Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134 results about "Catalyst nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanoparticle Catalysts. Nanoparticle catalysts have extensive surface area/unit volume when compared to traditional catalysts. This property makes them ideal for use in process intensified reactors such as the Holl-Reactor®. The catalyst mass rate can be dramatically lowered and still achieve high production rates.

Methods for producing and using catalytic substrates for carbon nanotube growth

InactiveUS20050112052A1Efficient CatalysisMaterial nanotechnologyElectric discharge heatingNucleationCatalyst nanoparticles

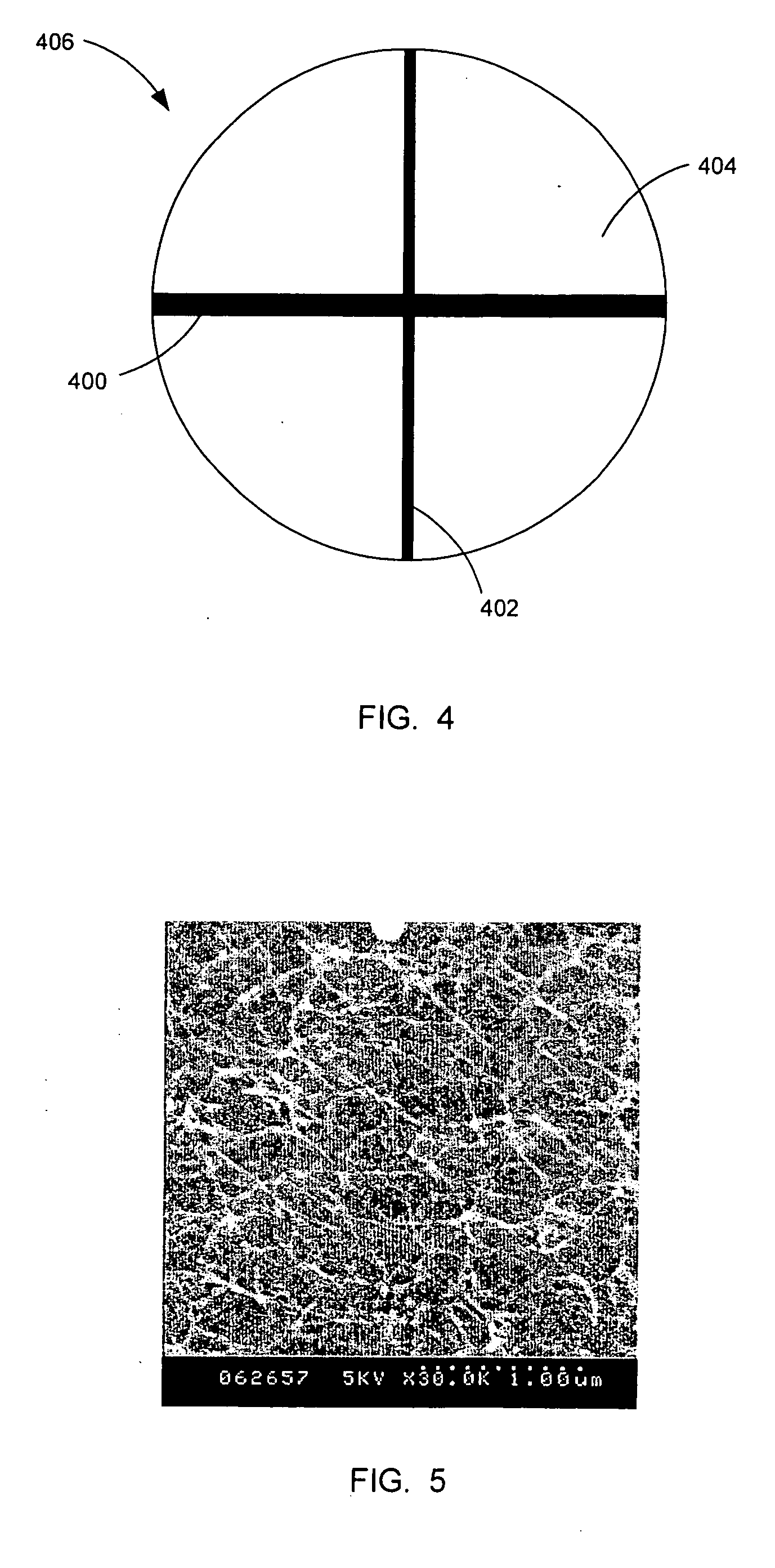

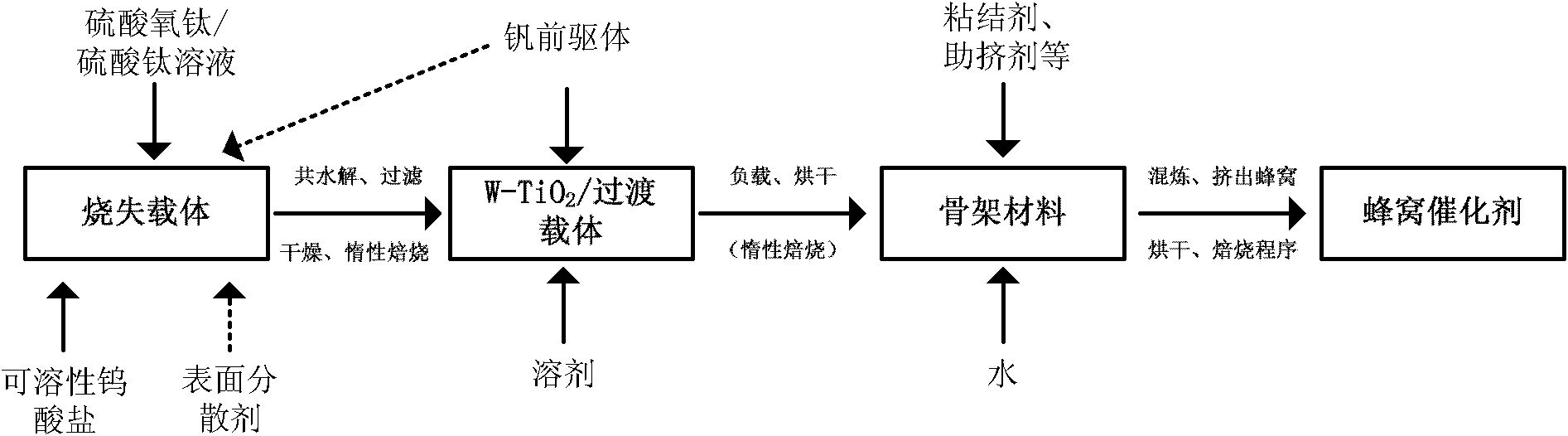

A catalyst material for carbon nanotube synthesis includes a uniform dispersion of host particles on a substrate. The host particles themselves include catalyst nanoparticles that are effective to catalyze nanotube syntheses reactions and provide nucleation sites. Methods for preparing catalyst materials include co-sputtering a catalytic species and a host species to form a precursor thin film on a substrate, followed by an oxidation reaction of the precursor thin film in air. The precursor thin film can be patterned on the substrate to limit the locations of the catalyst material to well-defined areas. Methods for nanotube synthesis employ CVD in conjunction with the catalyst materials of the invention. During the synthesis, the catalyst nanoparticles catalyze carbon nanotubes to grown from a carbon-containing gas.

Owner:MOLECULAR NANOSYST

Titania nanotube arrays, methods of manufacture, and photocatalytic conversion of carbon dioxide using same

InactiveUS20100213046A1Improve photocatalytic activityImprove efficiencyCatalyst activation/preparationLiquid hydrocarbon mixture productionTio2 nanotubeWater vapor

Nitrogen-doped titania nanotubes exhibiting catalytic activity on exposure to any one or more of ultraviolet, visible, and / or infrared radiation, or combinations thereof are disclosed. The nanotube arrays may be co-doped with one or more nonmetals and may further include co-catalyst nanoparticles. Also, methods are disclosed for use of nitrogen-doped titania nanotubes in catalytic conversion of carbon dioxide alone or in admixture with hydrogen-containing gases such as water vapor and / or other reactants as may be present or desirable into products such as hydrocarbons and hydrocarbon-containing products, hydrogen and hydrogen-containing products, carbon monoxide and other carbon-containing products, or combinations thereof.

