Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Formed easily and efficiently" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic fiber

InactiveUS6135987AFormed easily and efficientlyCeramic shaping apparatusBaby linensPolyesterVitrification

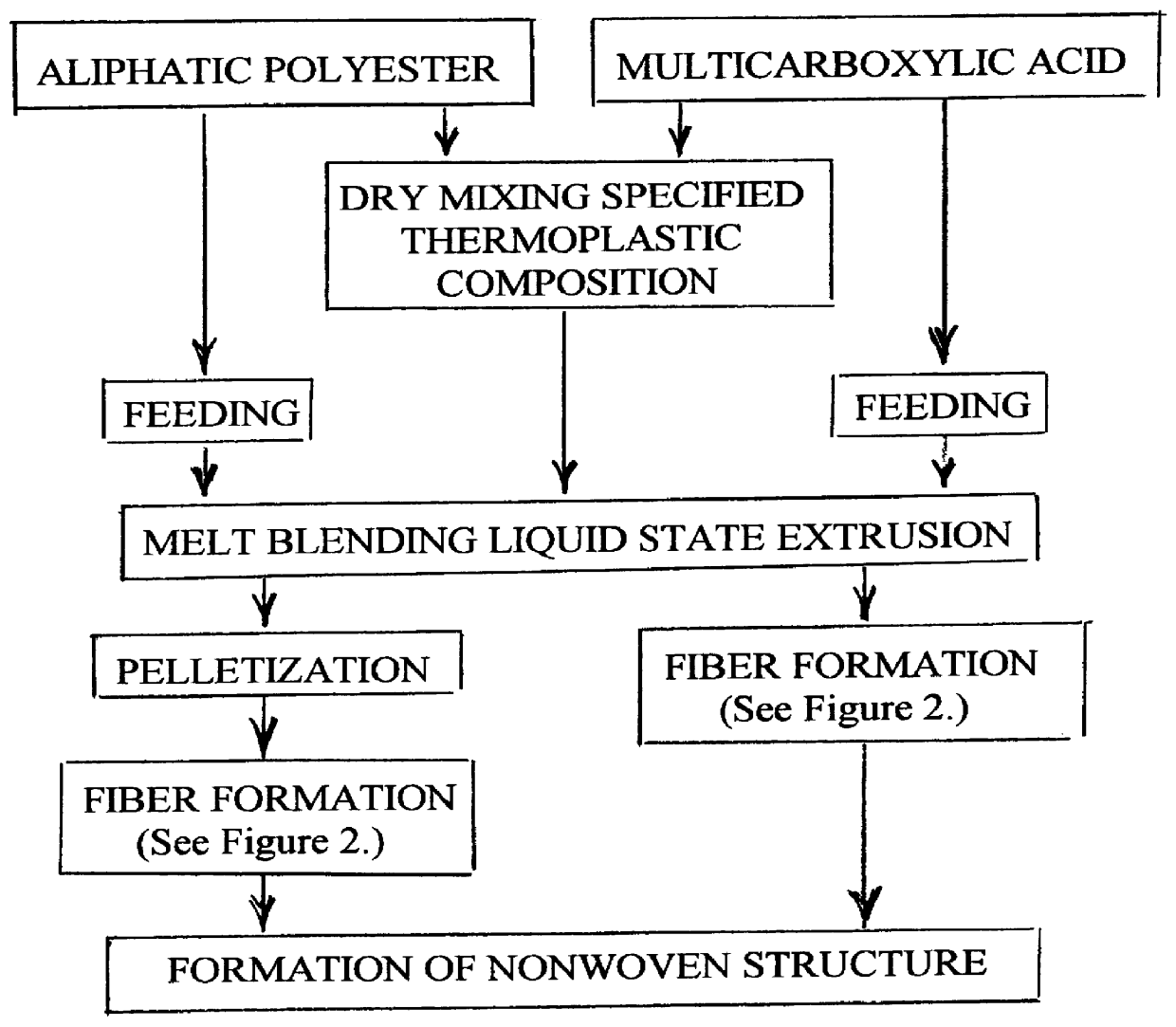

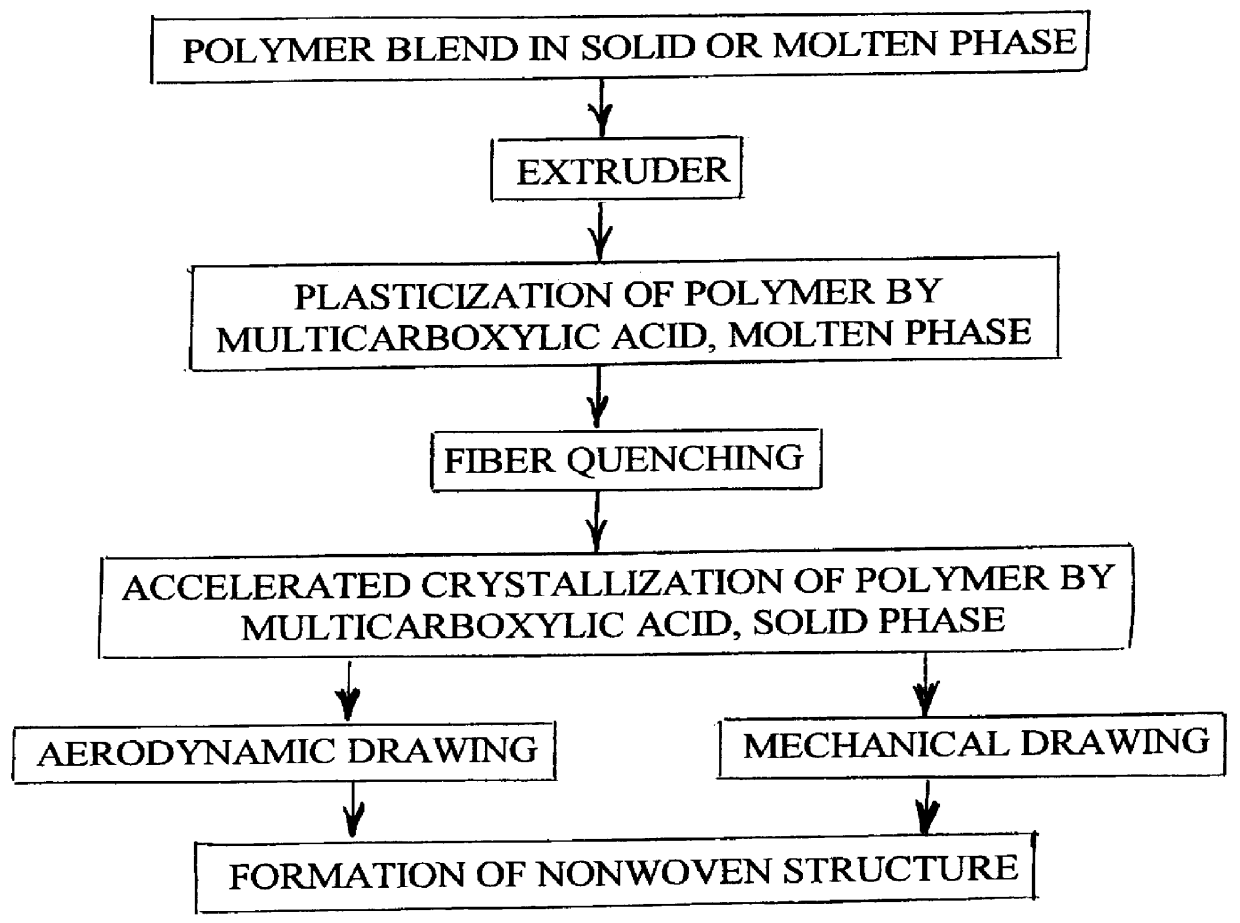

A process is disclosed for forming a synthetic fiber including providing a first component of an aliphatic polyester polymer a second component of a multicarboxylic acid, mixing the first component aliphatic polyester polymer and the second component multicarboxylic acid to form an unreacted specified thermoplastic composition, and melt blending the unreacted specified thermoplastic composition in an extruder or a mixer. The second component multicarboxylic acid lubricates the extruder and provides a nucleating agent for crystallizing the specified thermoplastic composition to form a mean crystal size less than about 120 Angstroms. Fiber composed of the specified thermoplastic composition has a mean crystal size less than about 120 Angstroms. The fiber has a glass transition temperature (Tg) less than about 55 DEG C. In one aspect, a first component of polylactic acid and a second component of adipic acid provide synthetic fibers in a nonwoven structure used in a biodegradable and compostable disposable absorbent product for the absorption and removal of body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

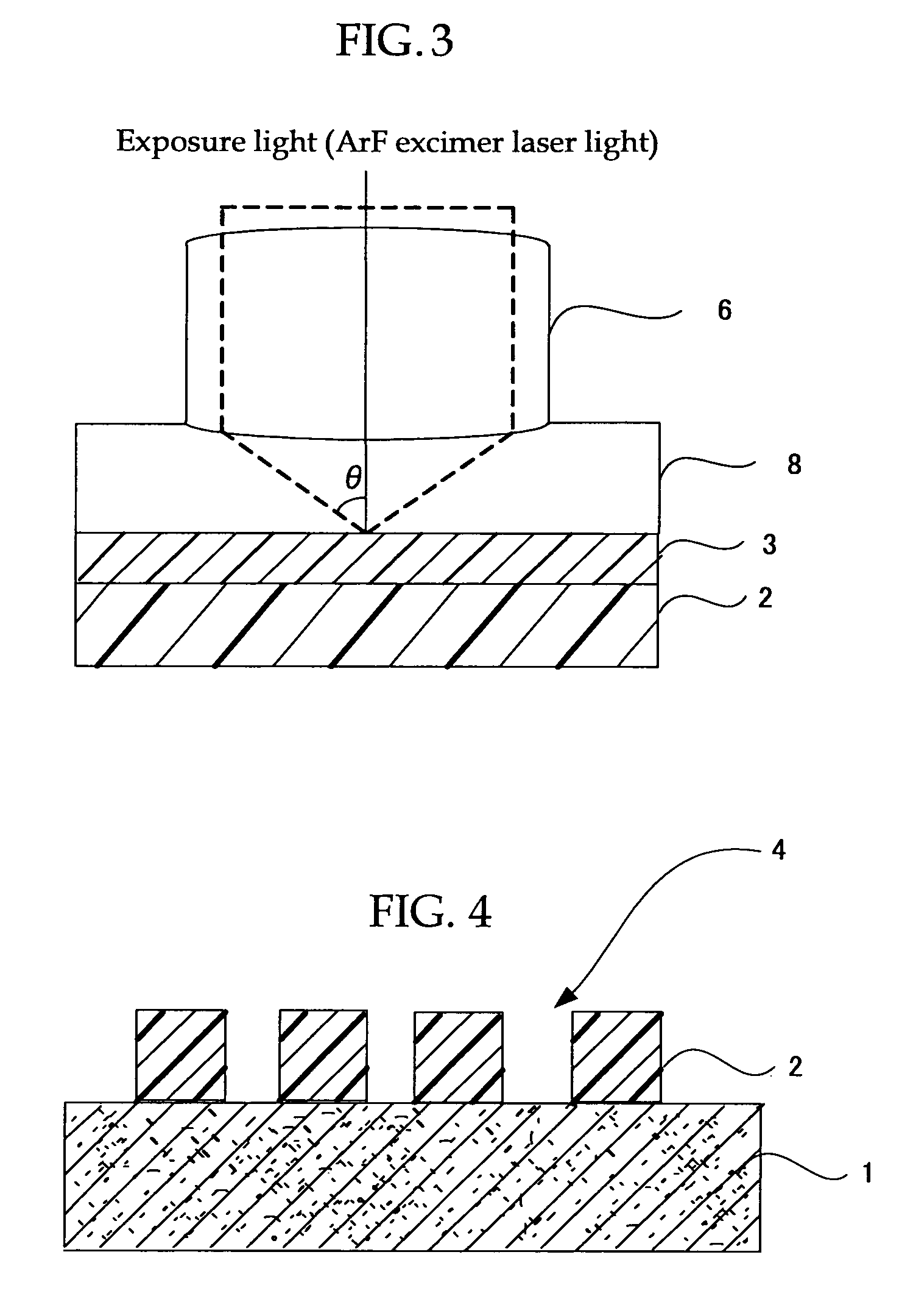

Resist cover film-forming material, process for forming resist pattern, semiconductor device and process for manufacturing the same

InactiveUS7608386B2High light transmittanceResist performance can not be impairedPhotosensitive materialsRadiation applicationsResistEngineering

Owner:FUJITSU LTD

Film with improved self-adhesive properties

InactiveUS6261278B1Formed easily and efficientlyFilm/foil adhesivesAdhesive dressingsPolyvinyl polymerPolymer science

A film that comprises a mixture of a block copolymer and a polyethylene polymer. One embodiment of such a film is a film comprising a block copolymer selected from the group consisting of poly(styrene)-co-poly(ethylene-butylene)-co-poly(styrene) copolymer and poly(styrene)-co-poly(ethylene-butylene) copolymer, and a polyethylene polymer. The film exhibits improved self-adhesive properties and is suitable for use in a disposable absorbent product intended for the absorption of fluids such as body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

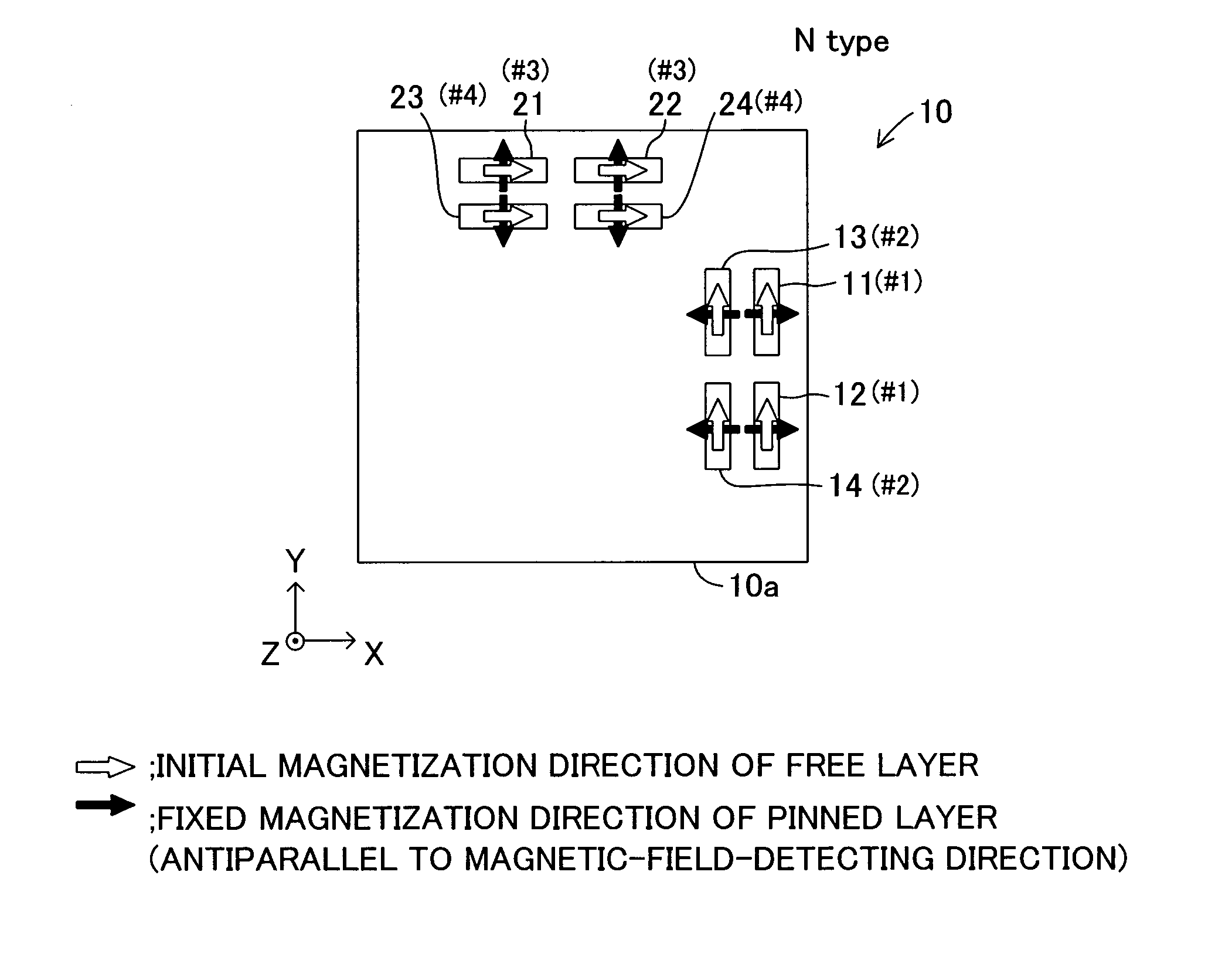

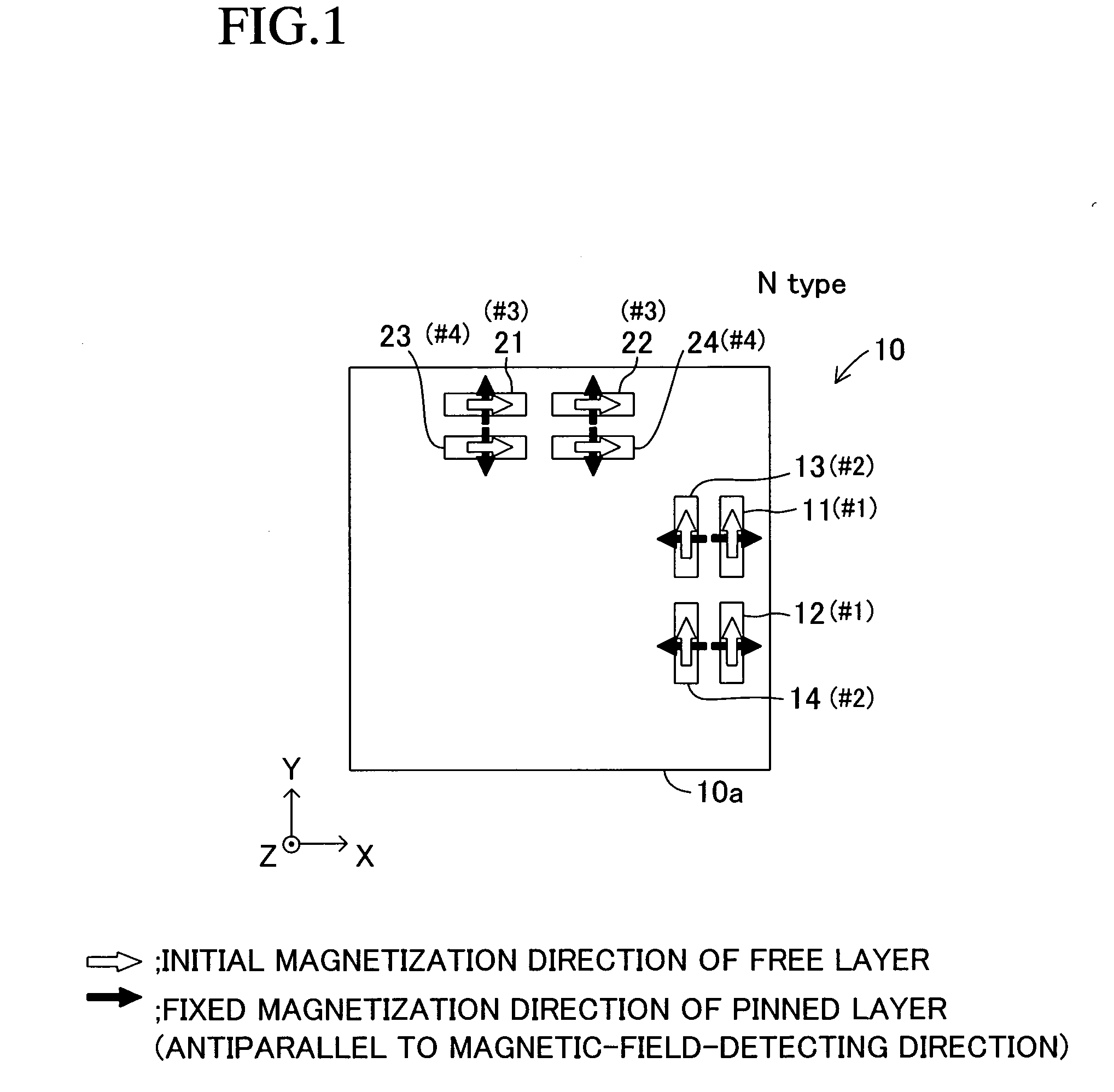

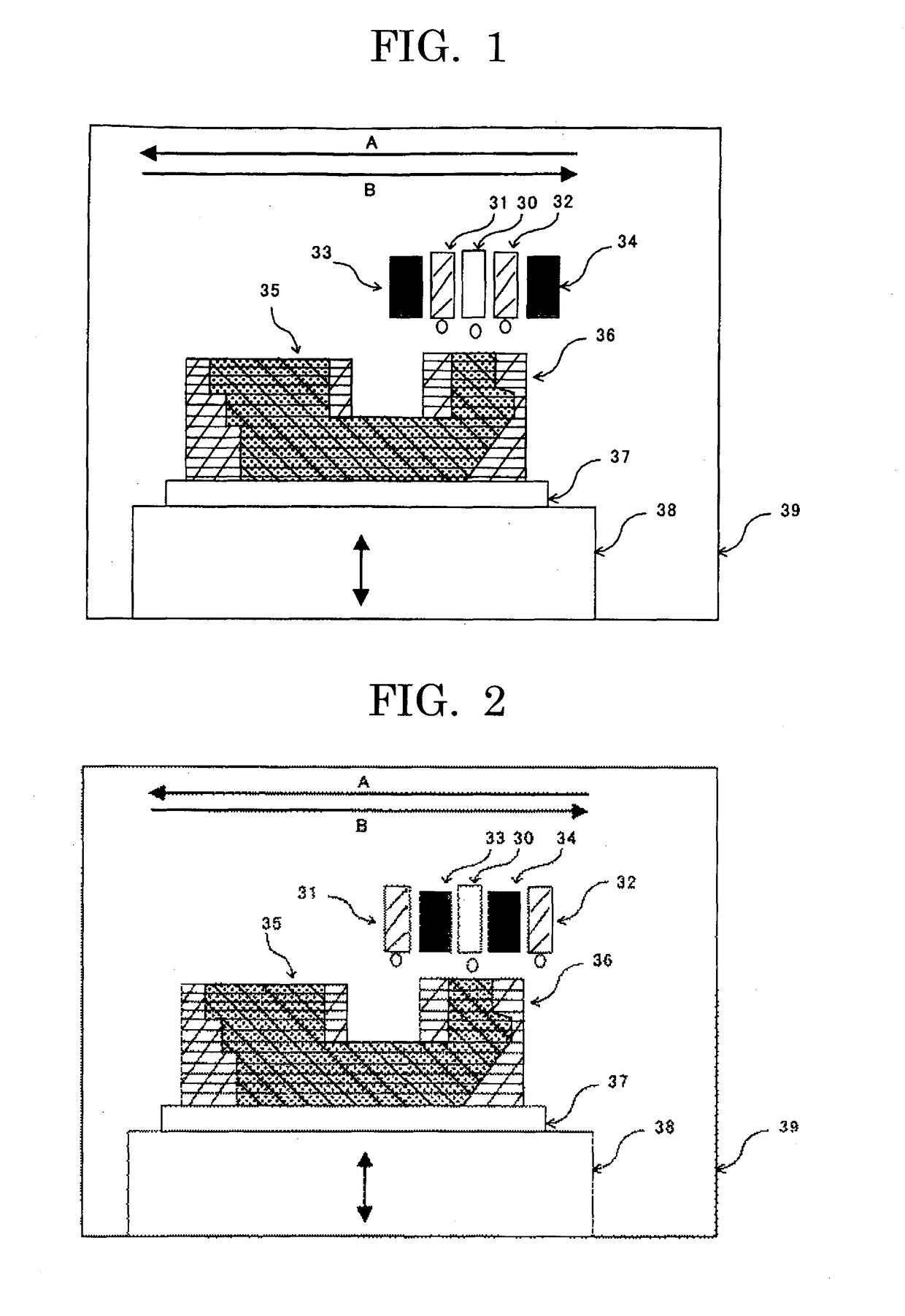

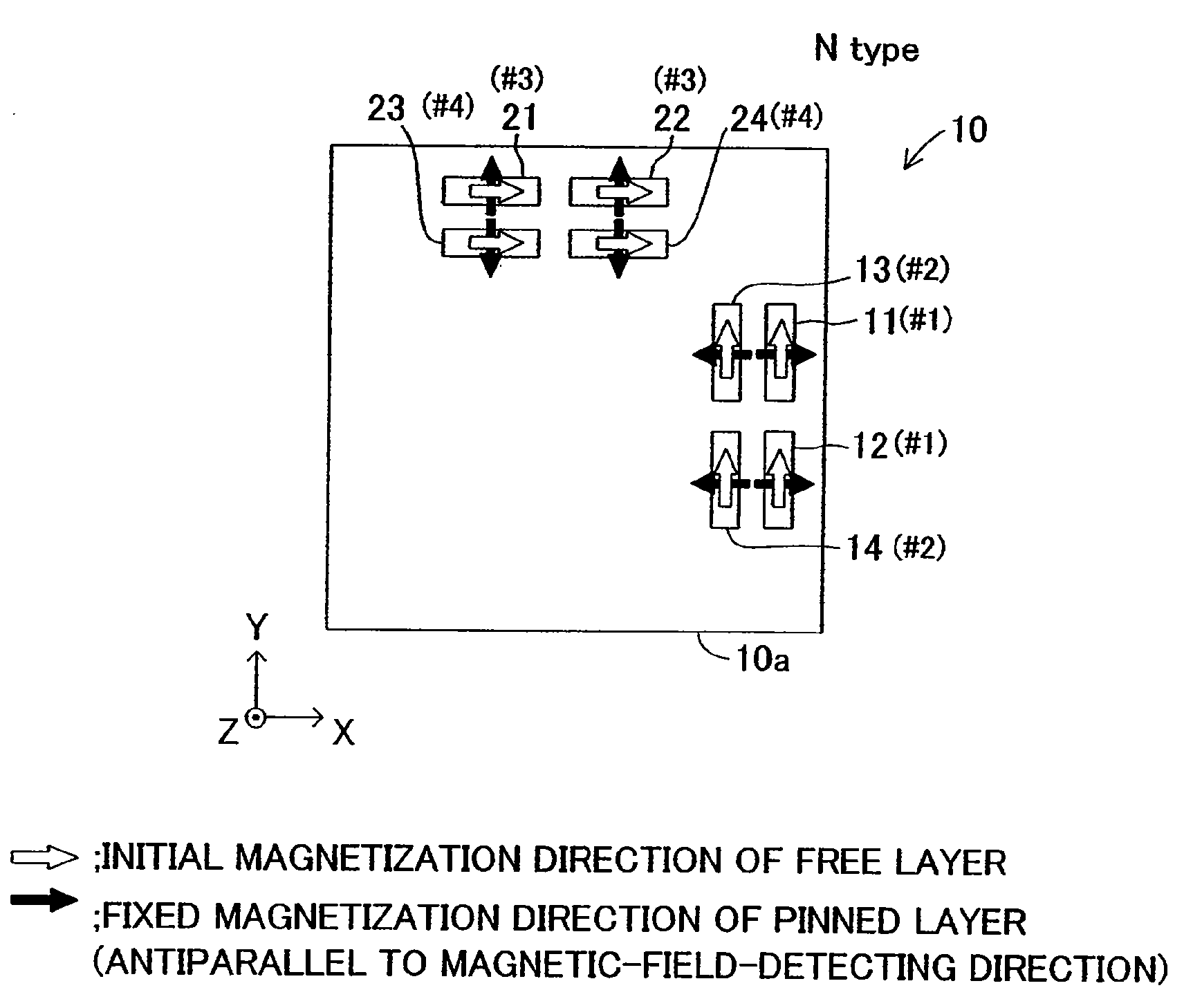

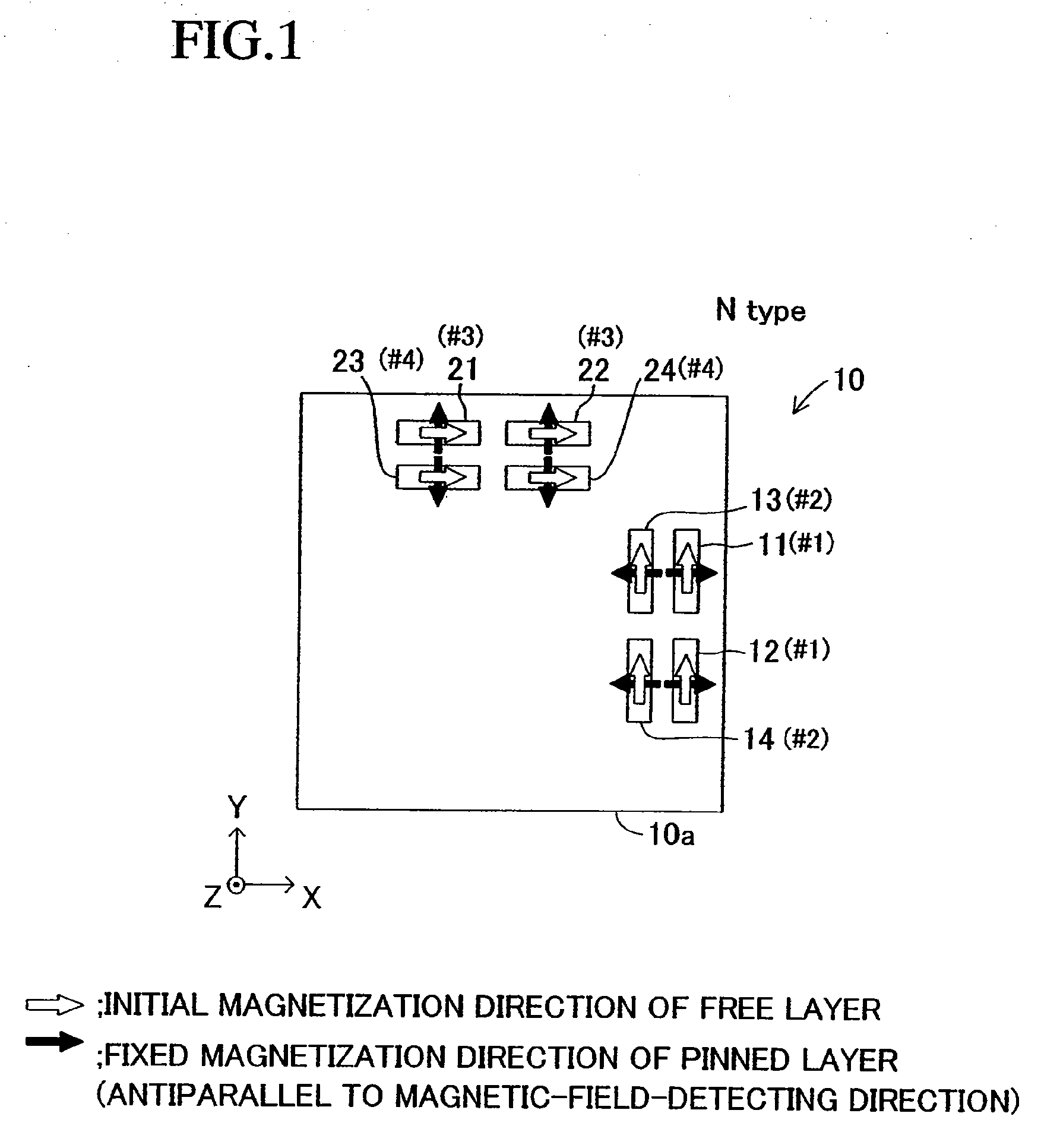

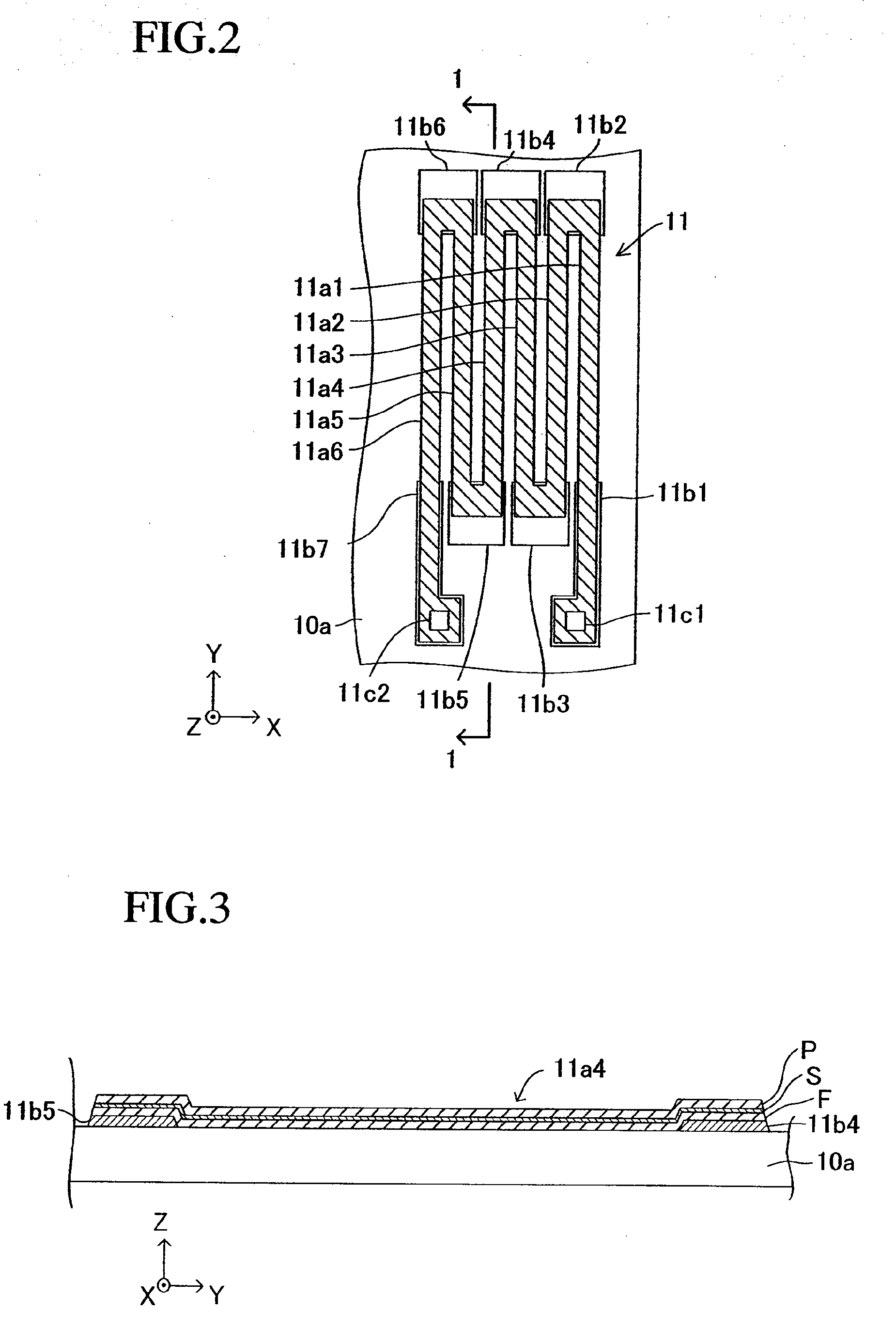

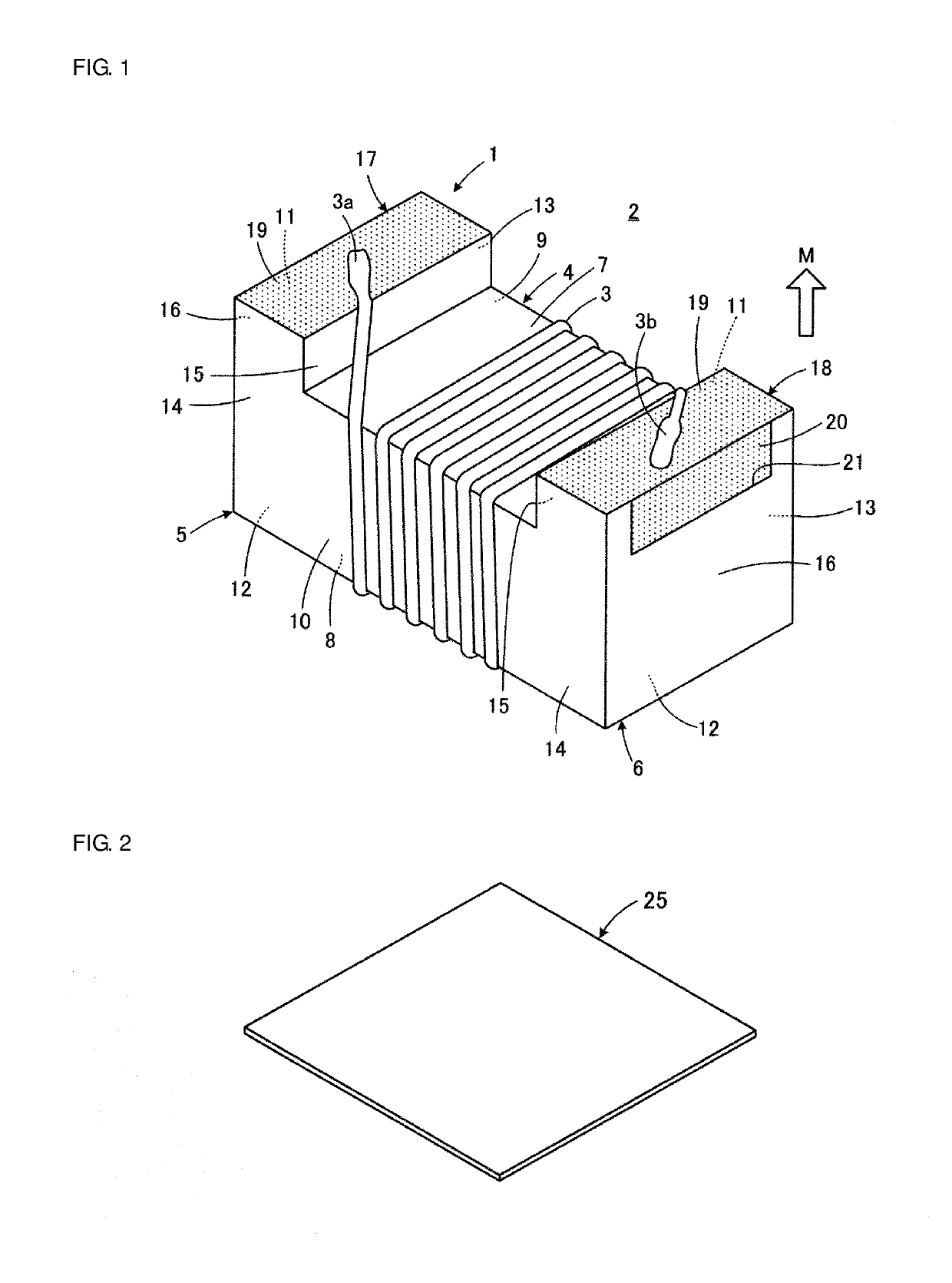

Magnetic sensor using giant magnetoresistive elements and method for manufacturing the same

InactiveUS20060072249A1Magnetic sensor can be very smallFormed easily and efficientlyNanomagnetismMagnetic measurementsRotary valveSpin valve

A magnetic sensor includes a single substrate, a conventional GMR element formed of a spin-valve film including a single-layer-pinned fixed magnetization layer, and a SAF element formed of a synthetic spin-valve film including a plural-layer-pinned fixed magnetization layer. When the spin-valve film intended to act as the conventional GMR element and the synthetic spin-valve film intended to act as the SAF element are subjected to the application of a magnetic field oriented in a single direction at a high temperature, they become giant magnetoresistive elements whose magnetic-field-detecting directions are antiparallel to each other. Since films intended to act as the conventional GMR element and the SAF element can be disposed close to each other, the magnetic sensor which has giant magnetoresistive elements whose magnetic-field-detecting directions are antiparallel to each other can be small.

