Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

991 results about "Planar substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Planar Substrate, Window Board. A substrate for polishing and processing of optical glass with high precision, with increased surface accuracy and parallelism.

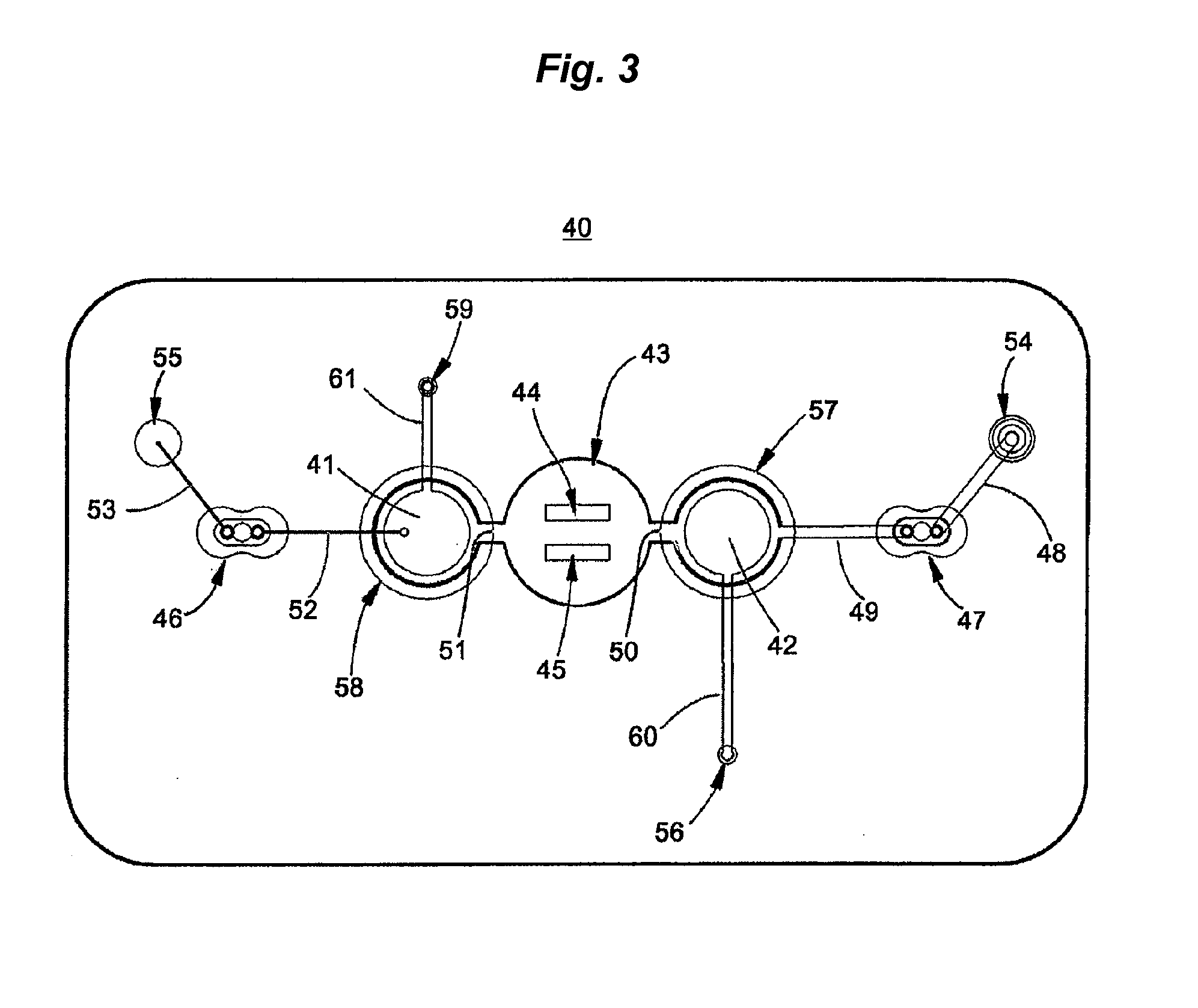

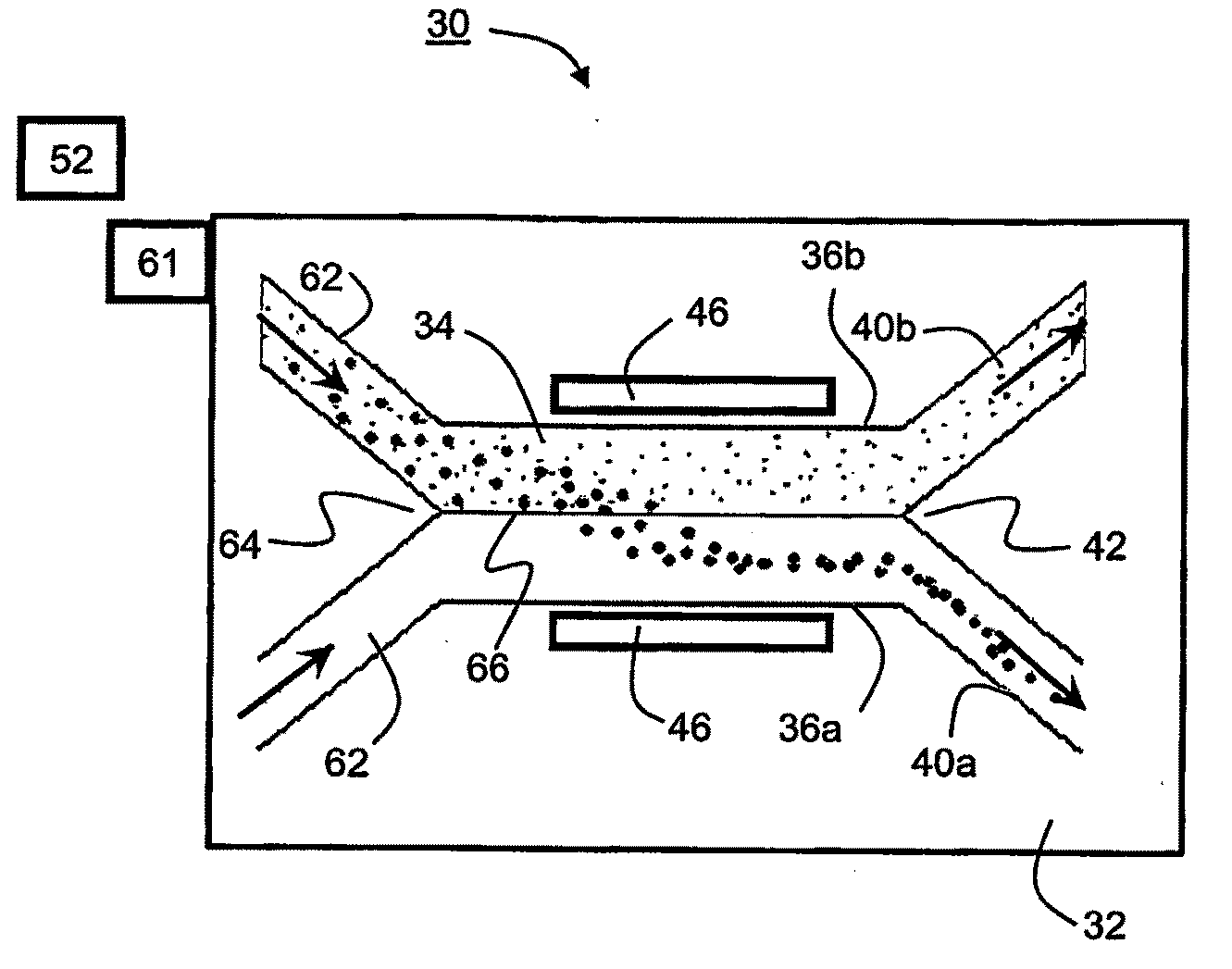

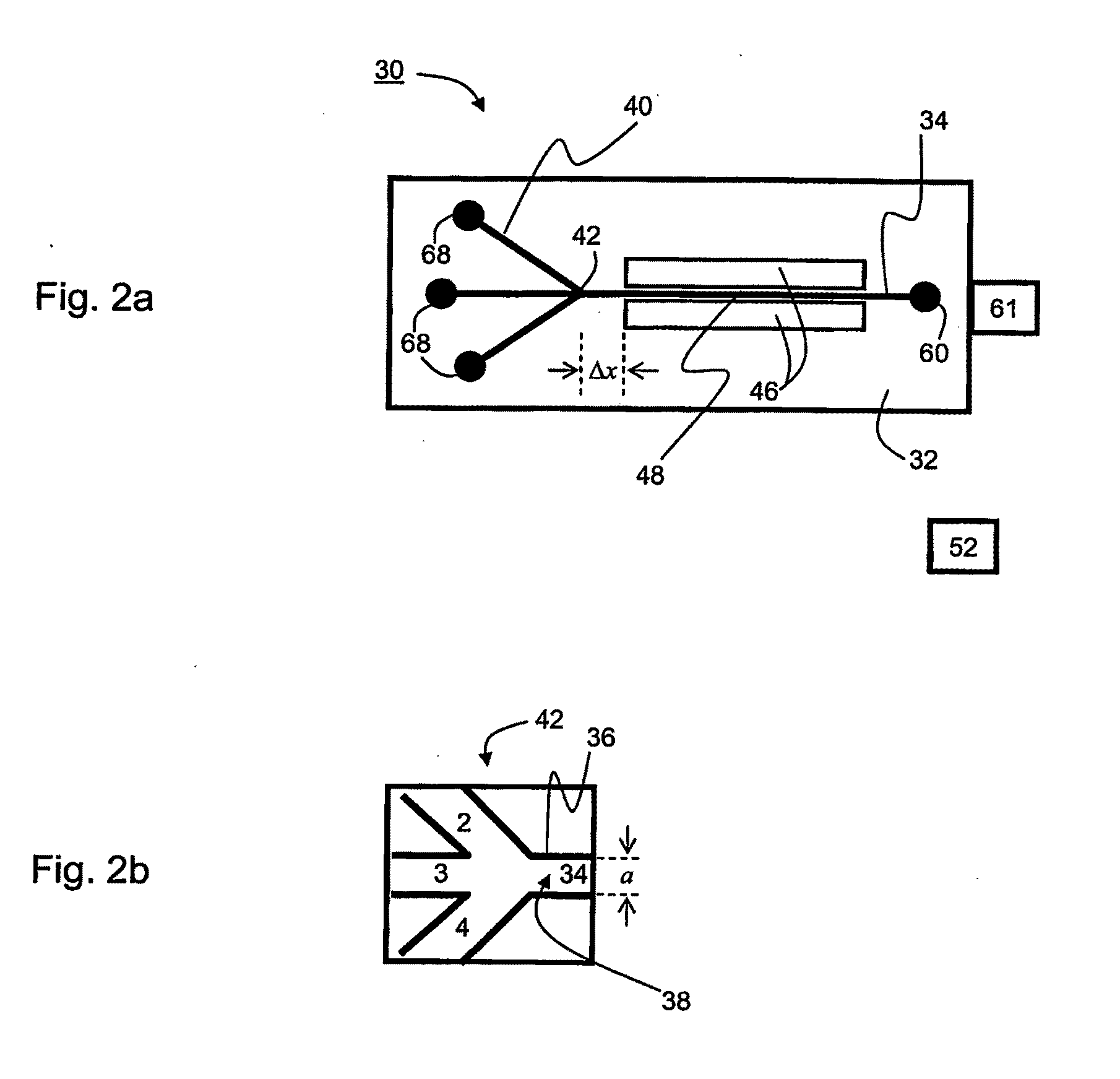

Capillary electroflow apparatus and method

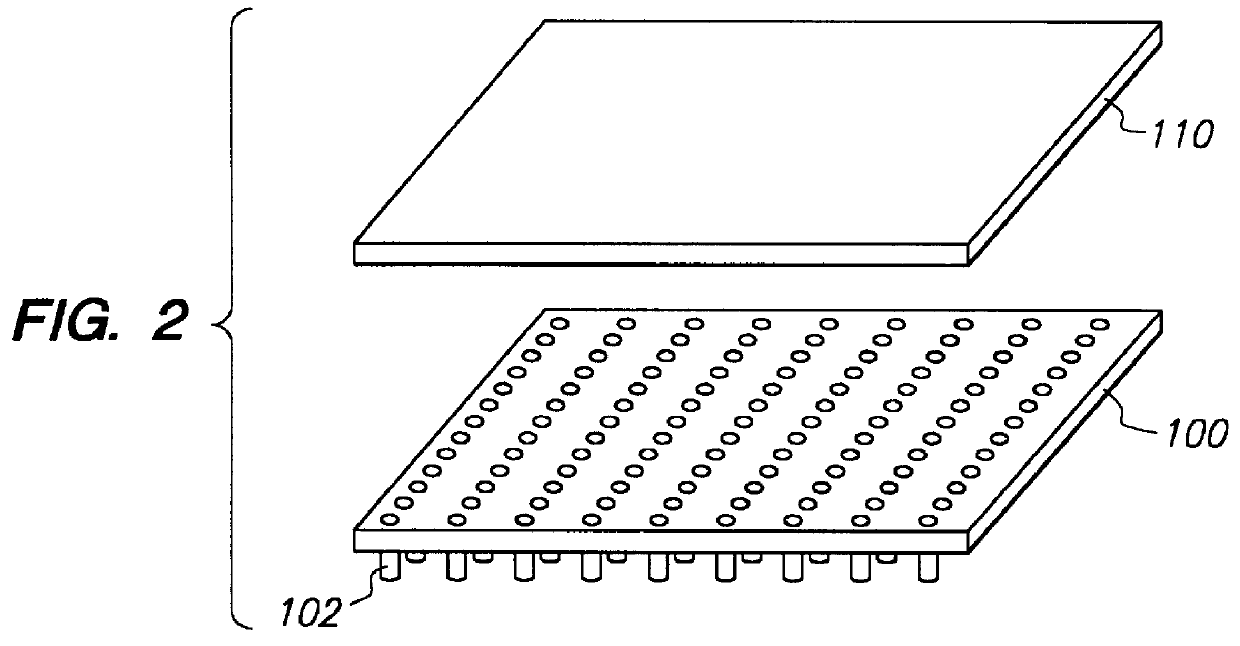

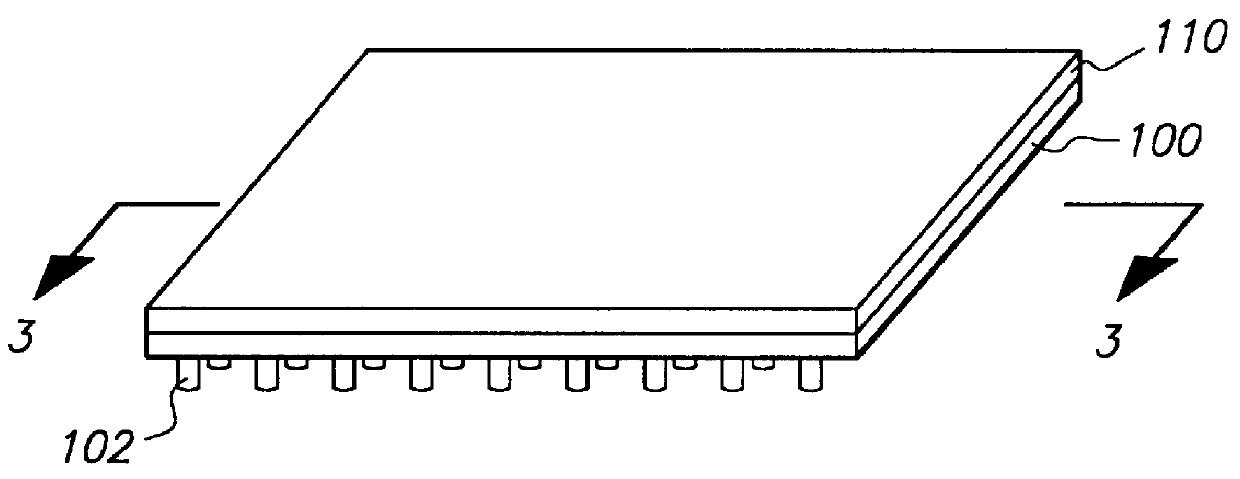

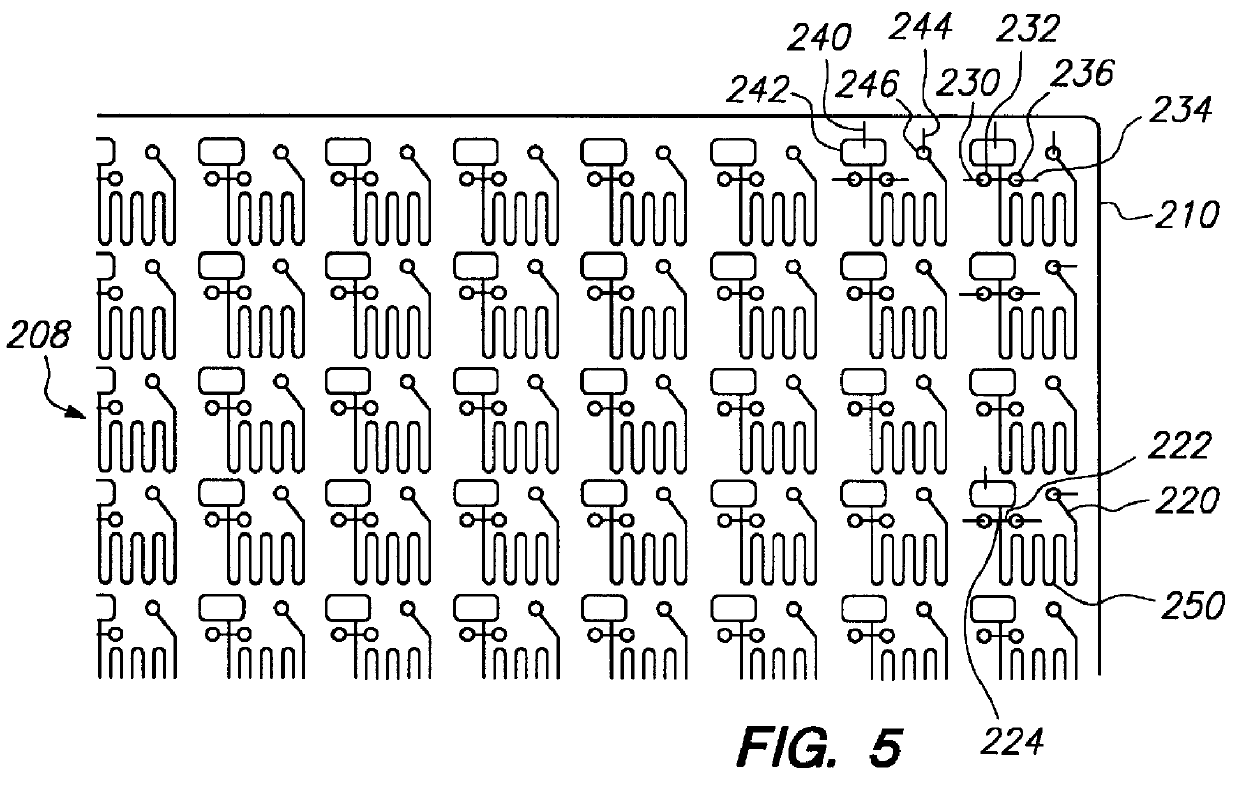

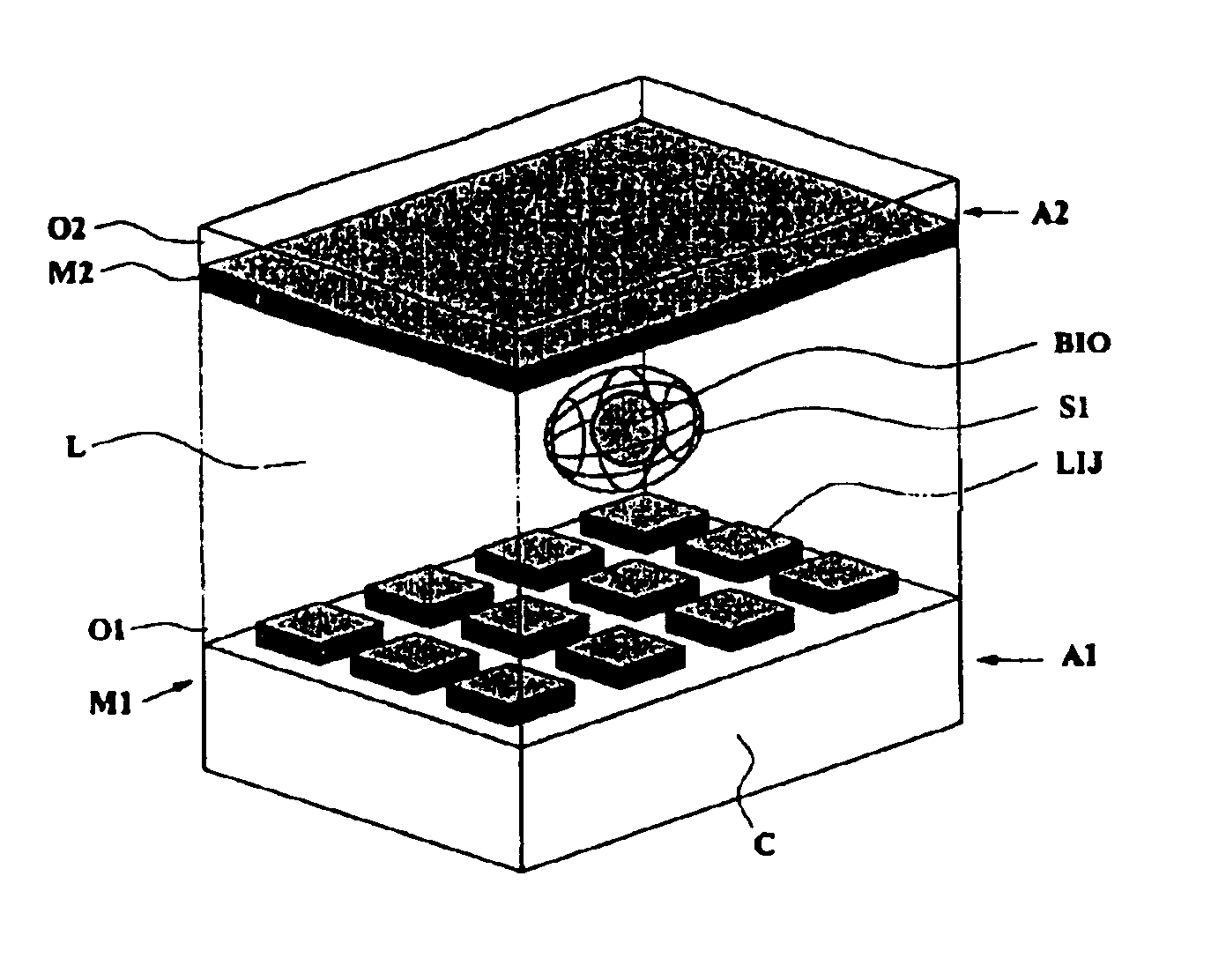

The present invention concerns an apparatus for conducting a microfluidic process. The apparatus comprises integral first and second plates. The first plate comprises an array of sample receiving elements for receiving a plurality of samples from an array of sample containers and dispensing the samples. The second plate comprises a planar array of microfluidic networks of cavity structures and channels for conducting a microfluidic process. Also disclosed is a method for processing an array of samples. At least a portion of each sample in an array of sample wells is simultaneously transferred to a corresponding array of microfluidic networks of cavity structures and channels by means of a corresponding array of sample receiving elements that is in integral fluid communication with the array of microfluidic networks. The samples are then processed. Also disclosed is a device for conducting a microfluidic process wherein the device comprising a planar substrate having a planar array of microfluidic networks of cavity structures and channels for conducting a microfluidic process. A plurality of such devices may be present on a continuous sheet. The invention further includes kits for carrying out microfluidic processes comprising an apparatus as described above.

Owner:ACLARA BIOSCIENCES INC

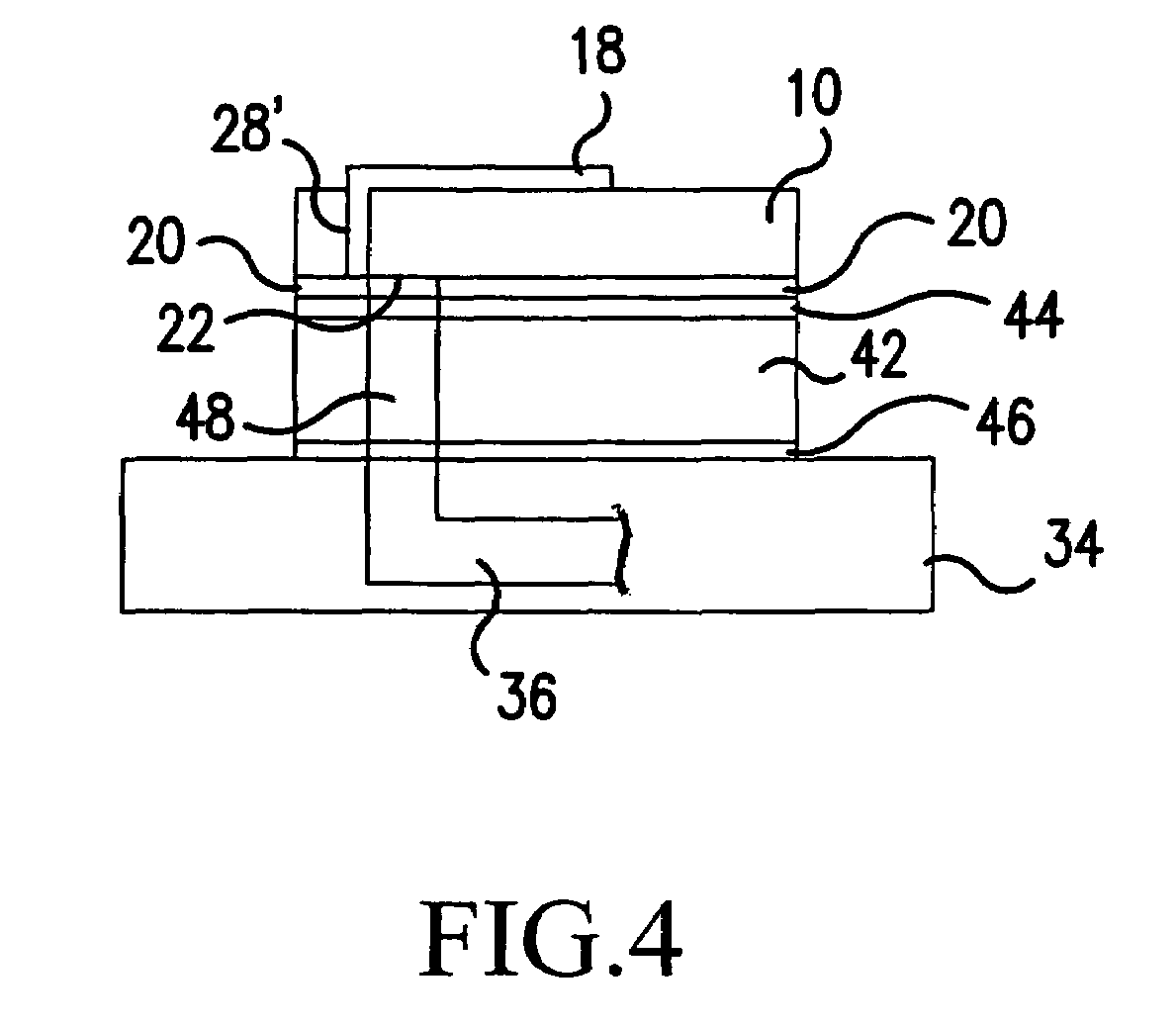

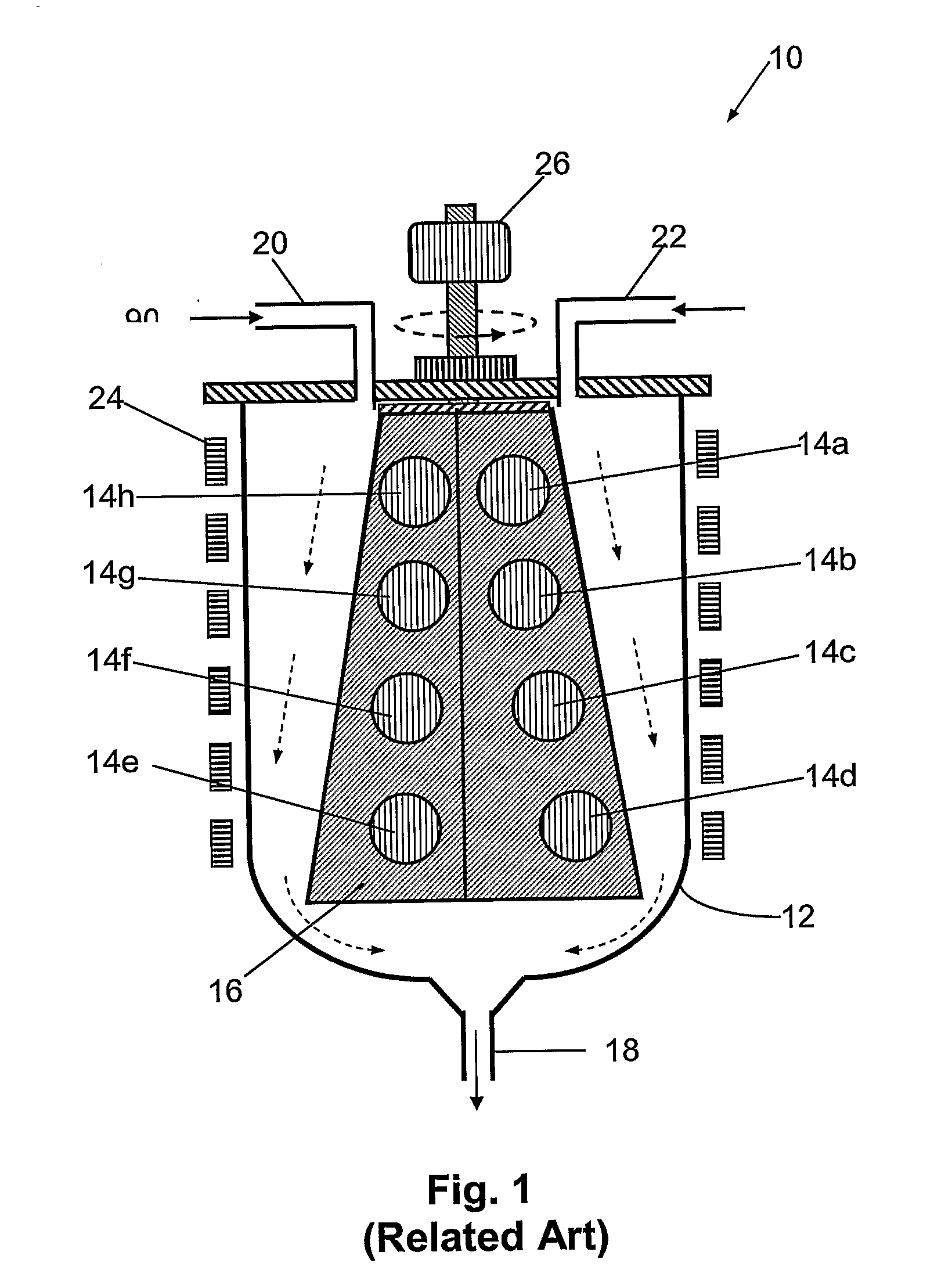

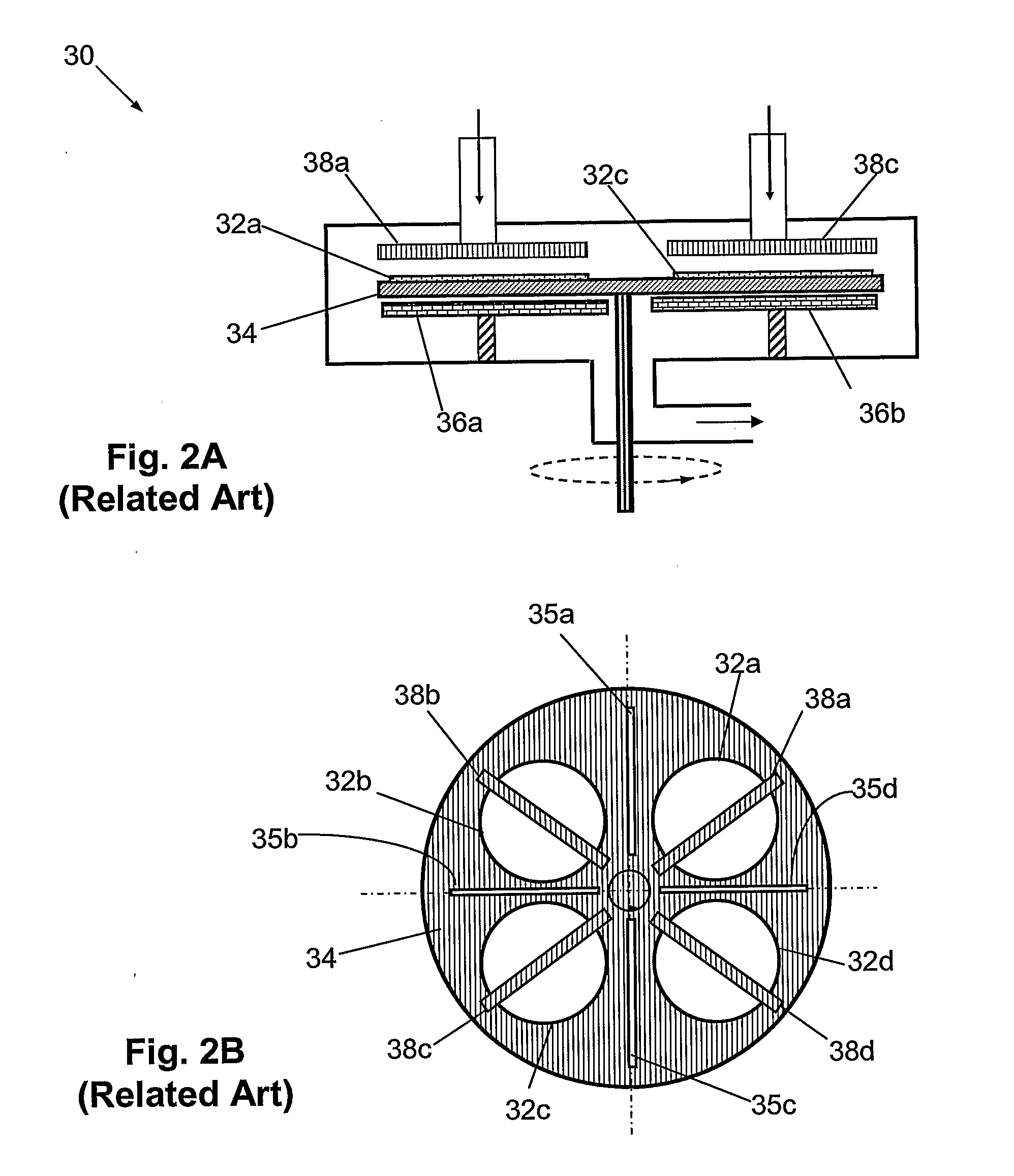

Atomic layer deposition apparatus

ActiveUS20080069955A1Shorten the timeVacuum evaporation coatingSputtering coatingProduction ratePlanar substrate

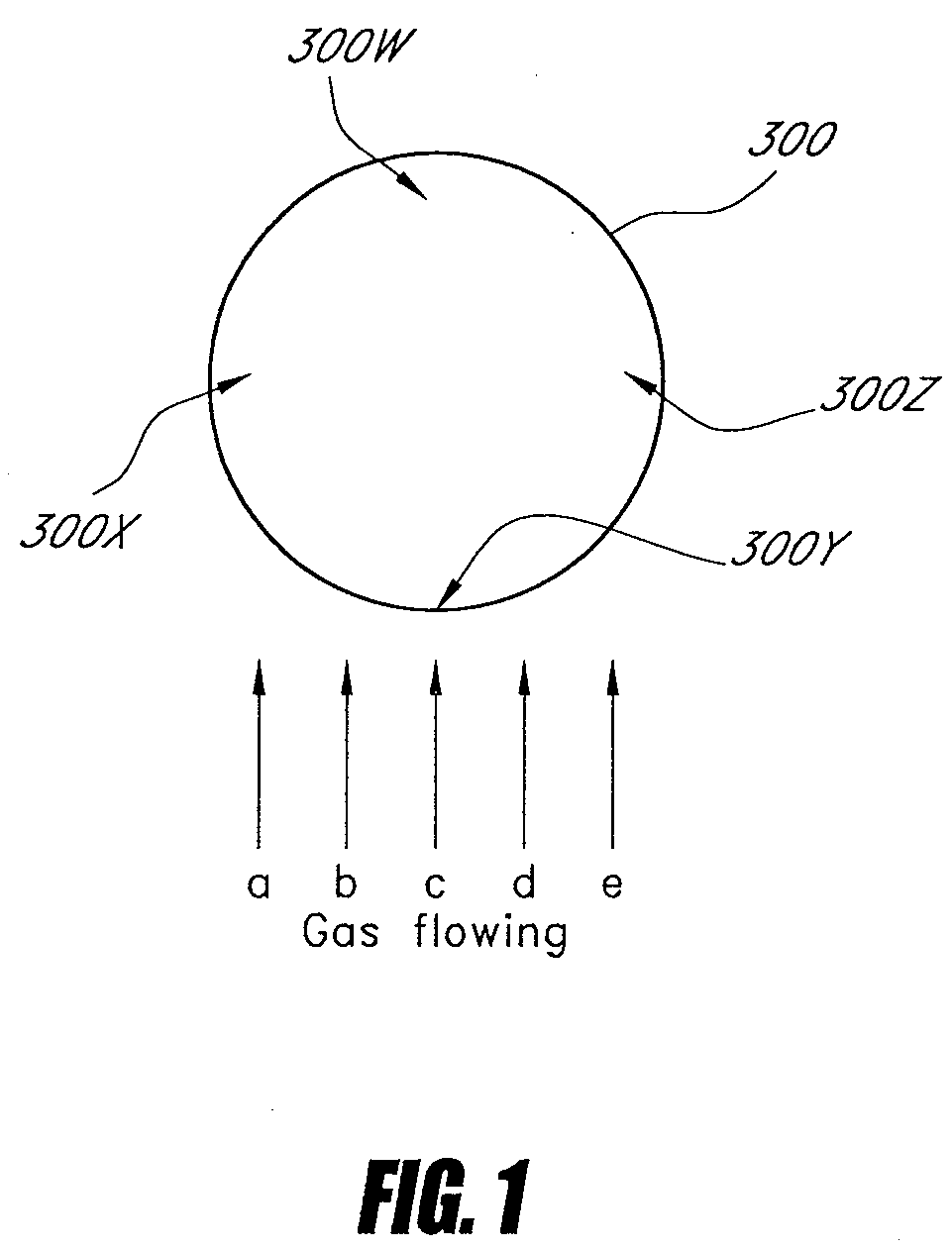

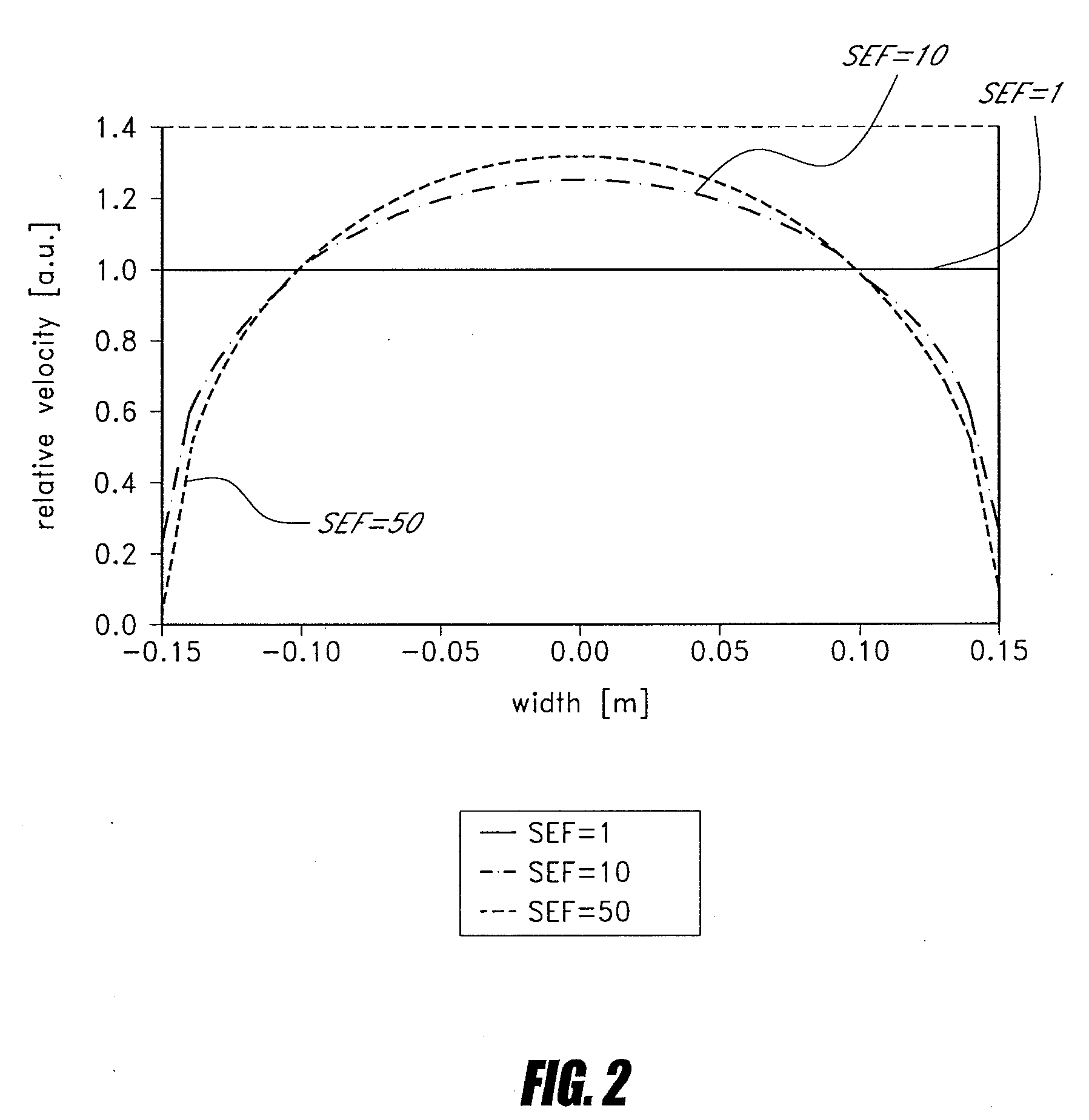

The present invention relates to an ALD apparatus, and particularly relates to an ALD apparatus that is suitable for rapidly depositing a thin film on a substrate having an actual area that is larger than a planar substrate. In the reaction chamber of the ALD apparatus according to an exemplary embodiment of the present invention, more gas is supplied to a portion where more gas is required by having differences in the space for gas to flow rather than supplying the gas in a constant flux and a constant flow velocity such that the time required for supplying reactant gases and waste of reactant gases may be minimized to increase productivity of the ALD apparatus. The ceiling of the reaction space is shaped to provide a nonuniform gap over the substrate.