Owner:PENN STATE RES FOUND

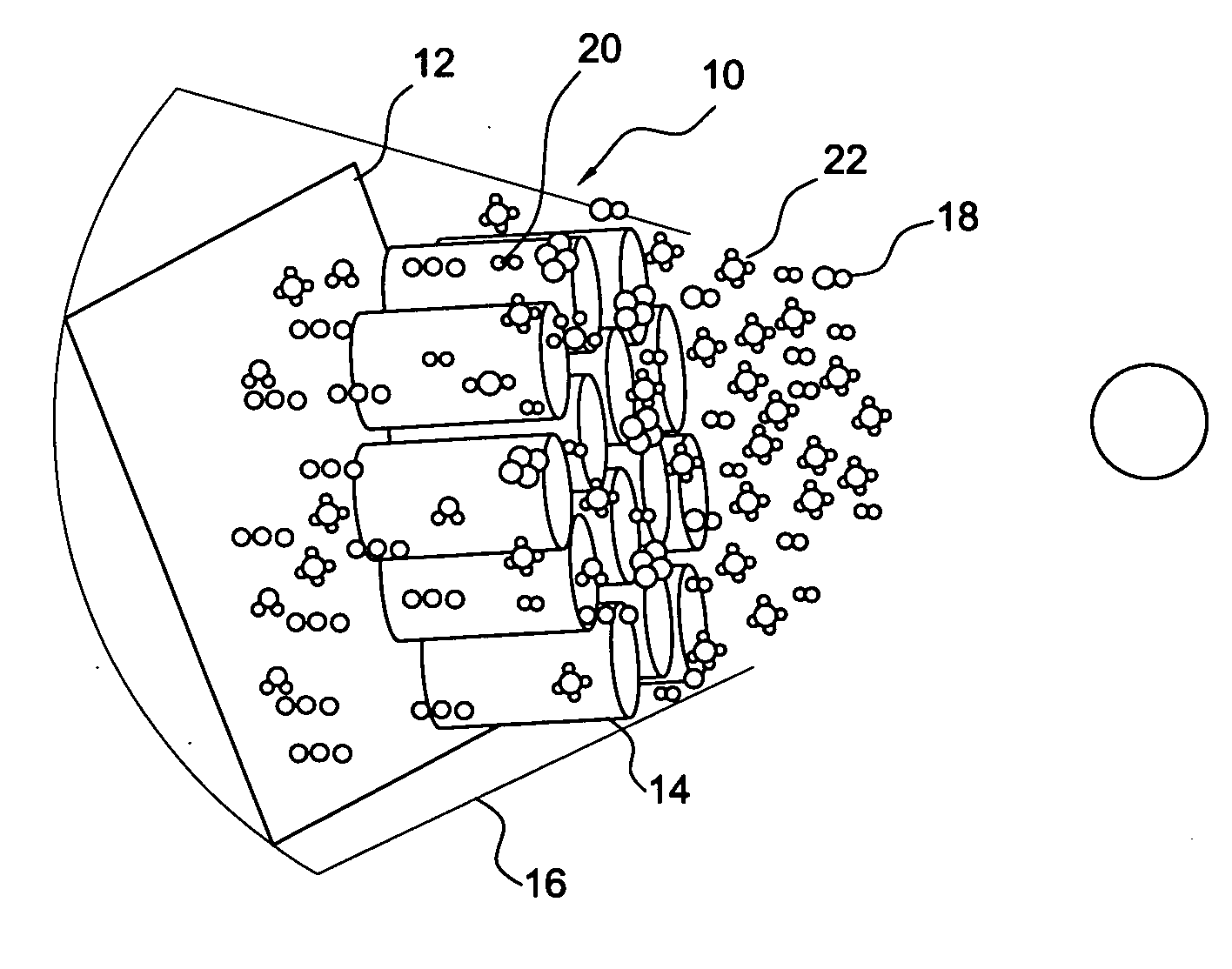

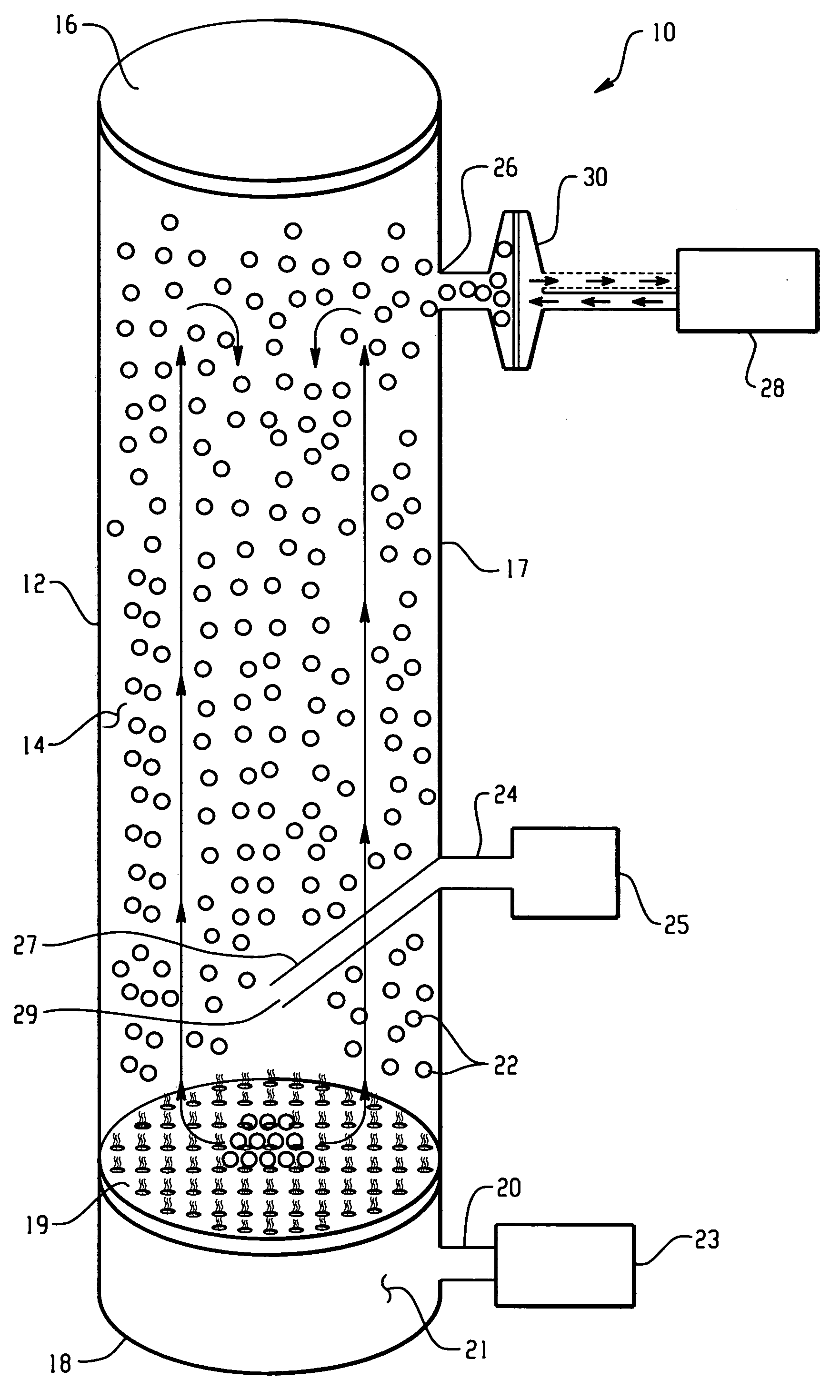

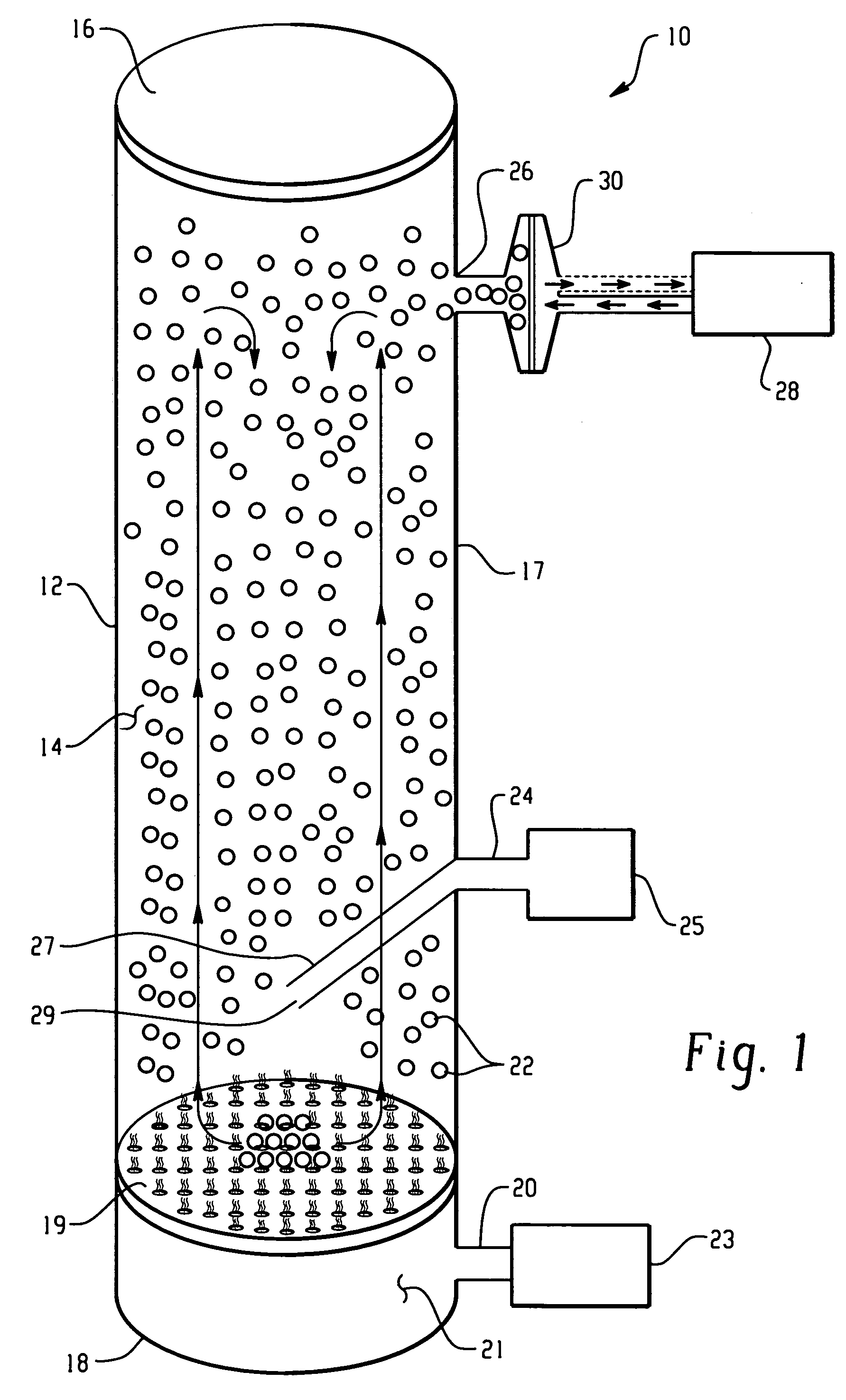

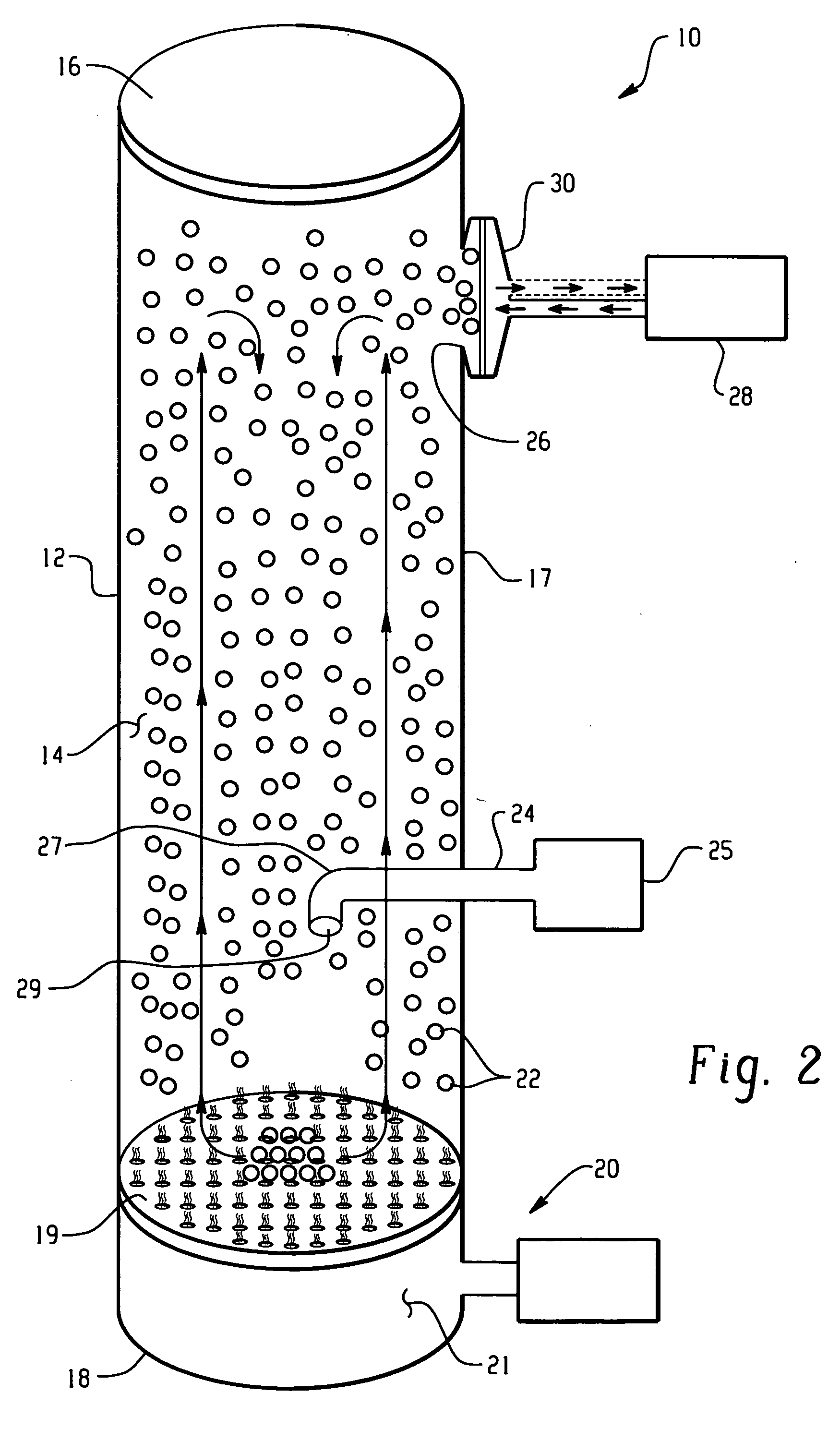

Fluidized-bed reactor system

A fluidized-bed reactor comprising a chamber defining a hollow interior region and having a lower surface; a first input for introducing a contaminated gas into the hollow interior region; a plurality of catalyst nanoparticles within the hollow interior region and located on the lower surface, and a fluidizing input for introducing a fluidizing material into the hollow interior region, said fluidizing input having an outlet directed at the lower surface of the chamber, wherein the introduction of the fluidizing material directed at the lower surface fluidizes at least a portion of the catlyst nanoparticles located on the lower surface to create a gaseous dispersion of catalyst nanoparticles that reacts with the contaminated gas to produce a decontaminated gas.

Owner:GM GLOBAL TECH OPERATIONS LLC

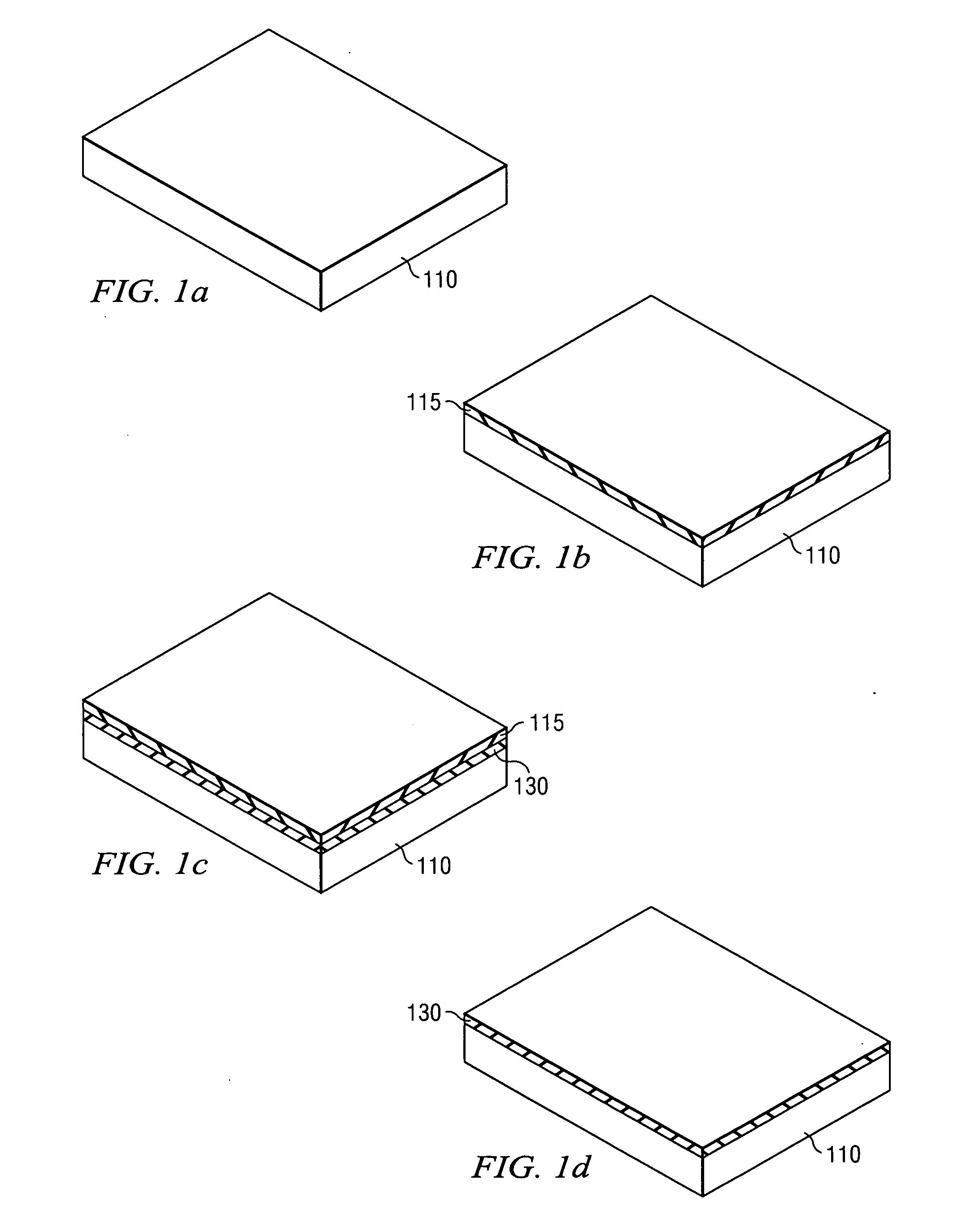

Method of and Printable Compositions for Manufacturing a Multilayer Carbon Nanotube Capacitor

InactiveUS20110204020A1Increase powerImprove cycle lifeMaterial nanotechnologyNanomagnetismElectrical conductorCatalyst nanoparticles

Multilayer carbon nanotube capacitors, and methods and printable compositions for manufacturing multilayer carbon nanotubes (CNTs) are disclosed. A first capacitor embodiment comprises: a first conductor; a plurality of fixed CNTs in an ionic liquid, each fixed CNT comprising a magnetic catalyst nanoparticle coupled to a carbon nanotube and further coupled to the first conductor; and a first plurality of free CNTs dispersed and moveable in the ionic liquid. Another capacitor embodiment comprises: a first conductor; a conductive nanomesh coupled to the first conductor; a first plurality of fixed CNTs in an ionic liquid and further coupled to the conductive nanomesh; and a plurality of free CNTs dispersed and moveable in the ionic liquid. Various methods of printing the CNTs and other structures, and methods of aligning and moving the CNTs using applied electric and magnetic fields, are also disclosed.

Owner:NTHDEGREE TECH WORLDWIDE

Catalyst nanoparticle

InactiveUS20070026294A1Reduced activityMaterial nanotechnologyMetal-working apparatusCatalyst nanoparticlesNanometre

Although nanoparticles capable of providing an extremely large active surface area have highly marked advantages, when a PEFC electrode utilizing nanoparticles is used for a prolonged period of time, the catalyst nanoparticles on carrier of the PEFC electrode because of the nano-size thereof migrate and aggregate together to result in a rapid loss of activity. Thus, there is a demand for inhibition of the above aggregation so as to prevent any drop of catalytic activity. According to the present invention the aggregation of nanoparticles can be inhibited by catalyst nanoparticles containing Pt wherein a porous matter containing an inorganic oxide is disposed on the surface of the catalyst nanoparticles. When use is made of nanoparticles whose surface has undergone specific modification, excellent activity can be realized. Therefore, there are provided surface-modified nanoparticles and catalyst and further a PEFC electrode utilizing these nanoparticles.

Owner:HITACHI LTD

System and method for controlling the size and/or distribution of catalyst nanoparticles for nanostructure growth

InactiveUS20080032238A1Material nanotechnologyLiquid surface applicatorsNanostructureCatalyst nanoparticles

