Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7197 results about "Inorganic materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

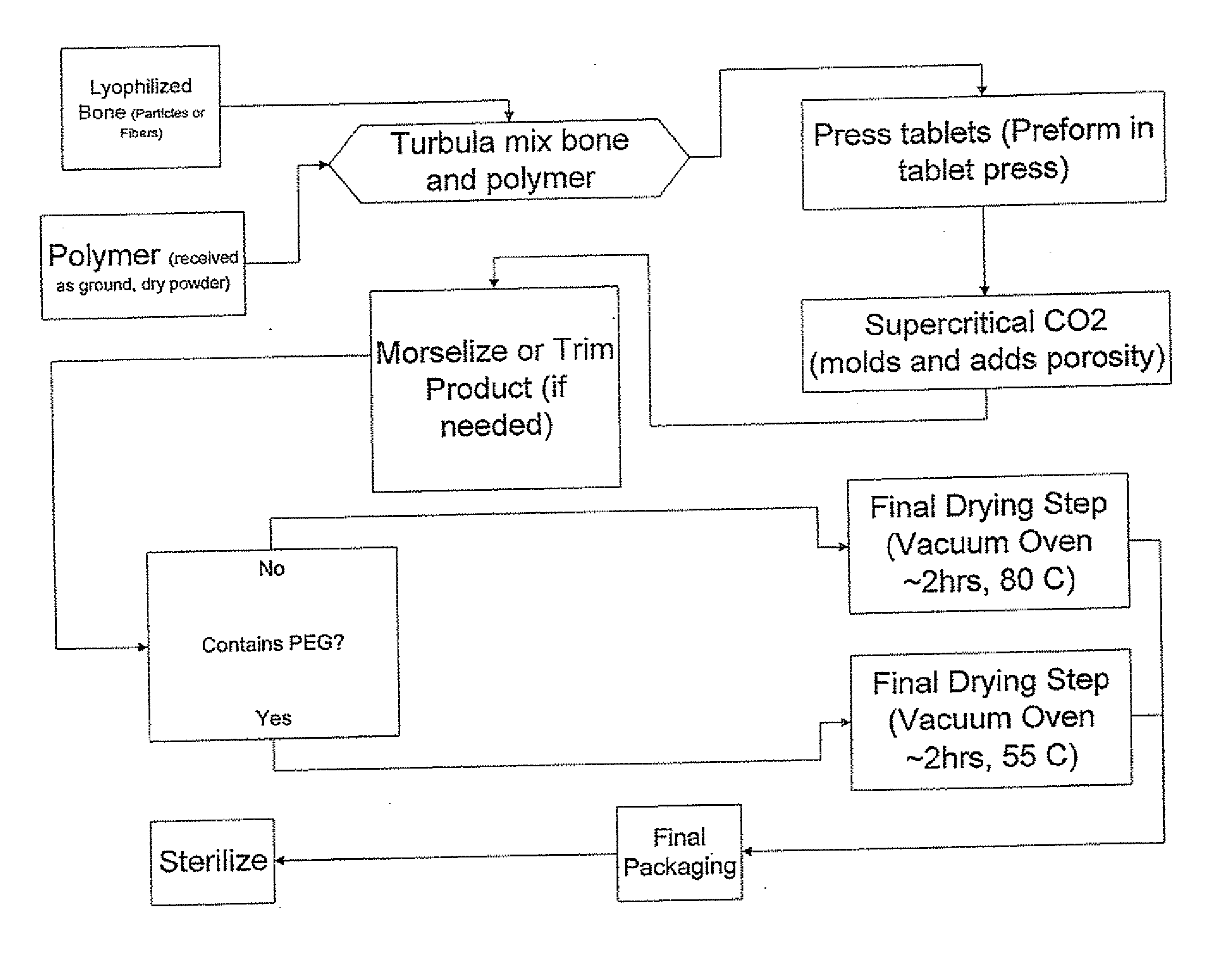

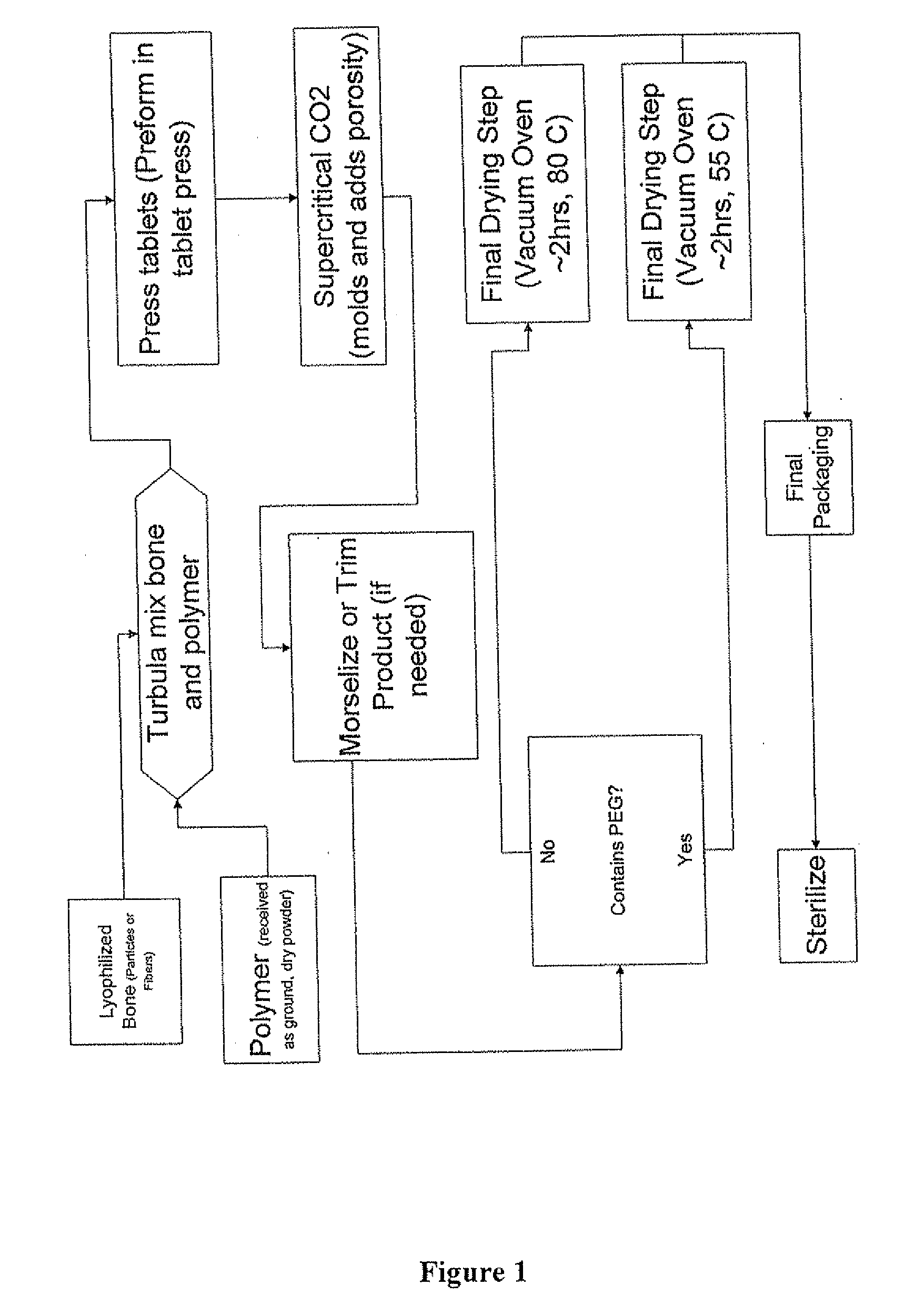

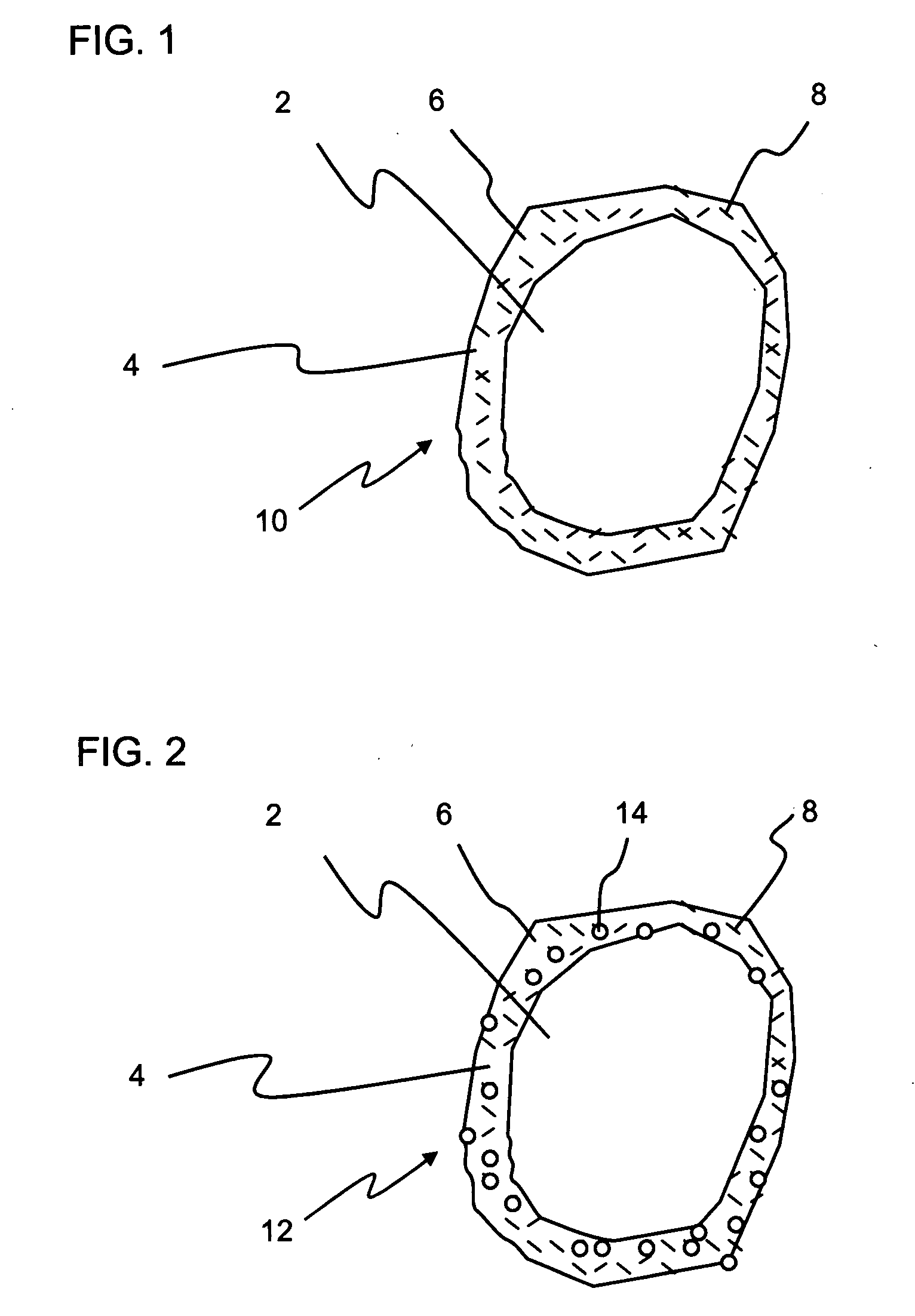

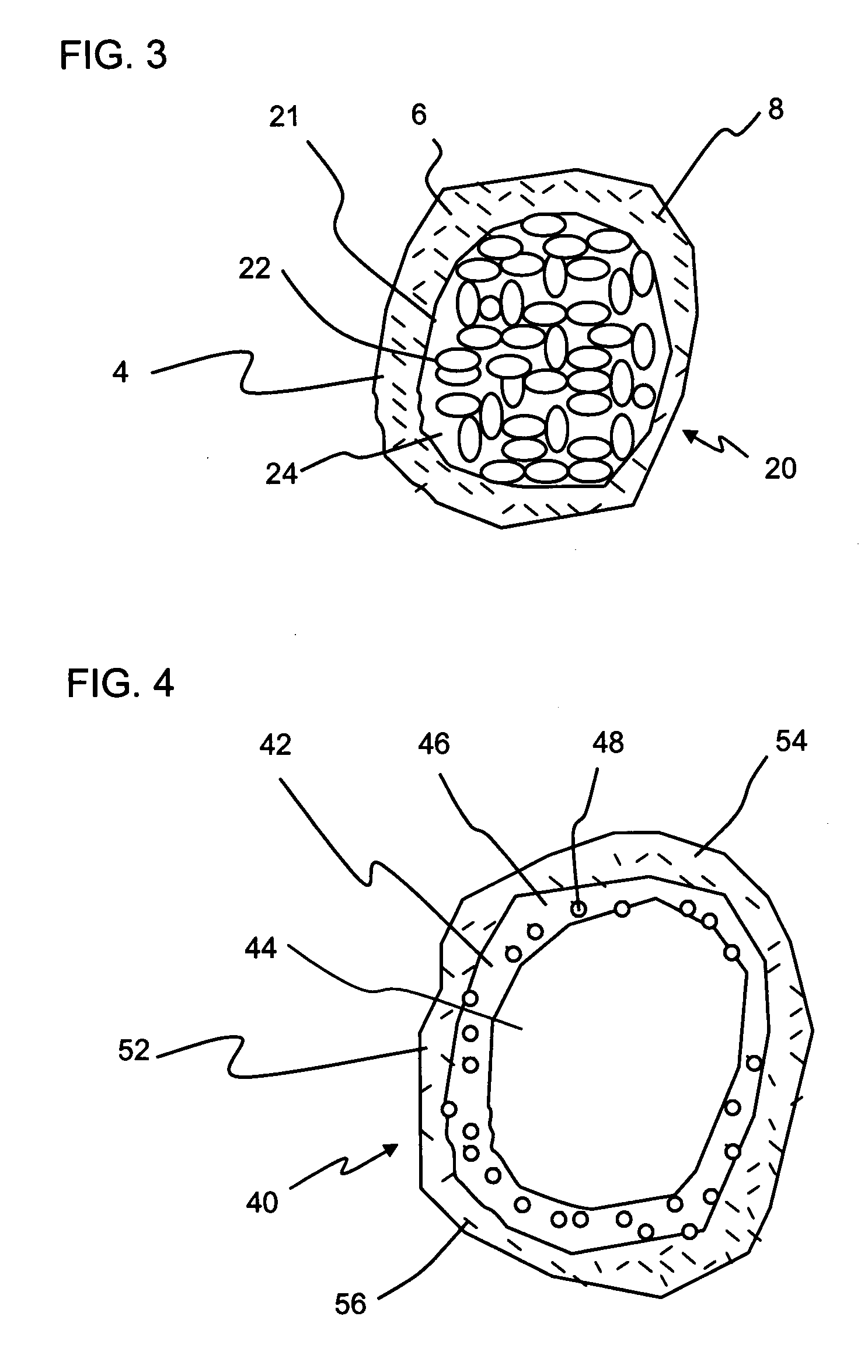

Methods for making and using composites, polymer scaffolds, and composite scaffolds

InactiveUS20070187857A1Promote safe productionTime-consumeDomestic articlesProsthesisOrganic solventTissue repair

The present invention relates to methods of making and using composites and scaffolds as implantable devices useful for tissue repair, guided tissue regeneration, and tissue engineering. In particular, the present invention relates to methods of making and using compression molded resorbable thermoplastic polymer composites which can be subsequently processed with non-organic solvents to create porous, resorbable thermoplastic polymer scaffolds or composite scaffold with interconnected porosity. Furthermore, these composites or scaffolds can be coated with an organic and / or inorganic material.

Owner:LOREM VASCULAR PTE LTD

Method of manufacturing inorganic nanotube

InactiveUS7005391B2Material nanotechnologyPolycrystalline material growthInorganic materialsAtomic layer deposition

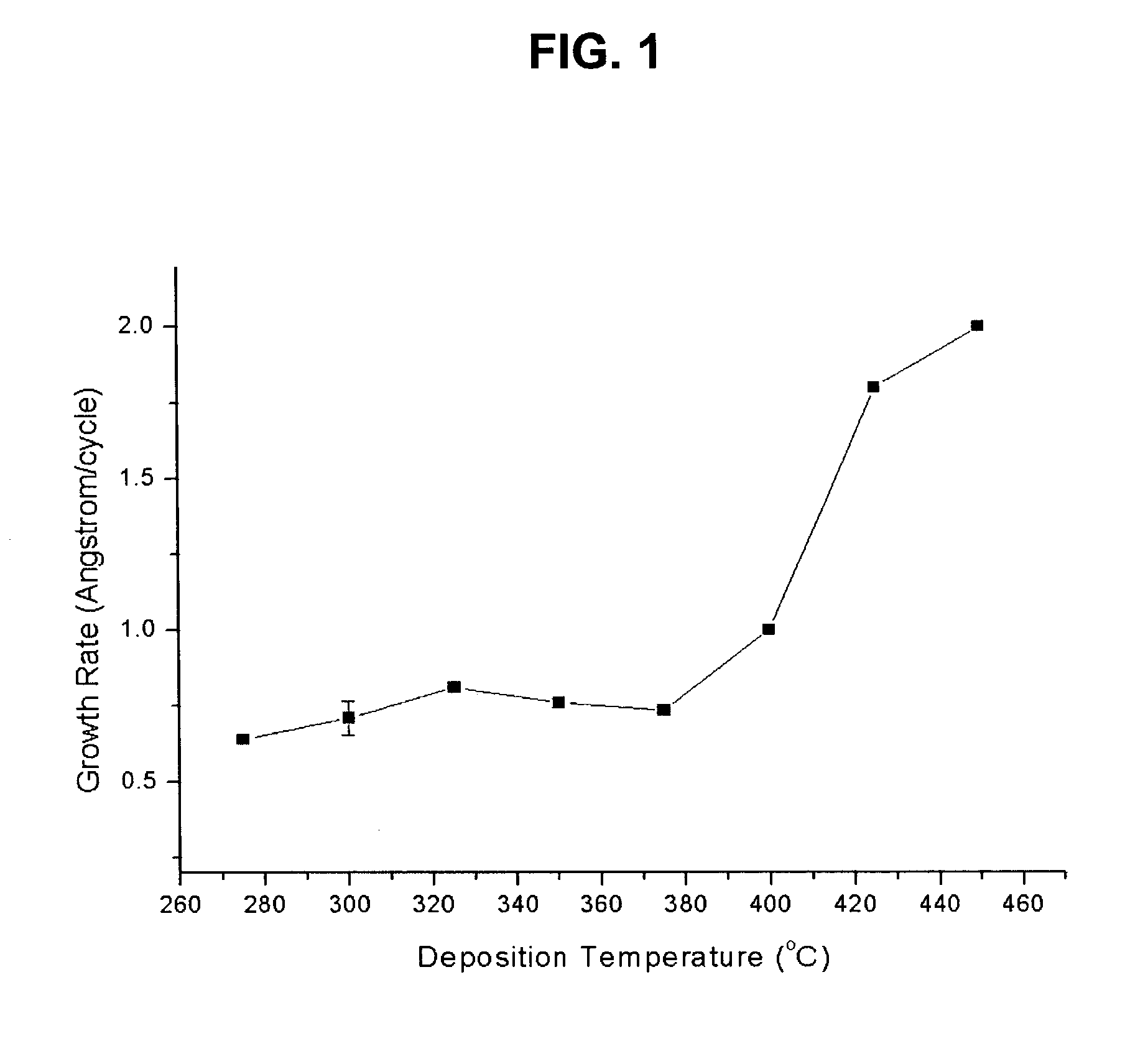

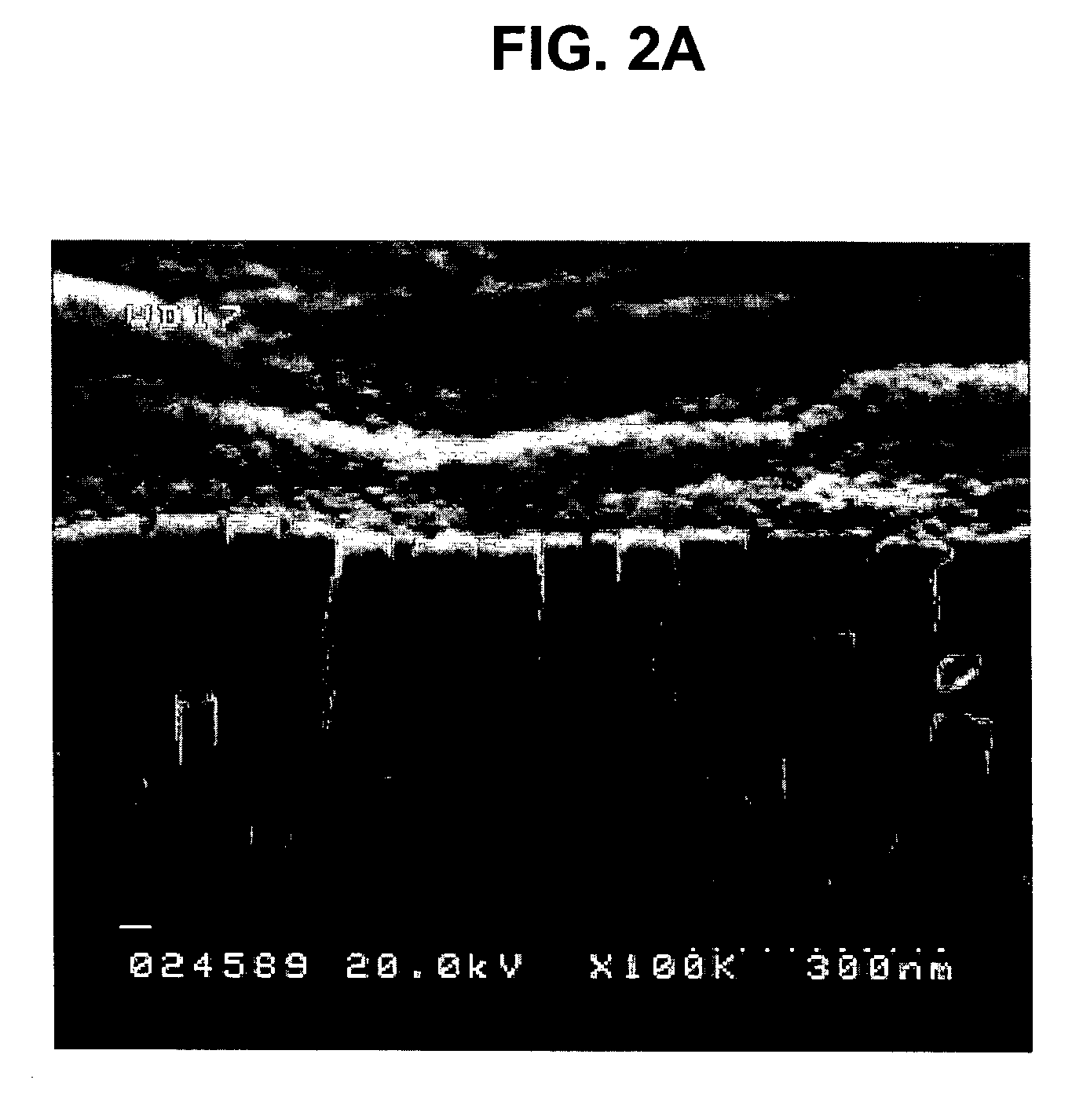

A method of manufacturing an inorganic nanotube using a carbon nanotube (CNT) as a template, includes preparing a template on which a CNT or a CNT array is formed, forming an inorganic thin film on the CNT by depositing an inorganic material on the template using atomic layer deposition (ALD), and removing the CNT to obtain an inorganic nanotube or an inorganic nanotube array, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for making a chemical contrast pattern using block copolymers and sequential infiltration synthesis

ActiveUS20140346142A1Decorative surface effectsPhotomechanical apparatusInorganic materialsAtomic layer deposition

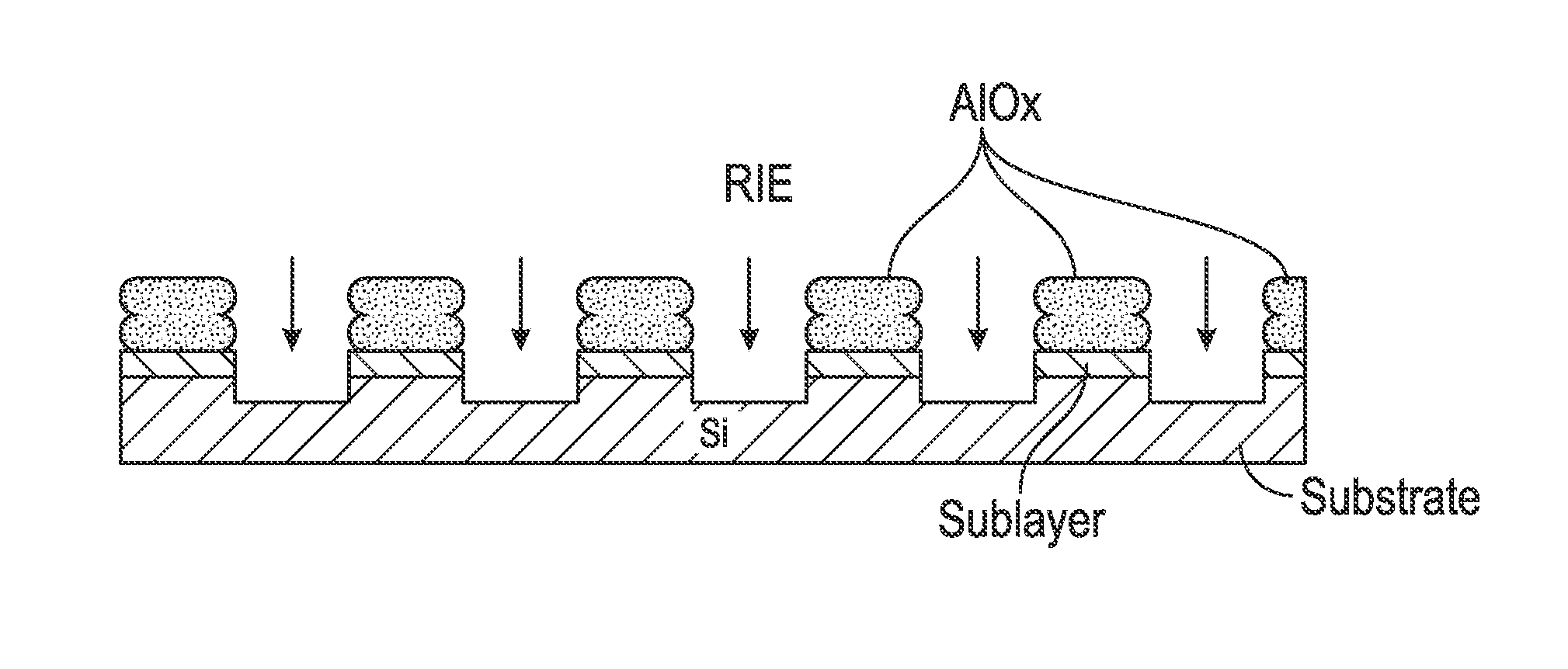

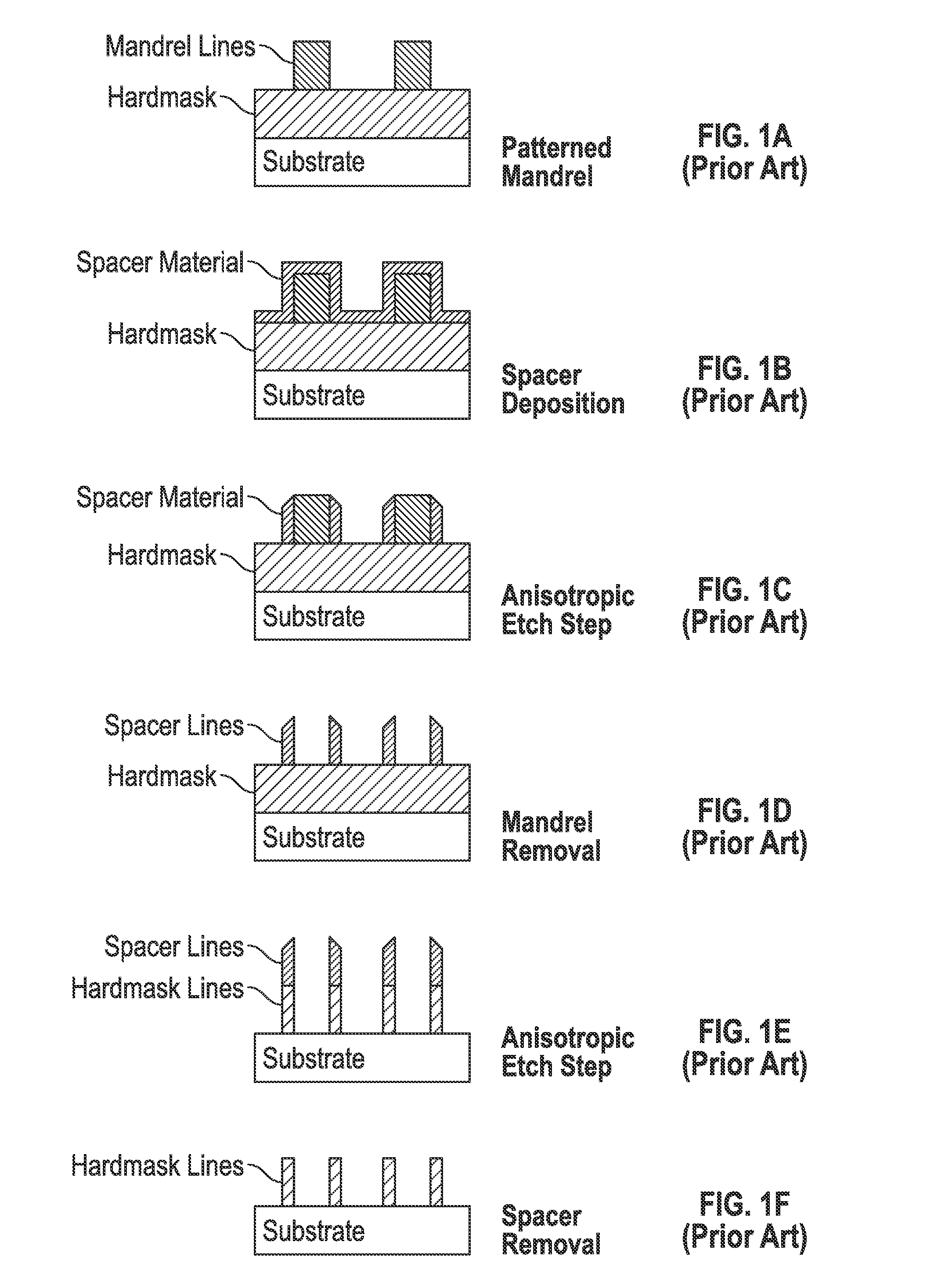

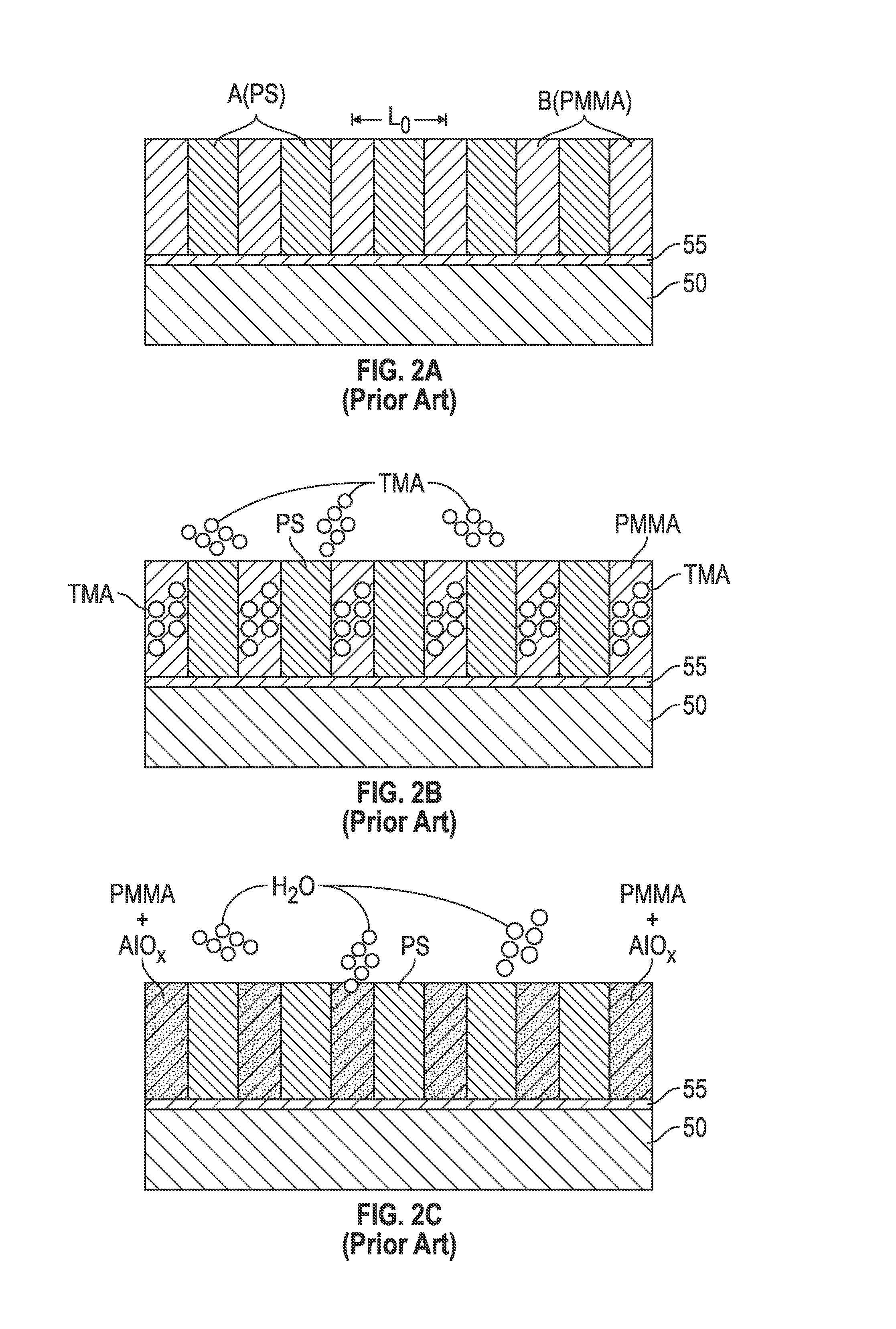

A method for making a chemical contrast pattern uses directed self-assembly of block copolymers (BCPs) and sequential infiltration synthesis (SIS) of an inorganic material. For an example with poly(styrene-block-methyl methacrylate) (PS-b-PMMA) as the BCP and alumina as the inorganic material, the PS and PMMA self-assemble on a suitable substrate. The PMMA is removed and the PS is oxidized. A surface modification polymer (SMP) is deposited on the oxidized PS and the exposed substrate and the SMP not bound to the substrate is removed. The structure is placed in an atomic layer deposition chamber. Alumina precursors reactive with the oxidized PS are introduced and infuse by SIS into the oxidized PS, thereby forming on the substrate a chemical contrast pattern of SMP and alumina. The resulting chemical contrast pattern can be used for lithographic masks, for example to etch the underlying substrate to make an imprint template.