Owner:YAMAHA CORP

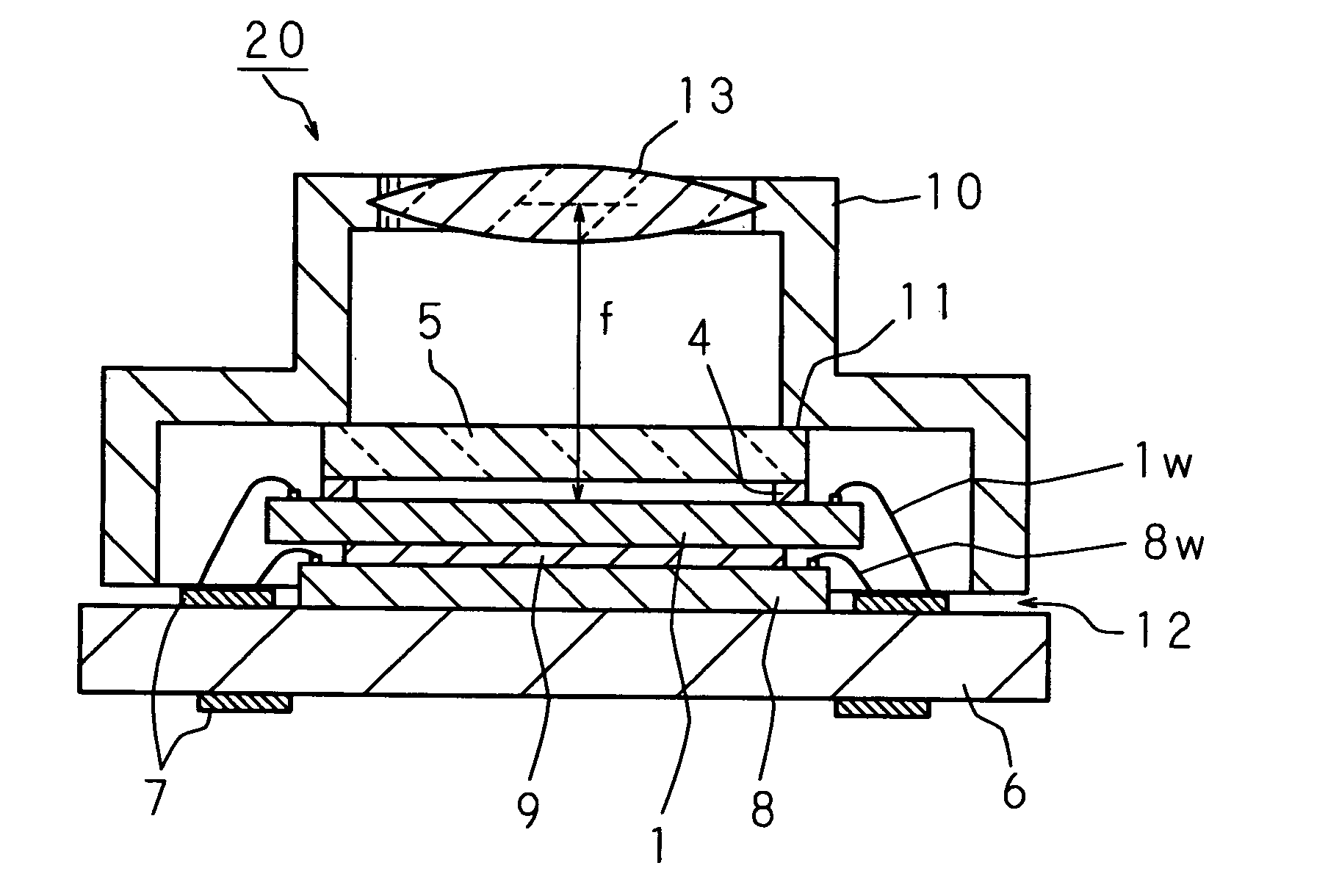

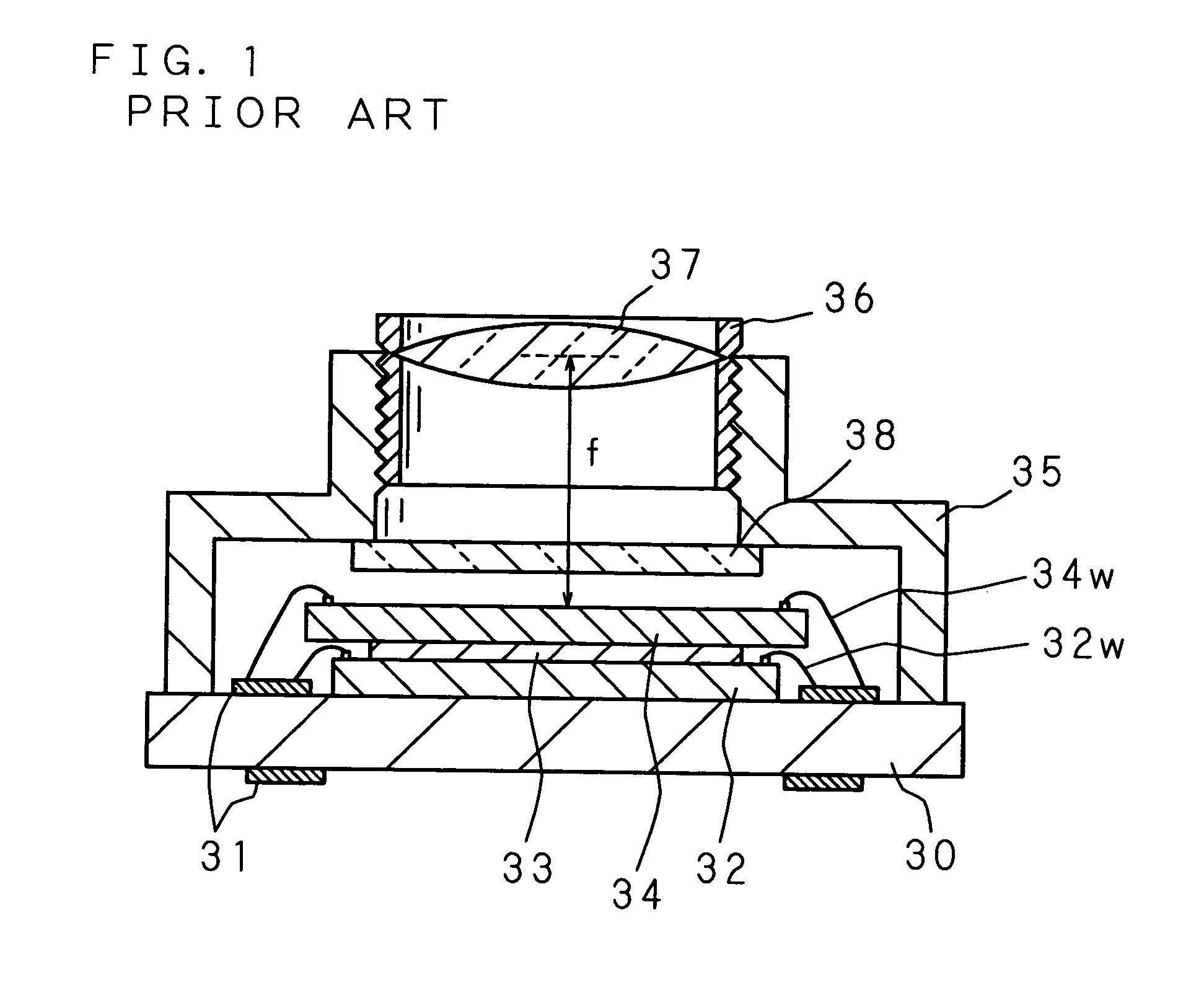

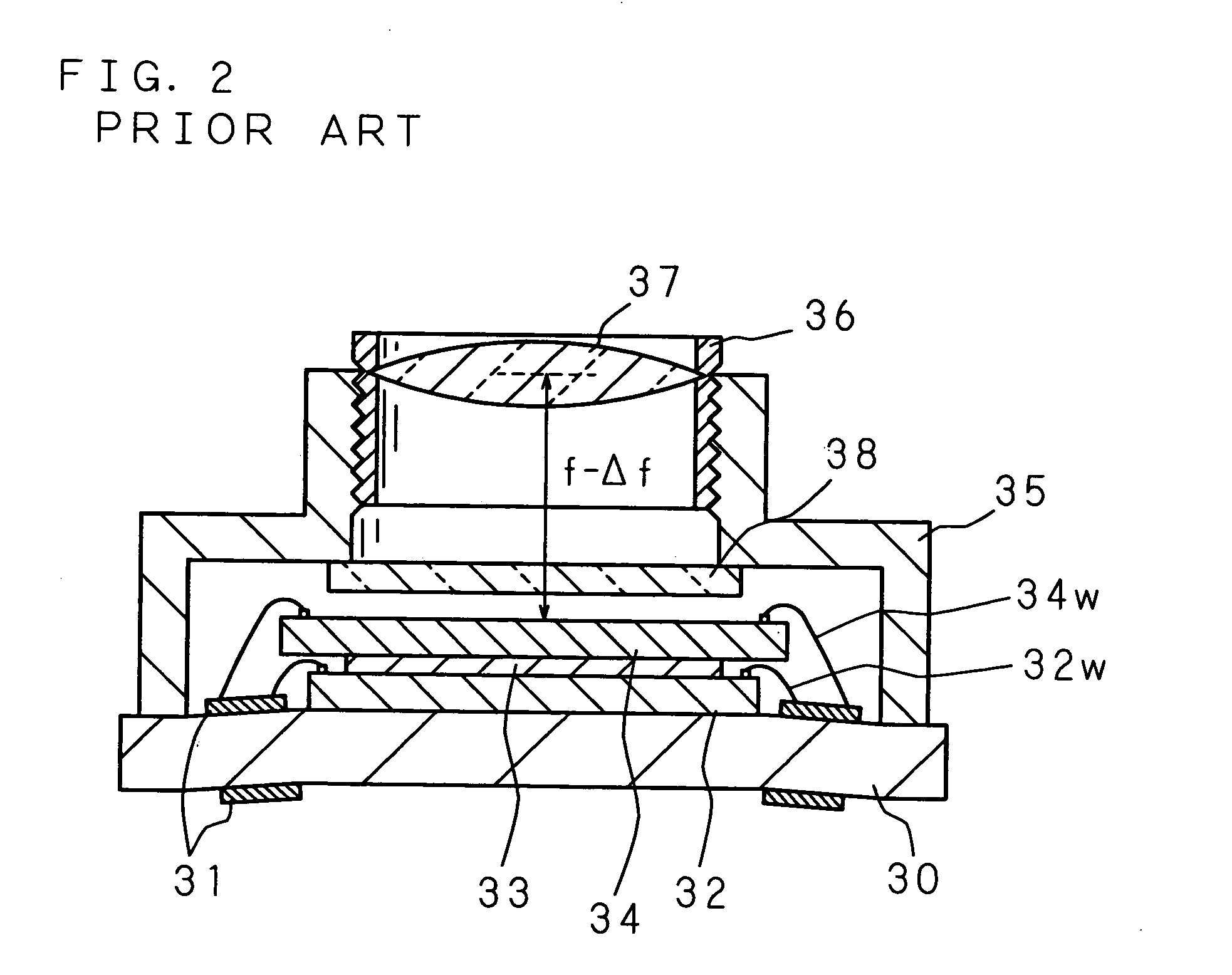

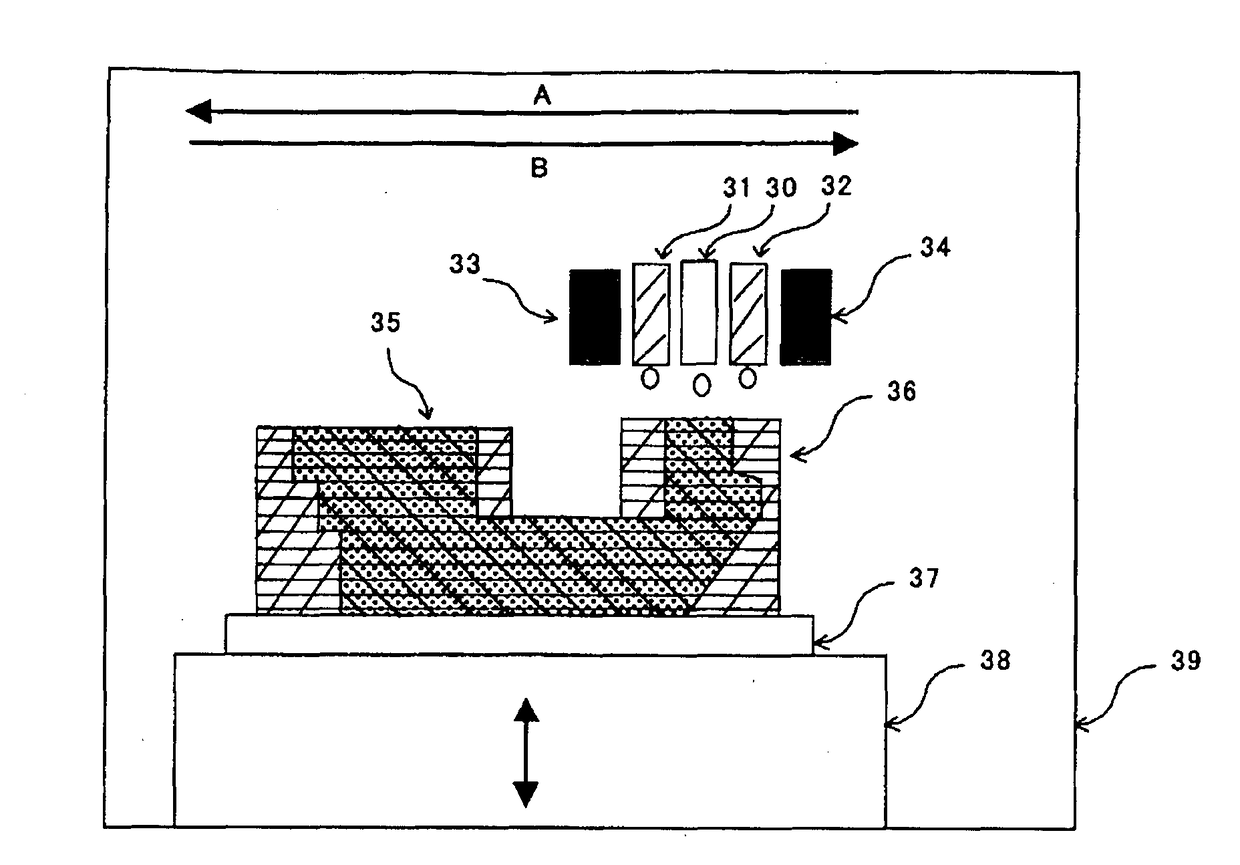

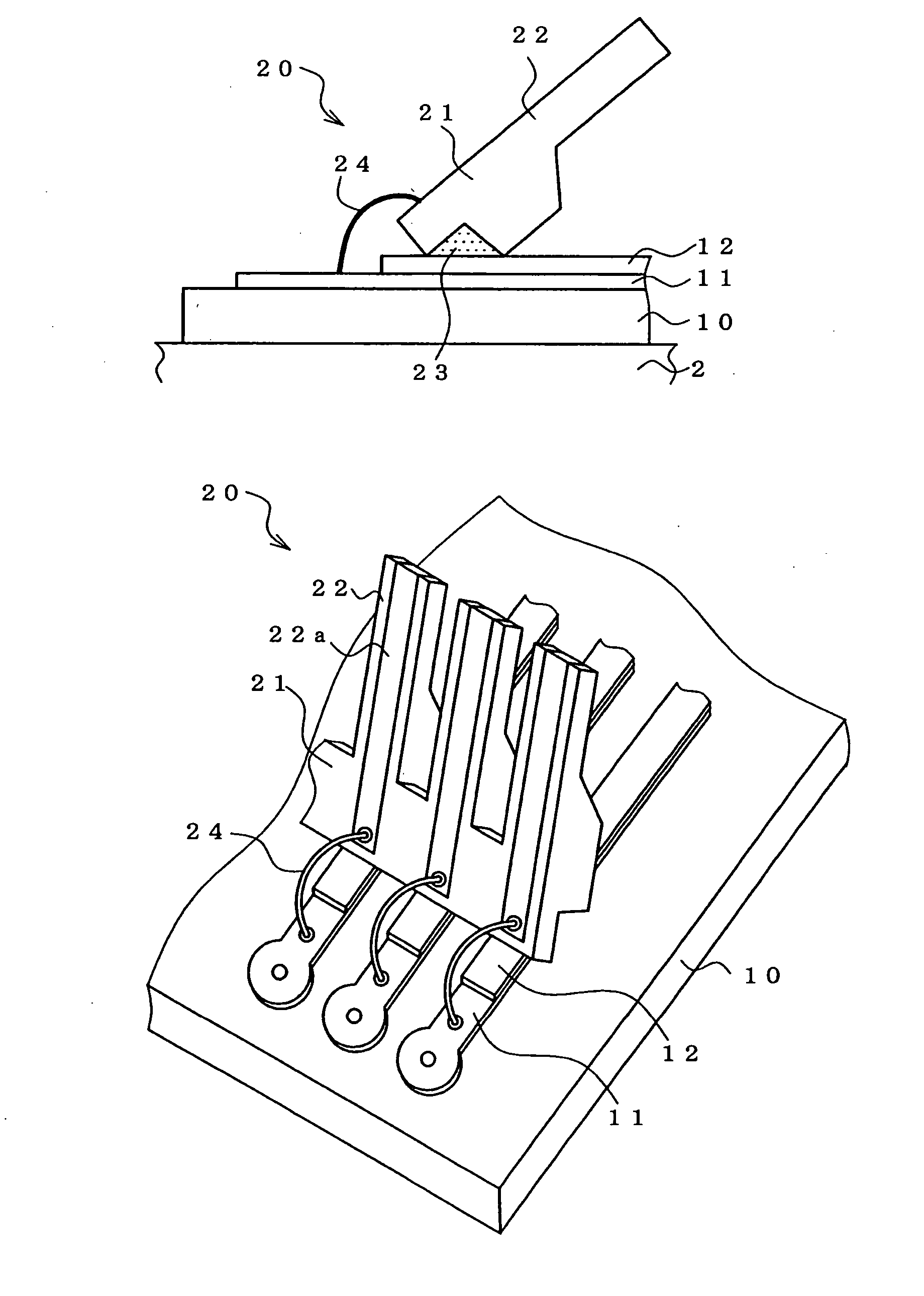

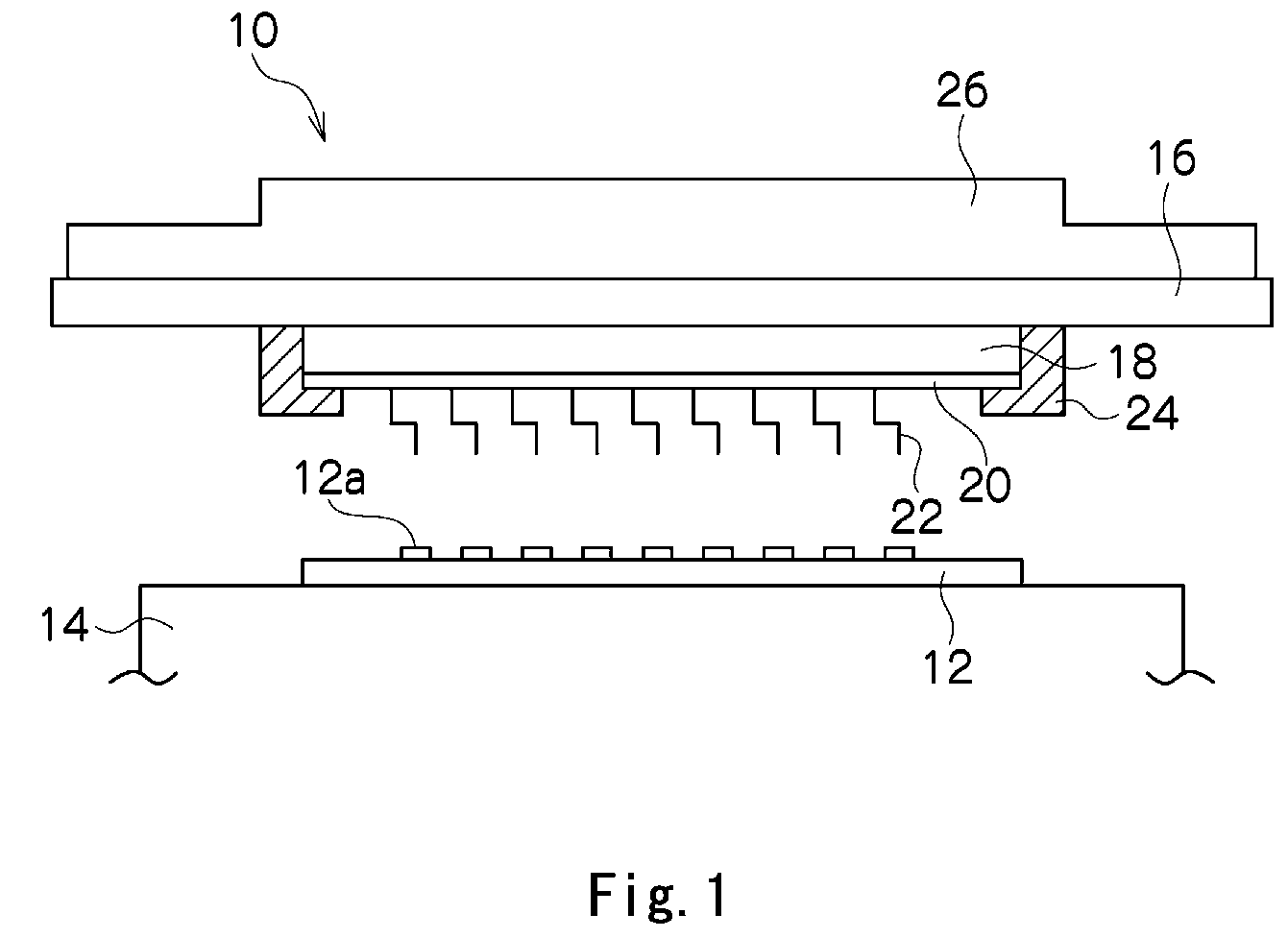

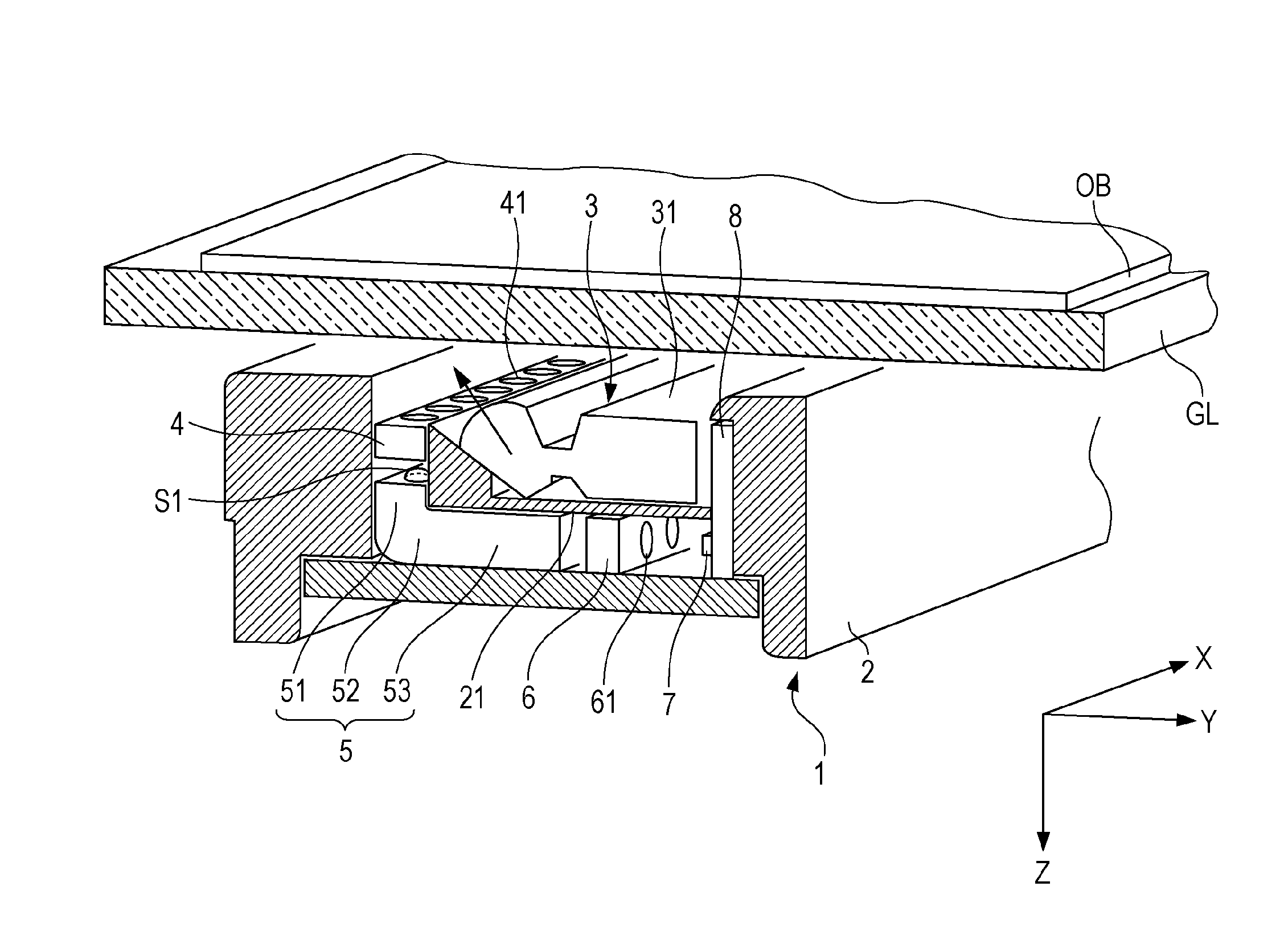

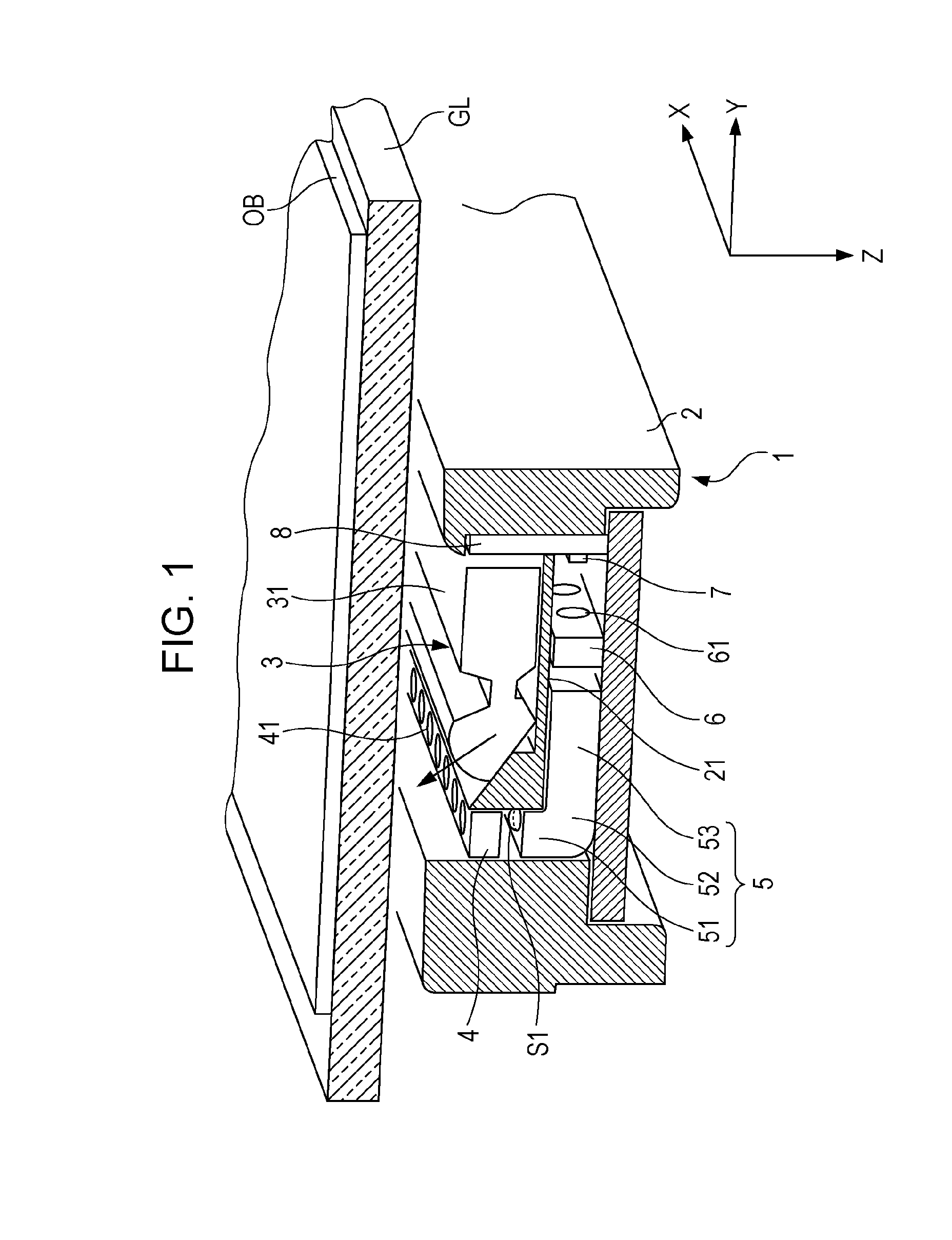

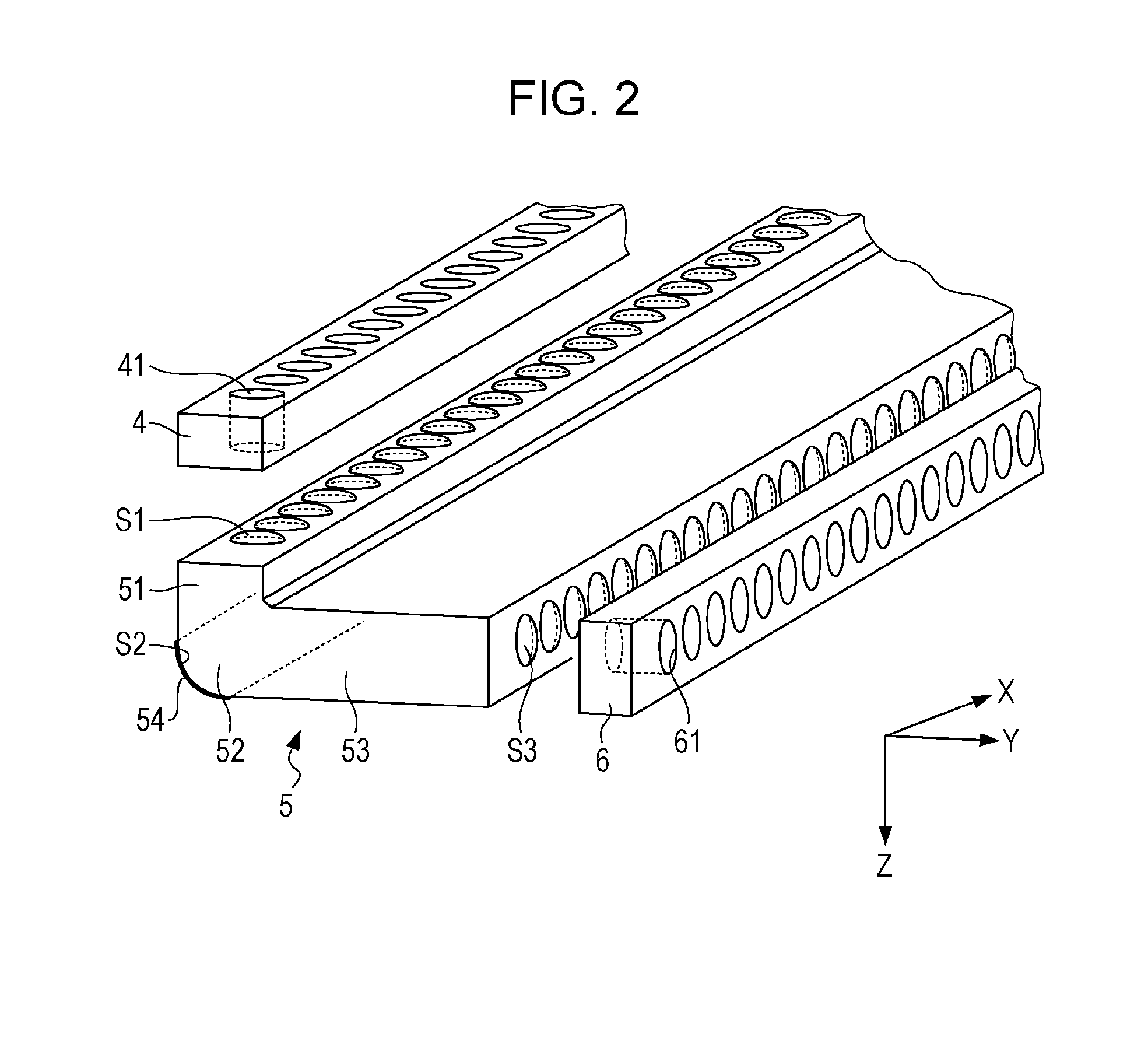

Module for optical device, and manufacturing method therefor

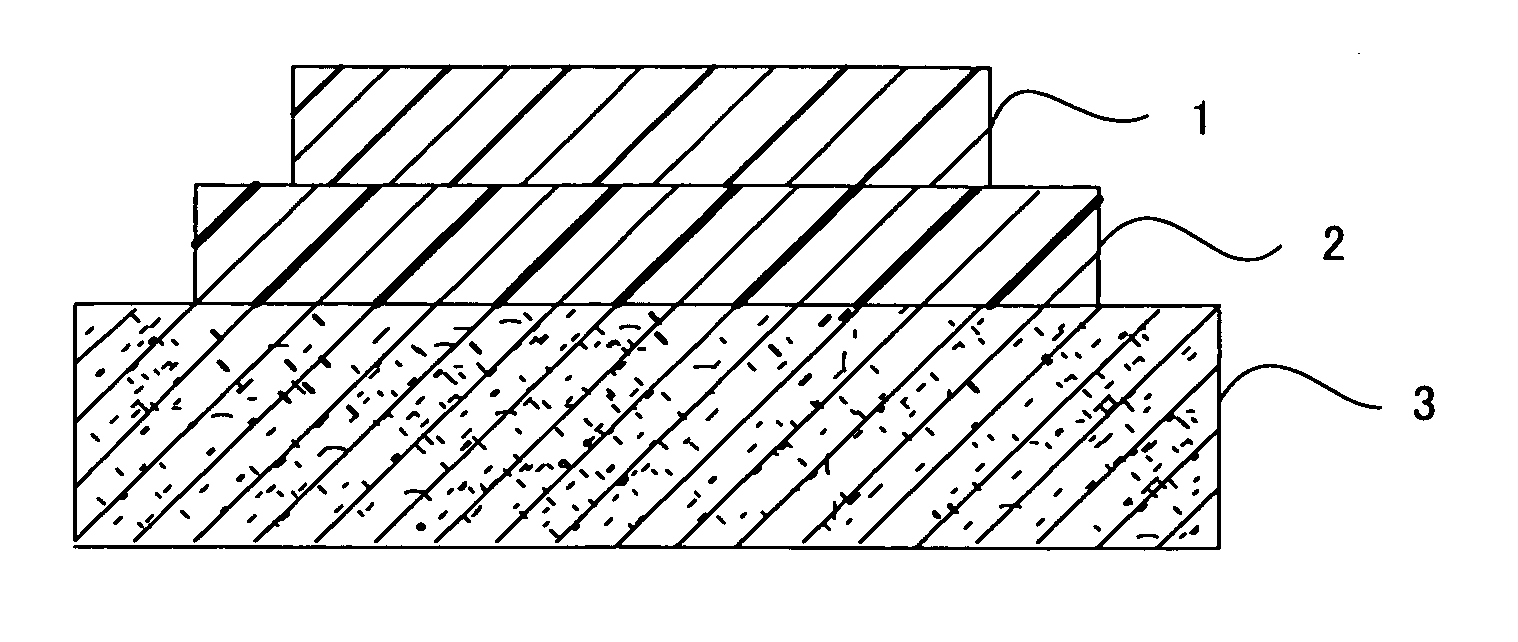

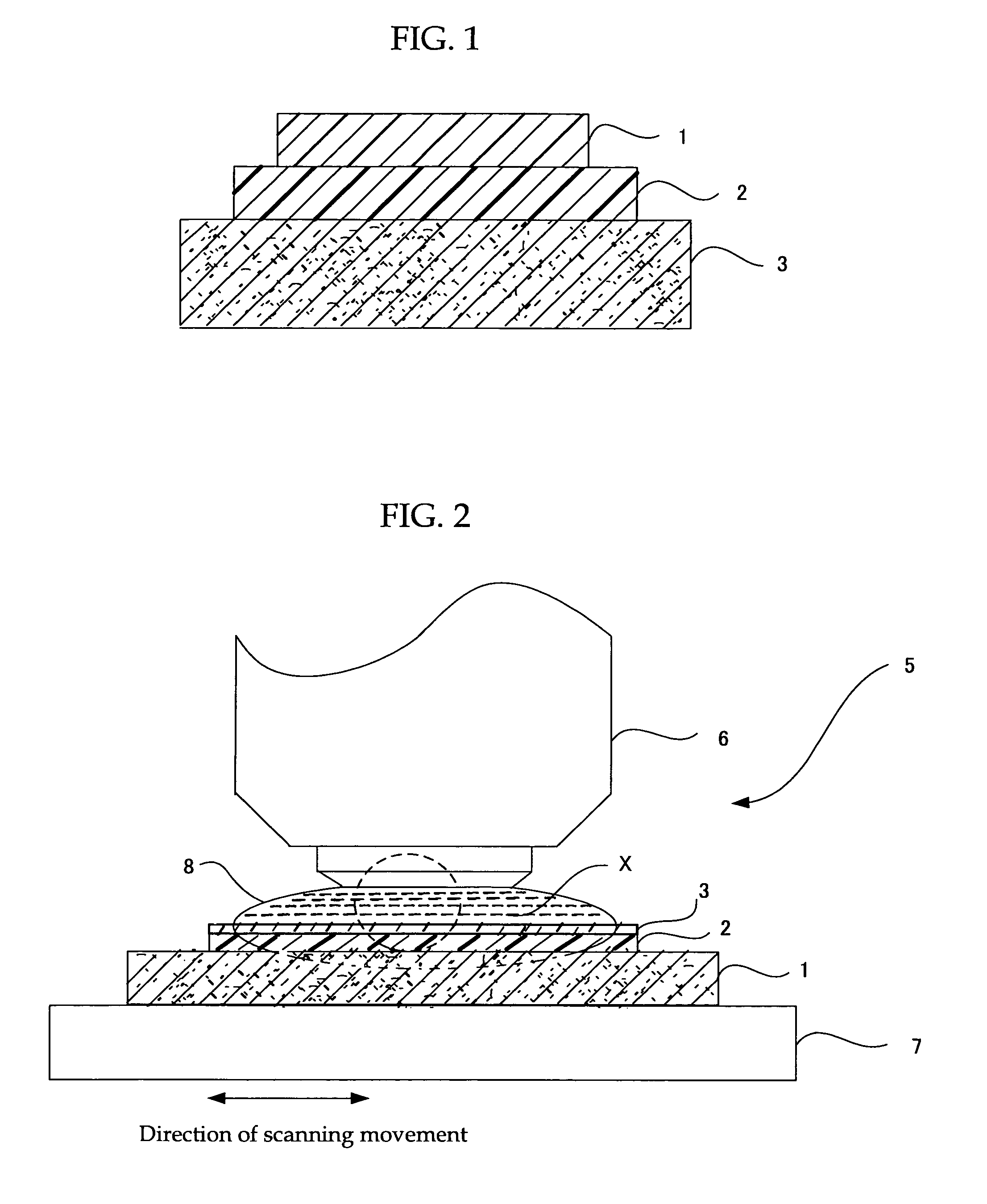

ActiveUS7112864B2Low costSimple processTelevision system detailsSemiconductor/solid-state device detailsEngineeringSolid-state

A module for an optical device being provided with a wiring substrate having a conductive wiring patterned thereon, a solid-state image sensor, a DSP for controlling the operation of the solid-state image sensor and processing a signal outputted from the same, and a lens holder being placed opposite to the solid-state image sensor and having a function of an optical path demarcating unit for demarcating the optical path to the solid-state image sensor, wherein a transparent cover bonded to the surface of the solid-state image sensor is joined to the lens holder at a joint portion. It is unnecessary to provide a focus adjuster for matching the optical distance between the lens and the solid-state image sensor with the focal length of the lens.

Owner:SHARP KK

Three-dimensional object and method for forming same

InactiveUS20170239886A1Formed easily and efficientlyAdditive manufacturing apparatusEducational modelsElectrical and Electronics engineering

