Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4921 results about "Glass cover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

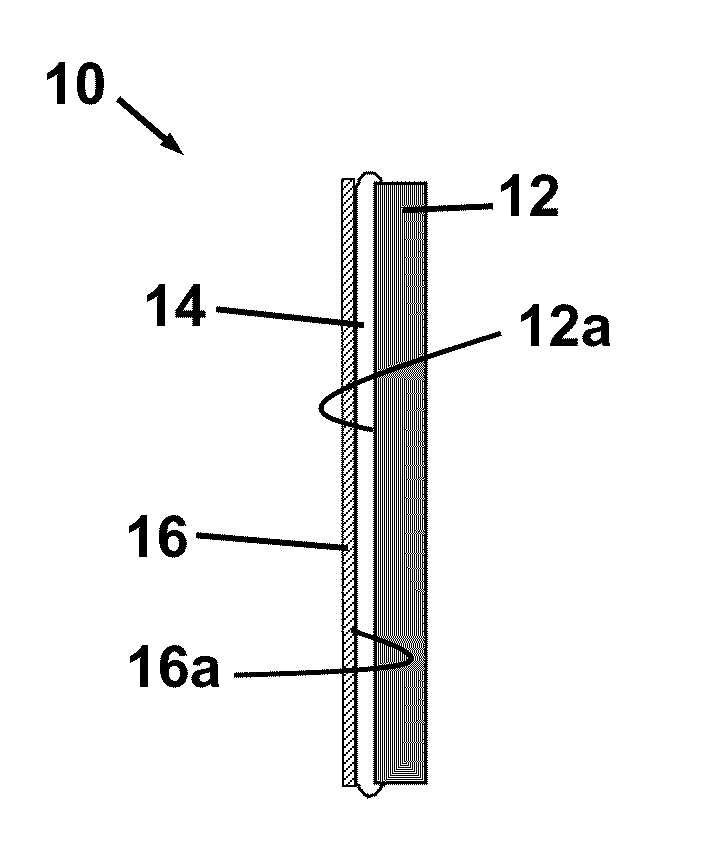

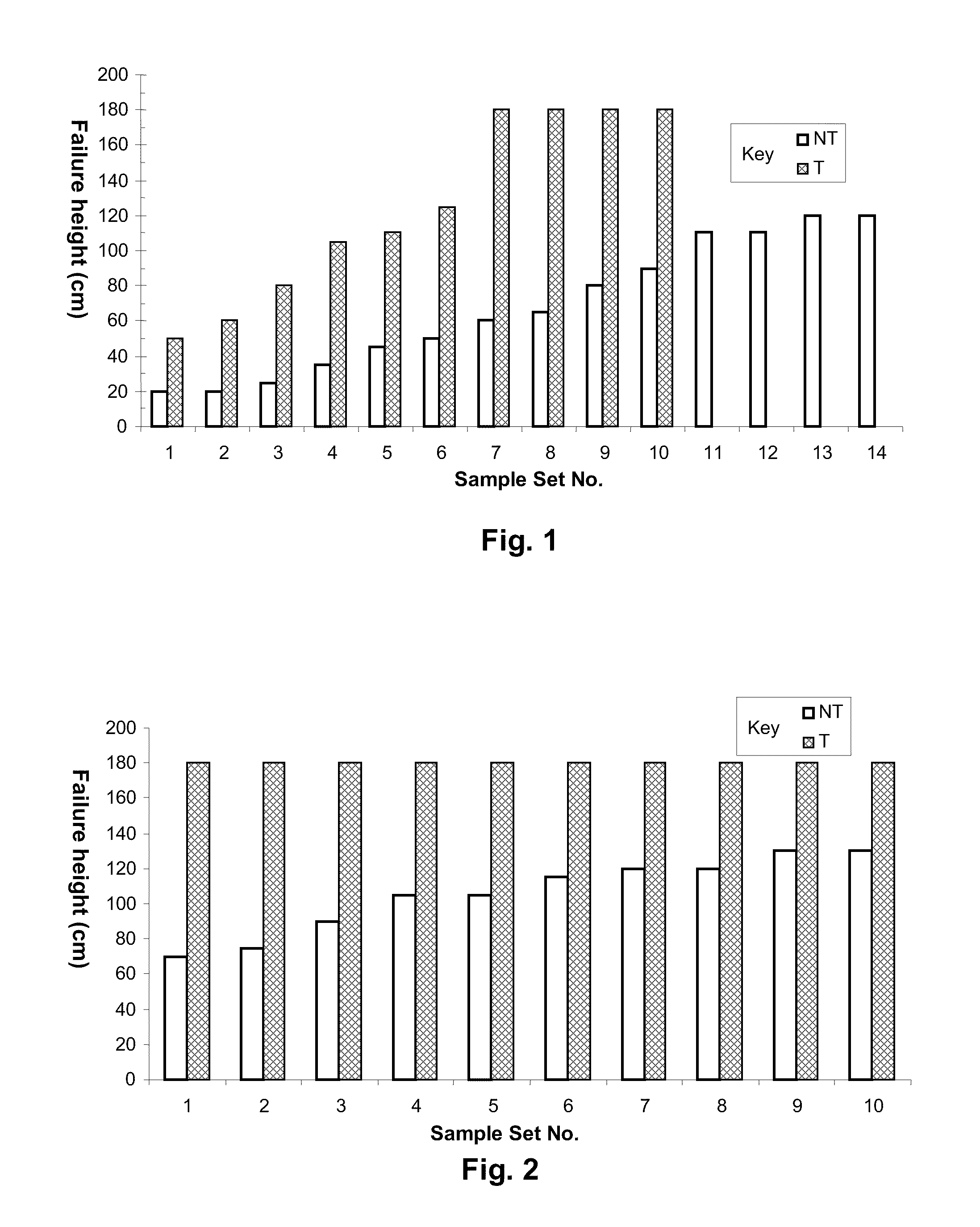

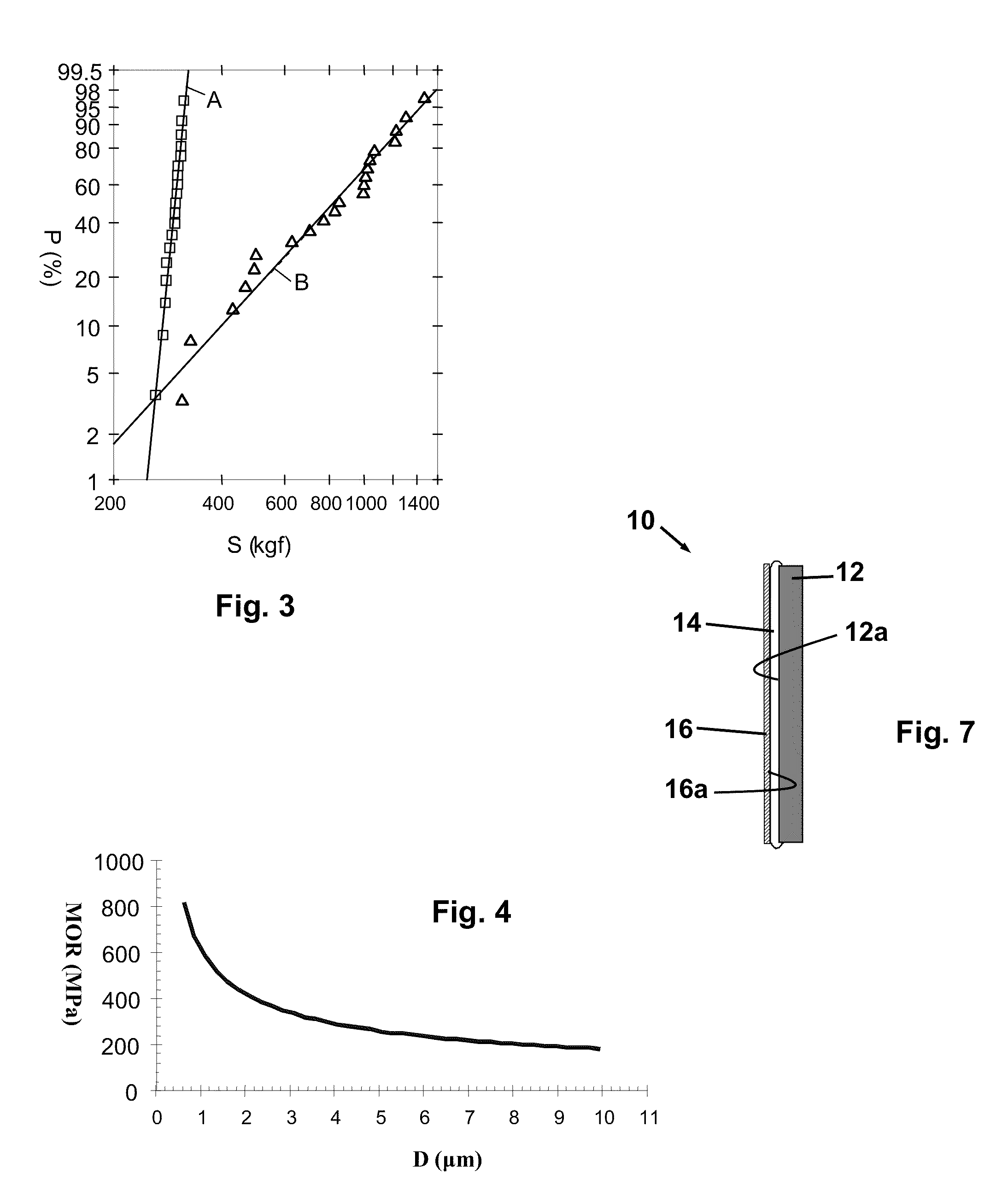

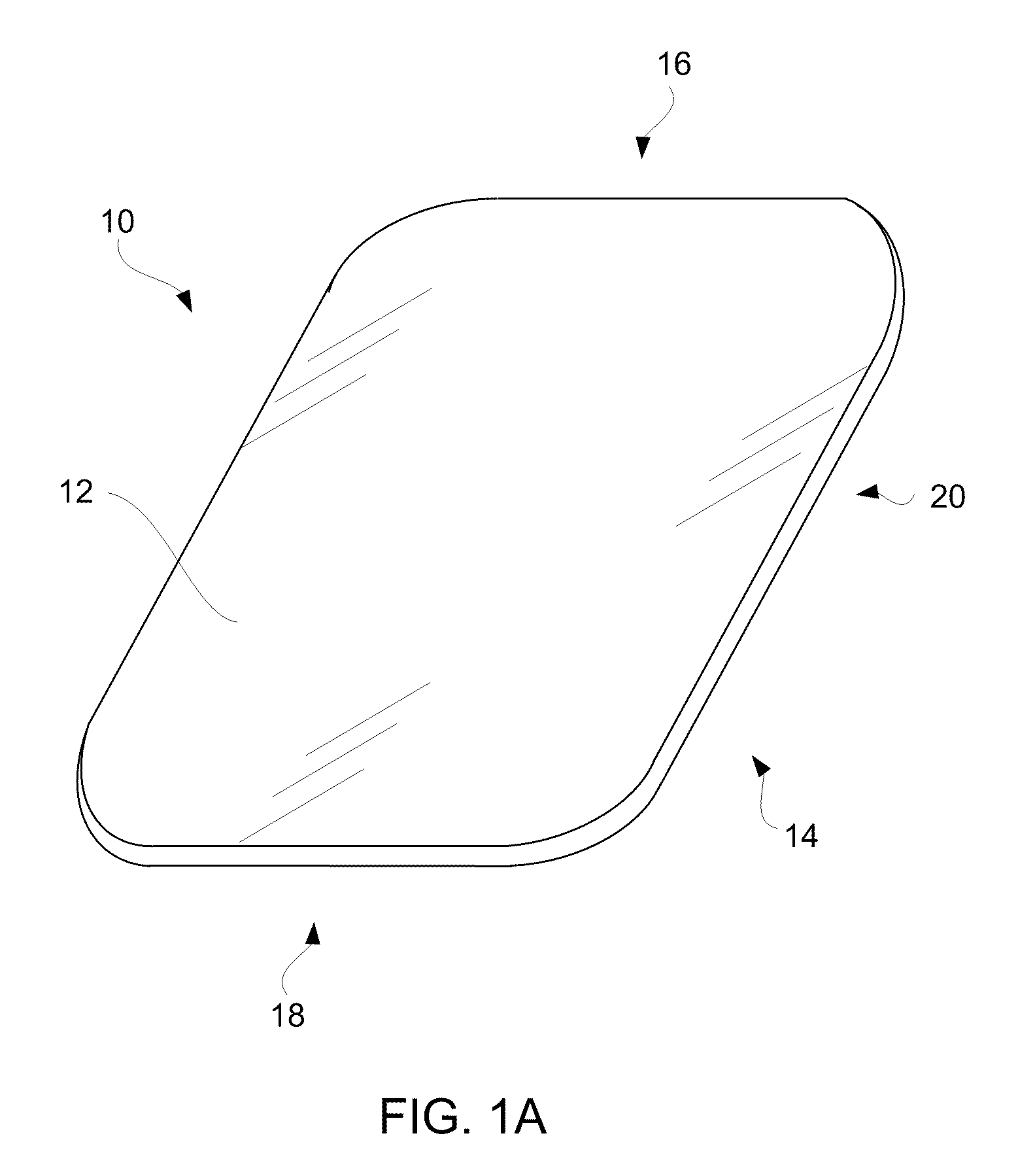

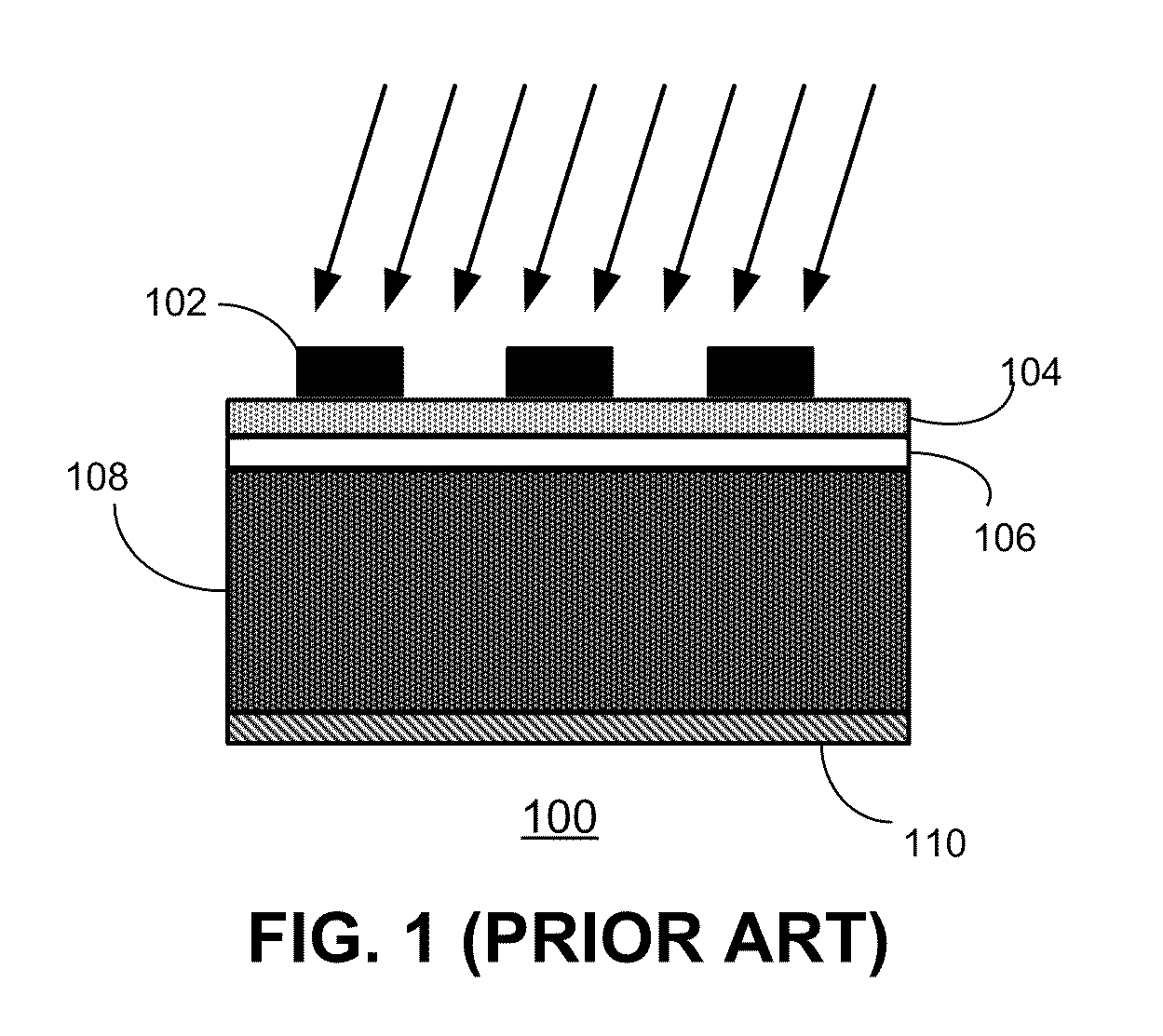

Impact-damage-resistant glass sheet

ActiveUS20110165393A1Increased and more consistent resistanceImprove flexural strengthSynthetic resin layered productsRecord information storageGlass coverDisplay device

Impact-damage-resistant glass sheet comprising at least one chemically etched surface in combination with a tempering surface compression layer, the glass sheet exhibiting a high standardized ball drop failure height and a high flexural modulus of rupture strength, useful to provide damage-resistant glass cover sheets for consumer electronic video display devices, is provided by subjecting thin glass sheet to a combination of a surface tempering treatment and a surface etching treatment that improves strength while maintaining the optical glass sheet properties required for video display applications.

