Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

432 results about "Electrochromic devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

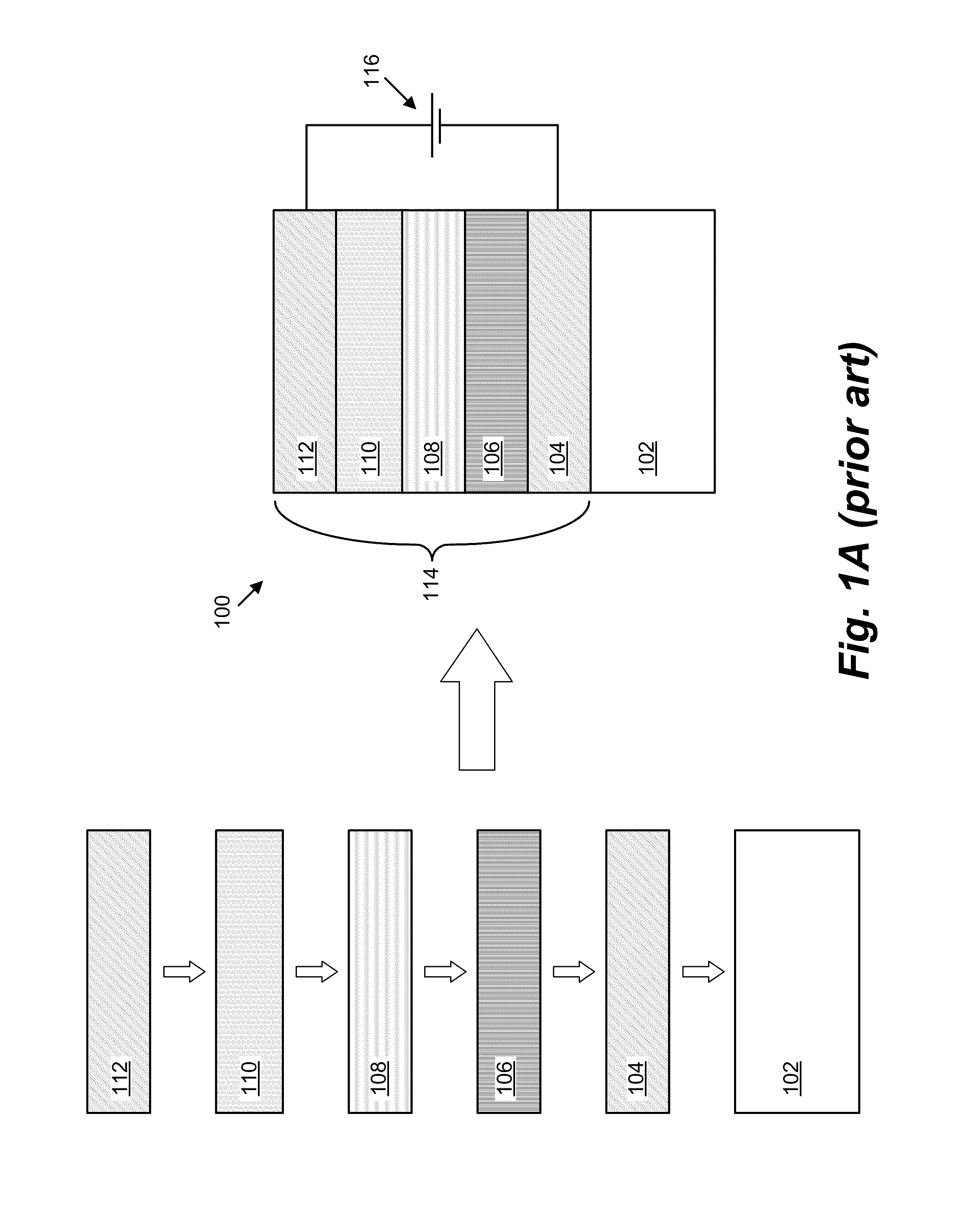

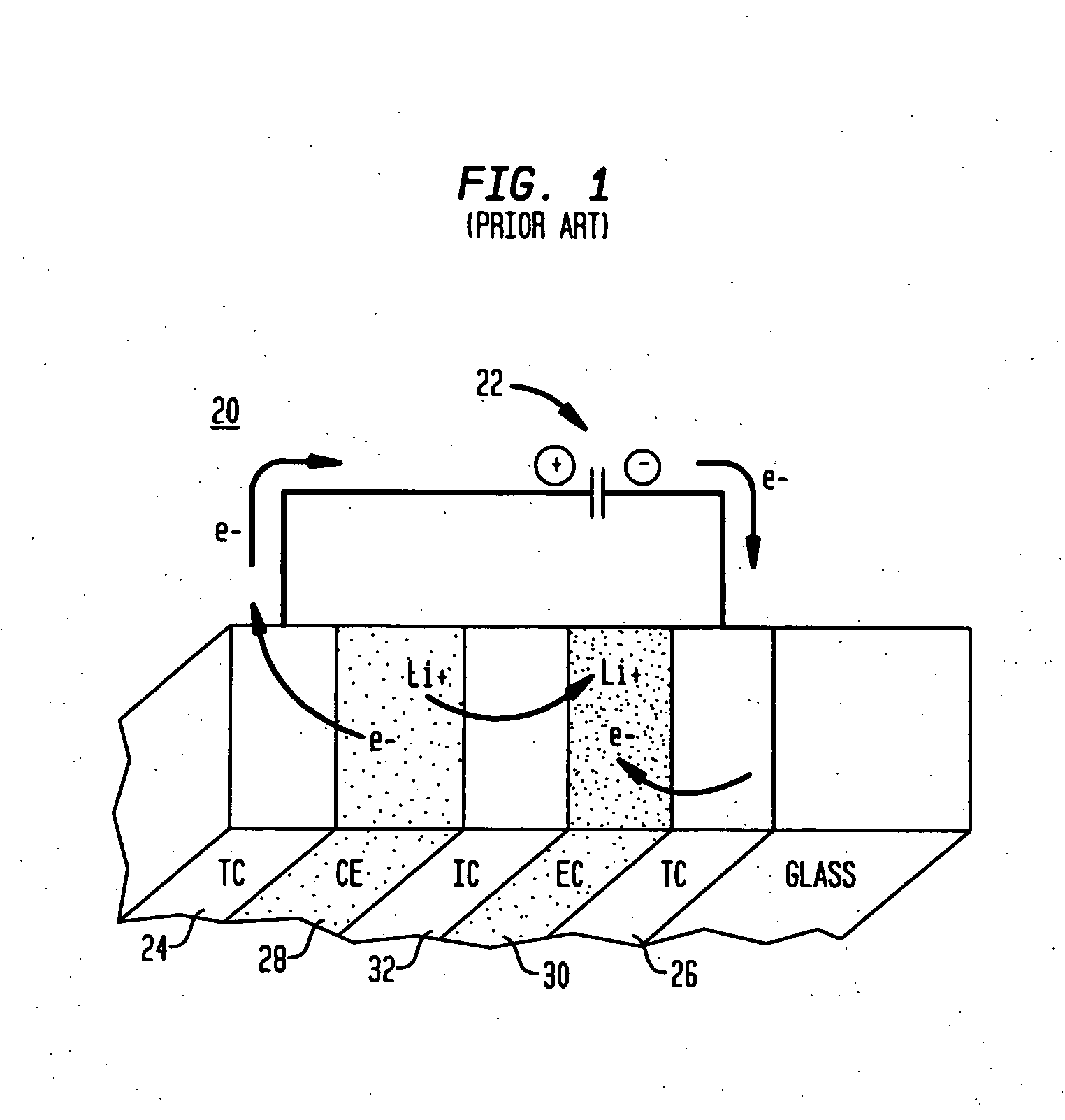

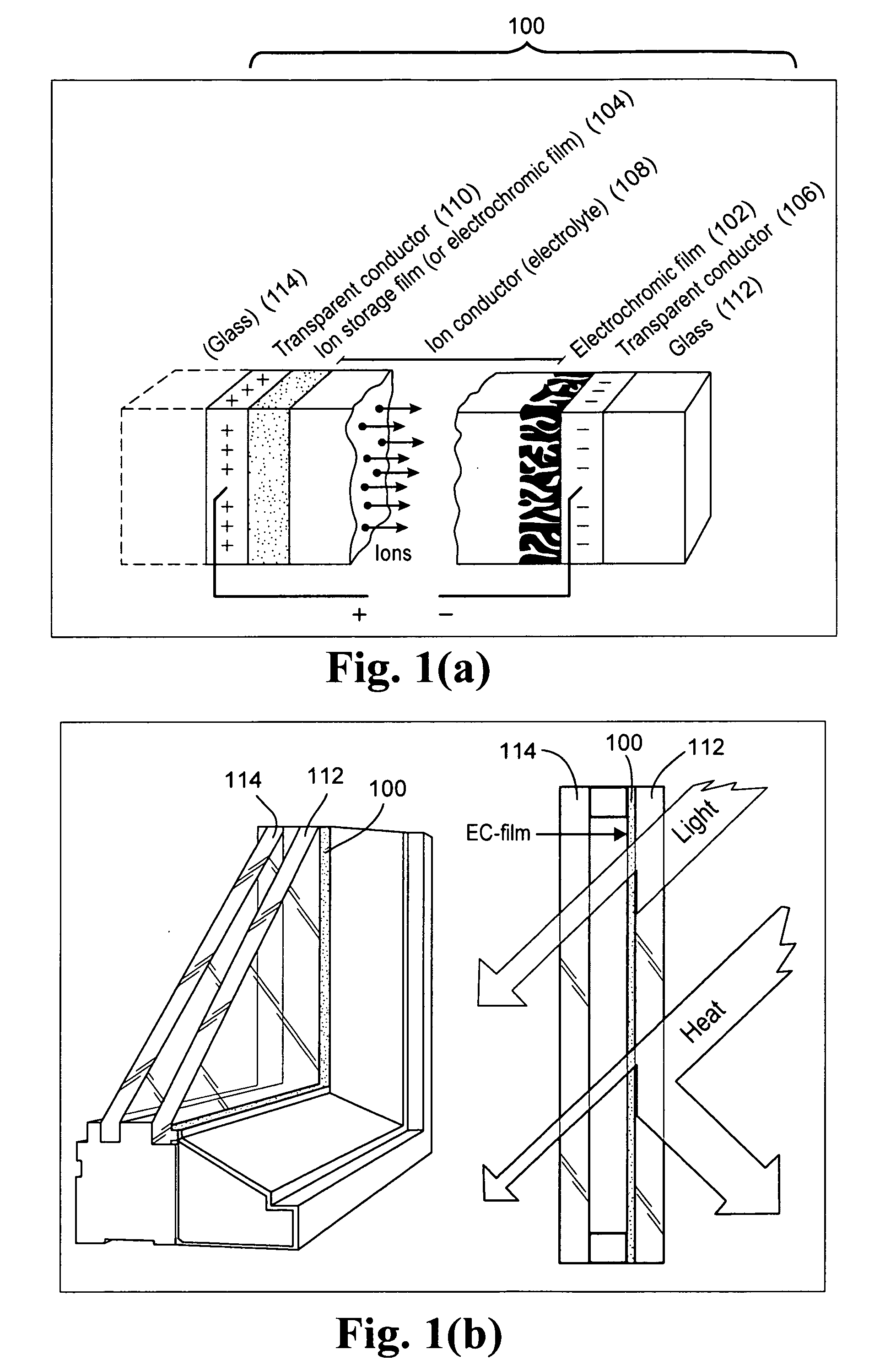

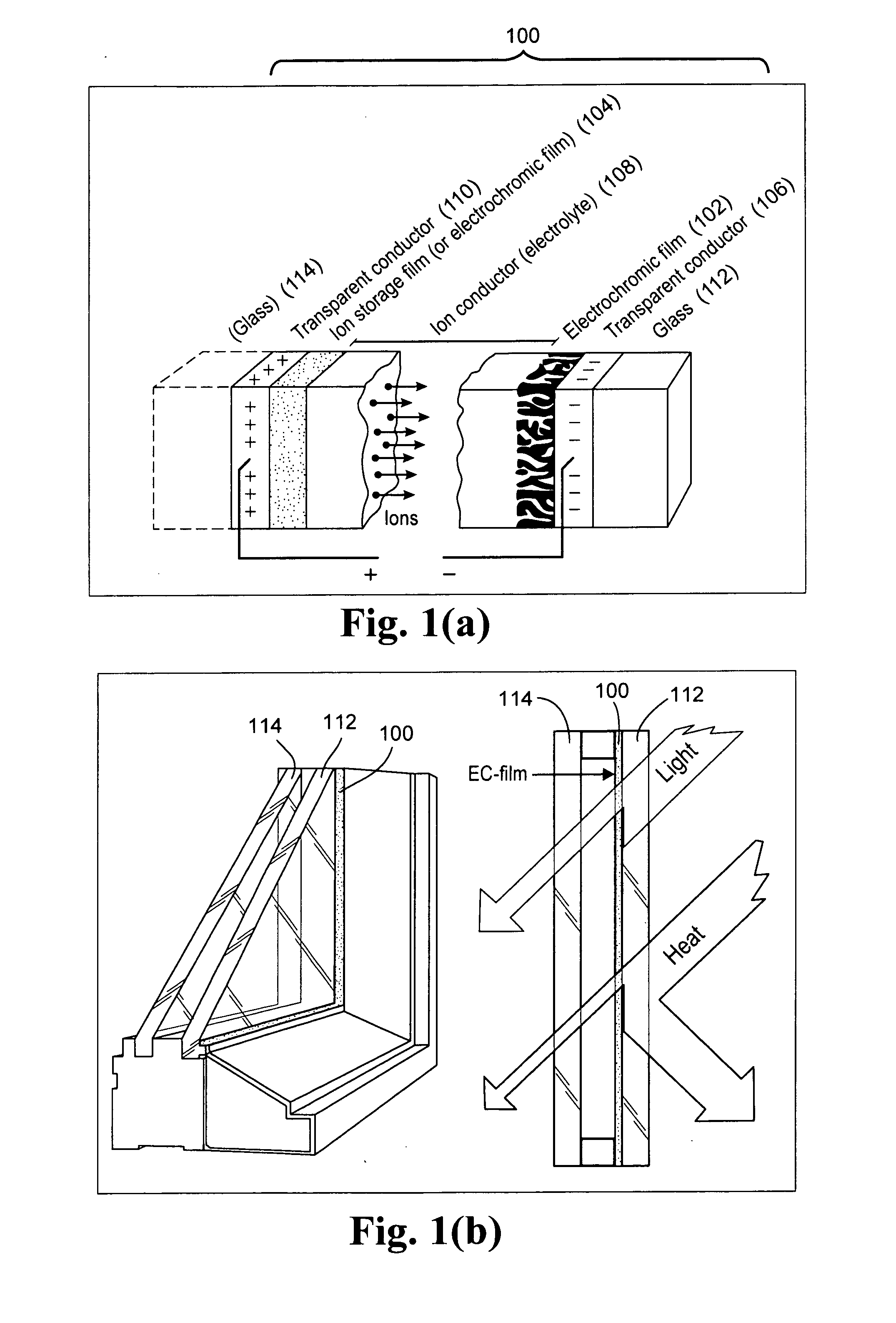

An electrochromic device (ECD) controls optical properties such as optical transmission, absorption, reflectance and/or emittance in a continual but reversible manner on application of voltage (electrochromism). This property enables an ECD to be used for applications like smart glass, electrochromic mirrors, and electrochromic display devices.

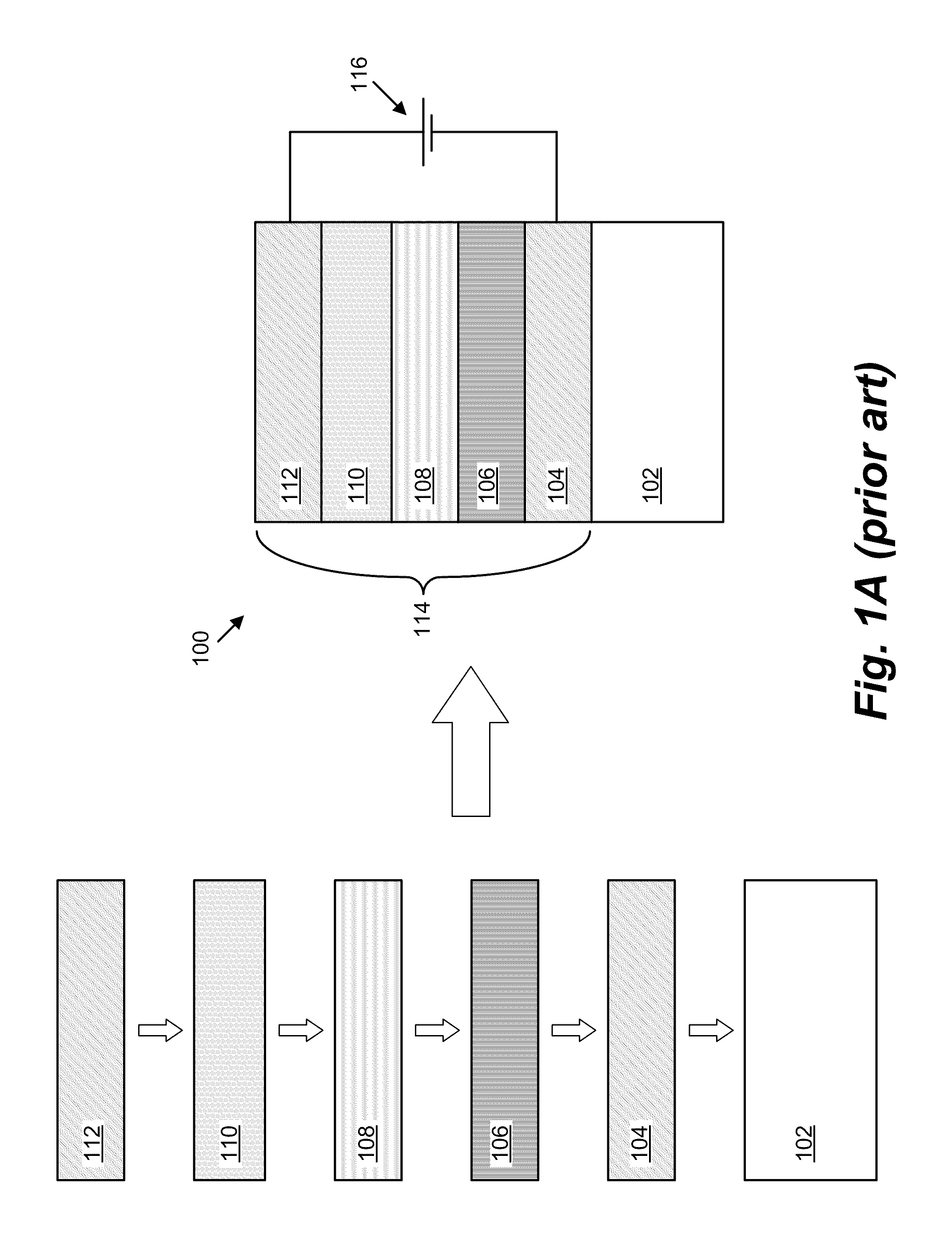

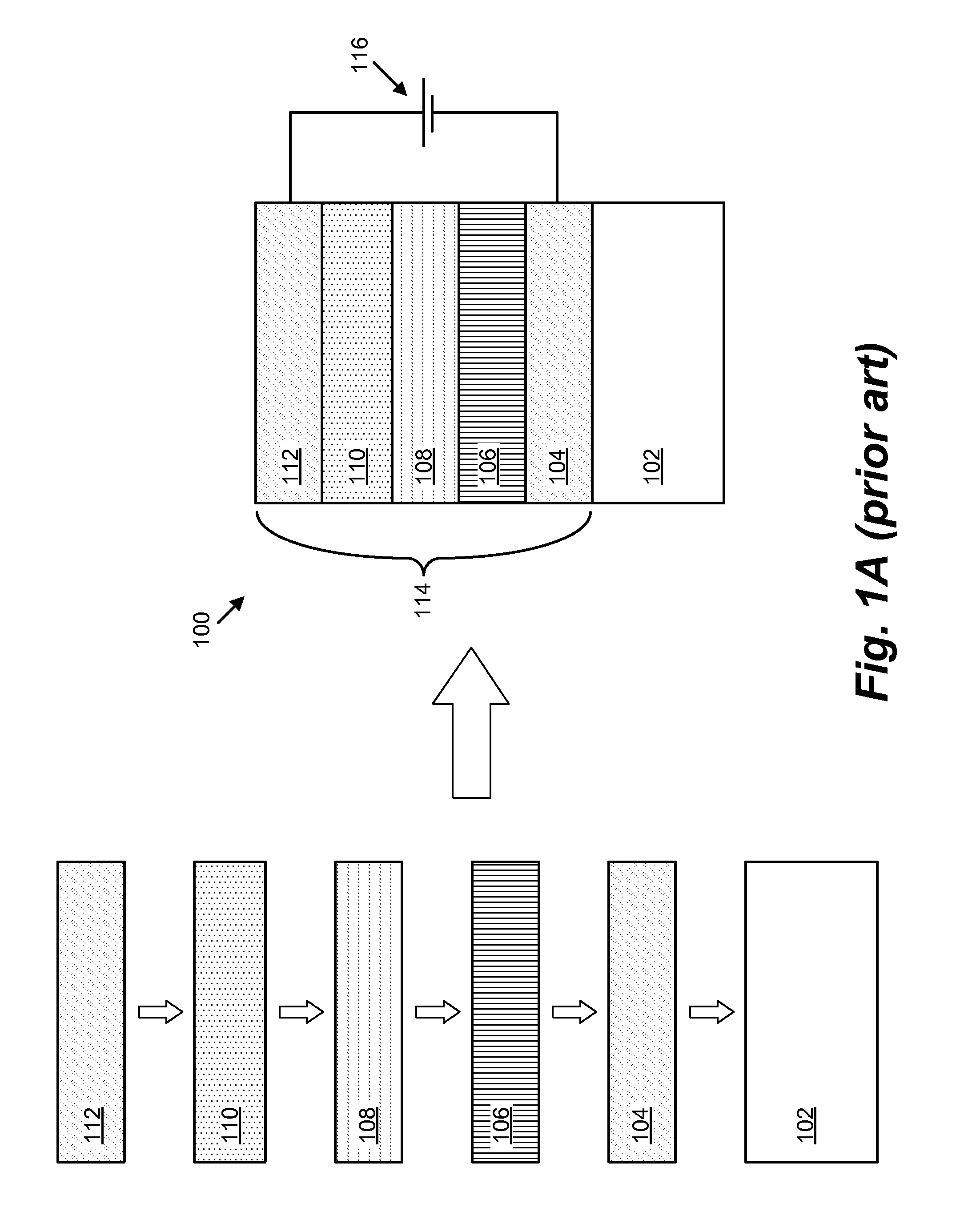

Fabrication of low defectivity electrochromic devices

ActiveUS20100243427A1High level of defectivityVacuum evaporation coatingSputtering coatingArchitectural glassGas phase