Owner:WESTERN DIGITAL TECH INC

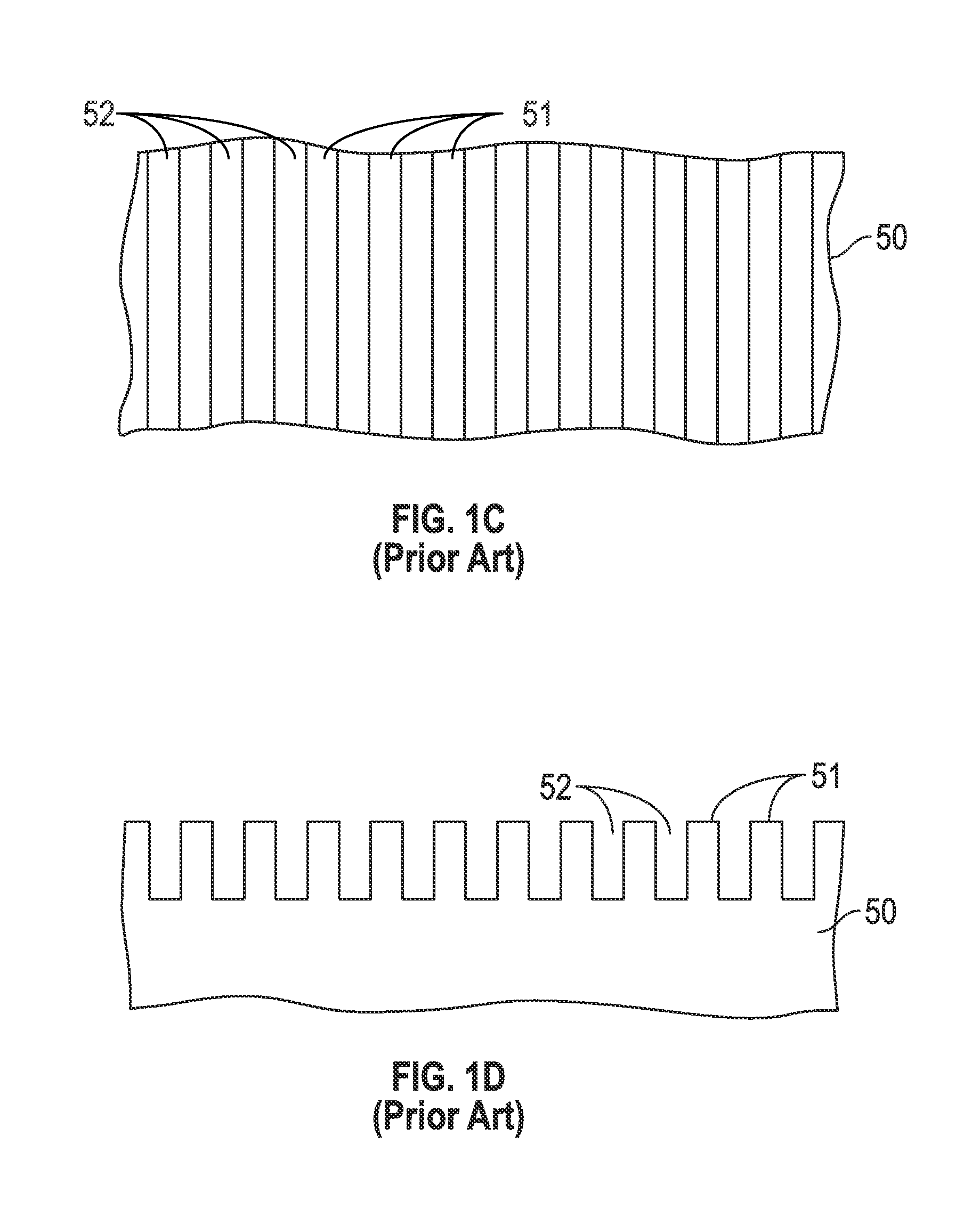

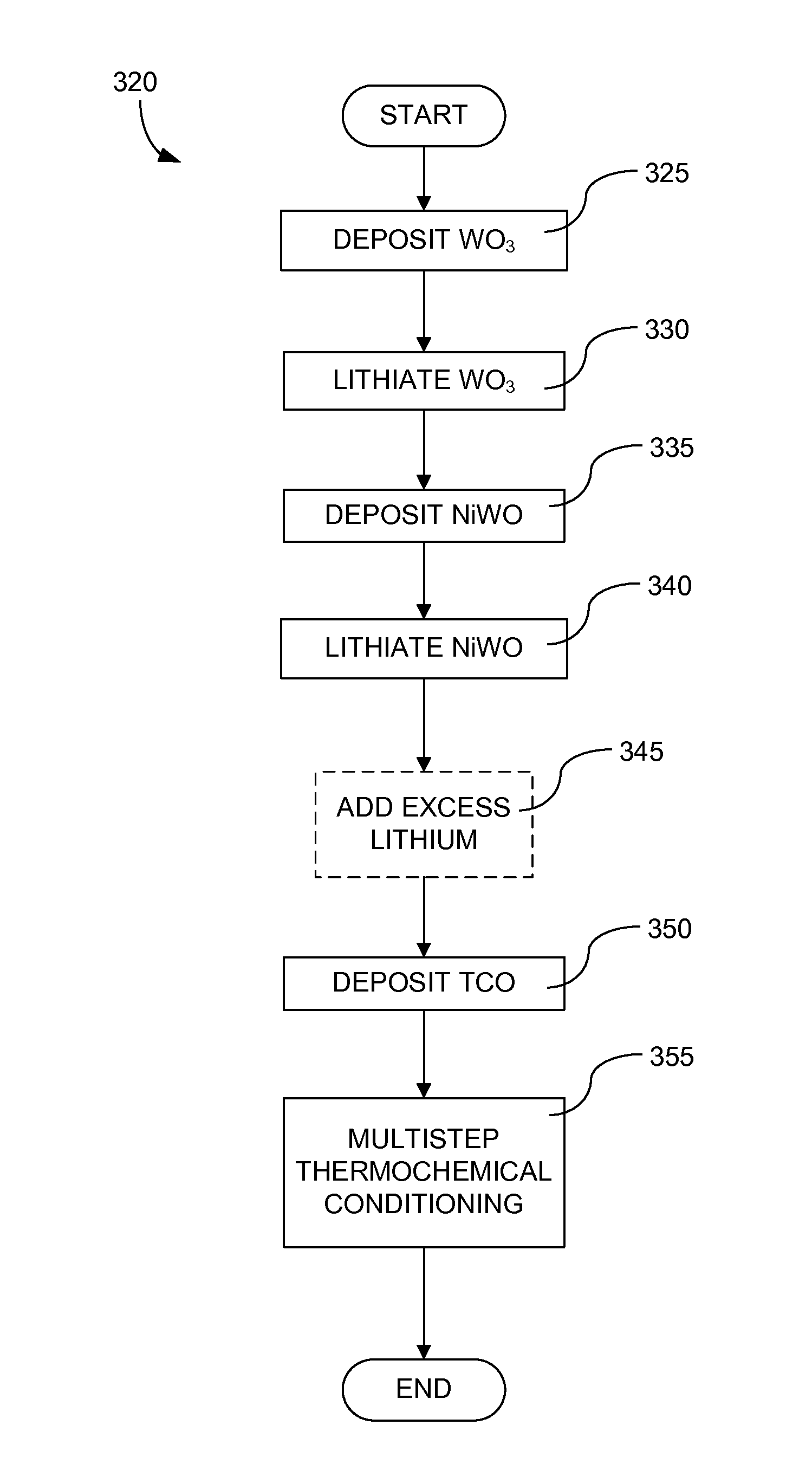

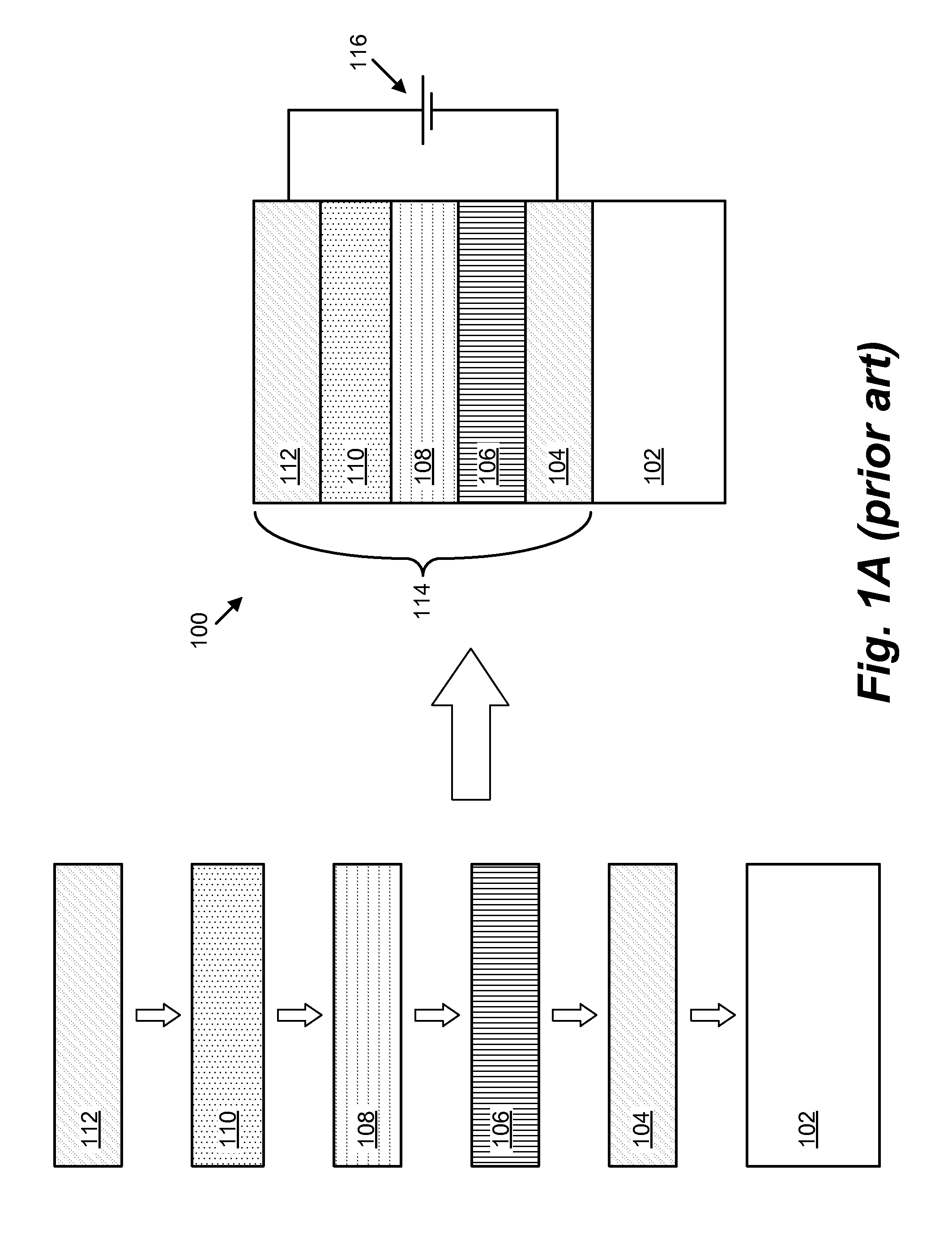

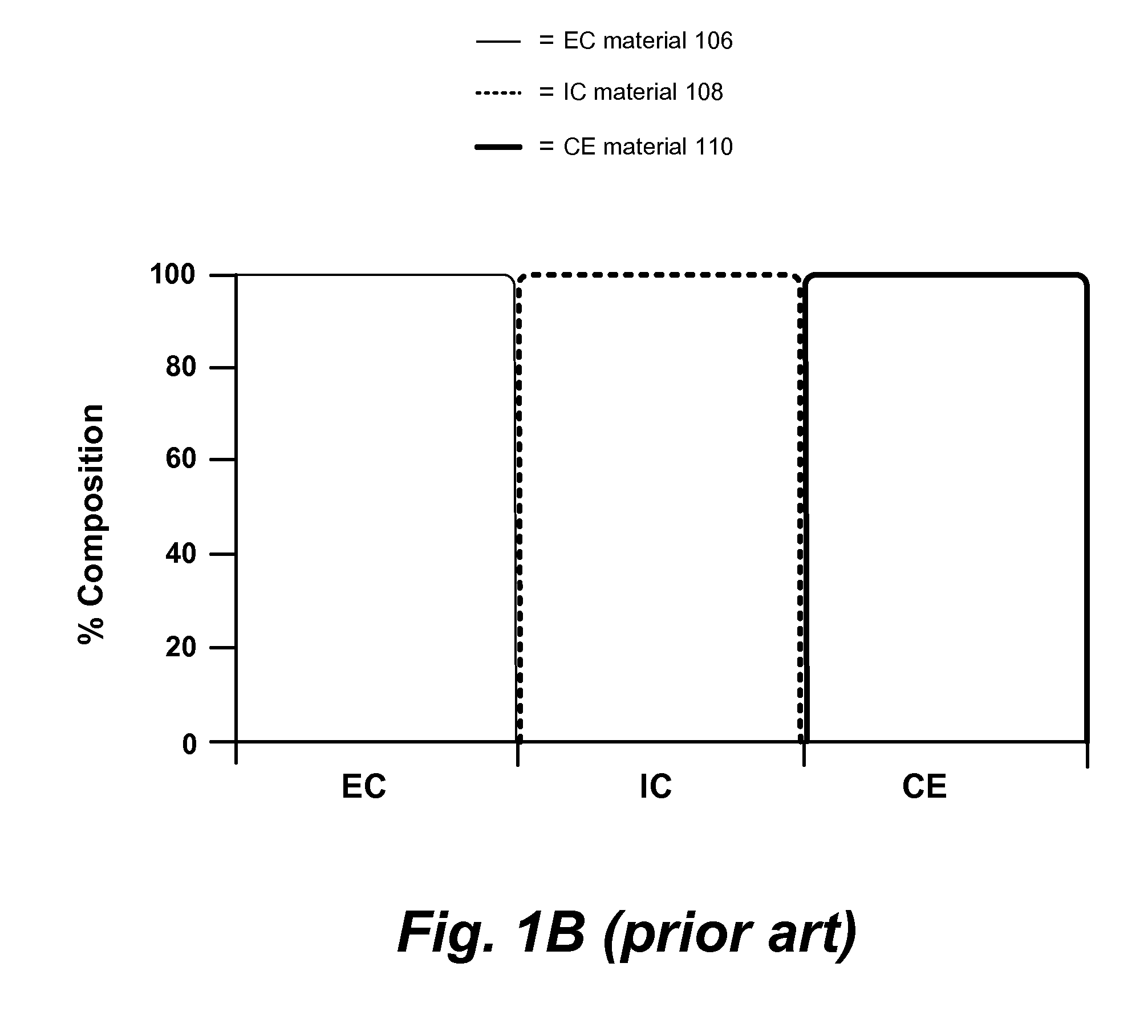

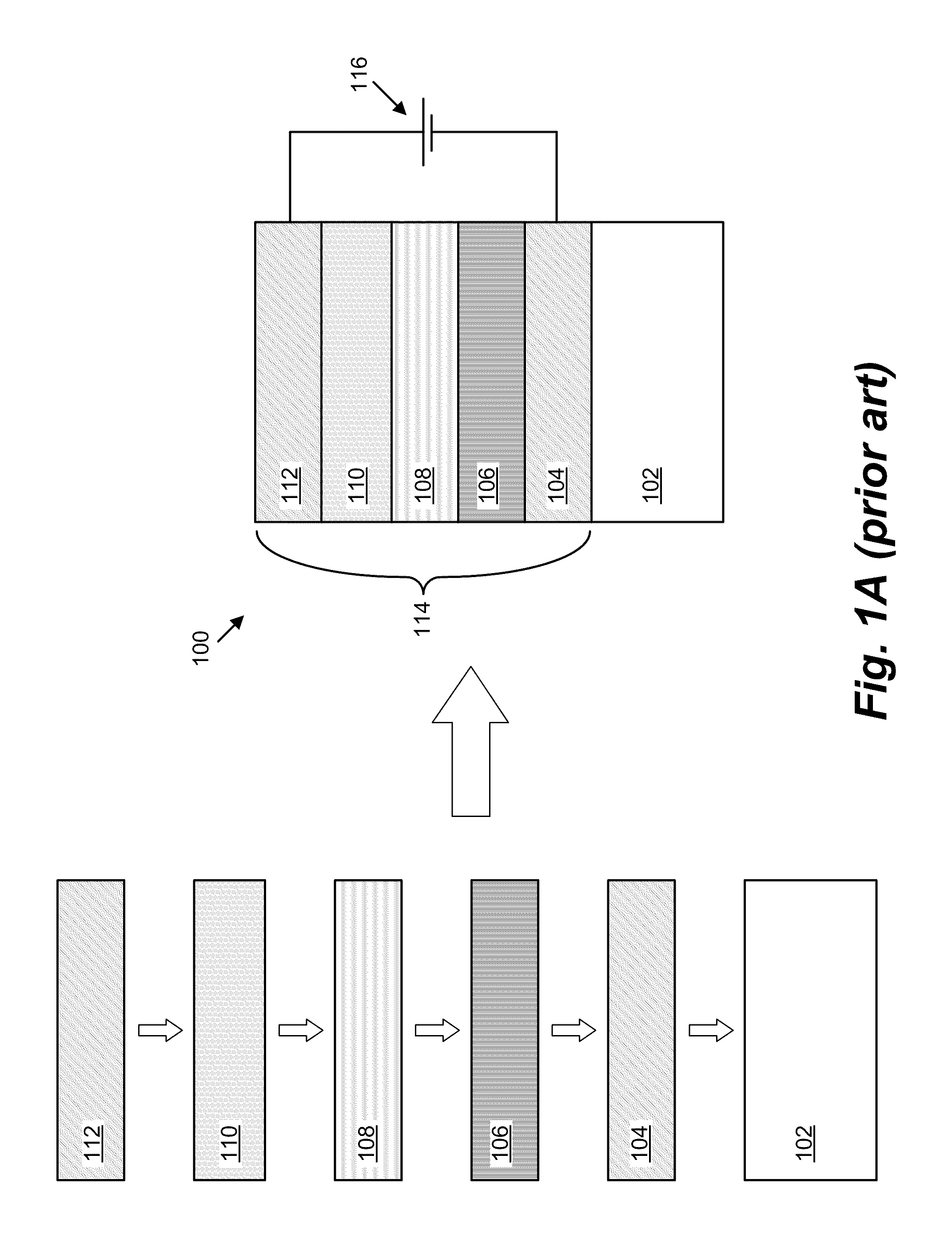

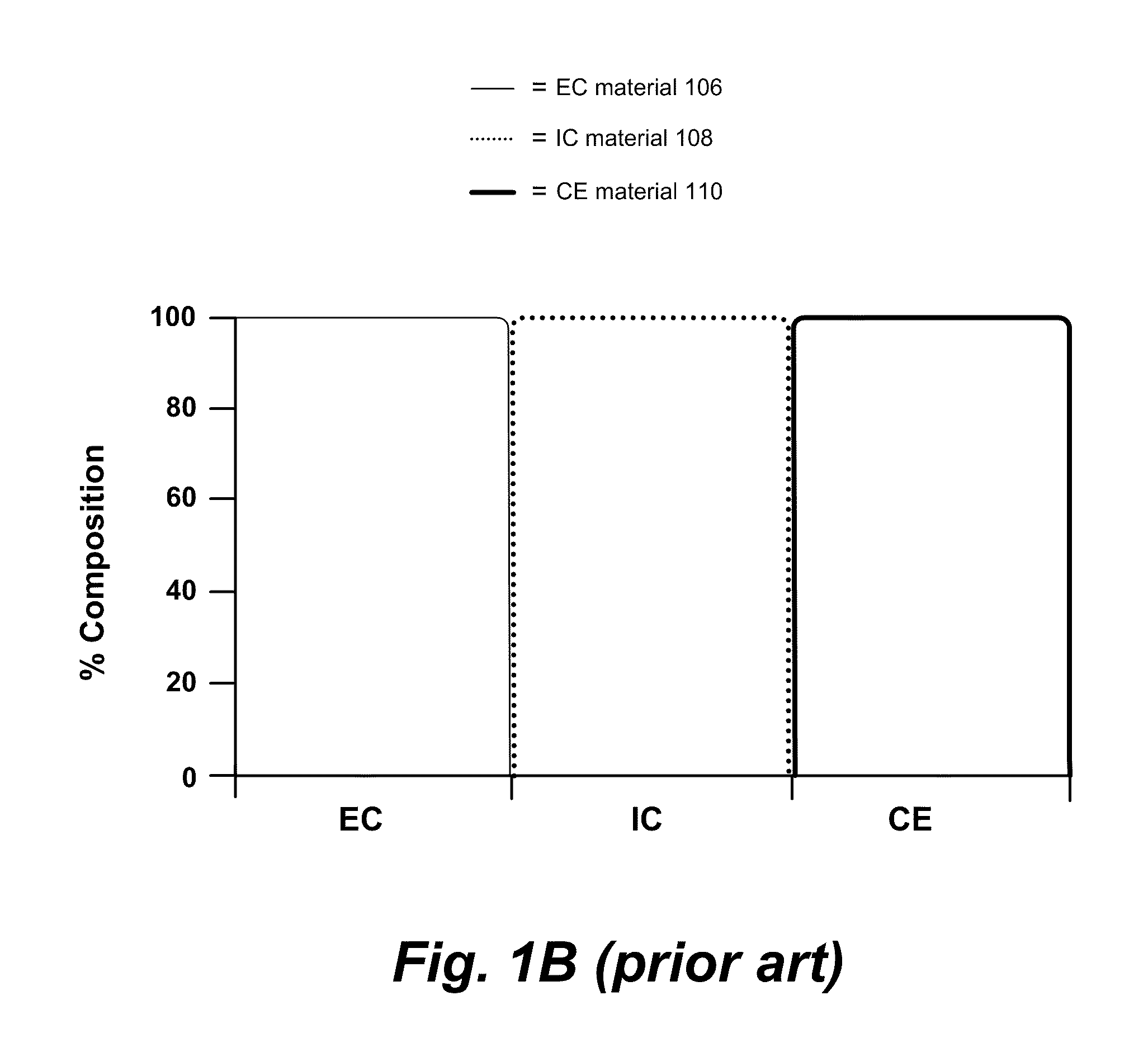

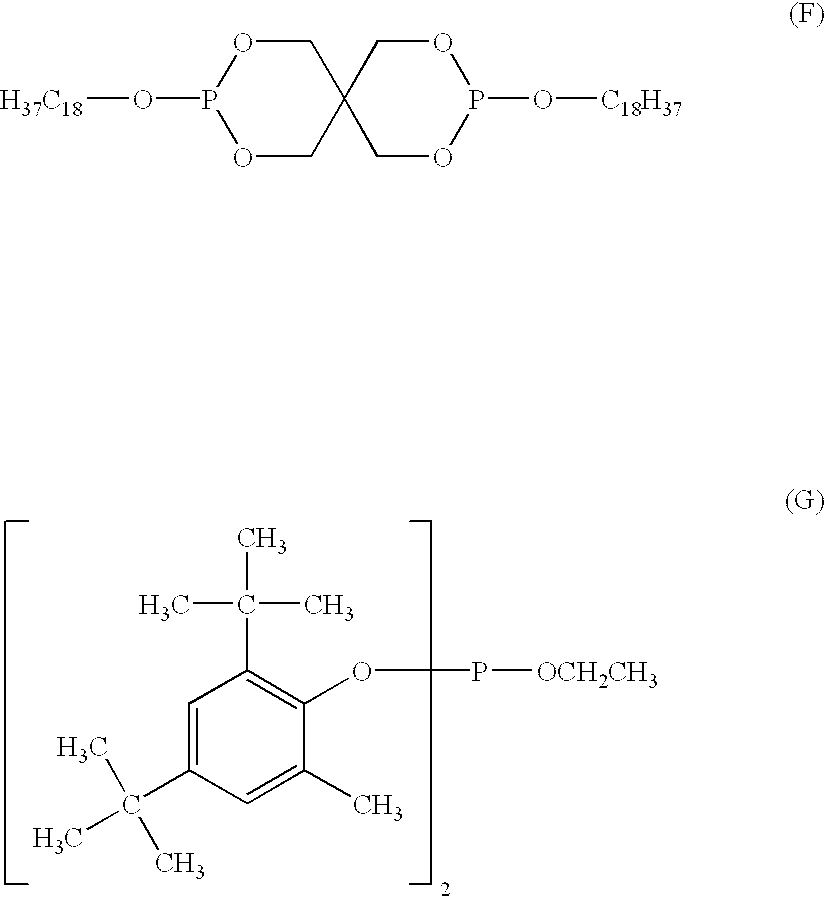

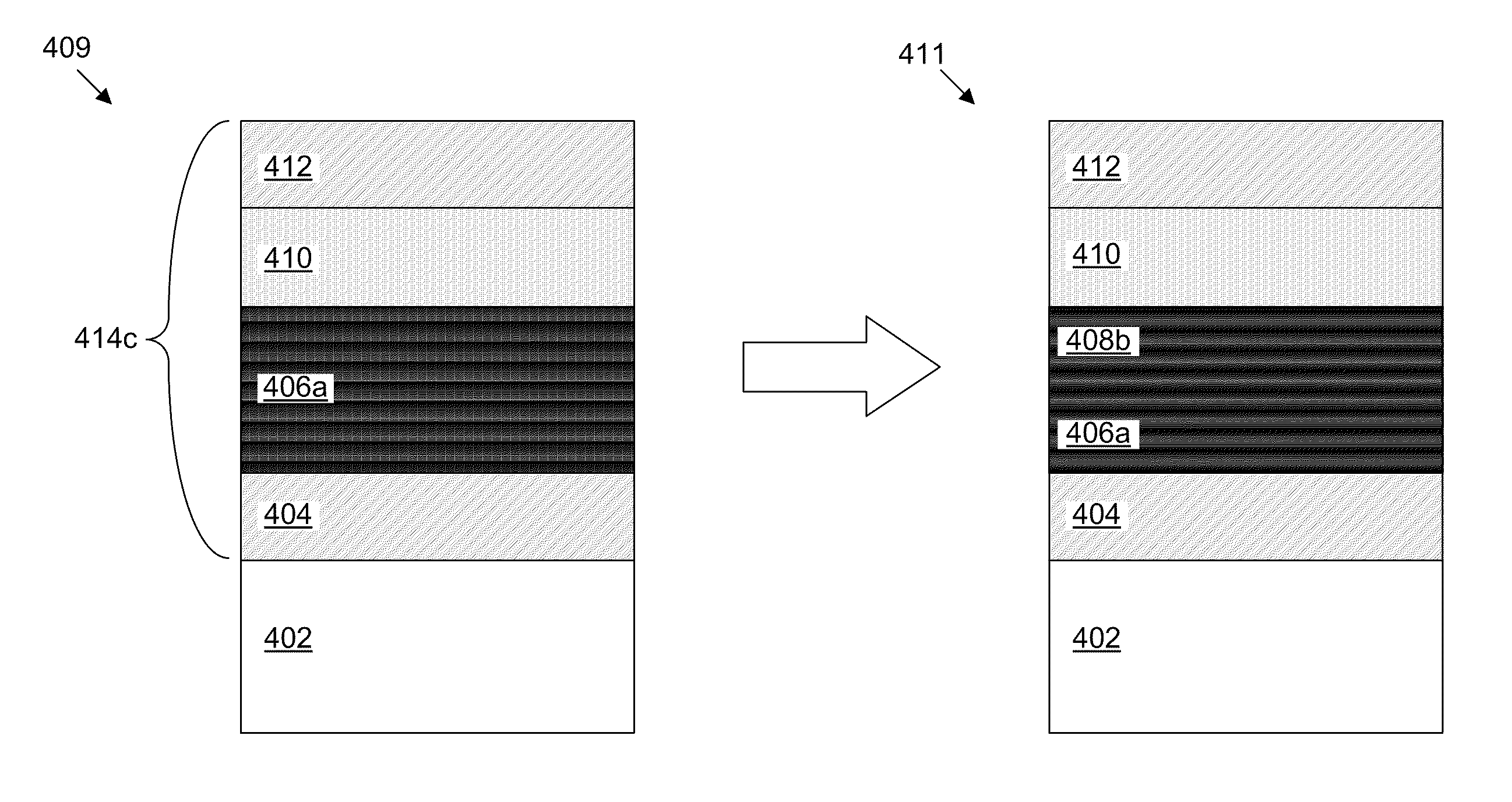

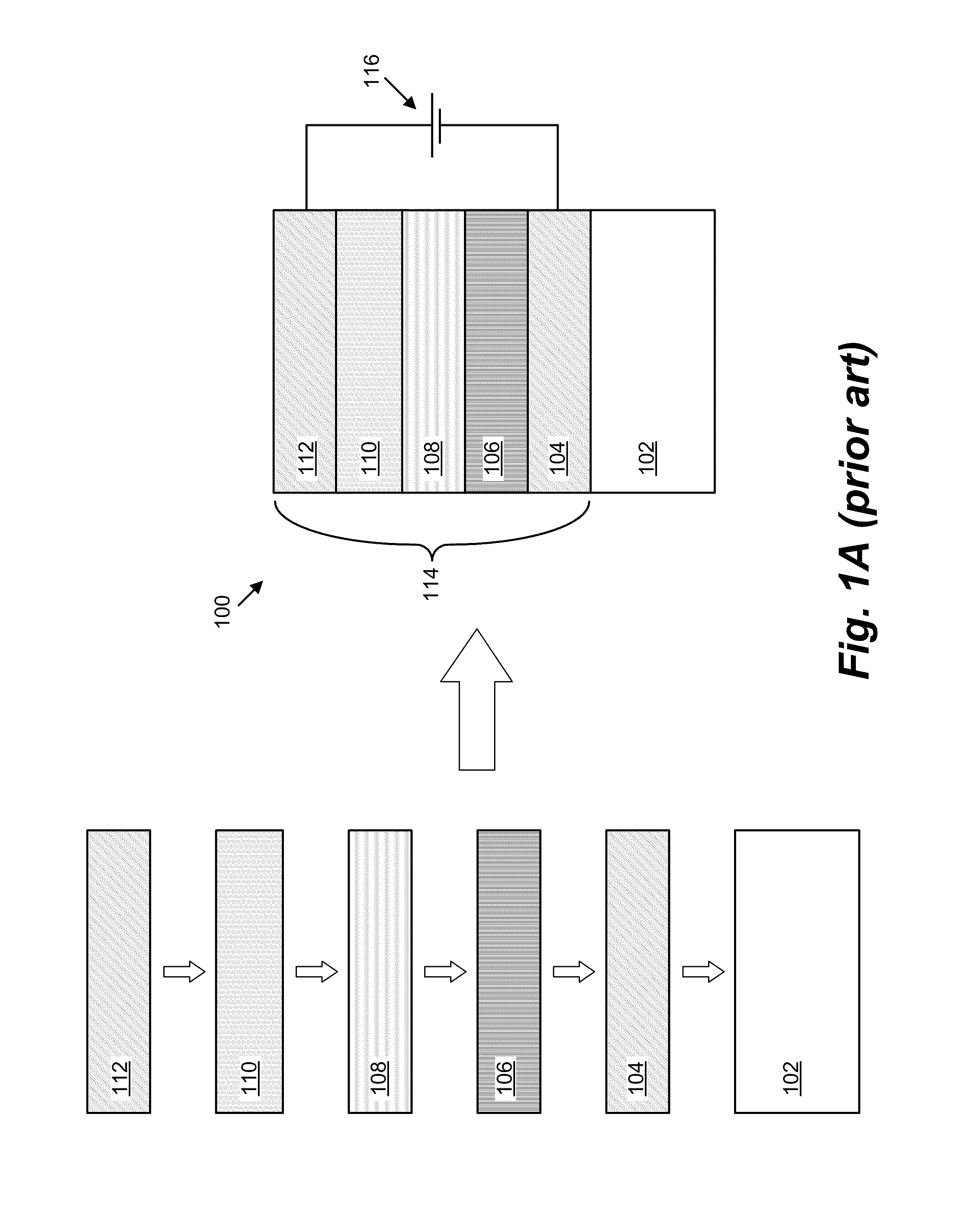

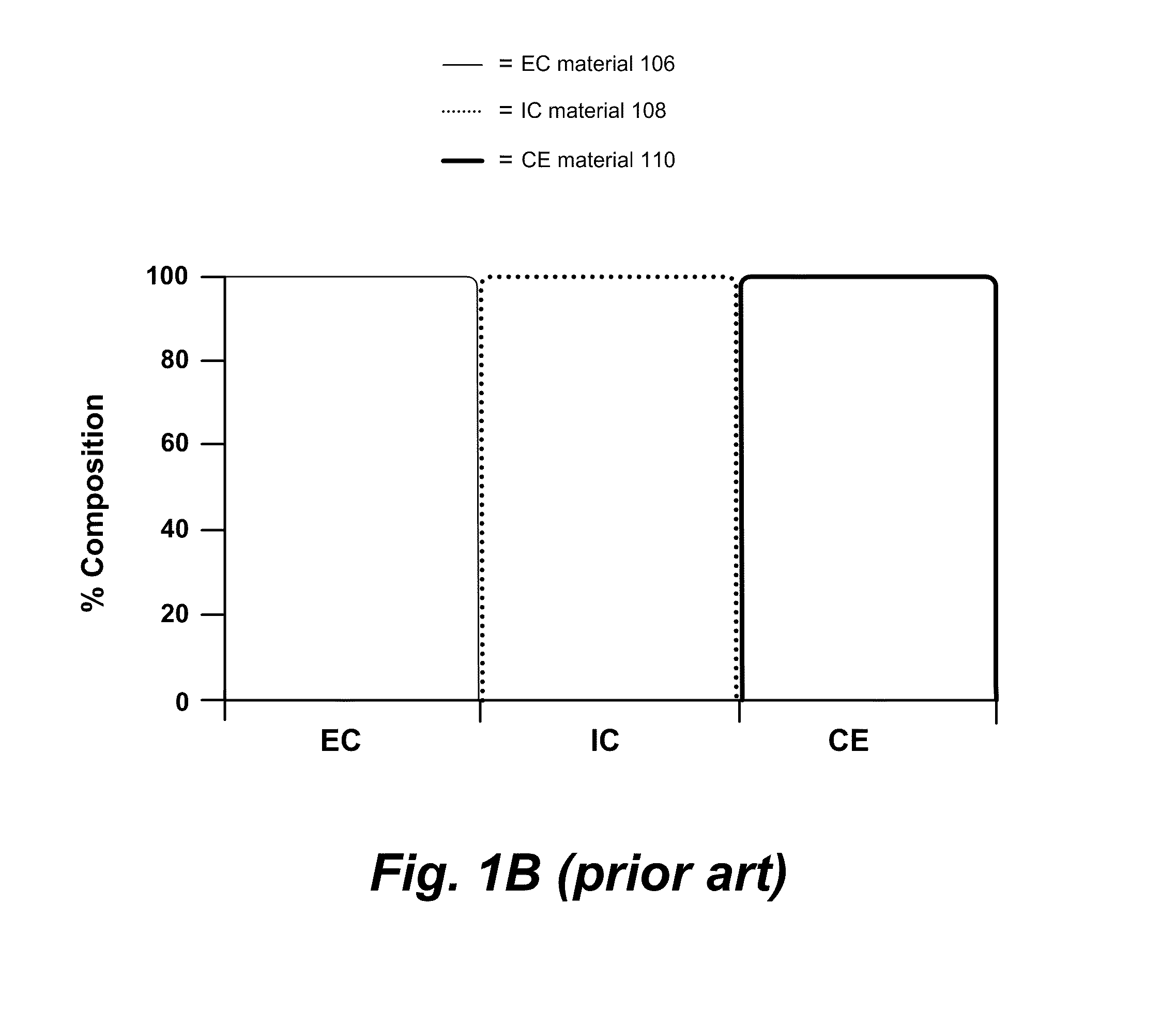

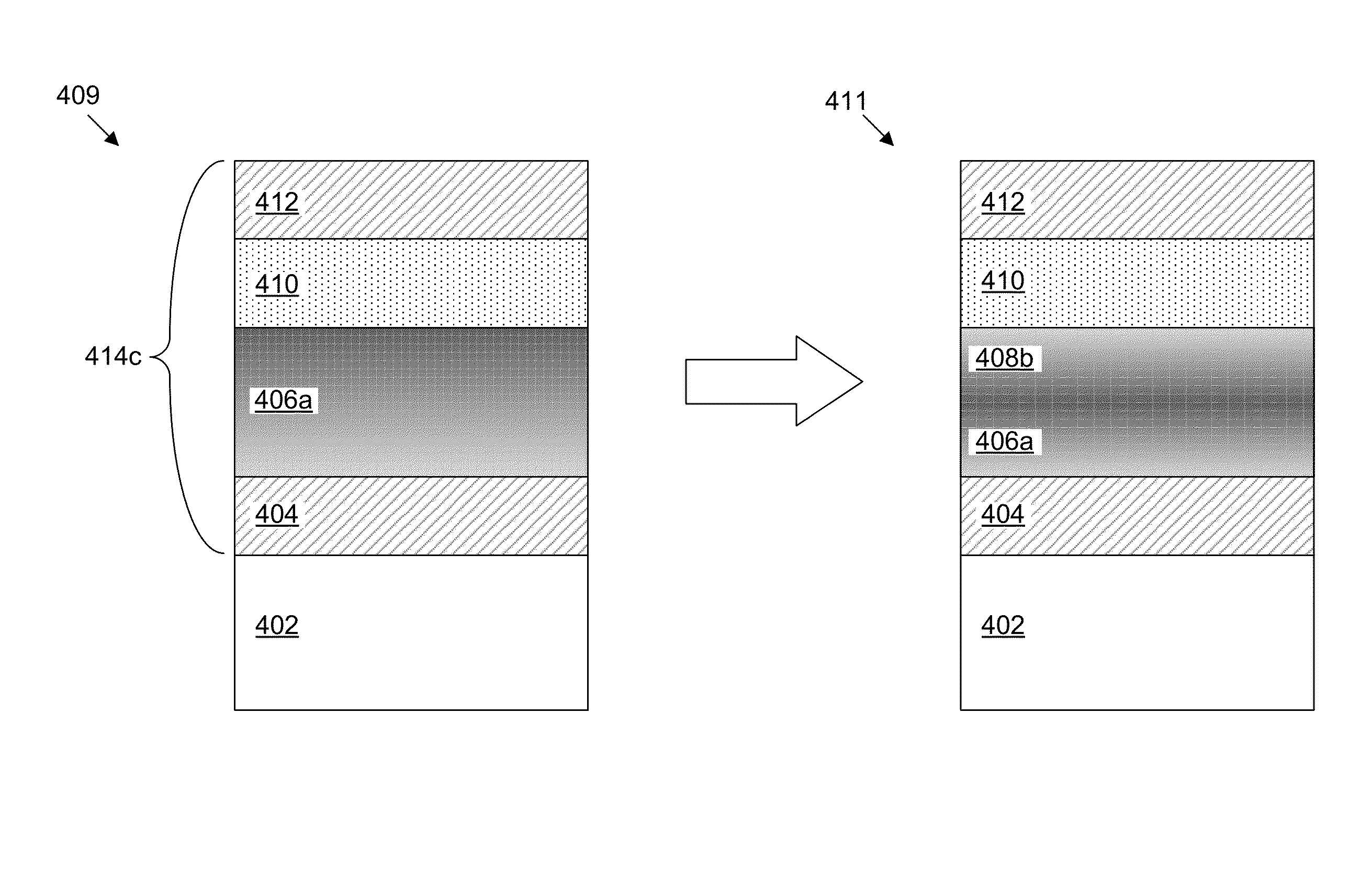

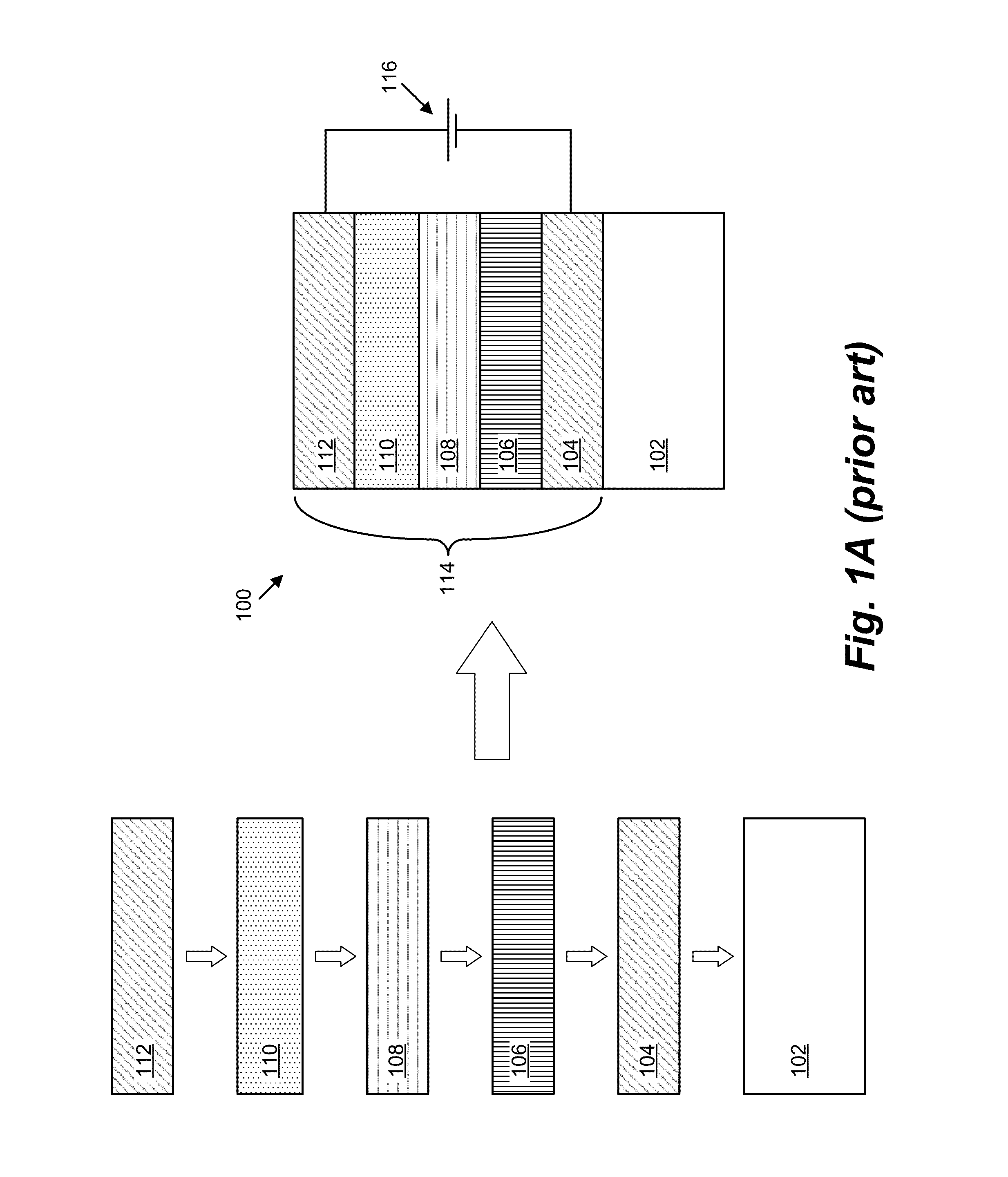

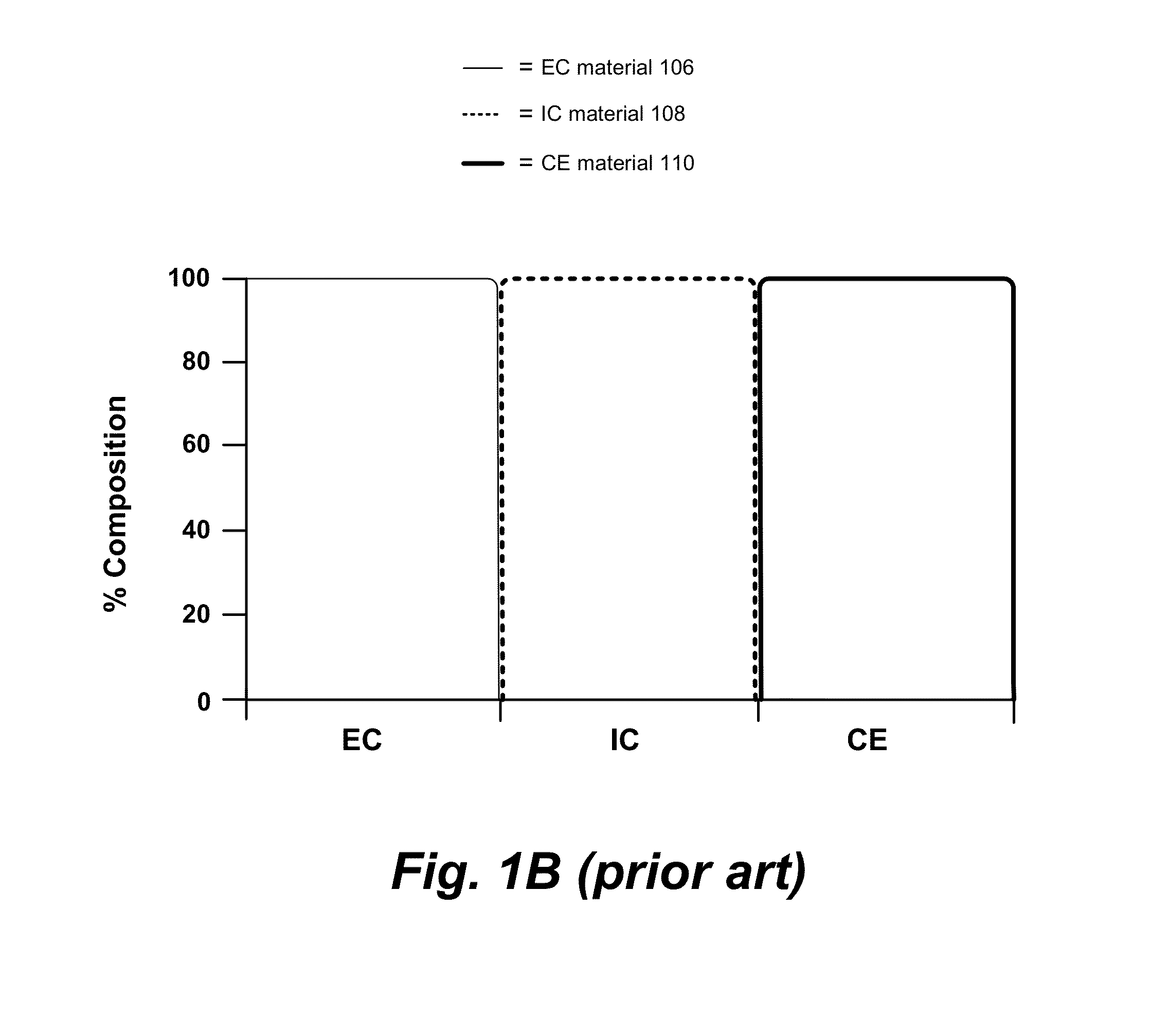

Electrochromic devices

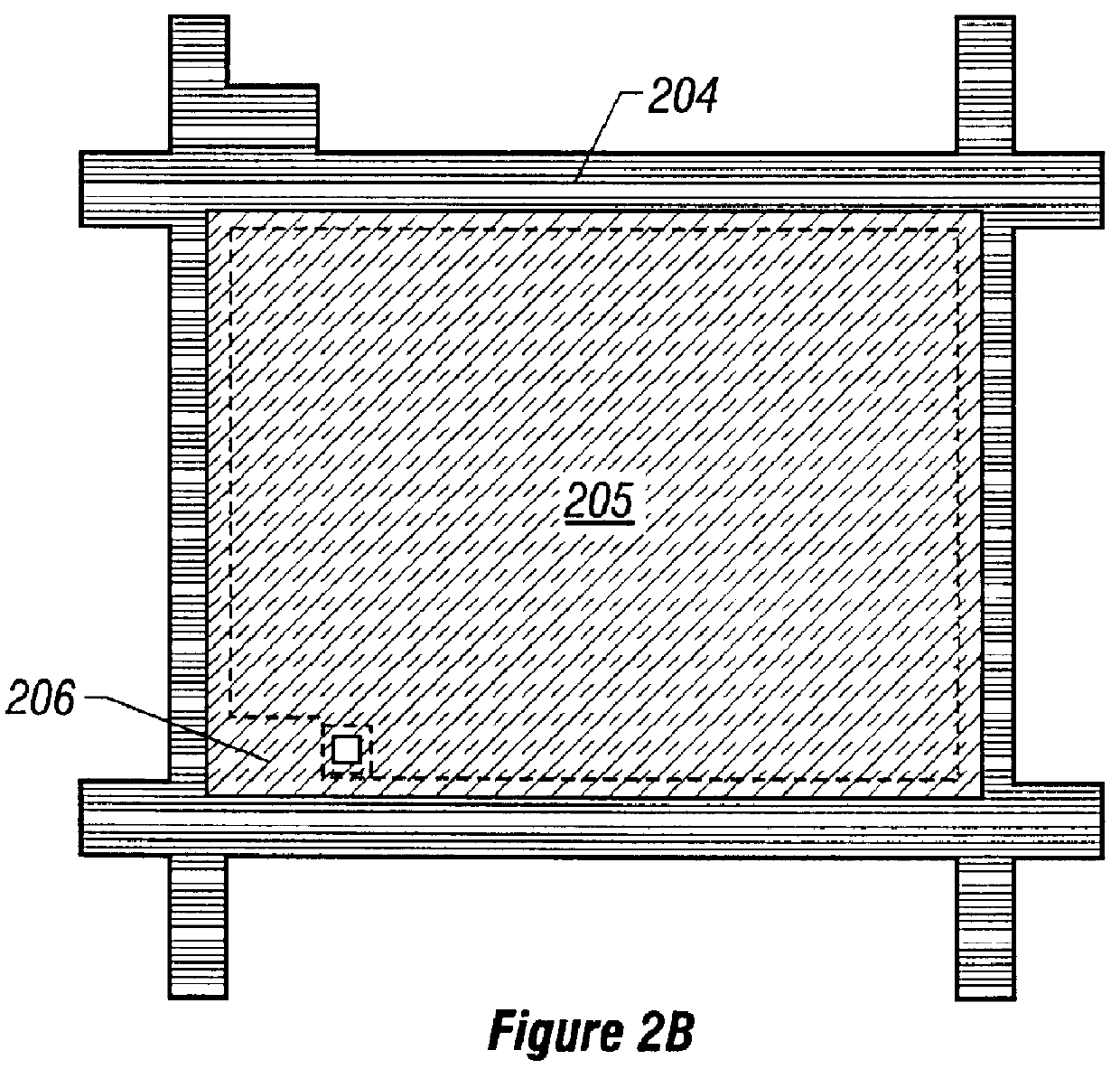

ActiveUS20110266138A1Improve conductivityIncrease resistanceVacuum evaporation coatingSputtering coatingElectricityOptoelectronics

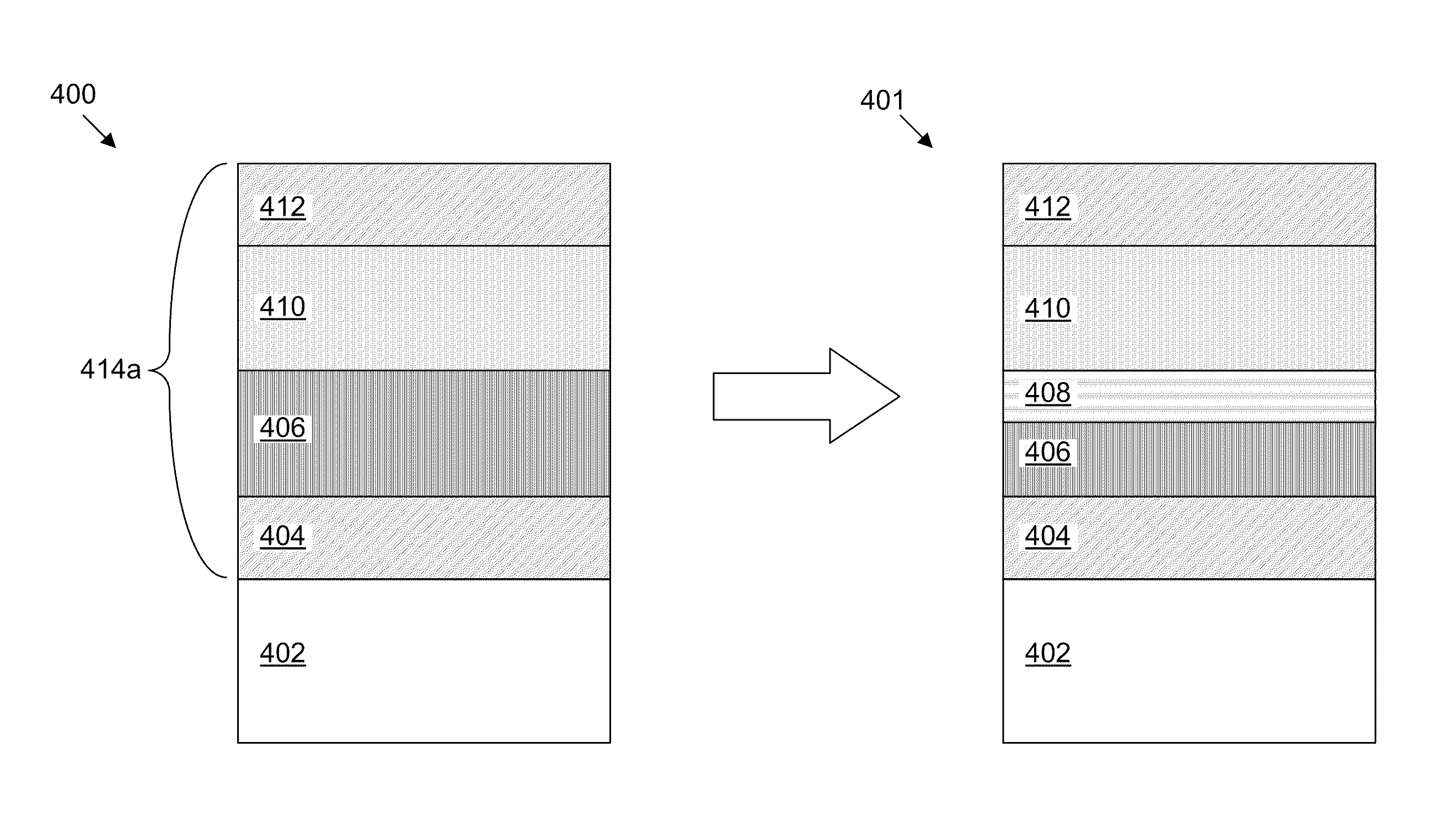

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically-insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically-insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

Method for line density multiplication using block copolymers and sequential infiltration synthesis

ActiveUS20150225850A1Decorative surface effectsPhotomechanical apparatusOptoelectronicsInorganic materials

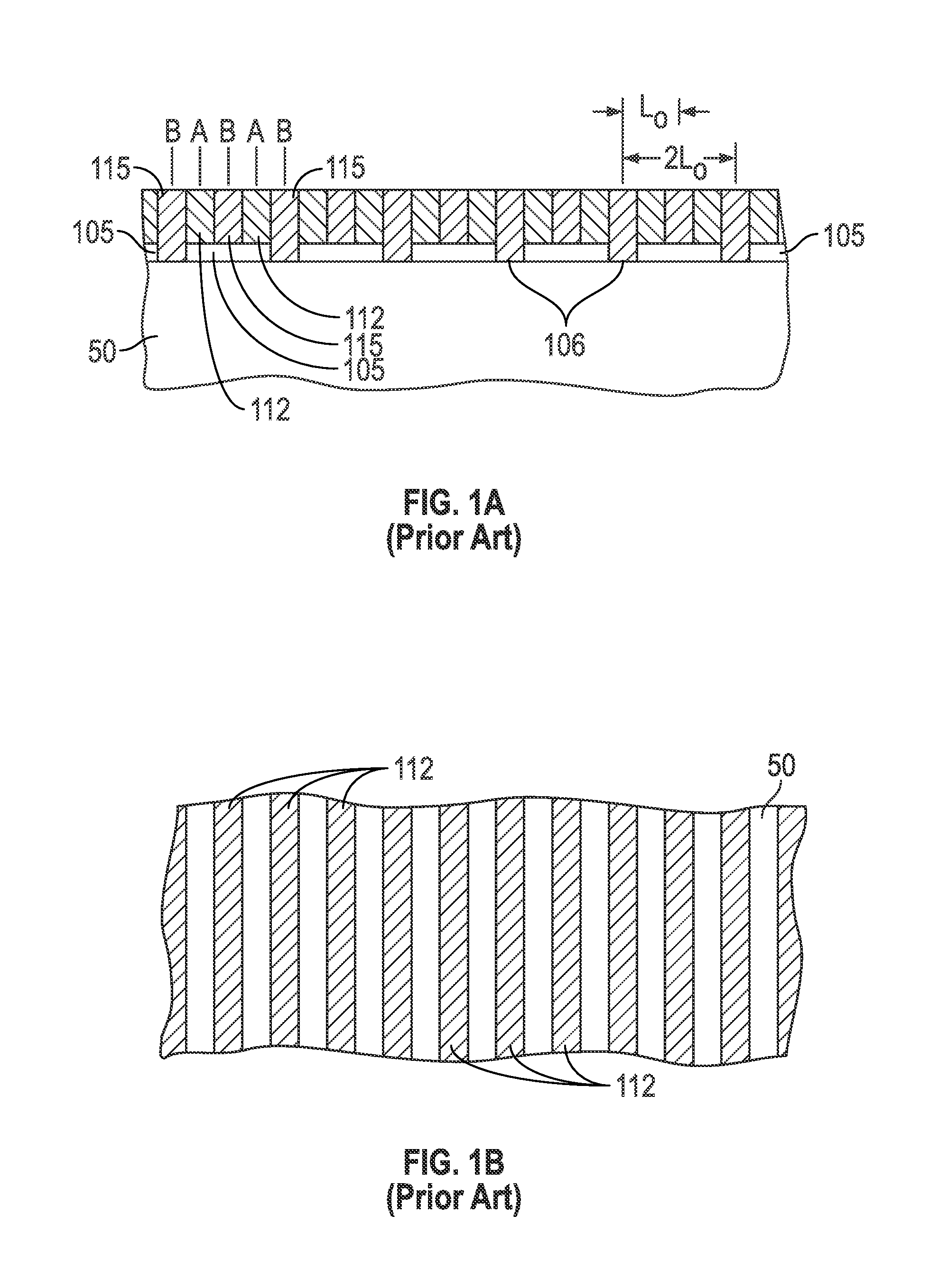