Owner:ASM KOREA LTD

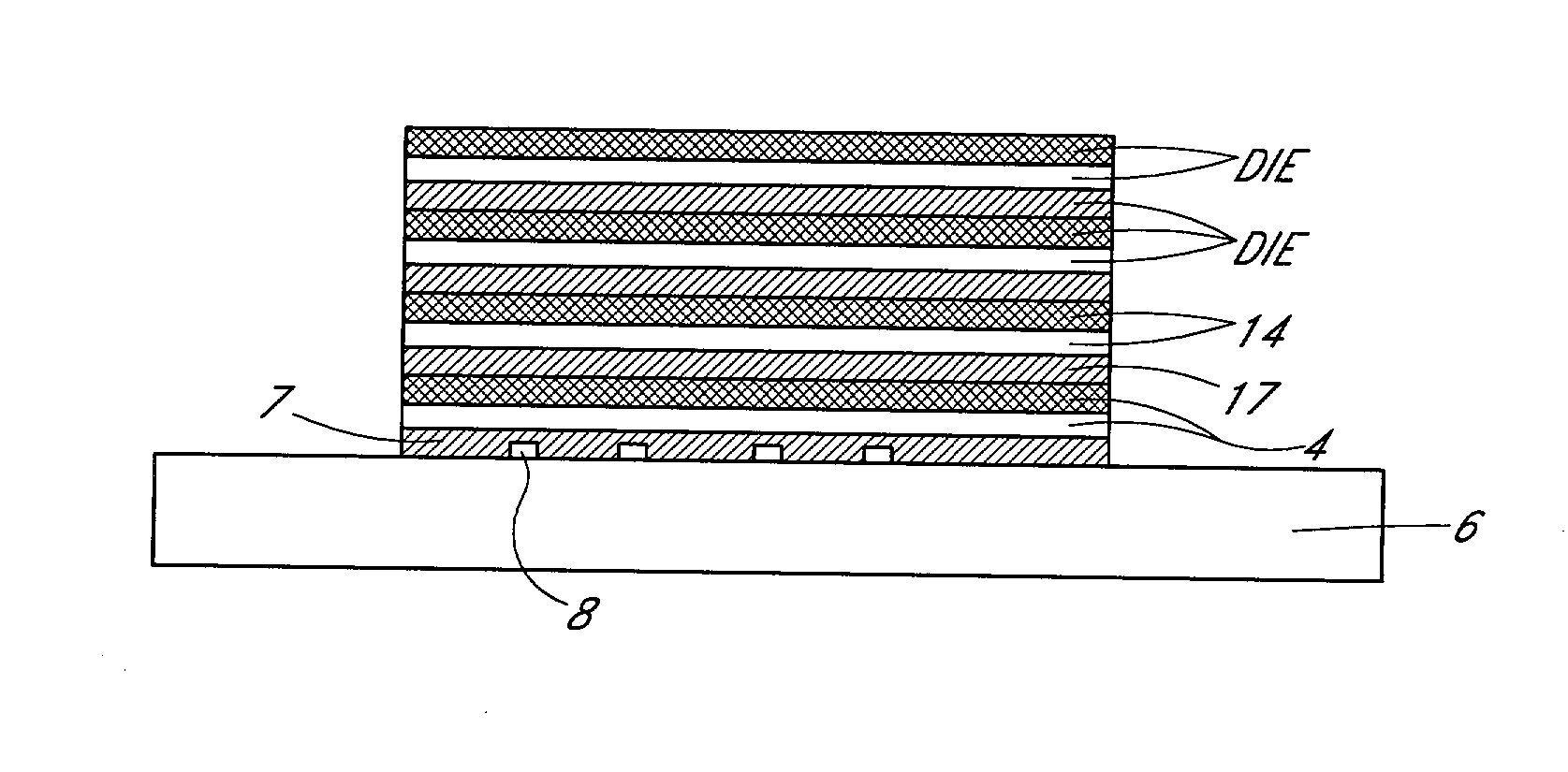

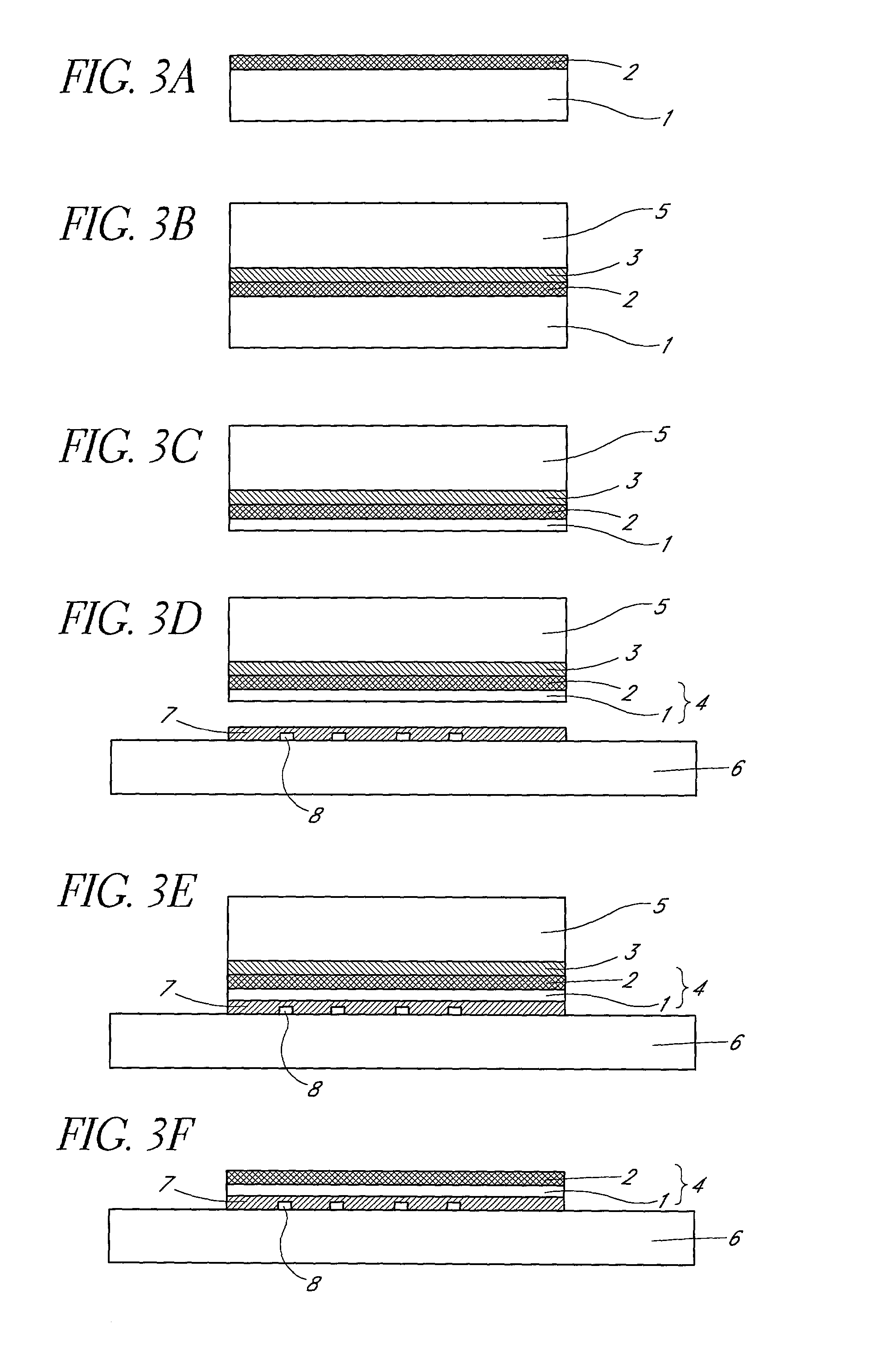

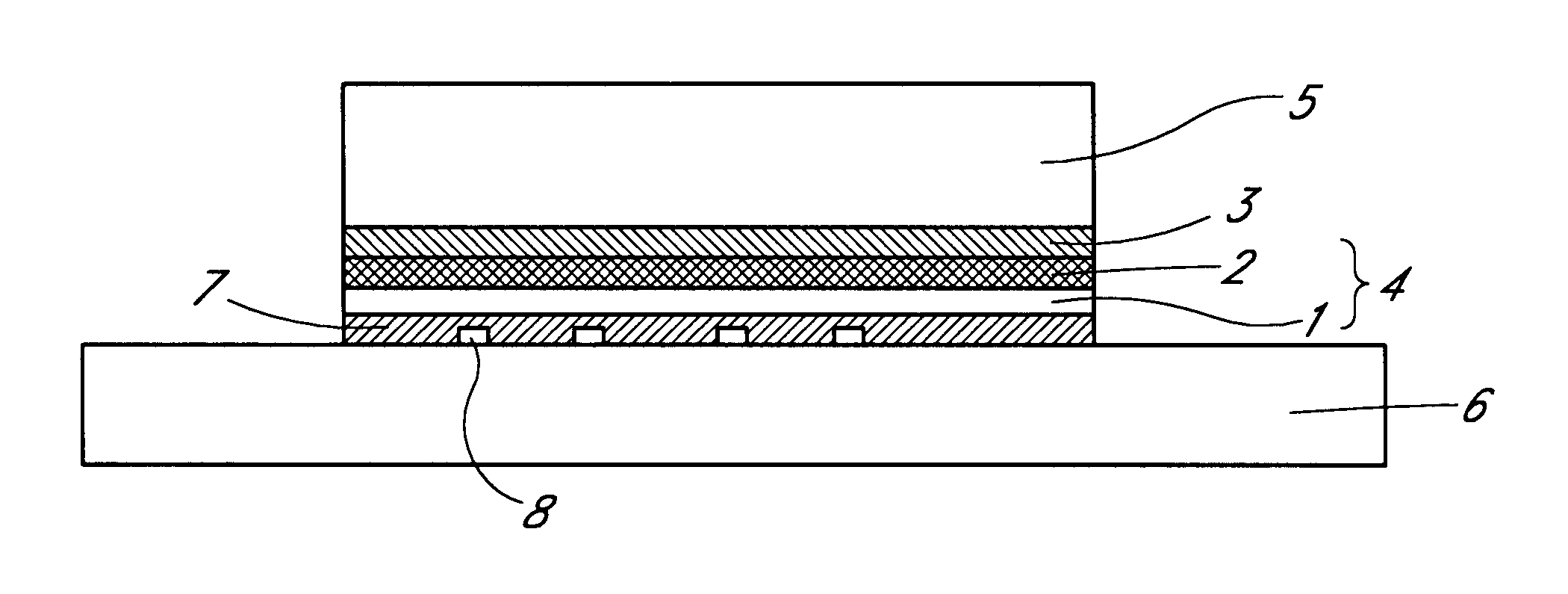

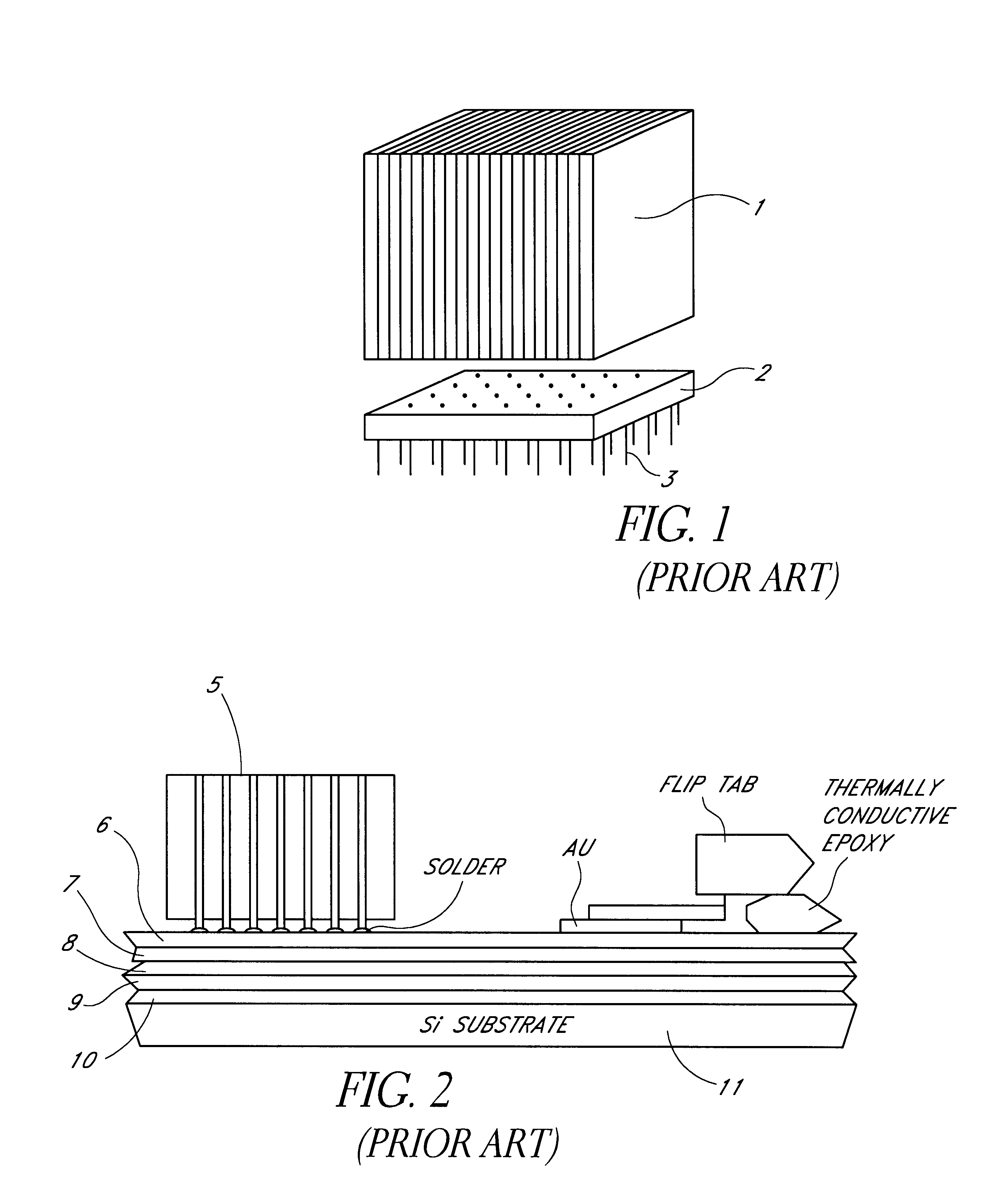

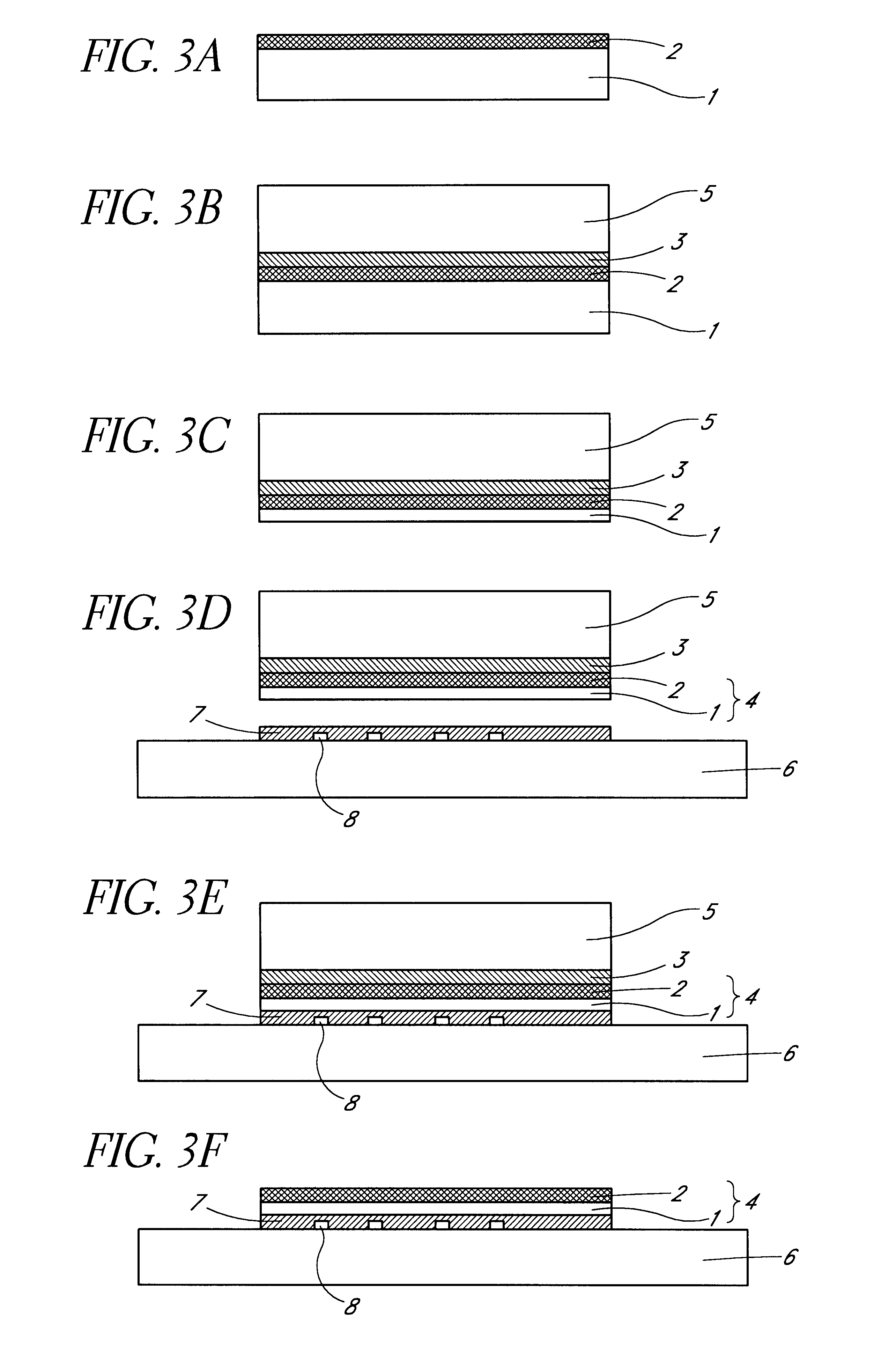

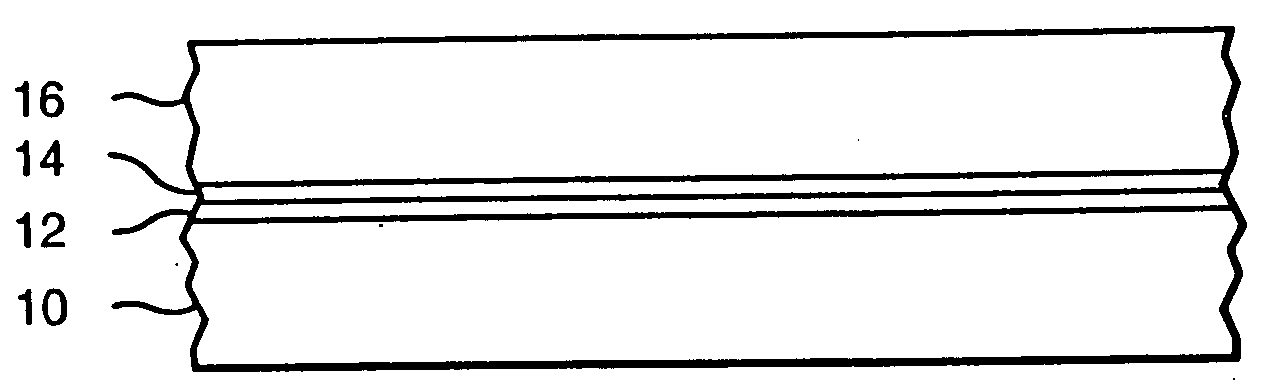

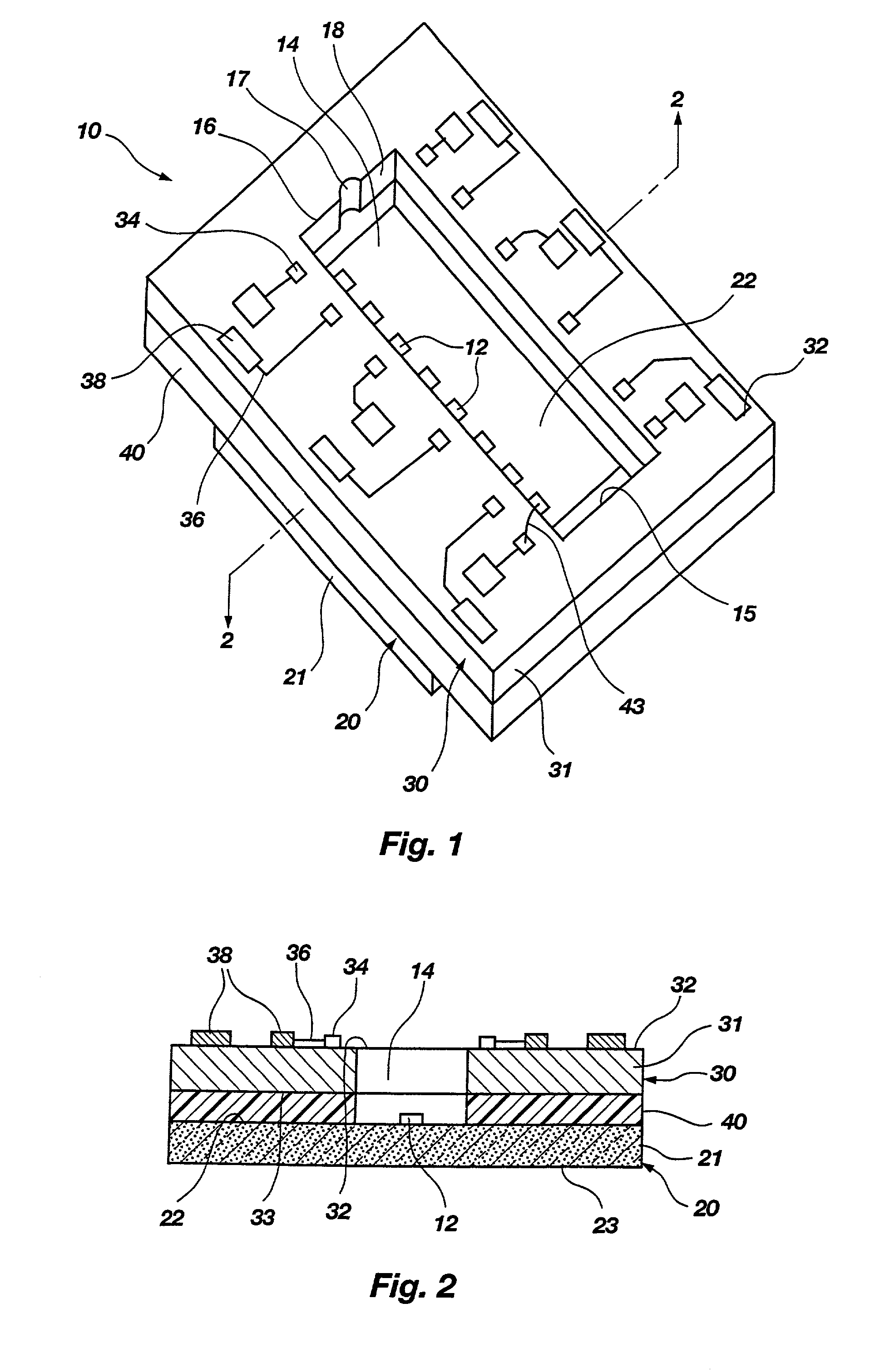

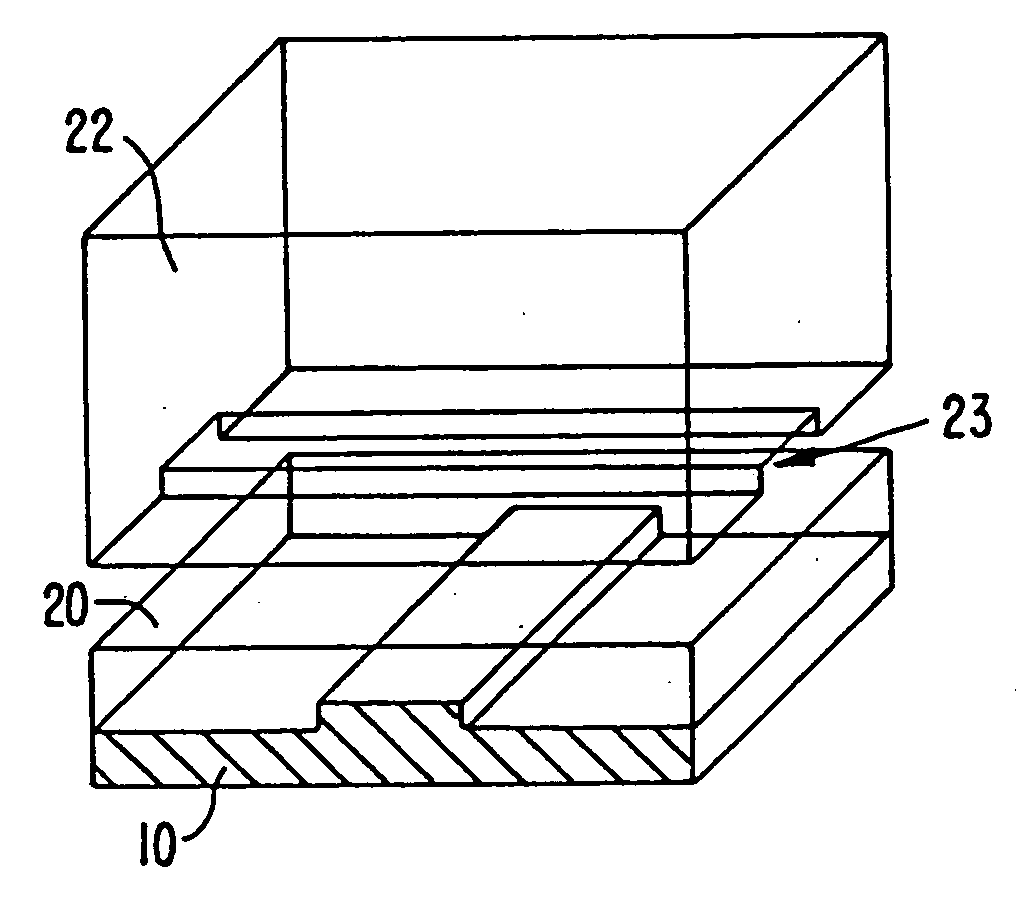

Method of transferring ultra-thin substrates and application of the method to the manufacture of a multi-layer thin film device

InactiveUS20030060034A1High densitySafe transferSemiconductor/solid-state device detailsSolid-state devicesPolymer adhesivePlanar substrate

The present invention provides a method of transfer of a first planar substrate with two major surfaces to a second substrate, comprising the steps of forming the first planar substrate, attaching one of the major surfaces of the first planar substrate to a carrier by means of a release layer attaching the other major surface of the first substrate to the second substrate with a curable polymer adhesive layer partly curing the polymer adhesive layer, disconnecting the release layer from the first substrate to separate the first substrate from the carrier, followed by curing the polymer adhesive layer. The method may be used to form a stack of dies (4, 14 . . . ) which are adhered together by cured polymeric layers (7, 17). Each die (4, 14 . . . ) may include a device layer and an ultra-thin substrate manufactured and assembled by the method described above.