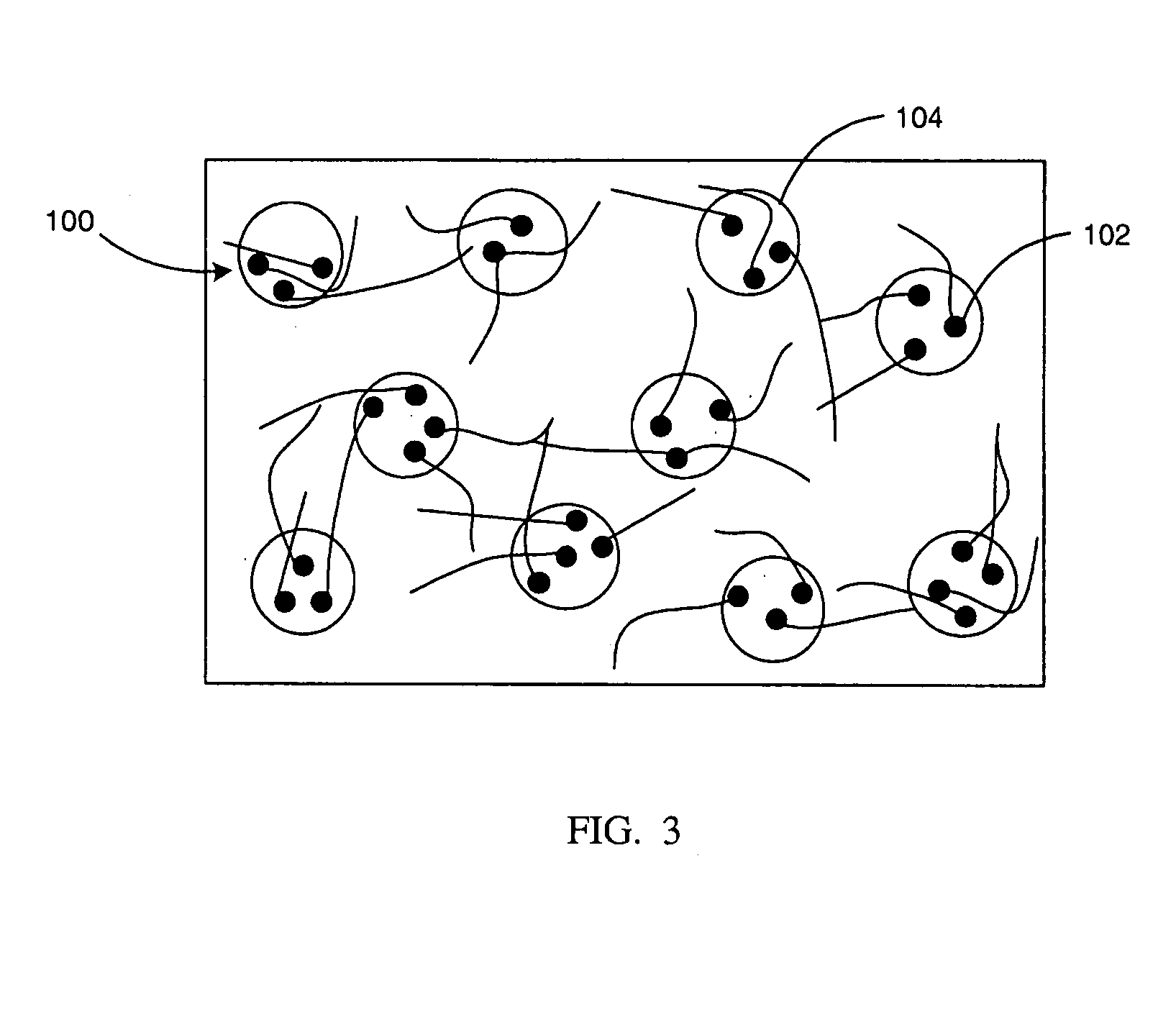

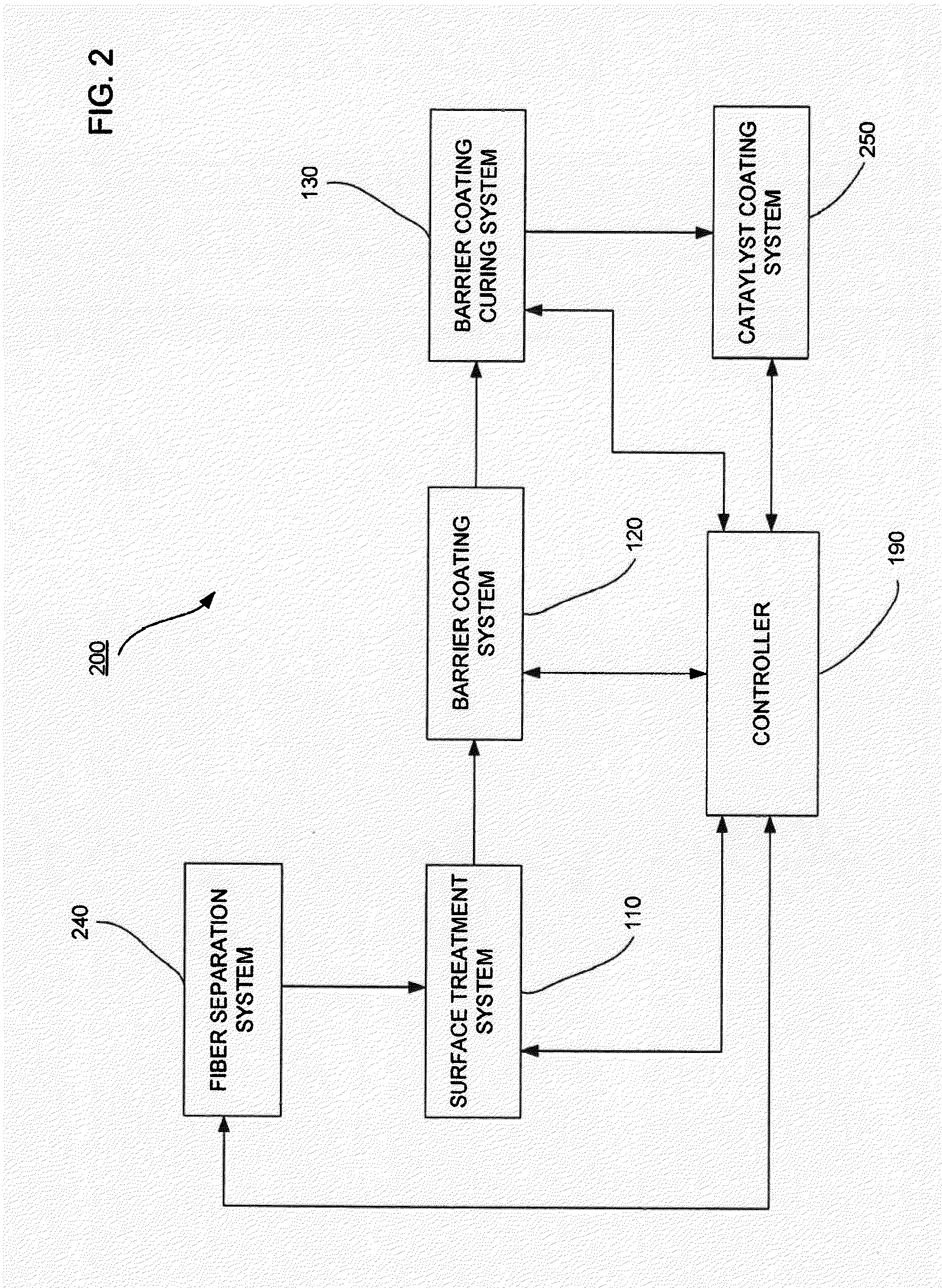

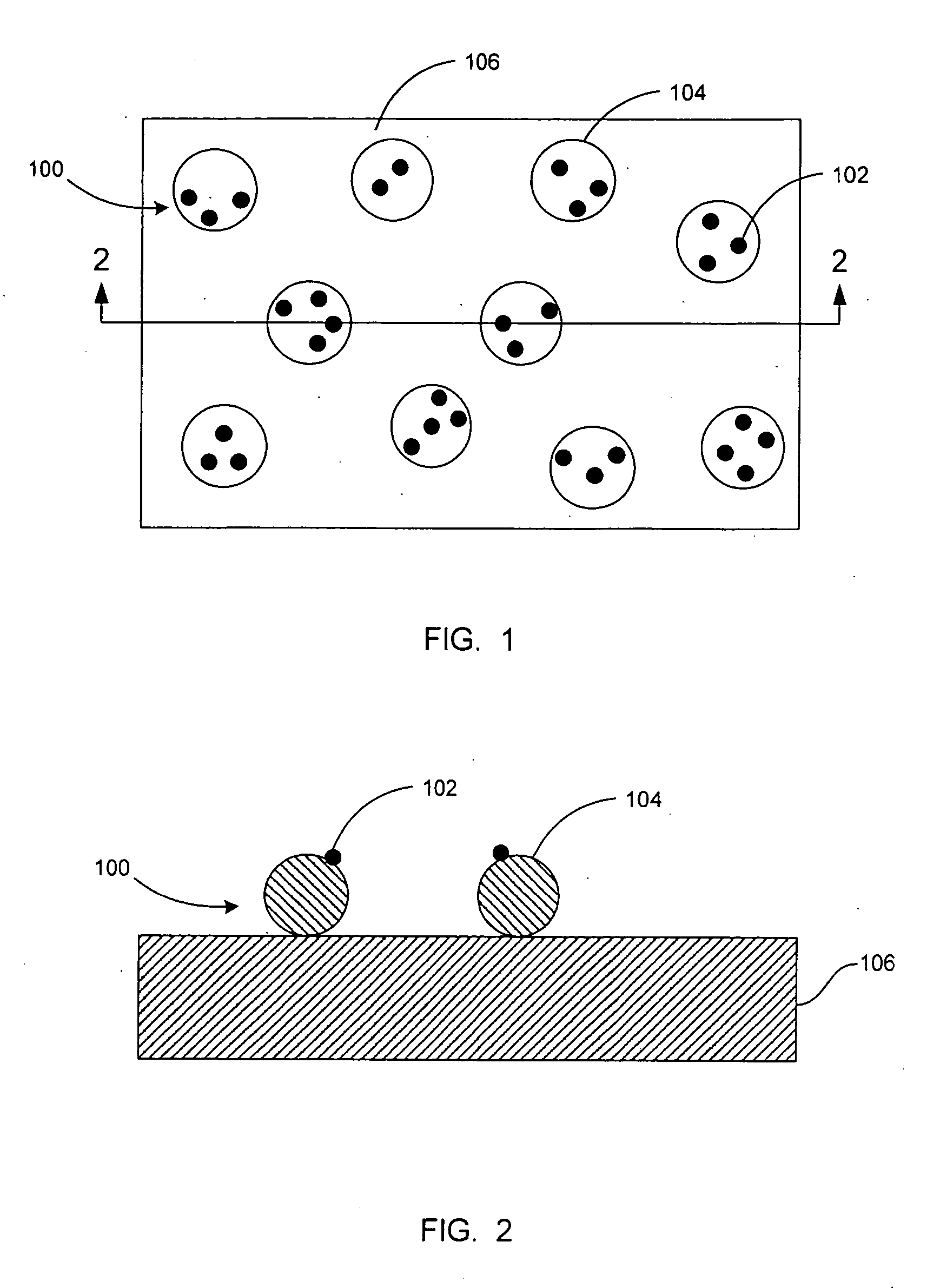

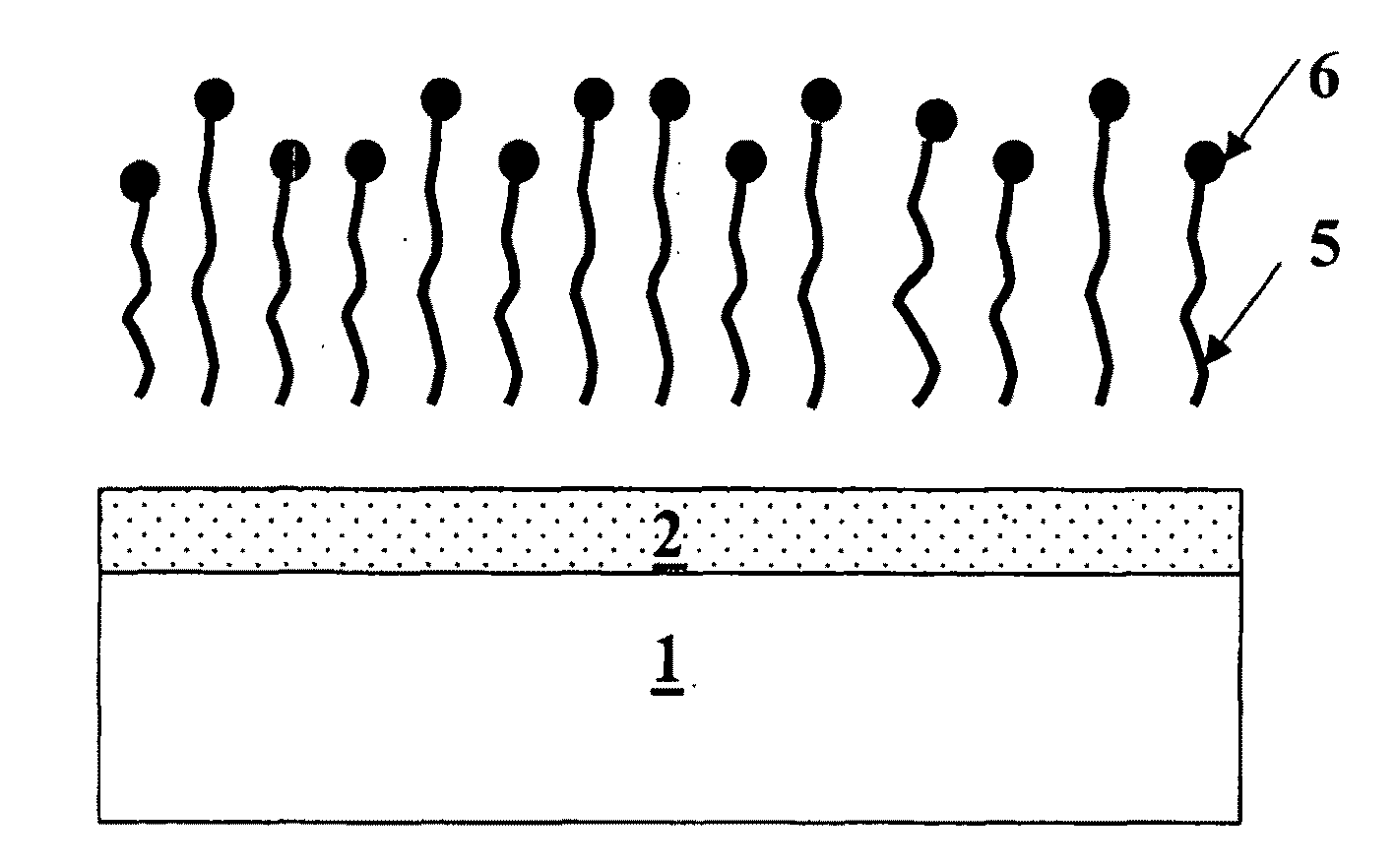

Techniques for controlling the size and / or distribution of a catalyst nanoparticles on a substrate are provided. The catalyst nanoparticles comprise any species that can be used for growing a nanostructure, such as a nanotube, on the substrate surface. Polymers are used as a carrier of a catalyst payload, and such polymers self-assemble on a substrate thereby controlling the size and / or distribution of resulting catalyst nanoparticles. Amphiphilic block copolymers are known self-assembly systems, in which chemically-distinct blocks microphase-separate into a nanoscale morphology, such as cylindrical or spherical, depending on the polymer chemistry and molecular weight. Such block copolymers are used as a carrier of a catalyst payload, and their self-assembly into a nanoscale morphology controls size and / or distribution of resulting catalyst nanoparticles onto a substrate.

