Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

448results about How to "Full penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

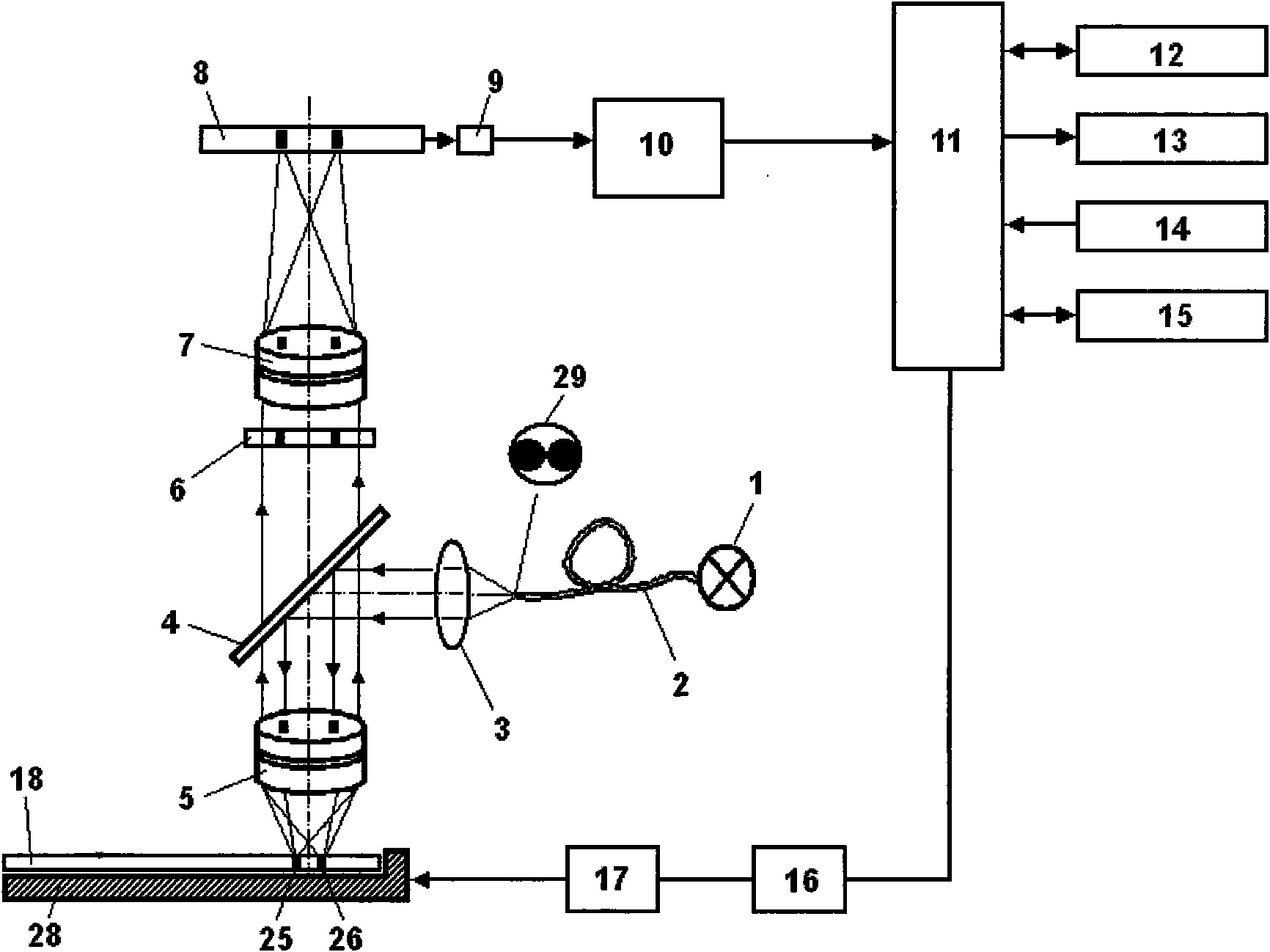

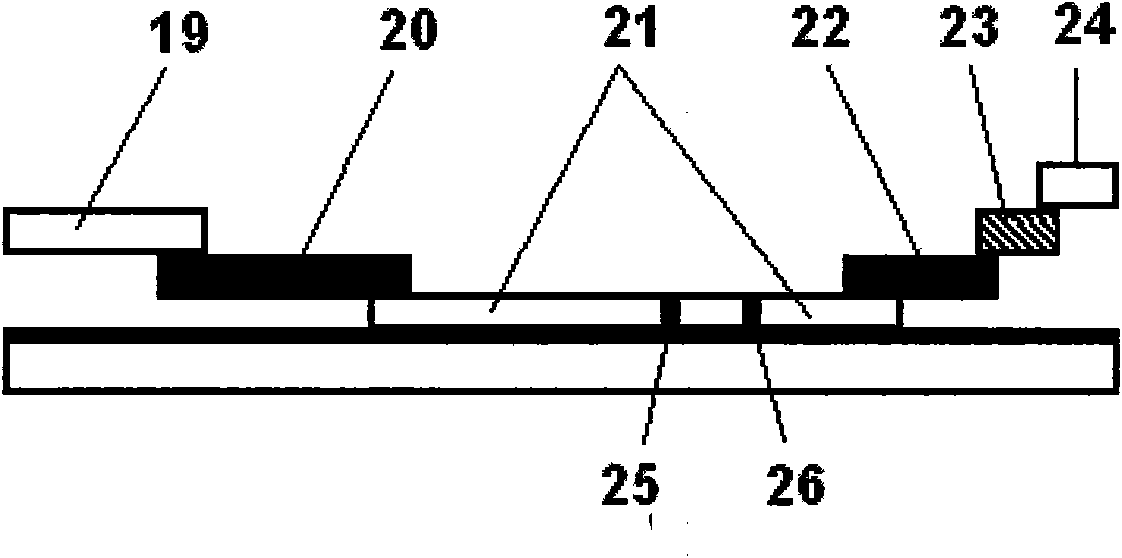

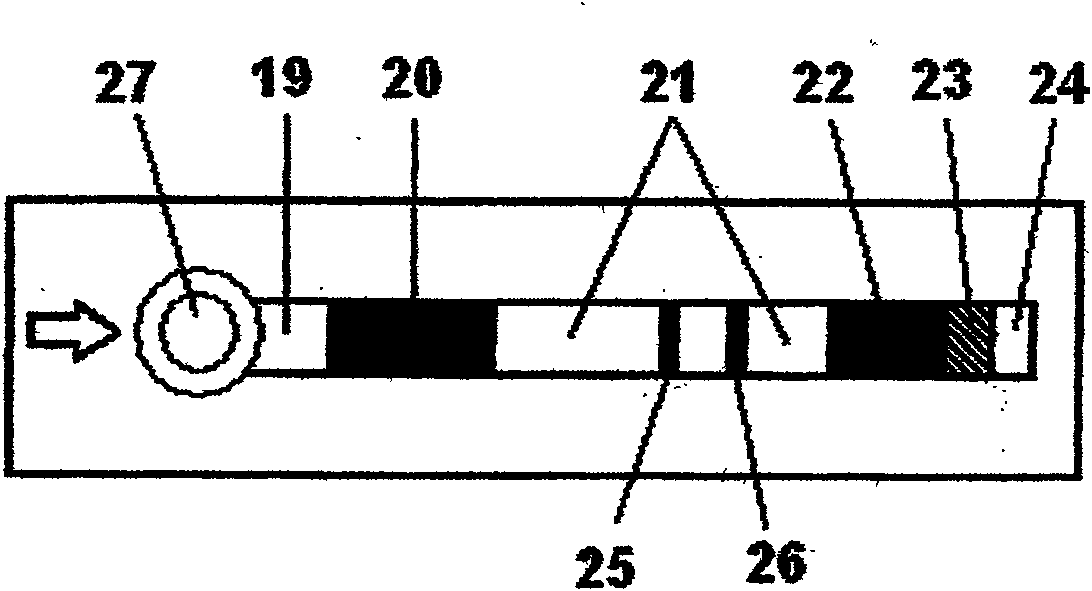

System and method for quantitative detection of test strips on basis of continuous fluorescent-substance markers

ActiveCN101592659AEmitting characteristic wavelengths with high fluorescence brightnessHigh fluorescence brightnessBiological testingFluorescence/phosphorescenceAcquired characteristicFluorescence

The invention belongs to the field of bio-medical instruments, and in particular relates to a system and a method for quantitative detection of test strips on the basis of continuous fluorescent-substance markers. The system comprises a continuous fluorescent-substance marker test strip, a test strip frame, a lighting system, an imaging system, a fluorescent image receiver, a signal amplifier, an analog / digital converter, a data processing-controlling system, an output display device, a printer, a keyboard and an IC card matched with the test strip. The data processing-controlling system reads parameters of the IC card and then controls the test strip frame to move so as to ensure that the light emitted by the lighting system is reflected via a dichroic mirror and then automatically scans the test strip; acquired characteristic wavelength reflection fluorescence is transmitted to the data processing-controlling system for optical density identification and concentration calculation via the fluorescent image receiver, the signal amplifier and the analog / digital converter; and the output display device displays results. The invention can quickly and accurately realize the quantitative or qualitative detection of single-component and multi-component samples. The system has the characteristics of high detection sensitivity, objective results, flexible use and the like.

Owner:马义才

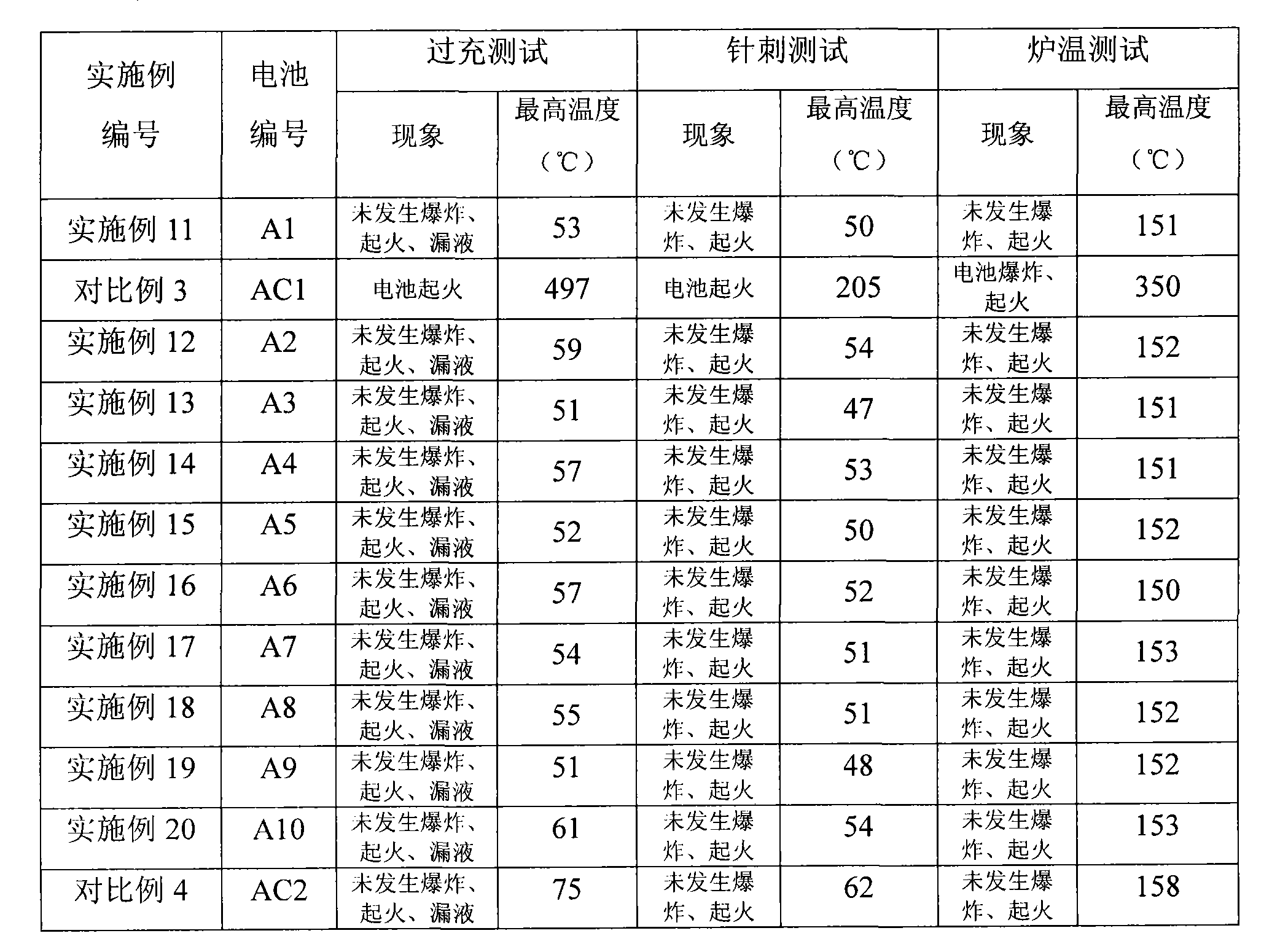

Negative electrode active substance of lithium ionic cell and preparing method thereof, negative electrode and cell

InactiveCN101425580AImprove ionic conductivityWeak electronic conductivityElectrode manufacturing processesSecondary cellsOxideLithium electrode

The invention relates to a cathode active substance of a lithium ion battery. The cathode active substance contains carbon material and metal oxide; the metal oxide is clad on the surface of the carbon material and adopts one or some of s IIA, IIIA, IB, IB, IIIB and IVB metal oxides in an element periodic table. The battery prepared and obtained by the cathode active substance has good safe performance and electrical chemical property.

