Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13787 results about "Glass sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

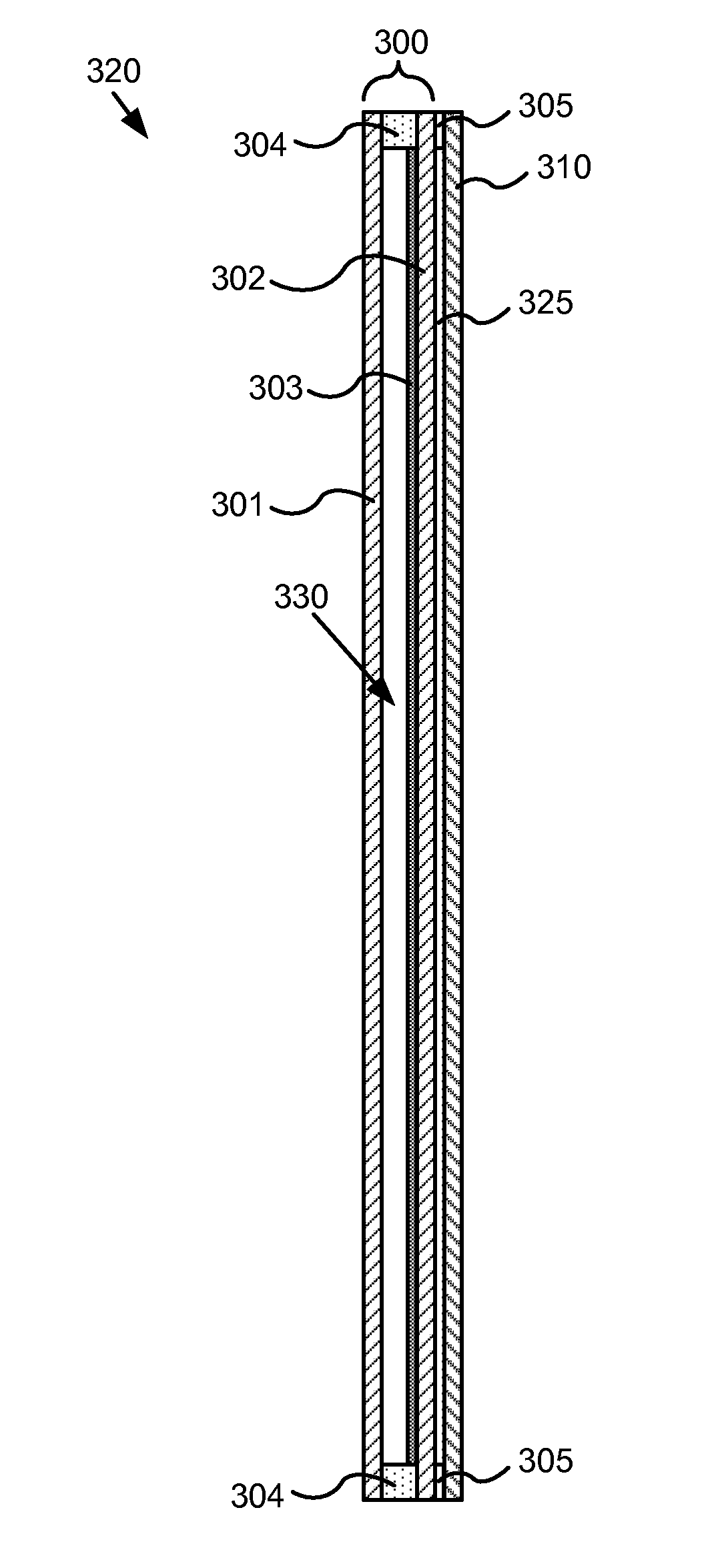

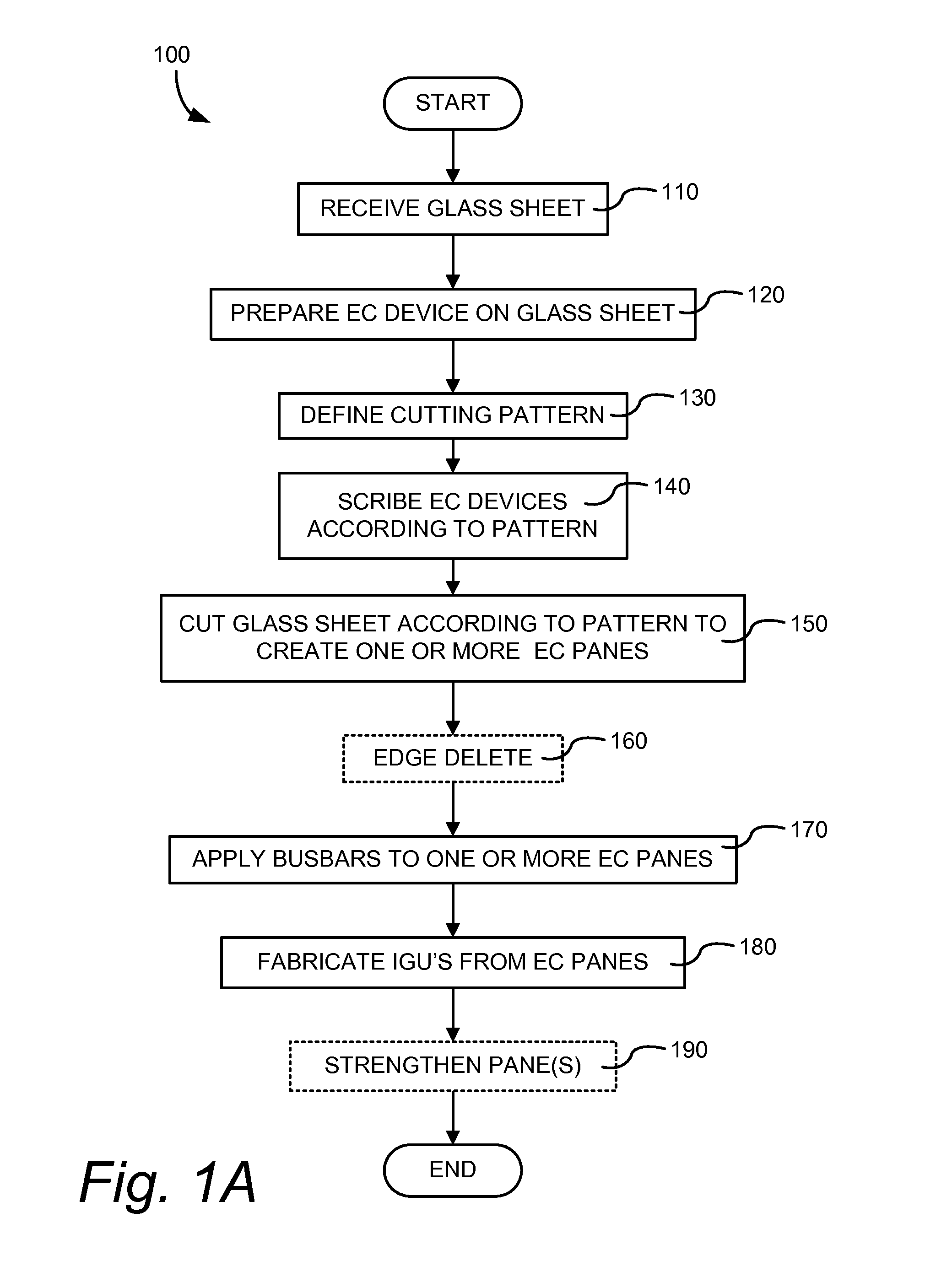

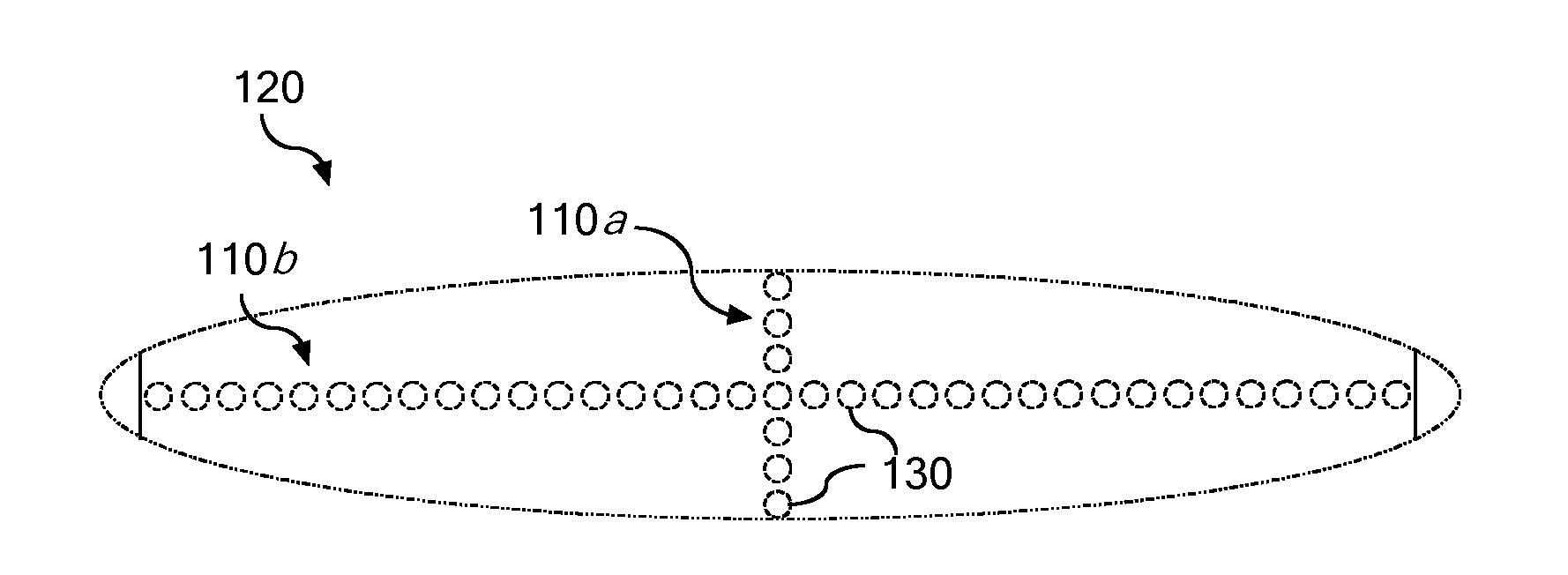

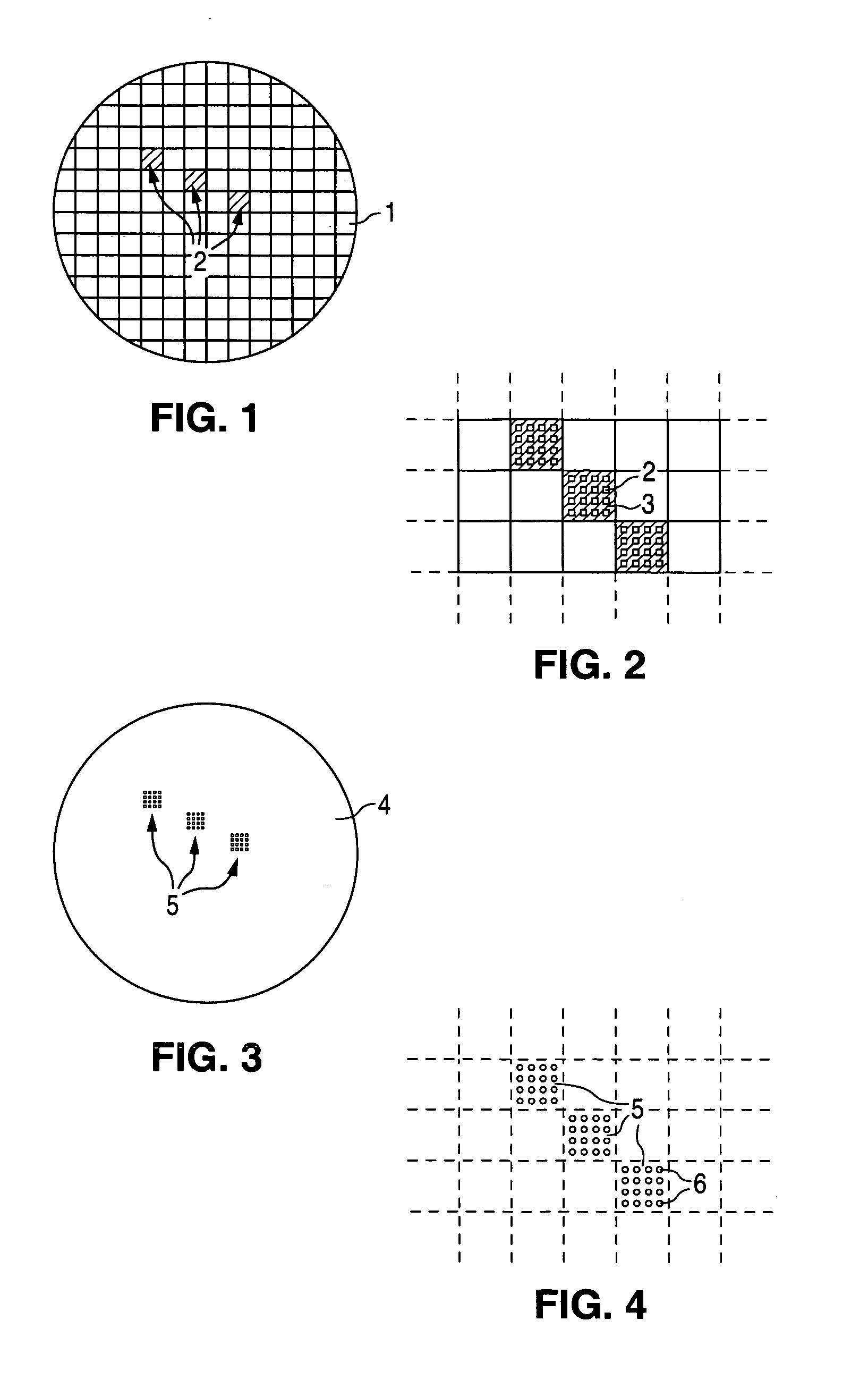

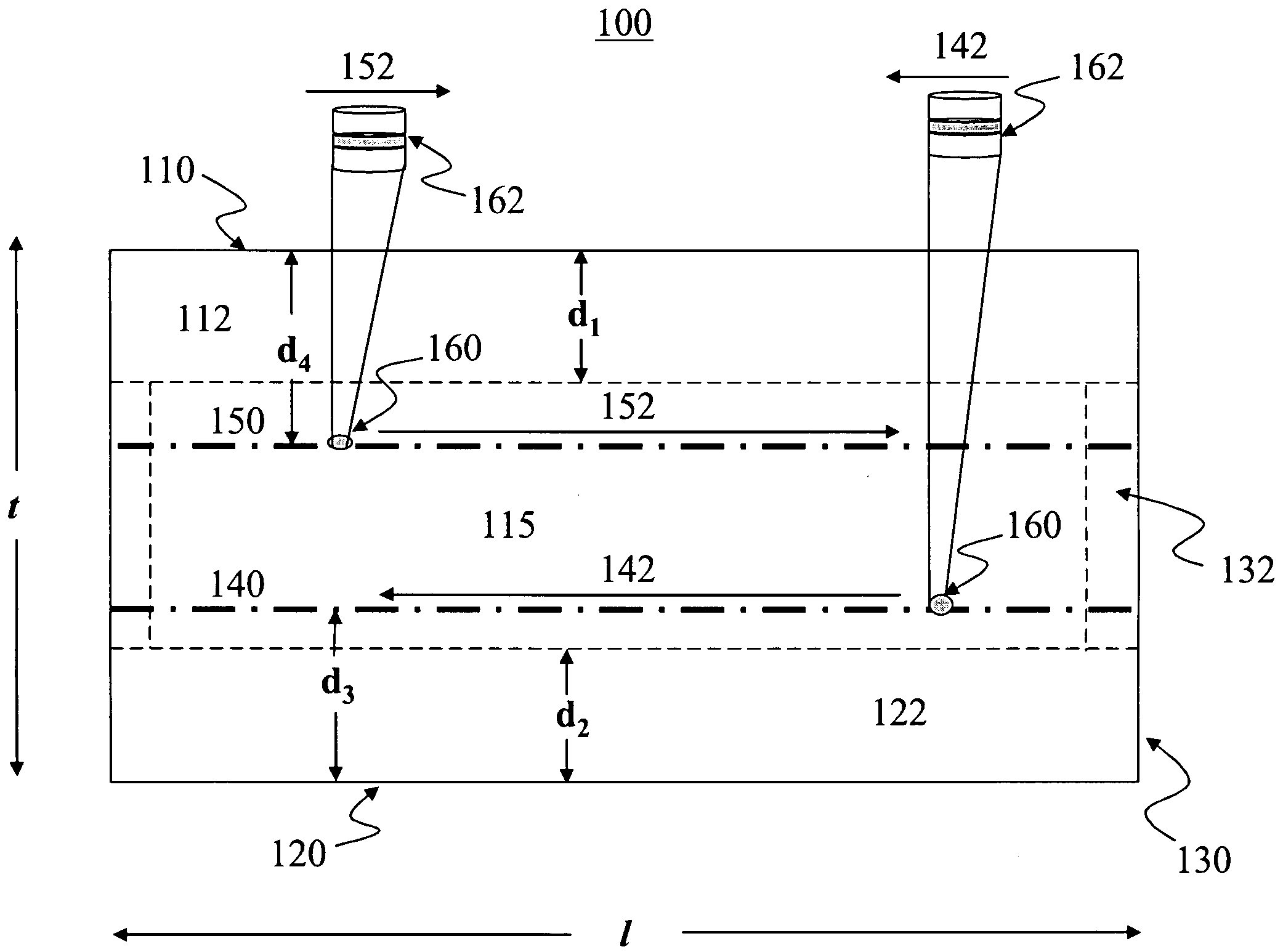

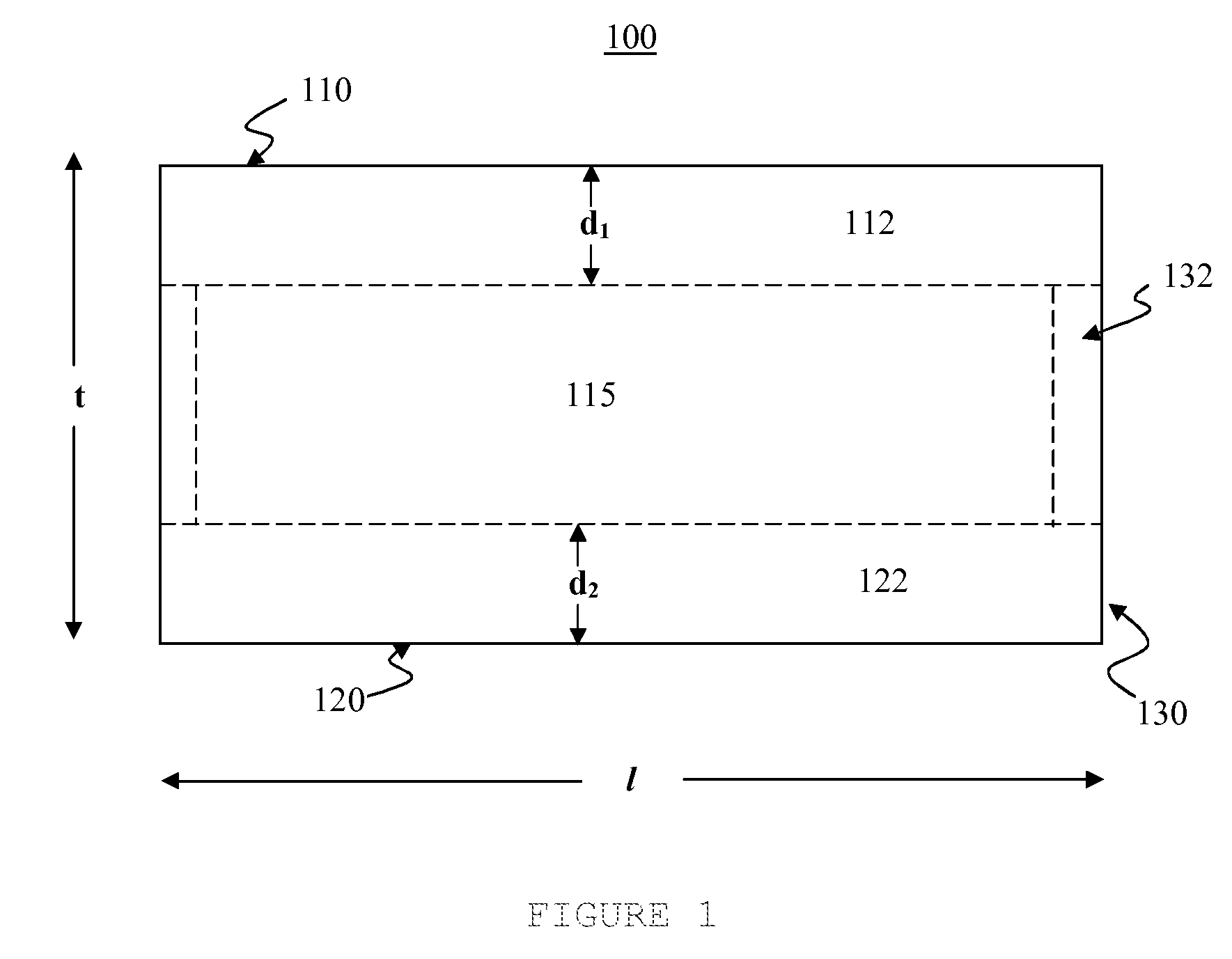

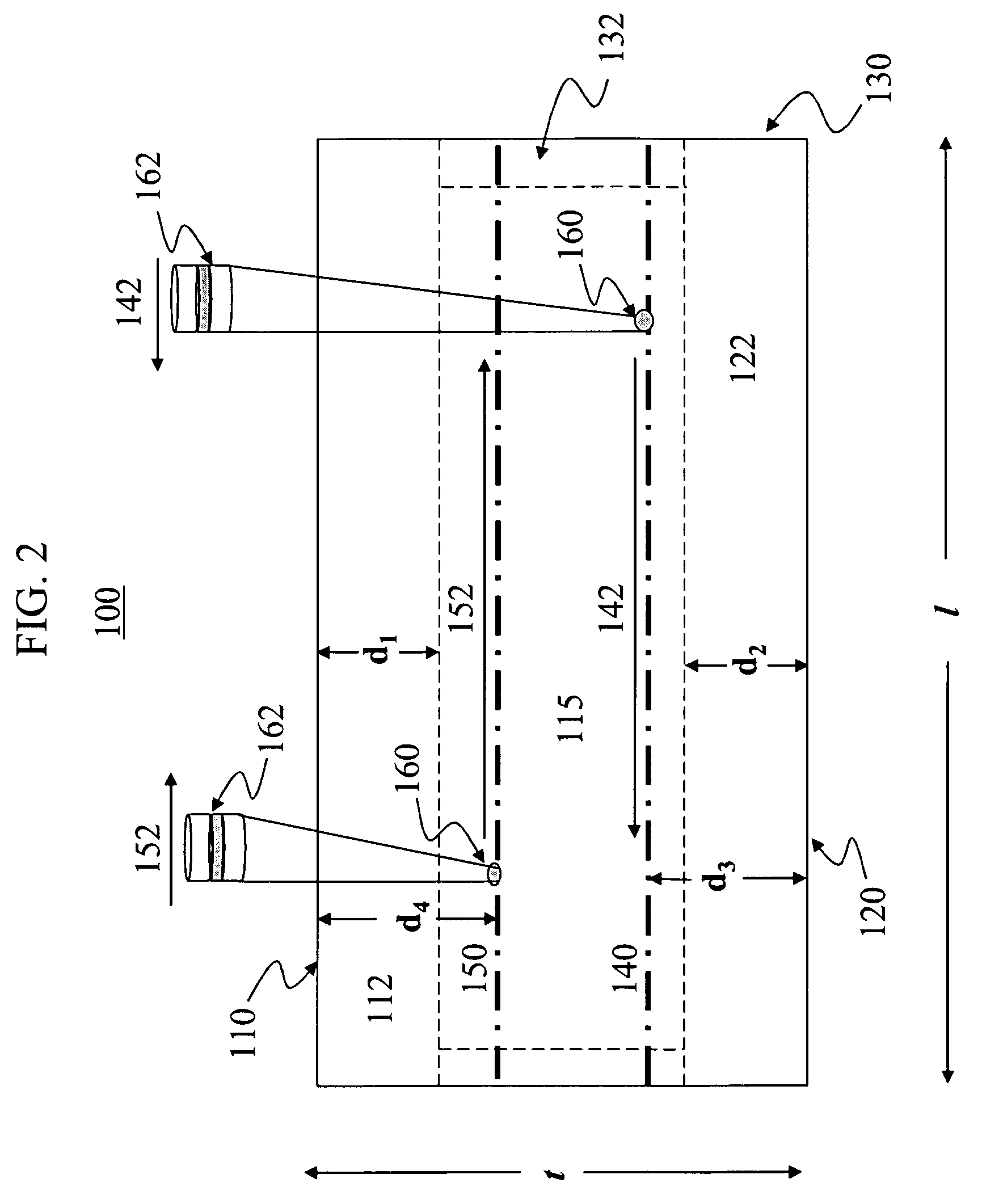

Electrochromic window fabrication methods

ActiveUS20120026573A1Maximize effective useLamination ancillary operationsLaminationEngineeringElectrochromism

Methods of manufacturing electrochromic windows are described. An electrochromic device is fabricated to substantially cover a glass sheet, for example float glass, and a cutting pattern is defined based on one or more low-defectivity areas in the device from which one or more electrochromic panes are cut. Laser scribes and / or bus bars may be added prior to cutting the panes or after. Edge deletion can also be performed prior to or after cutting the electrochromic panes from the glass sheet. Insulated glass units (IGUs) are fabricated from the electrochromic panes and optionally one or more of the panes of the IGU are strengthened.

Owner:VIEW INC

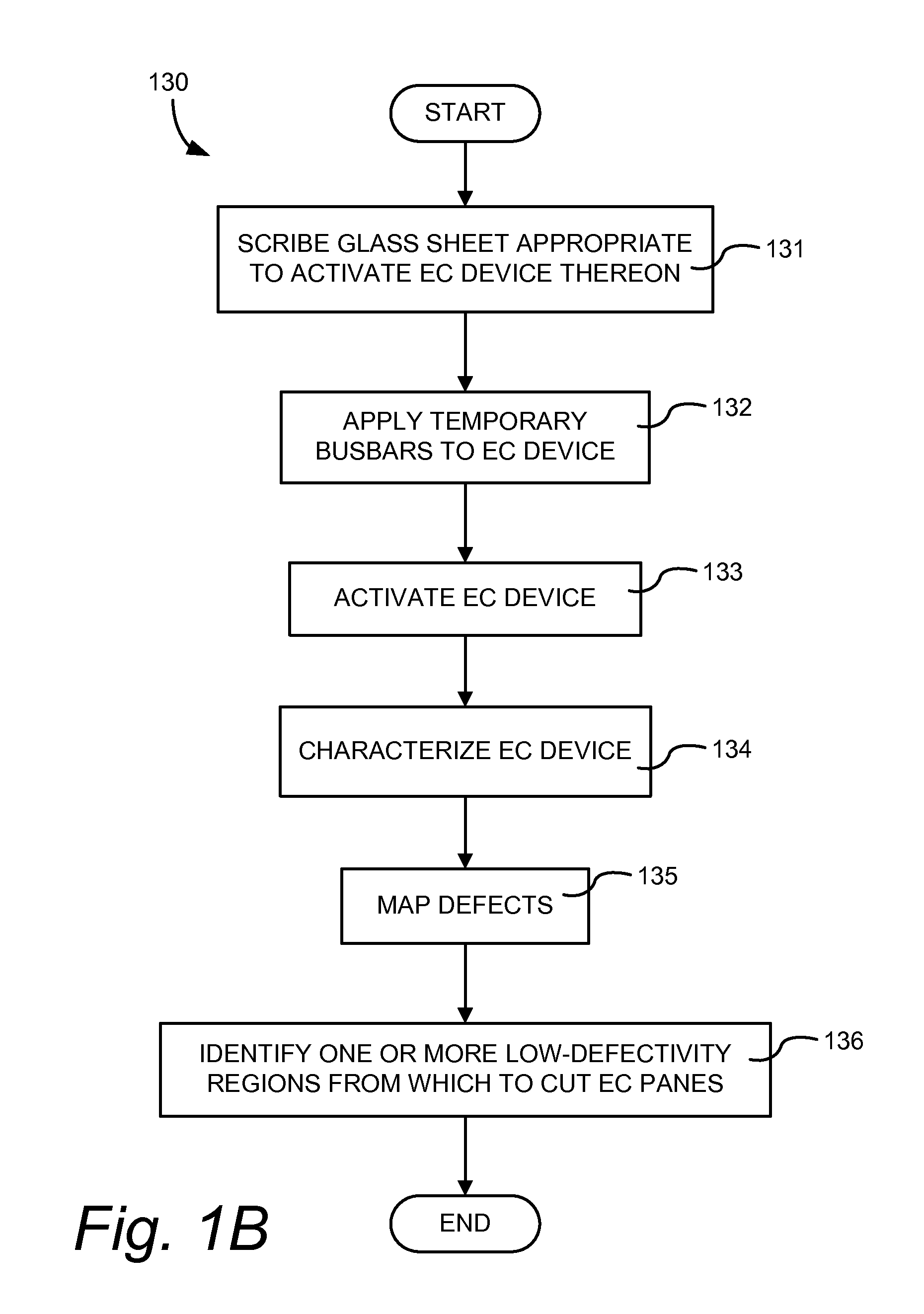

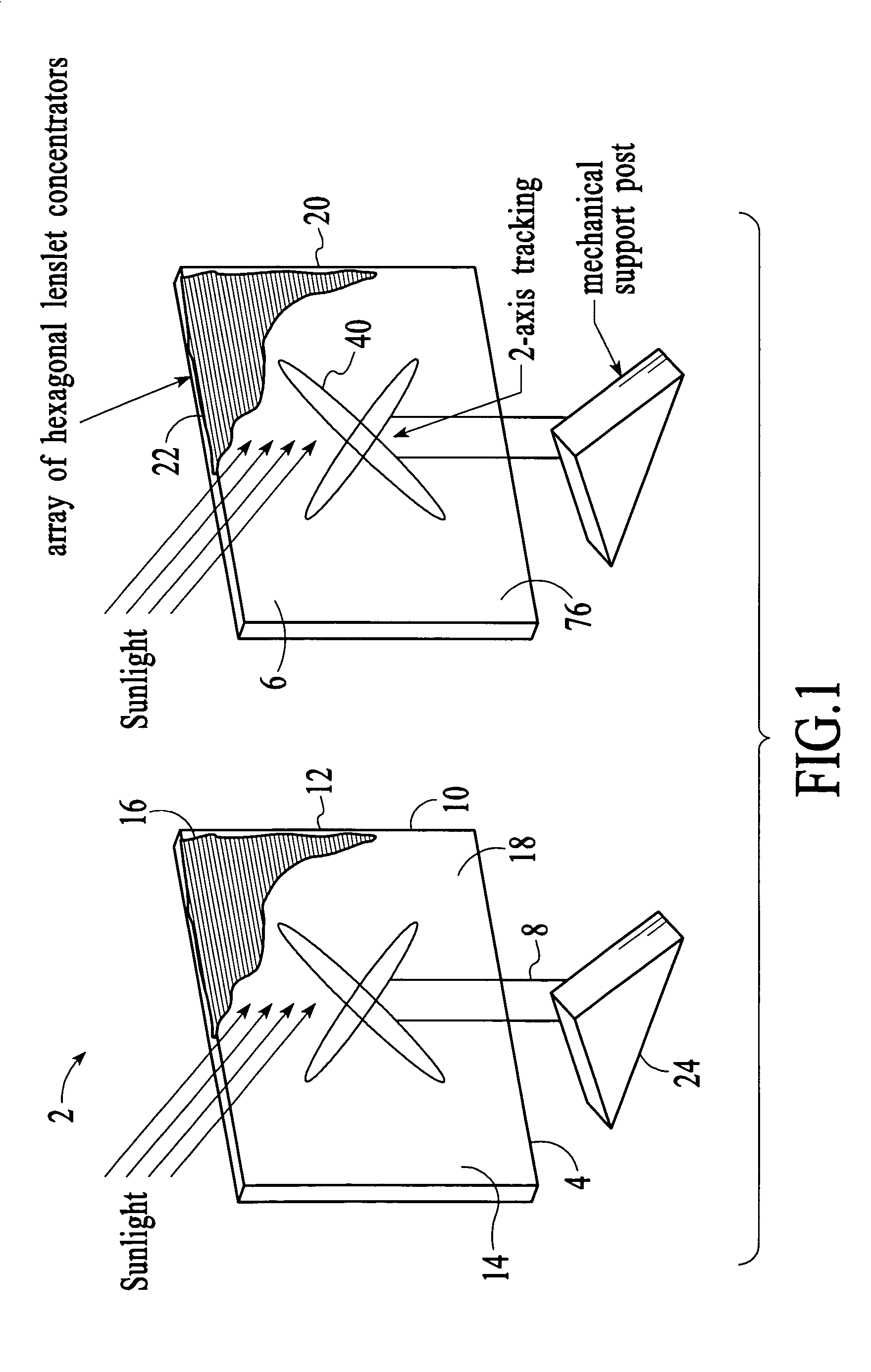

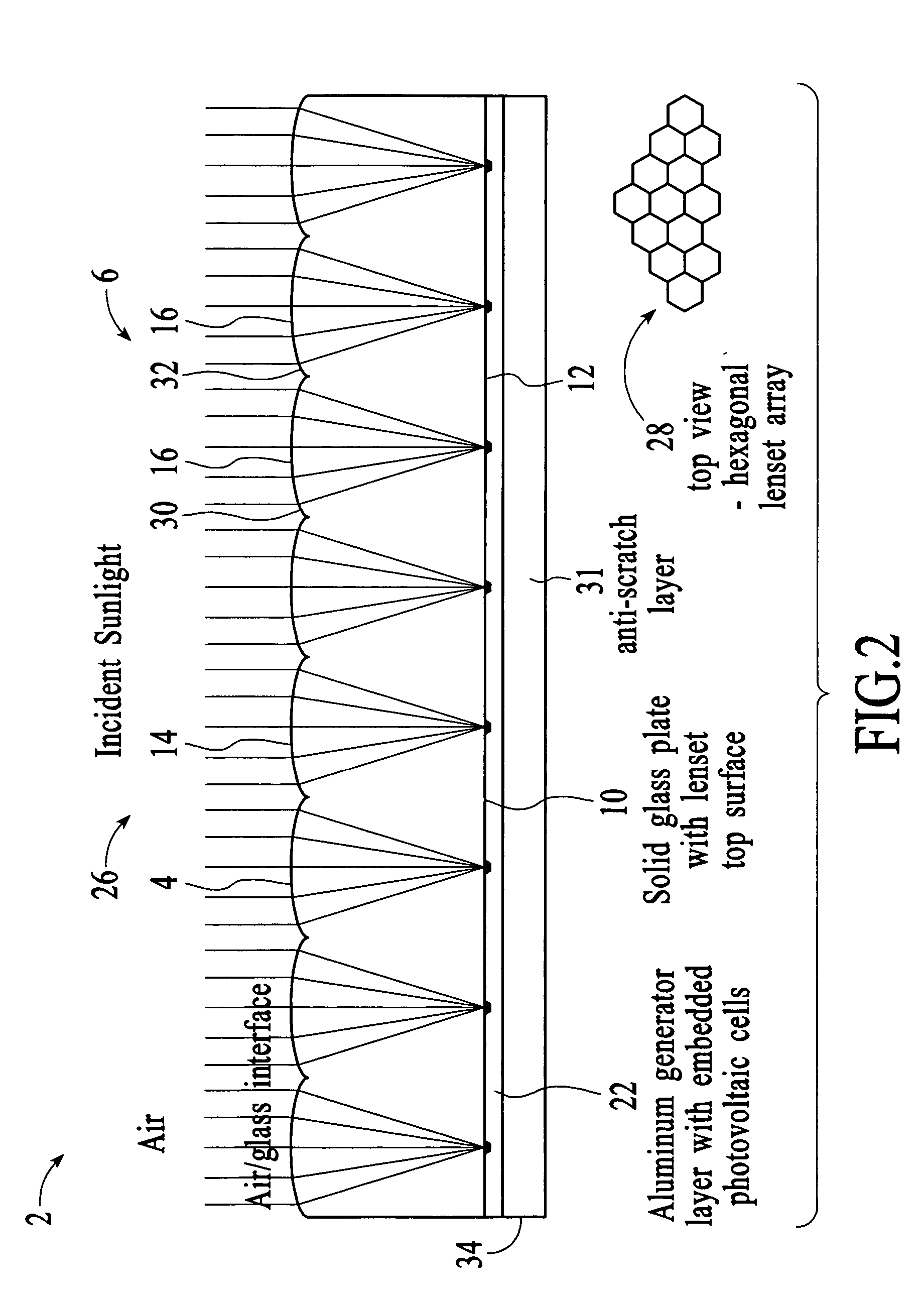

Method and apparatus for generation of electrical power from solar energy

InactiveUS20050081908A1Reduce usageLow costFinal product manufacturePV power plantsFlat glassConcentration ratio