Owner:CORNING INC

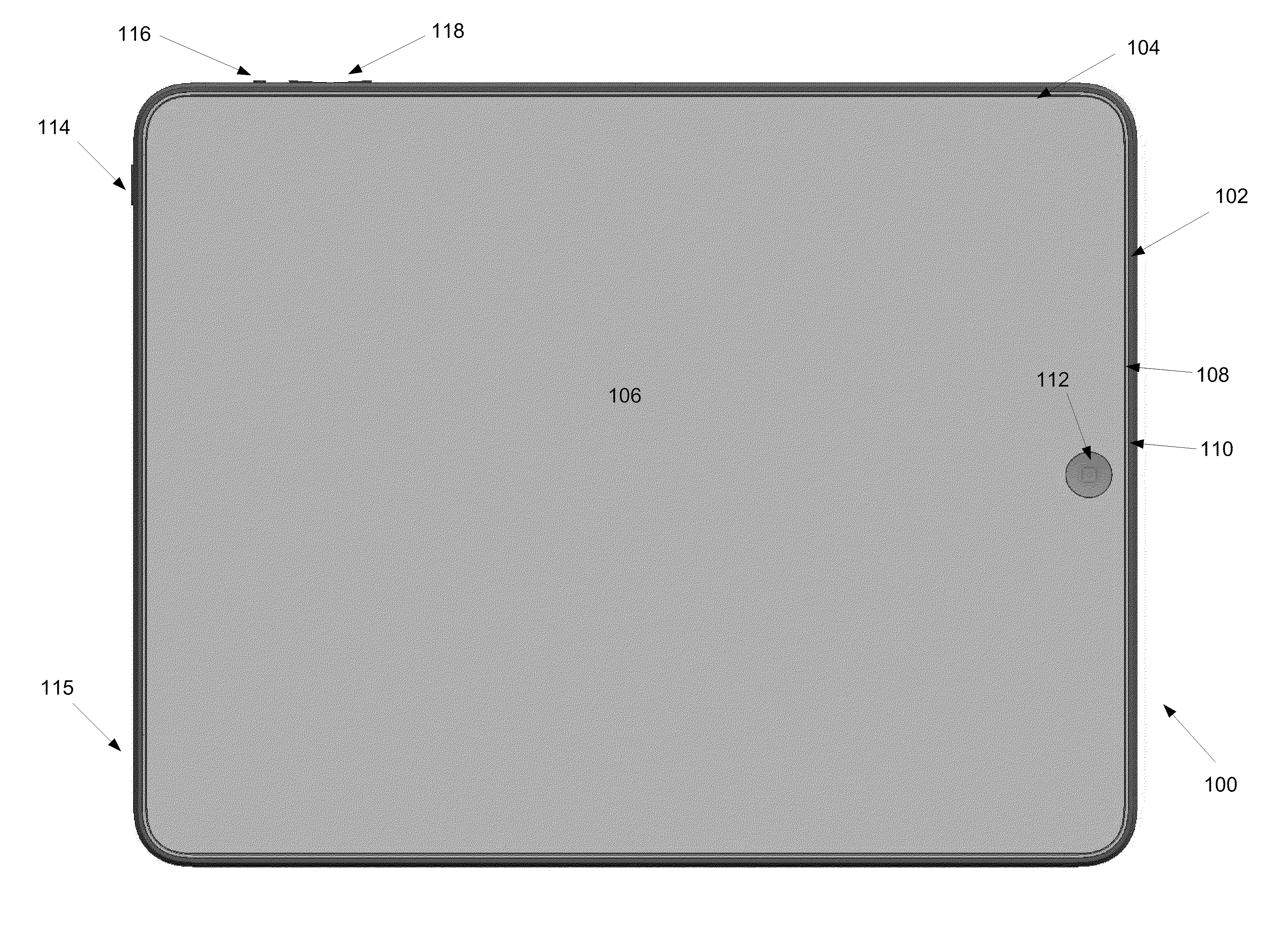

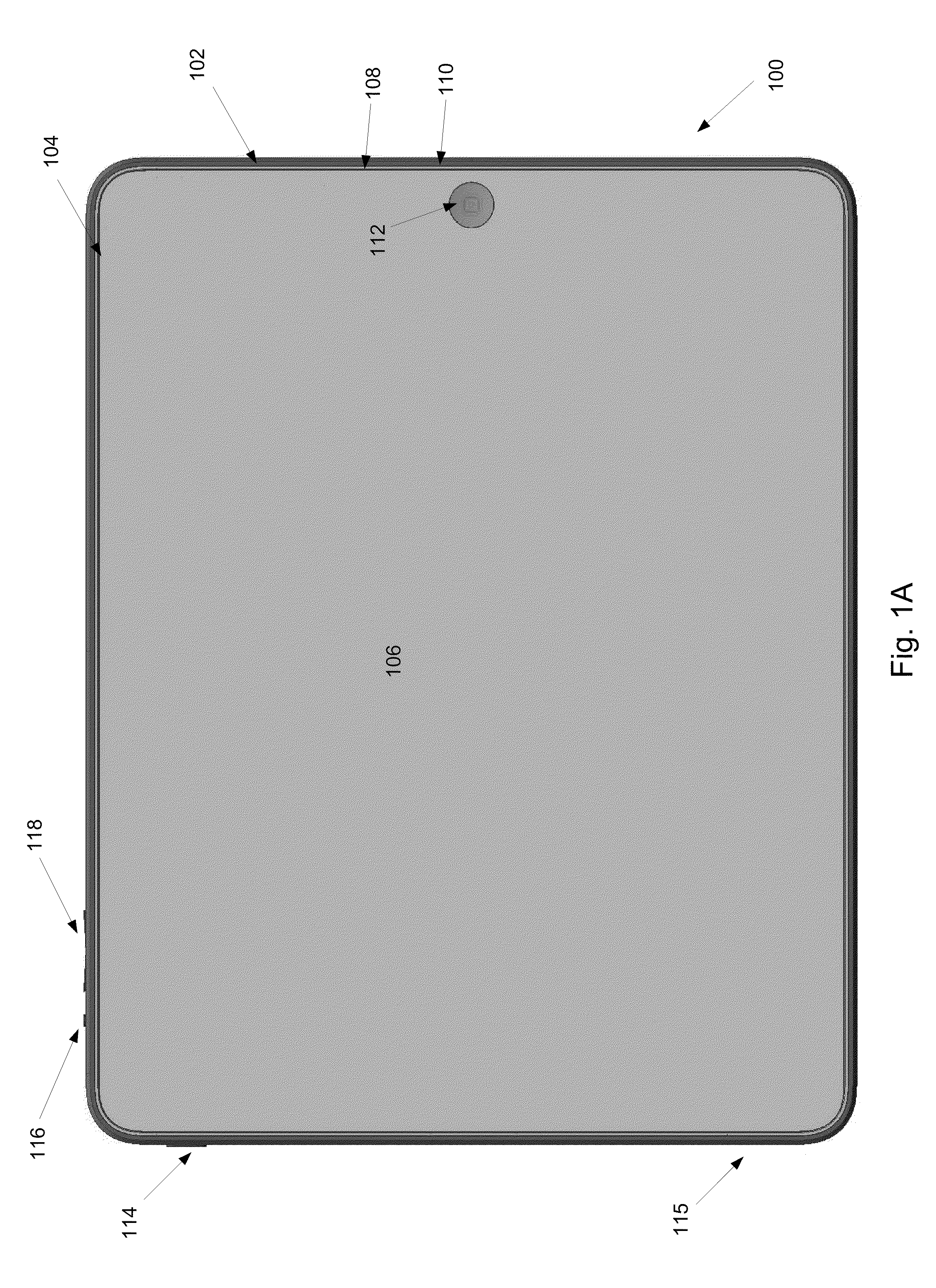

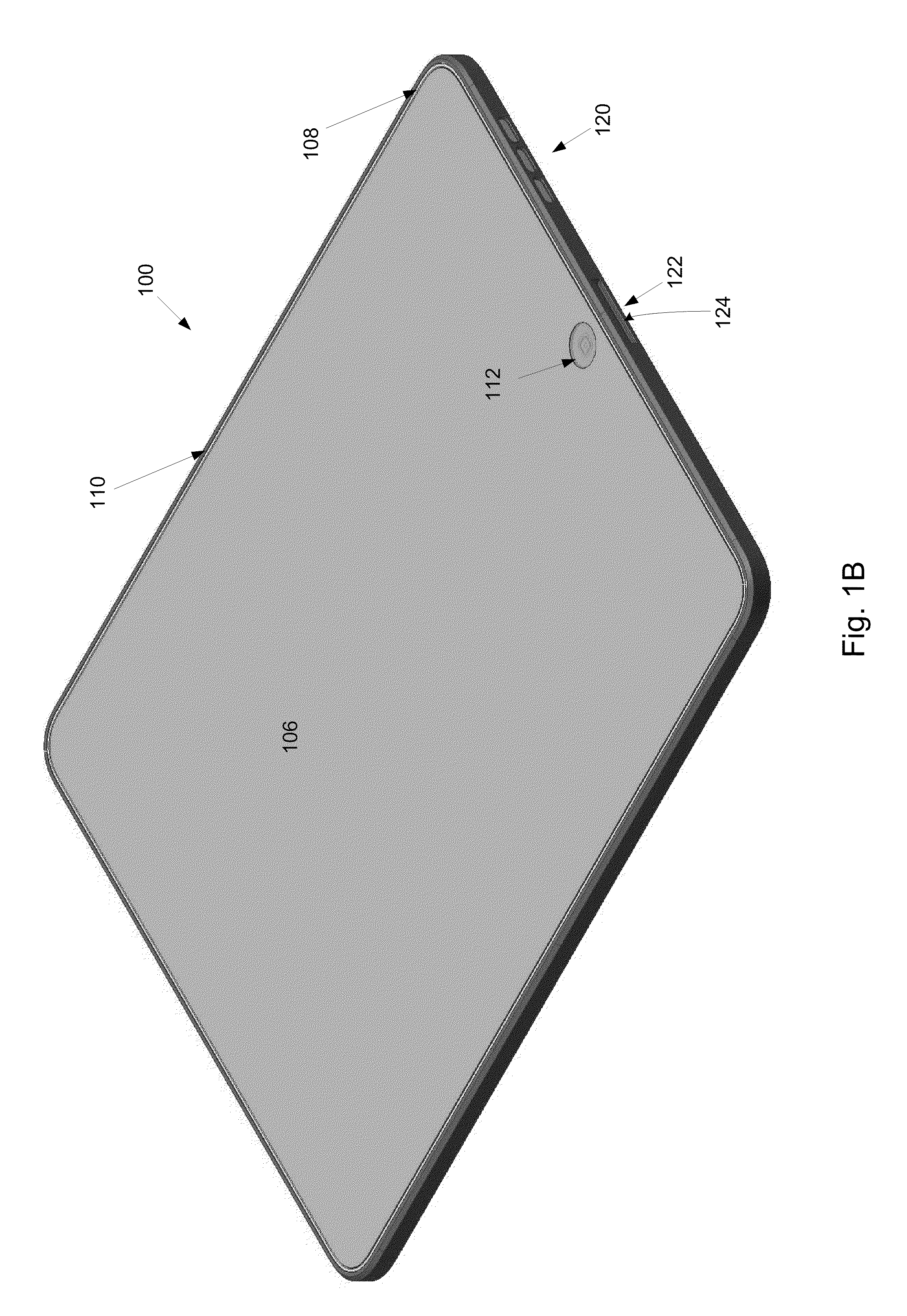

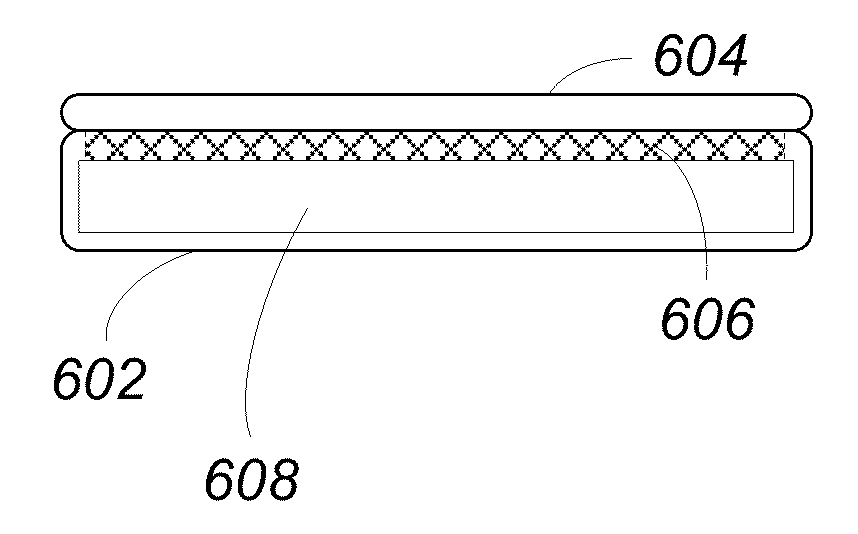

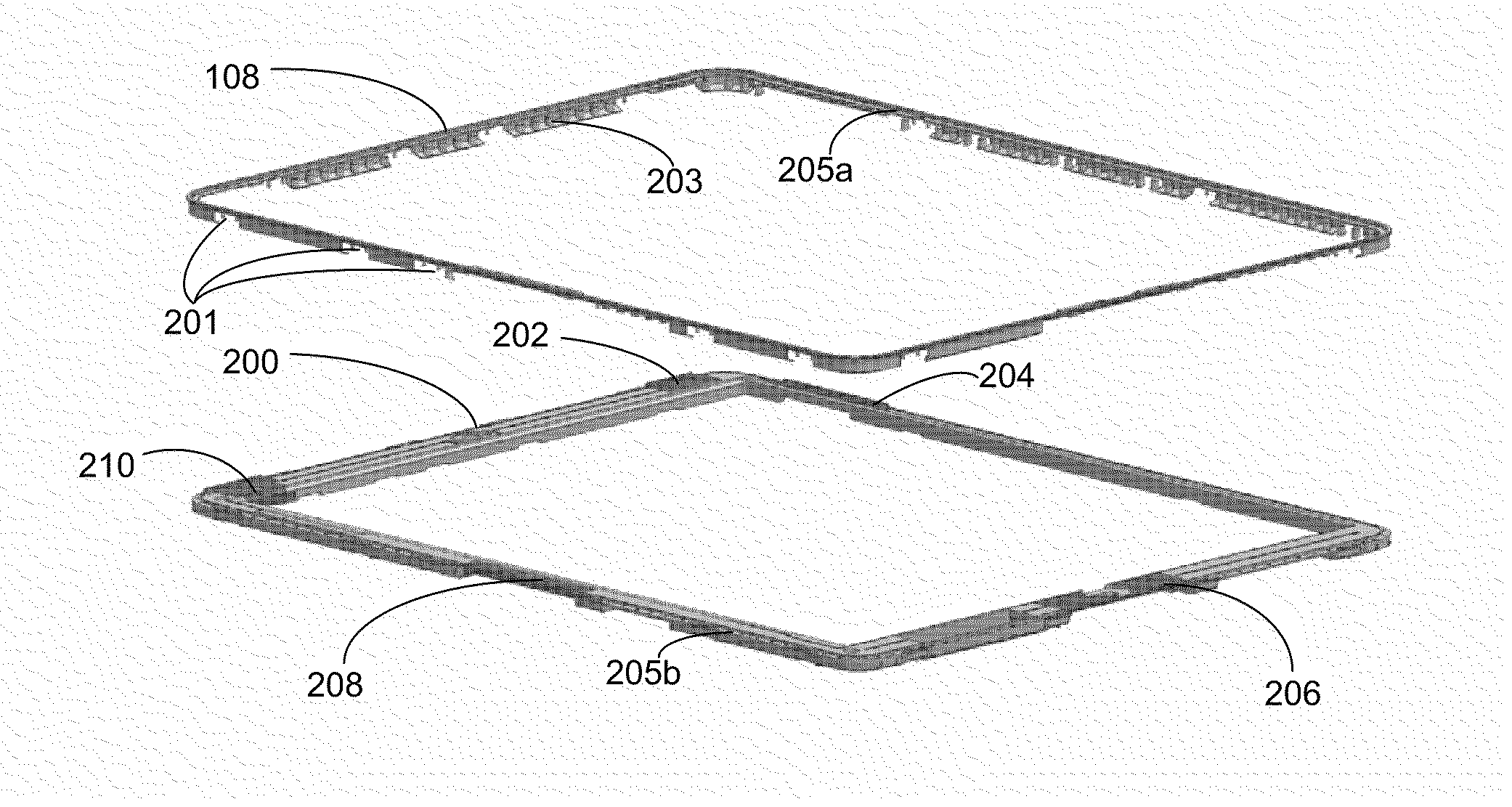

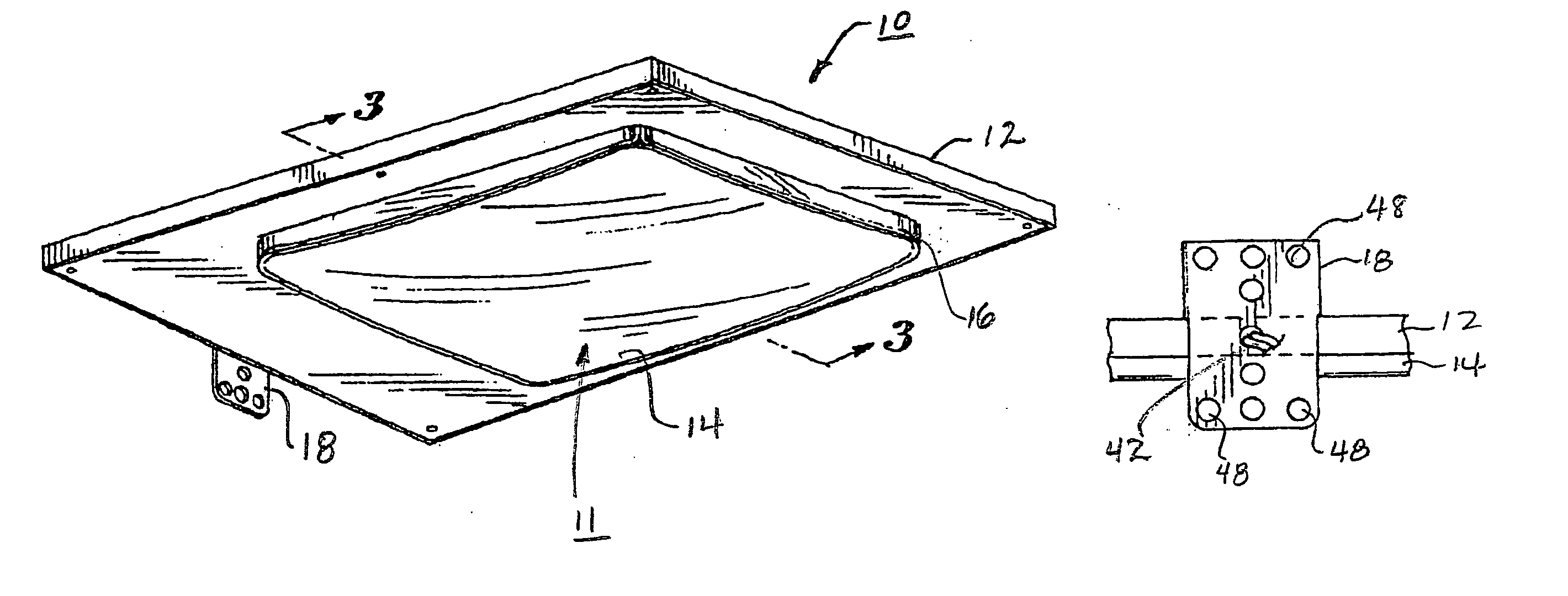

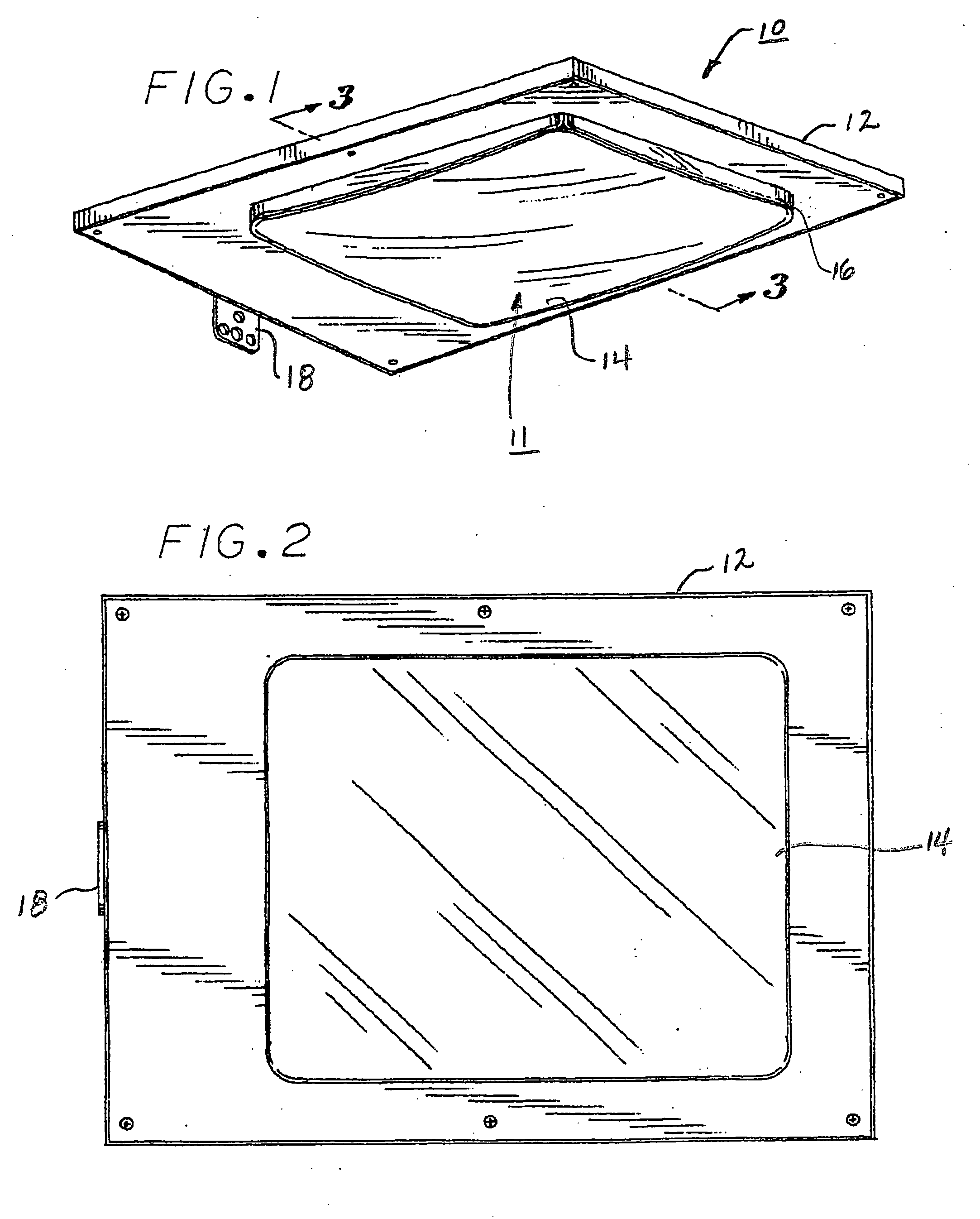

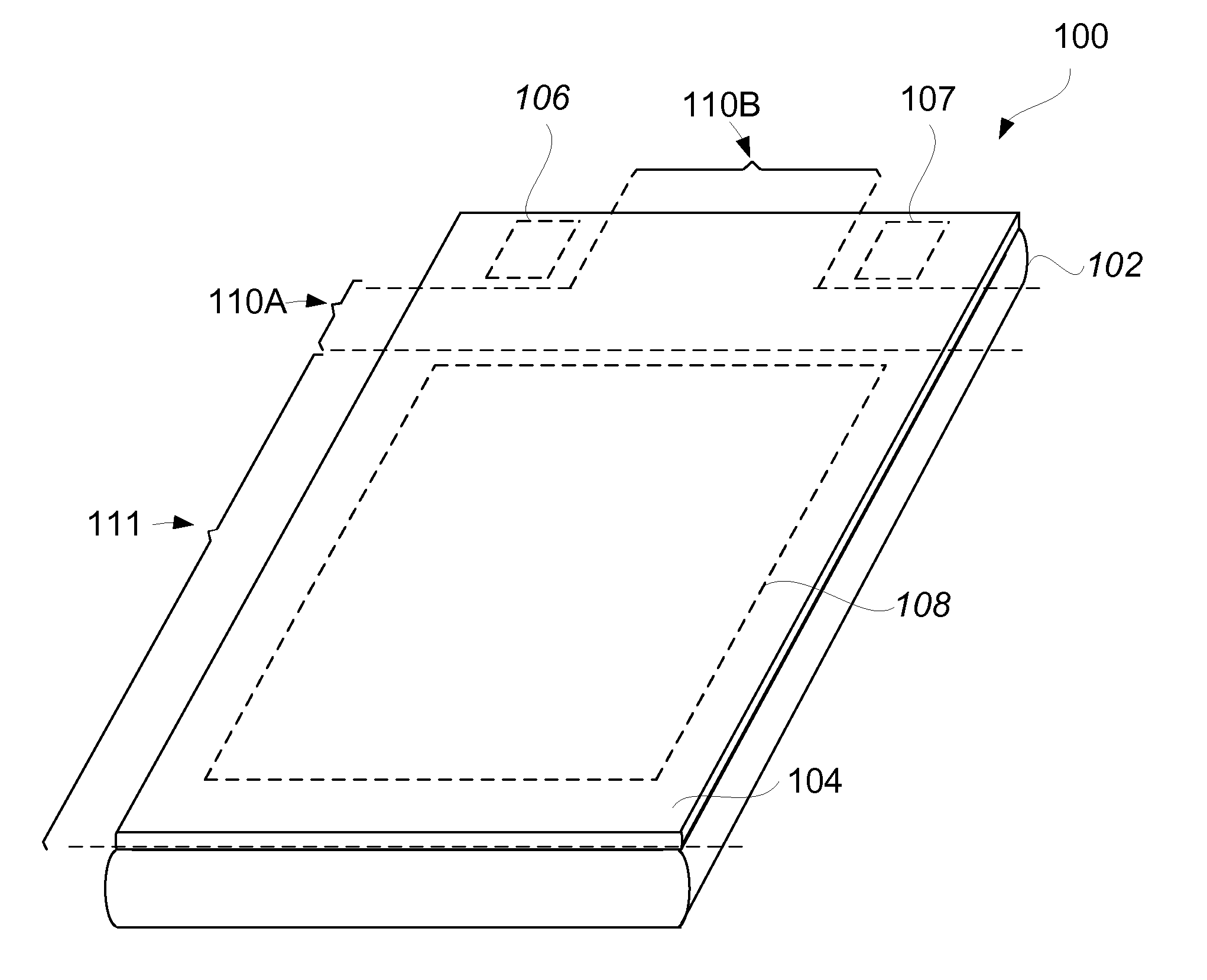

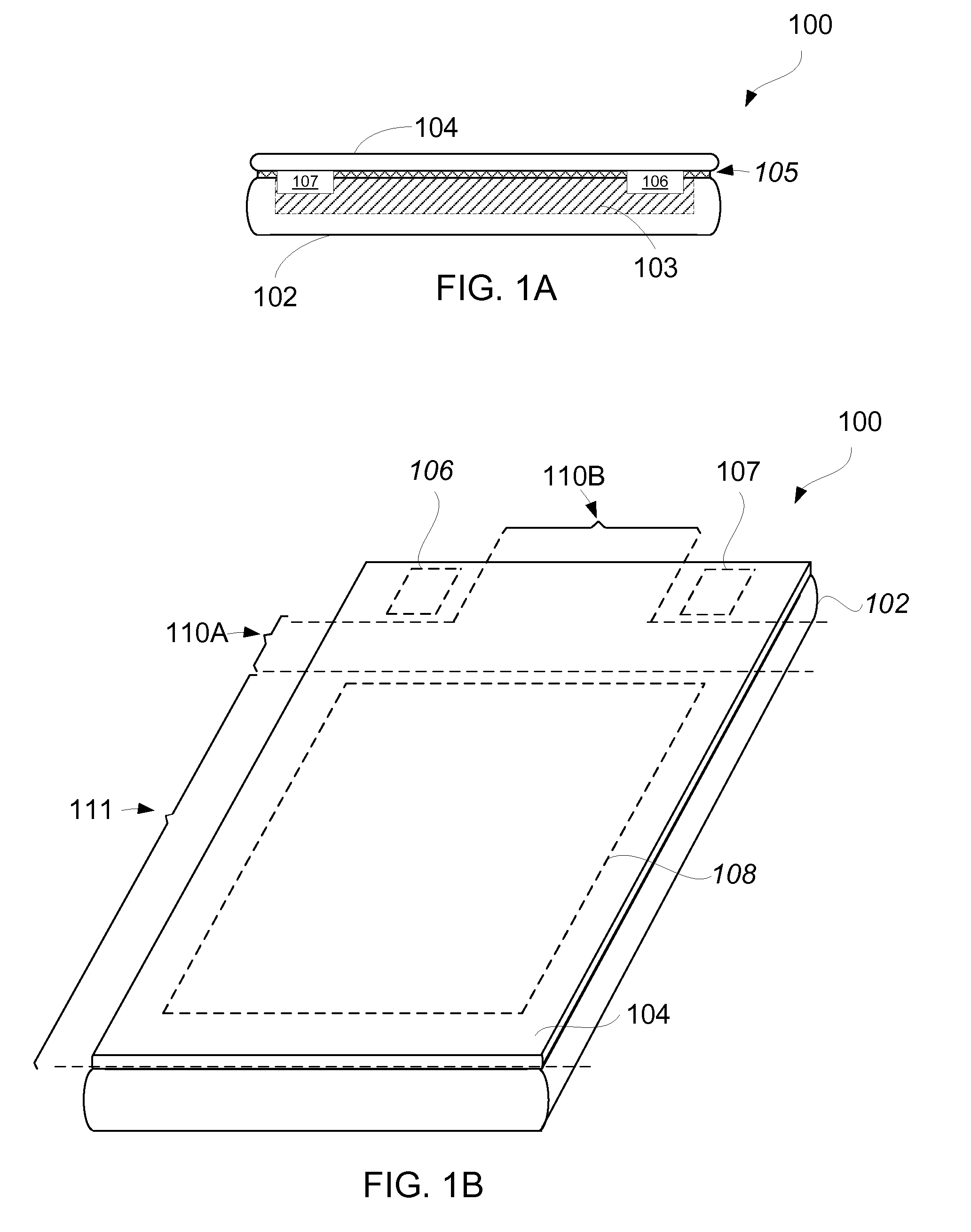

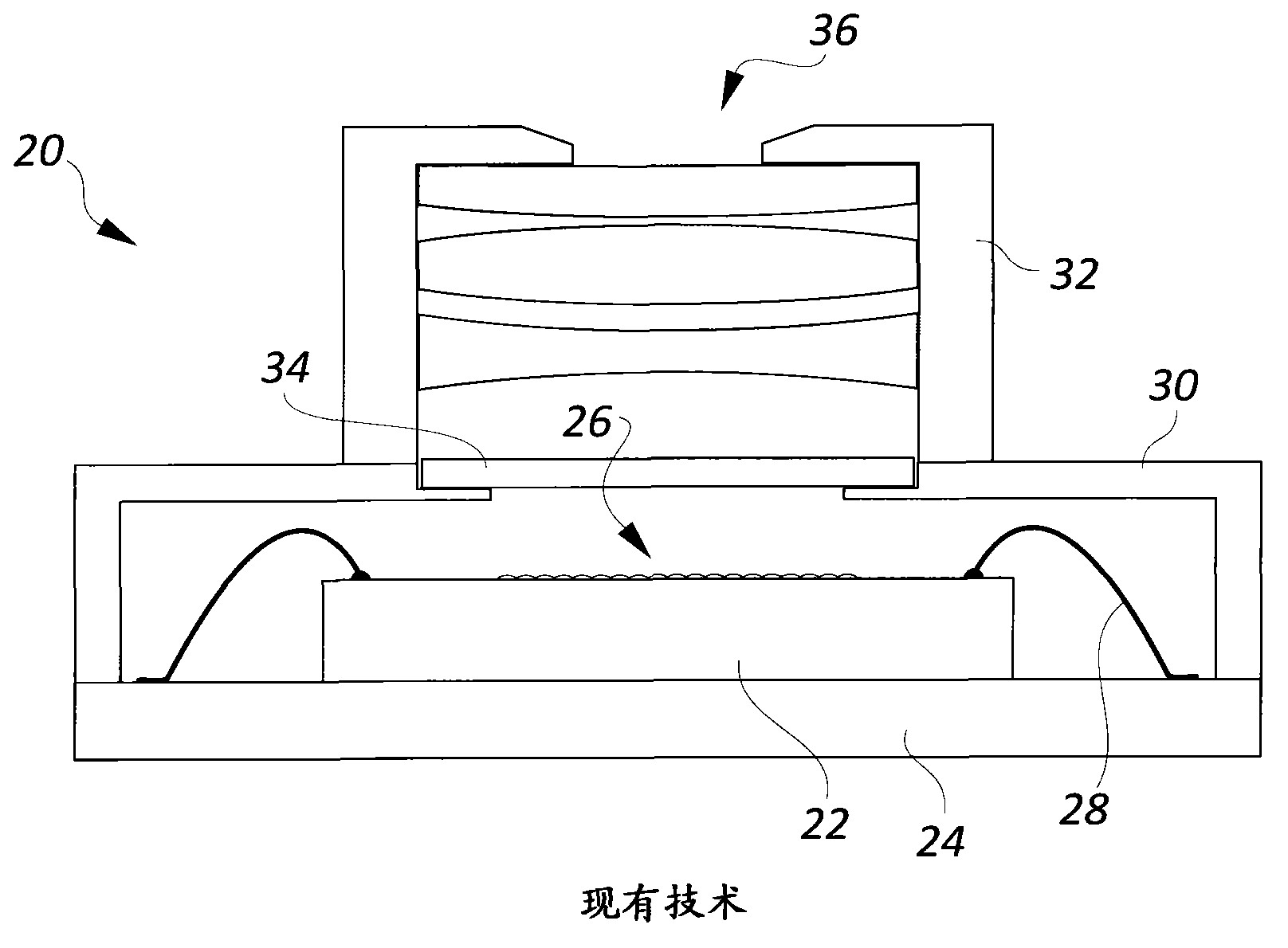

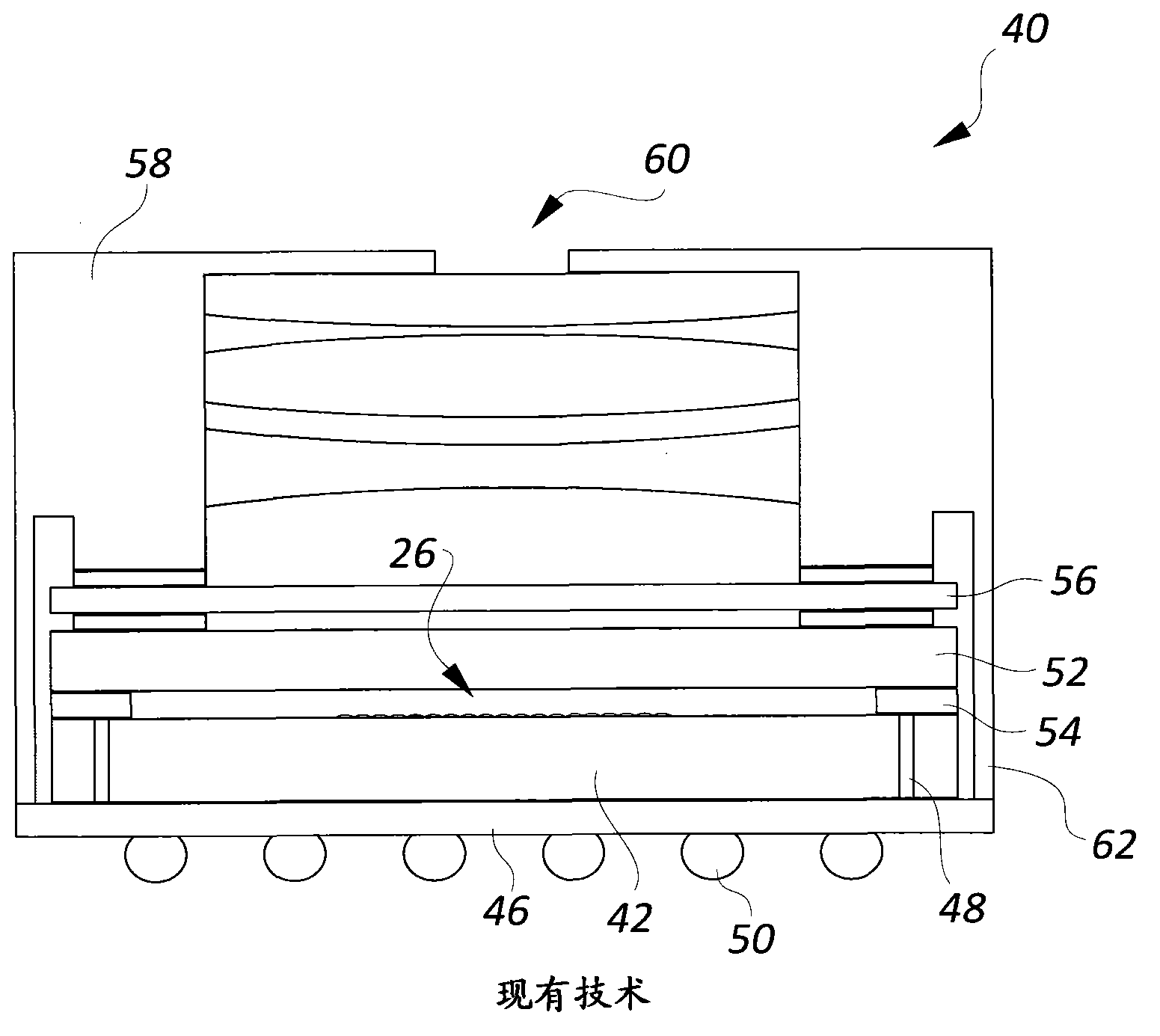

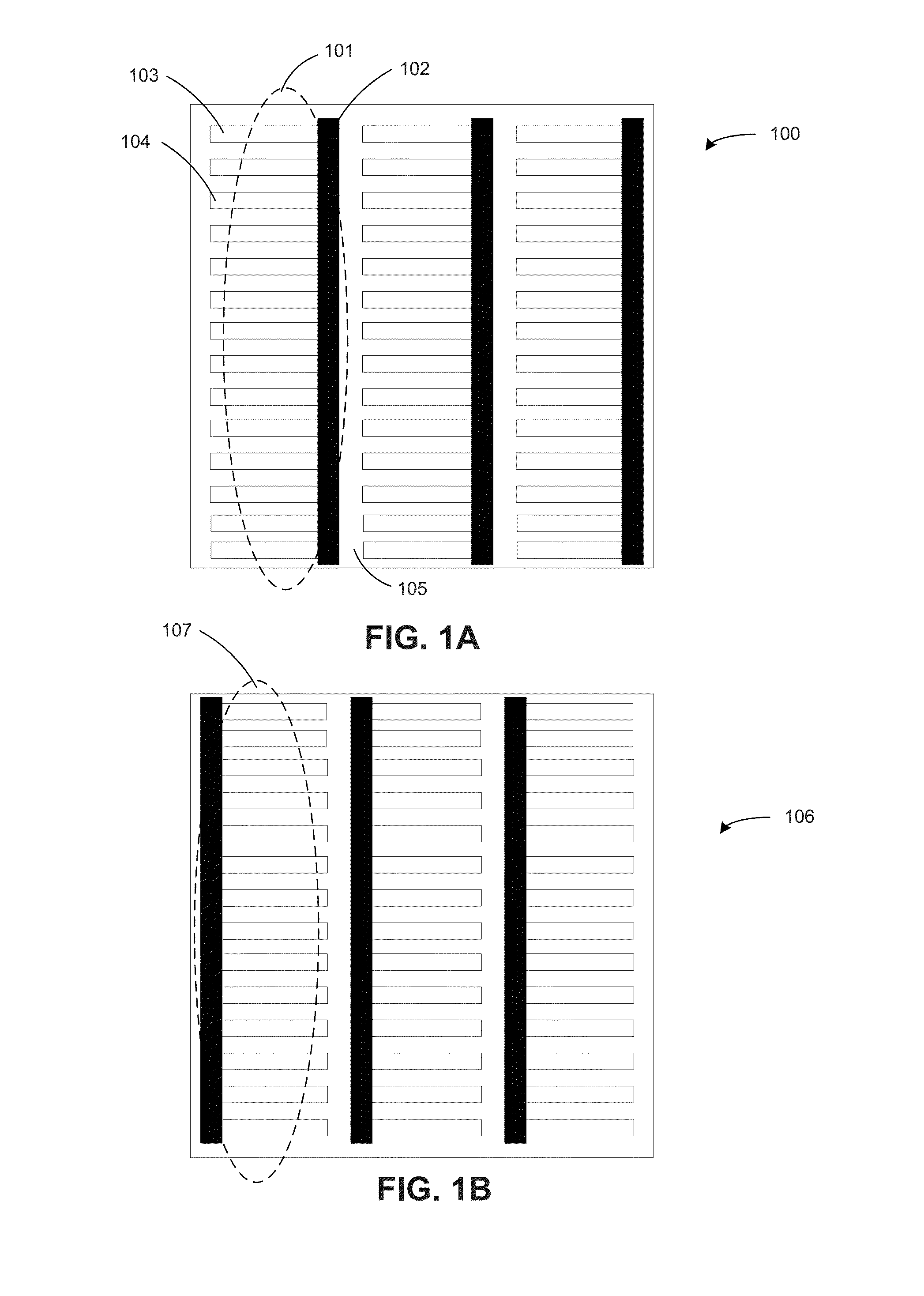

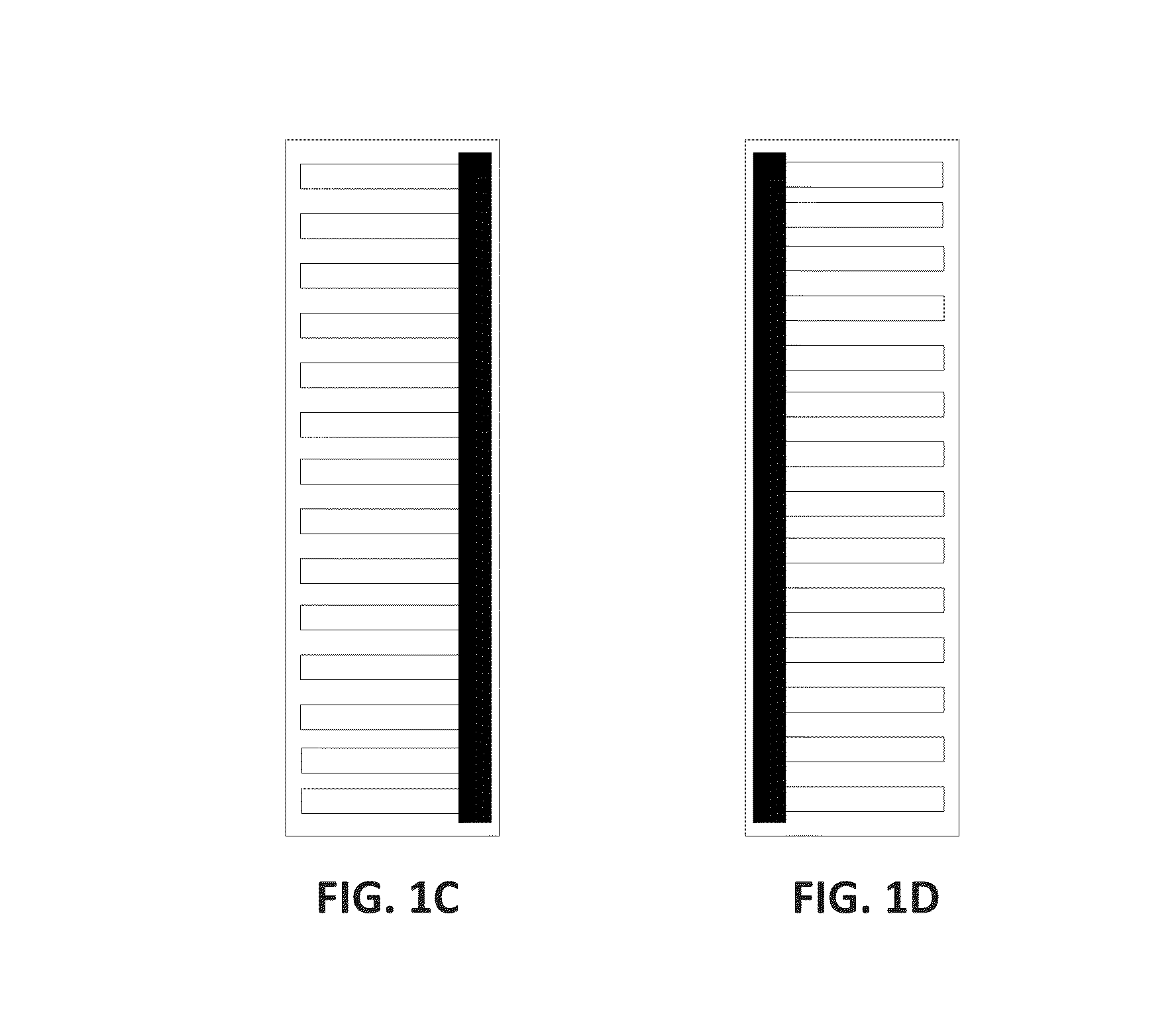

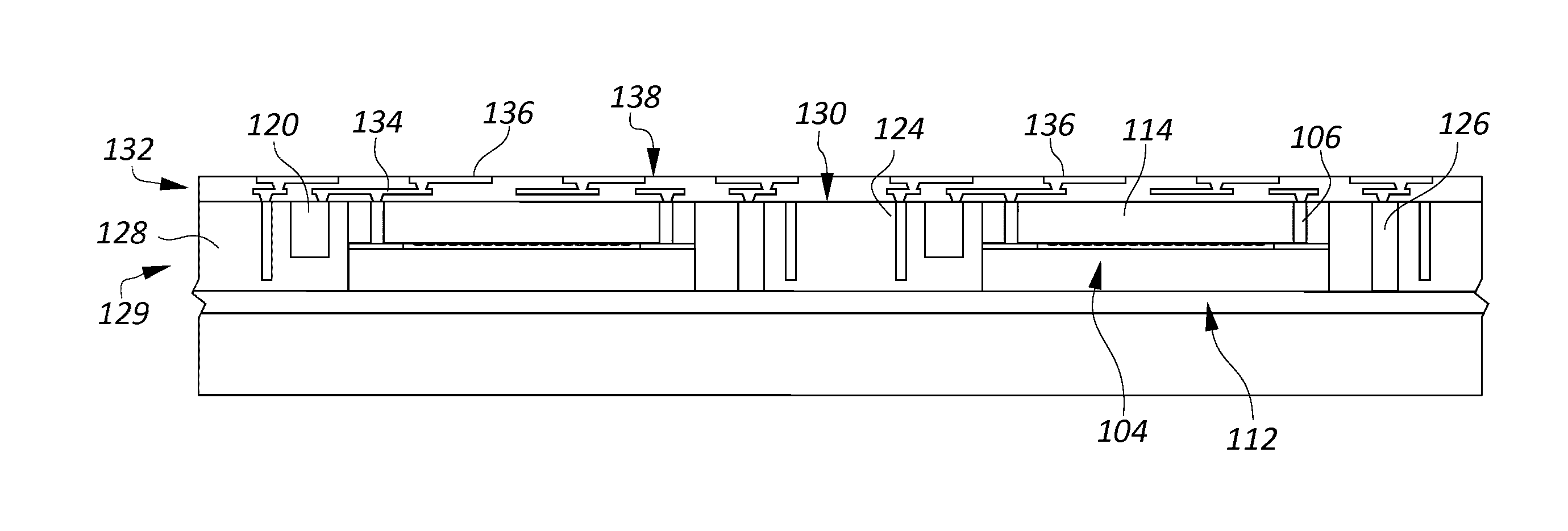

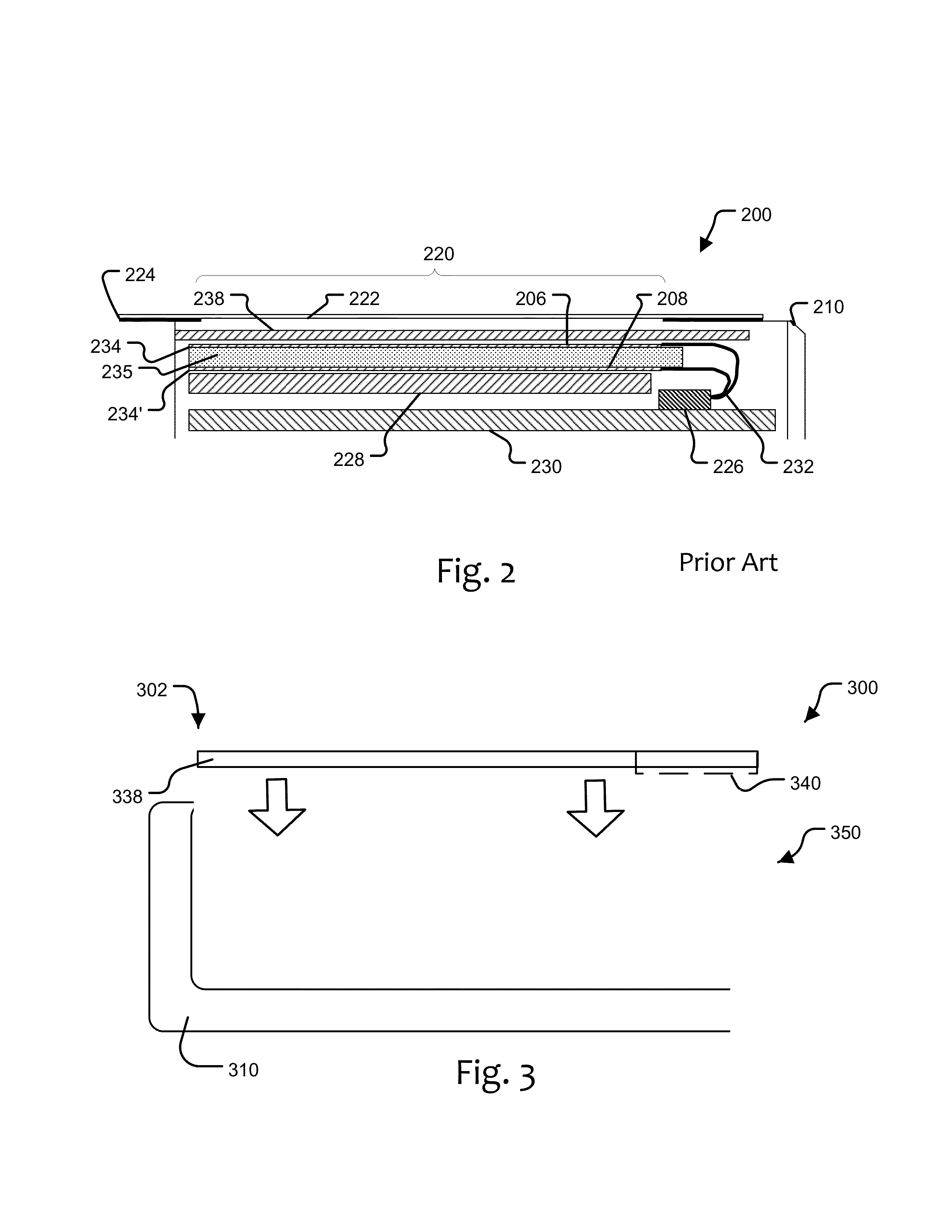

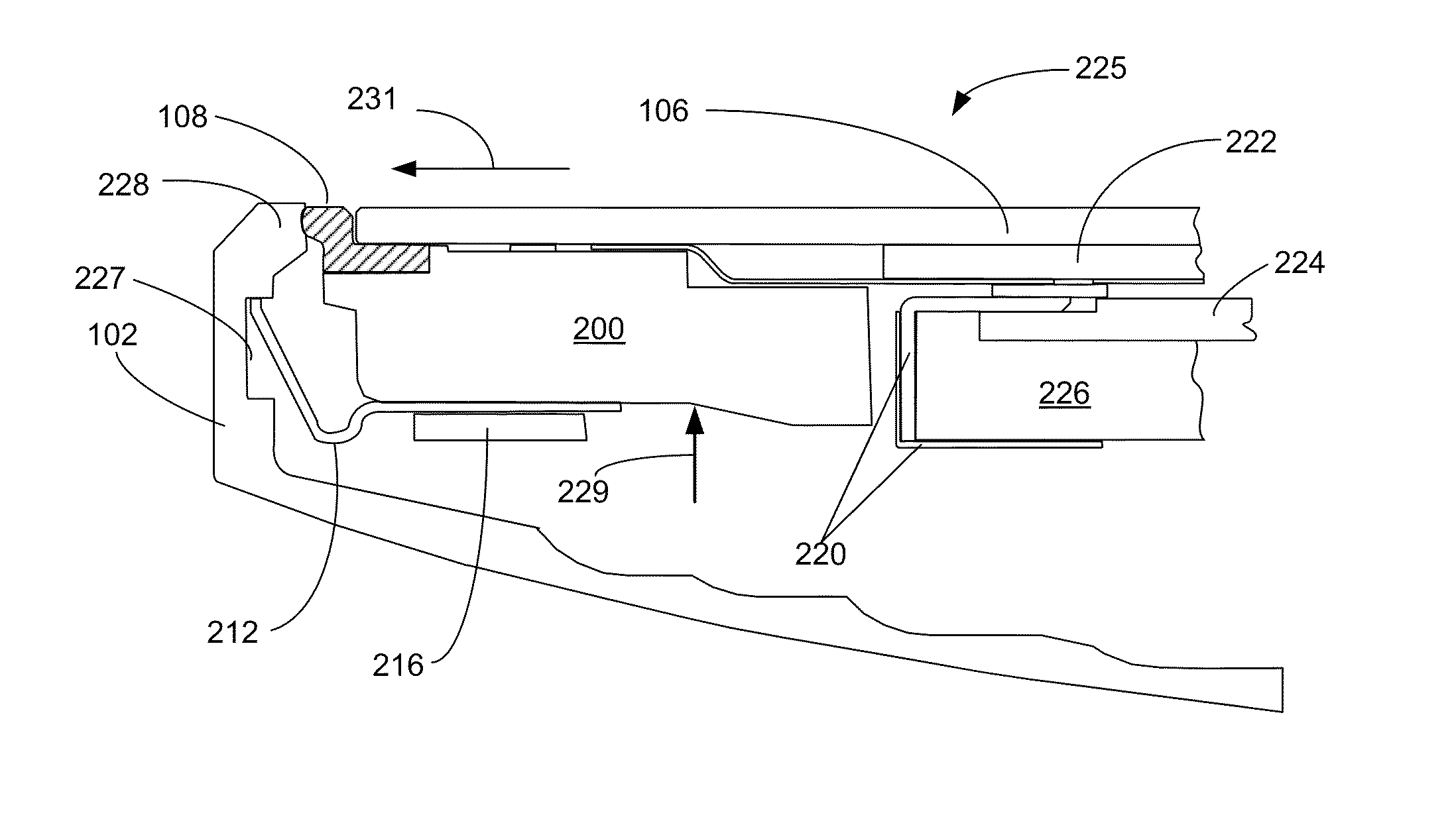

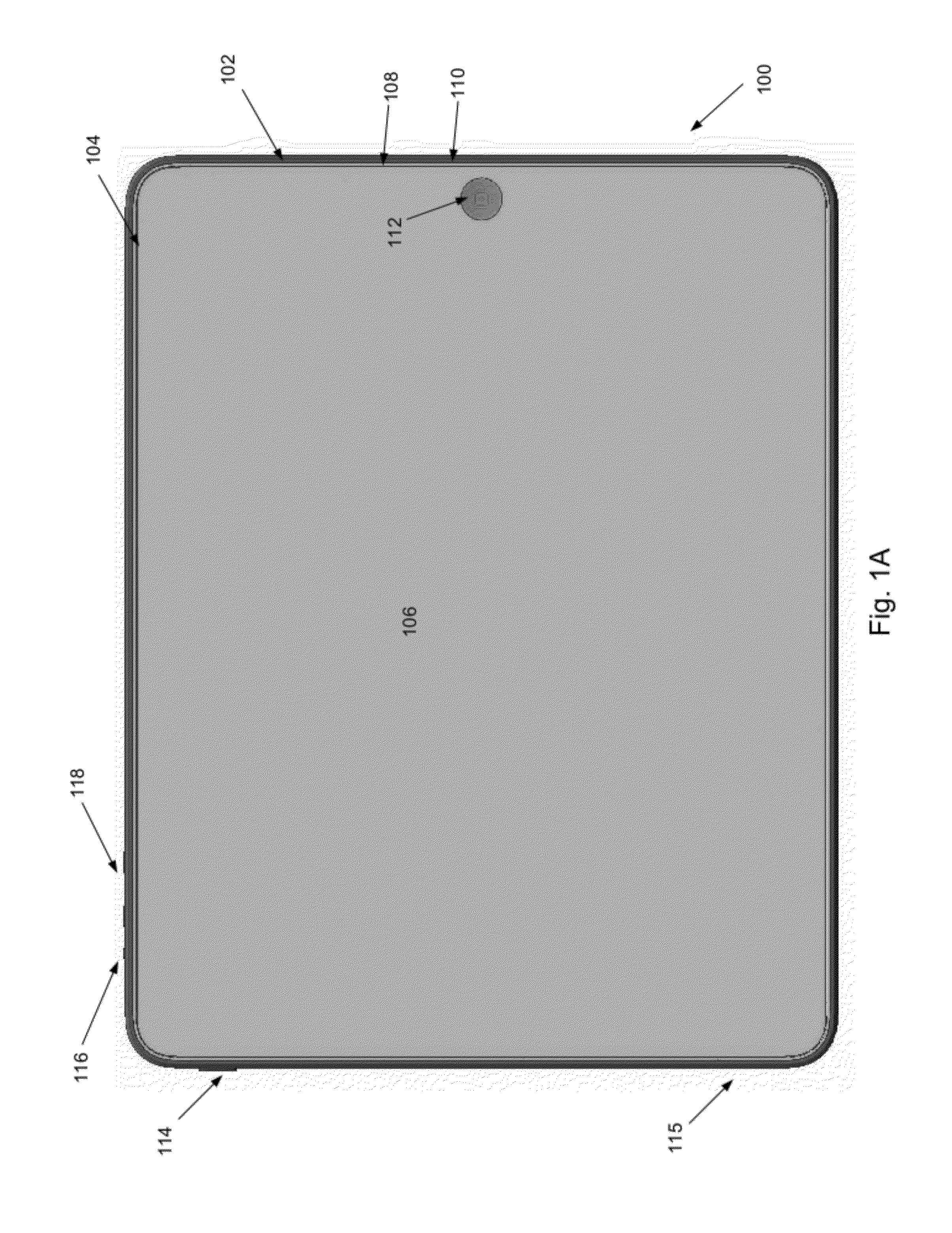

Assembly of display module

ActiveUS20110164370A1Maximum bending lengthCircuit bendability/stretchabilityWave amplification devicesTablet computerGlass cover

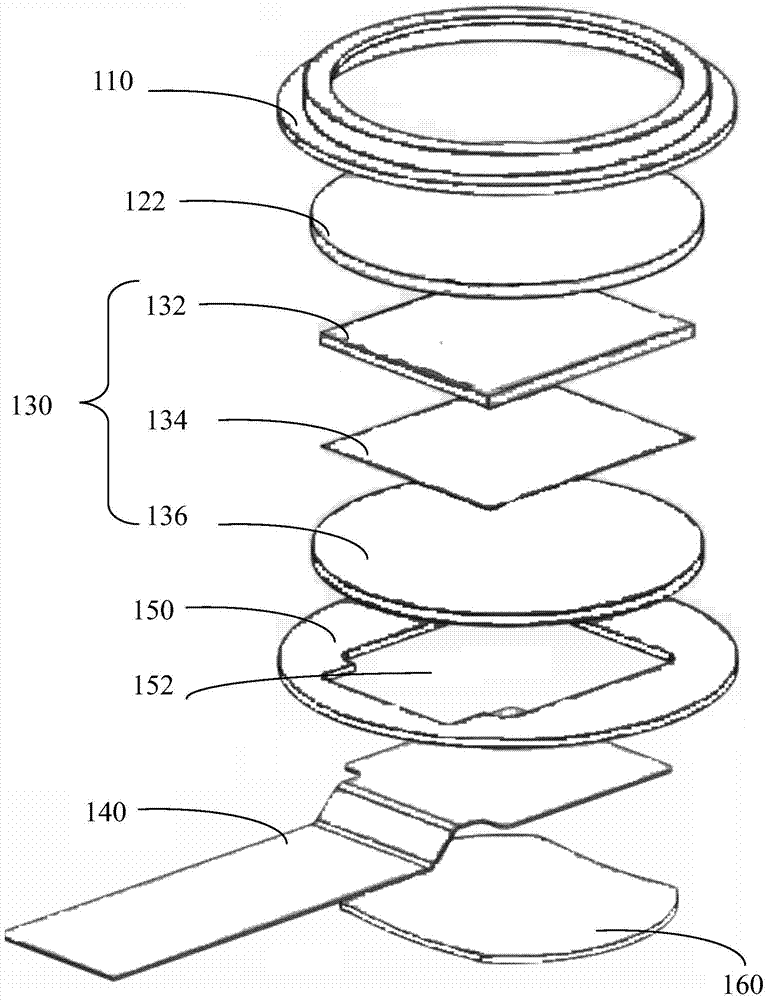

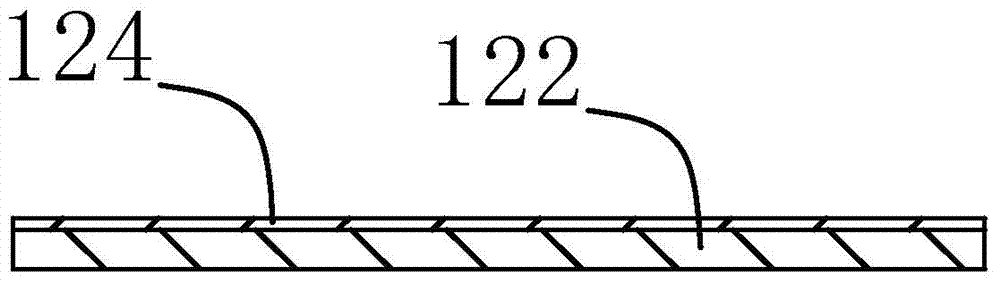

A portable computing device is disclosed. The portable computing device can take many forms such as a laptop computer, a tablet computer, and so on. The portable computing device can include a single piece housing and a display module. The display module can include a protective top glass cover that is bonded to a plastic display frame and surrounded by a seal frame. The display module can also include a display panel and its associated circuitry suspended from the display frame below the protective glass cover. The display module is coupled to the single piece housing mounting clips in a manner that allows the display module to move relative to the single piece housing during an impact event. The plastic display frame can include inserts that provide structural support near openings in the single piece housing.

Owner:APPLE INC

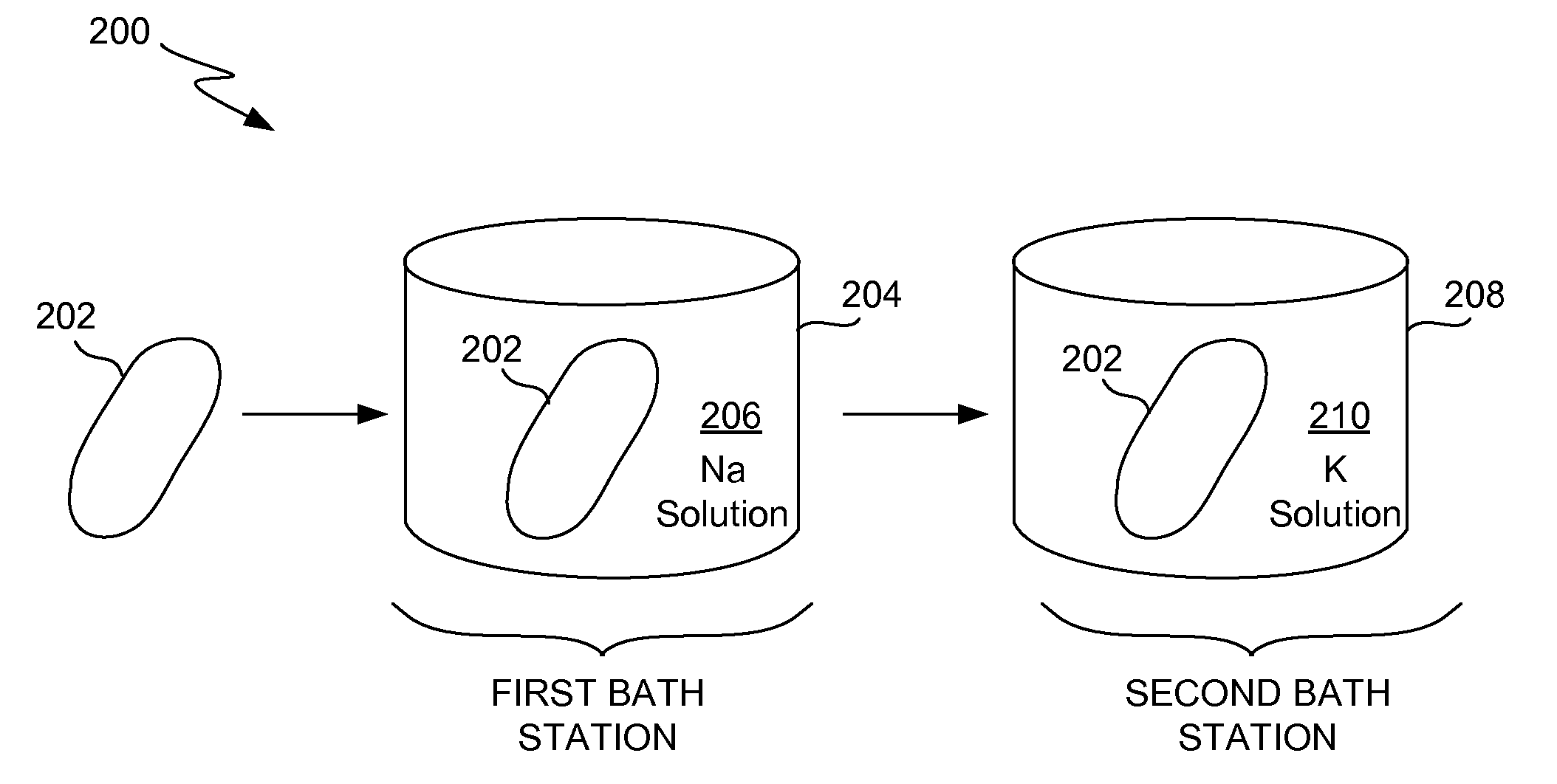

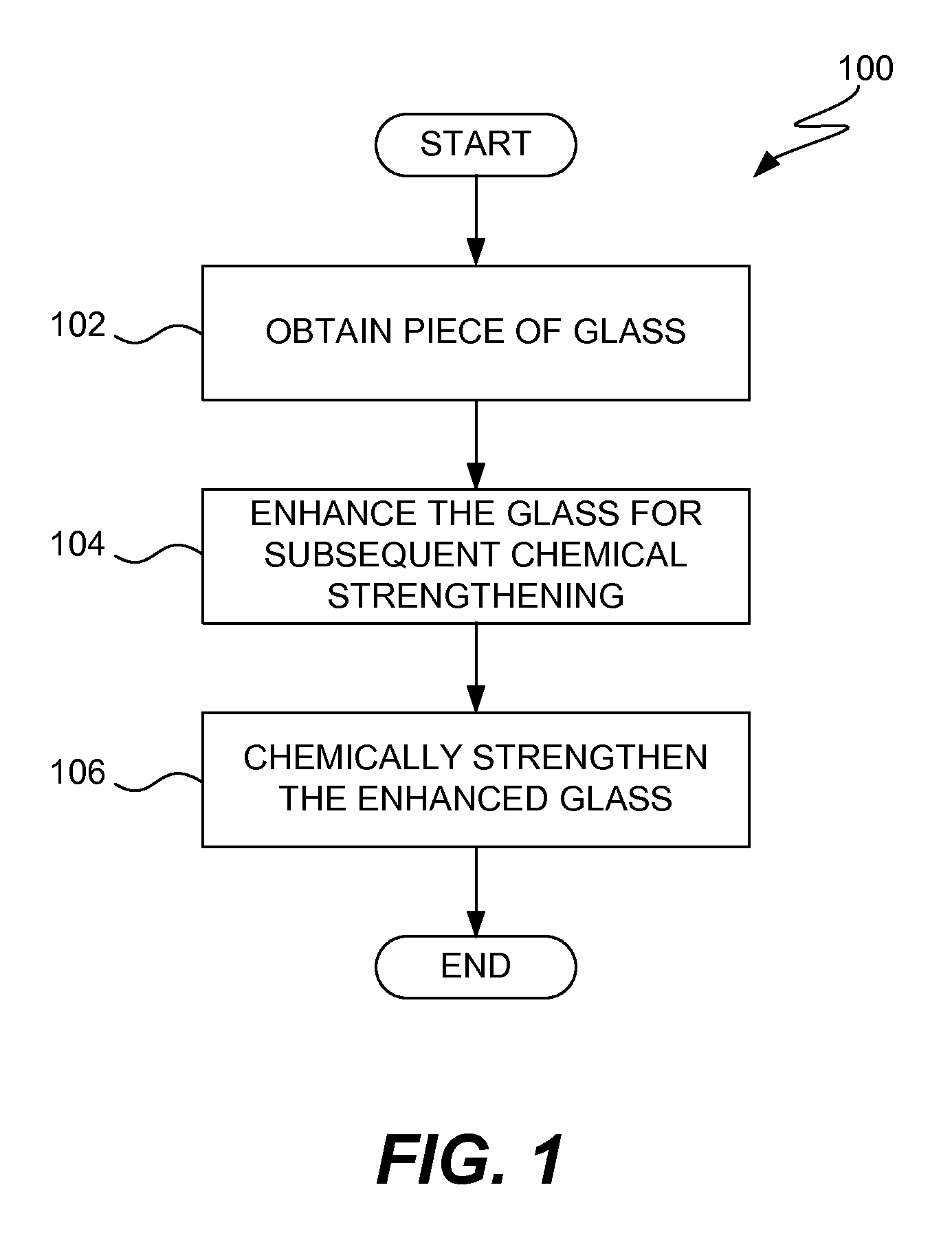

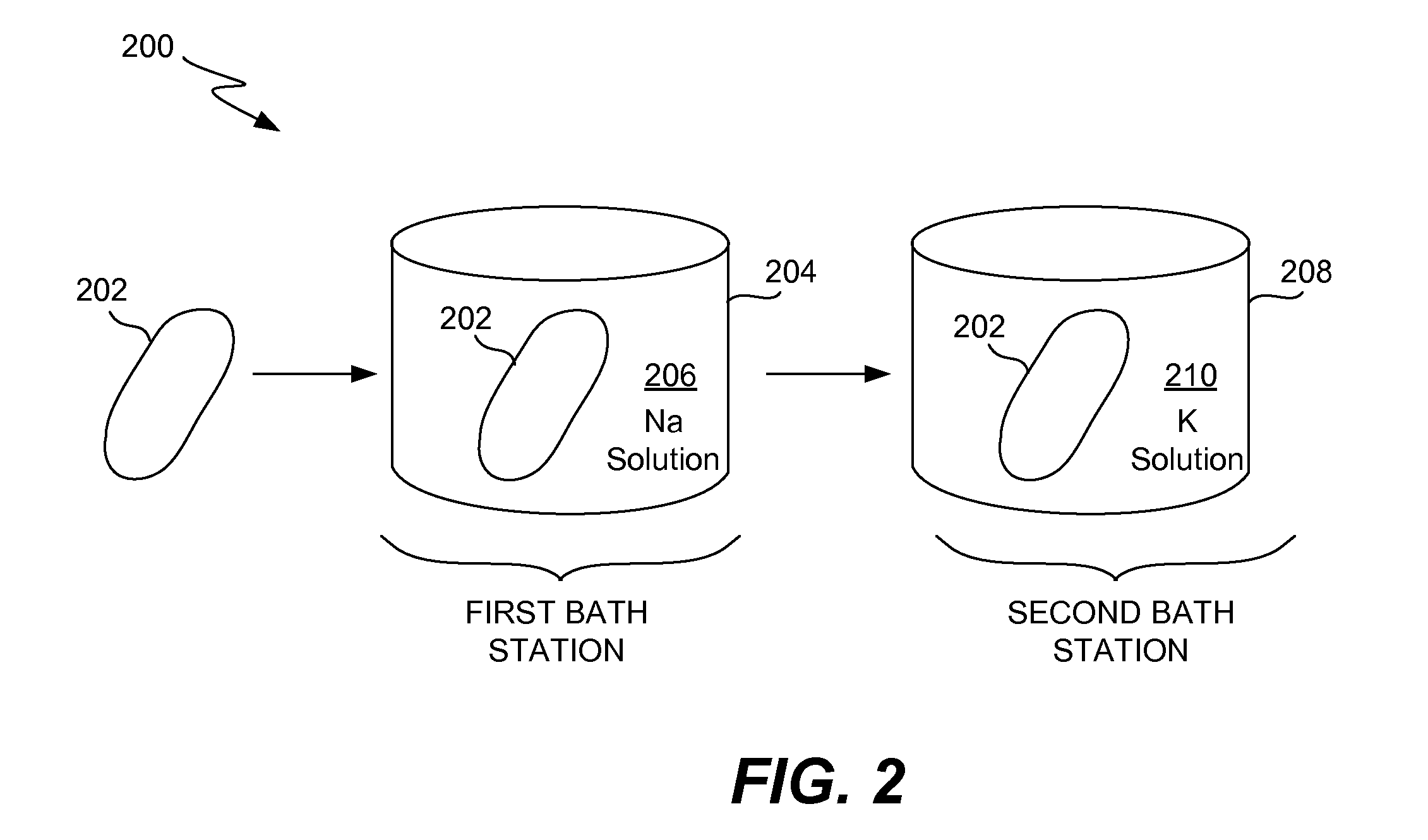

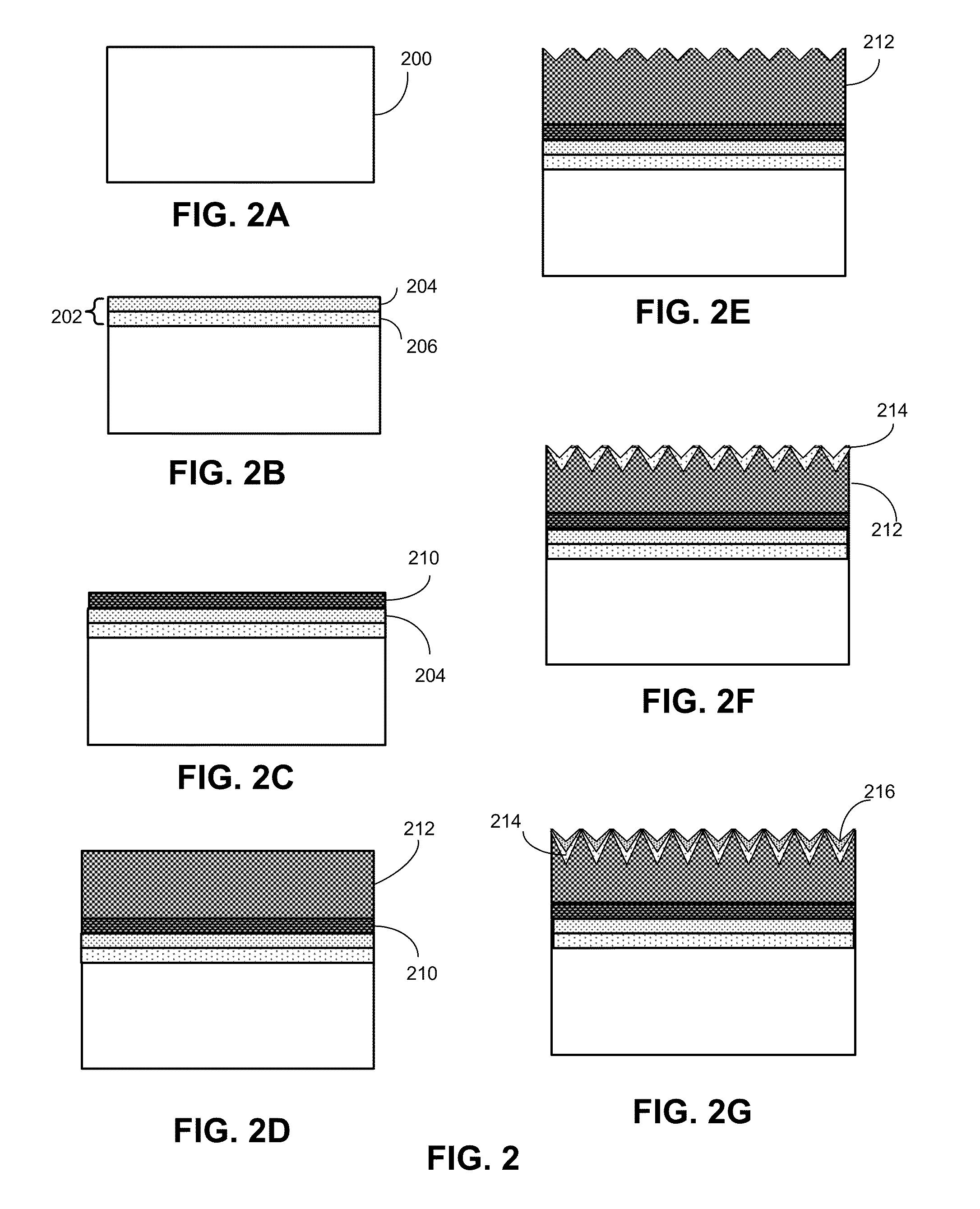

Enhanced Strengthening of Glass

ActiveUS20110067447A1Improve glass strengthImprove the level ofGlass drawing apparatusGlass transportation apparatusChemical treatmentGlass cover

Apparatus, systems and methods for improving strength of a thin glass member for an electronic device are disclosed. In one embodiment, the glass member can have improved strength by using multi-bath chemical processing. The multi-bath chemical processing allows greater levels of strengthening to be achieved for glass member. In one embodiment, the glass member can pertain to a glass cover for a housing of an electronic device.

Owner:APPLE INC

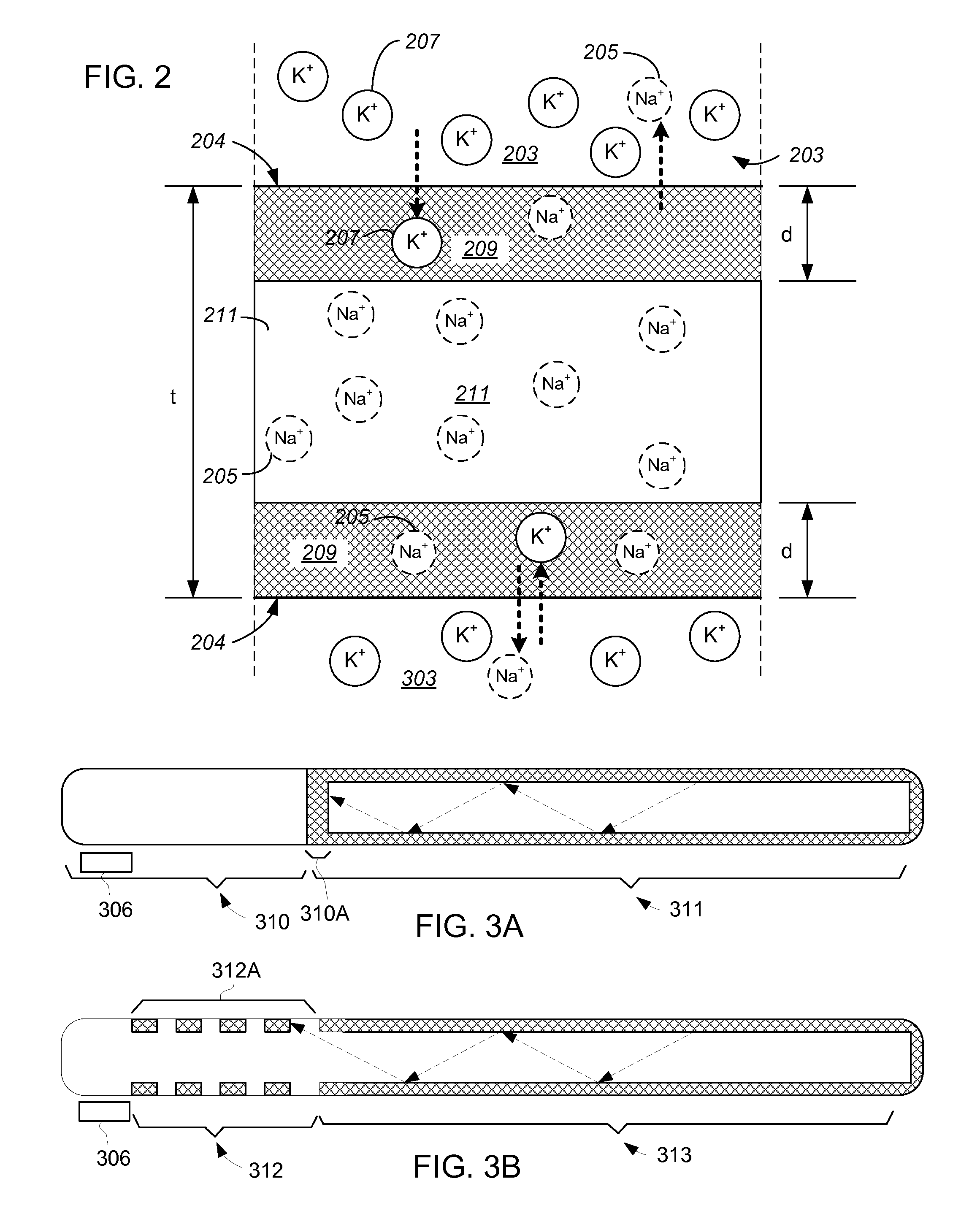

Techniques for Strengthening Glass Covers for Portable Electronic Devices

InactiveUS20110019354A1Improve glass strengthHigh strengthDigital data processing detailsElectrical apparatus contructional detailsLiquid-crystal displayGlass cover