Owner:RICOH KK

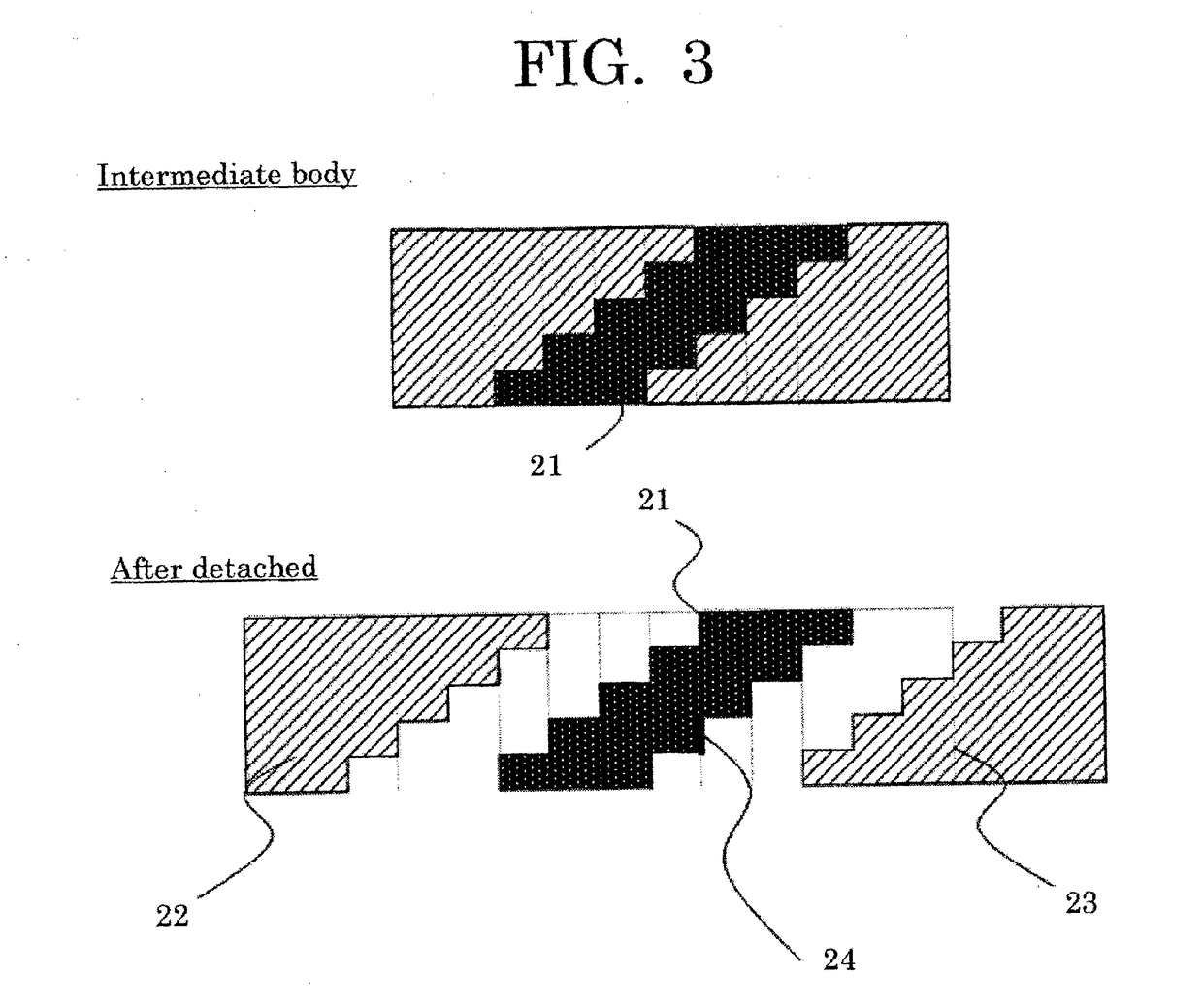

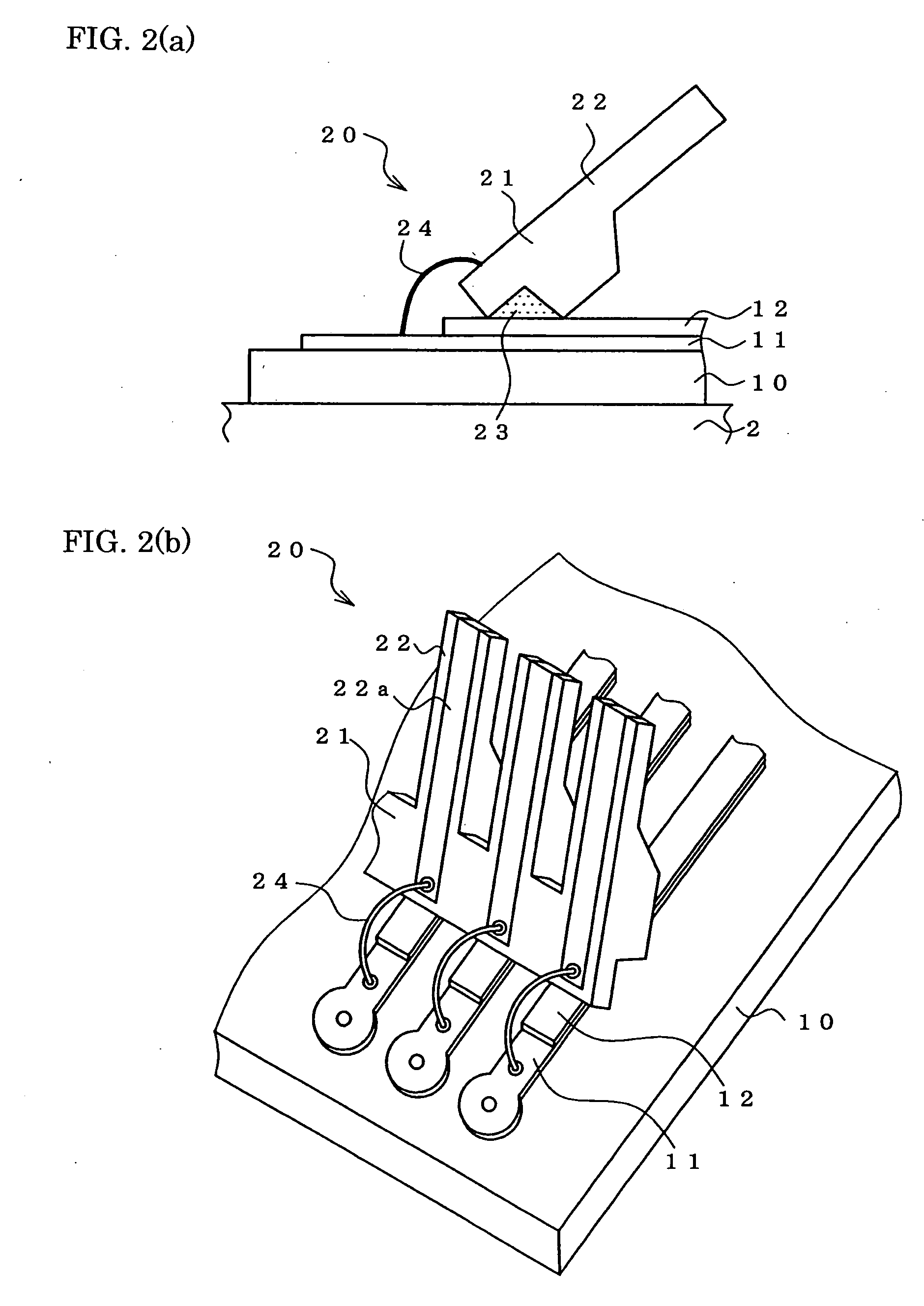

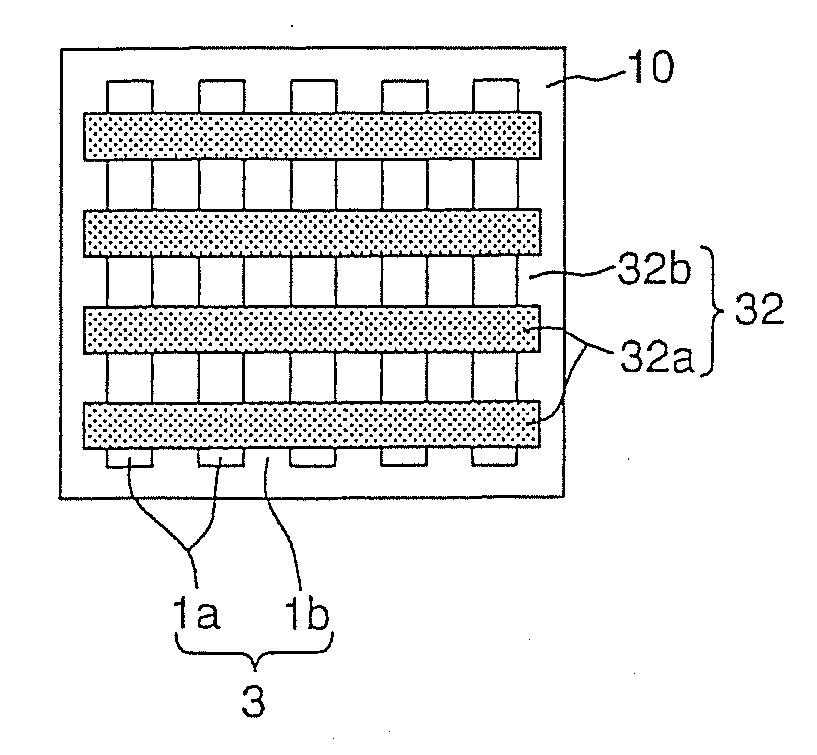

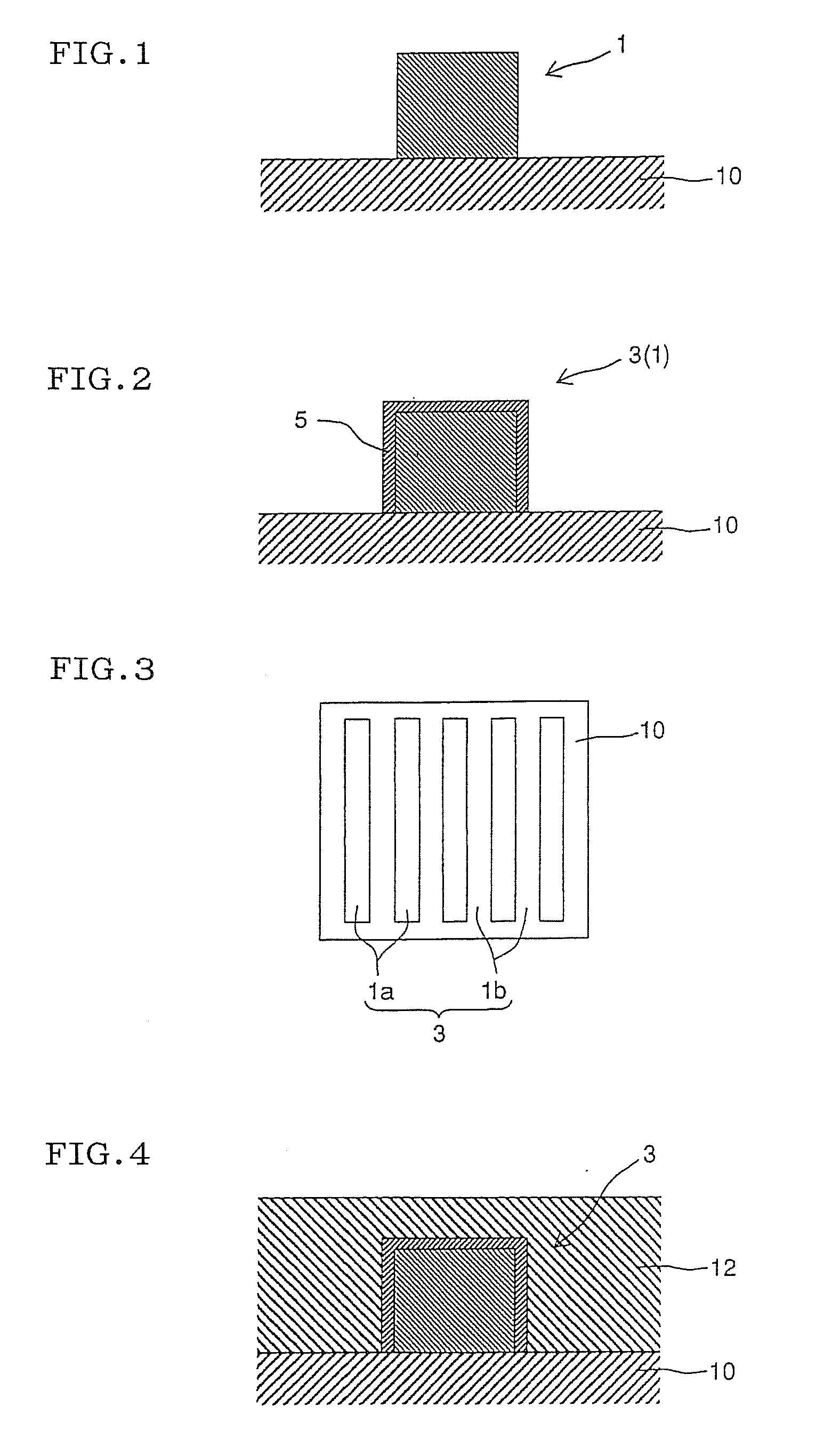

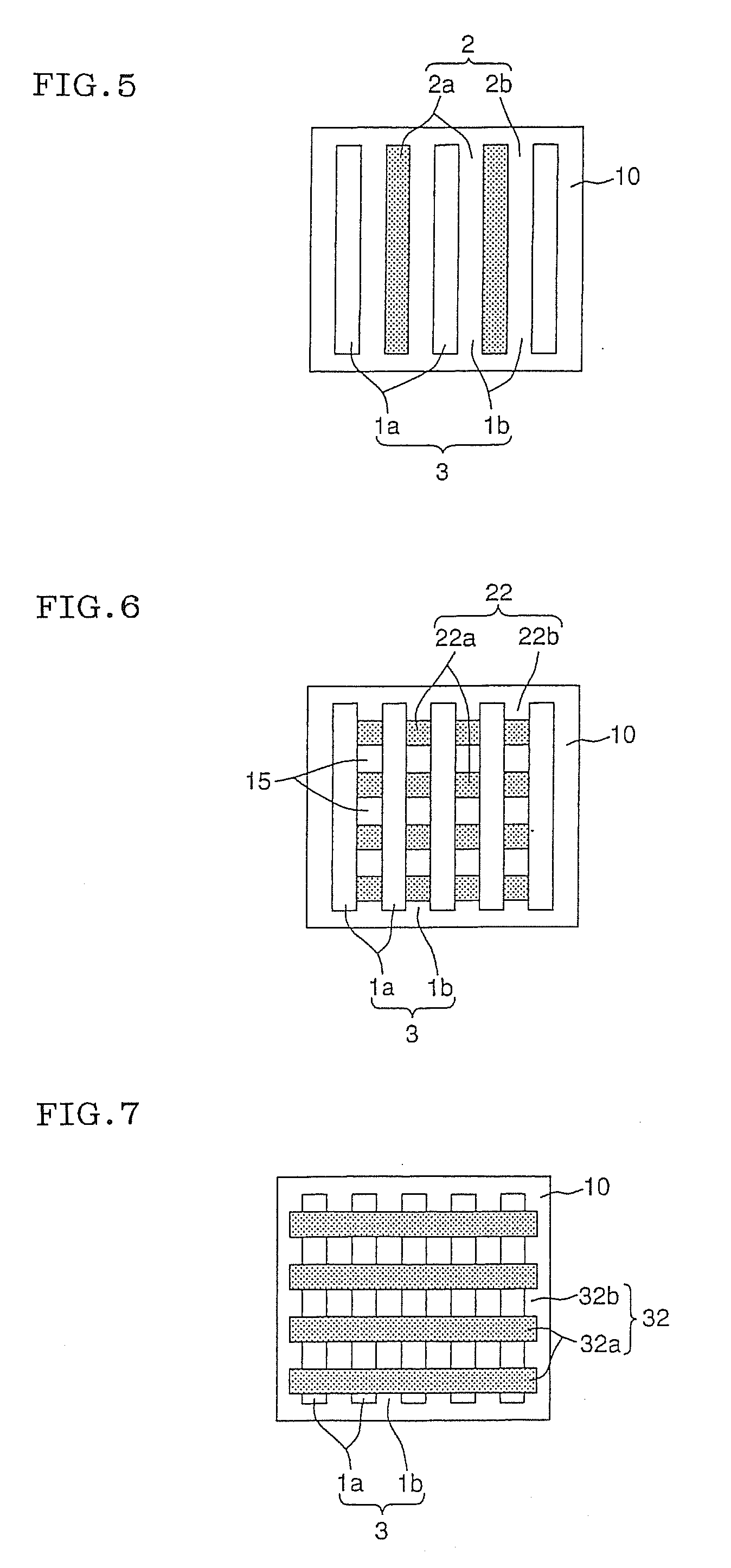

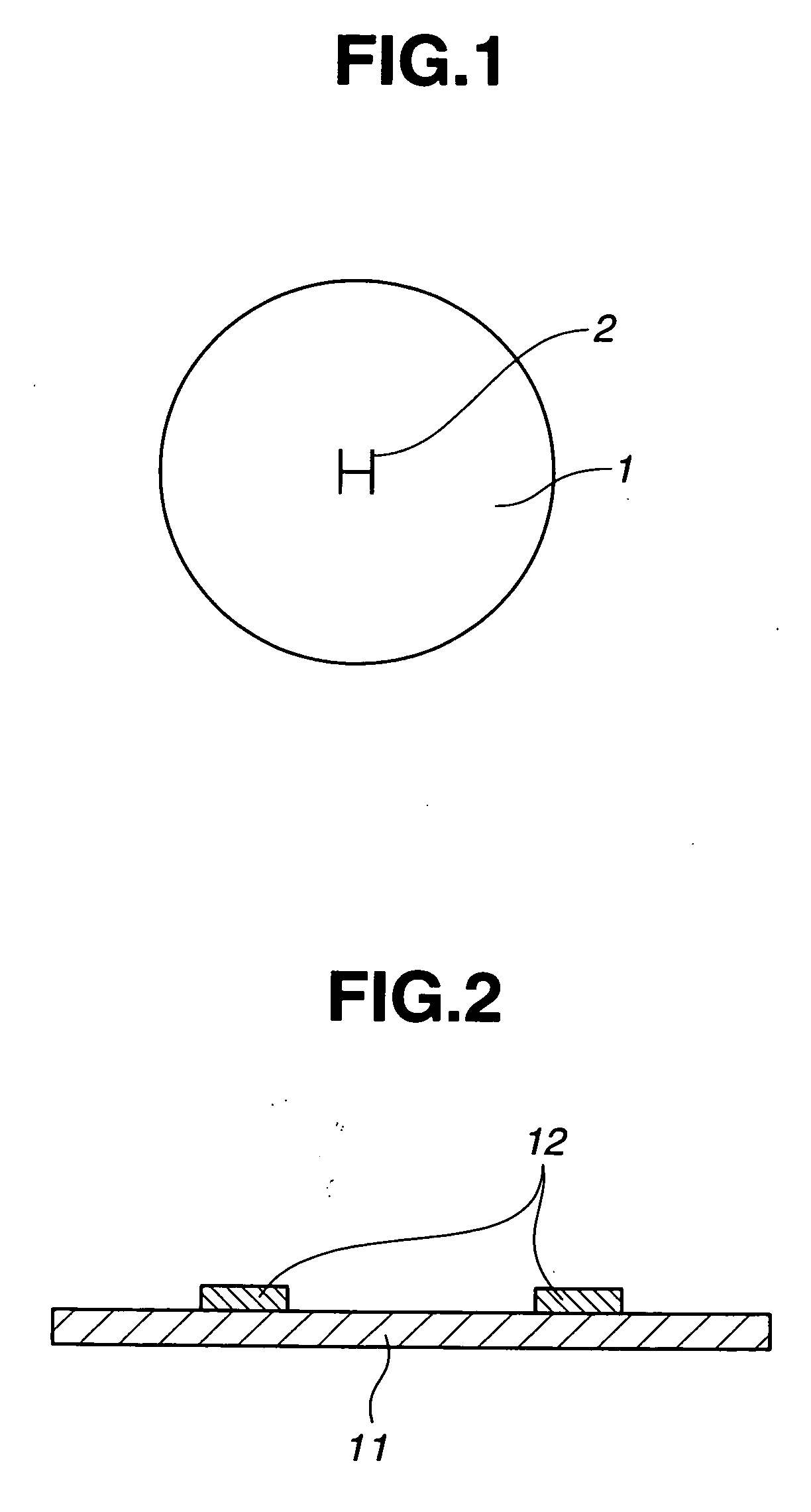

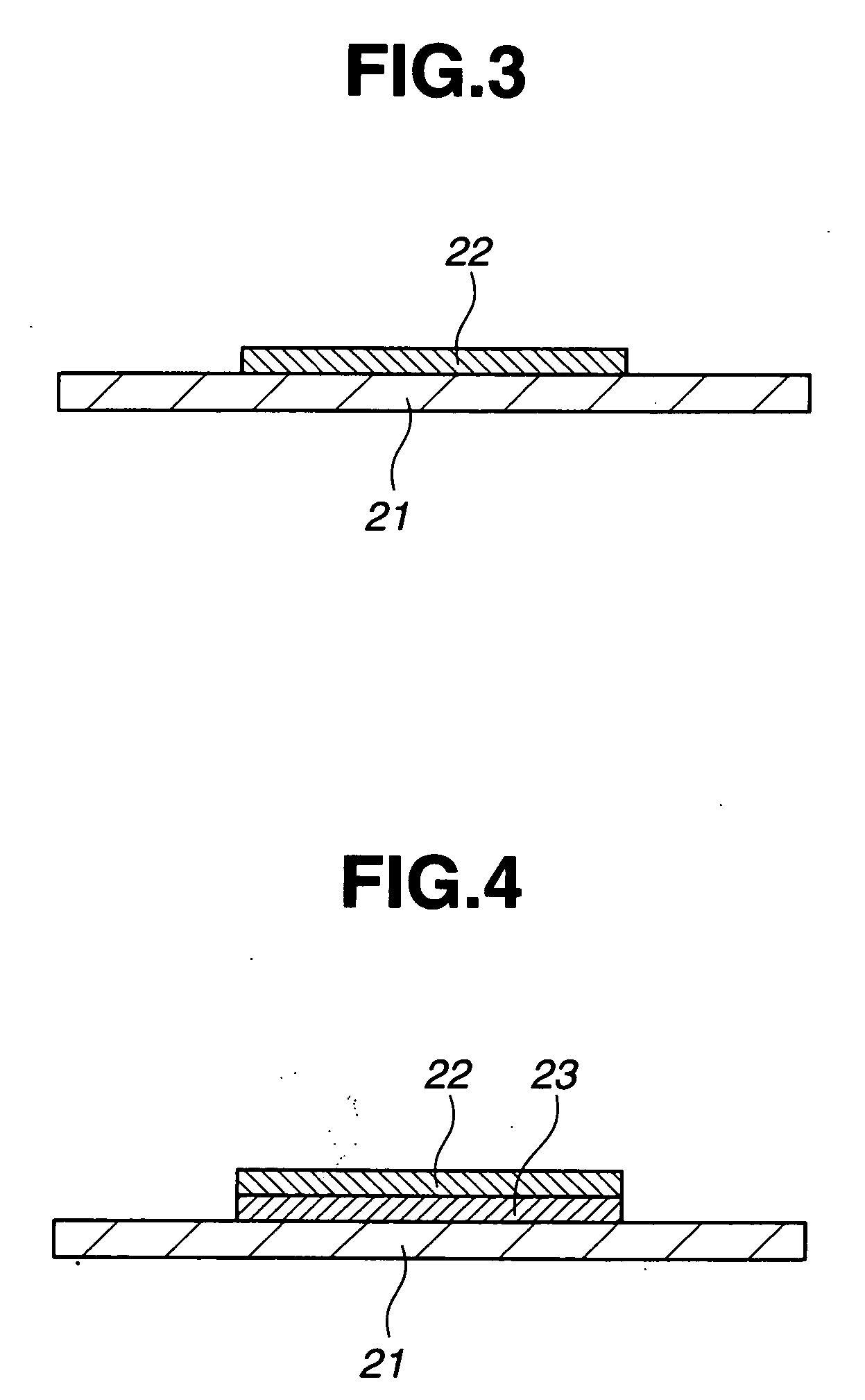

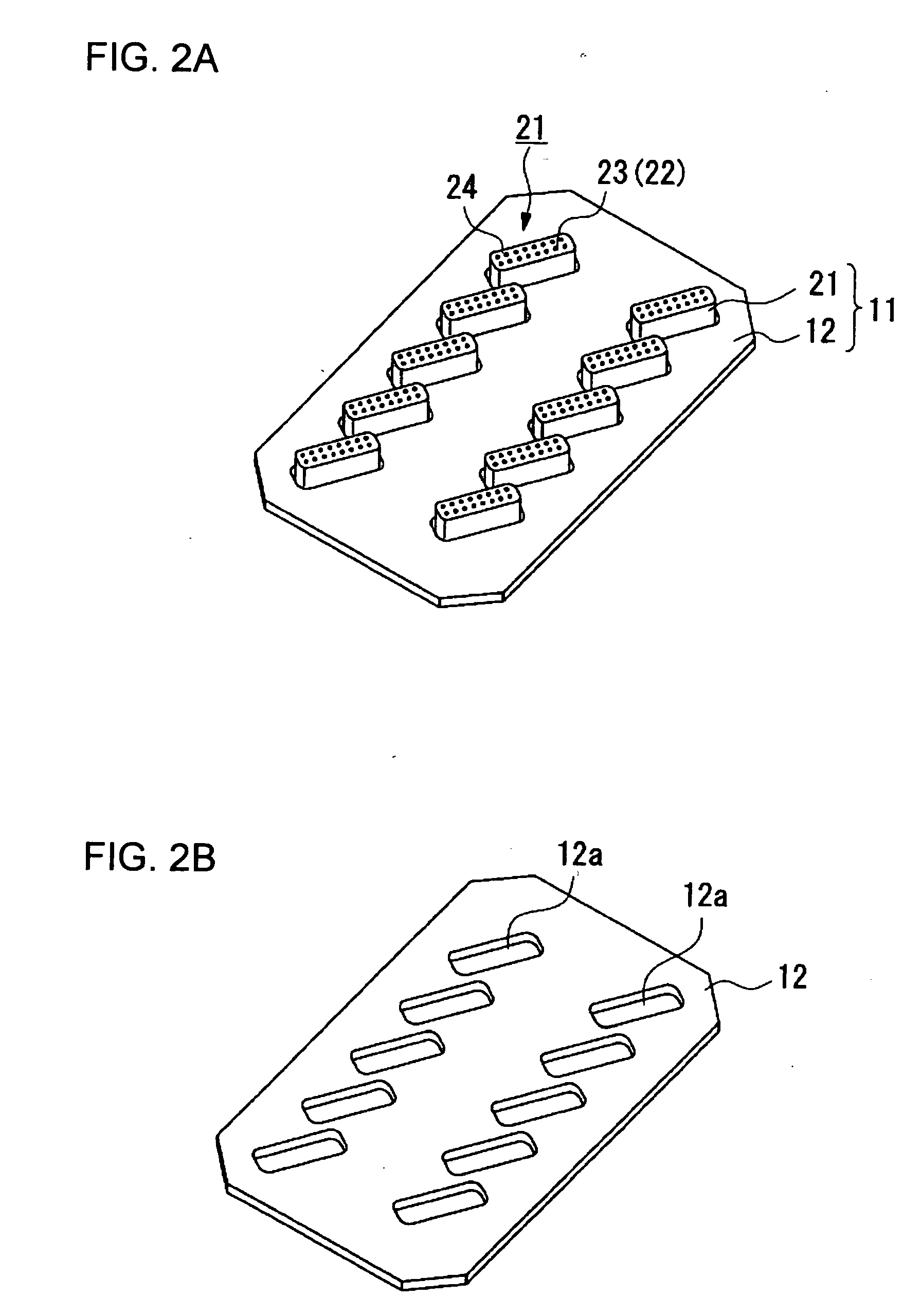

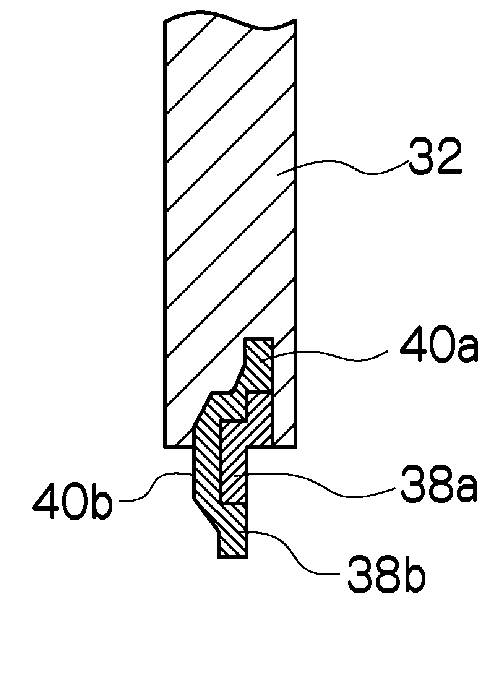

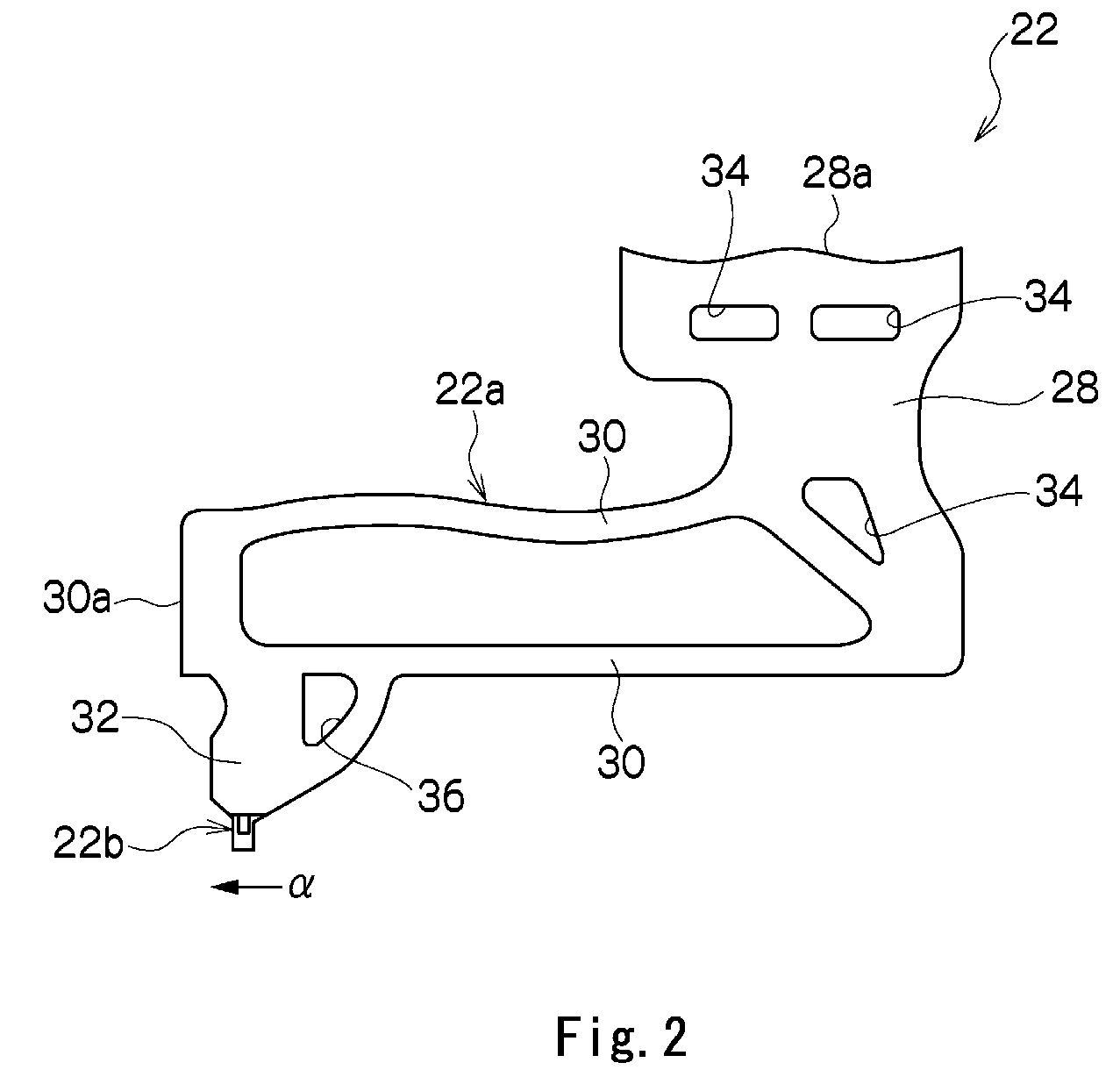

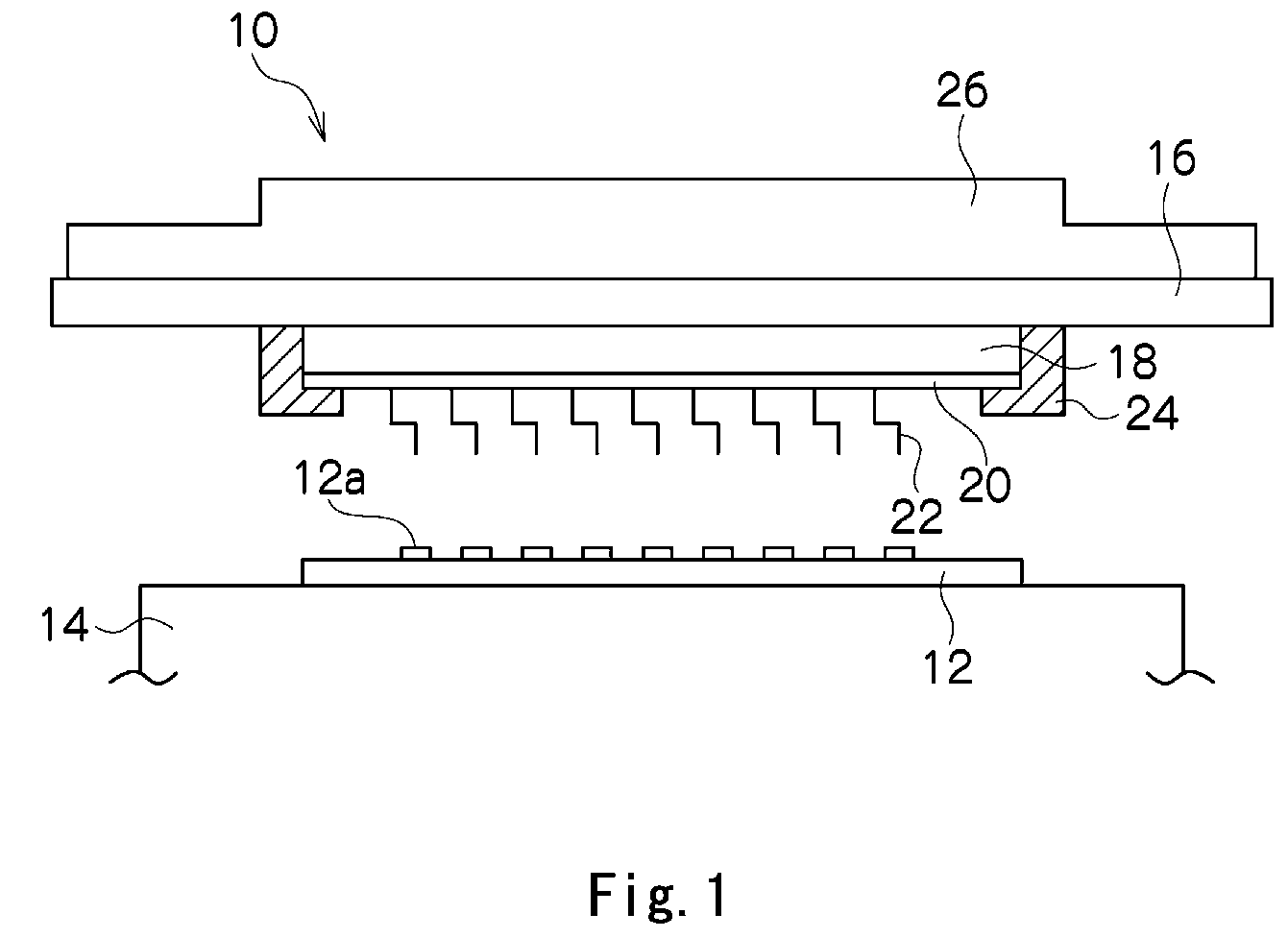

Probe card and method for manufacturing probe card

InactiveUS20050225336A1Well formedEasy to installSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsHigh densityProbe card

A probe card on which micro probe needles are arranged at high density and with high precision with neither the need of a complicated structure or variation in needle height. A probe card 1 installed in a wafer tester comprises a board 2 having a wiring pattern for transmitting a test signal to be impressed on a wafer under test, a built-up board 10 formed on the surface of the board 2, a comb-shaped silicon-made probe needle 20 arranged on the built-up board 10 and connected to the surface wiring pattern 11, and a flat portion 12 formed by plating on the surface wiring pattern 11 on the built-up board 10 and having a surface flattened by polishing. The probe needle 20 is loaded on the flat portion 12 and thus mounted on the board 2.

Owner:ADVANTEST CORP

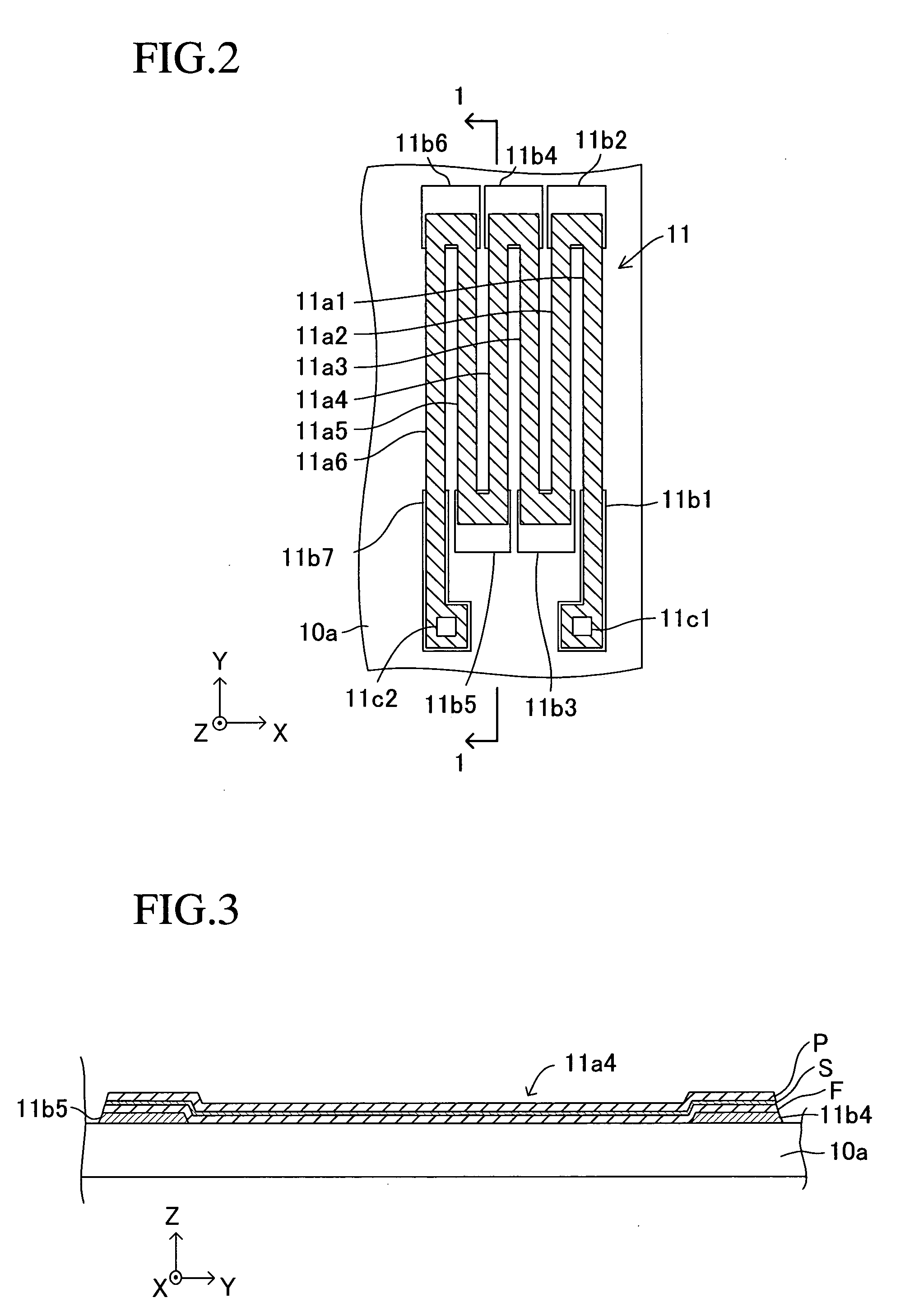

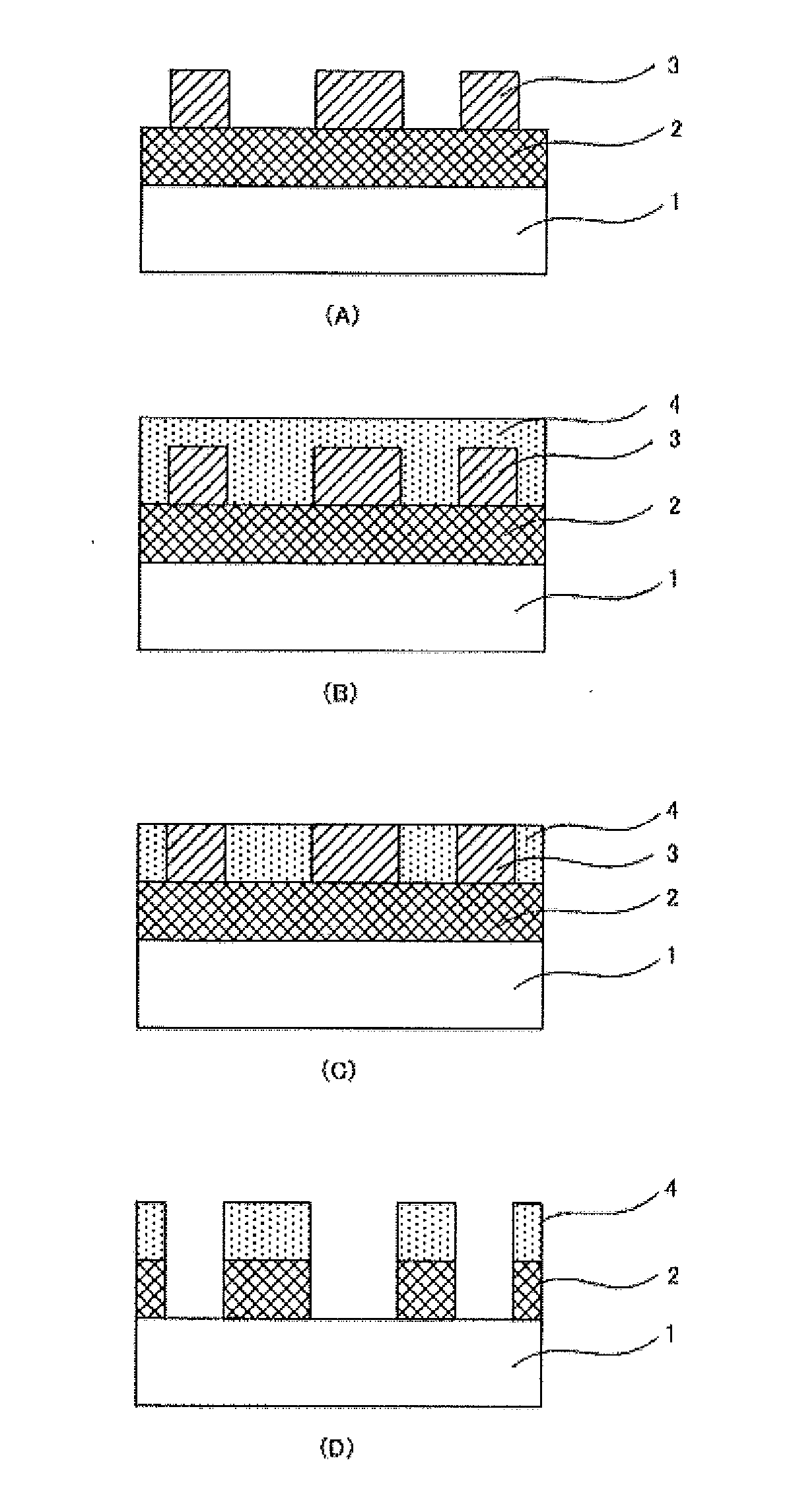

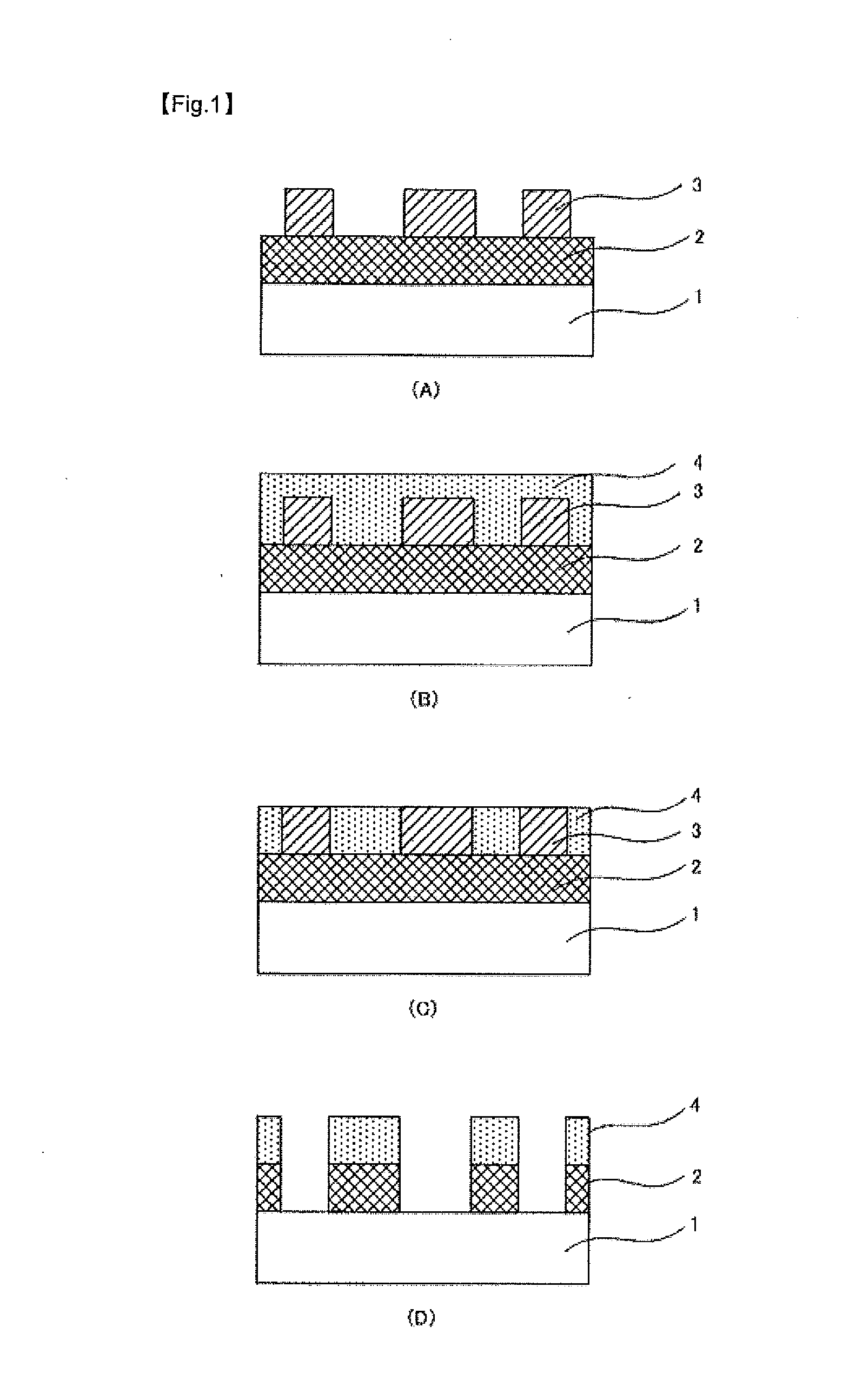

Resist pattern formation method, and resin composition capable of insolubilizing resist pattern

InactiveUS20100323292A1Fine can be formed efficientlyEfficiently formedPhotosensitive materialsSemiconductor/solid-state device manufacturingResistCooking & baking

A resist pattern formation method includes (1) a step of forming a first resist pattern which includes forming a first resist layer on a substrate, selectively exposing the first resist layer to radiation through a mask, and developing the exposed first resist layer, (2) a step of insolubilizing the first resist pattern by coating the first resist pattern with a resist pattern insolubilizing resin composition, baking or curing with UV, and developing the resist pattern insolubilizing resin composition, (3) a step of forming a second resist layer on the insolubilized resist pattern and selectively exposing the second resist layer to radiation through a mask, and (4) a step of developing the exposed second resist layer to form a second resist pattern.

Owner:JSR CORPORATIOON

Composition for forming tungsten oxide film and method for producing tungsten oxide film using same

ActiveUS20140356792A1Form easily and efficientlyImprove productivitySemiconductor/solid-state device manufacturingAnti-corrosive paintsResistWater soluble

Owner:MERCK PATENT GMBH

Magnetic sensor using giant magnetoresistive elements and method for manufacturing the same

InactiveUS20080274270A1Magnetic sensor can be very smallFormed easily and efficientlyNanomagnetismMagnetic measurementsSpin valveMono layer

A magnetic sensor includes a single substrate, a conventional GMR element formed of a spin-valve film including a single-layer-pinned fixed magnetization layer, and a SAF element formed of a synthetic spin-valve film including a plural-layer-pinned fixed magnetization layer. When the spin-valve film intended to act as the conventional GMR element and the synthetic spin-valve film intended to act as the SAF element are subjected to the application of a magnetic field oriented in a single direction at a high temperature, they become giant magnetoresistive elements whose magnetic-field-detecting directions are antiparallel to each other. Since films intended to act as the conventional GMR element and the SAF element can be disposed close to each other, the magnetic sensor which has giant magnetoresistive elements whose magnetic-field-detecting directions are antiparallel to each other can be small.