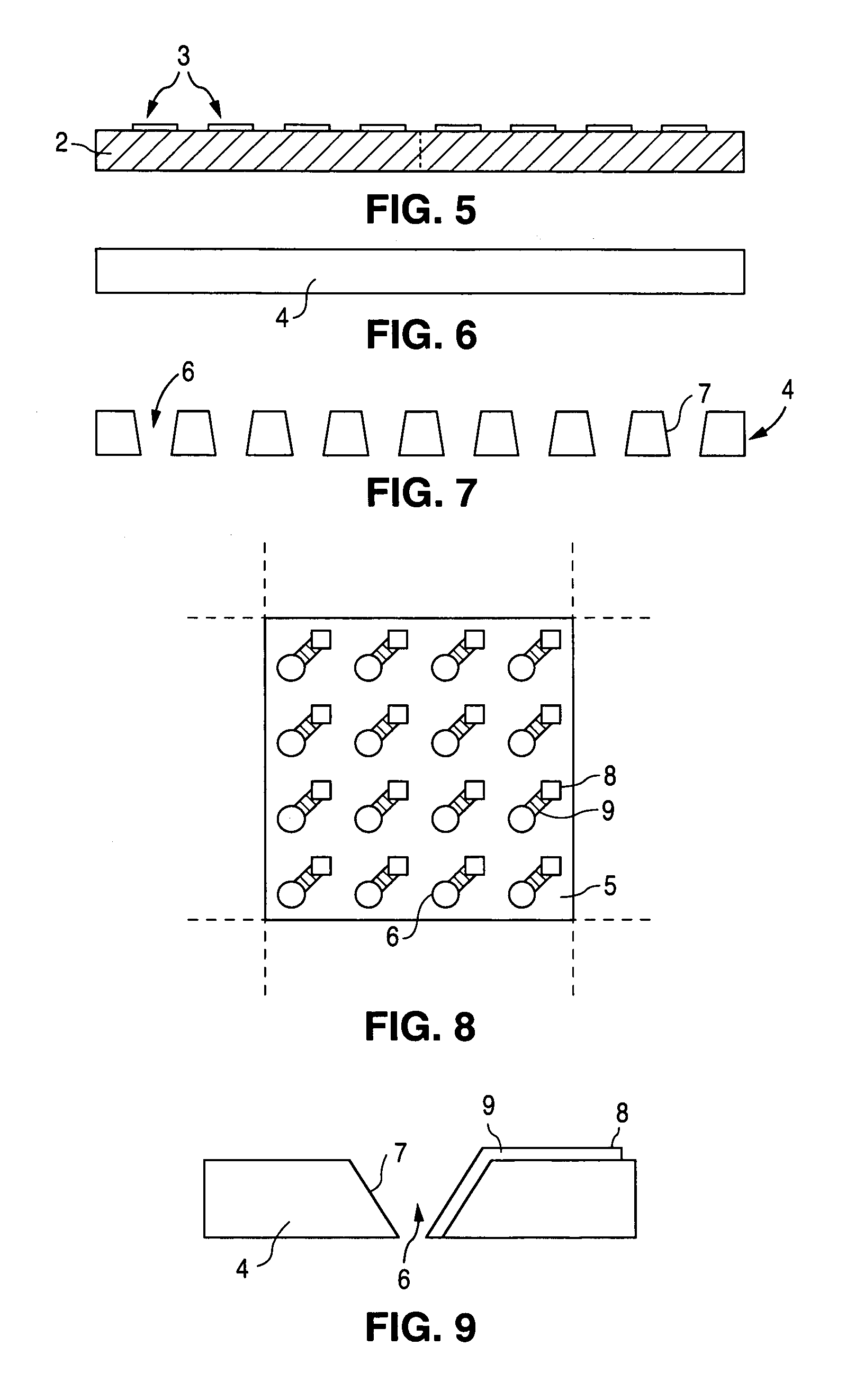

A method of providing an apparatus and system comprising a complete smart solar electrical power generator system integrated into the form of a thin flat glass plate. The novel elements include: a micro-scale optical array, a new type of miniaturized photovoltaic cell, an inside-the-lens concentrator design, integral heat sinking and mechanical support, a sealed solid-state design with no air gaps and a new process for building it, combined reflective / refractive light concentration around the photovoltaic cell, variable solar concentration ratios, and a new integrated structure for interconnecting the system together.

Owner:STEWART ROGER G

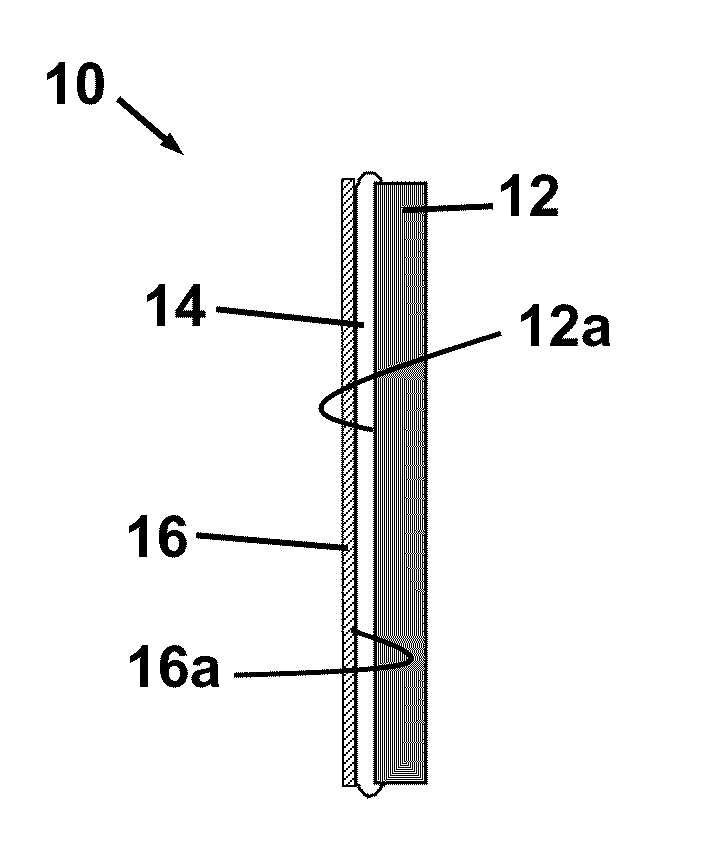

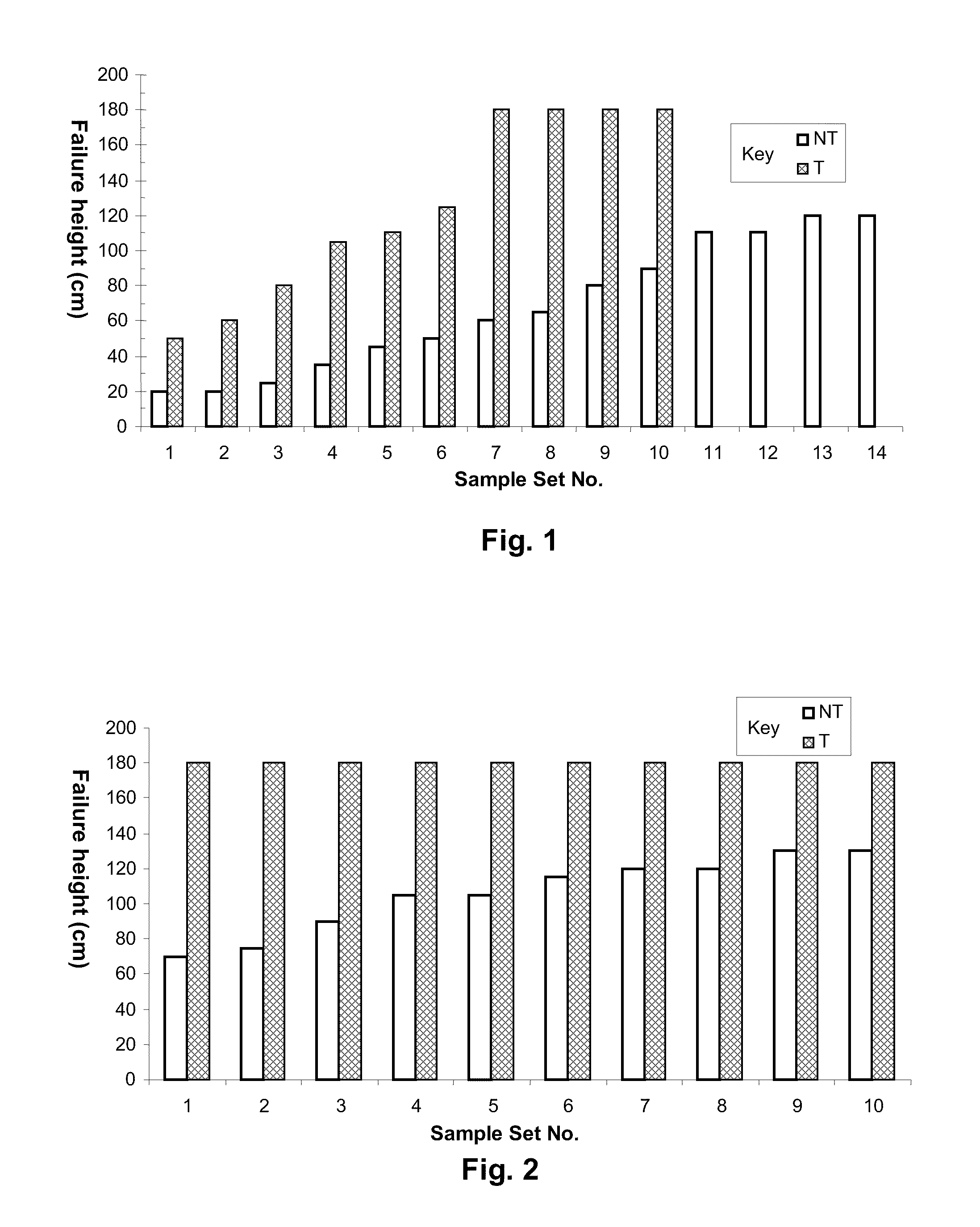

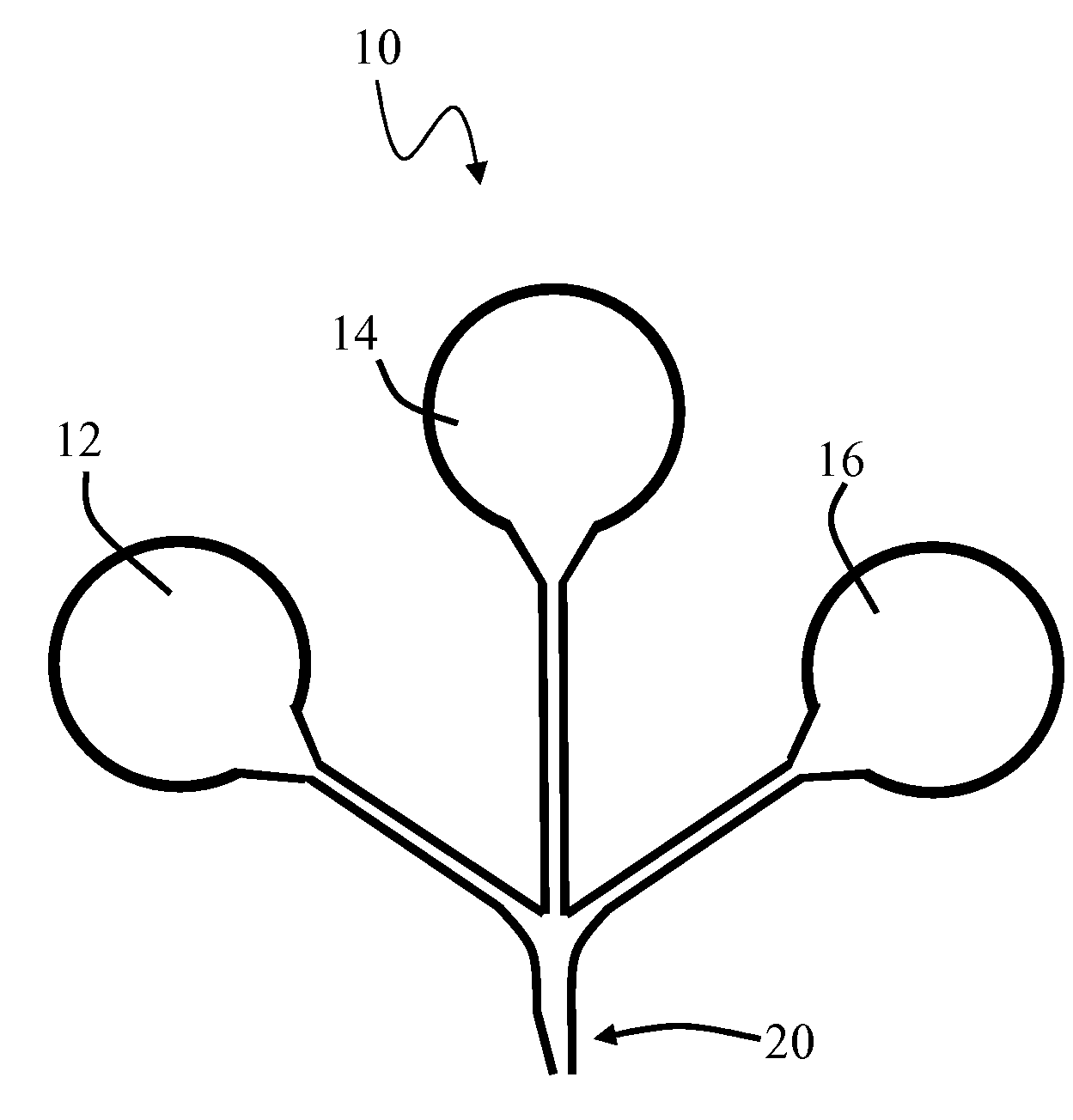

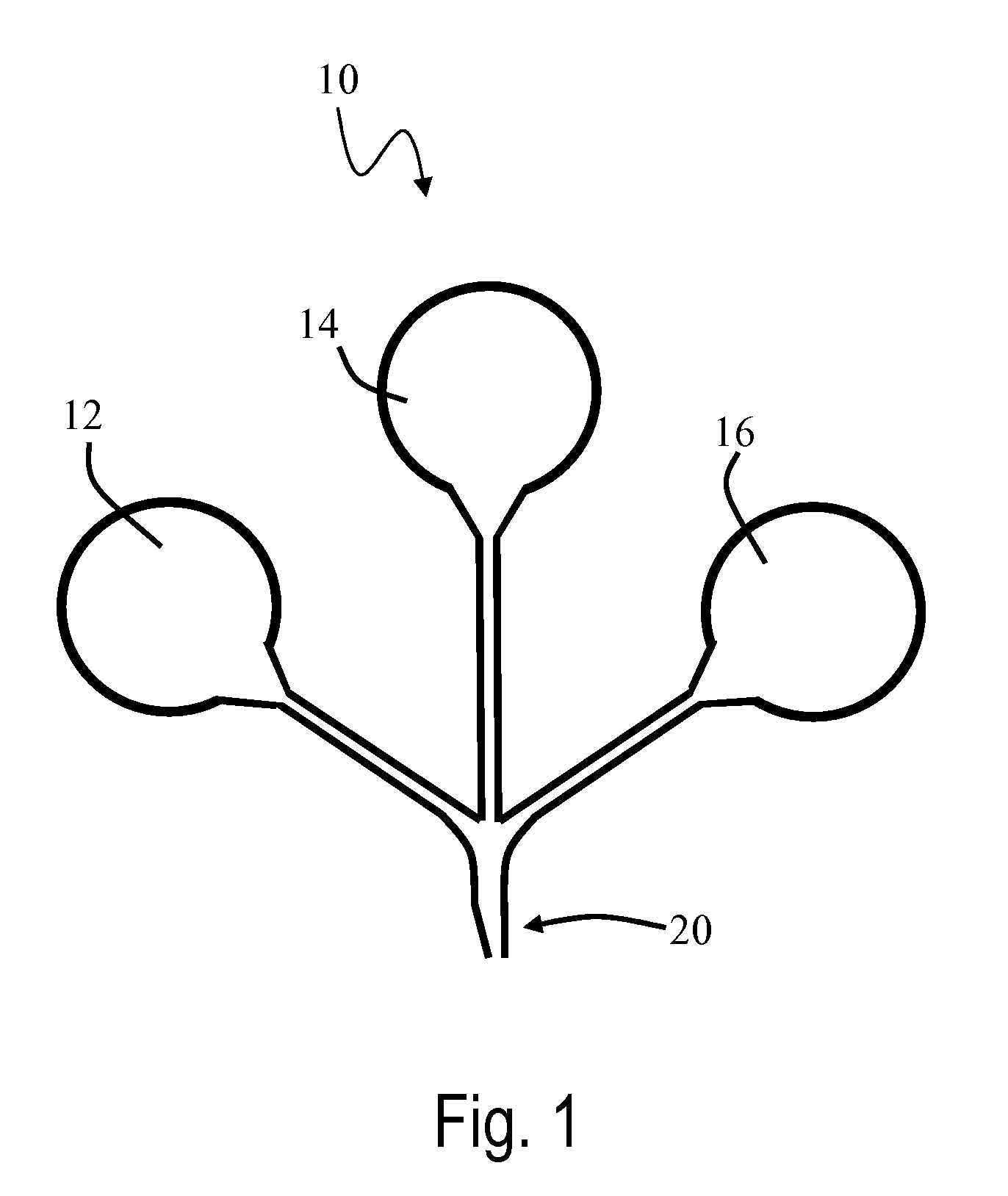

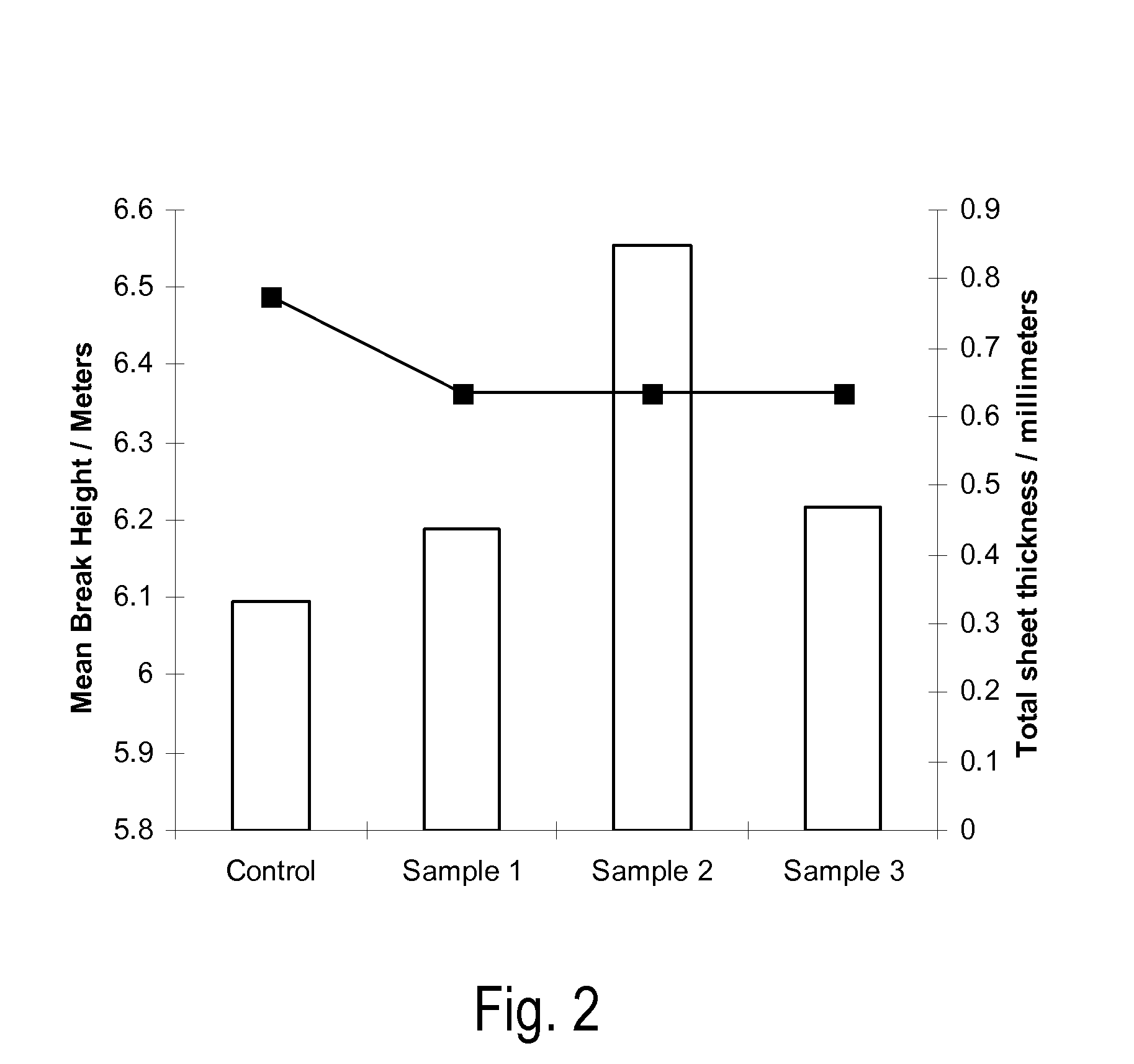

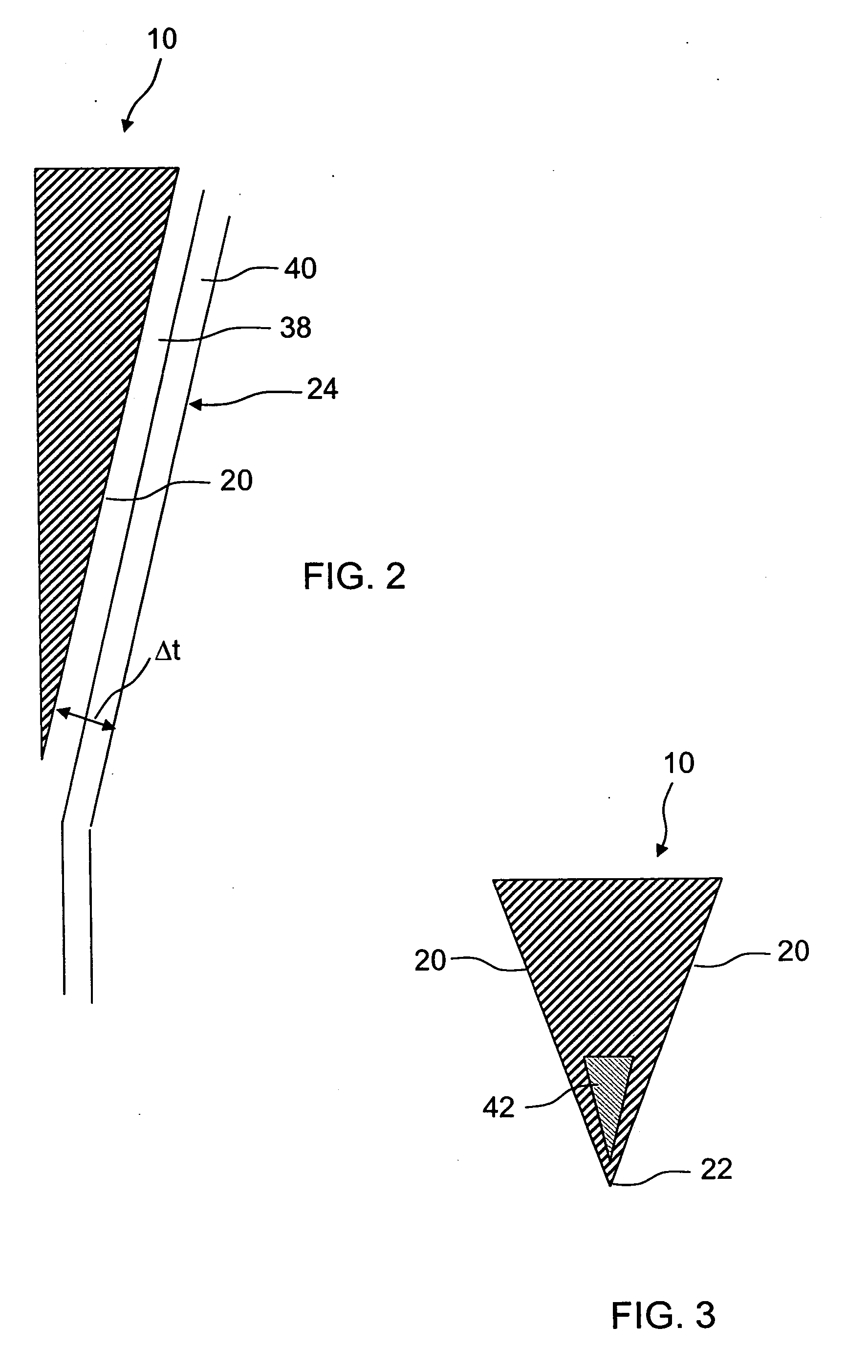

Impact-damage-resistant glass sheet

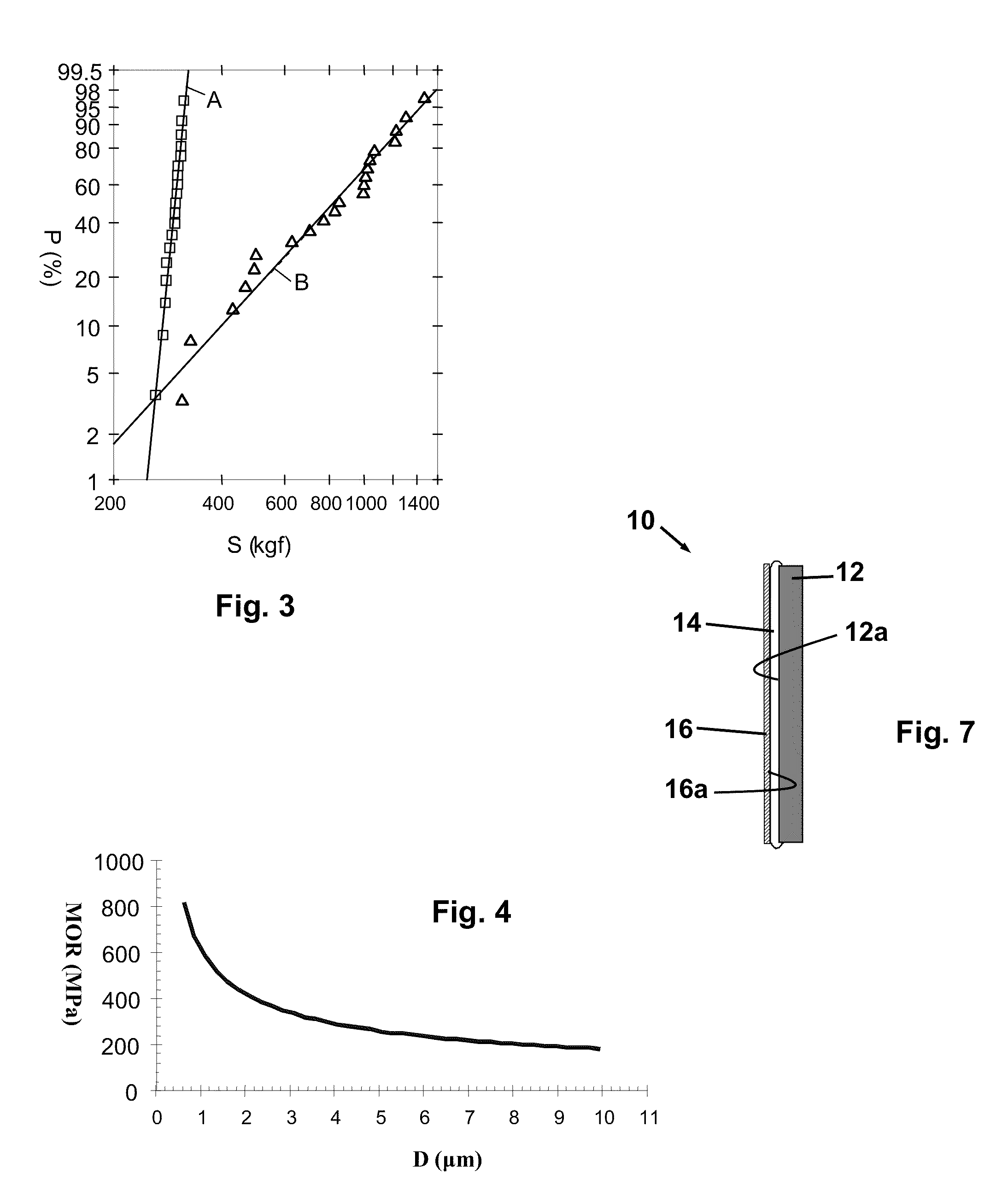

ActiveUS20110165393A1Increased and more consistent resistanceImprove flexural strengthSynthetic resin layered productsRecord information storageGlass coverDisplay device

Impact-damage-resistant glass sheet comprising at least one chemically etched surface in combination with a tempering surface compression layer, the glass sheet exhibiting a high standardized ball drop failure height and a high flexural modulus of rupture strength, useful to provide damage-resistant glass cover sheets for consumer electronic video display devices, is provided by subjecting thin glass sheet to a combination of a surface tempering treatment and a surface etching treatment that improves strength while maintaining the optical glass sheet properties required for video display applications.