Apparatus, systems and methods for improving strength of a thin glass cover for an electronic device are disclosed. In one embodiment, the glass member can have improved strength by chemical strengthening in a series of stages. The stages can, for example, have a first ion exchange stage where larger ions are exchanged into the glass cover, and a second ion exchange stage where some of the larger ions are exchanged out from the glass cover. Optionally, in one embodiment, the glass cover can improve its strength by forming its edges with a predetermined geometry. Advantageously, the glass cover can be not only thin but also adequately strong to limit susceptibility to damage. In one embodiment, the glass member can pertain to a glass cover for a housing for an electronic device. The glass cover can be provided over or integrated with a display, such as a Liquid Crystal Display (LCD) display.

Owner:APPLE INC

Display module

A portable computing device is disclosed. The portable computing device can take many forms such as a laptop computer, a tablet computer, and so on. The portable computing device can include a single piece housing and a display module. The display module can include a protective top glass cover that is bonded to a plastic display frame and surrounded by a seal frame. The display module can also include a display panel and its associated circuitry suspended from the display frame below the protective glass cover. The display module is coupled to the single piece housing mounting clips in a manner that allows the display module to move relative to the single piece housing during an impact event. The plastic display frame can include inserts that provide structural support near openings in the single piece housing.

Owner:APPLE INC

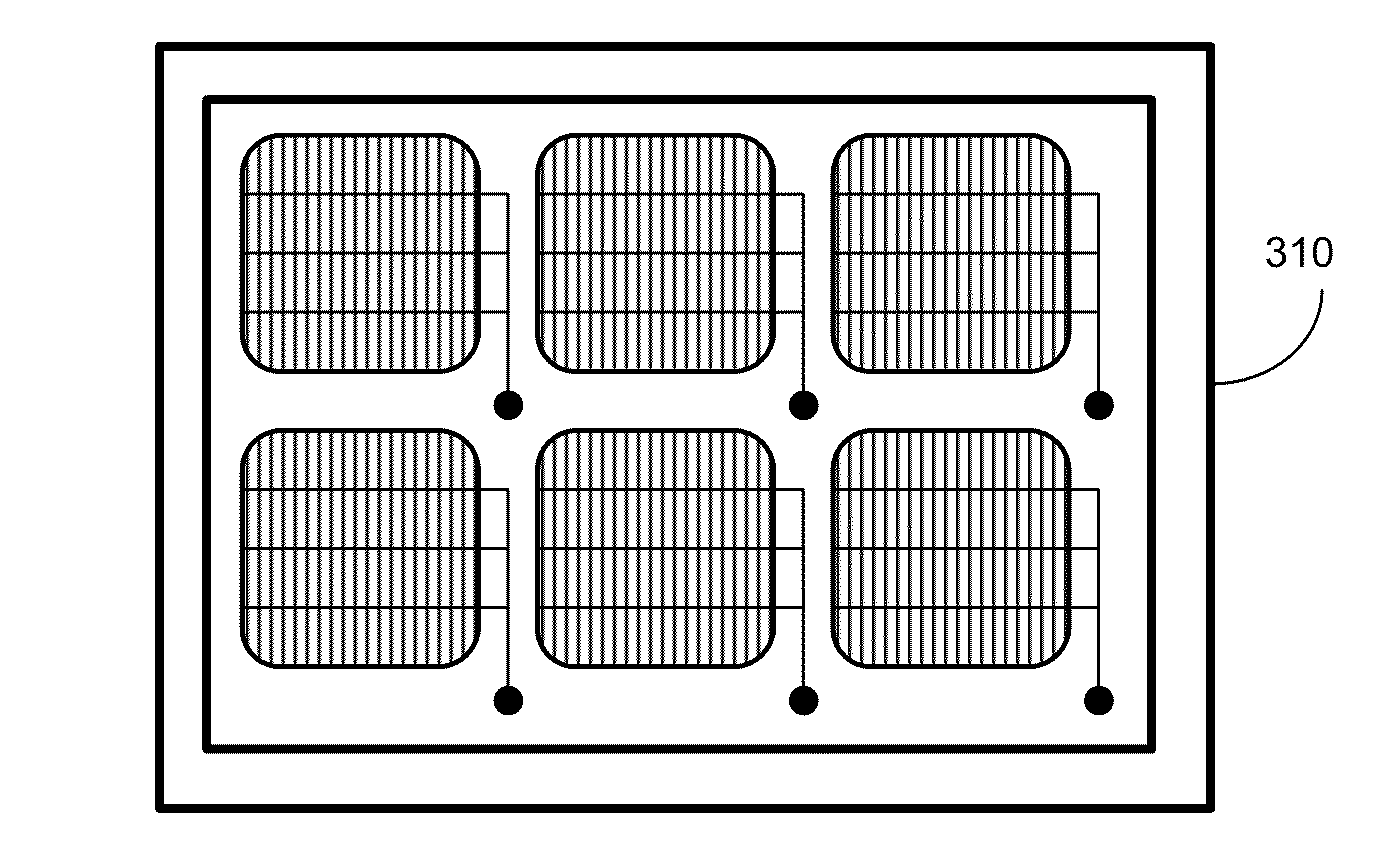

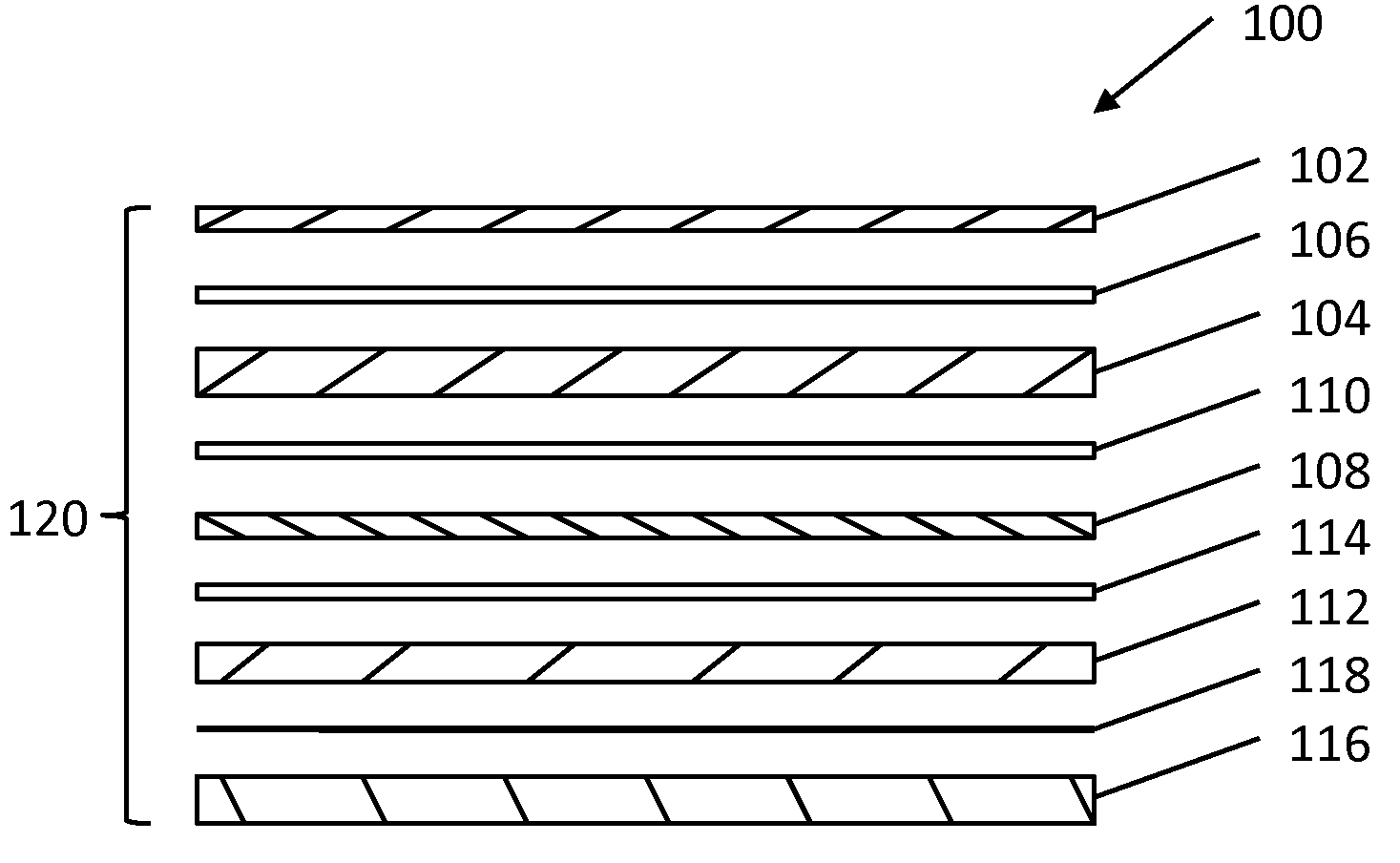

High efficiency low cost crystalline-si thin film solar module

One embodiment of the present invention provides a double-sided heterojunction solar cell module. The solar cell includes a frontside glass cover, a backside cover situated below the frontside glass cover, and a number of solar cells situated between the frontside glass cover and the backside glass cover. Each solar cell includes a semiconductor multilayer structure situated below the frontside glass cover, including: a frontside electrode grid, a first layer of heavily doped amorphous Si (a-Si) situated below the frontside electrode, a layer of lightly doped crystalline-Si (c-Si) situated below the first layer of heavily doped a-Si, and a layer of heavily doped c-Si situated below the lightly doped c-Si layer. The solar cell also includes a second layer of heavily doped a-Si situated below the multilayer structure; and a backside electrode situated below the second layer of heavily doped a-Si.

