Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

523 results about "Gel state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

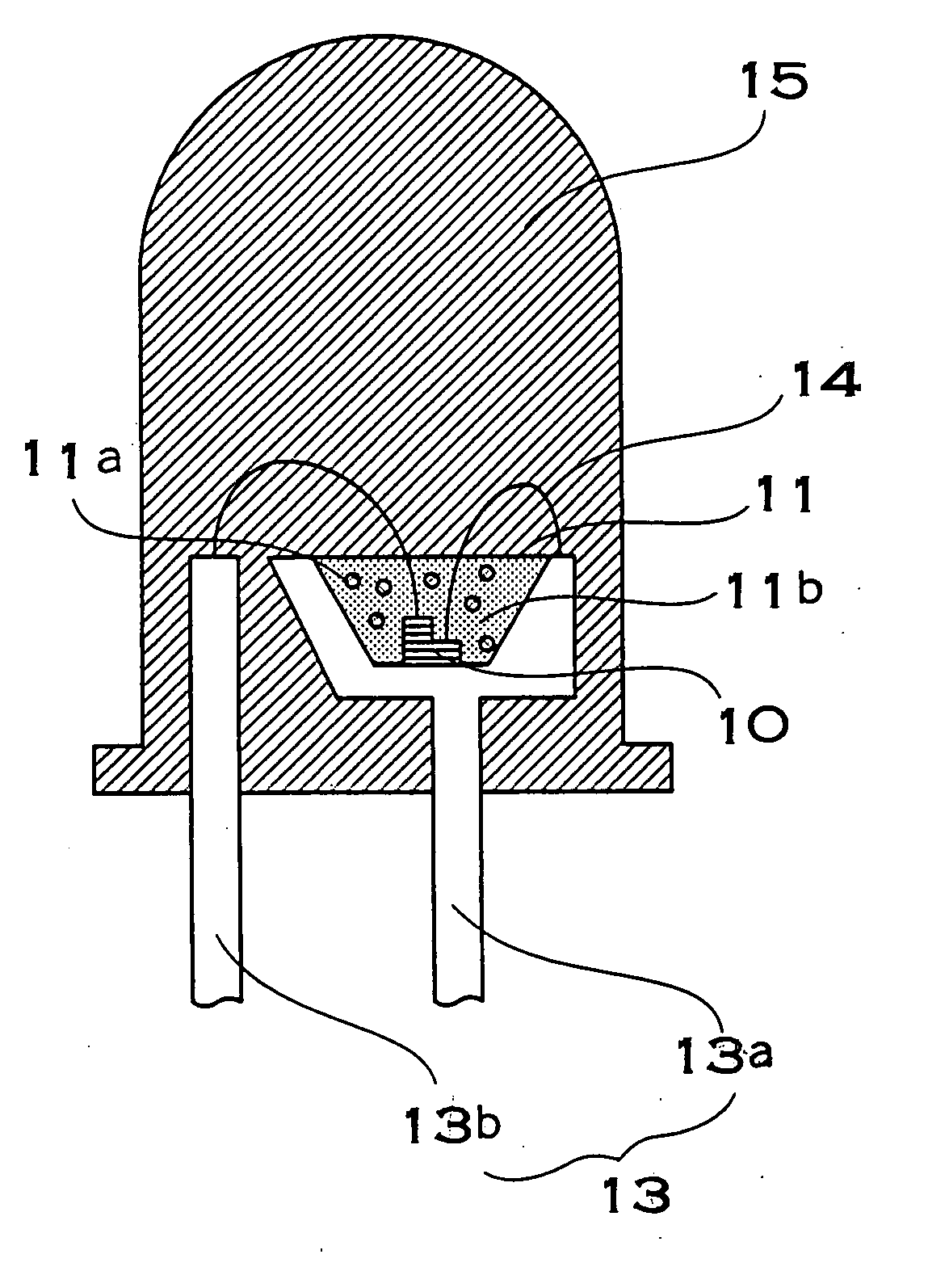

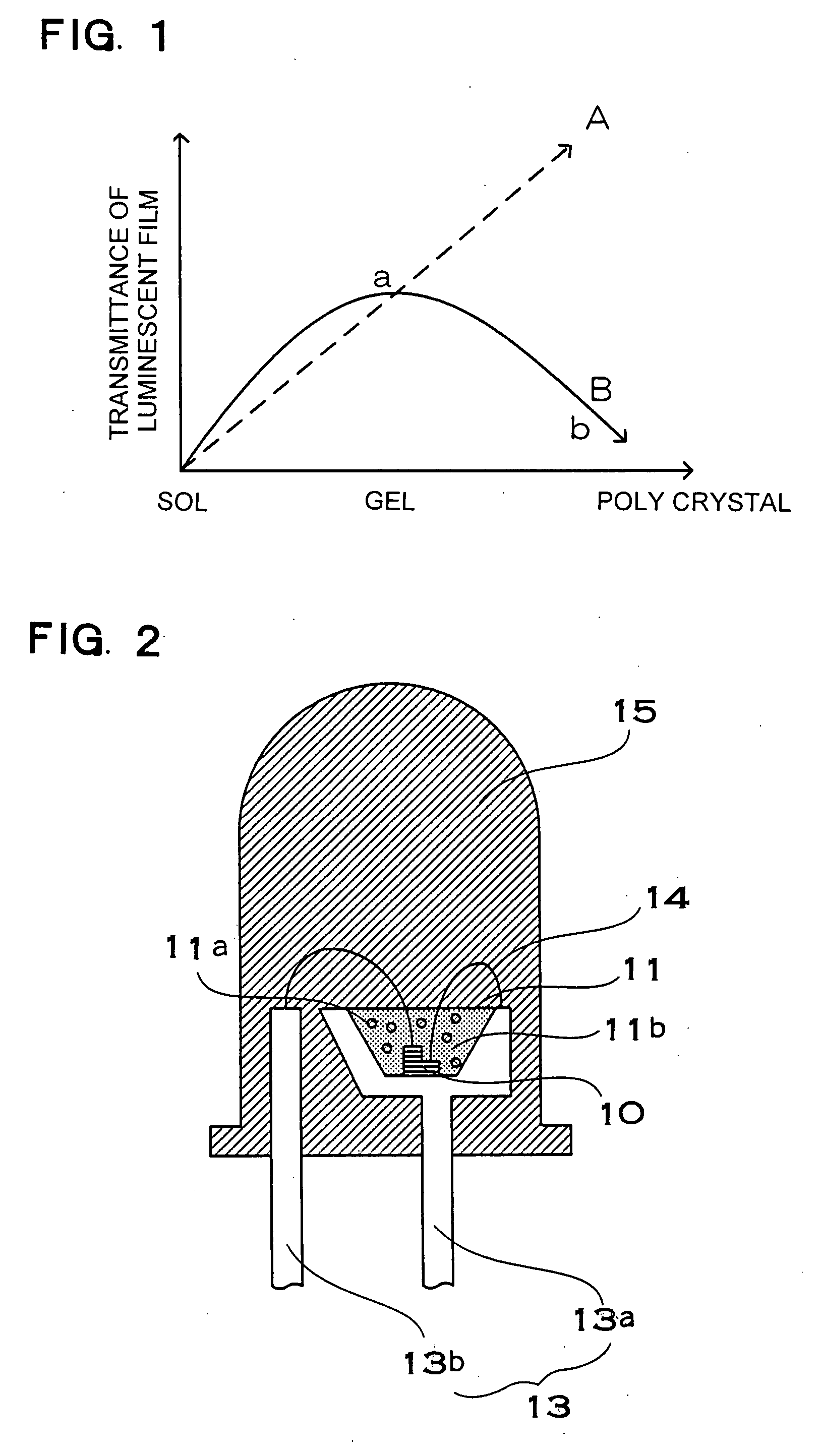

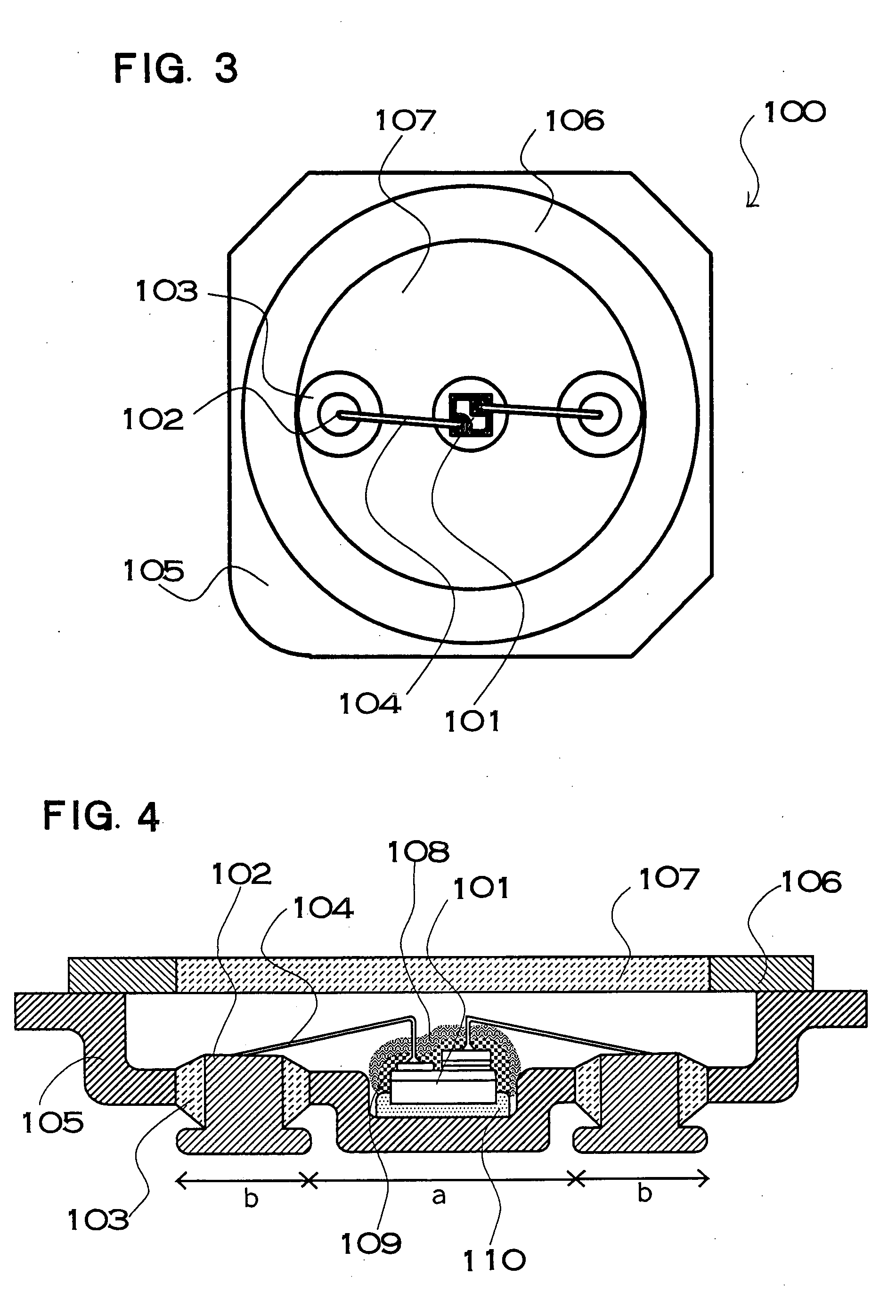

Light emitting film, luminescent device, method for manufacturing light emitting film and method for manufacturing luminescent device

InactiveUS20060170332A1High light-outgoing efficiencyHardness is easy to controlDischarge tube luminescnet screensLamp detailsPhosphorTransmittance

The present invention provides a reliable, long-life phosphor, or the like, which is prevented from darkening due to aging. A light emitting apparatus has a light emitting element and a phosphor layer. The phosphor layer has a phosphor excited by light from the light emitting element, and a binder which binds the phosphor. The binder is hydroxide oxide gel obtained by curing sol of a hydroxide oxide mixed with sol containing at least one metallic element selected from the group consisting of Al, Y, Gd, Lu, Sc, Ga, In, and B. Transmittance of hydroxide oxide in a gel state is higher than the transmittance in the polycrystal state where the sol-gel reaction is proceeded. In addition, the content of hydroxyl group or water of crystallization in the hydroxide oxide is 10% or less by weight.

