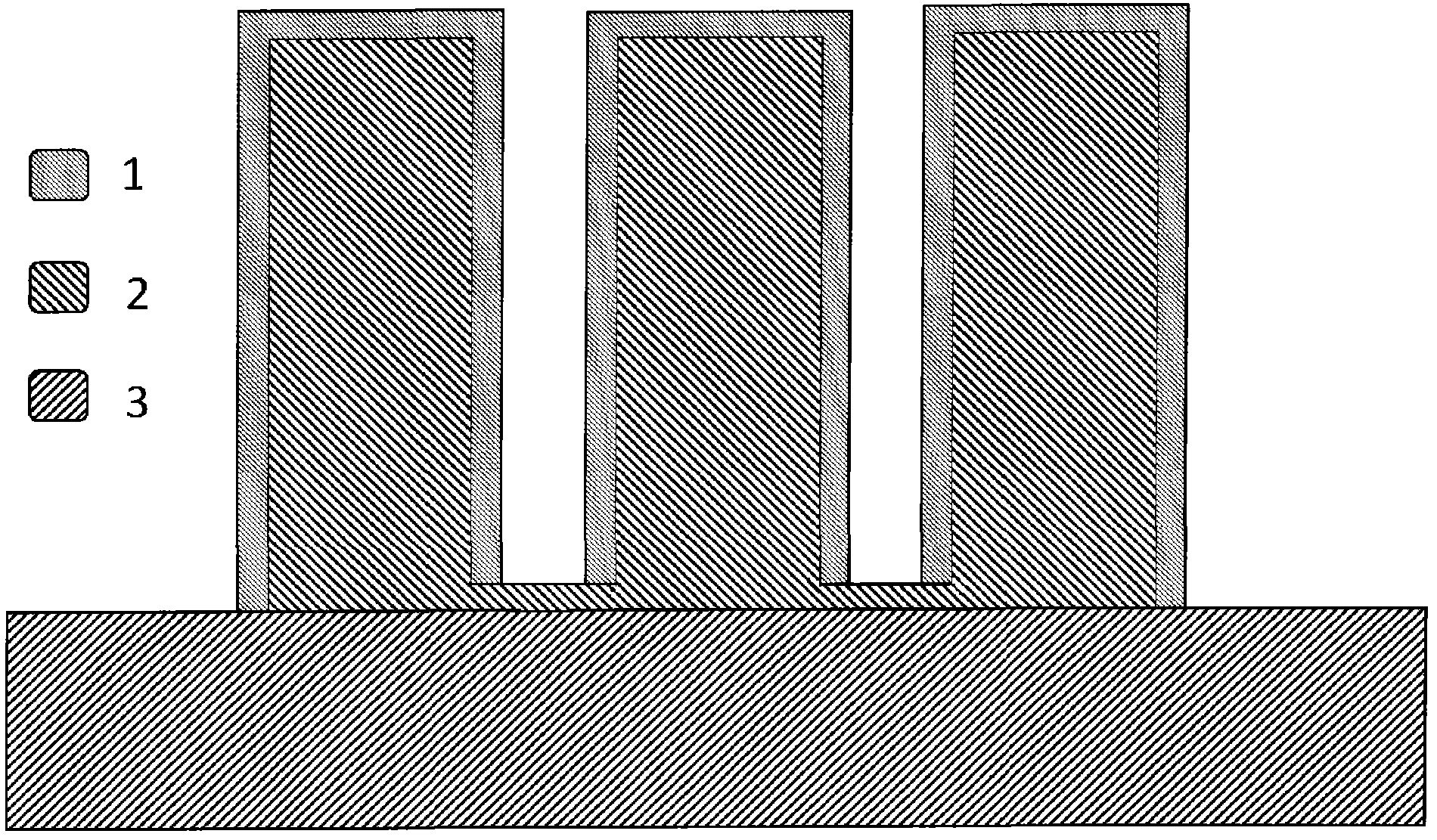

The invention relates to a negative electrode material used for a lithium battery and a preparation method and application thereof, the negative electrode material includes a conductive substrate material layer and a silicon based thin film material layer, the silicon based thin film material layer contains one or more components selected from the group consisting of silicon element, SiOX and silicon alloy, wherein, 0 < X =< 2; in the silicon based thin film material layer, silicon accounts for 10-100% of the weight of the silicon based thin film material layer; the silicon based thin film material layer is a thin film formed by regular and / or irregular columnar and / or fibrous micro nano naps, wherein the micro nano naps are connected with each other by root parts, and the root parts of the micro nano naps are connected with the conductive substrate material layer; gaps are existed among the micro nano naps, and the porosity among the micro nano naps is 2%-98%; the diameter size of the micro nano naps is 1 nm to 10 mum, and the thickness of the silicon based thin film material layer is 50 nm-10 mum.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

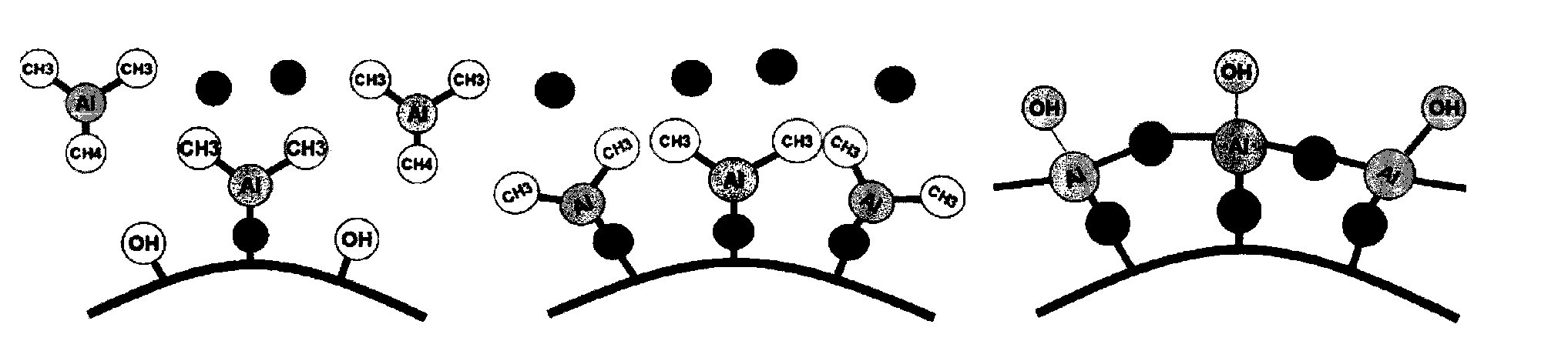

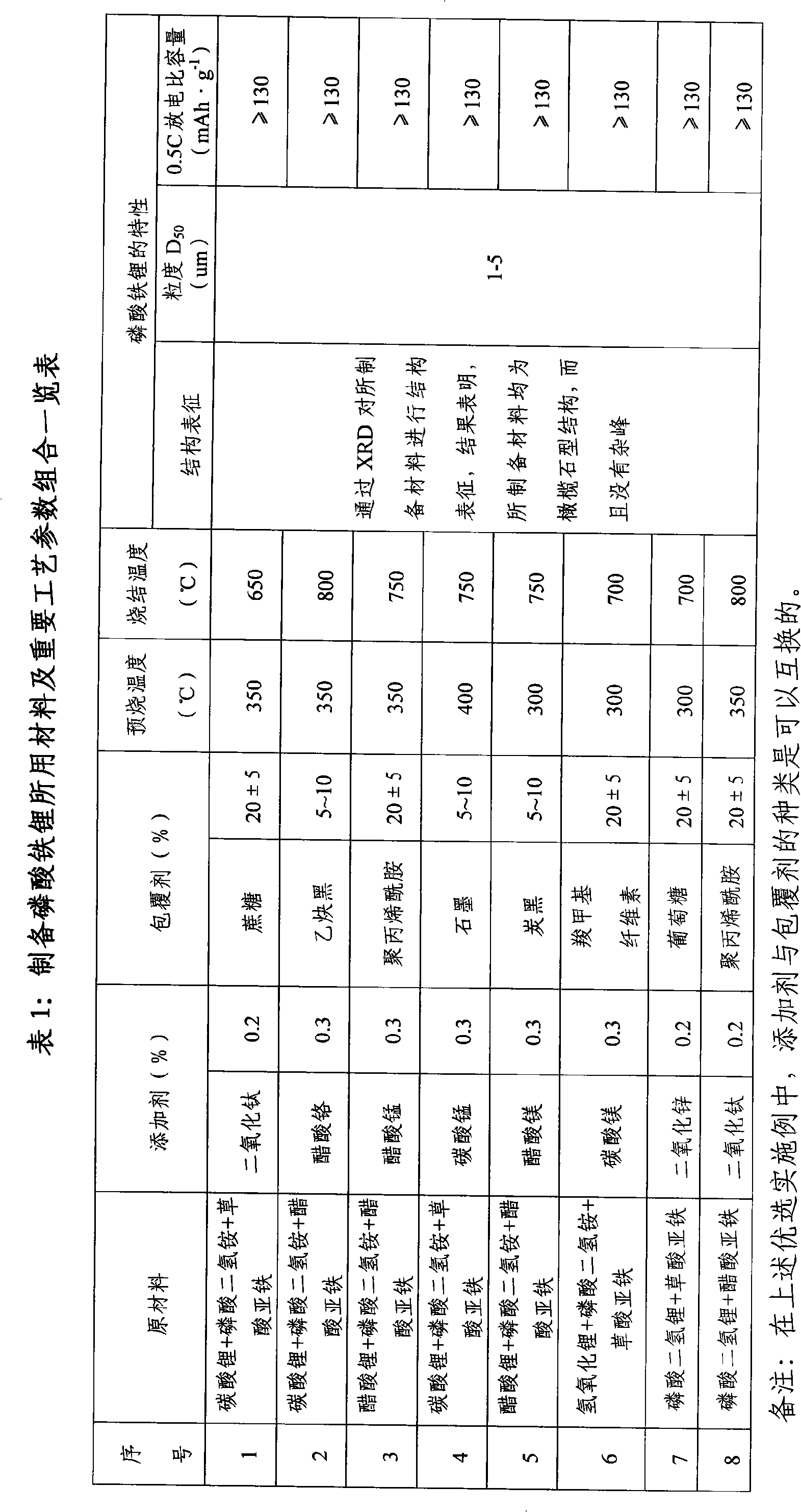

Preparation of lithium iron phosphate positive electrode material for lithium ion power cell

InactiveCN101339995ANo danger of flammabilityImprove securityElectrode manufacturing processesPhosphorus compoundsWater wetPhosphate

The invention discloses a preparation method of a lithium iron phosphate anode material used in a lithium-ion power battery. The preparation method takes ammonium dihydrogen phosphate and lithium carbonate or lithium hydroxide or lithium acetate and ferrous oxalate or ferrous acetate or takes the lithium dihydrogen phosphate and the ferrous oxalate or ferrous acetate as raw materials, the raw materials are prepared according to the ratio of Li, P and Fe of 1:1:1 or the ratio of LiH2PO4 to Fe of 1:1, and is added with micro amount of nano-metallic oxide or metal salt. After the process of mixing by a water wet method, spraying, drying, rolling and prilling, the mixture is pre-sintered for 10 minus or plus 2 hours at the constant temperature of 300-400 DEG C and is clad with carbon for prilling after being cooled; and then after the process of mixing by the water wet method, spraying, drying, rolling and prilling, the mixture is sintered for 10 minus or plus 2 hours at the temperature of 650-800 DEG C and then is cooled to obtain the lithium iron phosphate which is made after being crashed by gas stream and being compacted. The preparation method has the prominent advantages of safe preparation process, simple operation procedure, easy realization of industrialization and stable material performance of the product.

Owner:中国兵器工业第二一三研究所

Silicium cathode and lithium ion secondary battery containing the same, and method for preparing the same

ActiveCN101373826AReduce expansionNot easy to fall offElectrode manufacturing processesActive material electrodesLithiumConductive materials

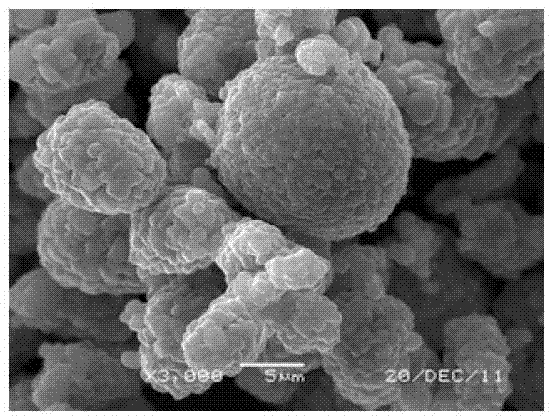

The invention relates to a silicon cathode of a lithium ion secondary battery. The silicon cathode comprises a conductive substrate and a material layer applied to the surface of the conductive substrate, wherein the material layer comprises at least two conductive material layers and at least one silicon-based material layer, the conductive material layers are attached to the conductive substrate, the silicon-based material layer and the conductive material layers are arranged at intervals, and the silicon-based material layer is positioned between the two conductive material layers. The lithium ion secondary battery prepared by adopting the silicon cathode has good volume specific capacity and good circulation performance.

