Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1507 results about "Reactor system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080216391A1Organic compound preparationHydrocarbon from oxygen organic compoundsFuranLiquid fuel

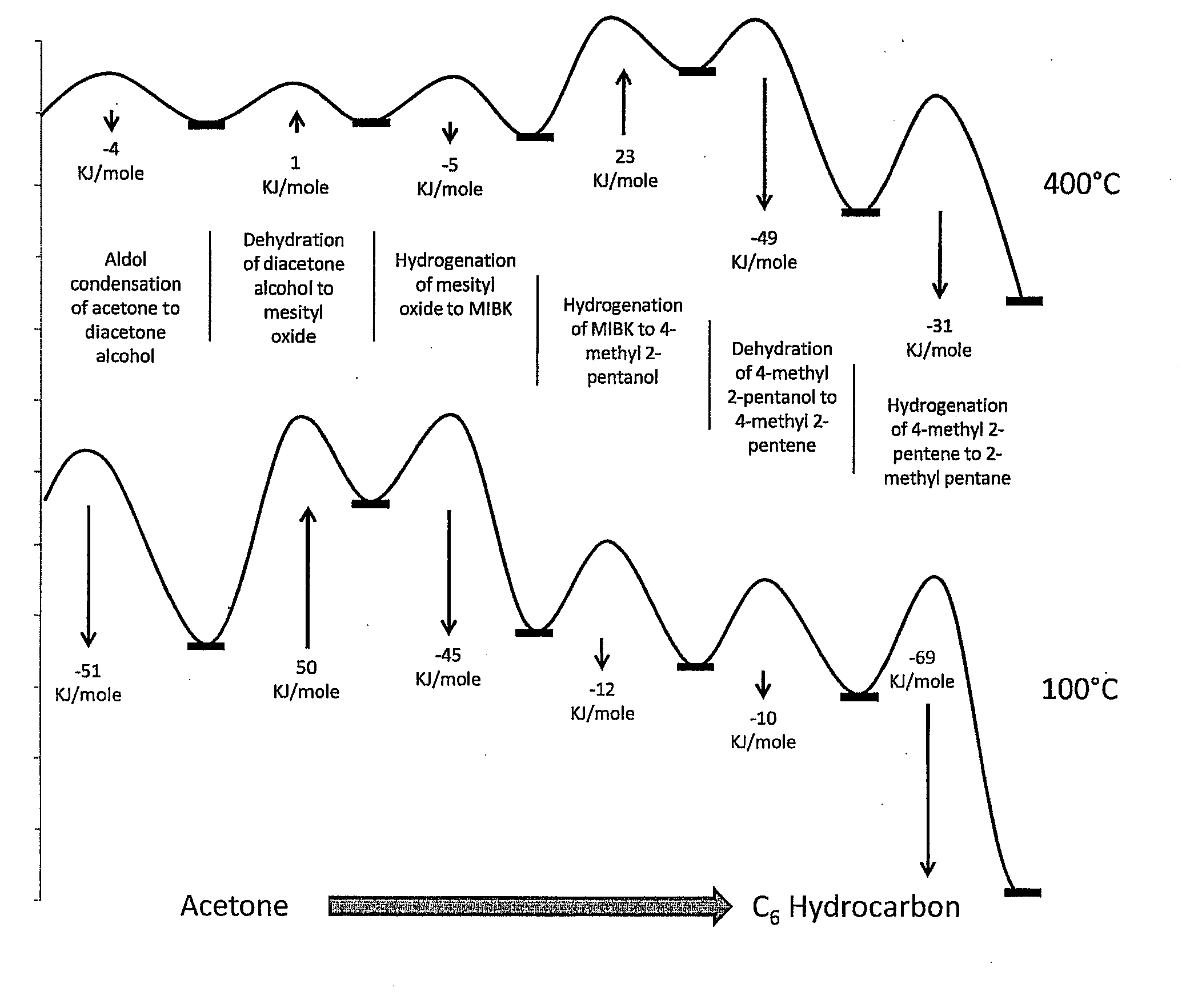

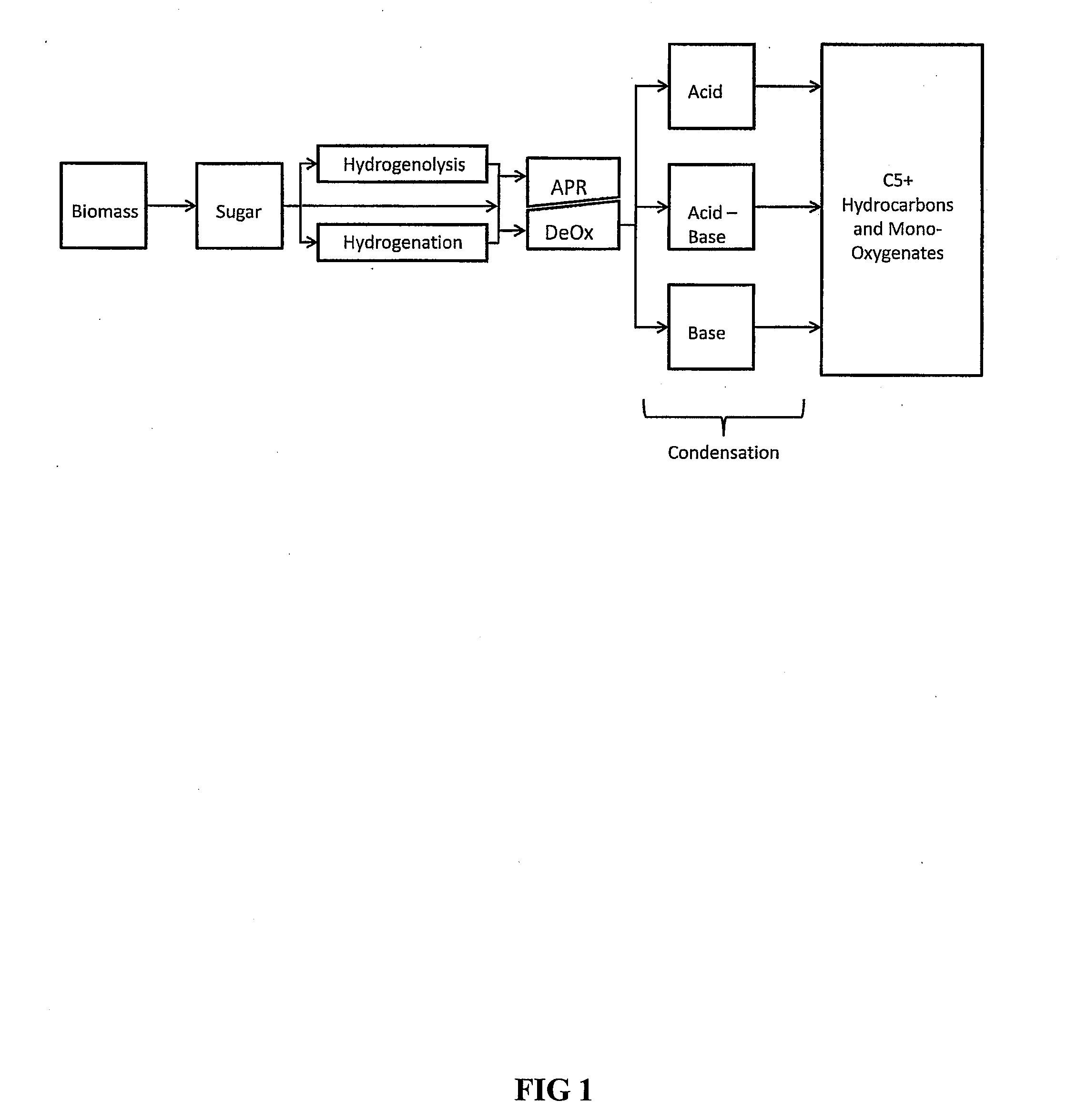

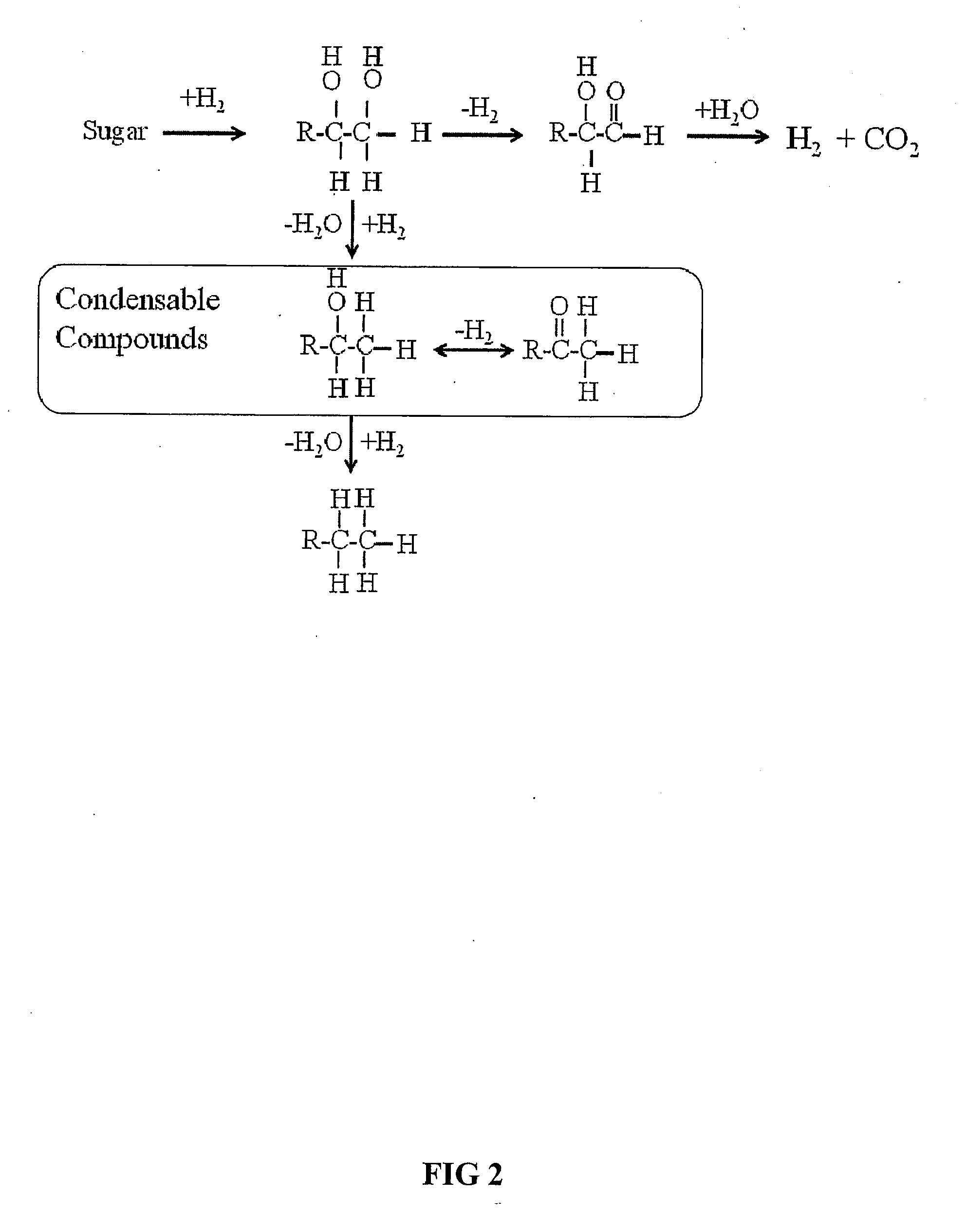

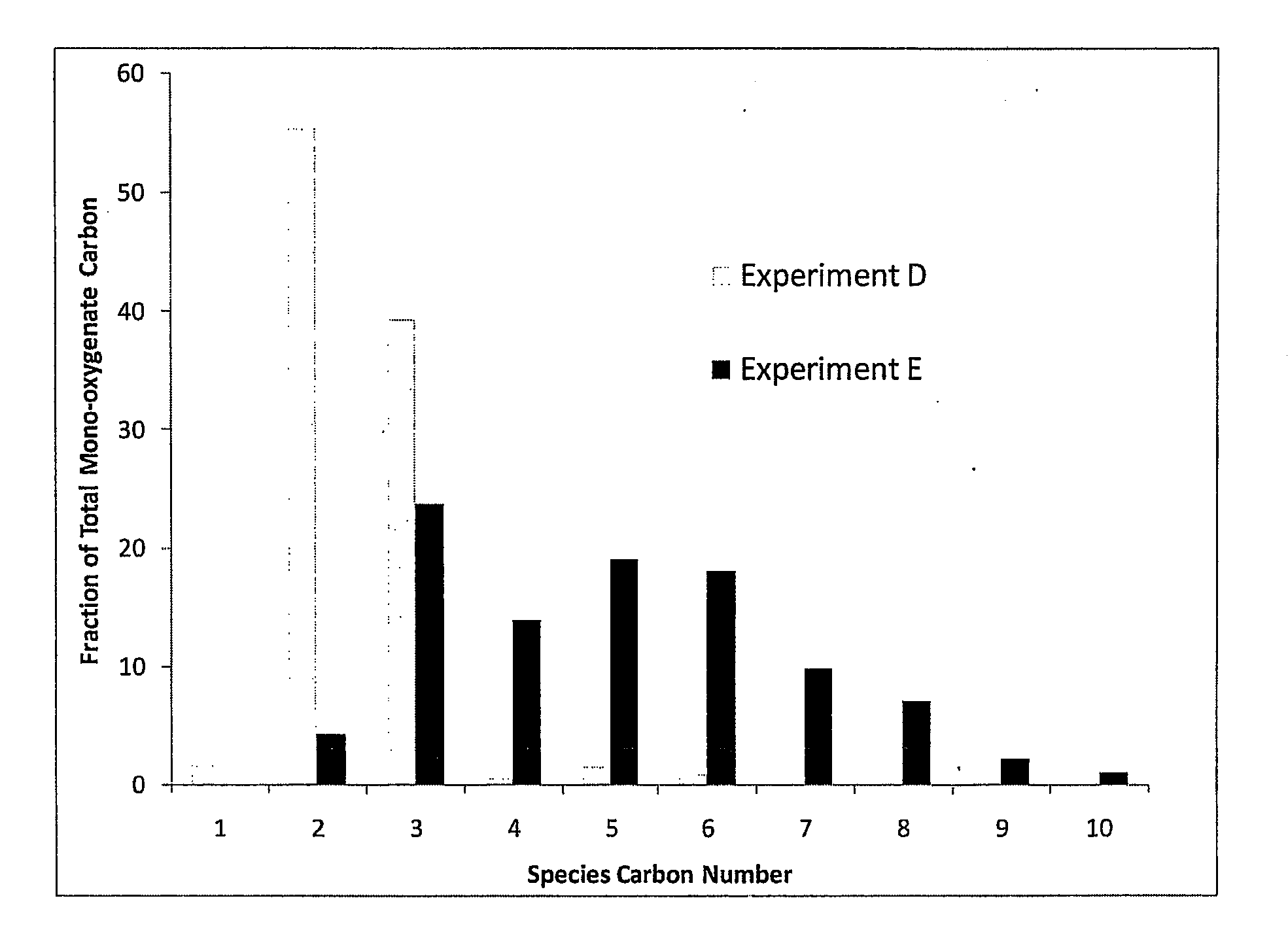

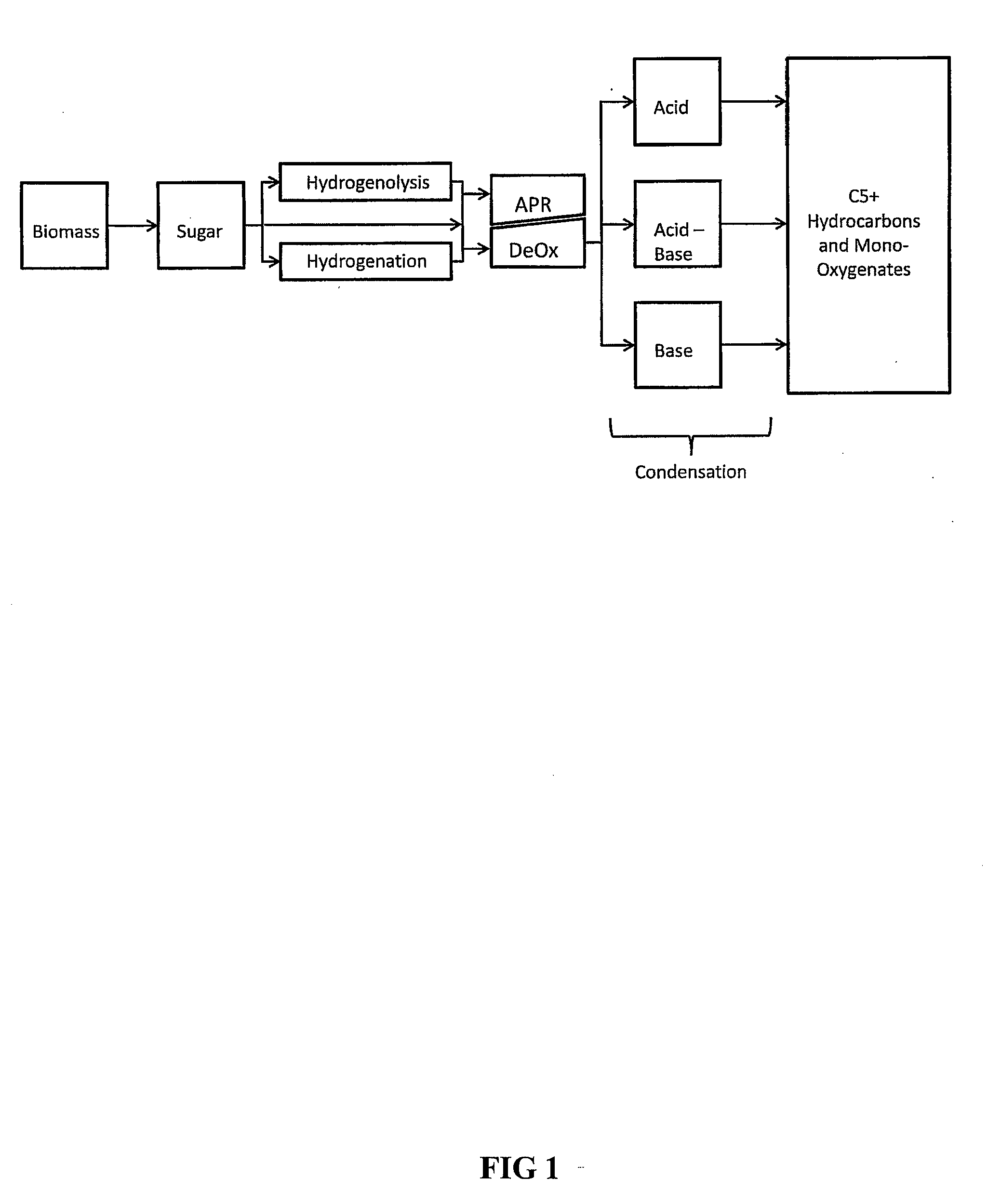

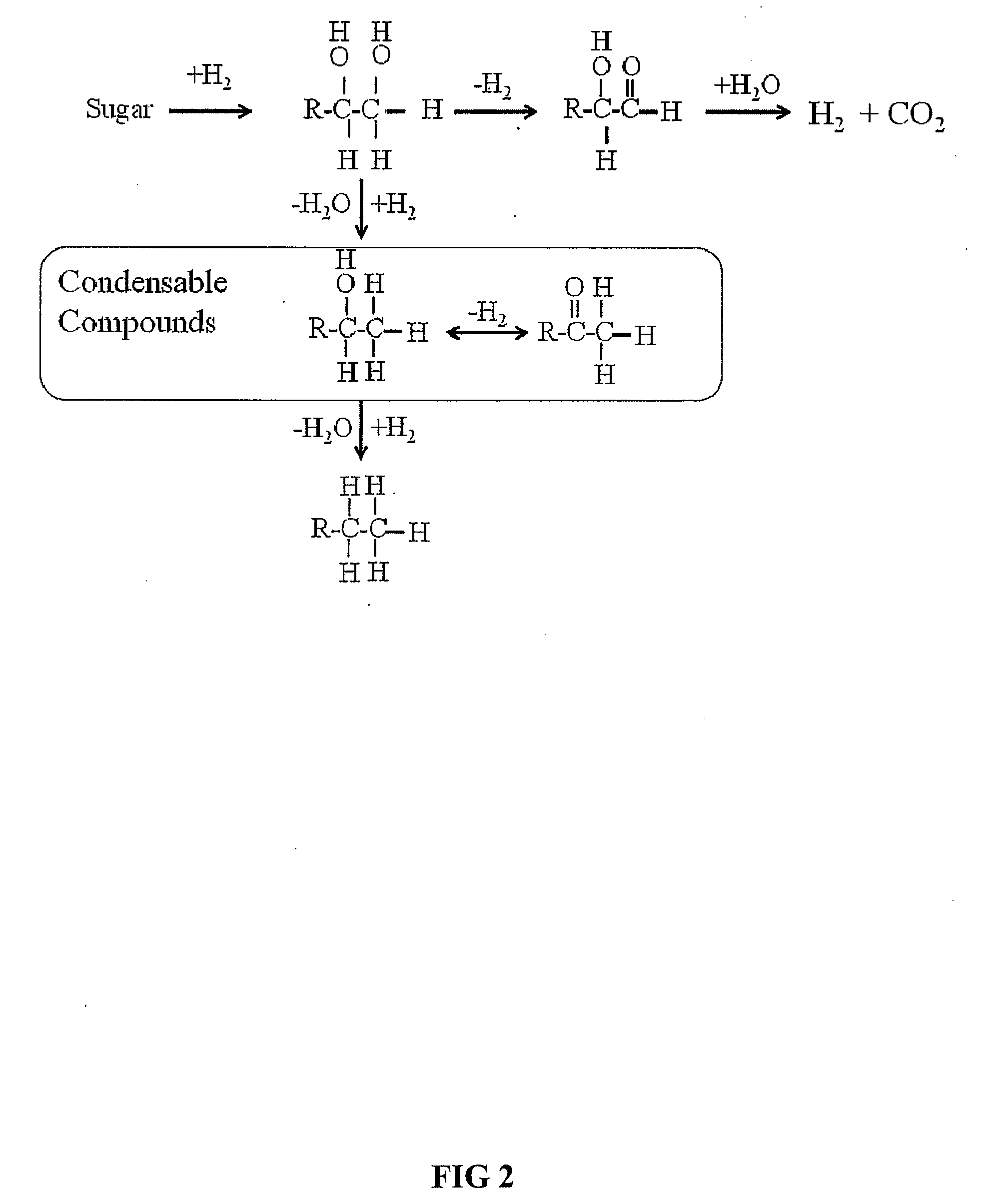

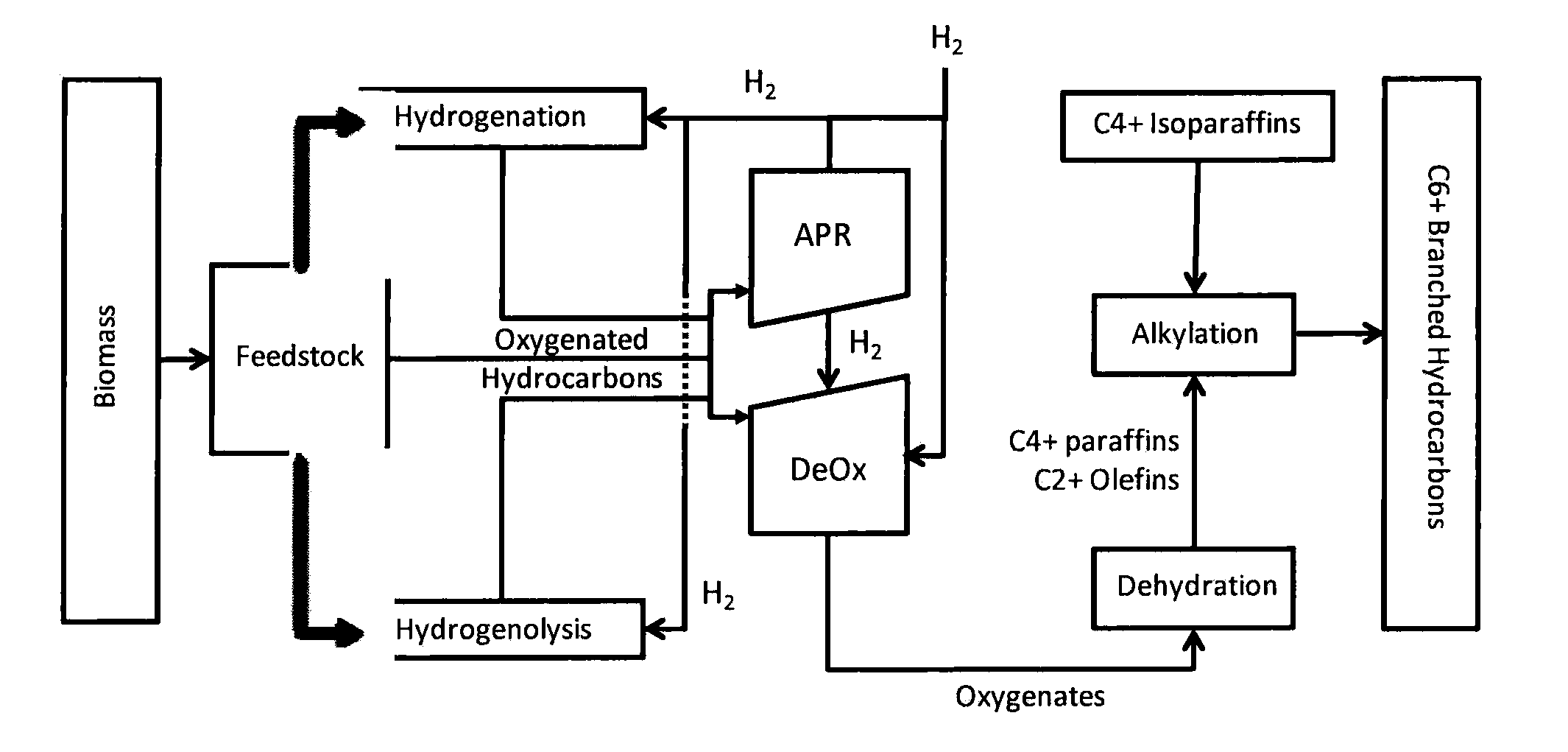

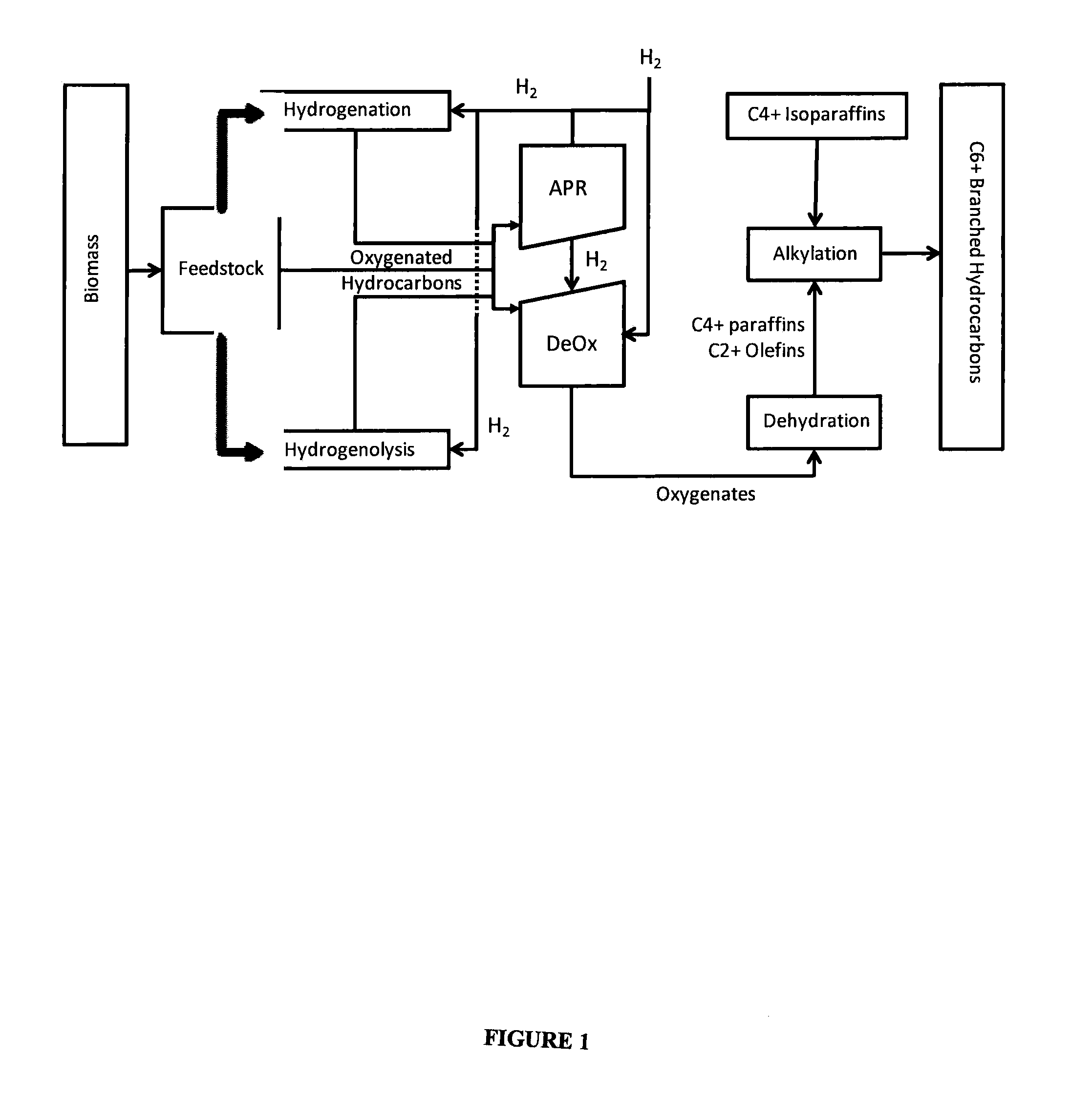

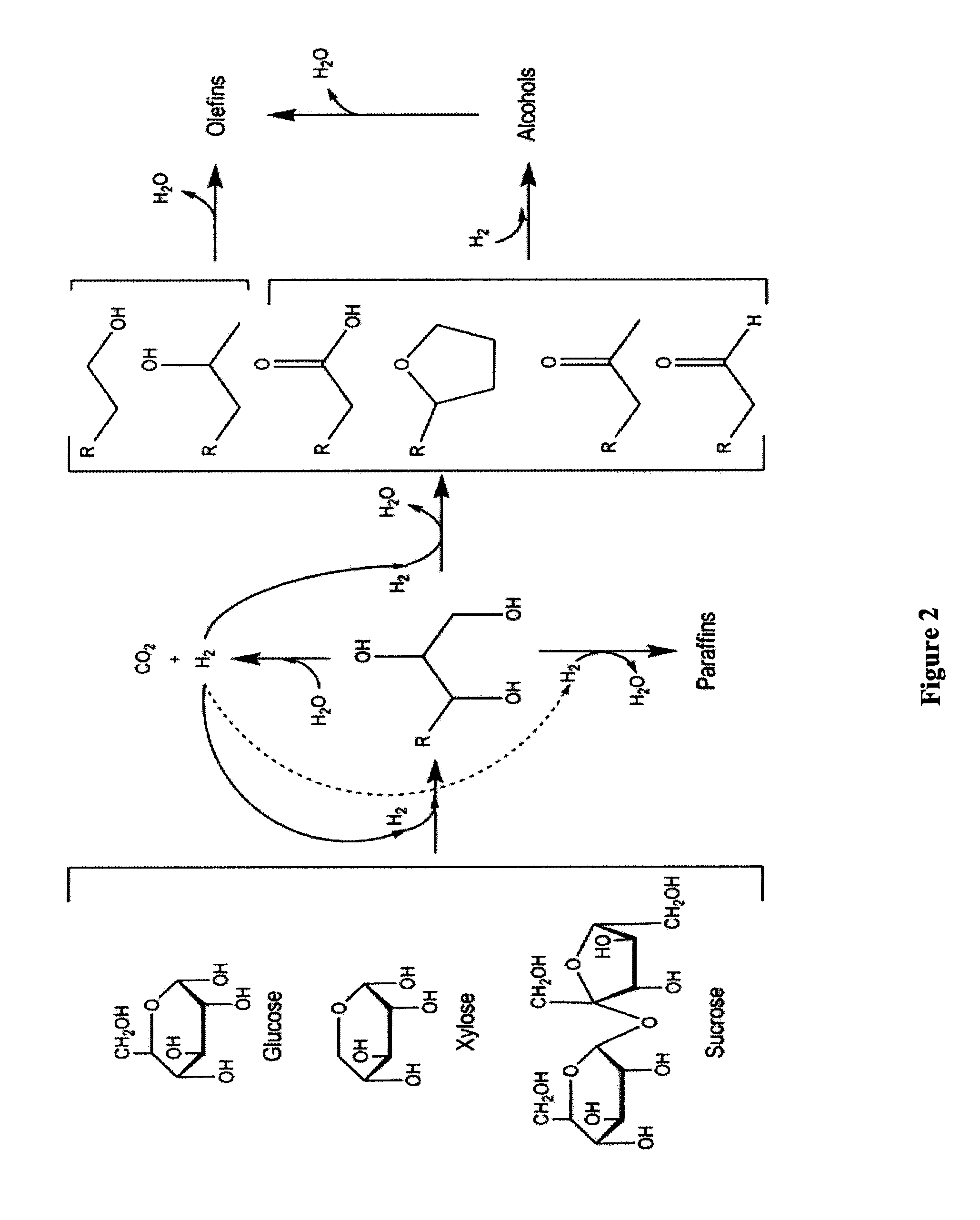

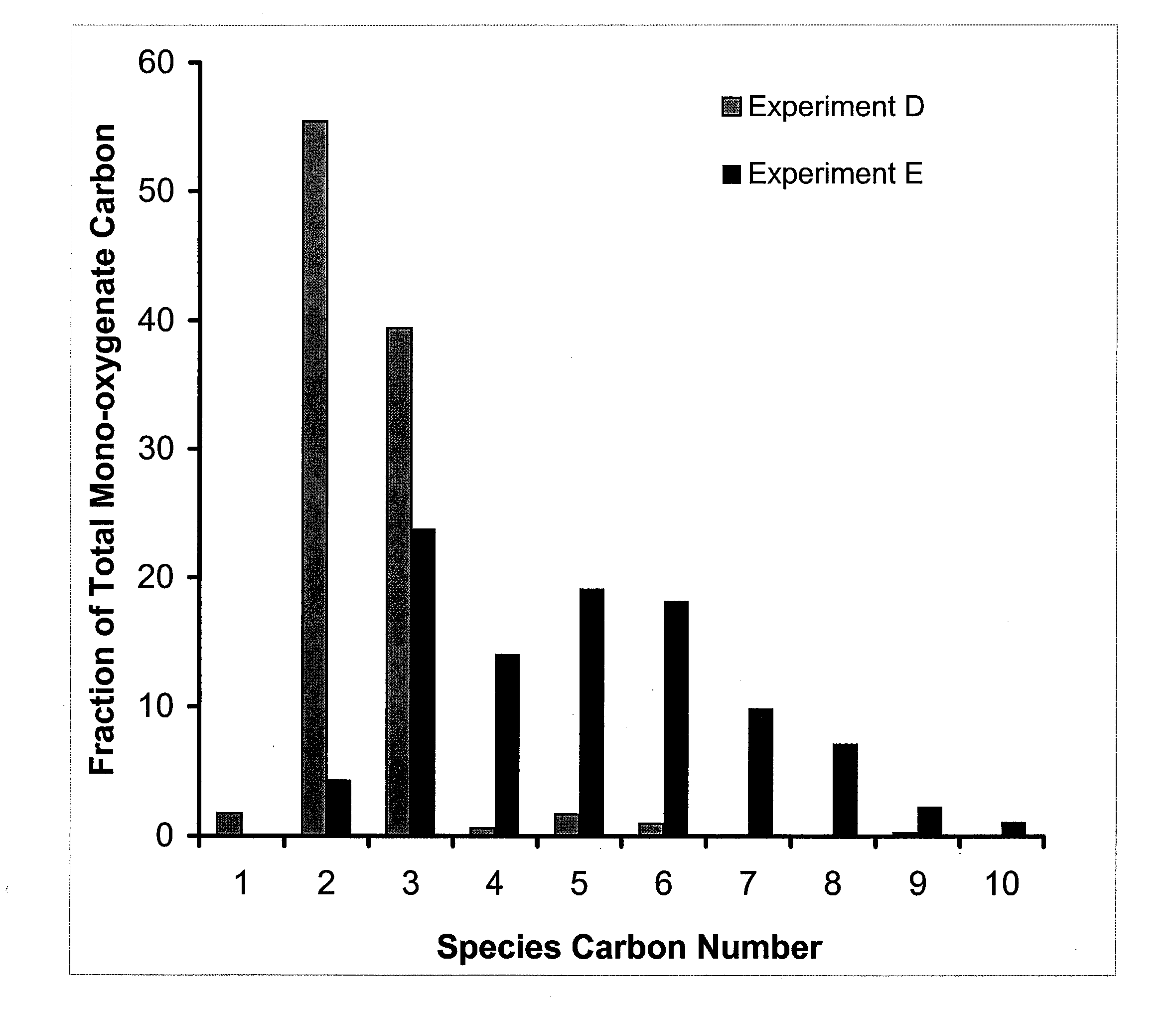

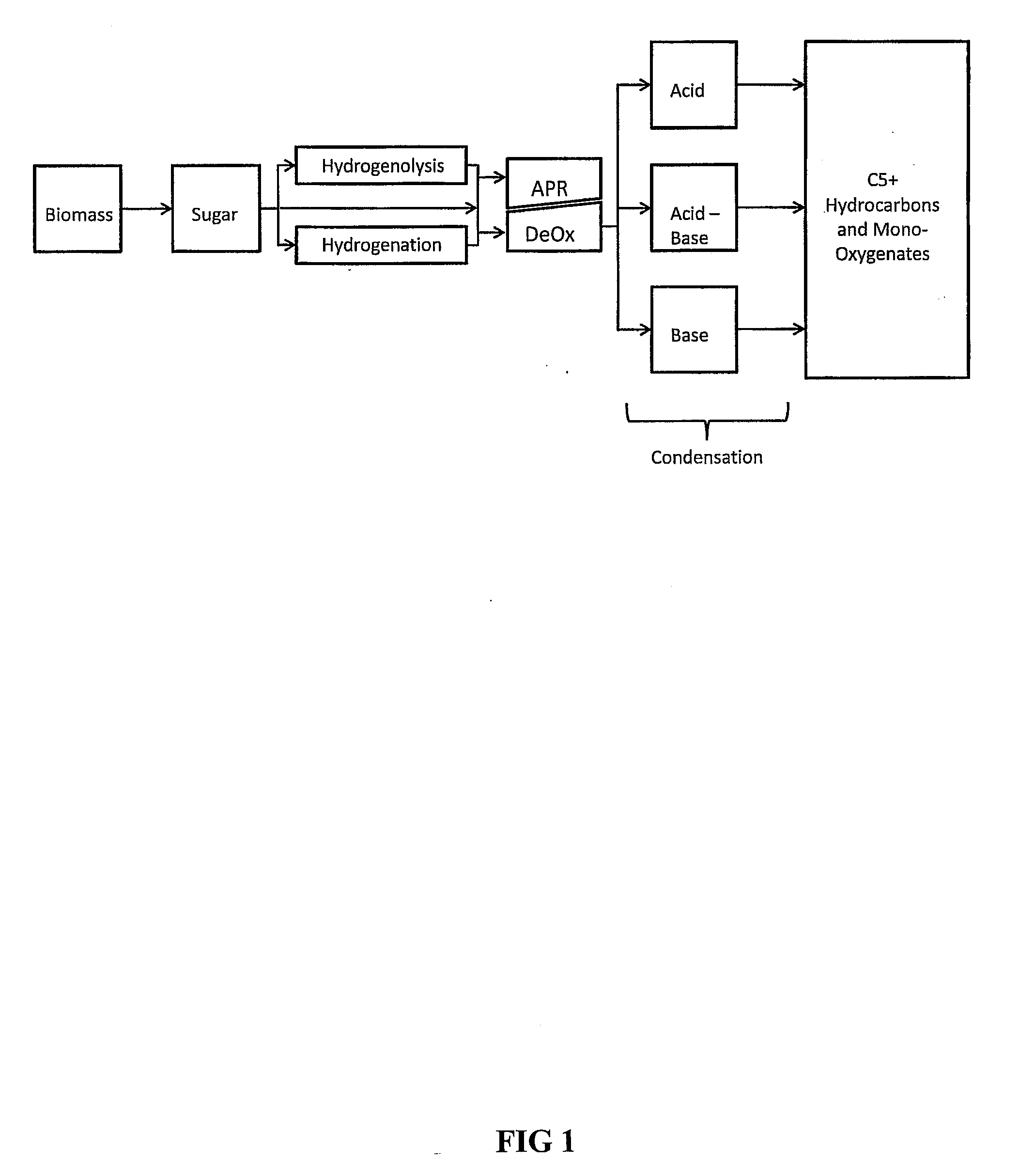

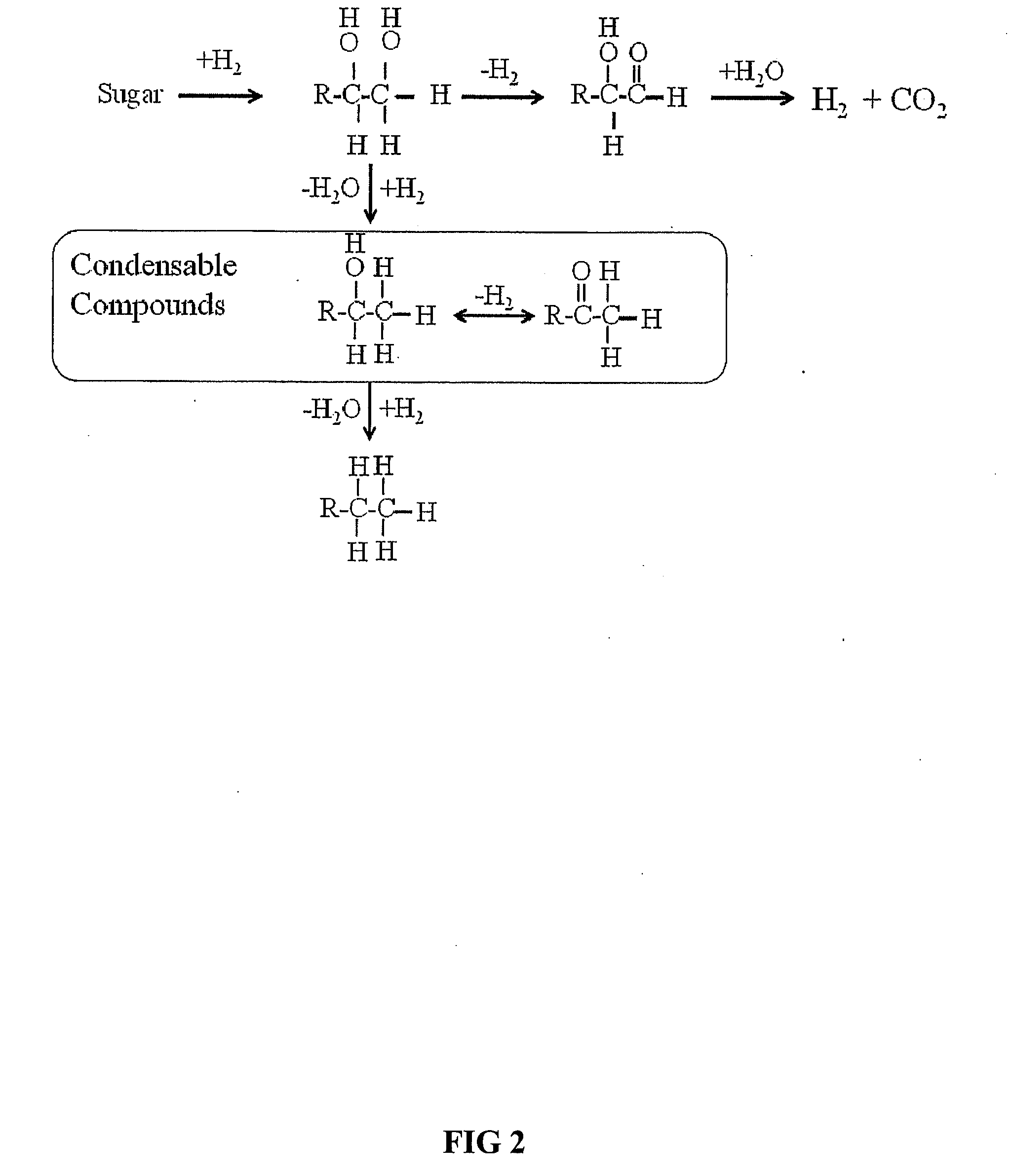