Owner:INTERUNIVIR MICRO ELEKTRONICA CENTRYM VZW IMEC

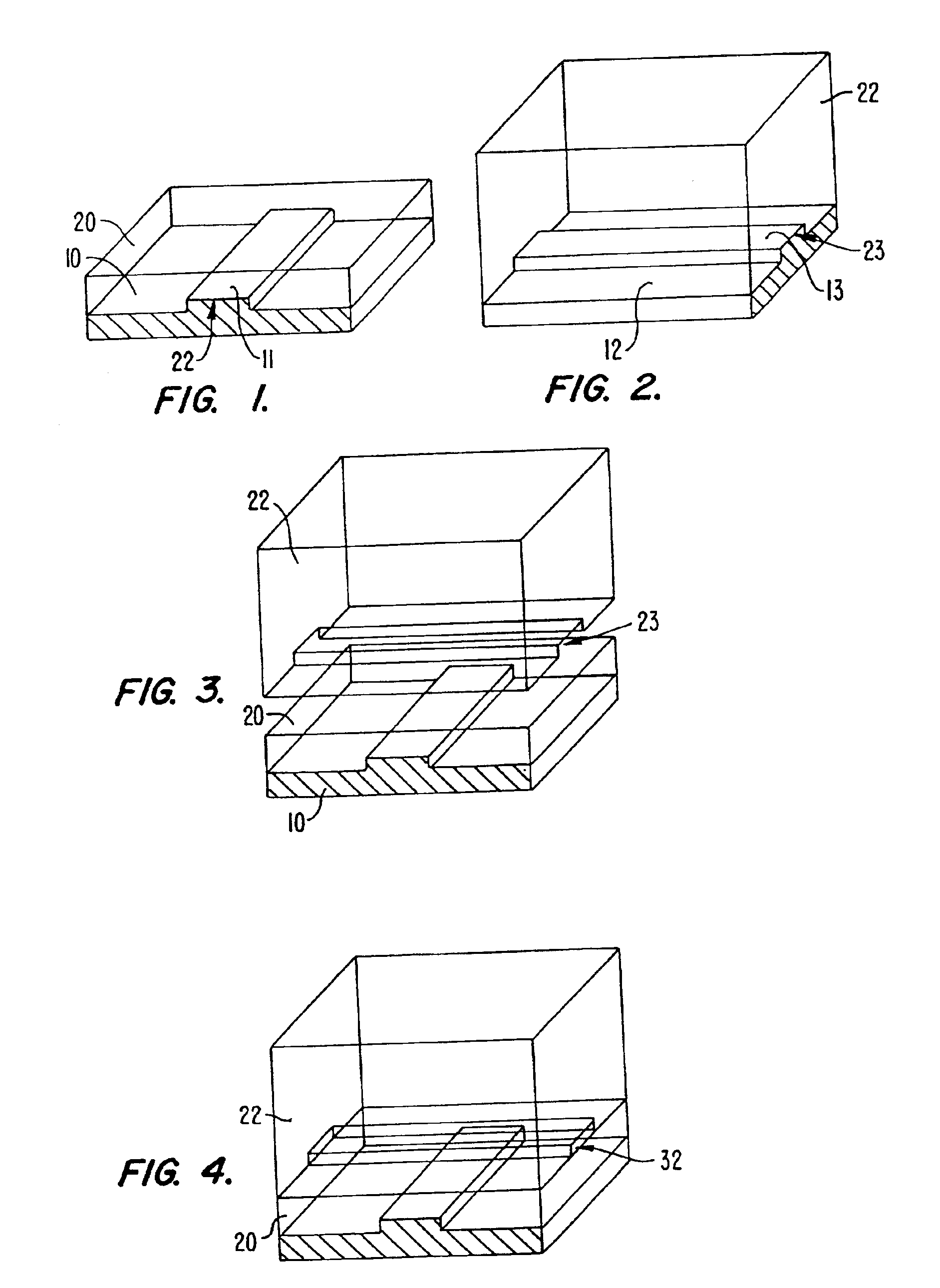

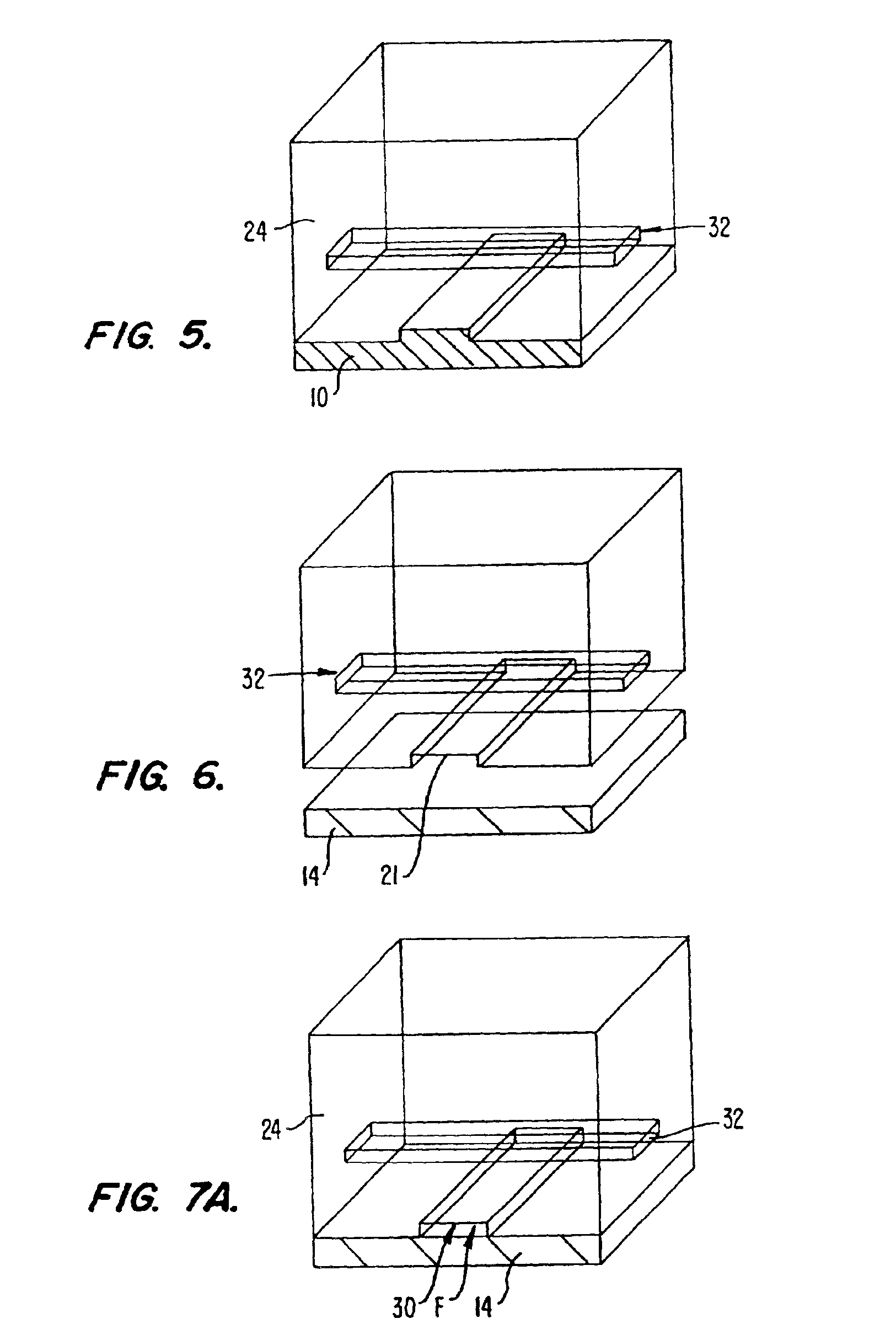

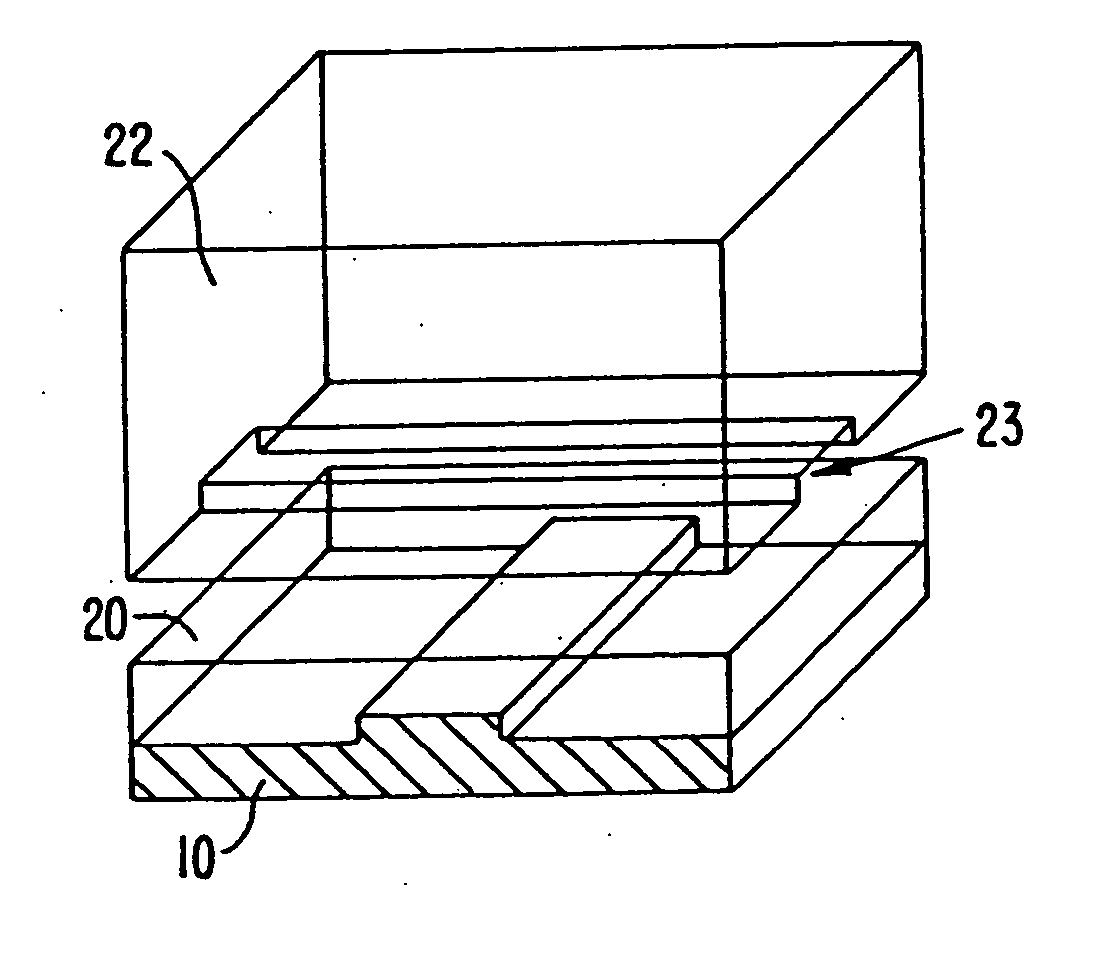

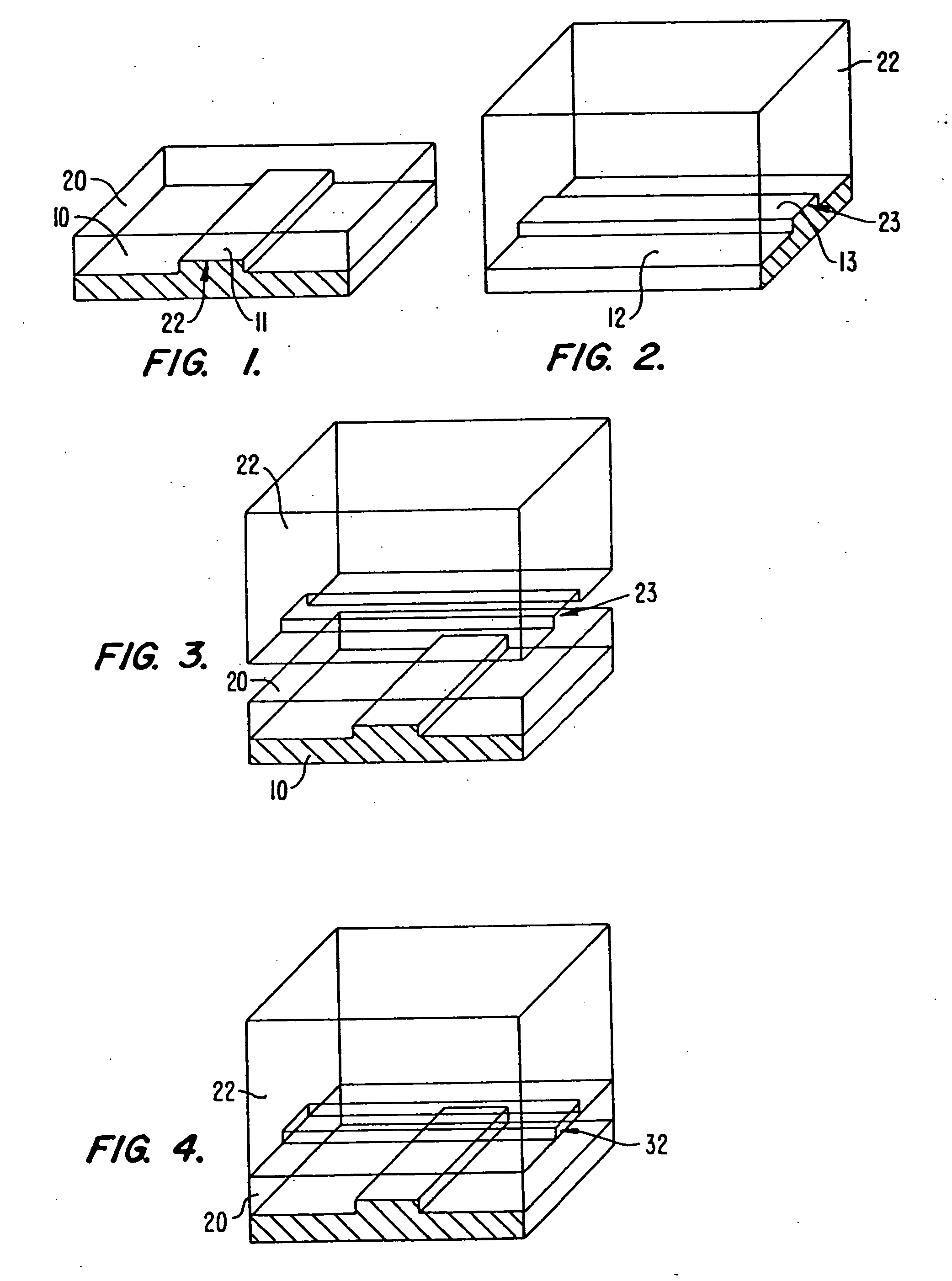

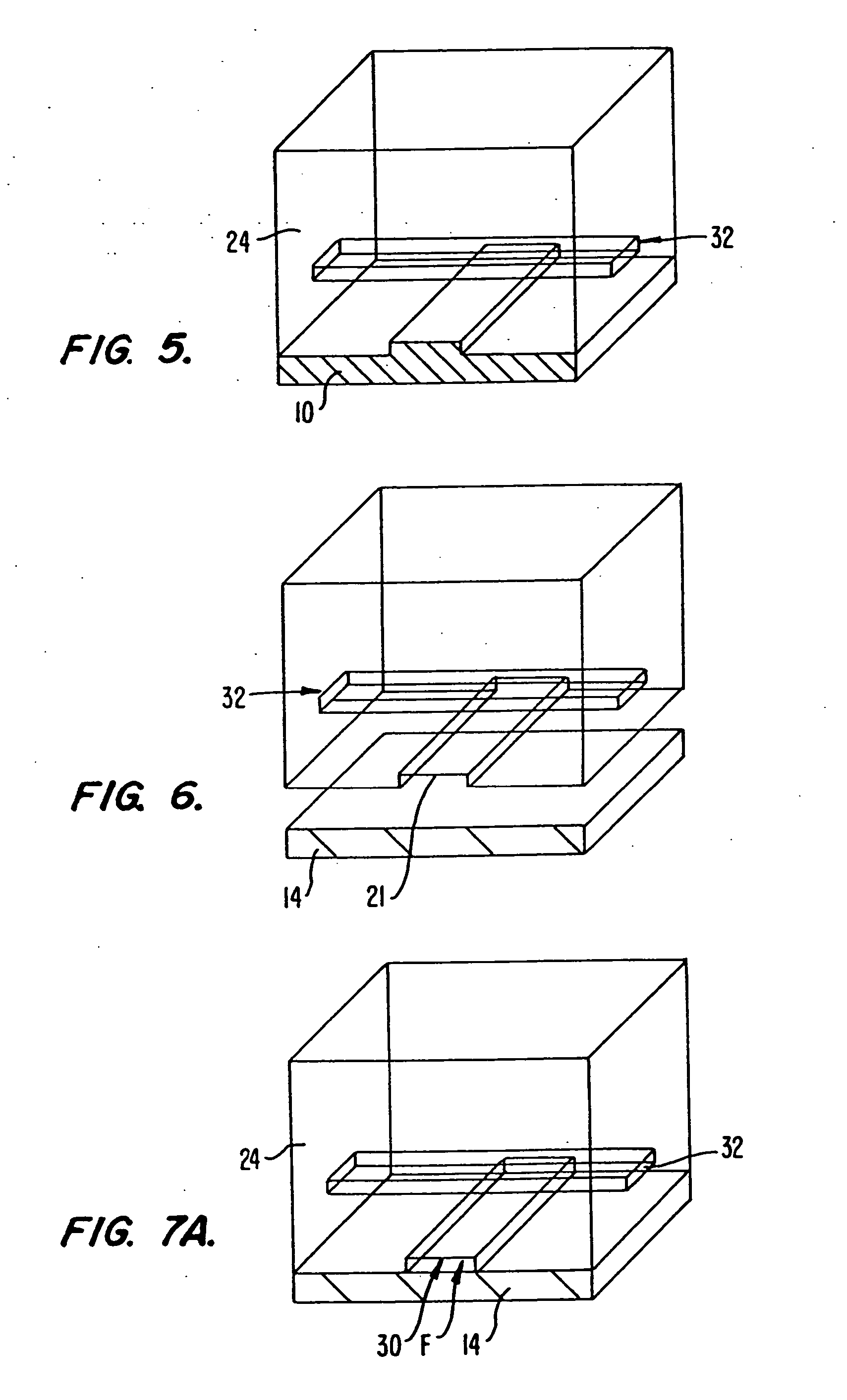

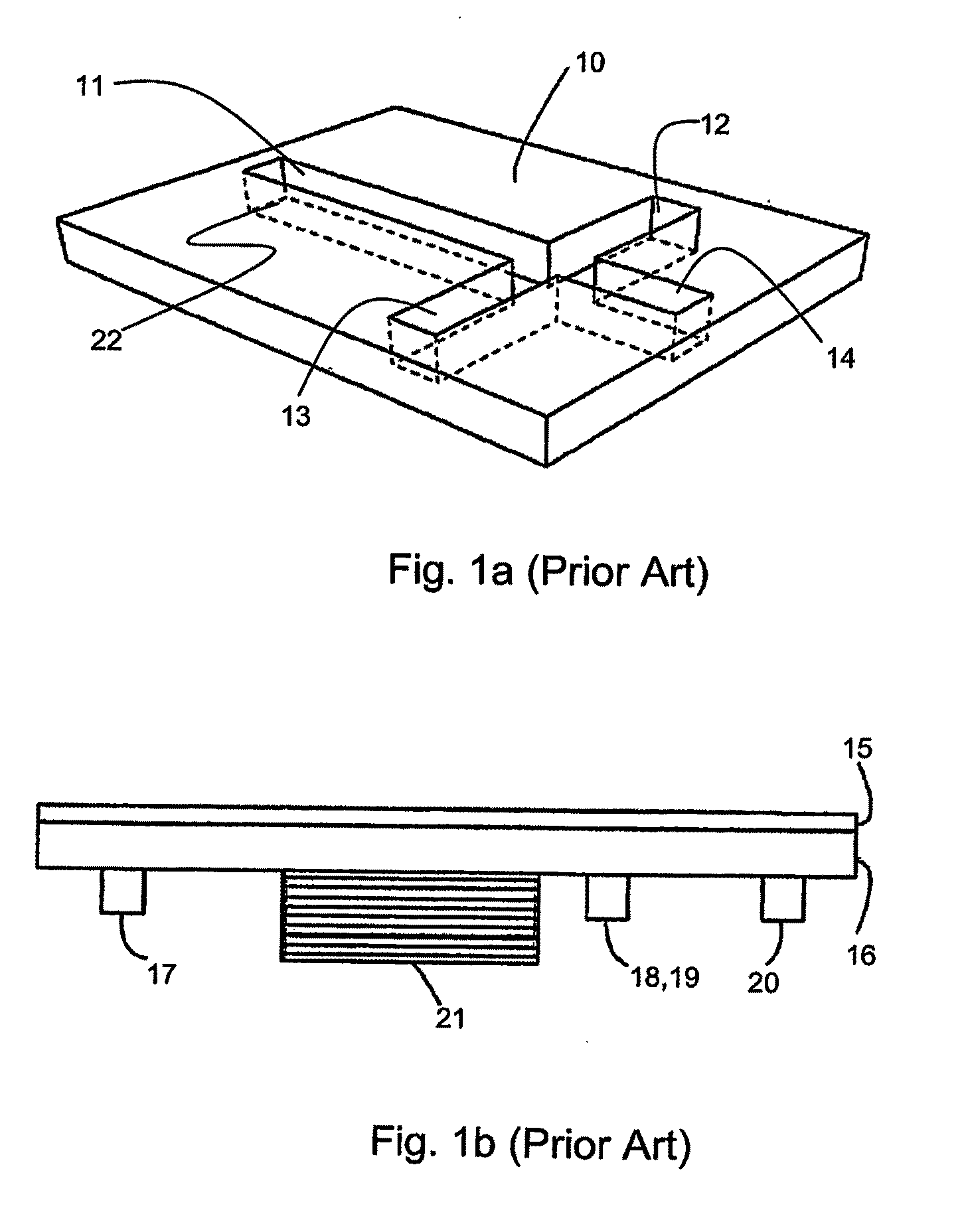

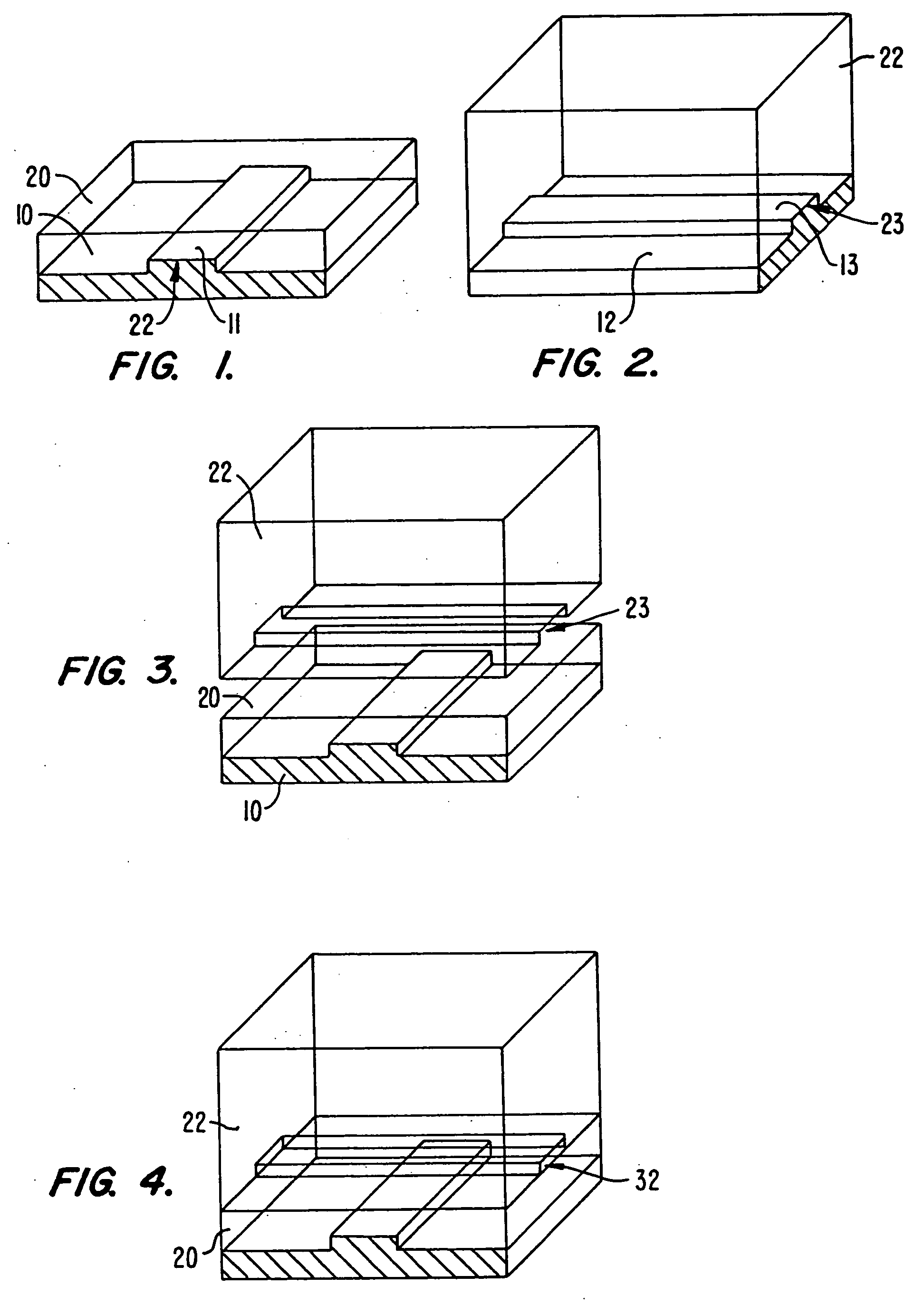

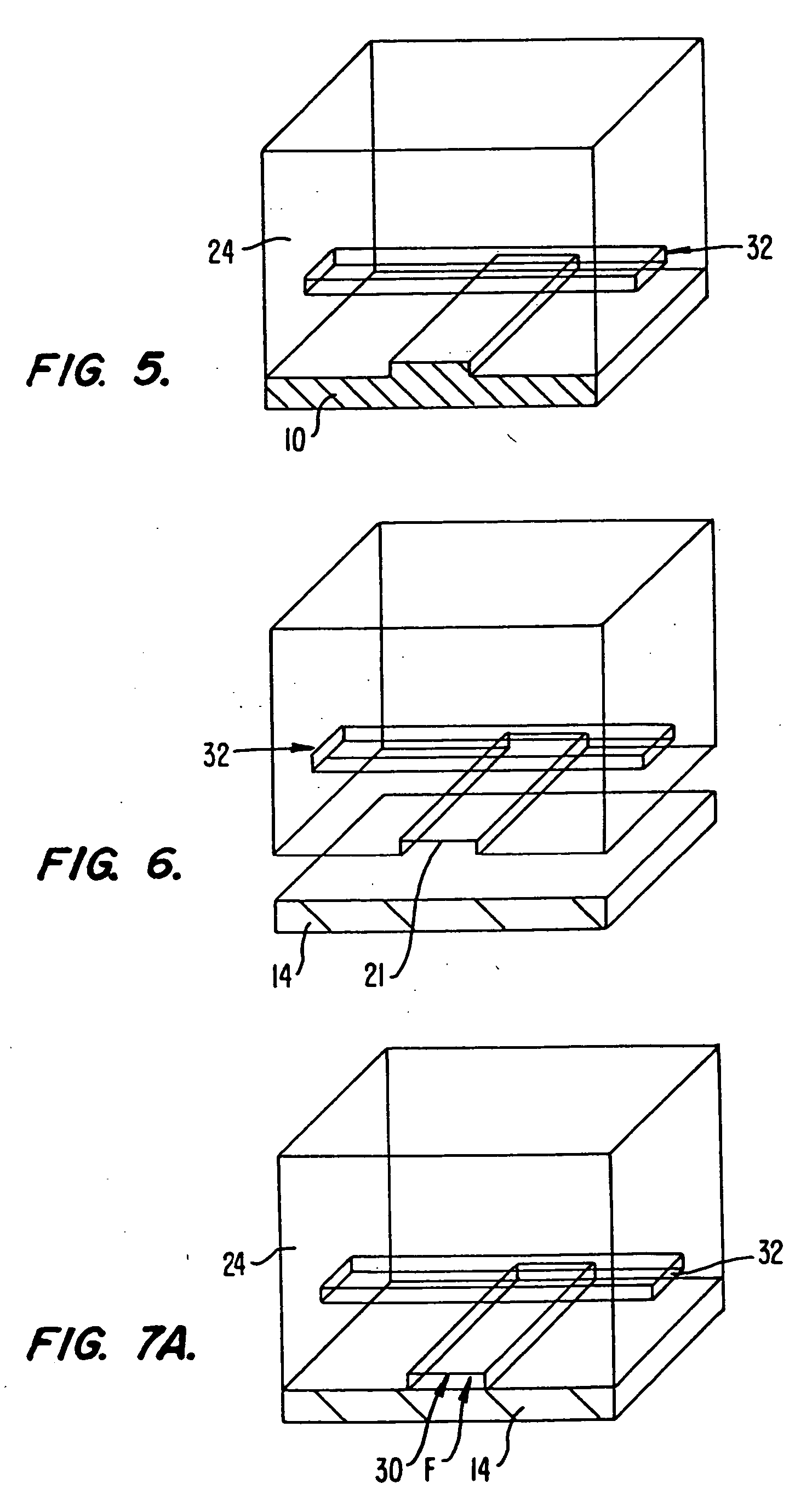

Microfabricated elastomeric valve and pump systems

InactiveUS6899137B2Increase speedSmall sizeFixed microstructural devicesVolume/mass flow measurementElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

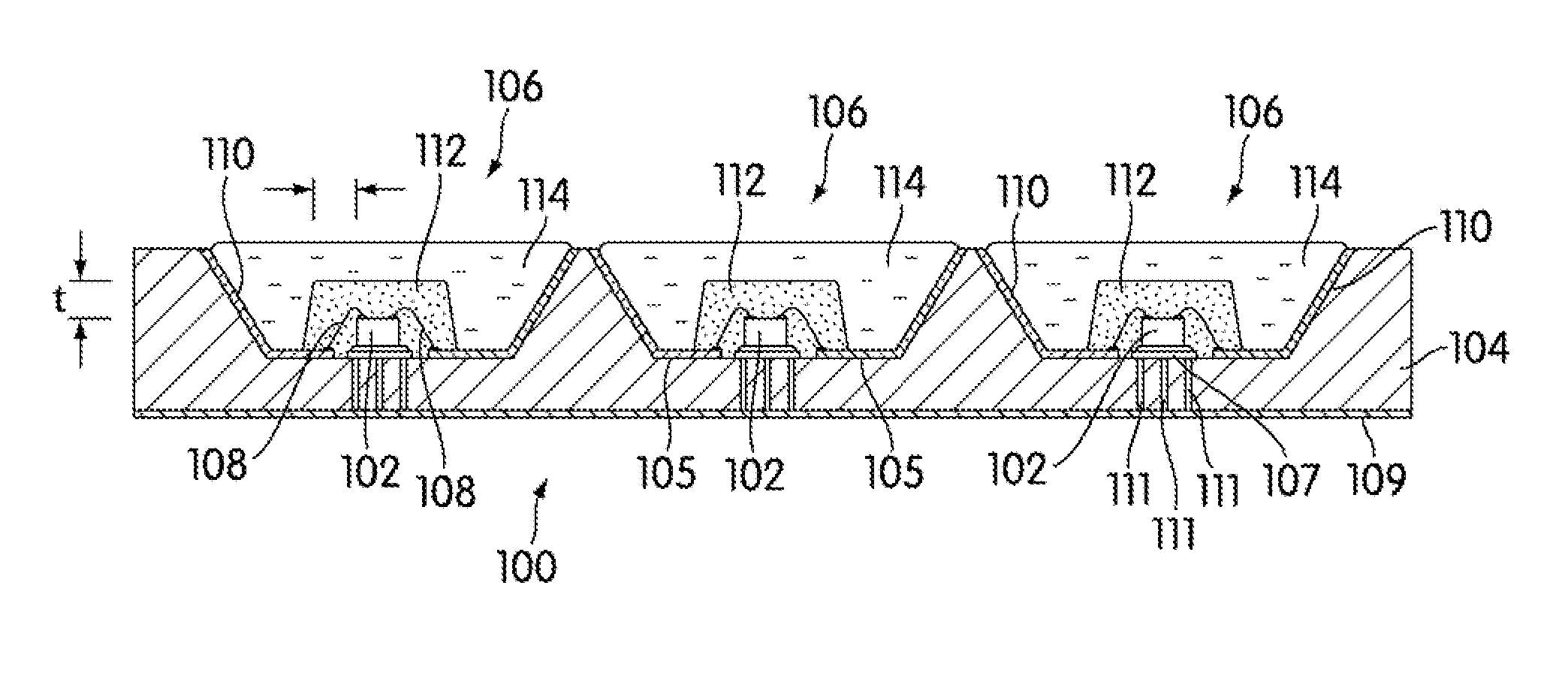

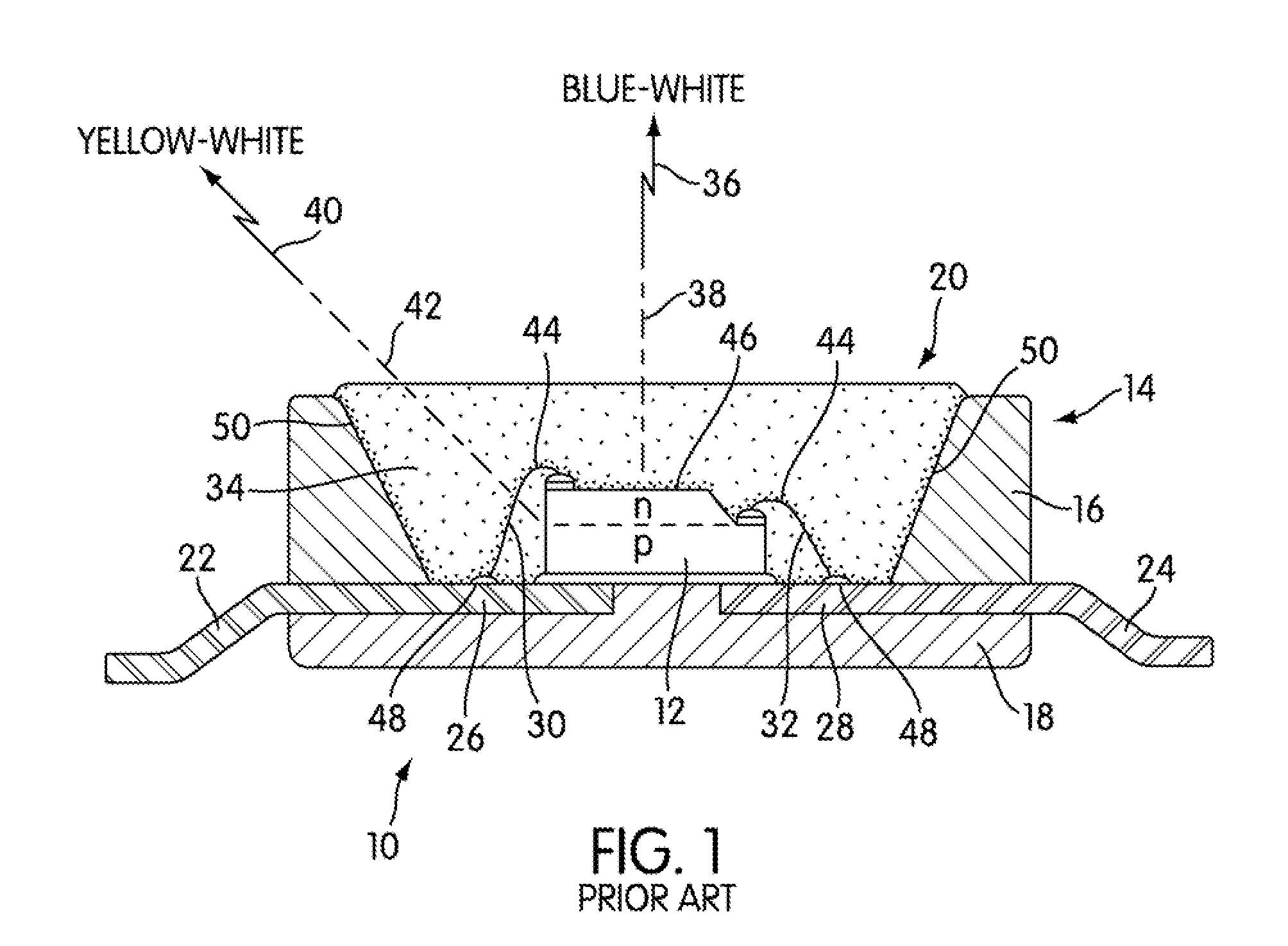

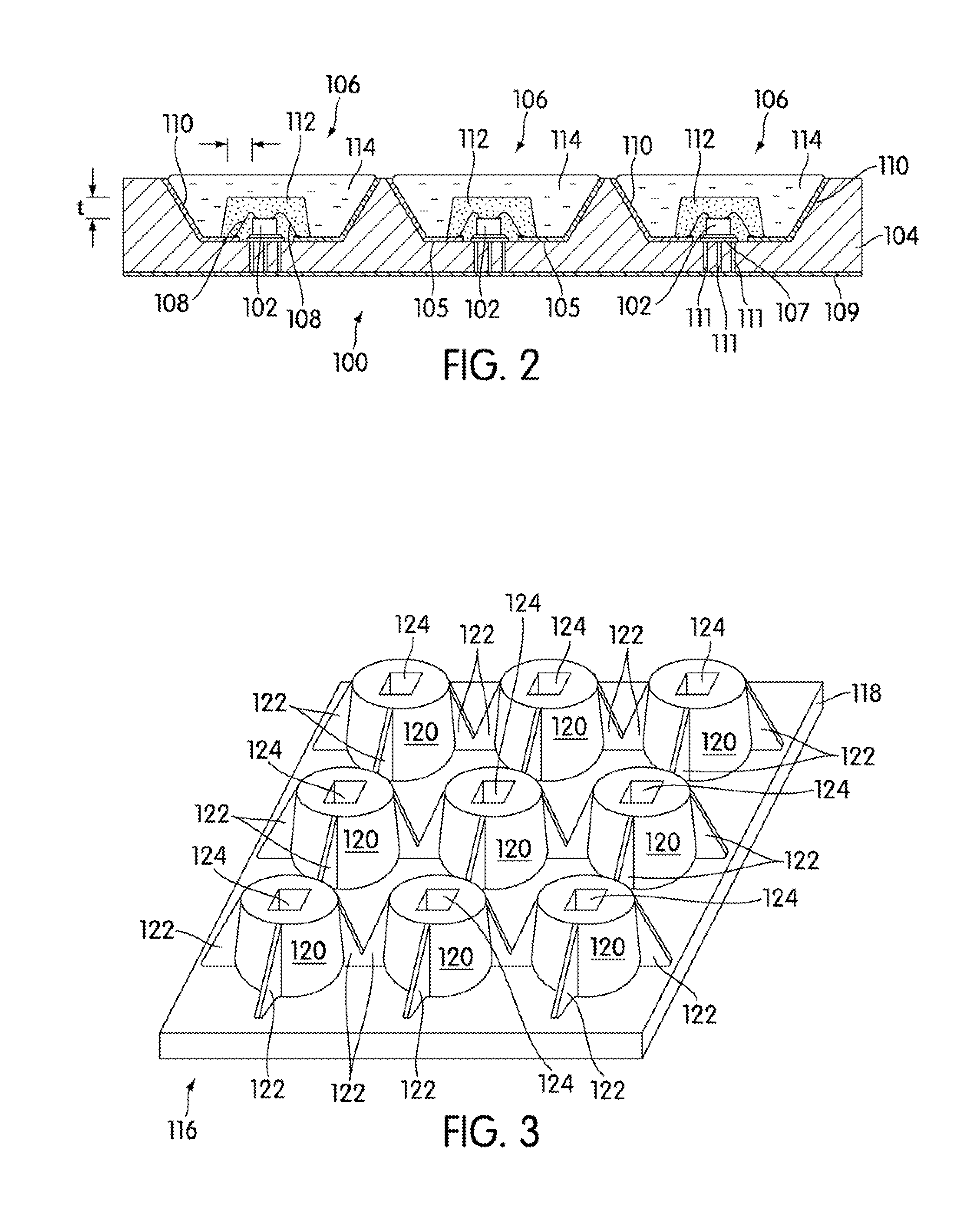

Light emitting devices with phosphor wavelength conversion and methods of manufacture thereof

InactiveUS20100181582A1Reduces the formation of air bubblesEasy to fillSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorPlanar substrate

A light emitting device comprises: a package (low temperature co-fired ceramic) having a plurality of recesses (cups) in which each recess houses at least one LED chip and at least one phosphor material applied as coating to the light emitting light surface of the LED chips, wherein the phosphor material coating is conformal in form. In another arrangement a light emitting device comprises: a planar substrate (metal core printed circuit board); a plurality of light emitting diode chips mounted on, and electrically connected to, the substrate; a conformal coating of at least one phosphor material on each light emitting diode chip; and a lens formed over each light emitting diode chip.

