Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

332results about "Liquid/gas/vapor treatment of propelled fabrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

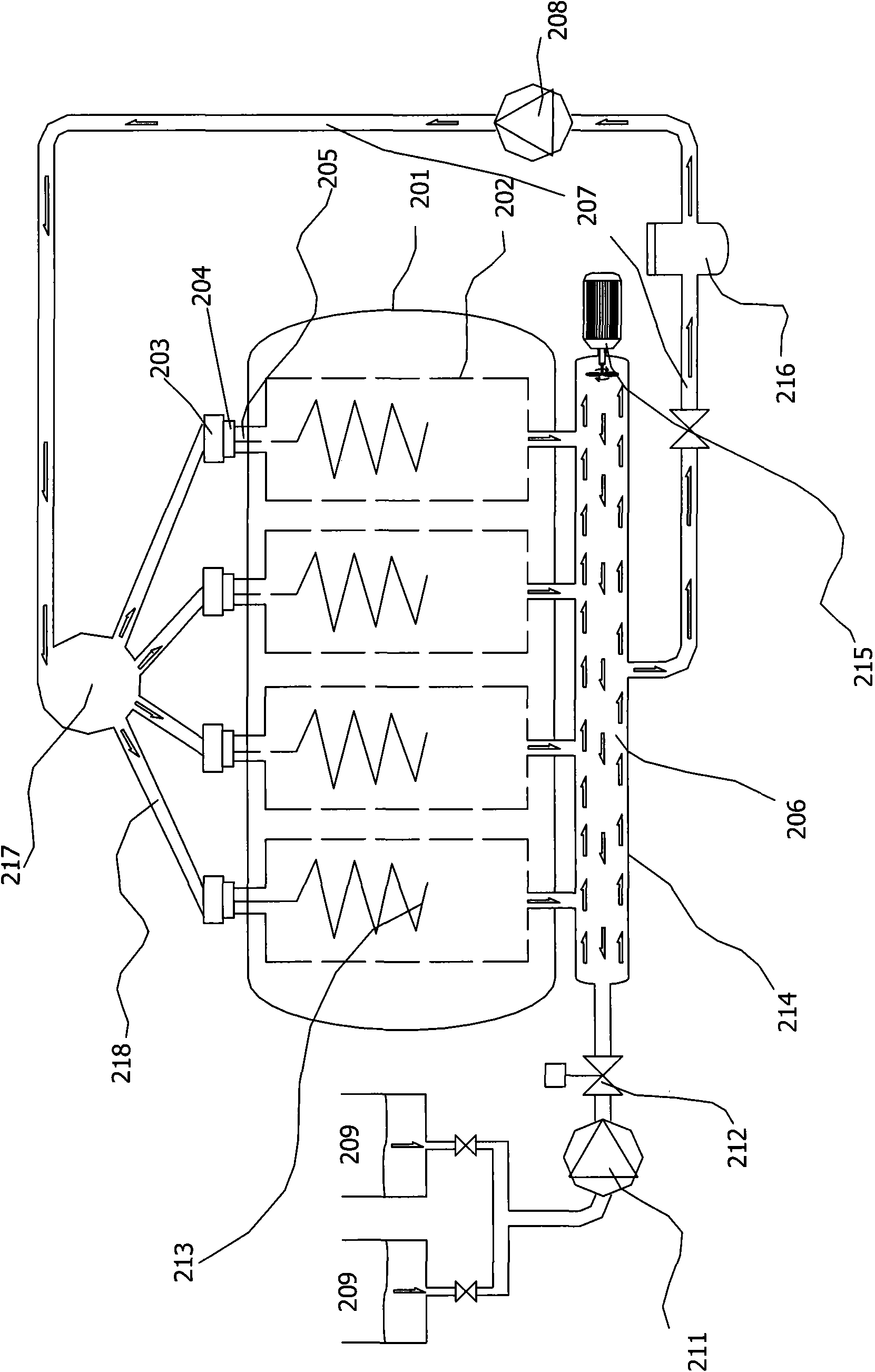

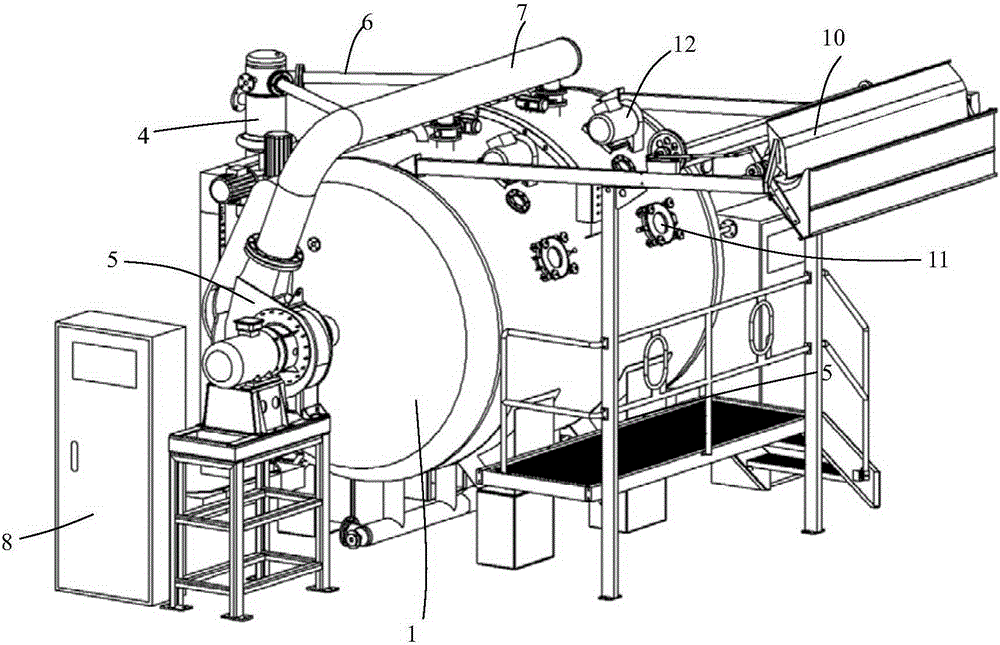

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

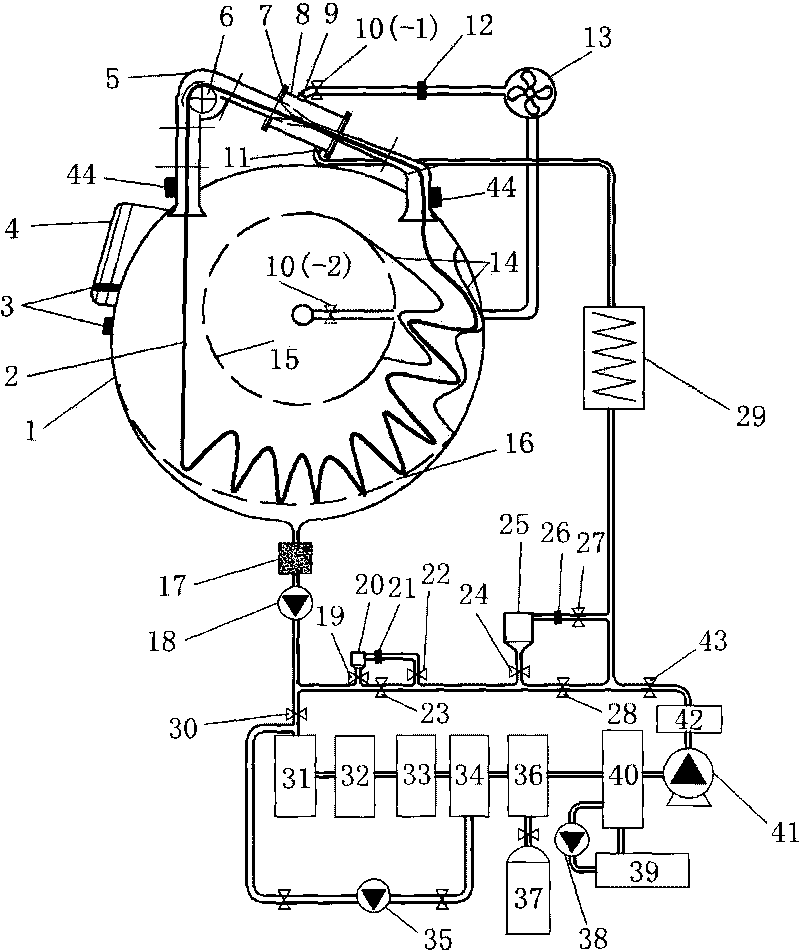

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

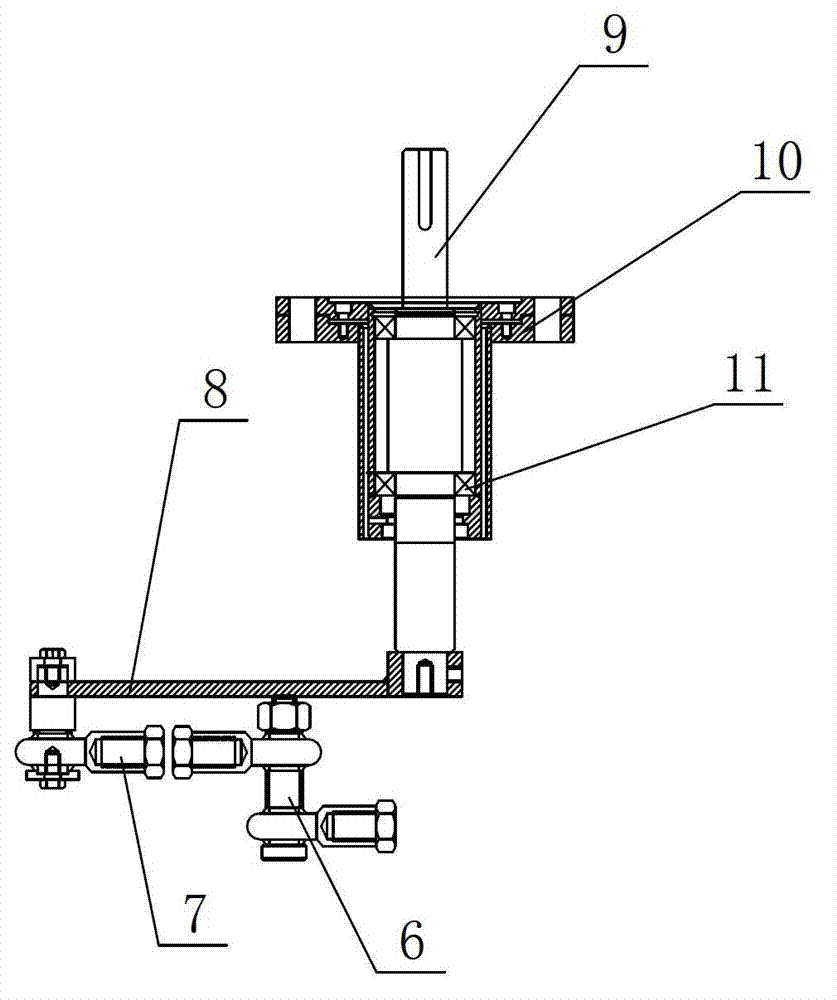

Atomizing nozzle structure of high-temperature high-voltage air flow dyeing machine and control method thereof

InactiveCN102080318AGood level dyeingSuitable for processing environmentLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsSpray nozzleHigh pressure

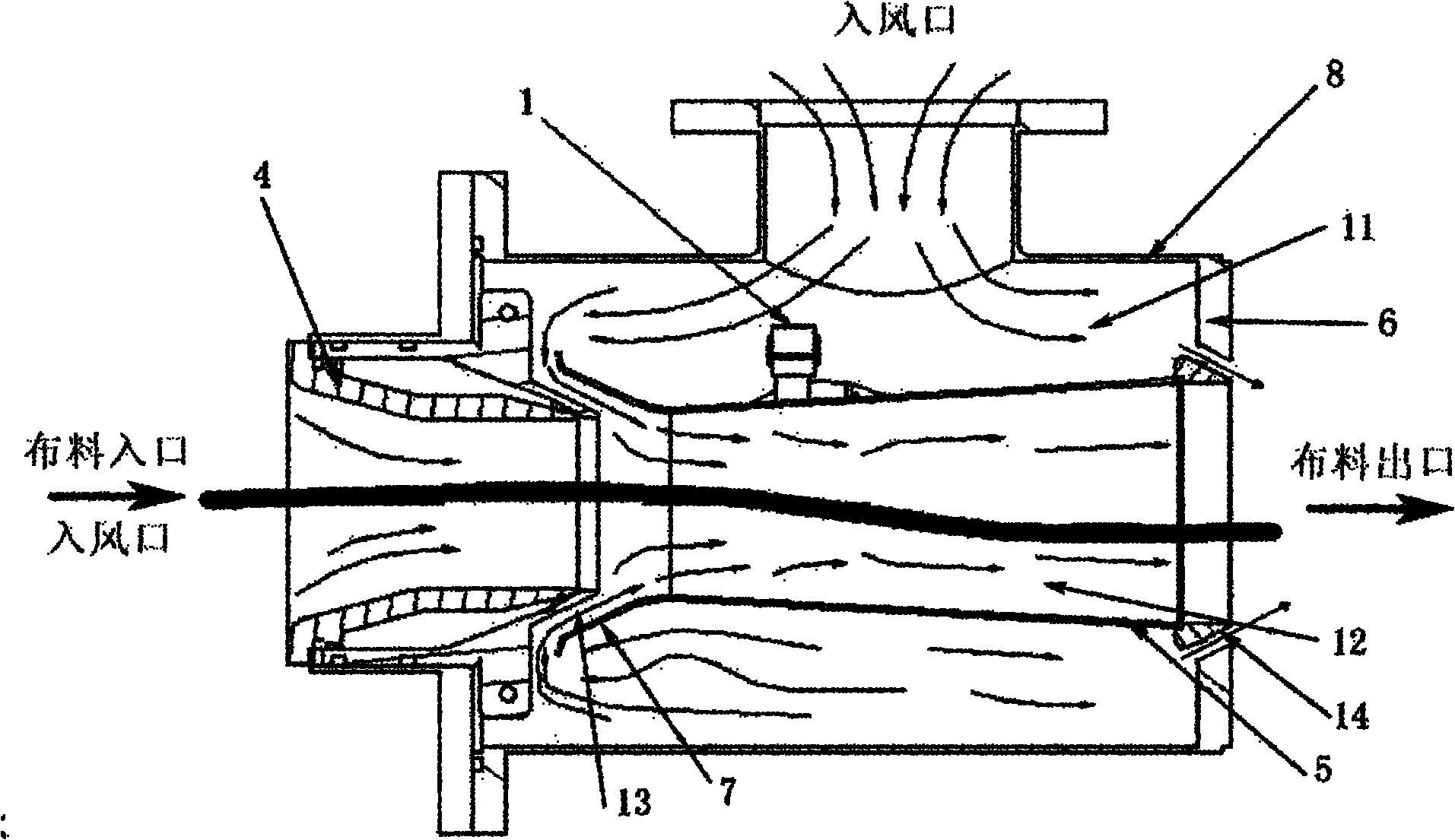

The invention discloses an atomizing nozzle structure of a high-temperature high-voltage air flow dyeing machine and control method thereof. The nozzle structure comprises a front nozzle cover, an inner main stream pipe, a rear nozzle head and a sleeve, wherein the sleeve is sleeved outside the inner main stream pipe, and two ends of the sleeve are respectively connected with the front nozzle cover and the rear nozzle head through a connecting piece; the sleeve is provided with an air inlet which is connected with a fan; and the sleeve and the inner main stream pipe form a circular outer chamber atomizing region; a nozzle head is arranged in the outer chamber atomizing region and is fixed on the outer wall of the inner main stream pipe, and the nozzle head is connected with a dye liquid pipeline; and the outer chamber atomizing region is provided with two outlets which are connected with a channel through which the cloth to be dyed passes in the inner main stream pipe. The invention also provides a control method based on the atomizing nozzle structure of the high-temperature high-voltage air flow dyeing machine. According to the types of the cloth to be dyed, the number of the nozzle heads started in the nozzle structure, the flow rate of the nozzle heads, the air flow of the fan and the temperature process curves adopted are defined. According to the invention, the levelling property is high, and the problem of cloth blocking can not happen.

Owner:高勋绿色智能装备(广州)有限公司

Nozzle of airflow dyeing machine

ActiveCN101613919AIncrease fluid pressureSpray evenlyLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsEngineeringPulp and paper industry

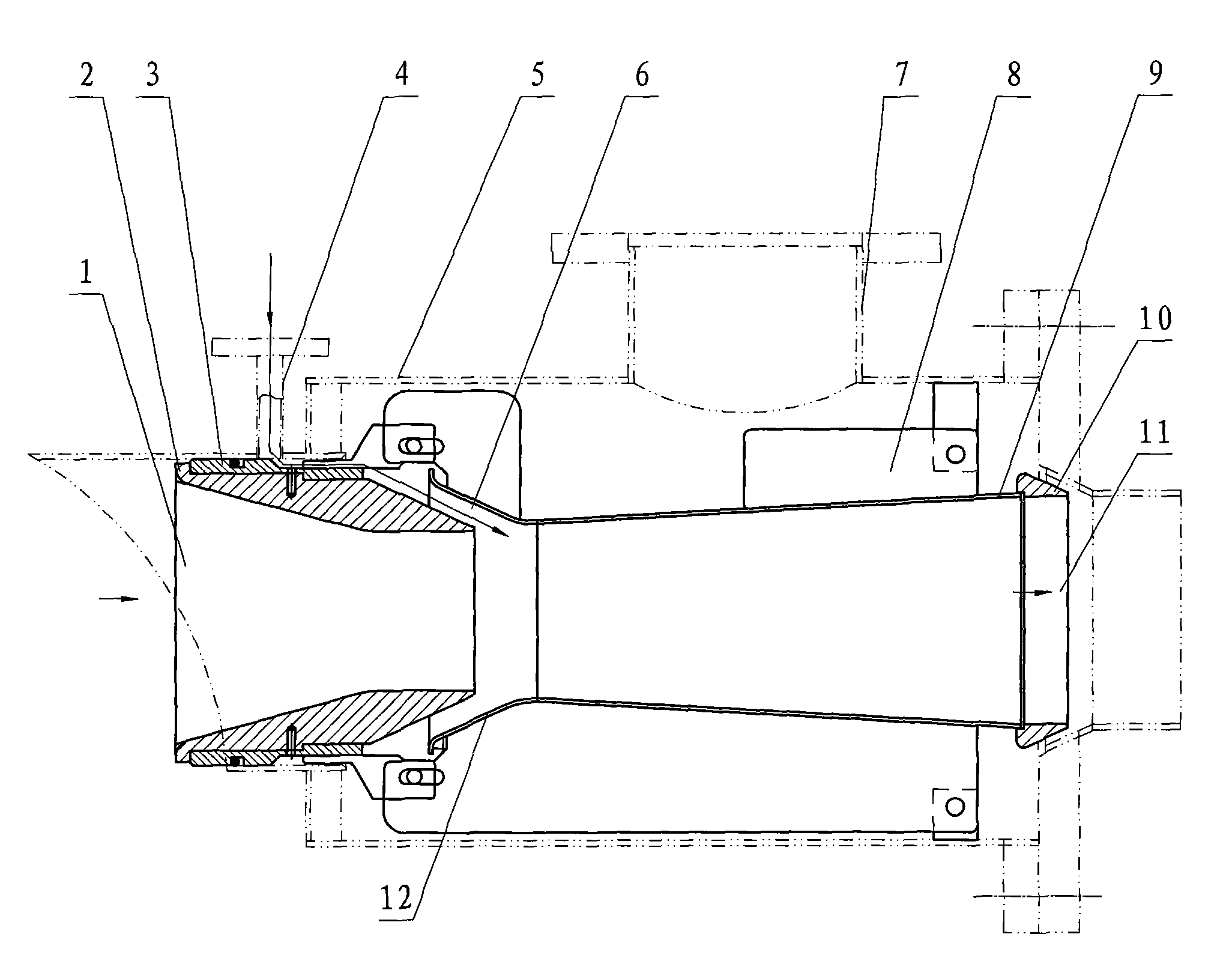

The invention relates to a nozzle of an airflow dyeing machine, which comprises a front nozzle cover, a positioning sleeve, a nozzle body and a back nozzle head; the front end of the nozzle body is provided with a front guide nozzle; the positioning sleeve is sleeved on the front nozzle cover, and is connected with the nozzle body through a connecting piece; an airflow inlet is arranged between the back end of the positioning sleeve and the front guide nozzle; a dye liquor chamber is arranged between the front nozzle cover and the positioning sleeve; the front nozzle cover is provided with a dye liquor outlet; the positioning sleeve is provided with a dye liquor inlet; and the dye liquor outlet and the dye liquor inlet are respectively communicated with the dye liquor chamber. The dye liquor chamber is arranged between the front nozzle cover and the positioning sleeve, and dye liquor is stored in the dye liquor chamber, so that the fluid pressure of the dye liquor is increased; and the front nozzle cover is provided with the dye liquor outlet, and the dye liquor is directly ejected onto cloth, not interfered by airflow and is ejected evenly.