Owner:YAMAHA CORP

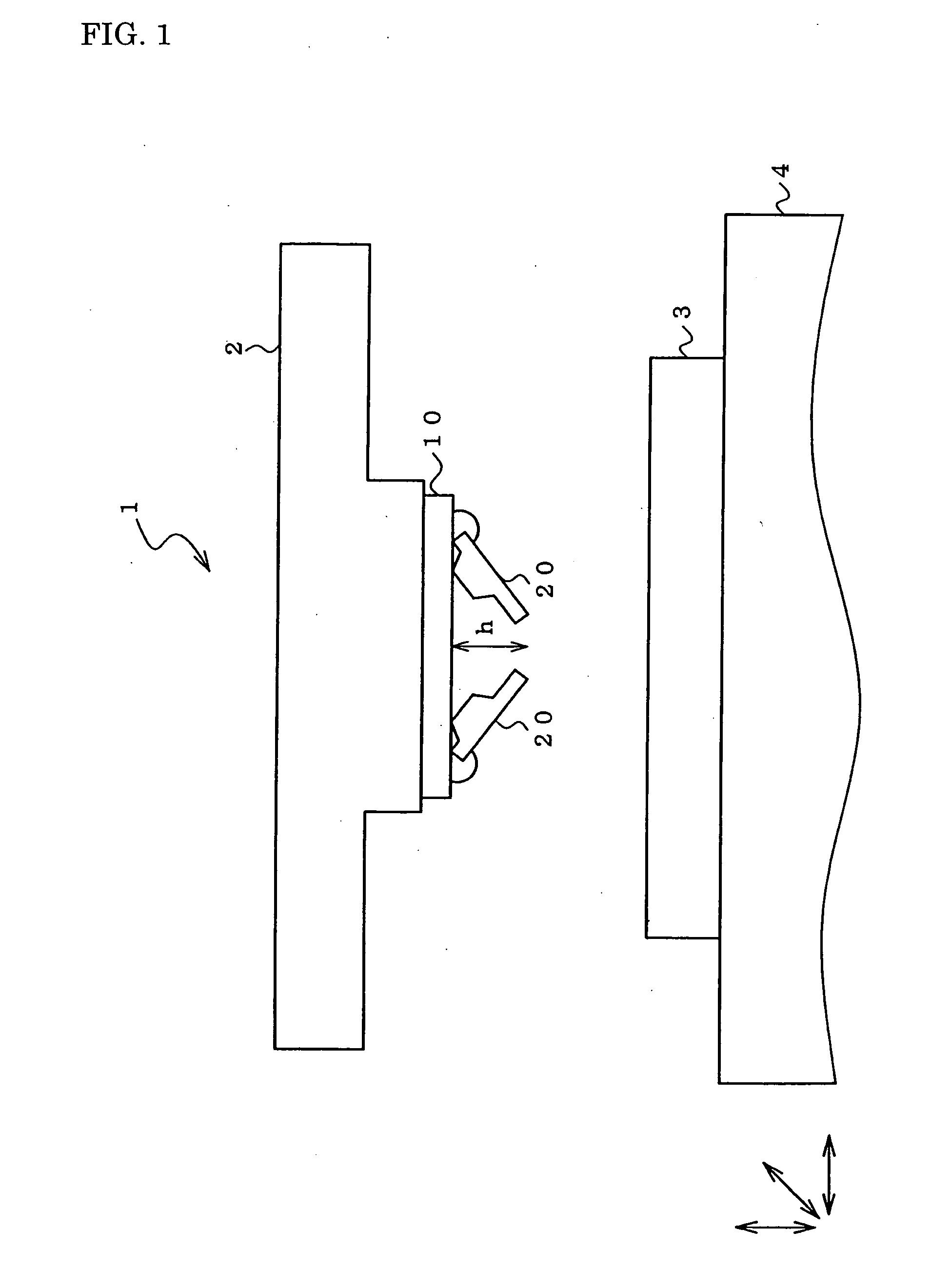

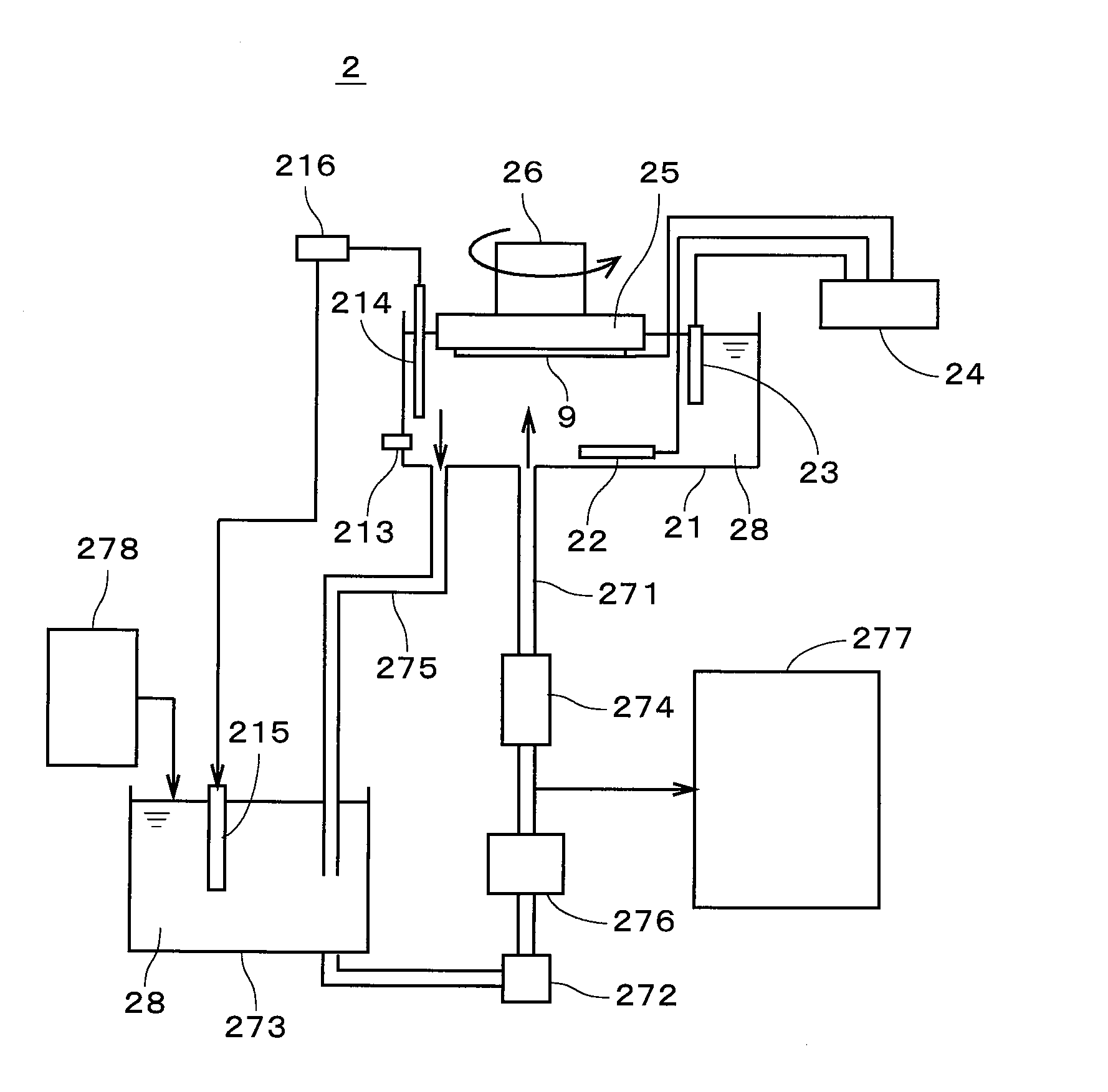

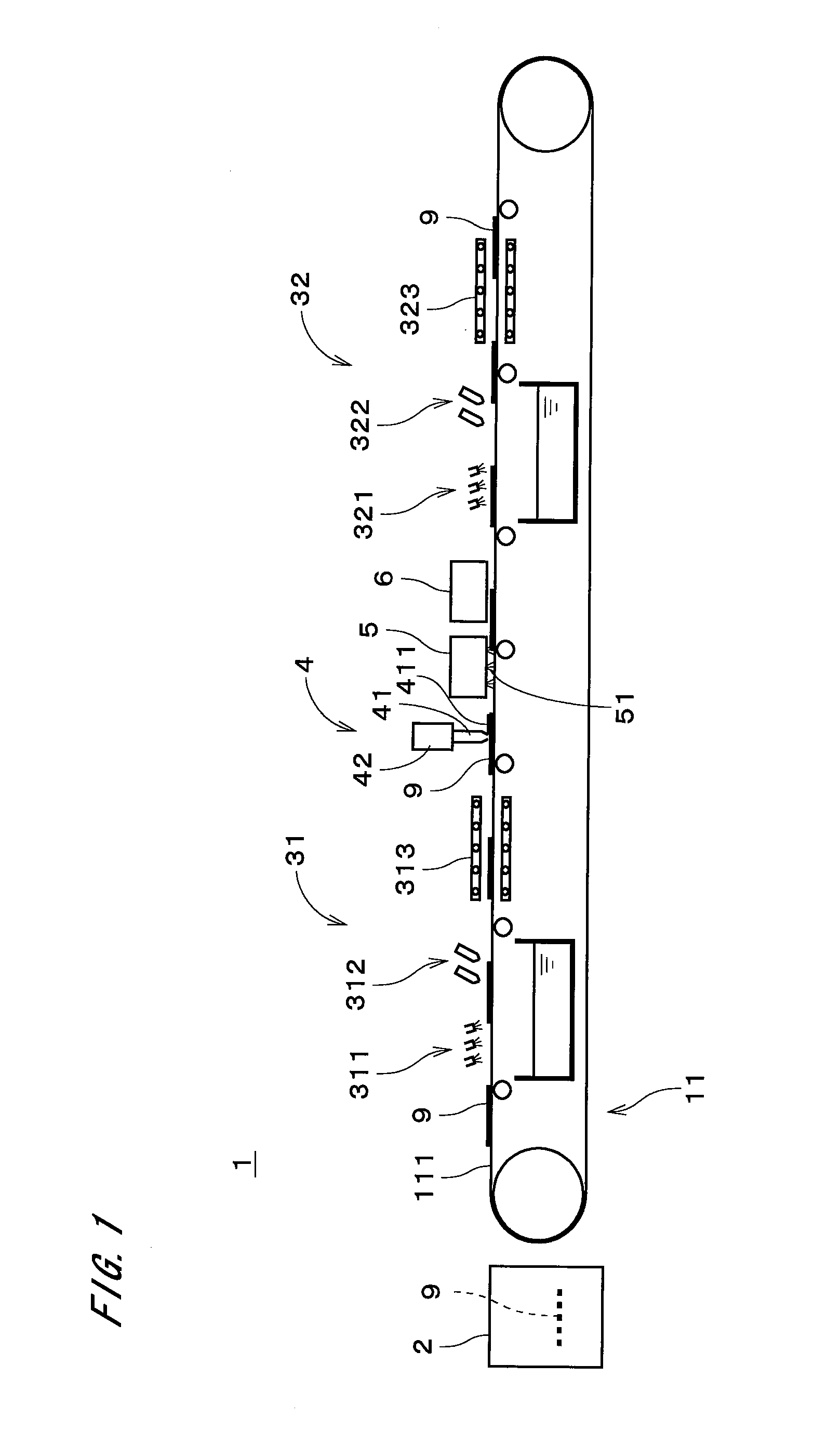

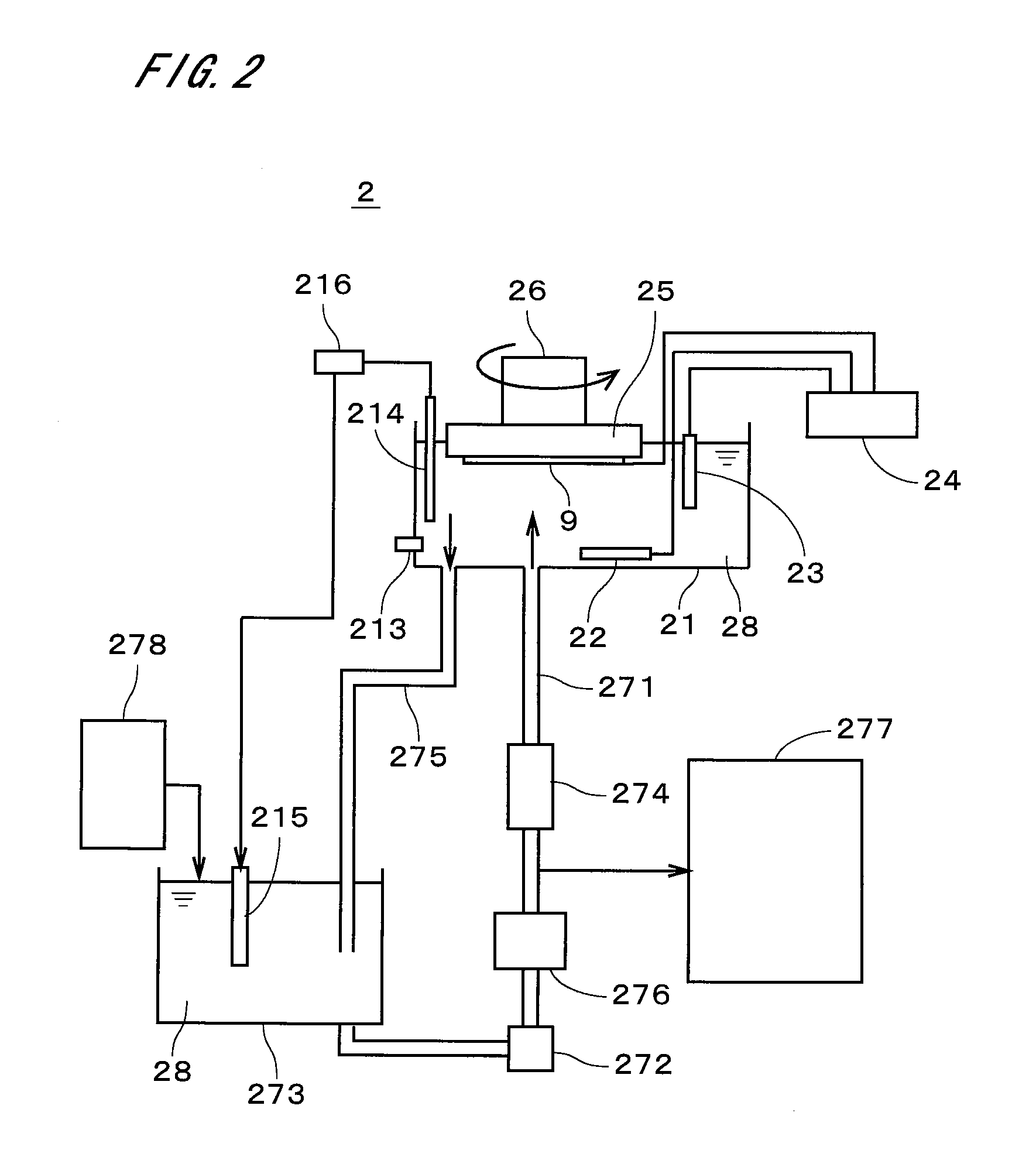

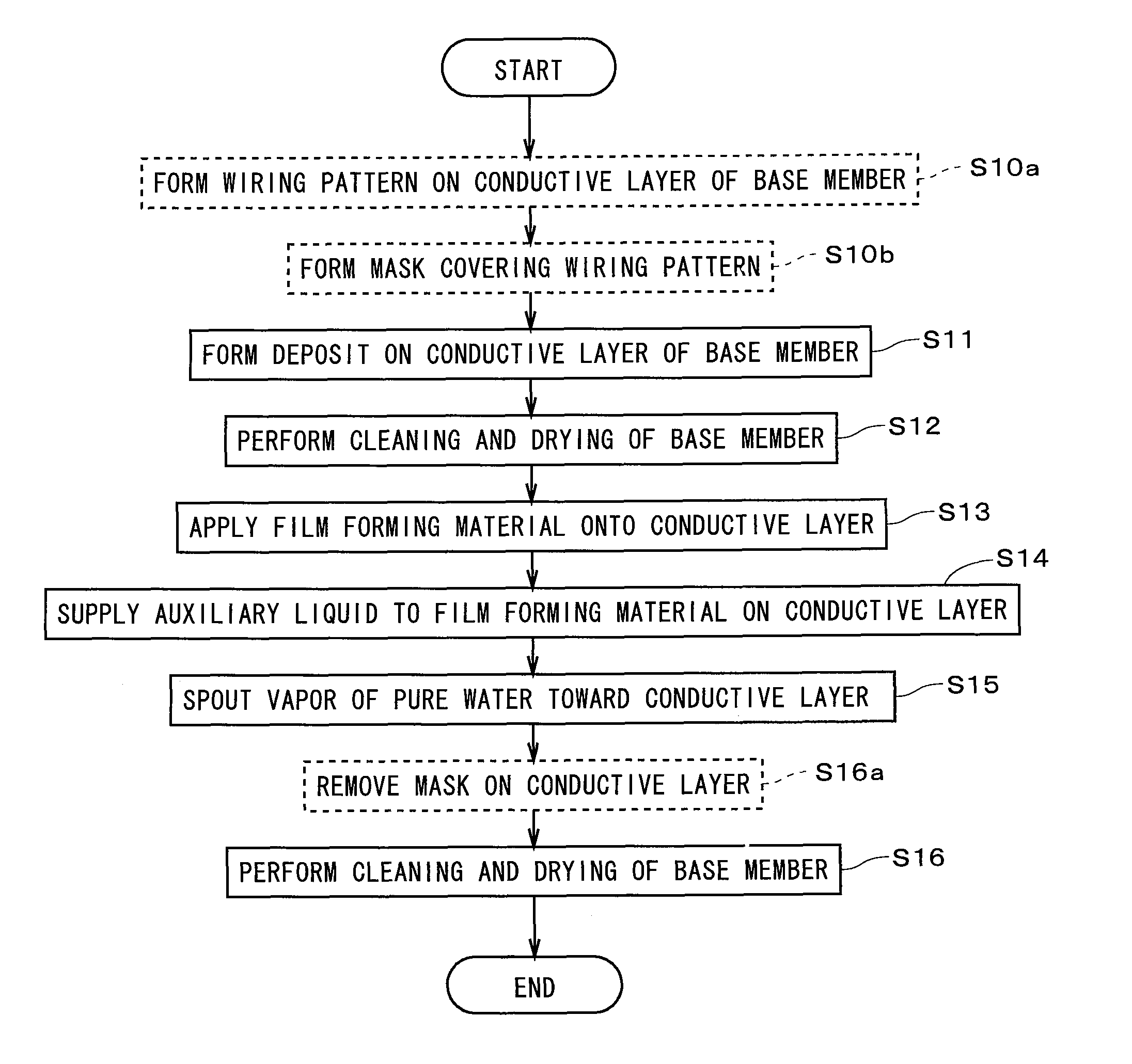

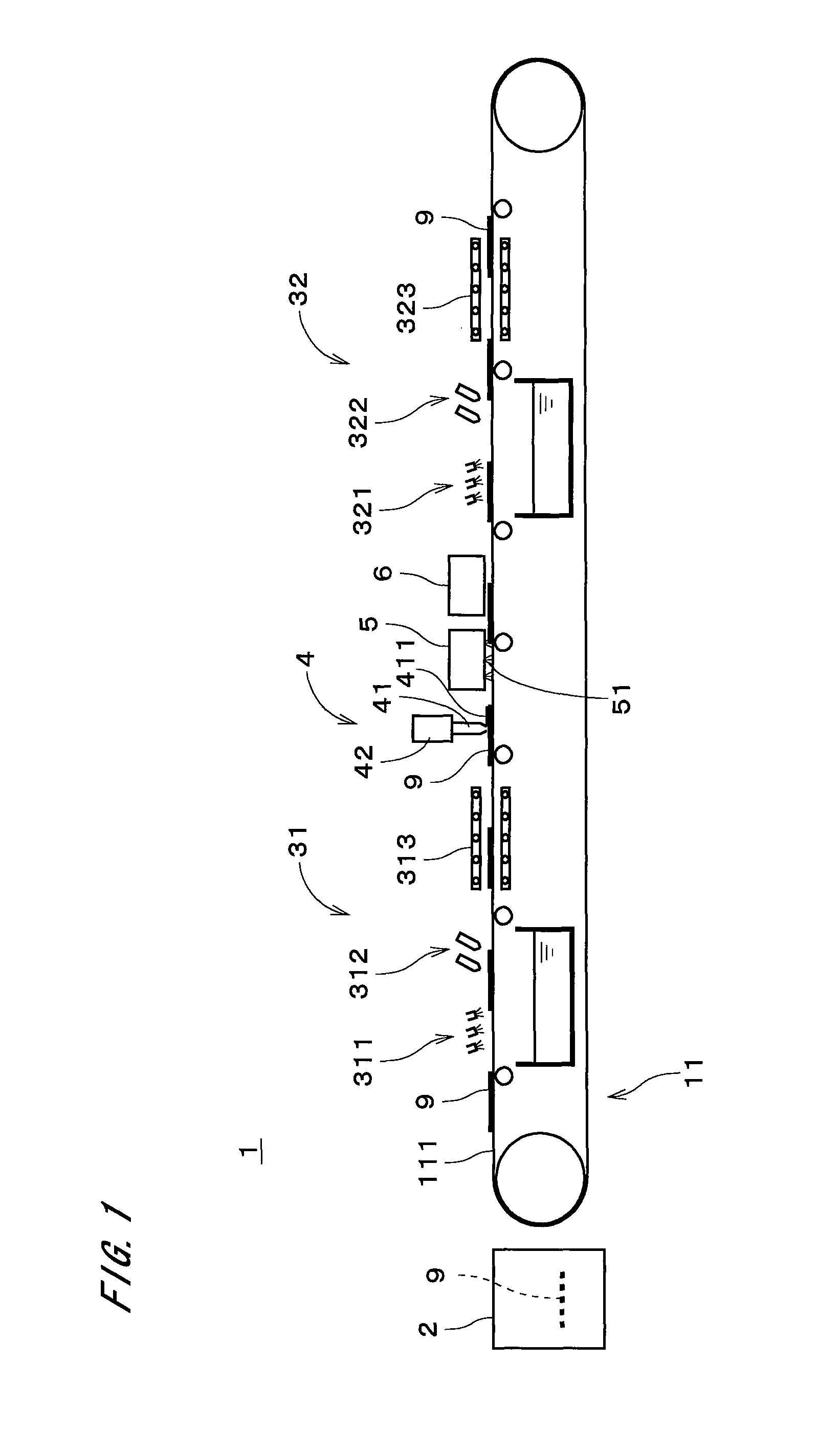

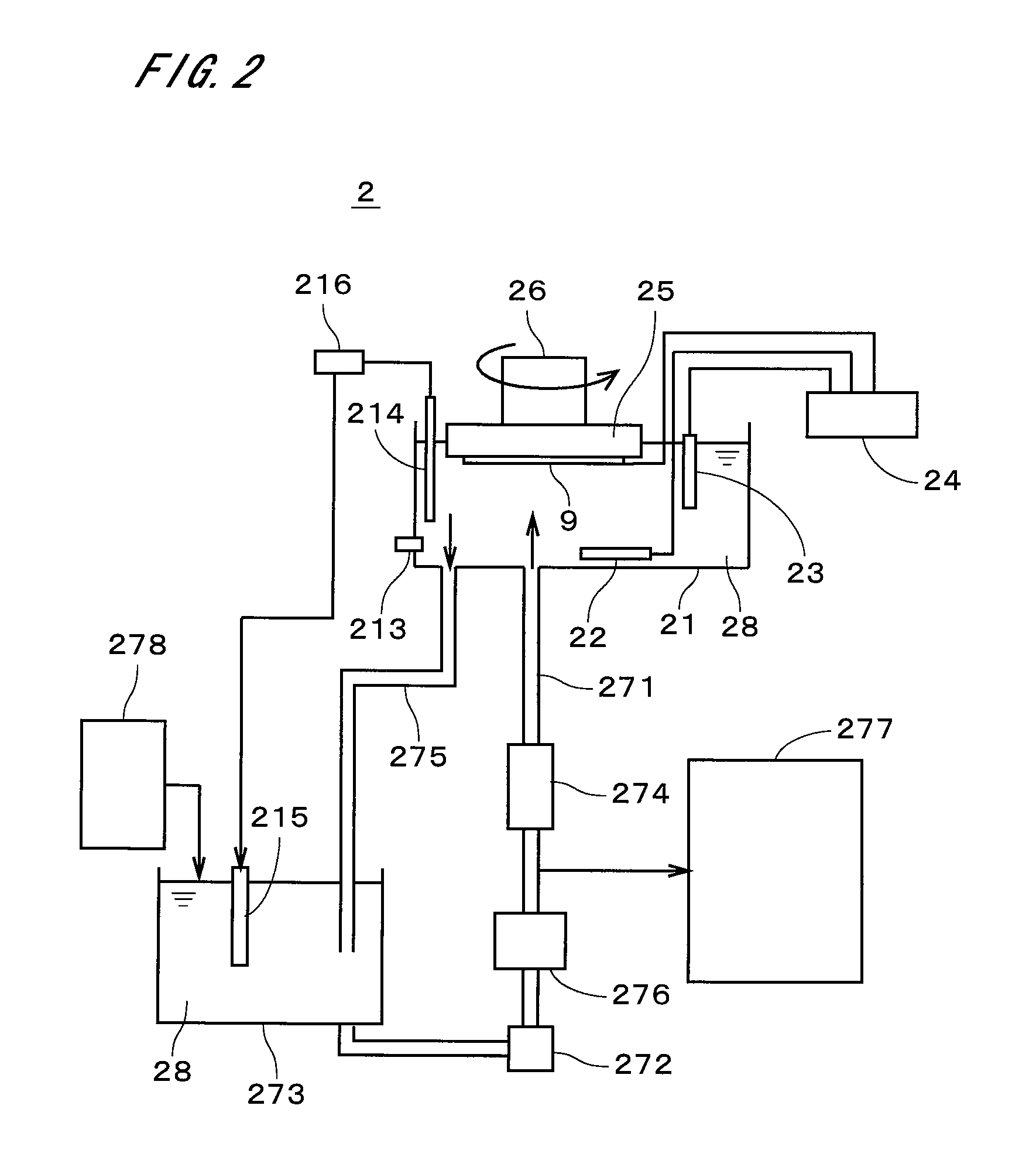

Zinc oxide film forming method and apparatus

InactiveUS20100167460A1Formed easily and efficientlyImprove adhesionCellsElectrolytic capacitorsOptoelectronicsSolvent

In the zinc oxide film forming apparatus (1), the deposit containing zinc oxide is formed on the conductive layer of the resin substrate (9) by electrodeposition in the deposition part (2), and the resin substrate (9) is carried to the applying part (4). Subsequently, the film forming material which is in liquid or paste form and contains particles of zinc oxide and solvent is applied onto the conductive layer, and then the solvent is removed from the film forming material on the conductive layer by volatilization. It is therefore possible to easily and efficiently form the porous zinc oxide film which has superior adhesion to the conductive layer of the resin substrate (9).

Owner:DAINIPPON SCREEN MTG CO LTD

Method for preparing golf ball with indicia having metallic luster

InactiveUS20070149319A1Formed easily and efficientlyLamination ancillary operationsDecorative surface effectsEngineeringGolf Ball