Owner:CORNING INC

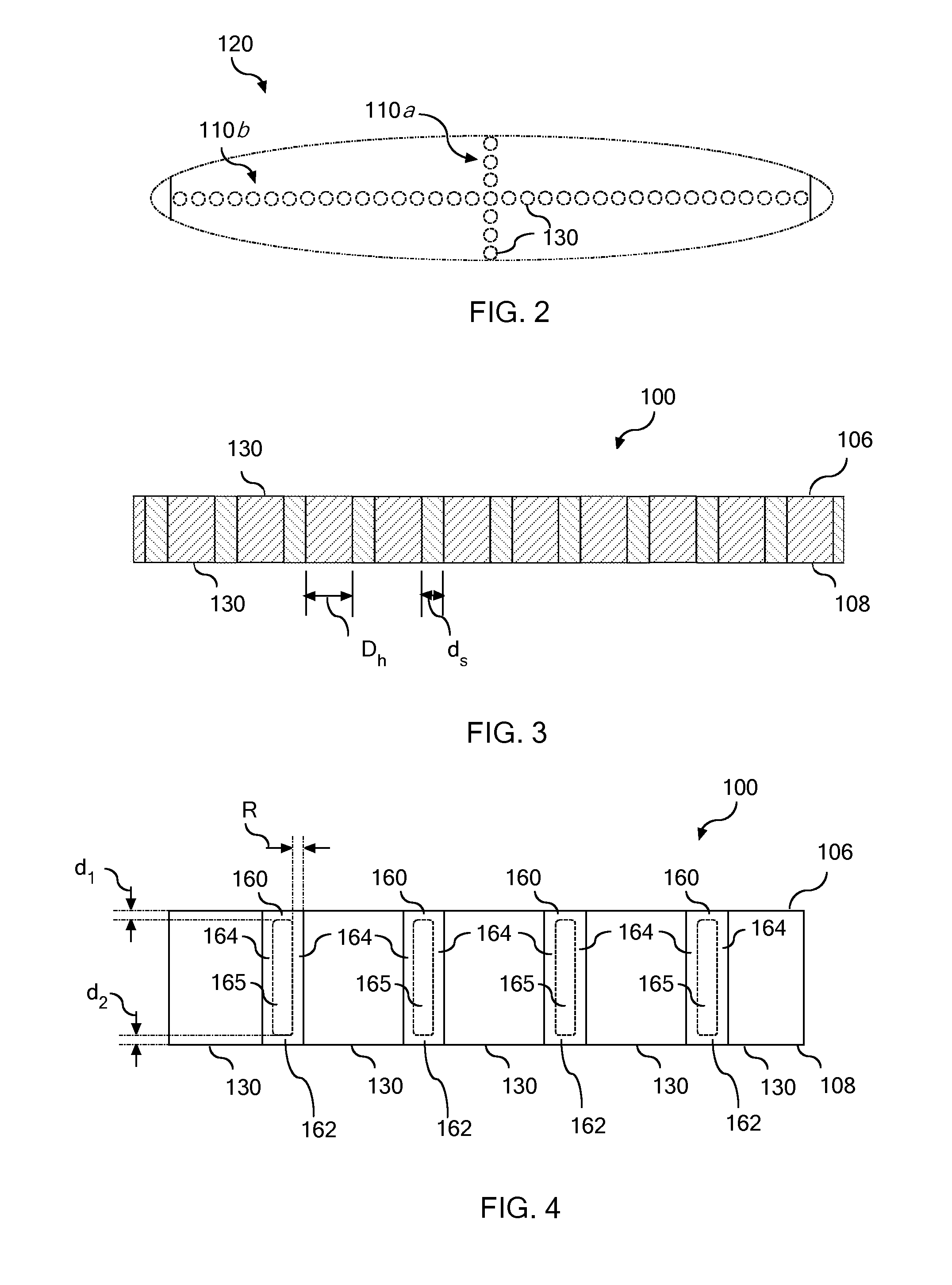

Strengthened glass substrate sheets and methods for fabricating glass panels from glass substrate sheets

Owner:CORNING INC

Glass plate for display devices

ActiveUS20090298669A1Low environmental loadQuality improvementGas discharge vessels/containersThin material handlingDisplay deviceGlass sheet

To provide a glass plate for display devices wherein without carrying out a post treatment, the depth of a compression stress layer is increased, while the surface compression stress is prevented from being excess only by chemical tempering.A glass plate for display devices, which is obtained by chemically tempering a glass plate comprising, as represented by mol % based on the following oxides, from 50 to 74% of SiO2, from 1 to 10% of Al2O3, from 6 to 14% of Na2O, from 3 to 15% of K2O, from 2 to 15% of MgO, from 0 to 10% of CaO and from 0 to 5% of ZrO2, wherein the total content of SiO2 and Al2O3 is at most 75%, the total content of Na2O and K2O, i.e. Na2O+K2O, is from 12 to 25%, and the total content of MgO and CaO, i.e. MgO+CaO, is from 7 to 15%.

Owner:ASAHI GLASS CO LTD

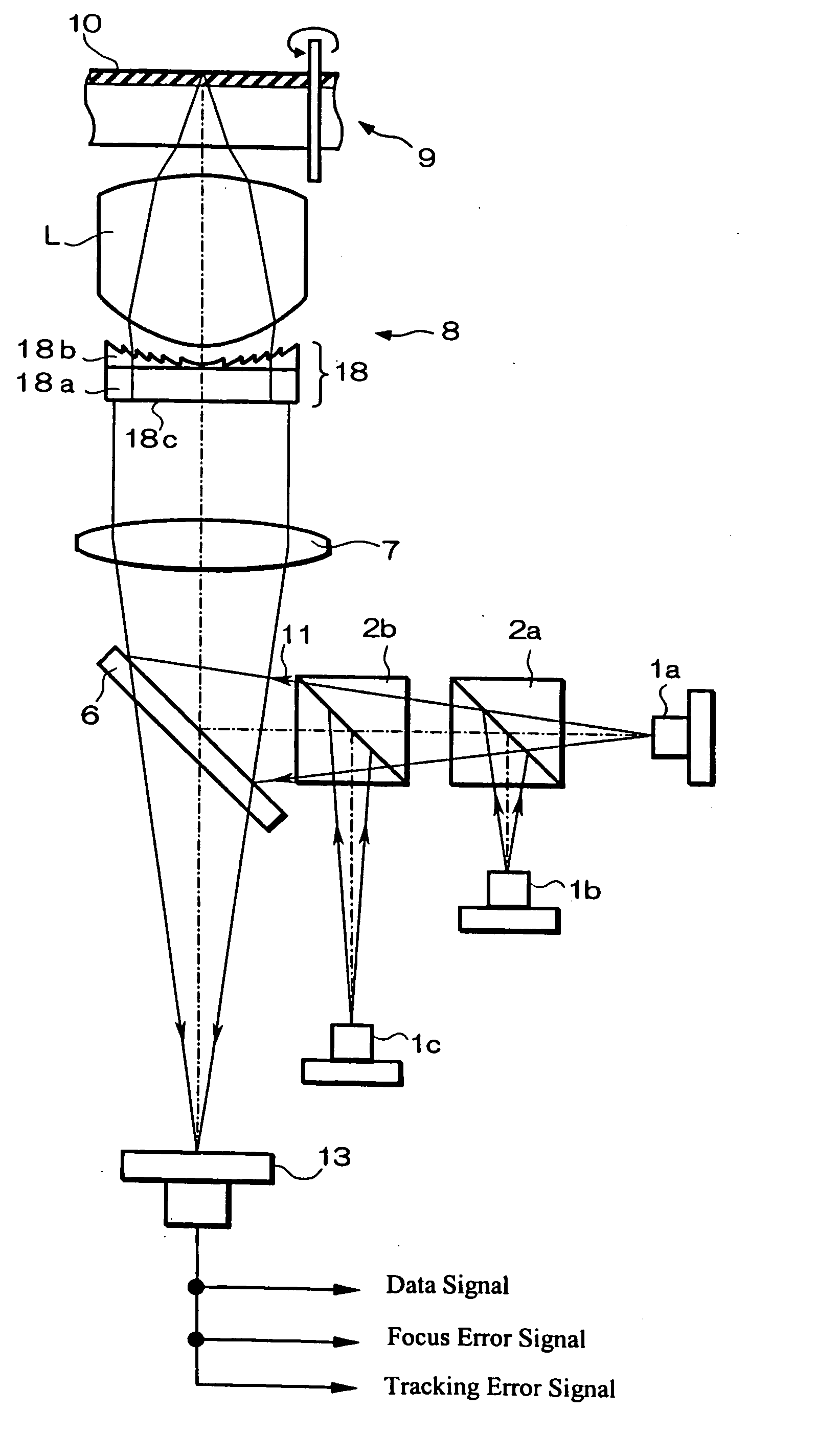

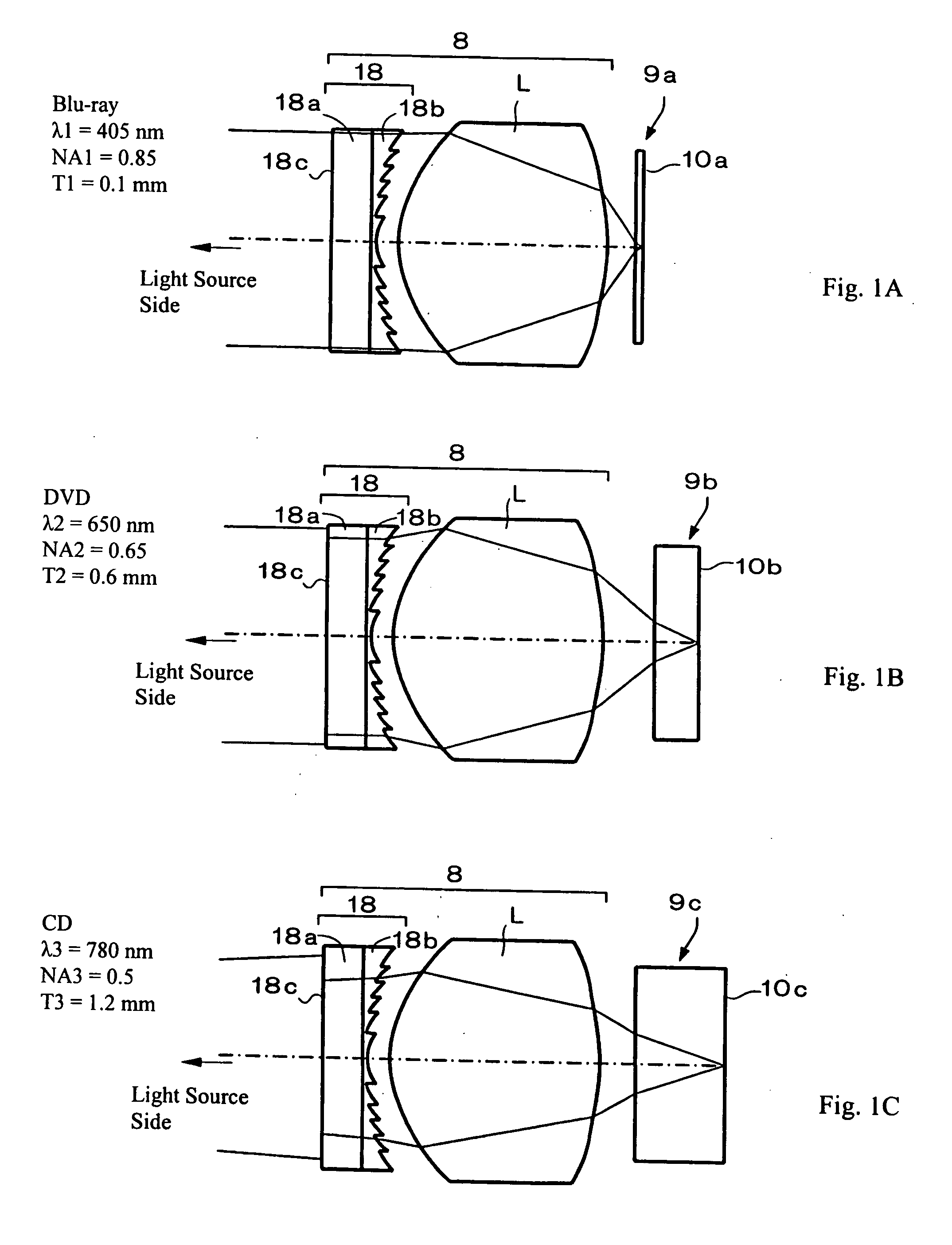

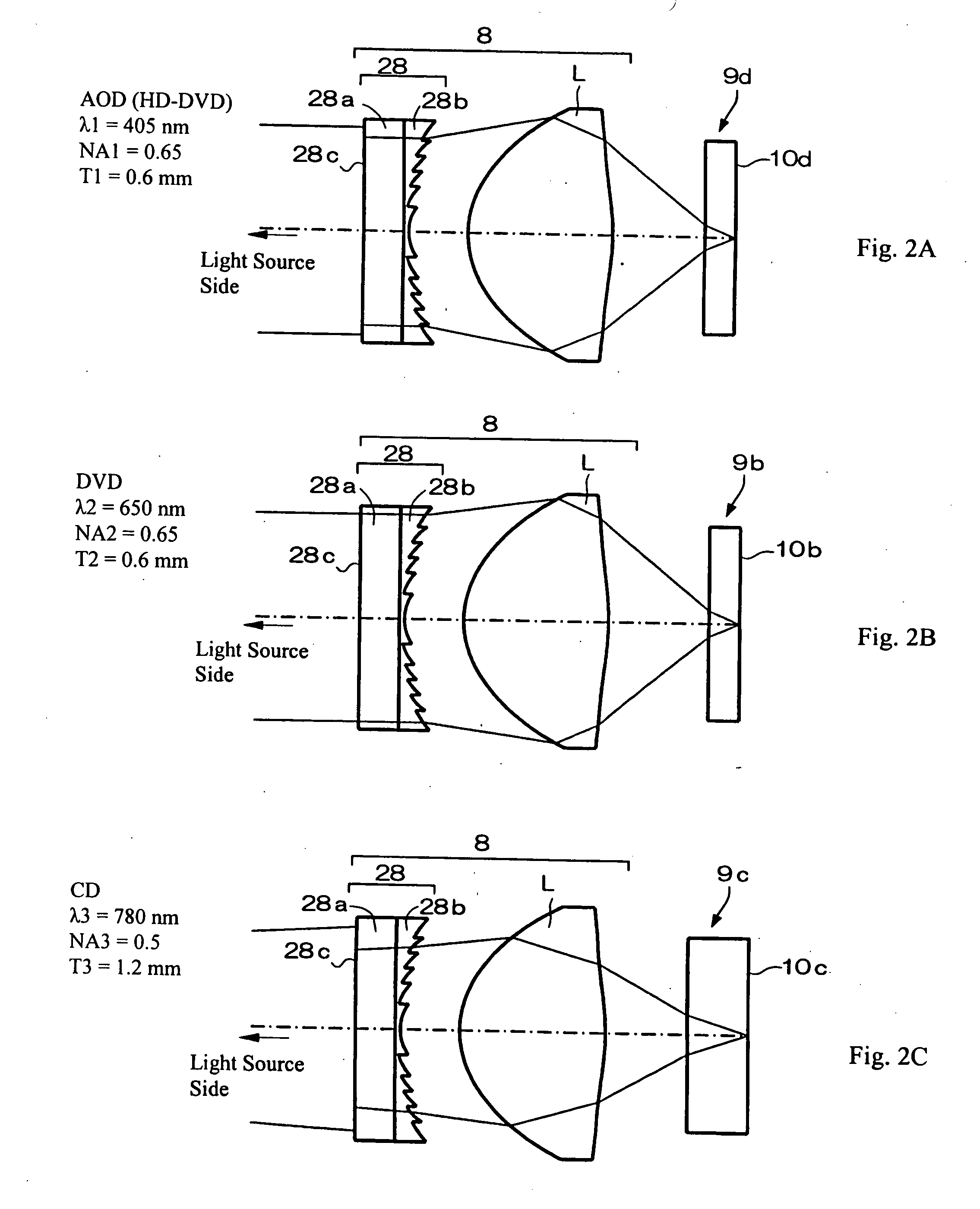

Objective optical system for optical recording media and optical pickup device using it

InactiveUS20060077795A1Good optical performanceEfficiently focusRecord information storageOptical beam guiding meansOptical pickupDiffraction optics

An objective optical system for focusing light from a light source onto optical recording media includes an aperture control filter with a diffractive optical function formed as a glass plate with an aperture control structure on one side and a diffractive optical structure, such as a plastic diffractive optical element adhered to the glass plate on the other side, and an objective lens. The objective optical system focuses three light beams of three different wavelengths at three different numerical apertures onto desired positions of three different recording media with substrates of different thicknesses, such as a BD (or an AOD), a DVD, and a CD, that introduce different amounts of spherical aberration in the focused beams. The objective optical system provides compensating spherical aberration to the three light beams while keeping constant the distance between the aperture control filter with a diffractive optical function and the objective lens.

Owner:FUJI PHOTO OPTICAL CO LTD

High impact polymer interlayers

InactiveUS20080268270A1Improve the level ofSynthetic resin layered productsConstructions elementsPlasticizerEngineering

The present invention provides multiple poly(vinyl butyral) layer interlayers that can be used in multiple layer glass panel type applications that require a high level of impact protection, for example in hurricane protection applications or in bullet proof glass applications. This effect is achieved by forming a poly(vinyl butyral) interlayer that has a relatively stiff poly(vinyl butyral) inner layer disposed between two relatively soft outer poly(vinyl butyral) layers, where the stiffness difference is achieved by a plasticizer differential that is achieved at least in substantial part by a residual hydroxyl content difference among the poly(vinyl butyral) layers.

Owner:SOLUTIA INC

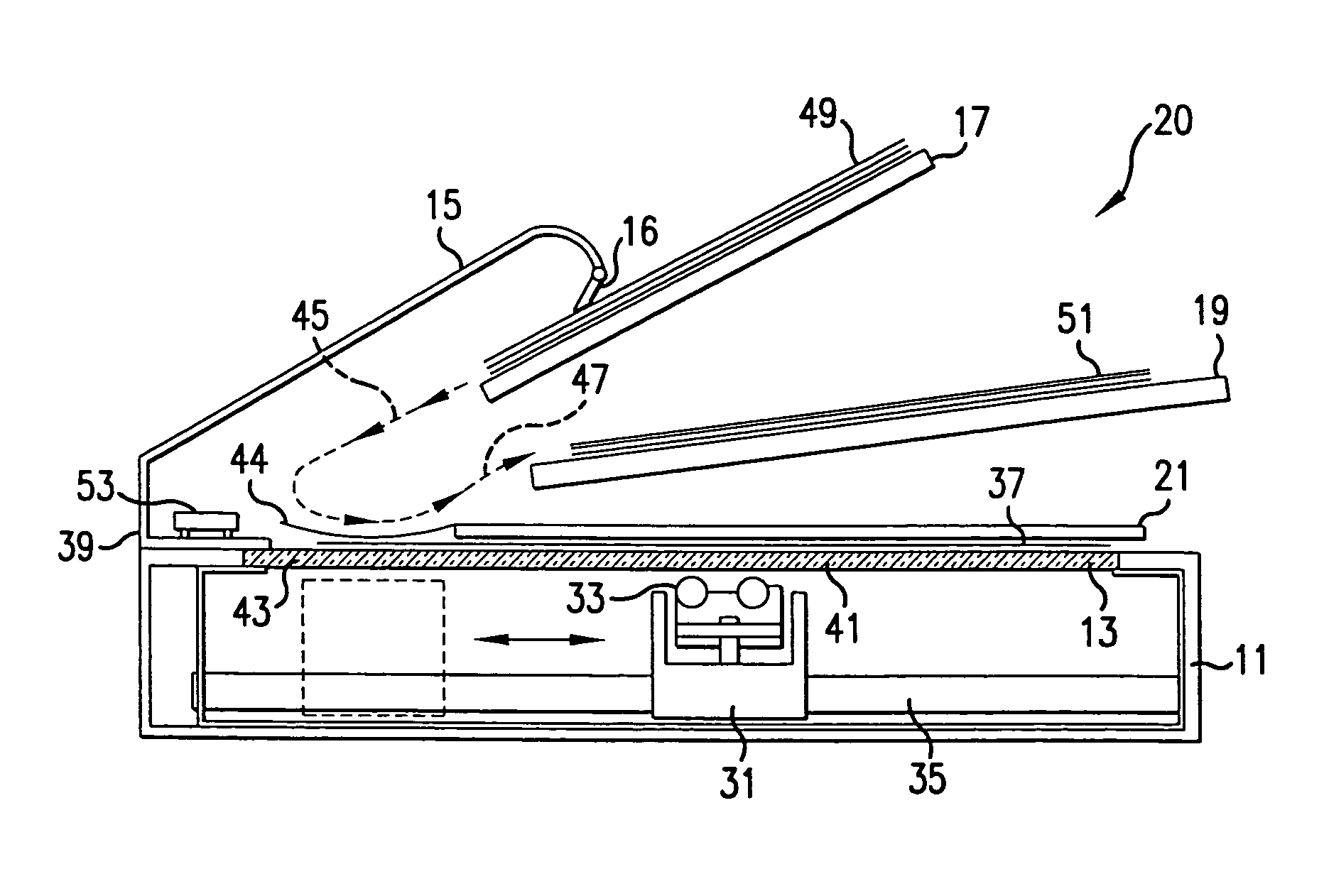

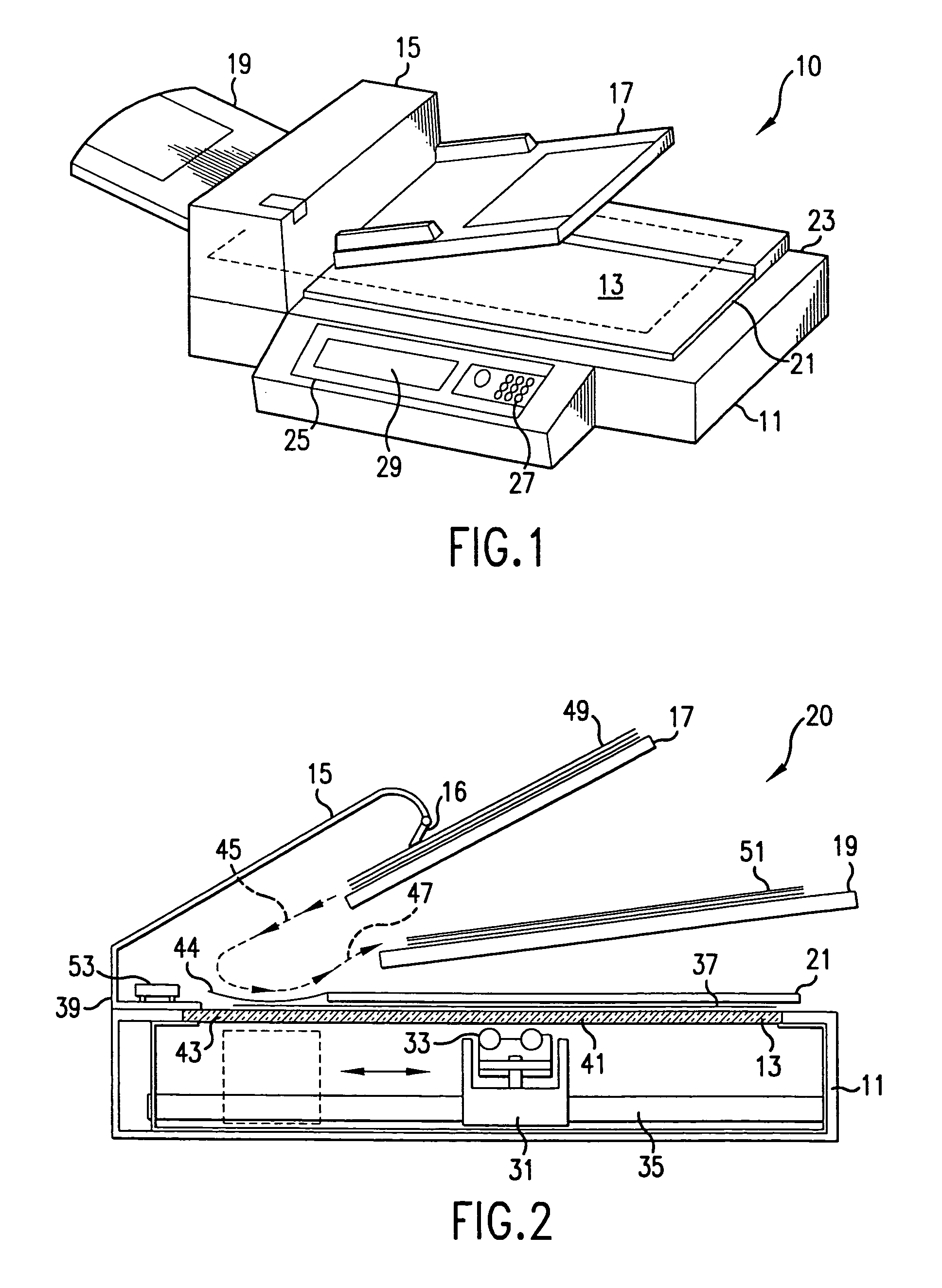

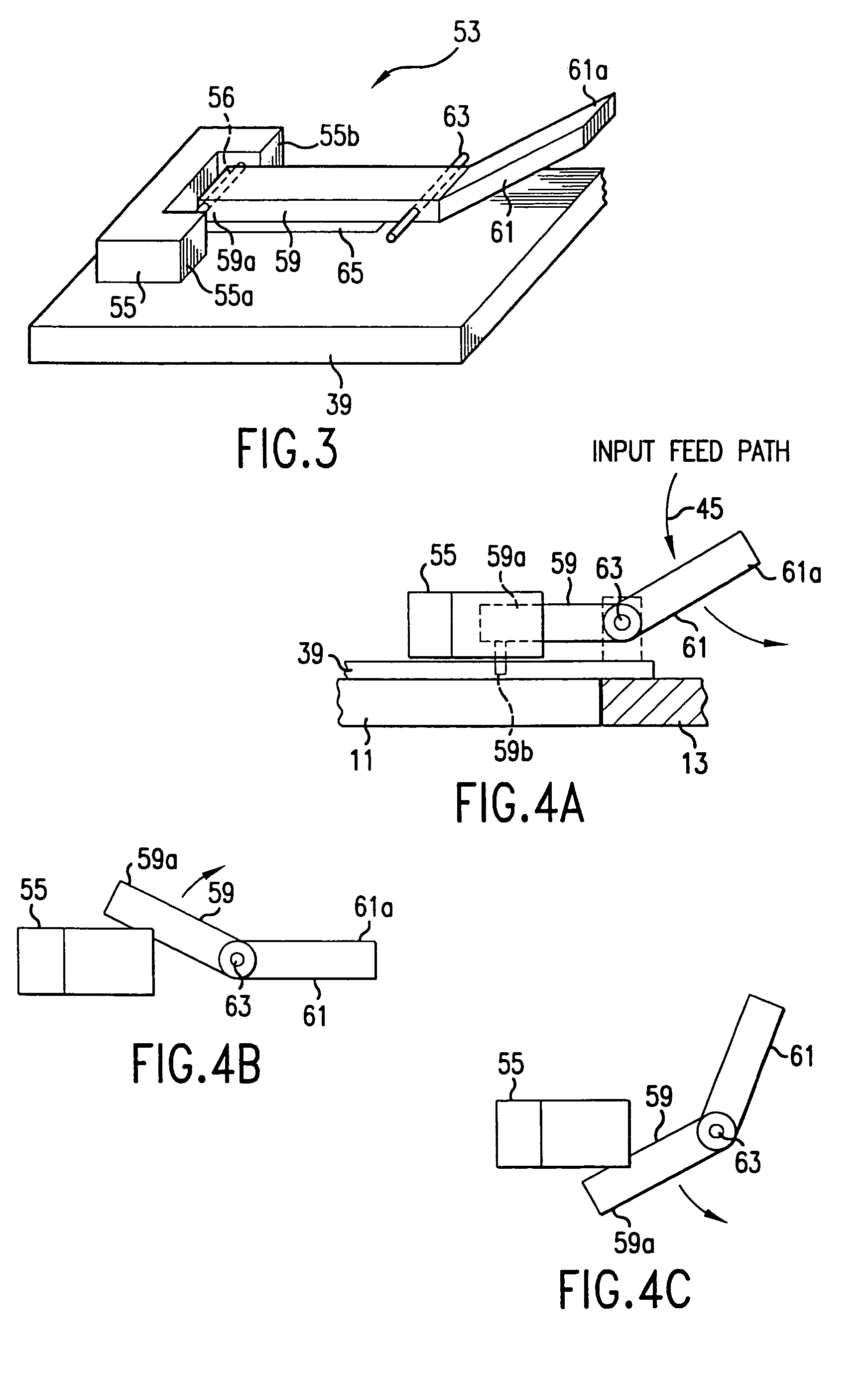

Single automatic document feeder sensor for media leading edge and top cover being opened detection

InactiveUS7139108B2Low costReduce the numberSolid-state devicesMaterial analysis by optical meansLeading edgeSingle plate

A single plate flatbed scanner utilizing a single sensor to detect both opening of a lid covering the plate and the leading edge of an automatically fed document. The flatbed scanner includes a contact glass plate defining a flatbed scanning area where a document to be scanned may be manually positioned. An automatic document feeder (ADF) scan window where ADF-fed documents are scanned is defined within the flatbed scanning area. An image sensor is maintained at a fixed position in the ADF scan window while scanning ADF-fed documents. To scan a manually fed document, the image sensor moves under the flatbed scanning area so as to scan an image of the document. Since the ADF scan window and the flatbed scanning area both are defined in the same area of the contact glass plate, a document inadvertently left on the contact glass blocks the ADF scan window and prevents the scanning of an ADF fed document. A single sensor is utilized to detect the opening of the ADF which uncovers the contact glass to allow manual placement of a document. Detecting the opening of the glass plate cover is used to determine whether or not a document has been left on the glass plate after scanning. The same sensor is also utilized to detect the leading edge of an ADF fed document to initiate the scanning process at the precise time the document reaches the ADF scan window.

Owner:HEWLETT PACKARD DEV CO LP

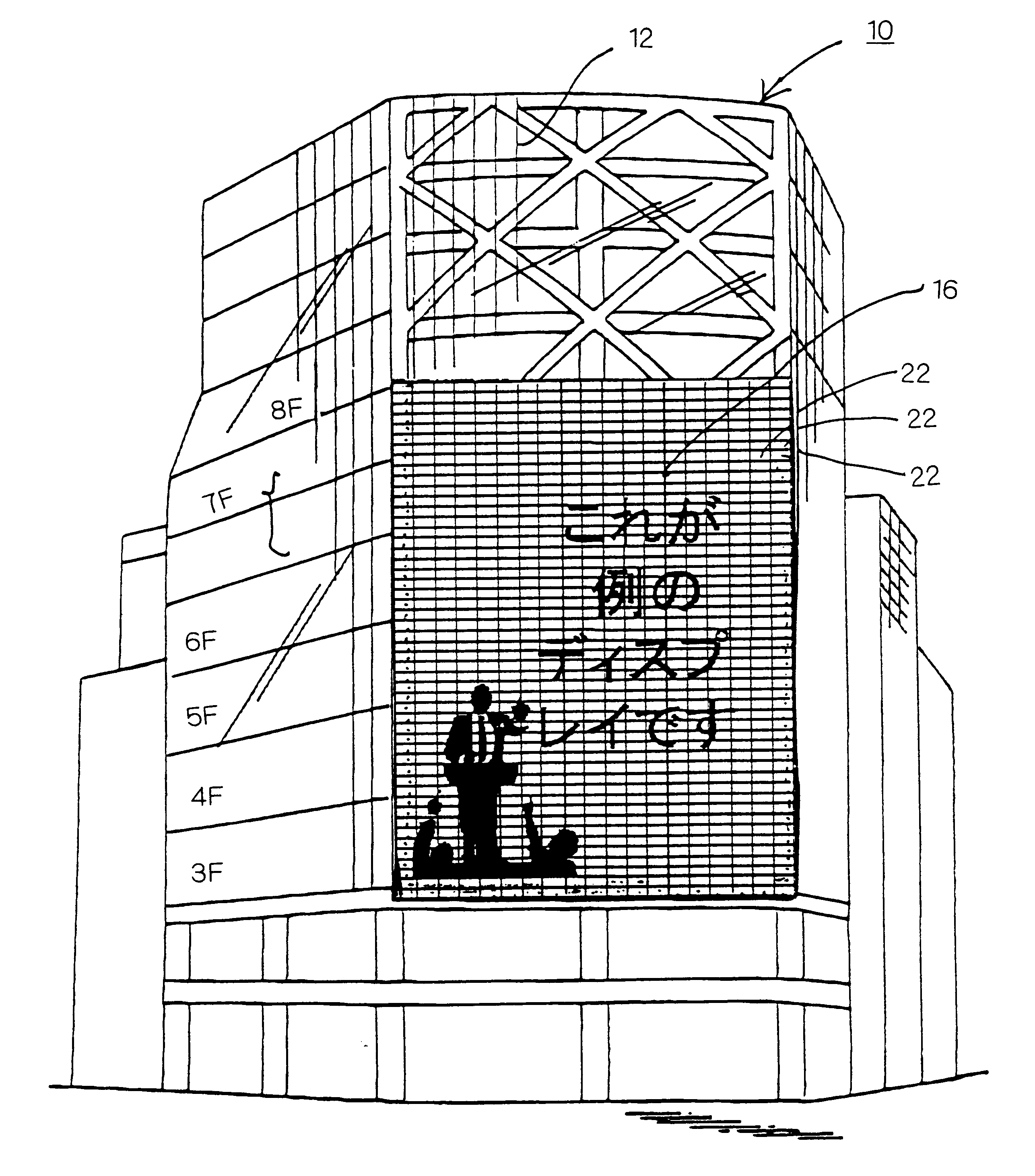

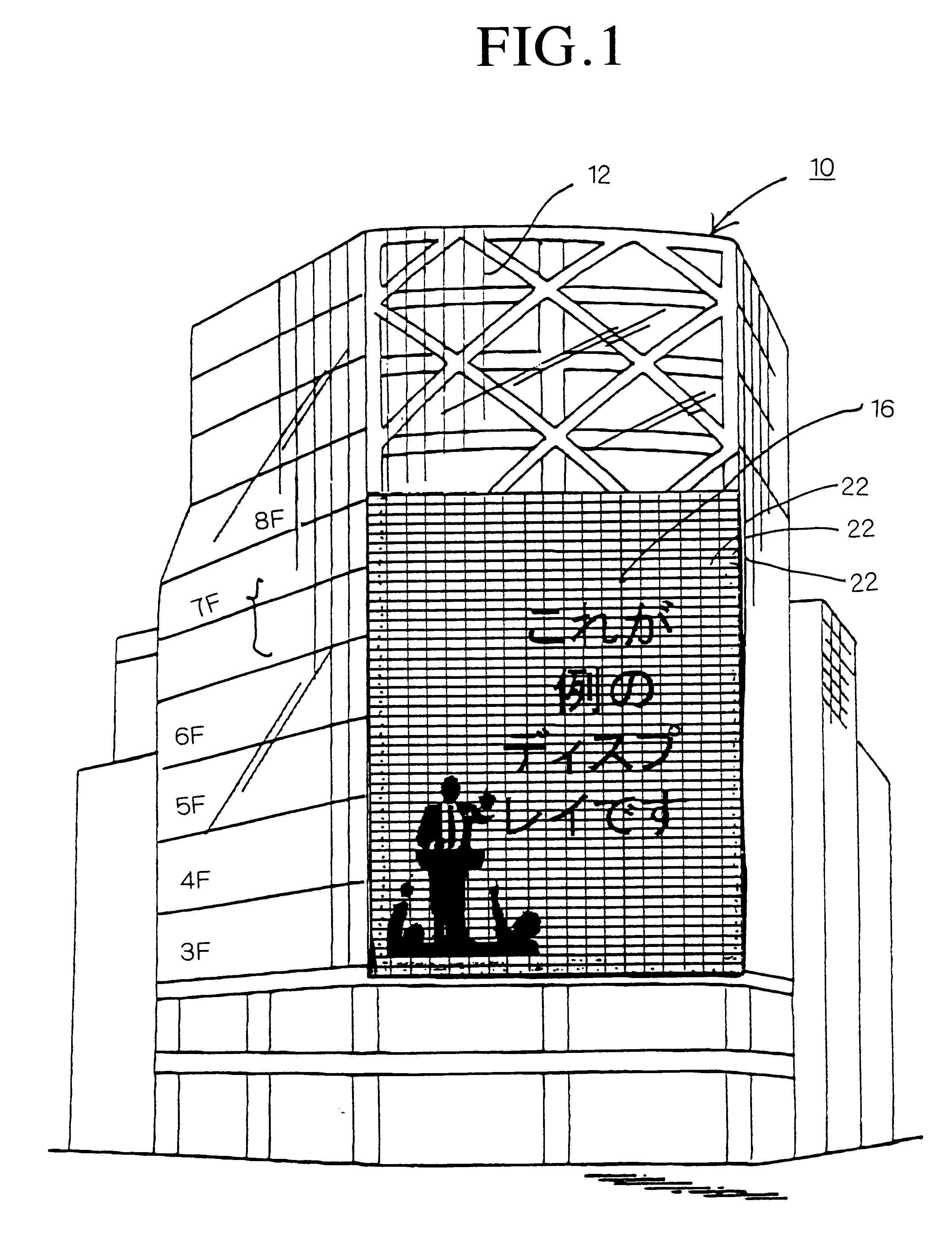

High-rise building with large scale display device inside transparent glass exterior