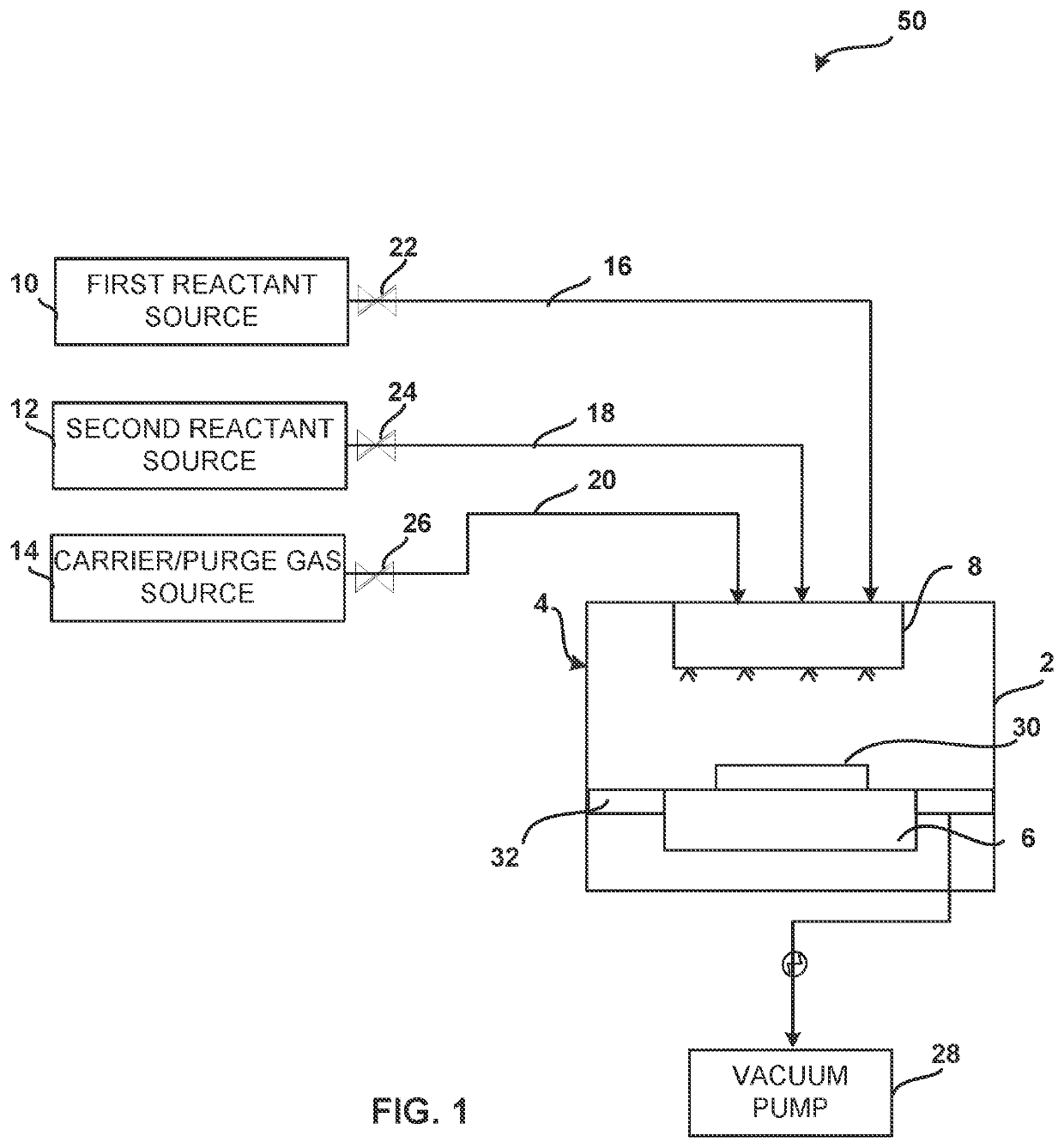

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

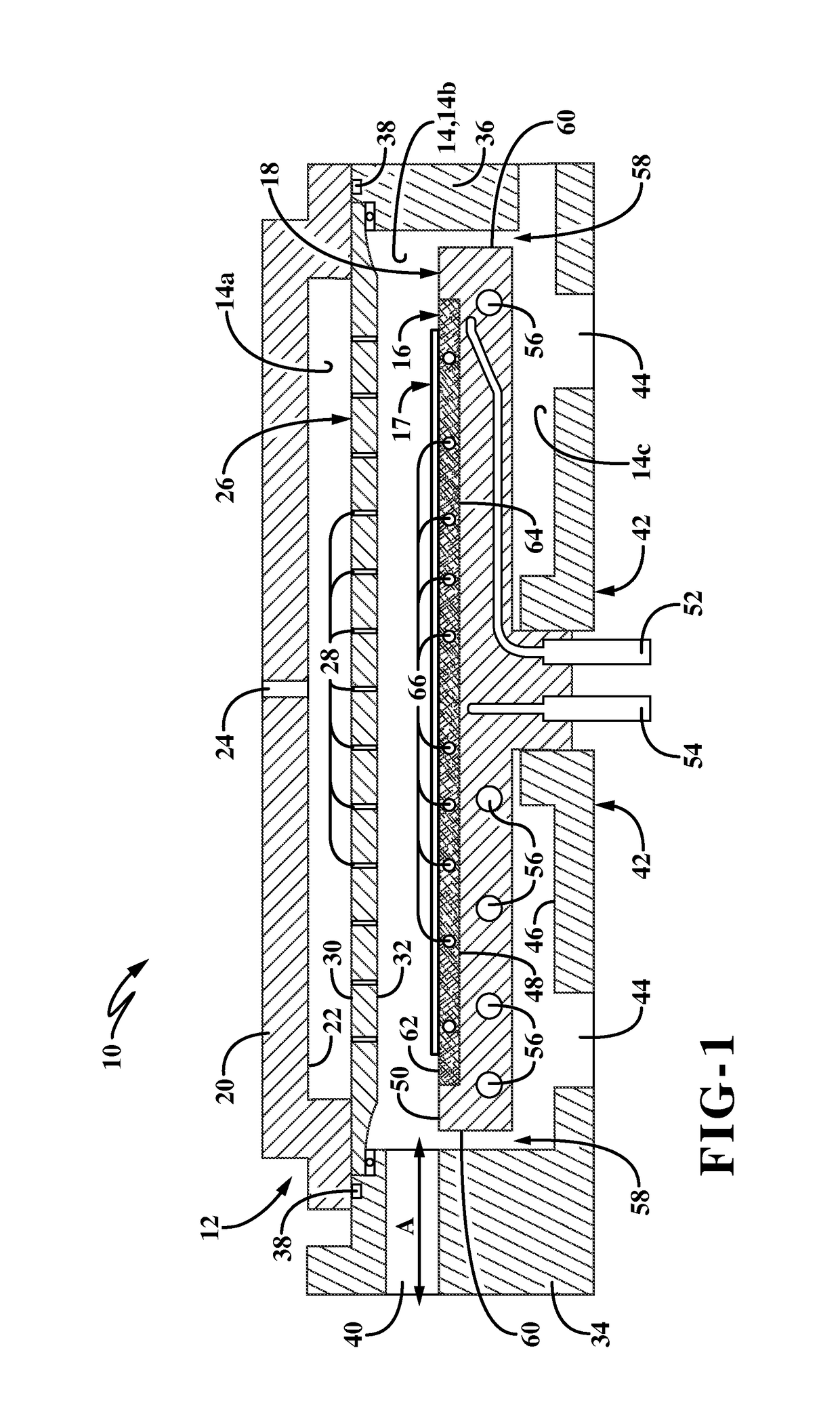

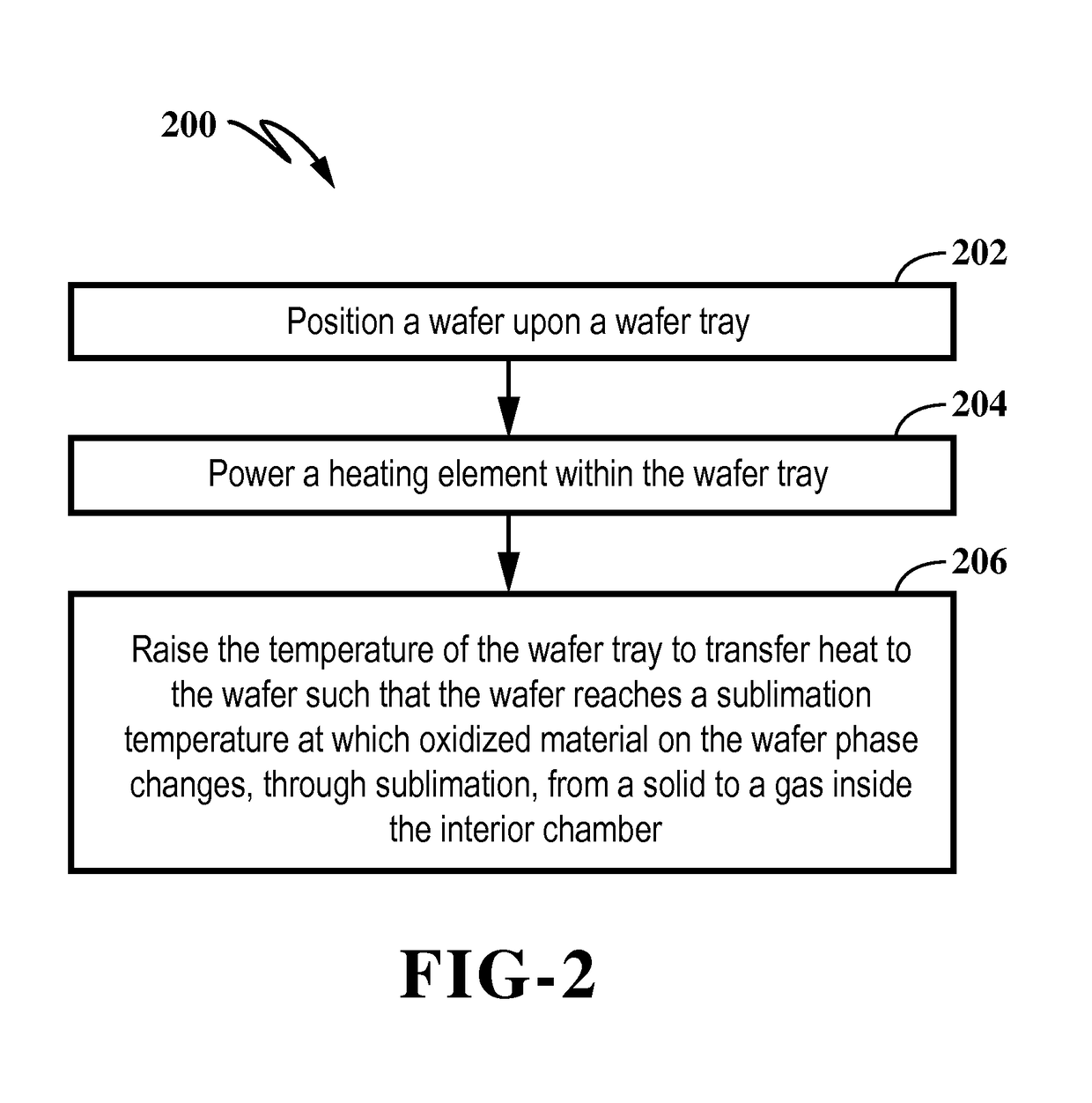

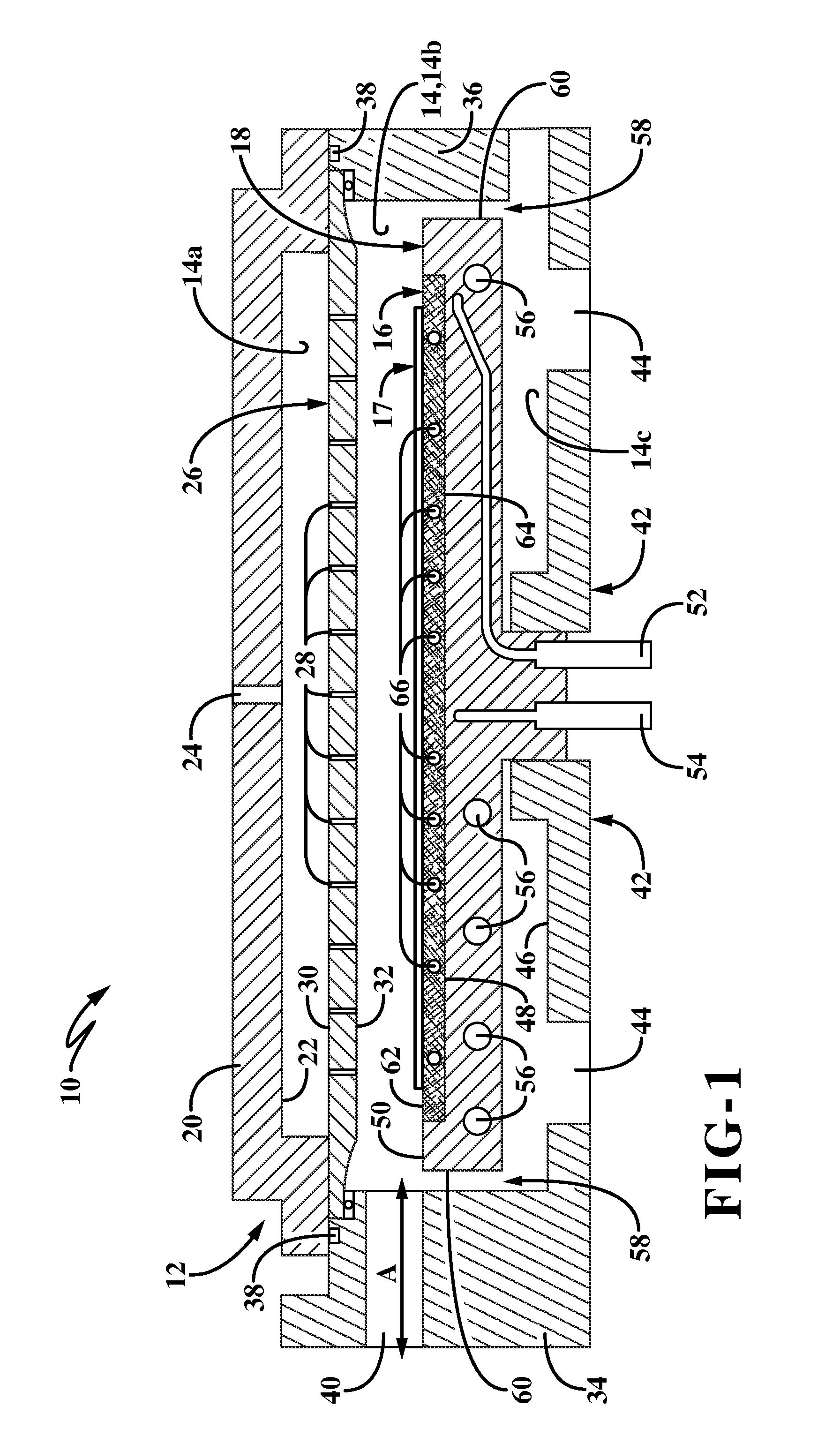

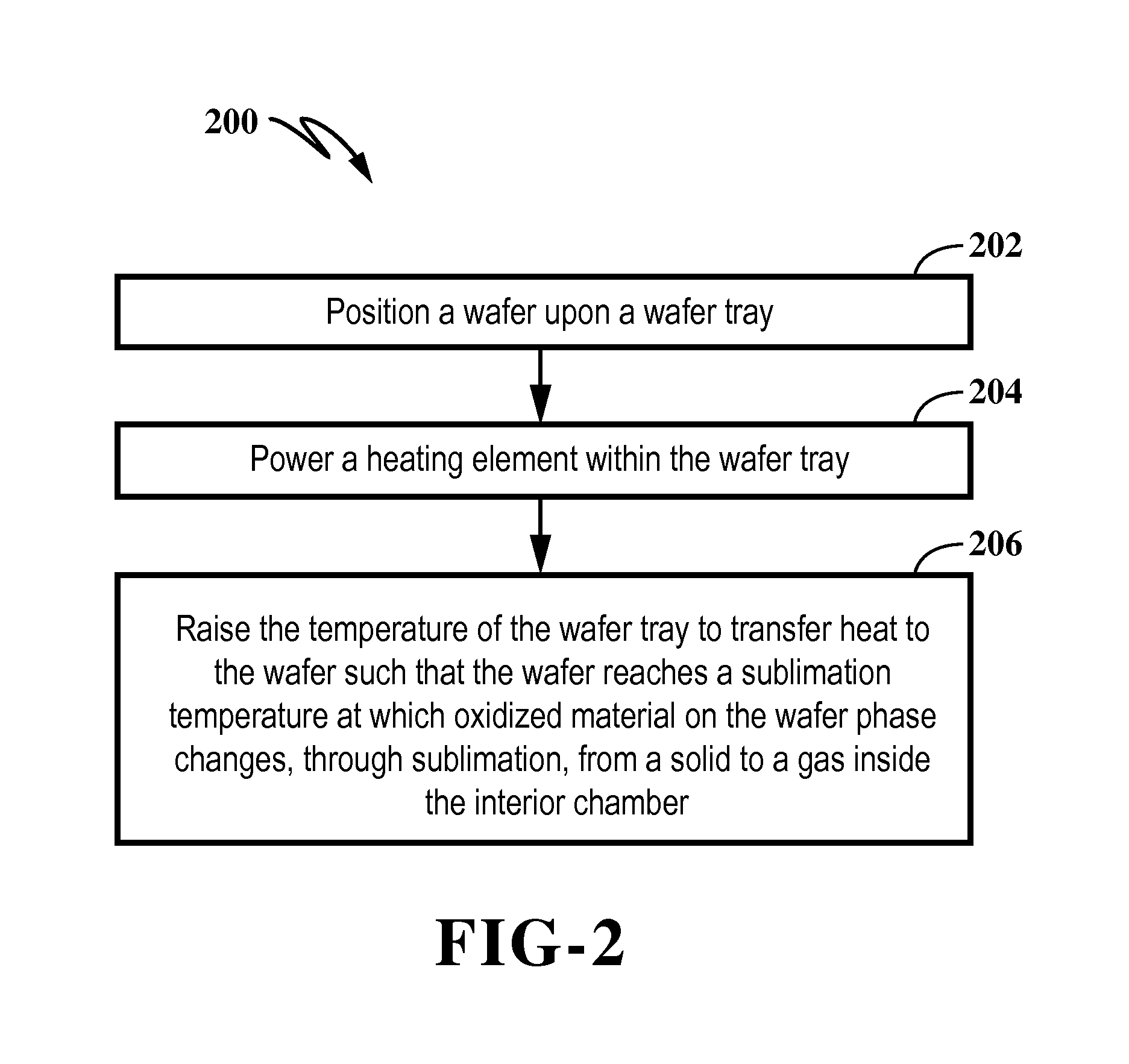

Reactor system for sublimation of pre-clean byproducts and method thereof

Owner:ASM IP HLDG BV

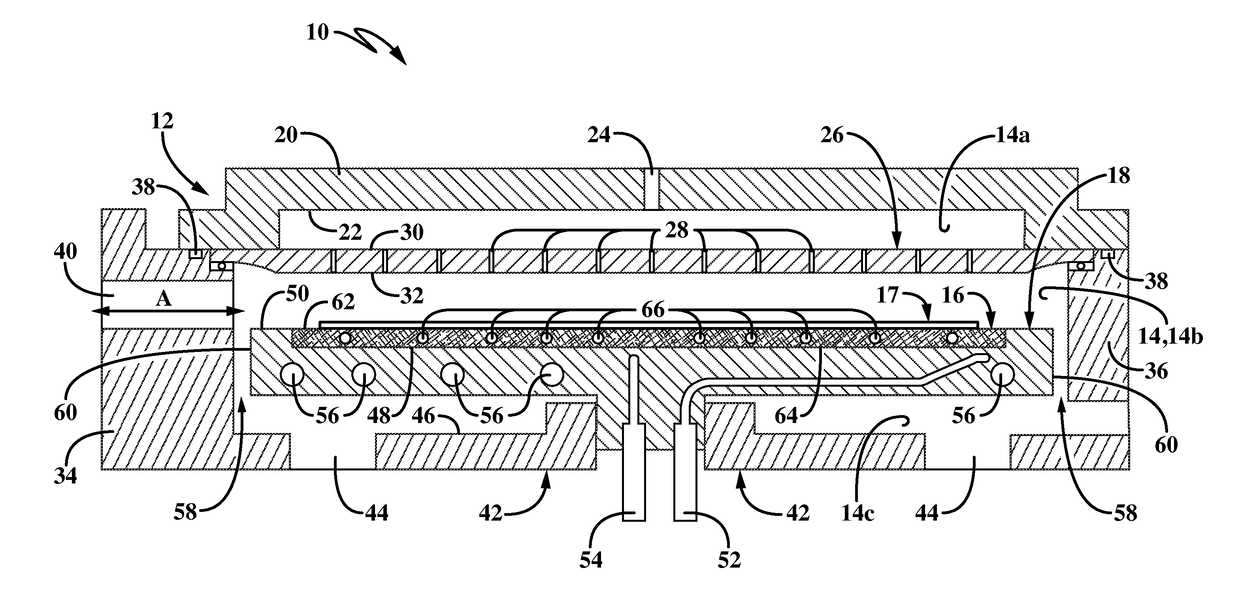

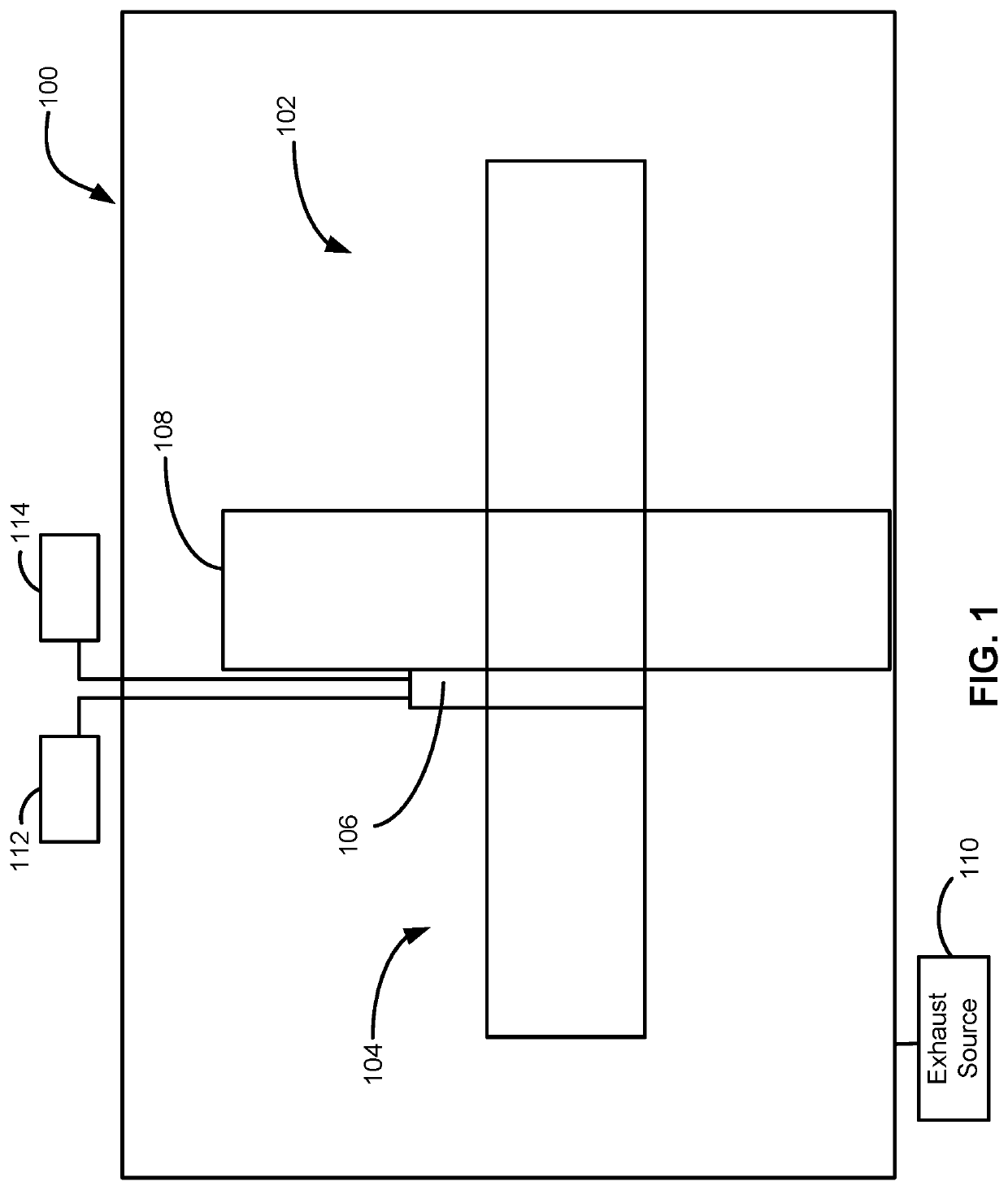

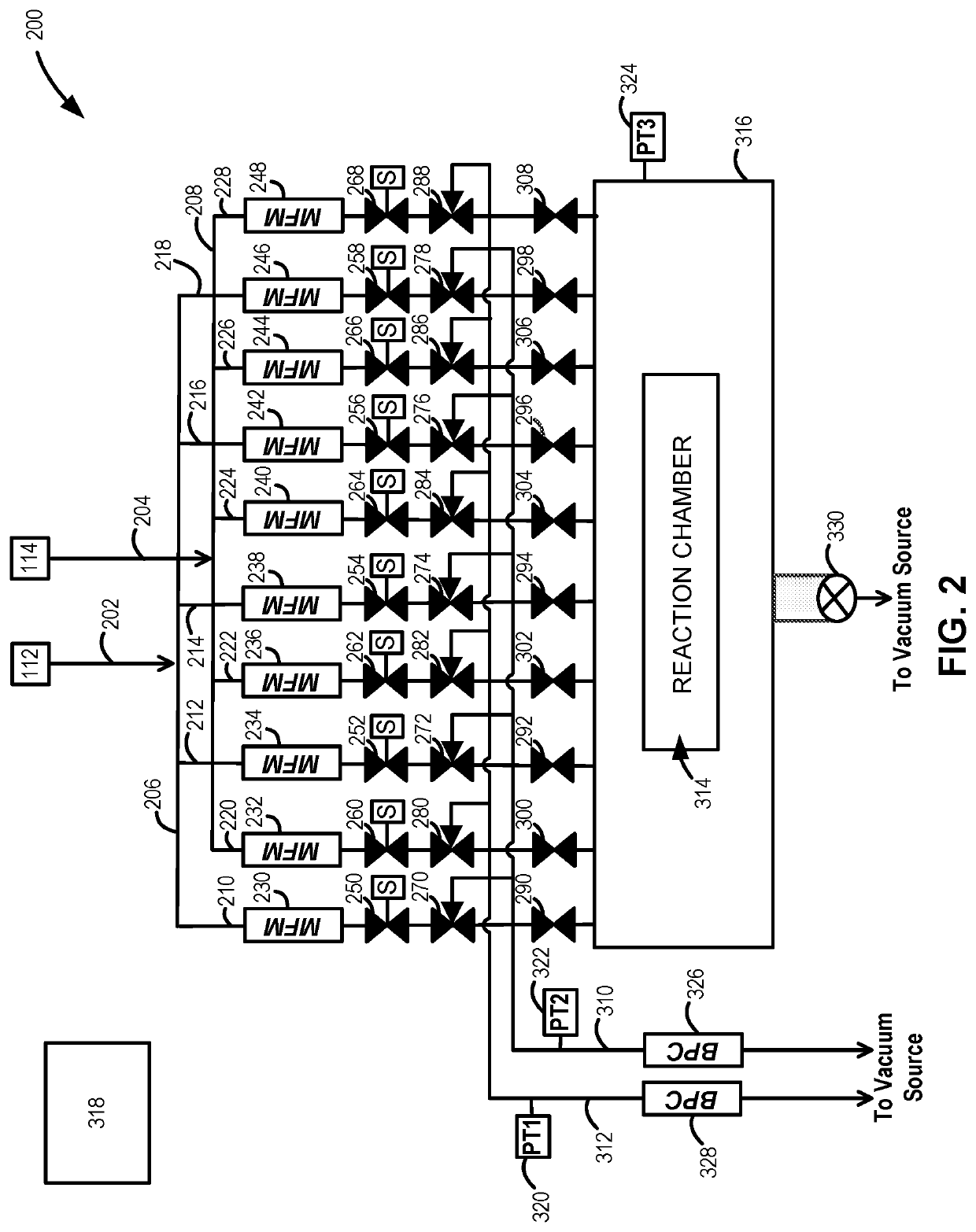

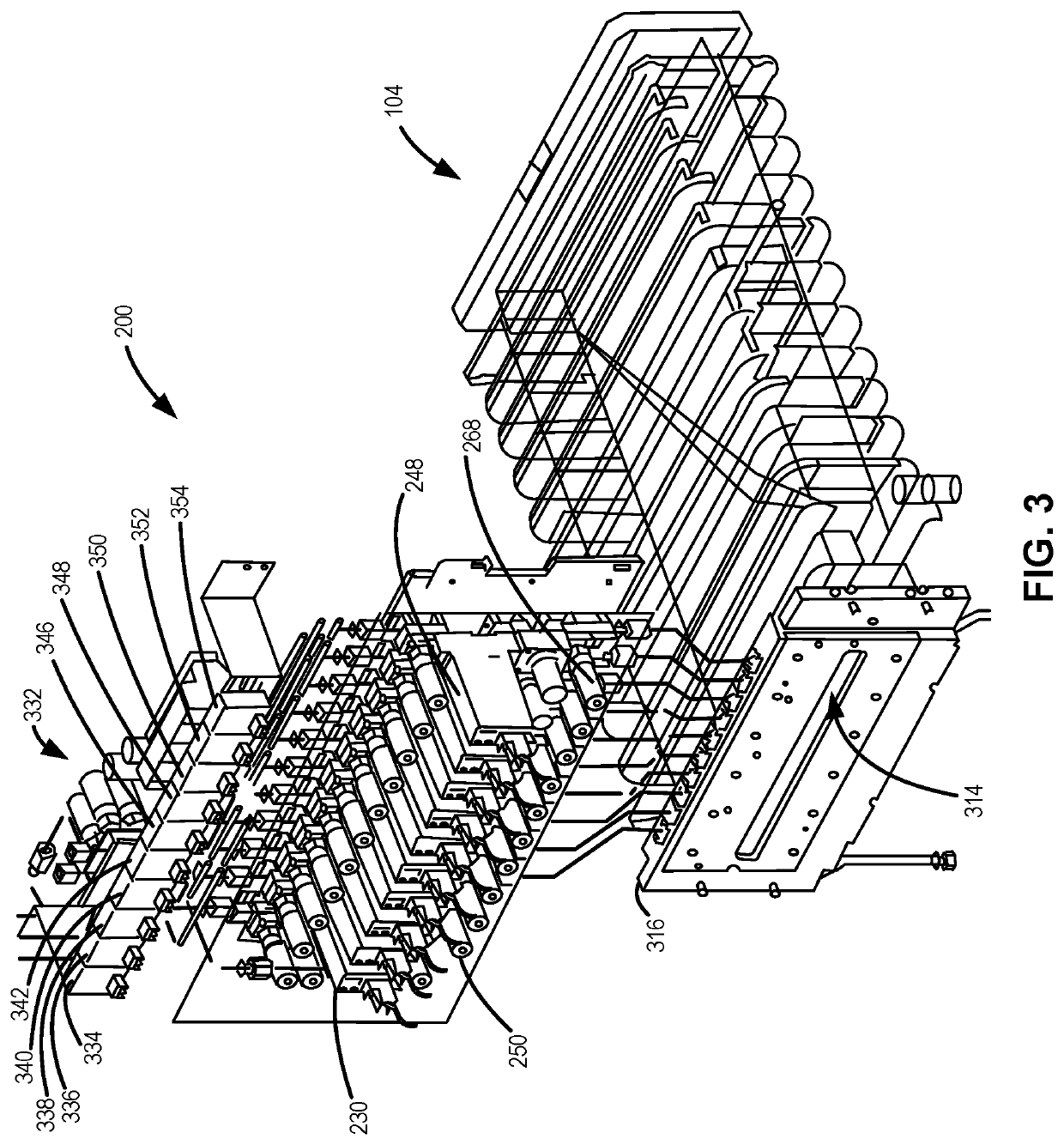

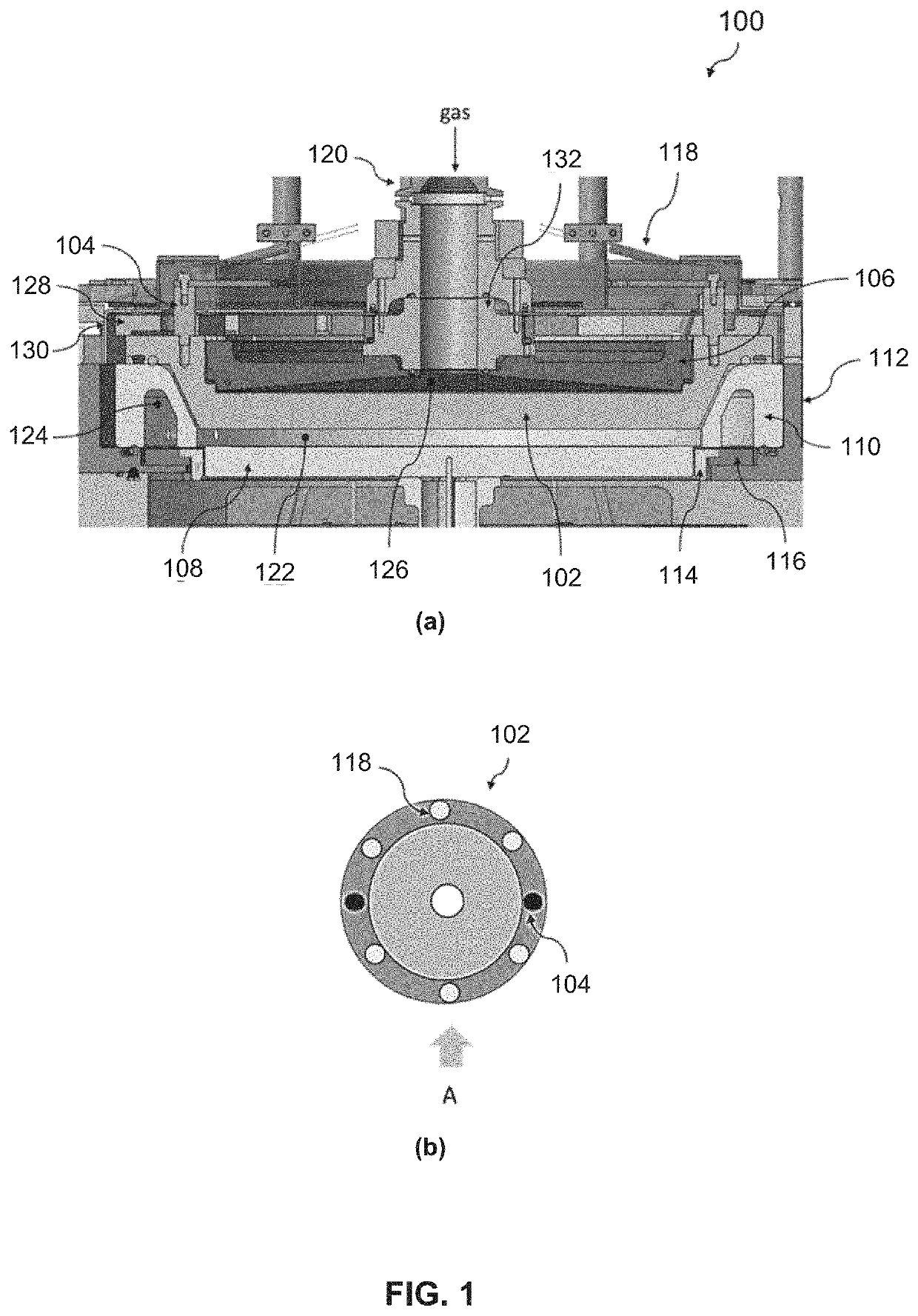

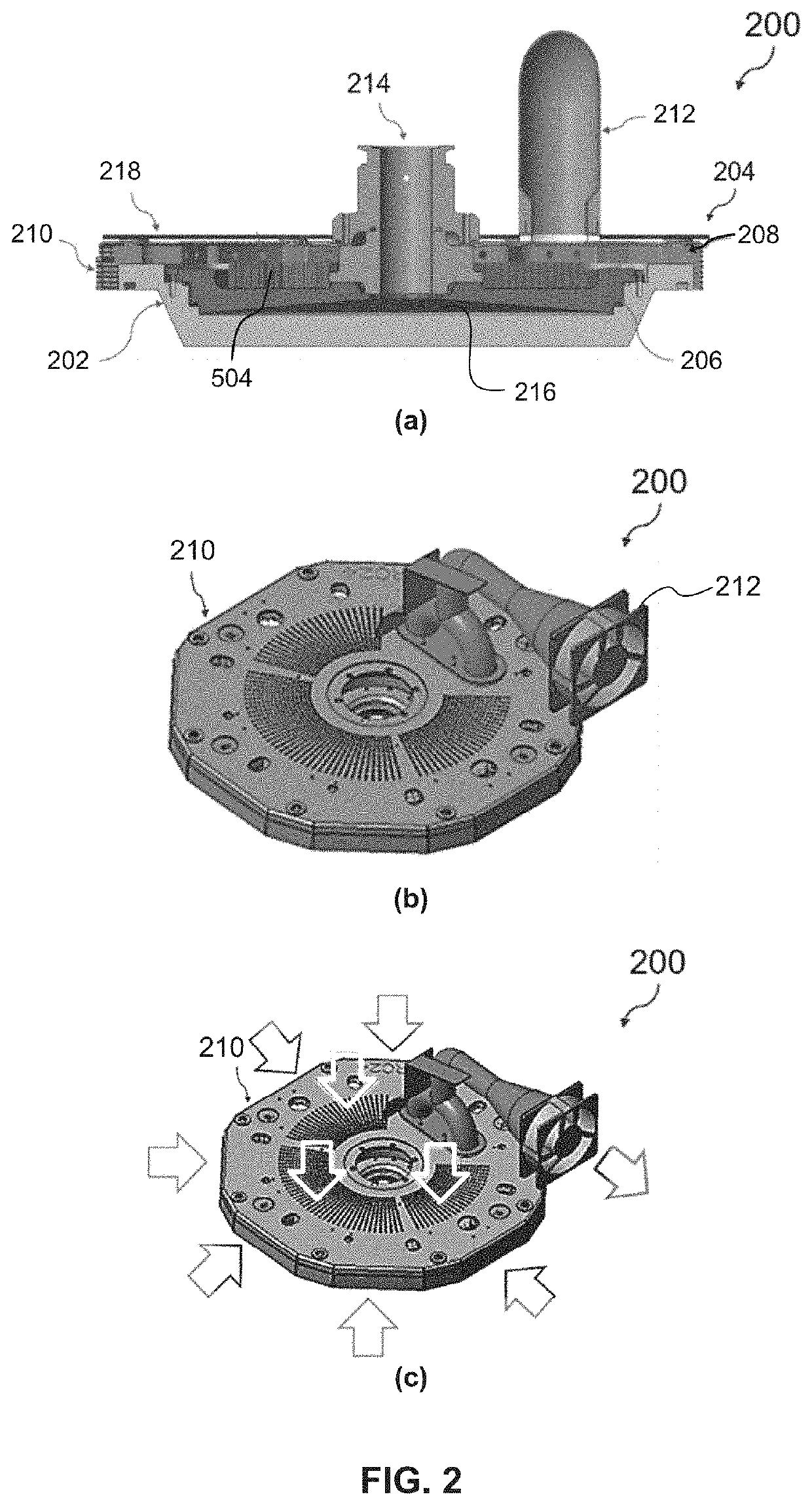

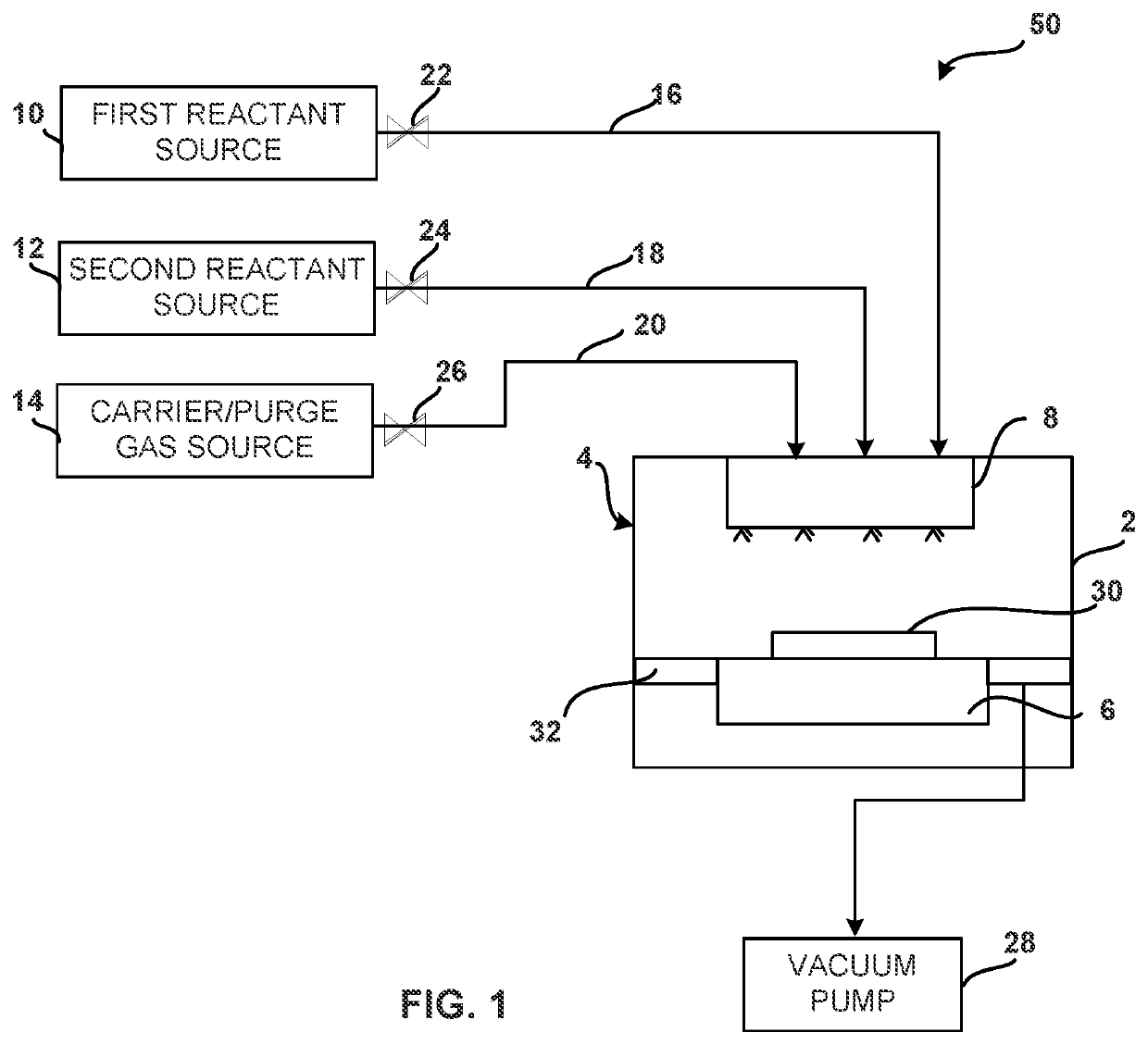

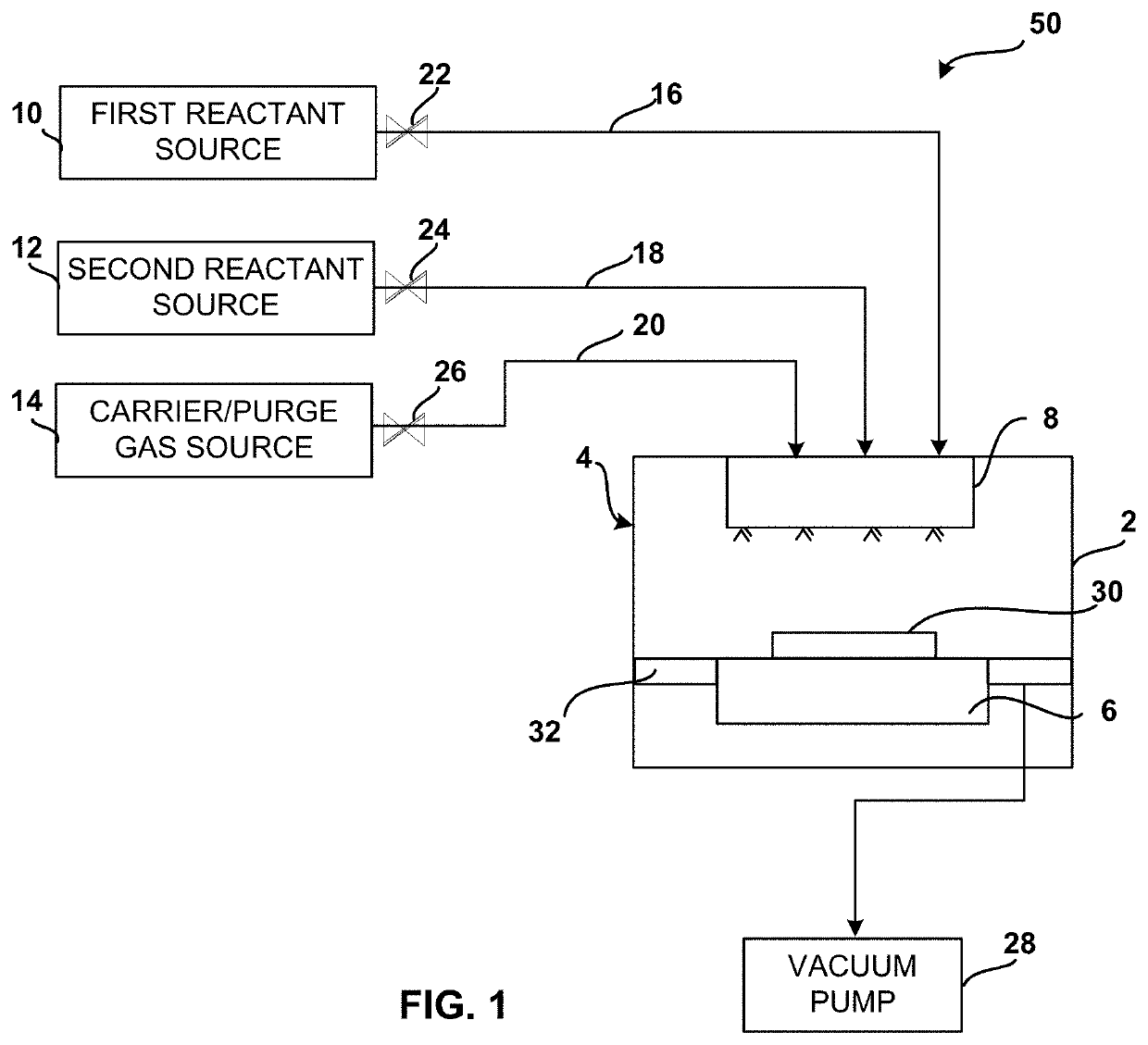

Gas distribution system, reactor including the system, and methods of using the same

