Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20020results about "Yarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

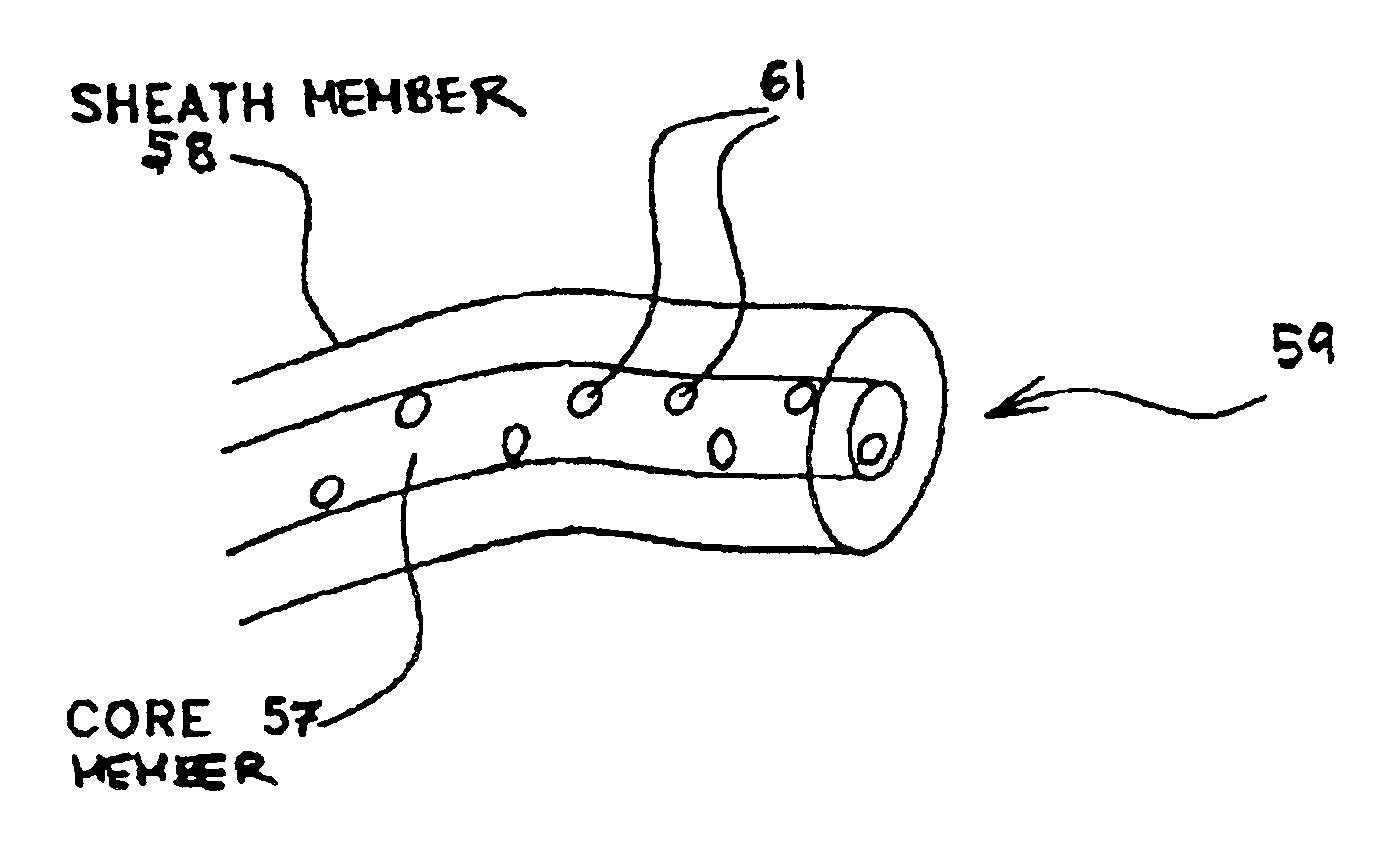

Controlling the dissolution of dissolvable polymer components in plural component fibers

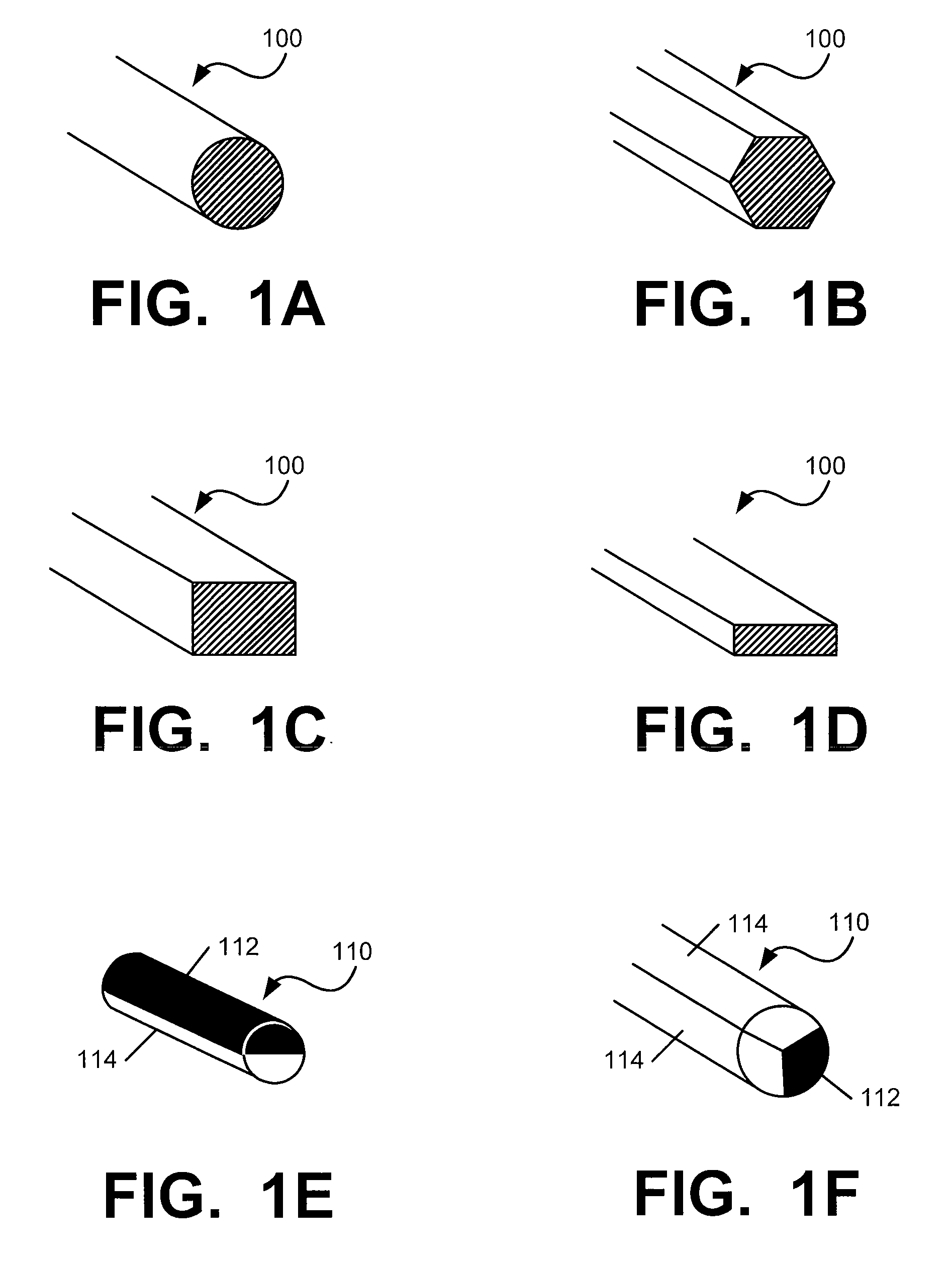

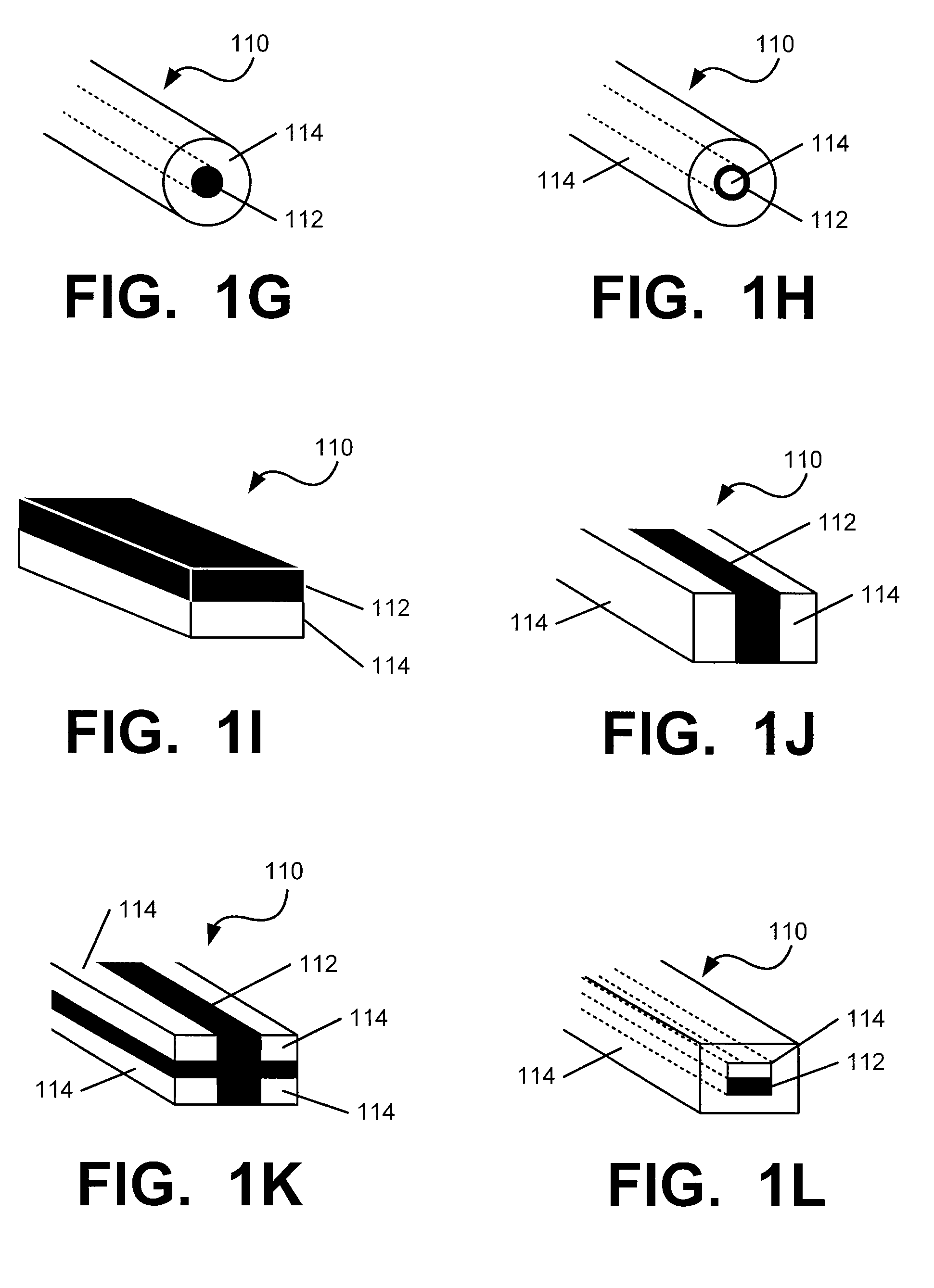

The dissolution of dissolvable components in plural component polymer fibers is achieved by providing a polymer fiber including at least two sections, where at least one fiber section includes a dissolvable component. The rate at which at least part of the fiber dissolves is controlled by at least one of a fiber section having a non-round cross-sectional geometry, and at least two fiber sections including two different dissolvable components. In an exemplary embodiment, island-in-the-sea fibers are formed with non-round and elongated cross-sectional geometries. In another embodiment, sheath-core fibers are formed in which the sheath and core include different dissolvable components.

Owner:HILLS CO

Porous medical device and method for its manufacture

ActiveUS7964206B2Thickness of device can be variedControllable porosityBiocideGenetic material ingredientsFiberBioceramic

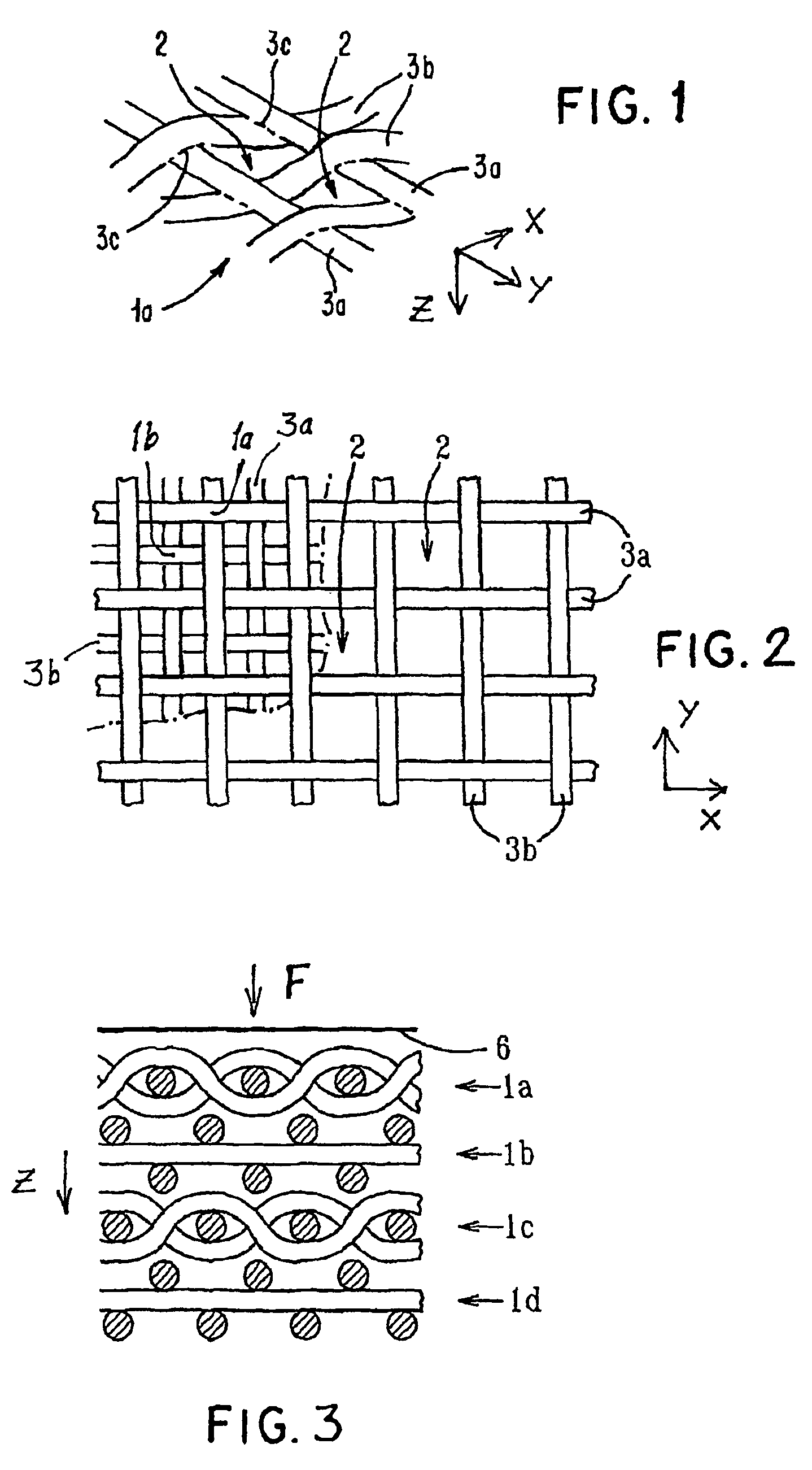

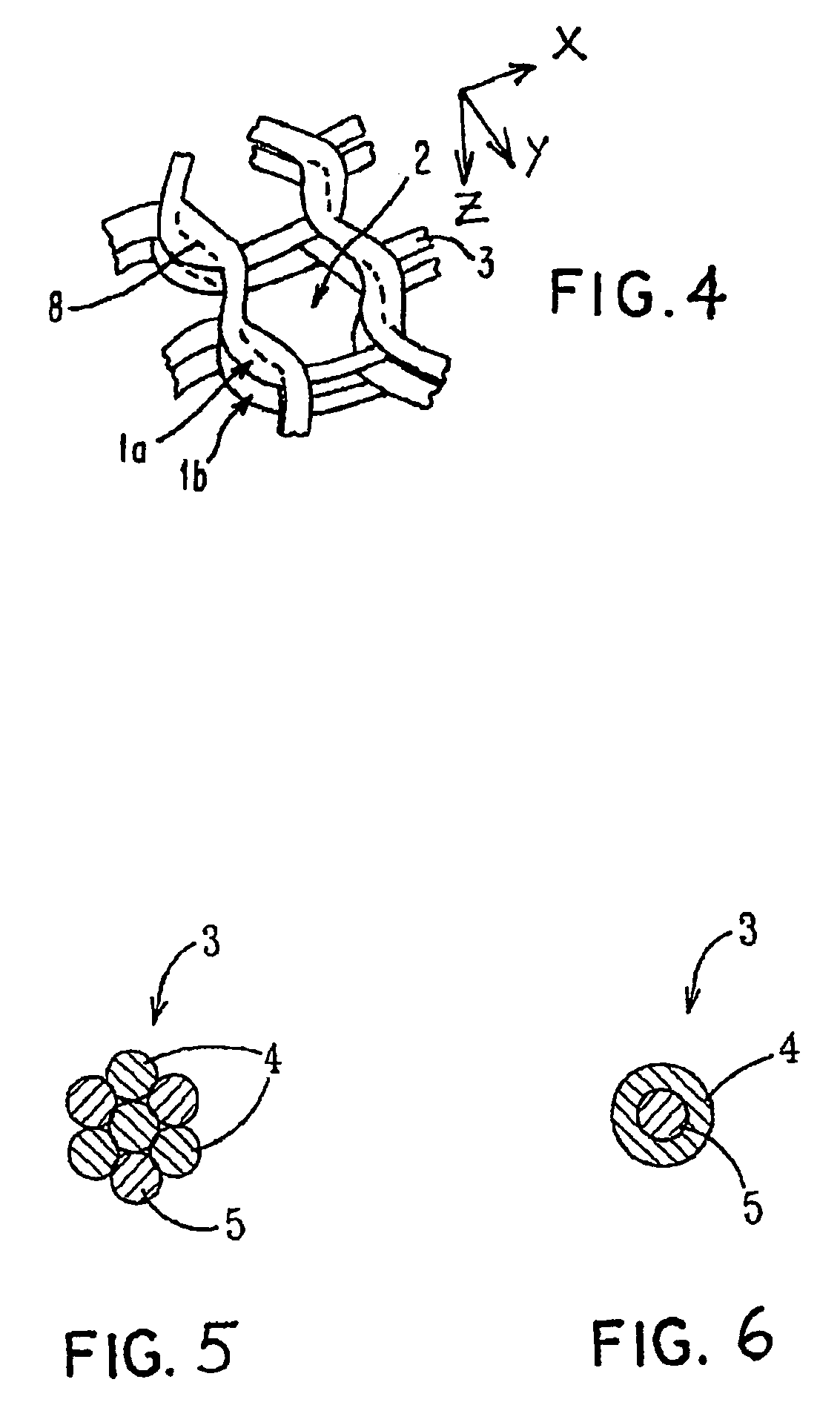

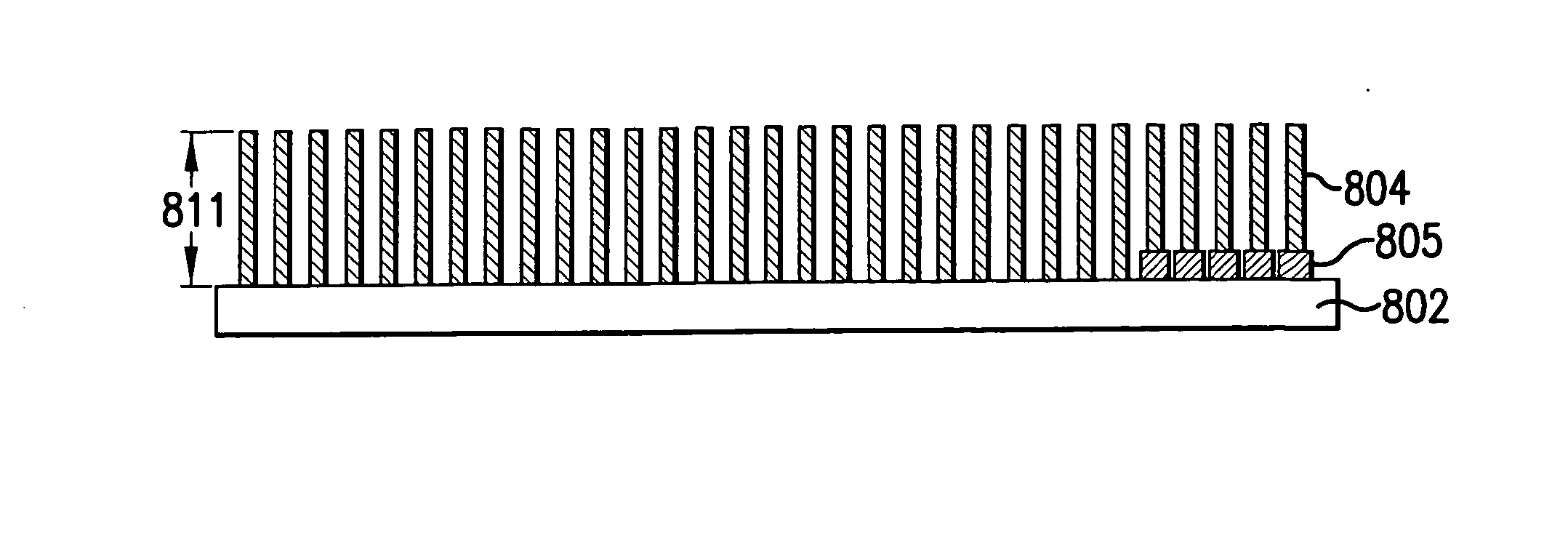

Porous bioabsorbable, bioactive and load-bearing composite medical device structure includes a plurality of regular textile planar layers (1a, 1b . . . ) formed of continuous bioabsorbable polymer matrix and bioceramic fibers acting as reinforcements, both included in continuous fibrous elements (3) forming the textile layers. The layers are placed on top of each other to form a structure having two dimensions (x, y) at right angles to each other according to the two dimensions of the textile layer and a third dimension (z) perpendicular to them and resulting from the piling of the layers. A plurality of passages extend through the layers as a result of the openings (2) defined by portions of the continuous fibrous elements (3) extending substantially in the direction of the plane. The continuous fibrous elements (3) comprise both bioactive ceramic reinforcing fibers which form a reinforcing structure and a bioabsorbable polymer matrix material which forms a matrix which binds the layers together and also binds the portions of continuous fibers defining the openings together, thereby forming the passages and stiffening the structure. This bioactive and bioabsorbable composite structure is suitable to be used as a basic structure in medical devices, especially in osteochondral applications where the load-bearing properties of implant are required.