Owner:BYD CO LTD

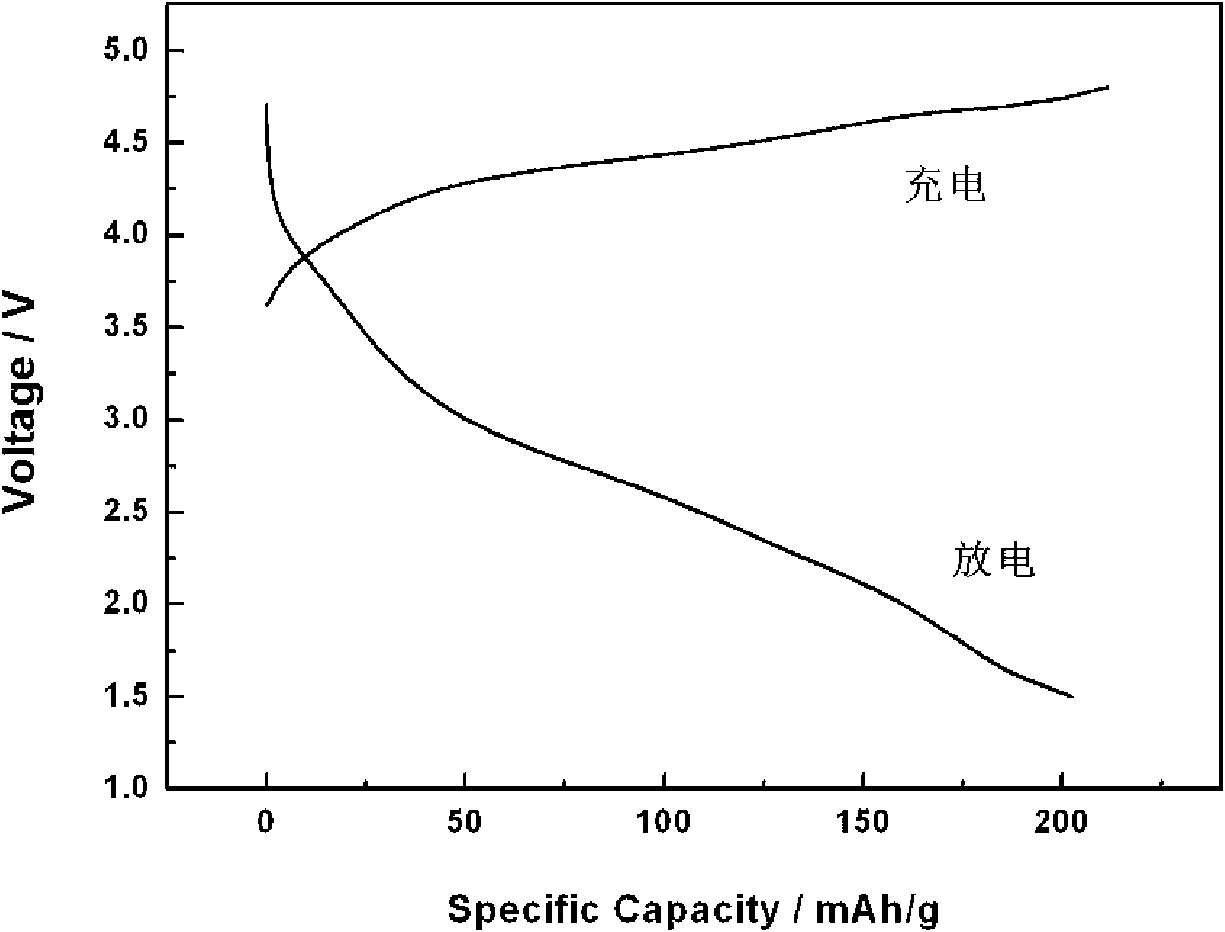

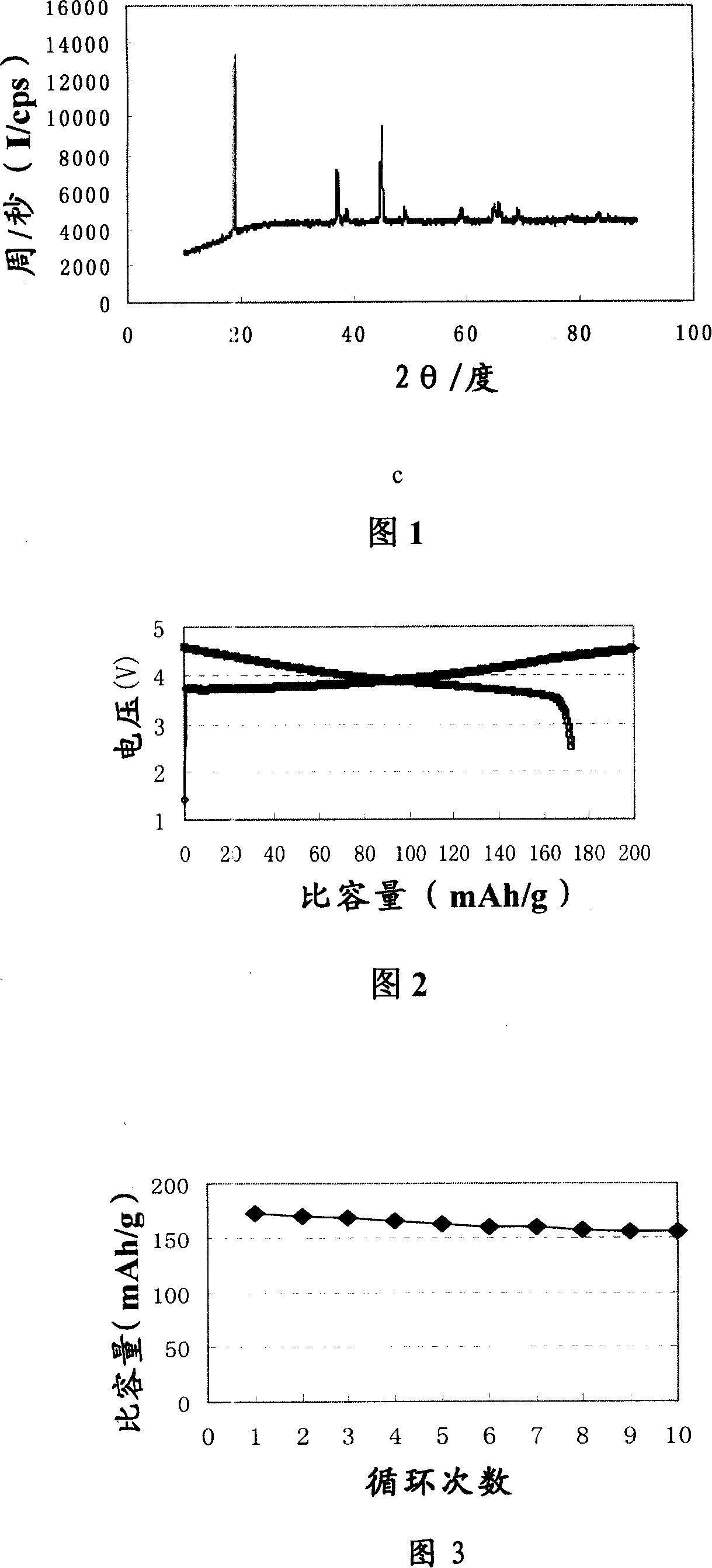

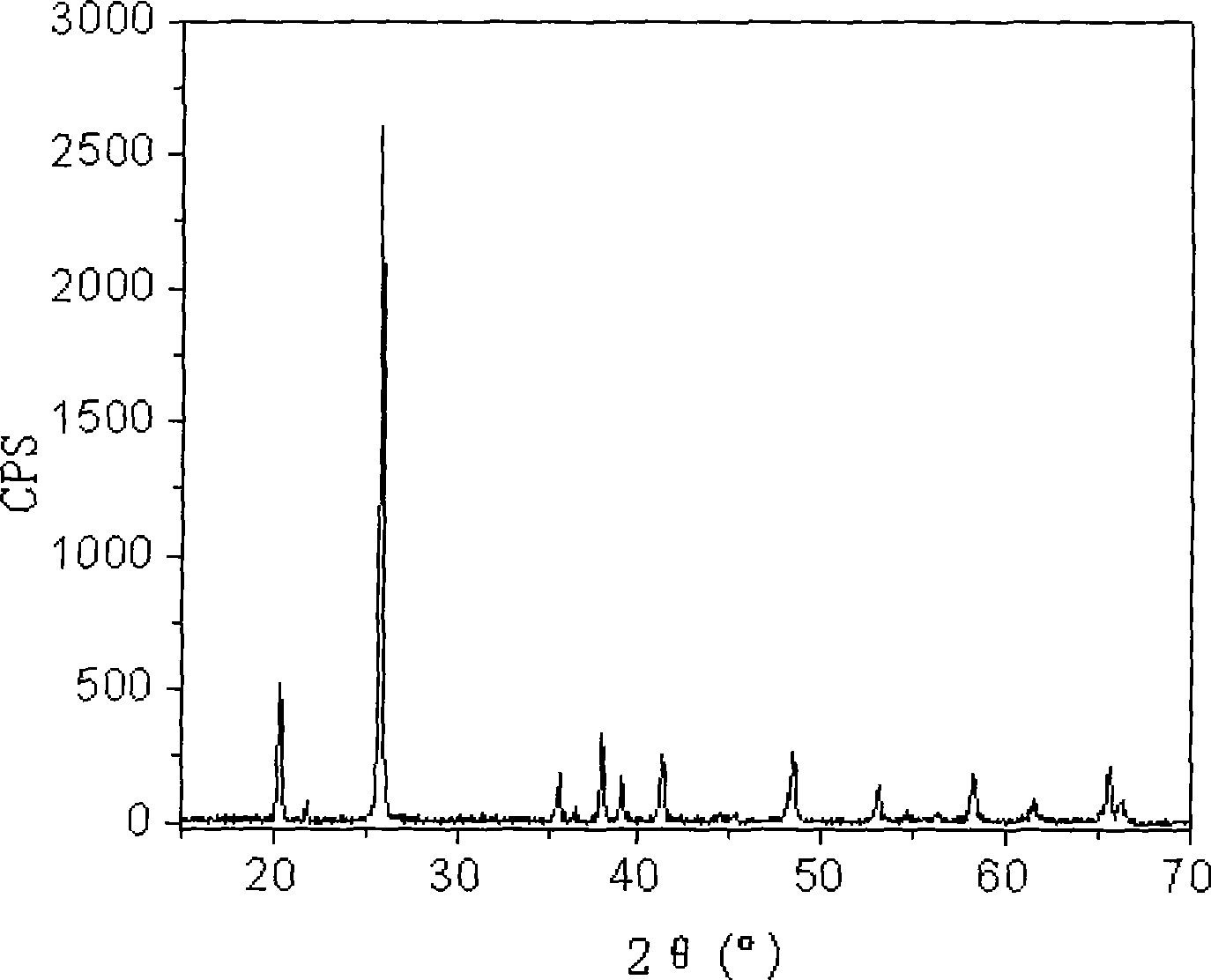

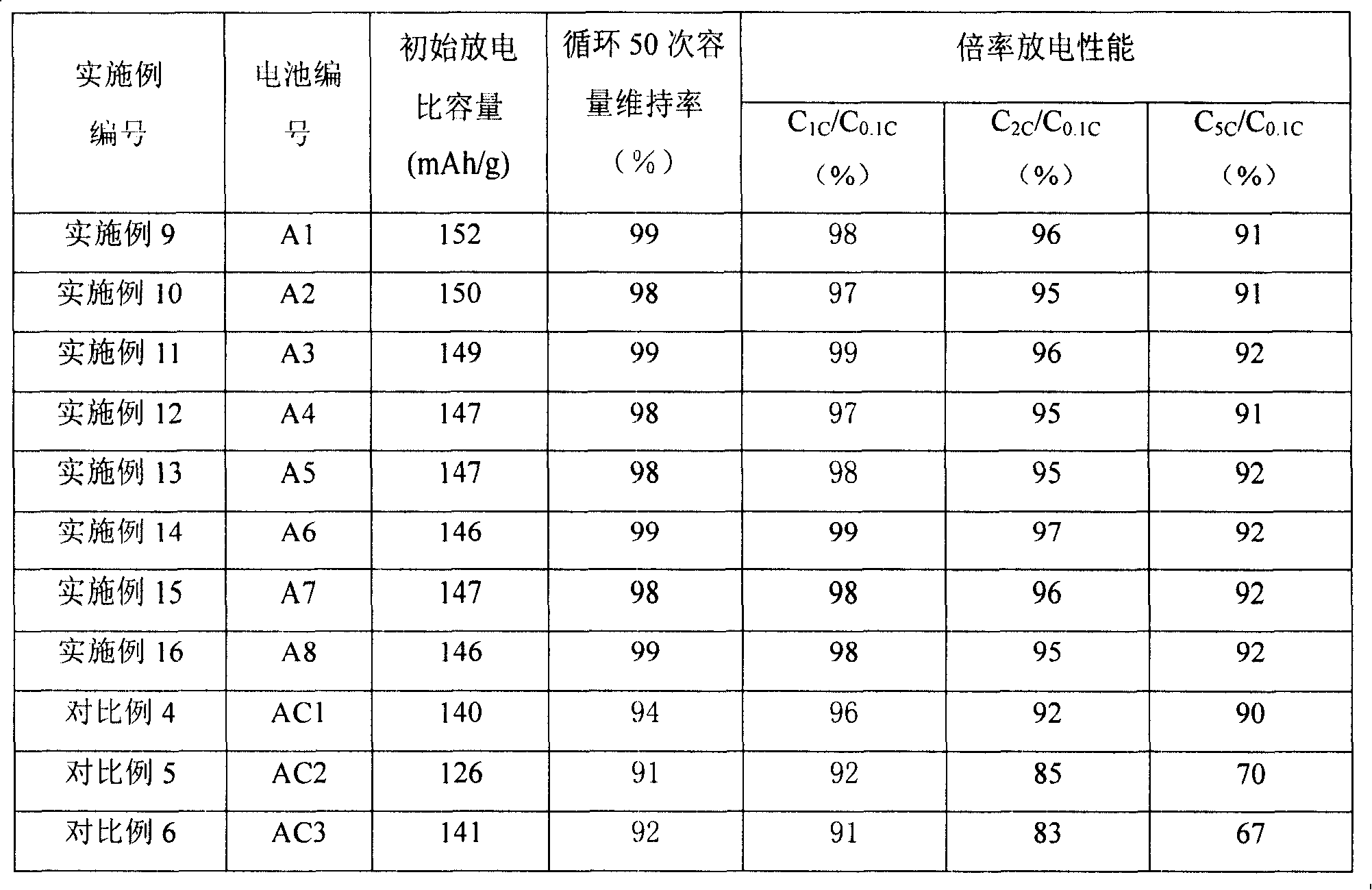

Silicate anodal material for lithium ion battery and preparation method thereof

ActiveCN101635345AImprove conductivityThe surface of the material is evenly distributedElectrode manufacturing processesActive material electrodesState of artMagnification

The invention discloses a silicate anodal material for lithium ion batteries and a preparation method thereof to solve the technical problem of the enhancement of the material density of the silicate anodal material. The general formula of the anodal material is Li2MSiO4 / D, wherein the Li2MSiO4 is the active substance of the silicate anodal material, D is a modifying agent doped and covered on the surface of the Li2MSiO4. The preparation method comprises the following steps: preparing a modifying agent source solution; putting the Li2MSiO4 into the solution to obtain a mixture; and carrying out spraying, drying, hot processing and fusion processing on the mixture. Compared with the prior art, the invention utilizes a liquid-phase method to cover, modify and fuse the silicate anodal material so as to ensure that the silicate anodal material has the characteristics of high stacking density, high compacted density, high volume specific capacity, favorable processing performance of batteries and low cost. Batteries produced by the silicate anodal material have higher safety performance, magnification performance and cyclic performance.

Owner:BTR NEW MATERIAL GRP CO LTD

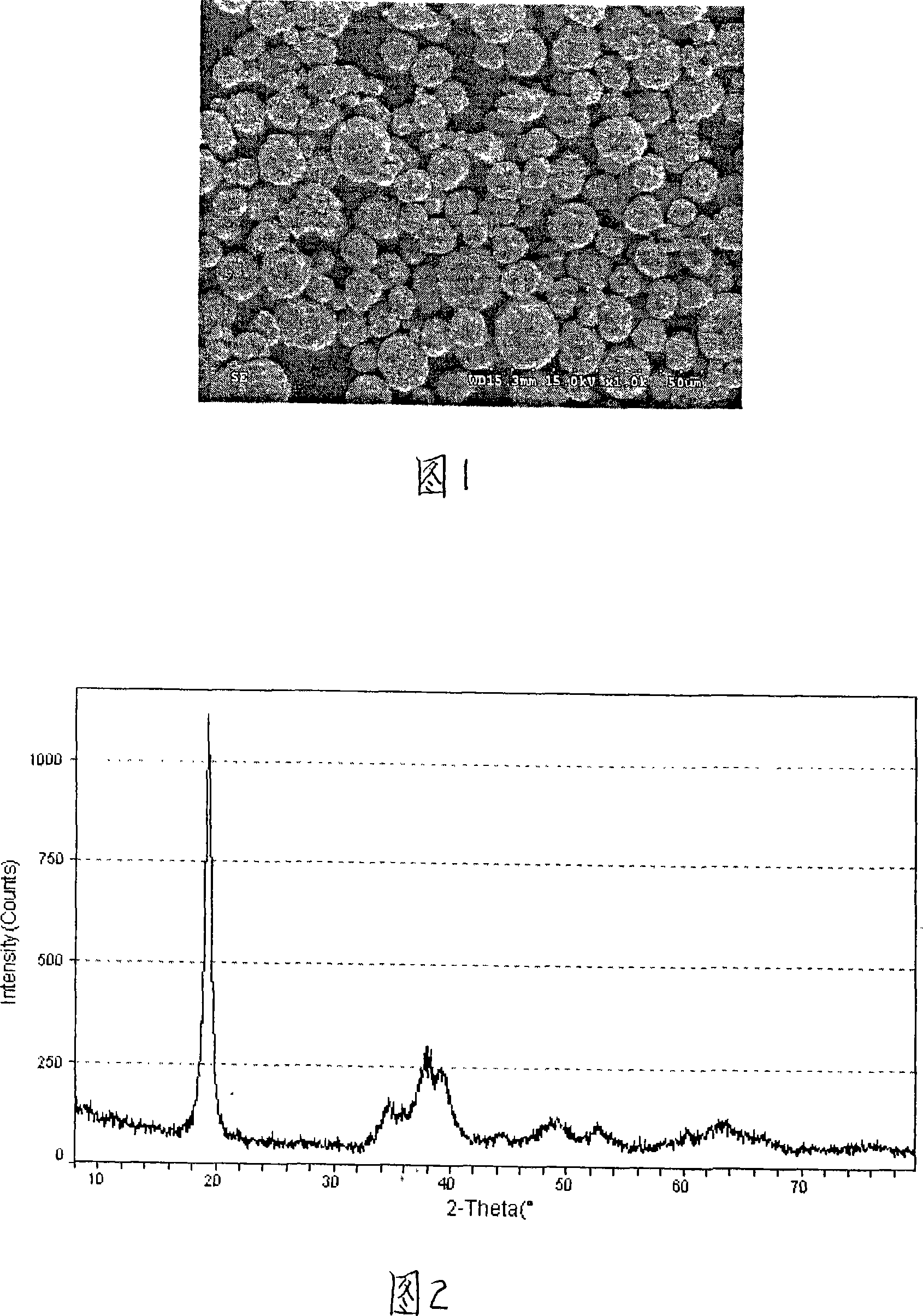

A ball hydroxide oxidated Ni-Co-Mn and its making method

InactiveCN101127398AHigh tap densityImprove electrochemical activityElectrode manufacturing processesCobalt compoundsReaction timingOxidizing agent

The utility model discloses a spherical hydroxyl nickel oxide cobalt manganese and the fabrication method, relating to the anode material of a lithium battery, and aiming to provide a spherical hydroxyl nickel oxide cobalt manganese and the fabrication method. The fabricated anode material of the lithium battery has the advantages of big tap density, good electrochemical activity, big specific volumetric capacity, low synthesis temperature and short reaction time. The key points of the technical proposal of the utility model are that: the general formula of the spherical hydroxyl nickel oxide cobalt manganese is Ni1-x-yCoxMnyOOH; the spherical hydroxyl nickel oxide cobalt manganese and the fabrication method comprise the following steps: (1)a mixed salt solution of nickel, cobalt and manganese is confected according to the ratio that Ni:Co:Mn=1:(1 / 5-2 / 5):(1 / 5-2 / 5); (2) an alkaline solution of two to ten mol / L is confected; (3) the mixed salt solution of nickel, cobalt and manganese, the alkaline solution and the ammonia are conducted to an reaction kettle; (4) the intermediate products are added to the reaction kettle according to the solid-liquid ratio of 1:2 to 10, and reacted with the oxidant to produce the utility model. The utility model is used as the anode material of lithium batteries.

Owner:HENAN NORMAL UNIV +1

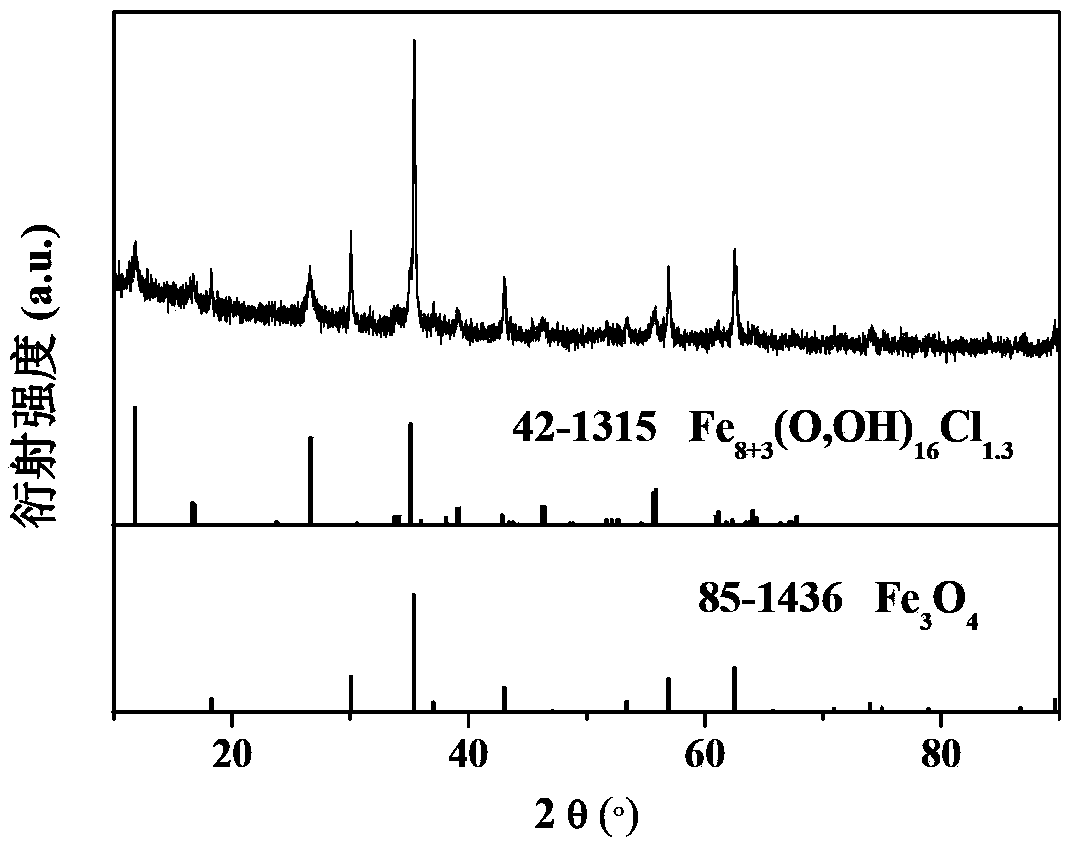

Iron oxide/carbon composite lithium ion battery anode material as well as preparation method and application thereof

ActiveCN103435105ALow priceSimple methodIron oxides/hydroxidesCell electrodesCarbon compositesIron salts

The invention relates to a preparation method for iron oxide / carbon composite material. The preparation method comprises the steps as follows: 1, taking a water-soluble iron salt as an iron source, taking a water-soluble organic carbon source as a carbon source, and uniformly mixing the iron salt water solution, ammonia water with the organic carbon source to form a liquid phase mixture; 2, performing spray drying, freeze drying or spray pyrolysis on the liquid phase mixture to form a powder precursor, and performing calcination on the precursor to prepare into the iron oxide / carbon composite material; or performing spray pyrolysis on the mixed solution directly to prepare into the iron oxide / carbon composite material. The preparation method for the iron oxide / carbon composite material, which is provided by the invention, is high in production efficiency and suitable for large-scale production; the utilization efficiency of the composite material is improved; the iron oxide / carbon composite material provided by the invention is taken as the anode material of a lithium ion battery, so that the lithium storage capacity of the anode material of the lithium ion battery is several times as much as that of commercial carbon anode material.