Owner:INTEMATIX

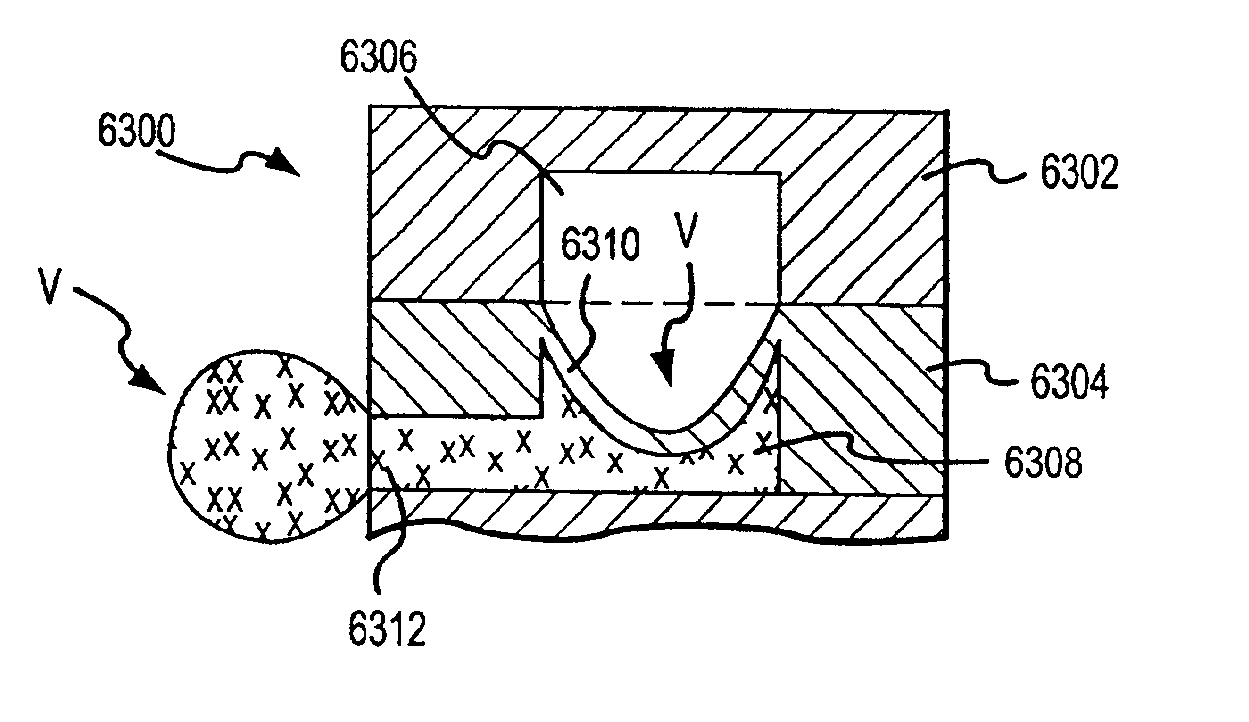

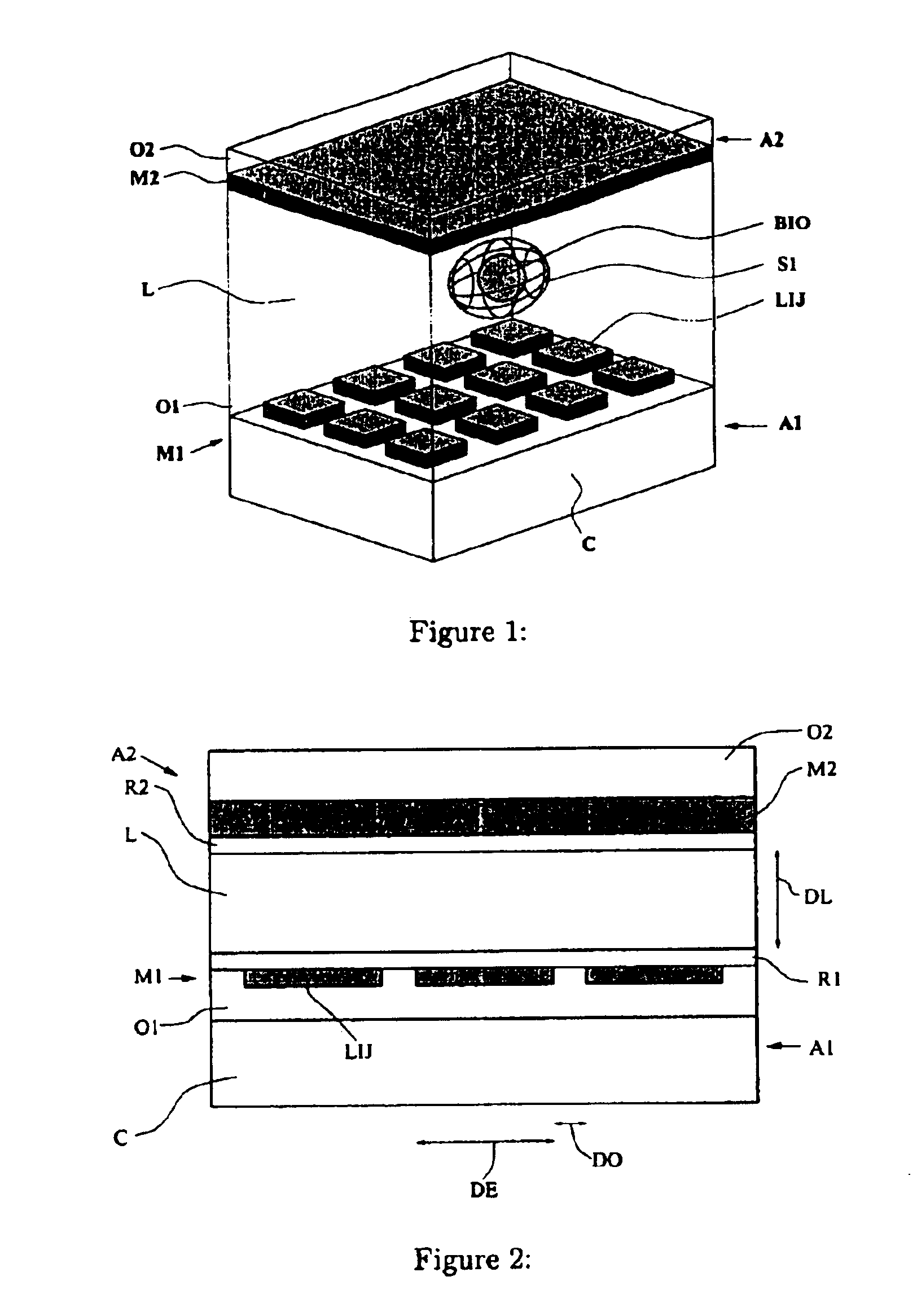

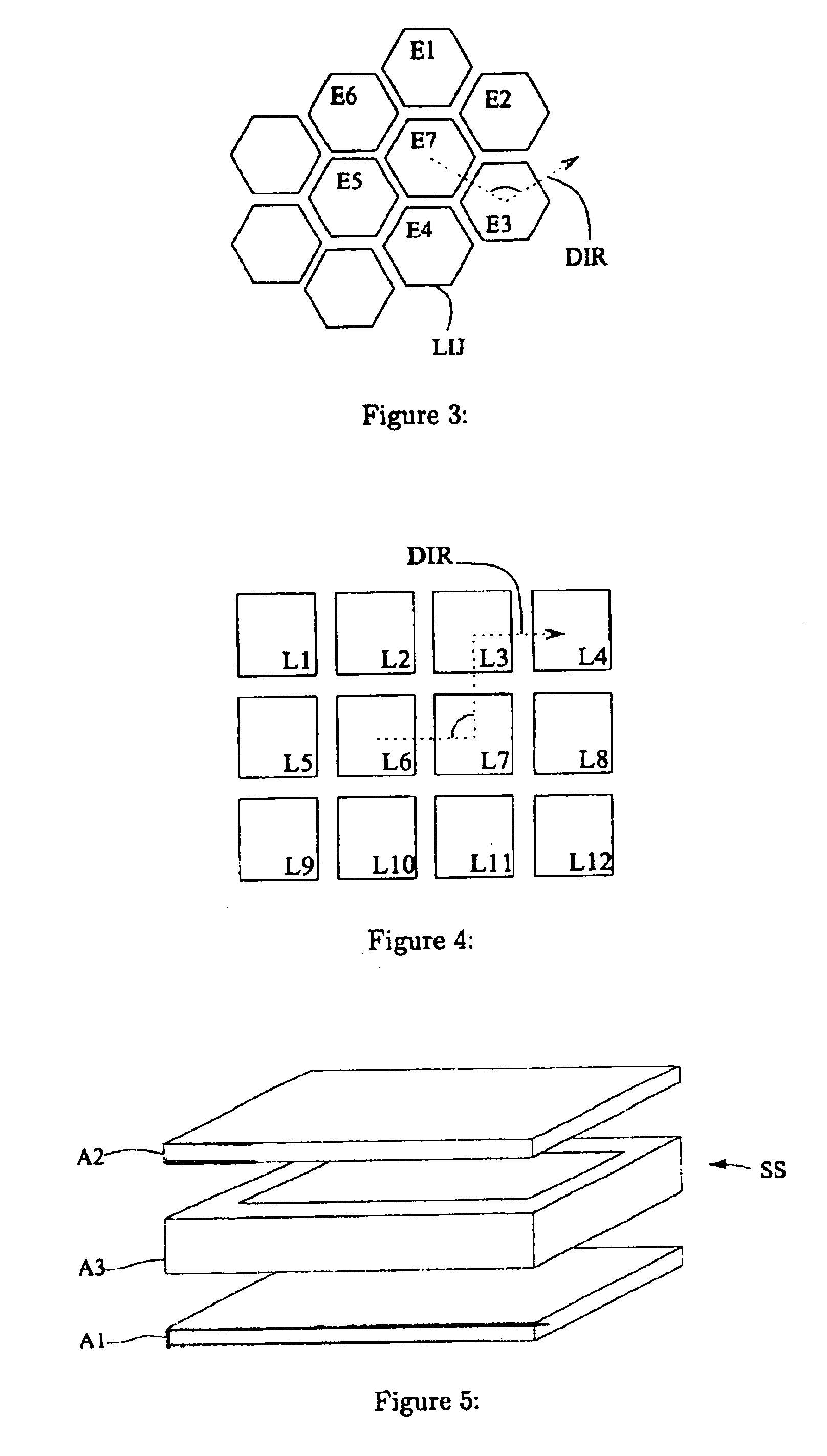

Method and apparatus for the manipulation of particles by means of dielectrophoresis

InactiveUS6942776B2Increase rangeAvoid the needElectrostatic separatorsSludge treatmentPlanar substrateEngineering

An apparatus and method for establishing closed dielectrophoretic potential cages and precise displacement thereof comprising a first array of selectively addressable electrodes, lying on a substantially planar substrate and facing toward a second array comprising one electrode. The arrays define the upper and lower bounds of a micro-chamber where particles are placed in liquid suspension. By applying in-phase and counter-phase periodic signals to electrodes, one or more independent potential cages are established which cause particles to be attracted to or repelled from cages according to signal frequency and the dielectric characteristics of the particles and suspending medium. By properly applying voltage signal patterns into arrays, cages may trap one or more particles, thus permitting them to levitate steadily and / or move. In the preferred embodiment, where one array is integrated on a semiconductor substrate, displacement of particles can be monitored by embedded sensors.

Owner:SILICON BIOSYSTEMS SPA +1

Transmission line to waveguide interconnect and method of forming same including a heat spreader

Owner:NORTHROP GRUMMAN SYST CORP

Pressure sensing or force generating device

ActiveUS20120055257A1Few contactsShorten the counting processPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCapacitanceCapacitive effect

In one aspect, the present invention relates to a pressure sensing / force generating device comprising a non-planar substrate, a printed pressure sensitive element comprising (a) a piezoelectric material containing ink composition capable of producing a piezoelectric effect / piezoresistive effect and / or (b) a dielectric material containing ink composition capable of producing a capacitive effect. It also includes a first printed electrode comprising a conductive ink composition, and a second printed electrode comprising a conductive ink composition. The first and second electrodes are in electrical contact with the printed pressure sensitive element. The first and second printed electrodes and the printed pressure sensitive element collectively form a pressure sensitive junction, which is coupled to the non-planar substrate. The present invention further relates to medical devices comprising the pressure sensing / force generating device and methods of making such devices.

Owner:MICROPEN TECH CORP

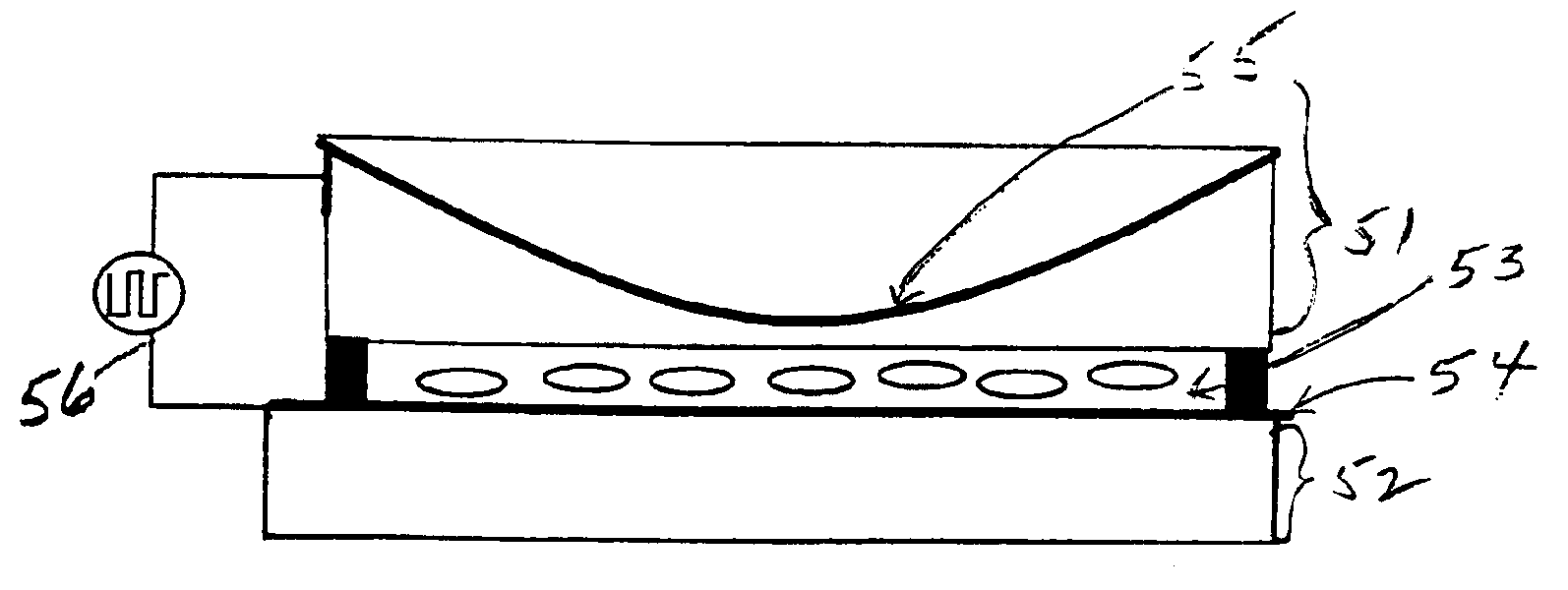

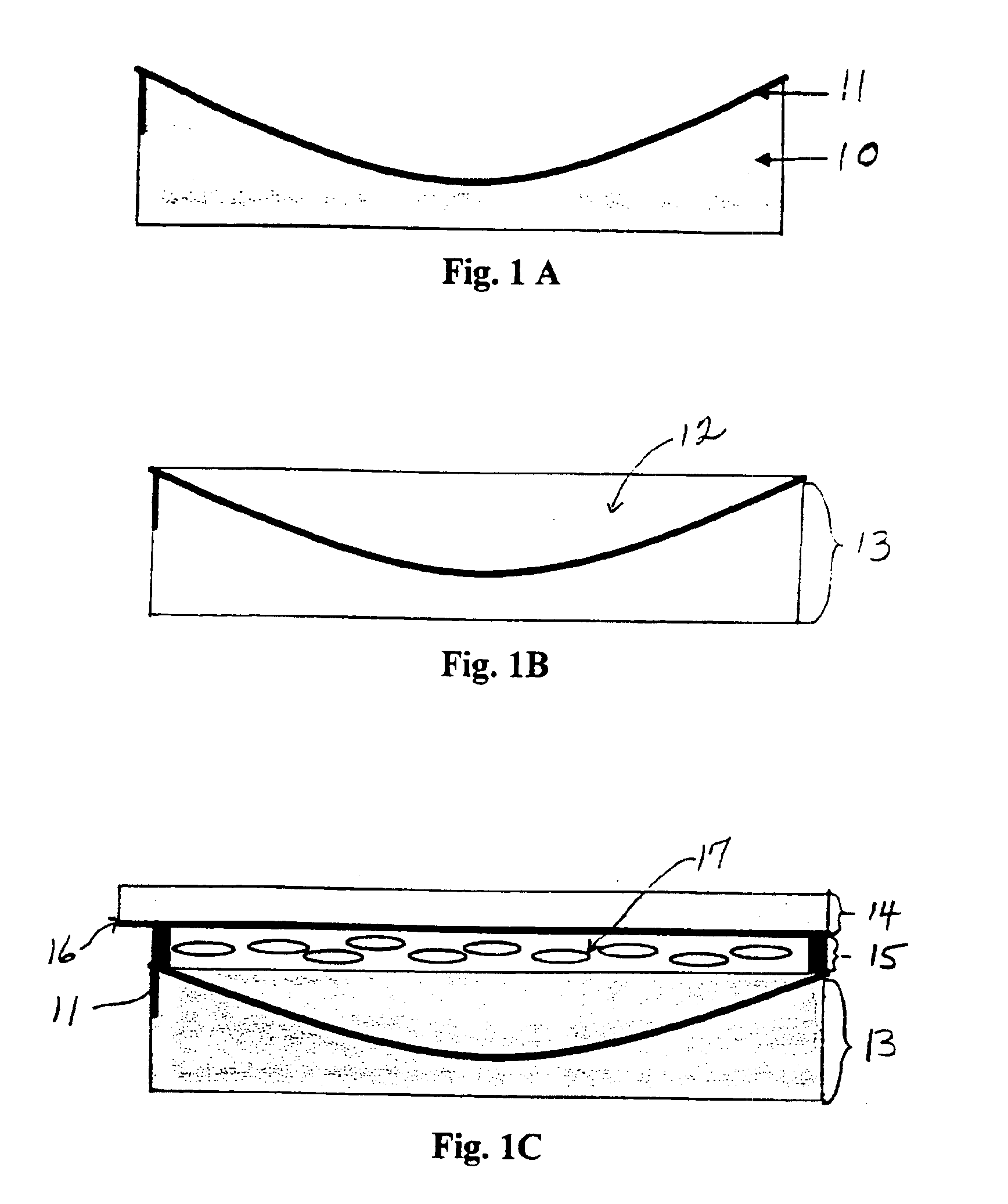

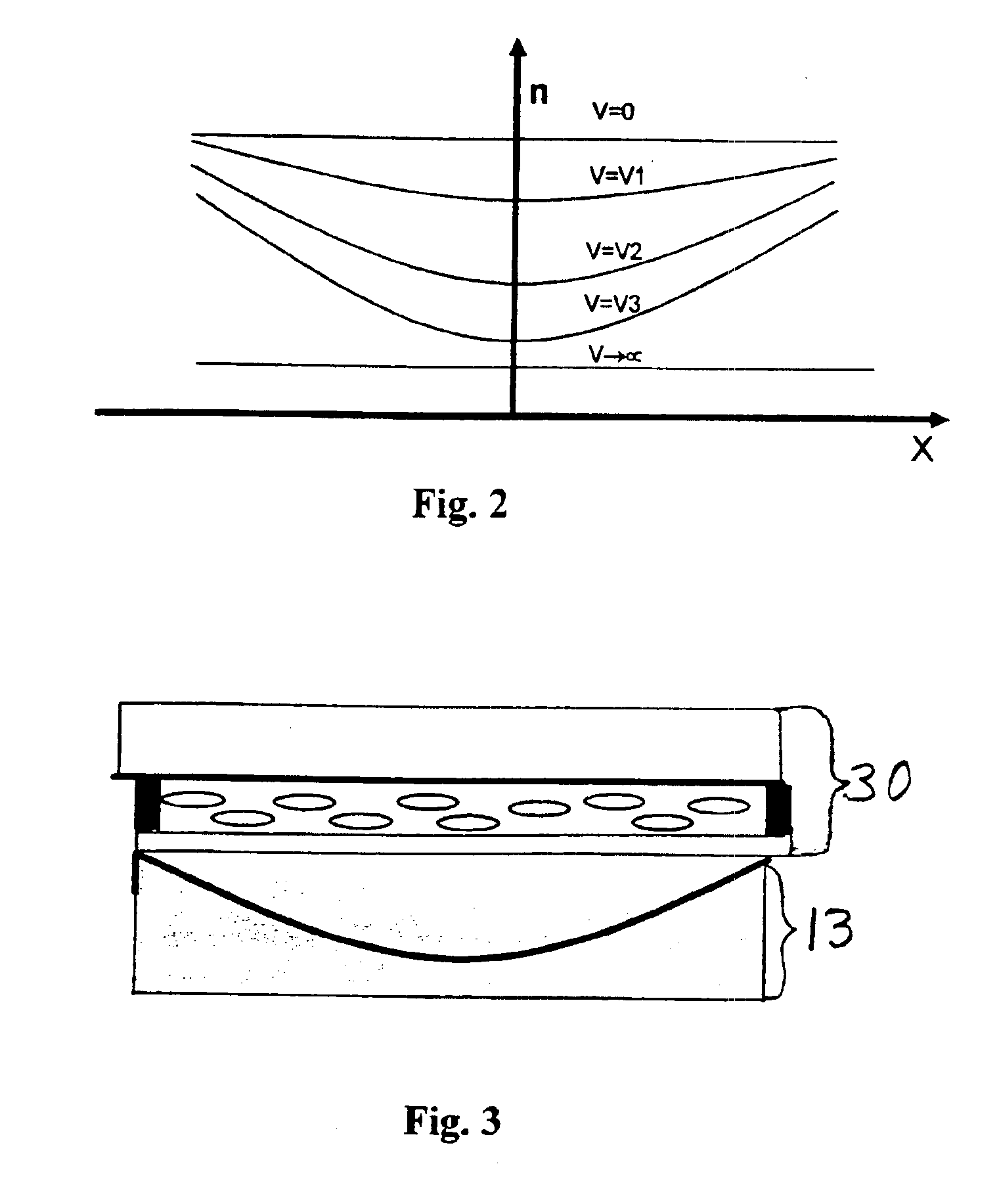

Adaptive liquid crystal lenses

An adaptive optical lens device, system and method of using the same is composed of at least two planar substrates and at least one homogeneous nematic liquid crystal (LC) layer. One planar substrate has a spherical or annular ring-shaped Fresnel grooved transparent electrode within it, the other has a transparent electrode coated on its inner surface. The thickness of the LC layer is uniform. When a voltage is applied across the LC layer, a centro-symmetrical gradient distribution of refractive index within LC layer will occur. Therefore, the LC layer causes light to focus. By controlling the applied voltage, the focal length of the lens is continuously tunable.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Method of transferring ultra-thin substrates and application of the method to the manufacture of a multi-layer thin film device

InactiveUS6506664B1High densityHigh-density productSemiconductor/solid-state device detailsSolid-state devicesPolymer adhesivePlanar substrate

The present invention provides a method of transfer of a first planar substrate with two major surfaces to a second substrate, comprising the steps of: forming the first planar substrate, attaching one of the major surfaces of the first planar substrate to a carrier by means of a release layer; attaching the other major surface of the first substrate to the second substrate with a curable polymer adhesive layer; partly curing the polymer adhesive layer, disconnecting the release layer from the first substrate to separate the first substrate from the camer, followed by coing the polymer adhesive layer.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

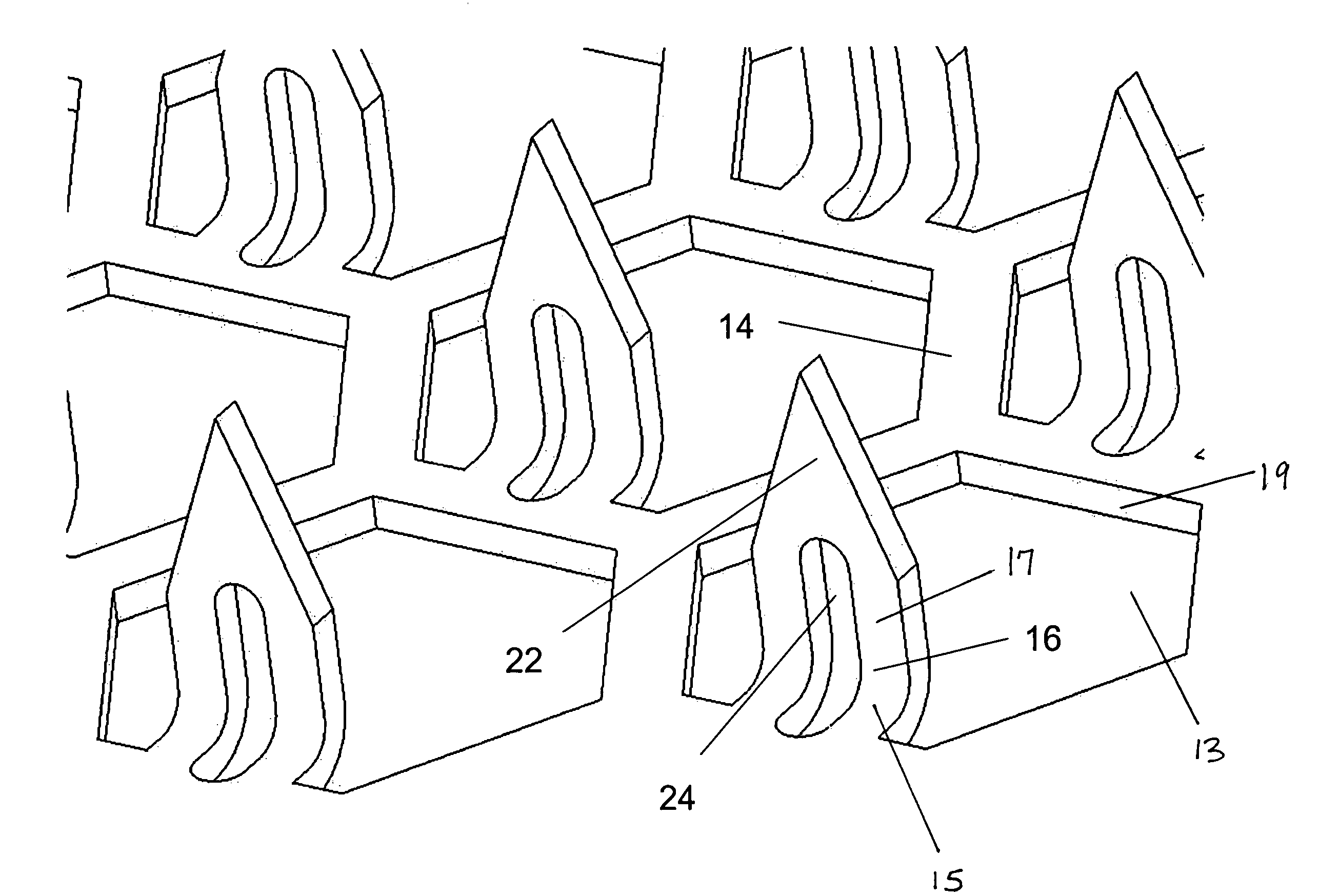

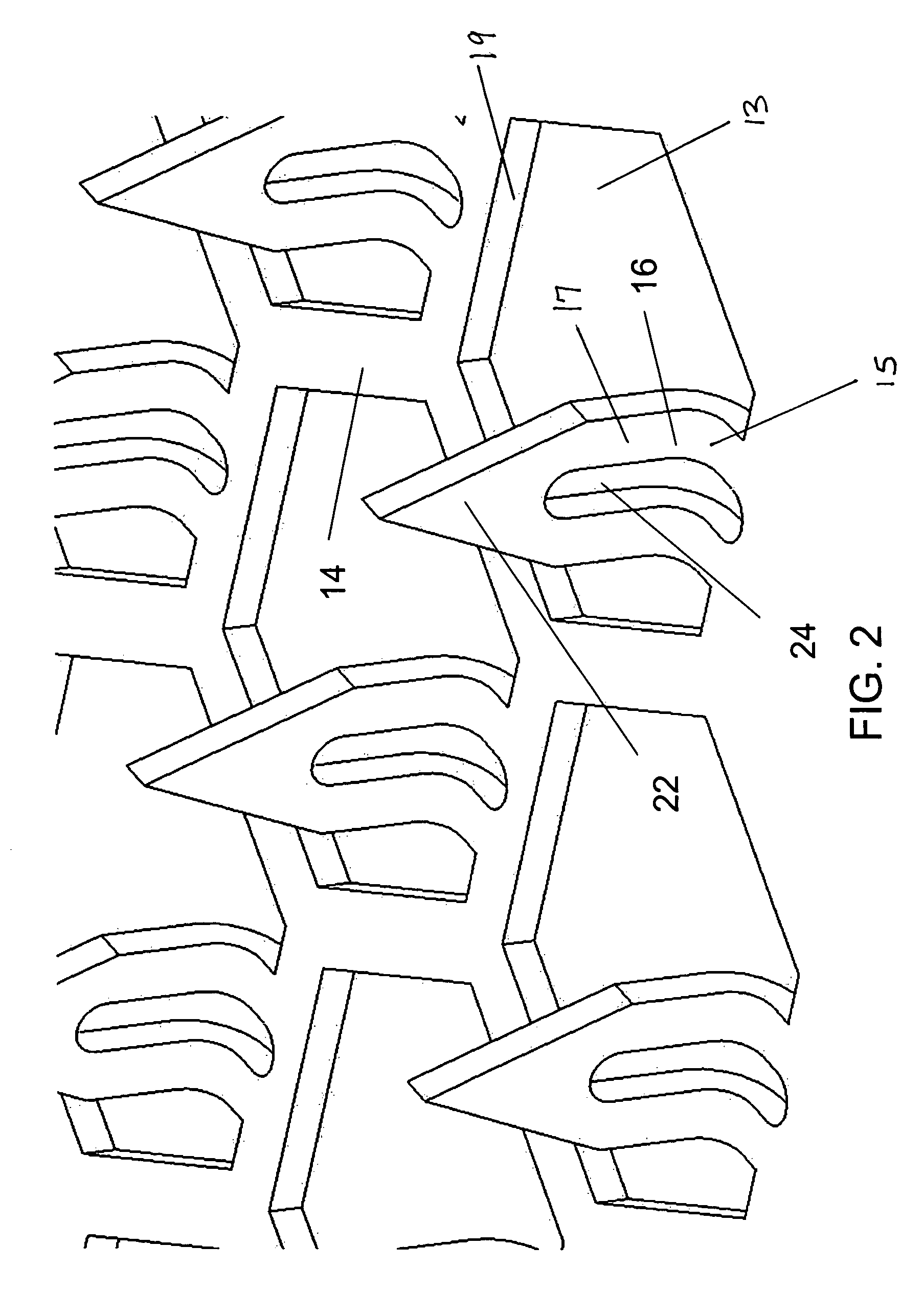

Microneedle array, patch, and applicator for transdermal drug delivery

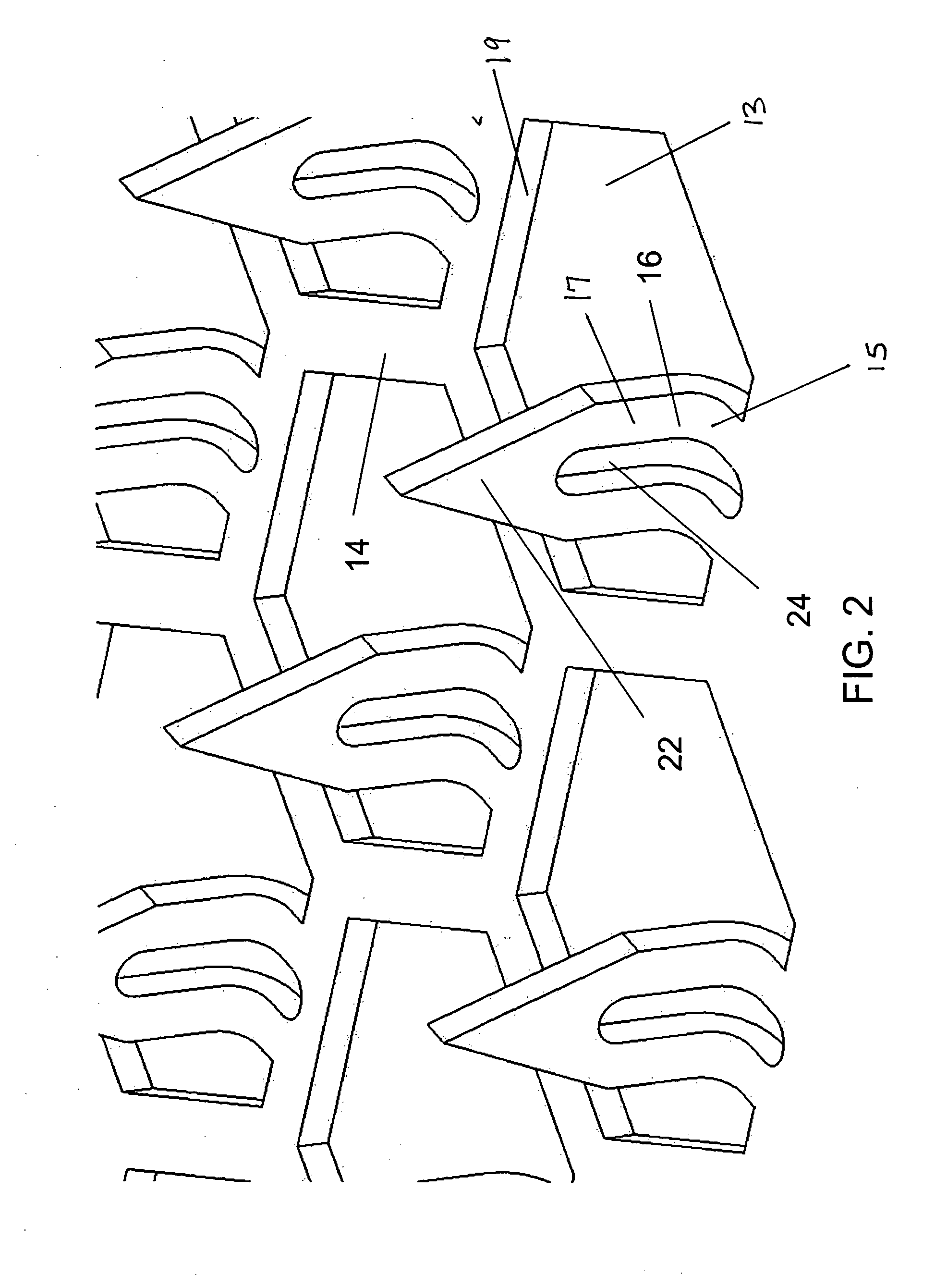

Microneedle arrays and drug delivery devices are provided for transdermally delivering a drug formulation to a patient. The microneedle array device includes a substantially planar substrate having an array of apertures; and a plurality of microneedles projecting at angle from the planar substrate, the microneedles having a base portion integrally connected to the substrate, a tip end portion distal to the base portion, and body portion therebetween, wherein each microneedle has at least one channel extending substantially from the base portion through at least a part of the body portion, the channel being open along at least part of the body portion and in fluid communication with at least one of the apertures in the substrate. In a preferred embodiment, each microneedle has a substantially rectangular cross-sectional shape and the channel is open to two opposing surfaces of the microneedle.

Owner:YUZHAKOV VADIM V

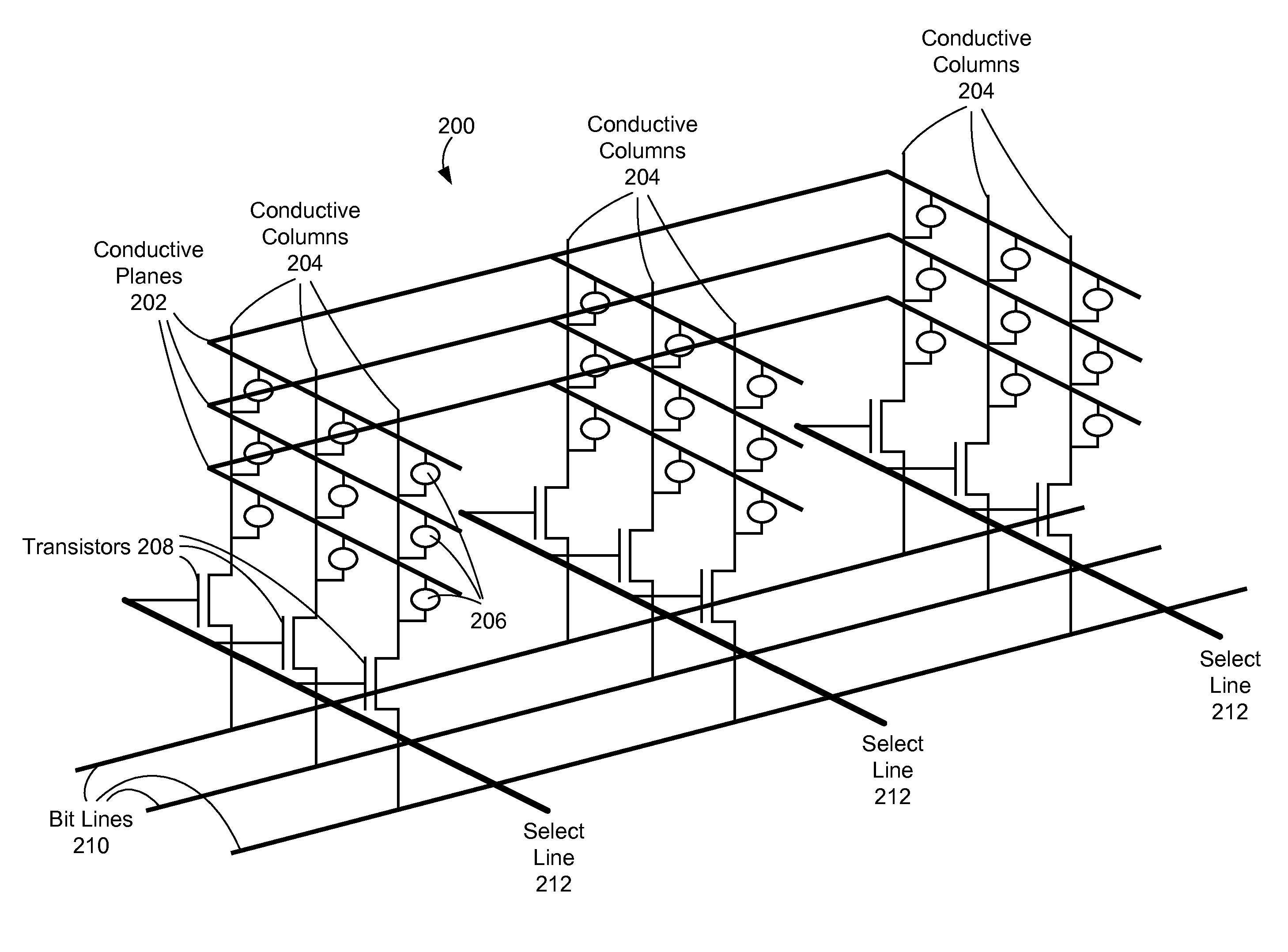

Three-dimensional memory array stacking structure

ActiveUS20120211722A1Solid-state devicesBulk negative resistance effect devicesPlanar substrateEngineering

A memory device includes a planar substrate, a plurality of horizontal conductive planes above the planar substrate, and a plurality of horizontal insulating layers interleaved with the plurality of horizontal conductive planes. An array of vertical conductive columns, perpendicular to the pluralities of conductive planes and insulating layers, passes through apertures in the pluralities of conductive planes and insulating layers. The memory device includes a plurality of programmable memory elements, each of which couples one of the horizontal conductive planes to a respective vertical conductive column.