Owner:BIORETEC

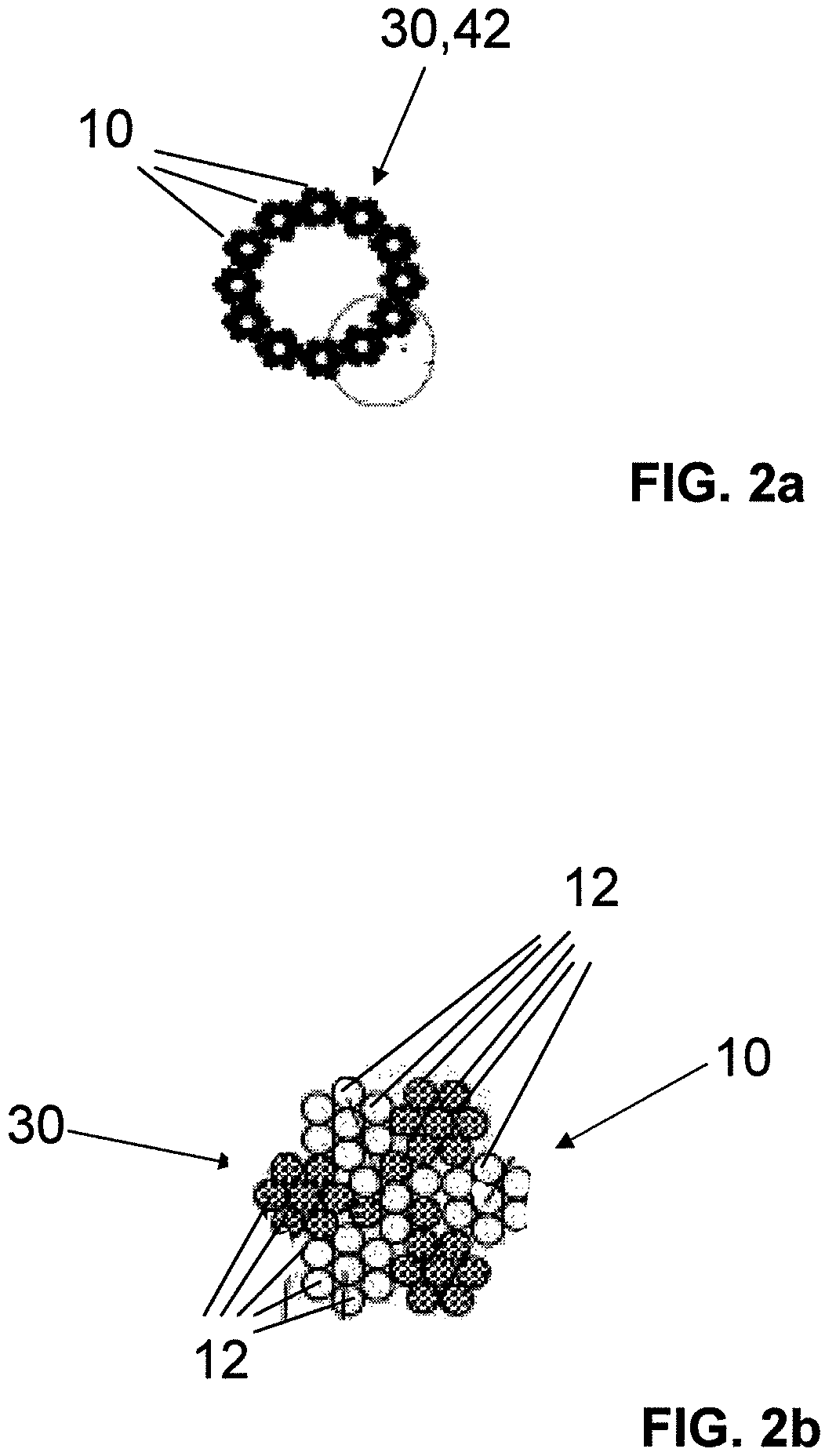

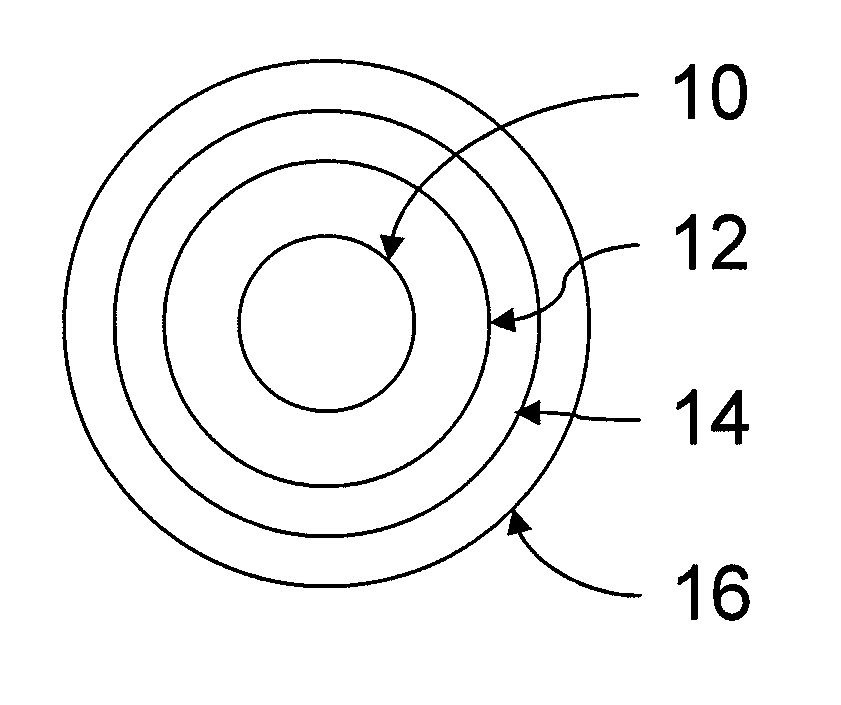

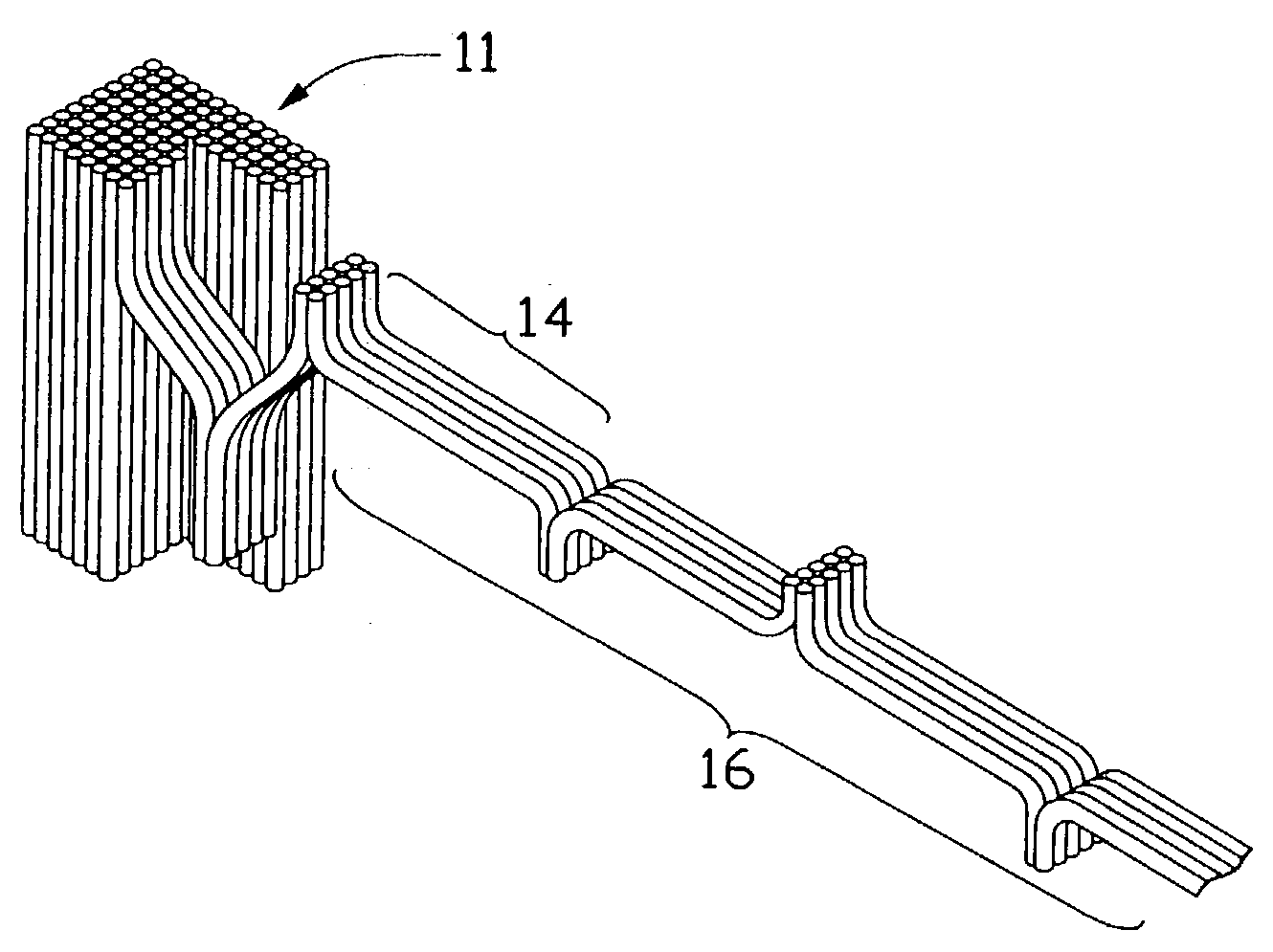

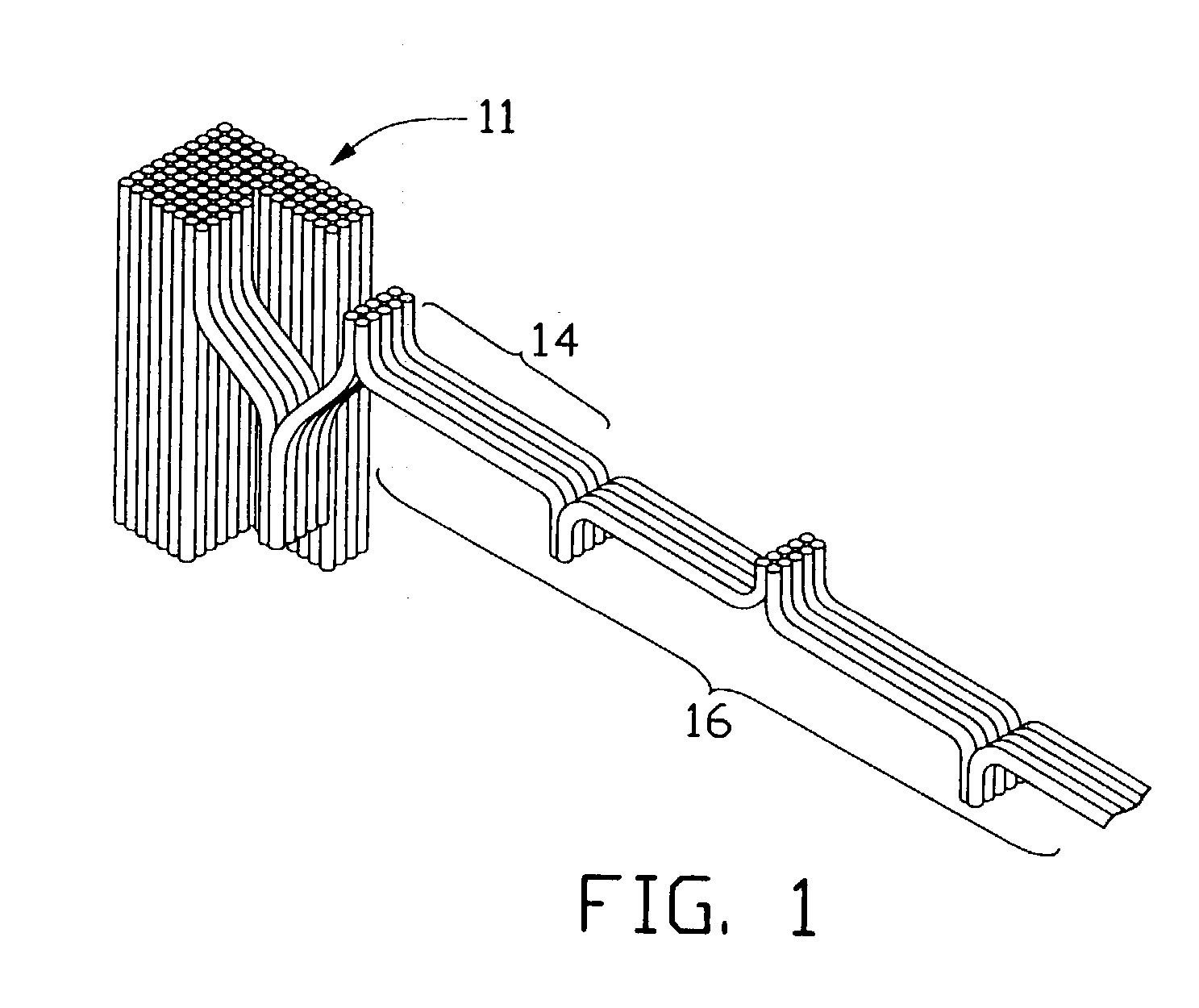

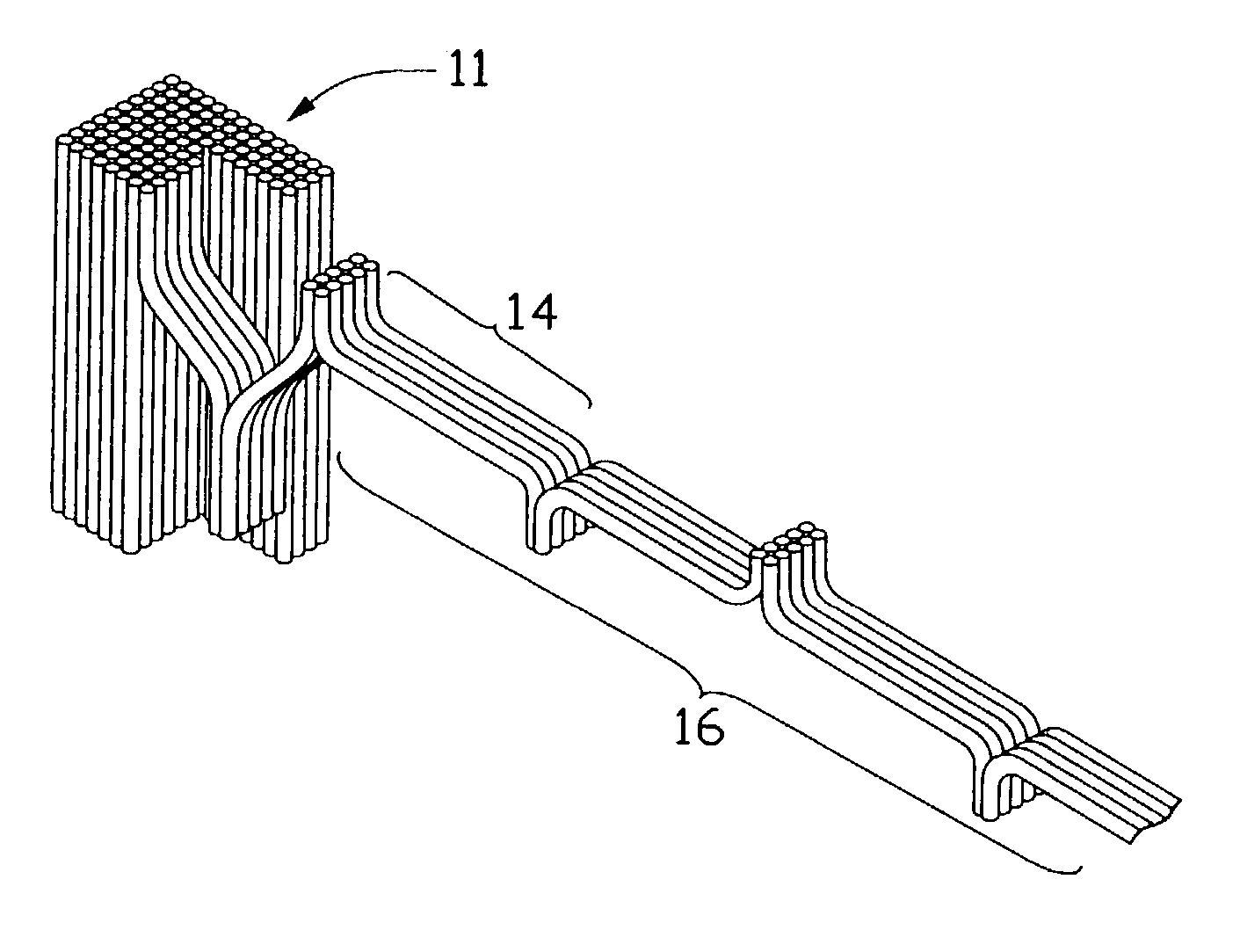

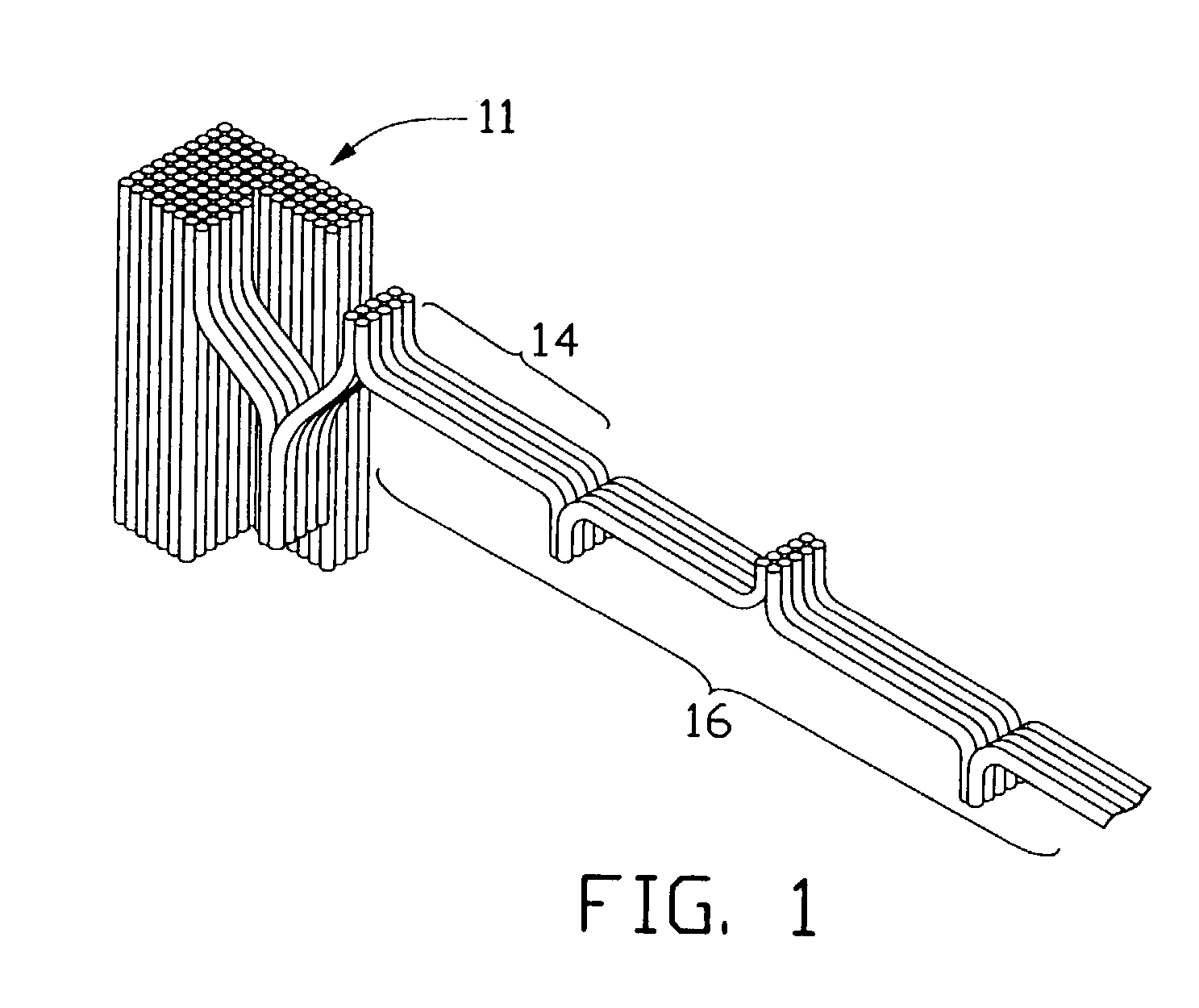

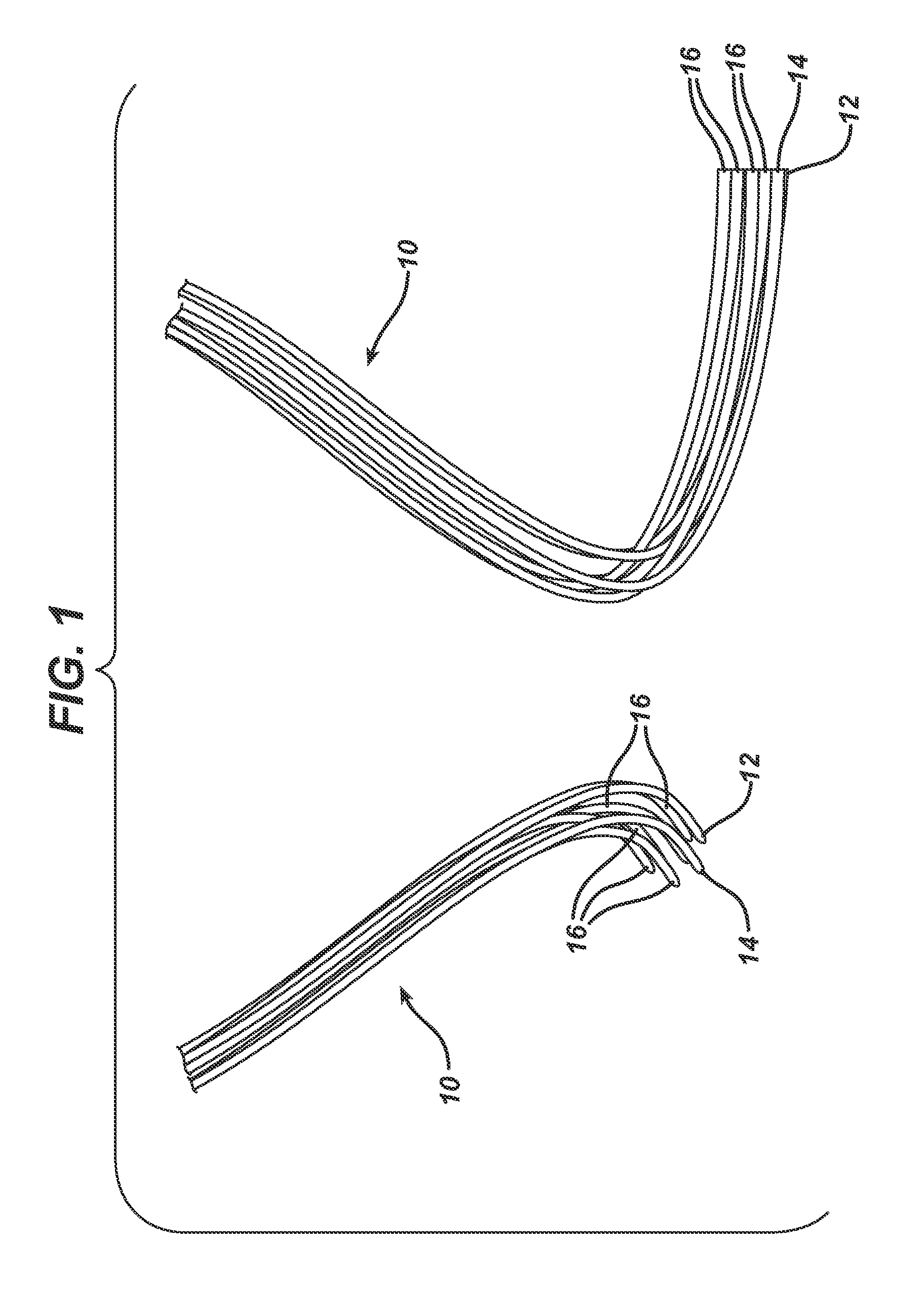

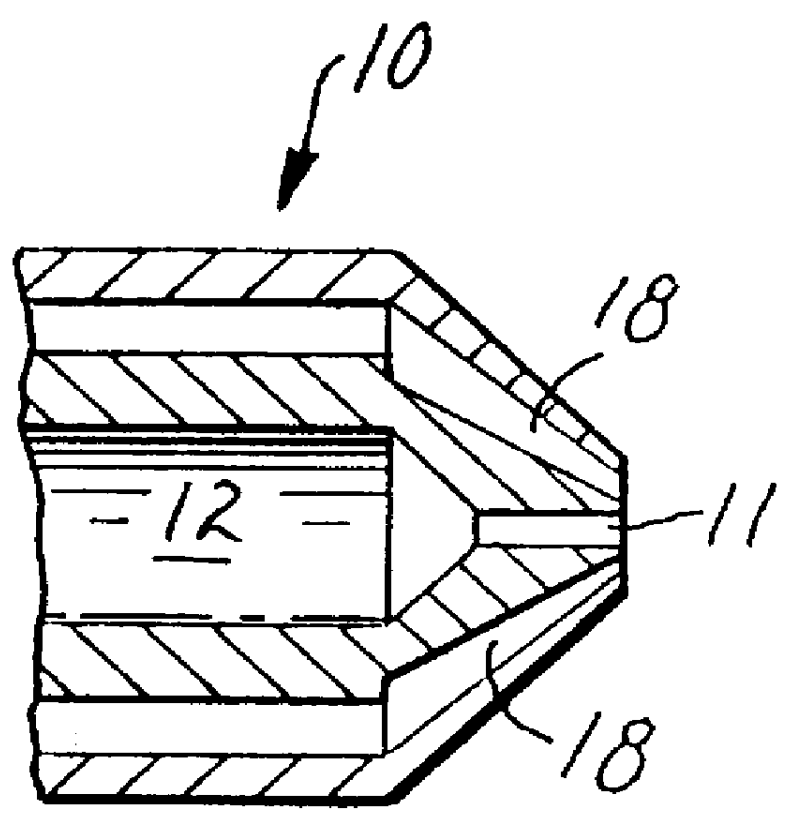

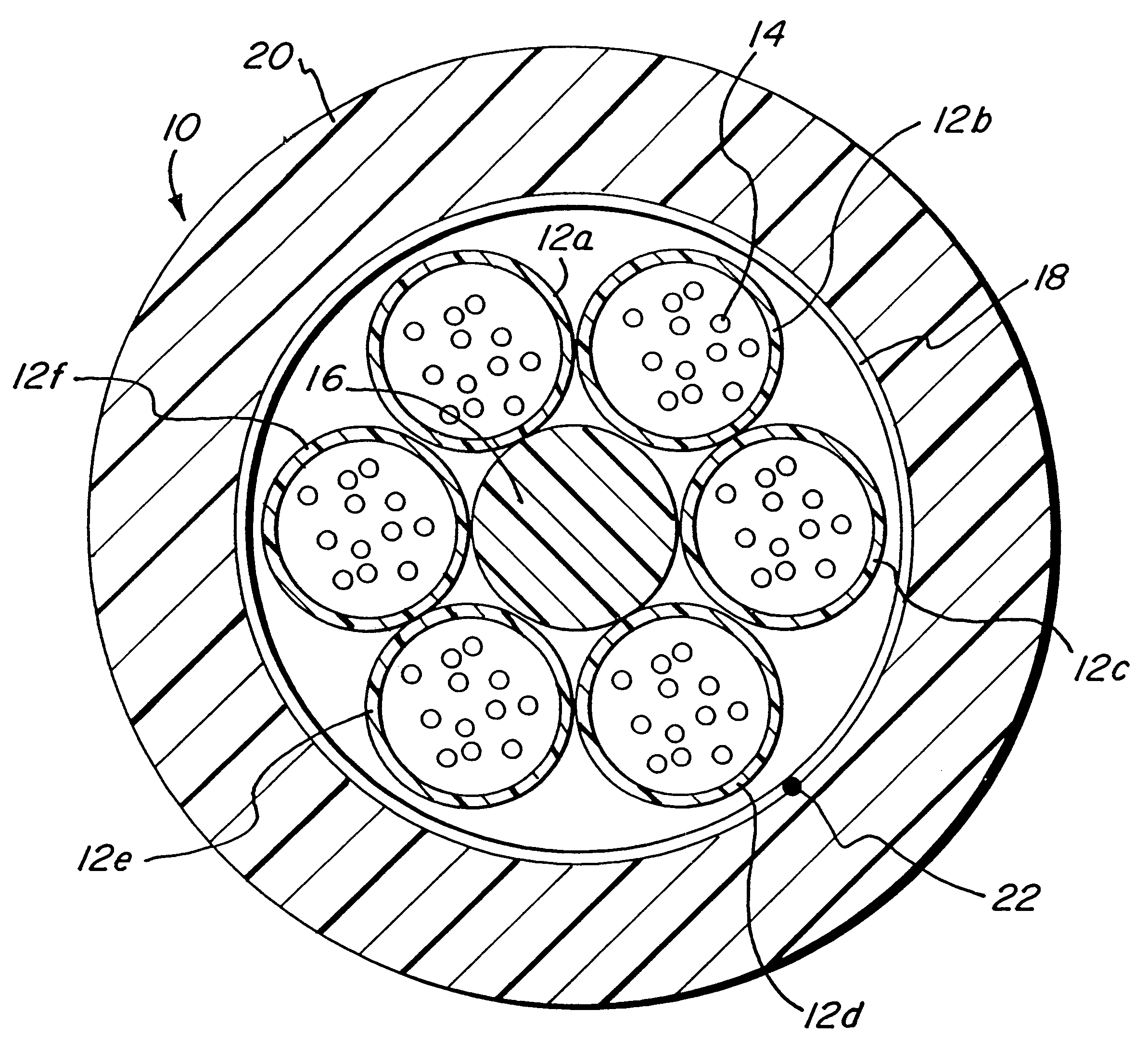

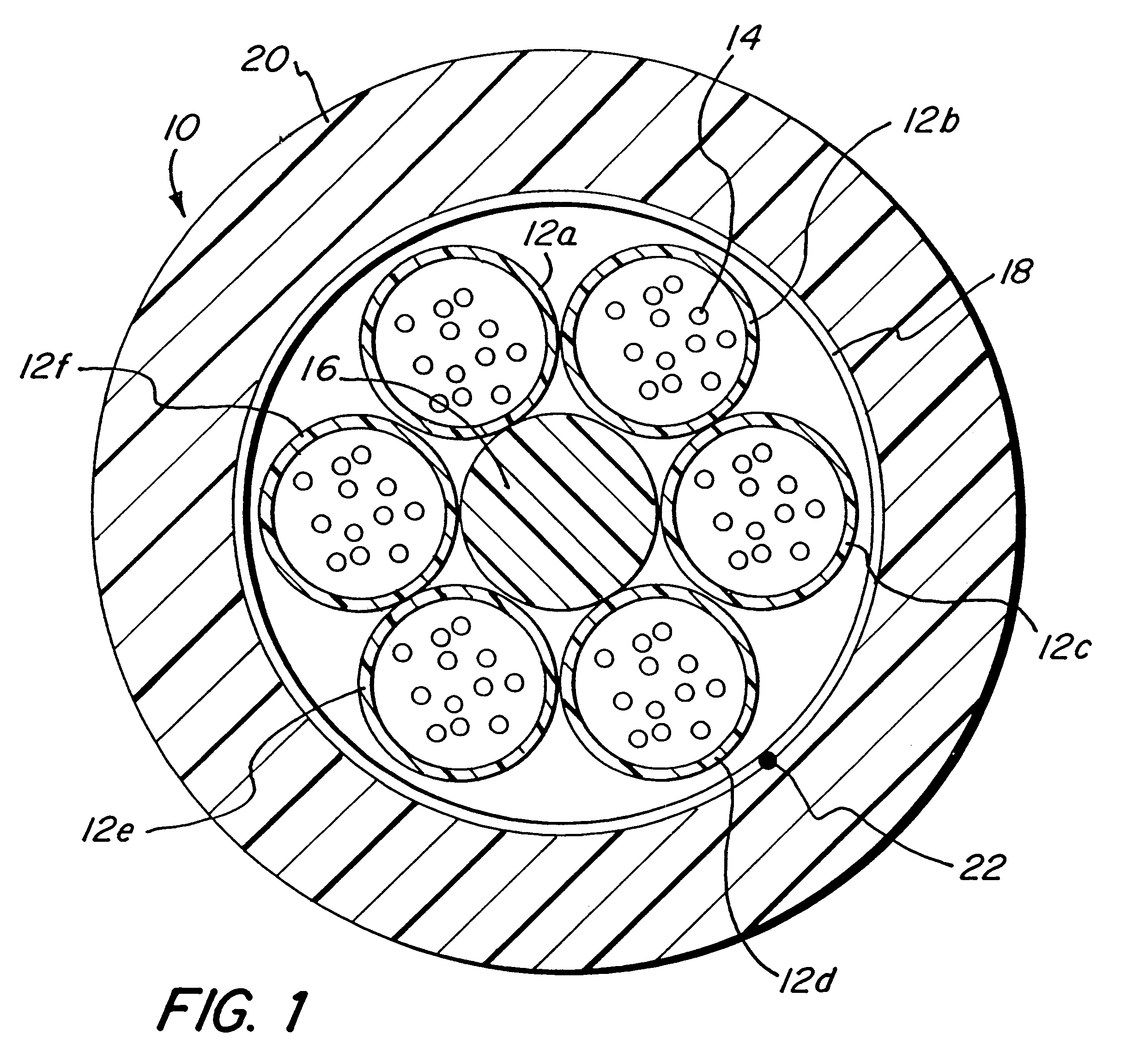

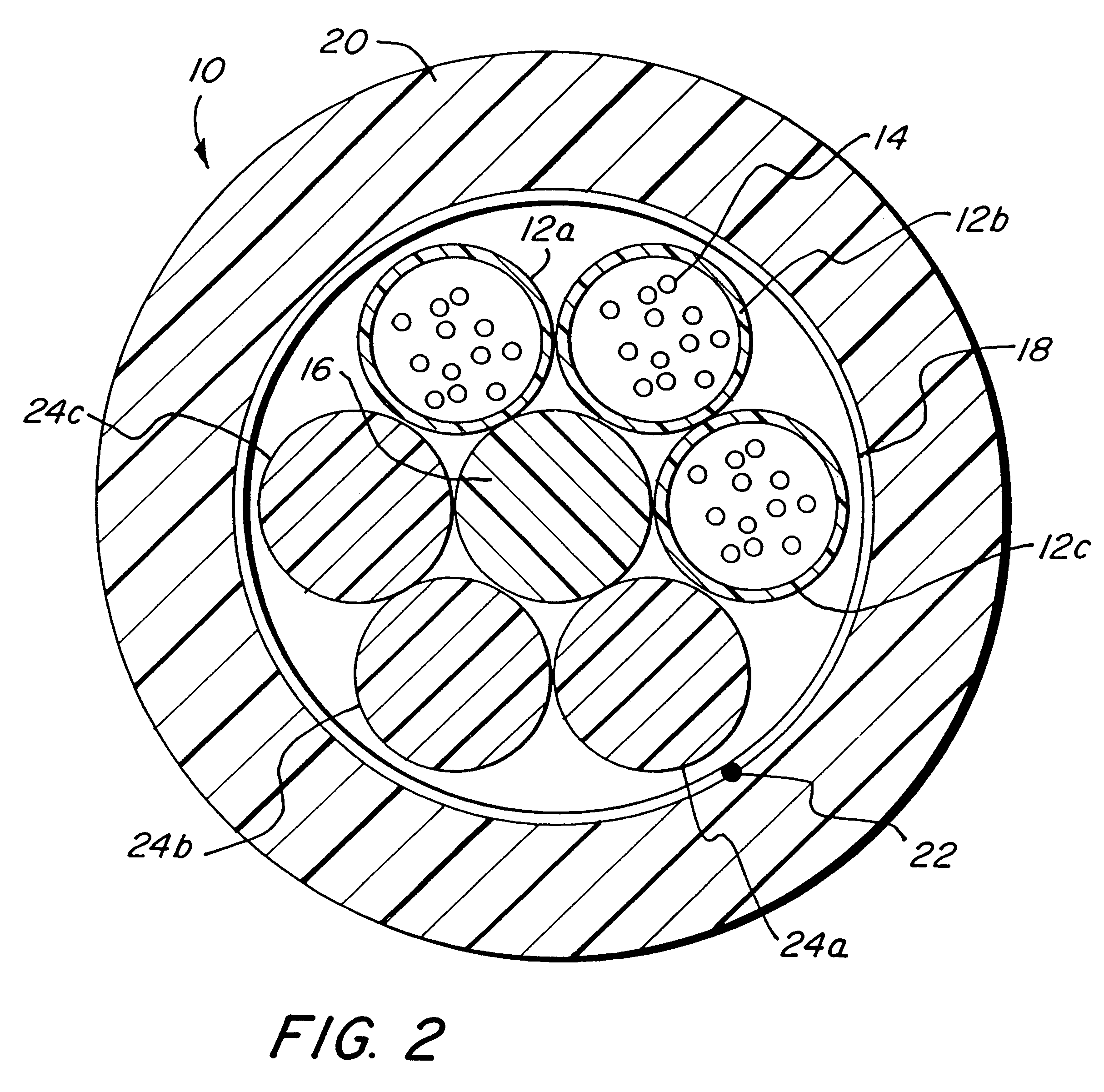

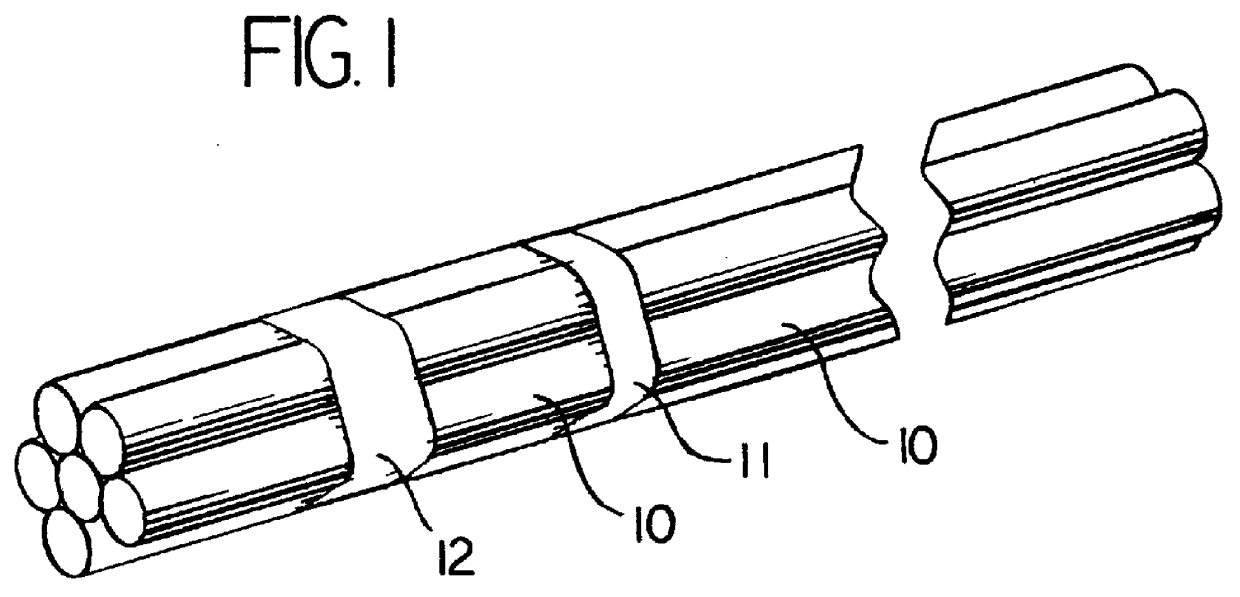

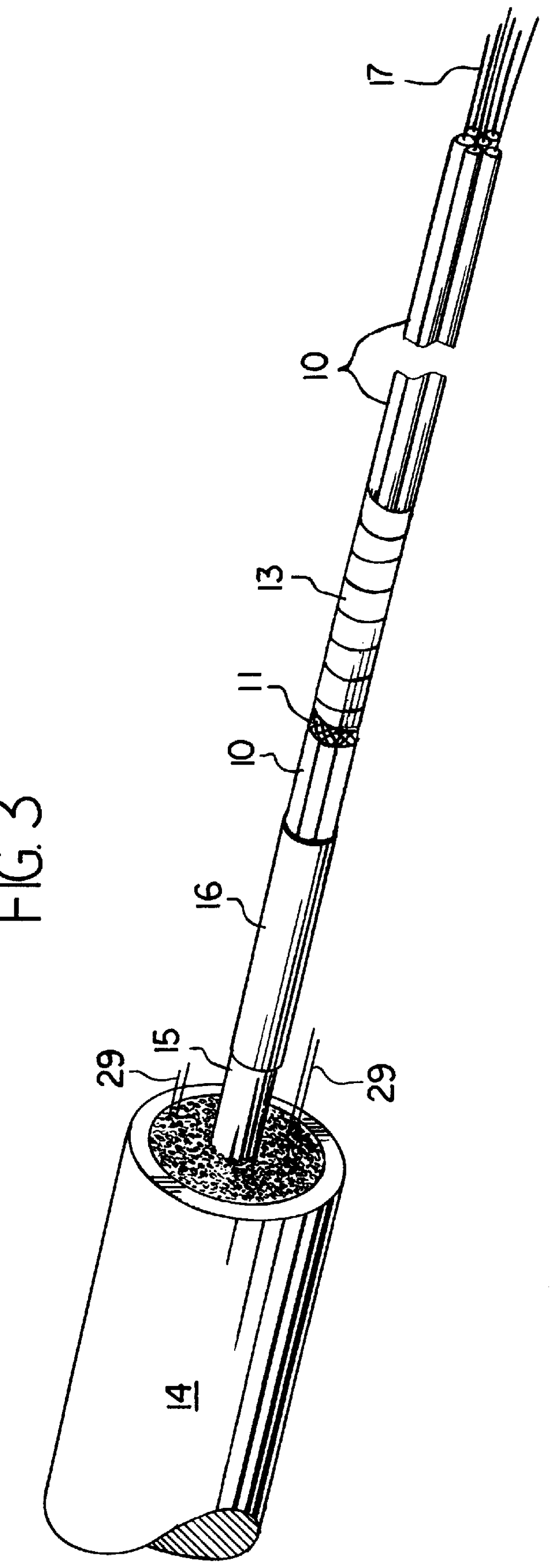

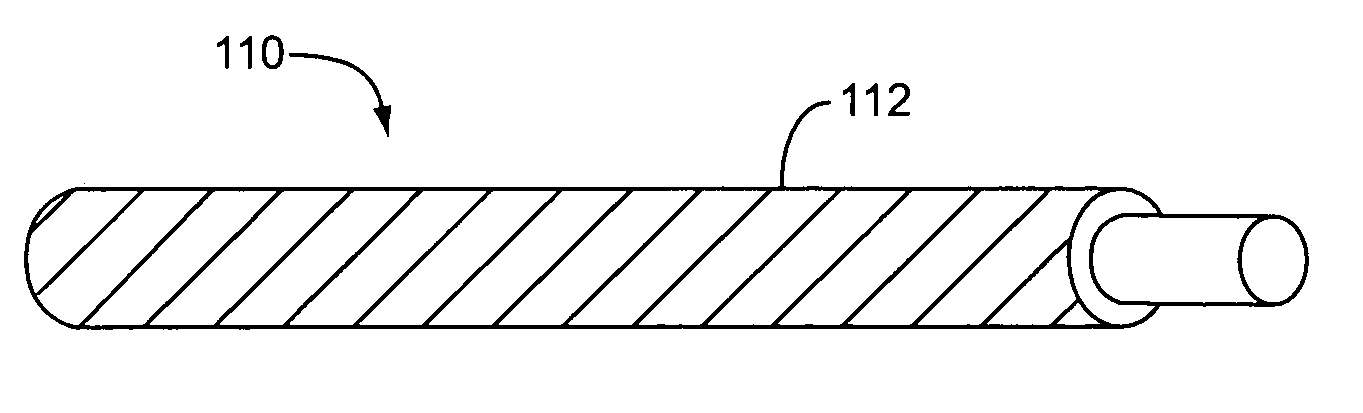

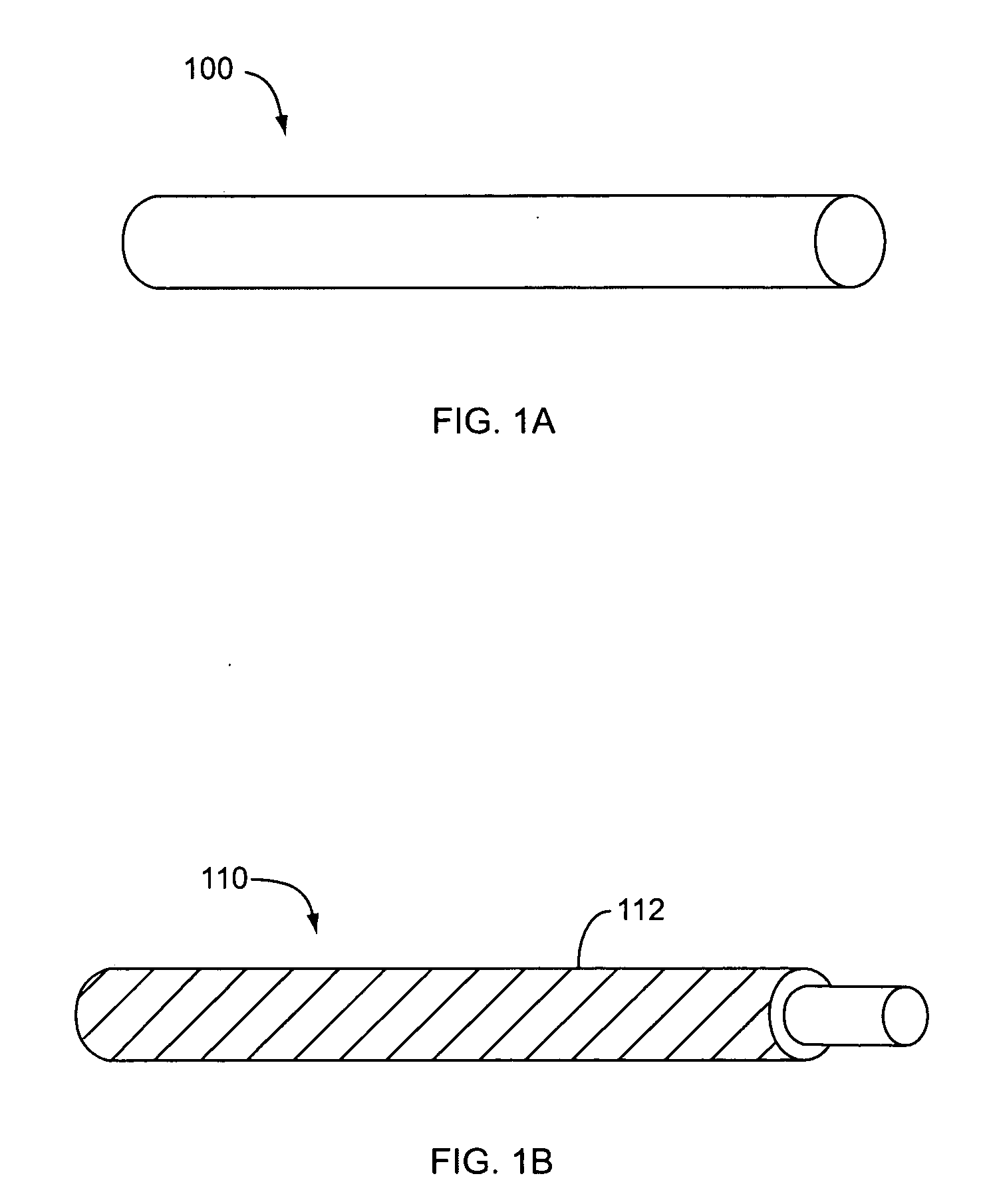

Fiber strand and implantable supporting body having a fiber strand

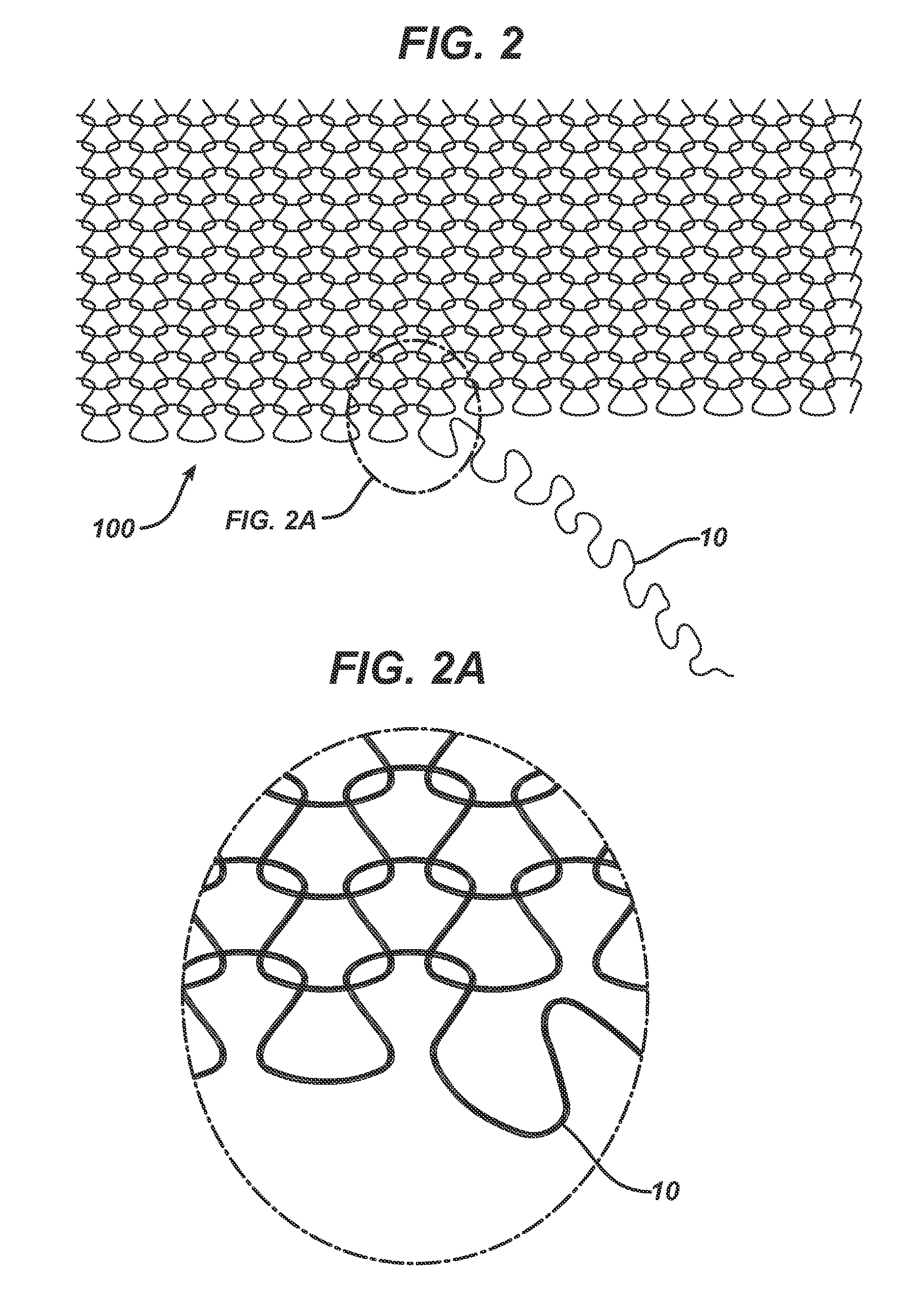

InactiveUS7997054B2Desired mechanical properties can be adjusted especially easilySignificant positive effectPowder deliveryStentsFiberBiomedical engineering

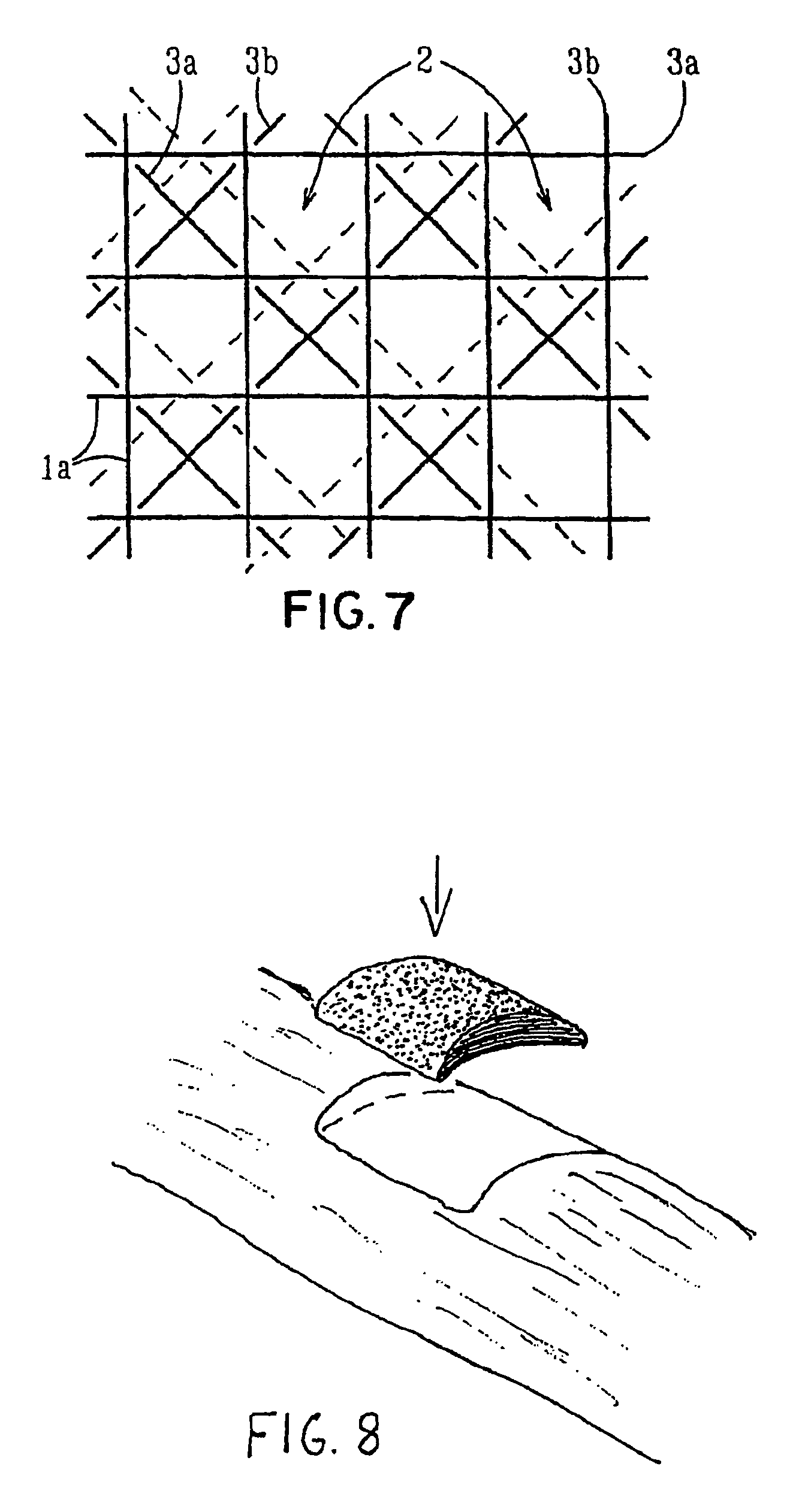

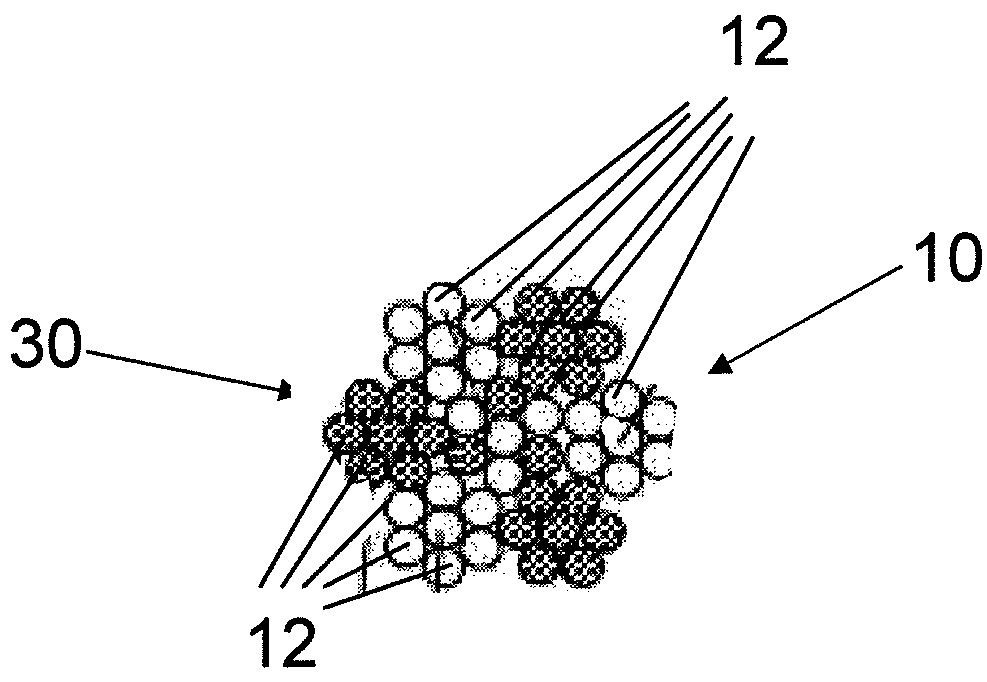

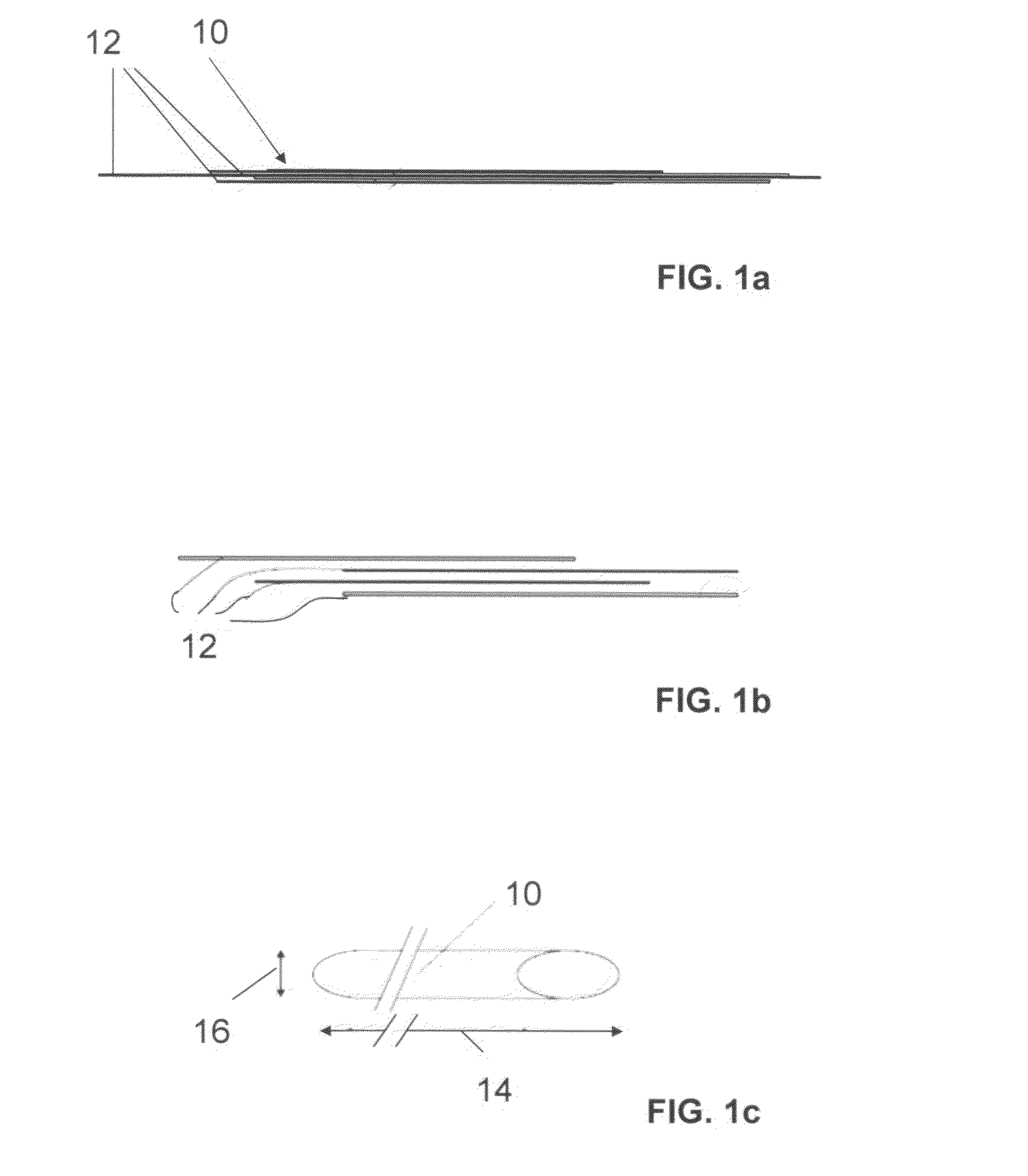

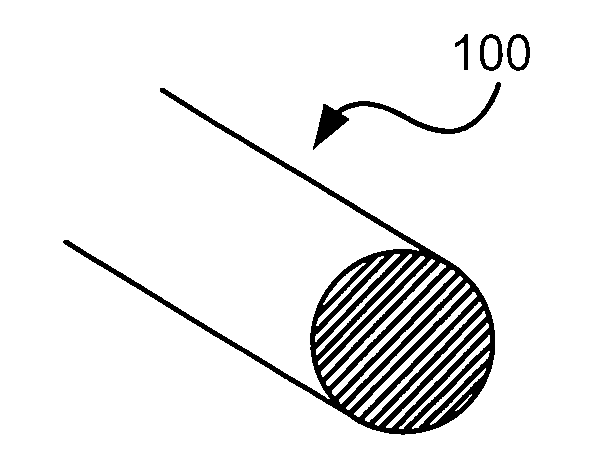

The invention relates to a fiber strand (10) for an implantable supporting body (100) comprising at least two individual fibers (12). The at least two individual fibers (12) are each shorter in their longitudinal extent than the longitudinal extent (14) of the fiber strand, and in their transverse extent they are each thinner than the transverse extent (16) of the fiber strand.

Owner:BIOTRONIK AG

Method for hydrophilizing materials using hydrophilic polymeric materials with discrete charges

A method of rendering materials having hard and soft surfaces hydrophilic or more hydrophilic is disclosed. The method involves hydrophilizing such materials by applying a high energy treatment and charged particles and / or one or more hydrophilic polymeric materials with discrete charges to such materials.

Owner:THE PROCTER & GAMBLE COMPANY