Owner:SOLARCITY +1

Light module using led clusters

InactiveUS20060056169A1Reduce power consumptionHigh color purityPlanar light sourcesMechanical apparatusGlass coverLED lamp

A streetlight wherein the conventional incandescent light bulb is replaced by sets of light-emitting LED clusters. The clusters comprise parallel circuits of LED bulbs mounted on a printed circuit board (PCB). Preferably, the configuration comprises ten clusters, each cluster having two parallel circuits of LEDs, each circuit having twenty LEDs. Each cluster may be connected separately to its own power source or a single power source can be used to power the entire set of clusters. The LED bulbs face downwards, and operate to disperse light directly onto the intended area of the road or street surface. The lamp is encased within a glass cover lens.

Owner:LEDTRONICS

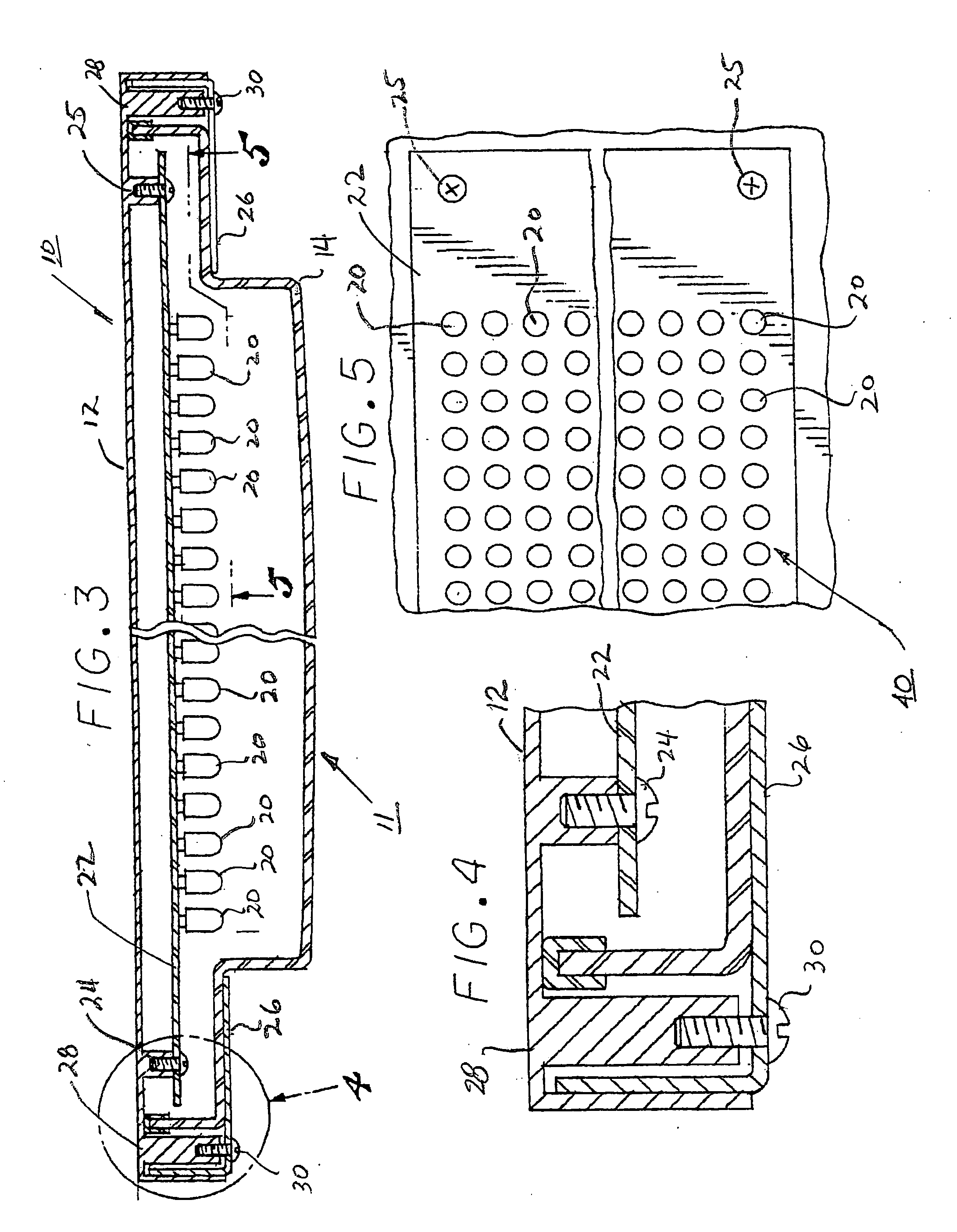

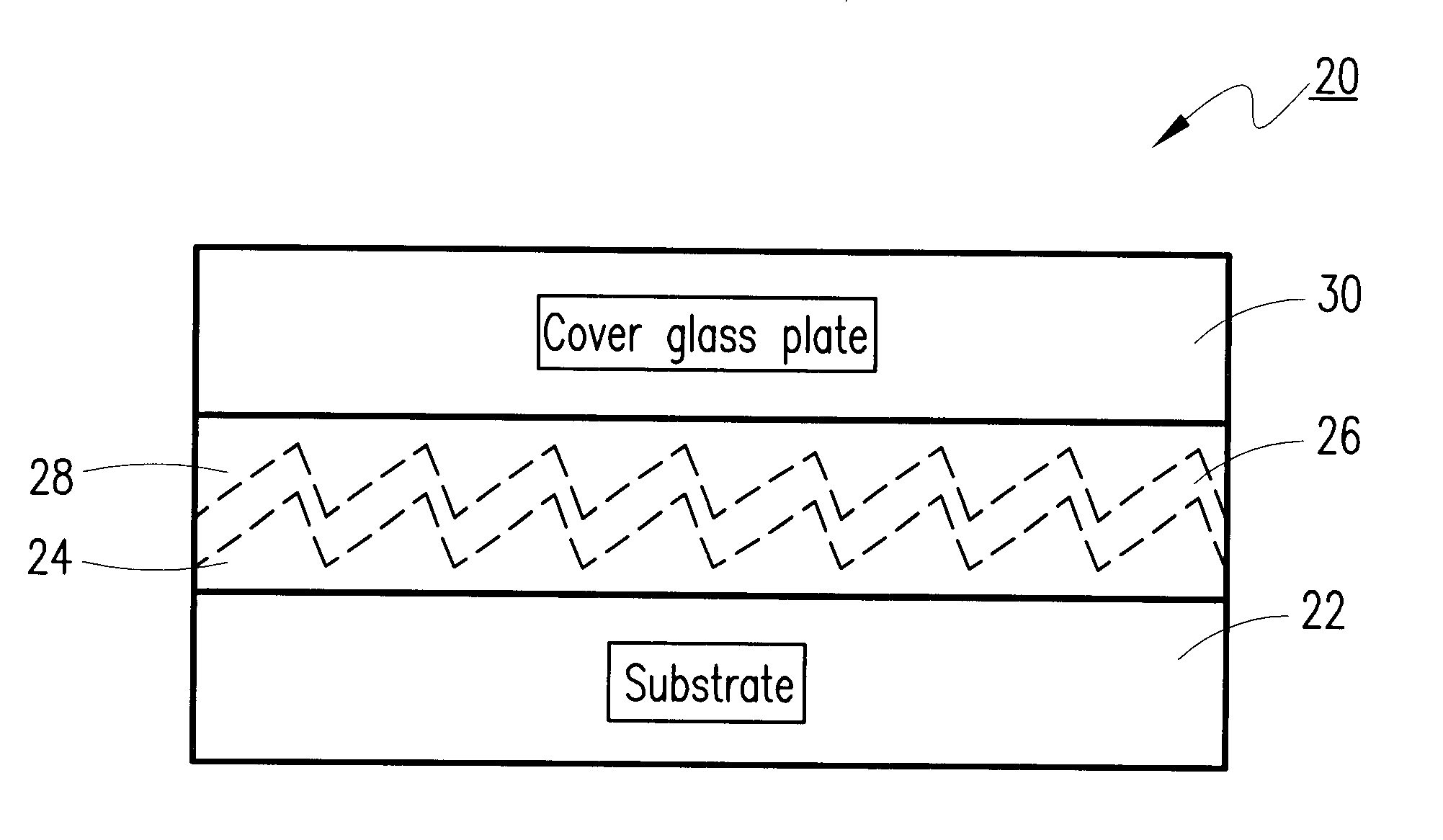

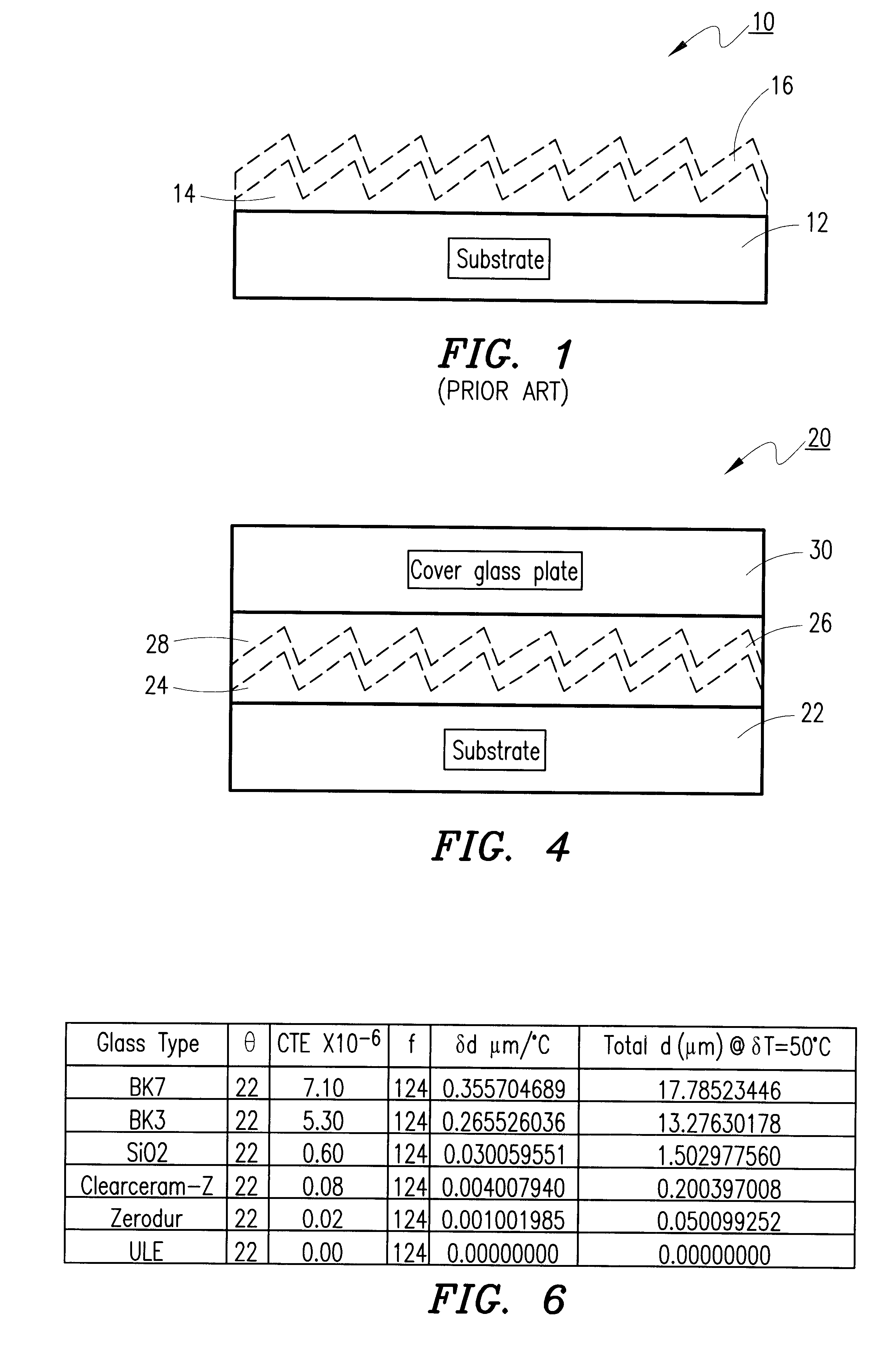

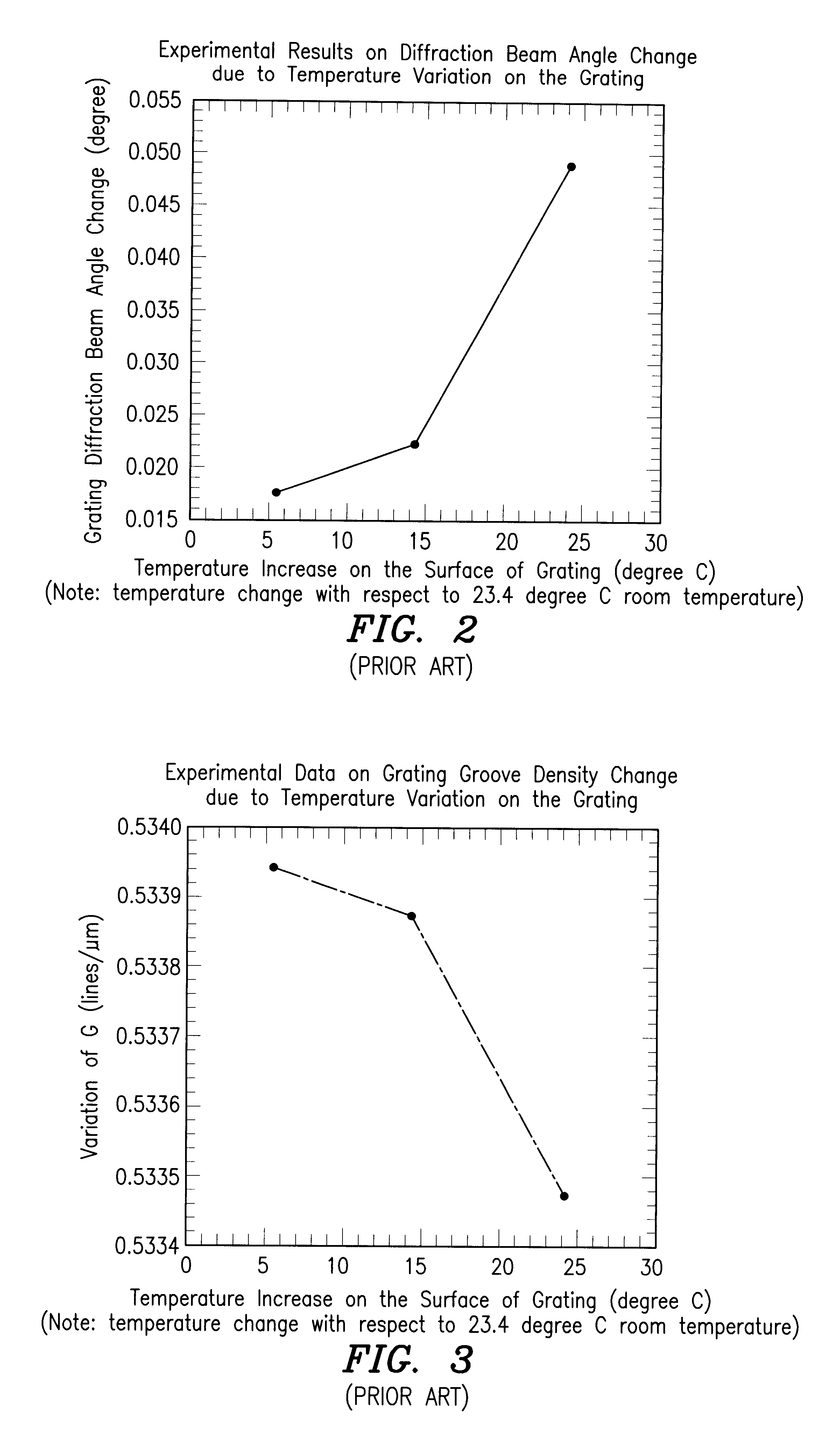

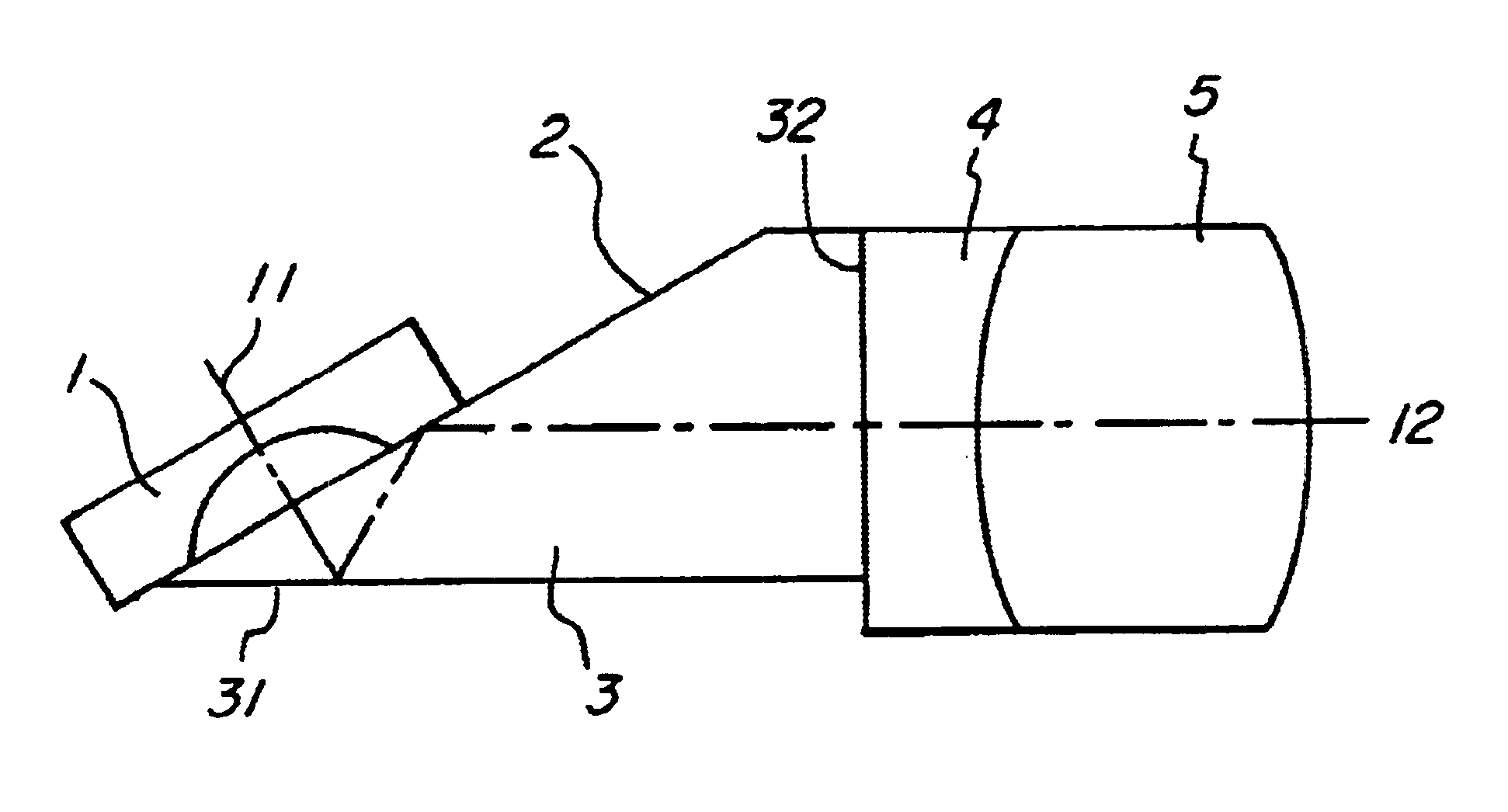

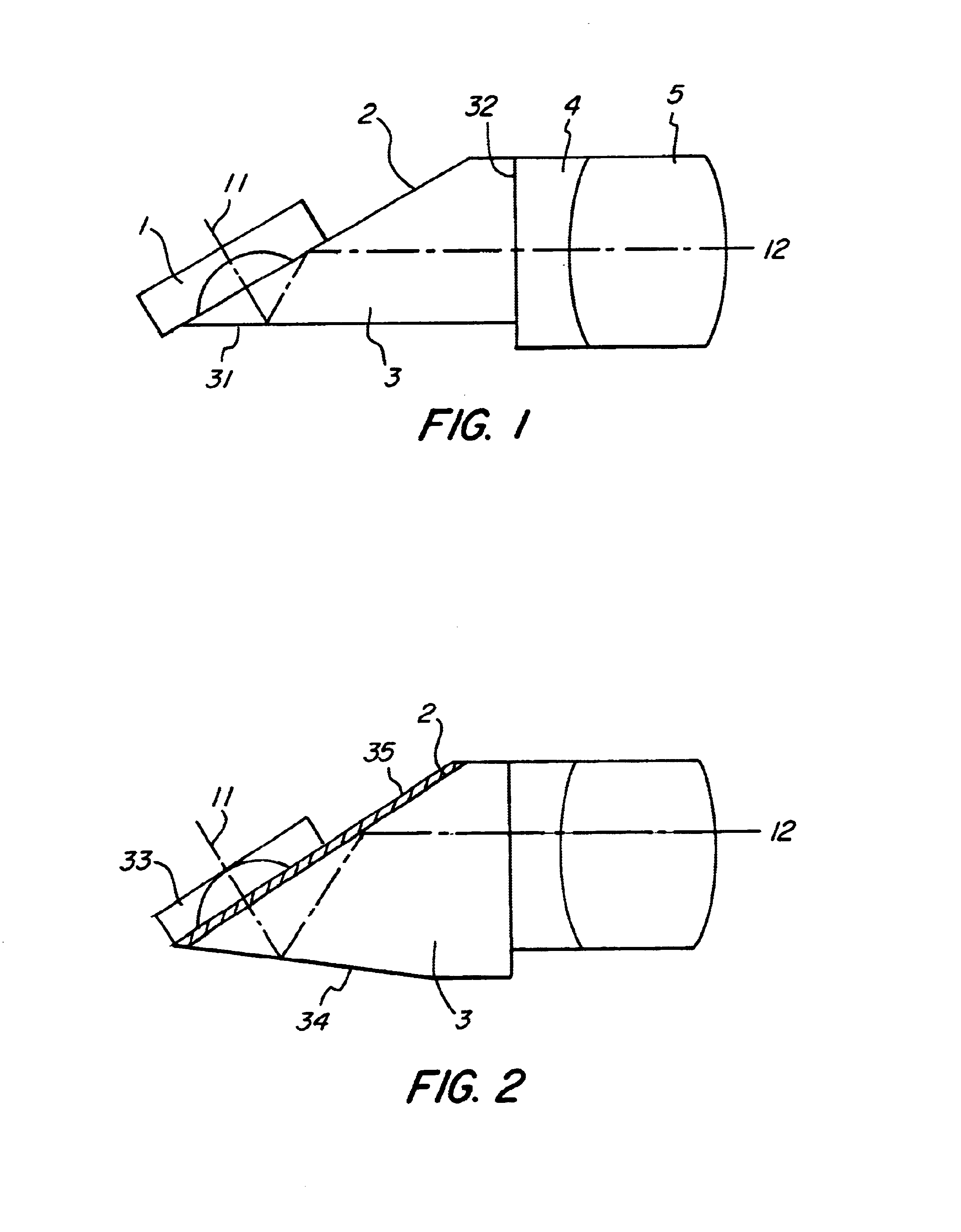

Diffraction grating for wavelength division multiplexing/demultiplexing devices

An improved diffraction grating for wavelength division multiplexing / demultiplexing devices is disclosed. The improved diffraction grating has a glass substrate, a polymer grating layer located adjacent to the glass substrate, and a metal coating layer located adjacent to the polymer grating layer. The improvement comprises a polymer coating layer located adjacent to the metal coating layer, and a glass cover located adjacent to the polymer coating layer, wherein the polymer coating layer and the glass cover compensate for thermal characteristics associated with the polymer grating layer and the glass substrate, respectively.

Owner:AUXORA

Amorphous and nanocrystalline glass-covered wires

InactiveUS6270591B2Prevent oxidationAvoid fragmentationInorganic material magnetismYarnGlass coverMetalloid

The invention refers to amorphous and nanocrystalline magnetic glass-covered wires. The wires consist of a metallic amorphous or nanocrystalline core with diameters by the order of 10-6 m, having compositions based on transition metal-metalloids and other additional metals and a glass cover, having a thickness of the wall by the same order of magnitude. The wires present high or medium saturation inducation, positive, negative or nearly zero magnetostriction and values of the coercive field and of the magnetic permeability in function of the requested applications in a field of electronics and electrotechnics to achieve sensors, transducers, inductive coils, trnasformers, magnetic shields, devices working on the basis of the correlation between the magnetic properties of the metallic core and the optical properties of the glass cover.

Owner:INSTL DE FIZICA TEHNICA IASI

Electronic Device Having Selectively Strengthening Glass Cover Glass

ActiveUS20120027399A1Reduce glareReducing glare at the cameraWave amplification devicesDiffusing elementsGlass coverOptical barrier

Embodiments disclosed therein generally pertain to selectively strengthening glass. More particularly, techniques are described for selectively strengthening cover glass, which tends to be thin, for electronic devices, namely, portable electronic devices. In certain embodiments, selectively strengthening glass, such as cover glass, can be used to provide optical barriers (or channels) internal to the glass. The electronic devices can also provide for camera integration behind the cover glass.

Owner:APPLE INC

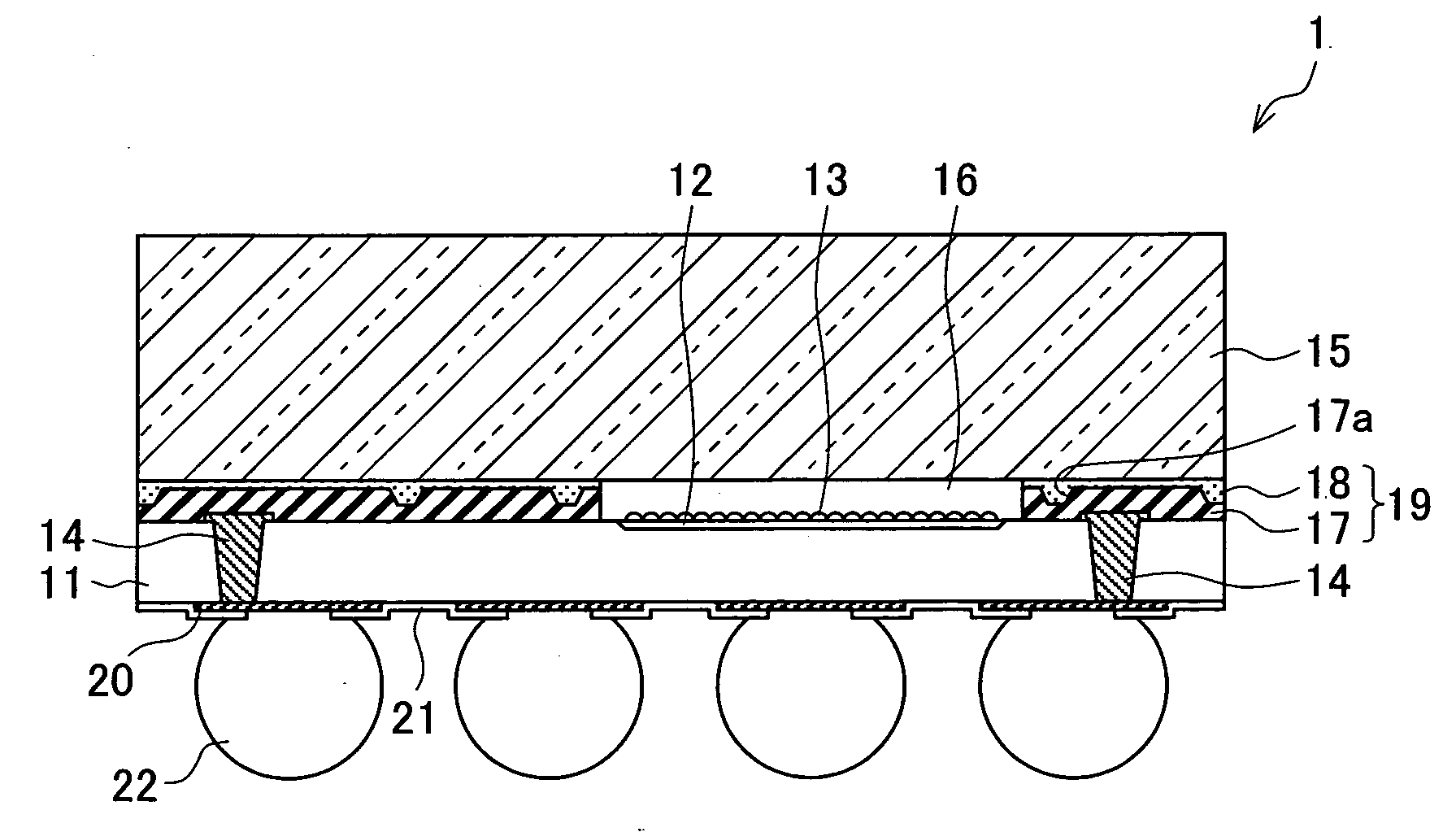

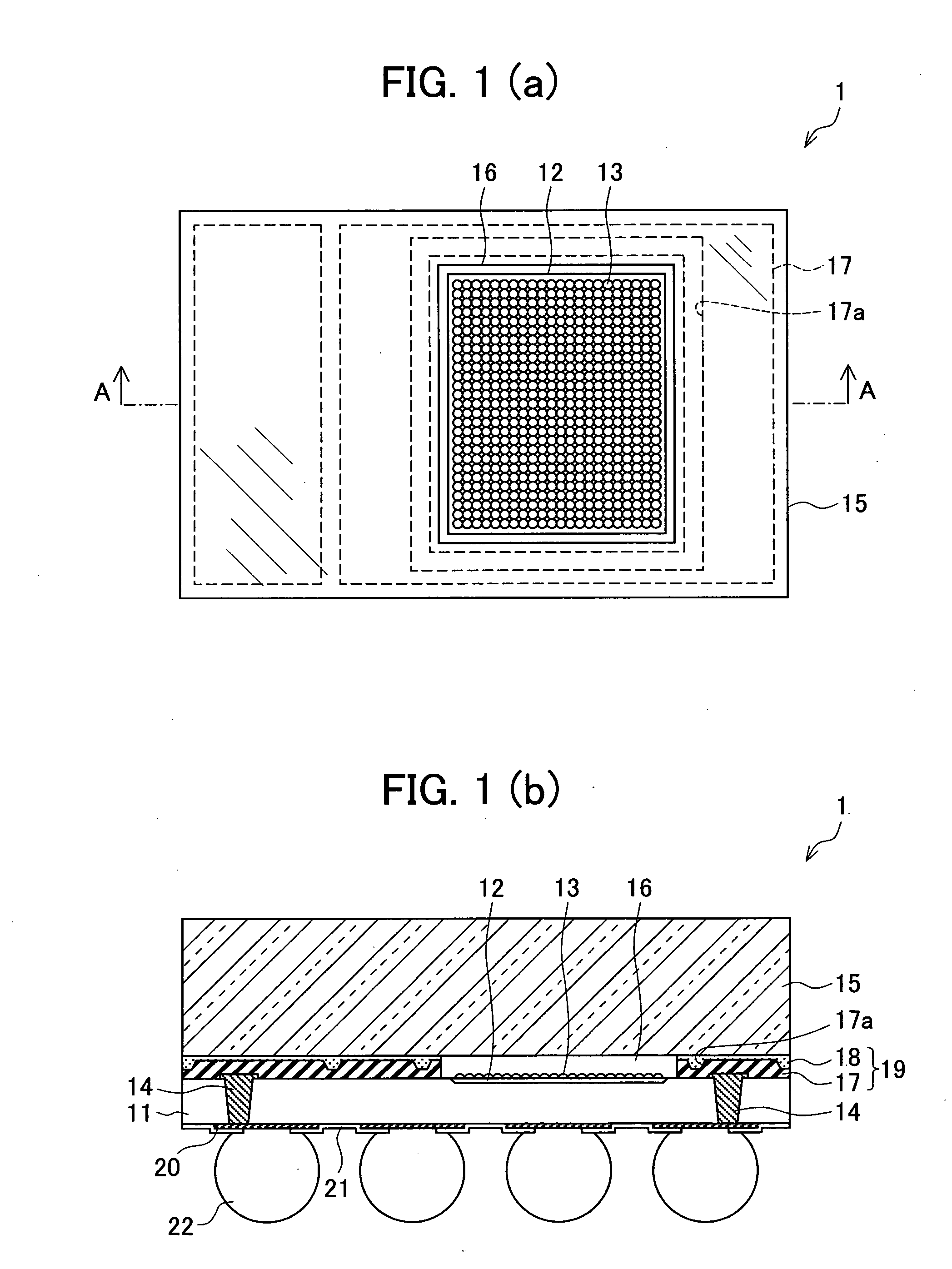

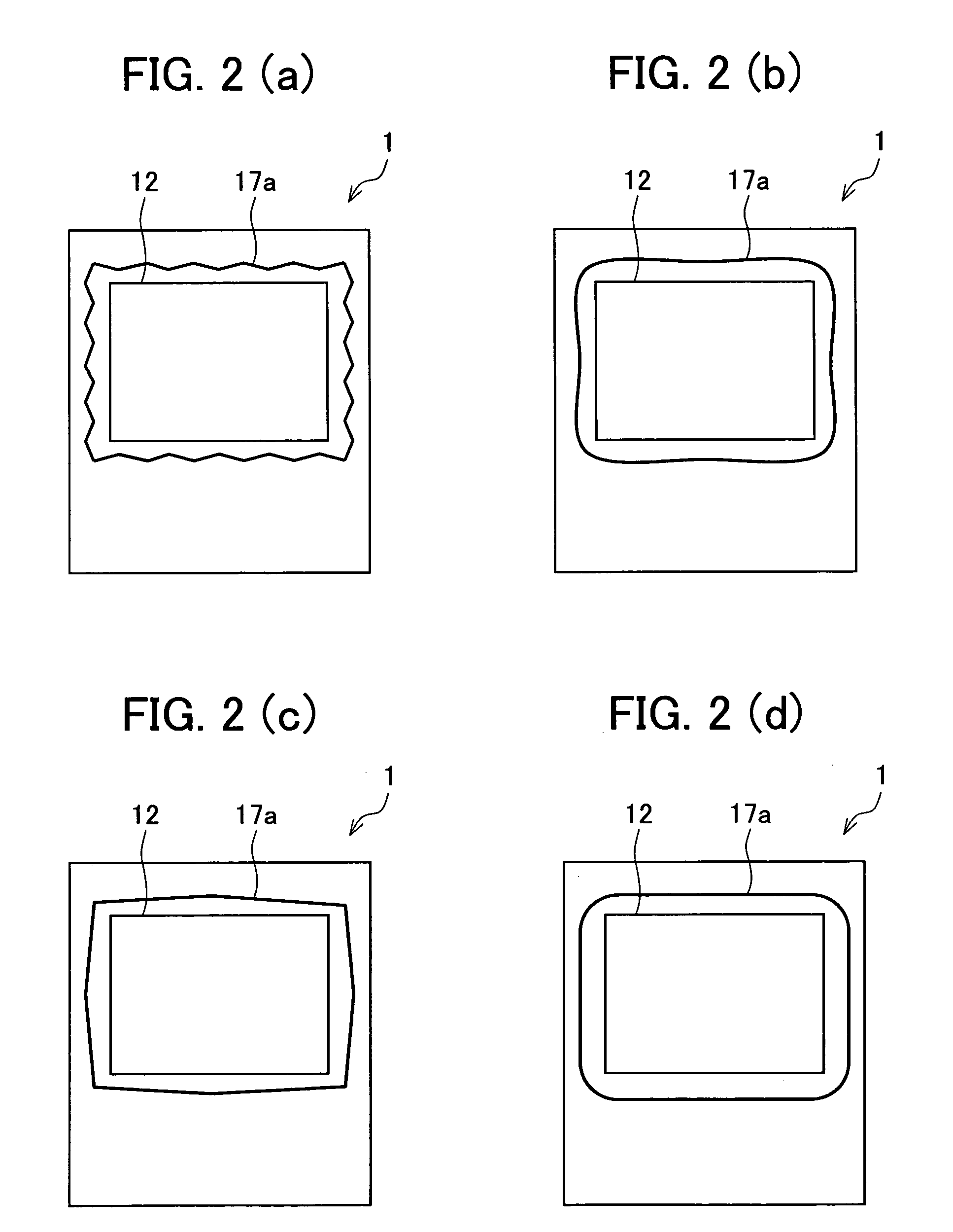

Semiconductor device, module for optical devices, and manufacturing method of semiconductor device

An image pickup element and a micro-lens part are formed on the front surface of a semiconductor substrate; through electrodes passing through the semiconductor substrate are formed; protruding parts protruding from the front surface toward a glass lid are formed in a thickness greater than the thickness of the micro-lens part on the through electrodes; and the protruding parts are interposed between the semiconductor substrate and the glass lid.