InactiveUS6237290B1Easy to carryImprove device performanceStampsPublic buildingsFloor slabWindow shutter

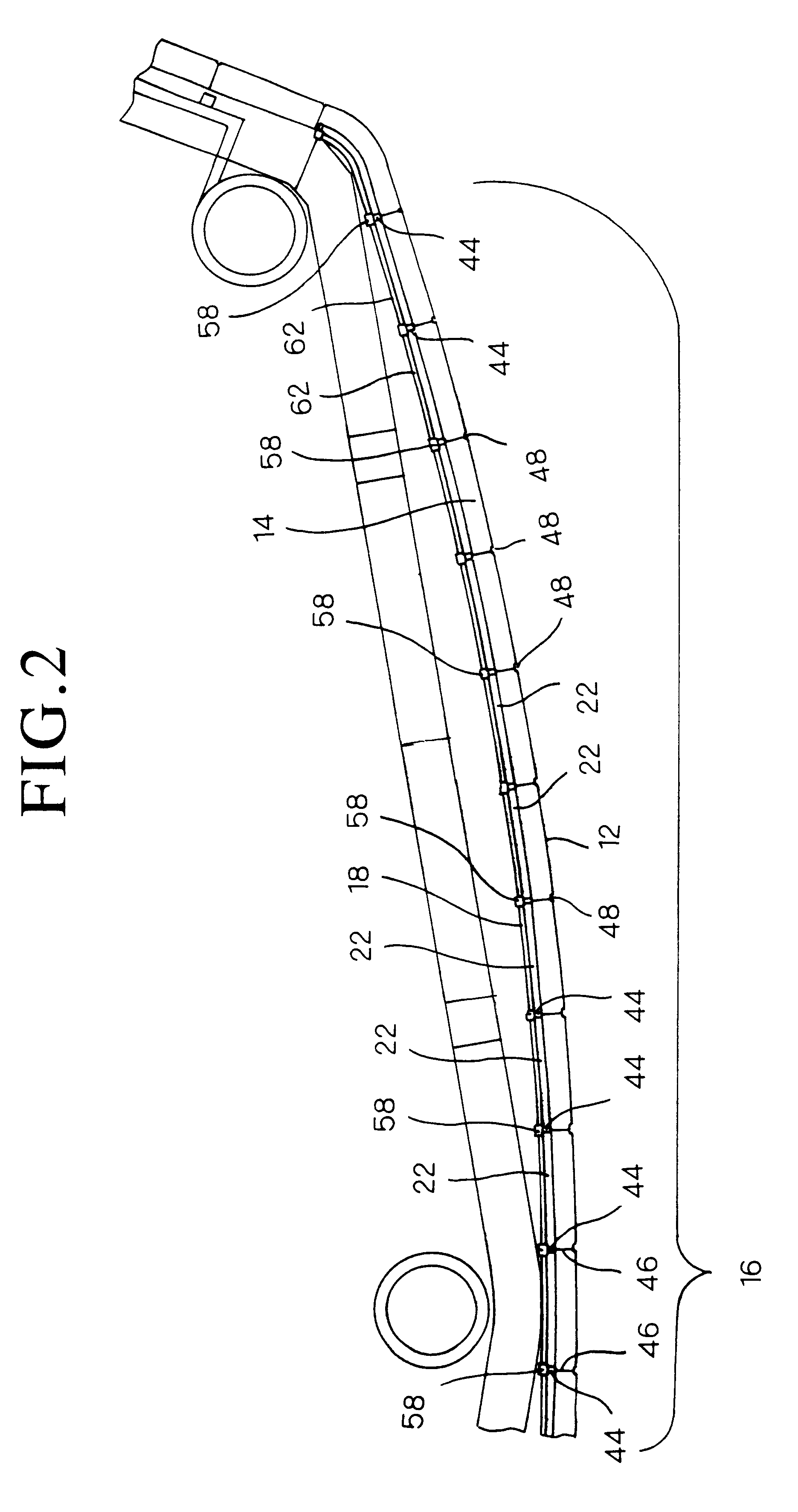

A high-rise building with a large scale dot-matrix display device is disclosed. The glass panels arranged in rows and columns form a curtain wall structured transparent outer wall 12 extending over an exterior of a building 10. Each panel is installed apart from end portions of floor slabs to form a void space therebetween. A plurality of louver structured modules 22 are arranged within the void space in rows and columns to form a large scale display area. Each module 22 has a louver-like structure formed of a plurality of posts 24 arranged in substantially parallel relationship and a plurality of parallel, uniformly spaced beams 26 connecting said adjacent posts 24. A plurality of LED combination lamps 28 are mounted on each beam 26 at uniform pitches as those between the adjacent beams 26. The LEDs are driven by drive circuits disposed in each beam 26. The vertical guide members 44 are fixed to the end portions of the floor slabs 20. The guide members 44 are arranged substantially in parallel relationship so that the modules 22 are supported between the adjacent guides 44 at the both lateral sides thereof. A plurality of vertical mullion members 48 fixed to the vertical guide members 44 as spaced apart from each of the vertical guides 44, so that the glass panels 12 are supported therebetween.

Owner:AVIX

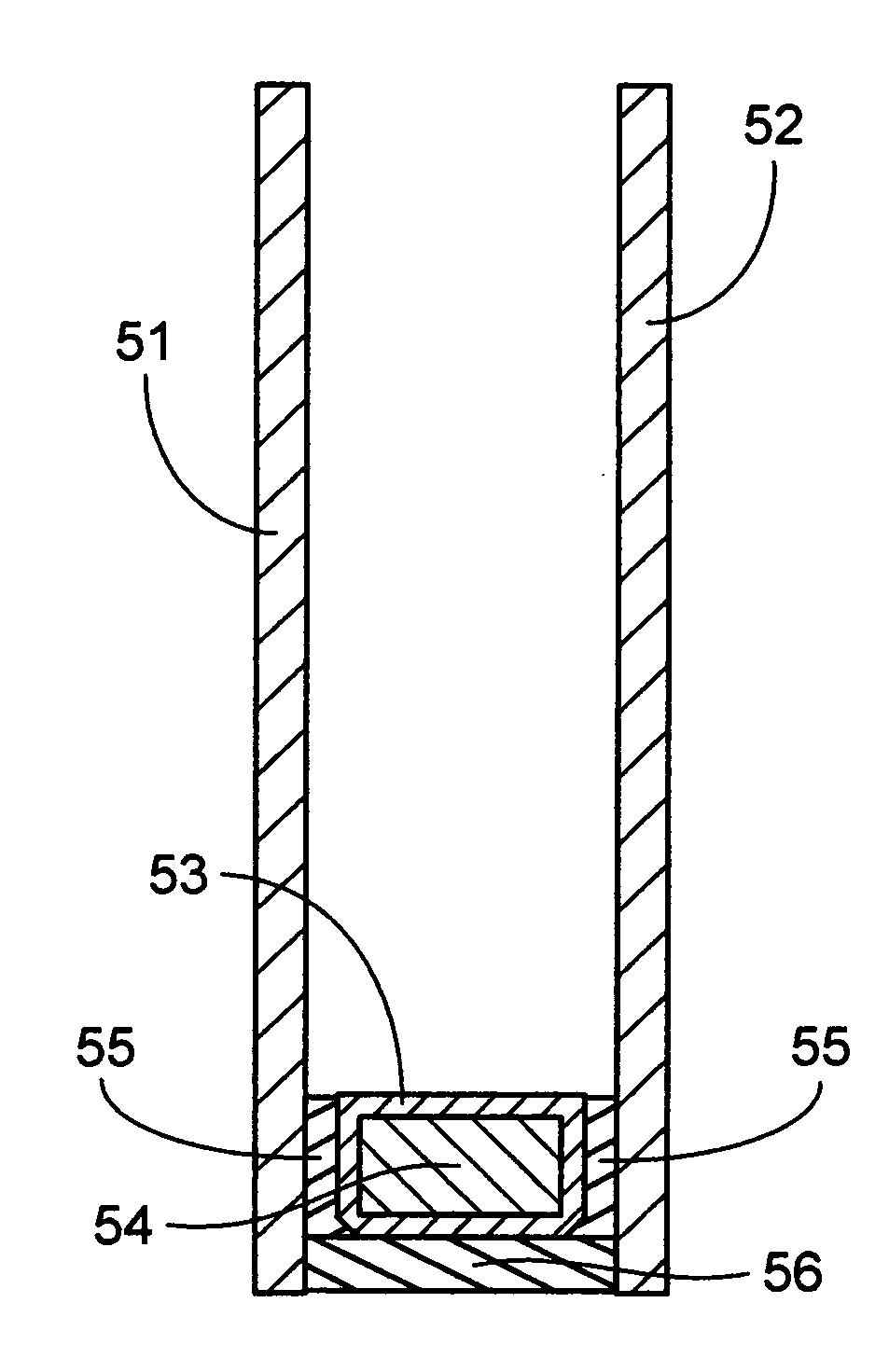

Vacuum IG pillar with lubricating and/or reflective coating

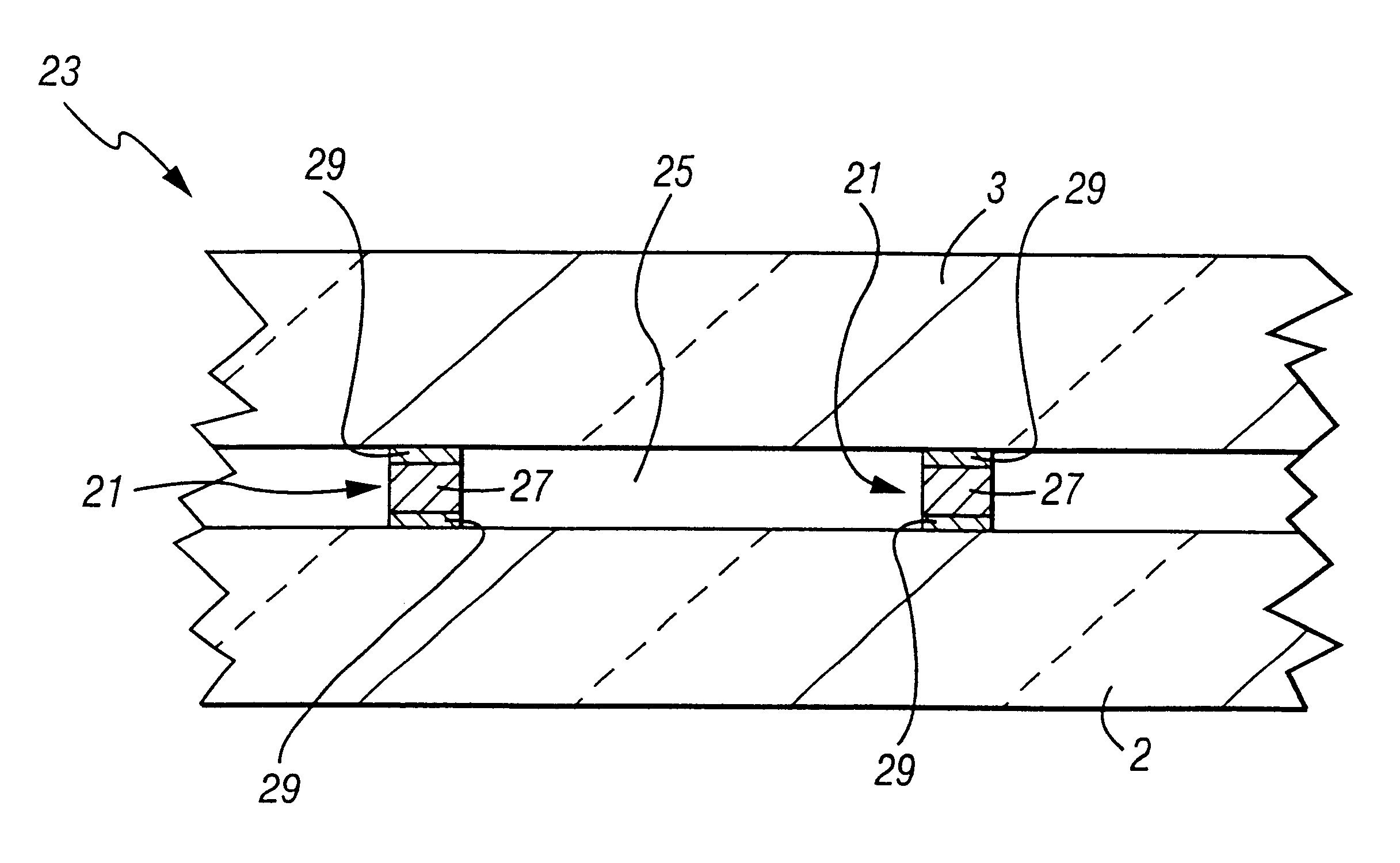

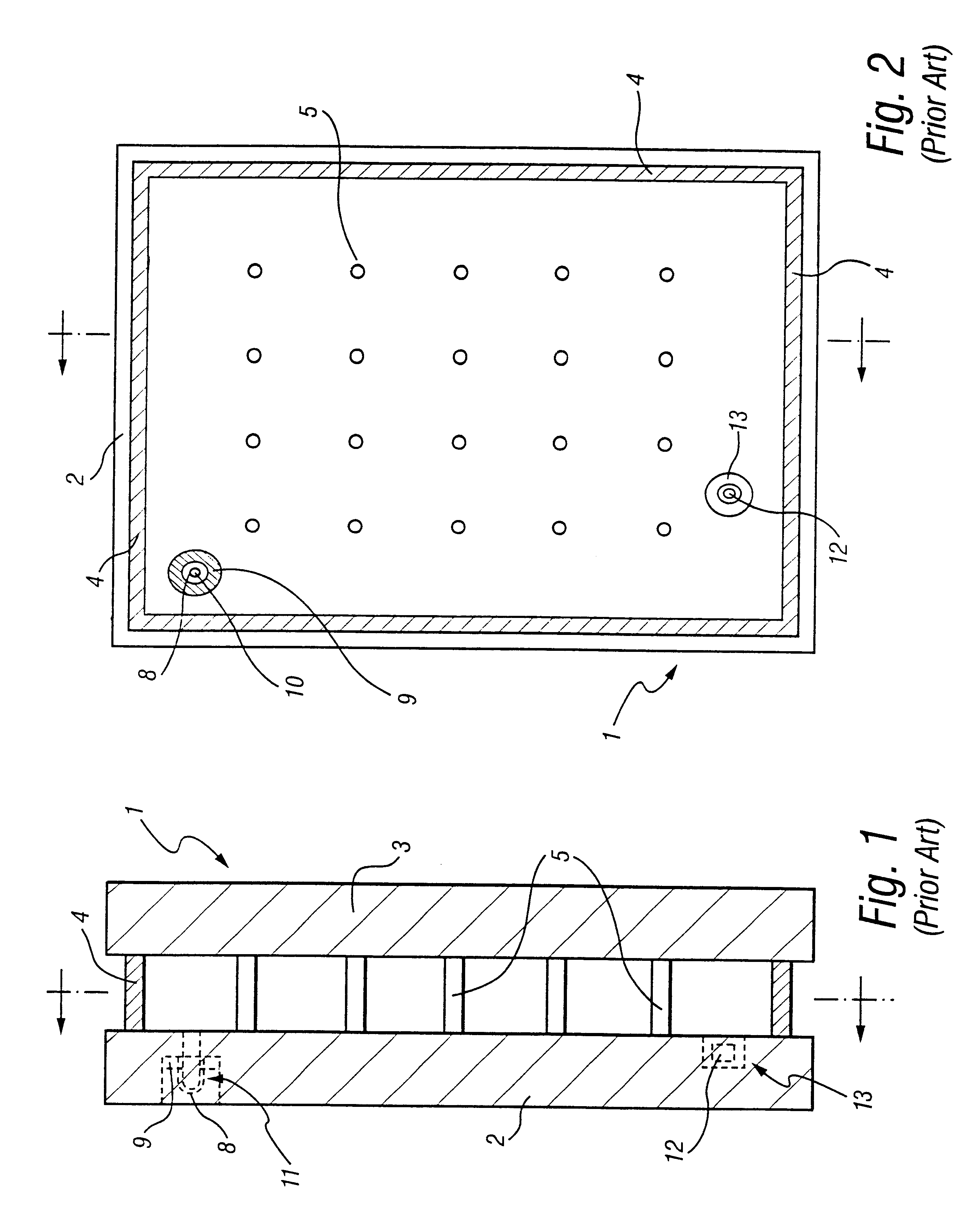

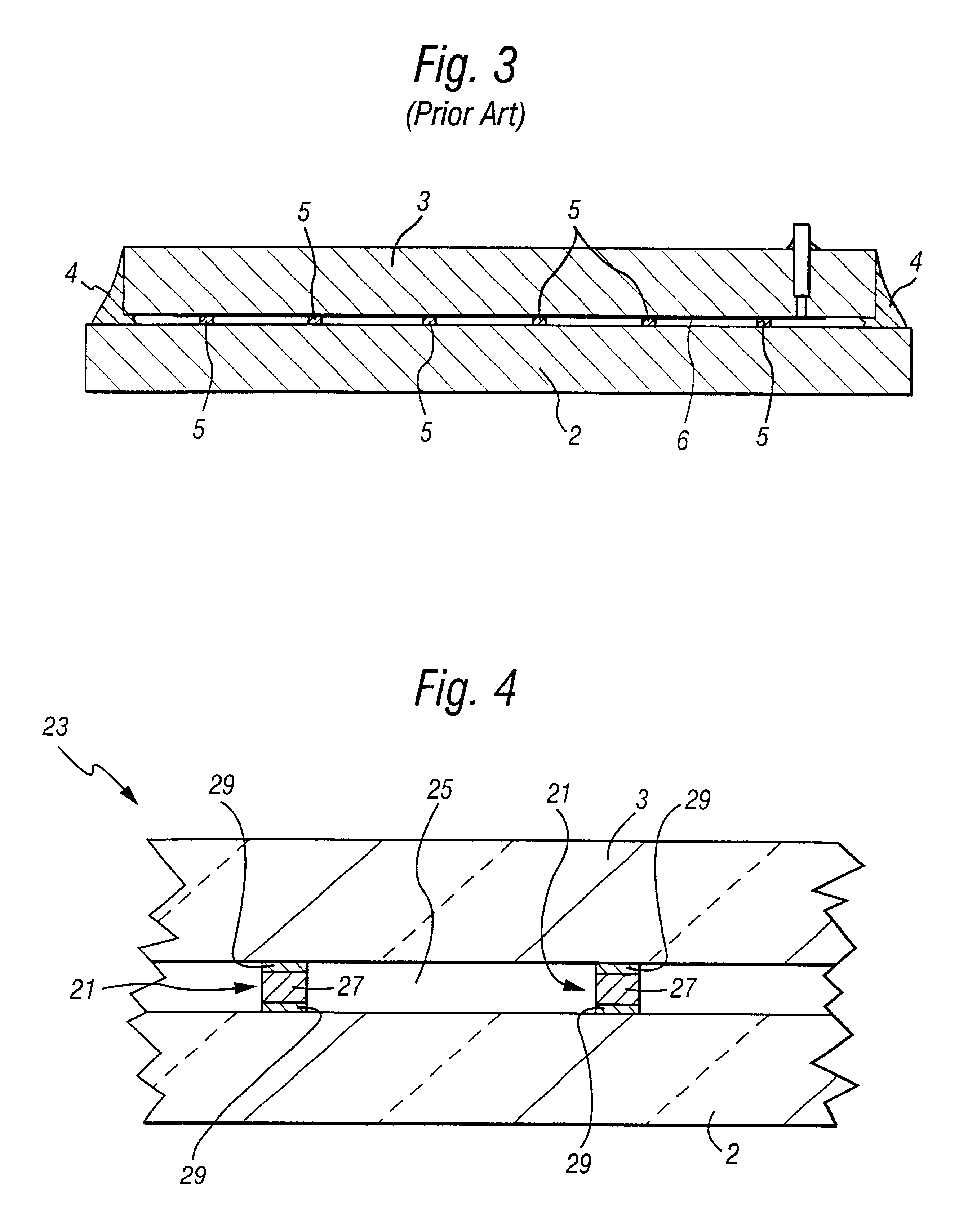

InactiveUS6946171B1Less visibly obtrusiveMinimize cracksClimate change adaptationWindows/door improvementChemical reactionThermal expansion

A vacuum insulating glass (IG) unit is provided with an array of spacers / pillars between opposing glass sheets. At least some of the spacers / pillars are coated on at least one surface thereof with a dry lubricant and / or reflective material such as silver. This coating permits the glass sheet(s) to move relative to one another during thermal expansion while minimizing the degree to which the spacers / pillars scratch or crack the glass during such relative movement. A method of making an exemplary spacer / pillar includes transforming by chemical reaction silver ions on a core into a metallic silver coating thereby resulting in a coated spacer / pillar.