Owner:WUXI DONGBAO MACHINERY MFG

Thin breathable warm fabric and manufacture method thereof

InactiveCN102605523AHigh standardFullnessWeft knittingLiquid/gas/vapor treatment of propelled fabricsYarnMoisture absorption

The invention relates to a thin breathable warm fabric, comprising a surface fabric and an inner layer fabric, wherein the inner layer fabric is a moisture absorption and heating layer; the surface fabric is a warm breathable and moisture-leading layer; the moisture absorption and heating layer is formed by blending 30-60% of moisture absorption and heating EKS fibers and 40-70% of ordinary acrylic fibers; the warm breathable and moisture-leading layer is formed by blending 15-40% of bulk acrylic fibers, 20-60% of superfine acrylic fibers and 0-65% of modal fibers. The invention further relates to a manufacture method of thin breathable warm fabrics, comprising the steps of preparing yarns, weaving, sanding, dyeing, finishing softly and shaping; and the thin breathable warm fabric provided by the invention has the advantages of high wearing comfort, good thin and breathable performance as well as good anti-dropping, anti-static and warmth retention performances.

Owner:SHENZHEN HUIJIE GROUP

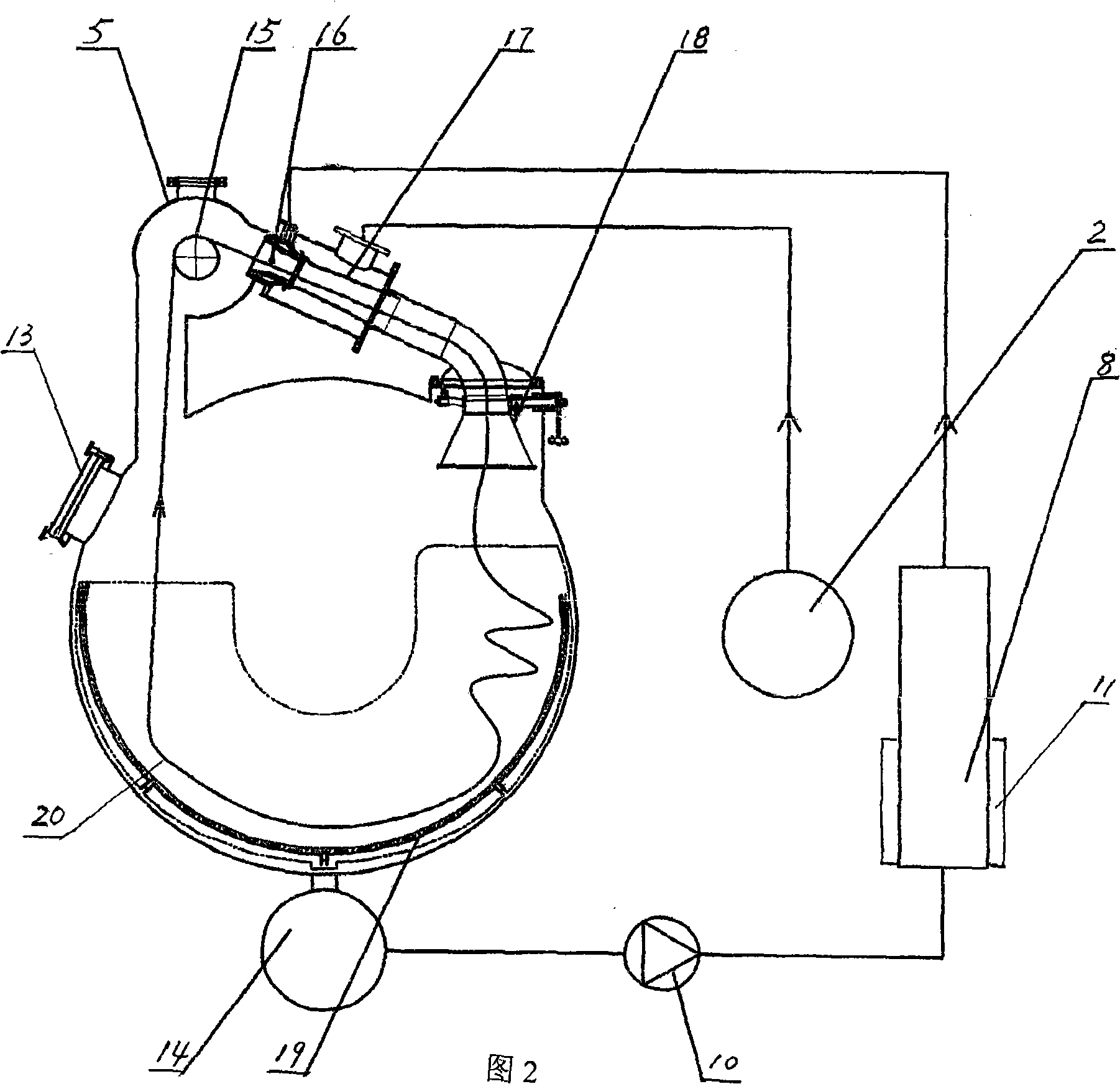

High-temperature high-pressure air flow dyeing machine

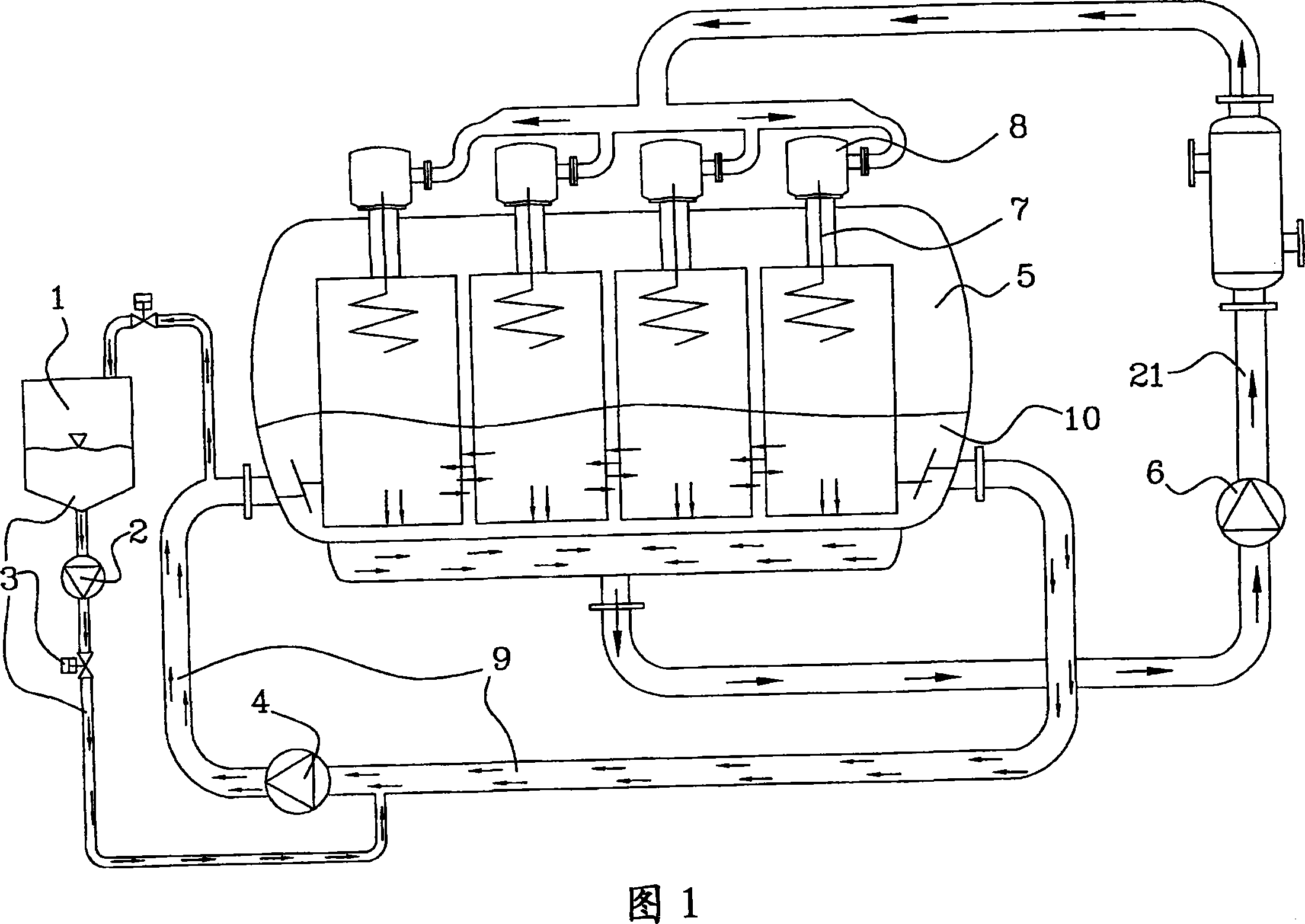

InactiveCN101280496AFully contactedReduce consumptionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsAir filterHigh pressure

The invention relates to a high temperature and high pressure air flow dyeing machine, in which the high pressure air flow is utilized for the dyeing of textiles after the dyeing atomization, which comprises a cylinder, a lifting wheel, and a feed cylinder and is characterized in that the cylinder is in a horizontal arrangement and internally provided with a dye vat. The upper wall of the cylinder corresponded to both ends of the dye vat is provided with two openings. The inside of one opening is provided with a cloth placing mechanism, and the upper part of the other opening is provided with a wheel shell communicated with the position between two openings through pipelines. The lifting wheel is disposed inside the wheel shell. The inside of the pipeline between the wheel shell and the cloth placing mechanism is provided with a nozzle and a spray head. The outside of the cylinder is provided with a heat exchanger, a feed pump and a fan. The lower part of the cylinder is provided with a backflow mechanism. The heat exchanger is provided with an inlet and an outlet. The outlet thereof is connected to a nozzle through the pipelines, and the inlet thereof is communicated with the feed cylinder, which is communicated to the bottom cavity of the cylinder through the feed pump, the backflow mechanism and the pipelines. The air outlet of the fan is linked with the spray head, and the air inlet of the fan is communicated to the cylinder through an air filter. With the adoption of such a dyeing machine to dye textiles, the production costs can be reduced.

Owner:唐佳伟

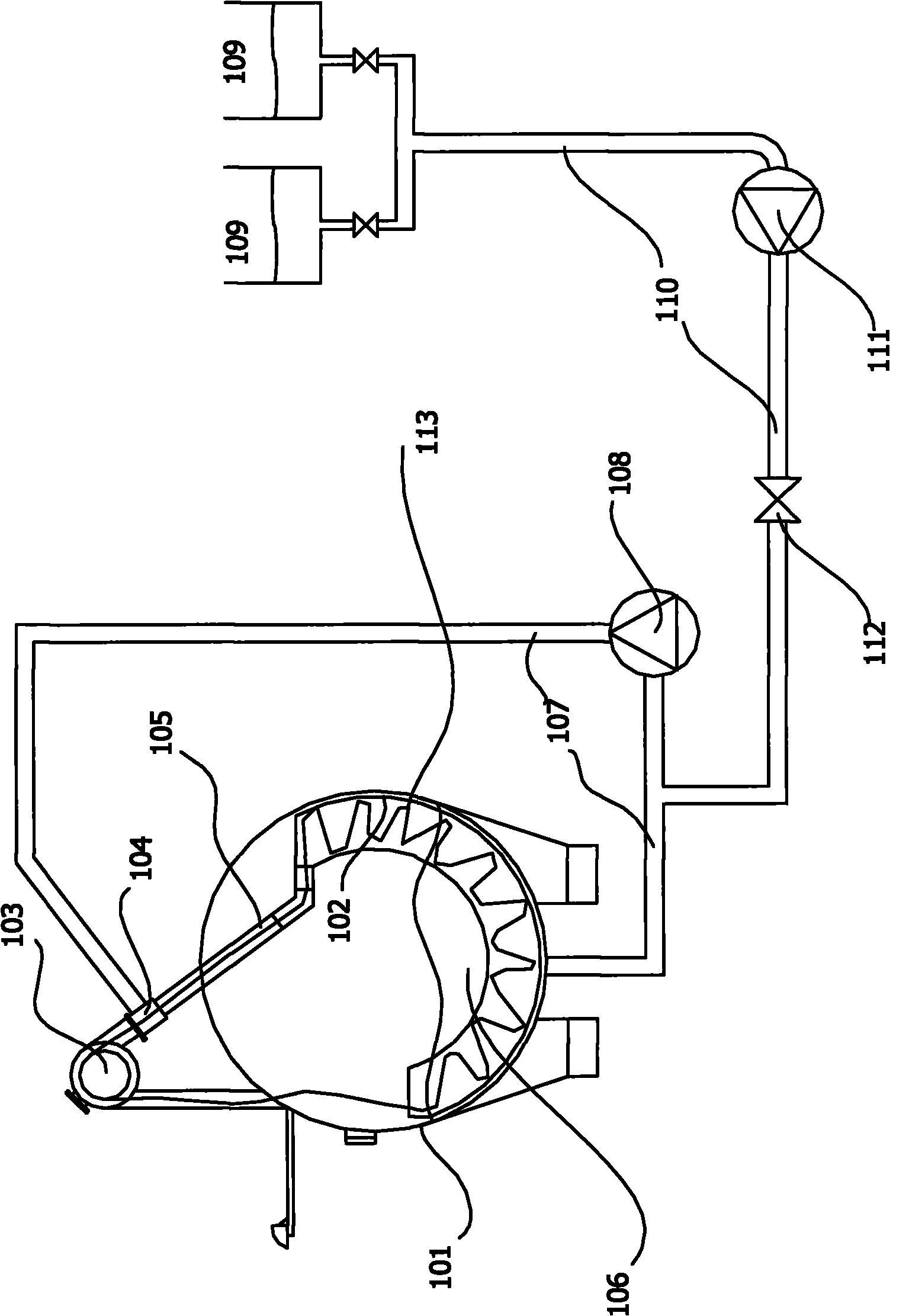

Overflow dyeing machine

InactiveCN101962887ASimple structureWell mixedTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsLiquid storage tankEngineering

The invention discloses an overflow dyeing machine. The overflow dyeing machine comprises a main machine body (201), wherein a dye vat (202) is arranged in the main machine body (201); a cloth lifting pulley (203) is arranged outside the main machine body (201); nozzles (204) are arranged over the main machine body (201); the outlet of the dye vat (202) is communicated with the inlets of the nozzles (204) through a circulation pipeline (207); the outlet of a chemical material vat (209) is communicated with the circulation pipeline (207); a liquid storage tank (214) is also arranged on the circulation pipeline (207); the liquid storage tank (214) is communicated with the outlet of the chemical material vat (209) and the outlet of the dye vat (202) respectively; and a main pump (208) is arranged on the circulation pipeline (207) which connects the outlet of the liquid storage tank (214) and the inlets of the nozzles (204). The overflow dyeing machine provided by the invention has the advantages that: the structure is simple; a dyeing liquid is uniformly mixed; due to the liquid supply balance among the plurality of nozzles, surface contamination of a fabric and blockage of the nozzles is effectively prevented and dyeing is more uniform; the working efficiency is improved; and the technical time is shortened.

Owner:田立法

Method for printing multi-component intrinsic flame-retardant fabric

ActiveCN104313924AColor point clearFull colorSucessive textile treatmentsLiquid/gas/vapor treatment of propelled fabricsFiberTextile printer

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a method for printing multi-component intrinsic flame-retardant fabric. The method comprises the following steps: selecting and matching cloth, pretreating the fabric, performing rotary screen printing, steaming at high temperature, rapidly performing wet steaming, oxidizing, soaping, performing softening and color fixing, and performing steam sanforizing. The invention provides the printing technology and method which can realize clear colorizing points, full color and high printing fastness of multi-component intrinsic flame-retardant printed fabric, do not influence the flame retardance, do not damage flame-retardant fibers, and do not influence the strength; the industrial production and application of the multi-component intrinsic flame-retardant printed fabric are realized; indeed, the multi-component intrinsic flame-retardant printed fabric is popularized and applied.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

Method for producing berber-fleece-like double-layer shell fabric with polyester yarns

InactiveCN102605524ASame style on both sidesFeel goodWeft knittingLiquid/gas/vapor treatment of propelled fabricsPolyesterYarn

The invention provides a method for producing a berber-fleece-like double-layer shell fabric with polyester yarns. The method comprises the steps of adopting 167dtex / 288F polyester low-stretch network yarns as fleece yarn raw materials (167dtex / 48F polyester low-stretch network yarns as bottom yarns), and performing weaving of a 16-needle weft knitting machine, presetting, colouration, dehydration and softening, intermediate setting, galling, carding, shearing, polar fleece and finish product setting. The method can allow the styles of both the front and back sides of the finished double-sided berber fleece shell fabric to be consistent basically, and the dual purposes of the front and back sides of the shell fabric are ensured. The fabric has the characteristics of good softness, uniformity and density, and gives a kind and comfortable feel to people.

Owner:CHANGSHU ZHONGJIE KNITTING

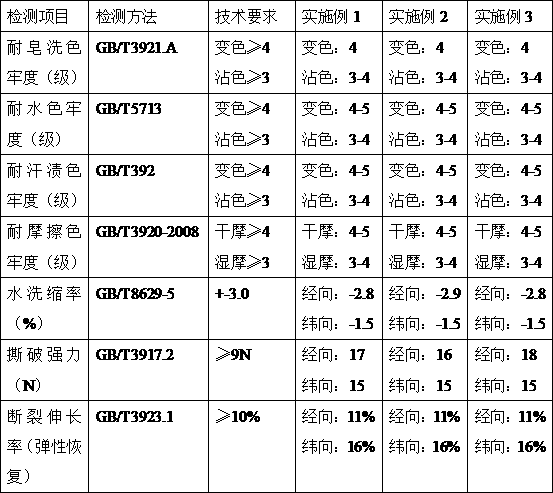

Slightly-creased nylon/cotton elastic fabric and production process thereof

ActiveCN105507037AStrong and goodGood resistance to soapingTextile storage in superimposed formLiquid/gas/vapor treatment of propelled fabricsTextile technologyPolymer science

The invention relates to a slightly-creased nylon / cotton elastic fabric and a production process thereof and belongs to the technical filed of textiles. The production process of the slightly-creased nylon / cotton elastic fabric comprises the following steps of 1, rolling; 2, cold padding; 3, sizing and pre-shrinking; 4, hair washing and removing through enzyme in a vat; 5, active cotton dyeing; 6, soaping; 7, nylon dyeing; 8, fixation; 9, cloth spreading; 10, drying and sizing; 11, finished product inspection and packaging. In the production process of the slightly-creased nylon / cotton elastic fabric, additives are reasonably applied to such steps as cold padding, hair washing through enzyme, active cotton dyeing, soaping, nylon dyeing and fixation and compounded, and processing parameters of all the steps of the process are researched, so that the obtained slightly-creased nylon / cotton elastic fabric has good strength, warp / weft tearing strength can reach 15N and above, a greater elastic effect is achieved, comfortable sensation generated when the fabric is worn is enhanced, meanwhile the slightly-creased effect is achieved, and aesthetic feeling generated when the fabric is worn is increased.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