Owner:宇恒电池股份有限公司 +1

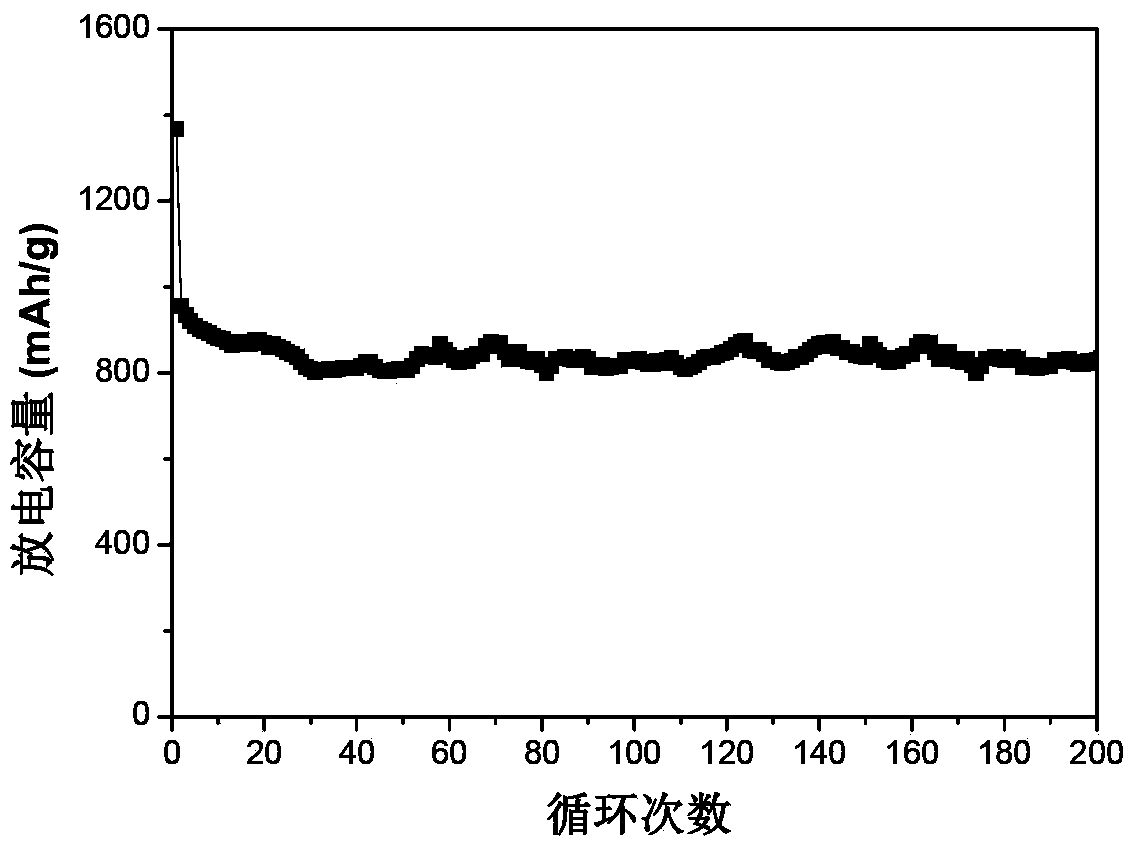

Isotropous graphite secondary particle, and preparation method and use thereof

ActiveCN102931381AImprove fast charge and discharge capabilityReduce entryCell electrodesPowder mixtureElectrical battery

The invention relates to a preparation method of an isotropous graphite secondary particle. The preparation method comprises the following steps: 1, mixing initial carbon material particles with modified asphalt particles to obtain a powder mixture with the initial carbon material particles as a continuous phase and the modified asphalt particles as a dispersion phase; 2, carrying out hot isothermal pressing treatment of the powder mixture, and removing the initial carbon material particles unbonded by the modified asphalt to obtain an isotropous graphite secondary particle precursor; and 3, sequentially carrying out heat treatments comprising non-melting treatment, charring treatment and graphitization treatment of the isotropous graphite secondary particle precursor. The isotropous graphite secondary particle macroscopically has the isotropy, can maintain the specific mass capacity of a cathode material, and simultaneously solves problems comprising low compacted density of a graphite cathode material piece and large baking expansion rate after the compacting of the piece, so the specific volume capacity of a lithium ion battery is improved.

Owner:内蒙古杉杉科技有限公司

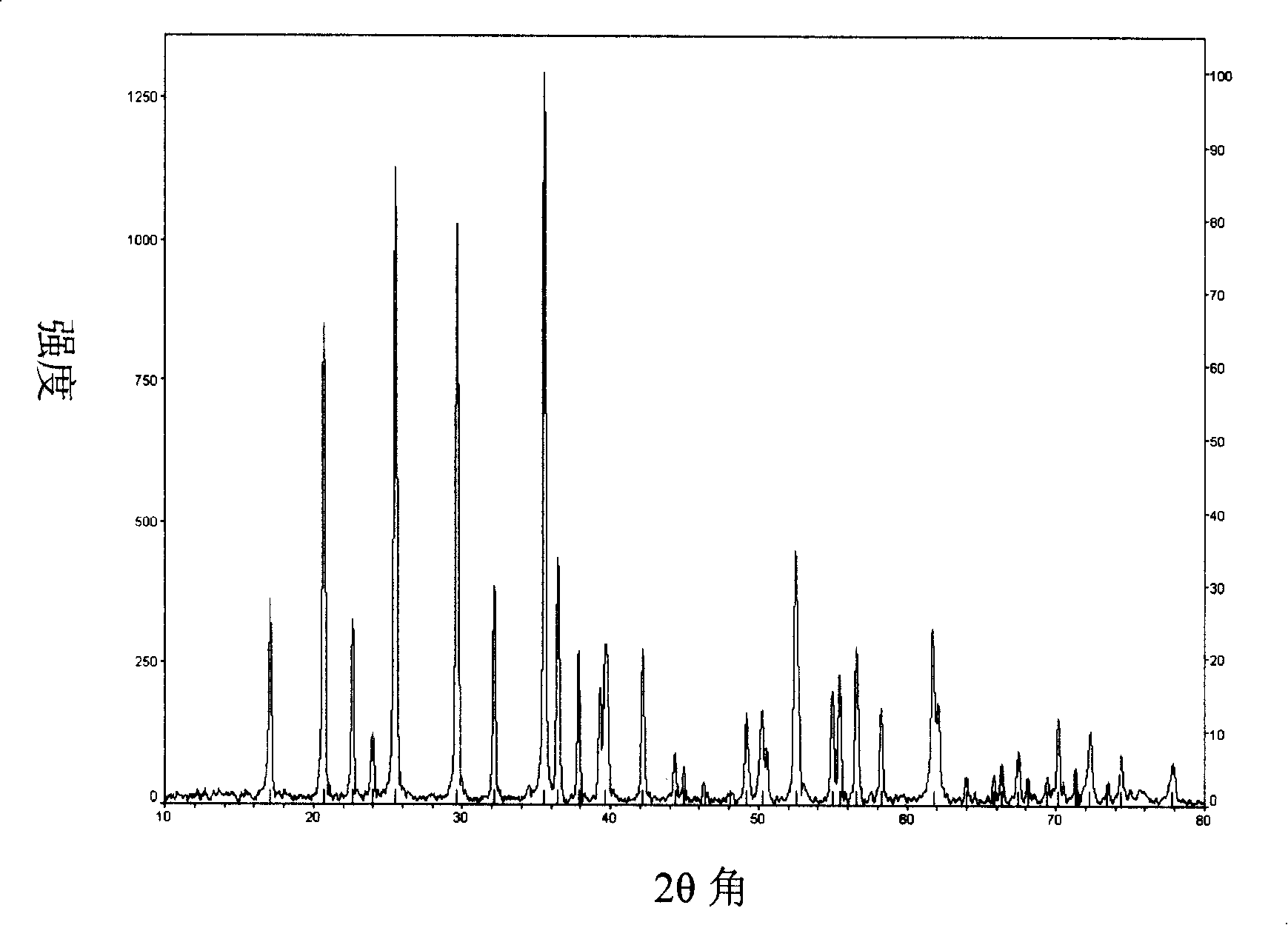

Multielement-doped lithium iron phosphate positive electrode material and preparation method thereof

InactiveCN101800315AIncrease volume capacityWide range of materialsCell electrodesLithium iron phosphateNiobium

The invention discloses a multielement-doped lithium iron phosphate positive electrode material and a preparation method thereof. The general formula of the multielement-doped lithium iron phosphate positive electrode material is Li1-xAxFe1-y-zNbyMzPO4, wherein x, y and z are more than zero and not more than 0.1. The preparation method comprises the following steps: mixing lithium source, iron source, phosphorus source, compound of A and carbon source, roasting at 400-800 DEG C, then quickly reducing the temperature to room temperature, crushing, grinding to obtain an intermediate, then mixing the intermediate with niobium compound, compound of M and carbon source, roasting at 400-850 DEG C, then quickly reducing the temperature to room temperature, grinding, and grading to obtain the product. The preparation method of the invention can obviously increase the tap density of the material; and the material can have higher specific capacity and volume specific capacity and excellent cycle performance, meanwhile the material is applicable to industrialized stable production and has wide application prospect in the battery positive electrode material field for energy sources.