Owner:NICHIA CORP

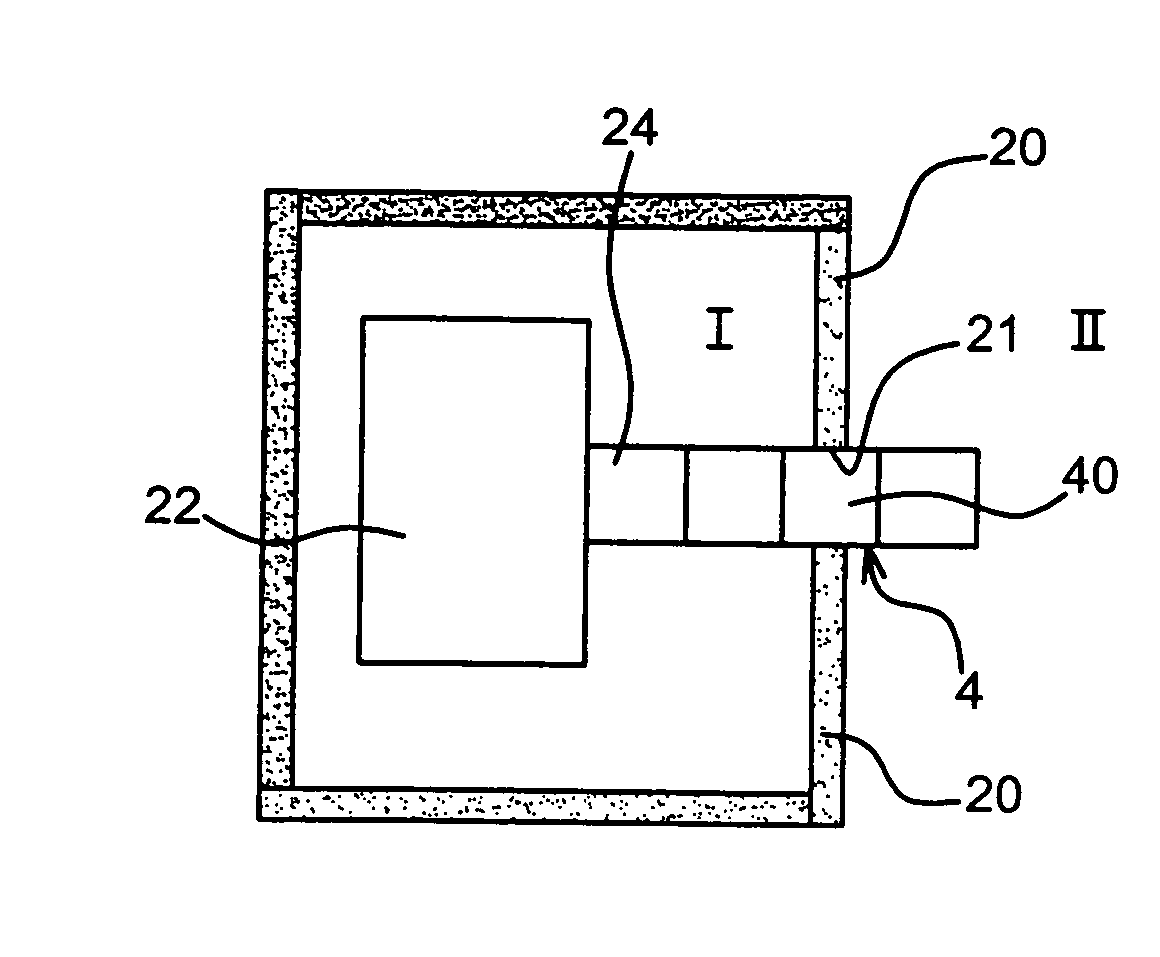

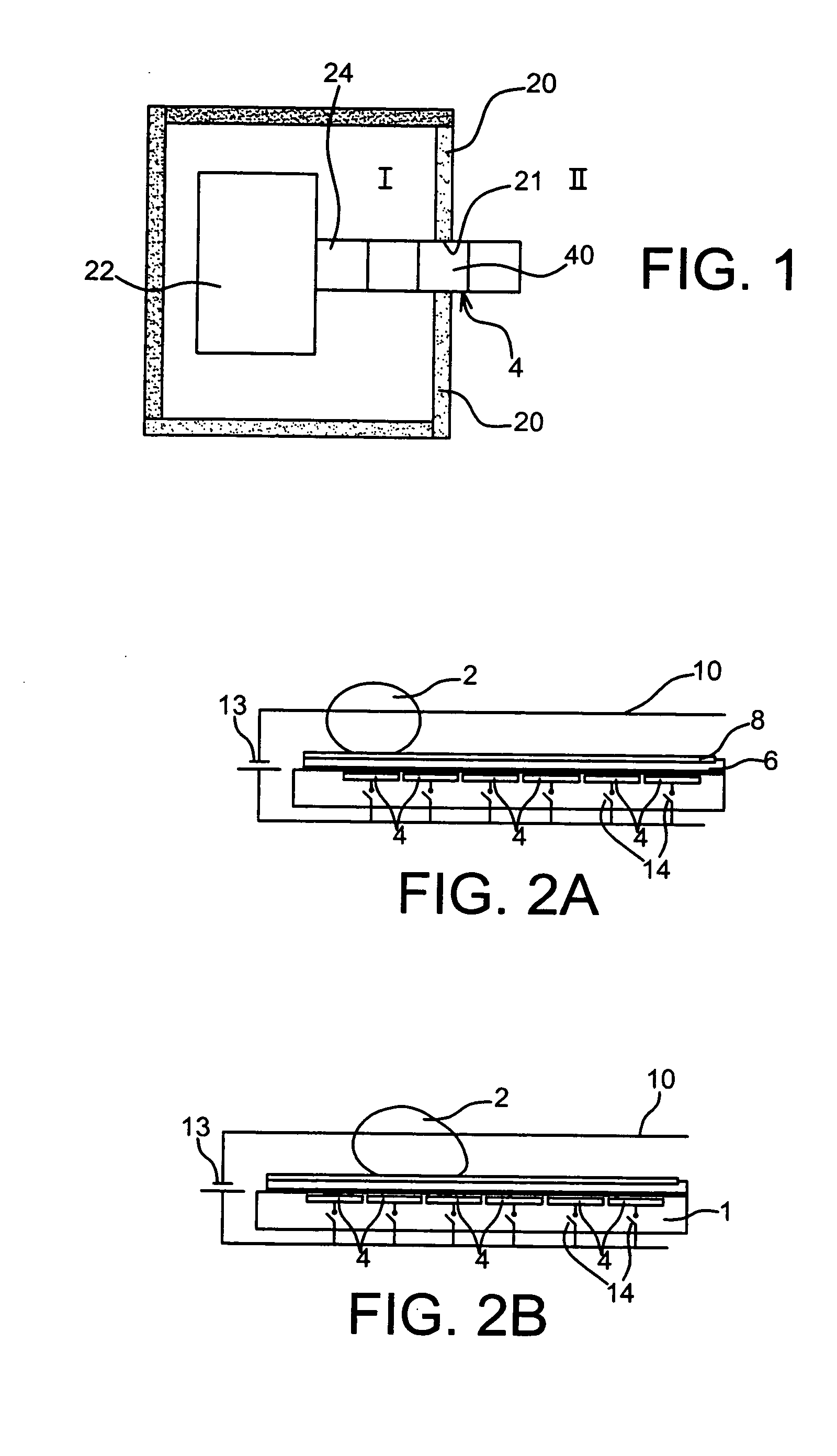

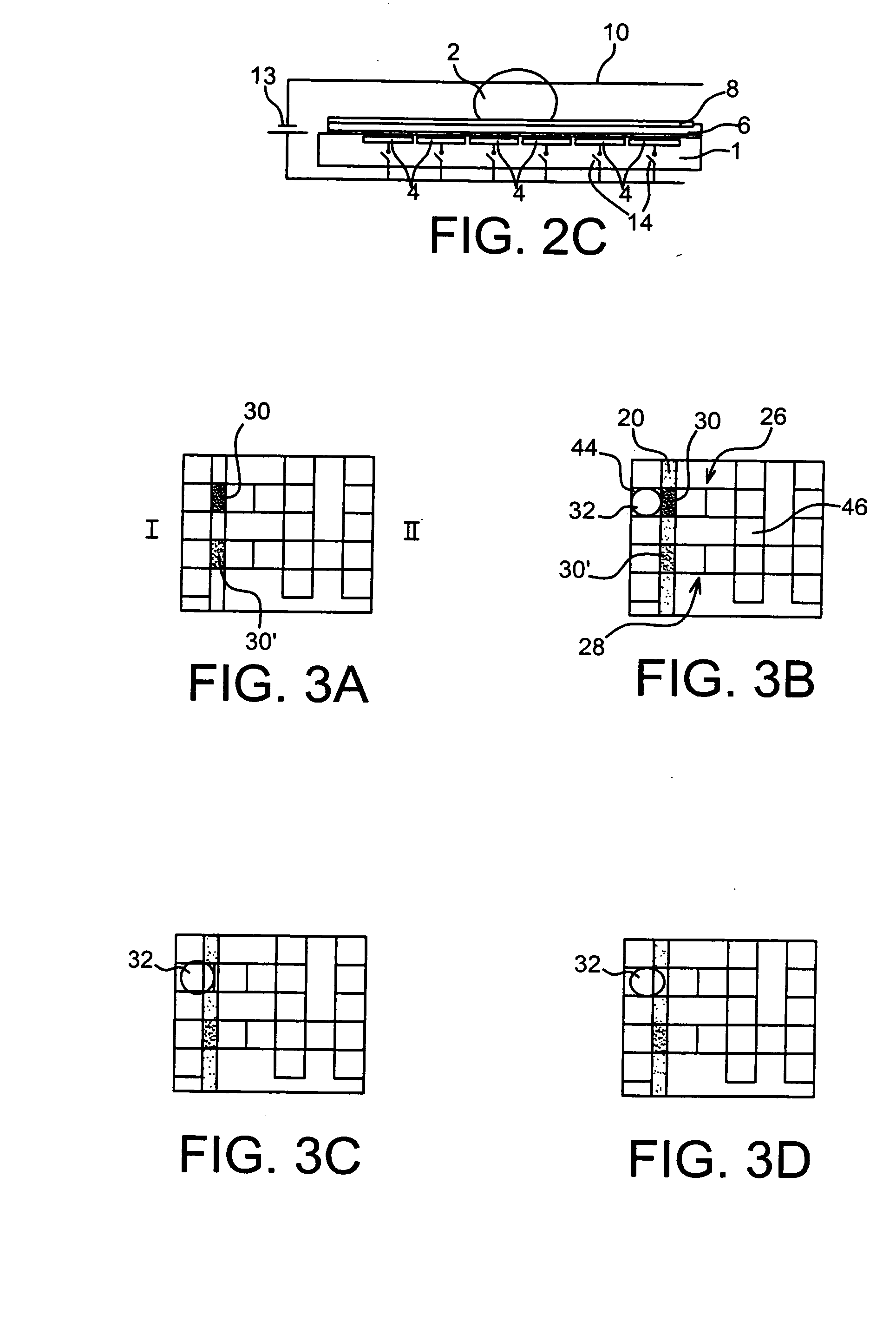

Method for Controlling a Communication Between Two Areas By Electrowetting, a Device Including Areas Isolatable From Each Other and Method for making Such a Device

InactiveUS20090134027A1Good flexibilityElectrostatic separatorsSludge treatmentLiquid stateBiomedical engineering

Device for displacing drops of liquid by electrowetting, and a method for isolating two areas delimited by at least one wall including a step for:placing by electrowetting, in an aperture of said wall, a substance capable of reacting to at least one external stimulus in order to pass from a liquid state to a gel or solid state, forming a closure member.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Composition for controlling wellbore fluid and gas invasion and method for using same

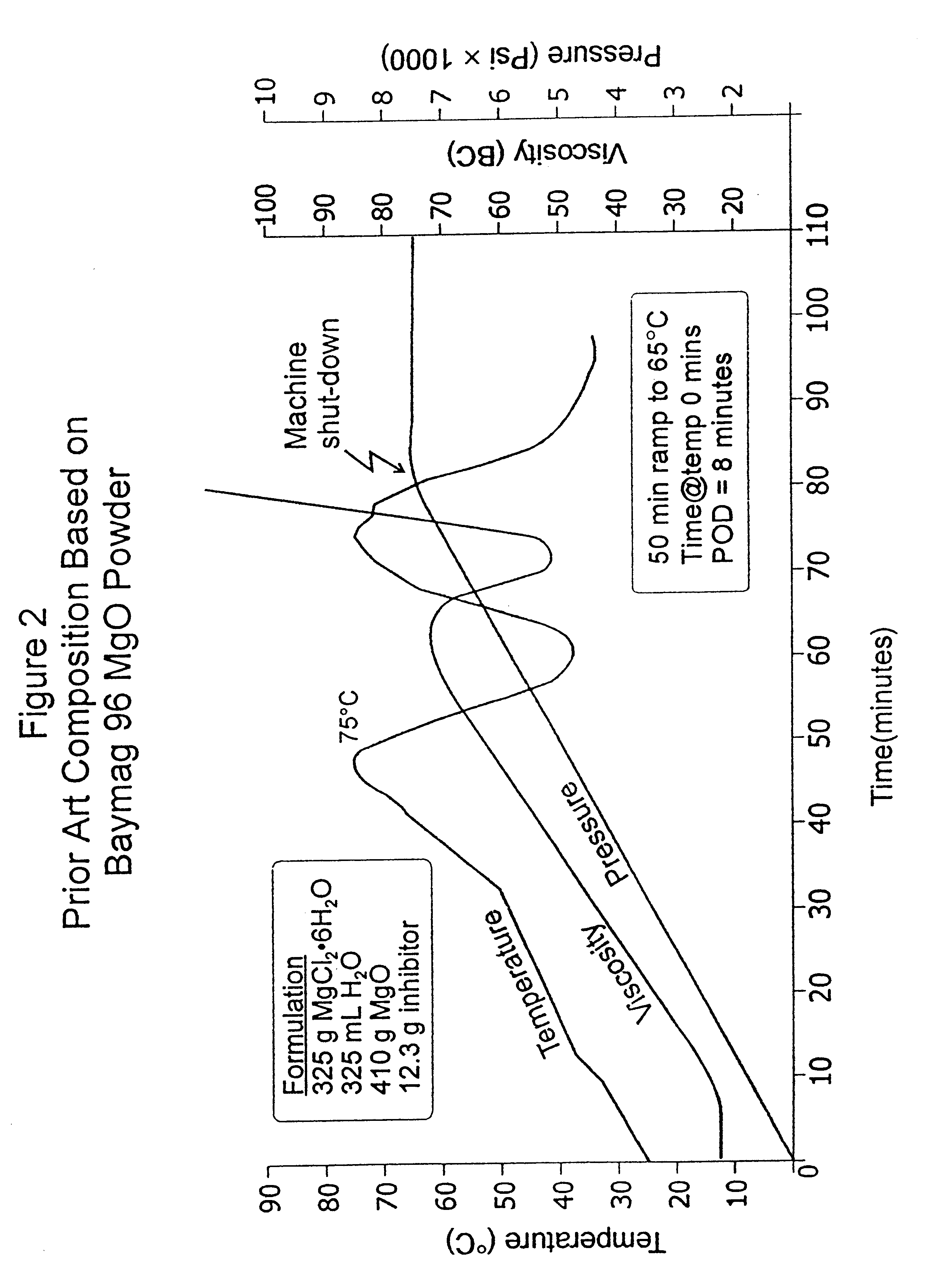

InactiveUS6664215B1Reduce hydrostatic pressureReadily cut through by a drill bitOther chemical processesFlushingLinear relationshipSlurry

