Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3345results about "Water/sewage treatment with mechanical oscillations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

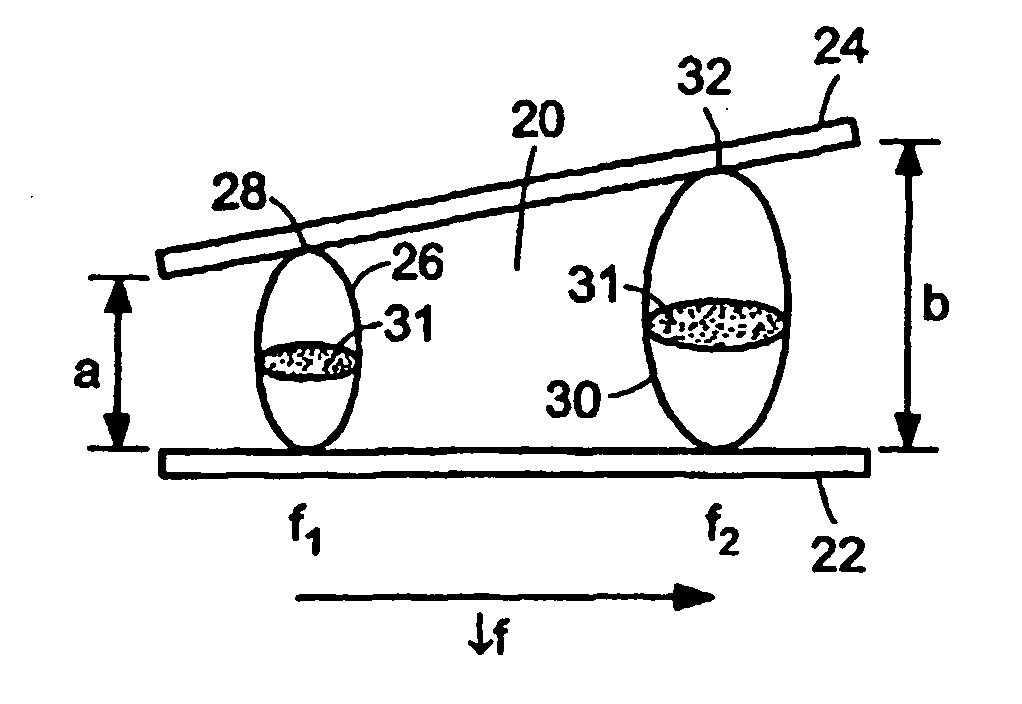

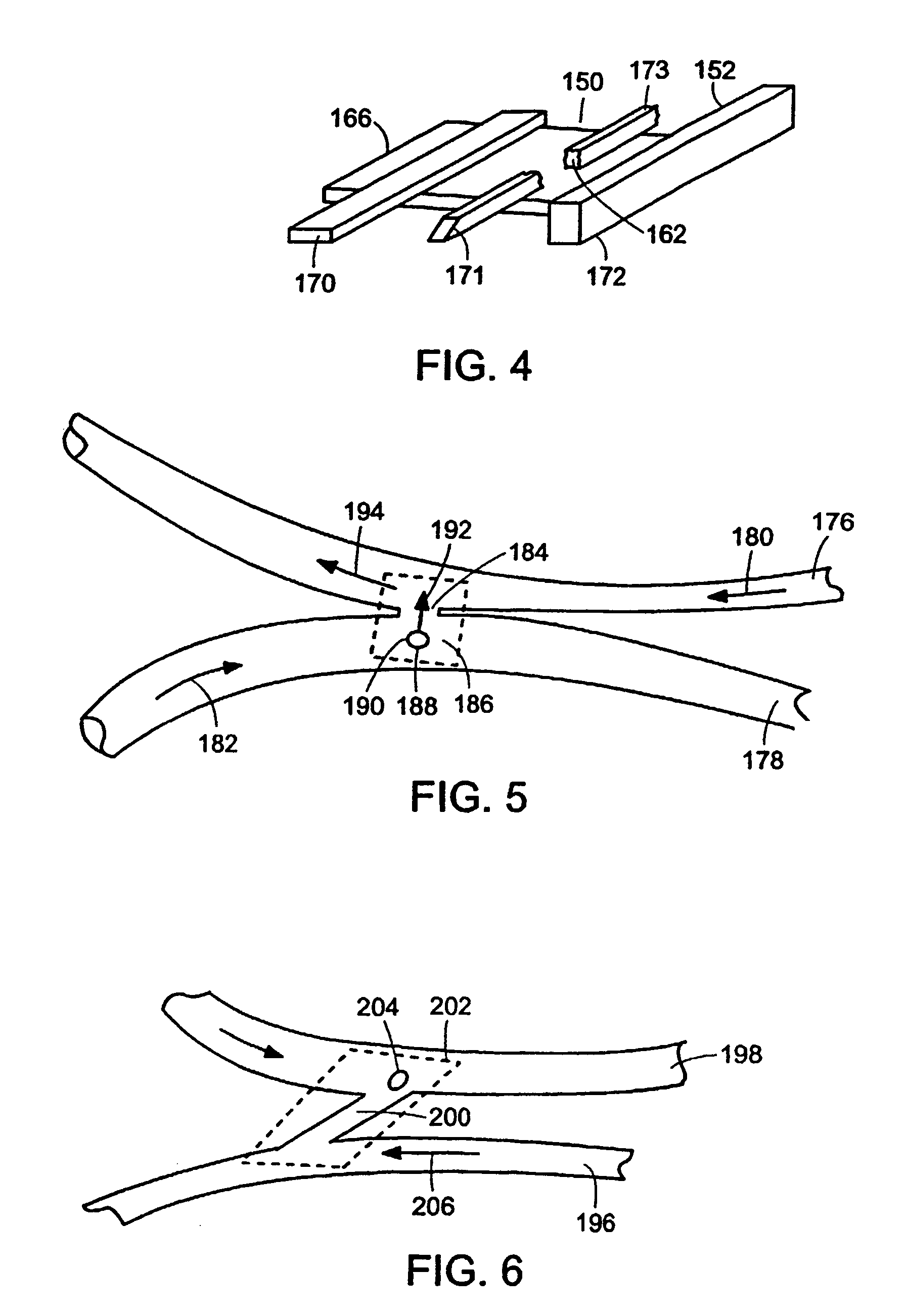

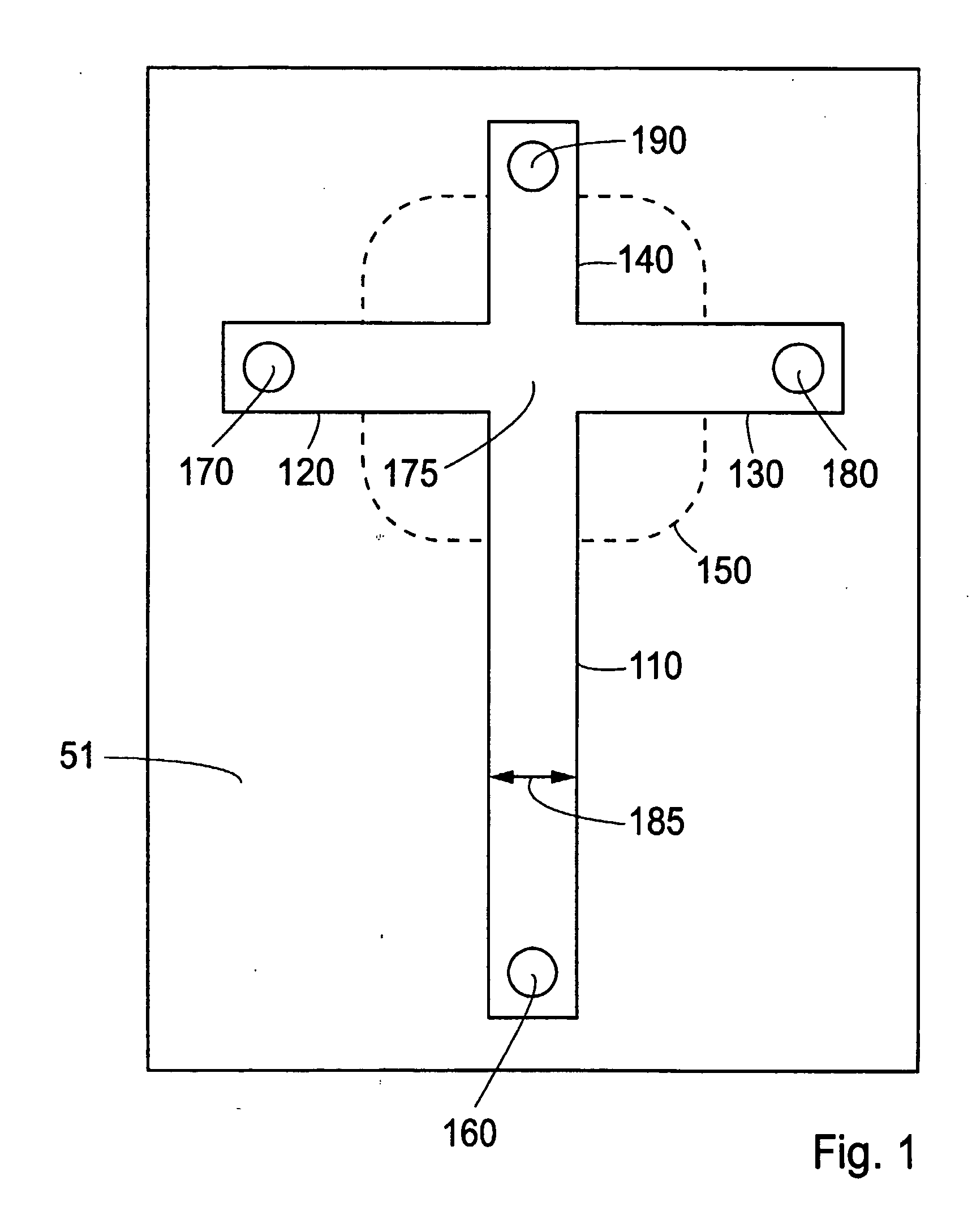

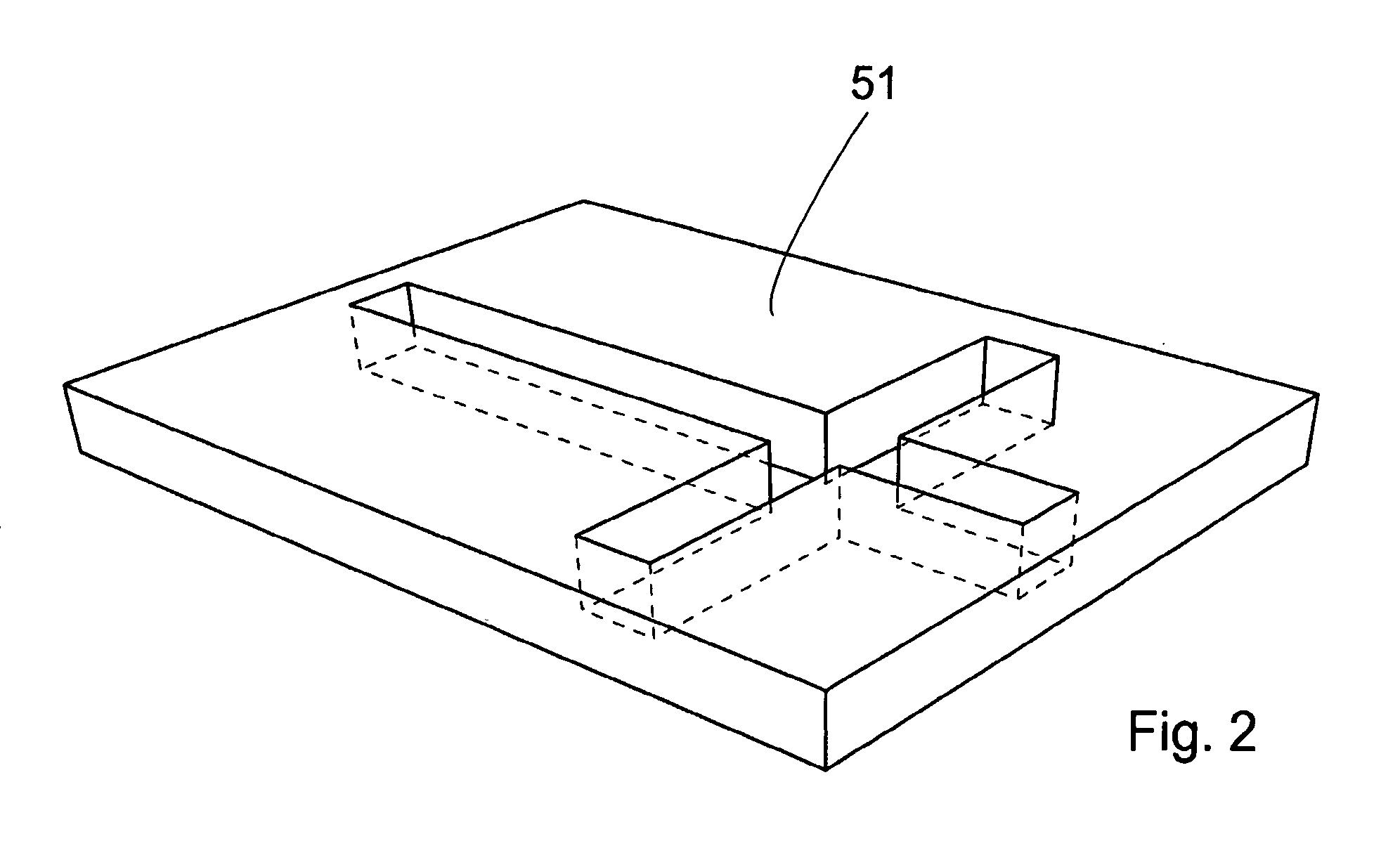

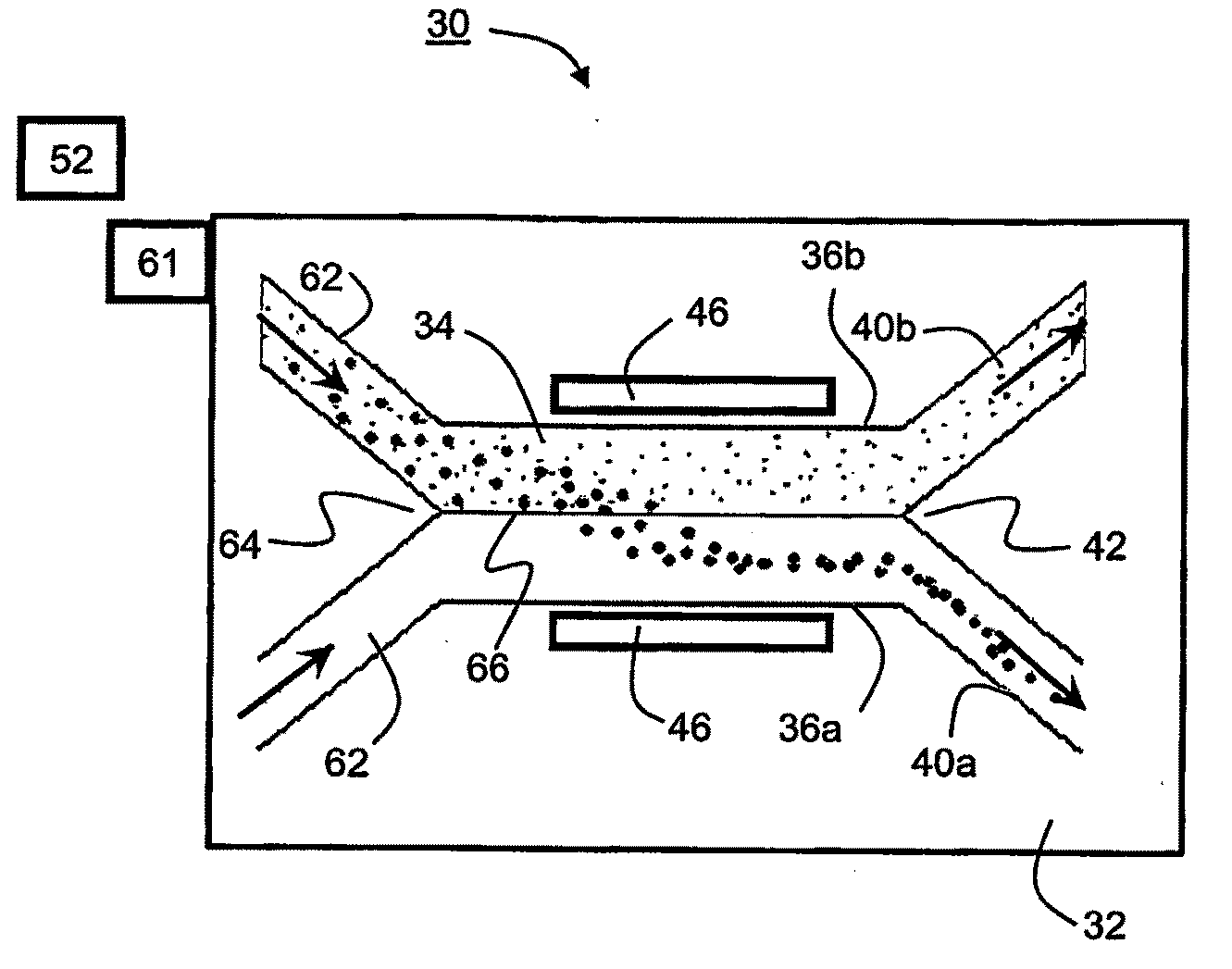

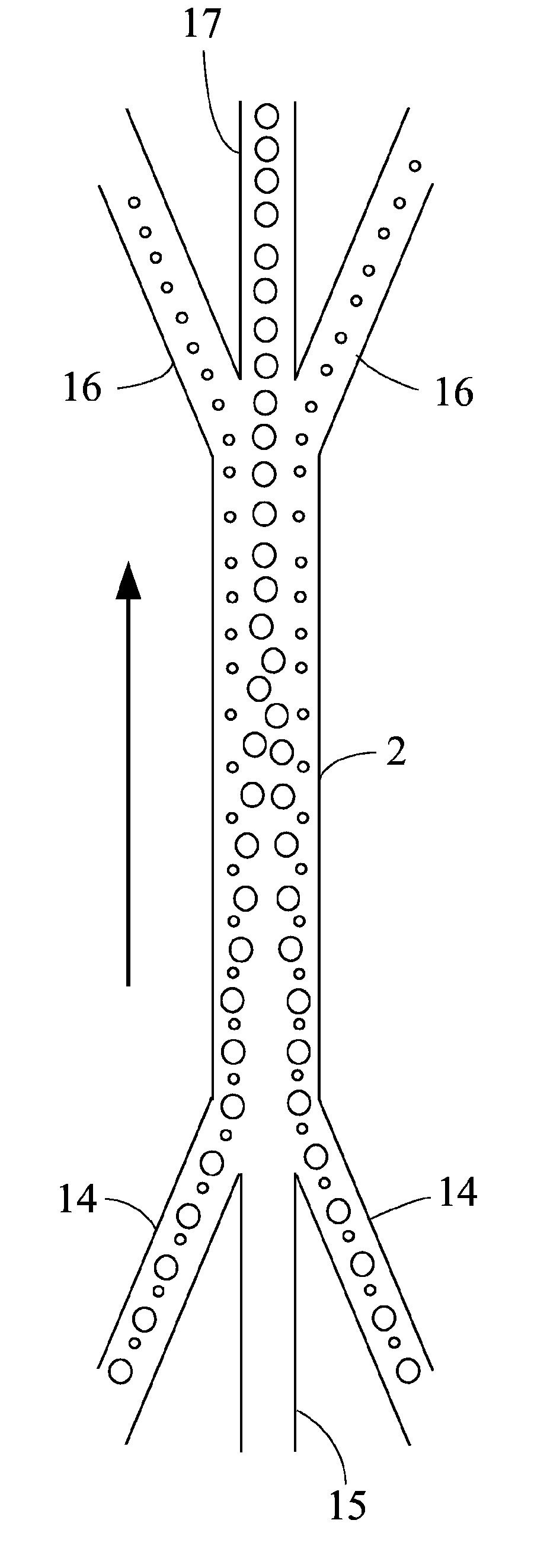

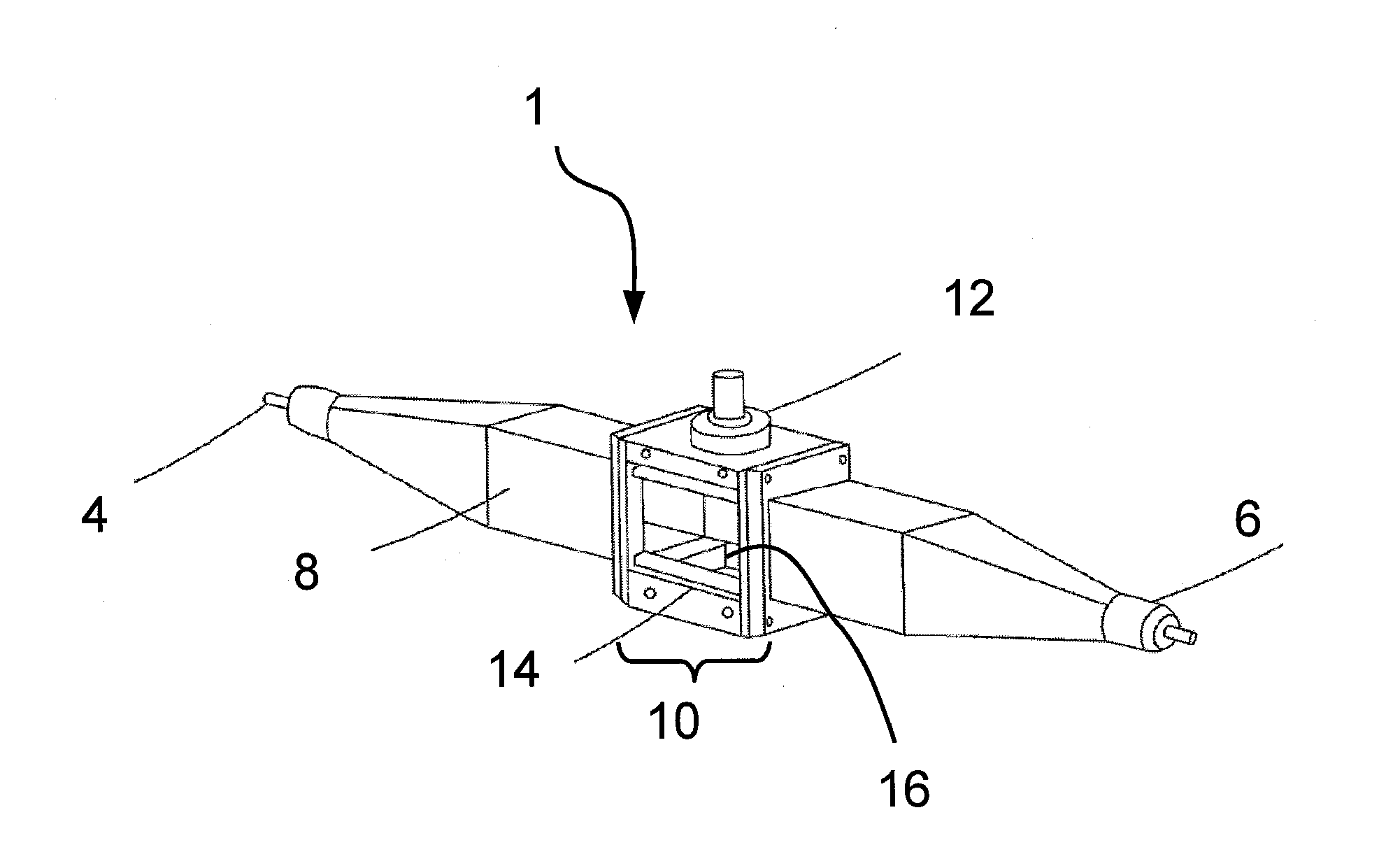

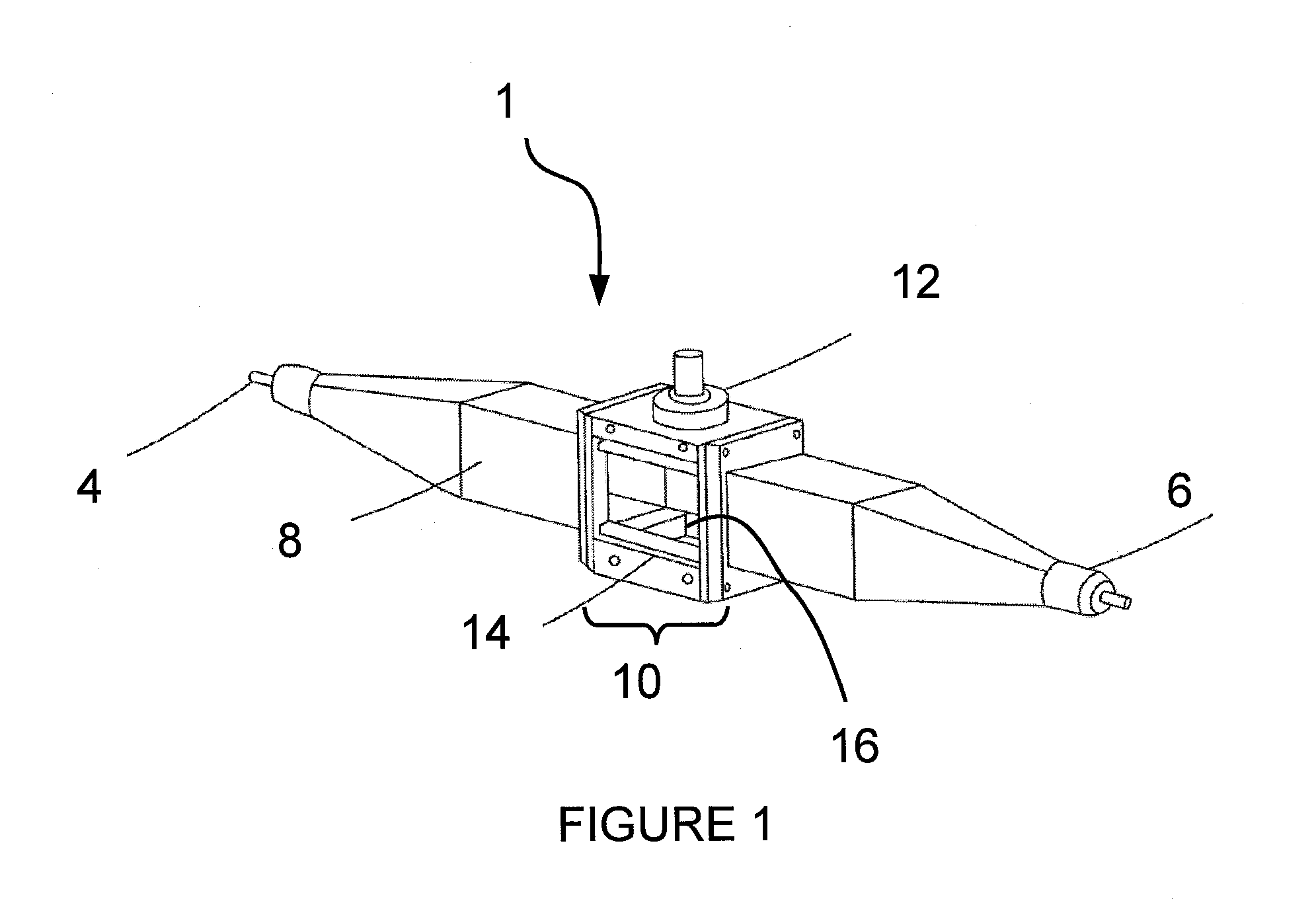

Method and device for ultrasonically manipulating particles within a fluid

InactiveUS20060037915A1Easy to operateAuxillary pretreatmentShaking/oscillating/vibrating mixersSolid phase extractionBiological particles

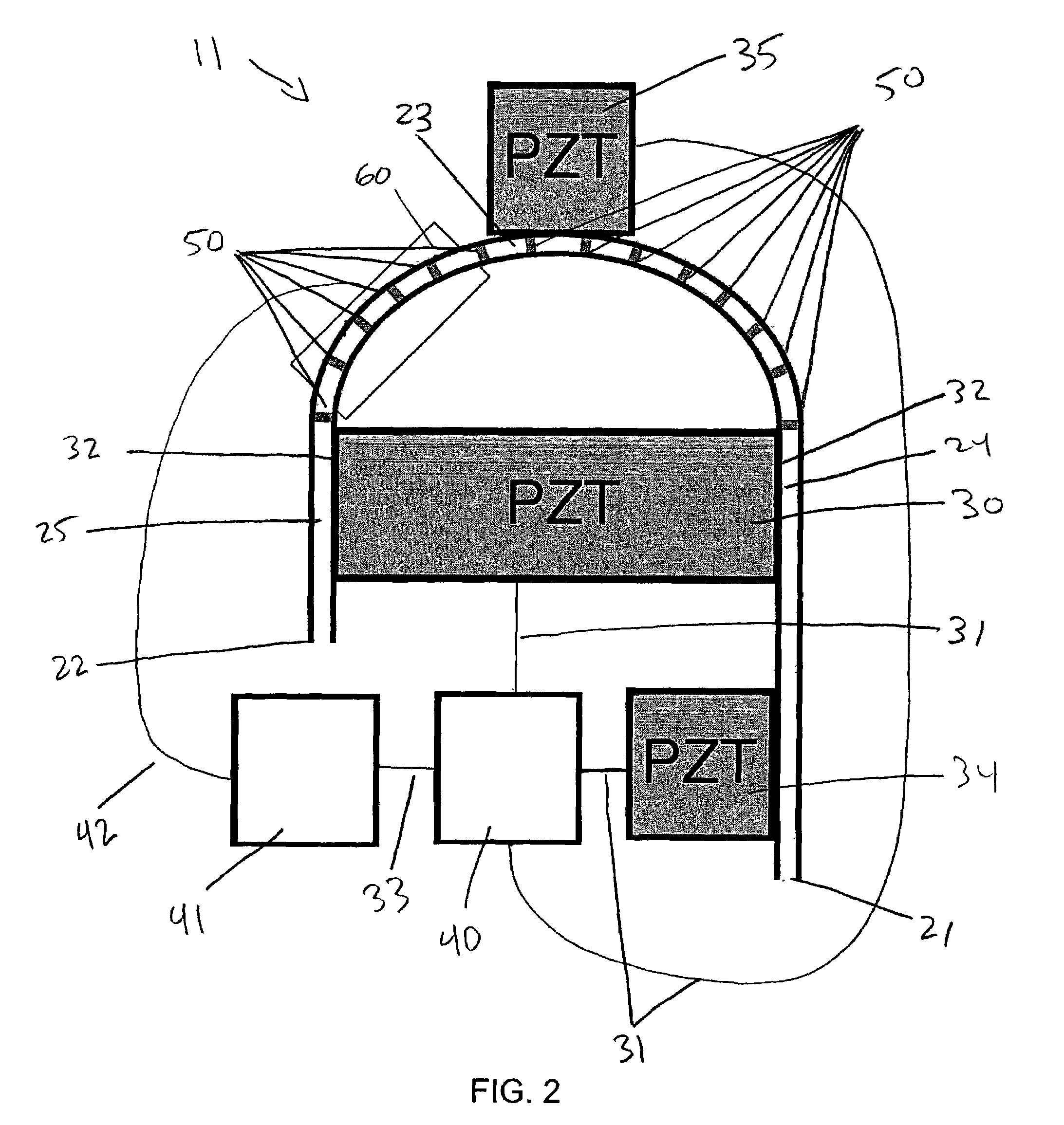

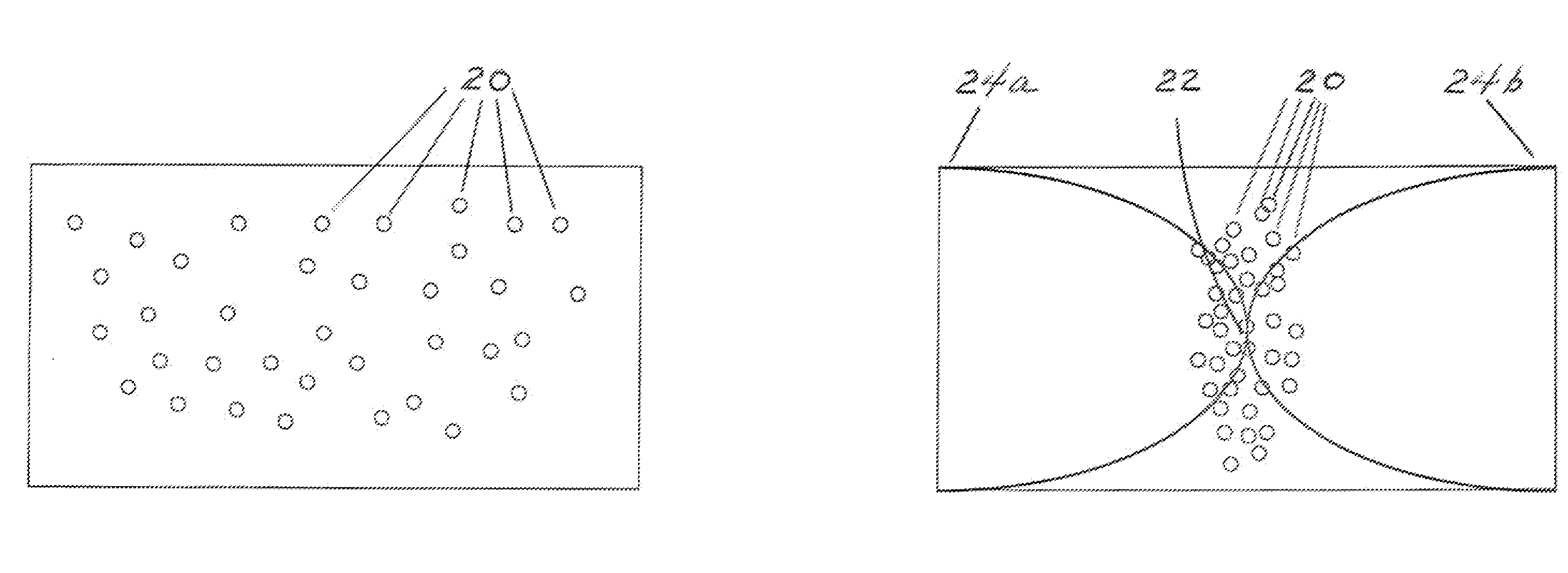

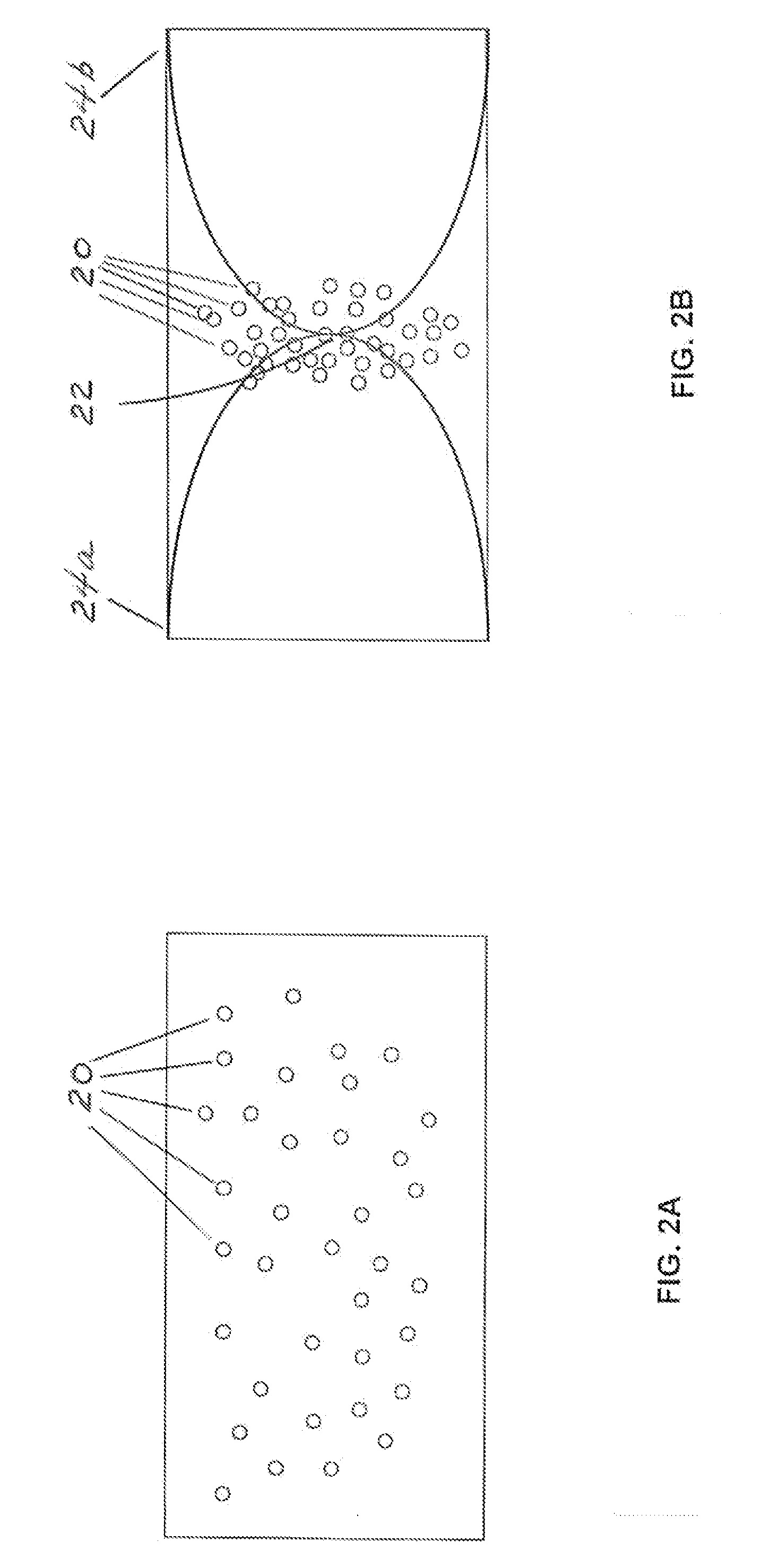

Fluid-handling methods and devices for ultrasonic manipulation of fluid-borne particles comprise a fluid-handling manifold and an ultrasonic particle manipulator defining an ultrasonic cavity within the manifold. Fluid-borne particles introduced into the manifold are manipulated by controlling ultrasonic standing waves at the ultrasonic cavity. Cavities having non-uniform configurations, asymmetric standing waves and / or multiple ultrasonic cavities within the manifold are operative to control the movement of the fluid-borne particles, optionally including collecting and holding such particles, transferring particles through an intersection from one channel to another, etc. Solid phase extraction (SPE) particles, biological particles and other fluid-borne particles can be manipulated within the fluid-handling manifold.

