Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

392results about "Metal silicides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

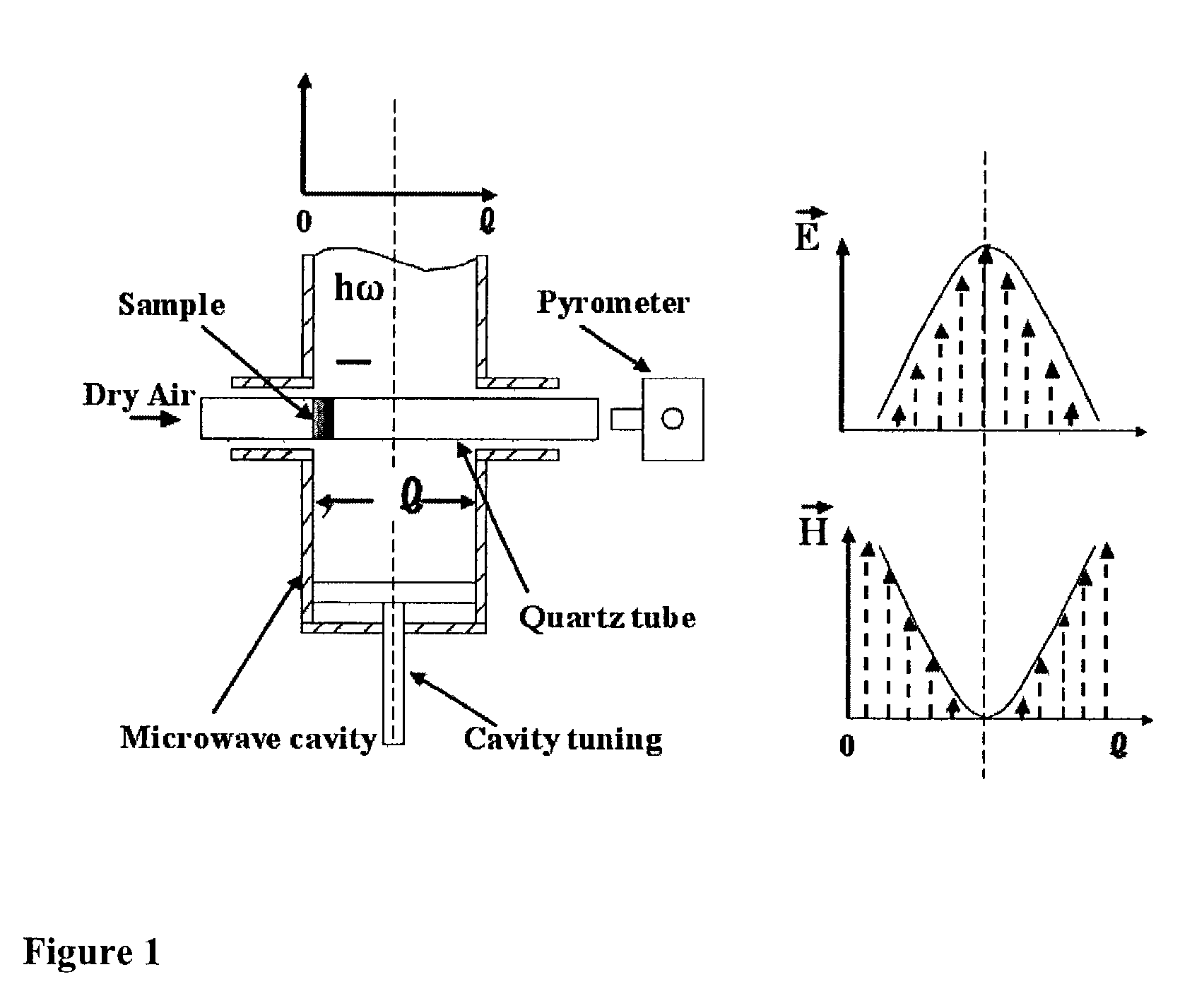

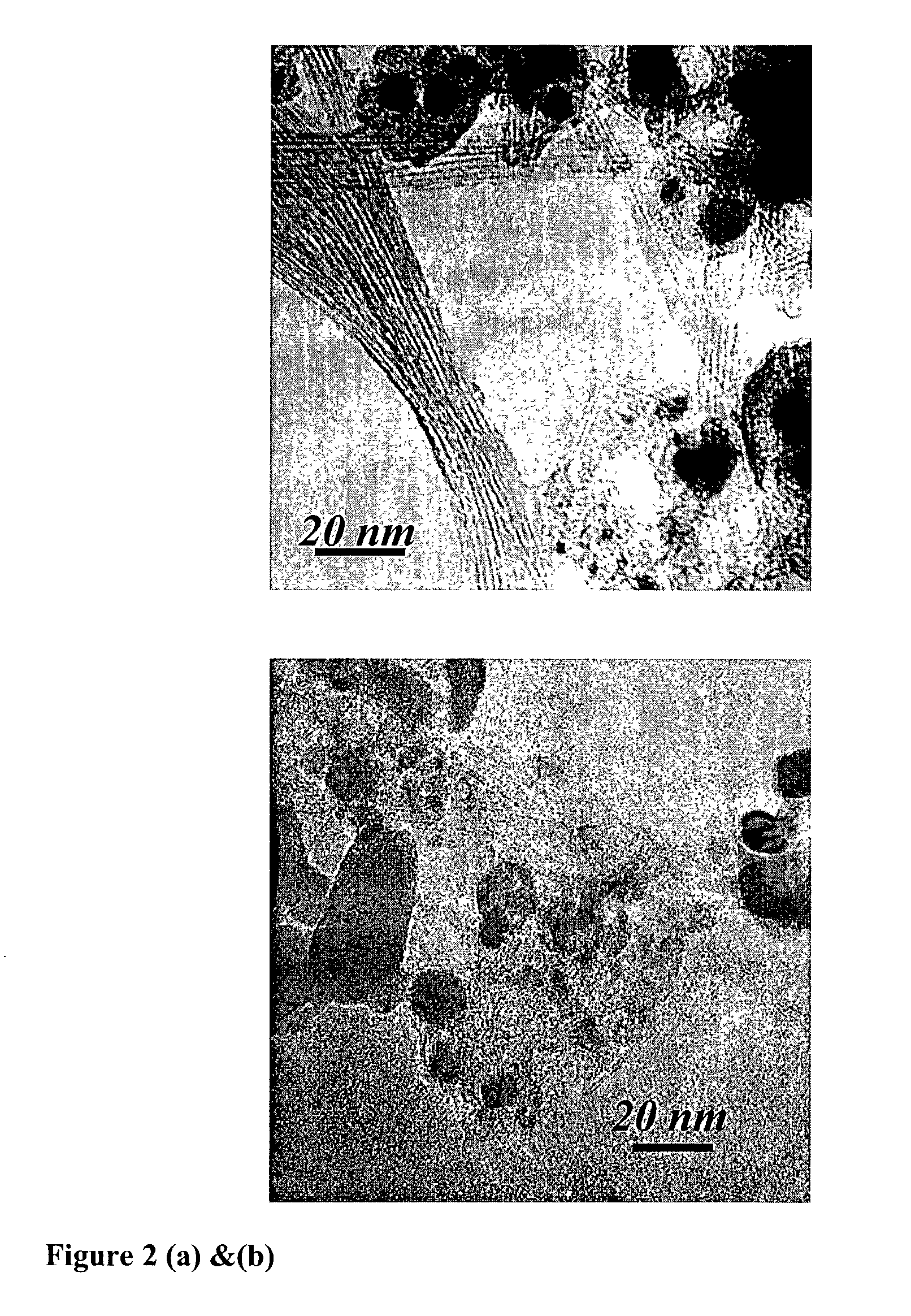

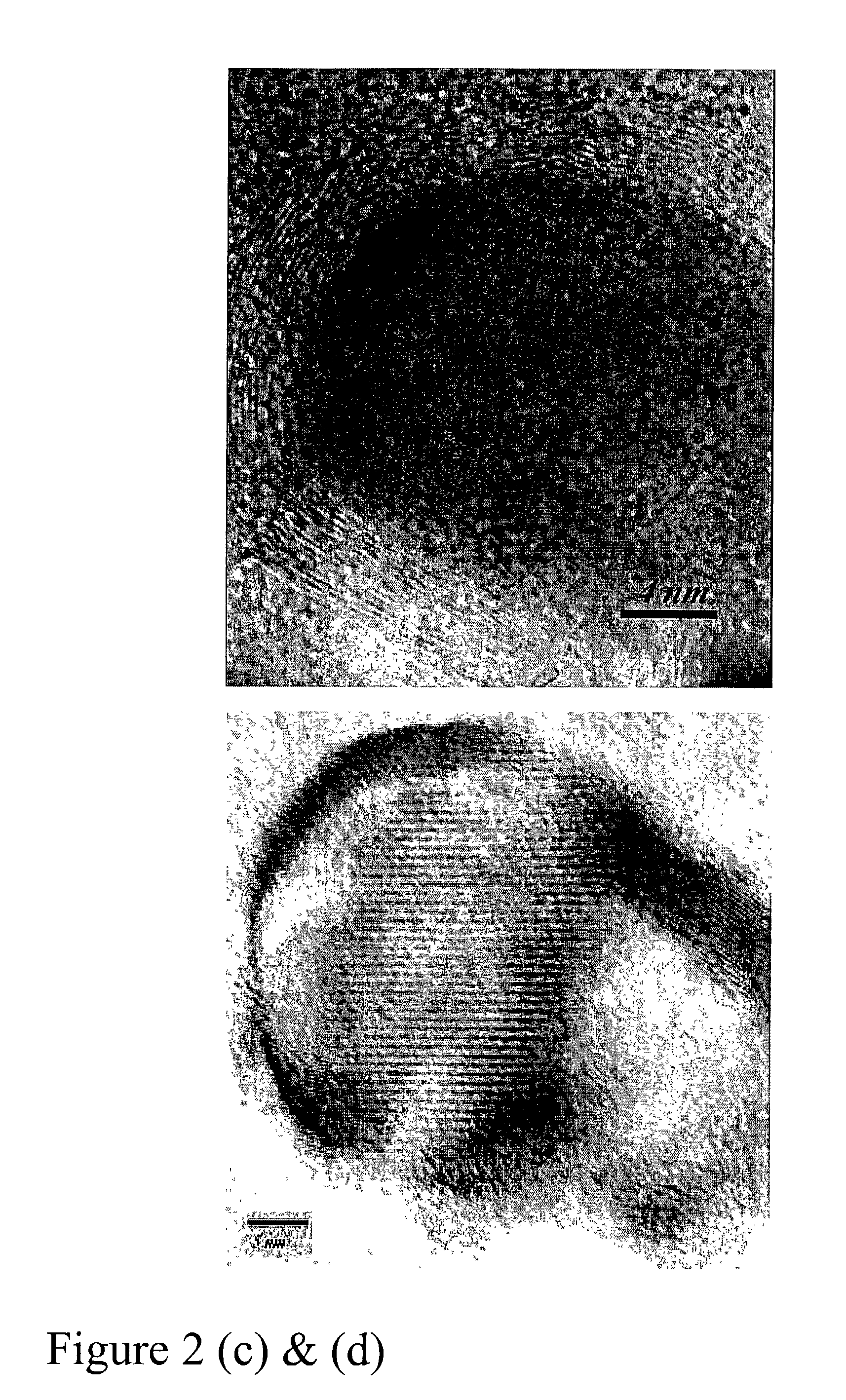

Method of purifying nanotubes and nanofibers using electromagnetic radiation

Disclosed are methods of purifying mixtures comprising nanofibers and / or nanotubes and residual catalyst particles that are covered by outer layers of the nanotube or nanofiber material. The mixtures are exposed to electromagnetic radiation, which induces localized heating in the residual catalyst particles. The localized heating creates breaches in the outer layers. Thereafter, the residual catalyst particles may be removed under relatively mild conditions that do not significantly affect the structural integrity of the nanotubes or nanofibers. The methods of the invention have been used to particular advantage in the purification of single wall carbon nanotubes (SWNTs) synthesized using metal catalysts. For these SWNTs, microwave radiation is preferably used to induce the localized heating, the outer layers are preferably removed at least in part by carrying out the localized heating under air, and the residual catalyst may be removed by exposure to relatively dilute aqueous acid.

Owner:PENN STATE RES FOUND

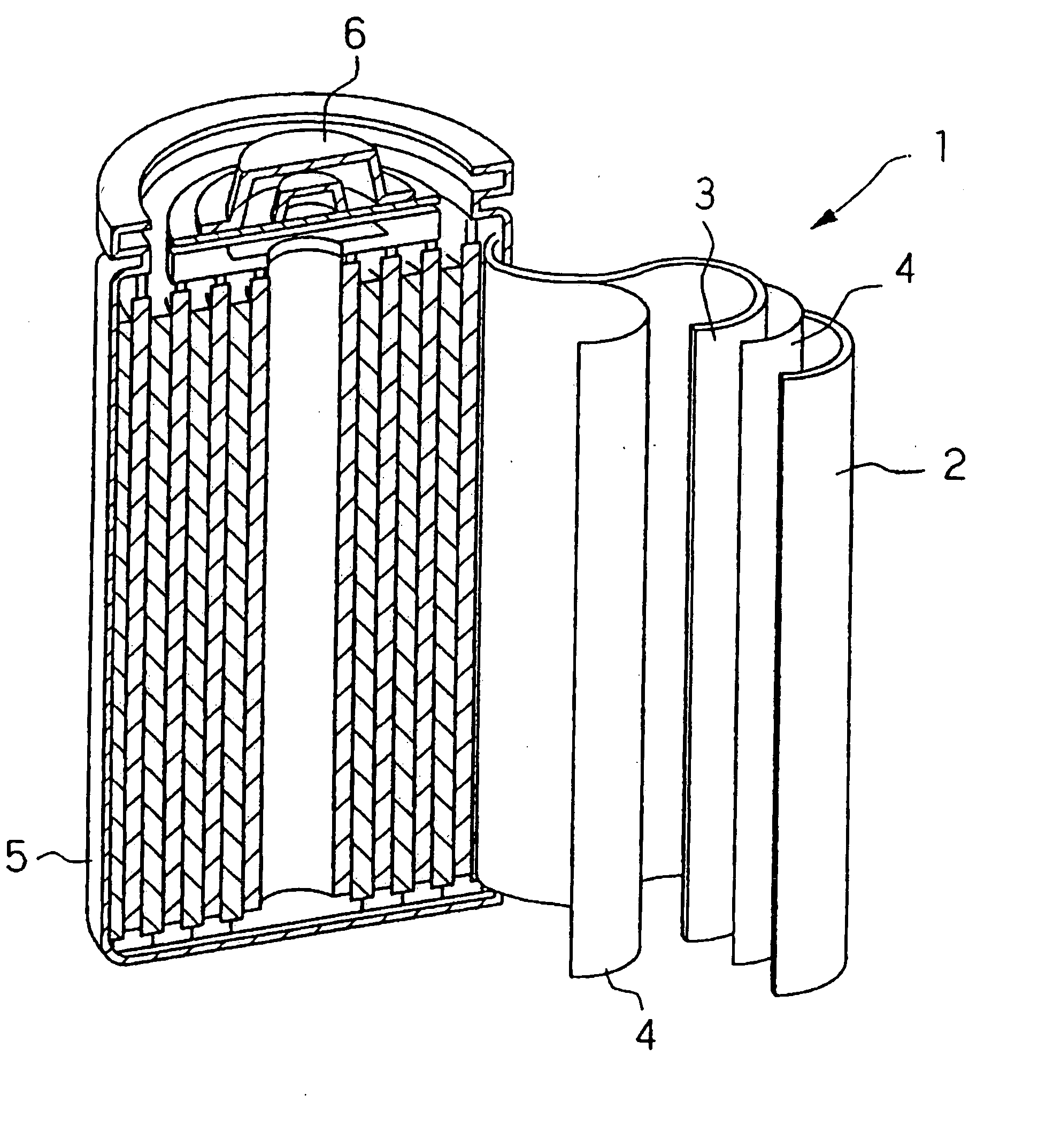

Silicon composite particles, preparation thereof, and negative electrode material for non-aqueous electrolyte secondary cell

ActiveUS20050214644A1Improve cycle performanceMinimize changesSilicaNitrogen compoundsSilicon alloyInorganic compound

Silicon composite particles are prepared by sintering primary fine particles of silicon, silicon alloy or silicon oxide together with an organosilicon compound. Sintering of the organosilicon compound results in a silicon-base inorganic compound which serves as a binder. Each particle has the structure that silicon or silicon alloy fine particles are dispersed in the silicon-base inorganic compound binder, and voids are present within the particle.