Owner:BYD CO LTD

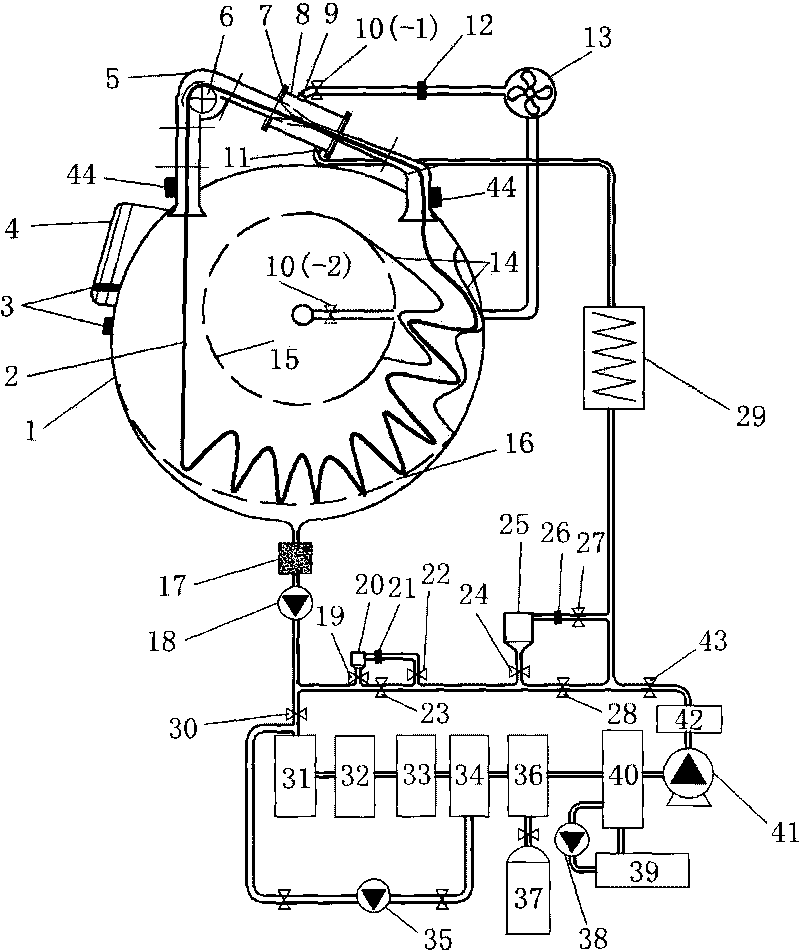

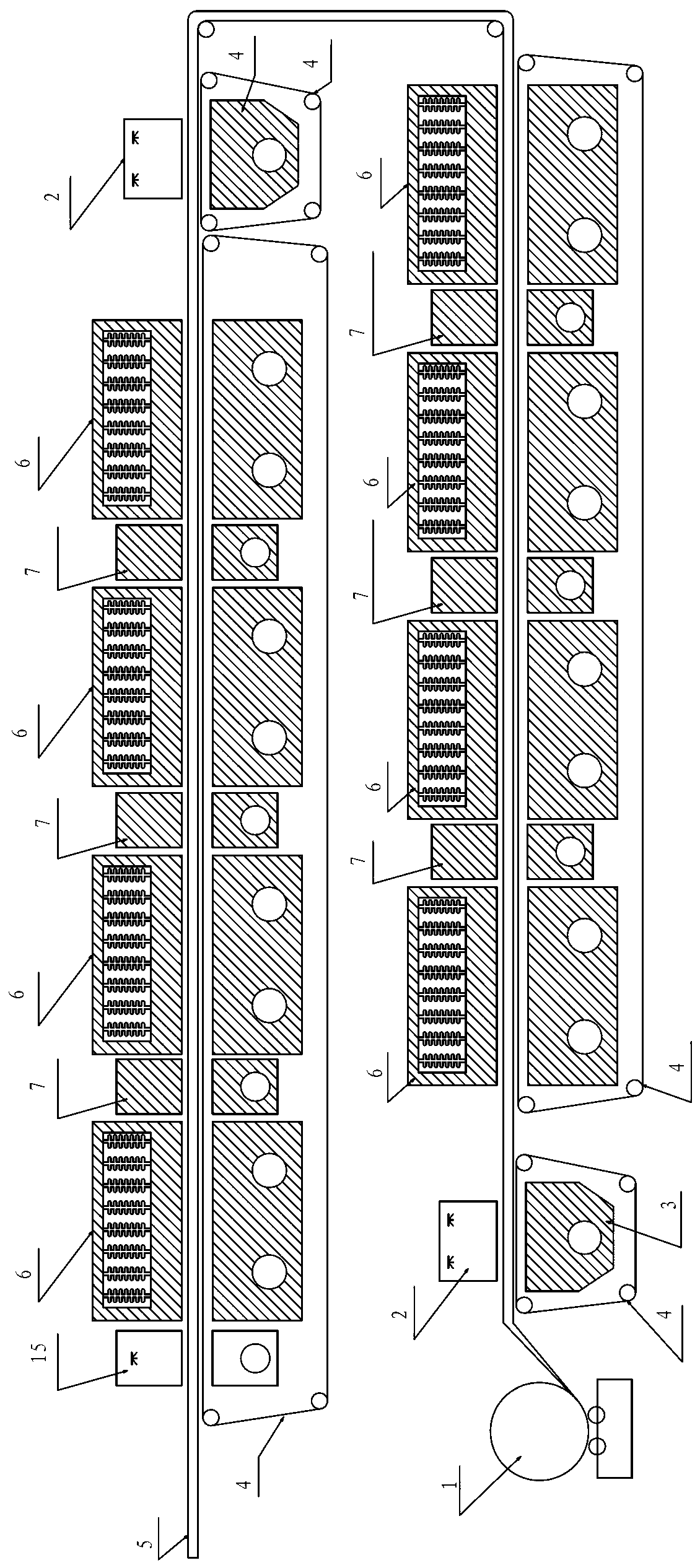

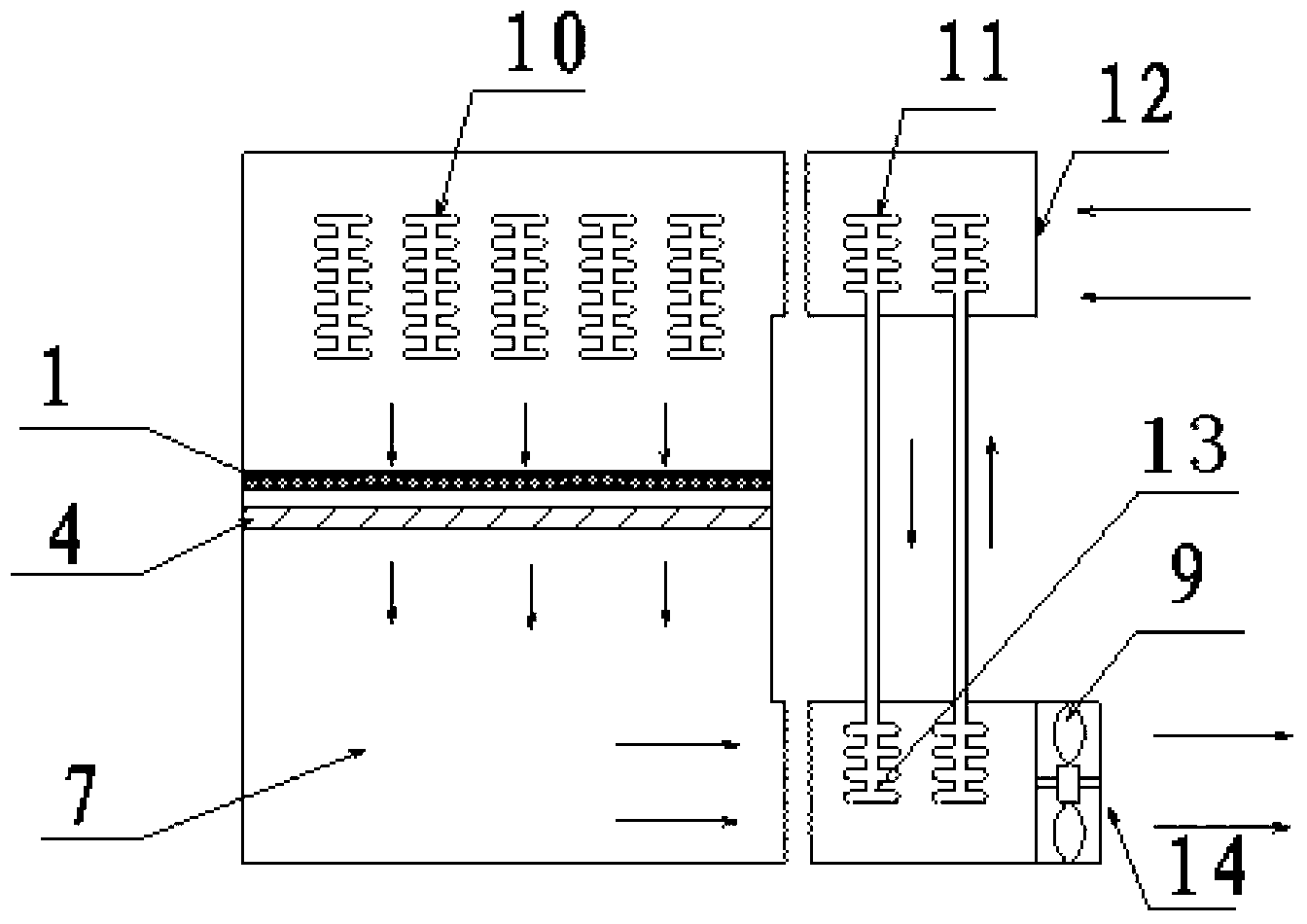

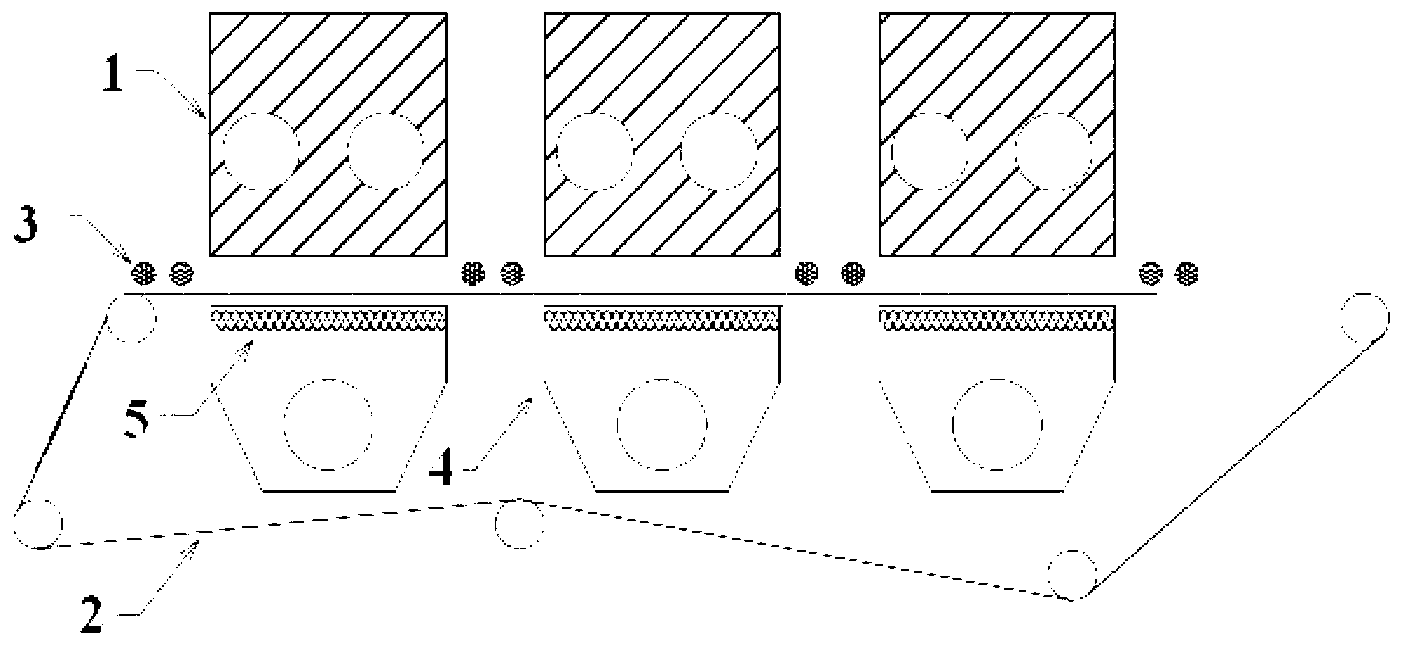

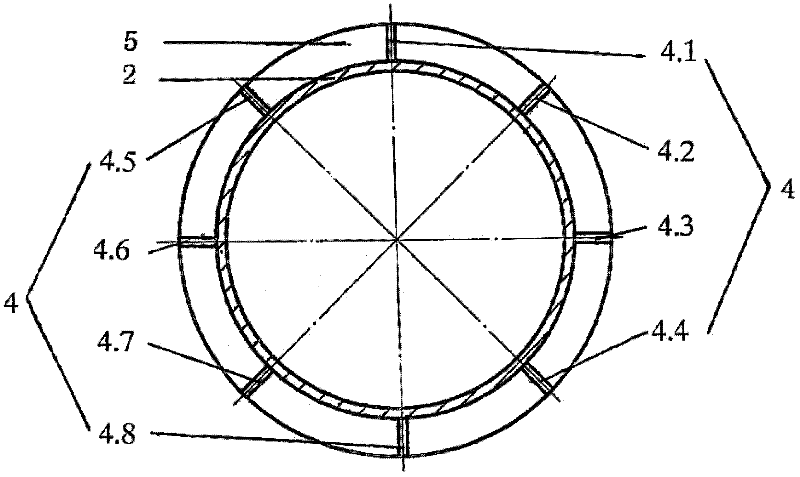

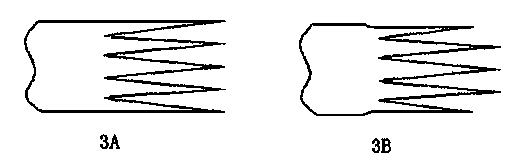

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

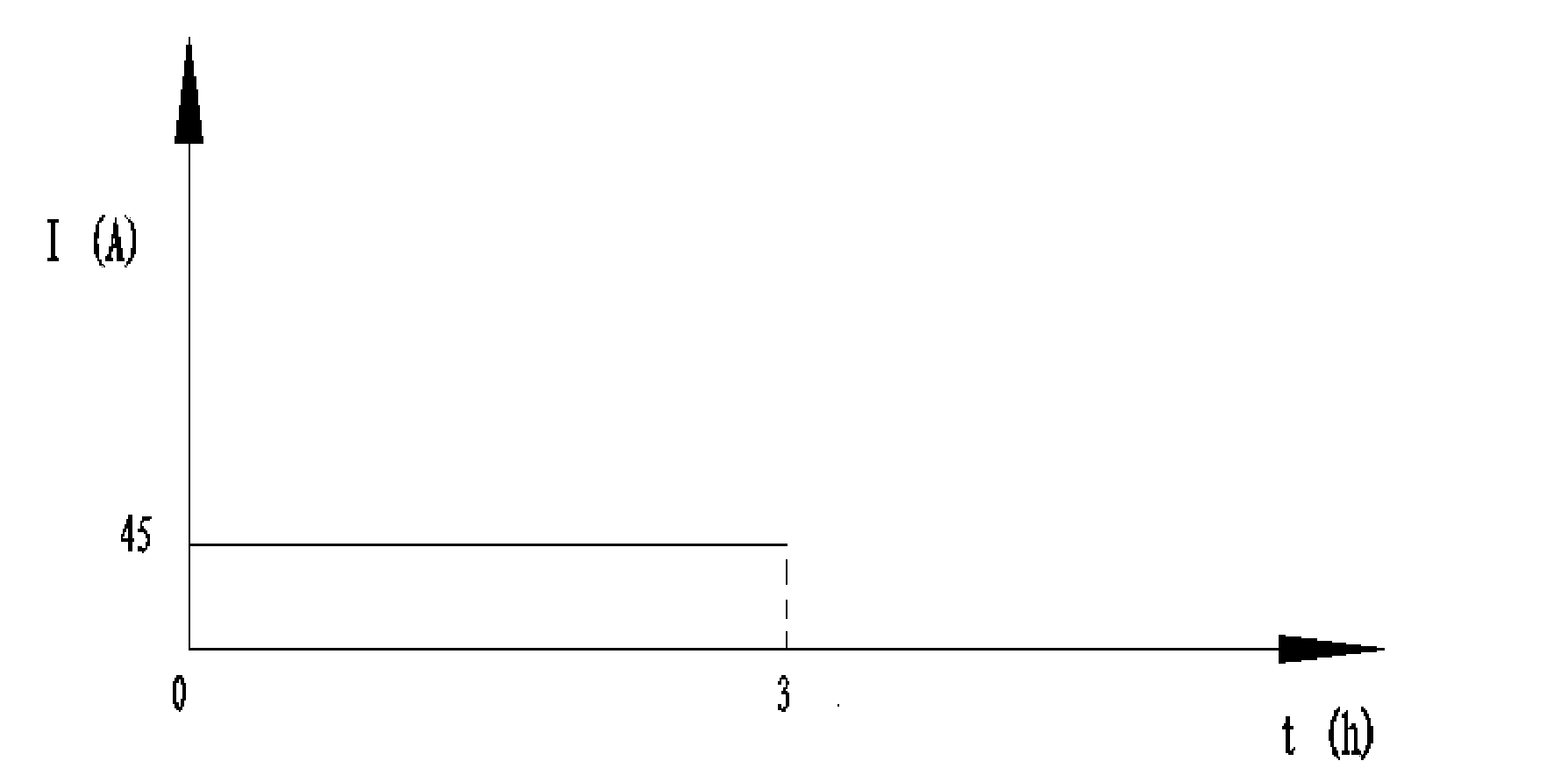

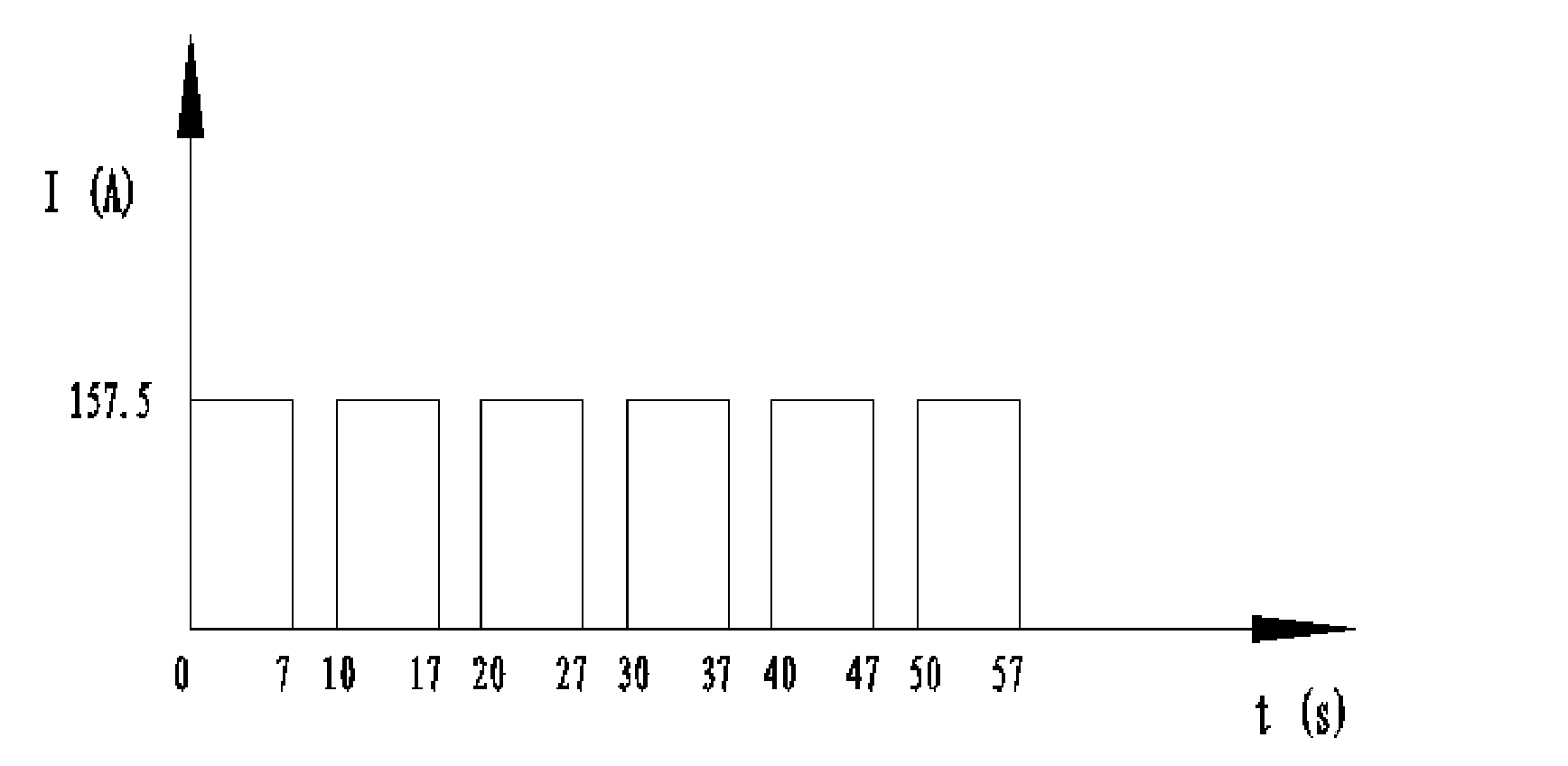

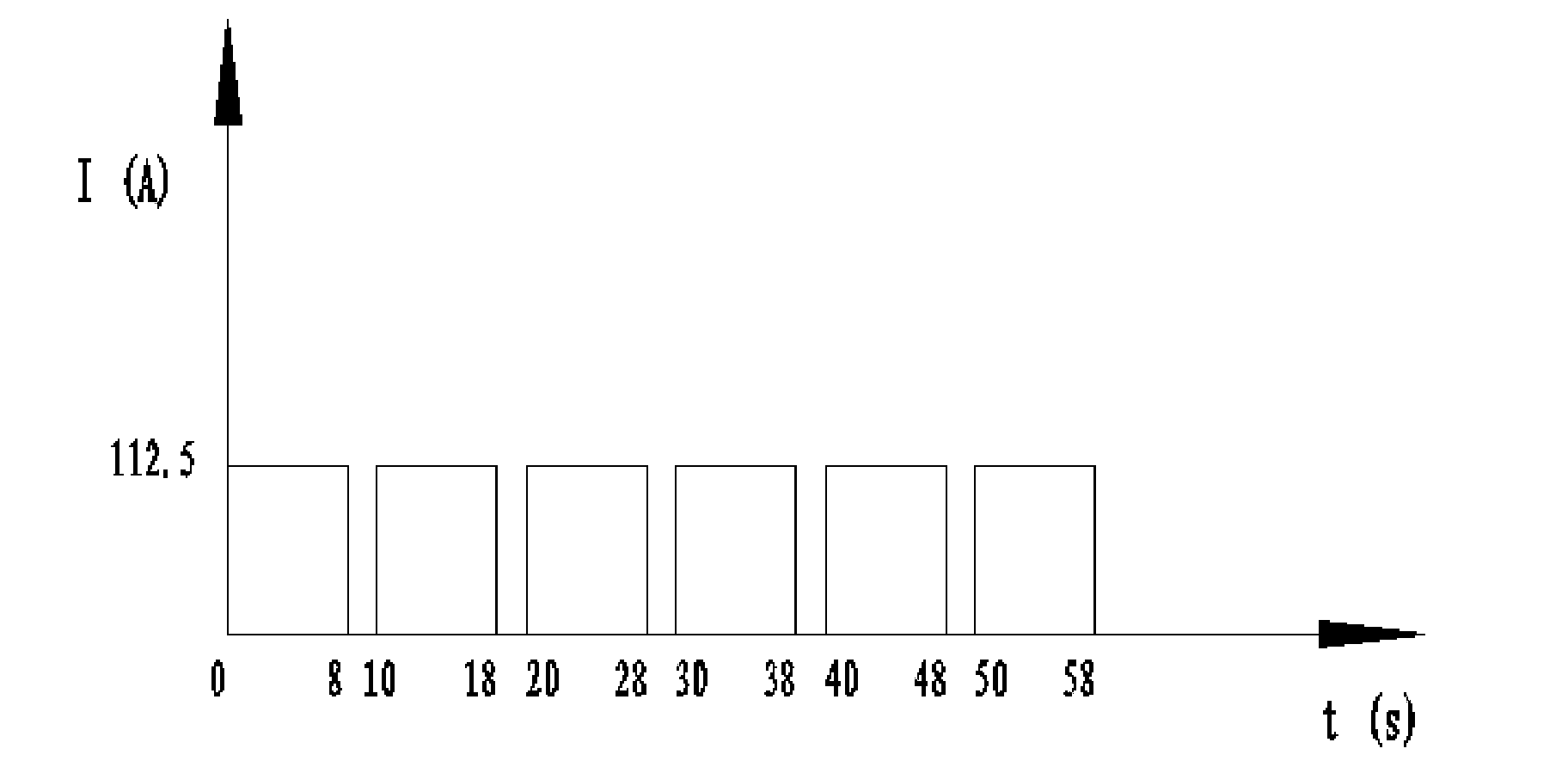

Pulse container formation method for high-capacity lead-acid battery

ActiveCN101877425AReduce shockImprove uniformityFinal product manufactureSecondary cells charging/dischargingEngineeringLow frequency

Owner:HUNAN FENGRI ELECTRIC GROUP

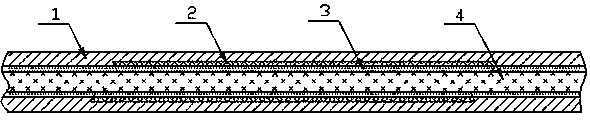

Perforated, Layered Wound Treatment Material

ActiveUS20140163447A1Improve compatibilityPromote absorptionButtonsNon-adhesive dressingsVacuum assistedBiomedical engineering

The present invention relates to wound treatment material comprising at least two perforated biomatrix layers interconnected by connecting means, as well as to methods for preparing such wound treatment materials and their use, in particular in the treatment of exuding wounds, and in the vacuum-assisted wound treatment therapy.

Owner:MEDSKIN SOLUTIONS DR SUWELACK AG

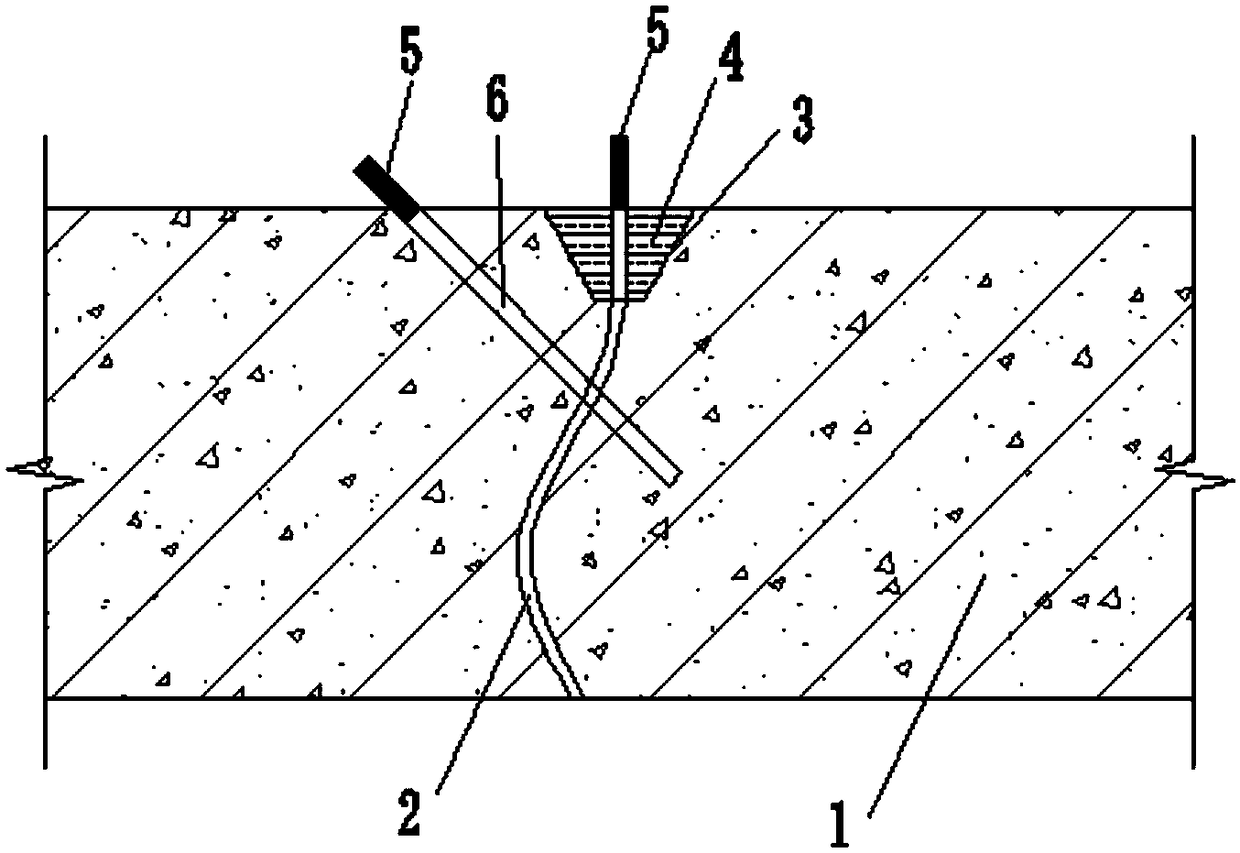

Concrete wall and bottom plate water seepage crack repair method

ActiveCN109457735AAvoid water leakage accidentsReduce water pressureArtificial islandsProtective foundationSlurryPressure grouting

The invention discloses a concrete wall and bottom plate water seepage crack repair method. The method comprises the following steps that wall and bottom plate cracks are found out and marked; the crack of which the width is larger than 0.3 mm is subjected to digging into a V-shaped groove; dust, dirt and loose parts of the surface of concrete in the V-shaped groove area are removed and washed with water; layered dense blocking and maintenance are conducted on the V-shaped groove through a waterproof leaking stoppage part, and meanwhile, a grouting nozzle is implanted; grouting holes are obliquely drilled in the two sides of the crack, and a grouting nozzle is installed; and after final set of the waterproof leaking stoppage part, the grouting holes are circularly subjected to pressure grouting; and after grout is completed solidified, the grouting nozzles are disassembled. According to the method, by obliquely drilling the grouting holes in the two sides of the crack and installing the grouting nozzle, a plurality of channels communicating with the interior of the crack are formed, the water pressure of the interior of the crack can be reduced, grout can be injected into the crackconveniently in the later period, through permeation of the grout, the water seepage crack is sealed after the grout is solidified, and accordingly, the water seepage crack leaking stoppage effect isachieved so that underground construction water seepage accidents can be avoided.

Owner:中铁二十三局集团第四工程有限公司

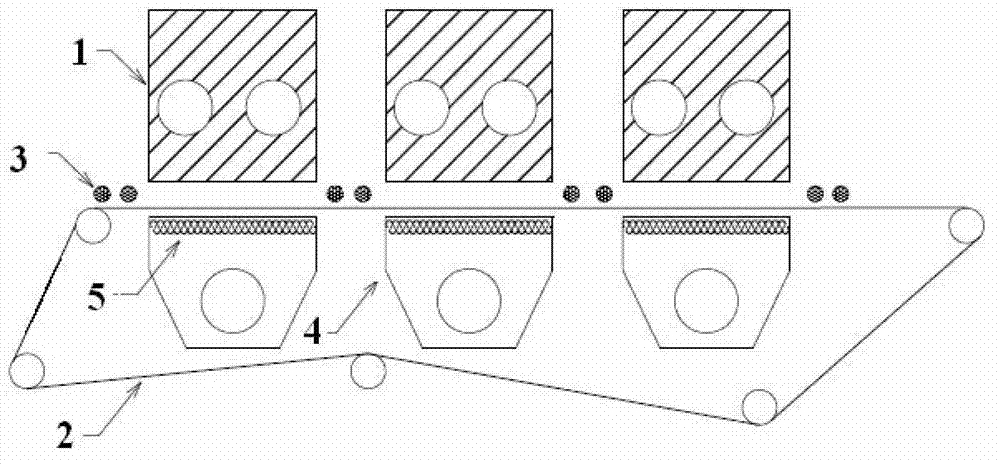

Method for manufacturing tobacco sheet taking substrate as carrier through dry paper making method