Owner:PROTASIS CORP

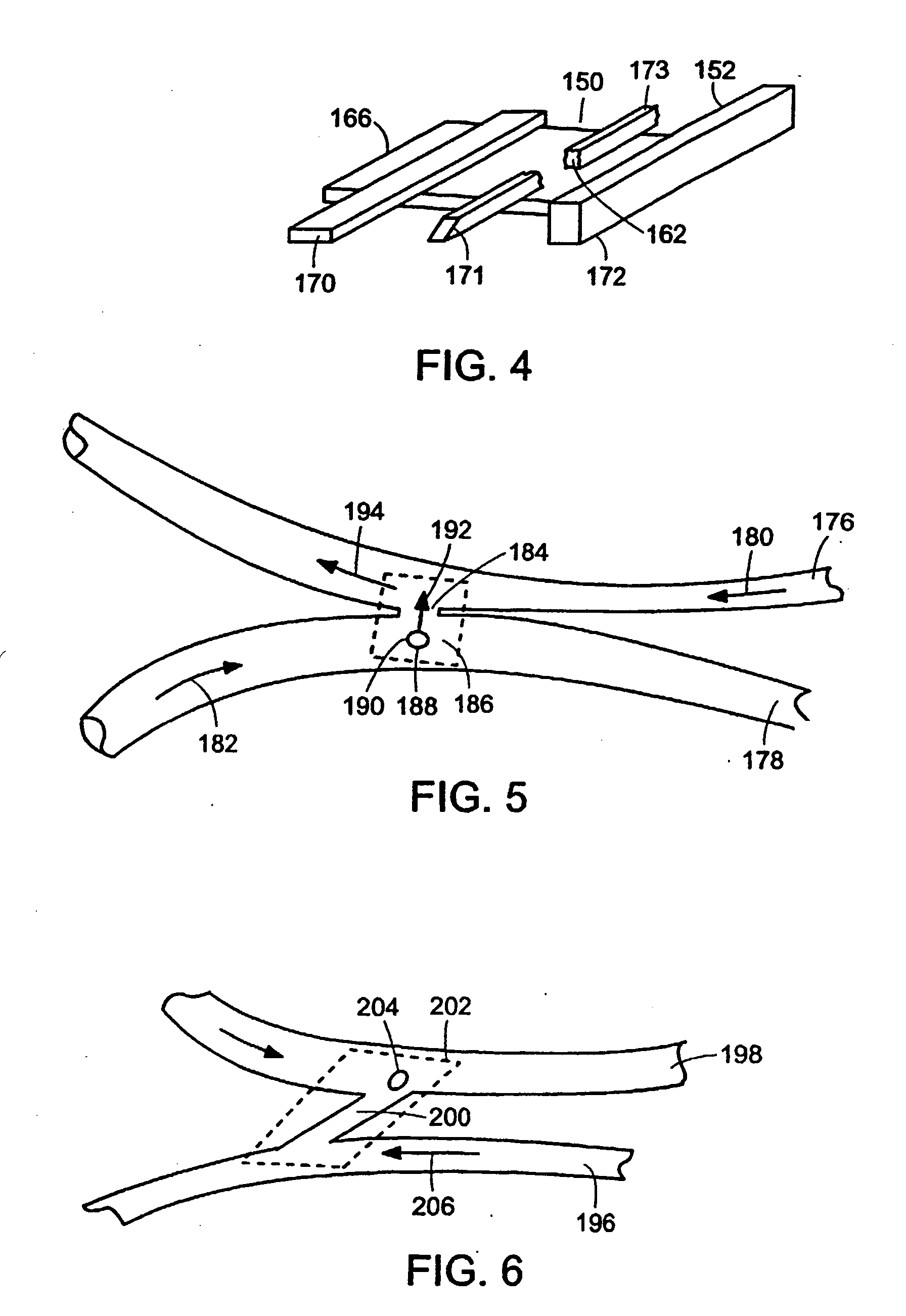

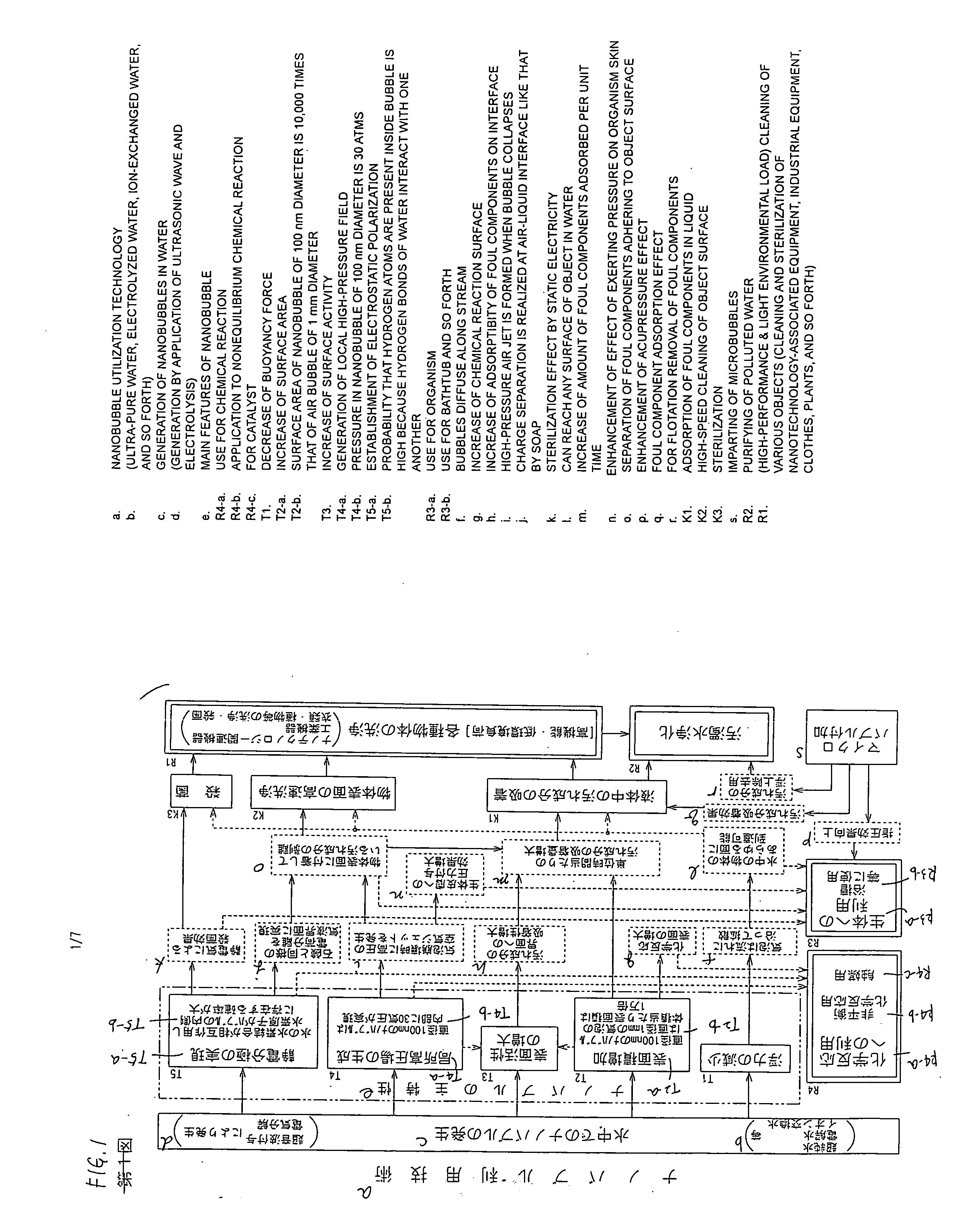

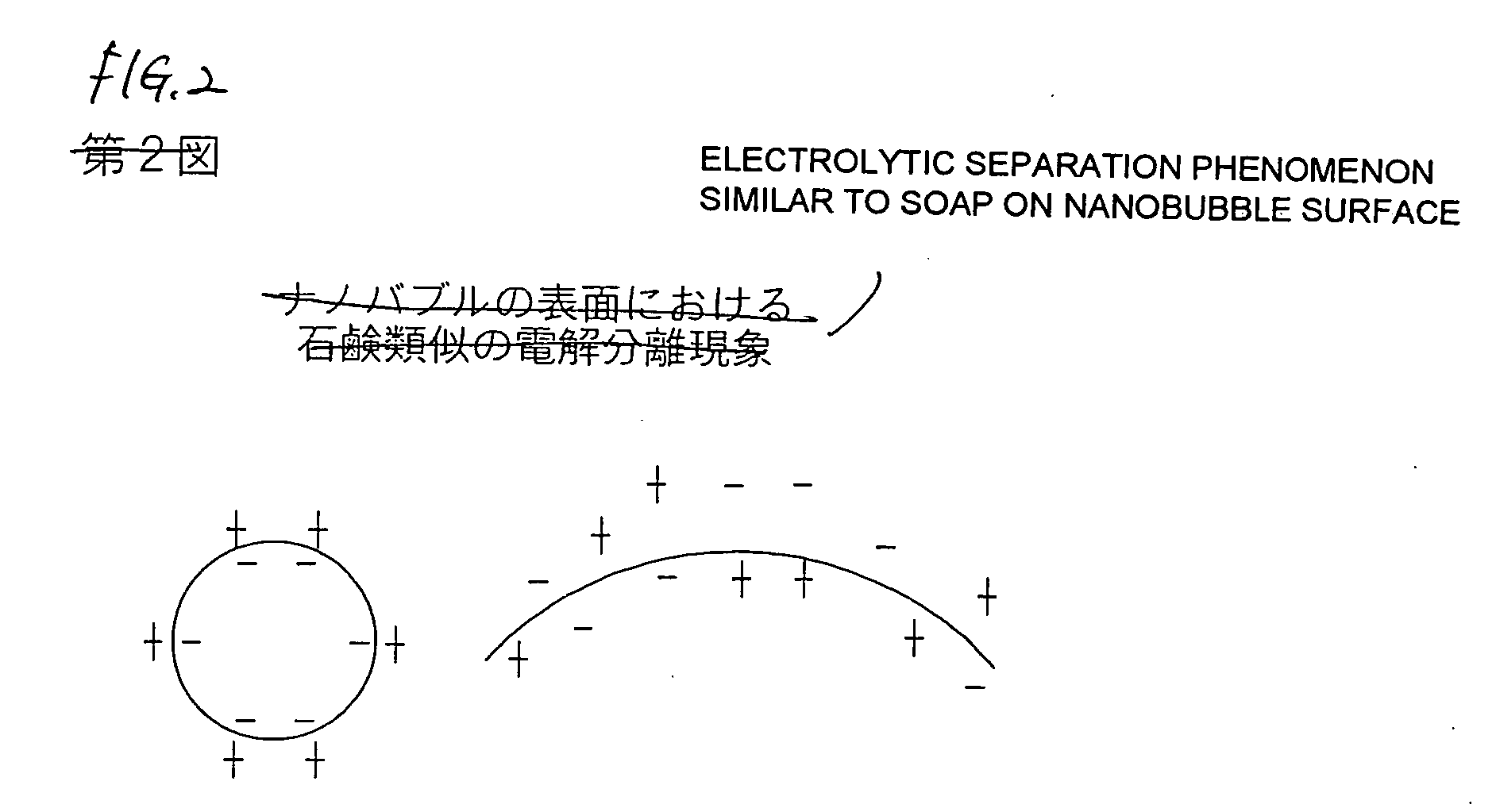

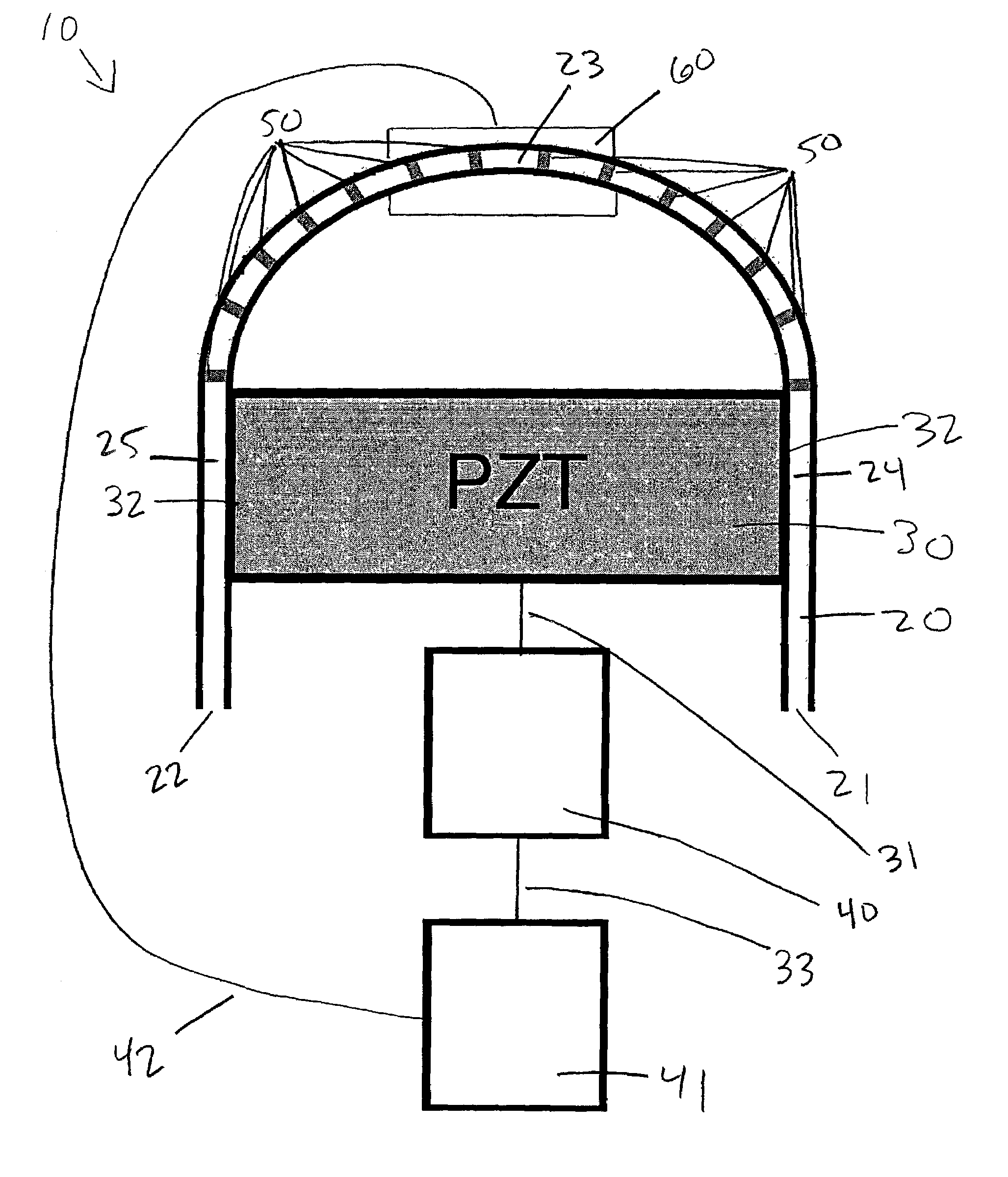

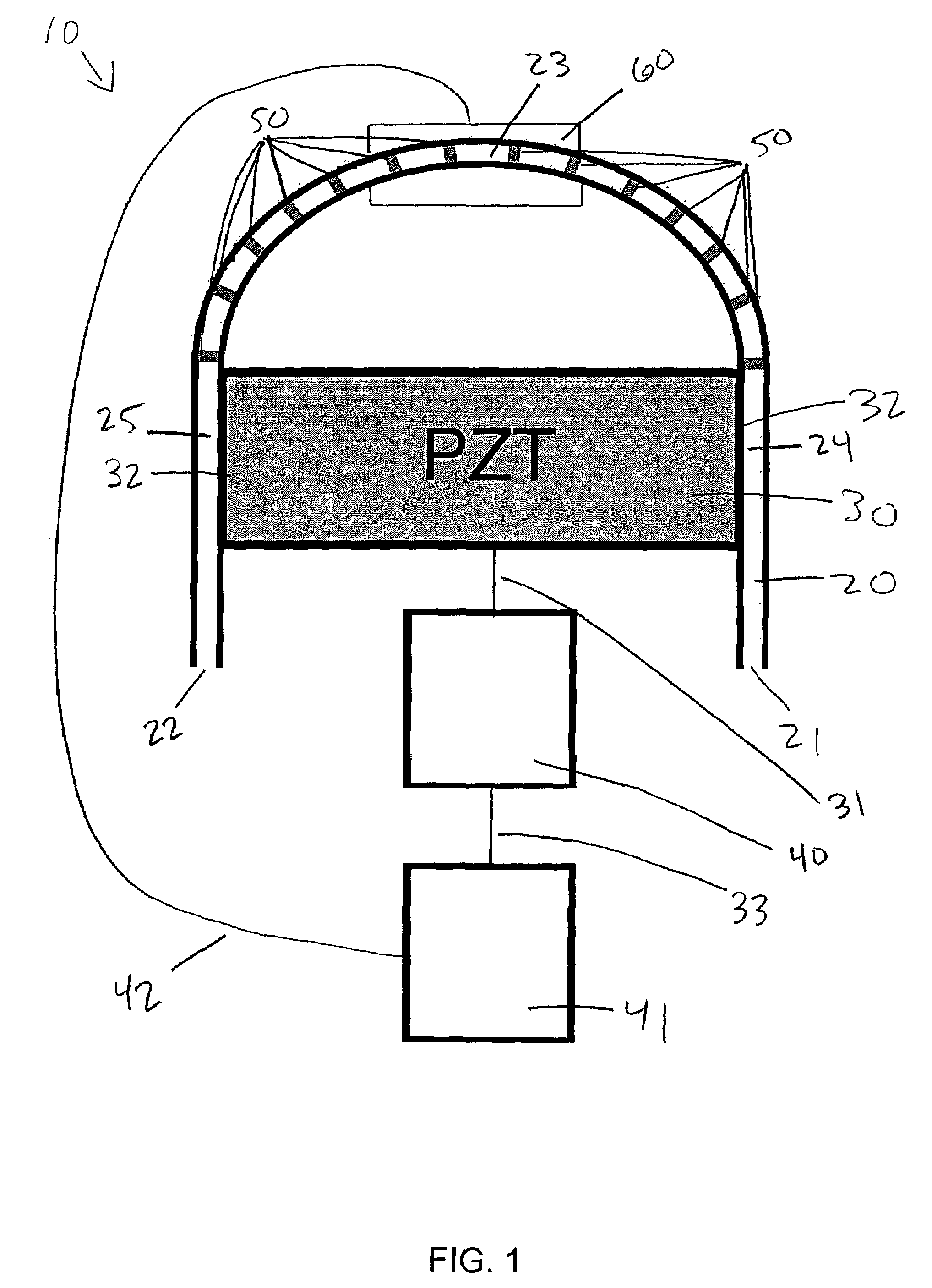

Nanobubble utilization method and device

InactiveUS20060054205A1Efficient use ofFast cleaningMaterial nanotechnologyVibration massageBiological bodyChemical reaction

The present inventors have found the presence of a nanobubble that has not been confirmed conventionally, and established a method for producing nanobubbles. The inventors have determined the theoretically expected characteristics of the produced nanobubbles, found new characteristics by analyzing data experimentally collected, and elucidated the relationship among the characters. Specifically, the inventors have found that a nanobubble has features such as decrease of the buoyant force, increase of the surface area, increase of the surface activity, generation of a local high-pressure field, interface activating action, and sterilizing action thanks to electrostatic polarization. By the association among the features, any of wide variety of objects can be cleaned with high performance and with light environmental load thanks to the function of adsorbing foul components, the function of cleaning the surface of an object quickly, and the sterilizing function, and polluted water can be purified. Nanobubbles can be applied to an organism to recover from fatigue and effectively used for chemical reactions.

Owner:NAT INST OF ADVANCED IND SCI & TECH

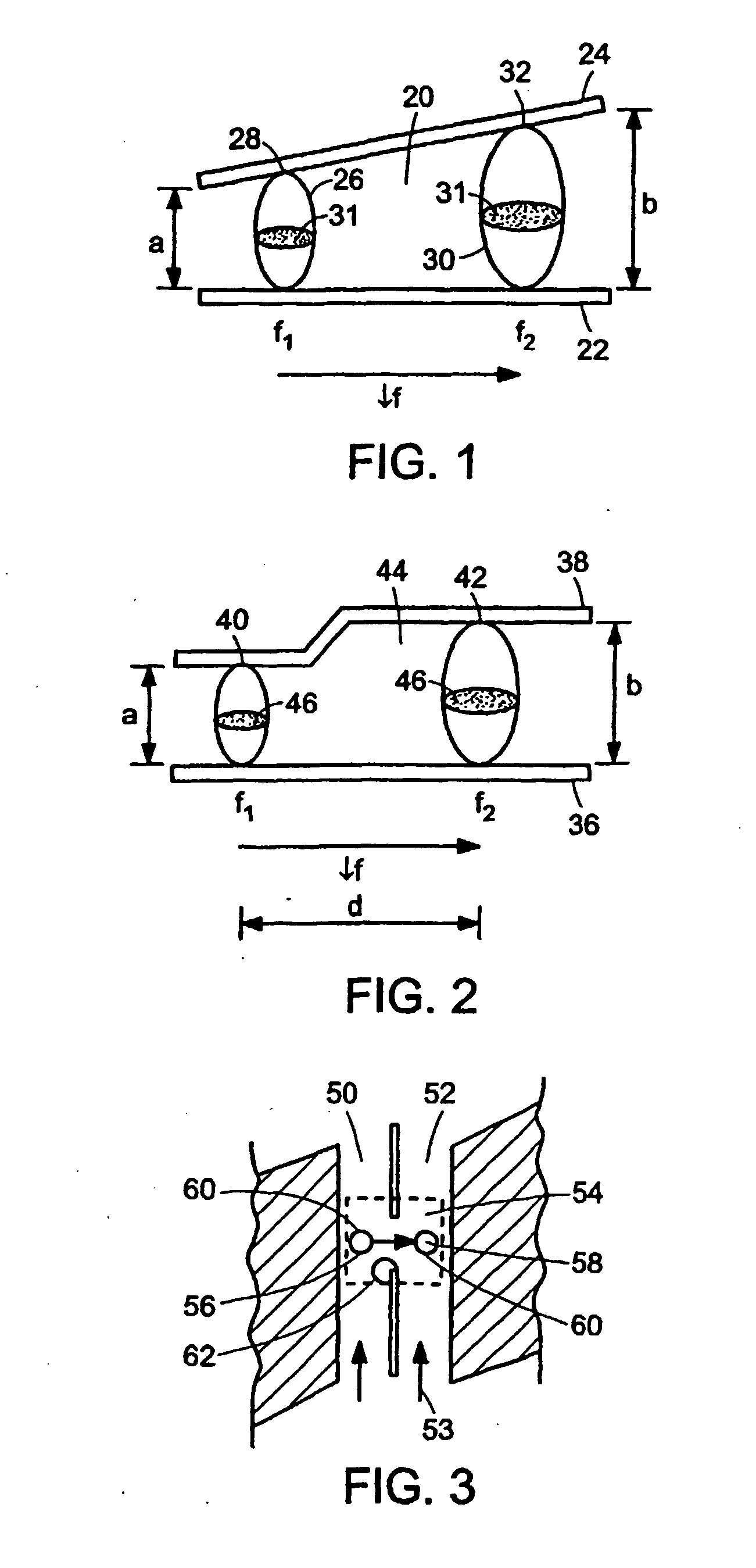

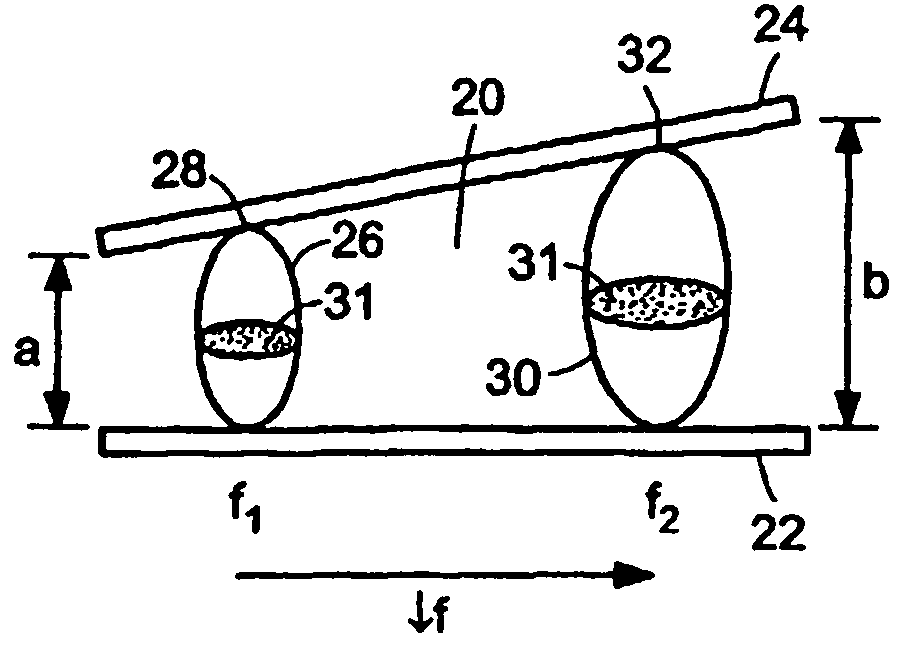

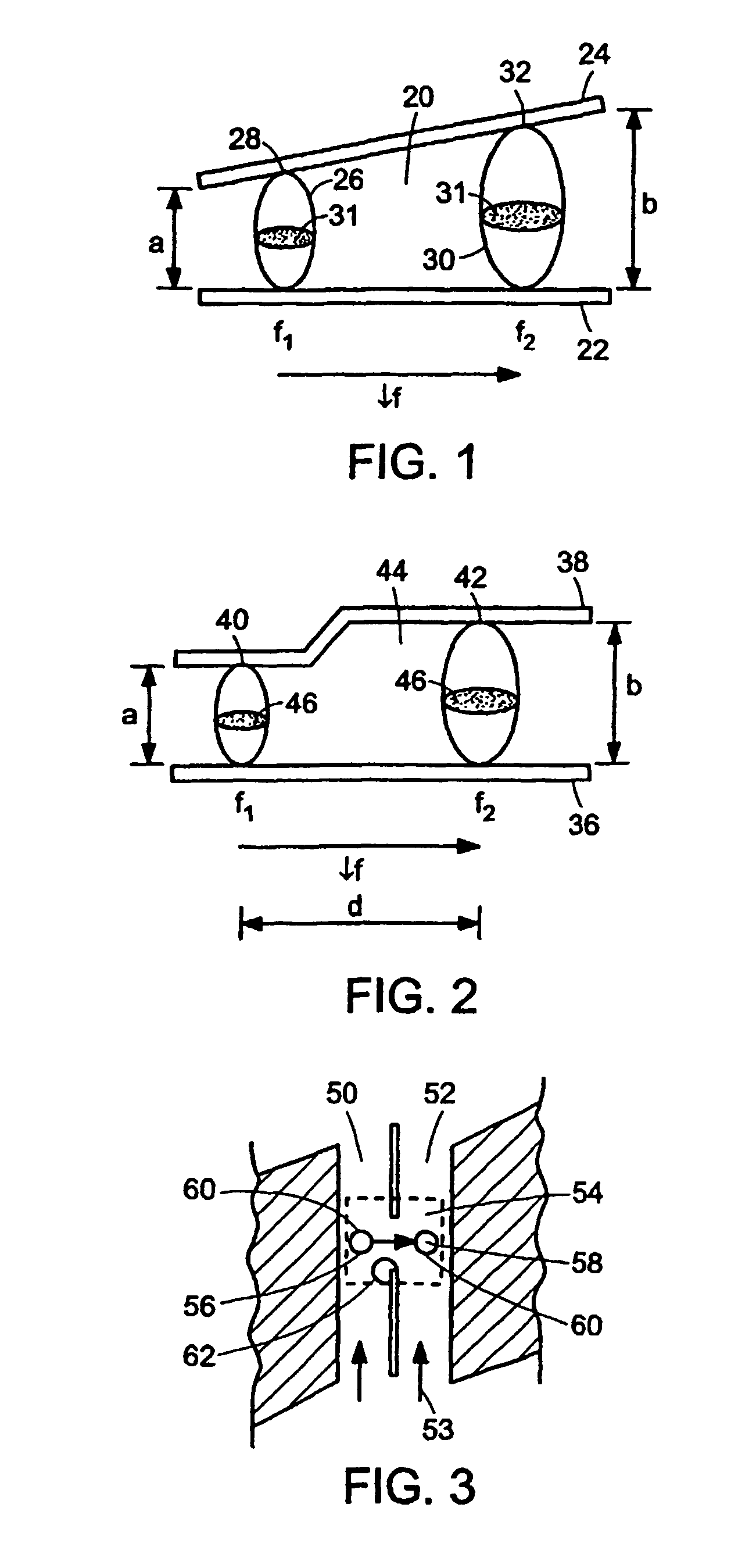

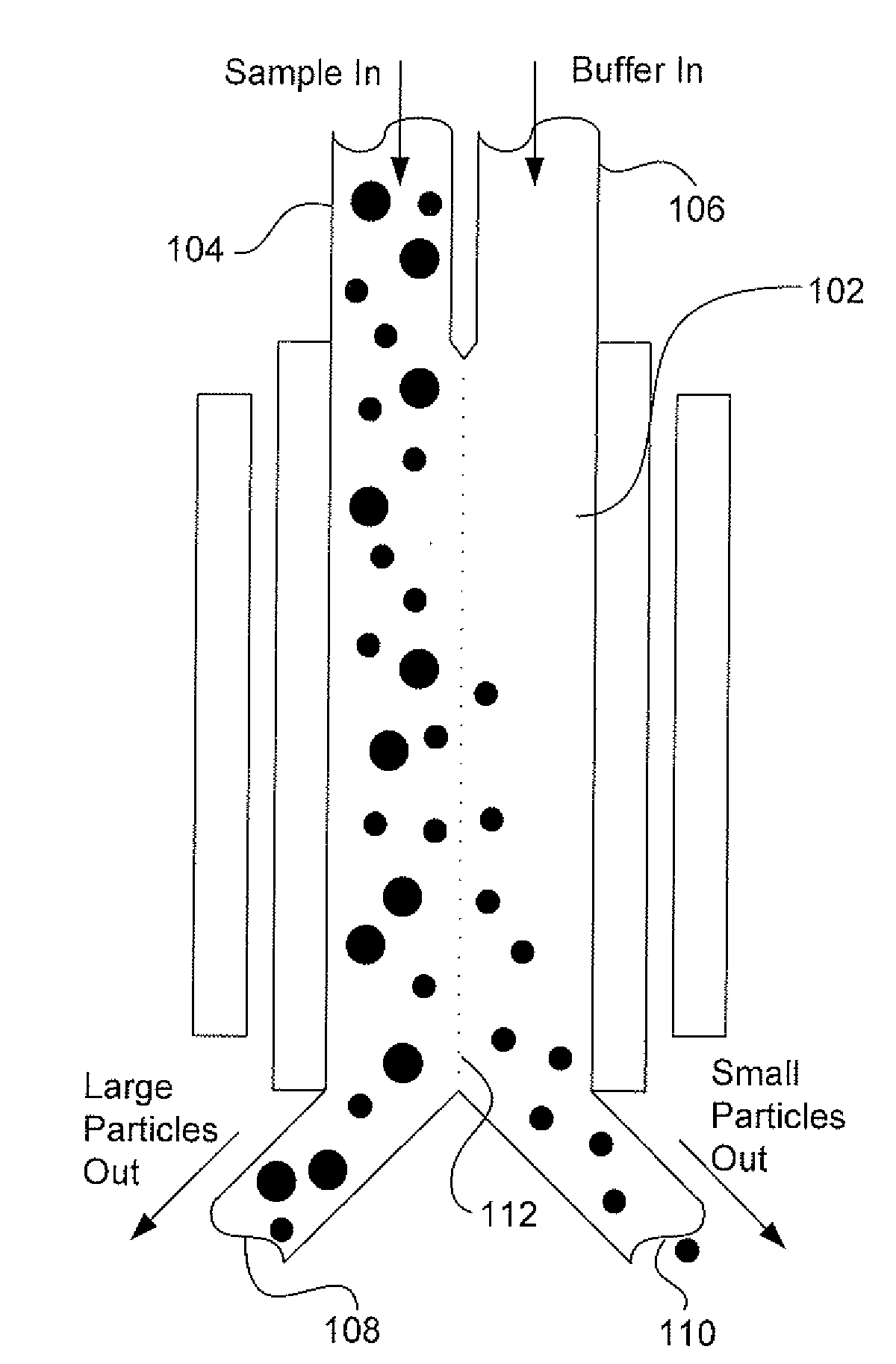

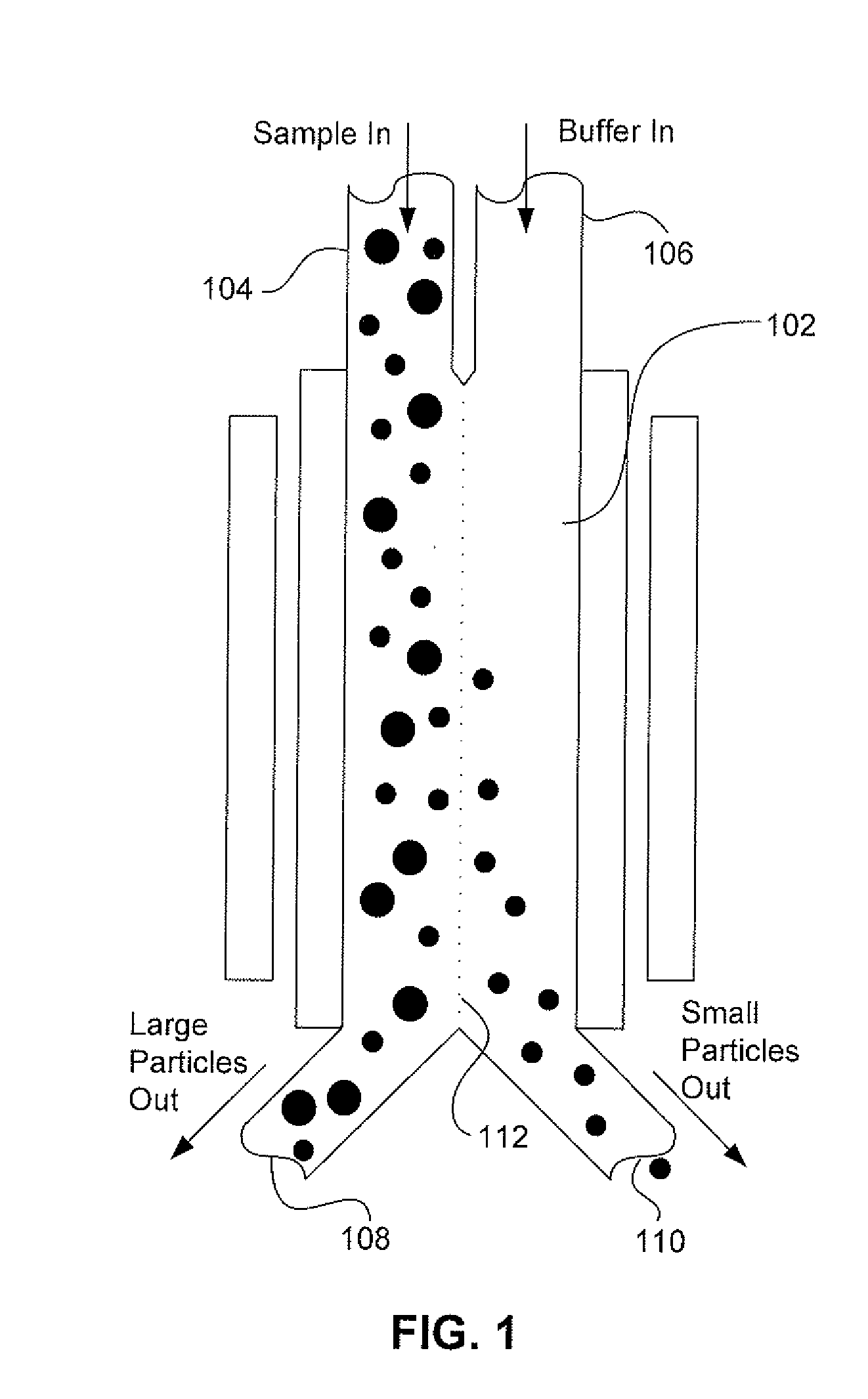

Method and apparatus for separating particles by size

InactiveUS7108137B2Easy to manufactureLow costWater/sewage treatment with mechanical oscillationsParticle size analysisUltrasonic radiationHigh pressure

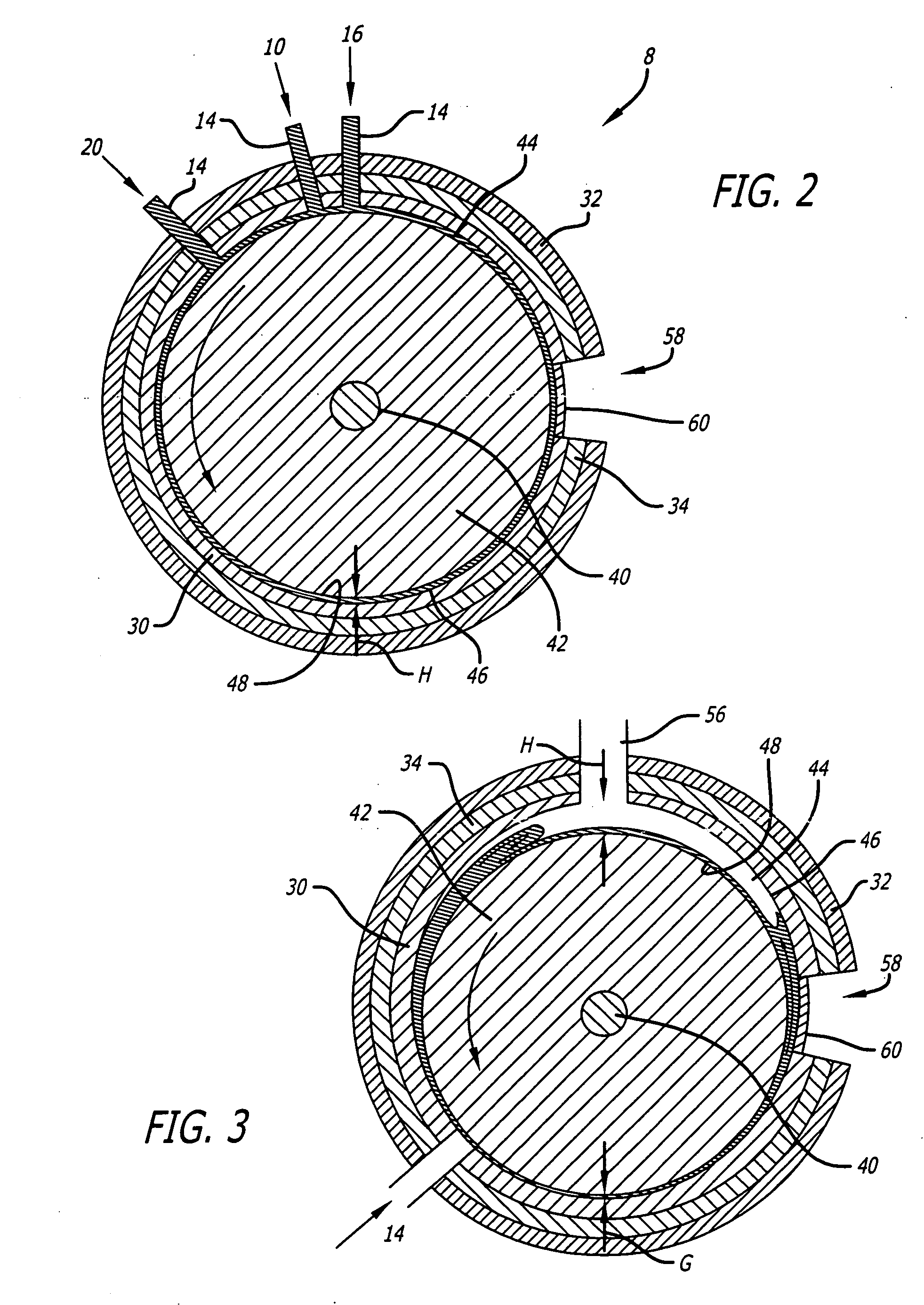

A method and apparatus for separating a mixture of particles of various sizes in a capillary tube into groups by size using multiple forces of controlled amplitude. Ultrasonic radiation at a first selected frequency is applied to set up a standing pressure wave in the capillary tube, resulting in a first aggregating force which causes particles of all sizes to aggregate at positions within the capillary tube which correspond to nodes or anti-nodes of the standing wave. Transverse vibrations are also applied to the capillary tube. The frequency of the ultrasonic radiation is adjusted to reduce the magnitude of the first aggregating force. Inertial forces resulting from the transverse vibrations then cause the particles to separate by size. The apparatus and method allows a mixture of particles to be separated by size quickly, without requiring the use of high voltages.