Owner:INVENSAS CORP

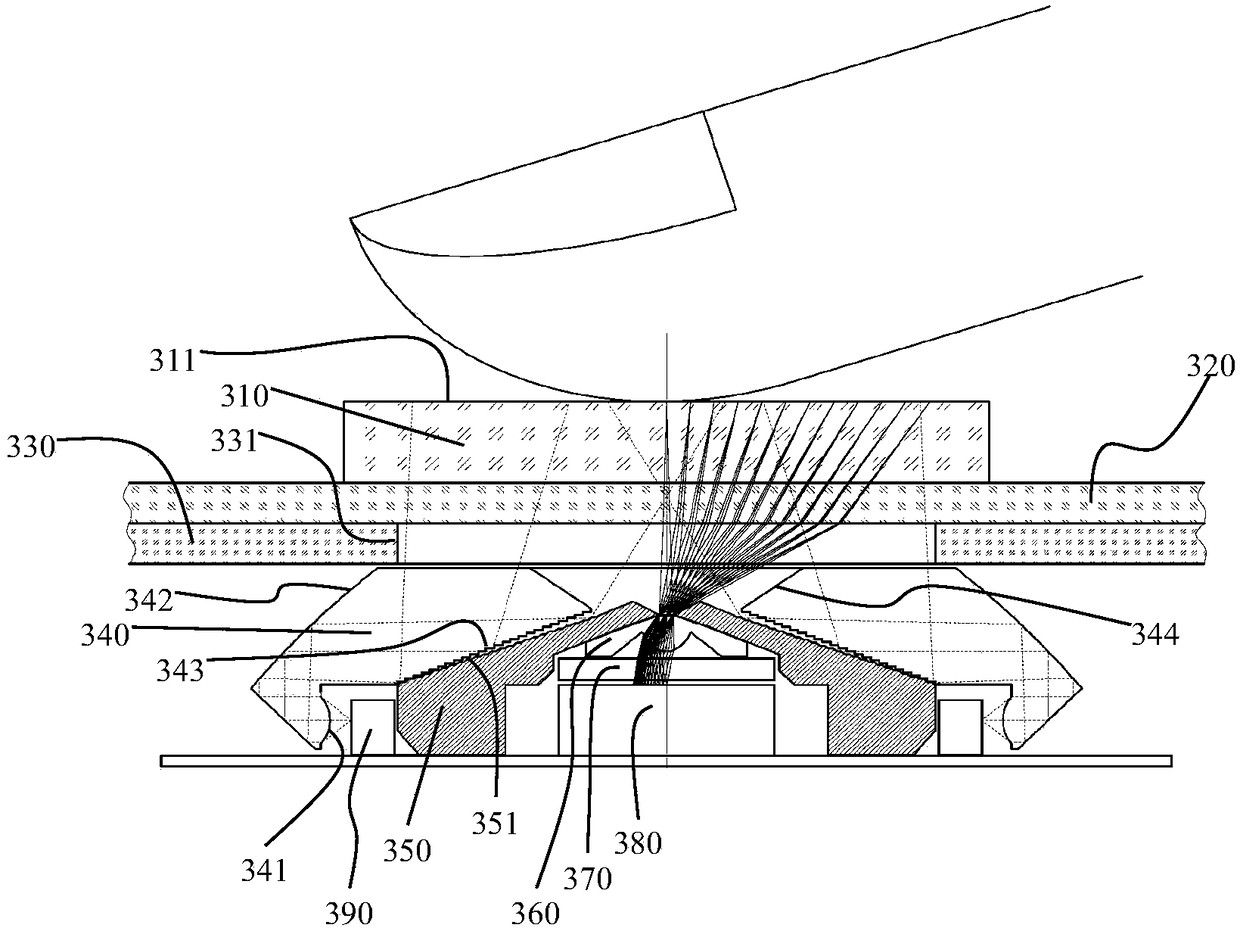

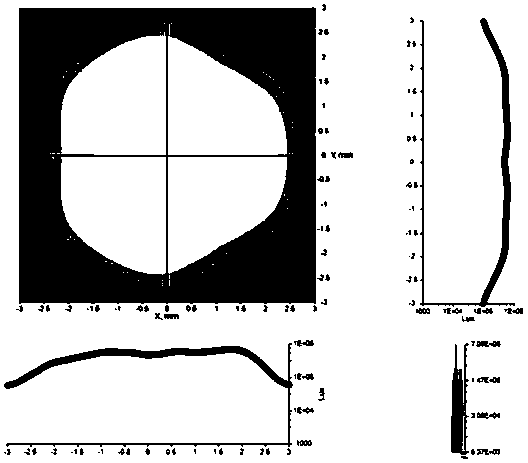

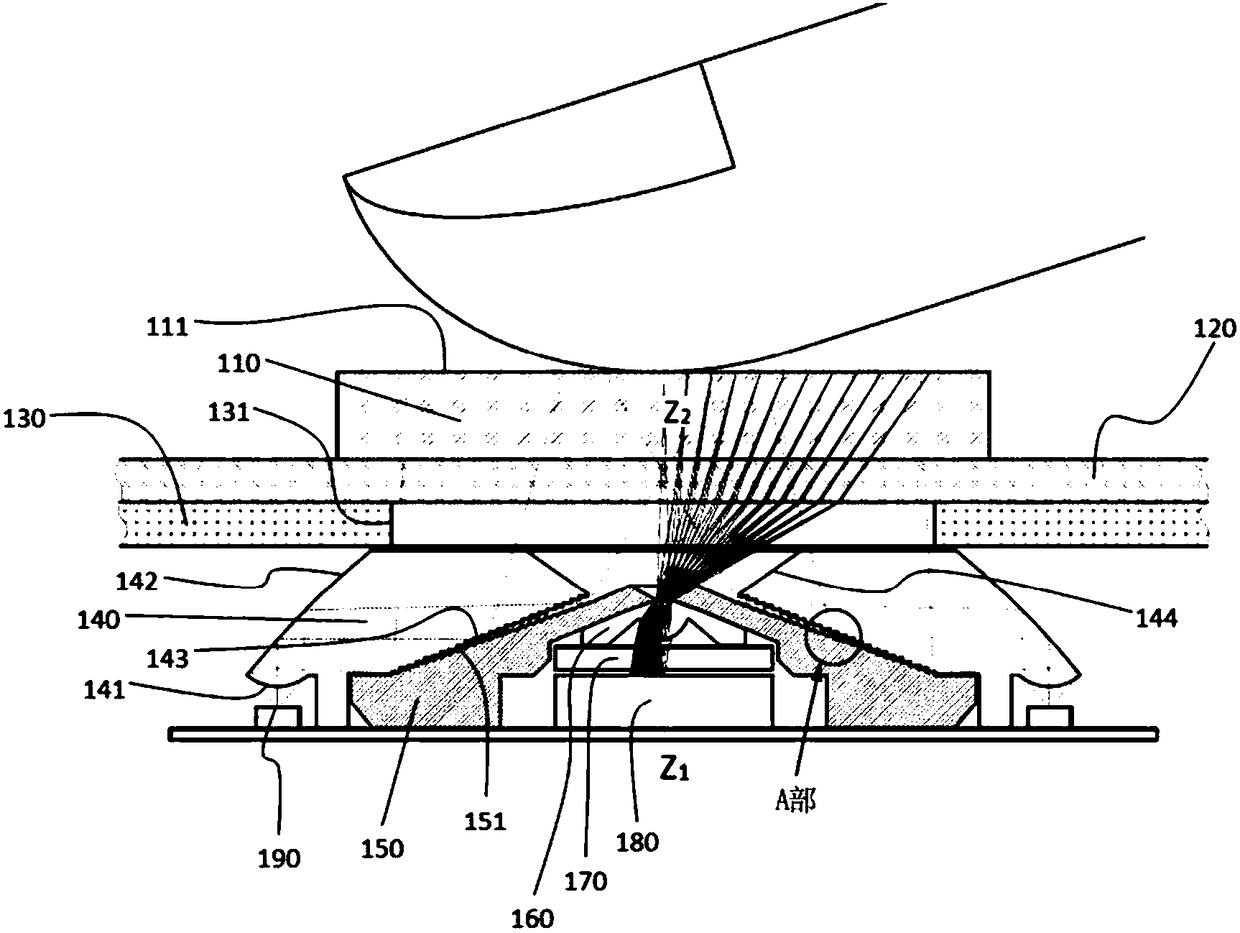

Fingerprint recognition module used under screen

PendingCN108446677AEliminate black spotsSimple structurePrint image acquisitionGlass coverBlack spot

The invention discloses a fingerprint recognition module used under a screen. The fingerprint recognition module comprises a screen component, a miniature backlight illumination system installed underthe screen component, and an imaging system installed in the miniature backlight illumination system. The screen component is installed above the micro backlight illumination system. The screen component includes a glass cover plate, a display screen arranged under the glass cover plate, and a light guide plate which is arranged under the display screen and is used for illuminating the liquid crystal display. The light guide plate is arranged above a light guide component. The miniature backlight illumination system includes the light guide component and a light emitting component which is installed at a side of the light guide component. The imaging system comprises an imaging lens for imaging and an image sensor which is installed under the imaging lens and is used for receiving an image. The fingerprint recognition module has the advantages of a simple structure, low cost, a long life and good reliability, at the same time, black spots caused by insufficient local brightness on thedisplay screen caused by holes of the light guide plate can be eliminated, and the fingerprint recognition module can be used for a common LCD touch display screen.

Owner:MIKOLTA OPTICAL TECH CO

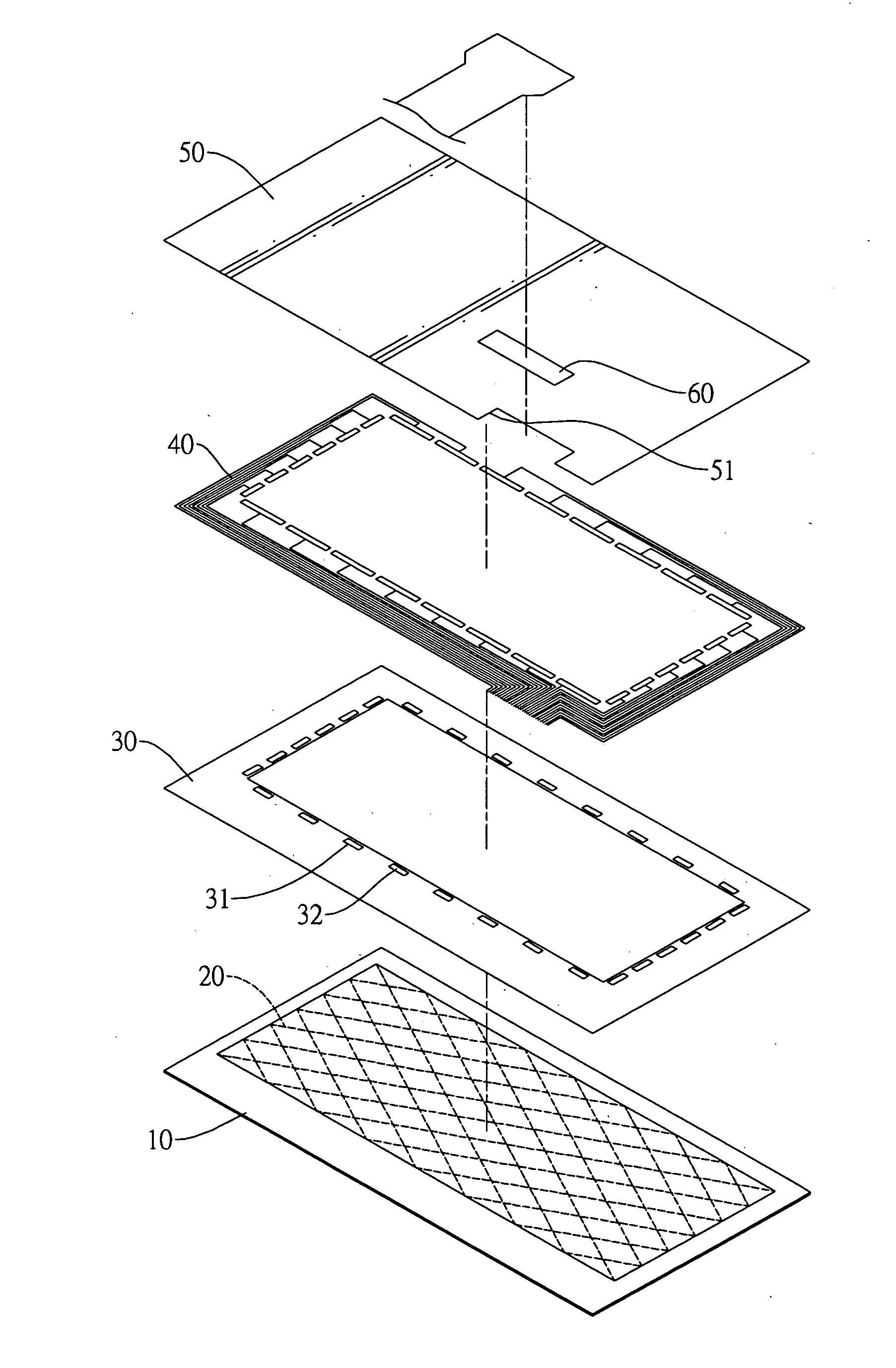

Single-layer projected capacitive touch panel and method of manufacturing the same

ActiveUS20110234526A1Improve permeabilityHigh yield ratePrinted circuit assemblingVessels or leading-in conductors manufactureGlass coverTouch Senses

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

Wafer level optical sensor package and low profile camera module, and method of manufacture

The invention provides a wafer lever optical sensor package and low profile camera module and a method of manufacture. The wafer-level camera sensor package includes a semiconductor substrate with an optical sensor on a front surface. Through-silicon-vias (TSV) extend through the substrate and provide I / O contact with the sensor from the back side of the substrate. A glass cover is positioned over the front surface, and the cover and substrate are embedded in a molding compound layer (MCL), the front surface of the MCL lying coplanar with the front of the cover, and the back surface lying coplanar with the back of the substrate. Surface-mount devices, electromagnetic shielding, and through-wafer-connectors can be embedded in the MCL. A redistribution layer on the back surface of the MCL includes bottom contact pads for mounting the package, and conductive traces interconnecting the contact pads, TSVs, surface-mount devices, shielding, and through-wafer-connectors. Anisotropic conductive adhesive is positioned on the front of the MCL for physically and electrically attaching a lens array.

Owner:STMICROELECTRONICS SRL

Systems, methods and apparatus for precision automation of manufacturing solar panels

Systems and methods for manufacturing solar panels are disclosed. Solar cells are placed on a conveyor that transports the cells from a start point to an end point. A laser scribing module scribes the cells at a predetermined depth. A paste dispensing module deposits a predetermined amount of conductive paste on the surface of the solar cells. A cleaving apparatus divides the cells into smaller strips. A shingling module creates a string of cells by overlapping the strips. A targeted annealing module cures the paste, and a layup module places the strings on a backsheet. A glass cover is then added to one side of the strings.

Owner:TESLA INC

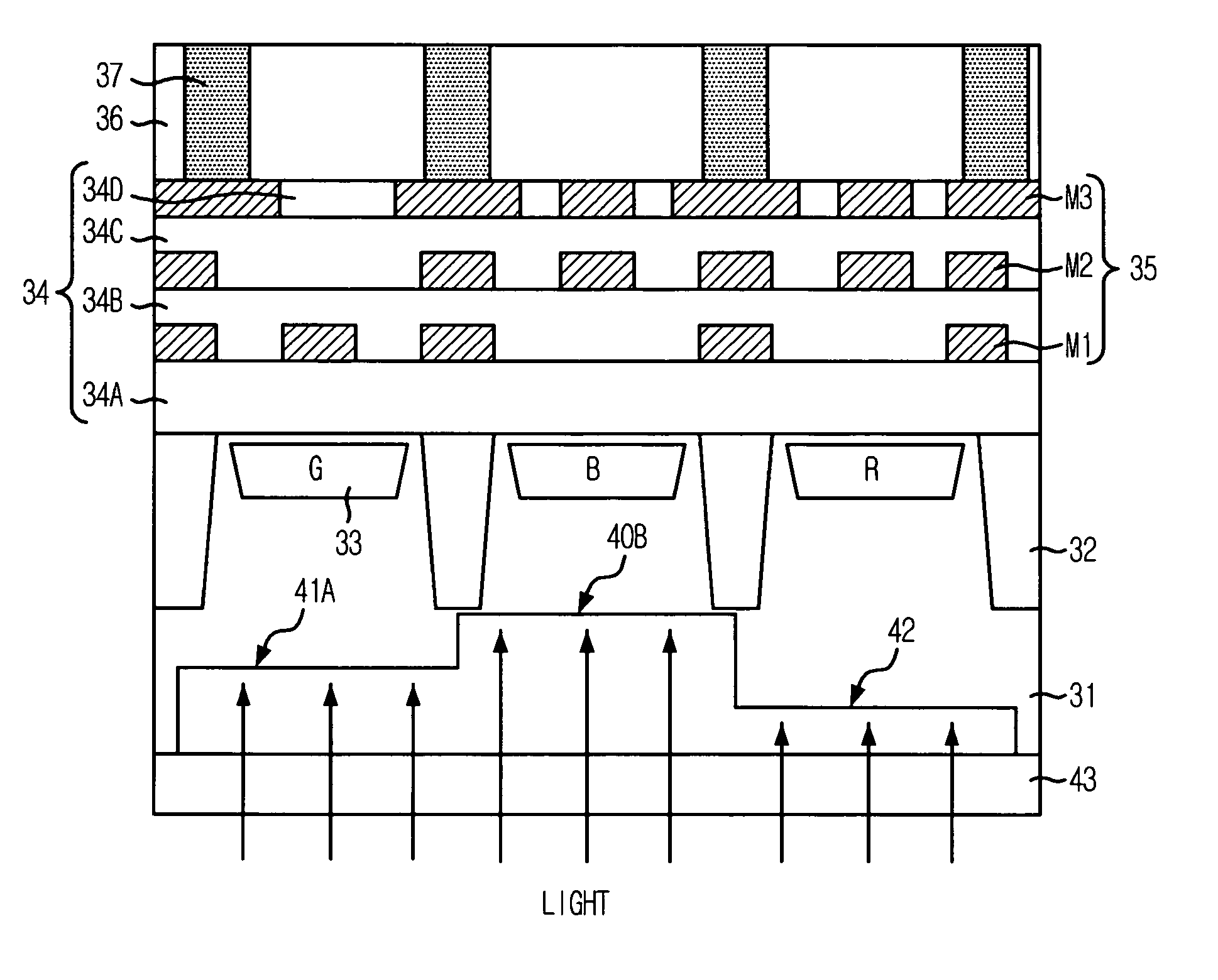

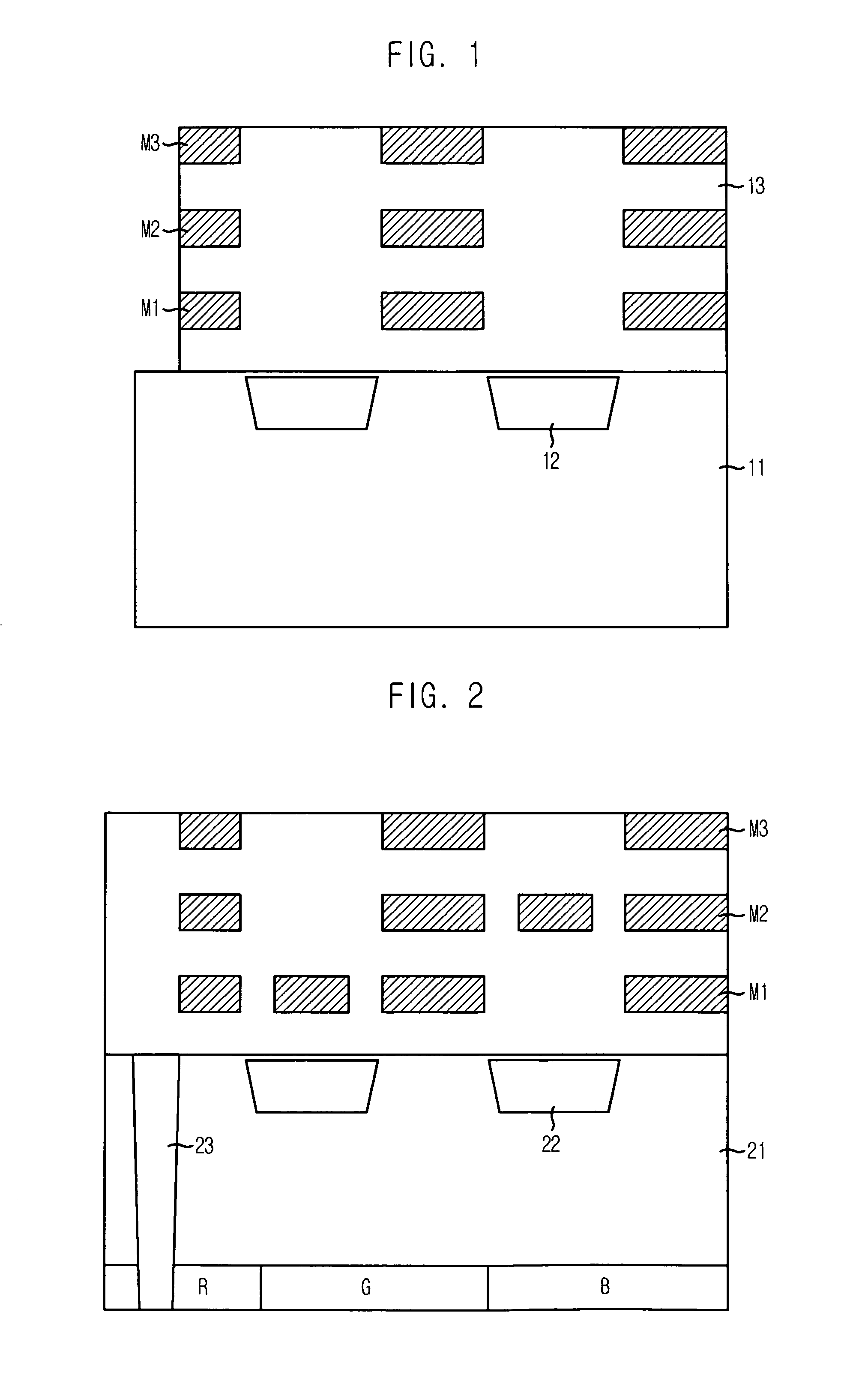

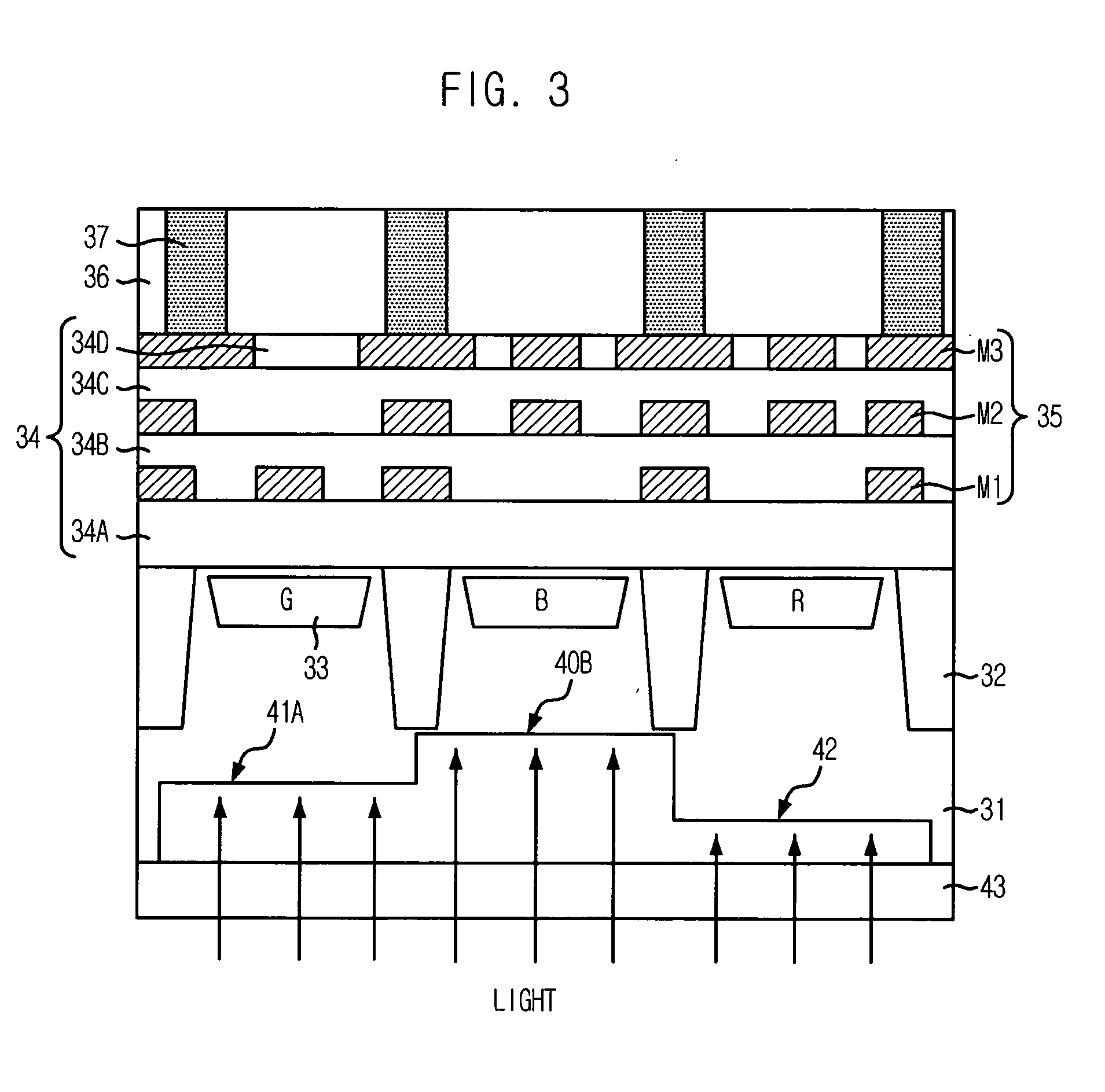

CMOS image sensor with backside illumination and method for manufacturing the same

A CMOS image sensor includes a plurality of pixel regions formed under a front surface of a substrate, and having photodiodes separated from each other by a field oxide, a multi-layered metal interconnection formed over the pixel regions of the front of the substrate, a bump connected to an uppermost metal interconnection of the multi-layered metal interconnection, a plurality of trenches formed in a backside of the substrate, wherein the trenches have different depths for each wavelength of light, and correspond to the respective pixel regions, and a glass covering the backside of the substrate.

Owner:INTELLECTUAL VENTURES II

Device with culture relics exhibiting and protecting function

InactiveCN101390700APrevent oxidationInhibition of photodegradationShow cabinetsShow shelvesMicroorganismGlass cover

The invention provides a device which can exhibit and protect cultural relics. The device is characterized in that the device comprises a base; a base plate is arranged at the top of the base; the bottom of a glass cover is fixed on the base plate through a safety lock reed, and a safety alarm is arranged on the safety lock reed; a gland bush is arranged at the butt joint of the glass cover and the base plate; a rotating bushing is arranged at the middle part of the base plate and a gland bush is arranged on the rotating bushing; rotating shafts are arranged inside the rotating bushing and the base; showcase stands are arranged at the top parts of the rotating shafts, and step motors are arranged at the tail ends of the rotating shafts; a temperature sensor, a pressure sensor, a humidity sensor and a gas composition sensor are arranged at two sides of the base plate; and a cavity refrigerating / heating device is arranged at the bottom of the base plate. The device has the advantages that the device can well exhibit the cultural relics and can create a manual protecting environment without damages. The device prevents oxidation, photodegradation, overheating volatilization, mould development and microorganisms and has the function of protecting the cultural relics and the precious article inside the cavity.