Owner:QUFU ENERGY

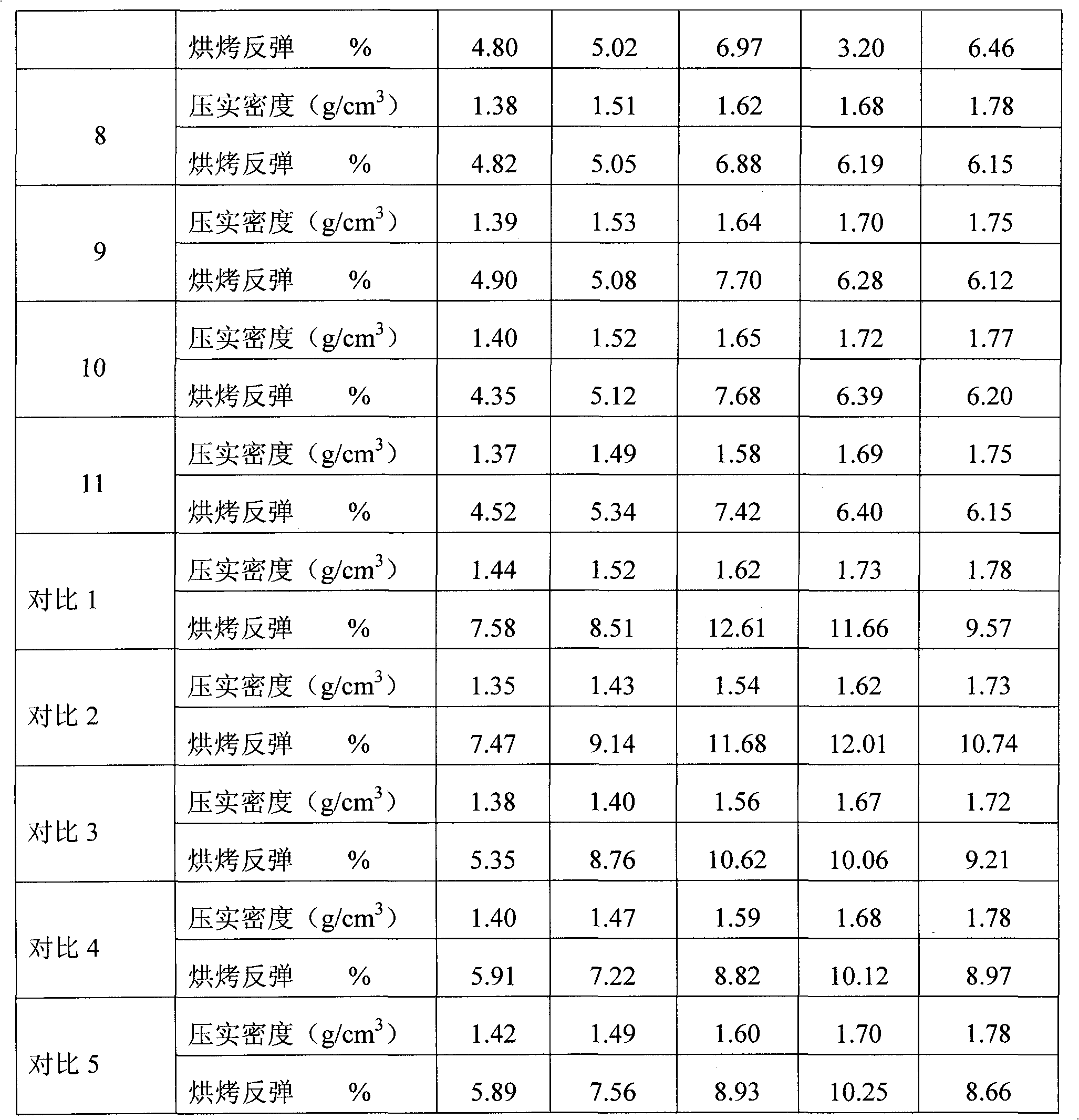

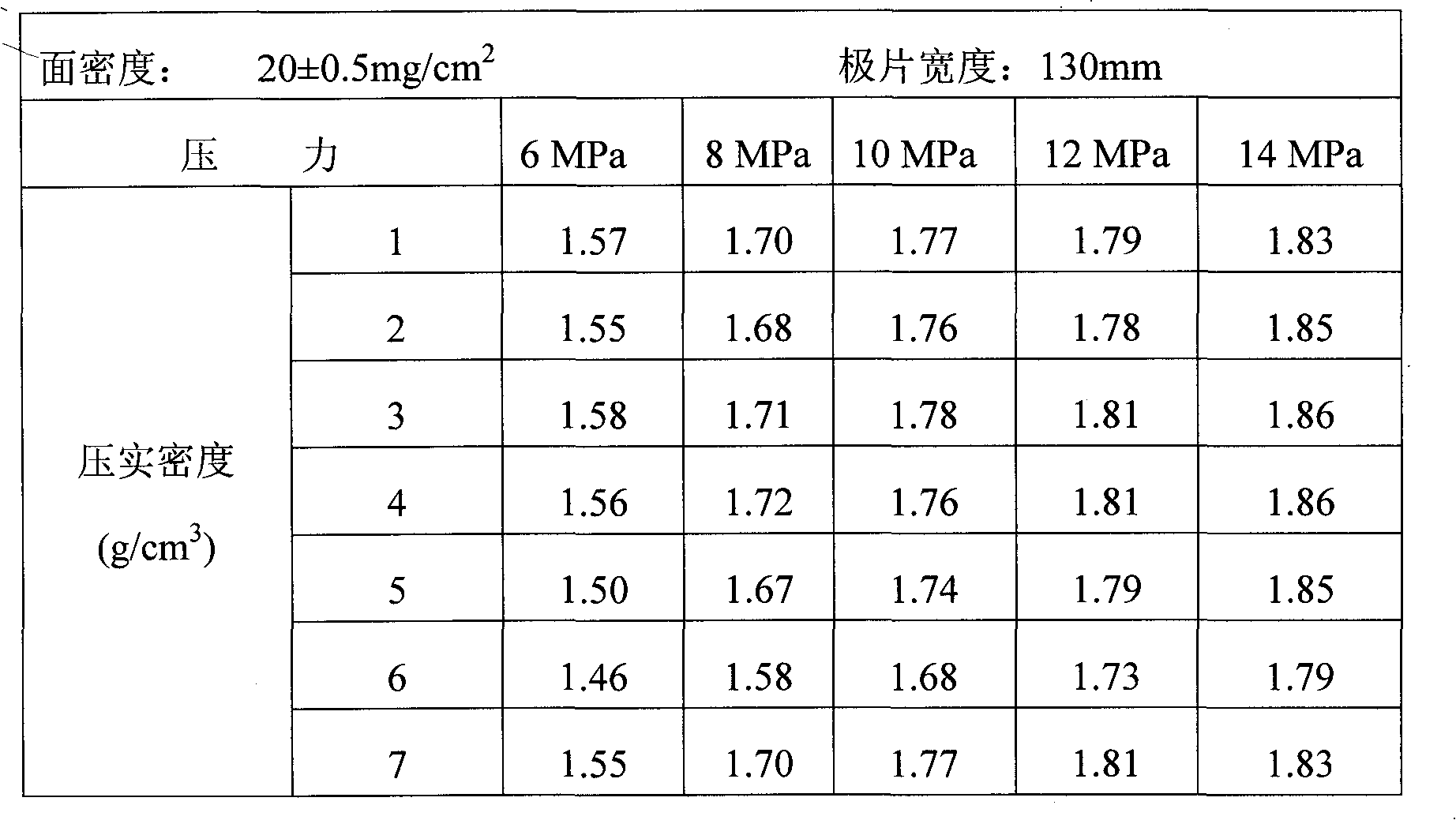

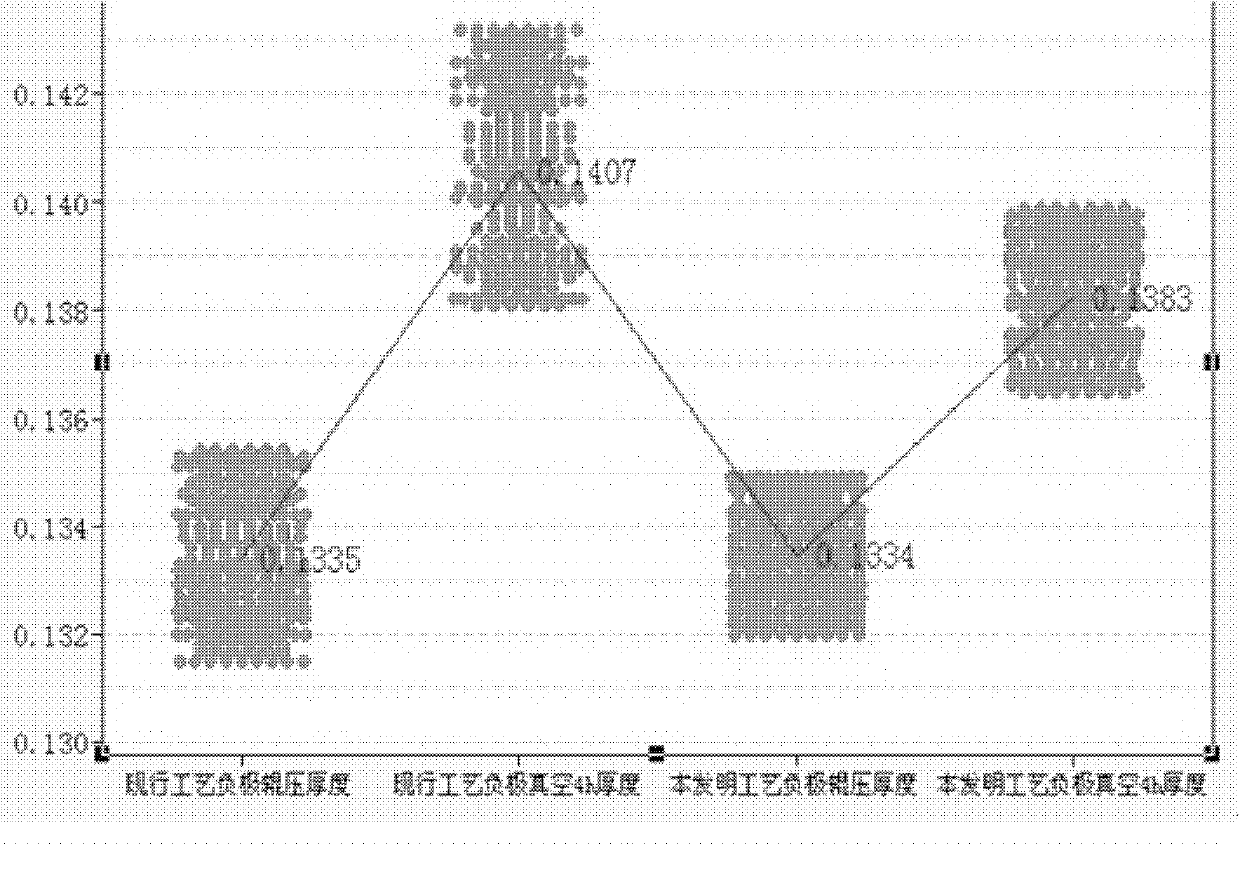

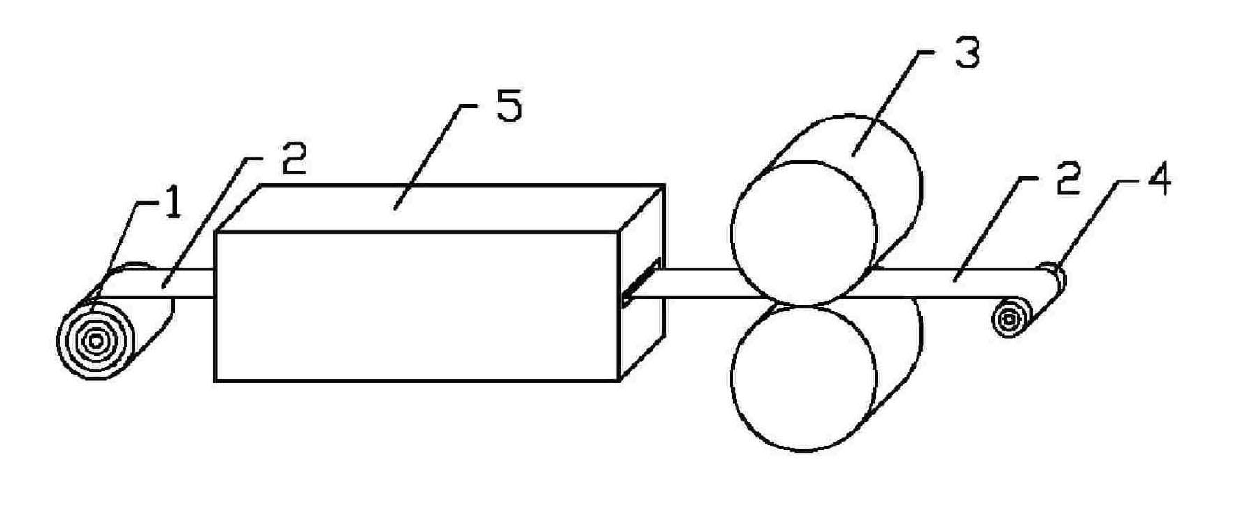

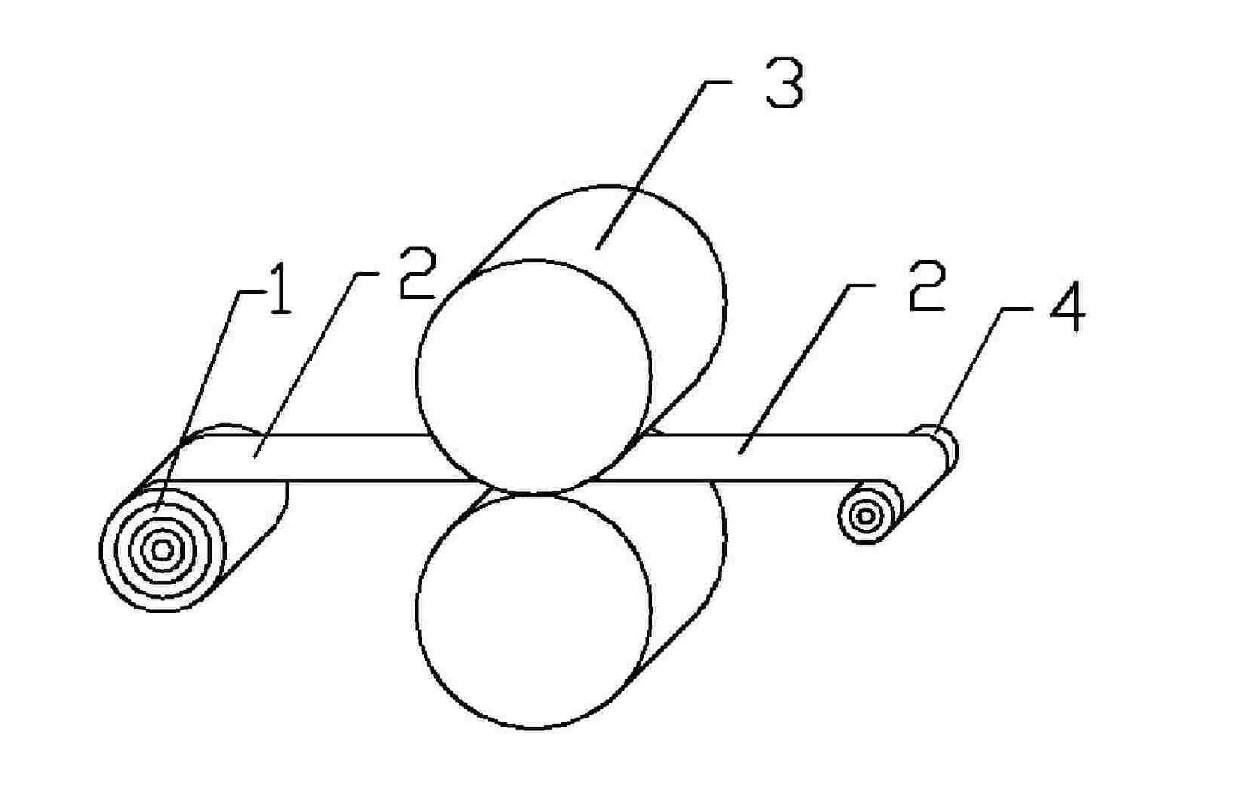

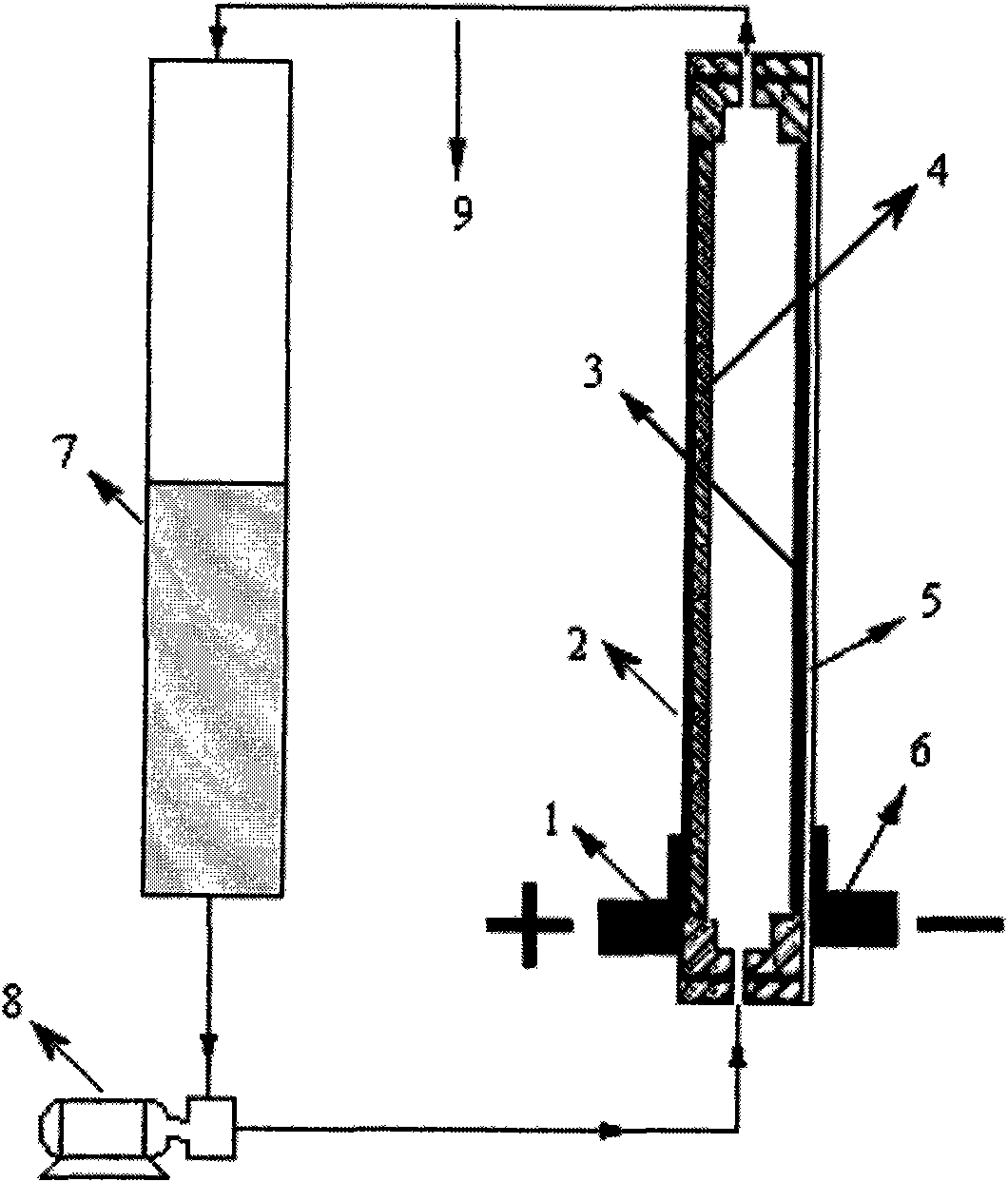

Continuous rolling process for lithium-ion battery electrode and device thereof

InactiveCN101877397AIncrease volume capacityImprove plasticityElectrode manufacturing processesRotary pressBiochemical engineeringVolumetric Mass Density

The invention discloses a continuous rolling process for a lithium-ion battery electrode and a device thereof. The process is characterized in that an electrode plate adopts a low-temperature hot rolling process. The used device is characterized in that a heating device is increased between an unrolling shaft and a roll. The process has the advantages of ensuring the dryness of the electrode, increasing the plasticity of the electrode plate, reducing the rebound rate of the rolled electrode plate and properly increasing the single-side density of the electrode plate, thereby promoting the volume rate capacity of the battery; and the device has a simple structure and convenient operation.

Owner:NINGBO VEKEN BATTERY

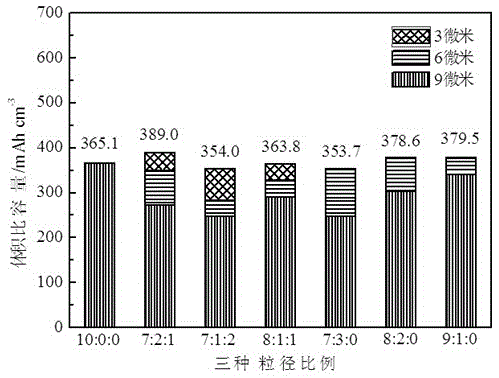

Method for improving tap density of ternary nickel-cobalt-manganese cathode material for lithium-ion battery

InactiveCN105489881AHigh tap densityIncrease volume capacitySecondary cellsPositive electrodesCyclic processManganese

The invention discloses a method for improving tap density of a ternary nickel-cobalt-manganese cathode material for a lithium-ion battery. The method comprises the following steps: (1) screening ternary material precursors Ni<x>Co<y>Mn<z>(OH)<2> with large, medium and small particle sizes; (2) carrying out ball-milling wet-mixing roasting on the ternary material precursors screened in the step (1) and a lithium salt respectively, so as to obtain ternary nickel-cobalt-manganese cathode materials with large, medium and small particle sizes; and (3) mixing the ternary nickel-cobalt-manganese cathode material with the large particle size obtained in the step (2) with the ternary nickel-cobalt-manganese cathode materials with the medium and / or small particle sizes, and then carrying out secondary low-temperature roasting to obtain the ternary nickel-cobalt-manganese cathode material with high tap density. According to the method, the tap density and the volumetric specific energy of the ternary nickel-cobalt-manganese cathode material for the lithium-ion battery can be improved; the gram volume of the material is improved on the basis of ensuring the stability of the material in the cyclic process; and the rate capability is improved.

Owner:HARBIN INST OF TECH

Method for preparing lithium vanadium phosphate as lithium ion battery anode material

InactiveCN101651205AUniform particle size distributionHigh specific capacityElectrode manufacturing processesMuffle furnacesLithium vanadium phosphate batteryMicrowave sintering

The invention discloses a method for preparing lithium vanadium phosphate as a lithium ion battery anode material, which comprises the following steps: (1) preparing reaction precursor gel of an anodematerial by a sol-gel method; (2) presintering the reaction precursor gel prepared in the step (1); and (3) placing a material obtained by presintering into a microwave sintering furnace to sinter. The invention combines the sol-gel method with a microwave sintering method and can prepare a product with favorable electrode plate processing ability, electrical conductivity and electrochemical performance by sintering in tens of minutes. The method has high production efficiency, low energy consumption, easy control of technical parameter, favorable batch stability and low production cost and is suitable for mass industrial production.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Method for preparing layered lithium, nickel, cobalt and manganese oxide anode material for lithium ion battery

The present invention relates to a method to prepare cathode material of layered lithium-nickel-cobalt-manganese oxide applied to lithium ion battery. The corresponding materials of metal manganese powers, compounds of lithium, metal cobalt or compounds of cobalt and compounds of nickel are weighted according to the molar ratio expressed and required in the chemical formula LiyNixCo1-2xMnxO2. In the formula, x is more than zero but less than 0.5 and y is more than or equal to 0.9 but less than 1.1; a solvent is added in the materials for wetmilling; and to be dried after wetmilling; then the materials is sintered under high temperature and then to be grinded to acquire the cathode material of layered lithium-nickel-cobalt-manganese oxide. The present invention has the advantages that a wetmilling mixing method is adopted which improves the mixing effect of the materials; a solid phase method is adopted to compound which has the advantages of simple technics process and low cost and is suitable for Industrialized mass production and avoids the complex flows of the body of a wet method before preparation; the metal manganese powers are adopted to replace the traditional manganese compound as materials which greatly improves the tap density of products and can realize higher volume capacity.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Polymer electrolyte isolating membrane, preparation method and use thereof

InactiveCN102412378AReduce leakageGrowth inhibitionCell component detailsUltraviolet lightsLithium-ion battery

A polymer electrolyte isolating membrane, preparation method and use thereof, relating to a polymer electrolyte isolating membrane, preparation method and use thereof. The invention solves the problem in the current lithium ion battery liquid electrolyte that is easy to leak and hard to shape the gel state electrolyte and has bad safe performance and mechanical performance. The polymer electrolyte isolating membrane is made of a lithium salt, an organic solvent, a photosensitive monomer, a photoinitiator and a nano-filler. The method includes the steps as follows: adding the lithium salt into the organic solvent, magnetically stirring them to obtain the electrolyte solution; adding the photoinitiator into the photosensitive monomer, magnetically stirring them to form a mixed monomer; adding the electrolyte solution and the nano-filler into the mixed monomer; ultrasonically shaking them to obtain the mixed solution; coating the mixed solution on the surface of the release material; radiating on the surface of the release material coated with the mixed solution via an ultraviolet light to obtain the polymer electrolyte isolating membrane. The polymer isolating membrane of the invention has the advantages of good mechanical performance, easy formation, high conductivity and good battery performance after the battery is assembled.