Owner:WISCONSIN ALUMNI RES FOUND

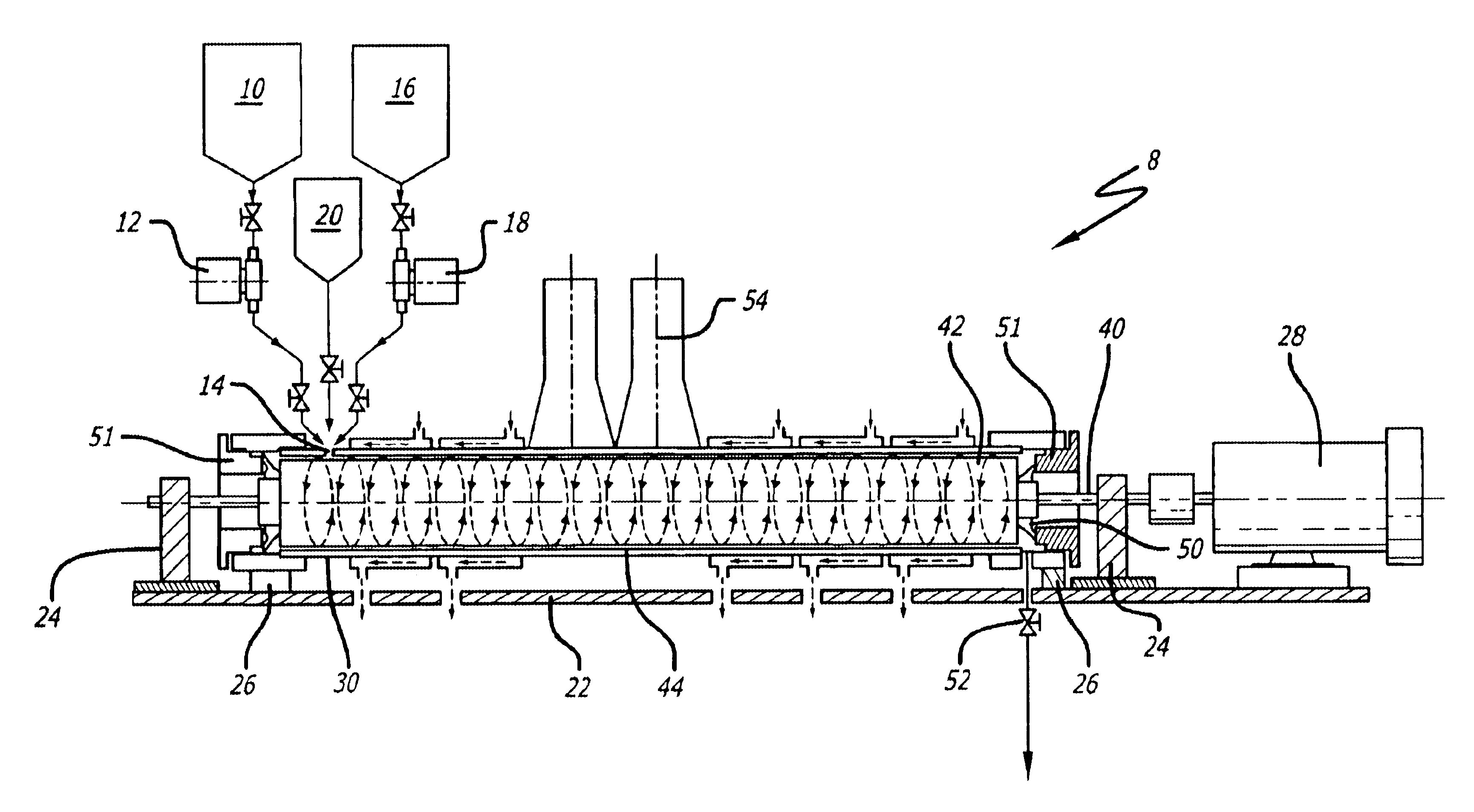

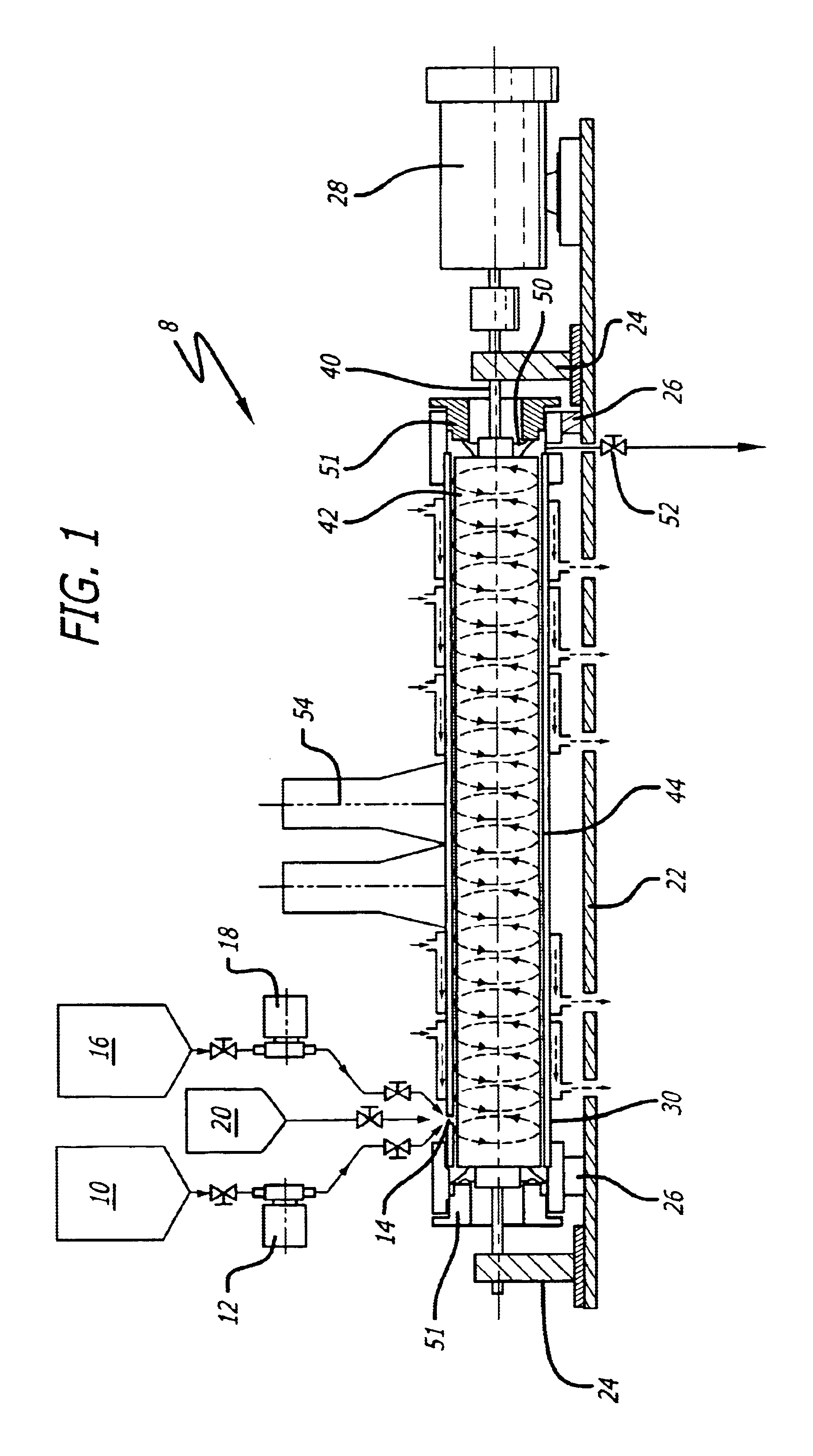

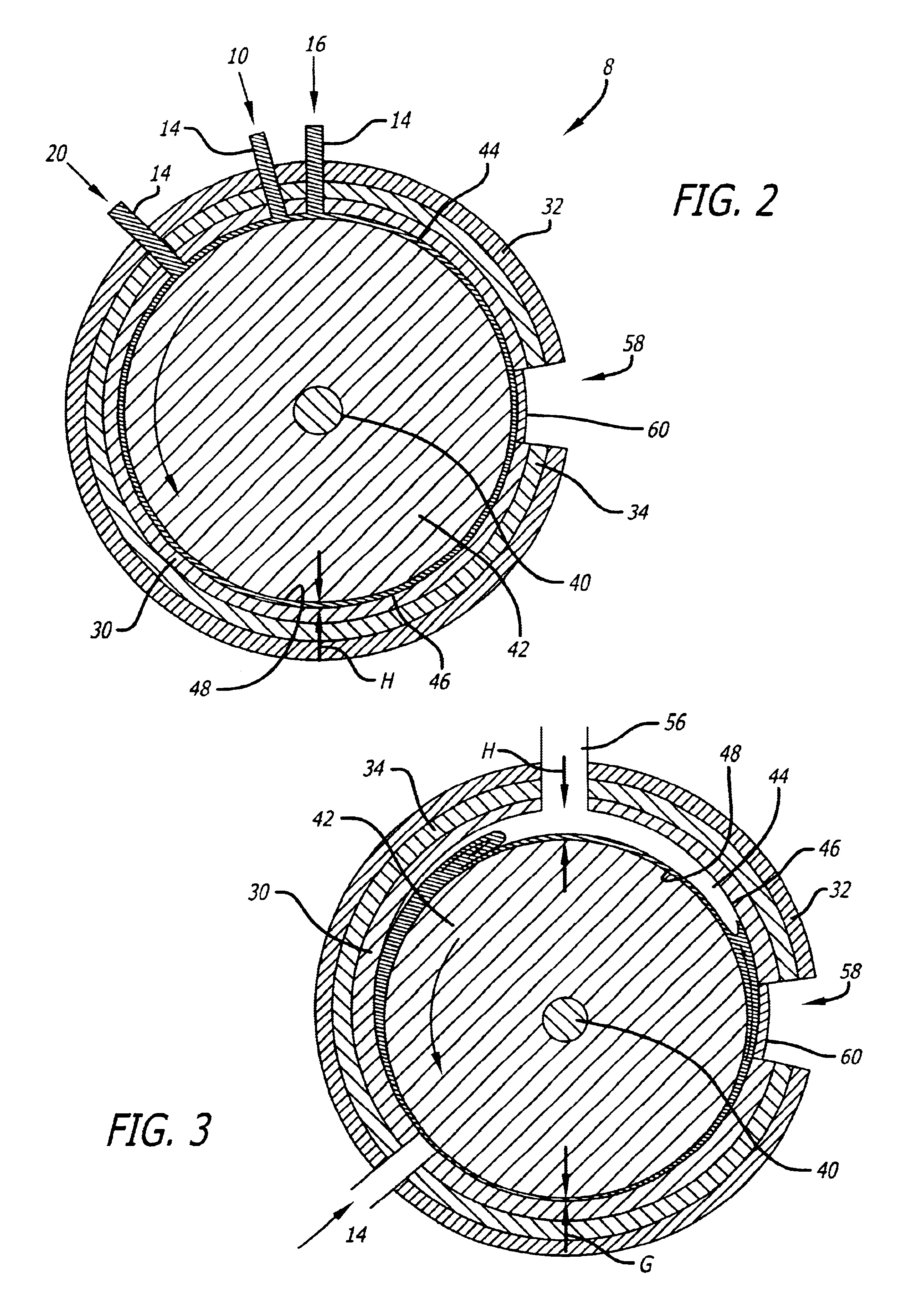

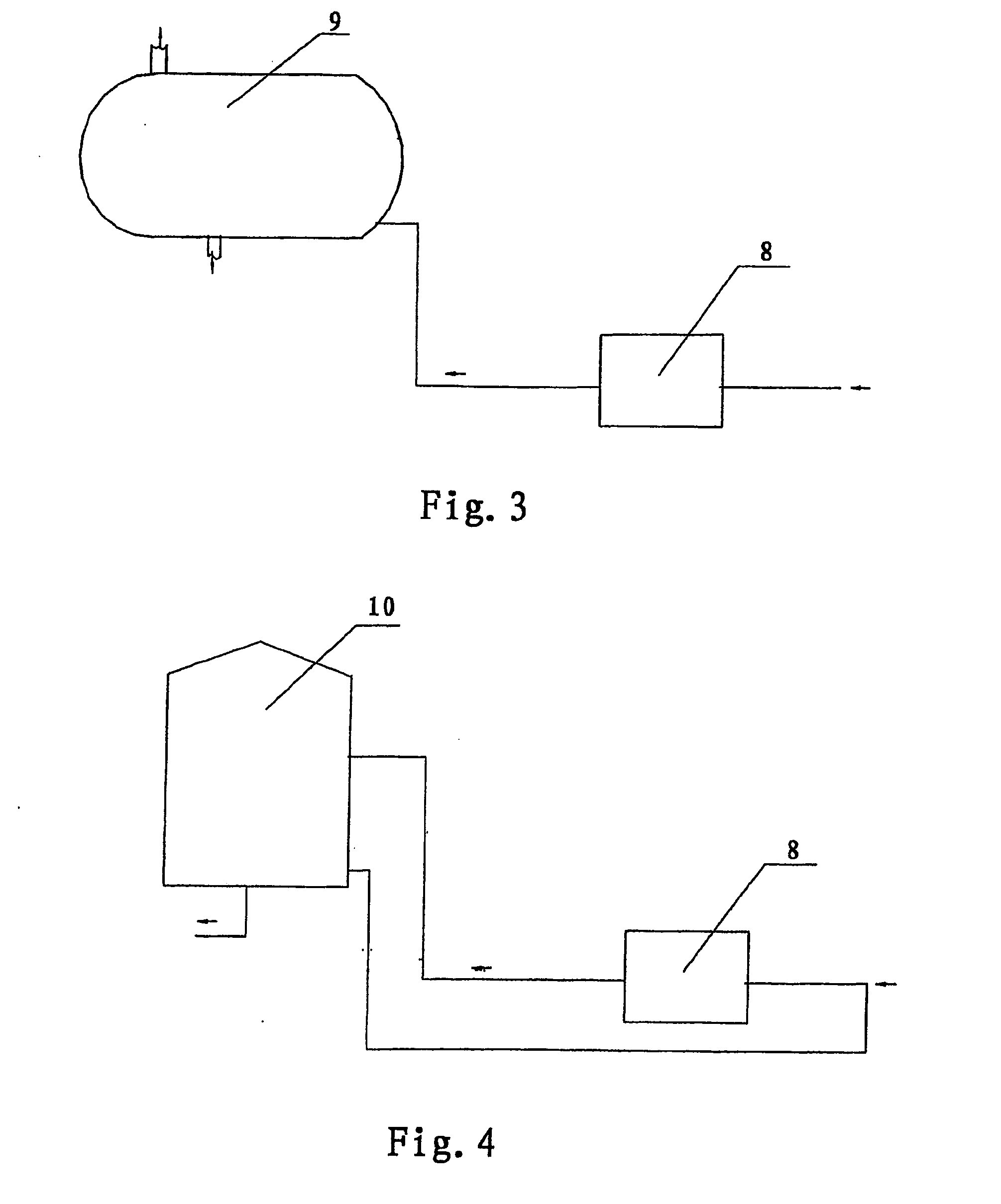

Process for high shear gas-liquid reactions

InactiveUS20050033069A1Superior and economical and efficientImprove responseRotary stirring mixersTransportation and packagingGas liquid reactionChemical reaction

A process for performing a chemical reaction between a plurality of chemical reactants in the presence of a catalyst, with at least a first reactant in a liquid phase and at least a second reactant in a gas phase, the first and second reactants mixing at least by interdiffusion. The process comprises supplying the reactants to a passage defined by a first surface and a second surface and optionally moving at least one of the first surface and second surface relative to each other. The reactants their mixture or reaction products form respective boundary layers against the first and second surfaces and the radial spacing between the first surface and second surface is equal to or less than the back-to-back radial thicknesses of the boundary layers.

Owner:323 TRUST +1

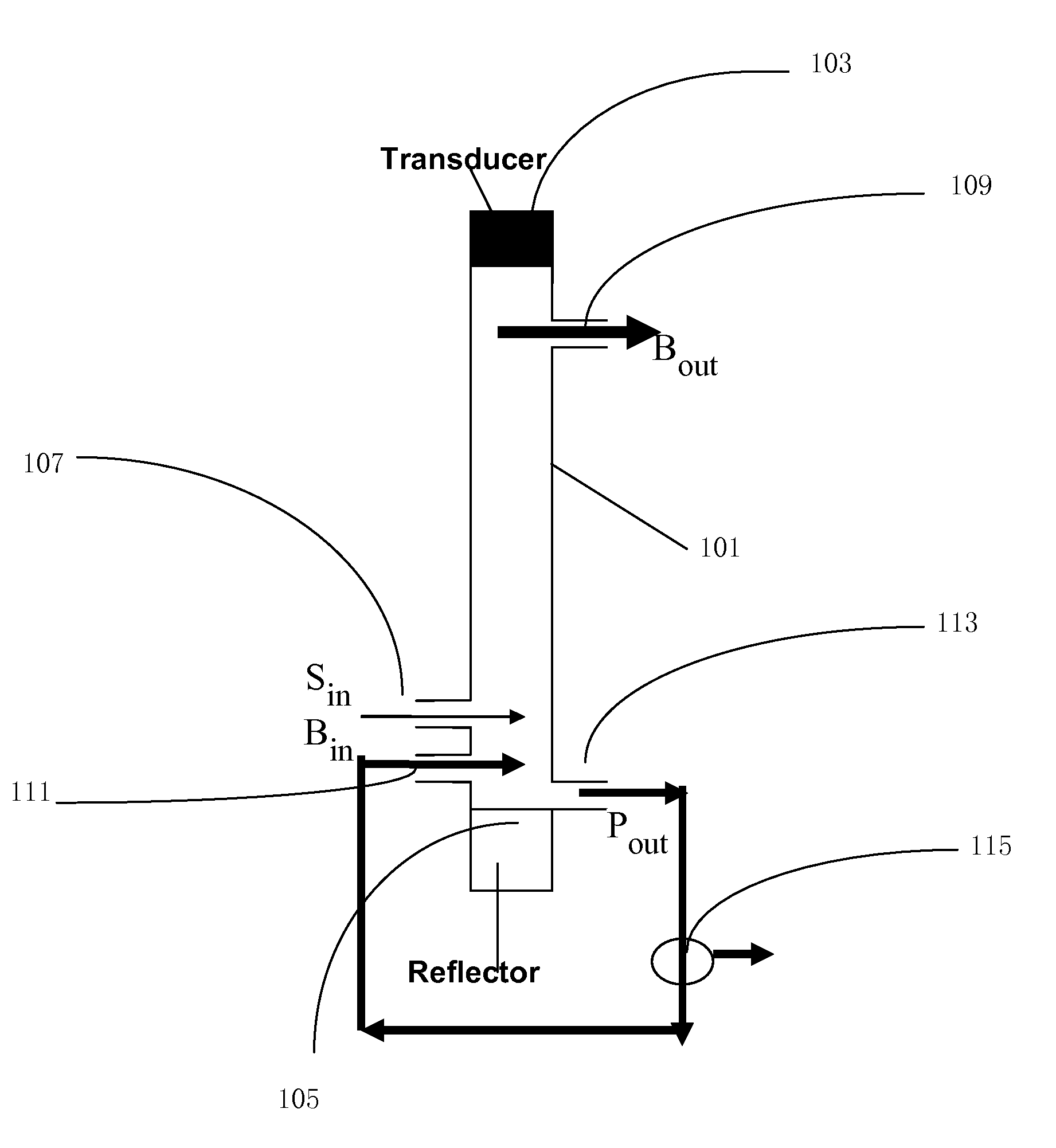

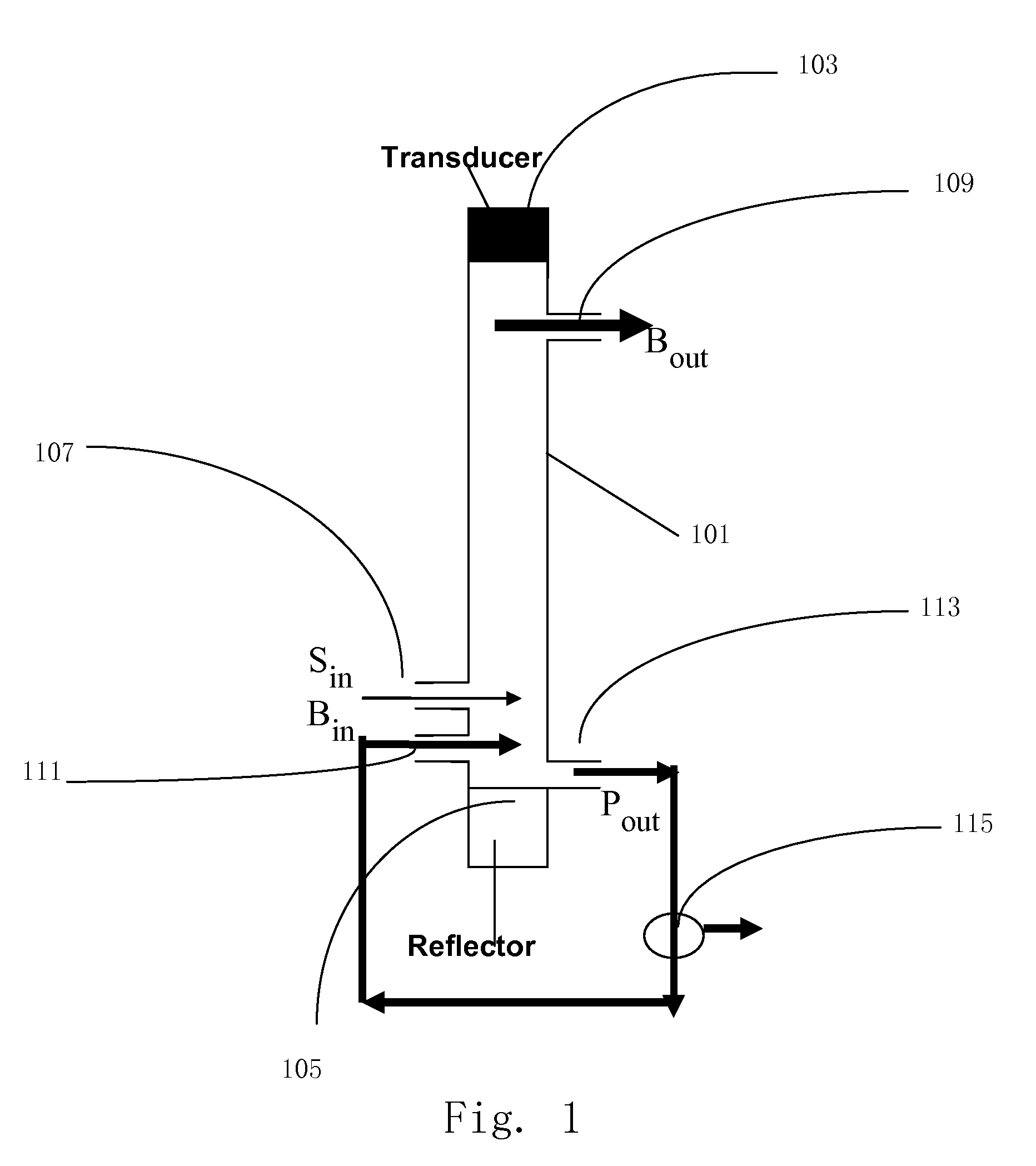

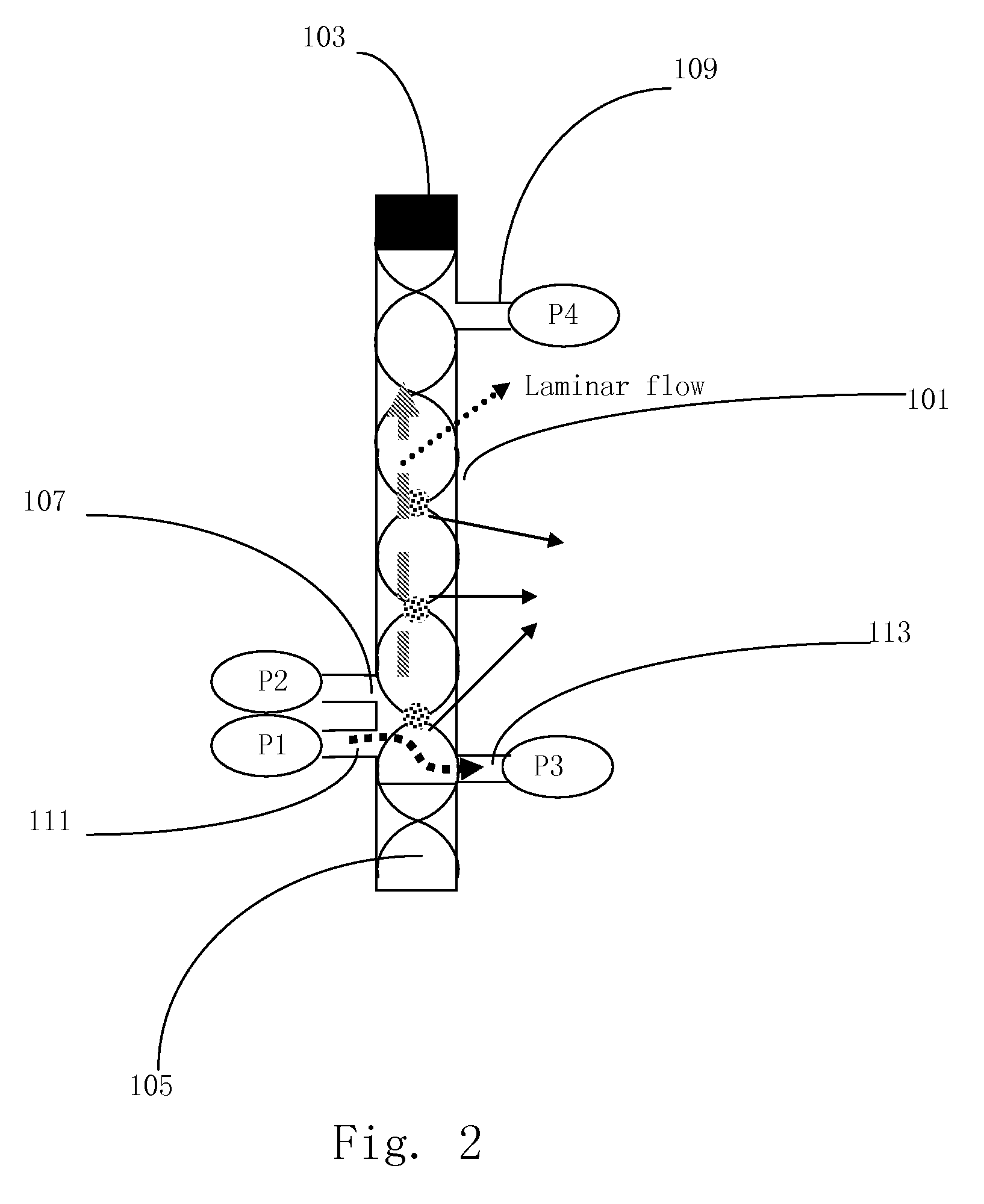

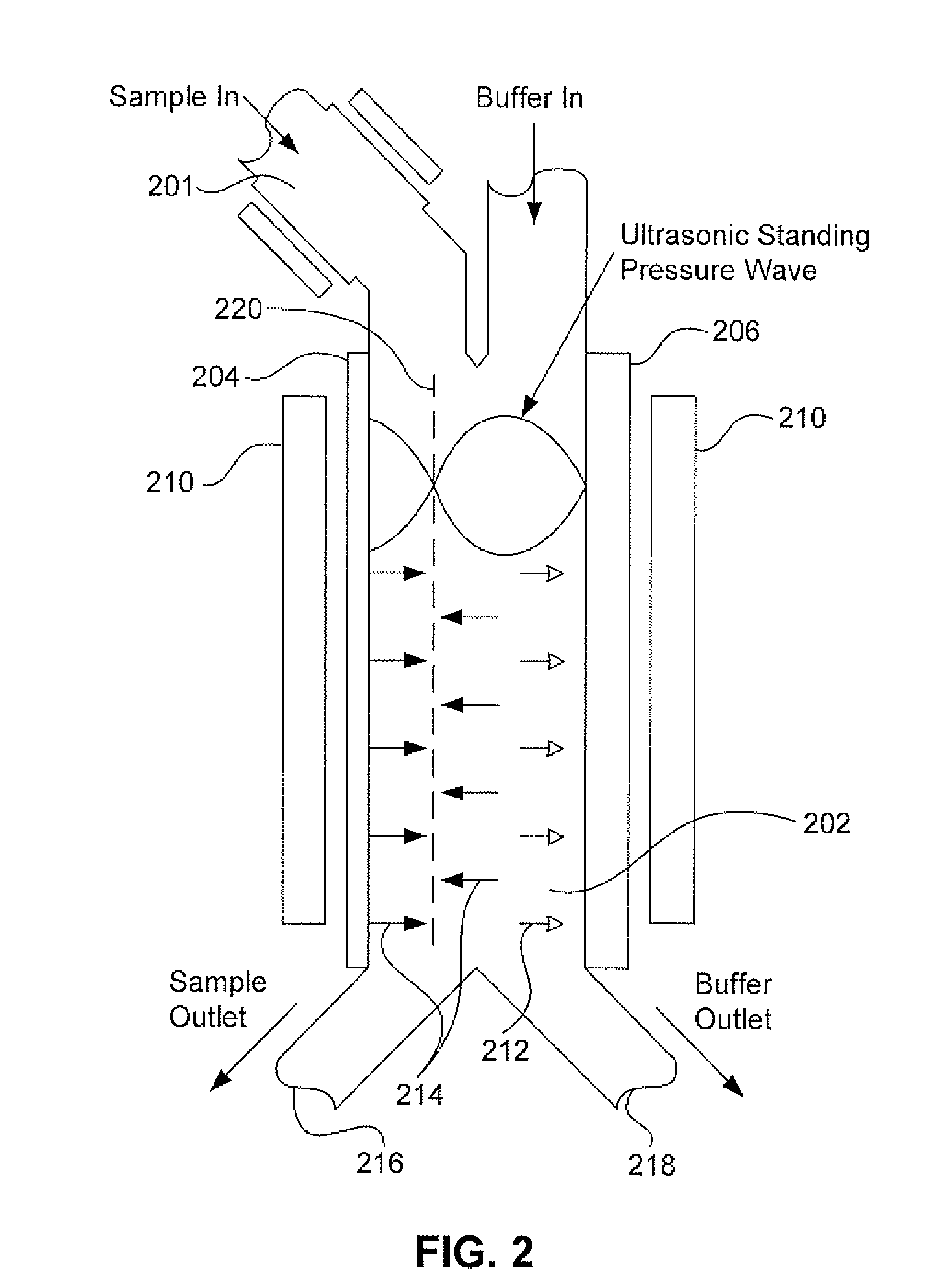

Apparatus and method for separation of particles suspended in a liquid from the liquid in which they are suspended

InactiveUS20100078384A1Improve concentrationAvoid turbulenceSemi-permeable membranesLiquid separation by electricityUltrasonic sensorCompressibility

A method for separating, or removing, particulate material, e.g., blood cells, from a sample of fluid, e.g., whole blood of a patient, in which the particulate material is suspended. In the case of separating blood cells from blood plasma or blood serum, the resulting samples of blood plasma or blood serum can be used for in vitro diagnostic applications. In normal practice, a whole blood sample of a patient are provided and then introduced into an apparatus that contains a flow channel. An acoustic field, which contains acoustic standing waves from external ultrasonic transducers, is located within the flow channel. Laminar flow is maintained in the flow channel. Blood cells and platelets are separated from blood plasma or blood serum at the end of the flow channel and collected. The method described herein allows fluid components to differentially migrate to areas of preferred acoustic interaction. The parameters that affect separation of particles are size, density, compressibility of the particles, and the fluid surrounding the particles.