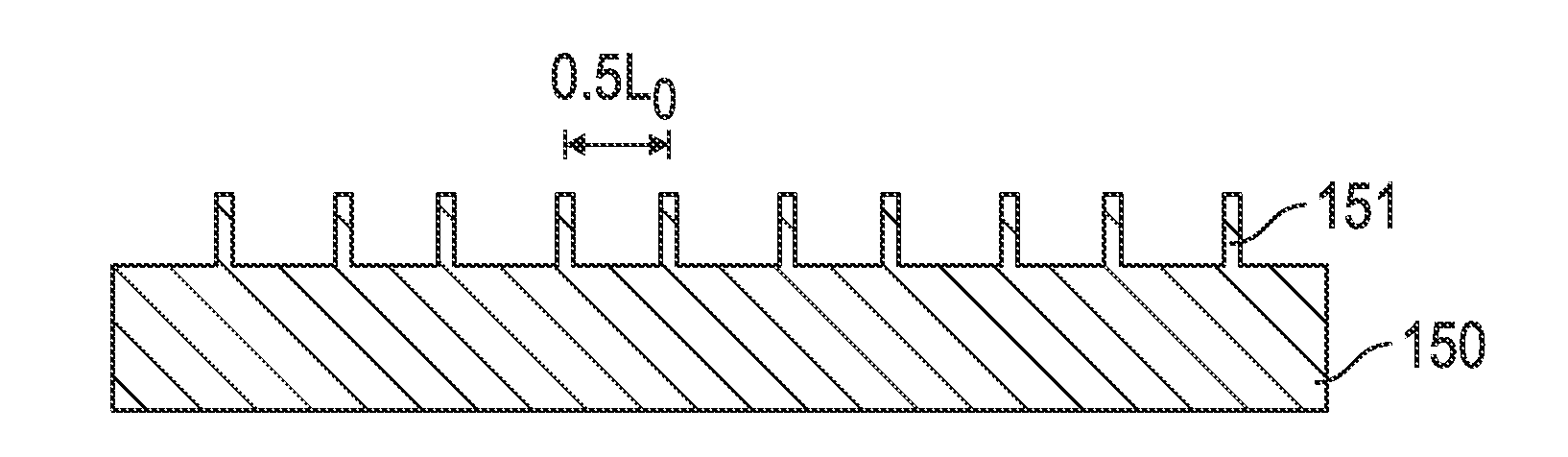

Block copolymers (BCPs) and synthetic infiltration synthesis (SIS) are used to double the line density on a substrate. The BCP comprises first and second interconnected BCP components with a functional group at the junction or interface of the components. After deposition of the BCP on the substrate and annealing, a pattern of parallel stripes of first and second BCP components is formed with a pattern of functional group interfaces between the components. Each of the BCP components is non-reactive with atomic layer deposition (ALD) precursors, while the functional group is reactive with the ALD precursors. The ALD results in the infiltration of inorganic material into the interfaces where the reactive functional groups are located but without affecting the BCP components. After removal of the organic material, a pattern of parallel lines of inorganic material remains with a pitch half that of the stripes of BCP components.

Owner:WESTERN DIGITAL TECH INC

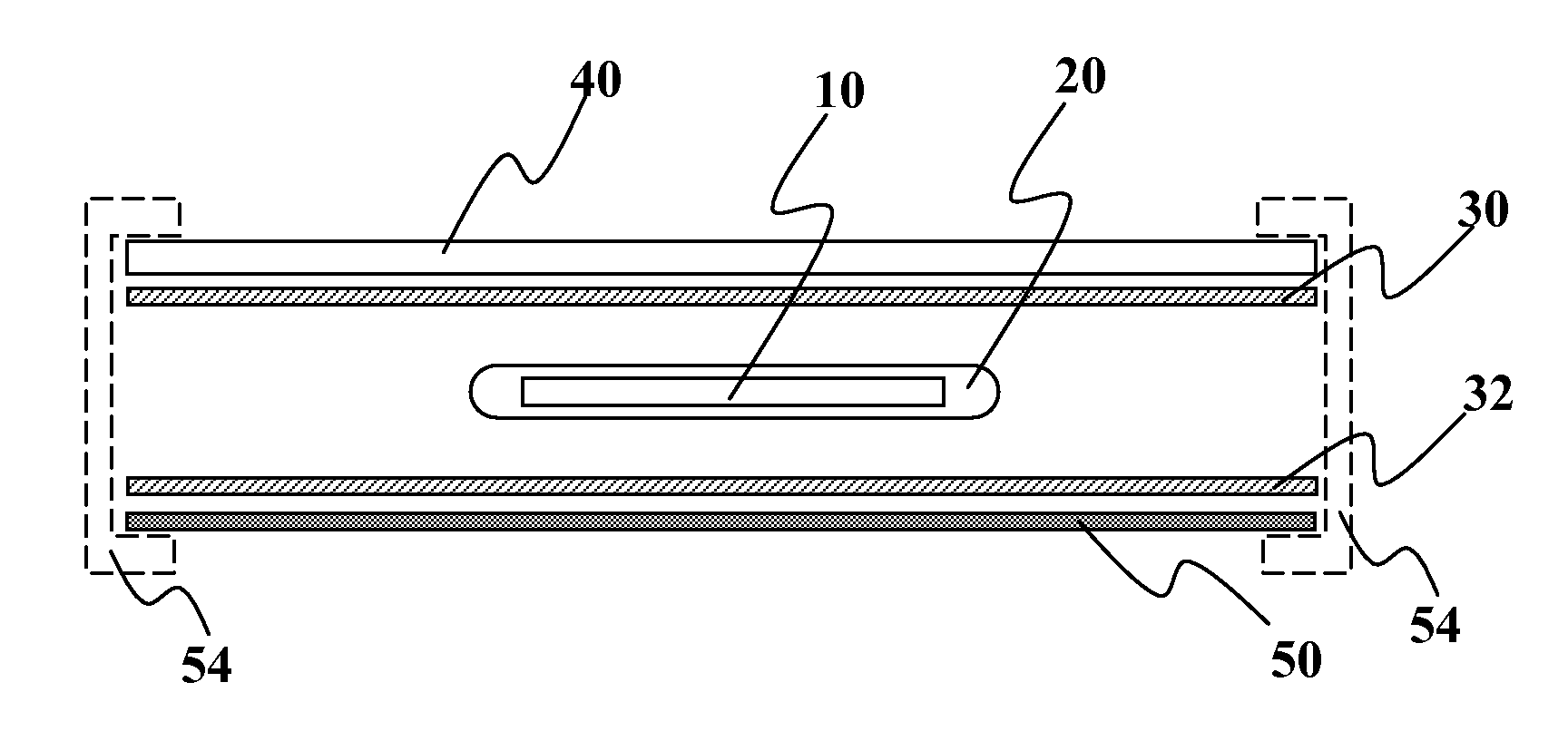

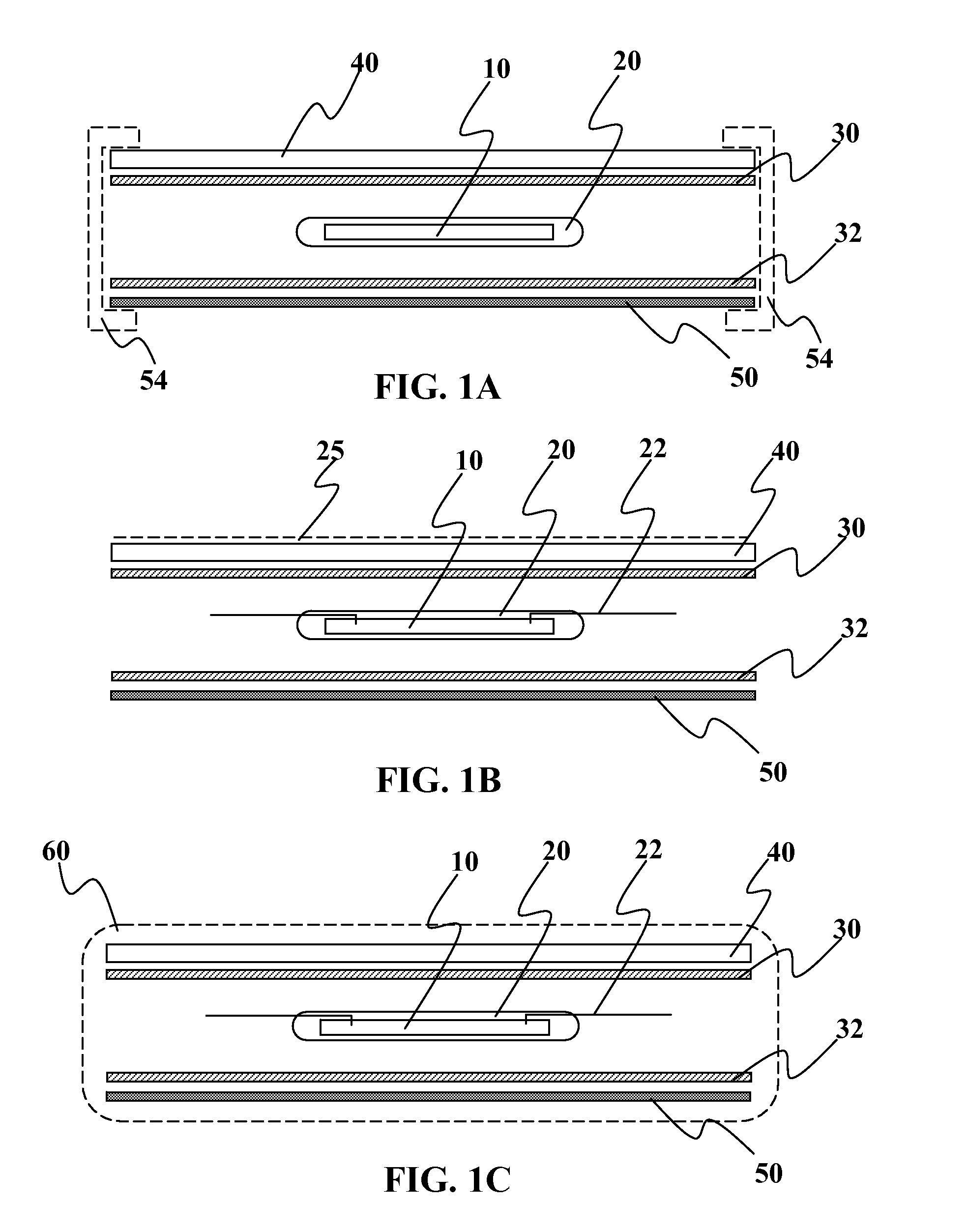

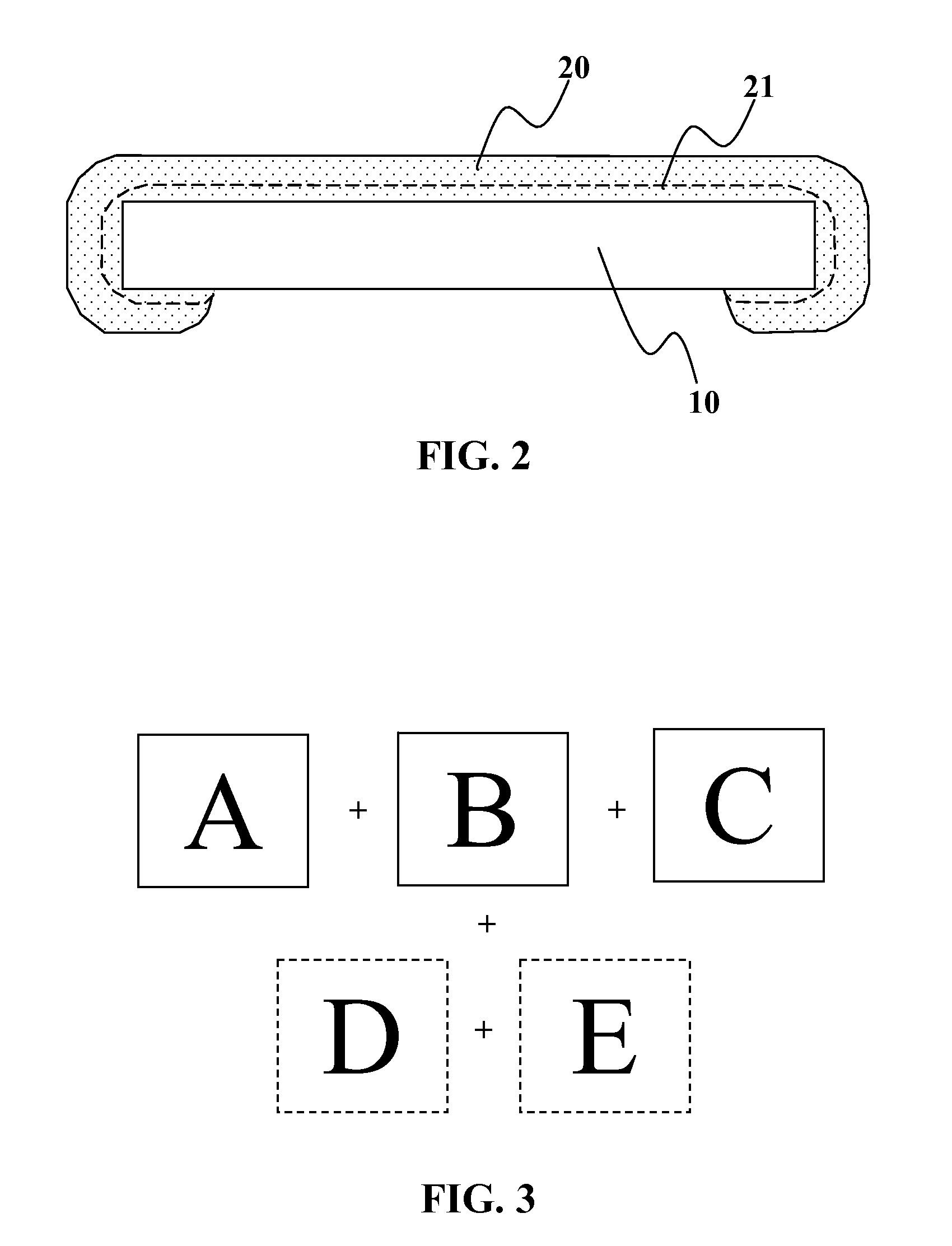

Gas barrier film, film substrate provided with gas barrier film, and electronic device including the film substrate