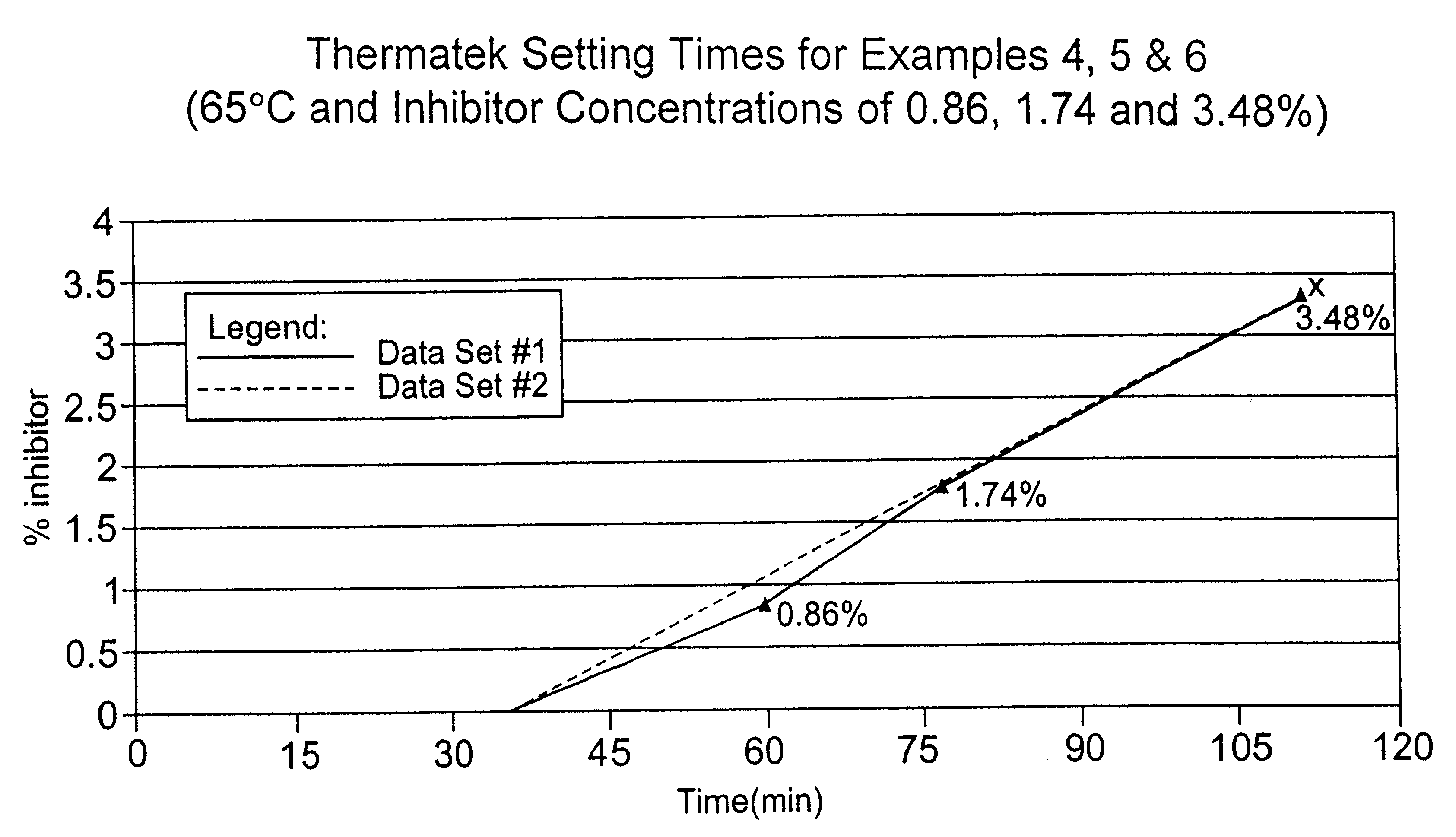

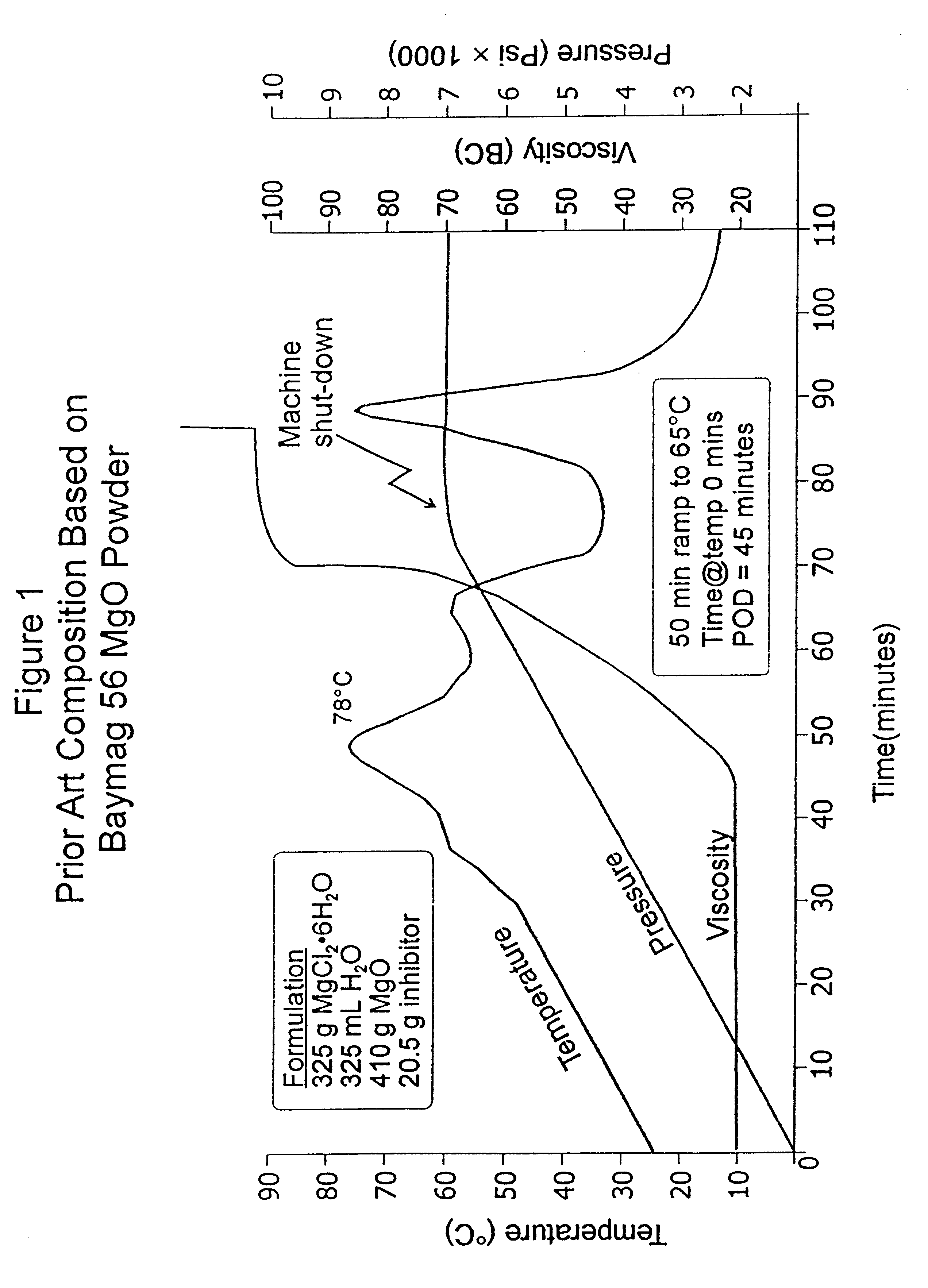

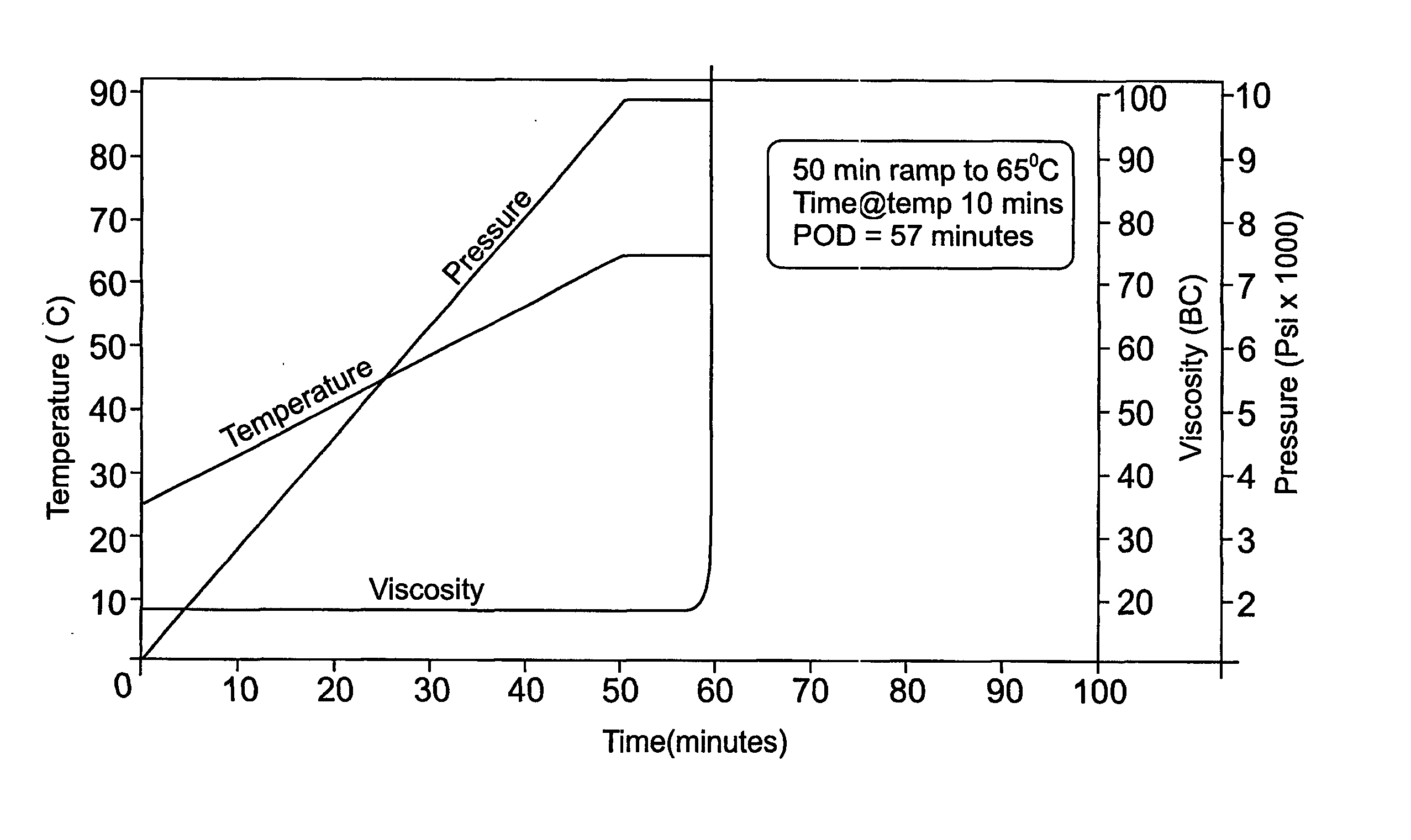

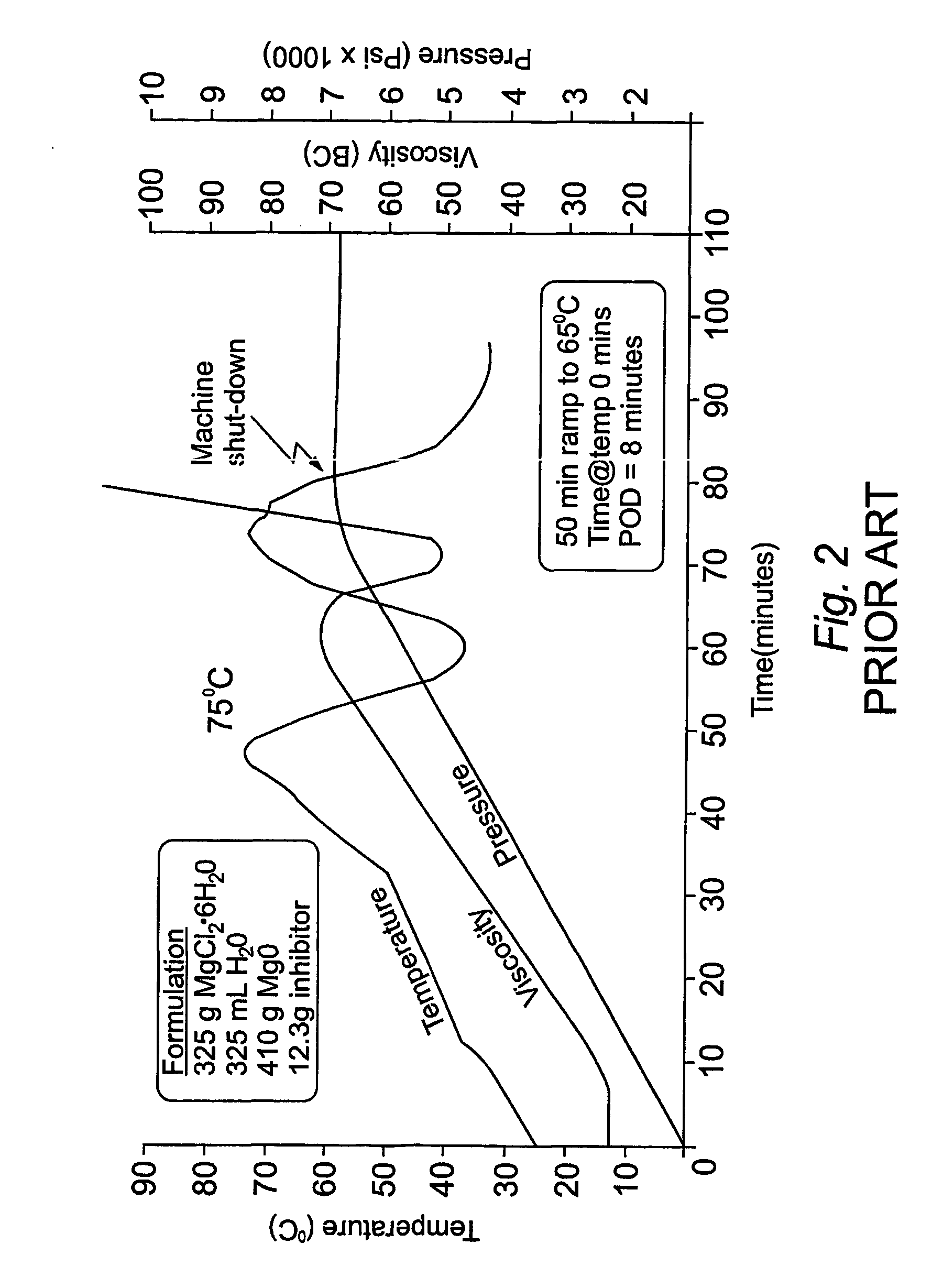

The disclosure is directed to a composition for controlling wellbore fluid and gas invasion including methods for using said composition. The composition of the invention is a flowable slurry preferably comprising about 70 to 30% by weight of magnesium oxychloride and about 70 to 30% by weight of water. The composition is a flowable slurry at composition temperatures below about 60° C. and sets to form a substantially solid mass upon reaching a composition temperature of about 60-68° C. The phase transition is rapid, thereby limiting or avoiding formation of gel states which contribute to incomplete wellbore seals. The rapid set of the slurry further avoids invasive contamination of earthen formations surrounding the wellbore. The composition has a near-linear relationship between the time required for the phase transition to occur and the composition temperature at which the phase transition occurs. This advantageous property permits the composition set time to be accurately determined and modified as required through the addition of accelerators and inhibitors. The phase transition occurs predictably at high pressures typical of those encountered in wellbore operations. Additives may be included to modify the properties of the composition. The method includes use of the composition to control the loss of fluids and gases from the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

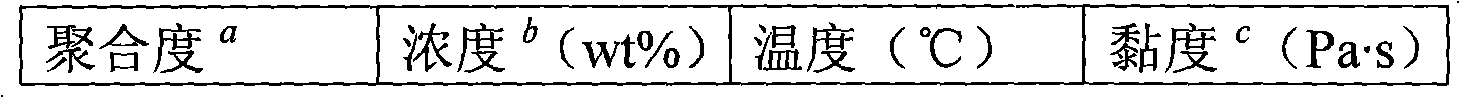

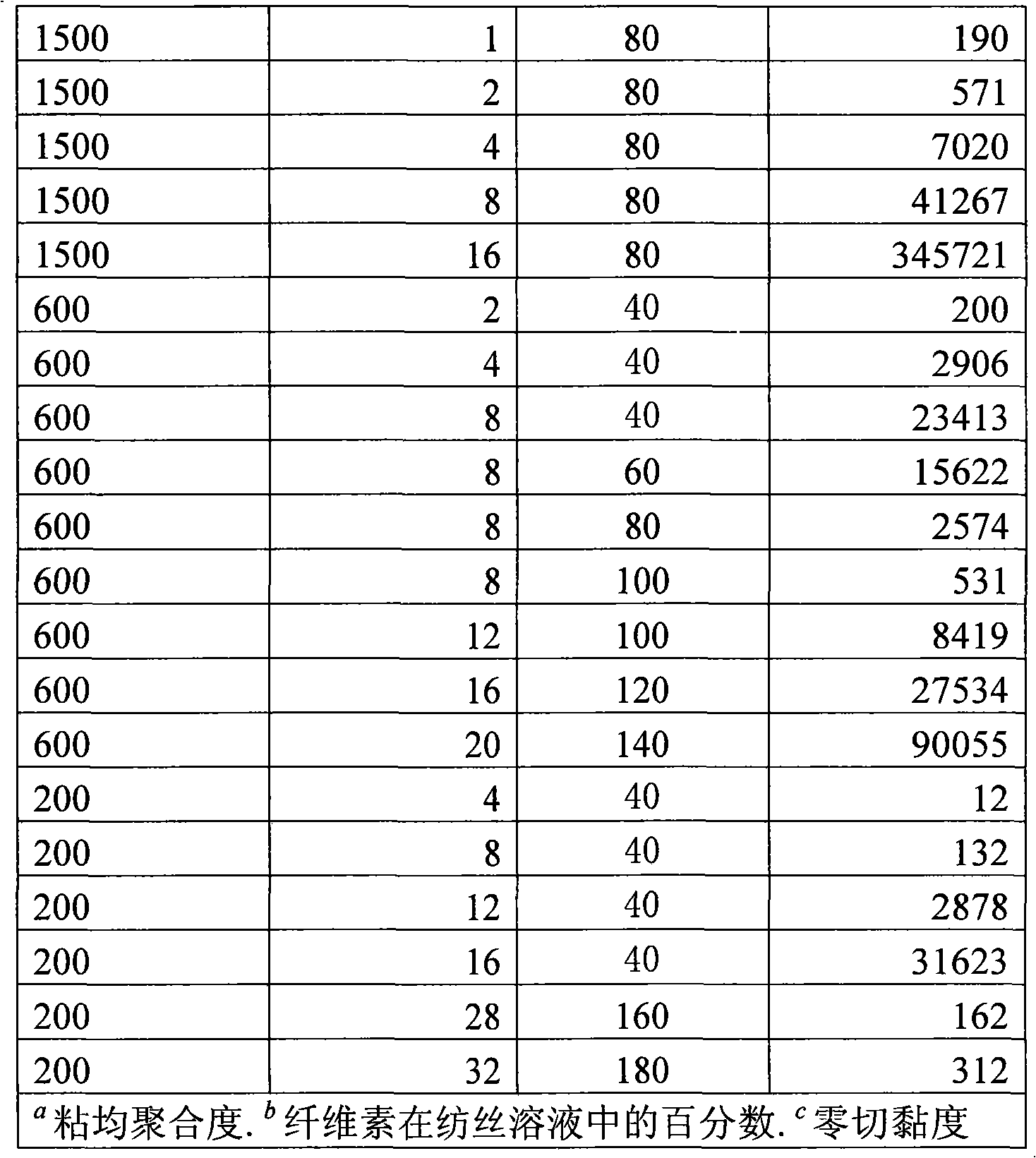

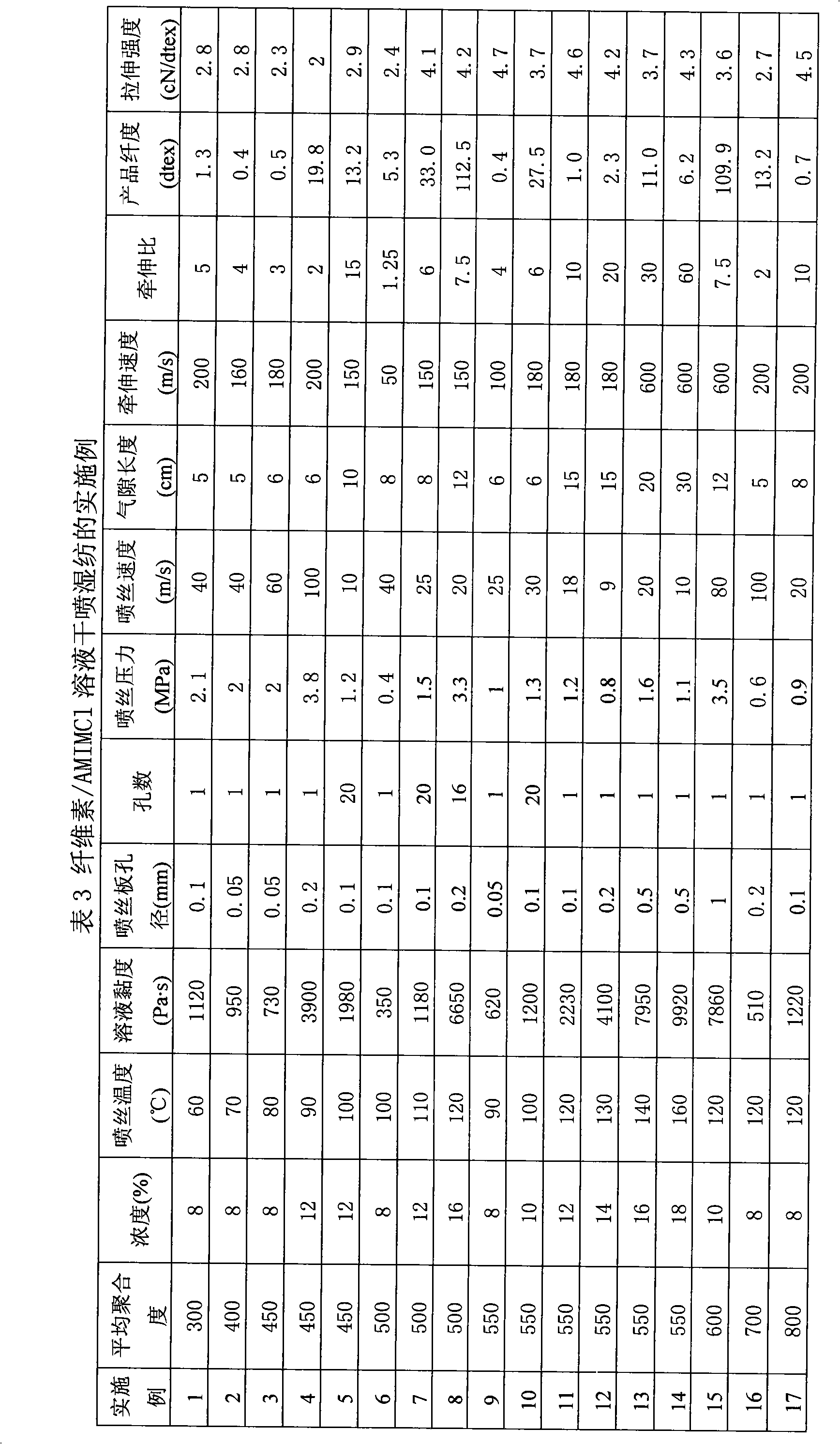

Method for continuously preparing regenerated cellulose fibre

InactiveCN101328626AReduce manufacturing costReduce the temperatureArtificial filament recoveryFibre treatmentPolymer scienceTetrafluoroborate

The invention discloses a method for continuously preparing regenerated cellulose fibers through the solvent method, comprising the following steps that: a cellulose raw material is dissolved into an ion liquid to prepare a spinning liquid; gel type regenerated cellulose fibers are obtained through spinning; and the regenerated cellulose fibers are obtained through cleaning, rear draft and drying, wherein, the ion liquid is selected from one or a plurality among the following ion liquids: a). an ion liquid with 1, 3-dialkyl imidazole as a cation and formiate radical, radical vinegar or propionate radical as an anion; and b). an ion liquid with 1-R1-3-R2- dialkyl imidazole as the cation and chlorine, bromine, iodine, formiate radical, radical vinegar, sulfate radical, nitrate radical, tetrafluoroborate radical, thiocyanate radical, hexafluorophosphate radical, p-toluenesulfonate radical or trifluoromethanesulfonic acid radical as the anion. The method has the advantages of wide technological range, mild temperature condition, adequate pressure, quick spinning speed and so on, can prepare the regenerated cellulose fibers with superior performance and complete specifications, and has low production cost, high production efficiency and wide application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Finishing of textile fibers, tissues and fabrics

InactiveUS7056845B2Improve the level ofImprove functional propertiesOther chemical processesPhysical treatmentTextile fiberEngineering

A method is provided for the application of a finishing layer to a textile support material. A water repellent or oil repellent layer, a so-called finishing layer, is applied to a textile support material selected from the group of fibers, tissues, and fabrics. The water repellent or oil repellent finishing layer comprises at least two water repellent or oil repellent components wherein a first component comprises one or more dispersants and a second component comprises one or more dispersed phases or colloids, and wherein the dispersant and the dispersed phase are present in the gel state.