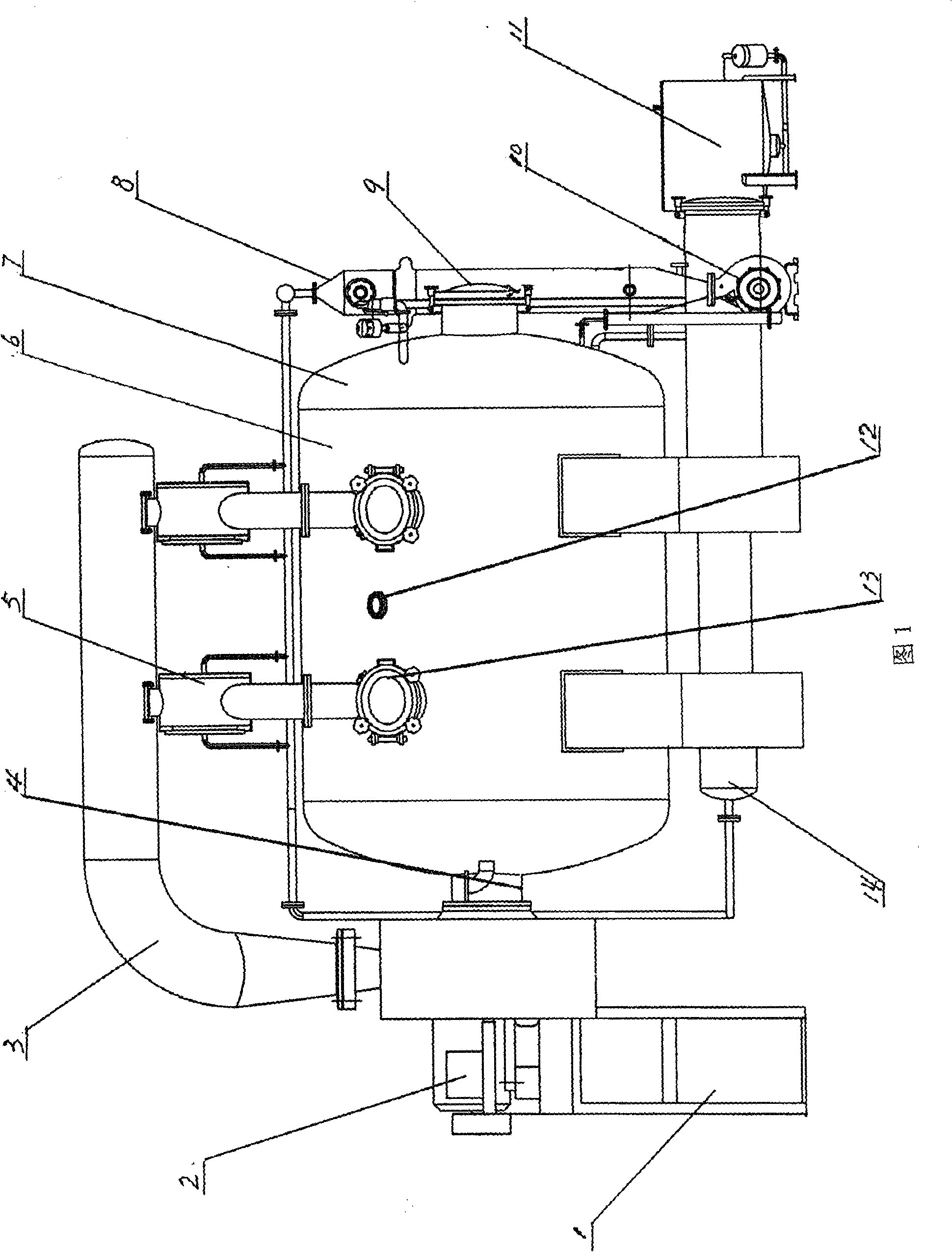

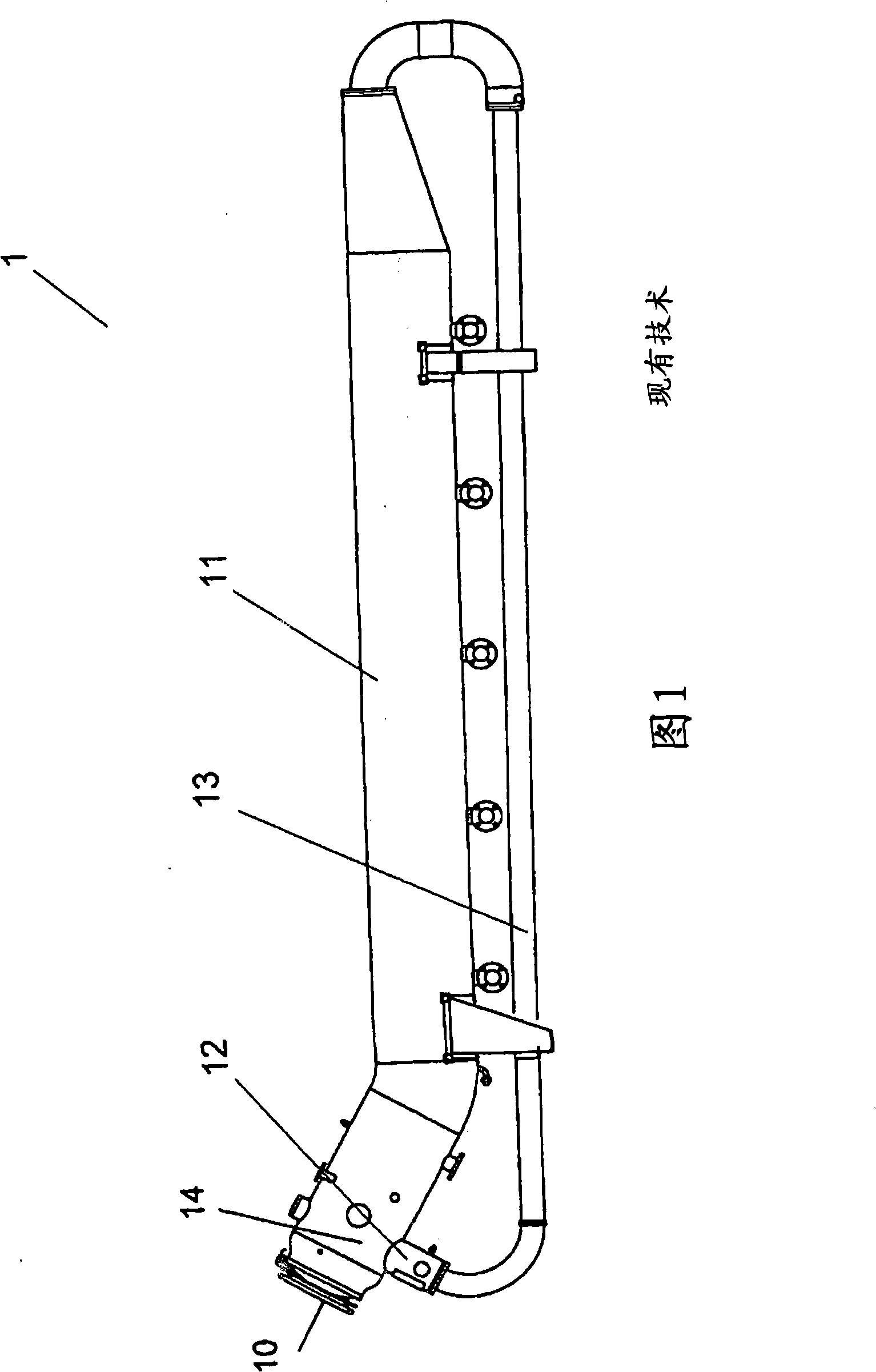

Machine for the discontinuous dyeing of fabric products

InactiveCN101117759AAvoid local increaseLarge dilution potentialLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsChemical productsEnvironmental engineering

A machine for the discontinuous dyeing of fabric products in rope form comprises an autoclave (5) which contains a bath (10) for the treatment of the fabric and a unit for the introduction into the bath of dyes and any auxiliary chemical products contained in at least one tank (1). The introduction unit provides a recirculation duct (9) between two points on the bath (10) in which a mixing pump (4) is fitted, and provides for the introduction of the products coming from at least one tank (1) into the recirculation duct (9).

Owner:苏州巴佐尼机械设备有限公司

Method for processing chenille-simulating warp-knitted fabric

InactiveCN103114379AImprove uniformityReduce weaving defectsLiquid/gas/vapor treatment of propelled fabricsWarp knittingEngineeringRaw material

The invention discloses a method for processing chenille-simulating warp-knitted fabric. The method includes: utilizing superfine terylene and cation-dyeable terylene; weaving via a special organization structure on a 3-4-comb tricot warp knitting machine; and dyeing and finishing via low-temperature shaping, fuzzing, polishing, shearing, alkali peeling, dyeing, shaping, polishing, shearing and shaping of finished products. A suede surface of finished fabric has the effect of camlet of chenille fabric, styles of roughness, fullness and thickness of the chenille fabric are realized, and the fabric after being processed can be used as upholstery like sofas, curtains, bedspreads and the like. The method for processing the chenille-simulating warp-knitted fabric is low in raw material cost and high in producing efficiency, and cost is reduced compared with that for the conventional chenille fabric.

Cloth swinging device of airflow dyeing machine

InactiveCN102851907ANot easy to creaseExquisite designTextile storage in superimposed formLiquid/gas/vapor treatment of propelled fabricsPulp and paper industryAirflow

The invention discloses a cloth swinging device of an airflow dyeing machine. The device comprises a dyeing machine barrel, and a cloth carrying wheel, a shell spraying assembly, a cloth through pipe and a net cage which are arranged in the dyeing machine barrel, wherein the cloth carrying wheel is arranged on one side of the shell spraying assembly which is connected with the cloth through pipe, the net cage is arranged under the cloth through pipe, the cloth through pipe is connected with a transmission component which is connected with one end of a connecting rod, the other end of the connecting rod is connected with a rotating shaft, the rotating shaft passes through the dyeing machine barrel in a sealing manner to be connected with a driving device, an adjusting plate is hinged on the net cage, the adjusting plate is connected with an adjusting shaft arranged on the net cage by a push rod, and the adjusting shaft is connected with an adjusting hand wheel which drives the adjusting shaft to rotate. According to the cloth swinging device of the airflow dyeing machine, the shell spraying assembly and the cloth through pipe are driven to move to and from left and right by a speed reducing motor through the transmission component, so that fabrics in the cloth through pipe is swung to stack in the net cage. The cloth swinging device of the airflow dyeing machine is delicate in design and folding marks on the fabrics are difficult to generate.

Owner:WUXI XINDA DYEING MACHINE FACTORY

Method for processing quasi-polyester-peach-skin fabric

ActiveCN104264321AFluffy and softShorten the timeLiquid/gas/vapor treatment of propelled fabricsTextile beetlingPolyesterFiber

The invention discloses a method for processing quasi-polyester-peach-skin fabric. The method includes the steps that (1) pre-processing is carried out, wherein singeing, whitening and drying are carried out on soybean fiber and cotton fiber blended fabric; (2) sueding is carried out, wherein metal abrasive grains are used for dry-method sueding; (3) polishing is carried out, wherein intermittent rope-form overflow dyeing equipment is used for polishing after two steps of complex enzyme processing; (4) dyeing is carried out according to a conventional method; (5) shaping and drying are carried out to obtain a finished product.

Owner:浙江泉能纺织股份有限公司

Preparation method for uvioresistant fabric and uvioresistant fabric

ActiveCN109056181AImproves UV resistanceGood far-infrared absorption functionLiquid/gas/vapor treatment of propelled fabricsWarp knittingPolyesterFiber

The invention discloses a preparation method for an uvioresistant fabric and the uvioresistant fabric. The method comprises the steps that uvioresistant fiber is prepared, wherein ceramic particles with the function of efficiently shielding ultraviolet ray and polymers containing hydroxyl are mixed for surface modification and drying, after the esterification and polycondensation reactions, polyester with the uvioresistant effect is prepared, and the uvioresistant is obtained through spinning; the uvioresistant fiber is subjected to weaving and dyeing by using dye; an uvioresistant finishing agent is prepared. According to the long-lasting uvioresistant fabric, the uvioresistant effect of products can be significantly improved, the initial ultraviolet penetration rate is less than or equalto 0.5%, the ultraviolet protection coefficient can reach UPF50+, after the fabric is washed twenty times, the ultraviolet penetration rate is less than or equal to 1.5%, the ultraviolet protection coefficient can still reach UPF50+, and the fabric further has a good infrared absorption function.

Owner:HAIAN QI HONG TEXTILE TECH CO LTD

Production process of wool terylene blended smooth double-faced woolen goods

ActiveCN108456965AEasy to organizeHair to smoothLiquid/gas/vapor treatment of propelled fabricsDyeing processYarnPulp and paper industry

The invention provides a production process of wool terylene blended smooth double-faced woolen goods. The production process of the smooth double-faced woolen goods includes the steps: sufficiently mixing wool fibers and terylene fibers; spinning the mixed wool fibers and terylene fibers into yarns of 13 / 1 metric number by an open-end spinning frame; weaving the spun yarns on a rapier loom; performing edge sewing, fulling, scouring, dewatering, drying, decating, teasel raising, drying, anti-shrinking finishing, dyeing, softening finishing, scalding, cutting, decating and the like on a woven gray fabric to prepare a finished product. The total number of warp yarns is 6100-6300, the acting reed width is 195-200cm, porter / permeating number is 35 / 9, weft density is 285-290 yarns / 10cm, and theweight of a fabric billet is 930-950g / m<2>. The fabric is fine, smooth and soft in hand feeling, compact in texture, bright in color and high in color fastness and does not easily felt after being washed with water.

Owner:江阴市长泾花园毛纺织有限公司

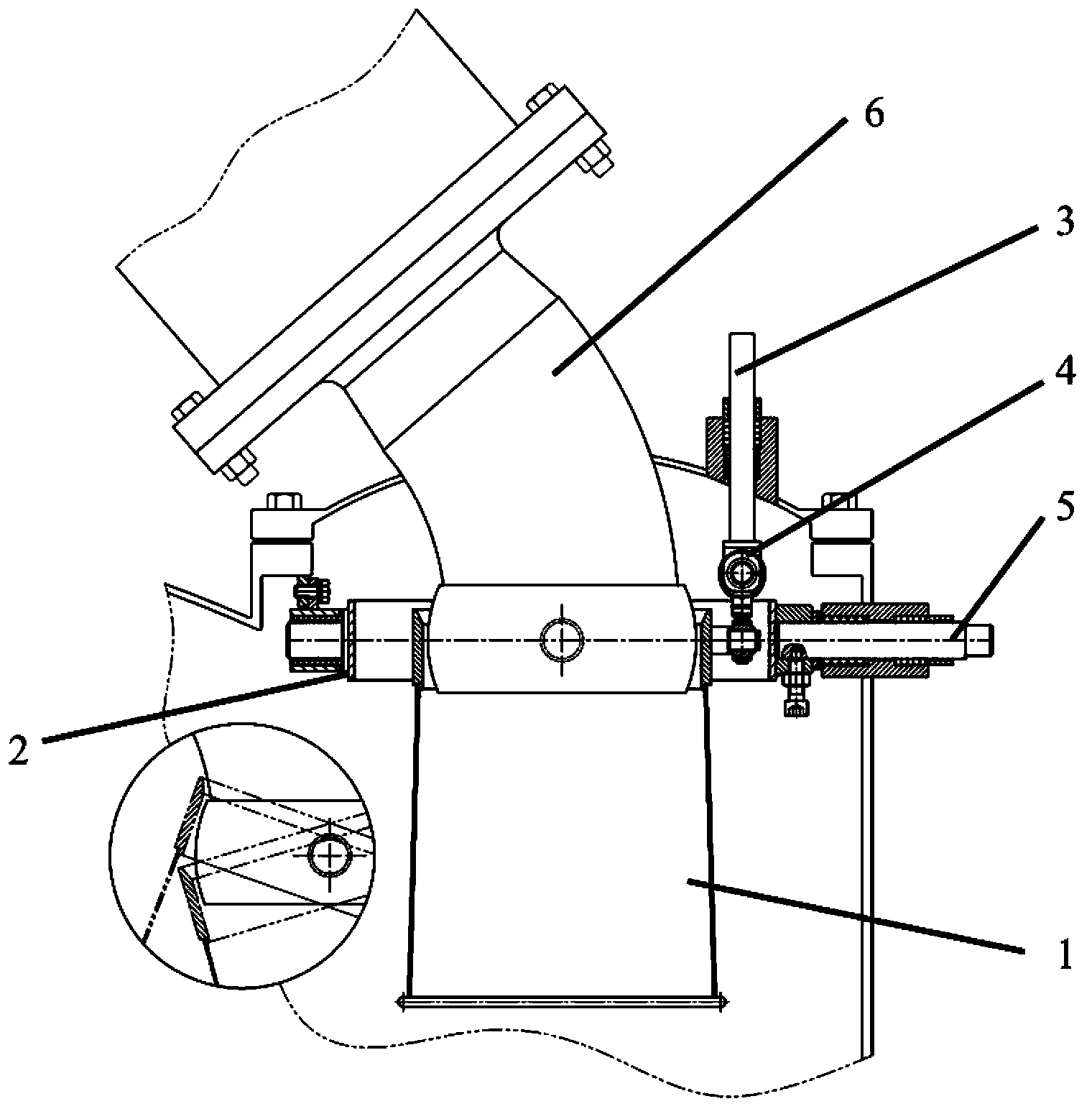

Quick-opening device of airflow dyeing machine

ActiveCN101613924ARealize safety interlock functionEasy to switchTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsEngineeringSafety Interlock

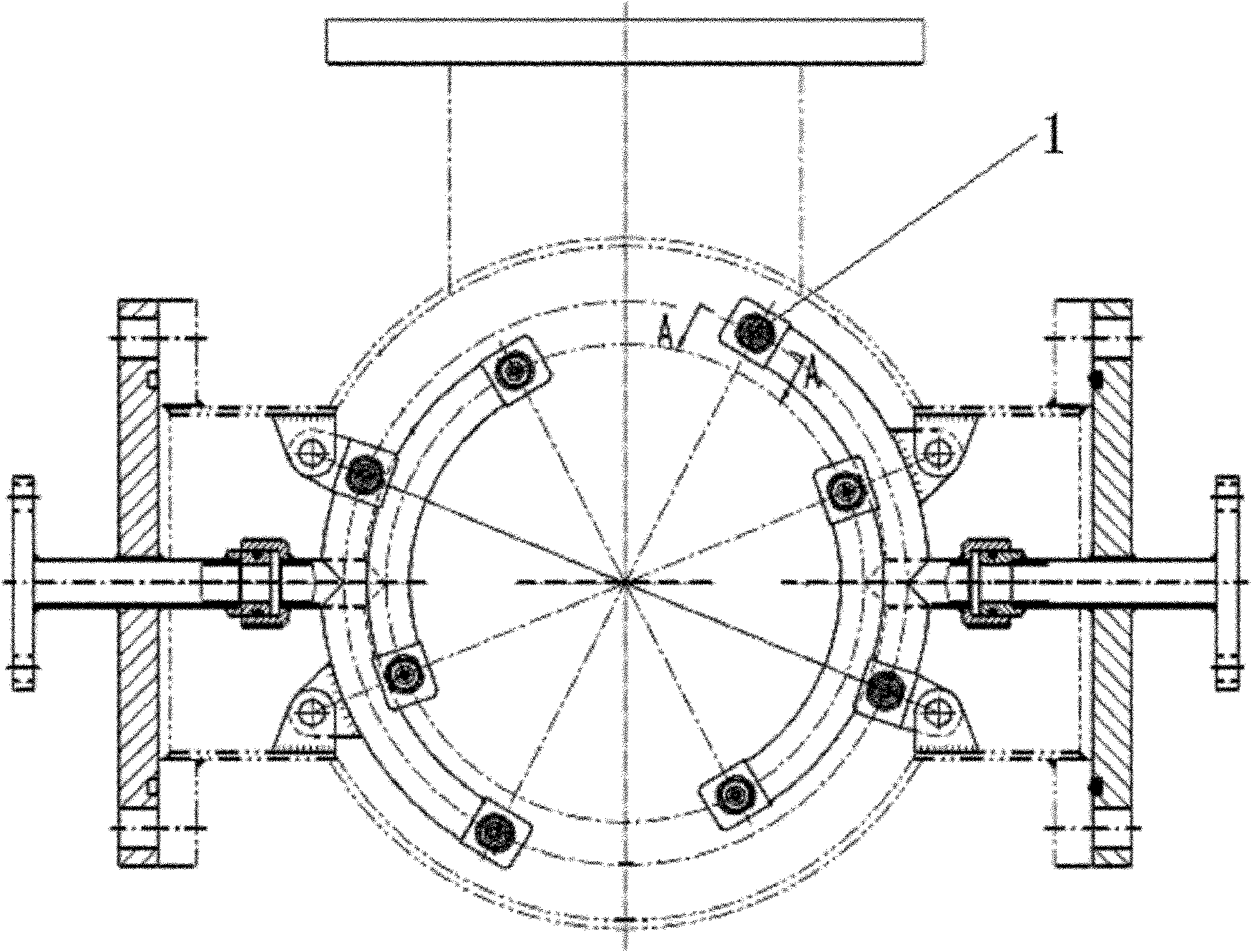

The invention relates to a quick-opening device of an airflow dyeing machine, which comprises a manhole flange and a manhole cover, wherein the manhole flange is hinged with a door ring; the manhole cover is rotationally arranged on the door ring, and is provided with a handle; the inner wall of the manhole flange is provided with internal teeth; the outer wall of the manhole cover is provided with external teeth; the number of the internal teeth is the same as that of the external teeth; the manhole cover is rotationally clamped in the manhole flange through the fit of the internal teeth andthe external teeth; the manhole flange is provided with a cylinder; a piston rod of the cylinder is matched with a fixed hole on the manhole cover; and a manual safety interlocking device is arrangedbetween the manhole flange and the manhole cover. The teeth structure is arranged between the manhole cover and the manhole flange, and the manhole cover can be opened by rotating by a tooth so as tohave convenient opening and closing and quick speed; and the manual safety interlocking device is matched with the cylinder to realize the safety interlocking function of the quick-opening device.