Owner:DONGHUA UNIV

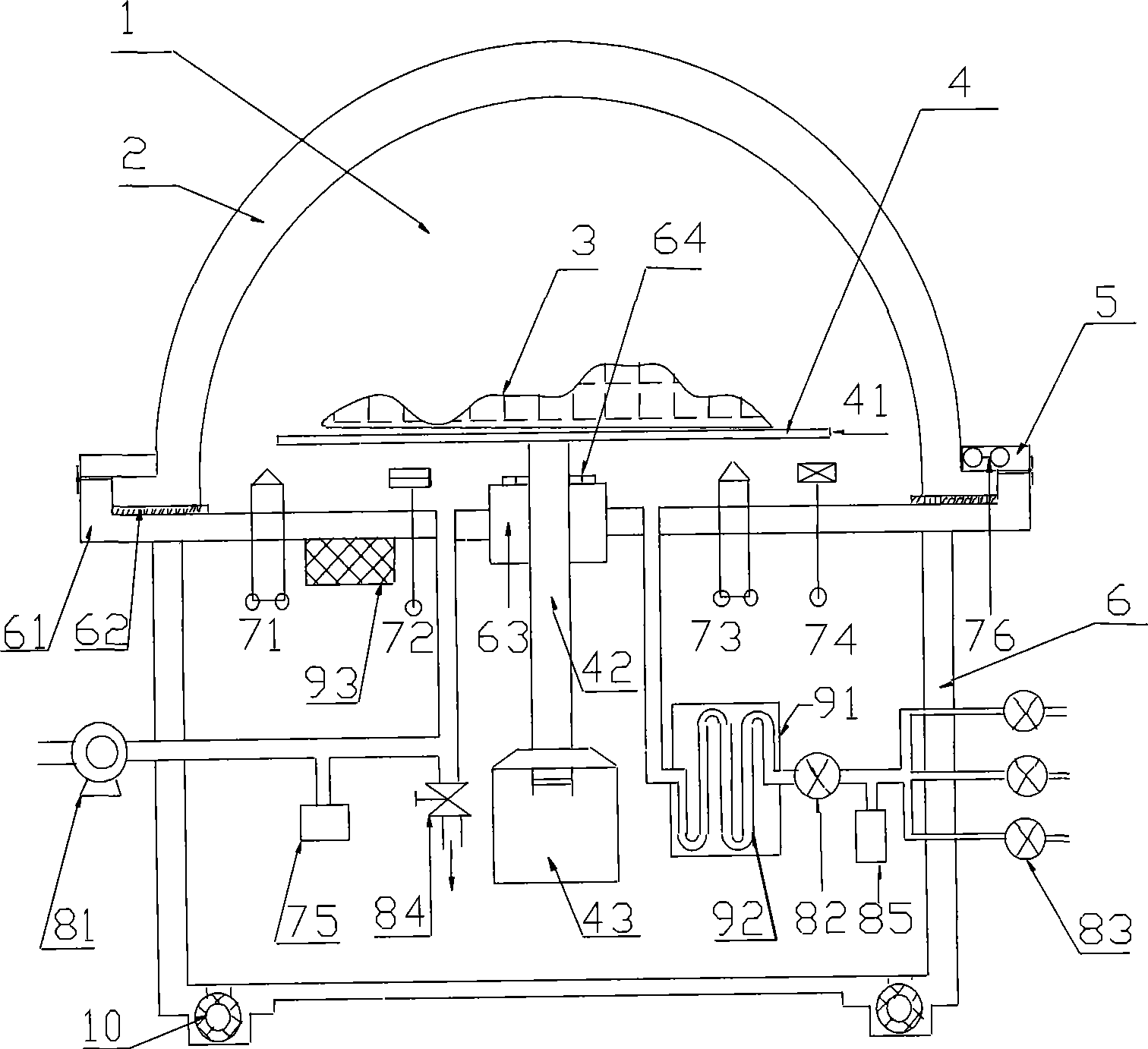

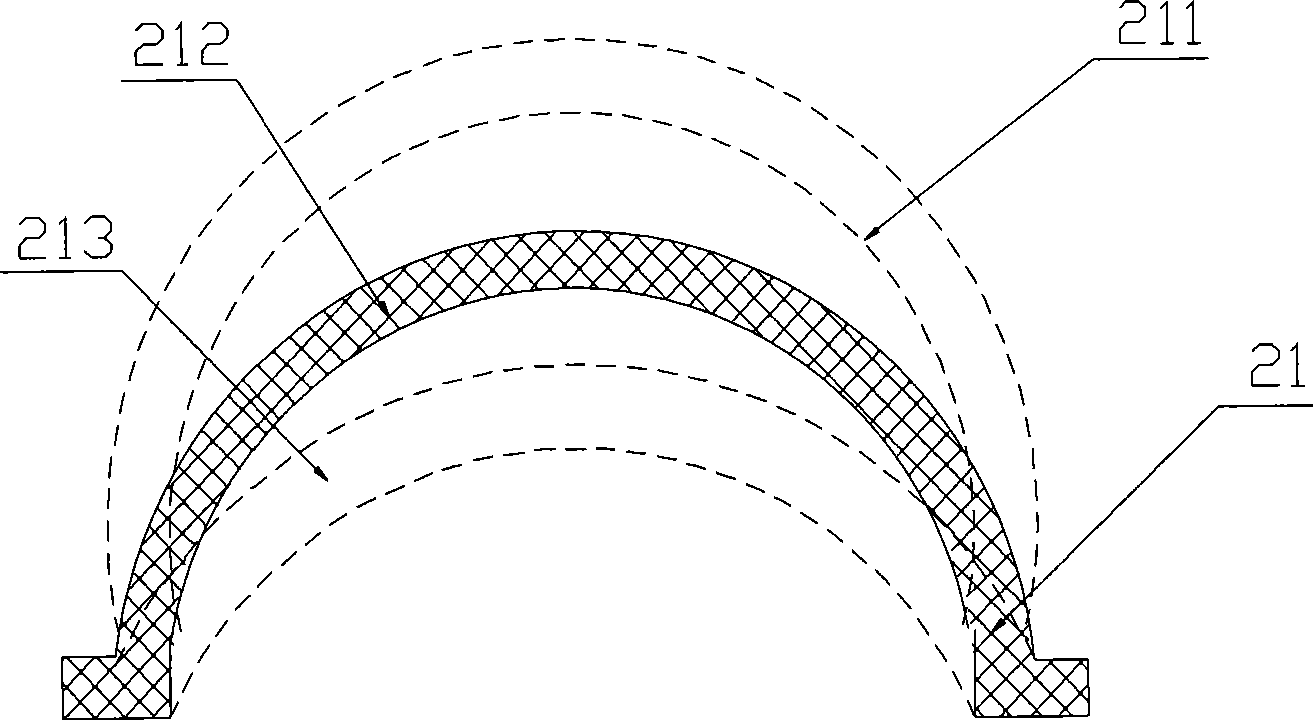

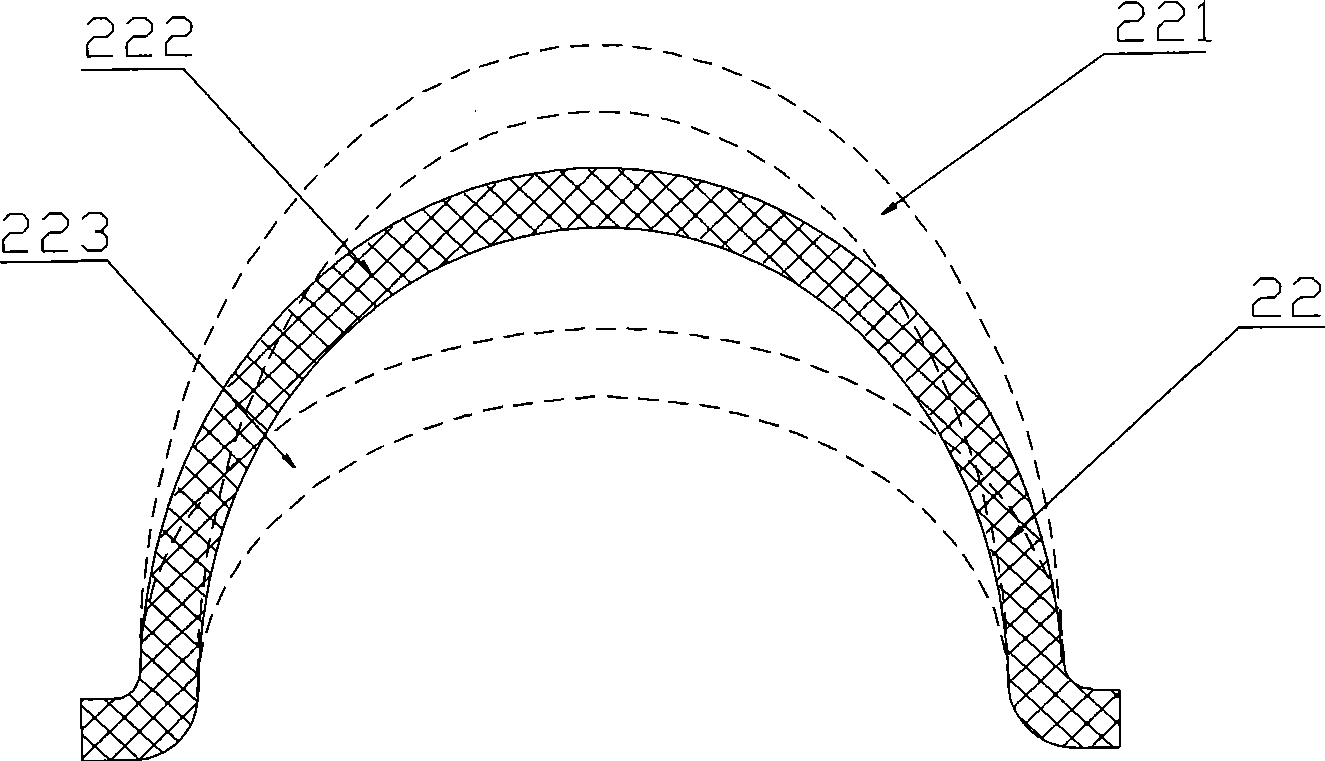

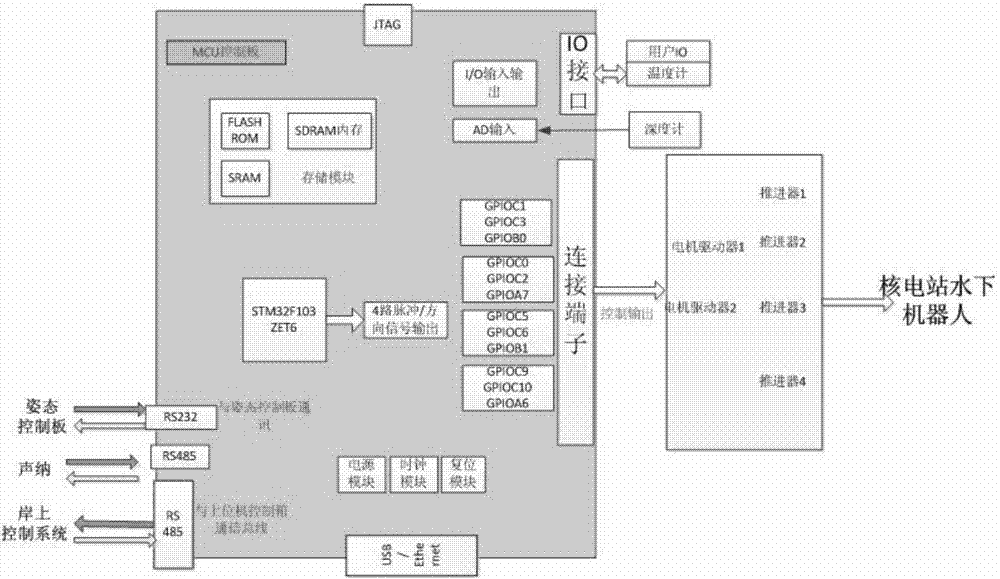

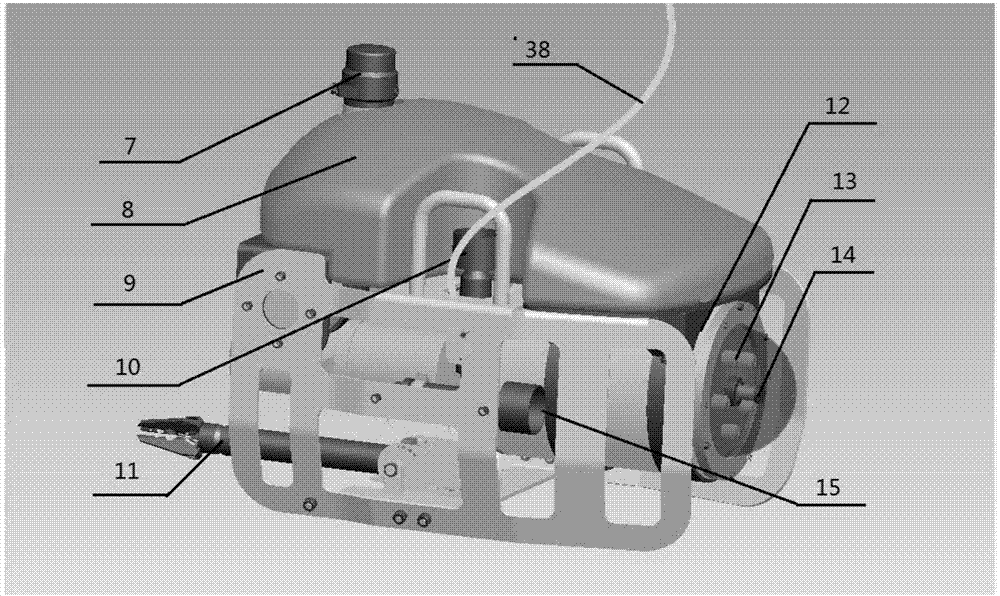

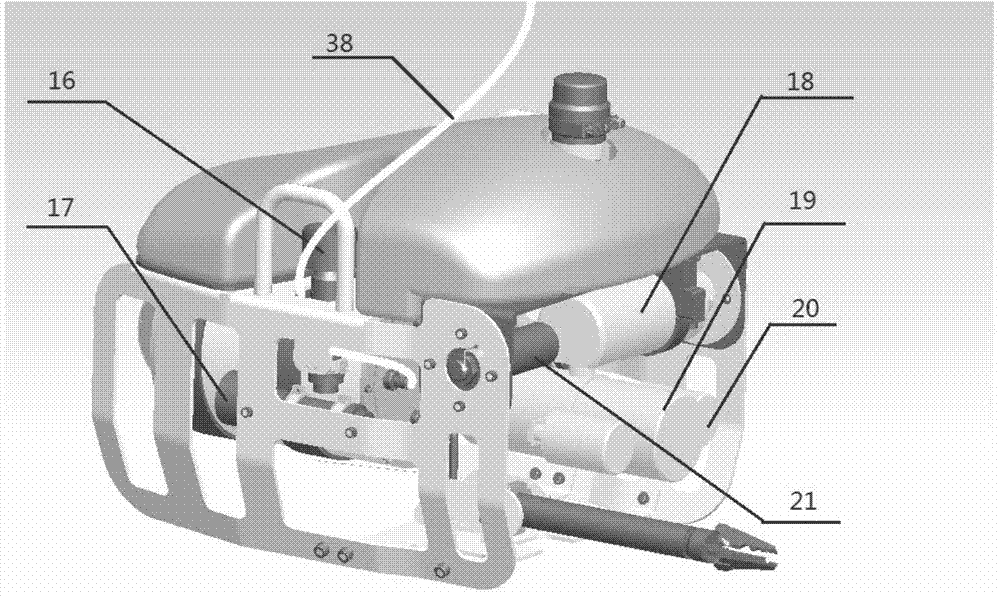

Microminiature operation underwater robot of nuclear power plant

The invention relates to a microminiature operation underwater robot of a nuclear power plant, and the robot comprises an underwater robot body and an onshore control system, wherein two propellers are respectively arranged in the horizontal and vertical directions of the robot body, a depth gauge is arranged on the right side of the front part of the robot body, a manipulator is arranged at the bottom in front of the robot body, and a sonar is arranged on the top of the robot body; a control cabin is arranged in the middle rear part of the robot body; an outer cabin is sealed by a transparent glass cover, and is provided with a rearview camera and an auxiliary lighting light-emitting diode (LED) lamp; a front-view camera system is arranged at the front part of the robot body, and comprises a zooming radiation resistant camera tube, a tripod head and a lighting lamp; a video image and control signal is transmitted to the onshore control system through a shield cable; and the control system comprises a movement control rod, a manipulator control button, a keyboard, a main display screen and a speed governing knob. The microminiature operation underwater robot of the nuclear power plant is used for the monitoring and the simple foreign body fishing of a core pool, a spent fuel pool and a component pool of the nuclear power plant.

Owner:BEIHANG UNIV

Wafer level optical sensor package and low profile camera module, and method of manufacture

ActiveUS20130320471A1Less spaceEliminates possible sourceSolid-state devicesSemiconductor/solid-state device manufacturingRedistribution layerContact pad

A wafer-level camera sensor package includes a semiconductor substrate with an optical sensor on a front surface. Through-silicon-vias (TSV) extend through the substrate and provide I / O contact with the sensor from the back side of the substrate. A glass cover is positioned over the front surface, and the cover and substrate are embedded in a molding compound layer (MCL), the front surface of the MCL lying coplanar with the front of the cover, and the back surface lying coplanar with the back of the substrate. Surface-mount devices, electromagnetic shielding, and through-wafer-connectors can be embedded in the MCL. A redistribution layer on the back surface of the MCL includes bottom contact pads for mounting the package, and conductive traces interconnecting the contact pads, TSVs, surface-mount devices, shielding, and through-wafer-connectors. Anisotropic conductive adhesive is positioned on the front of the MCL for physically and electrically attaching a lens array.