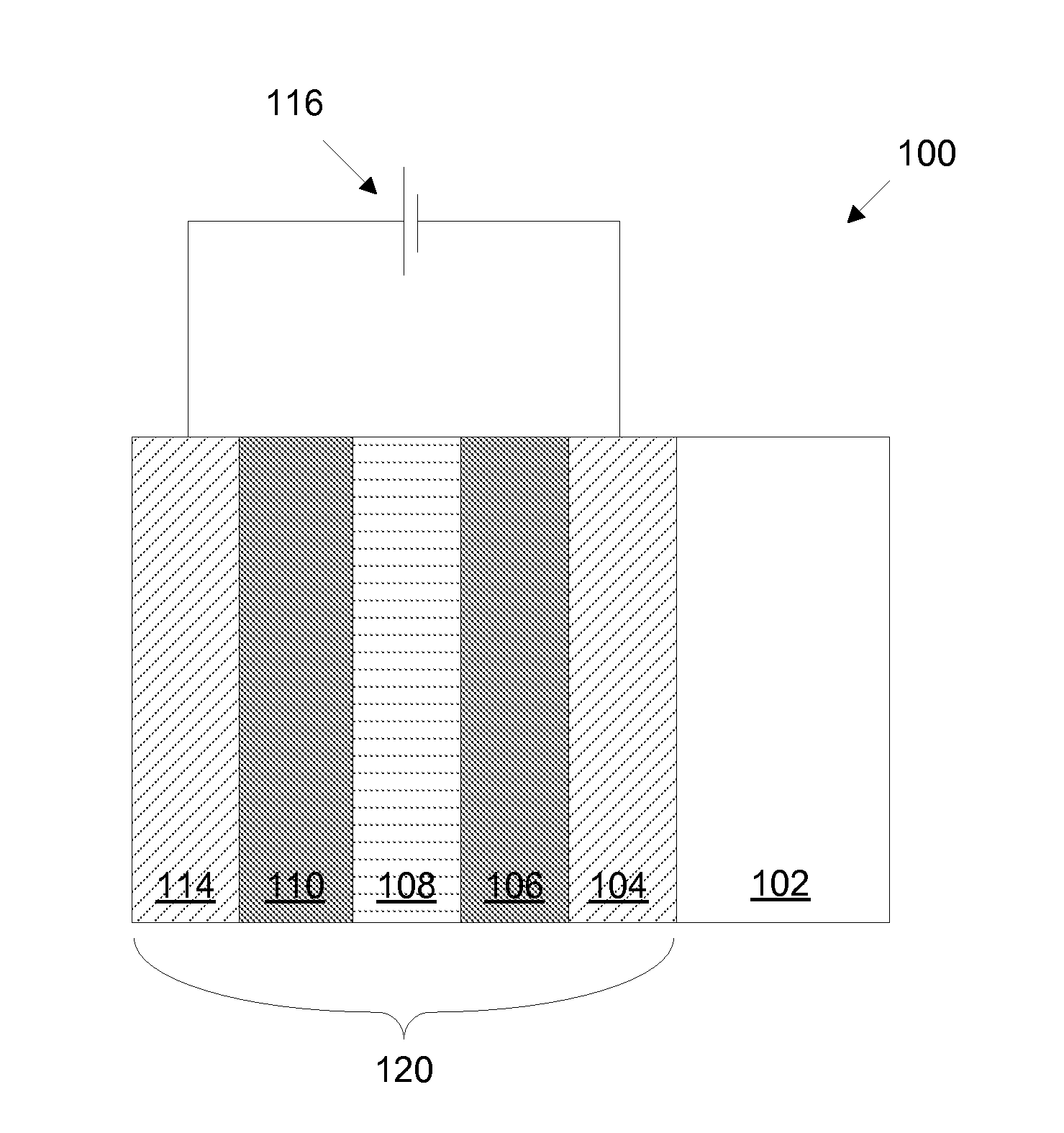

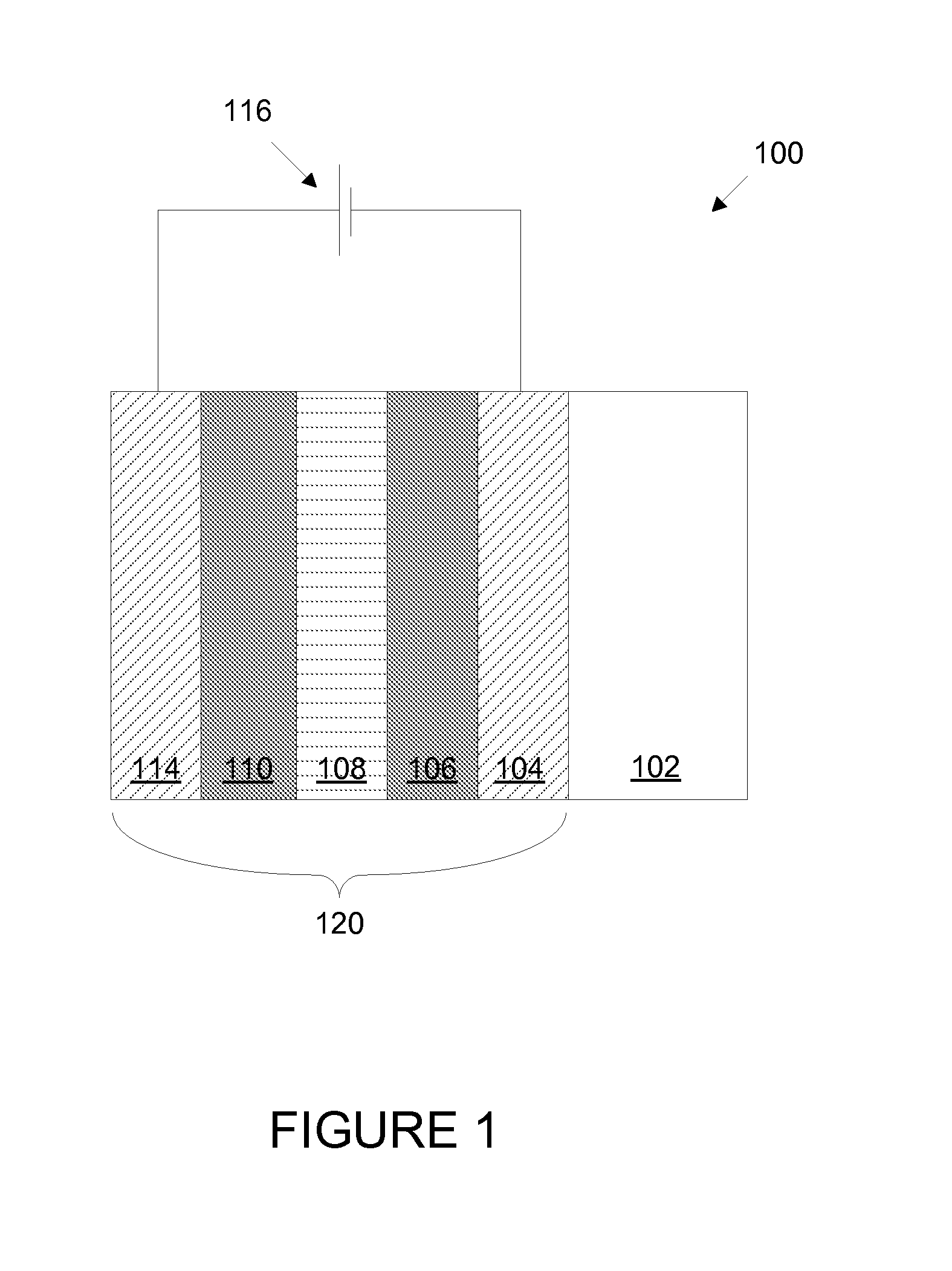

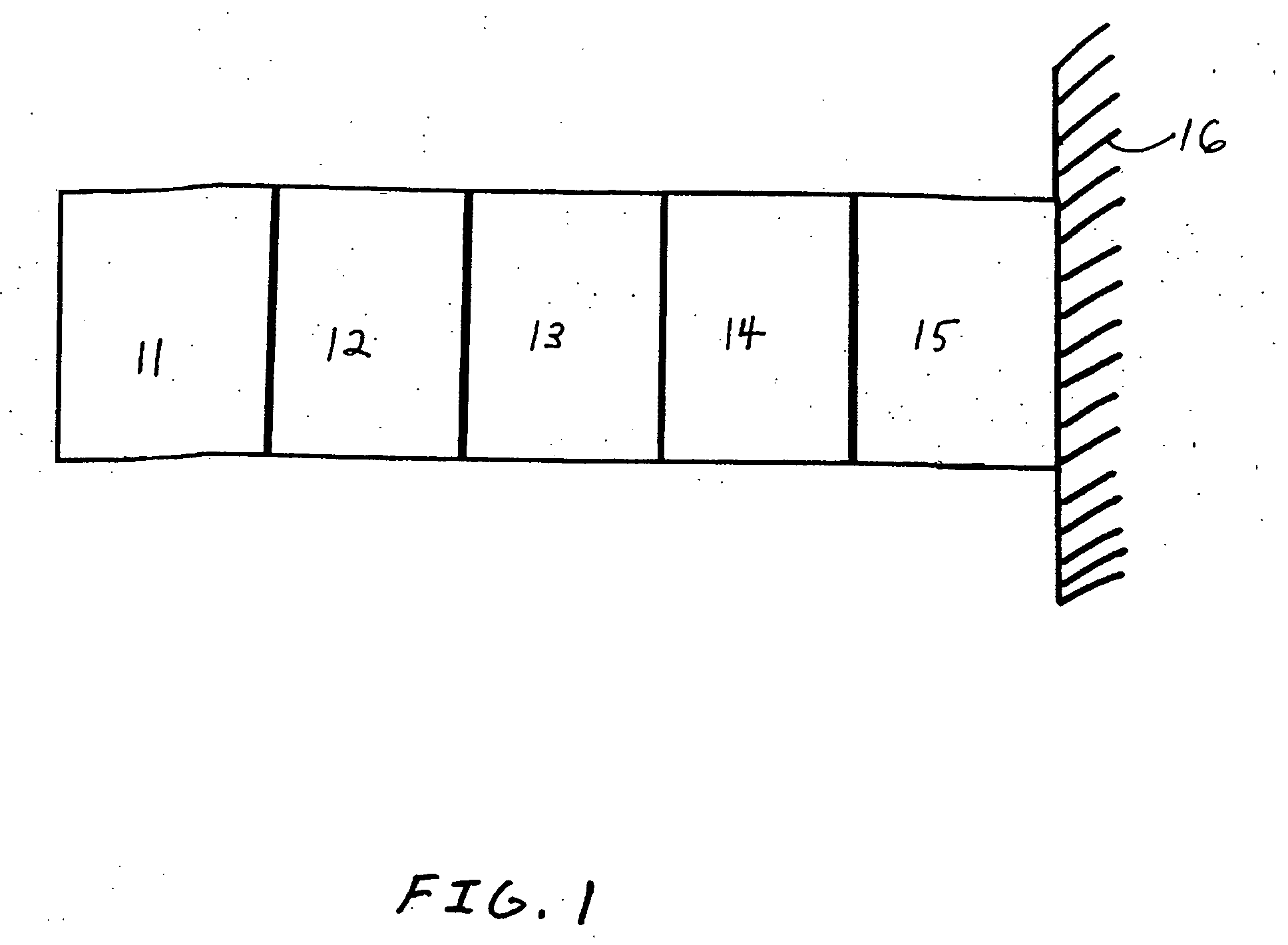

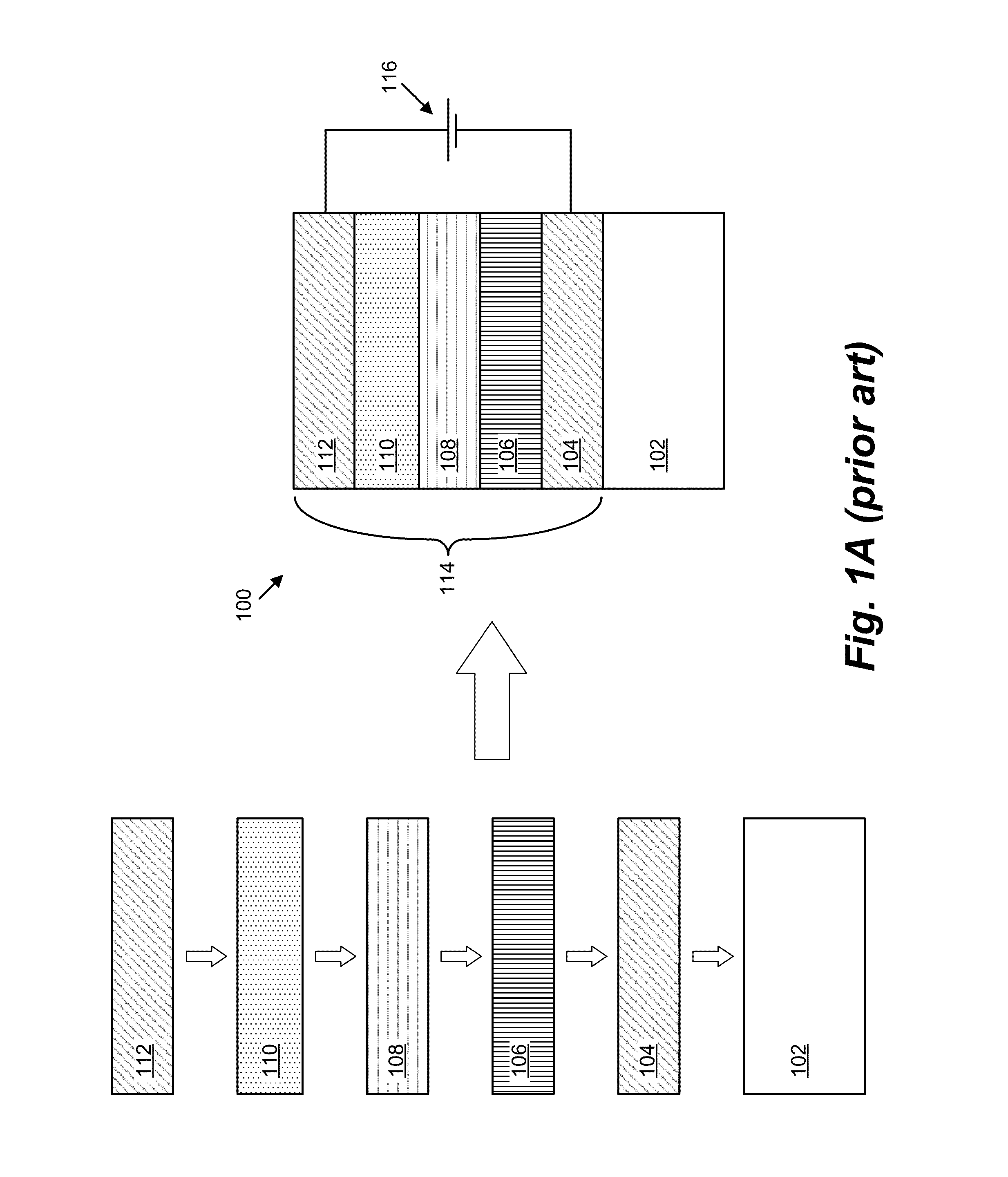

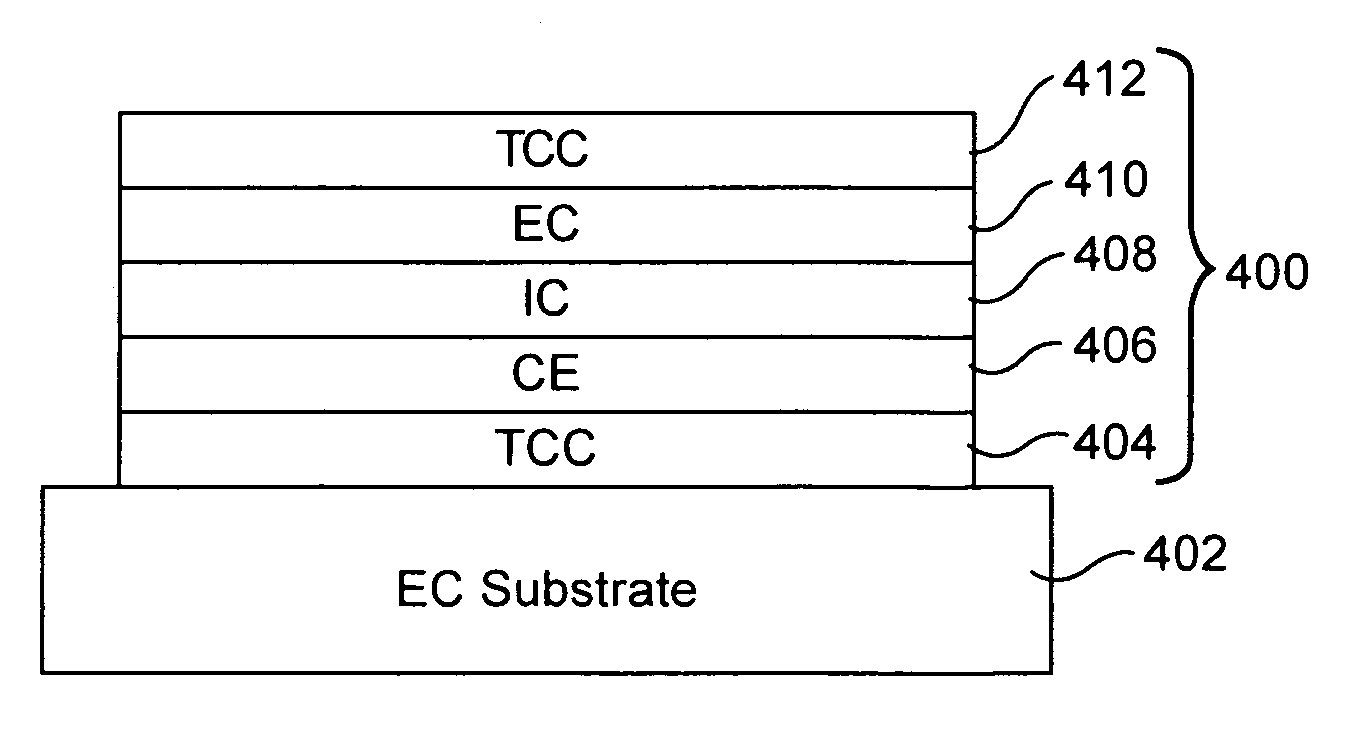

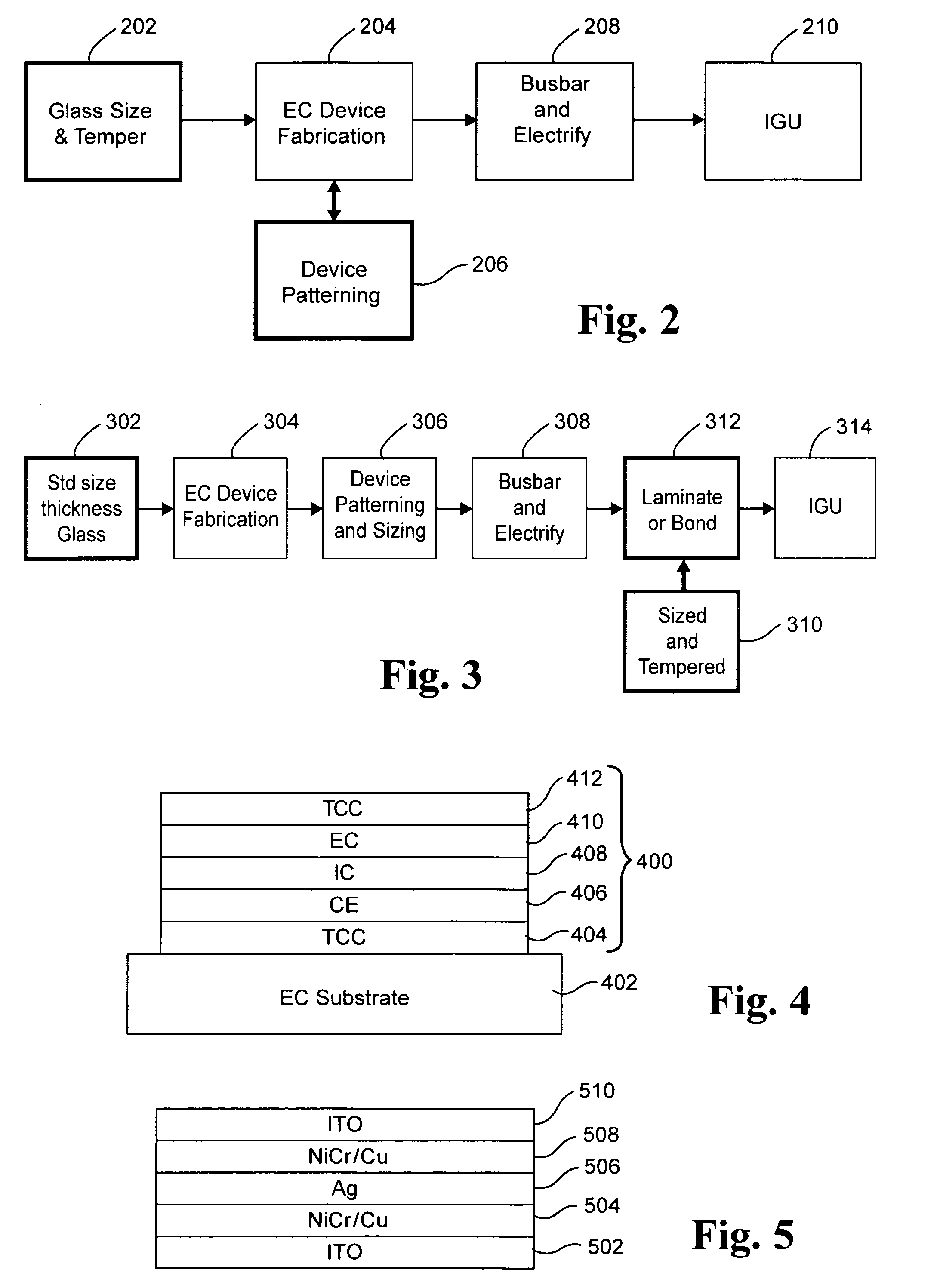

Prior electrochromic devices frequently suffer from high levels of defectivity. The defects may be manifest as pin holes or spots where the electrochromic transition is impaired. This is unacceptable for many applications such as electrochromic architectural glass. Improved electrochromic devices with low defectivity can be fabricated by depositing certain layered components of the electrochromic device in a single integrated deposition system. While these layers are being deposited and / or treated on a substrate, for example a glass window, the substrate never leaves a controlled ambient environment, for example a low pressure controlled atmosphere having very low levels of particles. These layers may be deposited using physical vapor deposition.

Owner:VIEW INC

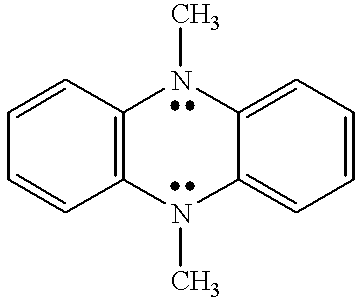

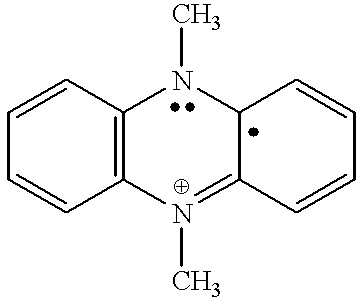

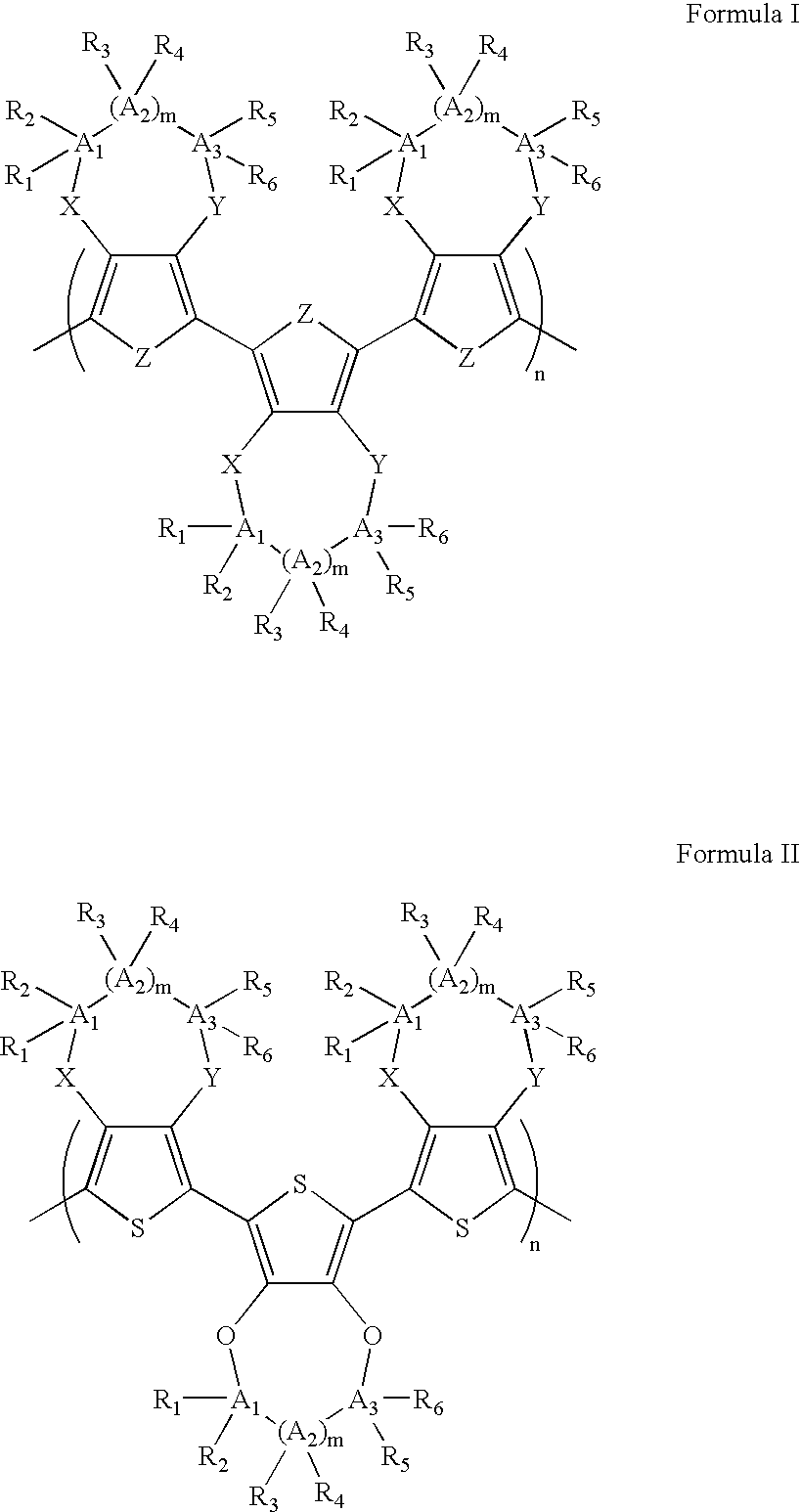

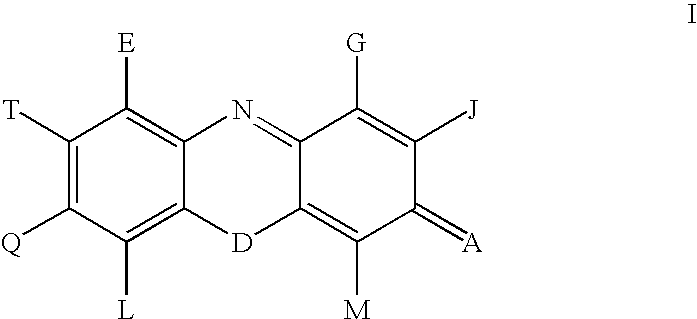

Coupled electrochromic compounds with photostable dication oxidation states

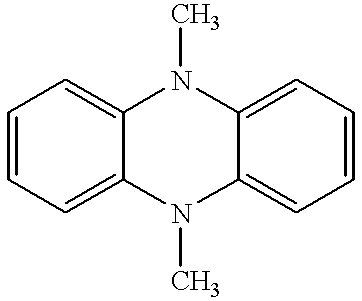

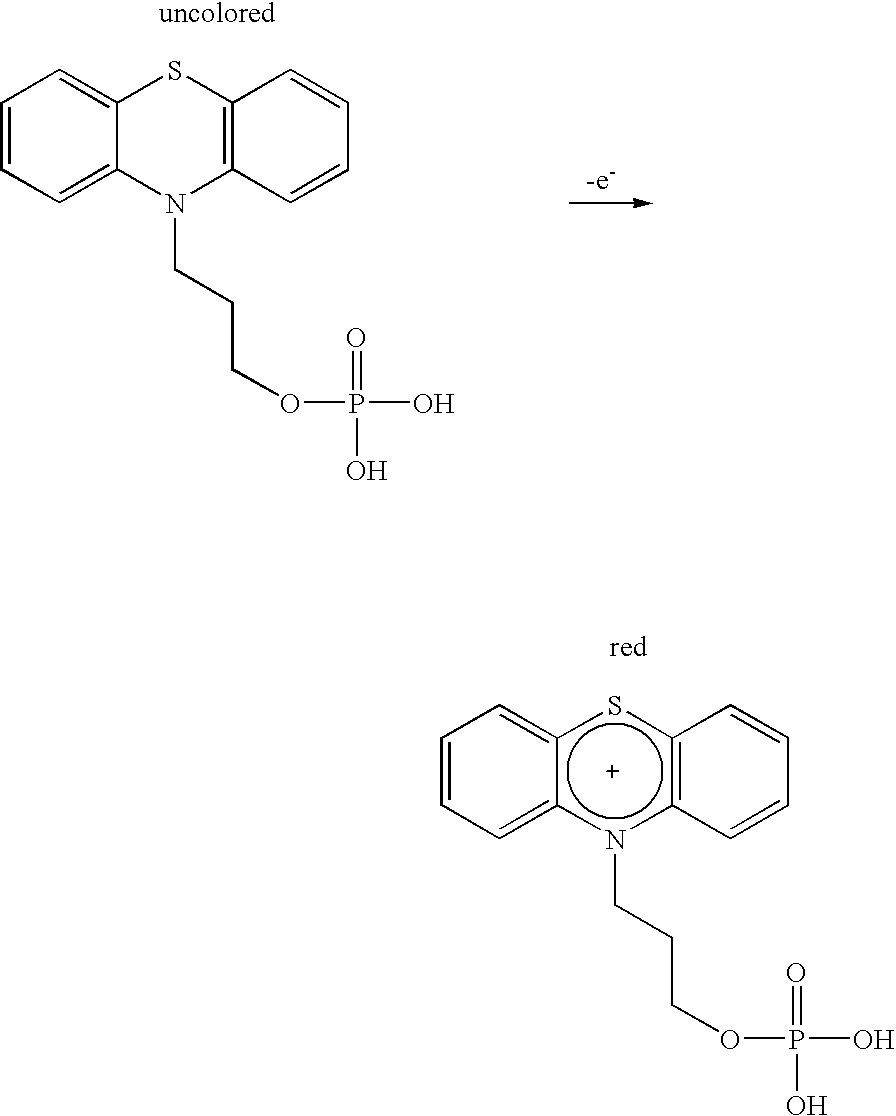

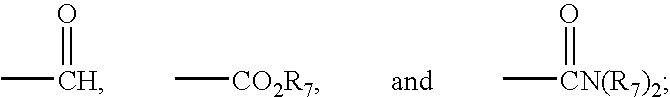

InactiveUS6249369B1High photochemical stabilityTenebresent compositionsNon-linear opticsAction spectrumElectronic communication

Coupling of anodic electrochromic compounds by a covalent bond or a bridge link which provides for electronic communication between the coupled electrochromic compounds results in coupled electrochromic compounds which exhibit greater stability as well as electrochromic activity that differs from the monomeric electrochromic compounds. Extension of the absorption spectrum into the near-infrared region of the spectrum is frequently observed. The coupled electrochromic compounds are highly suitable for use in electrochromic media used to produce electrochromic devices.

Owner:GENTEX CORP

Electrochromic devices

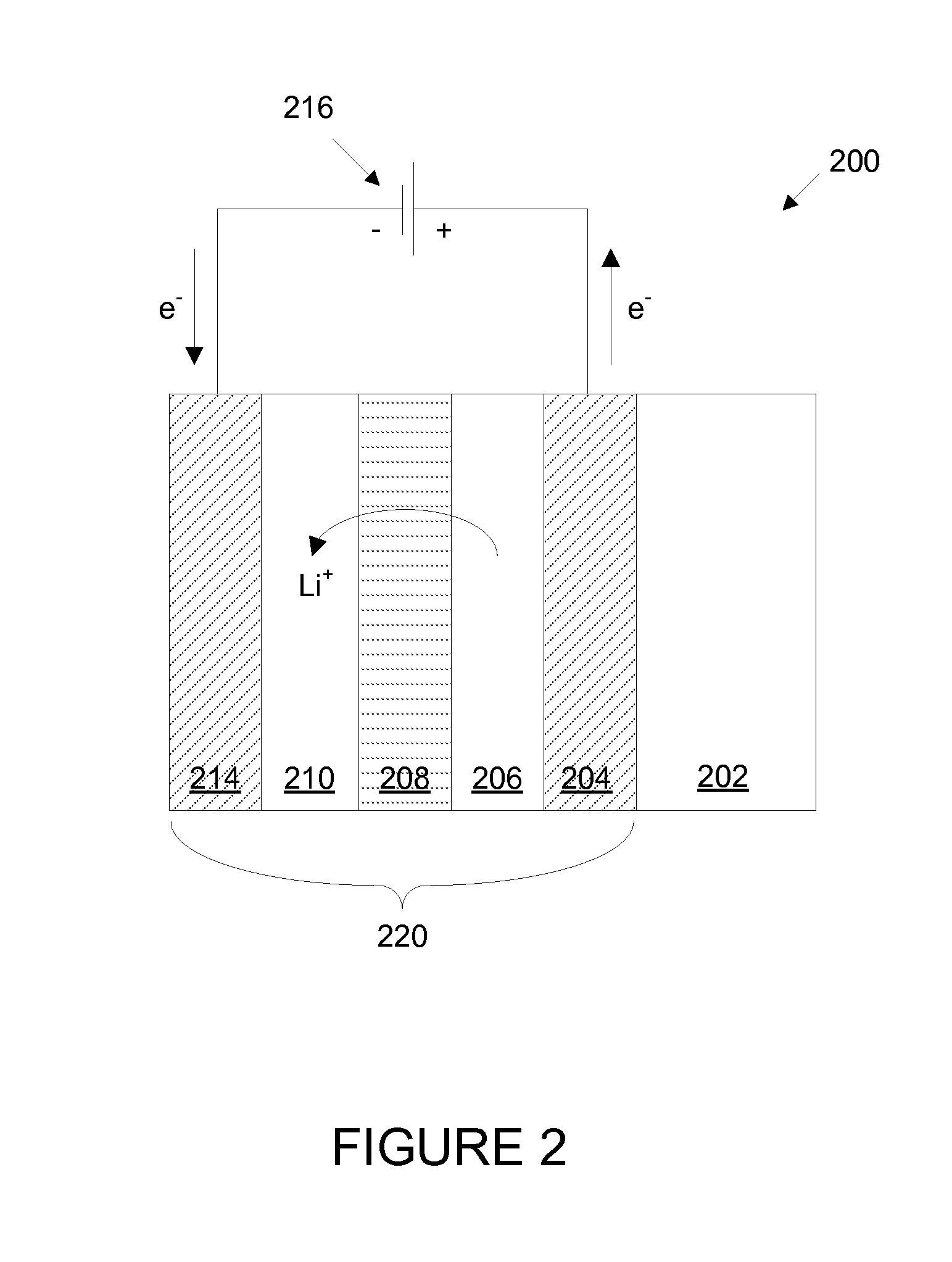

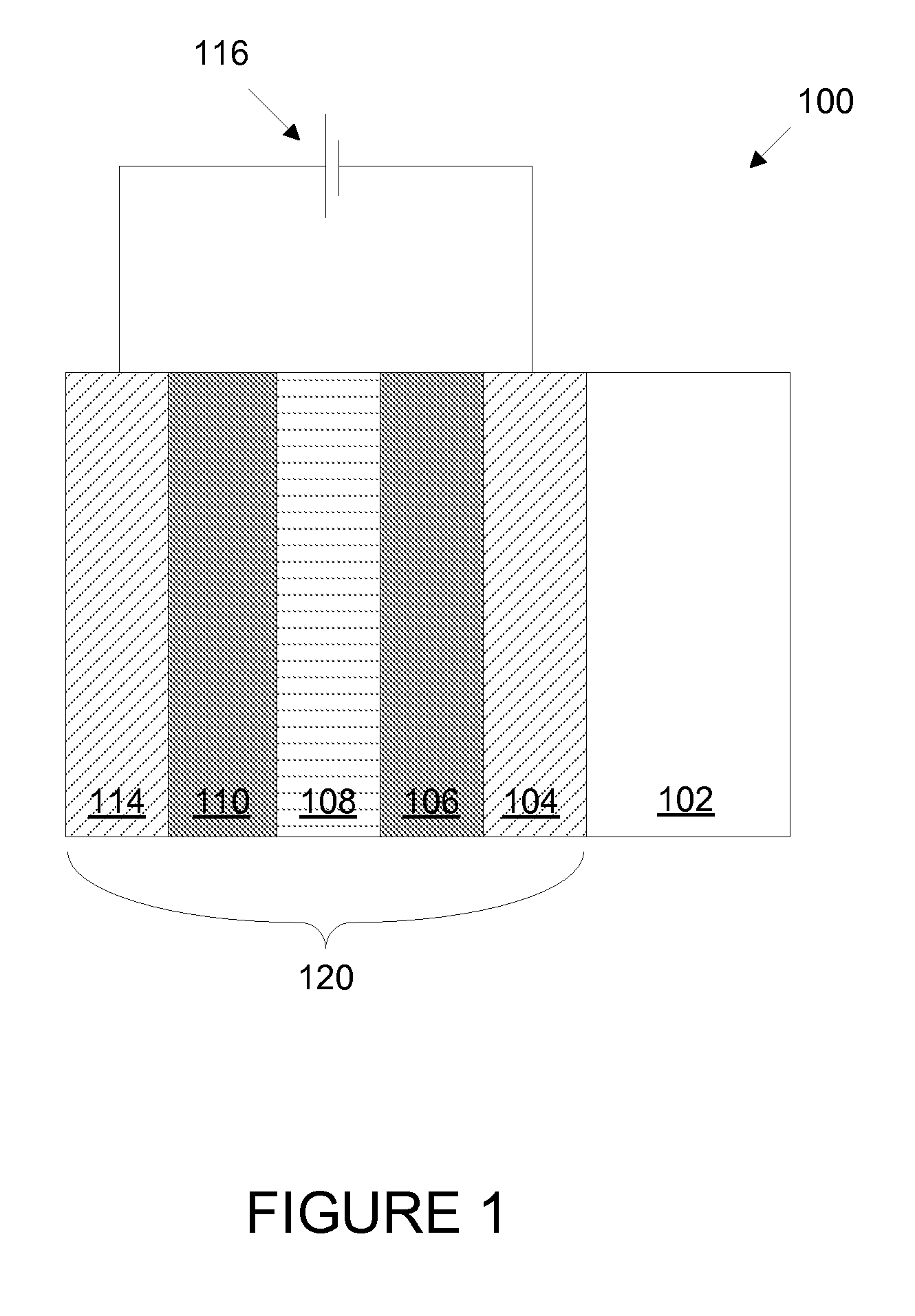

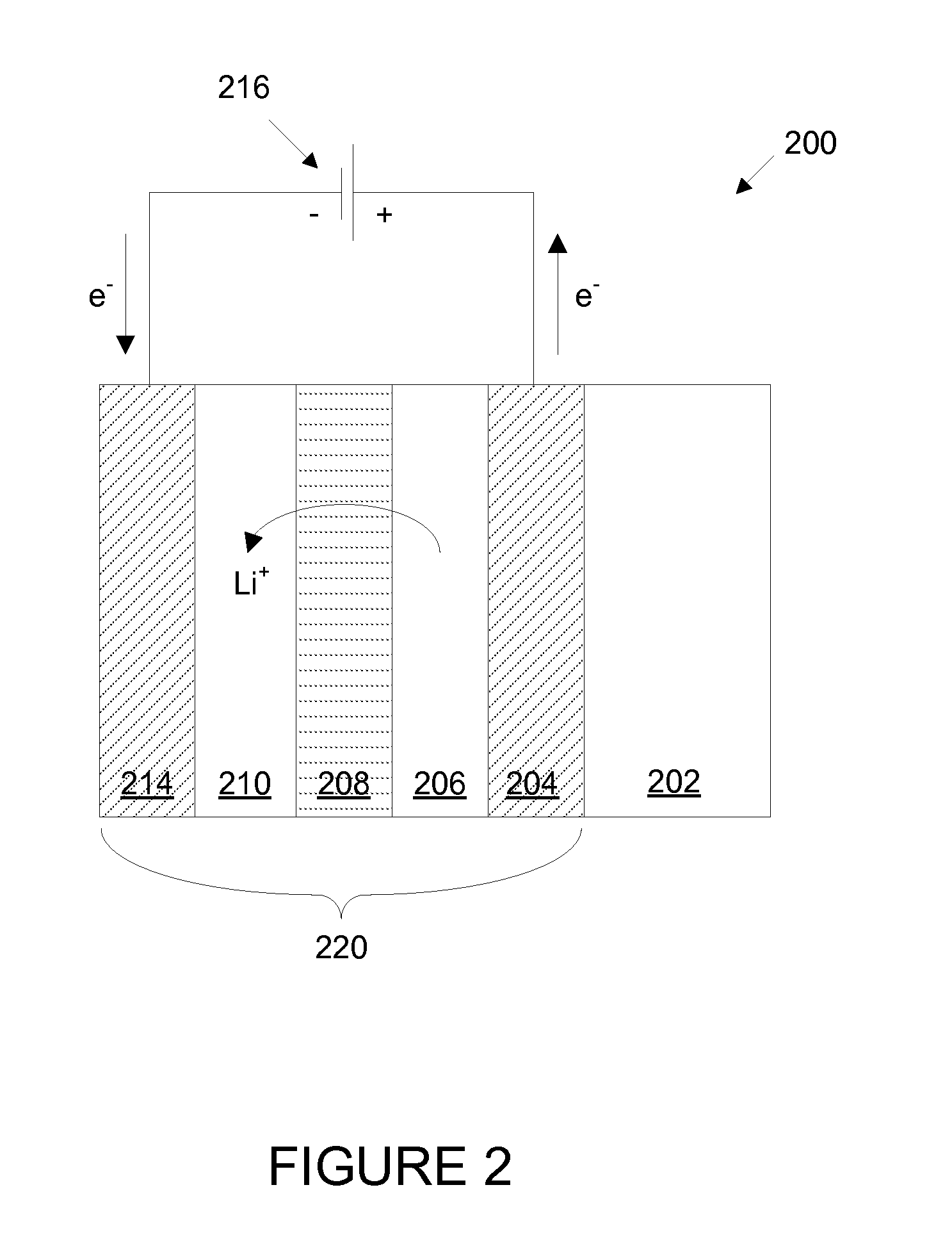

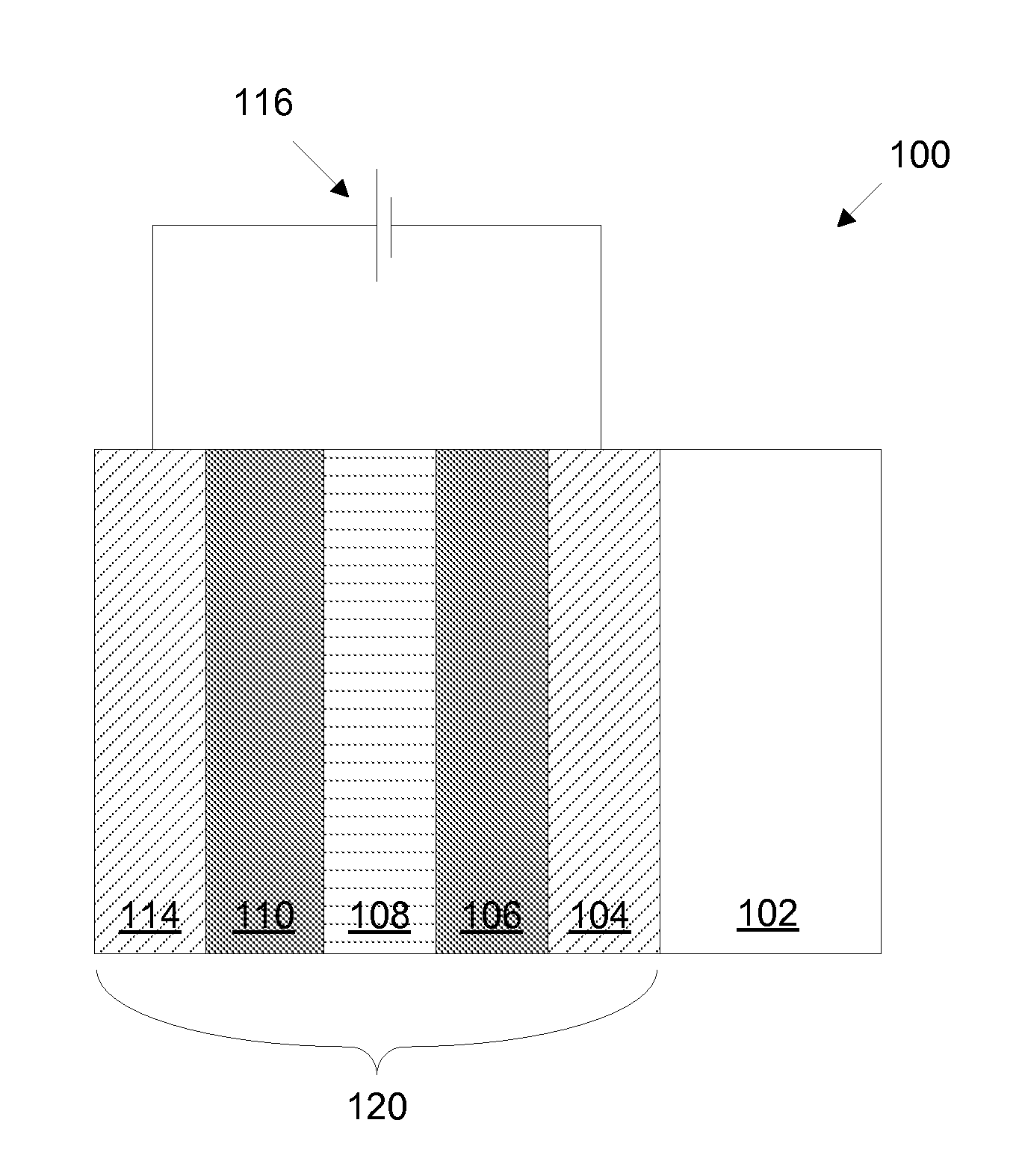

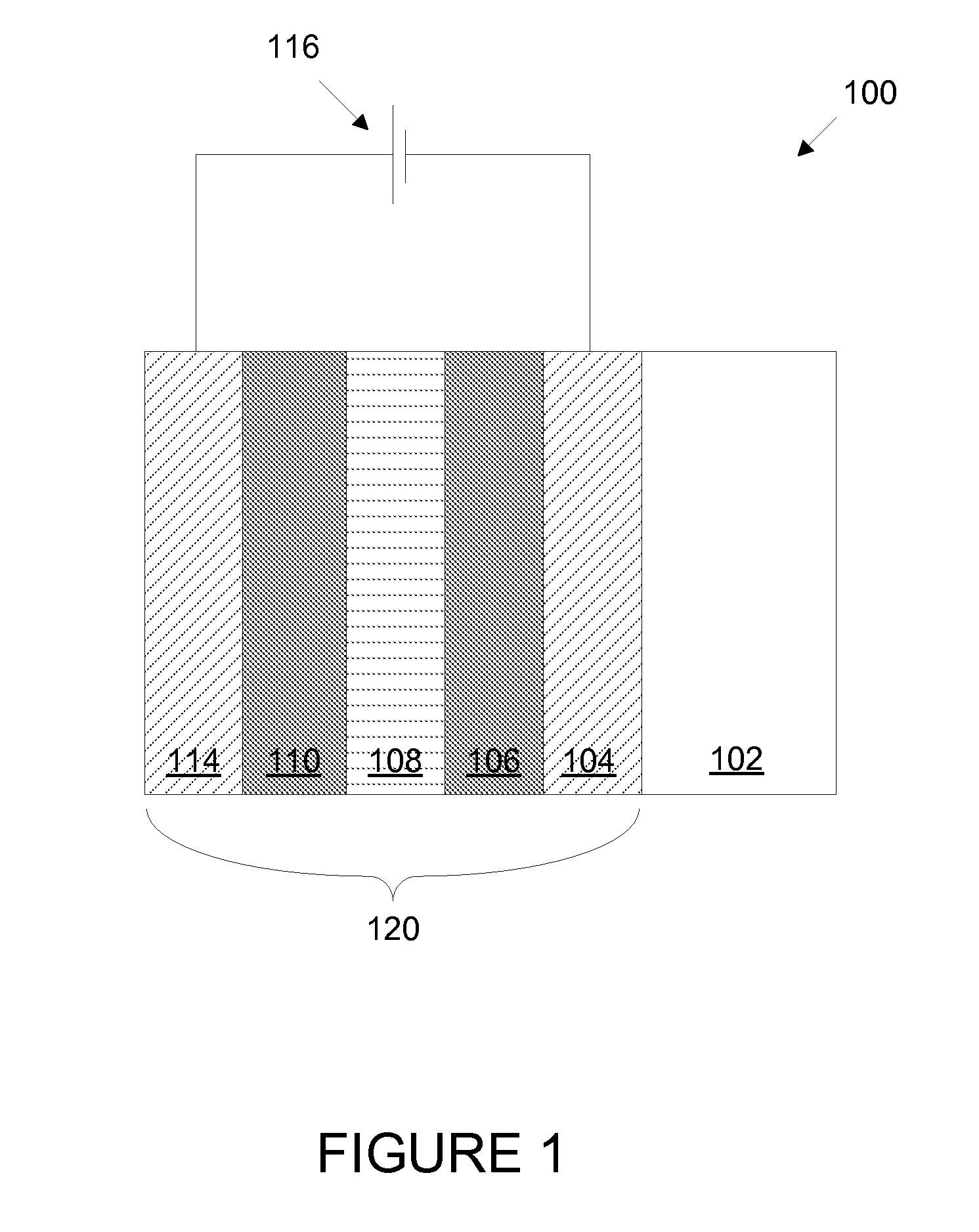

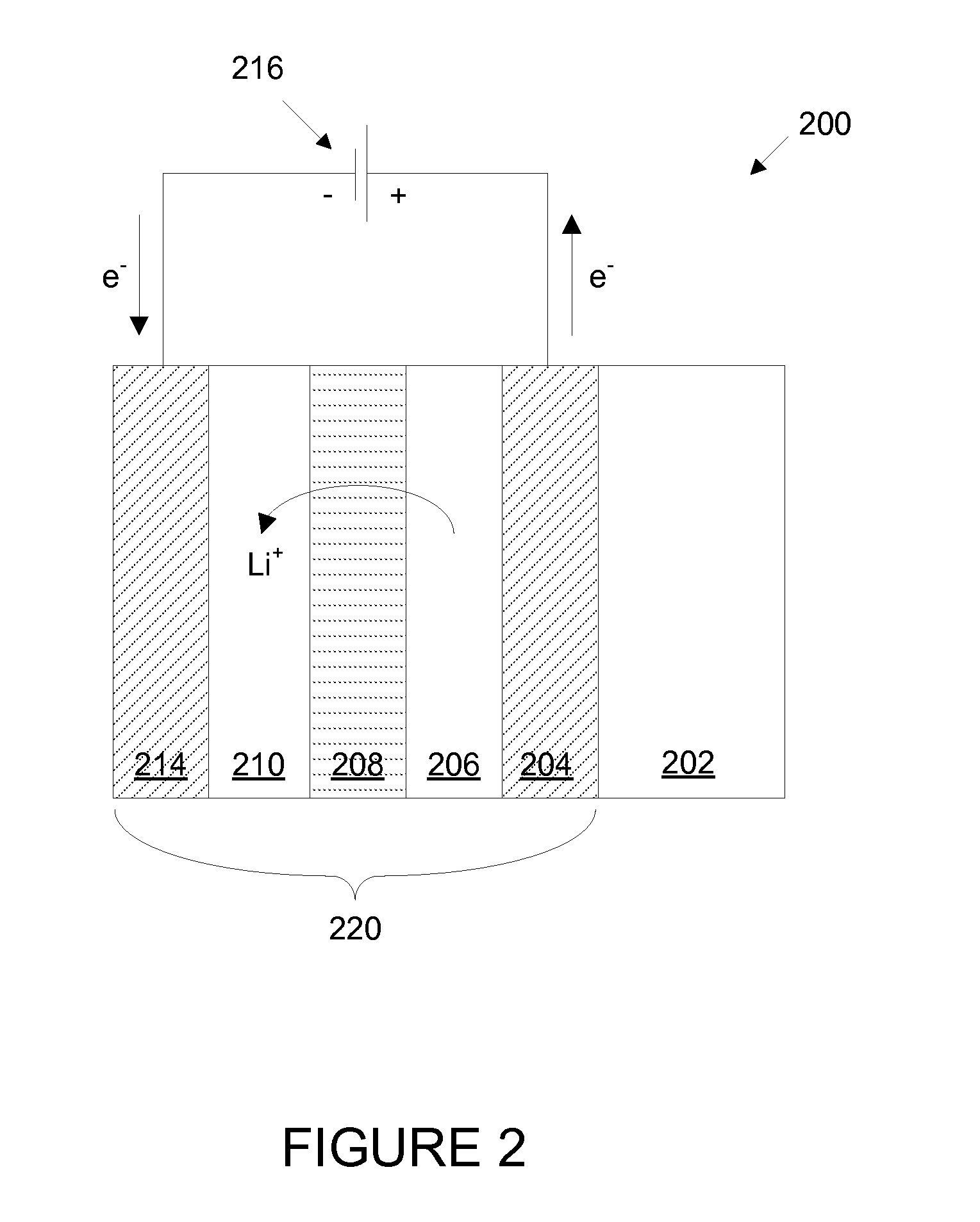

ActiveUS20100245973A1Improve equipment reliabilityImprove performanceVacuum evaporation coatingSputtering coatingElectricityLithium