Owner:SCHOELLER TEXTIL

Phase change inks containing gelator additives

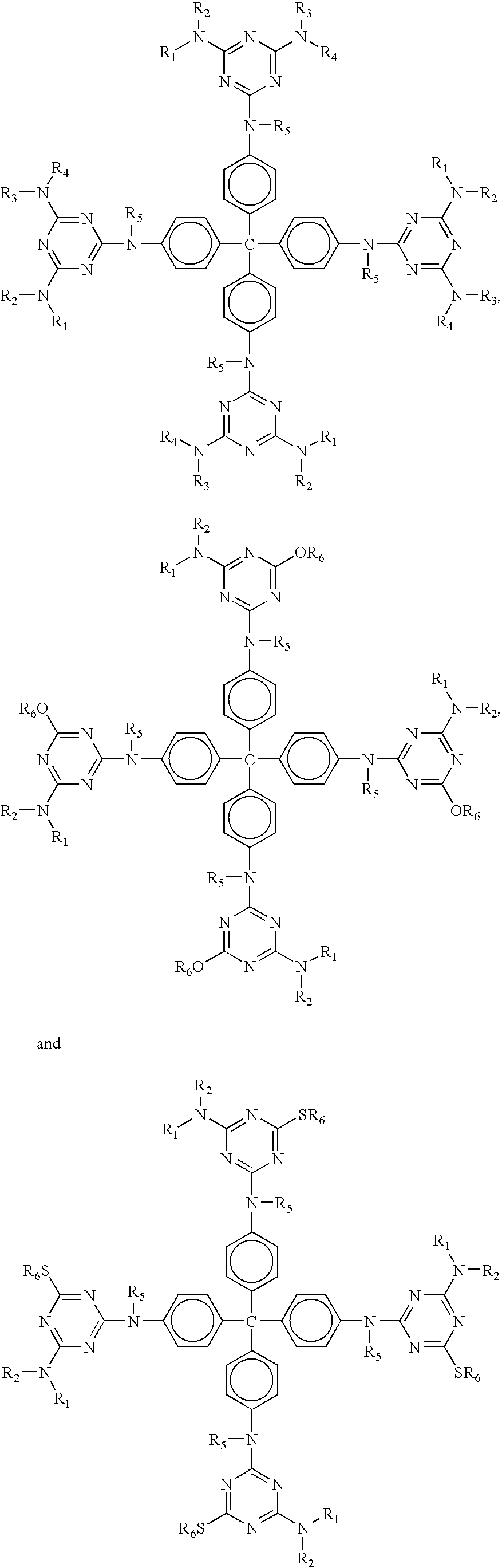

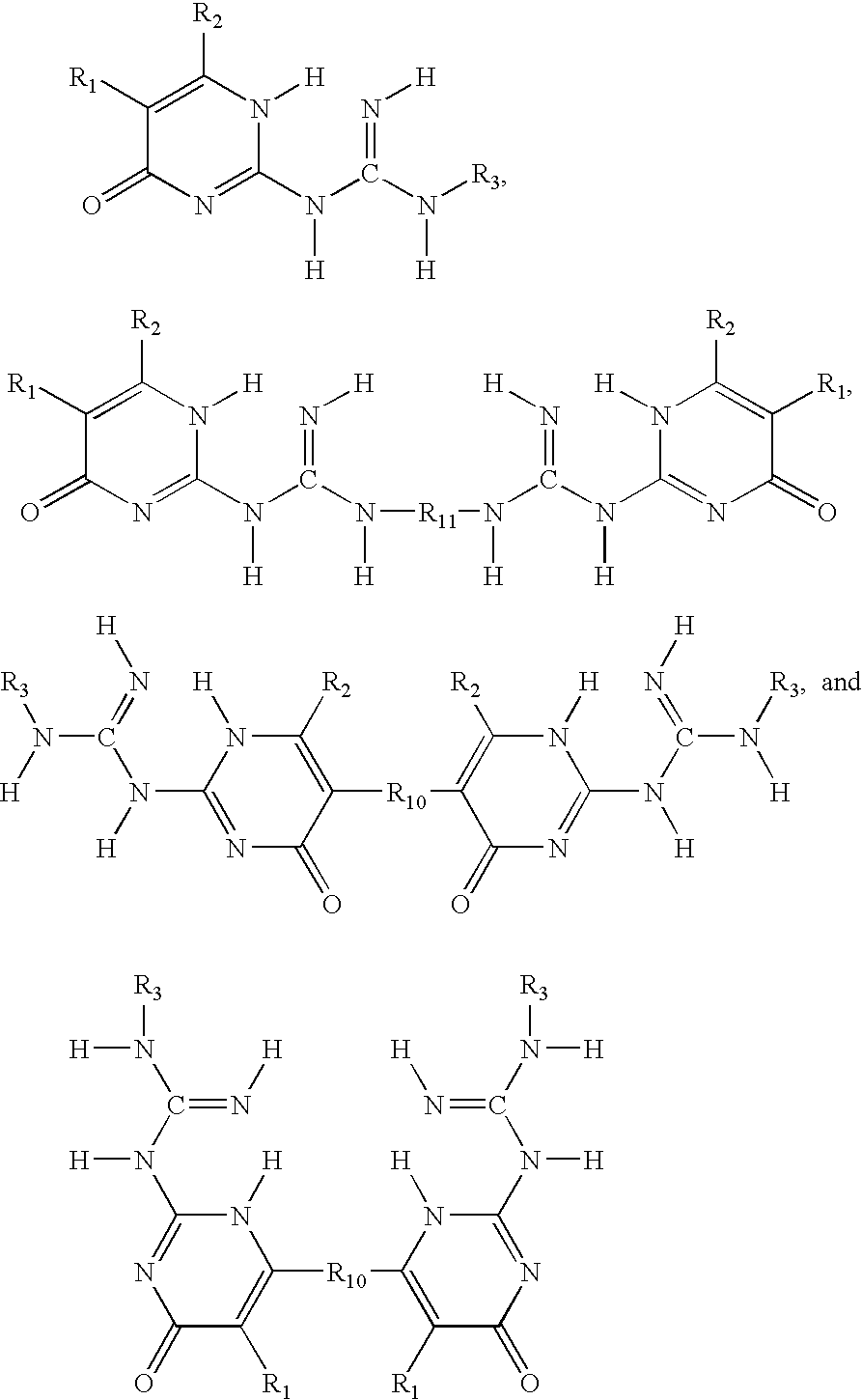

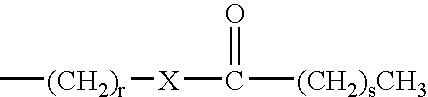

Disclosed is a phase change ink composition comprising an ink vehicle, a colorant, and a nonpolymeric organic gelator selected from the group consisting of anthracene-based compounds, steroid compounds, partially fluorinated high molecular weight alkanes, high molecular weight alkanes with exactly one hetero atom, chiral tartrate compounds, chiral butenolide-based compounds, bis-urea compounds, guanines, barbiturates, oxamide compounds, ureidopyrimidone compounds, and mixtures thereof, said organic gelator being present in the ink in an amount of no more than about 20 percent by weight of the ink, said ink having a melting point at or below which the ink is a solid, said ink having a gel point at or above which the ink is a liquid, and said ink exhibiting a gel state between the melting point and the gel point, said ink exhibiting reversible transitions between the solid state and the gel state upon heating and cooling, said ink exhibiting reversible transitions between the gel state and the liquid state upon heating and cooling, said melting point being greater than about 35° C., said gel point being greater than said melting point. Also disclosed are imaging processes employing phase change inks containing gelator additives.

Owner:MONTREAL UNIV OF

Injectable cross-linked polymeric preparations and uses thereof

ActiveUS20060083721A1Significant comprehensive benefitsOrganic active ingredientsBiocideCross-linkLiquid state

A therapeutic composition for treatment of a body tissue which includes an aqueous solution of a cross-linked polymer being capable of: (i) maintaining a liquid state in storage at room temperature for at least 24 hours; and (ii) assuming a gel state following deposition within the body tissue. The therapeutic composition can be effectively administered into a damaged body tissue via injection or catheterization, thereby treating the damaged body tissue.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

Porous complex gel-nanofiber oxygen permeation dressing and preparation method thereof

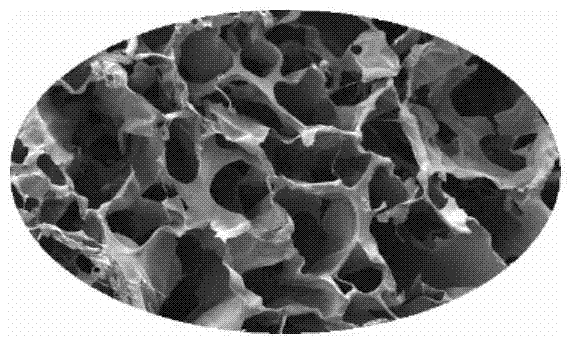

ActiveCN104491914AHigh oxygen permeabilityImprove antibacterial propertiesAbsorbent padsBandagesWound dressingFreeze-drying

The invention discloses a porous complex gel-nanofiber oxygen permeation dressing and a preparation method thereof. The method comprises the following steps: obtaining a collagen nanofiber membrane by adopting a collagen solution by virtue of an electrostatic spinning method; performing chemical crosslinking on two natural and non-toxic macromolecule polysaccharides such as chitosan and alginic acid, and preparing complex gel; and preparing the porous sponge-nanofiber double-layer composite material in a freeze-drying mode, wherein the upper gel layer of the dressing is in a sponge state during drying and is in a gel state after moisture absorption. The biological wound dressing is prepared under the condition that any toxic chemical crosslinking agent is not added, the process is simple, and the safety is high. The prepared biological wound dressing disclosed by the invention has the characteristics of excellent oxygen permeation performance, water-absorbing quality, water permeability, moisture penetrability and high biocompatibility, a physiological wet environment of the wound surface can be maintained, wound healing and effective haemostasis are promoted, wound infection can be avoided, the recovery is accelerated, the wound surface can be effectively recovered, and the dressing is applied to multiple wound surfaces such as trauma, burns and ulceration.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Image recording method and image recording apparatus

InactiveUS20070222811A1Reduce pile heightPrevent ink bleedingMaterial nanotechnologyDuplicating/marking methodsImage recordingComputer science

The image recording method for forming an image on a recording medium, includes the step of applying droplets of stimulus-responsive ink which responds to a stimulus so that the stimulus-responsive ink converts from a sol state to a gel state, on the recording medium, wherein each of the droplets of the stimulus-responsive ink has a volume of 0.5 pl to 2.5 pl.

Owner:FUJIFILM CORP

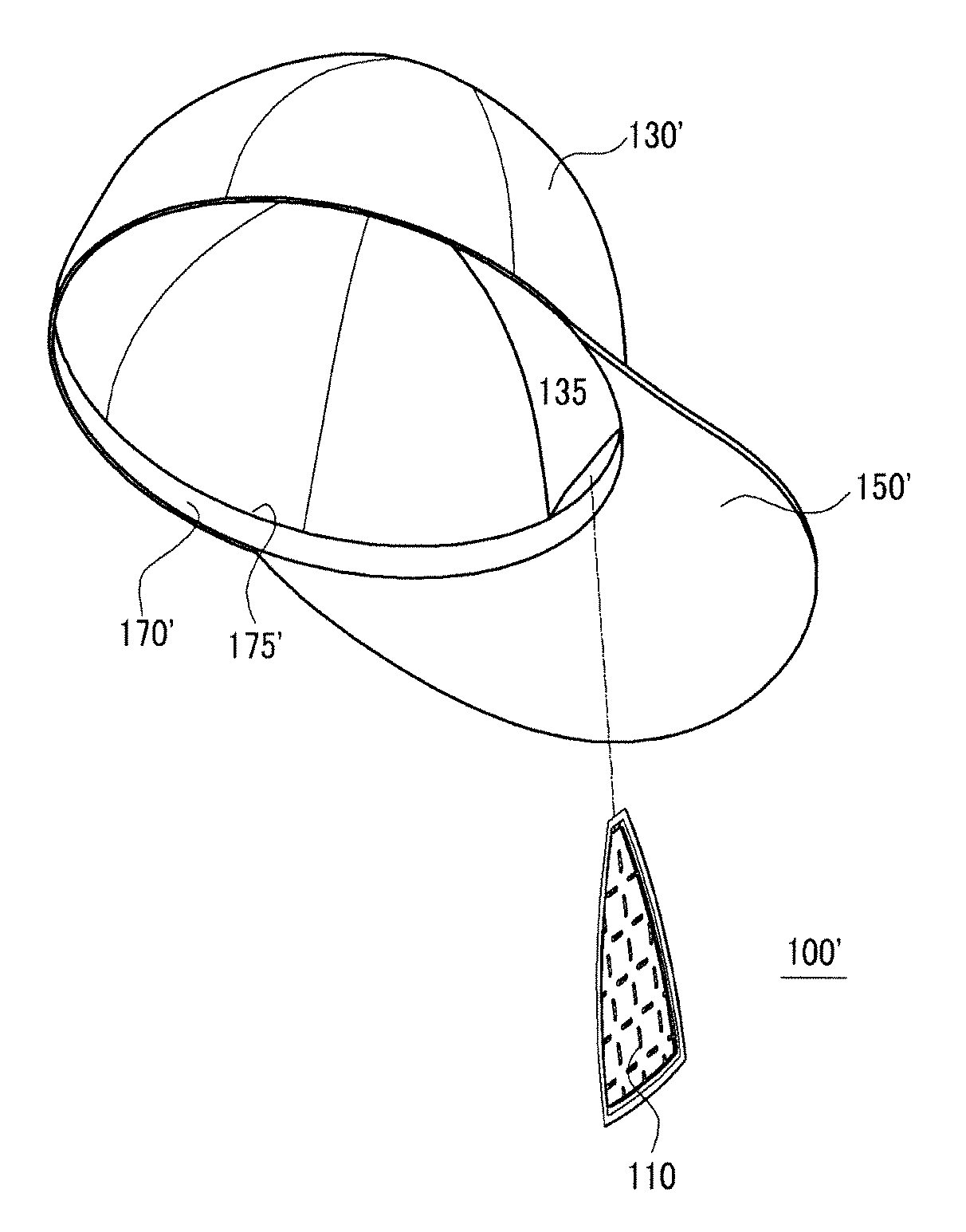

Flexile Plated Cooling Pack of Headwear and Method for Making the Same

ActiveUS20100083421A1Easy to carryEasy to keepHeat storage plantsHeat-exchange elementsCooling effectEngineering

The present invention relates to a flexible plated cooling pack for headwear and a method for making the same that is capable of providing a sufficient cooling effect with a small amount of coolant, not causing worry about leakage of the coolant, and providing a cushion effect without a volume variance regardless of many uses, as well as the cooling effect.The flexible plated cooling pack has an inner and outer synthetic resin film sheet bonded each other and a coolant filled therein, wherein the outer synthetic resin film sheet has a shape respectively corresponding to a piece of the crown portion and a sweatband and the coolant is always maintained in at least a gel state. The flexible plated cooling pack may be disposed in an inner portion of the crown portion and the sweatband of the headwear or may be inserted in a pocket formed at an inner portion of the crown portion and the sweatband of the headwear.

Owner:YUPOONG

Composition for inhibiting adhesion

InactiveUS20090196844A1Guaranteed safe retentionOrganic active ingredientsSurgical drugsPolymer solutionSol-Gel Phase Transition

There is provided in the present invention a composition for inhibiting adhesion comprising polymers that are dissolved in an aqueous solution and have temperature sensitivity showing a sol-gel phase transition dependant upon temperature, wherein the polymer solution in a sol state becomes a gel state by body temperature and is thus stably coated within tissues whereby it functions as a membrane inhibiting adhesion and as time lapses, it is degraded into low molecular weight surfactants and bio-degradable single molecular substances whereby they can be absorbed into body and the degraded products can bring about secondary adhesion inhibiting effects.

Owner:SAMYANG BIOPHARMLS CORP

Nano-composite phase-changing material and preparation method

InactiveCN101429423AGood compatibilityWill not affect the mechanical propertiesHeat-exchange elementsPhase changeProcess complexity

The invention provides a nano composite phase change material and a method for preparing the same, and belongs to the field of material application. The nano composite phase change material comprises the following components in weight portion: 10 to 15 portions of phase change material, 5 to 60 portions of layer-shaped silicate powder, and 20 to 70 portions of deionized water; the phase change point of the phase change material is between 20 and 80 DEG C; the phase change material is heated up to be completely melted; the layer-shaped silicate powder is dispersed in water by a high shear mixed emulsion machine to prepare layer-shaped silicate gel state aqueous dispersion; and the melted phase change material is added to the layer-shaped silicate gel state aqueous dispersion and stirred at high speed by the high shear mixed emulsion machine to obtain the nano composite phase change material with oil-in-water structure. The nano composite phase change material can be directly added to building base materials such as concrete, gypsum, thereby greatly reducing process complexity and preparation cost; moreover, the composite phase change material also has the advantages of simple preparation, large heat storage, and better application prospect.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

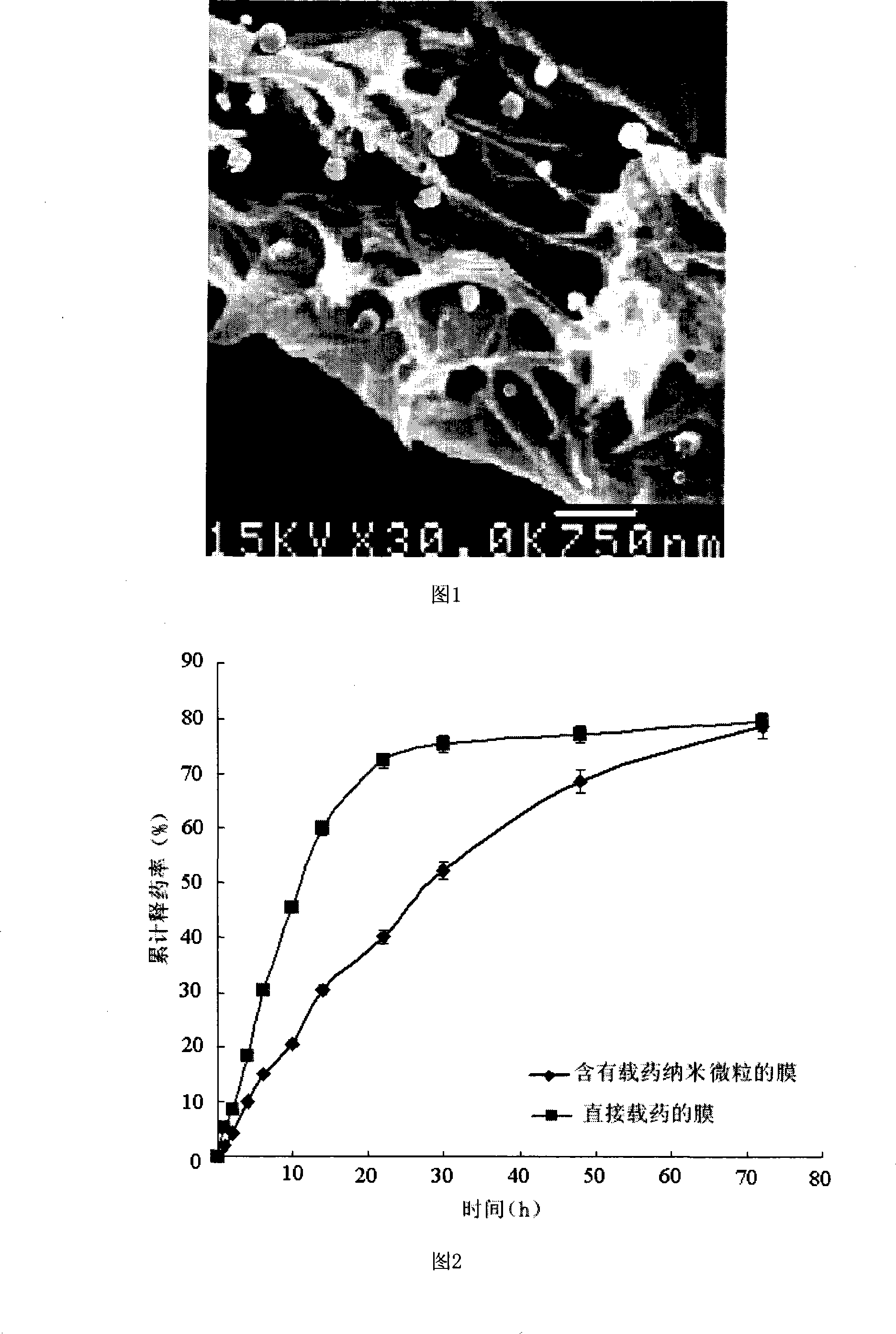

Medical wound dressing with anti-bacterial nanometer particulate

InactiveCN101224310AGood water vapor transmission rateImprove water absorptionAbsorbent padsBandagesParticulatesWound dressing