Owner:STMICROELECTRONICS PTE LTD

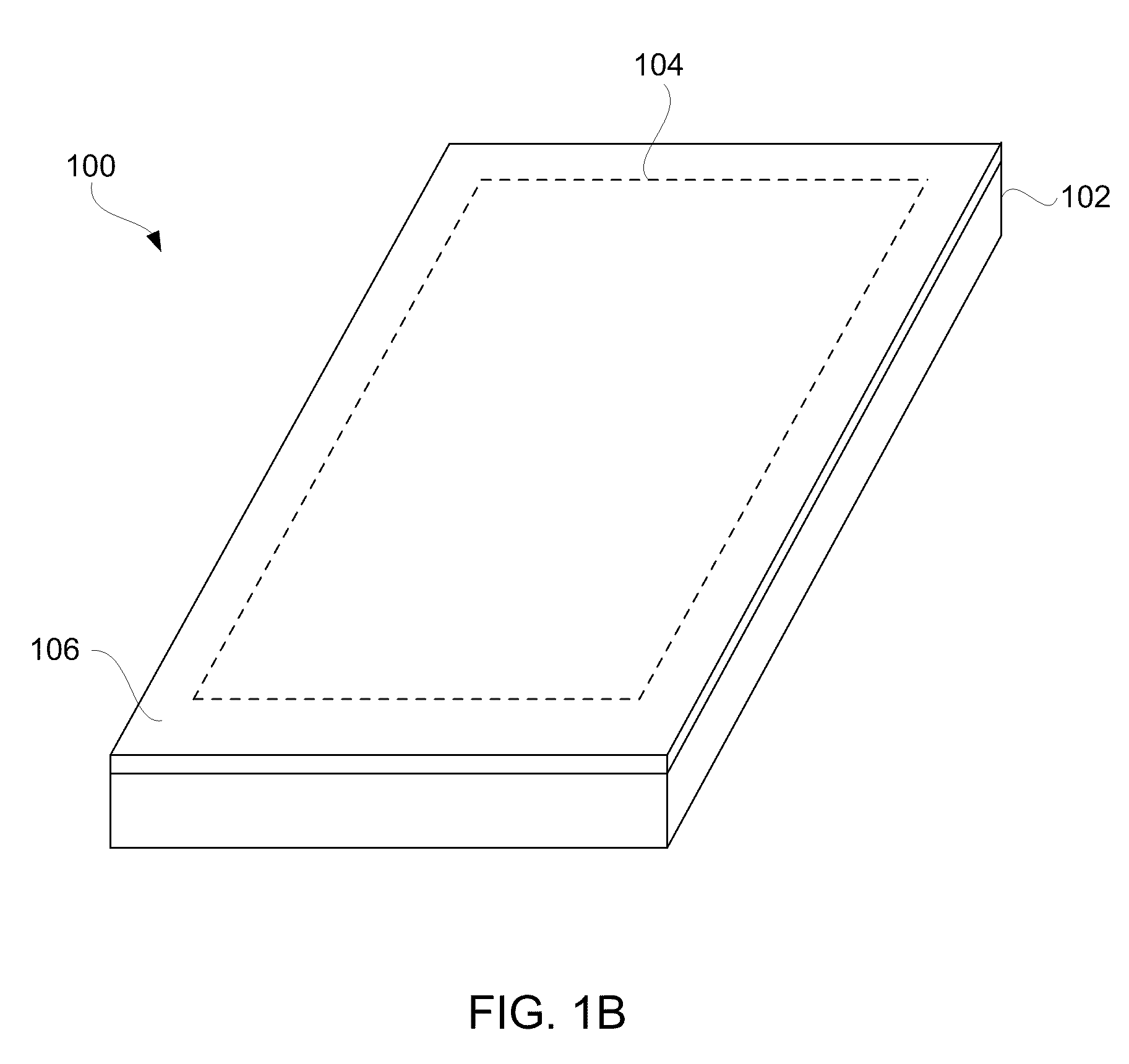

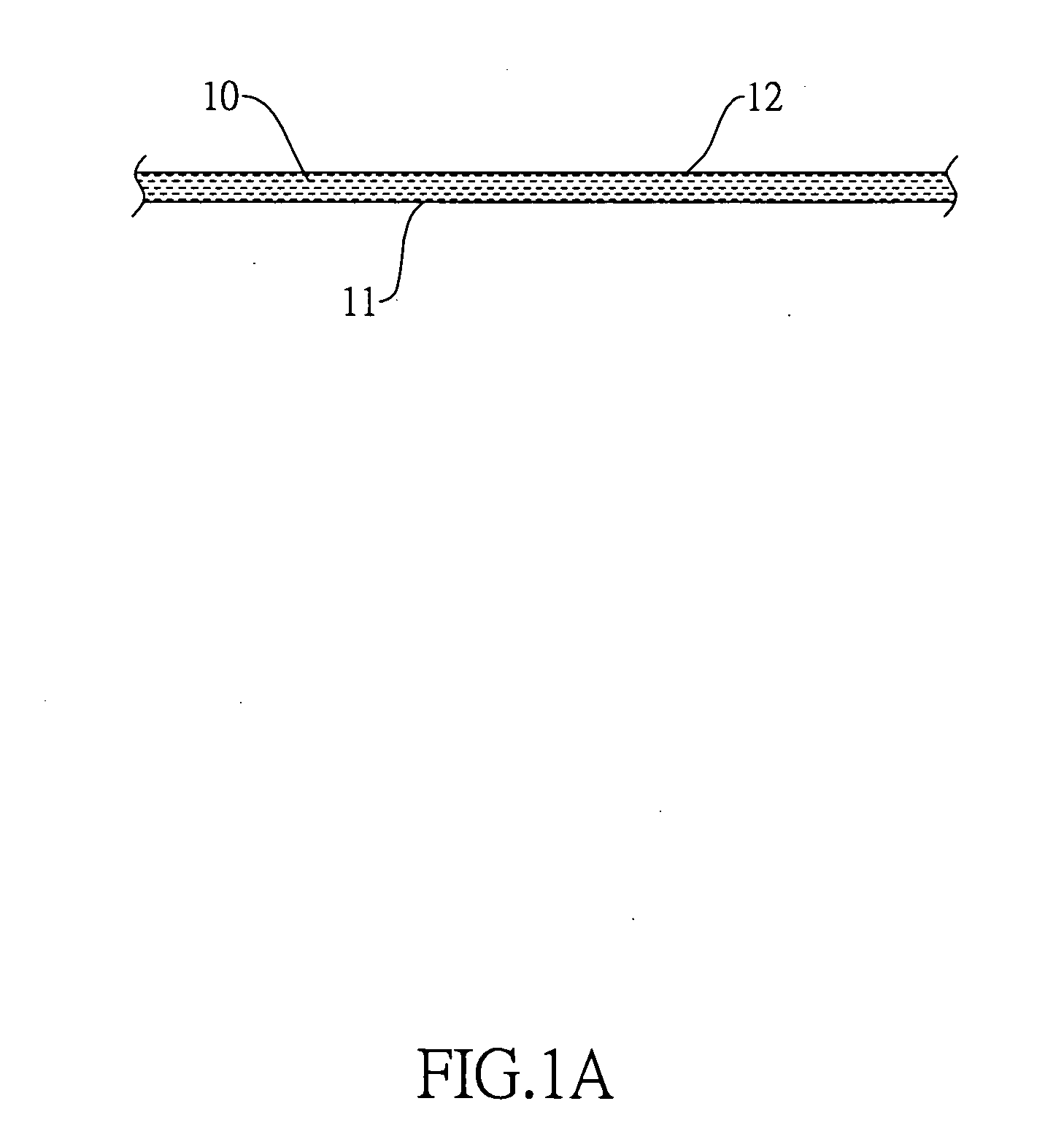

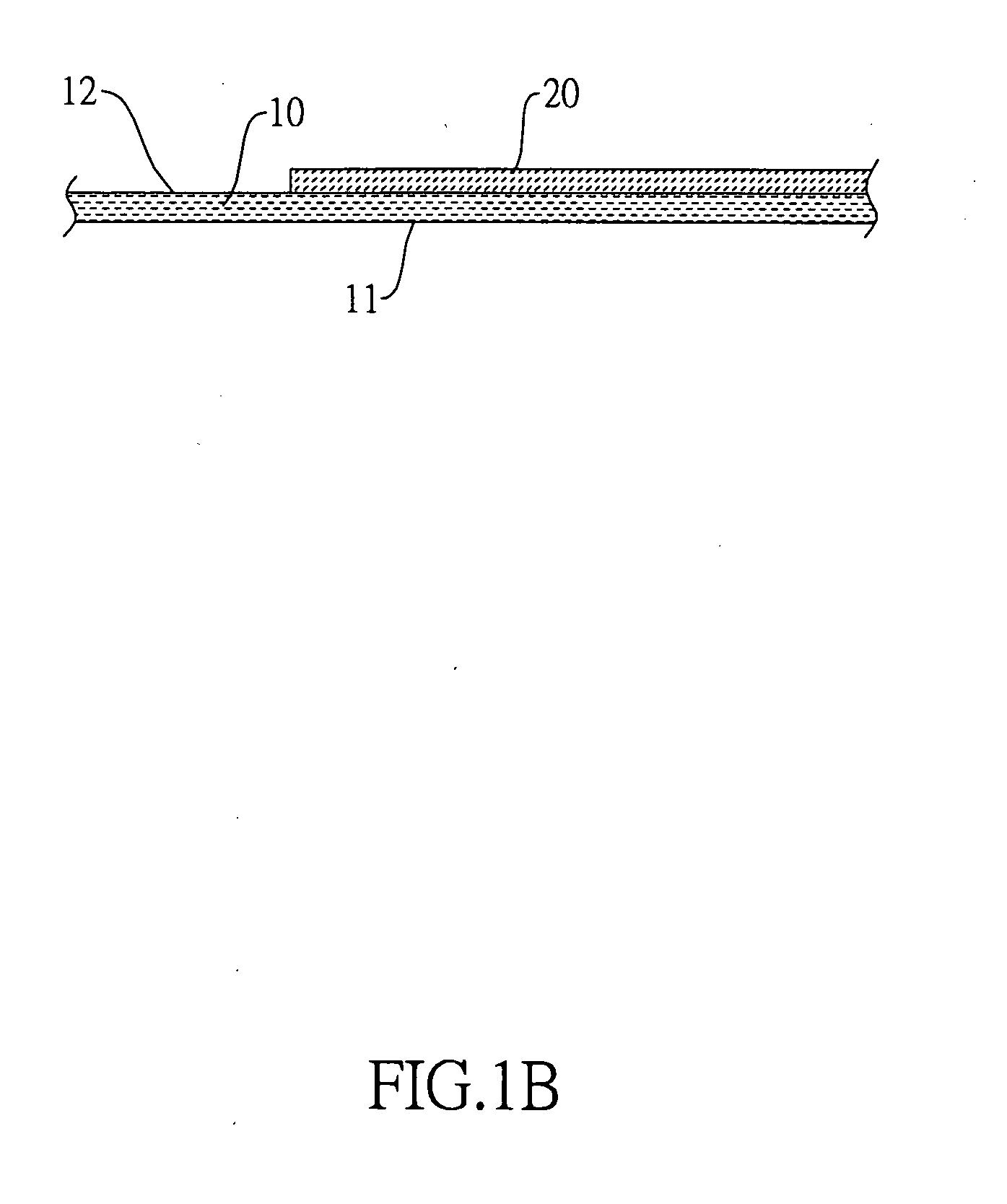

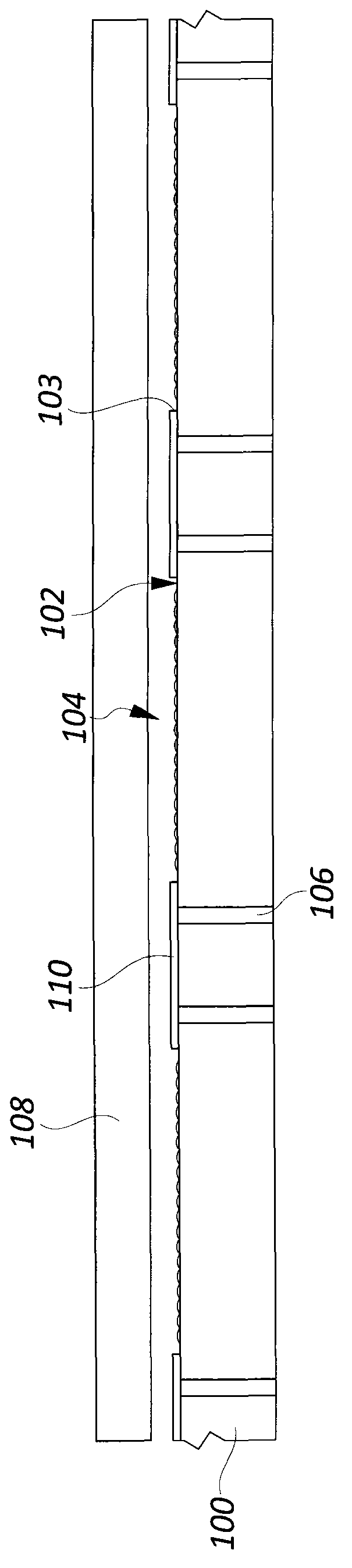

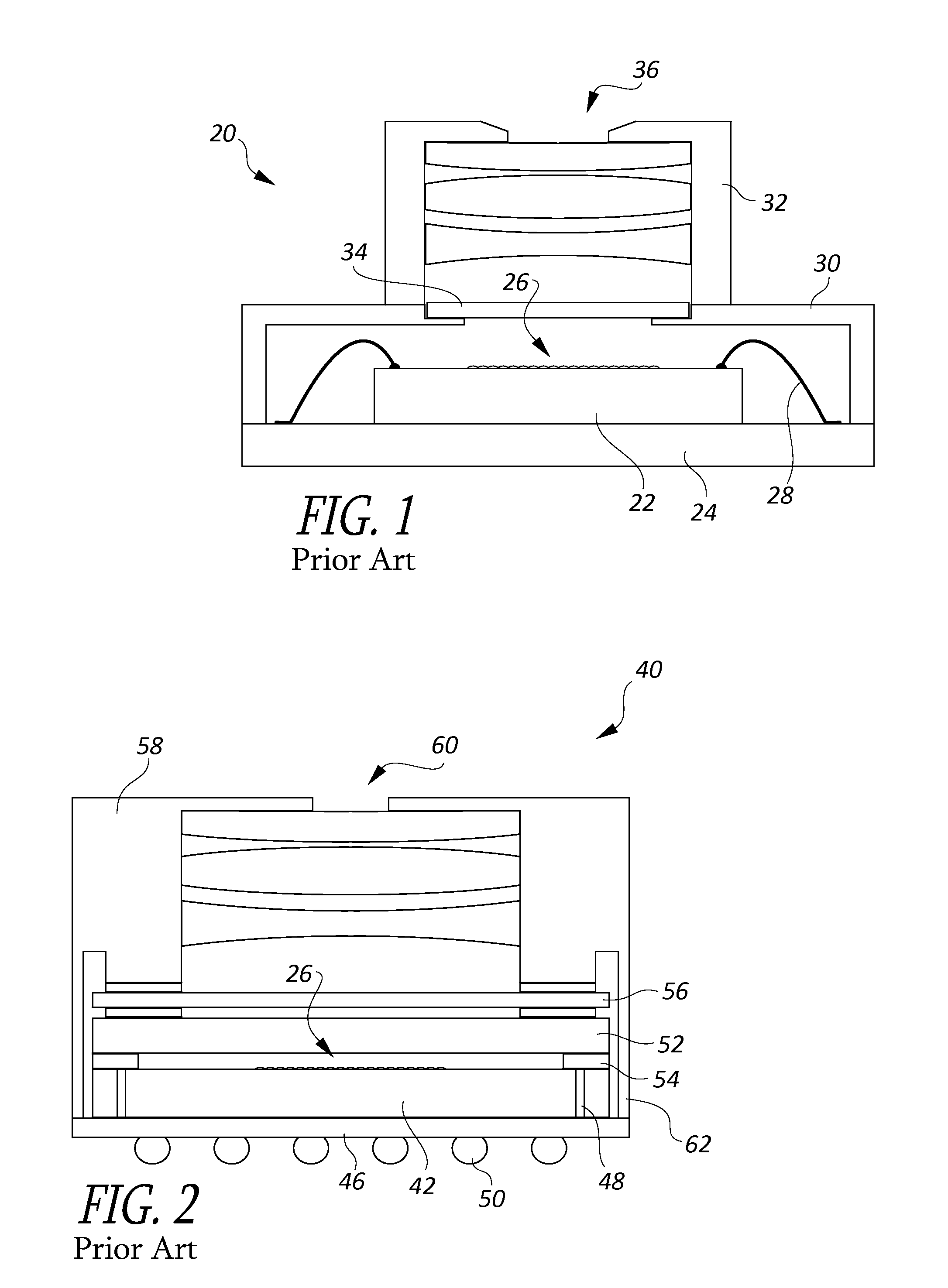

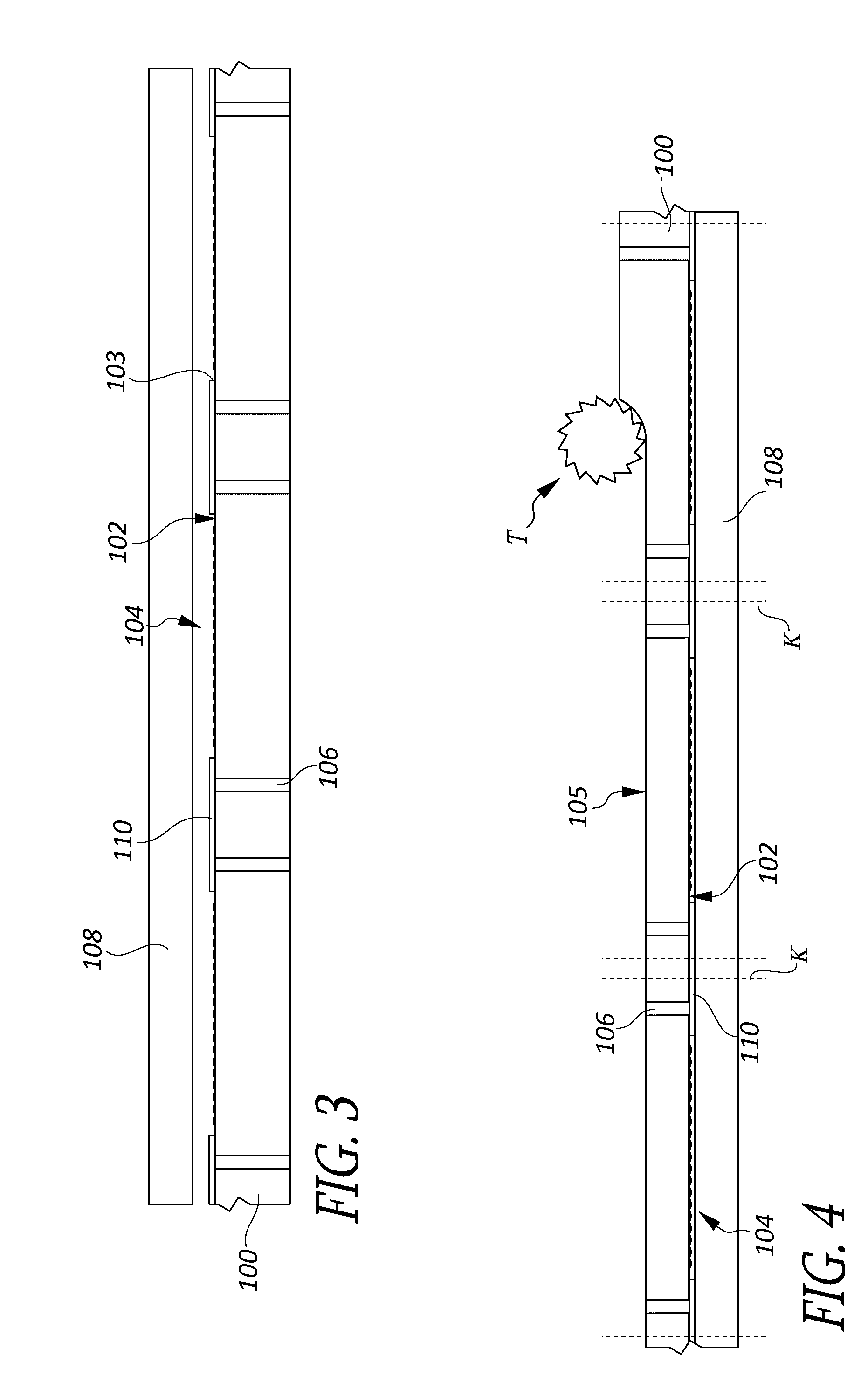

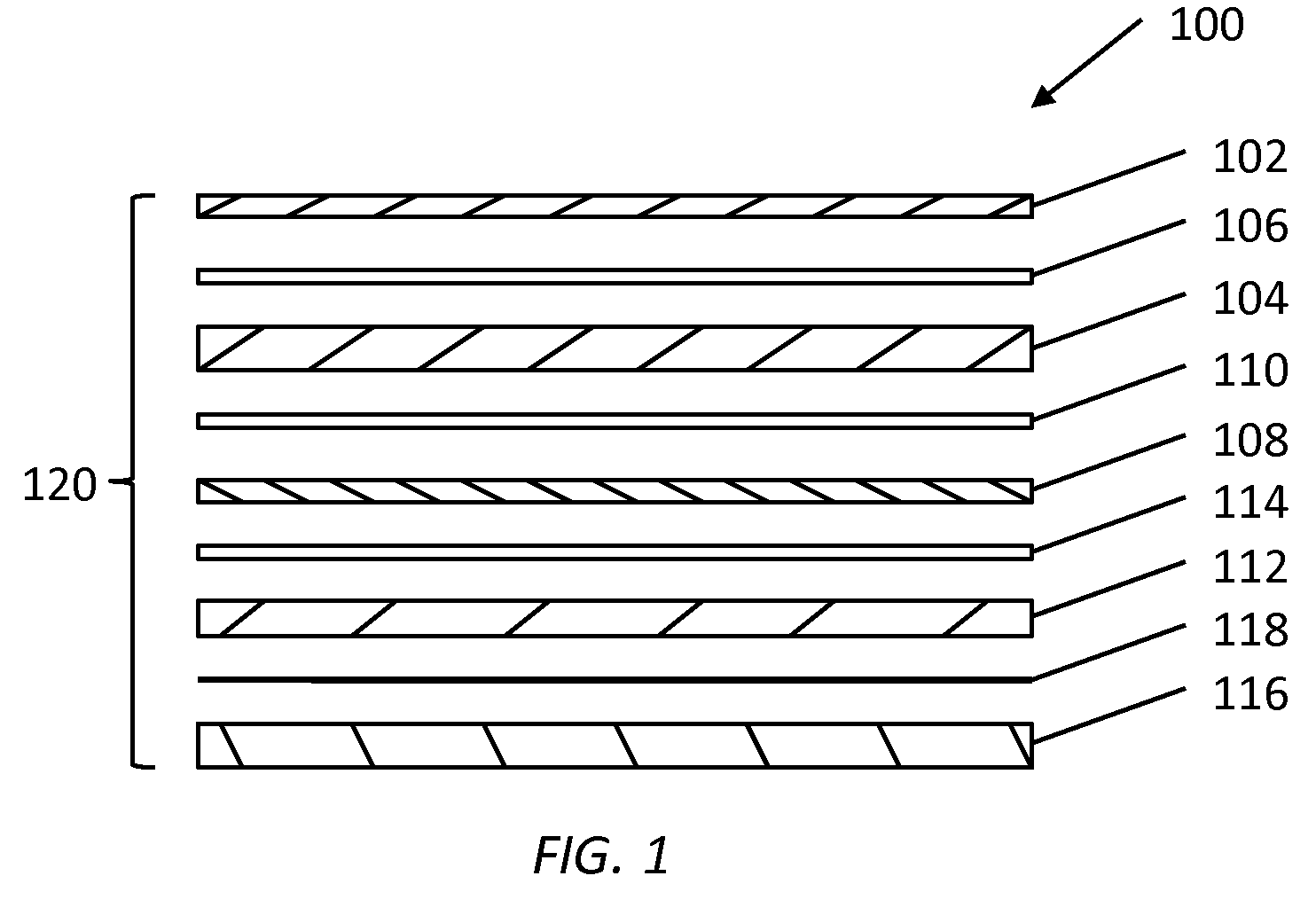

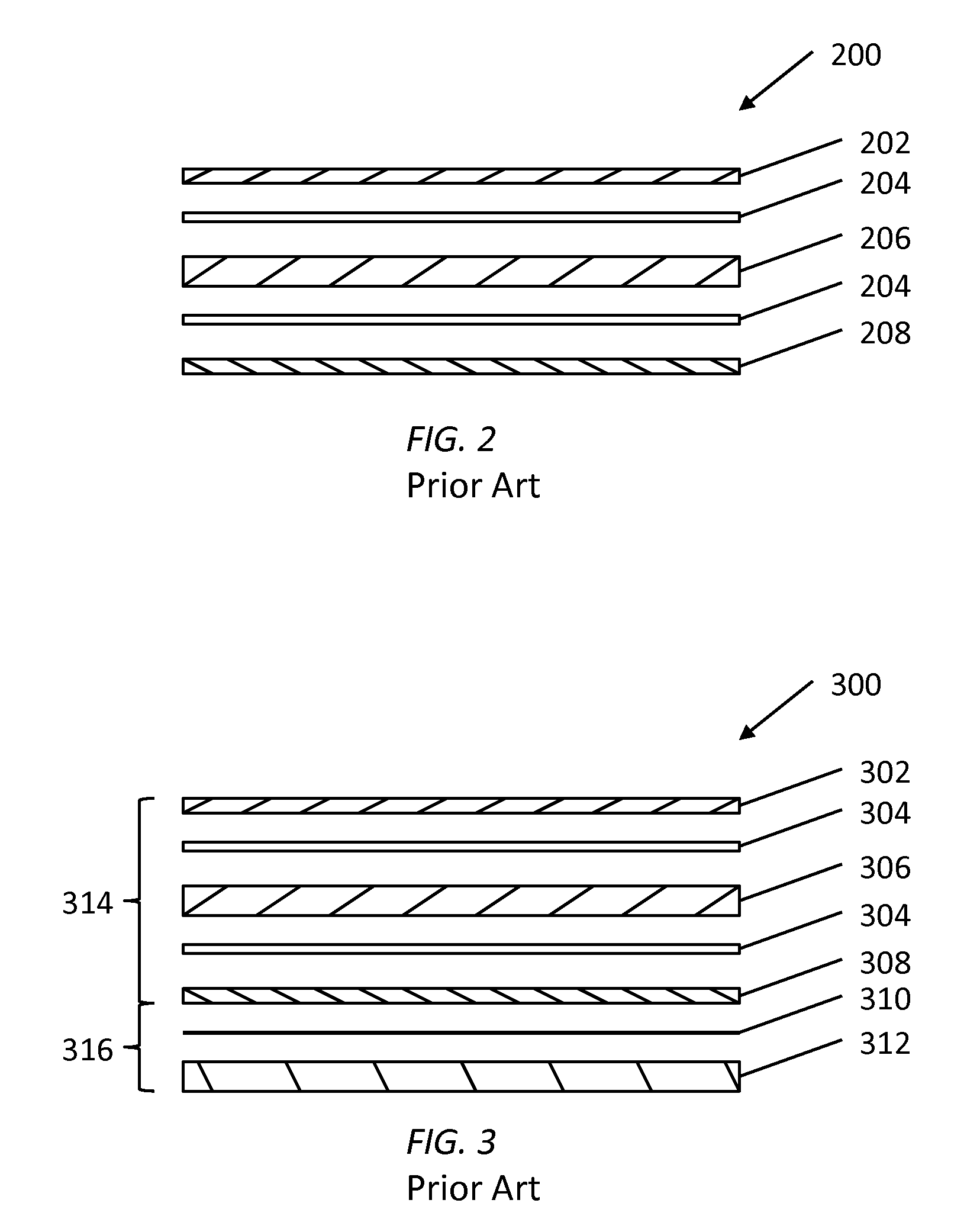

Structures and manufacturing methods for glass covered electronic devices

The disclosure is directed to electronic device displays which are constructed to withstand damage from an impact resistance test wherein a steel ball of 2 g having a diameter of 8 mm is dropped from a designated height greater than 1 ft, more preferably greater than 2 ft, even more preferably greater than 3 ft, still even more preferably greater than 4 ft, yet even more preferably greater than 5 ft and even more preferably greater than 6 ft. The displays are configured using, for example, ultrathin glass adhered to a base glass, wherein the adhesive layer is optimized for thinness and stiffness.

Owner:SYNAPTICS INC

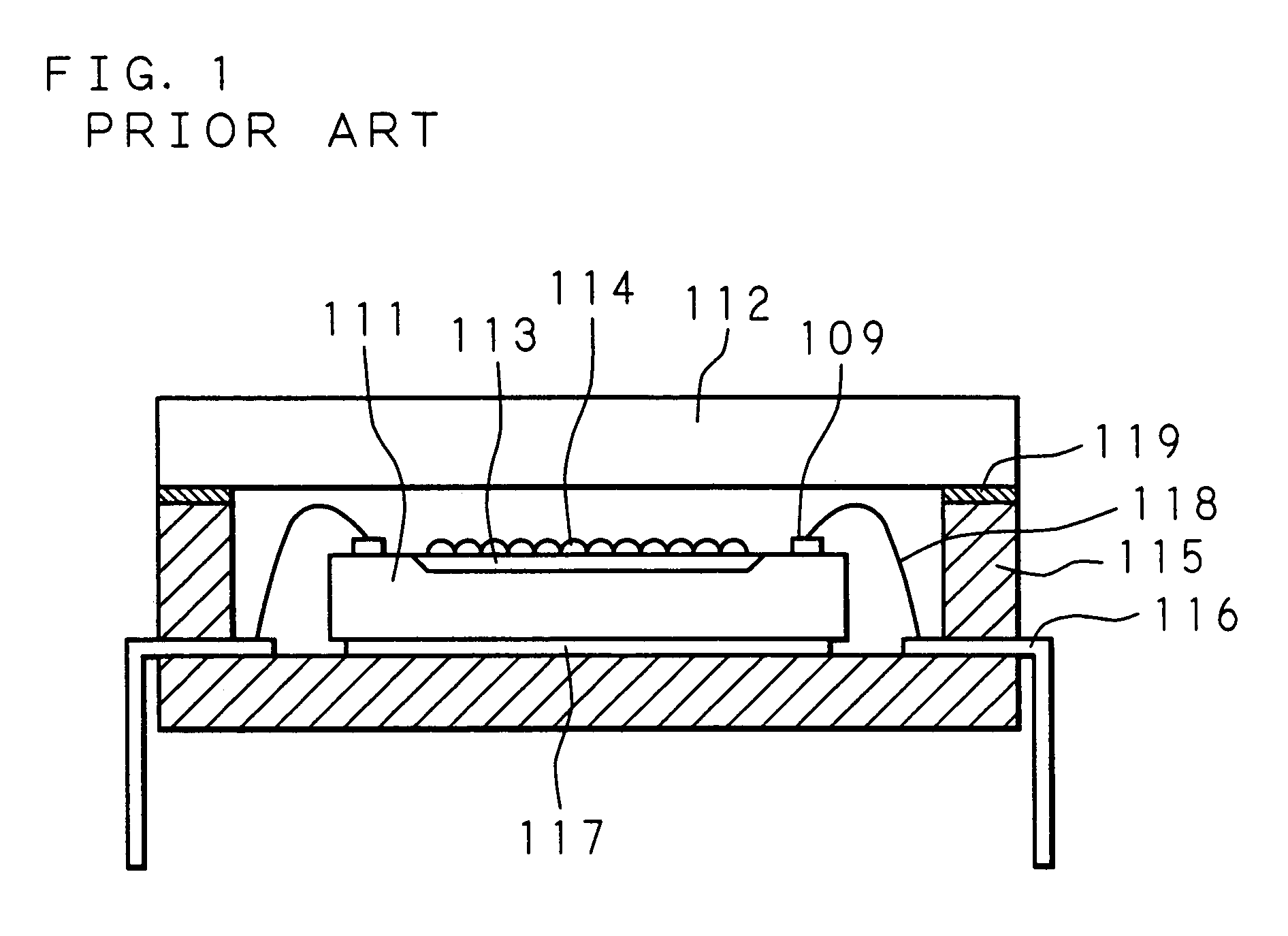

Semiconductor device and production method thereof

InactiveUS20060180887A1Reduce material costsUnnecessary useTelevision system detailsSolid-state devicesGlass coverDevice material

In a semiconductor device, a spacer layer is formed around an imaging element on a semiconductor substrate and a glass lid is combined to the spacer layer via an adhesive layer. A space is made between the semiconductor substrate and the glass lid so as to be positioned at a region where the imaging element is disposed. As a result, in forming a hollow section between a light transmitting material and an active element on the semiconductor substrate, it is unnecessary to apply a large load and to superimpose patterns when the light transmitting material is combined to the semiconductor substrate.

Owner:SHARP KK

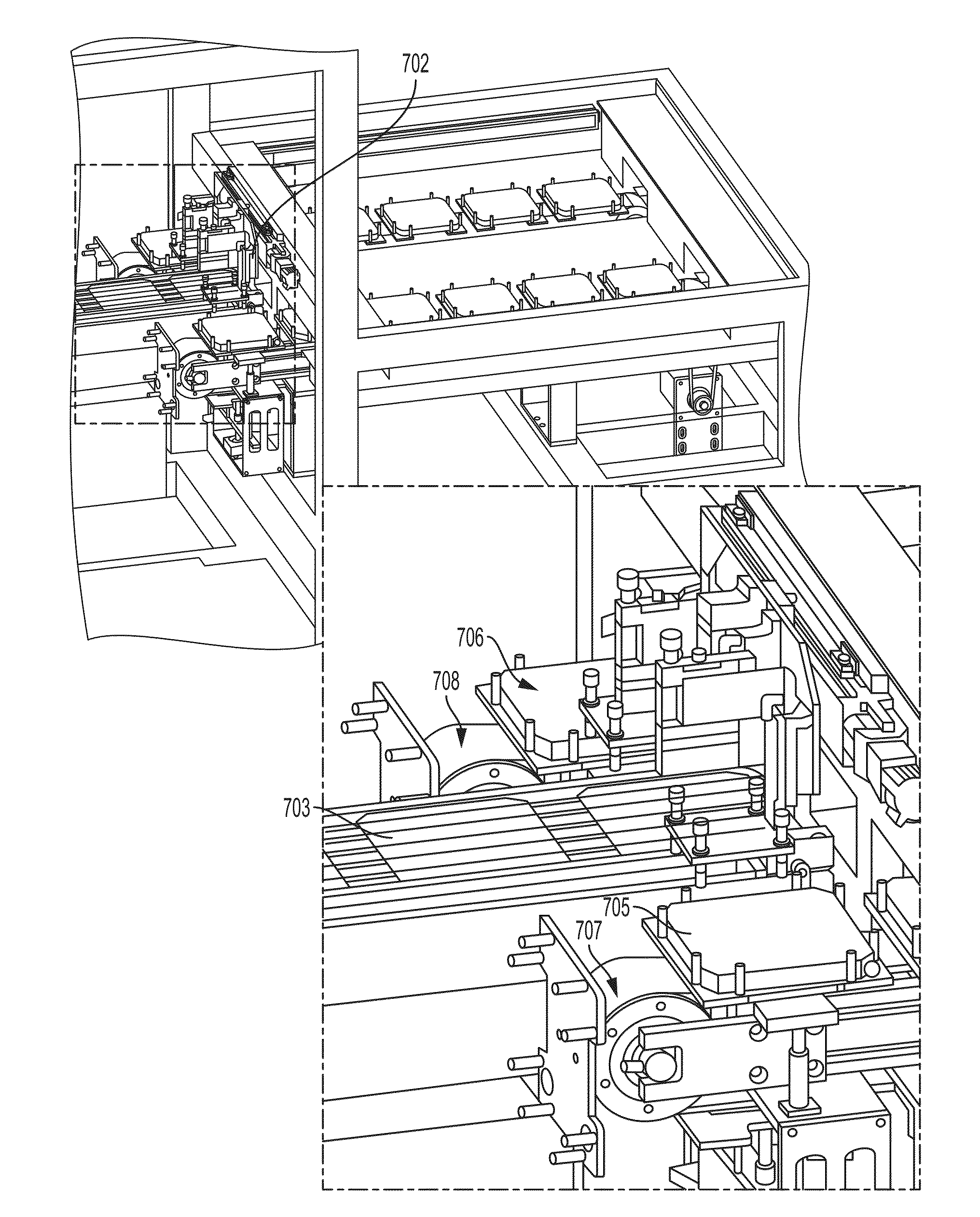

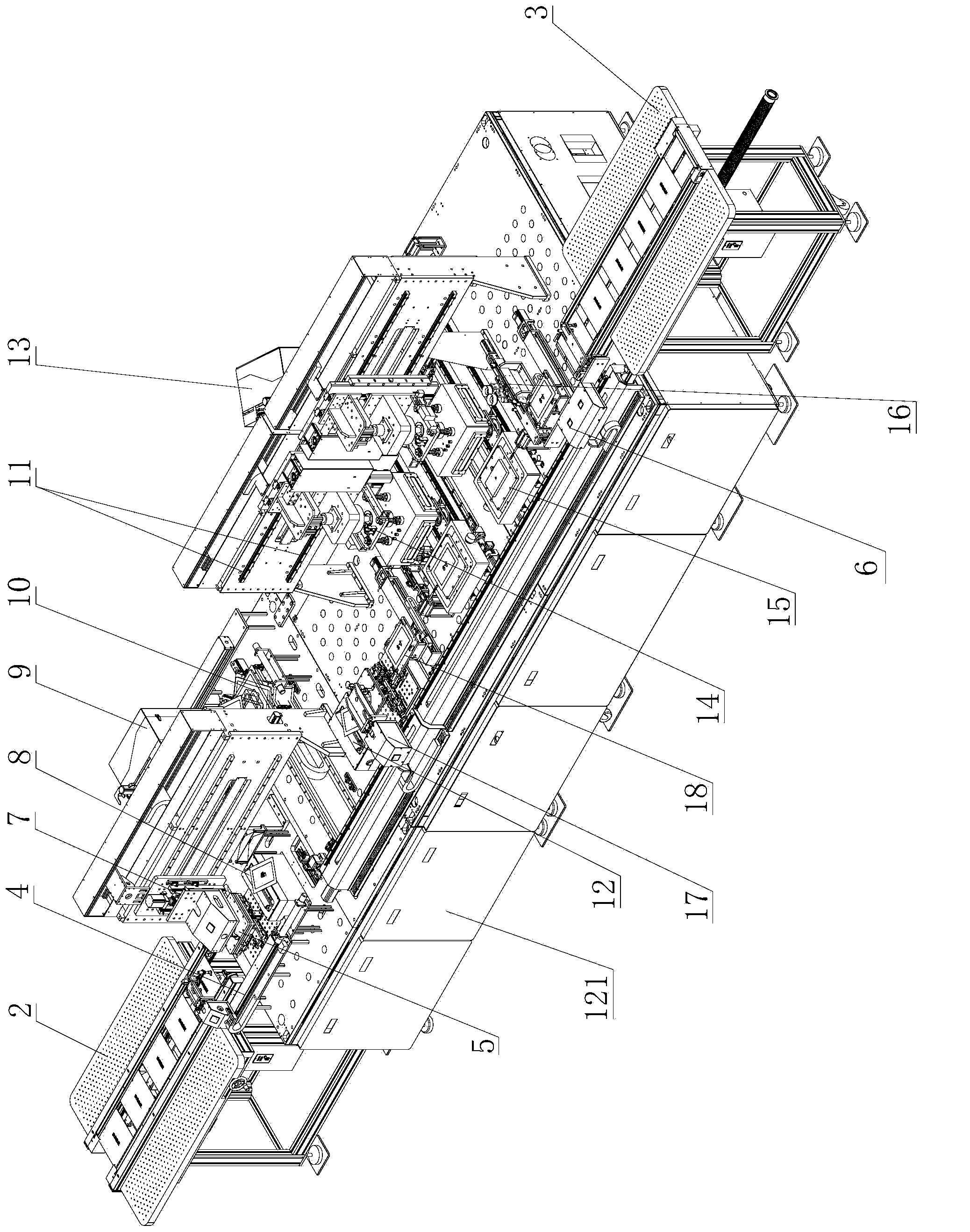

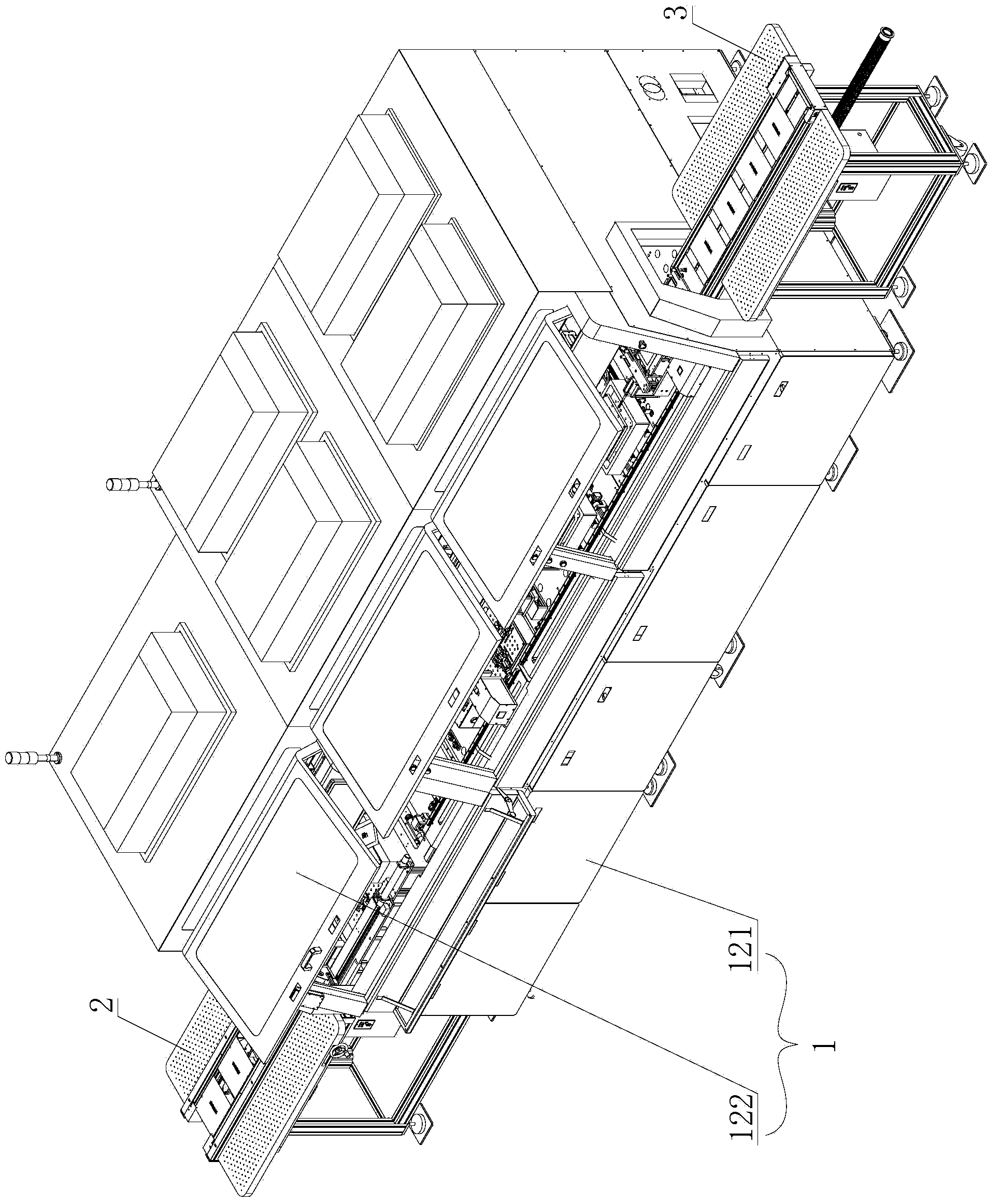

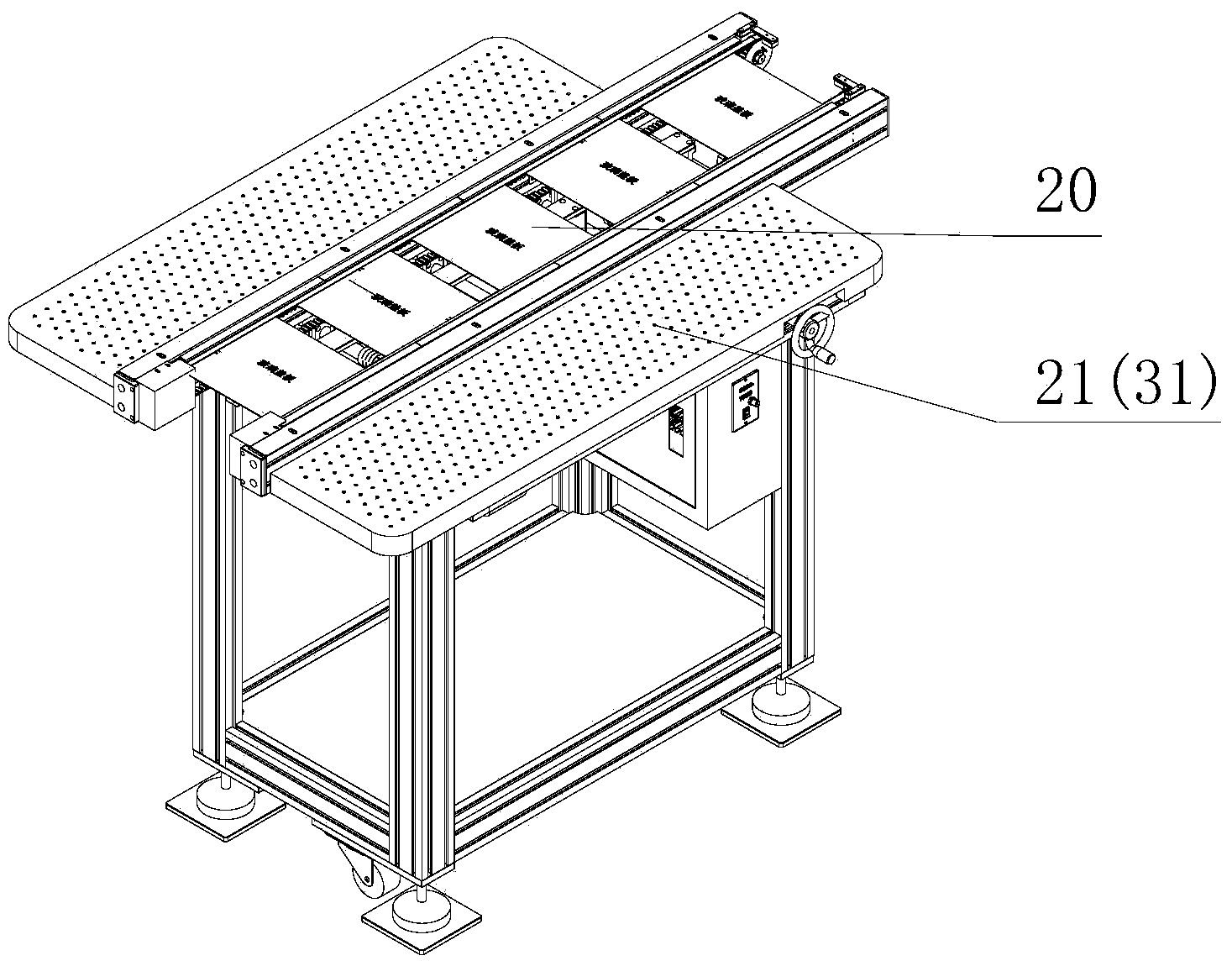

Full-automatic fitting assembling intelligent production line

ActiveCN104015454AEasy to operateHigh degree of automationLamination plant layoutLaminationProduction lineGlass cover

The invention relates to the technical field of production lines, and discloses a full-automatic fitting assembling intelligent production line. The full-automatic fitting assembling intelligent production line comprises a frame, and a material loading system and a feeding system arranged at two sides of the frame; the frame is provided with a material-loading manipulator, an automatic correction system, a first fitting system capable of fitting a glass cover plate with an optically clear adhesive, and a second fitting system capable of fitting the film-pasted glass cover plate with an LCD display module; and the full-automatic fitting assembling intelligent production line also comprises a material conveying system and an electric control system. According to the production line, the material-loading system and the feeding system are employed, and the two fitting systems help to realize fitting of the cover plate with the optically clear adhesive and fitting of the cover plate with the LCD display module. The production line has the advantages of being simple and convenient in operation, high in automation degree and reduced in manual operation.

Owner:SHENZHEN SKING INTELLIGENT EQUIP

Endoscope objective

InactiveUS6635010B1Simple and low-cost techniqueSmall reflectionSurgeryEndoscopesGlass coverRefractive index

Endoscope objective having a viewing direction including an angle< >0° relative to the longitudinal axis of the endoscope, comprising a lens system imaging the object field into a single image plane disposed orthogonally on the longitudinal axis, and a prism unit disposed downstream of the distal window of the endoscope along the imaging path, in which the beam is reflected on two boundary surfaces such that the beam will be deflected in the prism unit from the desired viewing direction into the longitudinal axis of the endoscope, wherein a coating is applied on at least one surface on the prism unit, which comprises a thin layer having a refractive index smaller than the refractive index of the material which said prism unit is made of, so that total reflection against the layer occurs. The invention is characterized by the provision that the coating is applied to that surface of the prism unit which faces the glass cover of the endoscope.

Owner:KARL STORZ GMBH & CO KG

Non-glass photovoltaic module and methods for manufacture

InactiveUS20090272436A1Avoid bendingAvoid crackingSemiconductor/solid-state device manufacturingPhotovoltaic energy generationGlass coverEngineering

A non-glass photovoltaic module including a non-glass cover layer, a photovoltaic layer, a back protection sheet layer, and a support layer, wherein the layers are adhesively bonded together to form a lamination.

Owner:CHEUNG OSBERT HAY

Fingerprint recognition sensor packaging structure, electronic device and method for manufacturing fingerprint recognition sensor

ActiveCN103793689ADoes not affect thicknessDoes not affect thickness designCharacter and pattern recognitionDielectricGlass cover

The invention relates to a fingerprint recognition sensor packaging structure and an electronic device with the fingerprint recognition sensor packaging structure. The fingerprint recognition sensor packaging structure comprises a control button and a fingerprint recognition sensor arranged below the control button, wherein the control button comprises a glass cover plate and a thin film which coats the surface of the glass cove plate and is made of non-anisotropic dielectric materials. The mode of combining the glass cover plate and the coated film is adopted by the control button, the hardness of the control button is ensured, meanwhile, cost is reduced, in addition, the thickness of the fingerprint recognition sensor packaging structure is not affected, and when the fingerprint recognition sensor packaging structure is embedded into the electronic device, the thickness design of the electronic device is not affected.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

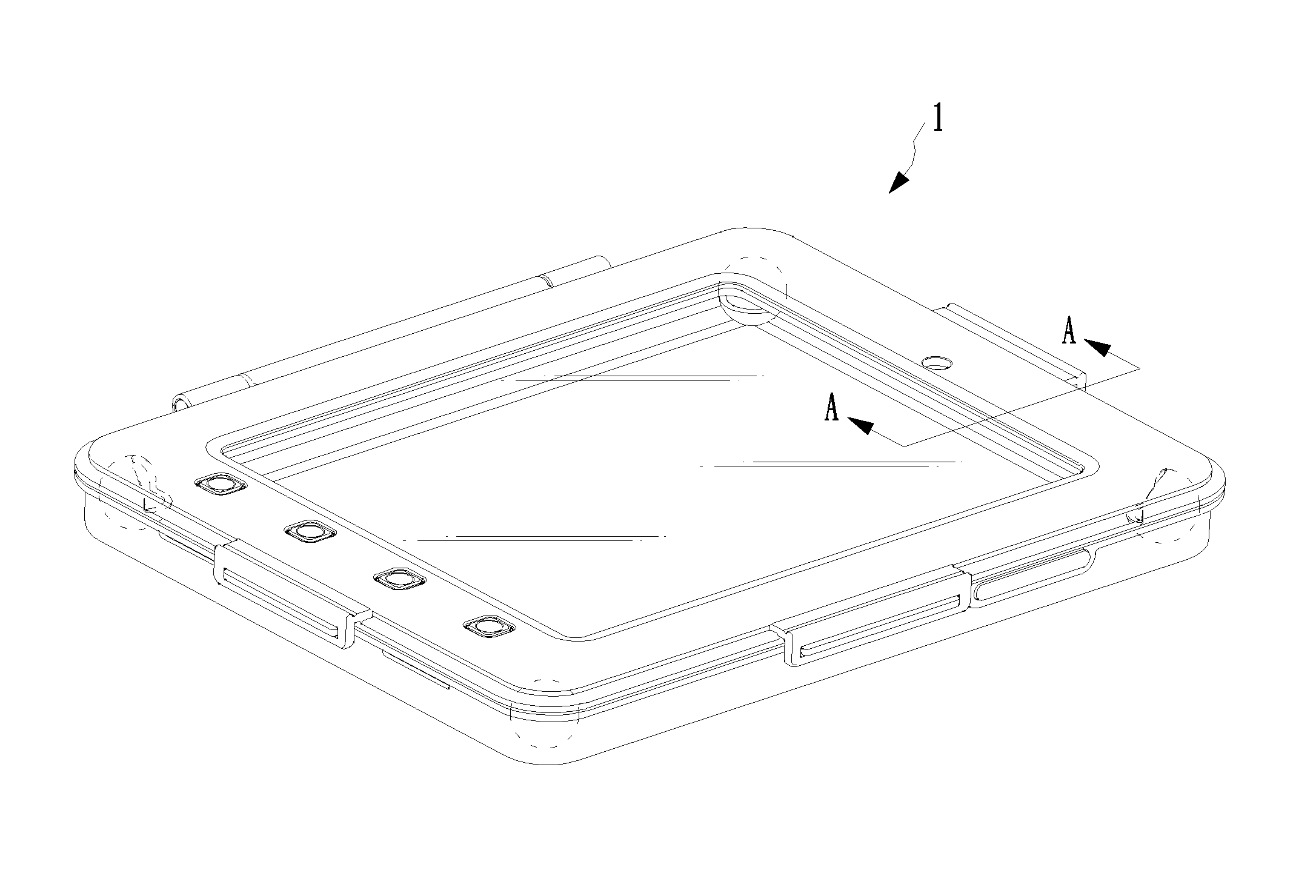

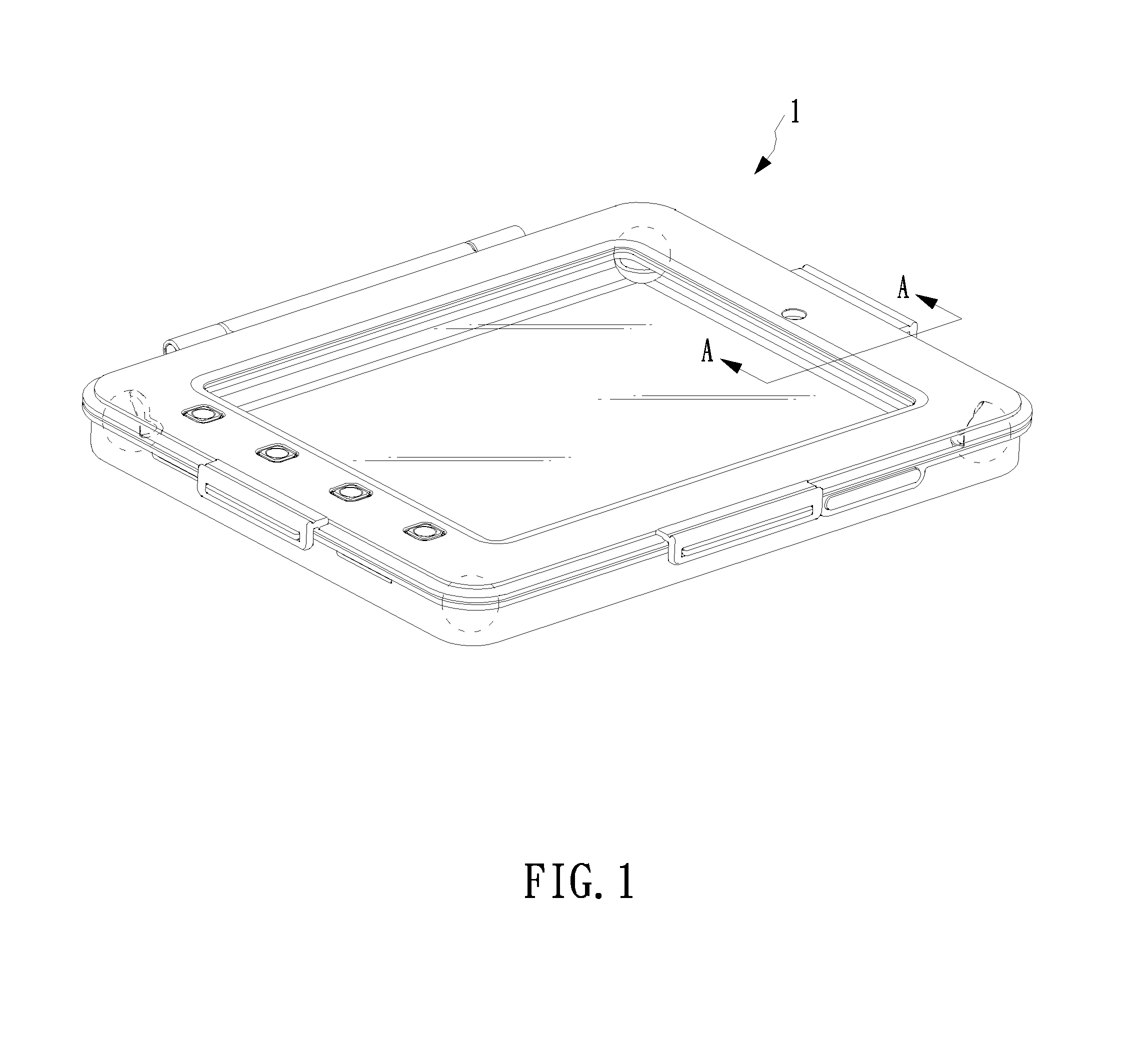

Waterproof and shockproof cover for a PAD computer

A waterproof and shockproof cover for a PAD computer is disclosed. The cover comprises an upper housing, a base housing, a glass, a first rubber ring, a second rubber ring and four shockproof elements. The base housing is corresponding to the upper housing, wherein the upper housing comprises a first connection and the base housing comprises a second connection corresponding to the first connection for fastening with each other. The upper housing comprises a viewing window hole and a first groove formed around the rim of the viewing hole, and the first rubber ring is disposed within the first groove. The glass covers the viewing window hole and the first rubber ring. The four shockproof elements disposed respectively at four corners of a rectangular accommodation space of the base housing for bearing the PAD computer.