Owner:RAMBUS INC

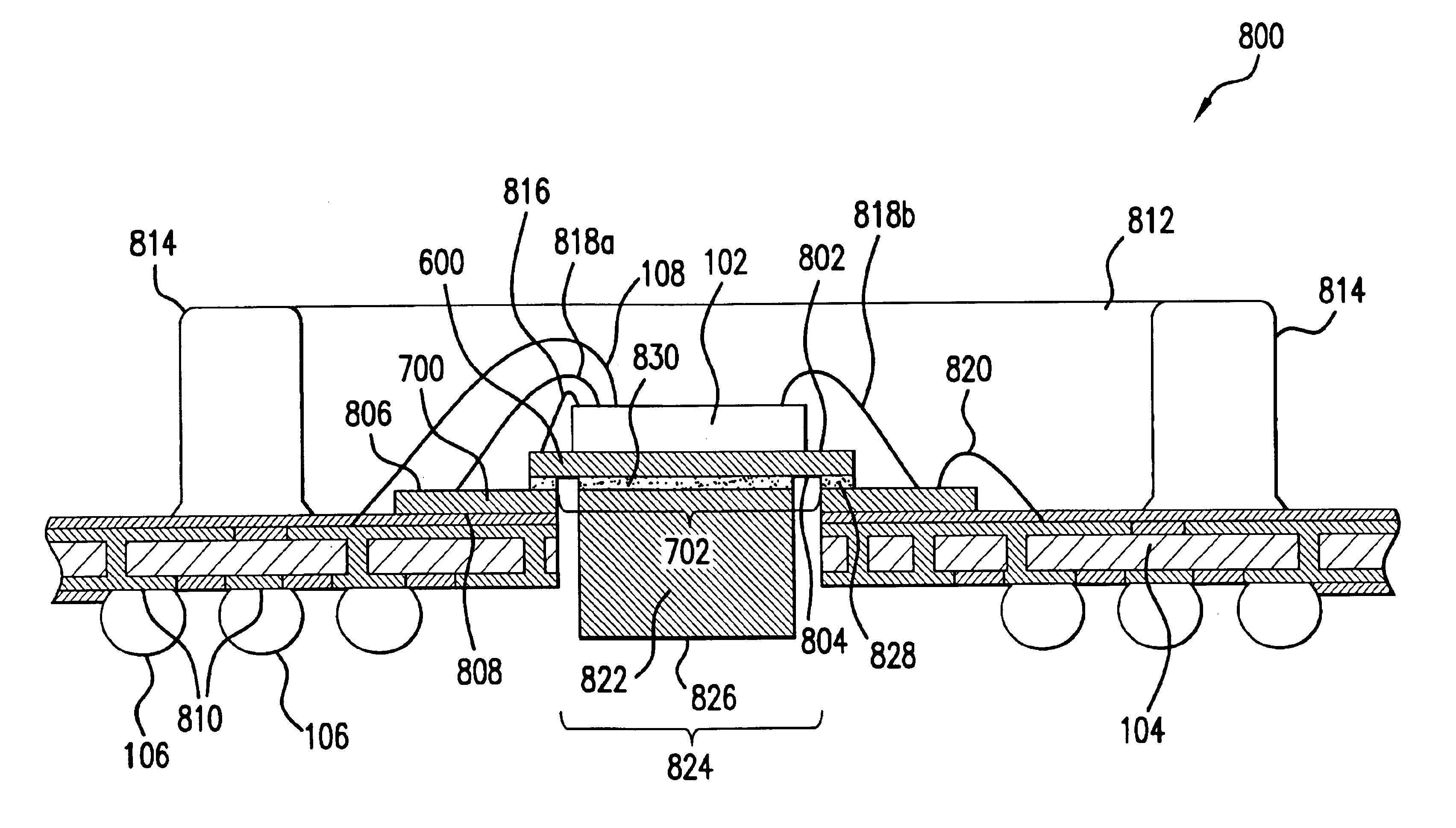

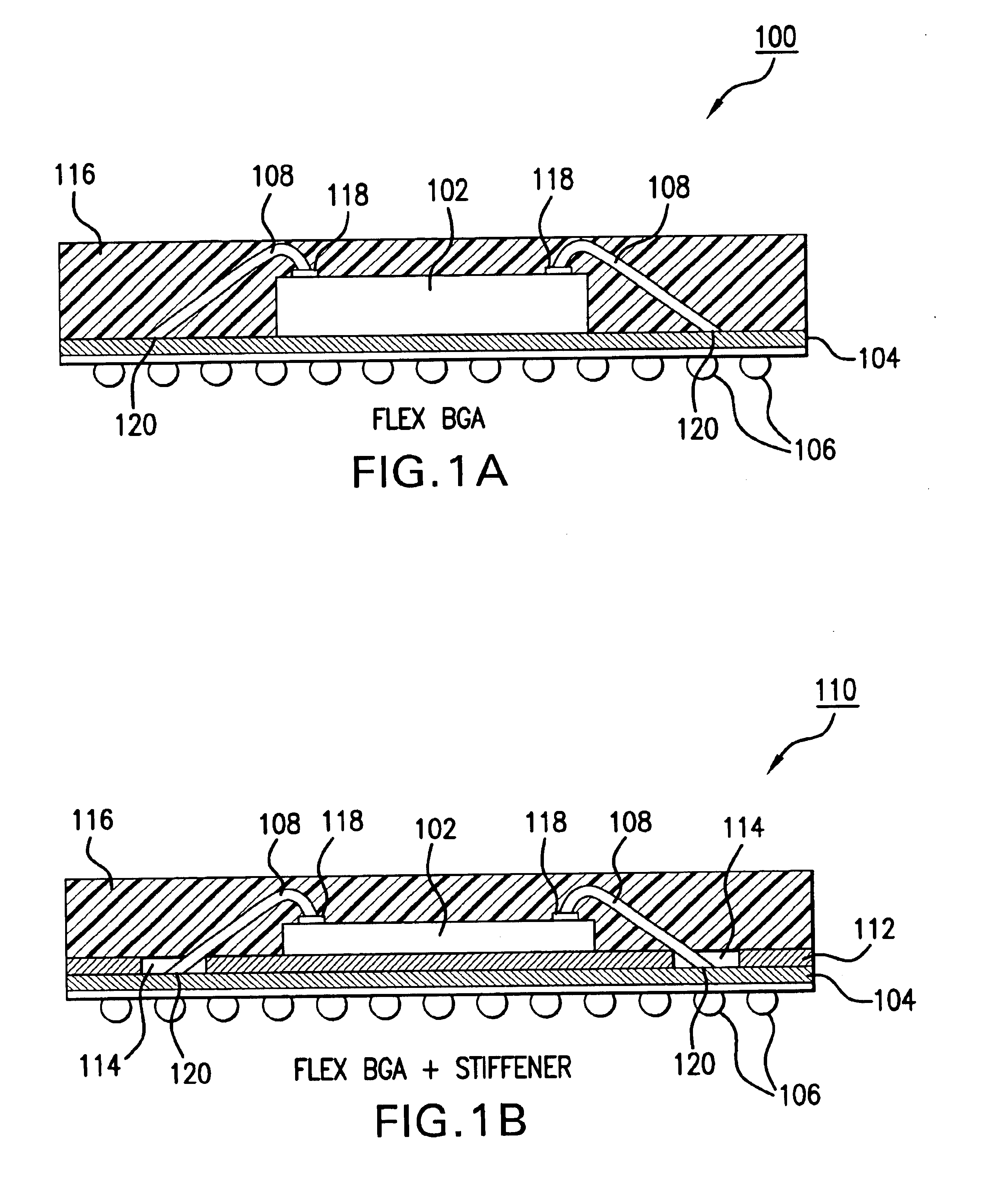

Ball grid array package with multiple interposers

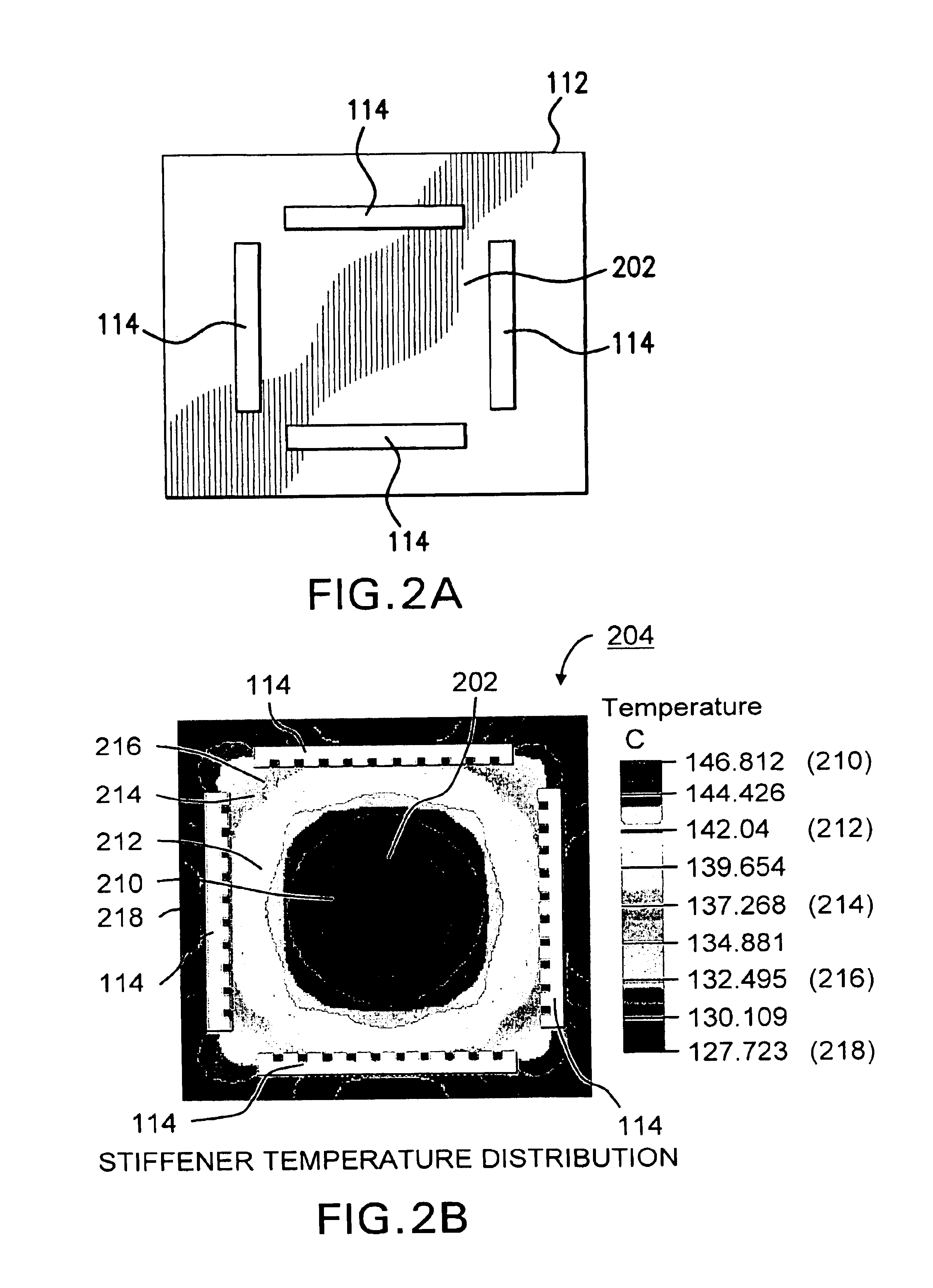

InactiveUS6861750B2Increase stiffness/rigidityImprove heat transfer performanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsContact padPlanar substrate

Electrically, thermally and mechanically enhanced ball grid array (BGA) packages are described. An IC die is mounted to a first surface of a first stiffener. A peripheral edge portion of a second surface of the first stiffener is attached to a first surface of a second stiffener to cover an opening through the second stiffener that is open at the first surface and a second surface of the second stiffener. The second surface of the second stiffener is attached to a first surface of a substantially planar substrate that has a plurality of contact pads on the first surface of the substrate. The plurality of contact pads are electrically connected through the substrate to a plurality of solder ball pads on a second surface of the substrate.

Owner:AVAGO TECH INT SALES PTE LTD

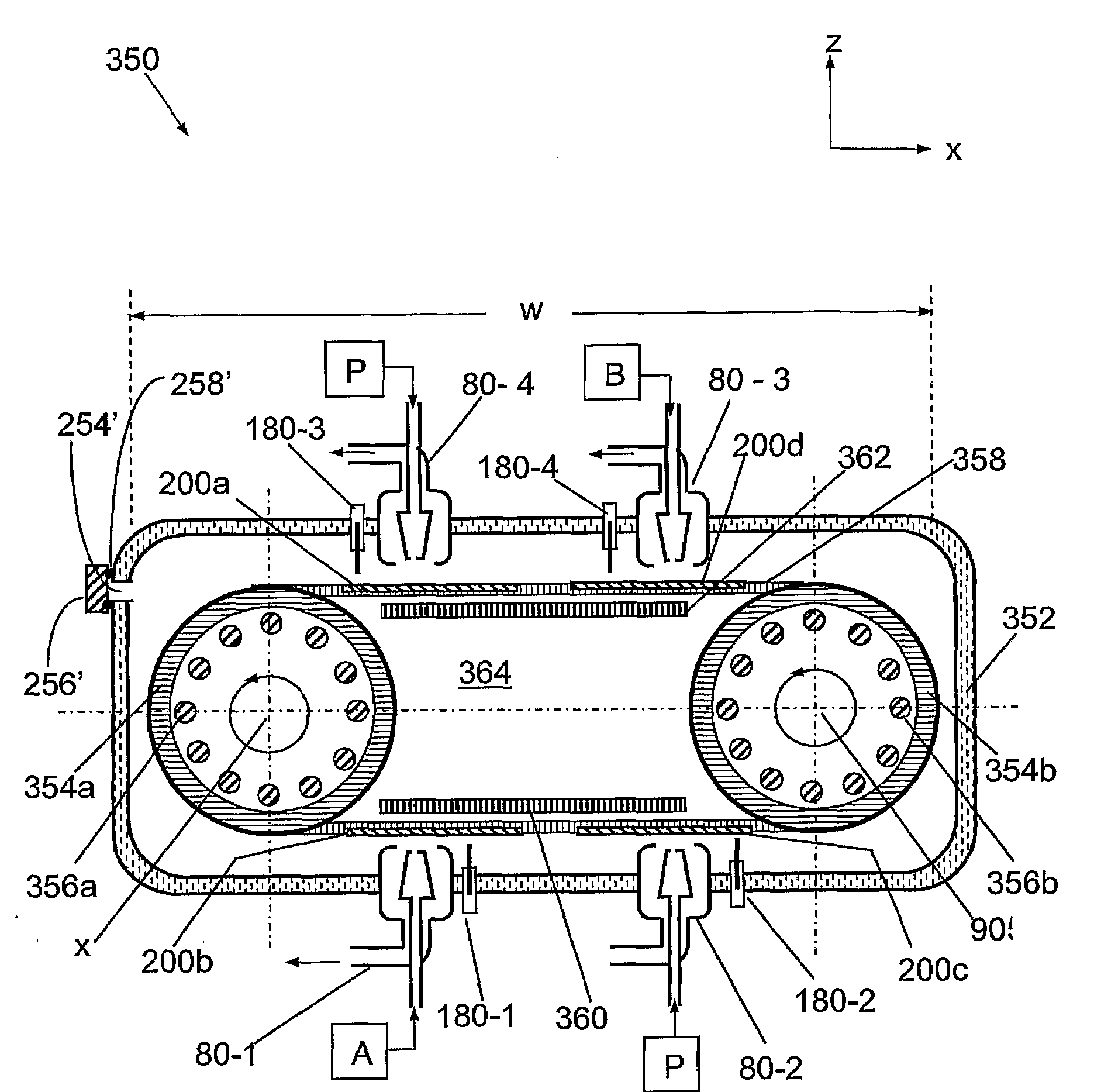

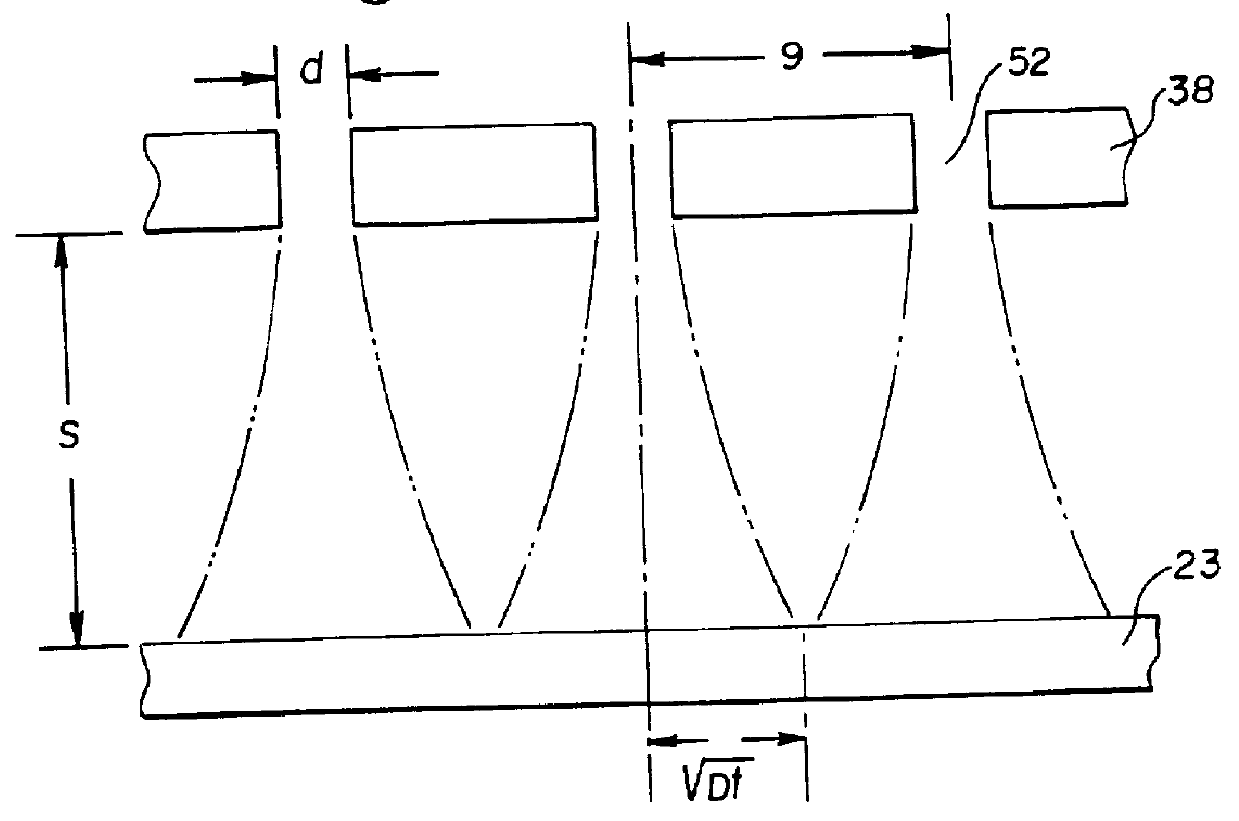

Apparatus and method for large area multi-layer atomic layer chemical vapor processing of thin films

An apparatus and method for large area high speed atomic layer chemical vapor processing wherein continuous and alternating streams of reactive and inert gases are directed towards a co-axially mounted rotating cylindrical susceptor from a plurality of composite nozzles placed around the perimeter of the processing chamber. A flexible substrate is mounted on the cylindrical susceptor. In one embodiment, the process reactor has four composite injectors arranged substantially parallel to the axis of rotation of the cylindrical susceptor. In the other embodiment, the susceptor cross section is a polygon with a plurality of substrates mounted on its facets. The reactor can be operated to process multiple flexible or flat substrates with a single atomic layer precision as well as high-speed chemical vapor processing mode. The atomic layer chemical vapor processing system of the invention also has provisions to capture unused portion of injected reactive chemical precursors downstream.

Owner:GADGIL PRASAD

Microfabricated elastomeric valve and pump systems

InactiveUS20050226742A1Fast formingEasy to manufactureFunctional valve typesEngine diaphragmsElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

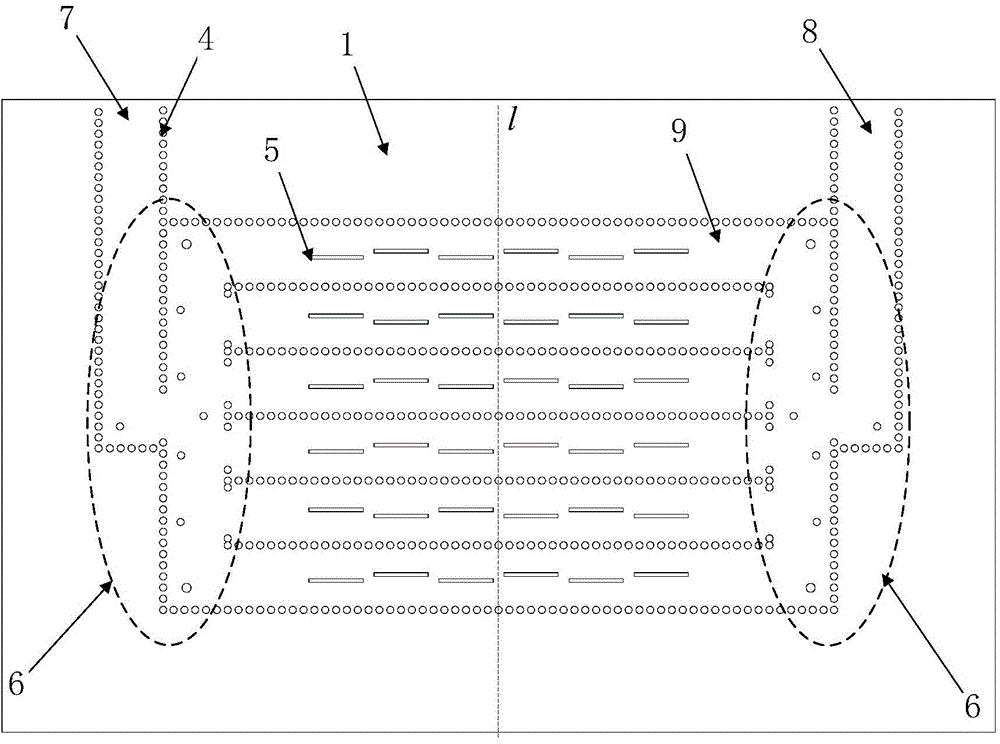

Balance feed differential slot antenna for restraining common-mode noise

ActiveCN104092028ASuppress emissionSuppress receptionAntenna couplingsSlot antennasPlanar substrateWaveguide

The invention discloses a balance feed differential slot antenna for restraining common-mode noise. Based on a planar substrate integrated waveguide structure, the slot antenna is adopted as a radiating unit; due to different electric field distributions in the substrate integrated waveguide under different stimulation modes, energy can be effectively radiated under the different-mode signal stimulation, and most of energy is reflected under the common-mode signal stimulation. Due to the adoption of the antenna of the structure, different-mode signals can be effectively transmitted and received, meanwhile, common-mode signals are restrained from being transmitted and received, and therefore the function of restraining common-mode noise is achieved.