A method for manufacturing tobacco sheet taking substrate as a carrier through a dry paper making method comprises the following steps: spraying slurry onto the right side of the substrate through a high pressure spraying method, and meanwhile carrying out negative pressure suction across a wire belt to the reverse side of the substrate; then sending the substrate into an oven and carrying out medium temperature baking and humidity discharging under the condition that the temperature of the substrate is 55 DEG to 70 DEG, and enabling hot air inside the oven to flow directional from the right surface of the substrate to the reverse surface of the substrate to carry out humidity discharging; sequentially, carrying out normal temperature humidity discharging treatment; setting medium temperature baking and humidity discharging time and the normal temperature baking and humidity discharging alternatively; and repeating the steps on the reverse side of the substrate, namely a tobacco sheet is prepared. The substrate is prepared by that scattered material is evenly paved and absorbed onto a formation fabric for dry paper making to form a fiber thin layer under the vacuumpumping of a vacuum air pumping device under the formation fabric, and carrying out antistatic-electricity treatment; and spraying adhesion agent onto a fiber thin layer, under the combination of mist spraying and vacuum take-off on sprayed back surface; and finally carrying out drying.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

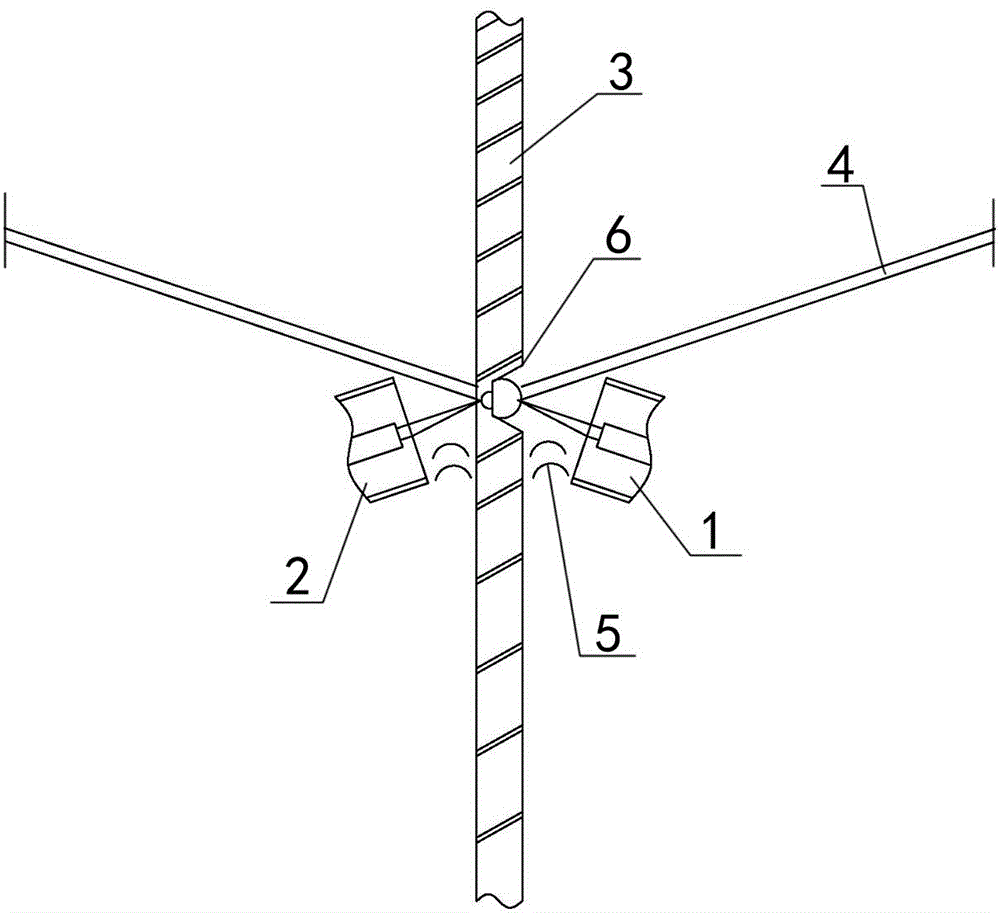

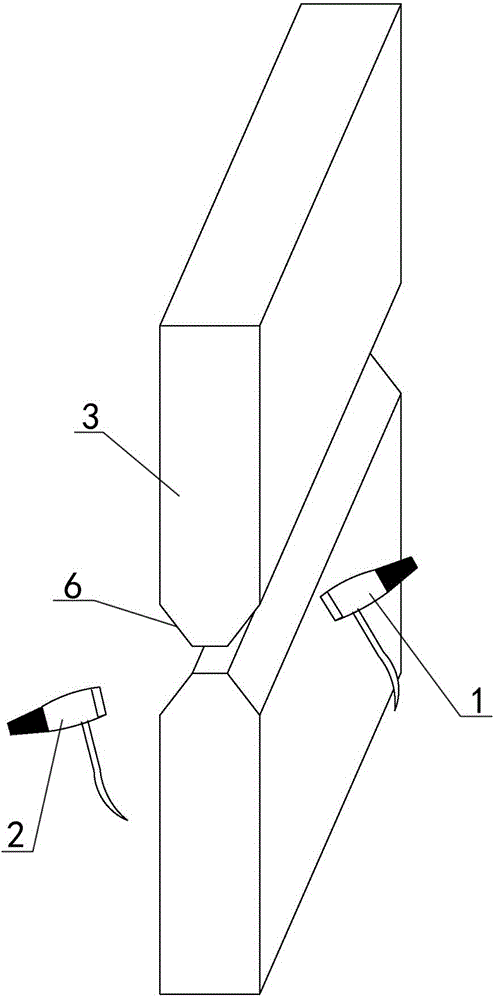

Double two-sided synchronous tungsten electrode high-frequency pulse argon arc welding butt welding method

InactiveCN104096954AAvoid drippingImprove liquidityArc welding apparatusDomestic vesselsButt weldingEngineering

A double two-sided synchronous tungsten electrode high-frequency pulse argon arc welding butt welding method is implemented by the following steps: cleaning up sundry, carrying out groove processing on the welding position of a wall plate of a stainless steel storage tank, welding position welding, choosing welding torch equipment, aligning a same weld pool by a main welding torch and an auxiliary welding torch from the inside and outside of a weld joint respectively synchronously, arcing synchronously by the main welding torch and the auxiliary welding torch, enabling the auxiliary welding torch to be moved synchronous to the main welding torch, welding along the same direction at the same speed, and stopping arcing by the main welding torch and the auxiliary welding torch synchronously. By adopting the double two-sided synchronous tungsten electrode high-frequency pulse argon arc welding butt welding method, the inner side forming of the weld joint is protected and penetrated, the defects of oxidation, overlap, lack of penetration and the like of the weld joint are avoided, the processes of root clearing, grinding and re-welding on the inner side are omitted, compared with the prior art, the method has the advantages of simple method and easy implementation, the production efficiency is greatly improved, and the labor intensity of workers is lowered.