Owner:FIRST INTERNATIONAL COMPUTER

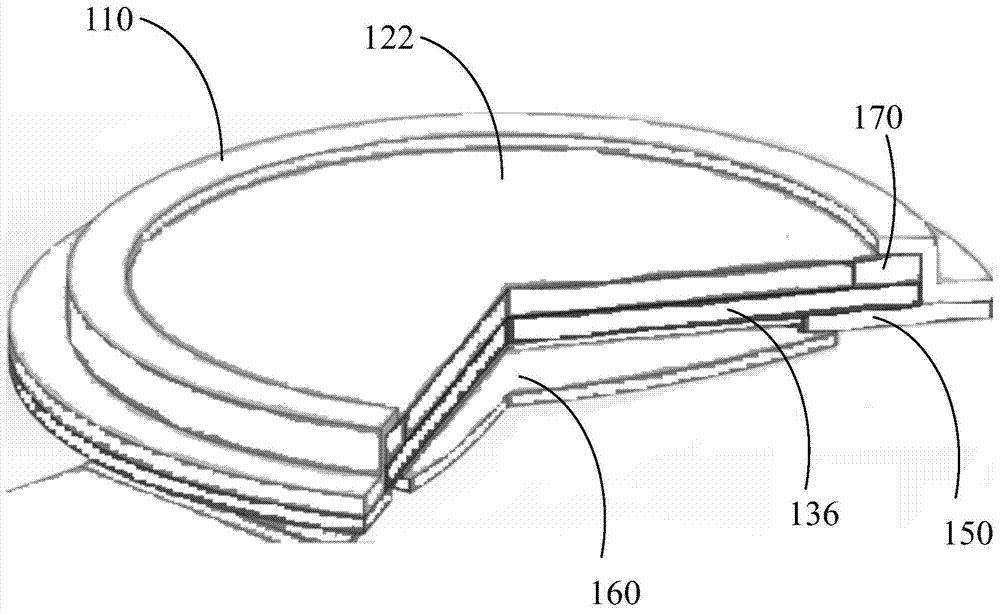

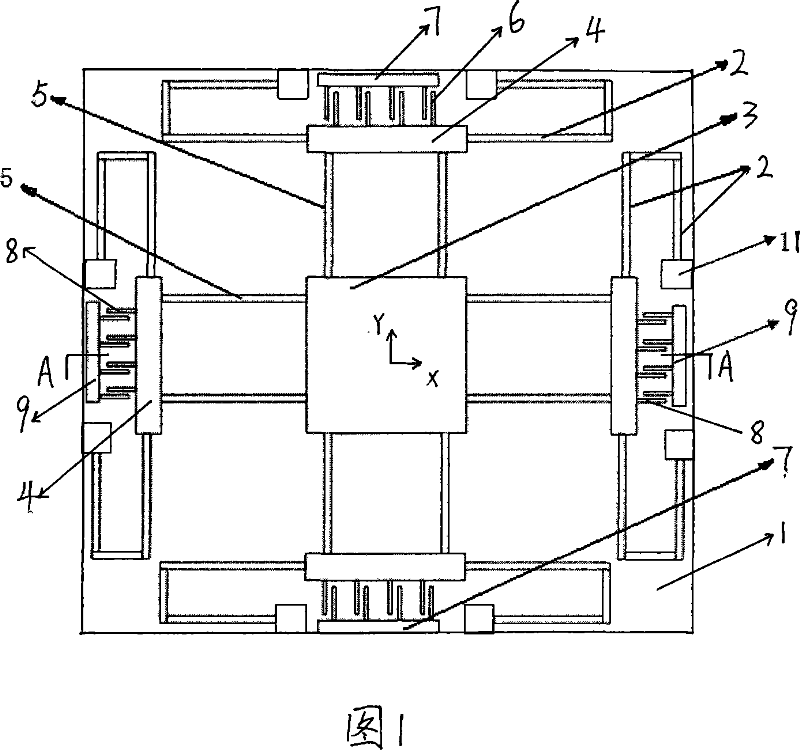

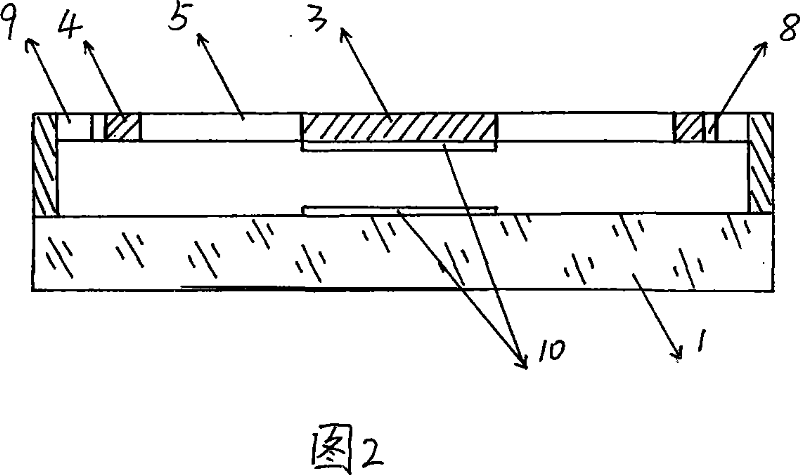

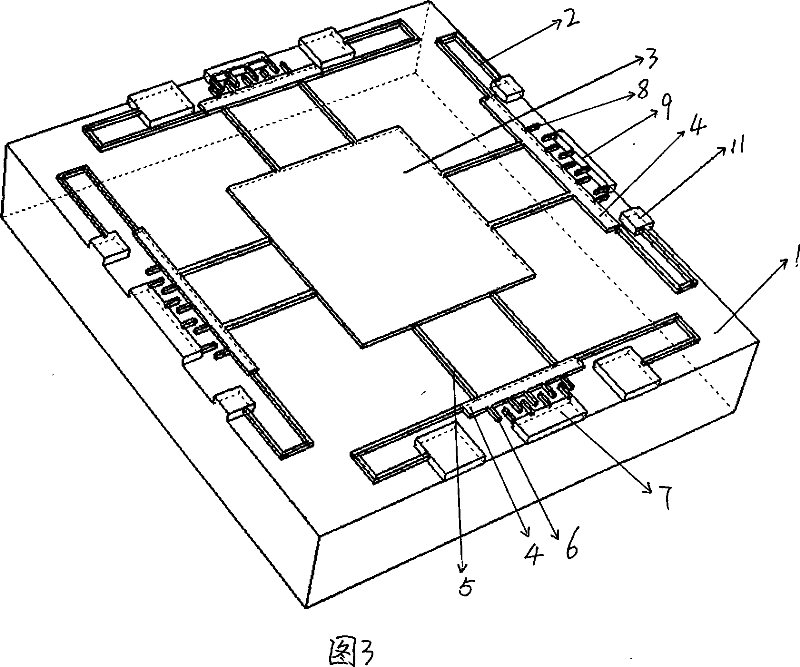

Uniaxle integrated inertia measurement device based on single mass-block

InactiveCN101038299AReduce the difficulty of separationSimple designSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesCapacitanceGlass cover

The present invention which relates to the micro-mechanism electric technology provides a single-shaft and integrated device for measuring the inertia based on the single quality block. And the present solves the problems of the prior single-shaft and integrated assembly for measuring the inertia that the structure is complex, the volume and quality are big, etc. The single-shaft and integrated device for measuring the inertia includes a quality block and a glass cover bottom. The quality block which is hang on the upper of the glass cover bottom through a supporting beam includes a quality chip and four supporting bodies that are fixed with the four sides of the quality chip through the elastic beam. A moveable comb for detecting is fixed on the external of the supporting body relative to the Y direction and a moveable comb for driving is fixed on the external of the supporting body relative to the X direction. A fixed comb for detecting and a fixed comb for driving are fixed on the glass cover bottom, and electrodes for forming the capacitance are fixed on the lower end surface and the glass cover bottom of the quality chip. The device in the present invention has advantages of a reasonable structure, an easy processing, a high reliability, a small volume, a strong ability of resisting the interference, a high precision, a high precision of measuring the paralleling and orthogonality of the vectors, etc.

Owner:ZHONGBEI UNIV

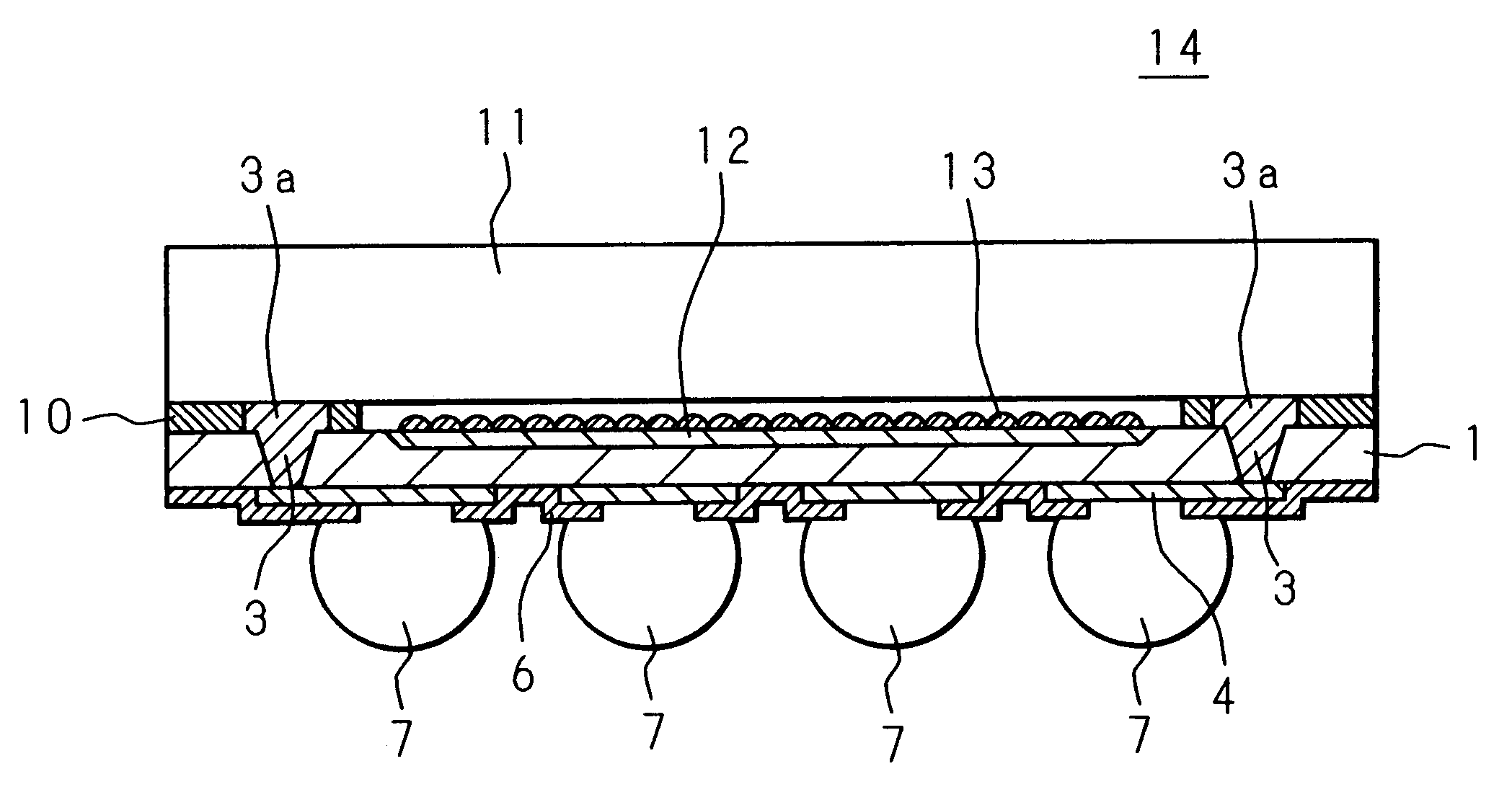

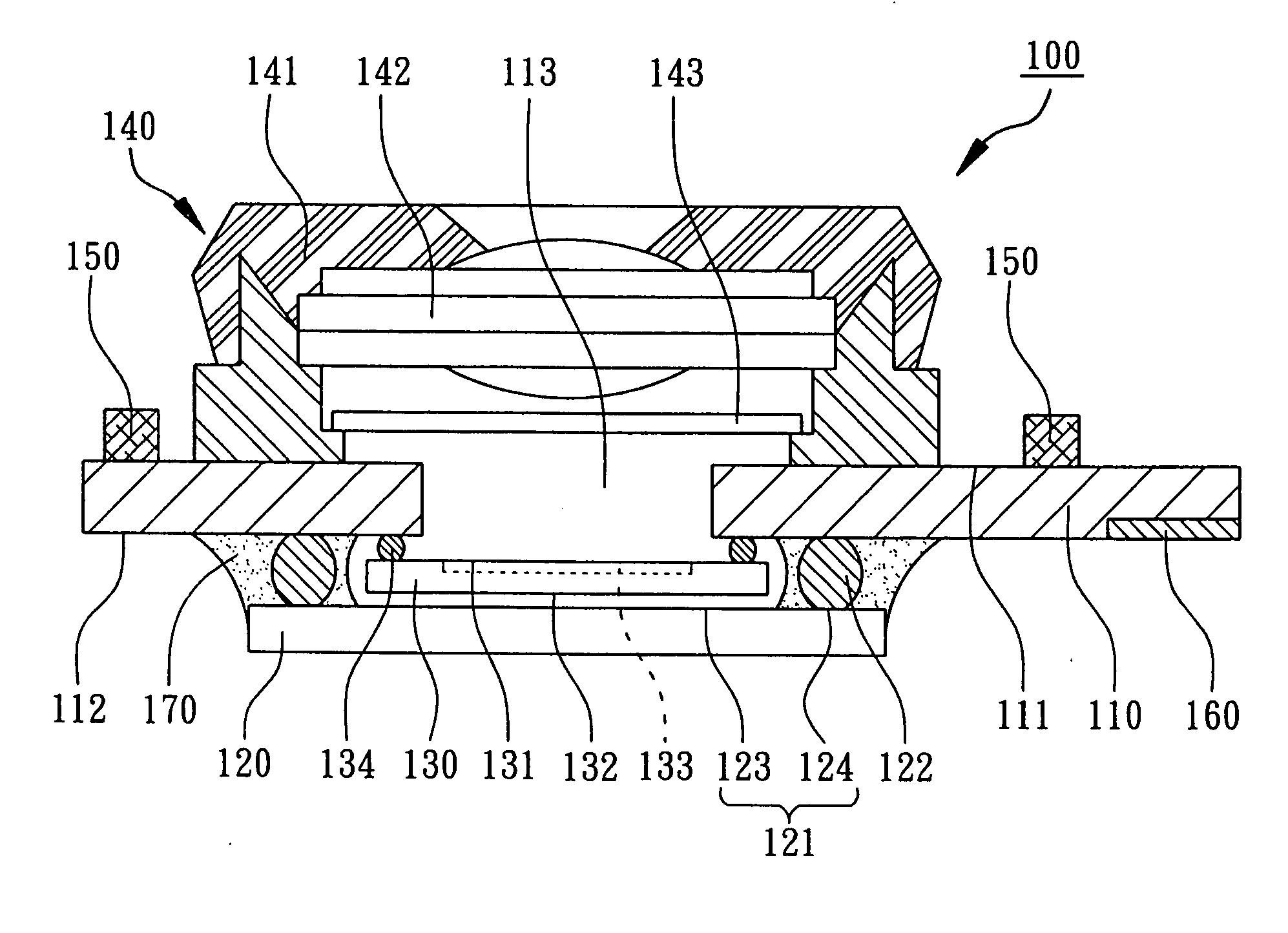

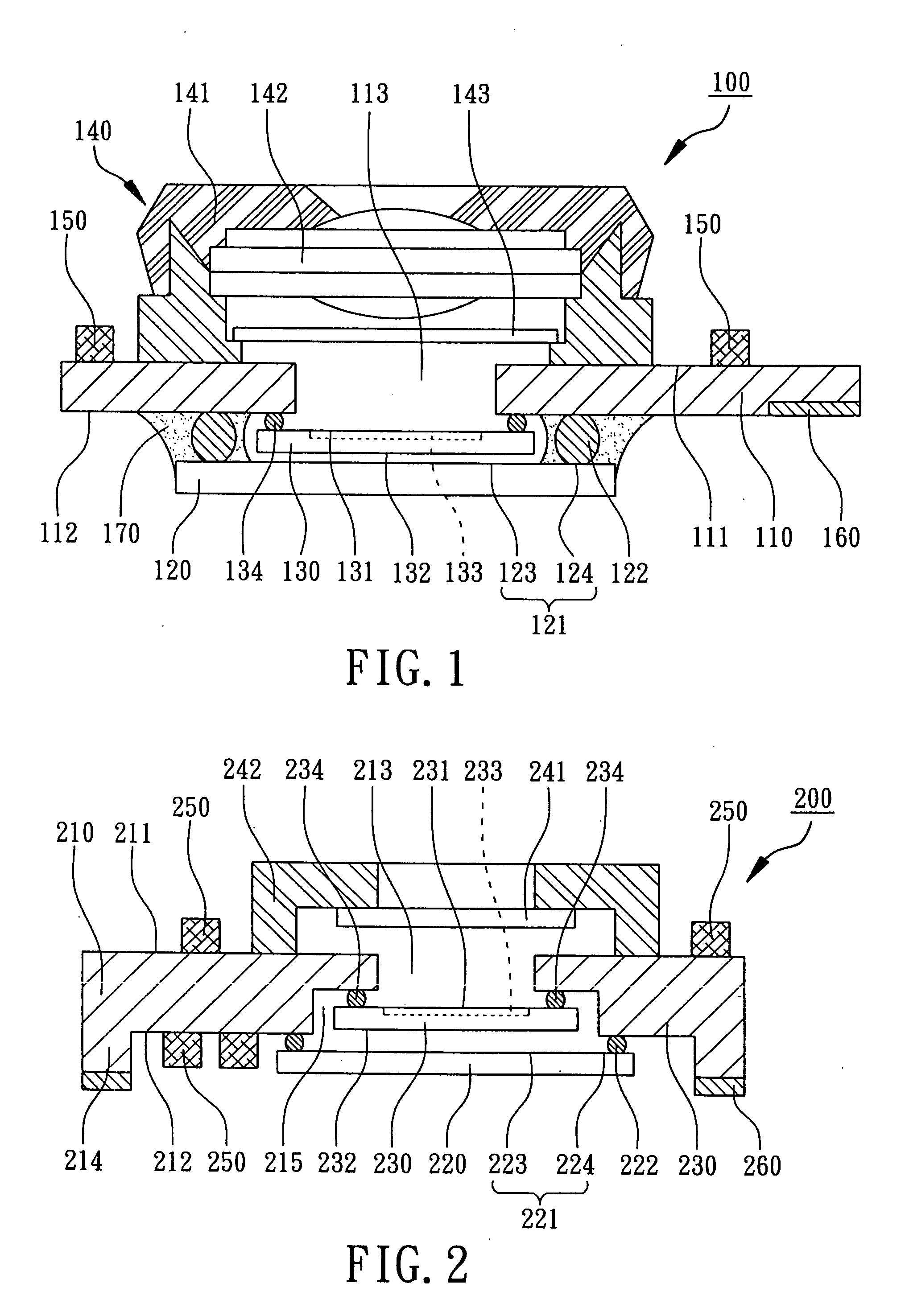

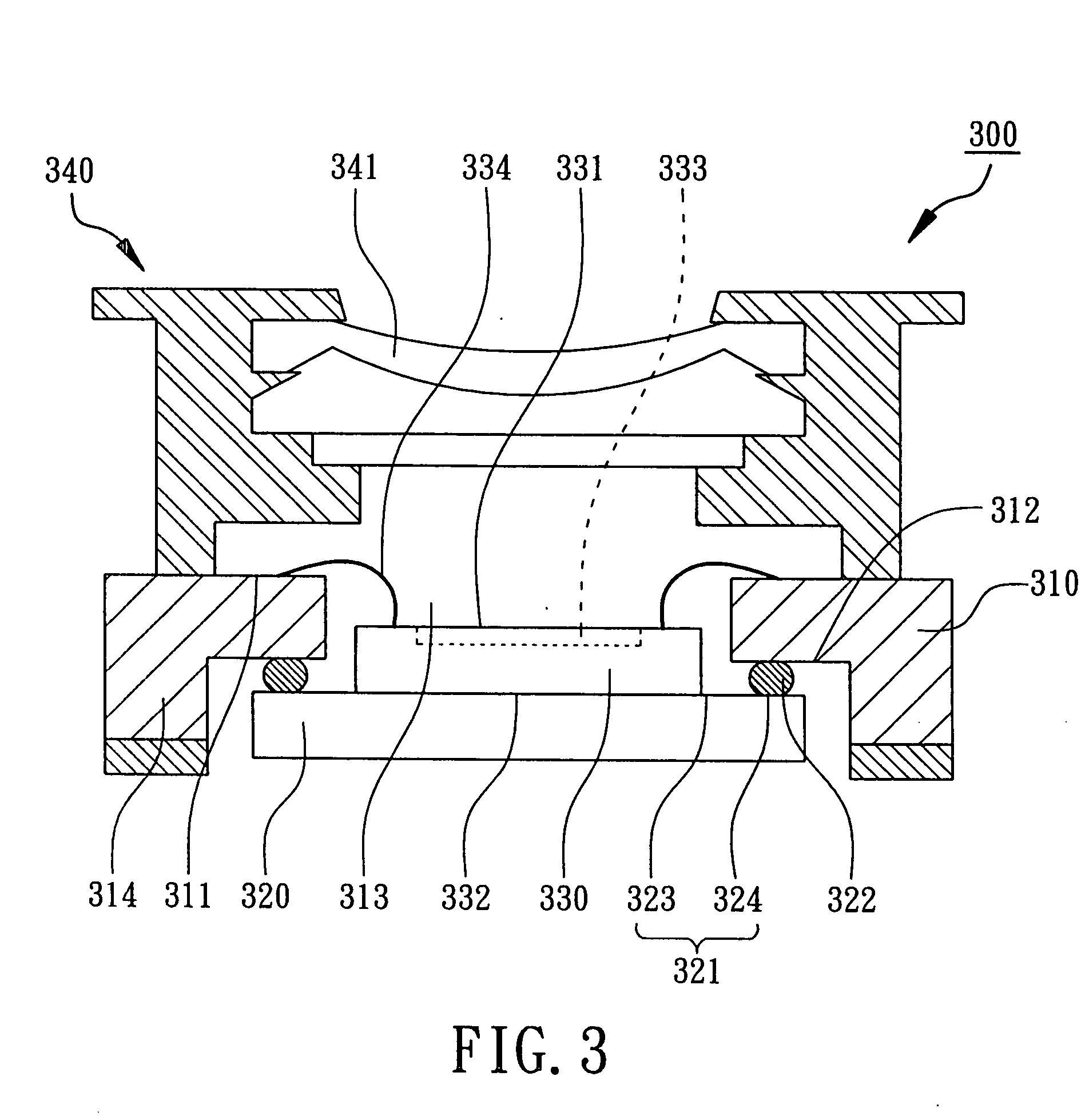

Multi-chip image sensor package module

InactiveUS20060016973A1Solve the thickerGood yieldSolid-state devicesMaterial analysis by optical meansGlass coverEngineering

A multi-chip image sensor package module includes a substrate having an opening, an IC chip, an image sensor chip and a glass cover. The IC chip includes a plurality of bumps on its mounting surface to mount on the lower surface of the substrate. The glass cover is disposed above the upper surface of the substrate. The image sensor chip is disposed between the mounting surface of the IC chip and the upper surface of the substrate by chip-to-chip attachment or flip-chip connection in a manner that the sensing region of the image sensor chip is aligned with the glass cover or a lens through the opening. Thus the multi-chip image sensor package module can have a thinner profile with lower assemble cost.

Owner:ADVANCED SEMICON ENG INC

Display module

A portable computing device is disclosed. The portable computing device can take many forms such as a laptop computer, a tablet computer, and so on. The portable computing device can include a single piece housing and a display module. The display module can include a protective top glass cover that is bonded to a plastic display frame and surrounded by a seal frame. The display module can also include a display panel and its associated circuitry suspended from the display frame below the protective glass cover. The display module is coupled to the single piece housing mounting clips in a manner that allows the display module to move relative to the single piece housing during an impact event. The plastic display frame can include inserts that provide structural support near openings in the single piece housing.

Owner:APPLE INC

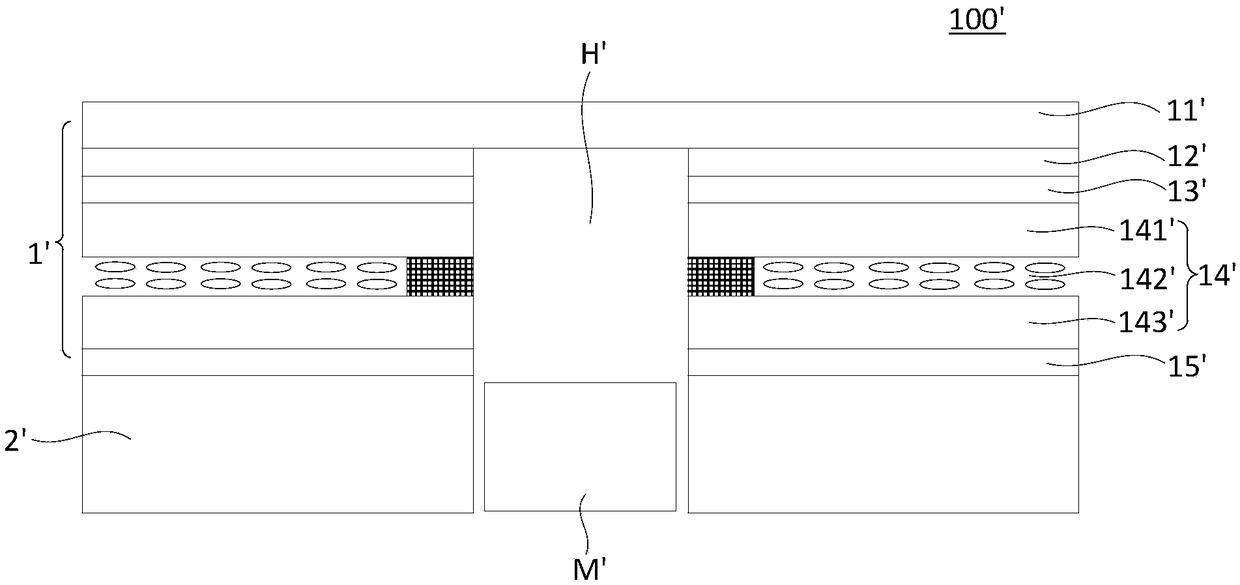

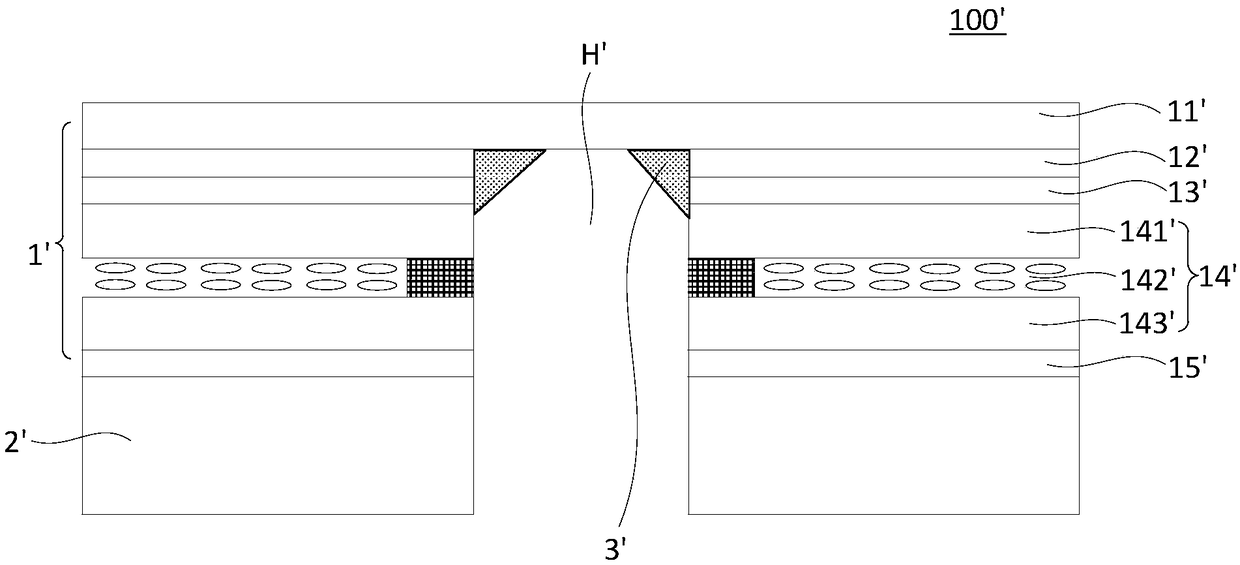

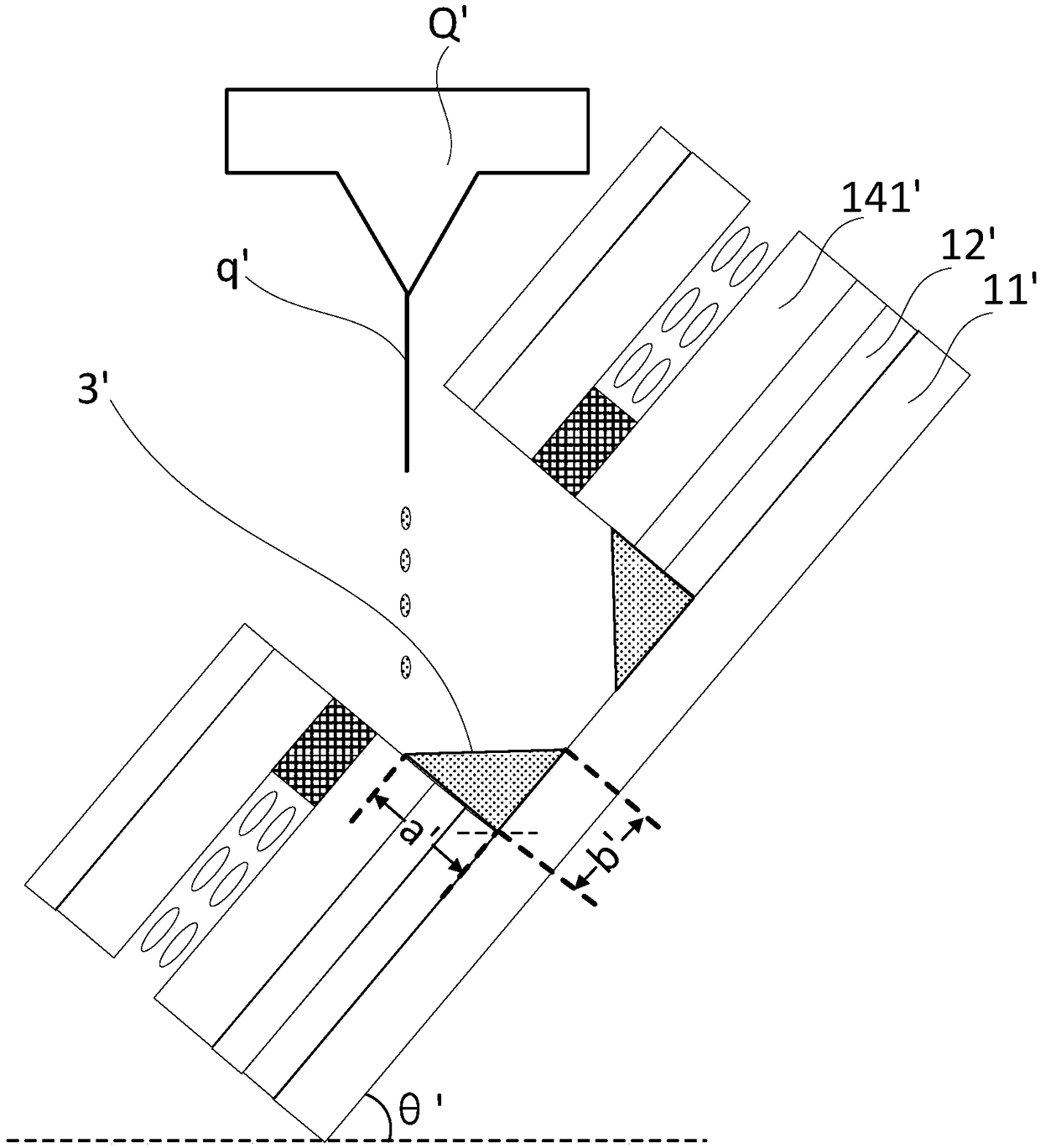

Display module, display device and display device manufacturing method

ActiveCN109445171AAvoid light leakageAvoid affecting the display effectPrintersProjectorsGlass coverAdhesive

The invention provides a display module, a display device and a display device manufacturing method. The display module comprises a first substrate, a second substrate, an optical adhesive and shadingglue. The first substrate and the second substrate are in opposite arrangement; the optical adhesive is used for adhering a glass cover plate and the first substrate and comprises an optical adhesiveopening, the first substrate comprises a first substrate opening which includes the optical adhesive opening in a direction perpendicular to the display panel, and an area, exceeding the first substrate, of the optical adhesive is a first step area; the shading glue and the first step area are coincided in a direction perpendicular to the display panel and cover one side, close to the first substrate opening, of the first substrate. The first substrate opening is larger than the optical adhesive opening, so that a first step is formed; the first step is capable of blocking up the shading glueand beneficial for the shading glue to cover the lateral side, close to a porous area, of the first substrate, and accordingly light leakage of the first substrate is avoided.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com