Owner:HARBIN INST OF TECH

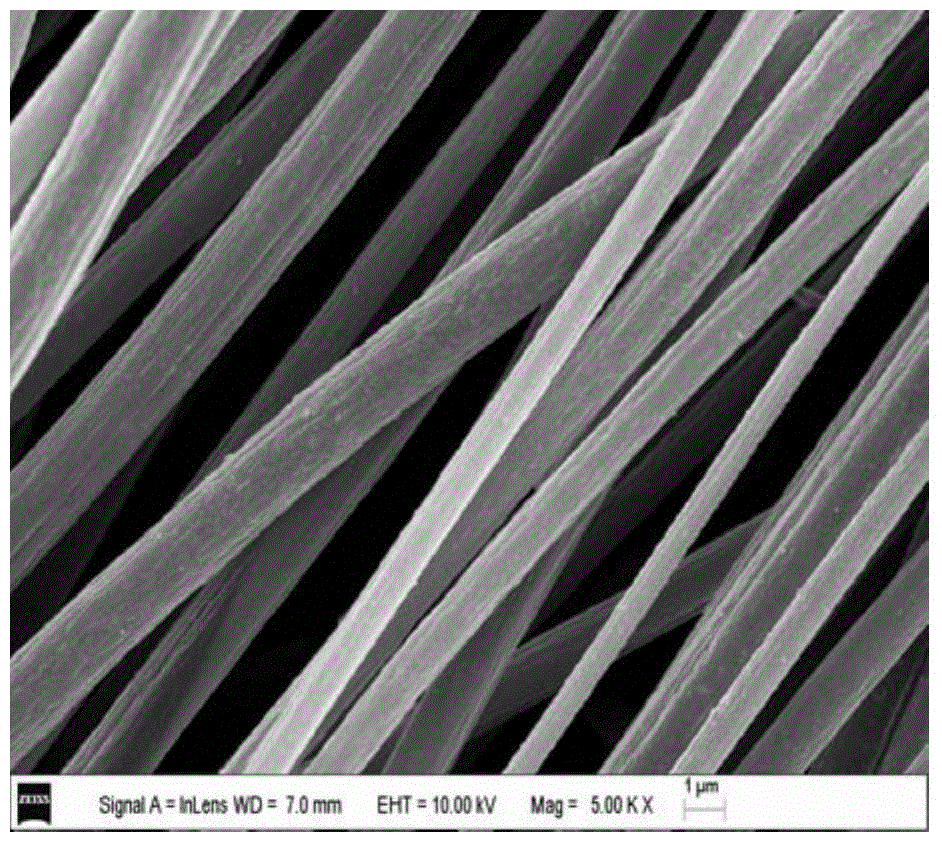

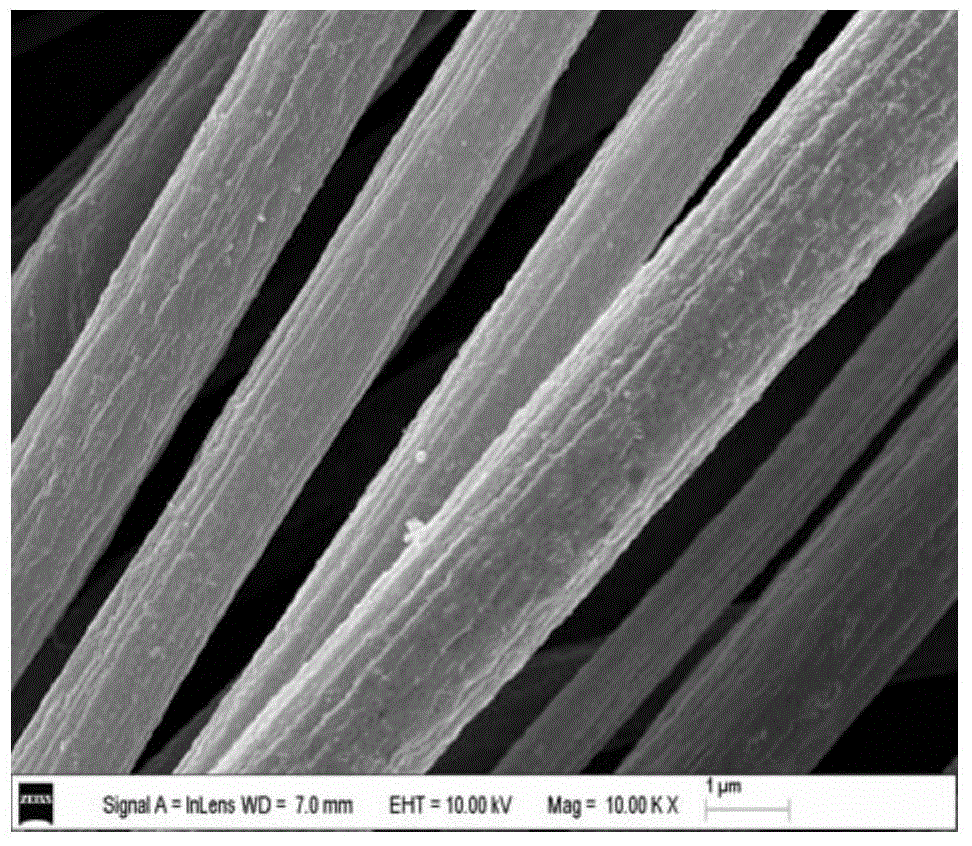

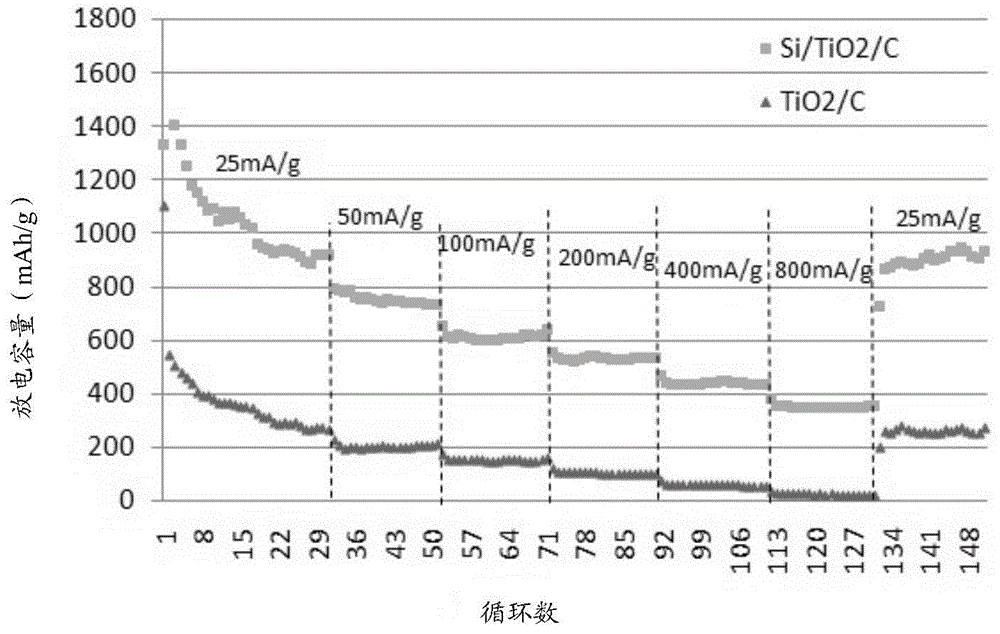

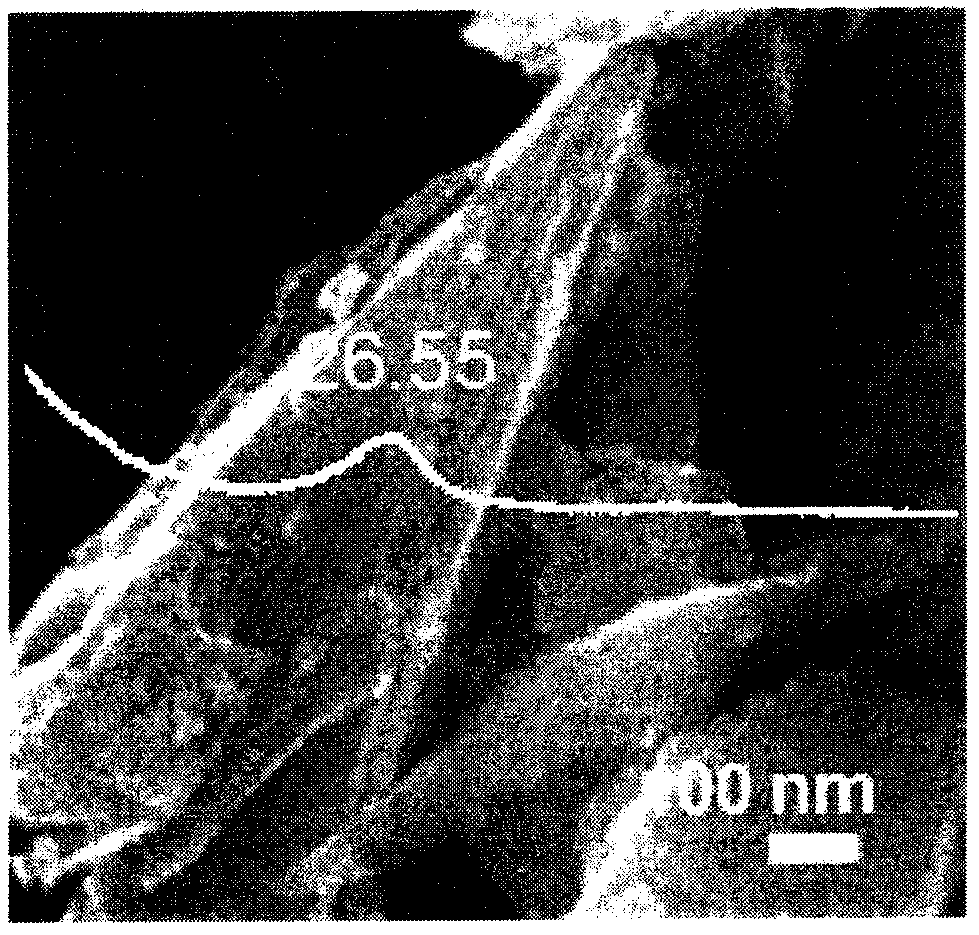

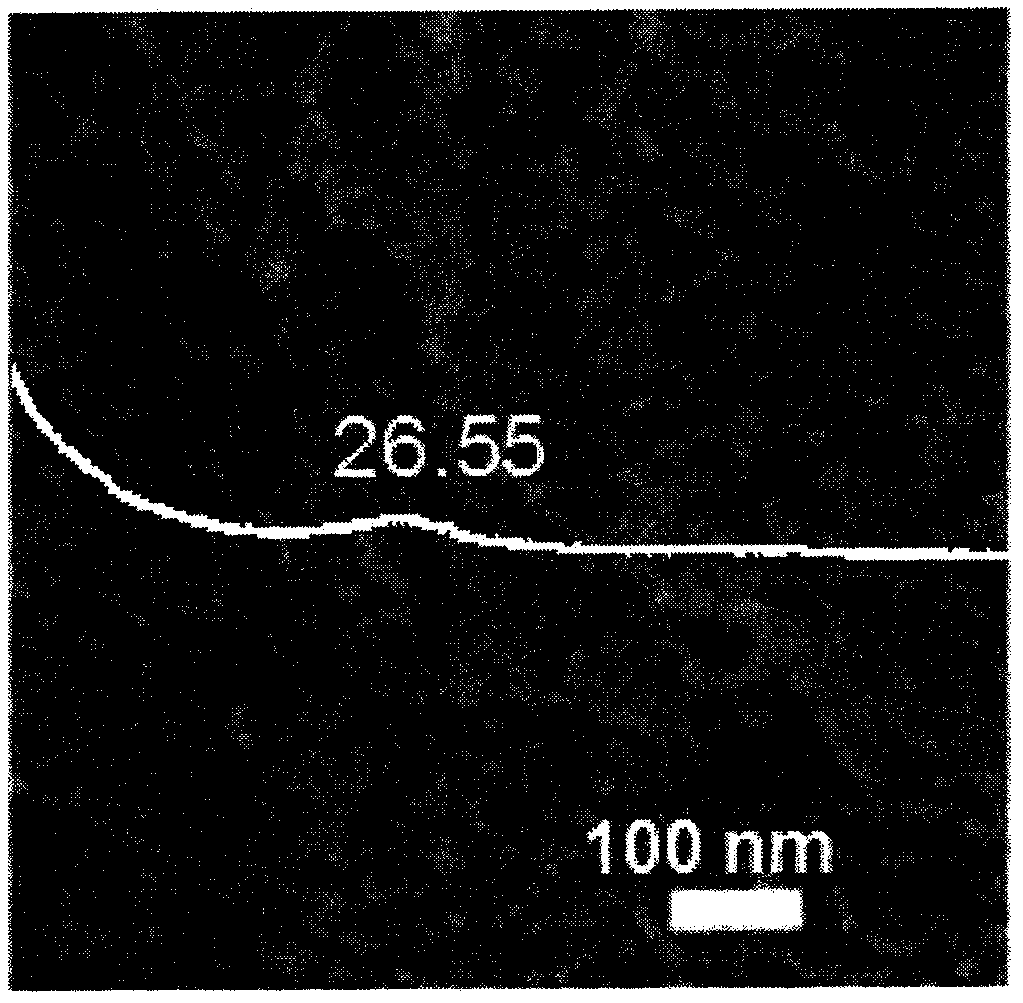

Si-TiO2-C nano fiber composite thin film, preparation method and application thereof

ActiveCN104835949AImprove the preparation of Si-TiO

<sub>2</sub>

Efficiency of -C nanofiber composite filmsImprove efficiencyMaterial nanotechnologyCell electrodesFiberNano silicon

The invention provides a Si-TiO2-C nano fiber composite thin film, a preparation method and an application thereof. The preparation method for preparing the Si-TiO2-C nano fiber composite thin film includes following steps: (1) providing a spinning liquid which contains nano silicon powder, a titanium precursor and a carbon precursor; (2) performing electrostatic spinning to the spinning liquid to prepare a nano fiber film; (3) pre-oxidizing the nano fiber film under an oxygen-containing atmosphere at 100-300 DEG C to obtain a stabilized nano fiber film; and (4) carbonizing the stabilized nano fiber film under an non-oxidizing atmosphere at 500-1000 DEG C to obtain the Si-TiO2-C nano fiber composite thin film. By means of the method, the Si-TiO2-C nano fiber composite thin film can be prepared quickly and effectively. The preparation method is simple in operations, is convenient and quick, and can easily achieve large-scale production.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Silicon cathode, lithium ion secondary battery comprising the same and manufacturing method therefor

InactiveCN101393980AAvoid volumeAvoid problems such as electrode dropElectrode manufacturing processesFinal product manufactureLithiumSilicon

A silicon negative electrode of a lithium ion secondary battery comprises a conductive matrix and a material layer loaded on the surface of the conductive matrix, wherein the material layer is composed of a carbon material layer and a silicon layer; the carbon material layer is attached to the conductive matrix; and the silicon layer is attached to the carbon material layer. The battery prepared by the silicon negative electrode has both the higher volume ratio capacity and the favorable circulation performance.