Owner:SHIN ETSU CHEM IND CO LTD

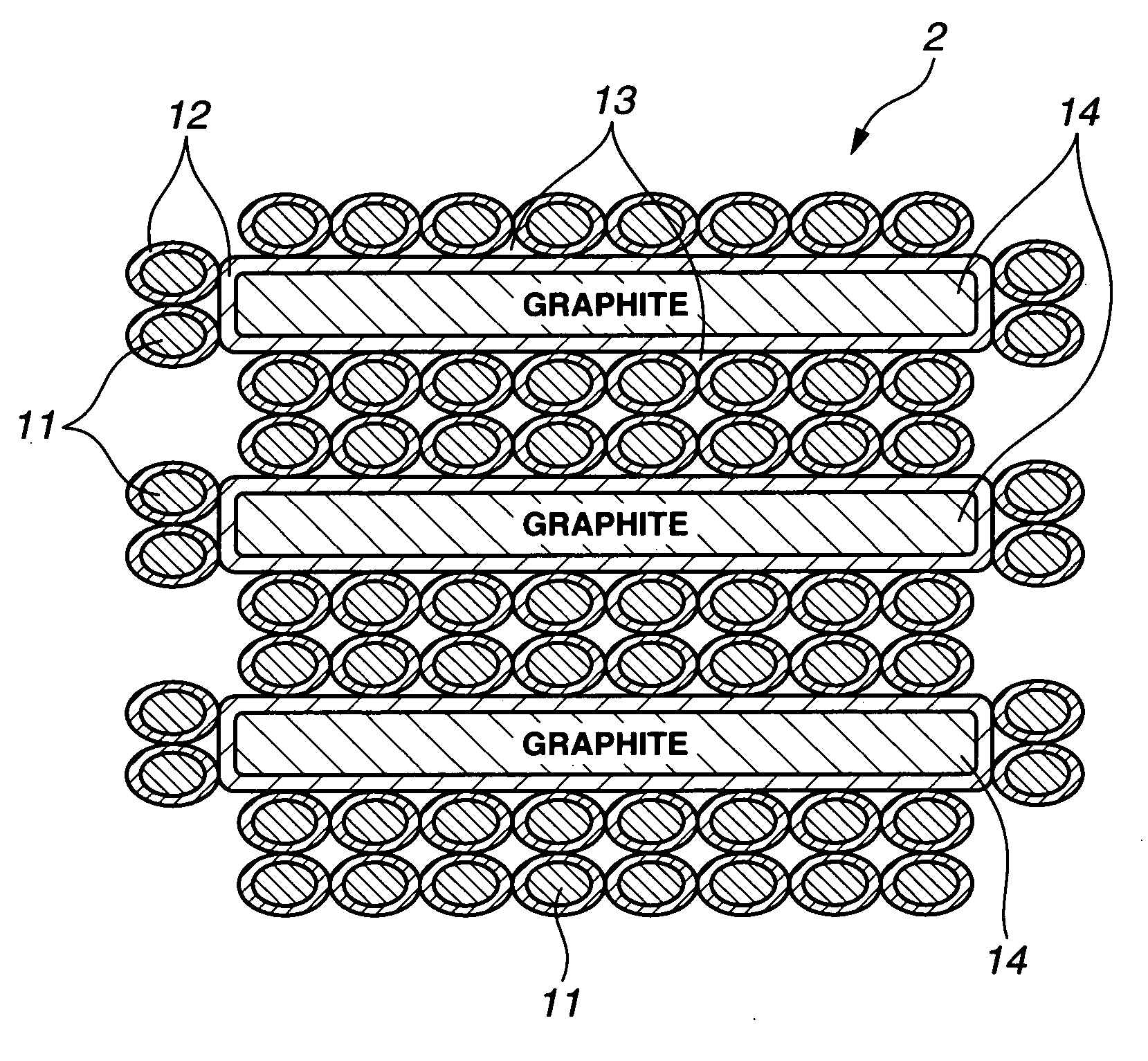

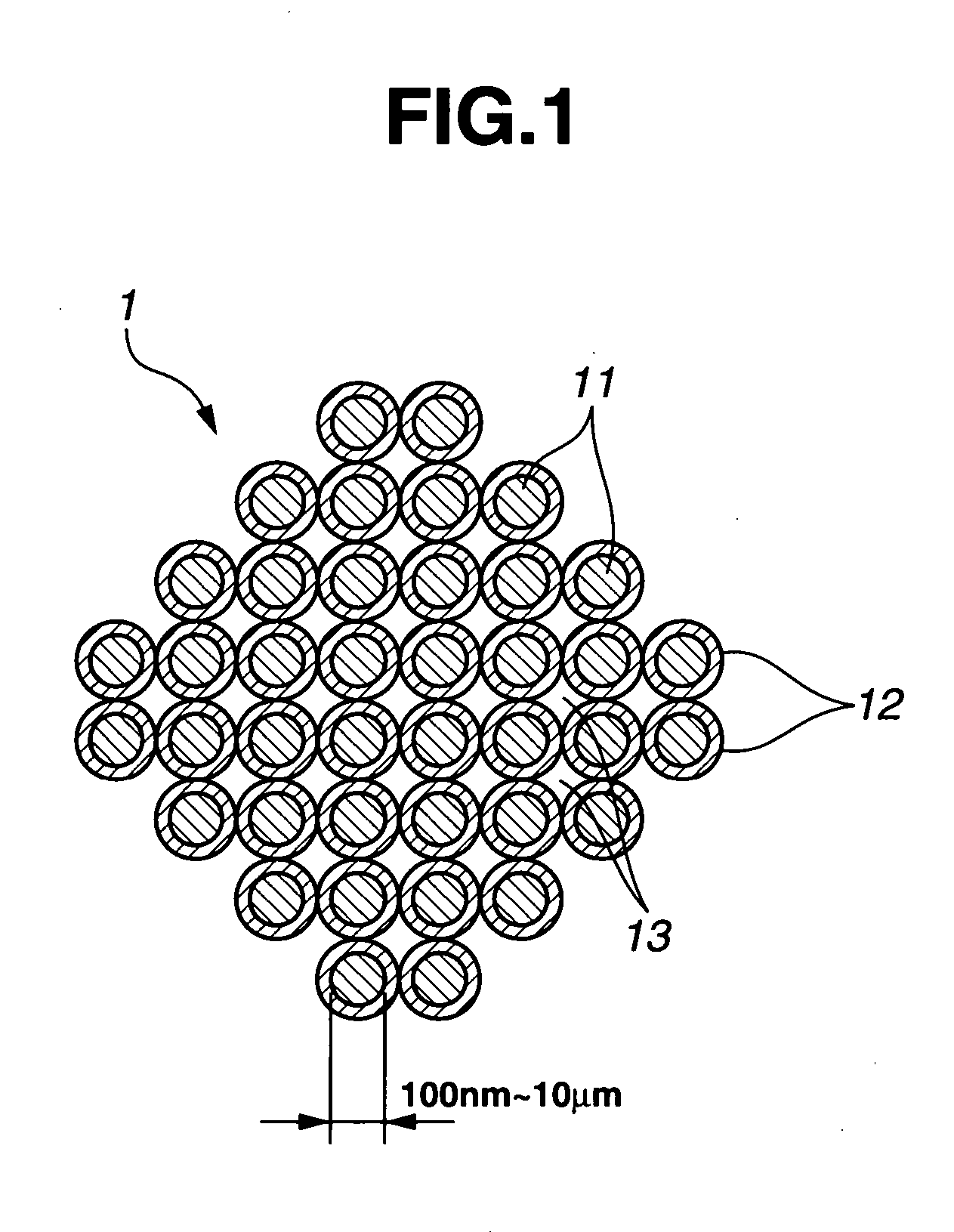

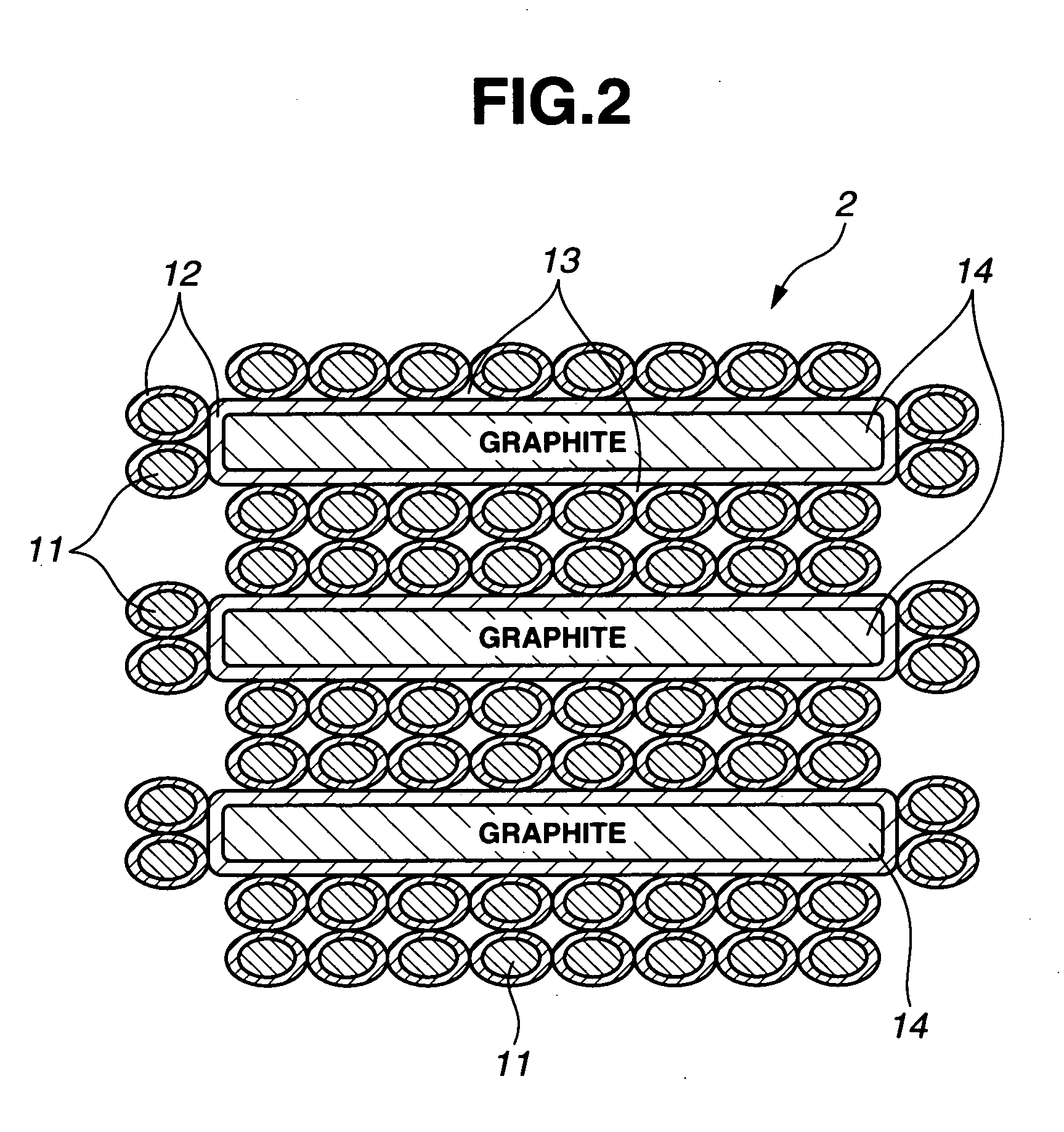

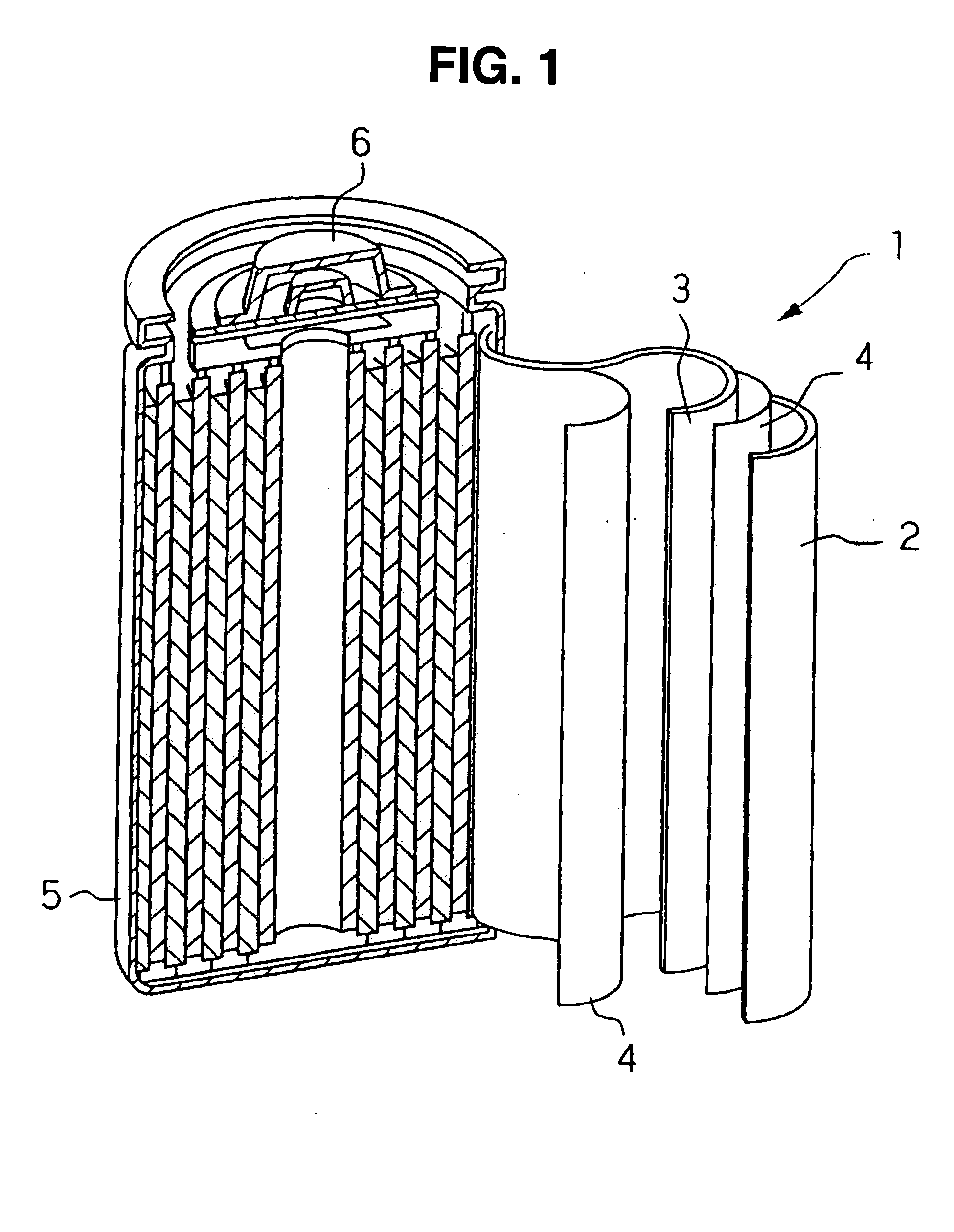

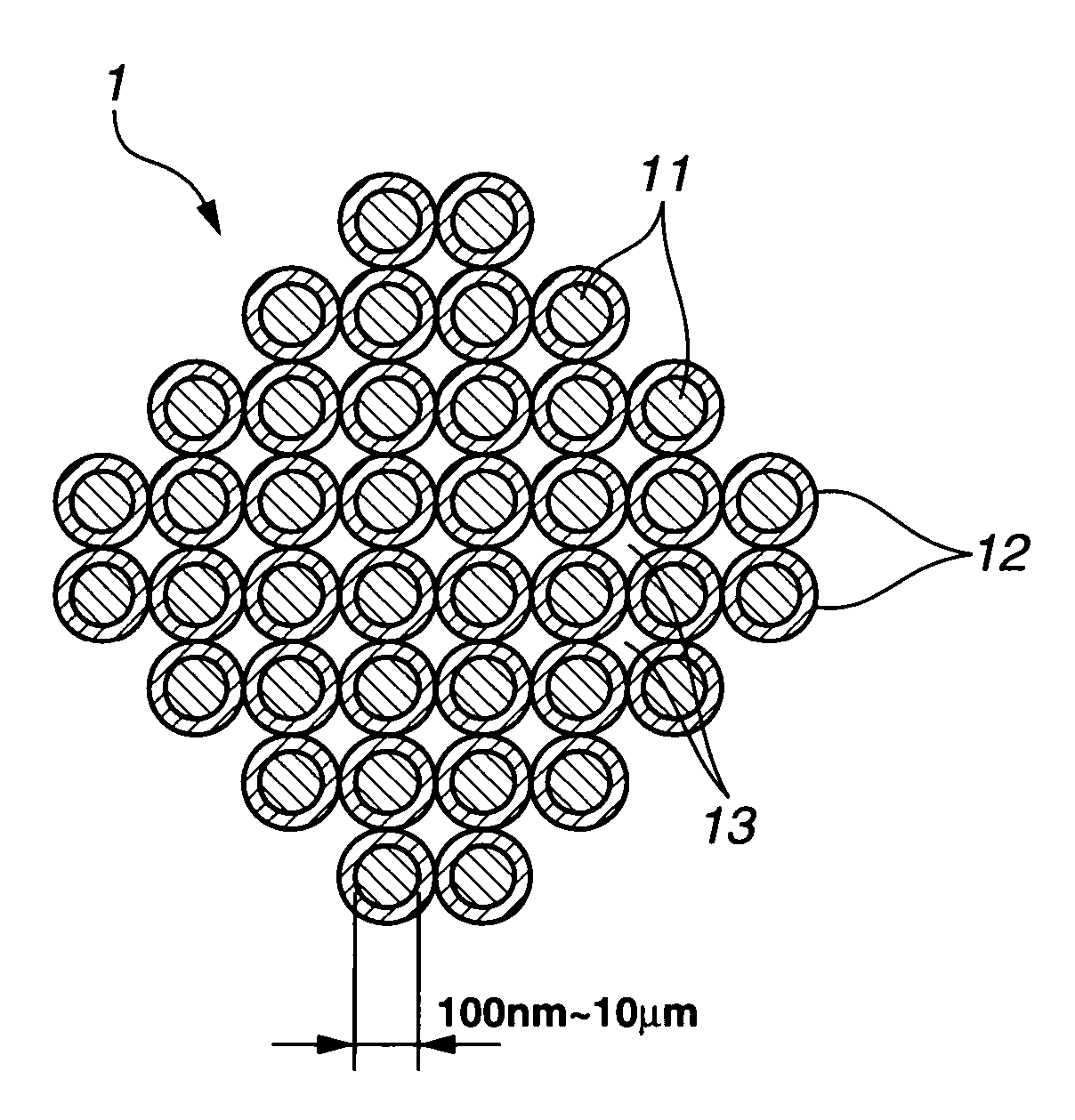

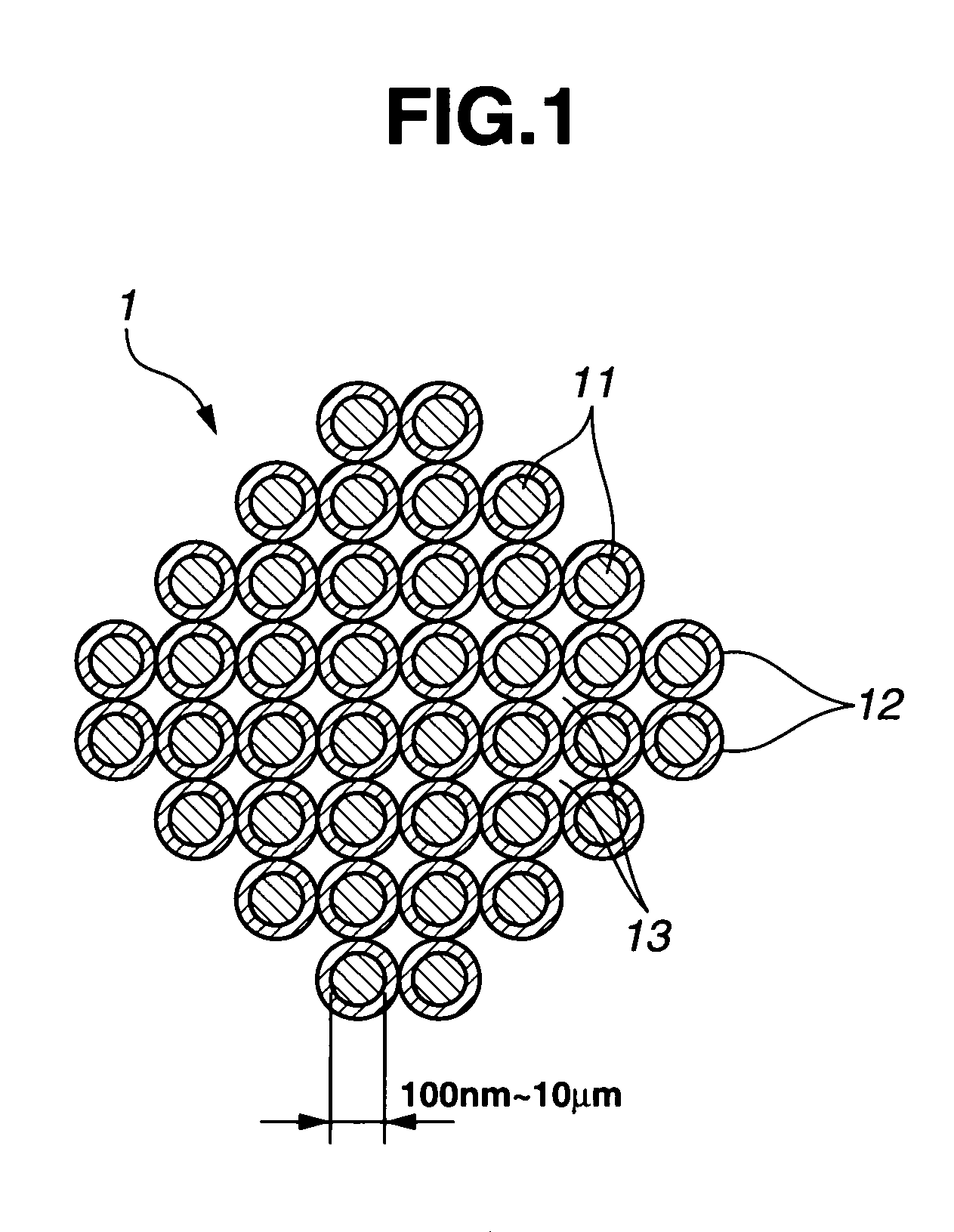

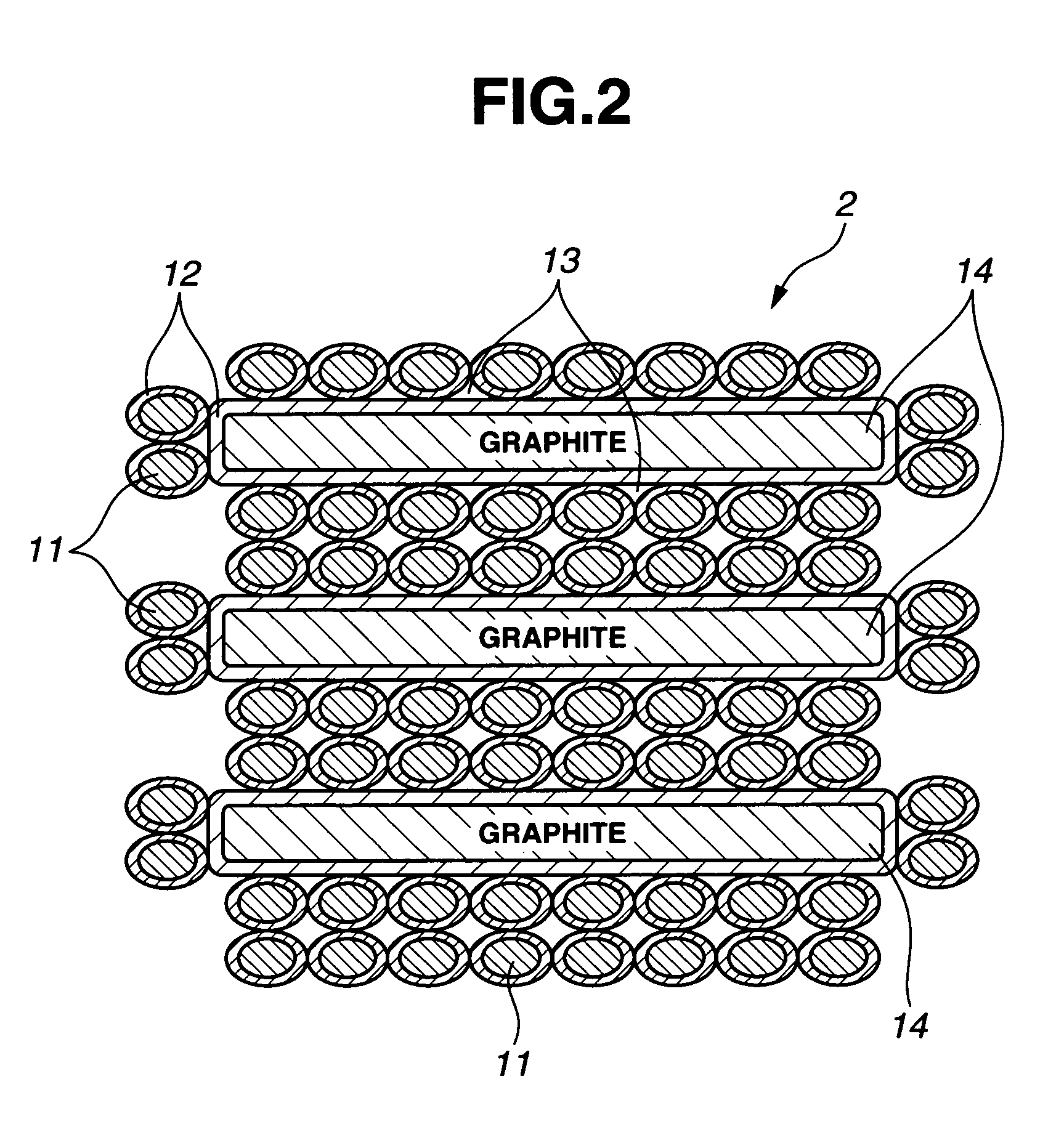

Carbon nanotube-coated silicon/metal composite particle, preparation method thereof, and anode for secondary battery and secondary battery using the same

InactiveUS20100092868A1Small volume changeImprove conductivityMaterial nanotechnologySiliconPhysical chemistryNanotube

Disclosed are a carbon nanotube-coated silicon / metal composite particle, a preparation method thereof, an anode for a secondary battery comprising the carbon nanotube-coated silicon / metal composite particle, and a secondary battery comprising the anode, wherein the carbon nanotube-coated silicon / metal composite particle characterized in comprising: a composite particle of silicon and metal; and a carbon nanotube coated on the surface of the composite particle of silicon and metal, wherein the carbon nanotube-coated silicon / metal composite particle may be prepared by preparing composite particle of silicon and metal, followed by treating the composite particles of silicon and metal with heat under a mixed gas atmosphere of an inert gas and a hydrocarbon gas.

Owner:KOREA INST OF SCI & TECH

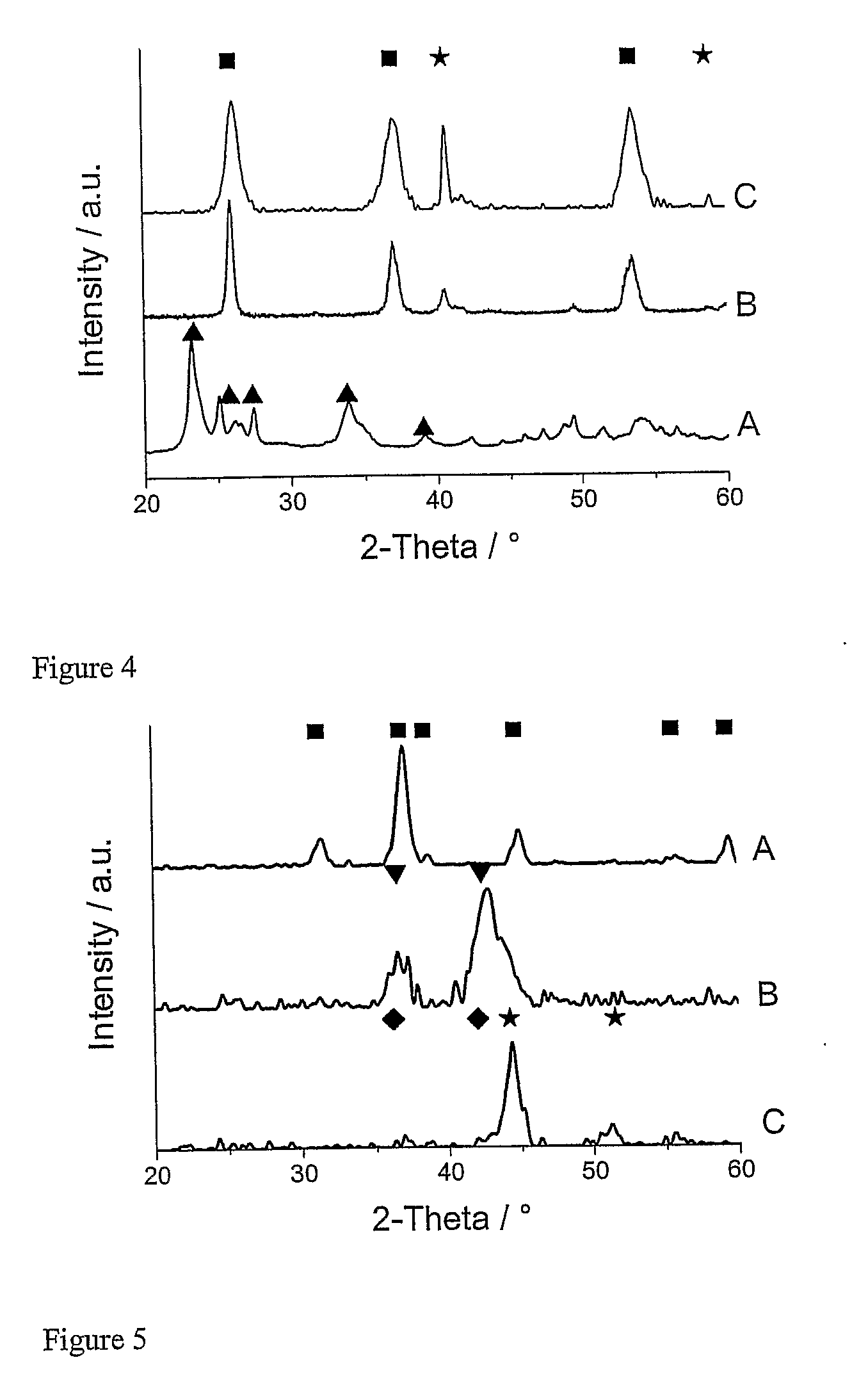

Silicide compositions containing alkali metals and methods of making the same

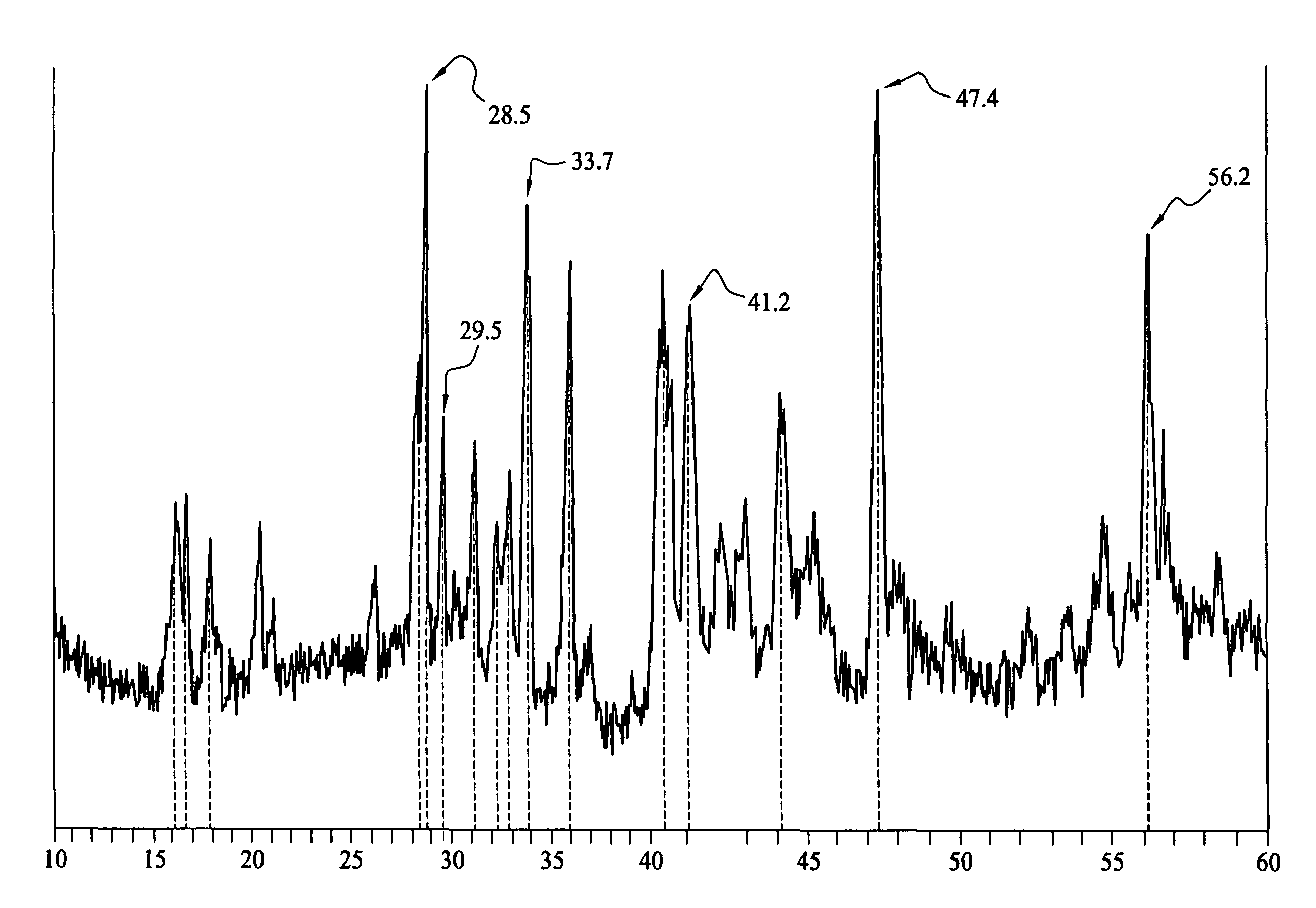

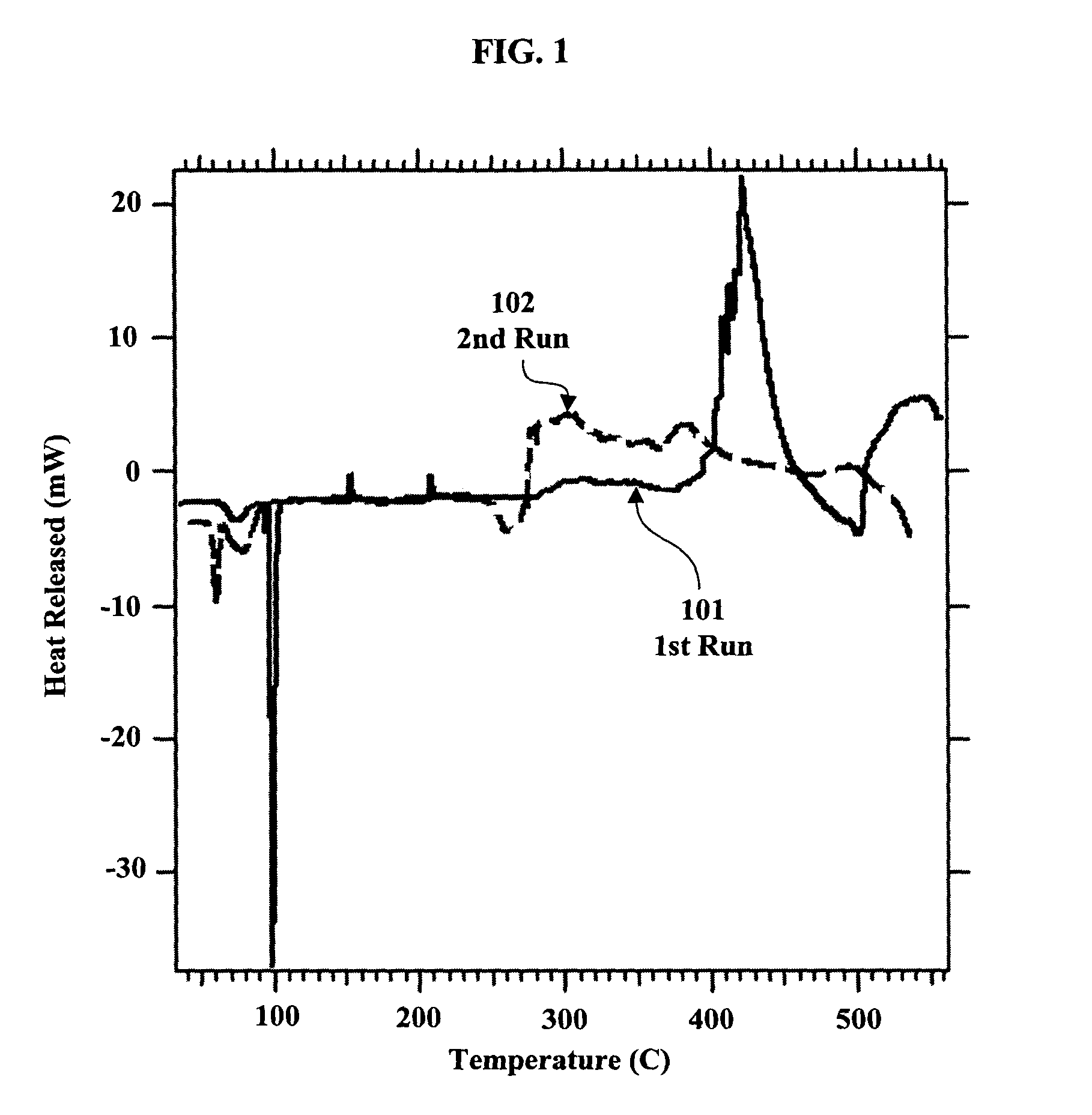

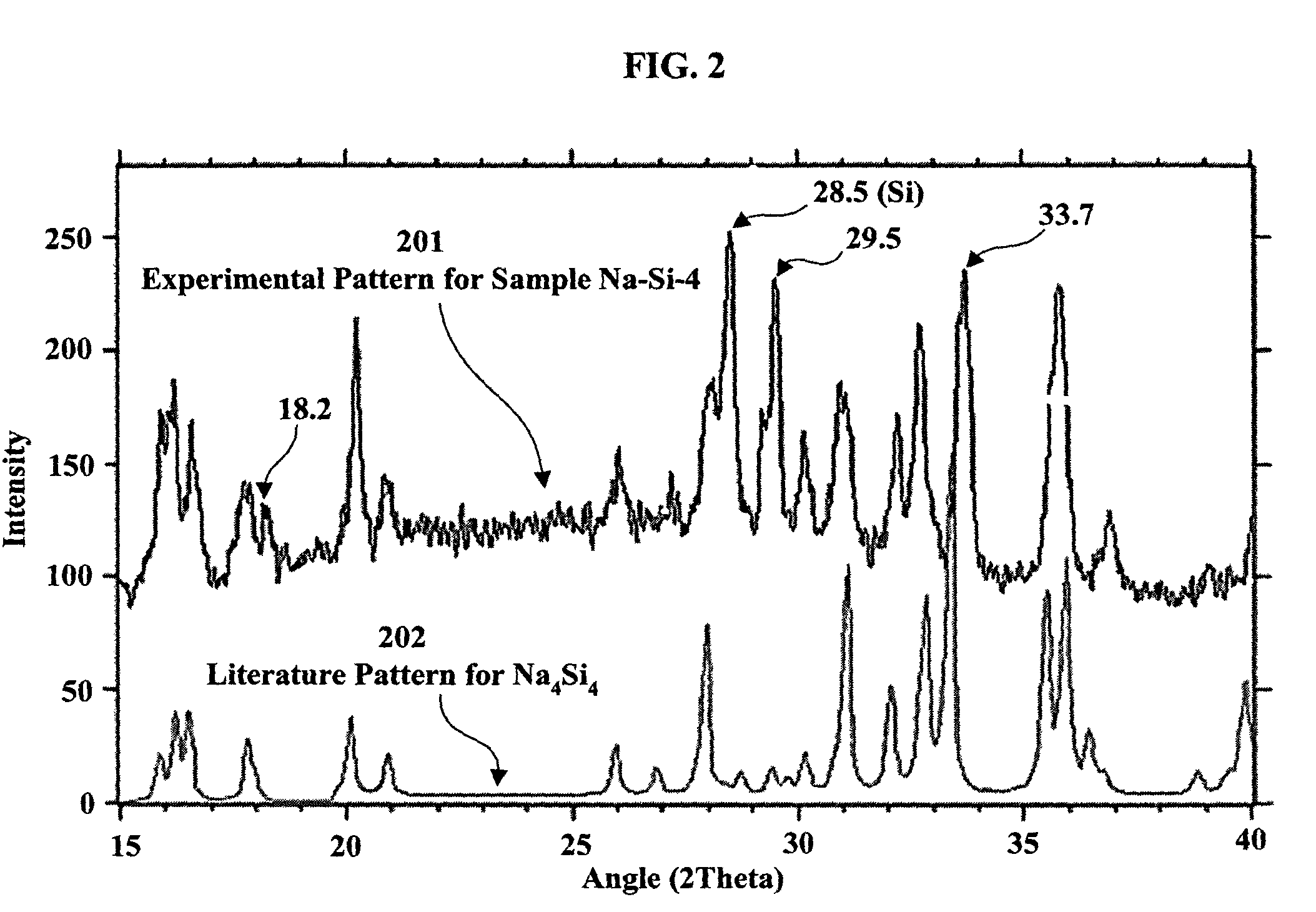

The invention relates to a method of making alkali metal silicide compositions, and the compositions resulting from the method, comprising mixing an alkali metal with silicon and heating the resulting mixture to a temperature below about 475° C. The resulting compositions do not react with dry O2. Also, the invention relates to sodium silicide compositions having a powder X-ray diffraction pattern comprising at least three peaks with 2Theta angles selected from about 18.2, 28.5, 29.5, 33.7, 41.2, 47.4, and 56.2 and a solid state 23Na MAS NMR spectra peak at about 18 ppm. Moreover, the invention relates to methods of removing a volatile or flammable substance in a controlled manner. Furthermore, the alkali metal silicide compositions of the invention react with water to produce hydrogen gas.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

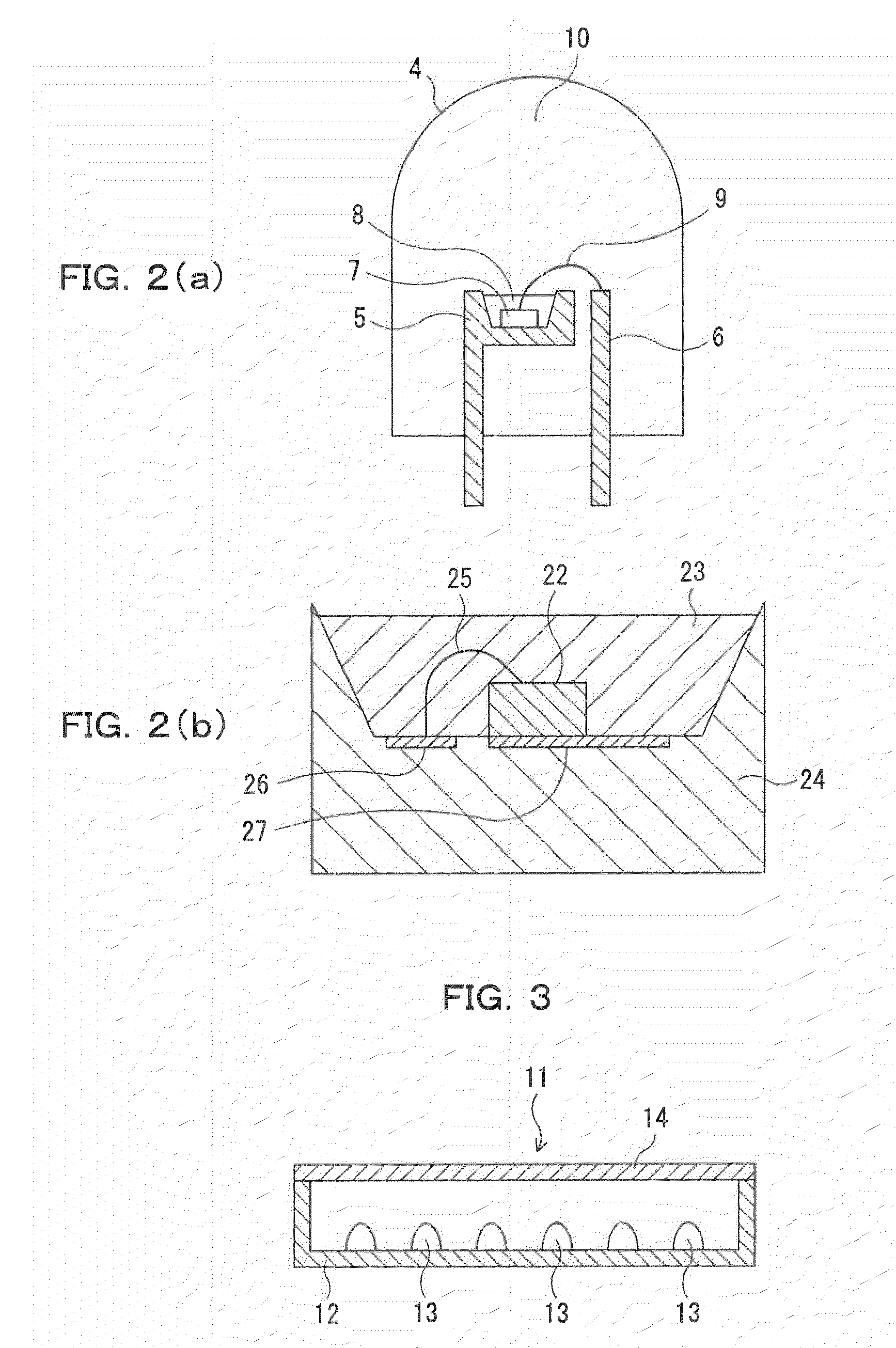

Silicon Nitride Powder for Siliconnitride Phosphor, CaAlSiN3 Phosphor Using Same, Sr2Si5N8 Phosphor Using Same, (Sr, Ca)AlSiN3 Phosphor Using Same, La3Si6N11Phosphor Using Same, and Methods for Producing the Phosphors

Provided are: a silicon nitride powder for siliconitride phosphors with higher luminance, which can be used for a fluorescent display tube (VFD), a field emission display (FED), a plasma display panel (PDP), a cathode ray tube (CRT), a light emitting diode (LED), and the like; a CaAlSiN3 phosphor, an Sr2Si5N8 phosphor, an (Sr, Ca)AlSiN3 phosphor and an La3Si6N11 phosphor, each using the silicon nitride powder; and methods for producing the phosphors. The present invention relates to a silicon nitride powder for siliconitride phosphors, which is characterized by being a crystalline silicon nitride powder that is used as a starting material for producing a siliconitride phosphor that includes silicon element and nitrogen element but does not contain oxygen element as a constitutent element, and which is characterized by having an oxygen content of 0.2% by weight to 0.9% by weight; a CaAlSiN3 phosphor, an Sr2Si5N8 phosphor, an (Sr, Ca)AlSiN3 phosphor and an La3Si6N11 phosphor, each using the silicon nitride powder; and methods for producing the phosphors.

