Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5188results about "Textile treatment carriers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

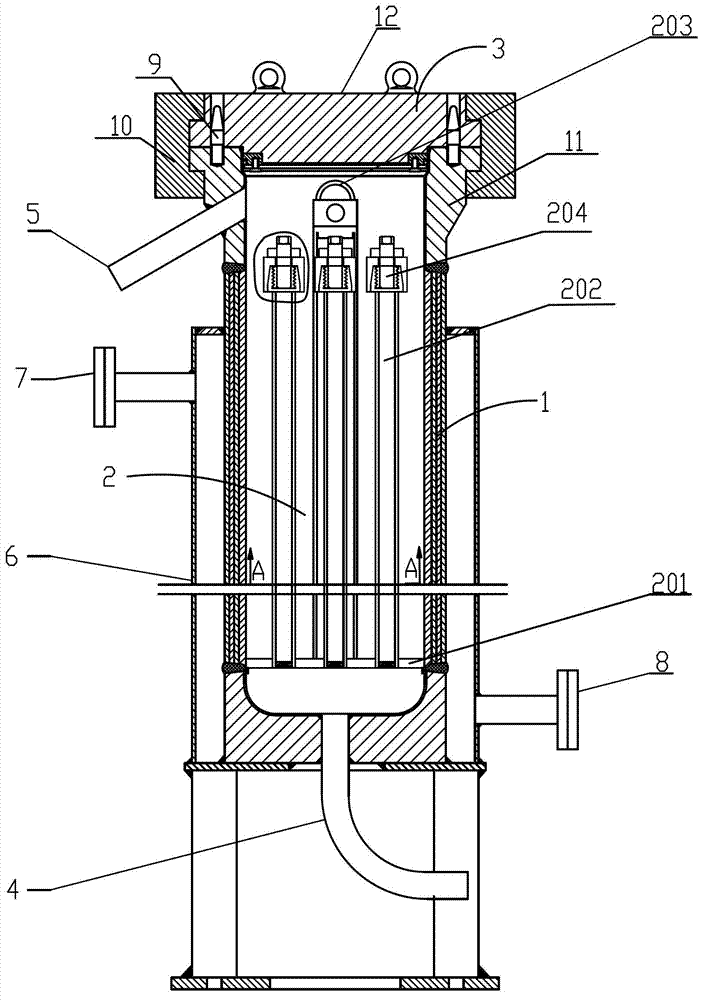

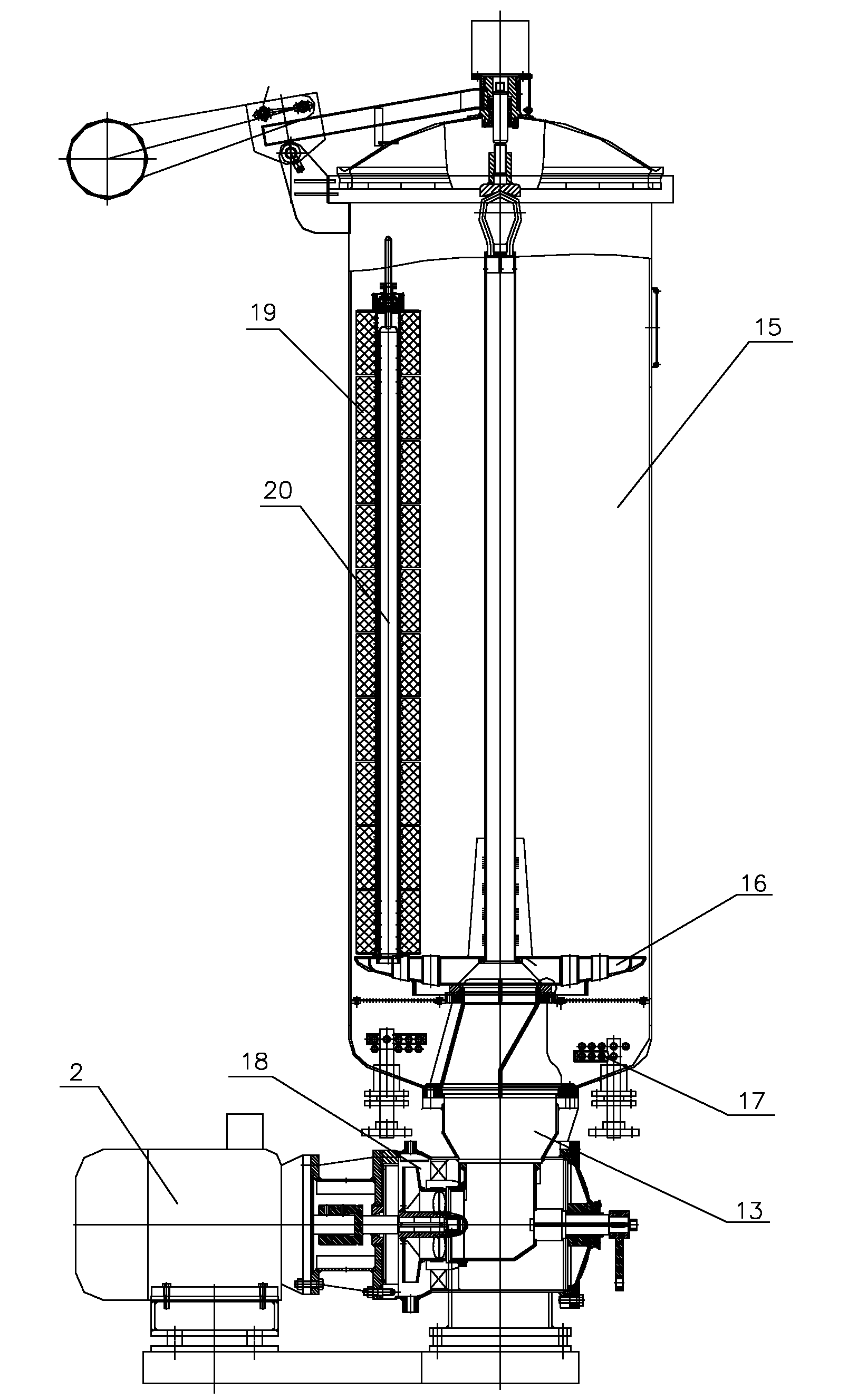

Supercritical carbon dioxide cheese dyeing kettle and waterless supercritical carbon dioxide cheese dyeing method