Owner:AGILENT TECH INC

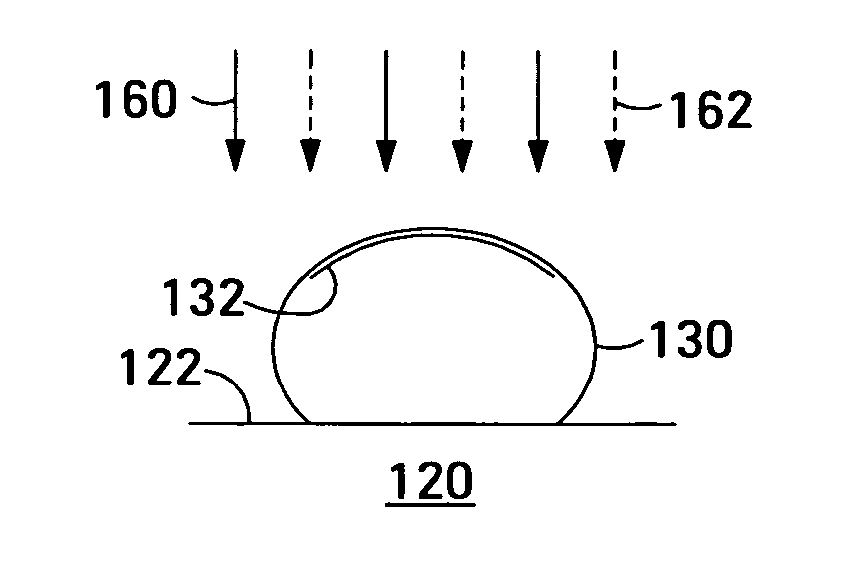

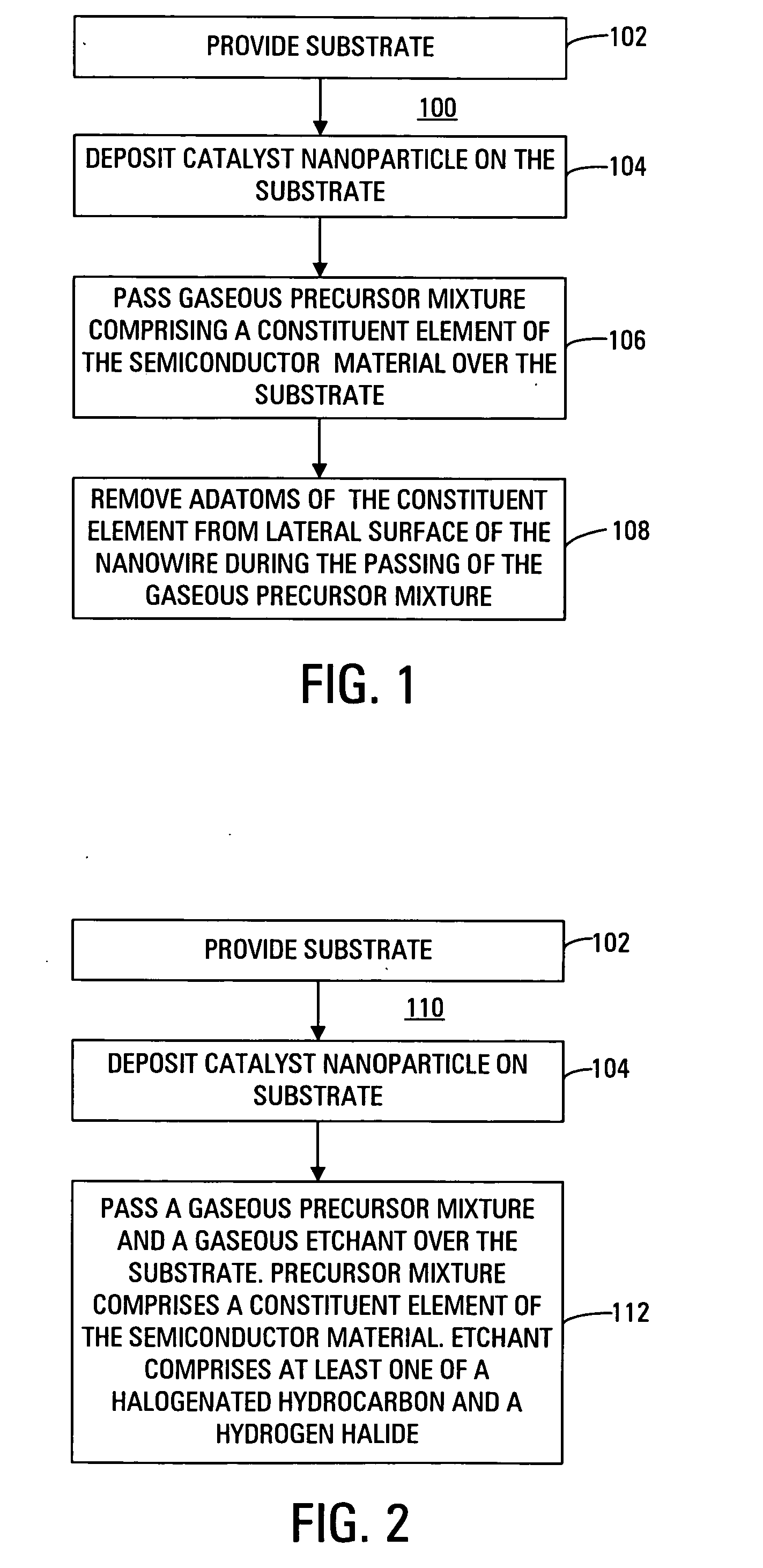

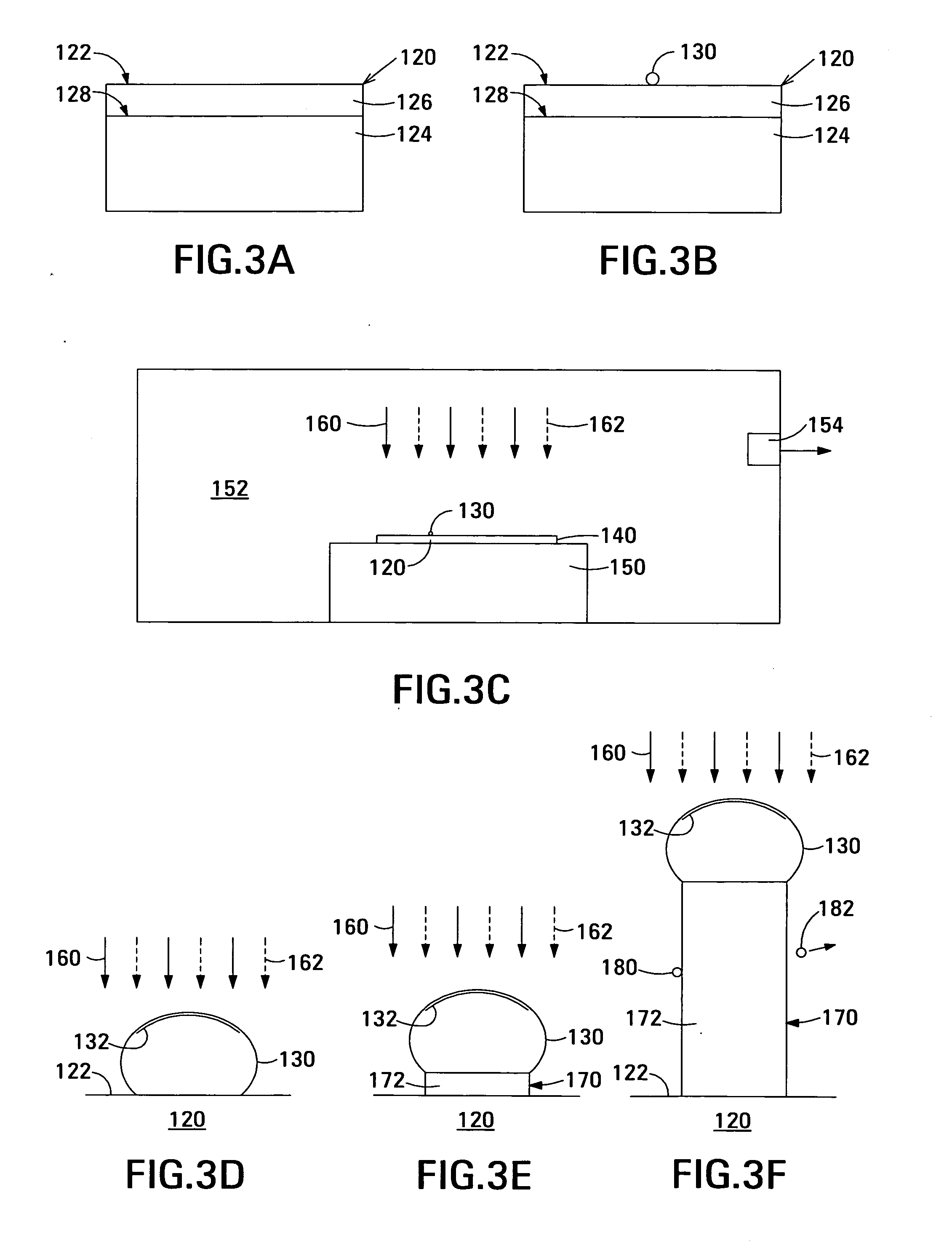

Method of growing semiconductor nanowires with uniform cross-sectional area using chemical vapor deposition

InactiveUS20050266662A1Uniform cross-sectional areaUniform areaMaterial nanotechnologyPolycrystalline material growthNanowireSemiconductor materials

A nanowire of a semiconductor material and having a uniform cross-sectional area along its length is grown using a chemical vapor deposition process. In the method, a substrate is provided, a catalyst nanoparticle is deposited on the substrate, a gaseous precursor mixture comprising a constituent element of the semiconductor material is passed over the substrate, and adatoms of the constituent element are removed from a lateral surface of the nanowire during the passing of the precursor mixture. Removing the adatoms of the constituent element before such adatoms are incorporated into the nanowire prevents such adatoms from accumulating on the lateral surface of the nanowire and allows the nanowire to grow with a uniform cross-sectional area along its length.

Owner:AGILENT TECH INC

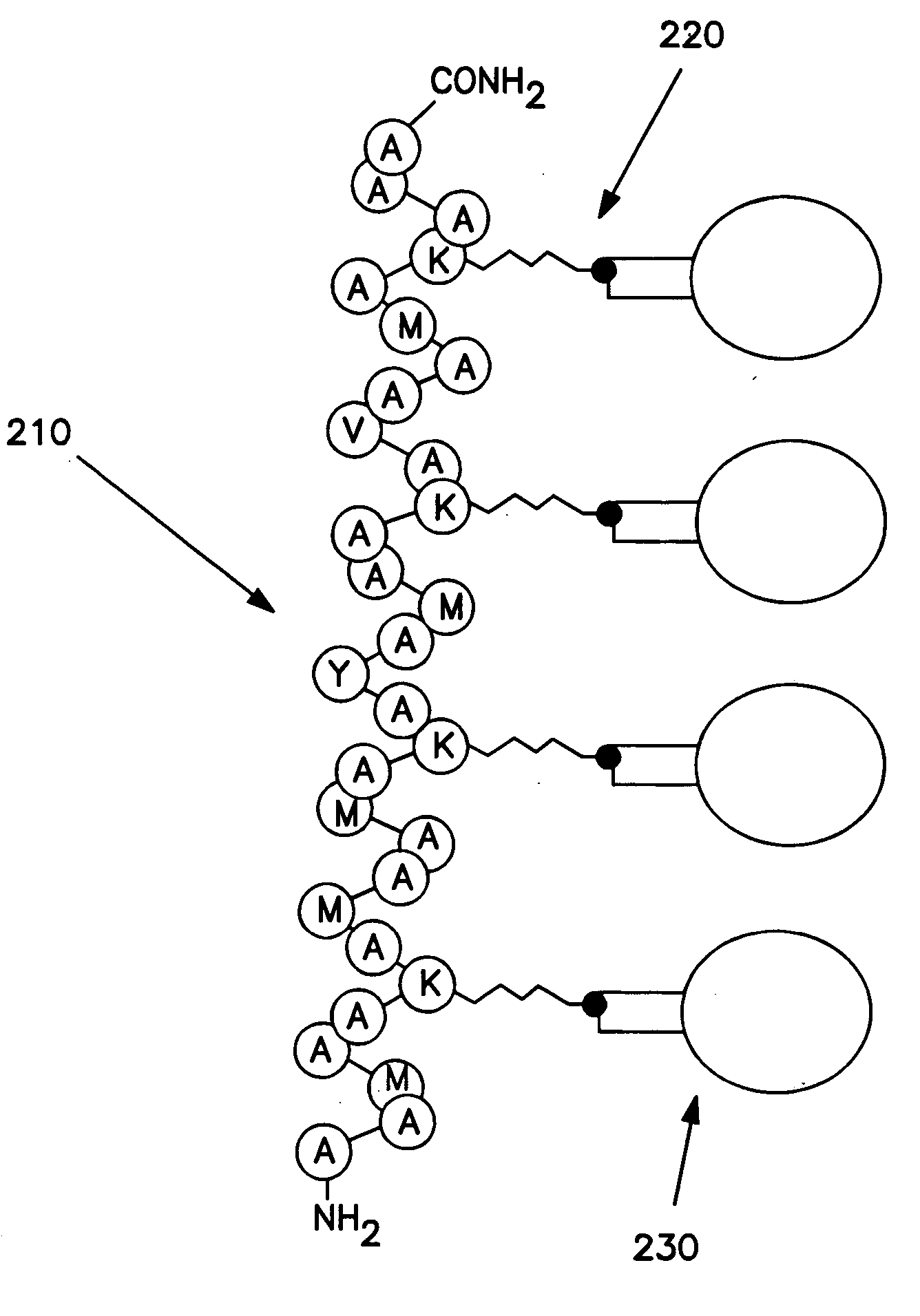

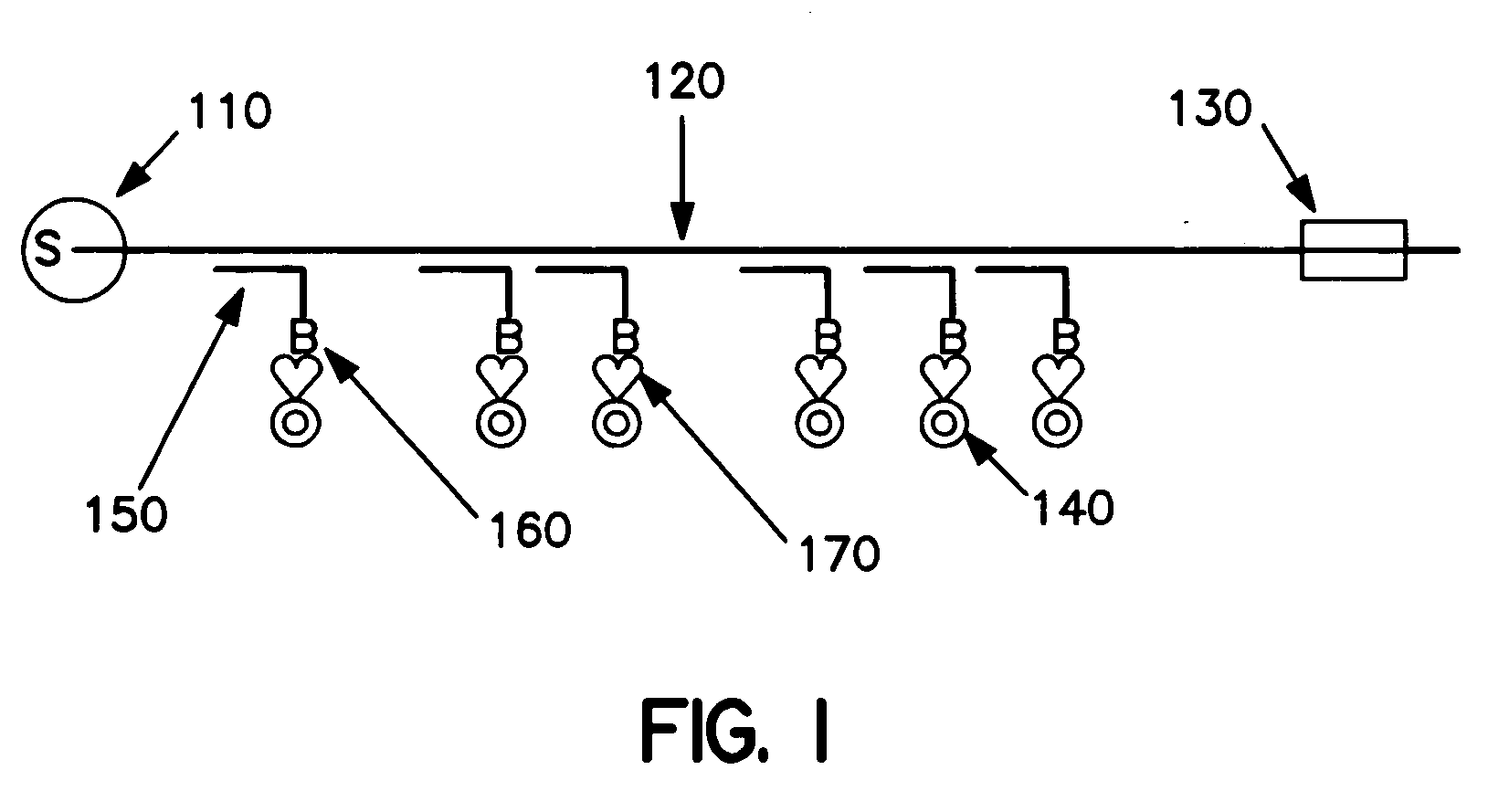

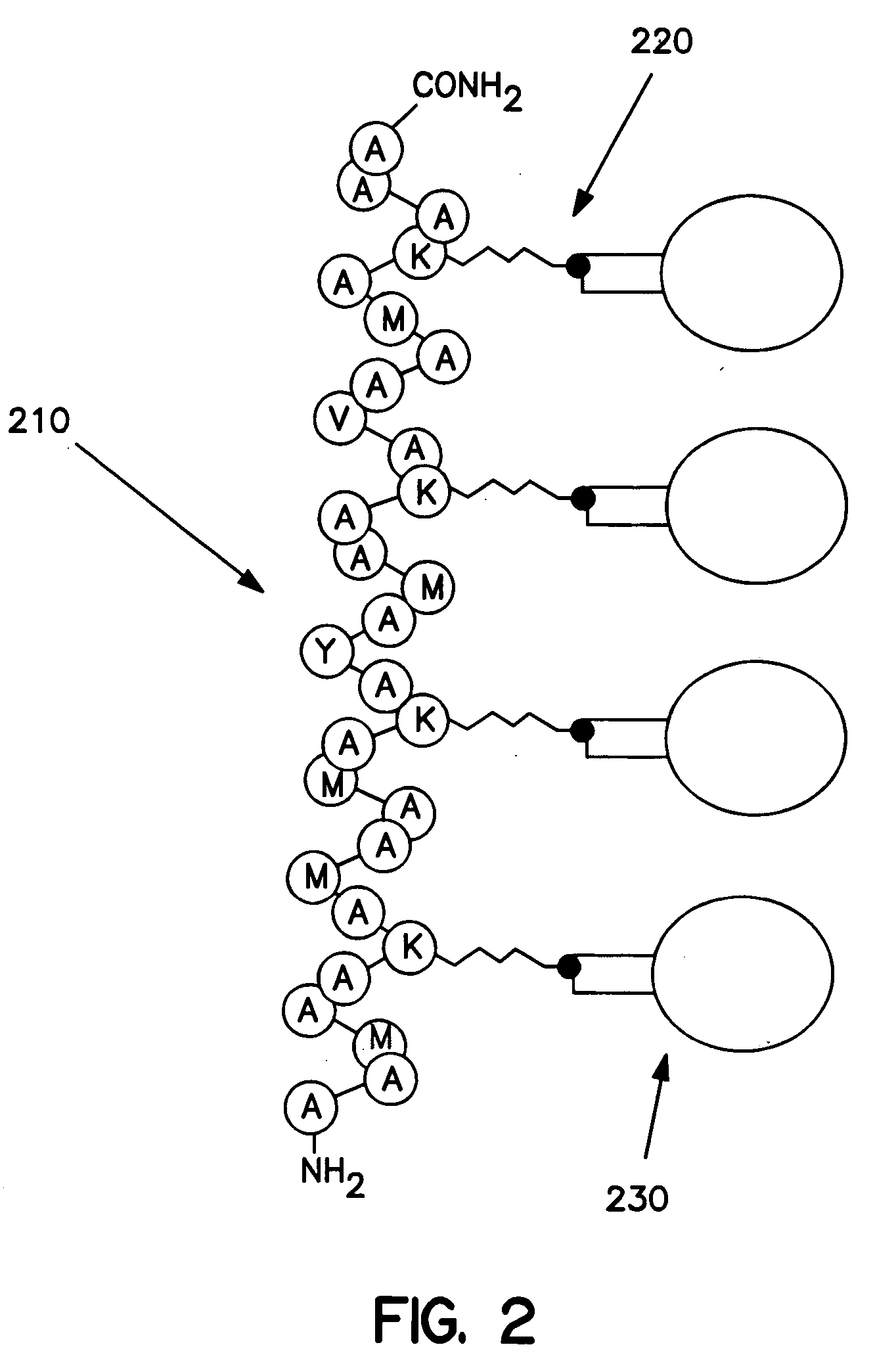

Methods of producing carbon nanotubes using peptide or nucleic acid micropatterning

InactiveUS20050151126A1Facilitates a predominantly 5′-attachmentMaterial nanotechnologyNanoinformaticsMolecular wireDouble stranded

The methods, apparatus and systems disclosed herein concern ordered arrays of carbon nanotubes. In particular embodiments of the invention, the nanotube arrays are formed by a method comprising attaching catalyst nanoparticles 140, 230 to polymer 120, 210 molecules, attaching the polymer 120, 210 molecules to a substrate, removing the polymer 120, 210 molecules and producing carbon nanotubes on the catalyst nanoparticles 140, 230. The polymer 120, 210 molecules can be attached to the substrate in ordered patterns, using self-assembly or molecular alignment techniques. The nanotube arrays can be attached to selected areas 110, 310 of the substrate. Within the selected areas 110, 310, the nanotubes are distributed non-randomly. Other embodiments disclosed herein concern apparatus that include ordered arrays of nanotubes attached to a substrate and systems that include ordered arrays of carbon nanotubes attached to a substrate, produced by the claimed methods. In certain embodiments, provided herein are methods for aligning a molecular wire, by ligating the molecular wire to a double stranded DNA molecule.