A method for preparing a golf ball with surface indicia such as a letter or image having metallic luster includes the steps of forming an adhesive indicia made of a thermoplastic resin on a golf ball surface, bonding the metal thin-film on a metal thin film-bearing film over the indicia under pressure or heat and pressure, then peeling off the film so as to leave a portion of the metal thin-film having the same shape as the indicia adhering to and laminated with the indicia.

Owner:BRIDGESTONE SPORTS

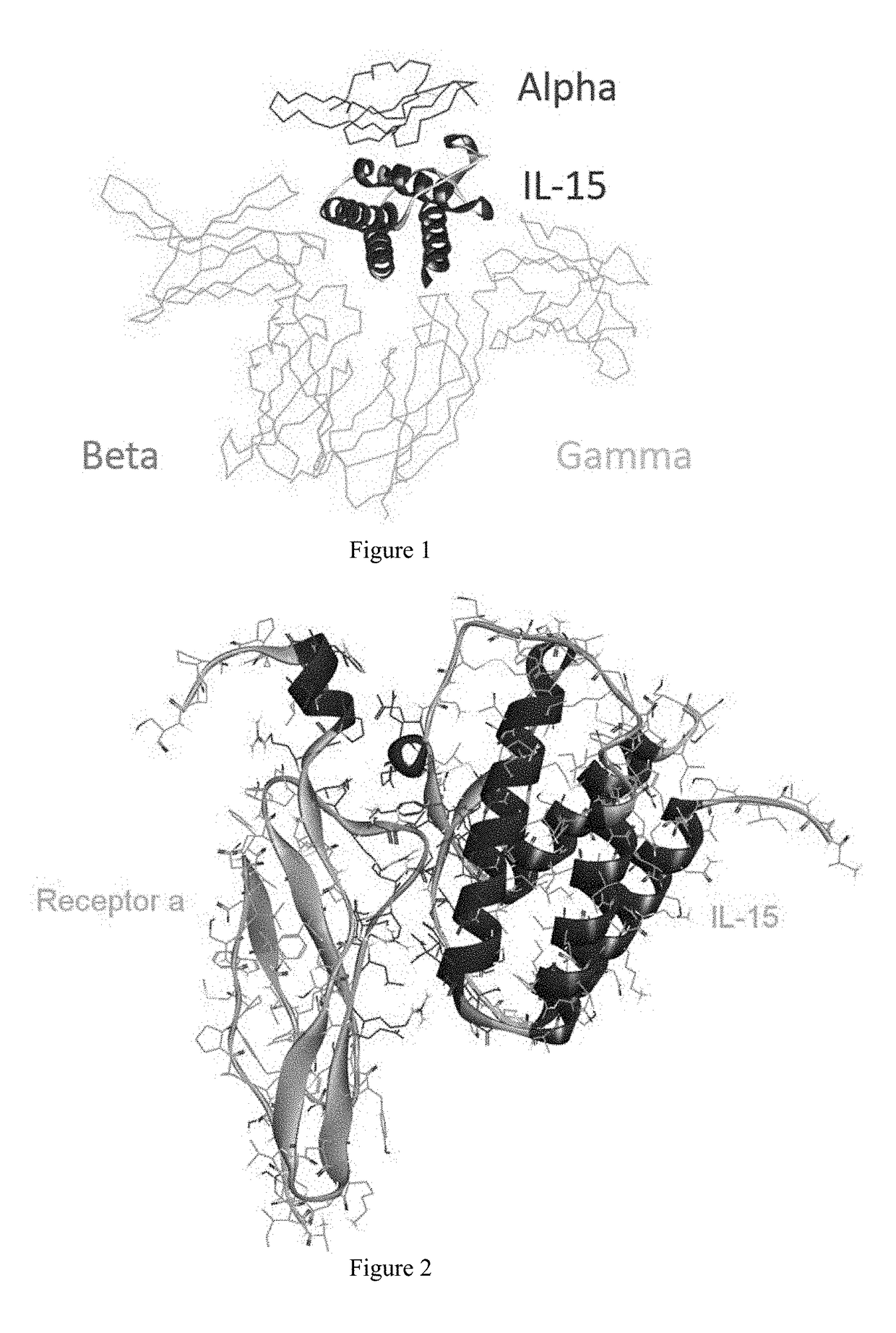

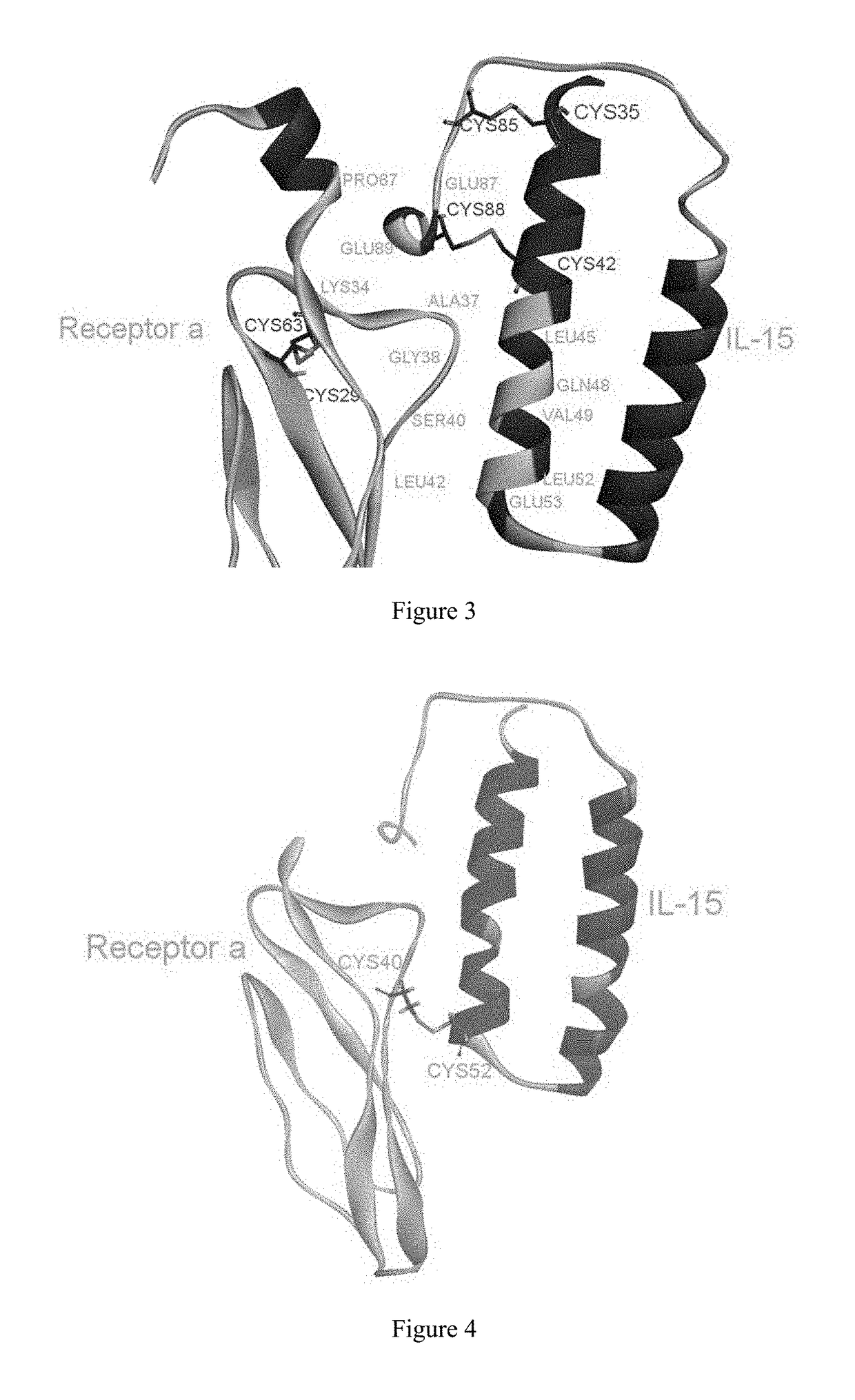

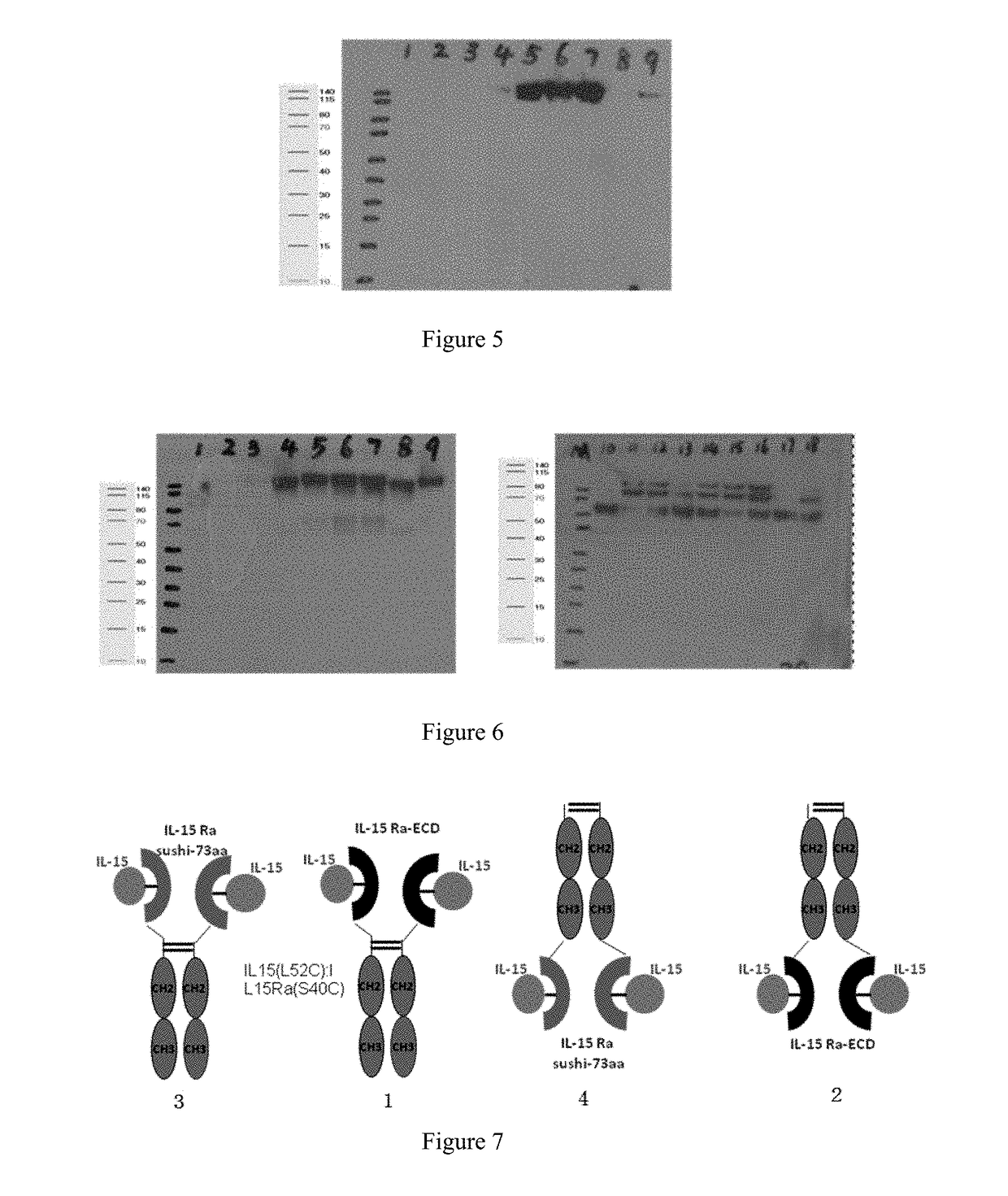

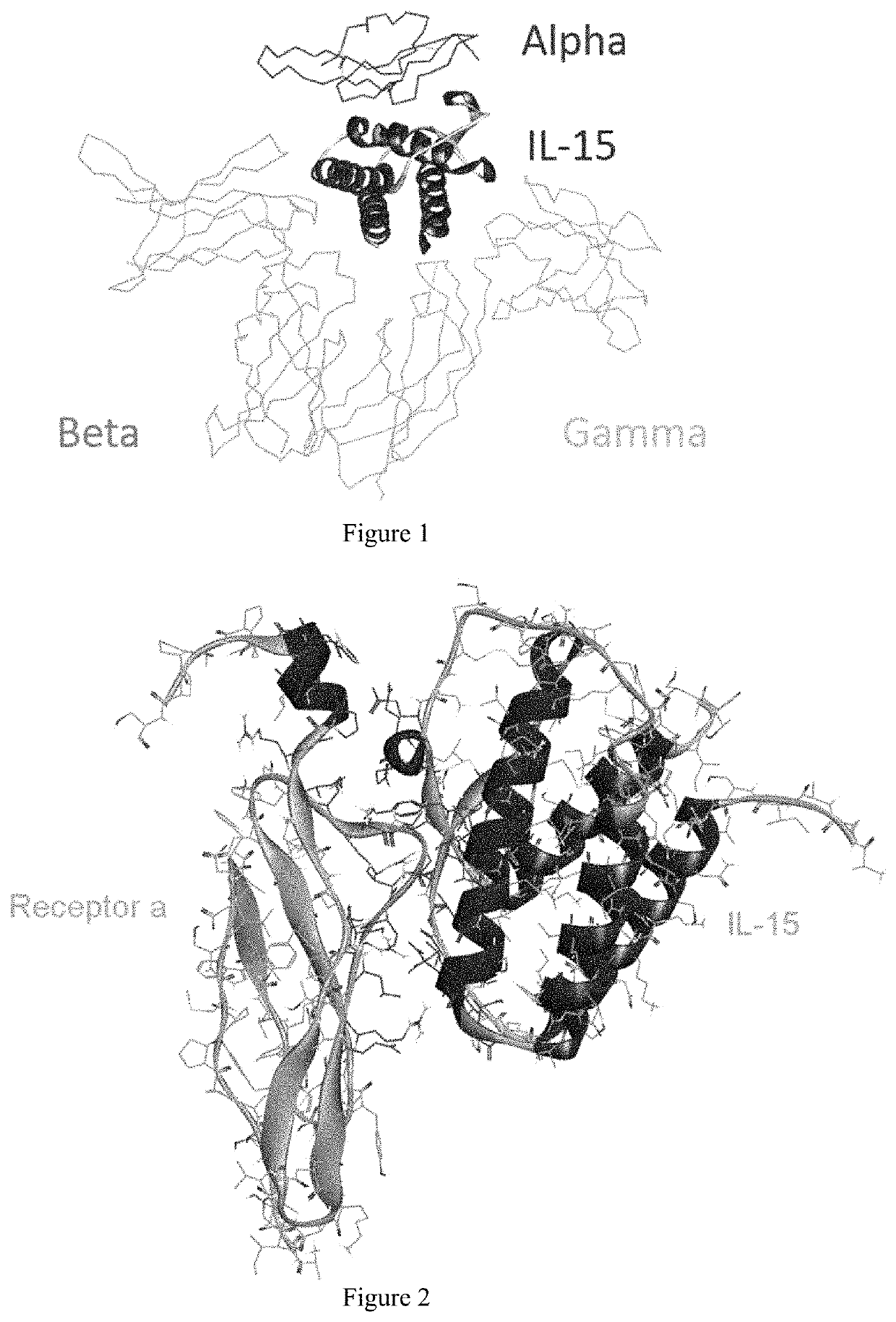

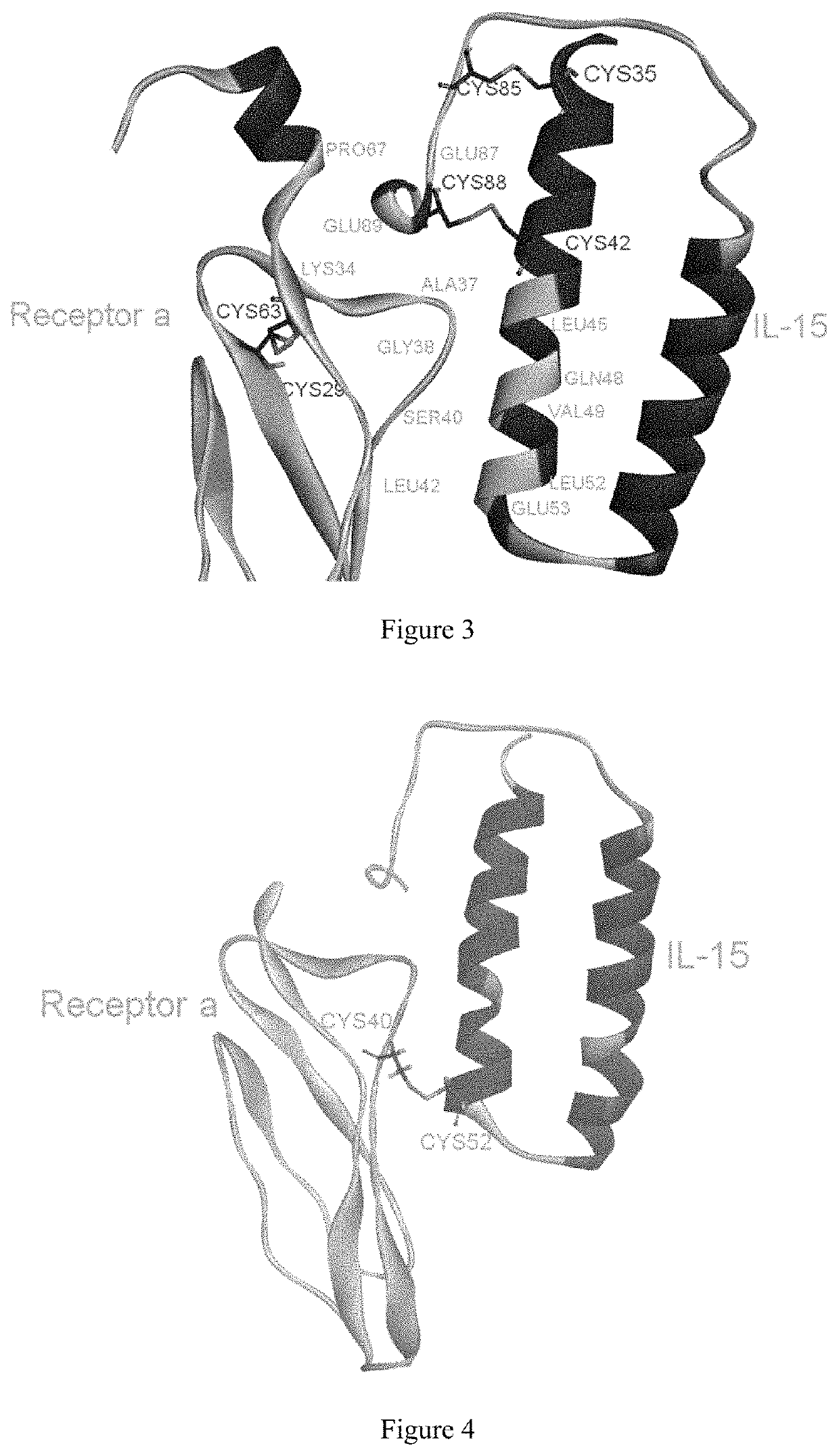

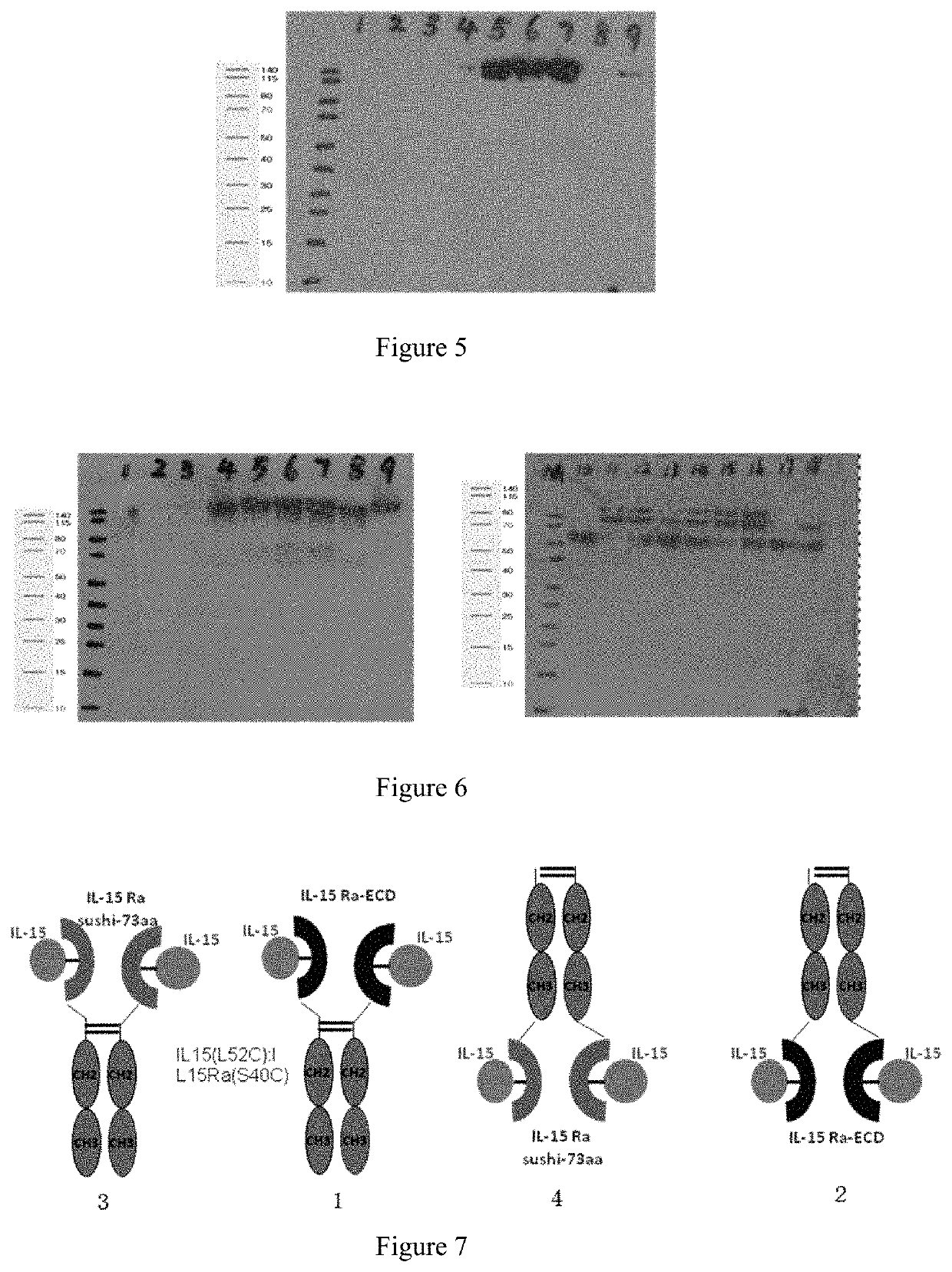

Interleukin 15 protein complex and use thereof

ActiveUS20190070264A1Prolong half-life in vivoImprove in vitro activityPeptide/protein ingredientsAntibody mimetics/scaffoldsADAMTS ProteinsProtein-protein complex

An interleukin 15 (IL-15) protein complex is provided. The IL-15 protein complex includes soluble fusion proteins (I) and (II), wherein the fusion protein (I) is an IL-15 polypeptide or a functional fragment thereof, and the soluble fusion protein (II) is an IL-15Rα polypeptide or a functional fragment thereof. The soluble fusion protein (I) has at least one amino acid residue mutated to a cysteine (Cys) residue, which pairs with a corresponding mutated Cys residue on the soluble fusion protein (II), or vice versa, to form one or more disulfide bonds. The IL-15 protein complex can be used for tumor therapy.