Owner:ABBOTT LAB INC

Method for separating single-wall carbon nanotubes and compositions thereof

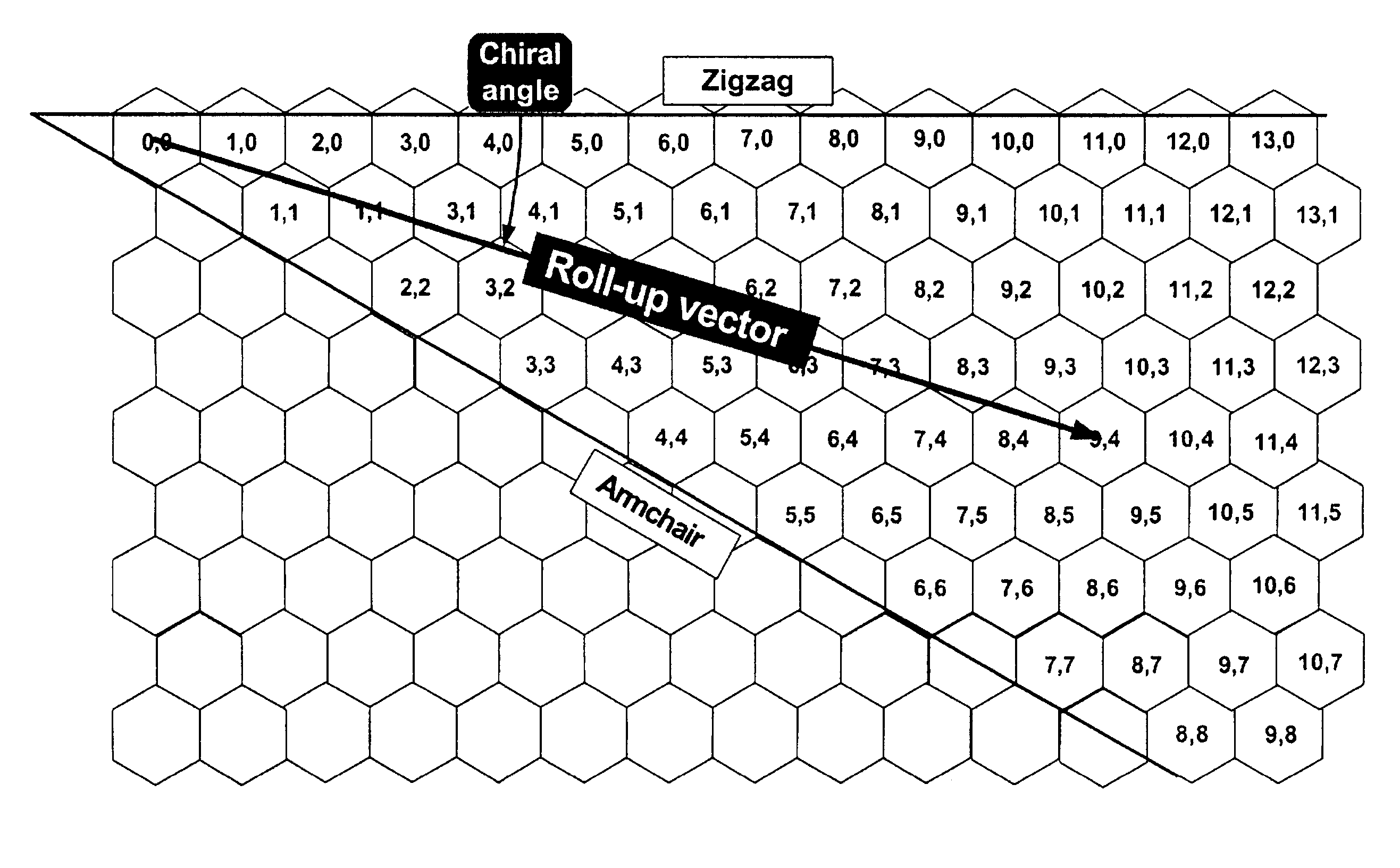

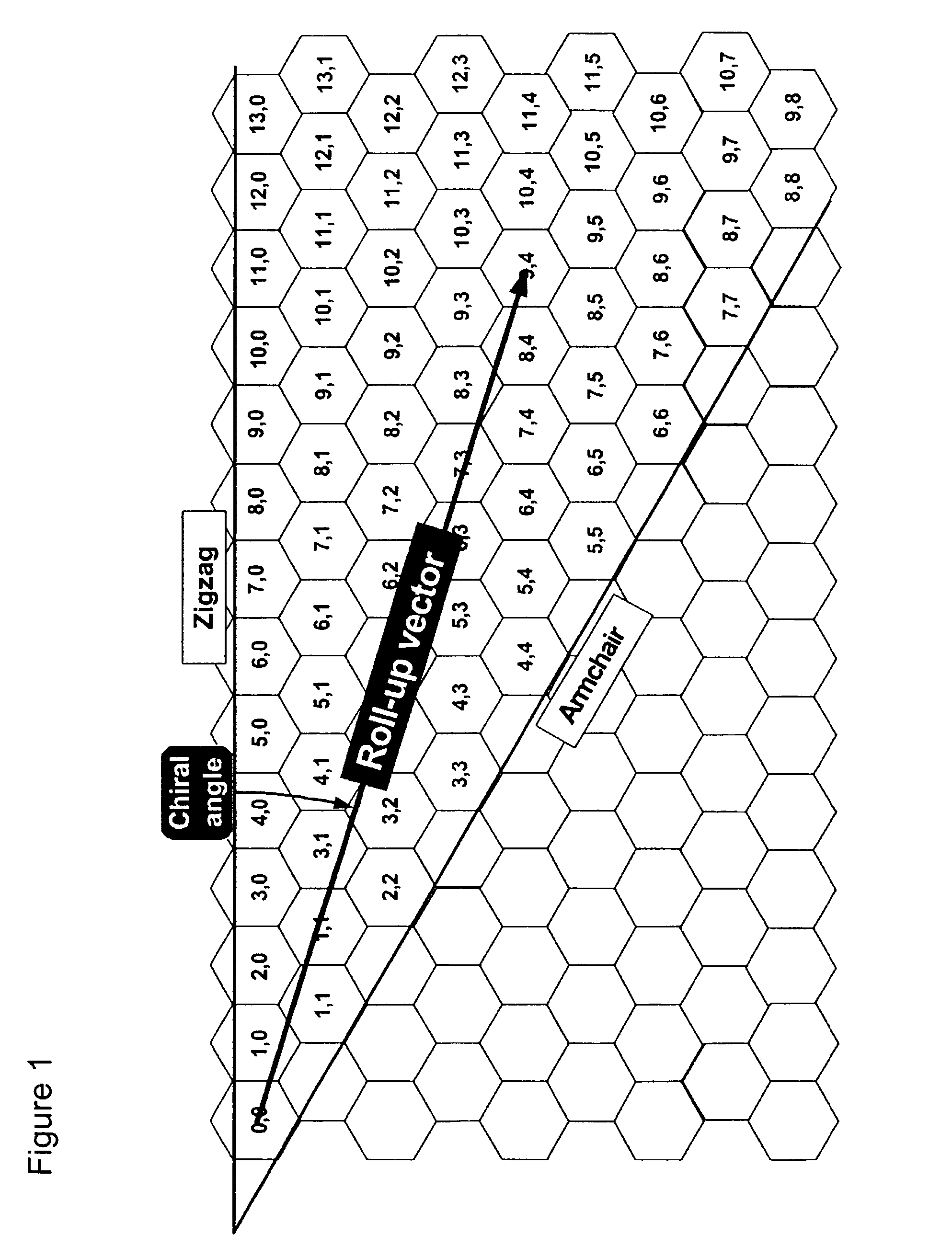

The invention relates to a process for sorting and separating a mixture of (n, m) type single-wall carbon nanotubes according to (n, m) type. A mixture of (n, m) type single-wall carbon nanotubes is suspended such that the single-wall carbon nanotubes are individually dispersed. The nanotube suspension can be done in a surfactant-water solution and the surfactant surrounding the nanotubes keeps the nanotube isolated and from aggregating with other nanotubes. The nanotube suspension is acidified to protonate a fraction of the nanotubes. An electric field is applied and the protonated nanotubes migrate in the electric fields at different rates dependent on their (n, m) type. Fractions of nanotubes are collected at different fractionation times. The process of protonation, applying an electric field, and fractionation is repeated at increasingly higher pH to separated the (n, m) nanotube mixture into individual (n, m) nanotube fractions. The separation enables new electronic devices requiring selected (n, m) nanotube types.

Owner:RICE UNIV

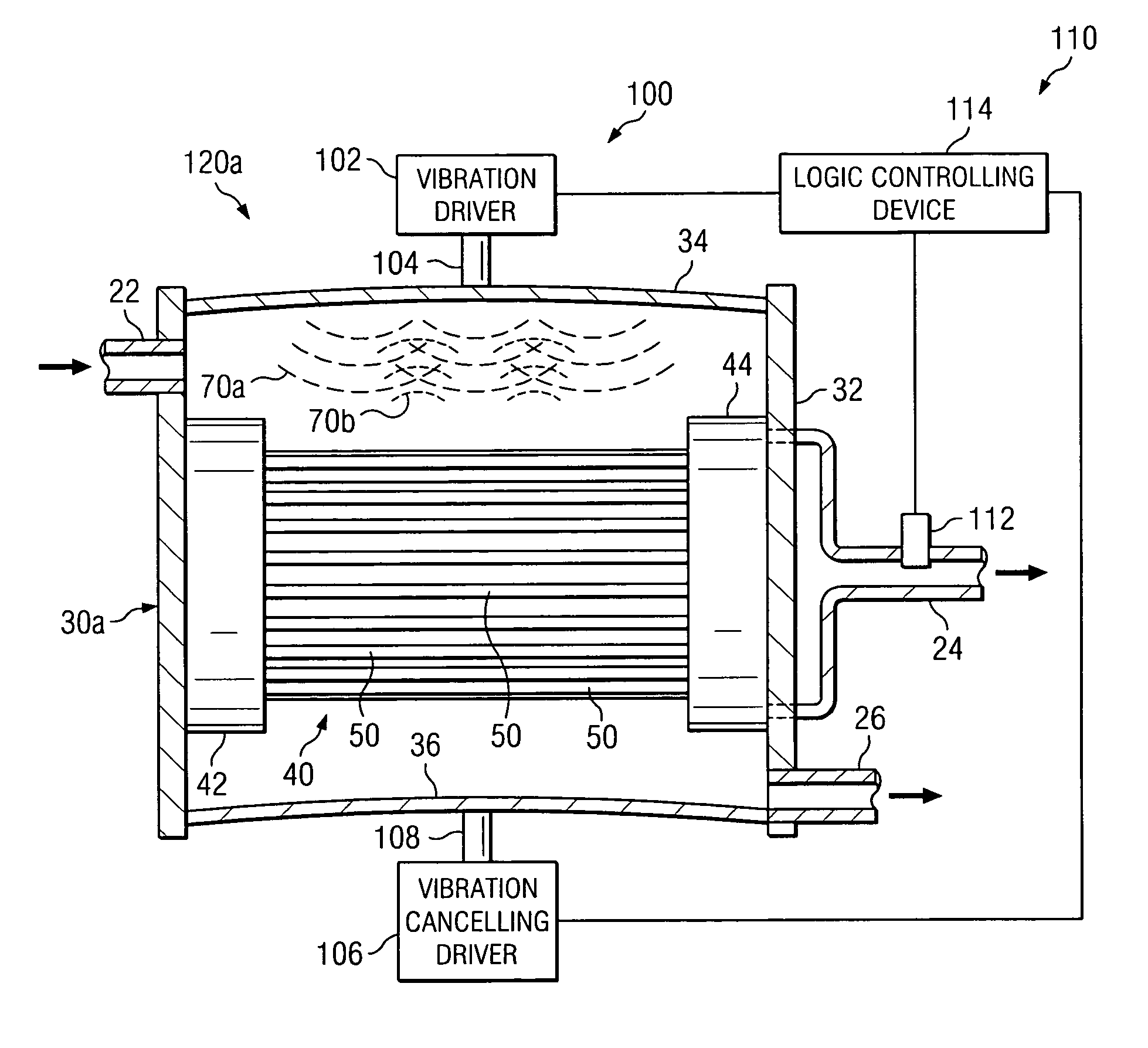

Cleaning hollow core membrane fibers using vibration

InactiveUS20050077227A1Minimize returnMinimize bounce backMembranesSpecific water treatment objectivesParticulatesFiber

A filtration system is provided with hollow membrane filter elements operable to remove solids, particulate and colloidal matter from a process fluid. Acoustic, vibration and ultrasonic energy may be used to clean exterior portions of the hollow membrane filter elements to allow substantially continuous filtration of process fluids. The filtration system may be satisfactorily used with process fluids having a relatively high concentrations of solids, particulate and colloidal matter.

Owner:PHASE

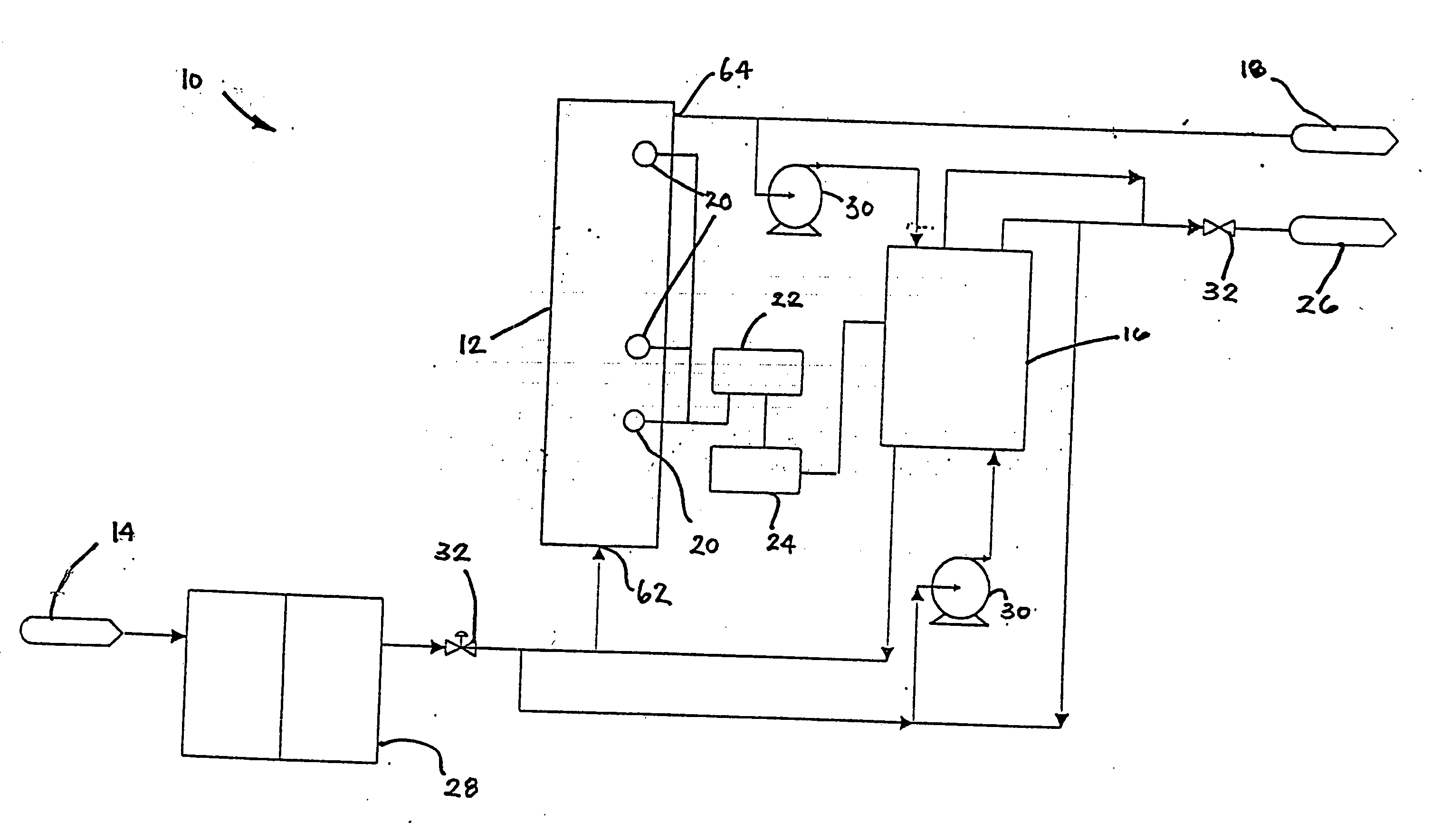

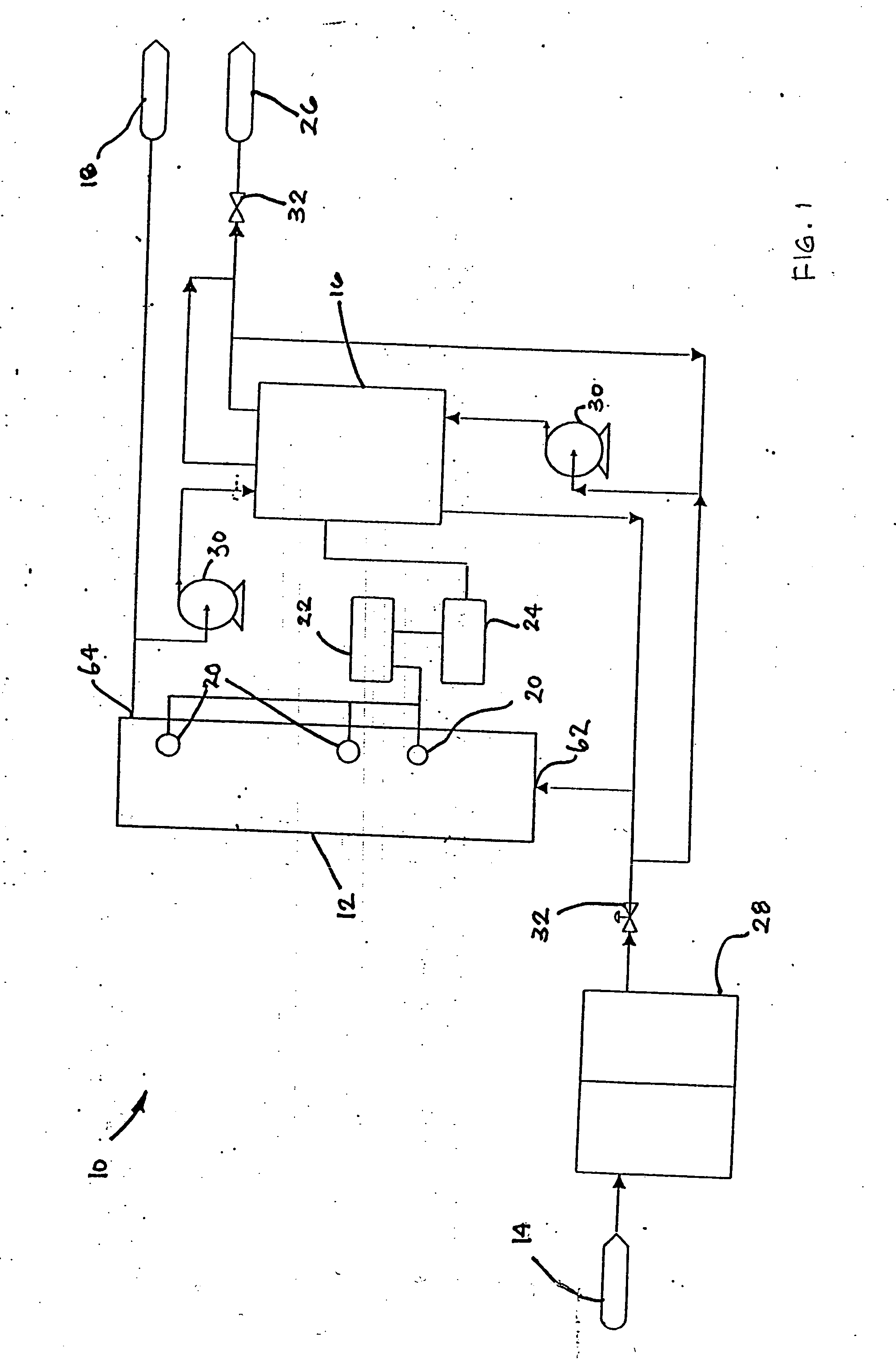

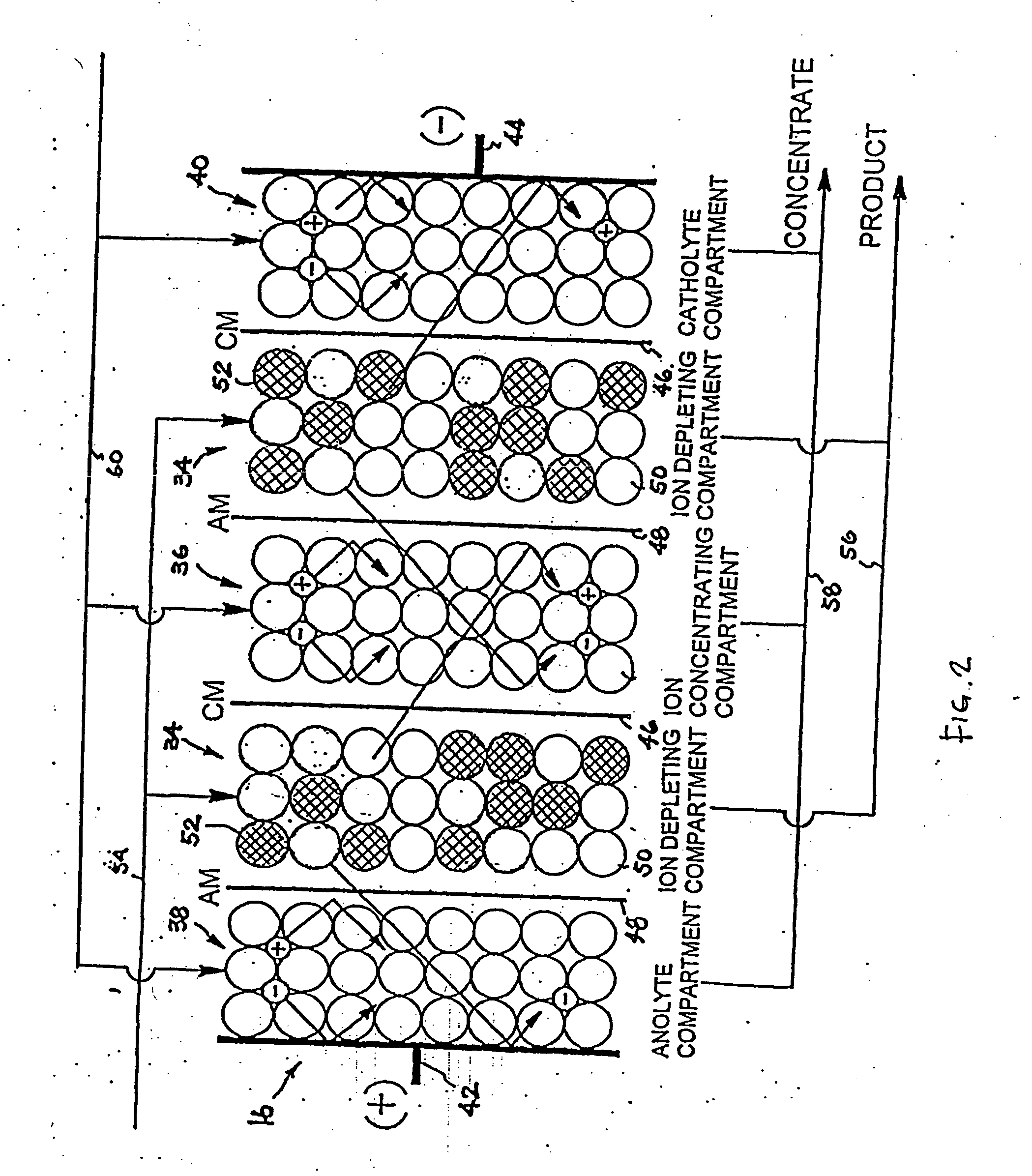

Water treatment system and method

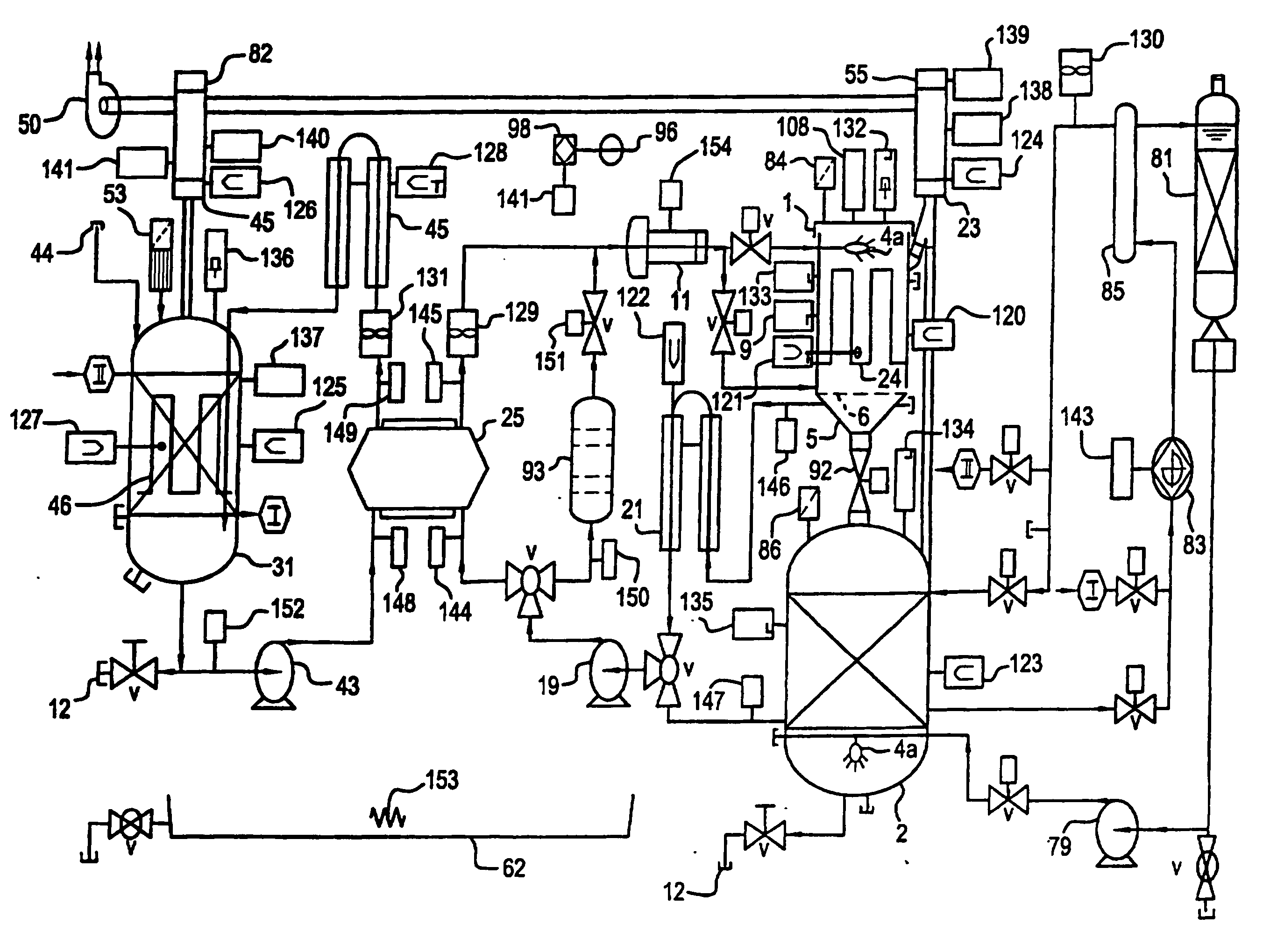

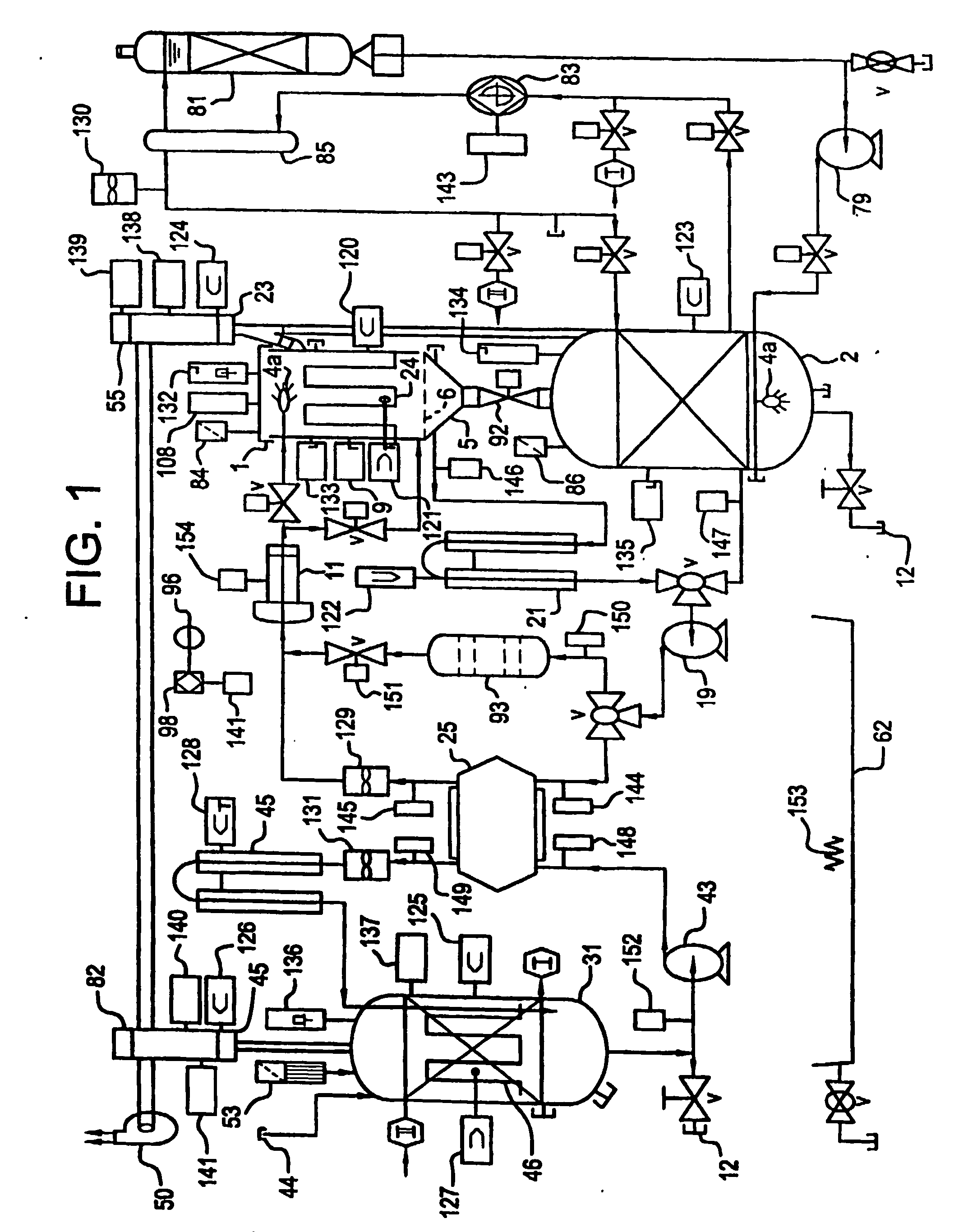

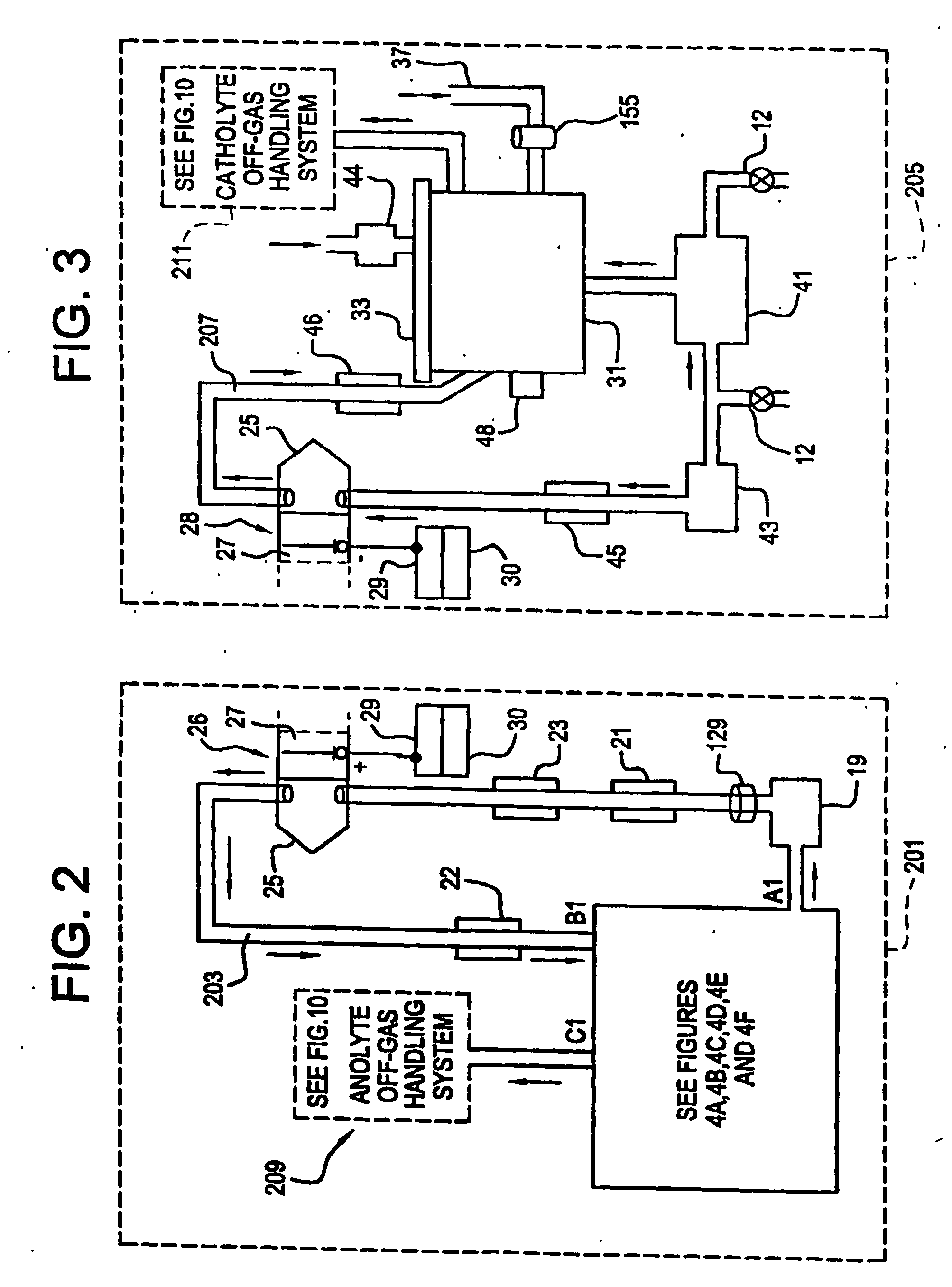

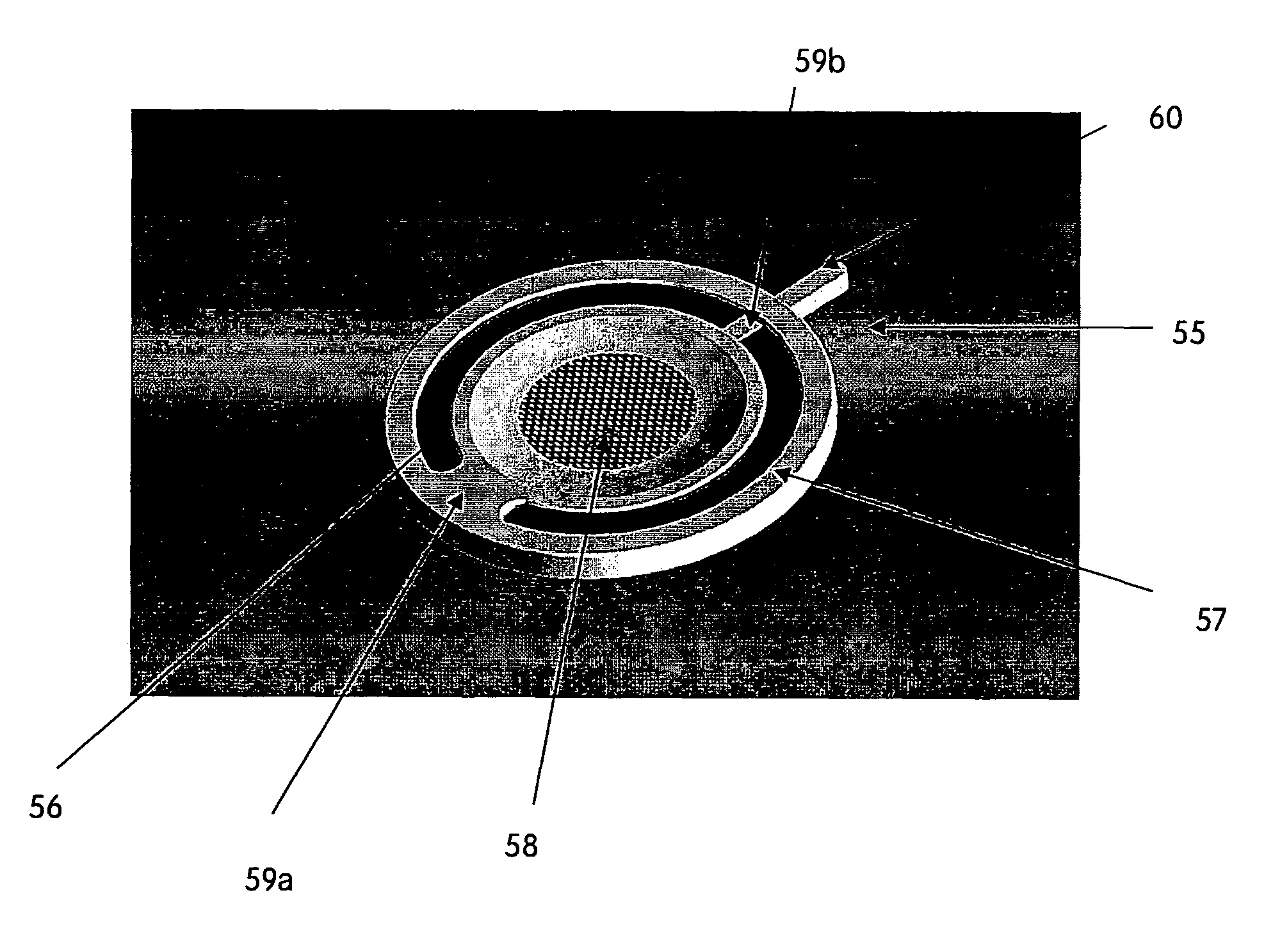

ActiveUS20050103722A1Water treatment parameter controlIon-exchange column/bed processesWater treatment systemWater source

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point of entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a reservoir system in line with an electrochemical device such as an electrodeionization device. The water treatment system has a sensor or a set of sensors for measuring at least one property of the water or an operating condition of the treatment system. The water treatment system also has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system to supply water tailored to quality requirements.