ActiveUS10167557B2Facilitate localized mixingChemical/physical/physico-chemical nozzle-type rreactorsEnergy based chemical/physical/physico-chemical processesReactor systemGas phase

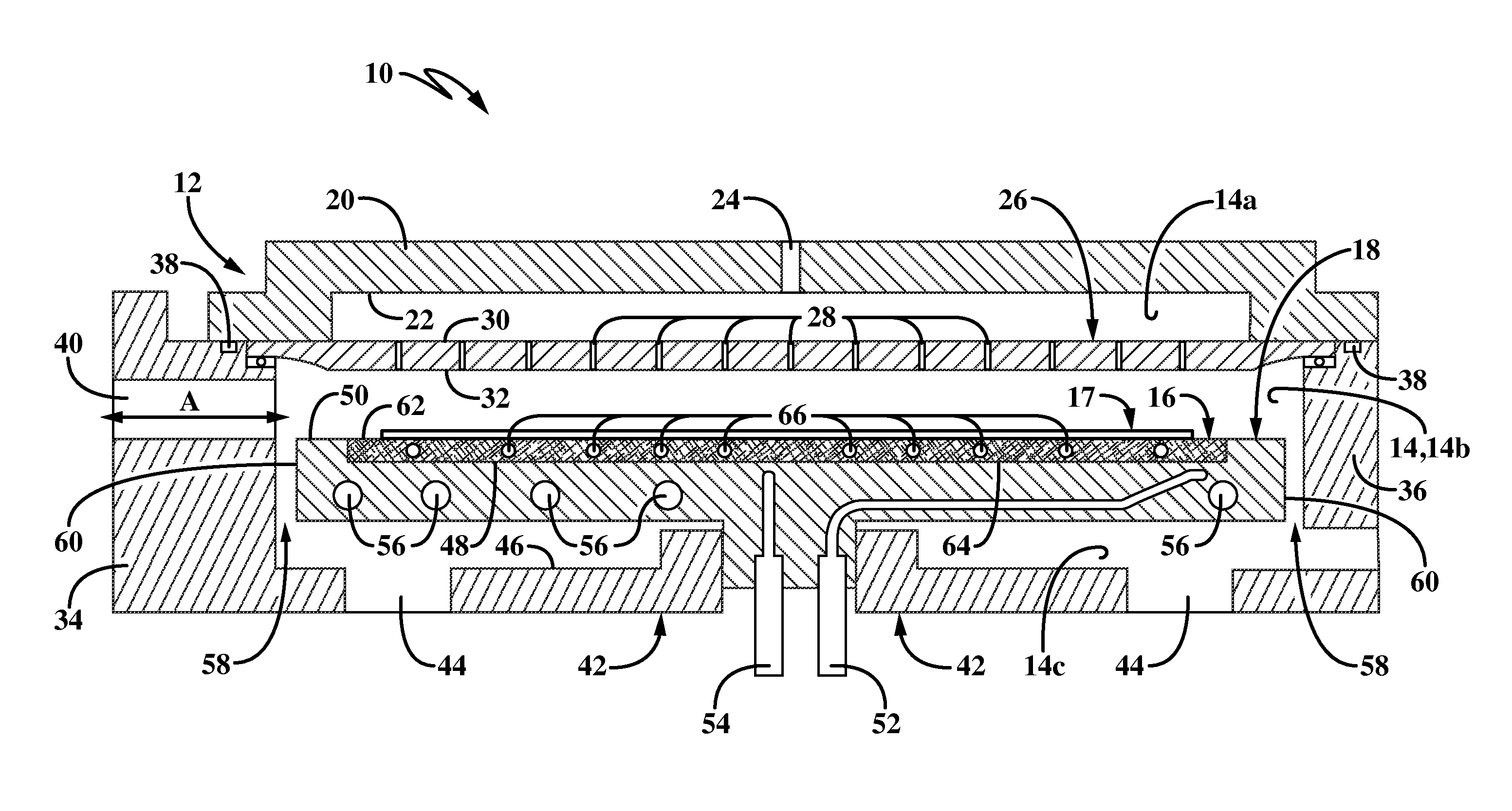

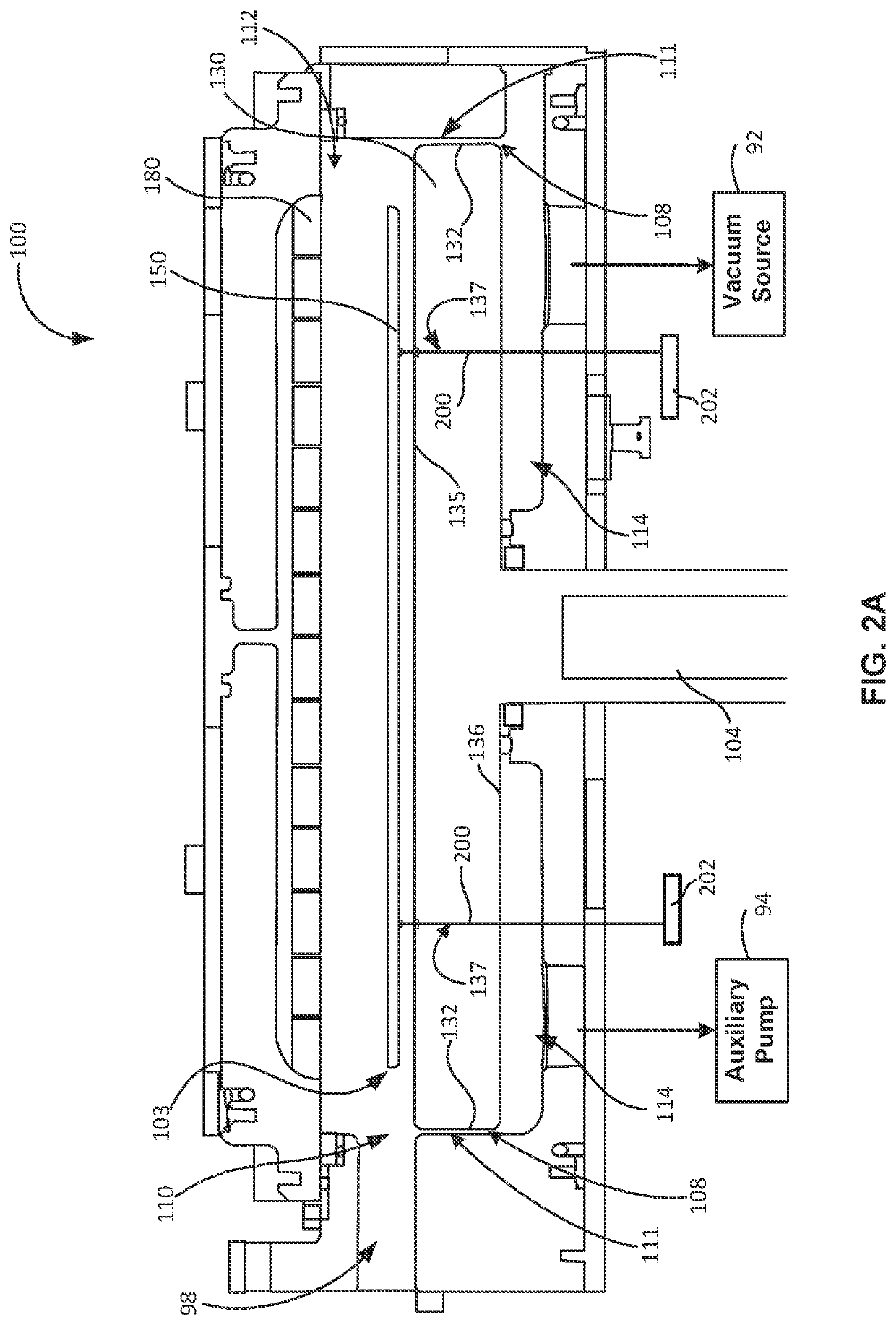

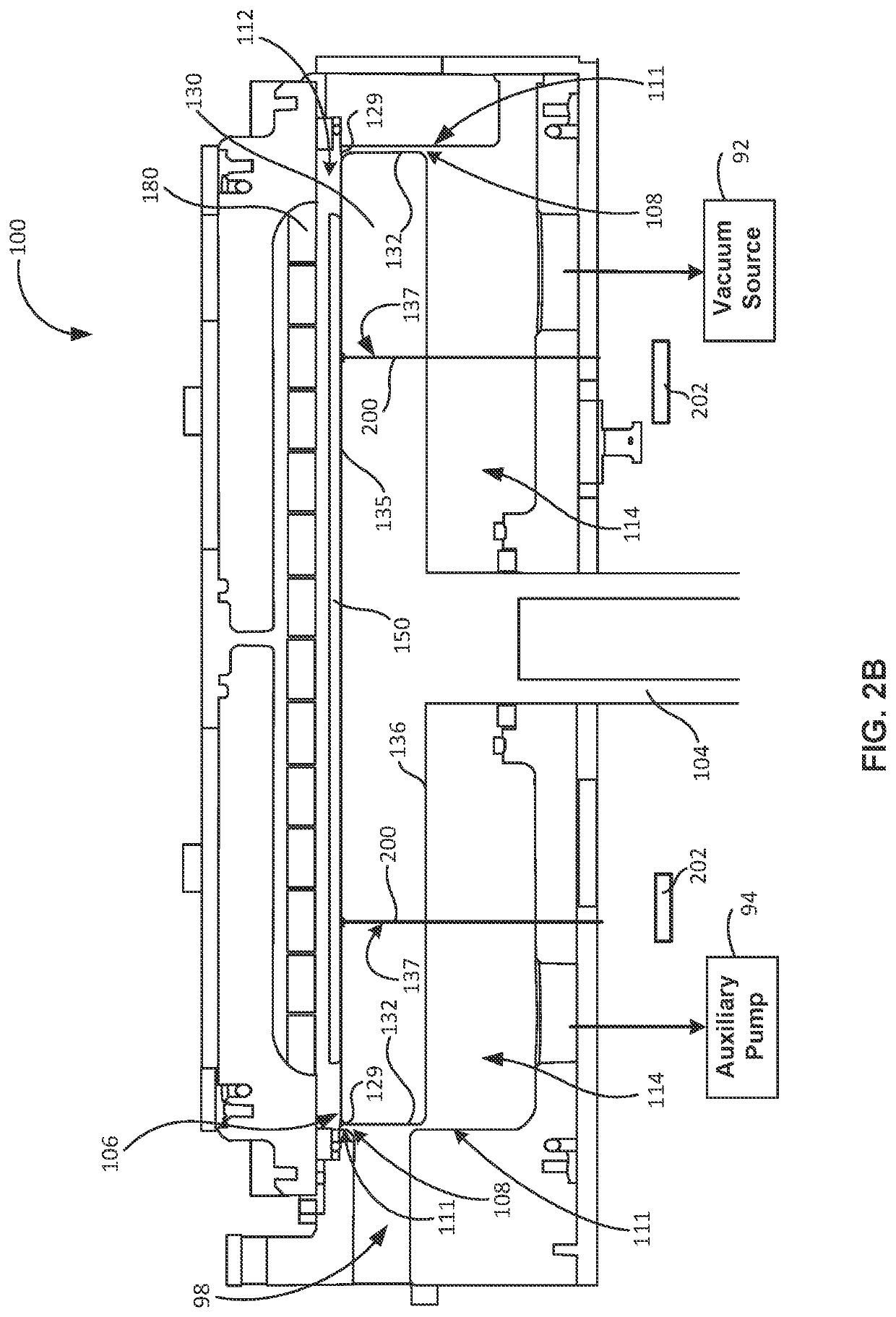

A gas distribution system, a reactor system including the gas distribution system, and method of using the gas distribution system and reactor system are disclosed. The gas distribution system can be used in gas-phase reactor systems to independently fine tune gas source locations and gas flow rates of reactants to a reaction chamber of the reactor systems.

Owner:ASM IP HLDG BV

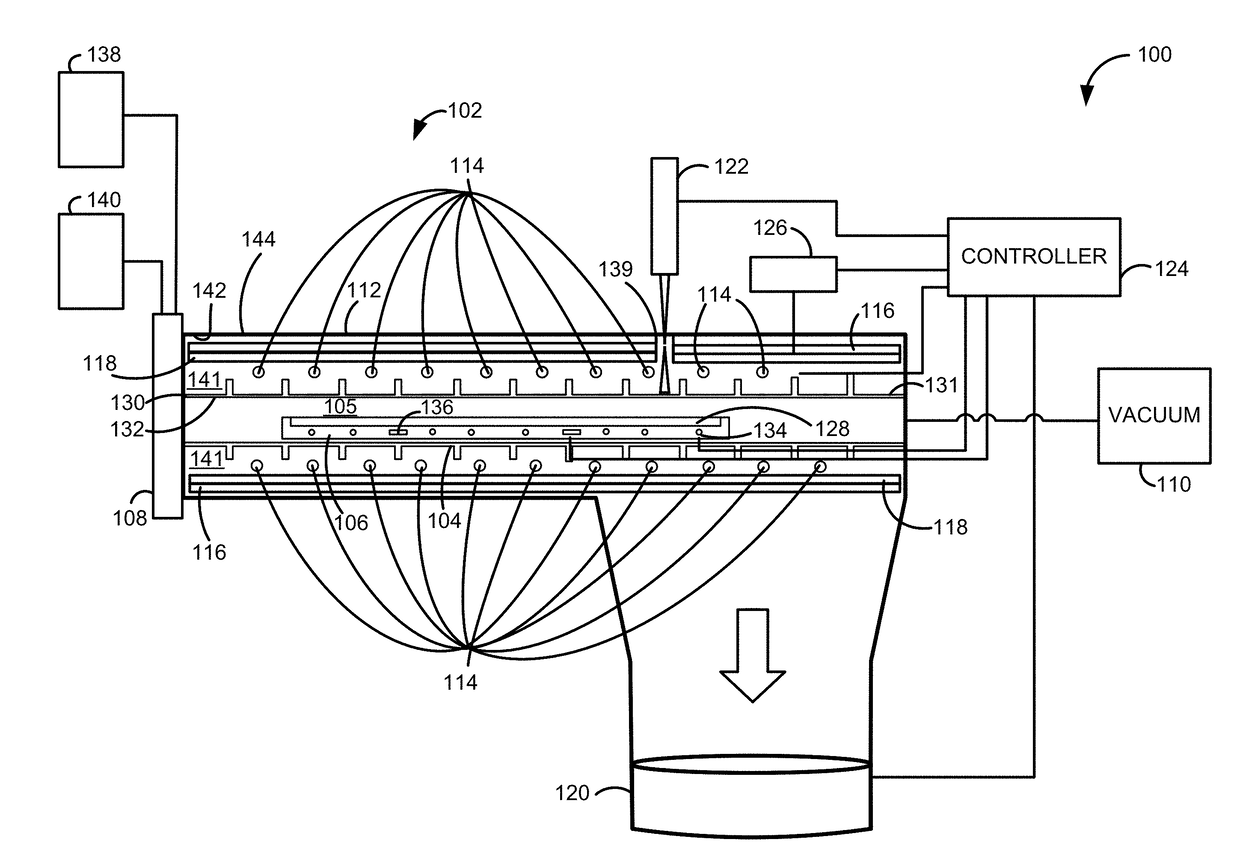

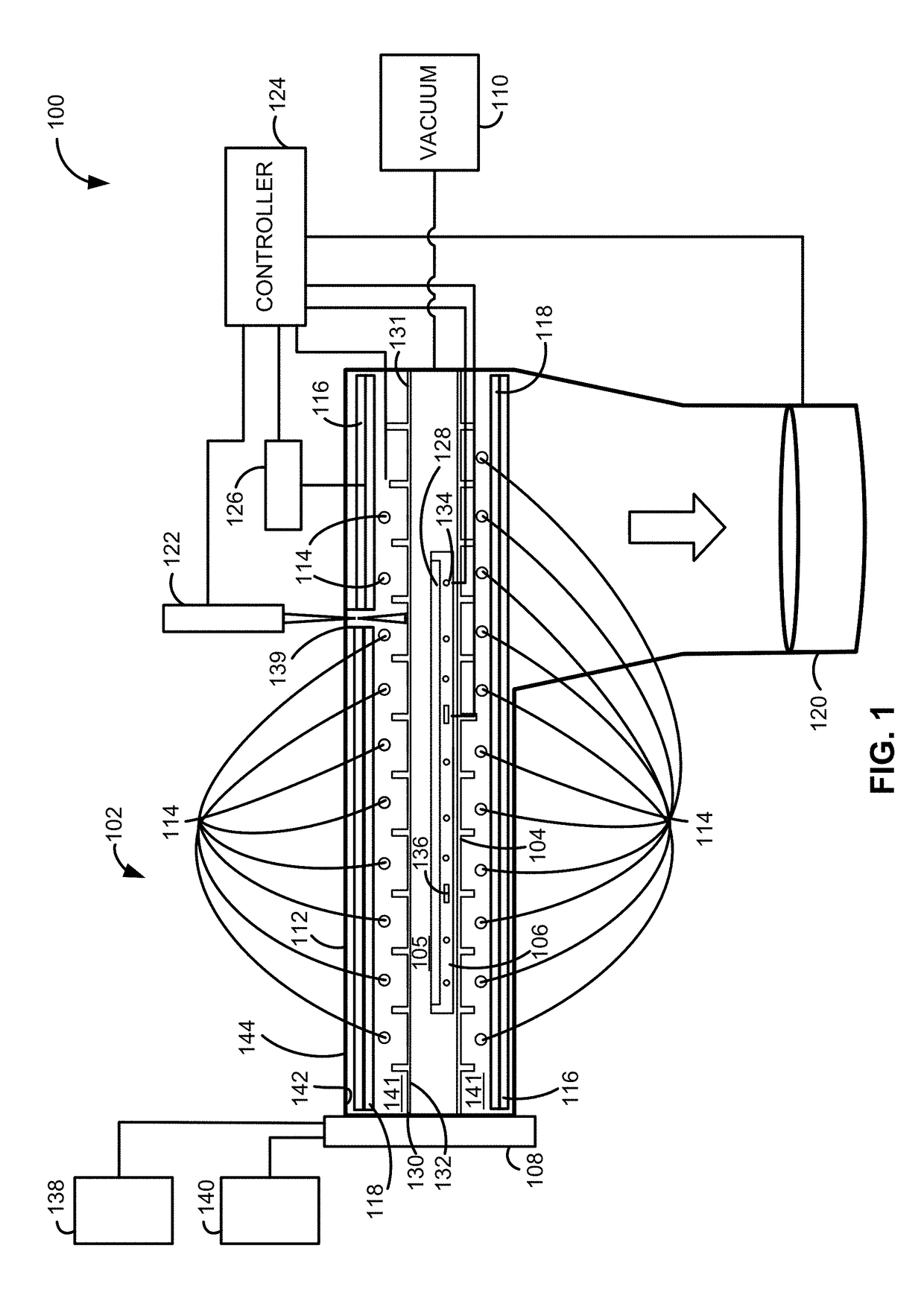

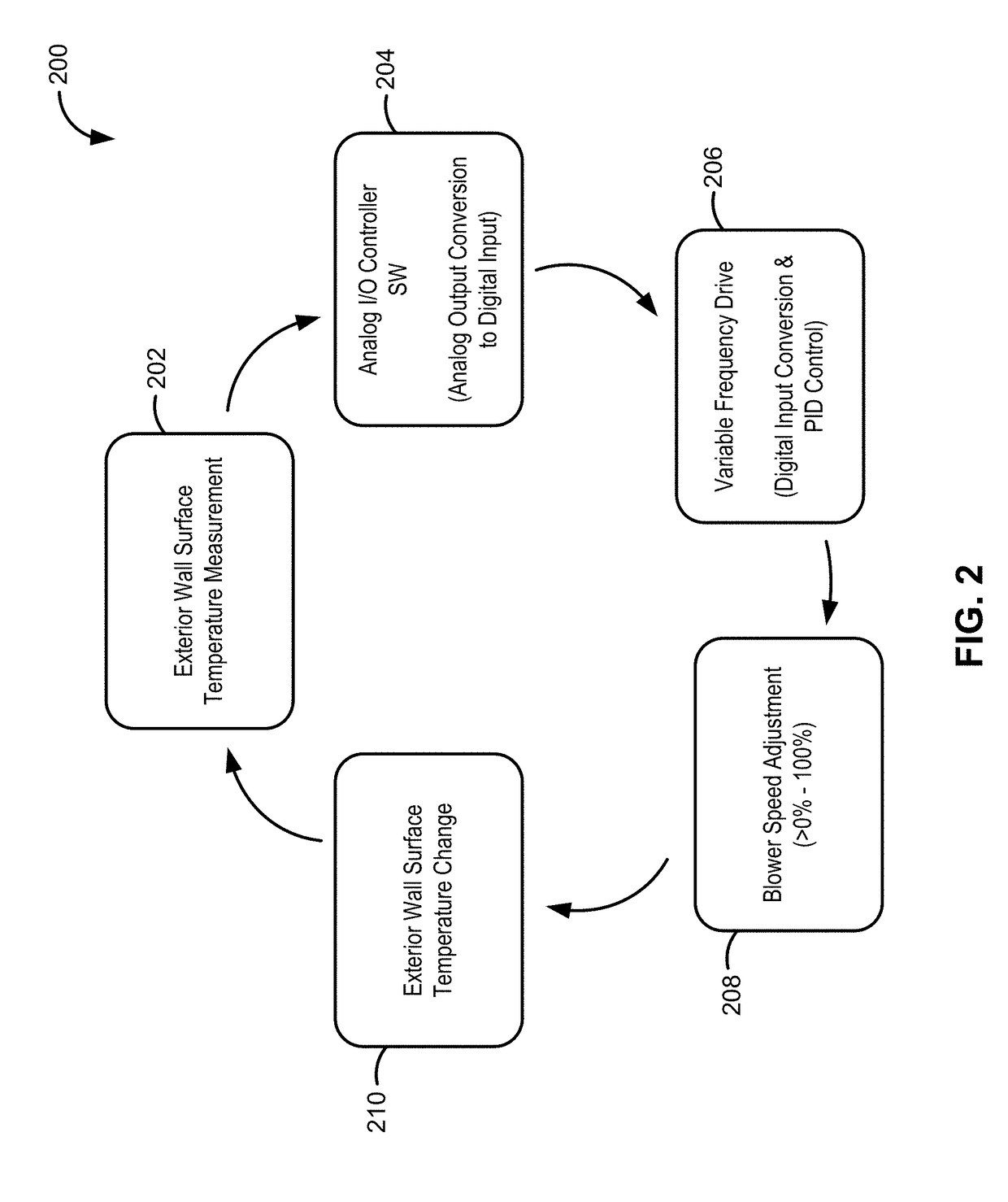

Reactor system and method to reduce residue buildup during a film deposition process

ActiveUS20180195174A1Mitigate formation of residueSubstrate throughput can be increasedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEtchingReactor system

A system and method for depositing a film within a reaction chamber are disclosed. An exemplary system includes a temperature measurement device, such as a pyrometer, to measure an exterior wall surface of the reaction chamber. A temperature of the exterior wall surface can be controlled to mitigate cleaning or etching of an interior wall surface of the reaction chamber.

Owner:ASM IP HLDG BV

Synthesis of liquid fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300435A1Oxygen-containing compound preparationLiquid hydrocarbon mixture productionFuranLiquid fuel

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Reactor system for sublimation of pre-clean byproducts and method thereof

A reactor system and related methods are provided which may include a heating element in a wafer tray. The heating element may be used to heat the wafer tray and a substrate or wafer seated on the wafer tray within a reaction chamber assembly, and may be used to cause sublimation of a native oxide of the wafer.

Owner:ASM IP HLDG BV

Temperature-controlled flange and reactor system including same

ActiveUS20200002811A1Reduce sealReduce condensationElectric discharge tubesVacuum evaporation coatingReactor systemMechanical engineering

A flange, flange assembly, and reactor system including the flange and flange assembly are disclosed. An exemplary flange assembly includes heated and cooled sections to independently control temperatures of sections of the flange. Methods of using the flange, flange assembly and reactor system are also disclosed.

Owner:ASM IP HLDG BV

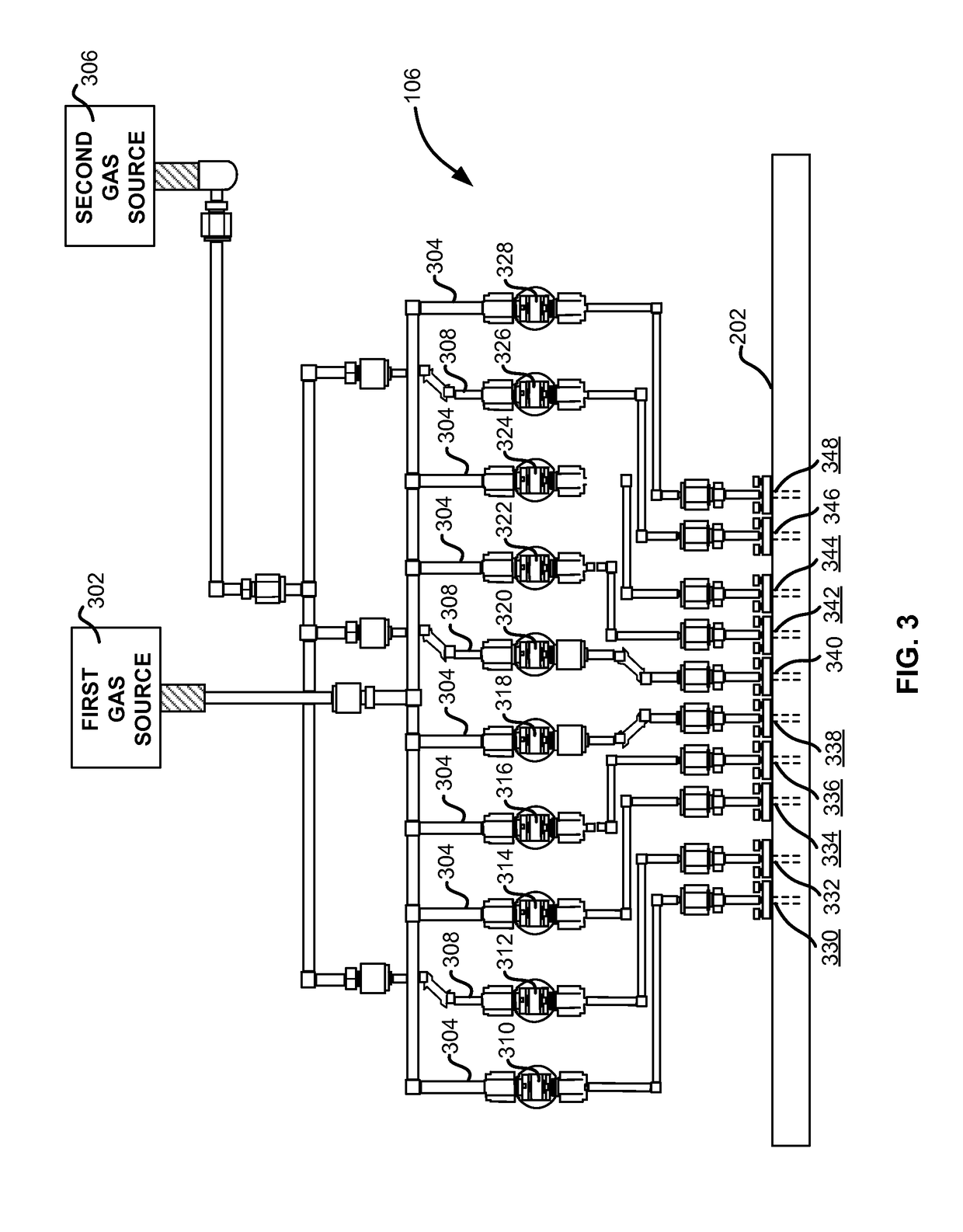

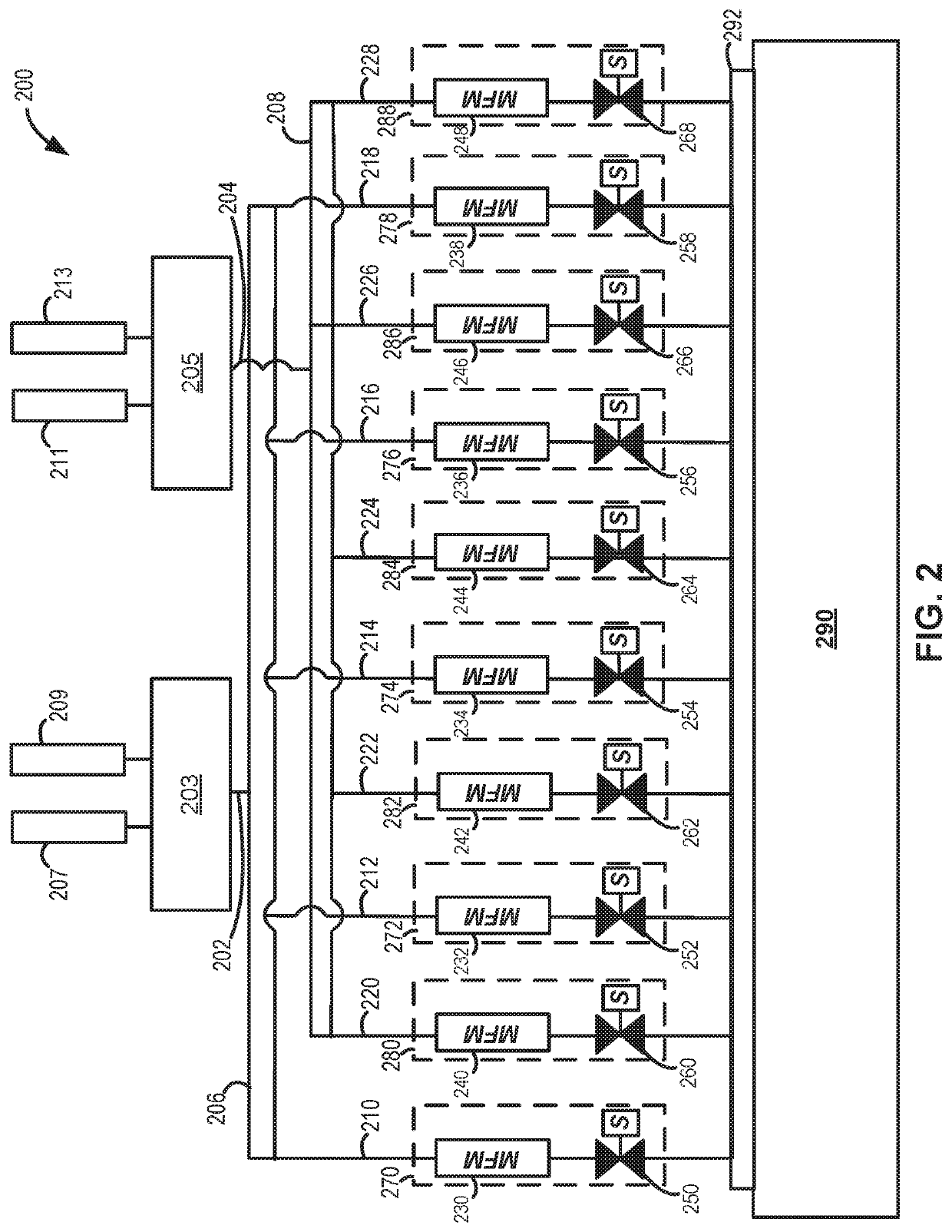

Gas distribution system and reactor system including same

PendingUS20190368041A1Easy to controlImprove flow stabilityElectric discharge tubesSemiconductor/solid-state device manufacturingThermodynamicsReactor system

A gas distribution system, a reactor system including the gas distribution system, and method of using the gas distribution system and reactor system are disclosed. The gas distribution system can be used in gas-phase reactor systems to independently monitor and control gas flow rates in a plurality of channels of a gas distribution system coupled to a reaction chamber.