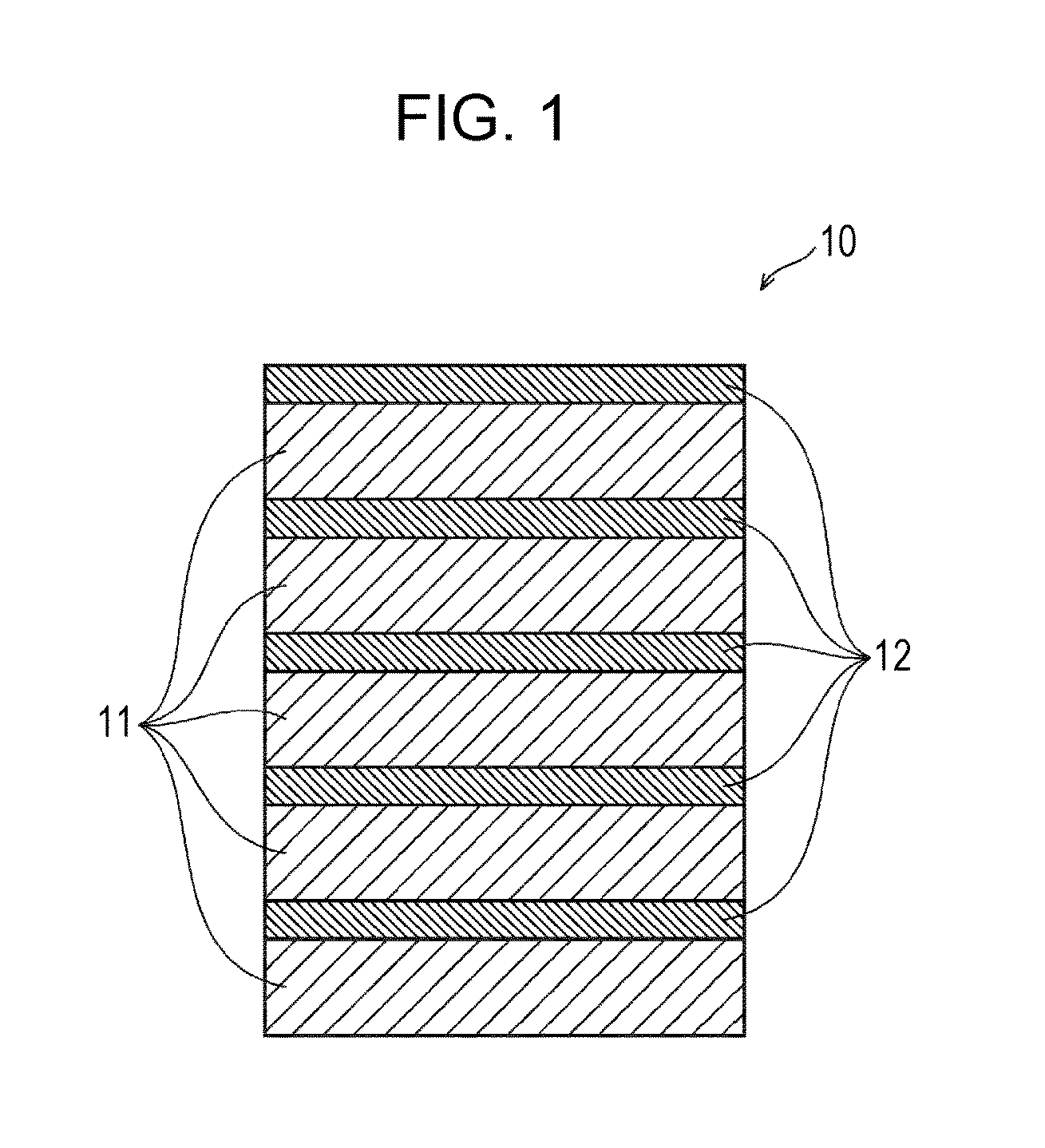

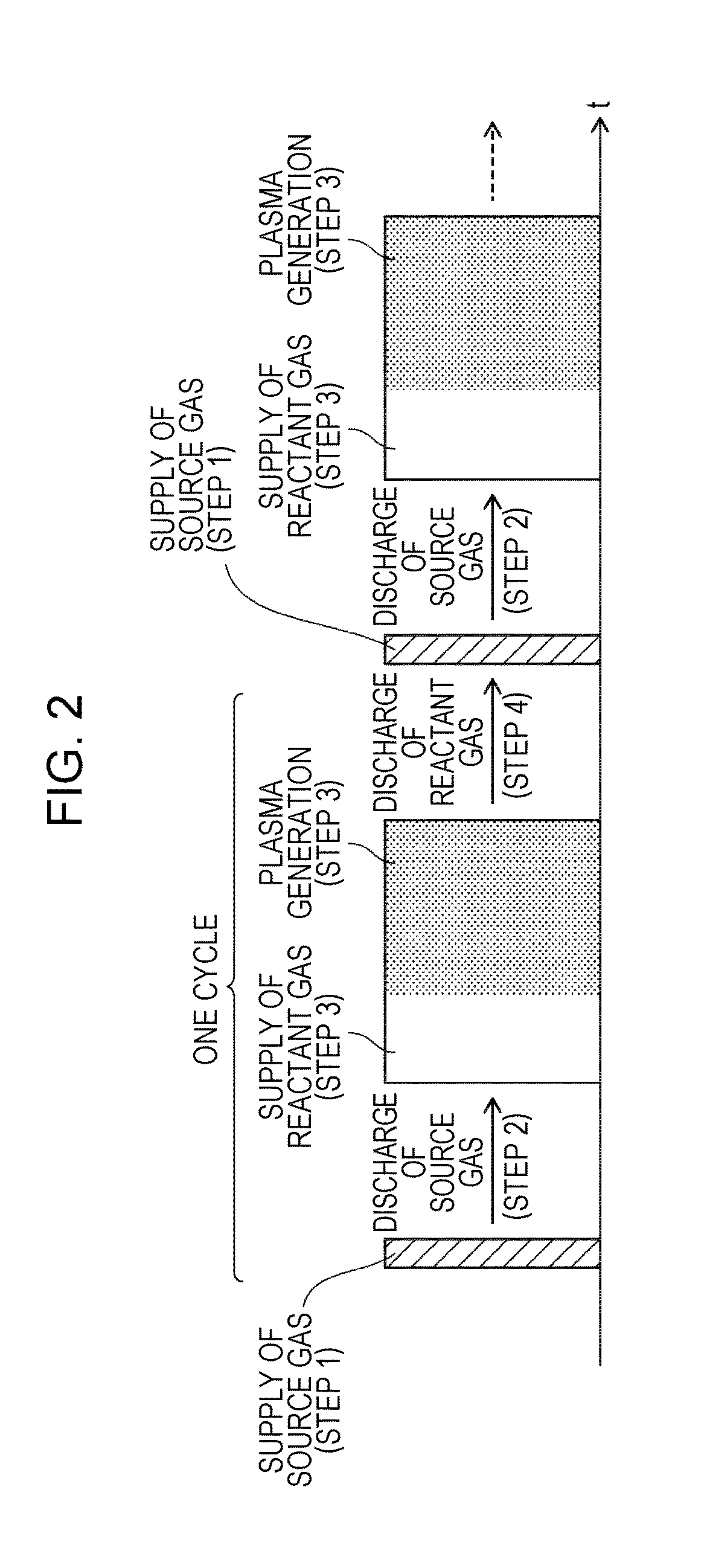

ActiveUS20150343741A1Excellent gas barrier performanceIncrease resistanceLayered productsRecord information storageThin membraneElectric devices

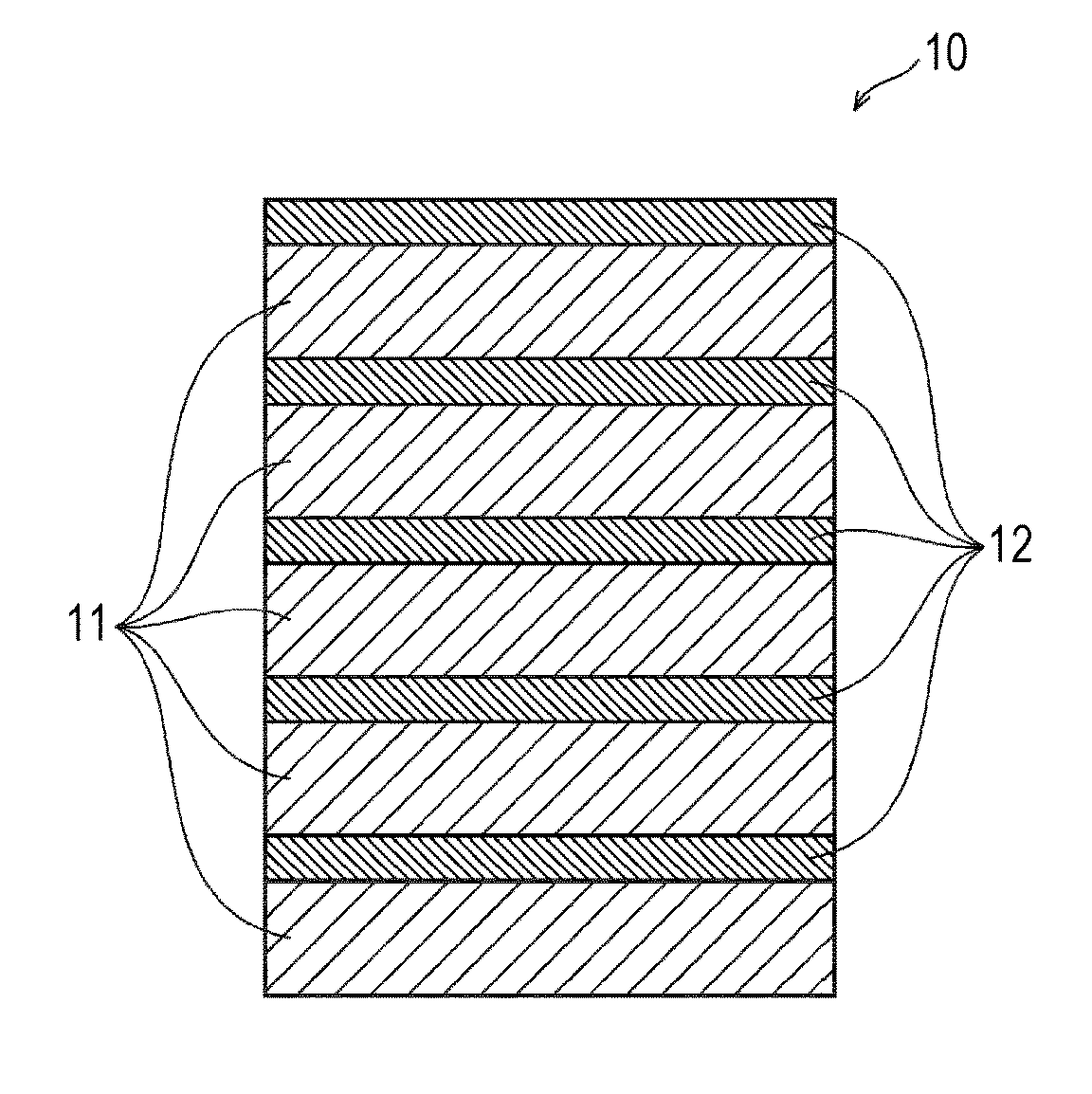

A gas barrier film includes two or more first barrier layers each made of a first inorganic material and one or more second barrier layers each made of a second inorganic material different from the first inorganic material. Each of the two or more first barrier layers and each of the one or more second barrier layers are alternately stacked. The first inorganic material comprises aluminum oxide. Each of the two or more first barrier layers has a thickness of 3 nm or more. The total thickness of the two or more first barrier layers is 20 nm or less. The two or more first barrier layers and the one or more second barrier layers are formed by atomic layer deposition.

Owner:SAMSUNG DISPLAY CO LTD

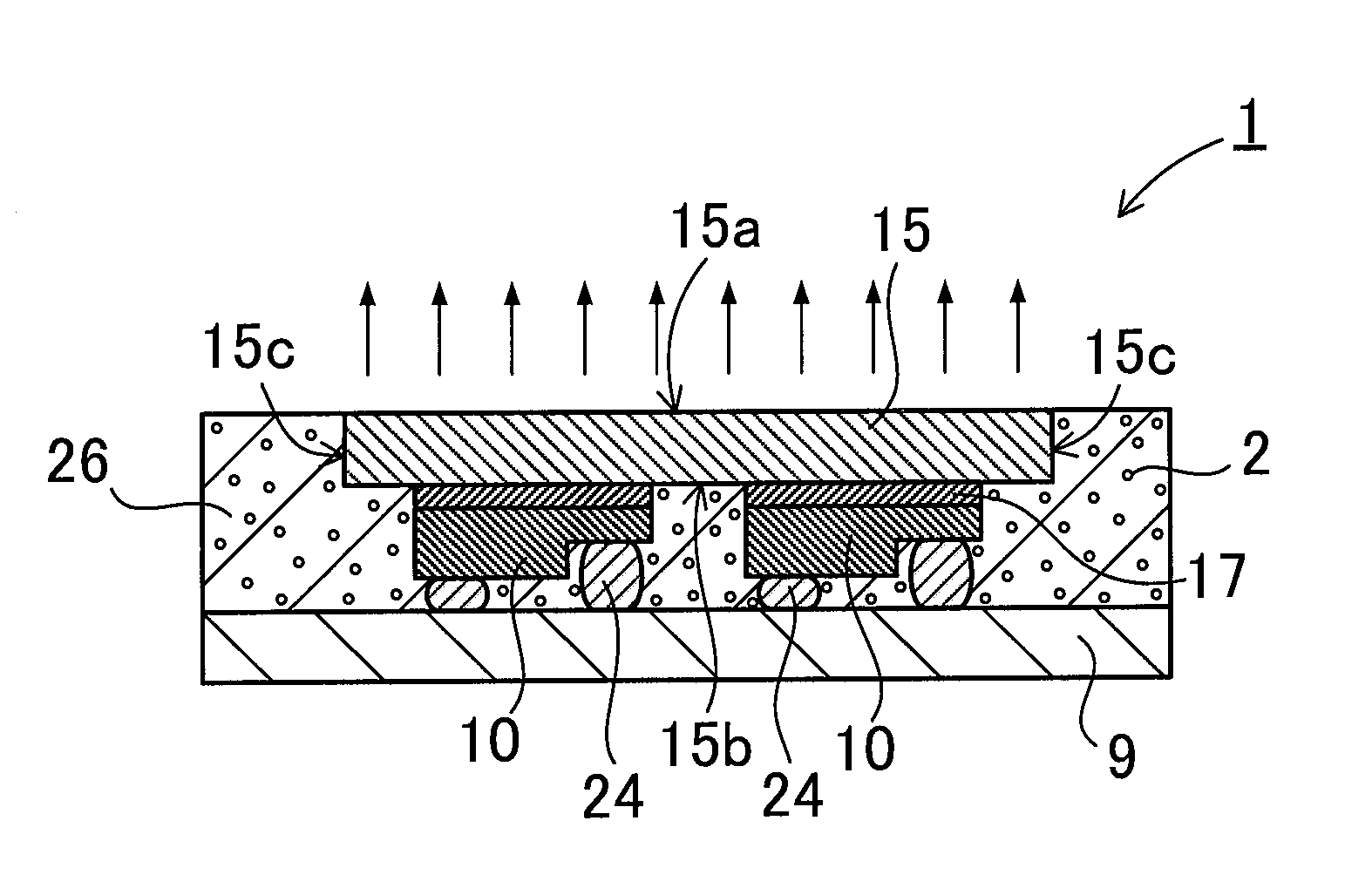

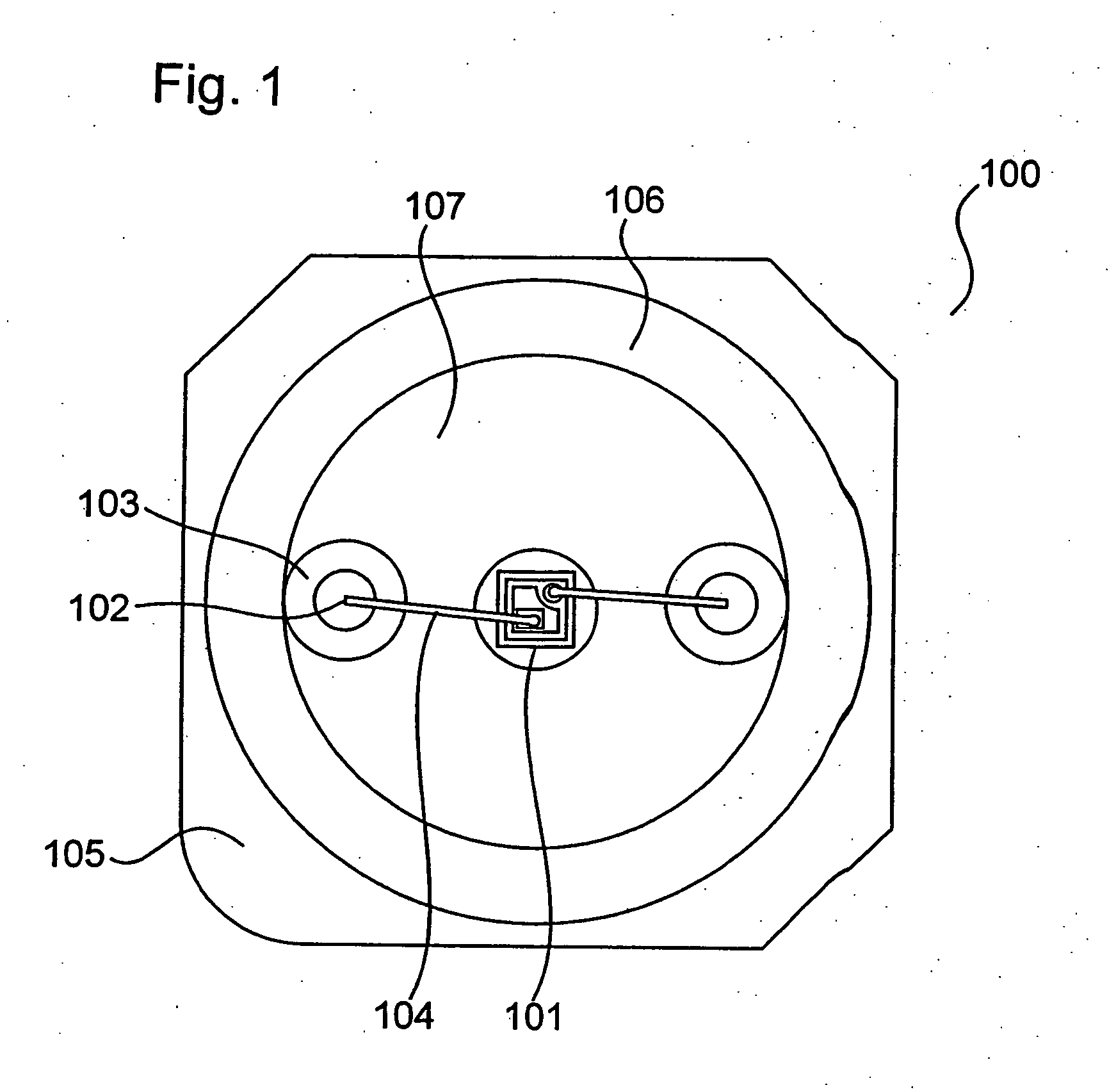

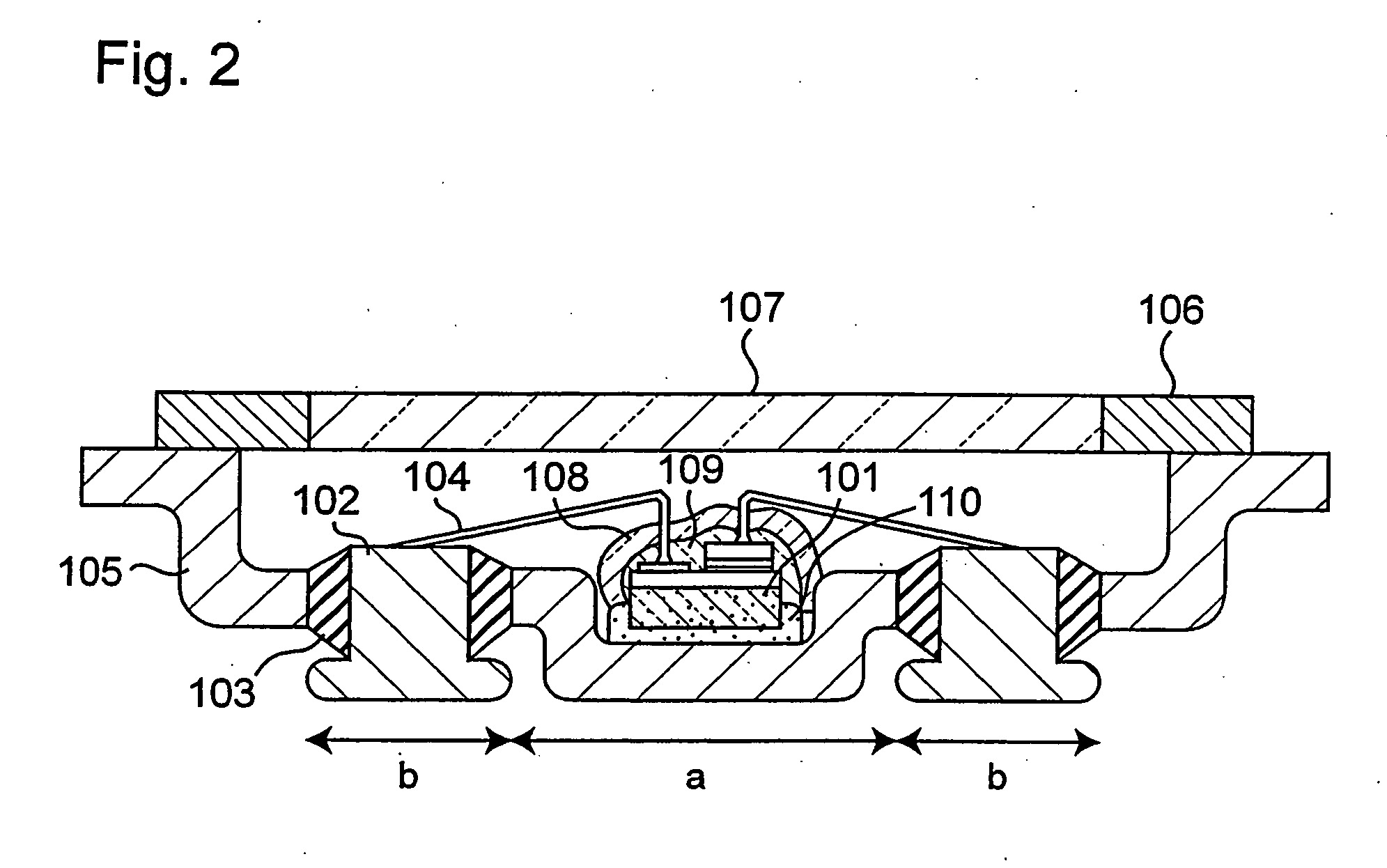

Light emitting apparatus and method of manufacturing the same

ActiveUS20040061433A1Facilitated DiffusionLarge particle sizeDischarge tube luminescnet screensLamp detailsAlkaline earth metalFluorescence

A light emitting apparatus comprising a light emitting device (101) disposed on a supporting body (105), and coating layers ((108, 109) that bind a fluorescent substance that absorbs light emitted by the light emitting device (101) and emits light of a different wavelength and secures the fluorescent substance onto the surface of the light emitting device (101). The coating layers (108, 109) are made of an inorganic material including an oxide and a hydroxide, each containing at least one element selected from the group consisting of Si, Al, Ga, Ti, Ge, P, B, Zr, Y, Sn, Pb and alkali earth metals. Also an adhesive layer (110) is made of the same inorganic material as that of the coating layers (108, 109).

Owner:NICHIA CORP

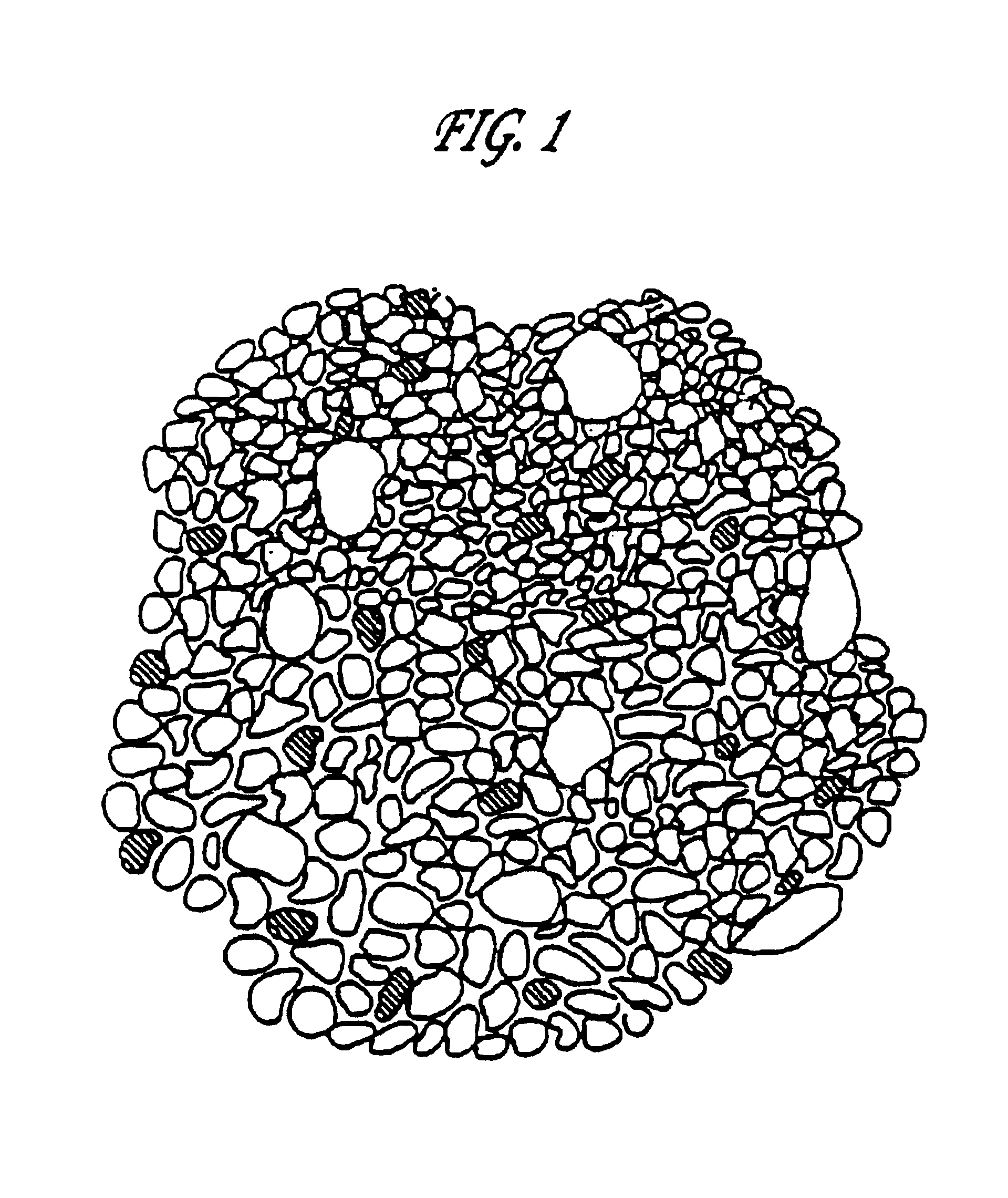

Injectable and moldable bone substitute materials

ActiveUS20070191963A1Reduce needEasy to manageBone implantPharmaceutical delivery mechanismBone implantFlowable Composite

An osteoimplant composite comprising a plurality of particles of an inorganic material, a bone substitute material, a bone-derived material, or any combination thereof; and a polymer material with which the particles are combined. The composite is either naturally moldable or flowable, or it can be made moldable or settable. After implantation, the composite may be set to provide mechanical strength to the implant. The inventive composite have the advantage of being able to fill irregularly shape implantation site while at the same time being settable to provide the mechanical strength required for most orthopedic applications. The invention also provides methods of using and preparing the moldable and flowable composites.

Owner:WARSAW ORTHOPEDIC INC

Electrochromic devices

ActiveUS8300298B2Improve conductivityIncrease resistanceDoors/windowsVacuum evaporation coatingElectricityOptoelectronics