Owner:SOUTHEAST UNIV

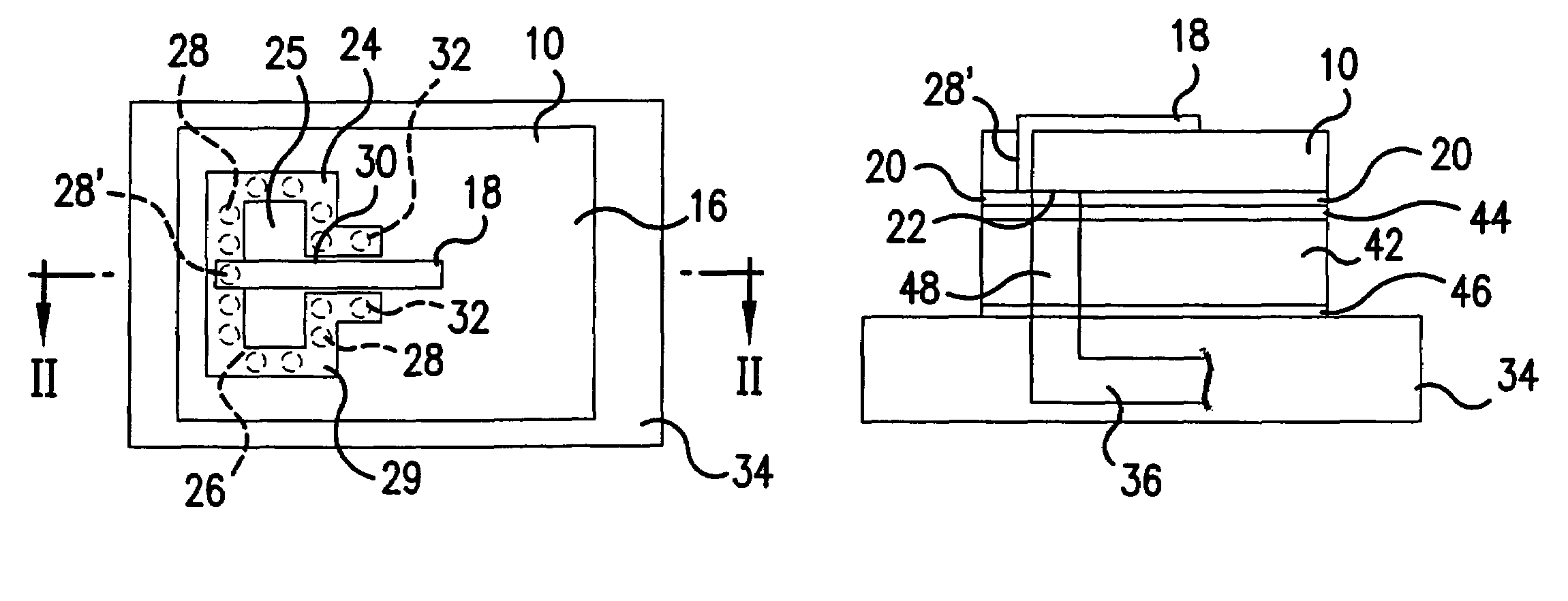

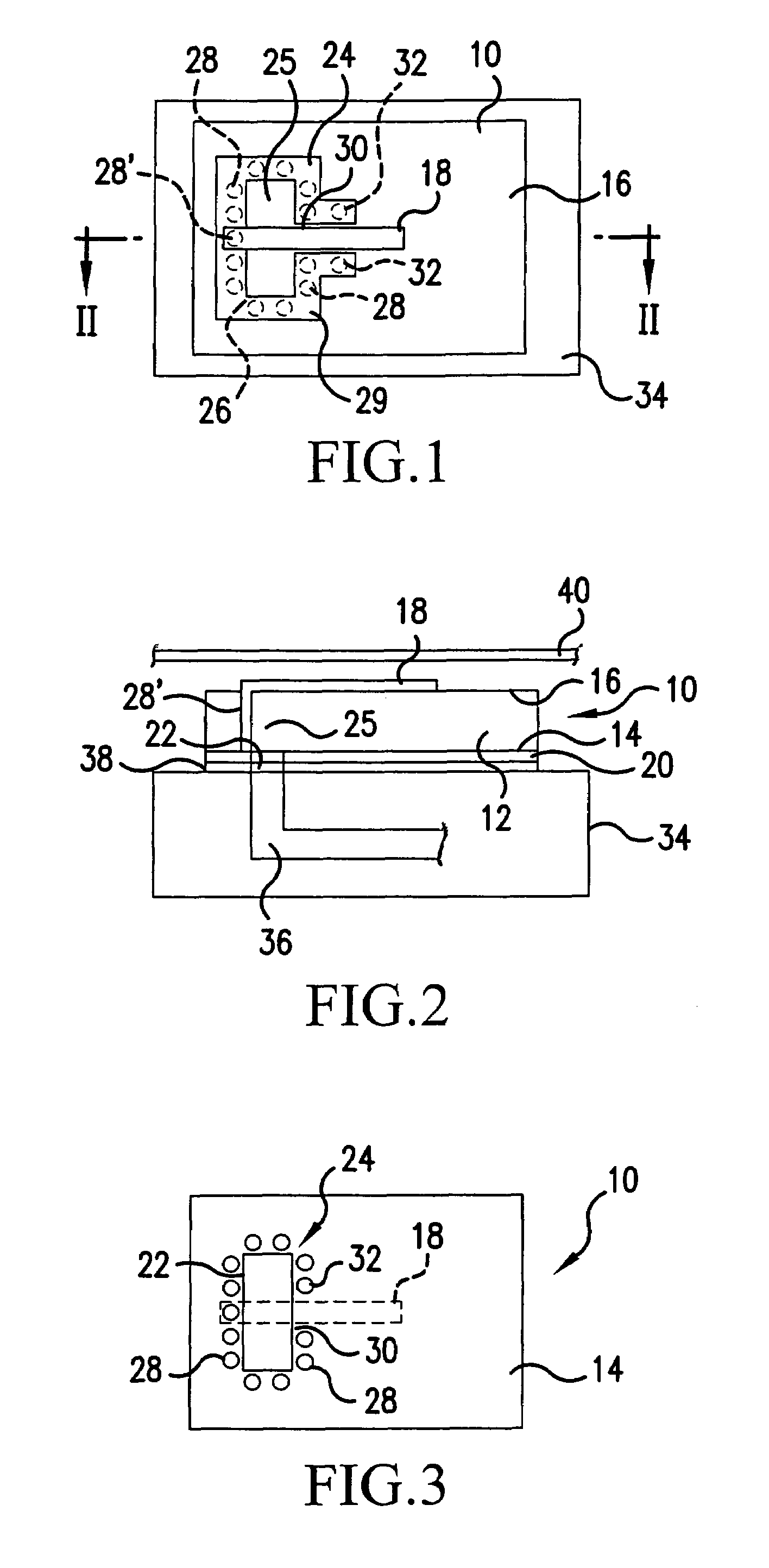

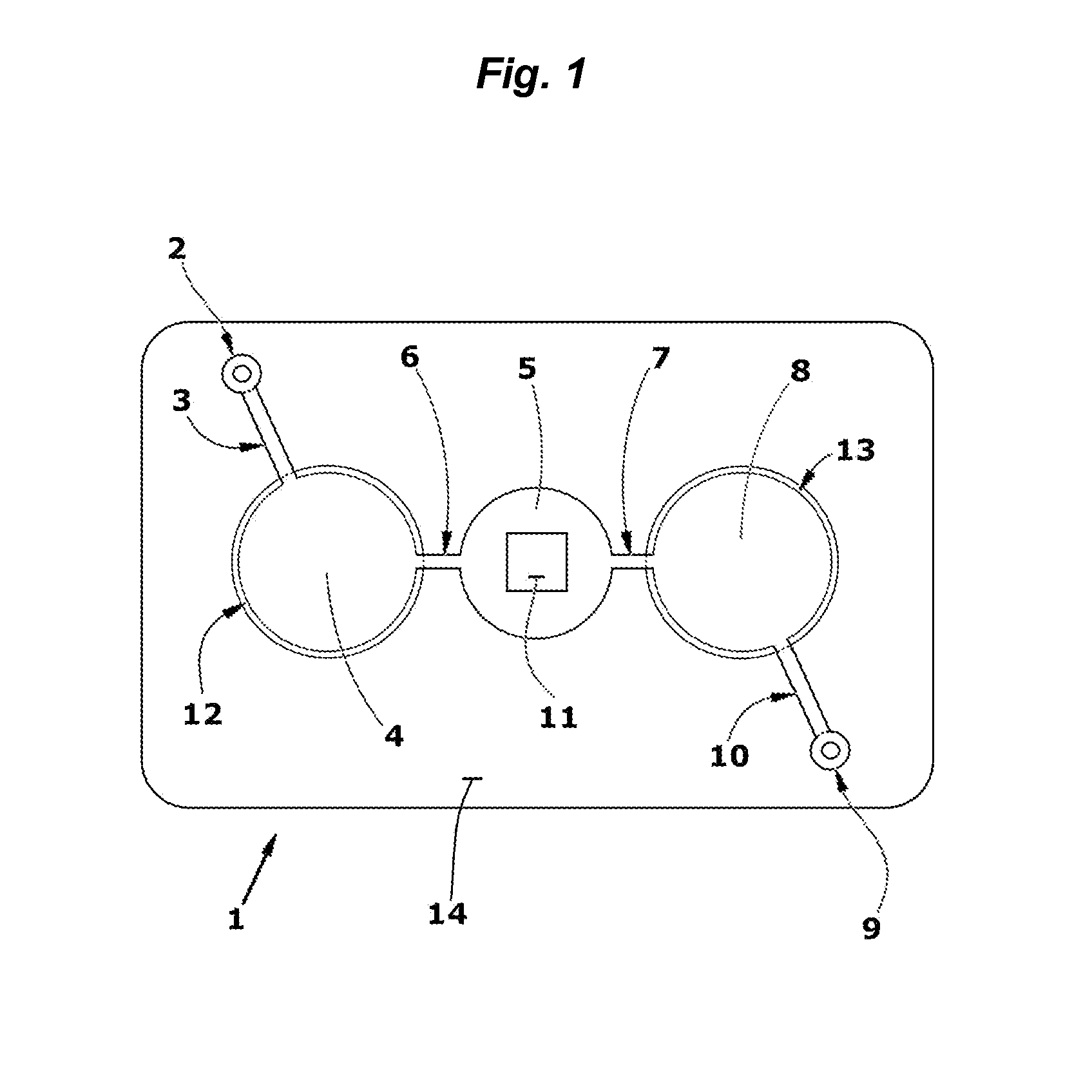

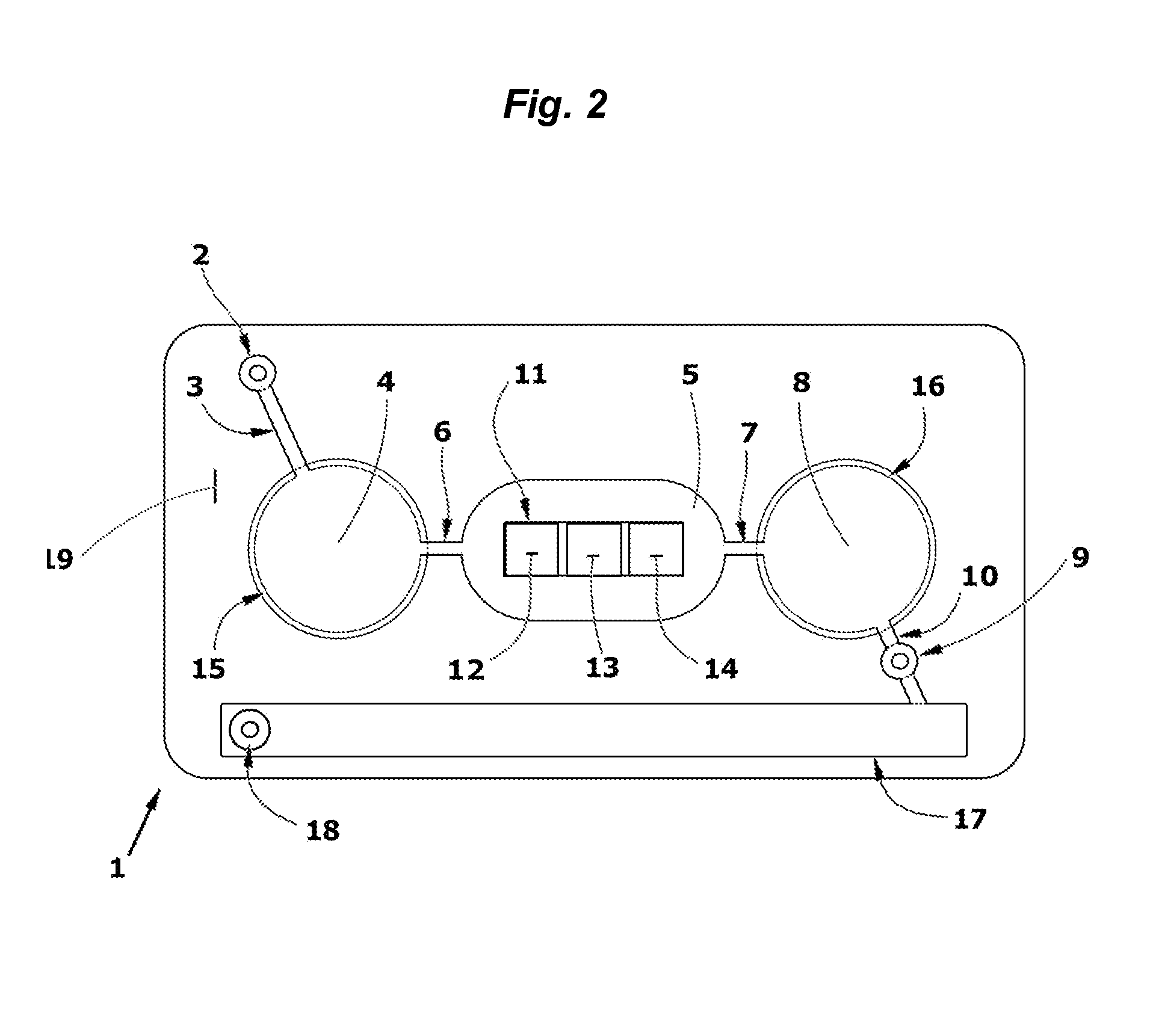

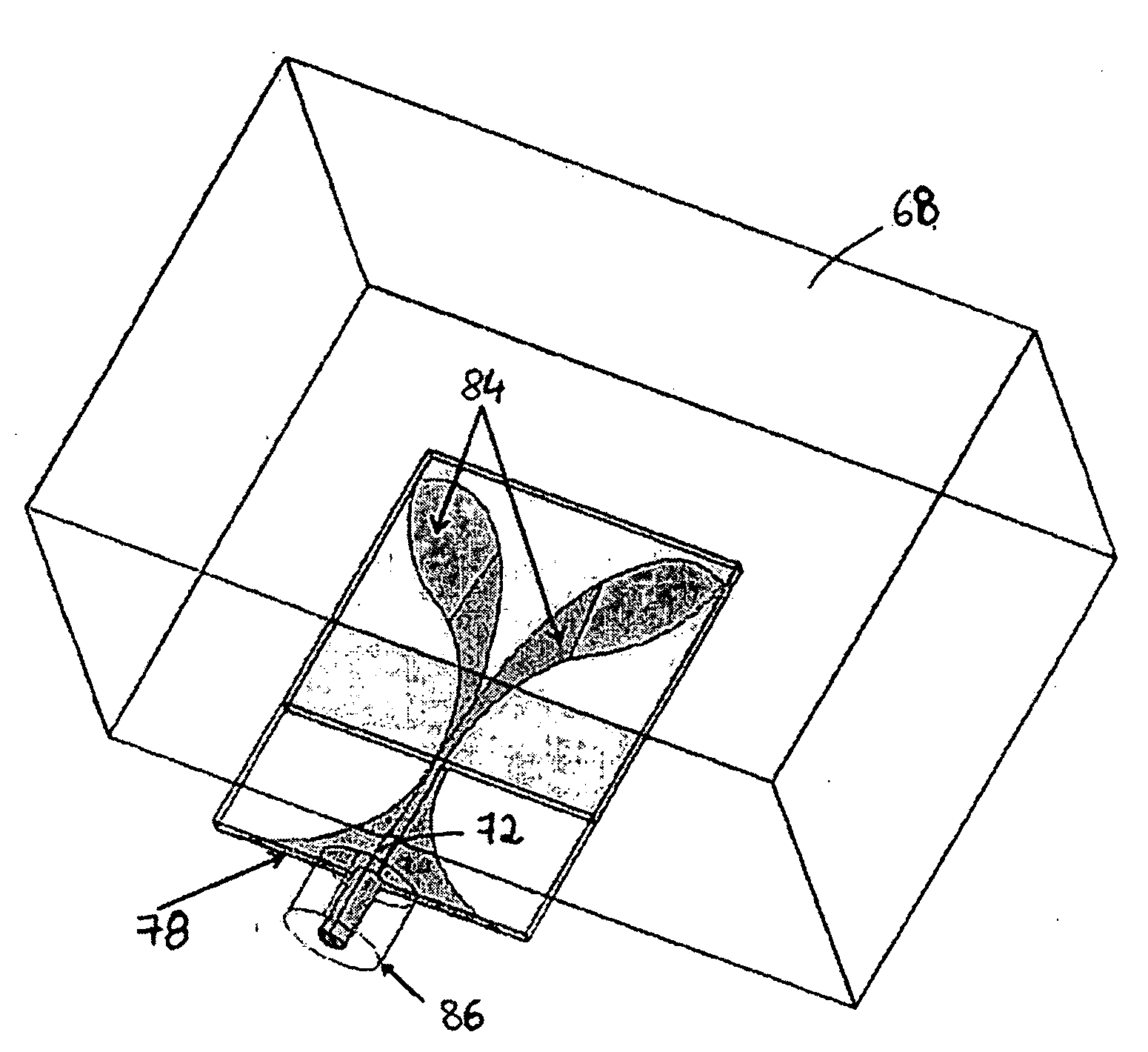

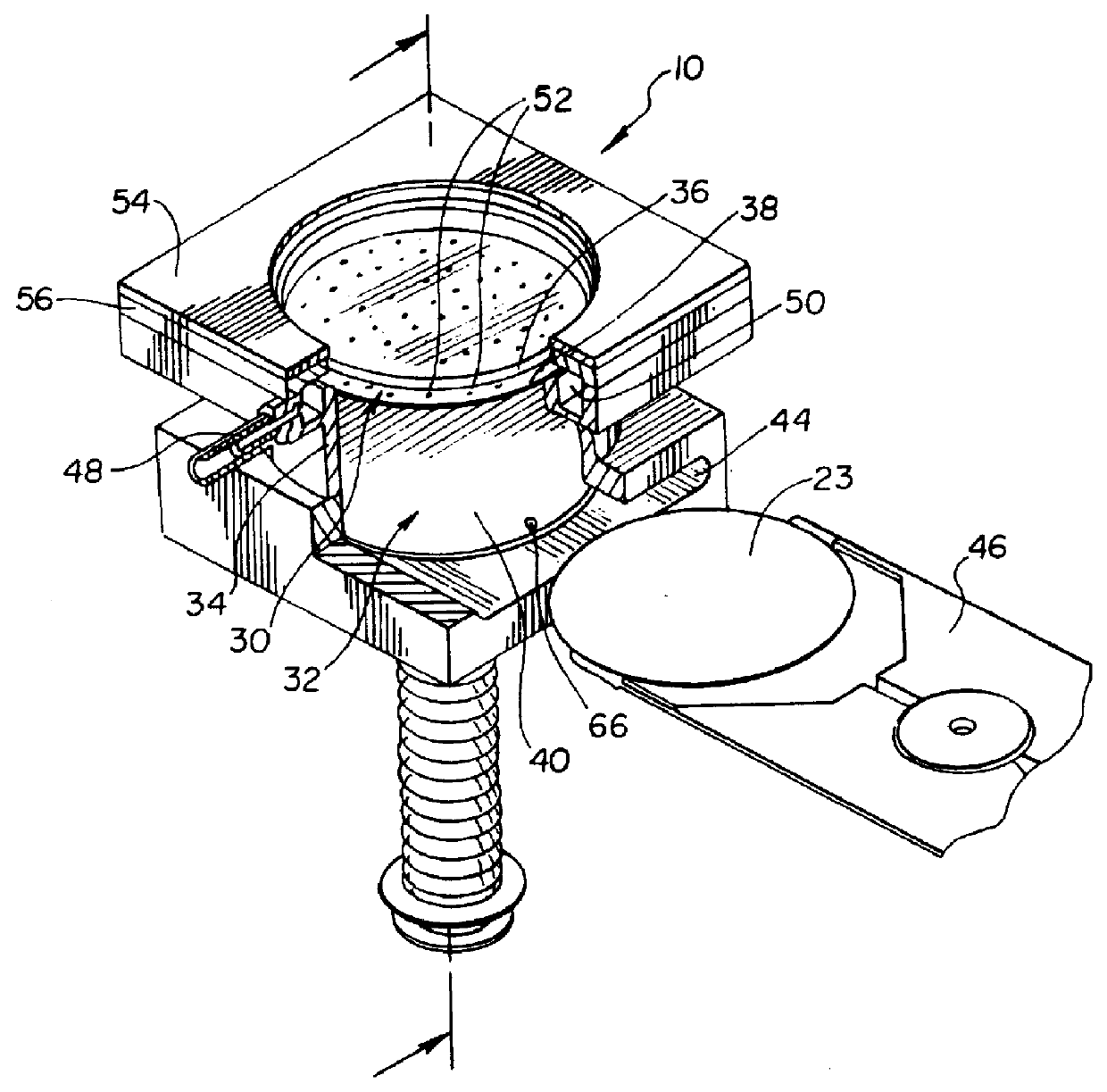

Microfluidic reactor system

ActiveUS20120177543A1Endpoint detectionReduce incubation timeShaking/oscillating/vibrating mixersTransportation and packagingDiaphragm pumpReactor system

A compact device for operatively coupling a solid planar substrate, for example a glass slide, to a microfluidic circuit and performing a reaction or reactions on organic matter bound to the face of the planar substrate. Typical reactions include binding, staining and / or labeling reactions. In use, a sealed reaction chamber is formed, the chamber enclosing the organic matter and at least a part of the solid substrate. Headspace in the sealed chamber between the solid substrate is generally of microfluidic dimensions, and diaphragm pump members are used to inject, exchange and / or mix the fluids in the chamber.

Owner:PERKINELMER HEALTH SCIENCES INC

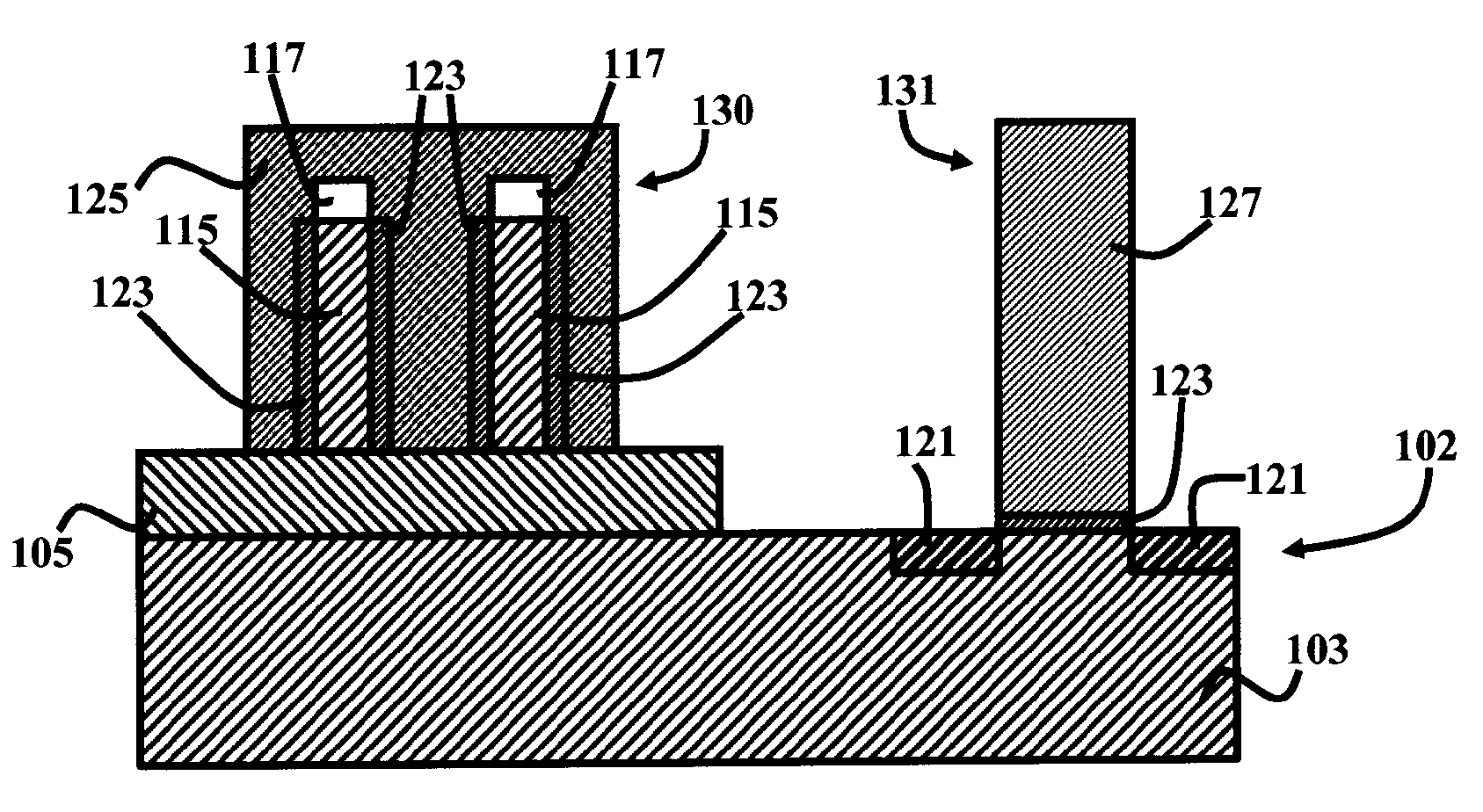

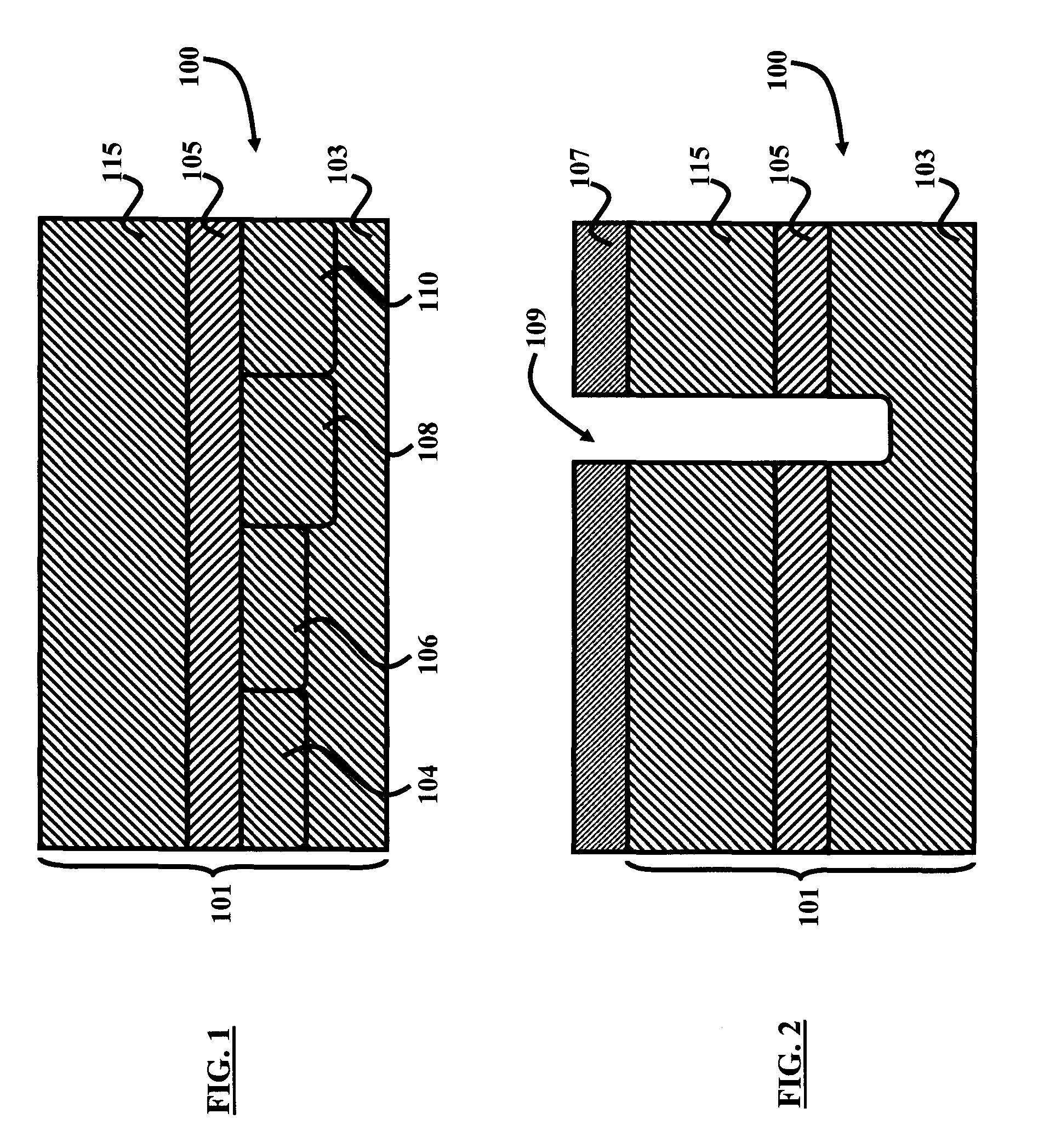

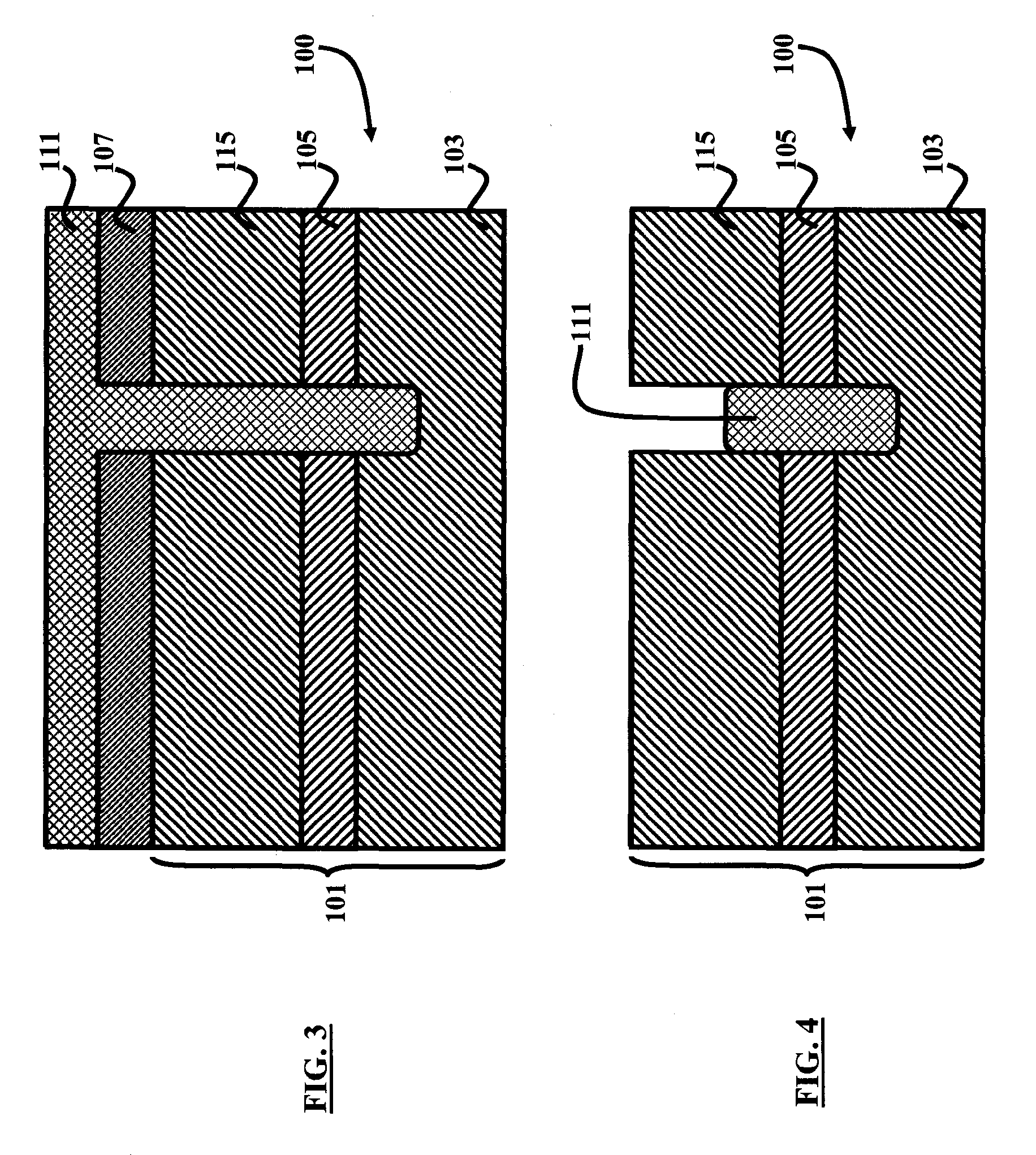

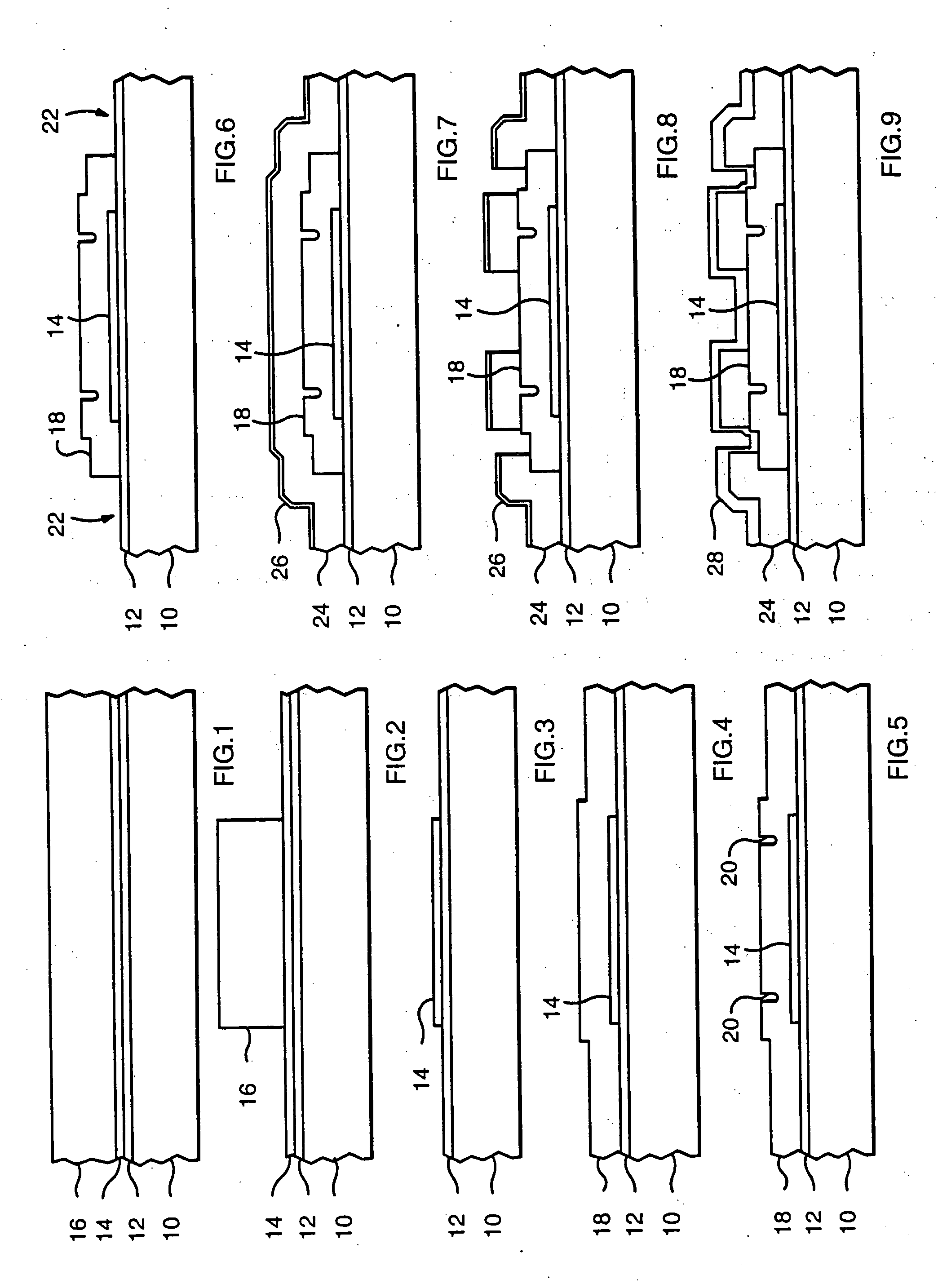

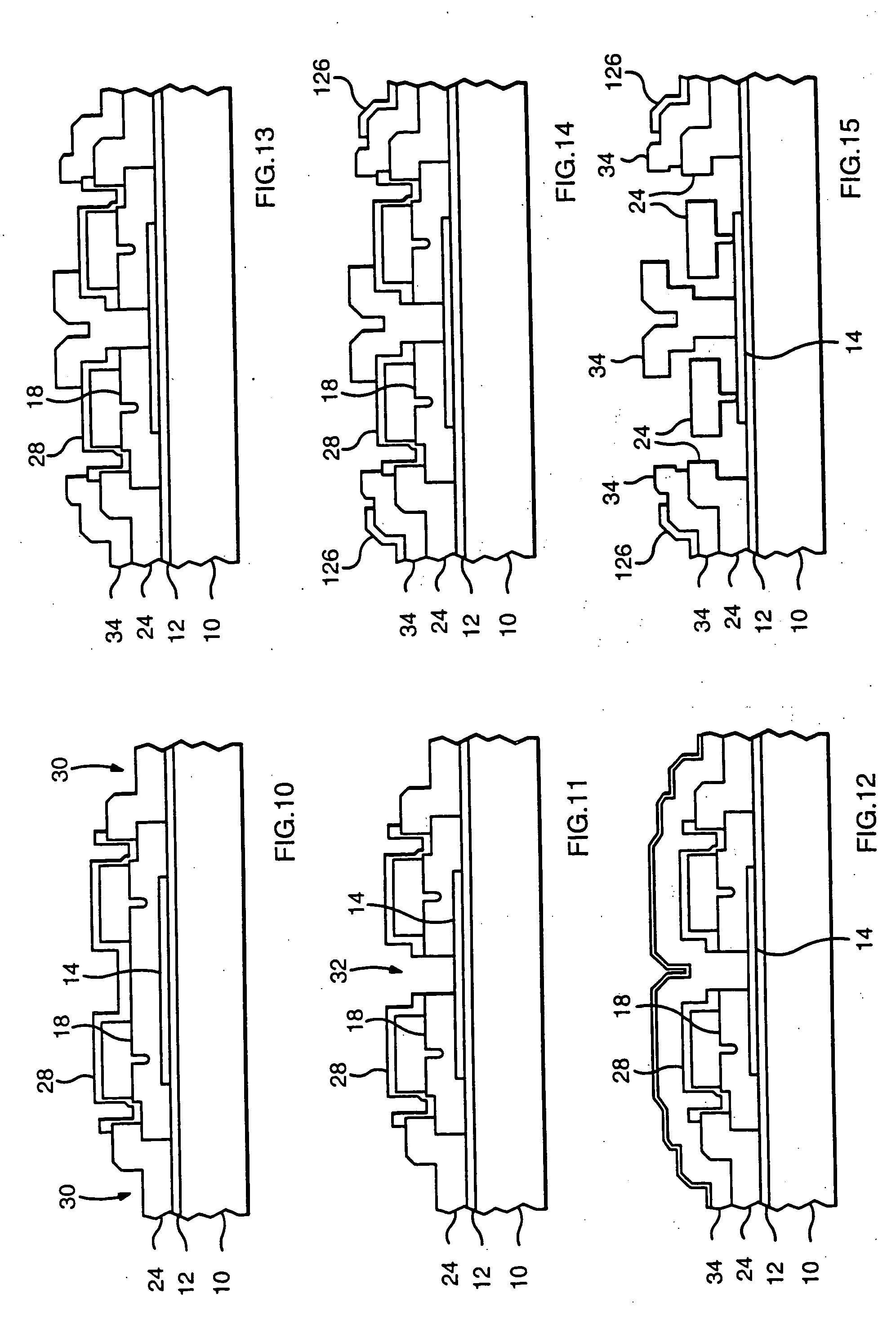

Planar substrate devices integrated with finfets and method of manufacture

ActiveUS6949768B1Reduce manufacturing stepsEasy to integrateTransistorSolid-state devicesPlanar substrateEngineering

A planar substrate device integrated with fin field effect transistors (FinFETs) and a method of manufacture comprises a silicon-on-insulator (SOI) wafer comprising a substrate; a buried insulator layer over the substrate; and a semiconductor layer over the buried insulator layer. The structure further comprises a FinFET over the buried insulator layer and a field effect transistor (FET) integrated in the substrate, wherein the FET gate is planar to the FinFET gate. The structure further comprises retrograde well regions configured in the substrate. In one embodiment, the structure further comprises a shallow trench isolation region configured in the substrate.