Owner:WUXI DONGBAO MACHINERY MFG

Jet fabric dyeing machine

InactiveCN101270541ATextile treatment containersLiquid/gas/vapor treatment of propelled fabricsEngineeringGuide tube

A fabric dyeing machine comprises a travelling tube, a storage chamber in communication with both ends of the travelling tube to form an endless travel path for an endless fabric rope, a nozzle operable to propel an endless fabric rope around the travel path by directing jets of dye liquor onto the endless fabric rope; and an outer vessel enclosing both the storage chamber and the travelling tube. The outer vessel may define the storage chamber, with the travelling tube located inside the outer vessel. The travelling tube and / or the storage chamber may be elongate and arranged along a slope at a few degrees to the horizontal, for example 3 to 5 degrees. A second travelling tube and nozzle can share the storage chamber to give a second endless travel path for the second endless fabric rope.

Owner:FALMER INVESTMENTS LTD

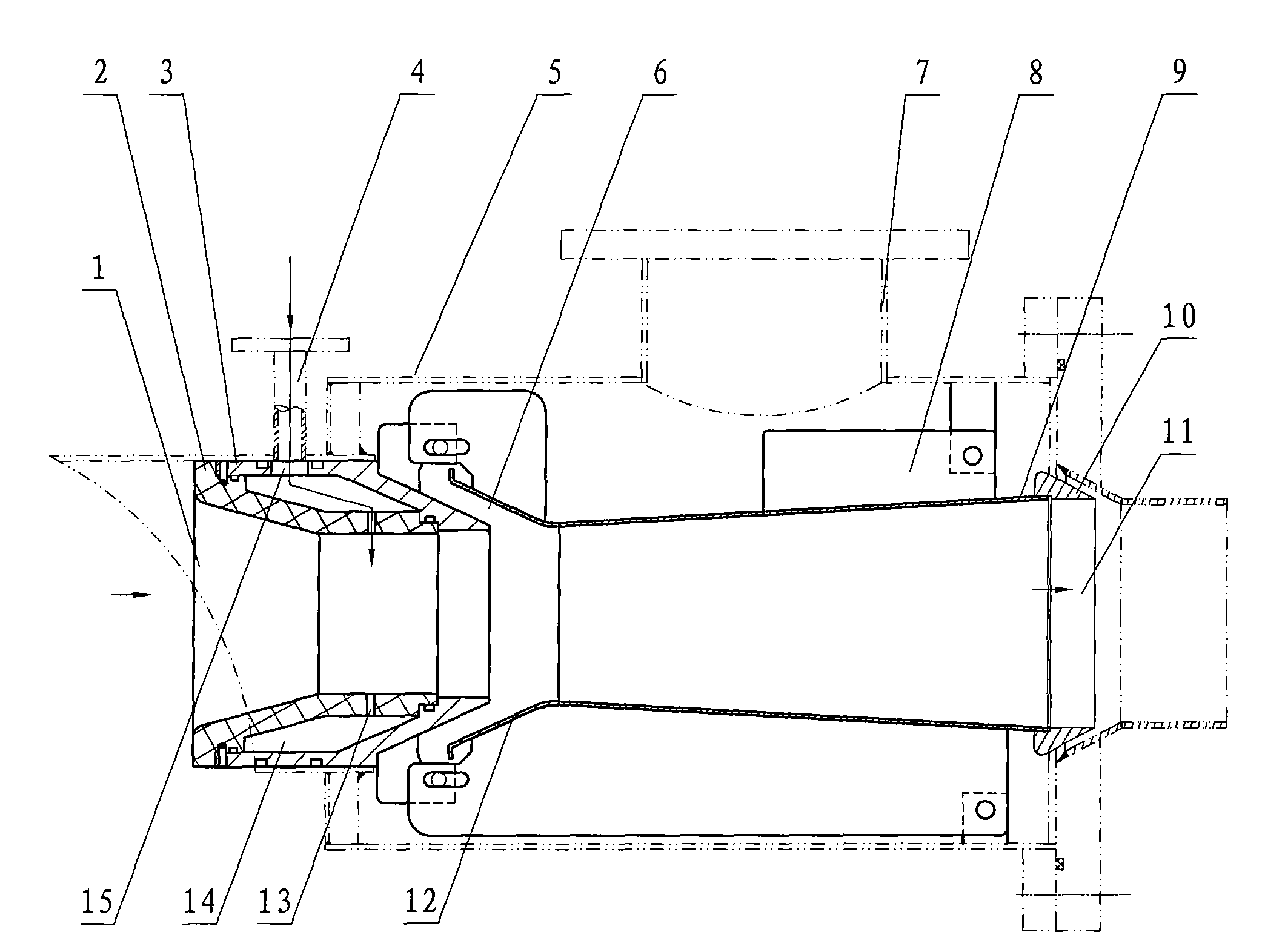

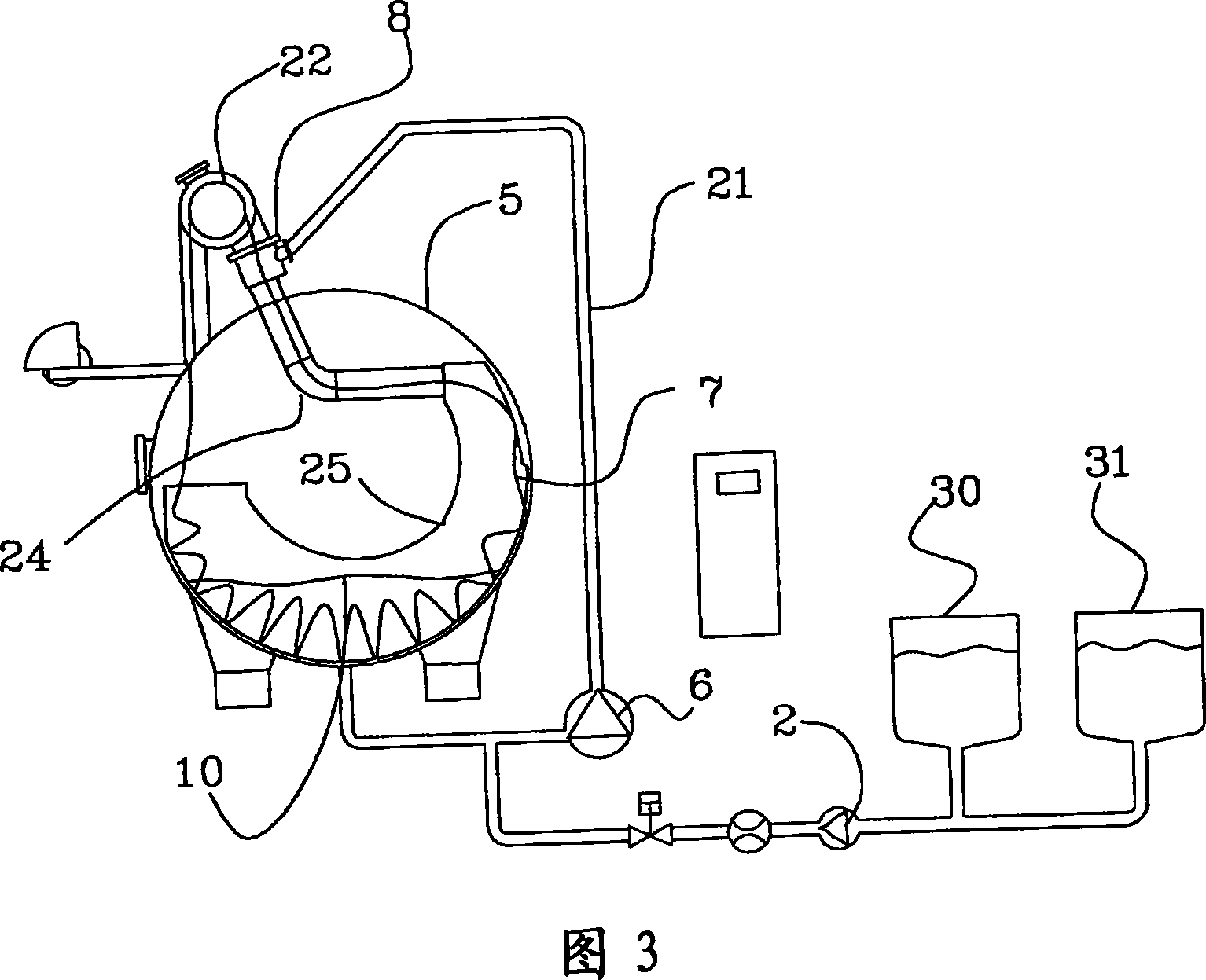

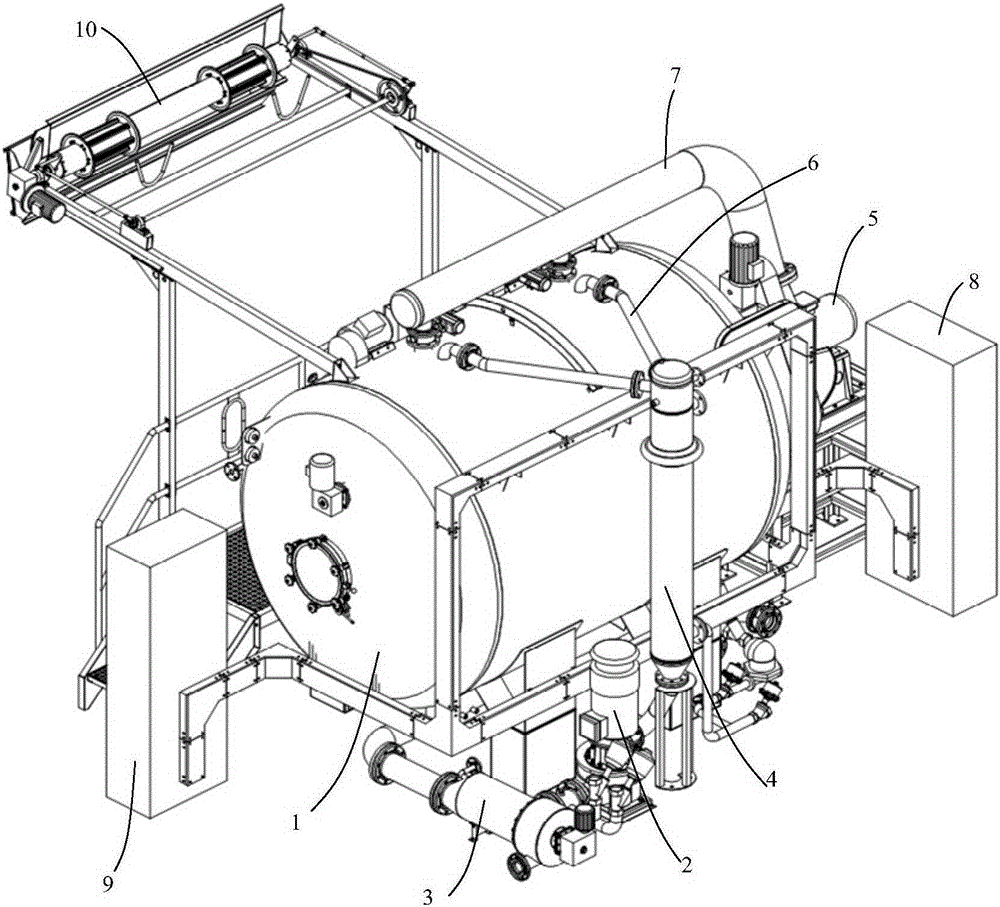

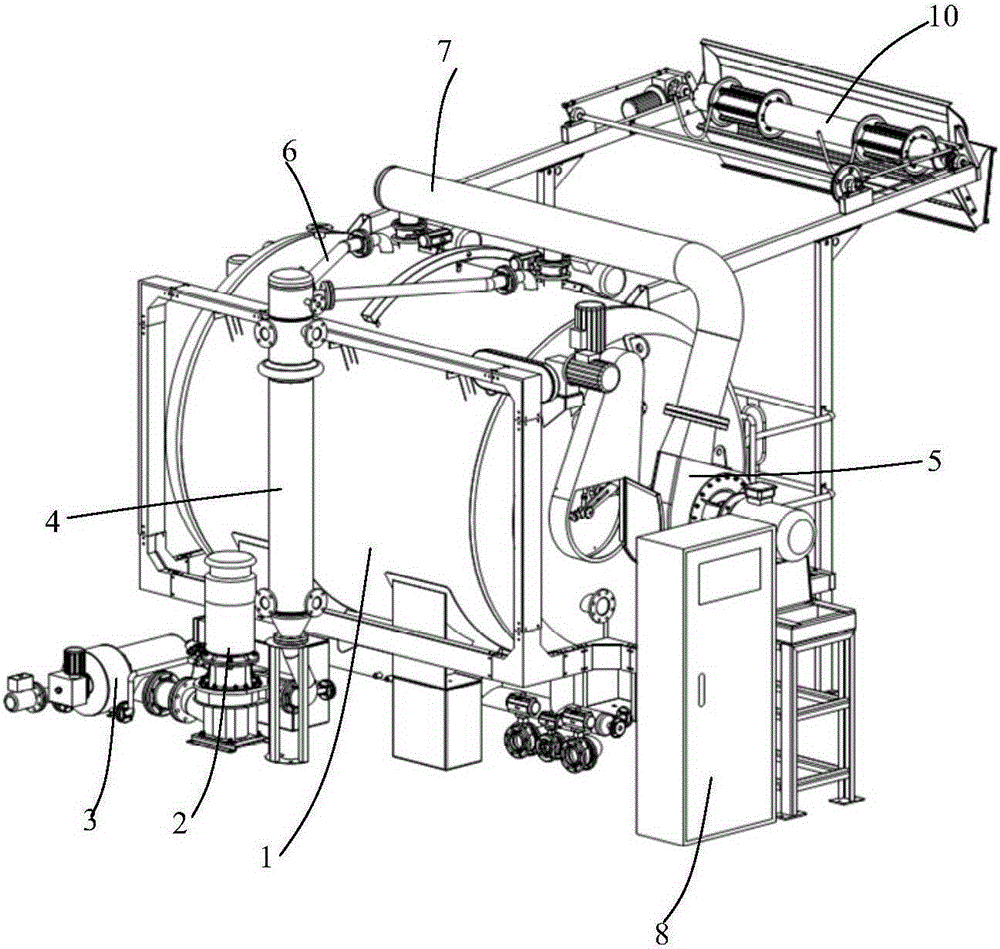

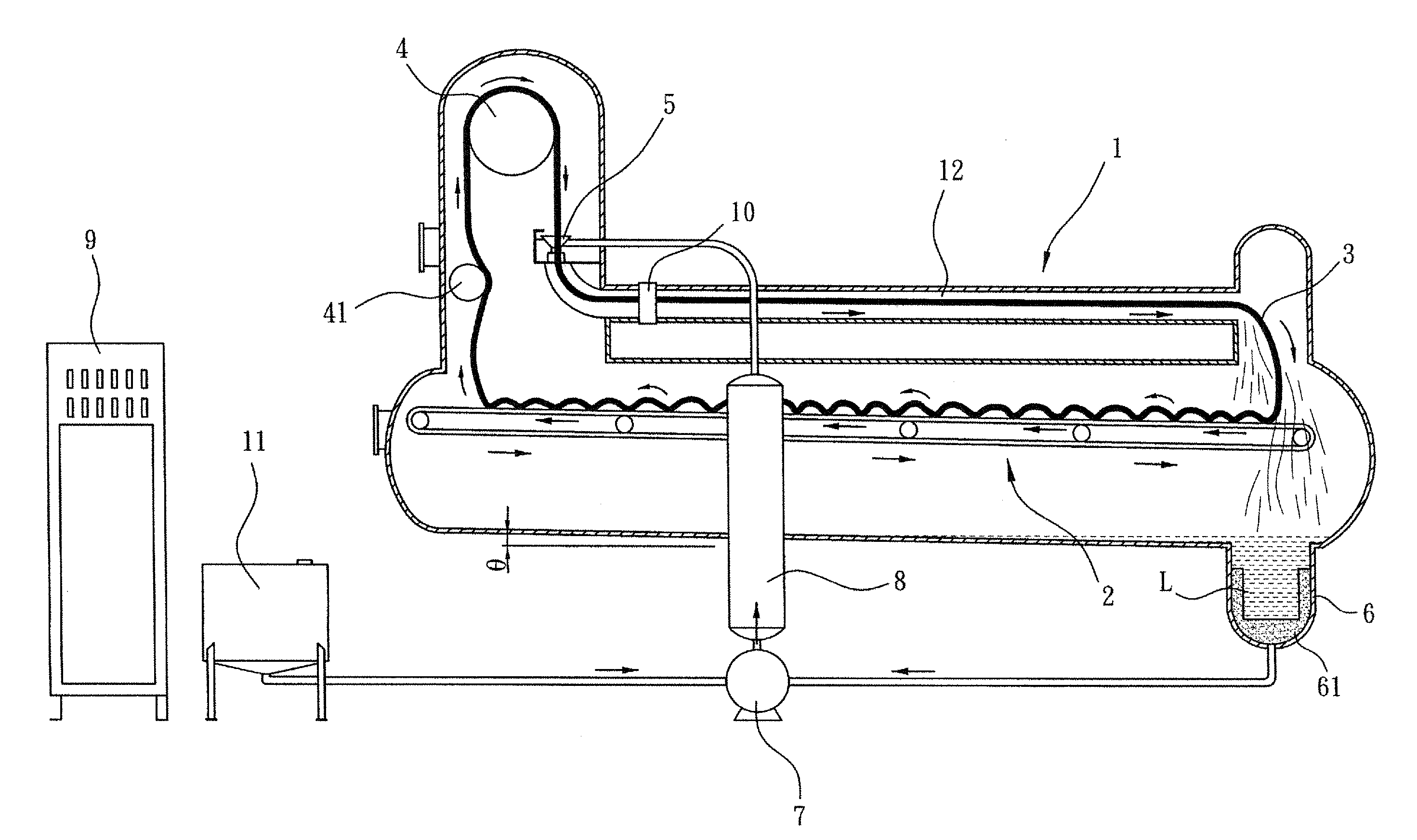

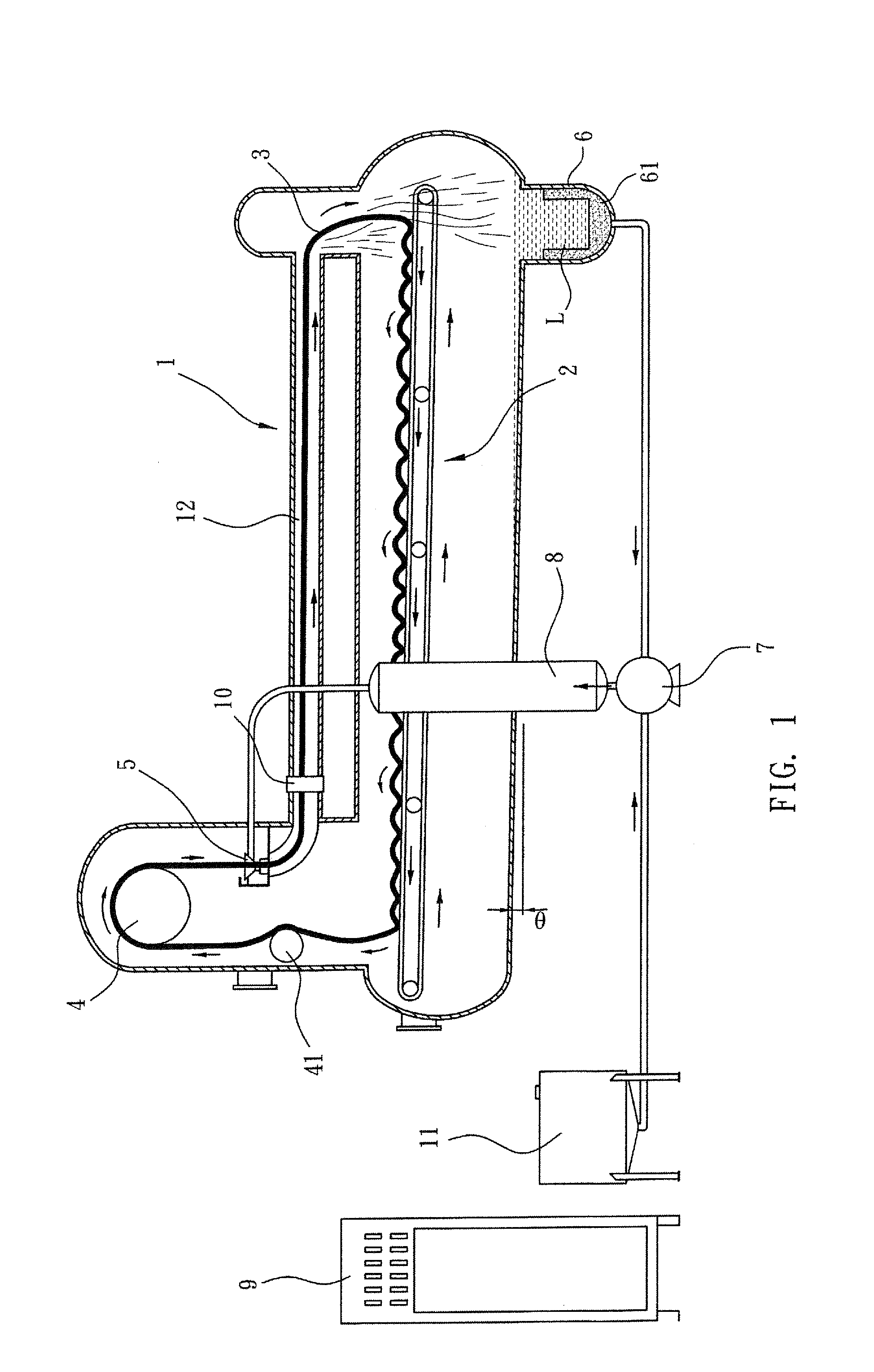

Ultralow liquor ratio gas-liquid splitting dyeing machine with built-in gas-liquid spray-dyeing system and cloth lifting system

ActiveCN105332179AShort tripImprove energy savingTextile storage in superimposed formTextile treatment containersElectric machineryProcess engineering

The invention discloses an ultralow liquor ratio gas-liquid splitting dyeing machine with a built-in gas-liquid spray-dyeing system and a built-in cloth lifting system. The dyeing machine comprises a cylinder body, a main pump, a broken wool filter, a heat exchanger, a blower fan, dye liquor shunt tubes, an air duct, a strong current cabinet, a weak current cabinet, a cloth discharge device, a fabric inlet and outlet, a cloth lifting motor, a cloth lifting wheel, a nozzle, a cloth swing system, a cloth storage groove, a broken wool filtering device, a dye liquor return pipe, and other components. The dyeing machine is compact in structure and simple in operation, and occupation area of the device is greatly reduced, and labor intensity of manufacturing workers is reduced. The machine overturns a blower fan, liquor ratio, cloth swing and folding, fabric operation, dye liquor automatic filtering, and other concepts of an airflow atomizing fabric dyeing machine in the same generation. The device is characterized by low liquor ratio, water saving and electricity saving, reduced emission, high automation degree, high dyeing process efficiency, good quality, high stability, and safe and reliable operation. The dyeing machine is substantial in energy saving and emission reduction effect, and is environmentally friendly and low-carbon. The dyeing machine plays roles of demonstration and leading in a dyeing and finishing equipment industry, and leads development directions of the industry.