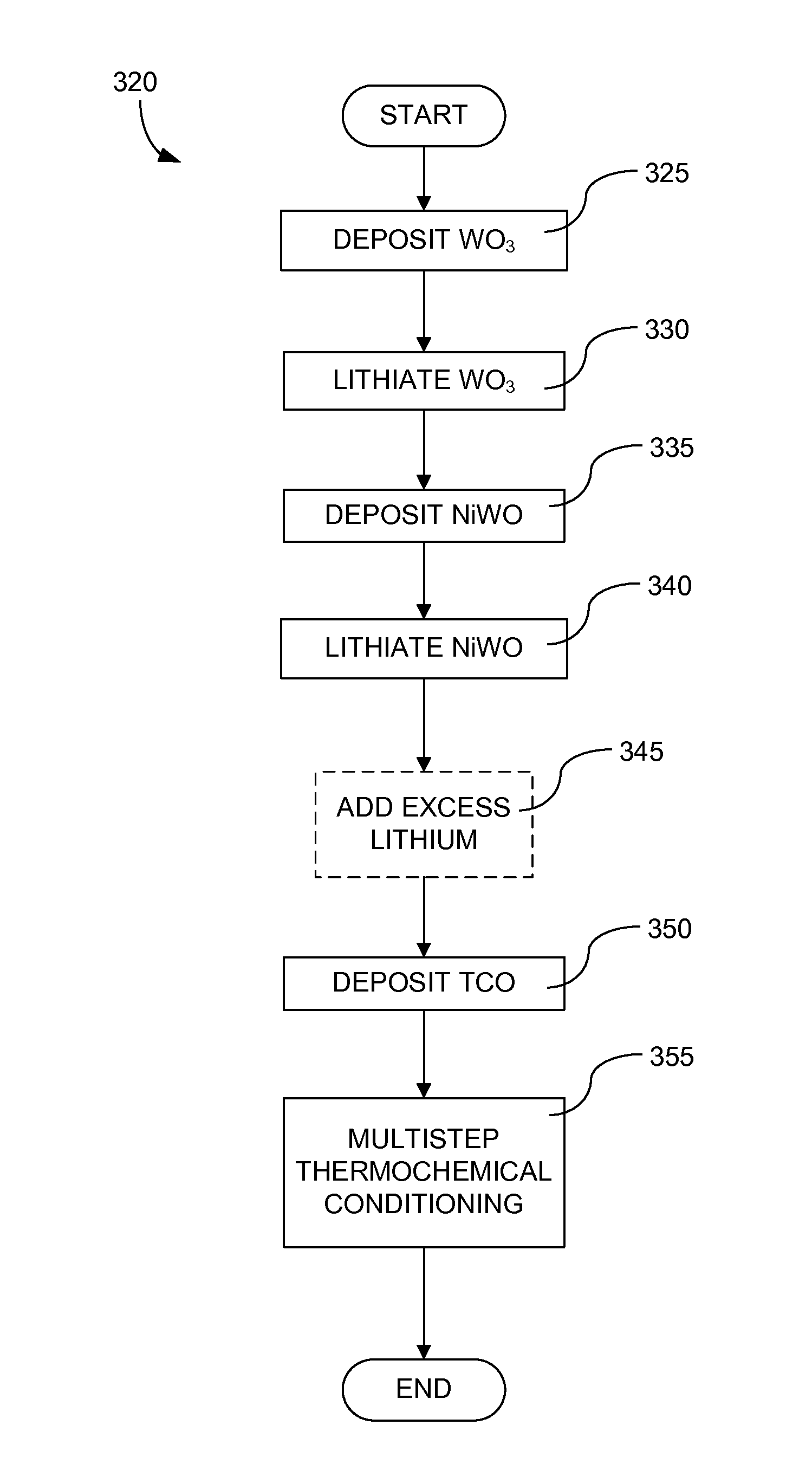

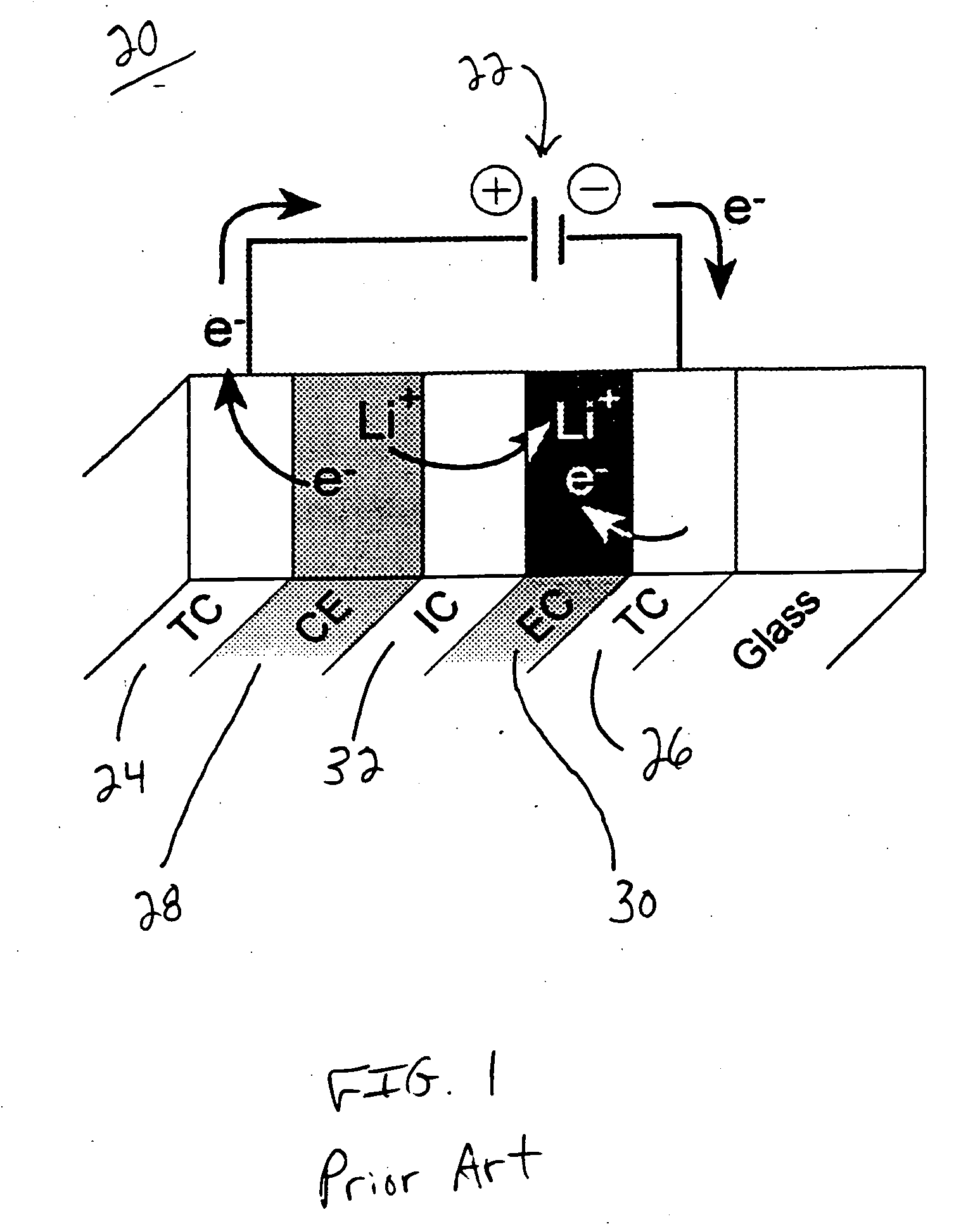

Prior electrochromic devices frequently suffer from poor reliability and poor performance. Some of the difficulties result from inappropriate design and construction of the devices. In order to improve device reliability two layers of an electrochromic device, the counter electrode layer and the electrochromic layer, can each be fabricated to include defined amounts of lithium. Further, the electrochromic device may be subjected to a multistep thermochemical conditioning operation to improve performance. Additionally, careful choice of the materials and morphology of some components of the electrochromic device provides improvements in performance and reliability. In some devices, all layers of the device are entirely solid and inorganic.