ActiveCN102787459ATextile treatment containersSolvent treatment with solvent recoveryEngineeringDrill

The invention relates to a supercritical carbon dioxide cheese dyeing kettle and a waterless supercritical carbon dioxide cheese dyeing method. In the dyeing kettle, when carbon dioxide fluid enters a distribution tray from an inlet, blades start rotating clockwise under the effect of pressure; inserted drill rods are driven to rotate by a rotation part; and the rotating speed of the inserted drill rods is increased along with the increase of pressure in a cylinder body. When a cheese is dyed, the cheese on the inserted drill rods is dyed at a speed of 0.2-0.5 r / s. When the rotating cheese is dyed, the cheese is subjected to the pressure of the fluid flowing out from a central shaft; the rotation and bicirculation of the cheese dyeing are realized; the uniform dyeing effect of the dyed cheese can be improved; and the migration ability and the diffusibility can be improved.

Owner:晋江国盛新材料科技有限公司

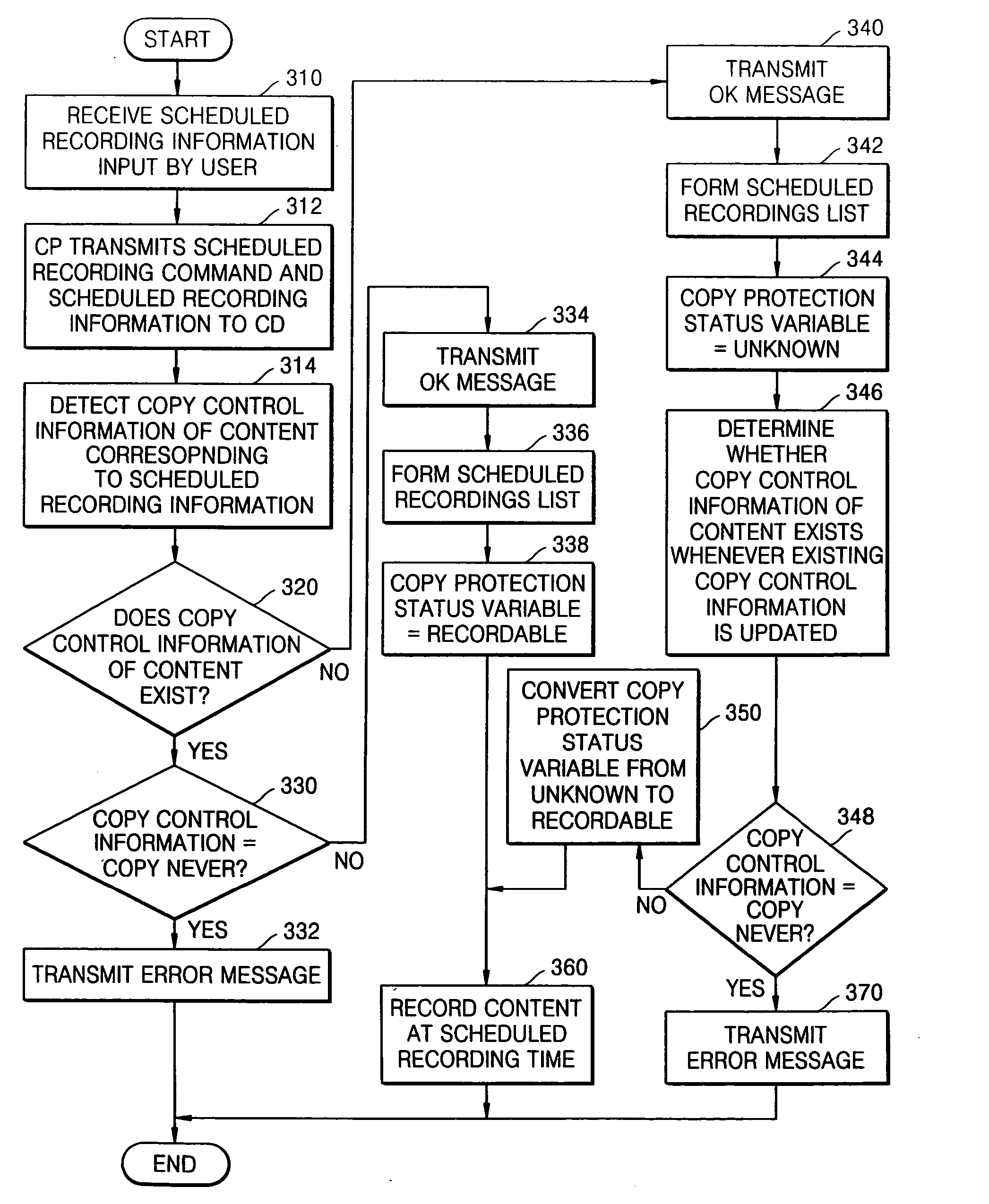

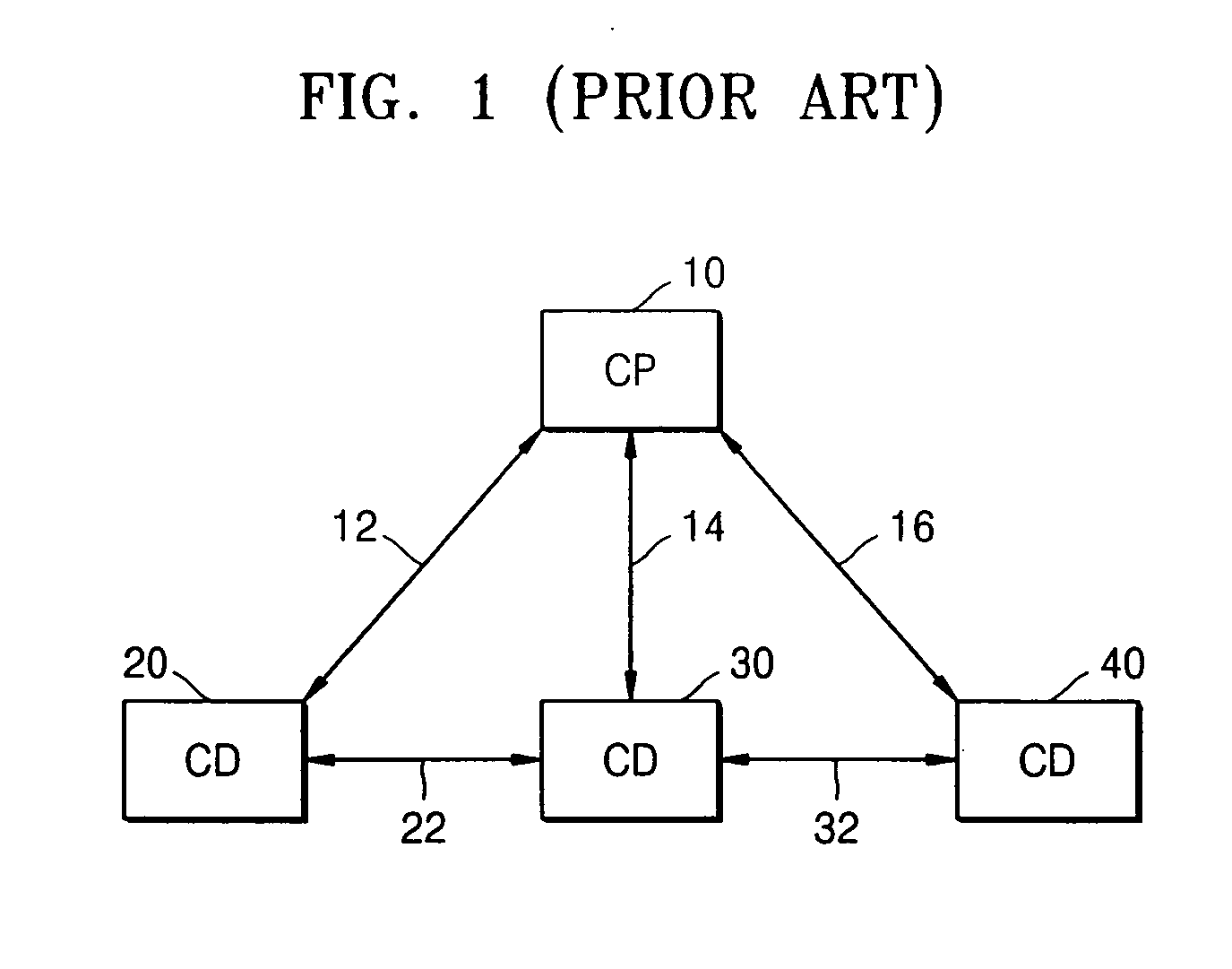

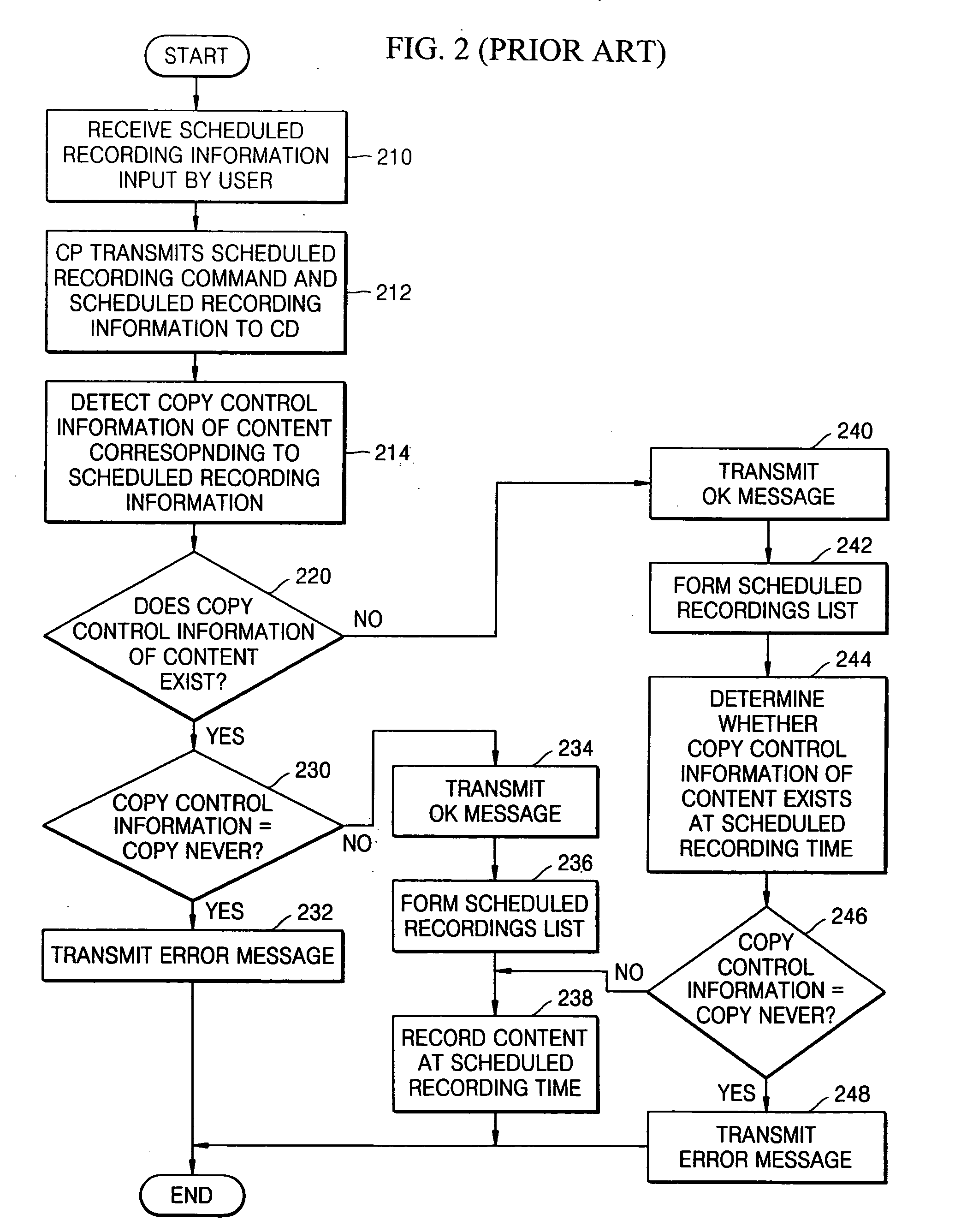

Scheduled-recording method that schedules recording of copy-protected content

InactiveUS20050238168A1Special service provision for substationTelevision system detailsCopy protectionCopy control

A scheduled recording method, which schedules recording of copy-protected content, is provided. The scheduled recording method involves determining whether copy control information of content of interest exists in a recording device storing various copy control information; if the copy control information does not exist in the recording device, newly receiving copy control information and then determining whether the copy control information exists among the newly received information; if