Owner:UBE IND LTD

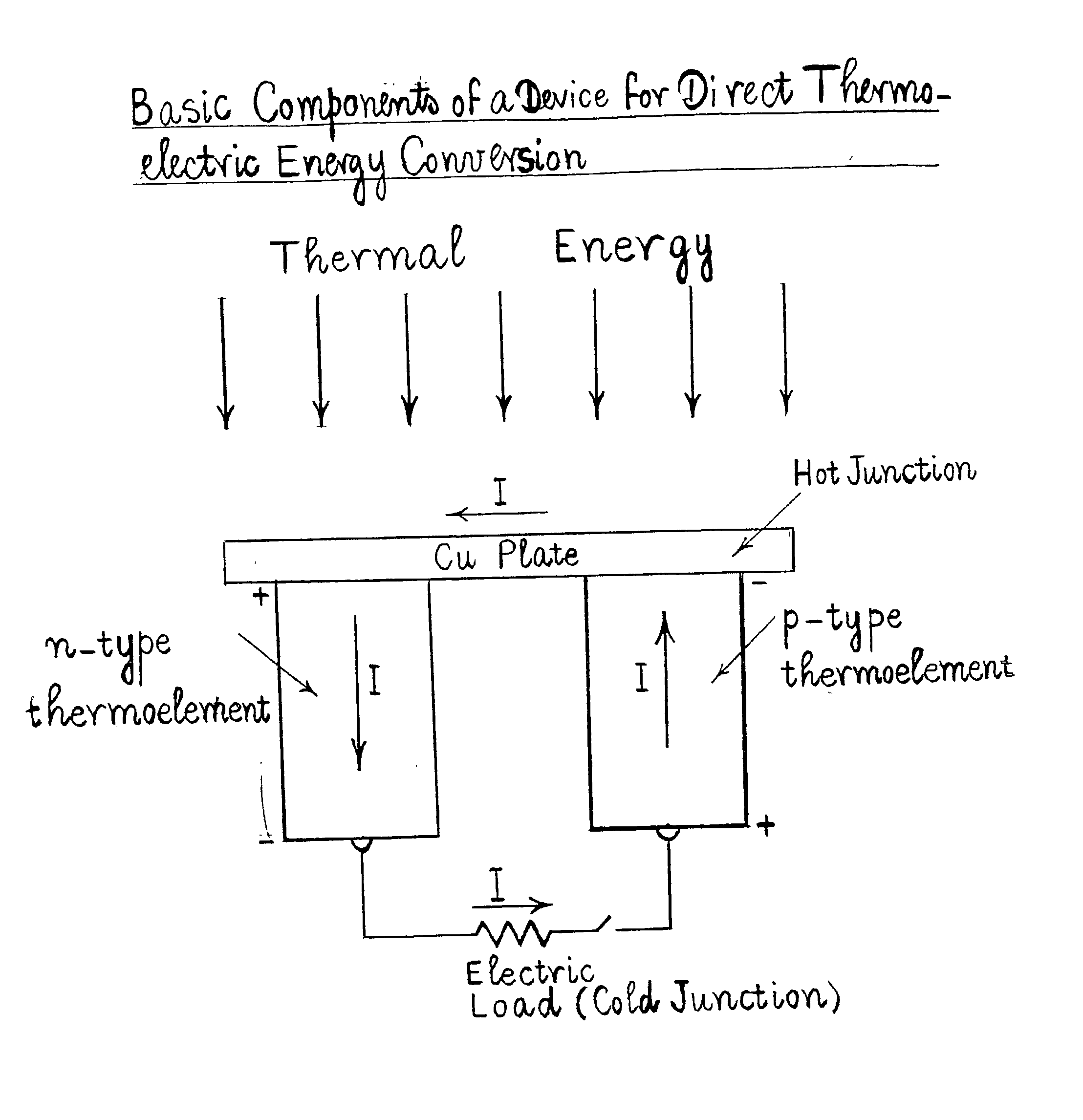

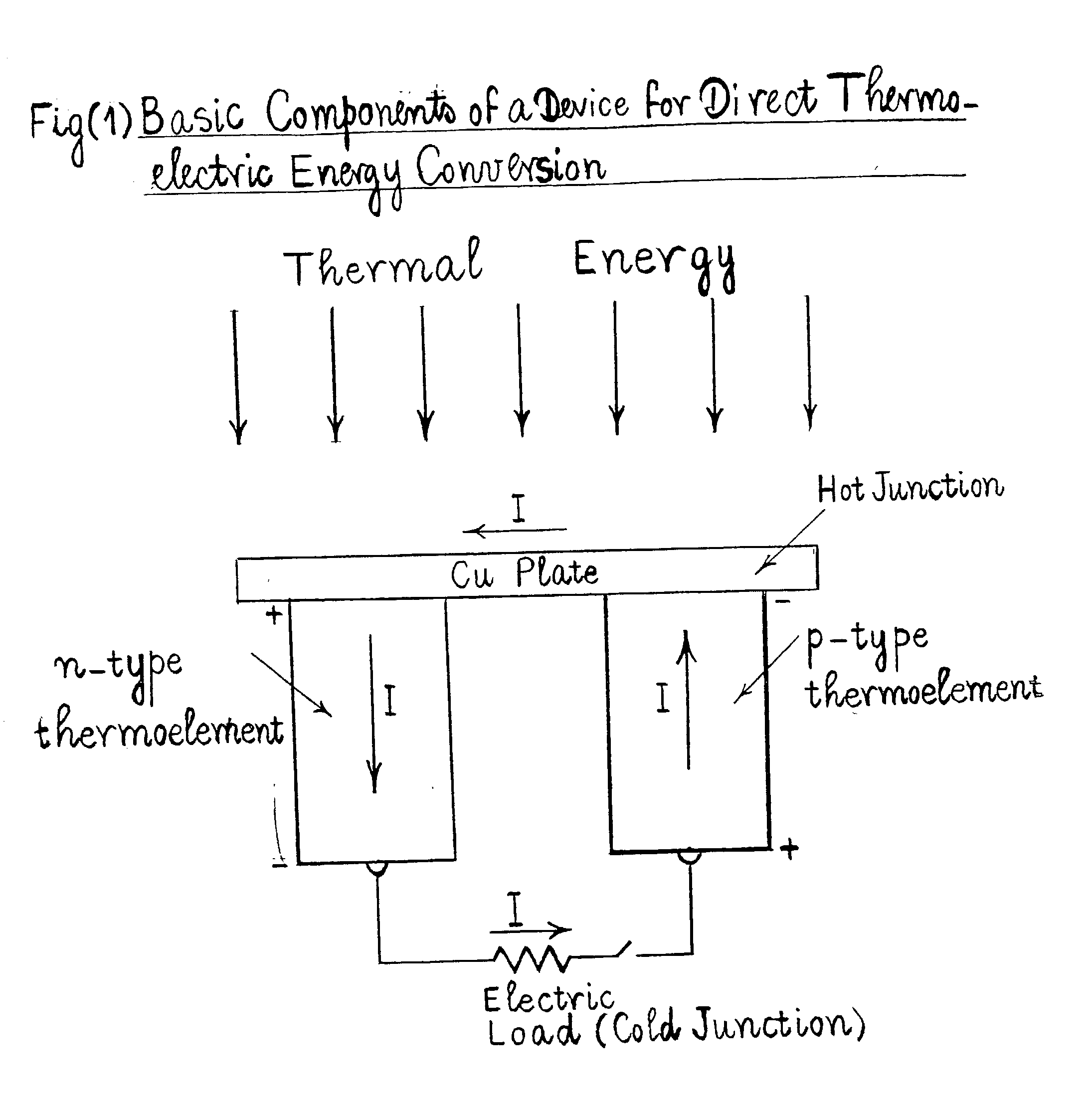

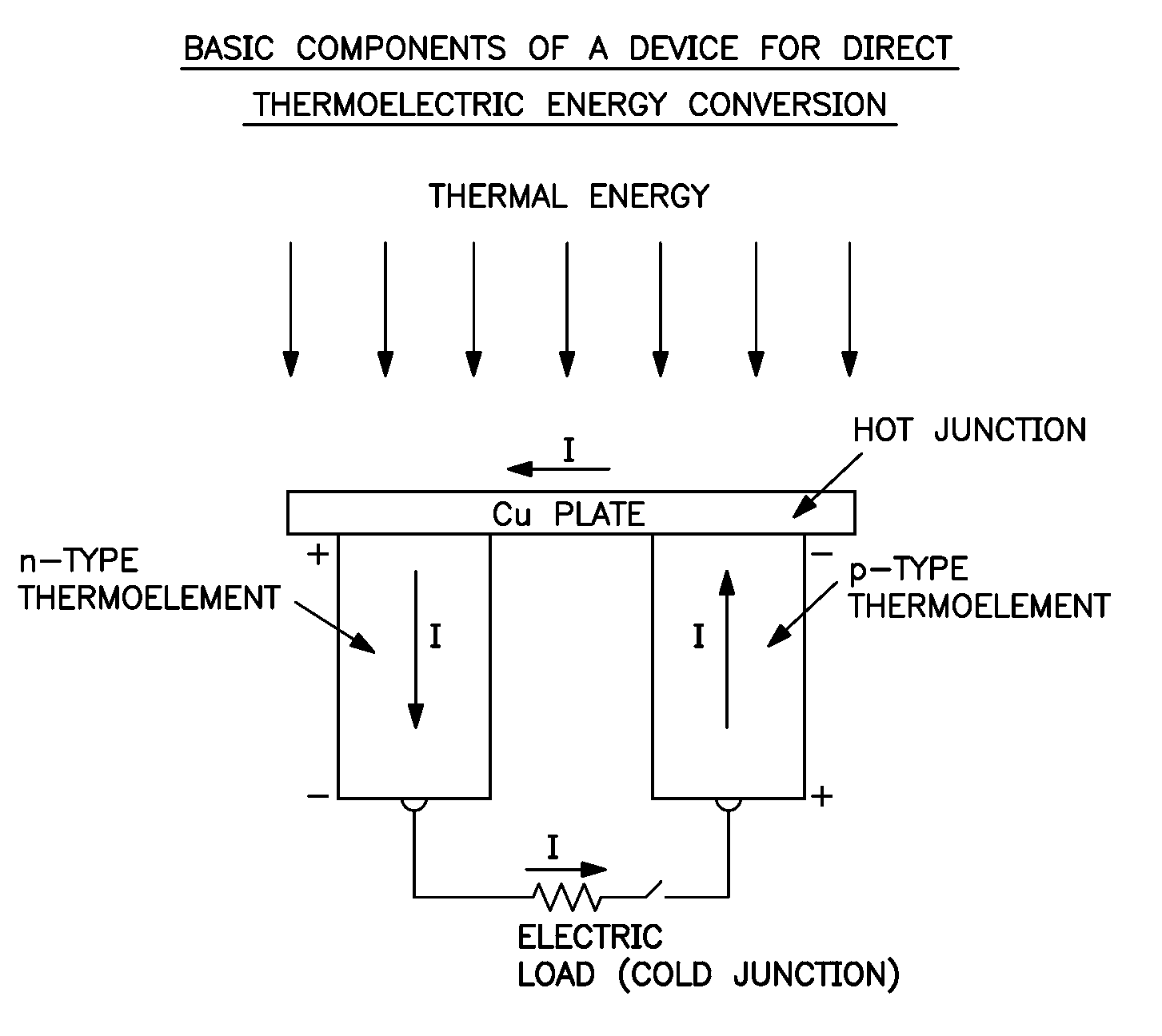

Method for producing a device for direct thermoelectric energy conversion

InactiveUS20030110892A1Polycrystalline material growthThermoelectric device manufacture/treatmentJunction temperatureEngineering

In devices used for the direct conversion of heat into electricity, or vice versa, known in the art as thermoelectric power generators, thermoelectric refrigerators and thermoelectric heat pumps, the efficiency of energy conversion and / or coefficient of performance have been considerably lower than those of conventional reciprocating or rotary, heat engines and / or vapor-compression systems, employing certain refrigerants. The energy conversion efficiency of power generating devices, for example, aside from the hot and cold junction temperatures, also depends on a parameter known in the art as the thermoelectric figure of merit Z=S2sigma / k, where S is the thermoelectric power, sigma is the electrical conductivity and k is the thermal conductivity, of the material that constitutes the p-type, and / or n-type, thermoelements, or branches, of the said devices. In order to achieve a considerable increase in the energy conversion efficiency, a thermoelectric figure of merit of the order of 10-2 K-1, or more, is needed. It is reasonably expected that such an order of magnitude, for the figure of merit, can be realized with a composition of matter, comprising magnesium, silicon, lead and barium, and optionally comprising one, or more, additional doping materials.

Owner:NICOLOAU MICHAEL C

Iron silicide sputtering target and method for production thereof

ActiveUS20060057014A1Reduce the amount requiredGeneration of particleNitrogen compoundsMetal silicidesSputteringIngot

Provided is an iron silicide sputtering target in which the oxygen as the gas component in the target is 1000 ppm or less, and a manufacturing method of such iron silicide sputtering target including the steps of melting / casting high purity iron and silicon under high vacuum to prepare an alloy ingot, subjecting the ingot to gas atomization with inert gas to prepare fine powder, and thereafter sintering the fine powder. With this iron suicide sputtering target, the amount of impurities will be reduced, the thickness of the βFeSi2 film during deposition can be made thick, the generation of particles will be reduced, a uniform and homogenous film composition can be yielded, and the sputtering characteristics will be favorable. The foregoing manufacturing method is able to stably produce this target.

Owner:JX NIPPON MINING& METALS CORP

Method for producing a device for direct thermoelectric energy conversion

InactiveUS7166796B2Improve energy conversion efficiencyReduced dimensionPolycrystalline material growthThermoelectric device manufacture/treatmentJunction temperatureEngineering

In devices used for the direct conversion of heat into electricity, or vice versa, known in the art as thermoelectric power generators, thermoelectric refrigerators and thermoelectric heat pumps, the efficiency of energy conversion and / or coefficient of performance have been considerably lower than those of conventional reciprocating or rotary, heat engines and / or vapor-compression systems, employing certain refrigerants. The energy conversion efficiency of power generating devices, for example, aside from the hot and cold junction temperatures, also depends on a parameter known in the art as the thermoelectric figure of merit Z=S2σ / k, where S is the thermoelectric power, σ is the electrical conductivity and k is the thermal conductivity, of the material that constitutes the p-type, and / or n-type, thermoelements, or branches, of the said devices. In order to achieve a considerable increase in the energy conversion efficiency, a thermoelectric figure of merit of the order of 10−2 K−1, or more, is needed. It is reasonably expected that such an order of magnitude, for the figure of merit, can be realized with a composition of matter, comprising magnesium, silicon, lead and barium, and optionally comprising one, or more, additional doping materials.

Owner:NICOLOAU MICHAEL C

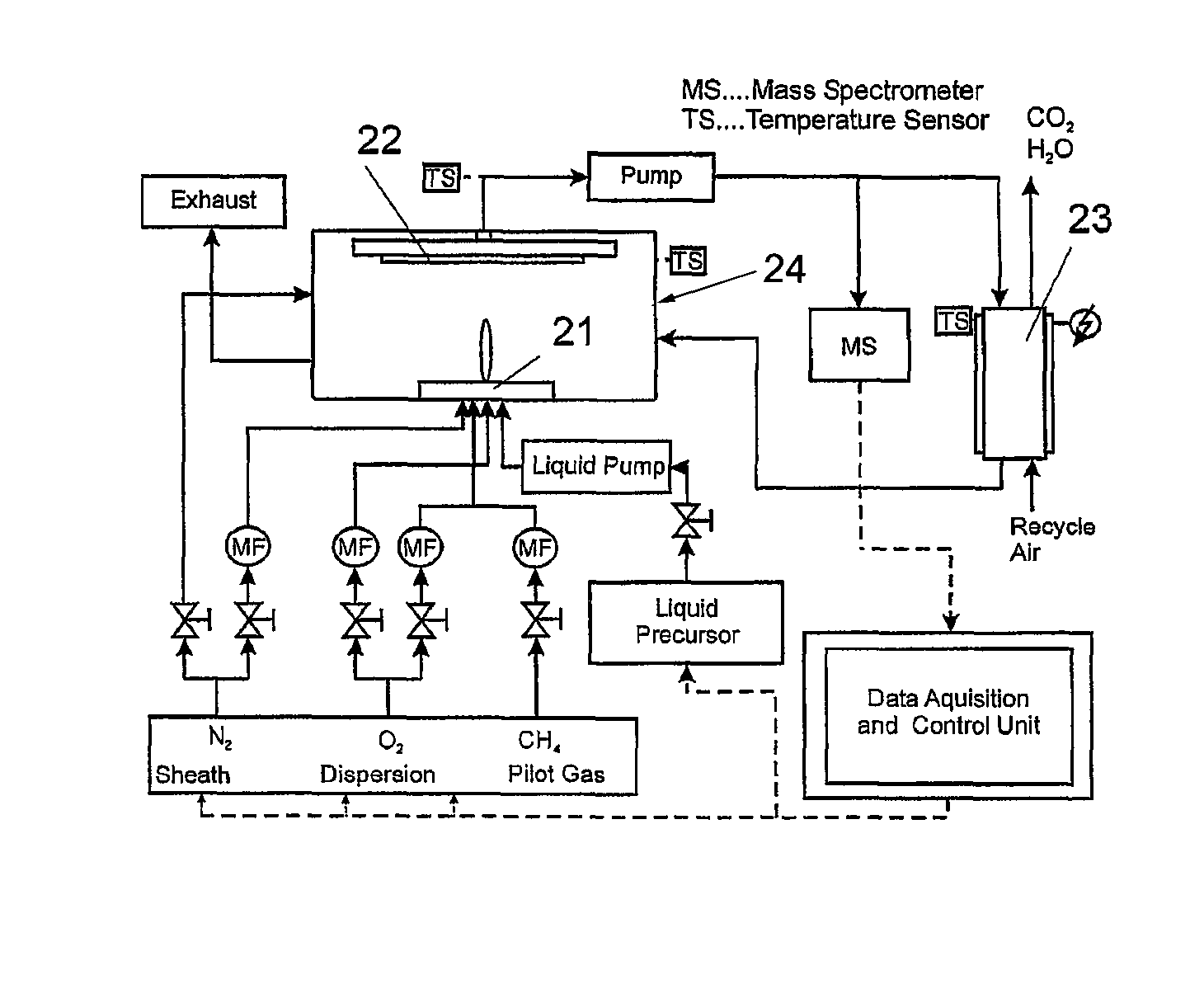

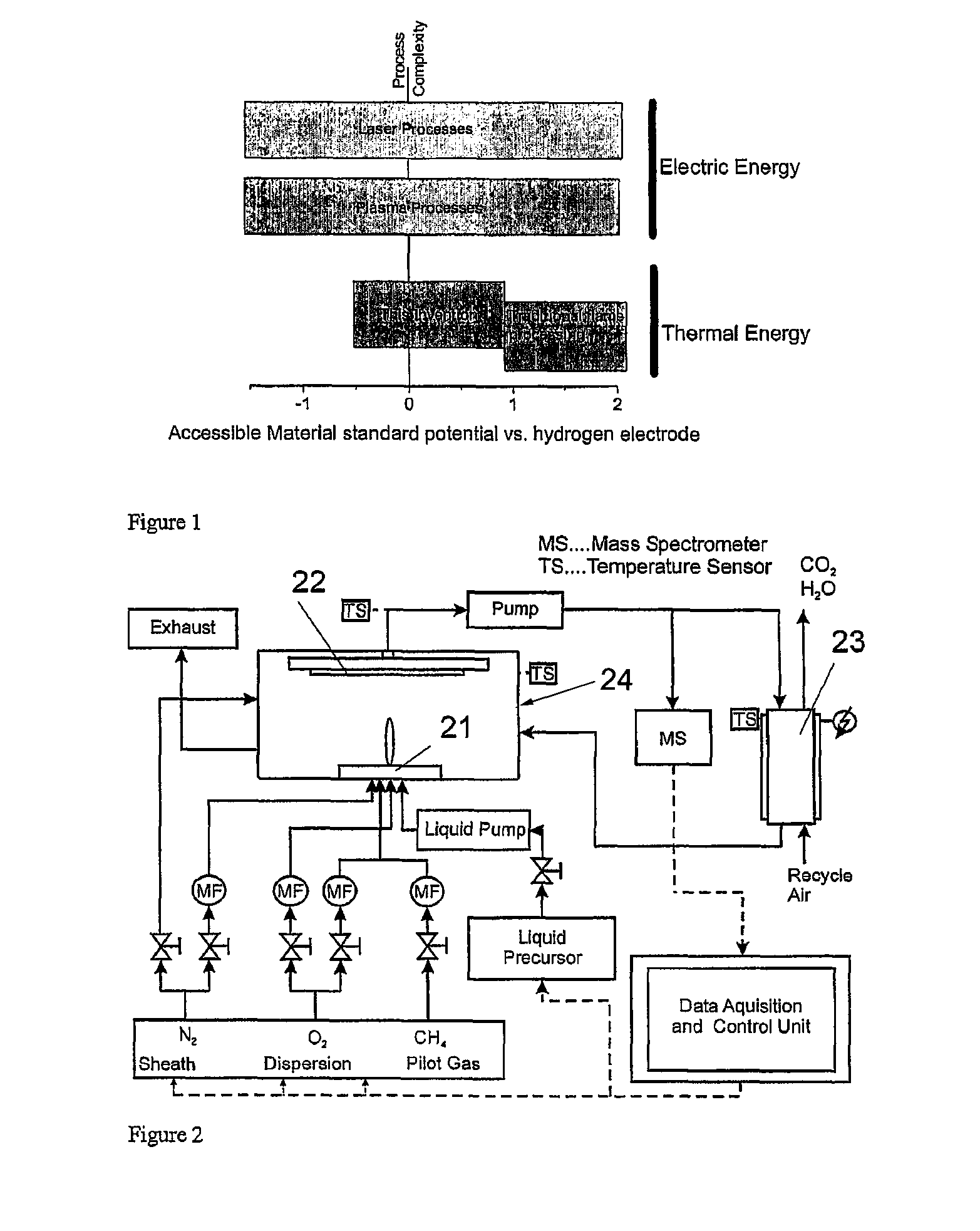

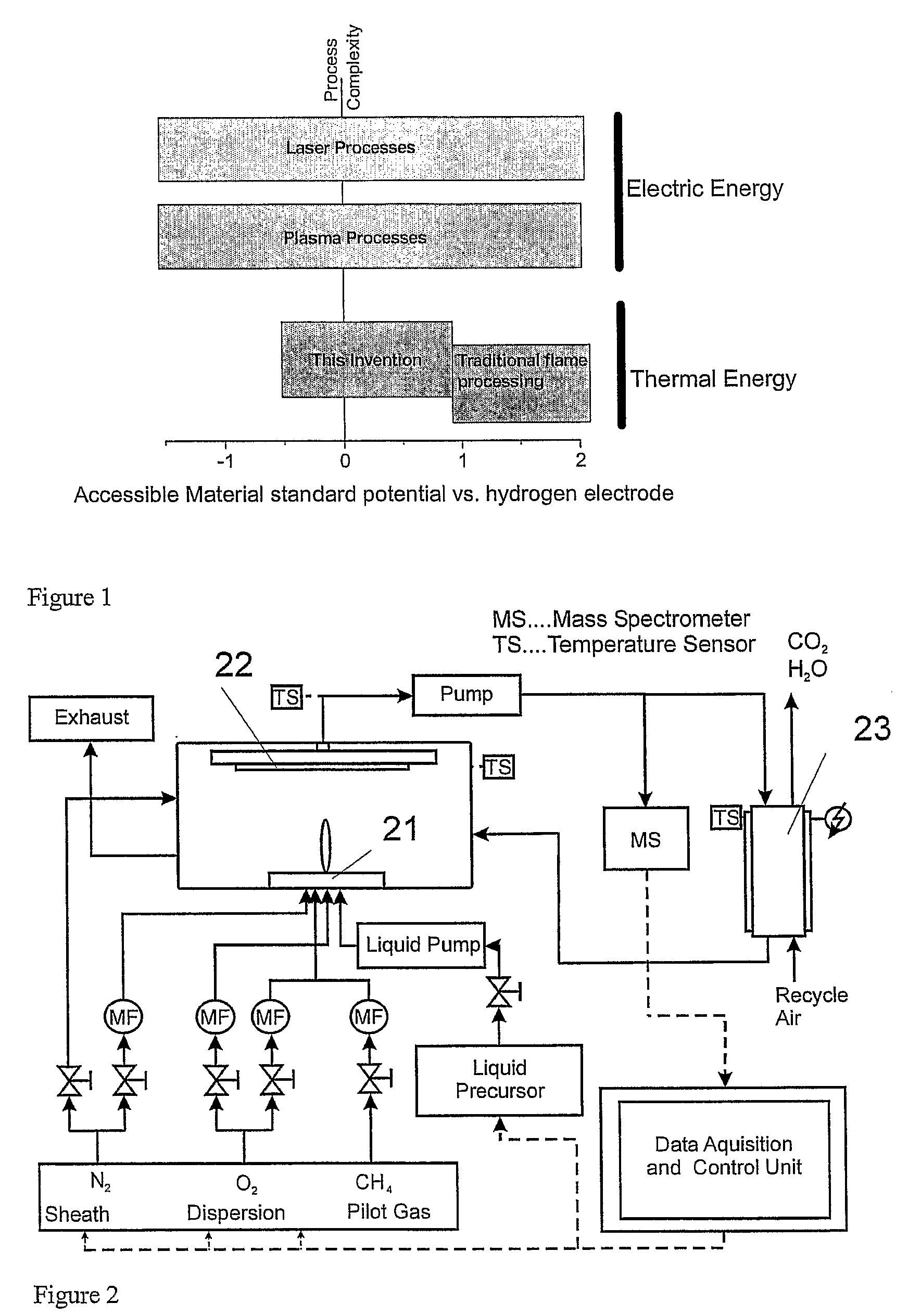

Methods and devices for flame spray pyrolysis

The present invention relates the manufacture of metal powders, non-oxidic ceramic powders and reduced metal oxide powders using an improved flame spray pyrolysis (“FSP”) process. The invention further relates to an apparatus specifically adapted to said process, to powders / naoncomposites obtained by said process and to the use of said powders / nanocompsites.