Owner:VIEW INC

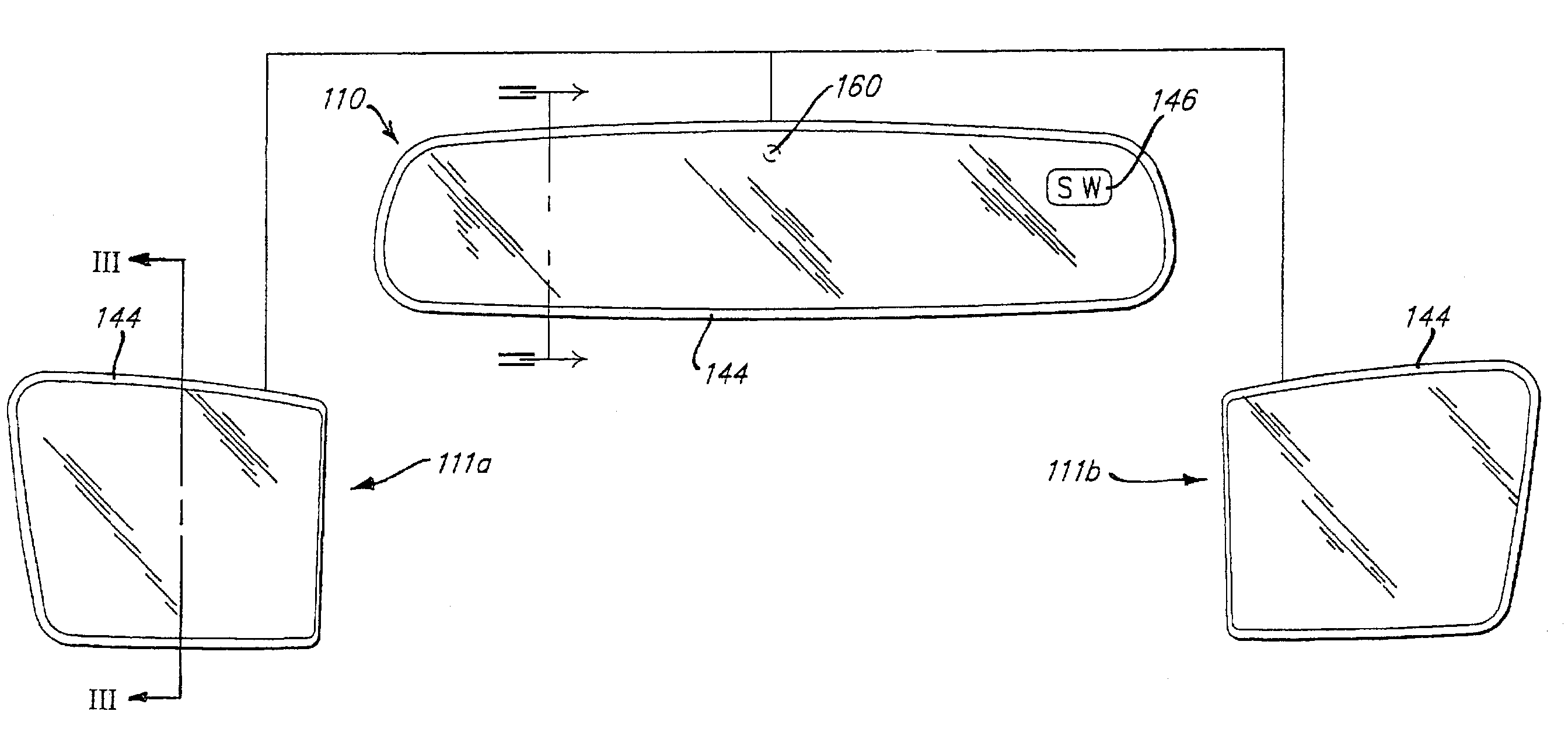

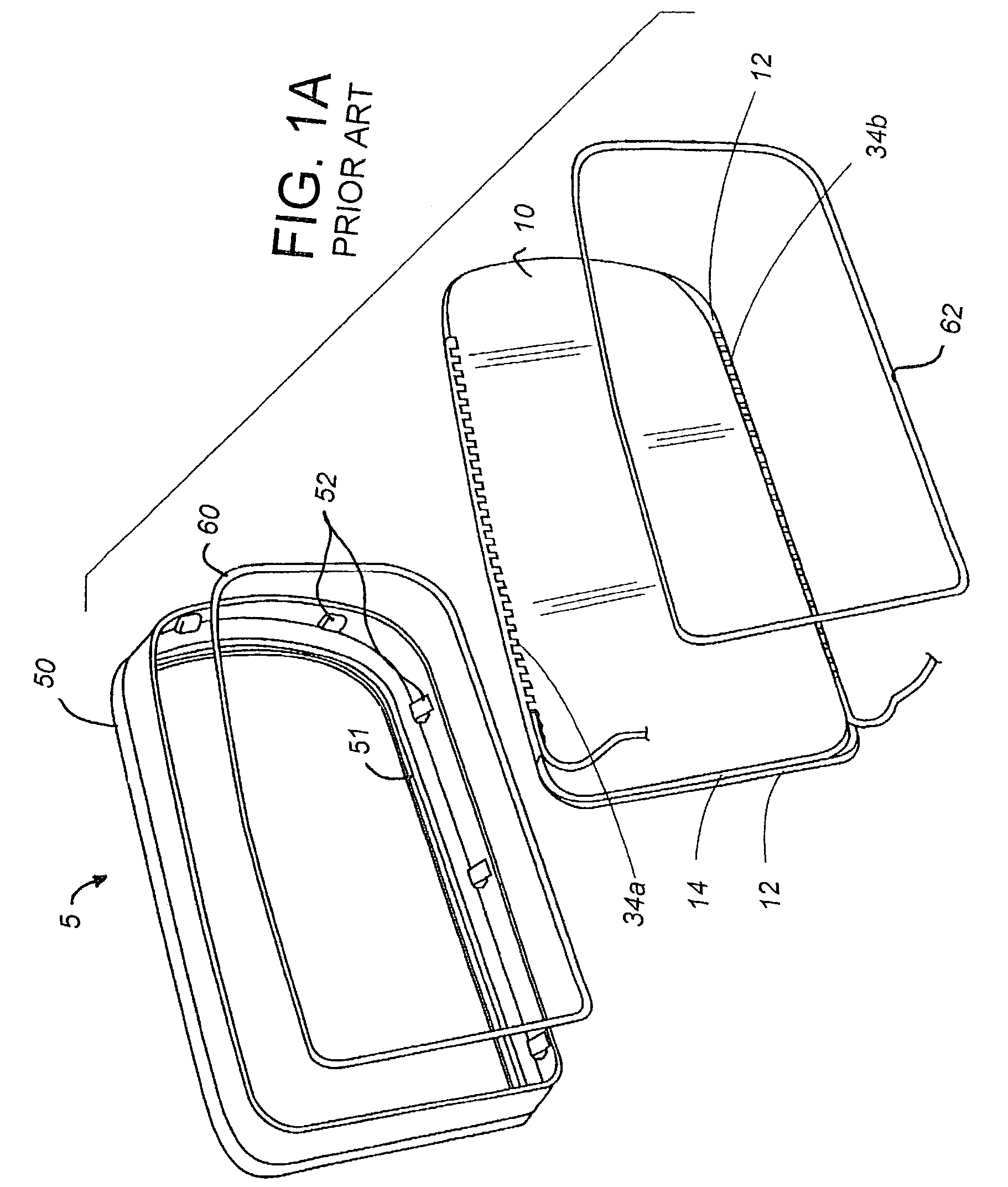

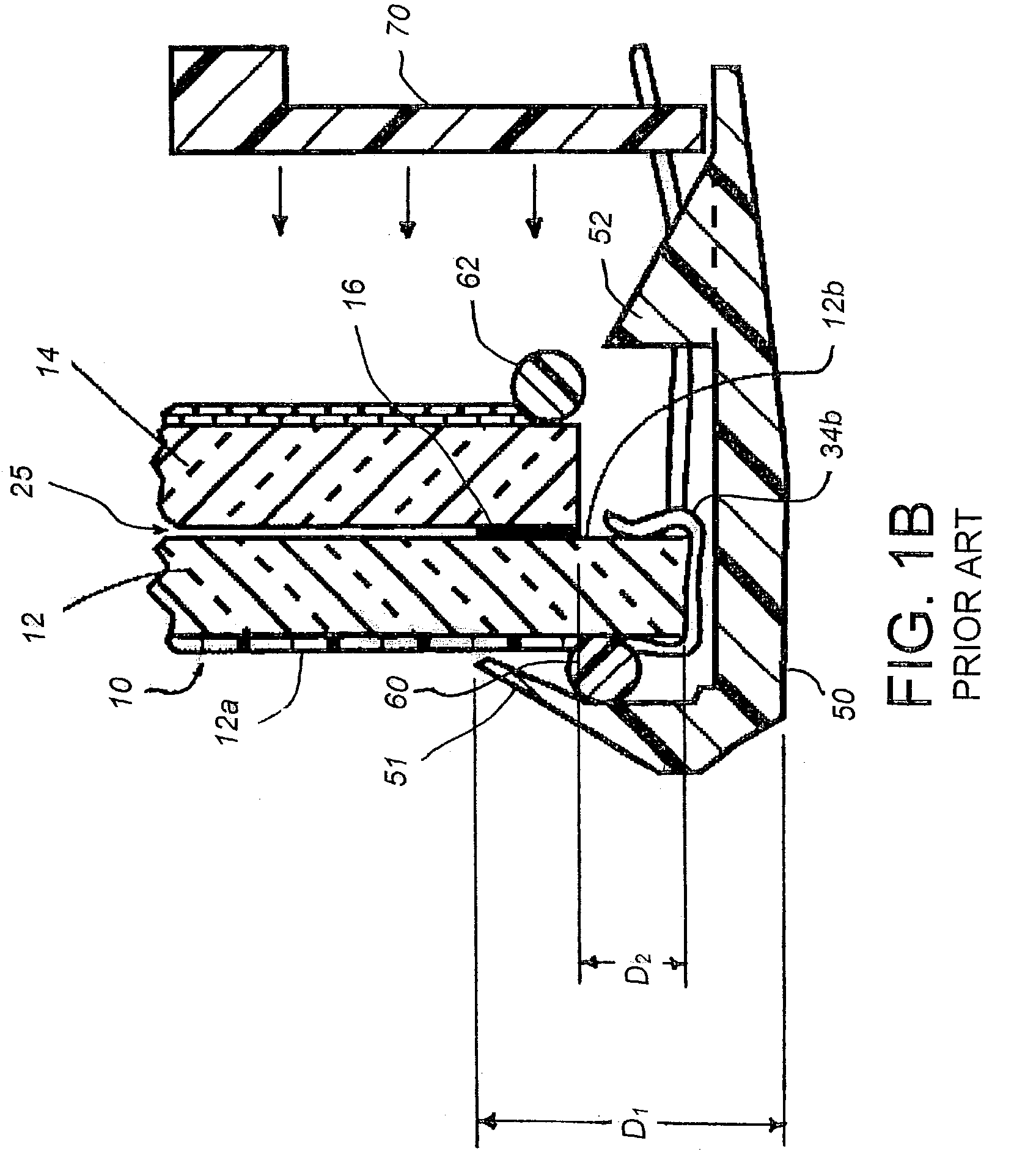

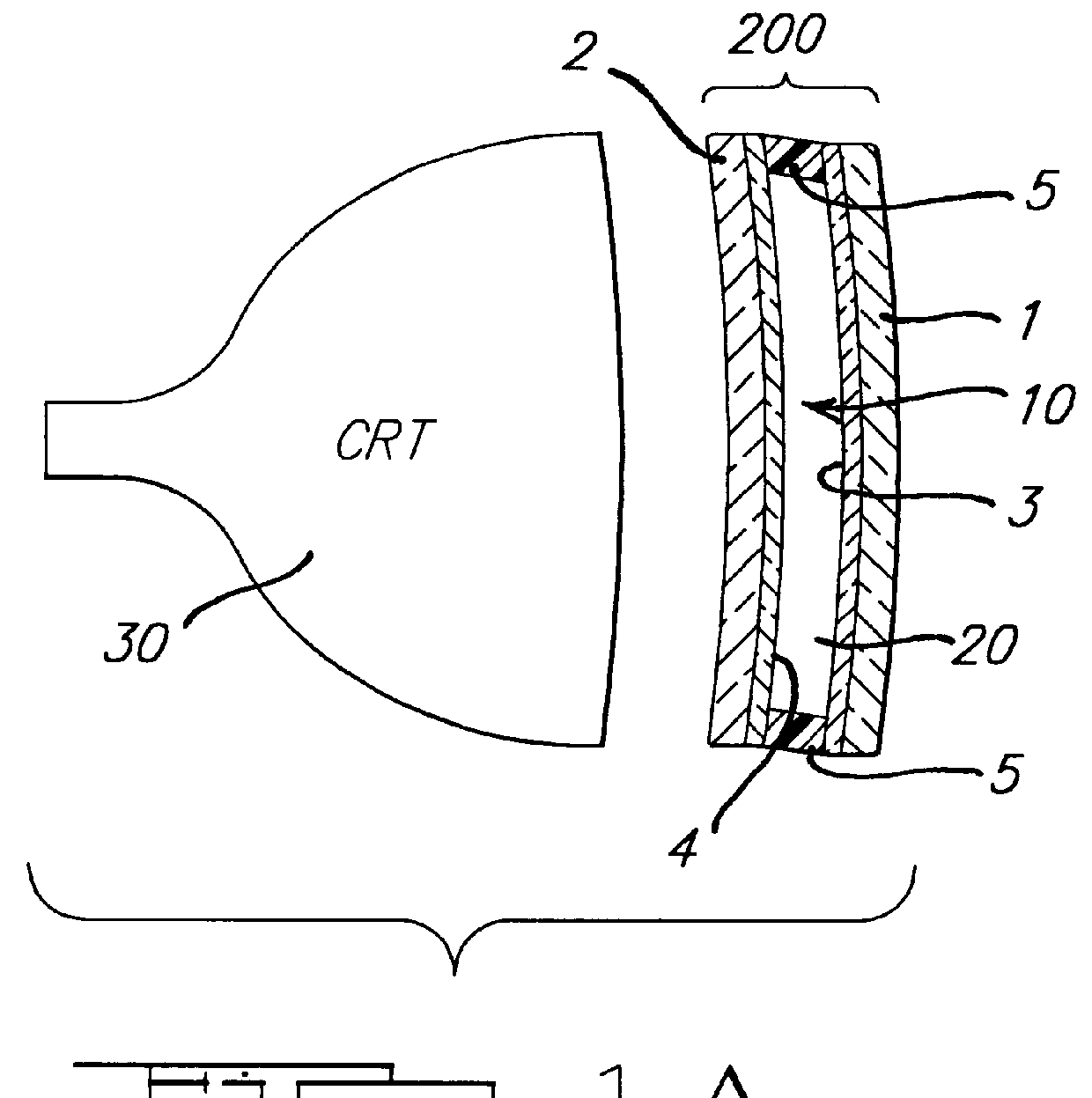

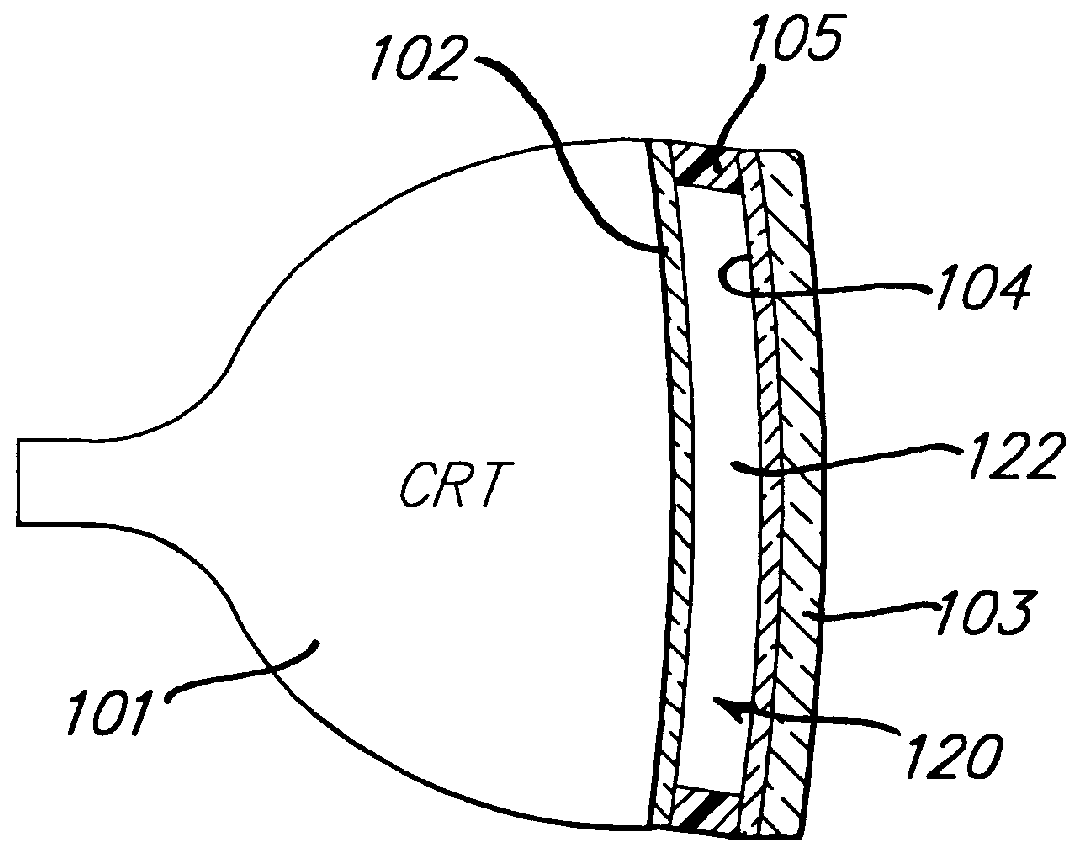

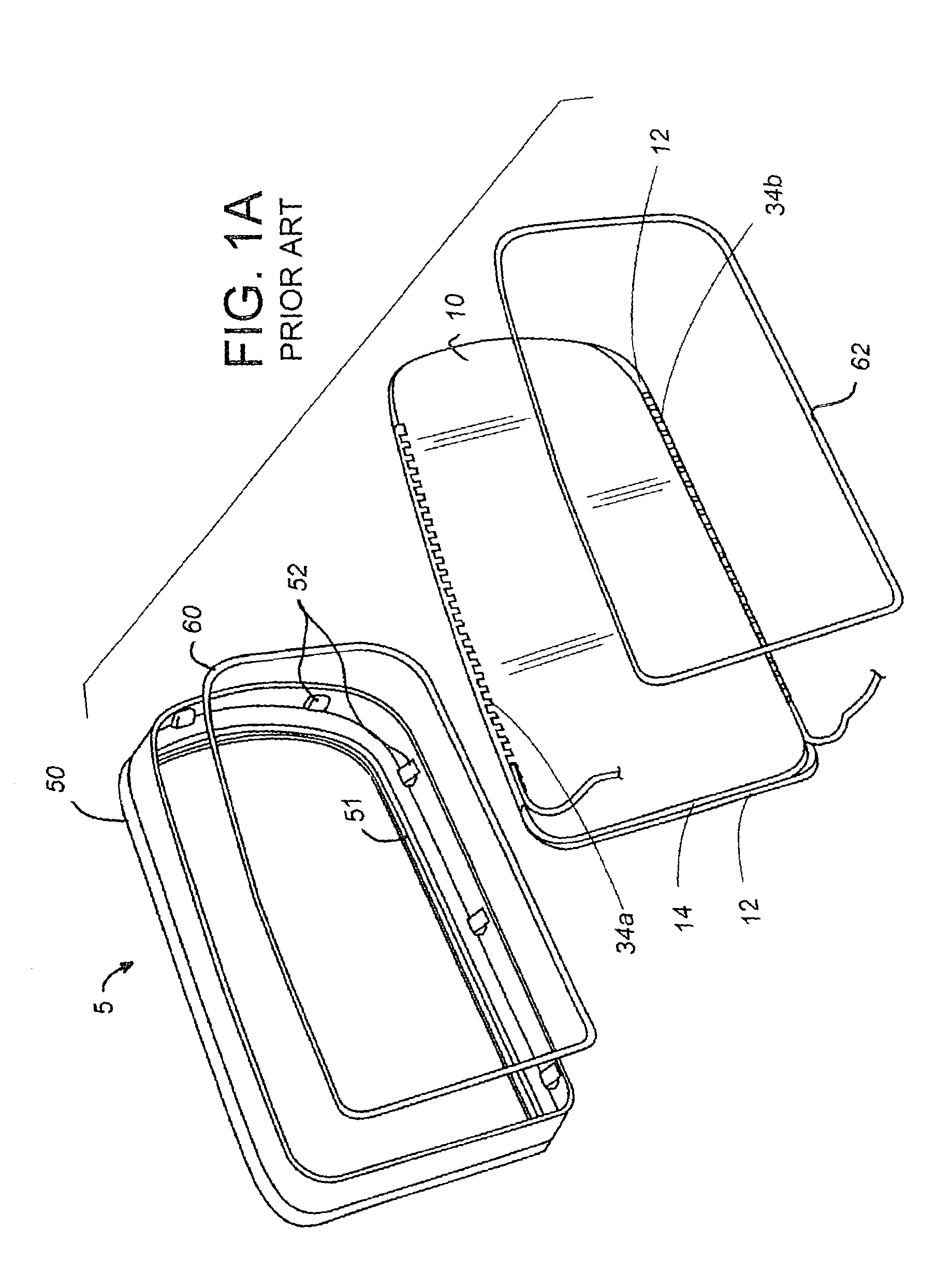

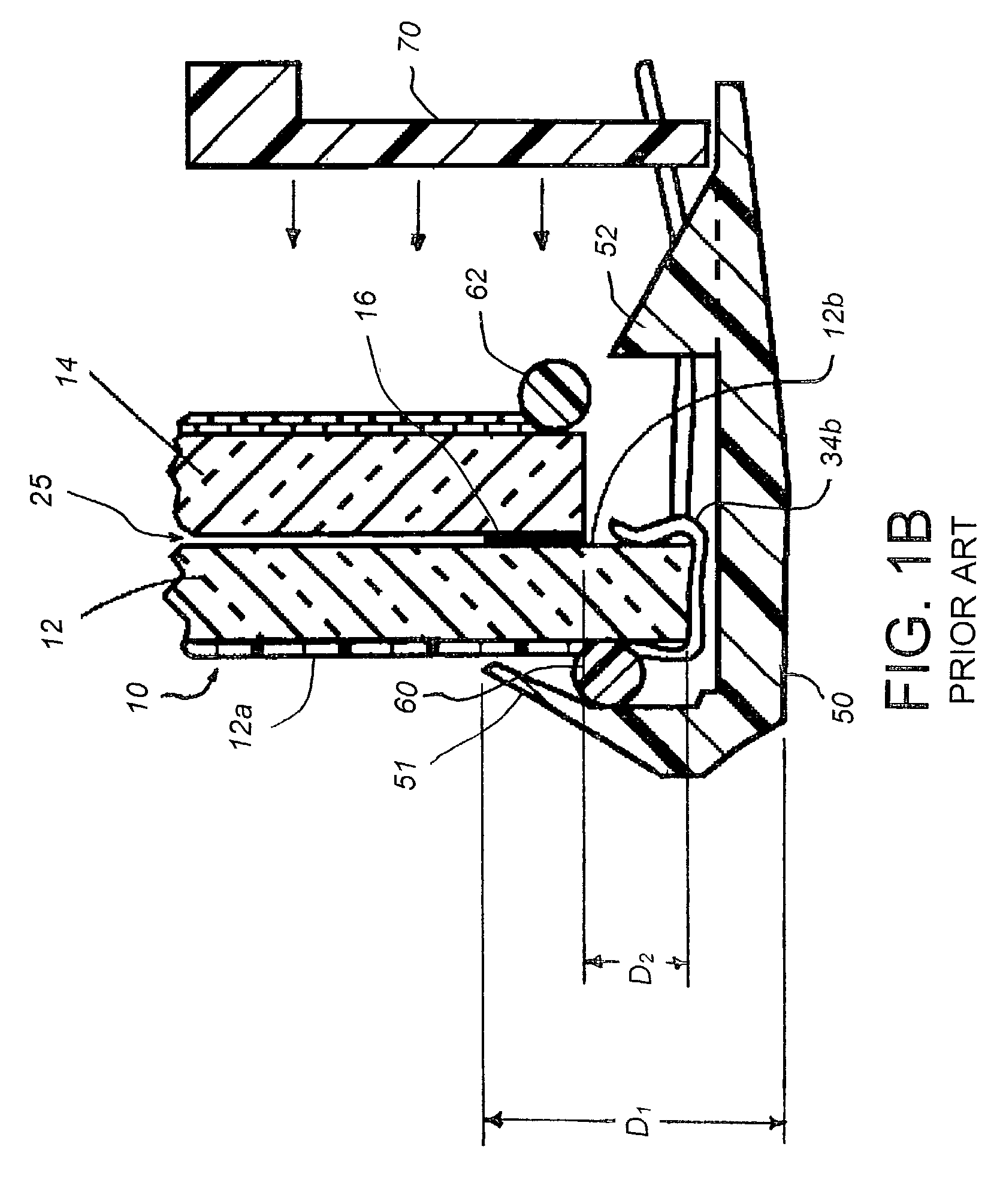

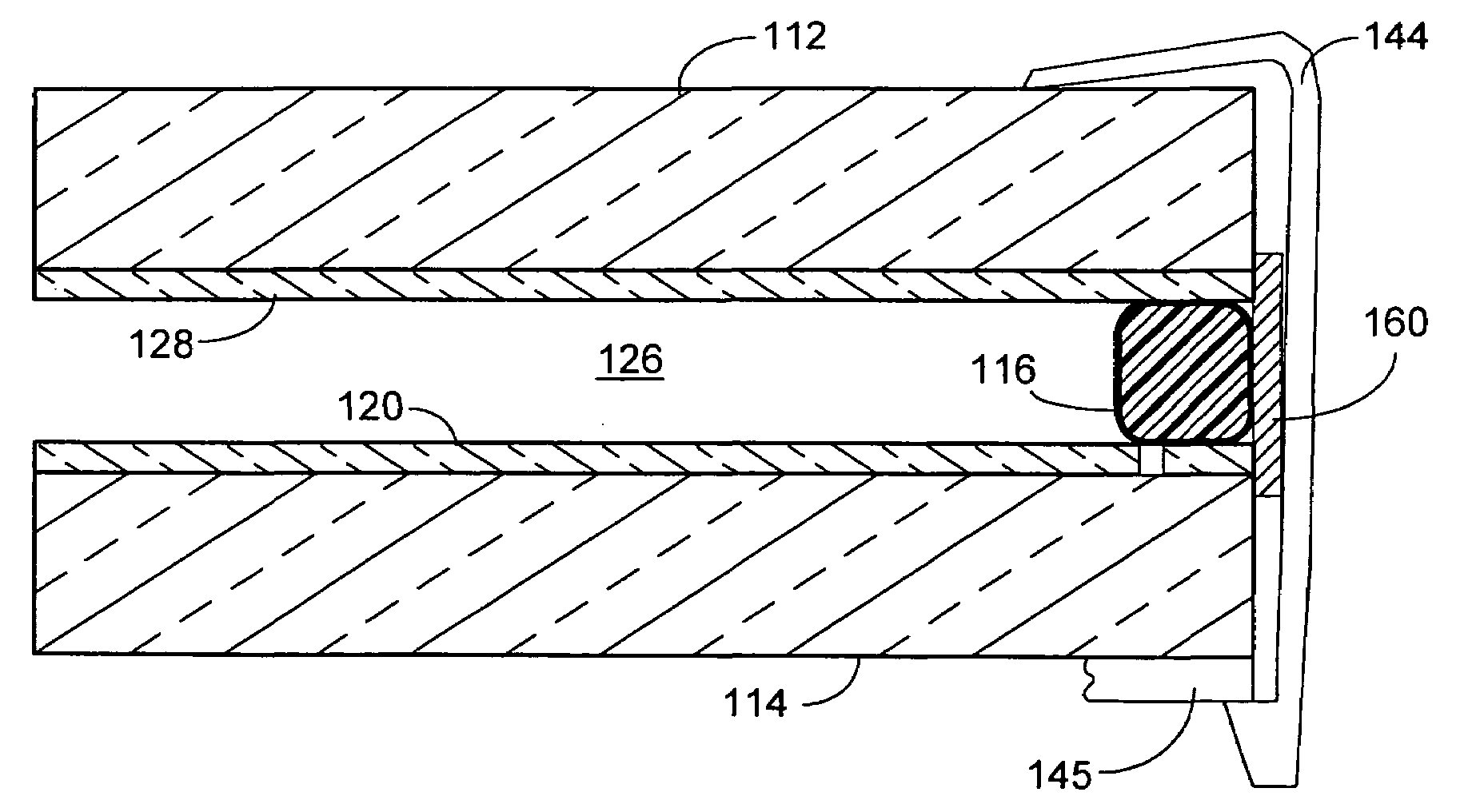

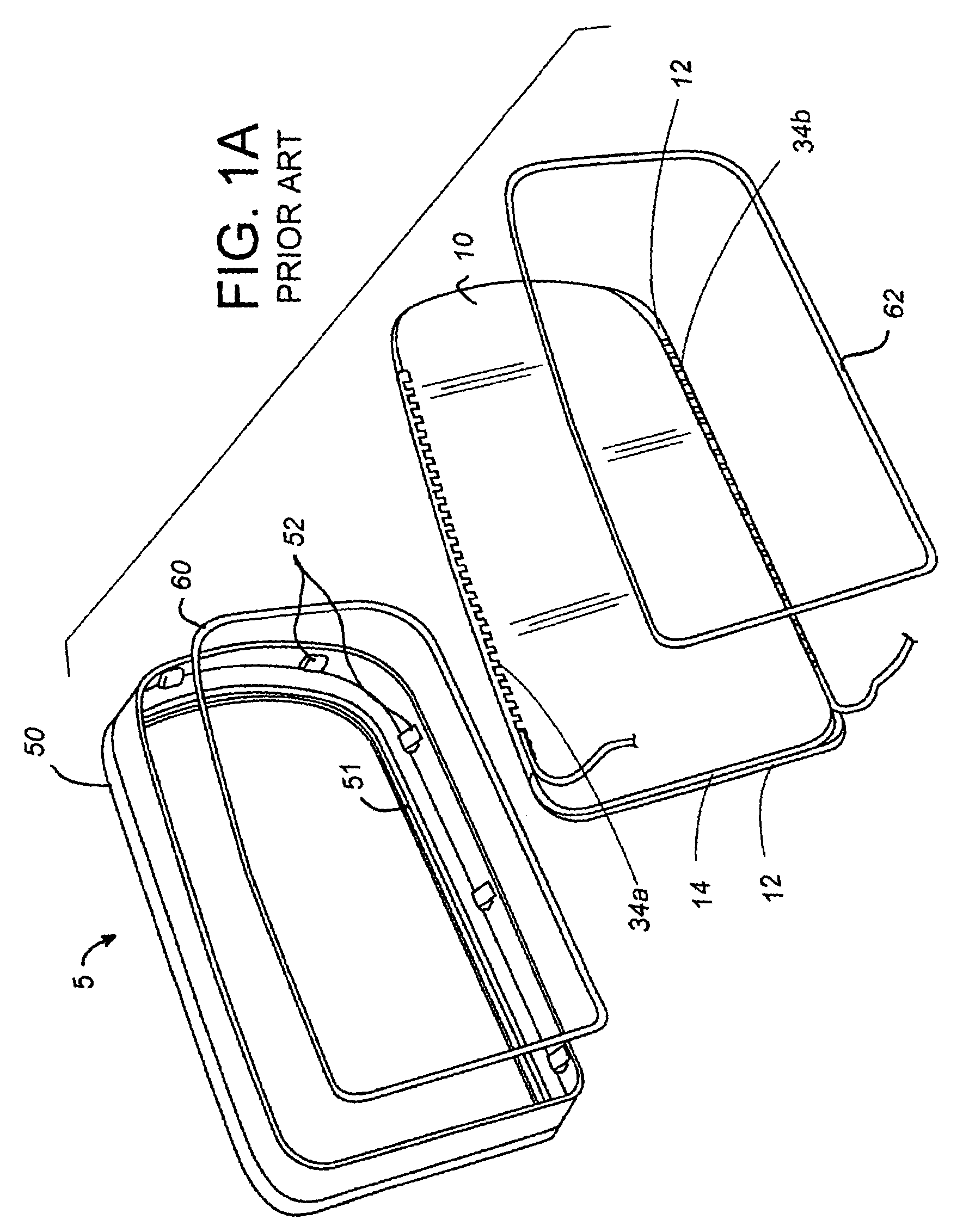

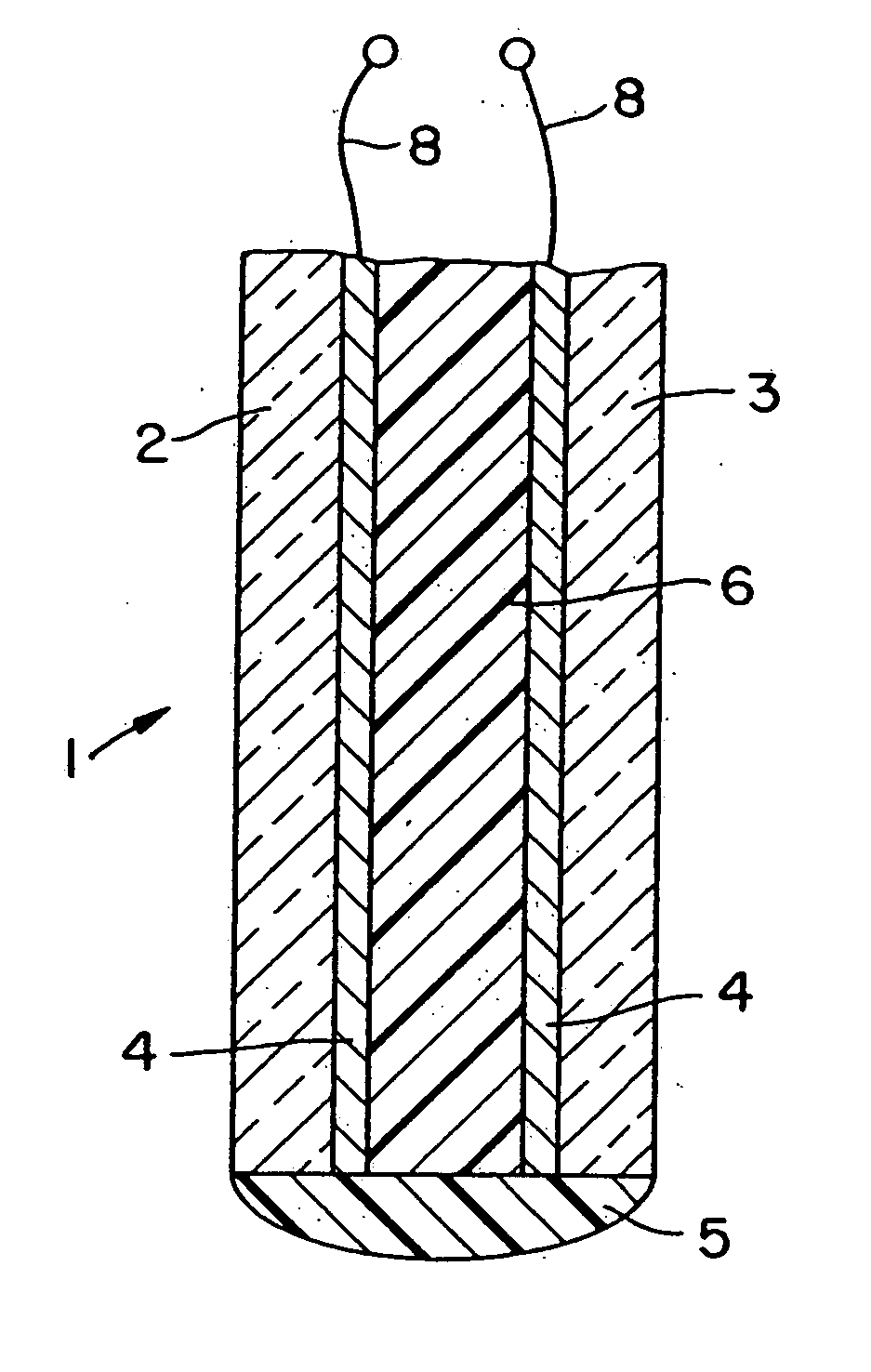

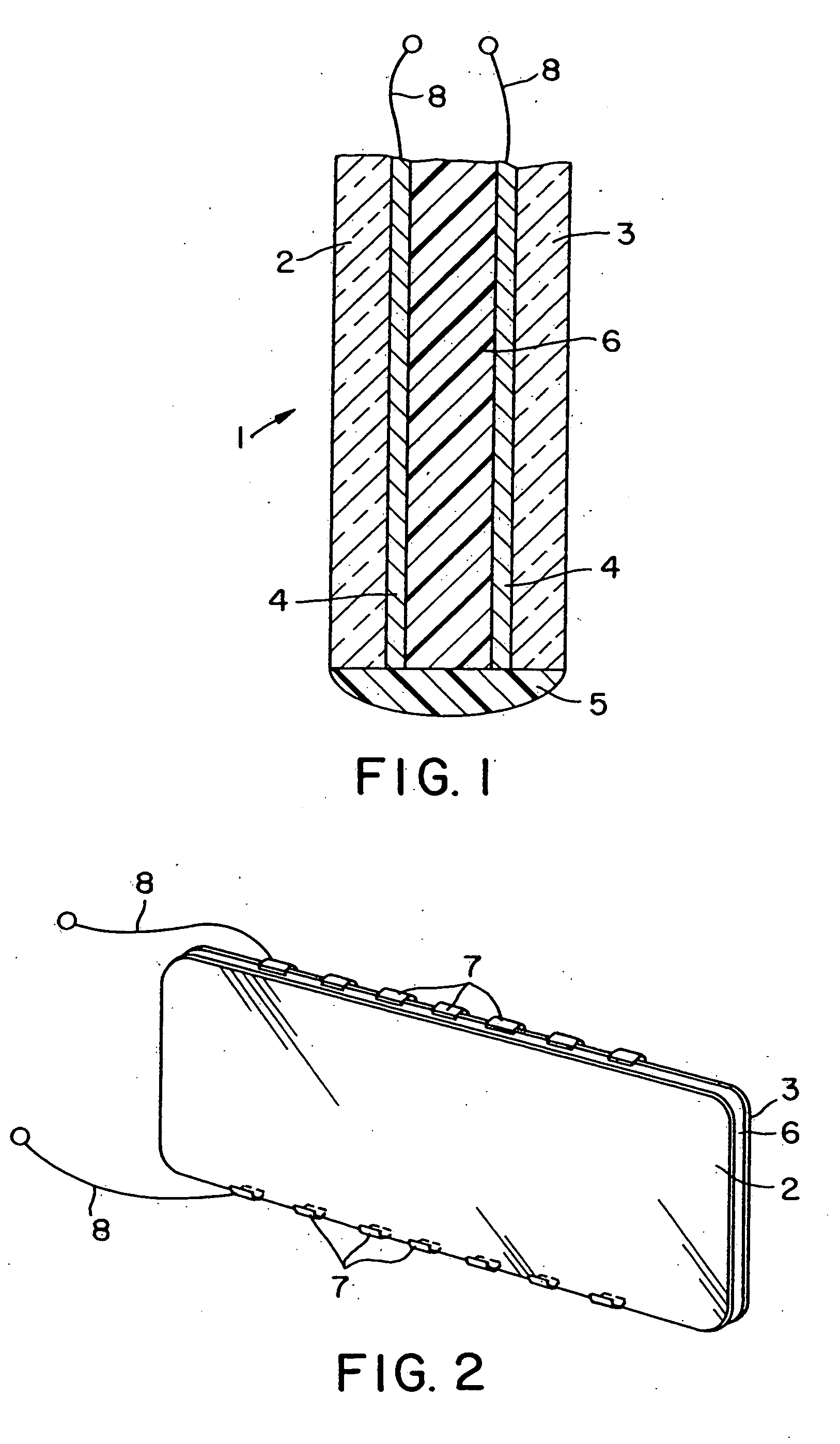

Electrochromic devices with thin bezel-covered edge

InactiveUS7324261B2Minimizing contributionUniform maintenanceTenebresent compositionsNon-linear opticsEngineeringElectrochromic devices

A mirror includes an electro-optic mirror subassembly, and a thin-profiled bezel attached around a perimeter of the electrochromic mirror subassembly. The electro-optic mirror subassembly is supported on a carrier by an adheringly bonded heater and foam tape in a laminar arrangement. The bezel may be bonded to an edge of the front surface of the front element of the electro-optic mirror subassembly, and / or may be bonded and / or interlockingly mechanically attached to an edge of the carrier. Alternatively, the bezel can be a strip of paint or thin coating material. The bezel can be molded in place, or can be pre-molded and elastically stretched to permit assembly. In one form, the bezel includes a laterally-extending fin that prevents seeing past the bezel into the inside of a mirror housing. In at least one embodiment, the assembly has no bezel or only a bezel on one edge.

Owner:GENTEX CORP

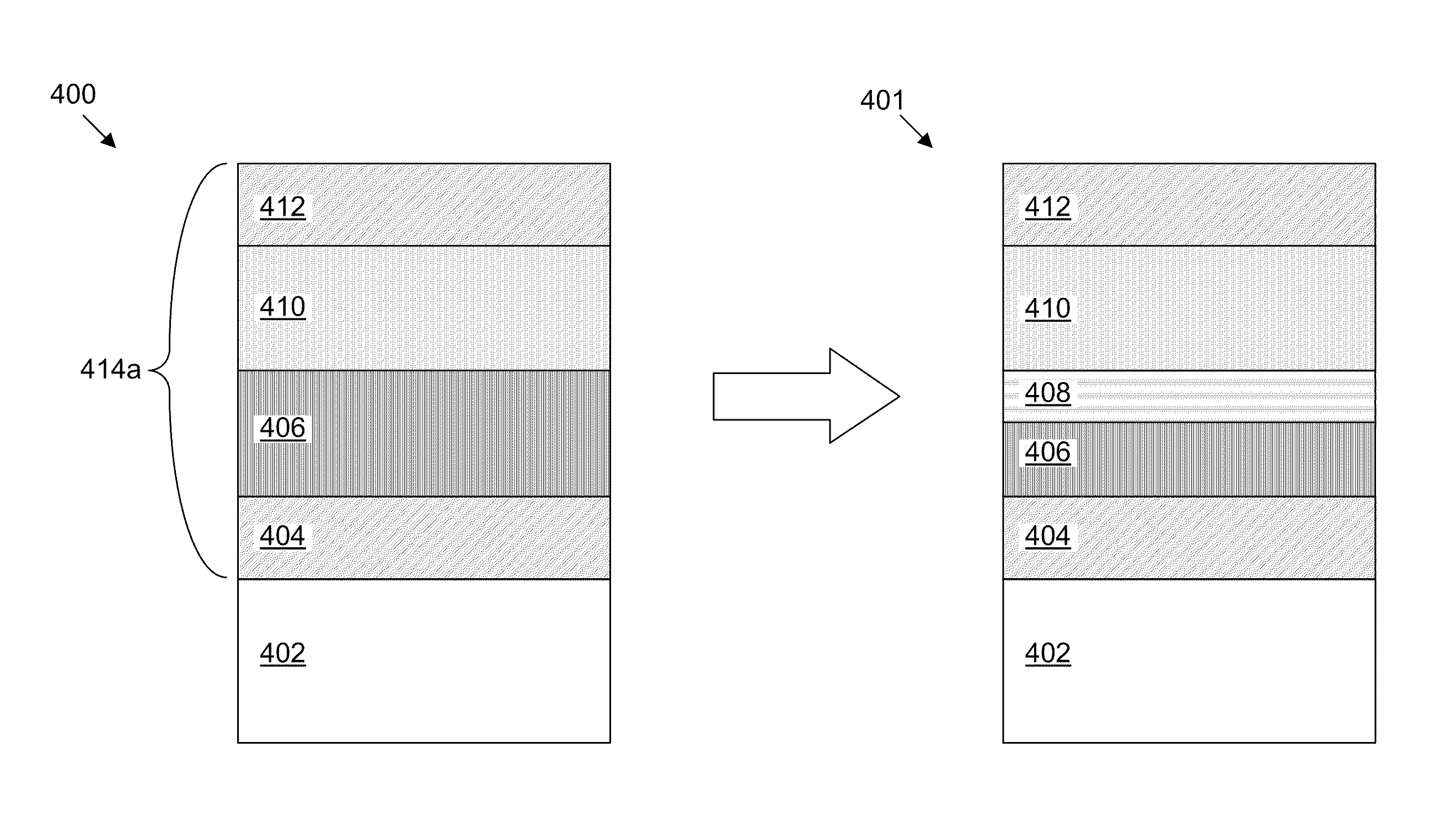

Electrochromic devices

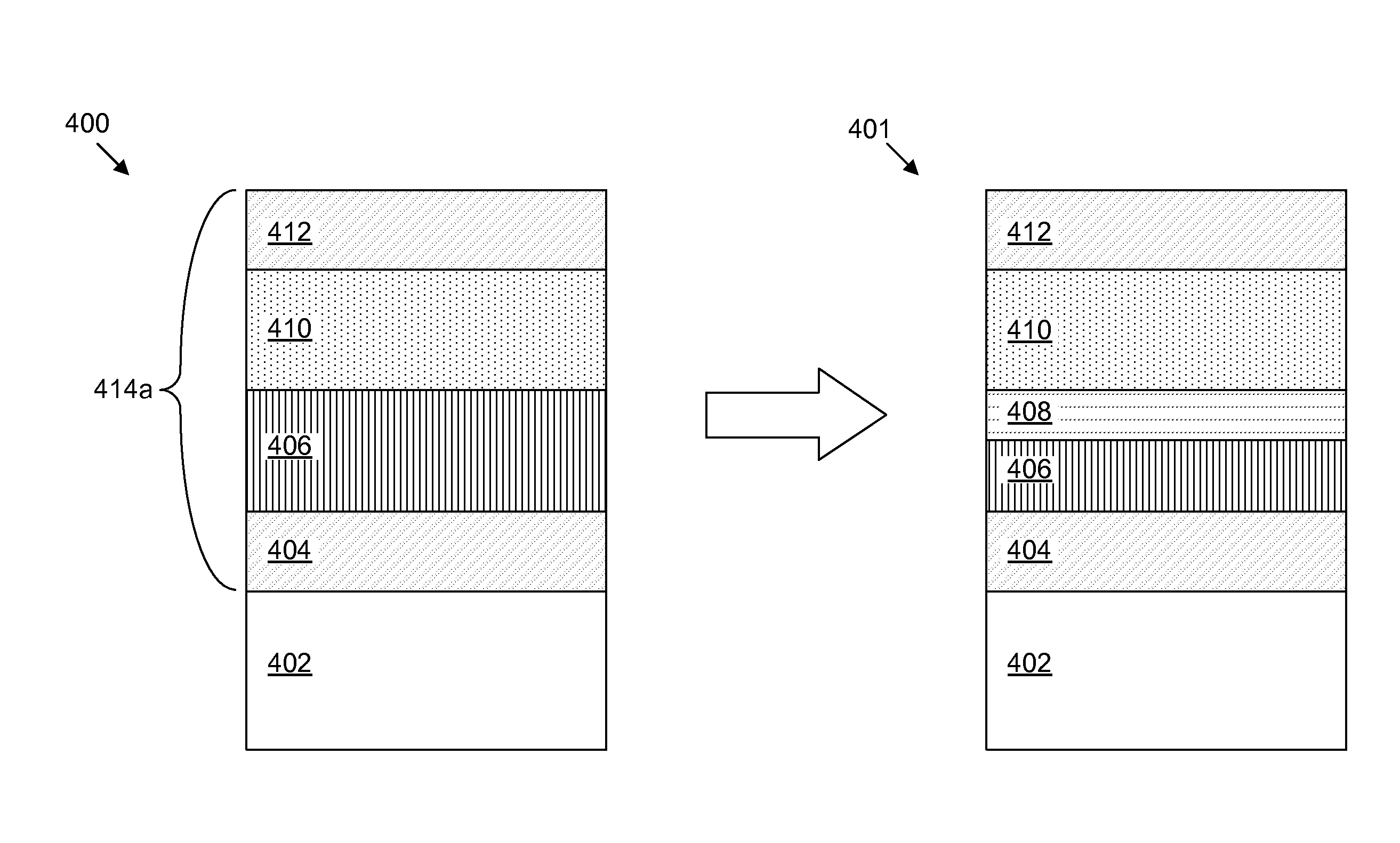

ActiveUS20110266138A1Improve conductivityIncrease resistanceVacuum evaporation coatingSputtering coatingElectricityOptoelectronics