The invention discloses a medical wound dressing which is loaded with antibiotic nanometer particles and which is in a spongy state when being dried and in a gel state after absorbing the moisture; the medical wound dressing is fixed in a spongy membrane prepared by chitosan and natural high molecular polymers and derivatives of the chitosan with the proportion of 10 to 19 percent of the spongy membrane and natural polymers by drug-loading nanometer particles; the drug-loading nanometer particles contains antibiotics with the particle size of 100nm to 1000nm, the encapsulation rate of 50 to 98 percent and the drug-loading rate of 5 to 60 percent and the weight percentage of 2 to 10 percent of the drug-loading nanometer particles in the wounding dressing. Combing the sustained and controlled release characteristic and the advantage of polysaccharide membrane, the invention has high water absorbability, air permeability, moisture permeability and good biological compatibility can keep the wound physiological moisture environment and promote the wound to recover and has hemostatic effect; at the same time, the invention has good slow release performance for the antibiotics, can prevent the infection of the wound and accelerate the recovery, thus being suitable for a plurality of wounds such as the traumas, burns and ulcers.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

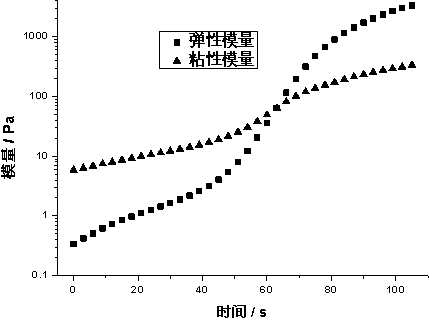

Chitosan double-network quick response-type injectable hydrogel and preparation method thereof

ActiveCN103937014AHigh mechanical strengthShort mechanical strengthFlow propertiesBiocompatibility TestingResponse type

The invention relates to chitosan double-network quick response-type injectable hydrogel and a preparation method thereof. The injectable hydrogel is prepared from chitosan or derivatives of the chitosan and sodium glycerophosphate serving as raw materials, and dialdehyde compounds or diepoxy compounds serving as crosslinking agents, wherein the mass ratio of the chitosan to the sodium glycerophosphate is 1:(0.5-10); the mass ratio of the crosslinking agents to the chitosan is (0.01-1):1. The method comprises the following steps: evenly mixing a hydrochloric acid aqueous solution of the chitosan with a sodium glycerophosphate solution in the environment at -1 to 5 DEG C, so as to obtain a solution of which the pH is 7-7.2, and evenly mixing the solution with a crosslinking solution at 35-37 DEG C. Transformation from a sol state to a gel state can be quickly finished under a specific condition, the process is irreversible, and the transition time is controllable. The chitosan double-network quick response-type injectable hydrogel has the advantages of simple reaction condition, short response time, good thermal stability of gel, high mechanical strength, good biocompatibility and the like. The chitosan double-network quick response-type injectable hydrogel is applied to the fields such as tissue filling and repairing, biological scaffolds, scar resistance and anti-adhesion, biogel, and quickly molding or three-dimensional printing materials and the like.

Owner:IMEIK TECH DEV CO LTD

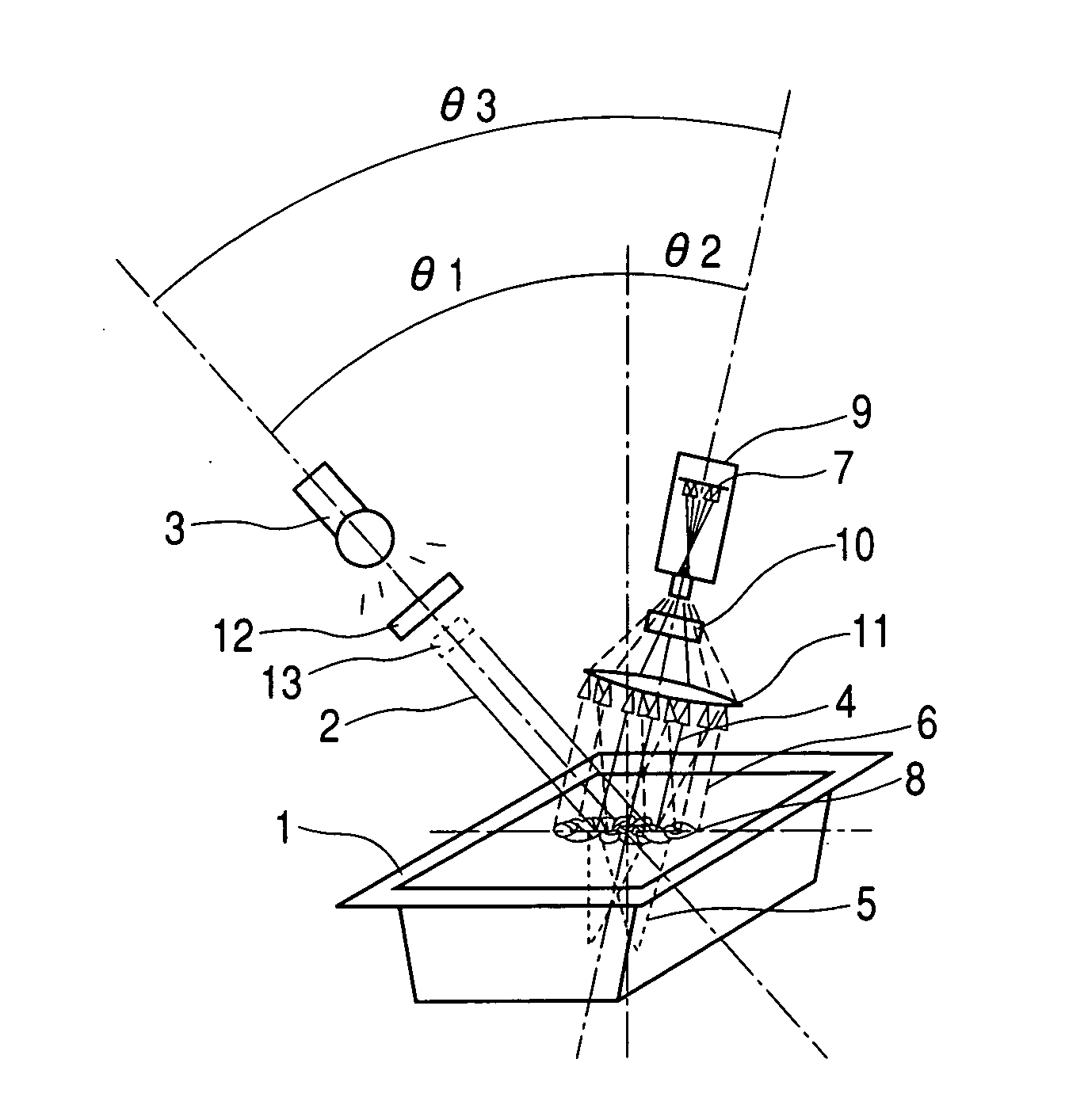

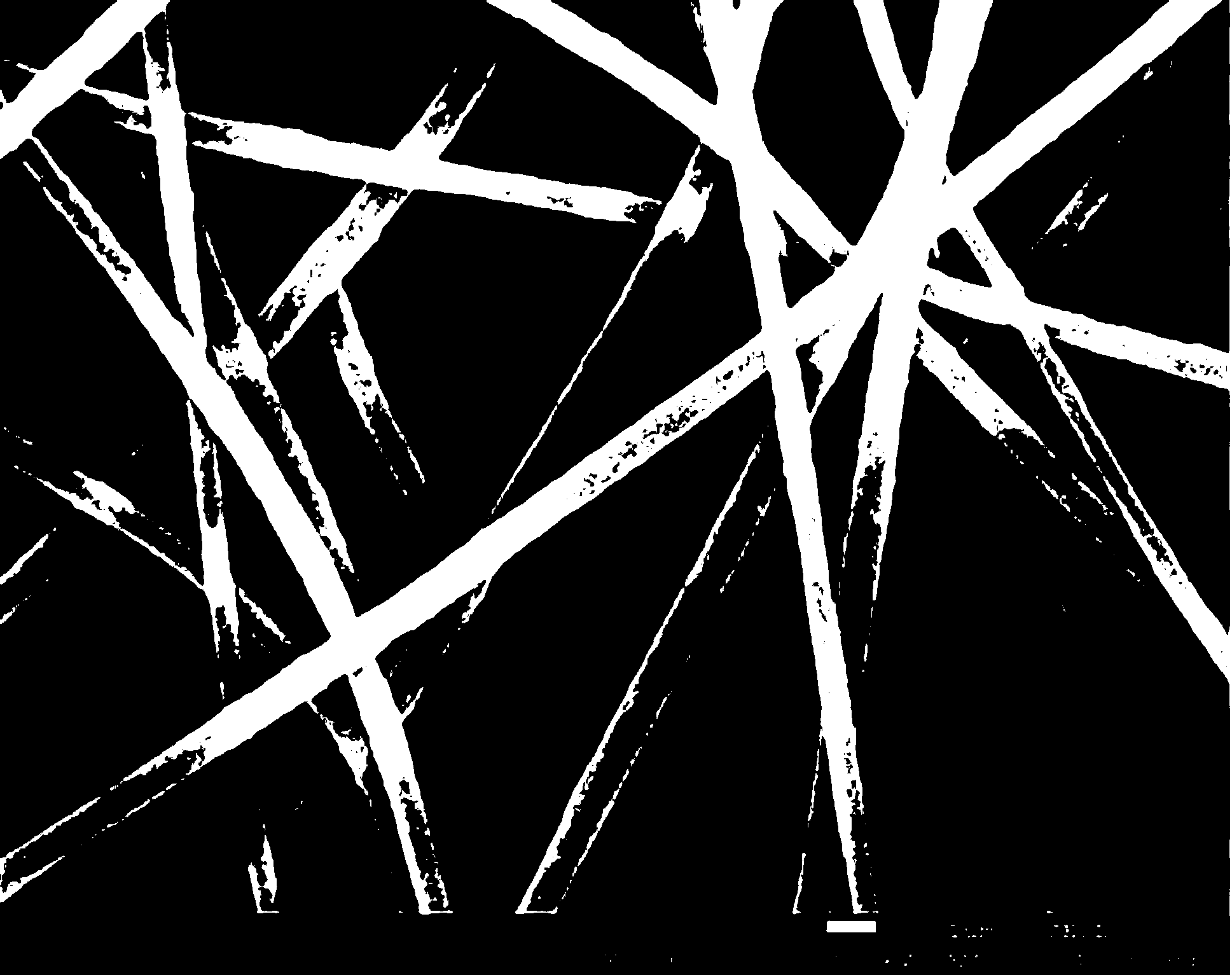

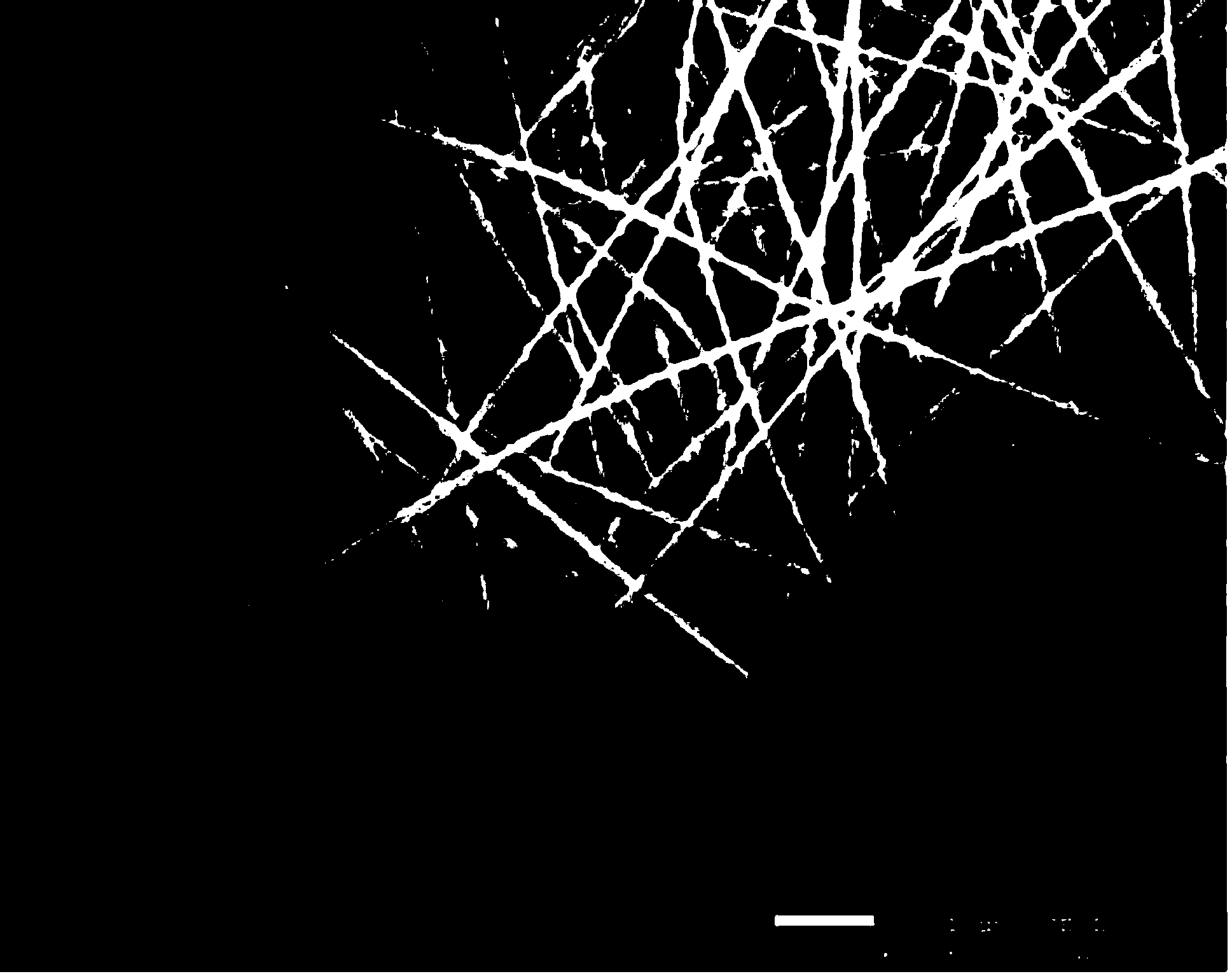

Evaluation method and device for gel state or sol-gel state change of object

InactiveUS20050225752A1Carry-out easily and inexpensivelyEasily and inexpensively productionScattering properties measurementsOptically investigating flaws/contaminationEngineeringCcd camera

The object of the invention is to solve the problems regarding the quality control of processed products (including packaged products and intermediate products during production processes) by establishing a non-destructive and non-contact type method for the measurement of gel state of a material body and a change in sol-gel state of the material body, and thereby to provide a quick automatic inspection system by which 100% inspection can be carried out easily and inexpensively on the production line. The problem is solved by observing an image formation or speckle pattern of a light section formed on the surface or observing face of the material body, using a light scattering observation system in which a coherent light (e.g., from near infrared as a laser beam) is applied to a gel material body or a material which causes a change in sol-gel state, and its reflection or permeated scattered light is image-formed by a two-dimensional image recognizing means, and analyzing and numerically treating conditions of the image (e.g., average brightness, shape, contrast of speckles and the like) and thereby evaluating gel conditions of the material body (concentration, hardness, viscosity, coagulation deterioration, texture and the like qualities and the like), conditional (quality) change from sol to gel and conditional (quality) change from gel to sol. The invention was completed by realizing a practically inexpensive, 100% inspection-performable, quick, non-contact and non-destructive automatic measuring system which is illustratively equipped with a laser beam irradiation source, a CCD camera or the like two-dimensional image recognizing means and a transferring means, can grasp an image or speckle pattern of a light section image-forming on the material body surface or light intercepting device, as a two dimensional image, and can judge the qualities of said material body by analyzing the image data.

Owner:TAKAI TOFU & SOYMILK EQUIP +1

Water-base joint grouting glue for normal temperature road

InactiveCN101643636AAct as a seam sealStrong viscosity and permeabilityMonocarboxylic acid ester polymer adhesivesOther chemical processesWater basedAdhesive

The invention relates to water-base joint grouting glue for a normal temperature road, namely an environment-friendly joint grouting and joint sealing material having high viscosity, high cementing power and high adhesive property, which is formed by special processes of copolymerizing water, a water-base adhesive, bitumen and a dispersing agent, then modifying a macromolecular water-soluble resinand a rubber latex, and adding the auxiliary agents of a stabilizing agent, a thickening material and the like, and can be used for treating and sealing various types of cracks of bitumen and cementroad surfaces and joint seams of cement road surfaces and bridge surfaces. The joint grouting glue is in a gel state at normal temperature, can be stirred but cannot flow, thus the joint grouting gluecan enter joints directly without slotting and cannot infiltrate downwards so as to play a role in sealing the joints; and simultaneously the joint grouting glue is soluble in water; therefore, the joint grouting glue can be mixed with water to prepare strong-permeability joint grouting materials with any viscosities, and can be effectively poured into deep parts of the cracks of road surfaces without slotting. The joint grouting glue combines the advantages of slotting and non-slotting repairing methods, and simultaneously avoids the disadvantages of the two methods.