Owner:ASM IP HLDG BV

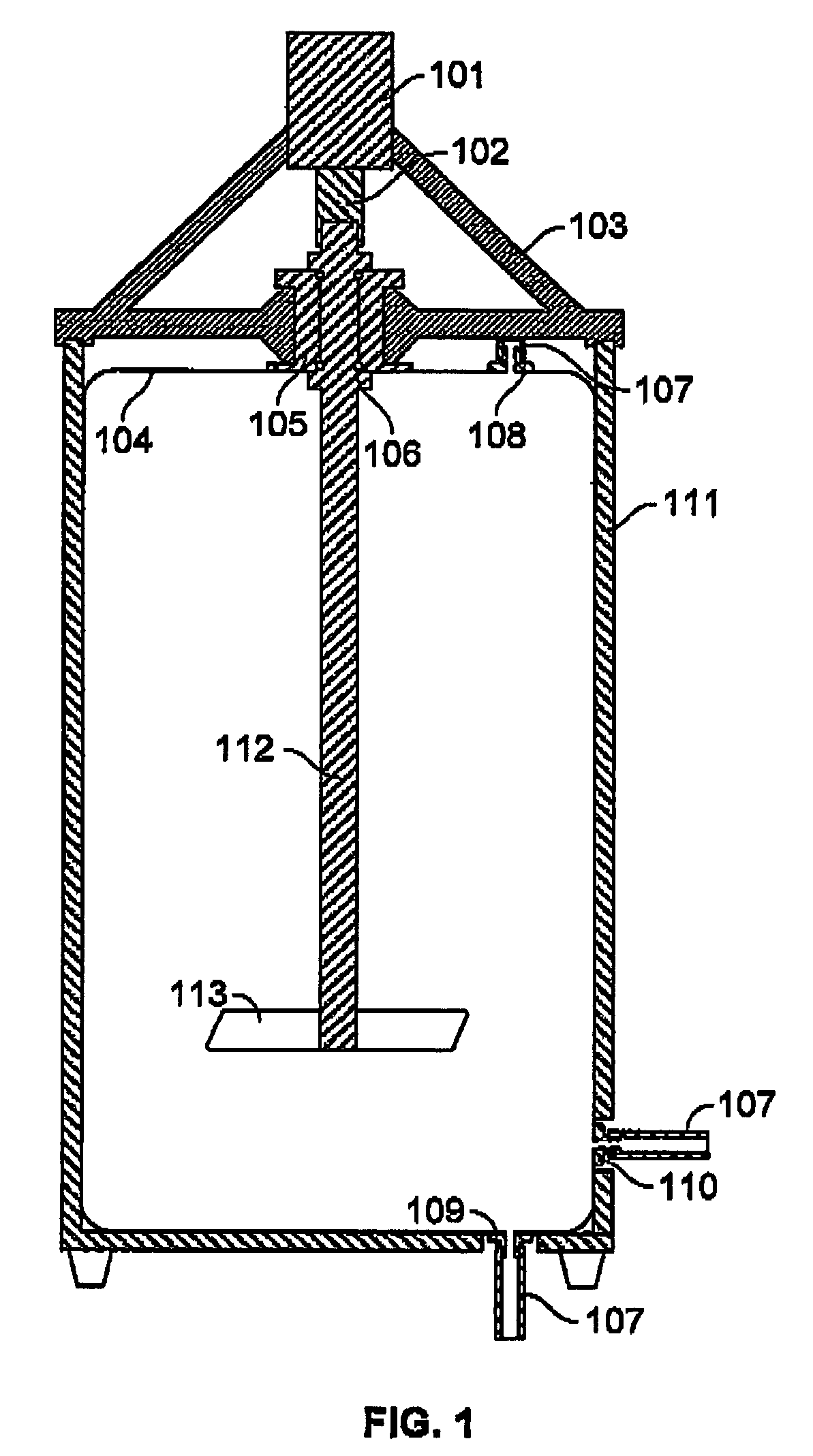

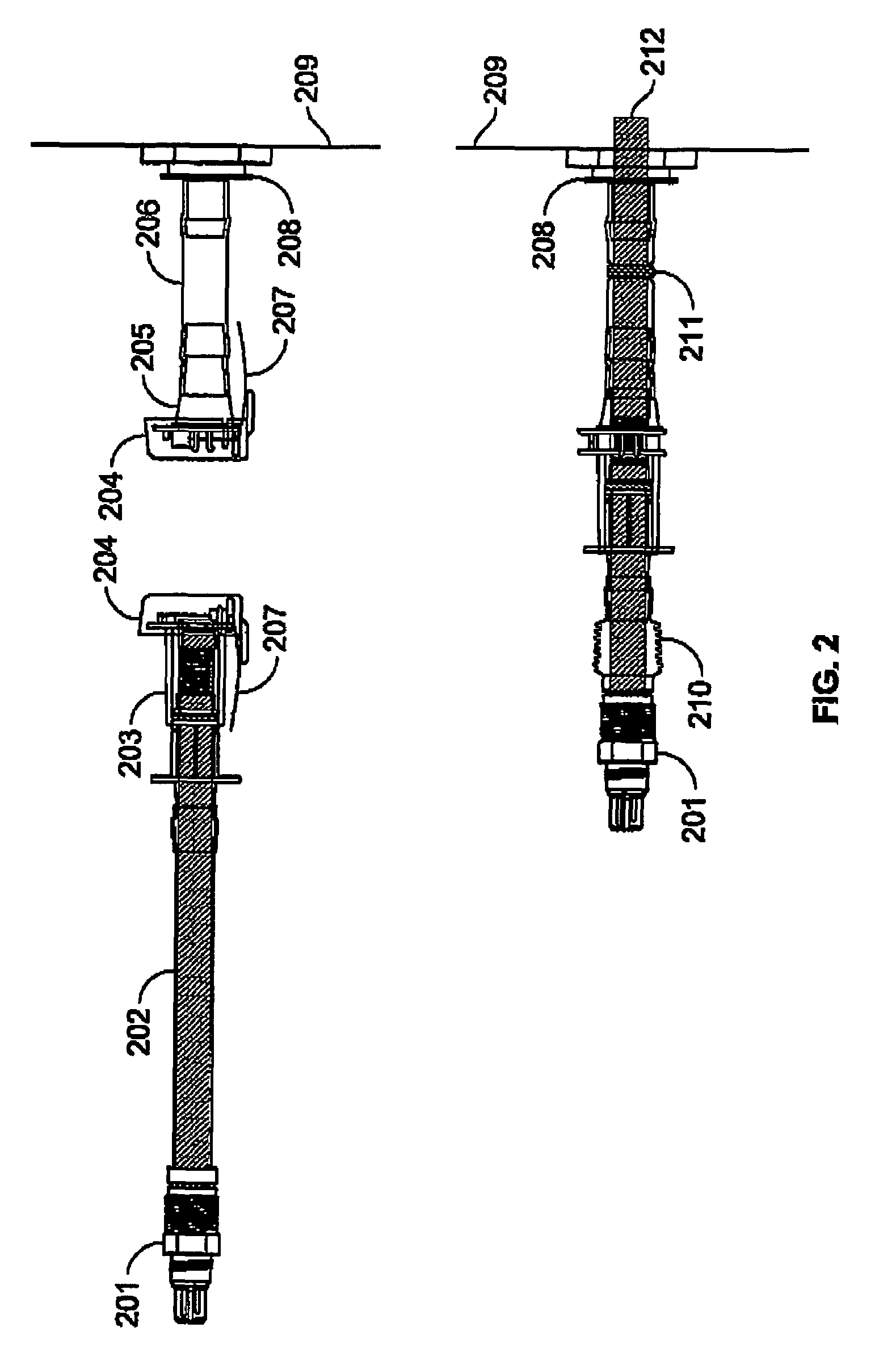

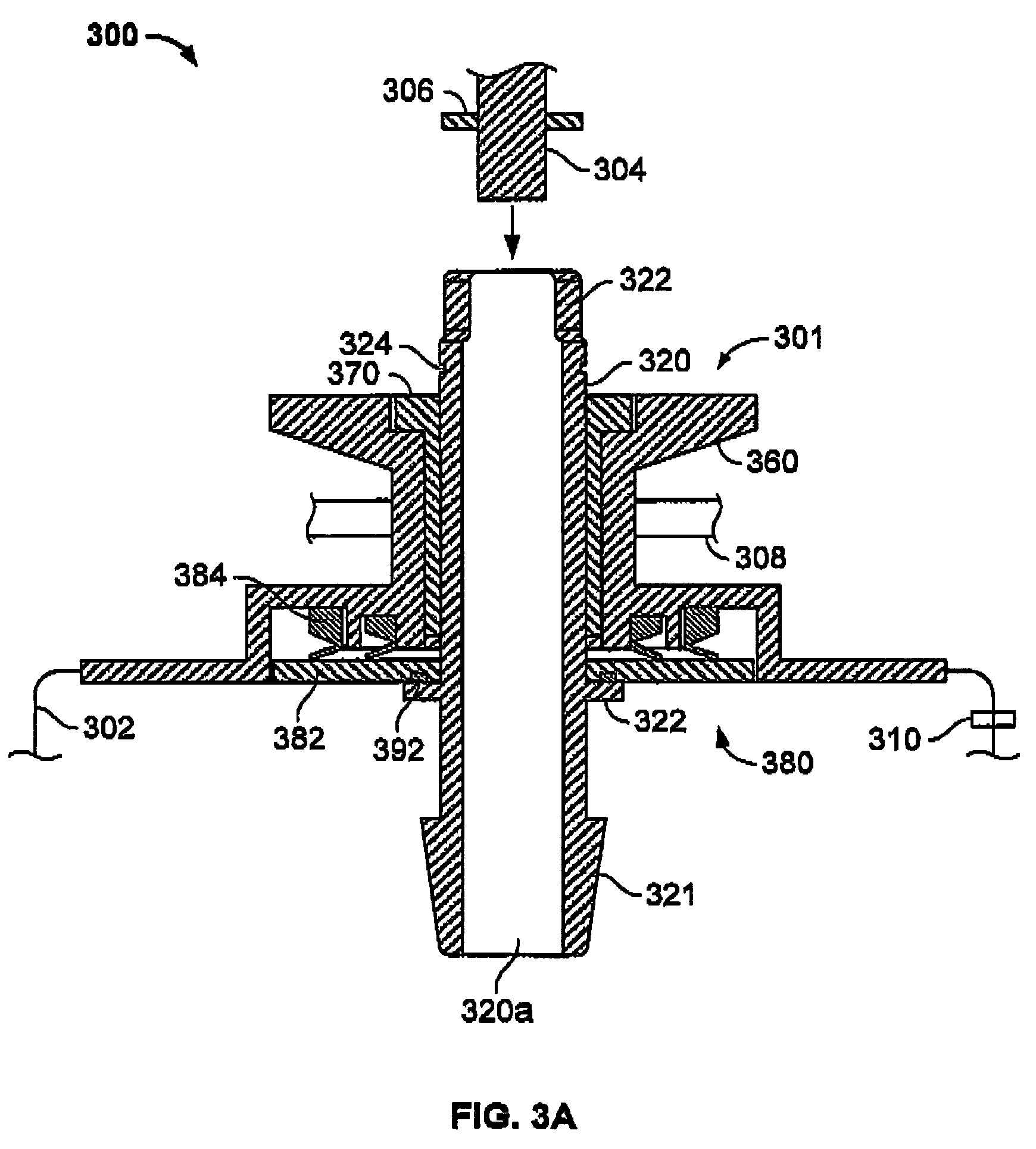

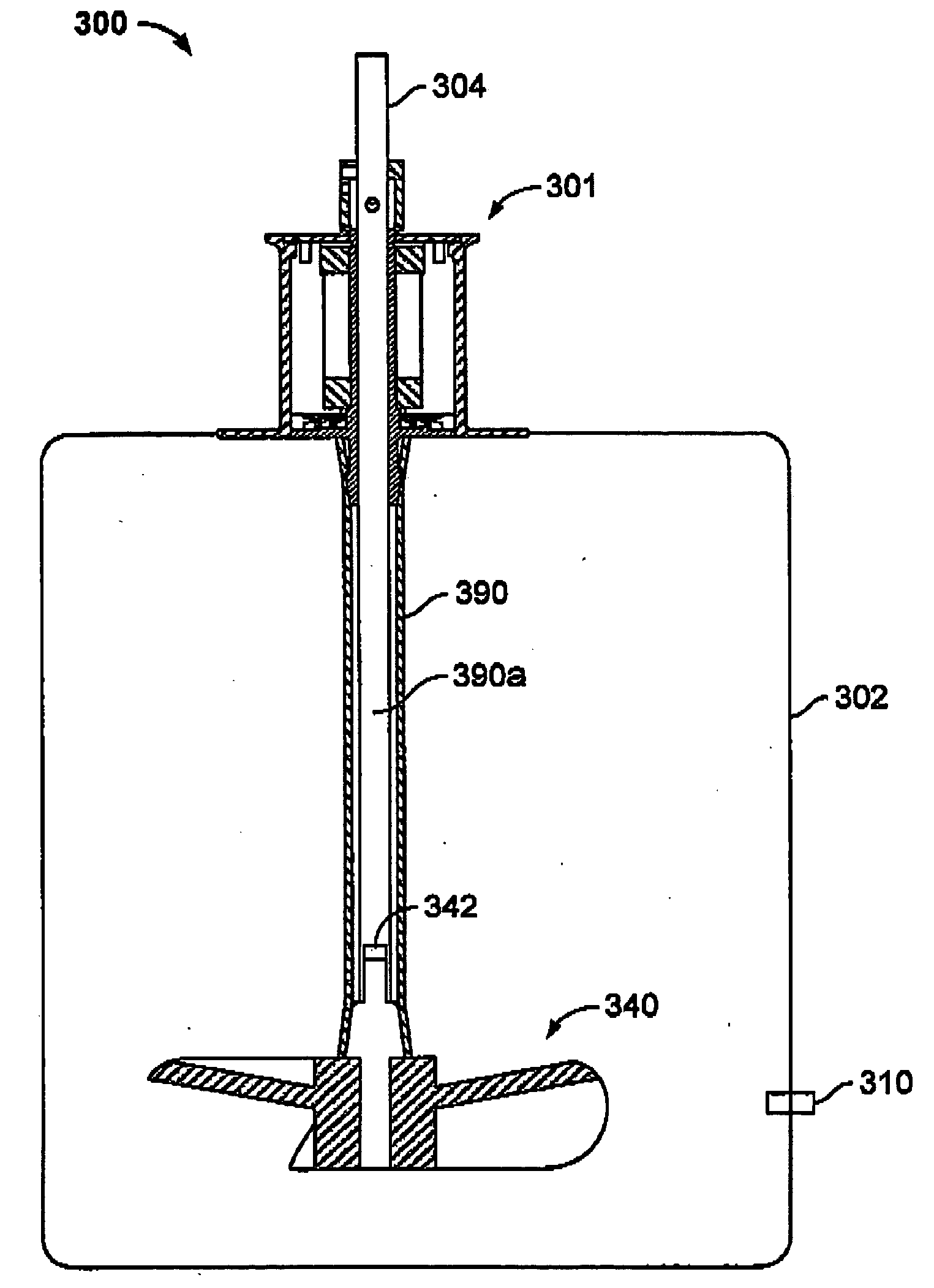

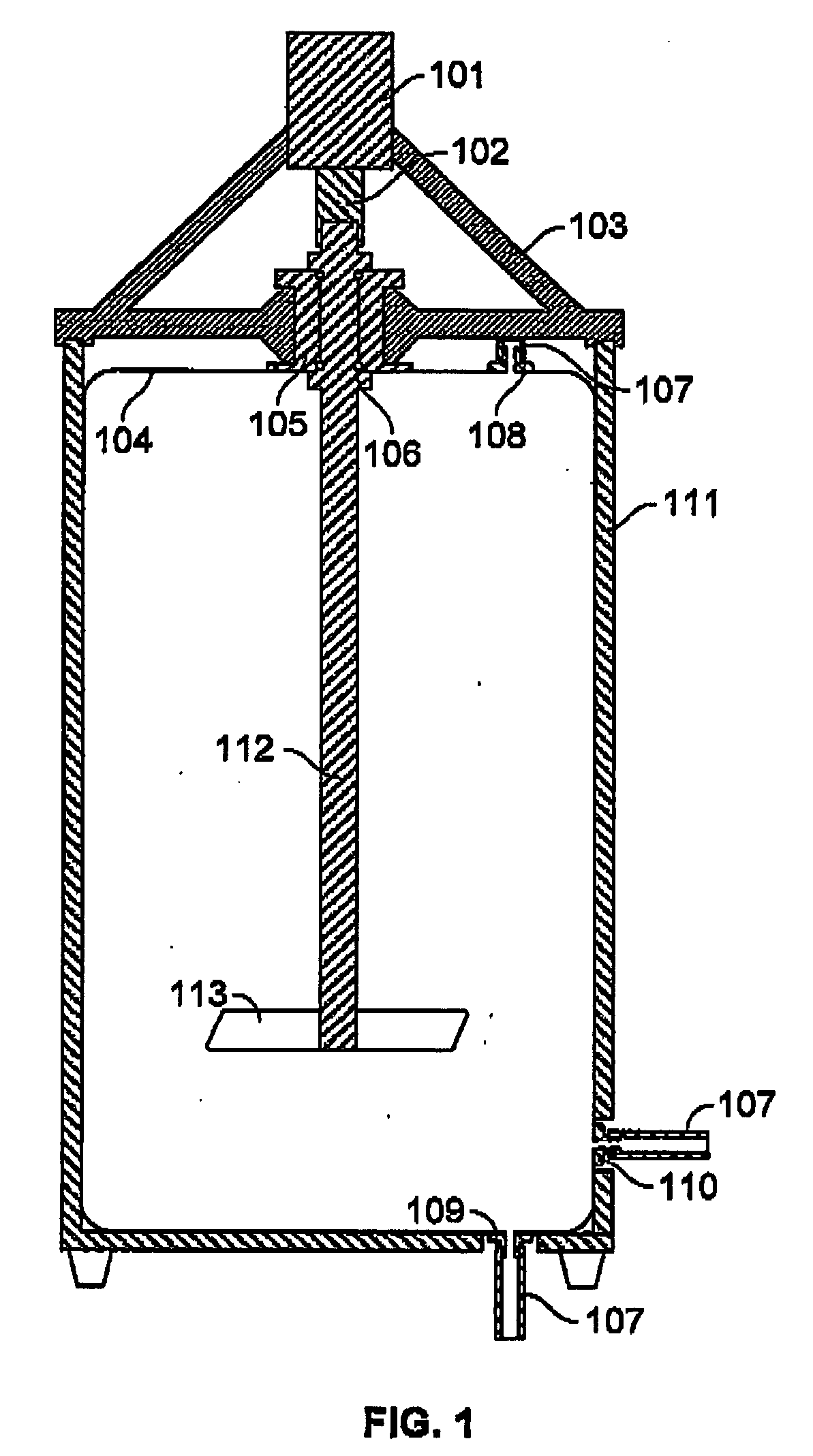

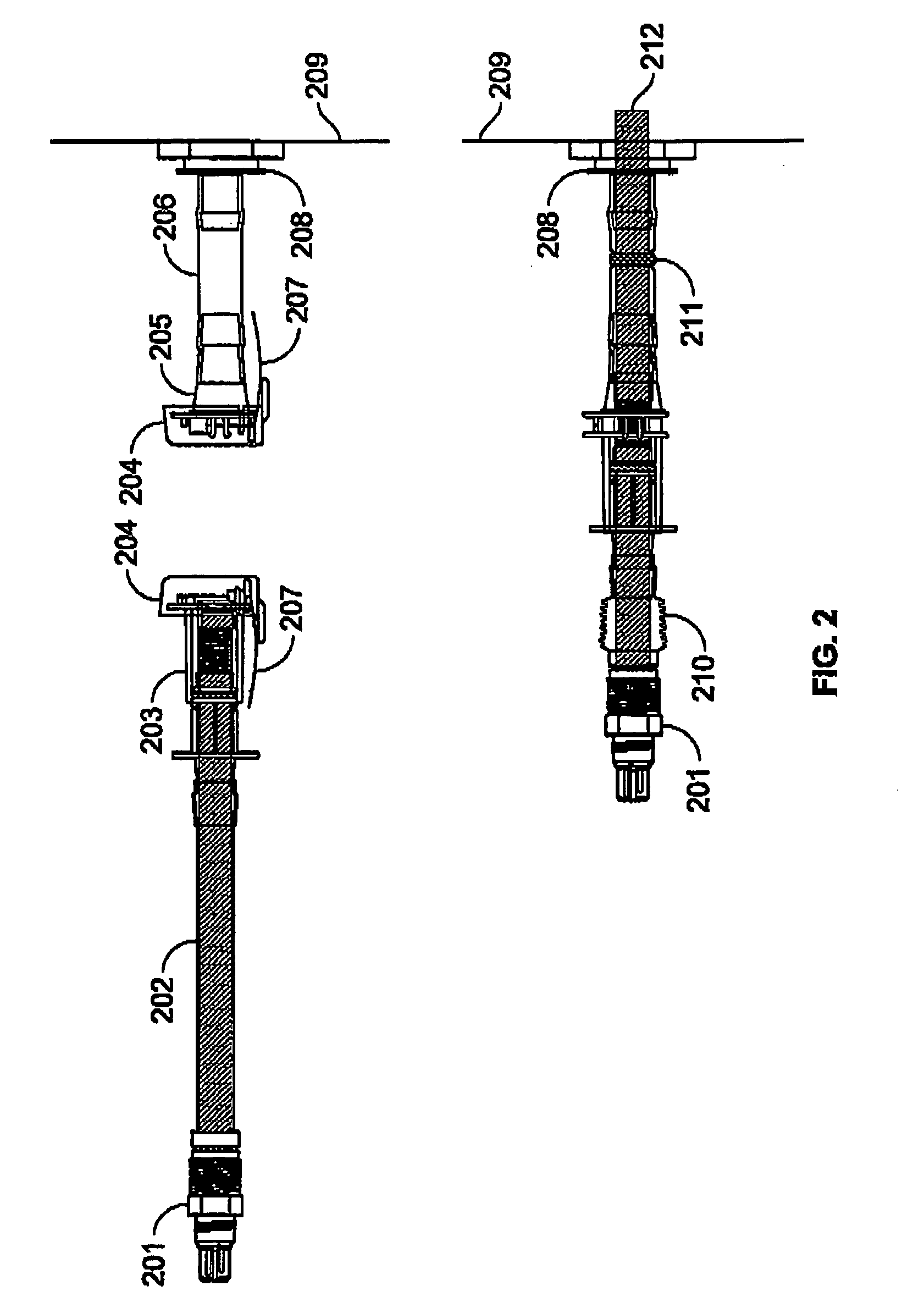

Stirred-tank reactor system

ActiveUS7384783B2Less regulatory controlMinimal or no preparation priorBioreactor/fermenter combinationsBiological substance pretreatmentsReactor systemNuclear engineering

The present invention relates to a stirred-tank reactor system and methods of preparing such systems. The present invention further encompasses the use of the stirred-tank reactor system as a disposable bioreactor and in kits with disposable elements.

Owner:TAKEDA PHARMA CO LTD +1

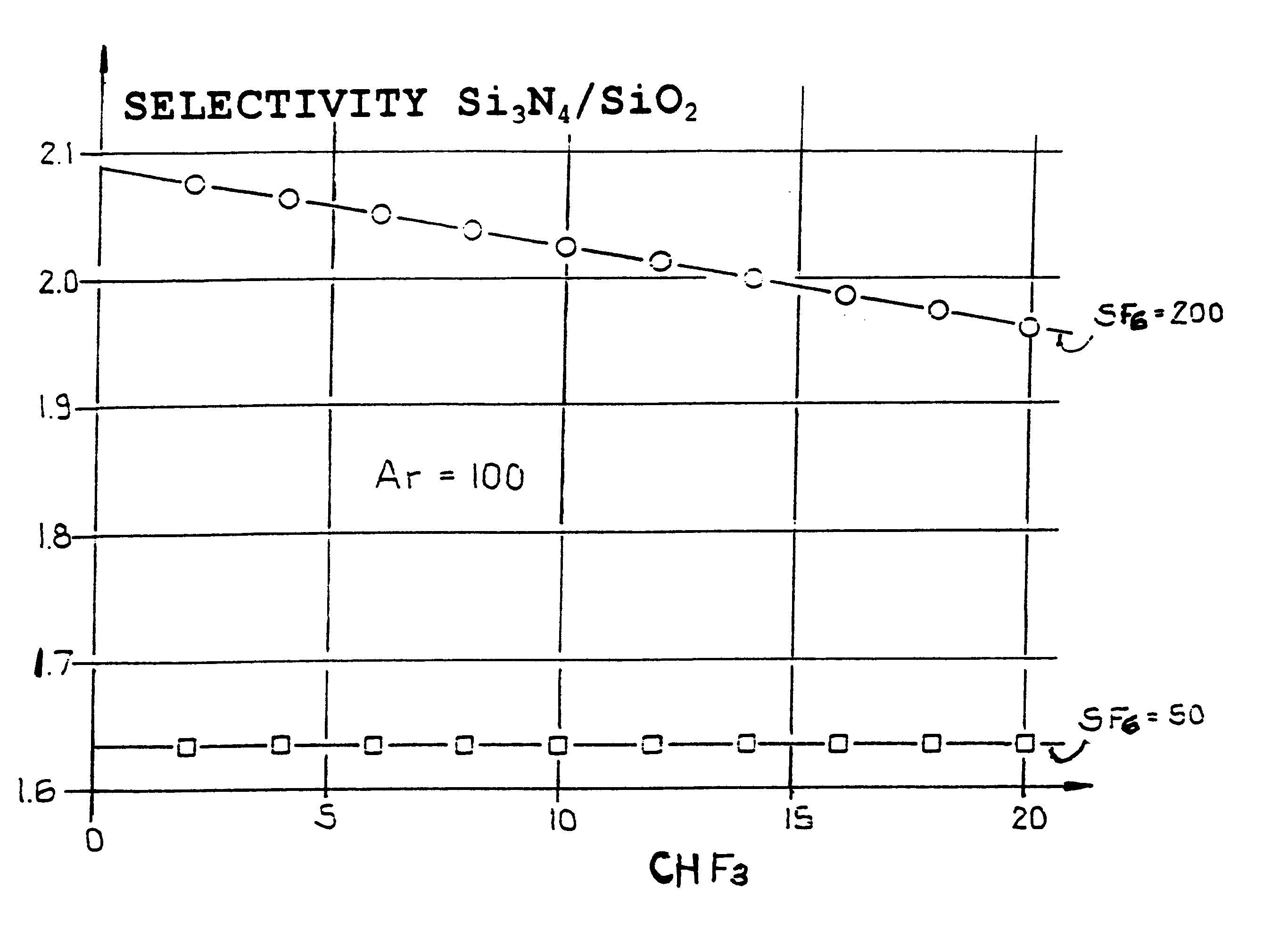

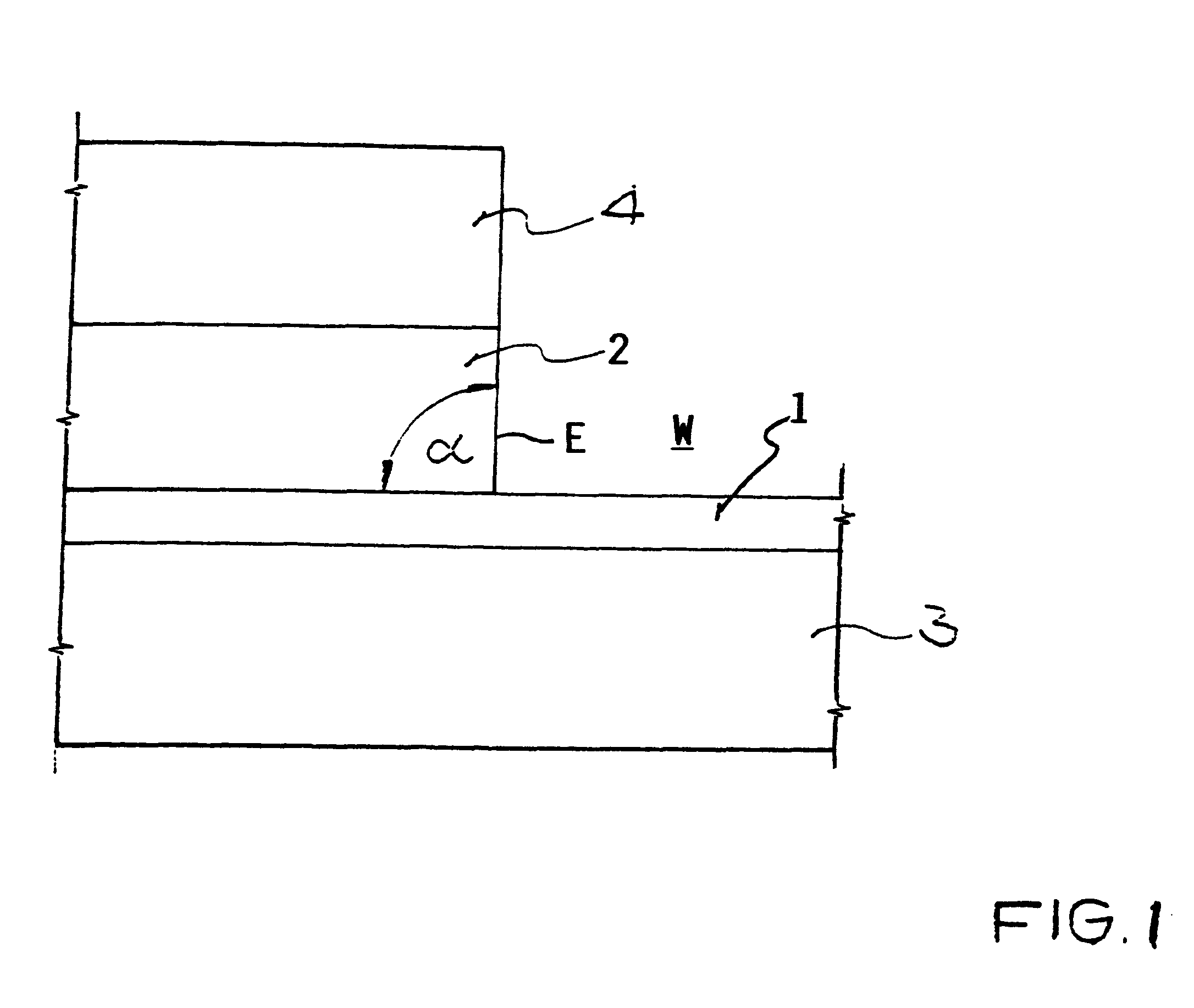

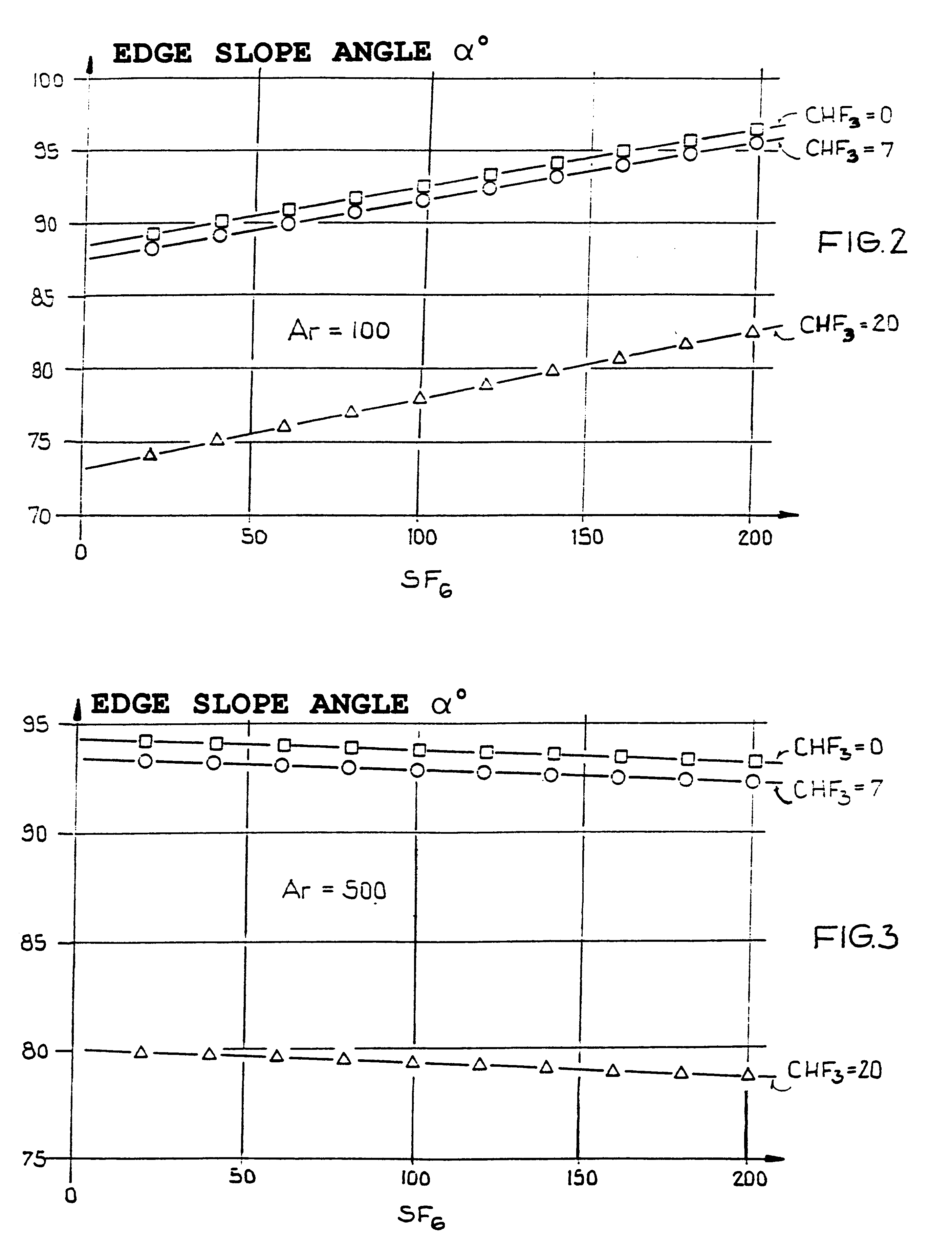

Method for anisotropic plasma-chemical dry etching of silicon nitride layers using a gas mixture containing fluorine

InactiveUS6569773B1Improve uniformityHigh atomic weightSemiconductor/solid-state device manufacturingSilicon oxideOxygen

An etching gas mixture containing CHF3, SF6 and a non-oxidizing gas such as Ar is used as an etching gas mixture for the anisotropic plasma-chemical dry-etching of a silicon nitride layer differentially or selectively relative to a silicon oxide layer. The gas mixture does not contain oxygen, chlorine, bromine, iodine or halides in addition to the above mentioned constituents, so that the process can be carried out in reactor systems equipped with oxidizable electrodes. By adjusting the gas flow rates or composition ratios of CHF3, SF6, and argon in the etching gas mixture, it is possible to adjust the resulting etching selectivity of silicon nitride relative to silicon oxide, and the particular edge slope angle of the etched edge of the remaining silicon nitride layer. A high etch rate for the silicon nitride is simultaneously achieved.

Owner:ATMEL CORP +1

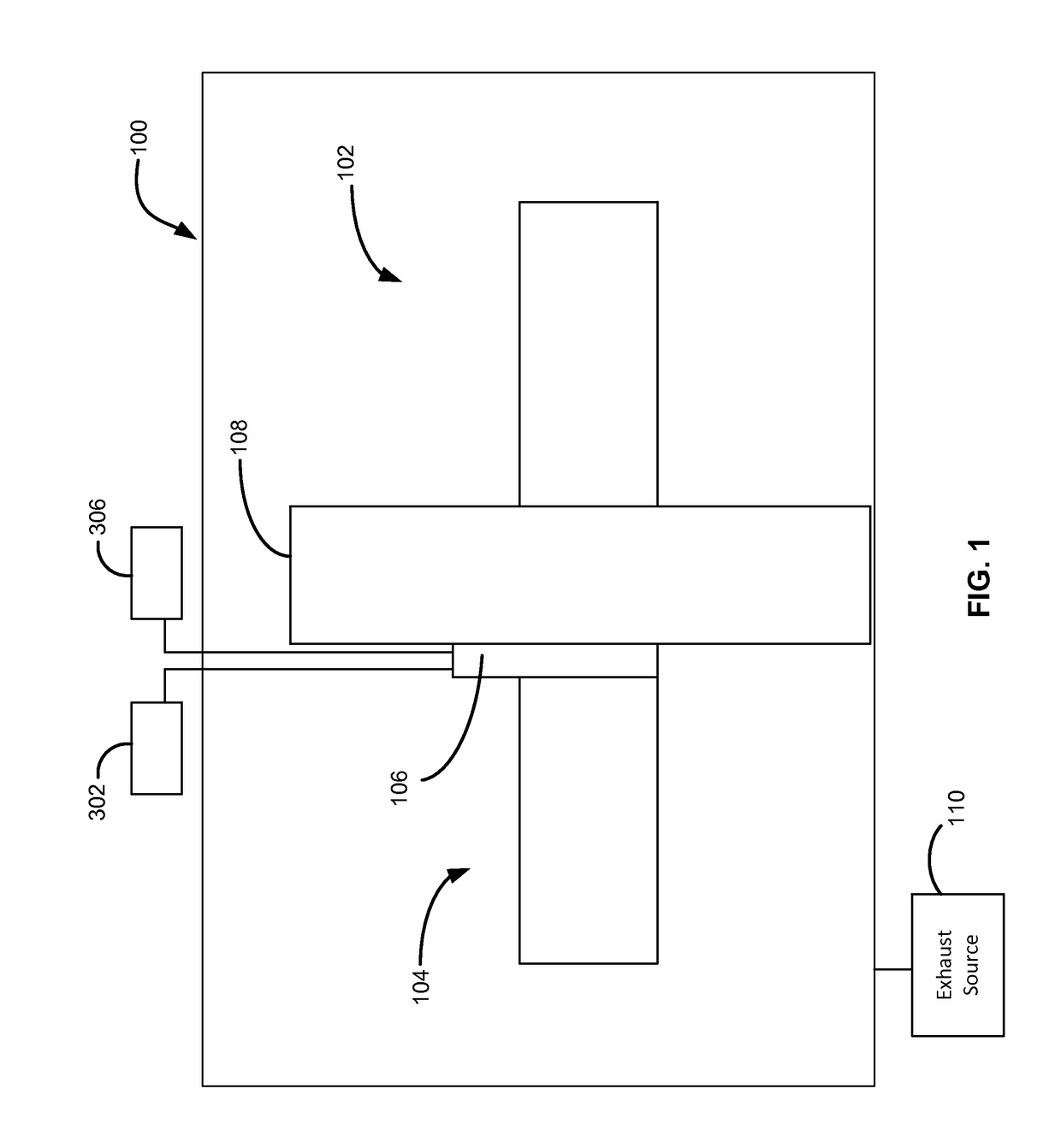

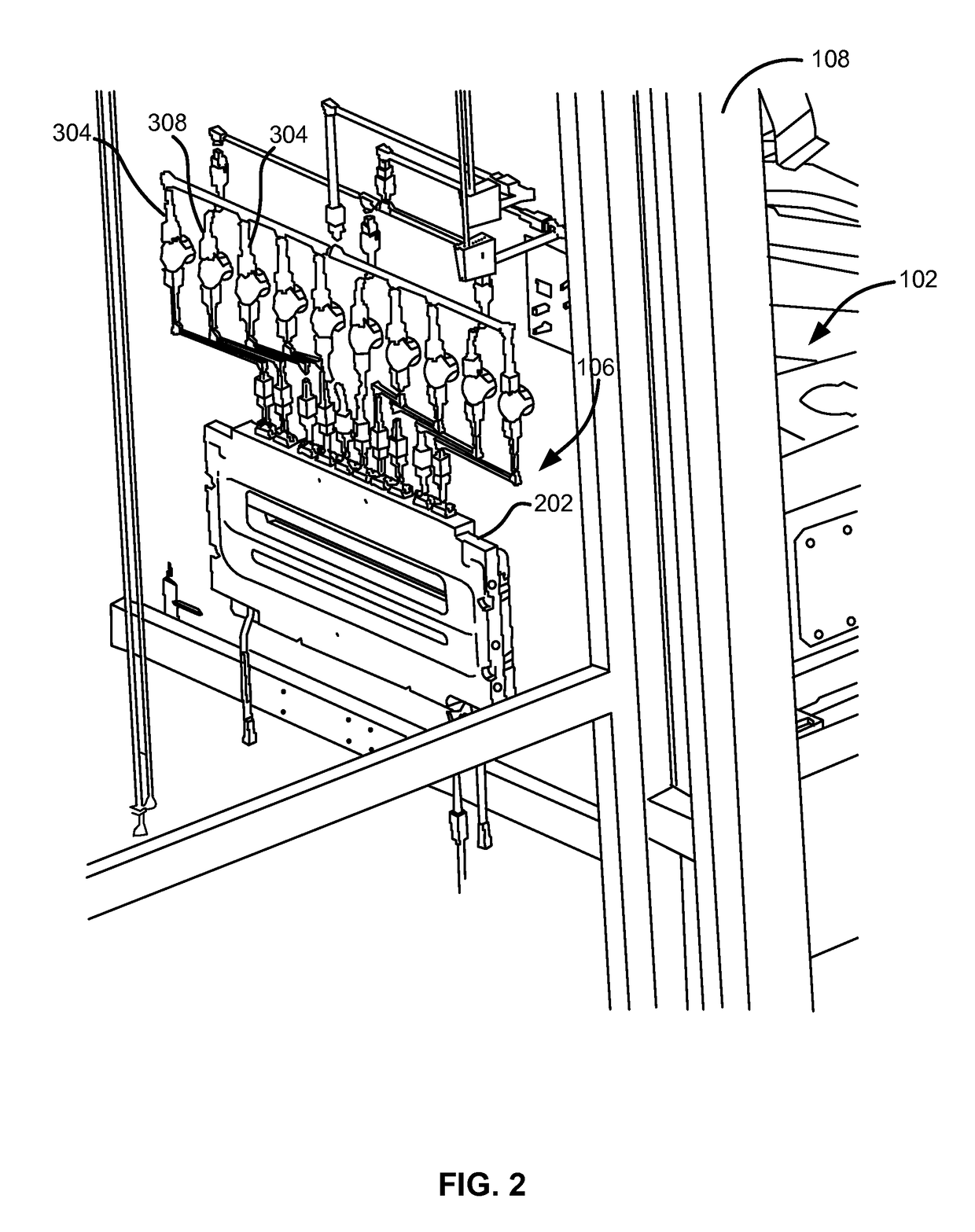

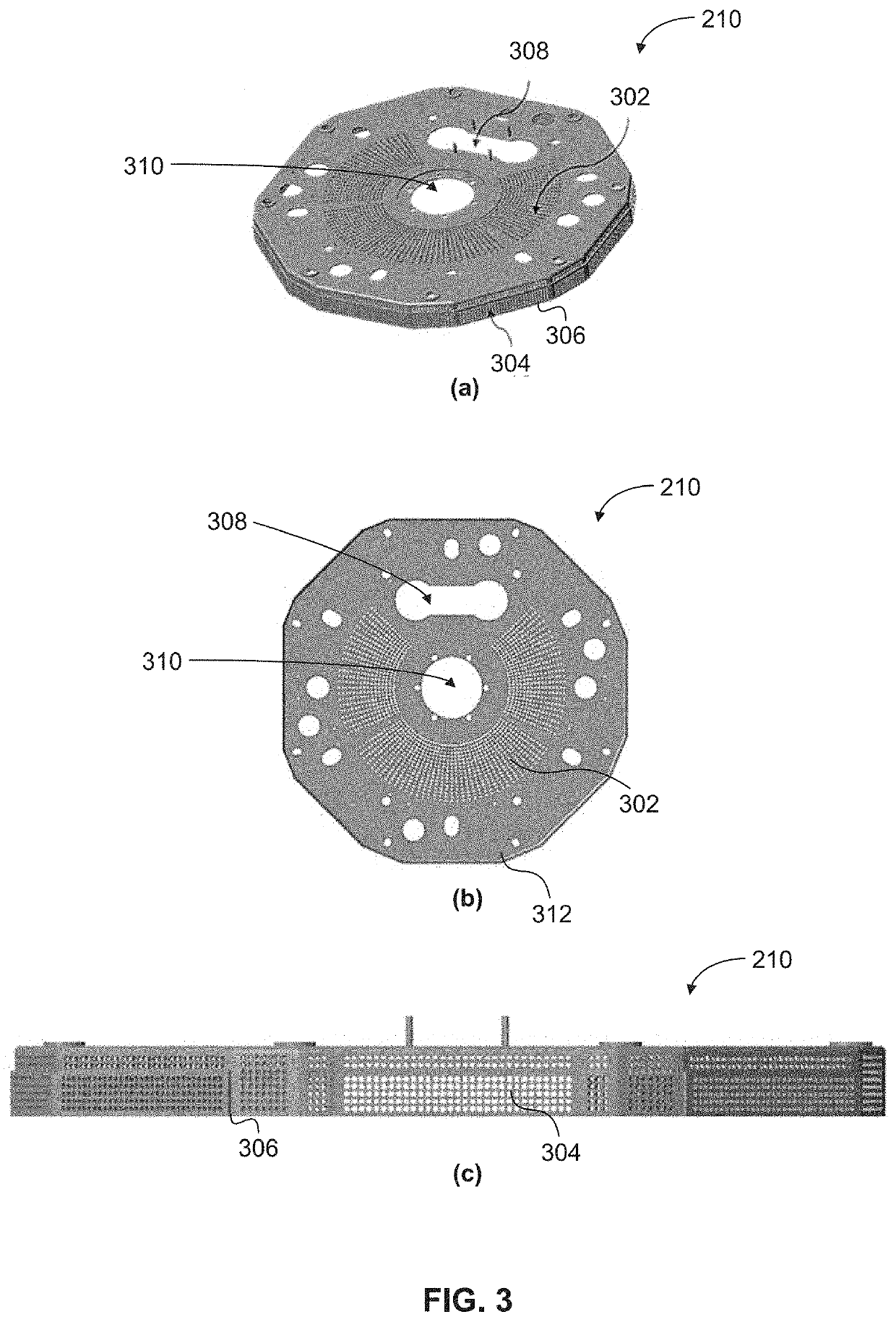

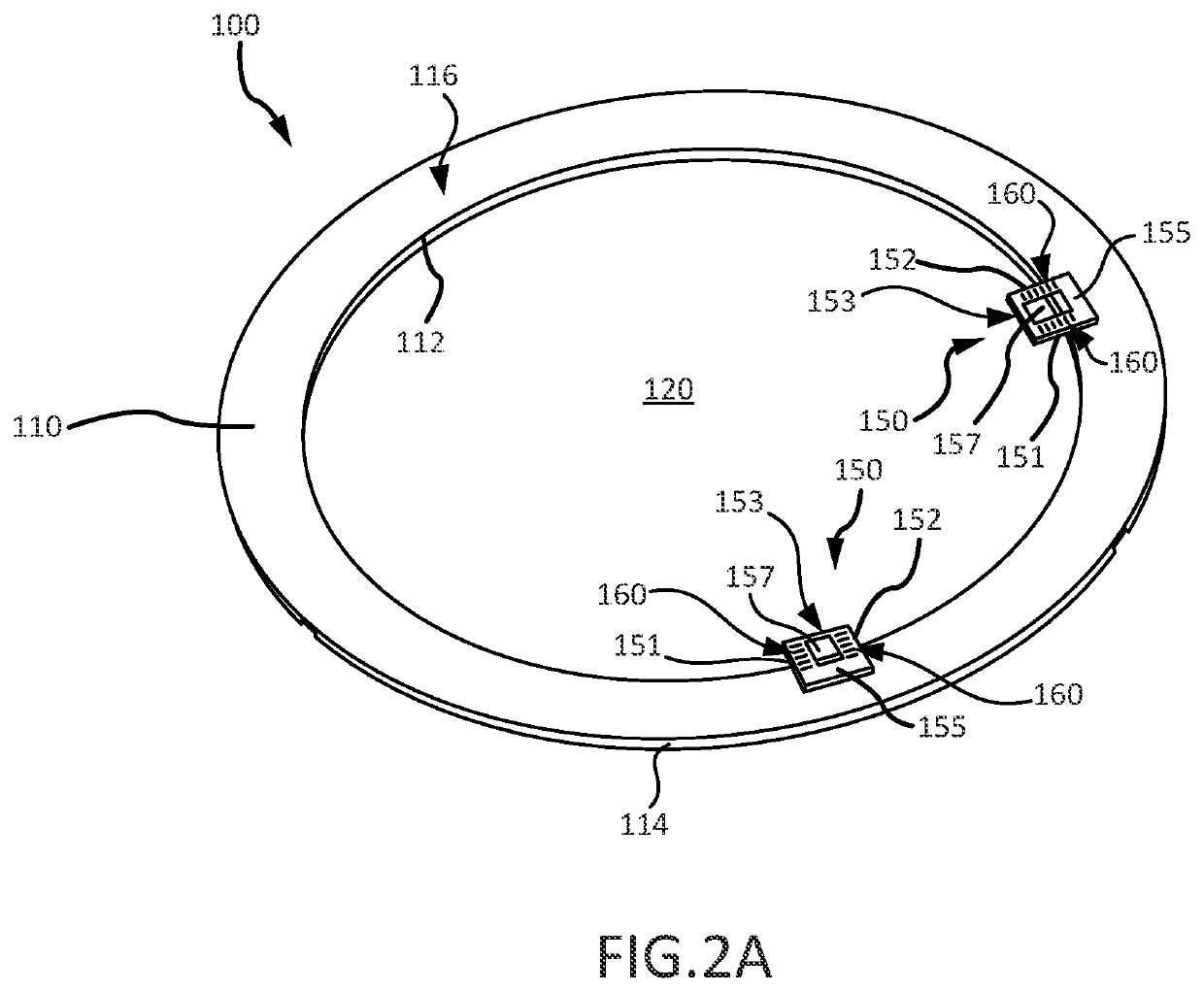

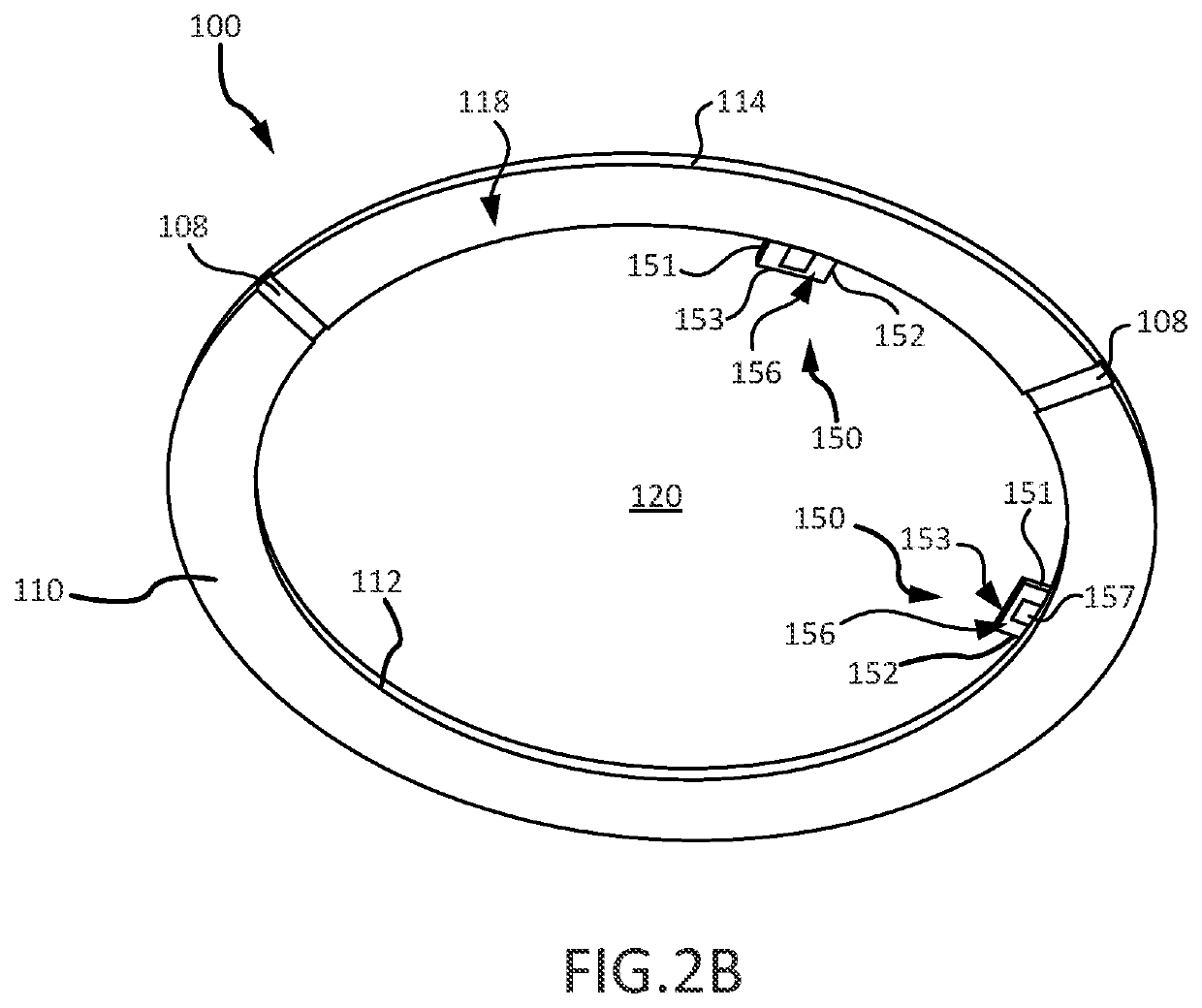

Multi-port gas injection system and reactor system including same

ActiveUS20200040458A1Easy to monitorEasy to controlElectric discharge tubesSemiconductor/solid-state device manufacturingThermodynamicsReactor system

A gas injection system, a reactor system including the gas injection system, and methods of using the gas injection system and reactor system are disclosed. The gas injection system can be used in gas-phase reactor systems to independently monitor and control gas flow rates in a plurality of channels of a gas injection system coupled to a reaction chamber.