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

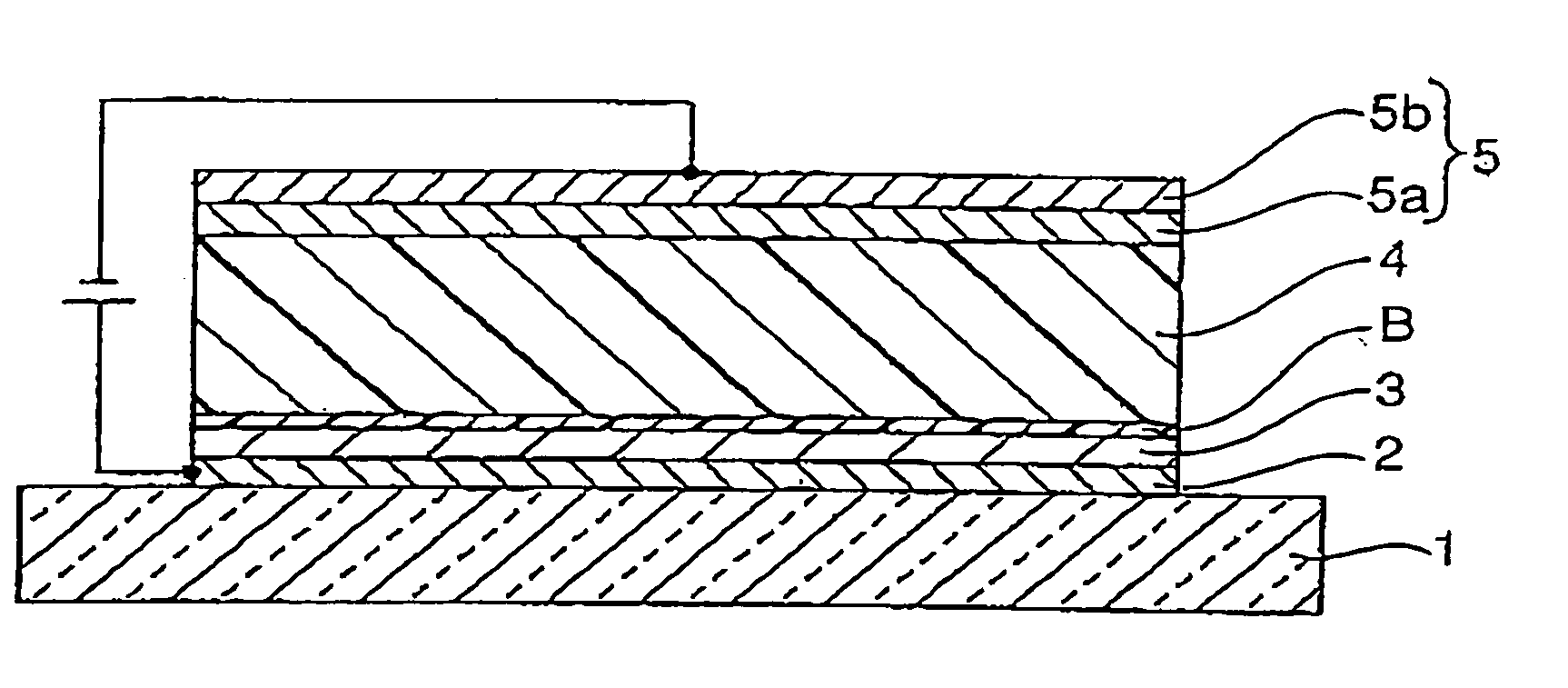

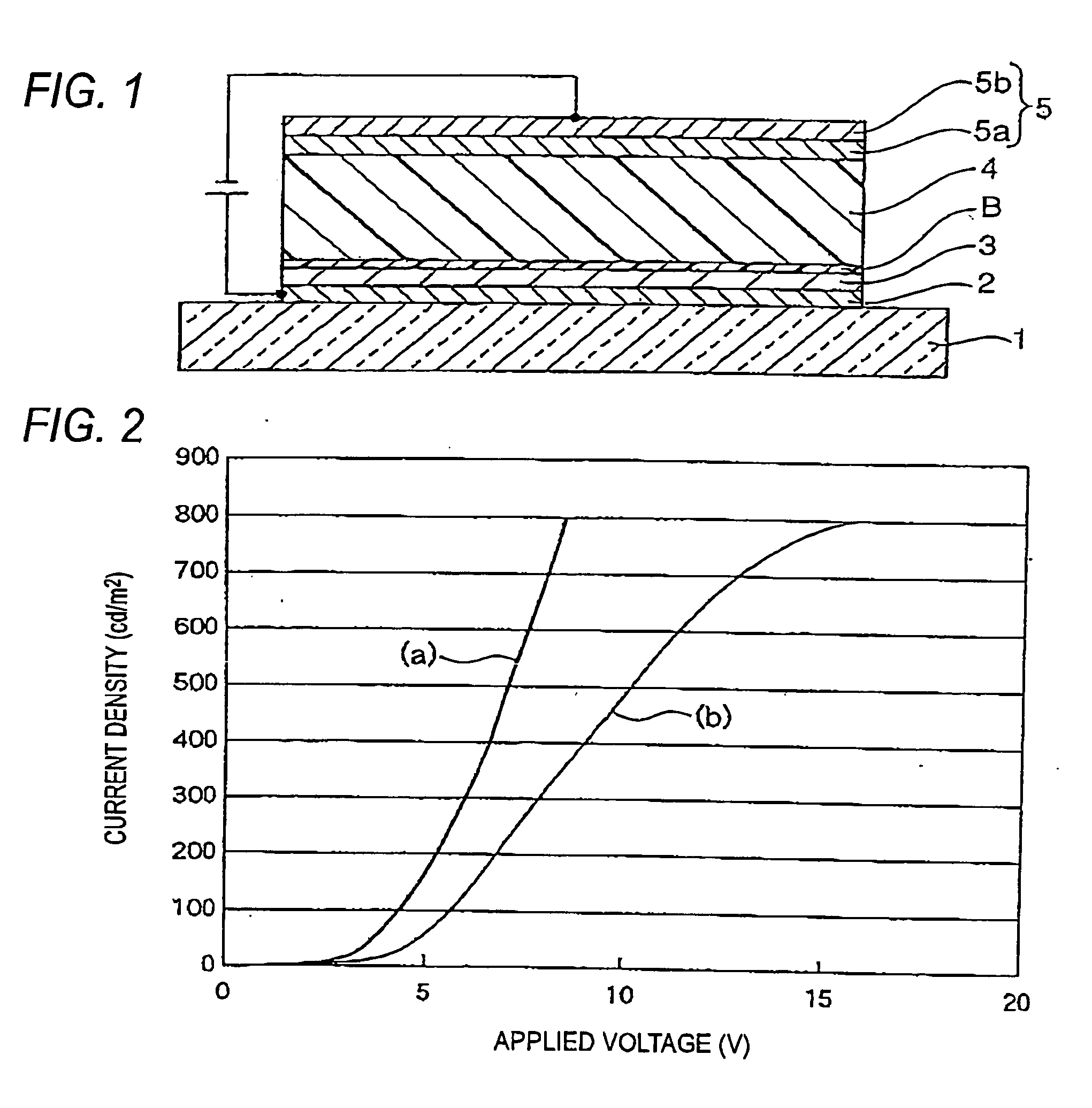

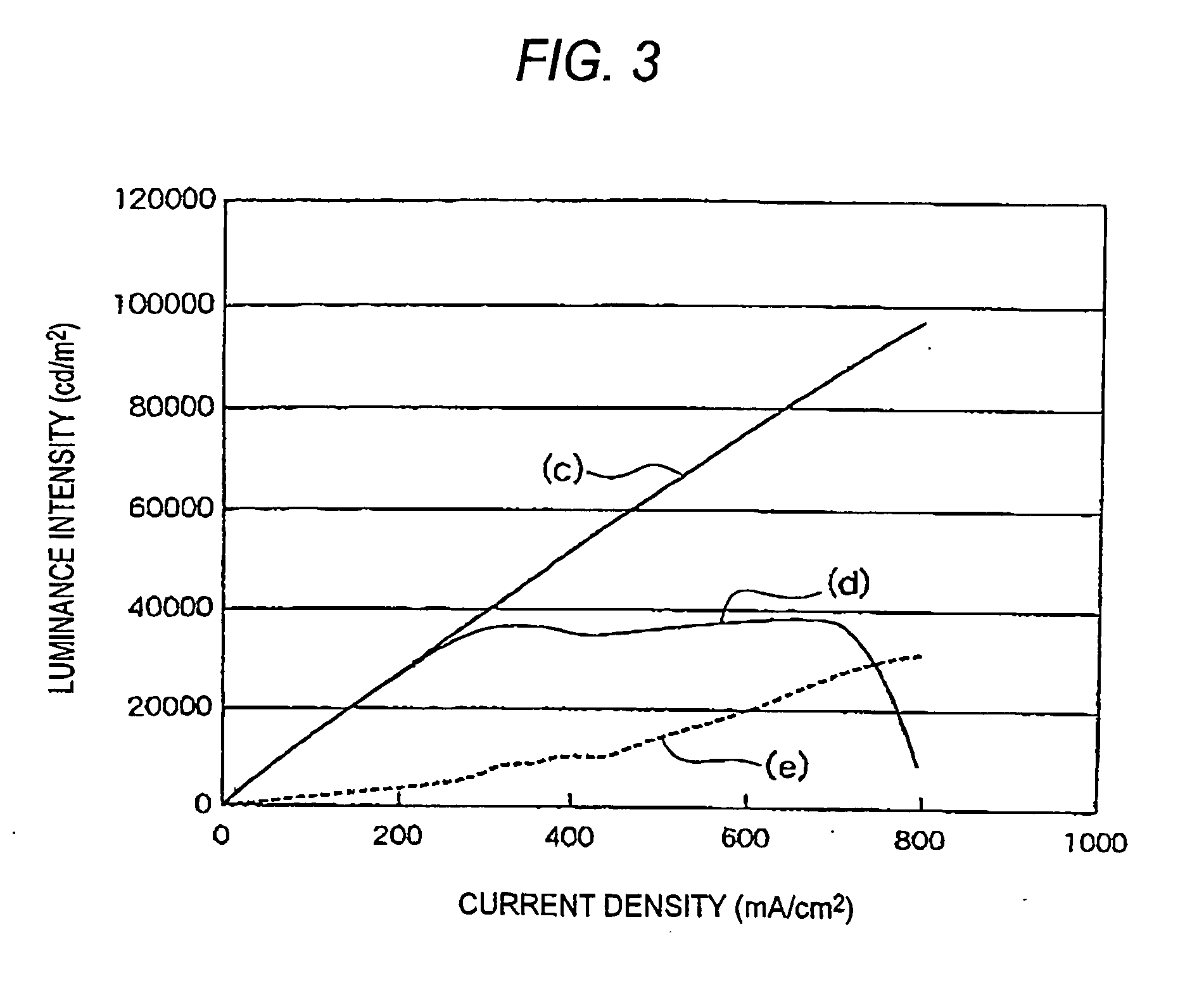

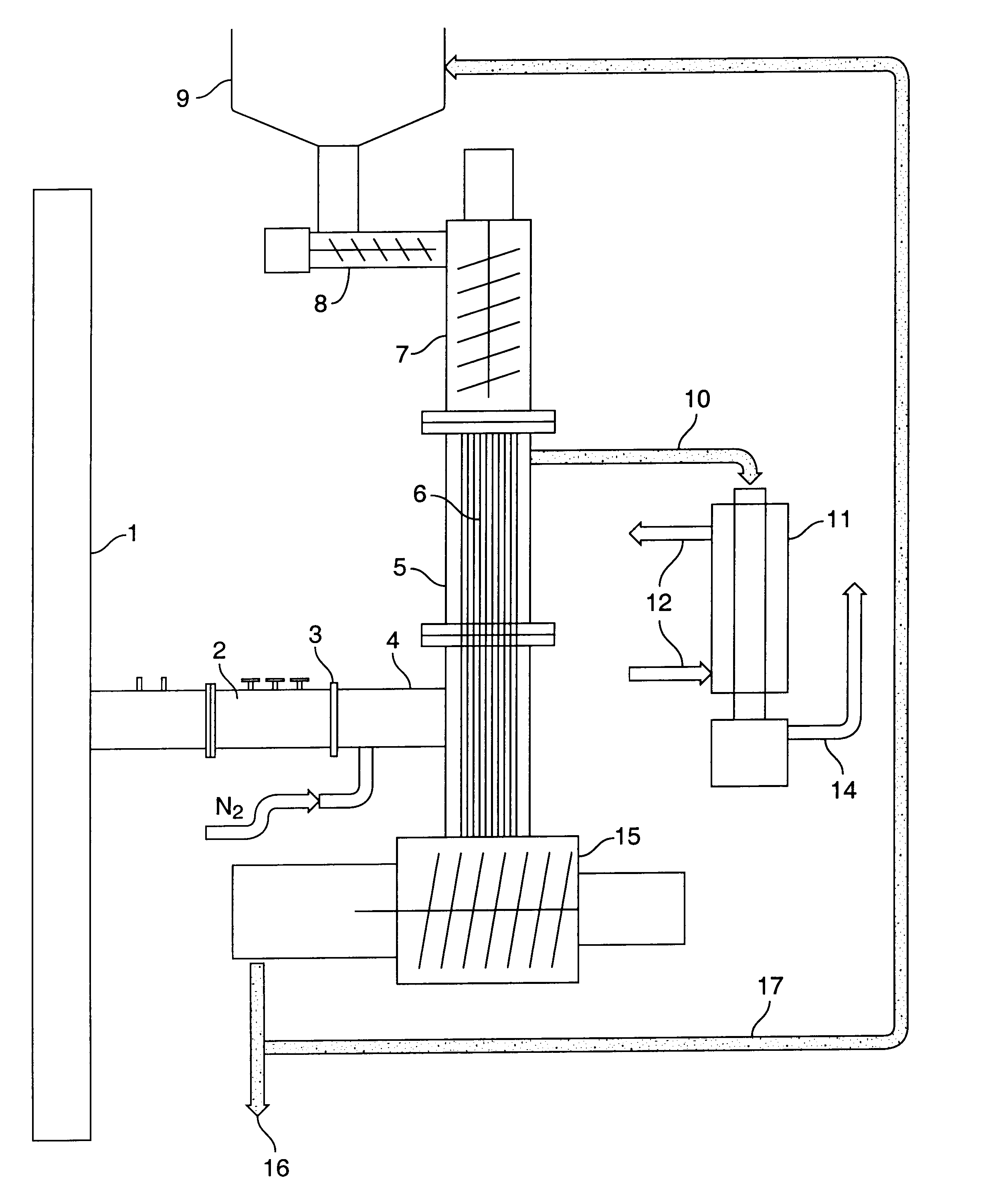

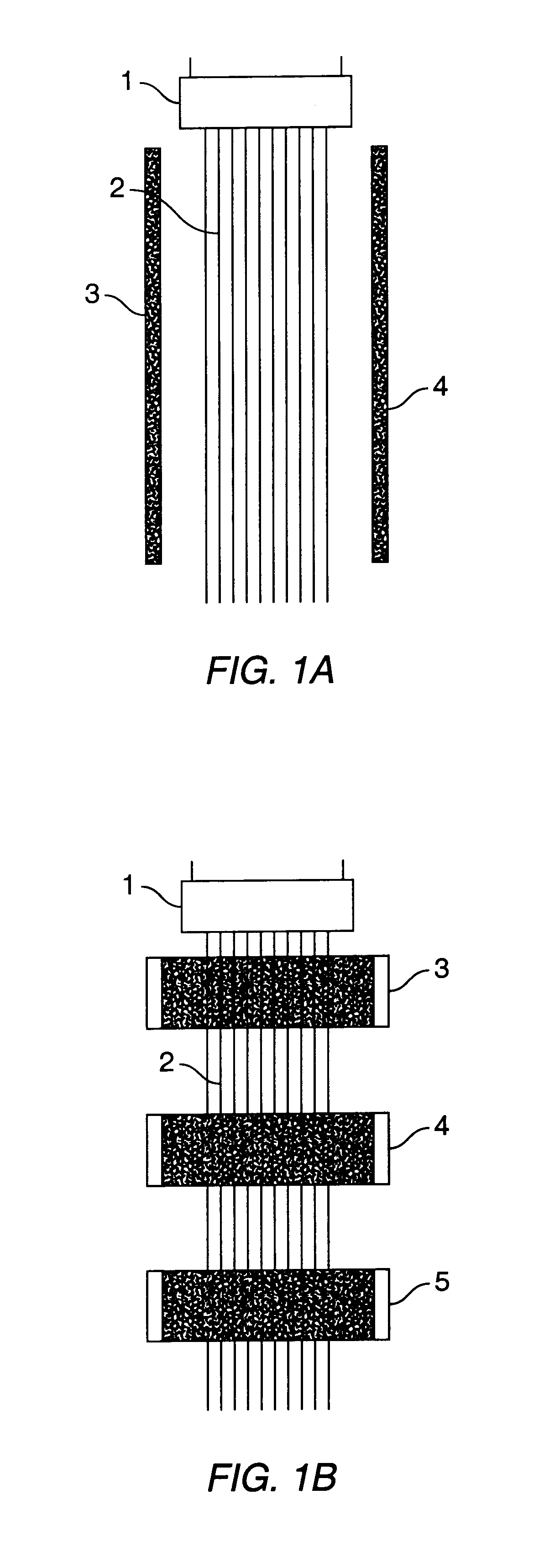

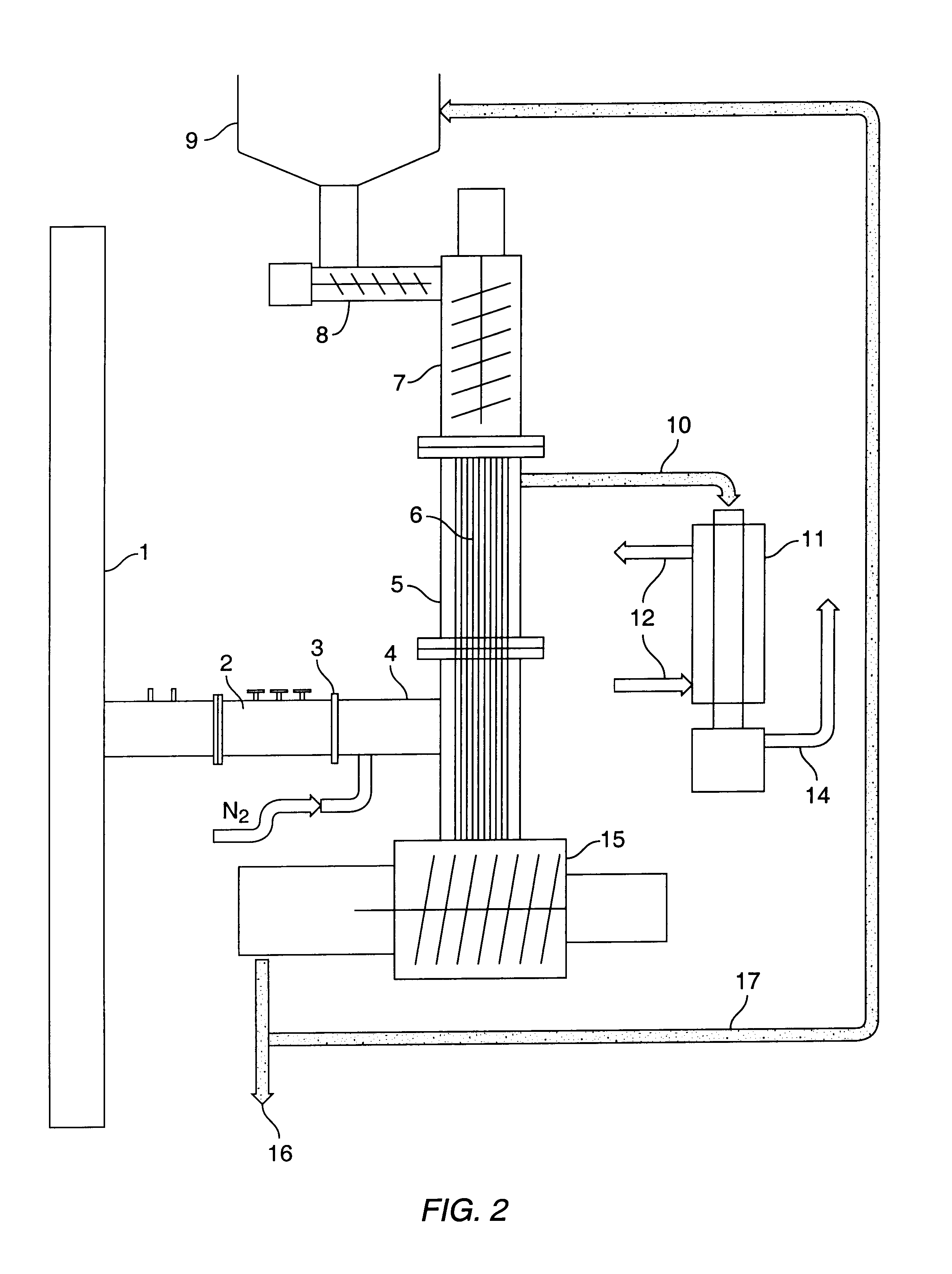

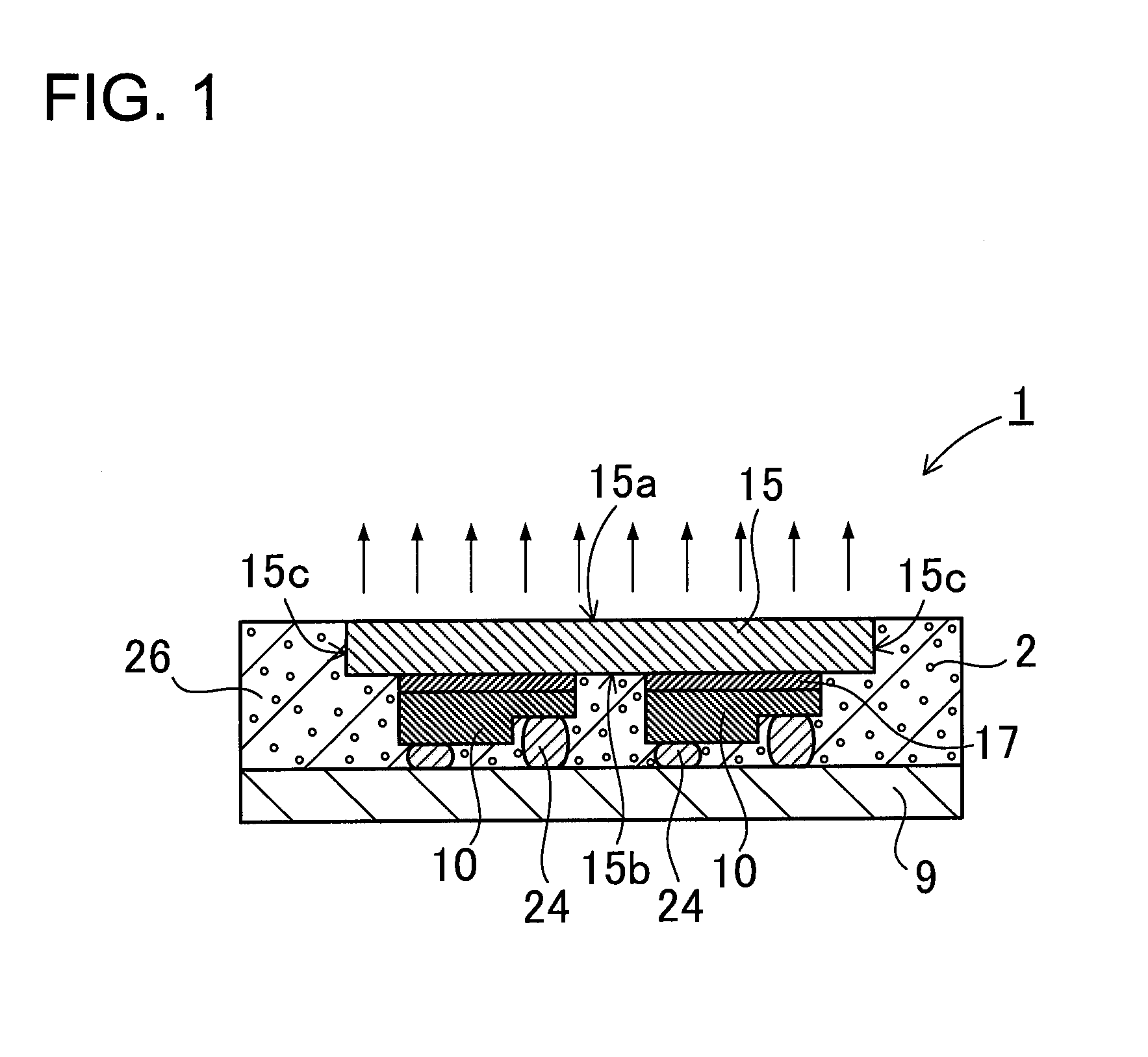

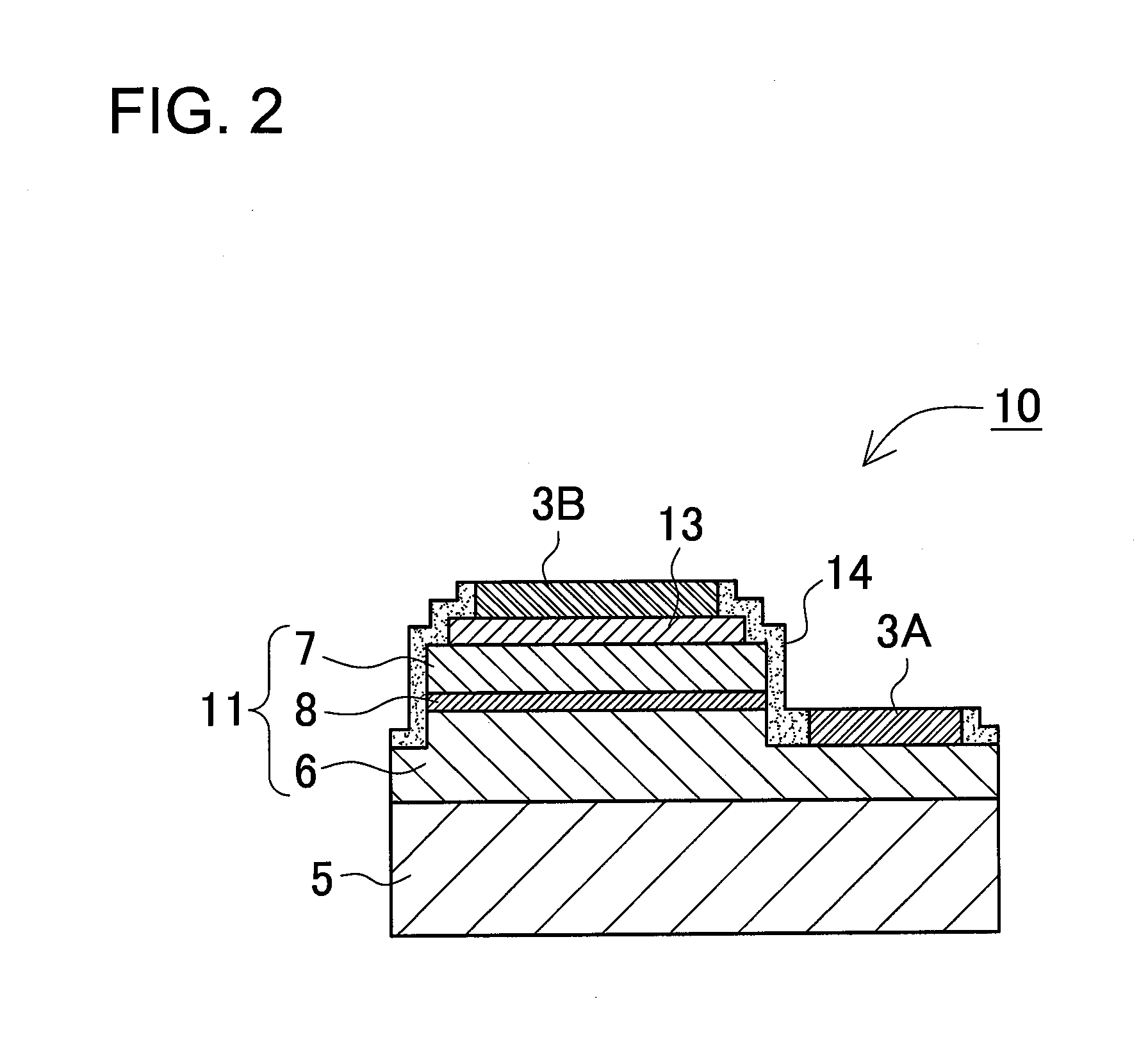

Organic electroluminescent device and method for manufacturing the same

InactiveUS20050170208A1Maintain good propertiesEasy to manufactureDischarge tube luminescnet screensElectroluminescent light sourcesCharge injectionOrganic solvent

An organic EL device which drives over a wide range from low brightness to high brightness for light source applications, operates stably over a wide range of brightness and has excellent life property is provided. The device comprises at least one pair of electrodes 2 and 5, and a plurality of functional layers disposed between the electrodes 2 and 5, the functional layers comprising a layer 4 having the light emitting function, which is composed of at least one polymeric material and contains an organic solvent and a charge injection layer 3 composed of at least one inorganic material.

Owner:JOLED INC

Process and reactor for microwave cracking of plastic materials

InactiveUS6184427B1Indirect and direct heating destructive distillationLiquid hydrocarbon mixture productionRadio frequency energyPlastic materials

A process of activated cracking of high molecular organic waste material which includes confining the organic waste material in a reactor space as a mixture with a pulverized electrically conducting material (sensitizer) and / or catalysts and / or "upgrading agents" and treating this mixture by microwave or radio frequency electro-magnetic radiation. Organic waste materials include hydrocarbons or their derivatives, polymers or plastic materials and shredded rubber. The shredded rubber can be the source of the sensitizer and / or catalyst material as it is rich in carbon and other metallic species. This sensitizer can also consist of pulverized coke or pyrolytically carbonized organic feedstock and / or highly dispersed metals and / or other inorganic materials with high dielectric loss which absorb microwave or radio frequency energy.

Owner:HIGHWAVE ACQUISITION

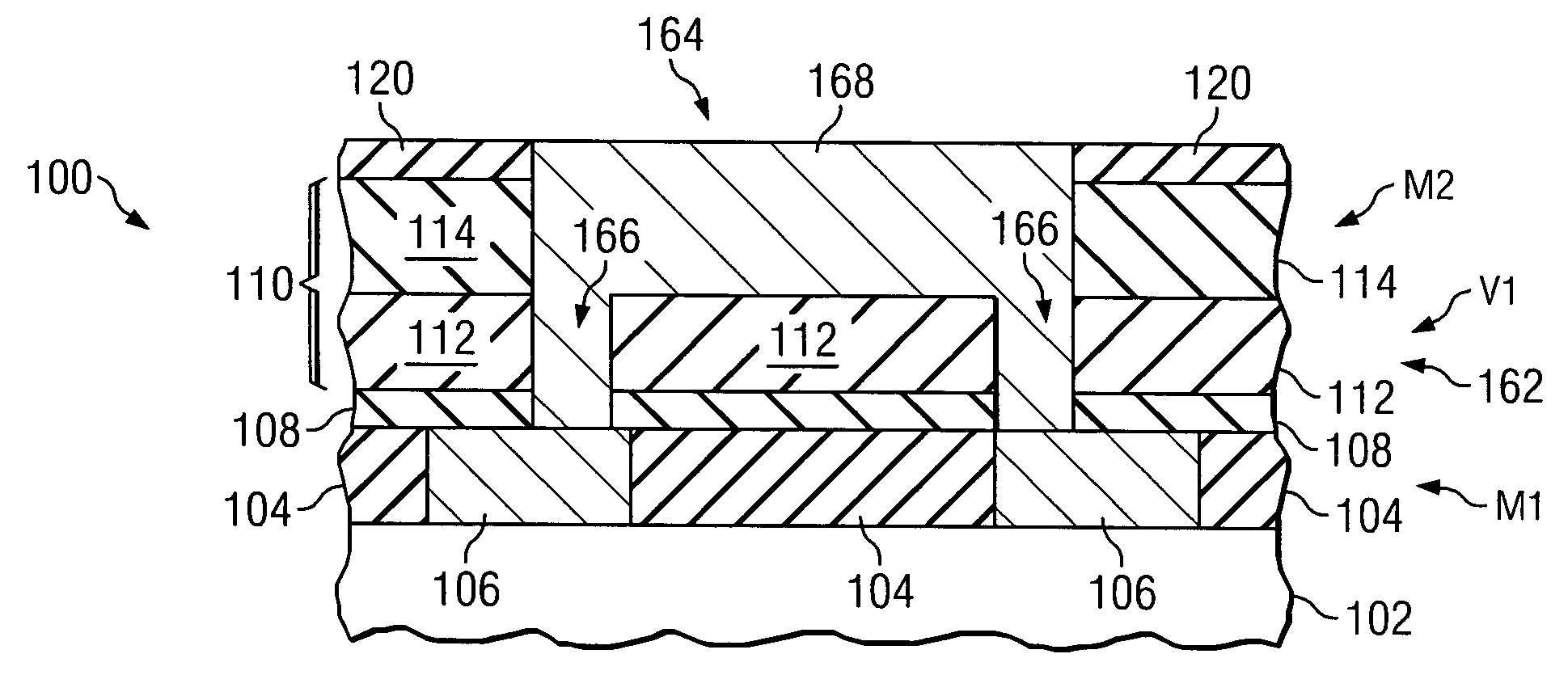

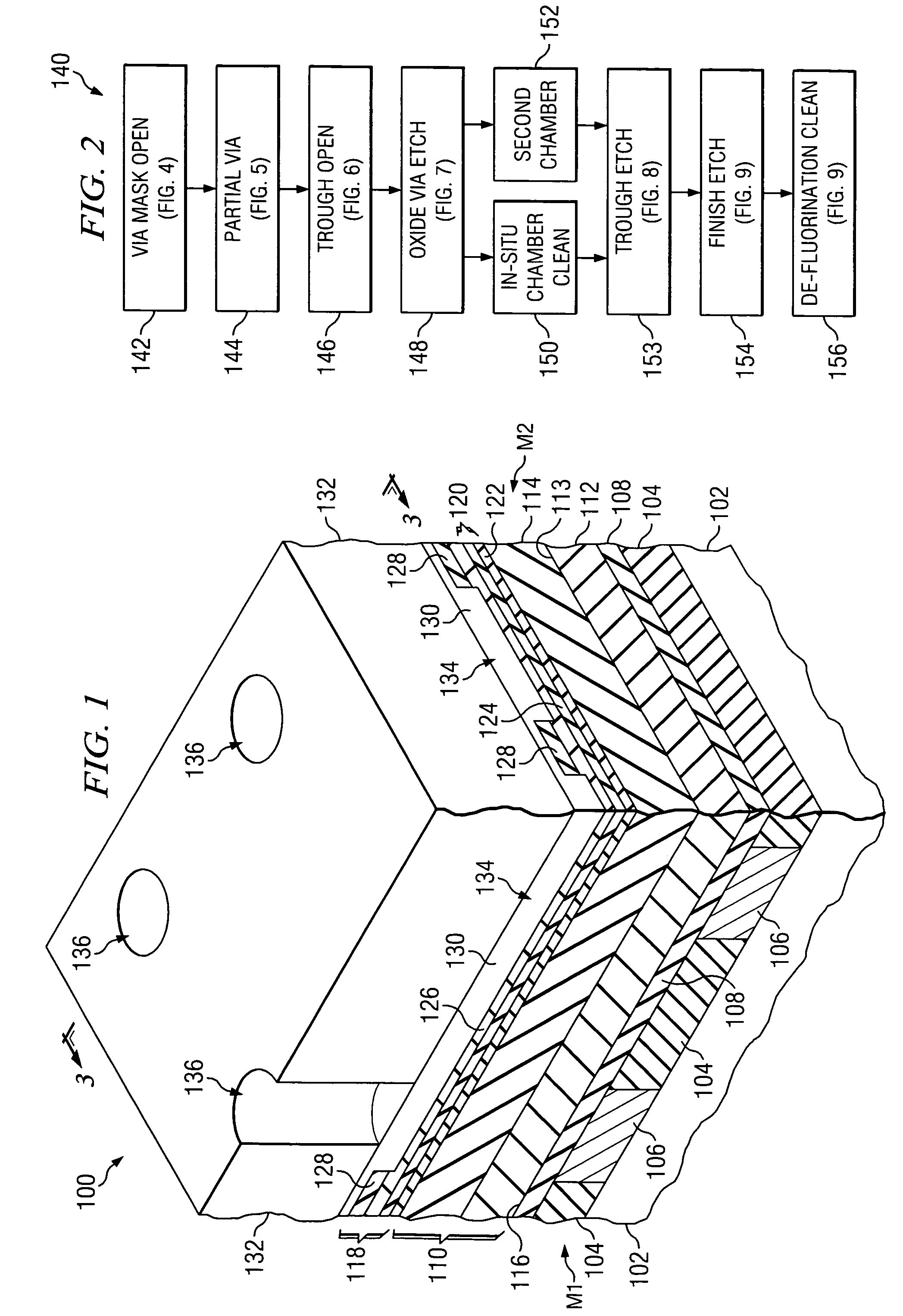

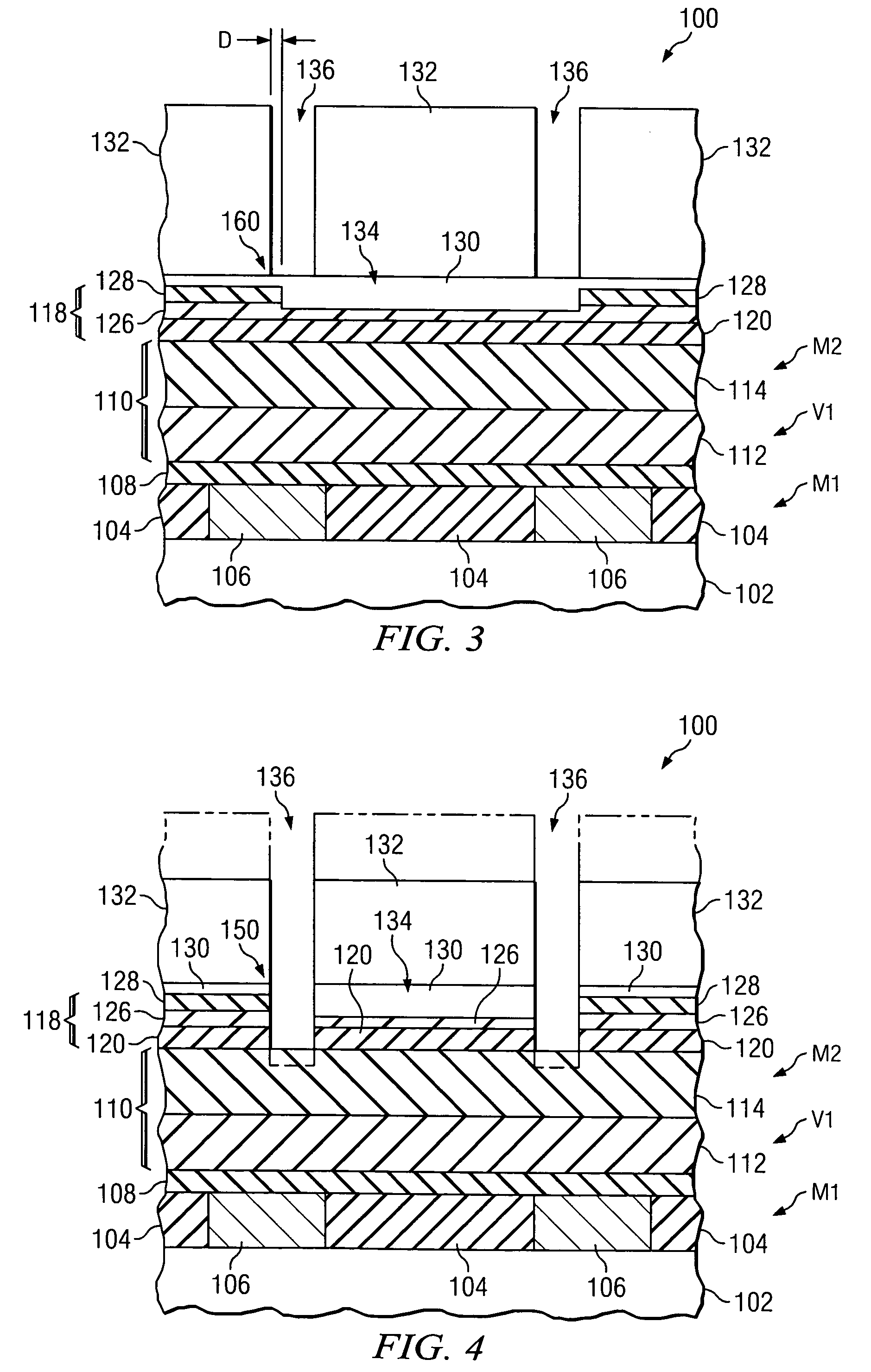

Dual damascene structure and method

ActiveUS20050079706A1Easy to controlEnhance the imageElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricInorganic materials

A dual damascene structure and method of fabrication thereof. An insulating layer comprises a first dielectric material and a second dielectric material, the second dielectric material being different from the first dielectric material. First conductive regions having a first pattern are formed in the first dielectric material, and second conductive regions having a second pattern are formed in the second dielectric material, the second pattern being different from the first pattern. One of the first dielectric material and the second dielectric material comprises an organic material, and the other dielectric material comprises an inorganic material. One of the first and second dielectric materials is etchable selective to the other dielectric material. A method of cleaning a semiconductor wafer processing chamber while a wafer remains residing within the chamber is also disclosed.

Owner:INFINEON TECH AG +1

Light emitting apparatus and method for producing the same

ActiveUS20100320479A1Inhibition lossIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingOptical controlInorganic materials

A light emitting apparatus and a production method of the apparatus are provided that can emit light with less color unevenness at high luminance. The apparatus includes a light emitting device, a transparent member receiving incident light emitted from the device, and a covering member. The transparent member is formed of an inorganic material light conversion member including an externally exposed emission surface, and a side surface contiguous to the emission surface. The covering member contains a reflective material, and covers at least the side surfaces of the transparent member. Substantially only the emission surface serves as the emission area of the apparatus. It is possible to provide emitted light having excellent directivity and luminance. Emitted light can be easily optically controlled. In the case where each light emitting apparatus is used as a unit light source, the apparatus has high secondary usability.

Owner:NICHIA CORP

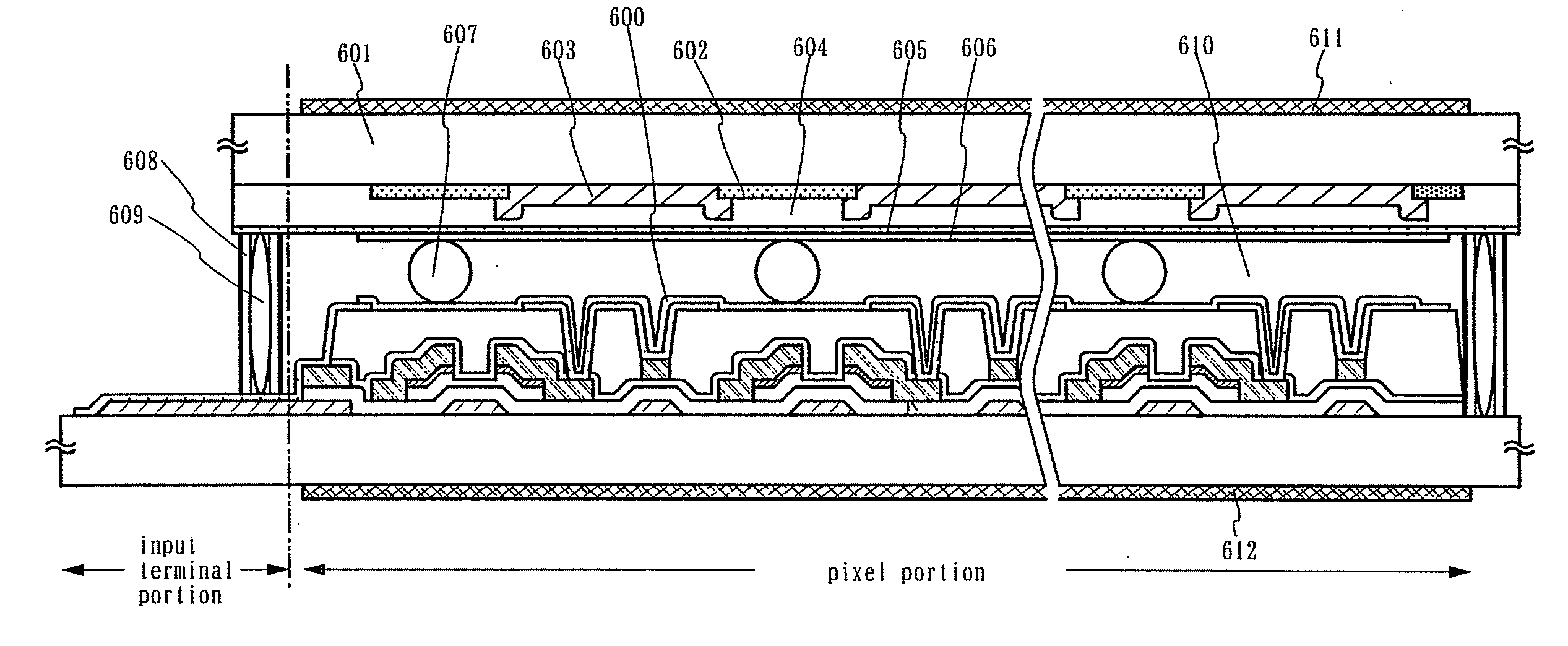

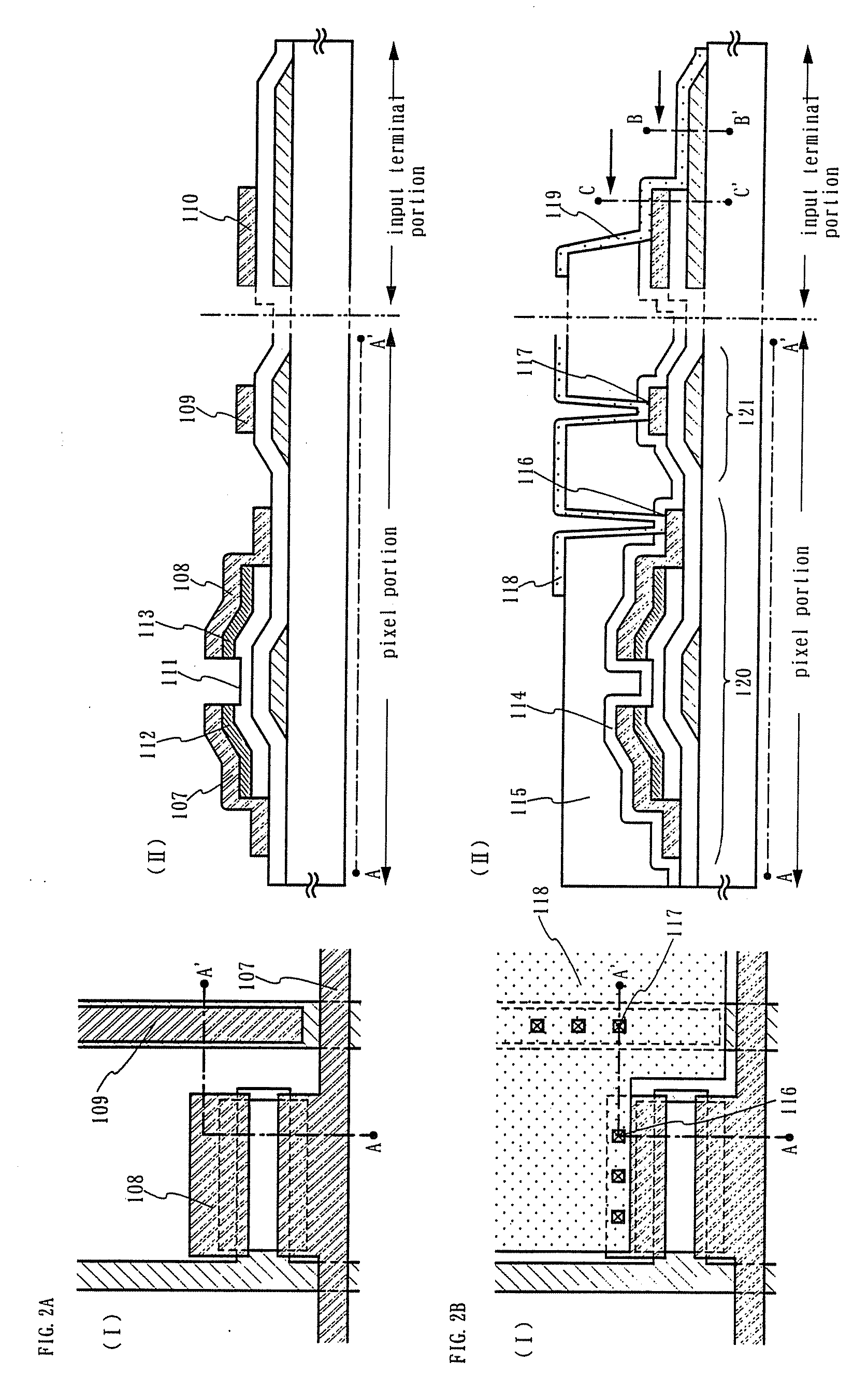

Semiconductor Device and Method of Manufacturing the Semiconductor Device

InactiveUS20090033818A1Reduce manufacturing costIncrease productionTransistorSolid-state devicesInorganic materialsPhotolithography

In a semiconductor device, a first interlayer insulating layer made of an inorganic material and formed on inverse stagger type TFTs, a second interlayer insulating layer made of an organic material and formed on the first interlayer insulating layer, and a pixel electrode formed in contact with the second interlayer insulating layer are disposed on a substrate, and an input terminal portion that is electrically connected to a wiring of another substrate is provided on an end portion of the substrate. The input terminal portion includes a first layer made of the same material as that of the gate electrode and a second layer made of the same material as that of the pixel electrode. With this structure, the number of photomasks used in the photolithography method can be reduced to 5.