Owner:GLOBALFOUNDRIES US INC

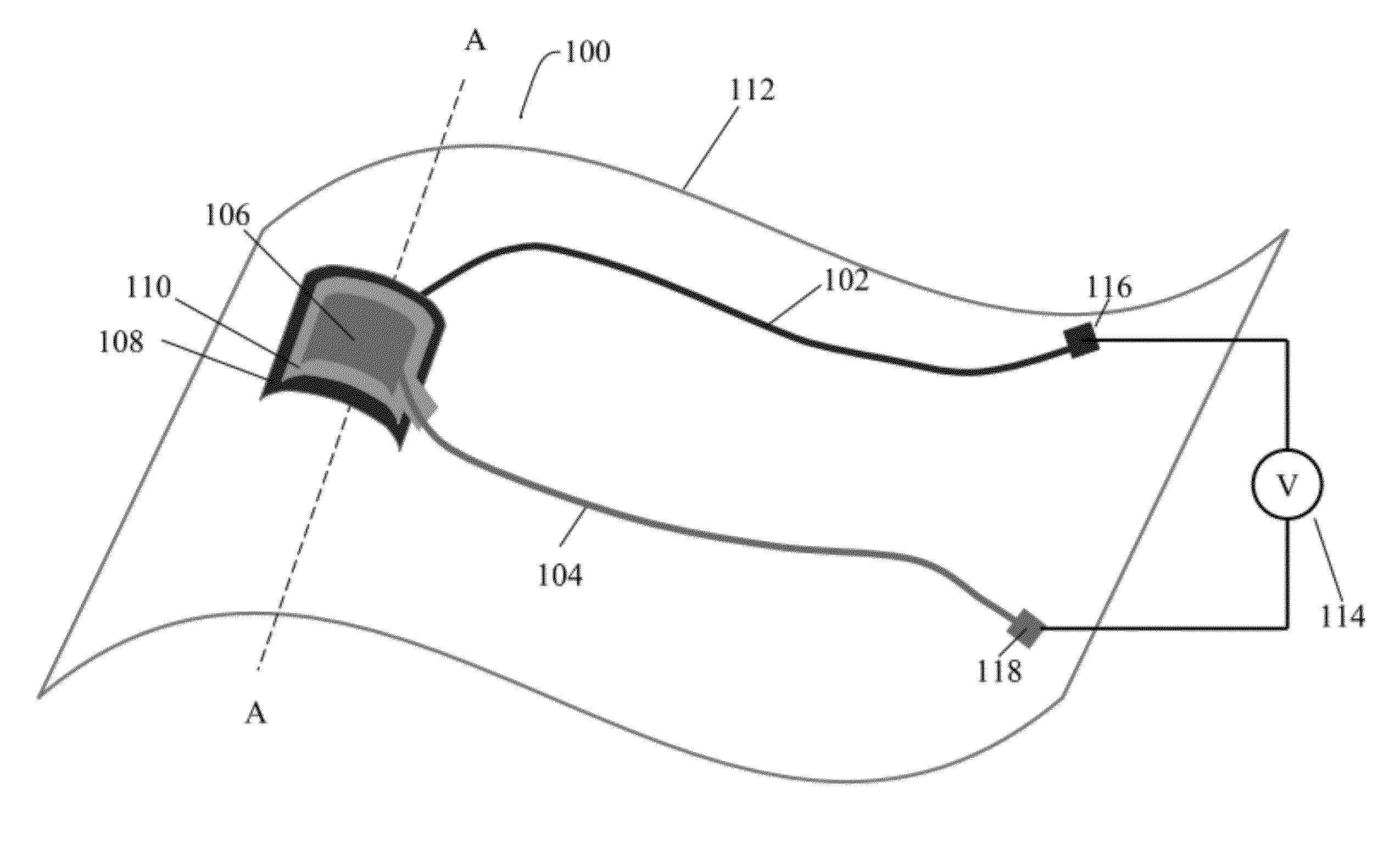

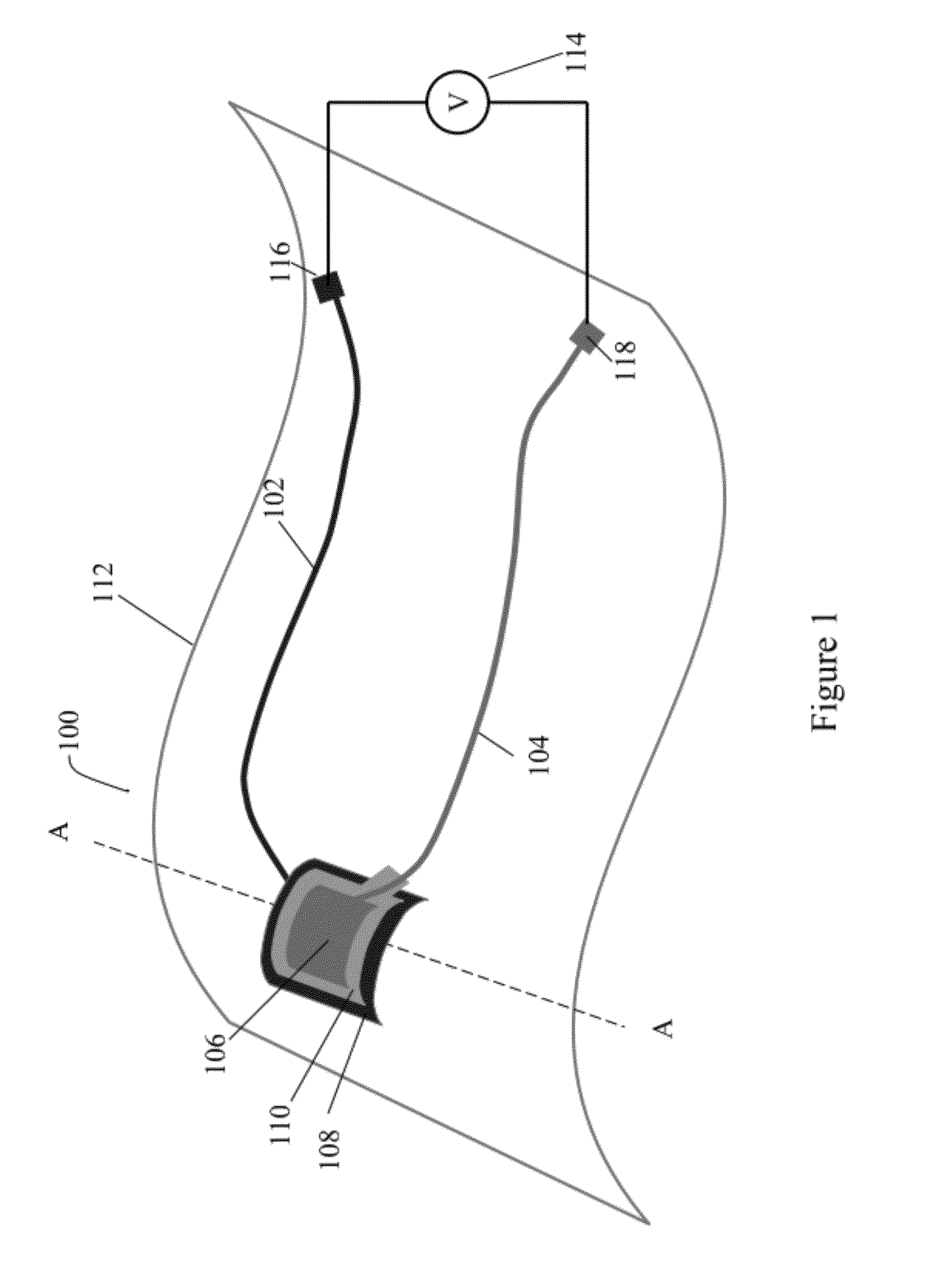

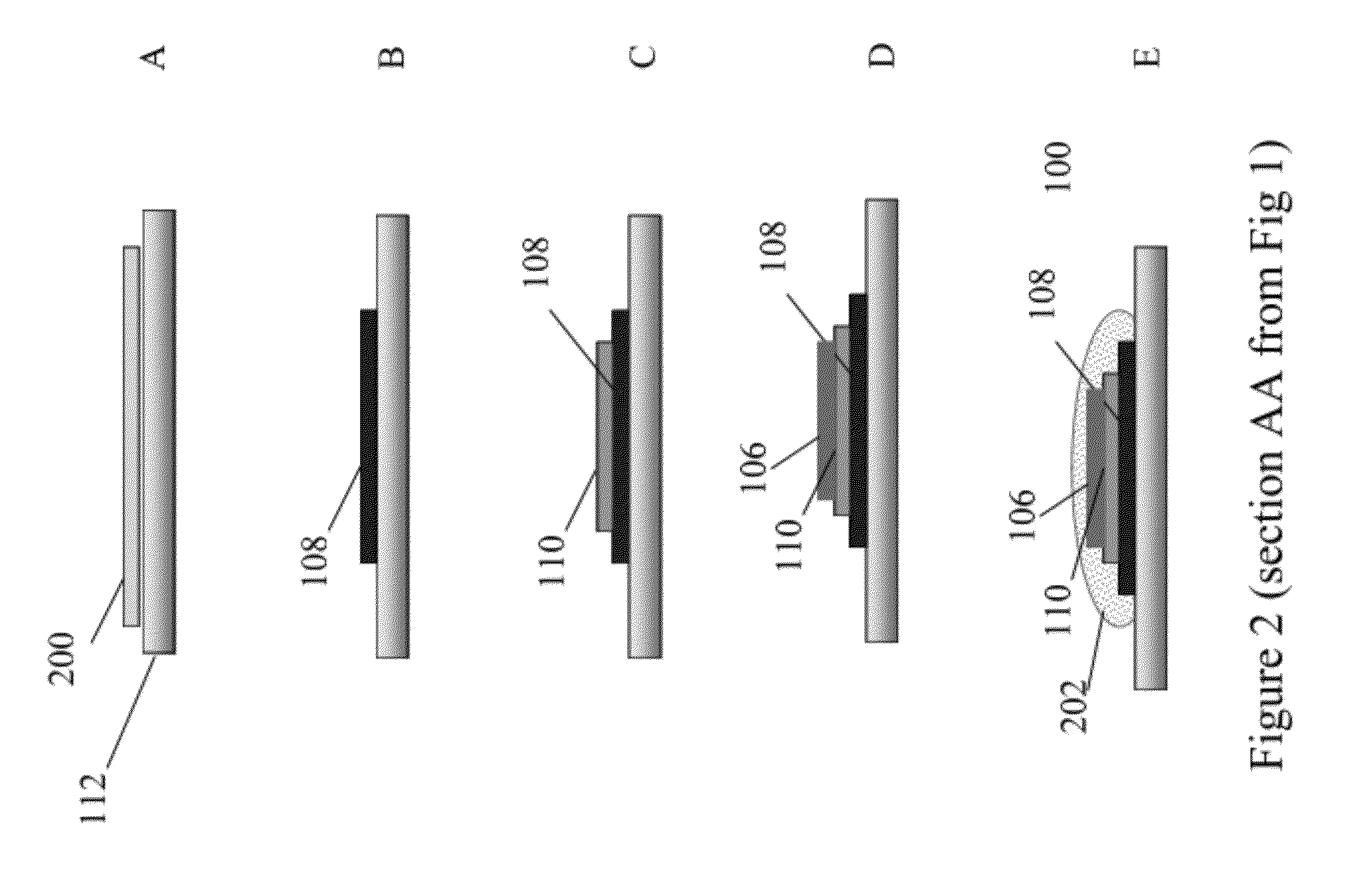

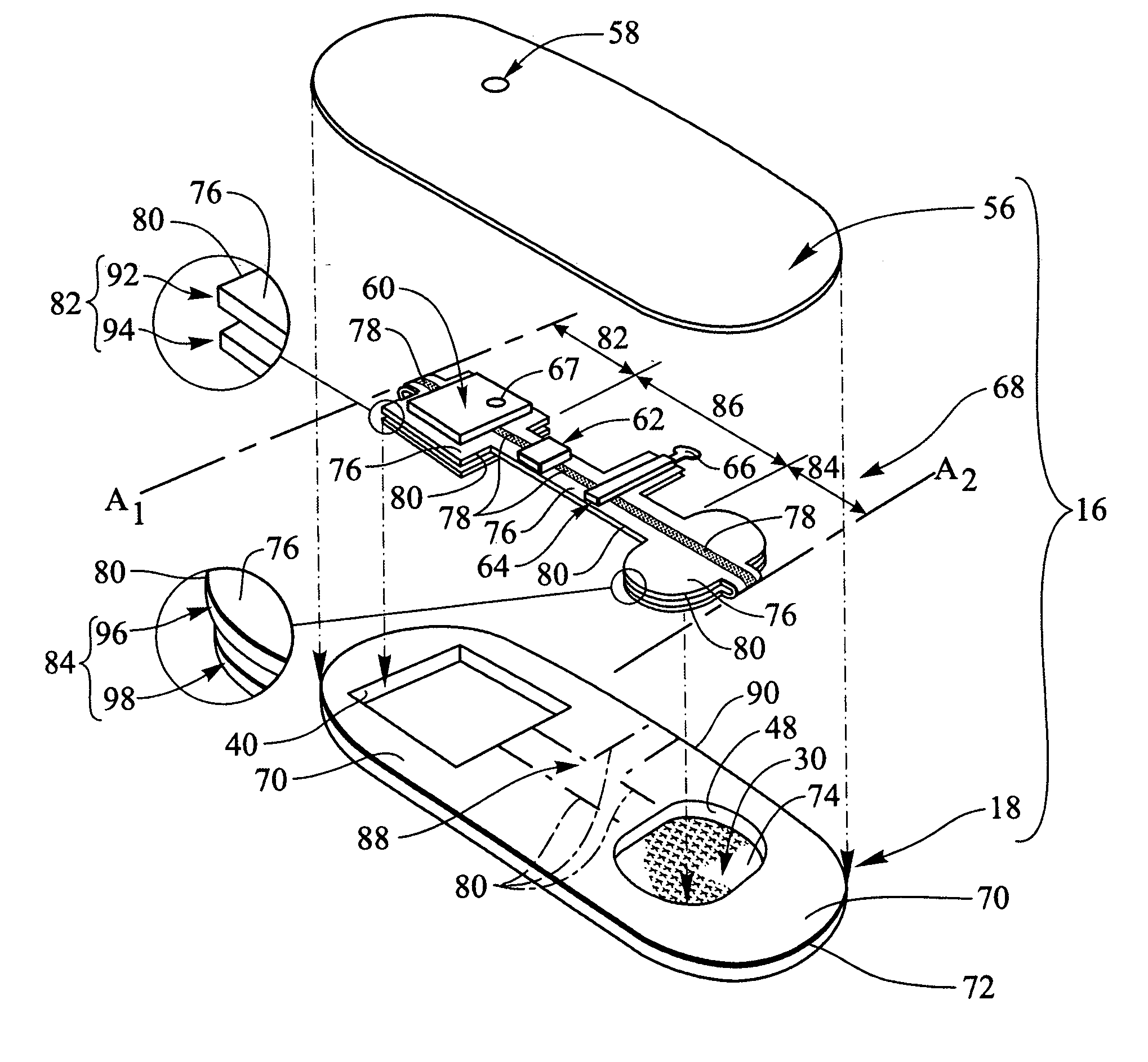

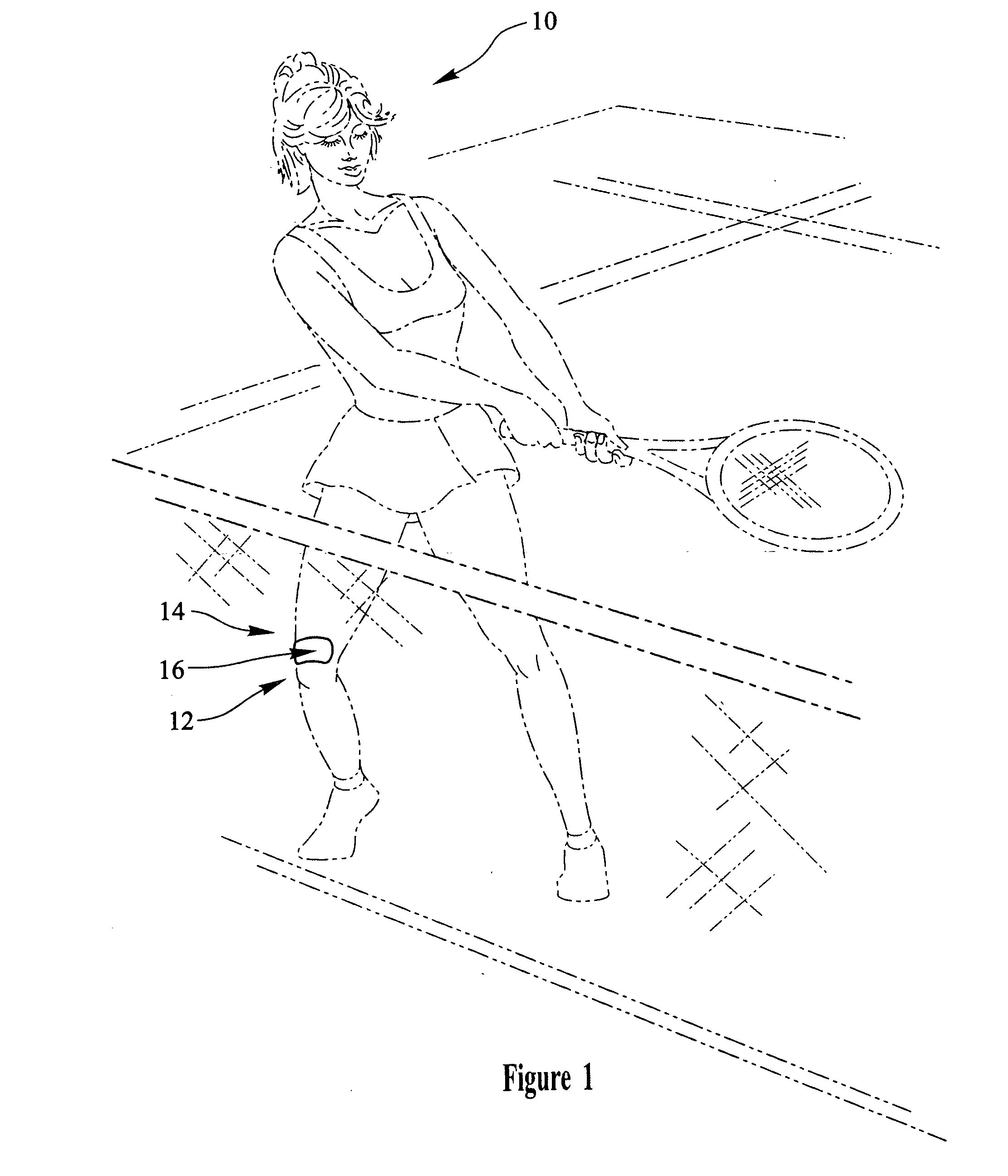

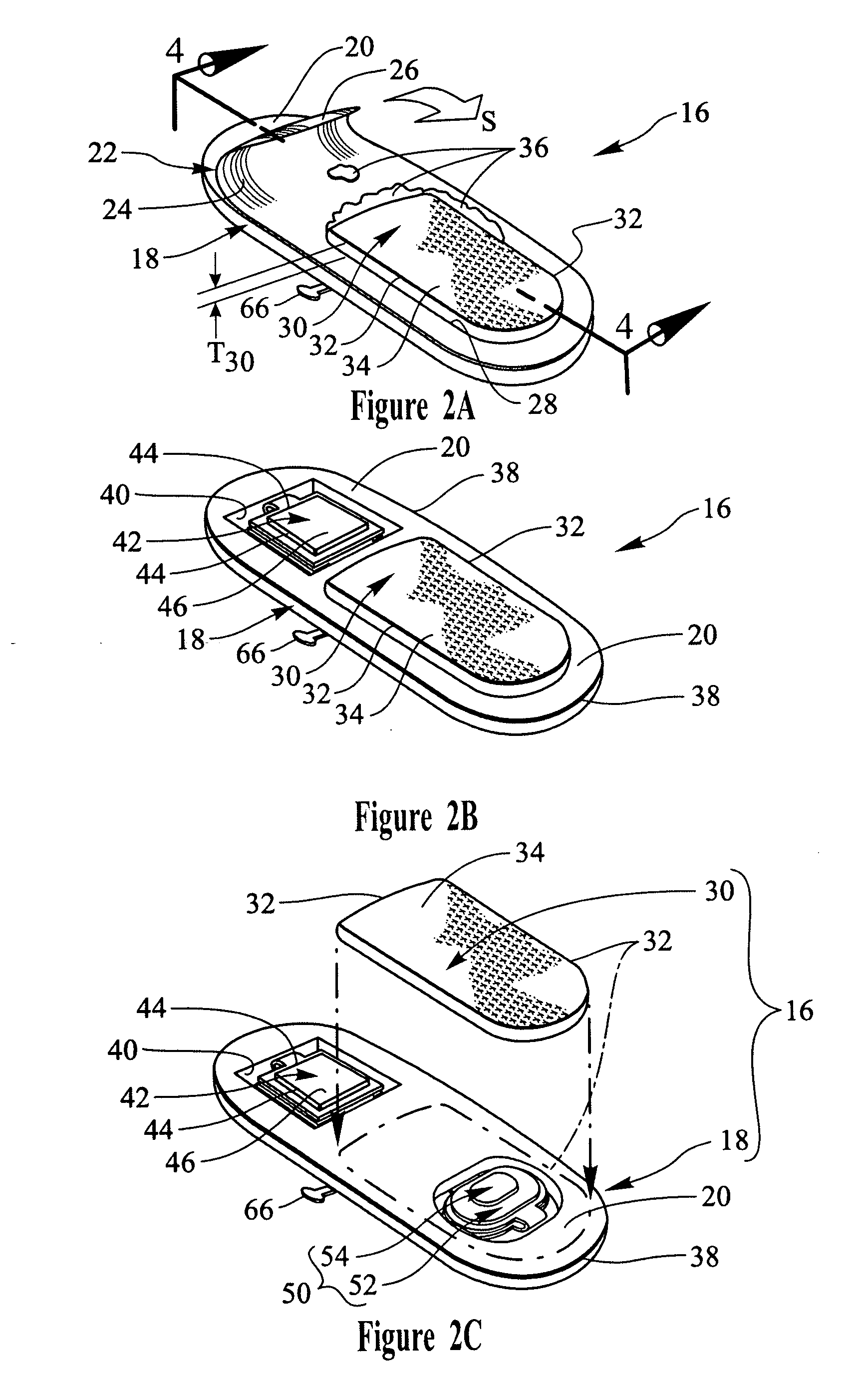

Active transdermal medicament patch

InactiveUS20080214985A1Improve securityReduce technical difficultyElectrotherapySheet deliveryPlanar substrateTransdermal medication

An active transdermal medicament patch includes a planar substrate with a therapeutic face releasably retainable against the skin of a patient. A return electrode and a medicament matrix susceptible to permeation by medicament are secured at separated locations on the therapeutic face. Each electrically conductively engages the skin, when the substrate is retained thereon. A power source carried on the substrate is electrically coupled between the medicament matrix and a programmed microprocessor also carried on the substrate. A substantially invariant voltage presented at an output contact of the microprocessor is applied during a predetermined therapy period across the skin between the medicament matrix and the return electrode, inducing transcutaneous migration of medicament into the skin at a substantially constant rate. A light-emitting diode carried on the substrate and coupled to the microprocessor communicates that the patch is operating.

Owner:ACTIVATEK

Microelectrical mechanical structure (MEMS) optical modulator and optical display system

InactiveUS20050002086A1Eliminating light attenuation of lightEliminating expenseTelevision system detailsColor television detailsPlanar substrateActuator

A MEMS optical display system includes an illumination source for providing illumination light, a collimating lens for receiving the illumination light and forming from it collimated illumination light, and a converging microlens array having an array of lenslets that converge the collimated illumination light. The converging microlens array directs the illumination light to a microelectrical mechanical system (MEMS) optical modulator. The MEMS optical modulator includes, for example, a planar substrate through which multiple pixel apertures extend and multiple MEMS actuators that support and selectively position MEMS shutters over the apertures. A MEMS actuator and MEMS shutter, together with a corresponding aperture, correspond to pixel. The light from the converging microlens array is focused through the apertures and is selectively modulated according to the positioning of the MEMS shutters by the MEMS actuators, thereby to impart image information on the illumination light. The light is then passed to a diffused transmissive display screen by a projection microlens array.

Owner:MICROSOFT TECH LICENSING LLC

Microfluidic surfaces

ActiveUS20020125135A1Easy to createStrong interactionSludge treatmentVolume/mass flow measurementPlanar substrateNon ionic

A microfluidic device comprising a set of one or more, preferably more than 5, covered microchannel structures manufactured in the surface of a planar substrate. The device is characterized in that a part surface of at least one of the microchannel structures has a coat exposing a non-ionic hydrophilic polymer. The non-ionic hydrophilic polymer is preferably attached covalently directly to the part surface or to a polymer skeleton that is attached to the surface.

Owner:GYROS

Microneedle array, patch, and applicator for transdermal drug delivery

Microneedle arrays and drug delivery devices are provided for transdermally delivering a drug formulation to a patient. The microneedle array device includes a substantially planar substrate having an array of apertures; and a plurality of microneedles projecting at angle from the planar substrate, the microneedles having a base portion integrally connected to the substrate, a tip end portion distal to the base portion, and body portion therebetween, wherein each microneedle has at least one channel extending substantially from the base portion through at least a part of the body portion, the channel being open along at least part of the body portion and in fluid communication with at least one of the apertures in the substrate. In a preferred embodiment, each microneedle has a substantially rectangular cross-sectional shape and the channel is open to two opposing surfaces of the microneedle.

Owner:YUZHAKOV VADIM V

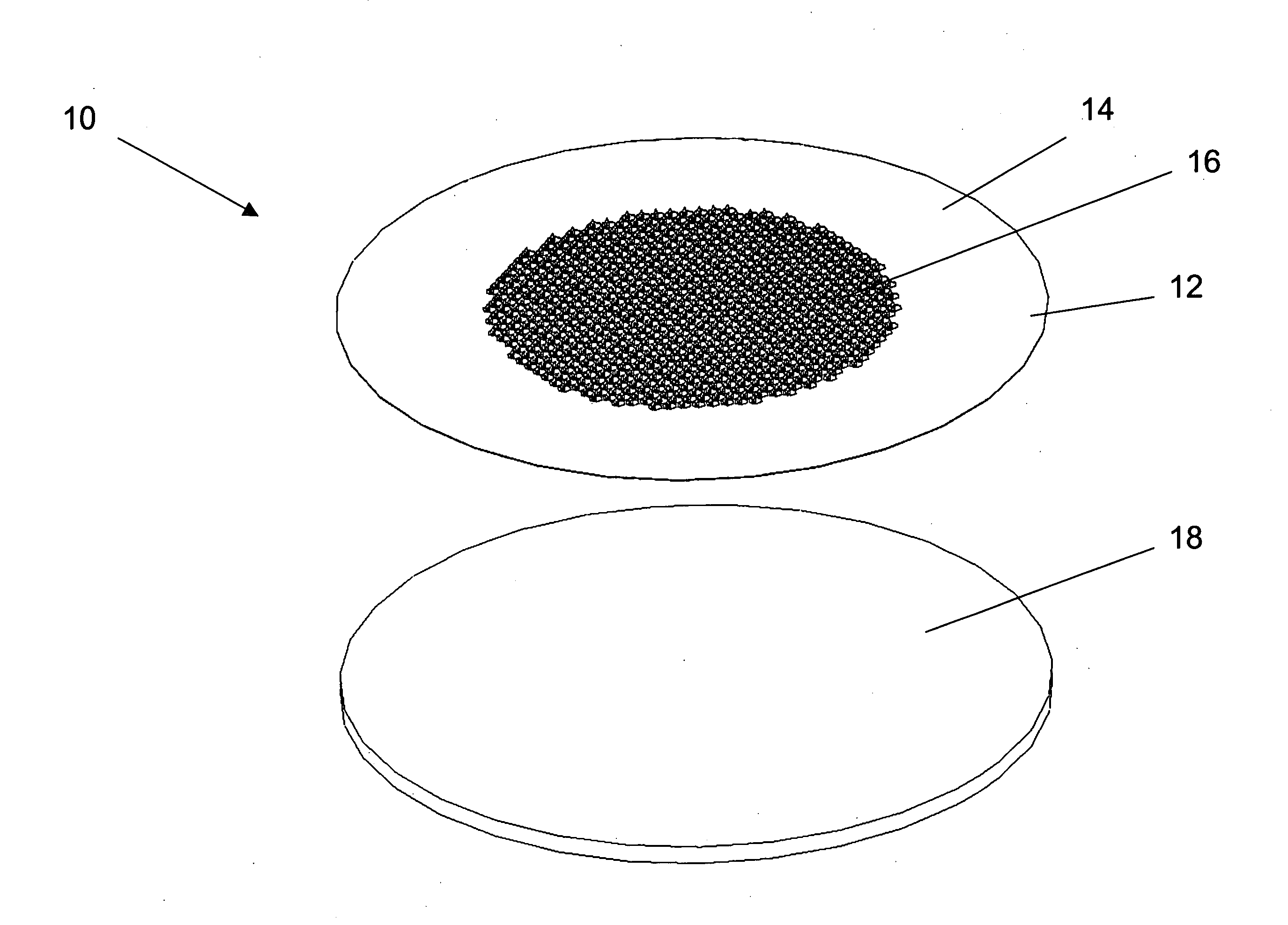

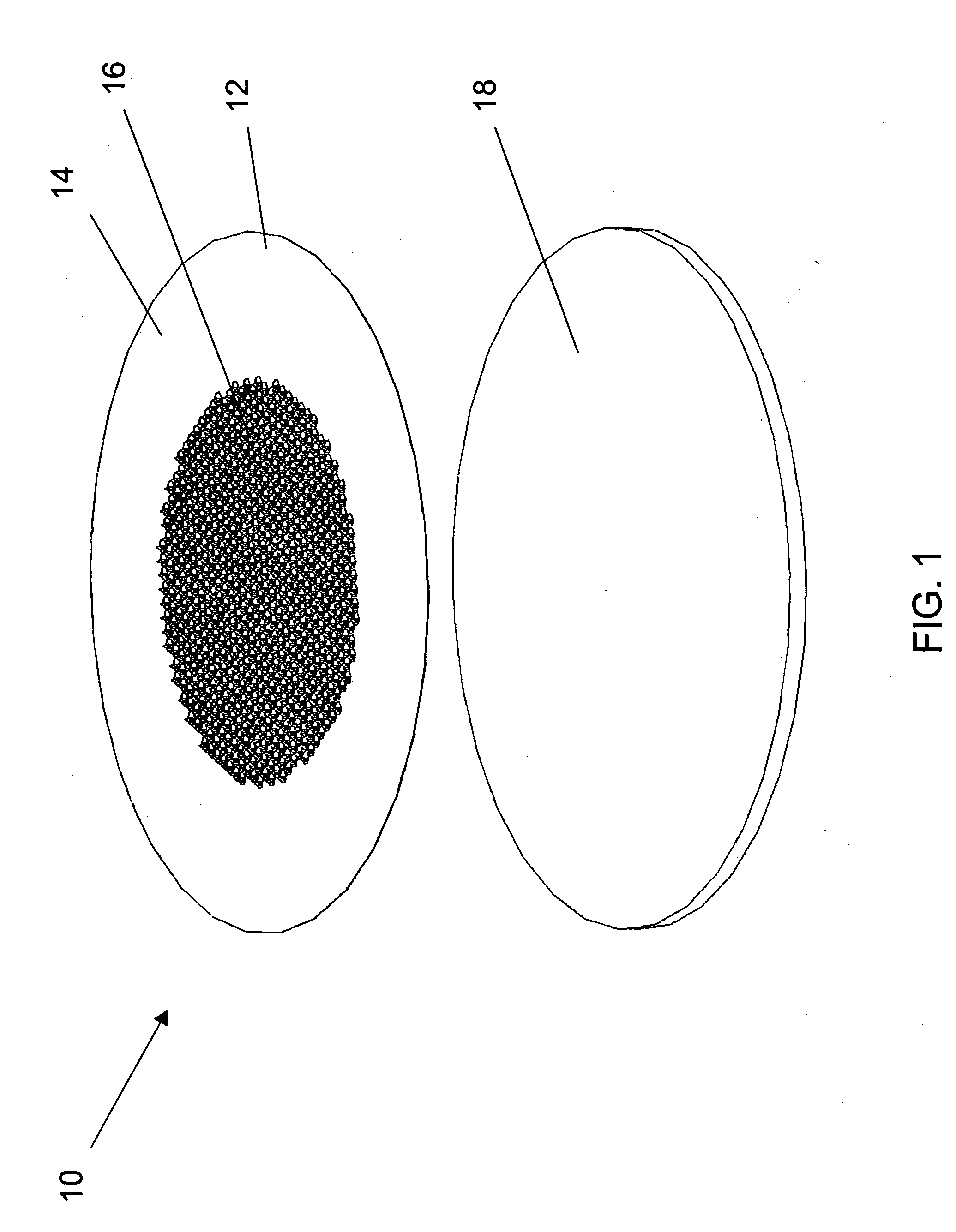

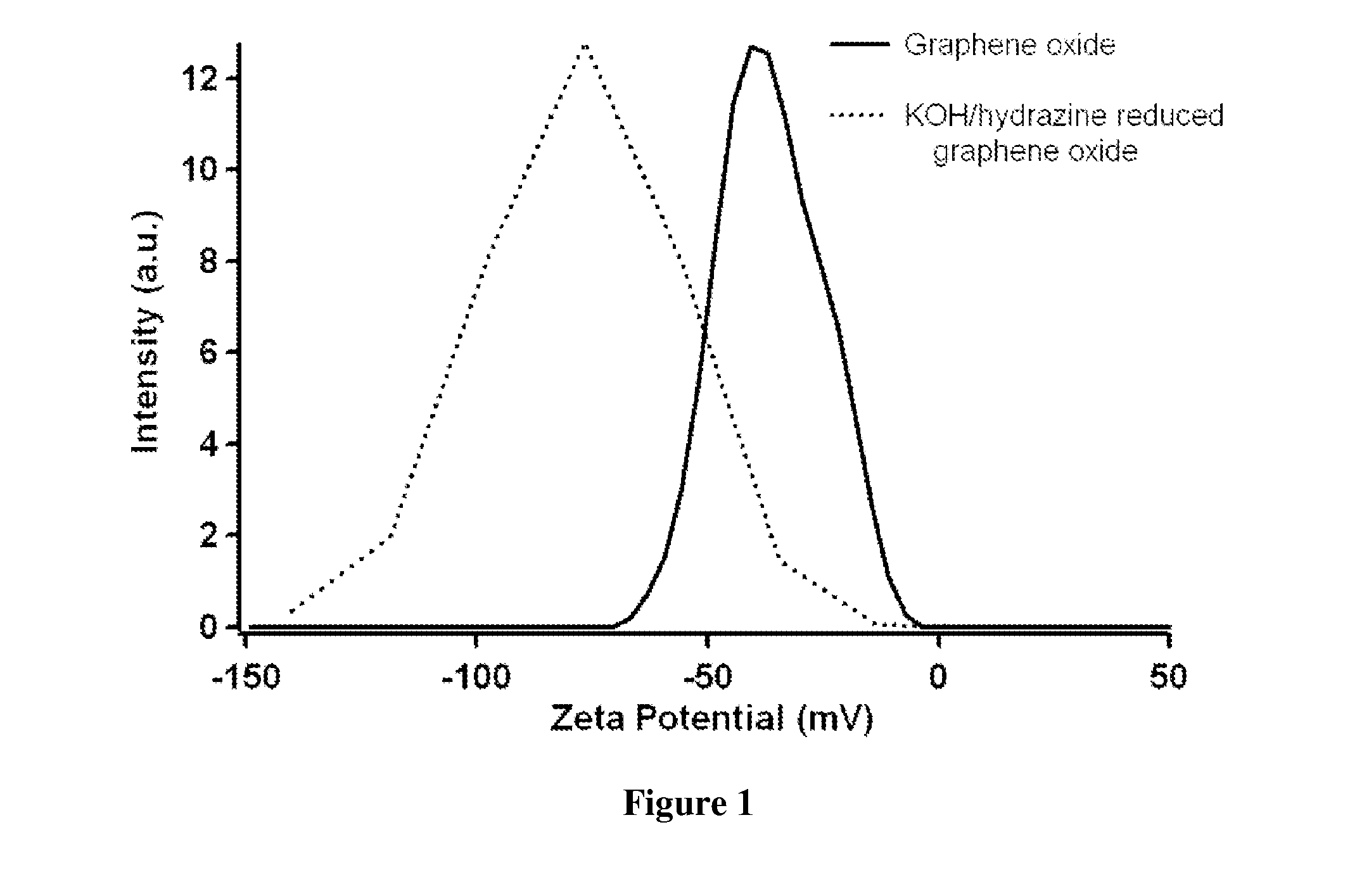

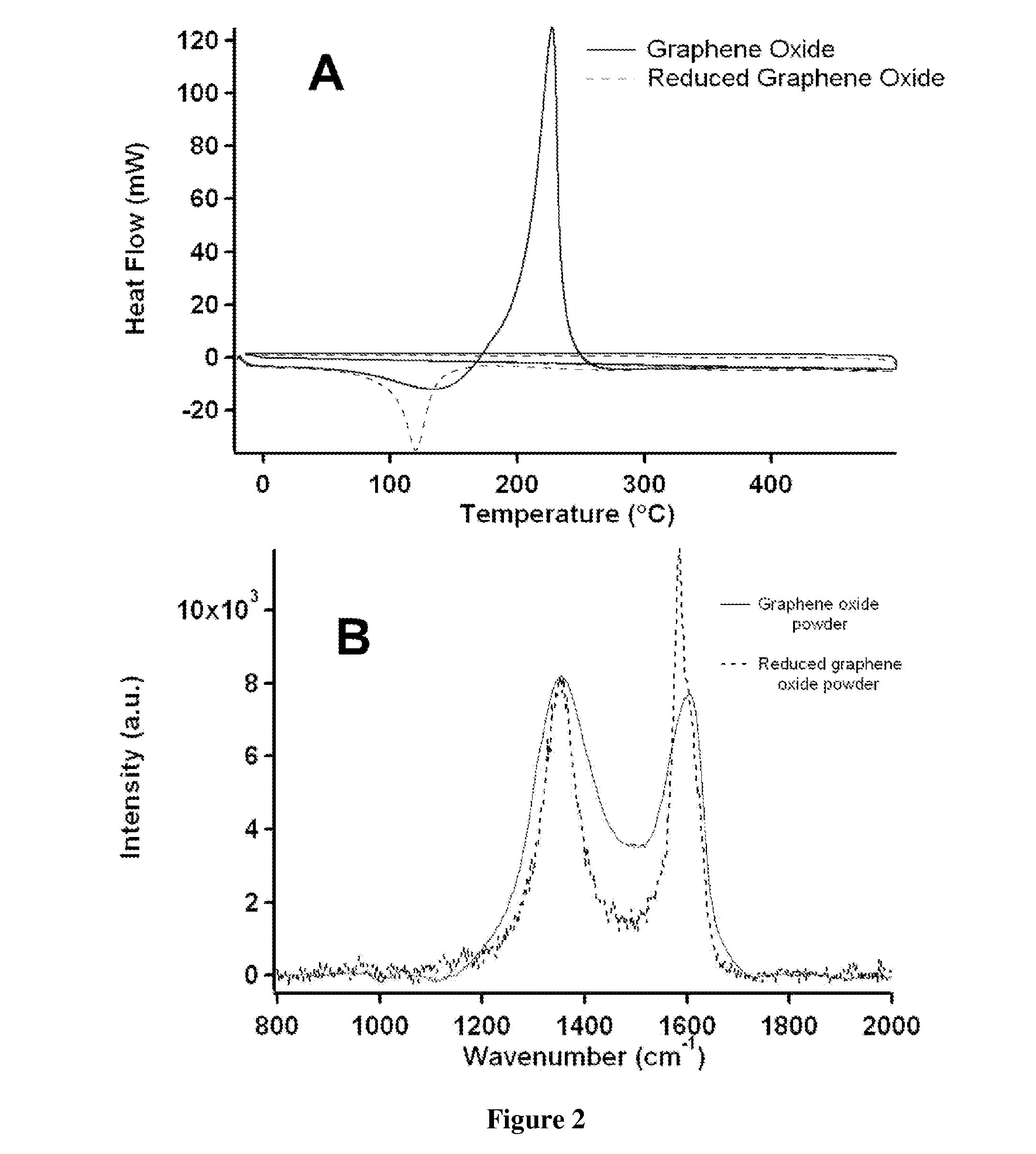

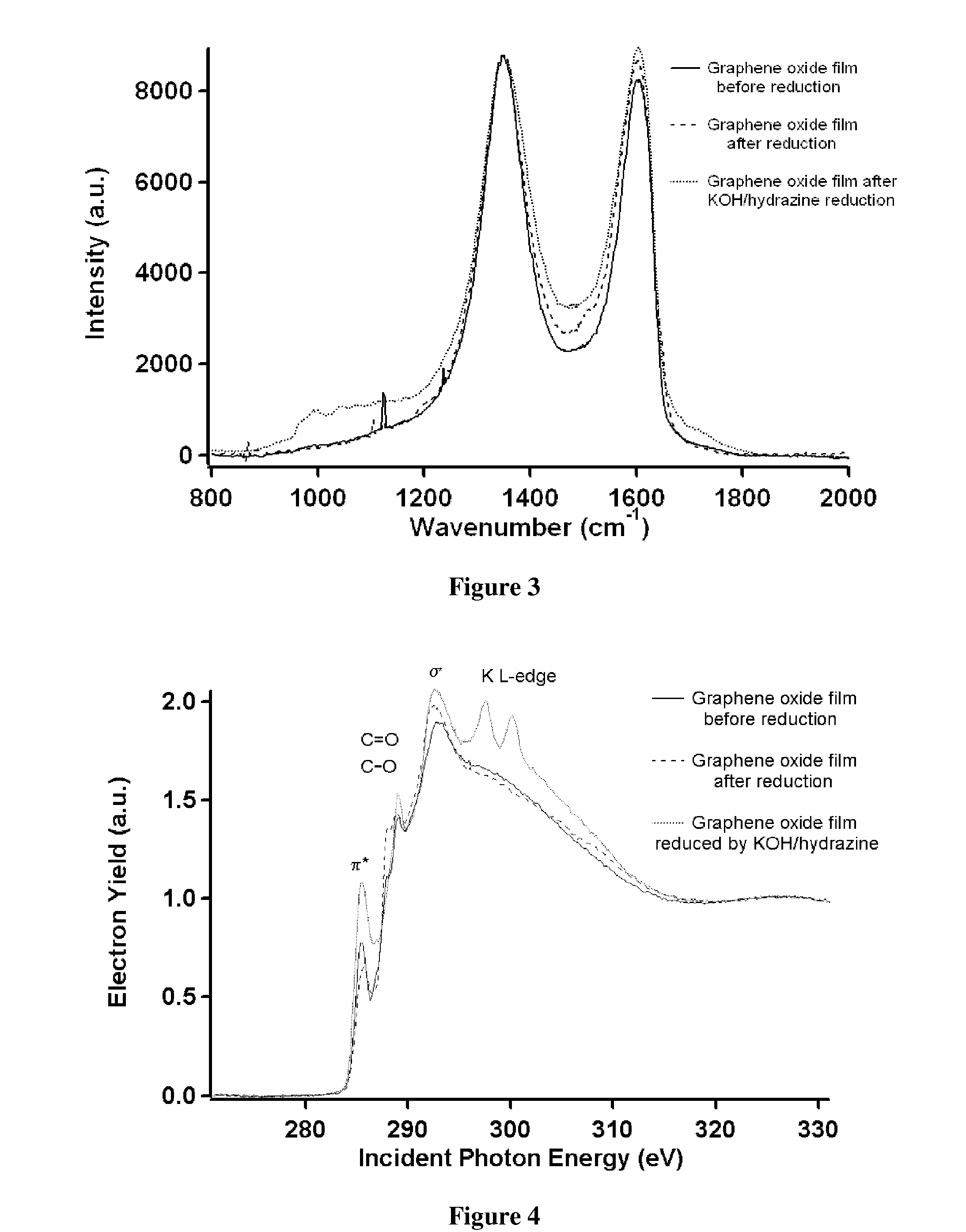

Graphene Films and Methods of Making Thereof

ActiveUS20130156678A1Material nanotechnologyElectrolysis componentsPlanar substrateConformal coating

Provided are methods for forming graphene or functionalized graphene thin films. Also provided are graphene and functionalized graphene thin films formed by the methods. For example, electrophoretic deposition methods and stamping methods are used. Defect-free thin films can be formed. Patterned films can be formed. The methods can provide conformal coatings on non-planar substrates.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

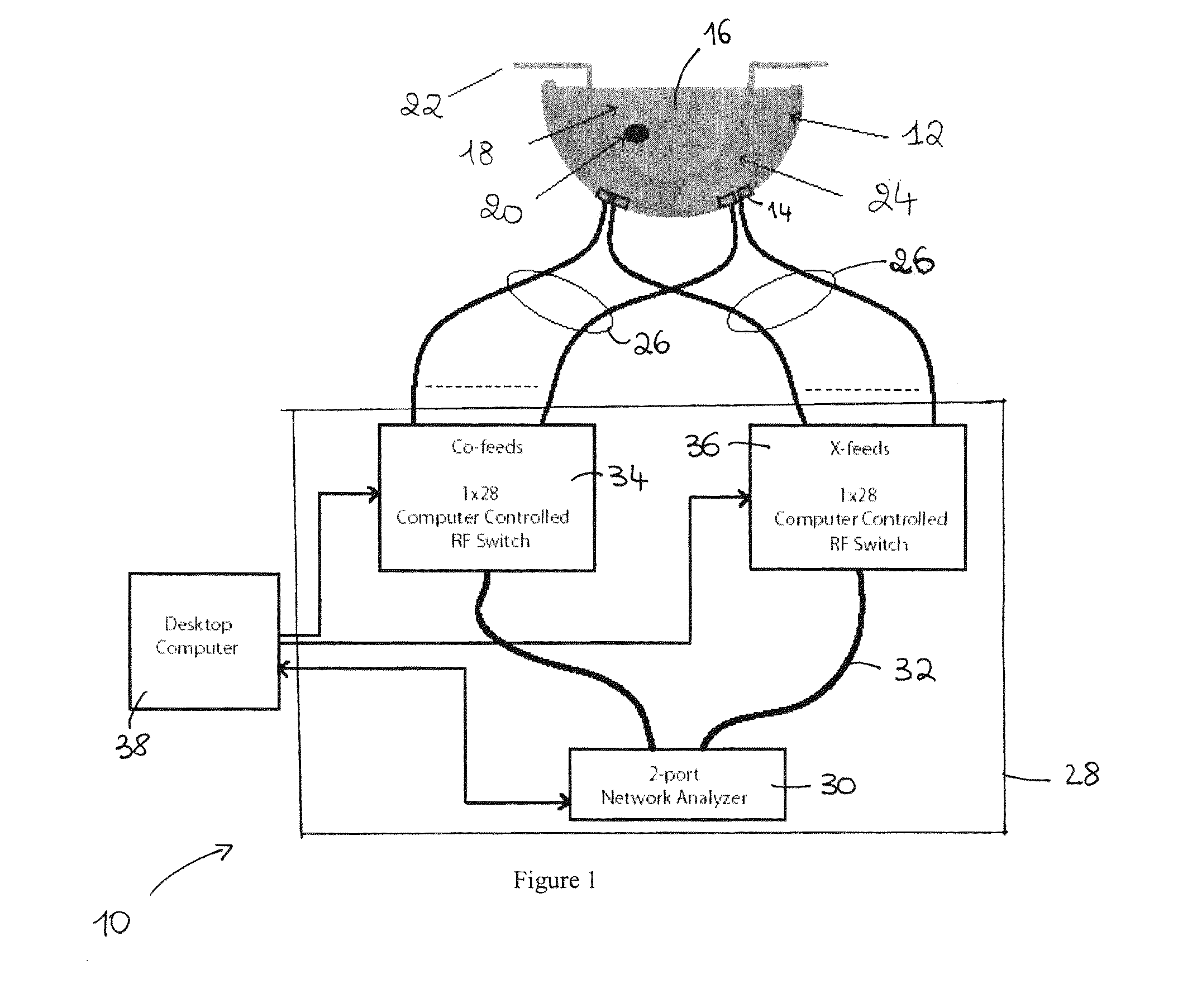

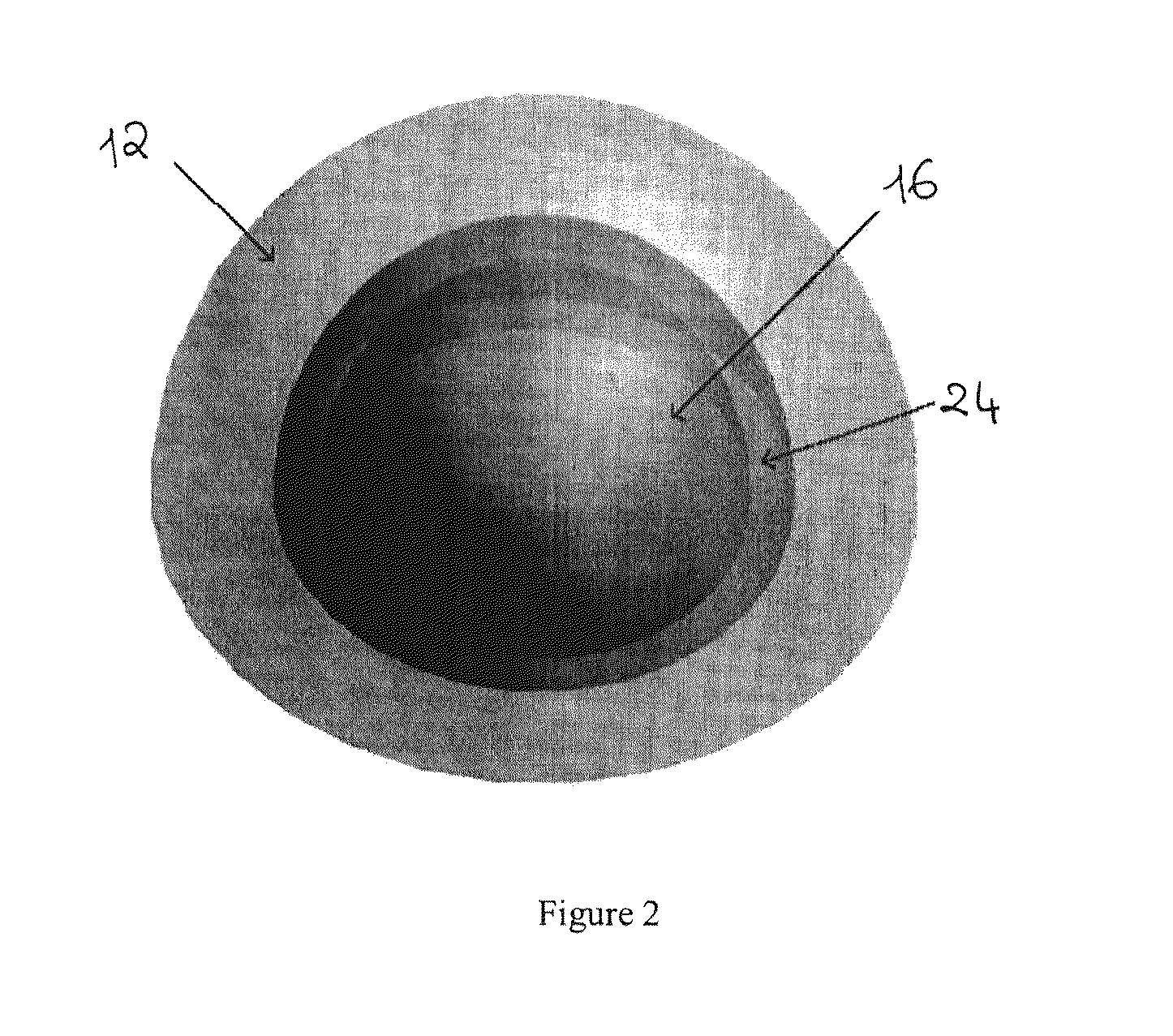

Microwave scanning system and miniaturized microwave antenna

InactiveUS20090015832A1Simultaneous aerial operationsMaterial analysis using microwave meansDielectricMicrowave

A micro strip antenna comprising a planar substrate fabricated from a dielectric material and a pair of like elements arranged in mirror image on the planar substrate, each of the elements comprising a radiating portion comprising an elongate conductive strip of a constant thickness, the elongate conductive strip comprising first arcuate side edges mutually diverging between a narrow end and a wide end.There is also disclosed a system for detecting the presence of a region having a first dielectric constant within a medium having a second dielectric constant different from the first dielectric constant, such as a tumour embedded in a fatty tissue. The system comprises a support fabricated from a material having a dielectric constant substantially the same as the second dielectric constant, a scanner array comprising a plurality of scanning elements embedded in the support, each of the scanning elements directing a series of microwave pulses into the medium and receiving backscatter returns resulting from the series of microwave pulses, and an analyzer coupled to each of the scanning elements, the analyzer collecting the backscatter returns and processing the backscatter returns to detect the region.