Owner:ETH ZZURICH

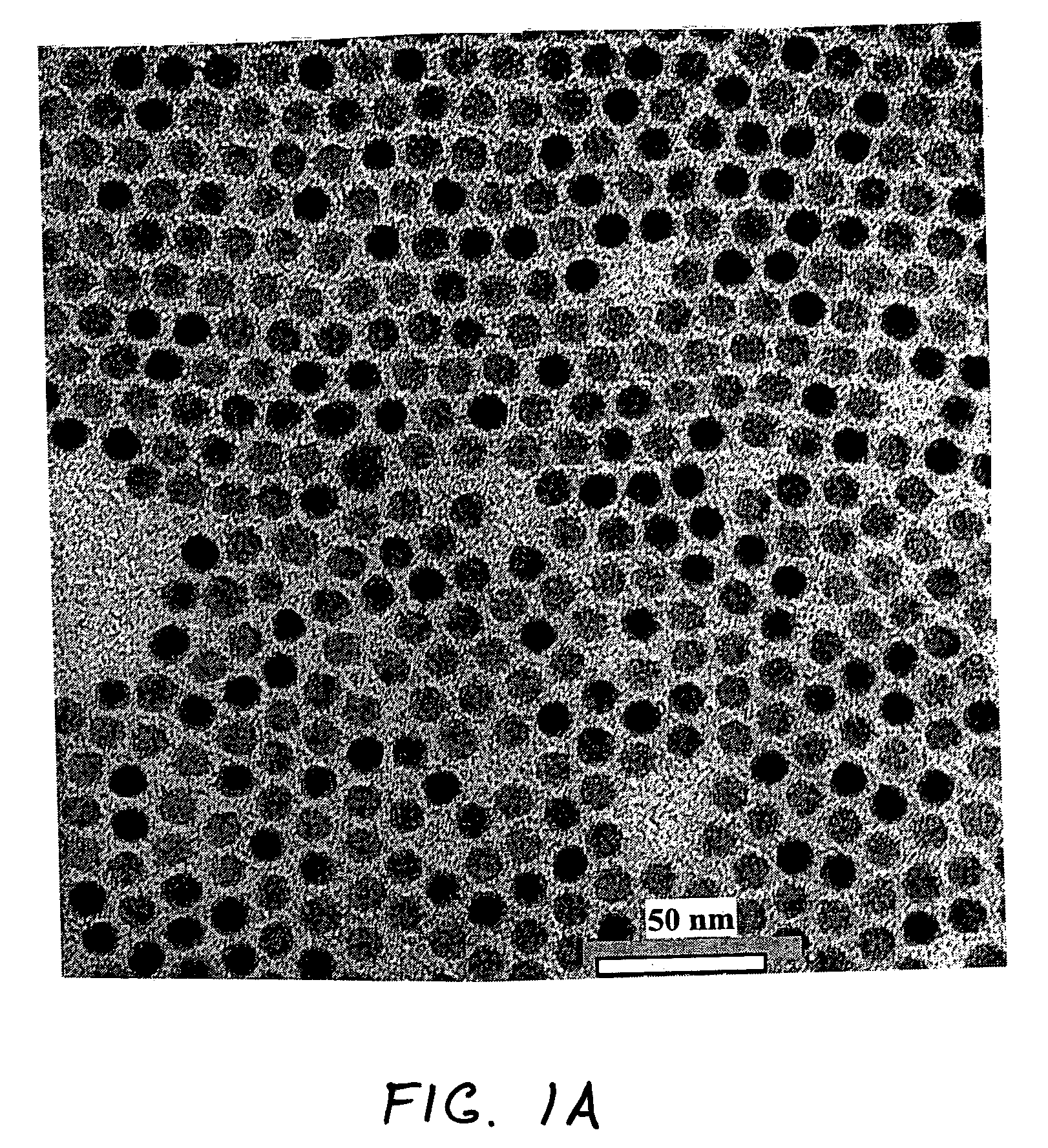

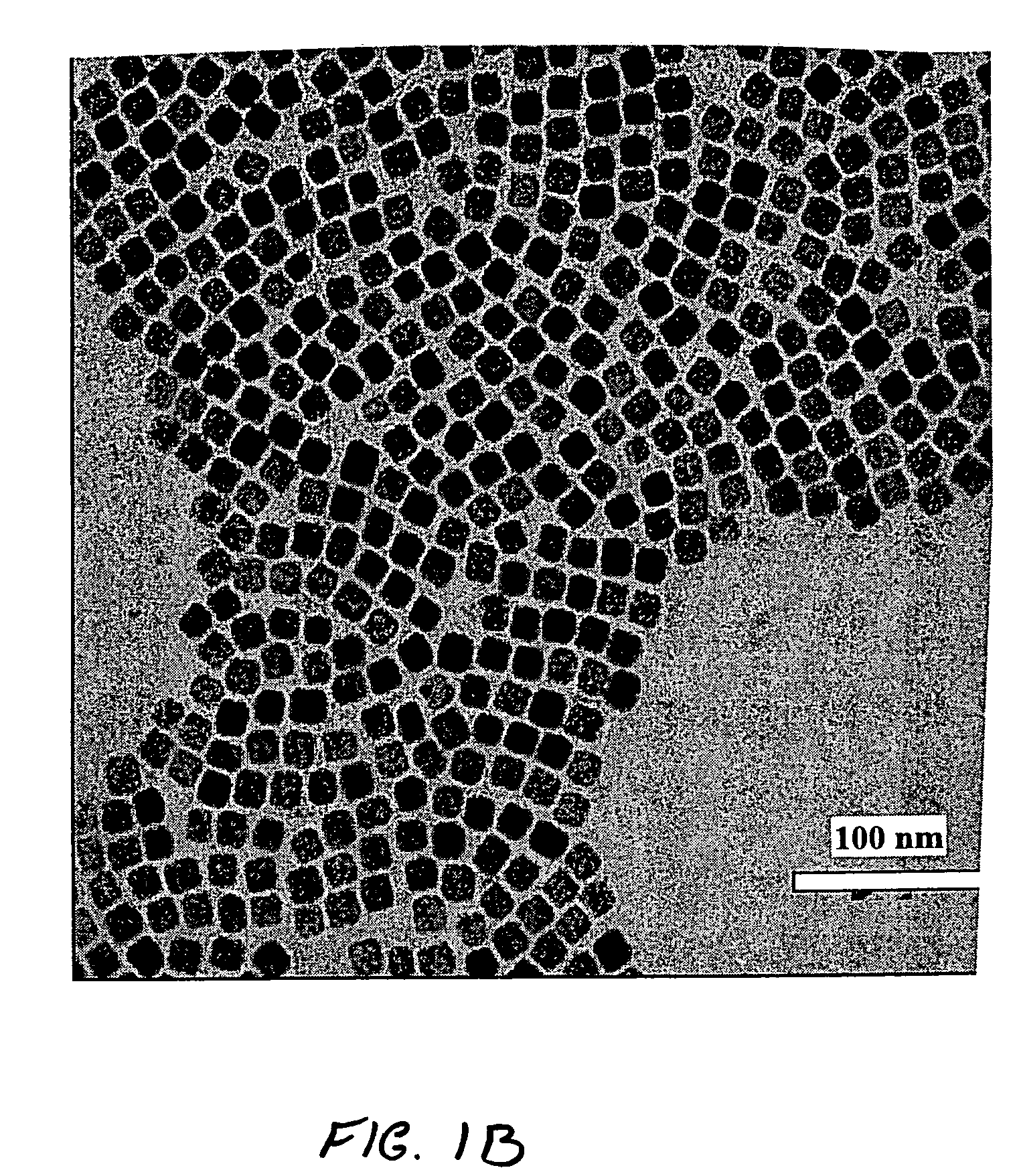

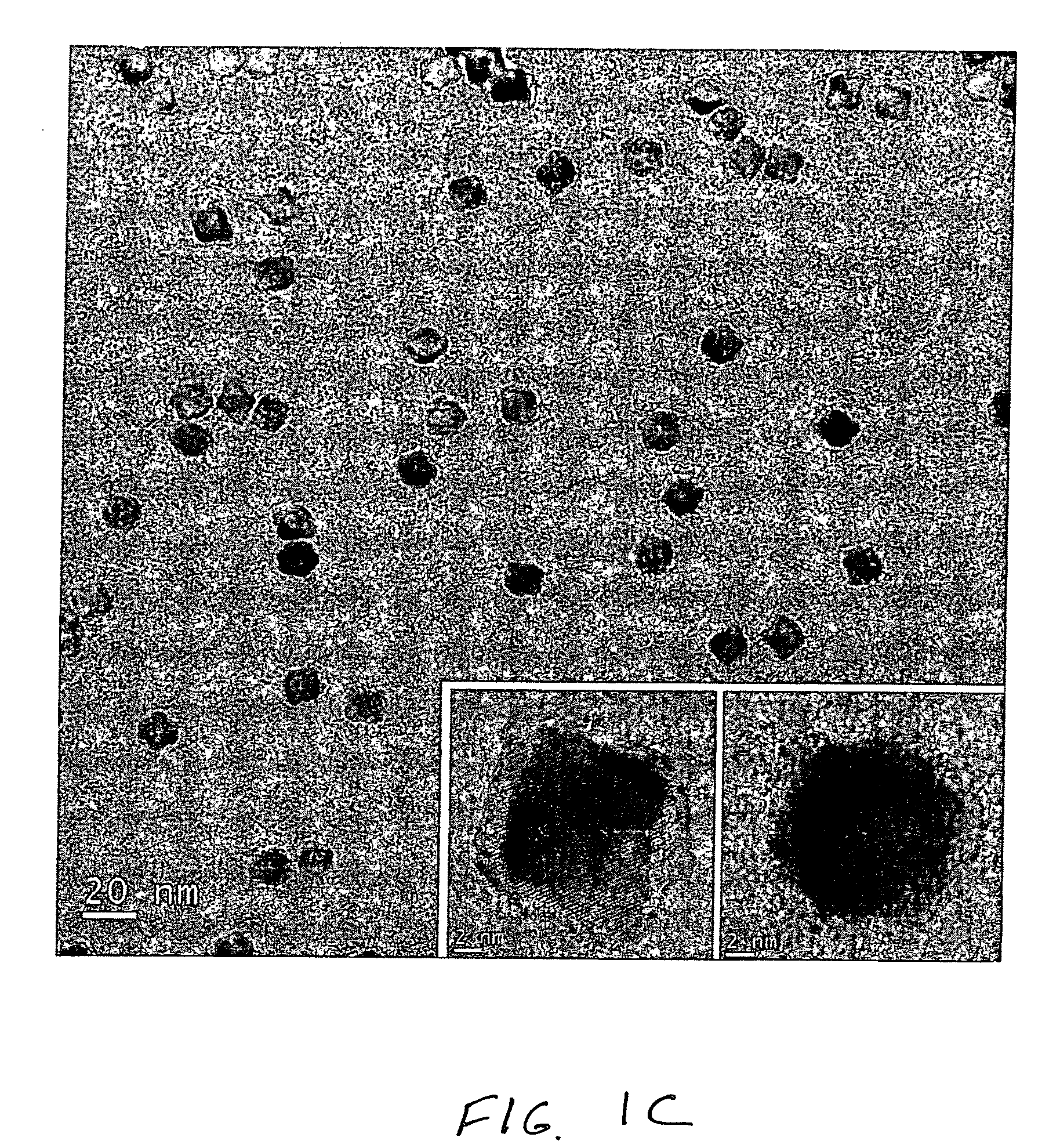

Method for the preparation of IV-VI semiconductor nanoparticles

InactiveUS20060110313A1Controlled in sizeControl shapeMaterial nanotechnologyNitrogen compoundsOrganic solventQuantum dot

A high temperature (on the order of about 90° C. or above) non-aqueous synthetic procedure for the preparation of substantially monodisperse IV-VI semiconductor nanoparticles (quantum dots) is provided. The procedure includes first introducing a first precursor selected from the group consisting of a molecular precursor of a Group IV element and a molecular precursor of a Group VI element into a reaction vessel that comprises at least an organic solvent to form a mixture. Next, the mixture is heated to a temperature of about 90° C. or above and thereafter a second precursor which is different from the first precursor and is selected from the group consisting of a molecular precursor of a Group IV element and a molecular precursor of a Group VI element is added into the heated mixture. The reaction mixture is then mixed to initiate nucleation of IV-VI nanocrystals and the temperature of the reaction mixture is controlled to provide substantially monodispersed IV-VI nanoparticles having a diameter of about 20 nm or less.

Owner:GLOBALFOUNDRIES INC +1

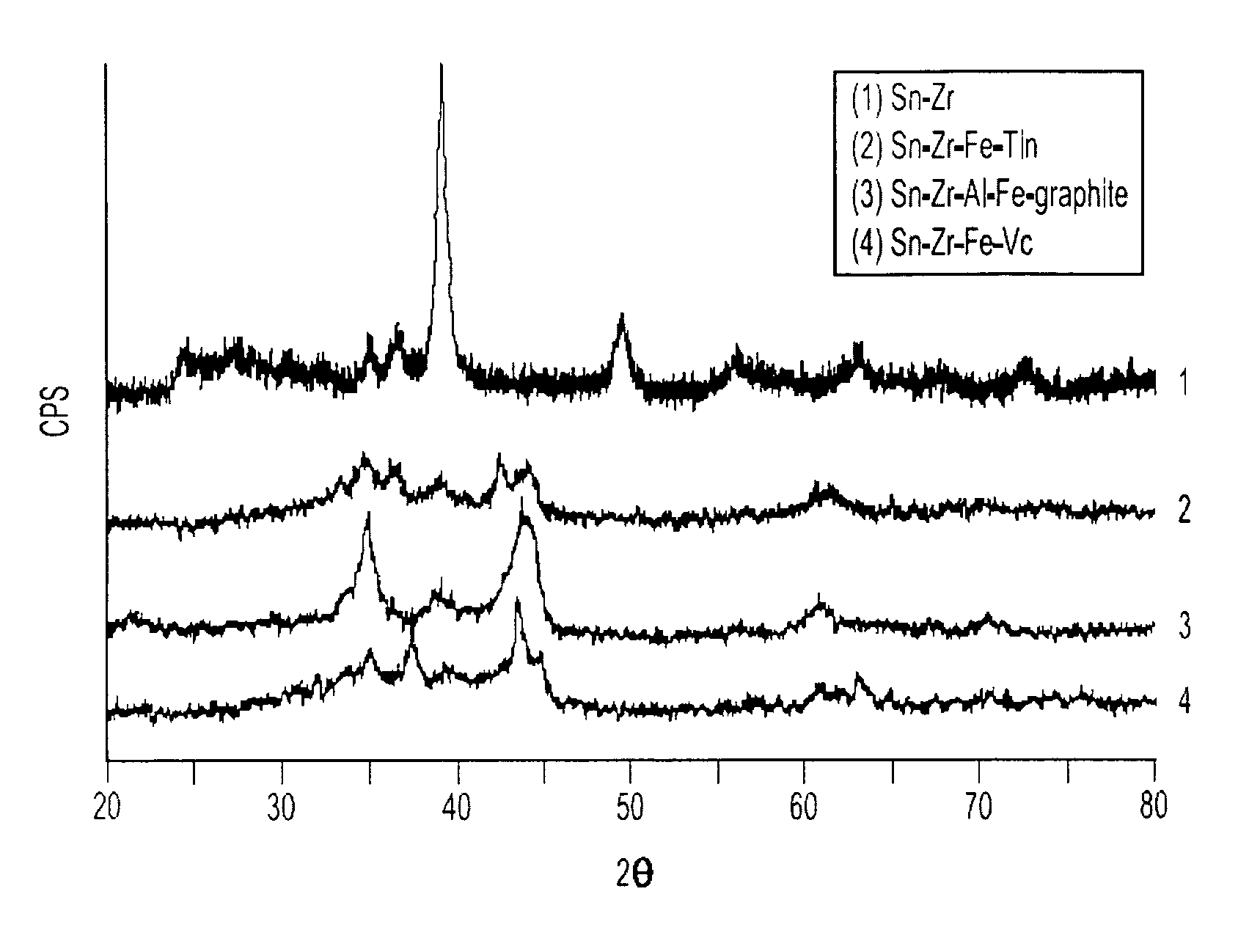

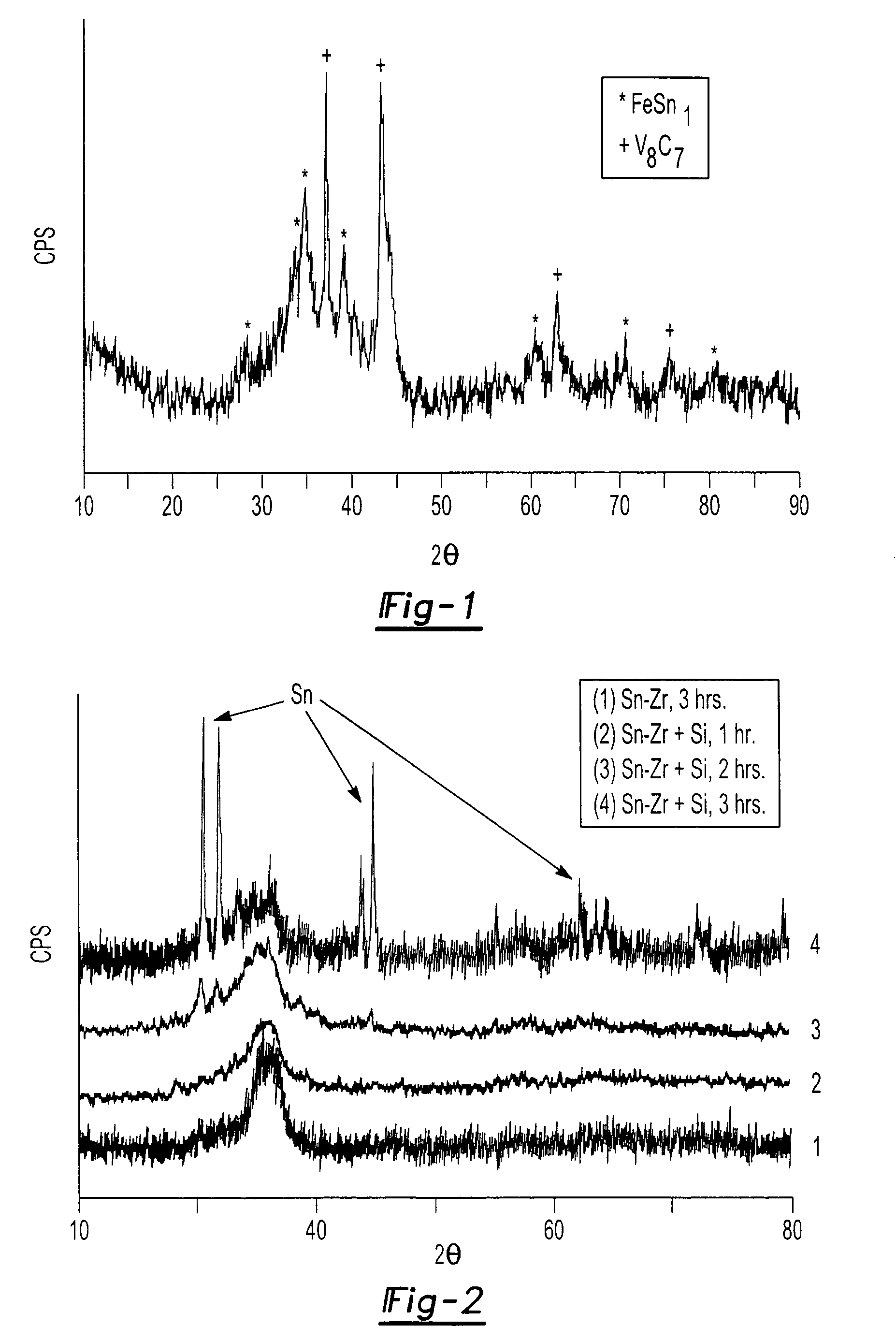

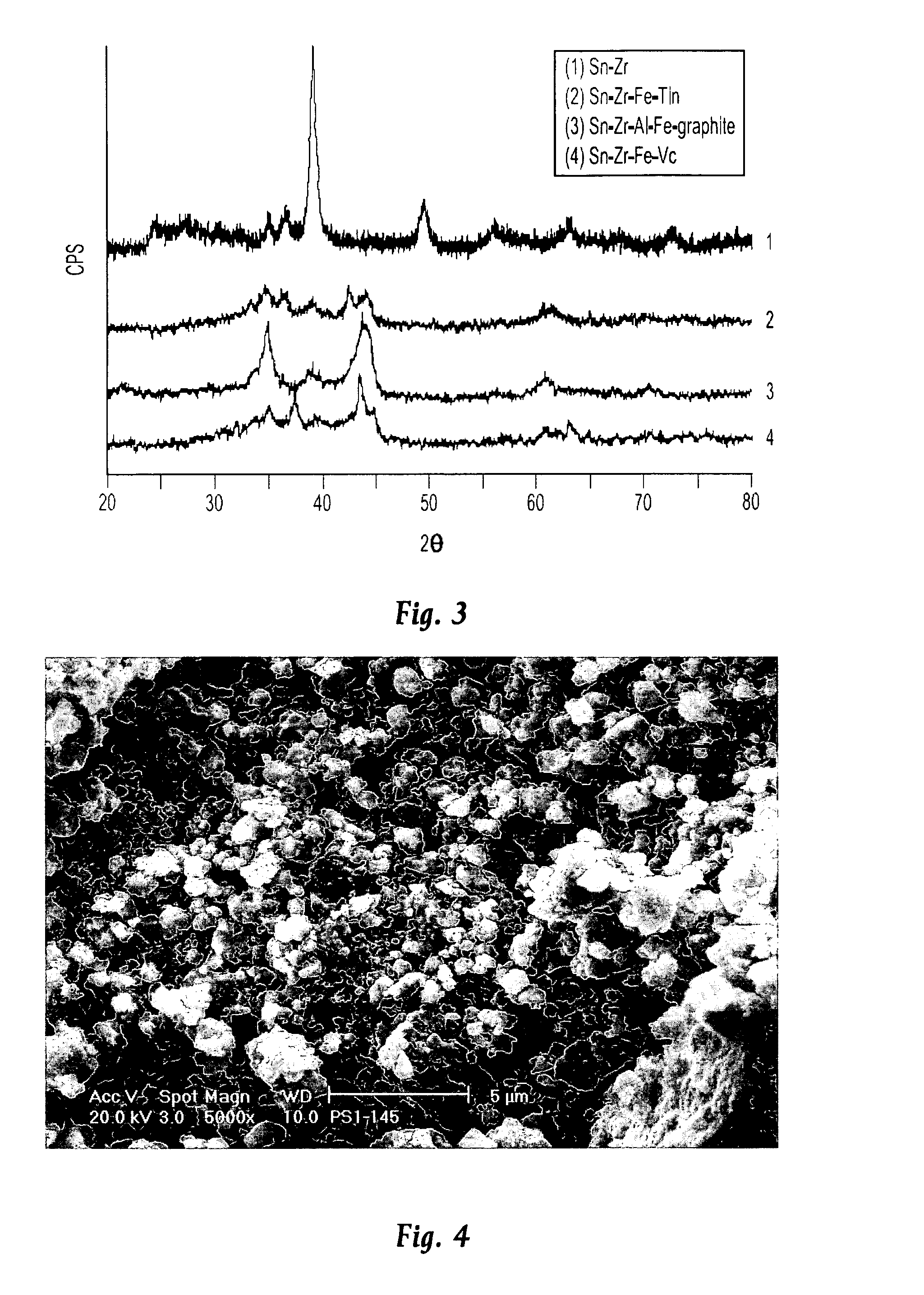

Multiphase nanocomposite material and method for its manufacture

A multiphase composite material having utility as an electrochemical electrode or catalyst includes a first active phase which is an amorphous, electrochemically active material; and a second, stabilizer phase which includes one or more of: metals, carbon, ceramics, and intermetallic compounds. The stabilizer phase is configured as a plurality of spaced apart regions having the active phase disposed therebetween. The active phase may comprise one or more of: Sn, Sb, Bi, Pb, Ag, In, Si, Ge, and Al. The stabilizer phase may include one or more of: Fe, Zr, Ti, and C. Also disclosed are electrodes and batteries which include the material as well as methods for manufacturing the material by using a mechanical alloying process.

Owner:A123 SYSTEMS LLC

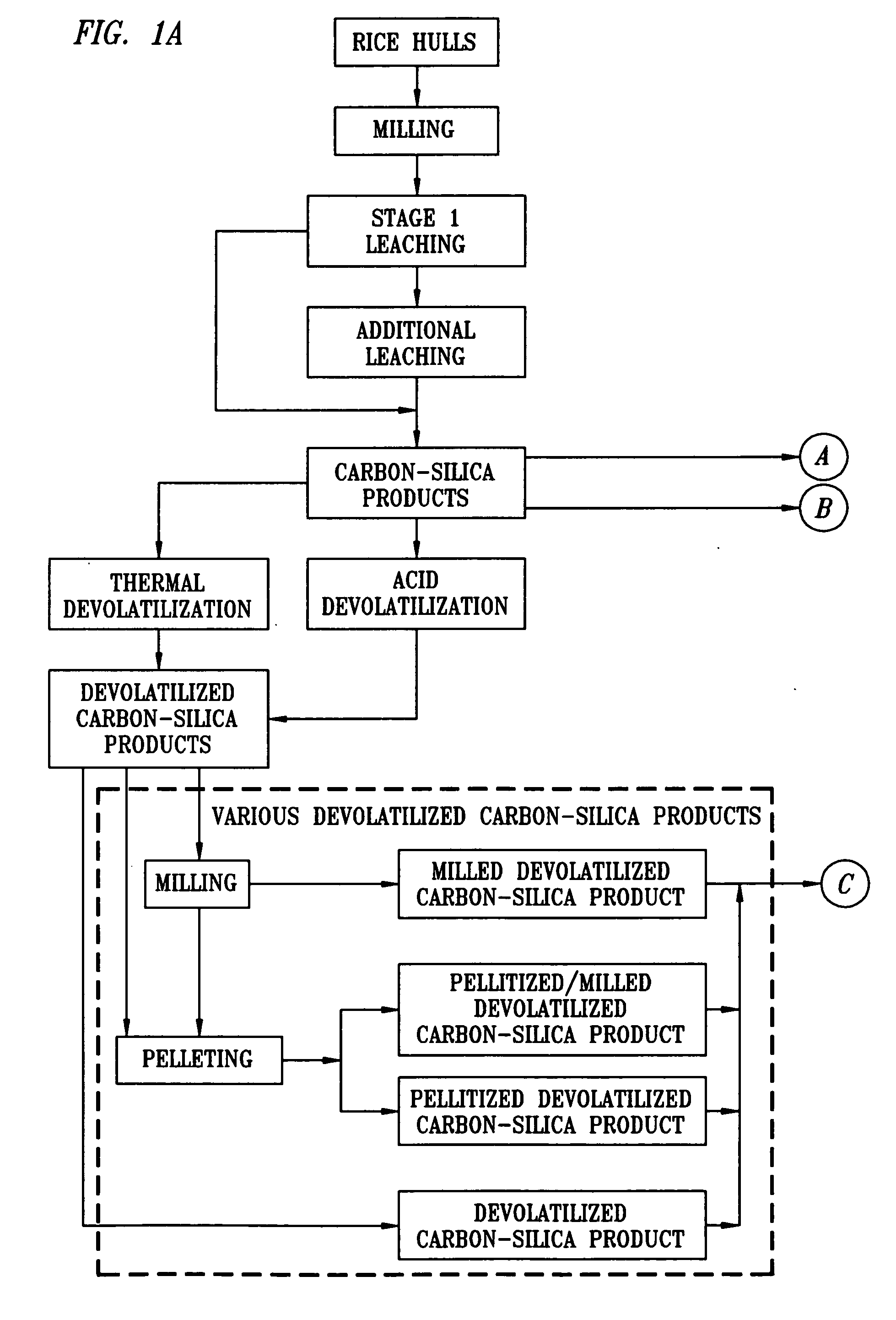

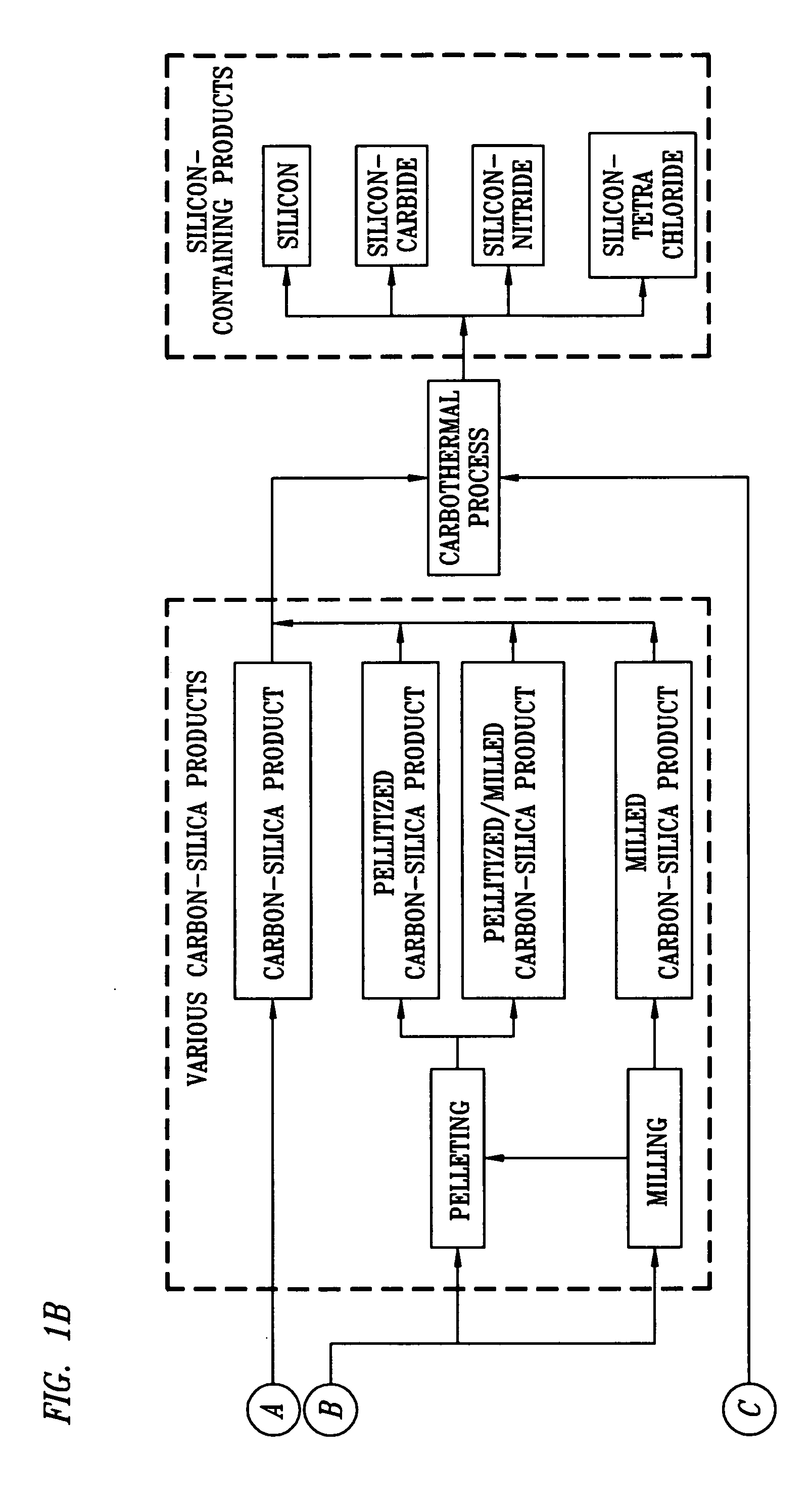

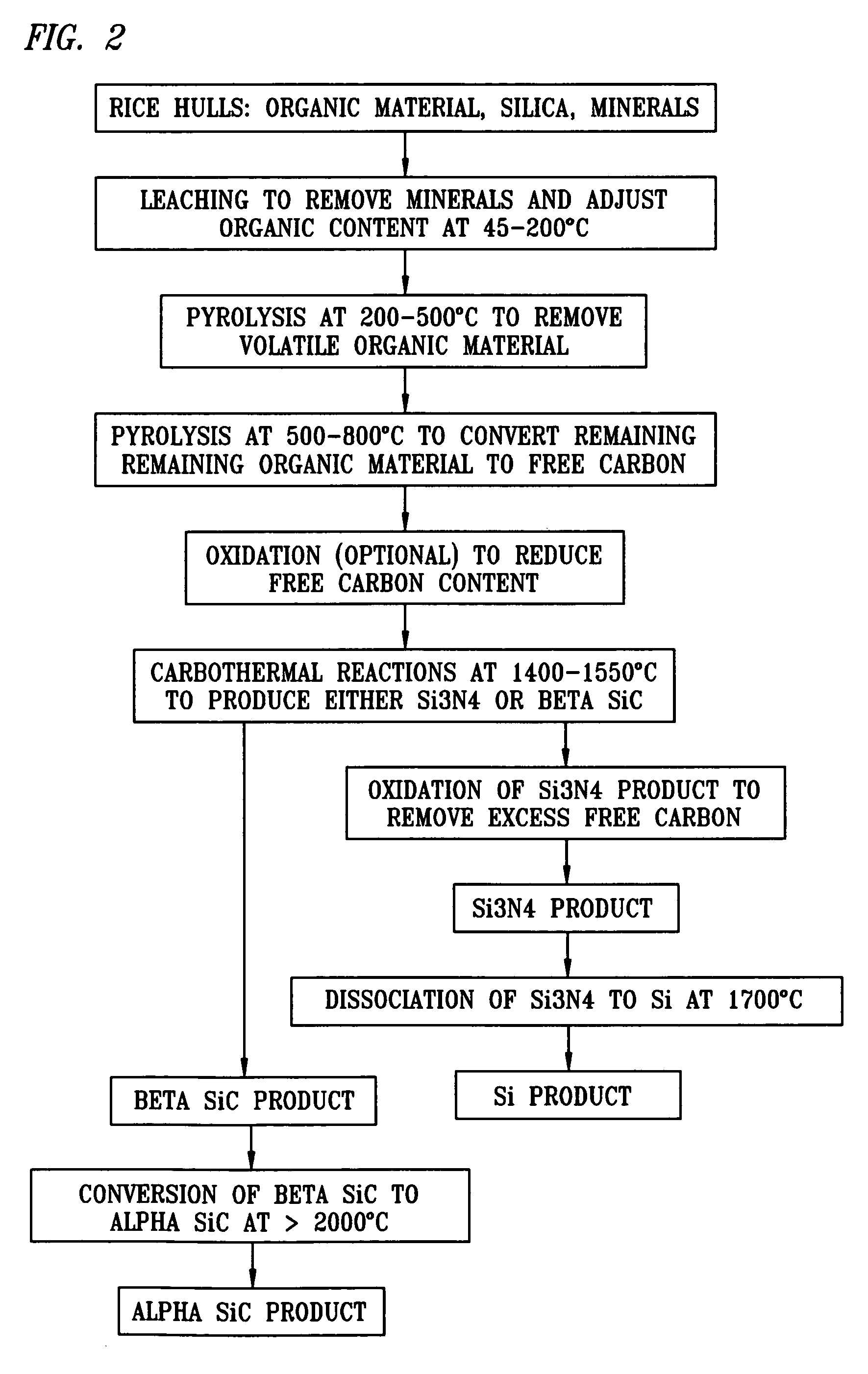

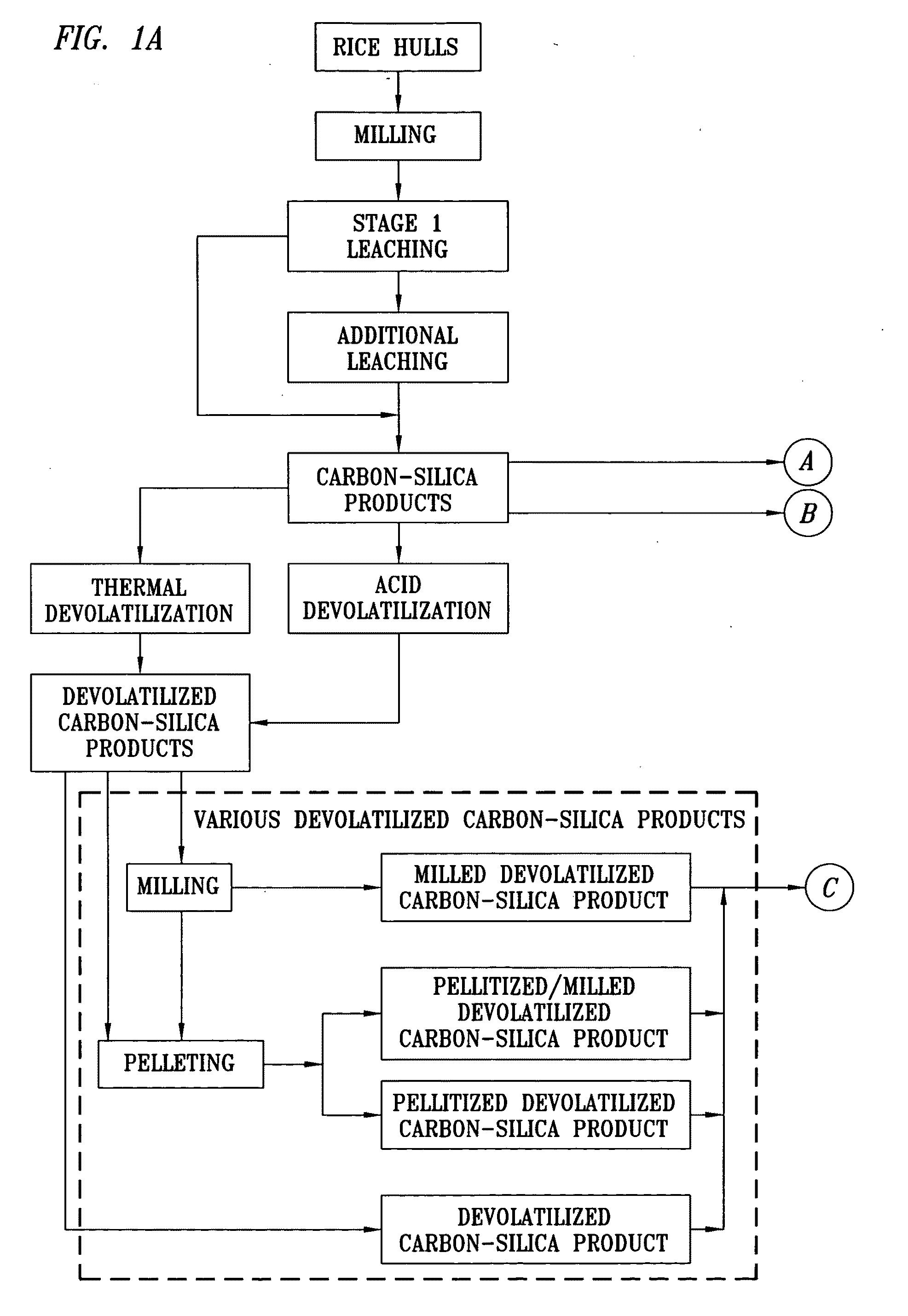

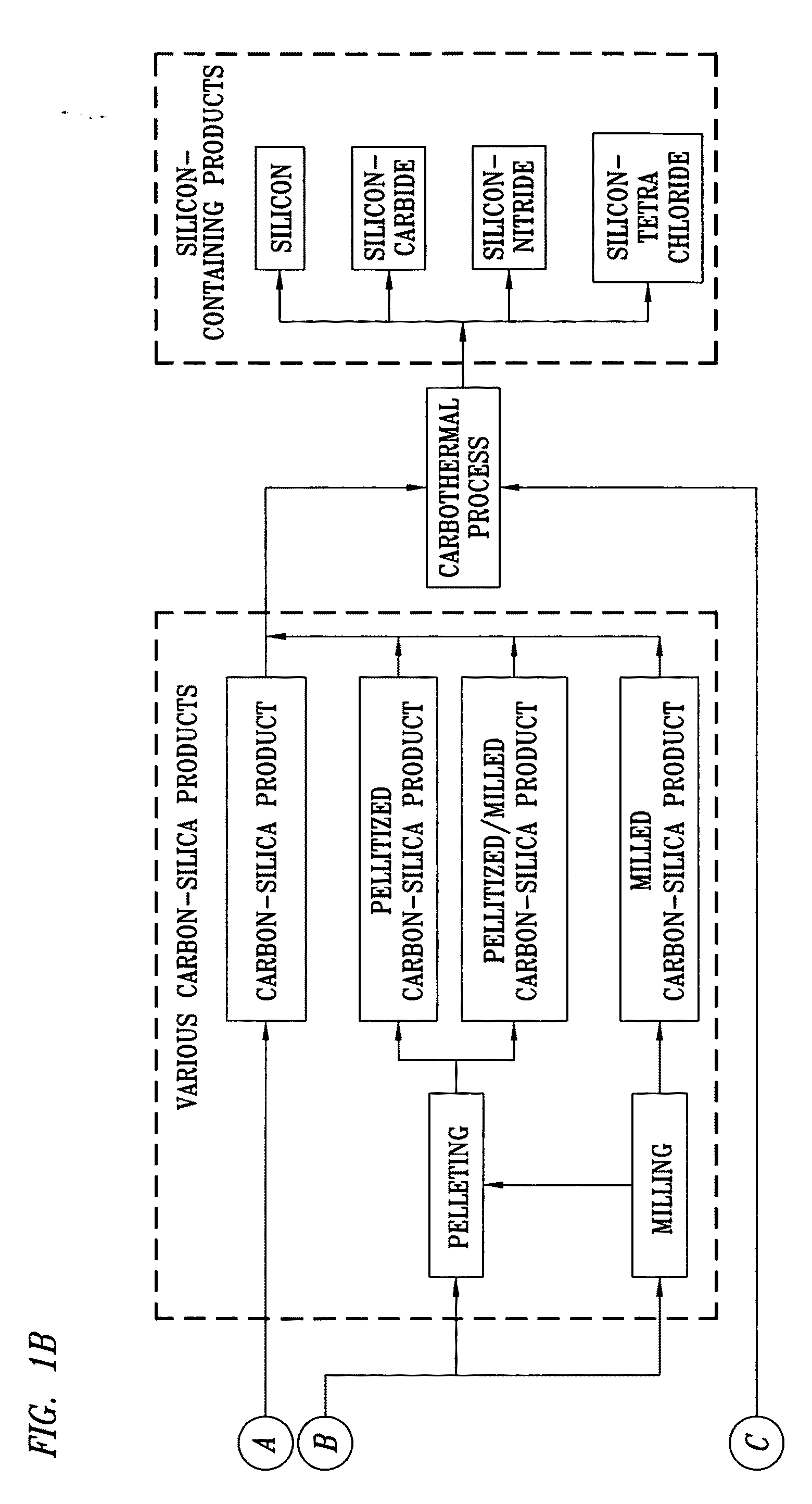

Composition and method for making silicon-containing products

Silicon-containing products, such as silicon, silicon carbide and silicon nitride, containing less than 0.01 weight percent total mineral impurities and selectively determined carbon-to-silicon ratios. The products are derived from plant matter, such as rice hulls and rice straw, containing at least three weight percent silica. Methods are provided for making such high purity silicon-containing products by leaching silica-containing plant matter with aqueous sulfuric acid under controlled temperatures, pressures and reaction times to remove minerals and metals while adjusting the mole ratio of fixed carbon to silica, and then thermally treating under controlled conditions to produce the desired product.