the copy control information of the content exists in the recording device, determining whether the copy control information “copy never”; and if the copy control information of the content is “copy never”, transmitting an error message to a user indicating that the content of interest is not recordable to a user. Accordingly, it is possible to let a user know about whether content is recordable by defining a copy protection status variable and determining whether the content is recordable whenever new copy control information is received.

Owner:SAMSUNG ELECTRONICS CO LTD

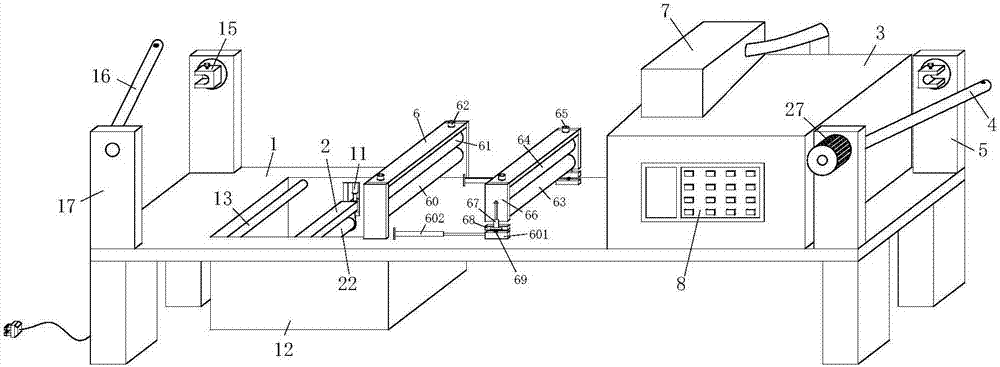

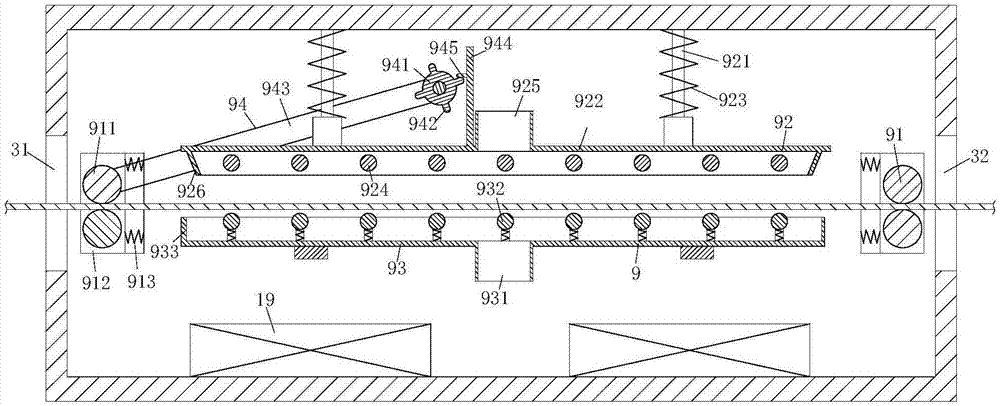

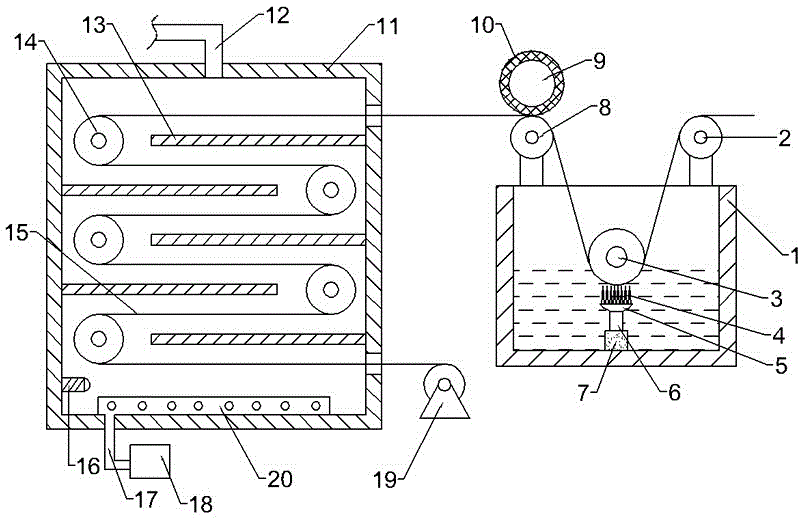

Textile fabric cleaning and drying integrated device

ActiveCN107354638AShorten the timeReduce investmentTextile treatment machine arrangementsLiquid/gas/vapor removal by vibrationAir blowerIntegrated devices