Owner:李志刚 +2

Polymer electrolyte, its preparation method and battery comprising the same

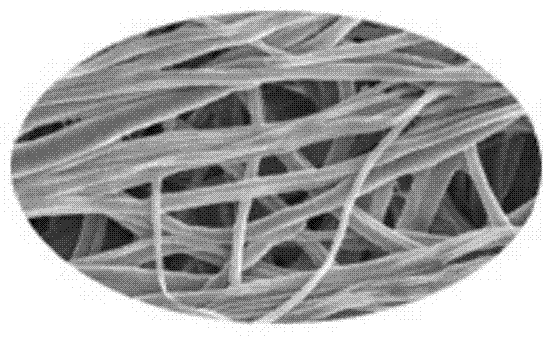

ActiveCN103700797AImprove electrochemical performanceGood flexibilityCell seperators/membranes/diaphragms/spacersFinal product manufactureFiberComposite electrolyte

The invention provides a polymer electrolyte, its preparation method and a battery comprising the polymer electrolyte. The polymer electrolyte contains a stance phase and an ionic conductive phase adsorbed on the stance phase. The stance phase is an electrostatic spinning fiber film, and the ionic conductive phase includes a polymer able to undergo complexation with lithium ions and a lithium salt. The polymer able to undergo complexation with lithium ions contains an ether oxygen functional group. A bi-continuous phase composite electrolyte film characterized by high mechanical strength, good flexibility, high ionic conductivity, good thermal stability, high interface stability and good electrochemical stability can be obtained, and the preparation process is simple and is low in cost. The prepared material can be widely used in mobile phones, notebook computers and other mobile devices, as well as electric vehicles and other fields, and has strong practical significance to development of the battery industry. The polymer battery involved in the invention is different from liquid or gel state batteries, is free of plasticizer, does not cause leakage and other potential safety hazards, so that it can be used in high temperature environment, and does not have combustion, explosion and other hidden dangers.

Owner:BYD CO LTD

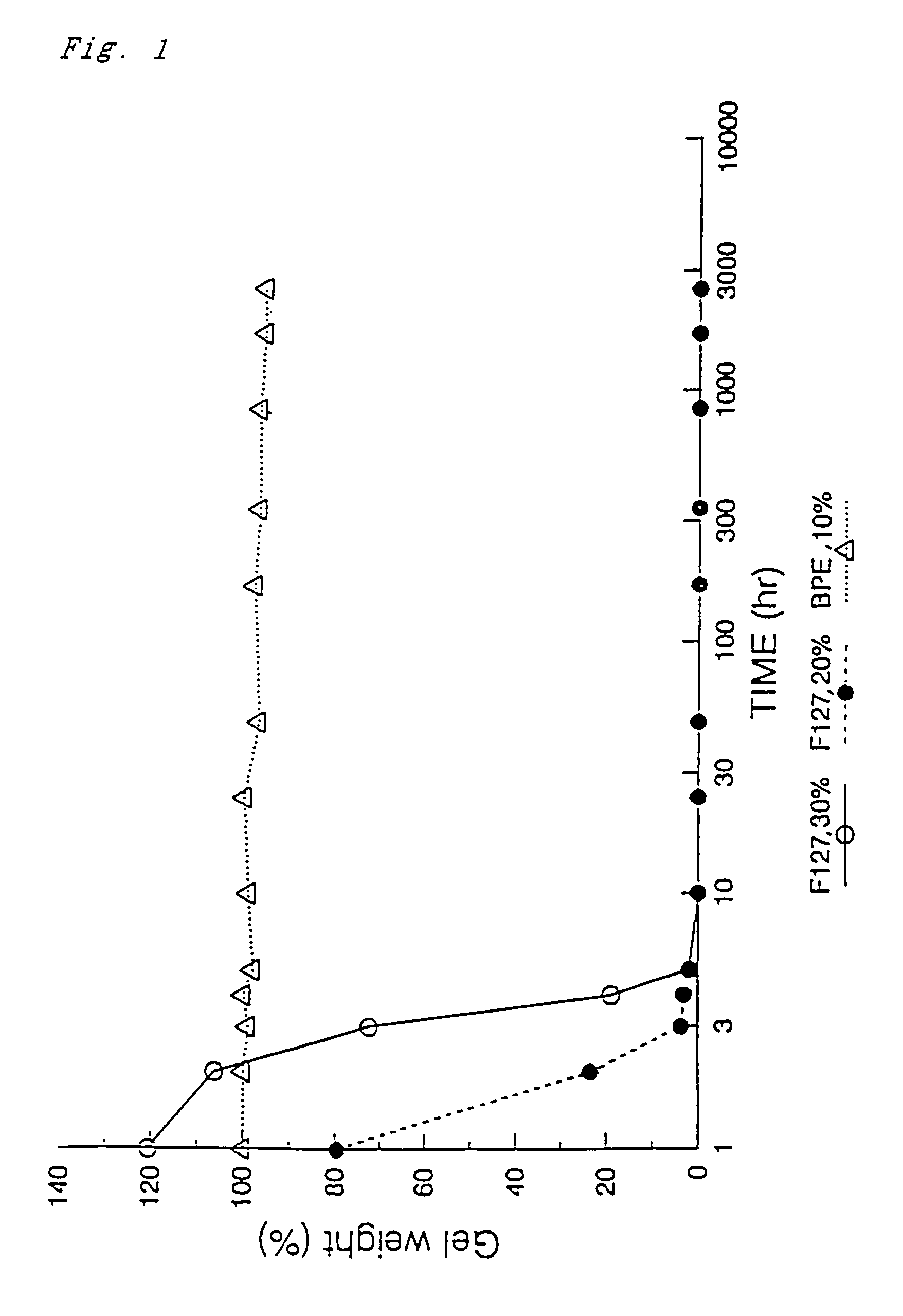

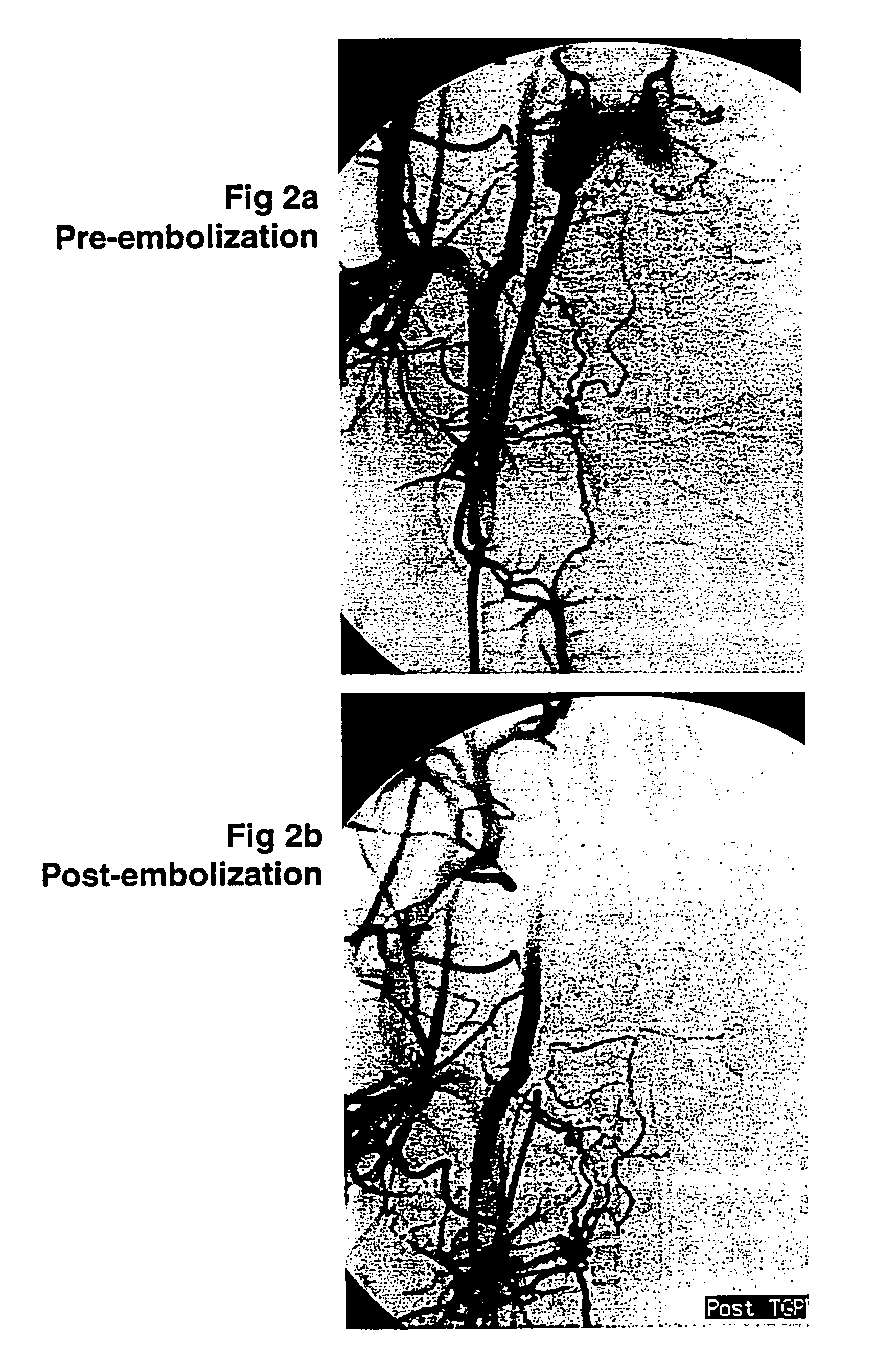

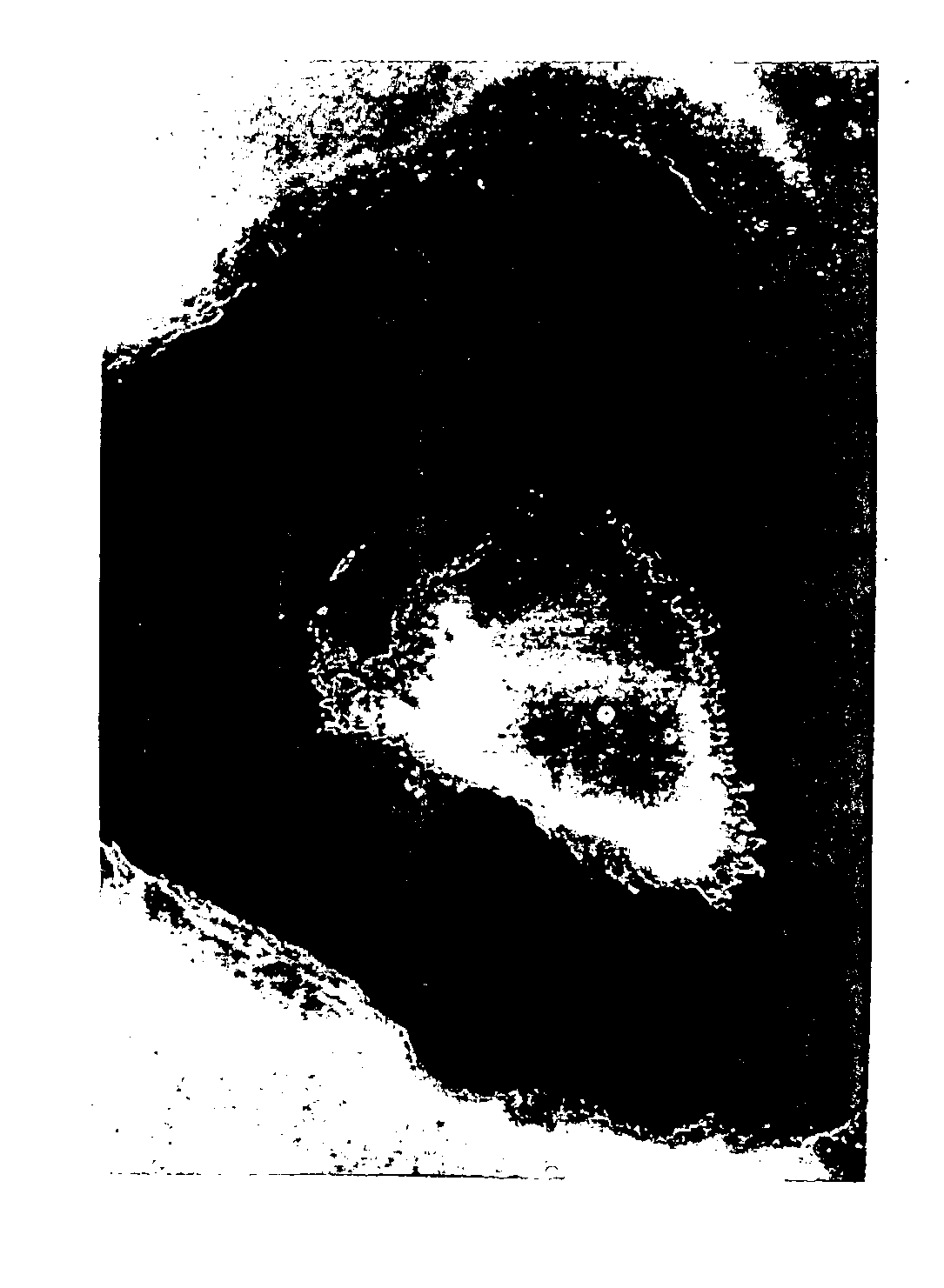

Thermo-reversible polymer for intralumenal implant

InactiveUS7485317B1Low toxicityEasy injectionPowder deliverySurgical adhesivesSolubilityVascular tissue

An intralumenal implant material, which comprises, a polymer having a sol-gel transition temperature in an aqueous solution thereof, shows a substantial water-insolubility at a temperature higher than the sol-gel transition temperature, and shows a thermo-reversible water-solubility at a temperature lower than the sol-gel transition temperature. Such an intralumenal implant is capable to be endovascularly or percutaneuosly delivered into a vascular lumen in a liquid state at the temperature lower than the sol-gel transition temperature, is capable to be instantly converted into a gel state in the vascular lumen at the blood temperature higher than the sol-gel transition temperature and is capable of occluding aneurysms, vascular tumors or vascular malformation. Such intralumenal implant material shows excellent biocompatibility and mechanical matching for the vascular tissue and the surrounding tissue because it is a highly water-containing hydrogel. In addition, biologically active substances for promoting a prompt neo-endothelium formation and / or endothelialization can be easily incorporated into such an intralumenal implant material.

Owner:RGT UNIV OF CALIFORNIA

Thickening agent for printing and preparation method thereof

The invention discloses a thickening agent for printing, which comprises the following components in parts by weight: 10-15 parts of etherified guar gum, 60-70 parts of sodium alginate, 30-50 parts of sodium carboxymethylcellulose, 20-30 parts of carboxymethyl starch, 12-20 parts of polyacrylic acid thickening agent blending stock, 10-20 parts of bentonites and 200-400 parts of water. The preparation method of the thickening agent comprises the following steps of: adding sodium alginate and sodium carboxymethylcellulose powder to water, and mechanically stirring till a solution is transparent and clear without a block; then adding the etherified guar gum, the carboxymethyl starch, the polyacrylic acid thickening agent blending stock and the bentonite, uniformly stirring, and standing to bulk the mixed solution so as to obtain the printing thickening agent. In the preparation process, with the bulking of the paste material, the sodium carboxymethylcellulose forms three-dimensional net structure among macromolecules of paste material or at the joints of molecular chain segments because of intermolecular attraction; moreover, besides a macromolecular chain hydration layer, a large amount of water is wrapped to form a gel state, so as to generate very high structural viscocity; therefore, a printing fabric has a clear outline.

Owner:ZHANGJIAGANG SHUNCHANG CHEM

Cell or tissue-culturing carrier, and culturing method

InactiveUS6897064B2Inhibiting and suppressing excessive growthPromote regenerationBacteriaVertebrate cellsGel basedCulture cell

A cell or tissue-culturing carrier which can effectively regenerate an intended a cell or tissue, while suppressing an excessive growth of fibroblasts, and a method of culturing a cell or tissue by using the above carrier, the cell or tissue-culturing carrier wherein fibroblasts showing substantially no growing property in a gel based on the hydrogel-forming polymer, is constituted by using a hydrogel-forming polymer; an aqueous solution of which shows a thermo-reversible sol-gel transition such that it assumes a sol state at a lower temperature and assumes a gel state at a higher temperature.