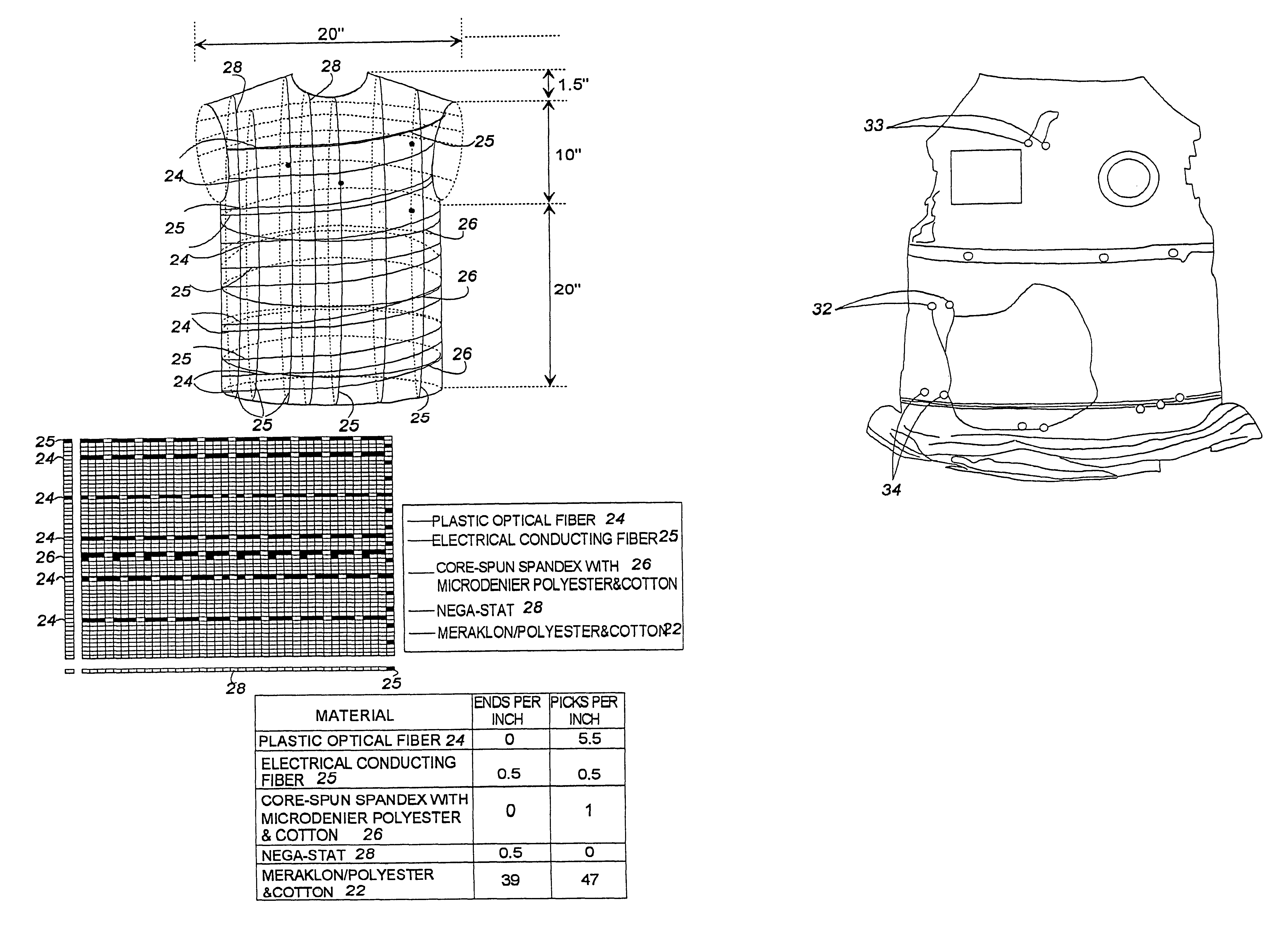

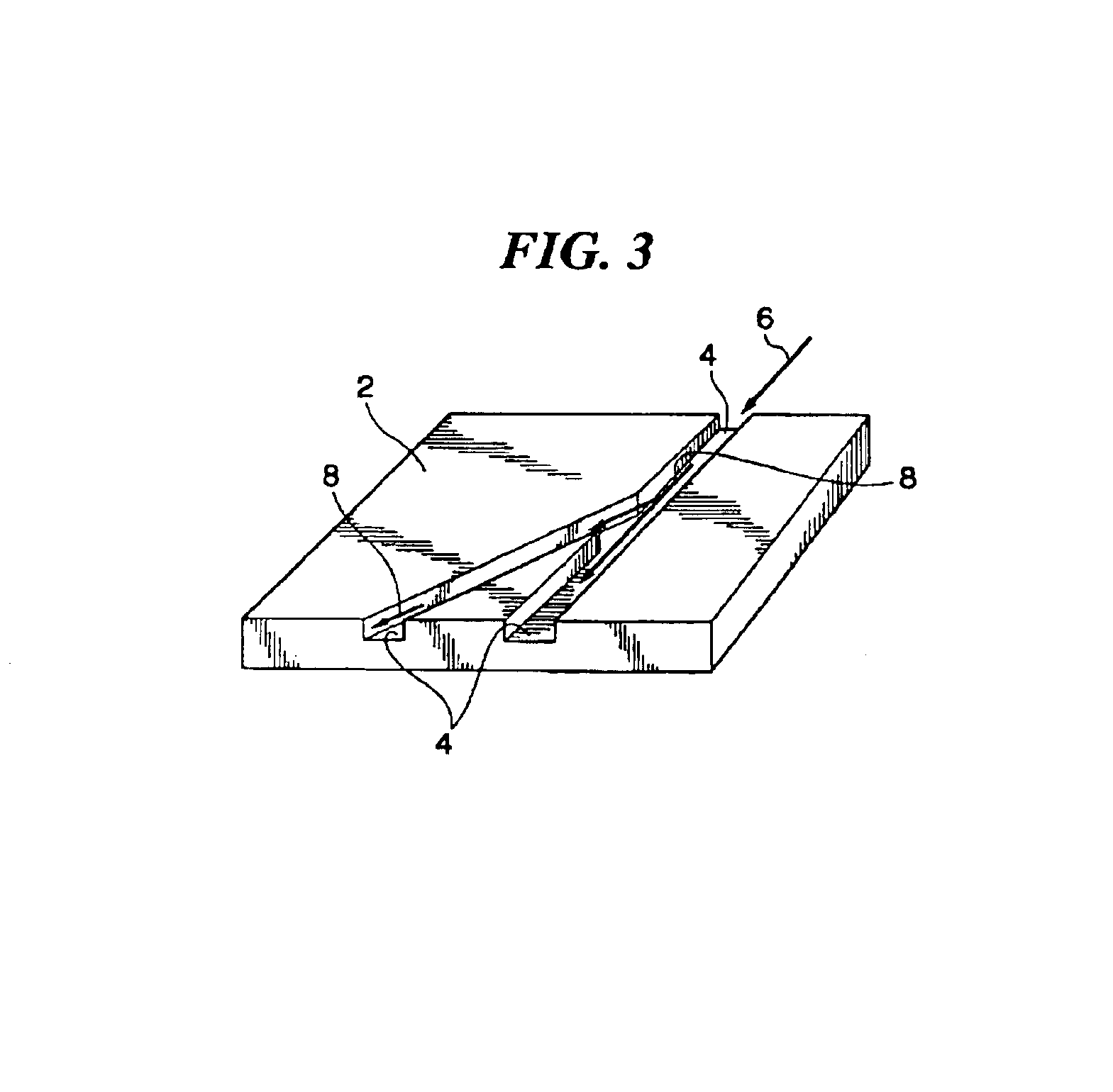

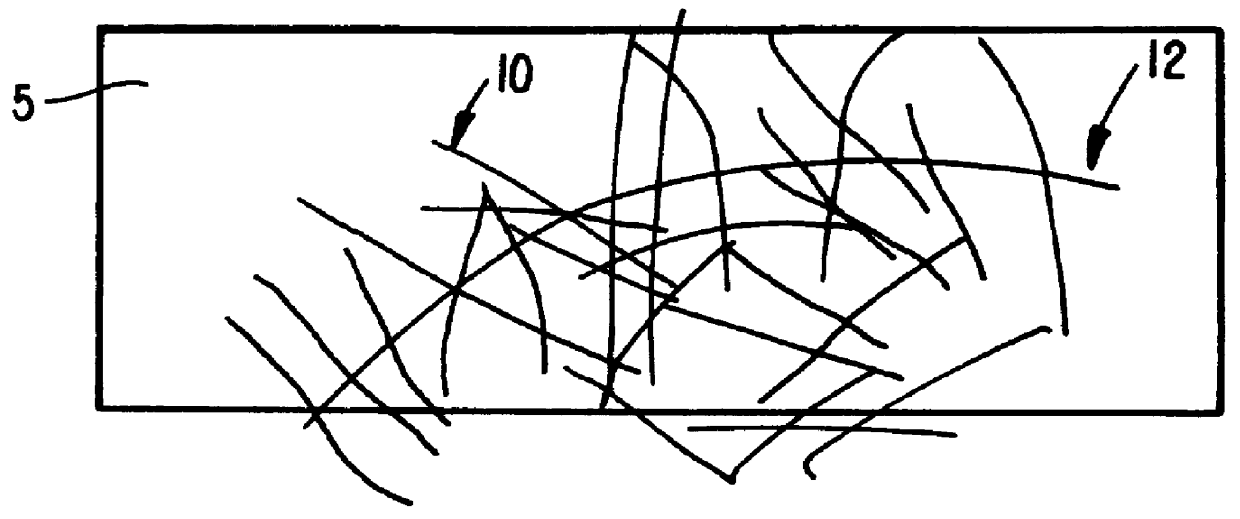

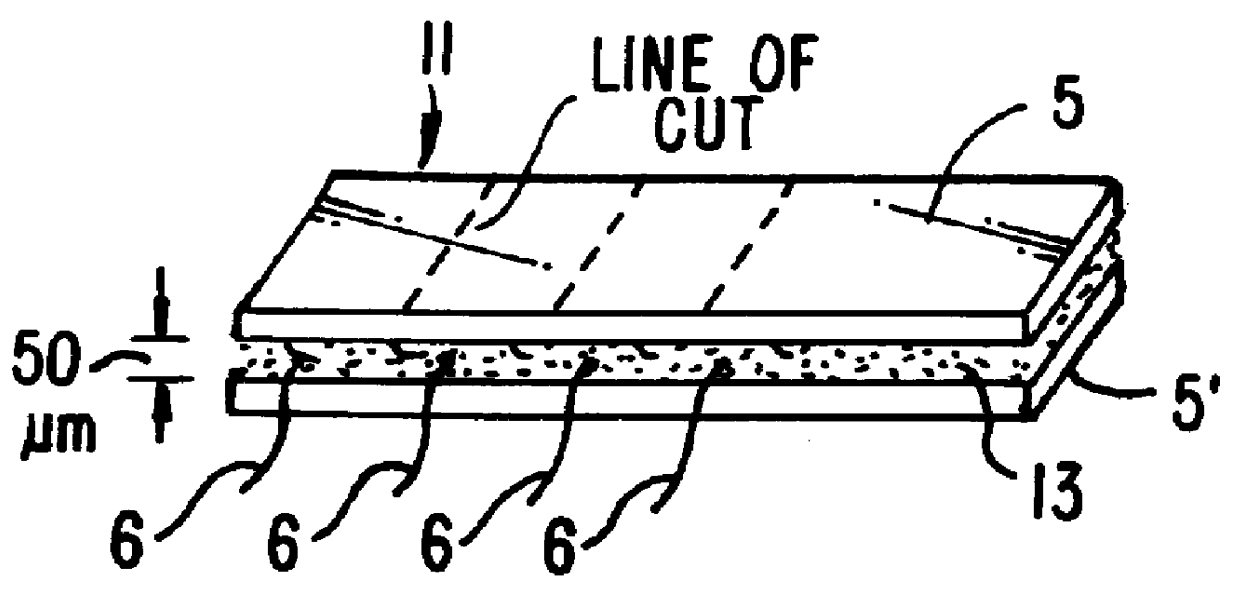

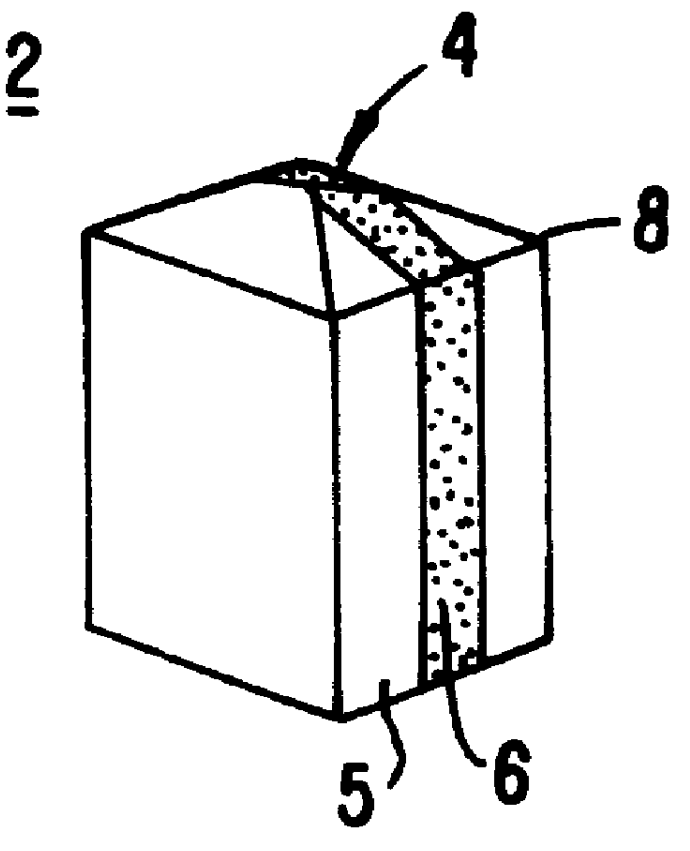

Fabric or garment with integrated flexible information infrastructure

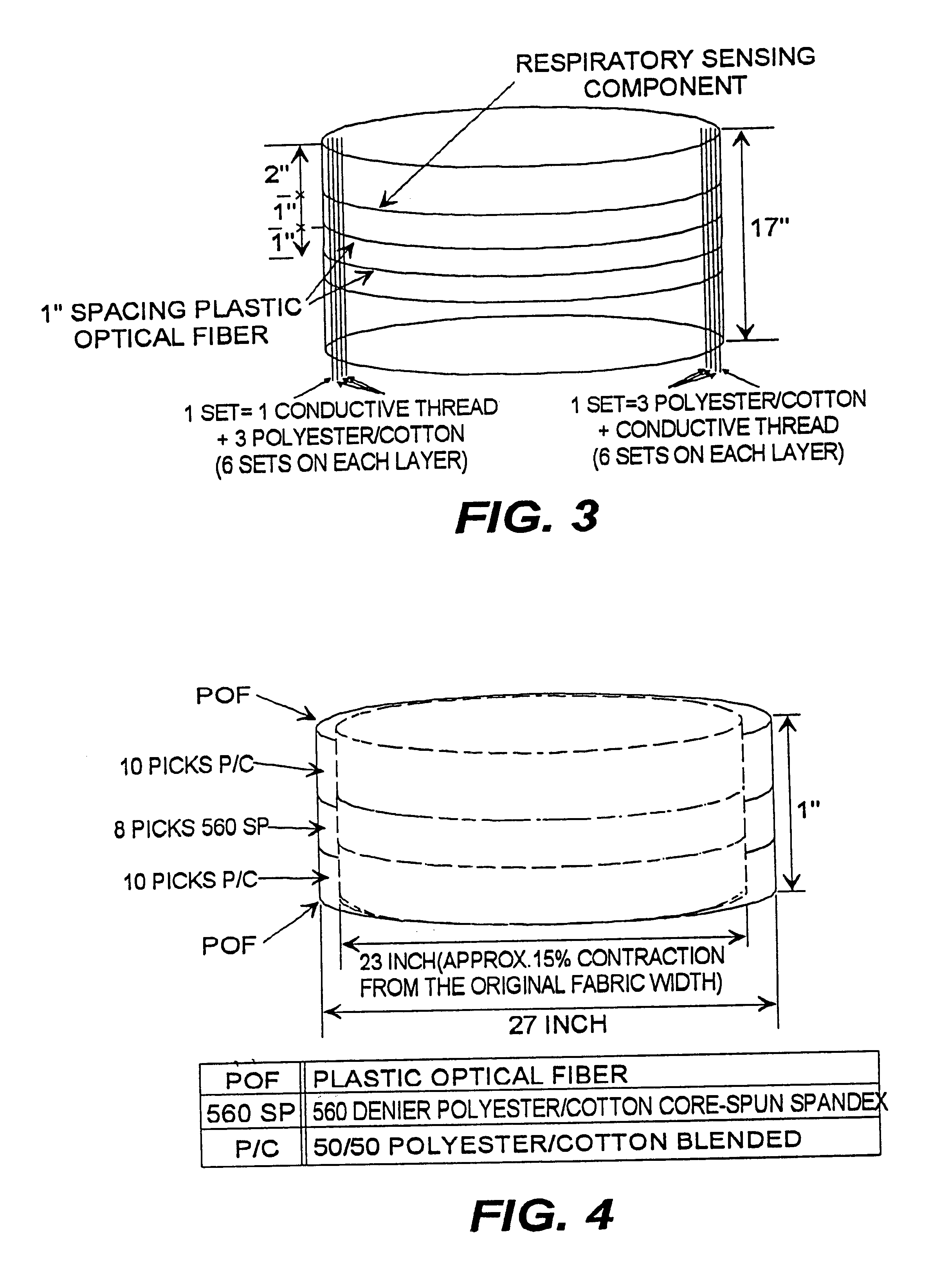

InactiveUS6381482B1Raise the ratioImprove high temperature stabilityWeft knittingOrnamental textile articlesInformation processingEngineering

A fabric, in the form of a woven or knitted fabric or garment, including a flexible information infrastructure integrated within the fabric for collecting, processing, transmitting and receiving information concerning-but not limited to-a wearer of the fabric. The fabric allows a new way to customize information processing devices to "fit" the wearer by selecting and plugging in (or removing) chips / sensors from the fabric thus creating a wearable, mobile information infrastructure that can operate in a stand-alone or networked mode. The fabric can be provided with sensors for monitoring physical aspects of the wearer, for example body vital signs, such as heart rate, EKG, pulse, respiration rate, temperature, voice, and allergic reaction, as well as penetration of the fabric. The fabric consists of a base fabric ("comfort component"), and an information infrastructure component which can consist of a penetration detection component, or an electrical conductive component, or both. The preferred penetration detection component is a sheathed optical fiber. The information infrastructure component can include, in addition to an electrically conductive textile yarn, a sensor or a connector for a sensor. A process is provided for making an electrical interconnection between intersecting electrically conductive yarns. Furthermore, a process is established for sheathing the plastic optical fiber and protecting it.