Owner:高勋绿色智能装备(佛山)有限公司

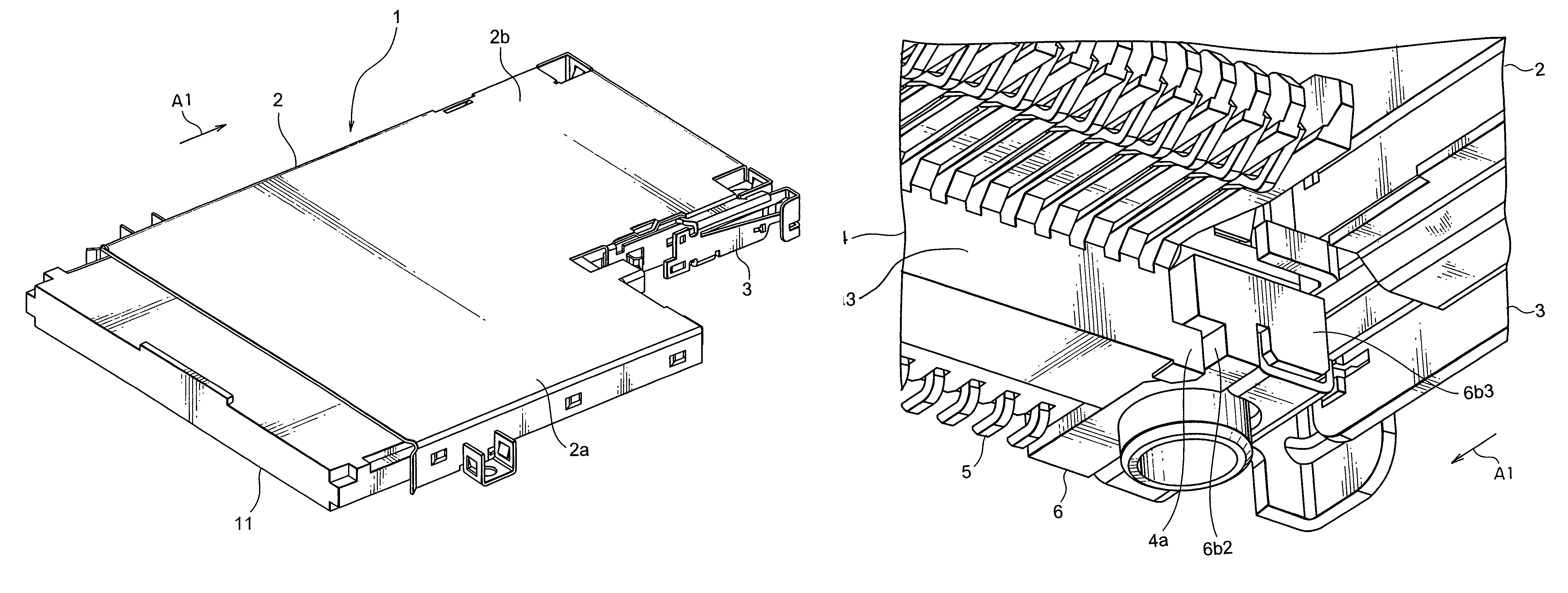

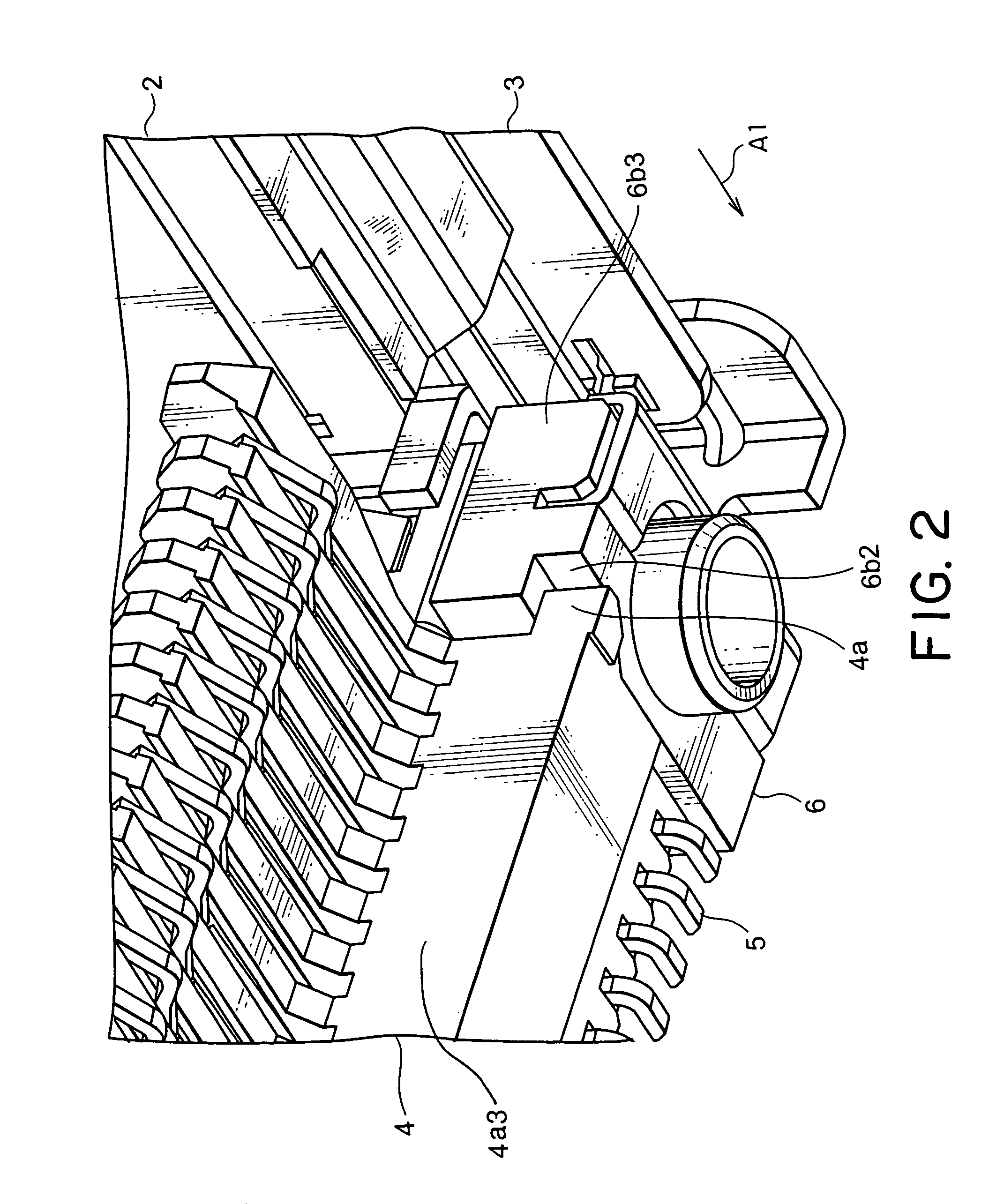

Card connector having a stopper to be fixed to a mounting object and adapted to come in contact with a card inserted into the card connector

InactiveUS7037123B2Engagement/disengagement of coupling partsLiquid/gas/vapor treatment of propelled fabricsEngineeringElectrical and Electronics engineering

Owner:JAPAN AVIATION ELECTRONICS IND LTD

All-cotton and high-count seersucker fabric and processing method thereof

InactiveCN108611737AFeel goodImprove durabilityFabric breaking/softeningLiquid/gas/vapor treatment of propelled fabricsPulp and paper industryYarn count

The invention discloses all-cotton and high-count seersucker fabric and a processing method thereof. The fabric is prepared from warp yarn and weft yarn by interweaving, wherein the warp yarn comprises two groups of warp yarn including pucker-warp and ground warp, the pucker-warp and the weft yarn are interwoven to form a fabric crinkled part, and the ground warp and the weft yarn are interwoven to form a fabric non-crinkled part; both the warp yarn and the weft yarn adopt all-cotton and high-count yarn, the yarn count of the pucker-warp is 40 S-60 S, the yarn count of the ground warp is 60 S-80 S, and the yarn count of the weft yarn is 60 S-80 S. The processing method of the all-cotton and high-count seersucker fabric sequentially comprises following technological processes: warping, slashing, drafting and reeding, beating-up, cropping detection, cloth turning and sewing, singeing, overflow finishing, overfeed soft shaping and airflow soft finishing. With the adoption of the method, the skin-friendly soft seersucker fabric with natural style, good endurance property and excellent breathability can be obtained.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Fabric swaying device of fabric dyeing machine

ActiveCN104109958ASolve the leakage problemClosely connectedTextile storage in superimposed formLiquid/gas/vapor treatment of propelled fabricsElectronic control systemEngineering

The invention discloses a fabric swaying device of a fabric dyeing machine. The fabric swaying device comprises fabric guide tubes of the dyeing machine, fabric swaying hoppers, a motor, cylinders and support rings. Shaft sleeves and rotary shafts are arranged on the support rings, the support rings are connected with the fabric swaying hoppers by shafts, and the fabric swaying hoppers are connected with pistons by ball chain devices. The rotary shafts are connected with rockers and are further connected with the motor by four-bar linkage structures, and the four-bar linkage structures comprise connecting bars and cranks. The pistons are connected with plungers of the cylinders. Pneumatic control and the motor can be operated by the aid of an electronic control system. The outer wall of the tail of each fabric guide tube is in the shape of a spherical surface, the circular top of each fabric swaying hopper covers the tail of the corresponding fabric guide tube, and various positions of the top of each fabric swaying hopper can closely cling to the corresponding fabric guide tube during swaying. The fabric swaying device can be provided with the multiple four-bar linkage structures, and each four-bar linkage structure is connected with the corresponding fabric swaying hopper. The fabric swaying device has the advantage that the fabric swaying device can be widely applied to the industry of printing and dyeing machinery.