Owner:BYD CO LTD

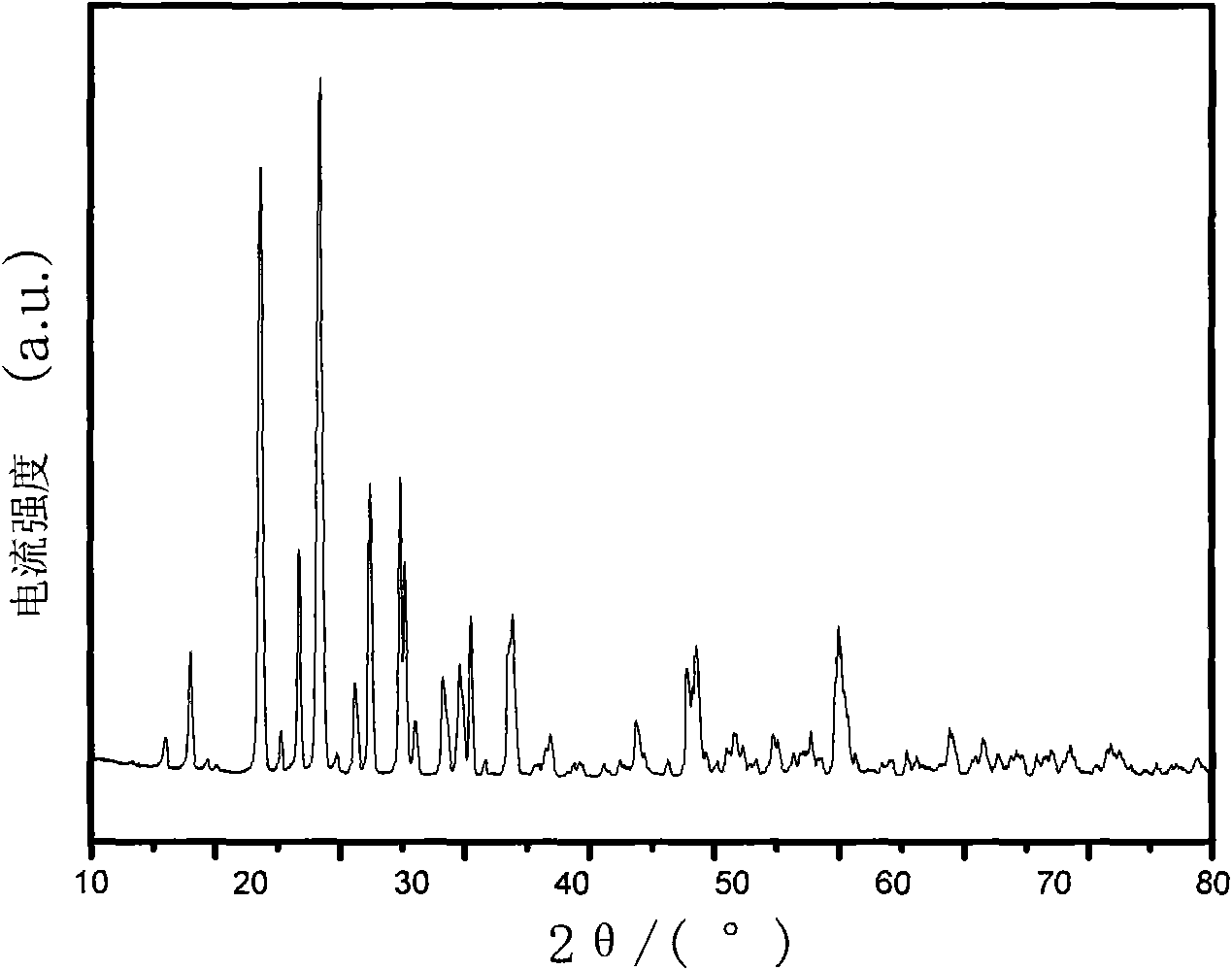

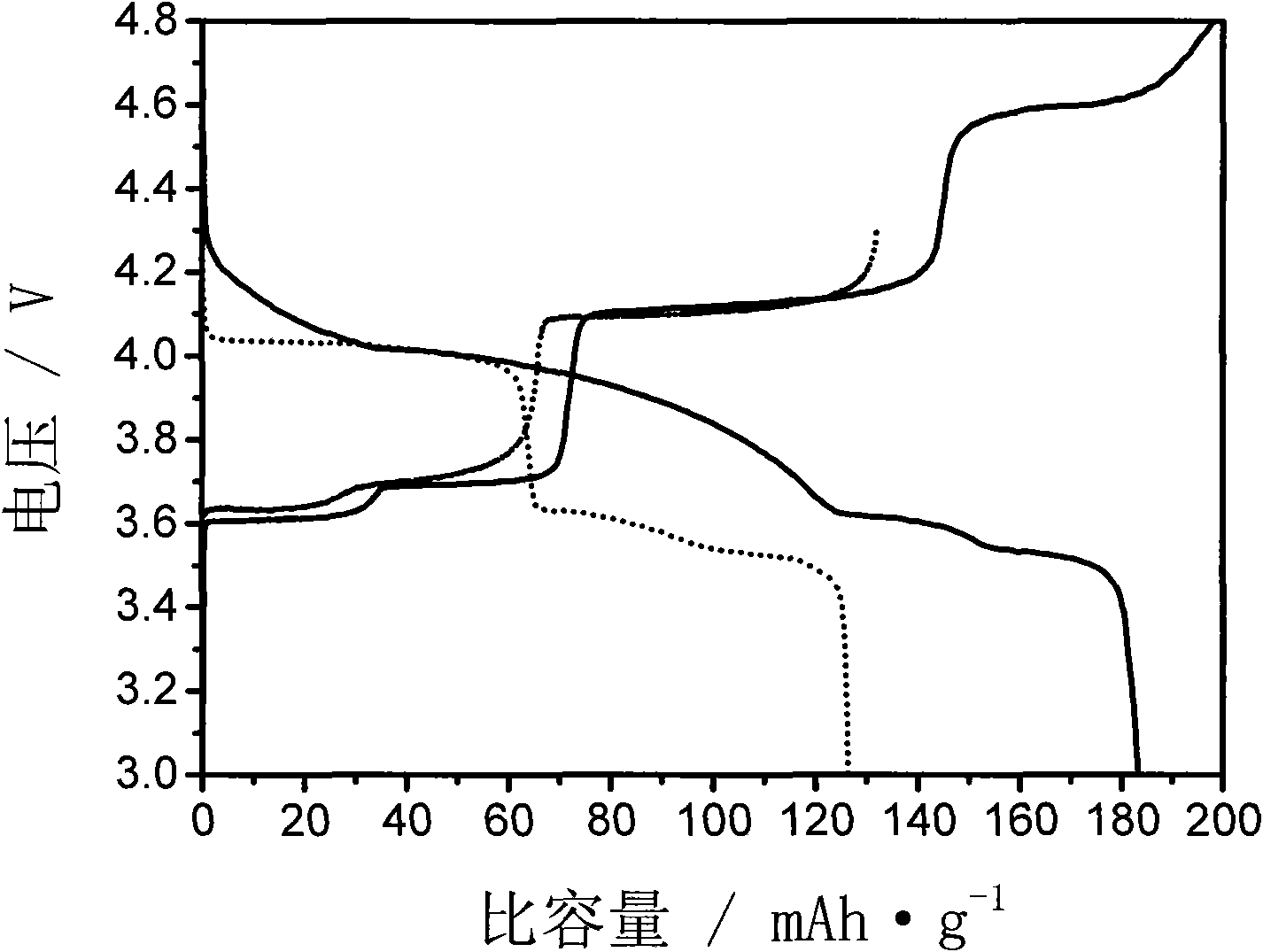

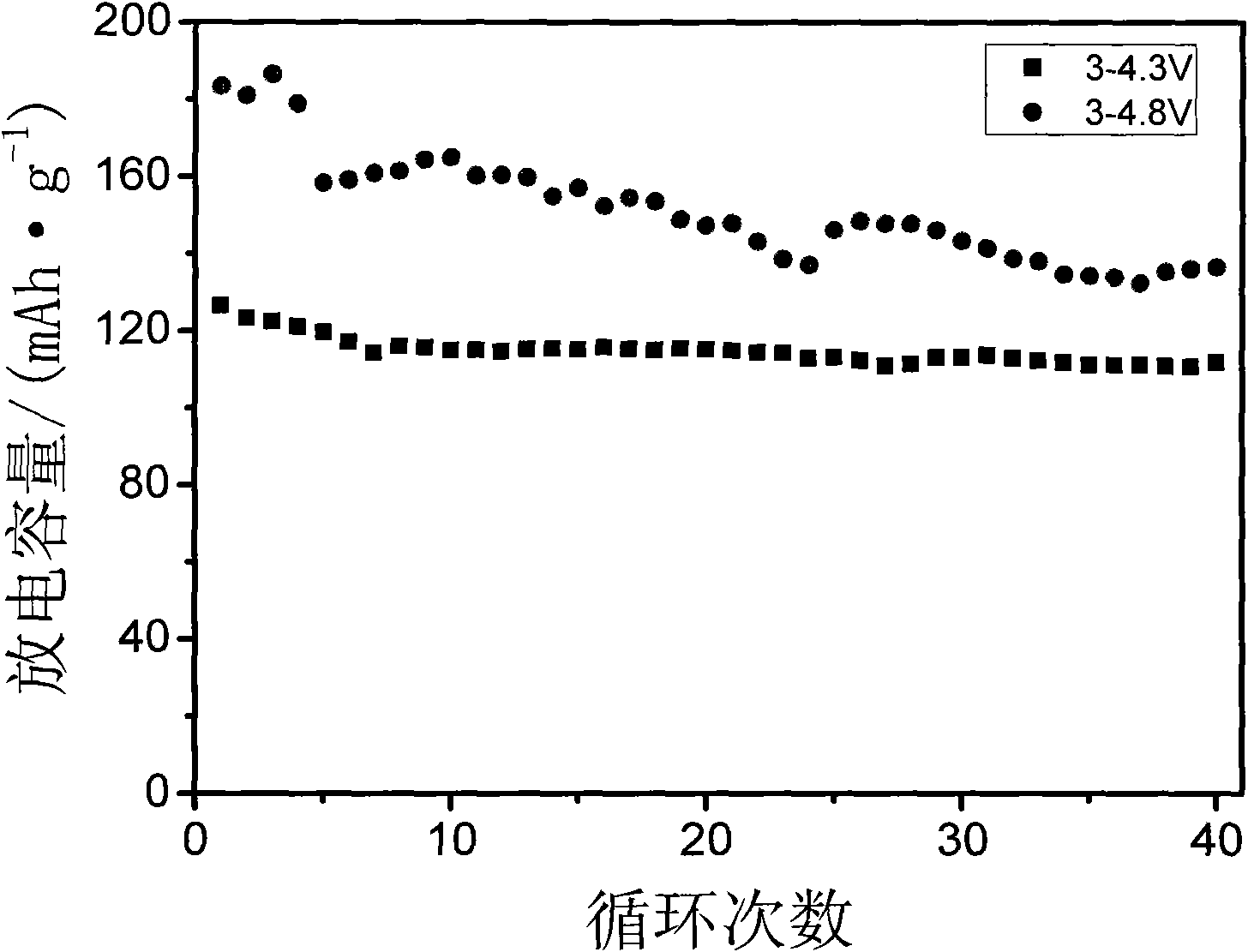

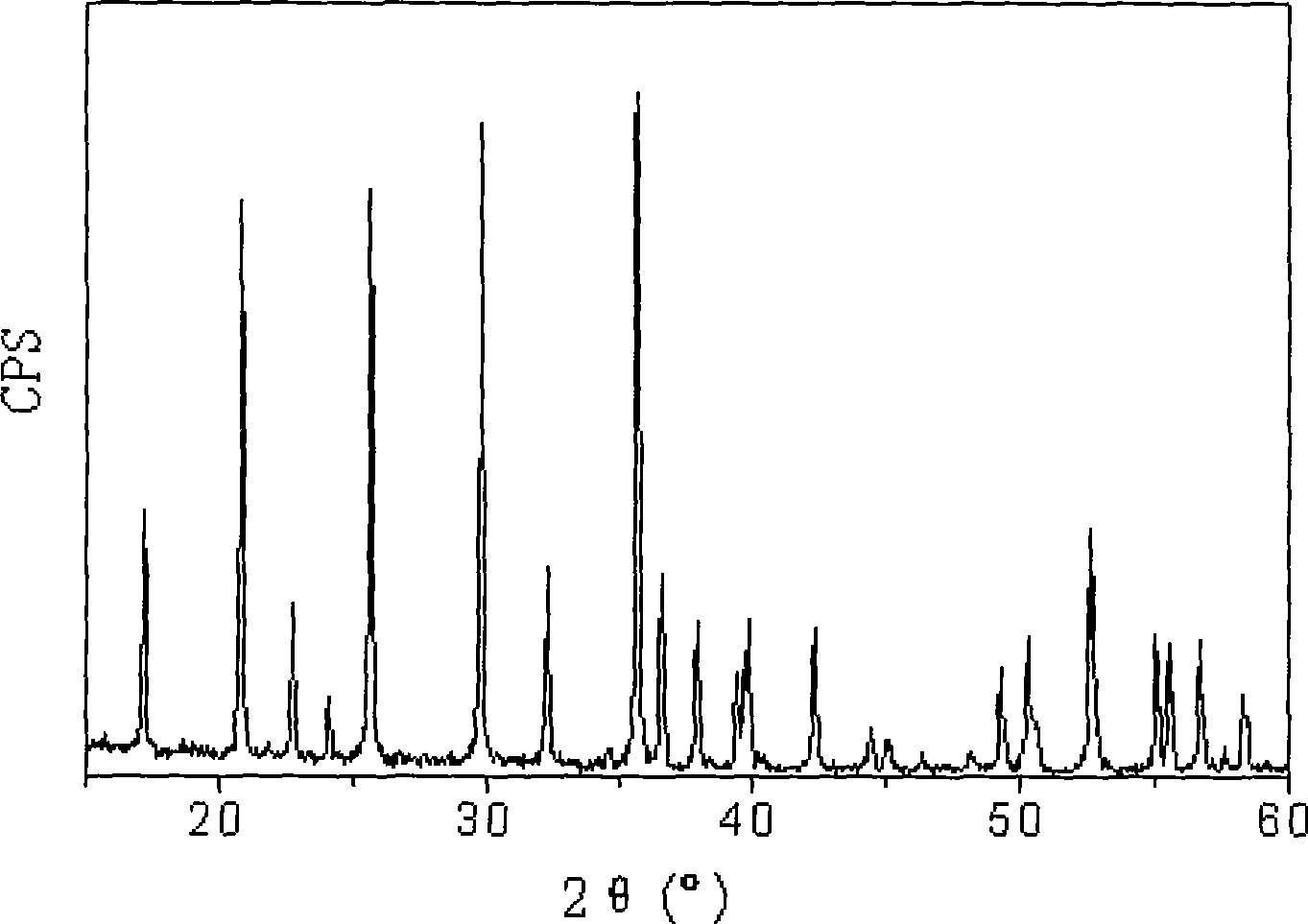

Lithium manganate based lithium ion battery positive electrode material as well as preparation method thereof

ActiveCN103794751AIncrease volume capacityImprove cycle performanceCell electrodesHigh densityManganate

The invention discloses a lithium manganate based lithium ion battery positive electrode material as well as a preparation method thereof. The lithium manganate based lithium ion battery positive electrode material is prepared by mixing modified lithium manganate with different particle sizes, and carrying out surface modification so as to obtain lithium manganate finished products. According to the invention, the volume capacity of the lithium manganate material is improved by mixing lithium manganate with different particle sizes so as to realize high density and high capacity; the structual stability of the lithium manganate based material is realized by surface treatment of doping vario-property, or coating and the like, and the cycle performance and the high-temperature performance of the material are improved.

Owner:NANTONG RESHINE NEW MATERIAL

Preparation method and application of nitrogen-doped porous carbon negative electrode material

InactiveCN107919461AImprove conductivityImproved rate cycle performanceCell electrodesSecondary cellsPorous carbonHigh energy

The invention belongs to the technical field of carbon material preparation, belongs to the category of alkali metal ion secondary energy storage and relates to a method for preparing nitrogen-doped porous carbon from perinone nitrogen-containing polycyclic aromatic hydrocarbon as a carbon source and an application of the nitrogen-doped porous carbon as a negative electrode or positive electrode material for an alkali metal ion secondary battery. According to the method, perinone nitrogen-containing conjugated polycyclic aromatic hydrocarbon is firstly mixed with a template or an activator andthermal decomposition carbonization is carried out at the temperature within a certain range to obtain a nitrogen-doped porous carbon negative electrode or positive electrode material. By adopting the perinone nitrogen-containing conjugated polycyclic aromatic hydrocarbon with large molecular weight as the carbon source, the loss of a nitrogen element in a thermal treatment process can be reduced, high-proportion nitrogen doping in the porous carbon is effectively achieved and electrochemical oxidation reduction sites are effectively increased. According to the method, the specific surface area of the porous carbon can be adjusted and controlled through the carbon source screening, thermal treatment carbonization temperature and the mass ratio of the template or the activator, the chargeexchange interface is increased and high energy storage is effectively achieved. The material has the advantages that (1) the structure is abundant and the perinone material is cheap and available; and (2) the material has relatively high energy density, magnification power density and cycling stability.

Owner:NANJING UNIV OF TECH

Preparation method of high-density non-ball shape ferric phosphate powder body

The invention discloses a preparation method of a high-density non-ball shape ferric phosphate powder body which relates to a ferric compound. The invention aims to provide the preparation method of a high-density non-ball shape ferric phosphate powder body, and the ferric phosphate prepared by the method has high jolt density, small granule size and high specific surface area. The adopted technical scheme is as follows: a mixed water solution with a certain concentration of (FeNO3)3.9H2O and H3PO4 is prepared, (the mole ratio of Fe and P is 0.9:1.0); the mixed water solution is placed into a reactor, an ammonia solution is gradually added under a certain temperature and agitation until the pH value of the reaction liquid reaches 1 to 4 to obtain ferric phosphate slurry; the slurry is injected into a plate and frame filter press to obtain a filtered cake by pressing and filtration, the filtered cake is dried, soluble impurity ions are removed by water washing, and the washed material is dried again, pulverized and sieved to obtain the ferric phosphate powder body. The invention is used for the anode material of lithium ion batteries.

Owner:HENAN NORMAL UNIV

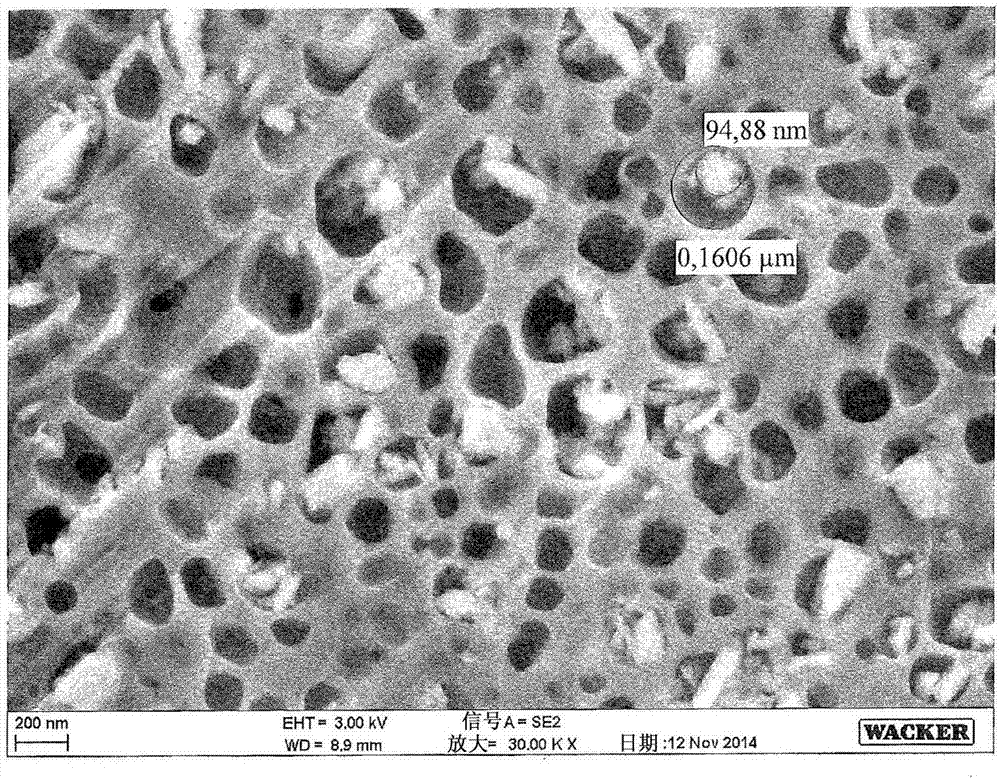

Composite core-shell particles

ActiveCN107431189AIncrease volume capacityImprove cycle stabilitySiliconSecondary cellsPorous carbonCarbonization

The invention relates to composite core-shell particles wherein the core is a porous, carbon-based matrix which contains silicon particles enclosed in pores of the matrix; the pores containing the silicon particles have a diameter of not less than 60 nm as determined by scanning electron microscopy (SEM); the shell can be obtained by carbonizing one or more carbon precursors selected from among the group comprising tars, pitches, hard carbon, soft carbon and hydrocarbons having 1 to 20 carbon atoms, resulting in a non-porous shell.