Owner:中建一局集团安装工程有限公司 +1

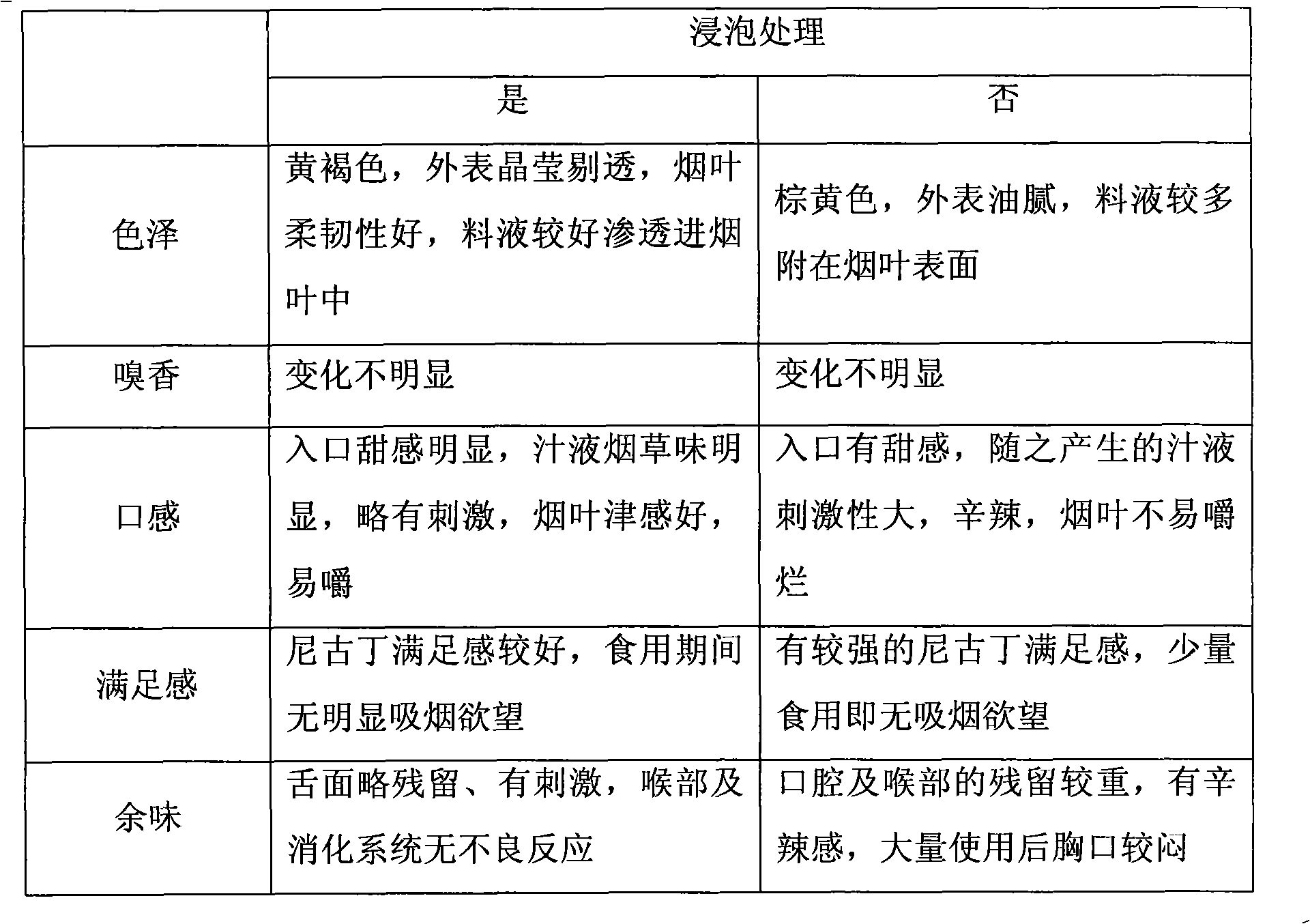

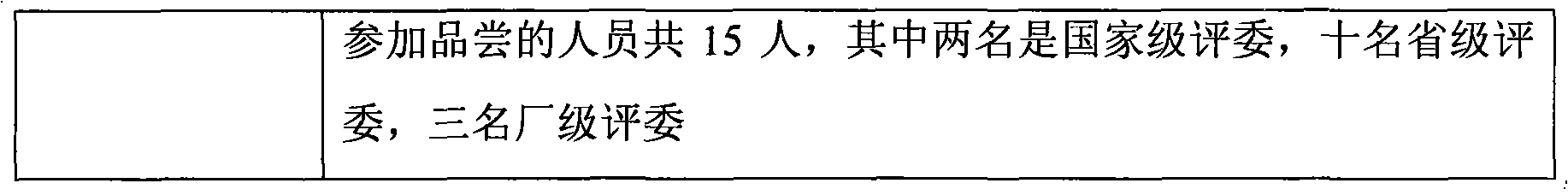

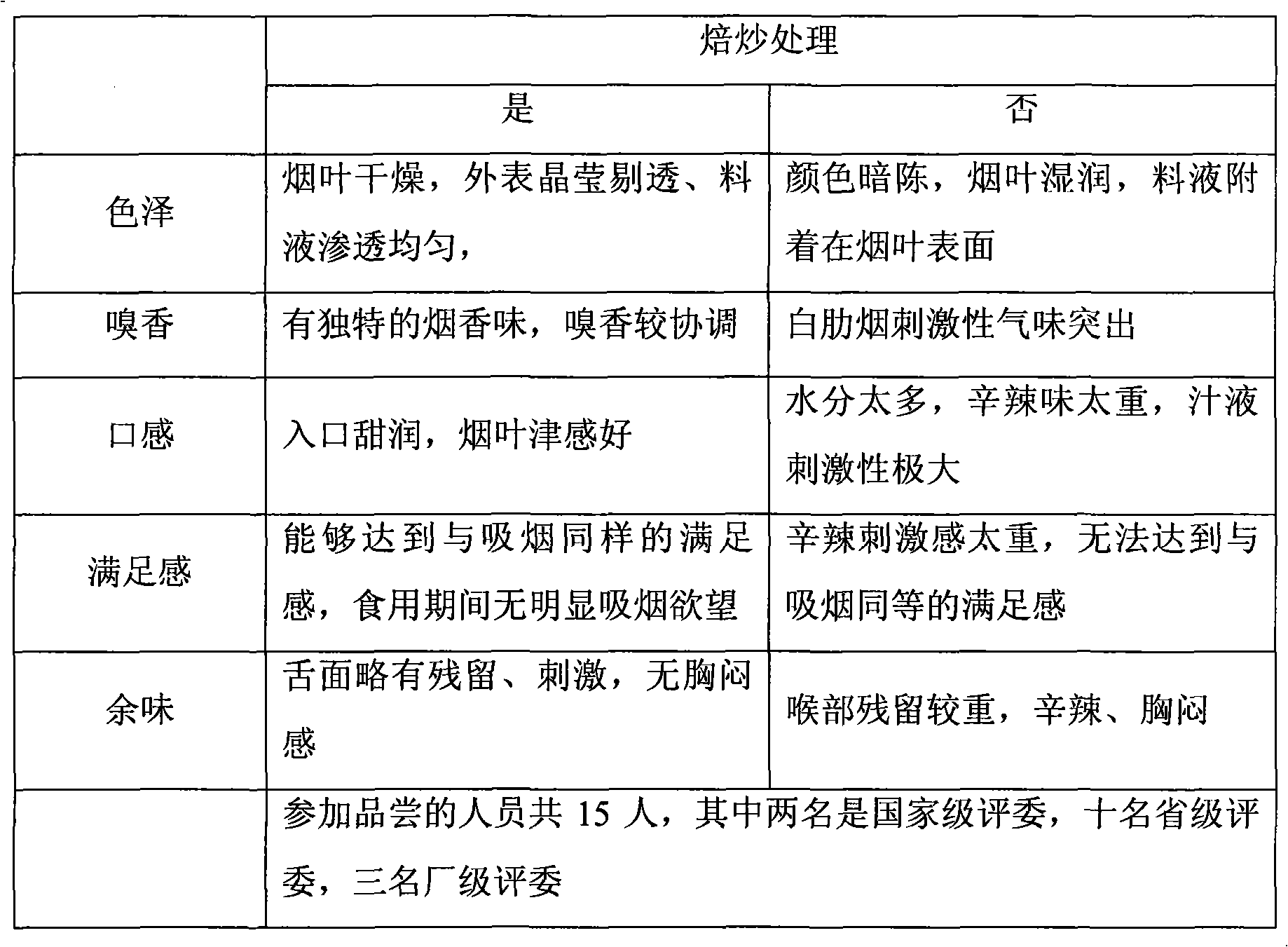

Chewing tobacco and preparation method thereof

ActiveCN101536737AImprove distributionLess irritatingTobacco treatmentFood preparationFlavorCocoa Powders

The invention discloses a chewing tobacco and a preparation method thereof, which belong to the technical field of tobacco. The chewing tobacco comprises the following components: 1 portion of burley tobacco leaf, 0.2 to 1 portion of honey, 0.01 to 0.25 portion of cocoa powder or coffee powder, 0.05 to 0.4 portion of maltose, 0.05 to 0.5 portion of apple juice extractum, and 0.02 to 0.1 portion of water. The preparation method comprises the following steps: (1) immersing and drying the tobacco leaves; (2) removing the stems, and slicing the tobacco leaves; (3) roasting the tobacco leaves; (4) roasting the tobacco leaves again; and (5) placing the tobacco leaves at a room temperature for 1 to 2 days and obtaining the product after packaging in required forms. The invention can provide the chewing tobacco with cocoa or coffee taste. The method is rapid, simple and feasible, and has low cost. The chewing tobacco prepared by the method can give off the flavor preferably, greatly reduce the biting taste and irritating sensation of the tobacco leaves, and make a person having the chewing tobacco get the satisfaction just like smoking.

Owner:HUBEI CHINA TOBACCO IND

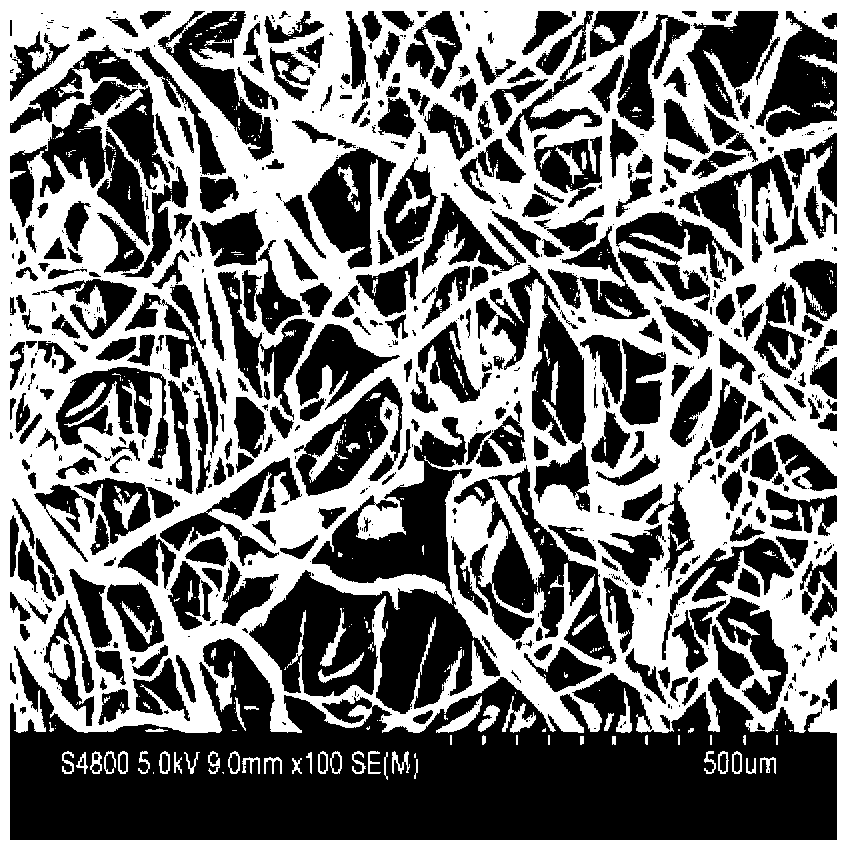

Method for manufacturing remanufactured tobacco base sheets with dry paper-making method

The invention discloses a method for manufacturing remanufactured tobacco base sheets with a dry paper-making method. The method comprises the steps as follows: raw materials including cabo and plant fibers are ground and broken into short fibers, and then fed by wind into a forming head box for breaking up; by the aid of the vacuum pumping action of a vacuum evacuating device under a forming net, the broken-up materials are uniformly laid and adsorbed on the forming net for dry paper-making, so that a thin fiber layer is formed; the thin fiber layer is sprayed with an adhesion agent, and a manner combing mist spraying and vacuum drawing of a prayed back surface is adopted; finally the materials are dried and the tobacco base sheets are obtained; an antistatic rope is laid between the forming net and the forming head box and / or between the forming net and an opening of a vacuum box; or / and an antistatic net is arranged between the forming net and the opening of the vacuum box; the adhesion agent comprises chitosan and the like; and the remanufactured tobacco base sheets having higher wet strength stretching-resistant capacity and filling value and good processing performance are prepared with the dry paper-making method successfully for the first time.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

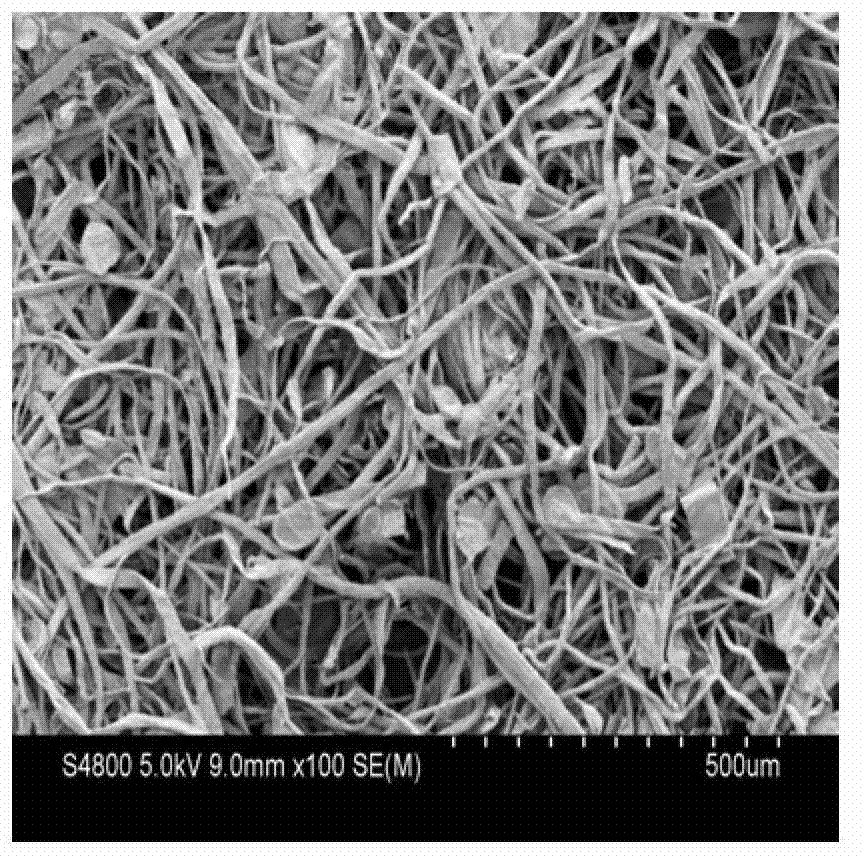

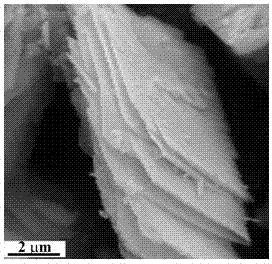

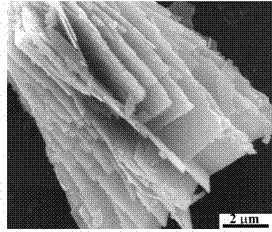

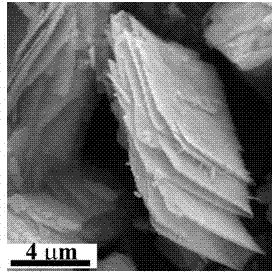

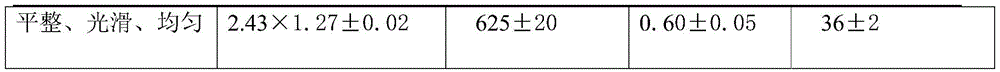

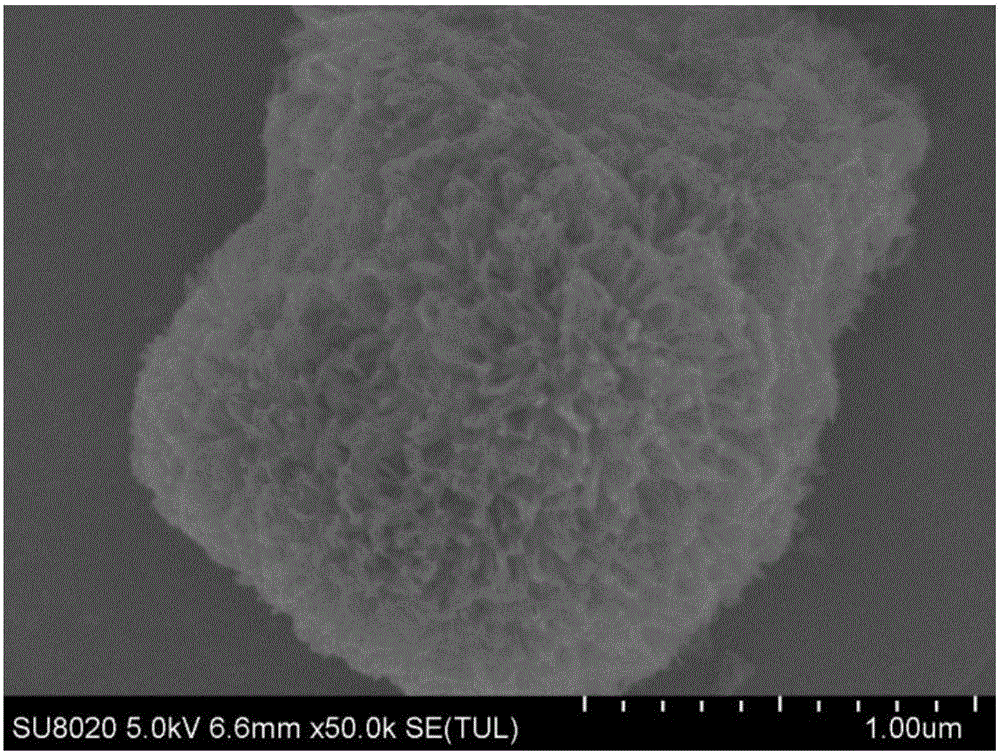

Co3O4 nano lamellar material and preparation method and application thereof

InactiveCN102412397AGood water solubilityPromote nucleationCell electrodesNanotechnologyCobalt saltLithium-ion battery

The invention discloses a Co3O4 nano lamellar material and a preparation method and application thereof. The preparation method comprises the following steps of: mixing cobalt salt, a surfactant, a precipitator and deioned water in stoichiometric ratio; transferring the mixed solution into a reaction kettle and carrying out hydro-thermal reaction for 17.5-18.5 hours at 115-125 DEG C; and then washing and drying to obtain a powdery mixed precursor; and carrying out heat treatment on the powdery mixed precursor in air to finally obtain the Co3O4 nano lamellar material. The prepared Co3O4 material is of a regular nano lamellar structure, and can be applied to the negative electrode of a chargeable lithium ion battery so as to improve the storage capacity of lithium.