Owner:MCGILL UNIV

Device and Method For Particle Manipulation in Fluid

InactiveUS20100193407A1Water/sewage treatment with mechanical oscillationsLaboratory glasswaresPlanar substrateEngineering

A device for manipulating particles present in a fluid medium is disclosed. The device comprises a planar substrate, formed with at least one primary microchannel to allow passage of the fluid medium therethrough. The primary microchannel(s) has walls and a base and being in fluid communication with a plurality of secondary microchannels via at least one branching point. The device further comprises one or more ultrasound transmission pairs, positioned at opposite sides of the walls to generate ultrasound waves propagating through the fluid medium, substantially parallel to the planar substrate, such as to form a standing wave within the primary microchannel.

Owner:YEDA RES & DEV CO LTD

Interposer, packages including the interposer, and methods

InactiveUS20020167092A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialPlanar substrate

An interposer including a substantially planar substrate element with a slot formed therethrough. The slot, through which bond pads of a semiconductor die are exposed upon assembly of the interposer with the semiconductor die, includes a laterally recessed area formed in only a portion of a periphery thereof. The laterally recessed area is positioned so as to expose at least a portion of an active surface of the semiconductor die located between a bond pad located adjacent an outer periphery of the semiconductor die and the outer periphery. The laterally recessed area facilitates access to the bond pad by apparatus for forming, positioning, or securing intermediate conductive elements. Semiconductor device assemblies and packages that include the interposer are also disclosed, as are methods for assembling semiconductor device components with the interposer and methods for packaging such assemblies.

Owner:MICRON TECH INC

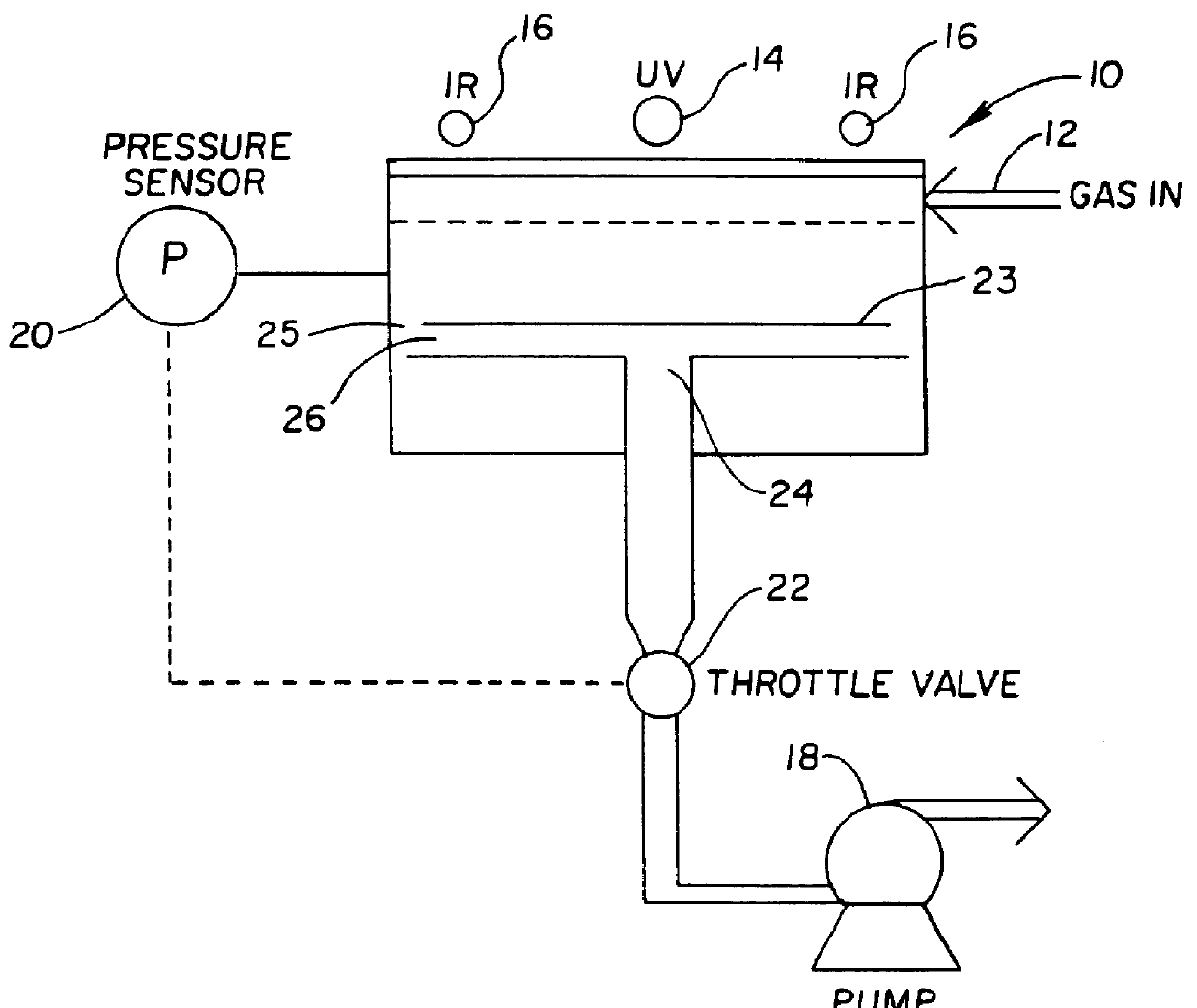

Method and apparatus for surface conditioning

InactiveUS6015503ADecorative surface effectsSemiconductor/solid-state device manufacturingLight activationChemical reaction

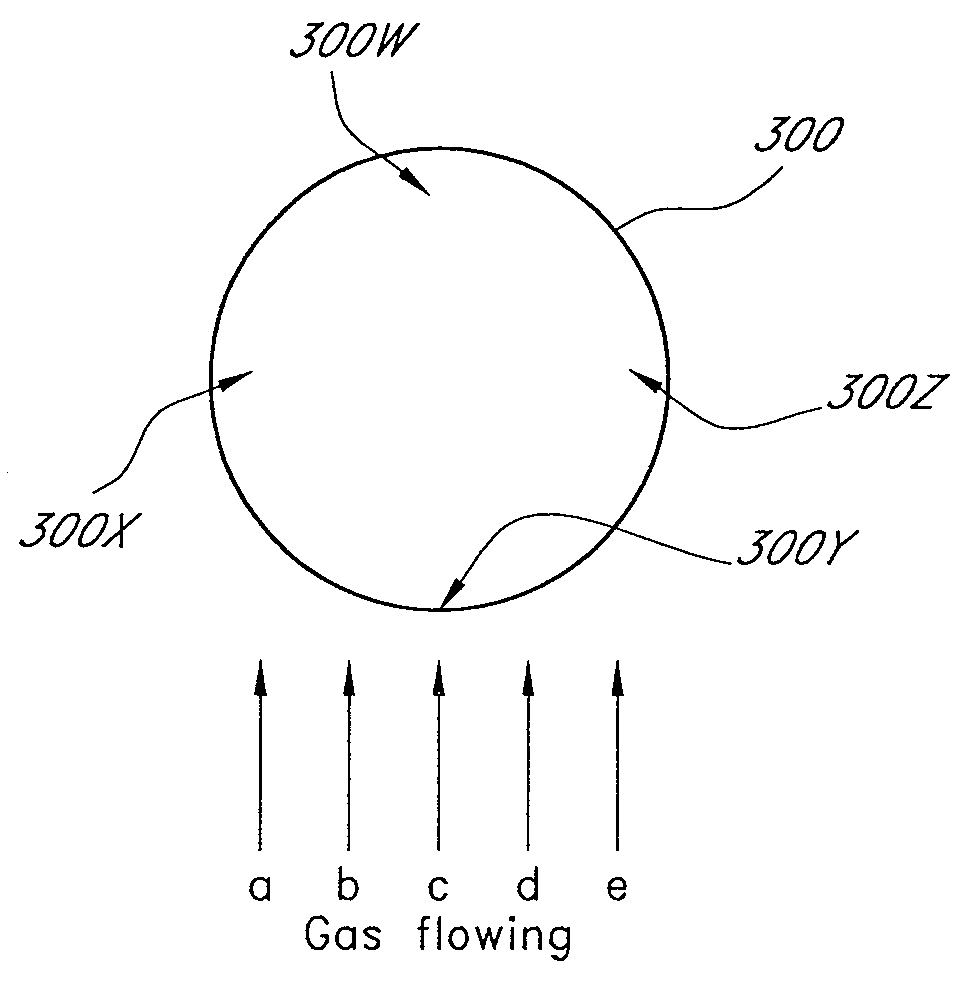

PCT No. PCT / US95 / 16649 Sec. 371 Date Sep. 2, 1997 Sec. 102(e) Date Sep. 2, 1997 PCT Filed Dec. 21, 1995 PCT Pub. No. WO96 / 19825 PCT Pub. Date Jun. 27, 1996Apparatus and process for conditioning a generally planar substrate, contained in a chamber isolatable from the ambient environment and fed with a conditioning gas which includes a reactive gas. The apparatus includes a support for supporting the substrate in the chamber, the substrate being in a lower pressure reaction region of the chamber. A gas inlet is provided for feeding conditioning gas into a gas inlet region of the chamber which is at a higher pressure than the lower pressure reaction region so that the pressure differential causes the conditioning gas to flow toward the surface of the substrate wherein the conditioning gas component will chemically react with and condition the substrate surface, both said higher and lower pressure regions operating in a viscous flow regime. The substrate is supported such that a pressure bias is created across the surface of the substrate so that the gas, after it has chemically reacted with the substrate surface, flows outward from where it has reacted, off the substrate toward the periphery of the chamber and out a peripheral or central underside exhaust outlet. Gas feed may be provided to one or both sides of the substrate and light activation of the substrate or conditioning gas may be provided on one or both sides.

Owner:FSI INTERNATIONAL INC

Microfabricated elastomeric valve and pump systems

InactiveUS20050112882A1Fast formingEasy to manufactureFunctional valve typesEngine diaphragmsElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

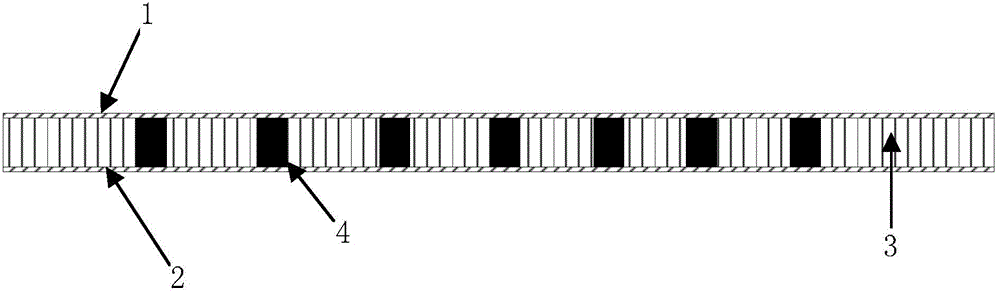

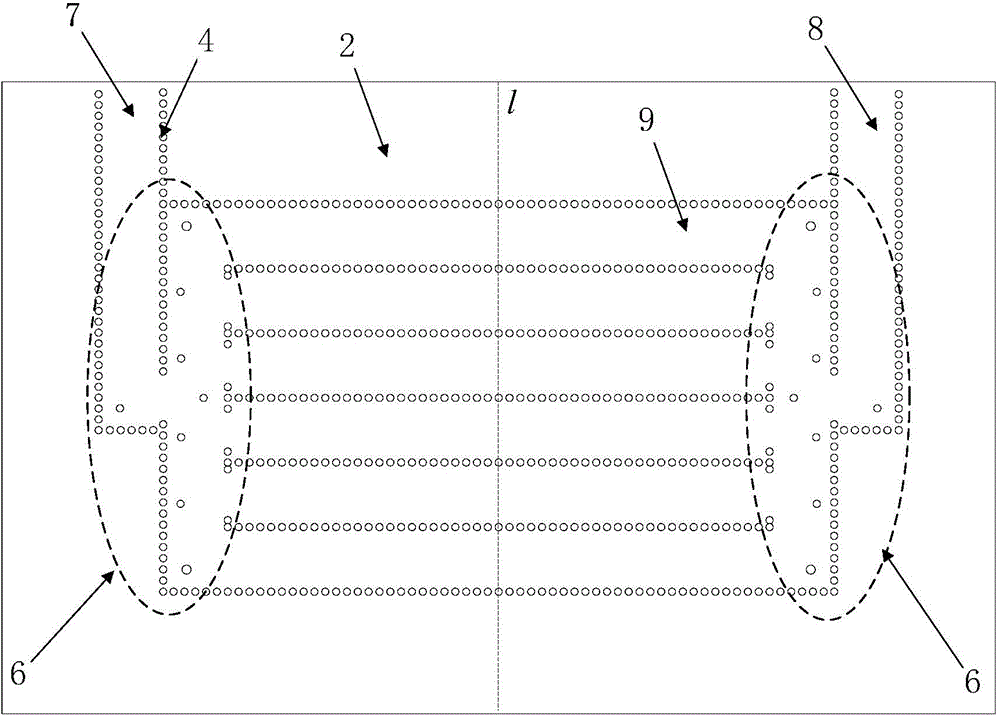

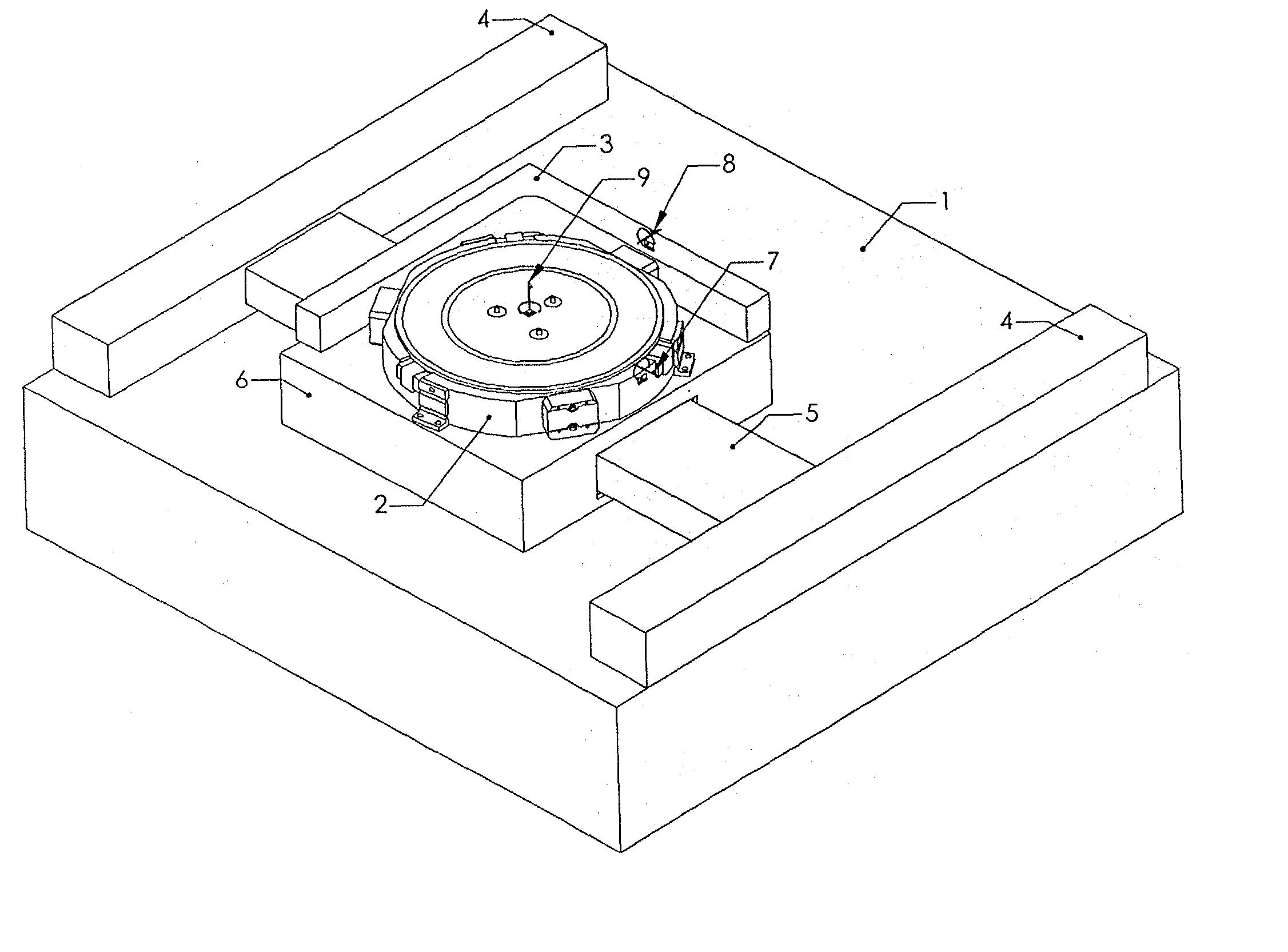

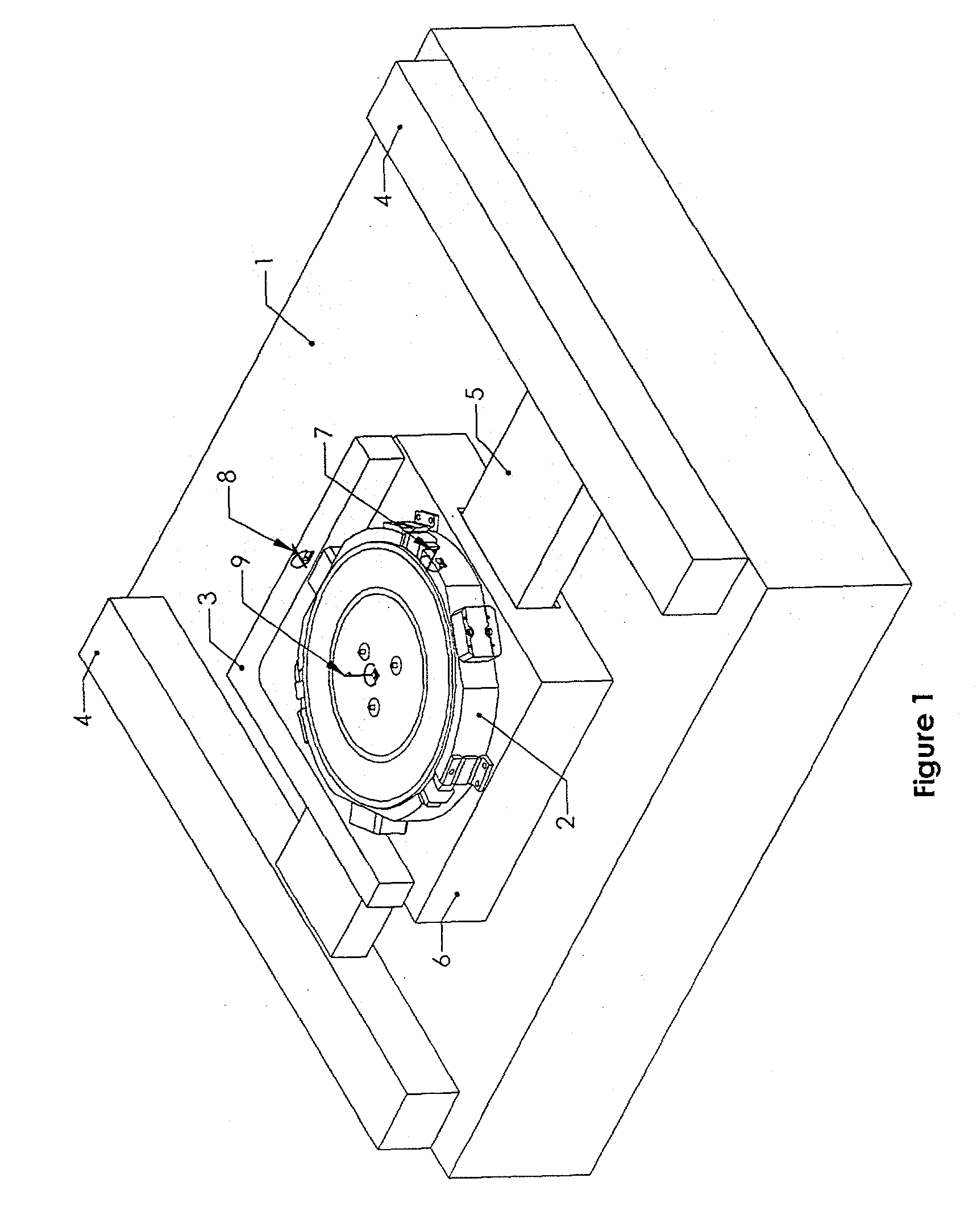

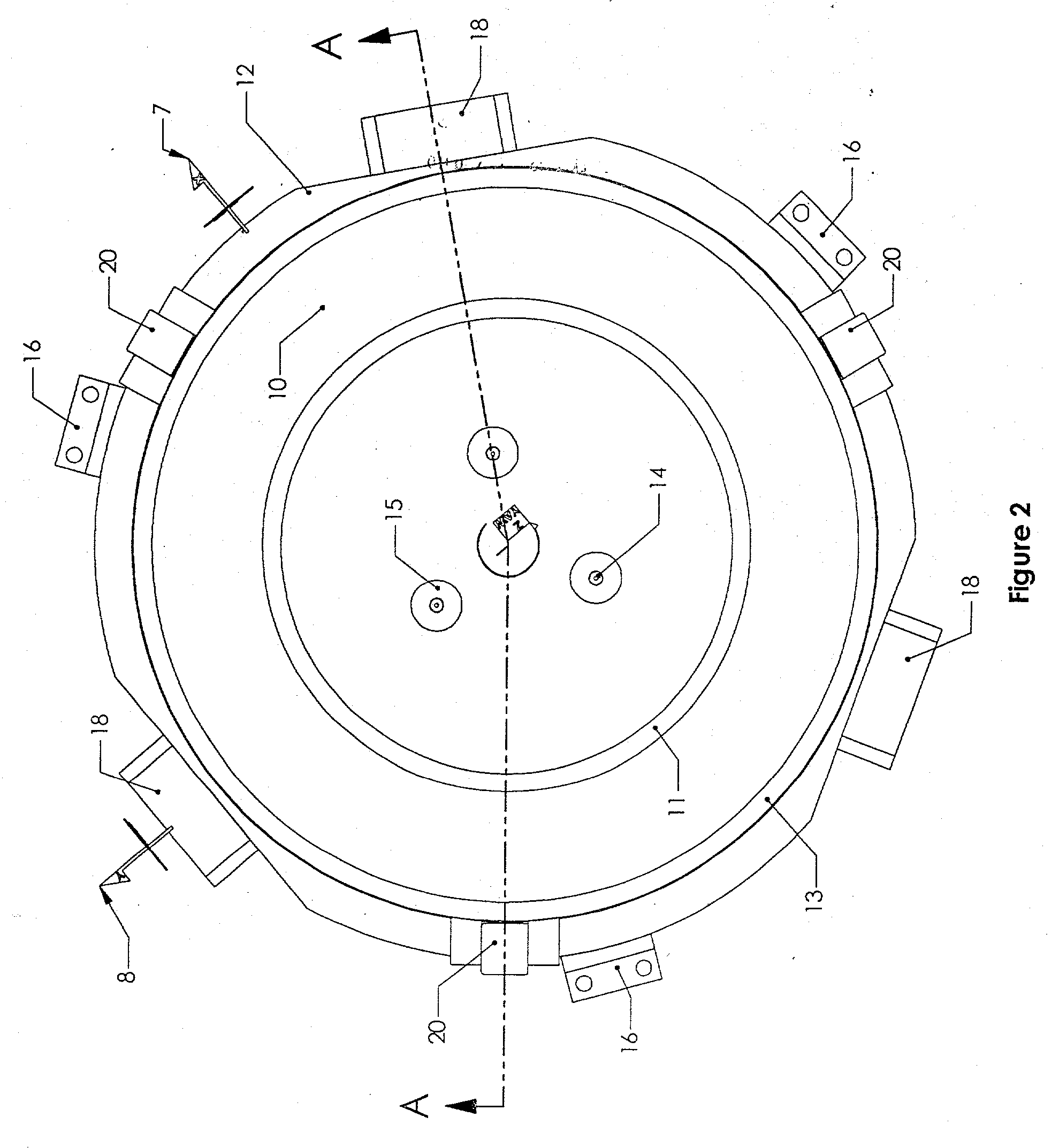

Multiple degree of freedom substrate manipulator

InactiveUS20030156270A1Reduce forceIncrease stiffnessMechanical apparatusMotor/generator/converter stoppersHigh bandwidthControl system

A system for manipulating a planar substrate such as a semiconductor wafer is provided. The manipulator is typically used in conjunction with an XY stage to focus and planarize a wafer with respect to a tool. The manipulator employs redundant actuators of different types and a control system that uses low-bandwidth, high efficiency actuators to provide low frequency forces and high-bandwidth, but less efficient, actuators to provide all other forces. The manipulator provides support and manipulation of a substrate while minimizing errors due to thermal distortion.

Owner:ACTIVE PRECISION

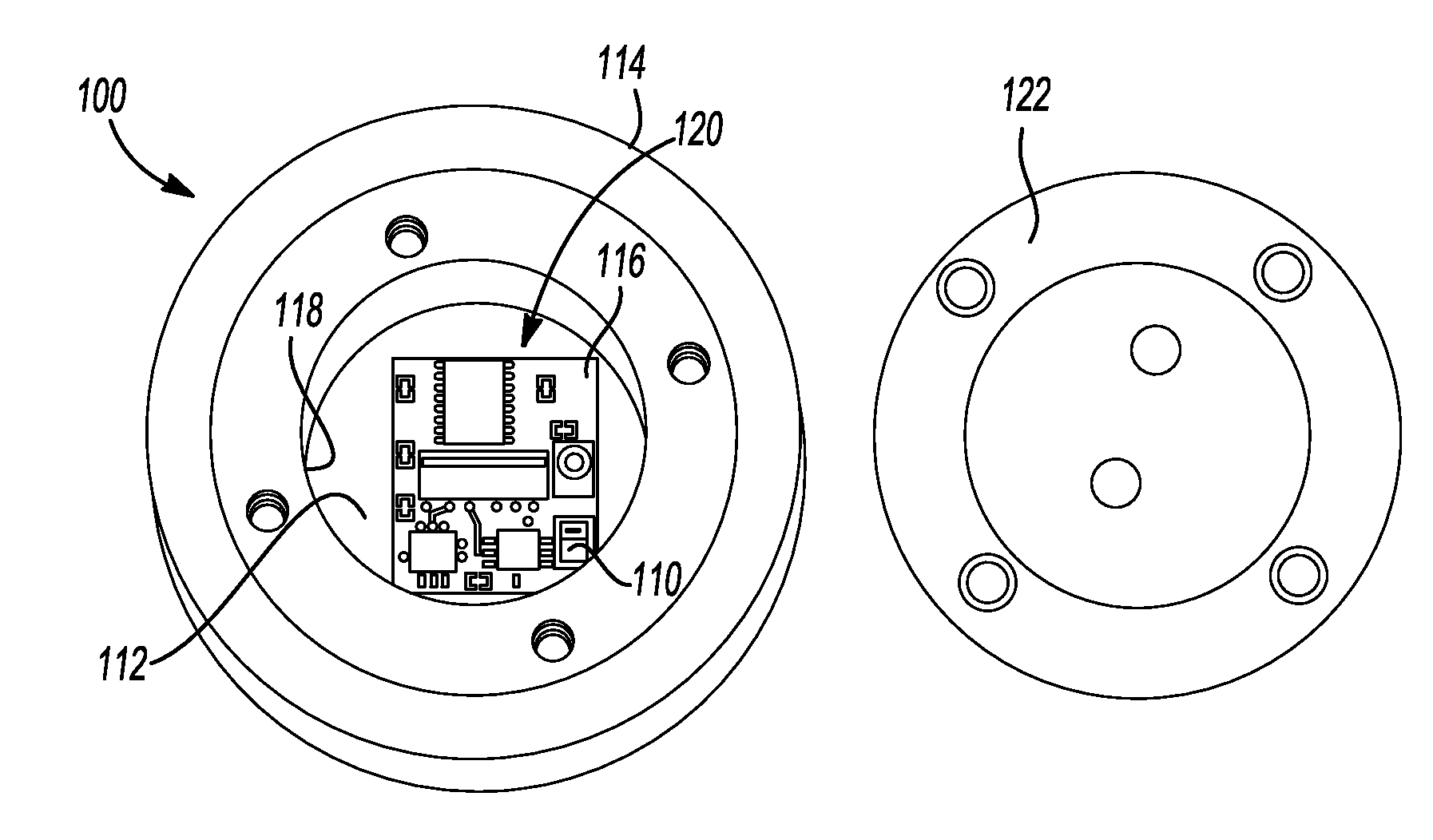

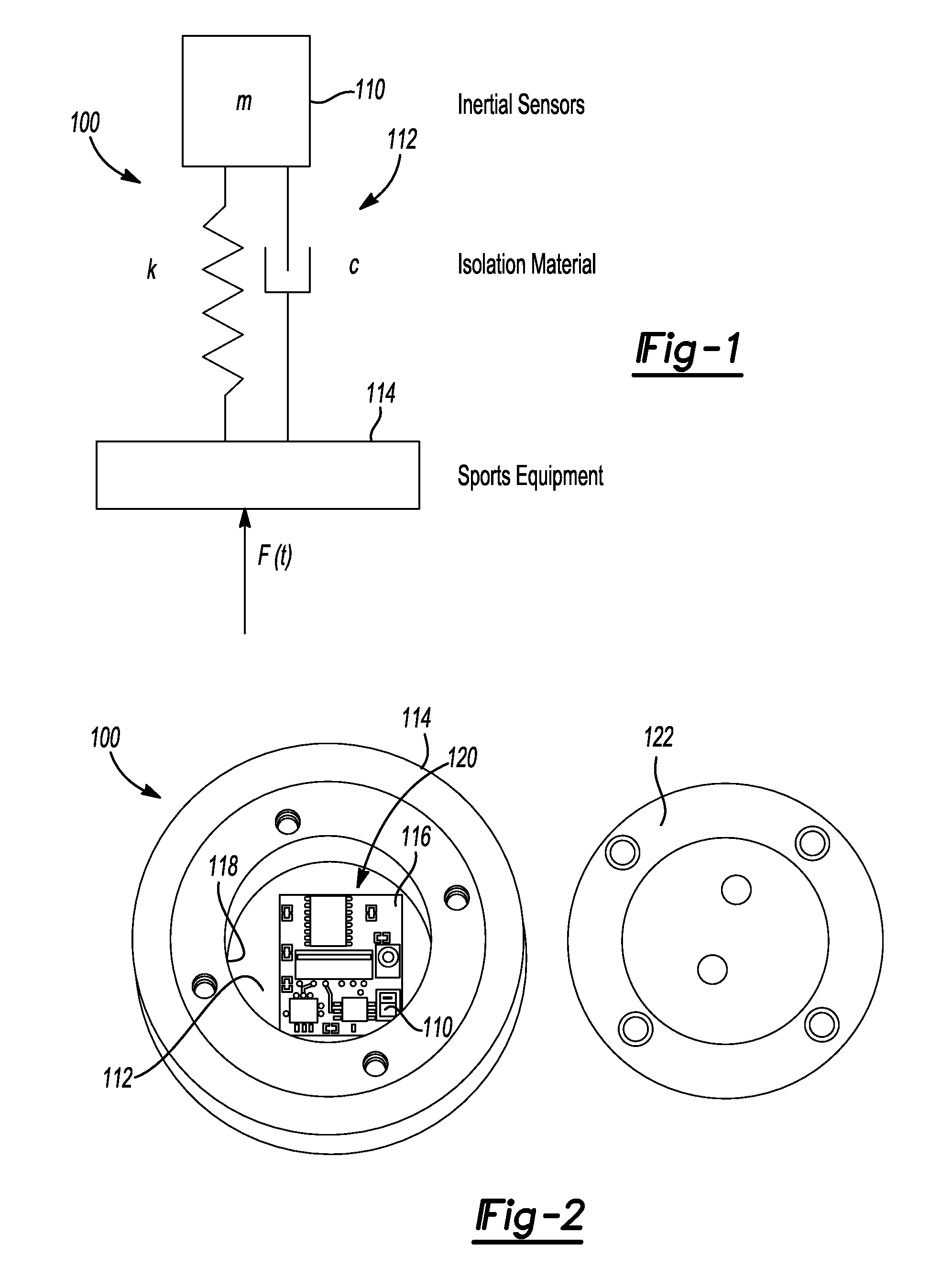

Apparatus and method for employing miniature inertial measurement units for deducing forces and moments on bodies

InactiveUS20130073248A1Reduce impactLess expensiveHollow inflatable ballsHollow non-inflatable ballsContinuous measurementAccelerometer

An apparatus for analyzing movement of equipment. The apparatus includes an inertial measurement unit continuously measuring six rigid body degrees of freedom of the equipment and outputting data representative thereof, wherein the inertial measurement unit defines a planar substrate having a single common plane. The inertial measurement unit further includes at least one angular rate gyro and at least one accelerometer sufficient to measure the six rigid body degrees of freedom and each being mounted on the single common plane. The apparatus further includes a processing unit determining the acceleration of the mass center of the equipment, the angular velocity and the angular acceleration of the equipment through a single derivative operation.

Owner:RGT UNIV OF MICHIGAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com