Owner:SEMICON ENERGY LAB CO LTD

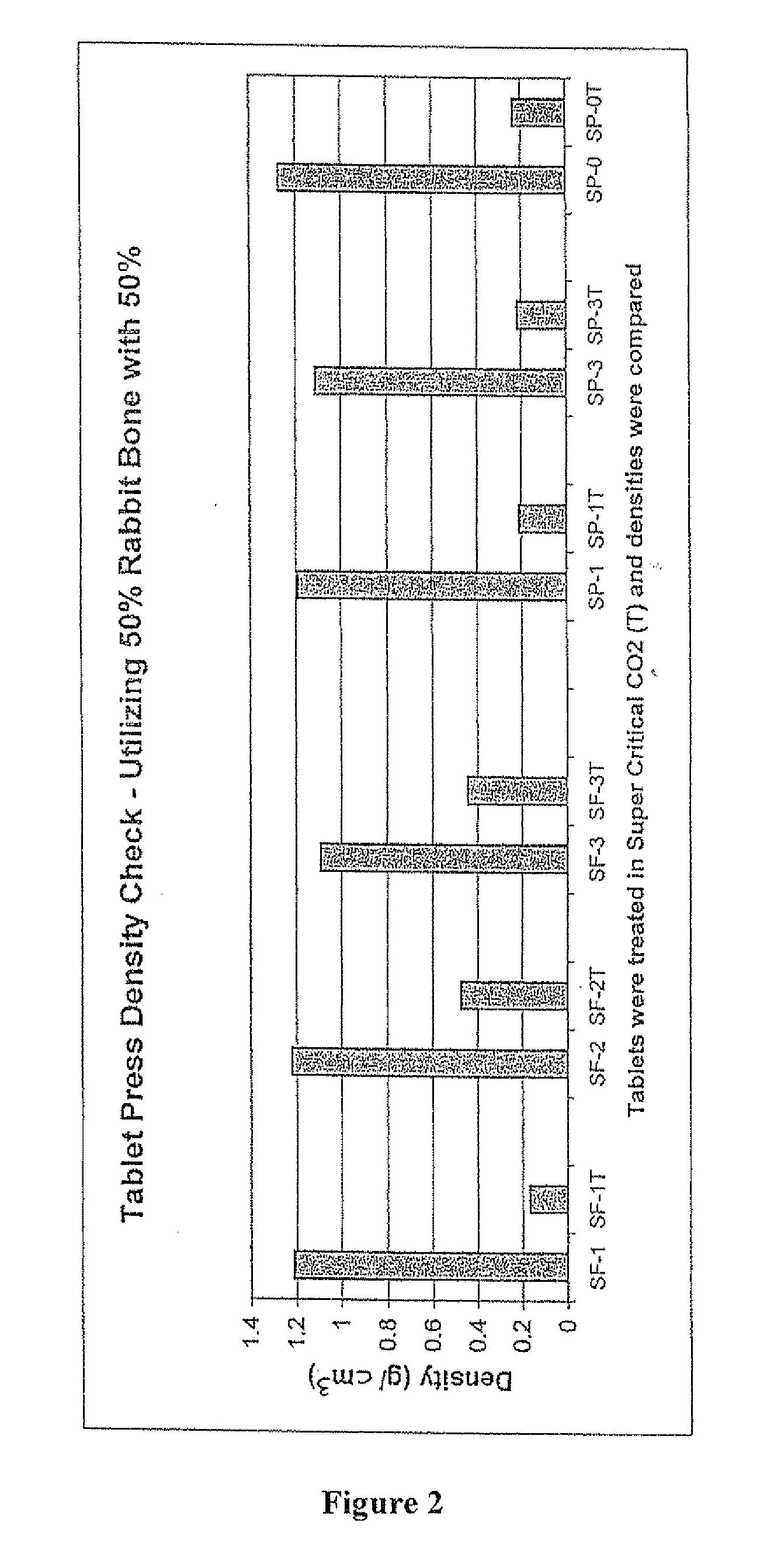

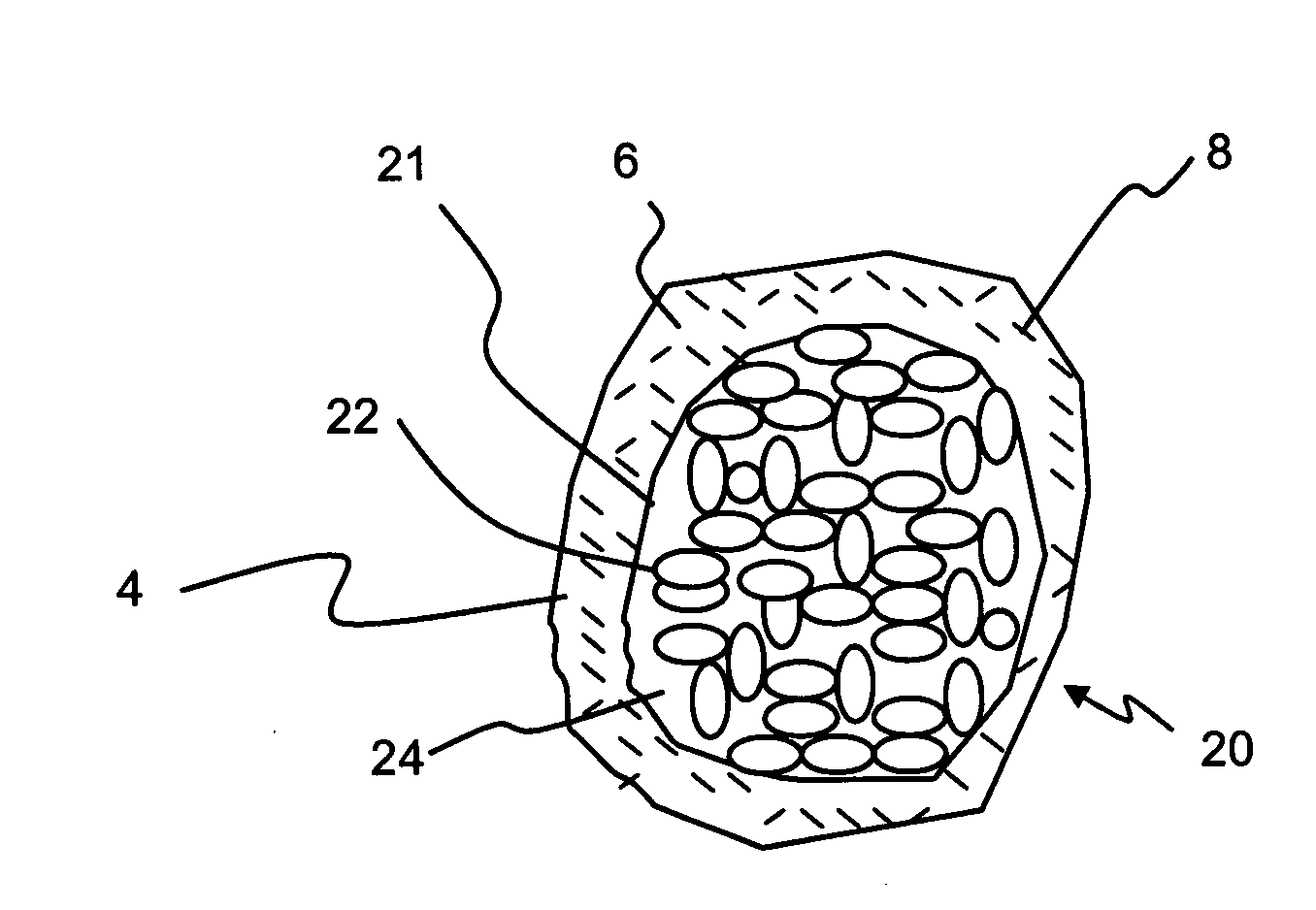

Porous osteoimplant

ActiveUS20080069852A1Accelerate the remodeling processImprove permeabilityBone implantSkeletal disorderBone growthBone defect

The invention is directed toward porous composites for application to a bone defect site to promote new bone growth. The inventive porous composites comprise a biocompatible polymer and a plurality of particles of bone-derived material, inorganic material, bone substitute material or composite material. In certain embodiments, the porous composites are prepared using a method that includes a supercritical fluid (e.g., supercritical carbon dioxide) treatment. The invention also discloses methods of using these composites as bone void fillers.

Owner:WARSAW ORTHOPEDIC INC

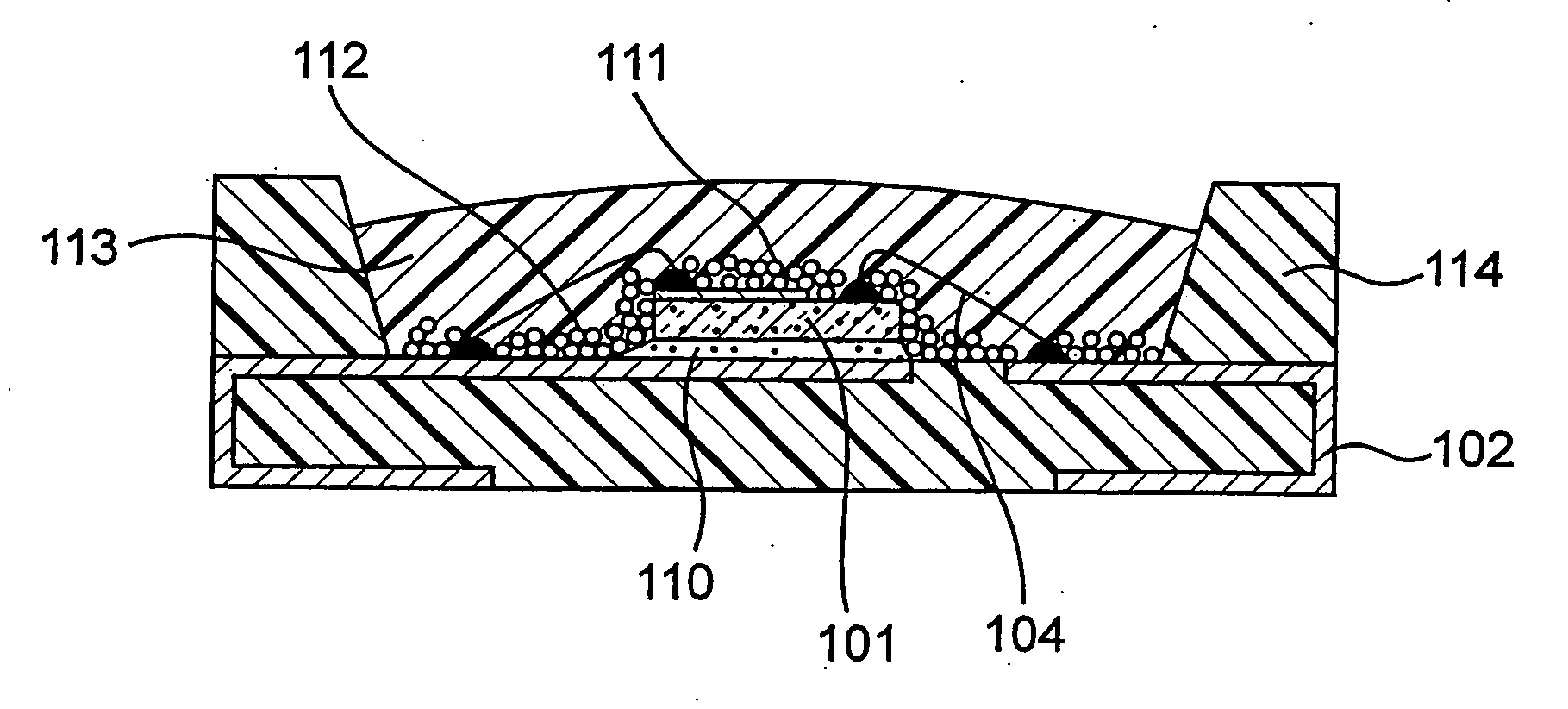

Light emitting apparatus and method of manufacturing the same

ActiveUS20060267042A1Improve reliabilityLess variabilitySolid-state devicesSemiconductor/solid-state device manufacturingAlkaline earth metalFluorescence

A light emitting apparatus comprising a light emitting device (101) disposed on a supporting body (105), and coating layers ((108, 109) that bind a fluorescent substance that absorbs light emitted by the light emitting device (101) and emits light of a different wavelength and secures the fluorescent substance onto the surface of the light emitting device (101). The coating layers (108, 109) are made of an inorganic material including an oxide and a hydroxide, each containing at least one element selected from the group consisting of Si, Al, Ga, Ti, Ge, P, B, Zr, Y, Sn, Pb and alkali earth metals. Also an adhesive layer (110) is made of the same inorganic material as that of the coating layers (108, 109).

Owner:NICHIA CORP

Composite shaped bodies and methods for their production and use

InactiveUS6863899B2Overcome the lack of robustnessNovel featuresCosmetic preparationsDental implantsCalcium biphosphatePlastic surgery

Shaped, composite bodies are provided. One portion of the shaped bodies comprises an RPR-derived porous inorganic material, preferably a calcium phosphate. Another portion of the composite bodies is a different solid material, preferably metal, glass, ceramic or polymeric. The shaped bodies are especially suitable for orthopaedic and other surgical use.

Owner:ORTHOVITA INC

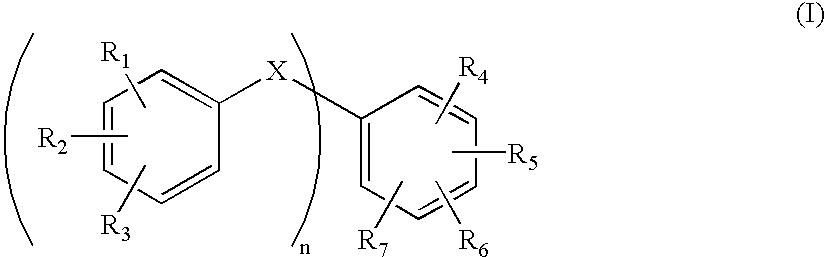

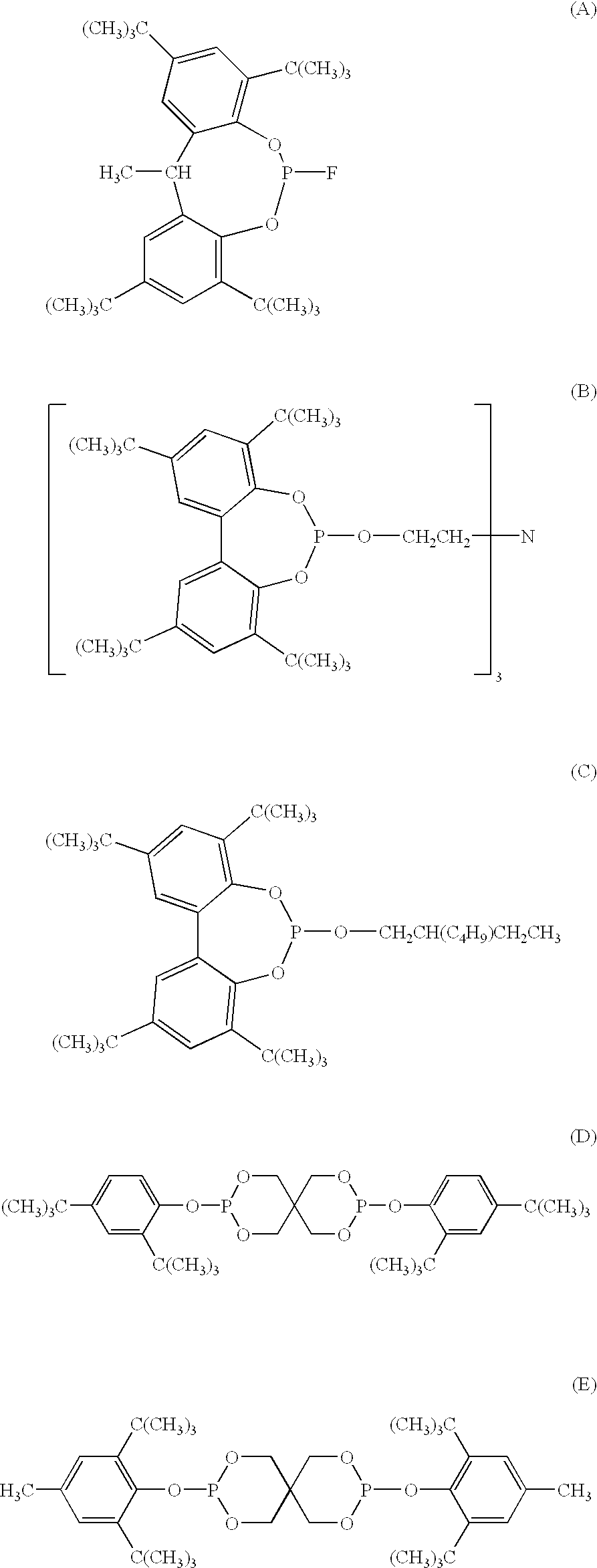

Mixtures of phenolic and inorganic materials with antimicrobial activity

InactiveUS6585989B2Excellent discoloration resistanceMaintain physical propertiesBiocideHeavy metal active ingredientsFiberAntibacterial activity

Plastic films, fibers and articles are provided long-term antimicrobial activity with a combination of certain phenolic and inorganic antimicrobial agents. The plastic films, fibers and articles with antimicrobial activity exhibit superior resistance to discoloration, may be processed at high temperature, and maintain physical properties upon weathering, especially upon exposure to ultraviolet radiation.

Owner:BASF SE

Electrochromic devices

ActiveUS8764950B2Improve conductivityIncrease resistanceVacuum evaporation coatingSputtering coatingElectricityOptoelectronics

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically-insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically-insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

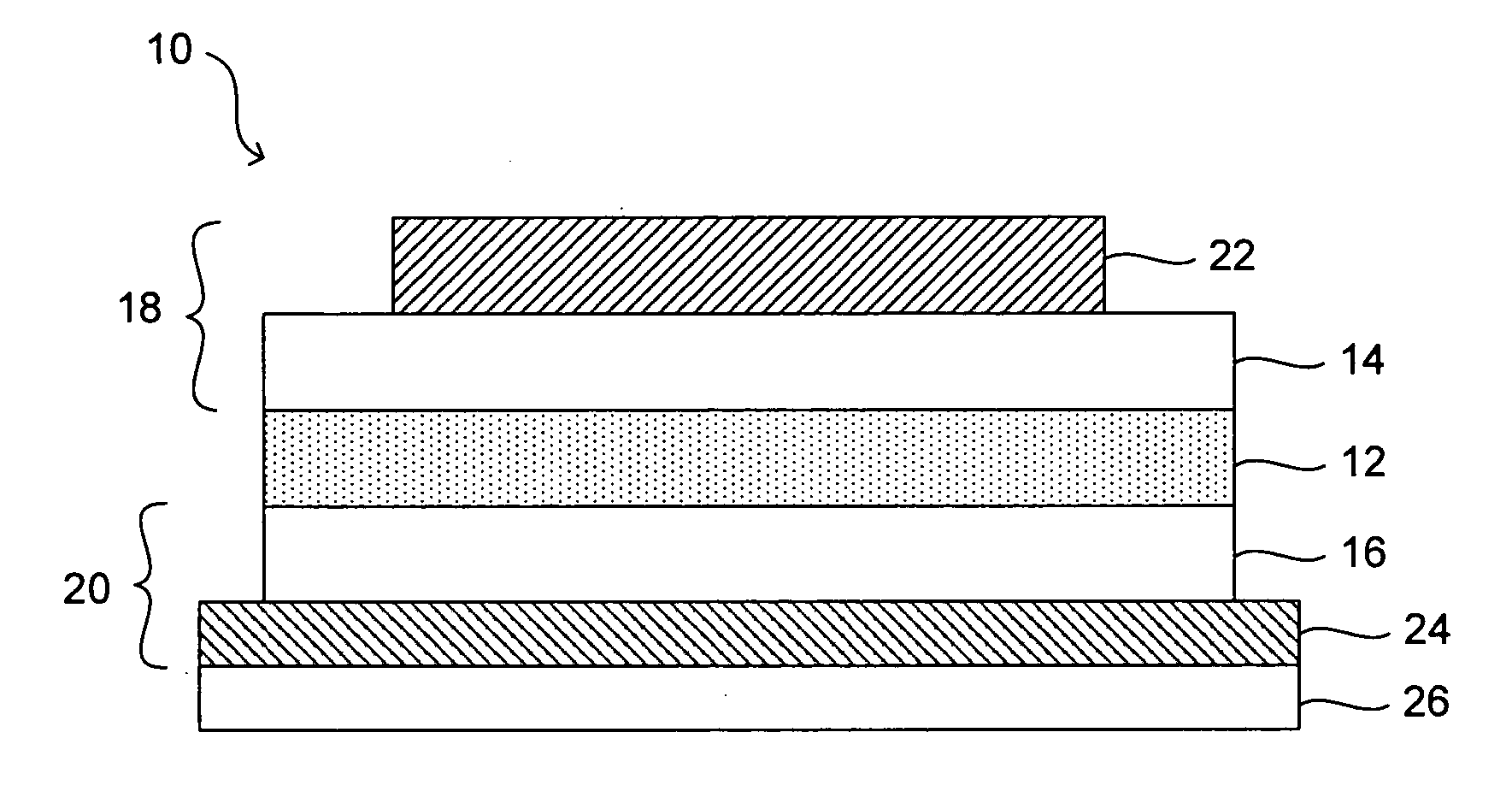

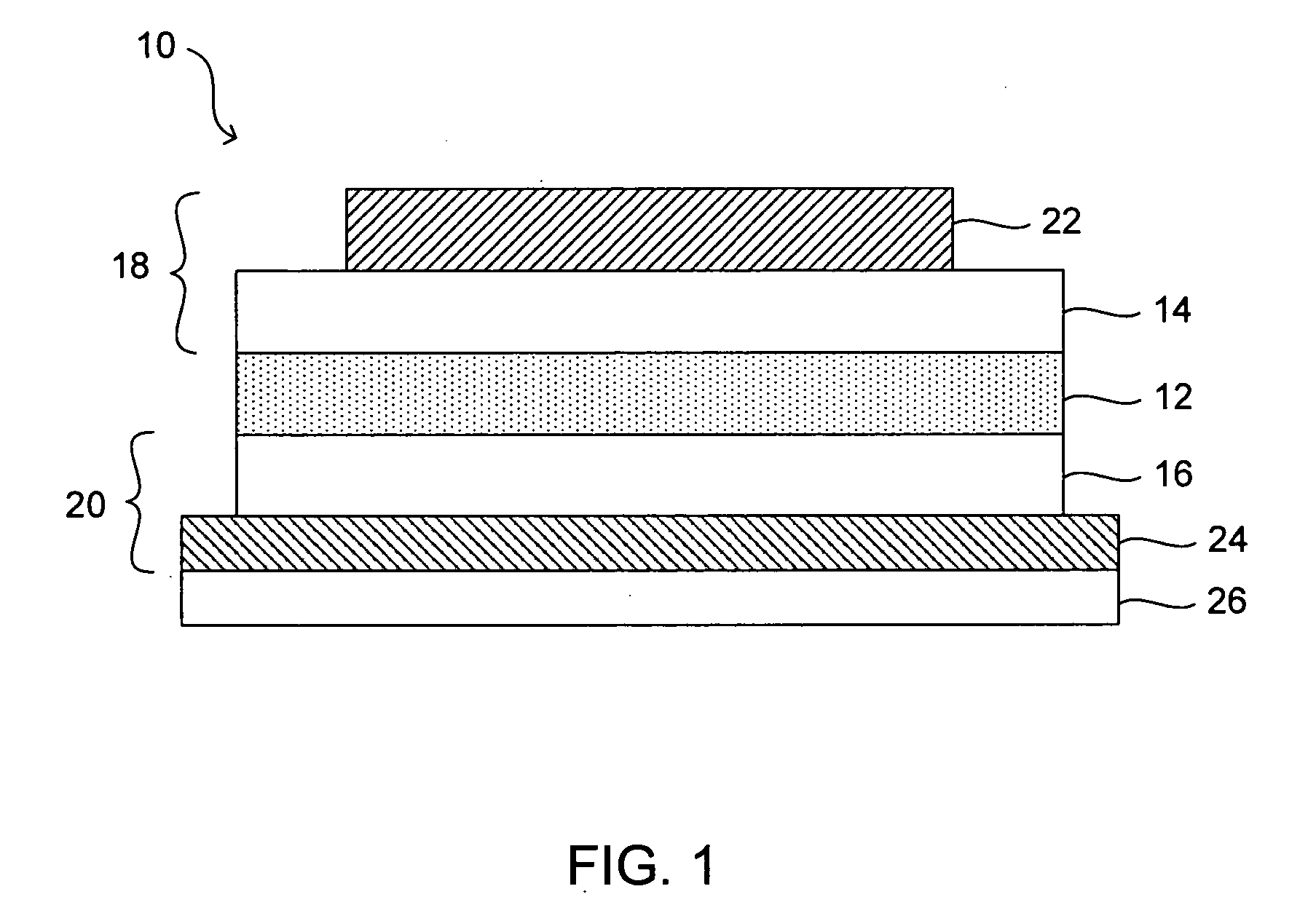

Individually encapsulated solar cells and solar cell strings having a substantially inorganic protective layer

InactiveUS20070295390A1Avoid moisture damageLow costPhotovoltaic supportsPV power plantsChemical compositionEngineering

Methods and devices are provided for improved environmental protection for photovoltaic devices and assemblies. In one embodiment, the device comprises of an individually encapsulated solar cell, wherein the encapsulated solar cell includes at least one protective layer coupled to at least one surface of the solar cell and the protective layer may be formed from a substantially inorganic material. The protective layer has a chemical composition that prevents moisture from entering the solar cell and wherein light passes through the protective layer to reach an absorber layer in the solar cell.

Owner:NANOSOLAR

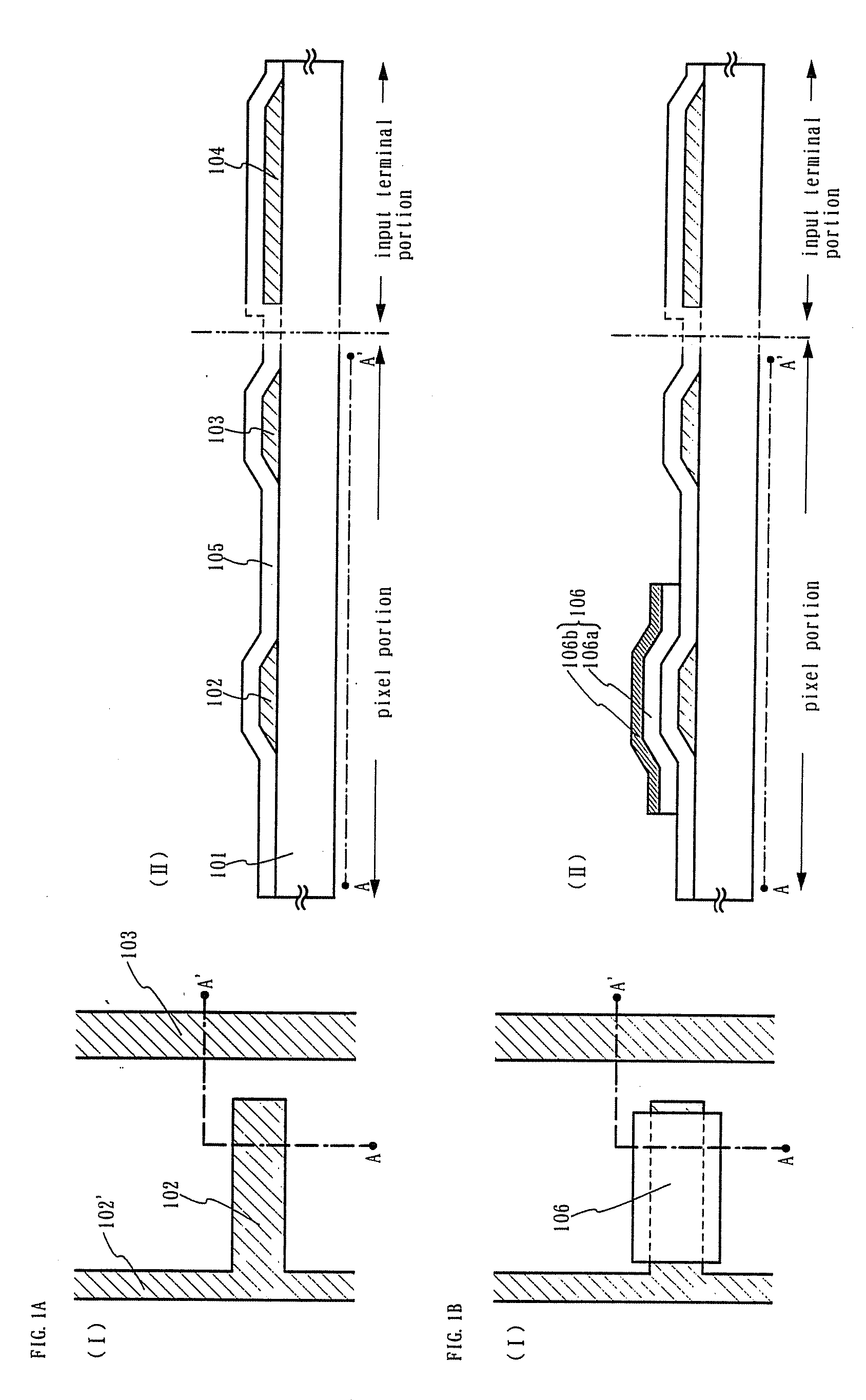

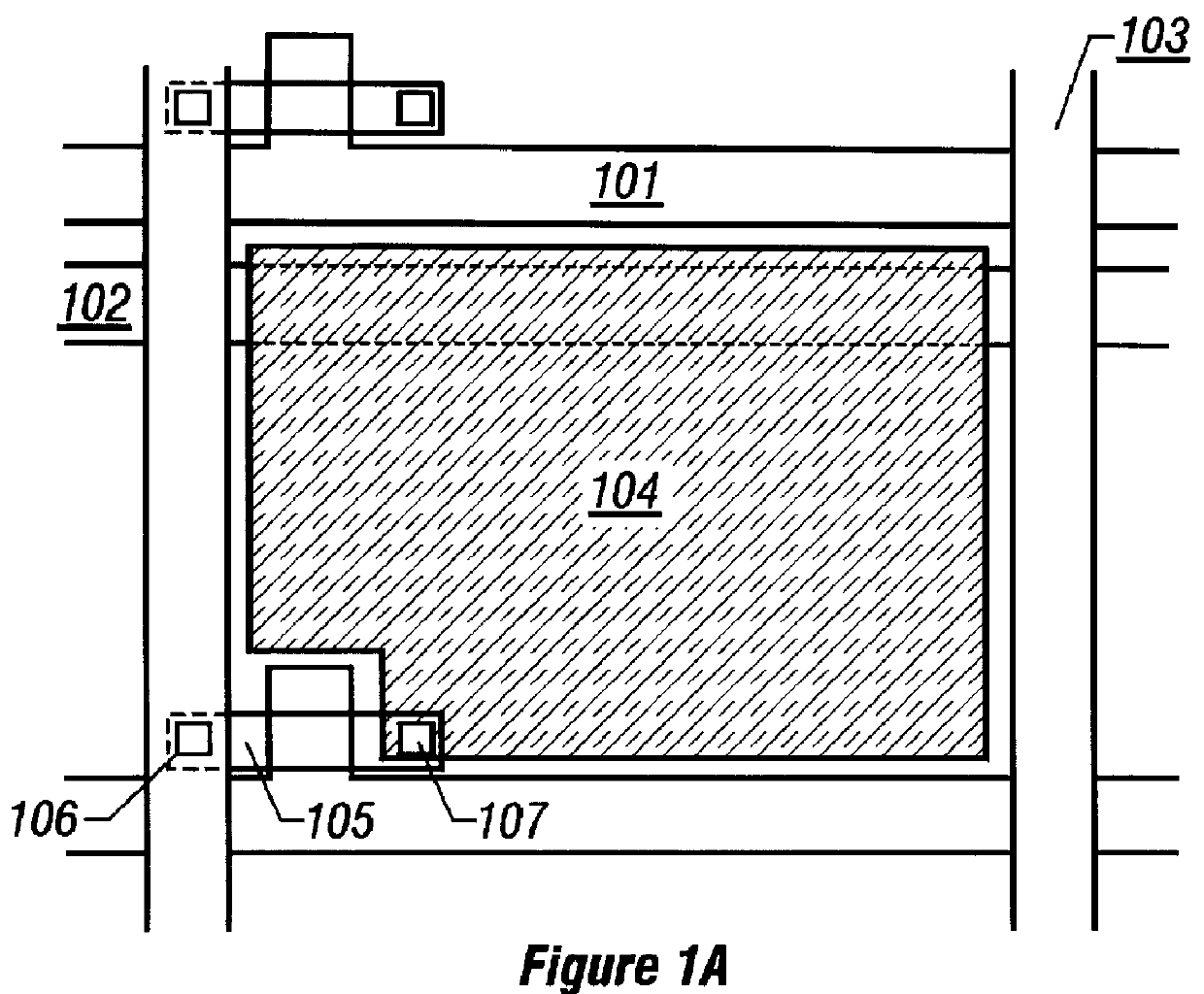

Electro-optical device and method of fabricating same

InactiveUS6118506ATransistorSolid-state devicesActive-matrix liquid-crystal displayLiquid-crystal display

An active matrix liquid crystal display having a high aperture ratio is provided. Retaining capacitors are created between a black matrix and pixel electrodes via a dielectric layer made from an organic resinous material or inorganic material. Those regions of the black matrix which cover TFTs are fully utilized. Therefore, wider area can be used to display an image than heretofore. In the present invention, the difference in relative dielectric constant between different dielectric layers is employed. Therefore, retaining capacitors can be created without the need to take account of parasitic capacitance.