Owner:FONGS NAT ENG (SHENZHEN) CO LTD

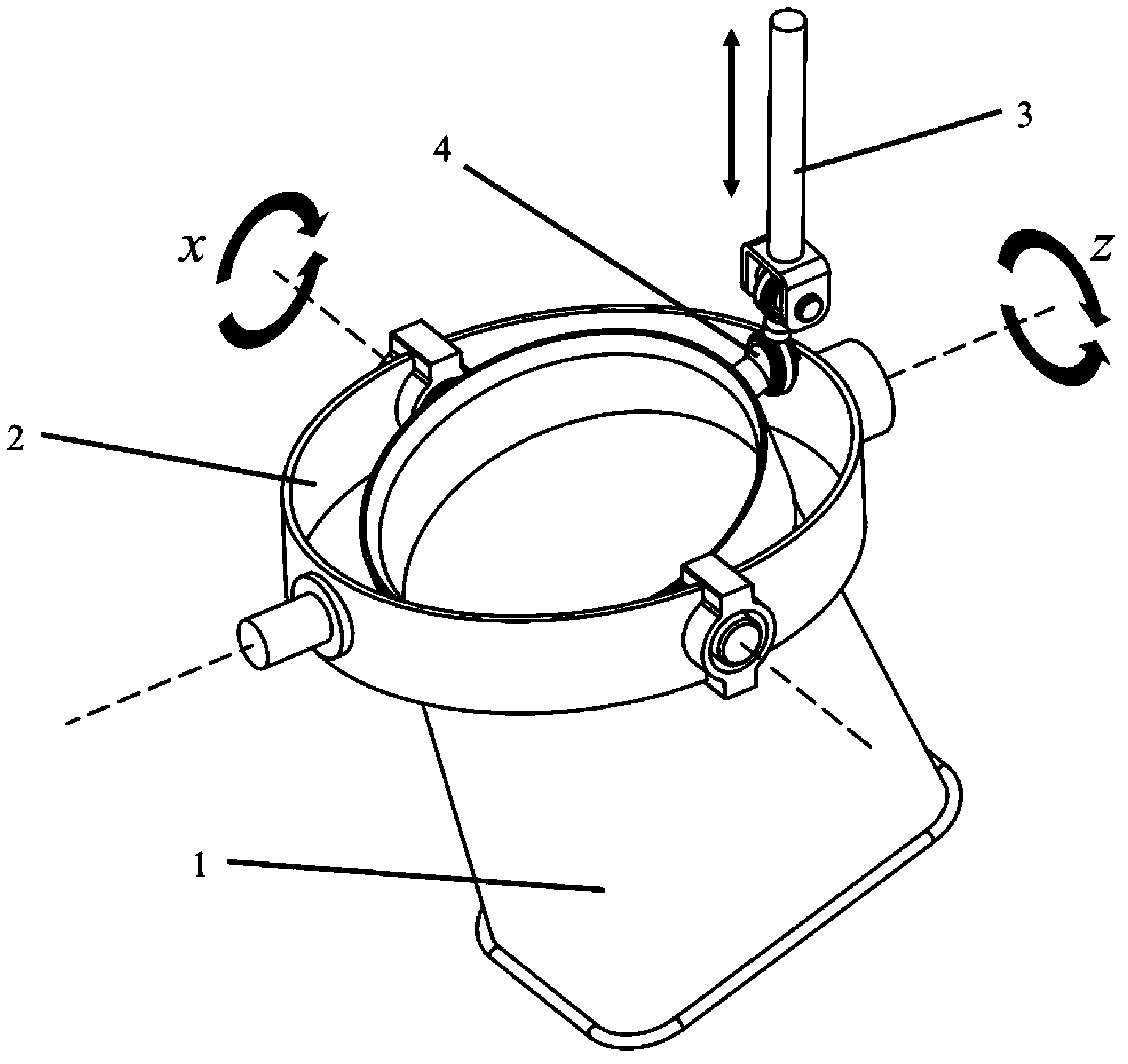

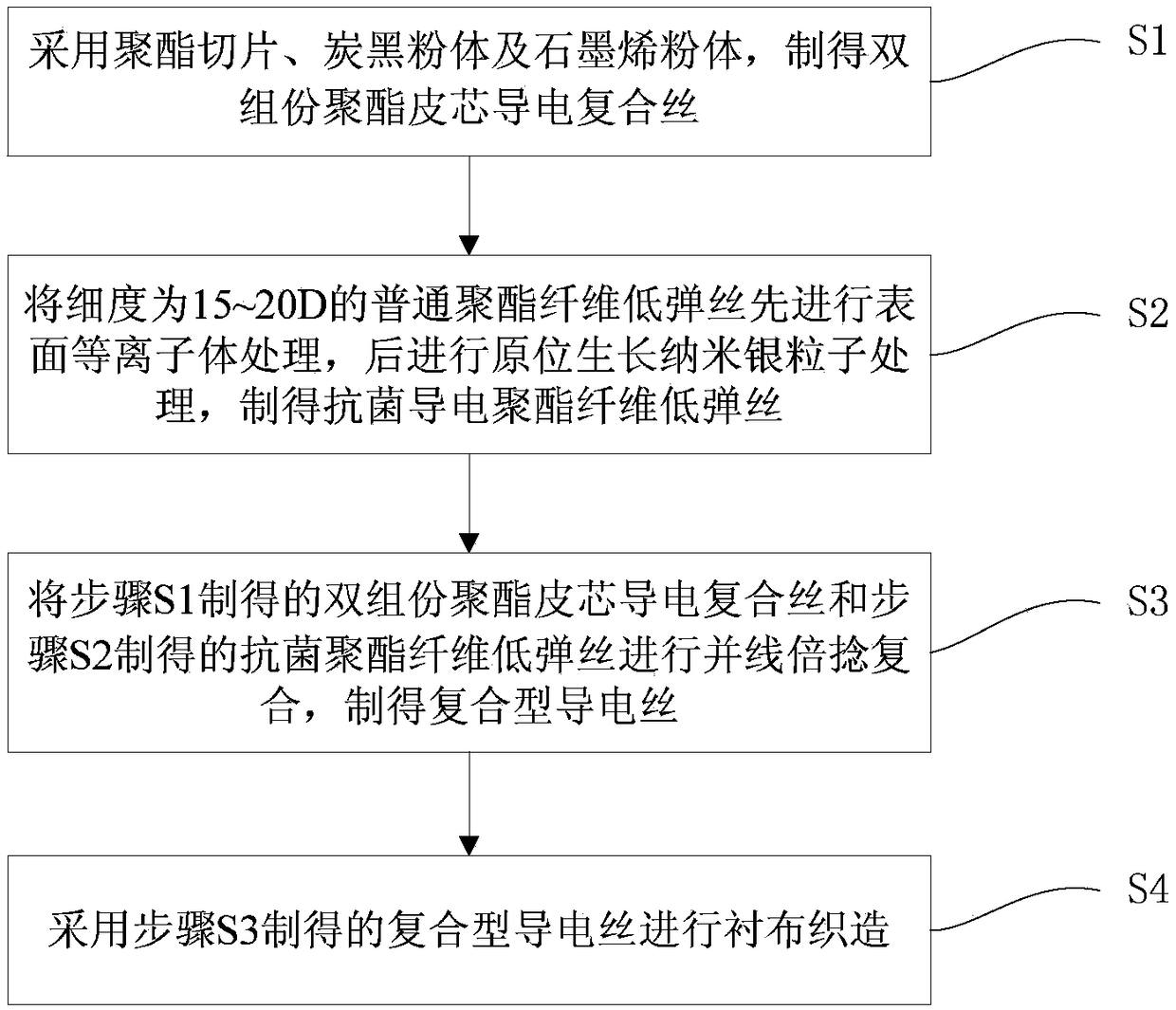

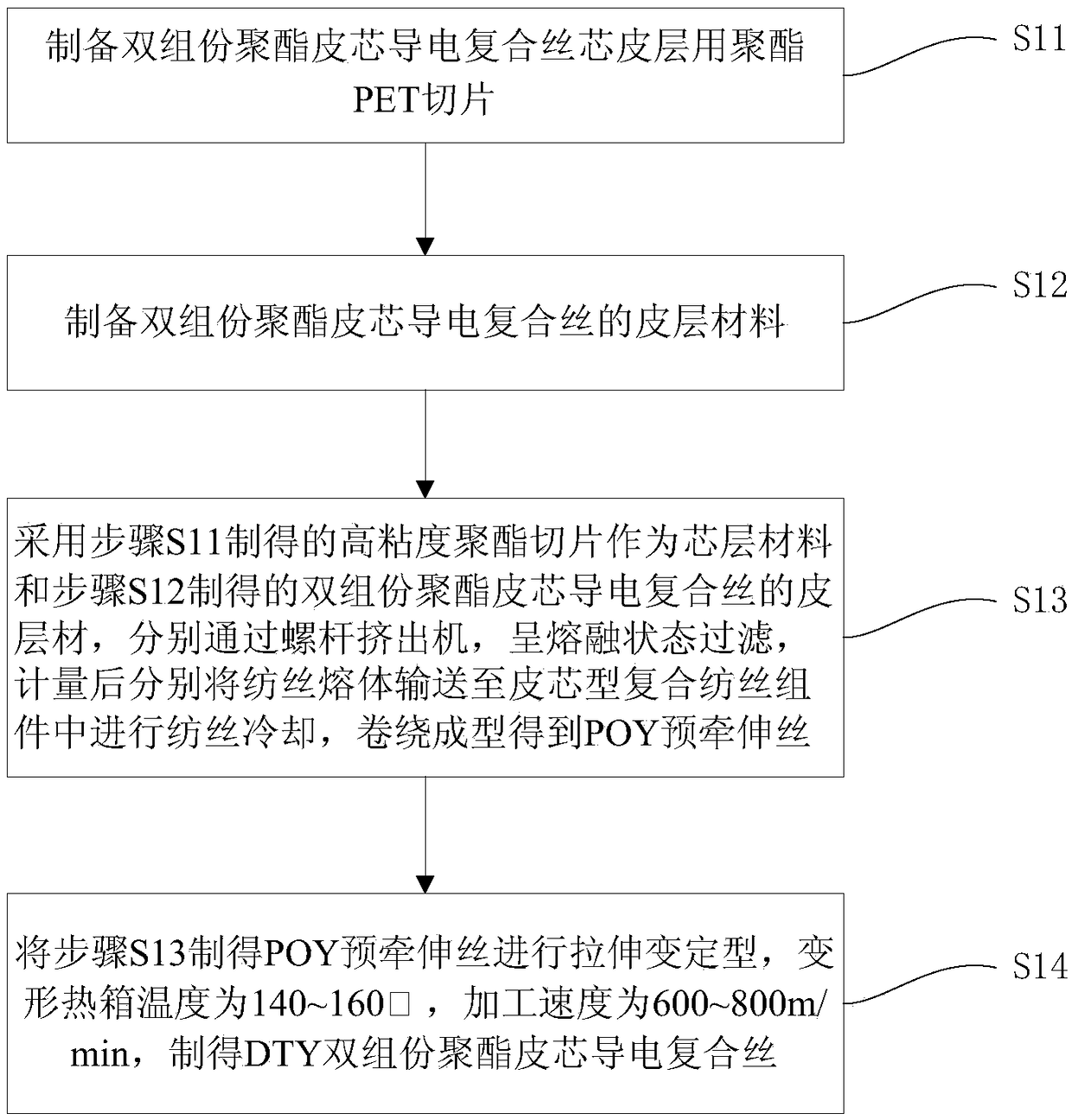

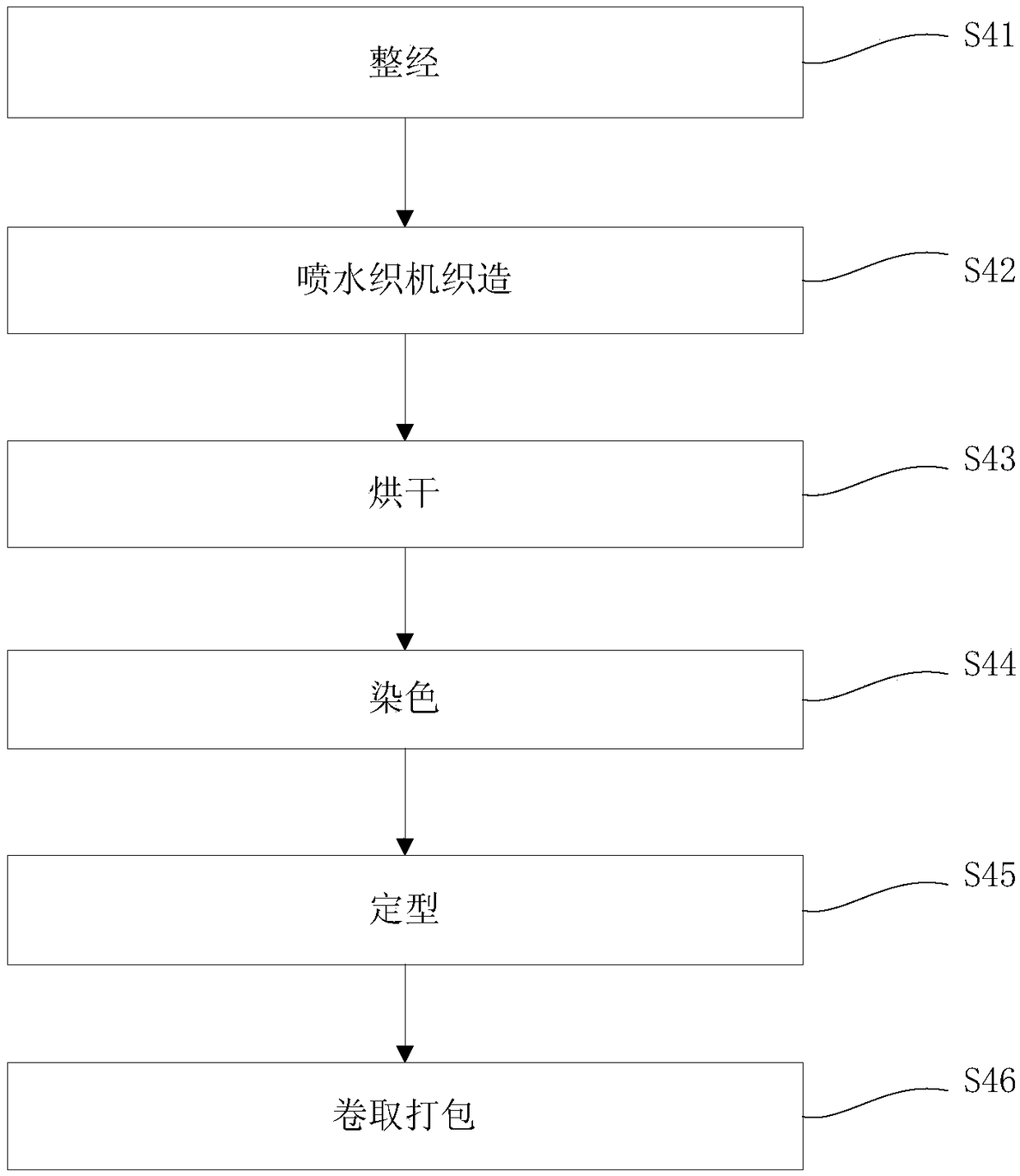

Dacron conductive lining cloth and production process thereof

ActiveCN109371527ASoft touchImprove washing resistanceElectroconductive/antistatic filament manufactureLiquid/gas/vapor treatment of propelled fabricsPolyesterYarn

The invention relates to a dacron conductive lining cloth and a production process thereof. The production process includes the following steps that polyester chips, carbon black powder and graphene powder are adopted, and double-component polyester skin core conductive composite filaments are prepared; common polyester fiber low stretch yarn is subjected to surface treatment, and antibacterial conductive polyester fiber low stretch yarn is prepared; the prepared double-component polyester skin core conductive composite filaments and the prepared antibacterial conductive polyester fiber low stretch yarn are subjected to doubling and double-twisting compounding, and composite conductive filaments are prepared; the composite conductive filaments are used for weaving the lining cloth. The defects such as poor conductivity, poor softness, washing intolerance and the complex processing process of conductive fibers in the prior art are overcome, the dacron conductive lining cloth has excellent washing resistance, dyeing performance and conductivity, is resistant to abrasion and bending and soft in hand feeling, still can keep good conductivity after being machine-washed multiple times, is good in strength, soft and not crispy, and meets the comprehensive requirements of the strength, softness and conductivity of high-grade antistatic clothing on antistatic lining cloths.

Owner:南通源佑纺织科技有限公司

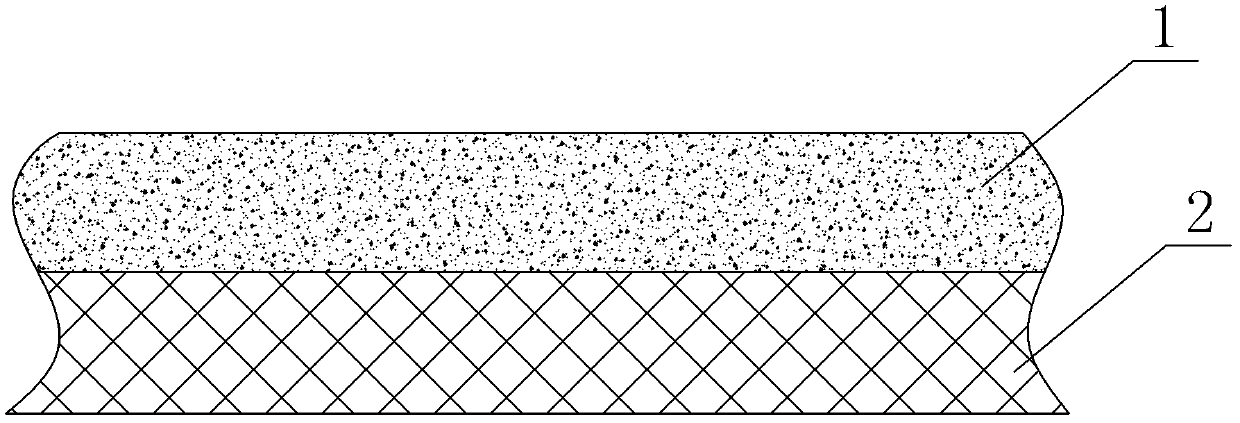

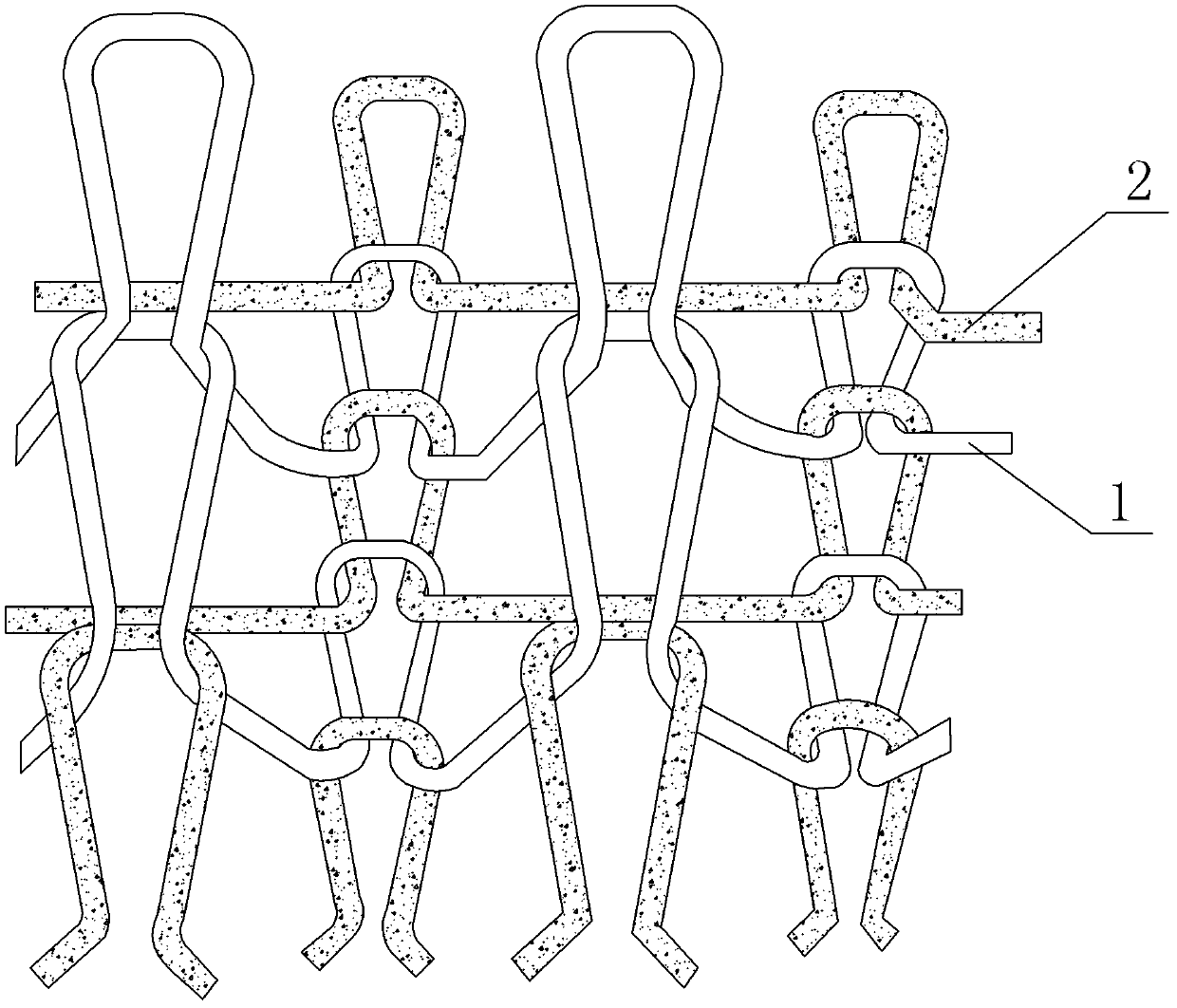

Two-needle tricot stitch weft insertion bidirectional elastic composite material and production process thereof

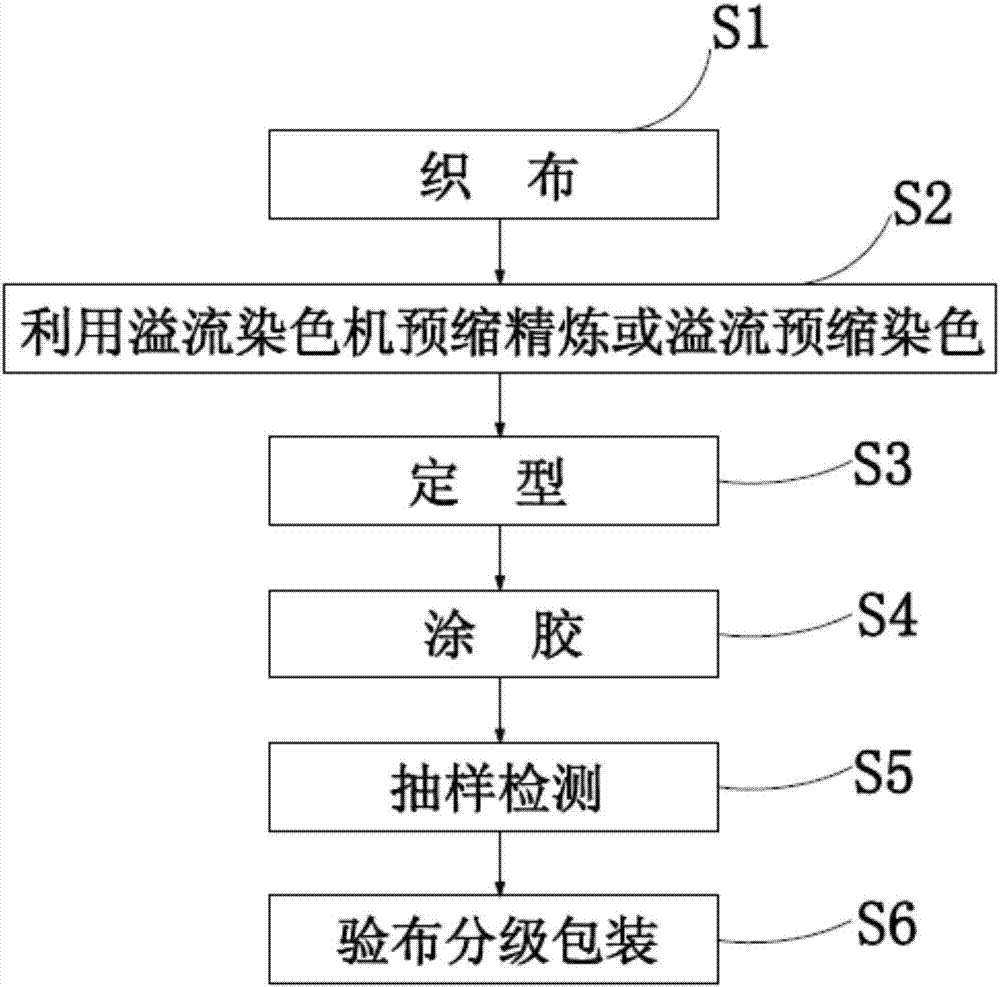

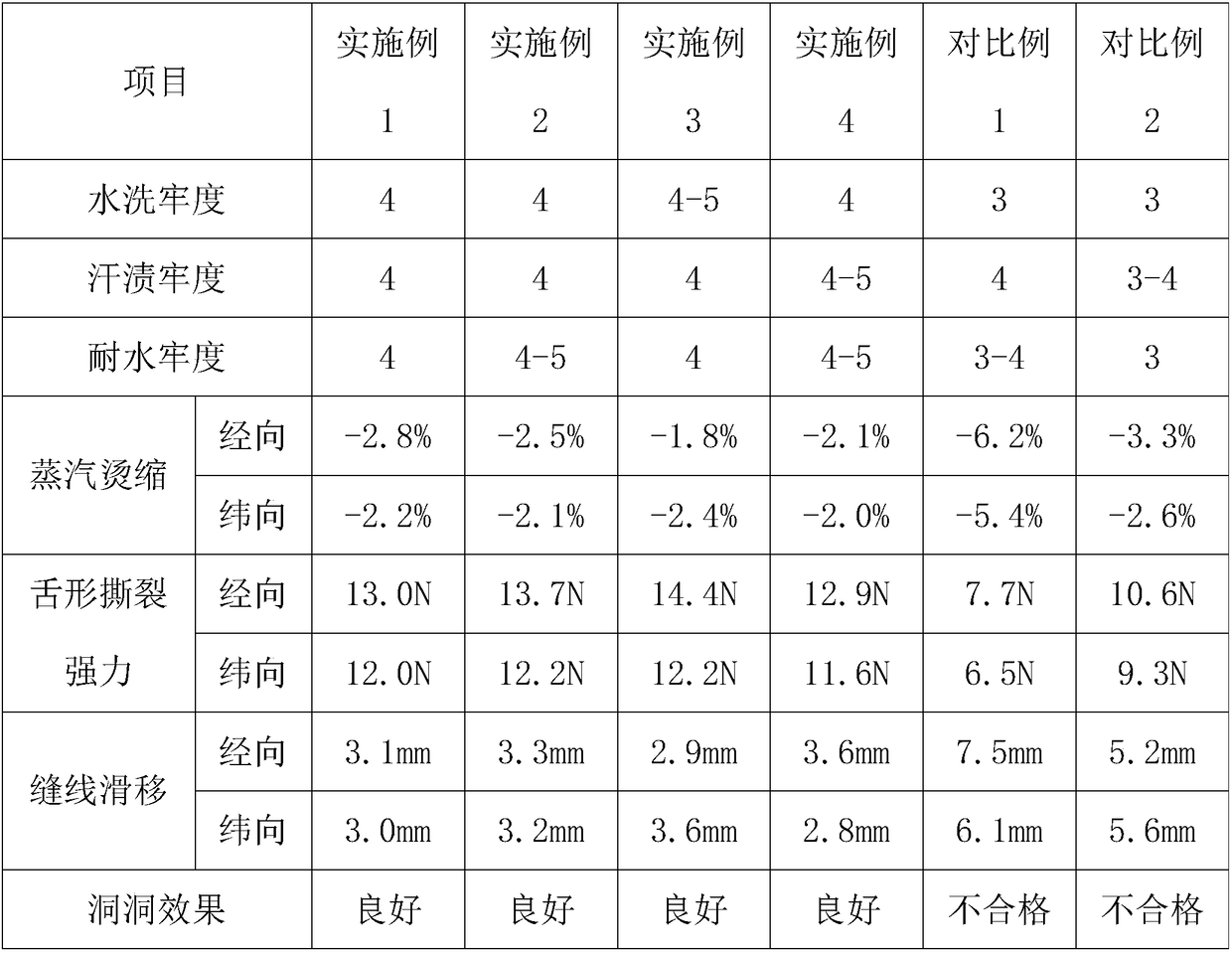

ActiveCN106906672AStable structureGood warp and weft deformation elongationLiquid/gas/vapor treatment of propelled fabricsCoatingsPolyesterEngineering

The invention provides a production process of a two-needle tricot stitch bidirectional elastic composite material. The production process includes the steps: taking polyester DTYs (draw texturing yarns) with the specification of 15D-100D as warp yarn materials, taking DTYs with the specification of 15D-600D as weft yarn materials and weaving a two-needle tricot stitch weft insertion gray fabric in a single guide bar full-set threading manner by a two-needle tricot stitch disk of a full weft warp knitting machine; performing pre-shrinking and refining or overflow pre-shrinking and dyeing by an overflow dyeing machine; performing sizing and gluing. The looming warp density of warp yarns is 7.5-13 yarns / cm, and the looming weft density of weft yarns is 6-25 yarns / cm. The two-needle tricot stitch weft insertion bidirectional elastic composite material produced by the production process of the two-needle tricot stitch weft insertion bidirectional elastic composite material is elastic in both a warp direction and a weft direction, superior in performance and low in cost. The invention further relates to the two-needle tricot stitch weft insertion bidirectional elastic composite material.