Owner:JIANGSU HENGRUI MEDICINE CO LTD +1

Resin composition for spacer, spacer, and liquid crystal display device

InactiveUS7323232B2High compressive strengthForm easily and efficientlyLiquid crystal compositionsElectrode assembly support/mounting/spacing/insulationChemistryLiquid-crystal display

To provide a resin composition for spacer useful for the formation of a pixel-patterned spacer on a substrate in a liquid crystal display device, a spacer using the composition, and a liquid crystal display device that can display high-quality images, a resin composition for spacer contains at least one resin selected from (1) an allyl-containing resin, (2) an allyl-and-hydroxyl-containing resin, and (3) a resin mixture of an allyl-containing resin and a hydroxyl-containing resin.

Owner:FUJIFILM HLDG CORP +1

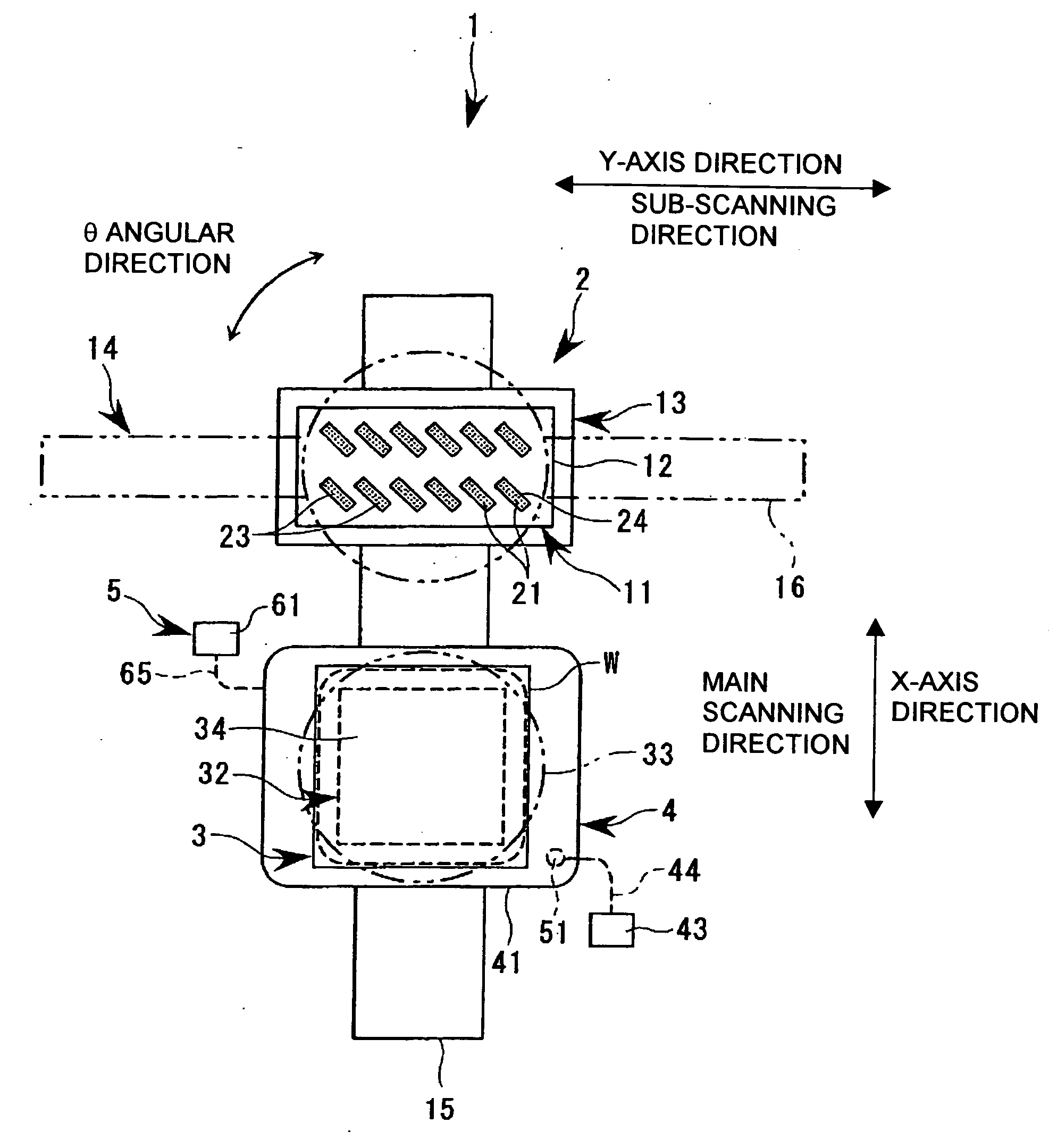

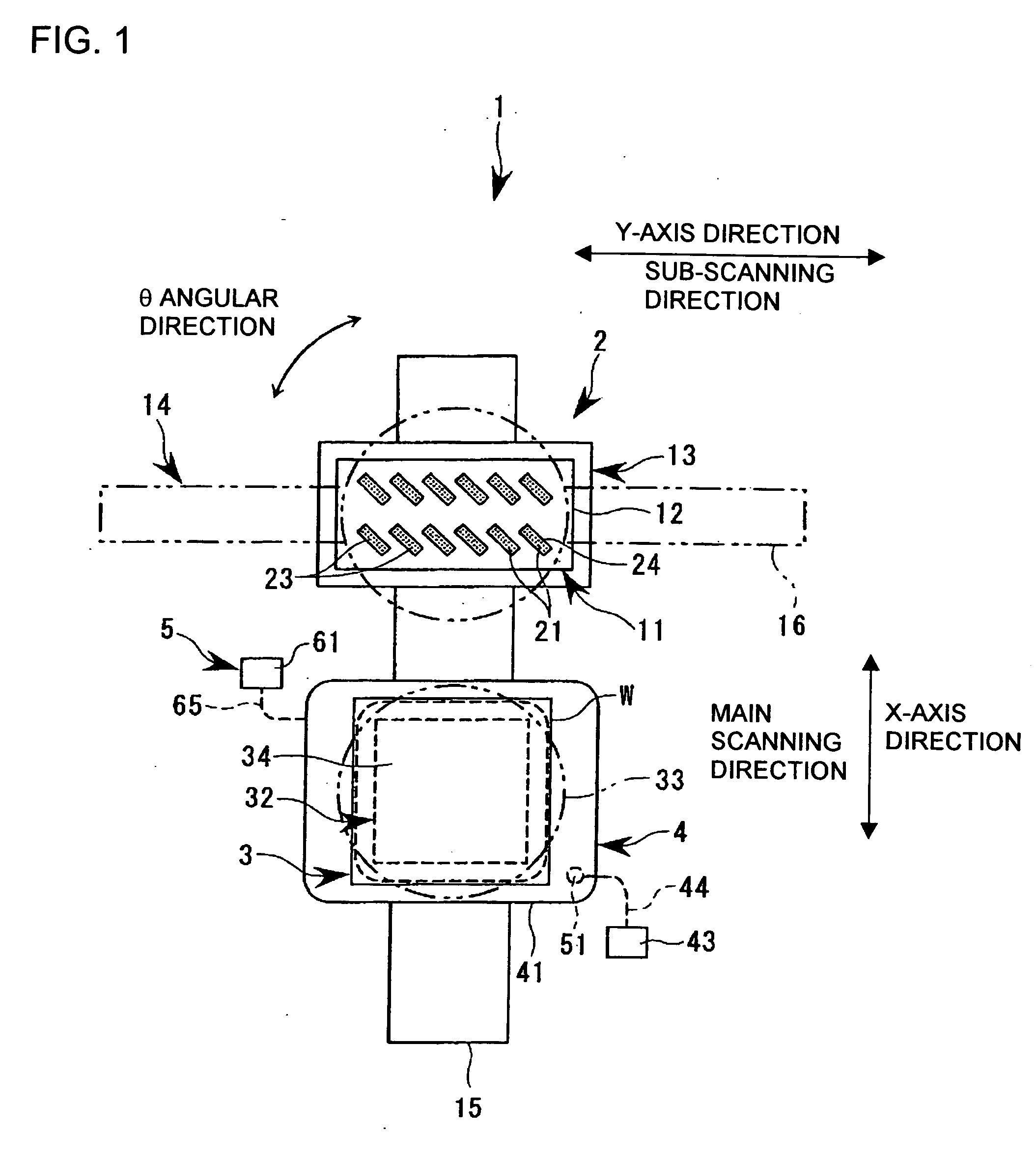

Film forming method, film forming apparatus, method of manufacturing device, and apparatus for manufacturing device

InactiveUS20070042111A1Reduce throughputFormed easily and efficientlyOptical filtersSolid-state devicesEngineeringLiquid drop

The invention provides a film forming method that improves throughput in a preliminary discharge. The film forming method according to the present invention can include a preliminary discharge step of preliminarily discharging liquid droplets from a head and a liquid droplet discharge step of relatively moving the head and the work to discharge the liquid droplets onto the surface of the work from the head. The preliminary discharge of the liquid droplets is carried out while the head and the work are moved relative to each other.

Owner:KATEEVA

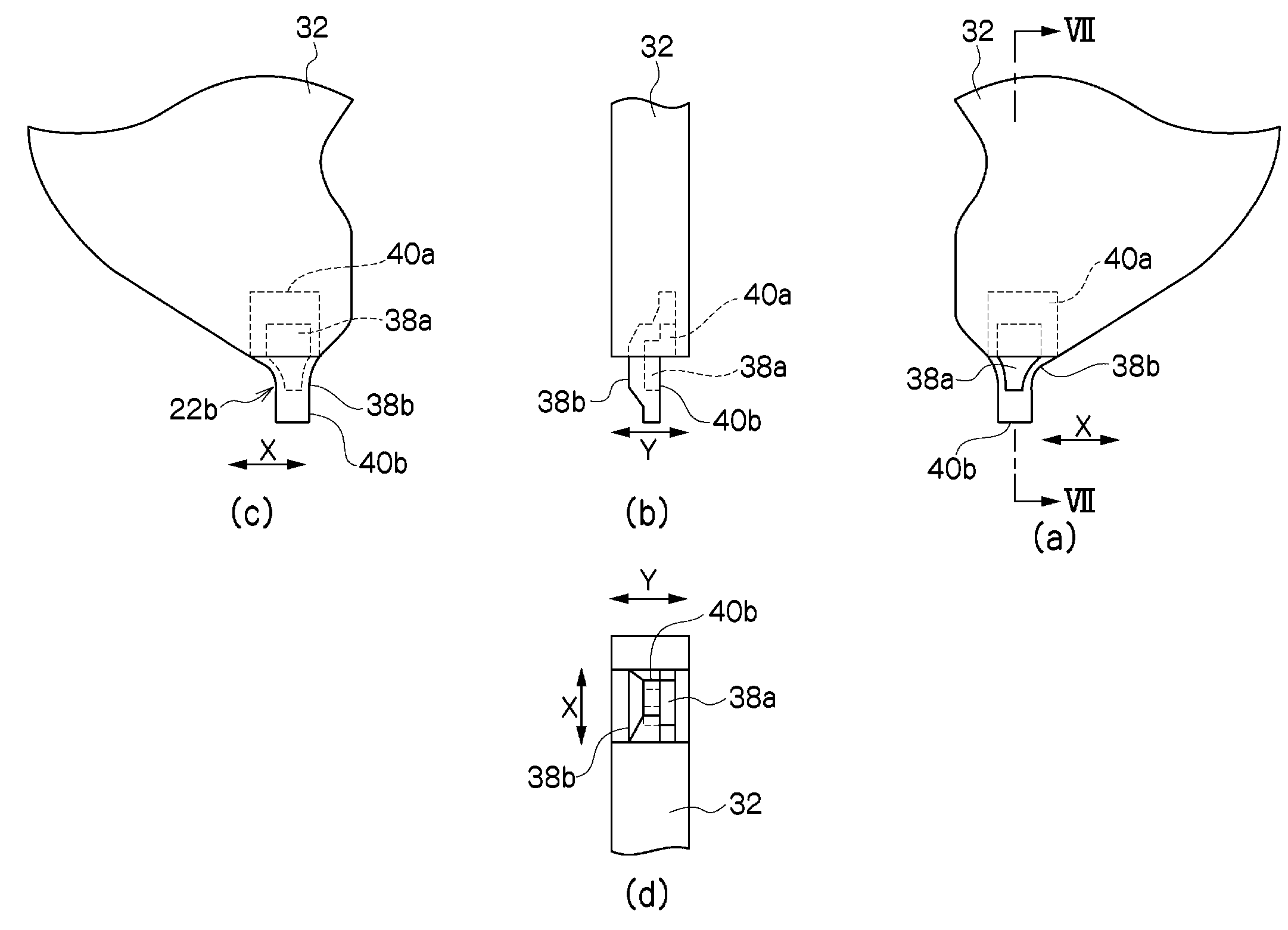

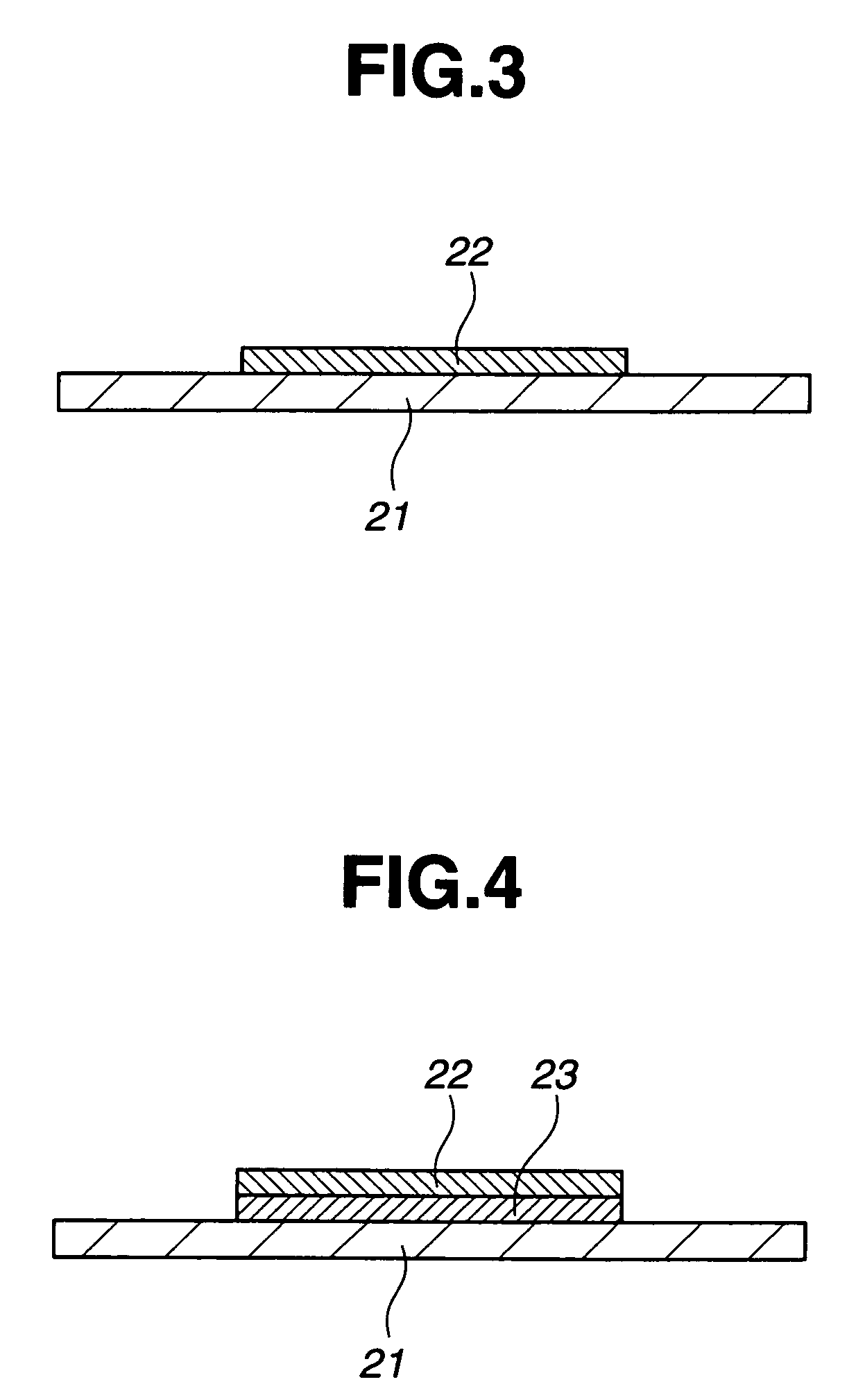

Method for manufacturing an electrical test probe

ActiveUS7736690B2Increased durabilityIncrease the cross-sectional areaContact member manufacturingElectrical measurement instrument detailsBiomedical engineeringTest probe

A probe tip section of an electrical test probe has a laminated structure consisting of a first deposition portion and a second deposition portion covering the first deposition portion, and by the laminated structure, a maximum cross-sectional area portion at which the cross-sectional area of the probe tip section is increased to a base portion is provided between a tip end of the probe tip section and the base portion in the probe tip section. At the maximum cross-sectional area portion, a dimension in the X direction as seen on a flat surface perpendicular to a protruding direction of the probe tip section is increased in a one-dimensional way, and in addition, a dimension in the Y direction perpendicular to the X direction is increased from the tip end toward the base portion, as a result of which the cross-sectional area of the probe tip section can be increased in a two-dimensional way. Thus, the cross-sectional area at the maximum cross-sectional area portion reaching the base portion of the probe tip section can be made to be larger than in the conventional case, and along with the increase of the cross-sectional area, the stress acting on the base portion can be lowered.

Owner:NIHON MICRONICS

Zinc oxide film forming method and apparatus

InactiveUS8361831B2Formed easily and efficientlyImprove adhesionElectrolytic capacitorsSemiconductor/solid-state device manufacturingOptoelectronicsSolvent

In the zinc oxide film forming apparatus (1), the deposit containing zinc oxide is formed on the conductive layer of the resin substrate (9) by electrodeposition in the deposition part (2), and the resin substrate (9) is carried to the applying part (4). Subsequently, the film forming material which is in liquid or paste form and contains particles of zinc oxide and solvent is applied onto the conductive layer, and then the solvent is removed from the film forming material on the conductive layer by volatilization. It is therefore possible to easily and efficiently form the porous zinc oxide film which has superior adhesion to the conductive layer of the resin substrate (9).

Owner:DAINIPPON SCREEN MTG CO LTD

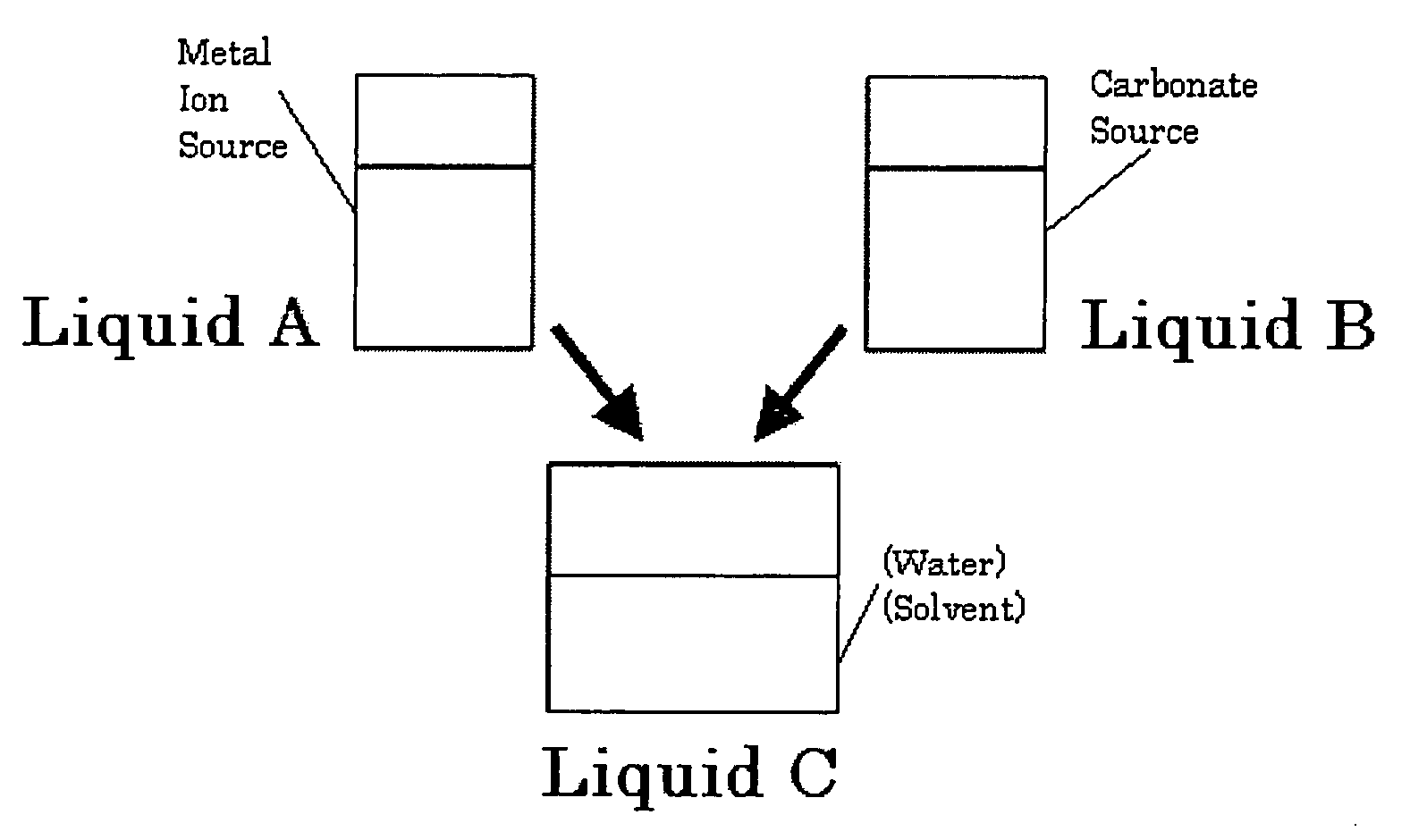

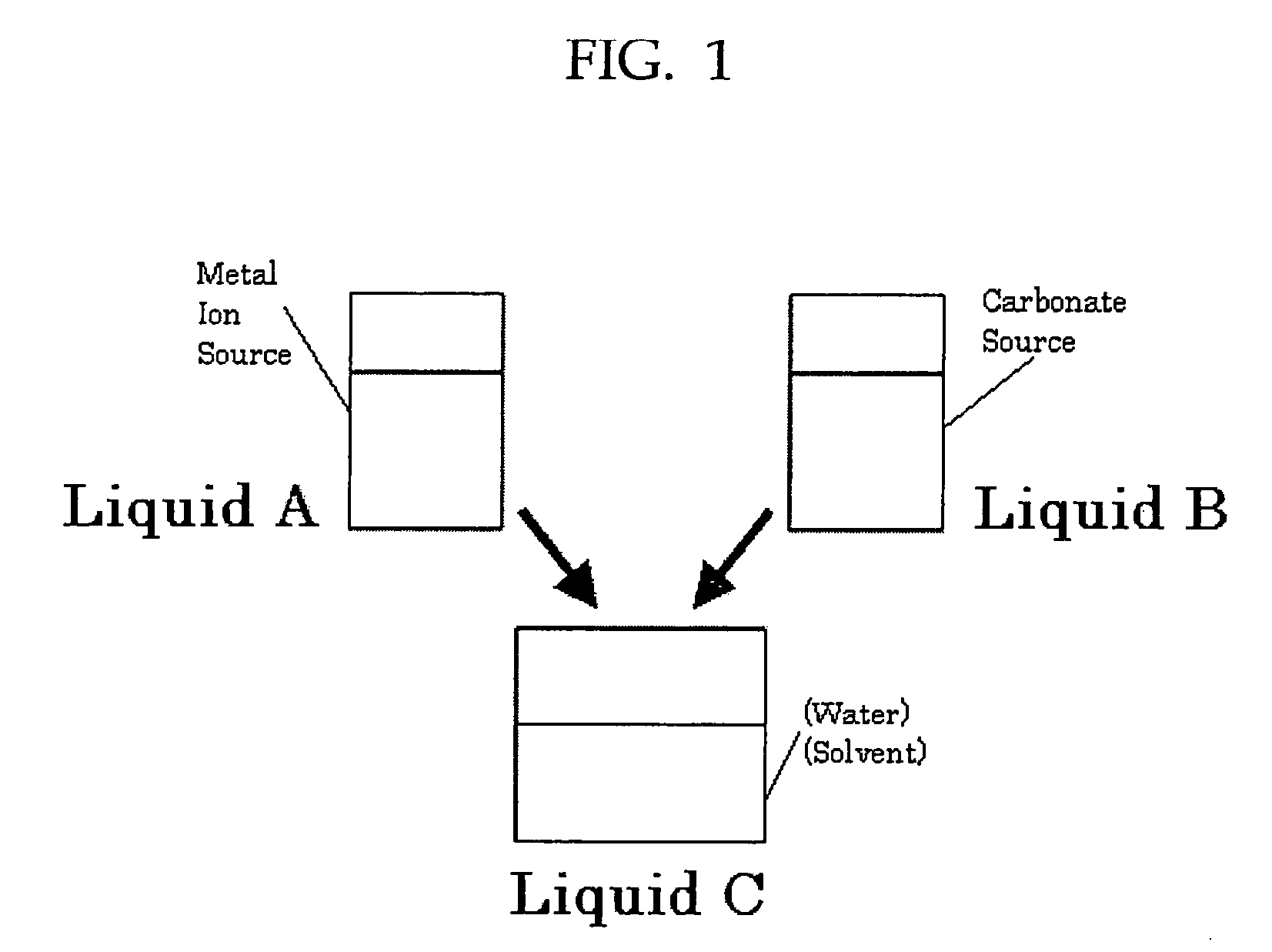

Carbonate Crystal, Manufacturing Method Thereof, And Transparent Optical Resin Composition

InactiveUS20090124744A1Large aspect ratioFormed easily and efficientlyMaterial nanotechnologyPolycrystalline material growthTransmittanceCarbonate

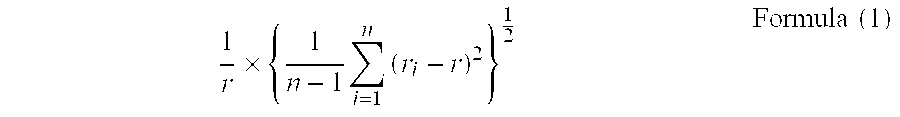

The object of the present invention is to provide a carbonate crystal, which has oriented birefringence, is needle- or rod-like, and is able to negate the birefringence without sacrificing the light transmittance of a transparent polymeric resin when it exists in the transparent resin; a manufacturing method of the carbonate crystal; and a transparent optical resin composition comprising the carbonate resin. The carbonate crystal has an aspect ratio of two or greater, the average major axis length of 400 nm or shorter, and the variation coefficient expressed in Formula (1) below is 0.40 or less:1r×{1n-1∑i=1n(ri-r)2}12Formula(1)wherein r denotes an average major axis length, n denotes the number of particles used for the measurement of the major axis length, and n denotes the major axis length of the ith particle measured.

Owner:FUJIFILM CORP

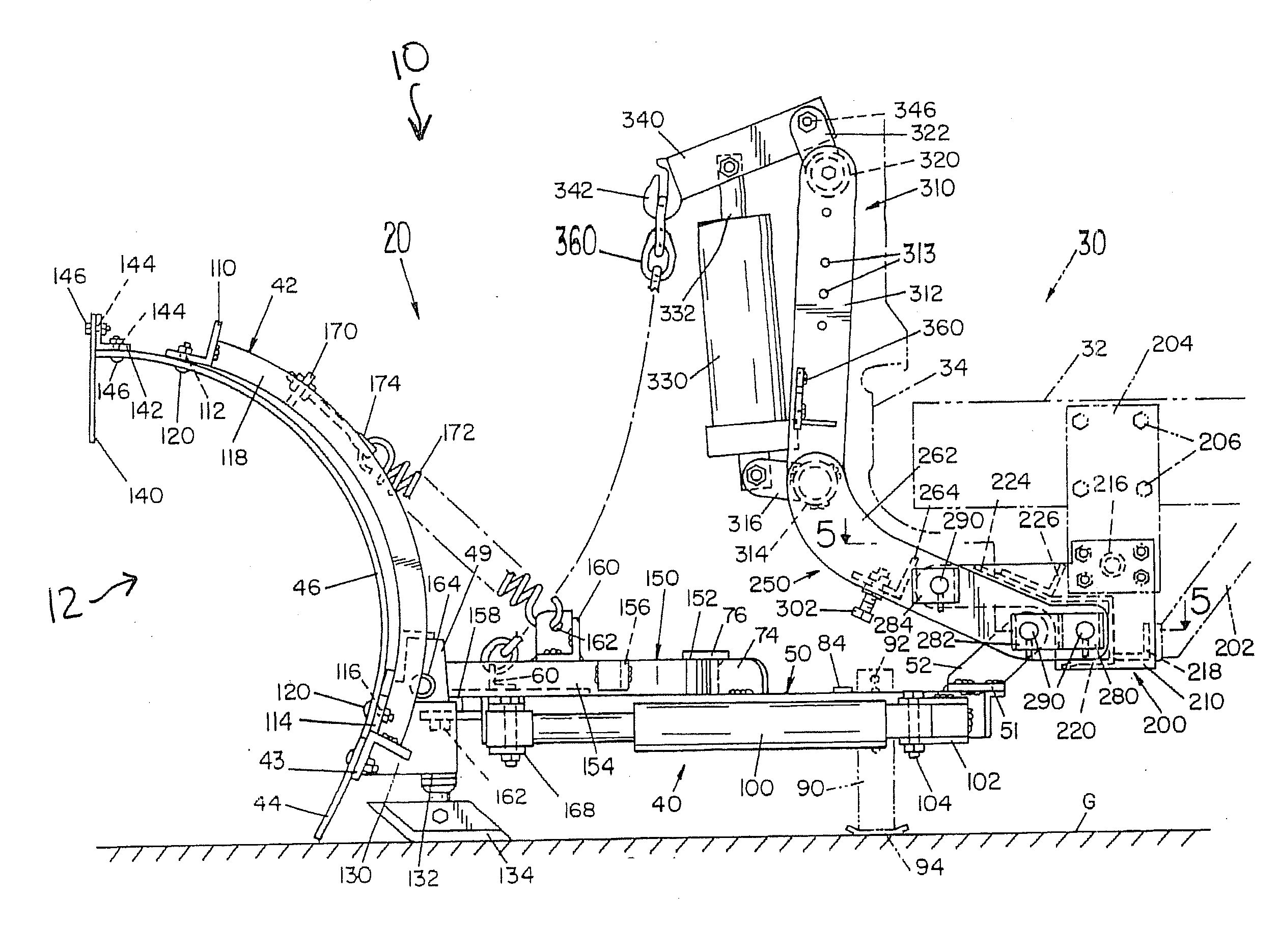

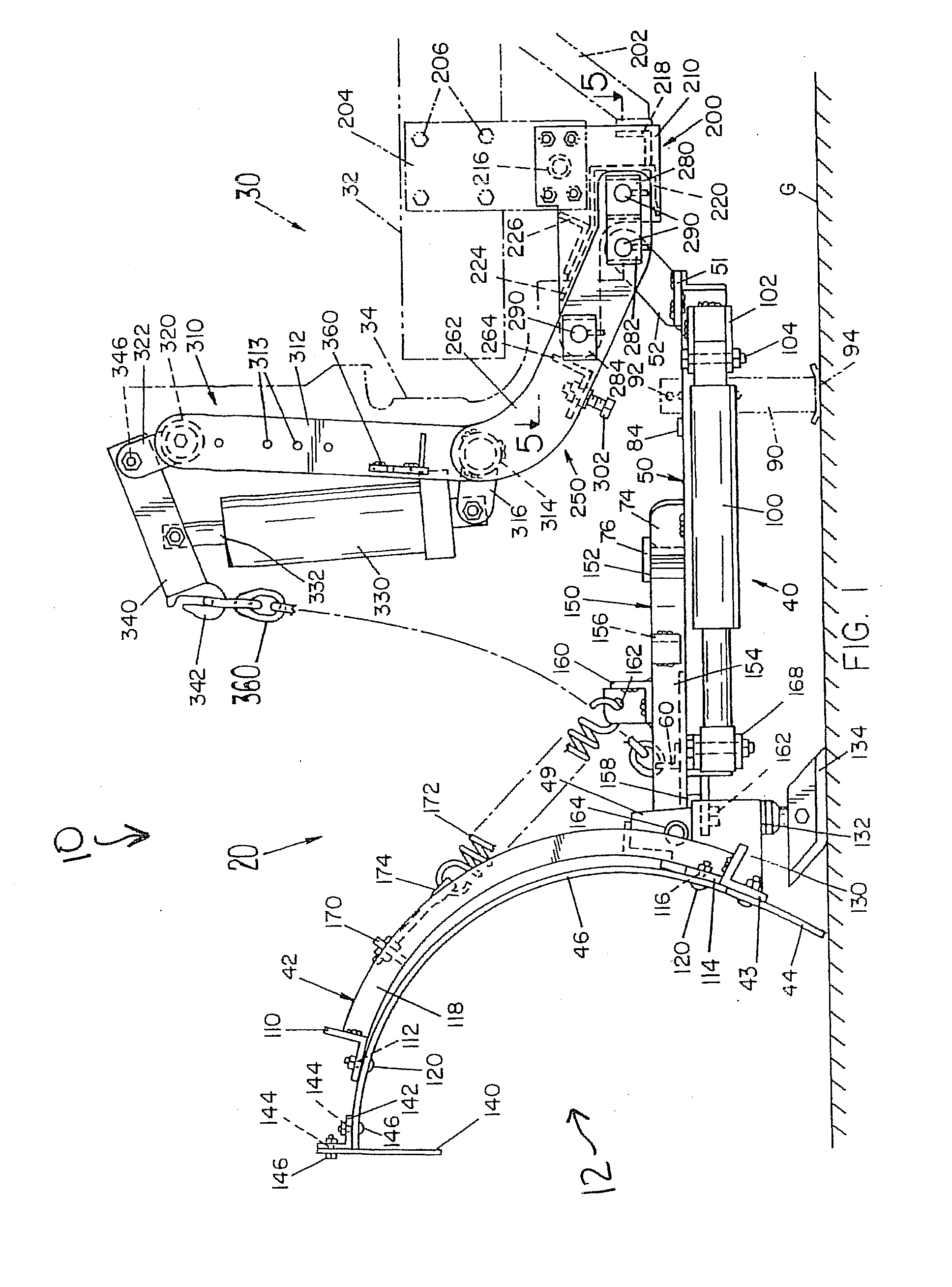

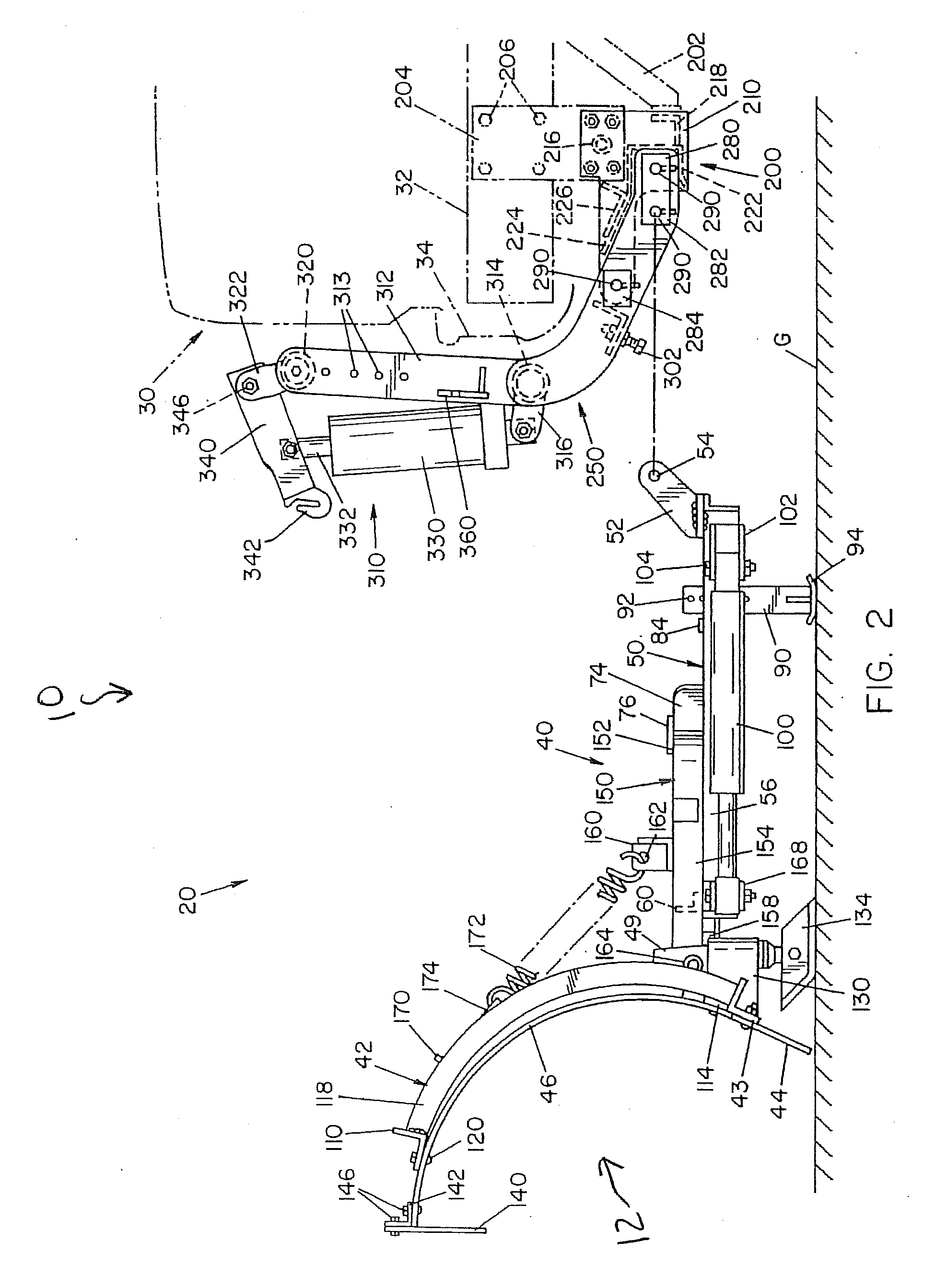

Snowplow formed of thermoplastic

InactiveUS20080072464A1Light to carryFormed easily and efficientlySnow cleaningThermoplasticEngineering

A snowplow assembly may include a snowplow mechanism having a mold board, a structural frame and a scraper blade all formed substantially of a thermoplastic. The mold board and structural frame may be molded together. An alternate snowplow assembly may include a mount assembly having a blade mount assembly, where the mold board, structural frame and blade mount assembly are all formed substantially of a thermoplastic. The mold board, the structural frame and the blade mount assembly may be molded together.