The invention relates to the technical field of spinning, in particular to a textile fabric cleaning and drying integrated device. A fabric taking-up roller and a fabric paying-off roller are installed at the front end and the rear end of a worktable, a water tank, a shaking unit and a drying box are sequentially arranged in the middle of the worktable from front to back, the shaking unit can shake off a cleaning fluid on a textile fabric, a hot-air blower in the drying box blows out hot air to dry the textile fabric, a flapping unit is installed in the drying box to flap the flap, and the cleaning fluid on the textile fabric can be rapidly separated from the textile fabric. The cleaning and drying of the textile fabric are organically combined together, the cleaned textile fabric can be dried during textile fabric cleaning, the time required for independent cleaning and independent drying is effectively shortened, meanwhile the input of the device is decreased, and the production cost is reduced.

Owner:XUZHOU ZHENFANG TEXTILE CO LTD

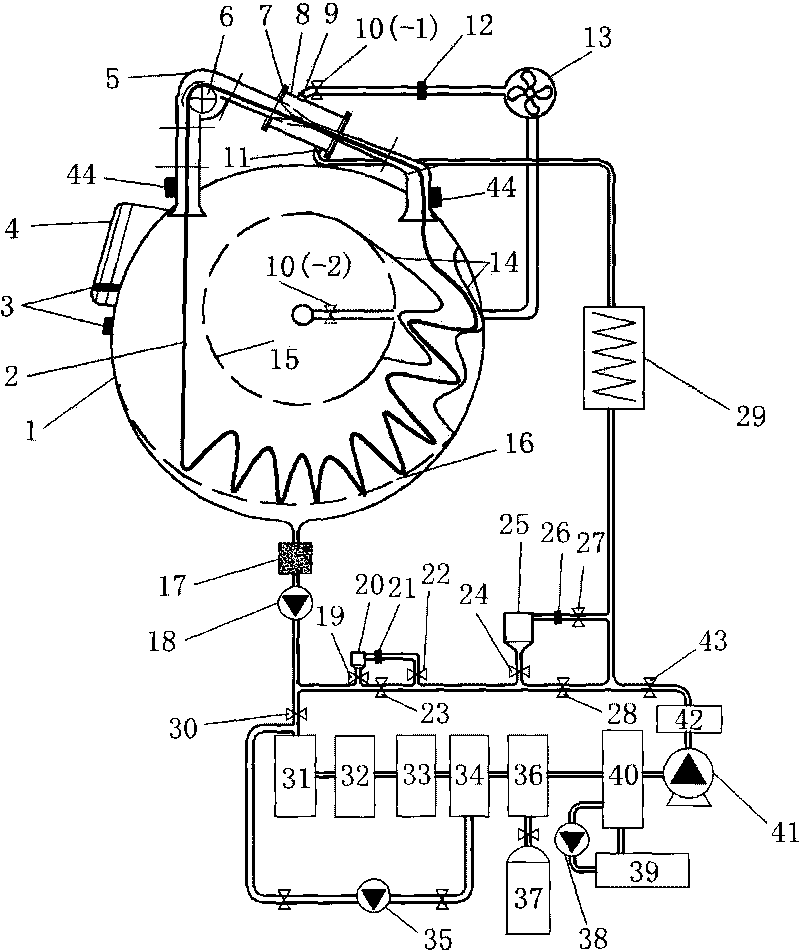