Owner:GUARDIAN GLASS LLC

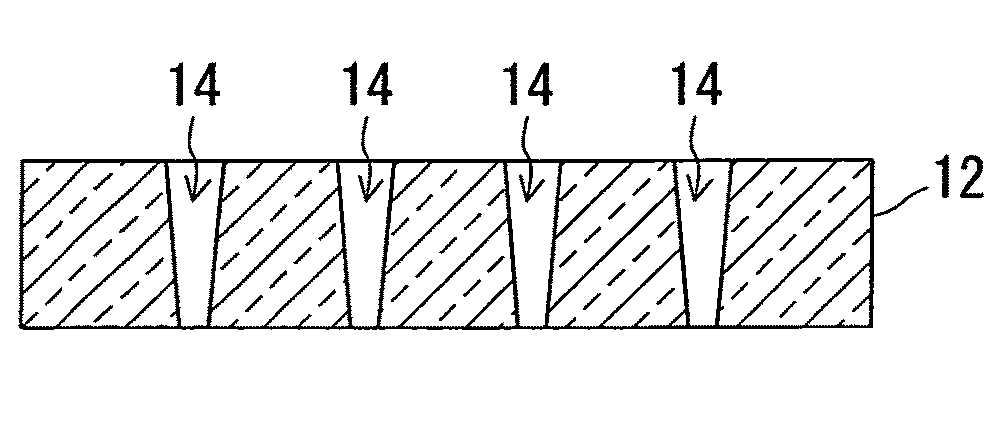

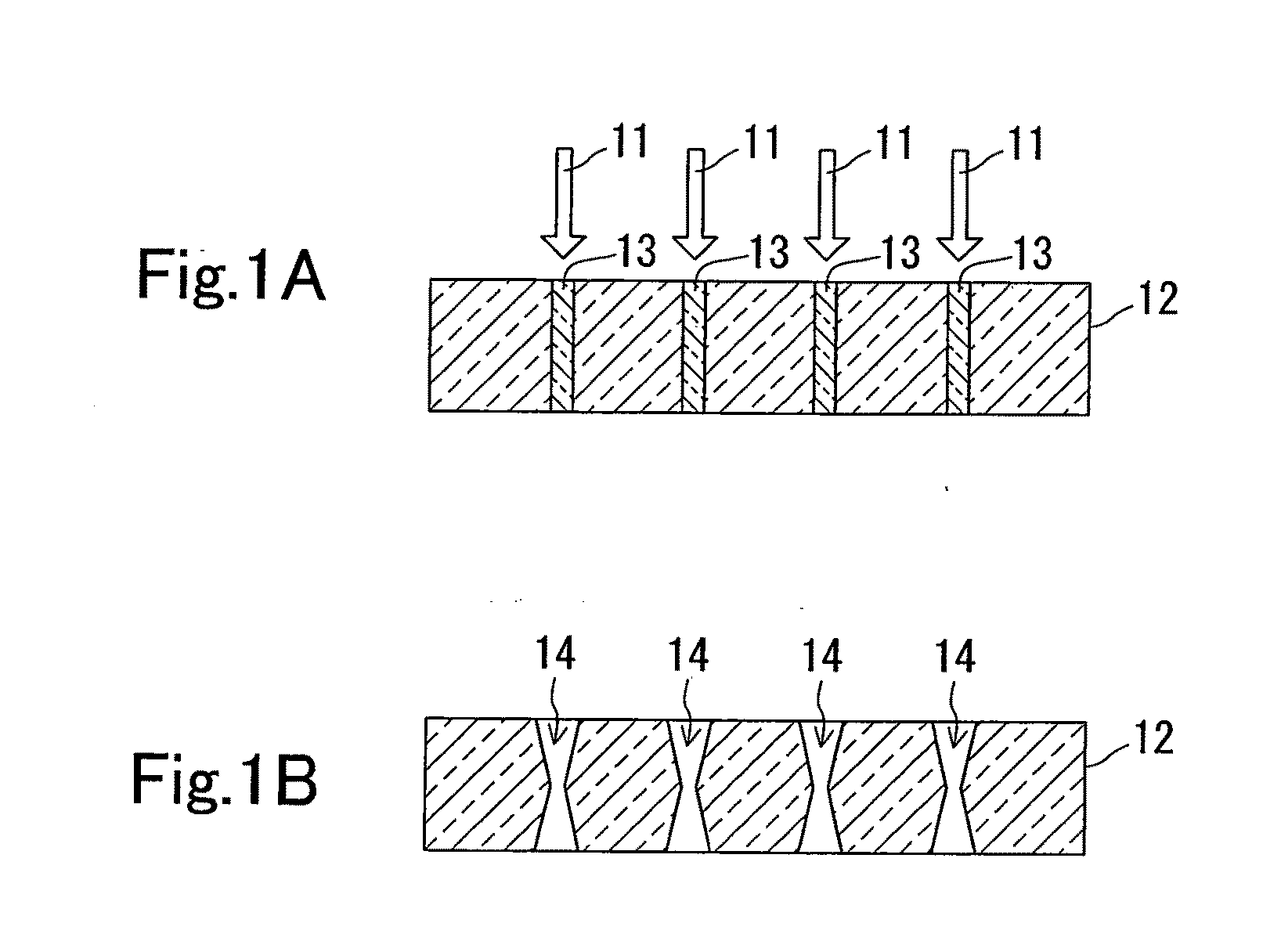

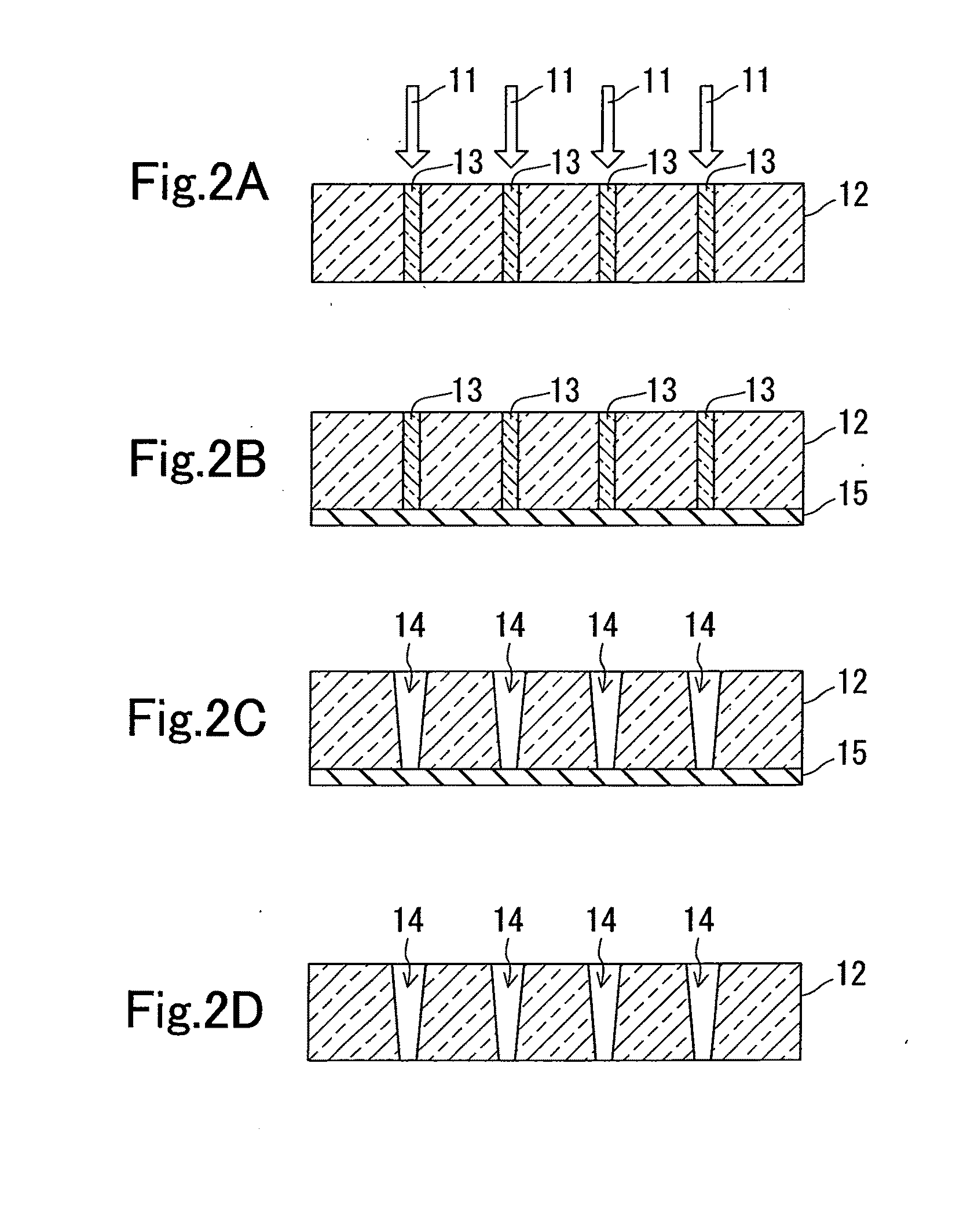

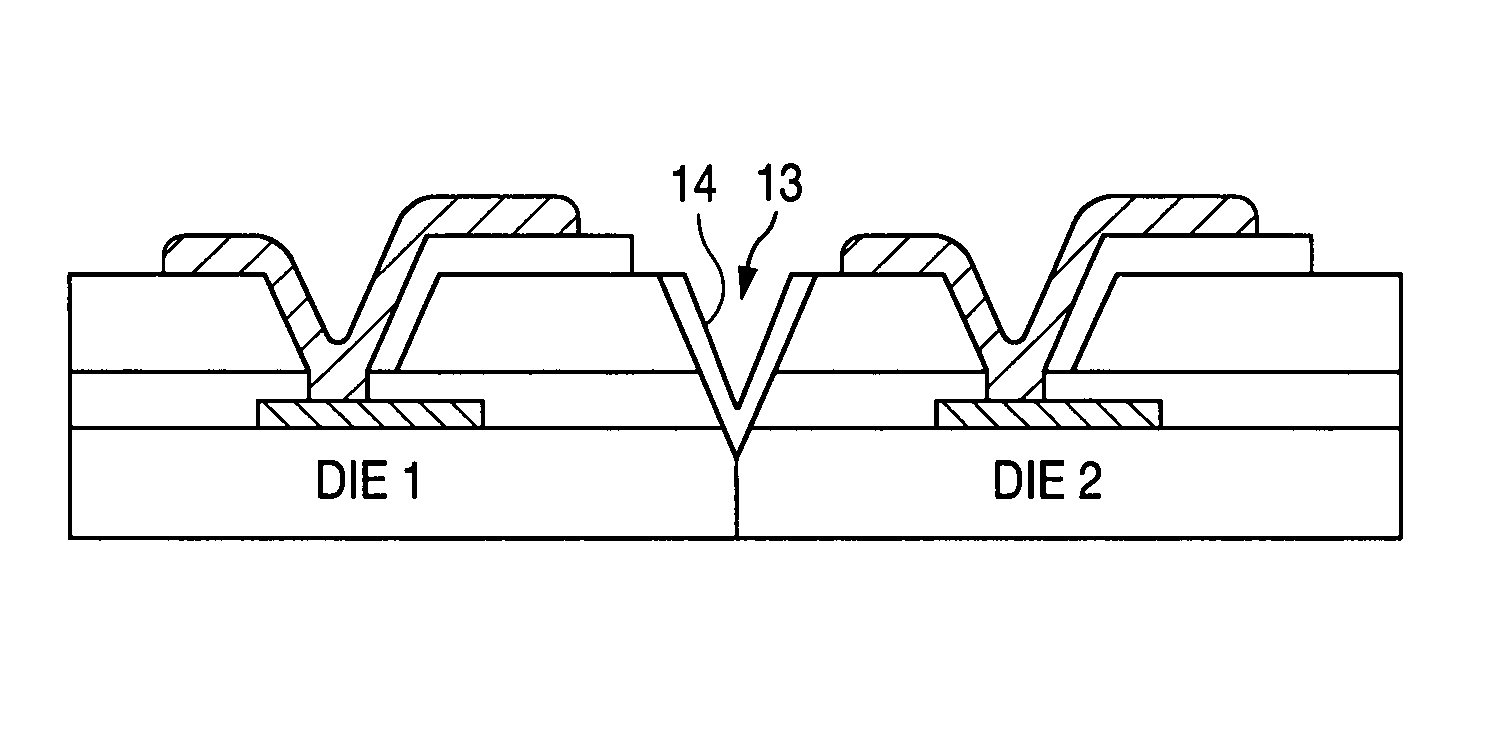

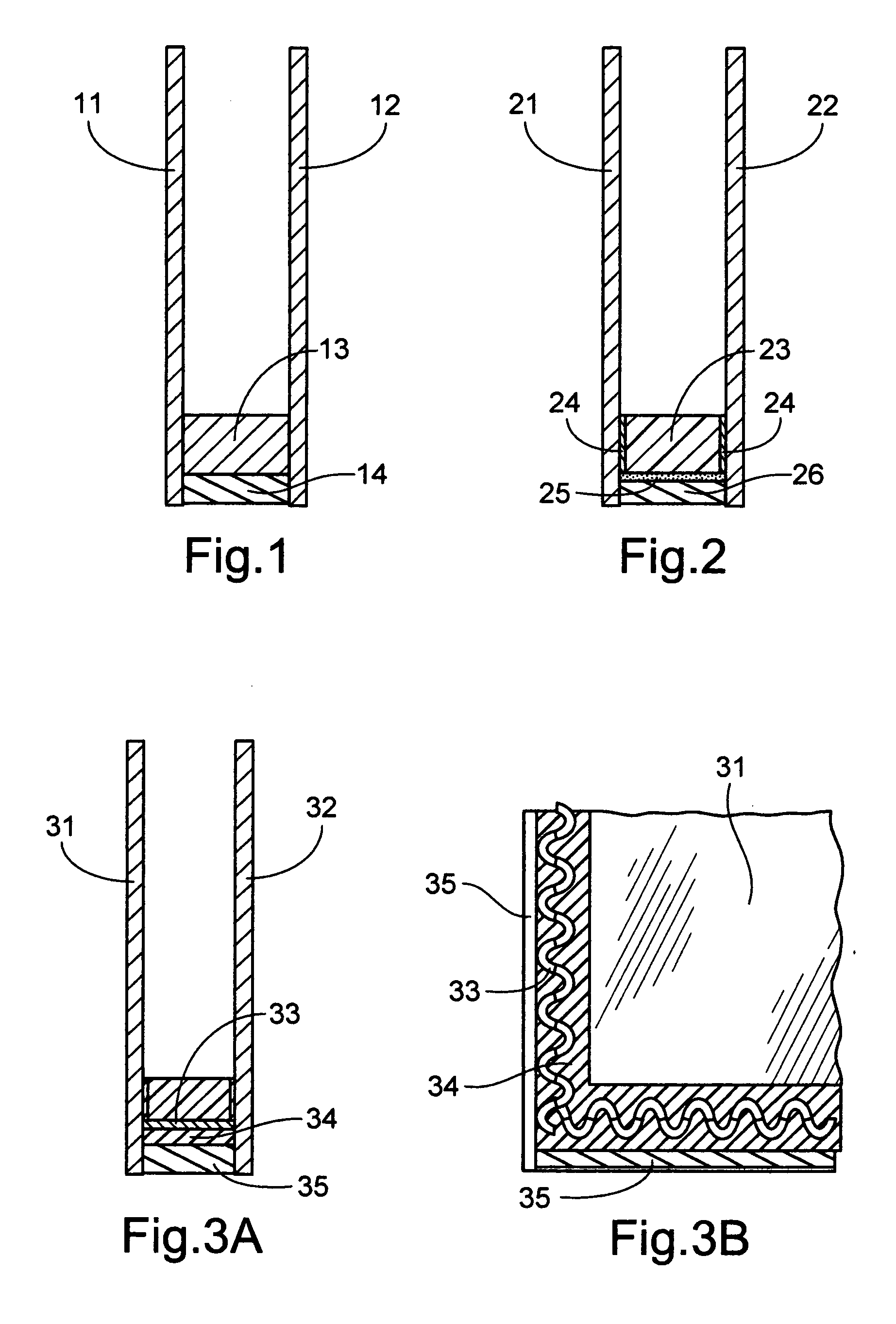

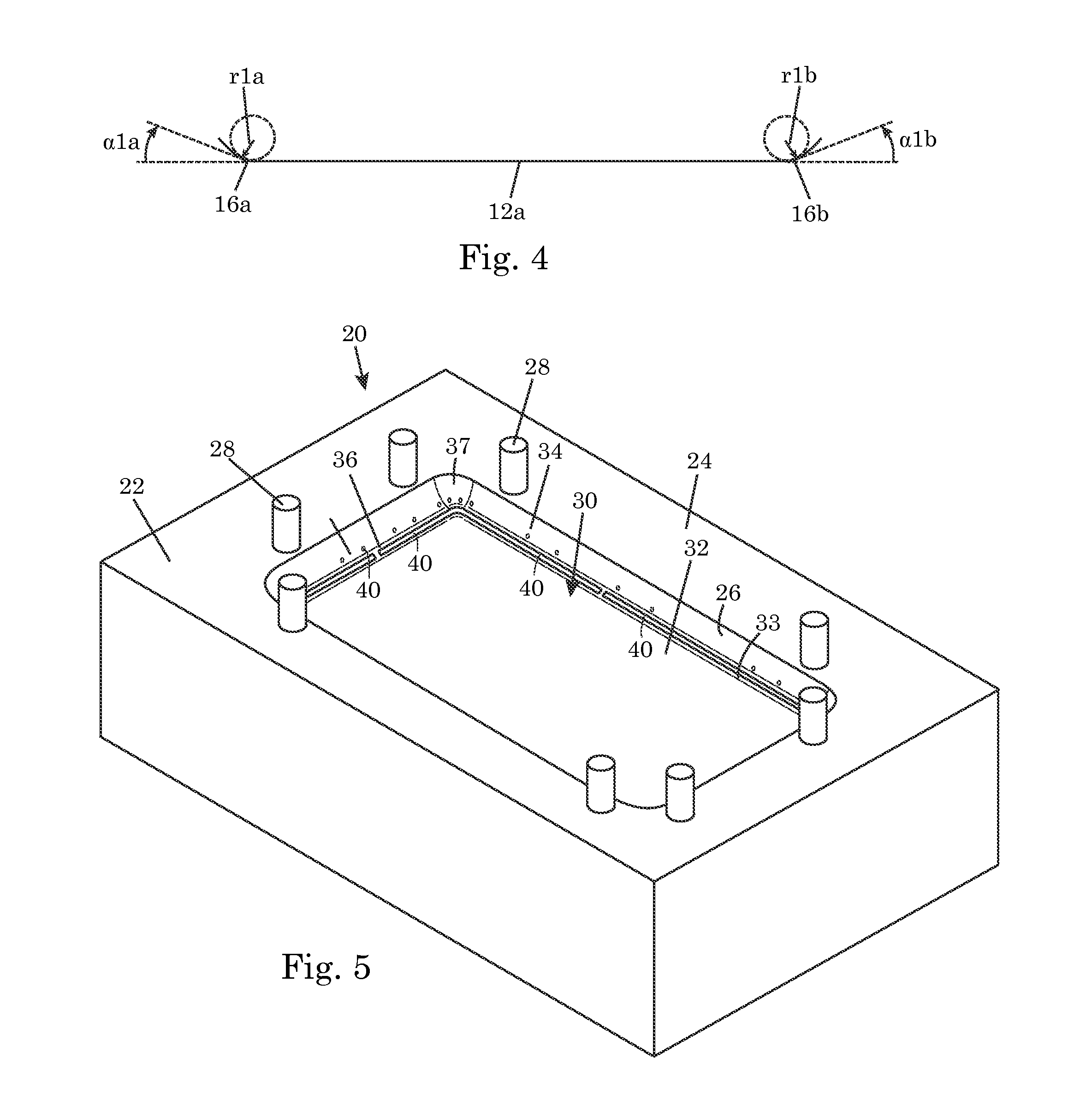

Glass Processing Method Using Laser and Processing Device

InactiveUS20090013724A1Suppress glass deformationProcess economyWelding/soldering/cutting articlesLaser beam welding apparatusBeam diameterLength wave

A glass processing method comprising steps (i), (ii) carried out in the order mentioned. In step (i), a laser pulse (11) with a wavelength λ is condensed by a lens and is applied to a glass plate (12) to form an altered portion (13) at the portion, irradiated with a laser pulse (11), of the glass plate (12). In step (ii), the altered portion (13) is etched by using an etchant having an etching rate larger for the altered portion (13) than that for the glass plate (12). The laser beam used includes the following conditions: The pulse width of a laser pulse (11) ranges from ins to 200 ns, with a wavelength λ being up to 535 nm. The absorption coefficient of the glass plate (12) at a wavelength λ is up to 50 cm−1. A value obtained from a lens focal distance L (mm) divided by the beam diameter D (mm) of the laser pulse (11) when entering the lens is at least 7.

Owner:NIPPON SHEET GLASS CO LTD

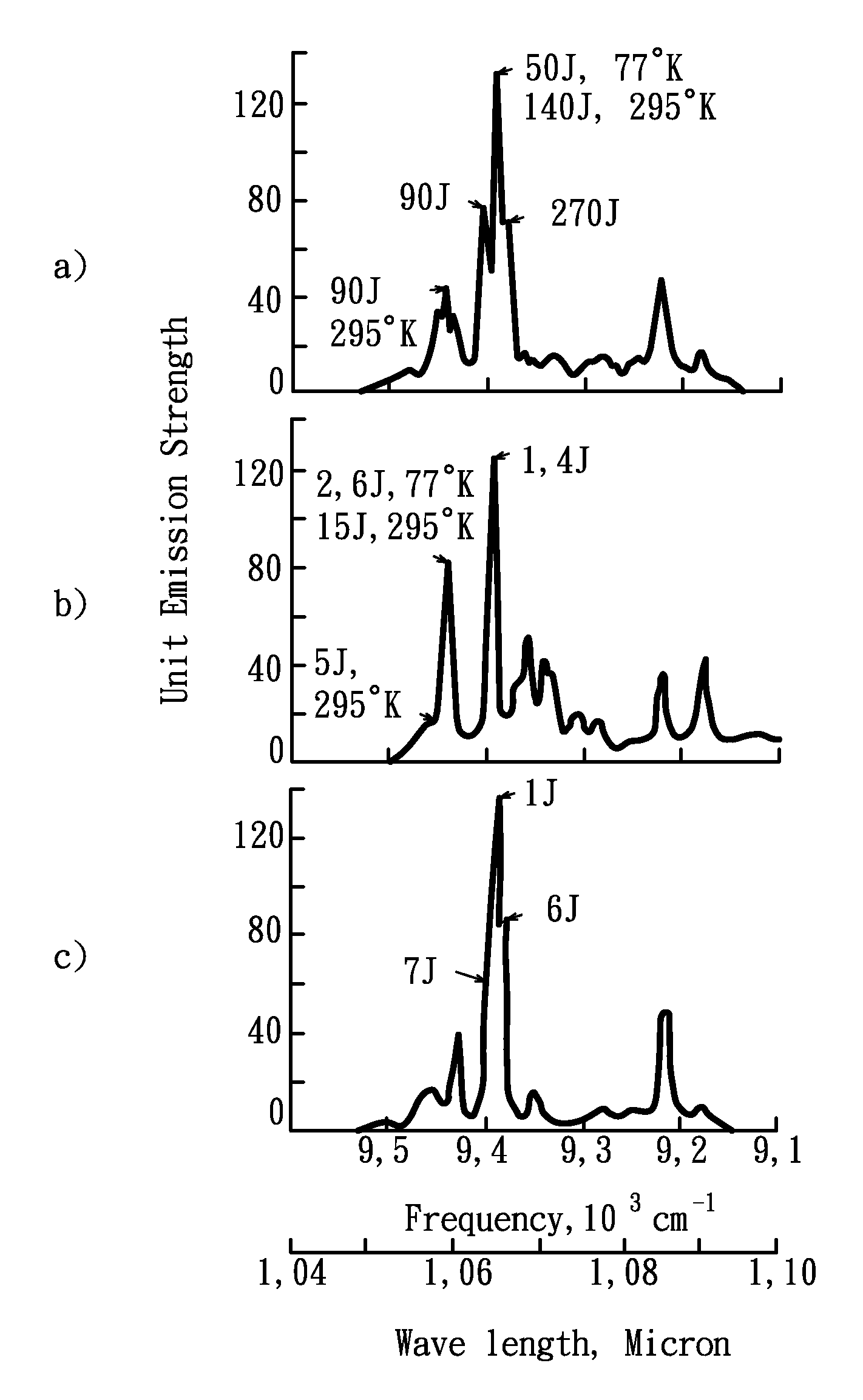

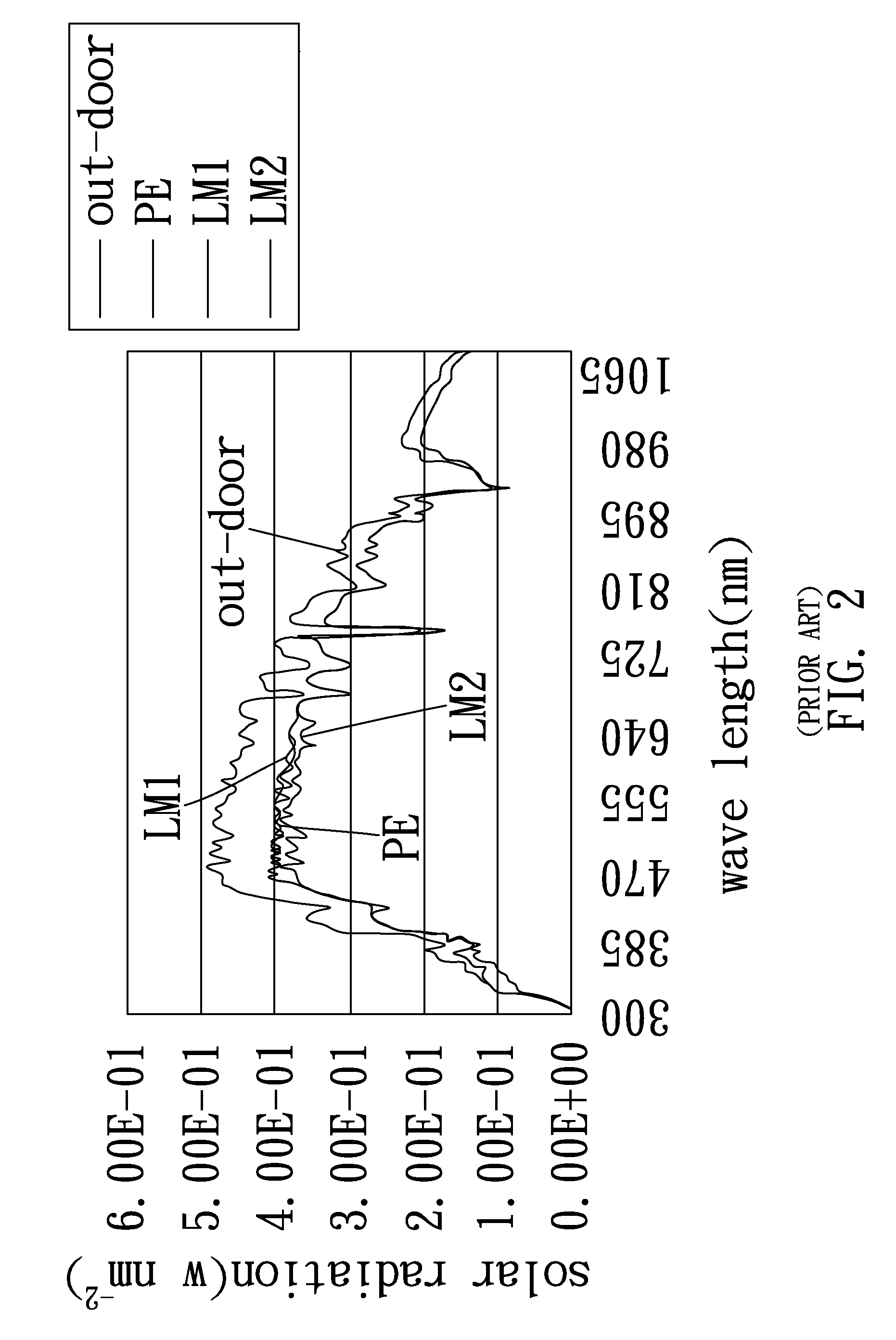

Solar cell and its spectrum converter

InactiveUS20090151785A1Increases electric parameterImprove efficiencyPhotovoltaic energy generationSemiconductor devicesPhotoluminescencePhosphor

A solar cell is disclosed to include a single crystal silicon chip, an electrode system, a glass plate cover, a polymer film set between the single crystal silicon chip and the glass plate cover, and a spectrum converter containing an inorganic phosphor, which absorbs radiation in purple, blue and green light of the Sun's solar radiation and converts the absorption into a photoluminescent light in yellow, orange-yellow and infrared area in the electromagnetic spectrum. The architecture characteristic of the solar cell increases the efficiency by about 20%.

Owner:LO WEI HUNG

Hermetic wafer scale integrated circuit structure

InactiveUS6982475B1Prevent surfaceDamaged and destroyedSemiconductor/solid-state device detailsSolid-state devicesScale structureHermetic seal

A wafer scale semiconductor integrated circuit packaging technique provides a hermetic seal for the individual integrated circuit die formed as part of the wafer scale structure. A semiconductor wafer is manufactured to include a number of individual semiconductor die. Each individual die formed on the wafer includes a number of bond pads that are exposed on the die surface in various locations to provide electrical connections to the circuitry created on the die. The wafer further includes a planar glass sheet that is substantially the same size as the wafer, the glass sheet being adhered to the wafer using a suitable adhesive. The glass sheet has a number of pre-formed holes in it, the arrangement of the pre-formed holes corresponding to the location of the bond pads at each of the individual semiconductor die formed as part of the wafer structure. Following adherence of the glass sheet to the semiconductor wafer utilizing the intermediate adhesive material, metal connections are made between pads formed on the glass sheet and the bond pads formed on the integrated circuit die. Solder balls are then attached to the pads on the glass sheet to provide a conductive flow between the solder balls and the bond pads. After the solder balls are attached, trenches are cut around each of the individual die on the wafer. The trenches are cut at an angle and extend through the glass sheet and the intermediate adhesive material and into the semiconductor substrate in which the integrated circuits are formed. After the trenches are cut around each individual semiconductor die, a noble metal is deposited on the sidewalls of the trench to extend over the interface between the glass sheet, the adhesive material and the semiconductor die. The wafer is then cut along the noble metal lined trenches to provide individual, hermetically sealed packaged integrated circuit die.

Owner:MICRO CHIP SCALE PACKAGING

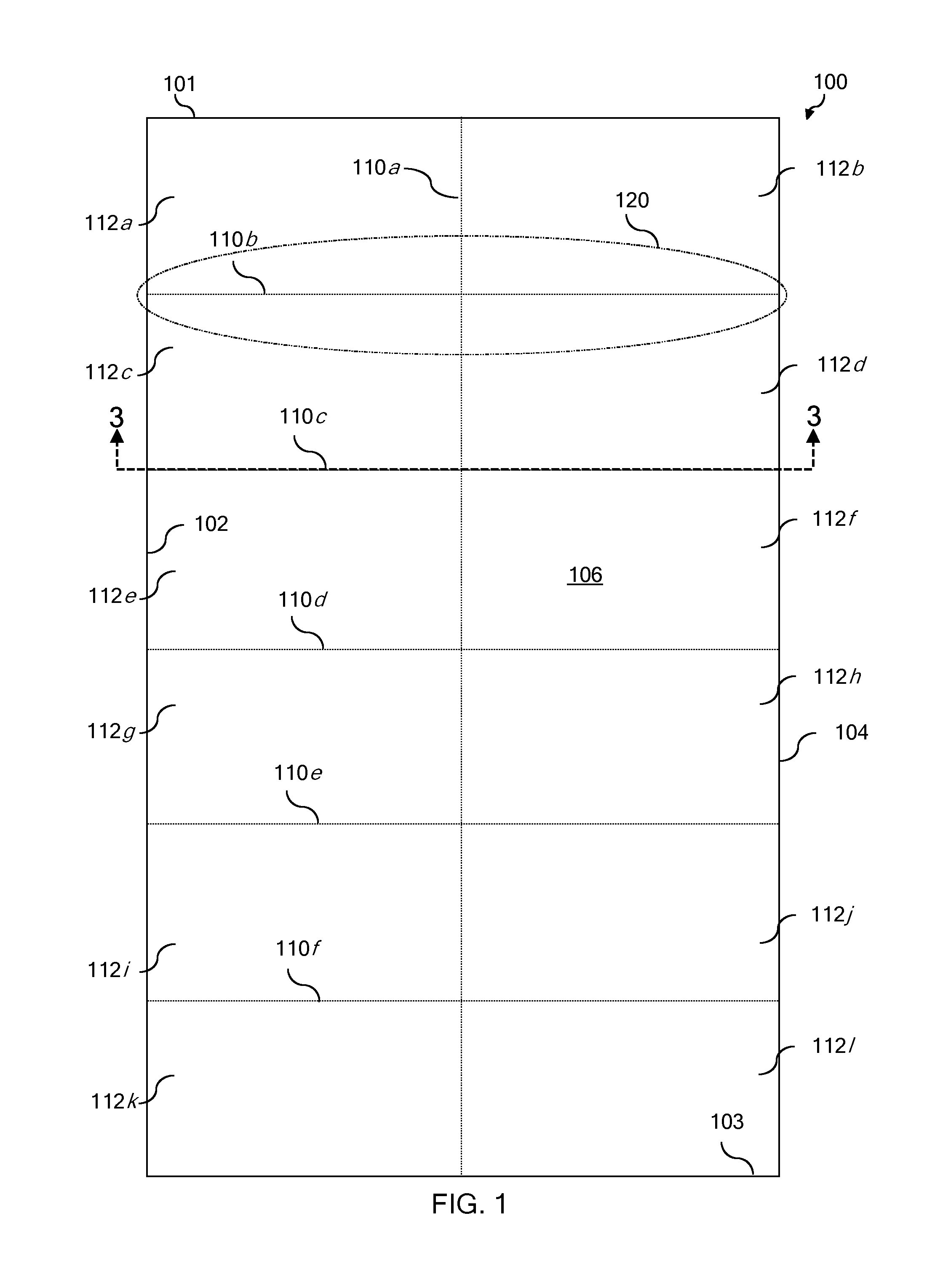

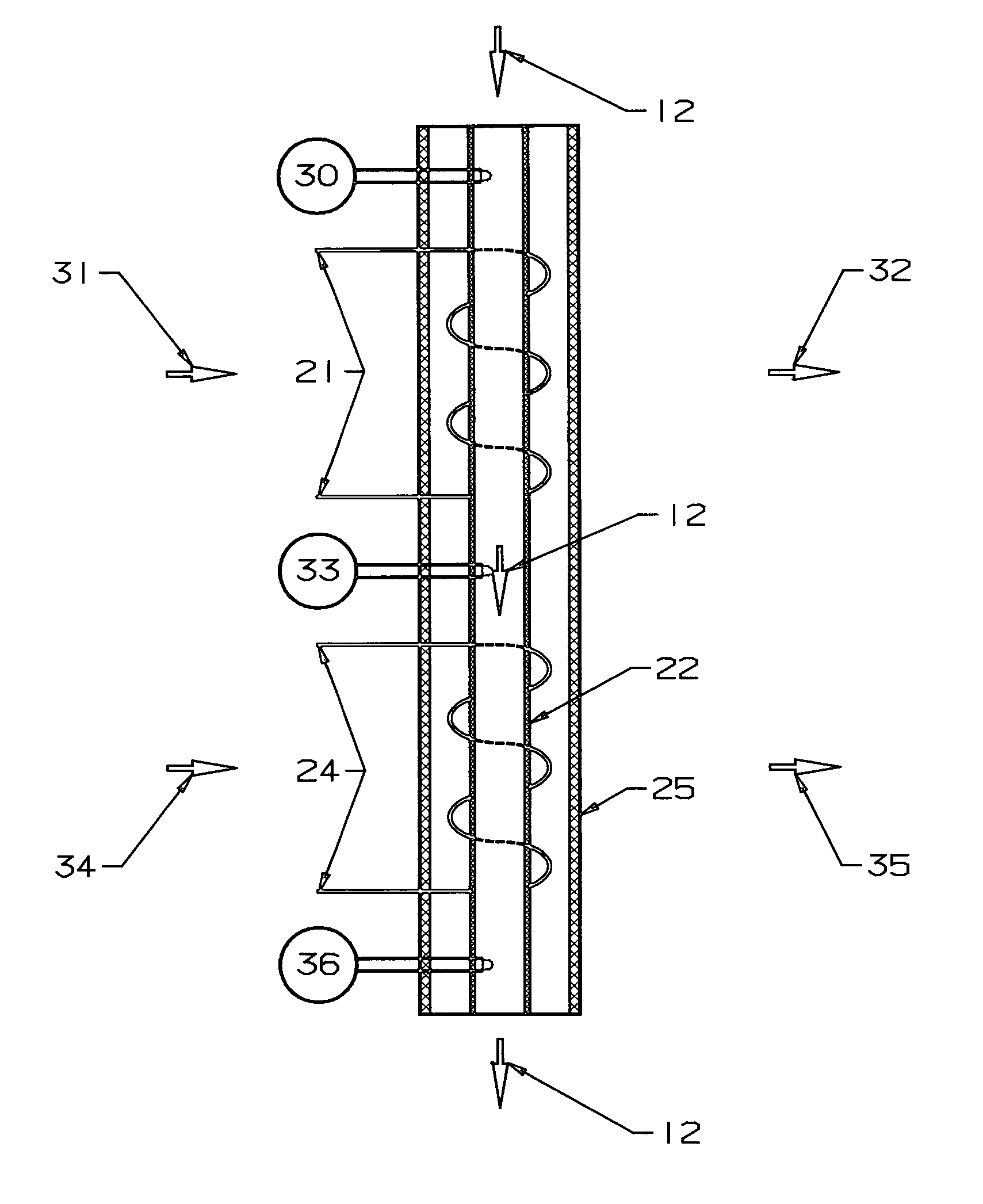

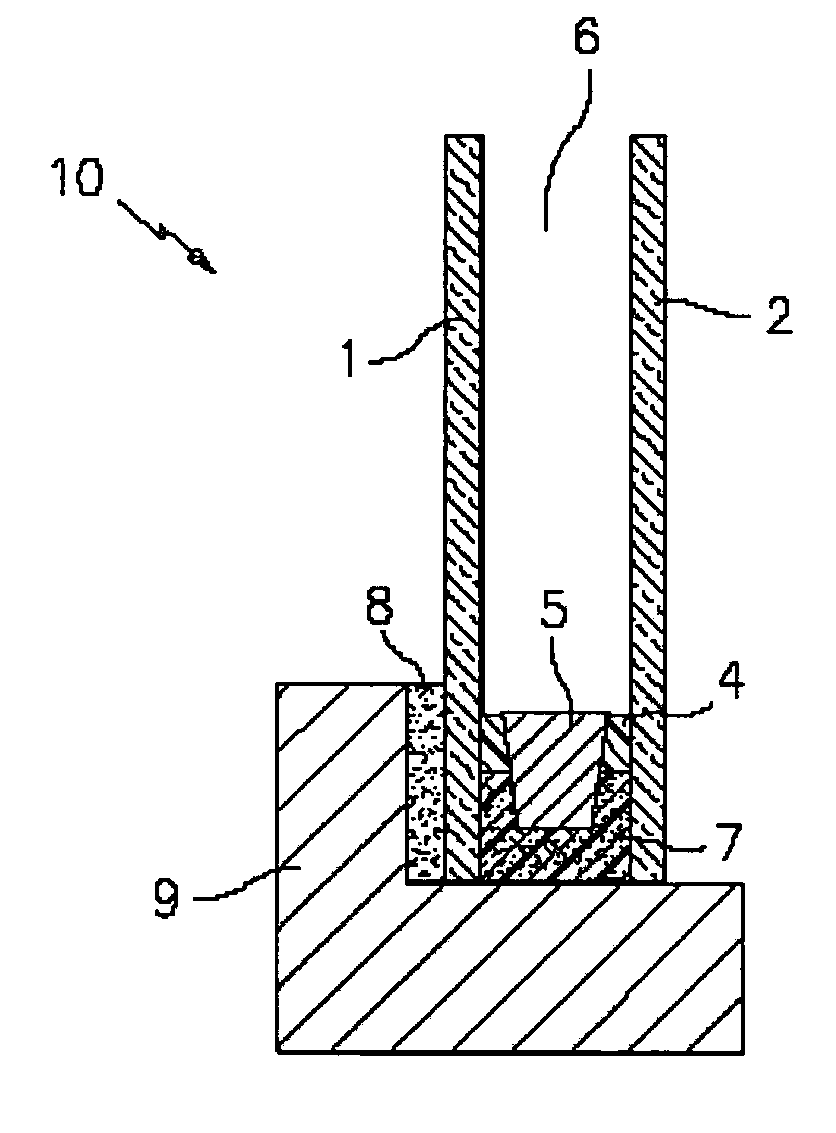

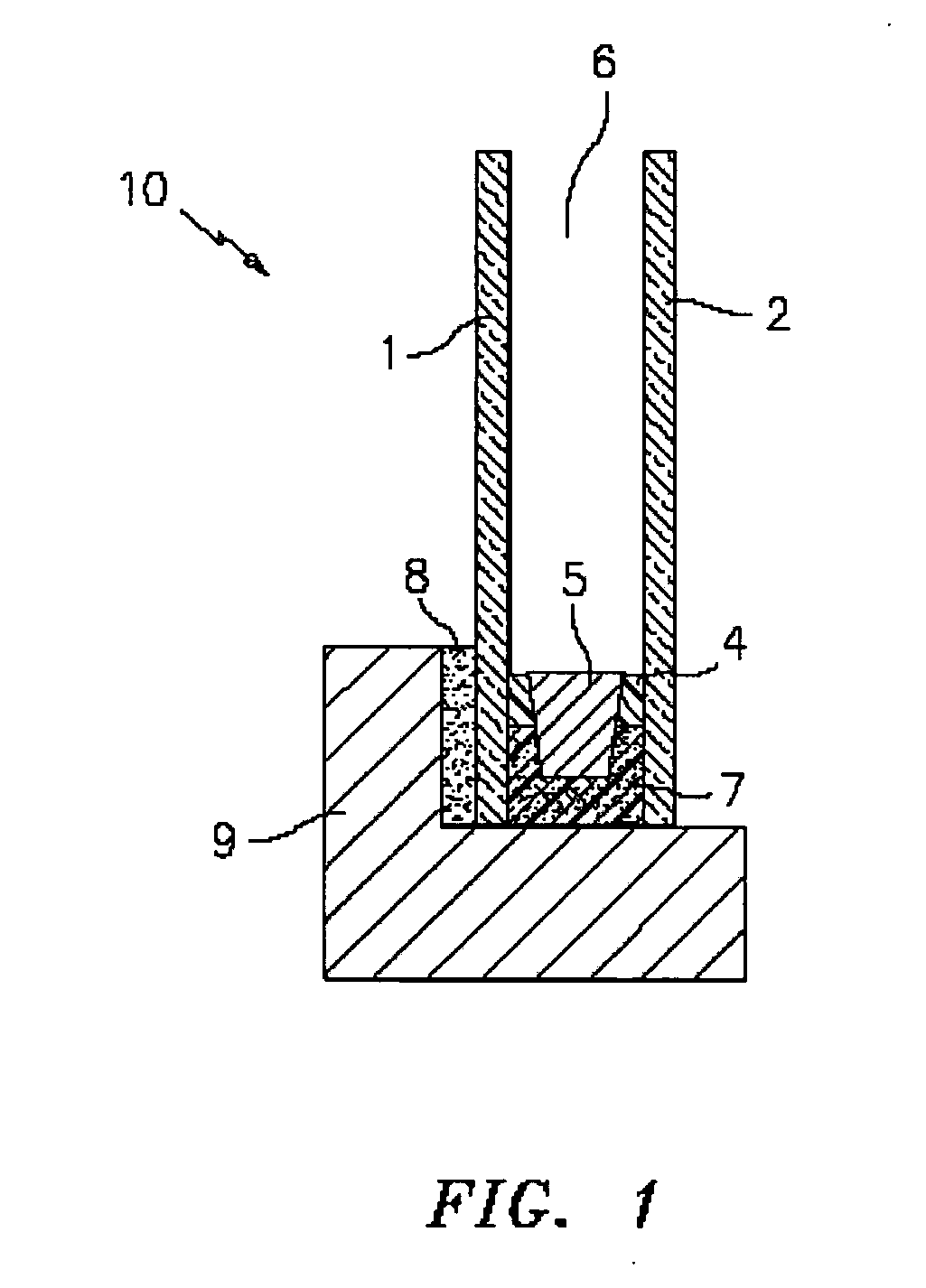

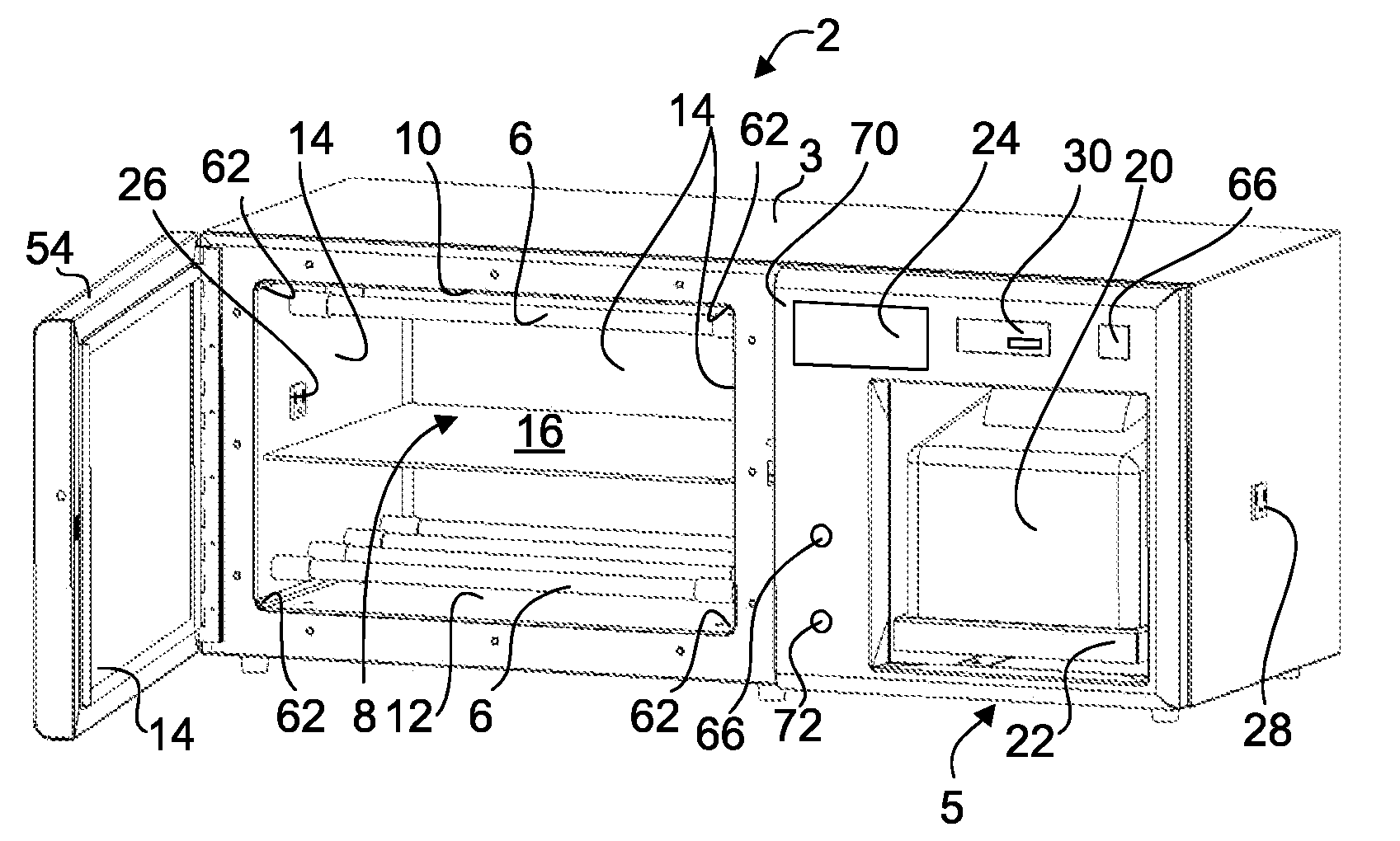

Insulating Glass Unit With An Electronic Device and Process For Its Production

A sealed insulating glass unit comprises two glass sheets held apart by a spacer, optionally with a sealant between the edges of the glass sheets outside the spacer. The insulating glass unit contains an electronic device, having information relating to the origin, manufacture and / or properties of the insulating glass unit capable of being read from the device by means actuated from outside the insulating glass unit. The device is embedded within the spacer or sealant so that it is concealed within the insulating glass unit.