Owner:ASM IP HLDG BV

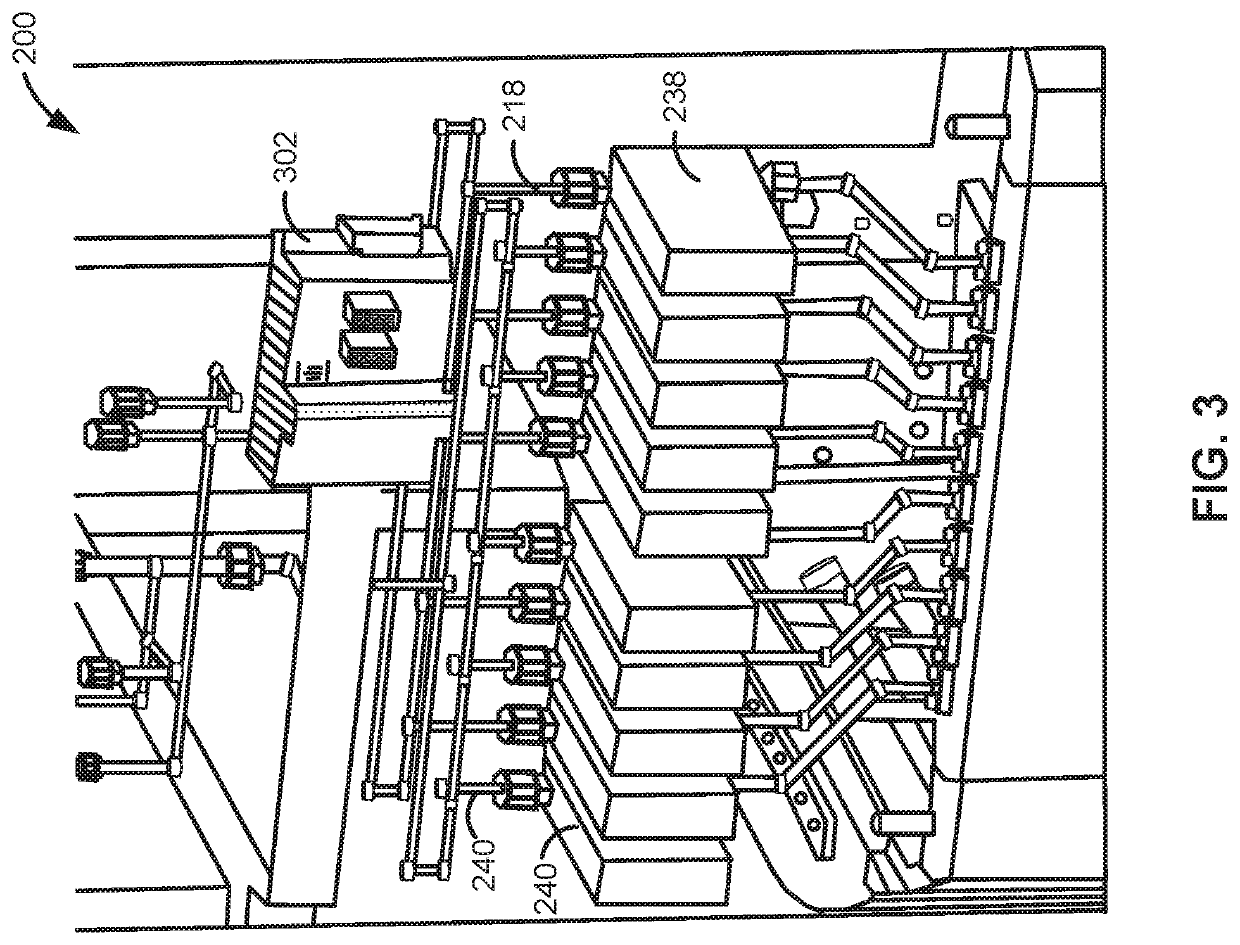

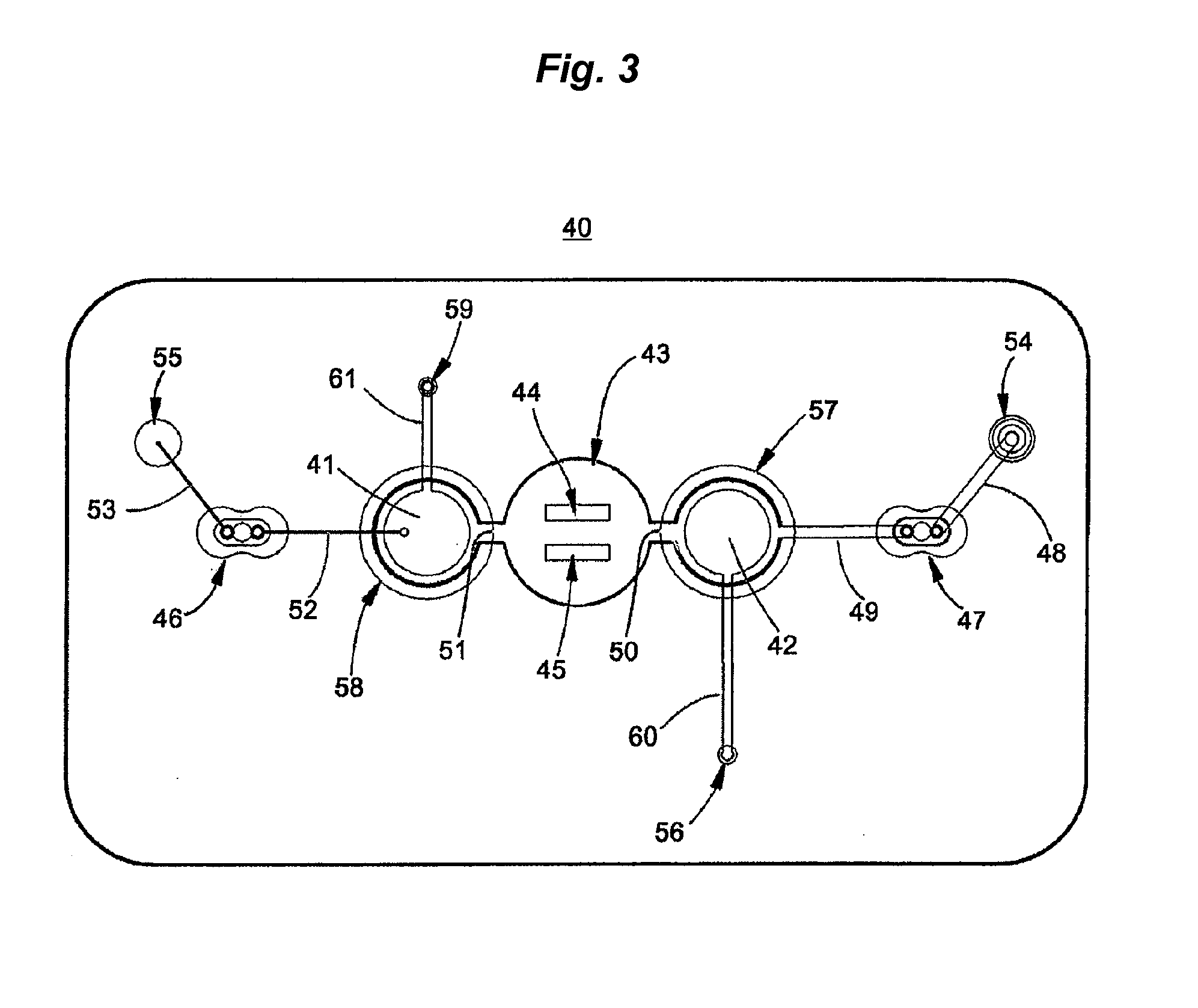

Stirred-tank reactor system

ActiveUS20050239199A1Less regulatory controlConsiderable cost advantageBioreactor/fermenter combinationsBiological substance pretreatmentsReactor systemNuclear engineering

The present invention relates to a stirred-tank reactor system and methods of preparing such systems. The present invention further encompasses the use of the stirred-tank reactor system as a disposable bioreactor and in kits with disposable elements.

Owner:TAKEDA PHARMA CO LTD +1

Synthesis of liquid fuels from biomass

ActiveUS20100076233A1Hydrocarbon by metathesis reactionLiquid hydrocarbon mixture productionFuranAlkane

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to paraffins useful as liquid fuels. The process involves the conversion of water soluble oxygenated hydrocarbons to oxygenates, such as alcohols, furans, ketones, aldehydes, carboxylic acids, diols, triols, and / or other polyols, followed by the subsequent conversion of the oxygenates to paraffins by dehydration and alkylation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

Synthesis of liqiud fuels and chemicals from oxygenated hydrocarbons

ActiveUS20080300434A1Oxygen-containing compound preparationHydrocarbon purification/separationFuranCarboxylic acid

Processes and reactor systems are provided for the conversion of oxygenated hydrocarbons to hydrocarbons, ketones and alcohols useful as liquid fuels, such as gasoline, jet fuel or diesel fuel, and industrial chemicals. The process involves the conversion of mono-oxygenated hydrocarbons, such as alcohols, ketones, aldehydes, furans, carboxylic acids, diols, triols, and / or other polyols, to C4+ hydrocarbons, alcohols and / or ketones, by condensation. The oxygenated hydrocarbons may originate from any source, but are preferably derived from biomass.

Owner:VIRENT

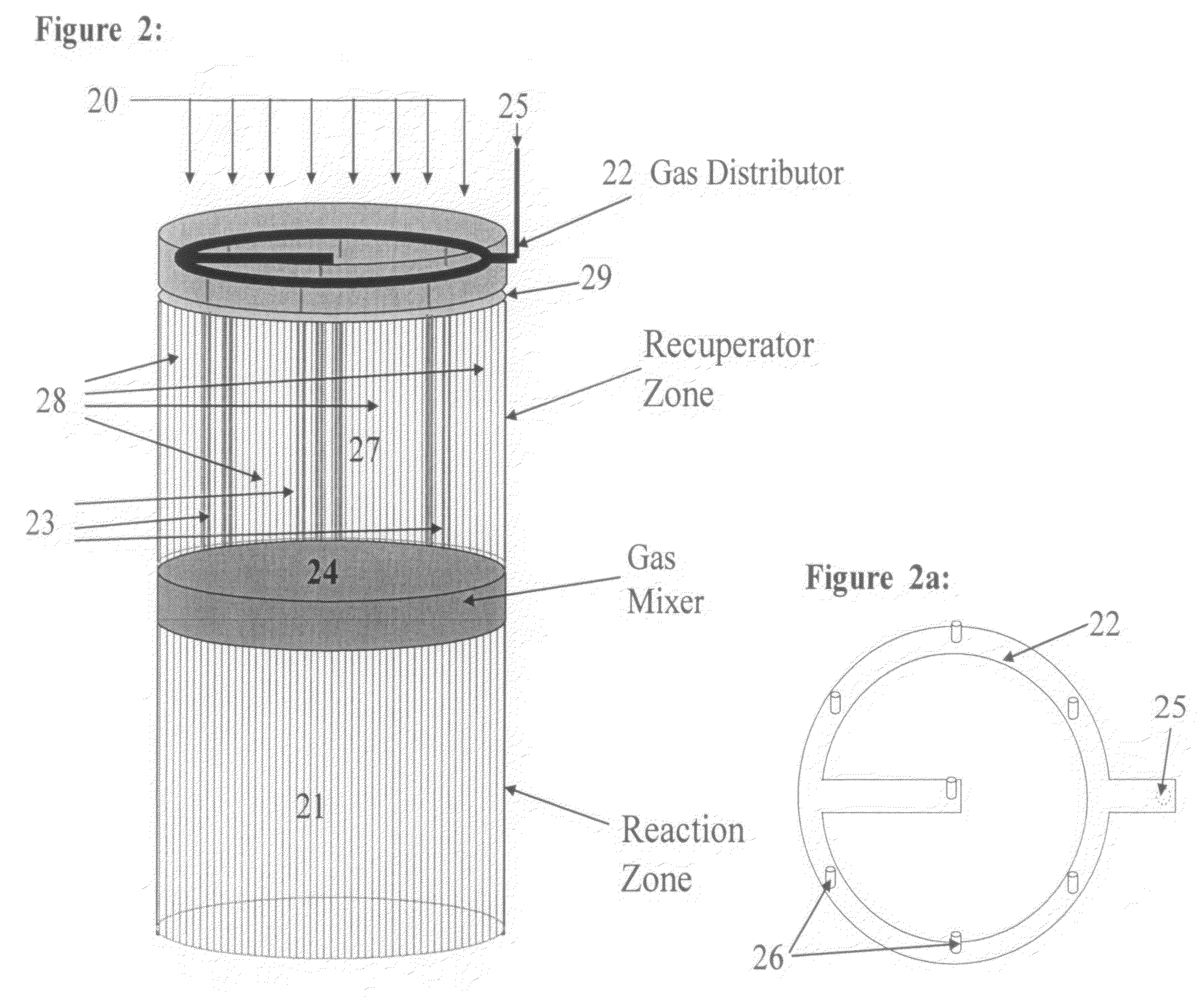

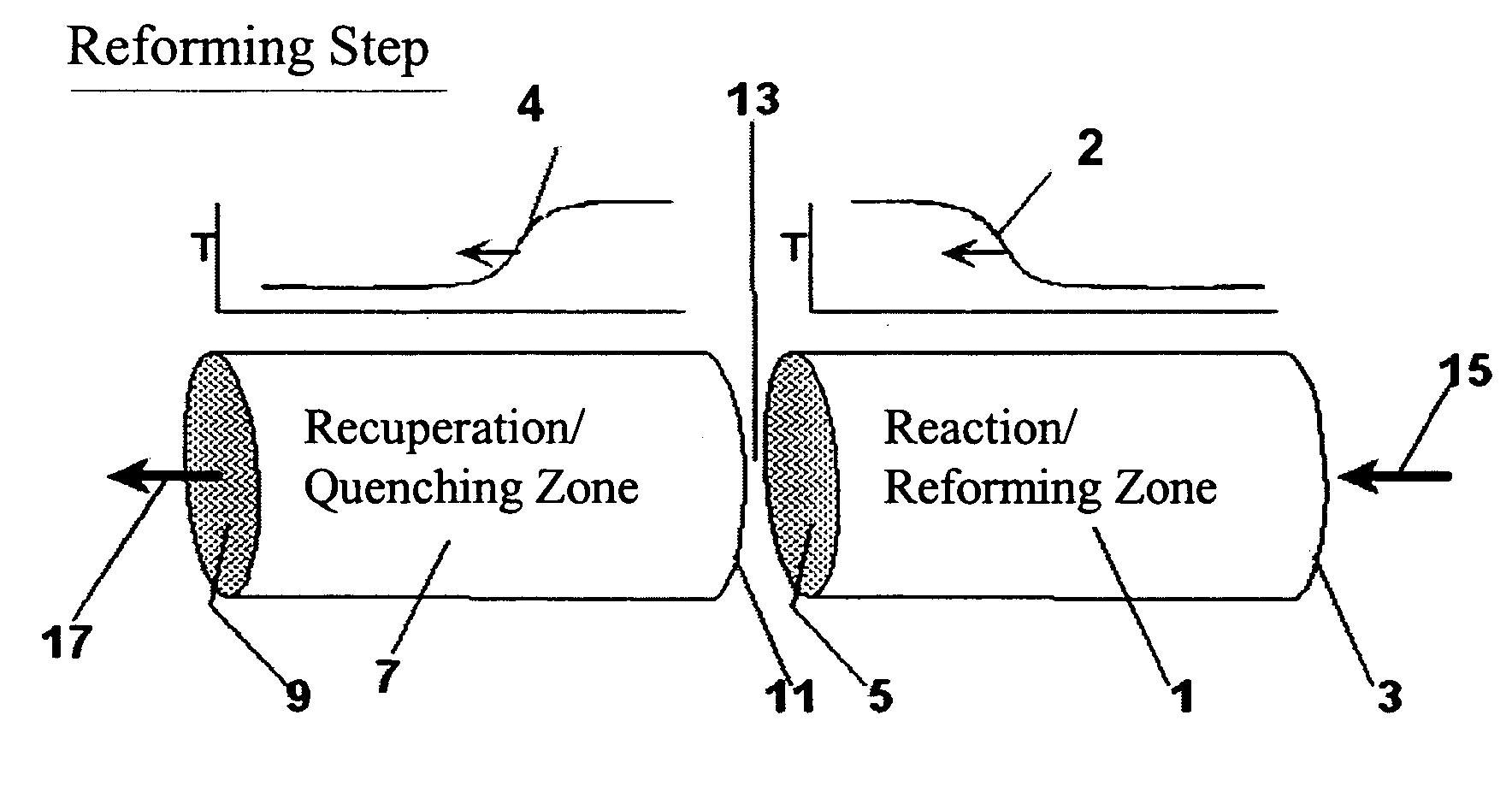

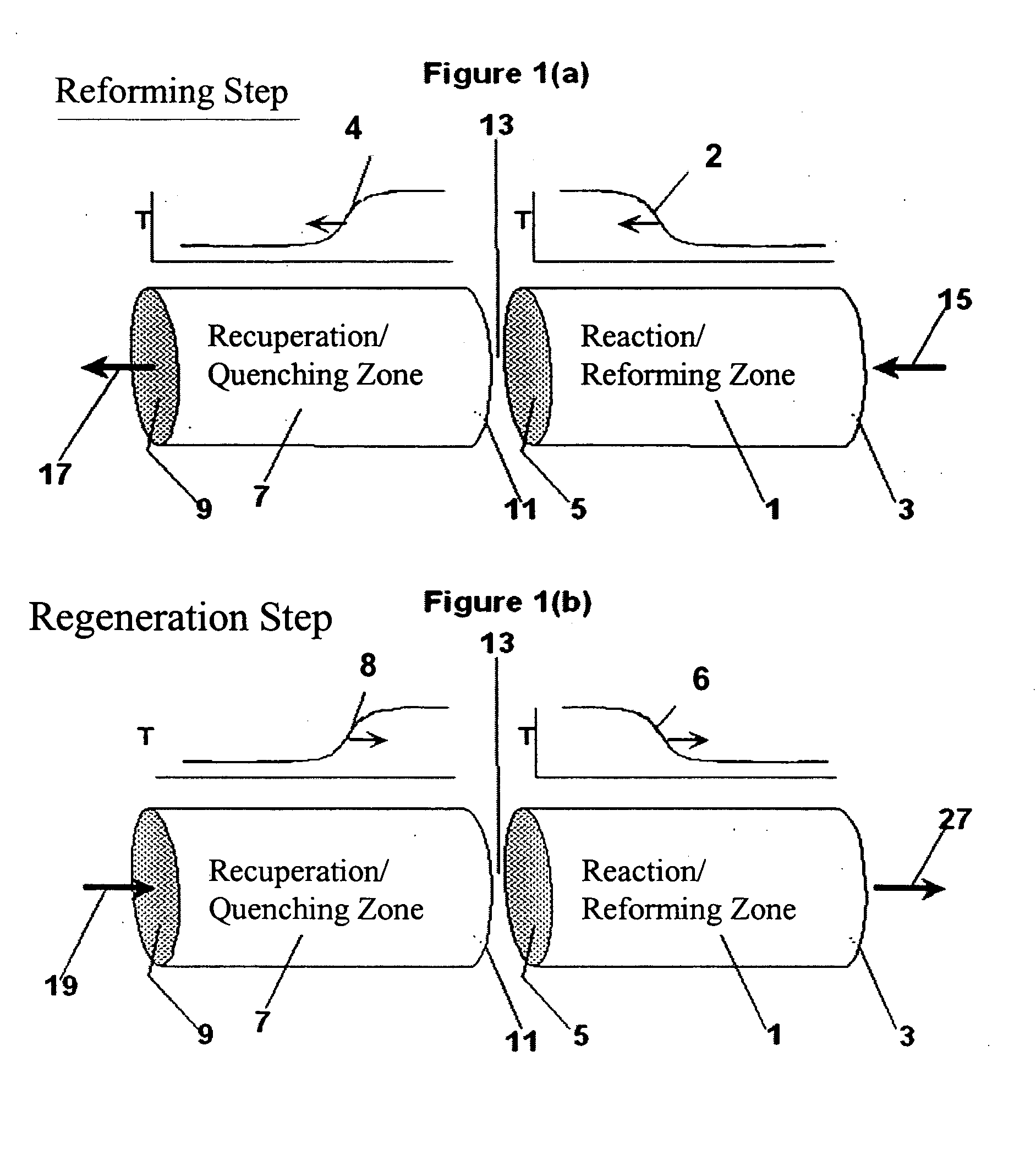

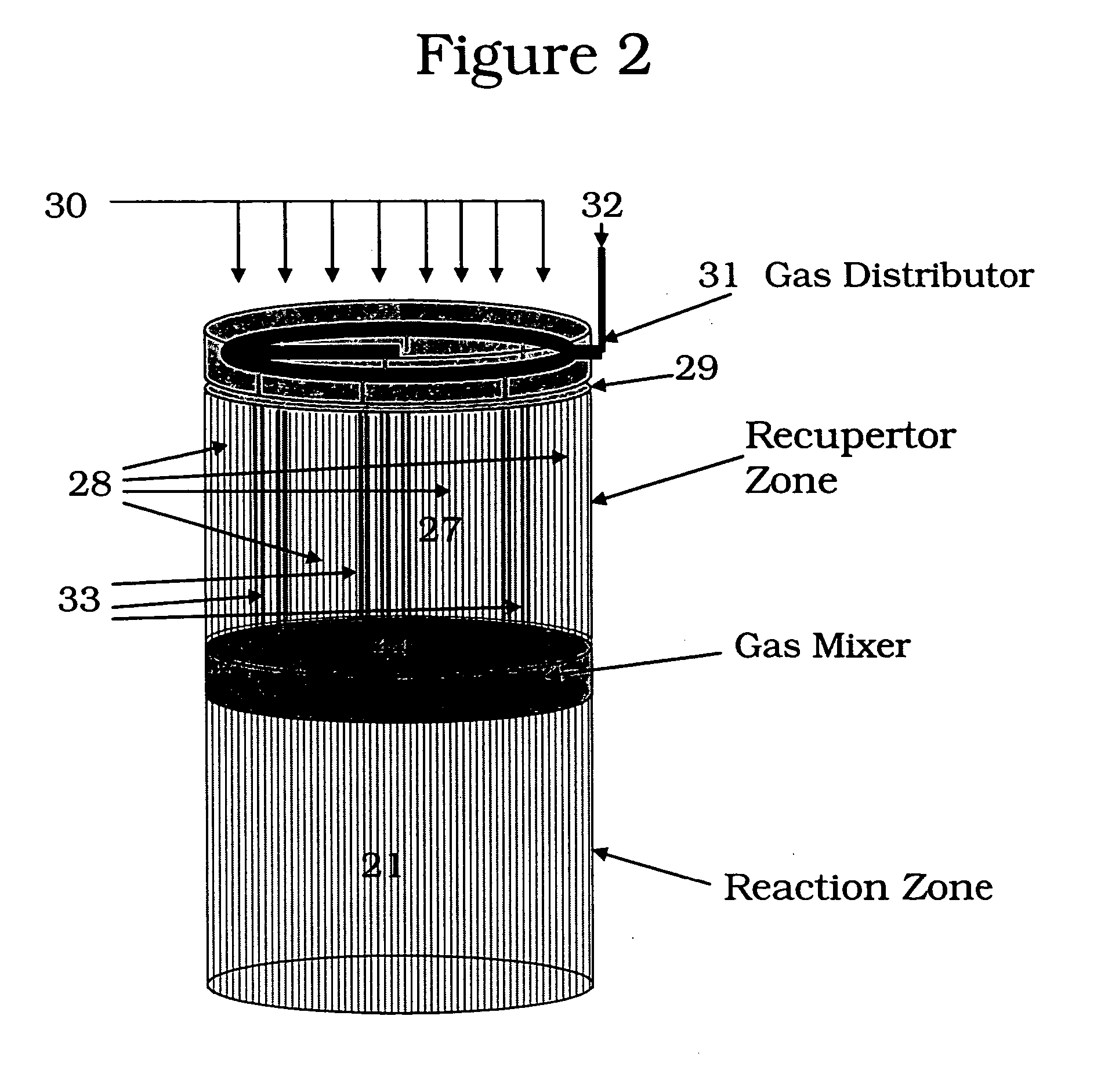

Controlled combustion for regenerative reactors with mixer/flow distributor

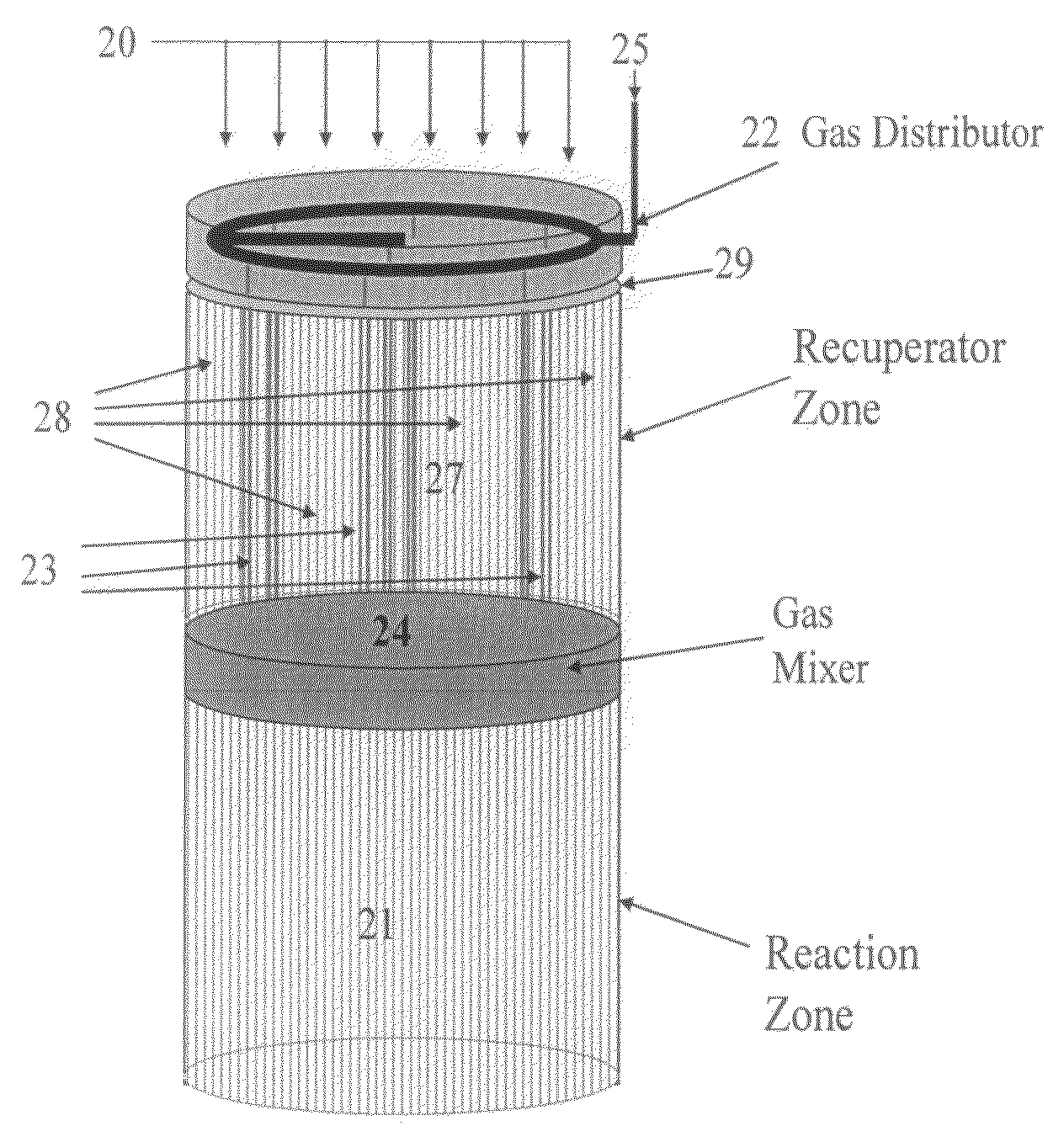

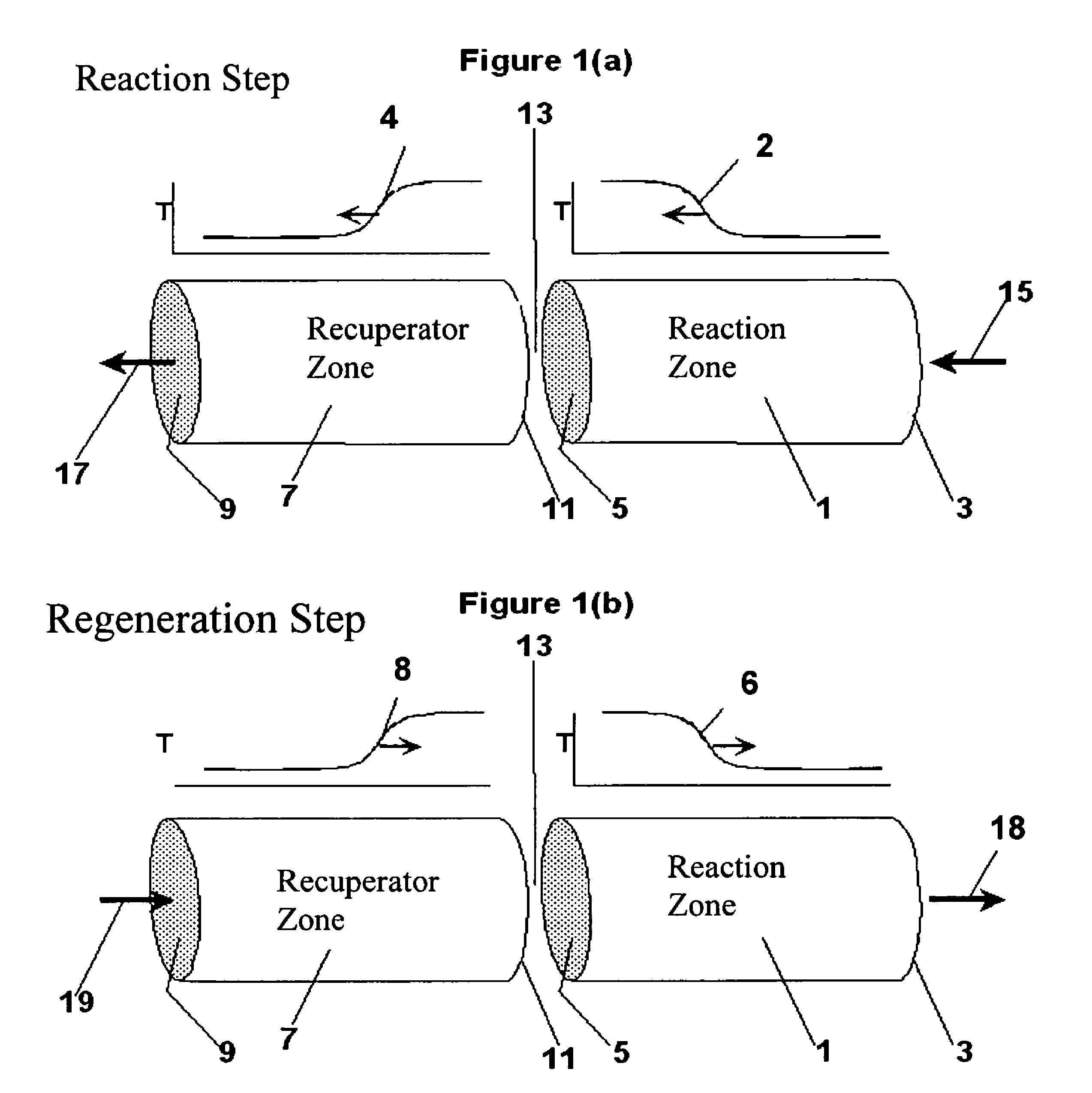

ActiveUS7815873B2Efficient transferEvenly distributedHydrocarbon by dehydrogenationFlow mixersReactor systemCombustion

The overall efficiency of a regenerative bed reverse flow reactor system is increased where the location of the exothermic reaction used for regeneration is suitably controlled. The present invention provides a method and apparatus for controlling the combustion to improve the thermal efficiency of bed regeneration in a cyclic reaction / regeneration processes. The process for thermal regeneration of a regenerative reactor bed entails(a) supplying the first reactant through a first channel means in a first regenerative bed and supplying at least a second reactant through a second channel means in the first regenerative bed,(b) combining said first and second reactants by a gas mixing means situated at an exit of the first regenerative bed and reacting the combined gas to produce a heated reaction product,(c) passing the heated reaction product through a second regenerative bed thereby transferring heat from the reaction product to the second regenerative bed.

Owner:EXXON RES & ENG CO

Methane conversion to higher hydrocarbons

ActiveUS20070191664A1Efficient preparationValid conversionGenerators with non-automatic water feedFlow mixersReactor systemReagent

The present invention provides a process for the manufacture of acetylene and other higher hydrocarbons from methane feed using a reverse-flow reactor system, wherein the reactor system includes (i) a first reactor and (ii) a second reactor, the first and second reactors oriented in a series relationship with respect to each other, the process comprising supplying each of first and second reactant through separate channels in the first reactor bed of a reverse-flow reactor such that both of the first and second reactants serve to quench the first reactor bed, without the first and second reactants substantially reacting with each other until reaching the core of the reactor system.

Owner:EXXONMOBIL CHEM PAT INC

Gas-phase reactor system and method of using same

PendingUS20200340138A1Readily apparentElectric discharge tubesSemiconductor/solid-state device manufacturingReactor systemPhysical chemistry

Gas-phase reactor systems and methods suitable for use with precursors that are solid phase at room temperature and pressure are disclosed. The systems and methods as described herein can be used to, for example, form amorphous, polycrystalline, or epitaxial layers (e.g., one or more doped semiconductor layers) on a surface of a substrate.

Owner:ASM IP HLDG BV

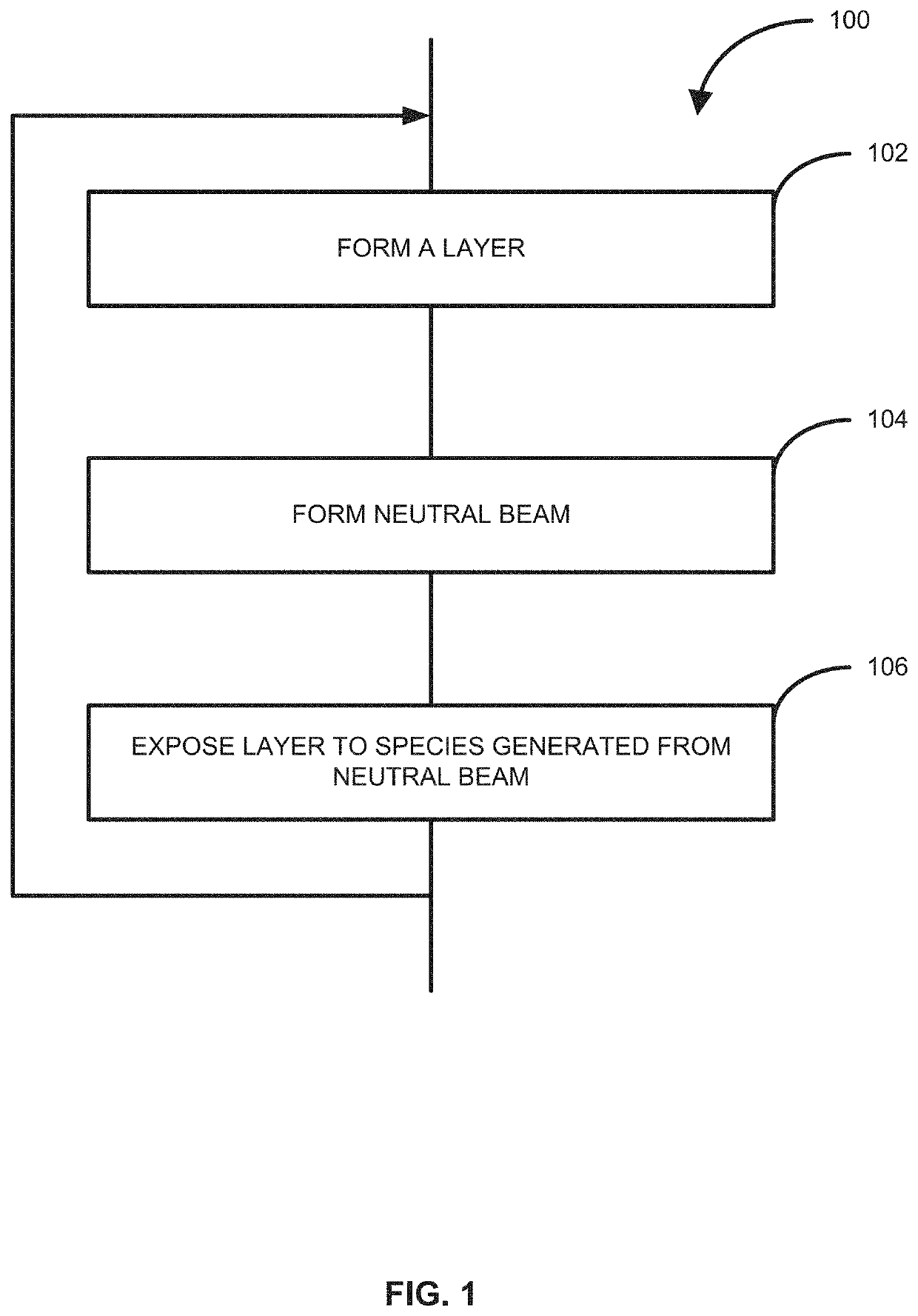

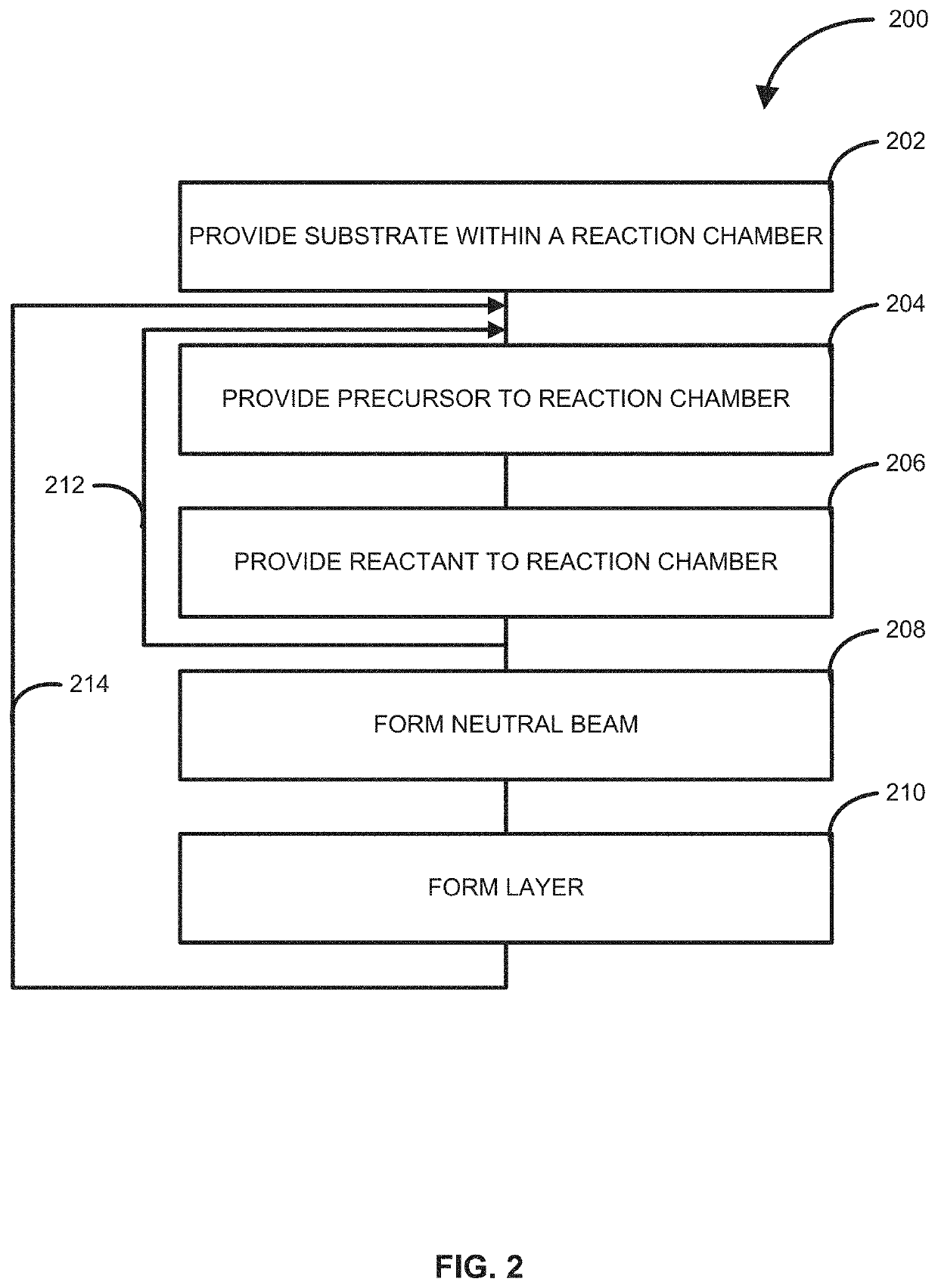

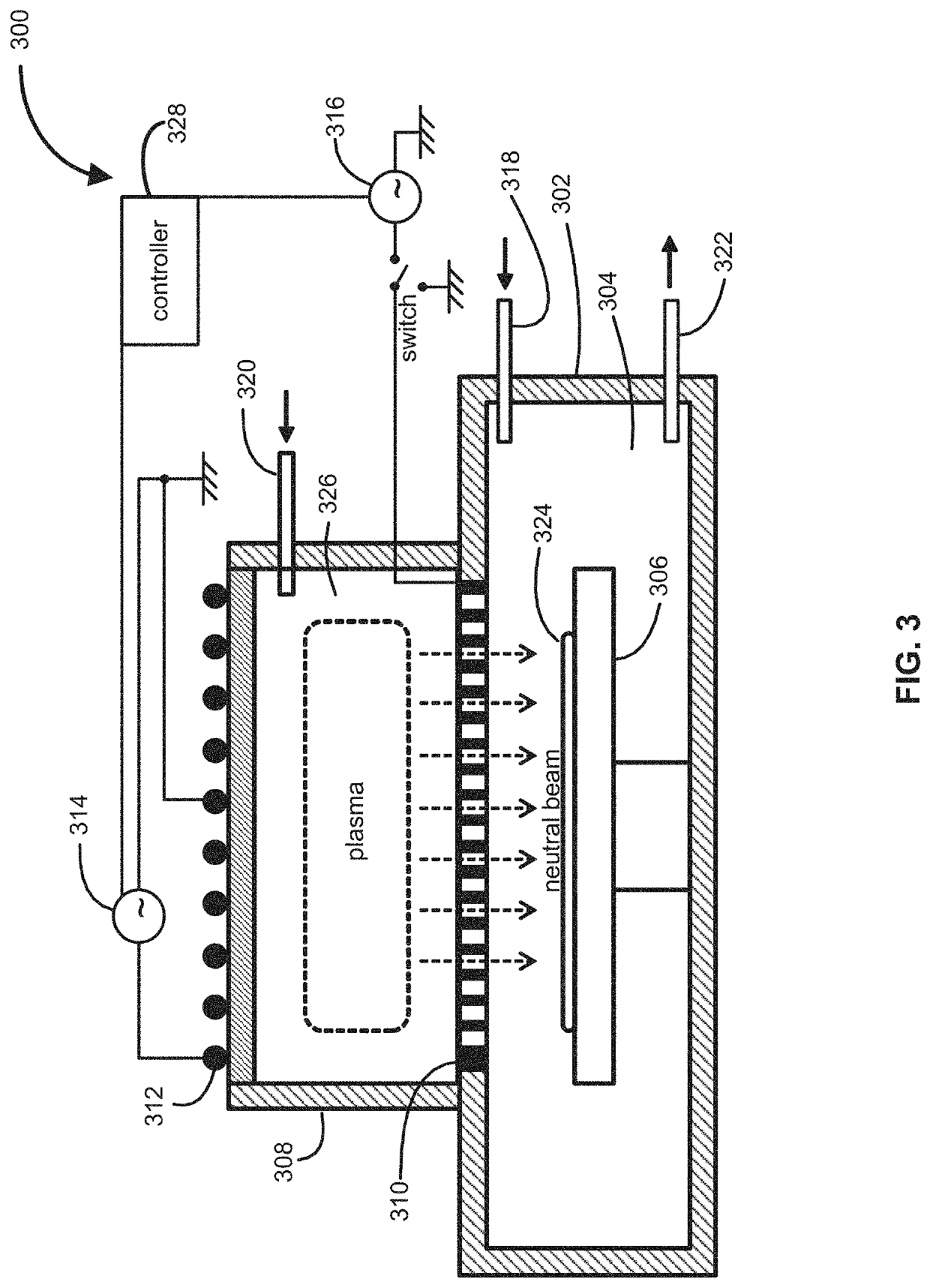

Method of forming structures using a neutral beam, structures formed using the method and reactor system for performing the method