Owner:MEBIOL

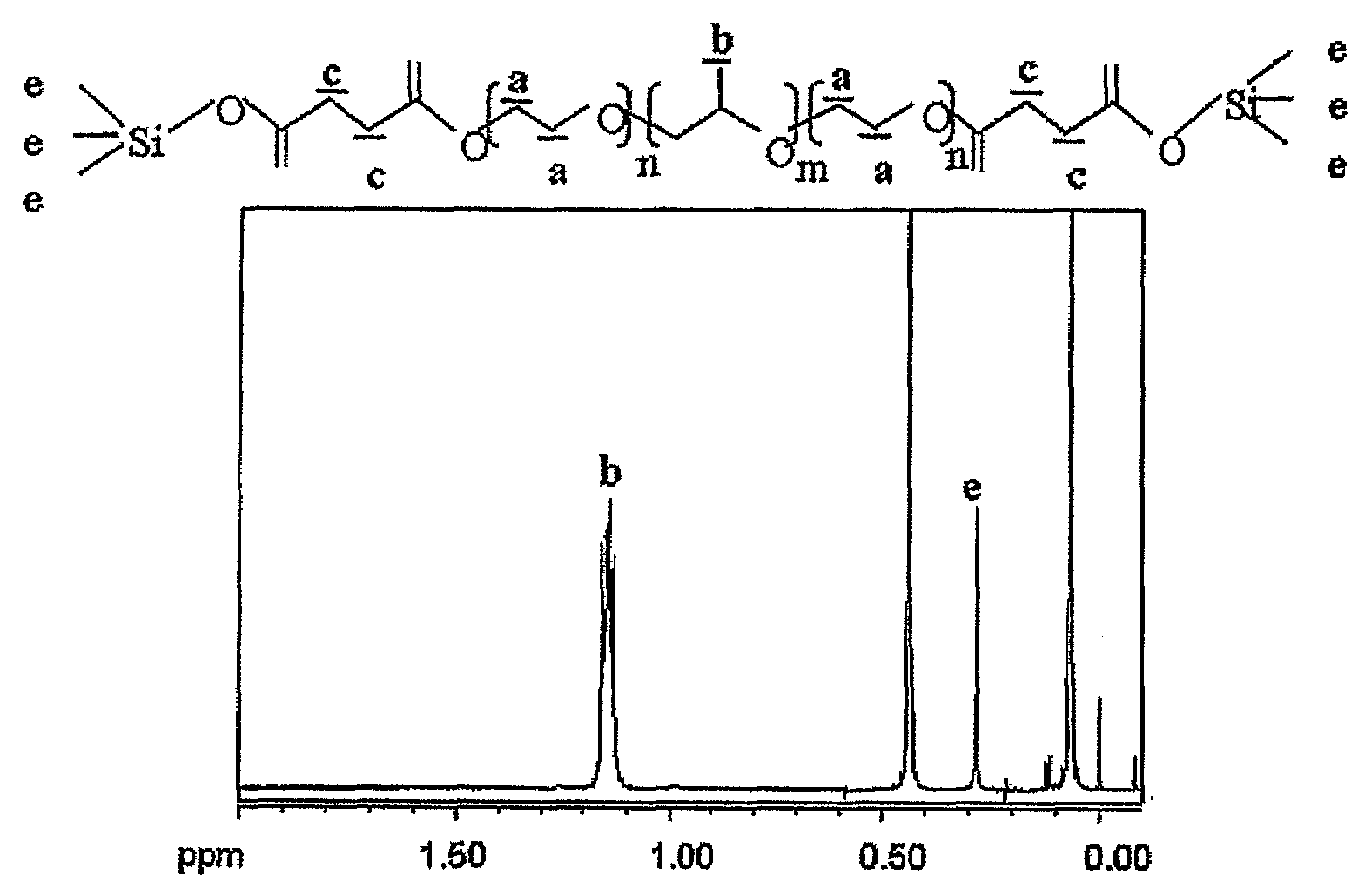

Photoelectric conversion apparatus and gelling agent

InactiveUS20070175510A1Large specific surface areaImprove performanceElectrolytic capacitorsPhotovoltaic energy generationPhotoelectric conversionSemiconductor

A photoelectric conversion apparatus is provided. The photoelectric conversion apparatus includes an electrolyte layer interposed between a semiconductor layer and a counter electrode. The electrolyte layer includes an electrolyte solution retained in a fibrous inorganic matrix in a gel state.

Owner:SONY CORP

Composition for controlling wellbore fluid and gas invasion and method for using same

InactiveUS20040040711A1Reduce hydrostatic pressureReadily cut through by a drill bitFluid removalFlushingLinear relationshipSlurry

The disclosure is directed to a composition for controlling wellbore fluid and gas invasion including methods for using said composition. The composition of the invention is a flowable slurry preferably comprising about 70 to 30% by weight of magnesium oxychloride and about 70 to 30% by weight of water. The composition is a flowable slurry at composition temperatures below about 60° C. and sets to form a substantially solid mass upon reaching a composition temperature of about 60-68° C. The phase transition is rapid, thereby limiting or avoiding formation of gel states which contribute to incomplete wellbore seals. The rapid set of the slurry further avoids invasive contamination of earthen formations surrounding the wellbore. The composition has a near-linear relationship between the time required for the phase transition to occur and the composition temperature at which the phase transition occurs. This advantageous property permits the composition set time to be accurately determined and modified as required through the addition of accelerators and inhibitors. The phase transition occurs predictably at high pressures typical of those encountered in wellbore operations. Additives may be included to modify the properties of the composition. The method includes use of the composition to control the loss of fluids and gases from the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

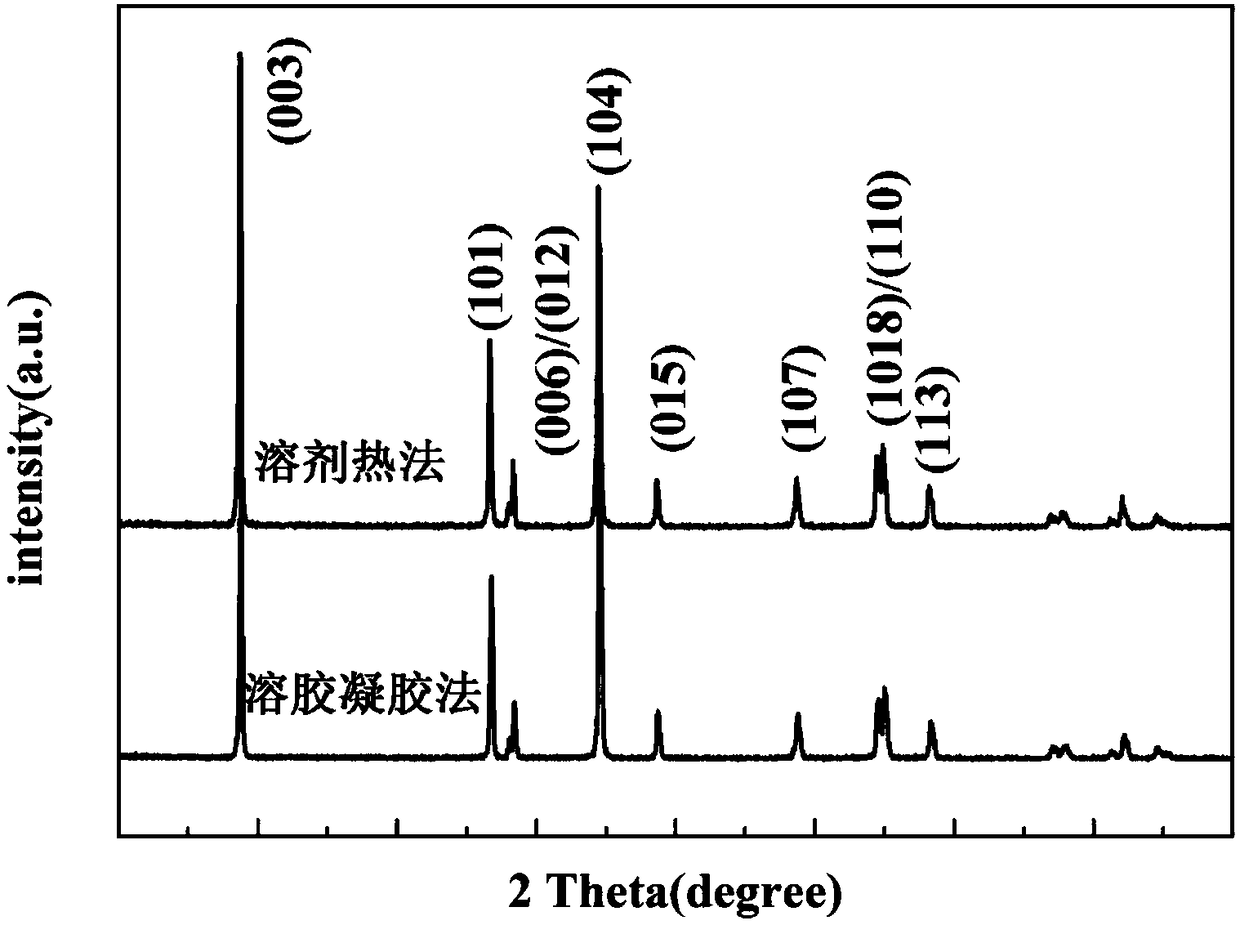

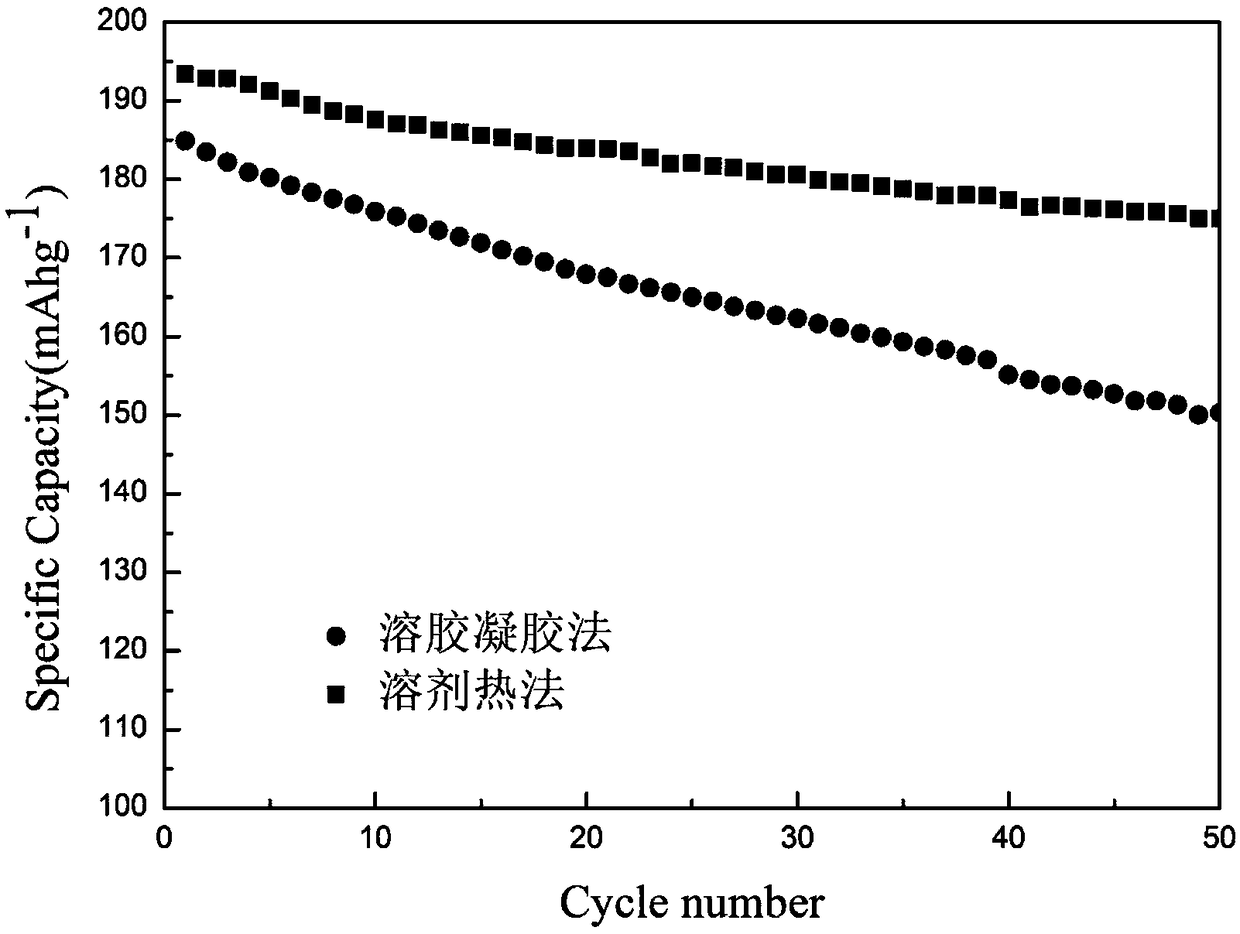

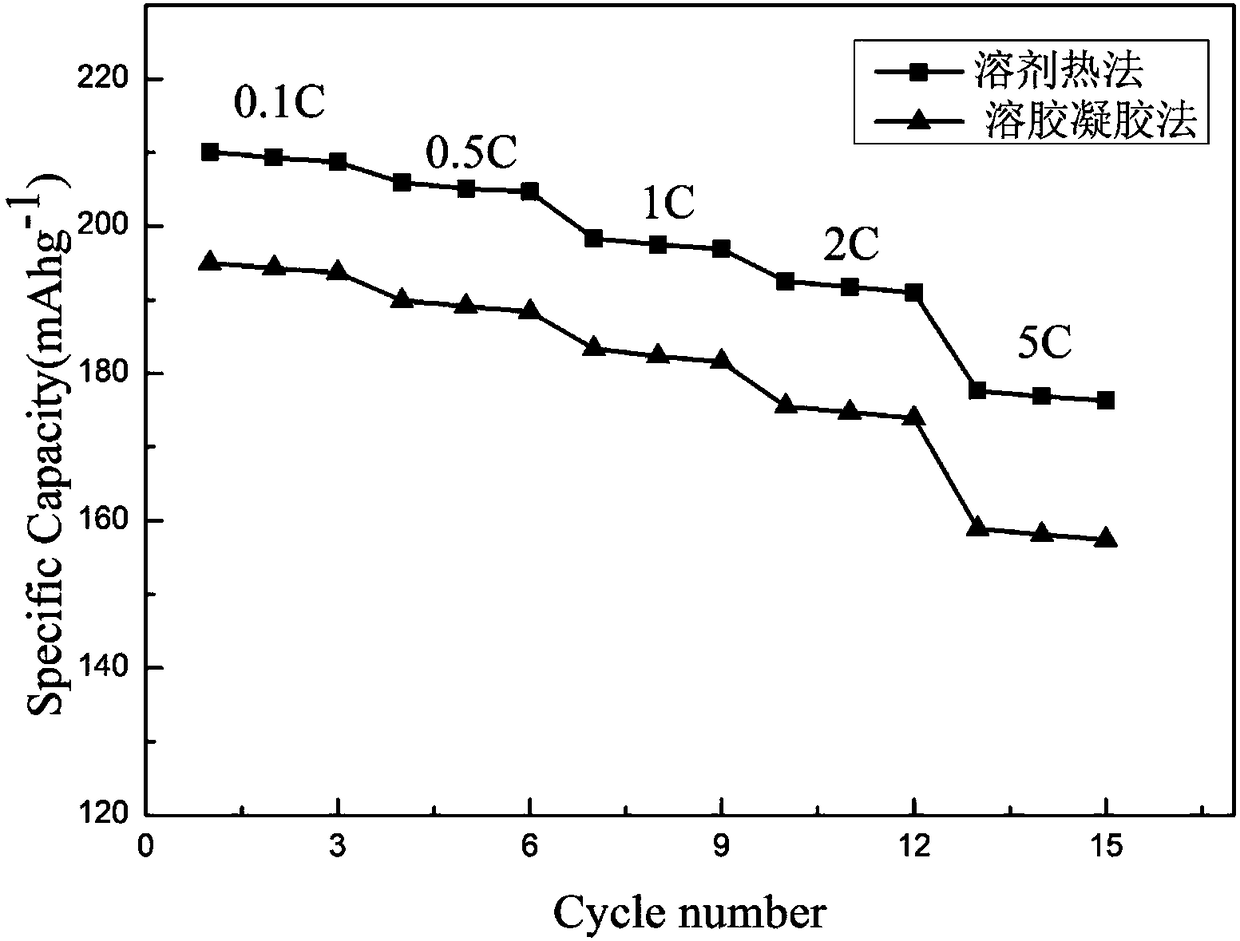

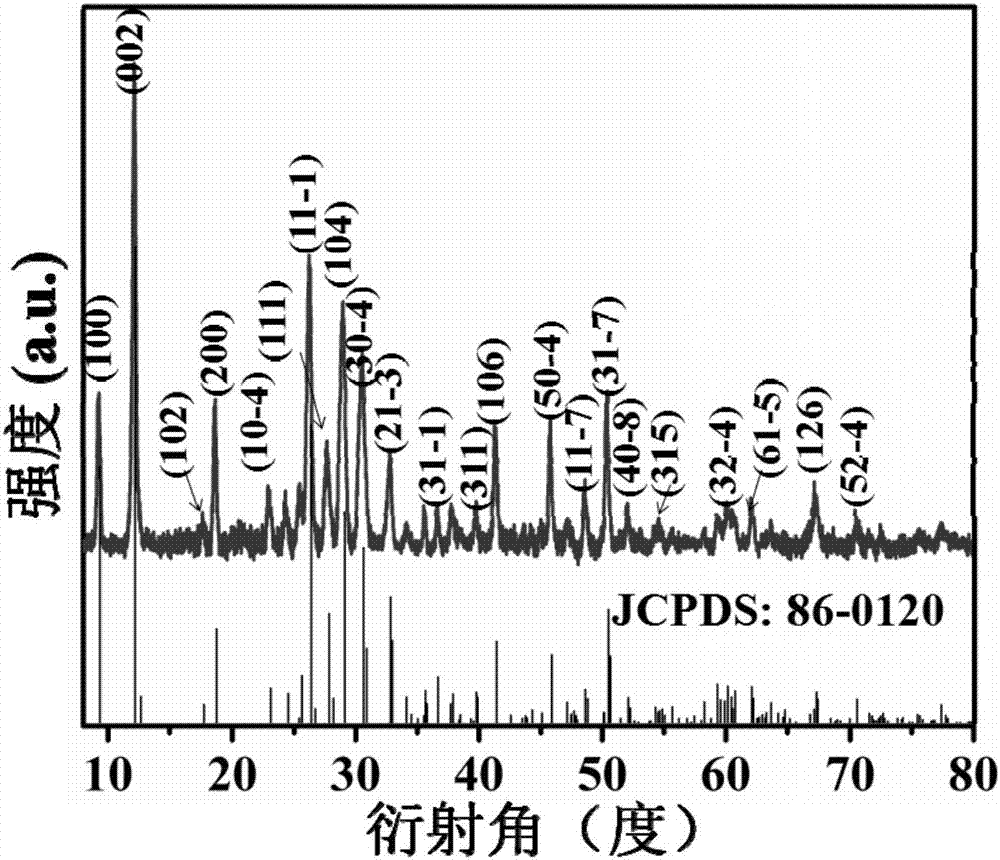

Coating method for improving electrochemical property of high-nickel ternary nickel cobalt manganese anode material

ActiveCN108321366AImprove electrochemical performanceAvoid direct contactCell electrodesSecondary cellsManganeseElectrochemistry

The invention discloses a coating method for improving electrochemical properties of a high-nickel ternary nickel cobalt manganese anode material. The coating method comprises the following steps: dissolving a titanium source into a solvent so as to obtain a solution, dissolving a lithium source, and further adding citric acid so as to obtain a mixed solution; uniformly dispersing a high-nickel ternary nickel cobalt manganese anode material into a solvent, adding the mixed solution, uniformly mixing, and performing a hydrothermal reaction or a solvent thermal reaction so as to obtain a reaction solution; evaporating the reaction solution to a gel state, and drying so as to obtain an anode material mixture; calcining the anode material mixture, thereby obtaining the high-nickel ternary nickel cobalt manganese anode material with a lithium titanate coating layer. The coating method for improving the electrochemical properties of the high-nickel ternary nickel cobalt manganese anode material, which is disclosed by the invention, is simple in process, low in cost and good in repeatability, the obtained coating layer is high in crystallization degree, small in particle size and good inuniformity, and the charge and discharge specific capacity, the circulation property and the multiplying power of the high-nickel ternary nickel cobalt manganese anode material can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Thermal interface materials

InactiveUS6908669B2Minimize size of deviceHeat storage plantsSemiconductor/solid-state device detailsPolymer scienceElectronic component

A crosslinkable thermal interface material is produced by combining at least one rubber compound, at least one amine resin and at least one thermally conductive filler. This interface material takes on the form of a liquid or “soft gel”. The gel state is brought about through a crosslinking reaction between the at least one rubber compound composition and the at least one amine resin composition. Once the foundation composition that comprises at least one rubber compound, at least one amine resin, and at least one thermally conductive filler has been prepared, the composition must be compared to the needs of the electronic component, vendor, or electronic product to determine if a phase change material is needed to change some of the physical properties of the composition. A method for forming the crosslinkable thermal interface materials disclosed herein comprises a) providing at least one saturated rubber compound, b) providing at least one amine resin, c) crosslinking the at least one saturated rubber compound and the at least one amine resin to form a crosslinked rubber-resin mixture, d) adding at least one thermally conductive filler to the crosslinked rubber-resin mixture, and e) adding a wetting agent to the crosslinked rubber-resin mixture. This method can also further comprise adding at least one phase change material to the crosslinked rubber-resin mixture. The contemplated thermal interface material can be provided as a dispensable liquid paste, a gel, a tape, or a film. Applications of the contemplated thermal interface materials described herein comprise incorporating the materials into a layered material, an electronic component or a finished electronic product.