Owner:GEORGIA TECH RES CORP

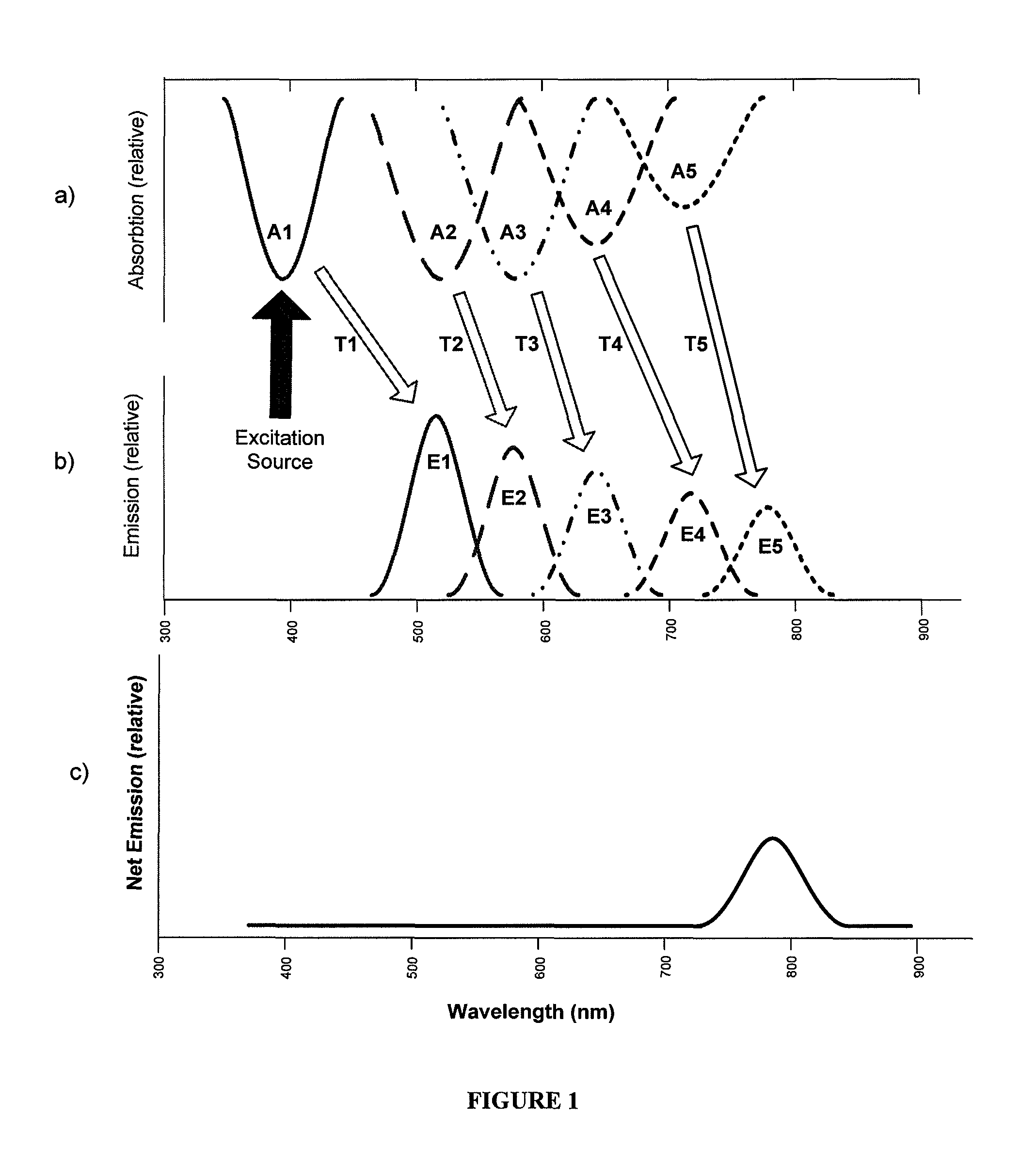

Photoluminescent fibers, compositions and fabrics made therefrom

Disclosed are photoluminescent fibers containing photoluminescent phosphorescent materials and photoluminescent fluorescent materials whose emission signature lies partly or fully in the infrared region of the electromagnetic spectrum. Also disclosed are the use of the inventive fibers, fabrics made therefrom, and objects containing the fiber.

Owner:PERFORMANCE INDICATOR LLC

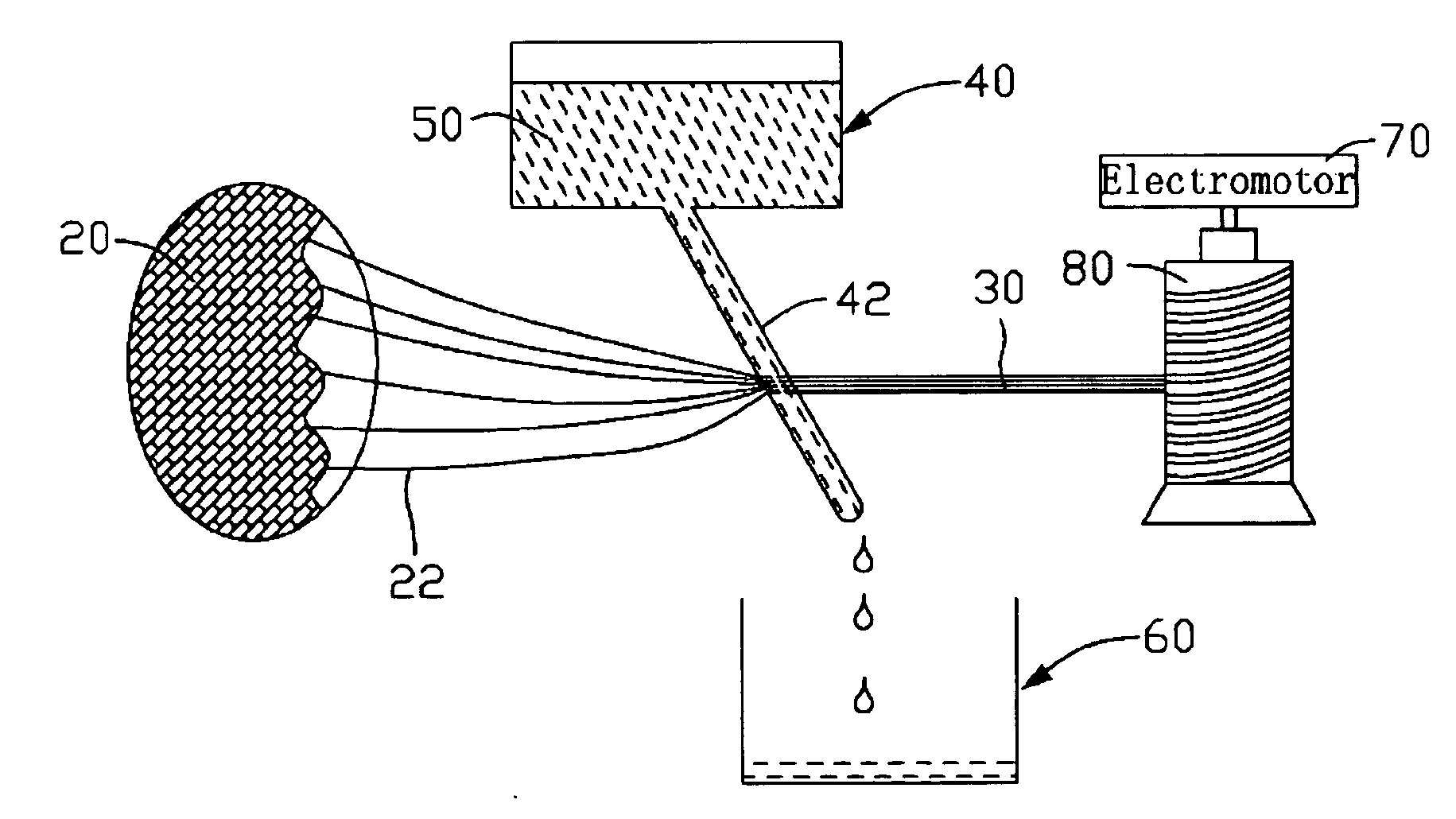

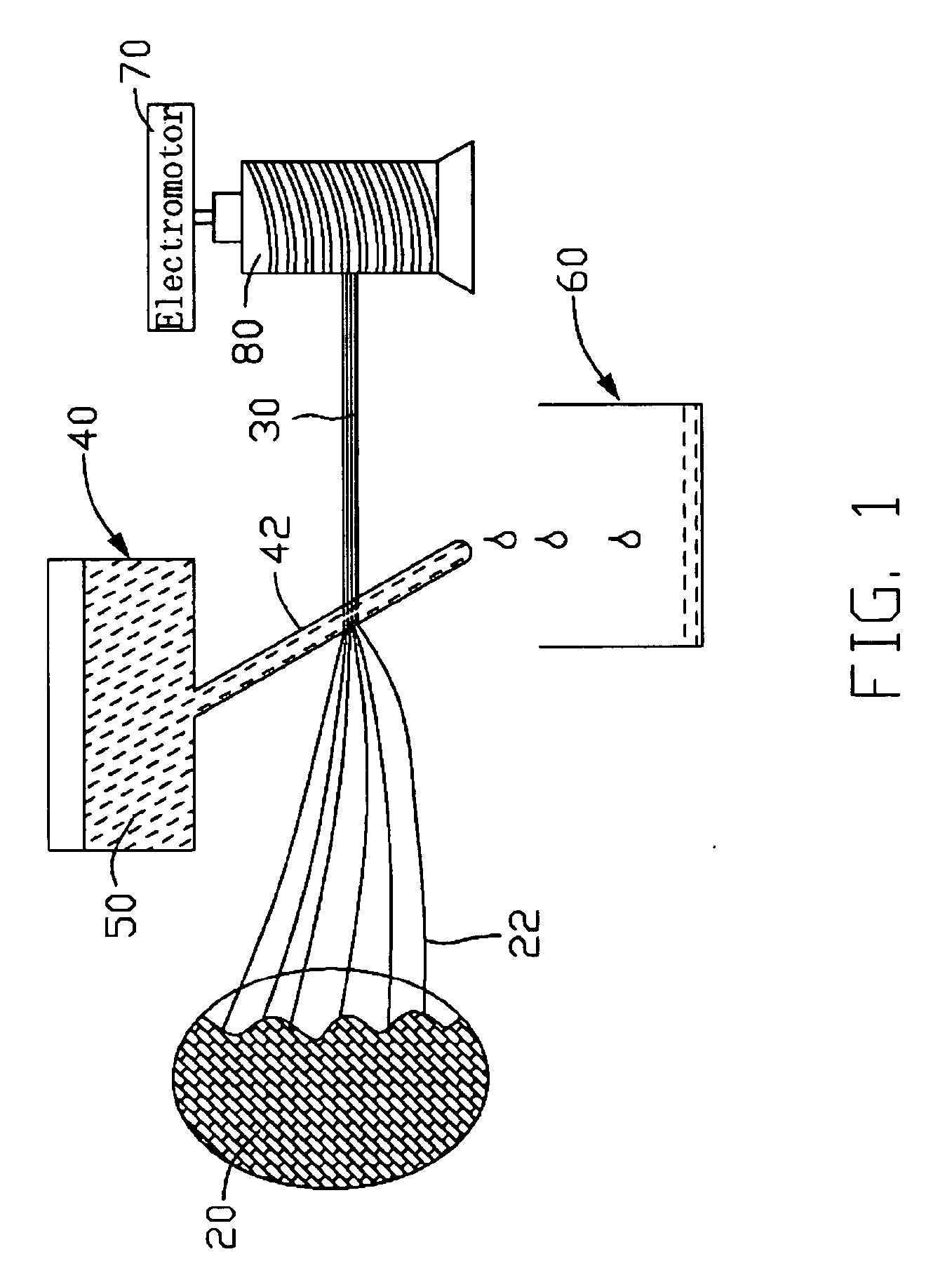

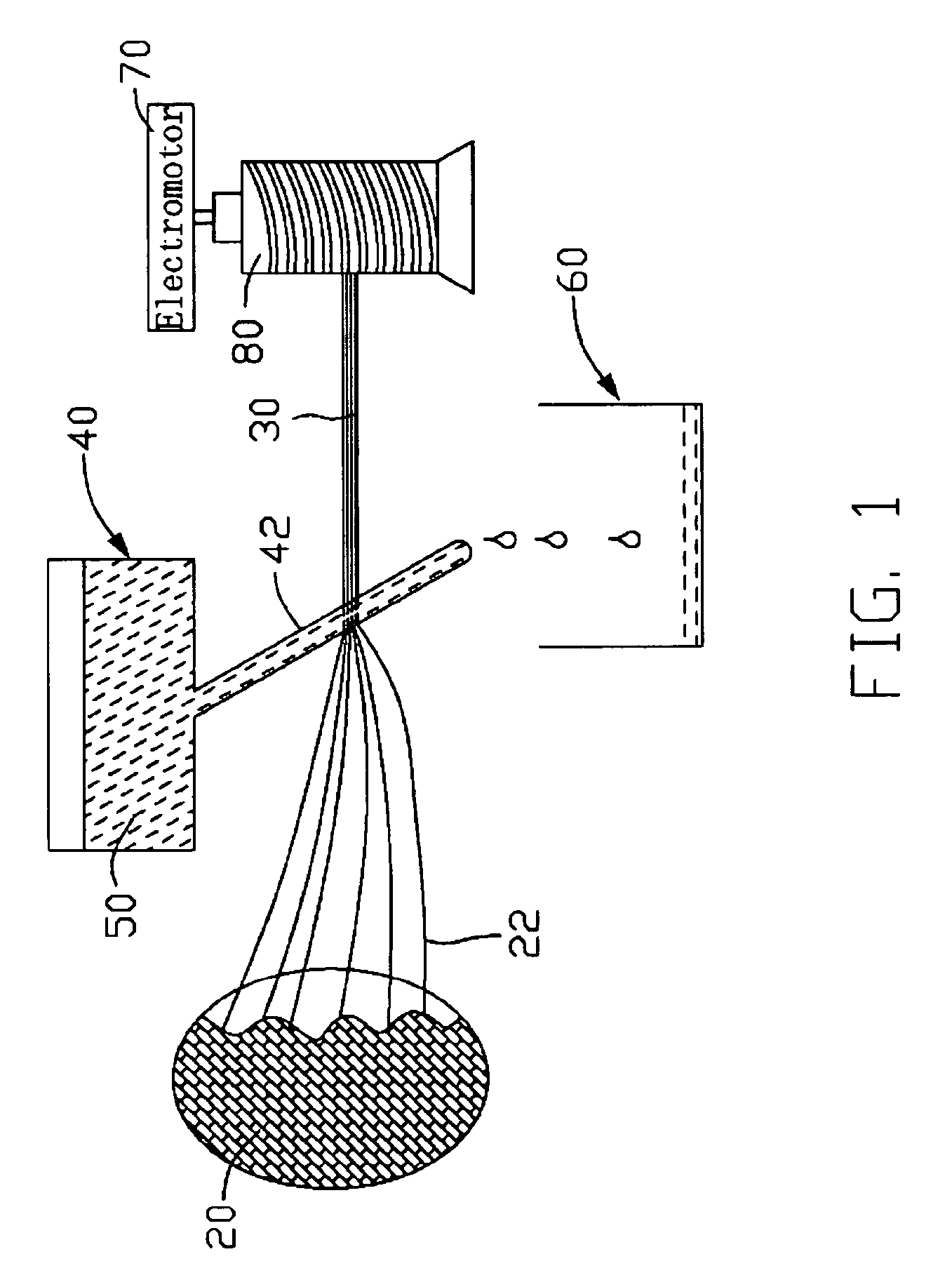

Method for fabricating carbon nanotube yarn

ActiveUS20040053780A1Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

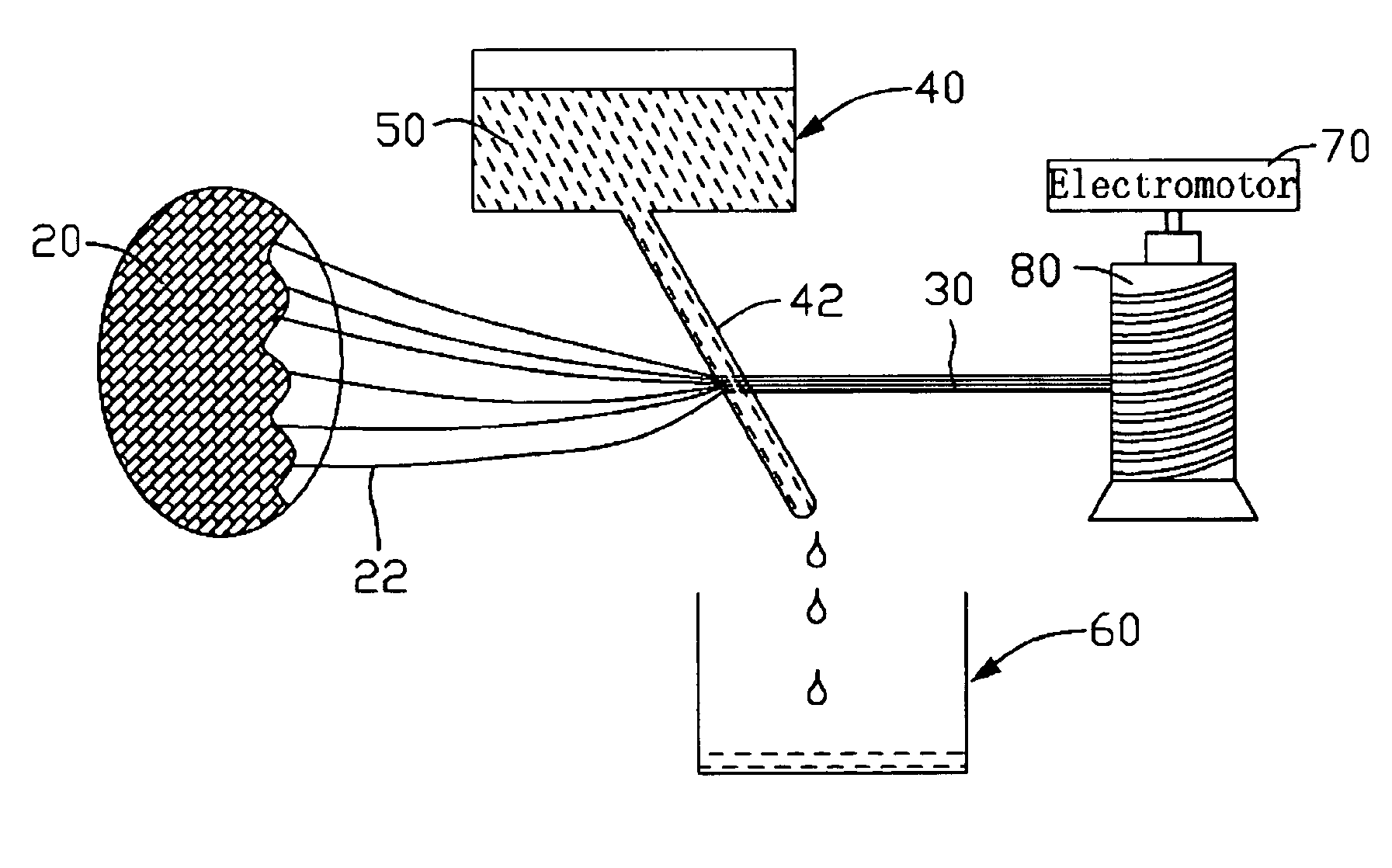

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

Method for fabricating carbon nanotube yarn

ActiveUS7045108B2Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

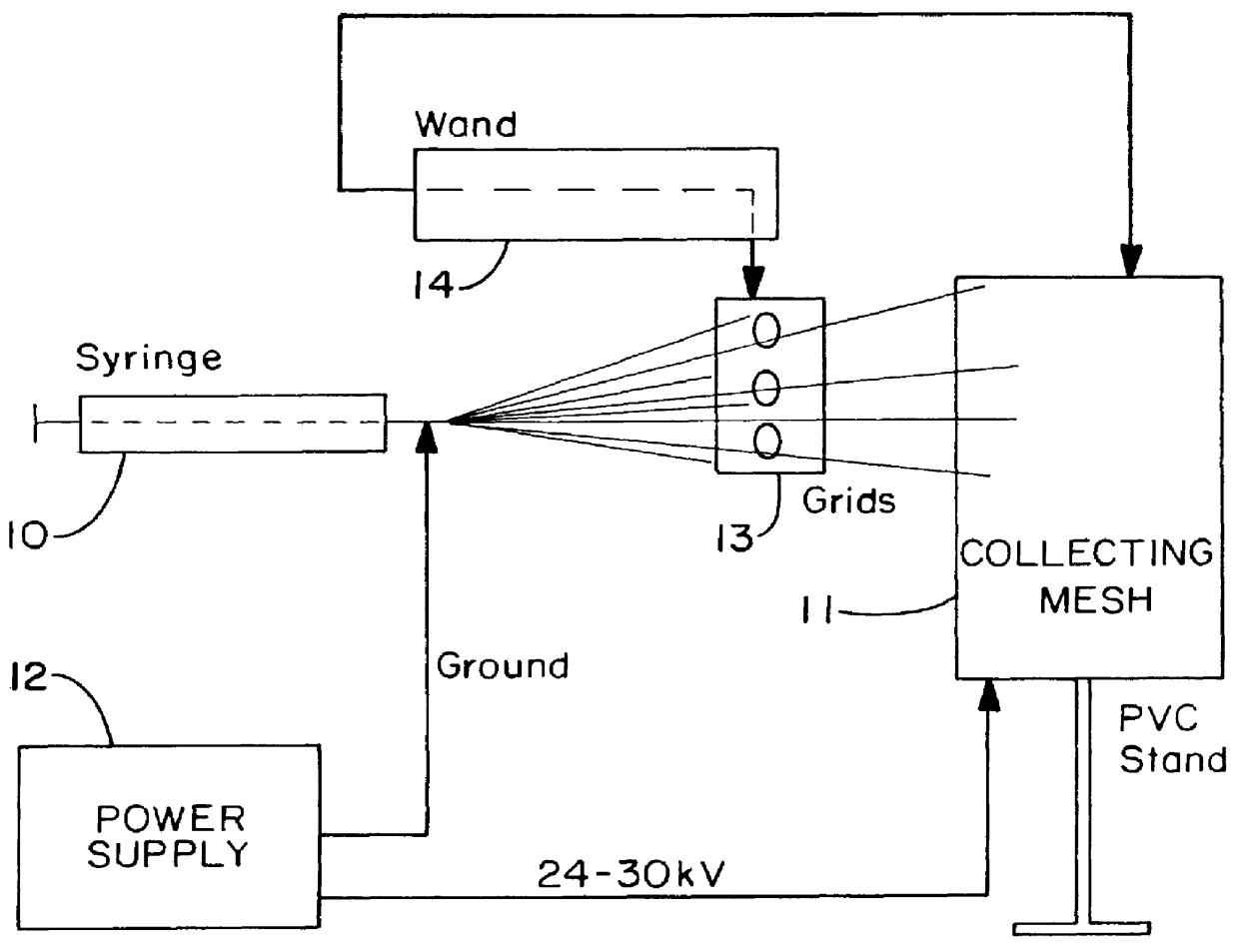

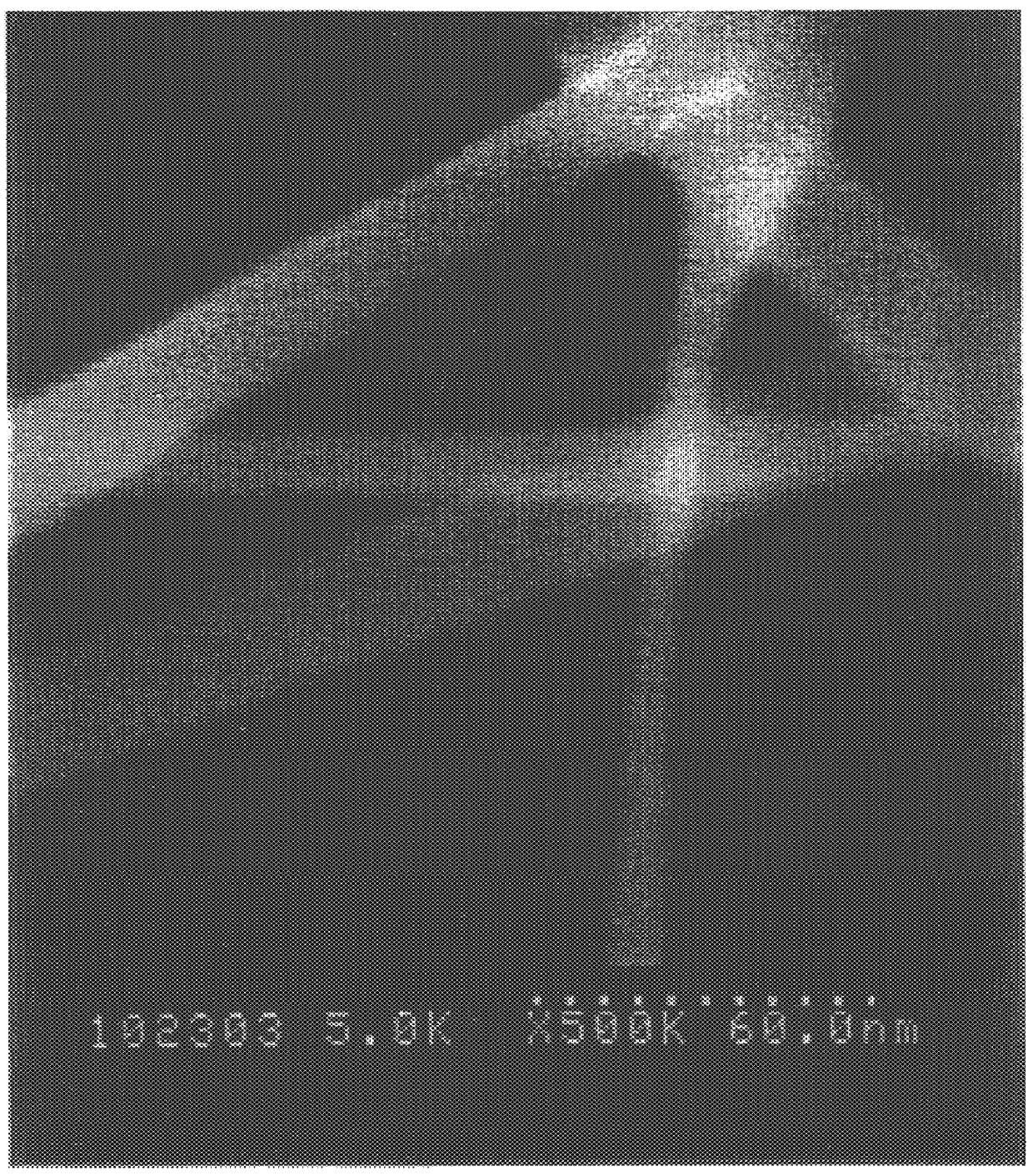

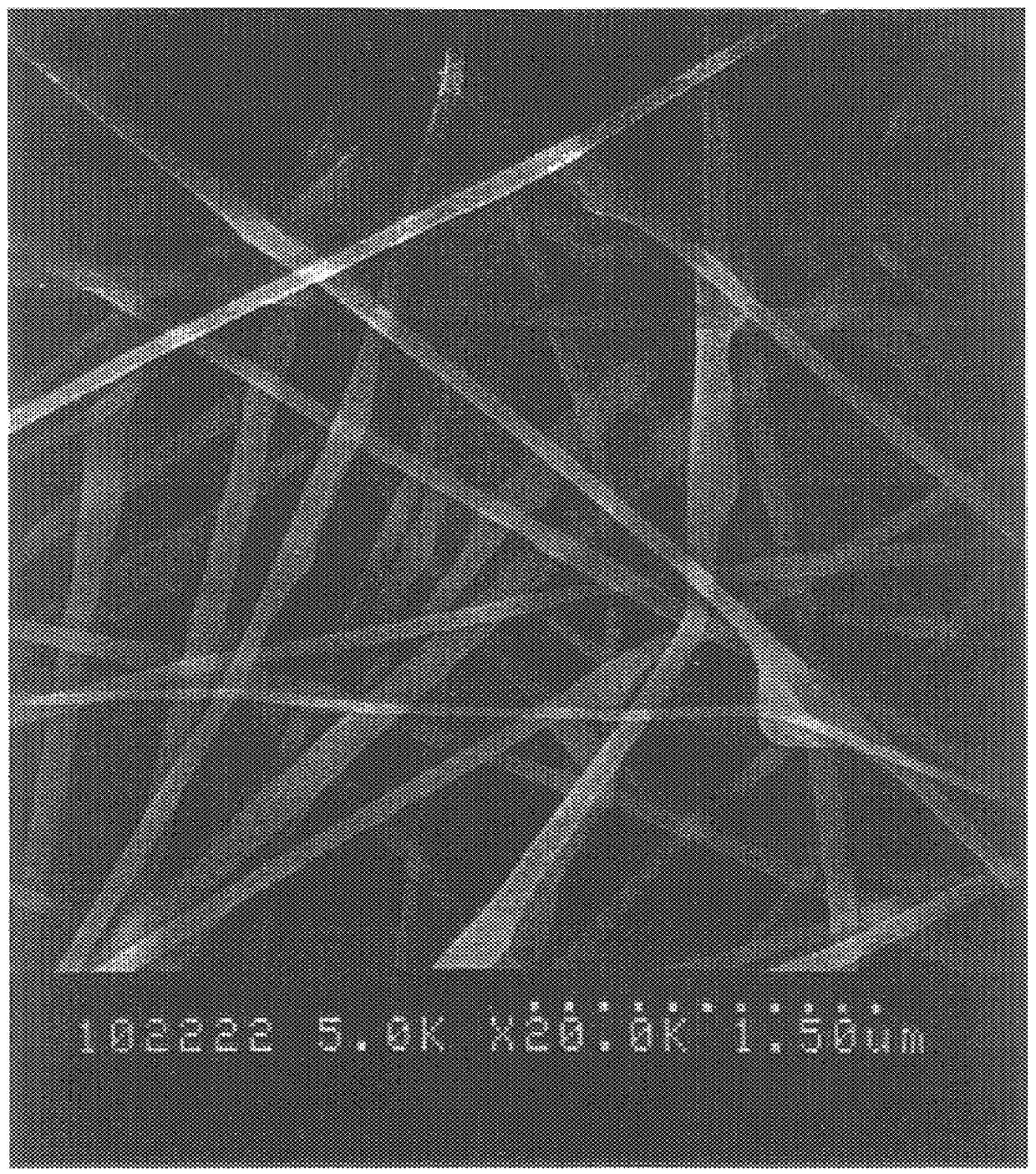

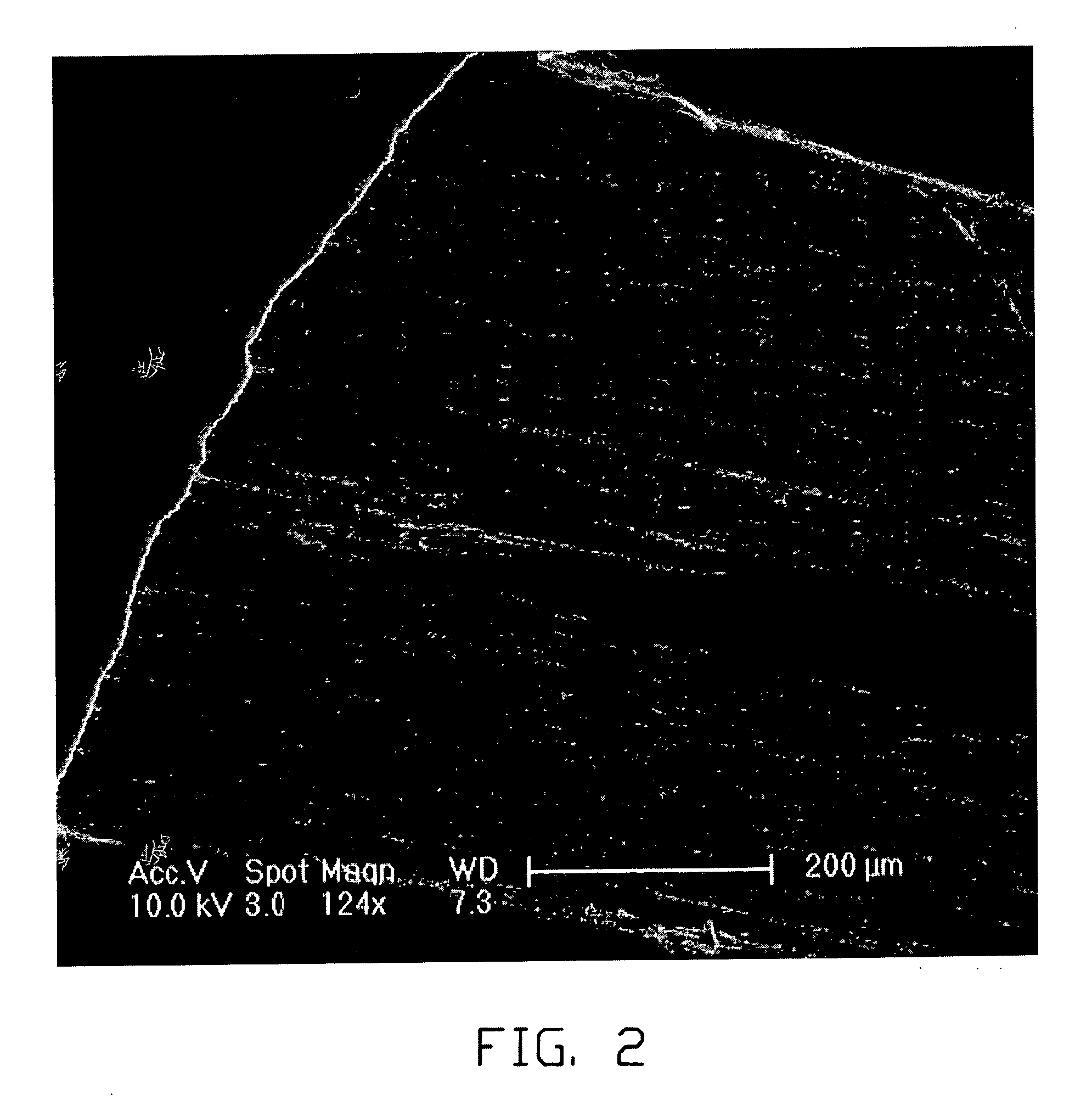

Synthetically spun silk nanofibers and a process for making the same

InactiveUS6110590AMonocomponent fibroin artificial filamentFilament/thread formingBombyx moriNanofiber