Owner:SI OPTIONS LLC

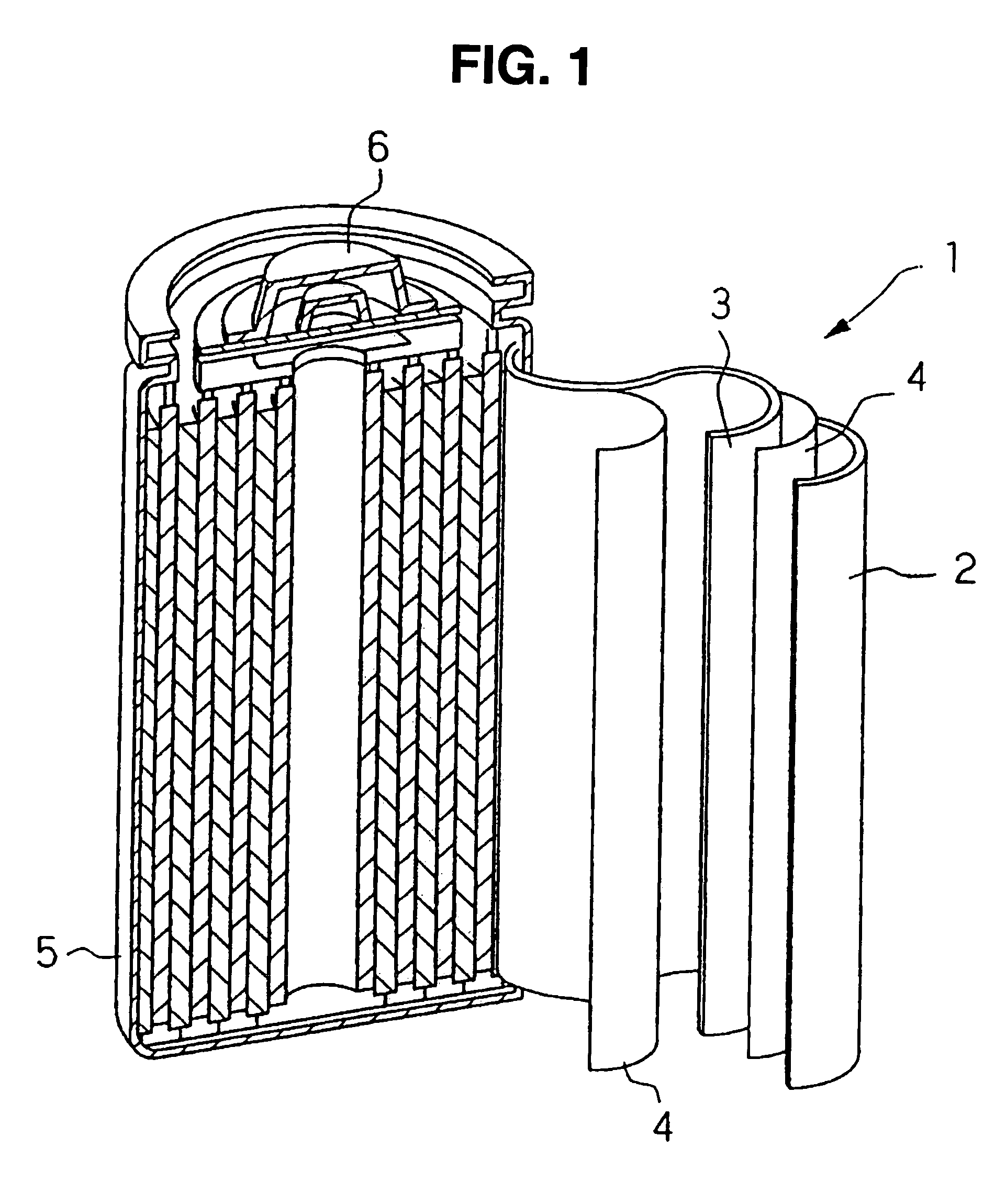

Electrode material for a lithium secondary battery, lithium secondary battery, and preparation method for the electrode material for a lithium secondary battery

Owner:SAMSUNG SDI CO LTD

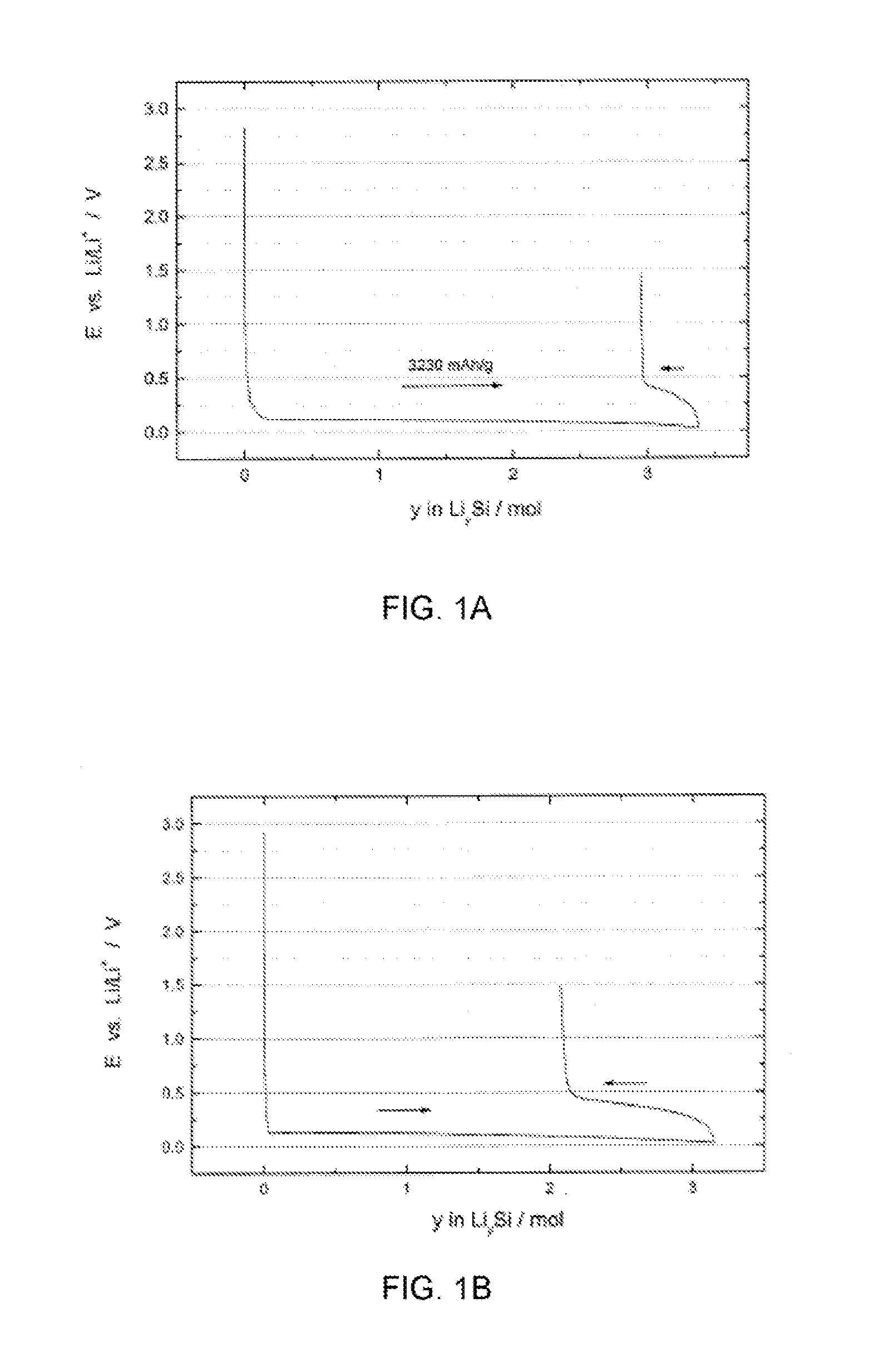

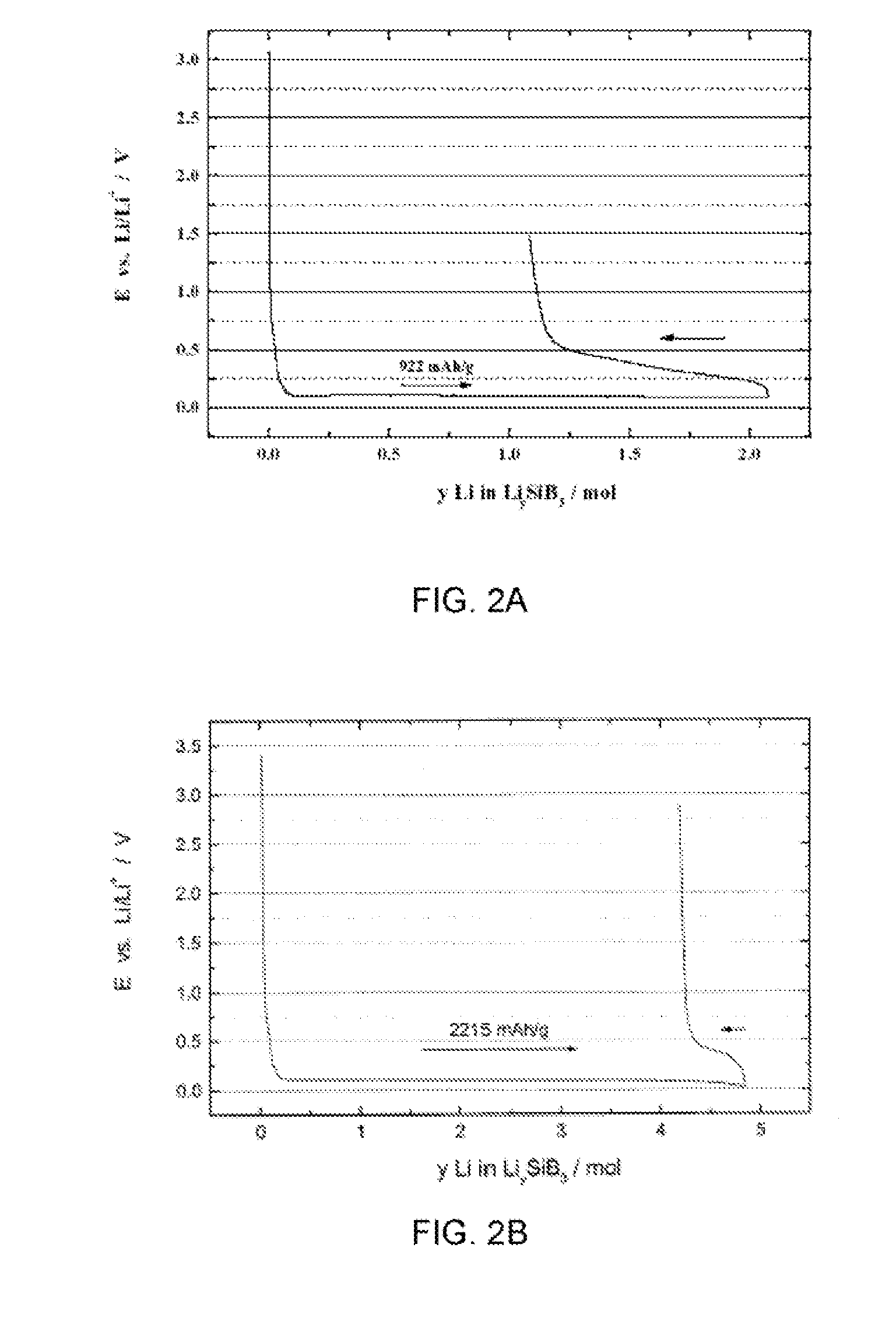

Silicon and/or boron-based positive electrode

An inorganic electroactive material is provided containing Si and / or B as a microstructural-defining element. The material allows for reversible electrochemical insertion / extraction of Li ions therein / therefrom. In addition, the material may have a high specific reversible capacity and may allow for the substantially reversible electrochemical reaction to be carried out at a high reversible potential versus Li / Li+. Also provided is an electrochemical cell using the material in a positive electrode and a method for preparing a positive electrode.

Owner:HUGGINS ROBERT A

Phosphor and production method thereof, crystalline silicon nitride and production method thereof, phosphor-containing composition, and light emitting device, display and illuminating device using the phosphor

InactiveUS20100213822A1Discharge tube luminescnet screensNitrogen compoundsQuantum efficiencyPhosphor

In order to improve quantum efficiency and / or durability of phosphors, a complex oxynitride phosphor is provided represented by the following formula, which can be obtained by firing a phosphor precursor in the presence of flux.M1xBayM2zLuOvNw (In the formula, M1 represents at least one kind of activation element selected from the group consisting of Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm and Yb, M2 represents at least one kind of bivalent metal element selected from the group consisting of Sr, Ca, Mg and Zn, L represents a metal element selected from the metal elements belonging to the fourth group or the fourteenth group of the periodic table, and 0.00001≦x≦3, 0≦y≦2.99999, 2.6≦x+y+z≦3, 0<u≦11, 6<v≦25, and 0<w≦17.)

Owner:MITSUBISHI CHEM CORP

High Purity Silicon-Containing Products and Method of Manufacture

InactiveUS20110008236A1Lower energy requirementsImprove throughputSilicaNitrogen compoundsSilicon dioxideImpurity

Silicon-containing products, such as silicon, silicon carbide and silicon nitride, containing less than 0.01 weight percent total mineral impurities and selectively determined carbon-to-silicon ratios. The products are derived from plant matter, such as rice hulls and rice straw, containing at least three weight percent silica. Methods are provided for making such high purity silicon-containing products by leaching silica-containing plant matter with aqueous sulfuric acid under controlled temperatures, pressures and reaction times to remove minerals and metals while adjusting the mole ratio of fixed carbon to silica, and then thermally treating under controlled conditions to produce the desired product.

Owner:SI OPTIONS LLC

Silicide compositions containing alkali metals and methods of making the same

The invention relates to a method of making alkali metal silicide compositions, and the compositions resulting from the method, comprising mixing an alkali metal with silicon and heating the resulting mixture to a temperature below about 475° C. The resulting compositions do not react with dry O2. Also, the invention relates to sodium silicide compositions having a powder X-ray diffraction pattern comprising at least three peaks with 2Theta angles selected from about 18.2, 28.5, 29.5, 33.7, 41.2, 47.4, and 56.2 and a solid state 23Na MAS NMR spectra peak at about 18 ppm. Moreover, the invention relates to methods of removing a volatile or flammable substance in a controlled manner. Furthermore, the alkali metal silicide compositions of the invention react with water to produce hydrogen gas.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

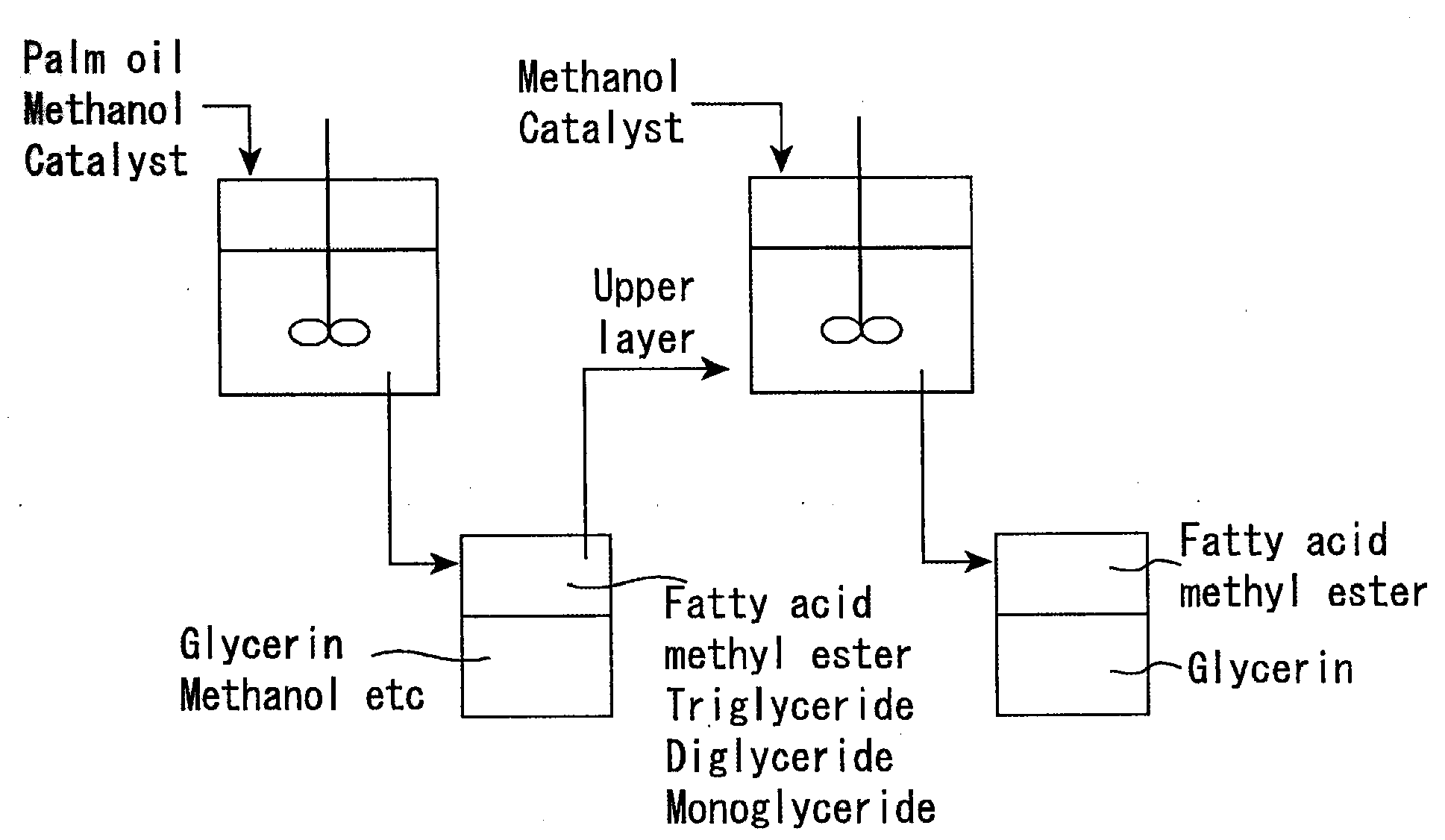

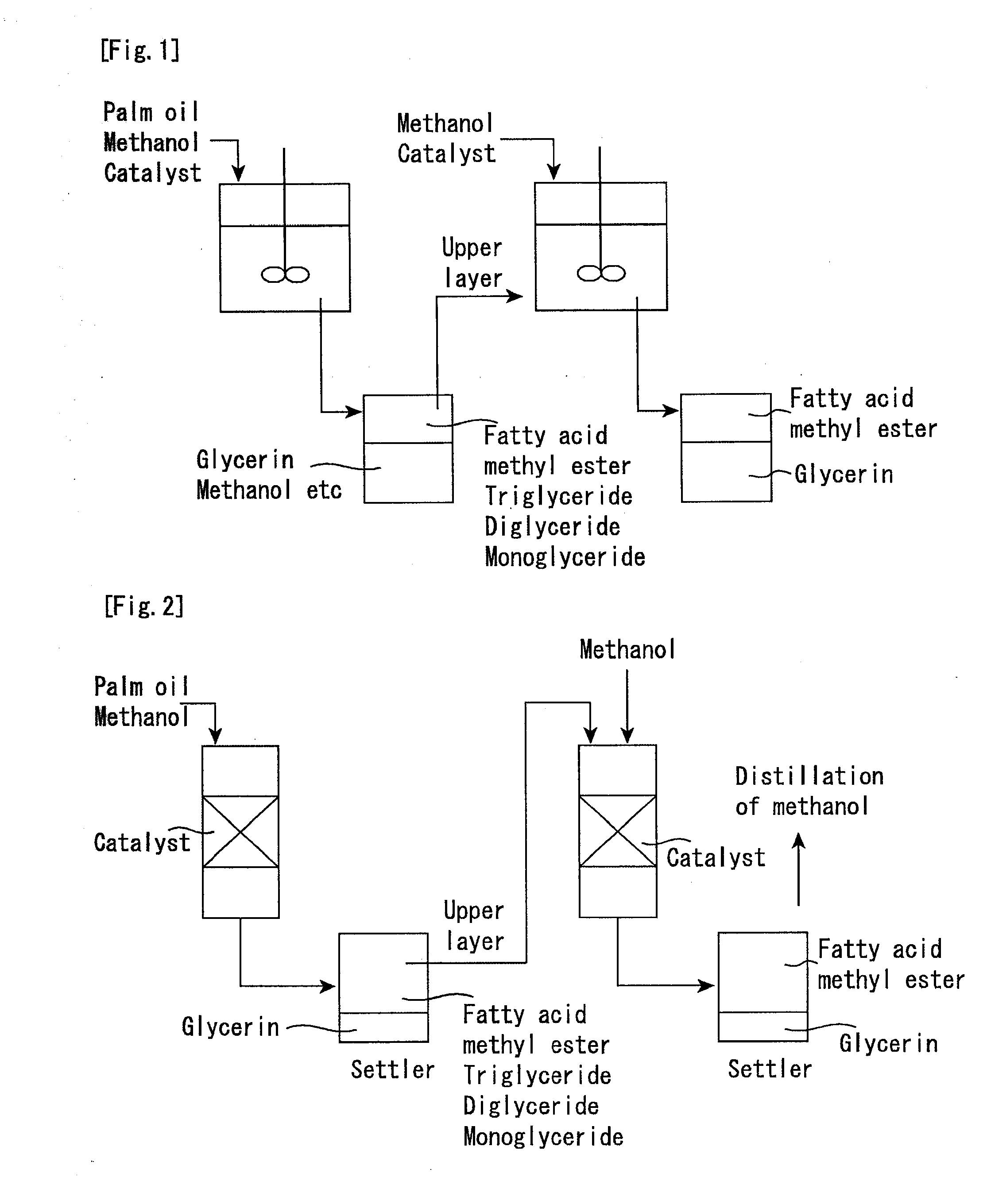

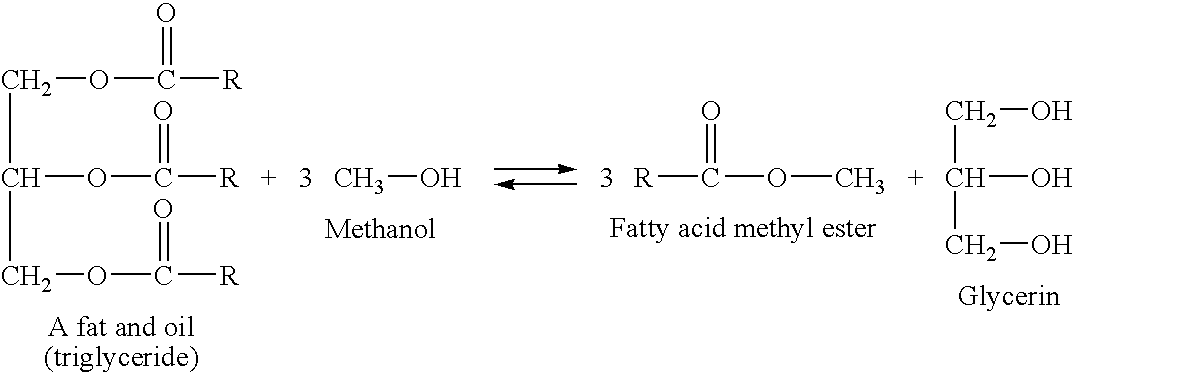

Method for producing fatty acid alkyl esters and/or glycerin

InactiveUS20090069586A1Reduce componentsAvoid leachingNitrogen compoundsFatty acid esterificationGlycerolHigh activity

To provide: a production method using a catalyst which can substantially suppress leaching of active metal components and exhibit high activity for both reactions of transesterification of glycerides and esterification of free fatty acids each contained in a fat or oil; and the catalyst. A method for producing fatty acid alkyl esters and / or glycerin comprising a step of bringing a fat or oil into contact with an alcohol in the presence of a catalyst, wherein the catalyst is at least one catalyst selected from the group consisting of the following (I) to (V):(I) a metal oxide having an ilmenite structure and / or a slyrankite structure;(II) an oxide containing a metallic element belonging to the Group 12 and a metallic element belonging to the Group 4;(III) a mixed oxide containing a metallic element belonging to the Group 12 and a tetravalent transition metallic element;(IV) a metal oxide containing zirconium and at least one metallic element selected from the group consisting of metallic elements belonging to the Groups 4, 5 and 8; and(V) a metal oxide containing anatase type titanium oxide and / or rutile type titanium oxide, and the metal oxide containing a sulfur component of 700 ppm or less.