Owner:INTEL CORP

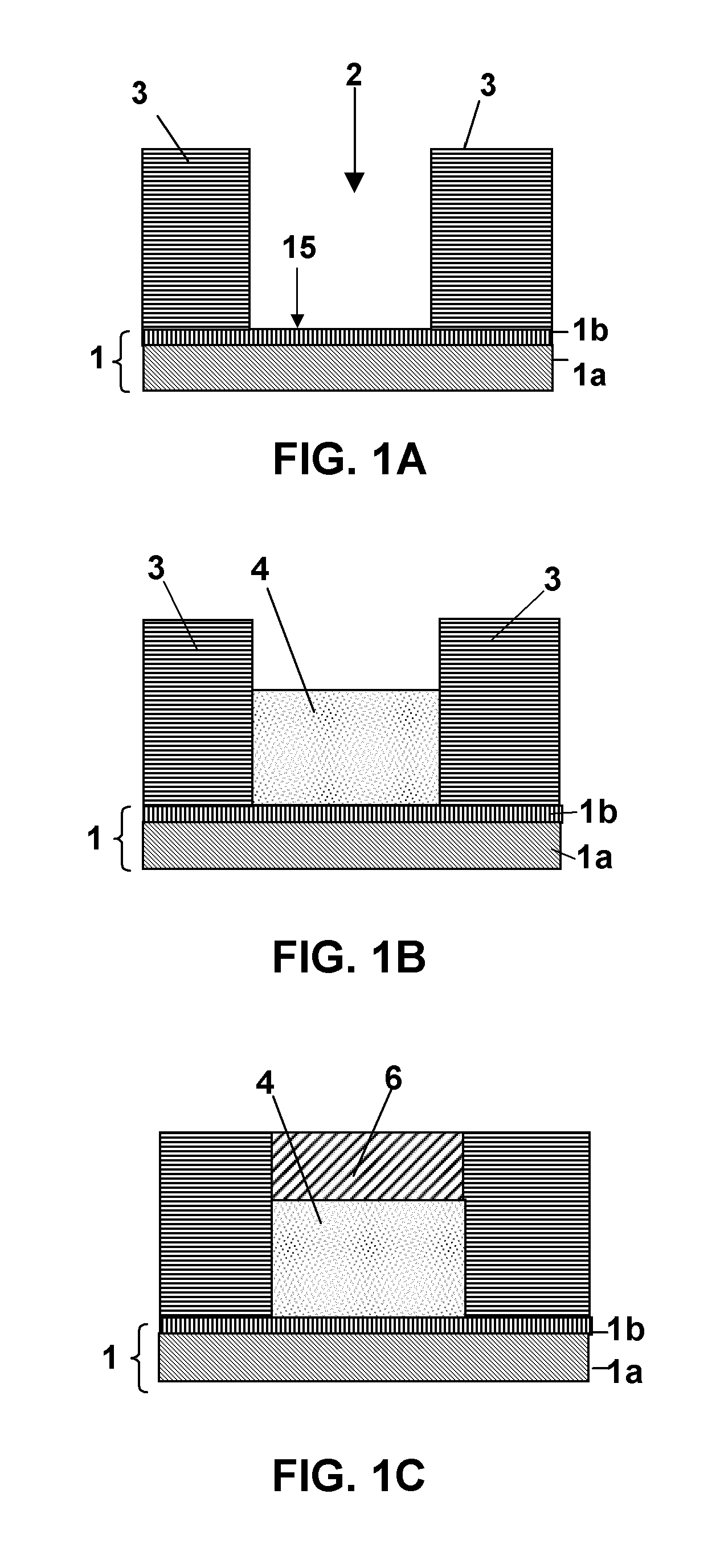

Method for forming catalyst nanoparticles for growing elongated nanostructures

InactiveUS20090072222A1Fully compatibleGrowth inhibitionMaterial nanotechnologyCarbon compoundsNanowireCatalyst nanoparticles

Preferred embodiments provide a method for forming at least one catalyst nanoparticle on at least one sidewall of a three-dimensional structure on a main surface of a substrate, the main surface lying in a plane and the sidewall of the three-dimensional structure lying in a plane substantially perpendicular to the plane of the main surface of the substrate. The method comprises obtaining a three-dimensional structure on the main surface, the three-dimensional structure comprising catalyst nanoparticles embedded in a non-catalytic matrix and selectively removing at least part of the non-catalytic matrix at the sidewalls of the three-dimensional structure to thereby expose at least one catalyst nanoparticle. According to preferred embodiments a method is also provided for forming at least one elongated nanostructure, such as e.g. a nanowire or carbon nanotube, using the catalyst nanoparticles formed by the method according to preferred embodiments as a catalyst. The methods according to preferred embodiments may be used in, for example, semiconductor processing. The methods according to preferred embodiments are scalable and fully compatible with existing semiconductor processing technology.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Methods for producing and using catalytic substrates for carbon nanotube growth

InactiveUS7235159B2Material nanotechnologyElectric discharge heatingNucleationCatalyst nanoparticles

A catalyst material for carbon nanotube synthesis includes a uniform dispersion of host particles on a substrate. The host particles themselves include catalyst nanoparticles that are effective to catalyze nanotube syntheses reactions and provide nucleation sites. Methods for preparing catalyst materials include co-sputtering a catalytic species and a host species to form a precursor thin film on a substrate, followed by an oxidation reaction of the precursor thin film in air. The precursor thin film can be patterned on the substrate to limit the locations of the catalyst material to well-defined areas. Methods for nanotube synthesis employ CVD in conjunction with the catalyst materials of the invention. During the synthesis, the catalyst nanoparticles catalyze carbon nanotubes to grown from a carbon-containing gas.

Owner:MOLECULAR NANOSYST

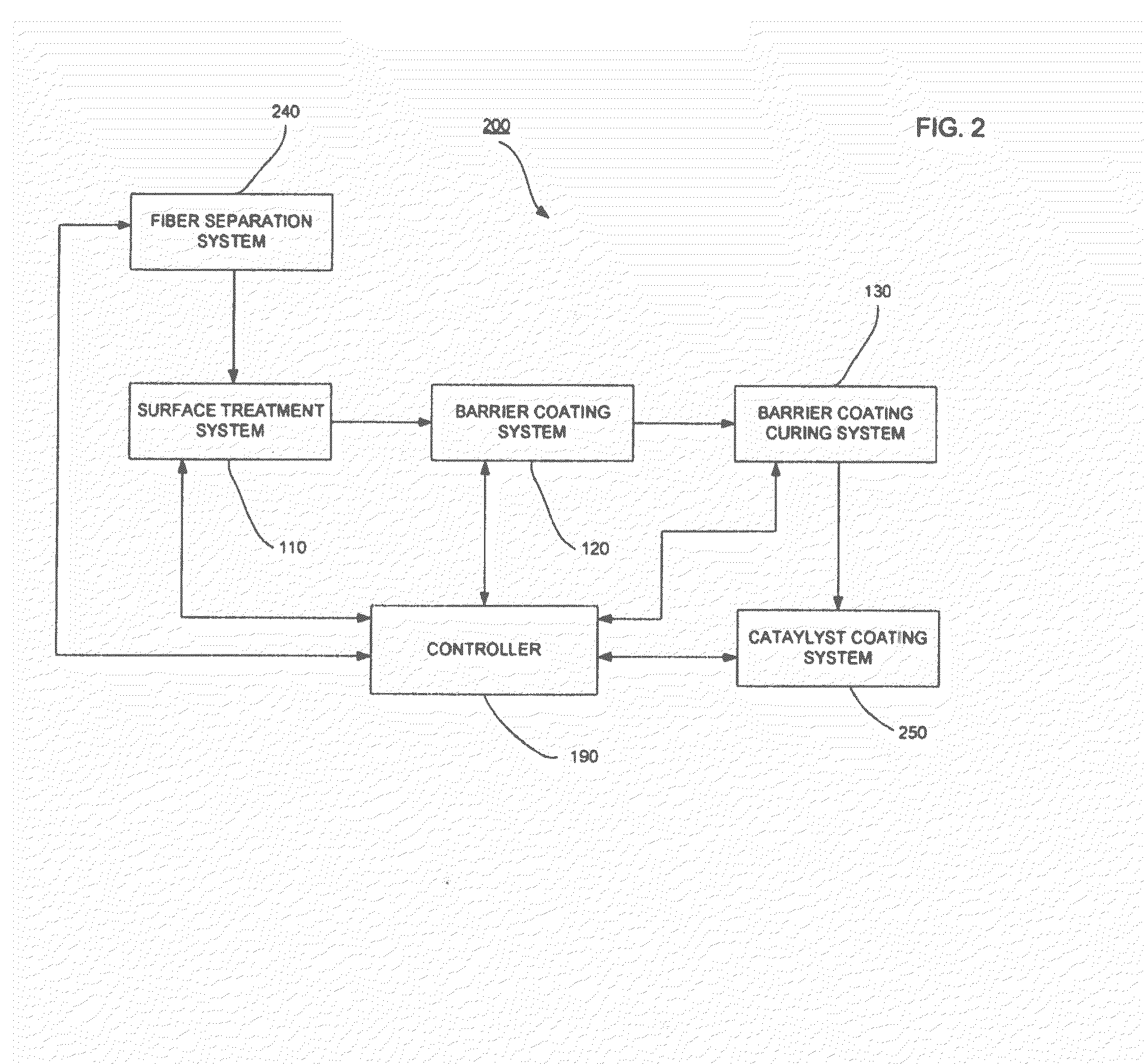

System and method for surface treatment and barrier coating of fibers for in situ cnt growth

InactiveUS20100224129A1Easy to receiveMaterial nanotechnologyLiquid surface applicatorsFiberCatalyst nanoparticles