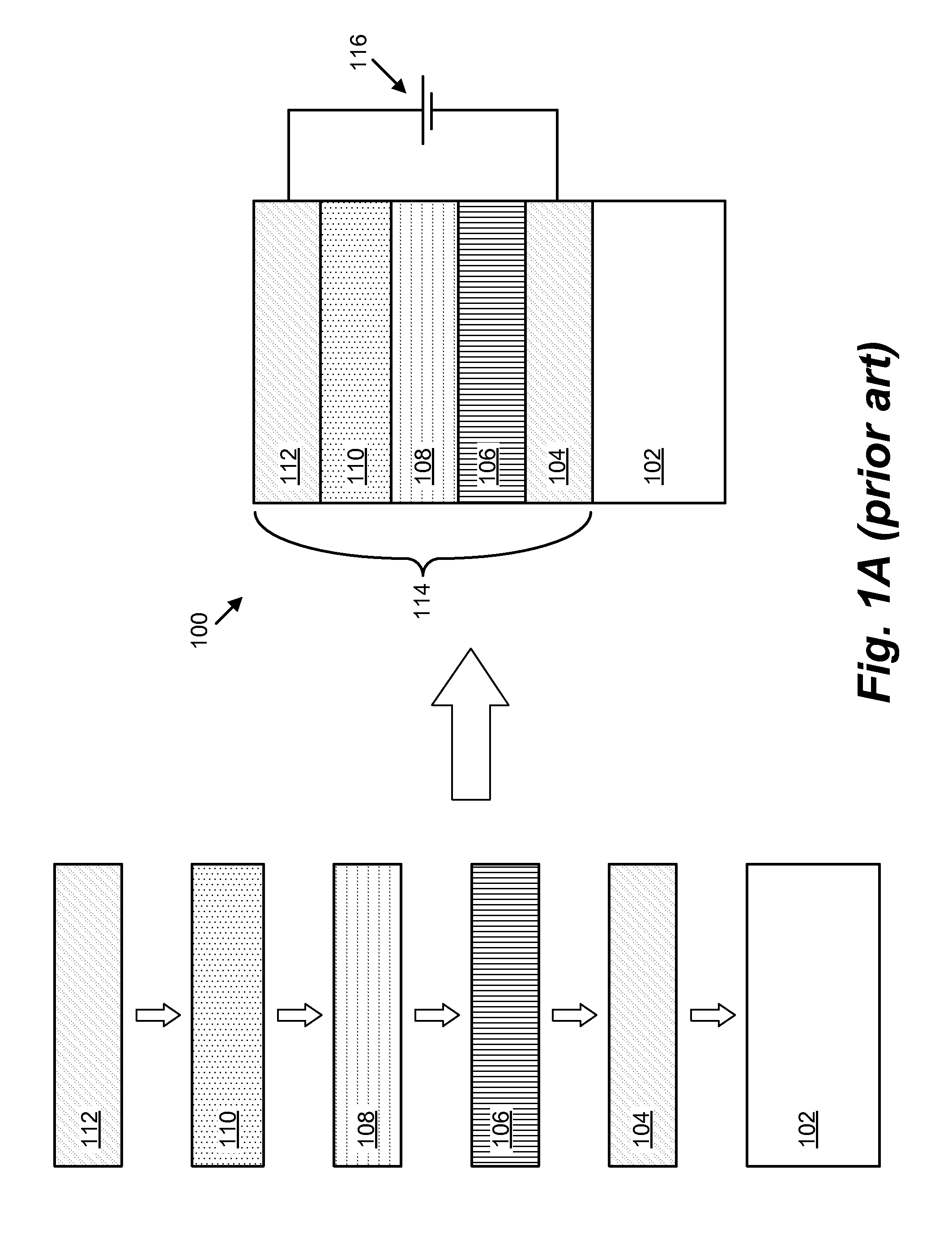

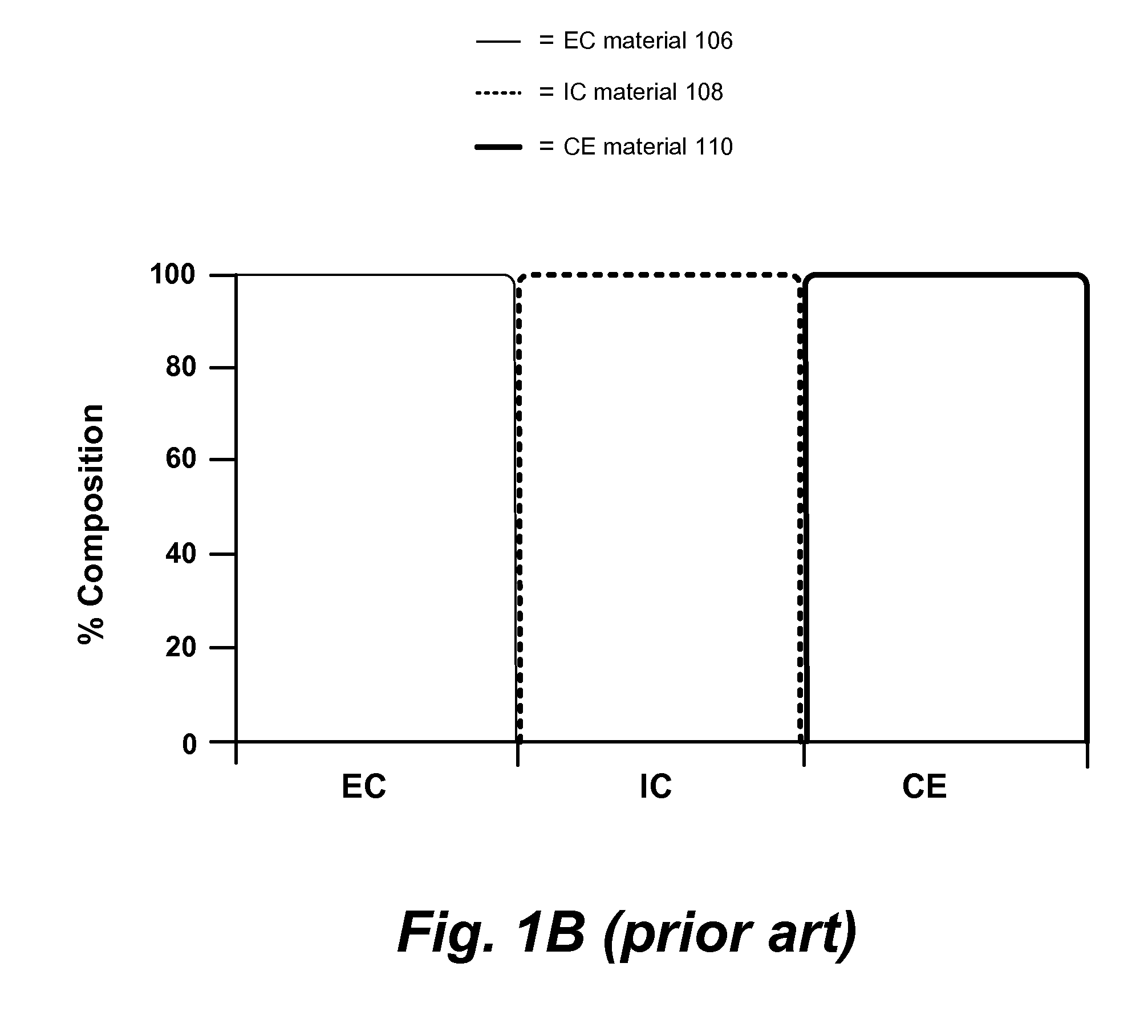

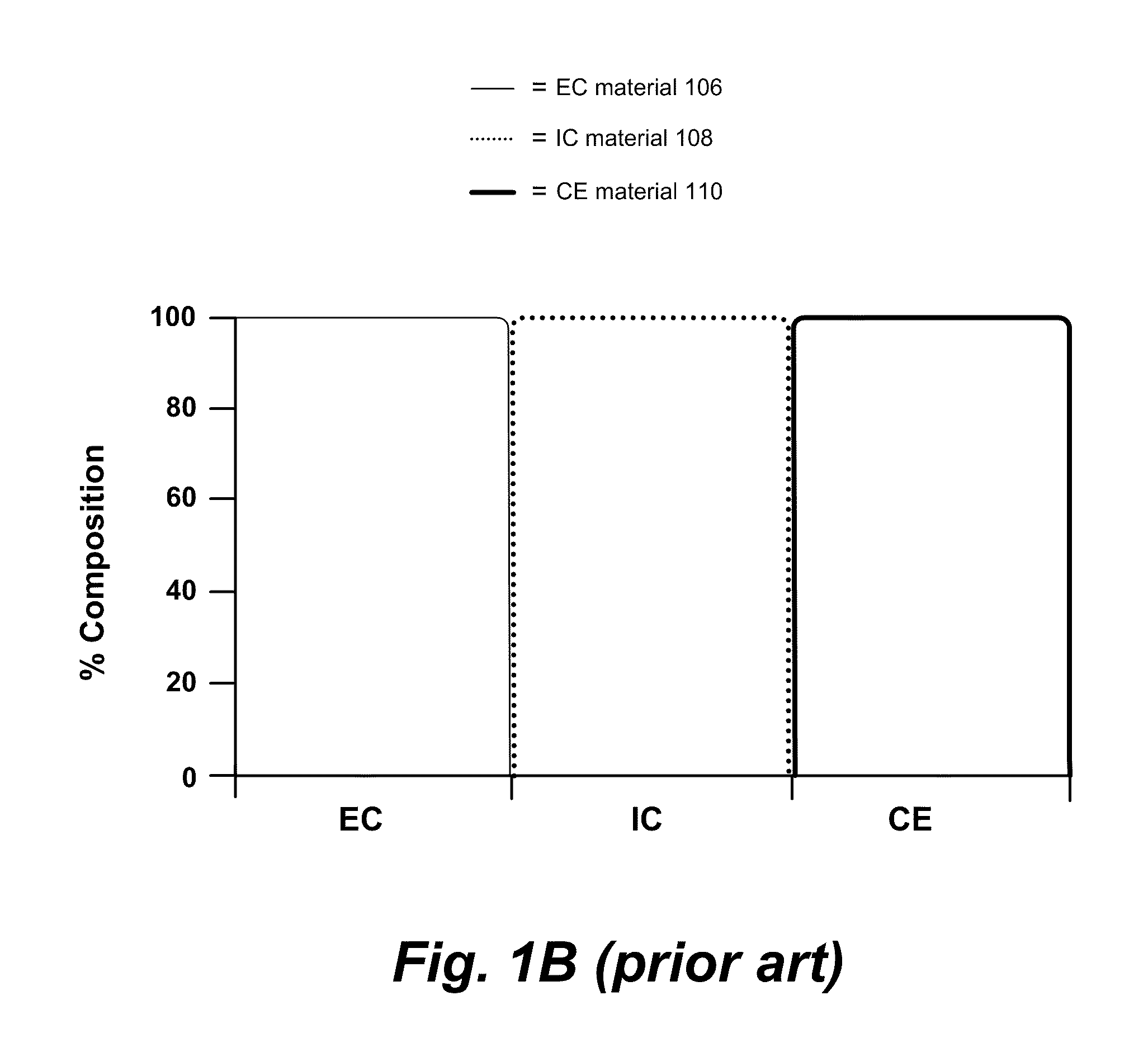

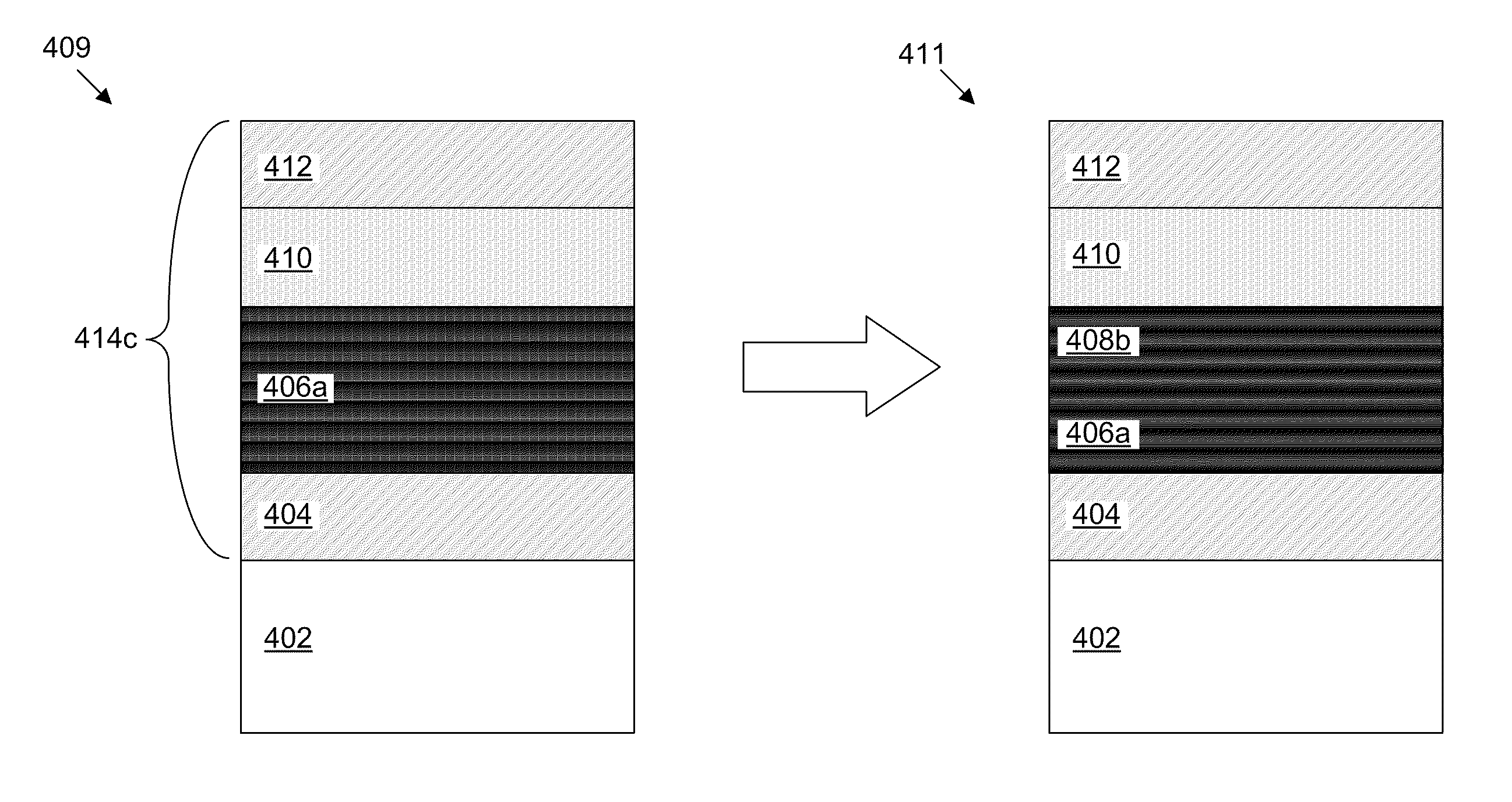

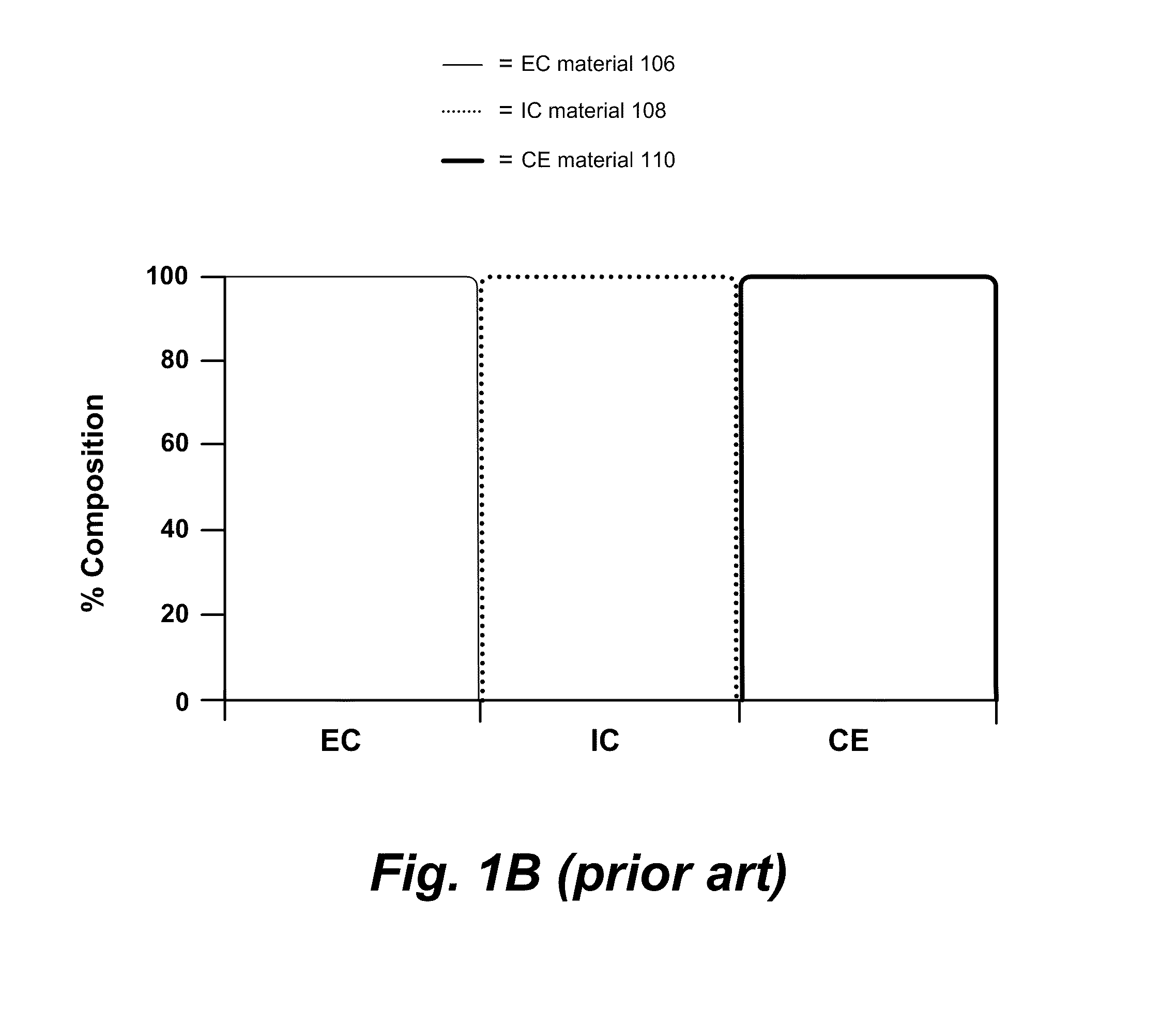

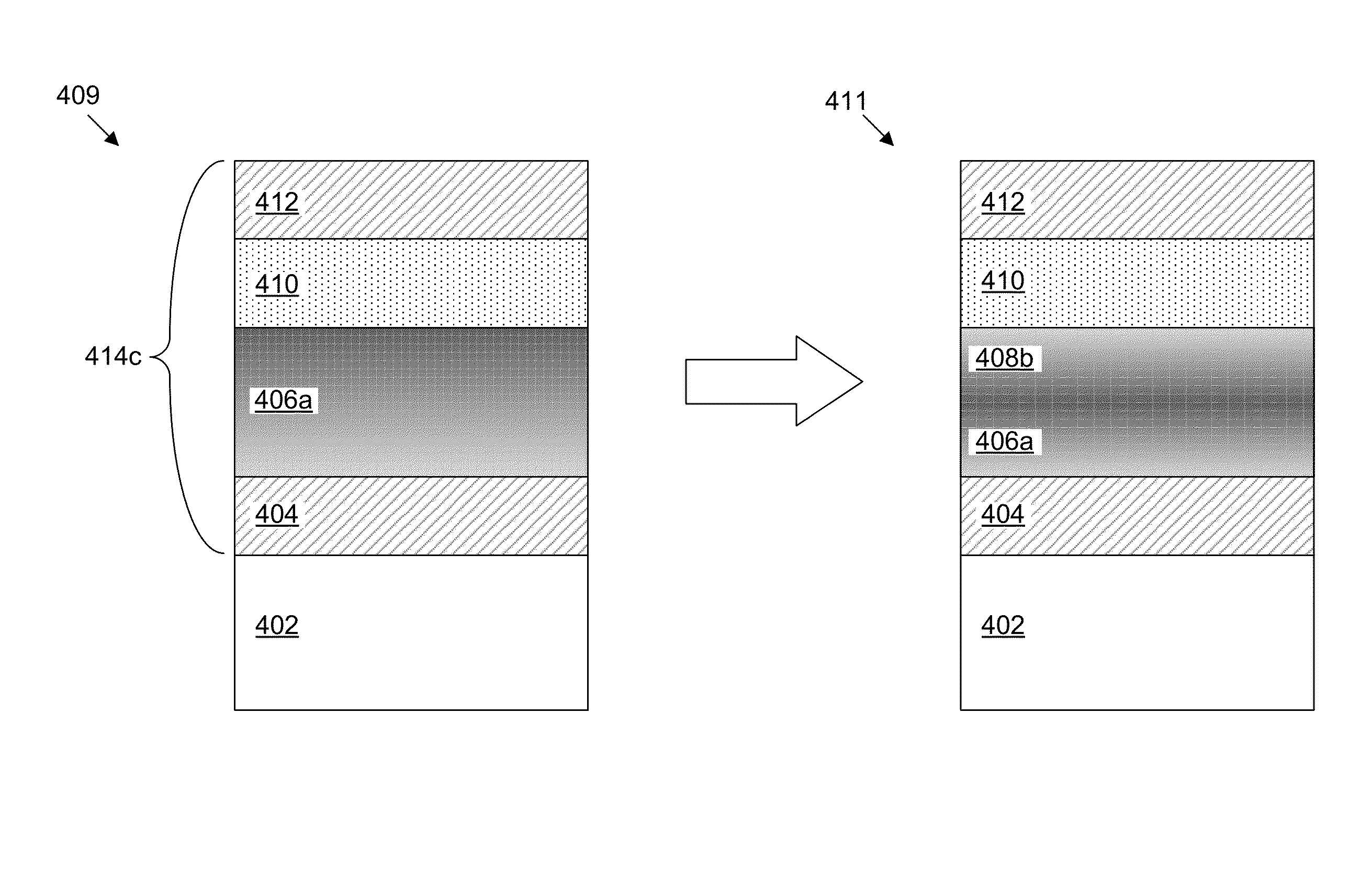

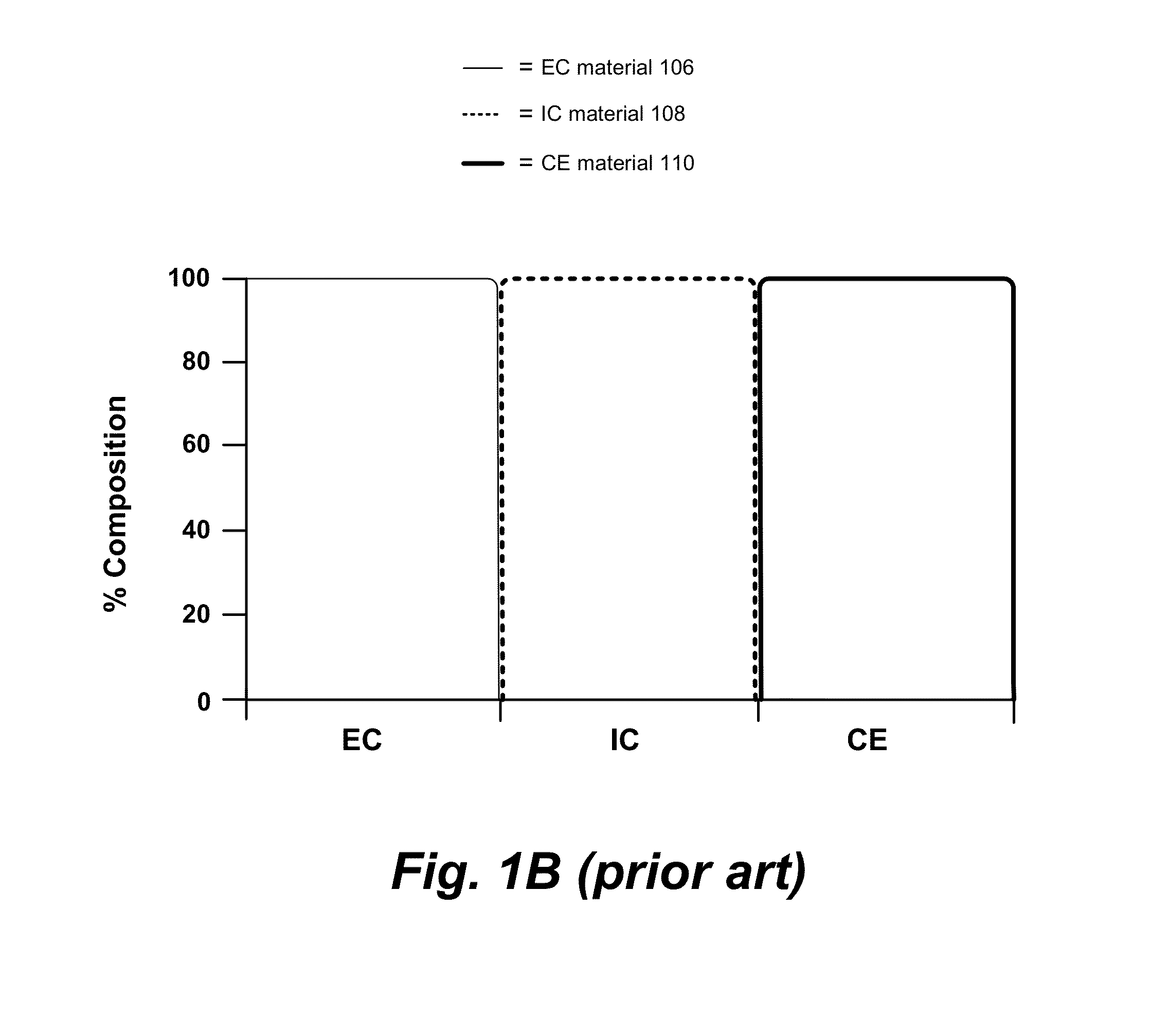

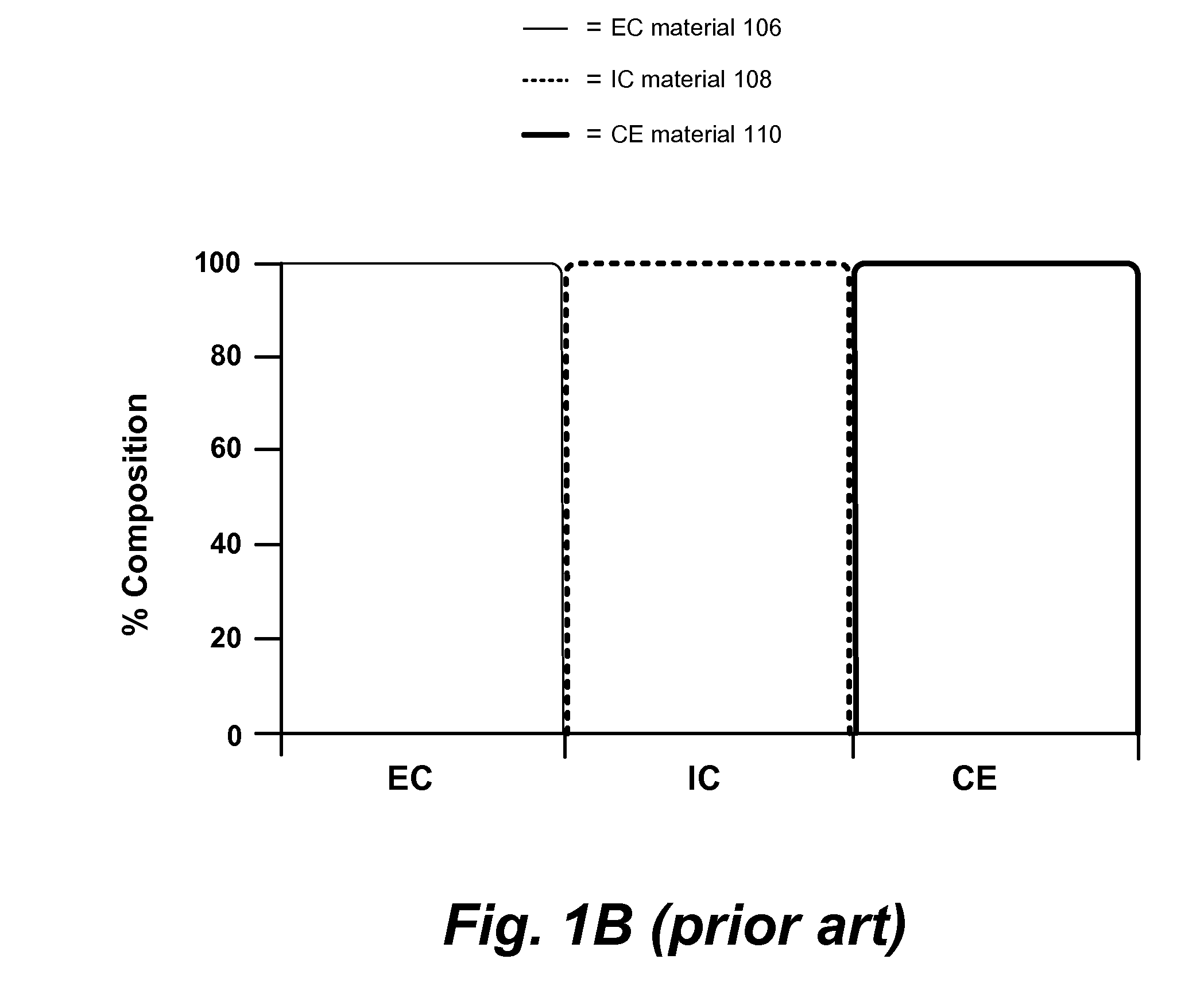

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically-insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically-insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

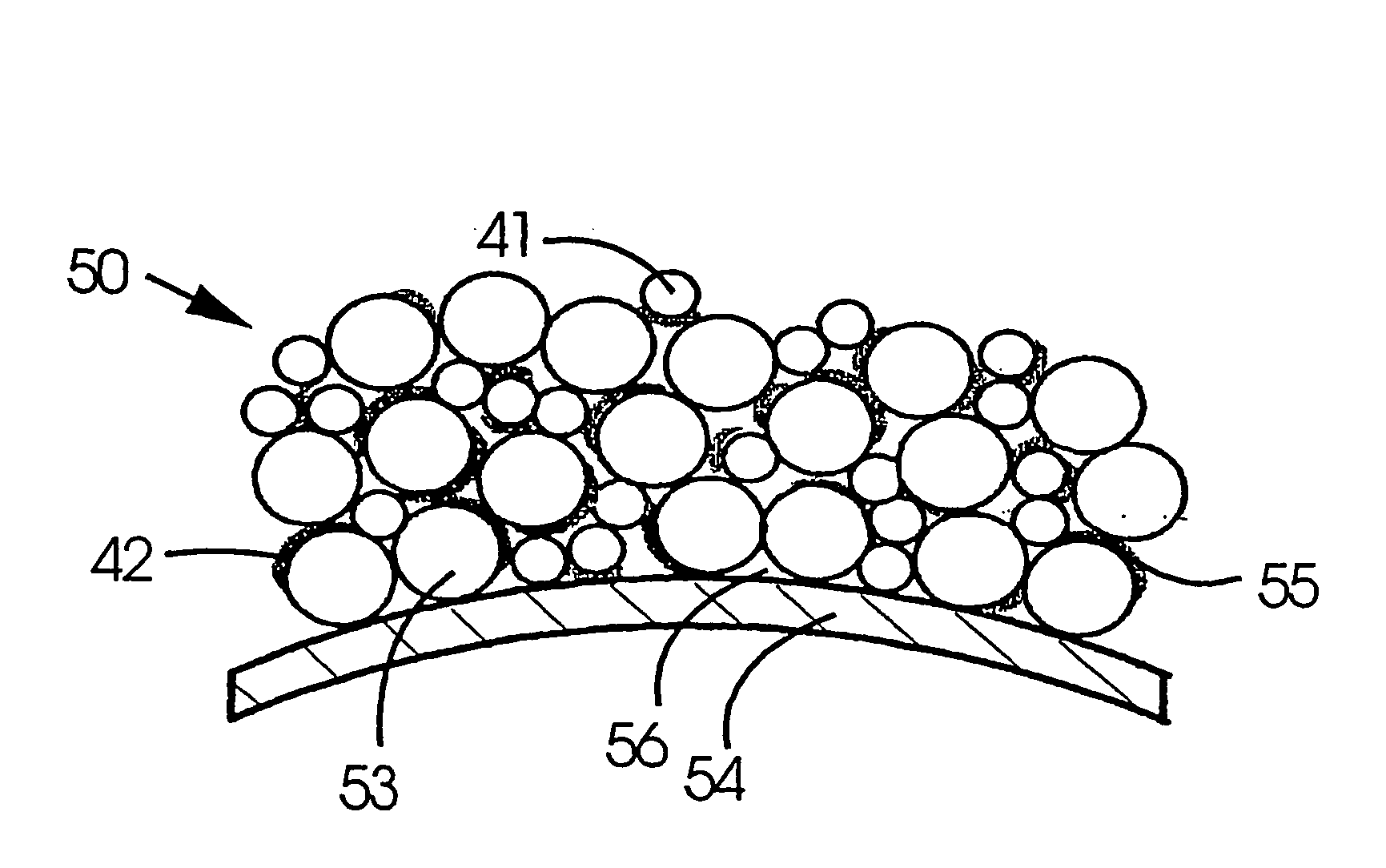

Mesoporous network electrode for electrochemical cell

InactiveUS20040131934A1Simplifies production of cellFull penetrationMaterial nanotechnologyElectrode manufacturing processesLithiumNanoparticle

A high kinetics rate electrochemical cell in which at least one of the electrodes is composed of a mesostructural electroactive material comprising nanoparticles forming a three-dimensional framework structure of mesoporous texture having a bicontinuous junction of large specific surface area with the electrolyte. A low temperature method of preparation of the electrodes employs a high-speed deposition of the electrically active material in the form of a thin film. The application of said electrodes in high power lithium ion insertion batteries, photovoltaic cells, supercapacitors and fast electrochromic devices is disclosed.

Owner:FRANCOIS SUGNAUX

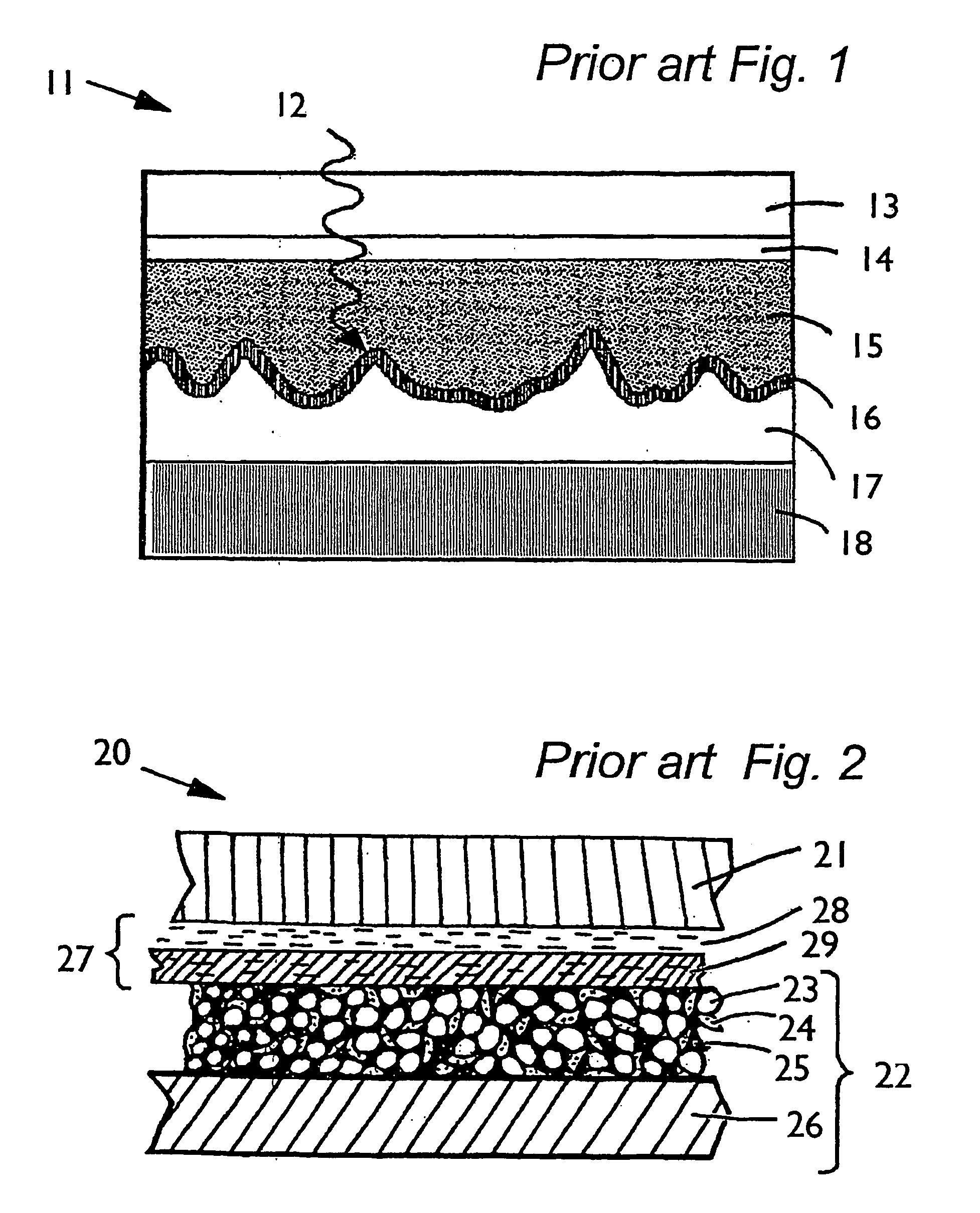

Transformable pressure sensitive adhesive tape and use thereof in display screens

InactiveUS20060100299A1Easy and safe applicationLow level of VOC 'sNanostructure manufactureGas-filled discharge tubesDisplay deviceLight-emitting diode

A transformable pressure sensitive adhesive composition comprised of from about 15 to about 80% by weight of a polymer having a softening point greater than 60° C.; from about 20 to about 85% by weight of a polymerizable resin having a softening point less than 30° C.; a latent initiator in an amount sufficient to cause a reaction between said polymer and said resin; and optionally, a crosslinking agent. The transformable pressure sensitive adhesive has particular applicability in connection with organic light emitting diode display devices, light emitting diode display devices, medical diagnostic testing devices, flexible or rigid LCD display devices, plasma display devices, and electrochromic devices.

Owner:ADHESIVES RES

Electrochromic media for producing a preselected color

InactiveUS6141137AHigh proportionSignificant contributionOrganic chemistryTenebresent compositionsElectricityRedox

Electrochromic compositions suitable for use in electrochromic media in electrochromic devices contain minimally two electrochromic compounds of the same redox type, whose redox potentials are greater than 30 mV. The lower redox potential electrochromic compound makes a large contribution to the absorbancy of the electrochromic medium despite being present in only minor concentration.

Owner:GENTEX CORP

Electrochromic devices

ActiveUS8300298B2Improve conductivityIncrease resistanceDoors/windowsVacuum evaporation coatingElectricityOptoelectronics

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

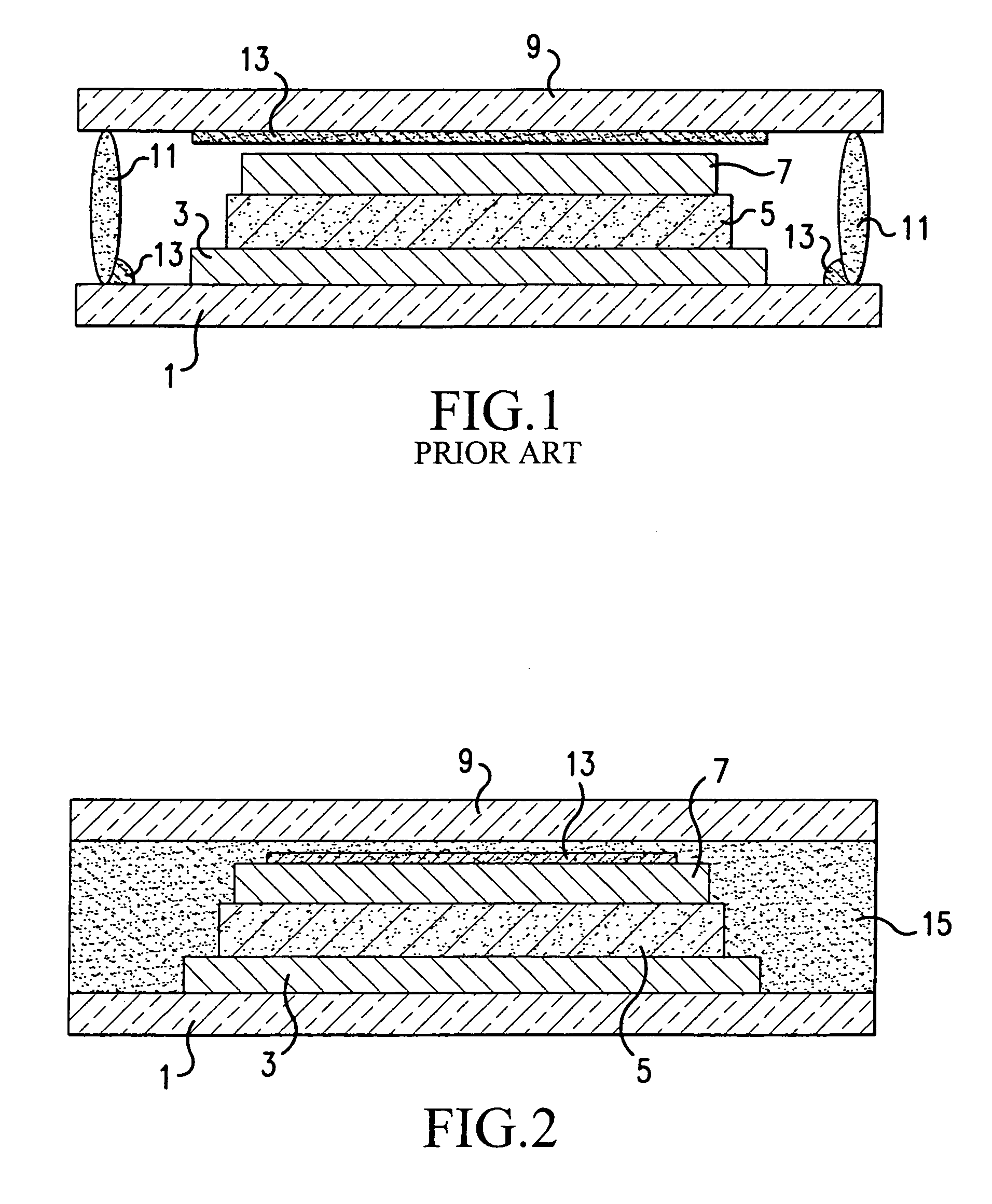

Electrochromic devices having no positional offset between substrates

To allow an electrochromic device to have little or no offset between its front and rear elements, an electrical conductor may be provided to electrically couple a portion of a first conductive layer provided on the rear surface of the front element with a portion of a second conductive layer provided on the front surface of the rear element. The electrical conductor may be in the form of a conductive portion of the seal. To prevent shorting across the electrochromic medium, at least one of the first and second conductive layers is separated into a first portion and a second portion that is electrically isolated from the first portion and is in electrical contact with the electrochromic material. An elastomeric bezel may be utilized. Also, an edge seal may optionally be employed so as to reduce the need or width of the bezel.

Owner:GENTEX CORP

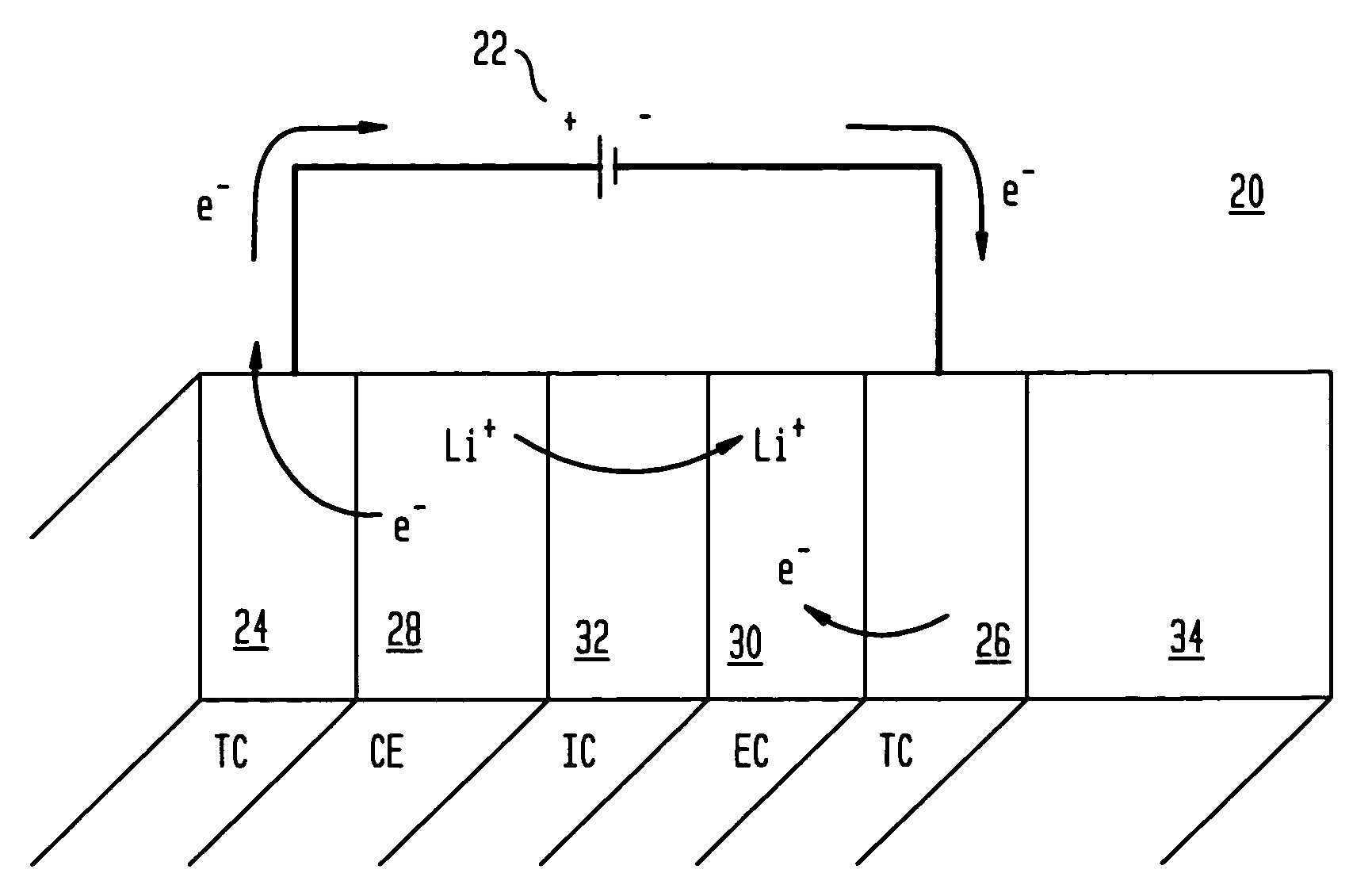

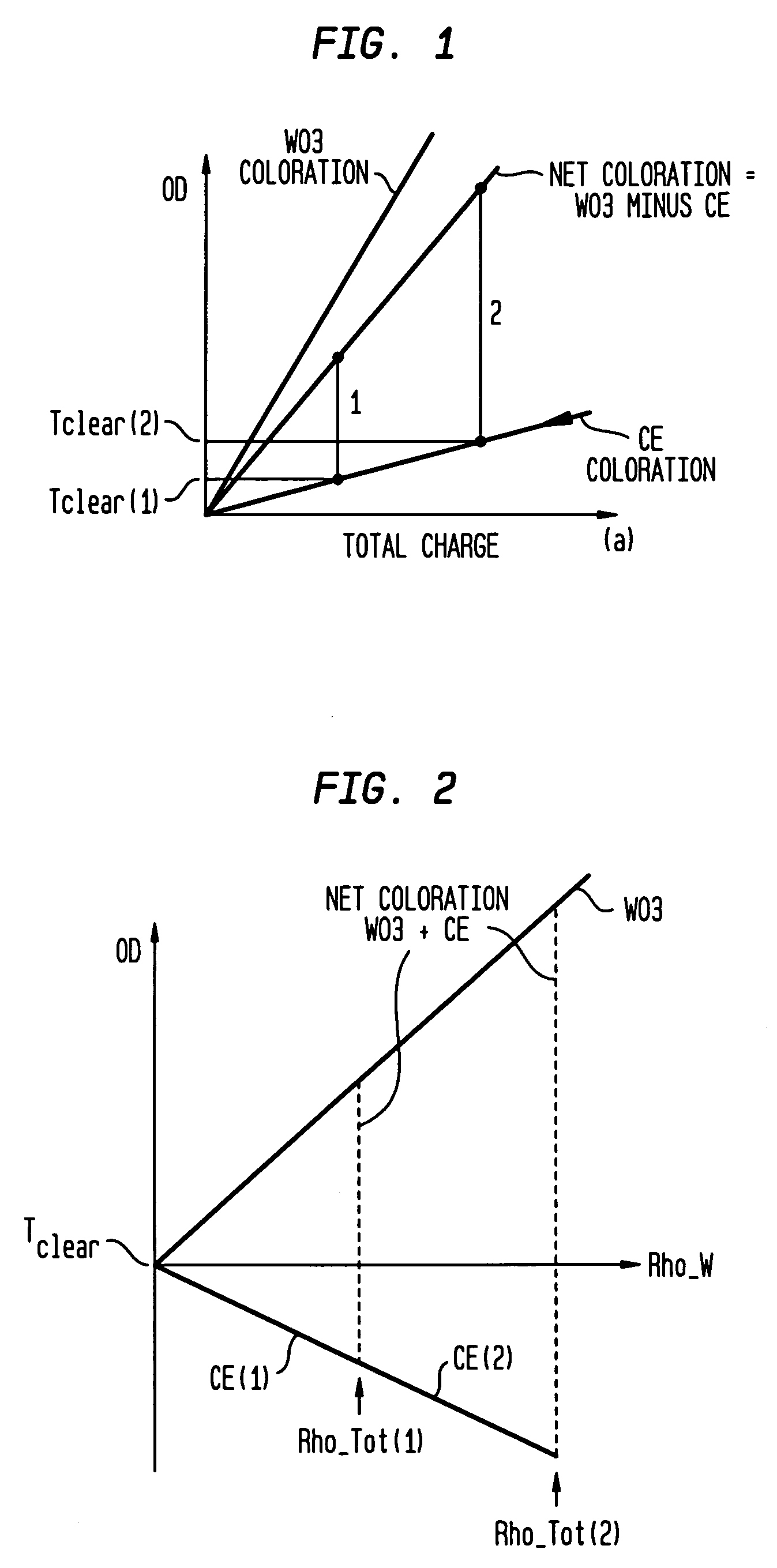

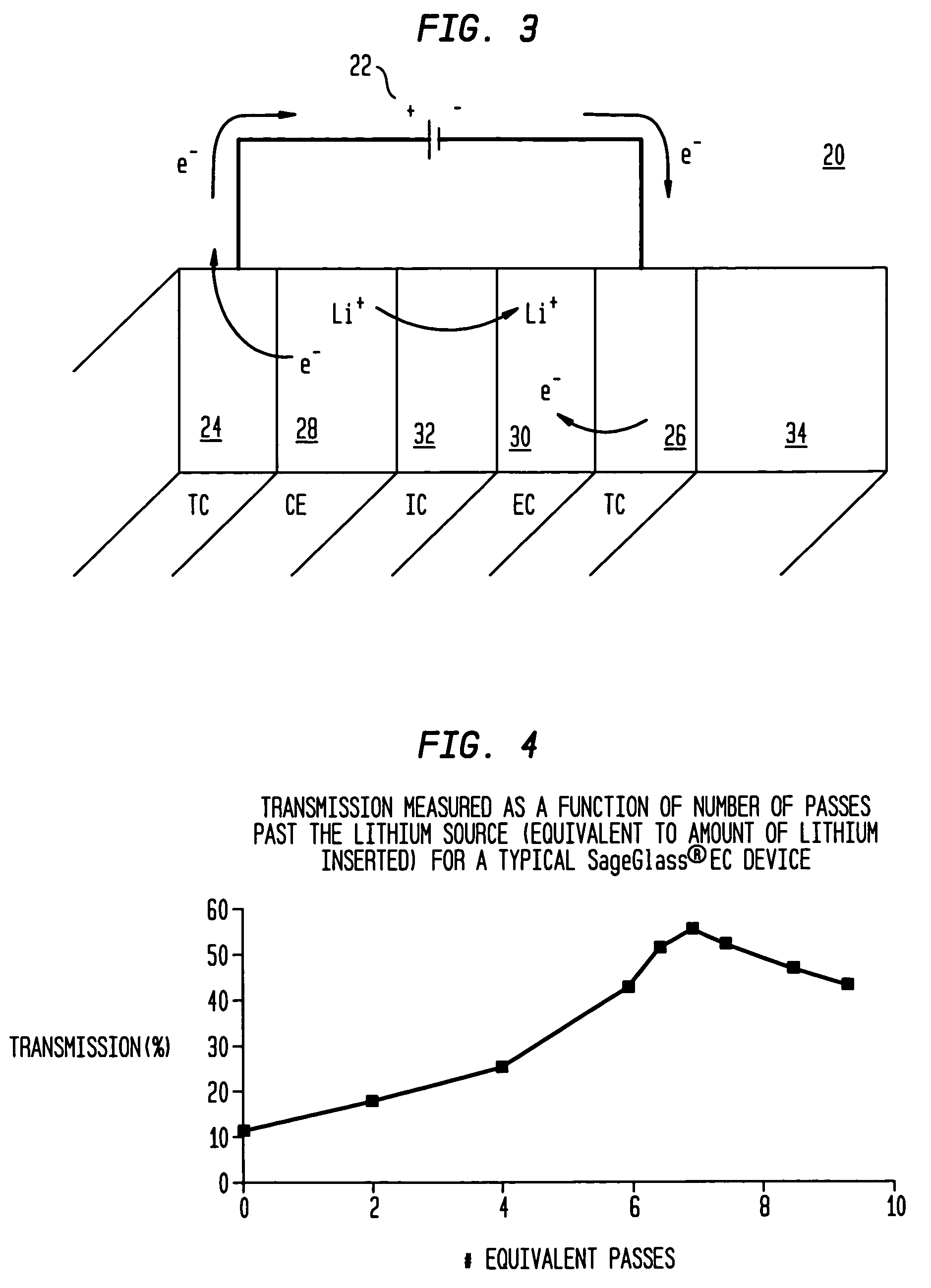

Electrochromic devices and methods

A heat treated electrochromic device comprising an anodic complementary counter electrode layer comprised of a mixed tungsten-nickel oxide and lithium, which provides a high transmission in the fully intercalated state and which is capable of long term stability, is disclosed. Methods of making an electrochromic device comprising an anodic complementary counter electrode comprised of a mixed tungsten-nickel oxide are also disclosed.

Owner:SAGE ELECTROCHROMICS

Electrochromic devices having no positional offset between substrates

To allow an electrochromic device to have little or no offset between its front and rear elements, an electrical conductor may be provided to electrically couple a portion of a first conductive layer provided on the rear surface of the front element with a portion of a second conductive layer provided on the front surface of the rear element. The electrical conductor may be in the form of a conductive portion of the seal. To prevent shorting across the electrochromic medium, at least one of the first and second conductive layers is separated into a first portion and a second portion that is electrically isolated from the first portion and is in electrical contact with the electrochromic material. An elastomeric bezel may be utilized. Also, an edge seal may optionally be employed so as to reduce the need or width of the bezel.