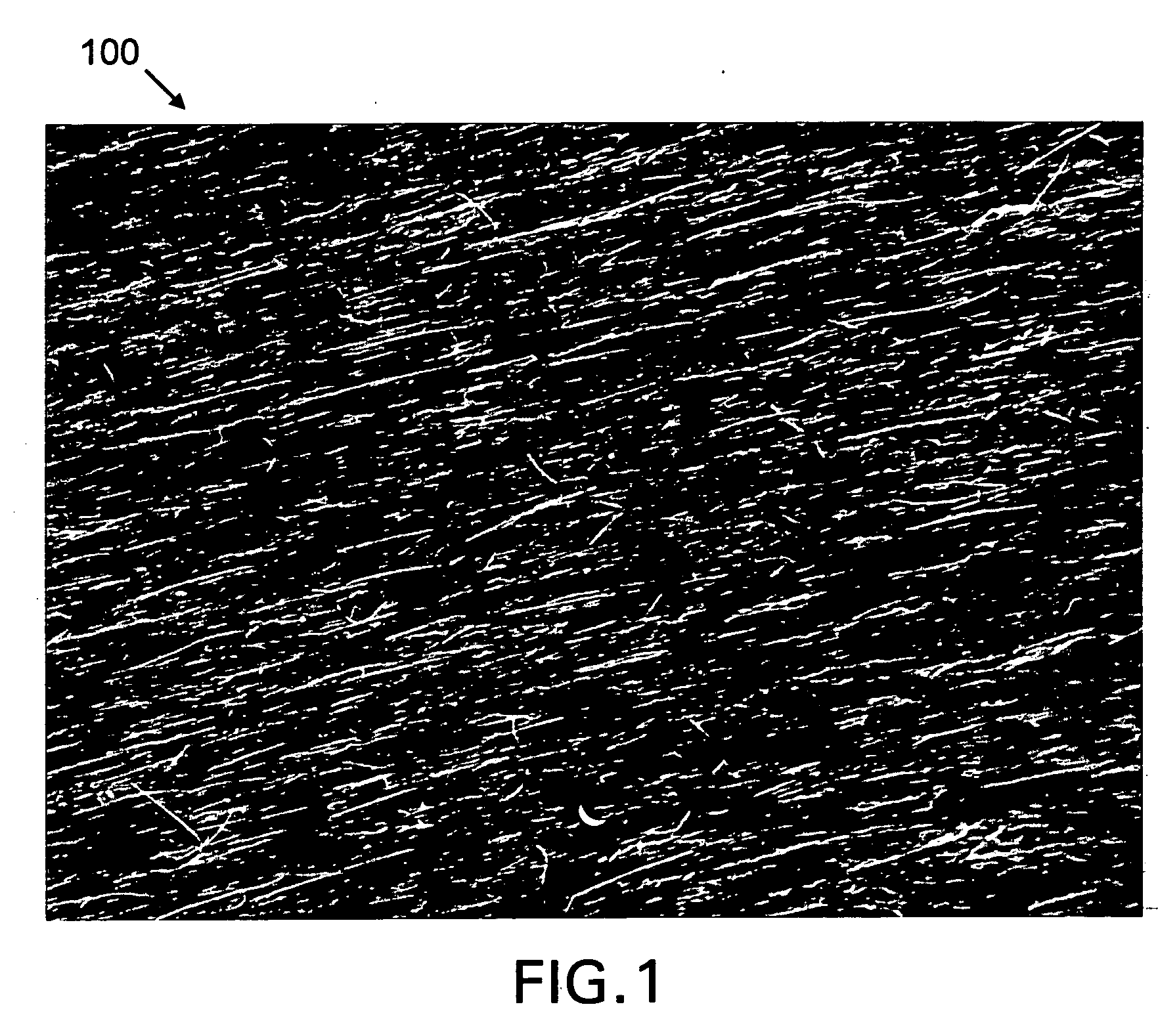

A silk nanofiber composite network produced by forming a solution of silk fiber and hexafluroisopropanol, wherein the step of forming is devoid of any acid treatment, where the silk solution has a concentration of about 0.2 to about 1.5 weight percent silk in hexafluroisopropanol, and where the silk is selected from Bombyx mori silk and Nephila clavipes silk; and electrospinning the solution, thereby forming a non-woven network of nanofibers having a diameter in the range from about 2 to about 2000 nanometers.

Owner:THE UNIVERSITY OF AKRON

Method of forming an implantable device

ActiveUS9352071B2Greater and beneficial tissue ingrowthLow melting pointWeft knittingMedical devicesImplanted devicePliability

Owner:ETHICON INC

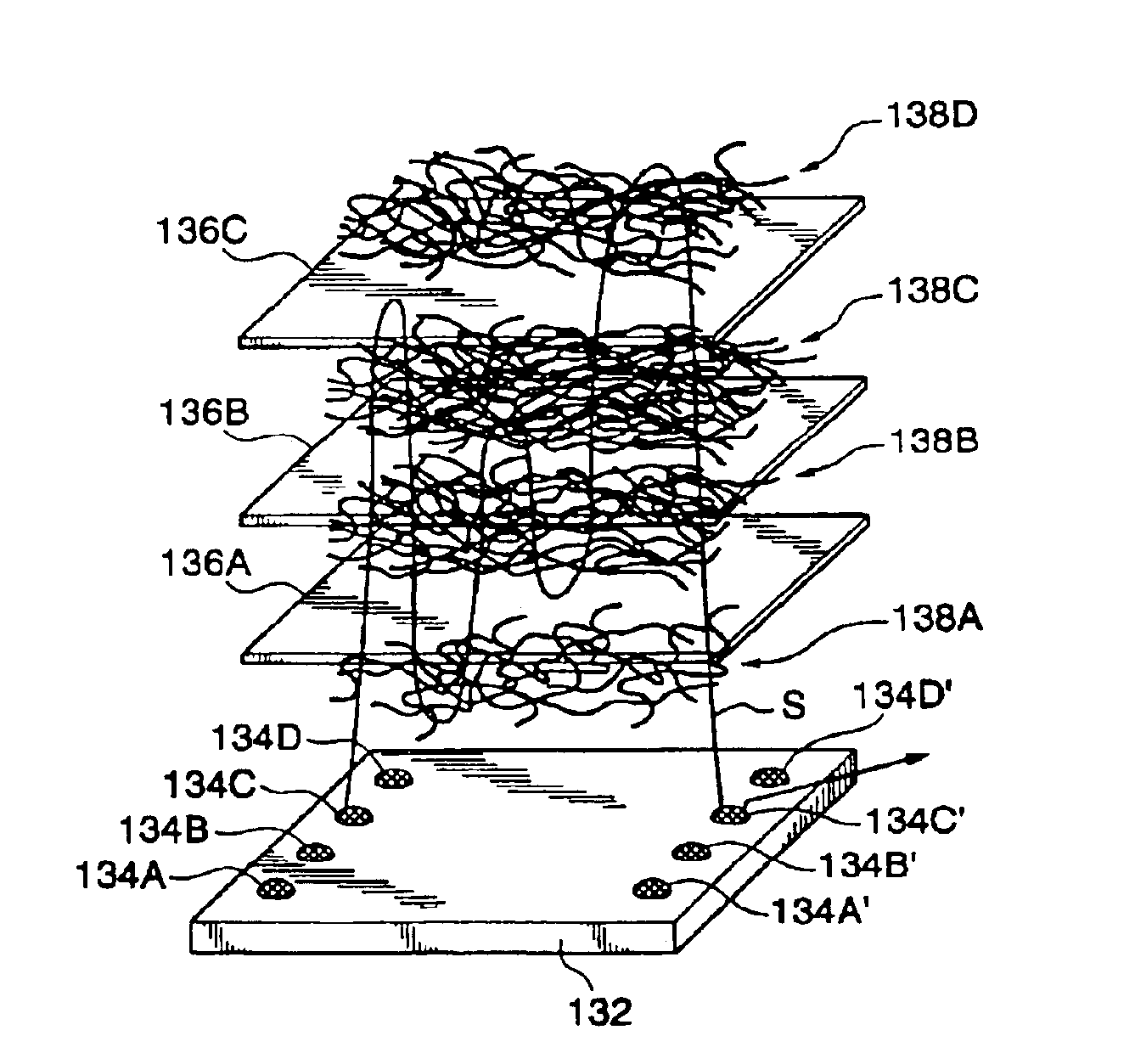

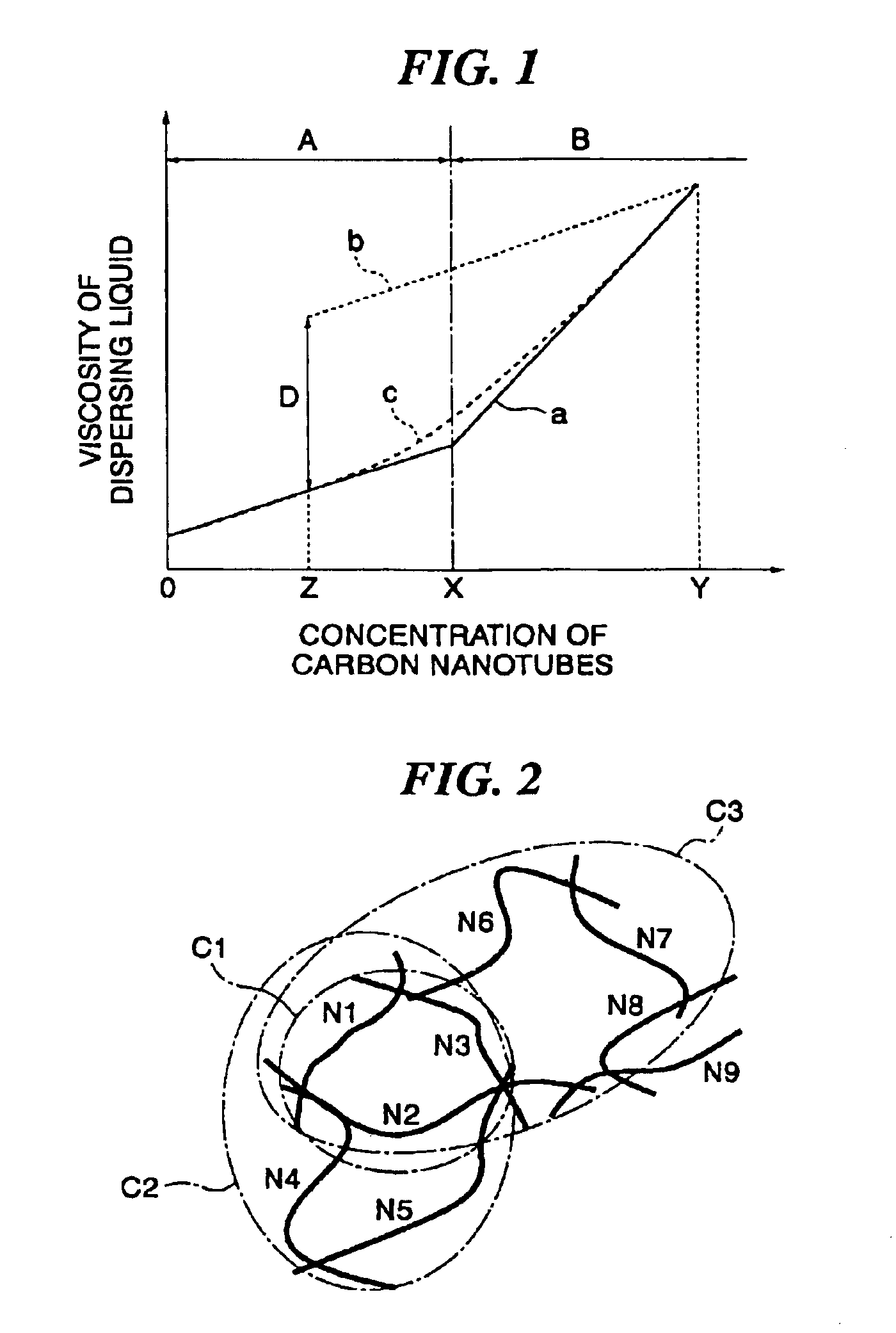

Carbon nanotube structures, carbon nanotube devices using the same and method for manufacturing carbon nanotube structures

InactiveUS6921575B2Easy to manufactureMaterial nanotechnologyCarbon compoundsElectricityCarbon nanotube

Carbon nanotube structures are provided, in which the networks with a desired area and volume, where the carbon nanotubes are electrically or magnetically connected, are formed and the method for easily manufacturing the carbon nanotube structures with less carbon nanotube structures. Carbon nanotube devices are also provided, to which the useful carbon nanotube structures mentioned above are applied. A method for manufacturing carbon nanotube structures includes the steps of applying carbon nanotubes to a low-viscosity dispersion medium to obtain a high-viscosity dispersing liquid which includes carbon nanotubes, and forming a network of the carbon nanotubes having electrical and / or magnetic connections therebetween by removing the low-viscosity dispersion medium from the high-viscosity dispersed liquid.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Field emission electron source

InactiveUS6057637AStable and reproducible current-voltage characteristicStraightforward and commercially feasibleElectric discharge tubesLayered productsElectron currentElectron source

A novel field emitter material, field emission electron source, and commercially feasible fabrication method is described. The inventive field emission electron source produces reliable electron currents of up to 400 mA / cm2 at 200 volts. The emitter is robust and the current it produces is not sensitive to variability of vacuum or the distance between the emitter tip and the cathode. The novel emitter has a sharp turn-on near 100 volts.

Owner:RGT UNIV OF CALIFORNIA

Isosorbide containing polyesters and methods for making same

InactiveUS6063464AHigher inherent viscosityInherent viscosityBottlesSynthetic resin layered productsPolyesterDiol

A polyester polymer and method for making the polyester, wherein the polyester is prepared by (1) combining in a reactor a monomer containing a diacid moiety; a monomer comprising a diol moiety; and a monomer containing an isosorbide moiety; with a condensation catalyst suitable for condensing aromatic diacids and diols; and (2) heating the monomers and catalyst to polymerize the monomers to yield a polyester having an inherent viscosity of at least about 0.15 dL / g.

Owner:EI DU PONT DE NEMOURS & CO

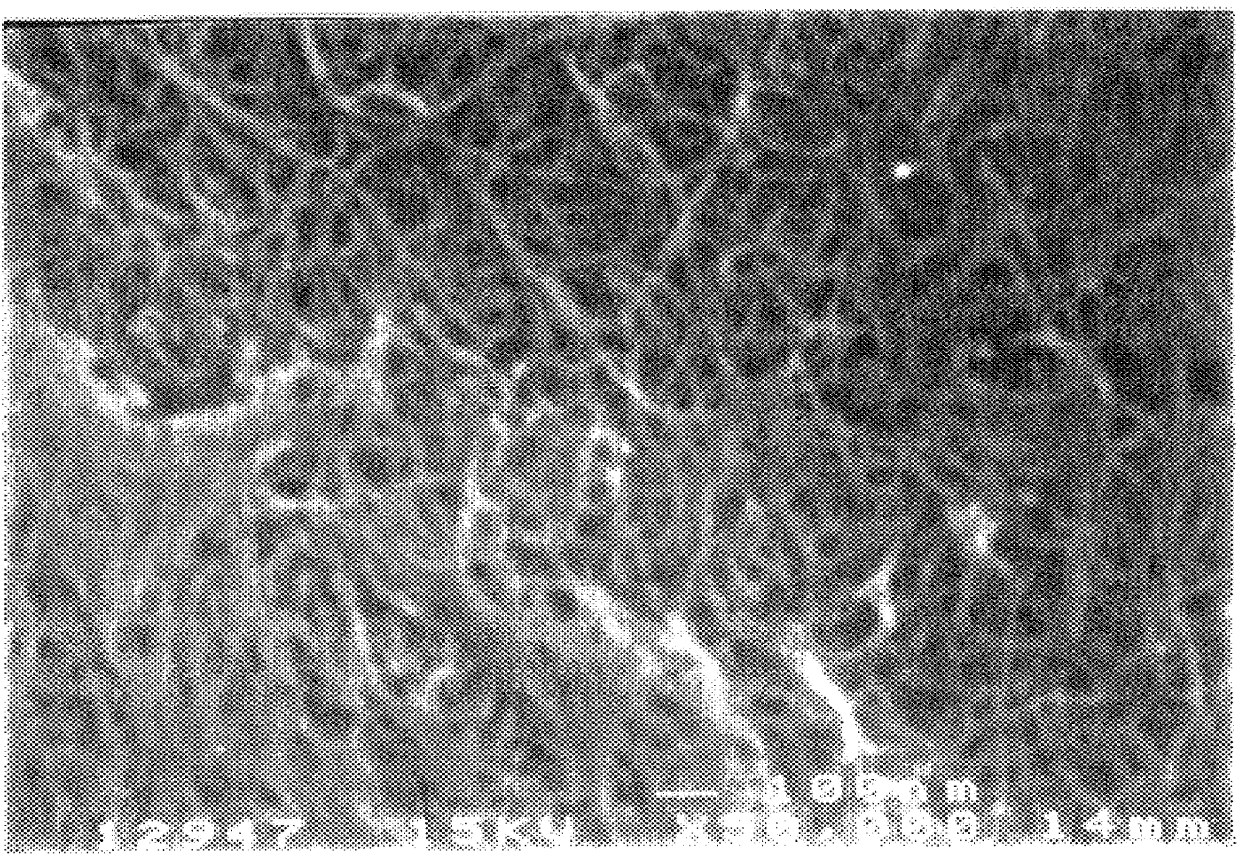

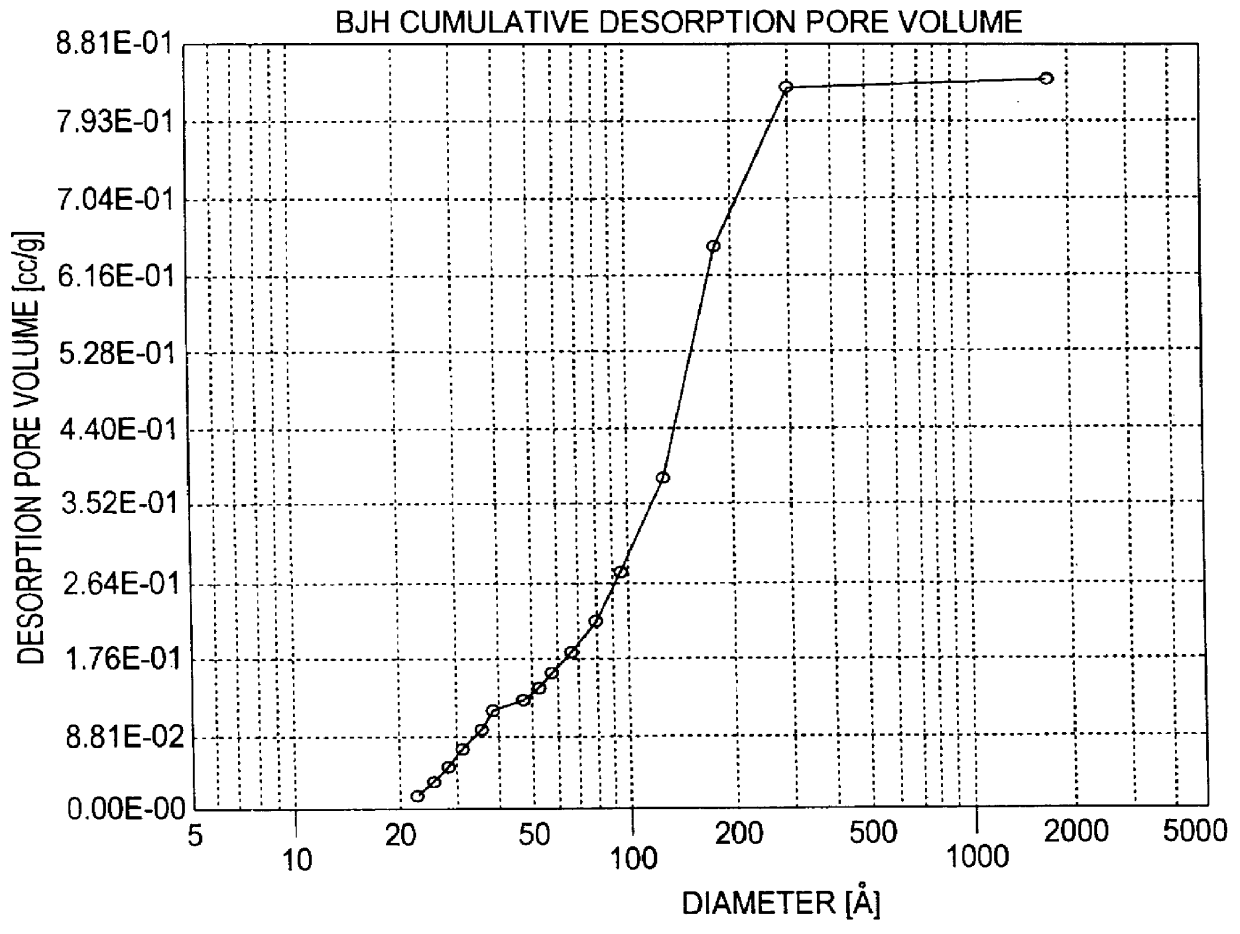

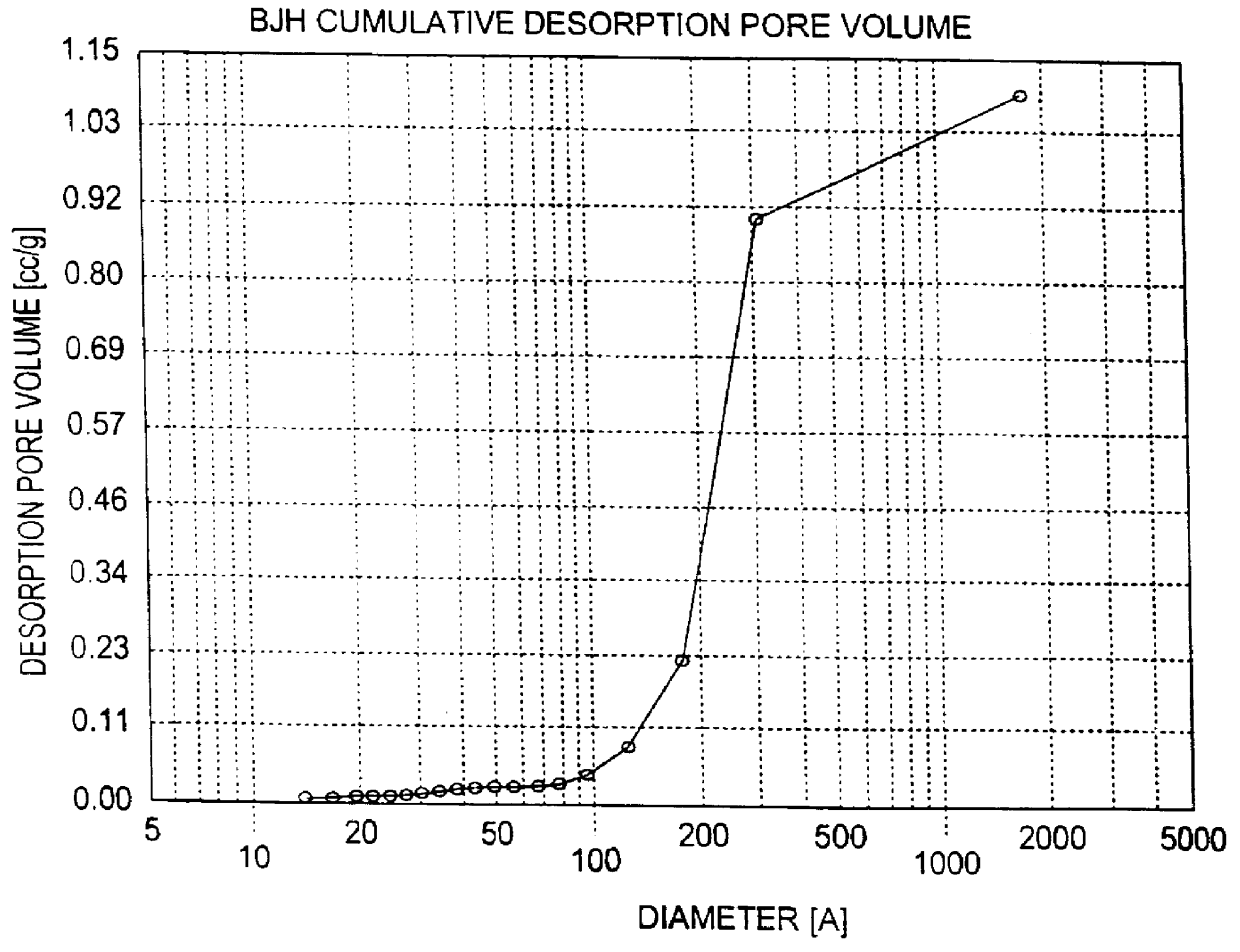

Rigid porous carbon structures, methods of making, methods of using and products containing same

InactiveUS6099965AHigh accessible surface areaHigh activityPigmenting treatmentMaterial nanotechnologyFiberPorous carbon

This invention relates to rigid porous carbon structures and to methods of making same. The rigid porous structures have a high surface area which are substantially free of micropores. Methods for improving the rigidity of the carbon structures include causing the nanofibers to form bonds or become glued with other nanofibers at the fiber intersections. The bonding can be induced by chemical modification of the surface of the nanofibers to promote bonding, by adding "gluing" agents and / or by pyrolyzing the nanofibers to cause fusion or bonding at the interconnect points.

Owner:HYPERION CATALYSIS INT

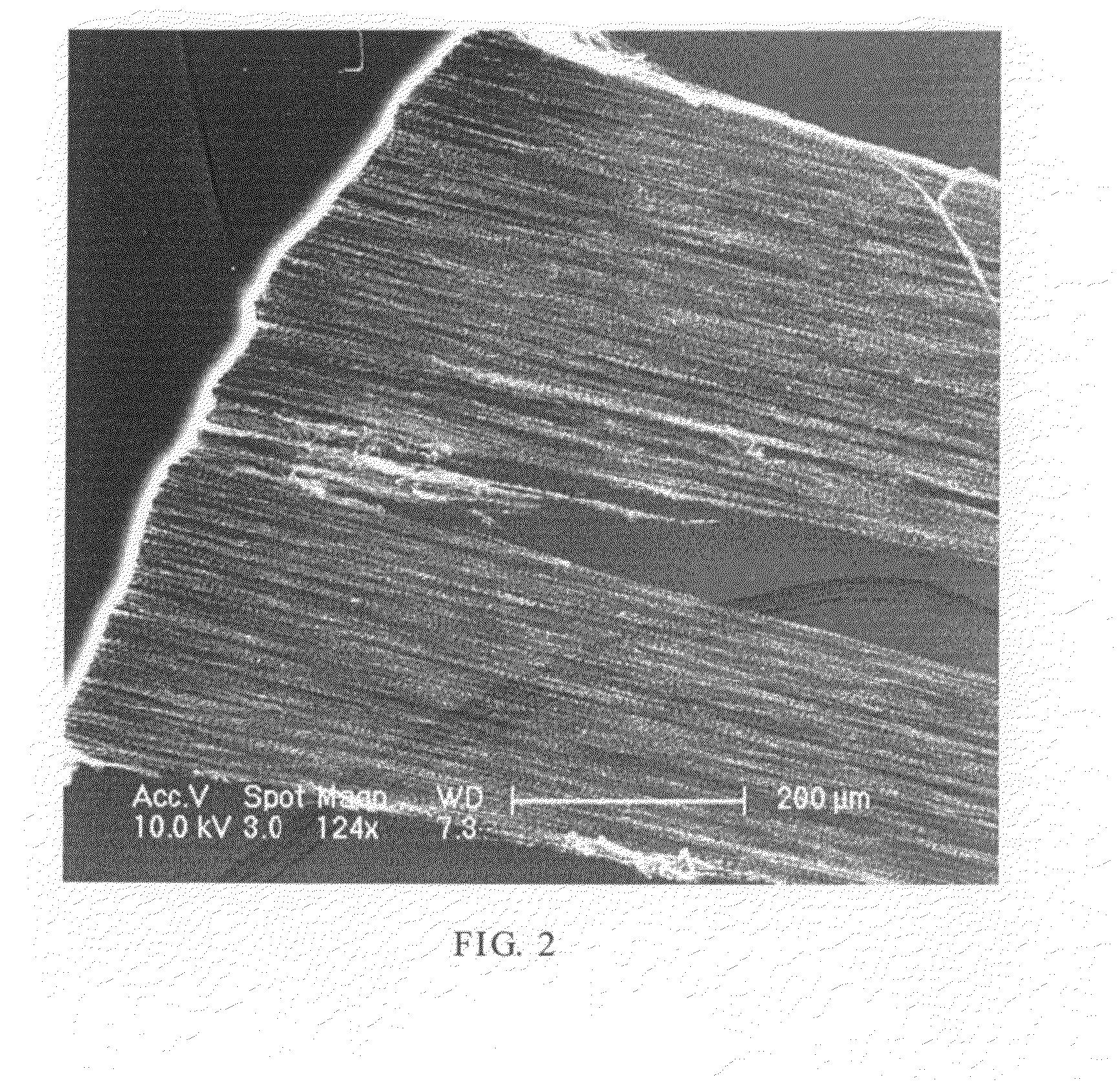

Carbon nanotube yarn and method for making the same

A carbon nanotube yarn includes a number of carbon nanotube yarn strings bound together, and each of the carbon nanotube yarn strings includes a number of carbon nanotube bundles that are joined end to end by van der Waals attractive force, and each of the carbon nanotube bundles includes a number of carbon nanotubes substantially parallel to each other. A method for making the carbon nanotube yarn includes soaking the at least one carbon nanotube yarn string drawn out from a carbon nanotube array in an organic solvent to shrink it and then collecting it.