Owner:EVOQUA WATER TECH LLC

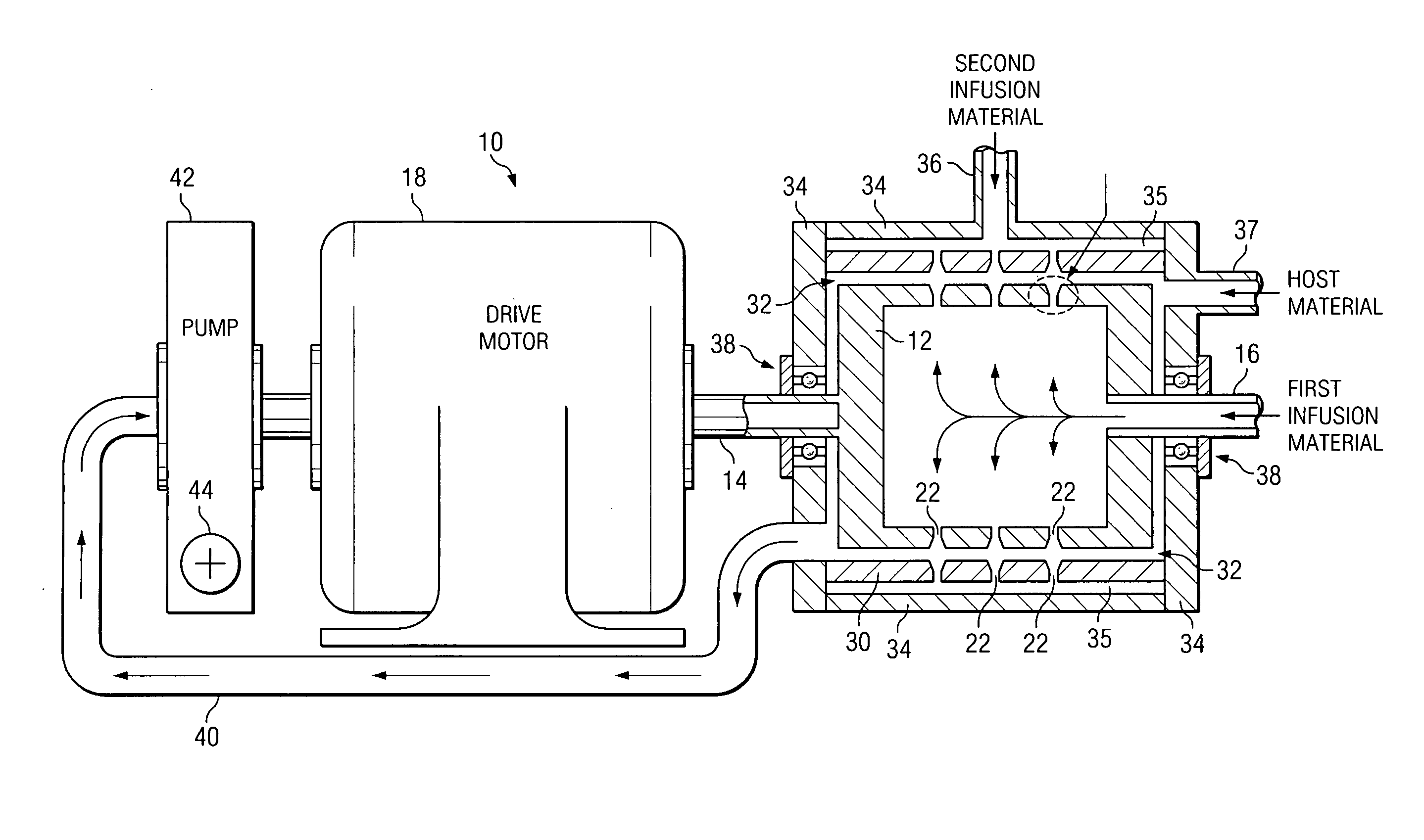

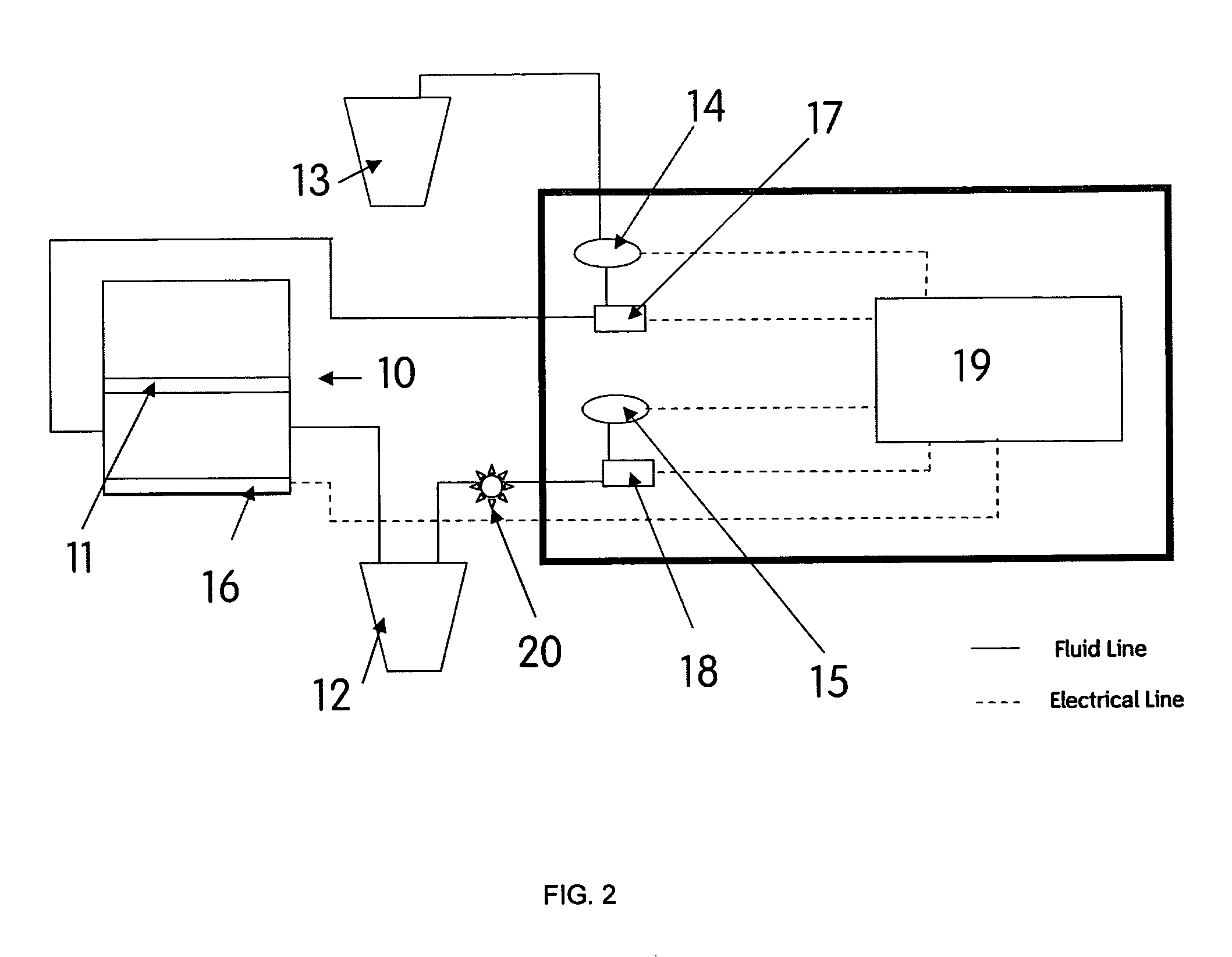

System and method for therapeutic application of dissolved oxygen

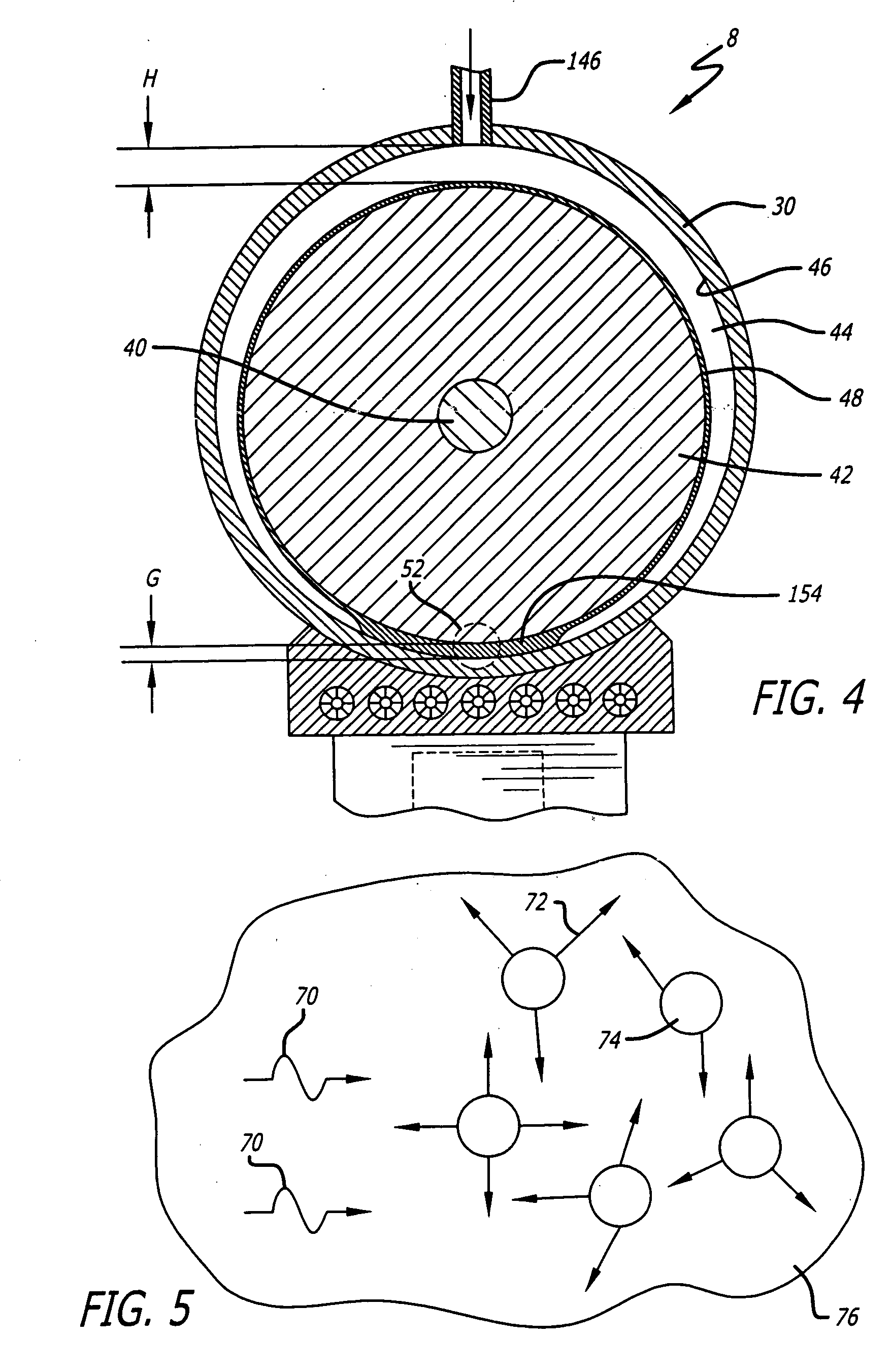

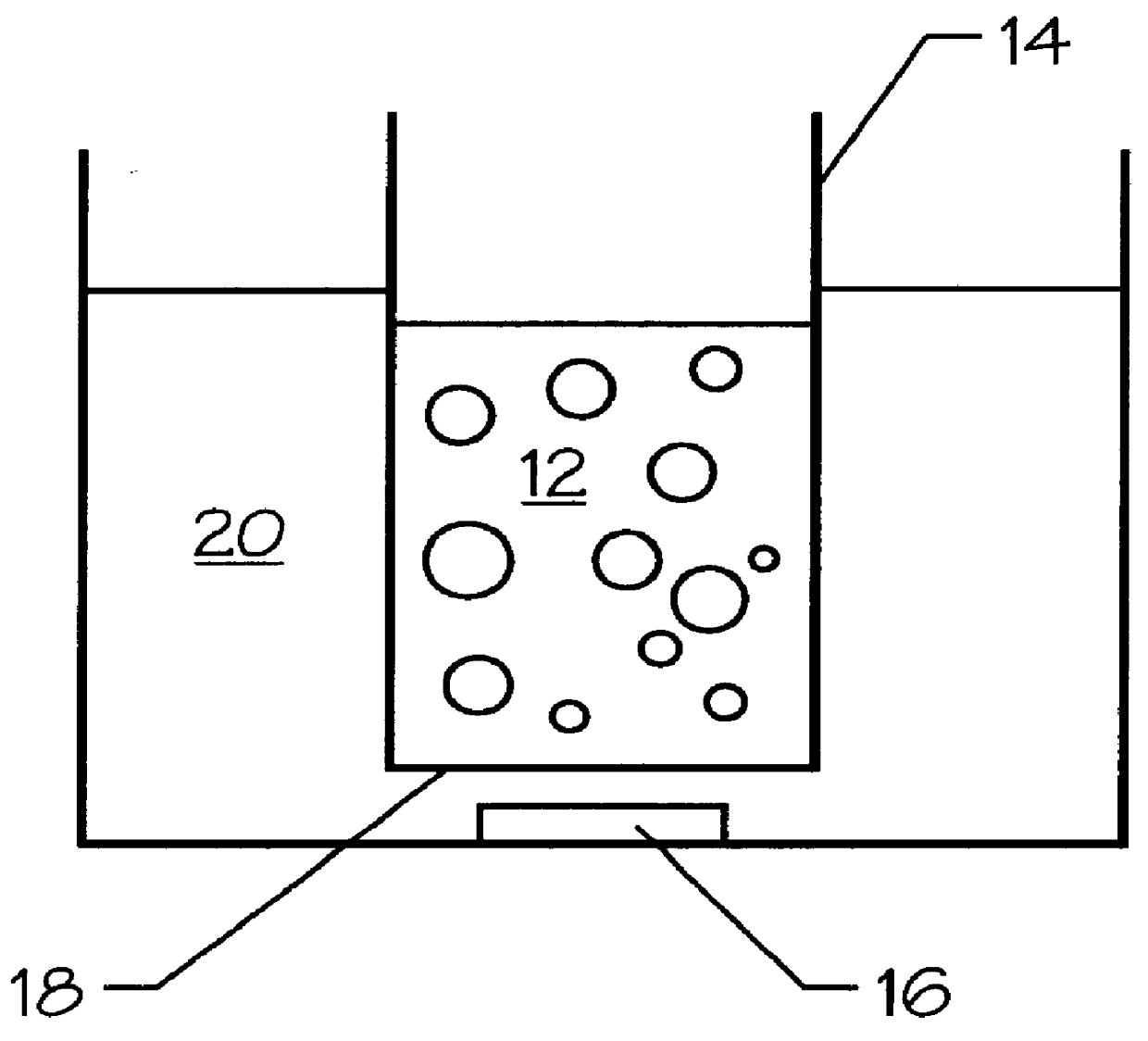

InactiveUS20050047270A1Rotary stirring mixersUsing liquid separation agentCavitationAqueous solution

A system and method for generating an oxygen enriched aqueous solution for therapeutic application includes a diffuser comprising a first diffusing member having a surface incorporating surface disturbances, and a second diffusing member positioned relative to the first diffusing member to form a channel through which an aqueous solution and oxygen gas may flow. A reservoir containing the aqueous solution is connected to a pump that draws the aqueous solution from the reservoir and inputs the aqueous solution into the diffuser. The aqueous solution is moved through the channel relative to the surface disturbances to create cavitation in the aqueous solution to diffuse the oxygen gas into the aqueous solution to produce an oxygen enriched aqueous solution.

Owner:REVALESIO CORP

Method and apparatus for acoustically demixing aqueous solutions

InactiveUS6090295AWater/sewage treatment with mechanical oscillationsWater/sewage treatment by magnetic/electric fieldsAqueous solutionNuclear chemistry

A method and apparatus for demixing an aqueous solution is provided. The aqueous solution has at least two aqueous phases. The method comprises applying acoustic energy to the aqueous solution. The apparatus comprises a mechanism for applying acoustic energy to the aqueous solution until the aqueous solution is demixed to clarity.

Owner:UNIV TECH

Process for high shear gas-liquid reactions

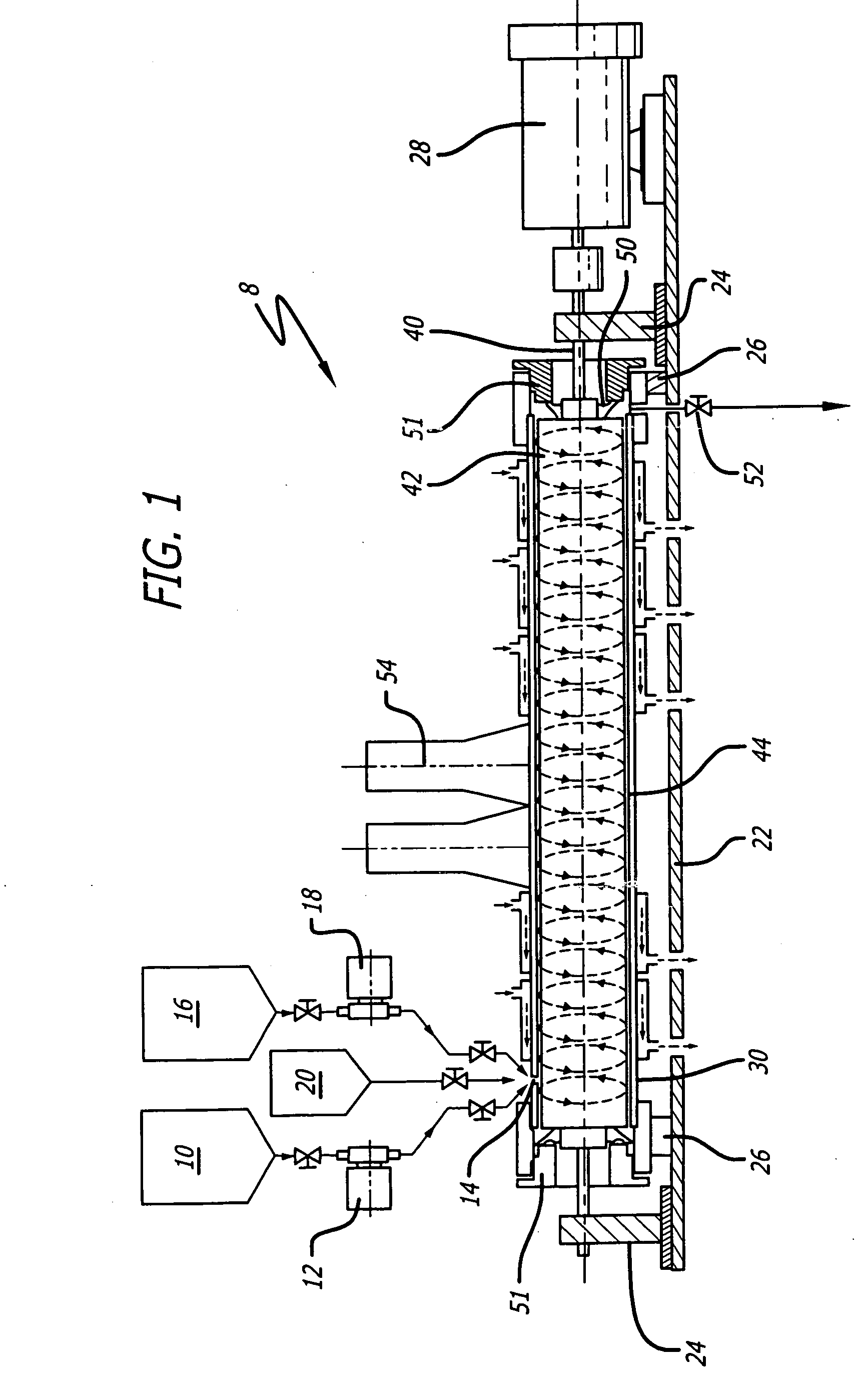

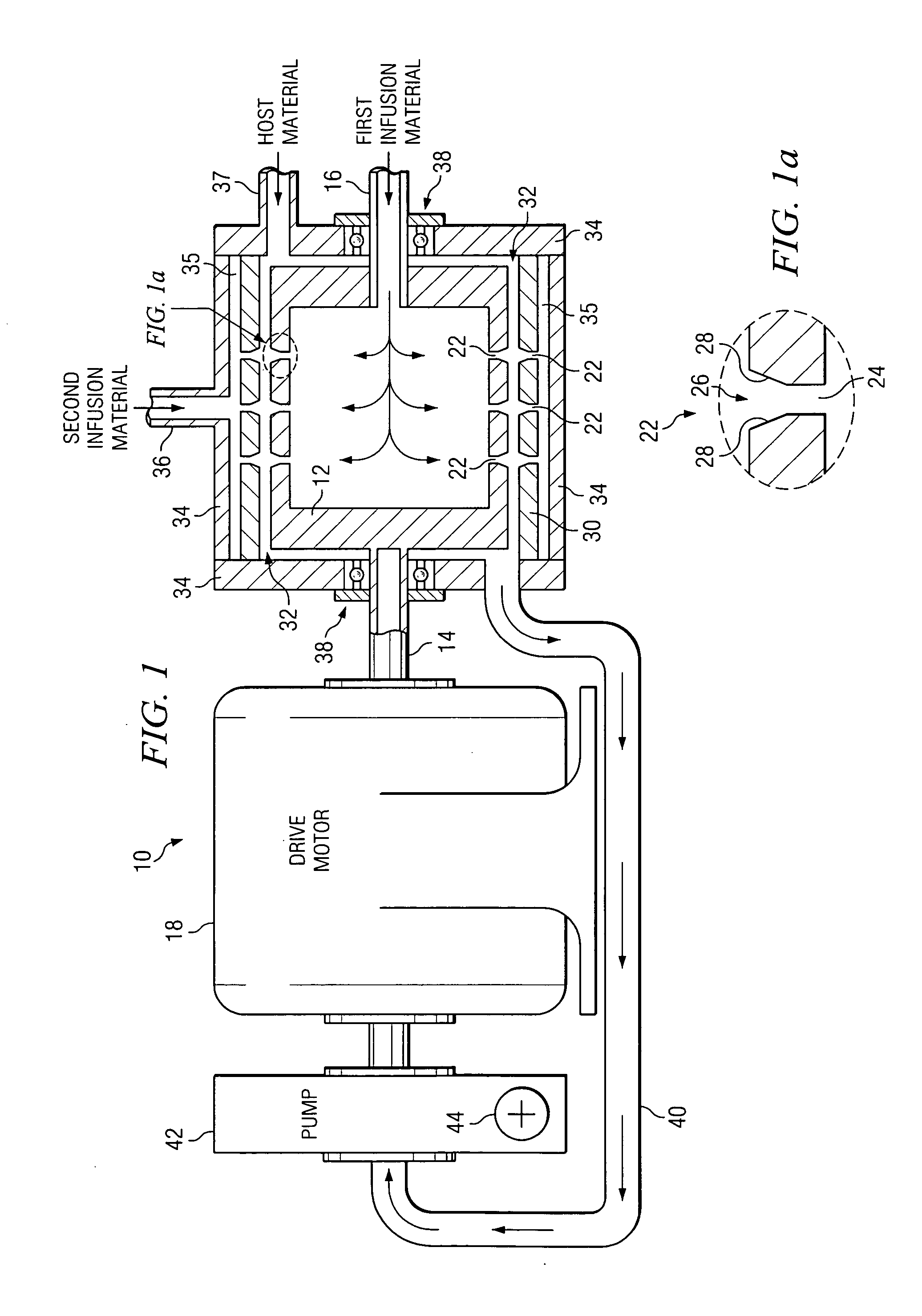

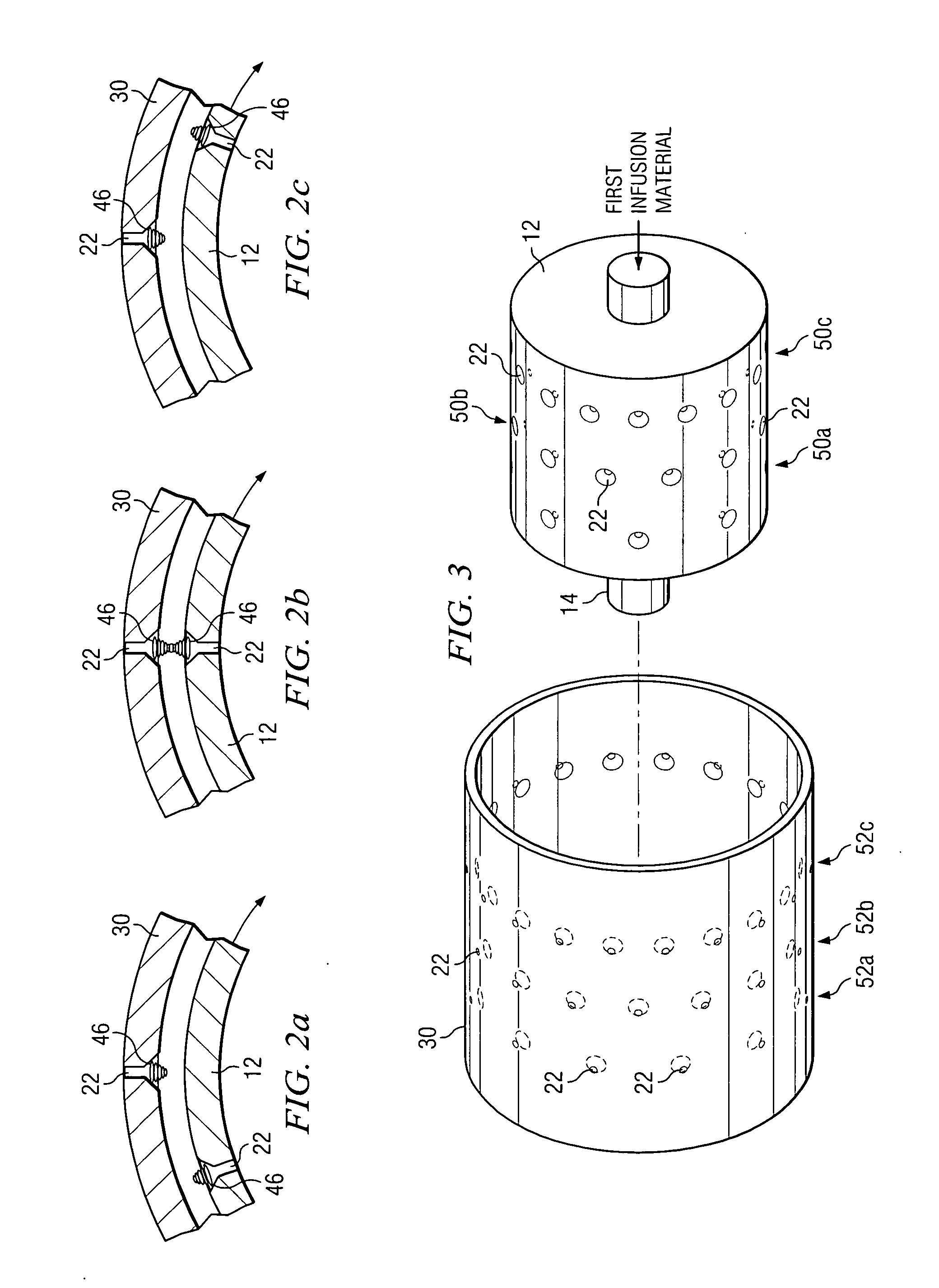

A reactor produces a gas-in-liquid emulsion for providing increased interfacial contact area between the liquid and the gas for improved reaction of the gas with the liquid, or more rapid solution or reaction of a difficulty soluble or immiscible gas in or with a liquid. The reactor is suitable for a continuous or batch type process. Rotor and stator cylindrical members are mounted for rotation relative to one another and have opposing surfaces spaced to form an annular processing passage. The gap distance between the opposing surfaces and the relative rotation rate of the cylindrical members are such as to form a gas-in-liquid emulsion of the gas in the liquid. The liquid and gas pass through the processing passage, changing into the gas-in-liquid emulsion.

Owner:323 TRUST

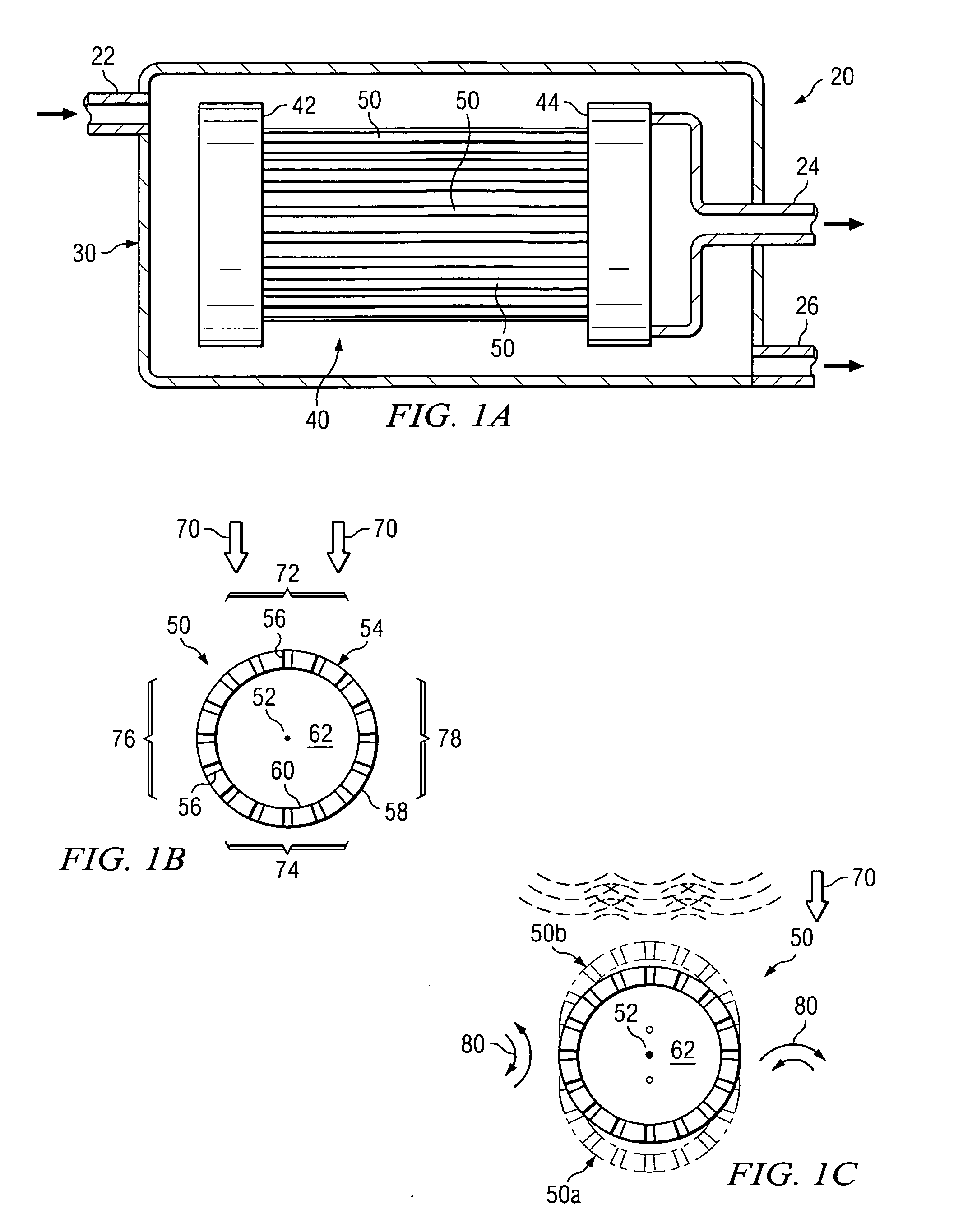

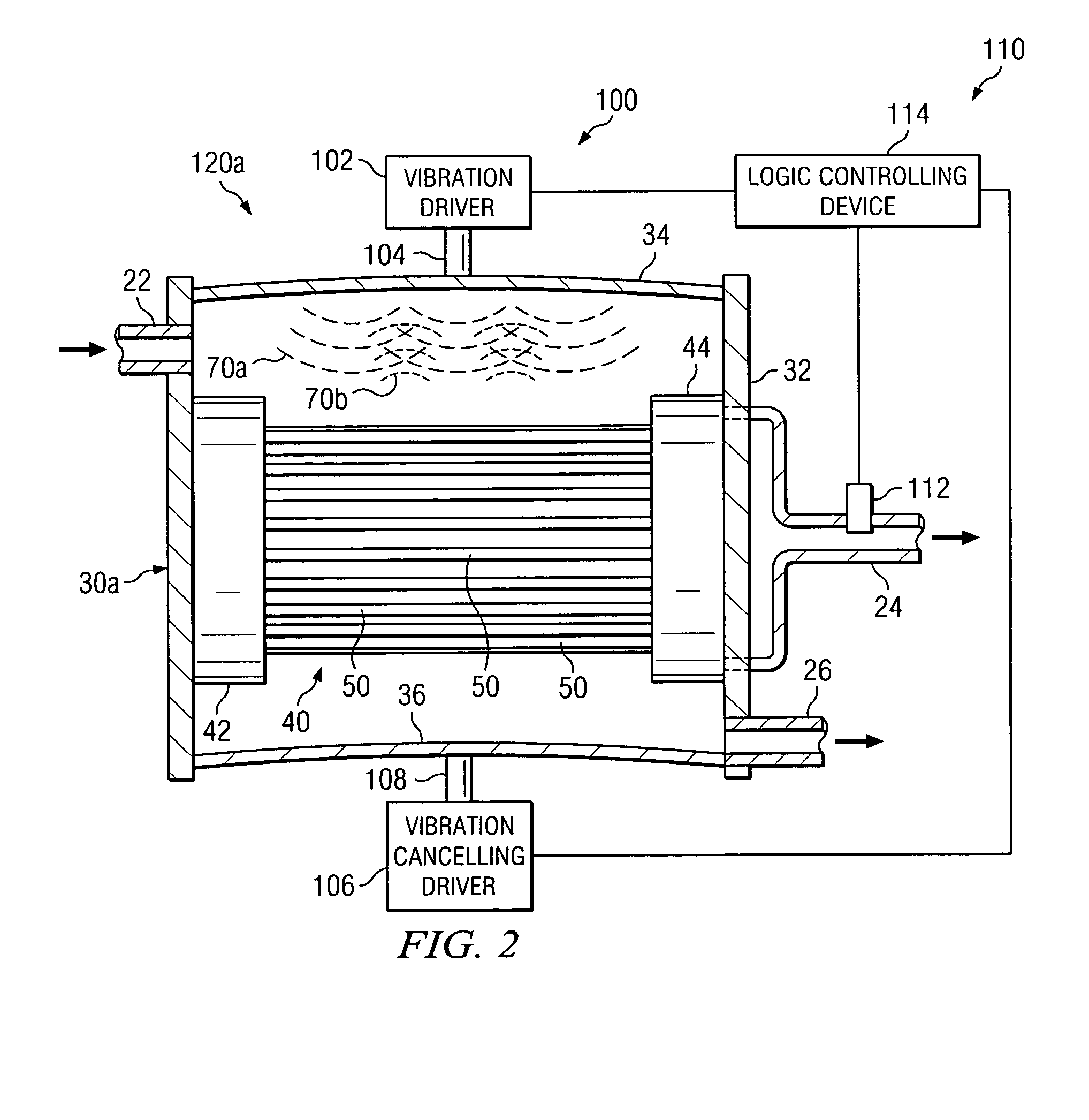

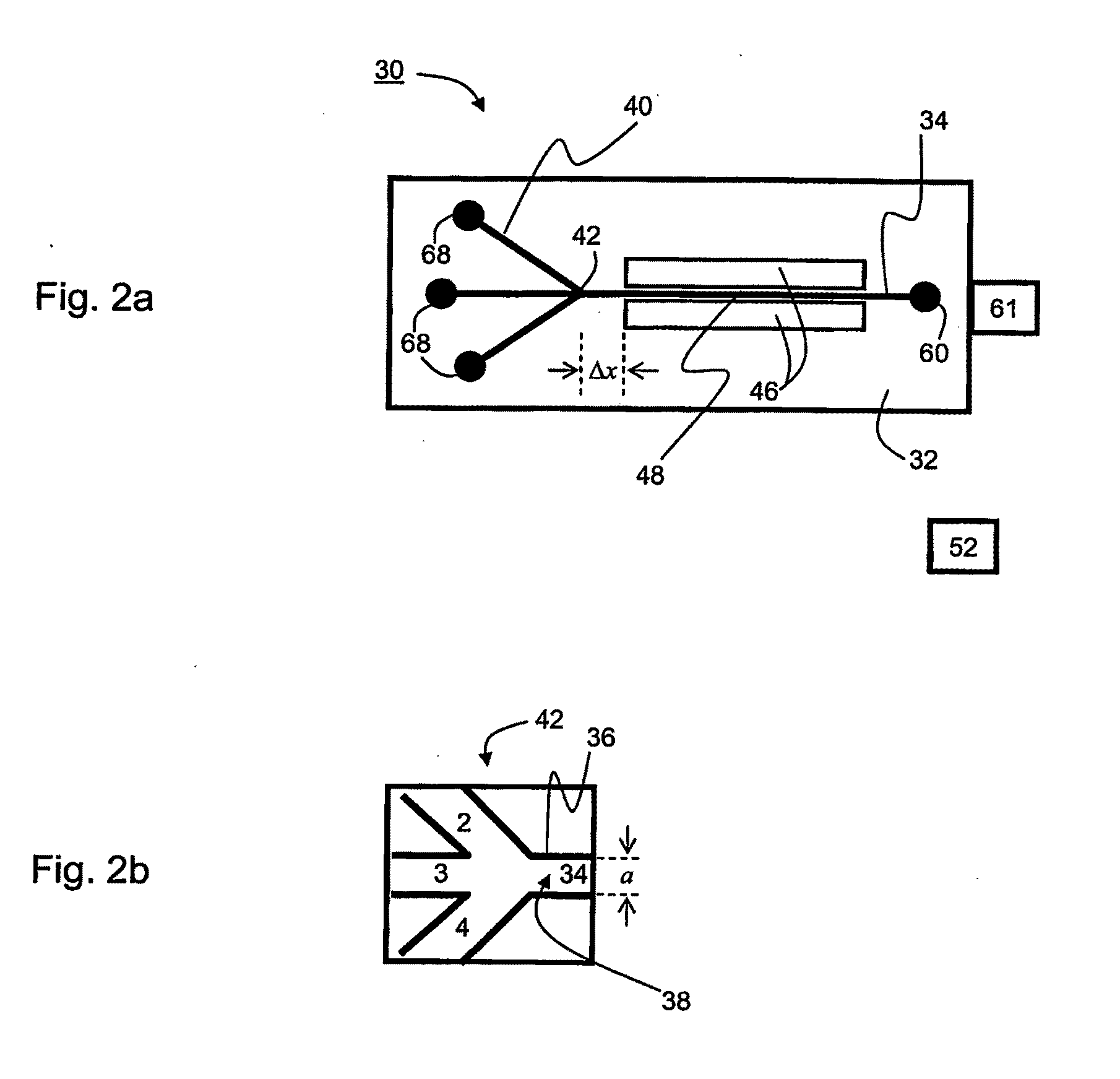

Method and device for ultrasonically manipulating particles within a fluid

InactiveUS7846382B2Easy to operateAuxillary pretreatmentShaking/oscillating/vibrating mixersBiological particlesSolid phase extraction

Fluid-handling methods and devices for ultrasonic manipulation of fluid-borne particles comprise a fluid-handling manifold and an ultrasonic particle manipulator defining an ultrasonic cavity within the manifold. Fluid-borne particles introduced into the manifold are manipulated by controlling ultrasonic standing waves at the ultrasonic cavity. Cavities having non-uniform configurations, asymmetric standing waves and / or multiple ultrasonic cavities within the manifold are operative to control the movement of the fluid-borne particles, optionally including collecting and holding such particles, transferring particles through an intersection from one channel to another, etc. Solid phase extraction (SPE) particles, biological particles and other fluid-borne particles can be manipulated within the fluid-handling manifold.