Owner:SHANGHAI INST OF TECH

Method for preparing eucalyptus and poplar mixture material bleached chemical thermomechanical pulp

ActiveCN101418531ASolve the shortage of resourcesFull penetrationPretreatment with water/steamNon-fibrous pulp additionAccelerantEnergy consumption

The invention belongs to the technical field of preparing bleached chemical thermomechanical pulp and in particular relates to a process method for preparing the bleached chemical thermomechanical pulp from eucalyptus and poplar. The process method adopts the eucalyptus and the poplar as raw materials to prepare the bleached chemical thermomechanical pulp; through the addition of a pulp grinding accelerant, the process reduces energy consumption of pulp grinding by 10 to 15 percent compared with the prior process for the bleached chemical thermomechanical pulp, reduces production cost, saves energy and simultaneously reduces the content of pulping fasciculus.

Owner:山东晨鸣纸业集团股份有限公司 +1

ITO-Ag-ITO etching liquid for AM-OLED display screen and preparation method

ActiveCN105176533AAdjust densityConsistent etch rateSurface treatment compositionsAcetic acidO-Phosphoric Acid

The invention discloses ITO-Ag-ITO etching liquid for an AM-OLED display screen and a preparation method. The etching liquid is prepared from phosphoric acid, acetic acid, nitric acid, additives, surfactants and pure water. The preparation method of the etching liquid comprises the steps that the rotating speed of a stirrer of a dosing tank is kept at normal temperature and pressure, the pure water, the phosphoric acid, the acetic acid, the nitric acid, the additives, the surfactants and the balance pure water are sequentially added into the dosing tank, and after full stirring is conducted, the ITO-Ag-ITO etching liquid is prepared by introducing a fully-stirred mixture into a filter for filtration. According to the ITO-Ag-ITO etching liquid for the AM-OLED display screen and the preparation method, the ITO-Ag-ITO etching liquid is small in particle size and high in purity, the etching rate to different metal is basically the same, and reaction is stable; the etching rate can be controlled by adjusting the concentrations of the phosphoric acid and the nitric acid, the surface of a substrate etched through the etching liquid is clean and tidy, residues do not exist, the intermetallic layering phenomenon does not exist, remaining lines are flat and smooth, and the etching angle is kept between 70 degrees to 90 degrees.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

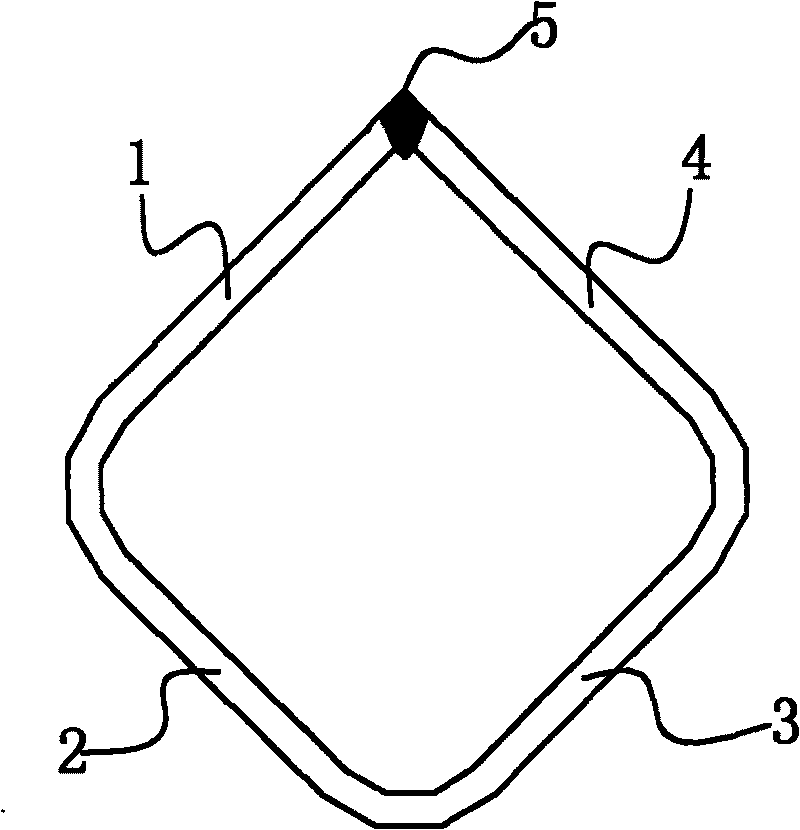

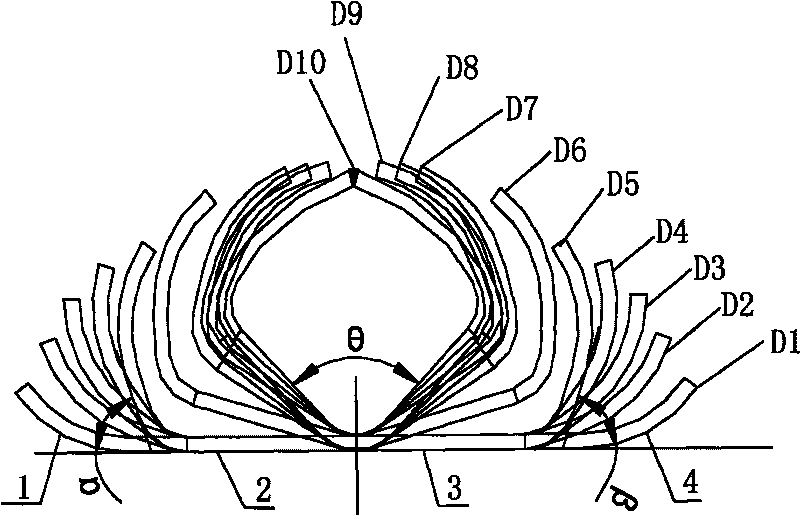

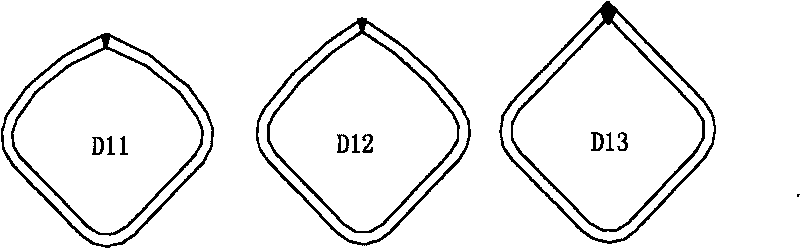

Method for processing open-web sharp-angled rhomboid tube

The invention discloses a method for processing an open-web sharp-angled rhomboid tube. The open-web sharp-angled rhomboid tube comprises a first side, a second side, a third side and a fourth side which are sequentially connected, wherein the fourth side and the first side are in butt joint to form a sharp angle. The processing method comprises the following steps of: A, rolling areas corresponding to the first side and the fourth side on two sides of a steel band by a roller to enable partial areas of the first side and the fourth side to become arc faces; B, rolling and bending the junction of the first side and the second side and the junction of the fourth side and the third side; C, rolling and bending the junction of the second side and the third side by the roller to enable an inclined angle of the second side and the third side to be gradually reduced until the first side and the fourth side are nearly closed; D, carrying out stitch welding to completely close and weld the first side and the fourth side together; E, scraping a vertex angle at the welded part into a sharp angle by a scraper; and F, reshaping the first side and the fourth side into a plane and simultaneously reshaping the sizes and inclined angles of various sides to the final requirements.

Owner:上海佳冷冷弯科技股份有限公司 +1

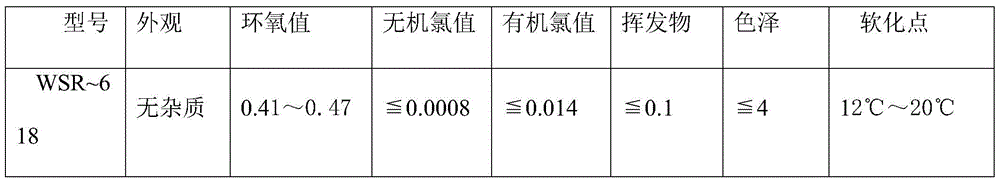

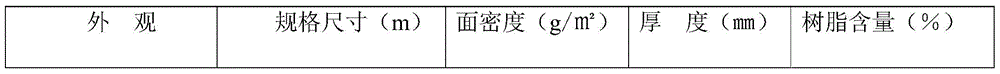

High-performance non-metal puncture-proof sheet

InactiveCN105696357AHigh hardnessImprove stab resistanceLamination ancillary operationsSynthetic resin layered productsEpoxyMass ratio

This patent application discloses a stab-proof sheet, especially relates to a high-performance non-metallic stab-proof sheet and its manufacturing process. The high-performance non-metal stab-proof sheet is made by painting a certain proportion of mixed resin on both sides of the aramid woven fabric, and then performing molding and drying and curing. By adding a resin matrix to the aramid woven fabric to increase the hardness of the material and enhance its mechanical properties such as impact resistance and shear strength. The mixed resin is formed by stirring epoxy resin and acetone into a mixture at a mass ratio of 3.7-4.3:1, and then mixing the mixture with polyamide resin at a mass ratio of 2:1-1.2. This patent overcomes the defects of low anti-stab performance, poor stability and high production cost in the existing non-metallic anti-stab material technology, and provides a anti-stab material with low cost, strong anti-stab performance and high stability , the cost is lower than that of imported anti-stab film.

Owner:CHONGQING SHIELD KING IND

High-permeability resin type timber enhancing modifier and efficient immersion treatment control method

InactiveCN105563579AFull penetrationImprove performanceWood treatment detailsPressure impregnationSolubilityPermeation

The invention belongs to a high-permeability resin type timber enhancing modifier and an efficient immersion treatment control method. The method includes: preparing materials according to mole ratio of melamine to formaldehyde to methanol to urea being 1:2-2.5:0.5-1.0:0.2-1.0, wherein the adding amount of flexibilizer is 10-30% of the amount of the melamine. Modified melamine urea resin with good water solubility, high permeability and low molecular weight and used for immersion is prepared by adjusting raw material proportion, using a low-temperature long-time multistage synthesizing process and adding alcohol flexibilizer, polymerization inhibitor and the like. The permeation channels of timber hard in immersion are opened through a multi-time alternating breathing type immersion treatment process, the timber can be permeated evenly, and timber performance is improved greatly. The high-permeability resin type timber enhancing modifier and the efficient immersion treatment control method have the advantages that the timber hard in immersion can be permeated sufficiently, and various performance of the timber can be improved evidently; the fast-growing timber, modified by the method, of a man-made forest is high in density, high in strength, good in toughness, stable in size, flame retardant, capable of preventing mildew and corrosion, good in processing performance, environmental friendly in production, good in use effect, high in additional value, and the like.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

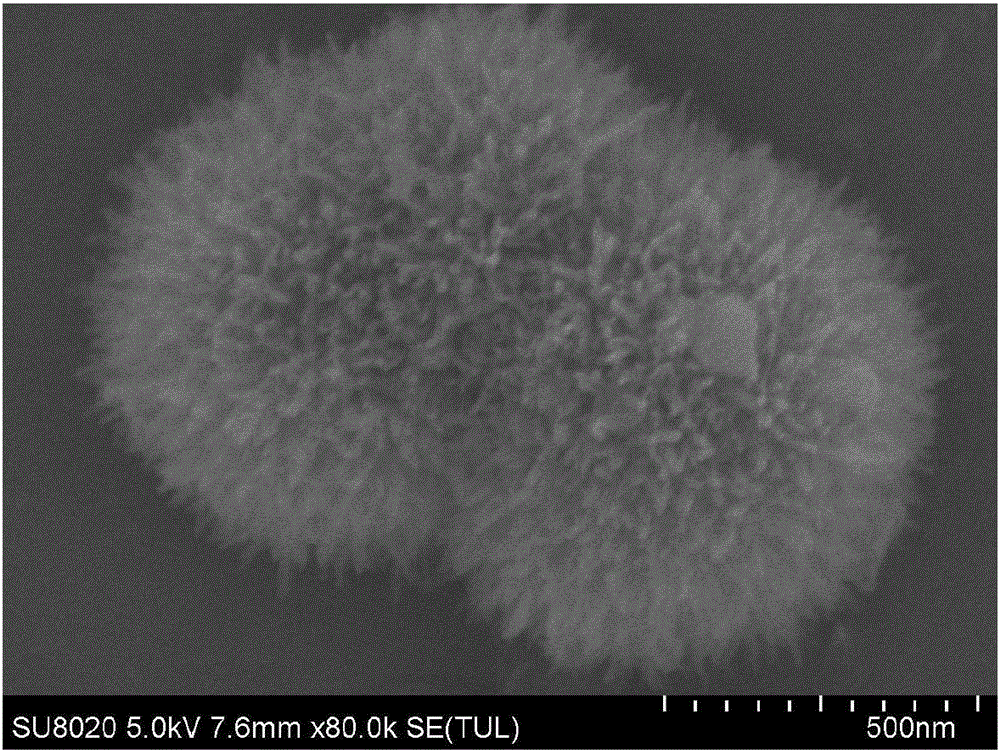

Method for preparing supercapacitor electrode material basic nickel-cobalt carbonate through hydrothermal method

InactiveCN106587171AFully moistenedFull penetrationHybrid capacitor electrodesNickel carbonatesNickel saltHigh pressure

The invention discloses a method for preparing a supercapacitor electrode material basic nickel-cobalt carbonate through a hydrothermal method. The method comprises the following steps that metal nickel salt and / or metal cobalt salt and urea are weighed separately and mixed with deionized water, and stirring is performed so that solids can be dissolved to obtain a mixed solution; the mixed solution is poured into a high-pressure reactor, sealing is performed for performing a reaction for 10-16 h under the temperature of 80-110 DEG C, and a reaction product is obtained; the reaction product is separated, washed and dried to obtain basic nickel-cobalt carbonate. According to the method for preparing the supercapacitor electrode material basic nickel-cobalt carbonate through the hydrothermal method, on the basis of control over raw material compatibility and reaction conditions, the three-dimensional porous structure and morphology can be obtained, sufficient wetting and permeation of an electrolyte are promoted, the superficial area of active substances is sufficiently utilized, and the electrochemical performance is improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