Owner:TSINGHUA UNIV

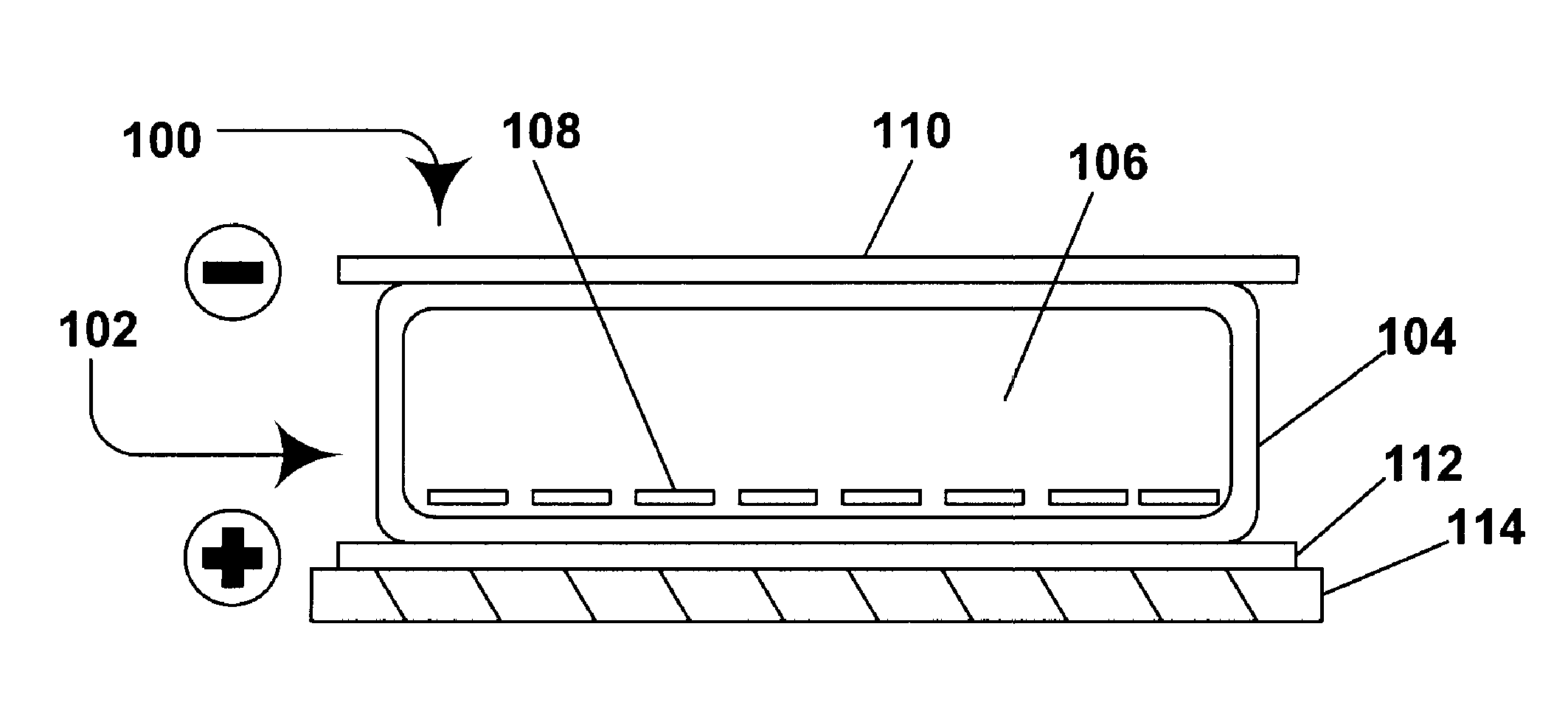

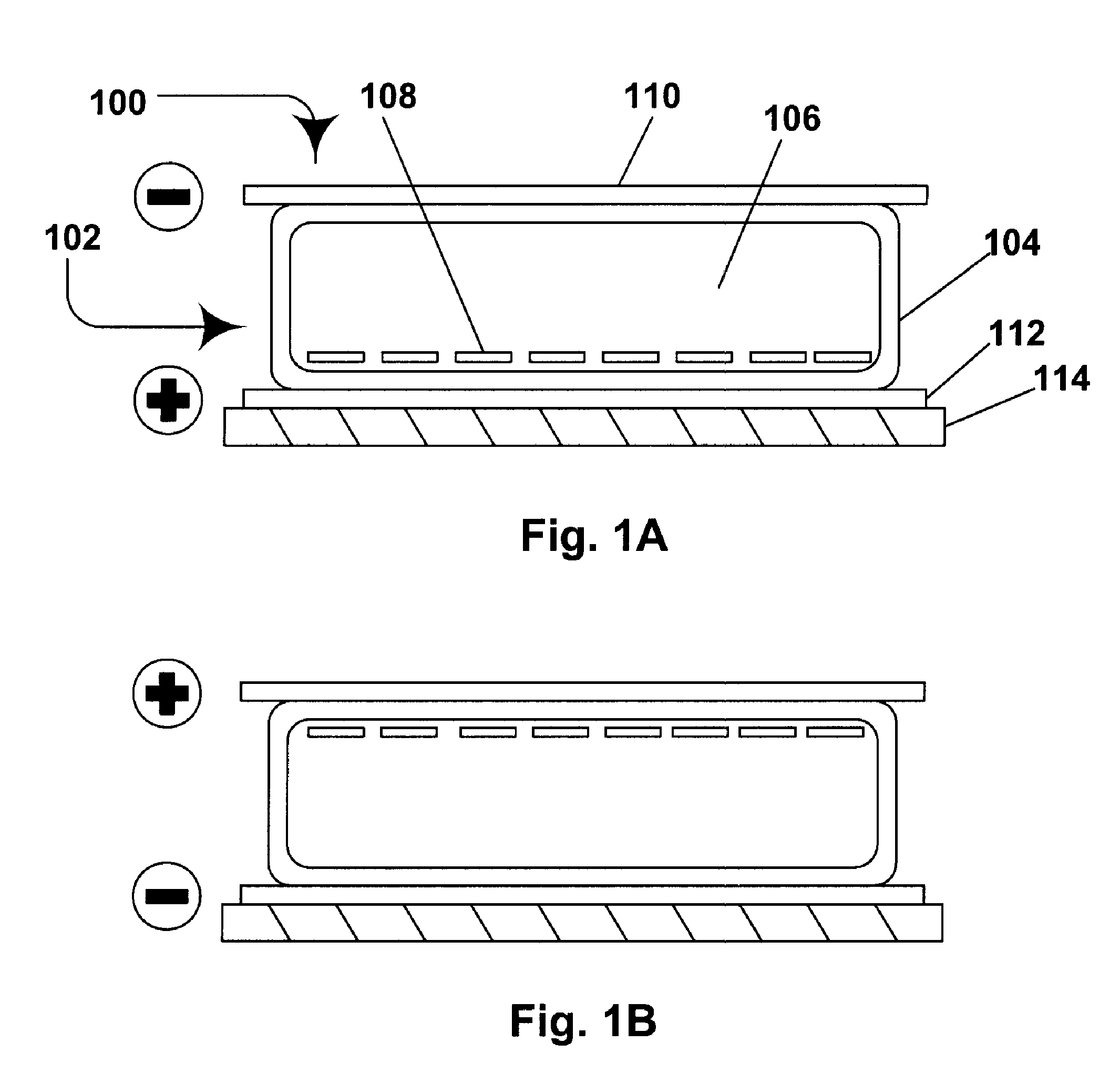

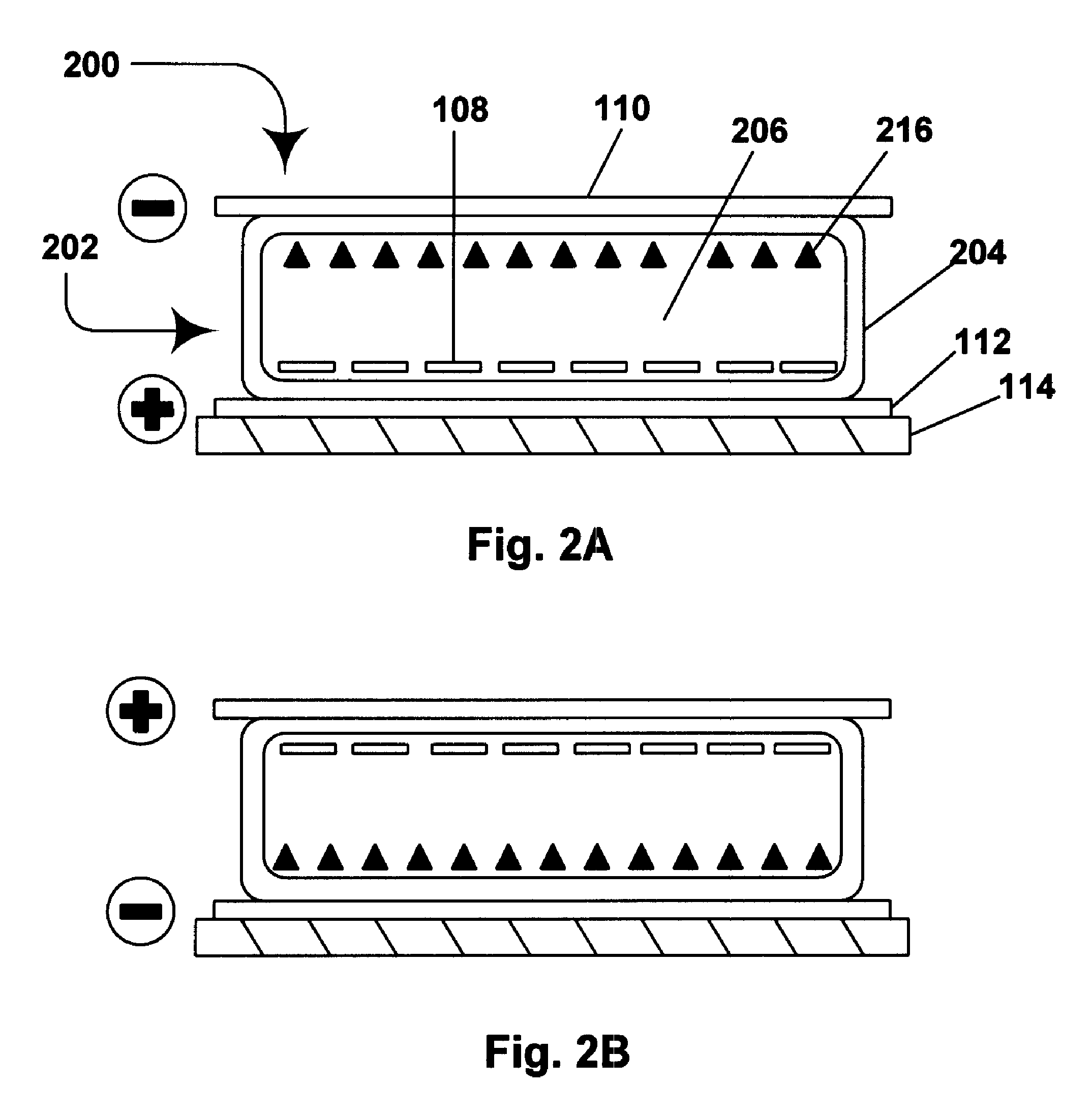

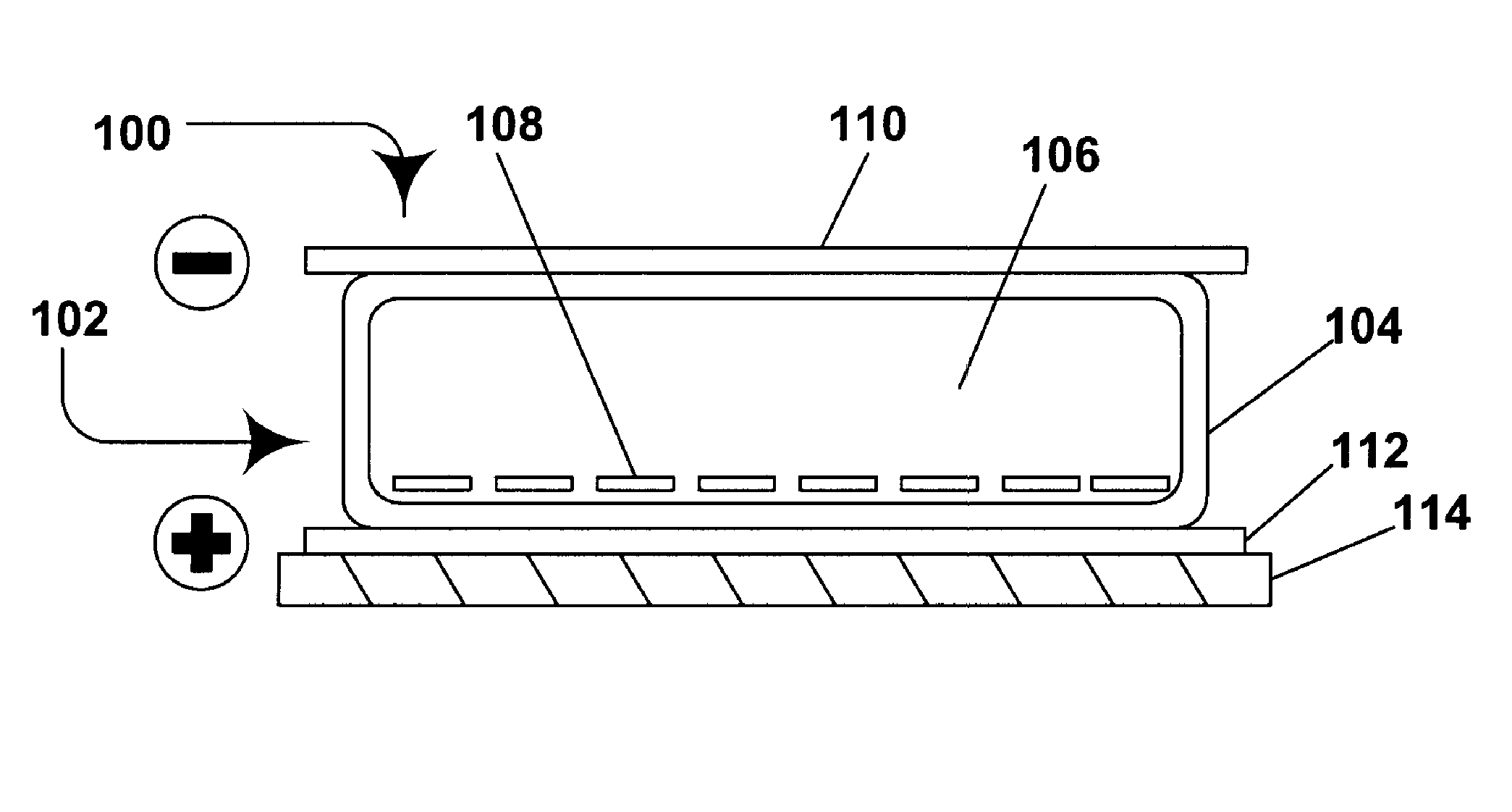

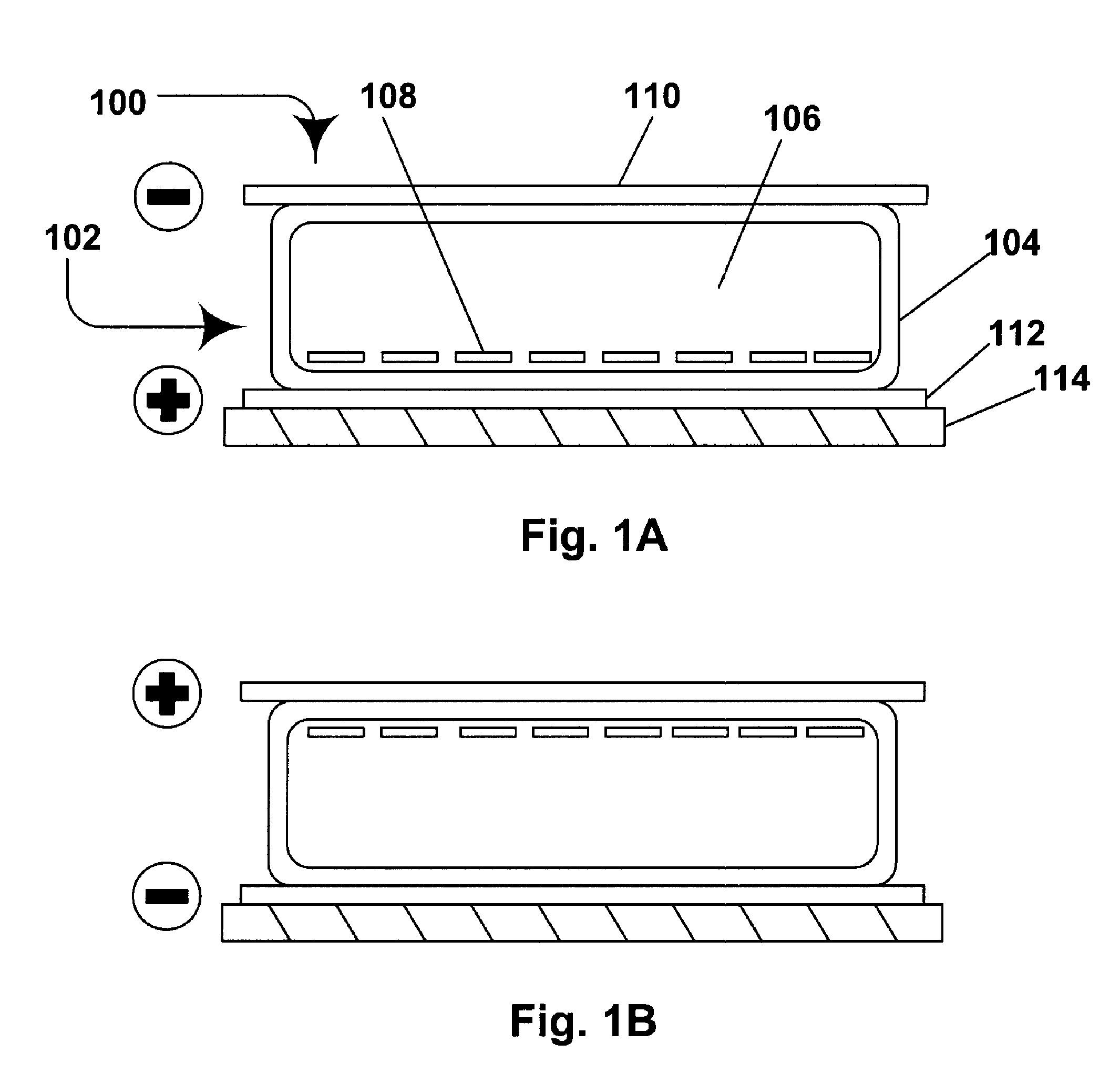

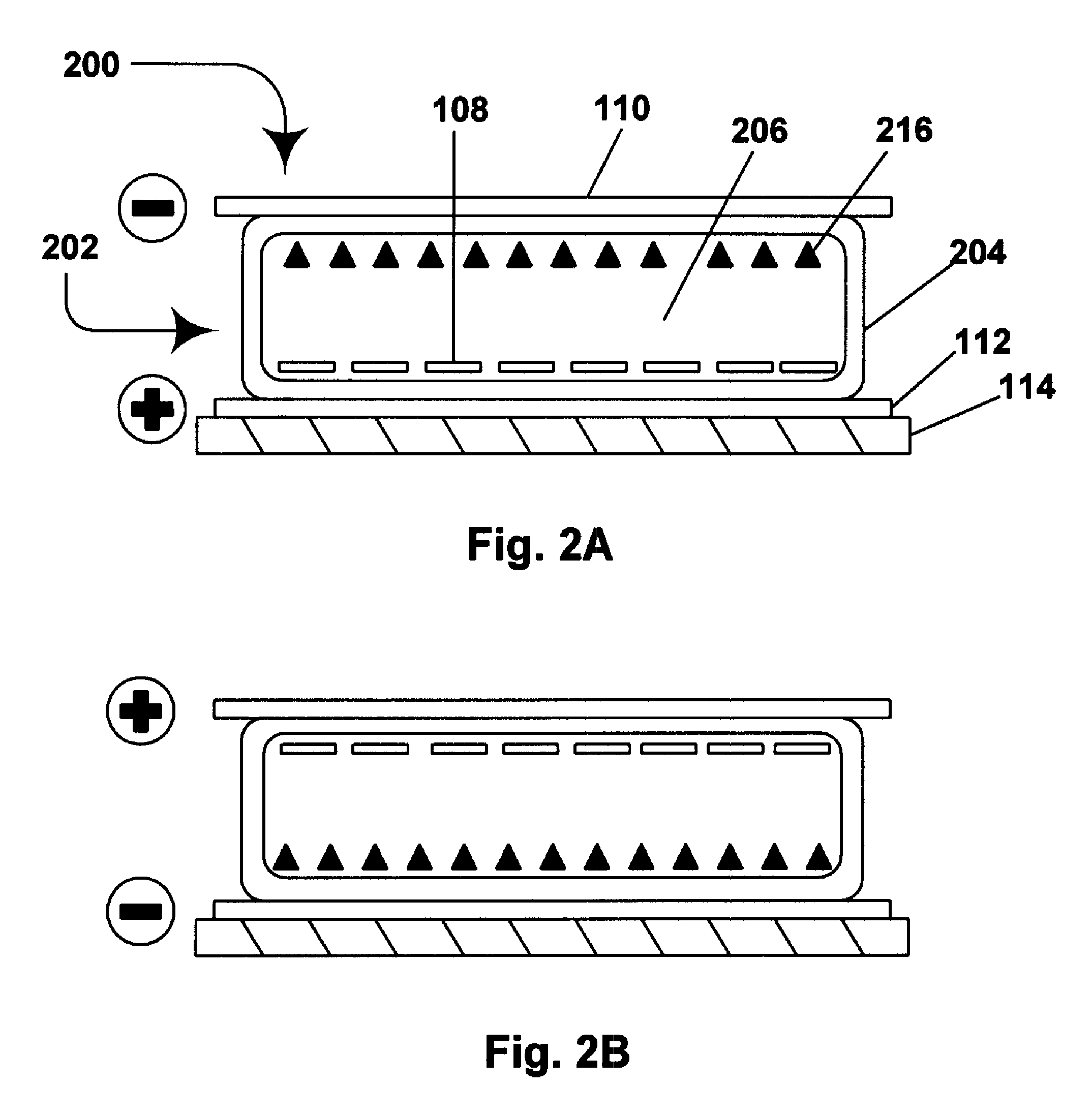

Electrophoretic media containing specularly reflective particles

ActiveUS20040094422A1Good flexibilityImprove uniformitySludge treatmentStatic indicating devicesElectrophoresisSpecular reflection

An electrophoretic medium (100) comprises at least one type of particle (108) suspended in a suspending fluid (106) and capable of moving therethrough on application of an electric field to the medium, the particles (108) including at least one electrophoretically mobile specularly reflective particle.

Owner:E INK CORPORATION

Electrophoretic media containing specularly reflective particles

ActiveUS7312916B2Improve reflectivityReduces backplane scatteringSludge treatmentStatic indicating devicesElectrophoresisSpecular reflection

An electrophoretic medium (100) comprises at least one type of particle (108) suspended in a suspending fluid (106) and capable of moving therethrough on application of an electric field to the medium, the particles (108) including at least one electrophoretically mobile specularly reflective particle.

Owner:E INK CORPORATION

Synthetic fiber

InactiveUS6135987AFormed easily and efficientlyCeramic shaping apparatusBaby linensPolyesterVitrification

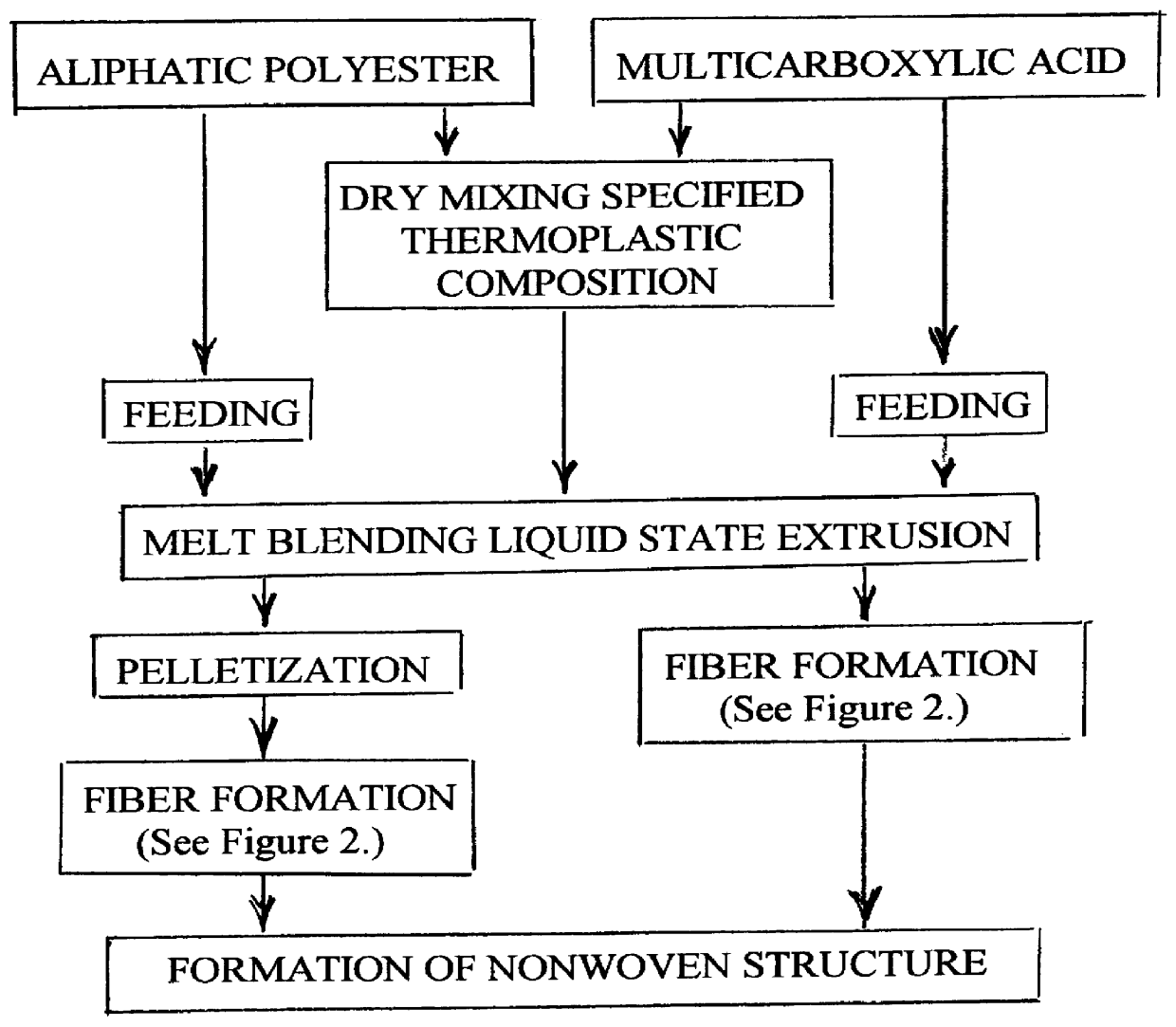

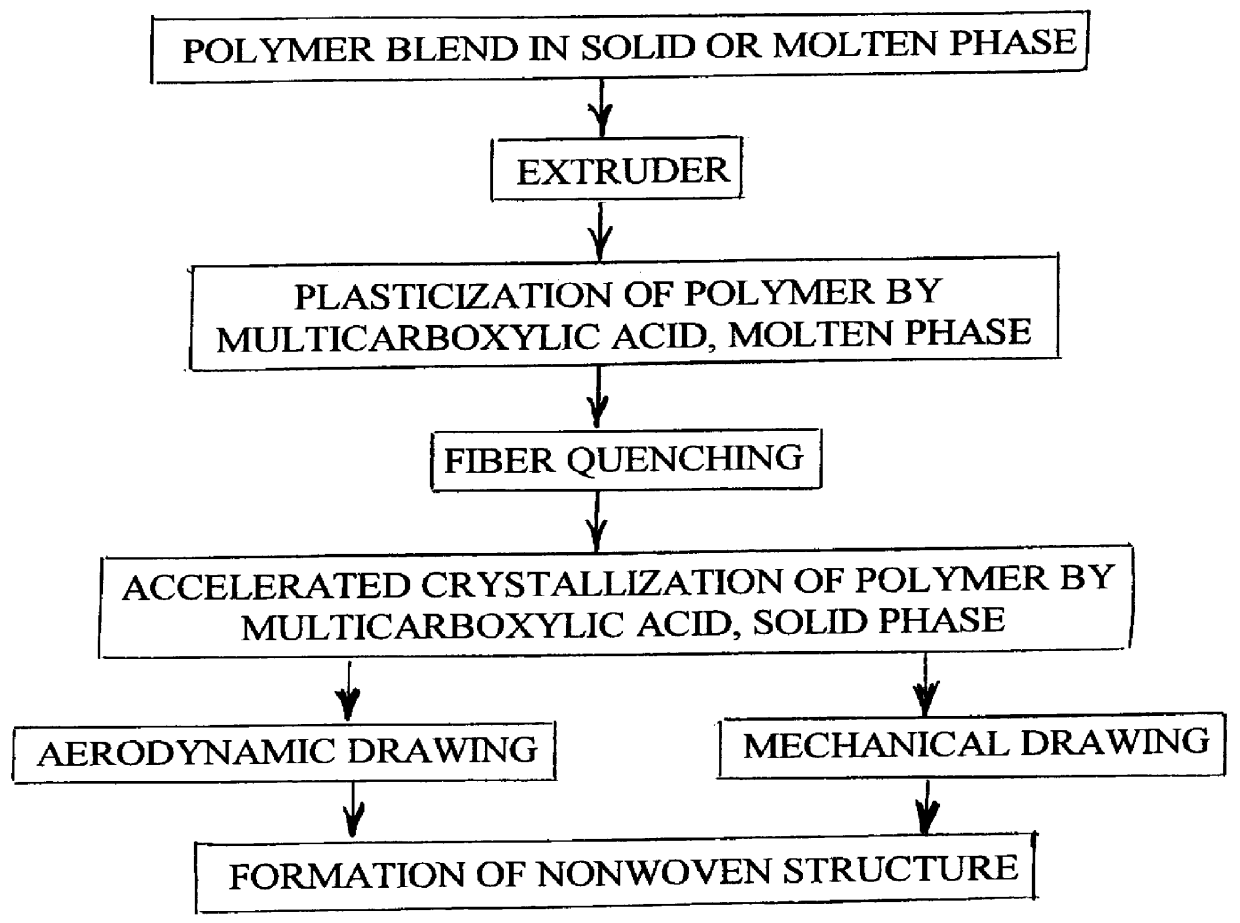

A process is disclosed for forming a synthetic fiber including providing a first component of an aliphatic polyester polymer a second component of a multicarboxylic acid, mixing the first component aliphatic polyester polymer and the second component multicarboxylic acid to form an unreacted specified thermoplastic composition, and melt blending the unreacted specified thermoplastic composition in an extruder or a mixer. The second component multicarboxylic acid lubricates the extruder and provides a nucleating agent for crystallizing the specified thermoplastic composition to form a mean crystal size less than about 120 Angstroms. Fiber composed of the specified thermoplastic composition has a mean crystal size less than about 120 Angstroms. The fiber has a glass transition temperature (Tg) less than about 55 DEG C. In one aspect, a first component of polylactic acid and a second component of adipic acid provide synthetic fibers in a nonwoven structure used in a biodegradable and compostable disposable absorbent product for the absorption and removal of body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

System and process for producing nanowire composites and electronic substrates therefrom

The present invention relates to a system and process for producing a nanowire-material composite. A substrate having nanowires attached to a portion of at least one surface is provided. A material is deposited over the portion to form the nanowire-material composite. The process further optionally comprises separating the nanowire-material composite from the substrate to form a freestanding nanowire-material composite. The freestanding nanowire material composite is optionally further processed into a electronic substrate. A variety of electronic substrates can be produced using the methods described herein. For example, a multi-color light-emitting diode can be produced from multiple, stacked layers of nanowire-material composites, each composite layer emitting light at a different wavelength.