Owner:MEYER PRODS

Electrical test probe and method for manufacturing the same

ActiveUS20080186038A1Reduce stressIncreased durabilityContact member manufacturingElectrical measurement instrument detailsBiomedical engineeringTest probe

A probe tip section of an electrical test probe has a laminated structure consisting of a first deposition portion and a second deposition portion covering the first deposition portion, and by the laminated structure, a maximum cross-sectional area portion at which the cross-sectional area of the probe tip section is increased to a base portion is provided between a tip end of the probe tip section and the base portion in the probe tip section. At the maximum cross-sectional area portion, a dimension in the X direction as seen on a flat surface perpendicular to a protruding direction of the probe tip section is increased in a one-dimensional way, and in addition, a dimension in the Y direction perpendicular to the X direction is increased from the tip end toward the base portion, as a result of which the cross-sectional area of the probe tip section can be increased in a two-dimensional way. Thus, the cross-sectional area at the maximum cross-sectional area portion reaching the base portion of the probe tip section can be made to be larger than in the conventional case, and along with the increase of the cross-sectional area, the stress acting on the base portion can be lowered.

Owner:NIHON MICRONICS

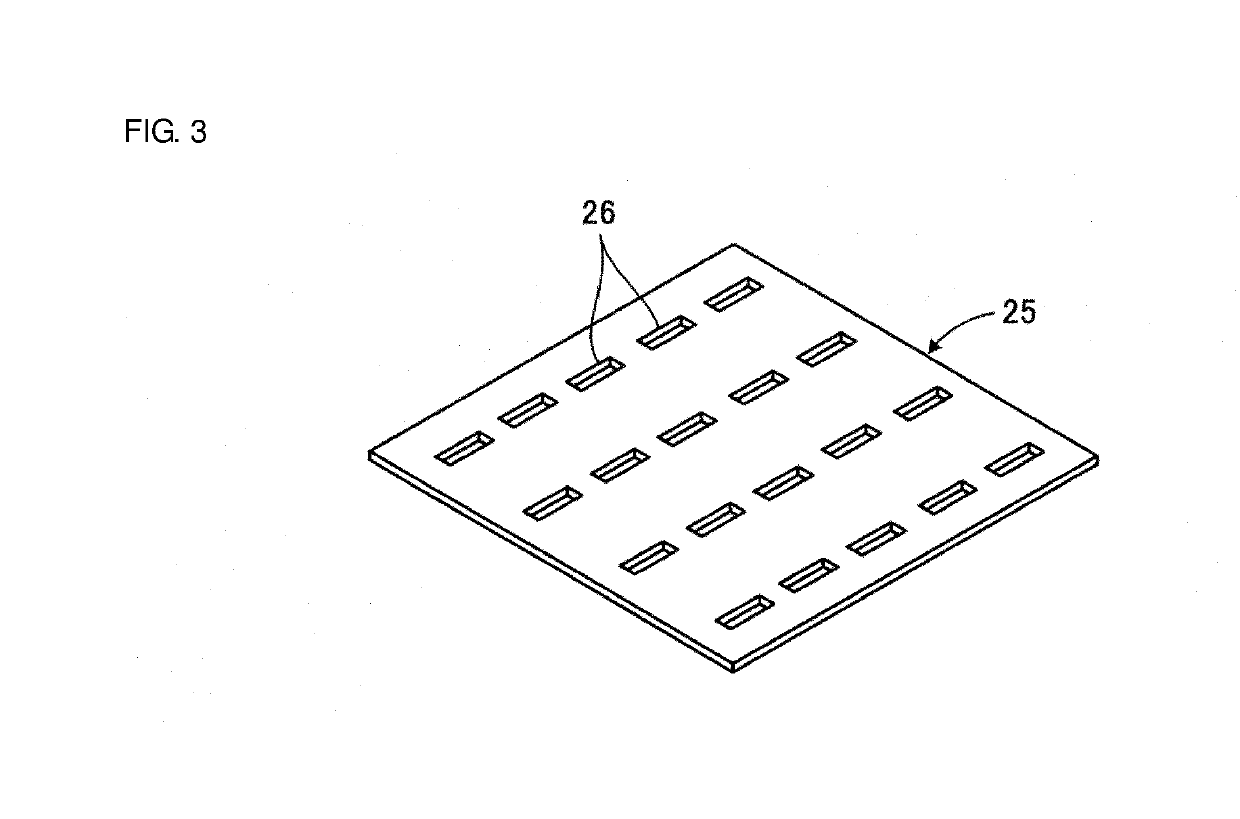

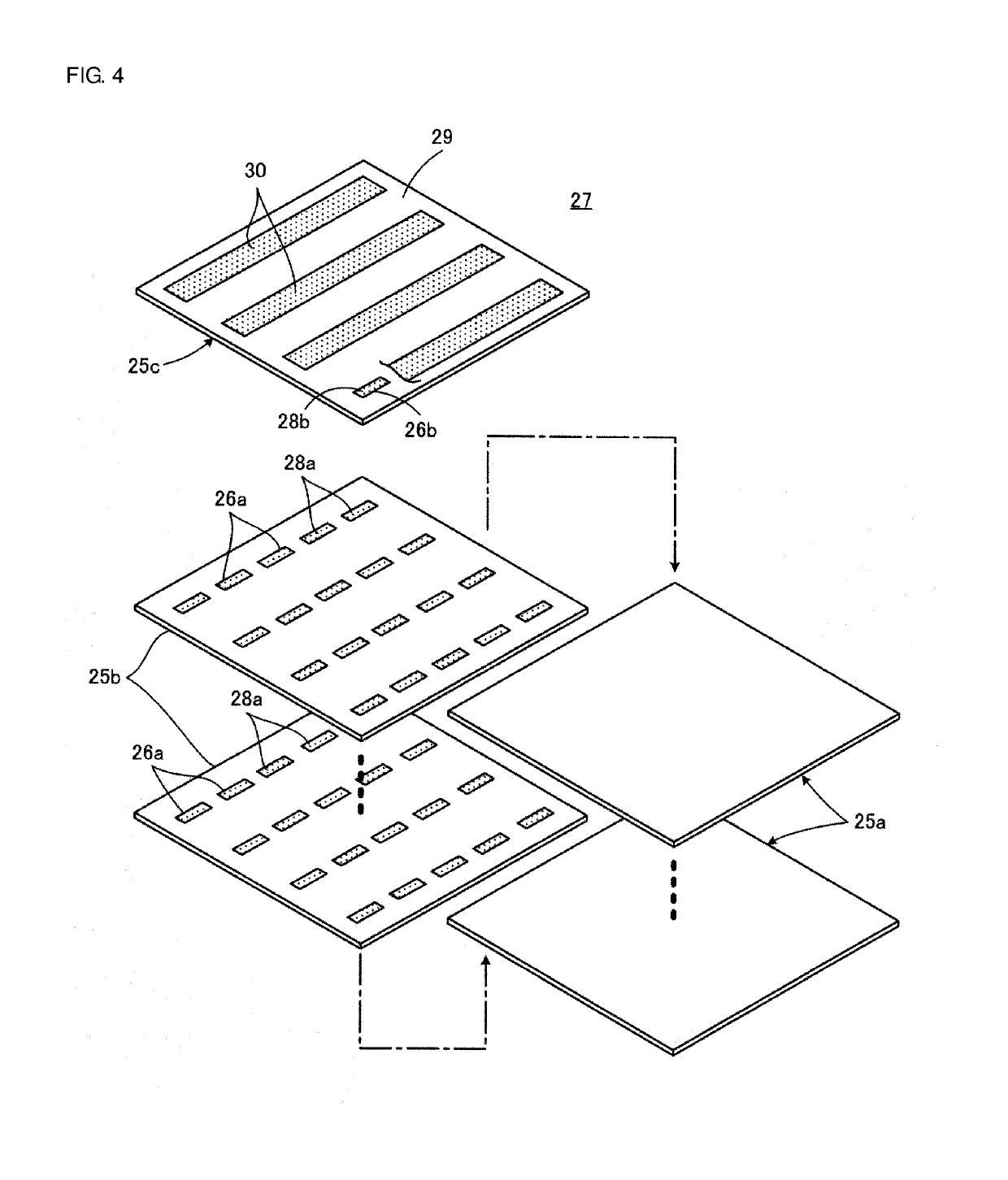

Wire-wound core, wire-wound core manufacturing method, and wire-wound-equipped electronic component

ActiveUS20190115140A1Improve productivitySmall sizeTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureElectrical conductorEngineering

A wire-wound core includes a core portion extending in a longitudinal direction, first and second flange portions respectively disposed at first and second end portions of the core portion in the longitudinal direction, and at least one terminal electrode disposed at each of the first and second flange portions. When a face to be oriented toward a mount board and a face of the first flange portion facing an outer side are respectively called a bottom surface and an outer end surface, the outer end surface has a recessed portion that reaches the bottom surface. The terminal electrode disposed at the first flange portion includes a bottom surface electrode portion formed of a film conductor extending along the bottom surface of the first flange portion and an end surface electrode portion formed of a conductor filling the recessed portion and being in contact with the bottom surface electrode portion.

Owner:MURATA MFG CO LTD

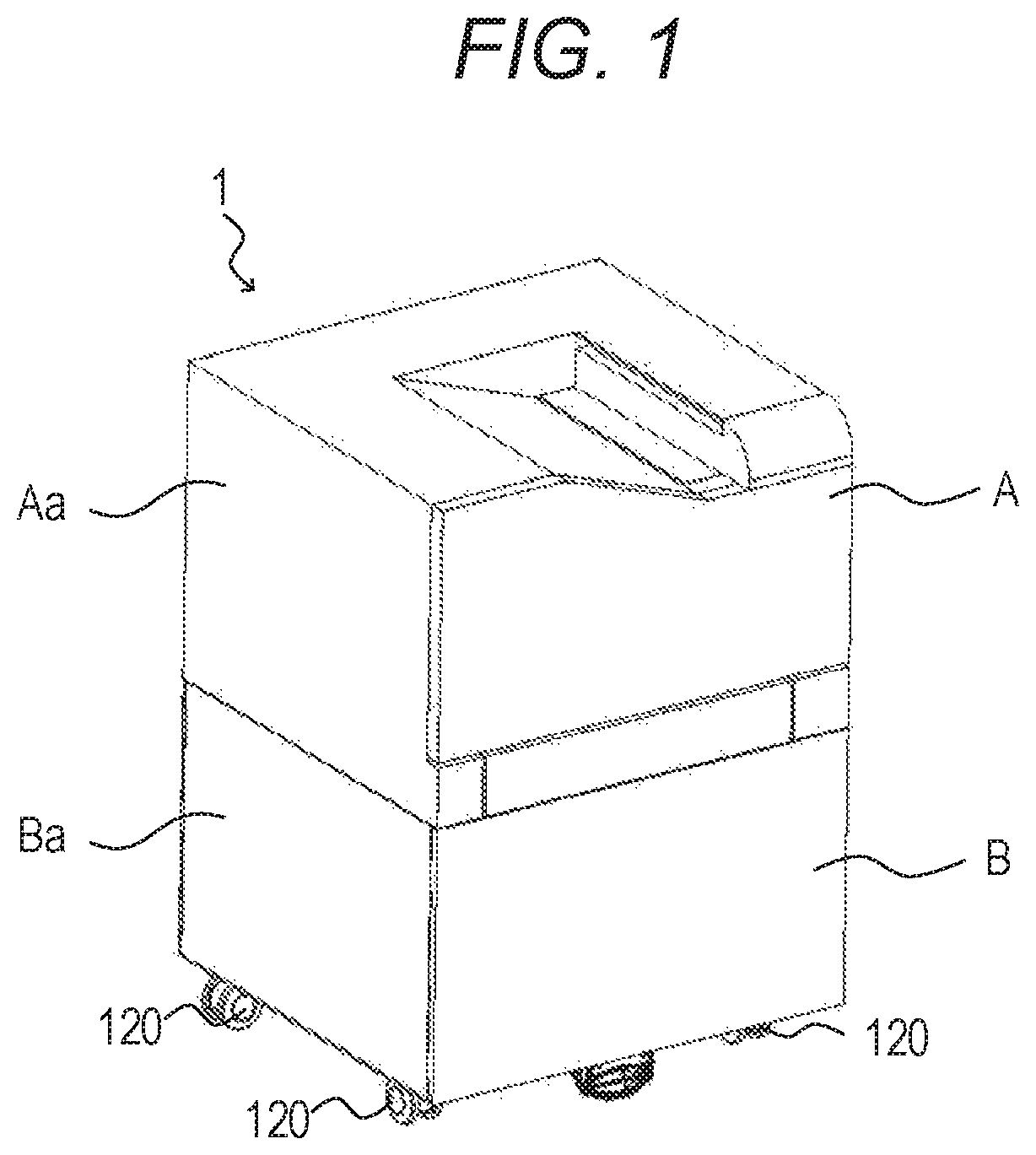

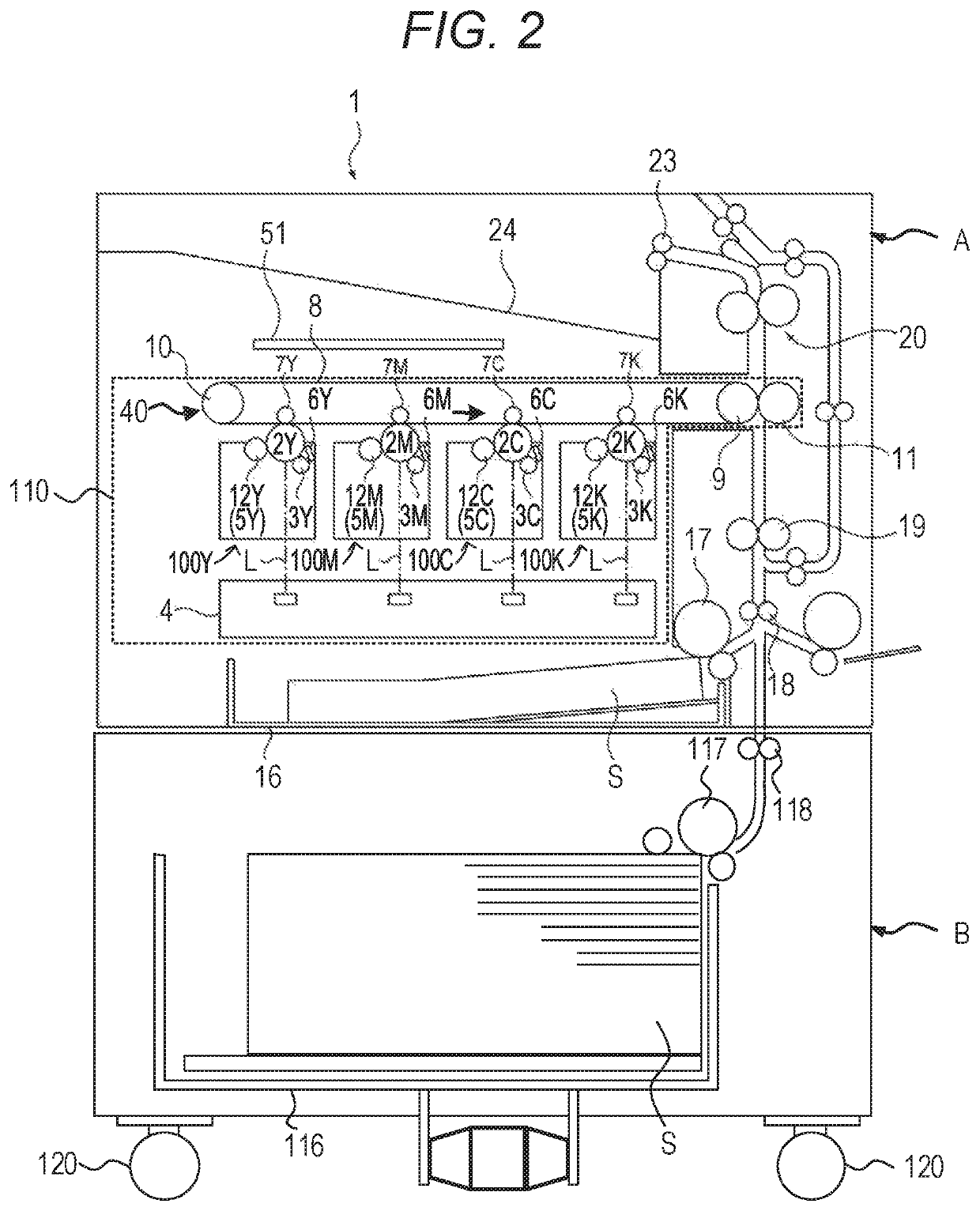

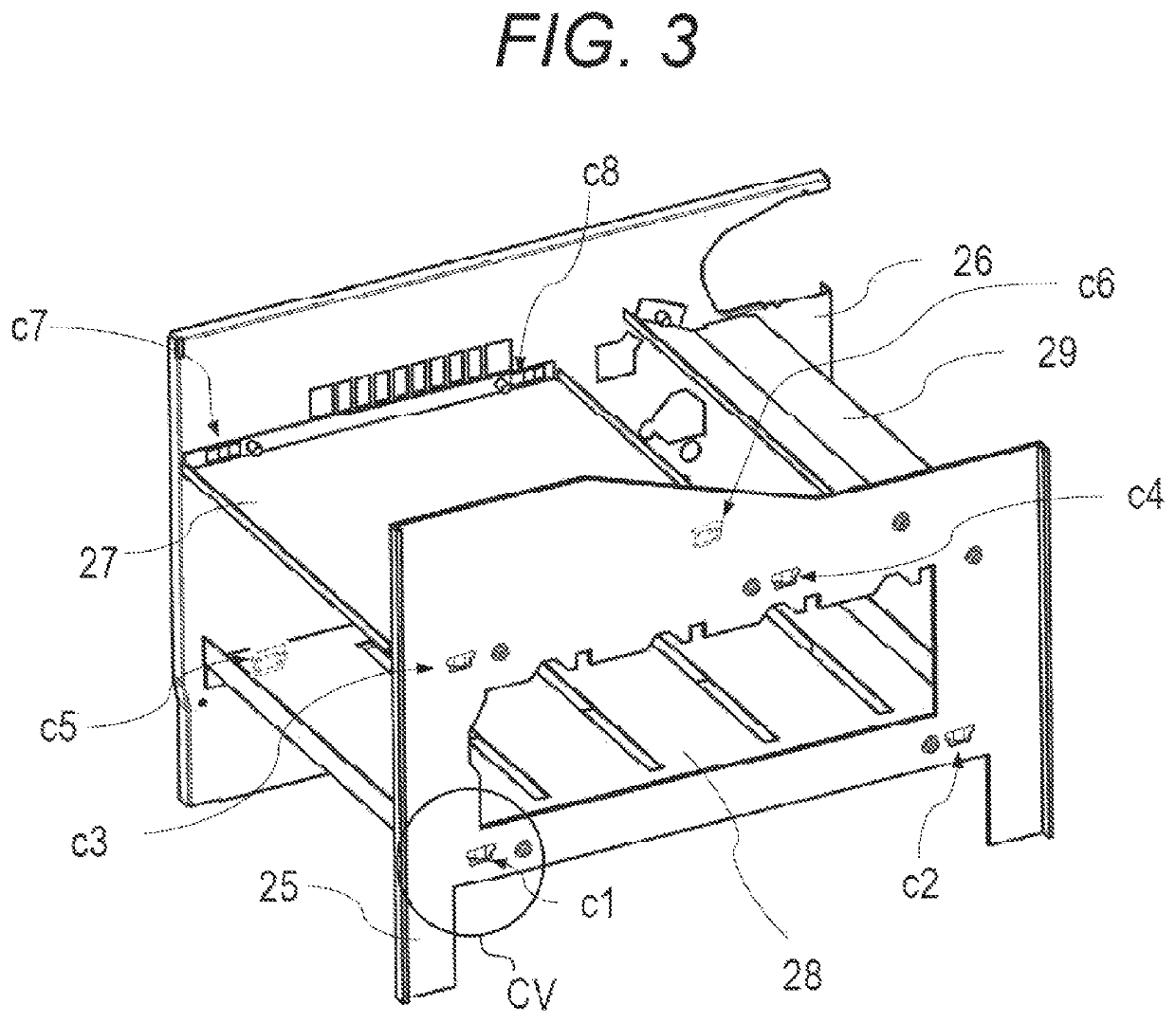

Image forming apparatus having a frame formed by adhering with adhesive

ActiveUS11281148B2Formed easily and efficientlyElectrographic processImage formationStructural engineering

An image forming apparatus includes a frame having a first metal plate and a second metal plate where the first metal plate has a recess portion. The frame supports an image forming member that forms an image on a sheet. The first metal plate and the second metal plate are positioned to each other and an adhesive is in a space formed between the recess portion and the second metal plate. The space is such that it receives the adhesive by injection.