Owner:DOW SILICONES CORP +1

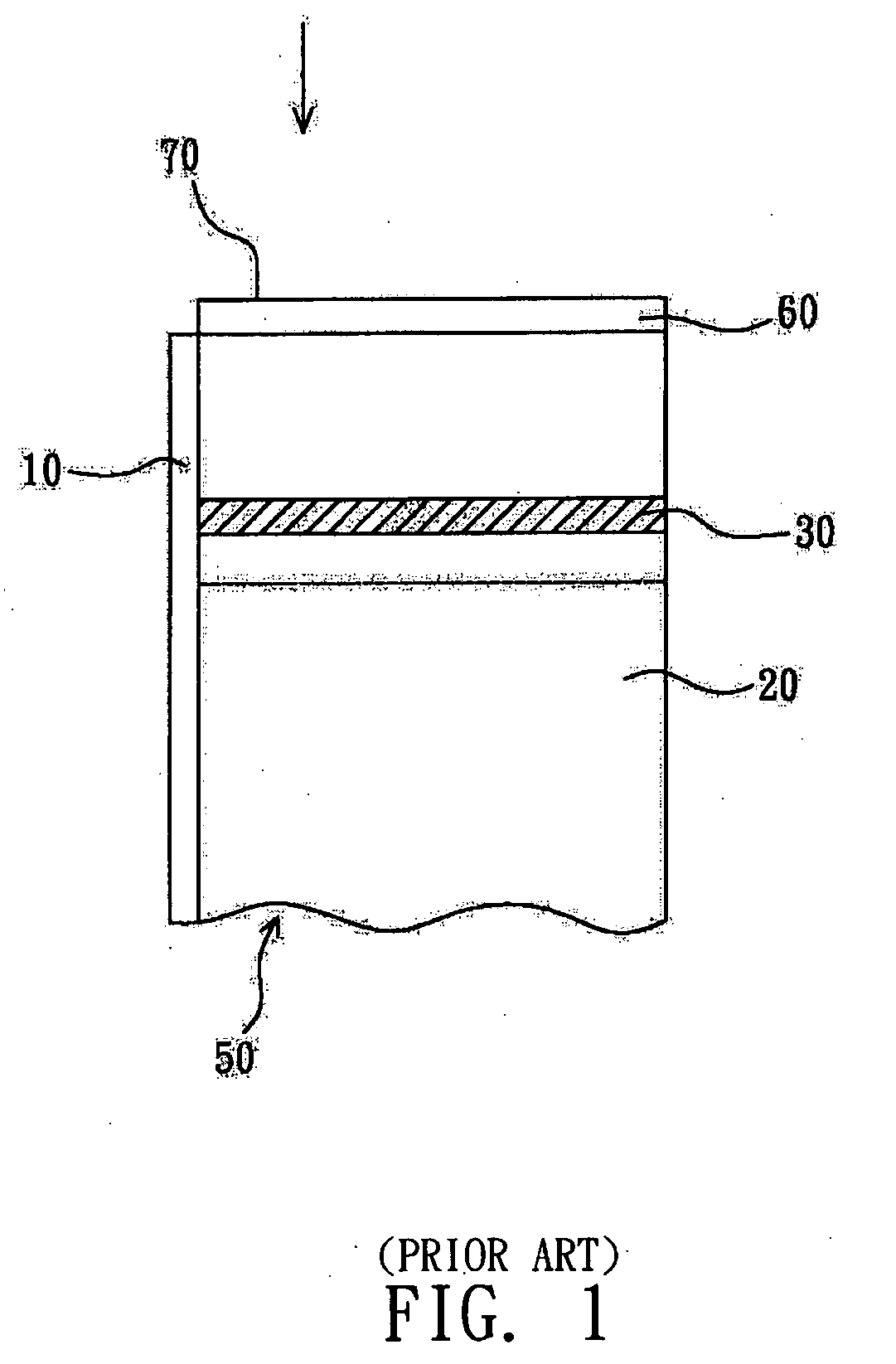

Solar laminates as laminated safety glass

InactiveUS20050284516A1High tensile strengthPrevent penetrationPV power plantsSolid-state devicesEngineeringUltimate tensile strength

Solar modules, with the properties of laminated safety glass, comprising a laminate containing a) a glass pane b) at least one solar cell unit that is located between two PVB-based films, and c) a rear covering and at least one of the PVB-based films has a tensile strength of at least 16 N / mm2, are suitable for use as a facade component, roof surface, winter garden covering, soundproofing wall, or as a component of windows.

Owner:KURARAY EURO GMBH

Colored film-coated ultraviolet/infrared absorbent glass plate and window glass of vehicle

InactiveUS6340646B1Reduced durabilityIncrease temperatureCeramic layered productsGlass/slag layered productsTO-18Ultraviolet

A colored film-coated ultraviolet / infrared absorbent glass plate is formed of base glass, colorants, and a colored film. The base glass includes 65 to 80 wt. % SiO2; 0 to 5 wt. % Al2O3; 0 to 10 wt. % MgO; 5 to 15 wt. % CaO; 10 to 18 wt. % Na2O; 0 to 5 wt. % K2O; 5 to 15 wt. % total amount of MgO and CaO; 10 to 20 wt. % total amount of Na2O and K2O; 0.05 to 0.3 wt. % of SO3; and 0 to 5 wt. % B2O3. The colorants includes 0.35 to 0.55 wt. % total iron oxide (T-Fe2O3) expressed as Fe2O3; 0.08 to 0.15 wt. % FeO; 0.8 to 1.5 wt. % CeO2; and 0 to 0.5 wt. % TiO2. FeO expressed as Fe2O3 is equal to or more than 20 wt. % and less than 27 wt. % of T-Fe2O3. The colored film has a red color shade with a thickness between 30 nm and 300 nm and includes fine particles of gold and silicon oxide of more than 50 wt. % and equal to or less than 95 wt. %. The colored film is applied onto a surface of the ultraviolet / infrared absorbent glass plate.

Owner:NIPPON SHEET GLASS CO LTD

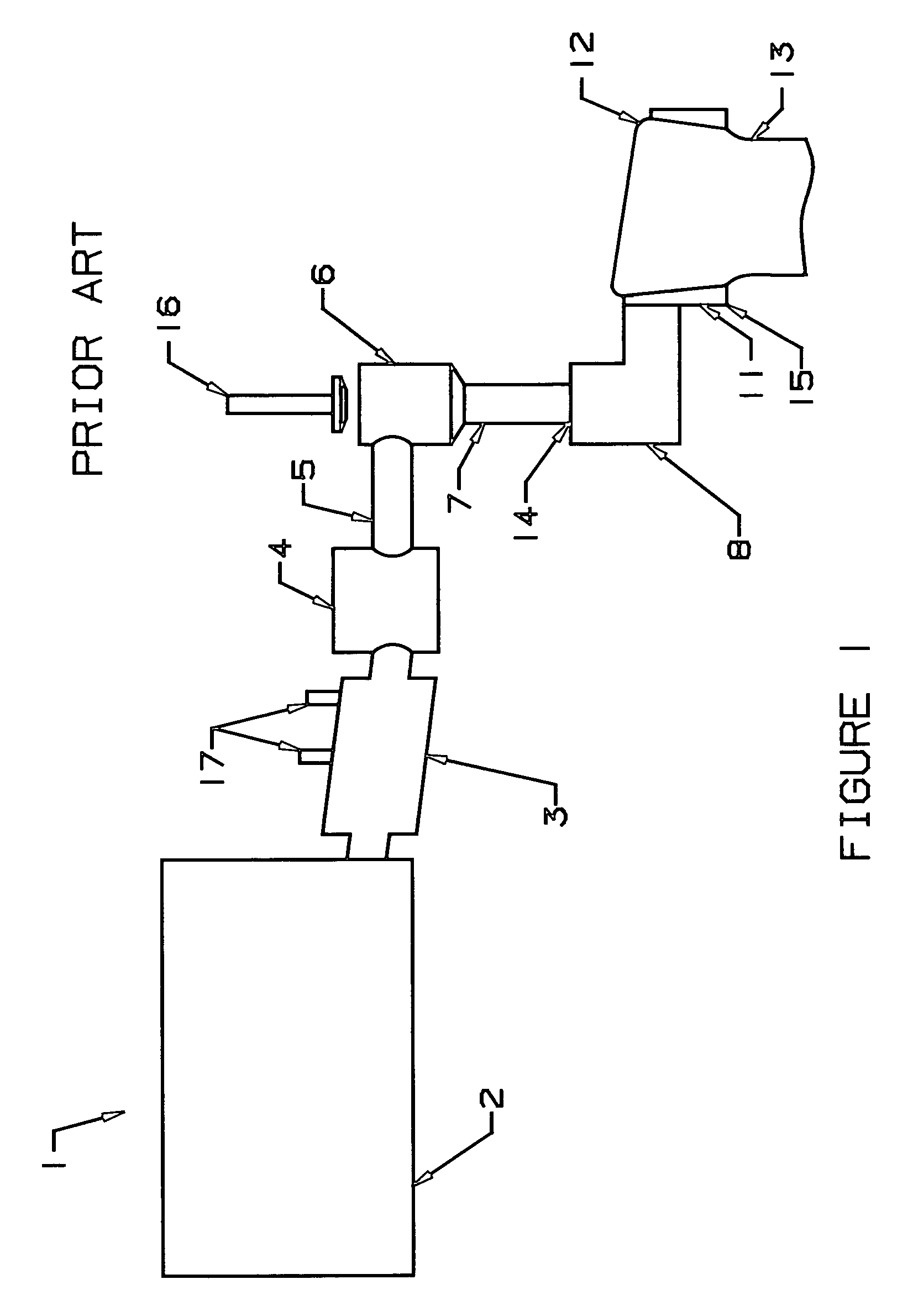

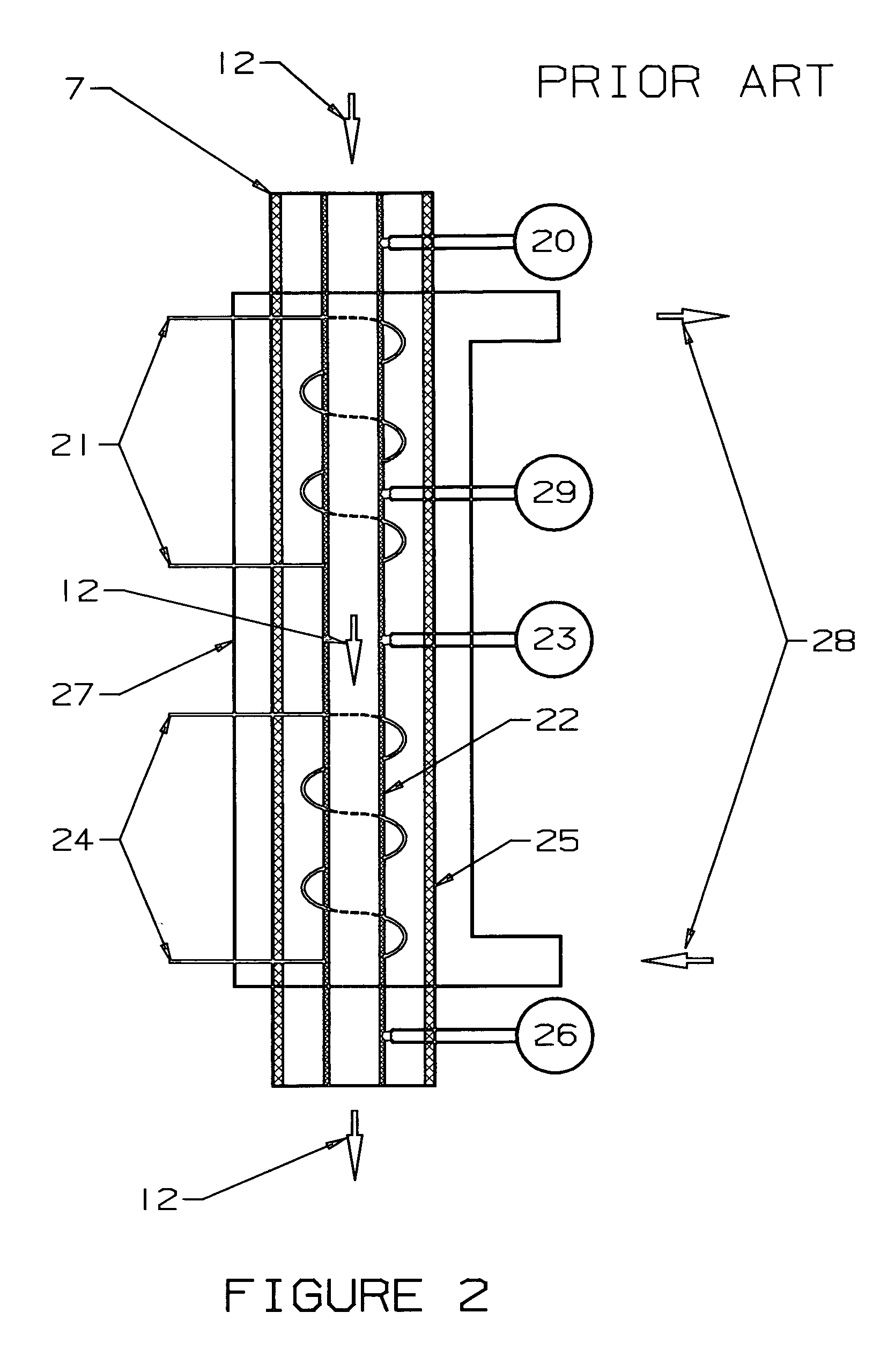

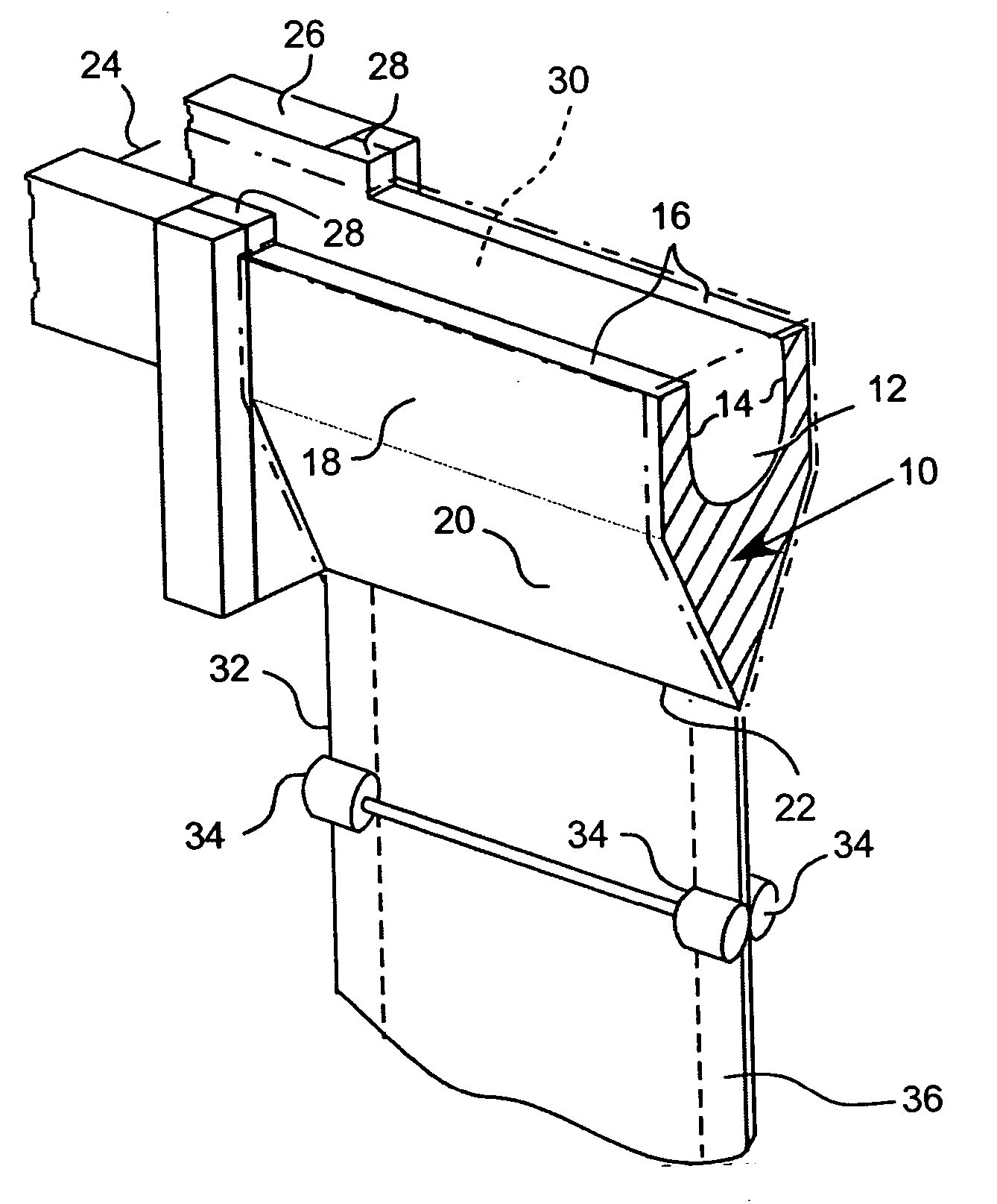

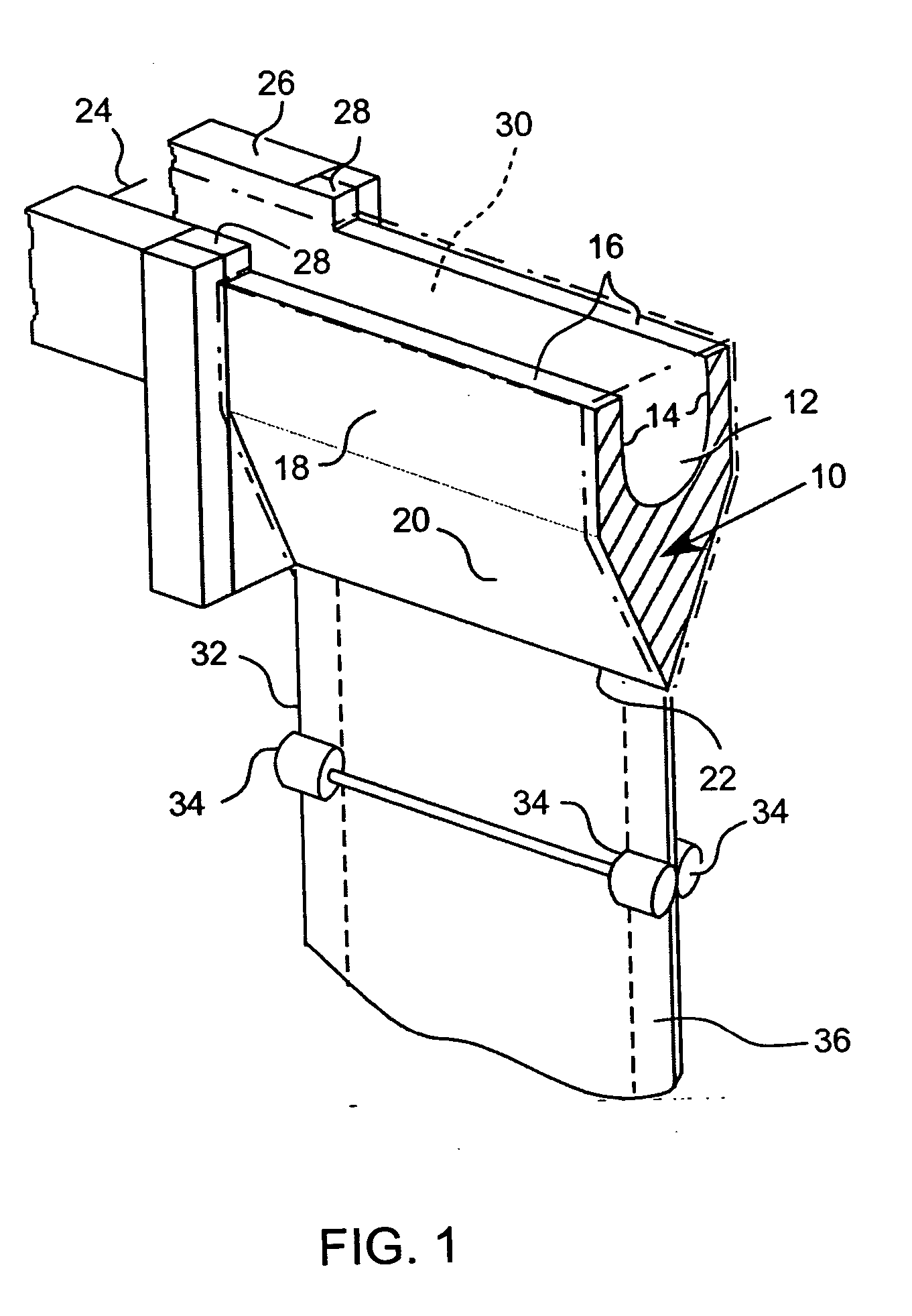

Overflow downdraw glass forming method and apparatus

ActiveUS20060016219A1Process can be modifiedMinimizing thickness variationGlass furnace apparatusVolume/mass flow measurementThermal creepEngineering

The present invention significantly modifies “The Overflow Process”. It includes a method and apparatus for measuring glass flow rate and maintaining a constant glass flow rate. It also embodies design features and methods that support and stress the forming apparatus in a manner such that the deformation that results from thermal creep is corrected, thus minimizing the effect of the thermal creep on the thickness variation of the glass sheet. The present invention also embodies design features that change the process from a single step (combined flow distribution and cooling) to a two step process; step one being flow distribution and step two being cooling.

Owner:CORNING INC

Method of separating strengthened glass

A method of cutting a glass sheet that has been thermally or chemically strengthened along a predetermined line, axis, or direction with high speed and with minimum damage on the cut edges. The strengthened glass sheet may be cut into at least two pieces, one of which having a predetermined shape or dimension. At least one damage line is formed within the strengthened glass sheet. The at least one damage line is formed outside the strengthened compressive stress surface layers and within the tensile stress layer of the strengthened glass sheet. The at least one damage line may be formed by laser treatment. A crack is initiated in the strengthened glass sheet and propagated along the at least one damage line to separate the strengthened glass sheet along the predetermined line, axis, or direction into at least two pieces.

Owner:CORNING INC

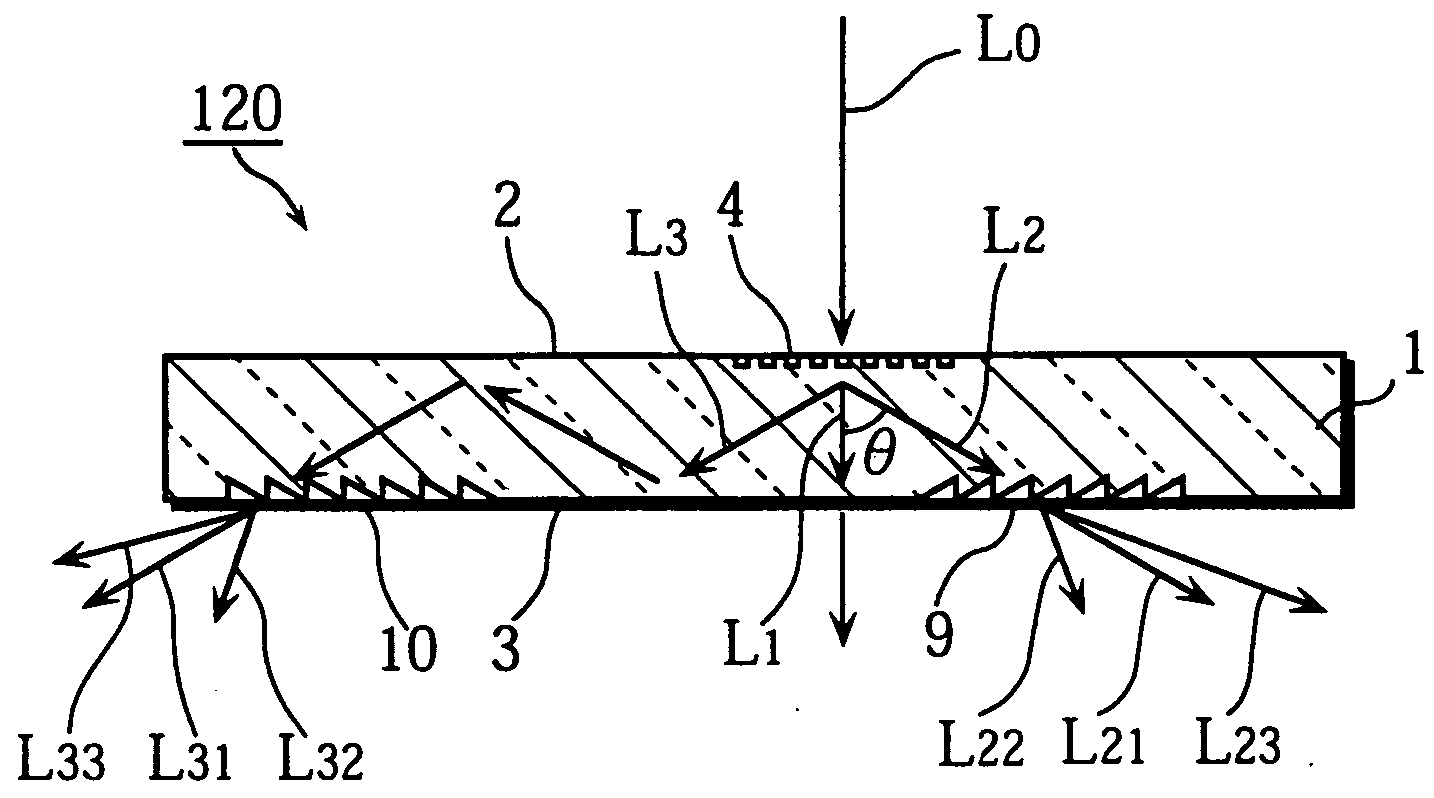

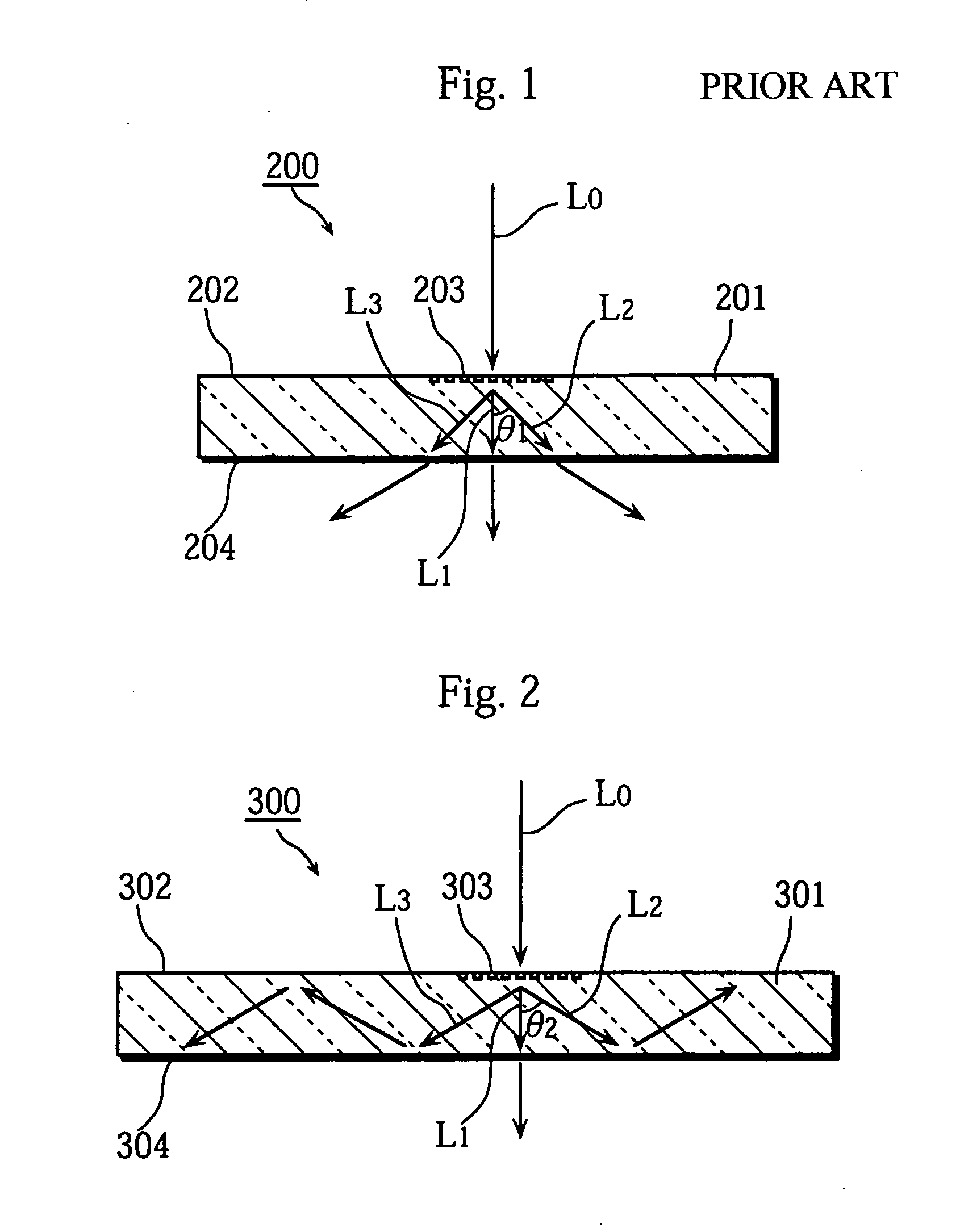

Diffractive optical element that polarizes light and an optical pickup using the same

InactiveUS20040233534A1Integrated optical head arrangementsPolarising elementsOptical pickupLength wave

A first diffractive optical element pattern with a pattern pitch that is no greater than a wavelength of incident light is formed on a first main surface of substrate such as a glass plate. Second diffractive optical element patterns are formed at positions that are respectively incident to positive first-order diffracted light and negative first-order diffracted light produced by the first diffractive optical element pattern. Negative first-order diffracted light produced by each second diffractive optical element pattern is incident upon a boundary face of the substrate at an angle that is smaller than the critical angle, and so exits the substrate.