Owner:ONED MATERIAL INC

Fibers made from copolymers of propylene/alpha-olefins

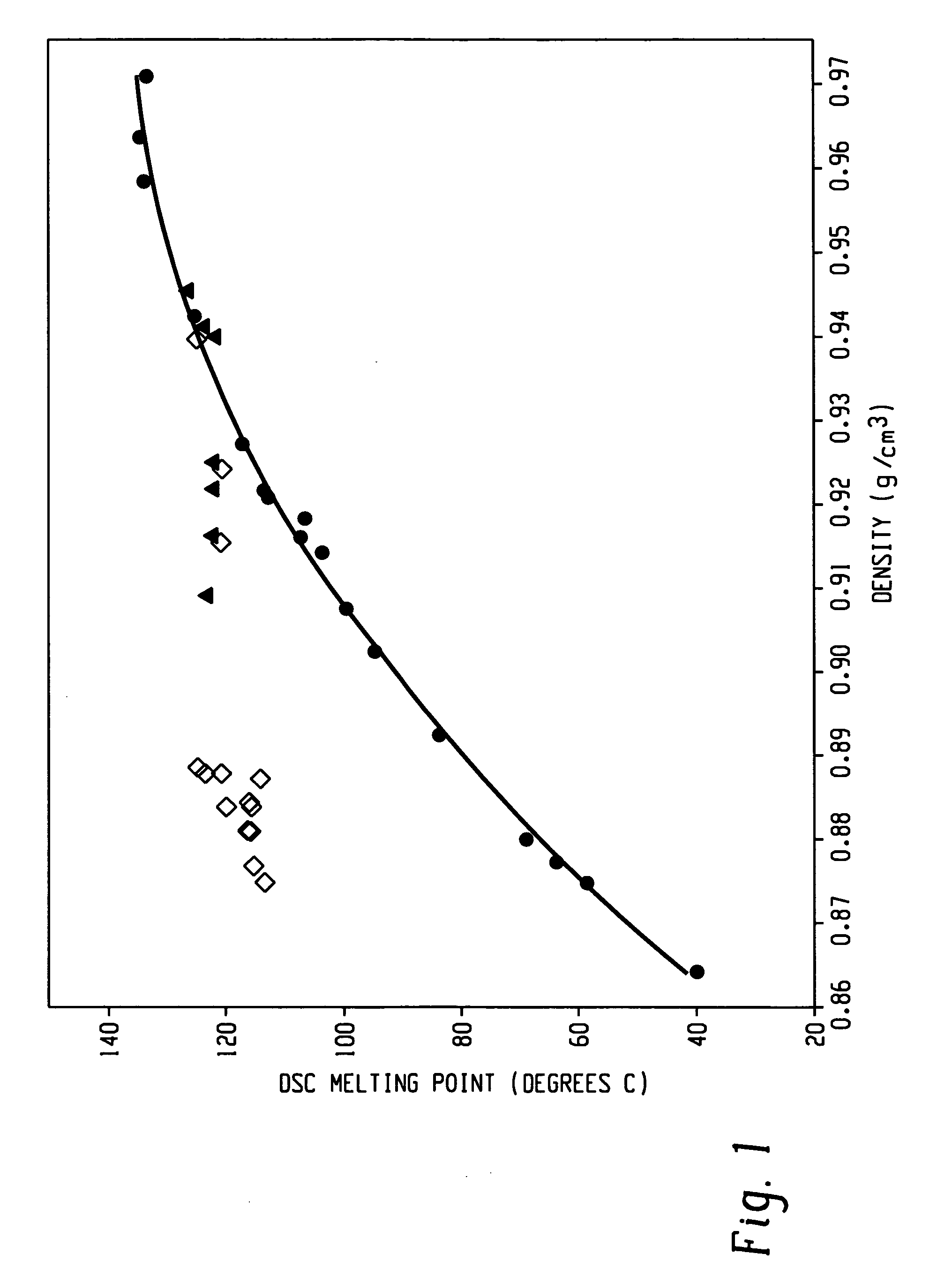

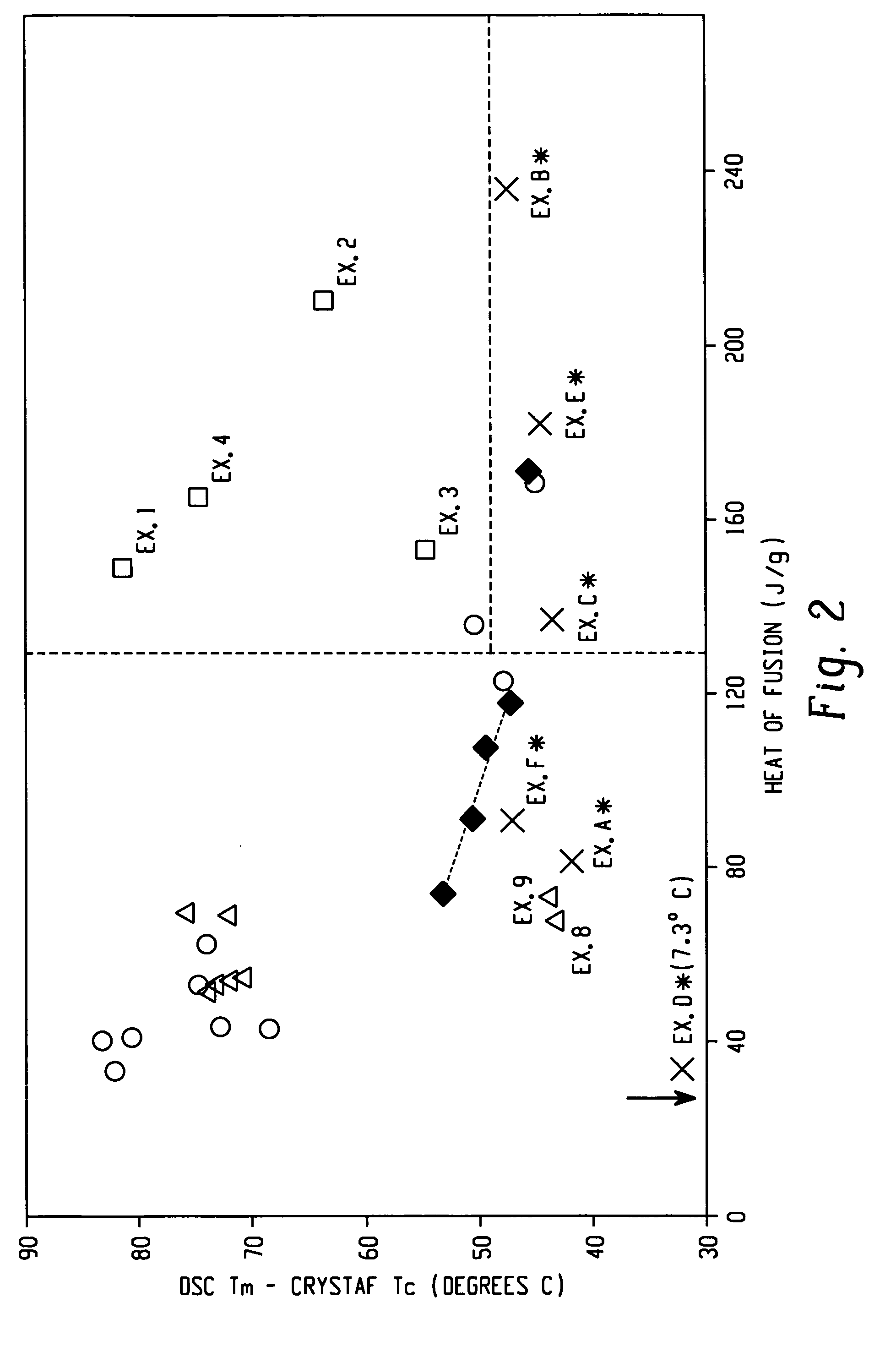

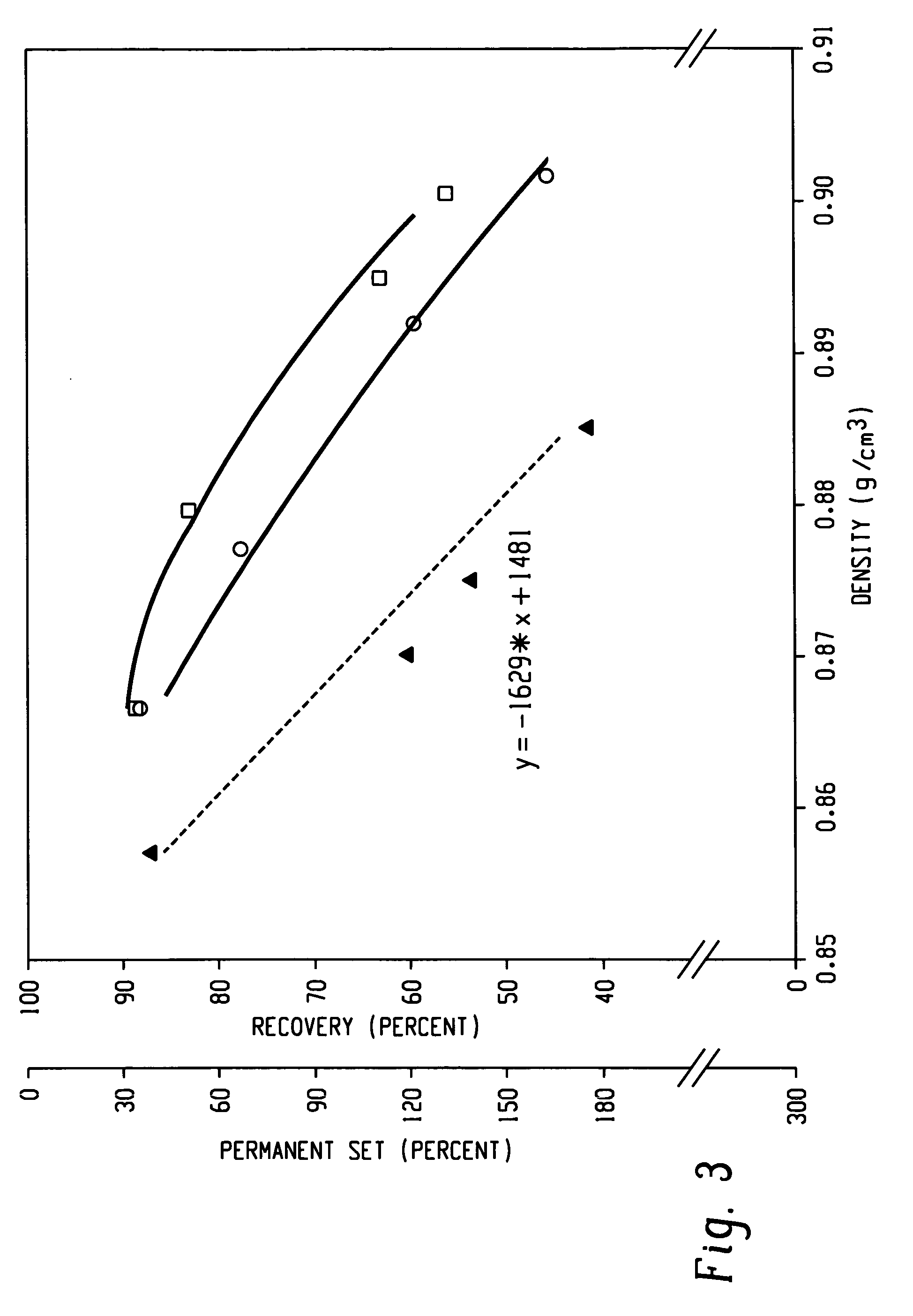

ActiveUS7504347B2Monocomponent synthetic polymer artificial filamentWoven fabricsFiberVolumetric Mass Density

A fiber is obtainable from or comprises a propylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481-1629 (d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

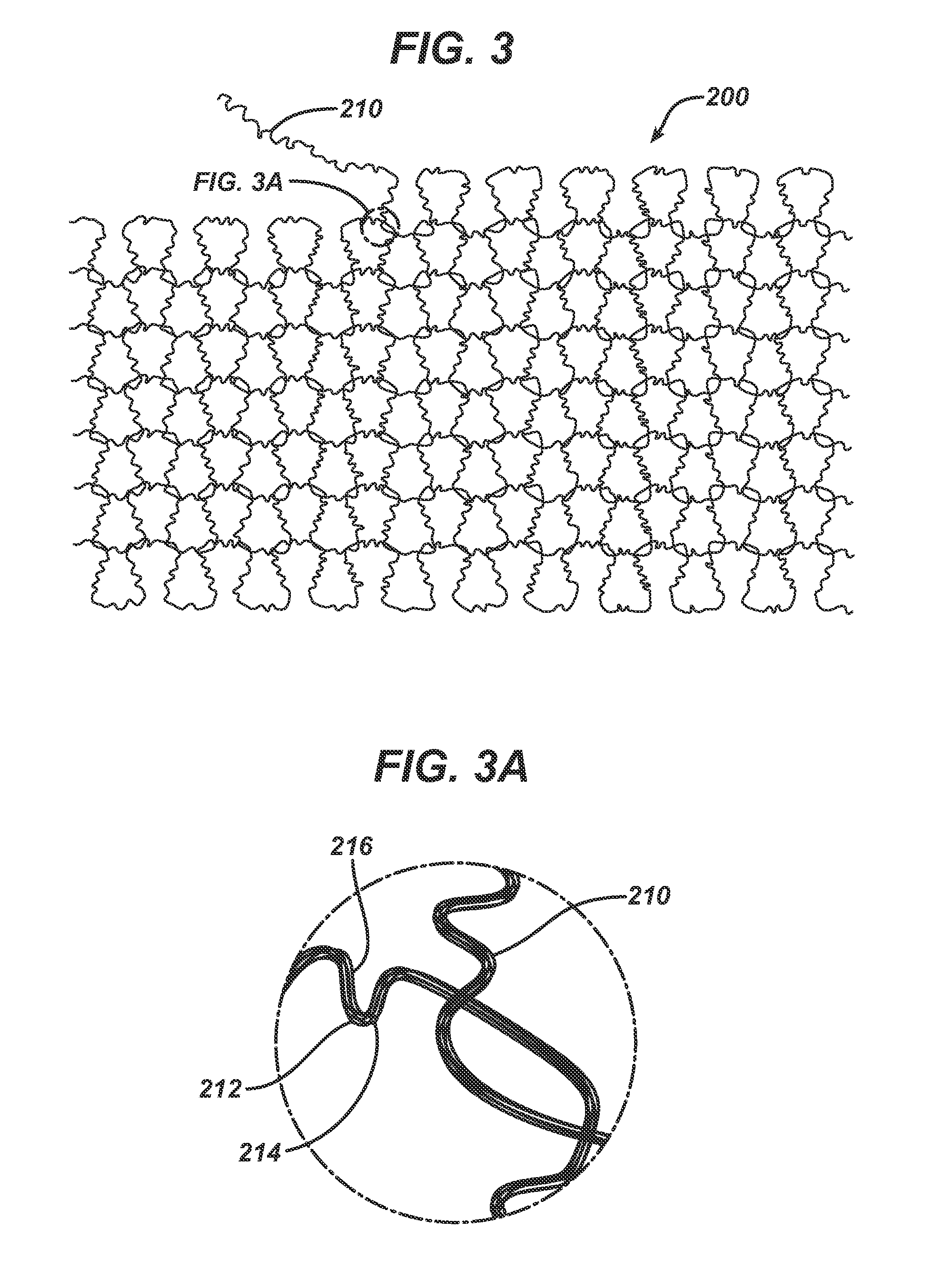

Fabrics and Garments with Information Infrastructure

Fabrics, articles of apparel, and / or garment structures include infrastructure for transmitting information, such as signals produced by a wearer or from another source. Such fabrics may include: a textile formed through a knitting or weaving process, wherein at least one yarn used in the knitting or weaving process is electrically conductive to form sensor regions and / or other integrated electrically conductive infrastructure for transmitting electrical signals. Additional information is provided relating to methods for forming fabrics, articles of apparel, and / or garment structures of the types described above, as well as methods of using such products, e.g., for monitoring and / or displaying information regarding one or more physical and / or physiological parameters.

Owner:SENSATEX

Method for making carbon nanotube yarn

A carbon nanotube yarn includes a number of carbon nanotube yarn strings bound together, and each of the carbon nanotube yarn strings includes a number of carbon nanotube bundles that are joined end to end by van der Waals attractive force, and each of the carbon nanotube bundles includes a number of carbon nanotubes substantially parallel to each other. A method for making the carbon nanotube yarn includes soaking the at least one carbon nanotube yarn string drawn out from a carbon nanotube array in an organic solvent to shrink it and then collecting it.

Owner:TSINGHUA UNIV

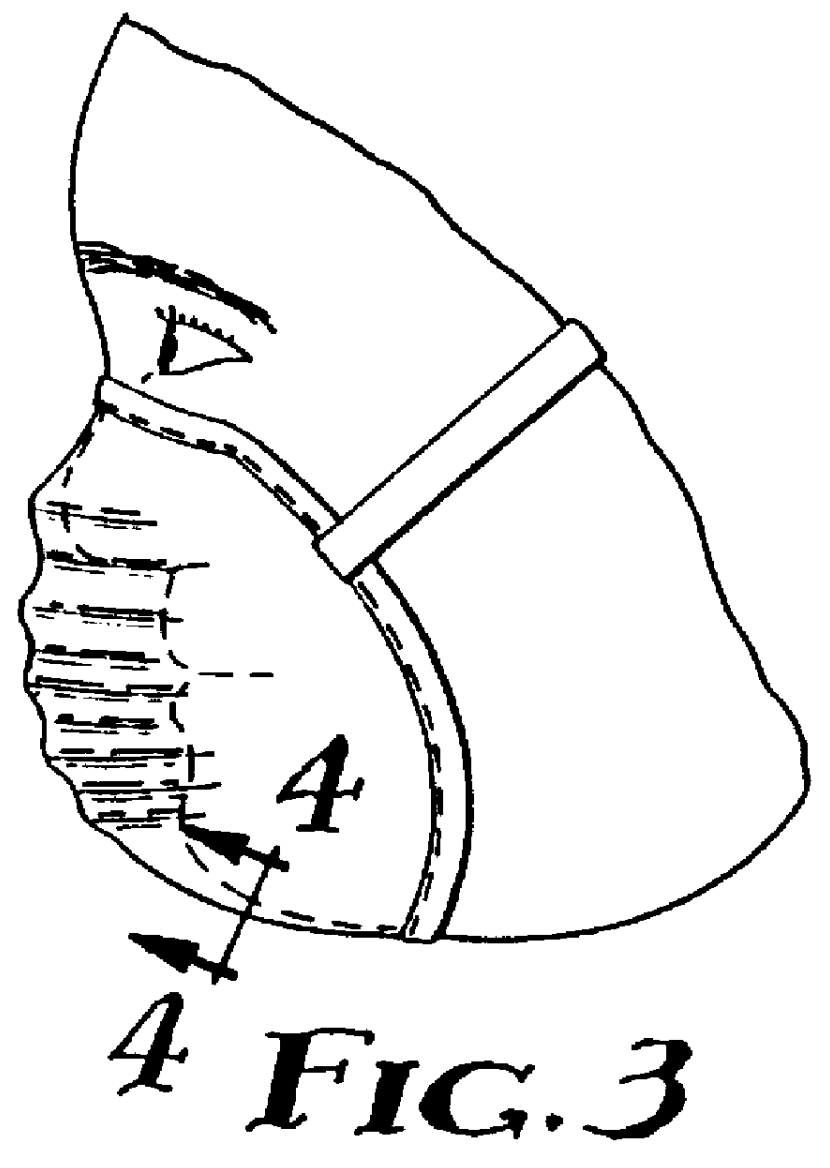

Web of biocomponent blown fibers

InactiveUS6057256AEasy to produceImprove filtering effectBreathing filtersFilament/thread formingFiberPolymer science

Owner:3M INNOVATIVE PROPERTIES CO

Polypropylene filler rods for optical fiber communications cables

InactiveUS6210802B1Synthetic resin layered productsFibre mechanical structuresLow-density polyethyleneEngineering

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

Fibers made from copolymers of ethylene/alpha-olefins

A fiber is obtainable from or comprises an ethylene / α-olefin interpolymer characterized by an elastic recovery, Re, in percent at 300 percent strain and 1 cycle and a density, d, in grams / cubic centimeter, wherein the elastic recovery and the density satisfy the following relationship: Re>1481−1629(d). Such interpolymer can also be characterized by other properties. The fibers made therefrom have a relatively high elastic recovery and a relatively low coefficient of friction. The fibers can be cross-linked, if desired. Woven or non-woven fabrics can be made from such fibers.

Owner:DOW GLOBAL TECH LLC

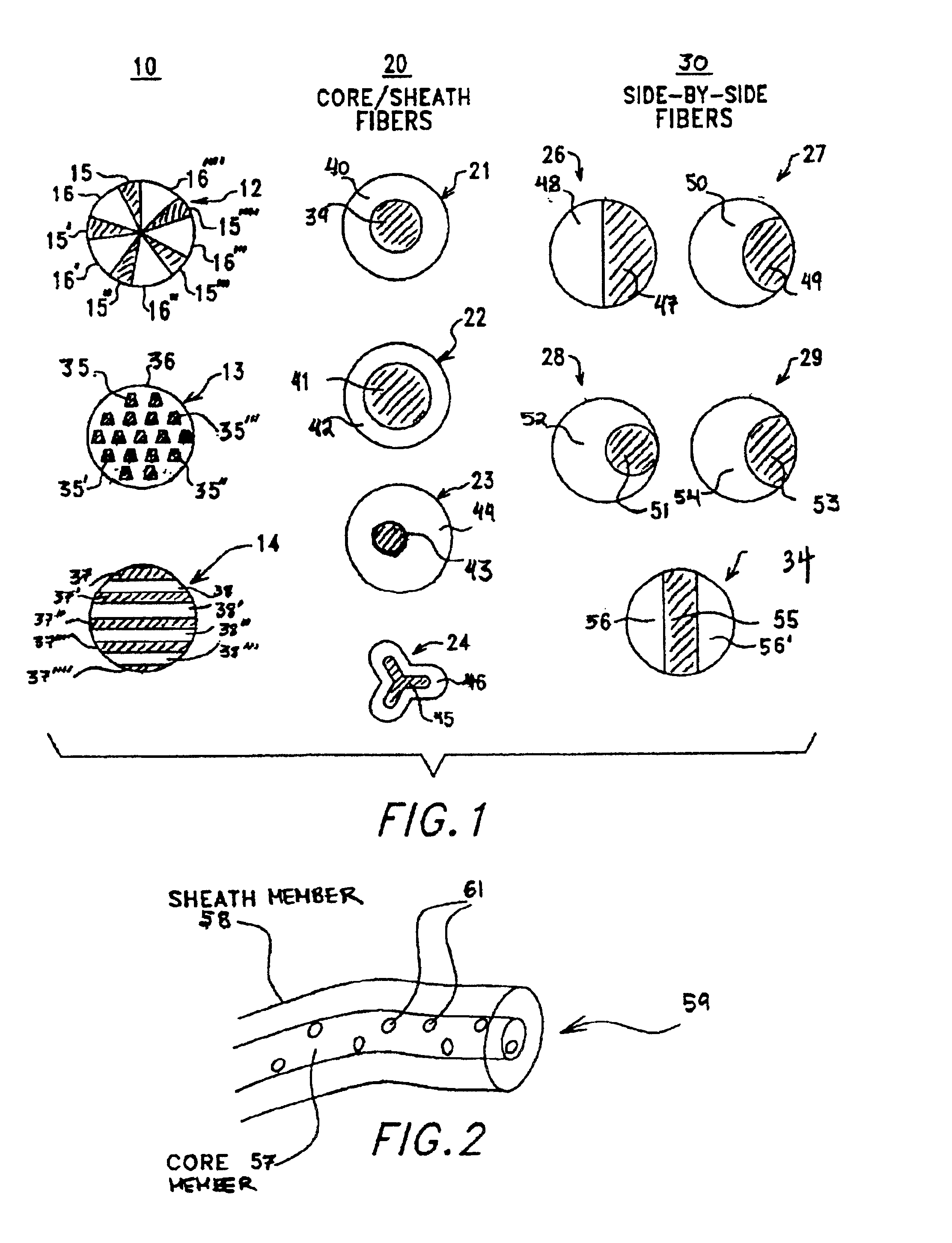

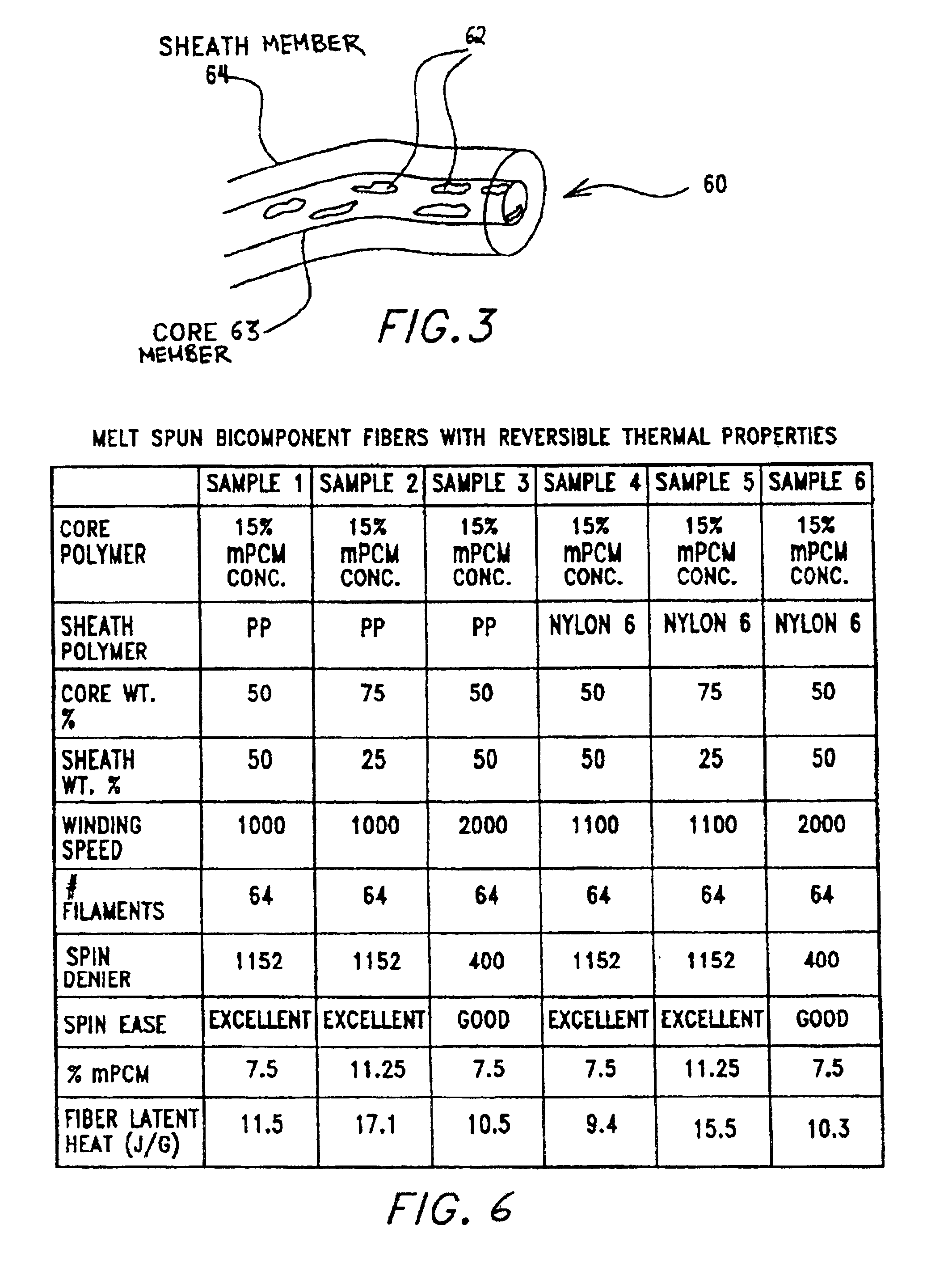

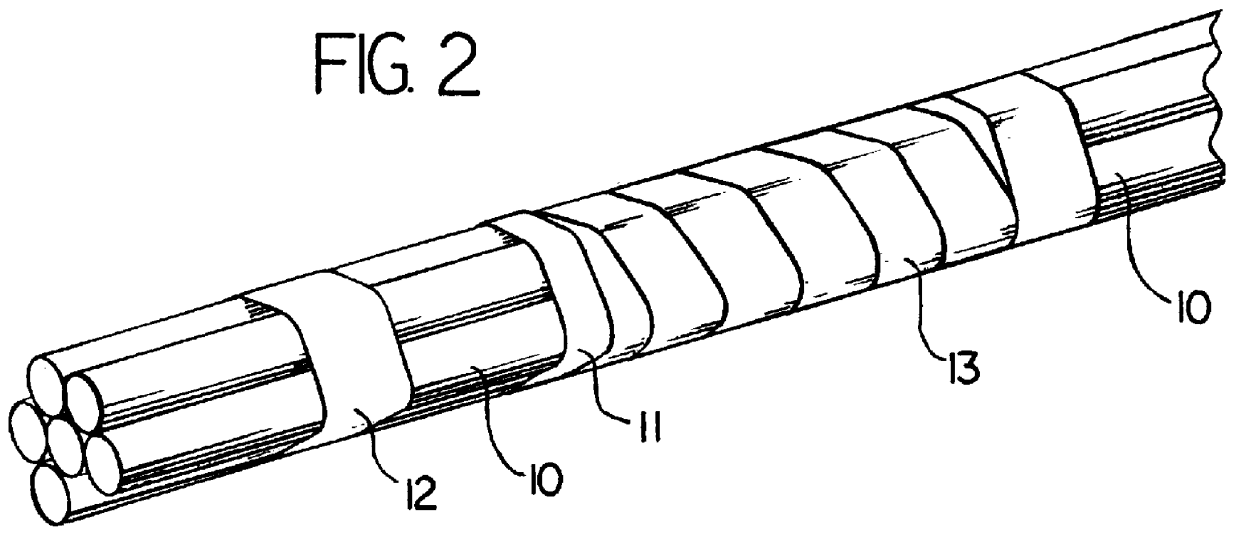

Multi-component fibers having enhanced reversible thermal properties and methods of manufacturing thereof

InactiveUS6855422B2Easy to processImprove propertiesHeat storage plantsWarp knittingMedical productPhase-change material

The invention relates to a multi-component fiber having enhanced reversible thermal properties and methods of manufacturing thereof. The multi-component fiber comprises a fiber body formed from a plurality of elongated members, at least one of the elongated members comprising a temperature regulating material dispersed therein. The temperature regulating material comprises a phase change material. The multi-component fiber may be formed via a melt spinning process or a solution spinning process and may be used or incorporated in various products where a thermal regulating property is desired. For example, the multi-component fiber may be used in textiles, apparel, footwear, medical products, containers and packagings, buildings, appliances, and other products.

Owner:HILLS CO

Optical receiver stub fitting

InactiveUSRE36592E1Eliminate pointLayered productsCommunication cablesEngineeringOptical fiber cable

A cable assembly for attachment to an entry port of an optical enclosure. The assembly includes a plug for an end of an optical cable in a sealed housing having a single rigid tube and a single sealed nut. Connectorized optical fibers or an optical ribbon extend from the plug into the equipment enclosure.

Owner:SIECOR A DELAWARE

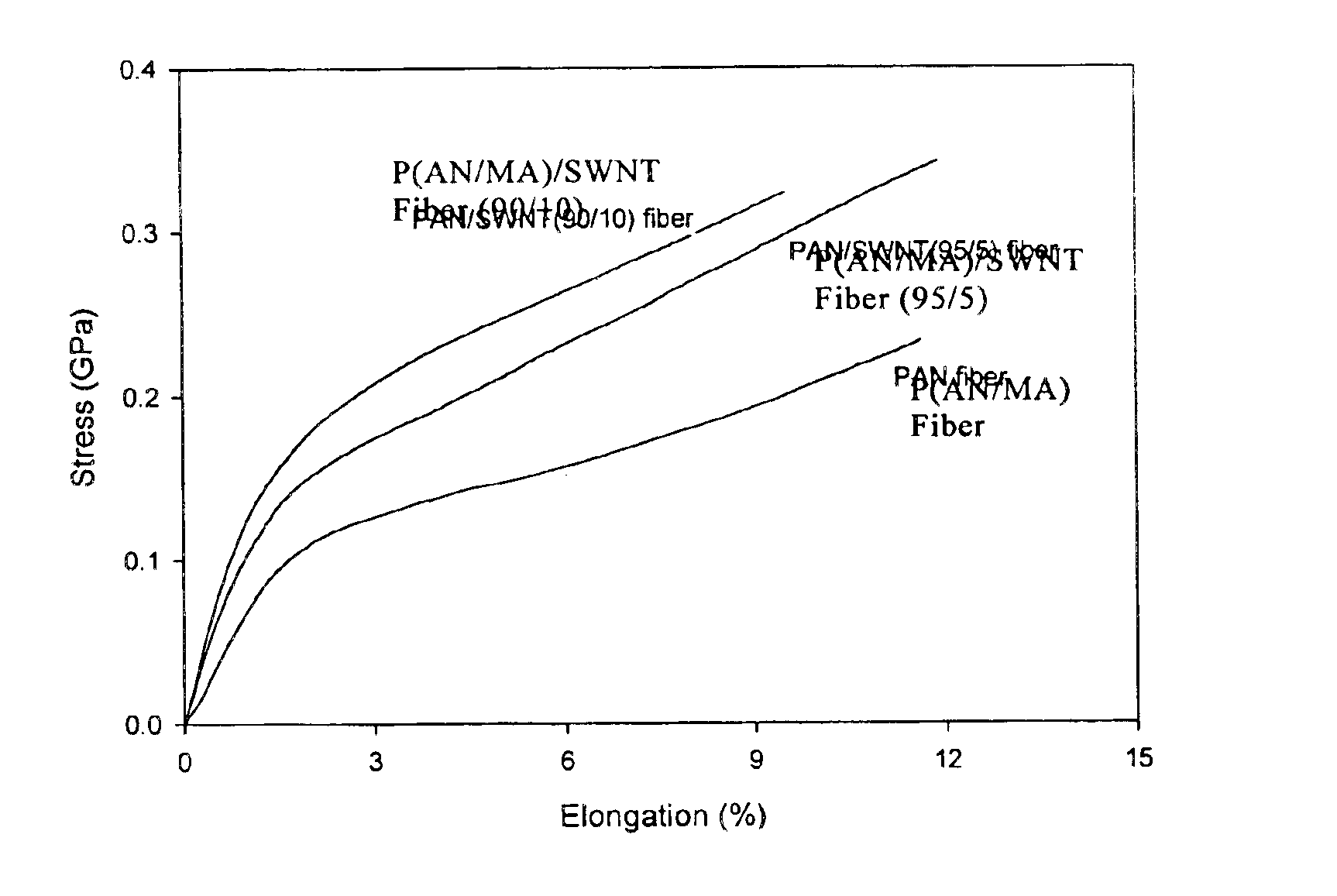

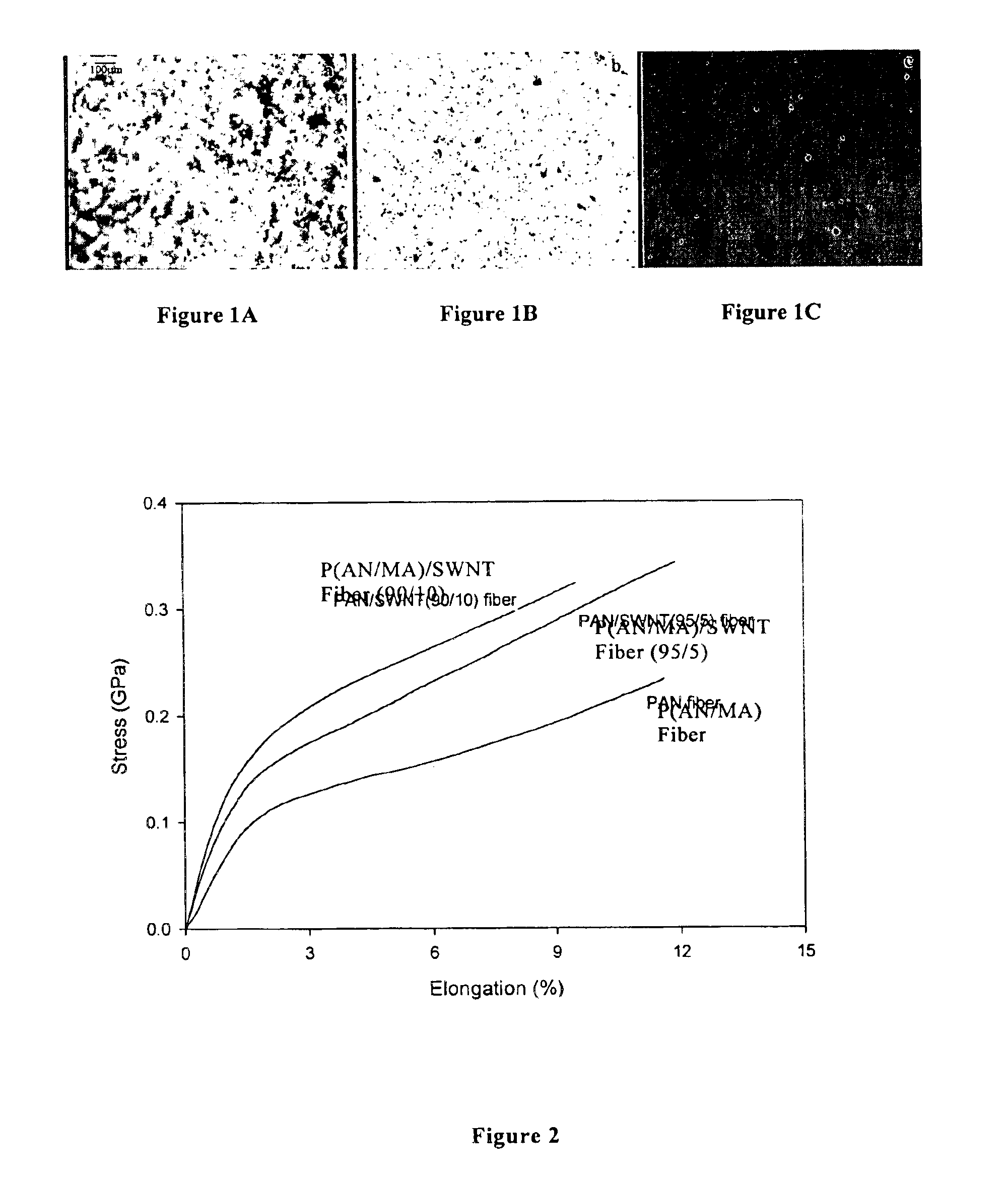

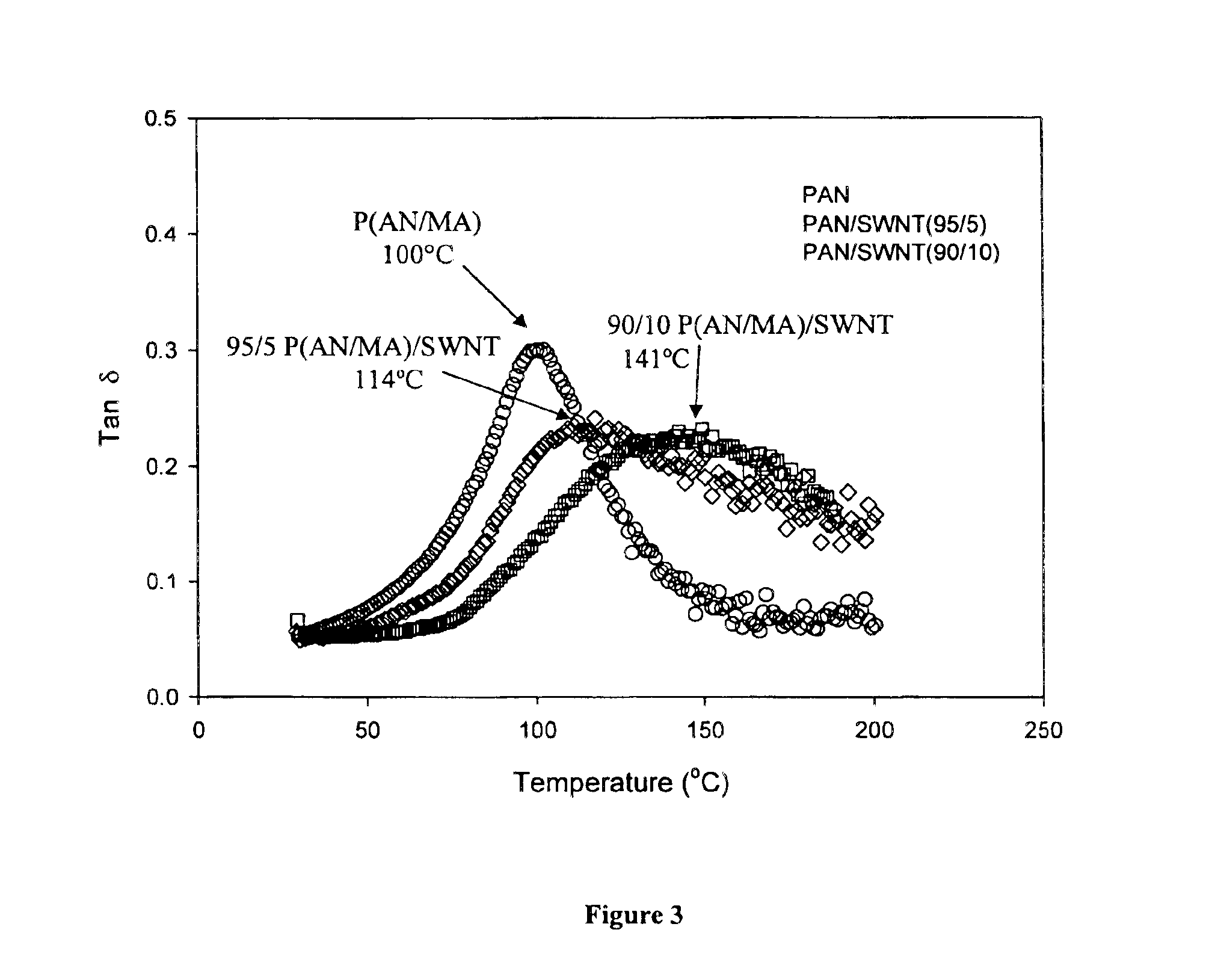

Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same

InactiveUS6852410B2Increased tensile modulusReduced thermal shrinkageMaterial nanotechnologyElectroconductive/antistatic filament manufactureVitrificationPolymer science

The present invention relates to a high modulus macroscopic fiber comprising single-wall carbon nanotubes (SWNT) and an acrylonitrile-containing polymer. In one embodiment, the macroscopic fiber is a drawn fiber having a cross-sectional dimension of at least 1 micron. In another embodiment, the acrylonitrile polymer-SWNT composite fiber is made by dispersing SWNT in a solvent, such as dimethyl formamide or dimethyl acetamide, admixing an acrylonitrile-based polymer to form a generally optically homogeneous polyacrylonitrile polymer-SWNT dope, spinning the dope into a fiber, drawing and drying the fiber. Polyacrylonitrile / SWNT composite macroscopic fibers have substantially higher modulus and reduced shrinkage versus a polymer fiber without SWNT. A polyacrylonitrile / SWNT fiber containing 10 wt % SWNT showed over 100% increase in tensile modulus and significantly reduced thermal shrinkage compared to a control fiber without SWNT. With 10 wt % SWNT, the glass transition temperature of the polymer increased by more than 40° C.