Owner:NIPPON SHOKUBAI CO LTD +1

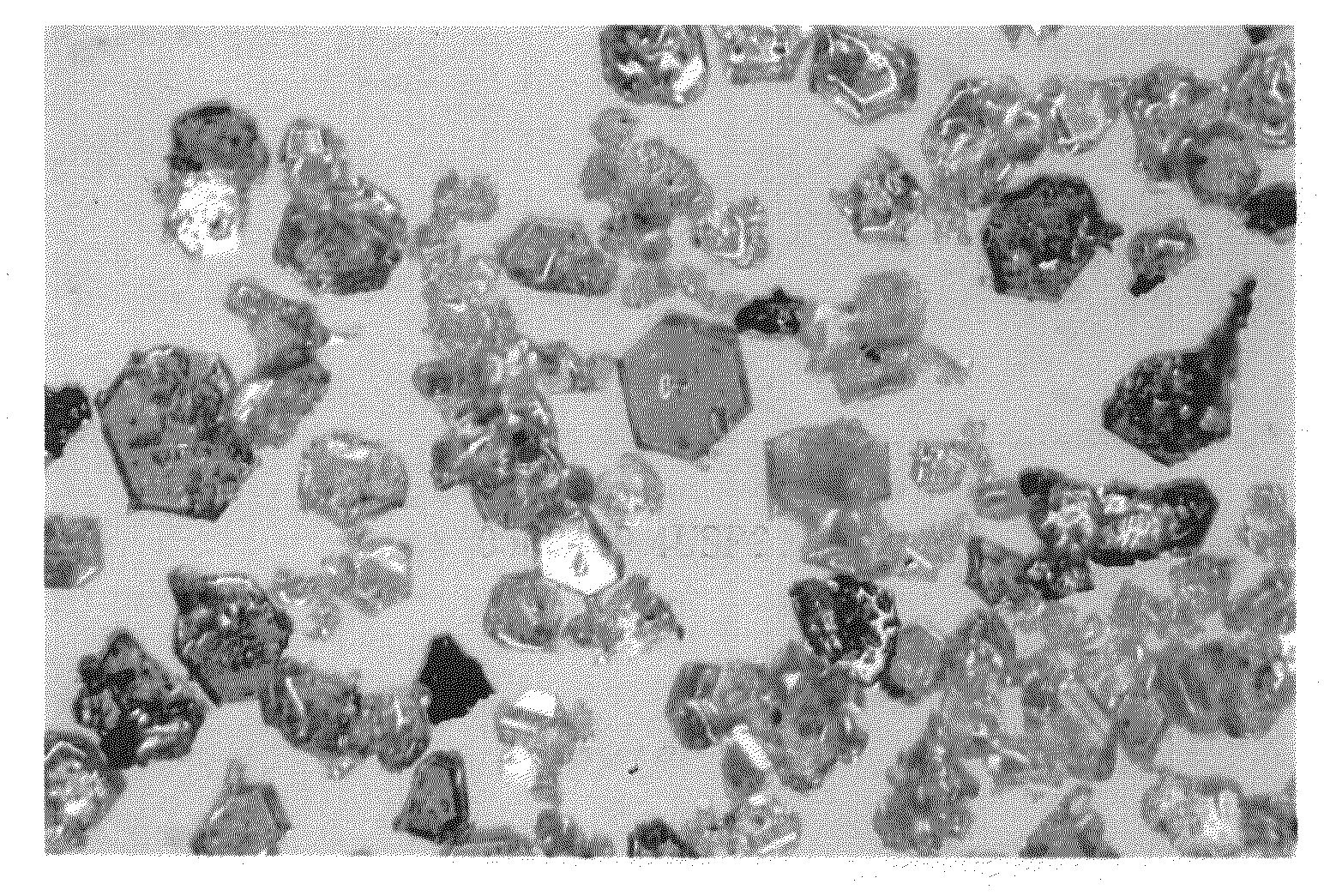

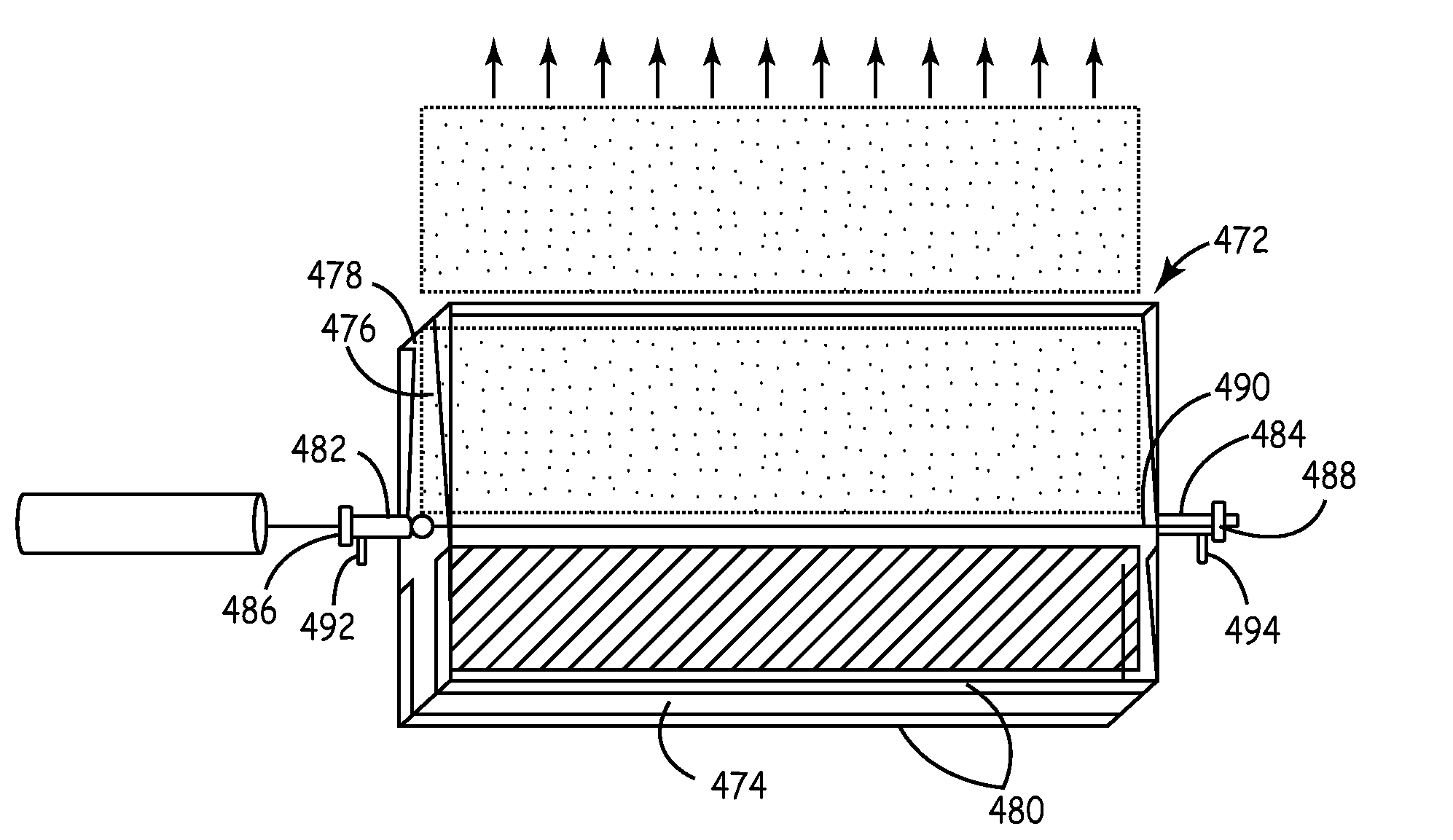

Methods for synthesizing submicron doped silicon particles

Methods are described that have the capability of producing submicron / nanoscale particles, in some embodiments dispersible, at high production rates. In some embodiments, the methods result in the production of particles with an average diameter less than about 75 nanometers that are produced at a rate of at least about 35 grams per hour. In other embodiments, the particles are highly uniform. These methods can be used to form particle collections and / or powder coatings. Powder coatings and corresponding methods are described based on the deposition of highly uniform submicron / nanoscale particles.

Owner:NANOGRAM

Electrode material for a lithium secondary battery, lithium secondary battery, and preparation method for the electrode material for a lithium secondary battery

Disclosed is an electrode material for a lithium secondary battery, a lithium secondary battery comprising the same, and a method for preparing the electrode material for a lithium secondary battery. The electrode material for a lithium secondary battery includes Si as a principal component, wherein the interplanar spacing of an Si (111) surface is between 3.15 Å and 3.20 Å using X-ray diffraction. This is achieve by first alloying Si with an element selected from the group consisting of Al, B, P, Ge, Sn, Pb, Ni, Co, Mn, Mo, Cr, V, Cu, Fe, Ni, W, Ti, Zn, alkali metals, alkaline earth metals, and combinations thereof, and then eluting X from the resulting alloy.

Owner:SAMSUNG SDI CO LTD

Silicon composite particles, preparation thereof, and negative electrode material for non-aqueous electrolyte secondary cell

ActiveUS7790316B2Improve cycle performanceMinimize changesSilicaNitrogen compoundsSilicon alloyInorganic compound

Silicon composite particles are prepared by sintering primary fine particles of silicon, silicon alloy or silicon oxide together with an organosilicon compound. Sintering of the organosilicon compound results in a silicon-base inorganic compound which serves as a binder. Each particle has the structure that silicon or silicon alloy fine particles are dispersed in the silicon-base inorganic compound binder, and voids are present within the particle.

Owner:SHIN ETSU CHEM IND CO LTD

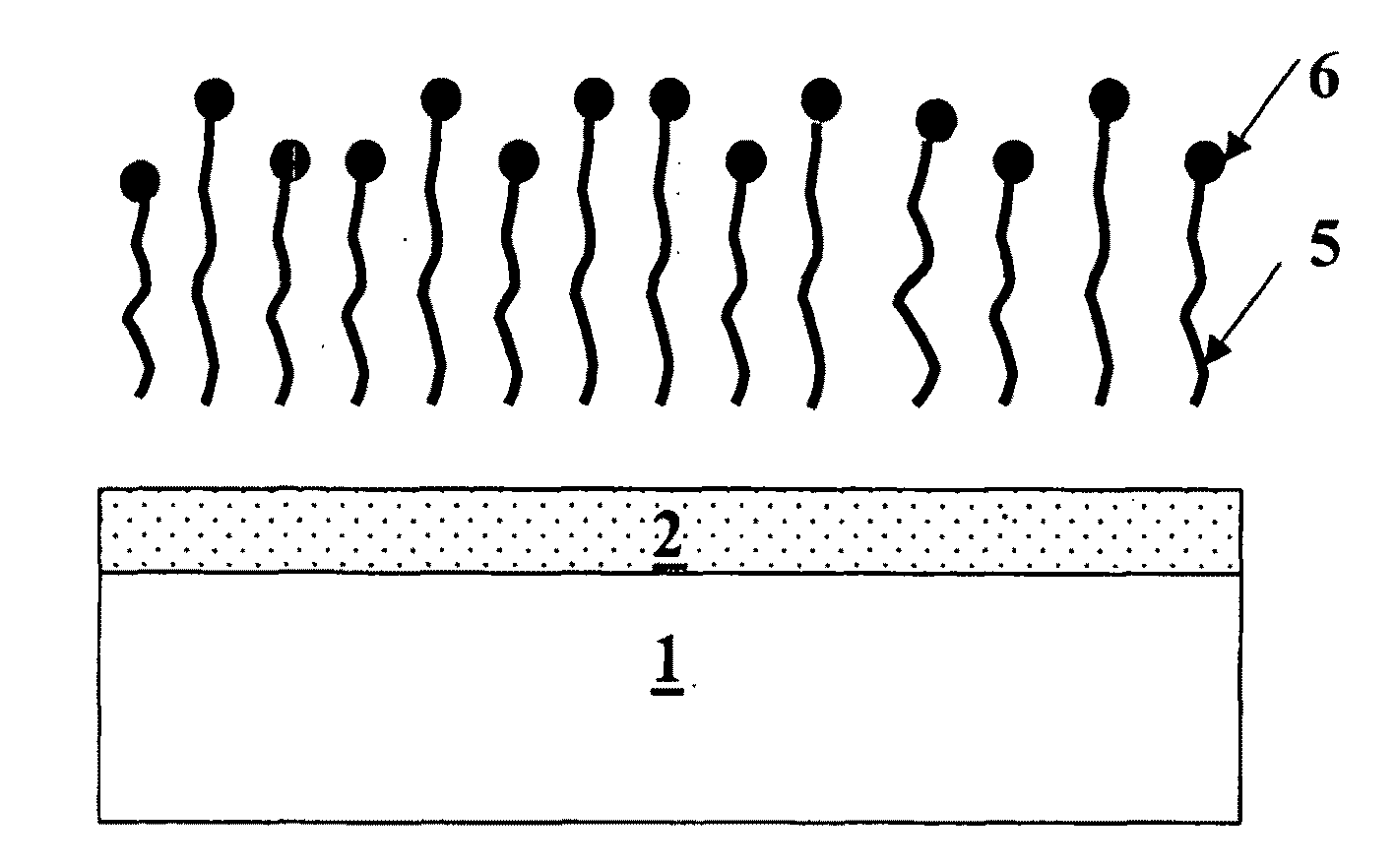

Formation of metal-containing nano-particles for use as catalysts for carbon nanotube synthesis

InactiveUS20100285656A1Reduce diameter sizeMassive growthMaterial nanotechnologyCarbon compoundsPorous substrateSalicide

The present invention relates to a method for forming metal-silicide catalyst nanoparticles with controllable diameter. The method according to embodiments of the invention leads to the formation of ‘active’ metal-suicide catalyst nanoparticles, with which is meant that they are suitable to be used as a catalyst in carbon nanotube growth. The nano-particles are formed on the surface of a substrate or in case the substrate is a porous substrate within the surface of the inner pores of a substrate. The metal-silicide nanoparticles can be Co-silicide, Ni-silicide or Fe-silicide particles. The present invention relates also to a method to form carbon nanotubes (CNT) on metal-silicide nanoparticles, the metal-silicide containing particles hereby acting as catalyst during the growth process, e.g. during the chemical vapour deposition (CVD) process. Starting from very defined metal-containing nanoparticles as catalysts, the diameter of grown CNT can be well controlled and a homogeneous set of CNT will be obtained.

Owner:KATHOLIEKE UNIV LEUVEN

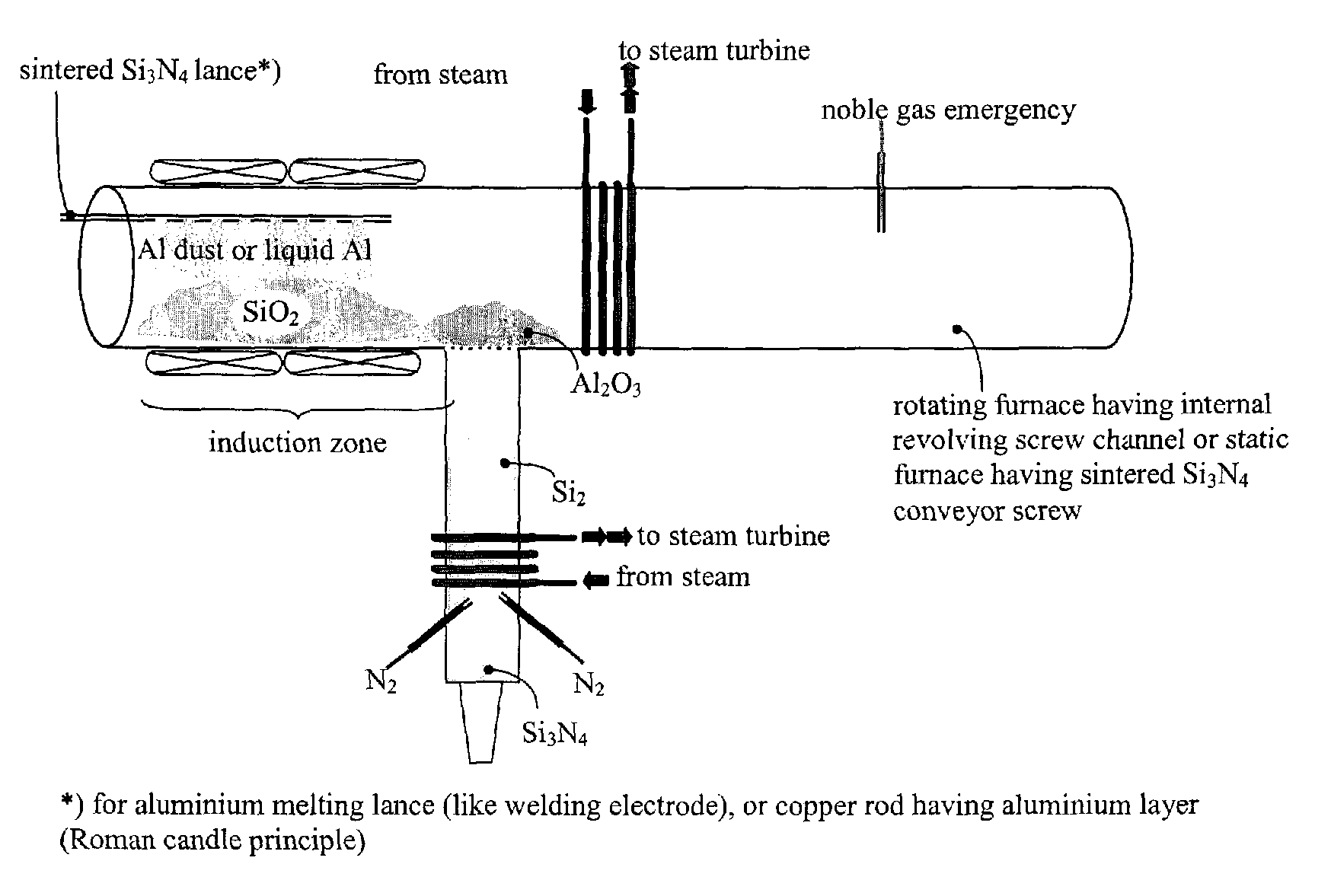

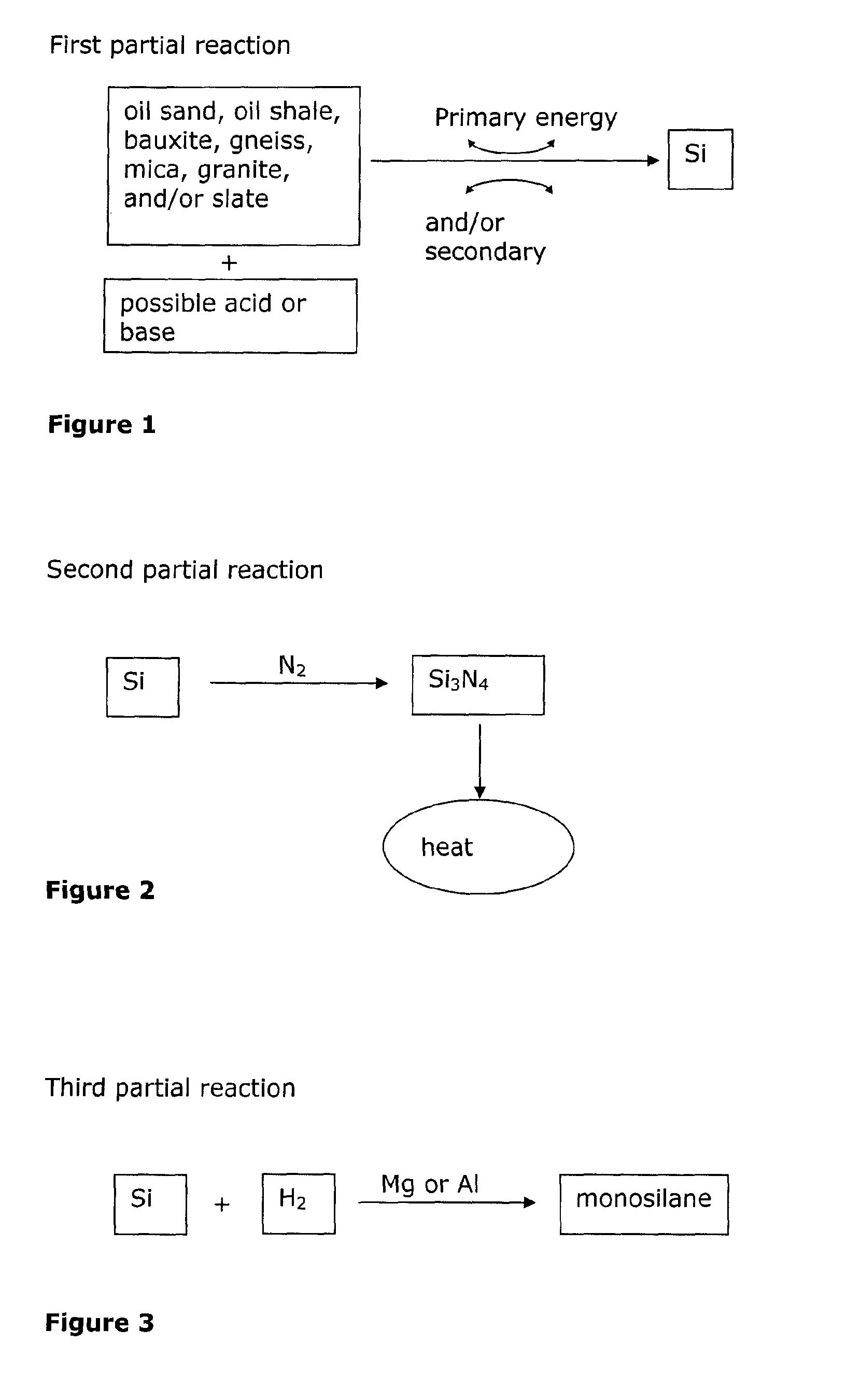

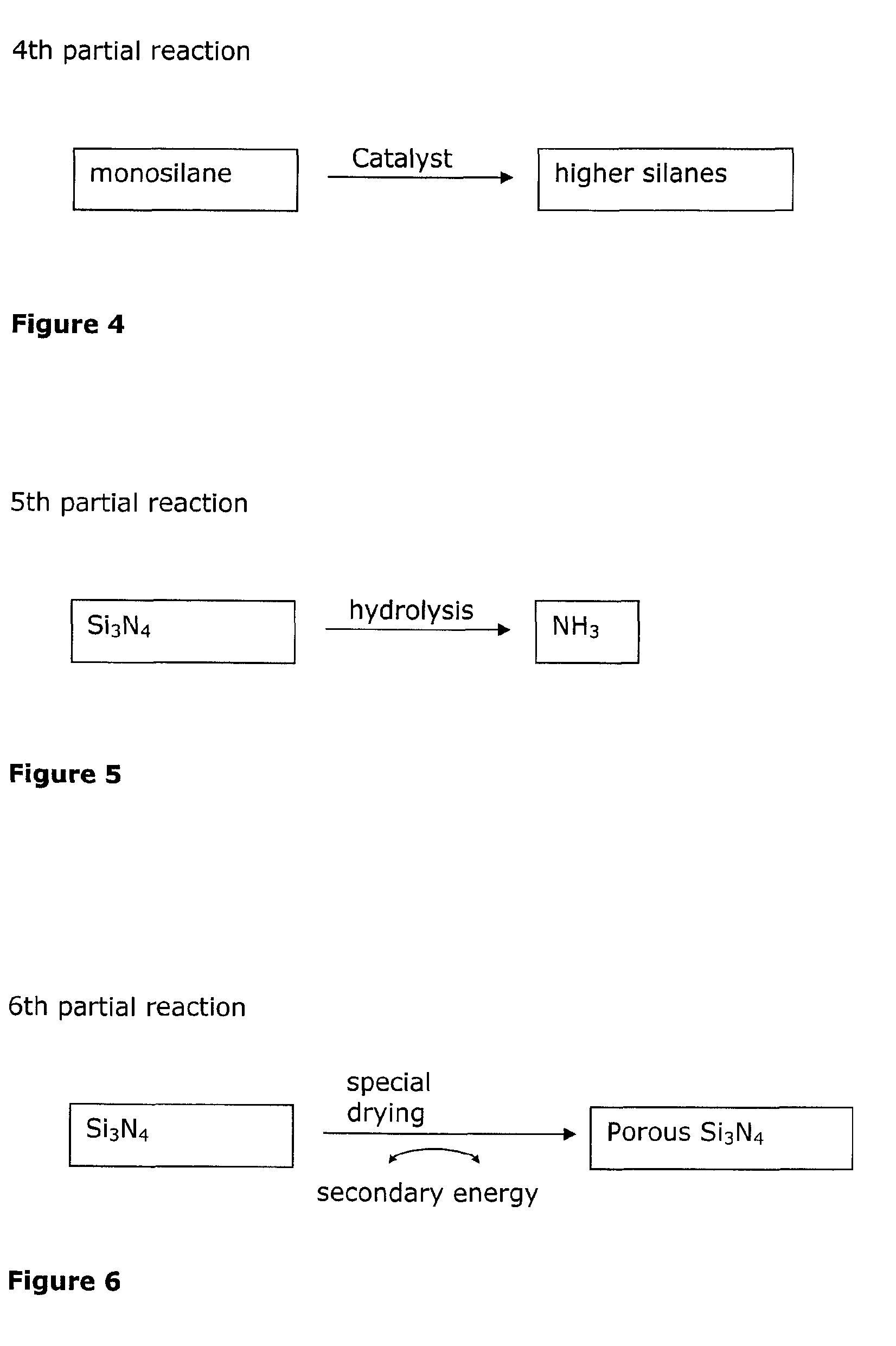

Cascaded power plant process and method for providing reversibly usable hydrogen carriers in such a power plant process

Owner:SILICON FIRE AG

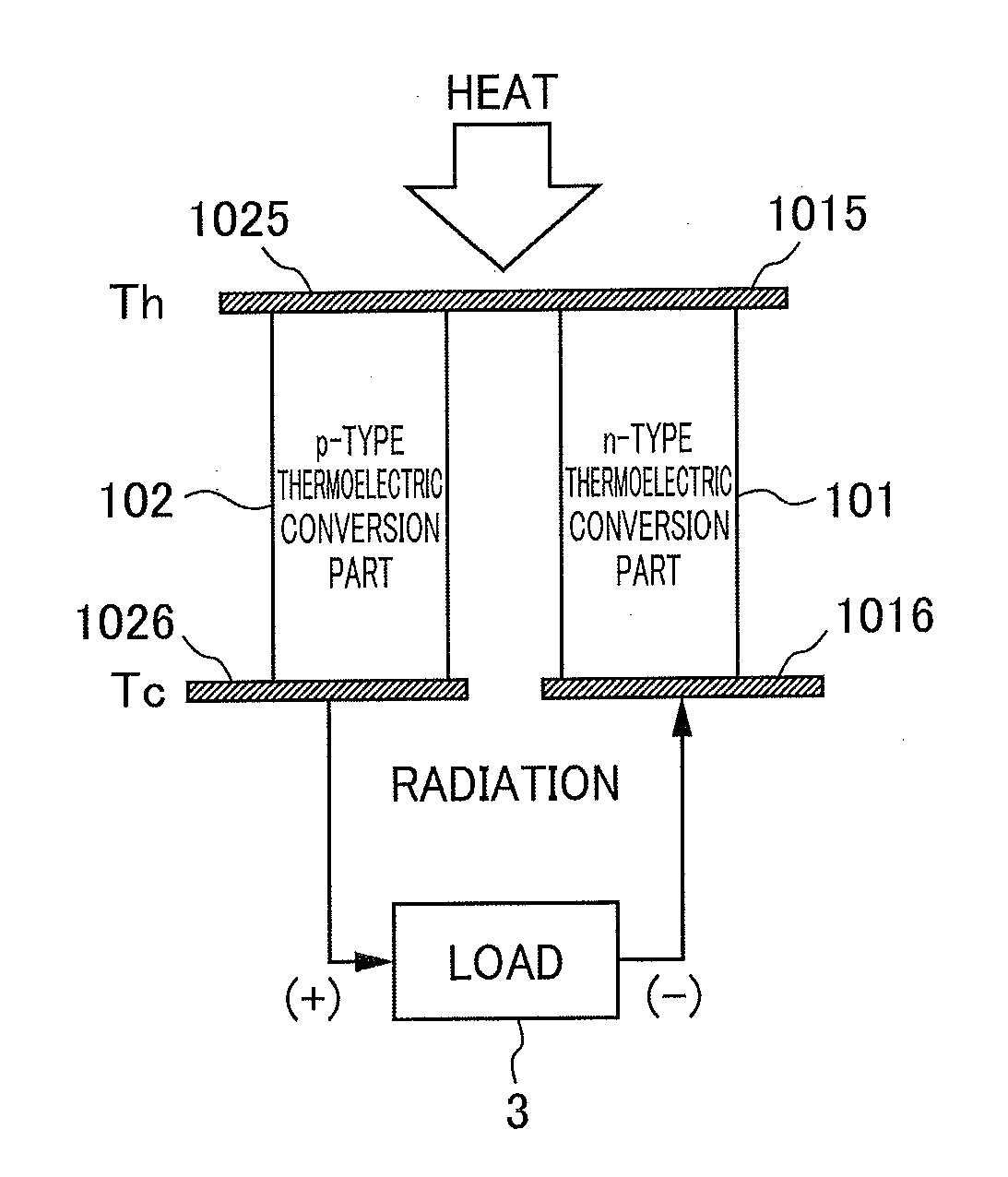

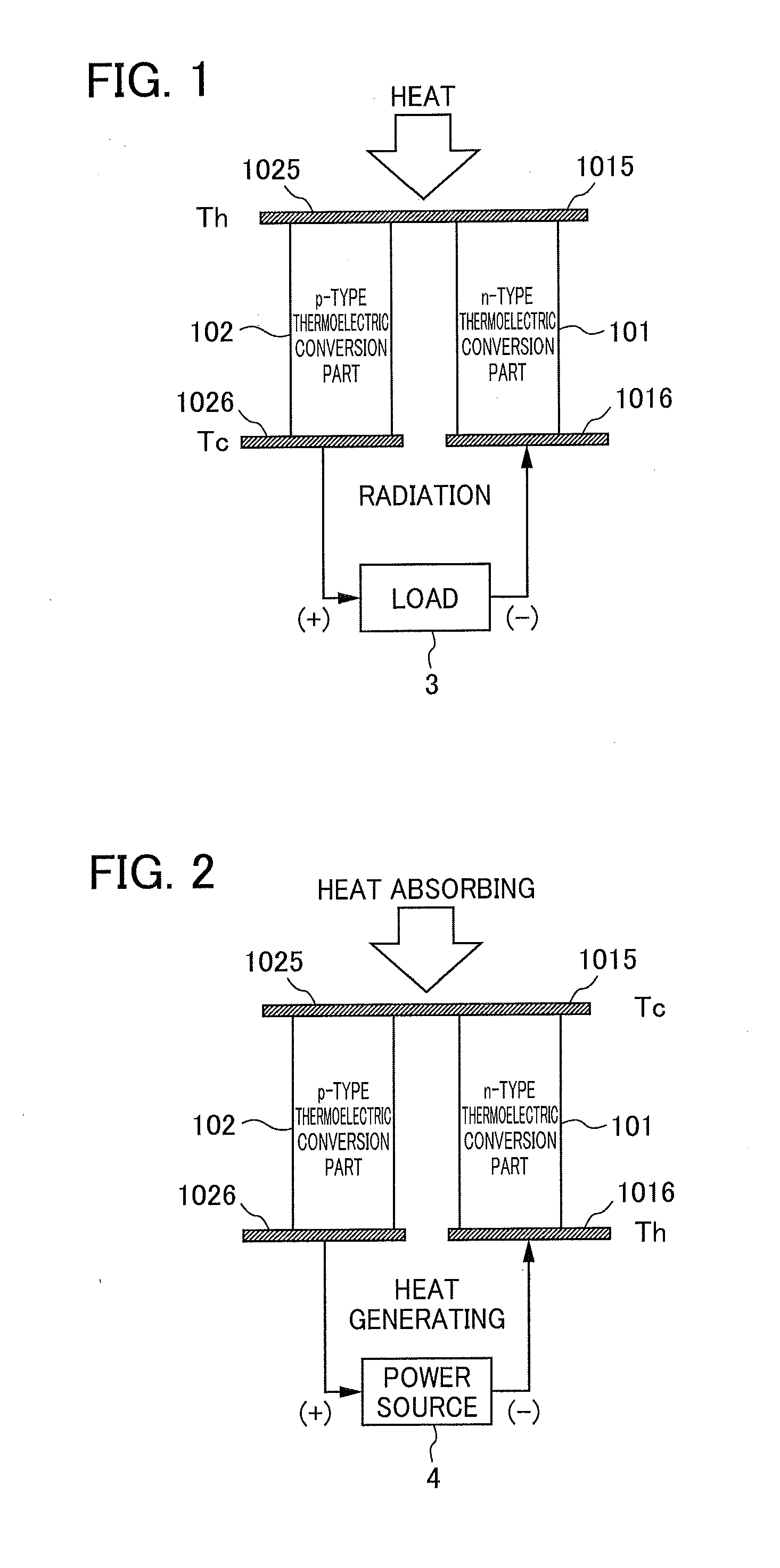

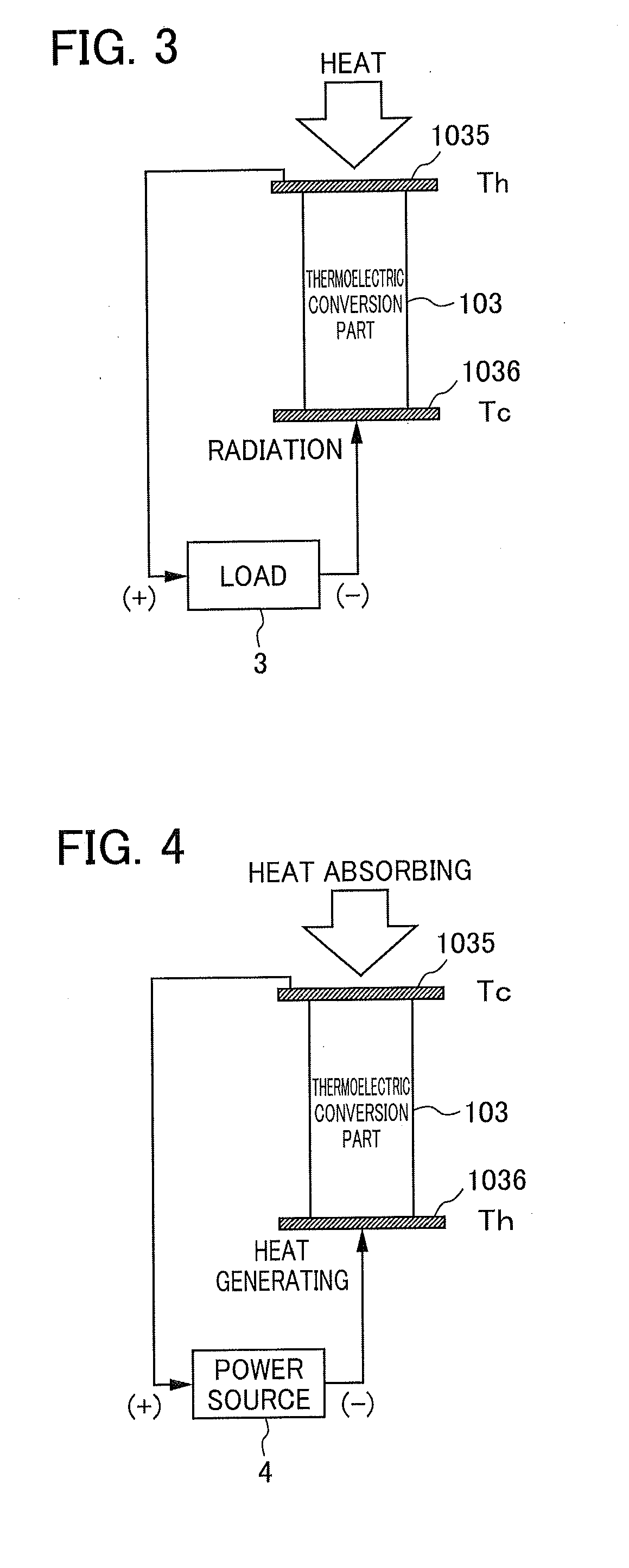

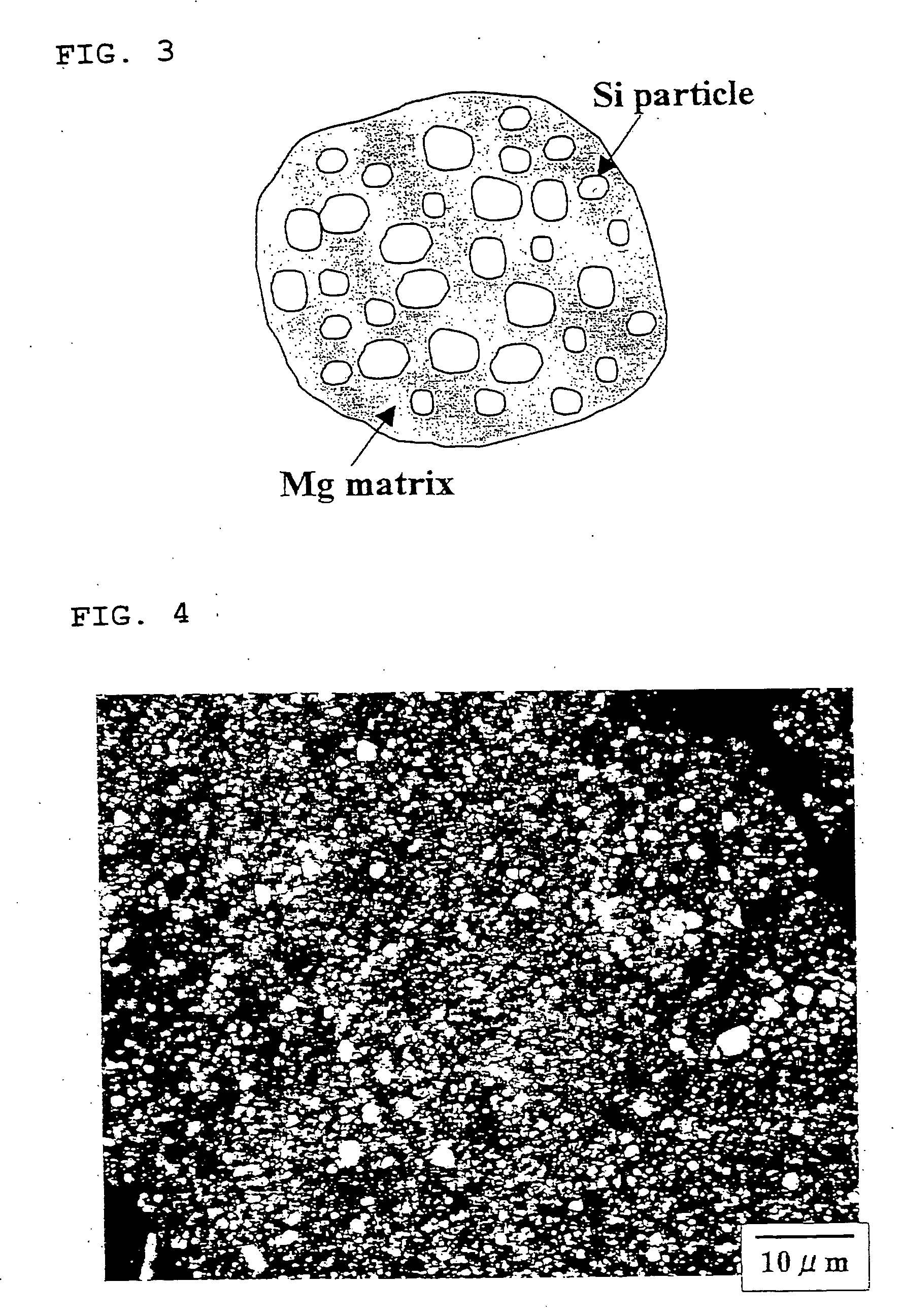

Magnesium-silicon composite material and process for producing same, and thermoelectric conversion material, thermoelectric conversion element, and thermoelectric conversion module each comprising or including the composite material