Owner:SEMICON ENERGY LAB CO LTD

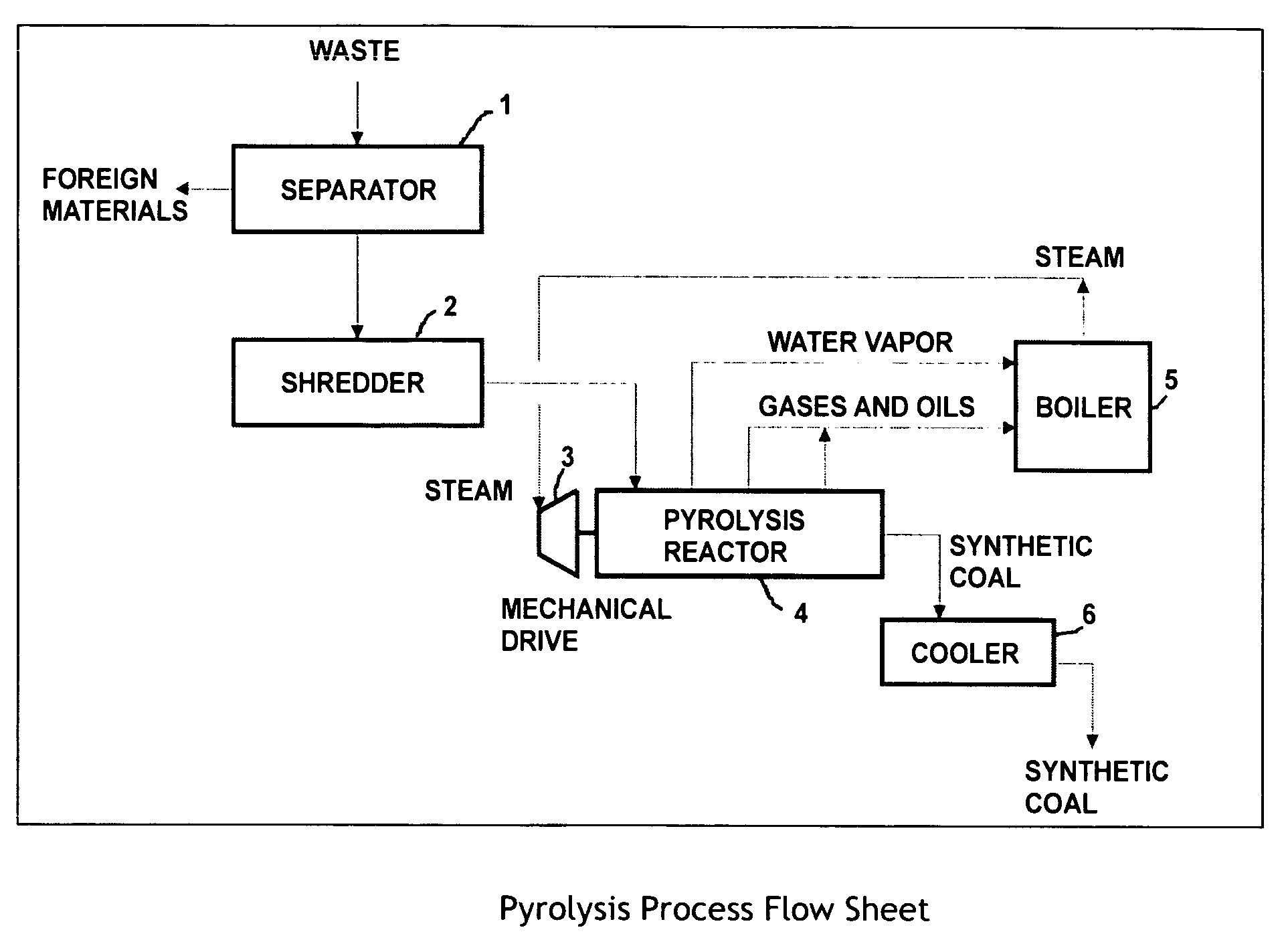

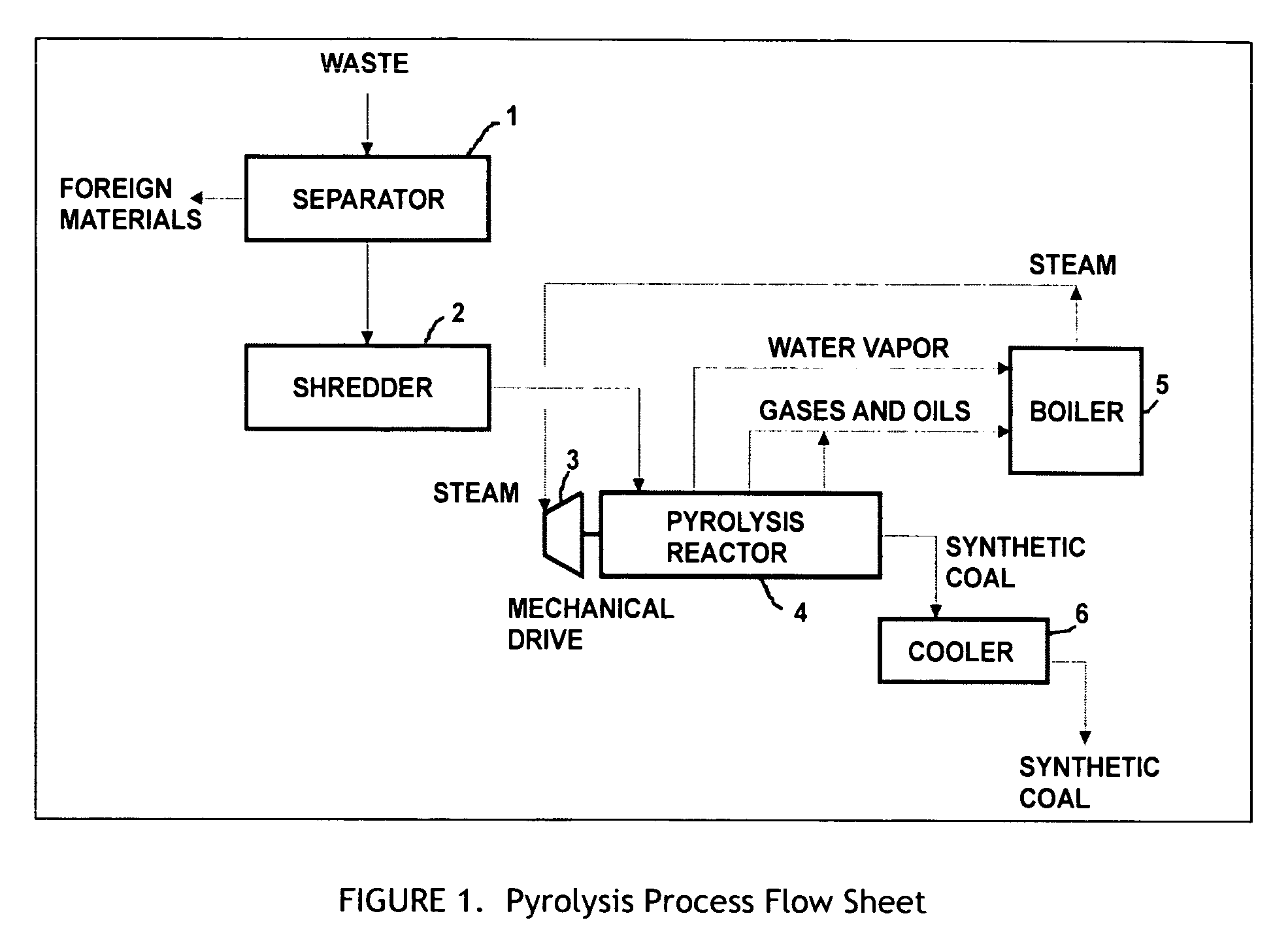

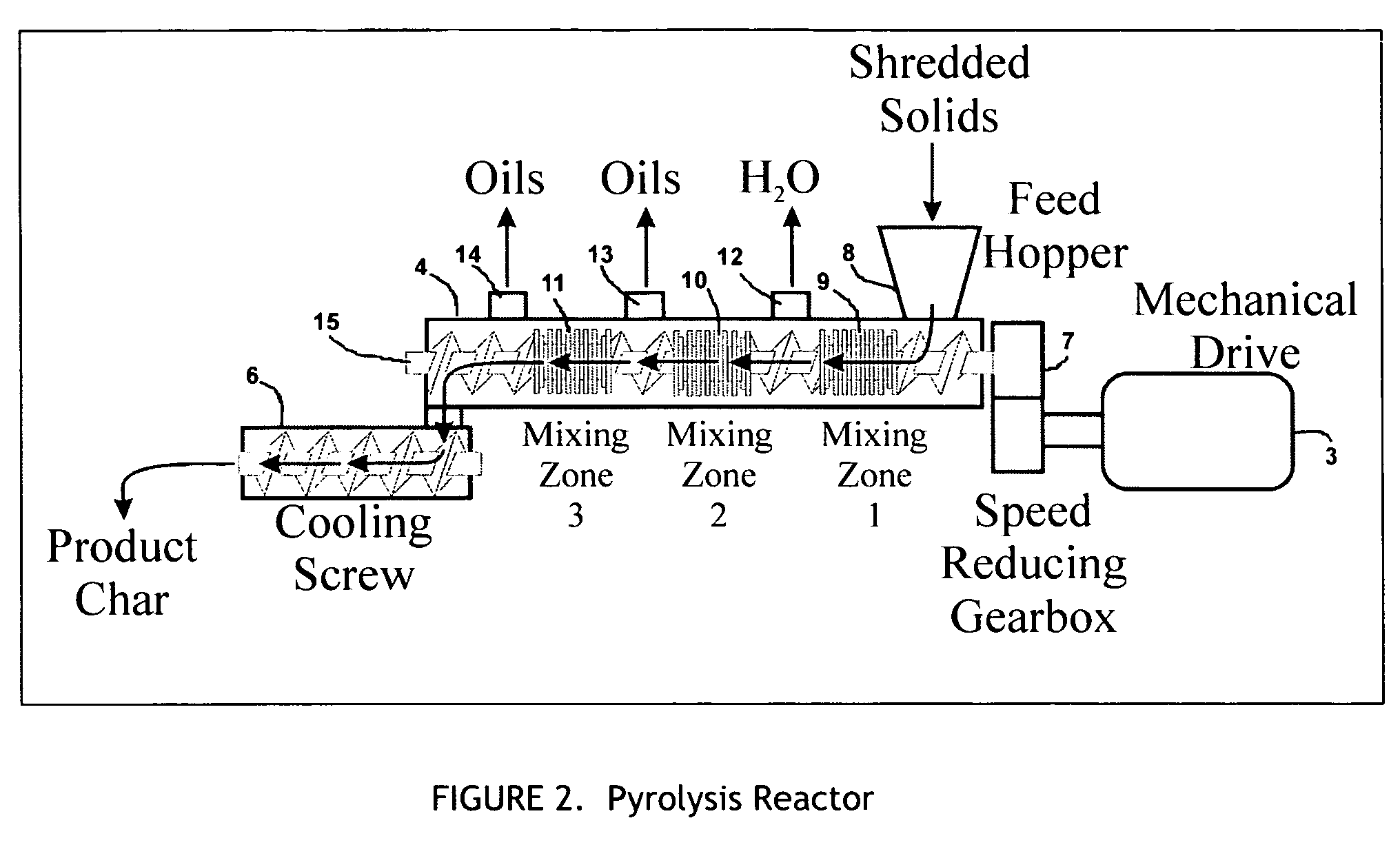

Waste conversion process

InactiveUS20060280669A1Good yieldMinimization requirementsBiofuelsIndirect and direct heating destructive distillationEnvironmental engineeringSand granules

A process for the preparation of high quality char from organic waste materials. The waste is first sorted to remove recyclable inorganic materials of economic value (metals, glass) and other foreign materials that would be detrimental to the quality of the final product (stone, sand, construction debris, etc.). After size reduction, the waste is pyrolyzed at a temperature range of 250 to 600° F., in a high capacity, continuous mixer reactor, using in-situ viscous heating of the waste materials, to produce a highly uniform, granular synthetic product similar in energy content and handling characteristics to, but much cleaner burning than, natural coal.

Owner:ENTROPIC TECH CORP

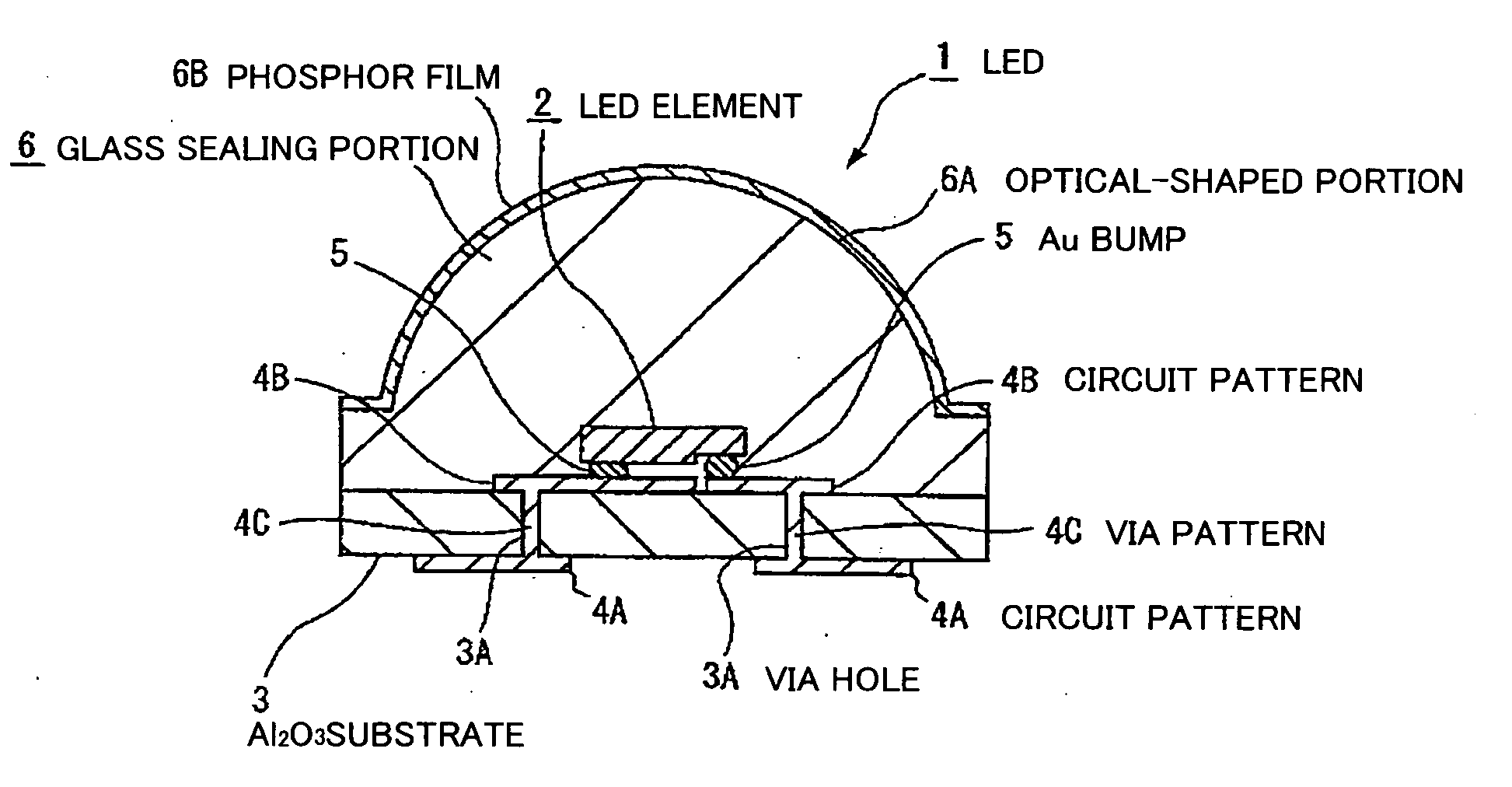

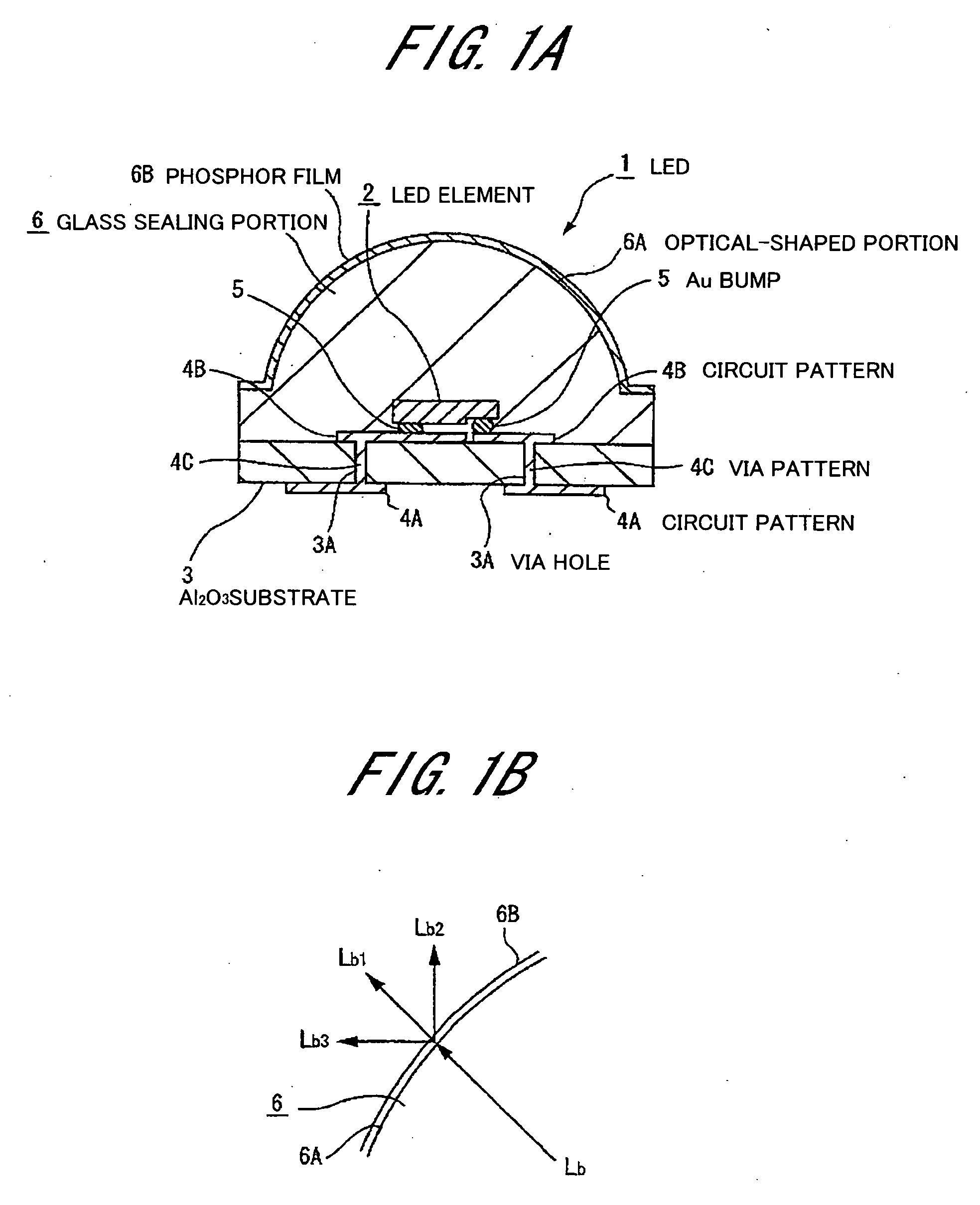

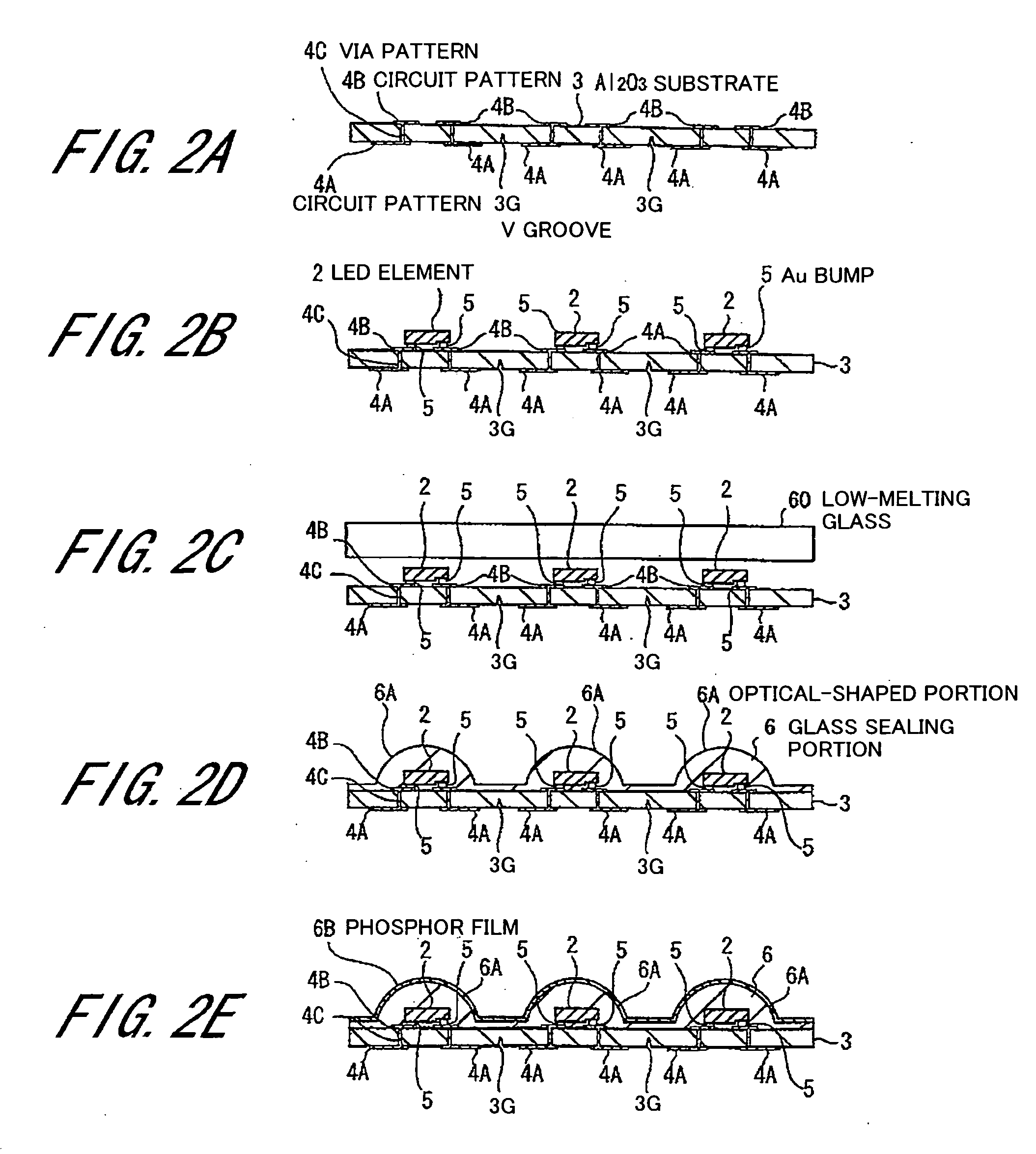

Light emitting device and method of making the same

InactiveUS20060171152A1Stable brightnessImprove propertiesNon-electric lightingSolid-state devicesInorganic materialsLight emitting device

A light emitting device having: a flip-mounting type light emitting element; a substrate on which the light emitting element is mounted, the substrate being of an inorganic material; a sealing portion to seal the light emitting element, the sealing portion being of an inorganic sealing material; an optical-shaped portion formed nearly semispherical, the optical-shaped portion being of the inorganic sealing material; and a phosphor portion formed covering the optical-shaped portion.

Owner:TOYODA GOSEI CO LTD

Electrochromic devices

ActiveUS8764951B2Improve conductivityIncrease resistanceVacuum evaporation coatingSputtering coatingEngineeringInorganic materials

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically-insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically-insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

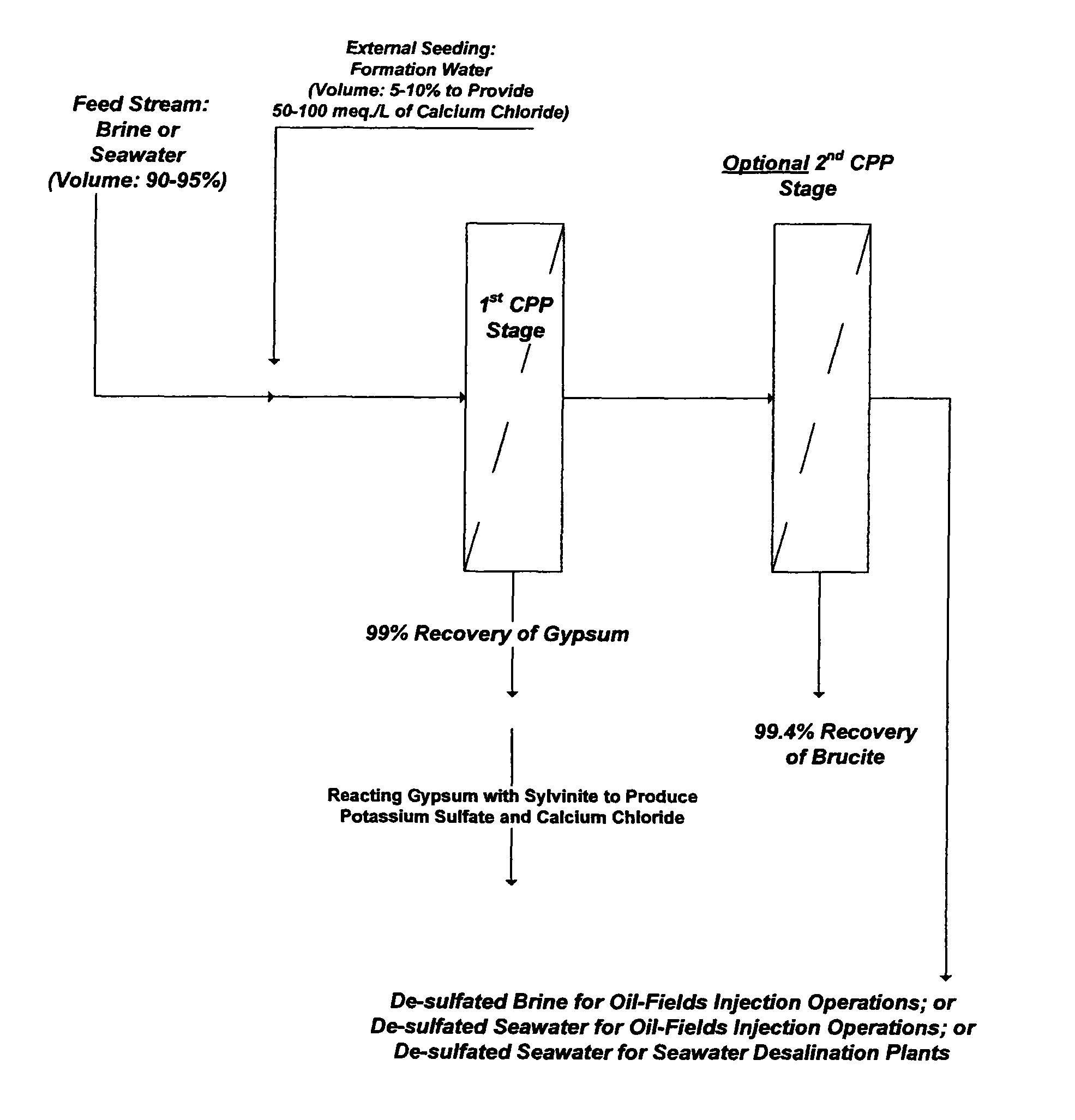

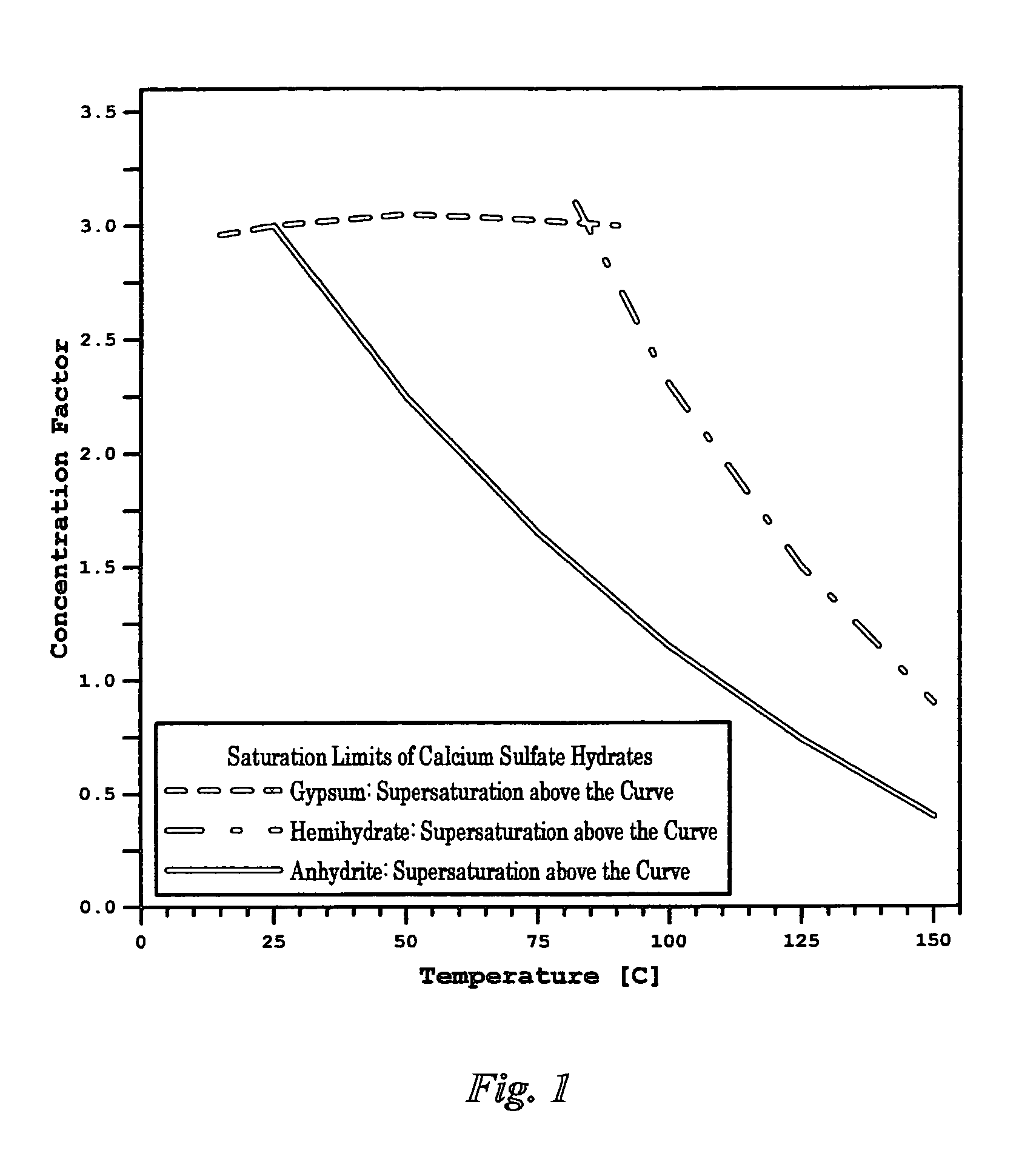

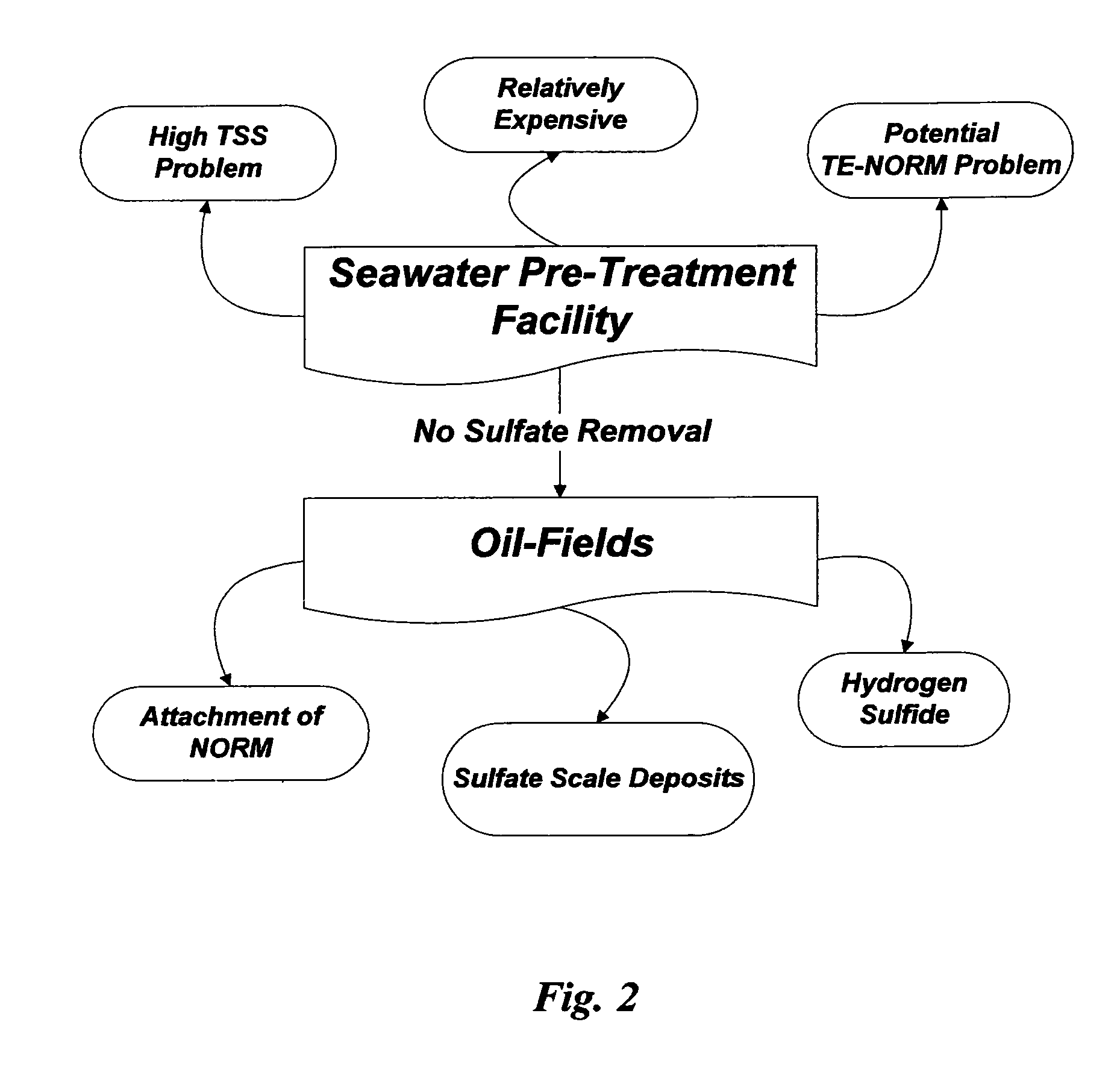

Methods to de-sulfate saline streams

ActiveUS7789159B1Avoid pollutionWaste water treatment from quariesSludge treatmentSaline waterInorganic materials

Methods are disclosed to de-sulfate saline streams such as seawater, brine from seawater desalination plants, and the like. The disclosed methods can also co-produce de-ionized water and inorganic materials from such de-sulfated saline streams.