Owner:GENTEX CORP

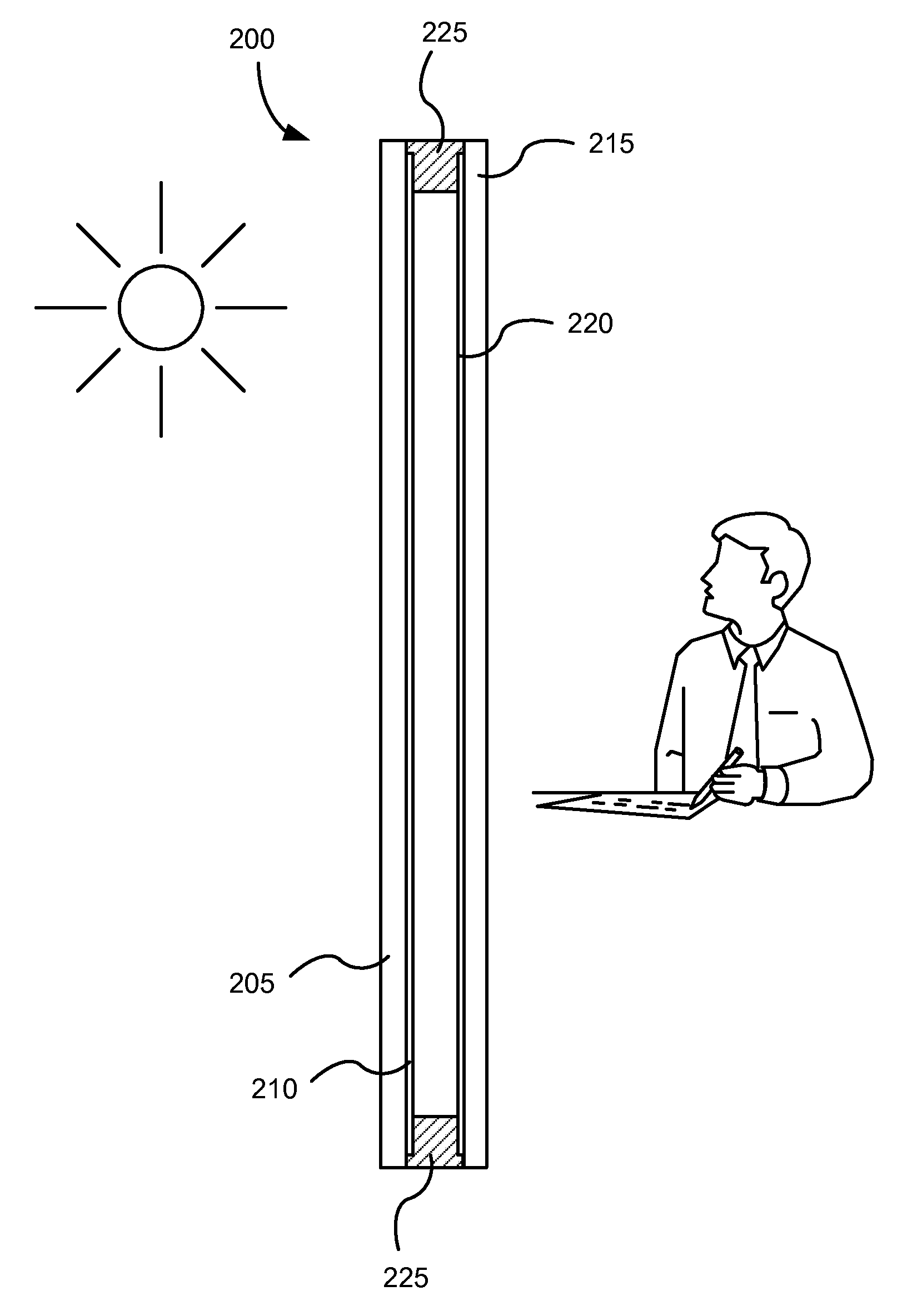

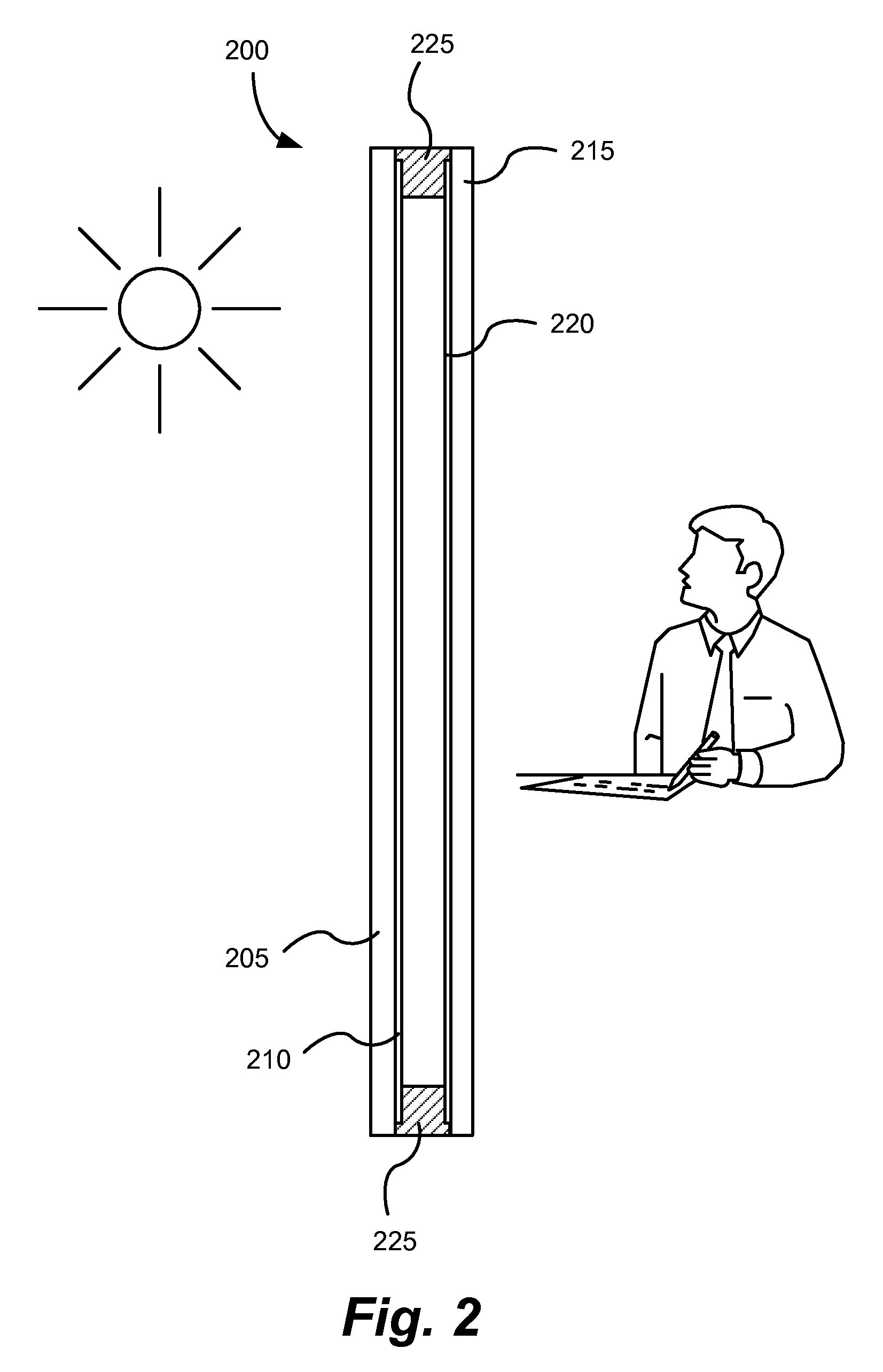

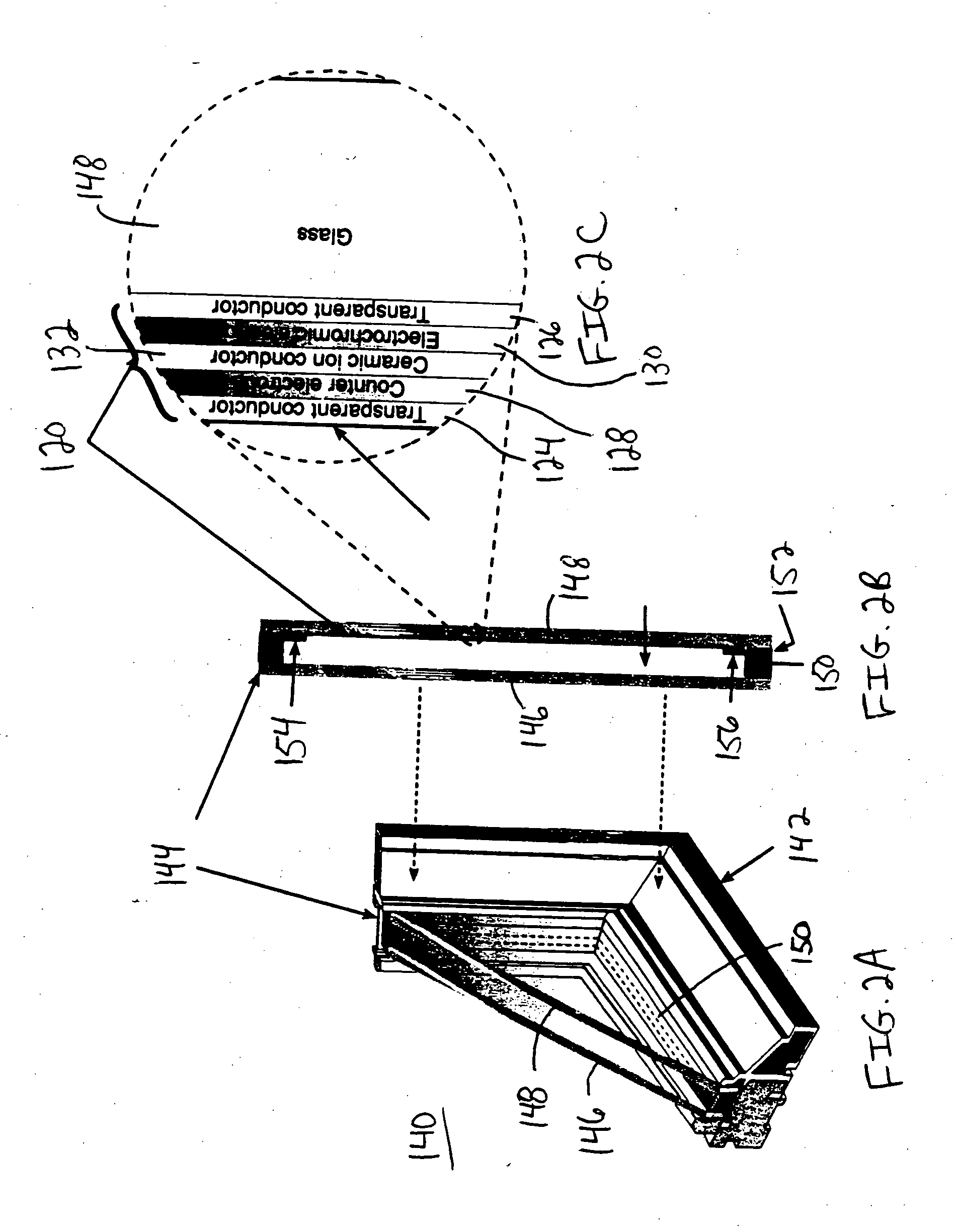

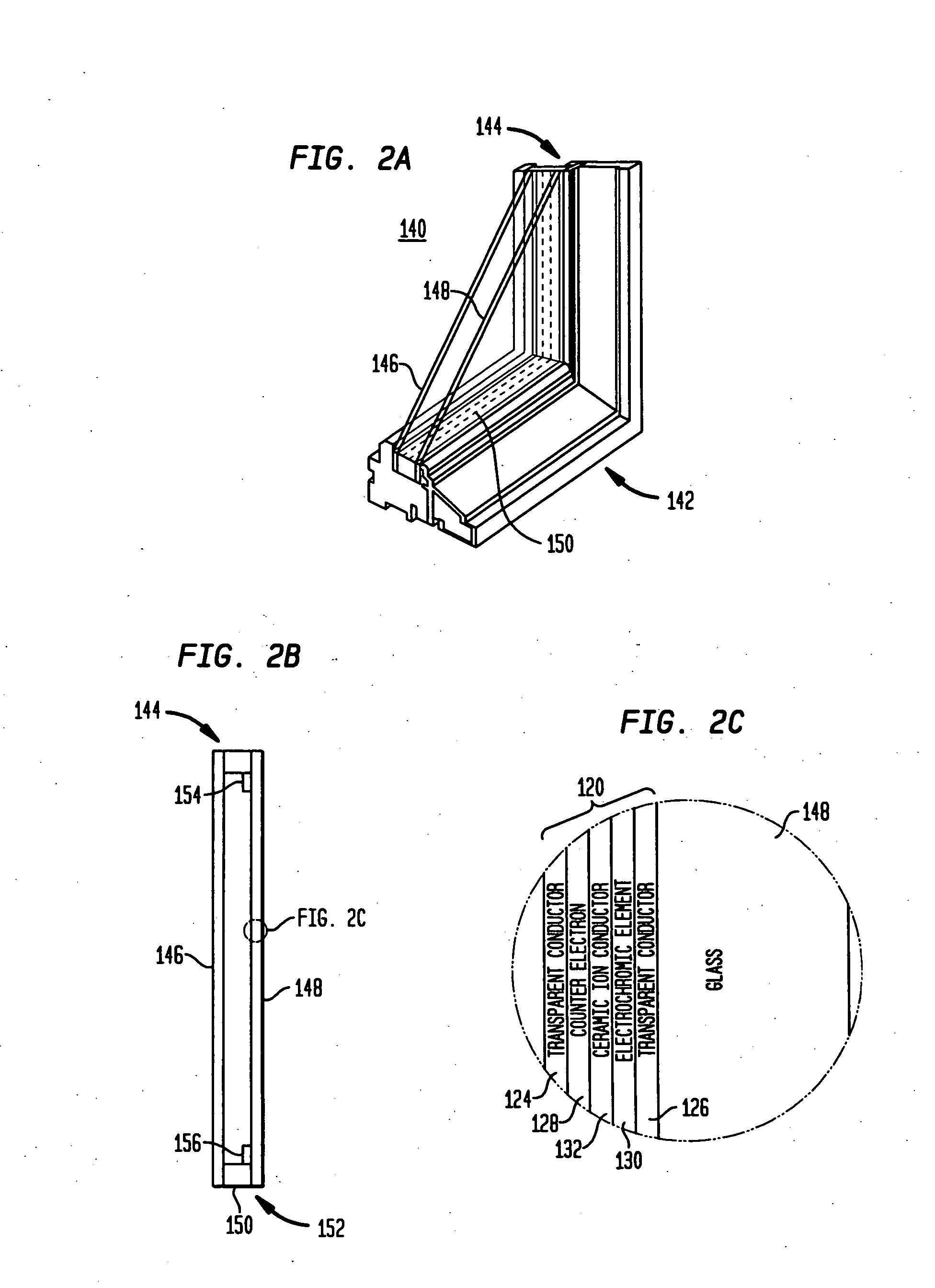

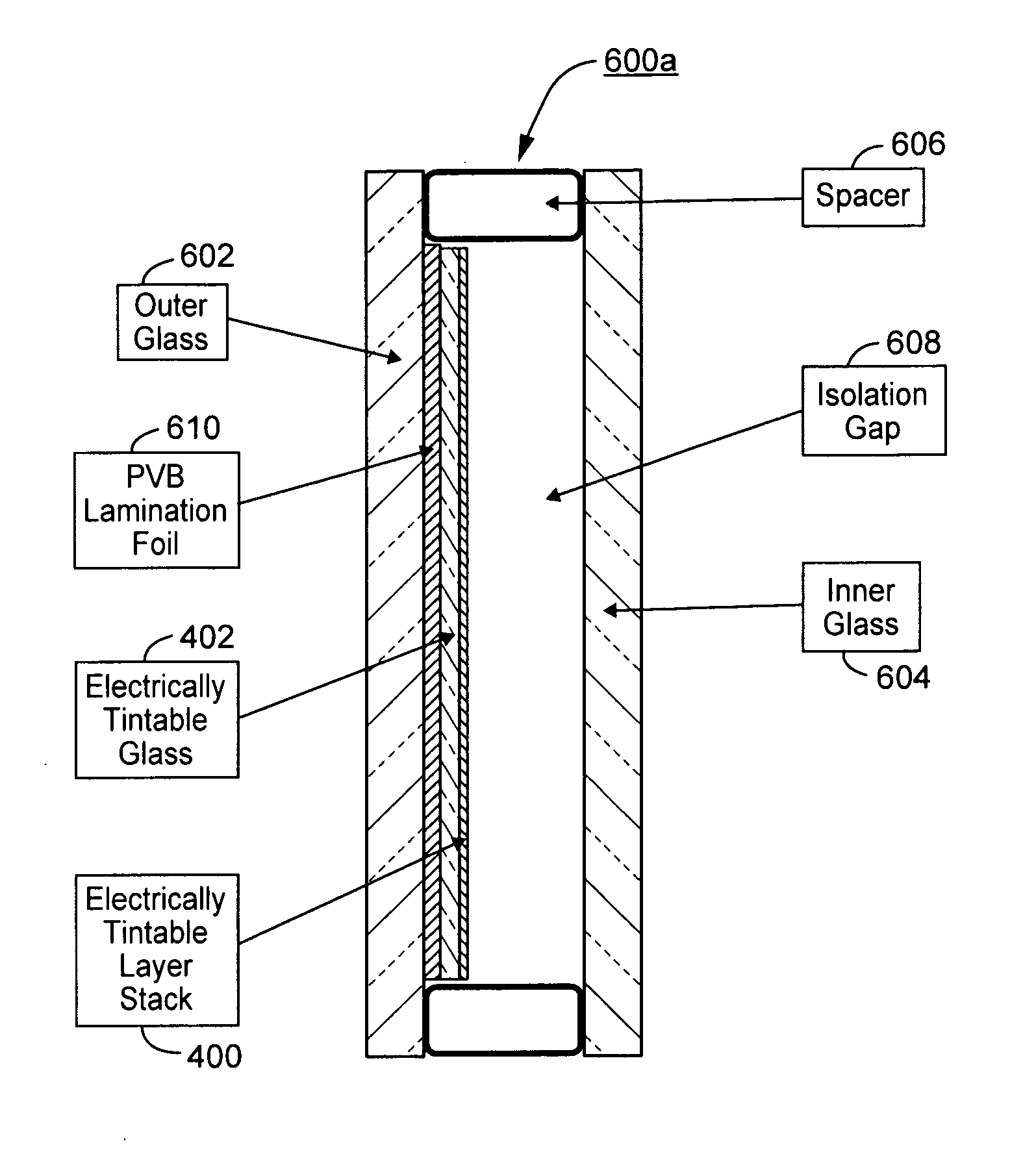

Multi-pane electrochromic windows

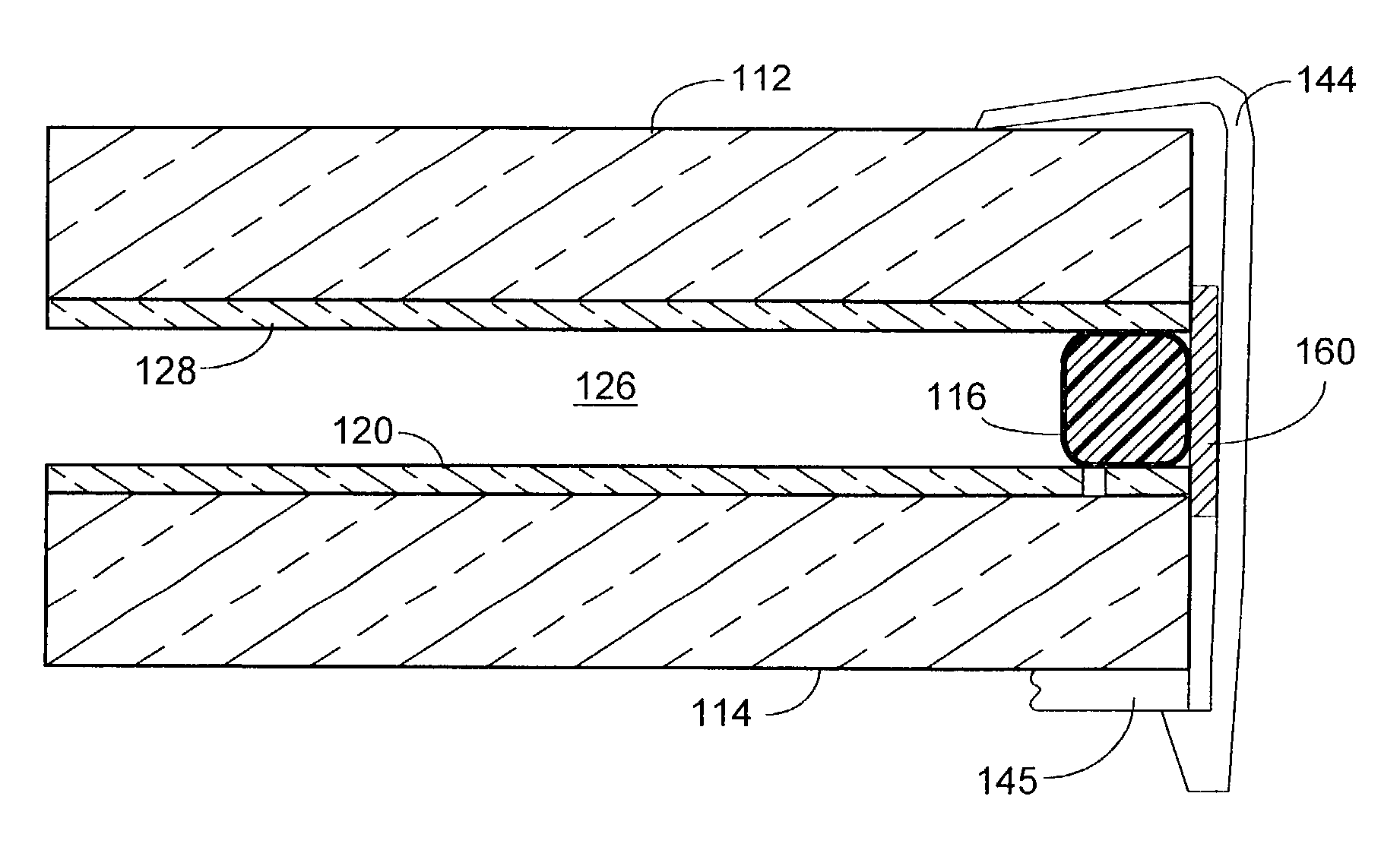

ActiveUS8270059B2Increased defectivityGood choiceTransparent/reflecting heating arrangementsLight protection screensElectricityElectrochromism

Window units, for example insulating glass units (IGU's), that have at least two panes, each pane having an electrochromic device thereon, are described. Two optical state devices on each pane of a dual-pane window unit provide window units having four optical states. Window units described allow the end user a greater choice of how much light is transmitted through the electrochromic window. Also, by using two or more window panes, each with its own electrochromic device, registered in a window unit, visual defects in any of the individual devices are negated by virtue of the extremely small likelihood that any of the visual defects will align perfectly and thus be observable to the user.

Owner:VIEW INC

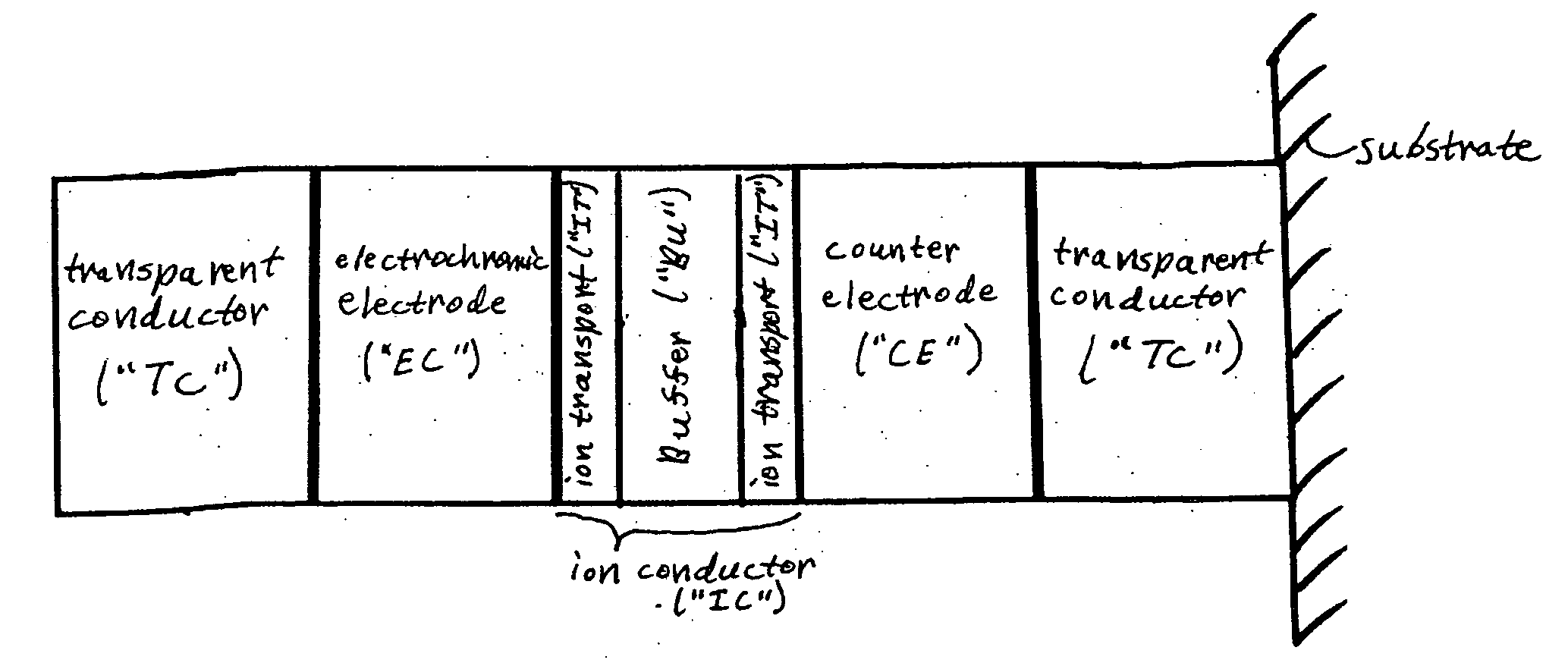

Electrochromic devices having improved ion conducting layers

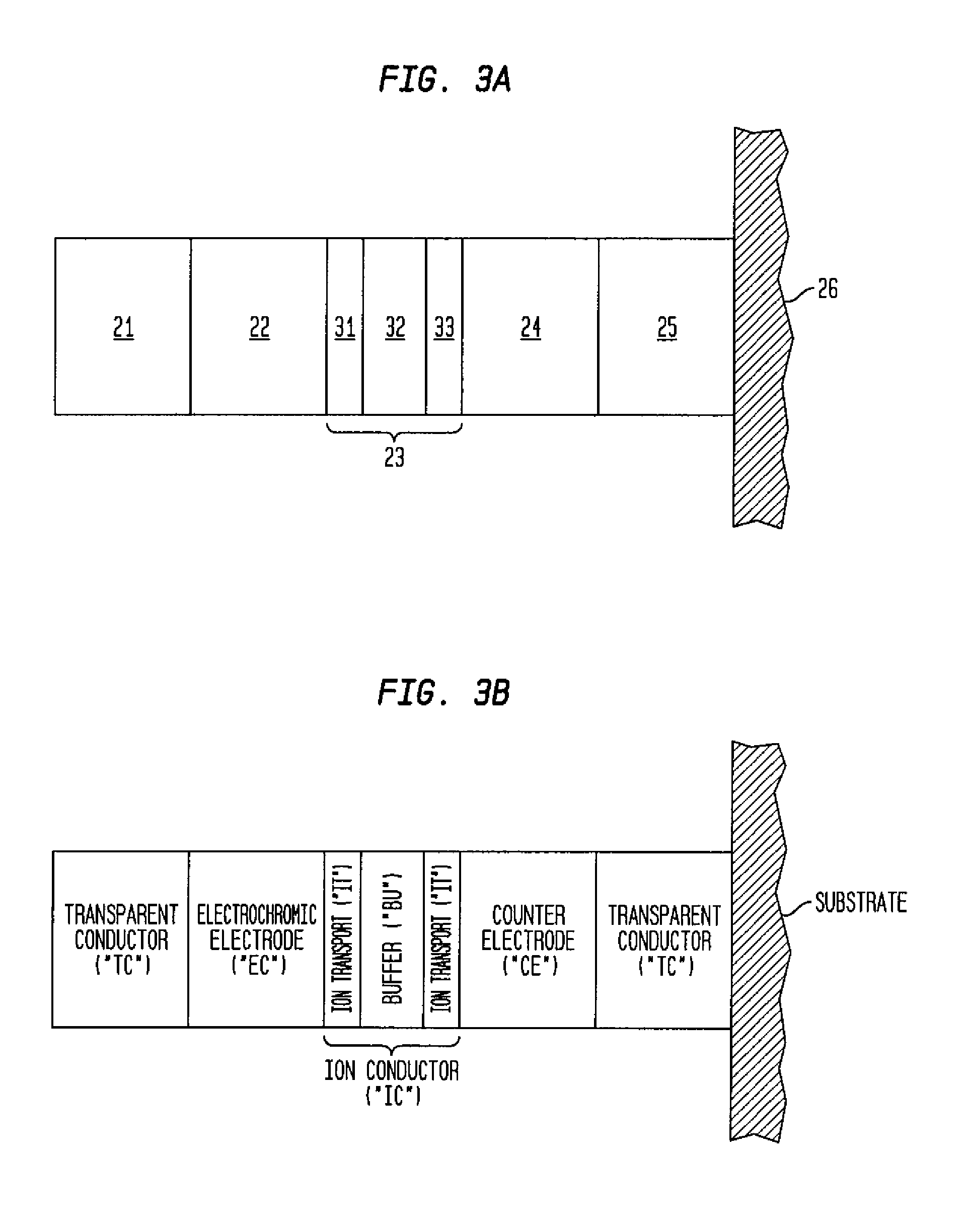

InactiveUS20070097481A1Less susceptible to electronic leakageHigh voltageNon-linear opticsElectricityElectrical conductor

An improved ion conductor layer for use in electrochromic devices and other applications is disclosed. The improved ion-conductor layer is comprised of at least two ion transport layers and a buffer layer, wherein the at least two ion transport layers and the buffer layer alternate within the ion conductor layer such that the ion transport layers are in communication with a first and a second electrode. Electrochromic devices utilizing such an improved ion conductor layer color more deeply by virtue of the increased voltage developed across the ion conductor layer prior to electronic breakdown while reducing the amount of electronic leakage. Also disclosed are methods of making electrochromic devices incorporating the improved ion conductor layer disclosed herein and methods of making ion conductors for use in other applications.