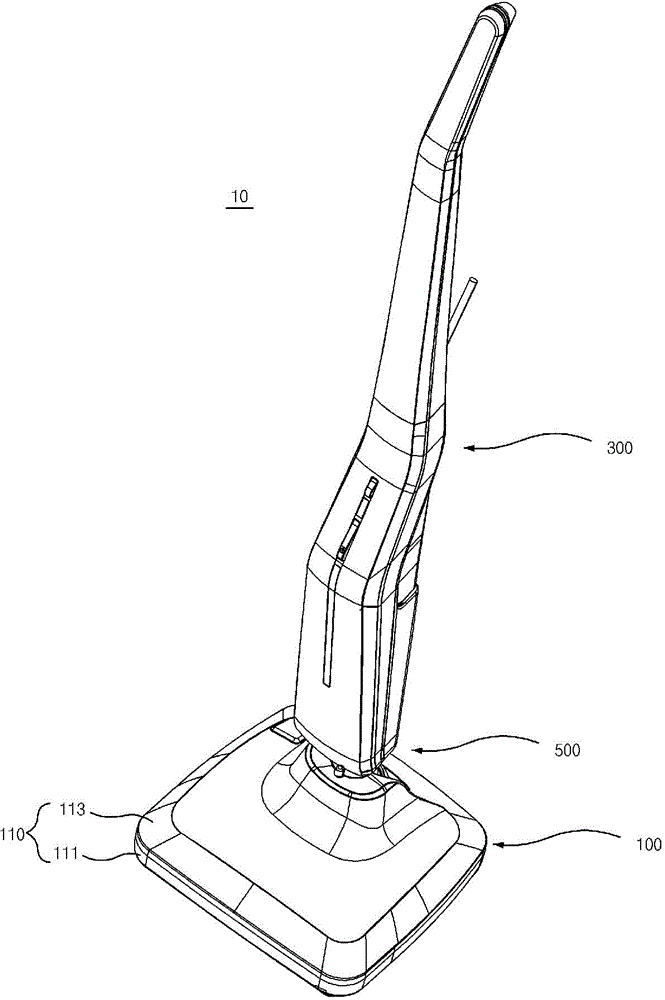

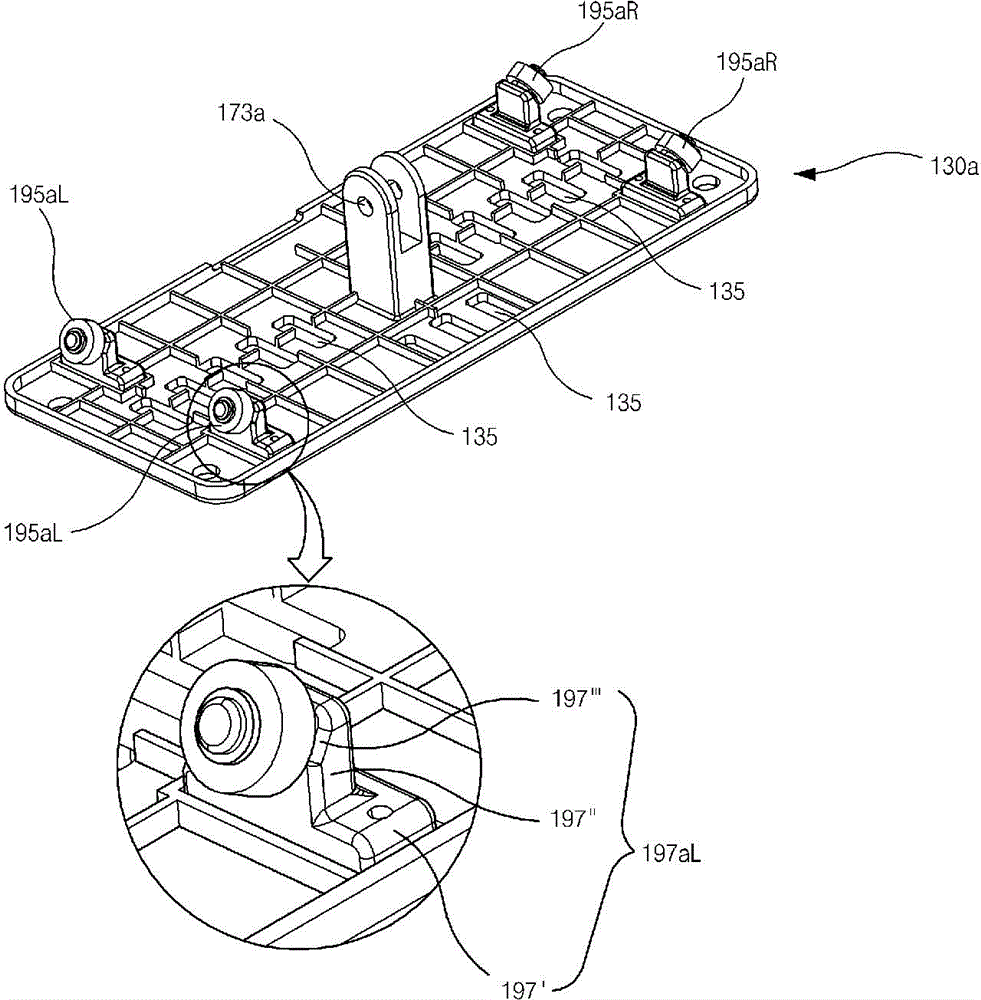

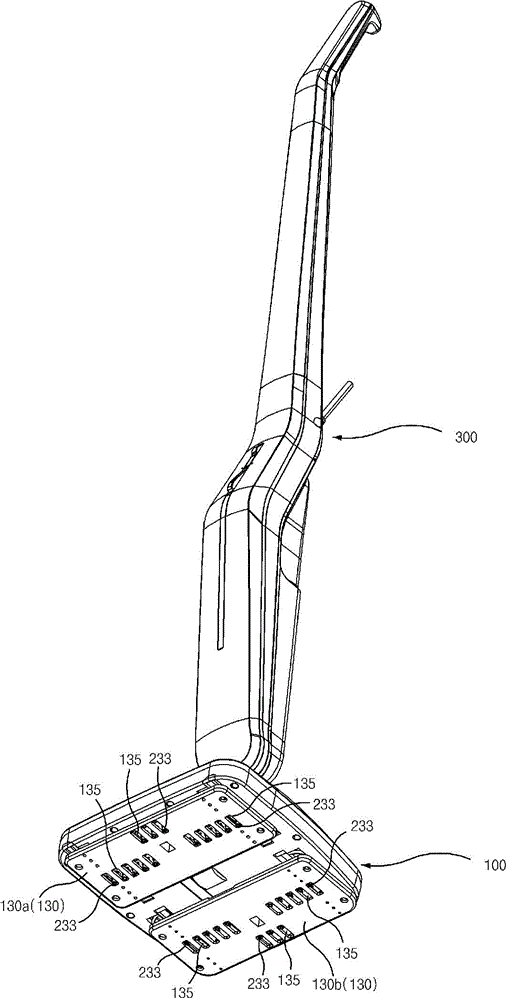

Base assembly for floor cleaner

InactiveCN102860797AAchieve bactericidal effectFull penetrationCarpet cleanersFloor cleanersEngineeringMechanical engineering

The present invention relates to a base assembly for a floor cleaner, which cleans a floor through that two rag-adhered pads mutually approach and move back to perform a straight reciprocating motion; in particular to a base assembly for a floor cleaner, which performs floor wiping and sterilization through spraying steam to the rag-adhered pads to perform reciprocating motion.

Owner:SUZHOU HAAN TECH +1

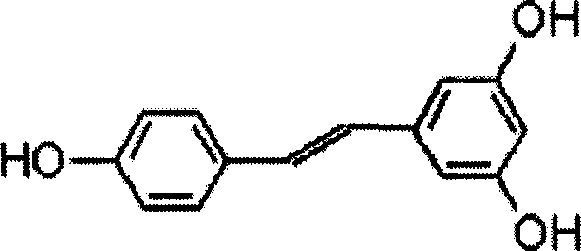

Coated nanoliposomes of resveratrol and preparation method thereof

InactiveCN1951369AWide range of drugsReduce dosageHydroxy compound active ingredientsPharmaceutical non-active ingredientsResveratrolLiposome

The invention discloses a dressed millimicron liposome of resveratrol, liposome comprises resveratrol, lecithin or soybean lecithin, cholesterin 50-85%, chloridized chitosan 0.5-1% and auxiliary materials 5-40%. The dressed liposome has the advantages of better adaptability for patients and simpler preparing process.

Owner:李万忠

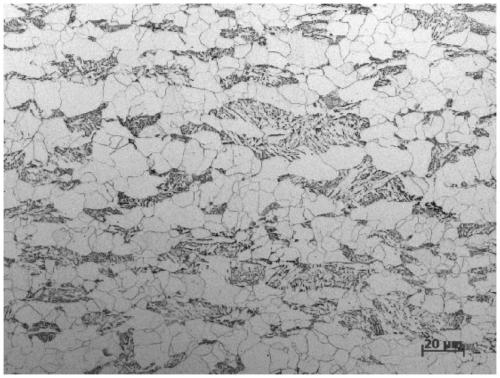

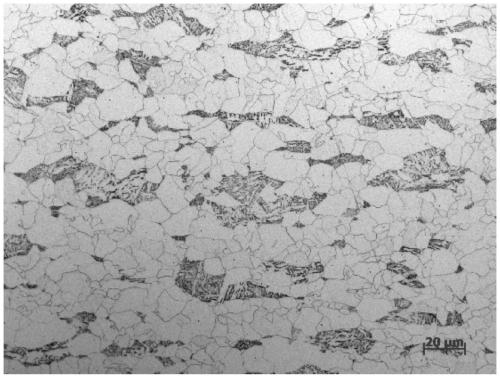

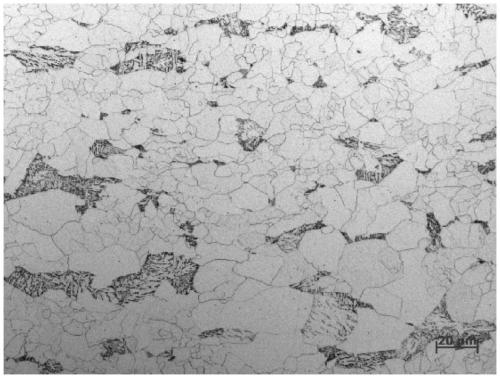

Large-wall-thickness X52MS acid-resistant pipeline steel plate produced by LF-RH refining process and manufacturing method thereof

The invention relates to a large-wall-thickness X52MS acid-resistant pipeline steel plate produced by an LF-RH refining process. The steel plate is characterized by being manufactured from the following chemical component percentage by weight: 0.03%-0.07% of C, 0.2%-0.4% of Si, 1.0%-1.4% of Mn, 0.02%-0.04% of Al, 0.02%-0.05% of Nb, less than or equal to 0.02% of V, 0.004%-0.012% of Ti, 0.1%-0.4% of Cr, 0.1%-0.2% of Mo, less than or equal to 0.0005% of B, less than or equal to 0.012% of P, less than or equal to 0.001% of S, less than or equal to 0.005% of [N], less than or equal to 0.005% of [O], less than or equal to 0.0015% of [H] and the balance being Fe and inevitable impurities, wherein the cold crack sensitivity coefficient Pcm is less than or equal to 0.19. The manufacturing method comprises the sequential steps of KR molten iron pretreatment, converter smelting, LF and RH refining, plate blank continuous casting, plate blank heating, rough rolling, intermediate blank cooling, finish rolling, ACC cooling and the like. The manufactured steel plate has thickness being 35.1-44.2 mm, yield strength being 380-440 MPa, tensile strength being 490-570 MPa, and elongation being greater than or equal to 33%, yield ratio being less than or equal to 0.09; an average shear plane ratio of drop hammer under the temperature of minus 5 DEG C is 85% or more; and the large-wall-thickness X52MS pipeline steel can meet the requirement of being used in an acidic environment, and has good HIC resistance and low-temperature toughness.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Method for manufacturing reconstituted tobacco substrate by using dry method of paper making

ActiveCN103222676AMake a qualitative leapNo significant emissionsTobacco preparationFiberCarrying capacity

A method for manufacturing a reconstituted tobacco substrate by using a dry method of paper making comprises the following steps: after tobacco stems, plant fiber materials become short fibers by crushing and fiber dissolving, the short fibers are conveyed to forming head boxes to be broken up by wind, and the broken-up materials are evenly laid and adsorbed on a forming net of the dry method of paper making by the vacuumizing effect of an air suction device below the forming net to form a fiber film; an adhesive is added into the fiber film in a spraying manner, wherein a manner combining spraying through mist spray with vacuum suction on the back face of the spraying is adopted; and finally the reconstituted tobacco substrate with a dimensional lattice structure is obtained by oven-drying. Antistatic ropes are laid between the upper part of the forming net and the forming head boxes or between the forming net and openings of vacuum boxes, and / or antistatic nets are laid between the forming net and the openings of the vacuum boxes. According to the invention, dry method of paper making is firstly used successfully to manufacture the reconstituted tobacco substrate which has better wet strength, a stronger tensile capacity, a high load-carrying capacity, a high filling value and an excellent processing capability.