Owner:PROTASIS CORP

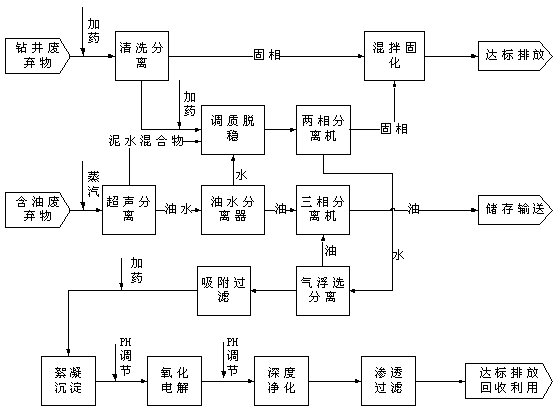

Method for comprehensive treatment of oilfield waste

ActiveCN102849880BSolve the use problemMeet the actual needs of protectionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesElectrolysisSludge

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

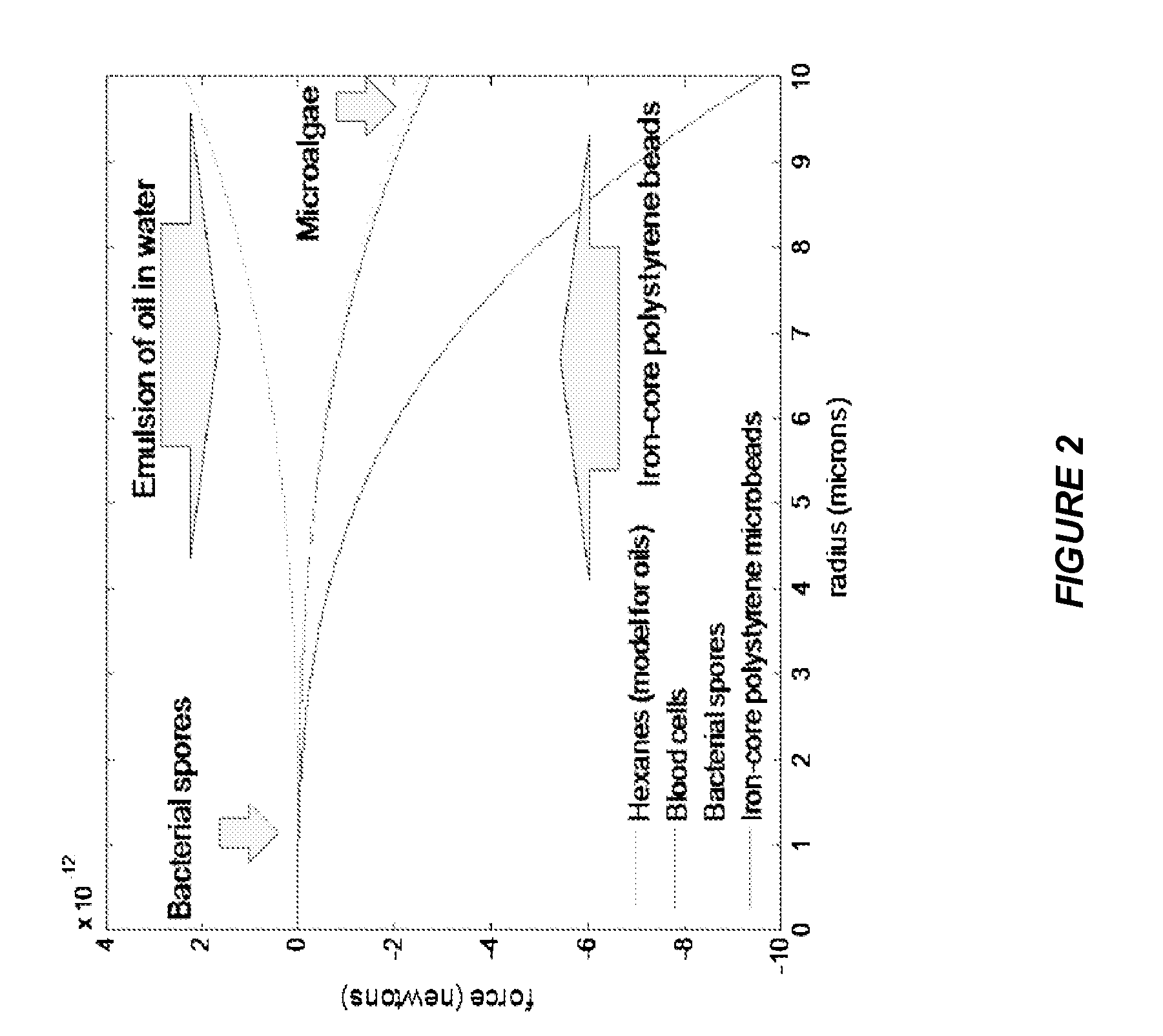

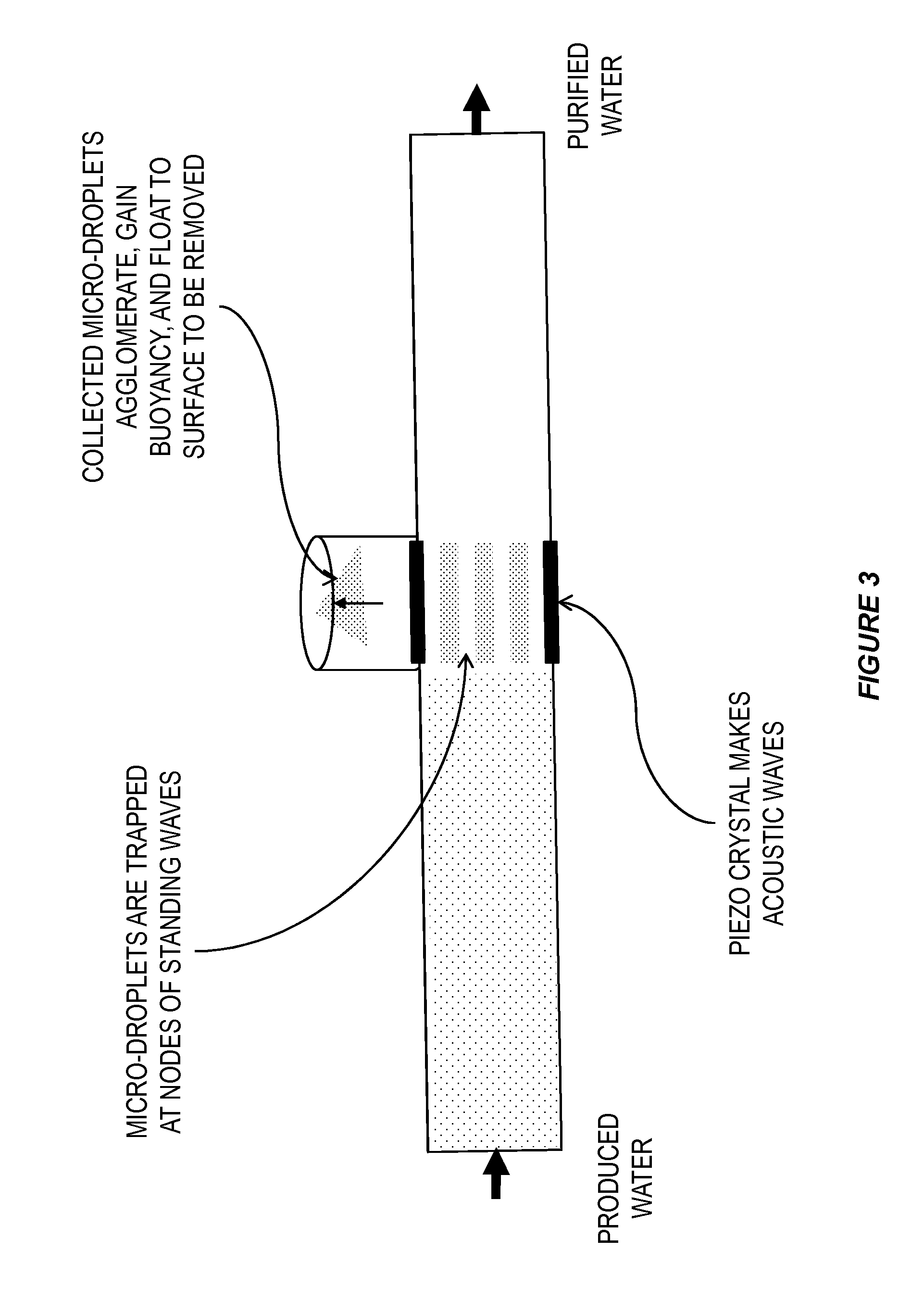

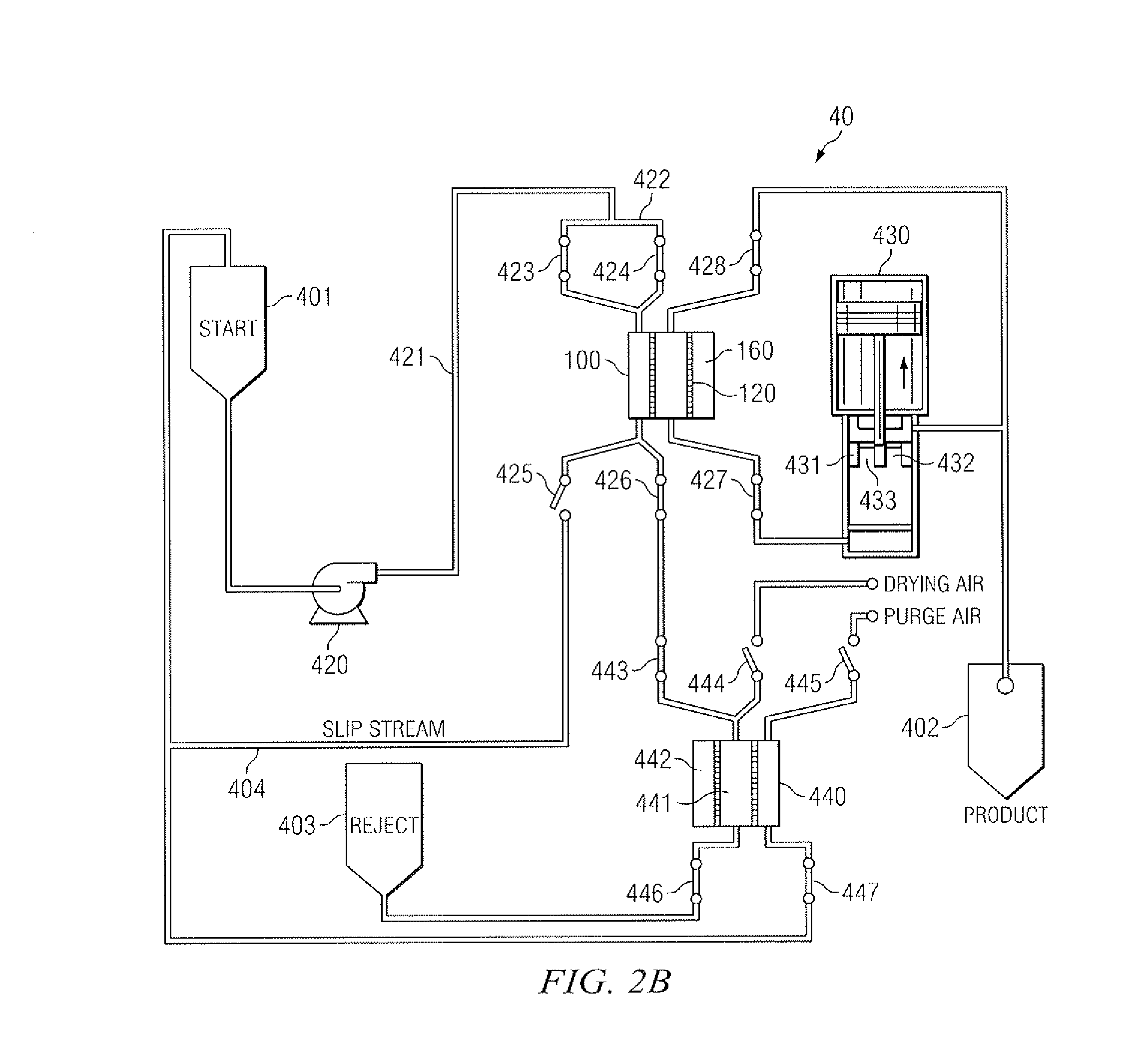

Ultrasound and Acoustophoresis Technology for Separation of Oil and Water, with Application to Produce Water

InactiveUS20110278218A1Maximize acoustic energy transferAvoid enteringWaste water treatment from quariesFatty/oily/floating substances removal devicesEmulsionResonance

Several prototype systems are described for separating oil and water from emulsions. The systems operate at ultrasonic resonance and are thus low power. Each system contains one or more acoustic transducers operating in the 100 kHz to 5 MHz range. Each system contains flow input for the emulsion and two or more flow outputs for the separated oil and water. Existing prototypes operate from 200 mL / min to >15 L / min. Each uses low power in the range of 1-5 W.

Owner:FLODESIGN SONICS

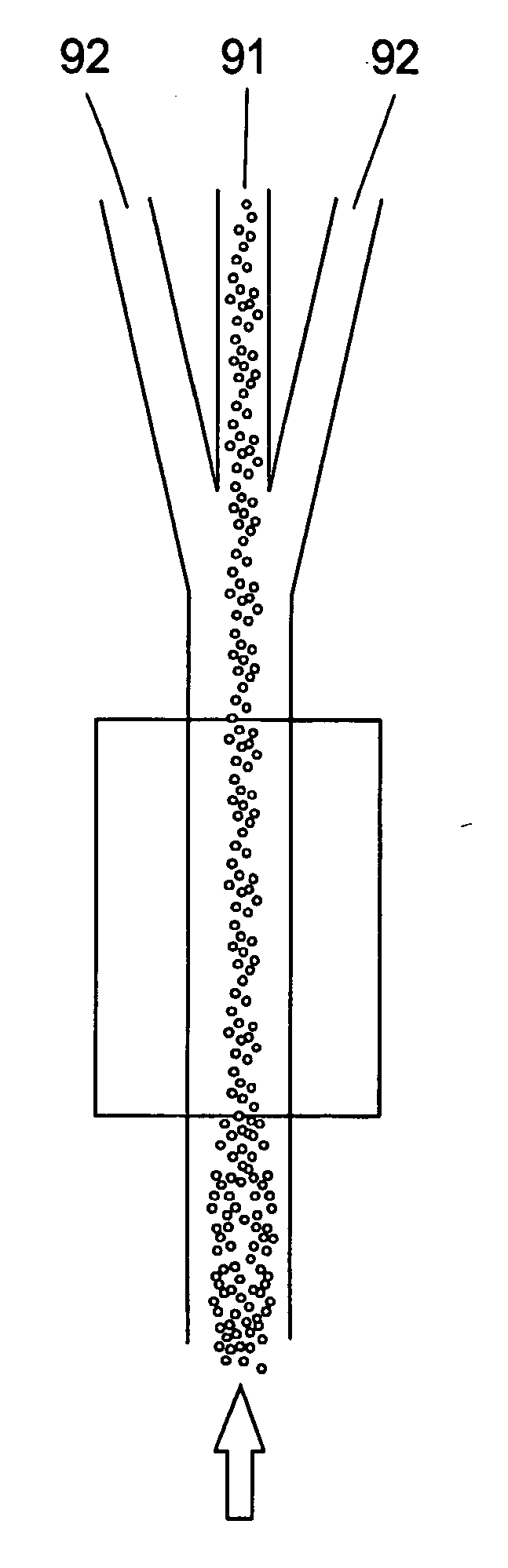

Device and method for separation

InactiveUS20040069717A1Raise the possibilityHigh particle separationOther blood circulation devicesHaemofiltrationElectricityEngineering

The present invention provides a device and a method for separating particles from fluids using ultrasound, laminar flow, and stationary wave effects comprisinga micro-technology channel system with an integrated branching point or branching fork, and a single ultrasound source. One of the characteristics of the invention is that the single ultrasound source, which generates the standing waves, excites the complete structure including the channel system. No special reflectors or the like are needed. Extremely thin dividers can separate the flow, thereby enhancing the effectiveness of the device. The device could be manufactured in silicon and the ultrasound energy could preferably be delivered by a piezoelectric element.

Owner:ERYSAVE

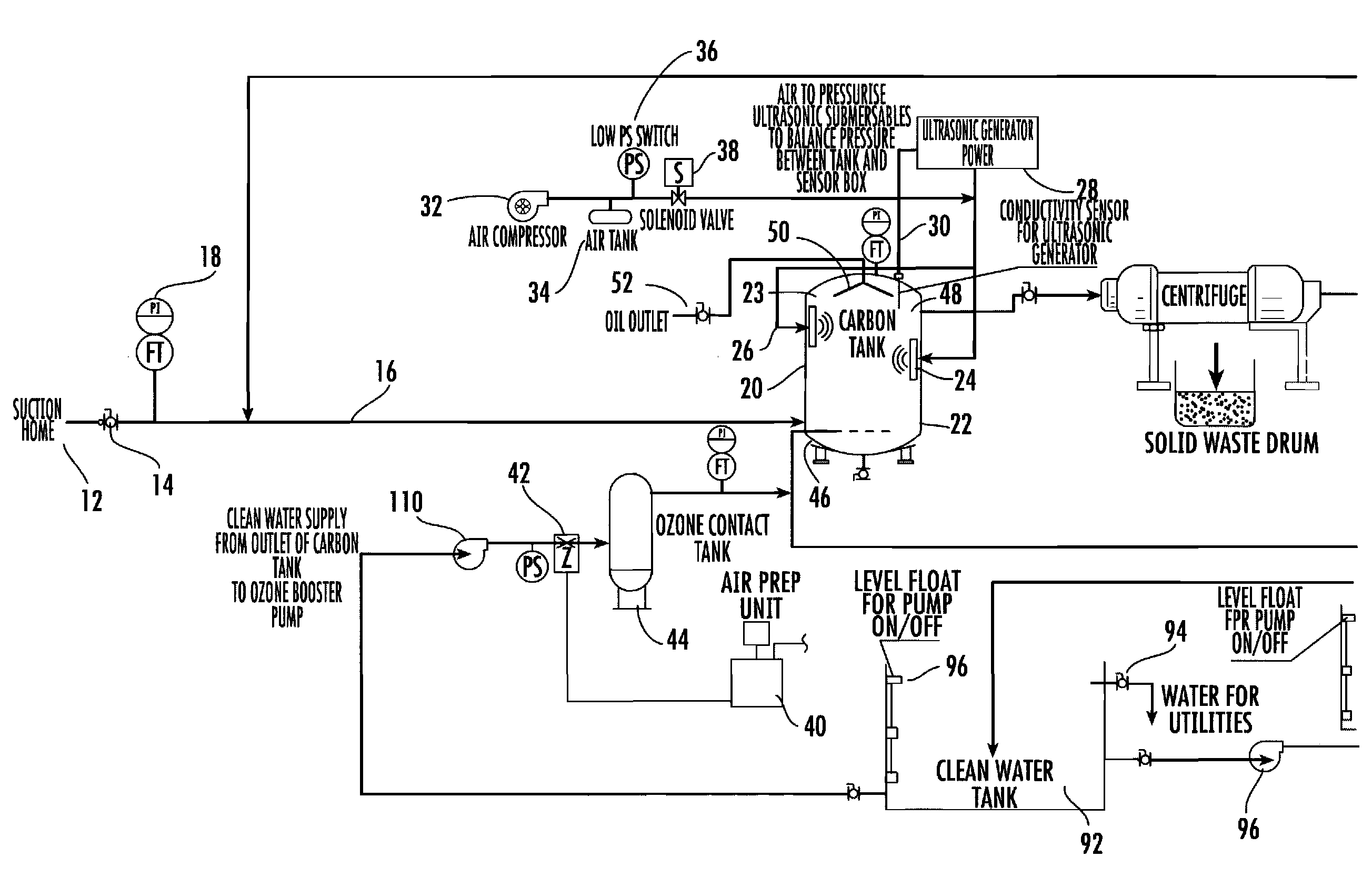

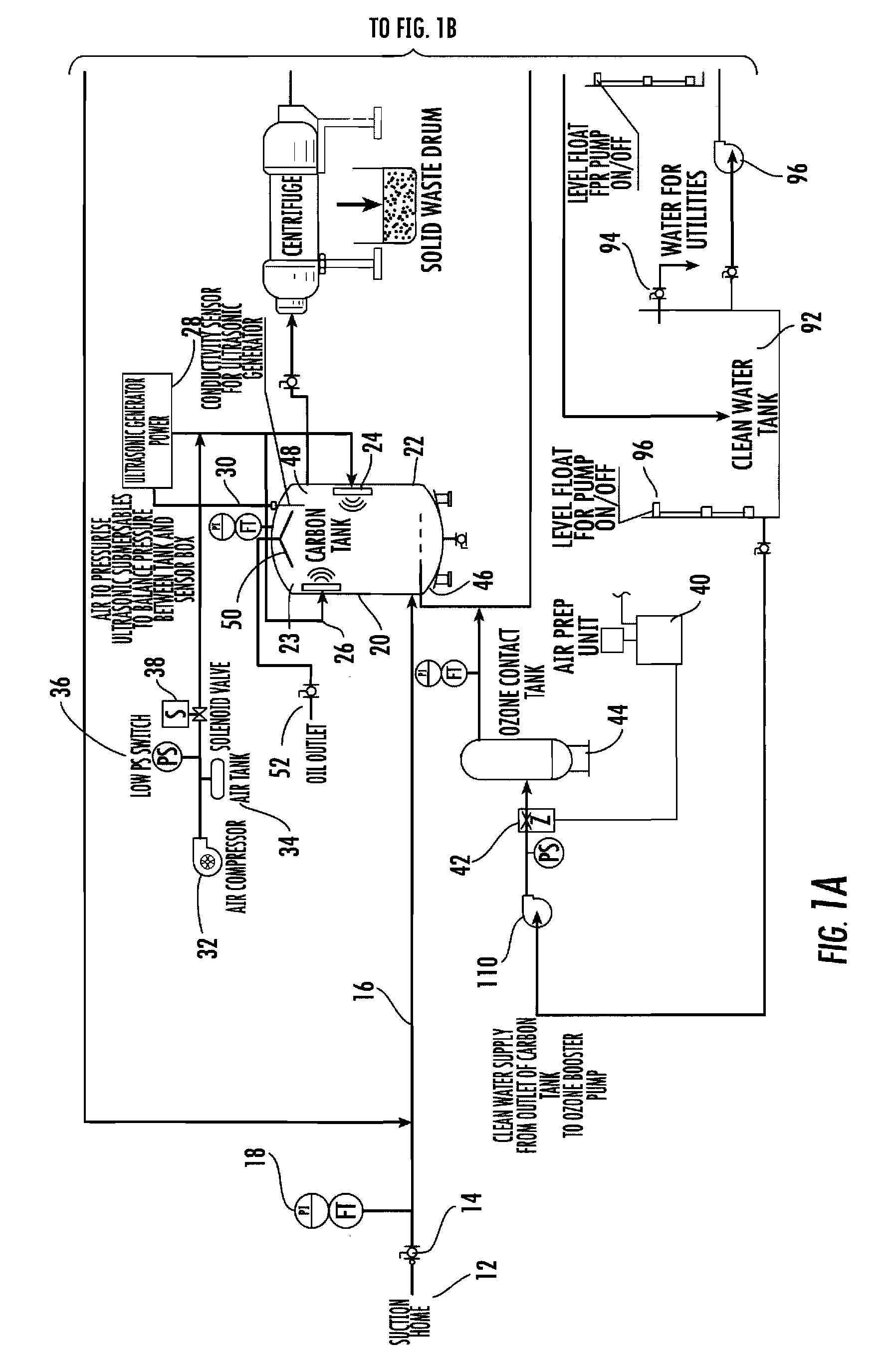

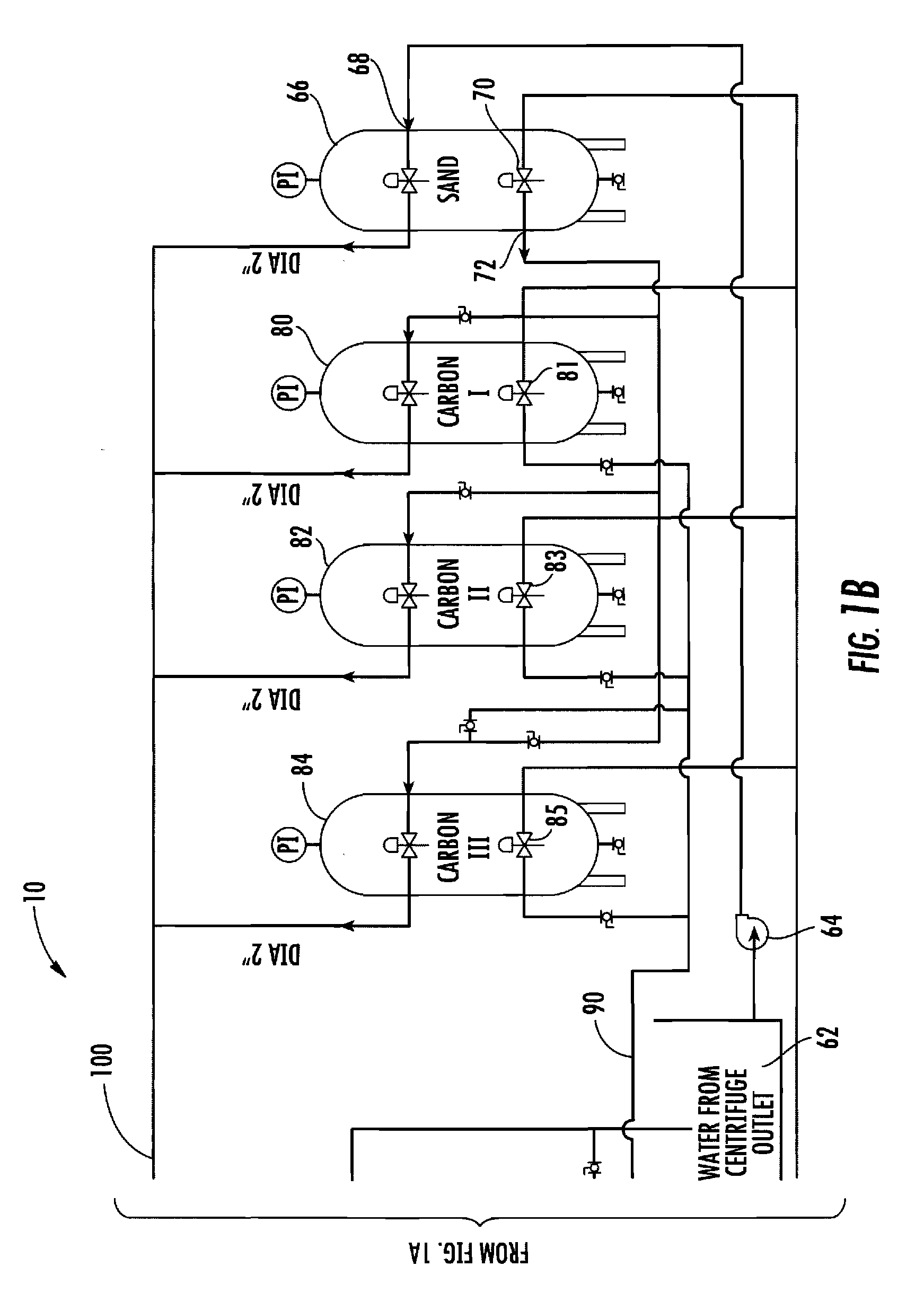

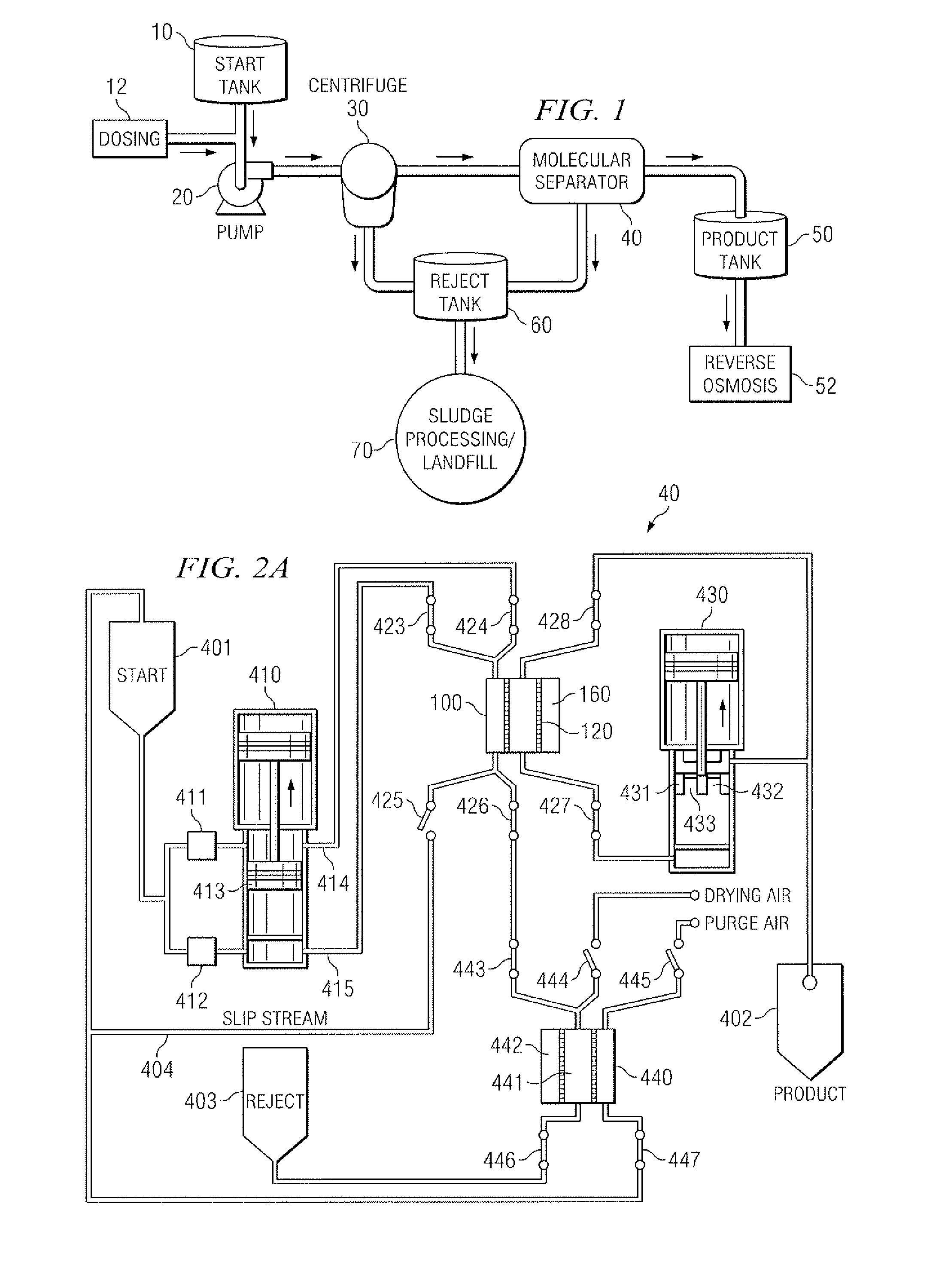

Enhanced water treatment for reclamation of waste fluids and increased efficiency treatment of potable waters

ActiveUS20090050572A1Low costCurrent expensiveWaste water treatment from quariesTreatment involving filtrationLiquid wastePotable water

Disclosed is a process for reclamation of waste fluids. A conditioning container is employed for receipt of waste material on a continuous flow for treatment within the container by immersible transducers producing ultrasonic acoustic waves in combination with a high level of injected ozone. The treated material exhibits superior separation properties for delivery into a centrifuge for enhanced solid waste removal. The invention discloses a cost efficient and environmentally friendly process and apparatus for cleaning and recycling of flowback, or frac water, which has been used to stimulate gas production from shale formations. The apparatus is mobile and containerized and suitable for installation at the well site.

Owner:BRISBEN WATER SOLUTIONS

Produced water treatment method and apparatus

InactiveUS20080156709A1Improve filtration efficiencyEnhanced cavitationUltrafiltrationLoose filtering material filtersCavitationWaste collection

The present invention discloses a method and apparatus for separating particles and dissolved matter from a produced water fluid stream. Specifically, the present invention includes a first pressure source which transports untreated produced water or contaminated aqueous fluid into a separator annulus with a filter element disposed therein. The untreated fluid is placed under appropriate pressure sufficient to produce turbulent flow, increased particle kinetics and / or cavitation allowing the desired fluid to penetrate and pass into and through the filter media. The treated fluid is then transported to a collection tank. The contaminant matter retained by the filter media may be removed by the nearly instantaneous reverse pressurization of the separator annulus by a second pressure source thereby removing the contaminant particles away from contact with the filter media, and which may then be transported to a waste collection tank or a separator for further treatment.

Owner:TERVITA +1

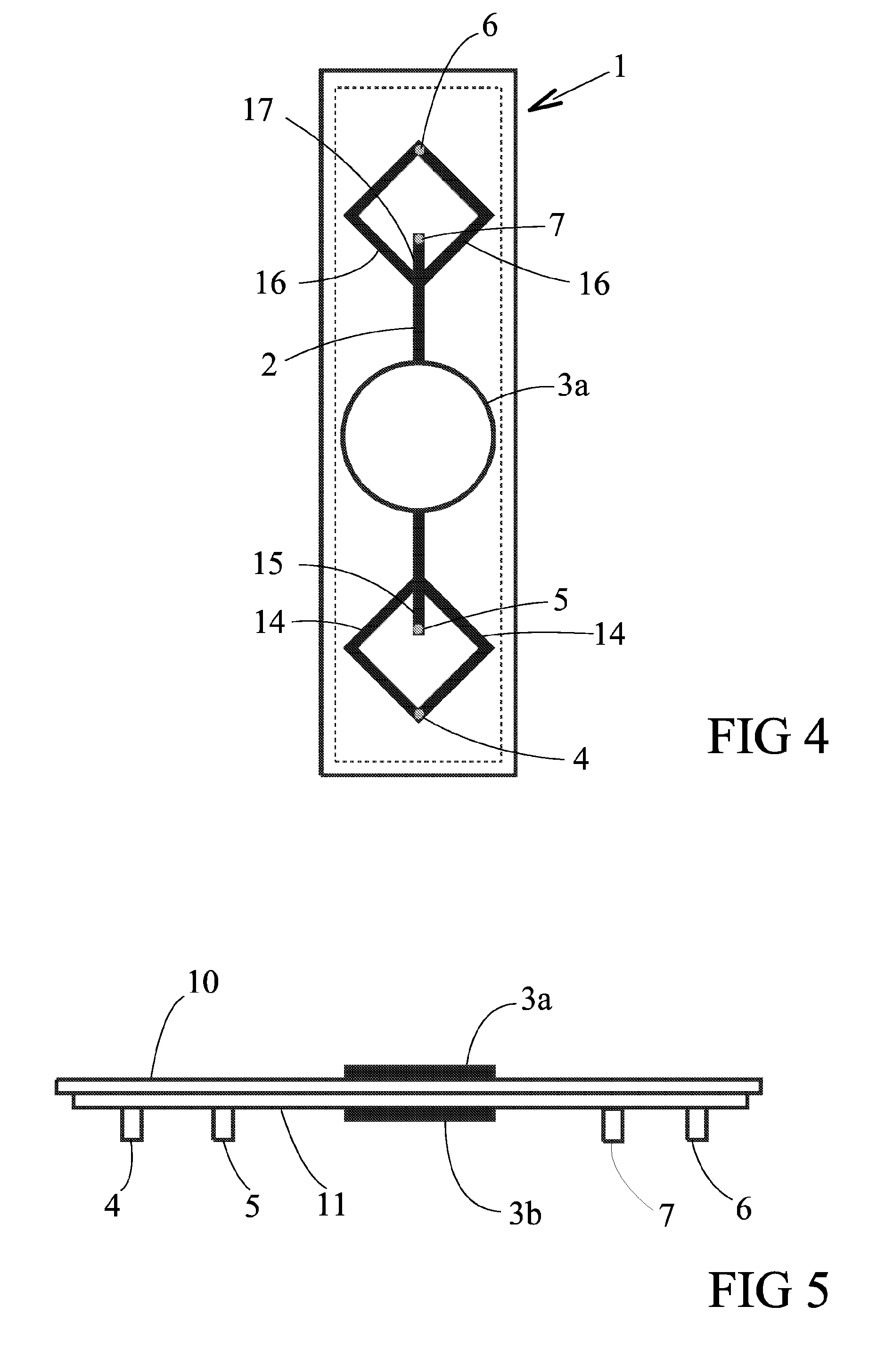

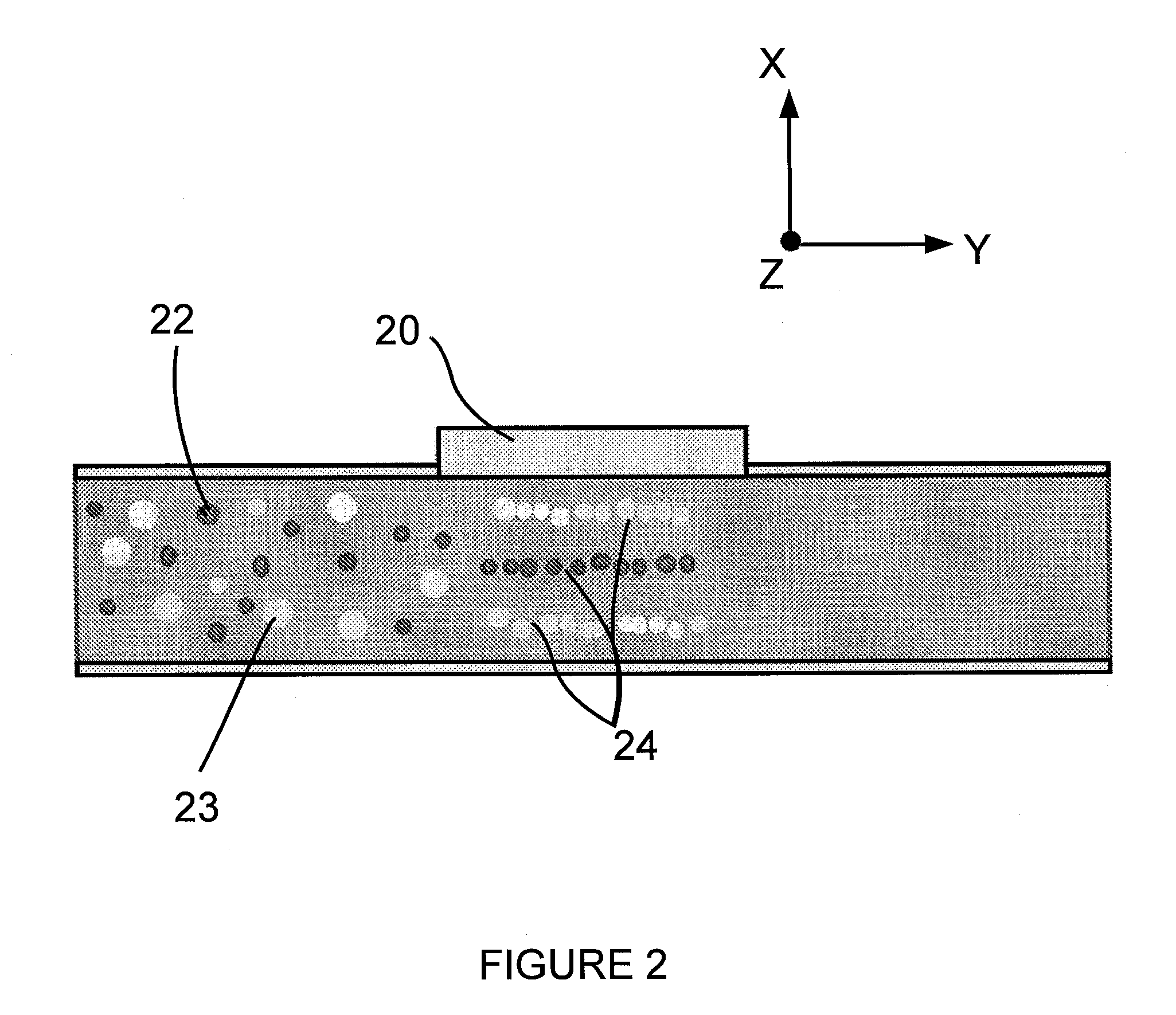

Device and Method For Particle Manipulation in Fluid

InactiveUS20100193407A1Water/sewage treatment with mechanical oscillationsLaboratory glasswaresPlanar substrateEngineering

A device for manipulating particles present in a fluid medium is disclosed. The device comprises a planar substrate, formed with at least one primary microchannel to allow passage of the fluid medium therethrough. The primary microchannel(s) has walls and a base and being in fluid communication with a plurality of secondary microchannels via at least one branching point. The device further comprises one or more ultrasound transmission pairs, positioned at opposite sides of the walls to generate ultrasound waves propagating through the fluid medium, substantially parallel to the planar substrate, such as to form a standing wave within the primary microchannel.