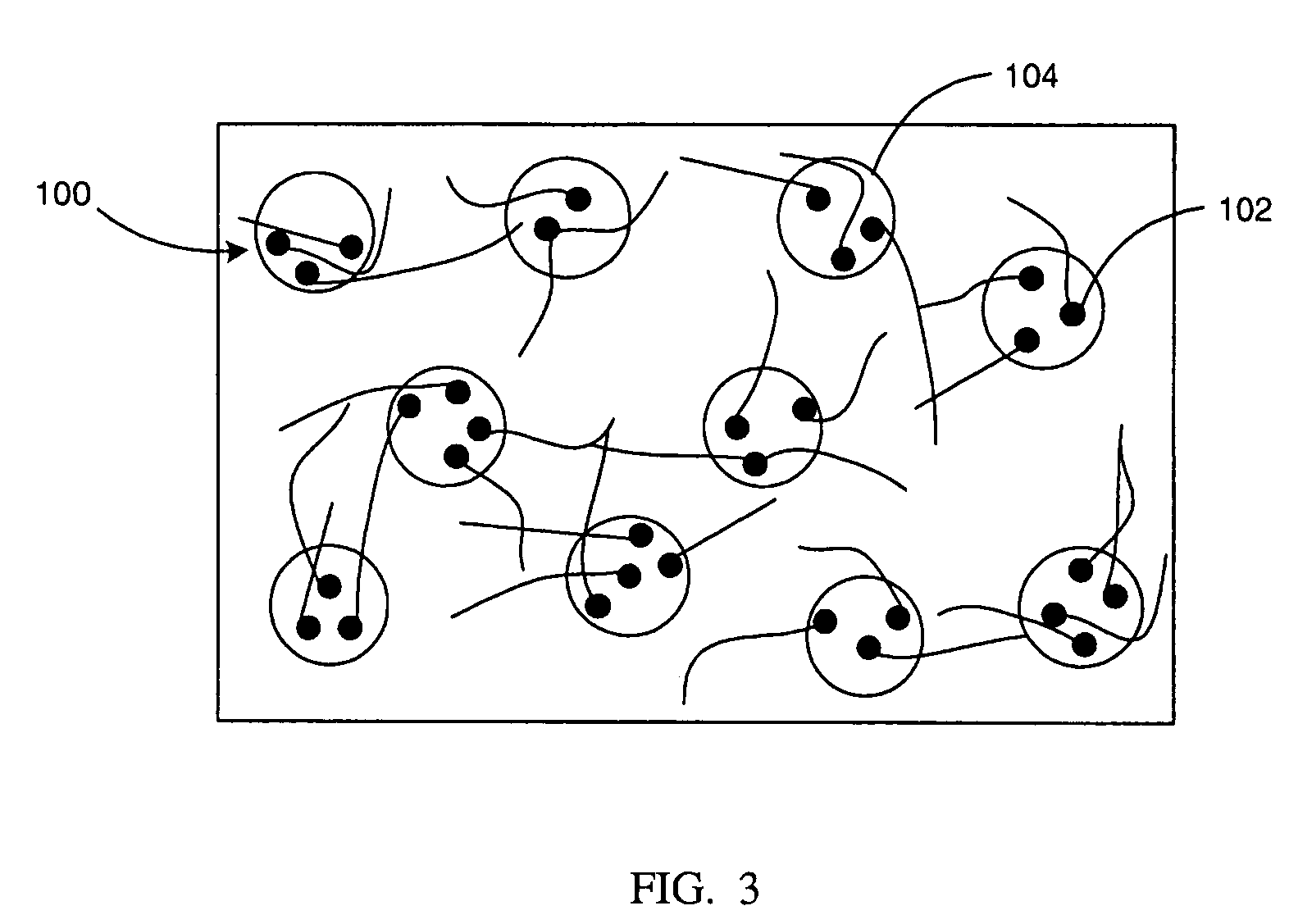

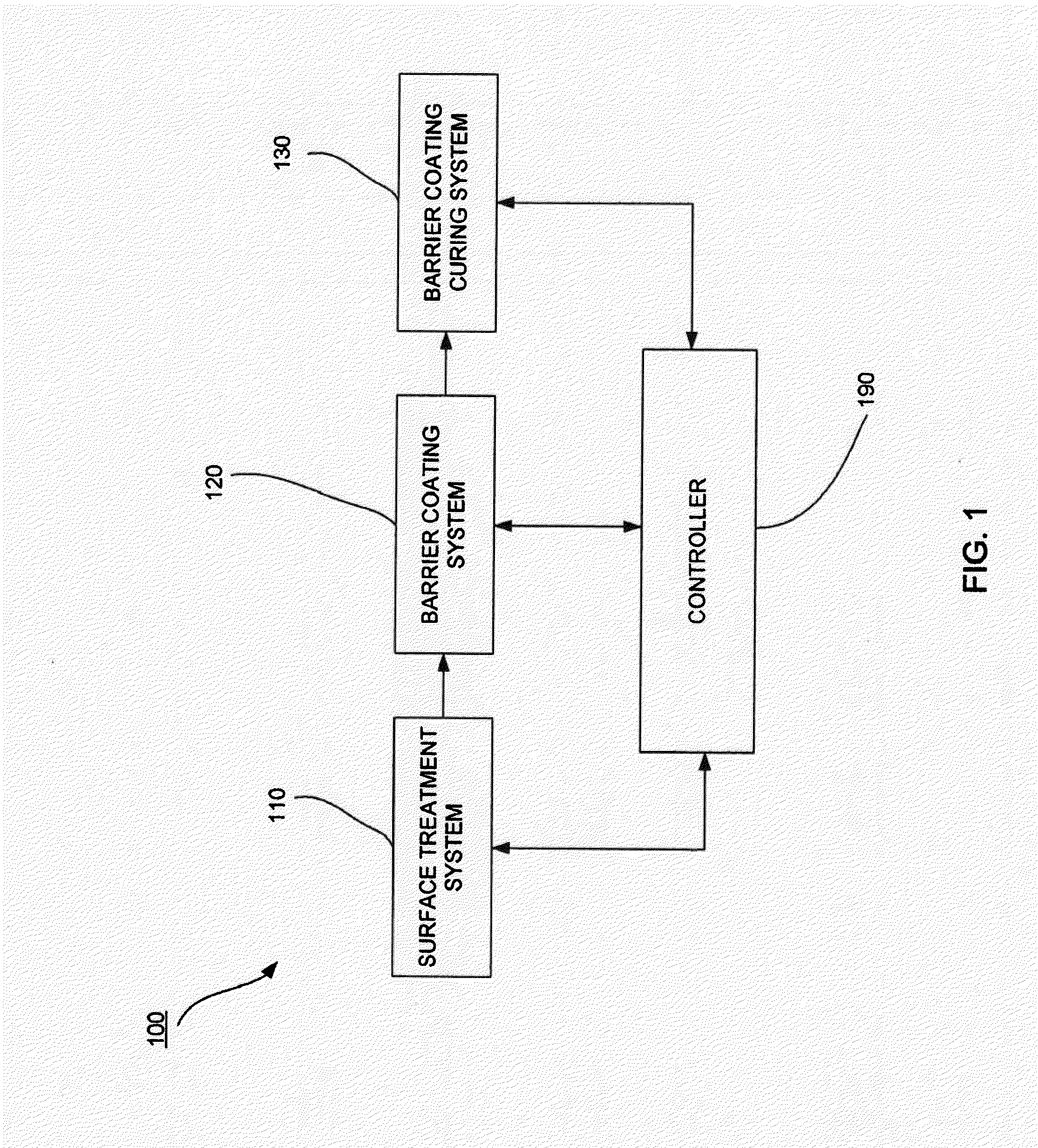

A system for synthesizing carbon nanotubes (CNT) on a fiber material includes a surface treatment system adapted to modify the surface of the fiber material to receive a barrier coating upon which carbon nanotubes are to be grown, a barrier coating application system downstream of the surface treatment system adapted to apply the barrier coating to the treated fiber material surface, and a barrier coating curing system downstream of the barrier coating application system for partially curing the applied barrier coating to enhance reception of CNT growth catalyst nanoparticles.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

Method for reducing NOx during combustion of coal in a burner

InactiveUS20060228282A1Reduce outputEasy to oxidizeNitrogen compoundsTobacco treatmentNano catalystSulfonyl halide

An organically complexed nanocatalyst composition is applied to or mixed with coal prior to or upon introducing the coal into a coal burner in order to catalyze the removal of coal nitrogen from the coal and its conversion into nitrogen gas prior to combustion of the coal. This leads to reduced NOx production during coal combustion. The nanocatalyst compositions include a nanoparticle catalyst that is made using a dispersing agent. The dispersing agent includes at least one functional group such as a hydroxyl, a carboxyl, a carbonyl, an amine, an amide, a nitrile, a nitrogen having a free lone pair of electrons, an amino acid, a thiol, a sulfonic acid, a sulfonyl halide, and an. acyl halide. The dispersing agent forms stable, dispersed, nano-sized catalyst particles. The catalyst composition can be formed as a stable suspension to facilitate storage, transportation and application of the catalyst nanoparticles to a coal material. The catalyst composition can be applied before or after pulverizing the coal material or it may be injected directly into the coal burner together with pulverized coal.

Owner:HEADWATERS TECH INNOVATION GRP

Methods for producing and using catalytic substrates for carbon nanotube growth

InactiveUS20050214197A1Efficient CatalysisMaterial nanotechnologyCarbon compoundsWater vaporNucleation

A catalyst material for carbon nanotube synthesis includes a uniform dispersion of host particles on a substrate. The host particles themselves include catalyst nanoparticles that are effective to catalyze nanotube syntheses reactions and provide nucleation sites. Methods for preparing a catalyst material includes co-sputtering a catalytic species and a host species to directly form the catalyst material. Methods for synthesizing generally aligned nanotubes are also provided. In these methods host particles comprise alumina and the catalyst nanoparticles comprise iron. Also in these methods nanotube synthesis is achieved in an atmosphere including a carbon-containing gas and water vapor.

Owner:MOLECULAR NANOSYST

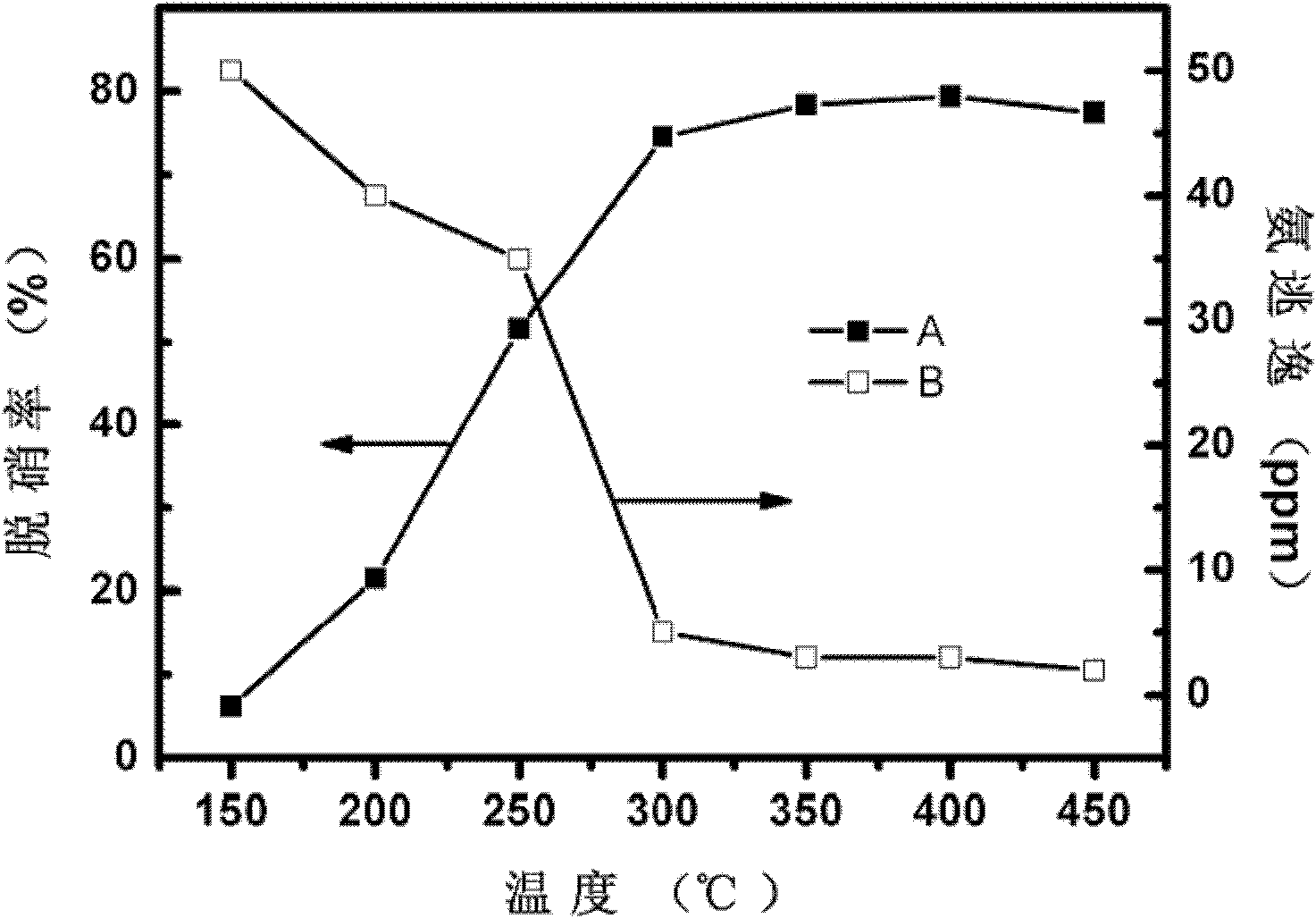

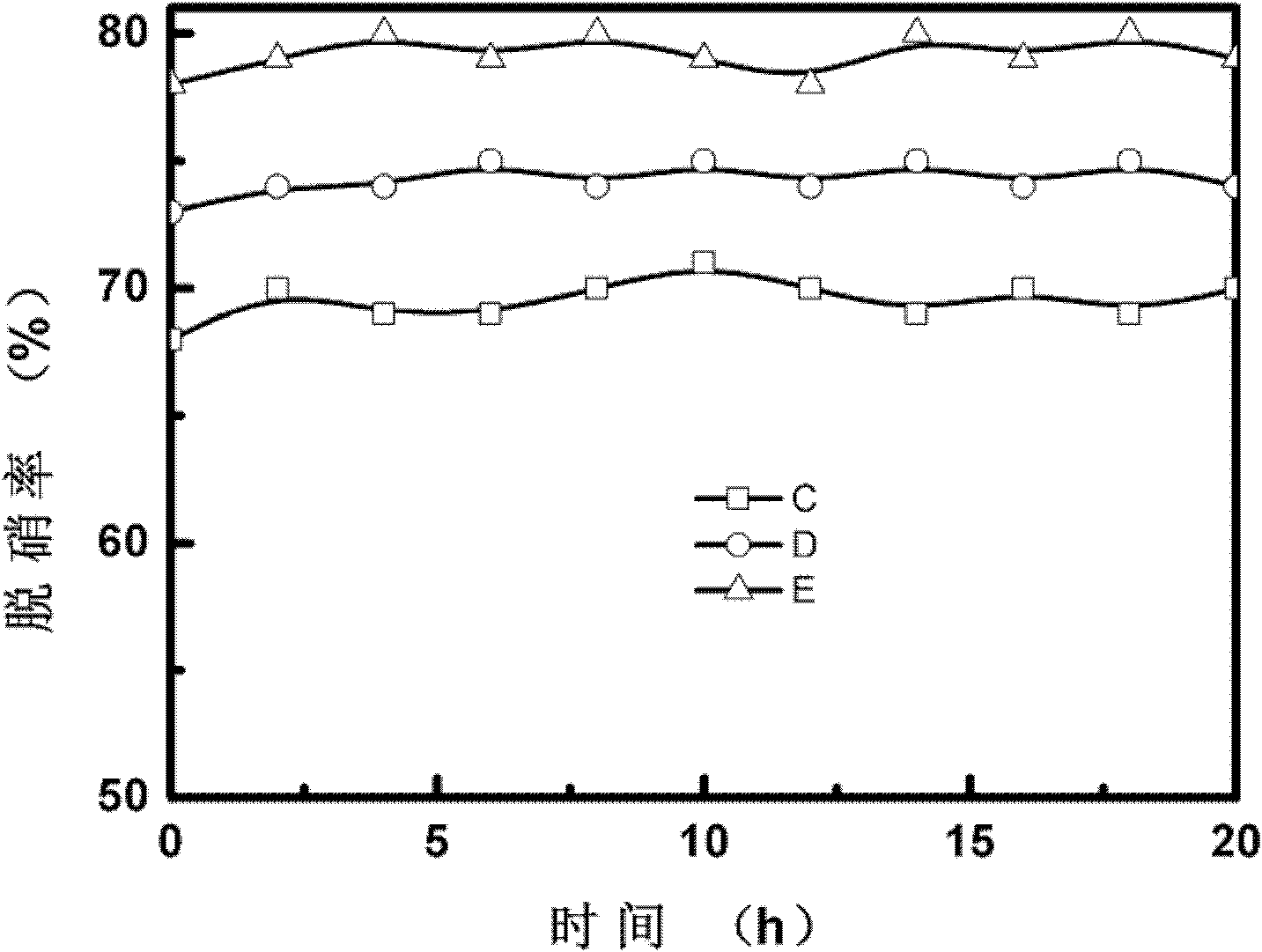

Surface deposition honeycomb flue gas denitration catalyst and preparation method thereof

ActiveCN102319559AWide active temperature windowAchieving Directional Selective LoadingDispersed particle separationCatalyst activation/preparationEnvironmental resistanceSlag

The invention relates to the environmental protection field of flue gas treatment of gas-fired boilers, in particular to a surface deposition honeycomb flue gas denitration catalyst and a preparation method thereof. The catalyst comprises a honeycomb framework which takes clay, soot dust or slag as a substrate; TiO2 is taken as an active carrier; WO3 and V2O5 serving as active ingredients are loaded on the TiO2 active carrier, and are uniformly distributed in the honeycomb framework; and the catalyst comprises the following components in percentage by weight: 60-80 percent of clay, soot dust or slag, 13-33 percent of TiO2, 1-5 percent of WO3 and 0.1-2 percent of V2O5. By transferring an ignition lost transition carrier, highly dispersion of catalyst nanoparticles on a molding catalyst pore cannel and an outer surface is realized, and the utilization ratio and catalytic activity of the active ingredients are increased greatly.

Owner:CHINA KINGSUN MATERIAL TECH

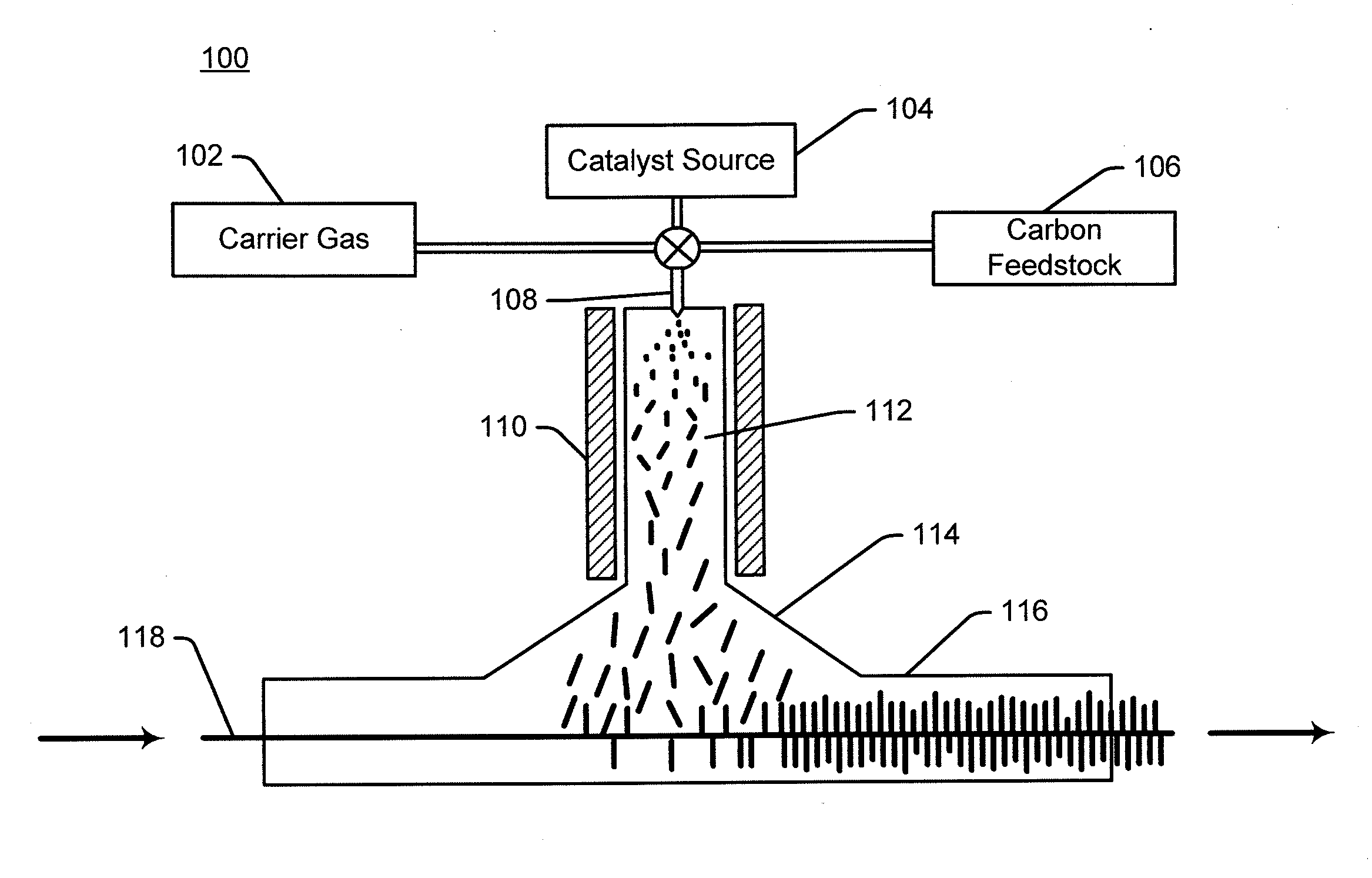

Method and apparatus for using a vertical furnace to infuse carbon nanotubes to fiber