Owner:SAGE ELECTROCHROMICS

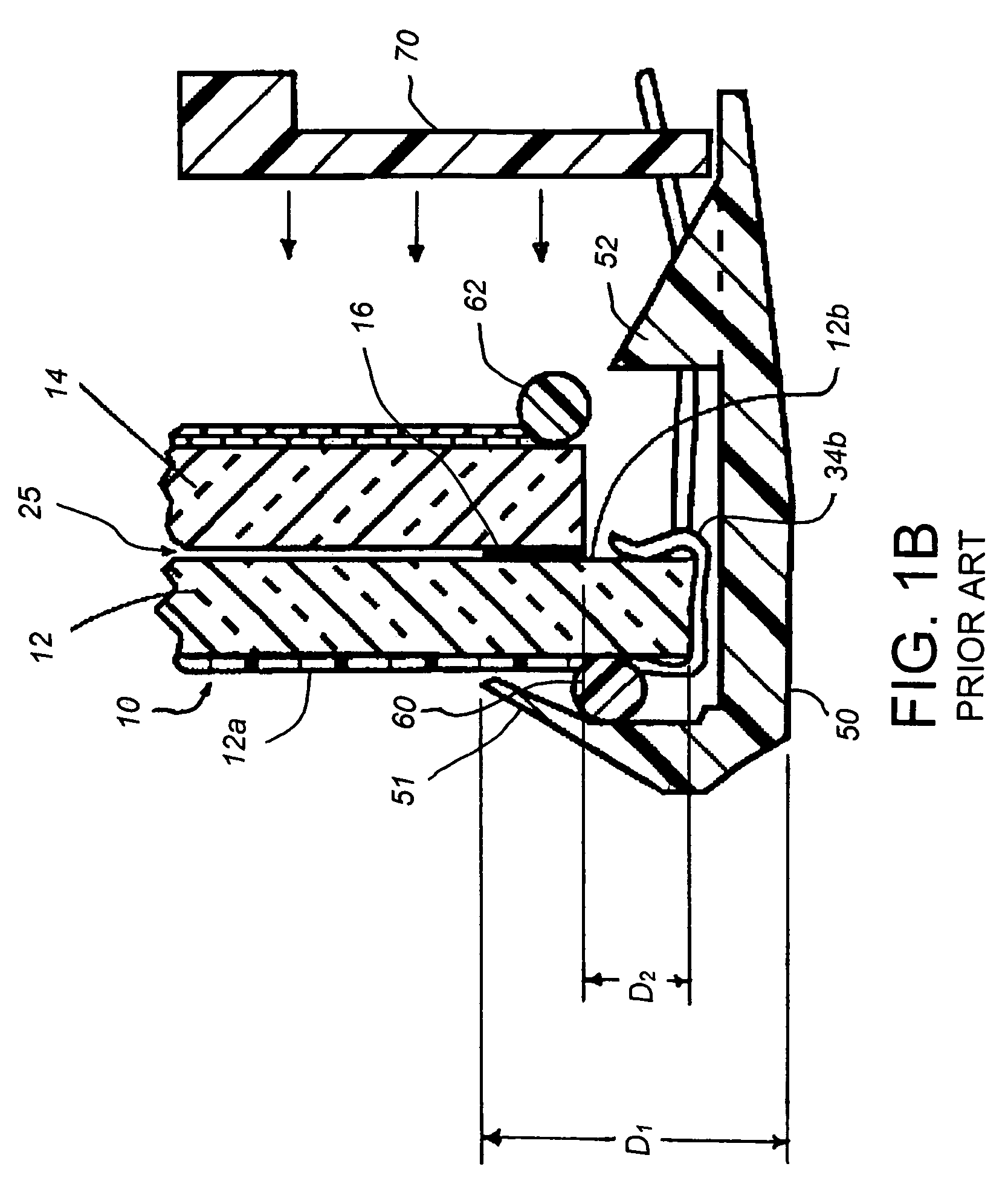

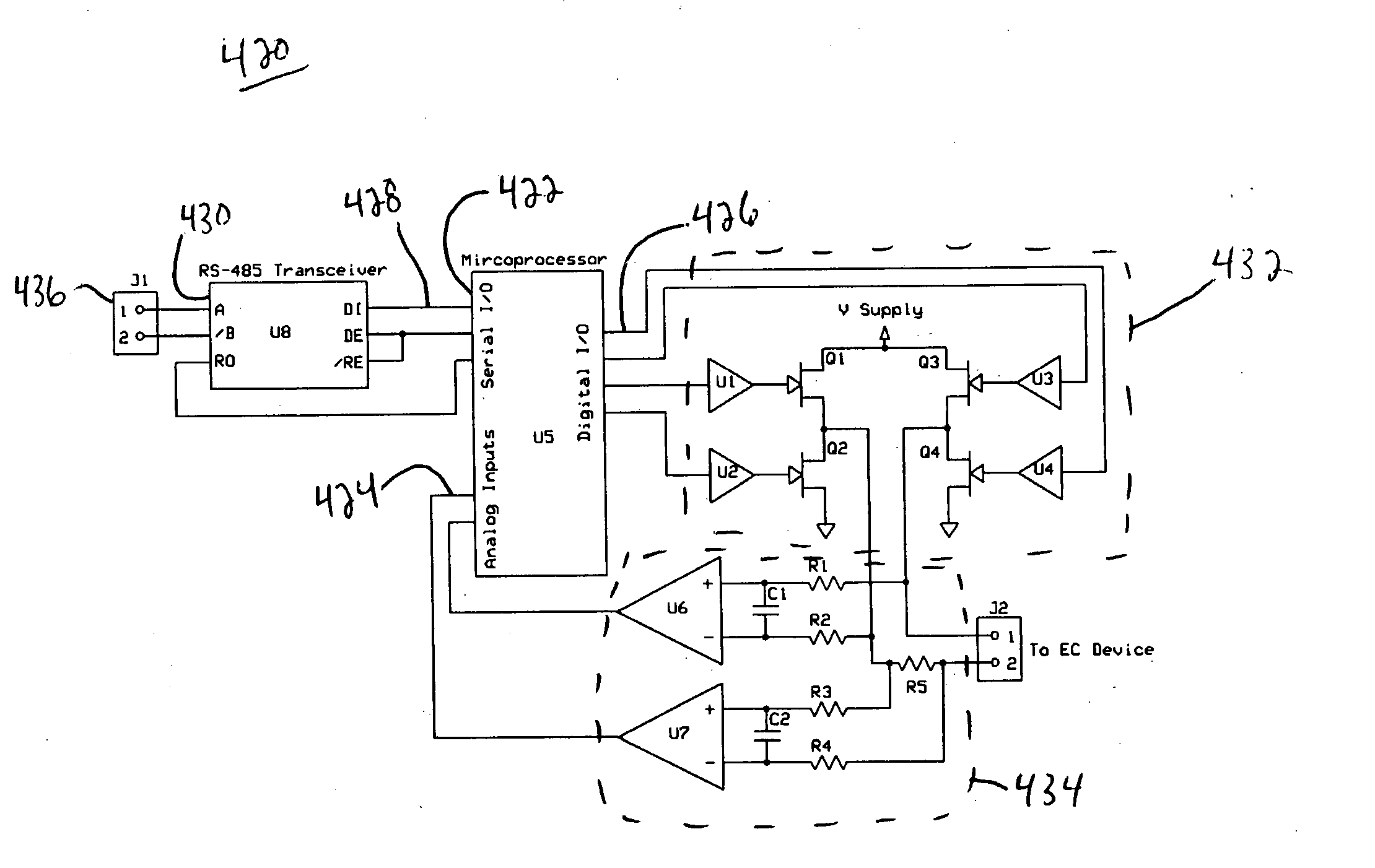

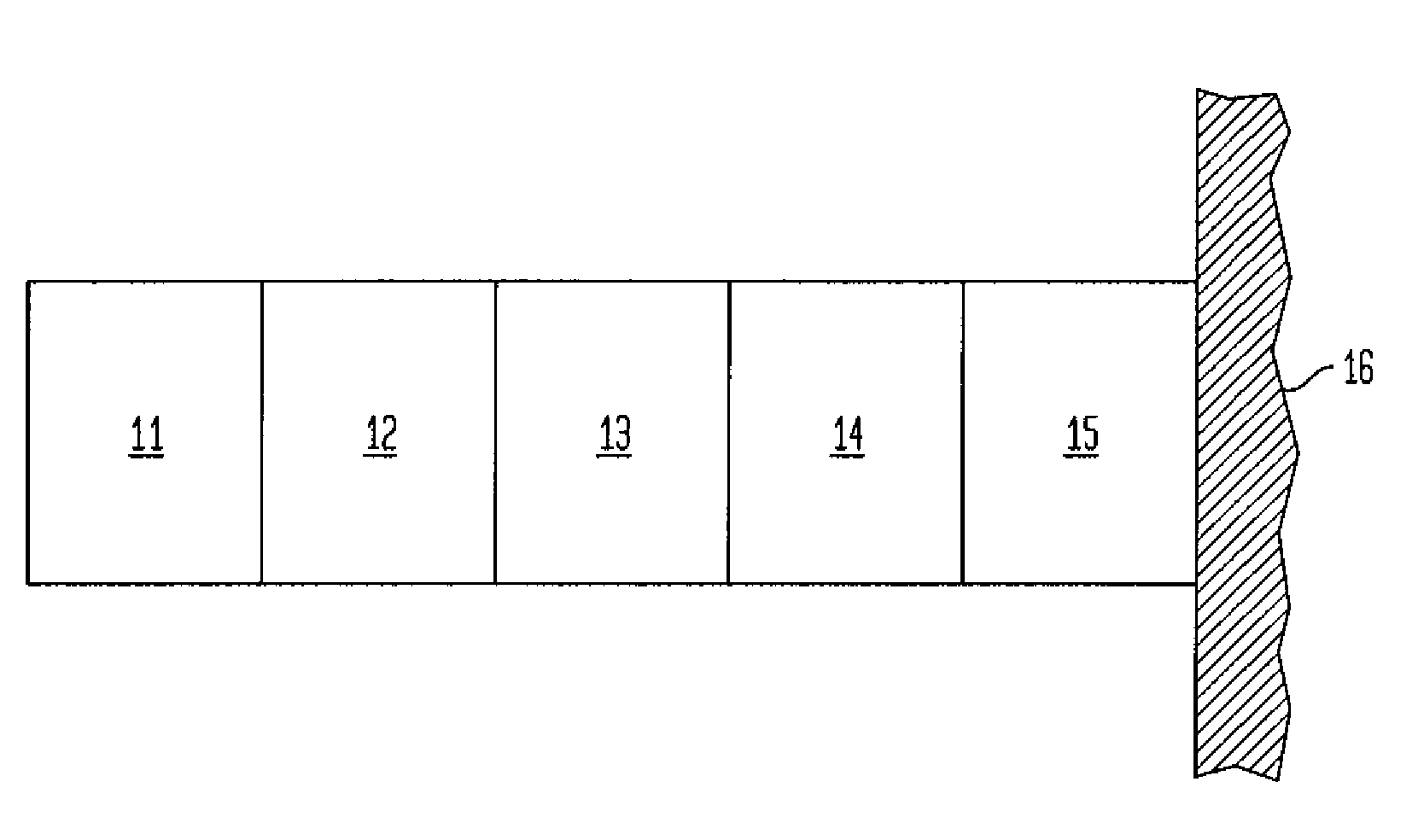

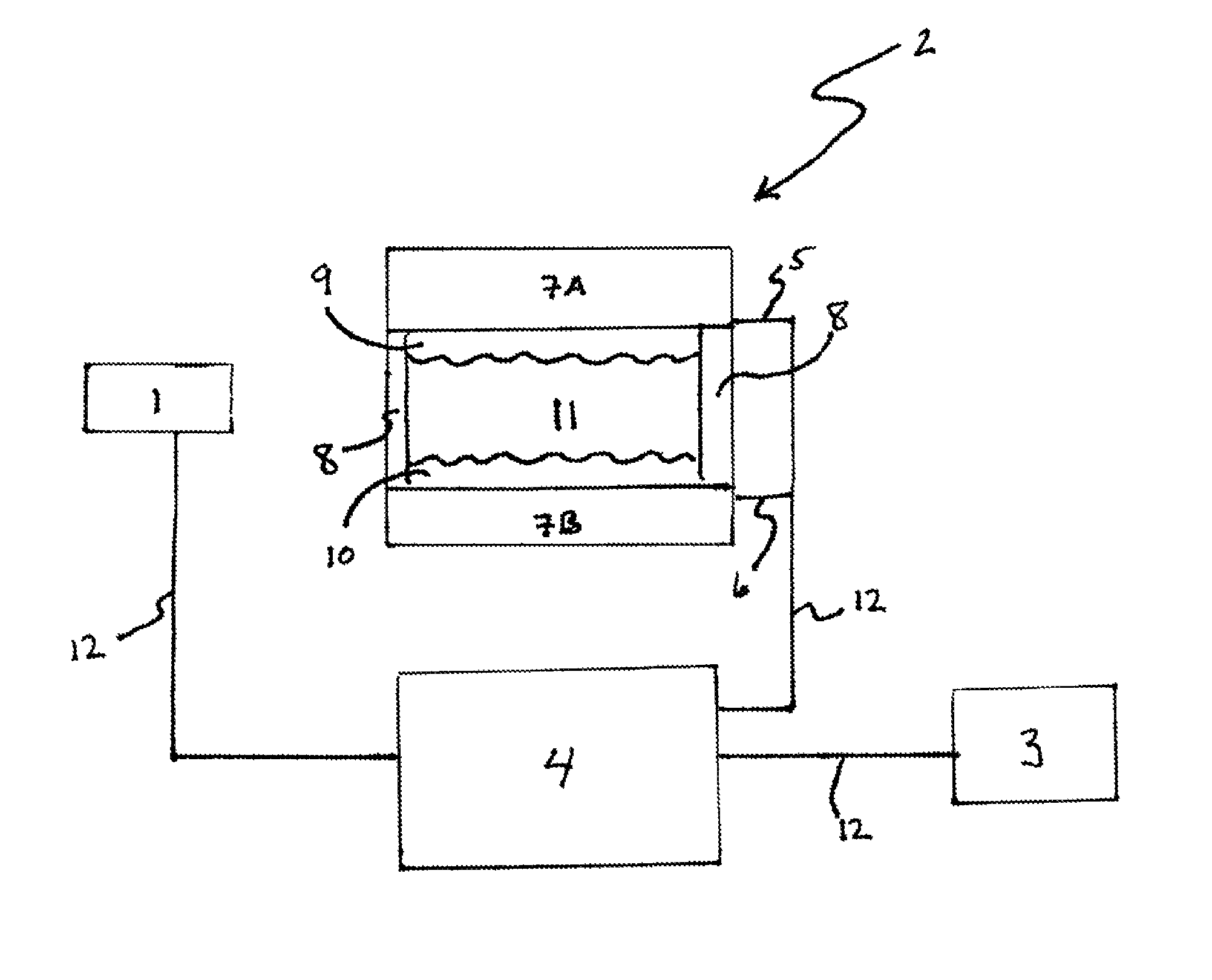

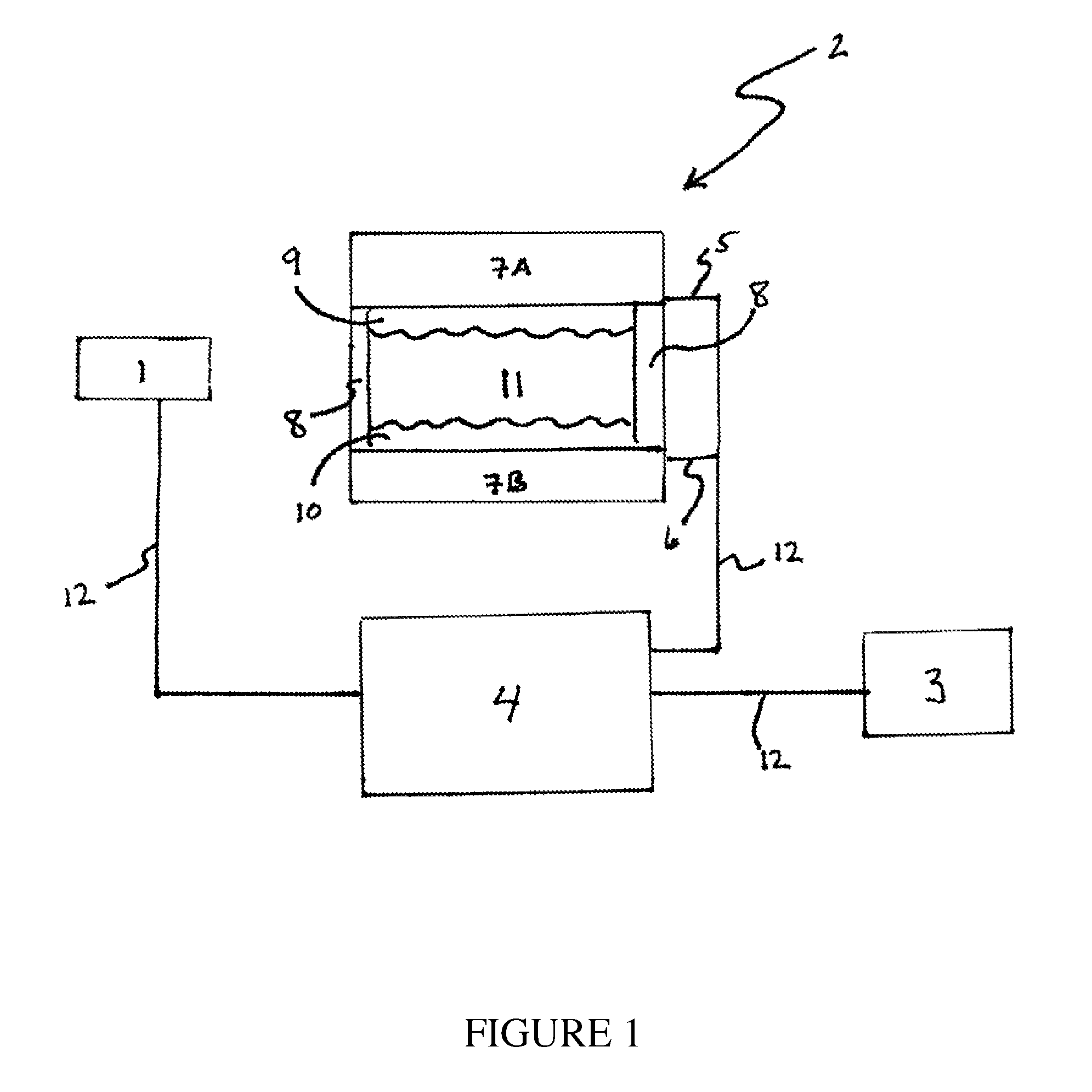

Dimming control system for an array of electrochromic devices

Electrochromic device control systems and methods are disclosed. In one embodiment, a window system includes a plurality of transparent windows, a plurality of electrochromic devices, a plurality of control modules, and a main controller. Each transparent window has an electrochromic device operatively associated therewith. A control module is operatively coupled to each electrochromic device and is adapted to controllably adjust an electric field to activate and de-activate the electrochromic device. Finally, the main controller is operatively coupled to the plurality of control modules and adapted to simultaneously adjust the electric fields of the plurality of electrochromic devices to activate and de-activate the plurality of electrochromic devices in unison. In one particular embodiment, a window dimming control system in accordance with the present invention may advantageously be incorporated into an existing cabin services system of a passenger aircraft.

Owner:THE BOEING CO

Electrochromic devices

ActiveUS8764950B2Improve conductivityIncrease resistanceVacuum evaporation coatingSputtering coatingElectricityOptoelectronics

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically-insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically-insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

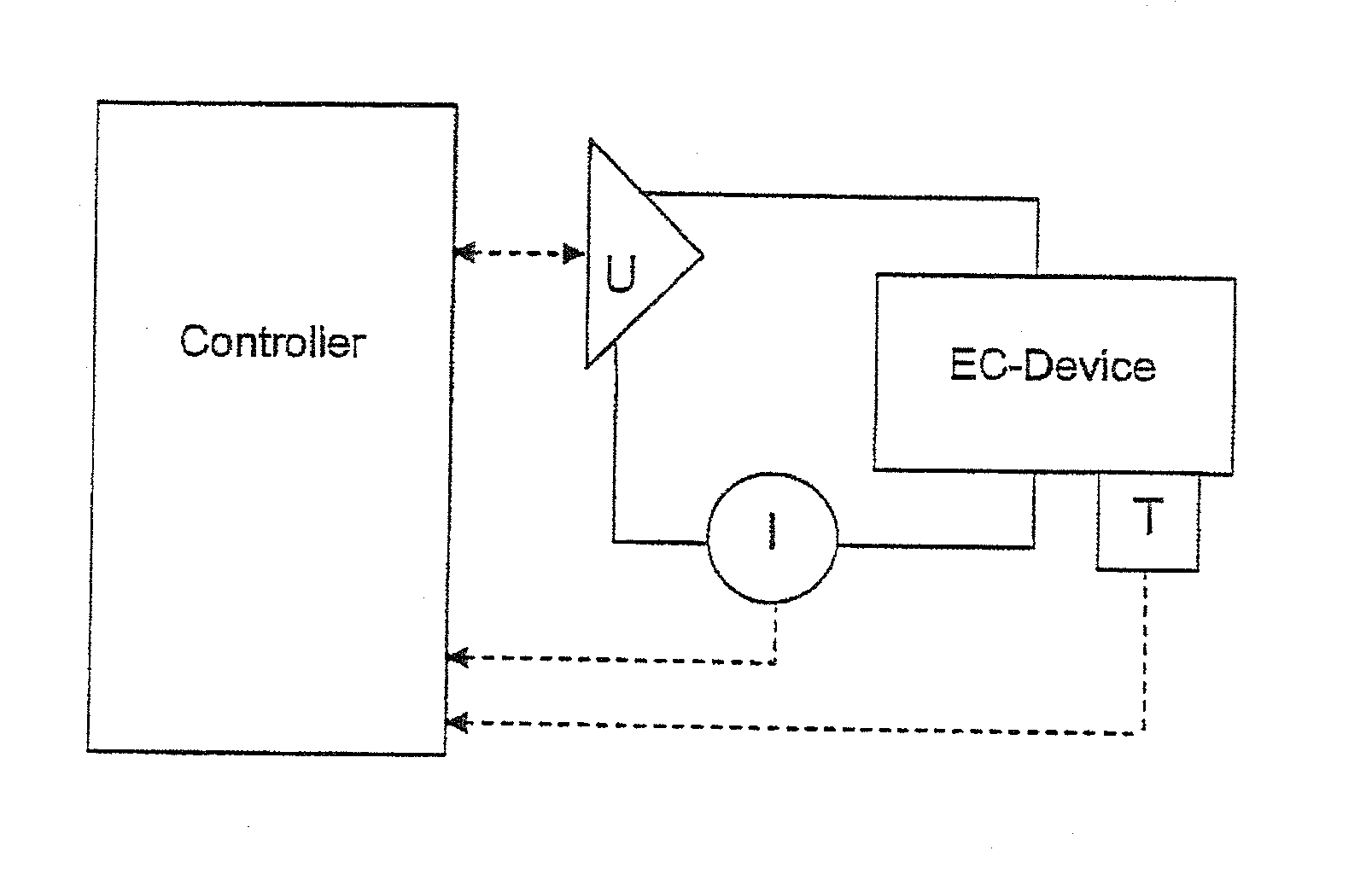

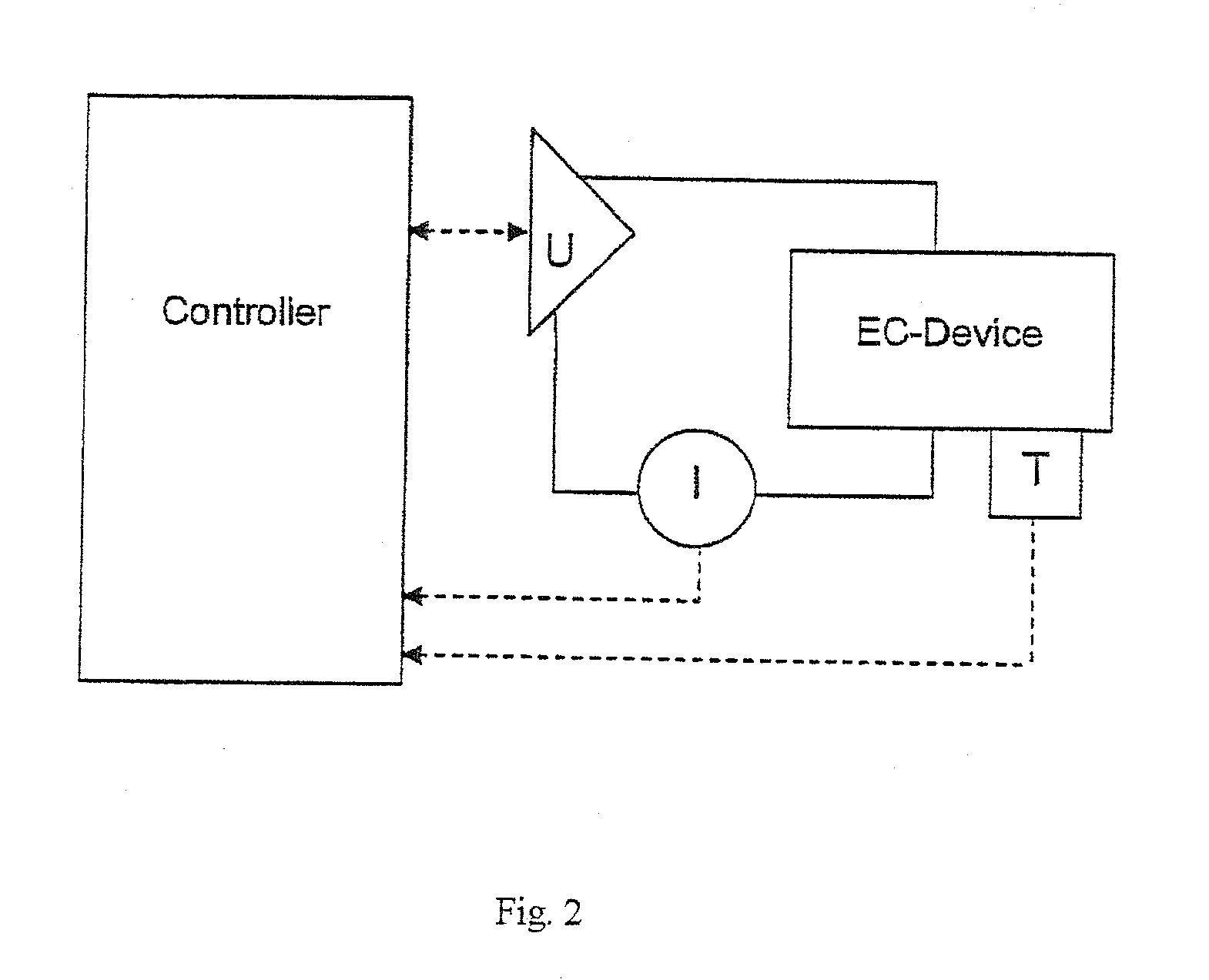

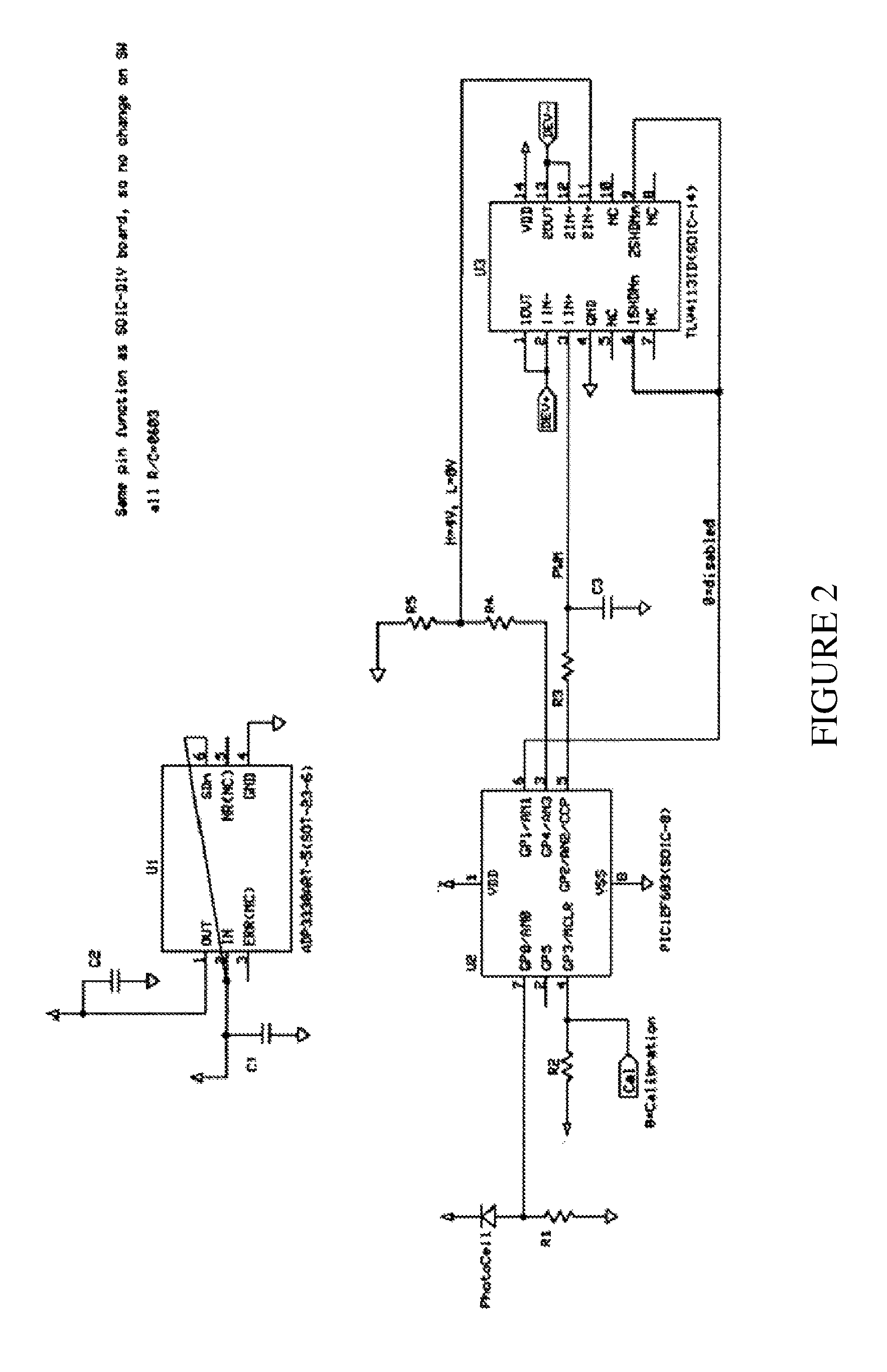

Control system for electrochromic devices

ActiveUS20060018000A1Effective controlBurglar alarm by glass breakingNon-linear opticsElectricityControl system

A control system for an electrochromic (EC) device is capable of monitoring the temperature of the EC device without requiring an external temperature monitoring element, and then controlling the EC device based, in part, upon the temperature readings. The control system also provides methods for heating the EC device using current flowing through the device and for simultaneously heating and changing the transmissivity level of the device. The controller also provides security feedback by detecting glass breakage via a high frequency impedance measurement of the EC device. The controller also provides for methods of determining the bleaching / coloring history of the EC device, determining the transmission state of the EC device and applying a holding voltage to maintain the transmission state of the EC device.

Owner:SAGE ELECTROCHROMICS

Electrochromic devices having improved ion conducting layers

InactiveUS7593154B2Less susceptible to electronic leakageHigh voltageNon-linear opticsElectricityElectrical conductor

An improved ion conductor layer for use in electrochromic devices and other applications is disclosed. The improved ion-conductor layer is comprised of at least two ion transport layers and a buffer layer, wherein the at least two ion transport layers and the buffer layer alternate within the ion conductor layer such that the ion transport layers are in communication with a first and a second electrode. Electrochromic devices utilizing such an improved ion conductor layer color more deeply by virtue of the increased voltage developed across the ion conductor layer prior to electronic breakdown while reducing the amount of electronic leakage. Also disclosed are methods of making electrochromic devices incorporating the improved ion conductor layer disclosed herein and methods of making ion conductors for use in other applications.

Owner:SAGE ELECTROCHROMICS

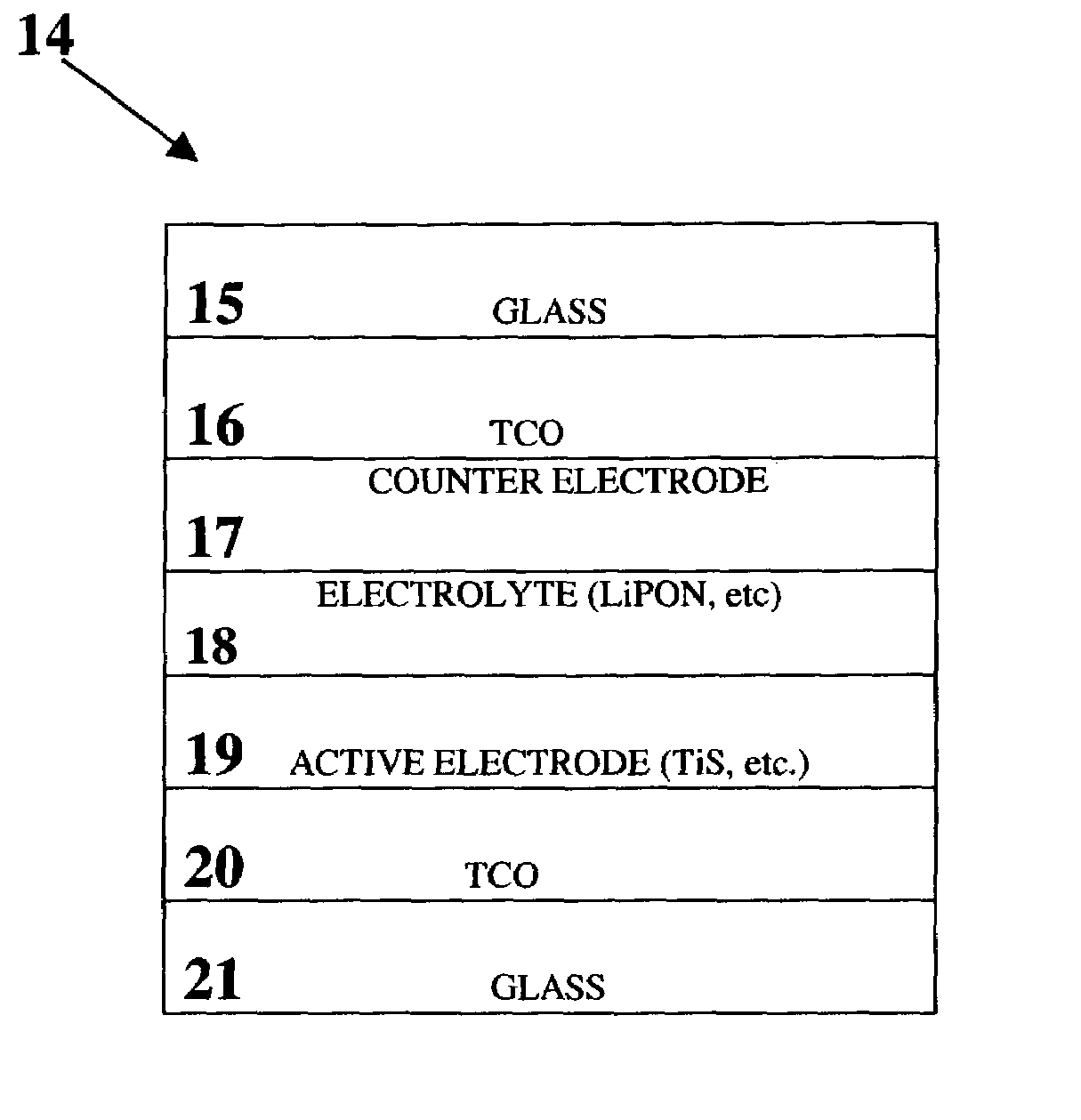

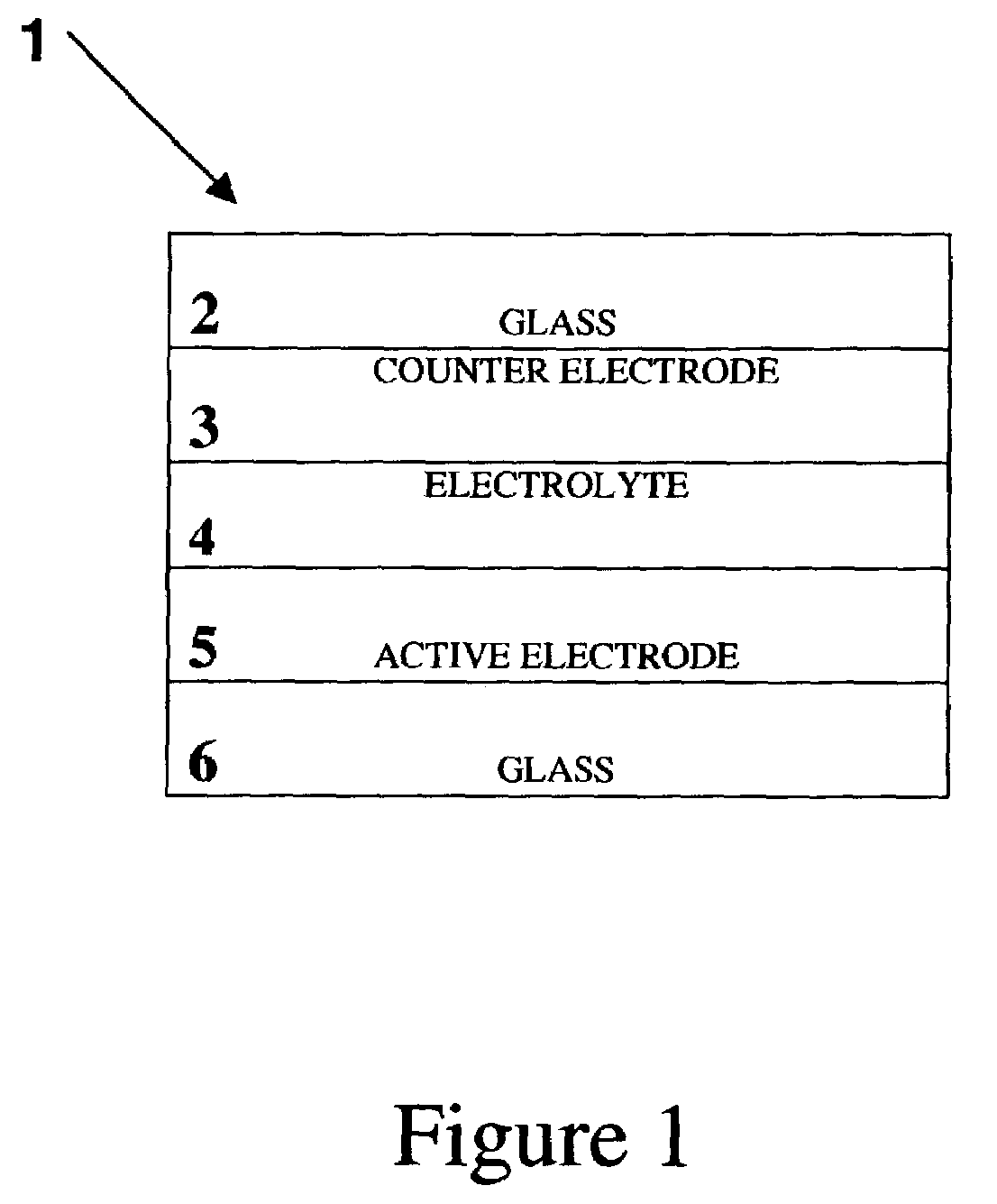

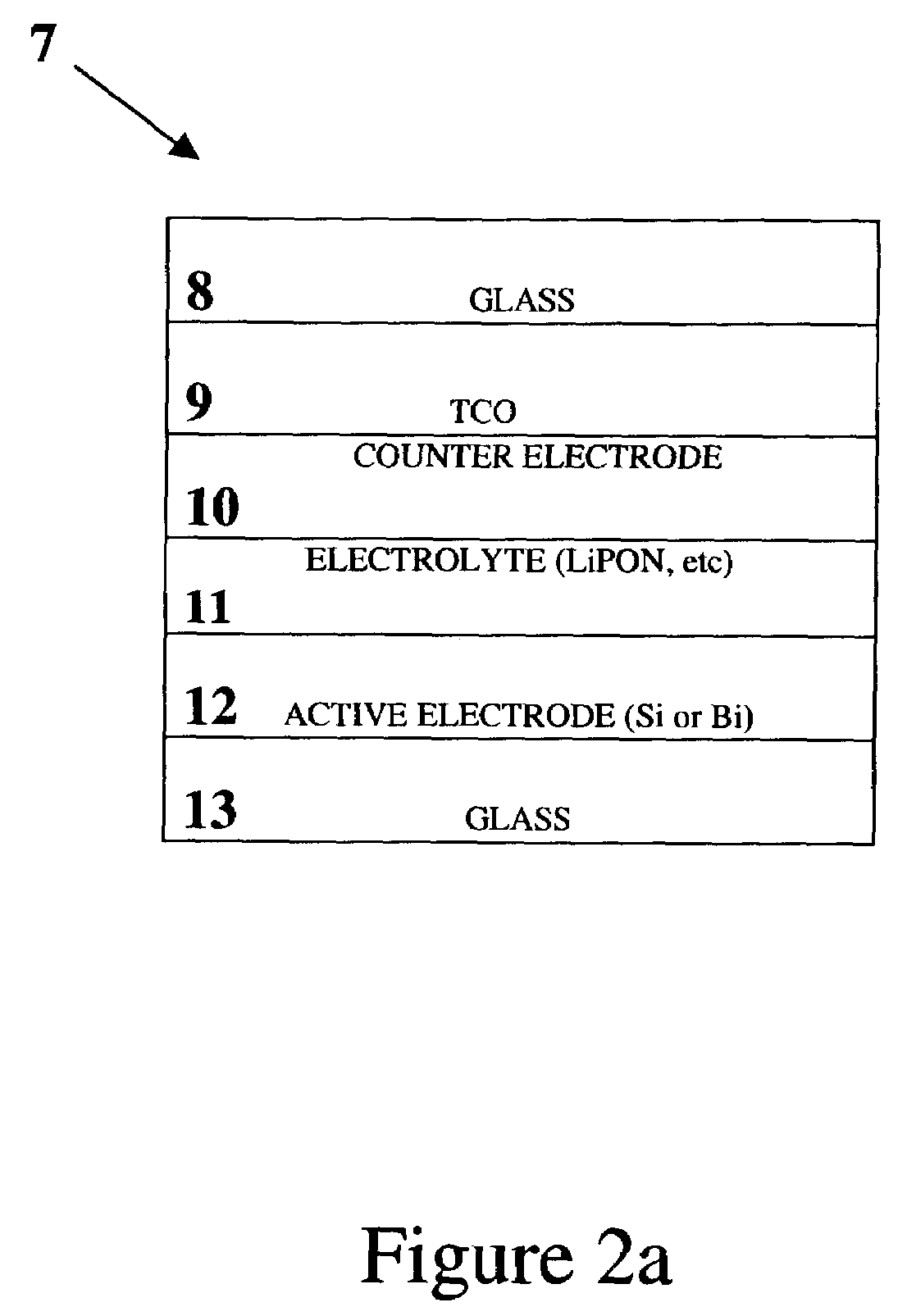

Electrochromic devices based on lithium insertion

Electrochromic devices having as an active electrode materials comprising Sb, Bi, Si, Ge, Sn, Te, N, P, As, Ga, In, Al, C, Pb, I and chalcogenides are disclosed. The addition of other metals, i.e. Ag and Cu to the active electrode further enhances performance.