Owner:WACKER CHEM GMBH

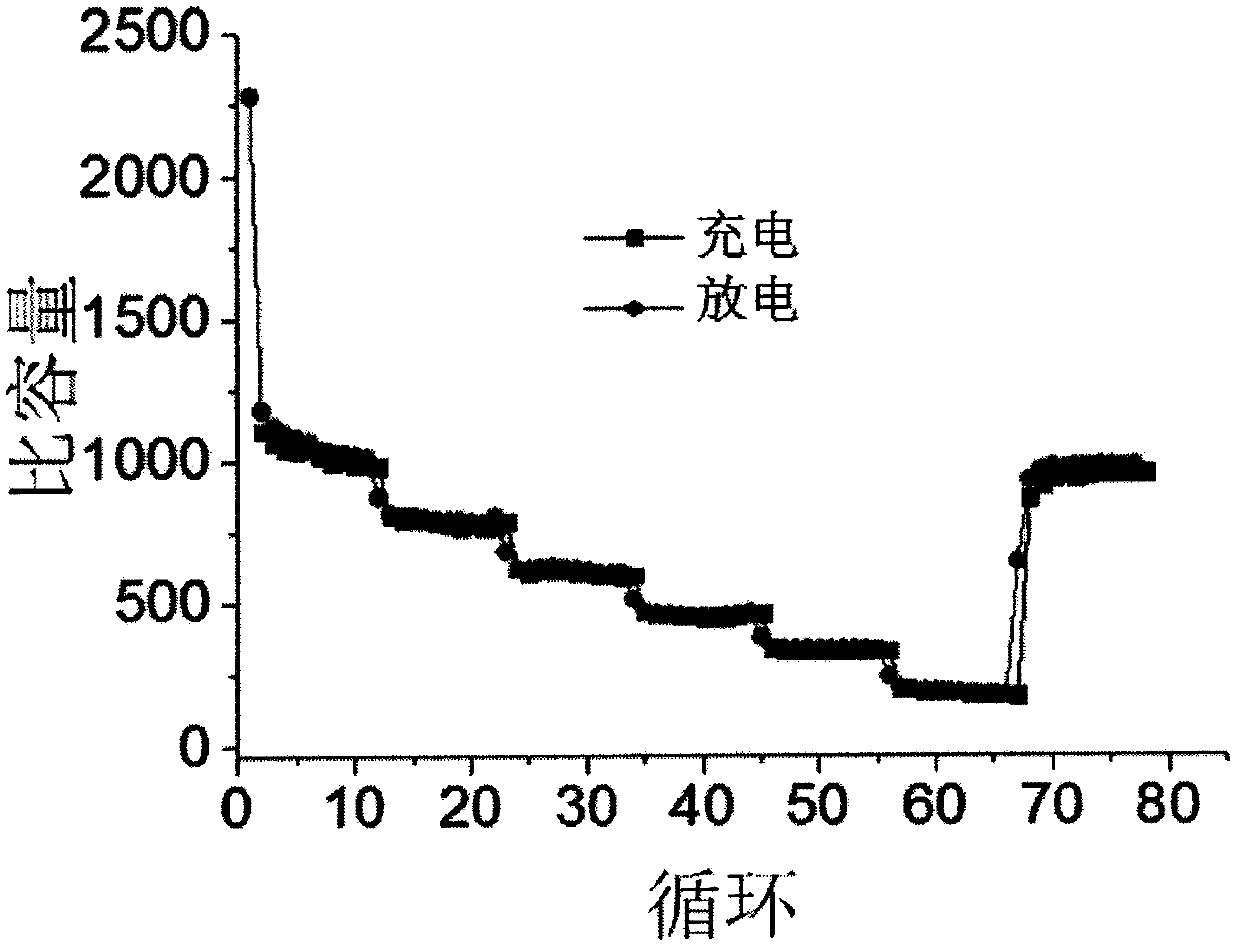

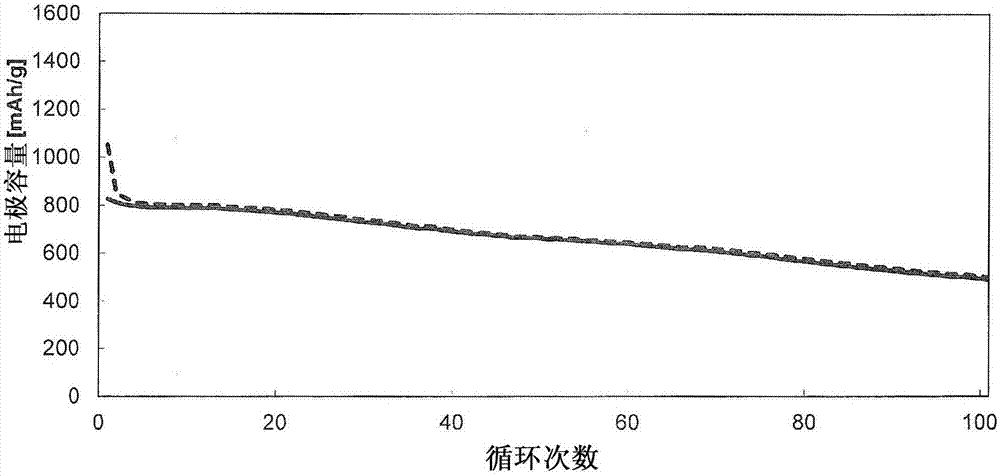

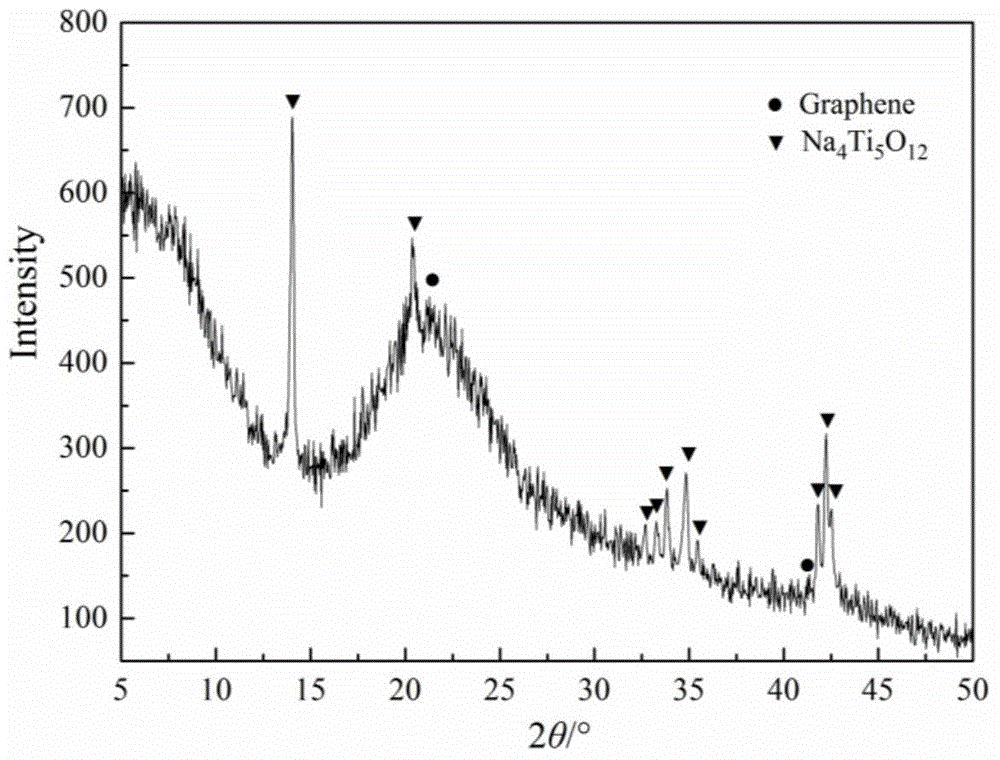

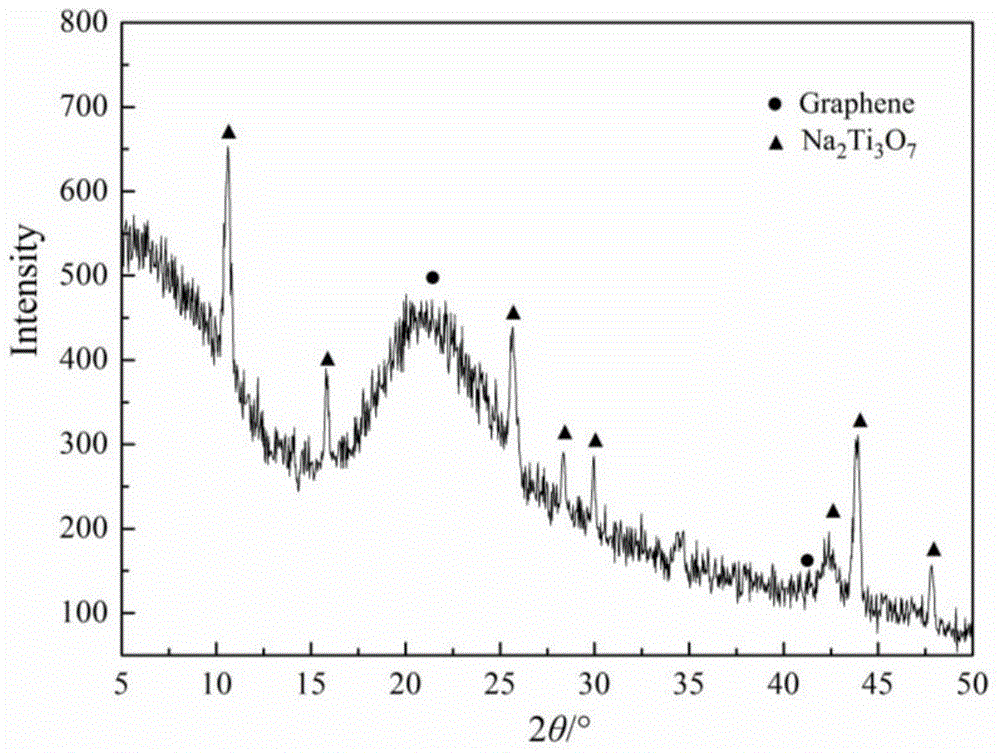

Preparation method of sodium titanate/graphene composite cathode material of sodium ion battery

ActiveCN104600271AEasy to storeFacilitated DiffusionCell electrodesSecondary cellsStrontium titanateHigh sodium

The invention provides a preparation method of a sodium titanate / graphene composite cathode material of a sodium ion battery, which is used for solving the problems in the prior art that no sodium ion battery cathode material with excellent comprehensive performance is provided, and belongs to the field of sodium ion secondary batteries. The method comprises the steps of dispersing graphene oxide to obtain a graphene oxide solution, mixing the graphene oxide solution, a sodium-containing compound and a titanium-containing compound, carrying out reaction to obtain a composite precursor, mixing the composite precursor with a binder, carrying out atomizing drying and granulating to obtain a spherical composite precursor, and finally burning the spherical composite precursor in an inert atmosphere to obtain a micro-scale spherical sodium titanate / graphene composite cathode material. The composite cathode material has the advantages of high sodium storage capacity, long cycle life, good large-current discharge property, high compaction density and the like, and the requirement of the high-performance sodium ion battery for the comprehensive performance of the cathode material can be met.

Owner:LIAONING TECHNICAL UNIVERSITY

Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

ActiveCN101209827AImprove conductivityImprove electrical conductivityCell electrodesPhosphorus compoundsLithium compoundAnode

The invention relates to a preparation method of lithium iron phosphate, an active substance applied in the anode of lithium-ion secondary batteries. The method comprises a mixture that contains lithium compound, iron compound, phosphorus compound and carbon source additive is sintered and cooled to get a sintering product; wherein, the sintering method comprises the step: the mixture that contains lithium compound, iron compound, phosphorus compound and partial carbon source additive is sintered at a first constant sintering temperature, then a mixture of the product acquired at the first sintering temperature and the residual carbon source additive is sintered at a second constant sintering temperature, and the second sintering temperature is at least 100 DEG C higher than the first sintering temperature. The batteries made of the lithium iron phosphate prepared by the method of the invention have markedly improved discharge performance at high current.

Owner:BYD CO LTD

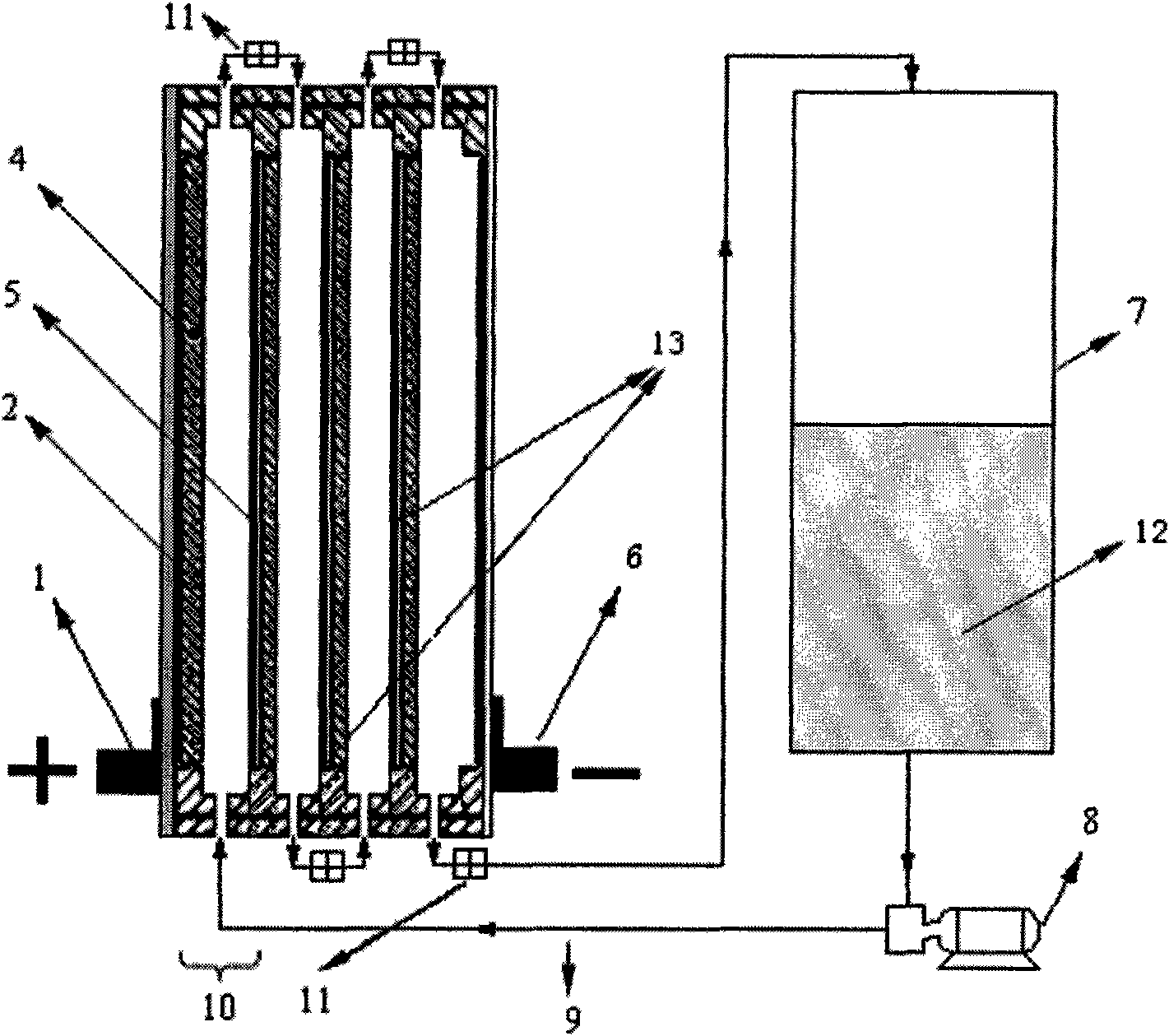

Acid single flow cell

InactiveCN101567459AIncrease discharge voltageIncrease transfer speedRegenerative fuel cellsSecondary cellsCurrent cellIndium

The invention relates to an acid single flow cell which can be applied to large-scaled energy storage and power generation. The cell comprises an electrolyte storage tank, a cadmium or indium deposited cathode current collector and a lead dioxide anode; an acid solution of soluble cadmium salt or indium salt is used as an electrolyte; and when the cell is charged, the cadmium or indium ions are deposited on the cathode current collector from the electrolyte, and when the cell is discharged, the metal cadmium or indium is dissolved in the electrolyte from the cathode current collector. The current cell has the advantages of simple structure, convenient preparation, high electric energy conversion efficiency, long cycle life, environmental protection, safe use, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Lithium ion battery cathode material and method for preparing same

The invention discloses a novel composite carbon-coated lithium titanate doped cathode material and method for preparing the same, which belong to the technical field of lithium ion battery manufacture. The method includes: using a titanium source, a lithium source and additives as raw materials, adding deionized water for wet grinding, vacuum drying, primarily synthesizing at the high temperature of 650-750 DEG C for 12-16 hours, cooling to the room temperature, adding organic carbon source materials, well mixing, secondarily synthesizing and coating carbon at the high temperature of 750-850 DEG C for 12-16 hours, cooling to the temperature below 80 DEG C, and discharging to obtain composite carbon-coated lithium titanate doped material (Li4Ti (5-x)YxOi2 / C). The lithium titanate material made by doping synthesis and carbon coating synthesis has the advantages of high conductivity, high crystallization level, uniformity in granularity, excellent processing performance, fine electrochemical performance and the like, and completely meets the requirements of automobile power lithium batteries and accumulation lithium ion batteries.