Owner:CANON KK

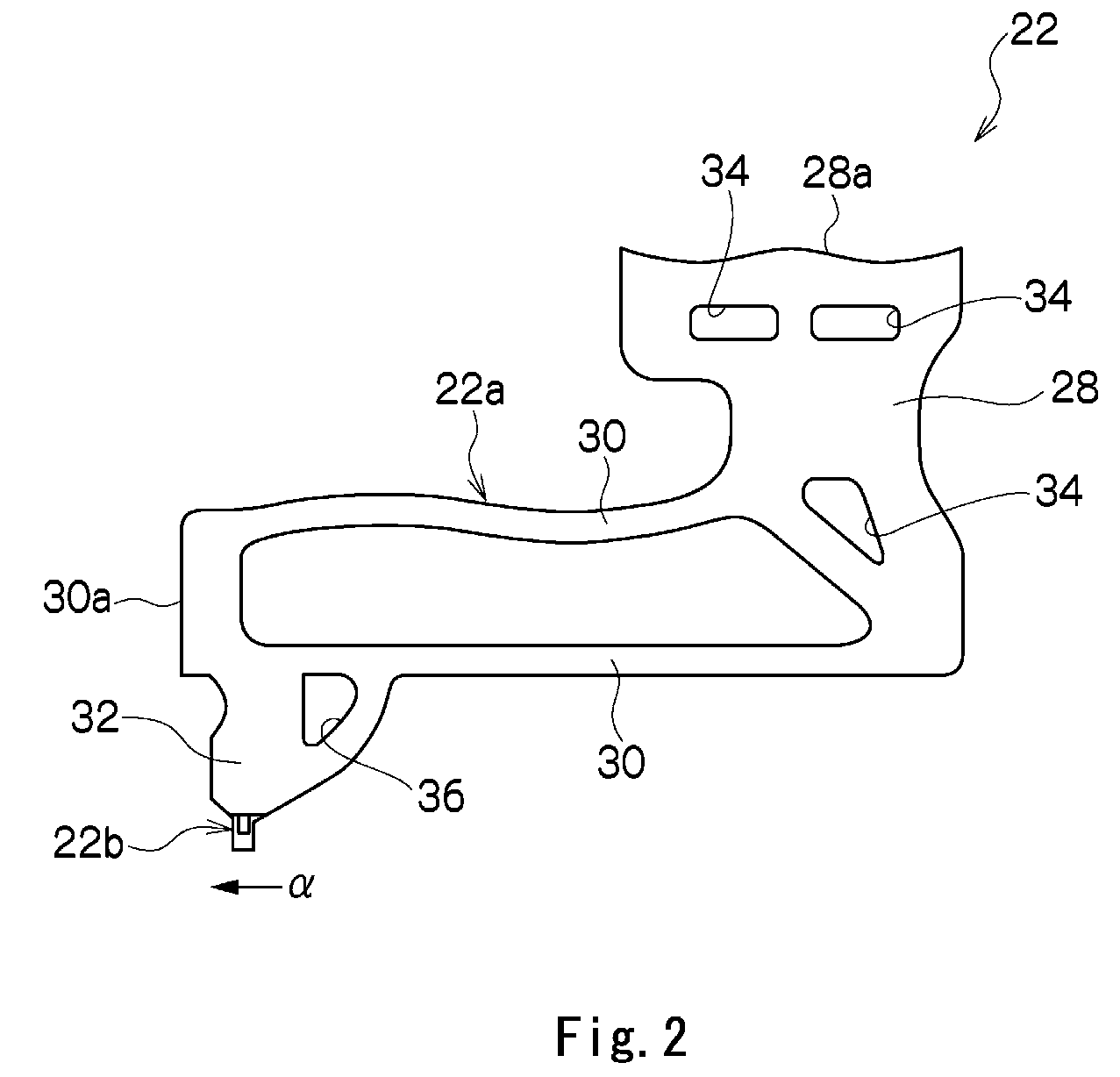

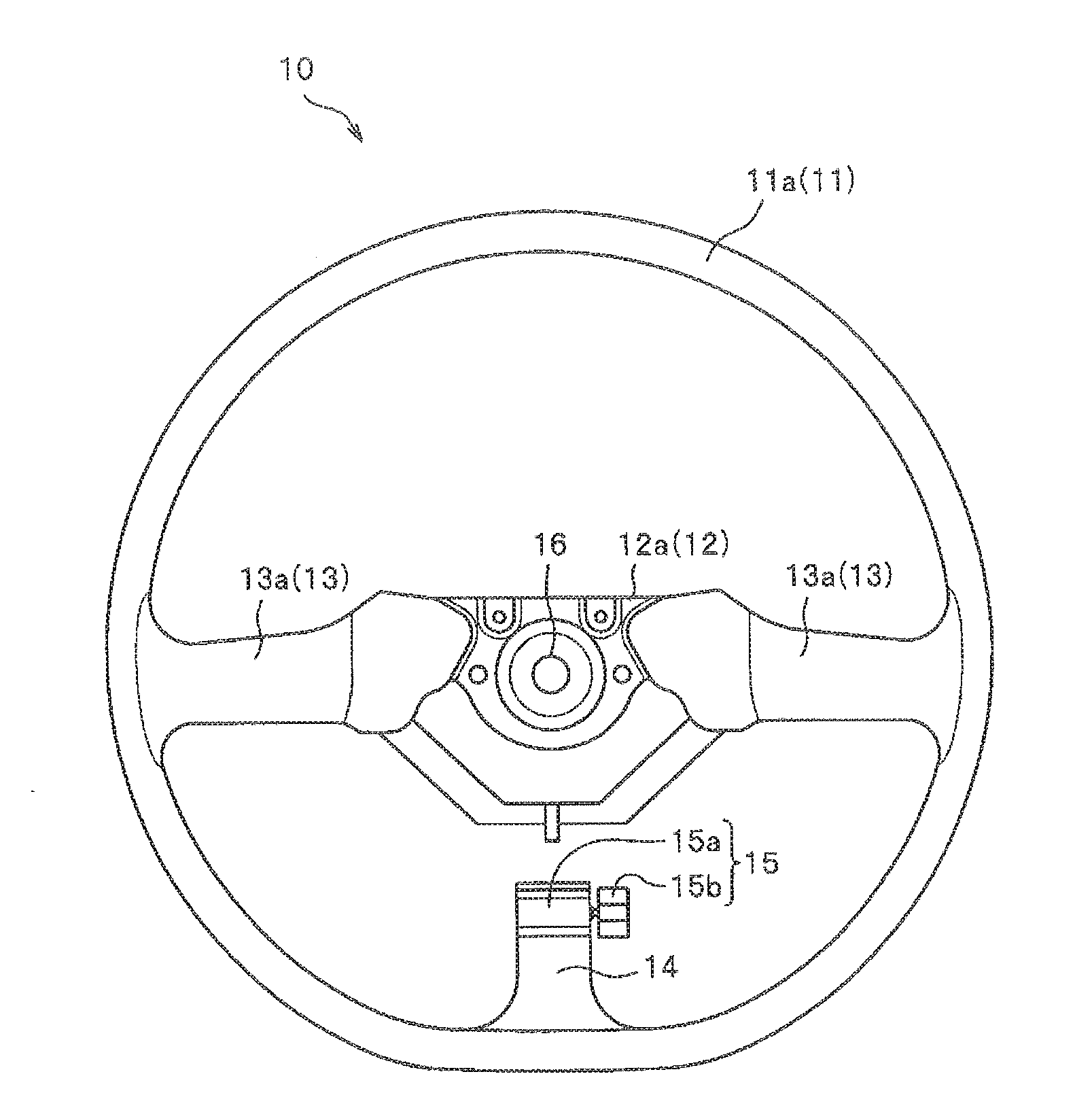

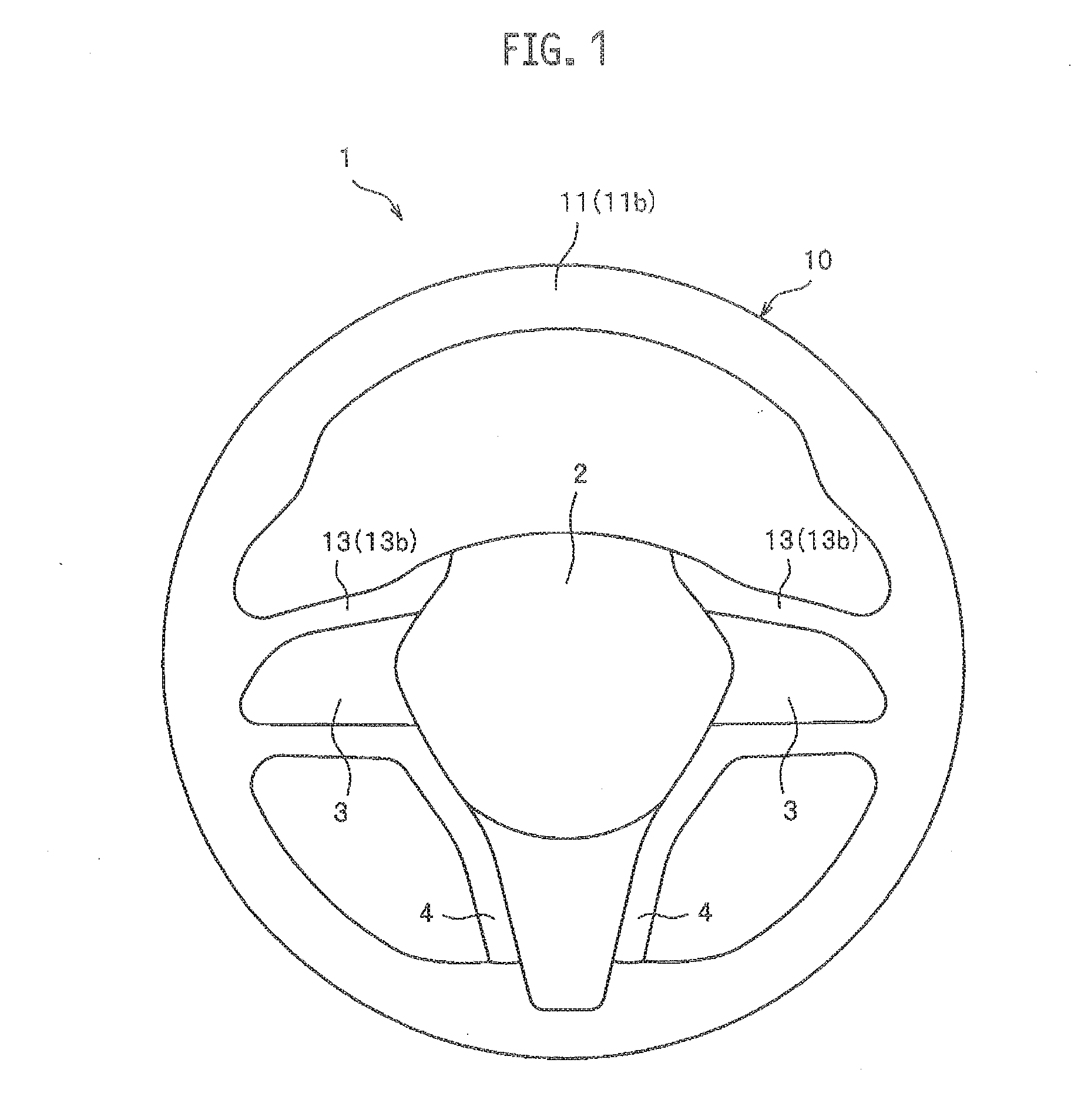

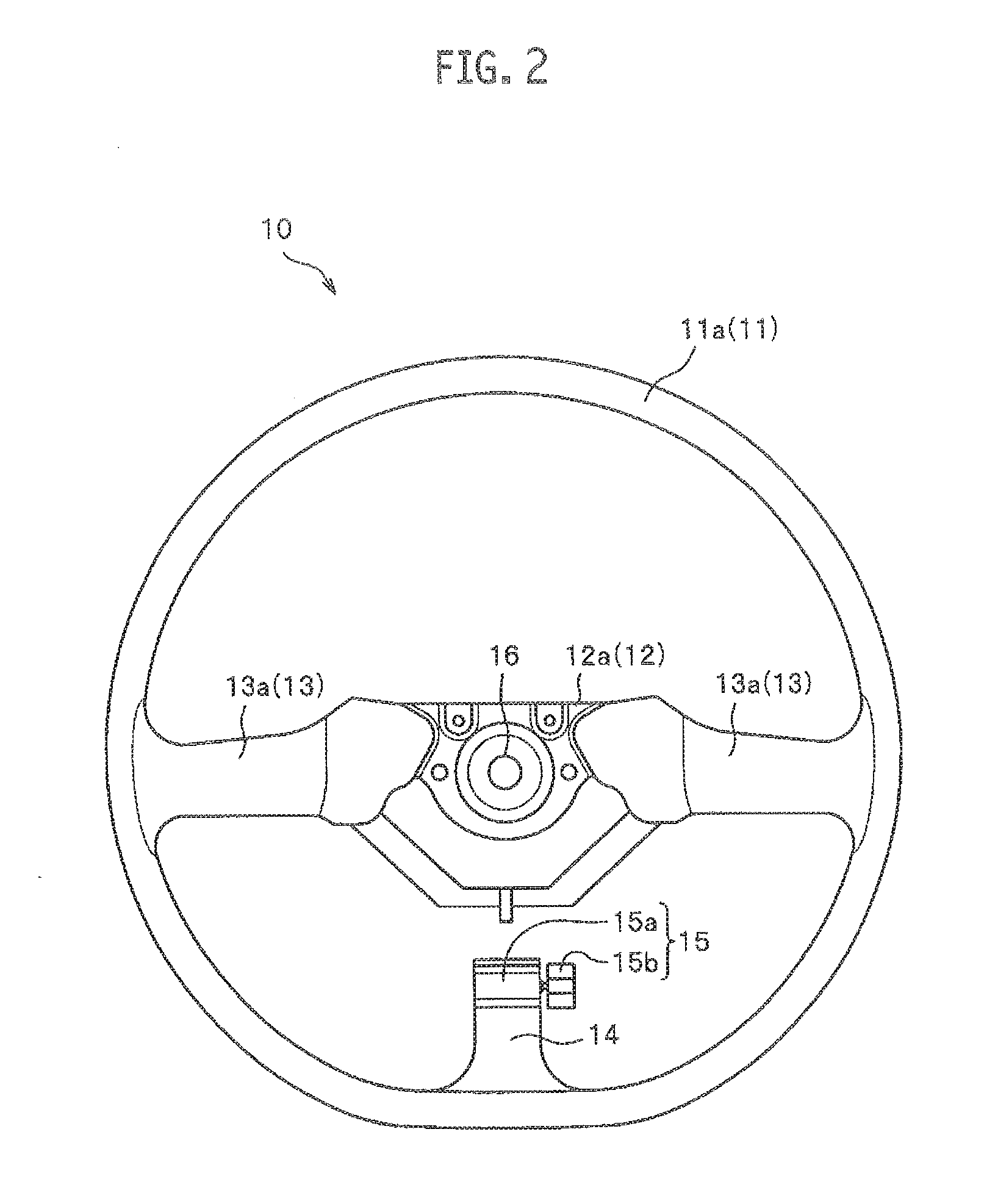

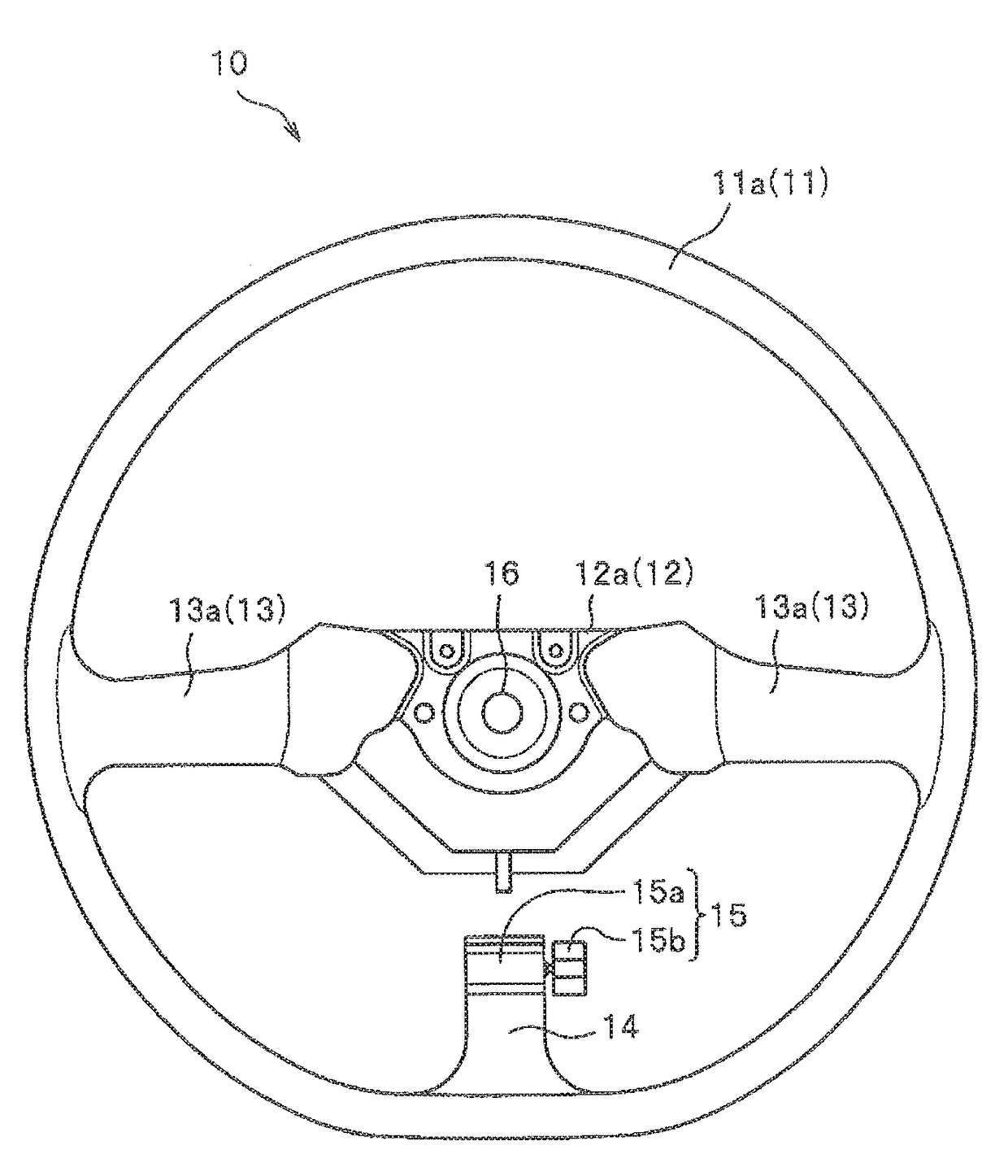

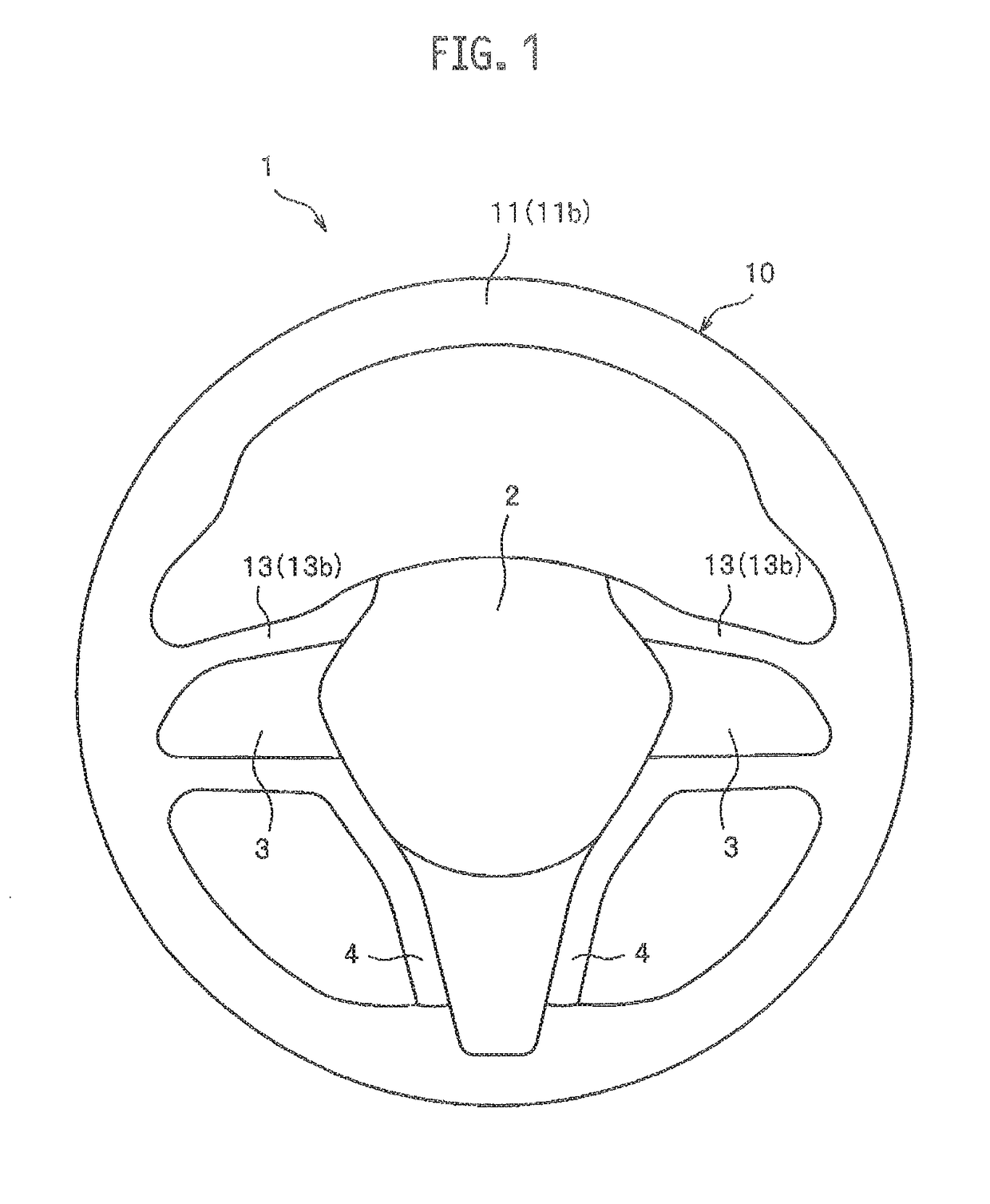

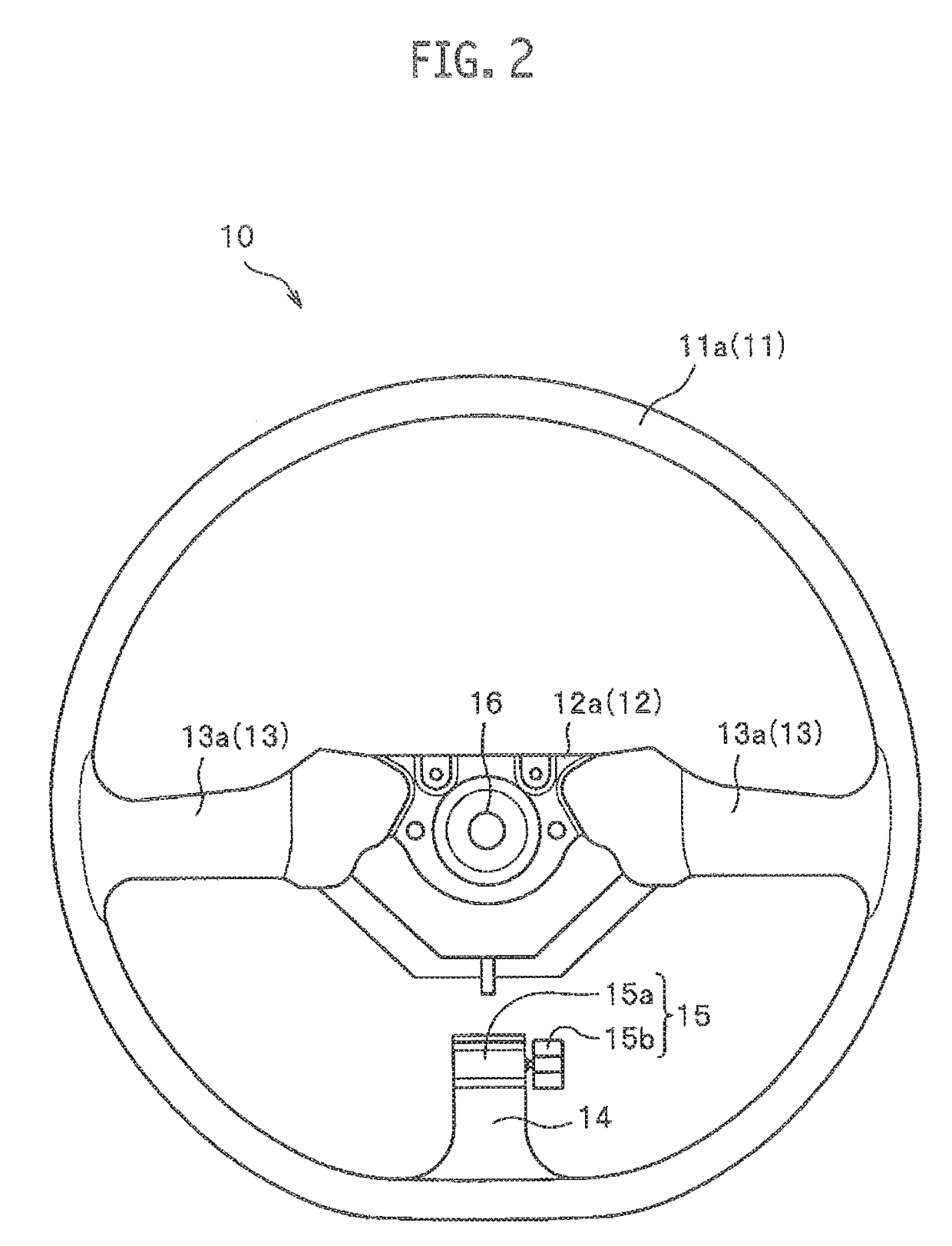

Steering wheel

ActiveUS20170021854A1Good adhesionKeep for a long timeHand wheelsMechanical vibrations separationSteering wheelEngineering

A steering wheel includes a ring-shaped rim is to be gripped by a driver (the rim includes a rim core and a rim molding portion covering the rim core), a boss disposed at the center of the rim, plural spokes connecting the rim with the boss, an arm whose base end portion is integrated with the rim core and that is extended toward the inside of the rim core in a cantilever manner, and a vibration generator attached to the arm for generating vibrations that are to be transmitted to the rim through the arm.

Owner:NIHON PLAST CO LTD

Interleukin 15 protein complex

ActiveUS10905743B2Prolong half-life in vivoSignificant anti-tumor activityPeptide/protein ingredientsAntipyreticDisulfide bondingWhite blood cell

An interleukin 15 (IL-15) protein complex is provided. The IL-15 protein complex includes soluble fusion proteins (I) and (II), wherein the fusion protein (I) is an IL-15 polypeptide or a functional fragment thereof, and the soluble fusion protein (II) is an IL-15Rα polypeptide or a functional fragment thereof. The soluble fusion protein (I) has at least one amino acid residue mutated to a cysteine (Cys) residue, which pairs with a corresponding mutated Cys residue on the soluble fusion protein (II), or vice versa, to form one or more disulfide bonds. The IL-15 protein complex can be used for tumor therapy.

Owner:JIANGSU HENGRUI MEDICINE CO LTD +1

Widening method

InactiveUS6079232AFormed easily and efficientlyTextile/flexible product manufactureFlat-bed knitting machinesYarnBiomedical engineering

A widened loop is formed by using a flat knitting machine which has at least a pair of needle beds and one of the needle beds can be moved sideways. A widening needle is made to be empty, and yarn is fed from one end of the knitting range to a needle short of the widening needle. Next, yarn is not fed to the widening needle but to a needle next to the widening needle. The yarn feeder is reversed and yarn is fed to the widening needle. Then the yarn feeder is reversed again and yarn is fed to a needle next to the needle to which yarn has been fed. According to the method loops 21, 23 on both sides of the widened loop 11 are connected together by a cross-over yarn 25, and the widened loop 11 is held by a loop 13 of the previous course. Therefore it will not be pulled up. Because of these arrangements, an open gap will be hardly generated around the widened loop 11.

Owner:SHIMA SEIKI MFG LTD

Image Forming Optical Element, Image Forming Optical Array, And Image Reading Device

ActiveUS20120188615A1Precise positioningSimple configurationDumb-bellsDevices for pressing relfex pointsIntermediate imageOptoelectronics

An image forming optical element is provided, in which an incident unit having a first lens face to which a light beam output from an original document (object) is input, an output unit having a second lens face outputting the light beam, and a bent unit connecting the incident unit and the output unit at an angle are integrally formed into a transparent medium. The bent unit has a reflection face reflecting the incident light beam input to the first lens face and guiding the light beam to the second lens face. The incident light beam is collected at any of the incident unit, the bent unit, and the output unit to form an intermediate image of the object, and the intermediate image is formed on the output side of the second lens face to form an erection image of the object.

Owner:SEIKO EPSON CORP

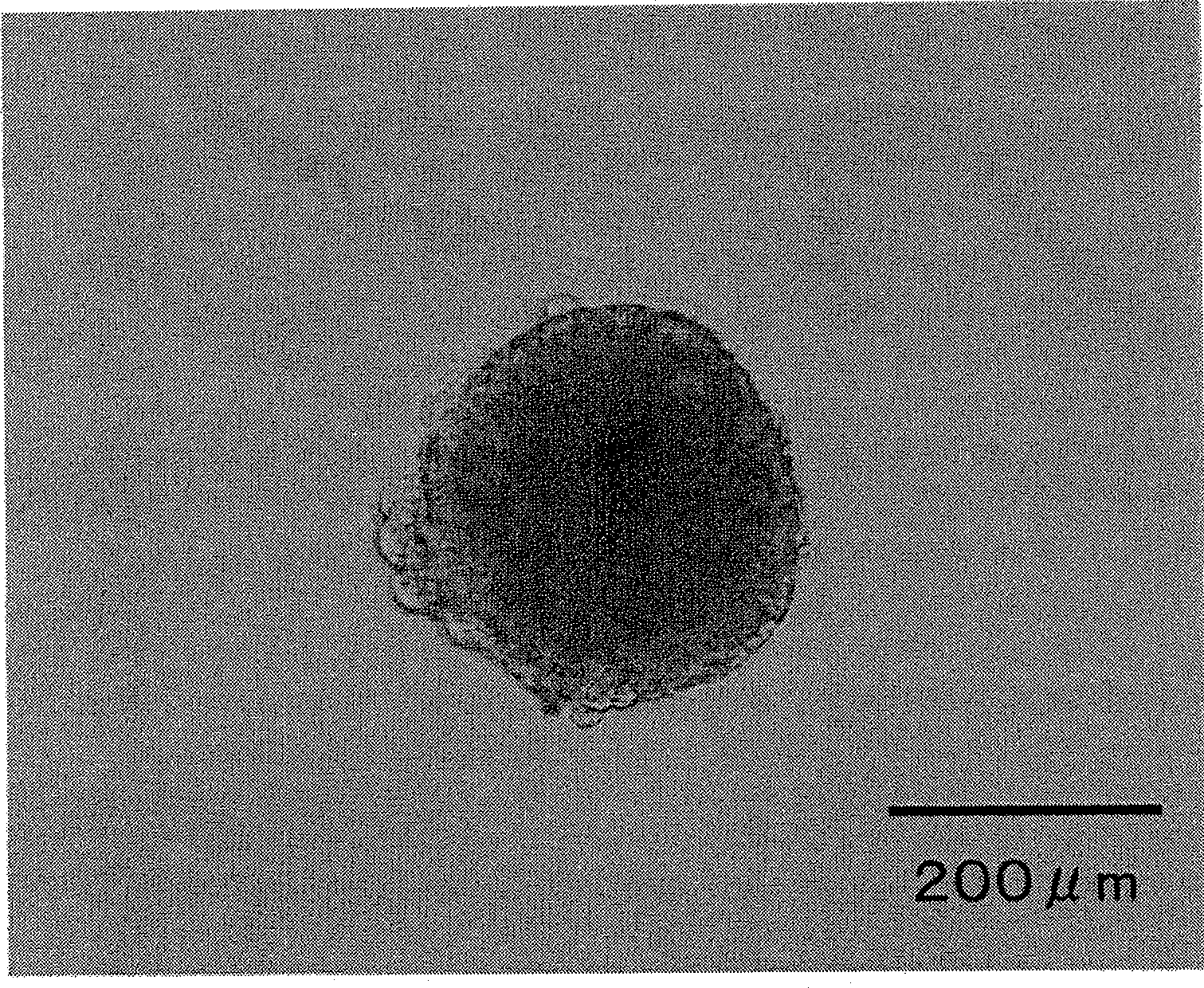

Container for germ layer formation and method of forming germ layer

ActiveUS20090246871A1Well formedEasy to trainBioreactor/fermenter combinationsBiological substance pretreatmentsGerm layerEngineering

The invention relates to a vessel for embryoid formation used for forming embryoid bodies from ES cells easily without complicated technique, and to a method for forming embryoid bodies easily and efficiently using the vessel. The method includes the steps of (A) providing a vessel for embryoid formation having a coating layer formed from a compound having a particular PC-like group on a vessel surface defining a region for floating culture of ES cells, and (B) floating culturing ES cells in the vessel to form embryoid bodies.

Owner:NOF CORP

Method for preparing golf ball with indicia having metallic luster

InactiveUS8002932B2Formed easily and efficientlyLamination ancillary operationsDecorative surface effectsEngineeringGolf Ball

A method for preparing a golf ball with surface indicia such as a letter or image having metallic luster includes the steps of forming an adhesive indicia made of a thermoplastic resin on a golf ball surface, bonding the metal thin-film on a metal thin film-bearing film over the indicia under pressure or heat and pressure, then peeling off the film so as to leave a portion of the metal thin-film having the same shape as the indicia adhering to and laminated with the indicia.

Owner:BRIDGESTONE SPORTS

Steering wheel

ActiveUS9884641B2Reduce weight and production costEffective vibrationHand wheelsMechanical vibrations separationSteering wheelEngineering

A steering wheel includes a ring-shaped rim is to be gripped by a driver (the rim includes a rim core and a rim molding portion covering the rim core), a boss disposed at the center of the rim, plural spokes connecting the rim with the boss, an arm whose base end portion is integrated with the rim core and that is extended toward the inside of the rim core in a cantilever manner, and a vibration generator attached to the arm for generating vibrations that are to be transmitted to the rim through the arm.

Owner:NIHON PLAST CO LTD

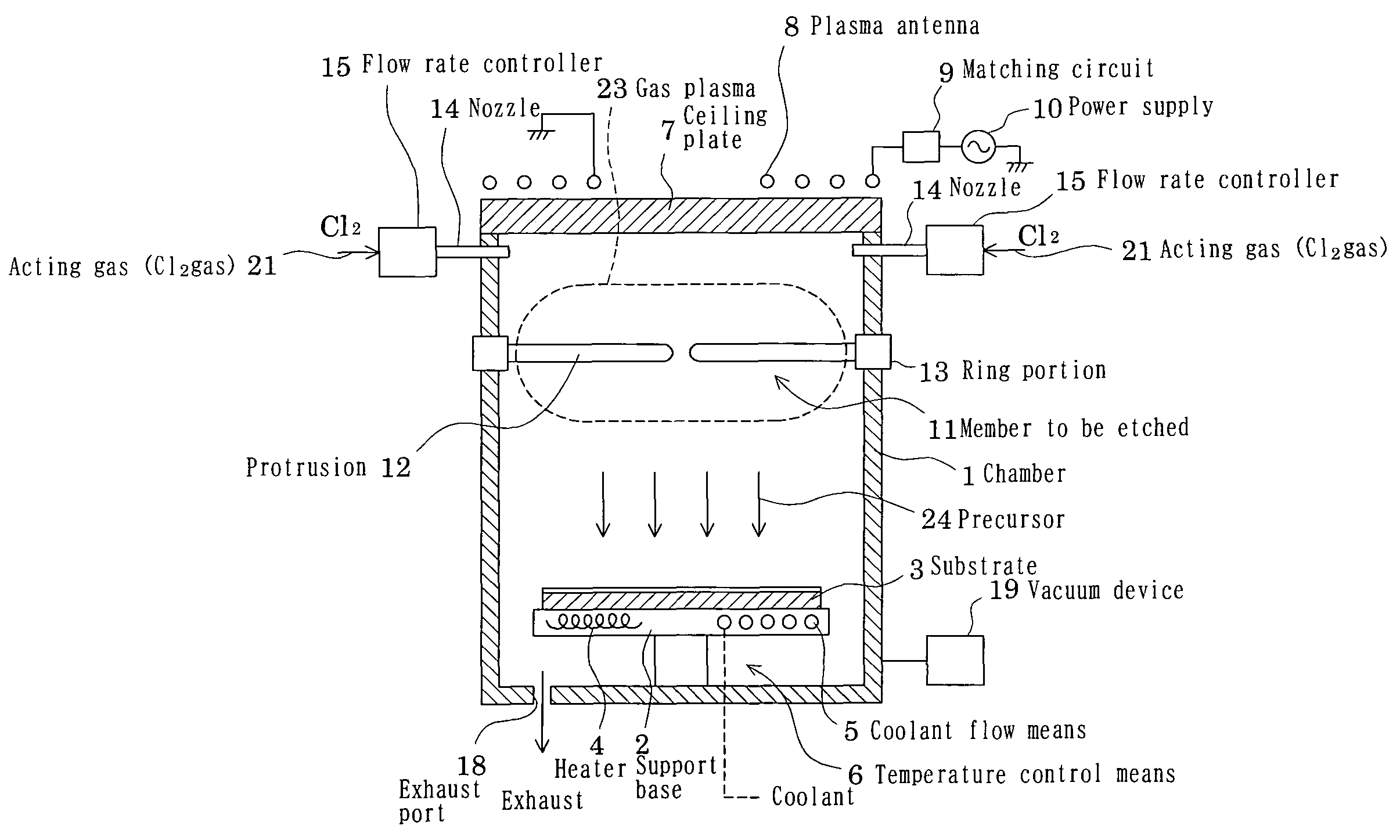

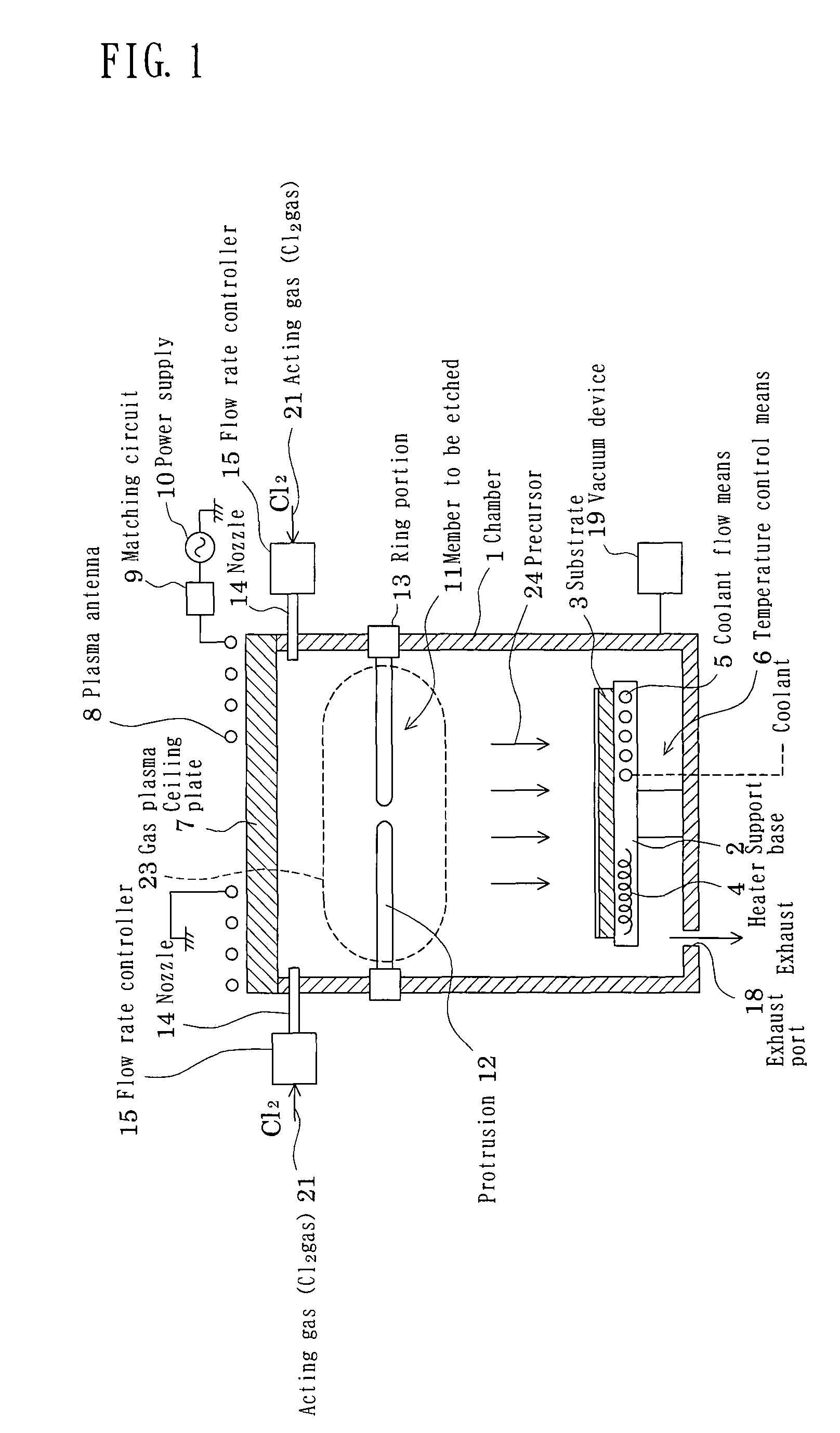

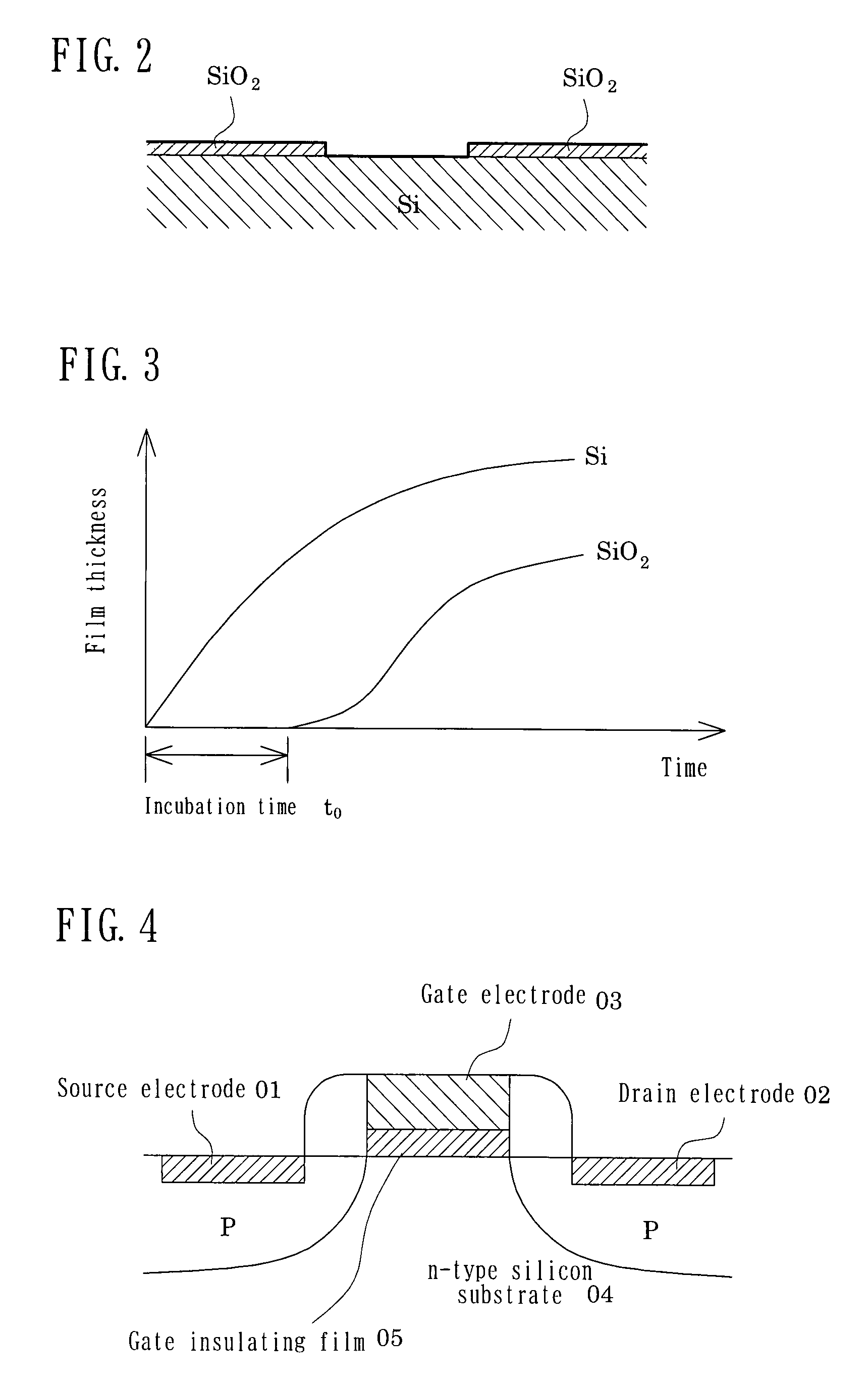

Process for producing silicon compound

InactiveUS7776751B2Free from deteriorationFormed easily and efficientlyDecorative surface effectsMetal silicidesCompound aHalogen

A process for producing a silicon compound can minimize the number of steps and can form a desired compound in a low-temperature environment. The process comprises: allowing a radical of a halogen gas to act on a member 11 to be etched, which is disposed within a chamber 1 and is formed of a material containing an element capable of forming a compound with Si, while keeping the member 11 at a relatively high temperature, to form a gas of a precursor 24, which is a compound of the material and the halogen; holding a substrate 3 accommodated within the chamber 1 at a relatively low temperature, with the Si interface of the substrate 3 being exposed, to adsorb the precursor 24 onto the Si interface of the substrate 3; and then allowing the radical of the halogen gas to act on the precursor 24 adsorbed onto the Si interface to reduce the precursor 24, thereby producing a compound of the material and Si.

Owner:CANON ANELVA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com