Owner:CHINA TOBACCO HUNAN INDAL CORP

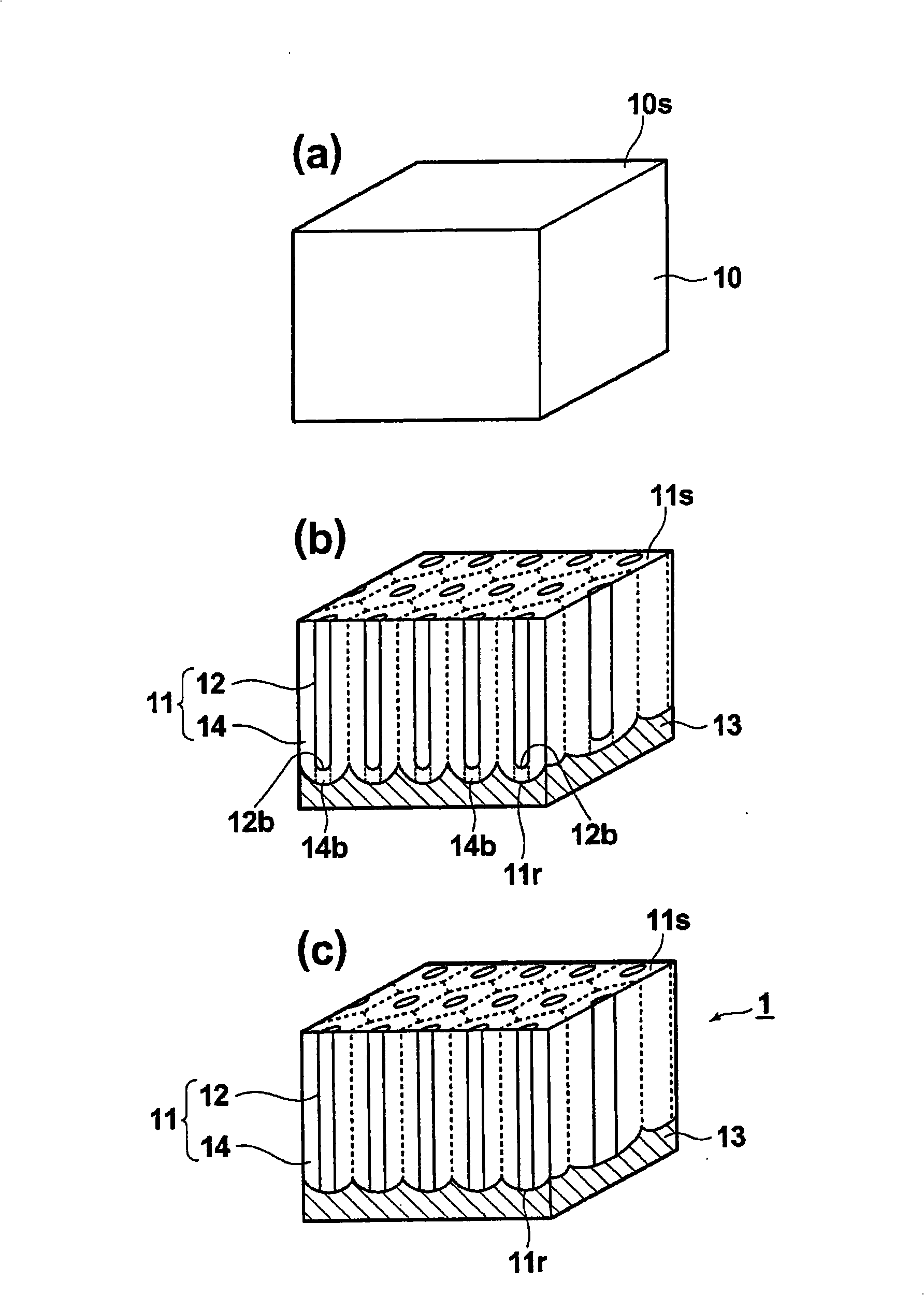

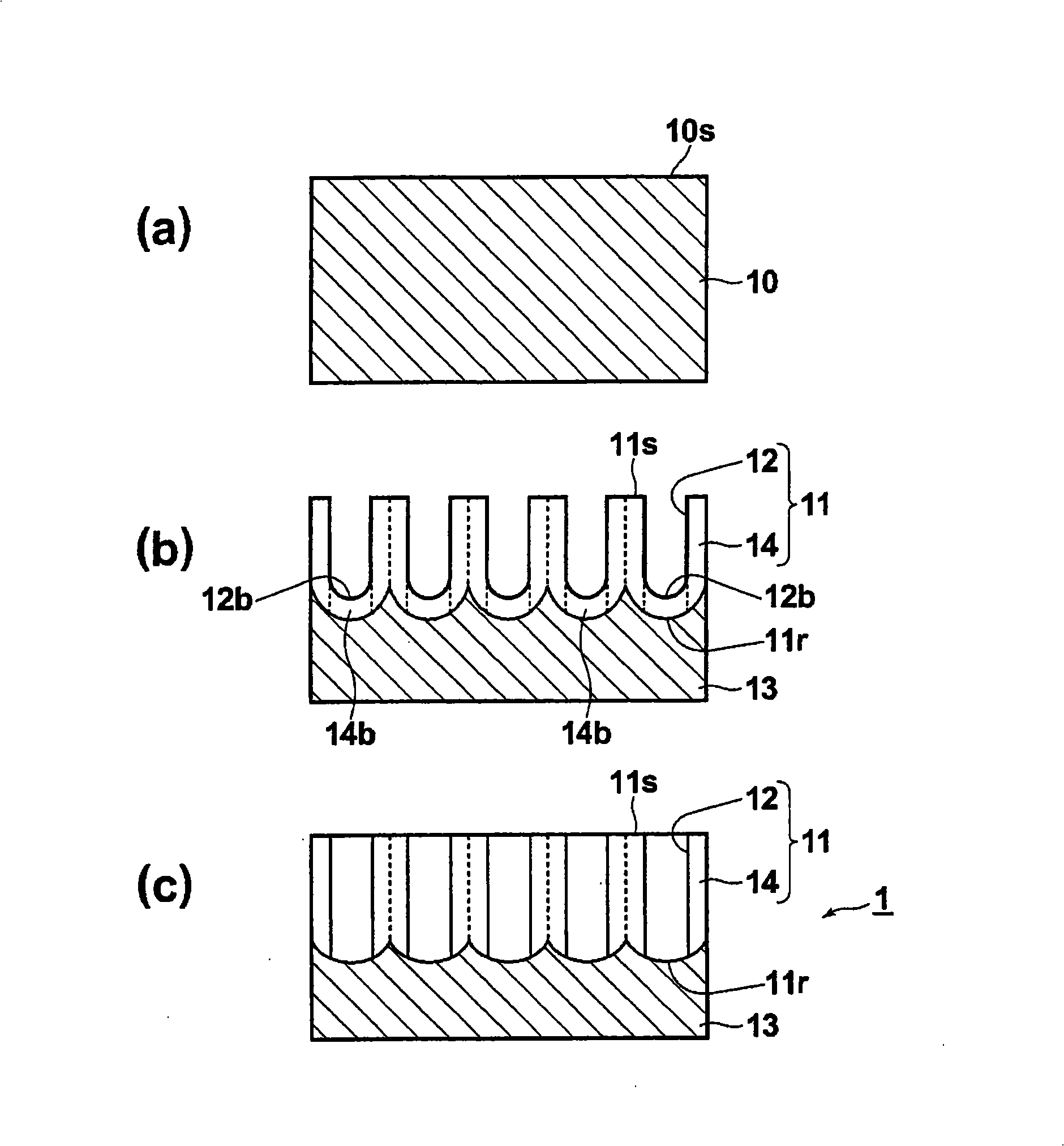

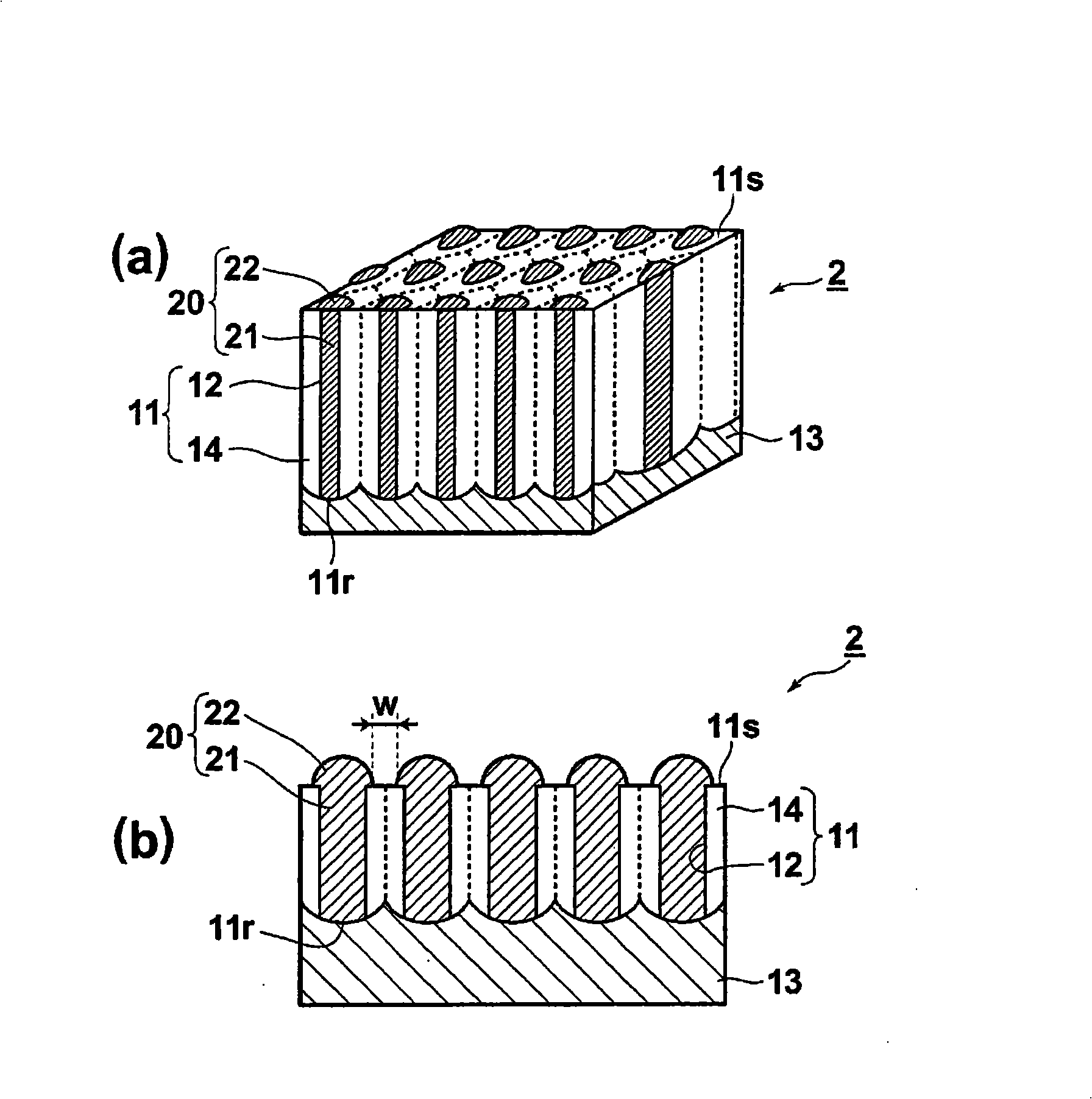

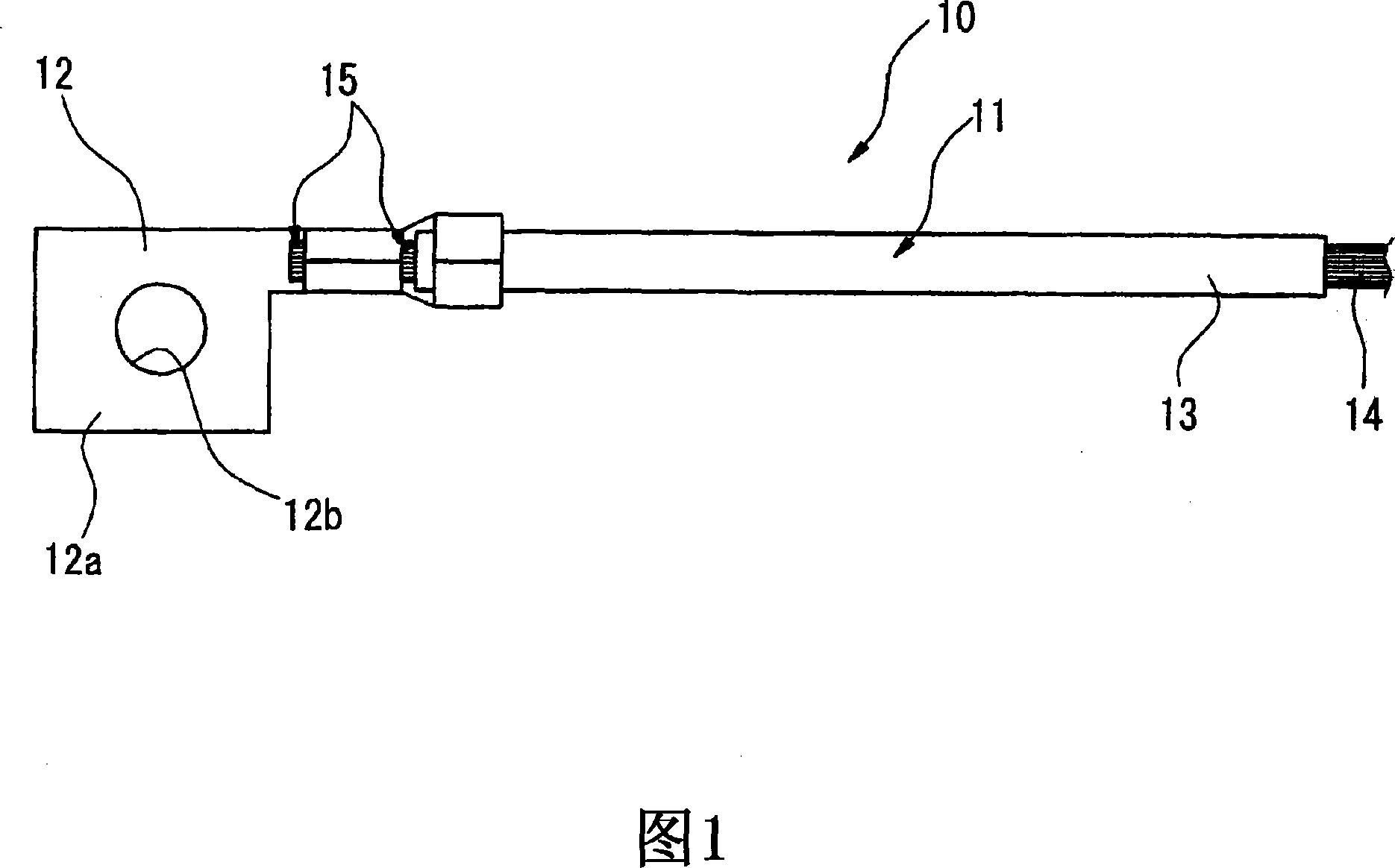

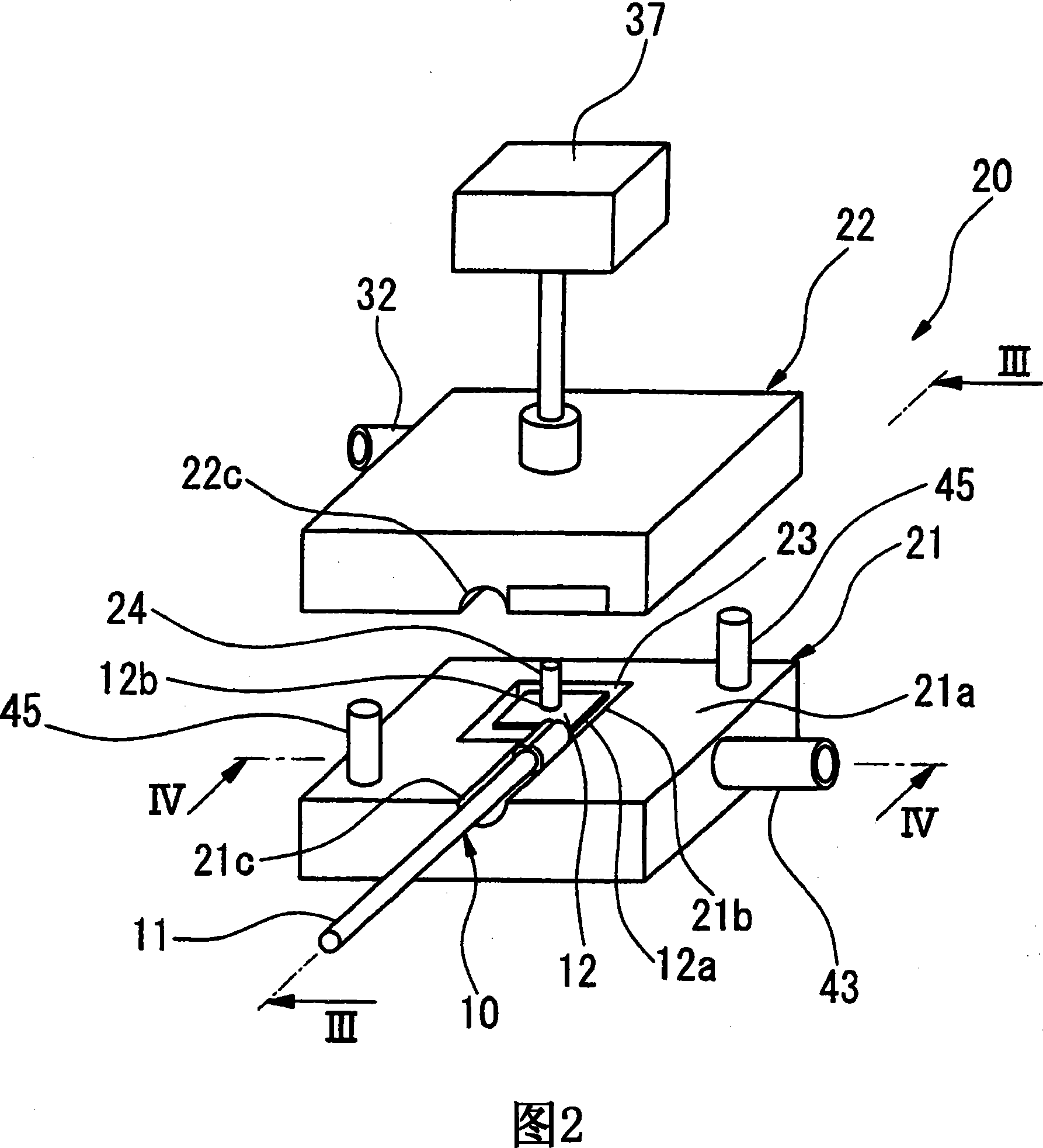

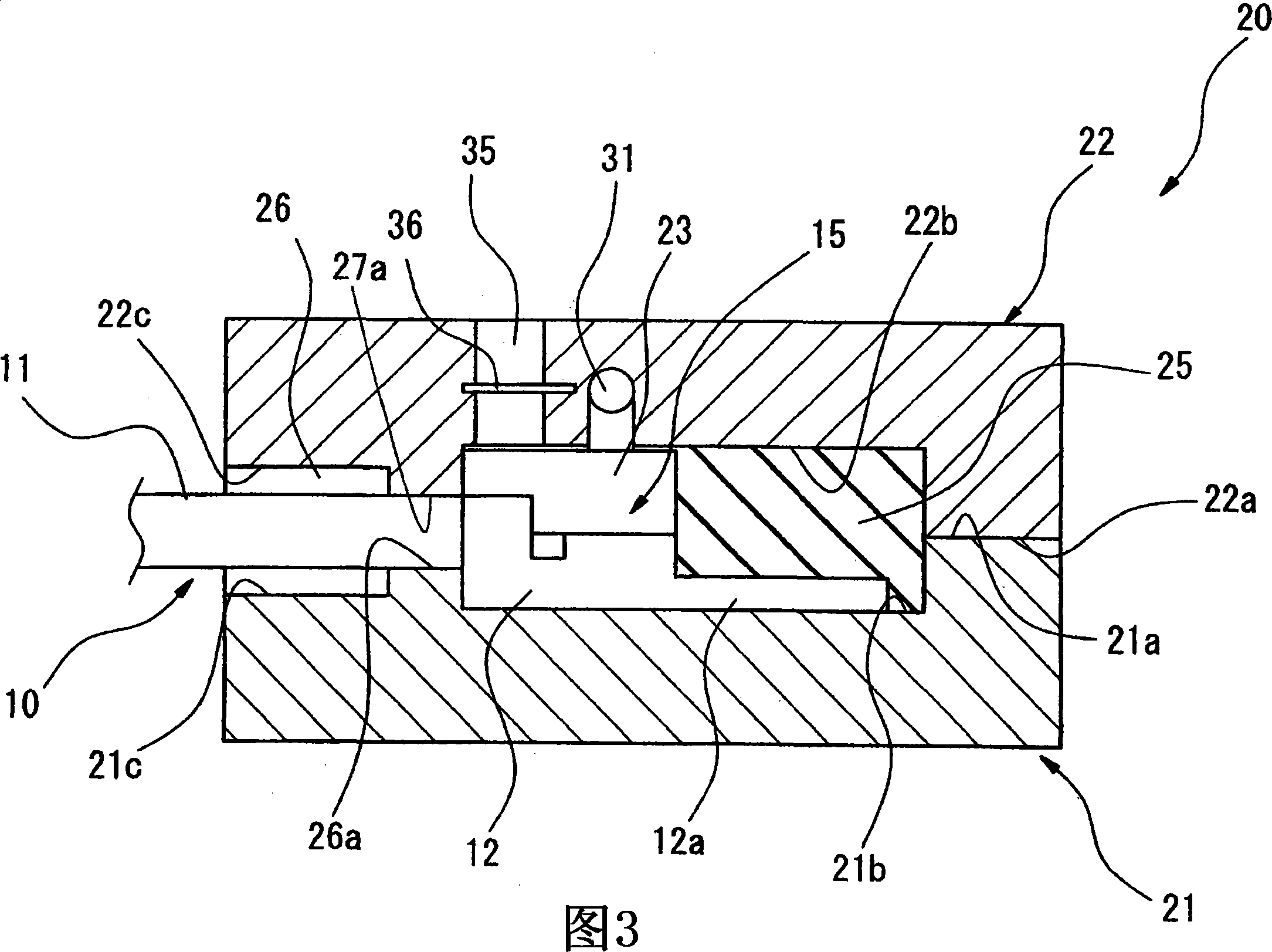

Microstructure body and manufacturing method thereof

InactiveCN101302639AWon't peel offWon't wasteAnodisationIndividual molecule manipulationElectrical conductorDry etching

A superfine construct and the method of producing the same; the method is able to simply produce the superfine construct having anodic oxide; the anodic oxide has a plurality of micro holes; the micro hole has excellent connectivity to connect to the electrical conductor. The method comprises: preparing anodized metal (10), anodizing the anodized metal (10), until the midway to form a plurality of anodized parts (11) having bottom micro holes (12) on the opening of the anodizing surface (10S) of the anodized metal (10) and non-anodized parts (13); dry etching the anodized part (14b) between bottom having a plurality of micro holes (12) and the non-anodized parts (13) to the non-anodized parts (13), thereby removing the same.

Owner:FUJIFILM CORP

Carburization prevention coating for ultralow carbon stainless steel casting

The invention discloses a carburization prevention coating for an ultralow carbon stainless steel casting. The carburization prevention coating is prepared by mixing 50 to 60 weight percent of white corundum powder, 5 to 10 percent of oxidant, 3 to 8 percent of sintering aid, 1 to 3 percent of organic binder, 2 to 5 percent of bentonite suspending agent, 0.2 to 0.4 percent of aid, and 28.8 to 38.2 percent of solvent; the granularity of the white corundum powder is less than or equal to 3 mu m, the granularity of the oxidant is less than or equal to 5 mu m, and the granularity of talcpowder isless than or equal to 5 mu m; the oxidant is one or more of potassium nitrate, potassium permanganate, potassium dichromate, and potassium chlorate; the sintering aid is one or more of talcpowder, feldspar powder, mica powder, and clay; and the organic binder is rosin or resin; and the solvent is ethanol or isopropanol, the concentration of ethanol is more than or equal to 95 percent, and the concentration of the isopropanol is more than or equal to 98 percent. The coating is poured into some ultralow carbon stainless steel castings of water turbine blades, and the thickness of a surface carburization layer of the ultralow carbon stainless steel casting on which the carburization prevention coating prepared according to the formula is poured is less than or equal to 3mm, and is obviously superior to that of the common coating.

Owner:SHENYANG RES INST OF FOUNDRY

Method for coating hollow bodies

InactiveUS6887519B1Increase specific densitySufficient flow propertyLiquid surface applicatorsSolid state diffusion coatingPowder mixtureMetal halides

A process for coating hollow bodies, in which a powder mixture including a metal donor powder, an inert filler powder and an activator powder including a metal halide is provided, the powder mixture is brought into contact with an inner surface, which is to be coated, of the hollow body and is heated, in which process, in order to increase the internal layer thicknesses, the inert filler powder is provided with a mean particle size which is approximately the same as the mean particle size of the metal donor powder.