InactiveUS20120097205A1Improve thermoelectric conversion efficiencyThermoelectric device with peltier/seeback effectCell electrodesThermoelectric conversionSilicon

Provided is a magnesium-silicon composite material which contains Mg2Si as an intermetallic compound imposing no burden on the environment, is suitable for use as a material for thermoelectric conversion modules, and has excellent thermoelectric conversion performance. The magnesium-silicon composite material has a dimensionless figure-of-merit parameter at 866K of 0.665 or larger. This magnesium-silicon composite material can have high thermoelectric conversion performance when used in, for example, a thermoelectric conversion module.

Owner:TOKYO UNIVERSITY OF SCIENCE

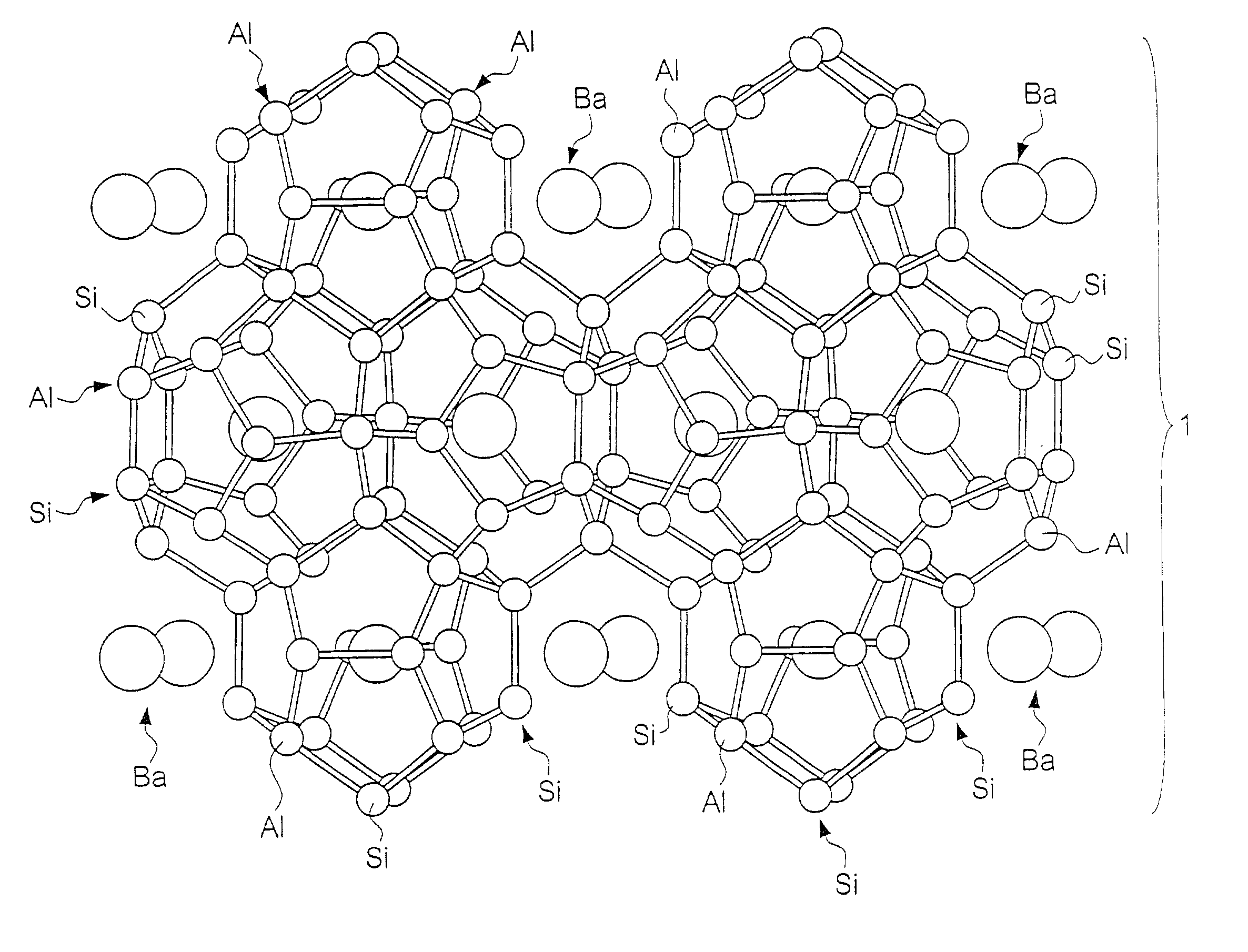

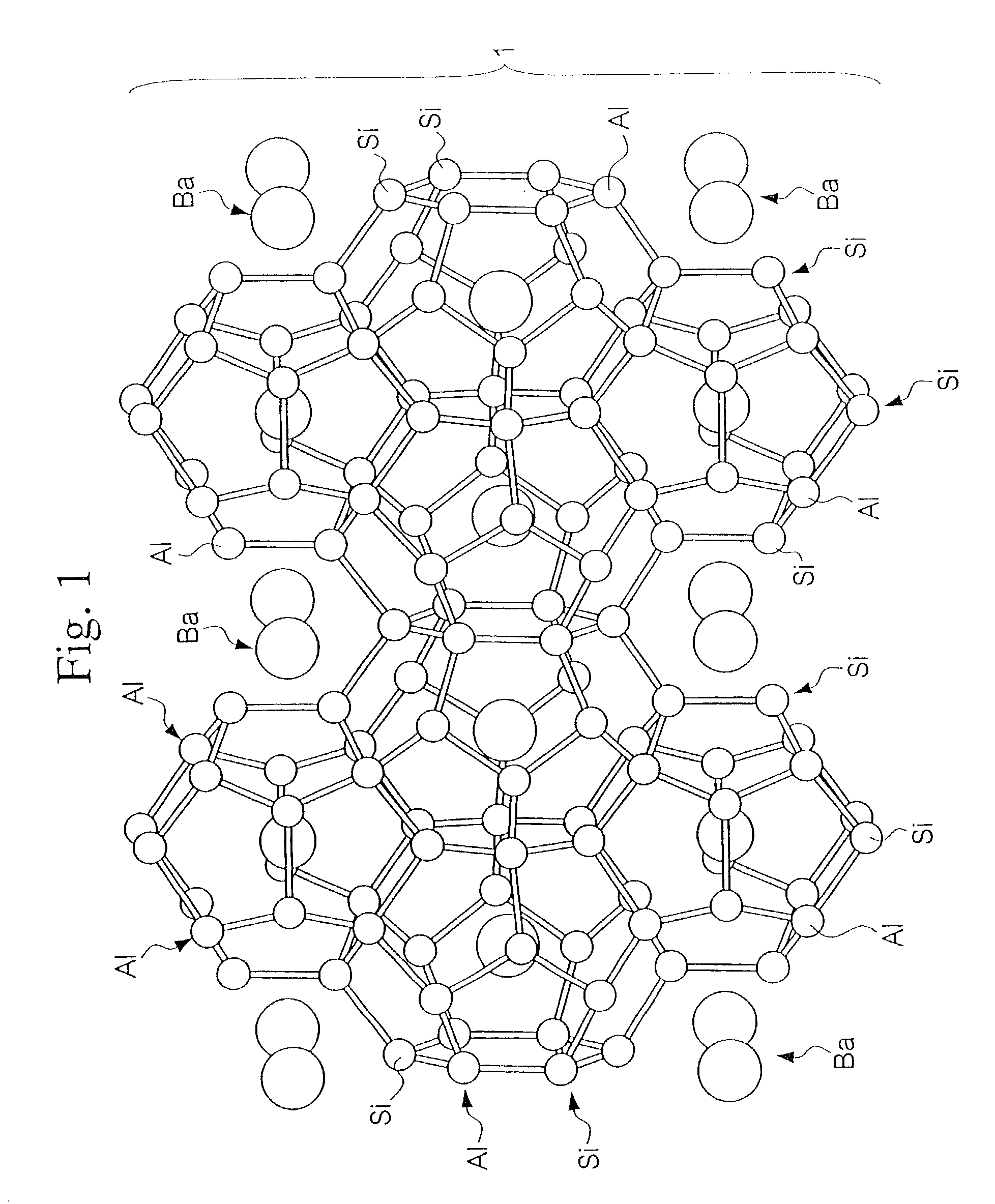

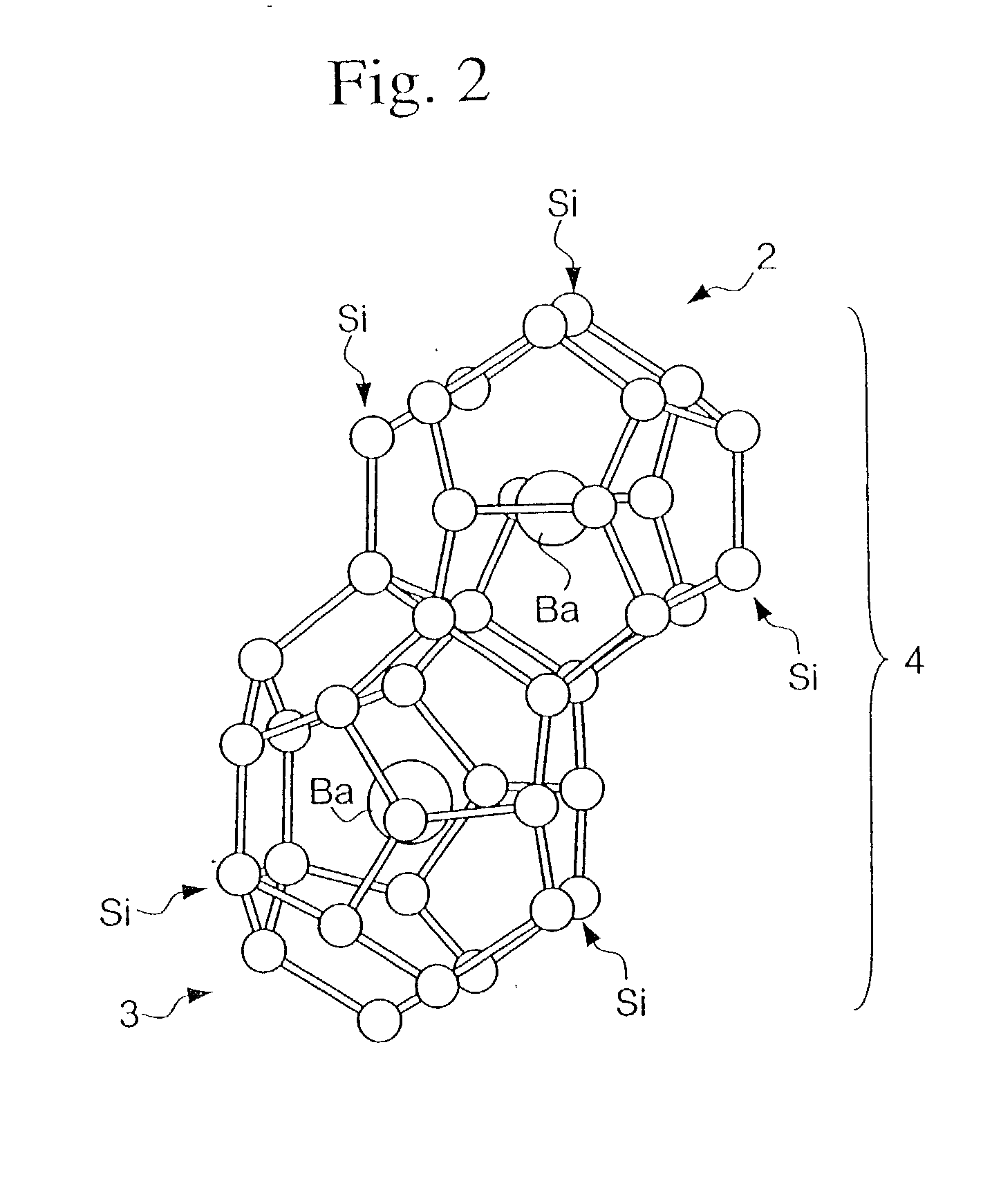

Clathrate compounds, manufacture thereof, and thermoelectric materials, thermoelectric modules, semiconductor materials and hard materials based thereon

InactiveUS20030197156A1High hardnessImprove applicabilityConductive materialMetal silicidesThermoelectric materialsSemiconductor materials

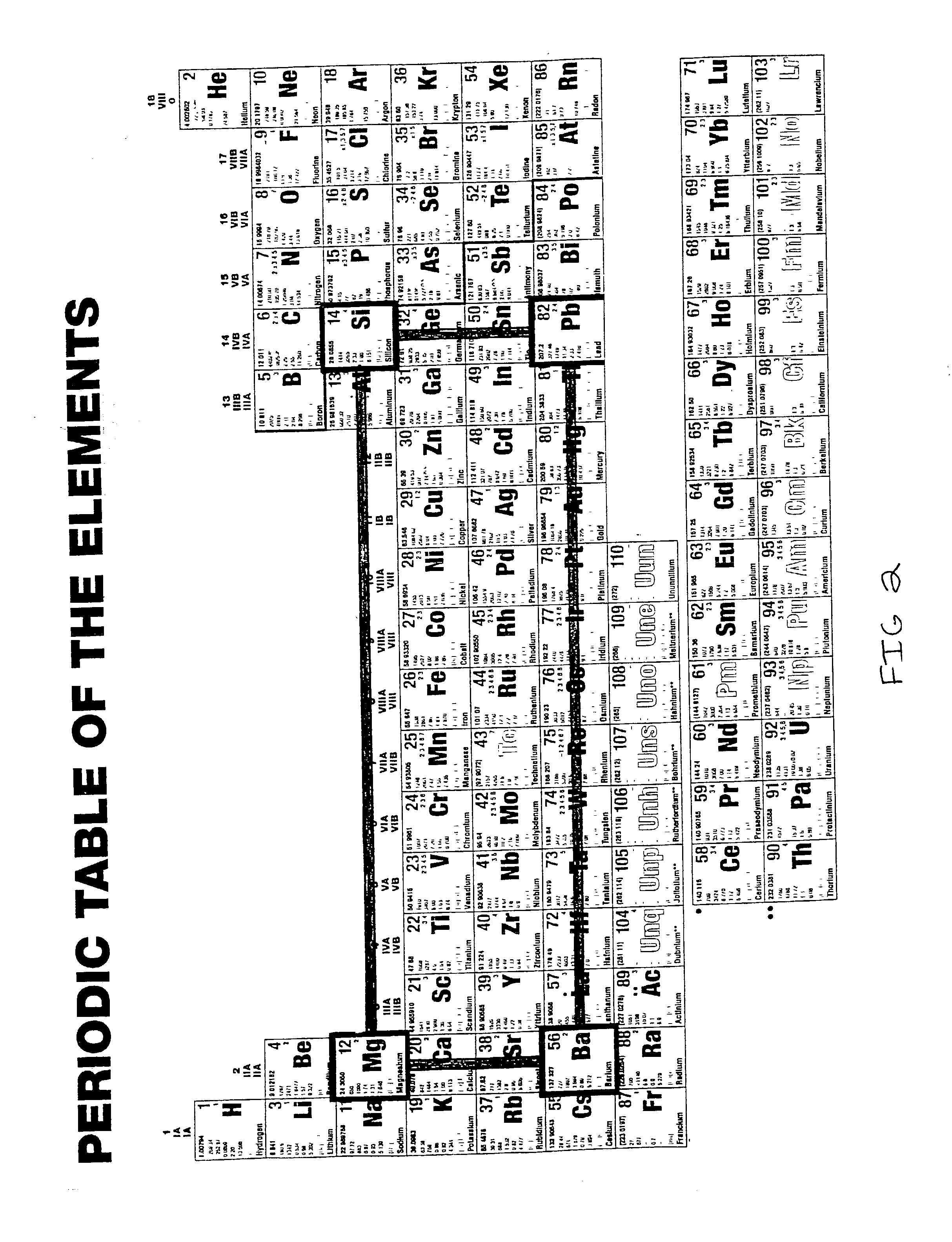

In high-tech fields such as electronics, the development of new high performance materials which differ from conventional materials has received much attention. An object of the present invention is to provide a clathrate compound which can be used as a thermoelectric material, a hard material, or a semiconductor material. Atoms of an element from group 4B of the periodic table are formed into a clathrate lattice, and a clathrate compound is then formed in which specified doping atoms are encapsulated within the clathrate lattice, and a portion of the atoms of the clathrate lattice are substituted with specified substitution atoms. Suitable doping atoms are atoms from group 1A, group 2A, group 3A, group 1B, group 2B, group 3B, group 4A, group 5A, group 6A, and group 8, and suitable substitution atoms are atoms from group 1A, group 2A, group 3A, group 1B, group 2B, group 3B, group 5A, group 6A, group 7A, group 5B, group 6B, group 7B, and group 8 of the periodic table. Suitable manufacturing methods include melt methods and sintering methods, and moreover intercalant intercalation compounds or the like may also be used as raw materials.