ActiveUS20210017648A1Readily apparentMasersChemical vapor deposition coatingReactor systemEngineering

Owner:ASM IP HLDG BV

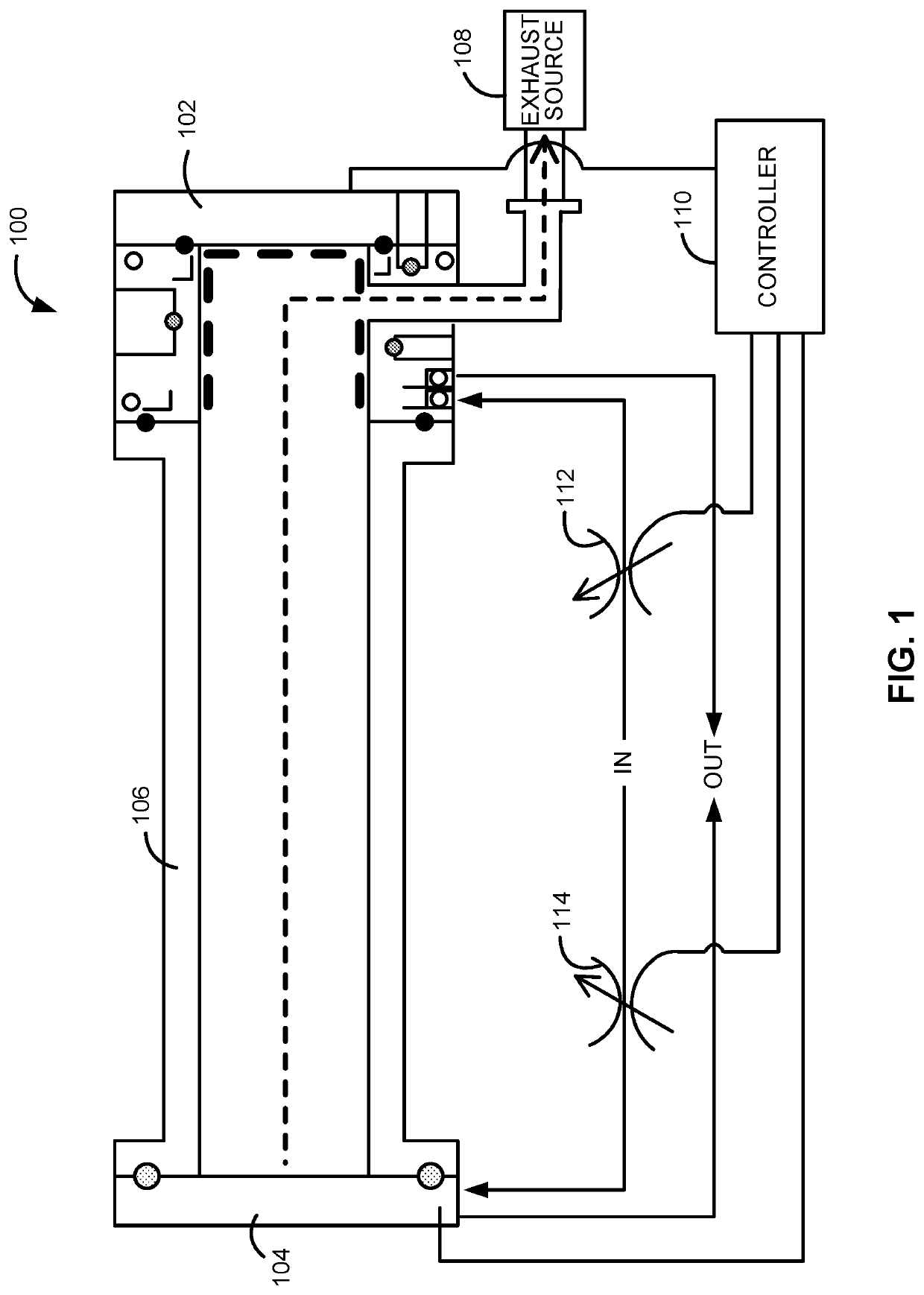

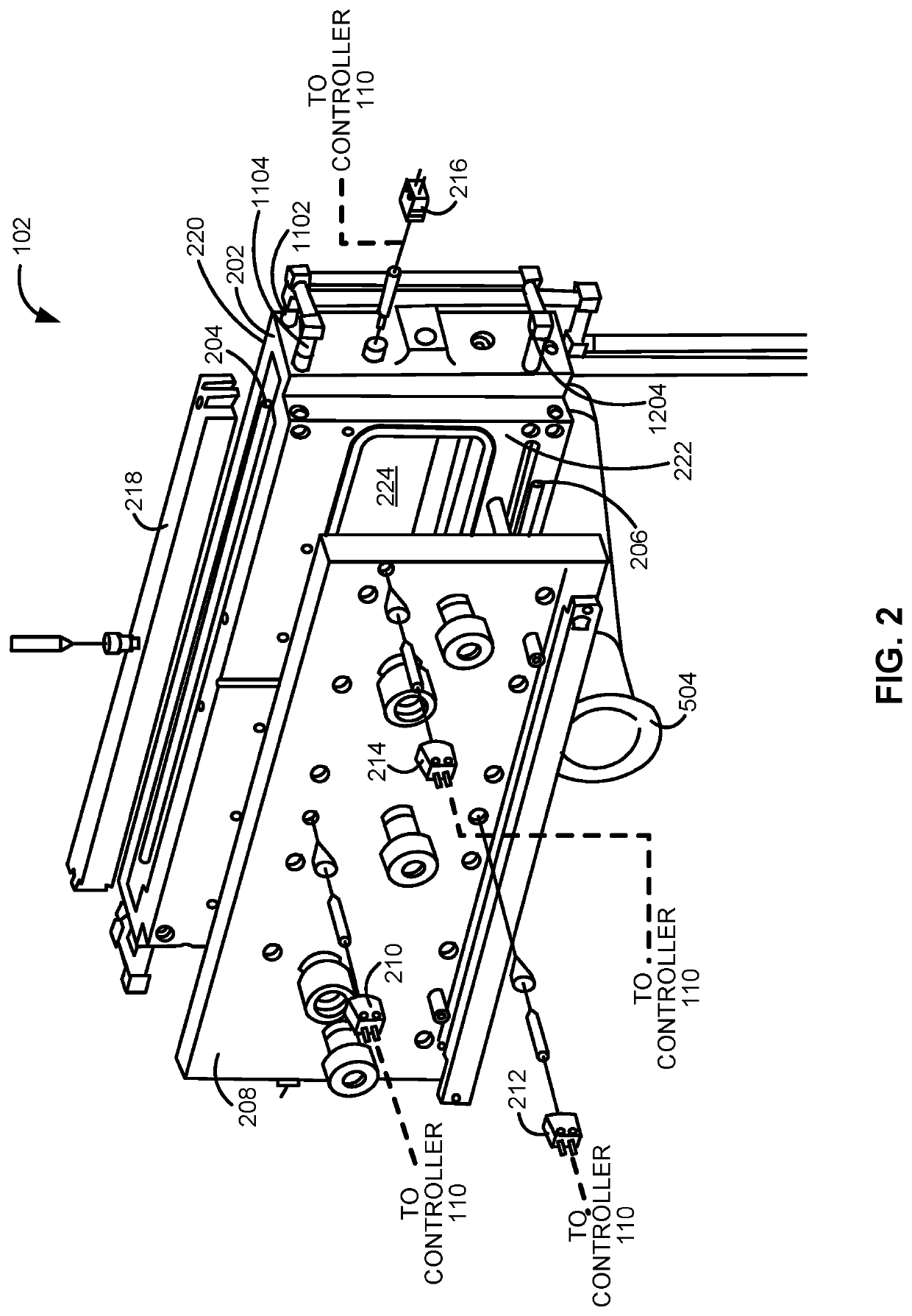

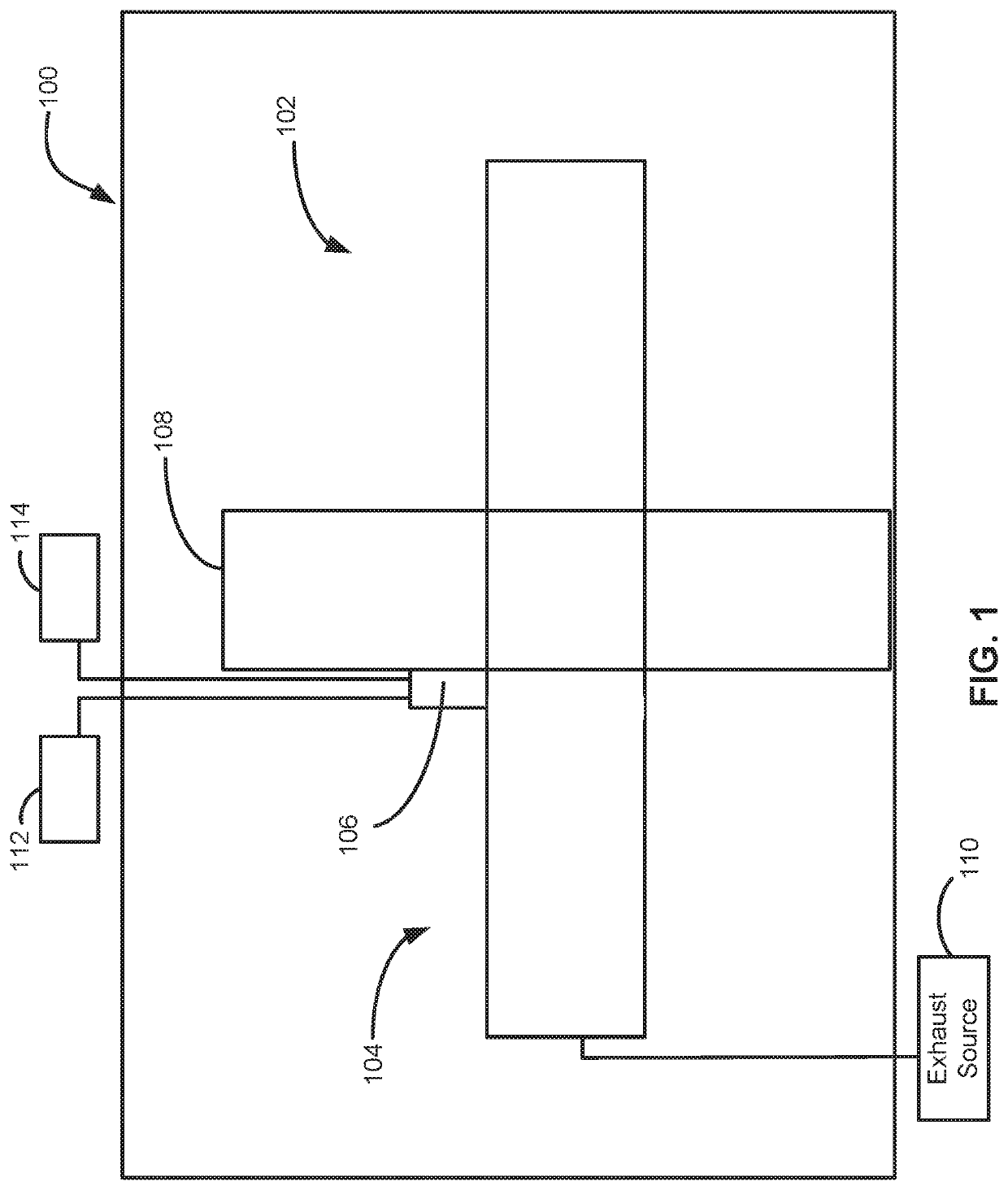

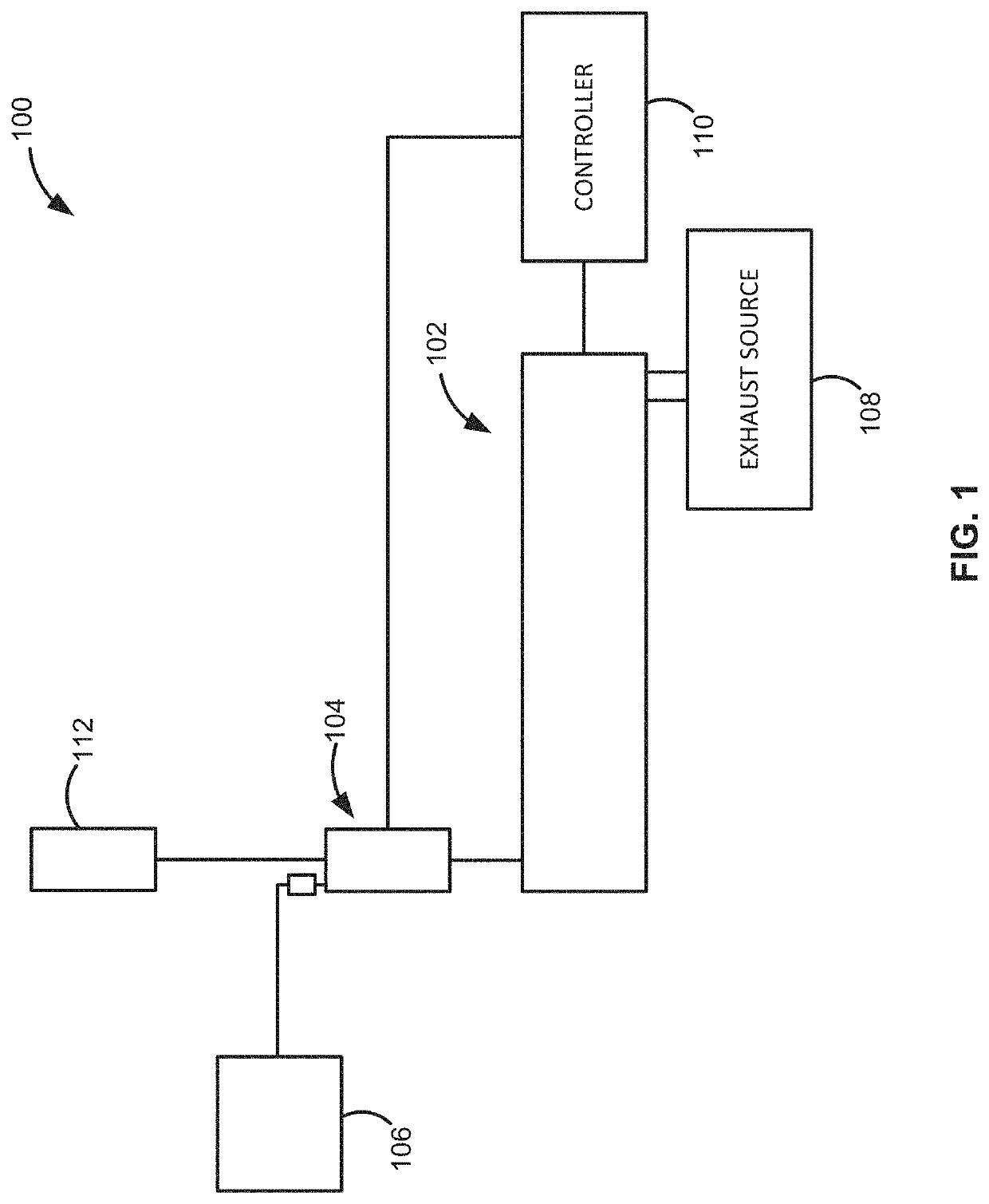

Temperature control assembly for substrate processing apparatus and method of using same

ActiveUS20210002762A1Readily apparentElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlReactor system

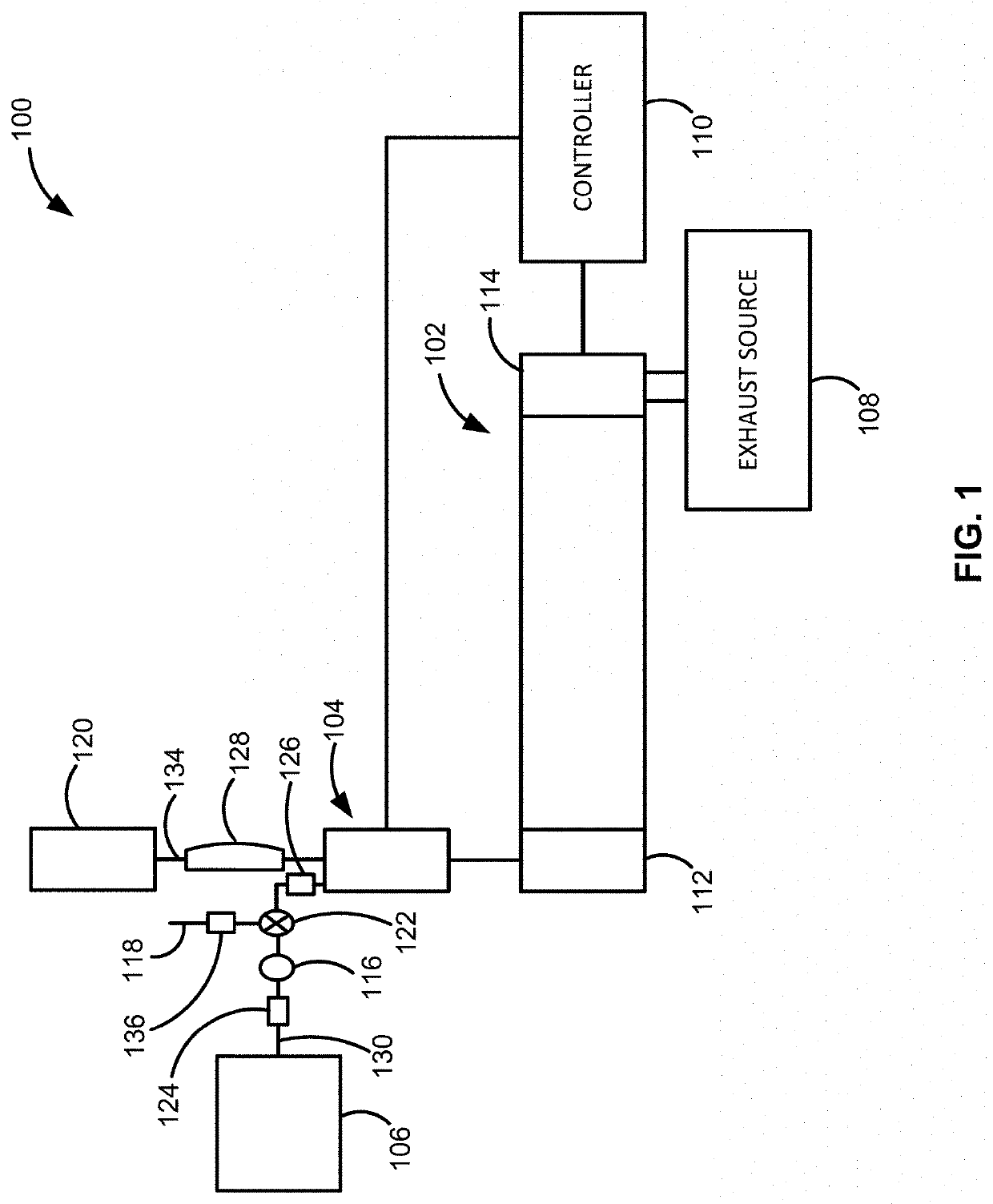

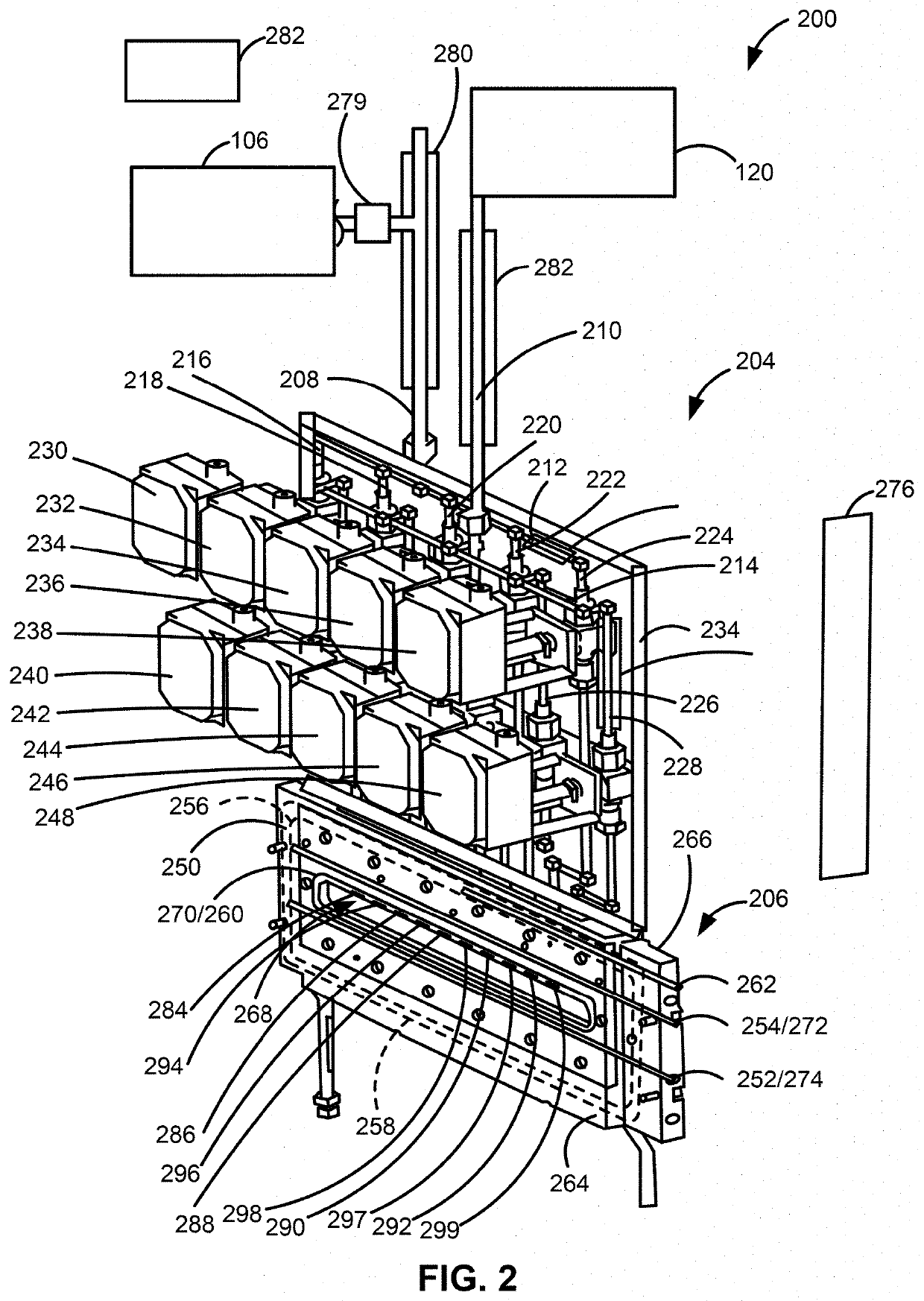

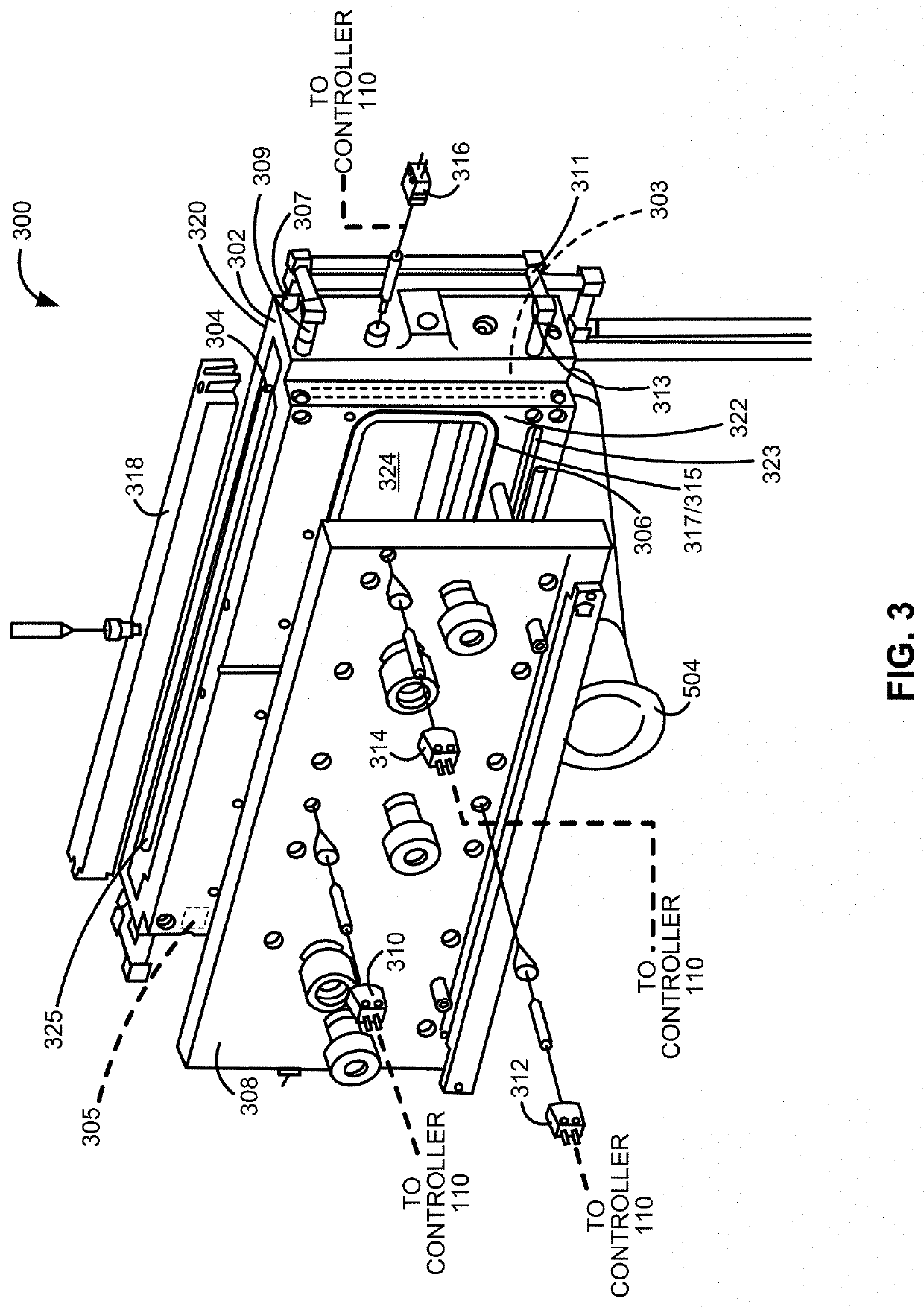

Exemplary embodiments of the disclosure provide improved reactor systems, assemblies, and methods for controlling a temperature within the reactor system, such as a temperature of a gas supply unit. Exemplary systems and methods employ an exhaust unit to cause movement of a fluid over a portion of the gas supply unit to better control the temperature of the gas supply unit.

Owner:ASM IP HLDG BV

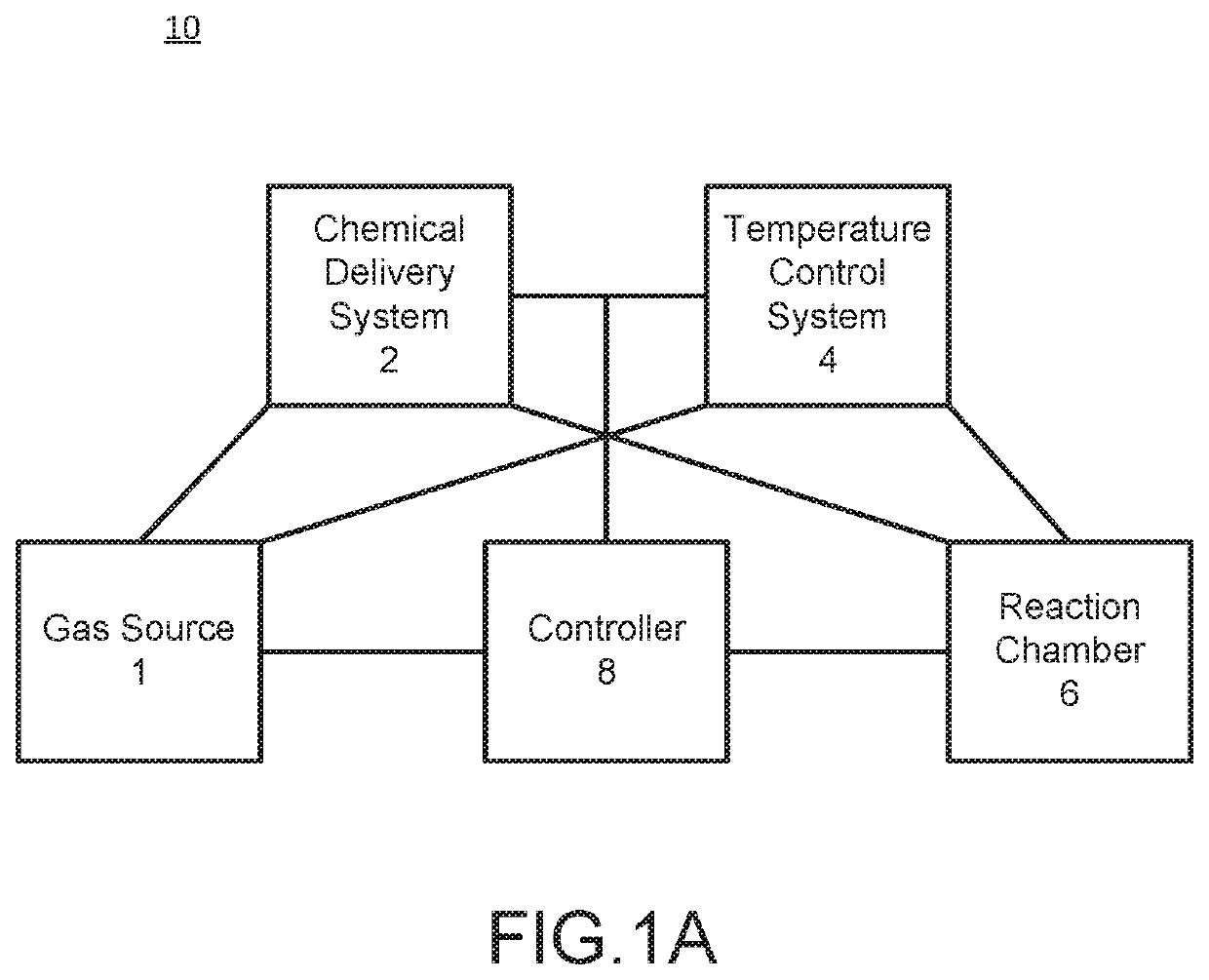

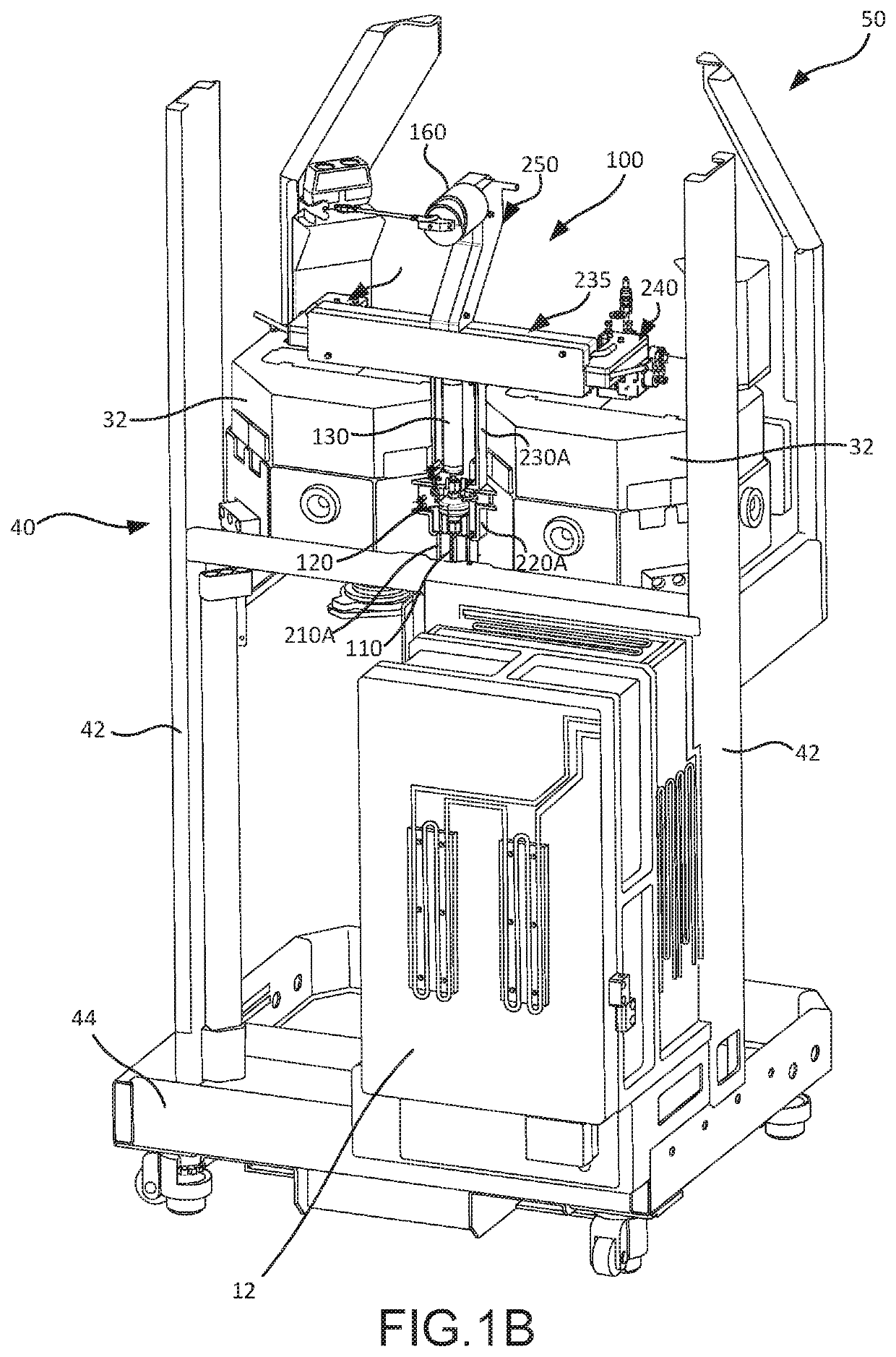

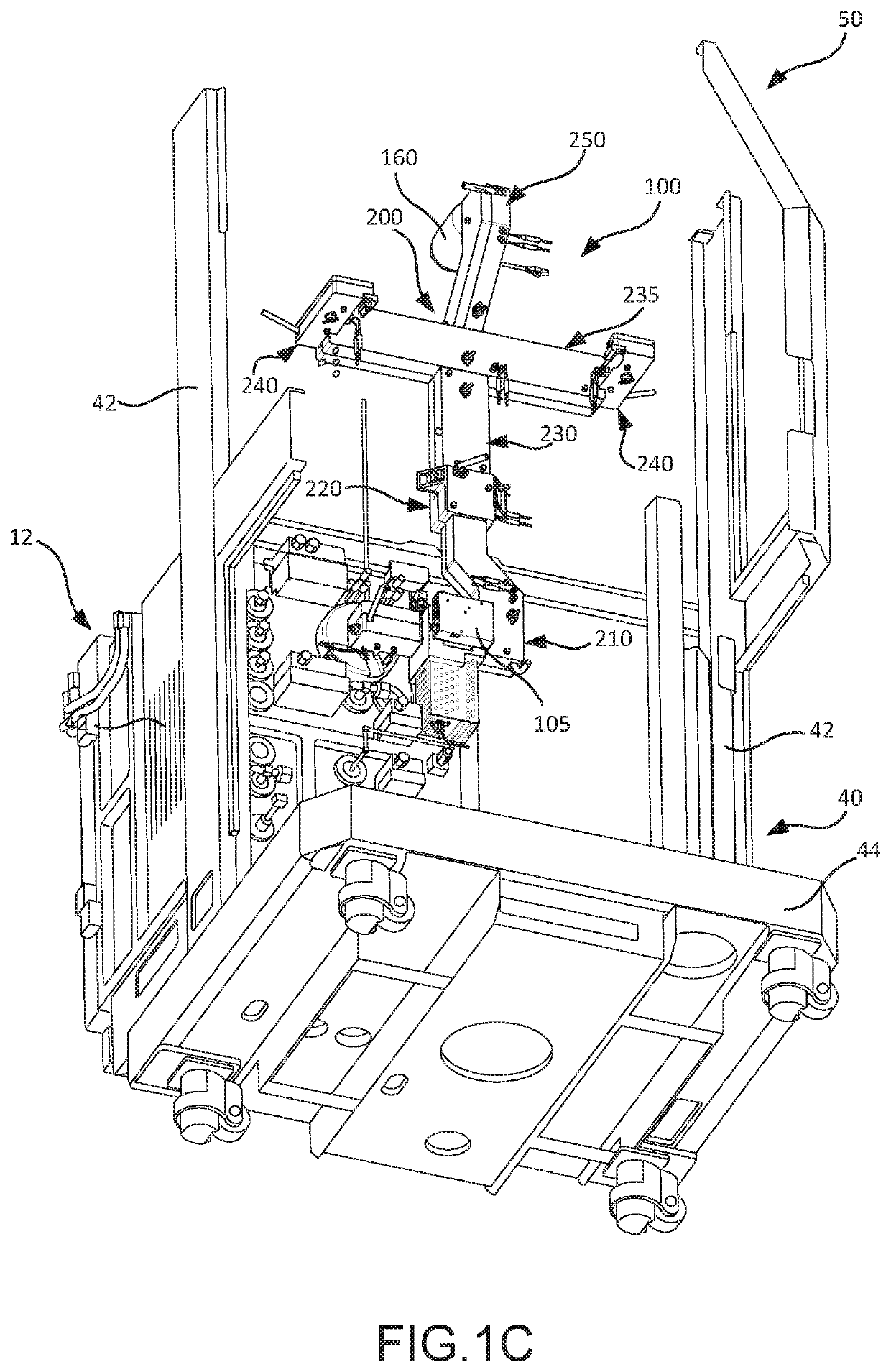

Temperature-controlled chemical delivery system and reactor system including same

PendingUS20210040615A1Semiconductor/solid-state device manufacturingFrom chemically reactive gasesTemperature controlReactor system

A temperature control system for a chemical delivery system (e.g., comprised in a reactor system) may comprise a temperature control shell coupled to and / or enclosing at least a portion of at least one component of the chemical delivery system. A chemical delivery system may comprise a filter, an accumulator, and / or a chemical application line fluidly coupled to one another in any suitable arrangement and / or configuration. A temperature control system for such a chemical delivery system may comprise a filter temperature control shell coupled to and / or enclosing at least a portion of the filter, an accumulator temperature control shell coupled to and / or enclosing at least a portion of the accumulator, and / or an application line temperature control shell coupled to and / or enclosing at least a portion of the chemical application line.