Owner:CPL NEW MATERIAL TECH CO LTD

Textile bleaching device

ActiveCN104480659AFast bleachingBleach evenlyTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsPropellerTextile bleaching

The invention discloses a textile bleaching device, which comprises a motor, a bleaching box, a bleaching separating plate, a main shaft and a plurality of propellers, wherein the bleaching box is provided with a material inlet and a material outlet which are positioned at the two sides of the bleaching box, the material inlet is positioned at the upper part of the bleaching box, the material outlet is positioned at the lower part of the bleaching box, the main shaft penetrates through the bleaching box, and is rotationally connected with the bleaching box, the propellers are arranged along the axial direction of the main shaft, the bleaching separating plate is in a cylinder shape, circulating holes are uniformly formed in the side wall of the bleaching separating plate along the circumferential direction, the bleaching separating plate is coaxial with the main shaft, the two ends of the bleaching separating plate are connected with the bleaching box, the propellers are positioned in the bleaching separating plate, and the main shaft is driven by the output end of the motor. The textile bleaching device has the advantages that the bleaching speed is high, and a textile can be uniformly bleached.

Owner:响水县连桥纺织有限公司

Dyeing and finishing process of polyester four-side elastic fabric with holes

ActiveCN109281205ANeck uniformGuaranteed aestheticsLiquid/gas/vapor treatment of propelled fabricsLiquid/gas/vapor removalPolyesterFiber

The invention relates to a dyeing and finishing process for a polyester four-side elastic fabric with holes. The dyeing and finishing process specifically comprises the following steps: unwinding, pre-shrinking, cold stacking, desizing, grey cloth setting, in-cylinder desizing, in-cylinder dyeing, dewatering and scutching, shaping, reeling and packaging, and the pre-shrinking step comprises the following steps: using warm water for pre-wetting and then drying by drying cylinders, wherein the vehicle speed is 65-70 m / min, the pressure of a roller is 1.5-2.0 kg / cm<2>. According to the invention,the fabric is subjected to the pre-shrinking, so that the shrinking amplitude of the fabric is uniform, and the wrinkling abnormity caused by high-temperature sudden contraction is avoided; the fabric can be sufficiently shrunk at a certain temperature by the cold stacking, so that fibers are more tightly, bulk and plump, by the grey cloth setting, the grey cloth of the fabric is uniformly pre-shrunk at a high temperature, and shaped, meanwhile, the molecular structures of the fibers are rearranged so as to facilitate dyeing; the attractiveness of clothes in the wearing process can be kept bythe polyester four-side elastic fabric with the holes prepared by the process, the surface of the fabric is smooth, the holes are soft and natural, and the comfort is excellent.

Owner:QUANZHOU LIUYUAN DYEING PRINTING WEAVING

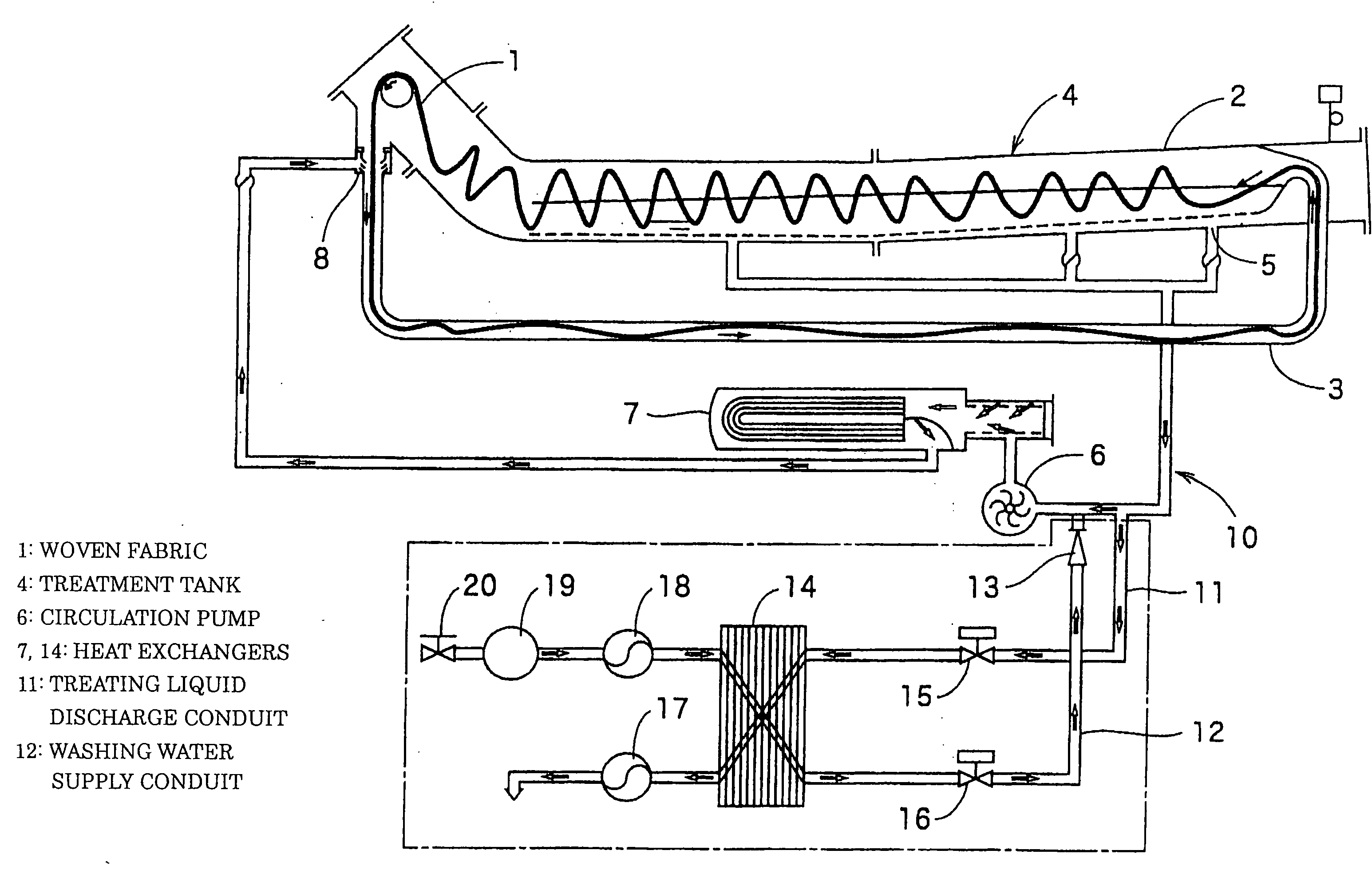

Method of washing a textile product and textile product treatment apparatus used therefore

InactiveUS20090013479A1Increase temperatureImprove washabilityLiquid/gas/vapor treatment of propelled fabricsOther washing machinesWaste managementTextile

There are provided a washing method using a treatment apparatus of the type, such as a liquid current treatment apparatus for treating a textile product by circulating a treating liquid that is capable of effectively washing a textile product in a shorter time, as well as a textile product treatment apparatus used therefore. A textile product 1 is loaded into a treatment tank 4 and a high-temperature treating liquid, which circulates inside and outside of the treatment tank 4, is brought into contact with the textile product, thus treating the textile product, and then the textile product is washed with a washing water, in which subsequent to the treatment by the high-temperature treating liquid, the high-temperature treating liquid is gradually discharged from the treatment tank 4 while the washing water is gradually supplied into the treatment tank 4, during which the discharged high-temperature treating liquid is heat exchanged with the supplied washing water, and the amount of the high-temperature treating liquid to be discharged is set to be equal to the amount of the washing water to be supplied so that the amount of liquid within the treatment tank 4 is kept constant.

Owner:HISAKA WORKS

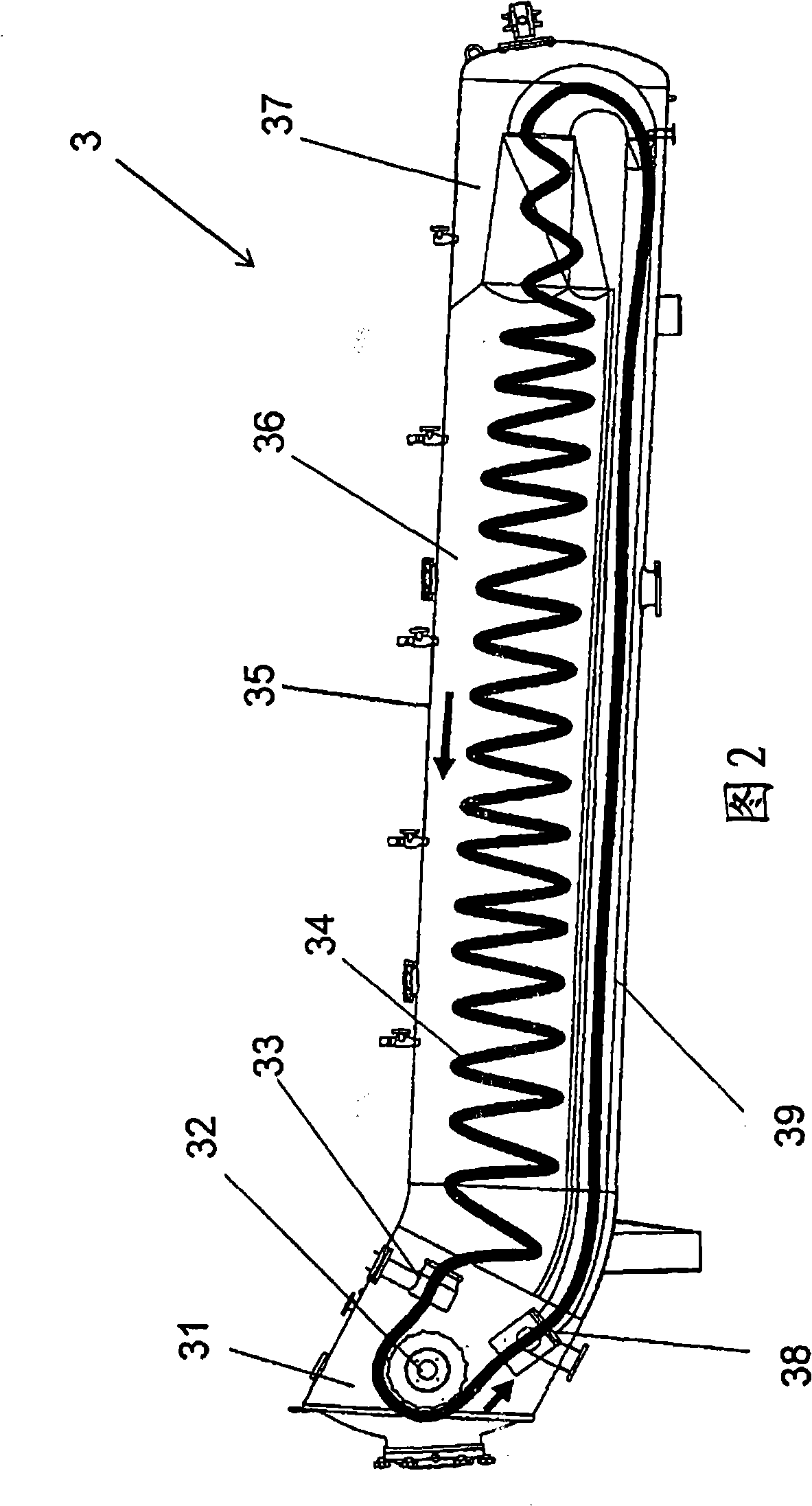

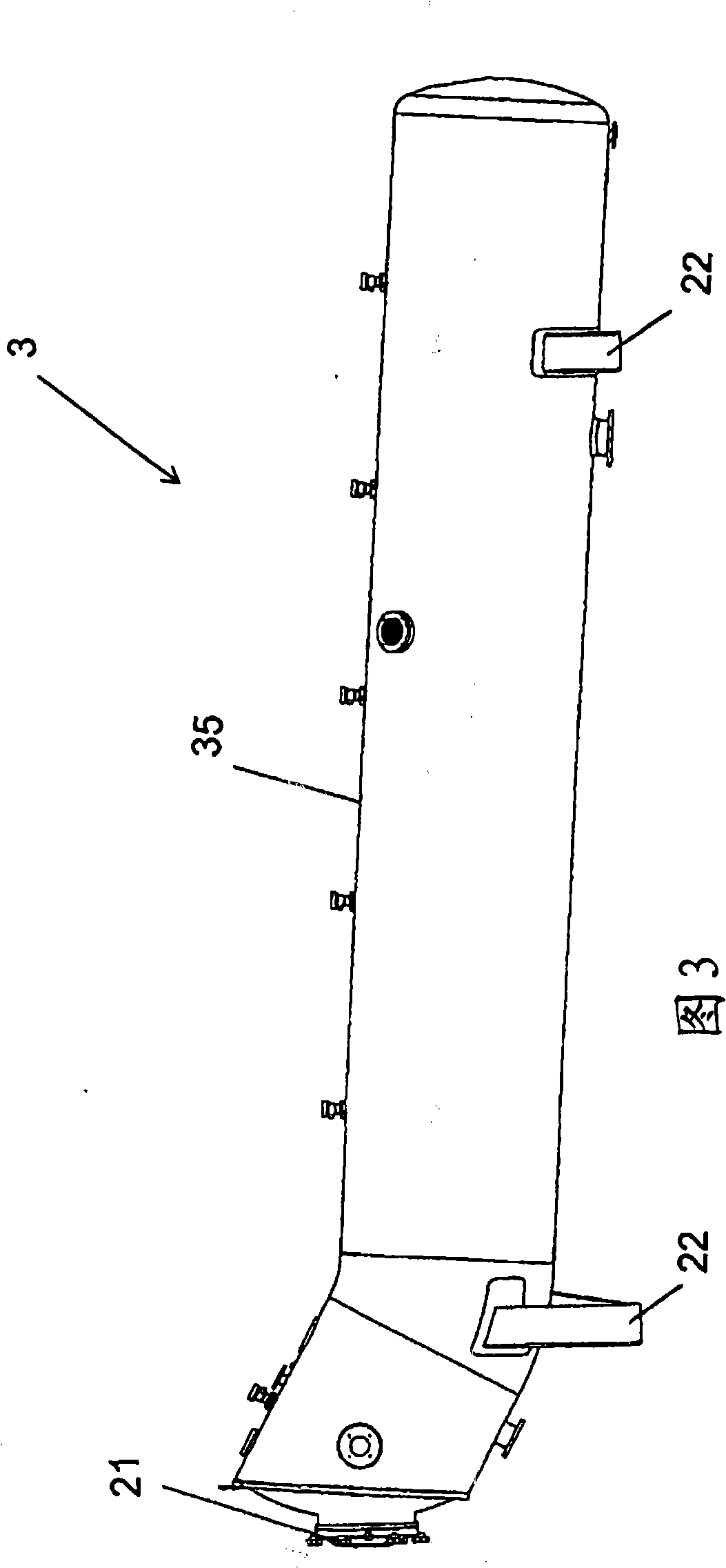

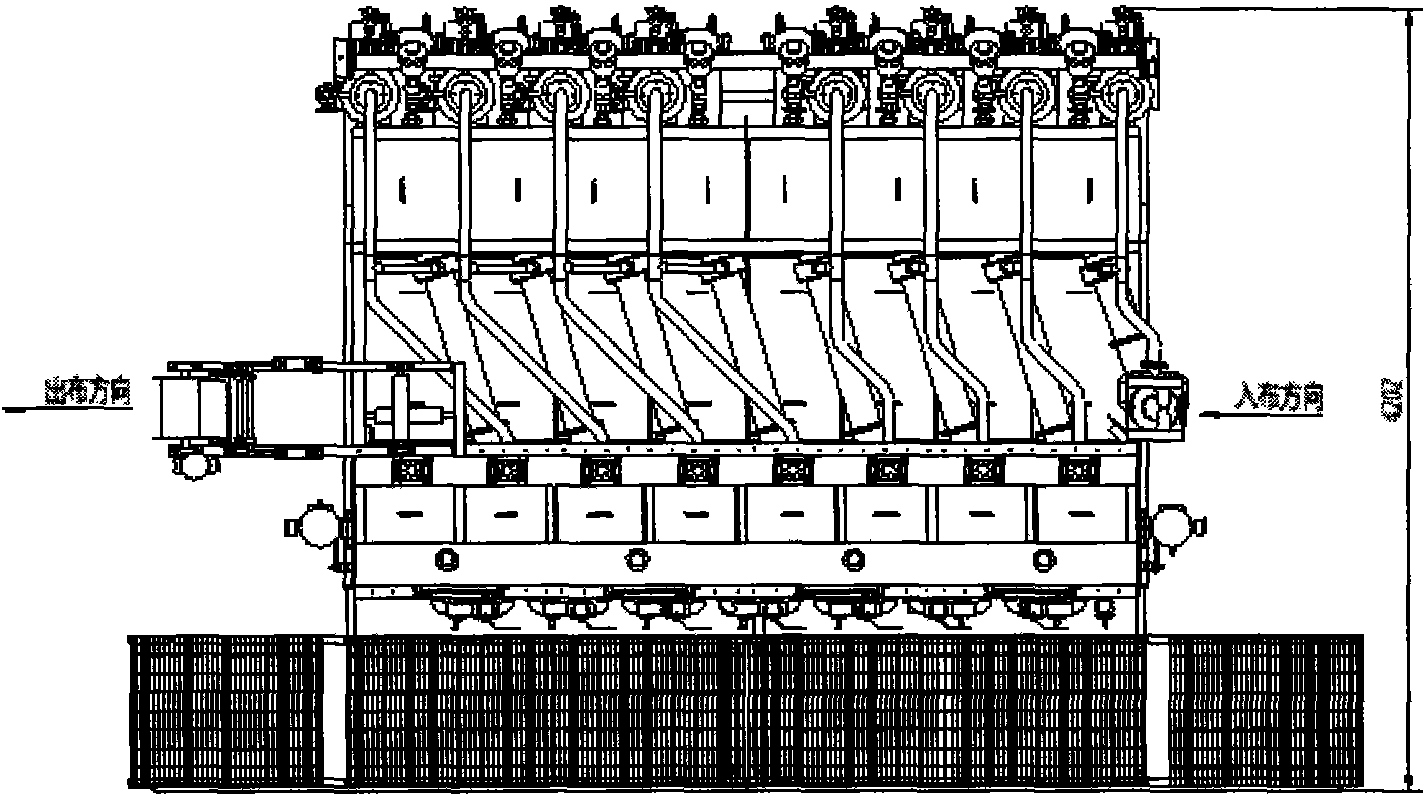

Continuous rope-shaped jet washing machine

ActiveCN103215777AImprove replacement efficiencyImprove washing efficiencyLiquid/gas/vapor treatment of propelled fabricsLiquid/gas/vapor roped fabric treatmentWater circulationWaste management

The invention relates to a continuous rope-shaped jet washing machine which comprises a body, lift cloth water rolling mechanisms, fabric flow channels and water circulation pipelines, wherein the body consists of a plurality of J-shaped troughs; the fabric flow channel is arranged above each J-shaped trough along the inclined direction; the lift cloth water rolling mechanism is arranged above the flat top of each J-shaped trough; each J-shaped trough is provided with the water circulation pipeline; and the plurality of J-shaped troughs are connected by a pipeline. The continuous rope-shaped jet washing machine is small in volume, high in efficiency and suitable for multiple fabric products.