Owner:YEDA RES & DEV CO LTD

Ultrasonic filtration for cmp slurry

InactiveUS20100206818A1Water/sewage treatment with mechanical oscillationsSedimentation separationFiltrationSlurry

The present invention relates to semiconductor processing. In particular, it relates to a tunable ultrasonic filter and a method of using the same for more effective separation of large particles from slurry. In one embodiment a standing wave is produced in the filter and large particles are accumulated at the nodes of the standing waves while the slurry is flowed out of the filter.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

Apparatus and process for mediated electrochemical oxidation of materials

A unique apparatus unique apparatus and process that uses mediated electrochemical oxidation (MEO) for: (1) Destruction of: a) nearly all organic solid, liquid, and gases materials, except fluorinated hydrocarbons; b) all biological solid, liquid, and gases materials; c) and / or dissolution and decontamination (such as cleaning equipment and containers, etc.) of nearly all inorganic solid, liquid, or gas where higher oxidation states exist which includes, but is not limited to, halogenated inorganic compounds (except fluorinated), inorganic pesticides and herbicides, inorganic fertilizers, carbon residues, inorganic carbon compounds, mineral formations, mining tailings, inorganic salts, metals and metal compounds, etc.); and d) combined materials (e.g. a mixture of any of the foregoing with each other); henceforth collectively referred to as materials. (2) Sterilization / disinfection of equipment, glassware, etc., by destroying all existing infectious materials. (3) Dissolution of transuranic / actinide materials and / or destruction of the oxidizable components in the hazardous waste portion of mixed waste. (4) Generation of hydrogen and oxygen from MEO of materials. (5) Alteration of organic, biological, and inorganic materials by MEO to produce other compounds from these materials. The materials are introduced into an apparatus for contacting the materials with an electrolyte containing the oxidized form of one or more reversible redox couples, at least one of which is produced electrochemically by anodic oxidation at the anode of an electrochemical cell. The oxidized forms of any other redox couples present are produced either by similar anodic oxidation or reaction with the oxidized form of other redox couples present and capable of affecting the required redox reaction. The oxidized species of the redox couples oxidize the materials molecules and are themselves converted to their reduced form, whereupon they are reoxidized by either of the aforementioned mechanisms and the redox cycle continues until all oxidizable material species, including intermediate reaction products, have undergone the desired degree of oxidation. The entire process takes place at temperatures between ambient and approximately 100° C. The oxidation process may be enhanced by the addition of reaction enhancements, such as: ultrasonic energy and / or ultraviolet radiation.

Owner:SCIMIST LNC

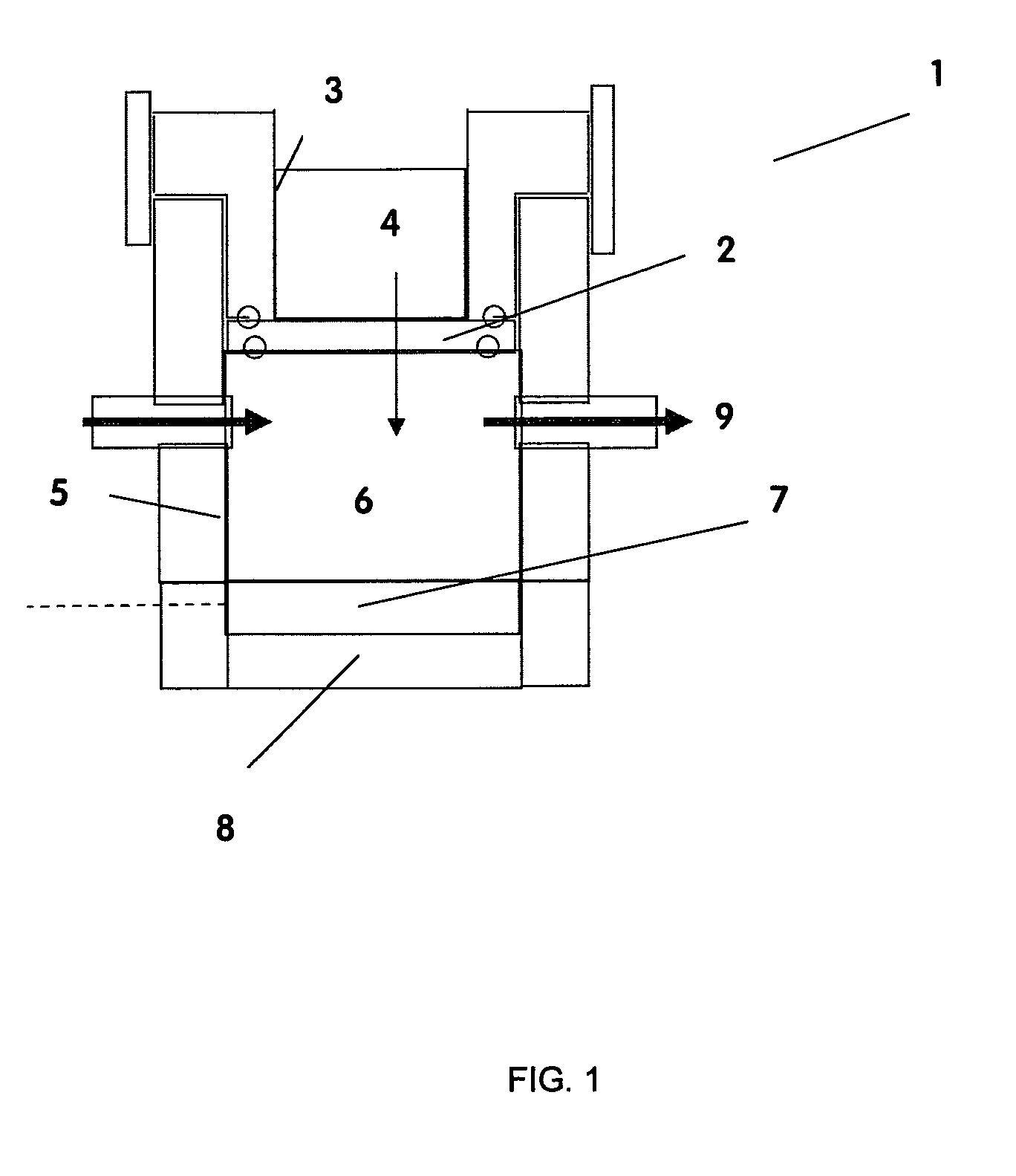

Apparatus and method for filter cleaning by ultrasound, backwashing and filter movement during the filtration of biological samples

InactiveUS8273253B2Minimises fouling and clogging of filterImprove overall efficiency and accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsCyclic processVacuum pressure

The present application is directed to the separation of—a solid fraction from a fluid sample particularly a therapeutic cellular fraction from a biological sample such as a bone marrow sample by a porous filter (2) which separates a filtration unit (1) into an upper pre-filtration chamber (3) into which a fluid sample (4) requiring cell separation is introduced and a lower post-filtration chamber (5) into which a fluid (6) capable of transmitting an acoustic standing wave is introduced. An acoustic element (8) is coupled to a substrate (7) which is located within and at the bottom of the lower chamber (5) and which resonates in response to the acoustic generating element (8) and generates a standing wave through the two fluid phases and the filter to agitate the sample (4). Simultaneously, a cyclic process of vacuum draw (9). causes movement of the sample (4) downwards through the filter (2). Vacuum pressure, fluid flow rate and frequency of vibration are controlled from a remote unit housing appropriate pumps and valves.

Owner:SMITH & NEPHEW INC

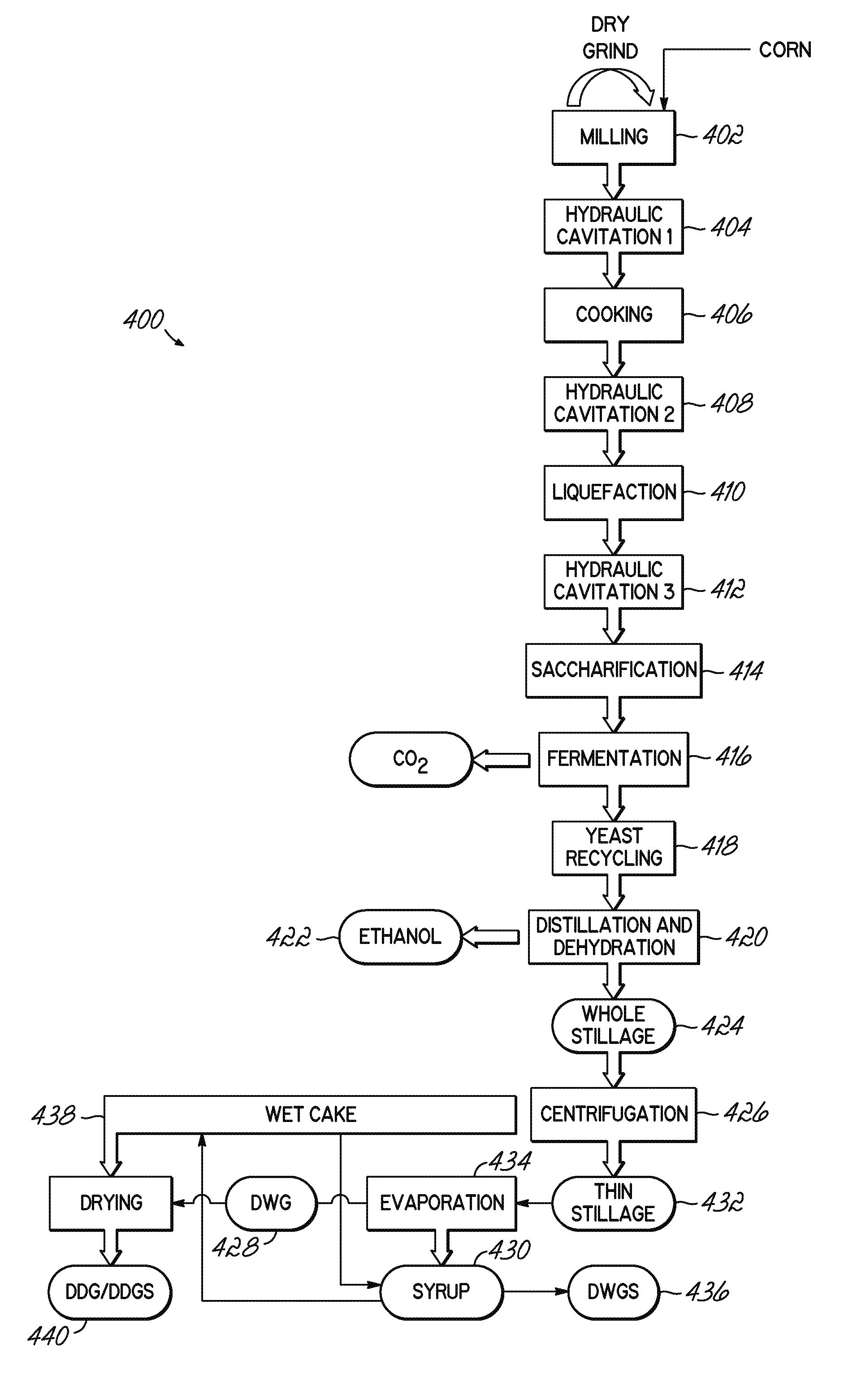

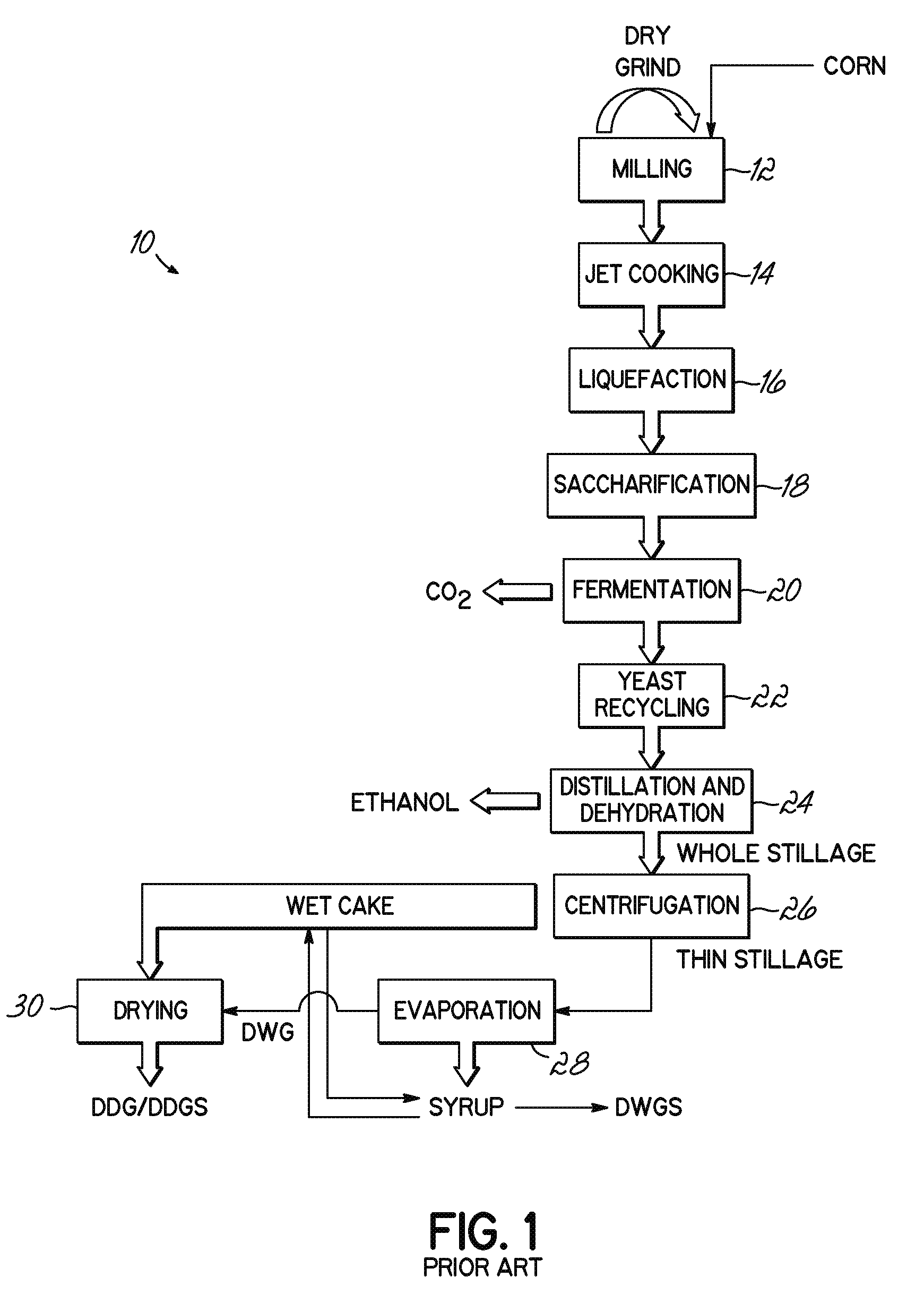

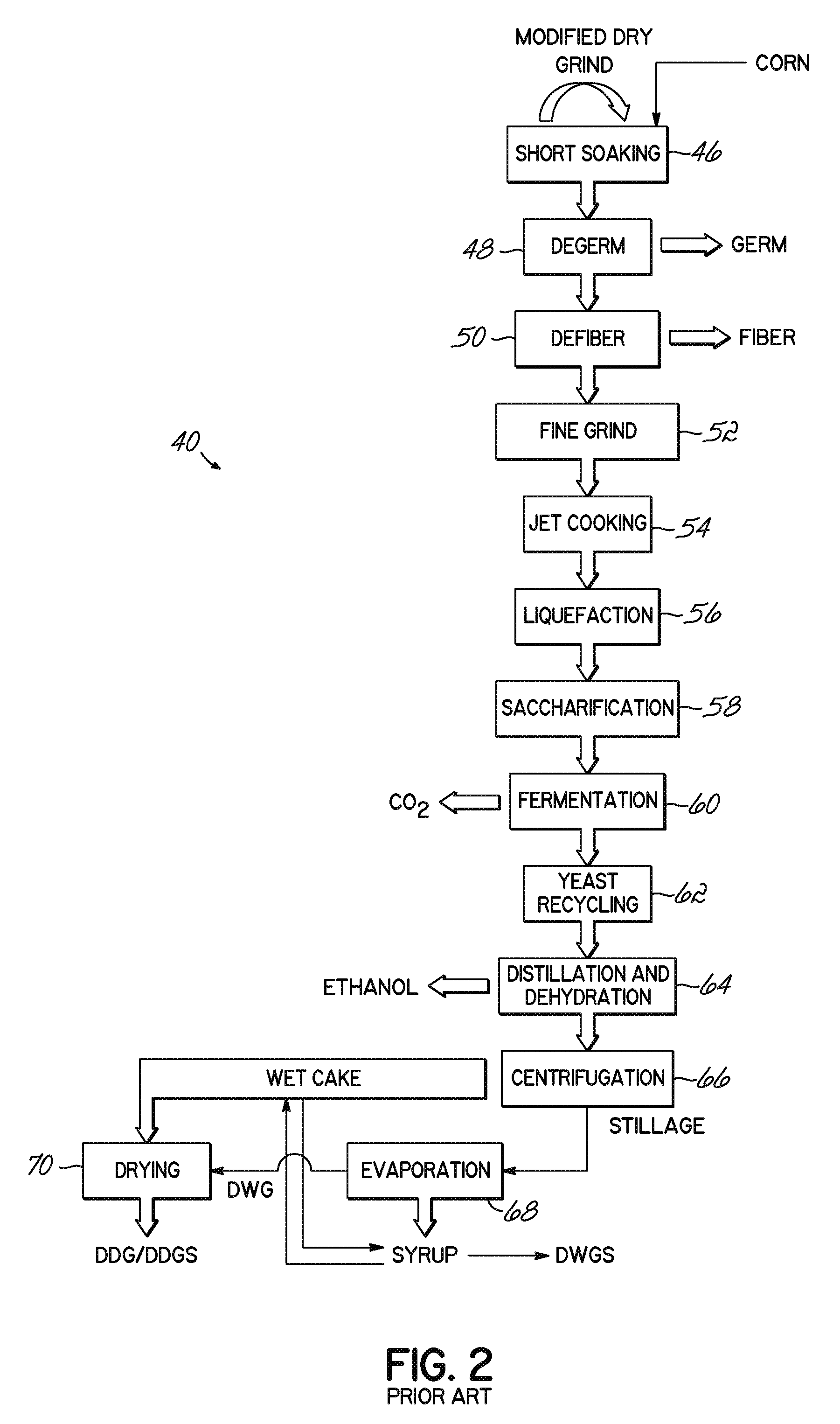

Alcohol production using hydraulic cavitation

InactiveUS20080277264A1Increase speedHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsCavitationLiquid medium

A system and method is provided which includes using a liquid treatment apparatus, which is equipped with cyclonettes, for example, to subject a liquid medium processing stream in an alcohol production process to hydraulic cavitation, i.e., to shear under vacuum, at one or more locations. The liquid treatment apparatus, in one embodiment, is directed to the formation of a central axial jet and a vacuum chamber that can be sealed by the exiting jet. Cavitation is generated by directing a high velocity jet of liquid medium processing stream through a volume of vapor under a vacuum created in the chamber through which the jet travels. This can reduce the production cost of alcohol, such as ethanol, by improving alcohol yield per bushel, among other benefits. In one embodiment, the alcohol production process is a dry grind process, a modified dry grind process, or a wet mill process. In one embodiment the alcohol production process utilizes grain as a starting material.

Owner:FLUID QUIP INC

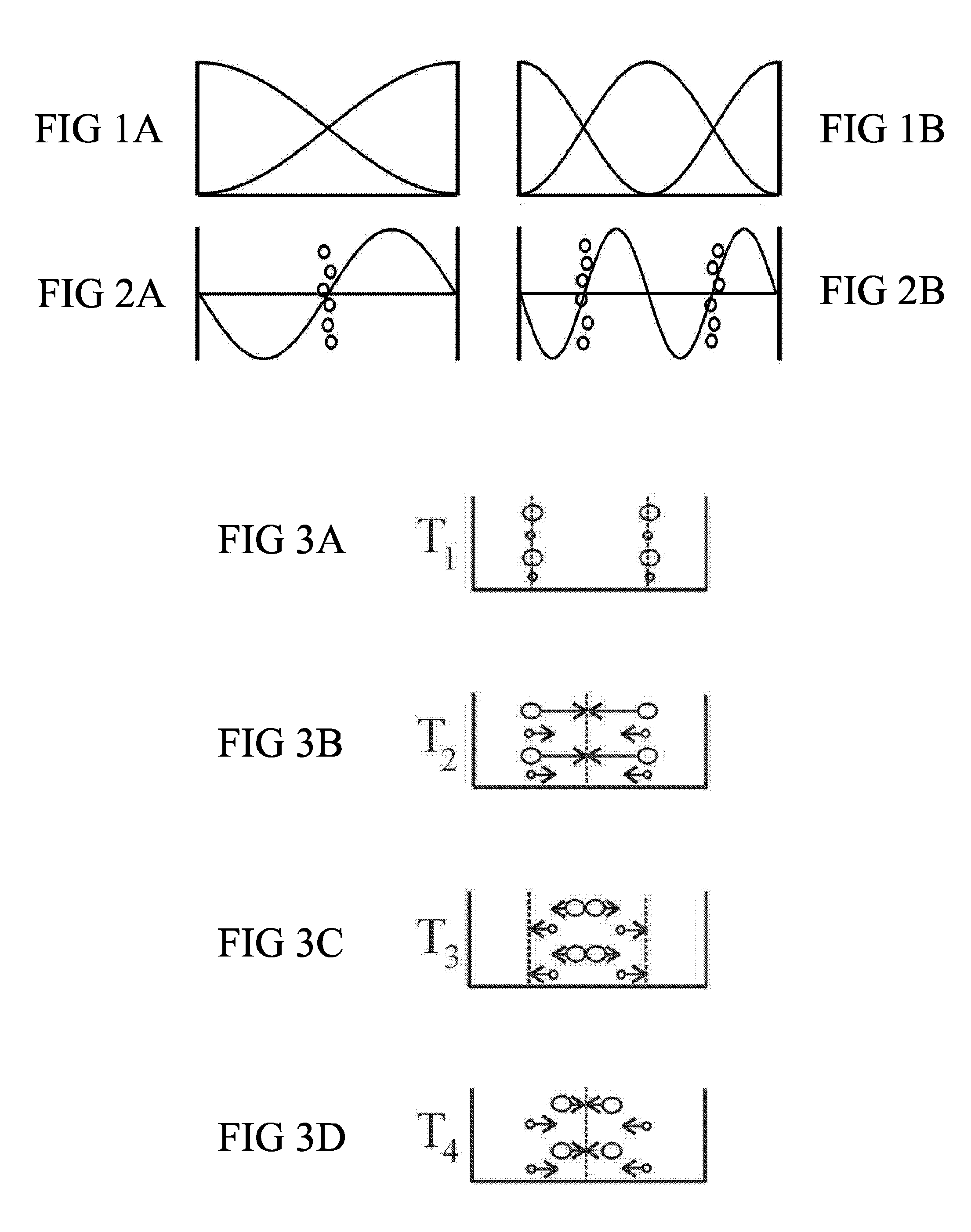

Method and Device for Separating Particles

InactiveUS20080217259A1Other blood circulation devicesWater/sewage treatment with mechanical oscillationsSonificationHarmonic

The invention relates to a method and a device for separating particles using ultrasonic standing waves which are switched between two different frequencies. A second order harmonic standing wave is used together with the fundamental standing wave. If the particles are exposed to the fundamental standing wave, the forces act to collect particles at the centre. If the particles are exposed to the second order harmonic standing wave, the forces act to collect particles at the two pressure nodes at the sides. By switching the frequency between the second order harmonic standing wave and the fundamental standing wave, particles with different properties will be exposed to different accelerations and are separated into two streams.

Owner:SPECTRONIC

Systems and Methods for Separating Particles and/or Substances from a Sample Fluid

ActiveUS20090194420A1Liquid separation auxillary apparatusSludge treatmentFluid systemAmount of substance

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

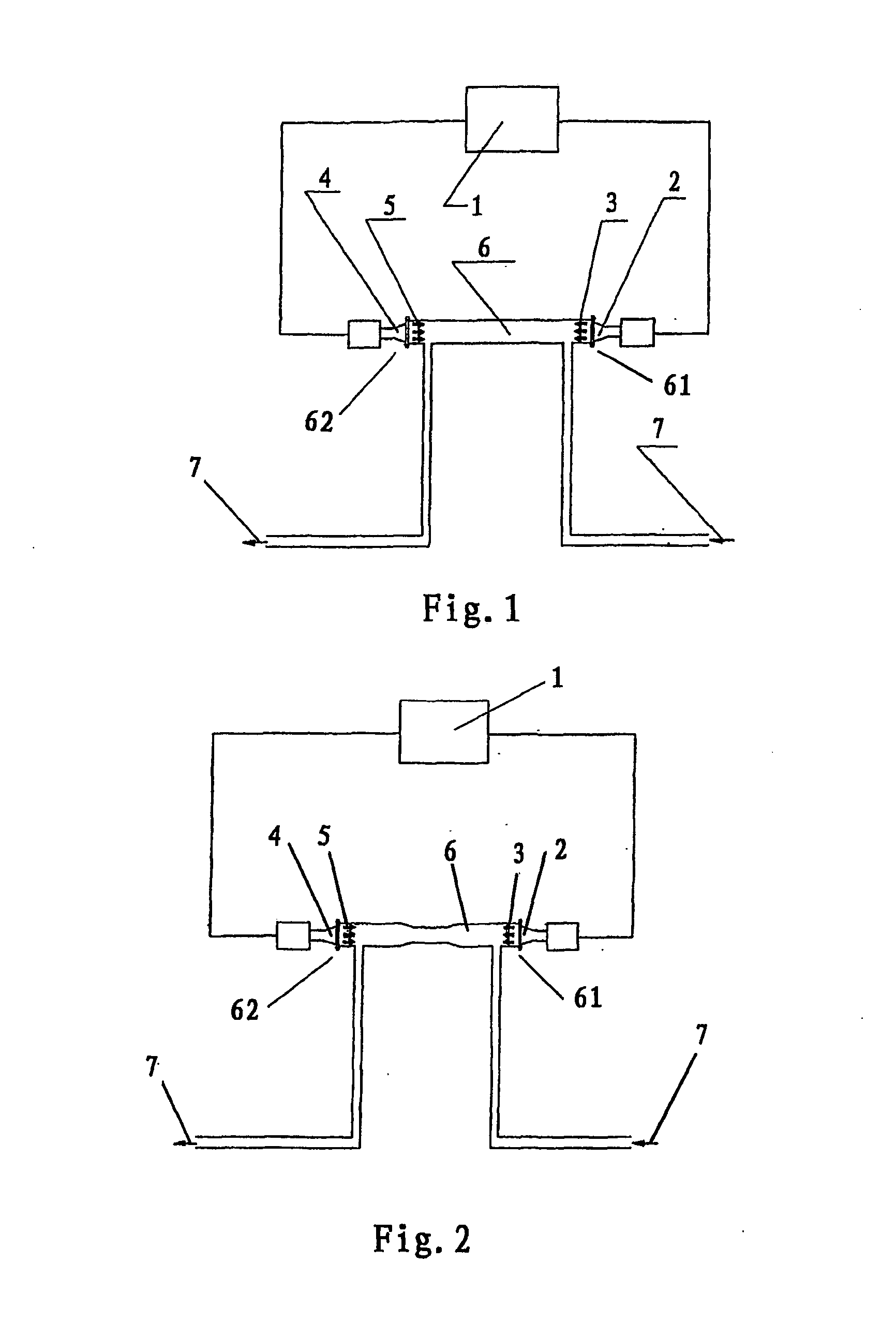

Method and Apparatus for Demulsifying an Oil-Water Emulsion Via Ultrasonic

ActiveUS20070272618A1Good effectExtension of timeDewatering/demulsification with mechanical meansLiquid separation by electricityUltrasound - actionOil water emulsion

A method for demulsifying water-oil emulsions through ultrasonic action, comprises a step of making the water-oil emulsions flow through at least one ultrasonic acting region in a flow direction, wherein: within the ultrasonic acting region, a concurrent ultrasonic wave whose traveling direction is the same as the flow direction of the water-oil emulsions is generated by at least a one first ultrasonic transducer provided at the upstream end of the ultrasonic acting region, and at same time, a countercurrent ultrasonic wave whose traveling direction is opposite to the flow direction of the water-oil emulsions is generated by at least a one second ultrasonic transducer provided at the downstream end of the ultrasonic acting region; and the concurrent ultrasonic wave and the countercurrent ultrasonic wave act simultaneously on the water-oil emulsions which flow through the ultrasonic acting region, so as to demulsify the water-oil emulsions. After being demulsified, the water-oil emulsions gravity settle and separate, or settle and separate under an electric field, so as to be dewatered. The present invention can apply to various water-oil separating technologies in the procedures from mining to processing of crude oil.

Owner:CHINA PETROCHEMICAL CORP

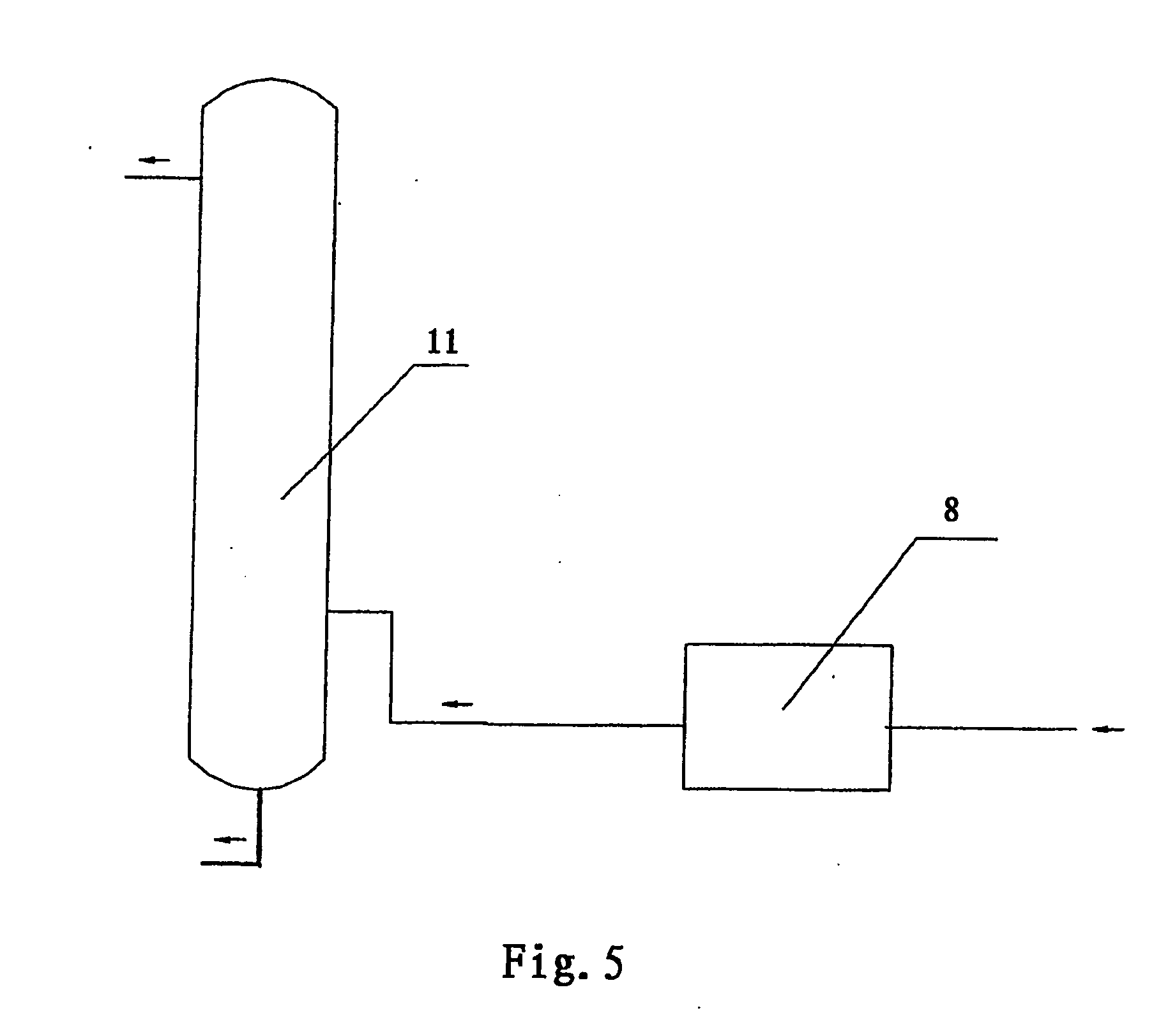

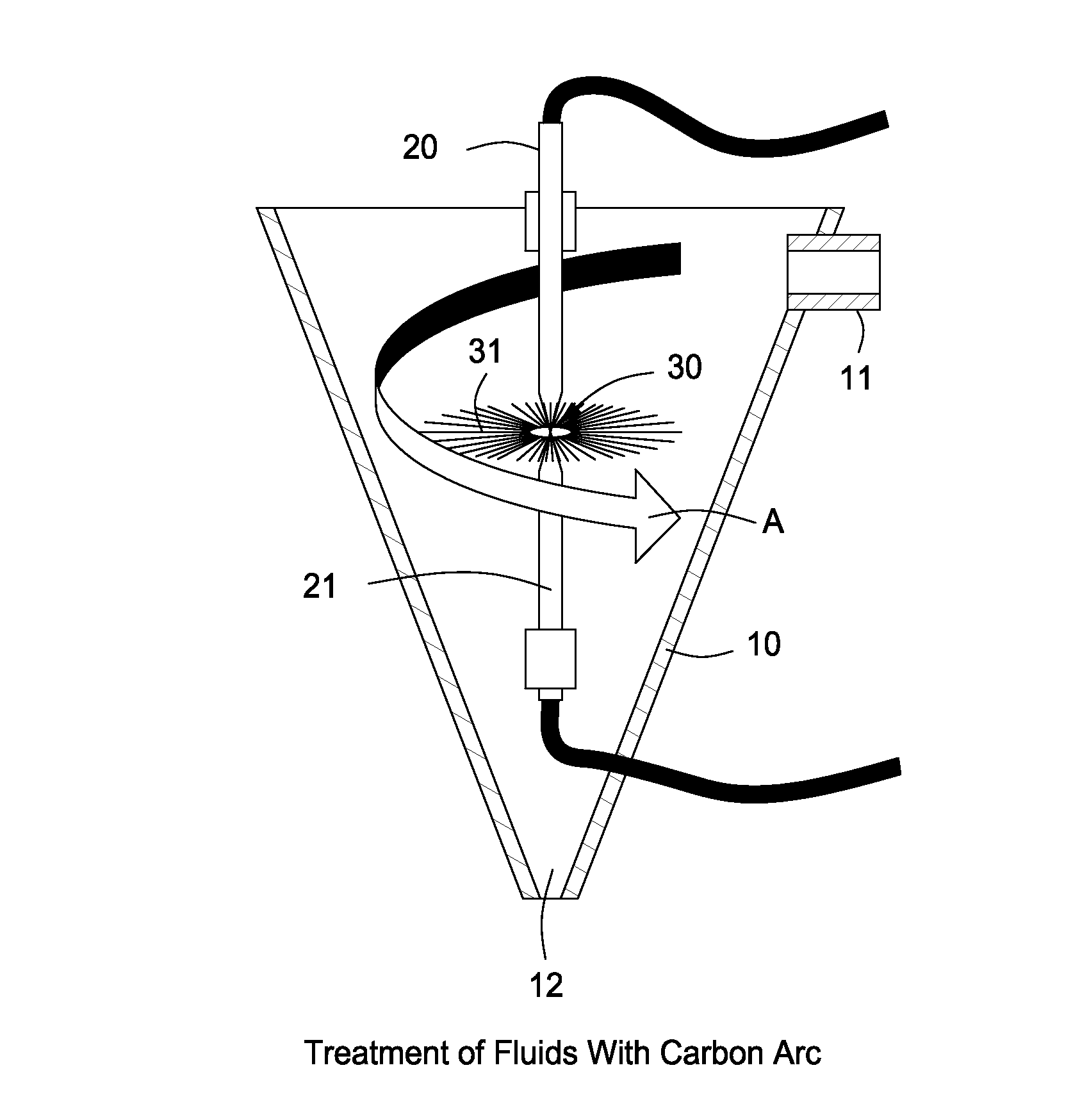

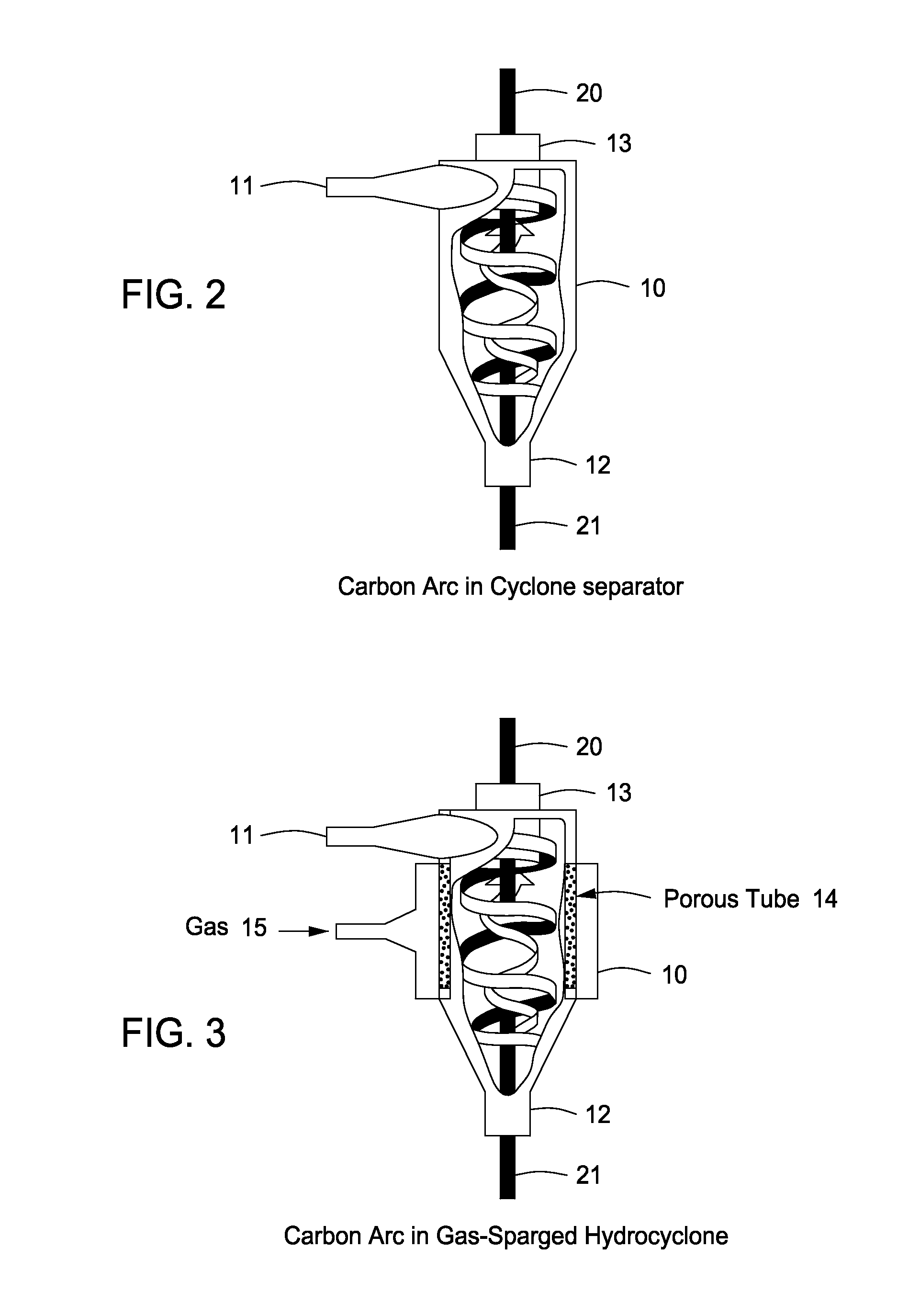

Treatment of fluids with wave energy from a carbon arc

ActiveUS7422695B2Superior wave energy deliveryEffective treatmentWater/sewage treatment by centrifugal separationReversed direction vortexCavitationPhysics

A method of and apparatus for treating liquids flowing in a thin film around a source of wave energy to directly expose the liquid to the wave energy, preferably generated in whole or part by an electrical arc between carbon electrodes. In addition to the wave energy generated by the electrical arc, energy generated by cavitation of the flowing liquid may be used in treating the liquid.