Owner:ASM IP HLDG BV

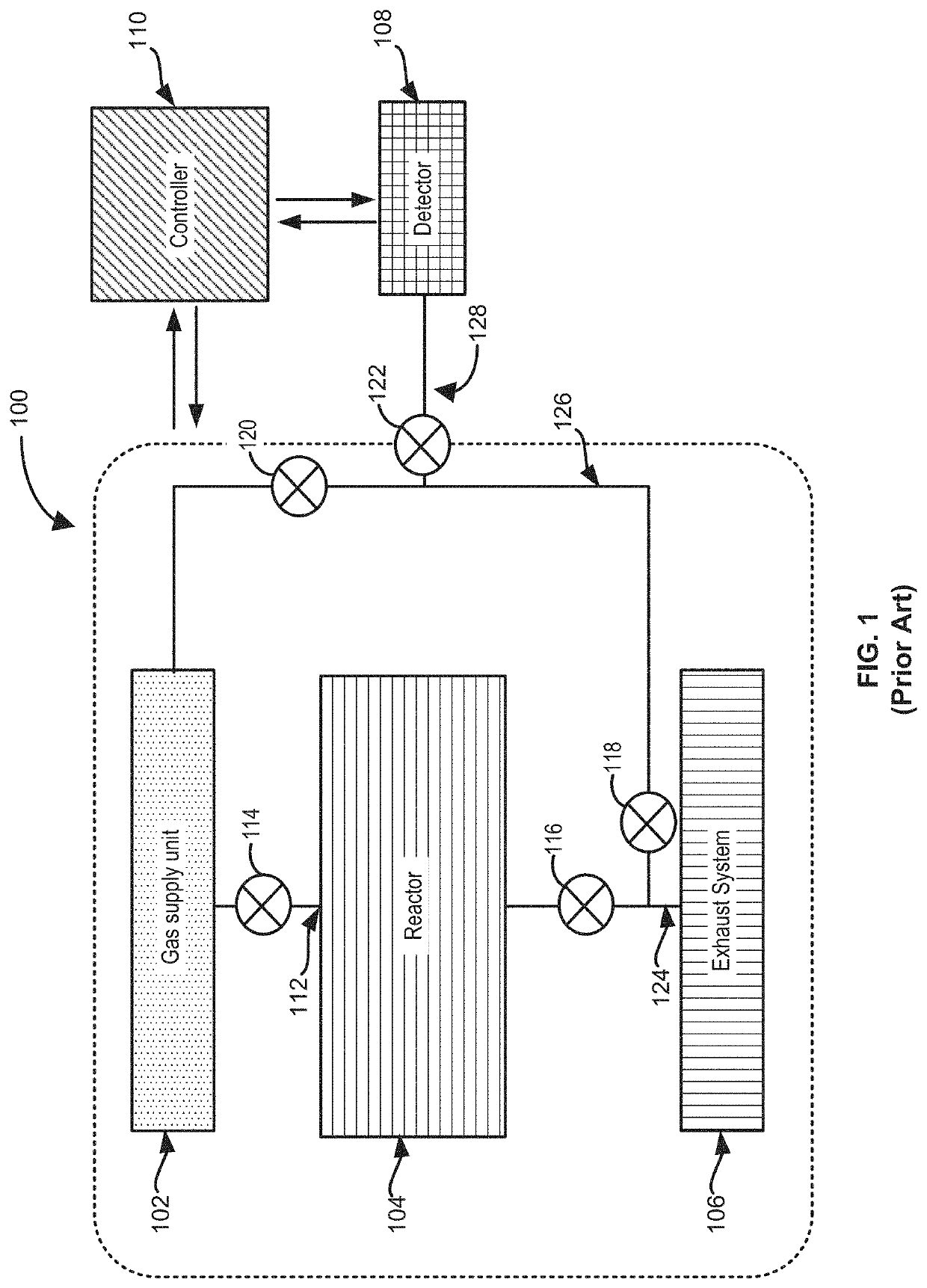

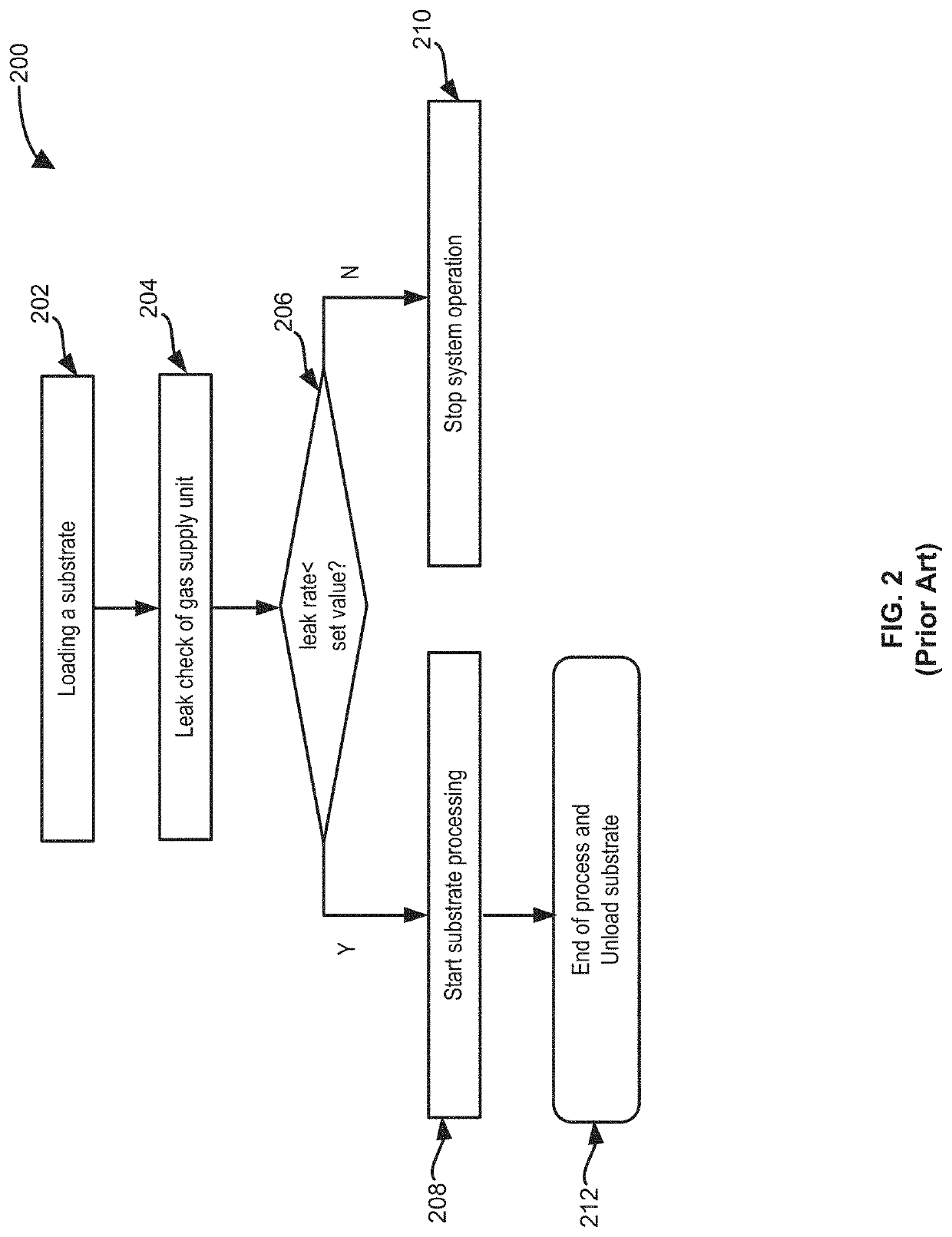

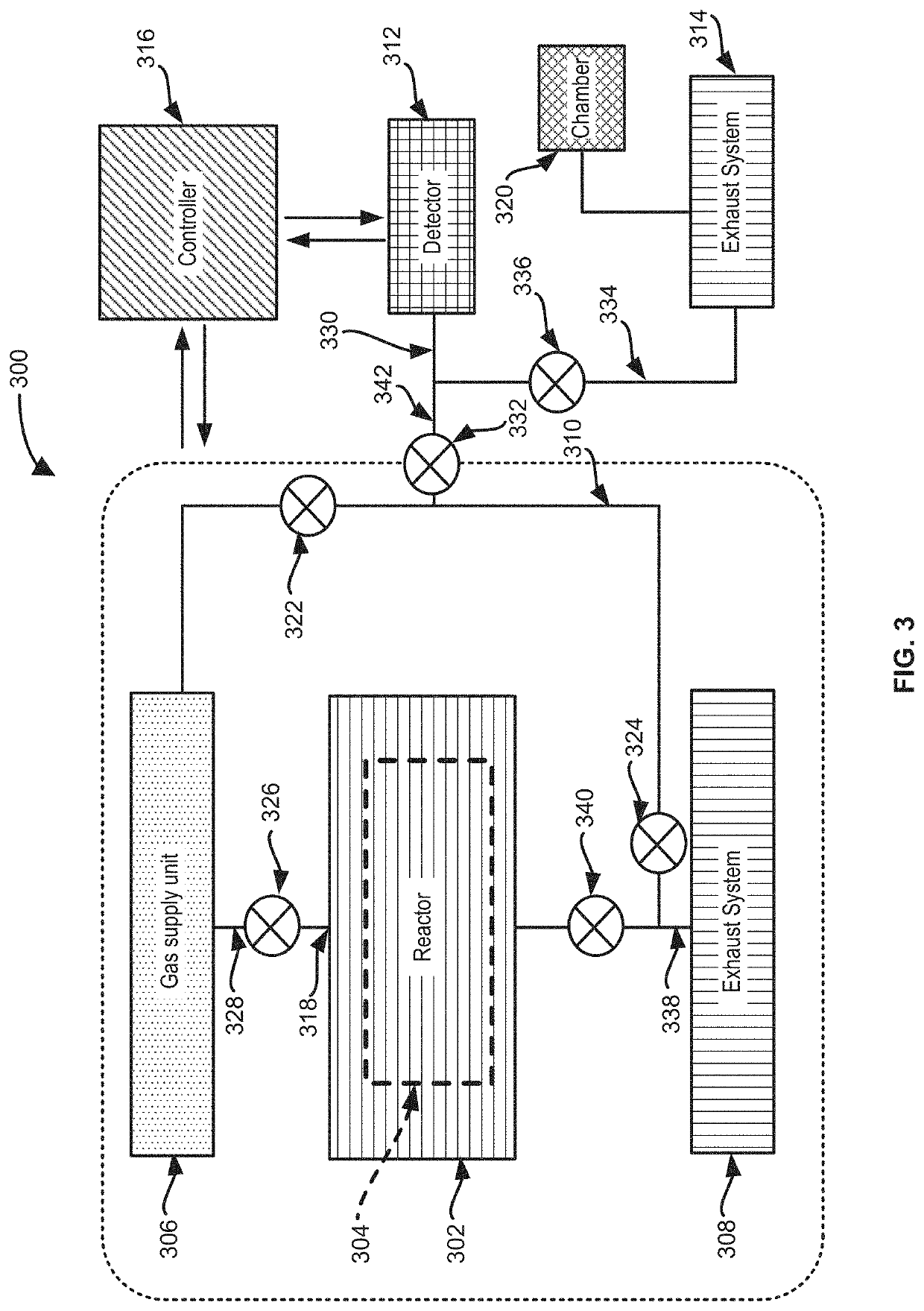

Method of using a gas-phase reactor system including analyzing exhausted gas

ActiveUS20200385868A1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateThermodynamicsReactor system

Methods of and systems for performing leak checks of gas-phase reactor systems are disclosed. Exemplary systems include a first exhaust system coupled to a reaction chamber via a first exhaust line, a bypass line coupled to a gas supply unit and to the first exhaust system, a gas detector coupled to the bypass line via a connecting line, a connecting line valve coupled to the connecting line, and a second exhaust system coupled to the connecting line. Methods include using the second exhaust system to exhaust the connecting line to thereby remove residual gas in the connecting line that may otherwise affect the accuracy of the gas detector.

Owner:ASM IP HLDG BV

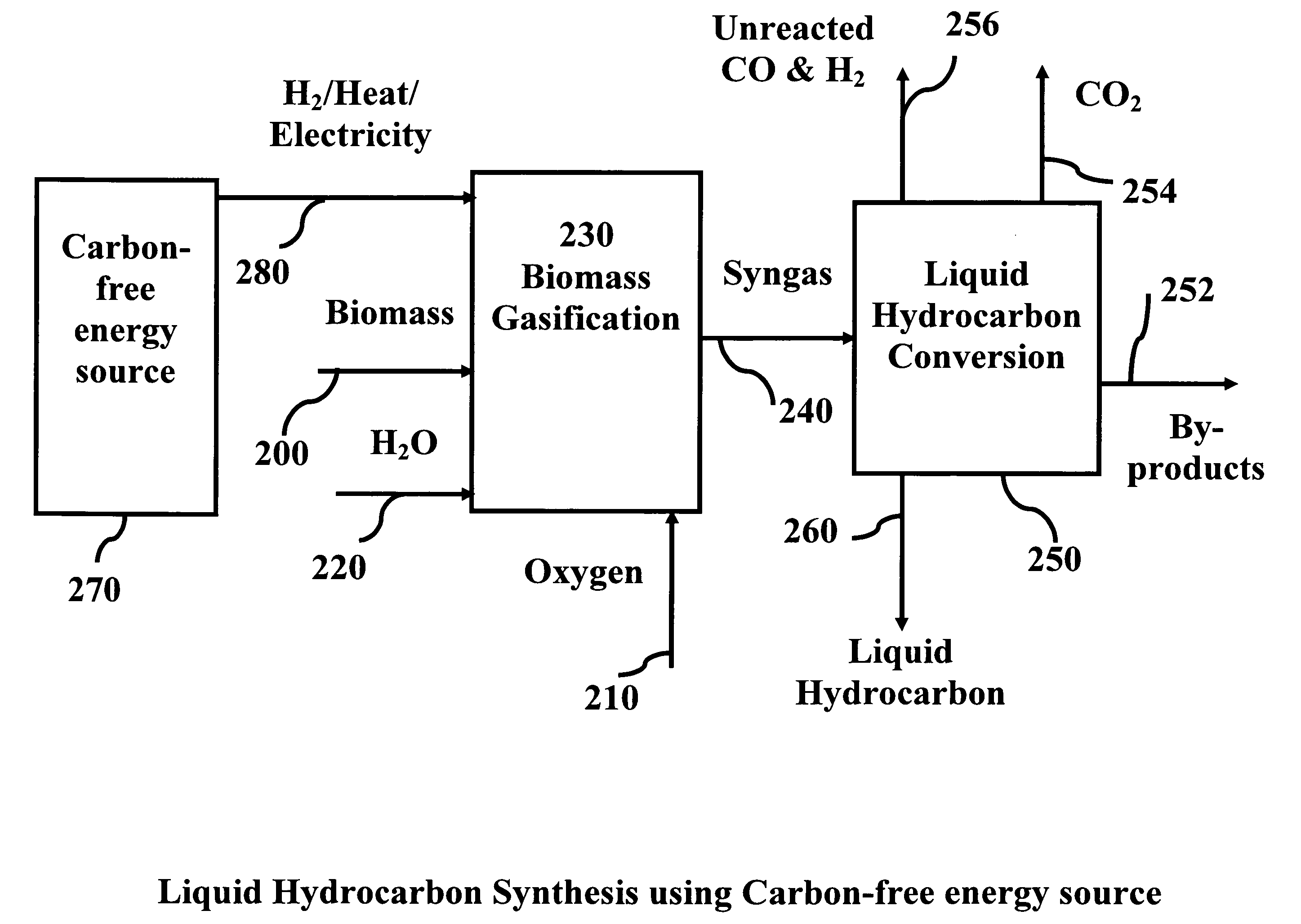

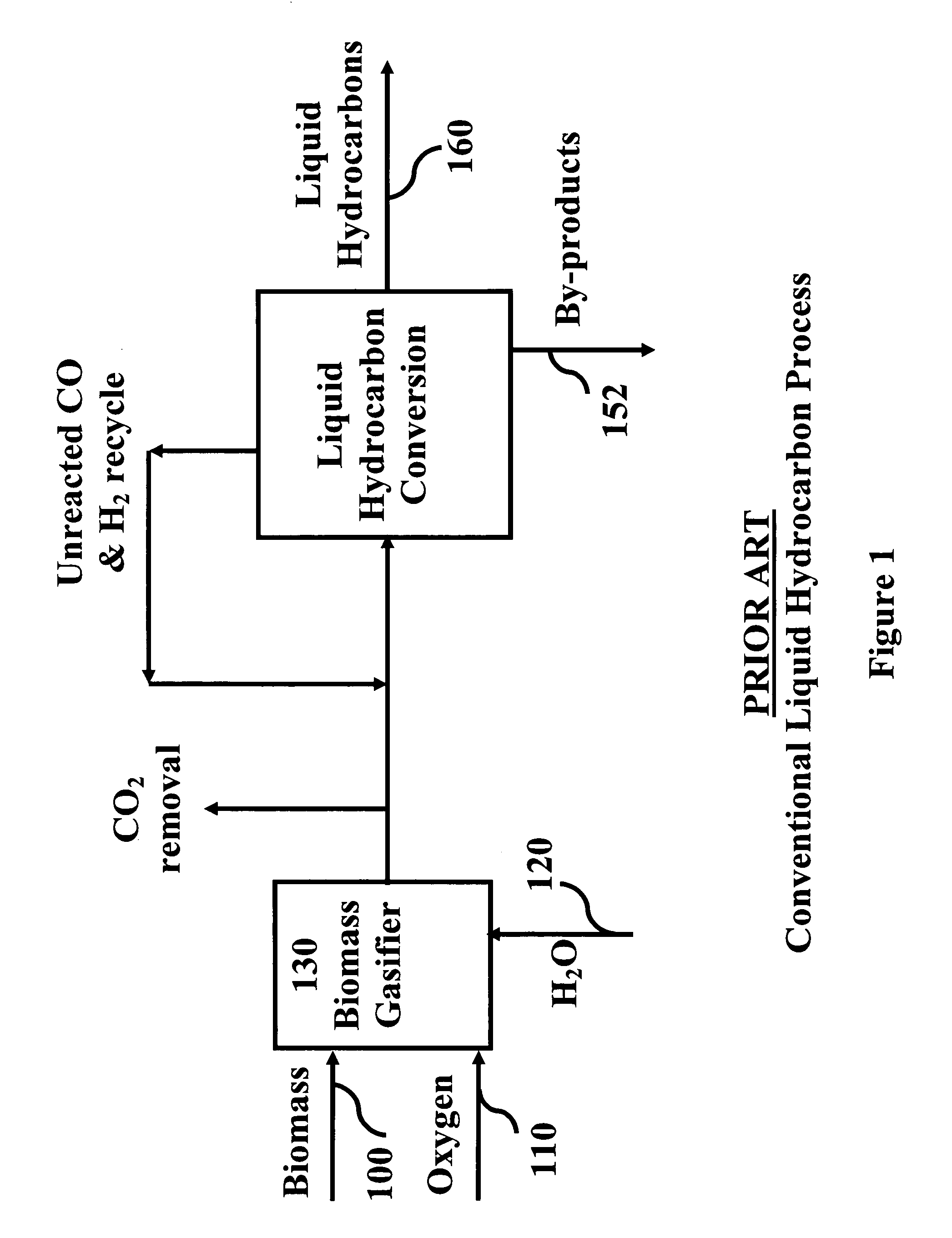

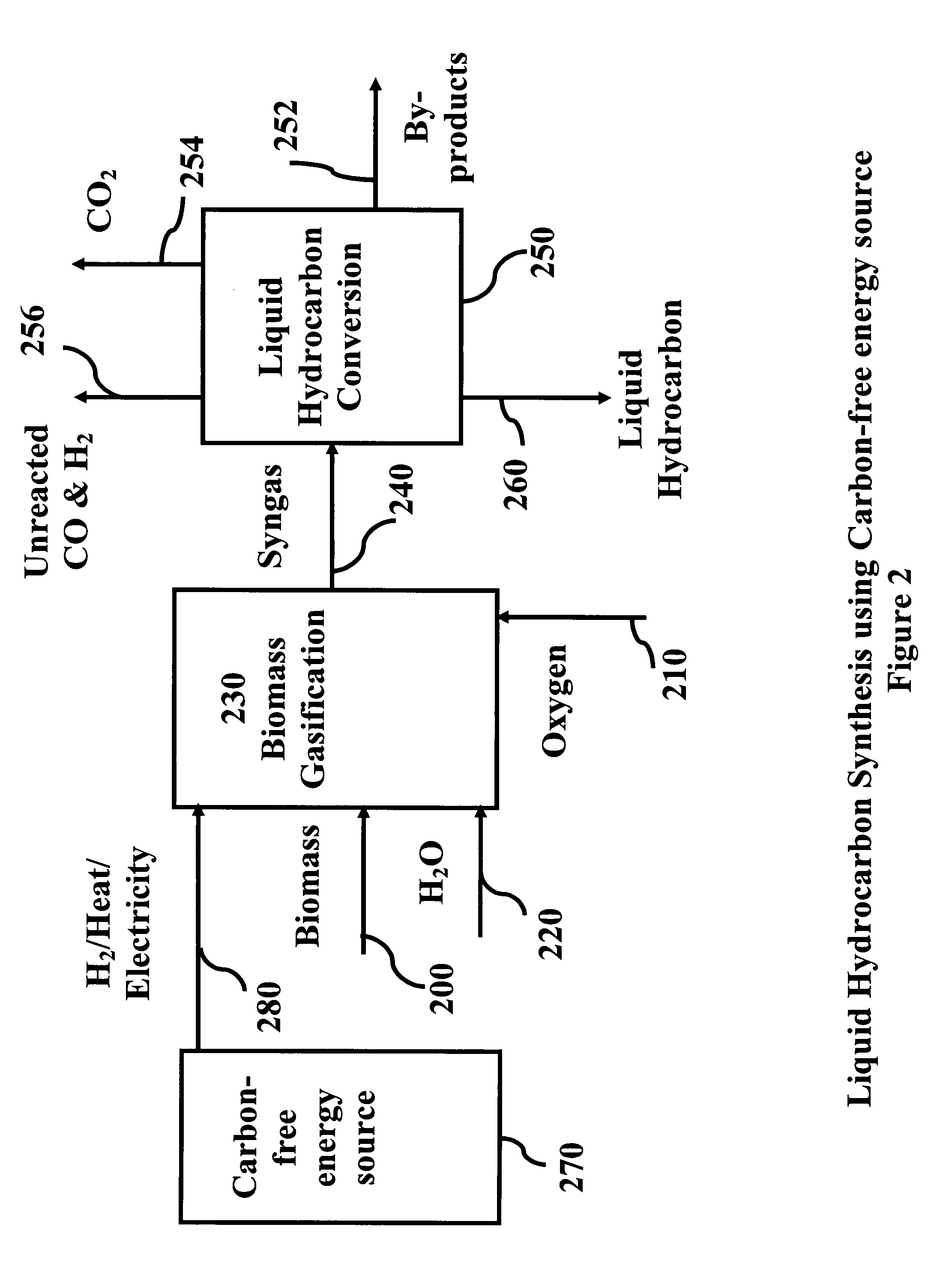

System and process for producing synthetic liquid hydrocarbon

ActiveUS20080115415A1Improve carbon efficiencyReduce area requirementsMuffle furnacesCarbon compoundsOxygenElectrolysis of water

Production of synthetic liquid hydrocarbon fuel from carbon containing moieties such as biomass, coal, methane, naphtha as a carbon source and hydrogen from a carbon-free energy source is disclosed. The biomass can be fed to a gasifier along with hydrogen, oxygen, steam and recycled carbon dioxide. The synthesis gas from the gasifier exhaust is sent to a liquid hydrocarbon conversion reactor to form liquid hydrocarbon molecules. Unreacted CO & H2 can be recycled to the gasifier along with CO2 from the liquid hydrocarbon conversion reactor system. Hydrogen can be obtained from electrolysis of water, thermo-chemical cycles or directly by using energy from carbon-free energy sources.

Owner:PURDUE RES FOUND INC

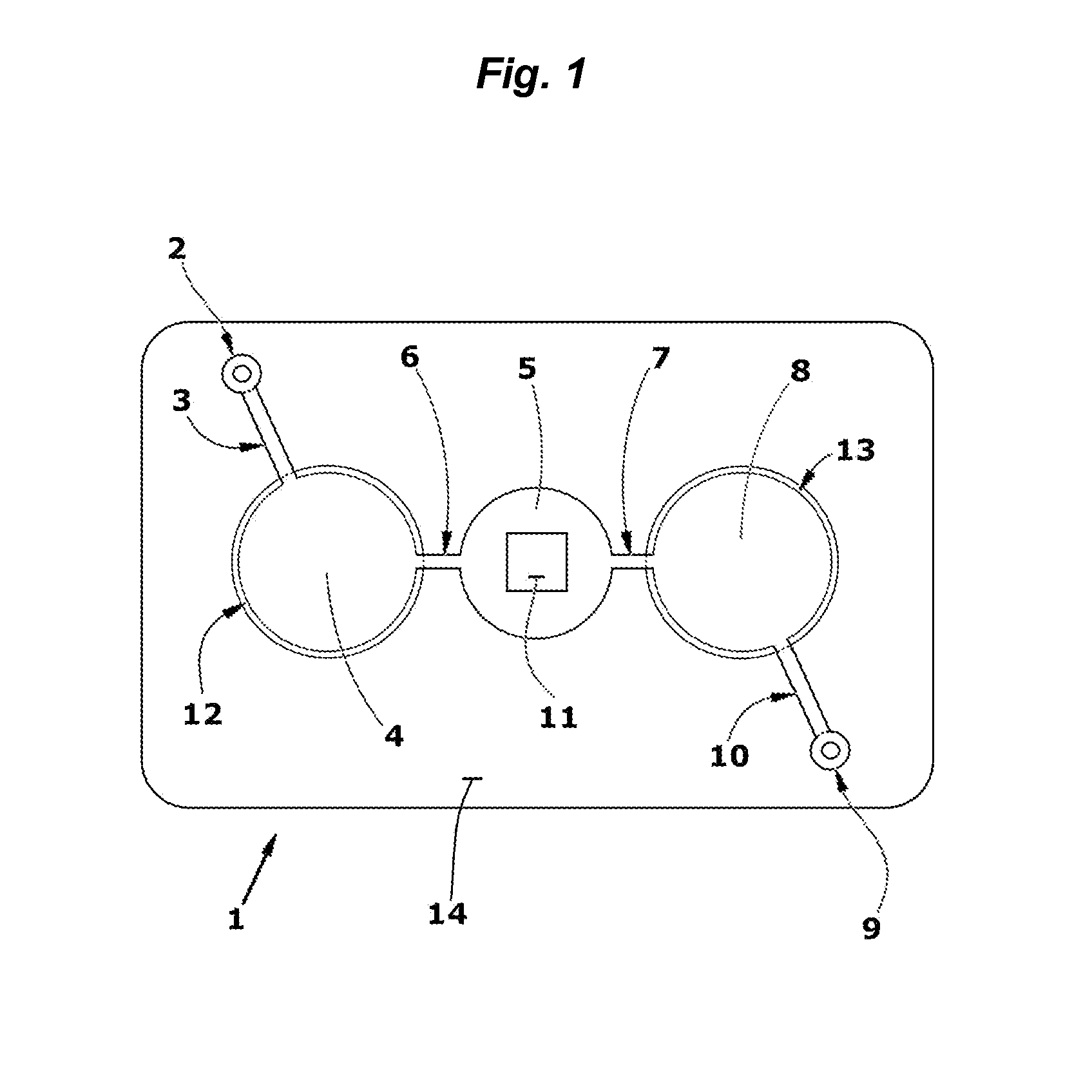

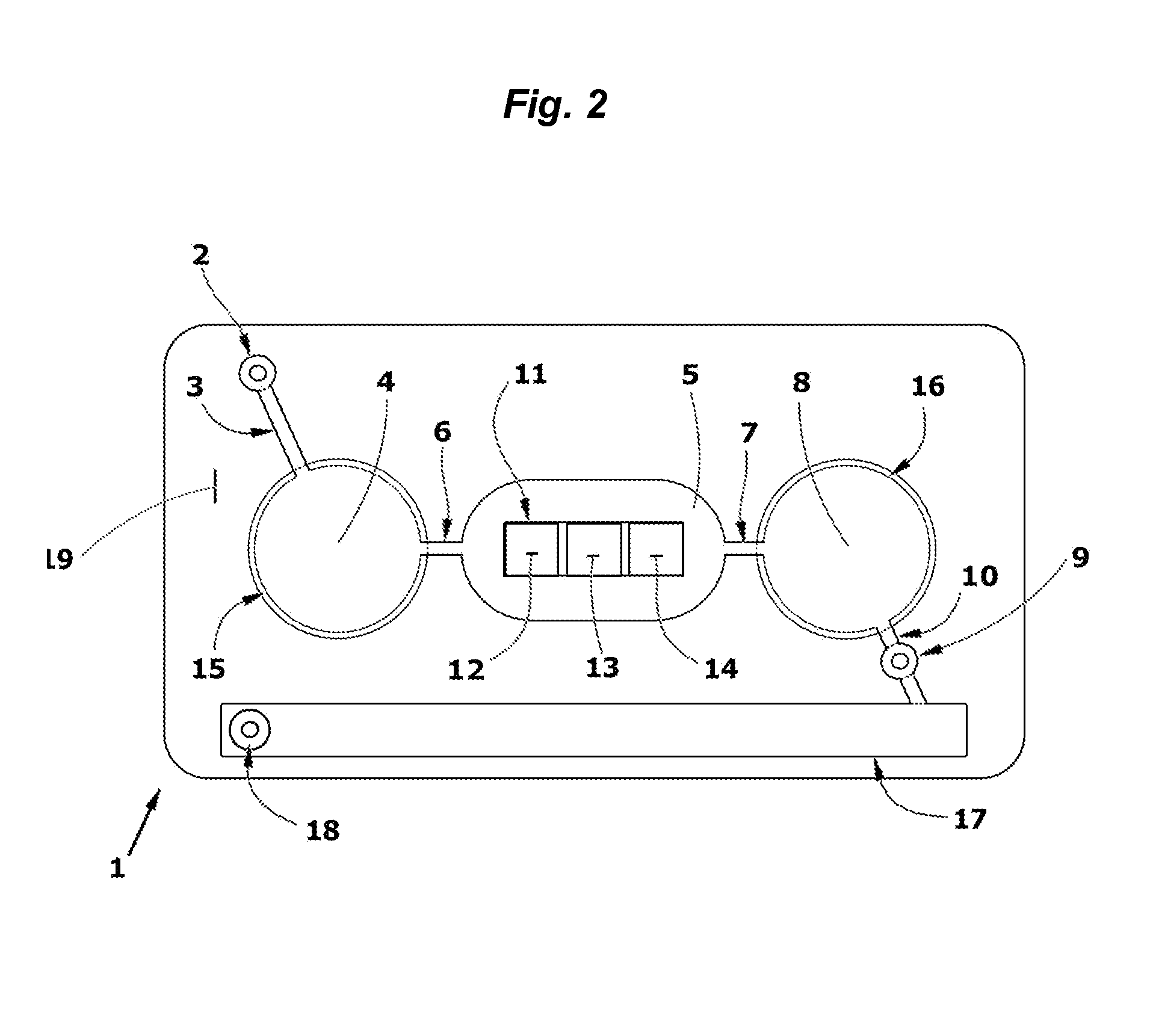

Microfluidic reactor system

ActiveUS20120177543A1Endpoint detectionReduce incubation timeShaking/oscillating/vibrating mixersTransportation and packagingDiaphragm pumpReactor system

A compact device for operatively coupling a solid planar substrate, for example a glass slide, to a microfluidic circuit and performing a reaction or reactions on organic matter bound to the face of the planar substrate. Typical reactions include binding, staining and / or labeling reactions. In use, a sealed reaction chamber is formed, the chamber enclosing the organic matter and at least a part of the solid substrate. Headspace in the sealed chamber between the solid substrate is generally of microfluidic dimensions, and diaphragm pump members are used to inject, exchange and / or mix the fluids in the chamber.

Owner:PERKINELMER HEALTH SCIENCES INC

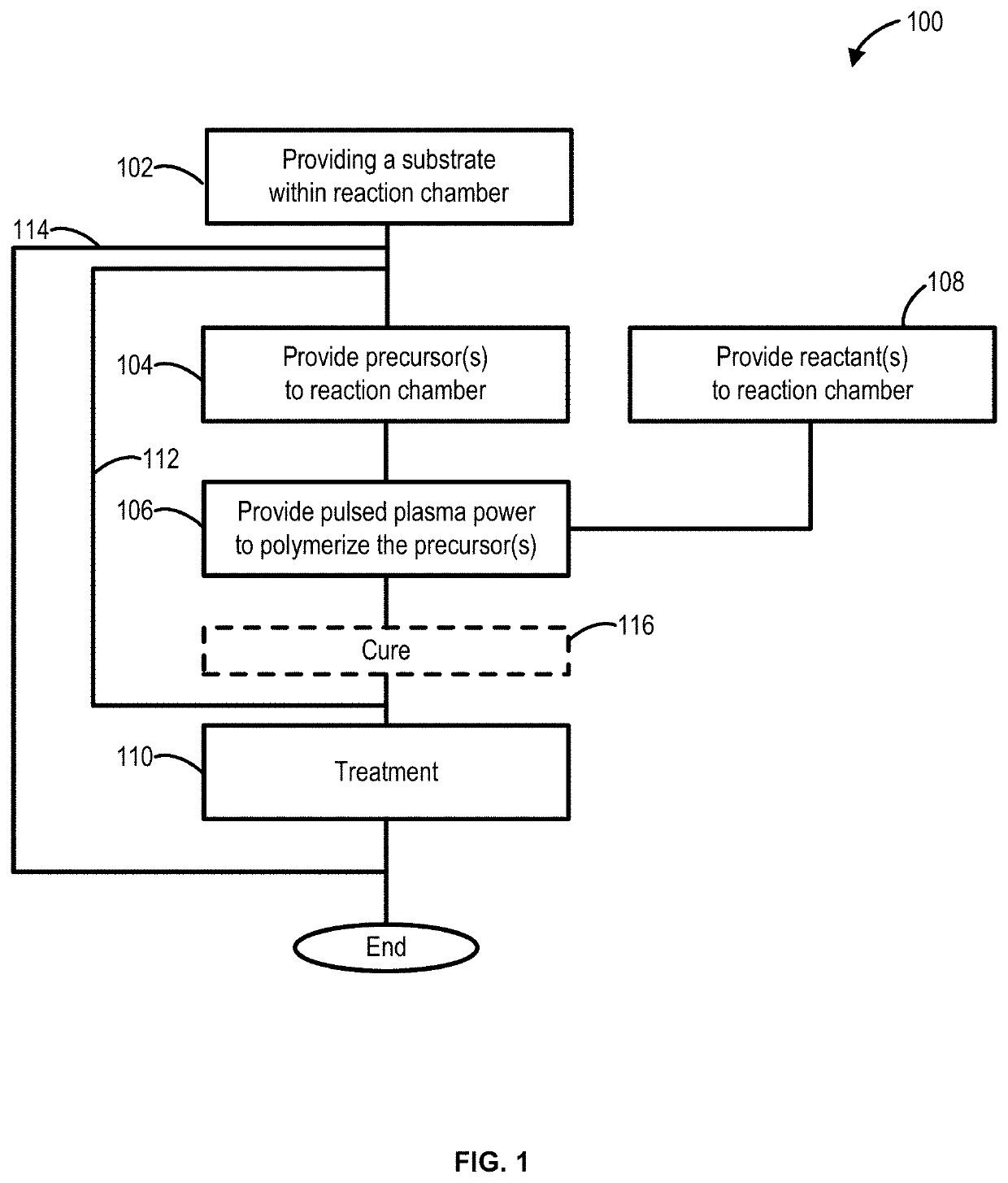

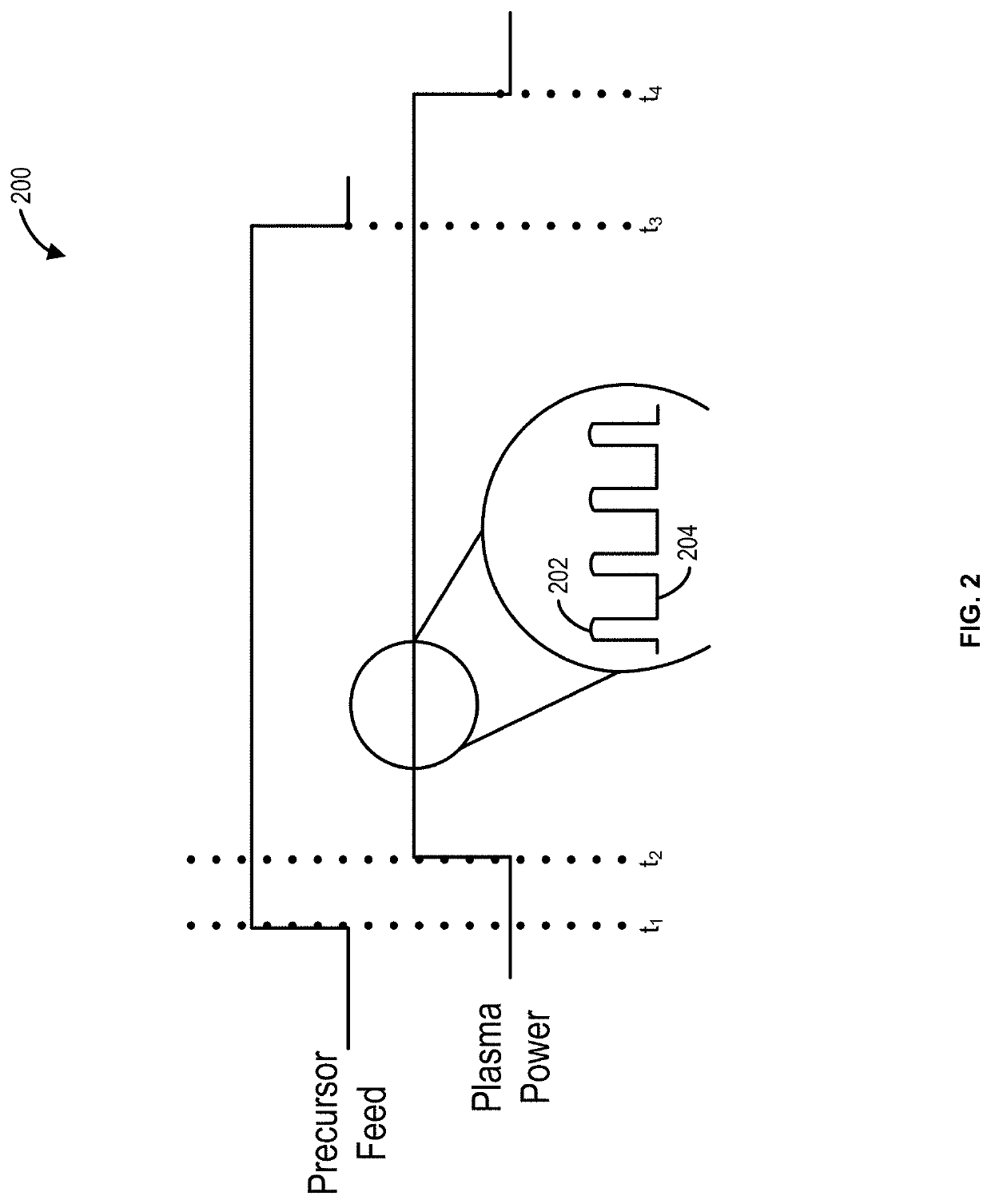

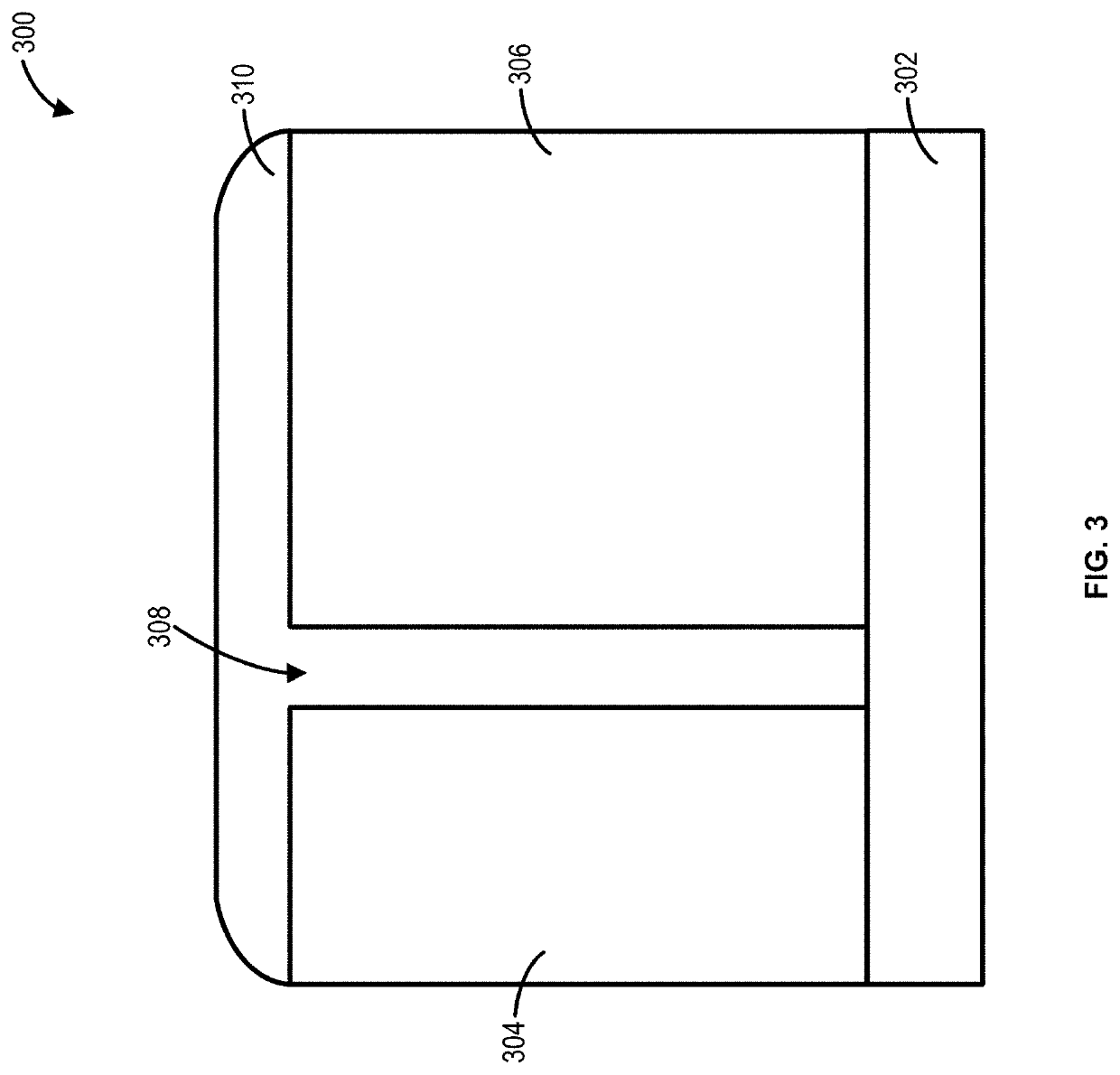

Method of forming dielectric material layers using pulsed plasma power, structures and devices including the layers, and systems for forming the layers

Methods and systems for forming a structure including a dielectric material layer on a surface of a substrate and structures and devices formed using the method or system are disclosed. Exemplary methods include providing a substrate within a reaction chamber of a reactor system, providing one or more precursors to the reaction chamber, and providing pulsed plasma power to polymerize the one or more precursors within the reaction chamber.