Owner:江阴市长江印机有限公司

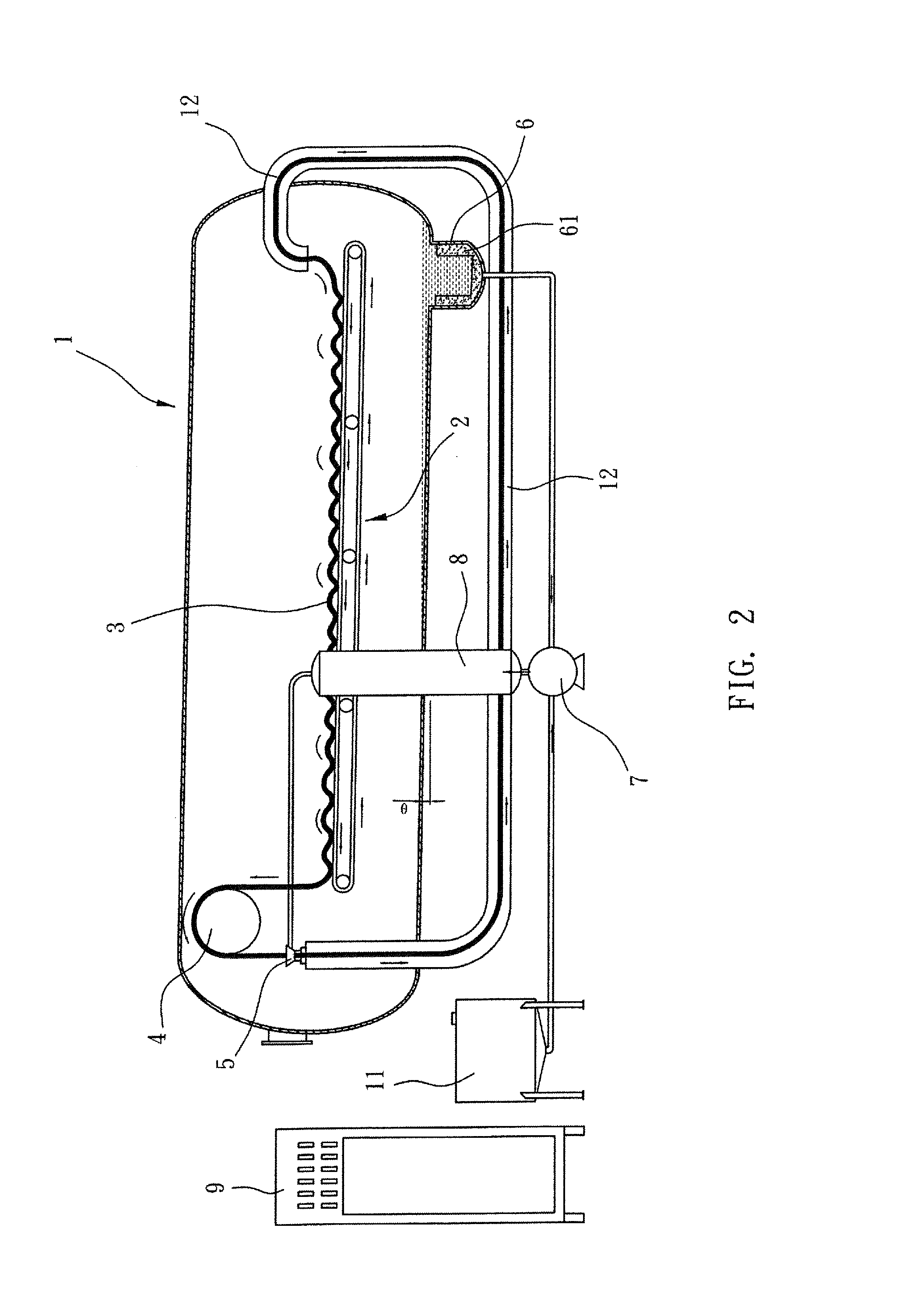

Up-Inclined Coveyor-Driving Fabric Dyeing Machine

InactiveUS20150337471A1Reduce the amount requiredGood effectLiquid/gas/vapor treatment machines driving mechanismsTextile treatment containersLiquid storage tankDyeing

An up-inclined conveyor-driving fabric dyeing machine includes a machine body that is arranged in a front-high-and-rear-low up-inclined configuration. A liquid storage tank is mounted to a bottom of a rear end of the machine body to receive dye liquid falling down from a rear end of a dyeing tube. Thus, the amount of the dye liquid used can be greatly reduced. Further, with such an up-inclined configuration of the dyeing machine, the dyeing tube can be arranged in a horizontal or slightly inclined manner to reduce the heights of a fabric guide roller and the conveyor and thus reduce the distance between the fabric guide roller and the conveyor device, thereby reducing the stretching force and tensile force applied to the fabric during the dyeing process.

Owner:CHANG

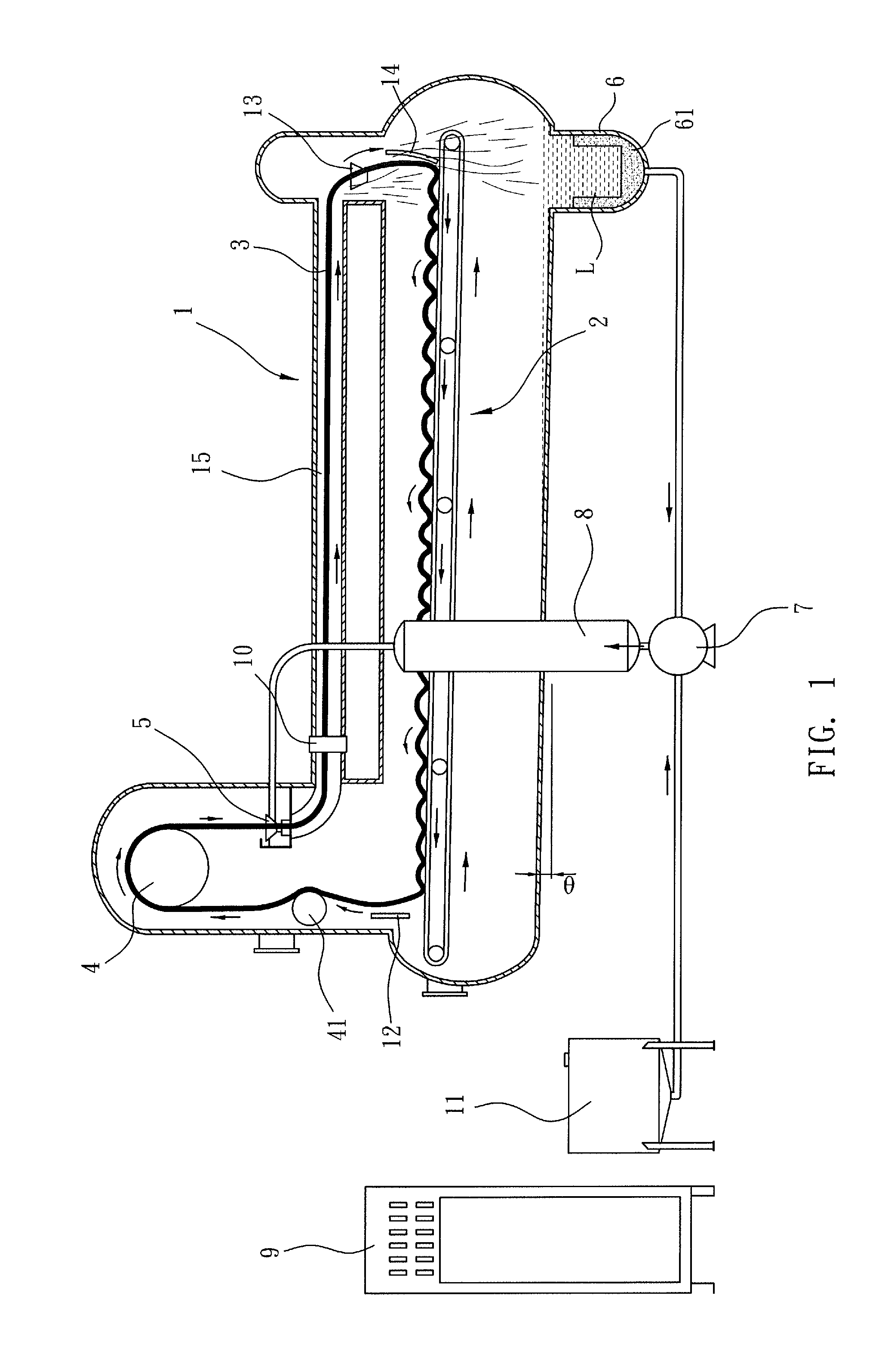

Circulation protection device of conveyor-driven fabric dyeing machine

ActiveUS20150337472A1Easy to operateImprove throughputLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor treatment of propelled fabricsEngineeringComputer program

A circulation protection device is provided for a conveyor-driven fabric dyeing machine that includes a machine body having a front end in which a fabric circulation detection idler and a fabric movement sensor are mounted and a rear end in which a rear fabric guide and a fabric management device are mounted. Control is conducted with a computer program so that when the fabric circulation detection idler detects the fabric is not in movement, the conveyor is shut down; and when the fabric movement sensor detects the fabric is moving excessively fast or slow or gets jamming and stopped, the conveyor is controlled to automatically adjust the speed thereof or stops operation. When the fabric falls from a dyeing tube down to a conveyor, the rear fabric guide adjusts an entry angle of the fabric and the fabric management device allows the fabric to be orderly deposited on the conveyor.

Owner:CHANG

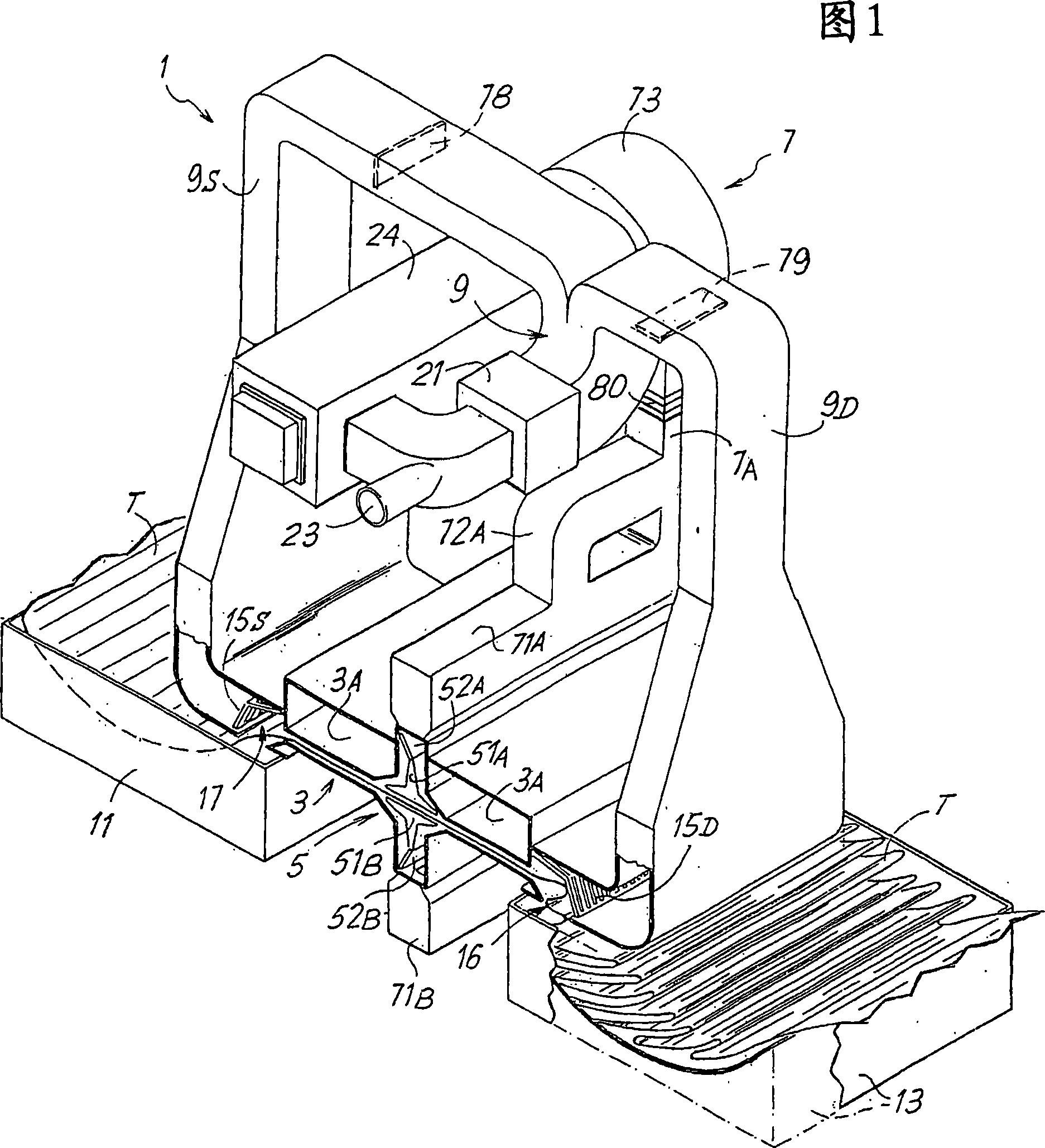

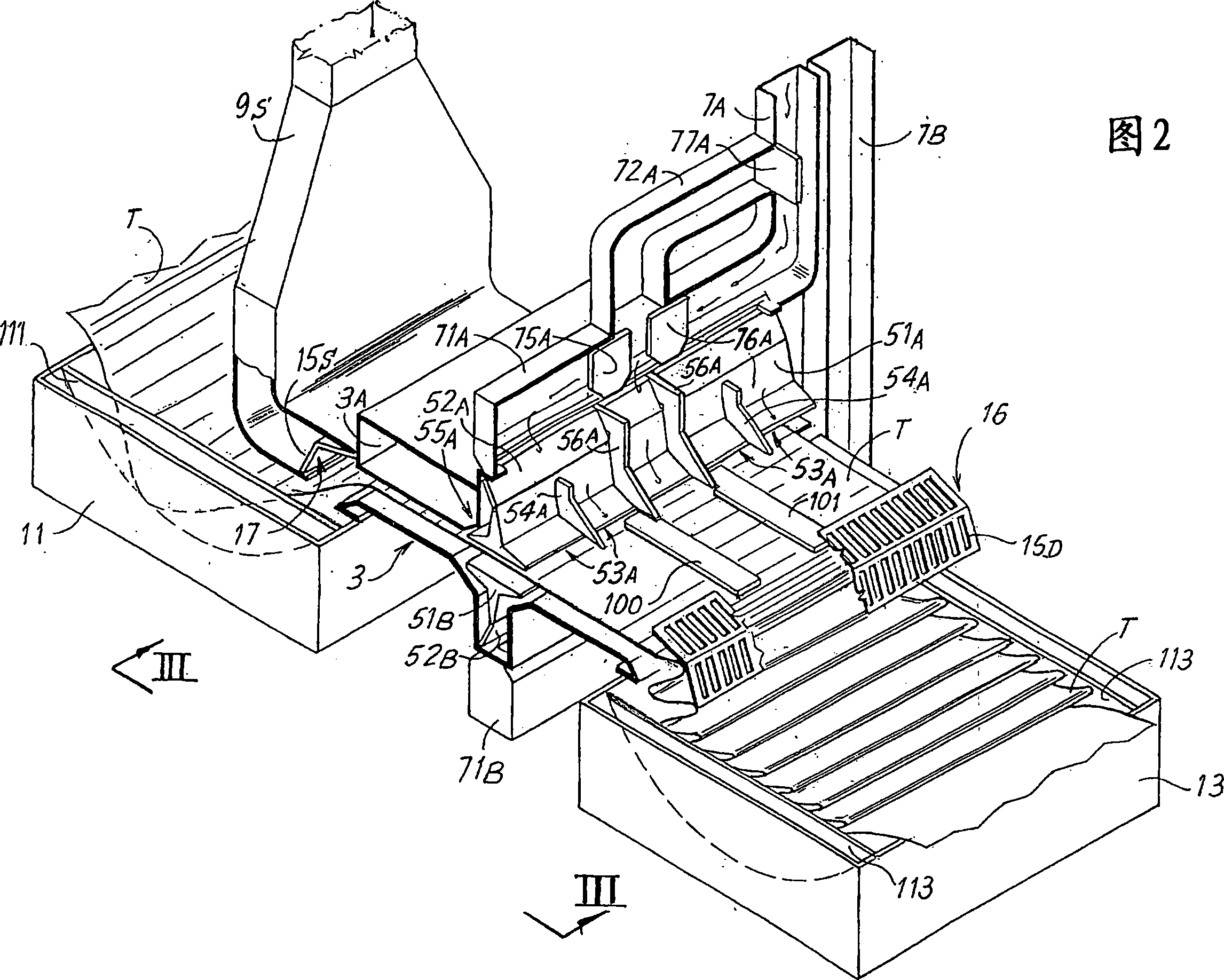

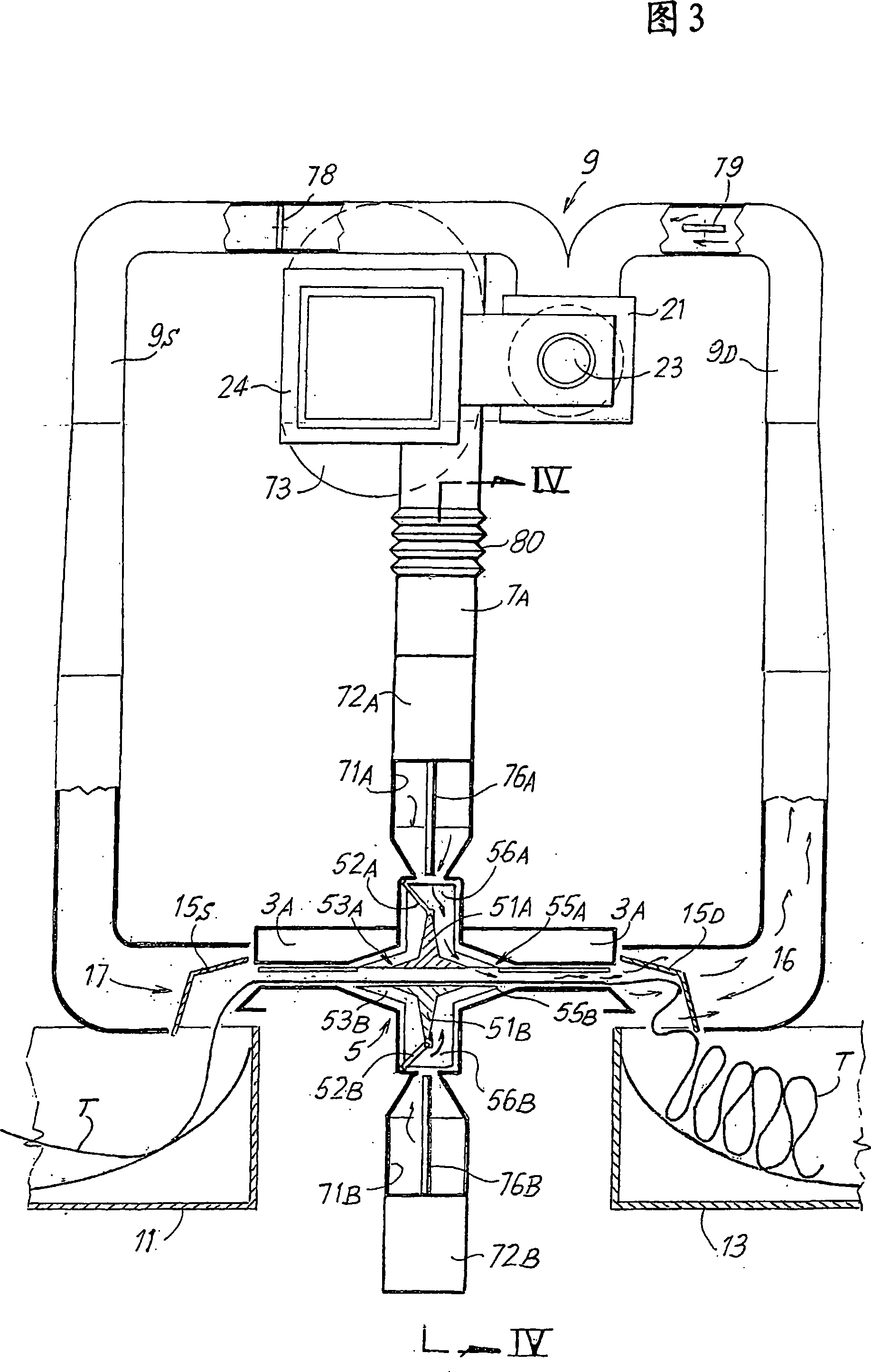

Machine and method for treating both an open width fabric and a fabric in rope form

InactiveCN101006220AImprove processing efficiencyIncrease heightFabric breaking/softeningLiquid/gas/vapor treatment of propelled fabricsTransfer systemIndustrial engineering

The machine provides a path (3) for feed of the fabric with a transfer system, for example a pneumatic system. Along the aforesaid path the fabric can be treated in rope form or in open width according to the machine settings.

Owner:CORAMTEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com