Owner:RGT UNIV OF CALIFORNIA

Electrochromic devices

ActiveUS8764951B2Improve conductivityIncrease resistanceVacuum evaporation coatingSputtering coatingEngineeringInorganic materials

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically-insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically-insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

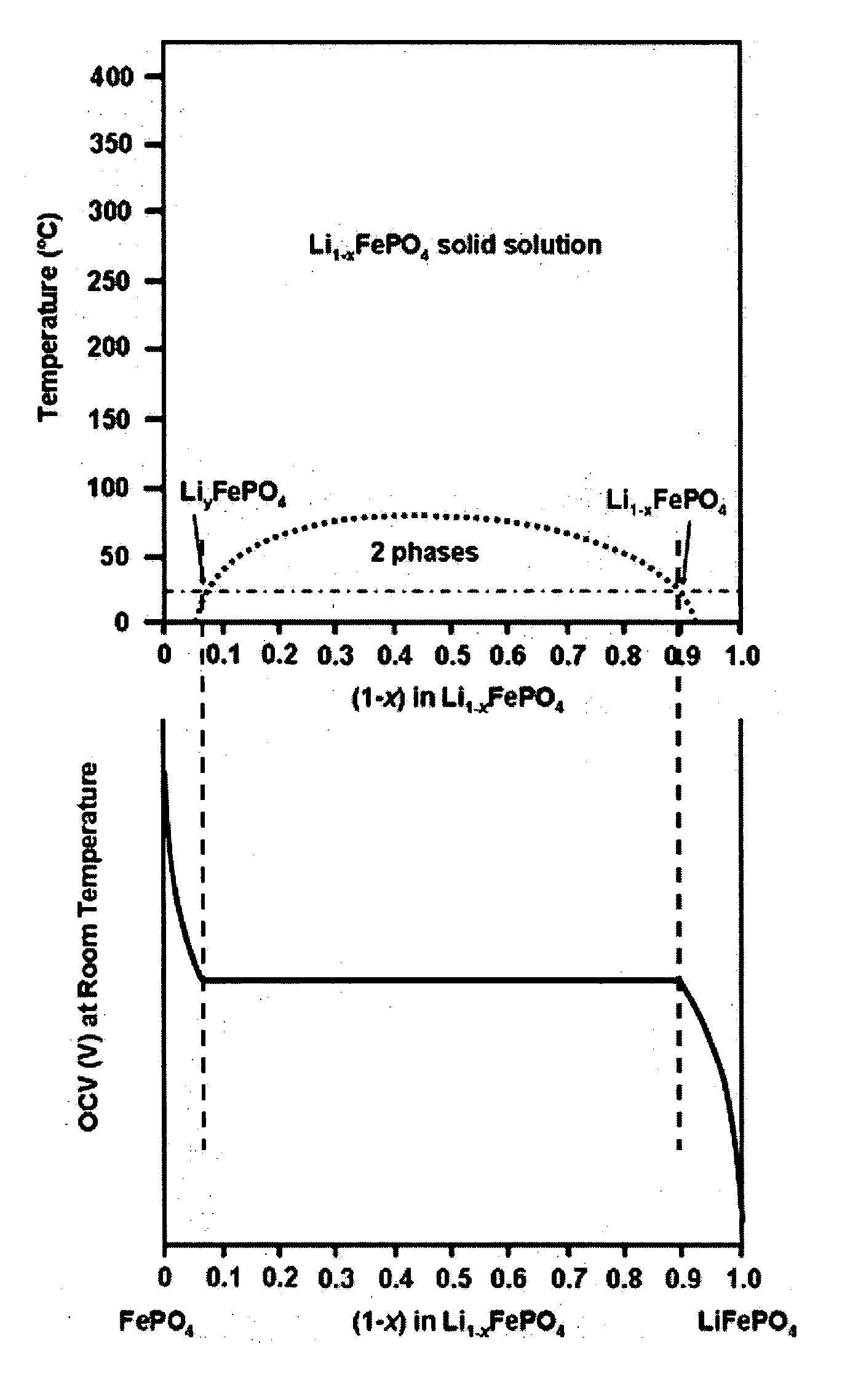

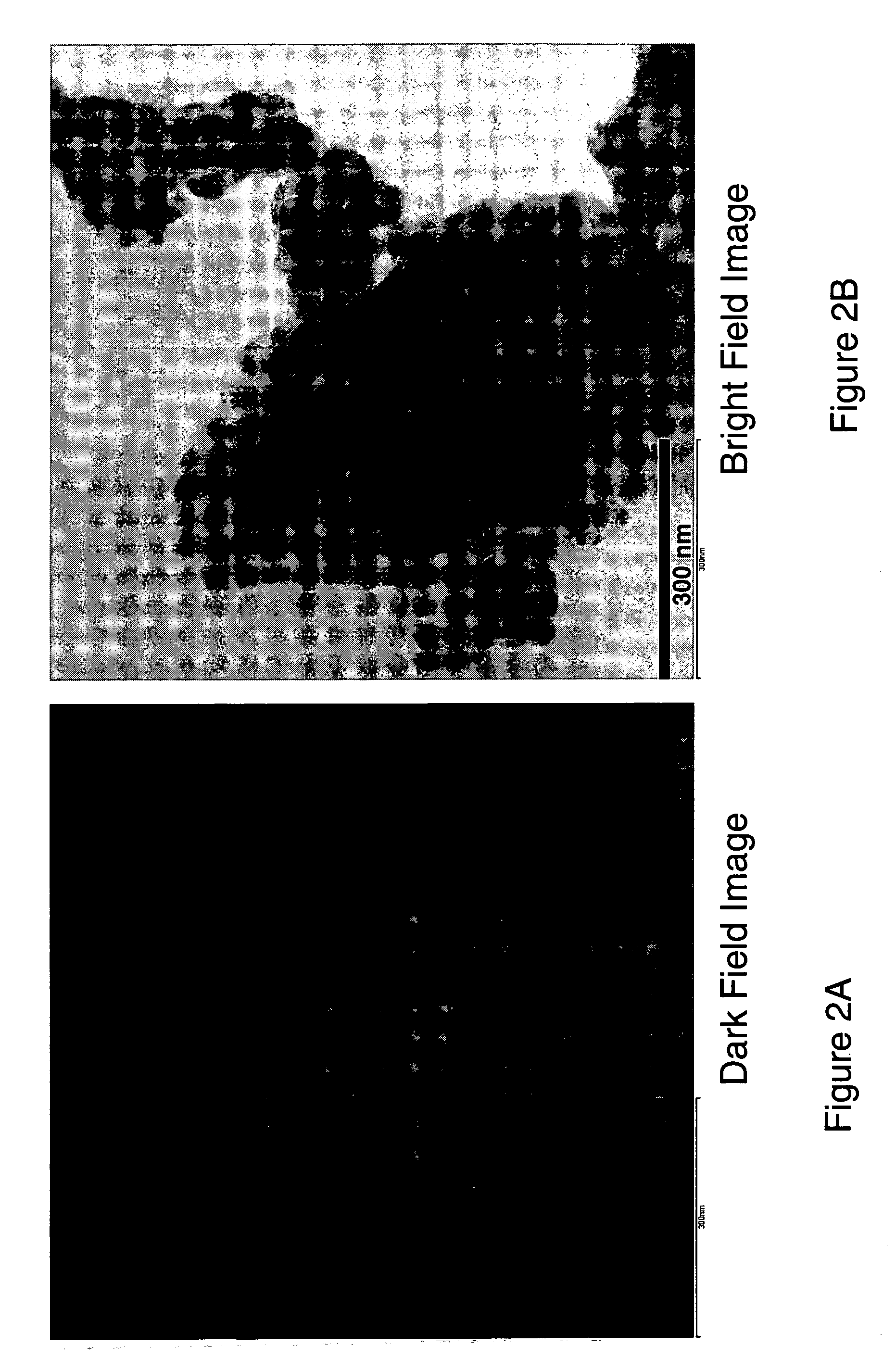

Nanoscale ion storage materials

ActiveUS20070031732A1Improve electronic conductivityImproved electromechanical stabilityMaterial nanotechnologyPhosphatesHigh ratePhosphate

Nanoscale ion storage materials are provided that exhibit unique properties measurably distinct from their larger scale counterparts. For example, the nanoscale materials can exhibit increased electronic conductivity, improved electromechanical stability, increased rate of intercalation, and / or an extended range of solid solution. Useful nanoscale materials include alkaline transition metal phosphates, such as LiMPO4, where M is one or more transition metals. The nanoscale ion storage materials are useful for producing devices such as high energy and high power storage batteries, battery-capacitor hybrid devices, and high rate electrochromic devices.

Owner:RIL USA INC +1

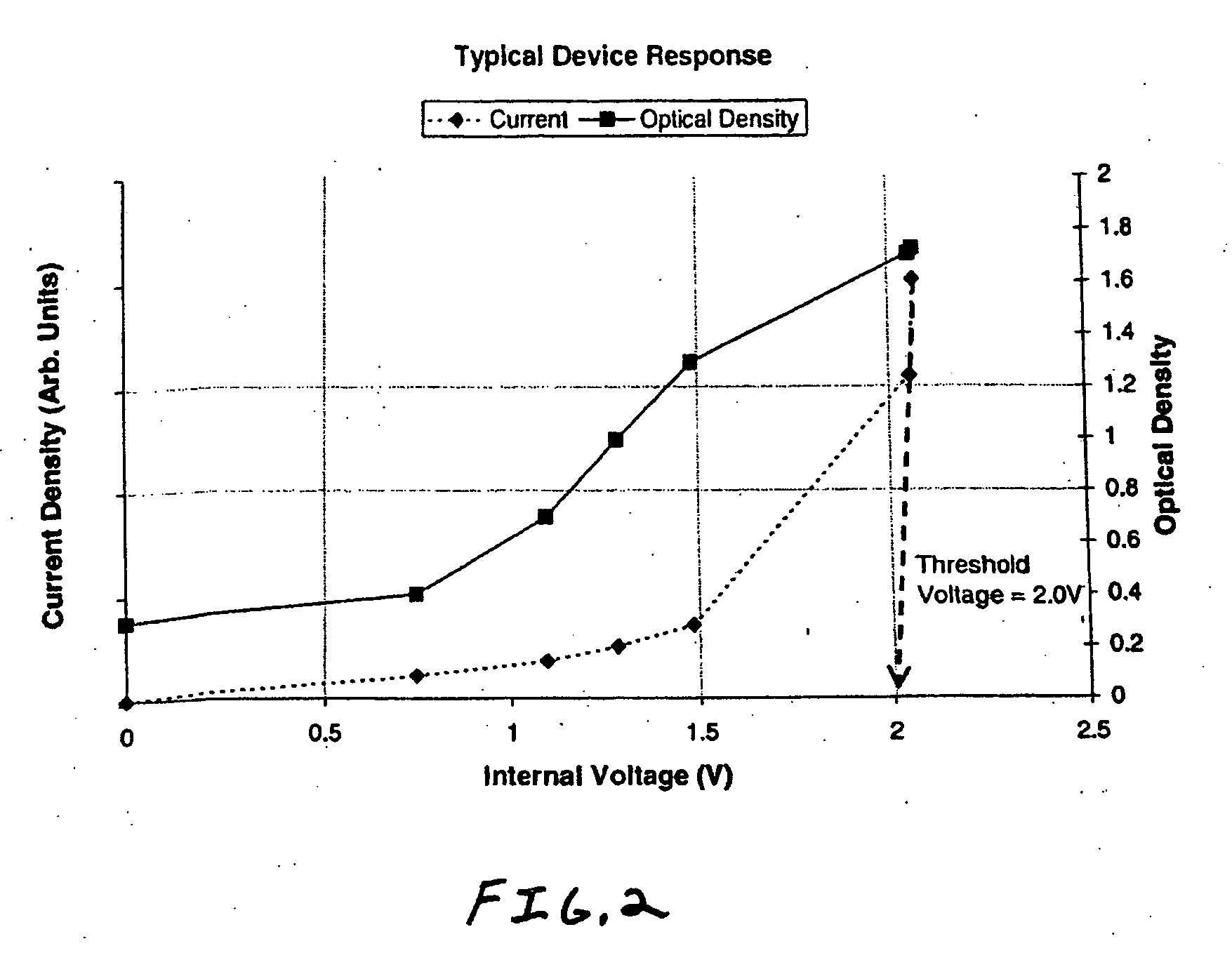

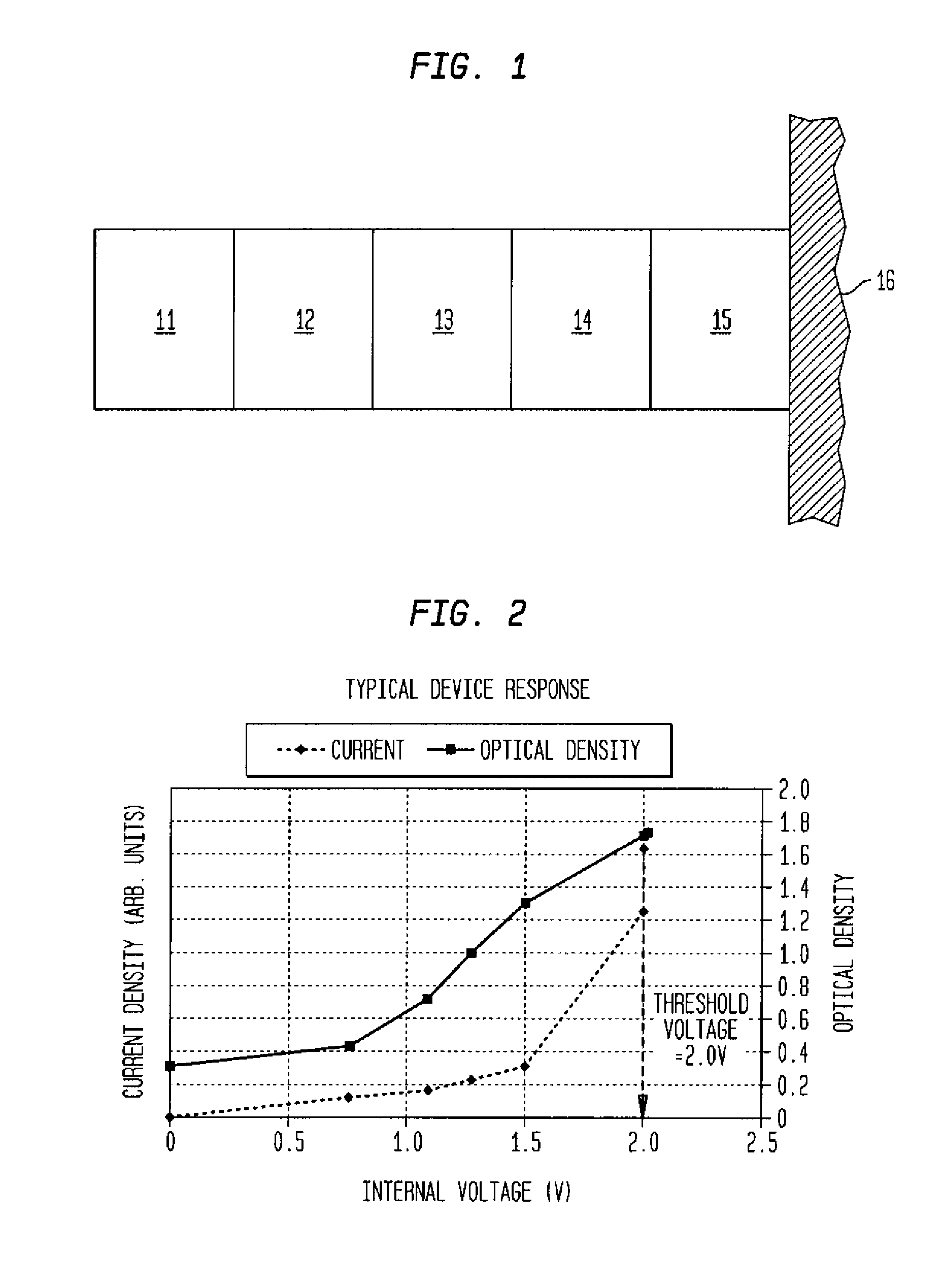

Control system for electrochromic devices

A method of determining the transmission state of an electrochromic device includes applying a voltage across the electrochromic device, using the applied voltage and current for calculating leakage current of the electrochromic device and determining ionic current as the difference between the applied current and the leakage current. The method includes using the ionic current for determining the transmission state of the electrochromic device.

Owner:SAGE ELECTROCHROMICS

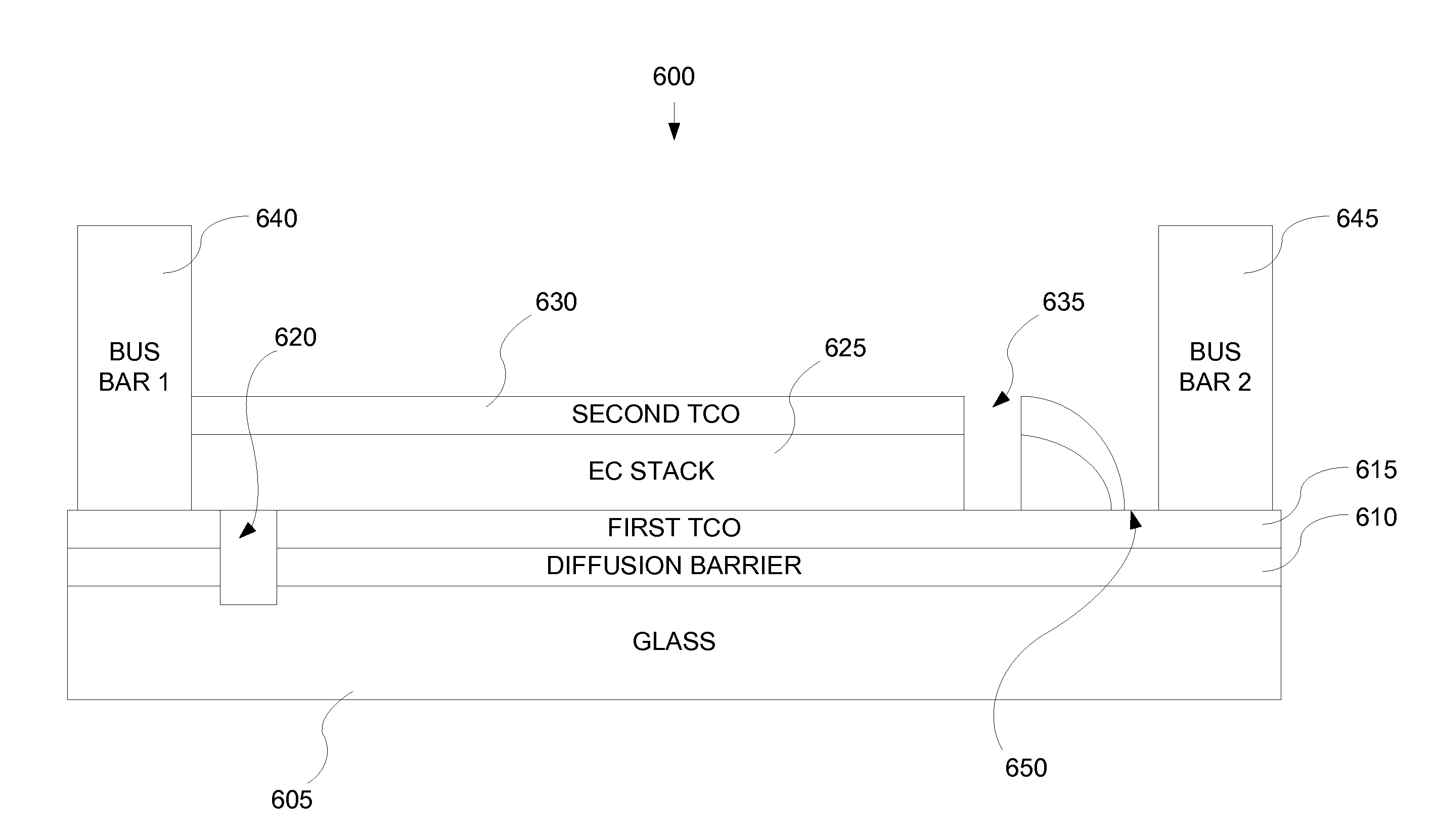

Fabrication of low defectivity electrochromic devices

Prior electrochromic devices frequently suffer from high levels of defectivity. The defects may be manifest as pin holes or spots where the electrochromic transition is impaired. This is unacceptable for many applications such as electrochromic architectural glass. Improved electrochromic devices with low defectivity can be fabricated by depositing certain layered components of the electrochromic device in a single integrated deposition system. While these layers are being deposited and / or treated on a substrate, for example a glass window, the substrate never leaves a controlled ambient environment, for example a low pressure controlled atmosphere having very low levels of particles. These layers may be deposited using physical vapor deposition.

Owner:VIEW INC

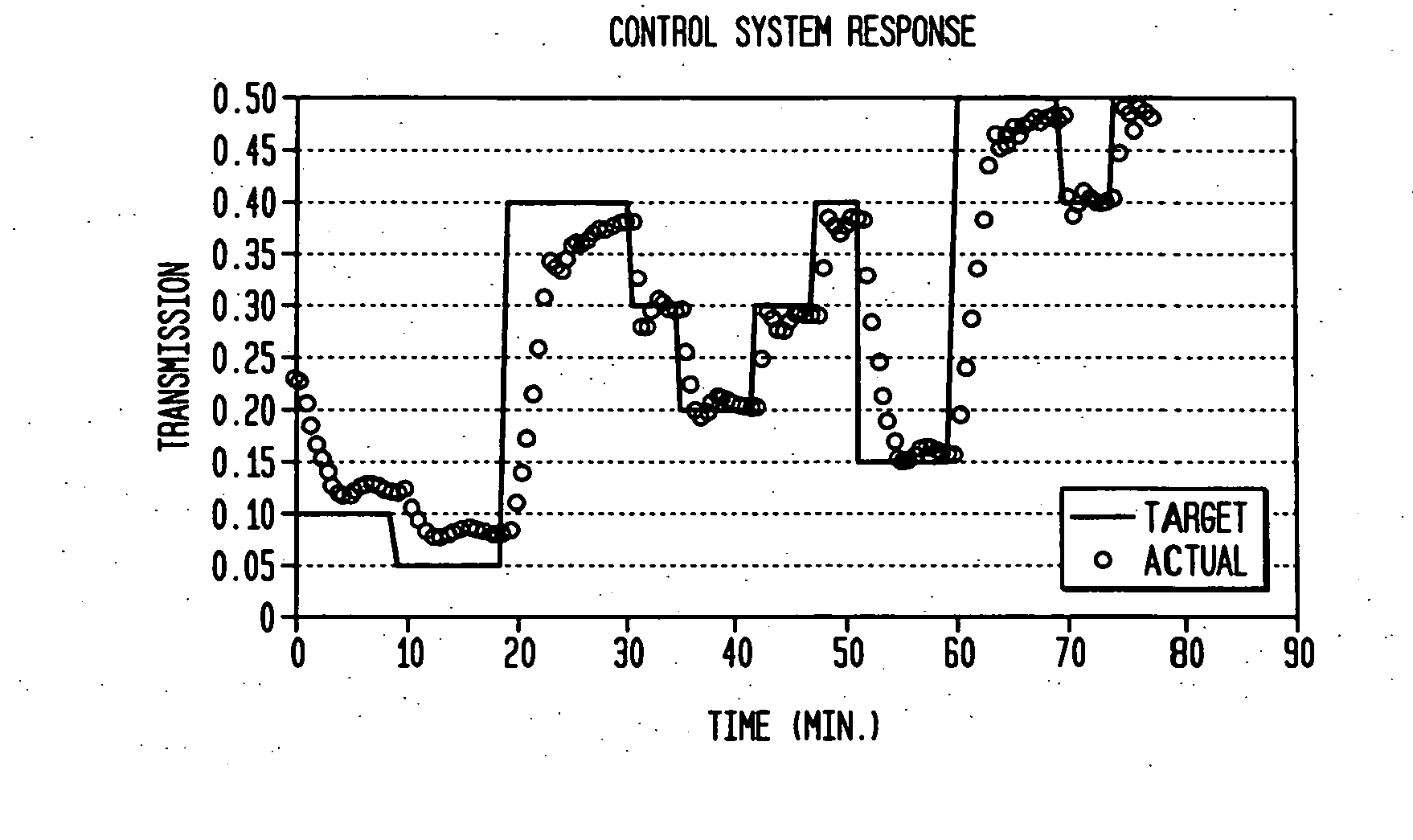

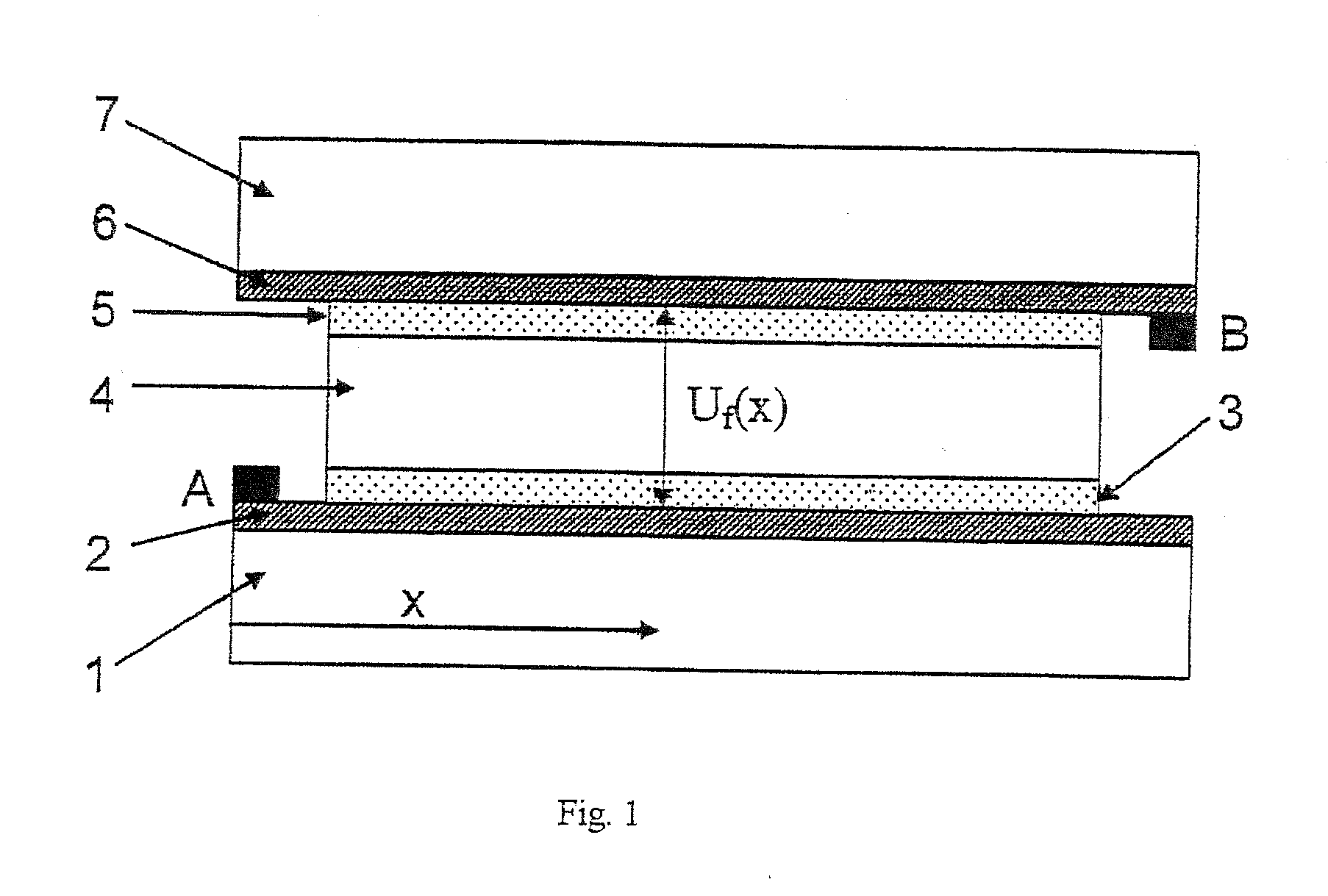

Process and apparatus for switching large-area electrochromic devices

A method is disclosed for controlling switching of an electrochromic device comprising at least the following components: a first and a second electrode layer, a first and a second layer in which ions can be reversibly intercalated, and a transparent ion-conducting layer. At least one of the layers in which ions may be reversibly inserted is electrochromic. The optical properties of the device are modified when a potential is applied between the electrode layers. The potential applied is limited such that the maximum generated potential difference never exceeds the safe redox limits, and that the current does not exceed some predetermined limit. Switching of electrochromic devices in this manner allows for maximum device lifetime, while simultaneously optimising switching speed and transmission homogeneity. The method is characterised in that the potential applied to the electrode layers is varied in the form of a stepped ramp, during which time the current is measured constantly.

Owner:ECONTROL GLAS

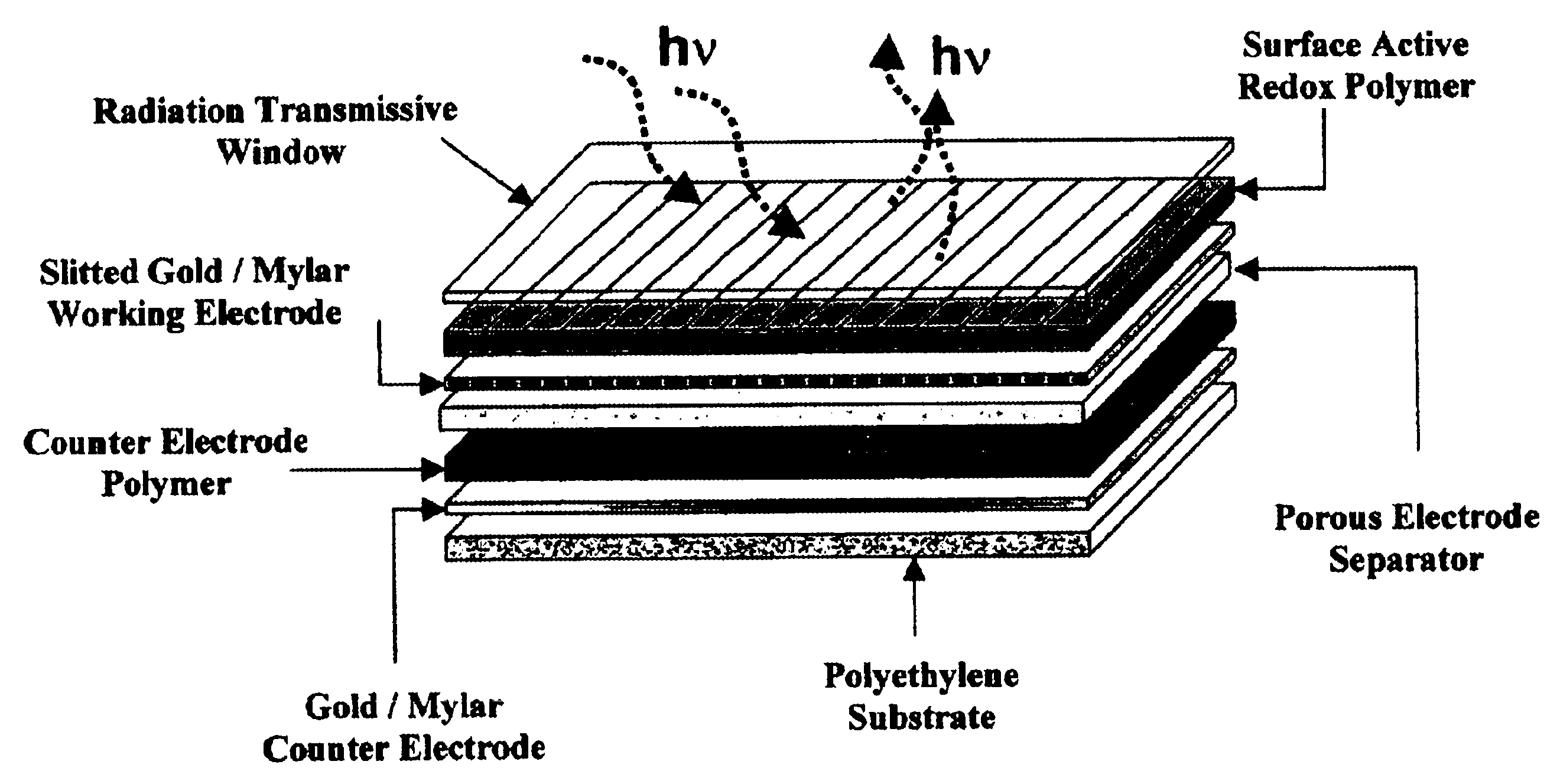

Electrochromic polymers and polymer electrochromic devices

InactiveUS6791738B2Increase the gapLess structural defectsPhotosensitive materialsElectrography/magnetographyPolymer scienceGas phase

The subject invention pertains to electrochromic polymers and polymer electrochromic devices. In a specific embodiment, two complementary polymers can be matched and incorporated into dual polymer electrochromic devices. The anodically coloring polymers in accordance with the subject invention can allow control over the color, brightness, and environmental stability of an electrochromic window. In addition, high device contrast ratios, high transmittance changes, and high luminance changes can be achieved, along with half-second switching times for full color change. Also provided are electrochromic devices such as advertising signage, video monitors, stadium scoreboards, computers, announcement boards, warning systems for cell phones, warning / information systems for automobiles, greeting cards, electrochromic windows, billboards, electronic books, and electrical wiring. The subject invention also provides for the use of complementary electrochromic polymers in the manufacture of electrochromic devices. In some embodiments, the devices of the invention can be prepared using metal vapor deposition or line patterning.

Owner:FLORIDA UNIV OF A FLORIDA

Electrochromic devices

ActiveUS20110249314A1Improve conductivityIncrease resistanceElectric discharge tubesVacuum evaporation coatingElectricityOptoelectronics

Conventional electrochromic devices frequently suffer from poor reliability and poor performance. Improvements are made using entirely solid and inorganic materials. Electrochromic devices are fabricated by forming an ion conducting electronically insulating interfacial region that serves as an IC layer. In some methods, the interfacial region is formed after formation of an electrochromic and a counter electrode layer. The interfacial region contains an ion conducting electronically insulating material along with components of the electrochromic and / or the counter electrode layer. Materials and microstructure of the electrochromic devices provide improvements in performance and reliability over conventional devices.

Owner:VIEW INC

Method and apparatus for control of electrochromic devices

ActiveUS8902486B1Fast switching speedShorten the switching timeNon-linear opticsOptical partsEngineeringElectrochromic devices

The present invention provides apparatuses and methods for modulating the transmissivity of electrochromic devices utilizing a controller that provides a continuous potential that may be pulsed to the electrochromic device.

Owner:ASHWIN USHAS

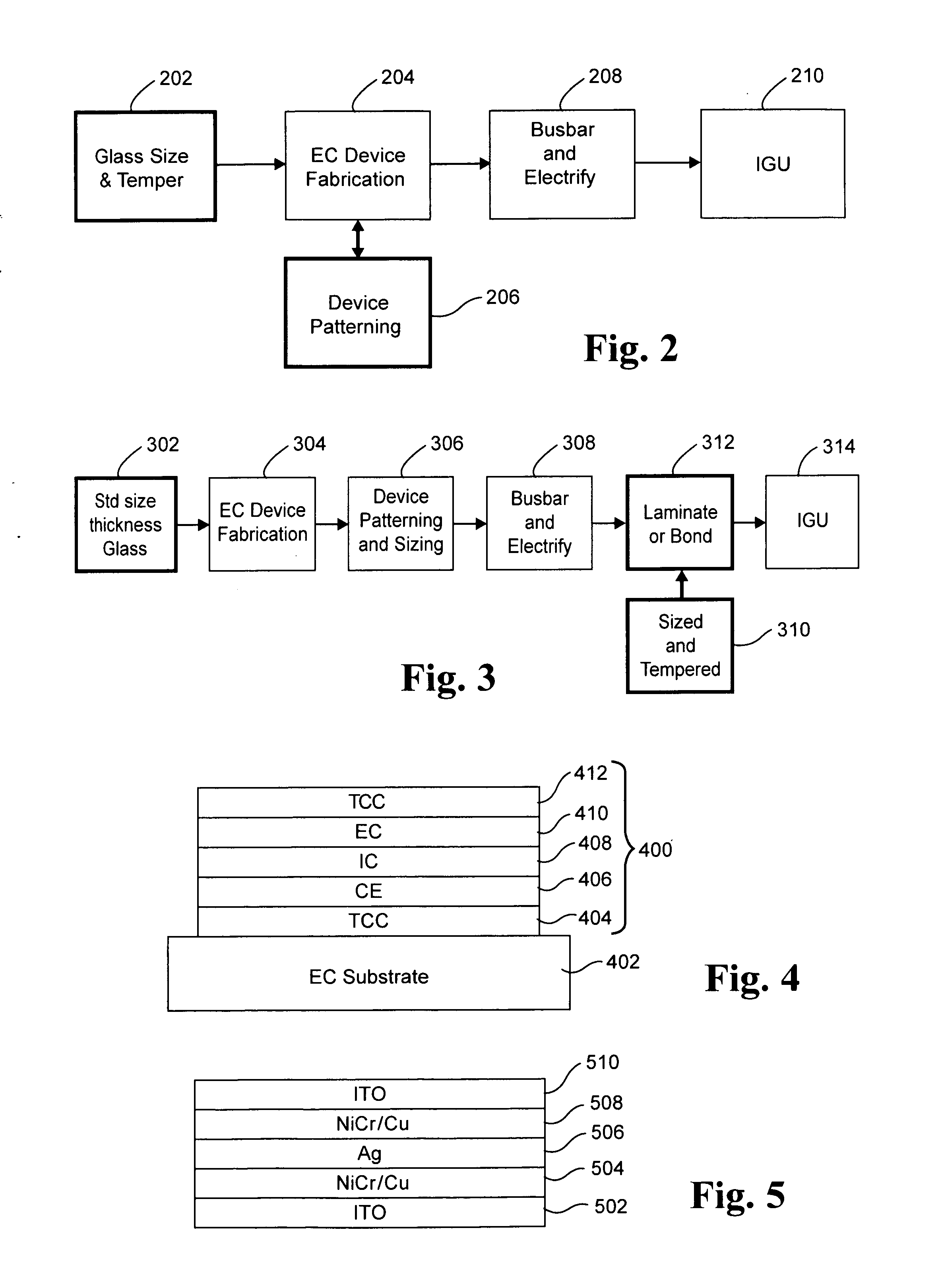

Electrochromic devices, assemblies incorporating electrochromic devices, and/or methods of making the same

ActiveUS20110048614A1Great visible transmissionGood lookingLamination ancillary operationsLight protection screensElectricityProcess integration

Certain example embodiments of this invention relate to electrochromic (EC) devices, assemblies incorporating electrochromic devices, and / or methods of making the same. More particularly, certain example embodiments of this invention relate to improved EC materials, EC device stacks, high-volume manufacturing (HVM) compatible process integration schemes, and / or high-throughput low cost deposition sources, equipment, and factories.

Owner:GUARDIAN GLASS LLC

Electrochromic polymeric solid films, manufacturing electrochromic devices using such solid films, and processes for making such solid films and devices

InactiveUS20050079326A1Low viscosityMinimal shrinkageSynthetic resin layered productsCellulosic plastic layered productsMonomer compositionPolymer science

An electrochromic mirror device suitable for use in a vehicle comprises a first transparent substrate having a transparent conductive layer on a surface thereof and a second substrate having a conductive layer on a surface thereof. The conductive layer of the first substrate opposes the second conductive layer of the second substrate in a spaced-apart relationship thereby forming an interpane distance between the substrates. A boundary seal is interposed between the first and second substrates spacing apart the substrates and forming a cavity wherein the interpane distance is at least about 10 microns. An electrochromic cross-linked polymeric solid film is disposed within the cavity. The electrochromic cross-linked solid polymeric film is formed from an electrochromic monomer composition that includes at least one cathodic electrochromic compound. The second conductive layer comprises a metallic reflective layer.

Owner:DONNELLY CORP

Electrochromic devices, assemblies incorporating electrochromic devices, and/or methods of making the same

ActiveUS20110051221A1Great visible transmissionGood lookingLight protection screensGlass/slag layered productsElectricityProduction rate

Certain example embodiments of this invention relate to electrochromic (EC) devices, assemblies incorporating electrochromic devices, and / or methods of making the same. More particularly, certain example embodiments of this invention relate to improved EC materials, EC device stacks, high-volume manufacturing (HVM) compatible process integration schemes, and / or high-throughput low cost deposition sources, equipment, and factories.

Owner:GUARDIAN GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com