Owner:湖南鸿跃新能源循环科技有限公司

Preparation method for lithium iron phosphate materials with high tap density

InactiveCN103165886AHigh tap densityIncrease volume capacityCell electrodesPhosphorus compoundsLithium iron phosphatePhosphor

The invention relates to preparation methods for lithium iron phosphate, in particular to a preparation method for lithium iron phosphate materials with high tap density. The preparation method for the lithium iron phosphate materials with the high tap density mainly solves the technical problems that in the prior art, lithium iron phosphate materials are low in tap density, small in volume capacity ratio, not prone to be widely used and the like. The preparation method comprises the steps of mixing lithium salt, ferric salt and phosphor salt, adding a doped modifying agent and a carbon source, carrying out wet process ball milling in a ball milling machine, carrying out spray drying, pre-sintering a dried precursor in inertia or reducing atmosphere, after preserving temperature, cooling to the room temperature along with a furnace, obtaining a pre-sintered product, sintering the pre-sintered product in an inertia or reducing atmosphere protective furnace at a high temperature, cooling to the room temperature along with the furnace, obtaining LiFePO4 / C, placing the LiFePO4 / C into a rotation type fusion balling machine for processing, and finally preparing the finished product of the lithium iron phosphate materials with the high tap density.

Owner:杭州金马新能源科技有限公司

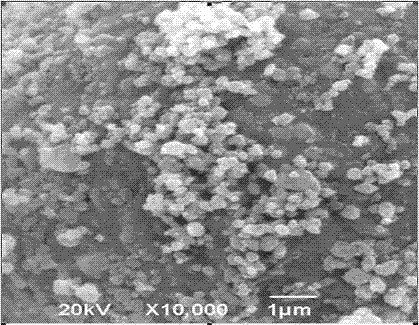

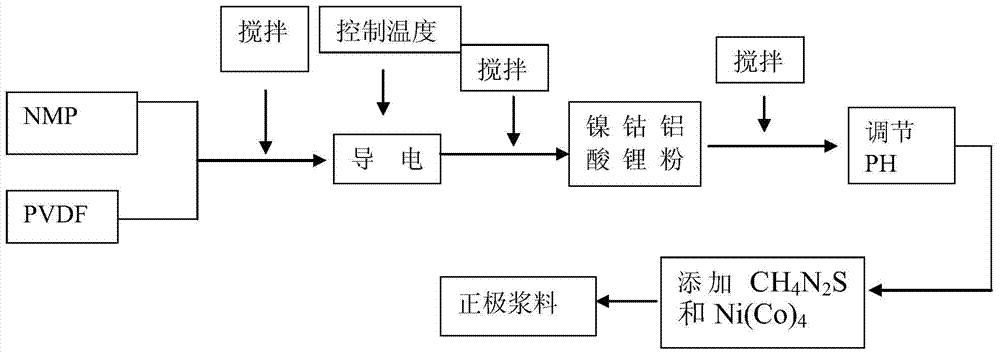

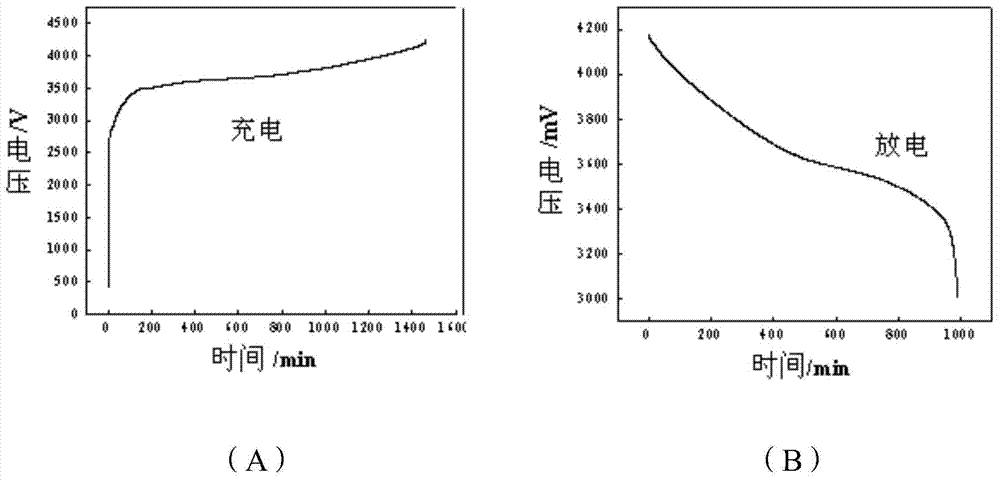

Positive slurry of lithium ion battery as well as preparation method and application of positive slurry of lithium ion battery

InactiveCN104332595AConductivity compensationIncrease electrolyte absorptionCell electrodesSlurrySodium-ion battery

The invention provides positive slurry of a lithium ion battery as well as a preparation method and application of the positive slurry of the lithium ion battery. The preparation method of the positive slurry of the lithium ion battery comprises the following steps: (1) uniformly agitating and mixing a solvent and an oily binding agent to obtain a mixture A; (2) adding graphene into the mixture A at 25-40 DEG C and agitating uniformly to obtain a mixture B; and (3) adding nickel cobalt lithium aluminate powder into the mixture B; agitating to obtain the positive slurry; and during the agitating period, adding oxalic acid to adjust the pH value of the slurry to 8-9.5. The battery prepared from the positive slurry of the lithium ion battery has the excellent charging / discharging circulating service life and has the high power and safety performance. The battery prepared by the invention is applicable to the fields of hybrid electric vehicles, telecommunication networks, outer spaces, defending equipment and the like.

Owner:SHENZHEN MOTTCELL NEW ENERGY TECH CO LTD

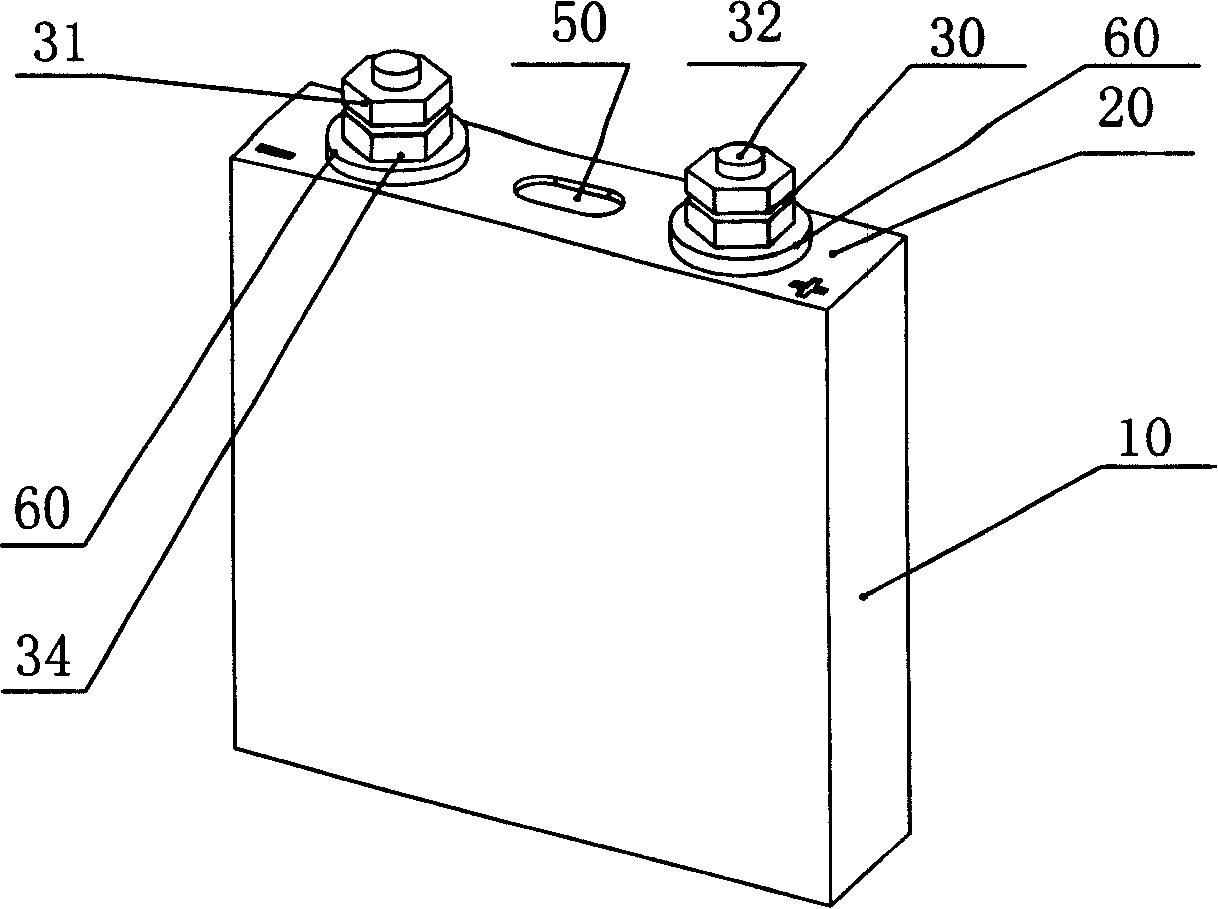

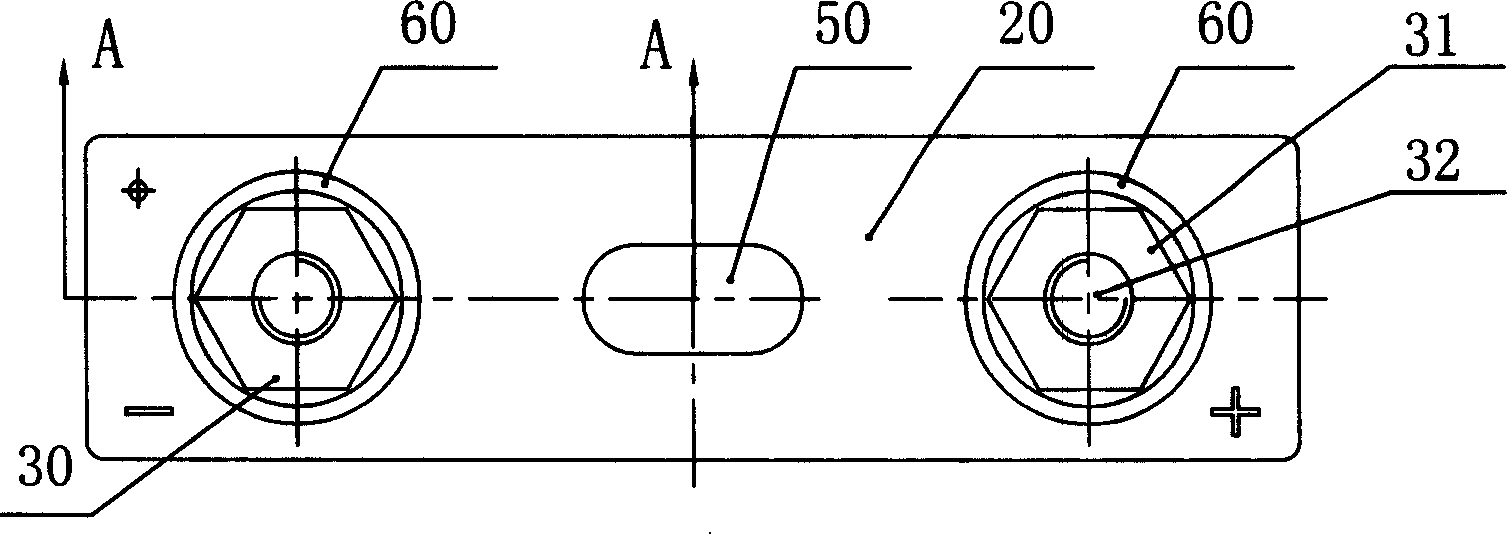

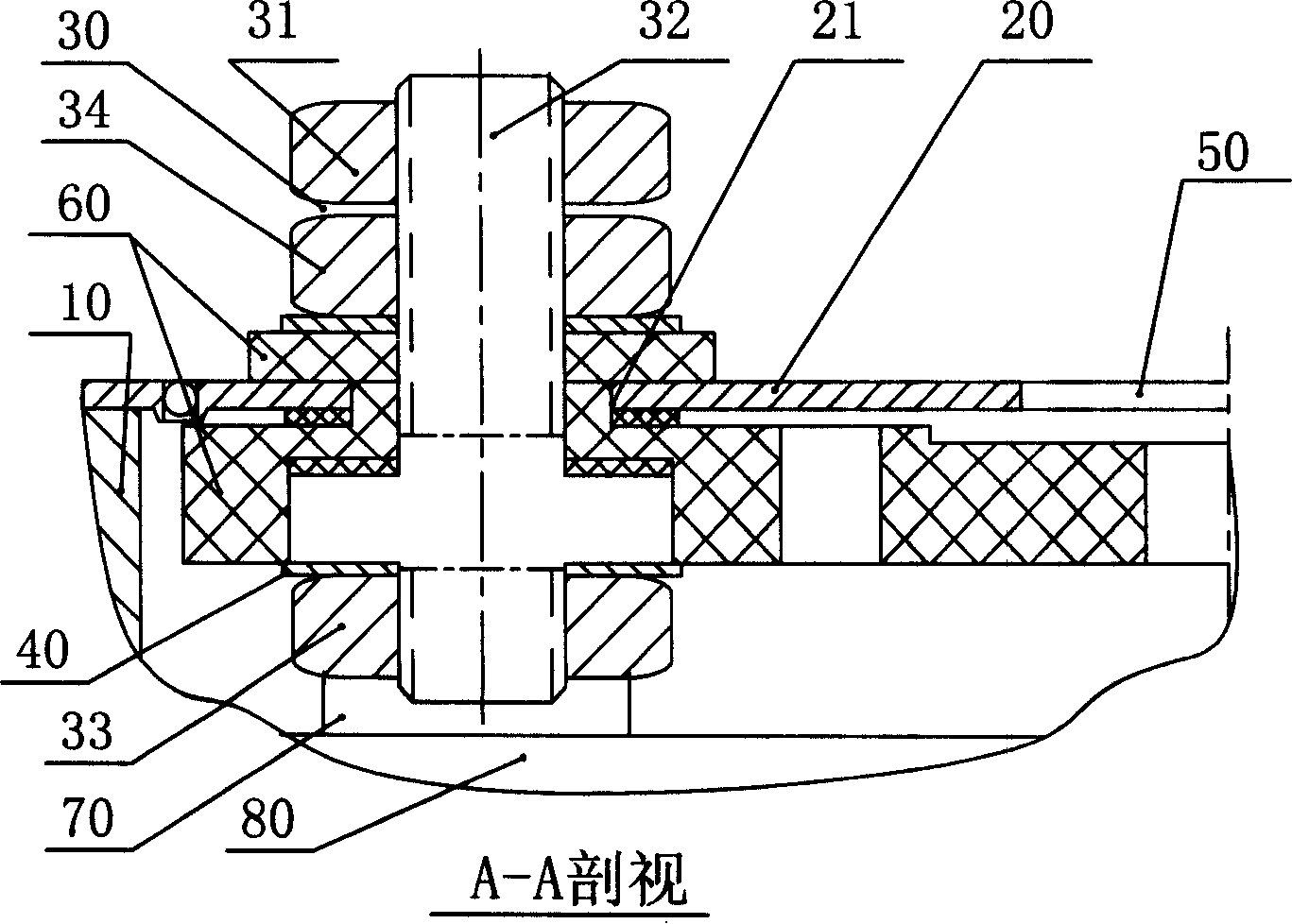

Battery cover plate with new type structure and secondary battery thereof

InactiveCN101232082AIncrease volume capacityImprove air tightnessFinal product manufactureSecondary cells manufactureEngineeringScrew thread

The invention relates to a battery cover plate with novel structure and a secondary battery thereof. The battery cover plate comprises a plate body with via-holes, positive / negative electrode connectors, positive / negative conductive sheets, an anti-explosion device and insulating gaskets arranged on the via-holes, wherein the positive / negative electrode connectors are respectively fixed on the plate body through respective insulating gaskets; the positive / negative conductive sheets are respectively connected with each electrode connector and fixed below the insulating gaskets; the electrode connector comprises two or more fasteners, an electrode press plate with fixing holes identical to the fasteners in number, and screw-thread connectors arranged on the electrode press plate for conductive connection; the via-holes on the plate body correspond to the fixing holes on the electrode press plate; and the fasteners penetrate through the via-holes and the fixing holes to fix the electrode press plate on the plate body. The battery cover plate and the positive / negative electrode connectors on the secondary battery of the invention have more stable sealing performance, more flexible external connection, maintenance and disassembly and more convenient usage.

Owner:HYB BATTERY

Preparation method of positive electrode material for lithium-sulfur battery

ActiveCN108172797AAlleviate volume expansionImprove cycle stabilityMaterial nanotechnologyCell electrodesMicrosphereCurrent technology

The invention discloses a preparation method of a positive electrode material for a lithium-sulfur battery. The method comprises the following steps of (1) preparing monodisperse polystyrene microspheres through a dispersion polymerization method; (2) preparing hollow silica microspheres; (3) synthesizing bimetallic oxide double-layer nano mesoporous microspheres; and (4) preparing a nickel-cobaltbimetallic oxide double-layer nano mesoporous microspheres / nano carbon / sulfur composite positive electrode material. Through a process of doping with nano sulfur and nano carbon black through ball-milling and hot melting methods, the nano carbon black is mixed in the sulfur doping process, so that the defects that the positive electrode material for the lithium-sulfur battery in the prior art islow in sulfur load, obvious in volume expansion effect and unstable in electrochemical properties are overcome.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com