Owner:PANASONIC CORP

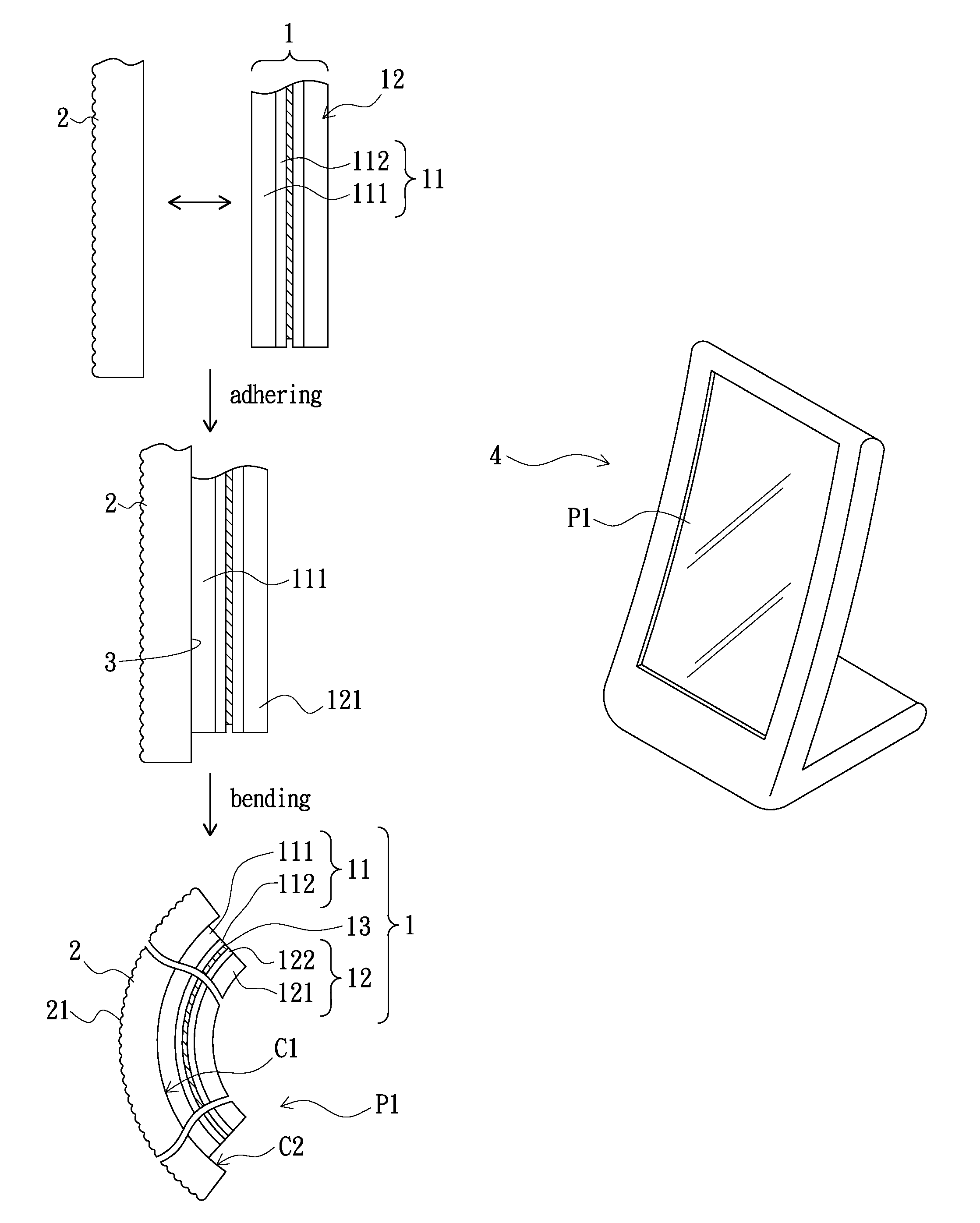

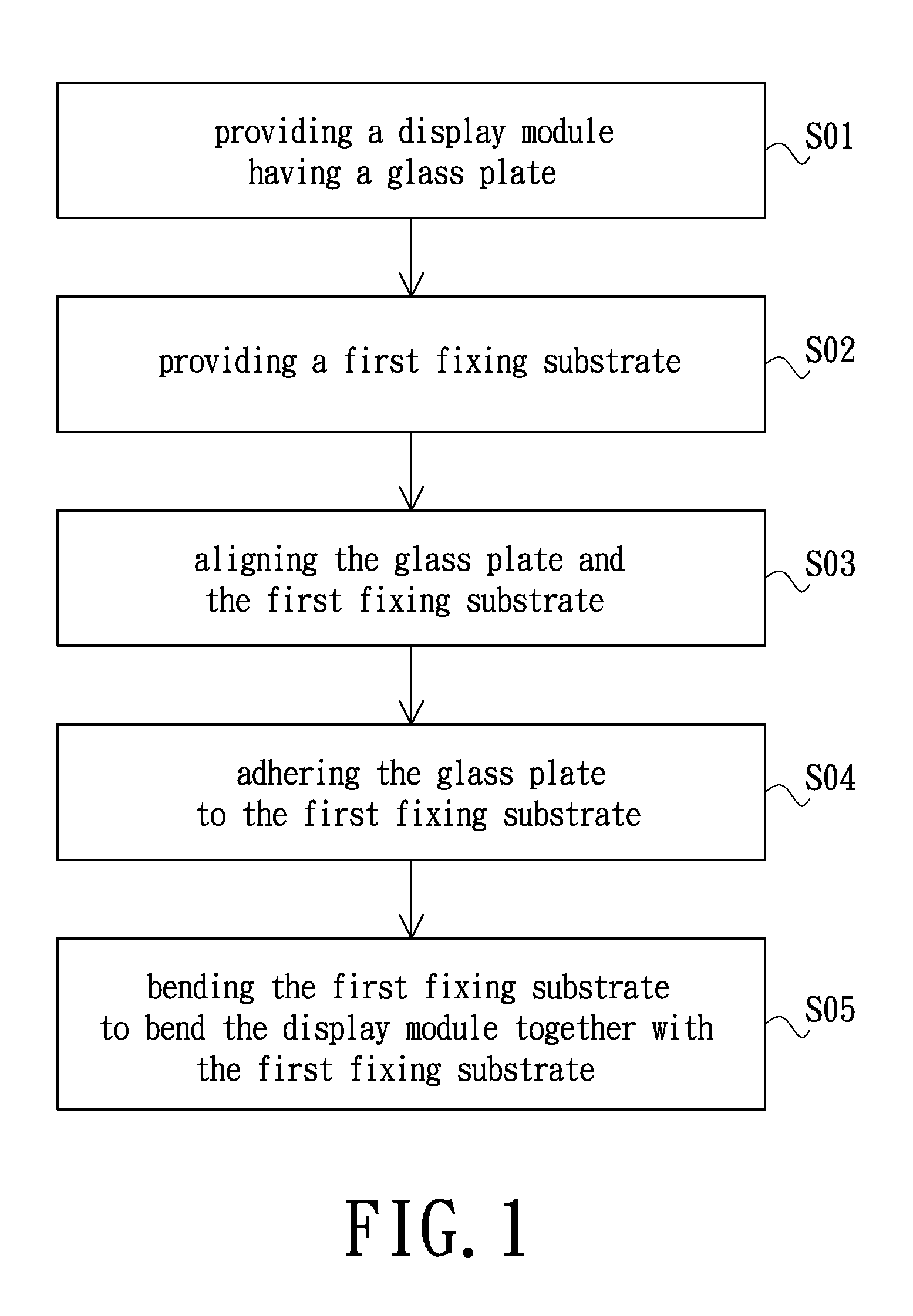

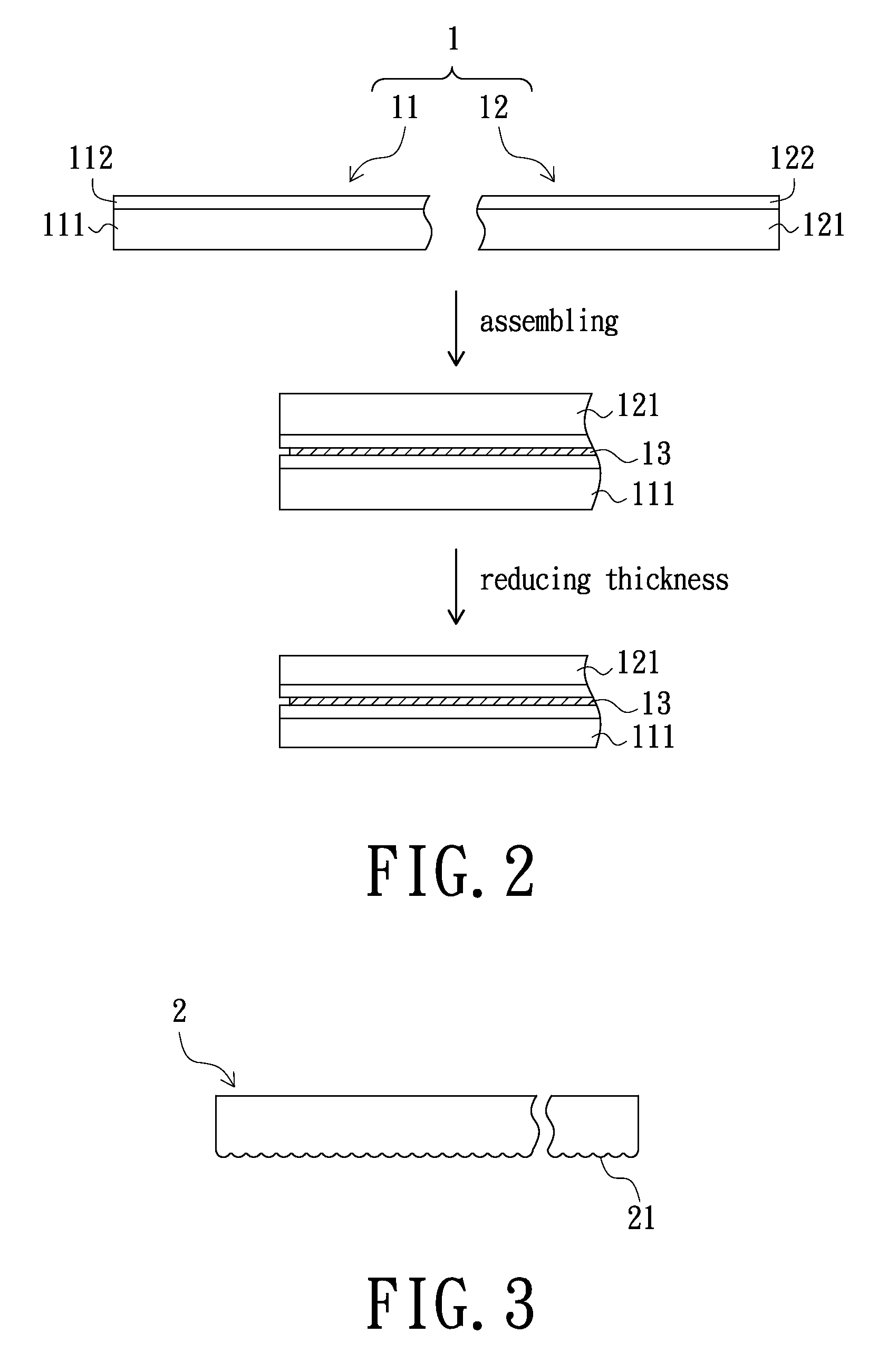

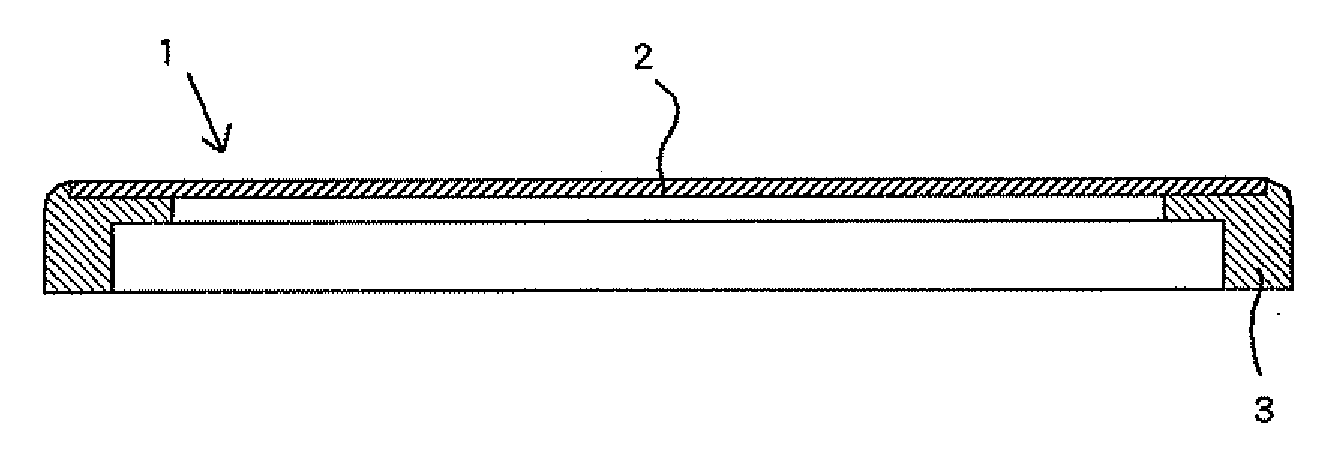

Curved display panel and method for manufacturing the same

ActiveUS8305743B2Improve production yieldIncrease stickinessDisposition/mounting of recording headsDigital data processing detailsEngineeringGlass sheet

Owner:OPTRONIC SCI LLC

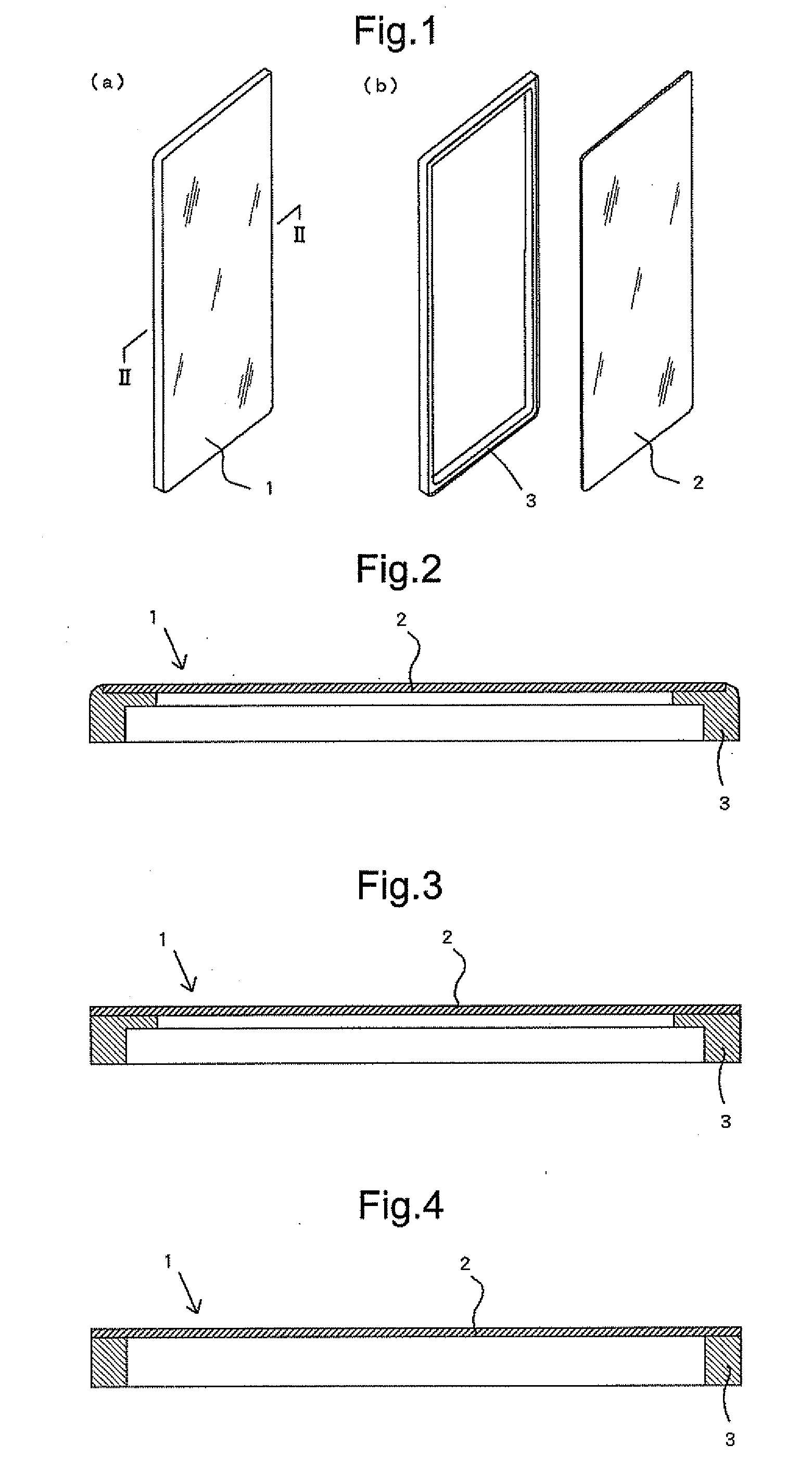

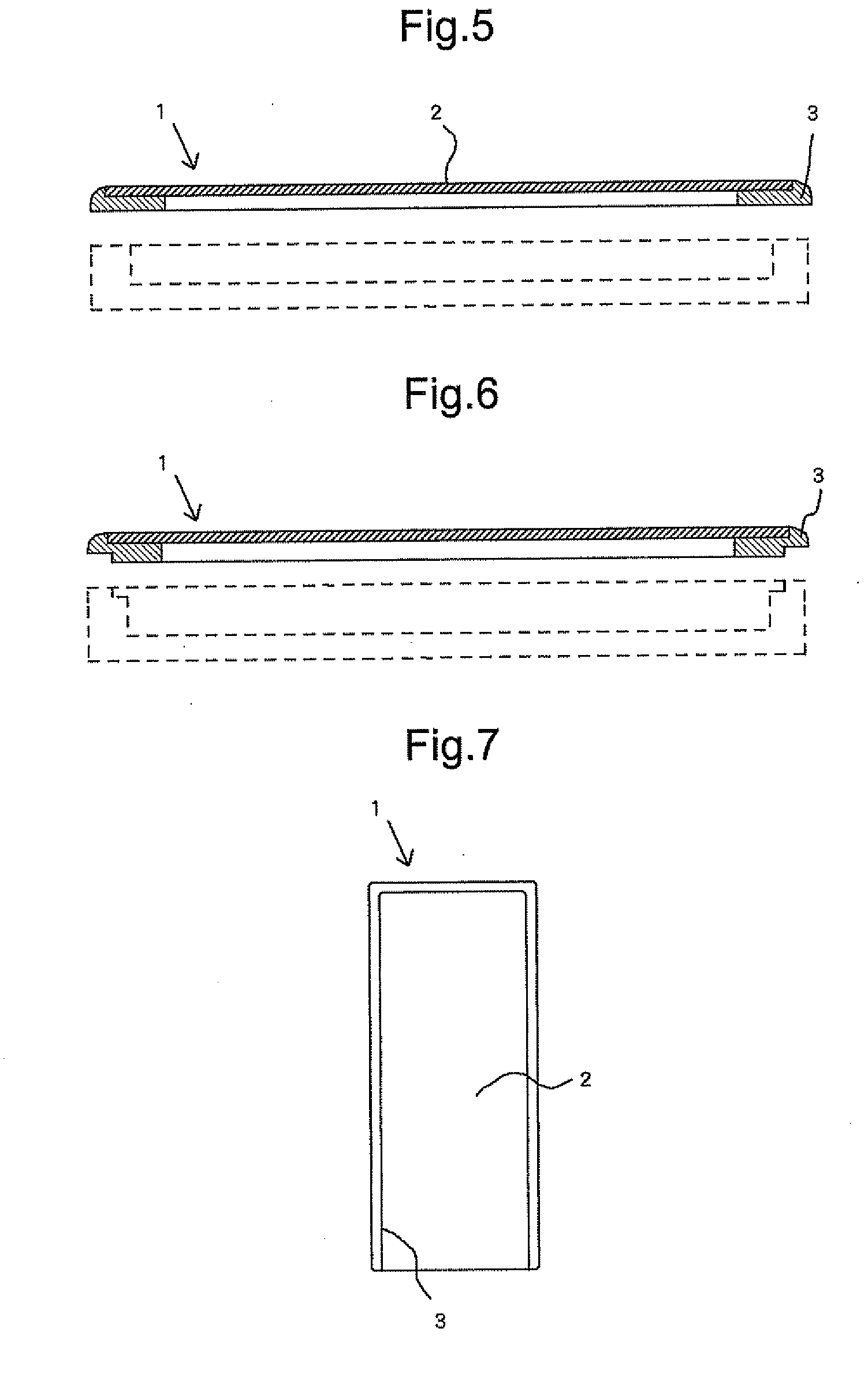

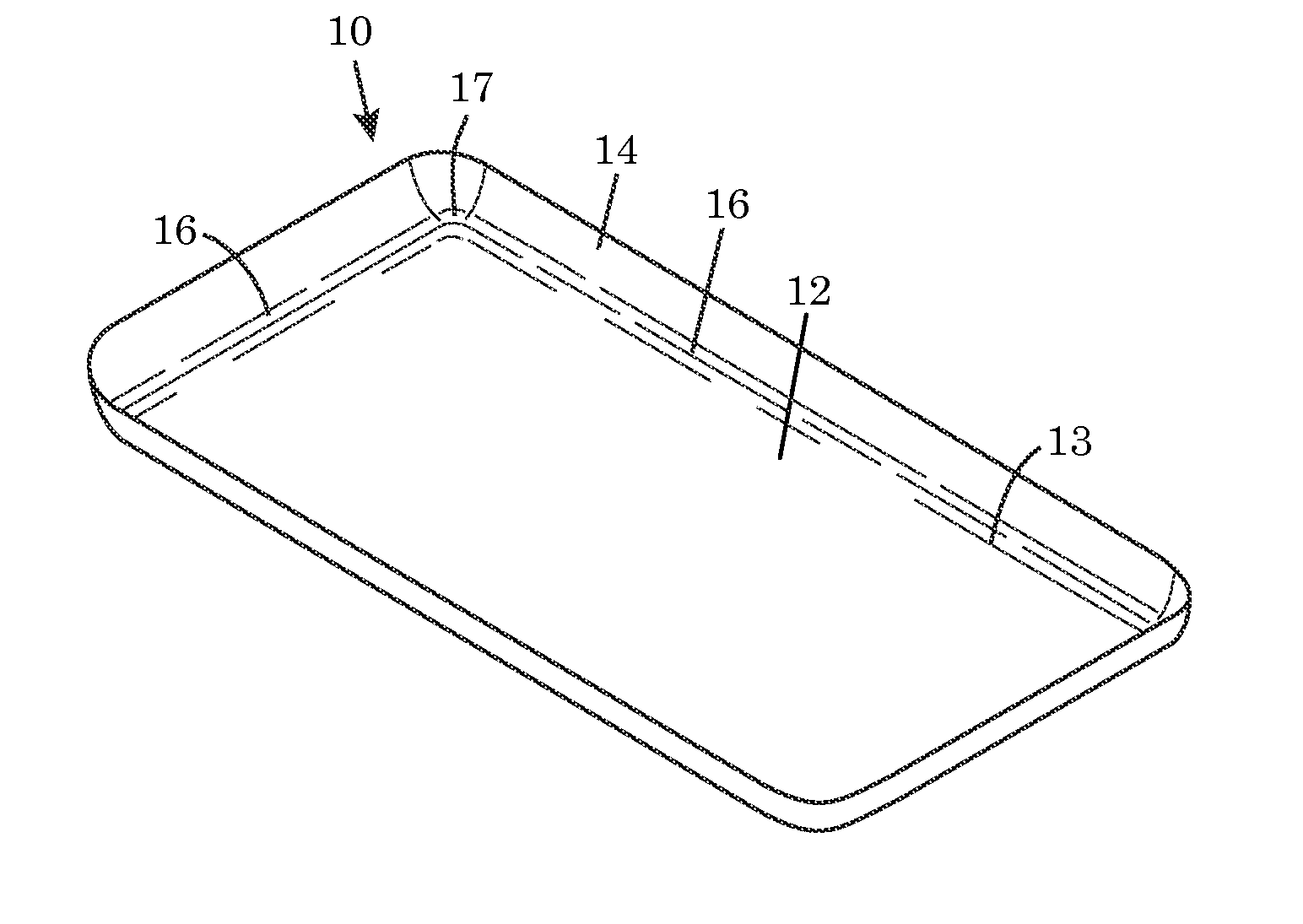

Housing Case, Method for Manufacturing Housing Case, and Glass Insert Molding Die Used in Same

ActiveUS20100014232A1Limit scopeDigital data processing detailsCasings with display/control unitsEngineeringGlass sheet

A housing case for a small electric device and communication device includes a flat plate having a dimension substantially the same as that of the front portion of the housing case and comprising at least a glass plate, and a resin frame integrated with the flat plate to support the backside periphery of the flat plate.

Owner:NISSHA PRINTING COMPANY

Method and apparatus for drawing a low liquidus viscosity glass

InactiveUS20070130994A1Easy to understandGlass furnace apparatusGlass drawing apparatusViscosityGlass sheet

A method of a drawing a glass ribbon from molten glass sheet via a downdraw process by creating a temperature drop across a thickness of the molten glass flowing over forming surfaces of a forming wedge. The forming wedge includes an electrically conductive material for heating the glass above the root.

Owner:CORNING INC

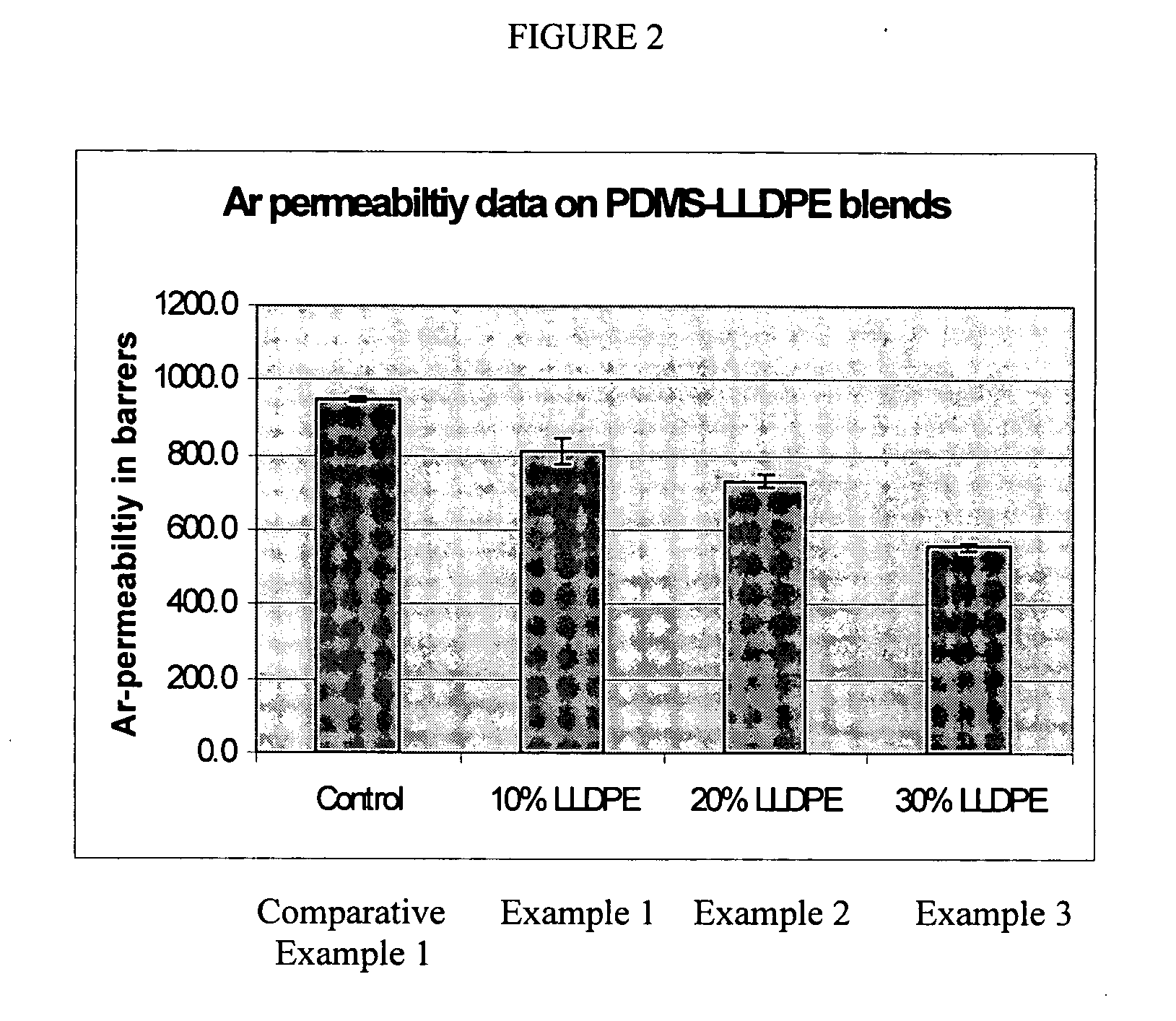

Insulated glass unit possessing room temperature-cured siloxane sealant composition of reduced gas permeability

InactiveUS20070116907A1Easy to useReduce air permeabilityAdhesivesUnits with parallel planesPolymer scienceInsulated glazing

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Interlayers Comprising Stabilized Tungsten Oxide Agents

ActiveUS20090035583A1Convenient lightingTimely maintenanceOrganic chemistrySynthetic resin layered productsPlasticizerUltraviolet lights

The present invention includes polymer interlayers that are used in multiple layer glazing panels. Interlayers of the present invention comprise a thermoplastic polymer, a plasticizer, a tungsten oxide agent, and a stabilizing agent that prevents the degradation of the tungsten oxide agent. Interlayers incorporating such components have improved ultraviolet light blocking character, and also maintain optical quality over time.

Owner:SOLUTIA INC

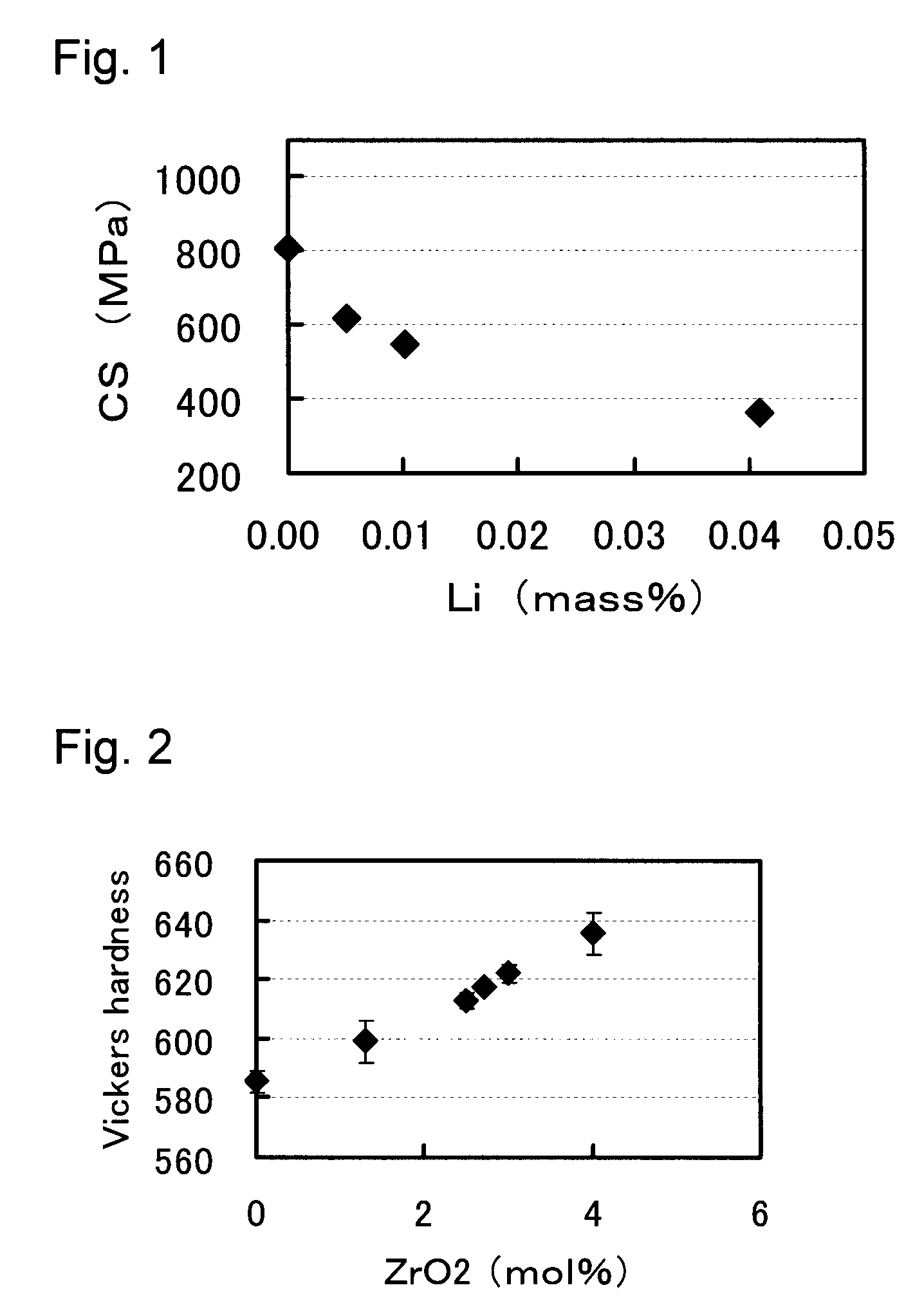

Glass for chemical tempering and glass plate for display device

InactiveUS20130011650A1High strengthReduced glass strengthSynthetic resin layered productsGlass/slag layered productsDisplay deviceGlass sheet

To provide glass to be used for chemically tempered glass which is hardly broken even when flawed.Glass for chemical tempering, which comprises, as represented by mole percentage based on the following oxides, from 65 to 85% of SiO2, from 3 to 15% of Al2O3, from 5 to 15% of Na2O, from 0 and less than 2% of K2O, from 0 to 15% of MgO and from 0 to 1% of ZrO2, and has a total content SiO2+Al2O3 of SiO2 and Al2O3 of at most 88%.