Owner:MTU AERO ENGINES GMBH

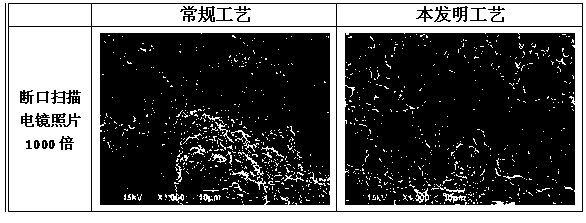

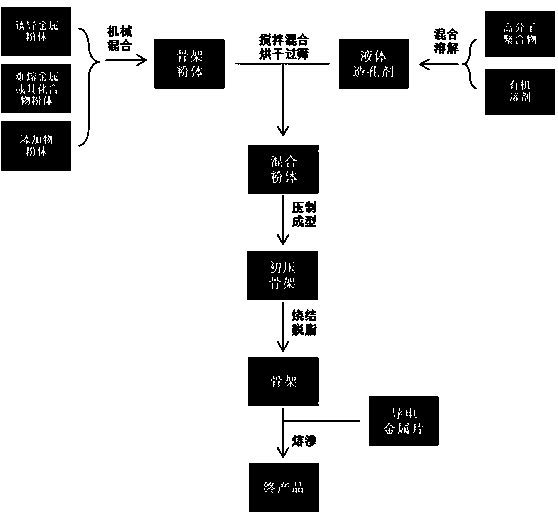

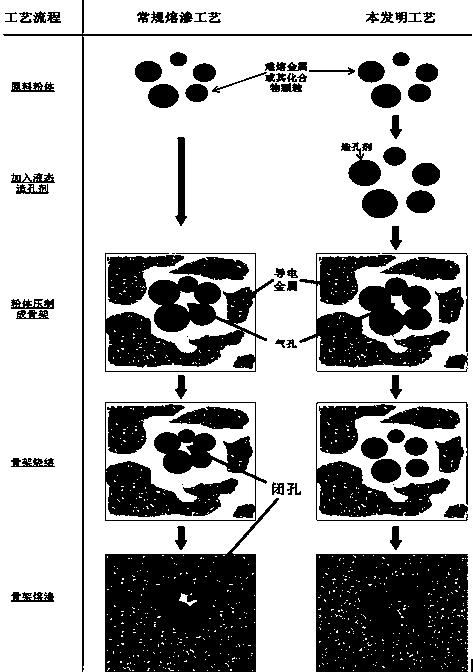

Manufacturing method of electrical contact

ActiveCN104209520AImprove infiltration effectFull penetrationElectric switchesOrganic solventPolymer

The invention relates to a manufacturing method of an electrical contact. A liquid material prepared by dissolving high-molecular polymer in an organic solvent is used as a pore-forming agent; blind holes are eliminated by the pore-forming agent; by eliminating the blind holes and simultaneously leading in a uniform and communicated pore network, infiltration performance of a skeleton is promoted; a smoother passage is created for flowing of conductive metal liquid, so that the conductive metal liquid more sufficiently permeates the skeleton to obtain an infiltration electrical contact product of which the tissues are more uniform and compact and are more firmly combined. The steps of eliminating the blind holes in the skeleton and forming the uniform and communicated pore network are implemented in a mode of leading in the liquid pore-forming agent in the powder manufacturing process and removing the liquid pore-forming agent after the skeleton is formed. By regulating the addition and the adding mode of the pore-forming agent, the form of the pores in the skeleton can be regulated so as to adapt to the requirements of different infiltration systems. The pore-forming agent used by the manufacturing method is the liquid material and can be completely gasified and removed at a specific temperature and liquid or solid residues cannot be formed in the skeleton, so that the skeleton is guaranteed to have excellent infiltration.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

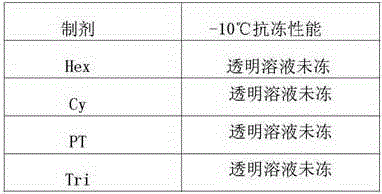

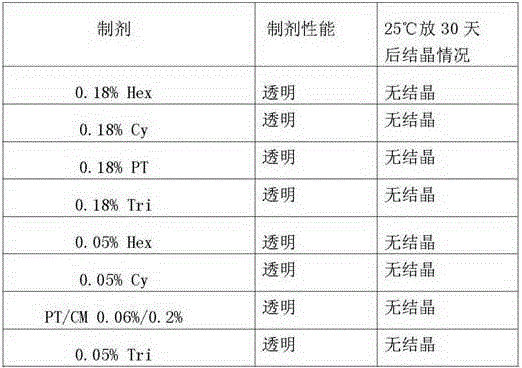

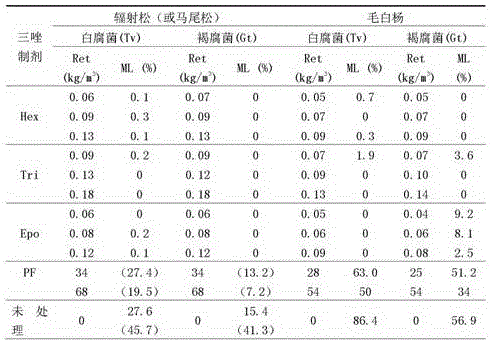

Wood bamboo material corrosion and discoloration prevention triazole composition and preparation method thereof

ActiveCN106003312AImprove anti-corrosion performanceImprove mildew resistanceWood treatment detailsReed/straw treatmentFatty alcoholHexaconazole

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Water stopping method, wire harness processed by the method and water stopping apparatus

ActiveCN101237109AImprove permeabilityPenetration reliableLine/current collector detailsClimate change adaptationStructural engineeringMechanics

A waterproofing device that allows a waterproofing material to penetrate into exposed core wires of a covered electric wire constituting a wire harness includes a pair of a pair of exposed core wire portions of the wire harness that can be disposed by abutting against each other to form a pressurized space. A mold, a filling part that fills the pressurized space in which the core wire exposed portion is arranged with a waterproof material, and a pressurizing part that supplies pressurized gas into the pressurized space and pressurizes the pressurized space.

Owner:YAZAKI CORP

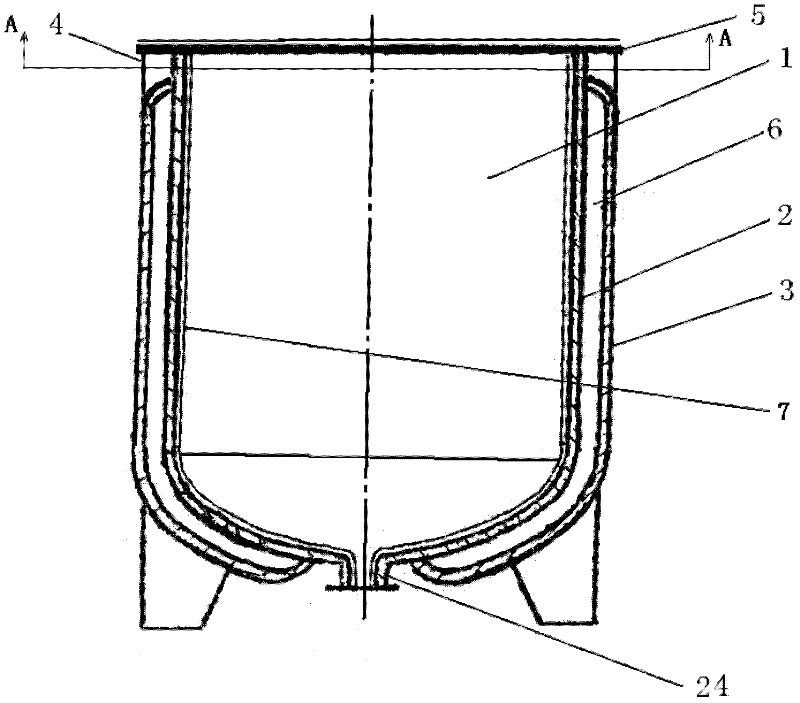

New glass-lined reactor and manufacturing method thereof

InactiveCN102389758AQuality improvementFully combinedChemical/physical/physico-chemical processesTemperature controlManufacturing technology

The invention relates to a new glass-lined reactor and a manufacturing method thereof which are used in the chemical and pharmaceutical industries and belong to the field of pressure vessels. The reactor is characterized in that new inner cylinder bodies and new outer jackets are welded into an integral structure; glass-lined protection glaze layers are coated and fired on the surfaces of butt welds on the inner cylinder bodies and the outer jackets; and the Supervision Regulation on Safety Technology for Pressure Vessel is comprehensively realized. The manufacturing method is characterized in that a precisely controlled inner heated electric furnace formed by intelligent temperature program controllers / regulators / recorders is adopted to implement staged controlled firing and an integral firing process with jackets; and full-automatic glaze slurry spraying equipment and an electrical heating and temperature controlling insulating cylinder are adopted for manufacturing. The reactor and the manufacturing method have the following advantages: the reactor initiates and lays a foundation for that the manufacturing technology standards of the glass-lined reactors in China all realize the Supervision Regulation on Safety Technology for Pressure Vessel and initiates and lays a foundation for datamation and automation of the core technology of controlled enamelling; the integral quality of the reactor is obviously superior to the current national standard; the reactor steps and is developed to innovate and be ahead of the conditions that the international outer heated electric furnace iron billets have no alternative to secondary forming during manufacturing and the core technology of controlled enamelling has the defect of uneven heating; and the integral quality of the reactor is superior to the international leading level, therefore the reactor has global market competitiveness.

Owner:朱文华

Finger-shaped connector of aramid fiber conveying belt and preparation method of finger-shaped connector

The invention relates to a finger-shaped connector of an aramid fiber conveying belt and a preparation method of the finger-shaped connector. The preparation method comprises the following steps: stripping coverage glue, cleaning residual glue, cutting finger shapes, coating mucilage, splicing the finger shapes, forming and coating glue, reinforcing by a fabric layer, covering glue, and sulfurizing a specimen, thereby obtaining the finger-shaped connector on the aramid fiber conveying belt. According to the invention, the problems of extraction, edge wrapping, water seepage, glue failure of seams and the like of the connector of the conveying belt in the dynamic running process are solved; a certain gap is reserved in splicing the finger shapes so as to guarantee that the pasting glue can seep fully toward the finger shapes, the extraction force is increased, the stress uniformity is improved, and the phenomena of extraction and cracking which are caused by stress uniformity are prevented; the length of the stripped coverage glue is greater than the length of each finger by 5cm, and the connector glue and the coverage glue are lapped into an oblique slope, so that the phenomenon of water seepage of a framework material because of glue failure of the seam is prevented, and the service life of the connector of the aramid fiber conveying belt is prolonged greatly.

Owner:YANKUANG GRP CO LTD +1

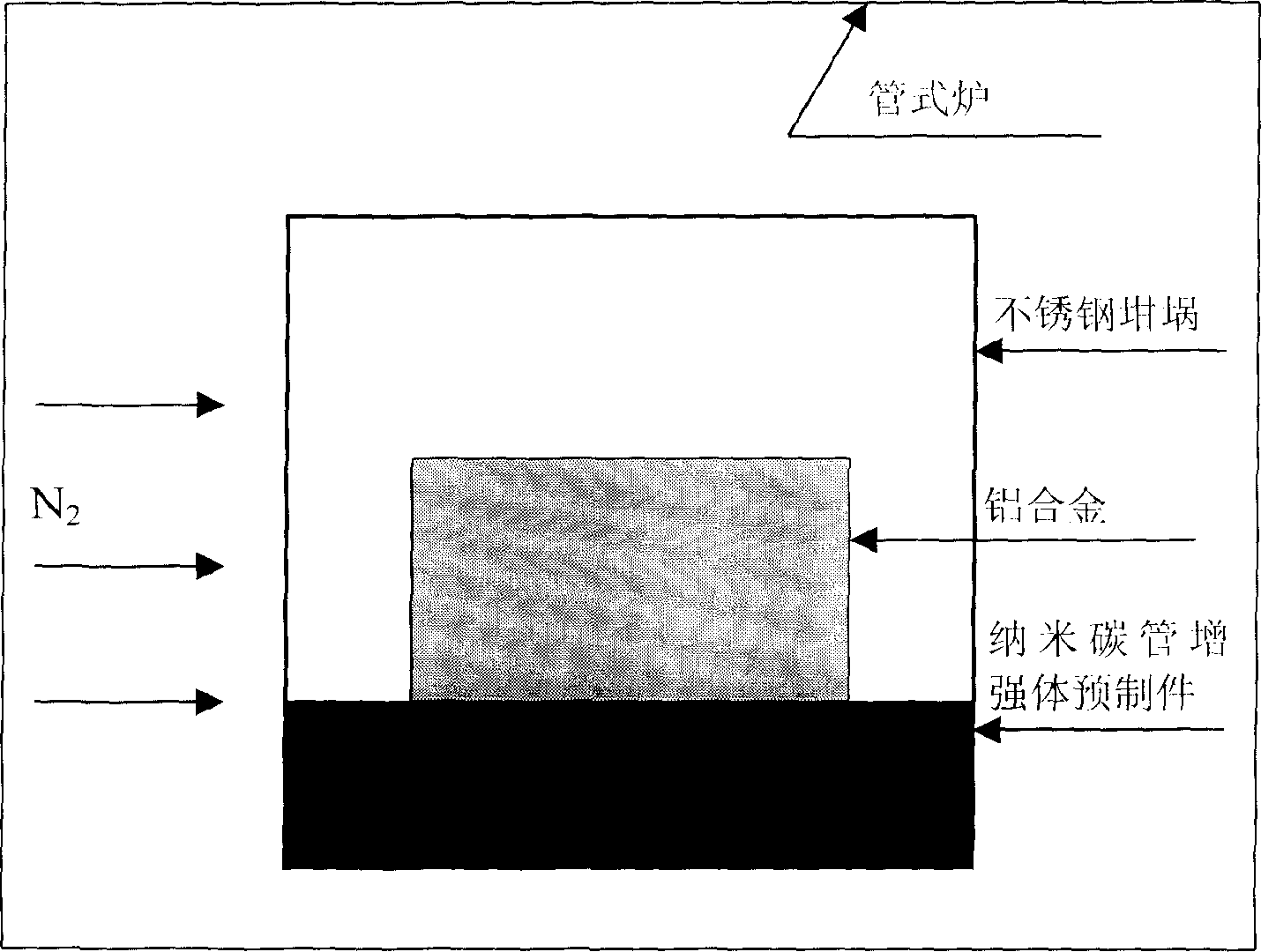

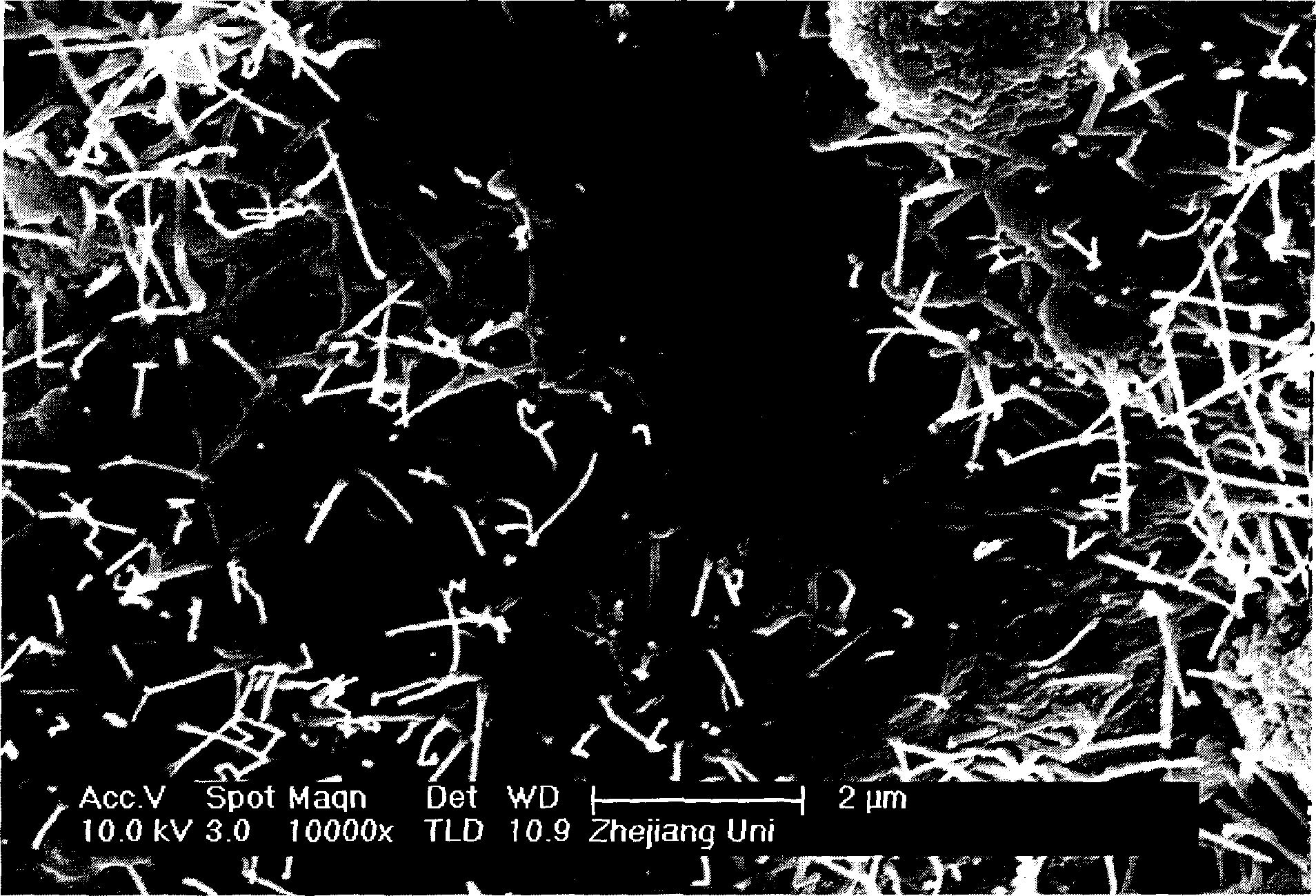

Zero pressure and permeation for preparation of carbon nanometer tube reinforced aluminum base composite material

The invention relates to a zero pressure and permeation for preparation of carbon nanometer tube reinforced aluminum base composite material which comprises, mixing nano carbon tube, magnesium powder and aluminium powder of a finite proportion through mechanical mode or ball mill blending in stainless steel tank with the existence of argon shield, loading into stainless steel crucible or moulding the ball milled powder into pre-cast members, placing into stainless steel crucible, heating pure aluminium or aluminium alloy in nitrogen atmosphere to 750-1000 deg. C, thermal insulation for a finite period of time, cooling down and discharging.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com