A method for forming a CNT infused substrate comprises exposing a catalyst nanoparticle, a carbon feedstock gas, and a carrier gas to a CNT synthesis temperature, allowing a CNT to form on the catalyst nanoparticle, cooling the CNT, and exposing the cooled CNT to a surface of a substrate to form a CNT infused substrate.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

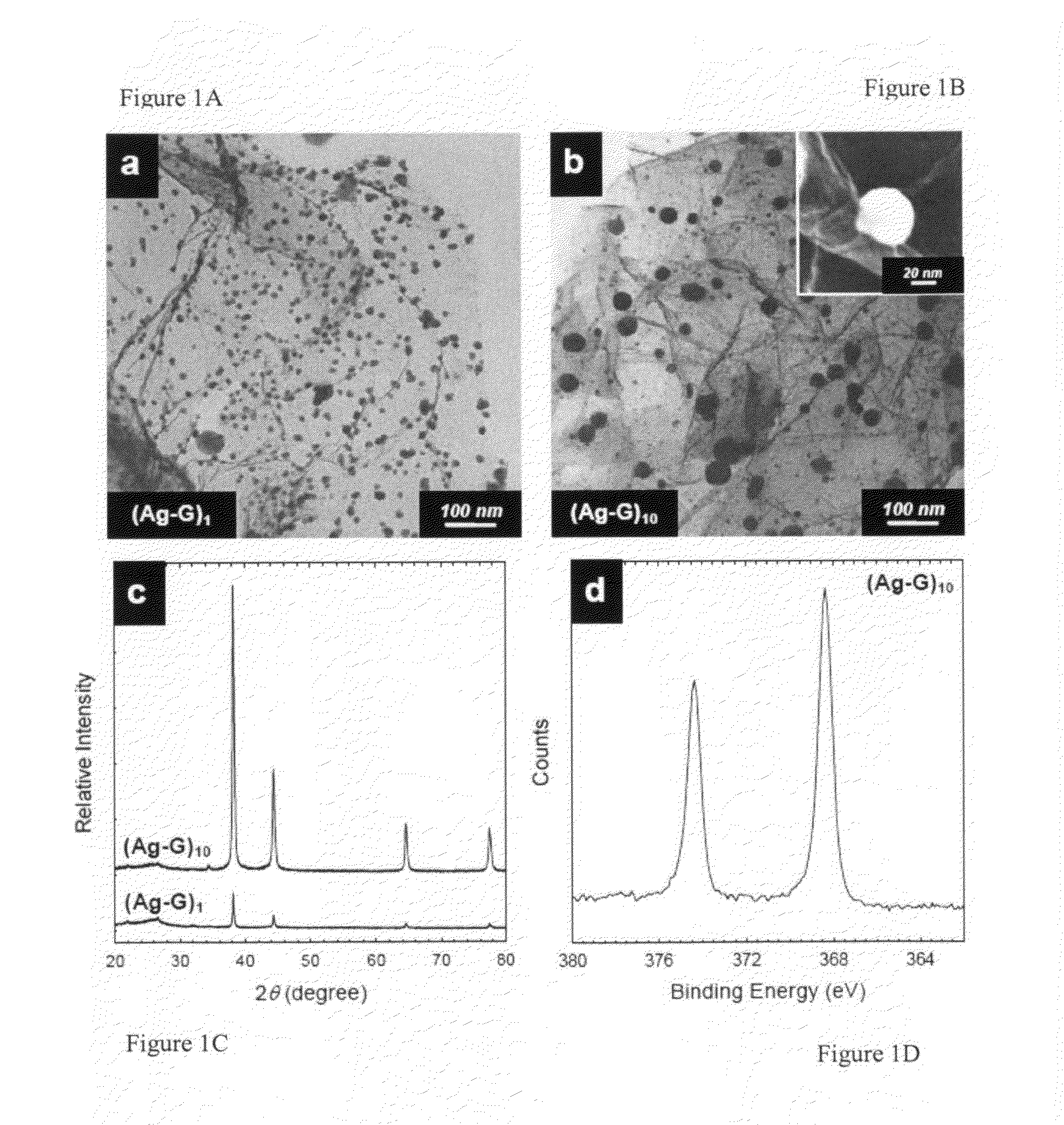

Bulk preparation of holey graphene via controlled catalytic oxidation

A scalable method allows preparation of bulk quantities of holey carbon allotropes with holes ranging from a few to over 100 nm in diameter. Carbon oxidation catalyst nanoparticles are first deposited onto a carbon allotrope surface in a facile, controllable, and solvent-free process. The catalyst-loaded carbons are then subjected to thermal treatment in air. The carbons in contact with the carbon oxidation catalyst nanoparticles are selectively oxidized into gaseous byproducts such as CO or CO2, leaving the surface with holes. The catalyst is then removed via refluxing in diluted nitric acid to obtain the final holey carbon allotropes. The average size of the holes correlates strongly with the size of the catalyst nanoparticles and is controlled by adjusting the catalyst precursor concentration. The temperature and time of the air oxidation step, and the catalyst removal treatment conditions, strongly affect the morphology of the holes.

Owner:NAT INST AEROSPACE ASSOC +1

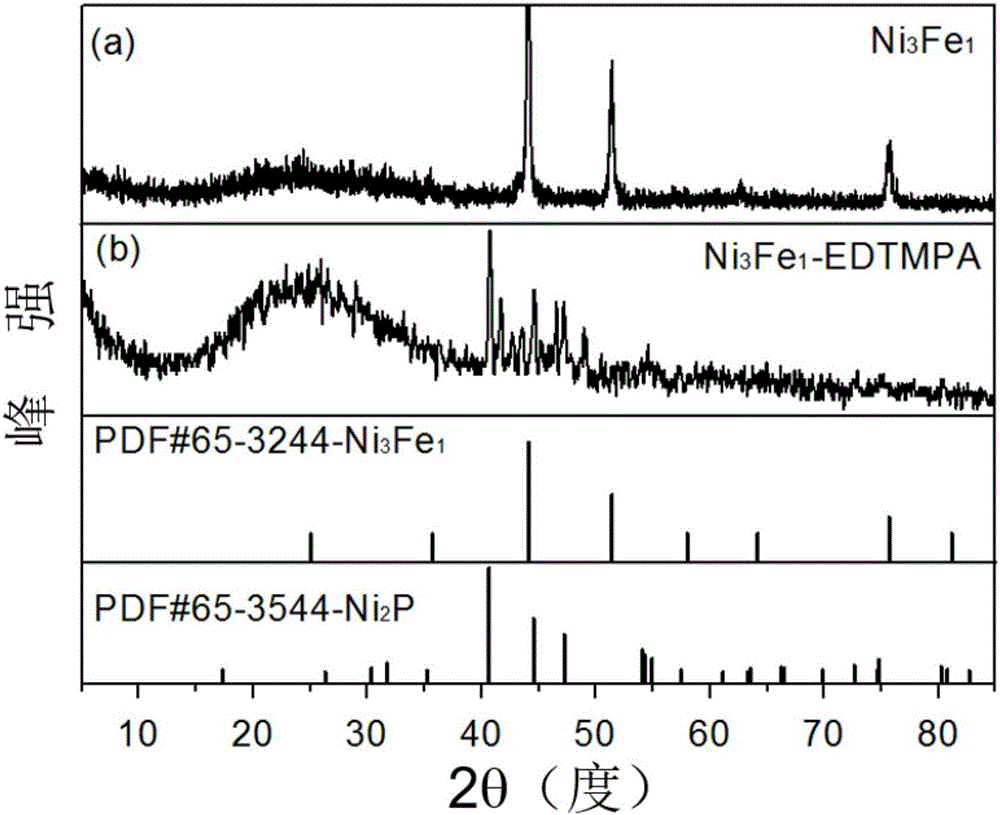

Transition metal embedded porous nitrogen-phosphorus-doped carbon material and preparation method and application thereof

ActiveCN106807427ALarge specific surface areaFully contactedPhysical/chemical process catalystsCell electrodesPhosphoric acidMetal particle

The invention provides a transition metal embedded porous nitrogen-phosphorus-doped carbon material, employing agar as a carbon source, metal ions as a fixing agent, and EDTMPA (ethylene diamine tetramethylene phosphoric acid) as a nitrogen and phosphorus source; the porous nitrogen-phosphorus-doped carbon material prepared has co-existing microscopic and mesoscopic structures and metal particles evenly distributed in a carbon carrier. Compared with the prior art, the preparation method according to the invention is simple, the cost of raw materials is low, nitrogen and phosphorus doping efficiency can be improved effectively, the specific surface area of the catalyst nanoparticles can be enlarged effectively, and the prepared porous nitrogen-phosphorus-doped carbon material has high surface active area and high graphitizing degree, is capable of increasing current intensity when the catalyst engages in catalytic reaction, and has excellent electrocatalytic activity and fast dynamical progress.

Owner:NANJING NORMAL UNIVERSITY

Formation of metal-containing nano-particles for use as catalysts for carbon nanotube synthesis

InactiveUS20100285656A1Reduce diameter sizeMassive growthMaterial nanotechnologyCarbon compoundsPorous substrateSalicide

The present invention relates to a method for forming metal-silicide catalyst nanoparticles with controllable diameter. The method according to embodiments of the invention leads to the formation of ‘active’ metal-suicide catalyst nanoparticles, with which is meant that they are suitable to be used as a catalyst in carbon nanotube growth. The nano-particles are formed on the surface of a substrate or in case the substrate is a porous substrate within the surface of the inner pores of a substrate. The metal-silicide nanoparticles can be Co-silicide, Ni-silicide or Fe-silicide particles. The present invention relates also to a method to form carbon nanotubes (CNT) on metal-silicide nanoparticles, the metal-silicide containing particles hereby acting as catalyst during the growth process, e.g. during the chemical vapour deposition (CVD) process. Starting from very defined metal-containing nanoparticles as catalysts, the diameter of grown CNT can be well controlled and a homogeneous set of CNT will be obtained.

Owner:KATHOLIEKE UNIV LEUVEN

Method for reducing NOx during combustion of coal in a burner

InactiveUS7357903B2Easy to oxidizePrevent and inhibitTobacco treatmentNitrogen compoundsNano catalystCombustor

An organically complexed nanocatalyst composition is applied to or mixed with coal prior to or upon introducing the coal into a coal burner in order to catalyze the removal of coal nitrogen from the coal and its conversion into nitrogen gas prior to combustion of the coal. This process leads to reduced NOx production during coal combustion. The nanocatalyst compositions include a nanoparticle catalyst that is made using a dispersing agent that can bond with the catalyst atoms. The dispersing agent forms stable, dispersed, nano-sized catalyst particles. The catalyst composition can be formed as a stable suspension to facilitate storage, transportation and application of the catalyst nanoparticles to a coal material. The catalyst composition can be applied before or after pulverizing the coal material or it may be injected directly into the coal burner together with pulverized coal.

Owner:HEADWATERS TECH INNOVATION GRP

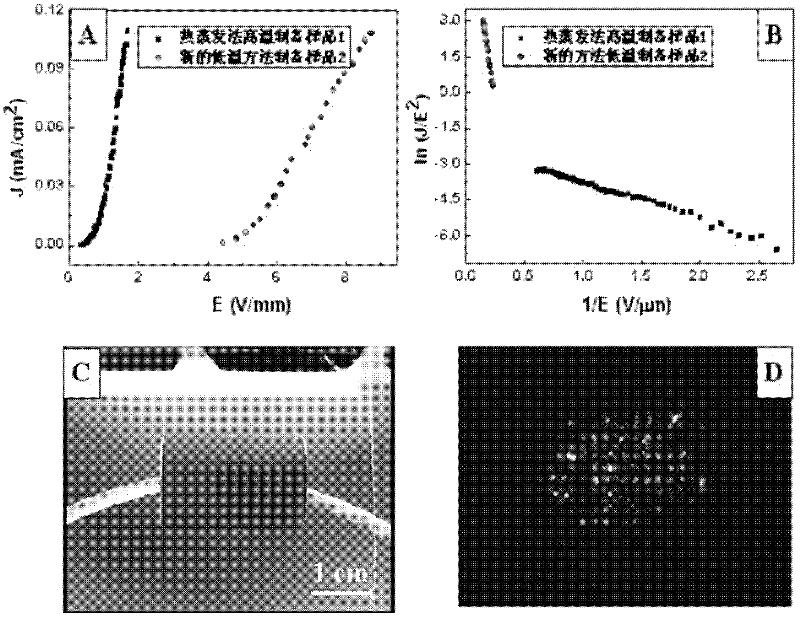

New method for synthesizing patterned single-crystal tungsten oxide nanowire arrays with catalyst localization technology

ActiveCN102358938AHigh Field Emission UniformityLow Field Emission UniformityChemical vapor deposition coatingSource materialReaction temperature

The invention discloses a new method for synthesizing patterned single-crystal tungsten oxide nanowire arrays with a catalyst localization technology. Employing a tungsten film as a source material and a metal nanoparticle film as a catalyst, the method comprises: (a) catalyst film localization synthesis: realizing film patterning through fixation of a ceramic template and a substrate material together or application of the exposure technology in a micromachining process, then enabling localization growth of the catalyst nanoparticle film in a vacuum plating instrument; (b) chemical vapor deposition: in a reaction gas atmosphere and at a temperature of 400-800DEG C, placing a W film into a CVD device for growth of 1-8h, then opening a fixation device or removing a photoresist, thus finally obtaining patterned tungsten oxide nanowire arrays. The preparation method of the invention not only can prepare patterned tungsten oxide nanowire arrays of different growth density, but also has the advantages of low reaction temperature (lower than 500DEG C) and suitability for the growth of low-melting point substrates.

Owner:SUN YAT SEN UNIV

Uniform single walled carbon nanotube network

InactiveUS20060194058A1Material nanotechnologyLayered productsChemical functionalizationCatalyst nanoparticles

An apparatus (50) and method is provided for growing a network of common diameter nanotubes (24). The apparatus comprises chemically functionalizing a portion (16) of a substrate (12); anchoring catalyst nanoparticles (22), each having substantially the same diameter, on the portion (16) of the substrate (12); and growing overlapping carbon nanotubes (24), each having substantially the same diameter, on the catalyst nanoparticles (22).

Owner:MOTOROLA INC

Controlled and selective formation of catalyst nanaoparticles

InactiveUS20090131245A1Accurate locationEasy to manufactureMaterial nanotechnologyCarbon compoundsNanostructureCatalyst nanoparticles

A method for forming catalyst nanoparticles on a substrate and a method for forming elongate nanostructures on a substrate using the nanoparticles as a catalyst are provided. The methods may advantageously be used in, for example, semiconductor processing. The methods are scalable and fully compatible with existing semiconductor processing technology. Furthermore, the methods allow forming catalyst particles and elongate nanostructures at predetermined locations on a substrate.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Vertically aligned nanostructure scanning probe microscope tips

InactiveUS20050103993A1Material analysis using wave/particle radiationNanosensorsComputational physicsCarbon nanofiber

Methods and apparatus are described for cantilever structures that include a vertically aligned nanostructure, especially vertically aligned carbon nanofiber scanning probe microscope tips. A method includes A method, includes fabricating a cantilever structure having a vertically aligned nanostructure including: forming a doped layer at a first side of a substrate; depositing an etch mask layer on a second side of the substrate; forming a plurality of alignment marks that are coupled to the first side of the substrate; depositing a catalyst nanoparticle at a deterministic site that is coupled to the doped layer; growing the vertically aligned nanostructure at the deterministic site with the catalyst nanoparticle; depositing a first protective layer that surrounds at least a portion of the vertically aligned nanostructure; patterning the first protective layer to define an outline of a cantilever body; transferring the outline of the cantilever body from the first protective layer into the doped layer to form the cantilever body from the doped layer; depositing a second protective layer that coats at least a portion of a surface of the cantilever body; patterning the etch mask layer to define an outline of a relieved volume; transferring the outline of the relieved volume from the etch mask layer into the second side of the substrate to remove the relieved volume from the substrate, where the cantilever body is not removed.