Owner:IHI CORP +1

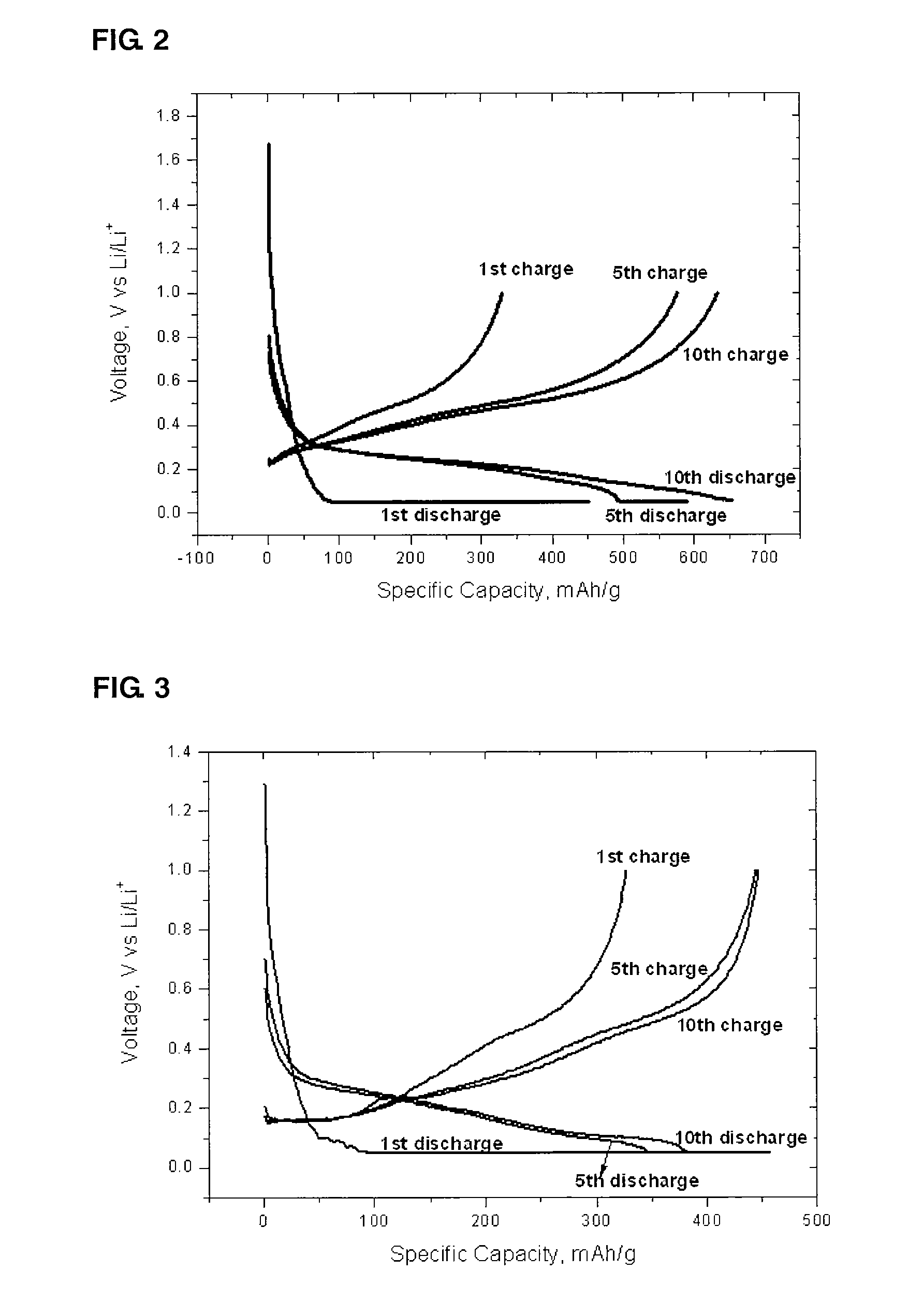

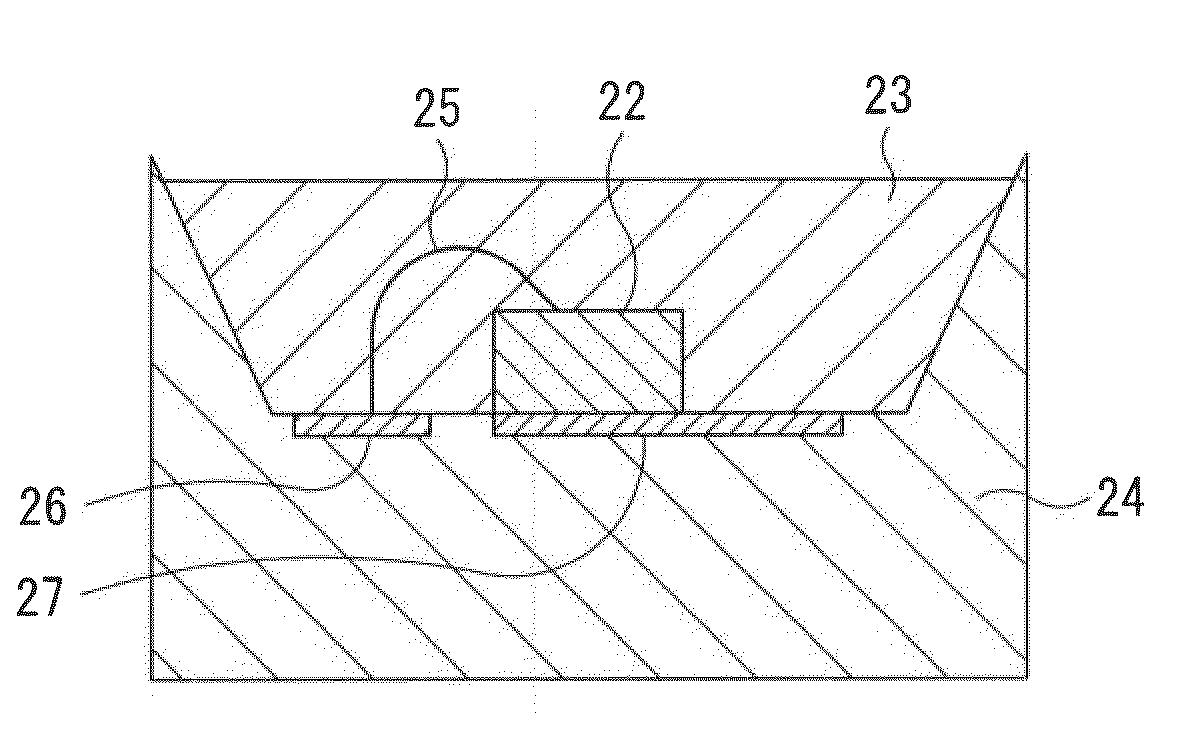

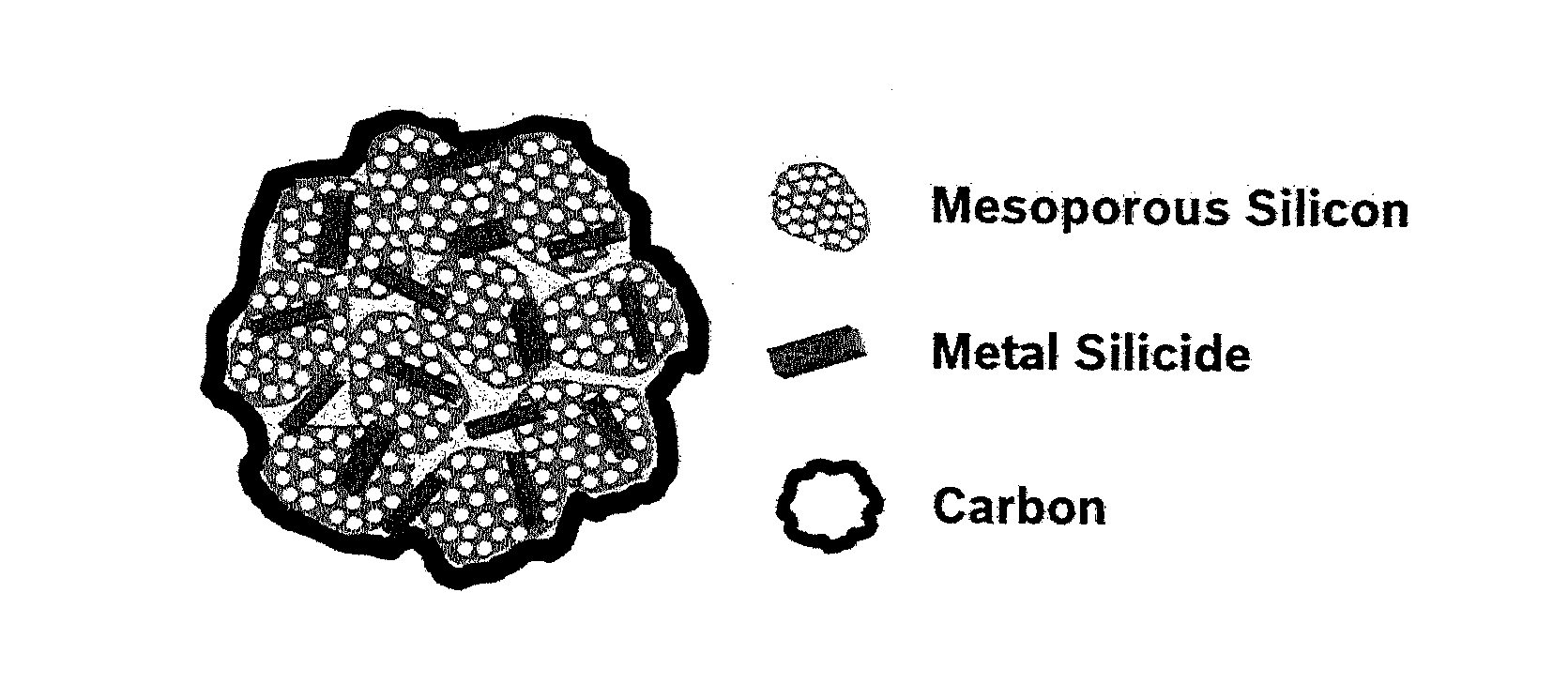

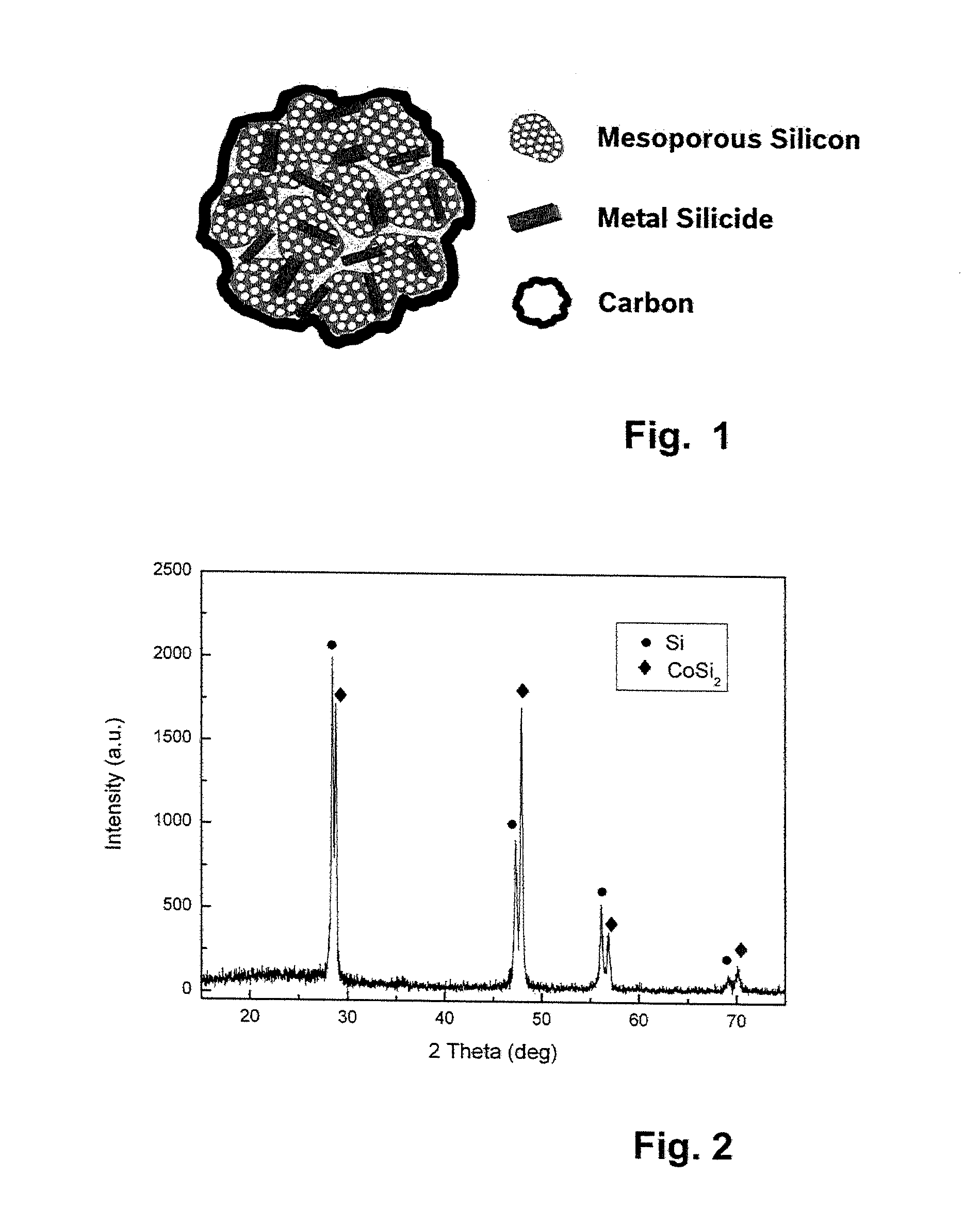

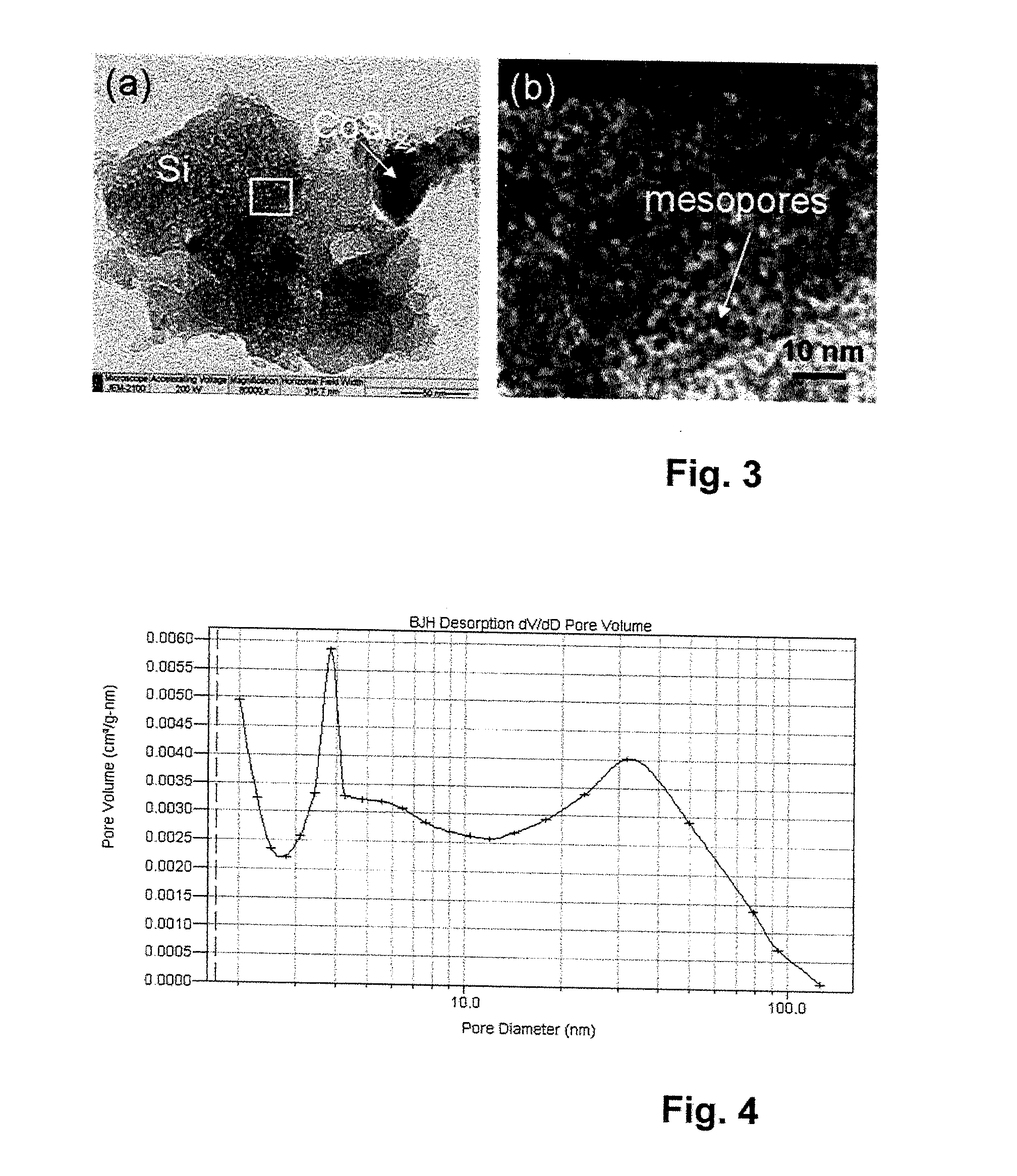

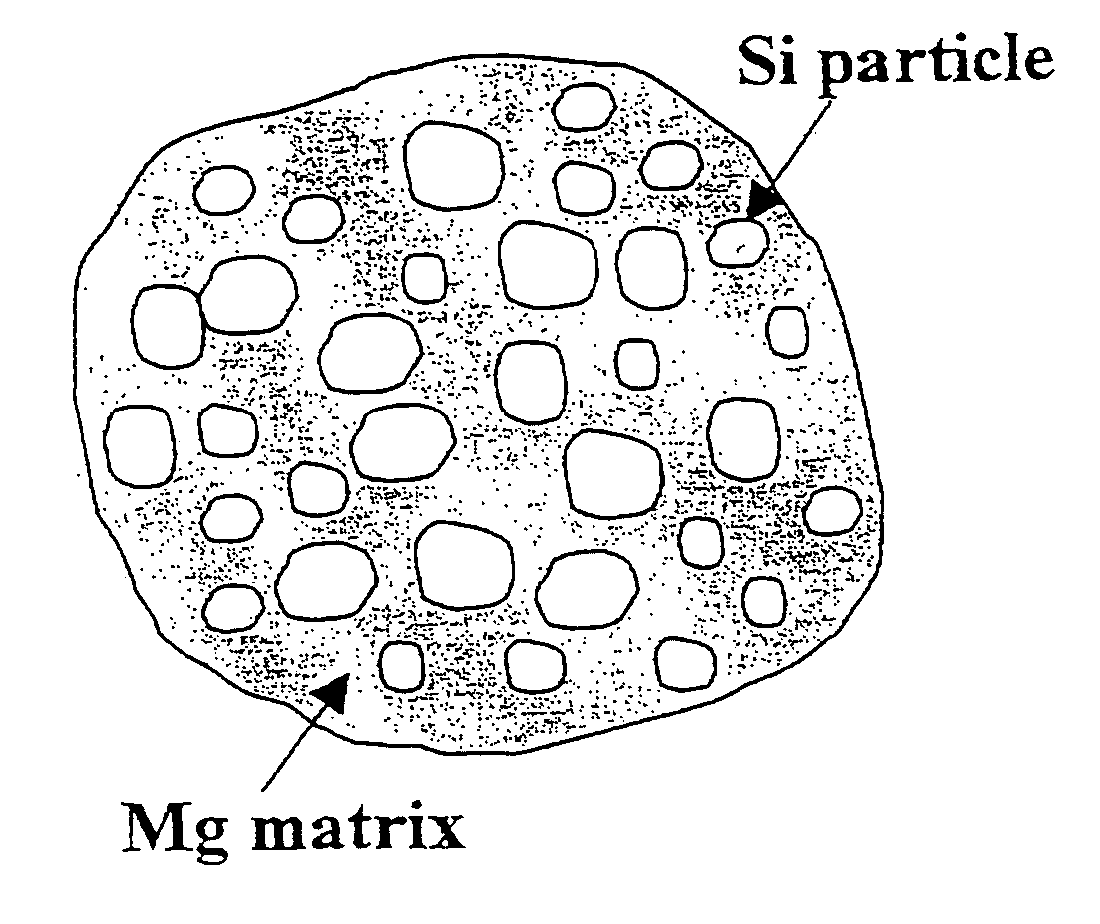

Mesoporous Silicon Compound used as Lithium-Ion Cell Negative Electrode Material and Preparation Method Thereof

ActiveUS20140234721A1High reversible capacityImprove cycle performanceElectrode thermal treatmentMetal silicidesCarbon layerLithium

A mesoporous silicon compound includes a mesoporous silicon phase, a metal silicide phase, and a carbon phase. The metal silicide is embedded in mesoporous silicon particles, the surfaces of which are coated with a carbon layer. A weight ratio of elemental silicon to the metal element is from 2:3 to 900:1. The pores of the mesoporous silicon particles have a size distribution from two nanometers to eighty nanometers.

Owner:ROBERT BOSCH GMBH

Magnesium base composite material

InactiveUS20050016638A1Improve mechanical propertiesReactionMetal silicidesMagnesium matrix compositeHardness

The present invention provides a magnesium-base composite material capable of suppressing coarse growth of a crystal particle size of a magnesium matrix and Mg2Si particles, thereby providing excellent mechanical properties such as strength and hardness, and a manufacturing method thereof. The manufacturing method includes the steps of: blending matrix powder containing Mg and Si powder to obtain a blended matter; applying a plasticization treatment to the resulting blended matter to form a solid body; heating the solid body to allow Mg and Si to react with each other to form a heat solid body containing Mg2Si; and applying a warm plasticization treatment to the heat solid body. Thus, it is possible to provide a magnesium-base composite material having a tensile strength from not less than 100 MPa to not more than 500 MPa.

Owner:TOUDAITLO LTD

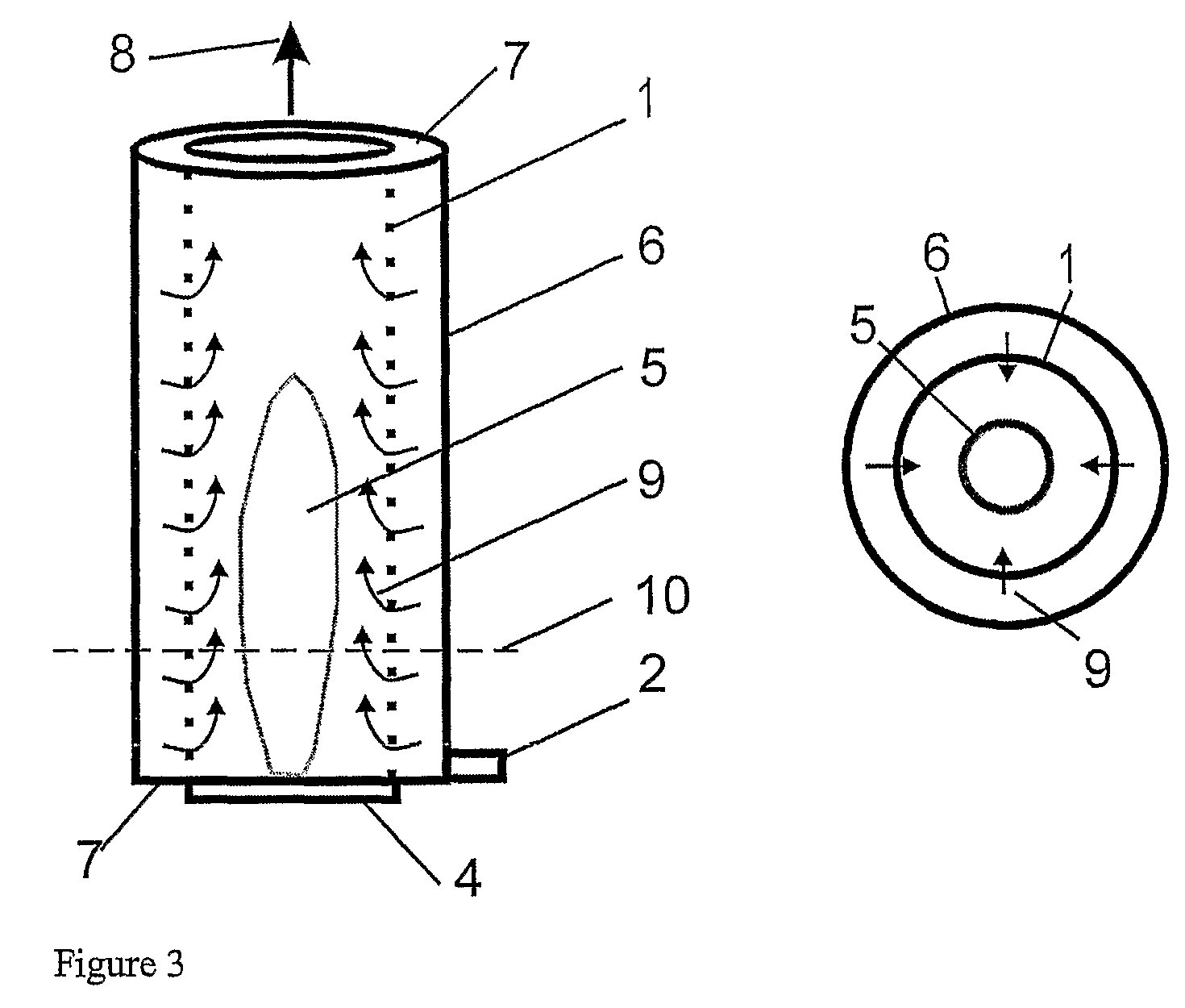

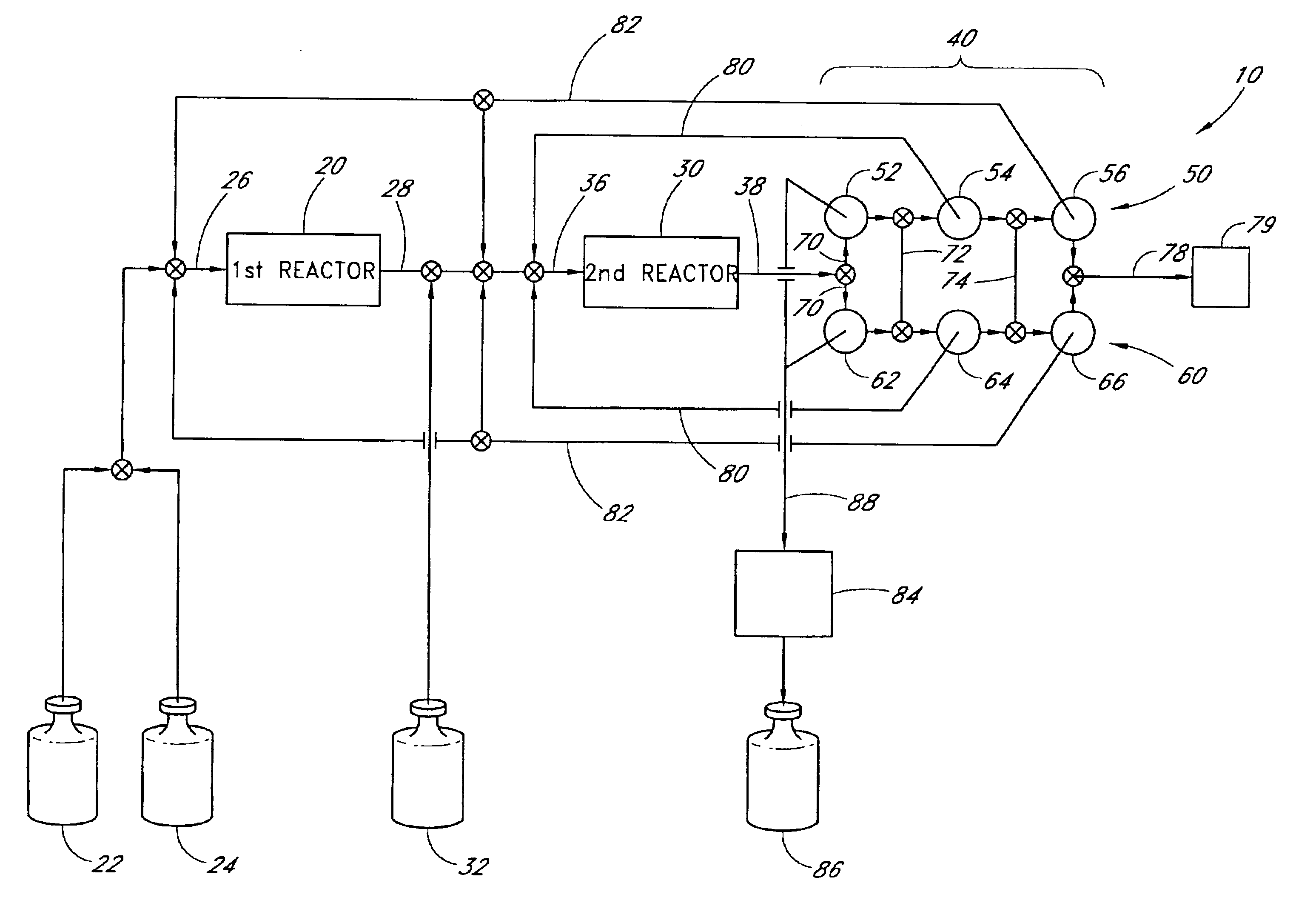

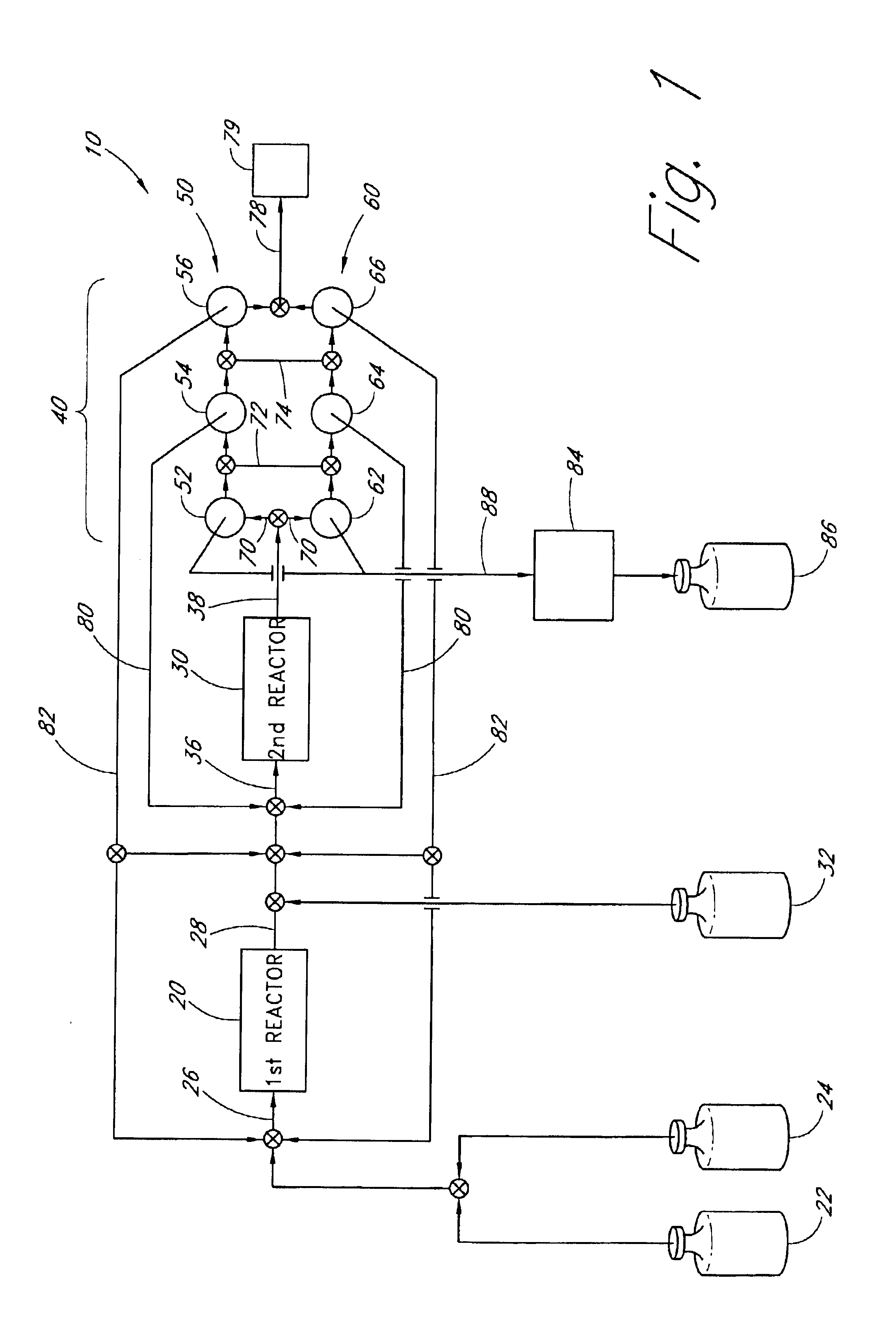

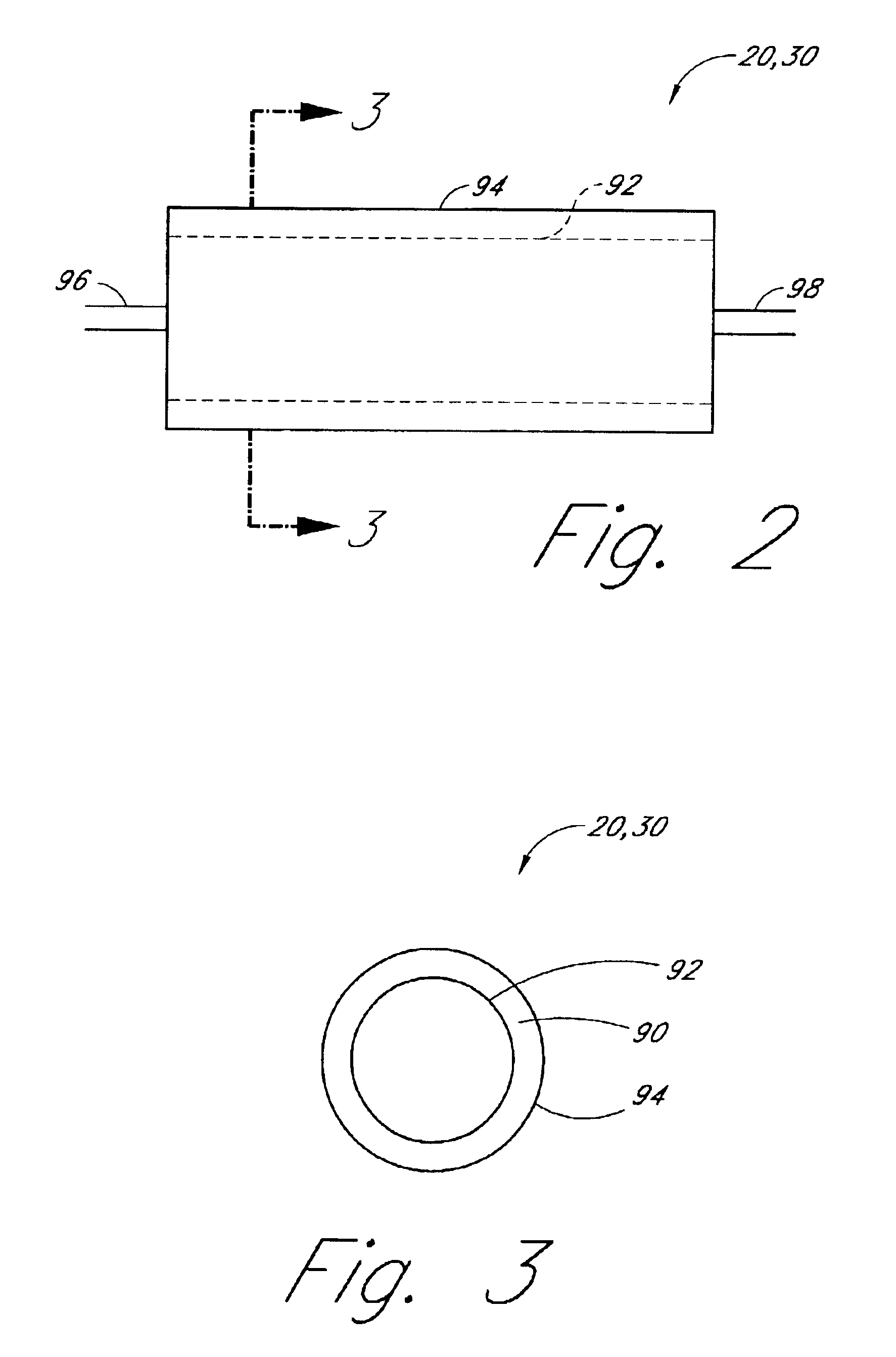

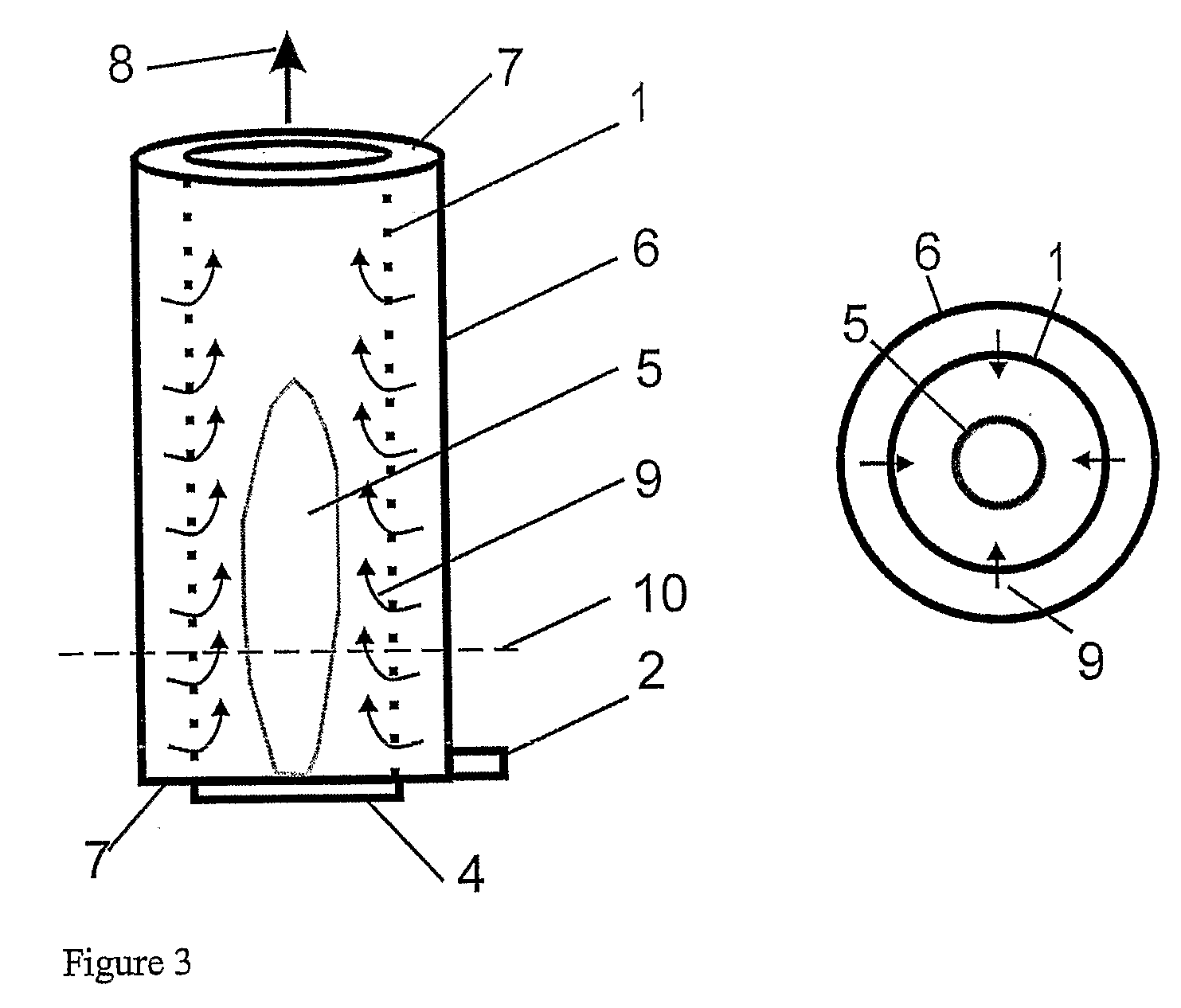

Method and apparatus for chemical synthesis

InactiveUS6858196B2Easy to operate continuouslyHighly orderedNitrogen compoundsMetal silicidesCondensation trapChemical synthesis

An apparatus is provided for synthesis and collection of higher order chemical compounds from lower order precursors. The apparatus includes a first silent electric discharge reactor configured to synthesize an intermediate product (e.g., disilane) from a precursor chemical (e.g., monosilane). A second silent electric discharge reactor is connected downstream of the first reactor. This second reactor is configured to convert the intermediate product into the higher order chemical compound (e.g., trisilane). Multiple condensation traps are also connected to receive effluent from the second reactor, which will generally include the compound of interest as well as unreacted precursor and intermediate product. In the illustrated embodiment, a parallel second condensation traps is also included to shunt flow and continue collection while the chemical of interest is removed for purification. Moreover, parallel second condensation traps for the intermediate product and unreacted (or recombined) precursor allow continued collection while the contents of the first traps are recycled in the reactor(s).

Owner:ASM IP HLDG BV

Methods and Devices for Flame Spray Pyrolysis

ActiveUS20080268246A1Light weightImprove conductivityMaterial nanotechnologyCarbon compoundsSpray pyrolysisMetal powder

The present invention relates the manufacture of metal powders, non-oxidic ceramic powders and reduced metal oxide powders using an improved flame spray pyrolysis (“FSP”) process. The invention further relates to an apparatus specifically adapted to said process, to powders / naoncomposites obtained by said process and to the use of said powders / nanocompsites.

Owner:ETH ZZURICH

Iron silicide powder and method for production thereof

InactiveUS20060002838A1Easy to crushHigh densityNitrogen compoundsMetal silicidesIron powderHydrogen

Provided is iron suicide powder in which the content of oxygen as the gas component is 1500 ppm or less, and a method of manufacturing such iron silicide powder including the steps of reducing iron oxide with hydrogen to prepare iron powder, heating the iron powder and Si powder in a non-oxidizing atmosphere to prepare synthetic powder containing FeSi as its primary component, and adding and mixing Si powder once again thereto and heating this in a non-oxidizing atmosphere to prepare iron suicide powder containing FeSi2 as its primary component. The content of oxygen as the gas component contained in the iron silicide powder will decrease, and the iron silicide powder can be easily pulverized as a result thereof. Thus, the mixture of impurities when the pulverization is unsatisfactory will be reduced, the specific surface area of the iron silicide powder will increase, and the density can be enhanced upon sintering the iron silicide powder.

Owner:JX NIPPON MINING& METALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com