Owner:GEORGIA TECH RES CORP

Systems and methods for harvesting and integrating nanowires

ActiveUS20060008942A1Ease of mass productionImprove device performanceLayered productsNanoinformaticsNanowireInk printer

The present invention is directed to methods to harvest, integrate and exploit nanomaterials, and particularly elongated nanowire materials. The invention provides methods for harvesting nanowires that include selectively etching a sacrificial layer placed on a nanowire growth substrate to remove nanowires. The invention also provides methods for integrating nanowires into electronic devices that include placing an outer surface of a cylinder in contact with a fluid suspension of nanowires and rolling the nanowire coated cylinder to deposit nanowires onto a surface. Methods are also provided to deposit nanowires using an ink-jet printer or an aperture to align nanowires. Additional aspects of the invention provide methods for preventing gate shorts in nanowire based transistors. Additional methods for harvesting and integrating nanowires are provided.

Owner:ONED MATERIAL INC

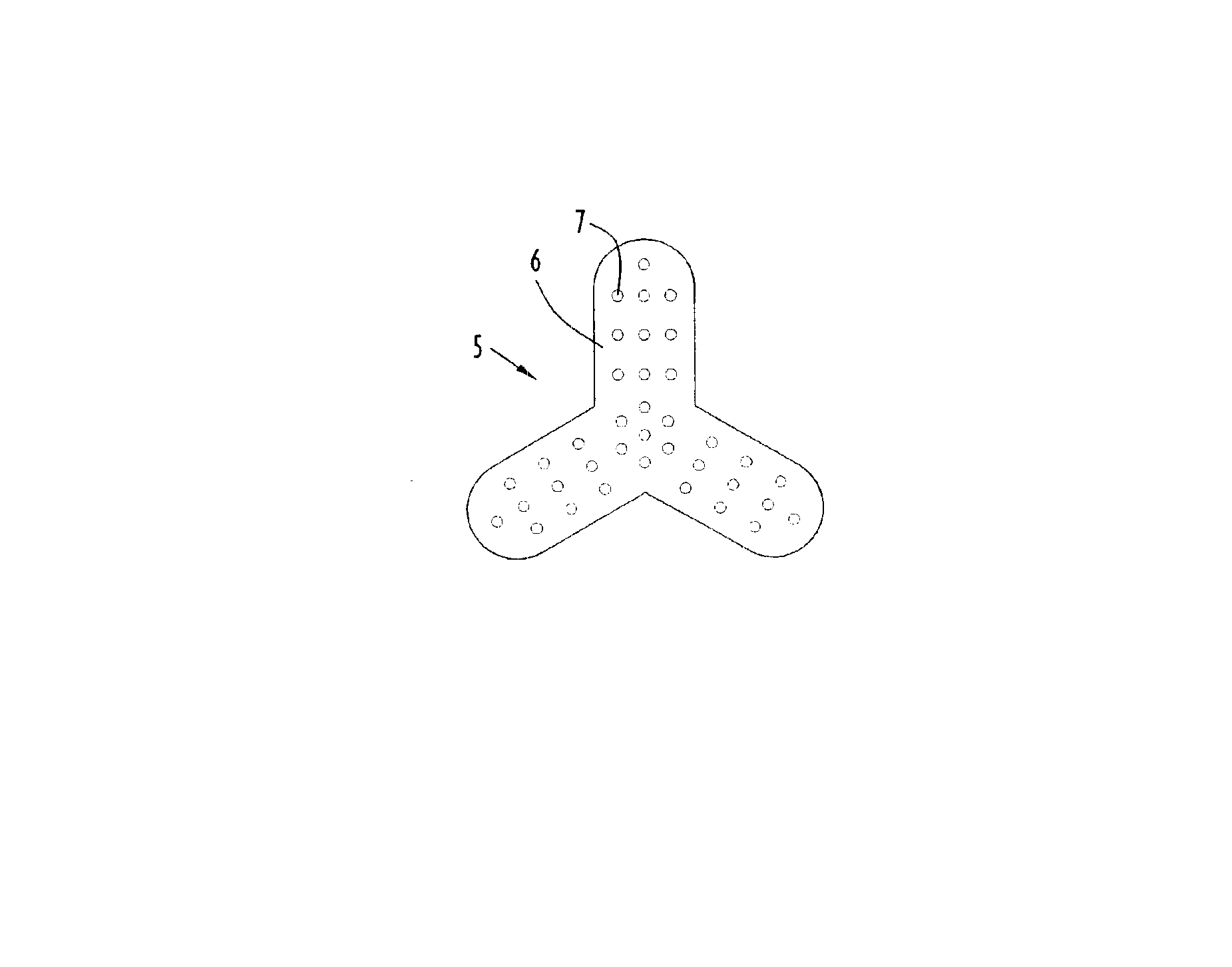

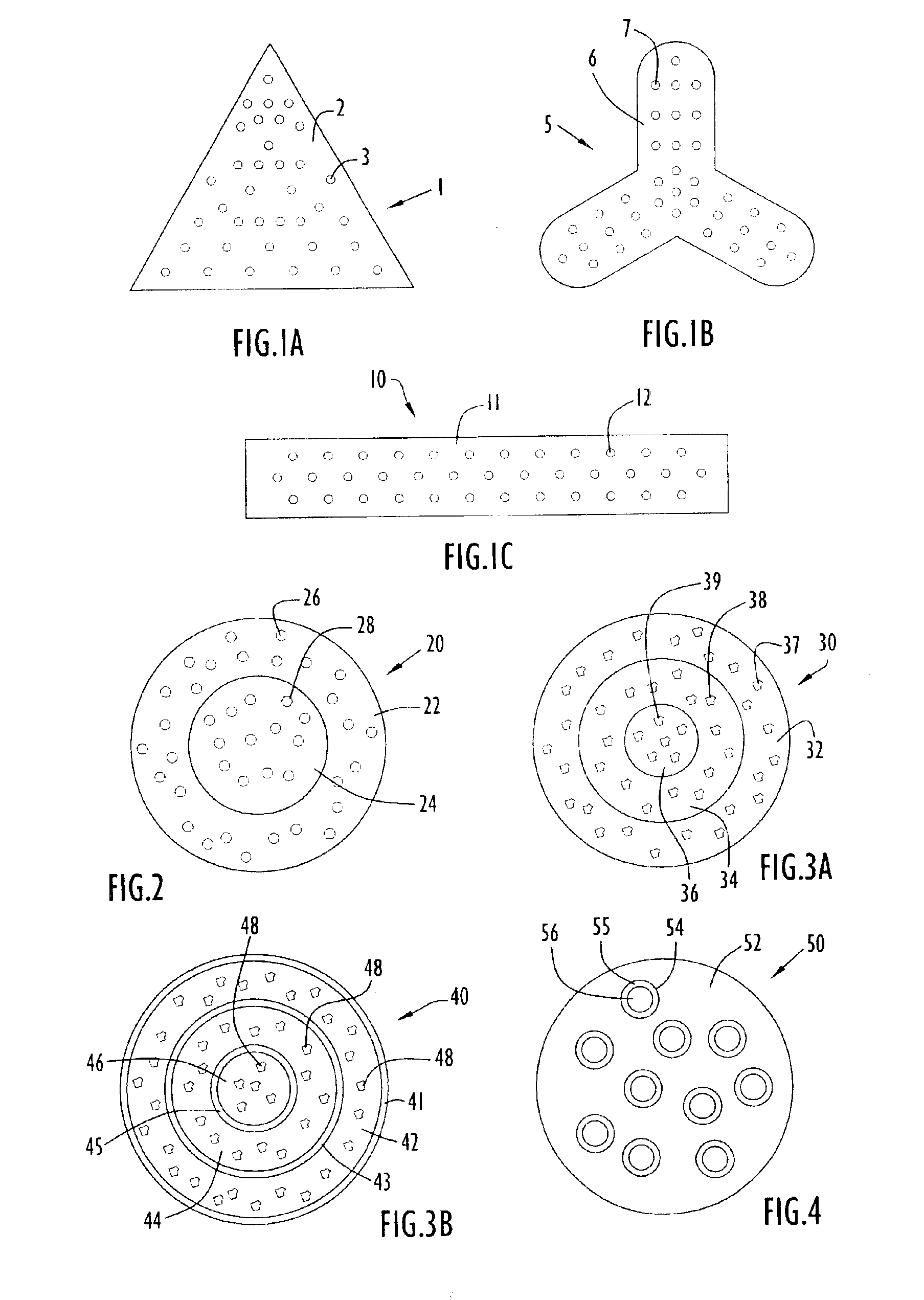

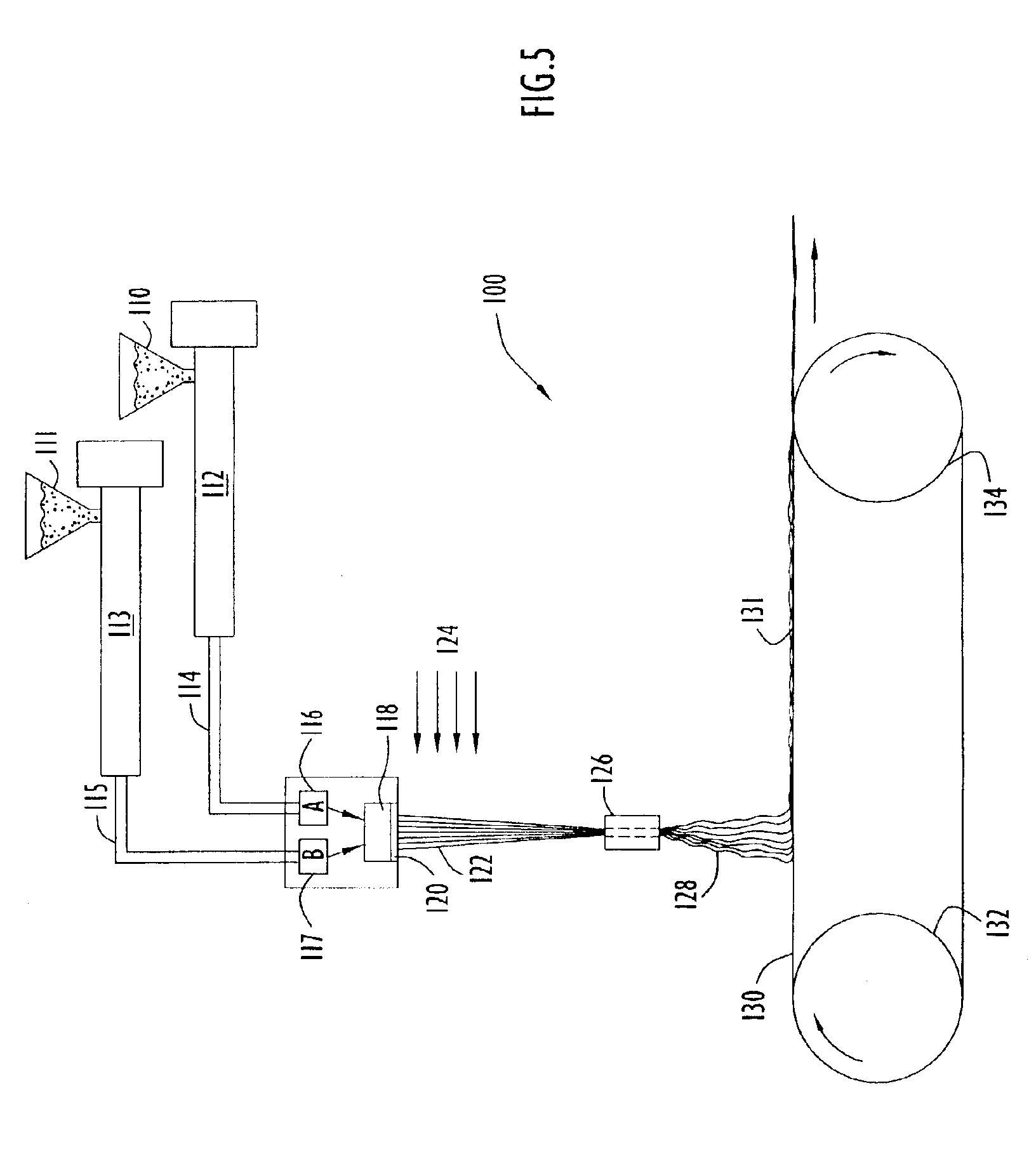

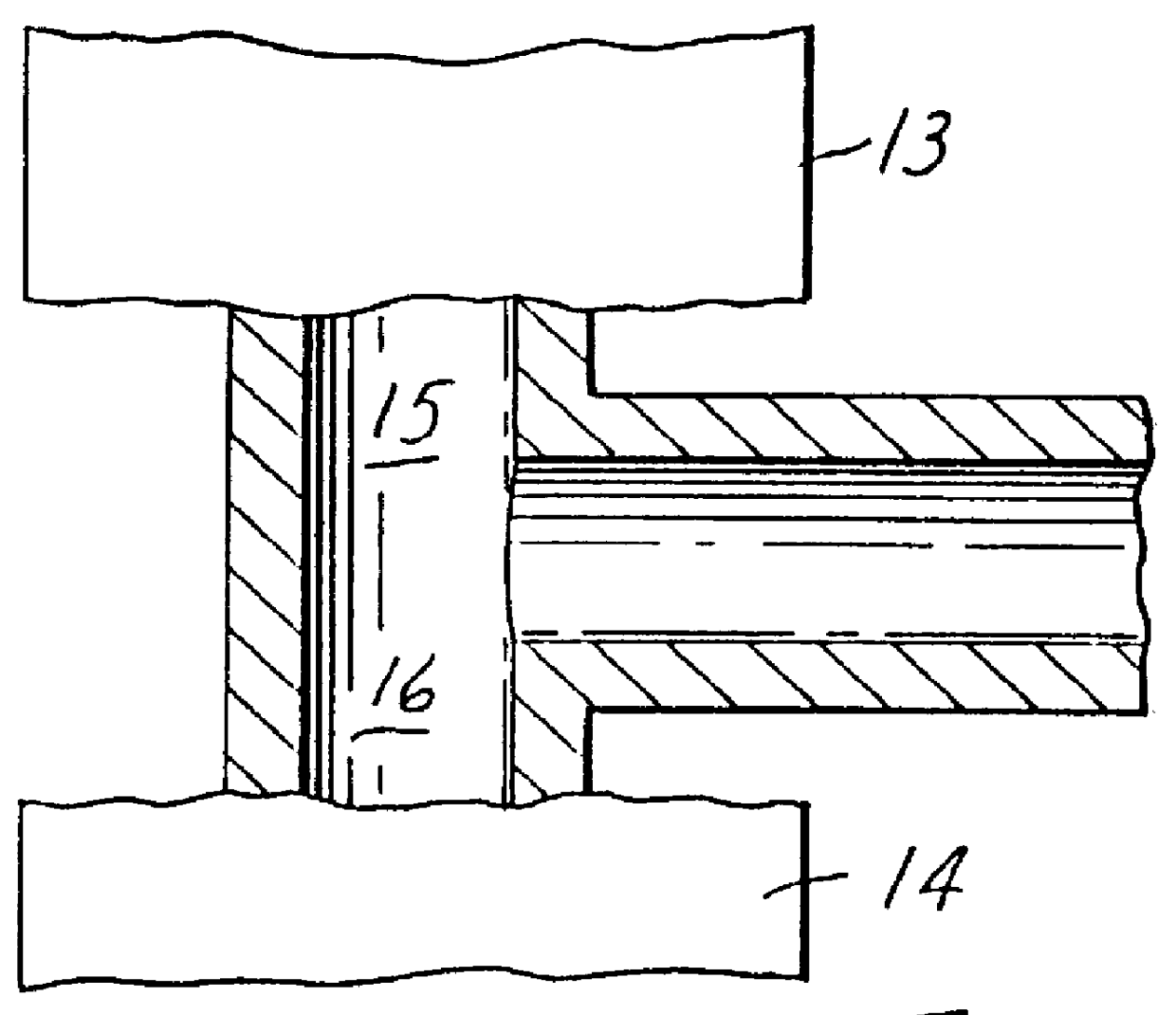

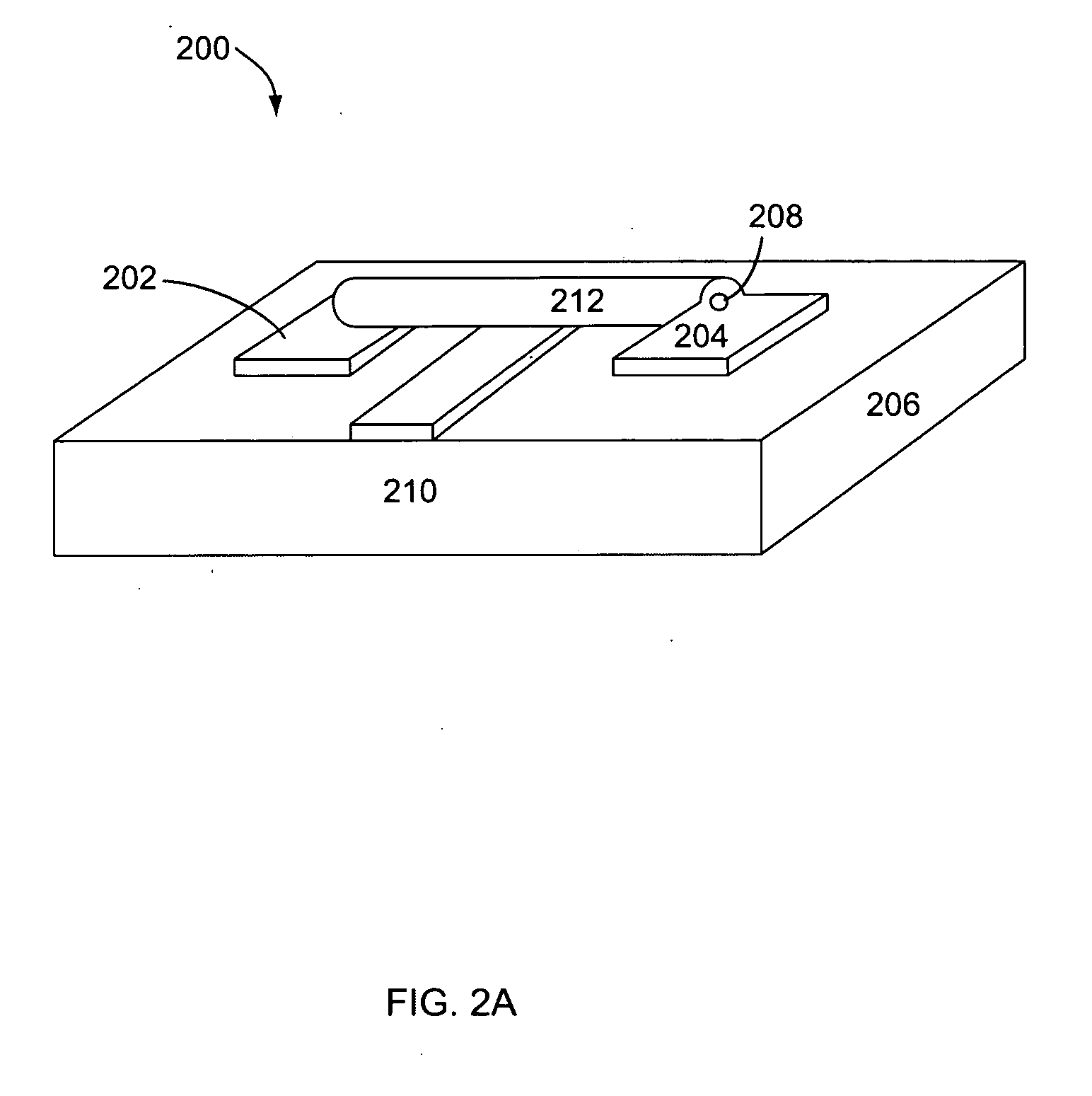

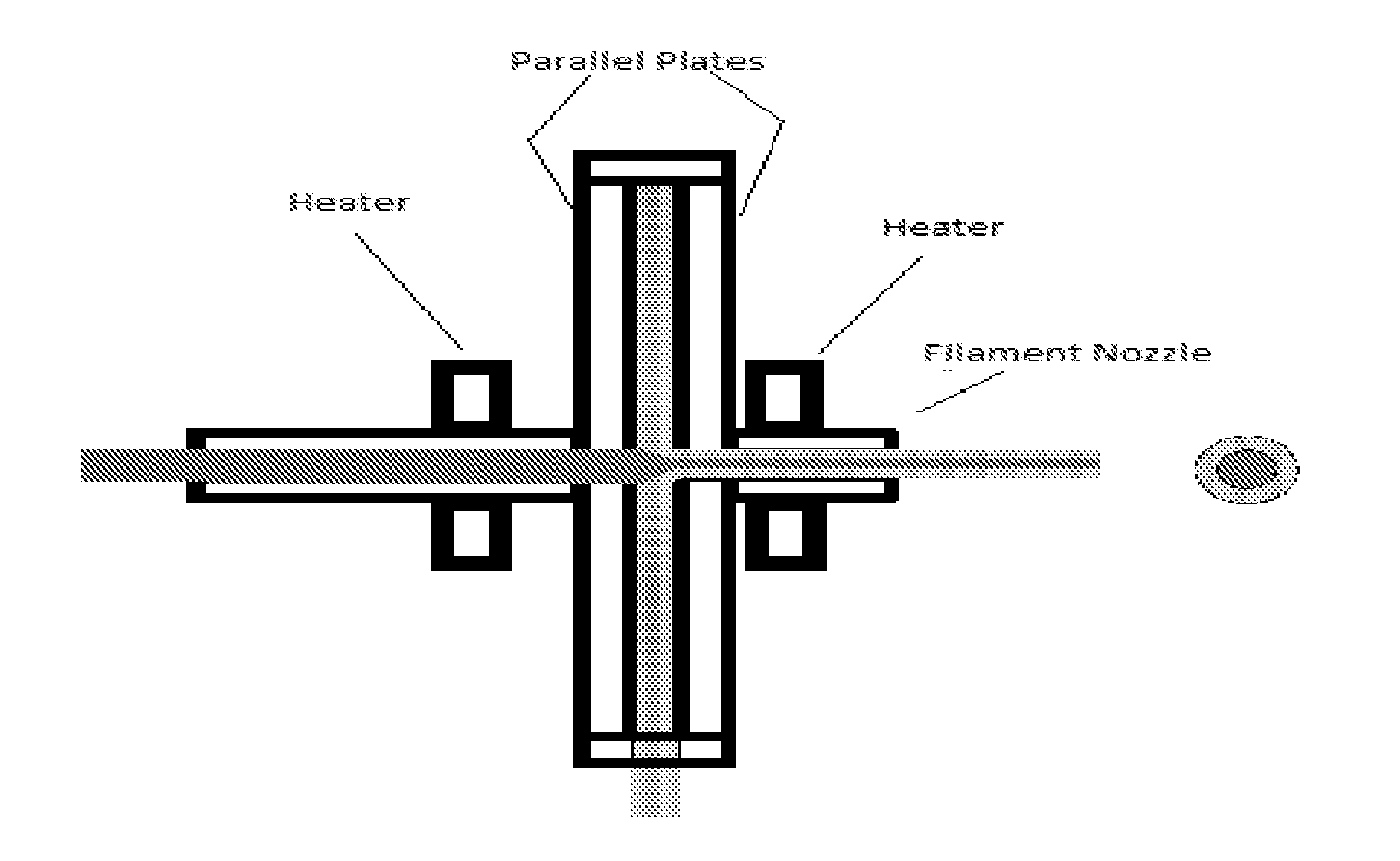

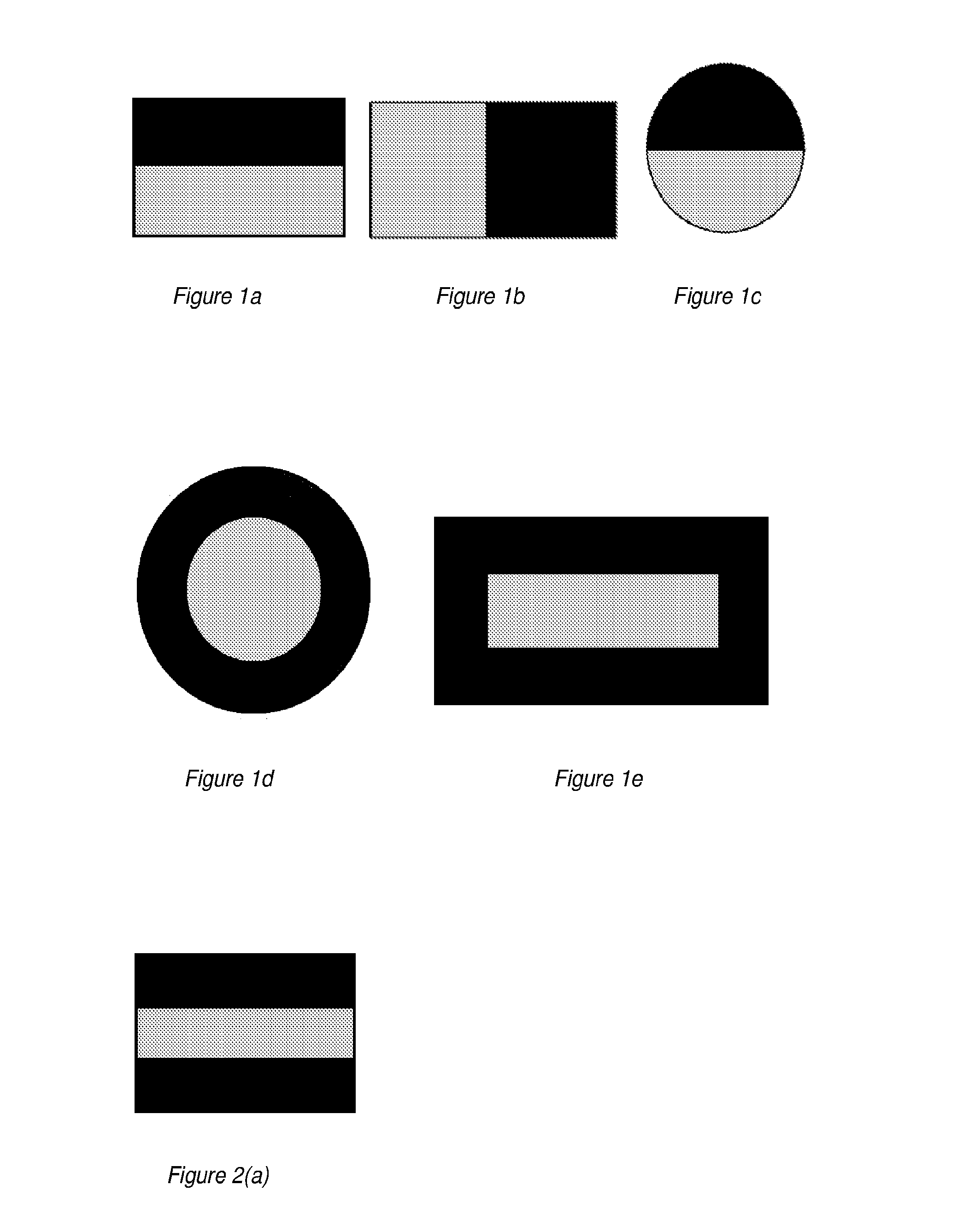

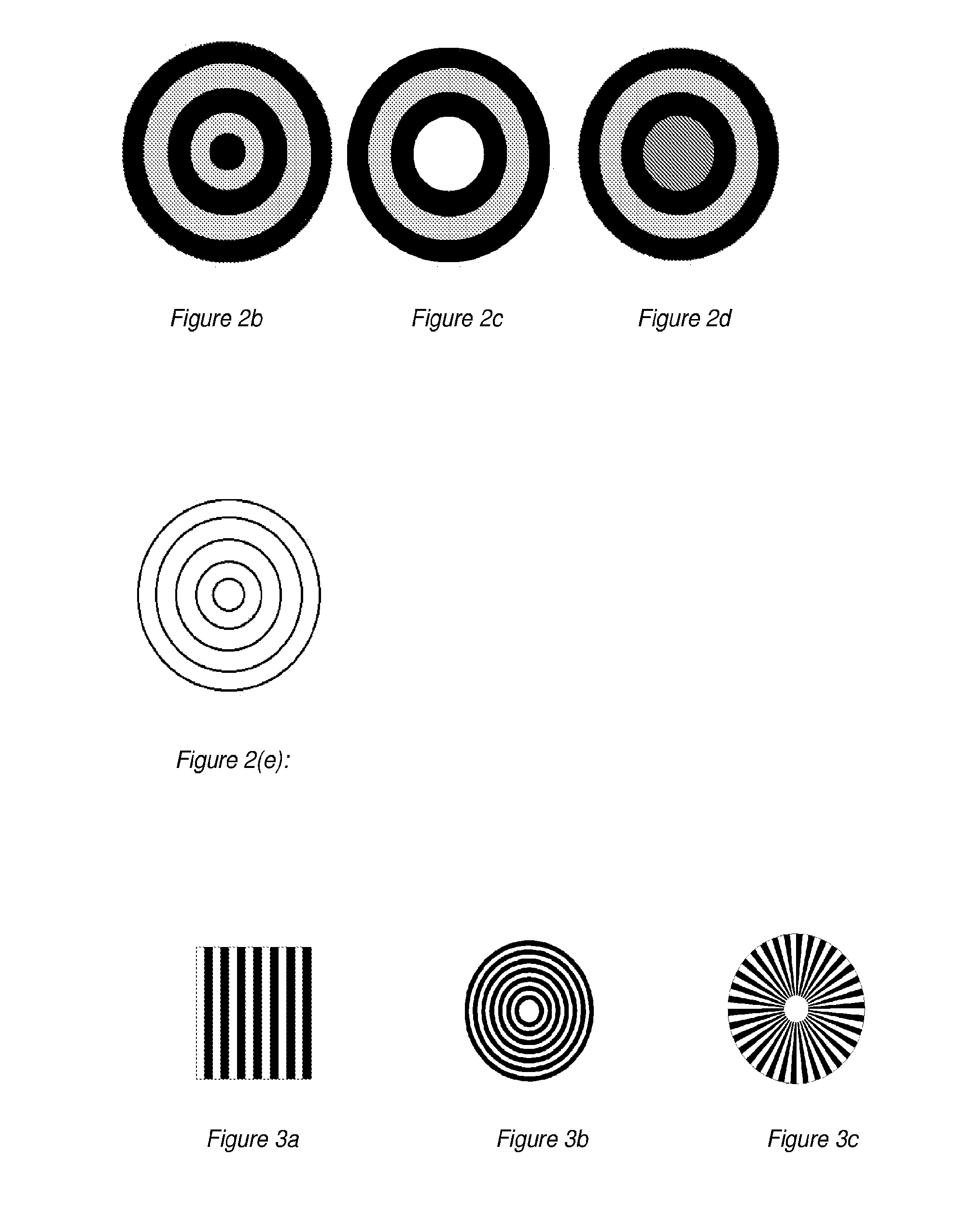

Coextruded, multilayer and multicomponent 3D printing inputs field

PendingUS20160297104A1Small sizeHigh viscosityAdditive manufacturing apparatusFilament/thread formingEngineering3d printer

The present invention relates to 3D printer inputs including filaments comprising separated layers or sections. These inputs particularly including filaments may be prepared by coextrusion, microlayer coextrusion or multicomponent / fractal coextrusion. These inputs and specifically filaments enable layering or combining different materials simultaneously through one or more nozzles during the so-called 3D printing process. These techniques facilitate smaller layer sizes (milli, micro, and nano) different layer configurations as well as the potential to incorporate materials that would otherwise not be usable in standard 3D printer methods.

Owner:GUILL TOOL & ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com