Owner:UT BATTELLE LLC

Carbon nanofibers containing catalyst nanoparticles

InactiveUS20110171565A1Efficient and cost-effectiveSmall fiber diameterMaterial nanotechnologyActive material electrodesFiberCarbon fibers

The invention relates a method for synthesizing carbon nanofibers containing catalytic material particles characterized in that it comprises the following steps:a) electrospinning a polymer solution and a catalytic material precursor for obtaining polymer fibers containing catalytic material precursor particles,b) reducing the product obtained in a) with a reducing agent to form polymer fibers containing catalytic material particles,c) heat treating the product obtained in b) for converting the polymer fibers containing catalytic material particles into carbon fibers containing catalytic material particles.The invention also relates to the intermediate products and products obtained by this method and use of these in various applications.

Owner:SABANCI UNIVERSITY +1

Heat treatment of anchored nanocatalysts in a non-zero oxidation state and catalysts made by such method

InactiveUS20060160695A1High activityImprove stabilityMaterial nanotechnologyMolecular sieve catalystsNano catalystSulfonyl halide

A catalyst manufacturing process includes heat treating an intermediate catalyst composition that includes catalyst nanoparticles having catalyst atoms in a non-zero oxidation state bonded to a dispersing / anchoring agent. The catalyst nanoparticles are formed using a dispersing agent having at least one functional group selected from the group of a hydroxyl, a carboxyl, a carbonyl, an amide, an amine, a thiol, a sulfonic acid, sulfonyl halide, an acyl halide, an organometallic complex, and combinations of these. The dispersing agent can be used to form single- or multicomponent supported nanocatalysts. The dispersing agent also acts as an anchoring agent to firmly bond the nanocatalyst to a support. Performing the heat treating process in an inert or oxidative environment to maintain the catalyst atoms in a non-zero oxidation helps maintains a stronger bonding interaction between the dispersing agent and the catalyst atoms. This, in turn, increases the dispersion and / or distribution of catalyst components throughout the supported catalyst.

Owner:HEADWATERS TECH INNOVATION GRP

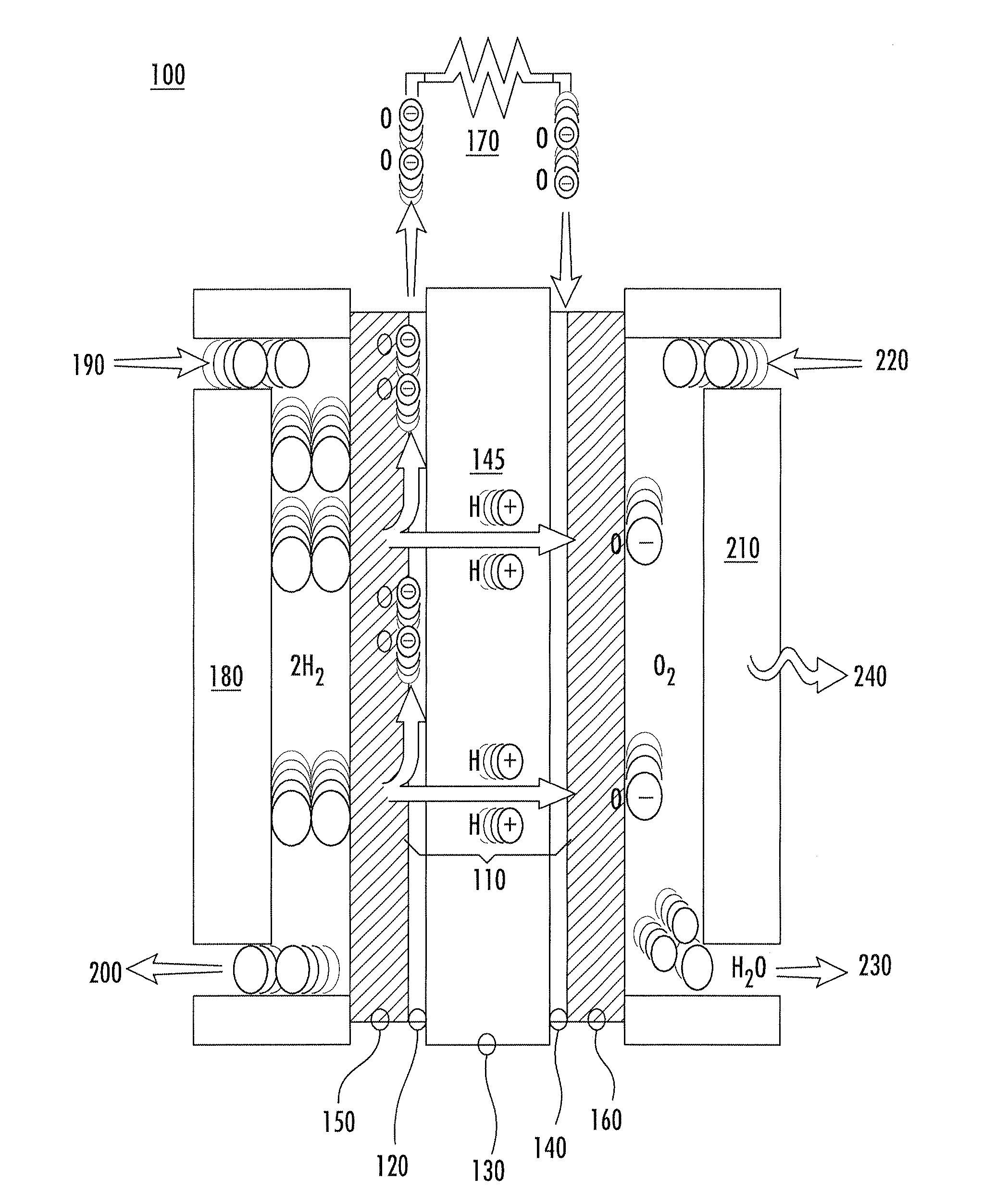

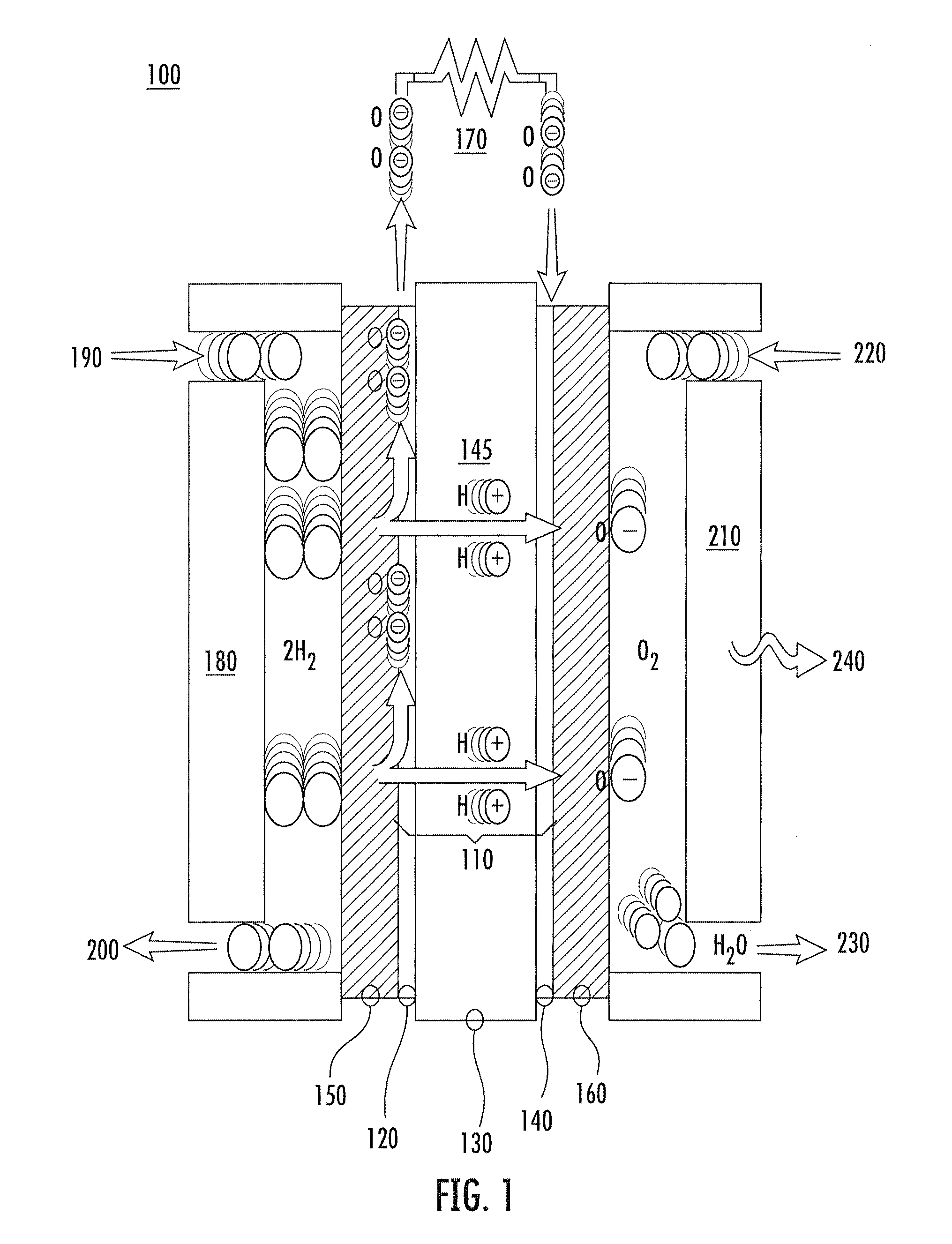

Catalytic electrode with gradient porosity and catalyst density for fuel cells

A membrane electrode assembly (110) for a fuel cell (100) comprising a gradient catalyst structure (120 or 140) and a method of making the same. The gradient catalyst structure (120 or 140) can include a plurality of catalyst nanoparticles, e. g. , platinum, disposed on layered buckypaper. The layered buckypaper can include at least a first layer and a second layer and the first layer can have a lower porosity compared to the second layer. The gradient catalyst structure (120 or 140) can include single-wall nanotubes, carbon nanofibers, or both in the first layer of the layered buckypaper and can include carbon nanofibers in the second layer of the layered buckypaper. The membrane electrode assembly (110) can have a catalyst utilization efficiency of at least 0. 35 gcat / kW or less.

Owner:FLORIDA STATE UNIV RES FOUND INC

Methods and Systems for Forming a Hydrocarbon Product

InactiveUS20160016862A1Improve conversion efficiencyInexpensive and simple to operateHydrocarbon from carbon oxidesCatalyst activation/preparationNanofiberCarbon oxide

A method of forming a hydrocarbon product comprises reacting at least one carbon oxide and at least one lower hydrocarbon in the presence of a plurality of catalyst-containing structures each comprising a nanofiber bound to at least one catalyst nanoparticle to form at least one higher hydrocarbon. Other methods of forming a hydrocarbon are also disclosed, as is a system forming a hydrocarbon product.

Owner:SEERSTONE

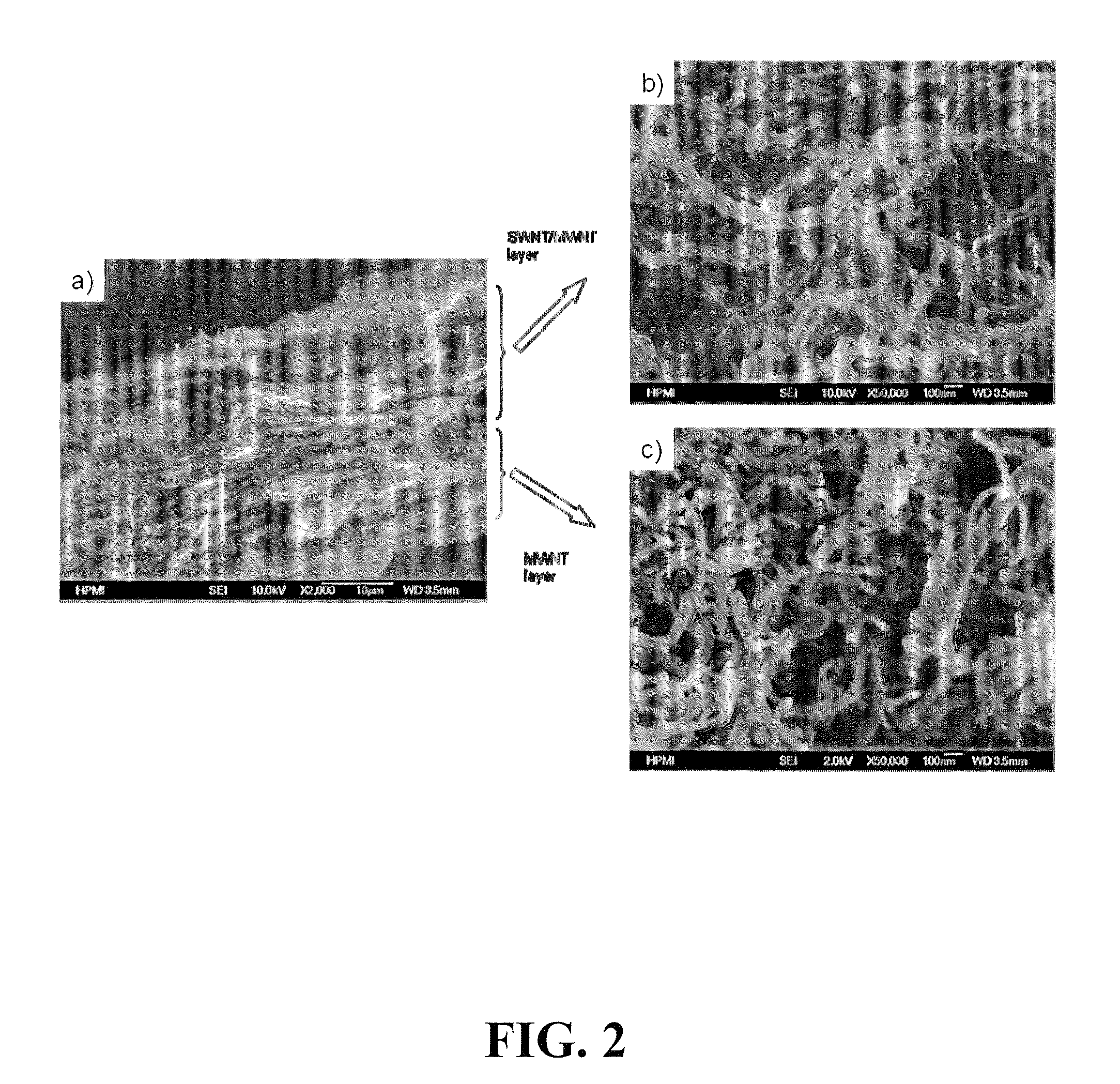

Carbon nanotube and nonofiber film-based membrane electrode assemblies

ActiveUS20100143822A1Improving electrical and mechanical propertyHigh rateMaterial nanotechnologyFinal product manufactureBuckypaperPlatinum

A membrane electrode assembly (MEA) for a fuel cell comprising a catalyst layer and a method of making the same. The catalyst layer can include a plurality of catalyst nanoparticles, e.g., platinum, disposed on buckypaper. The catalyst layer can have 1% or less binder prior to attachment to the membrane electrode assembly. The catalyst layer can include (a) single-wall nanotubes, small diameter multi-wall nanotubes, or both, and (b) large diameter multi-wall nanotubes, carbon nanofibers, or both. The ratio of (a) to (b) can range from 1:2 to 1:20. The catalyst layer can produce a surface area utilization efficiency of at least 60% and the platinum utilization efficiency can be 0.50 gPt / kW or less.

Owner:FLORIDA STATE UNIV RES FOUND INC

Methods of manufacturing fuel cell electrodes incorporating highly dispersed nanoparticle catalysts

InactiveUS20070060471A1Improve catalytic stabilityFunction increaseMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsFuel cellsSolvent

Nanoparticle catalysts are manufactured by first preparing a solution of a solvent and a plurality of complexed catalyst atoms. Each of the complexed catalyst atoms has at least three organic ligands. The complexed catalyst atoms are reduced to form a plurality of nanoparticles. During formation of the nanoparticles, the organic ligands provide spacing between the catalyst atoms via steric hindrances and / or provide interactions with a support material. The spacing and interactions with the support material allow formation of small, stable, and uniform nanoparticles. The supported nanoparticle catalyst is then incorporated into a fuel cell electrode.

Owner:HEADWATERS TECH INNOVATION GRP

System and method for surface treatment and barrier coating of fibers for in situ cnt growth

ActiveUS20140154412A1Easy to receiveMaterial nanotechnologyLiquid surface applicatorsFiberCatalyst nanoparticles

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com