Owner:BADER MANSOUR S

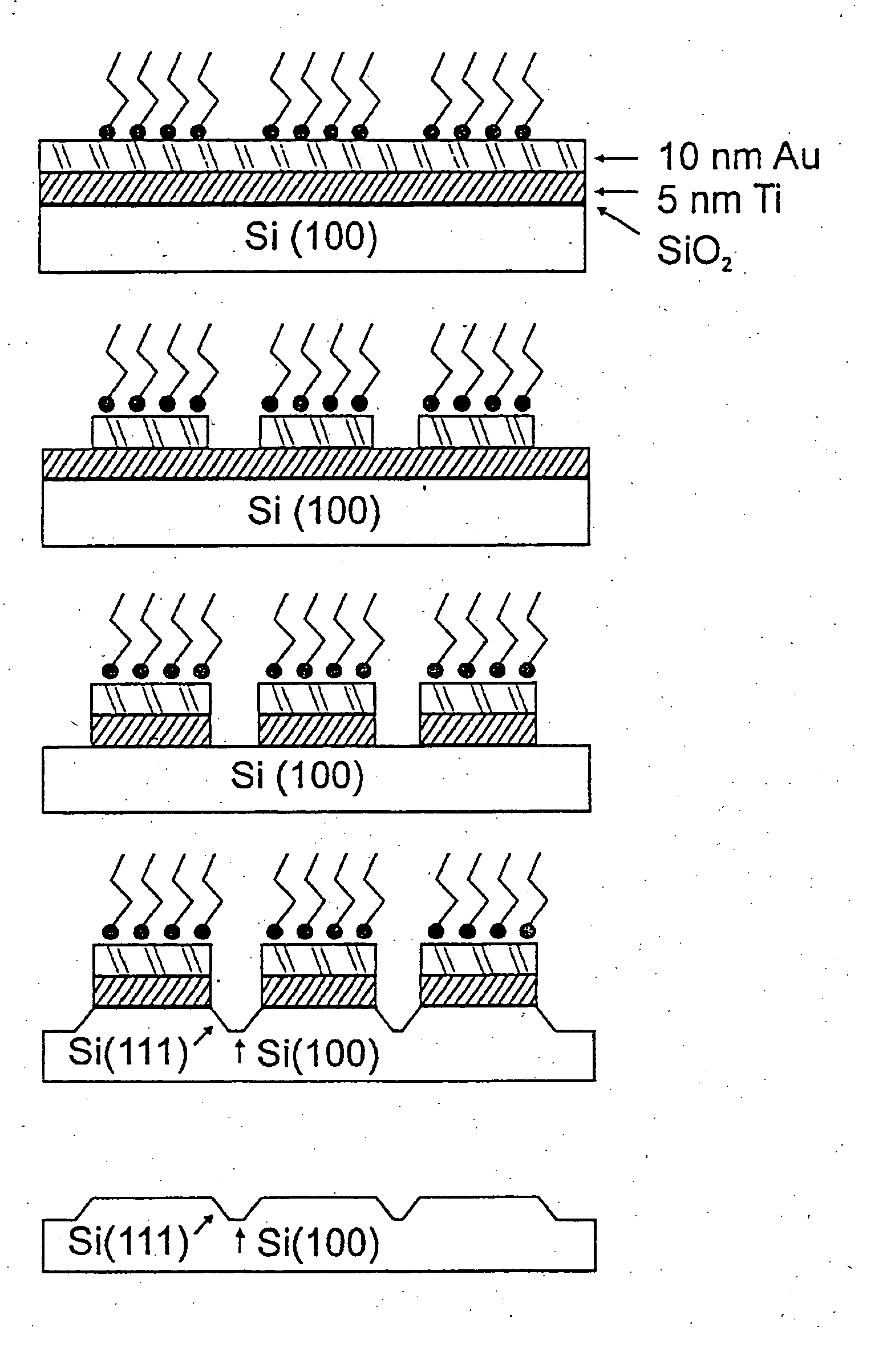

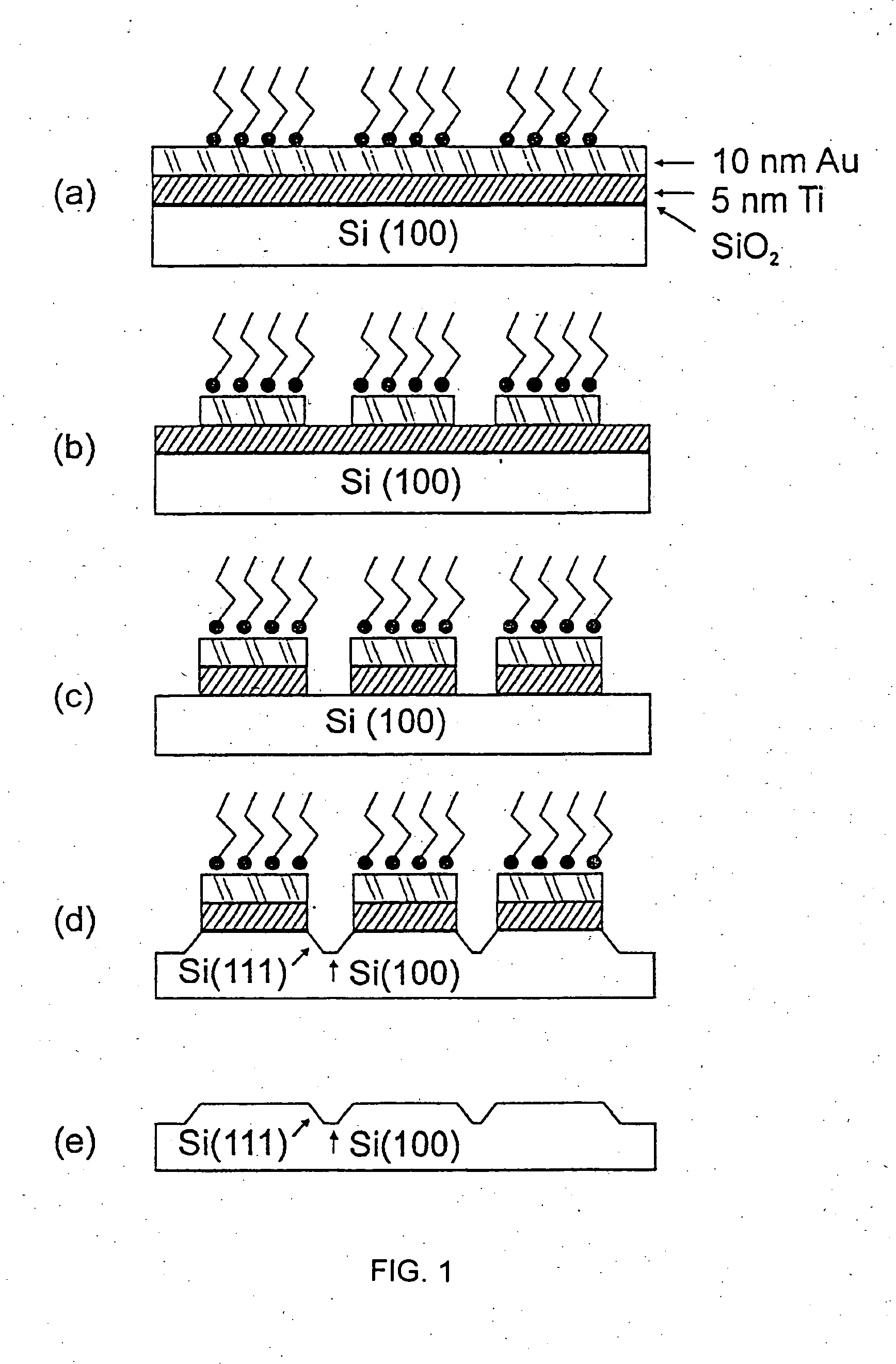

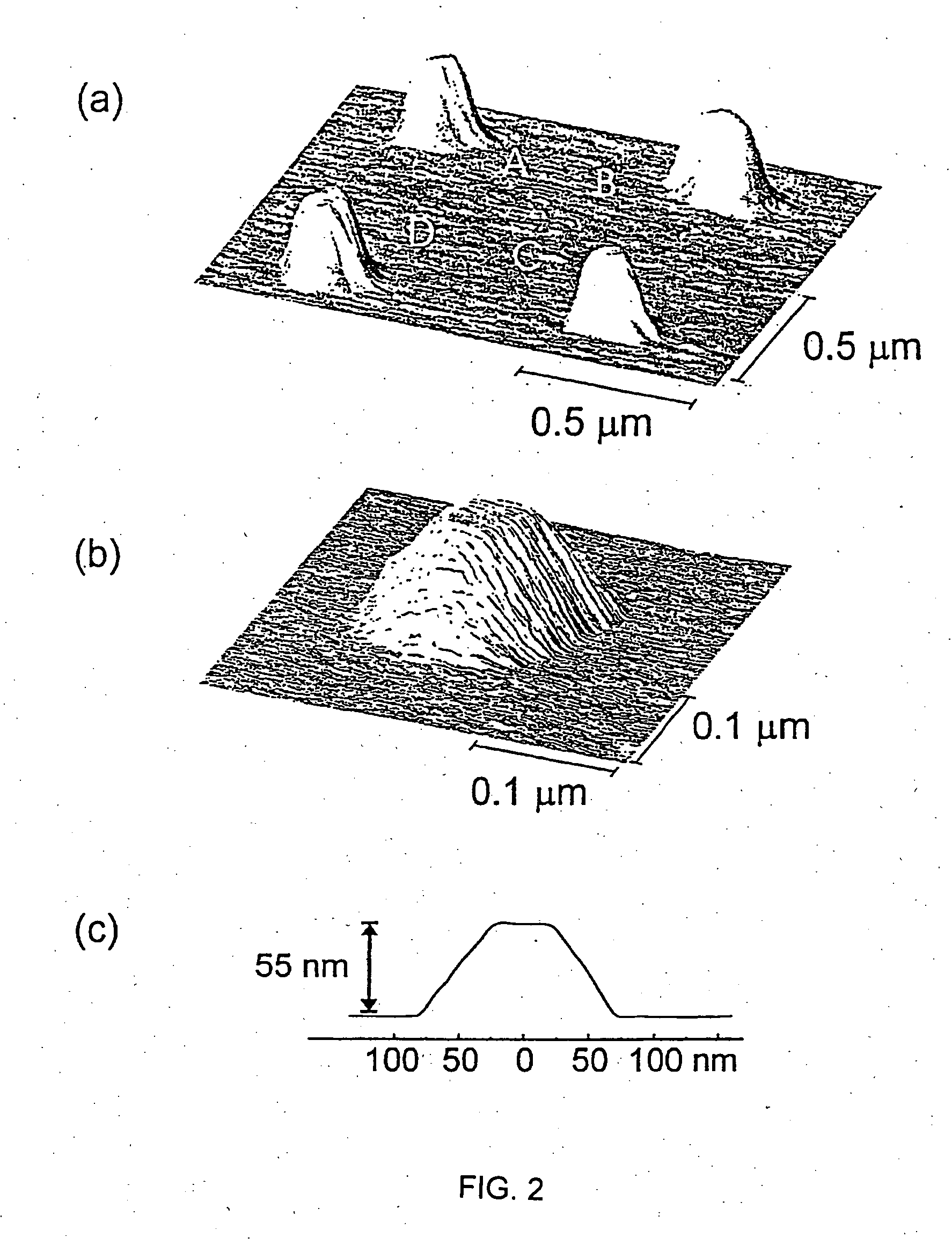

Fabrication of sub-50 nm solid-state nanostructures based on nanolithography

InactiveUS20060014001A1High resolutionMaterial nanotechnologyDecorative surface effectsResistDip-pen nanolithography

Combination of nanolithography and wet chemical etching including the fabrication of nanoarrays of sub-50 nm gold dots and line structures with deliberately designed approximately 12-100 nm gaps. These structures were made by initially using direct write nanolithography to pattern the etch resist, 16-mercaptohexadecanoic acid (MHA), on Au / Ti / SiOx / Si substrates and then wet chemical etching to remove the exposed gold. These are the smallest Au structures prepared by a wet chemical etching strategy. Also, Dip-Pen Nanolithography (DPN) has been used to generate resist layers on Au, Ag, and Pd that when combined with wet chemical etching can lead to nanostructures with deliberately designed shapes and sizes. Monolayers of mercaptohexadecanoic acid (MHA) or octadecanethiol (ODT), patterned by DPN, were explored as etch resists. They work comparably well on Au and Ag, but ODT is the superior material for Pd. MHA seems to attract the FeCl3 etchant and results in nonuniform etching of the underlying Pd substrate. Dots, lines, triangles and circles, ranging in size from sub-100 to several hundred nm have been fabricated on these substrates. These results show how one can use DPN as an alternative to more complex and costly procedures like electron beam lithography to generate nanostructures from inorganic materials.

Owner:NORTHWESTERN UNIV

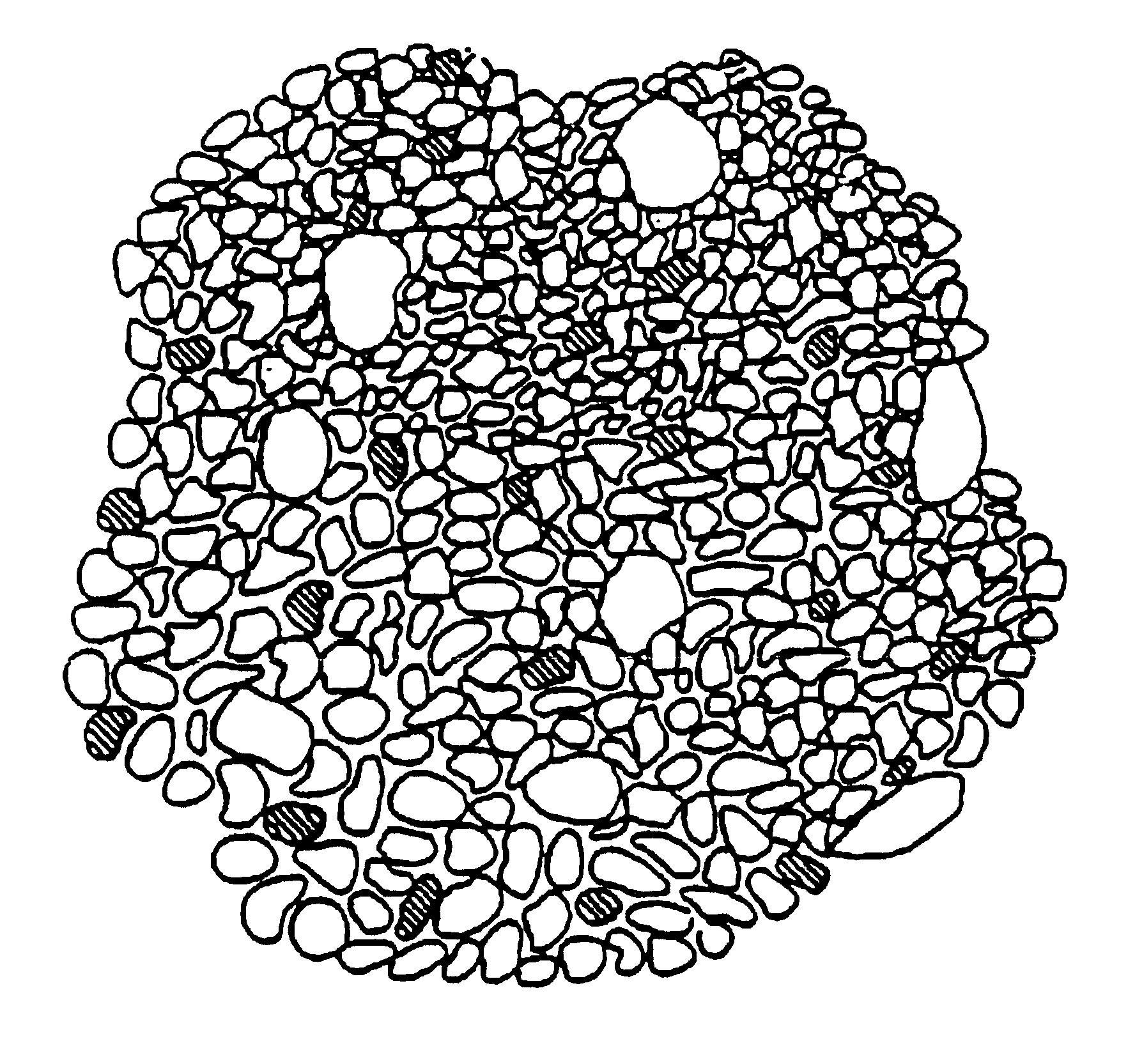

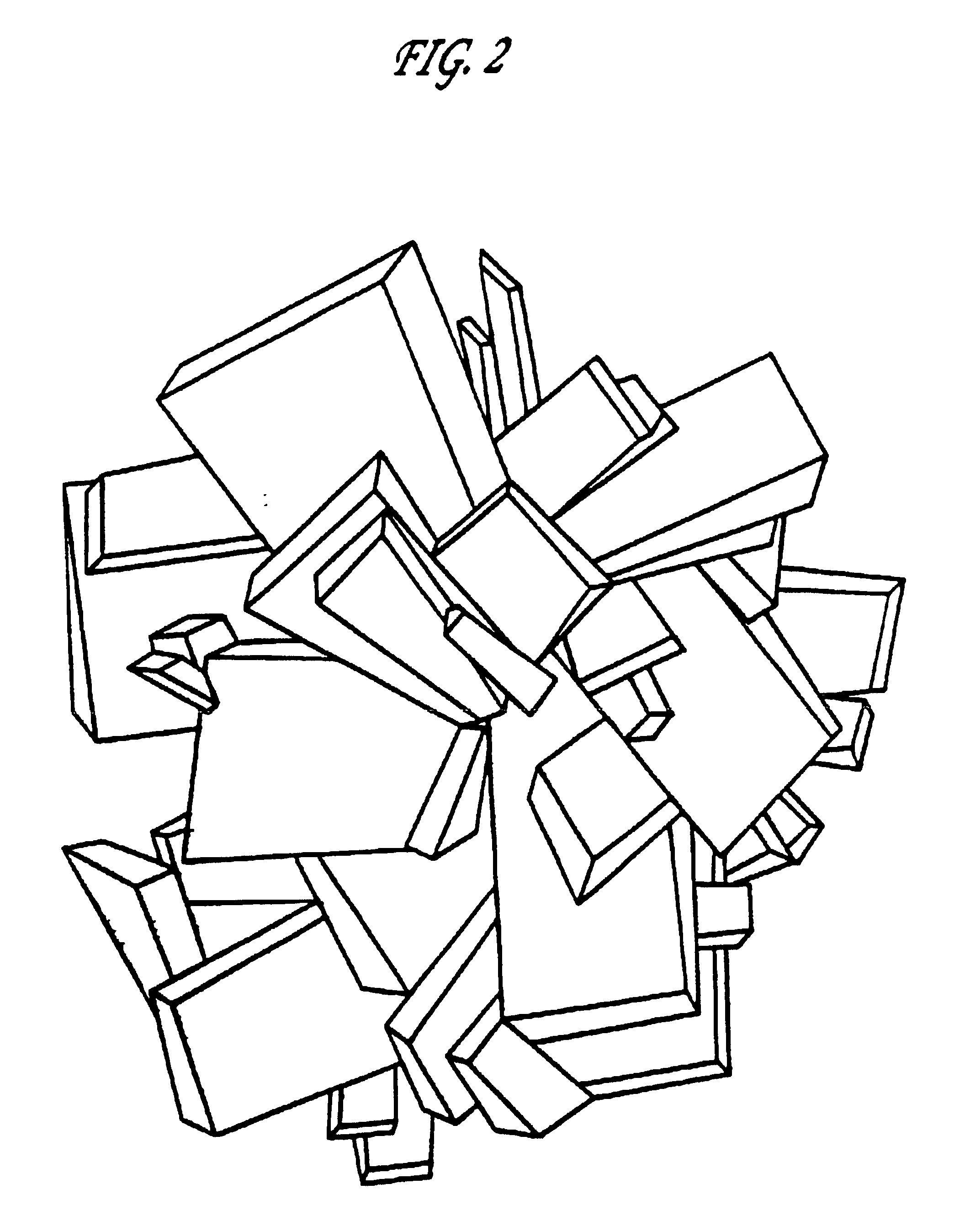

Low temperature coated particles for use as proppants or in gravel packs, methods for making and using the same

ActiveUS20080230223A1Improves unconfined compressive strength propertyImprove performanceLiquid surface applicatorsSynthetic resin layered productsPolyesterParticulates

Disclosed herein are free flowing coated particles and low temperature methods of making same. Each particle has a curable coating disposed upon a substrate. The substrate is a particulate substrate including an inorganic material, a particulate substrate including an organic material, a composite substantially homogeneous formed particle including a first portion of an at least partly cured binder and filler particles, or a hybrid particle having an inorganic particle as a core and a composite coating including at least partially cured resin and filler. The curable coating includes a continuous phase including resole resin and reactive powder particles embedded or adhered to the continuous phase. The reactive powder particles typically include resole resin, novolak resin, polyester, acrylic and / or urethane. A method including applying a coating including the continuous phase including resole resin and reactive or non-reactive powder particles embedded or adhered to the continuous phase.

Owner:HEXION INC

Nanostructure based light emitting devices and associated methods

InactiveUS20070001581A1Improved light emissionImprove developmentDischarge tube luminescnet screensLamp detailsNanostructureInorganic materials

A light emitting device can incorporate a plurality of nanostructures in a light emission layer. The device can include a donor electrode and an acceptor electrode which are light transmissive. At least one of the donor electrode and acceptor electrode can include an inorganic material. The light emission layer can be disposed between each of the donor material and the acceptor material.

Owner:HEWLETT PACKARD DEV CO LP

Method for producing ceramic surfaces with easily removable contact sheets

InactiveUS6139666AMinimizing the sharp edgeSemiconductor/solid-state device detailsPrinted circuit aspectsPlasticizerCompressibility

A method for making multilayer ceramic substrates having substantially reduced planar shrinkage and distortion resulting from the firing or sintering process. Contact sheets are employed in the fabrication process on the surface of the multilayer ceramic substrate to be fired with the contact sheets being prepared from a composition containing a non-sinterable non-metallic inorganic material such as alumina having an average particle size approximately about 1 micron or less and an organic binder and preferably a plasticizer. In a preferred embodiment of the invention, the multilayer structure to be fired containing the contact sheet of the invention is provided with a beveled or chamfered edge at an angle of greater than about 60 degrees. A fabrication process employing only chamfering of the edge or the use of a contact sheet of the invention also provides improved multilayer ceramic substrate products. A further feature is a method to control the surface topography of surface metallization by adjusting the compressibility of the contact sheets during fabrication of the substrate.

Owner:IBM CORP

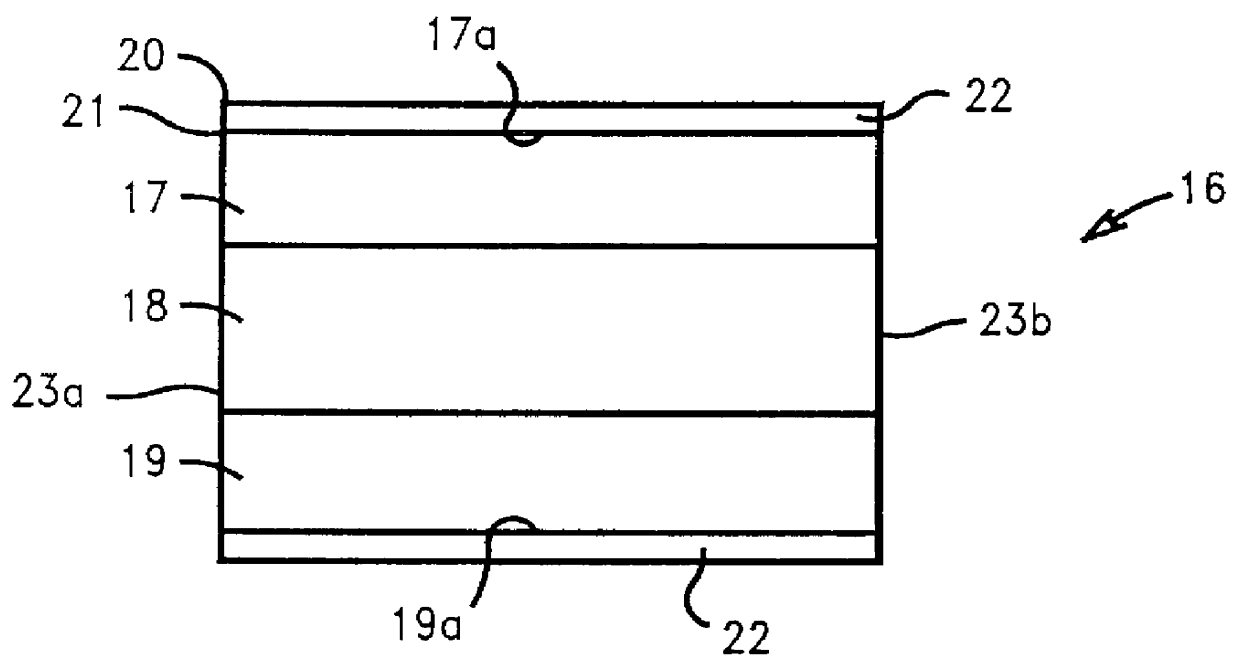

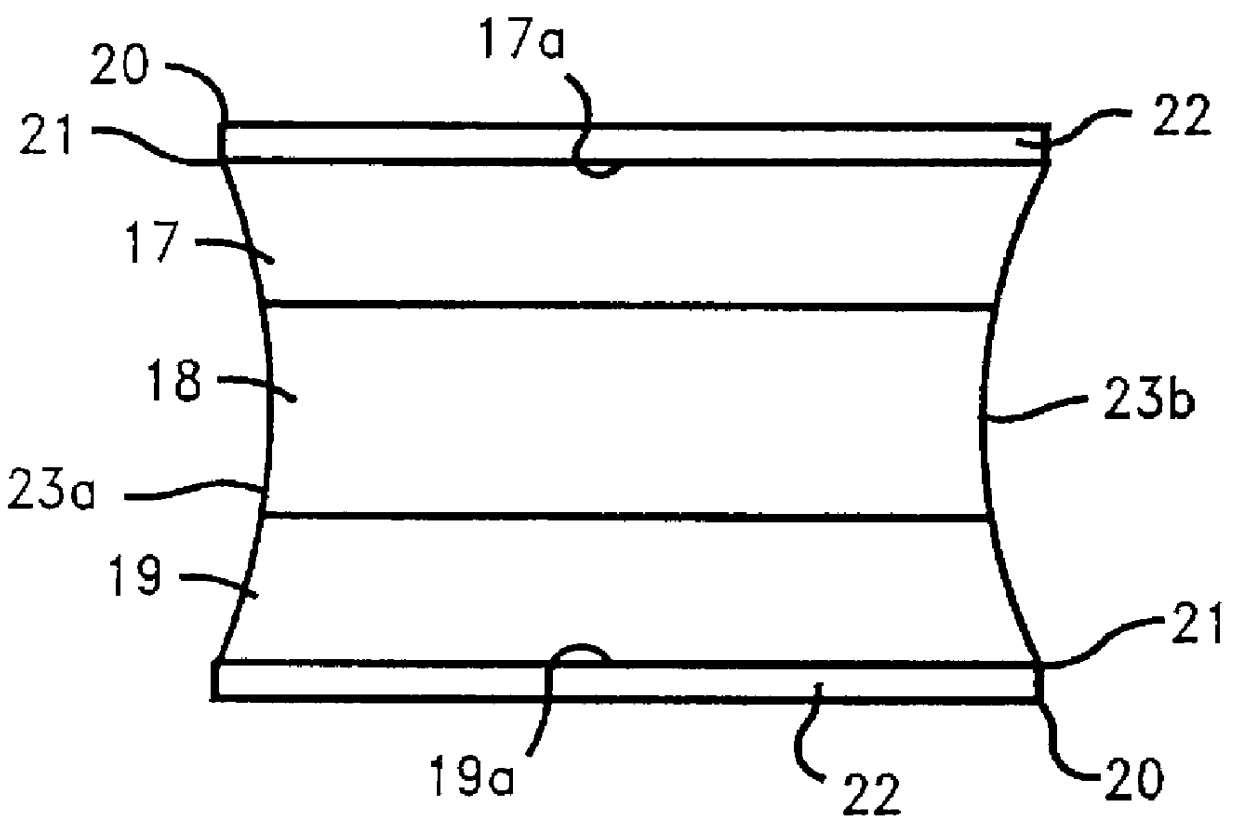

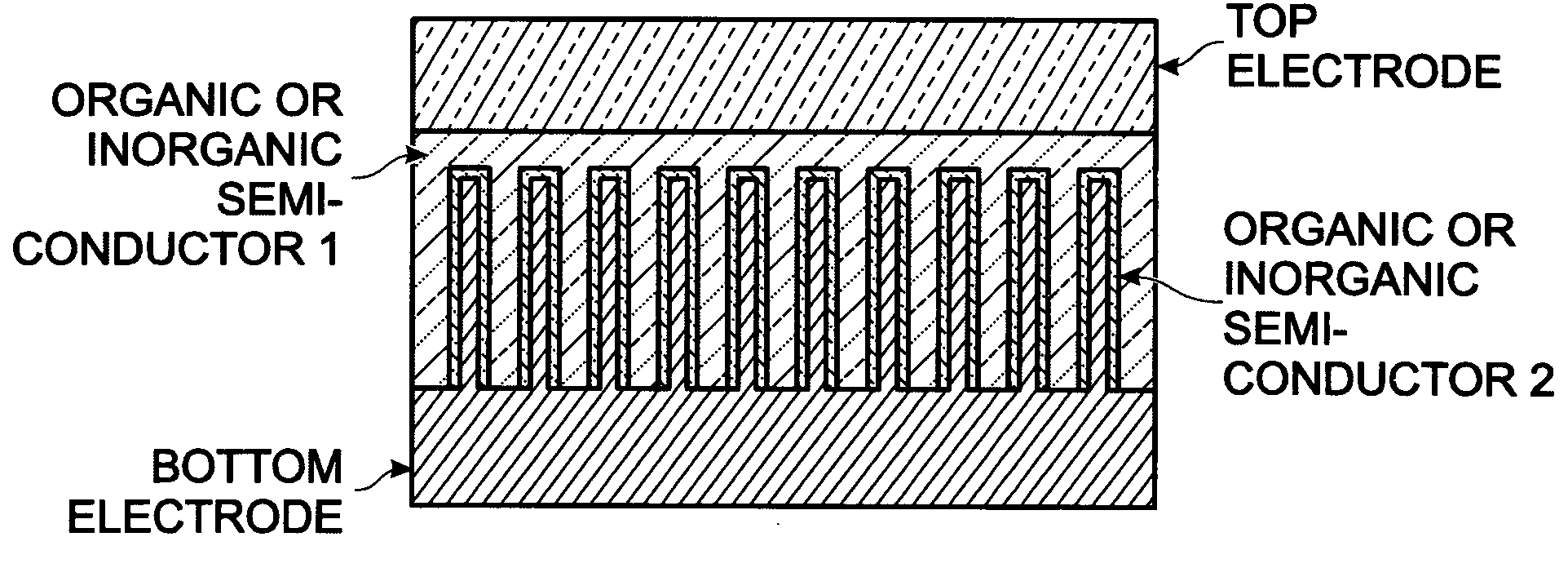

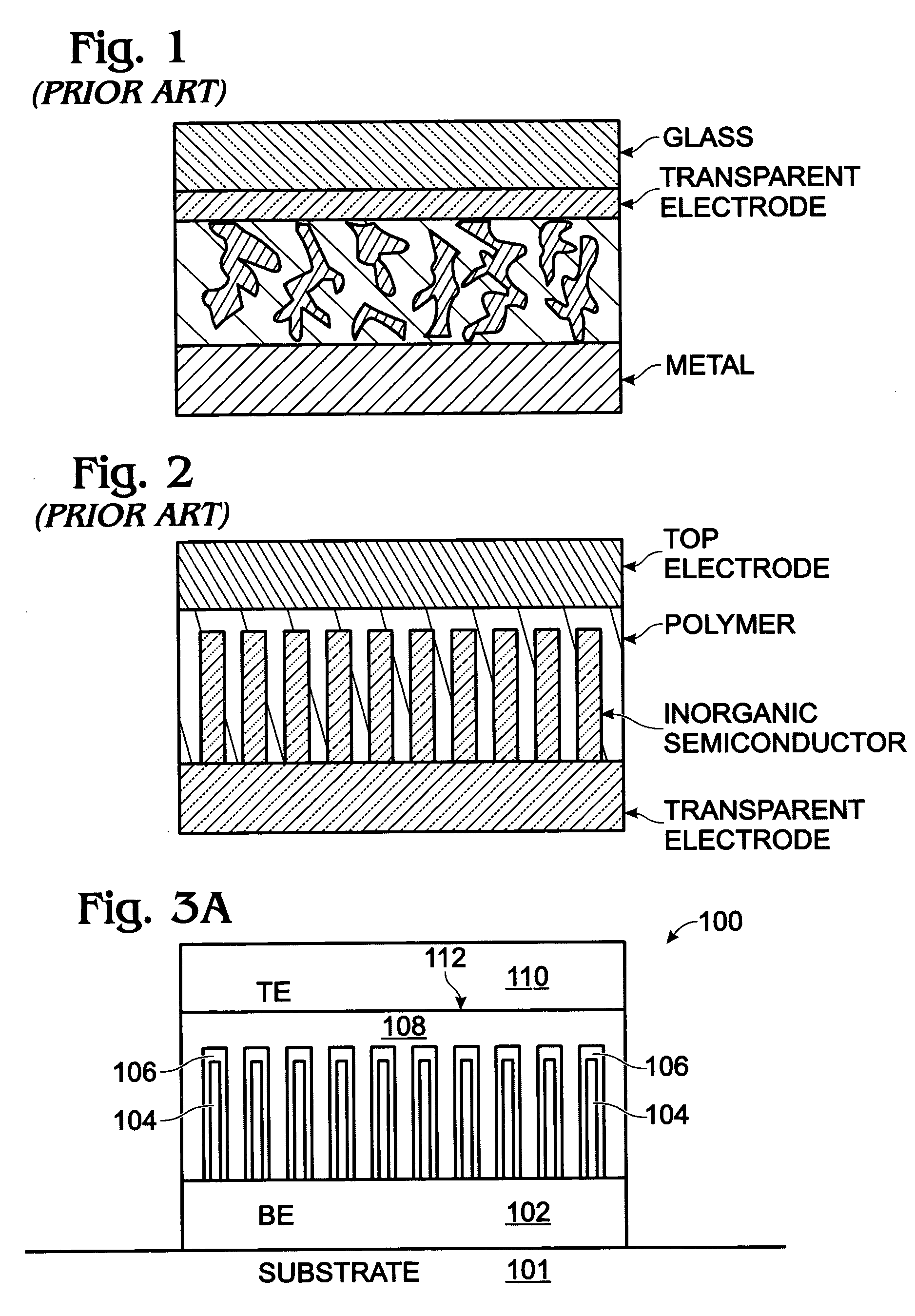

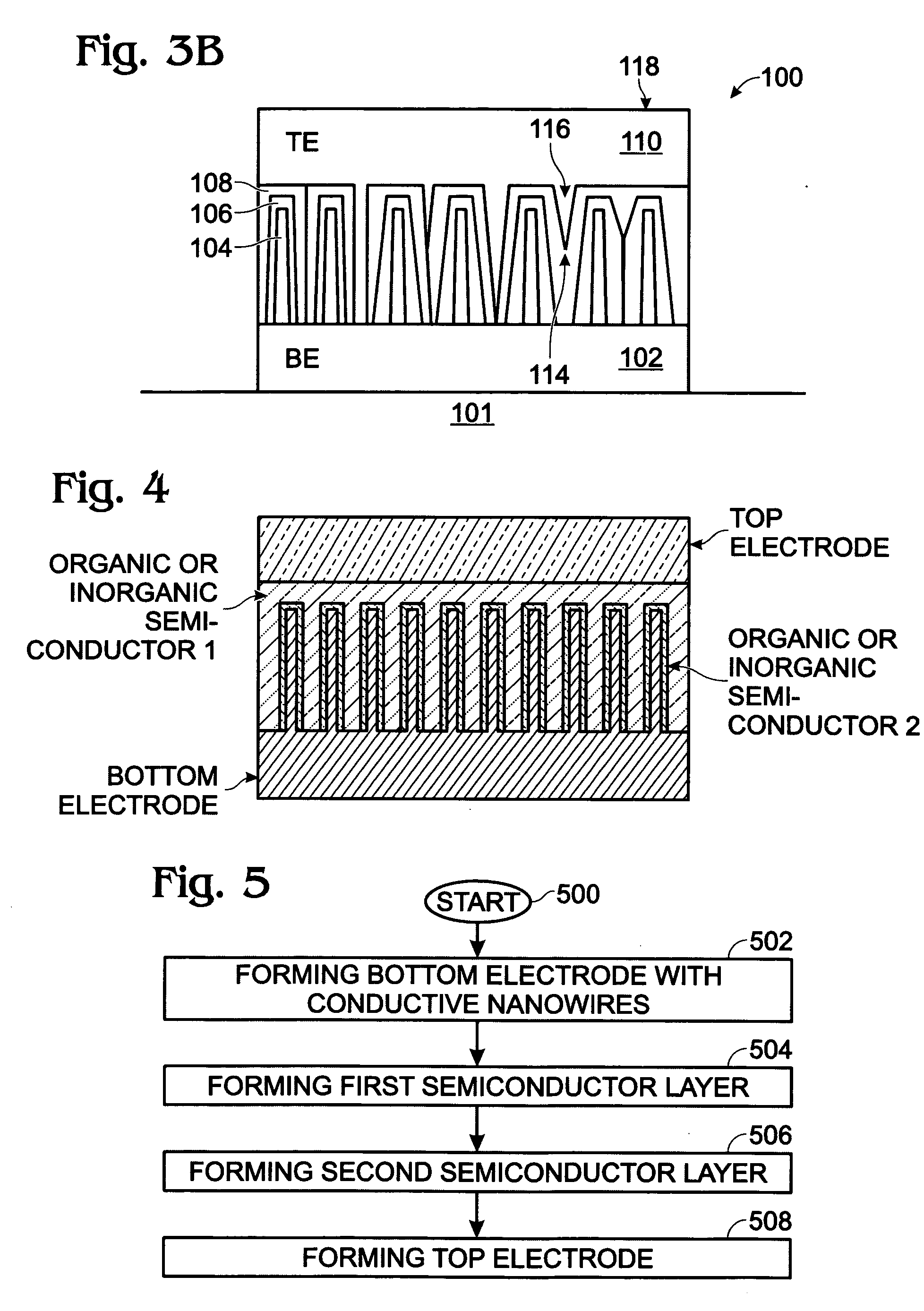

Photovoltaic structure with a conductive nanowire array electrode

A photovoltaic (PV) structure is provided, along with a method for forming a PV structure with a conductive nanowire array electrode. The method comprises: forming a bottom electrode with conductive nanowires; forming a first semiconductor layer of a first dopant type (i.e., n-type) overlying the nanowires; forming a second semiconductor layer of a second dopant type, opposite of the first dopant type (i.e., p-type), overlying the first semiconductor layer; and, forming a top electrode overlying the second semiconductor layer. The first and second semiconductor layers can be a material such as a conductive polymer, a conjugated polymer with a fullerene derivative, and inorganic materials such as CdSe, CdS, Titania, or ZnO. The conductive nanowires can be a material such as IrO2, In2O3, SnO2, or indium tin oxide (ITO).

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com