Owner:HONEYWELL INT INC

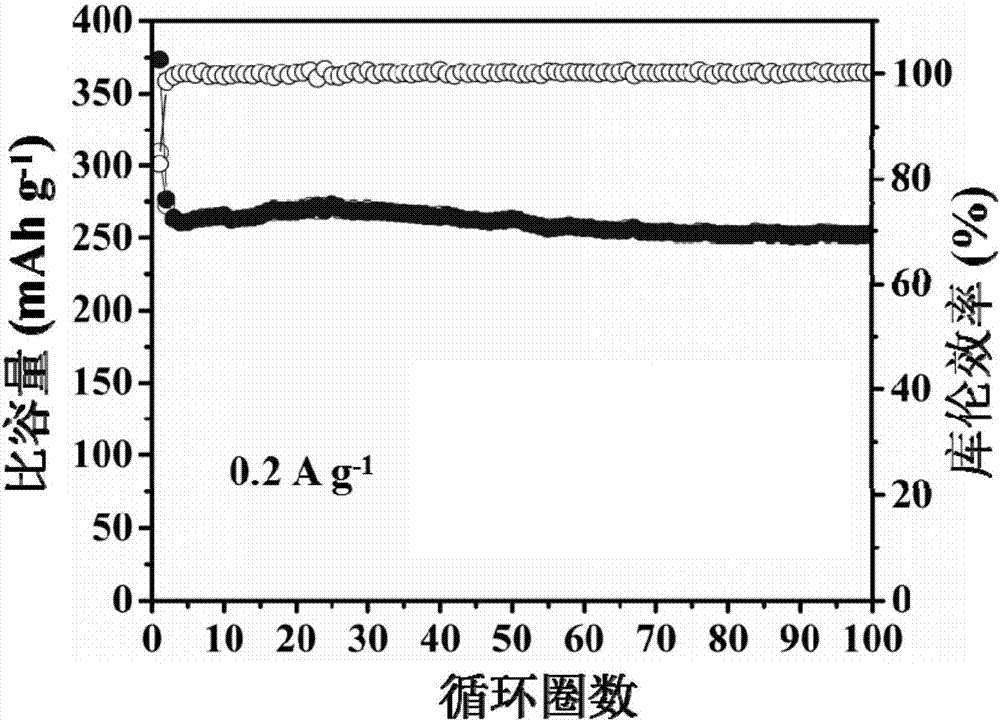

Rechargeable aqueous zinc ion battery

ActiveCN107221716AImprove cycle stabilityLow equipment requirementsFinal product manufactureCell electrodesHigh rateElectrical battery

The invention belongs to the field of a novel chemical power supply and a new energy material, and particularly relates to a novel rechargeable aqueous zinc ion battery taking a vanadate salt as an electrode active material. The rechargeable aqueous zinc ion battery comprises a positive electrode, a negative electrode, a separator and an electrolyte, wherein the separator is arranged between the positive electrode and the negative electrode, the electrolyte contains negative ions and positive ions and has ion conductivity, an active material of the positive electrode takes the vanadate salt to which zinc ions are intercalated / de-intercalated as main, the electrolyte takes a zinc soluble salt as a solute and water as a solvent, the concentration of the electrolyte is (0.1-5)mol / L, and the electrolyte is a liquid-state or gel-state material with ion conductivity. The material shows excellent high-rate performance, cycle stability and long lifetime when assembled to form the aqueous zinc ion battery, is a potential application material of the high-power and long-lifetime zinc ion battery and has a wide application prospect in an aspect of energy storage on a large scale.

Owner:WUHAN UNIV OF TECH

Method for planting and cultivating rhizoma gastrodiae

The invention belongs to agricultural cultivation, and particularly relates to a method for planting and cultivating rhizoma gastrodiae. The method comprises the steps that corn flour is boiled to paste and mixed with activated carbon powder so that a mixture of the corn paste and activated carbon can be produced; the mixture is laid on a flat plate; after the mixture is in a gel state, bacteria sticks and rhizoma gastrodiae seeds are tightly coiled and then planted. According to the method, the rhizoma gastrodiae seeds can tightly surround the bacteria sticks, so that the germination rate and the inoculation rate of the seeds are improved and finally, the yield of rhizoma gastrodiae of the method is more than two times as much as that of a traditional rhizoma gastrodiae sowing method. On one hand, the corn paste can serve as compost of the rhizoma gastrodiae, the activated carbon powder is added to the corn paste, and therefore the air permeability is guaranteed; on the other hand, when the rhizoma gastrodiae is planted, the phenomenon that the rhizoma gastrodiae is constrained or damaged is avoided along with the process that the corn paste is gradually dissolved, so that operation and later-period temperature and humidity management are facilitated and the operable sowing method is provided for rhizoma gastrodiae concentration seeding and efficient industrialized sowing. In addition, according to the method, special paper is not needed, the method is easy to achieve, and cost is saved.

Owner:CHONGQING FUXINYANG EDIBLE FUNGUS

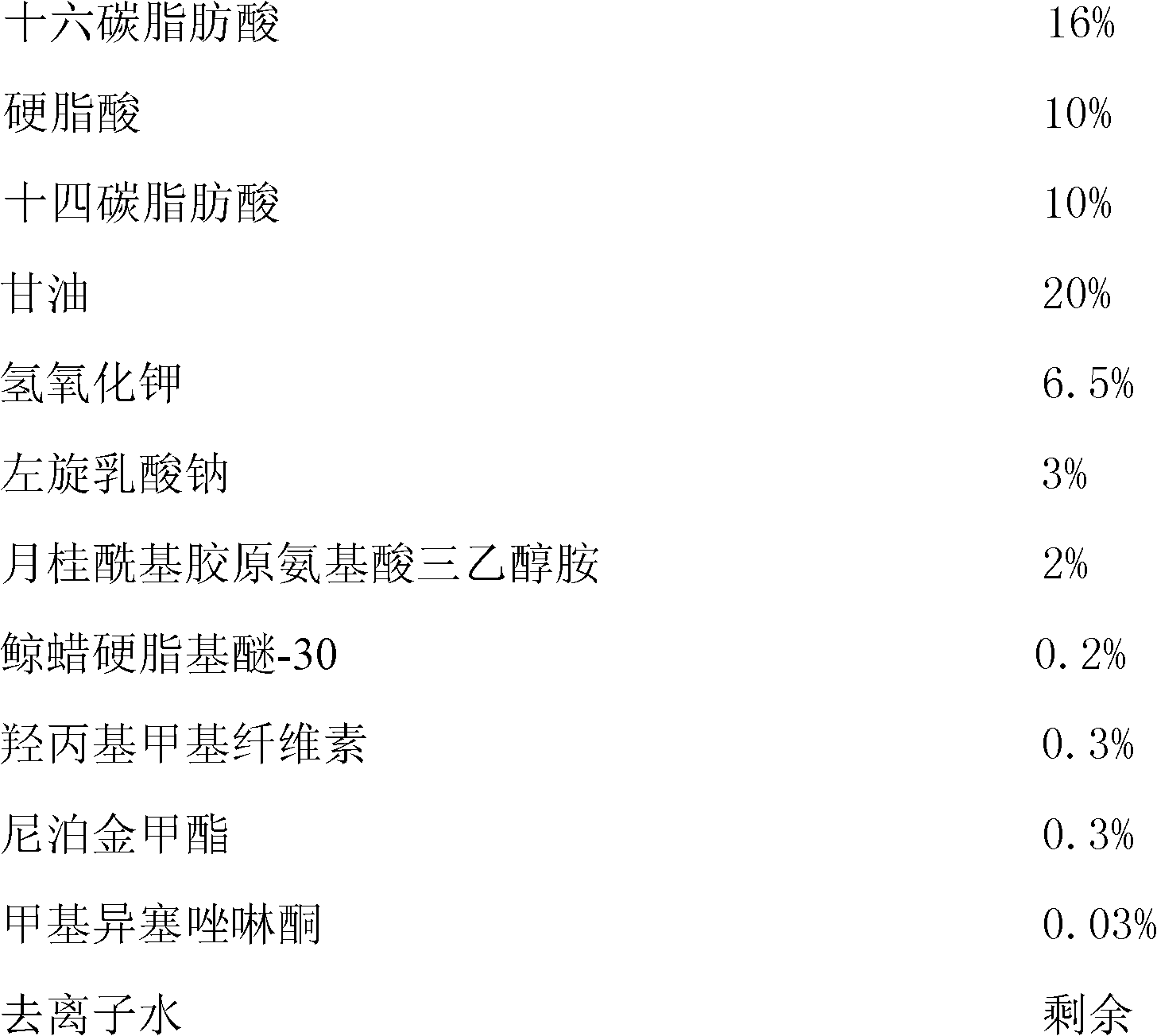

High-pearly-lustre high-foam soap base cleansing cream and preparation method thereof

ActiveCN102178611AGood dispersionAdd lessCosmetic preparationsToilet preparationsPolyolAdditive ingredient

The invention relates to high-pearly-lustre high-foam soap base cleansing cream comprising the following constituents in percentage by weight: 32-36% of fatty acid, 14-22% of polyalcohol, 6.5-8% of potassium hydroxide, 1-4% of sodium L-lactic acid, 0.5-10% of anionic surface active agent, 0.2-4% of non-ionic surface active agent and the balance of deionized water. A preparation method of the soapbase cleansing cream comprises the following steps of: A, adding the sodium L-lactic acid with a weight percentage of 1-4% into the ingredients of the soap base cleansing cream taking the fatty acid as the main material and placing into a reaction kettle; B, slowly heating to 70-78 DEG C under a normal pressure and stirring at a rotating speed of 300-500 revolutions per minute in the mean time; and C, keeping the temperature and stirring for 30-35 minutes, and then cooling to a normal temperature to obtain the high-pearly-lustre high-foam soap base cleansing cream. The high-pearly-lustre high-foam soap base cleansing cream provided by the invention has the characteristics of very fine foam and high-pearly lustre, meanwhile, the production technology is easy to control, and the gel state material is not generated.

Owner:PROYA COSMETICS

Injection-type cartilage bionic matrix for regenerative repair of cartilage and method for using same

InactiveCN101934092AReduce dwell timeSolve the problem of excessive degradationProsthesisCell-Extracellular MatrixMedicine

The invention discloses an injection-type cartilage bionic matrix for the regenerative repair of cartilage and a method for using the same. The materials, of which the main components are the same as those of the extracellular matrix of the normal articular cartilage, are used as a raw material, and the raw materials undergo dissolution and pH adjustment to form the injection-type cartilage bionic matrix which is in a sol state at the low temperature and at a gel state at the body temperature; and by using the injection-type cartilage bionic matrix as a carrier, the injection-type cartilage bionic matrix is mixed with seed cells at the low temperature and then injected in cartilage deficiency parts, the injected materials undergo phase change by raising the temperature of the deficiency area to turn into the gel, so that the seed cells are fixed in the deficiency parts to conduct the regenerative repair function. The method is simple and easily implemented, the product is conveniently used, the operation injury is small, and the repair effect of the deficiency parts is good; the raw material has high biocompatibility and safety, all components undergo intermolecular bonding under the preparation conditions of the invention, so that the problem that the single bionic material is degraded too fast is solved; and the seed cells are directly mixed with the raw materials, and the culture in vitro is unnecessary so that the detention time in vitro of the seed cells are shortened, and the clinical application is safer.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Method for preparing chitosan/cellulose composite material

InactiveCN101899171ATo achieve the dissolution effectGood mechanical propertiesConjugated cellulose/protein artificial filamentsWet spinning methodsCelluloseProtonation

The invention discloses a method for preparing a chitosan / cellulose composite material, and relates to a natural macromolecular composite material. The method for preparing the chitosan / cellulose composite material comprises the following steps of: dissolving cellulose in ionic liquid and heating to obtain solution A; dissolving chitosan into the ionic liquid and heating to obtain solution B; mixing the solution A and the solution B, levelling the mixed solution on a glass sheet, and immersing into a coagulating agent to obtain a membrane in a gel state; or spinning the mixed solution, immersing in the coagulating agent to obtain filaments in the gel state; and washing the membrane or the filaments, and drying to obtain a product. In the method, the cellulose and the chitosan are dissolved by the green solvent ionic liquid, the dissolution process depends on the powerful destruction capacity of hydrogen bonds, and an amino group of the chitosan is not protonized; and the composite material obtained by mixing the chitosan and the cellulose uniformly has excellent mechanical property, and the application of the composite material in fields of clinical medicine and the like can be expanded and promoted. The chitosan / cellulose composite material has the advantages of easy control of appearance, simple equipment requirement, simple and convenient operation, recyclability of the ionic liquid and environmental protection in the integral reaction process.

Owner:XIAMEN UNIV

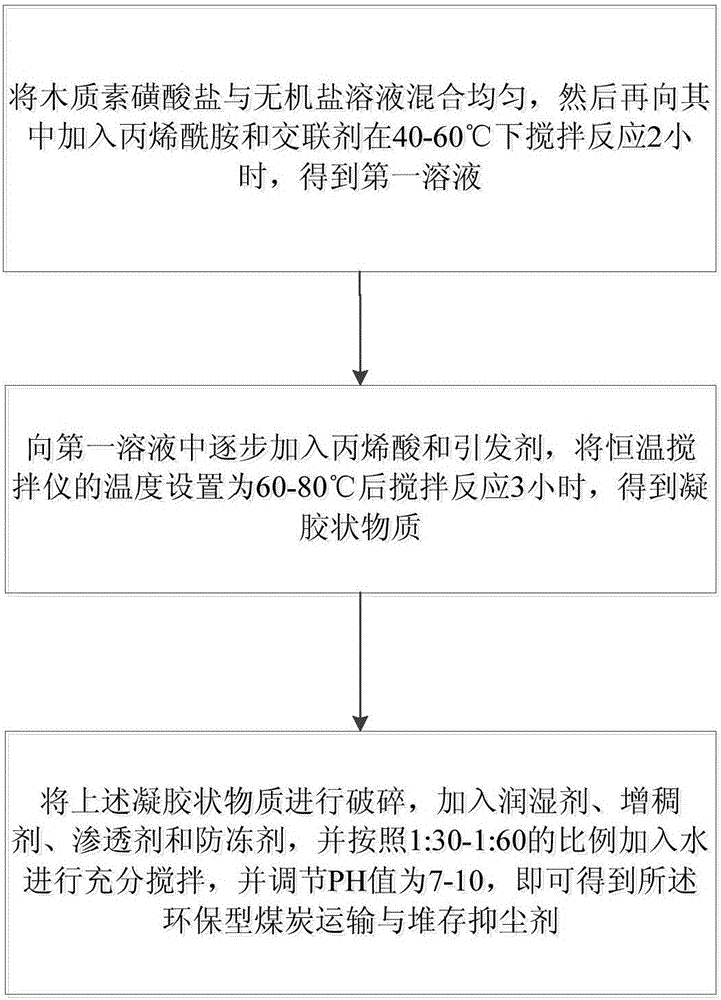

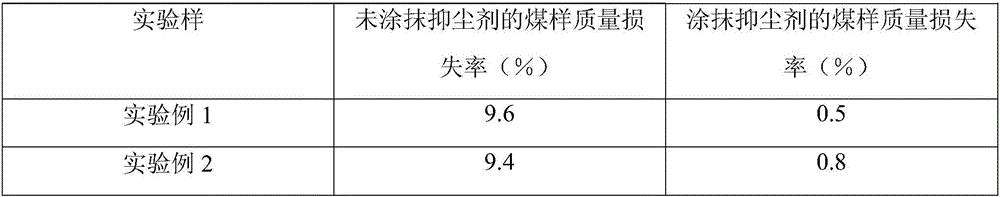

Environmentally-friendly coal transporting and stockpiling dust inhibitor and preparation method thereof

ActiveCN105950116ASuppress flyingImprove wettabilityOther chemical processesInorganic saltsLignosulfonates

The invention discloses an environmentally-friendly coal transporting and stockpiling dust inhibitor and a preparation method thereof. The dust inhibitor comprises, by mass, 5-10% of lignosulfonate, 5-10% of acrylamide, 10-15% of acrylic acid, 0.5-1.4% of a wetting agent, 0.4-0.9% of a thickener, 0.3-0.5% of an osmotic agent, 0.2-0.5% of an antifreeze agent, 0.05-0.1% of an initiator, 0.5-0.8% of a cross-linking agent, 0.2-0.5% of an inorganic salt, and the balance of water. A finally generated gel state substance has an obviously better coal wrapping effect than spraying, and can form a stable protection layer after the gel state substance is sprayed on the surface of coal. The dust inhibitor has the advantages of good wetting effect, fast solidification speed, and large hardness and obvious dust inhibiting effect of the formed protection layer.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com