Owner:FORET PLASMA LABS

Acoustophoretic separation of lipid particles from red blood cells

InactiveUS20130277316A1Other blood circulation devicesWater/sewage treatment with mechanical oscillationsLipid formationLipid particle

A system for removing lipids from blood during cardiopulmonary bypass surgery is disclosed. The system uses an acoustophoretic separator having improved trapping force. The transducer of the acoustophoretic seperator includes a ceramic crystal. Blood flows through the separator, and lipids are trapped and removed.

Owner:FLODESIGN SONICS

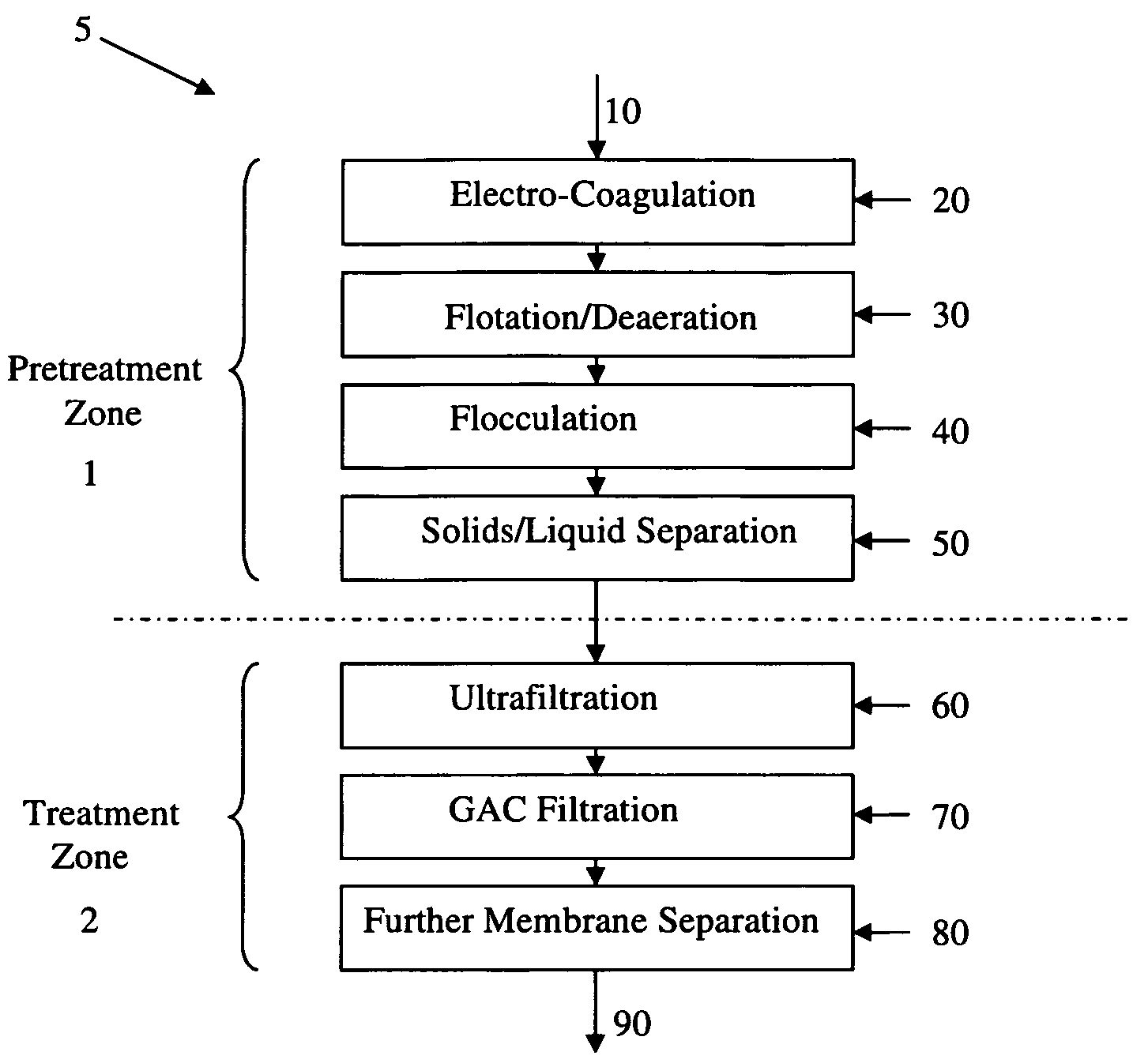

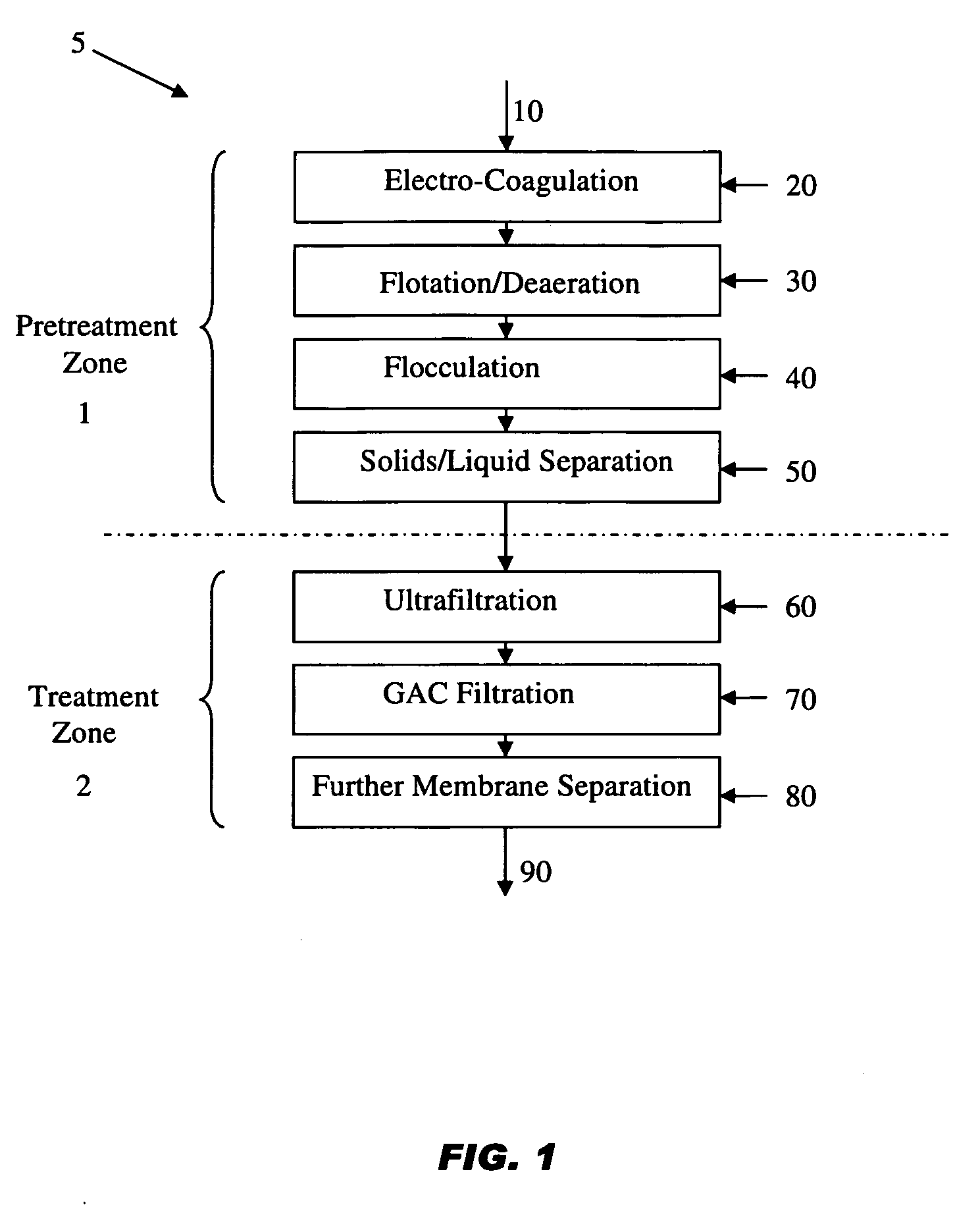

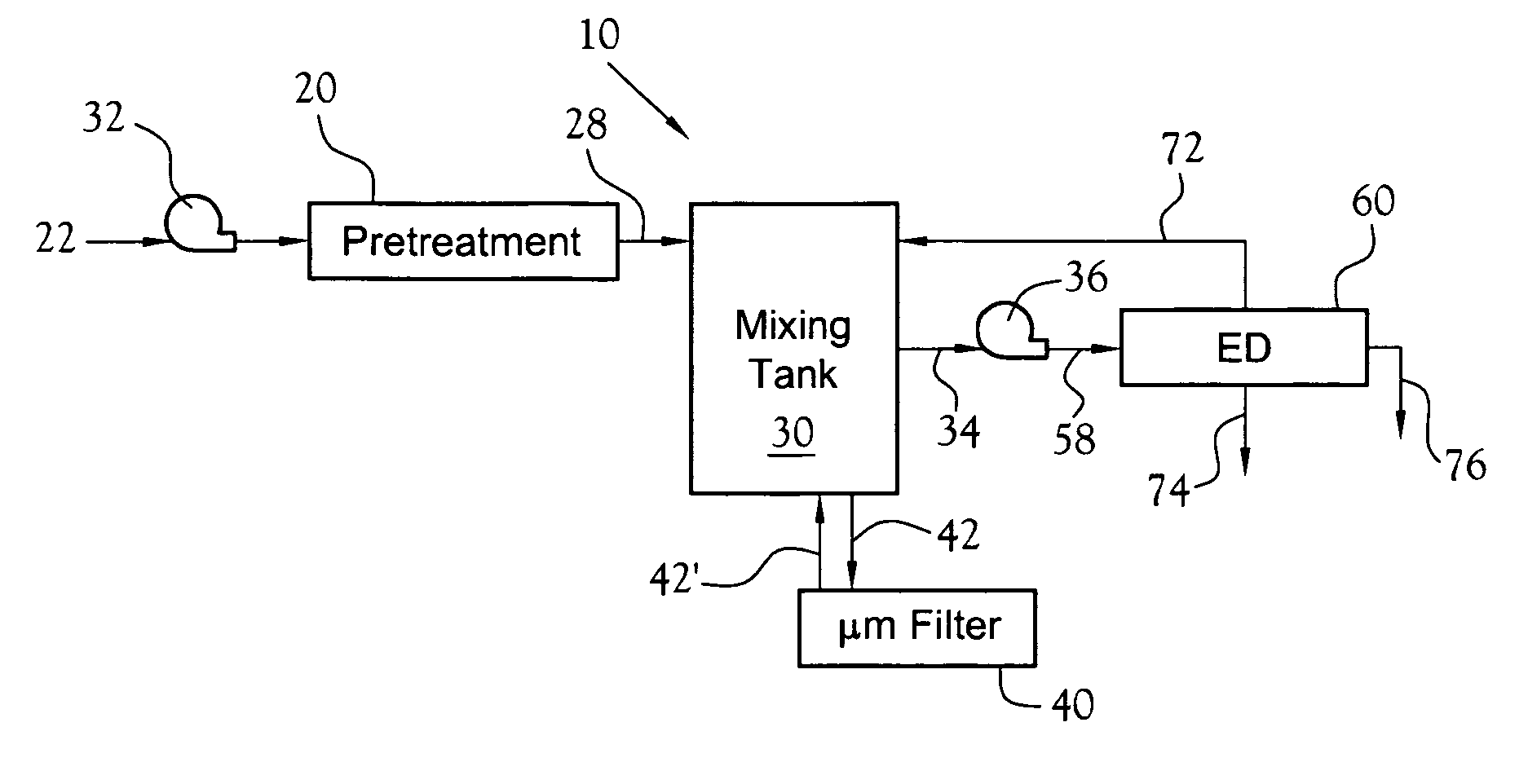

Treatment process and system for wastewater, process waters, and produced waters applications

A method for the removal of contaminants from a contaminated water stream, by pretreating the contaminated water stream to yield a pretreated water stream, wherein pretreating comprises passing the contaminated water stream to at least one electrocoagulation cell wherein coagulation of contaminants is promoted, yielding an electrocoagulated stream; and separating coagulated contaminants from the electrocoagulated stream.An electrocoagulation reactor comprising a plurality of electrodes positioned parallel to each other and provided with a means of energizing each electrode; a fluid inlet for an inlet stream comprising contaminated water; a fluid outlet for an outlet stream comprising electrocoagulated products; a flow distributor system; and a gas distribution system for injecting a gas into the electrocoagulation reactor. An electrocoagulation system for treating a contaminated water stream, the system comprising at least one electrocoagulation reactor.

Owner:ITS ENGINEERED SYST

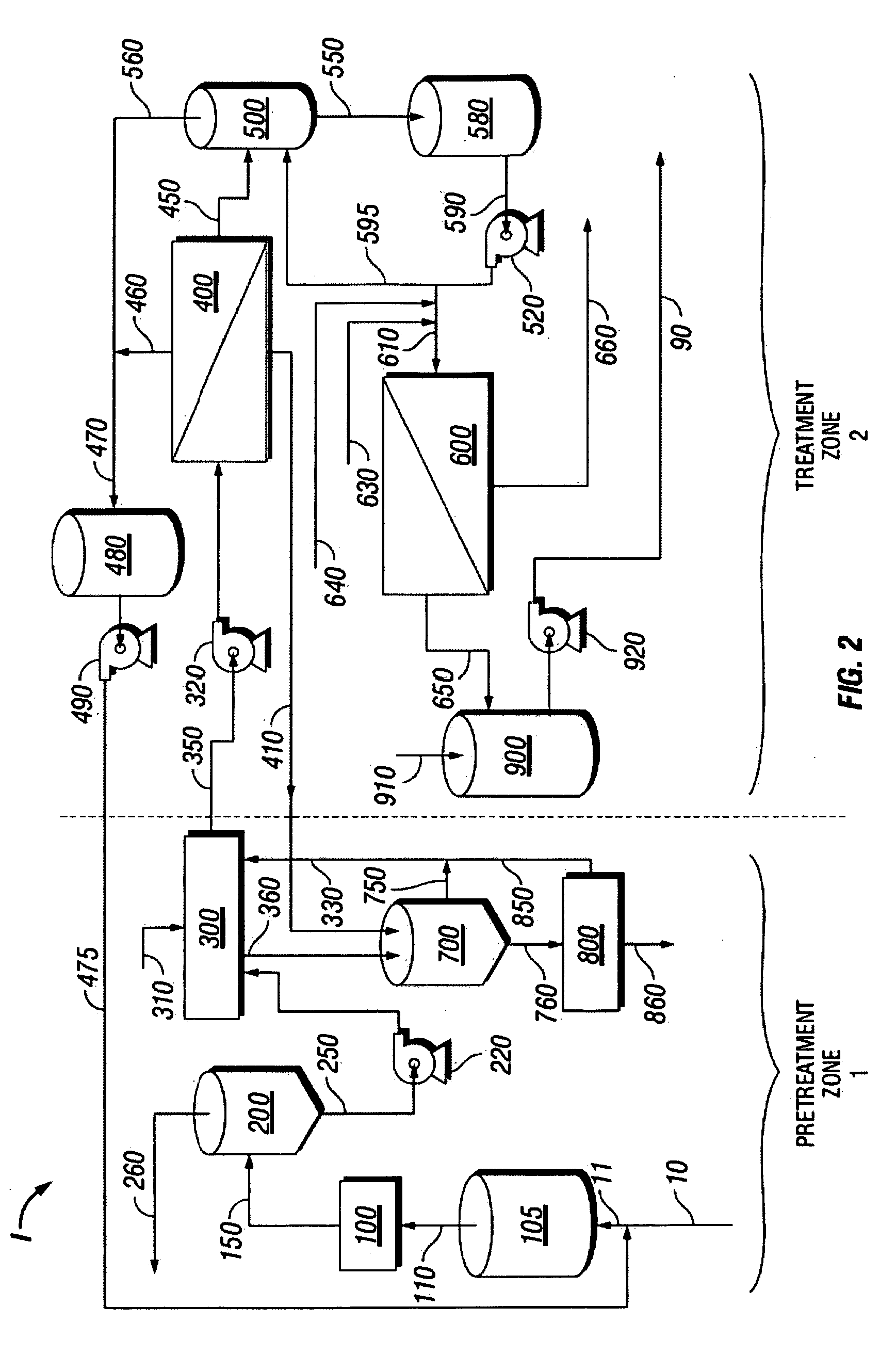

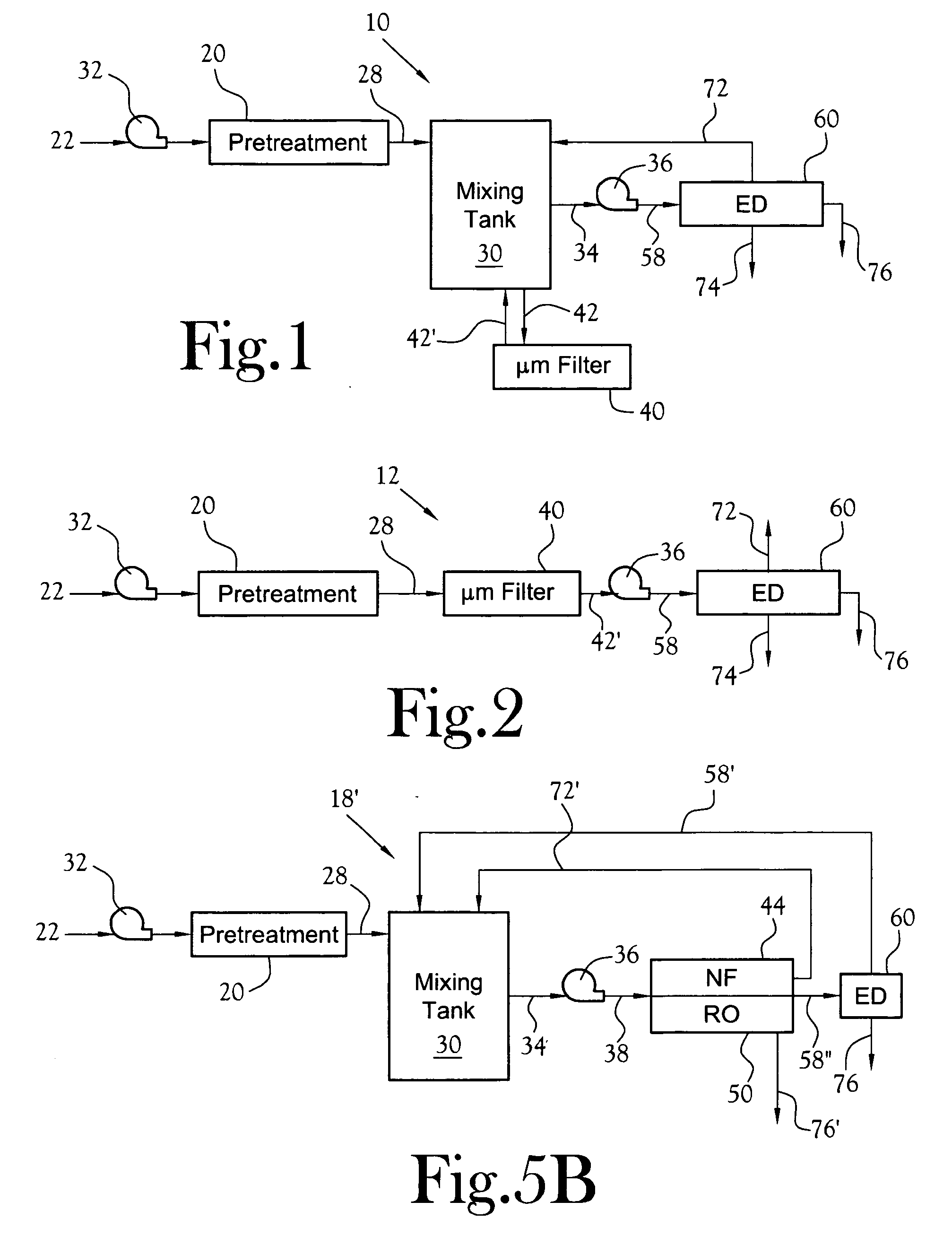

Integrated electro-pressure membrane deionization system

InactiveUS20060144787A1High capital costImprove utilization efficiencyLiquid separation auxillary apparatusVolume/mass flow measurementPressure.driveReverse osmosis

An integrated treatment system using electrodialysis and pressure-driven membranes for deionizing and decontaminating liquids to a near-pure quality for use or reuse in industrial or municipal operations. The integrated system includes steps of pre-filtering contaminated feed liquids blending the filtered liquids in preparation for treating the mixed liquids in parallel or sequential treatment steps utilizing nanofiltration or reverse osmosis, proceeded by or followed by an integrated electrodialysis treatment. A control means selectively directs mixed liquids to each of the treatment units for treatment in parallel or in series depending on the conductivity and residual contaminants in the mixed liquids. In comparison with nanofiltration or reverse osmosis only systems, or electrodialysis only systems, the integrated system provides improved efficiencies for treatment, requires less energy to operate, and reduces maintenance and capital costs.

Owner:EET TN

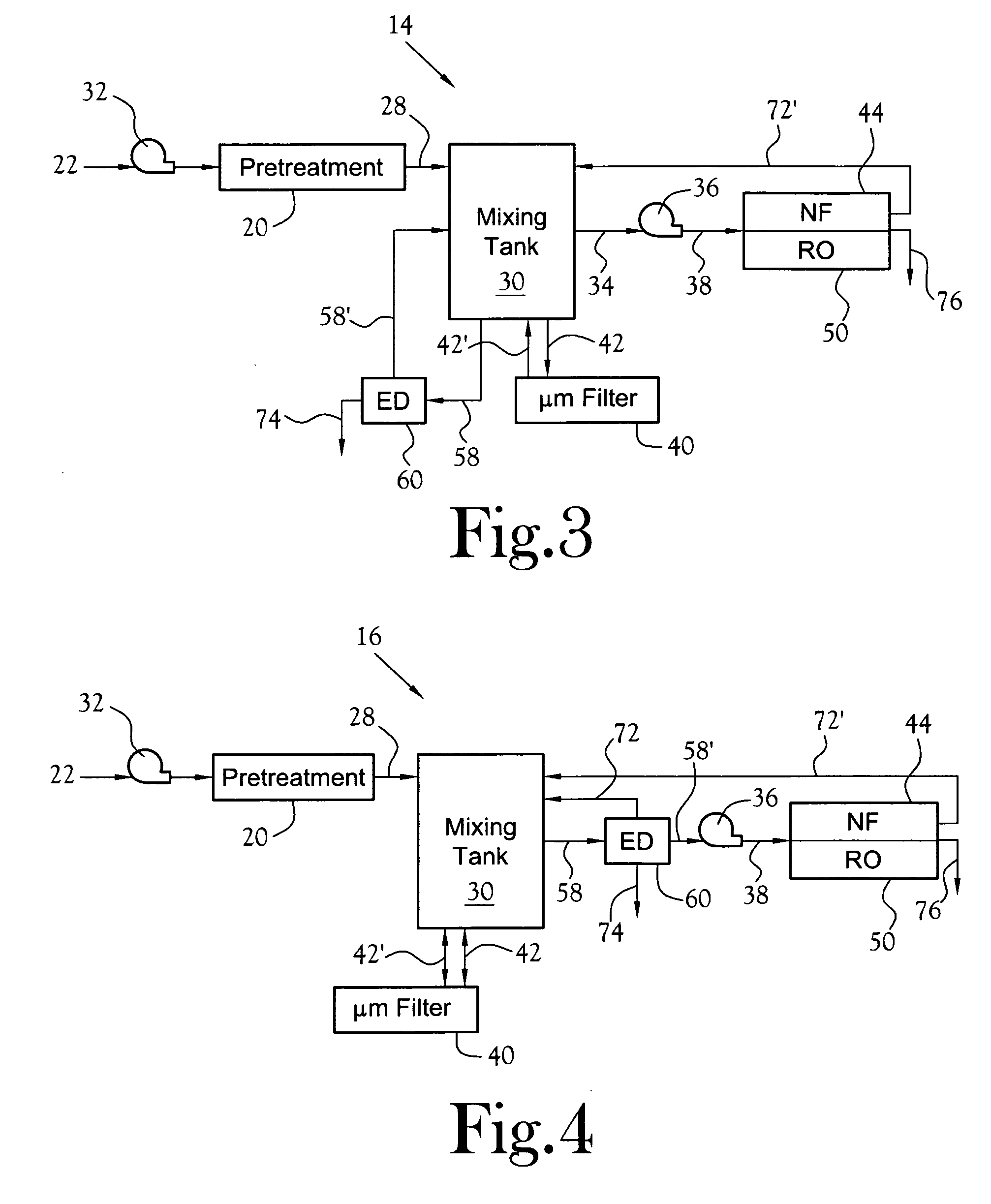

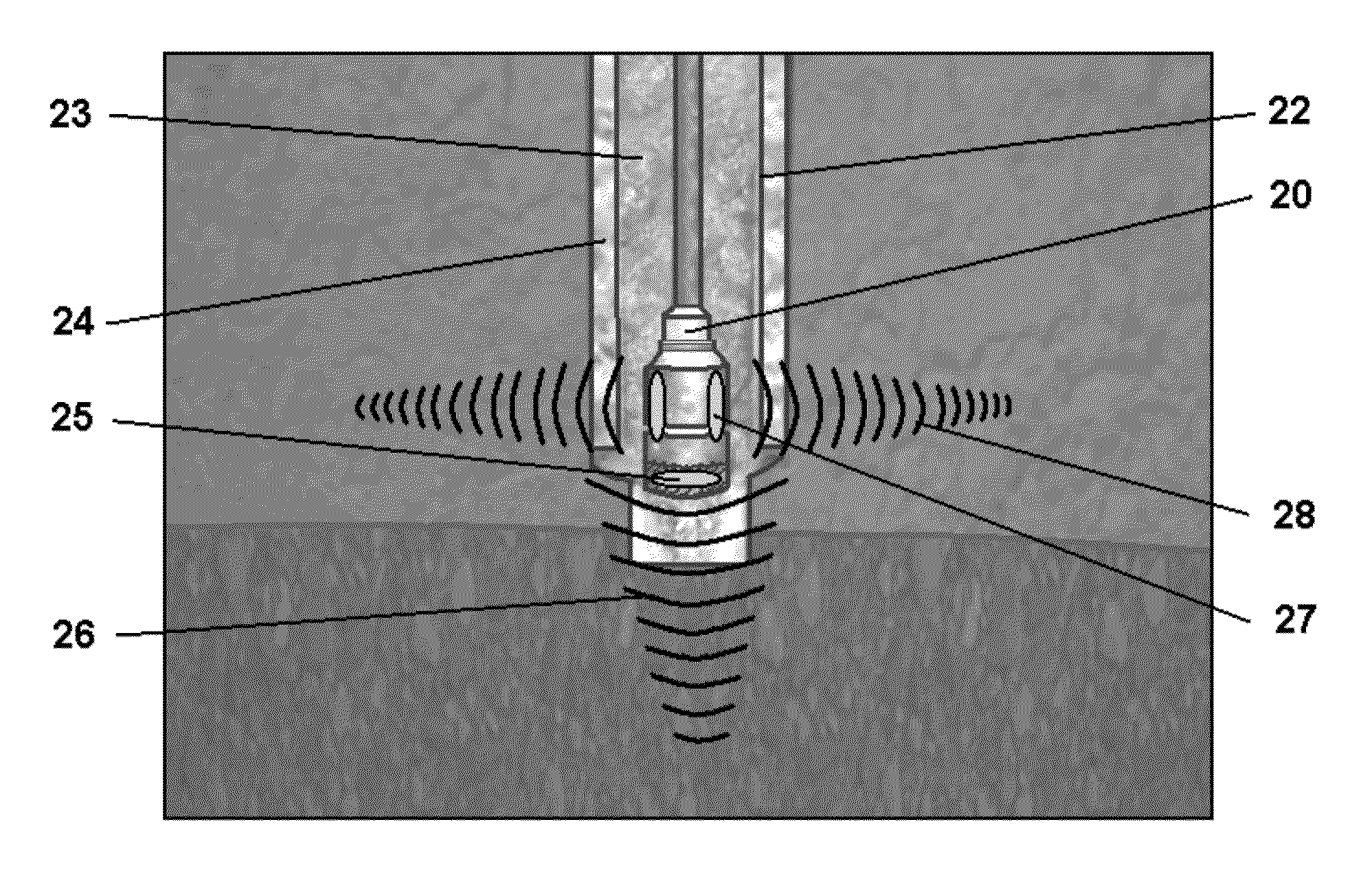

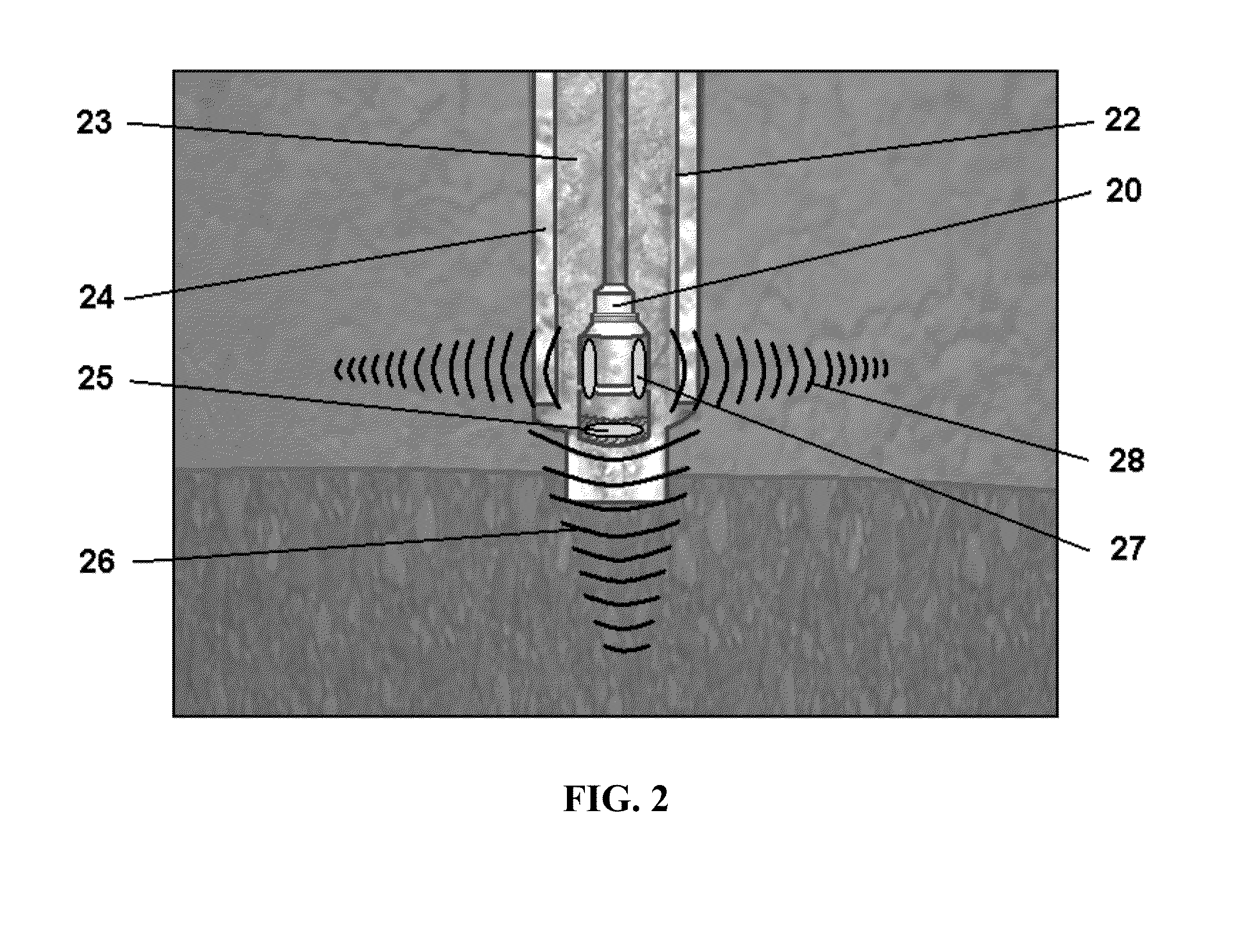

Apparatuses and methods for generating shock waves for use in the energy industry

ActiveUS20140305877A1Extend your lifeNeed can be fittedWaste water treatment from quariesFatty/oily/floating substances removal devicesShock waveFiber

Several methods and devices are provided herein to generate shock waves that are used in the oil industry for well drilling, hydrocarbon or gas exploitation, fracking process or improved oil recovery (IOR), enhanced oil recovery (EOR), cleaning of process waters, oil spills byproducts and oil pipes, which can be used as independent systems or as auxiliary systems concomitantly with other existing technologies. The different devices consist of generating shock waves utilizing either one or more laser sources, or a self-generated combustible gas supply, or a micro-explosive pellet, or piezocrystals, or a piezofiber composite structure.

Owner:SANUWAVE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com