Owner:ASM IP HLDG BV

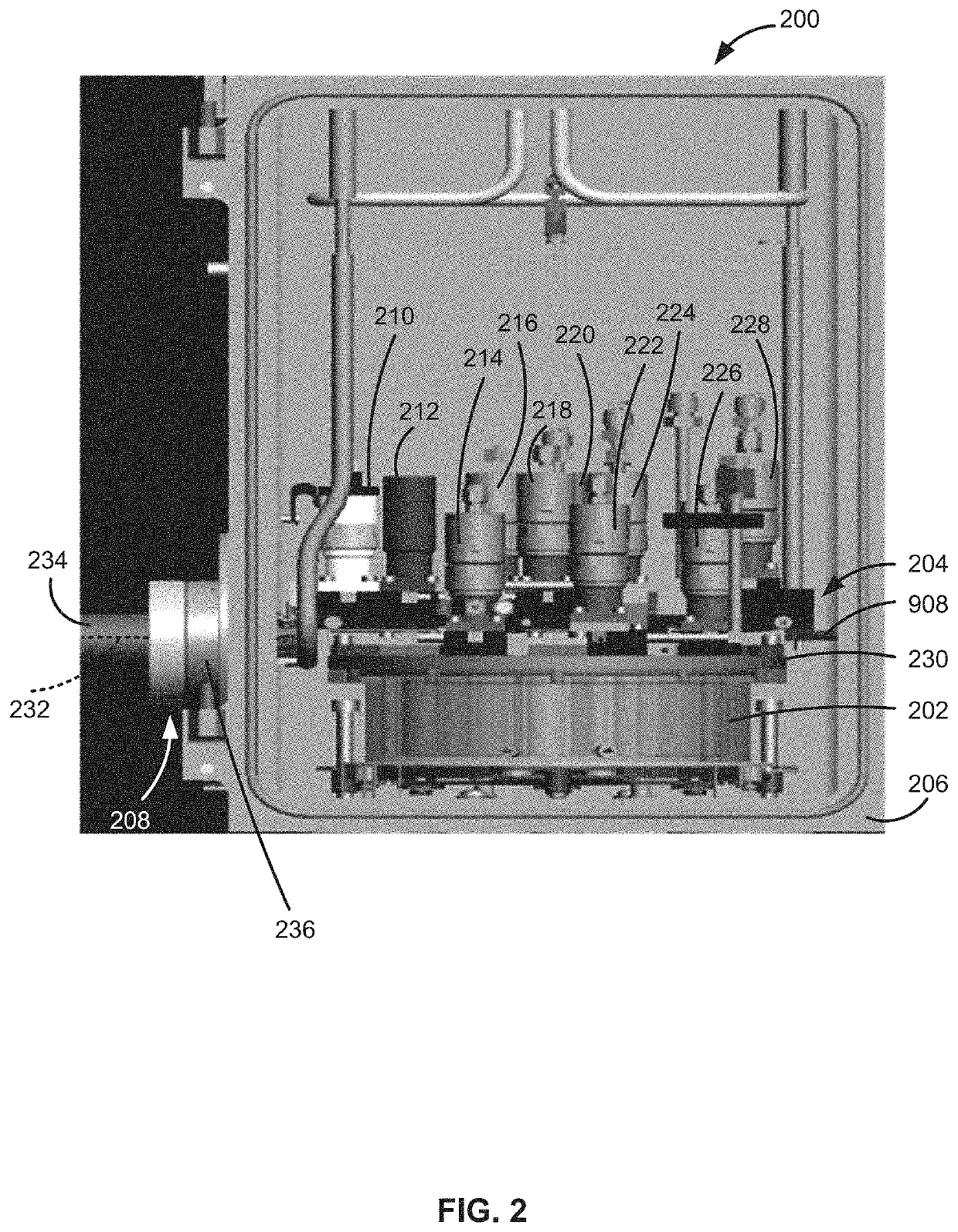

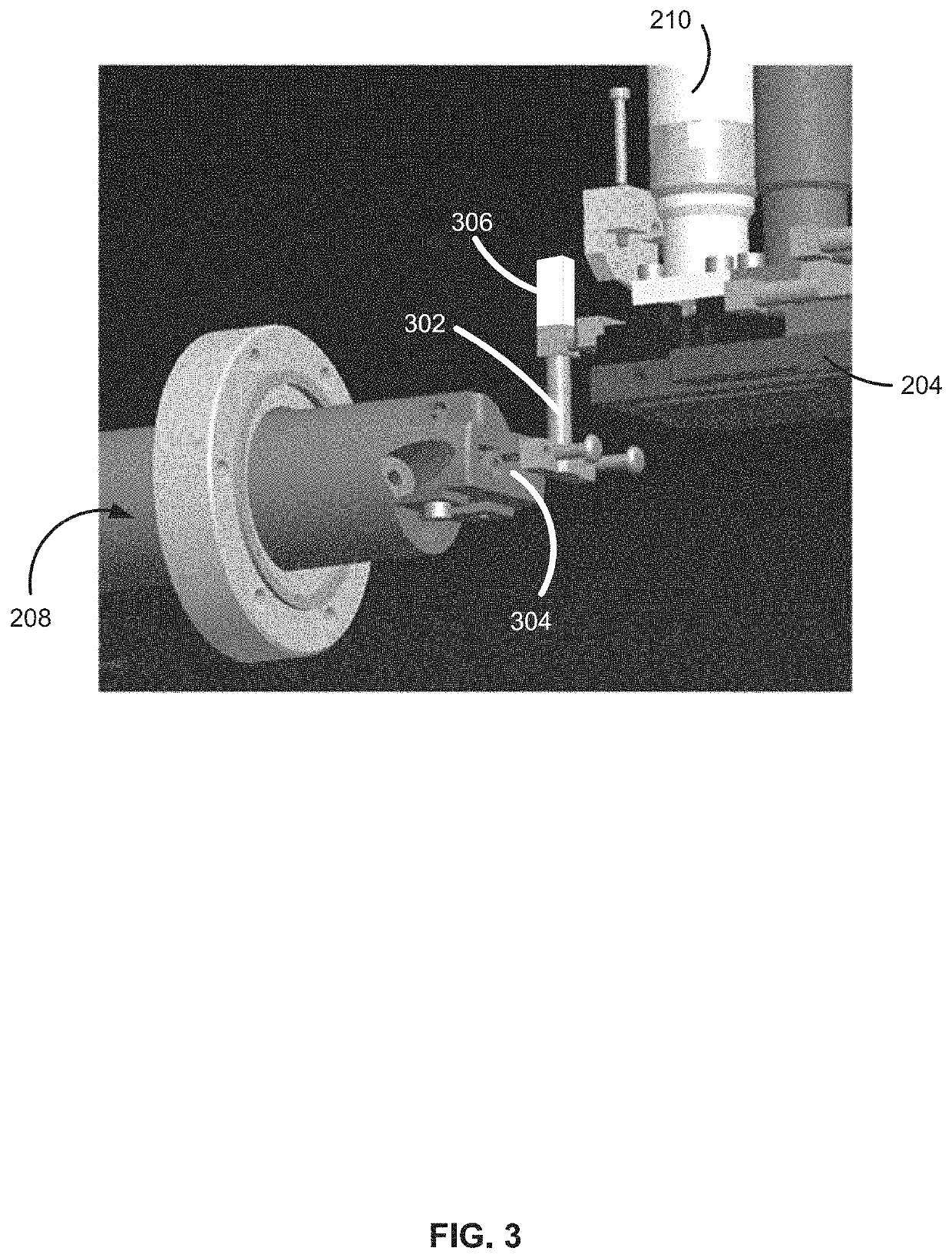

Alignment fixture for a reactor system

PendingUS20210280448A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingInterior spaceReactor system

An alignment fixture for a reactor system may comprise a fixture body comprising an inner perimeter at least partially defining a shape which comprises an inner space of the fixture body, wherein the inner space is configured to receive a susceptor of a reactor system; and / or a measuring protrusion coupled to the fixture body at a first position and protruding from the fixture body toward the inner space. The measuring protrusion may comprise an indicator between the fixture body and a measuring protrusion end of the measuring protrusion.

Owner:ASM IP HLDG BV

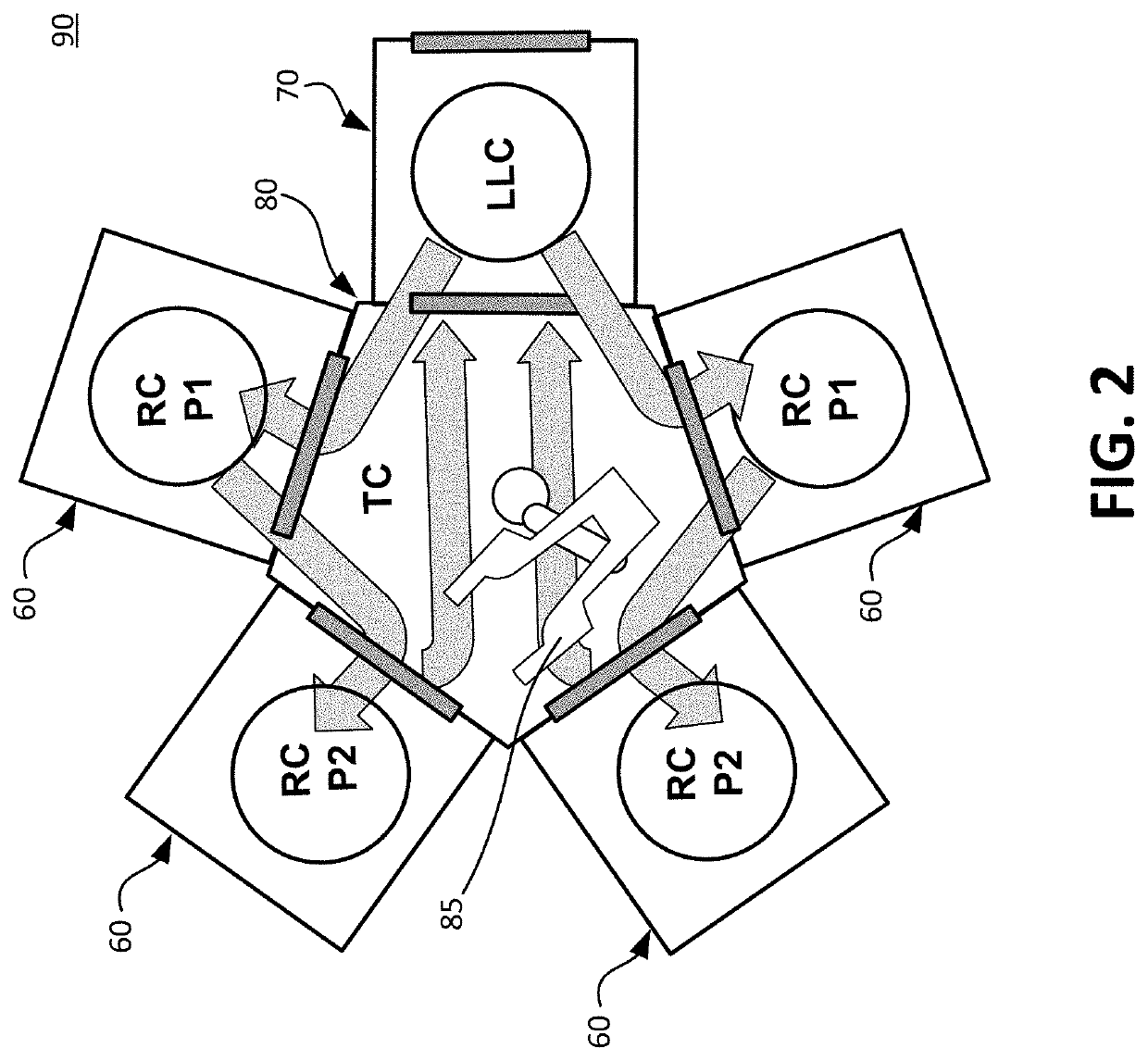

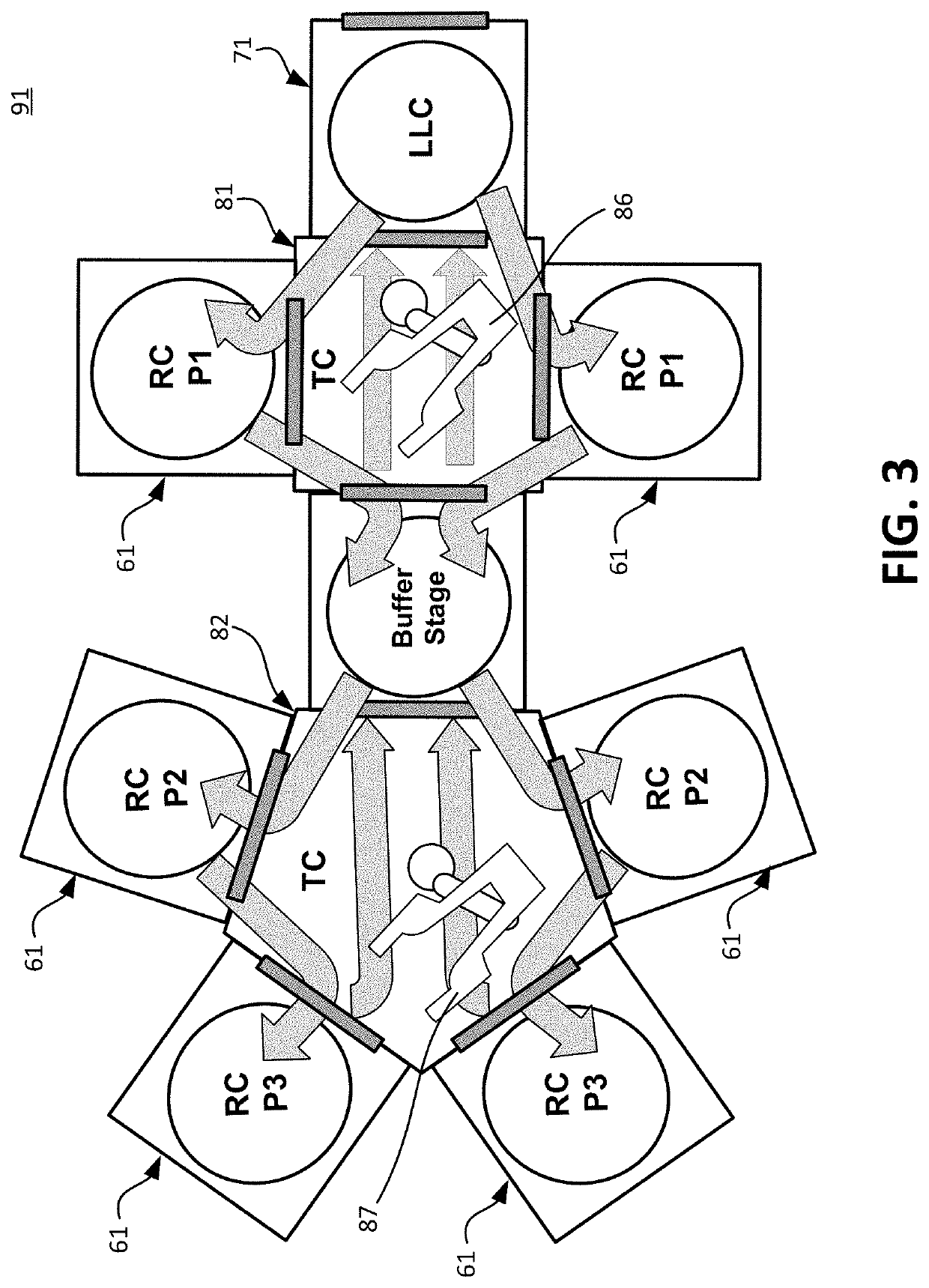

Reactor system with multi-directional reaction chamber

A reactor system may comprise a plurality of reaction chambers; a plurality of transfer chambers; and / or at least two gate valves coupled to each reaction chamber of the plurality of reaction chambers. A first gate valve of the at least two gate valves may fluidly couple a first respective reaction chamber of the plurality of reaction chambers to a first transfer chamber of the plurality of transfer chambers, and a second gate valve of the at least two gate valves may fluidly couple the first respective reaction chamber to a second transfer chamber of the plurality of transfer chambers. In various embodiments, each of the plurality of transfer chambers may comprise a transfer tool, wherein each transfer tool may be configured to transfer a substrate into and / or out of multiple reaction chambers.

Owner:ASM IP HLDG BV

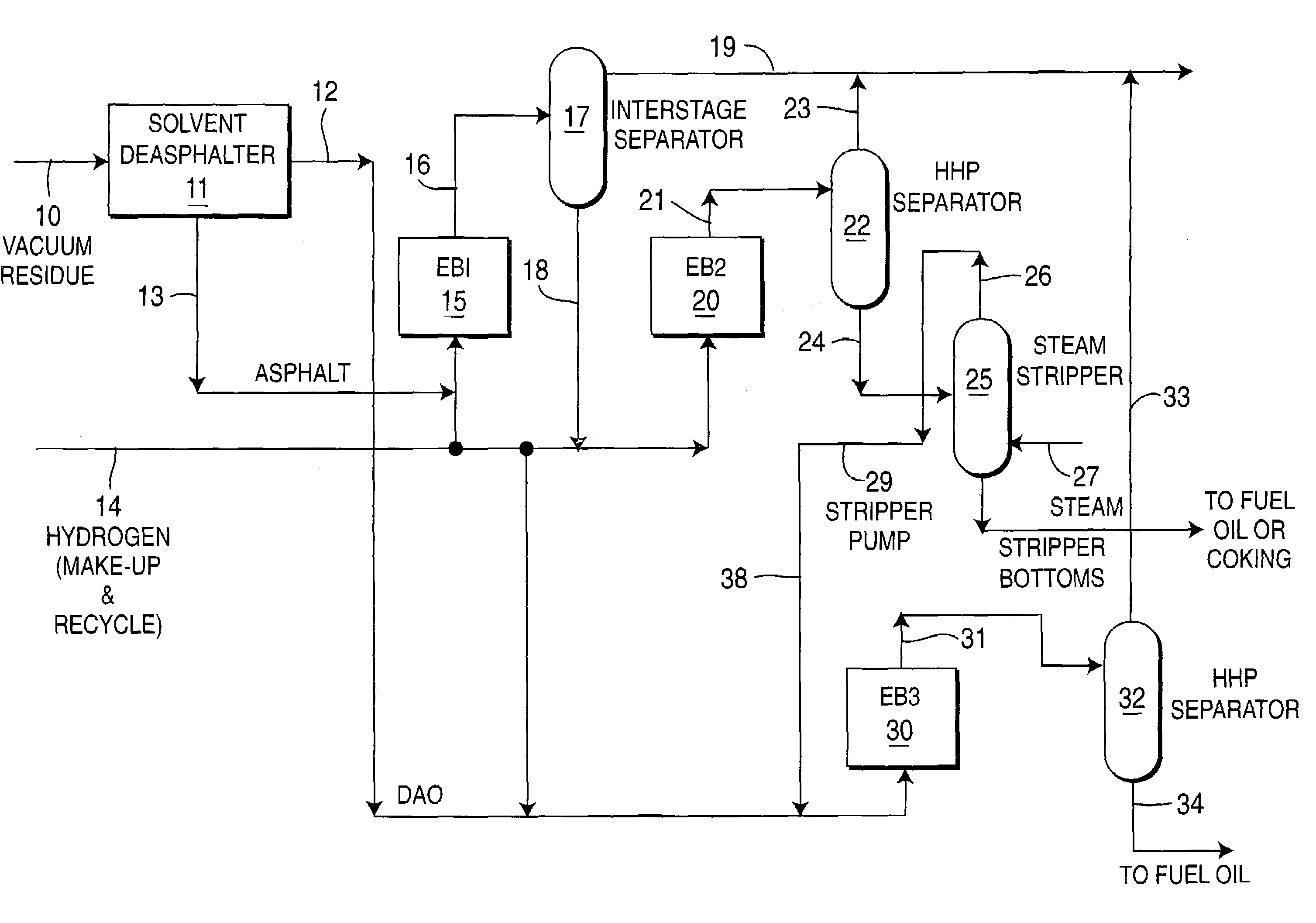

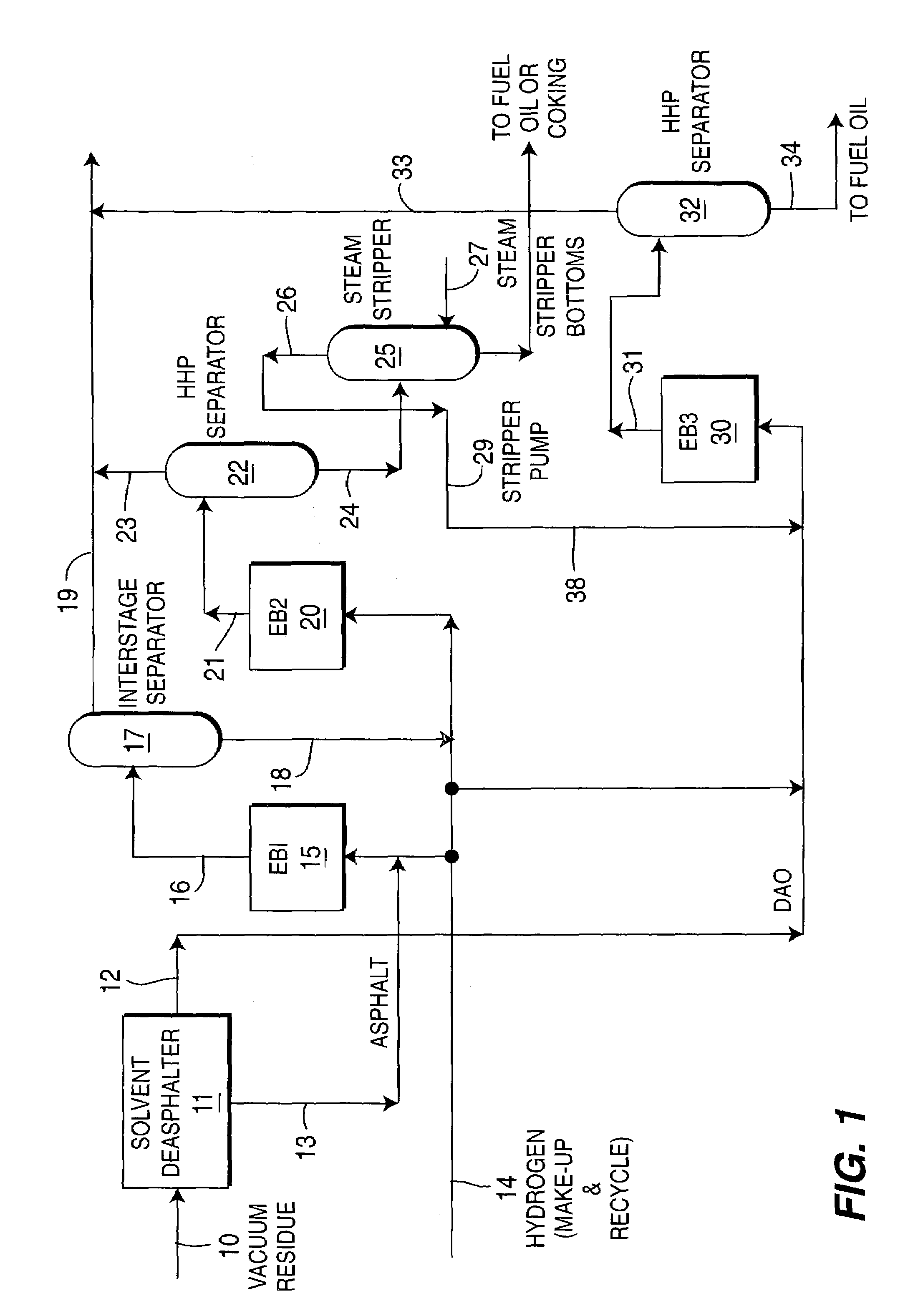

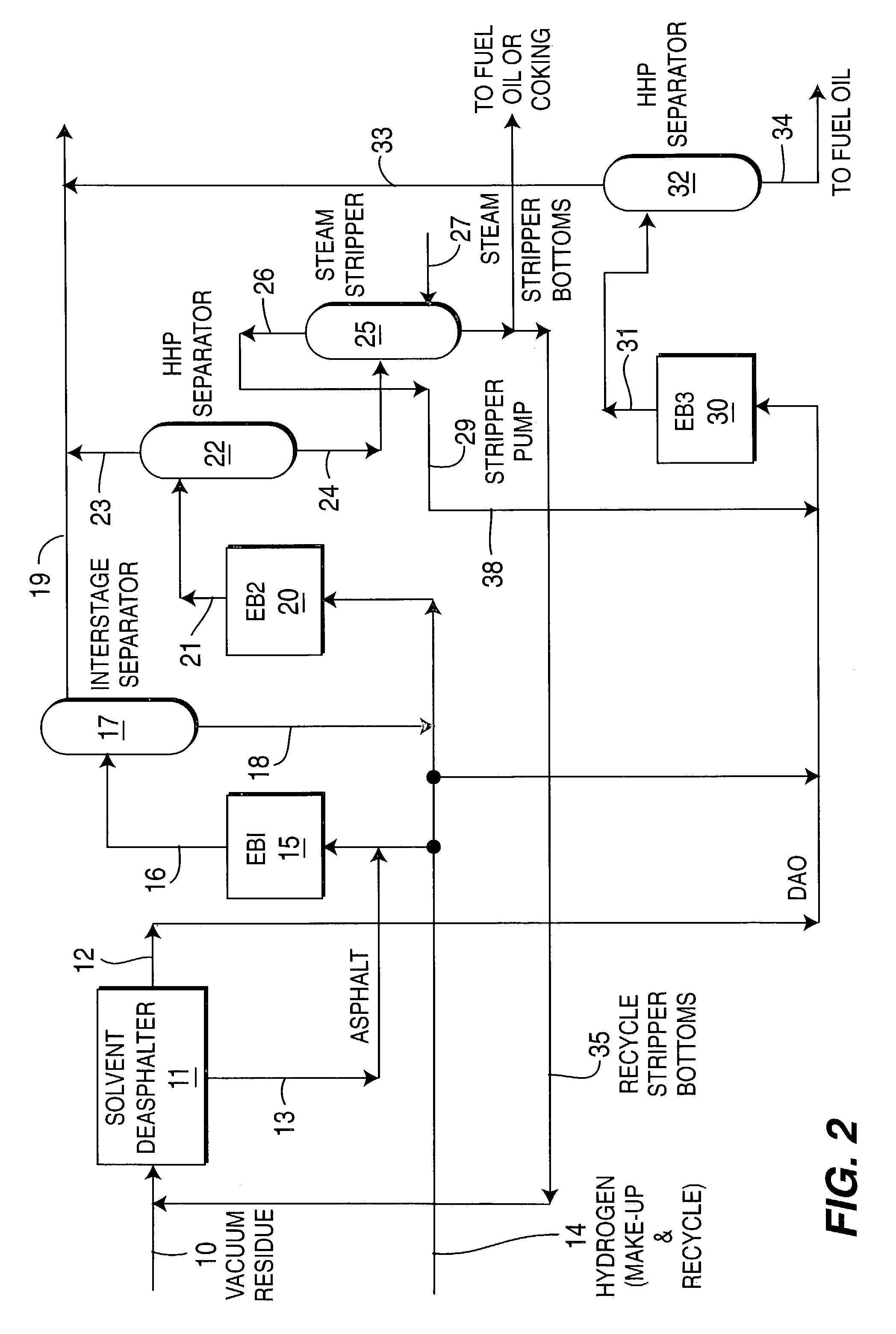

Effective integration of solvent deasphalting and ebullated-bed processing

InactiveUS7214308B2Reduced light gas yieldImprove hydrogen efficiencyTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyReactor systemHeavy crude oil

This invention relates to a novel method for economically processing vacuum residue from heavy crude oils by selectively processing the difficult and easy components in reactors whose design and operating conditions are optimized for the specific feed. The process utilizes an integrated solvent deasphalting (SDA) / ebullated-bed design wherein the heavy vacuum residue feedstock is initially sent to an SDA unit operated with C4 / C5 solvent to achieve a high deasphalted oil (DAO) yield. The resulting SDA products, namely asphaltenes and DAO are separately treated in ebullated-bed reactor(s) systems whose design and operating conditions are optimized for a particular feedstock. The resulting net conversion, associated distillate yield and product qualities are greatly improved relative to treatment of the entire residue feedstock in a common ebullated-bed reactor system.

Owner:INST FR DU PETROLE

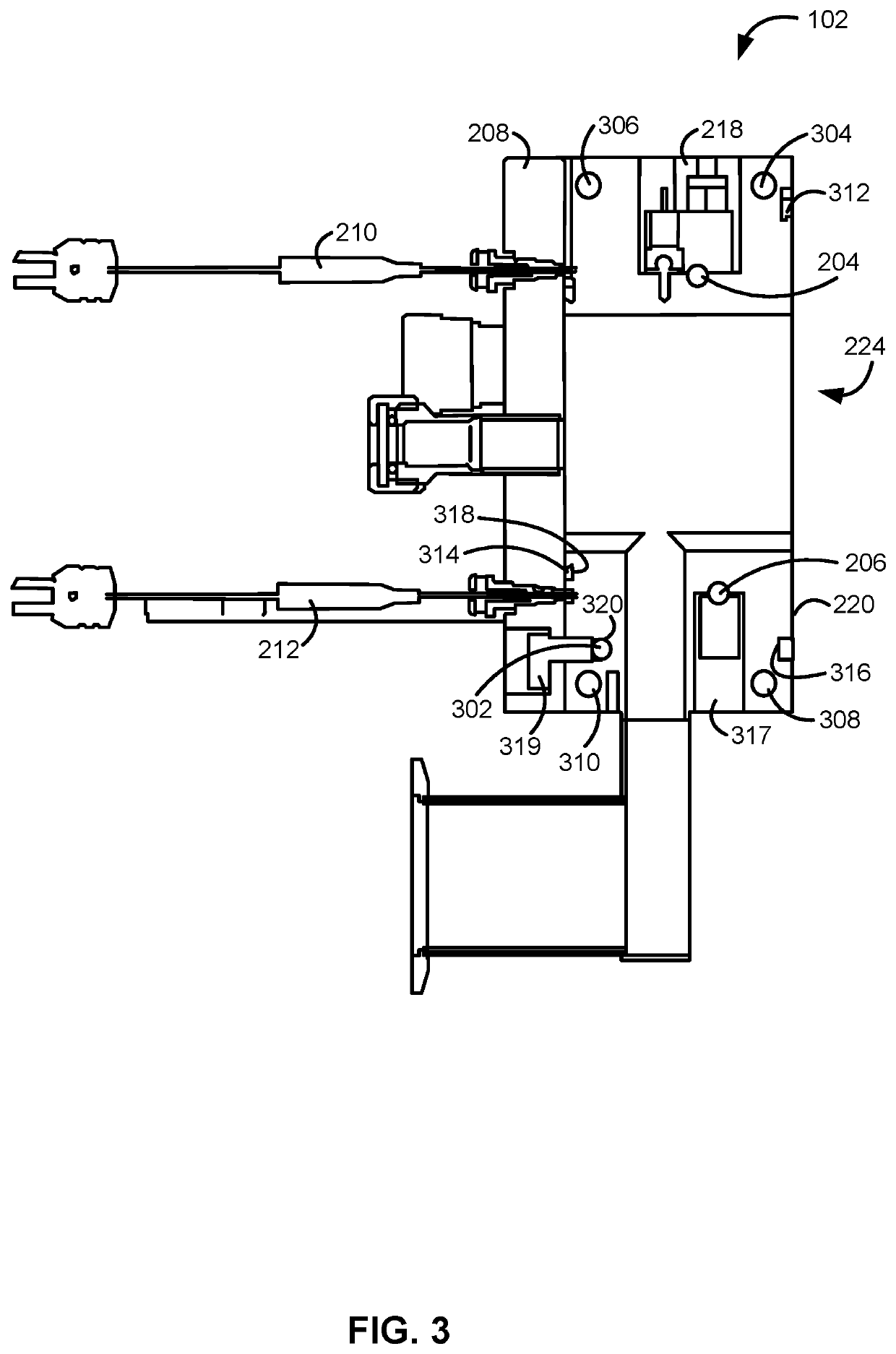

Gas supply assembly, components thereof, and reactor system including same

PendingUS20210207269A1Easy to assembleEngine diaphragmsServomotor componentsReactor systemGas supply

Gas supply assemblies and reactors systems including the gas supply assemblies are disclosed. An exemplary gas supply assembly includes a vessel, a valve plate, a housing encasing the vessel and the valve plate, a gas feedthrough having a first end interior of the housing and a second end exterior of the housing, and one or more valves attached to the valve plate, wherein at least one valve is fluidly coupled to an interior of the vessel. The assemblies can further include a removable gas line having a first end coupled to the at least one valve and a second end coupled to the gas feedthrough. Additionally or alternatively, a gas supply assembly can include one or more valve plate leveling devices coupled to the valve plate.

Owner:ASM IP HLDG BV

Channeled lift pin

PendingUS20210210373A1Reduce and prevent unwanted material depositionReduce and prevent deposition and patternVacuum evaporation coatingSputtering coatingReactor systemSusceptor

A reactor system may comprise a reaction chamber enclosed by a chamber sidewall, and a susceptor disposed in the reaction chamber between a reaction space and a lower chamber space comprised in the reaction chamber. The susceptor may comprise a pin hole disposed through the susceptor such that the pin hole is in fluid communication with the reaction space and the lower chamber space, and such that the reaction space is in fluid communication with the lower chamber space. A lift pin may be disposed in the pin hole. The lift pin may comprise a pin body comprising a pin channel, defined by a pin channel surface, disposed in the pin body such that the reaction space is in fluid communication with the lower chamber space when the lift pin is disposed in the pin hole.

Owner:ASM IP HLDG BV

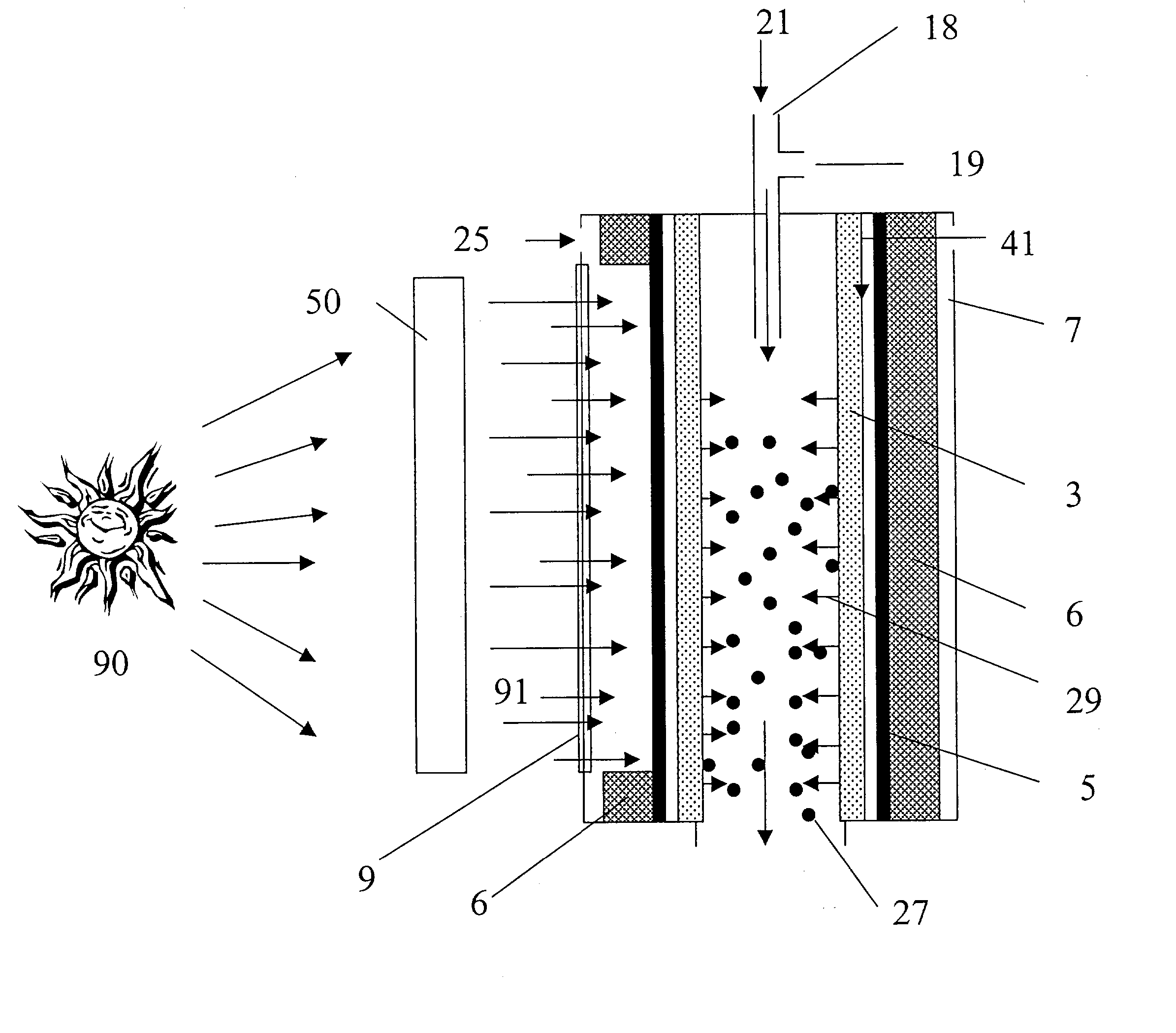

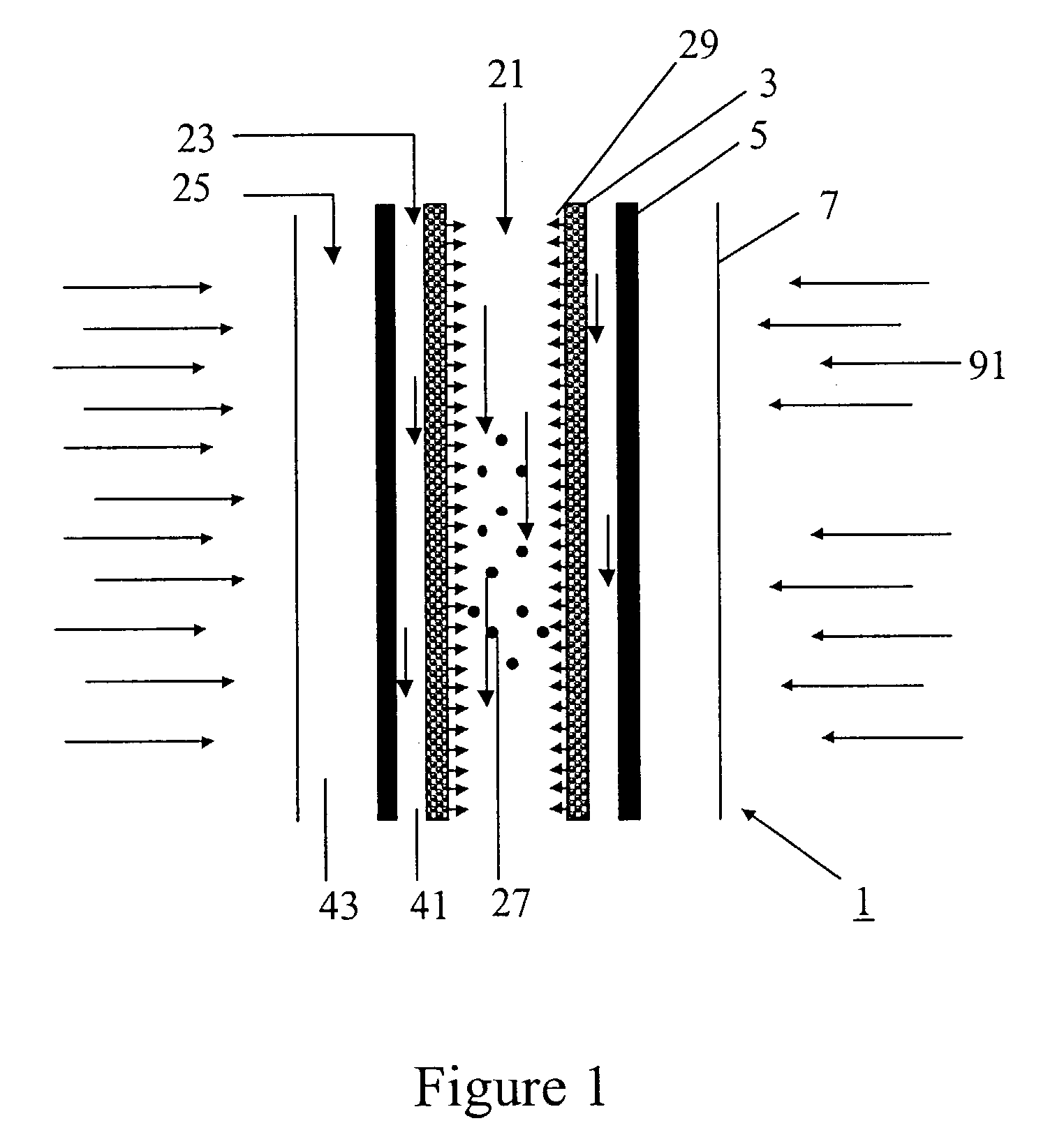

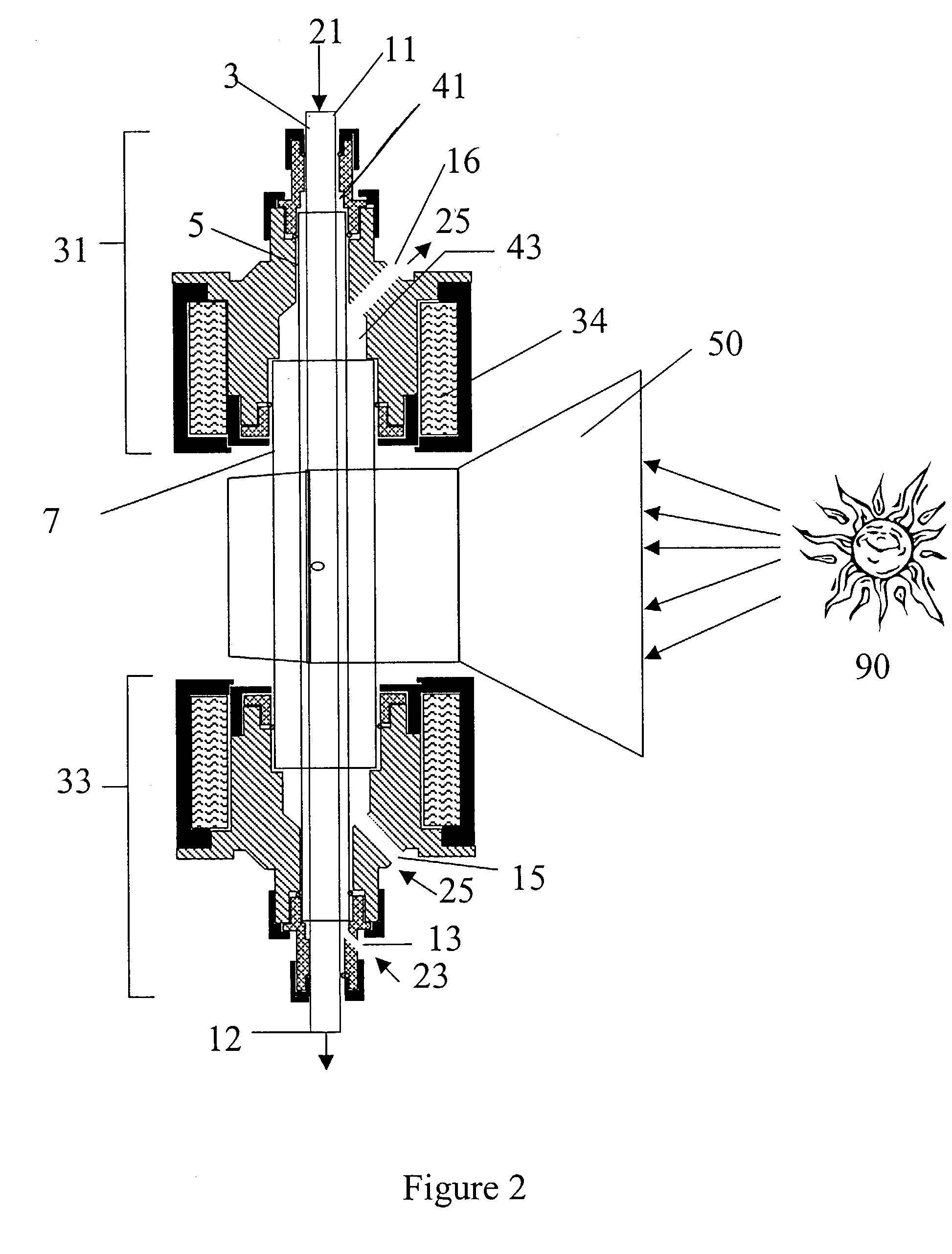

Solar-thermal fluid-wall reaction processing

InactiveUS7033570B2Reduce and preventShort stayThermal non-catalytic crackingSolar heating energyHydrogenReactor system

The present invention provides a method for carrying out high temperature thermal dissociation reactions requiring rapid-heating and short residence times using solar energy. In particular, the present invention provides a method for carrying out high temperature thermal reactions such as dissociation of hydrocarbon containing gases and hydrogen sulfide to produce hydrogen and dry reforming of hydrocarbon containing gases with carbon dioxide. In the methods of the invention where hydrocarbon containing gases are dissociated, fine carbon black particles are also produced. The present invention also provides solar-thermal reactors and solar-thermal reactor systems.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com