Owner:ASAHI GLASS CO LTD

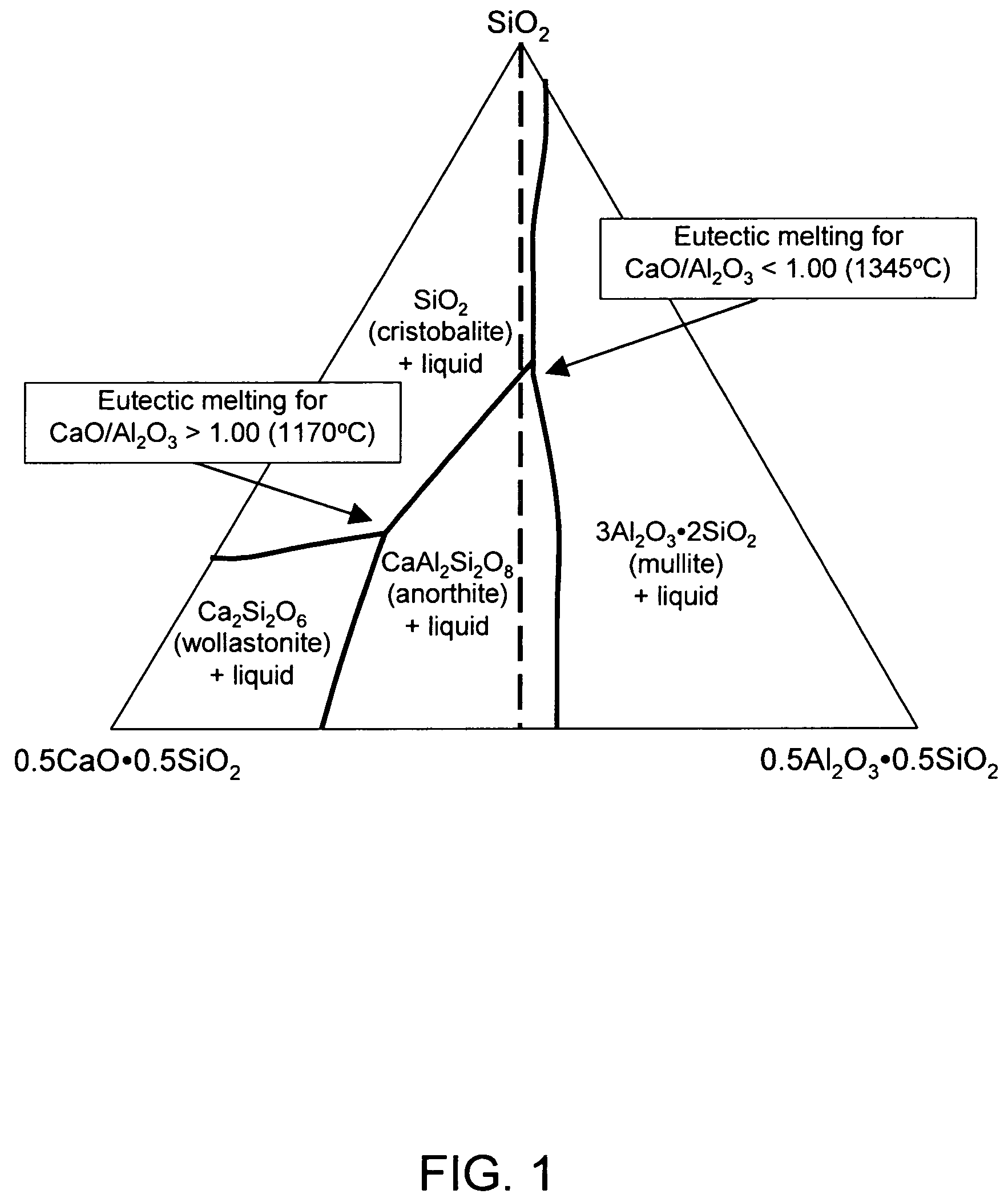

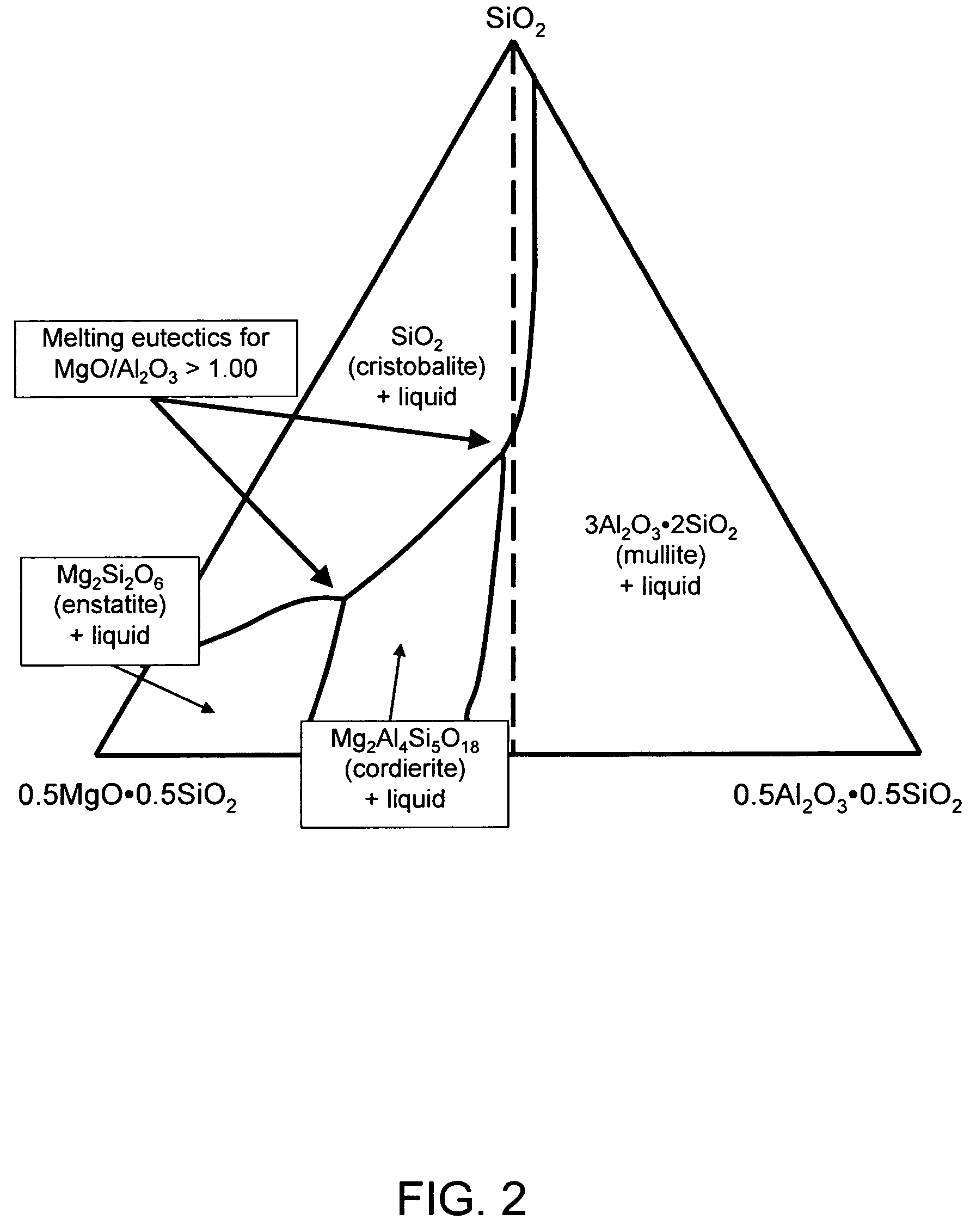

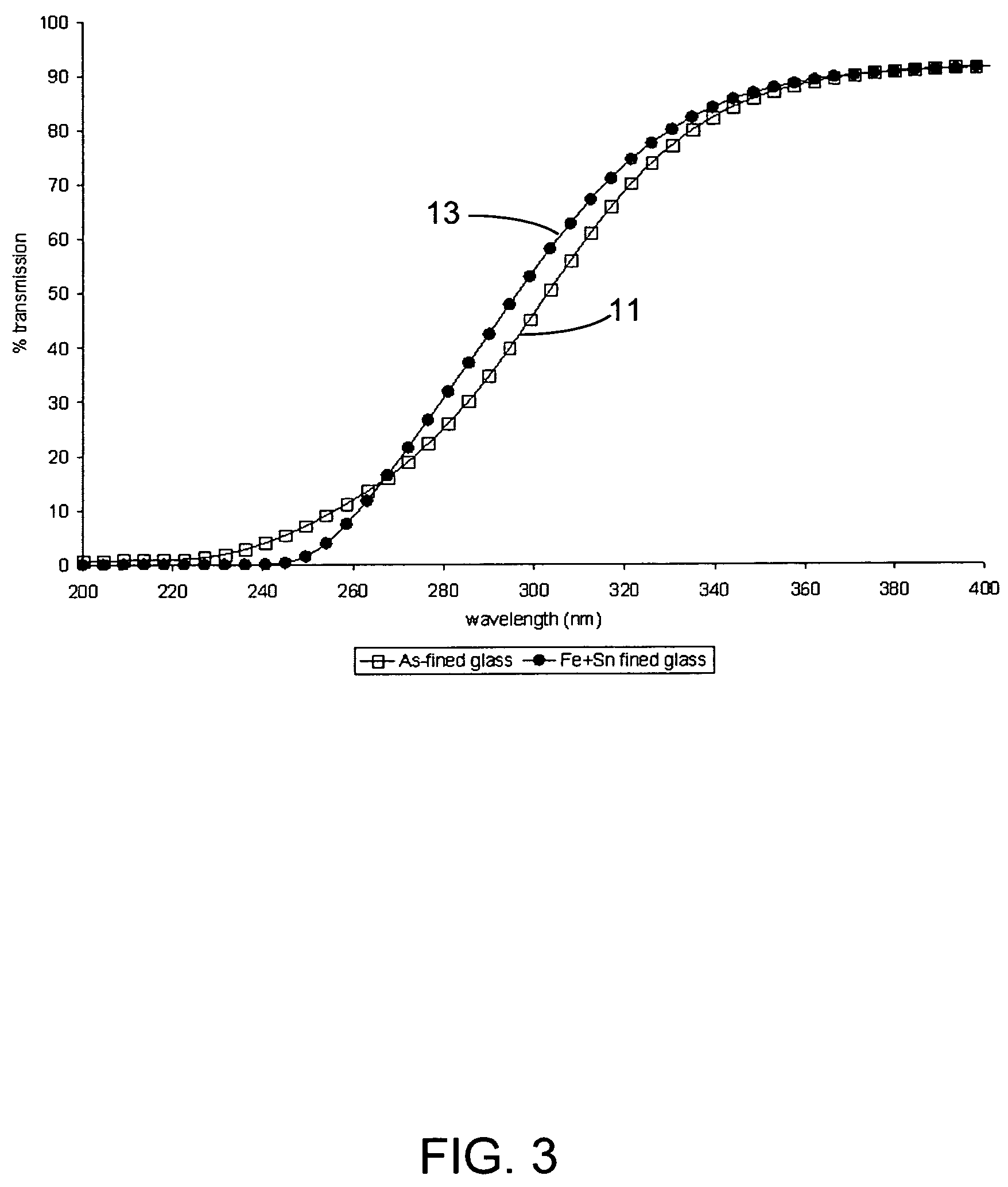

Alkali-free glasses containing iron and tin as fining agents

ActiveUS7534734B2Glass drawing apparatusGlass forming apparatusActive-matrix liquid-crystal displayAlkali free

Alkali-free glasses are disclosed which can be used to produce substrates for flat panel display devices, e.g., active matrix liquid crystal displays (AMLCDs). The glasses contain iron and tin as fining agents, and preferably are substantially free of arsenic and antimony. In certain embodiments, the glasses are also substantially free of barium. Methods for producing alkali-free glass sheets using a downdraw process (e.g., a fusion process) are also disclosed.

Owner:CORNING INC

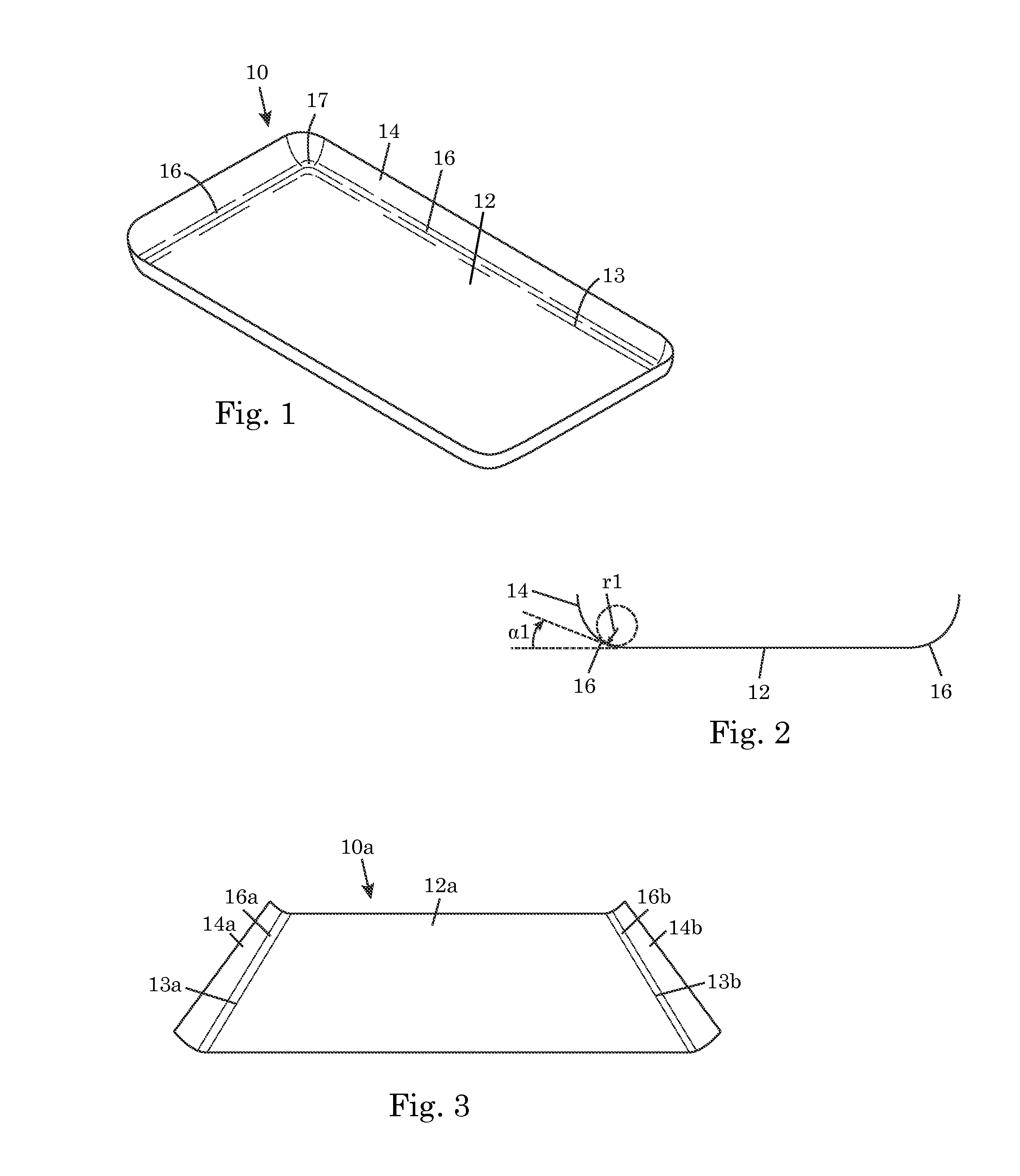

Method and system for forming shaped glass articles

ActiveUS20140234581A1Forming accuratelyLayered productsDigital data processing detailsPoiseGlass sheet

A method of forming a shaped glass article includes placing a glass sheet on a mold such that a first glass area of the glass sheet corresponds to a first mold surface area of the mold and a second glass area of the glass sheet corresponds to a second mold surface area of the mold. The first glass area and the second glass area are heated such that the viscosity of the second glass area is 8 poise or more lower than the viscosity of the first glass area. A force is applied to the glass sheet to conform the glass sheet to the mold surface. During the heating of the second glass area, the first mold surface area is locally cooled to induce a thermal gradient on the mold.

Owner:CORNING INC

Portable antimicrobial ultra violet sterilizer

InactiveUS20100266445A1Reduce manufacturing costLow priceSafety arrangmentsSamplingUVC RadiationWavelength

The present invention relates to a sterilization unit consisting of a cubical enclosure which uses a sequenced supply of ozone and ultraviolet radiation in the C band (UVC) wave length to sterilize. In use, an article to be sterilized is positioned atop a glass plate mounted between two sources of UVC radiation sources and ozone is first supplied to the enclosure for a period of 15 seconds to 60 minutes followed by a supply of UVC radiation for a period of 15 seconds to 60 minutes.

Owner:STER O WAVE LLC

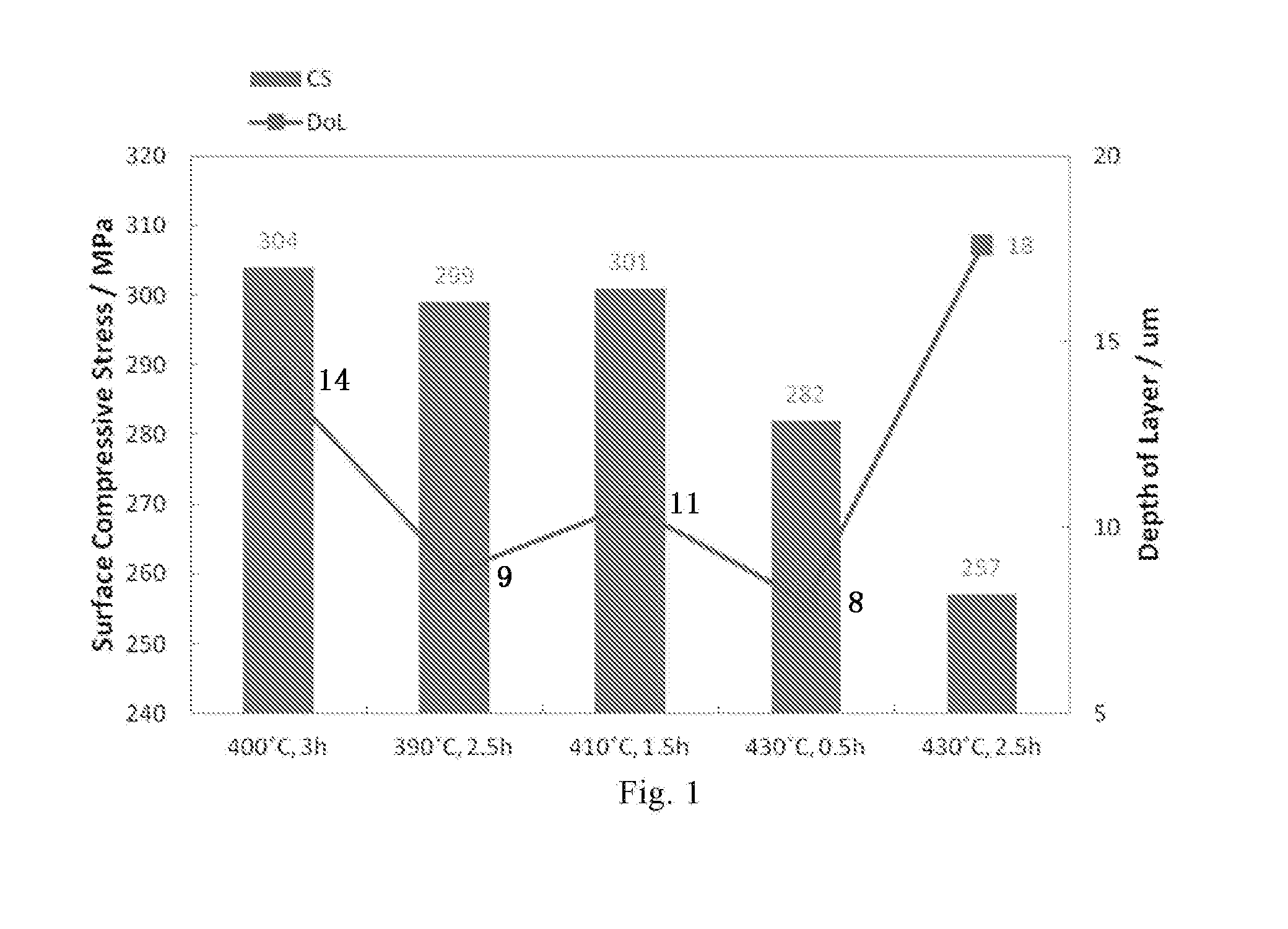

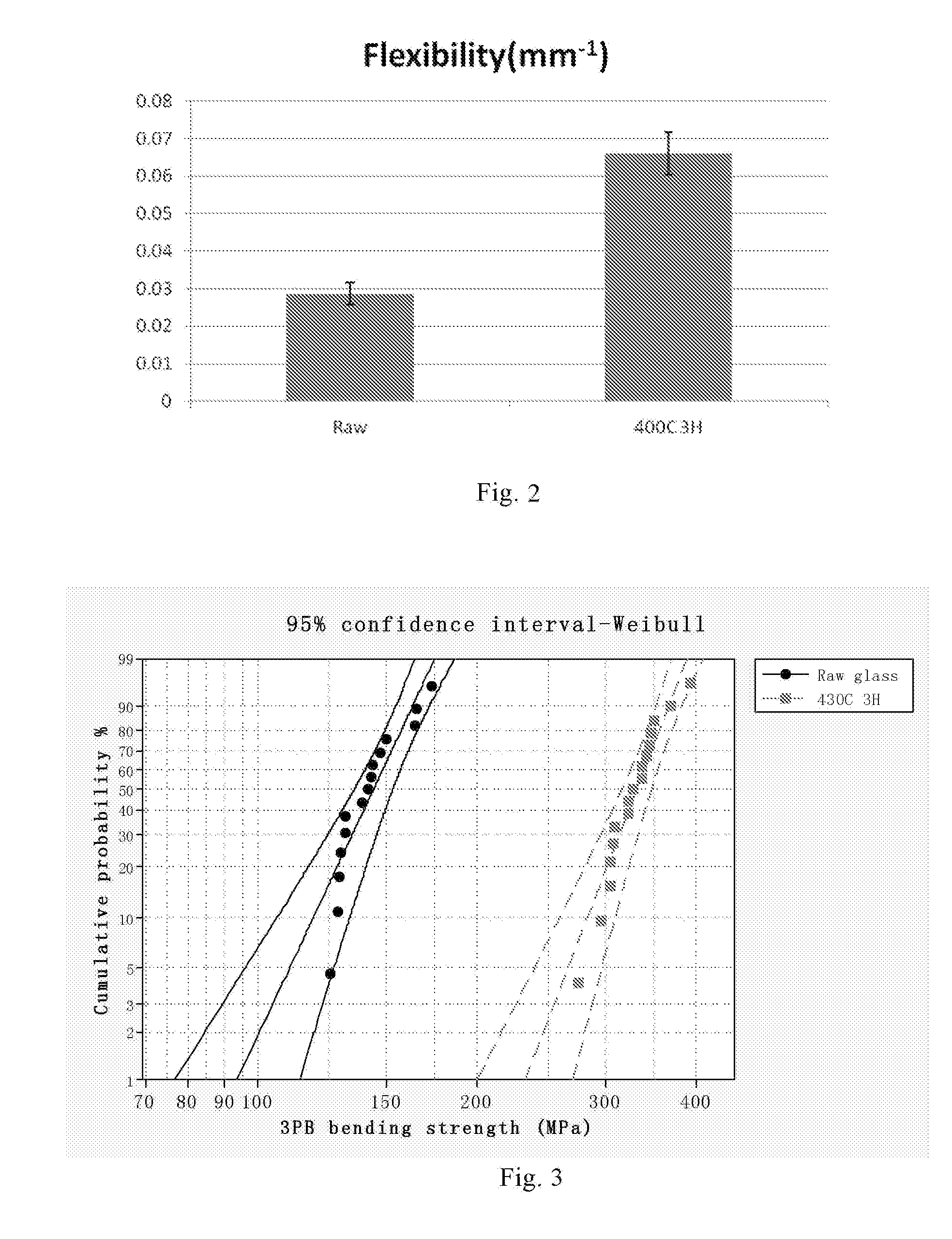

Chemically Toughened Flexible Ultrathin Glass

ActiveUS20160002103A1Reduce compressive stressIncrease flexibilityFilm/foil adhesivesSynthetic resin layered productsGlass sheetThermal shock

A chemically toughened ultrathin glass is provided. The glass has a thickness less than 500 μm and a surface compressive layer having a depth of at most 30 μm. The toughened ultrathin glass sheet is more flexible and has extraordinary thermal shock resistance with the glass being easier to handle for processing.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

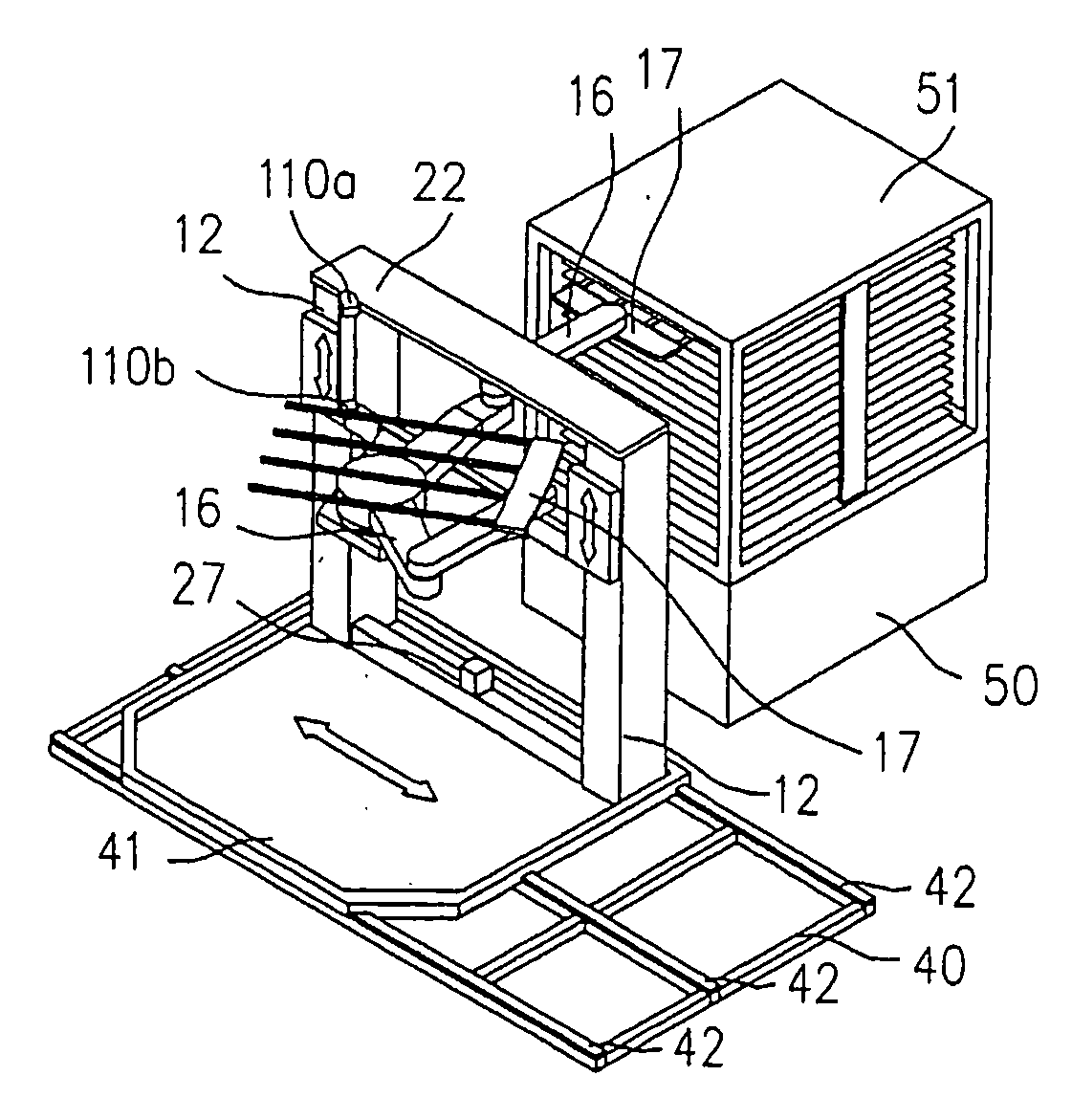

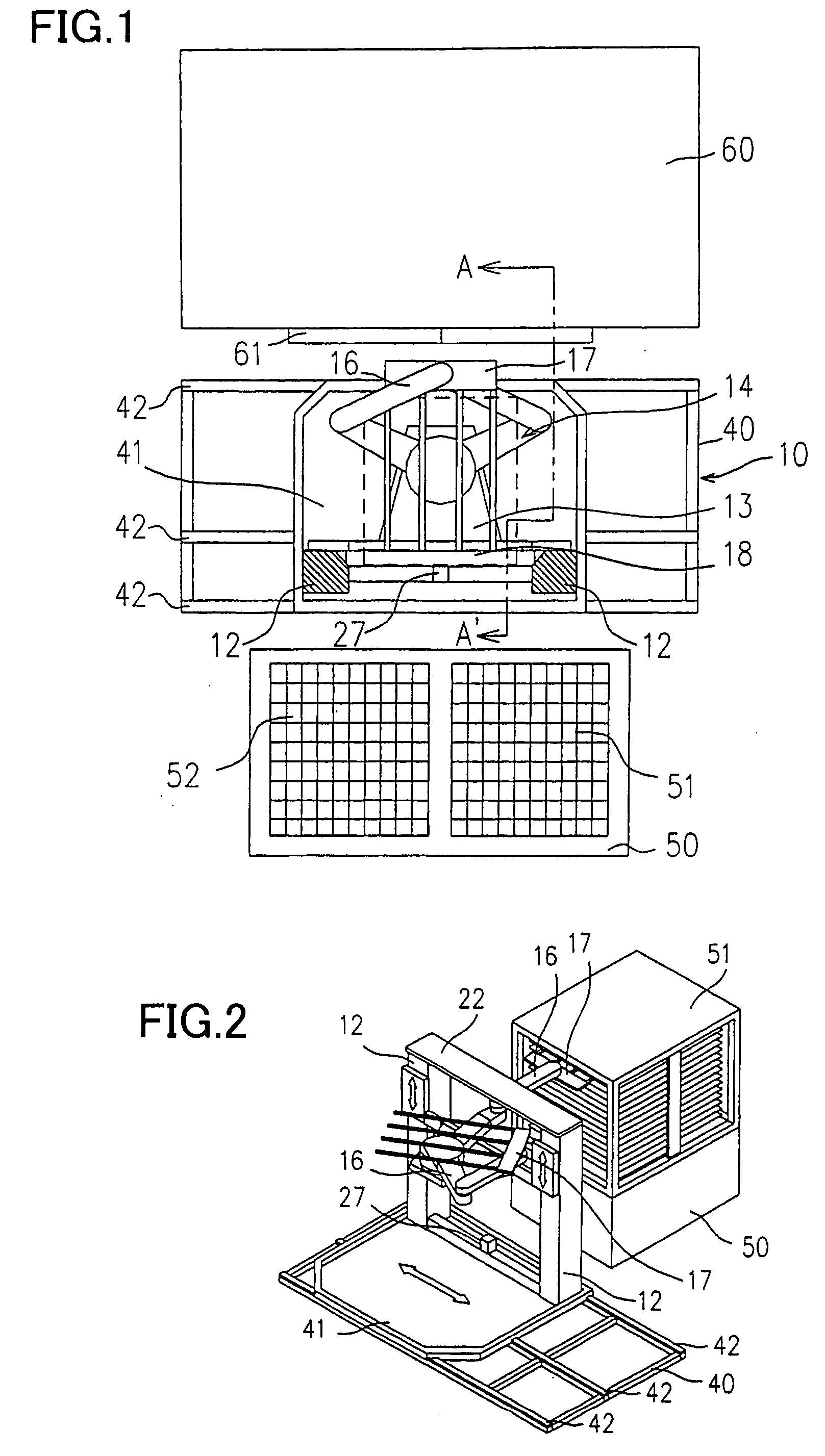

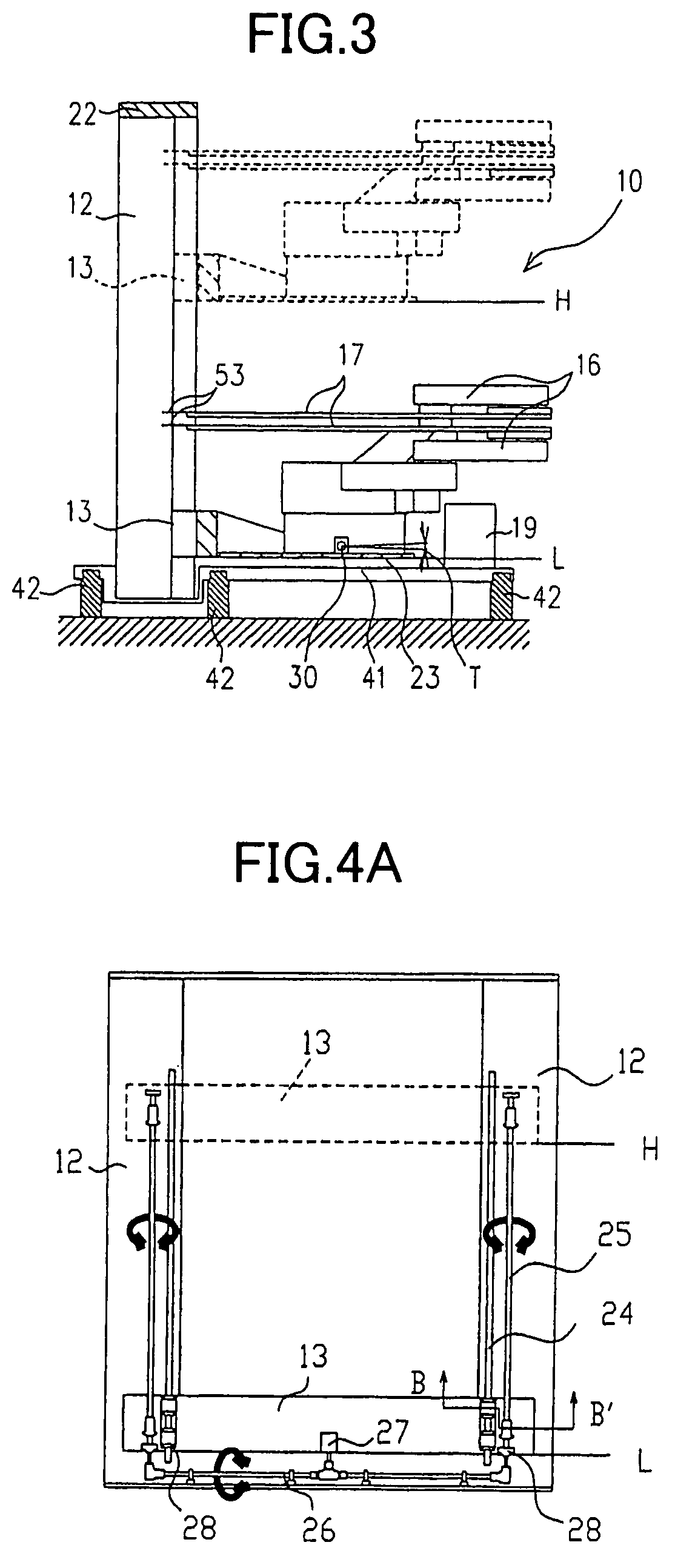

Carrying apparatus and carrying control method for sheet-like substrate

InactiveUS20060216137A1Freedom of movementPrecise positioningSemiconductor/solid-state device manufacturingArticle separationLiquid-crystal displayTransport system

The present invention relates to a transporting apparatus and a transporting control method for thin plates, the apparatus for transporting the thin plates such as liquid crystal display panels and glass plates into a processing chamber, comprising a rather large robot (14) having rotating arms (16) for transporting large-sized thin plates. The transporting apparatus and a thin plate transporting system can stably raise the plates up to the heights of approximately 2 m and can transporting the plates with the deflected amount of the extended rotating arms (16) compensated. A horizontal support table (13) liftably cantilevered on two upright support members (12) is provided in the apparatus, and the transporting robot (14) with the rotating arms (16) is placed on the horizontal support table (13). Also, the deflected amount of the extended rotating arms is compensated by raising the height of the horizontal support table (13) based on the deflected amount. The deflected amount can also be compensated by varying the installation angle of the robot (14) placed on the horizontal support table (13).

Owner:RORZE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com