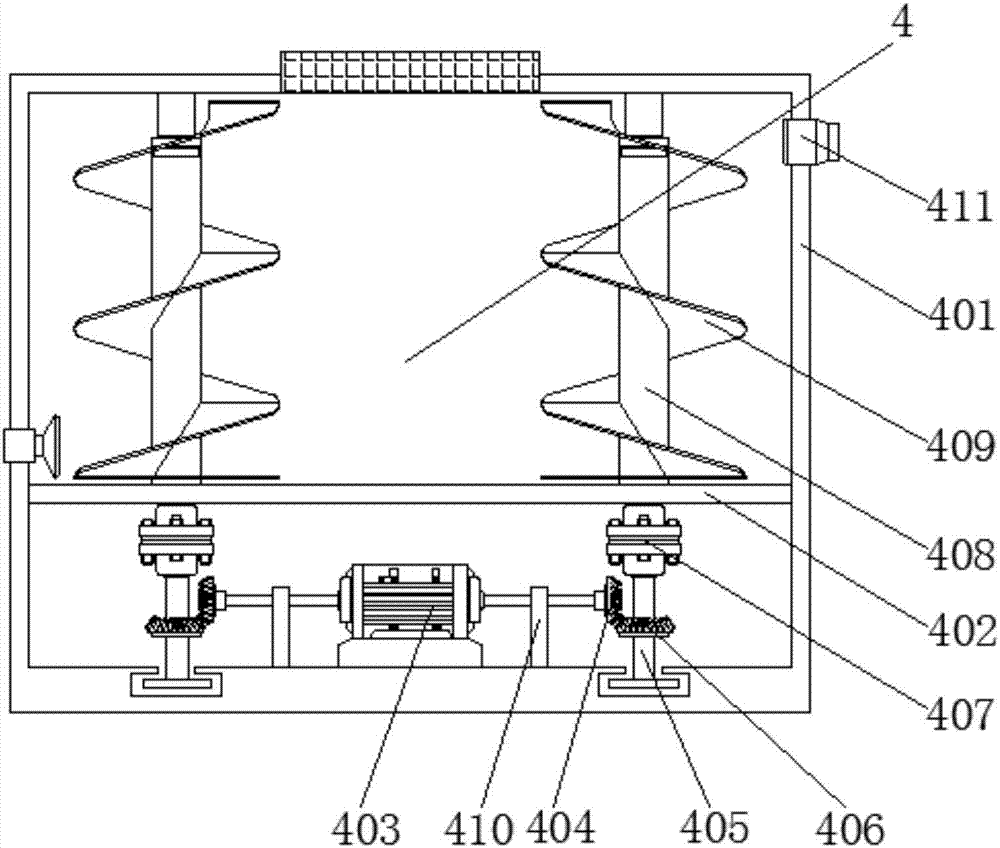

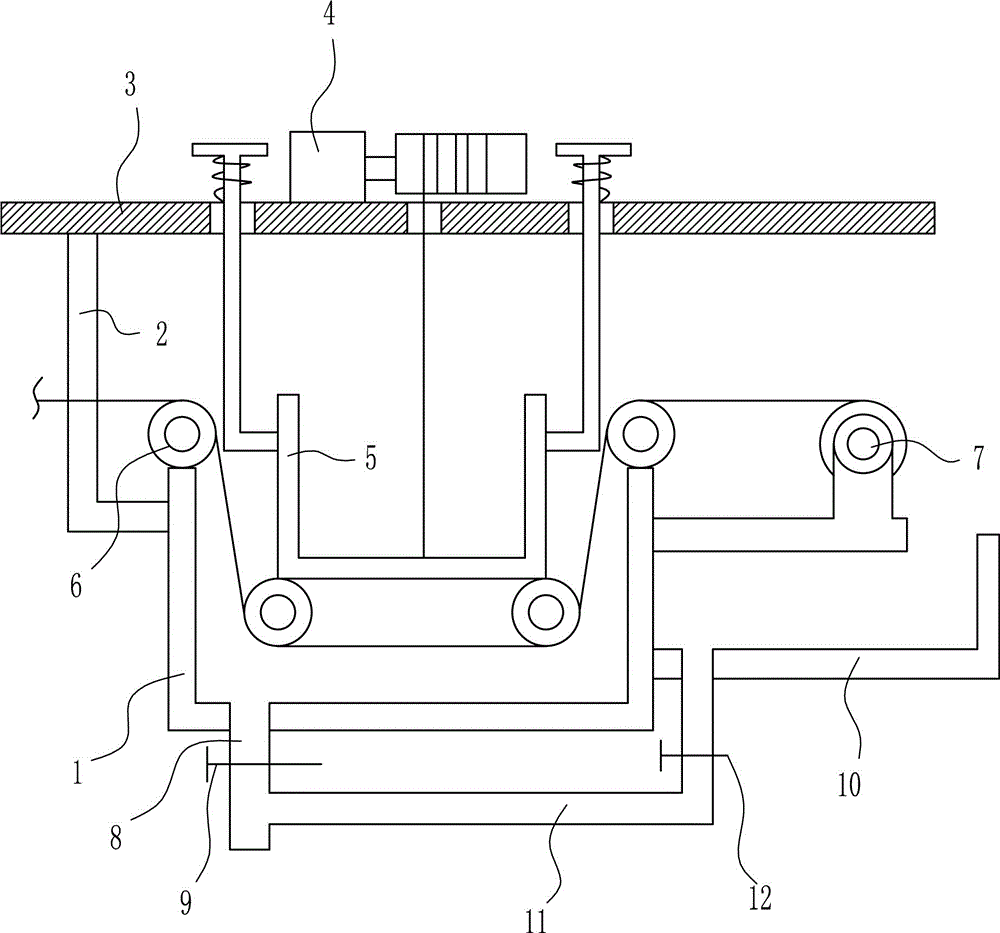

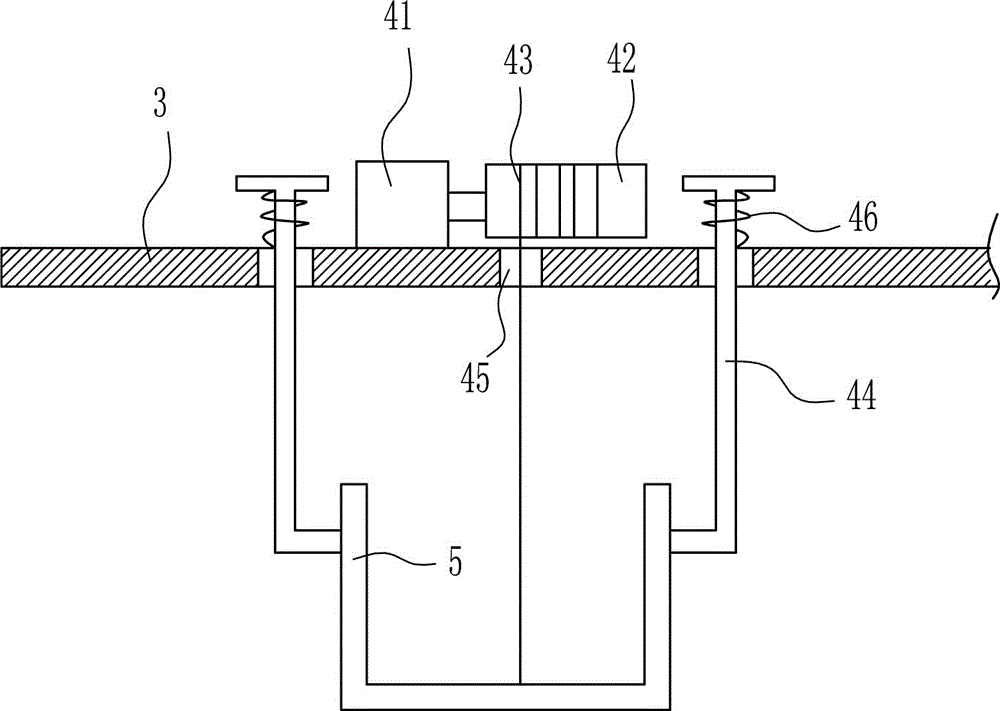

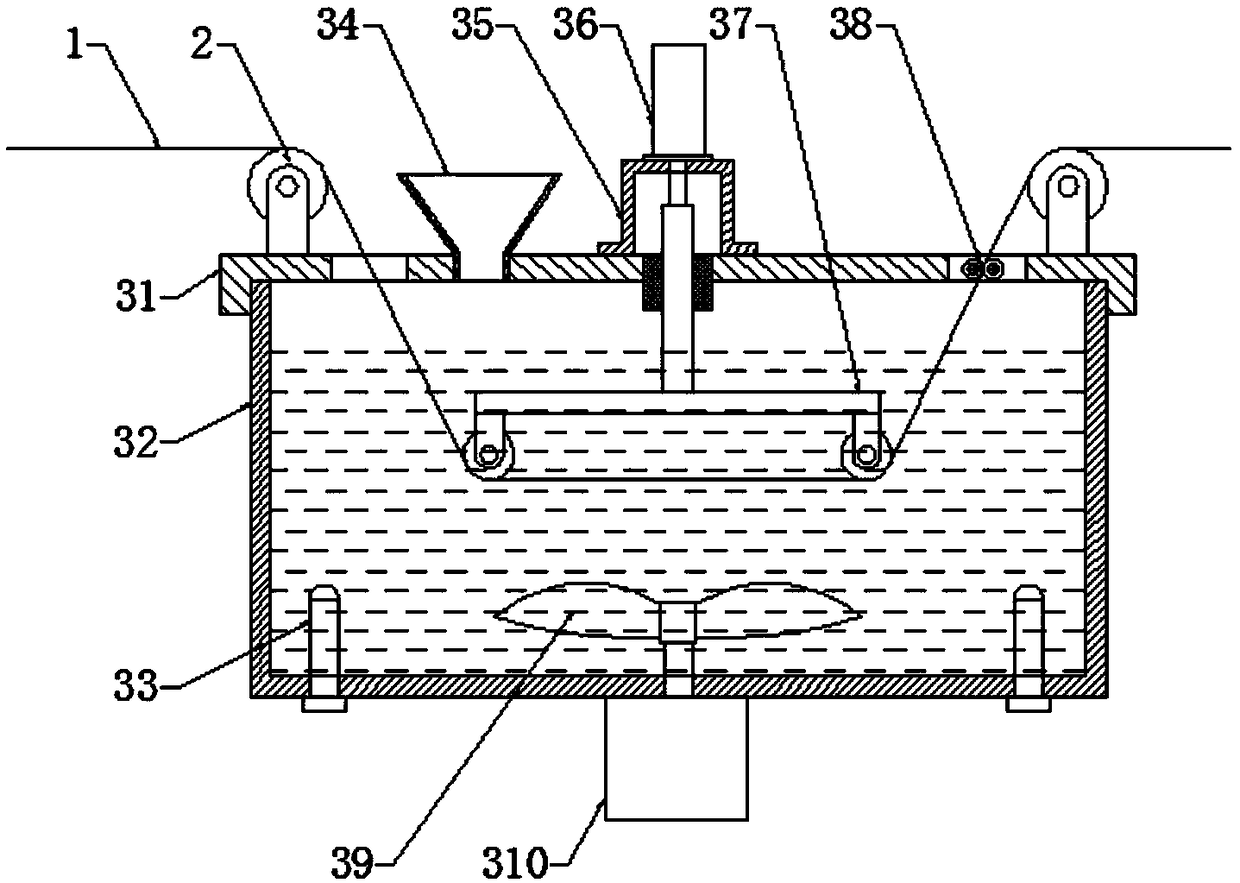

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

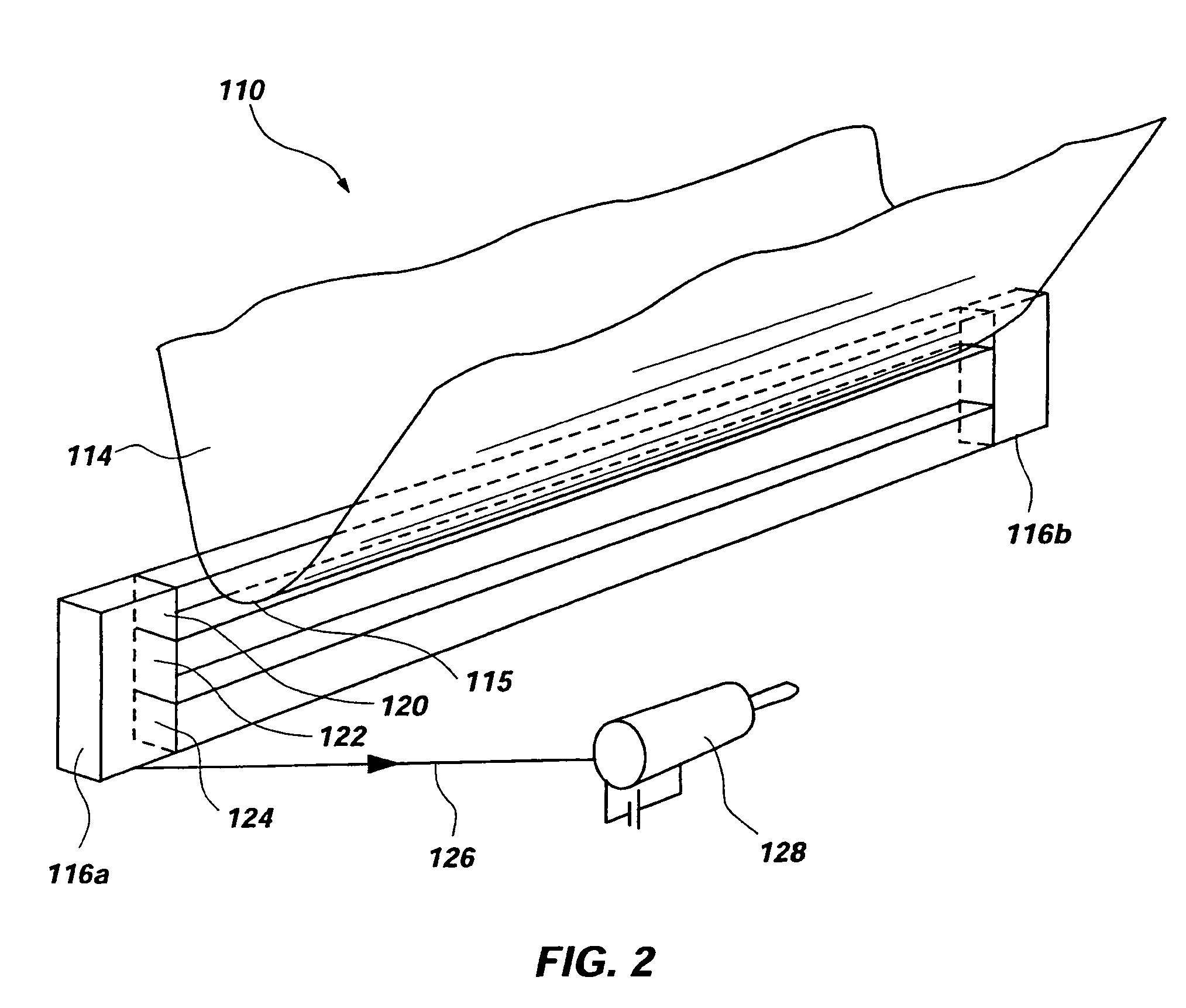

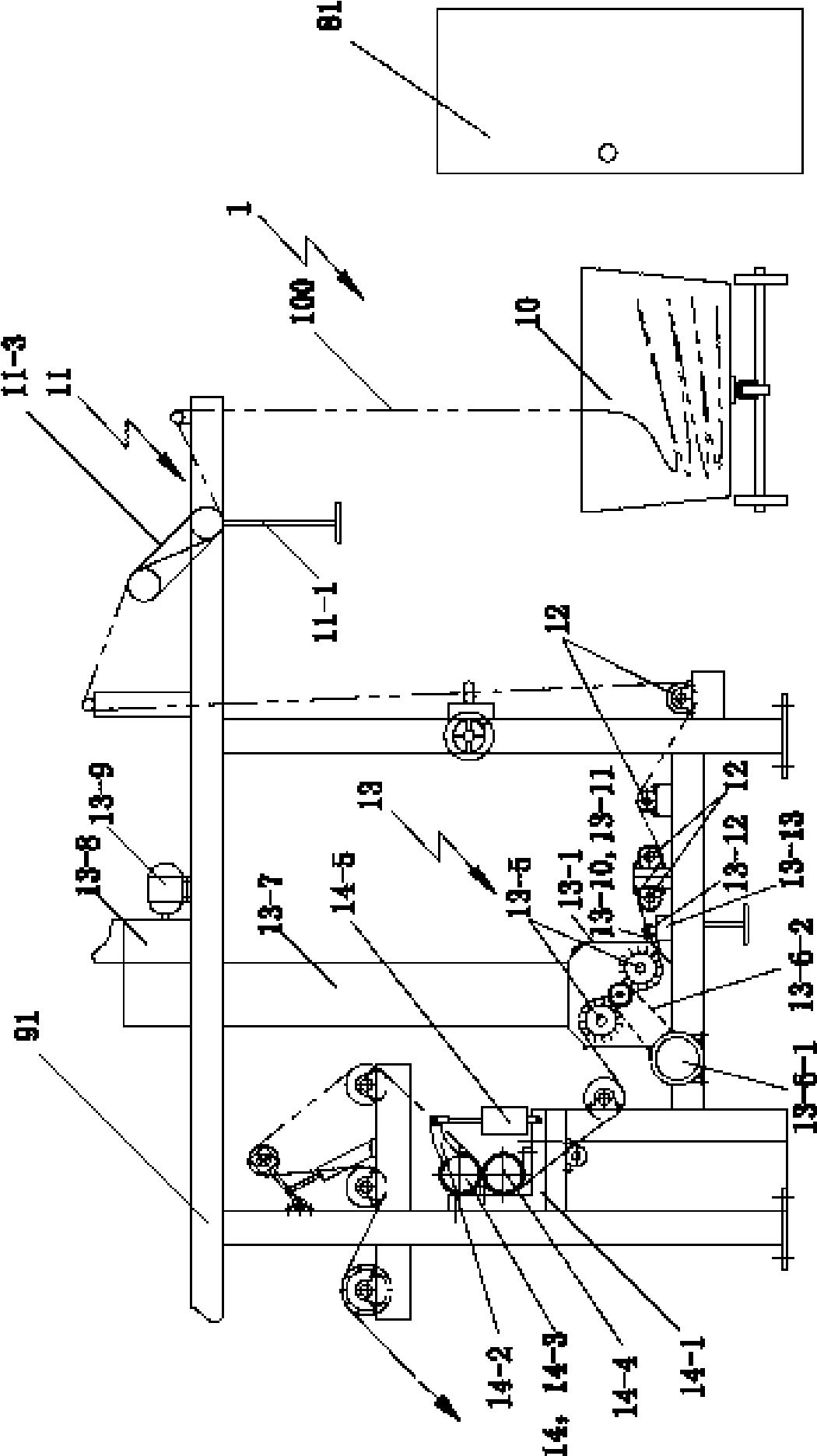

Unbacked fabric transport and condition system

An unbacked transport and conditioning printing system for printing a pattern on a fabric is disclosed. The system includes a fabric characterization and tension control subsystem for gathering information on variations in the fabric and an irregularity detection subsystem for detecting irregularities in the fabric, as well as, crease detection and removal. The fabric passes through a fabric drying and conditioning subsystem for characterization of the fabric. The system also includes a fabric control subsystem for advancing the fabric through a print zone, where a pattern is printed on an unbacked fabric. The fabric is transported through a drying and post-processing subsystem and a closed-loop color control subsystem.

Owner:HEWLETT PACKARD DEV CO LP

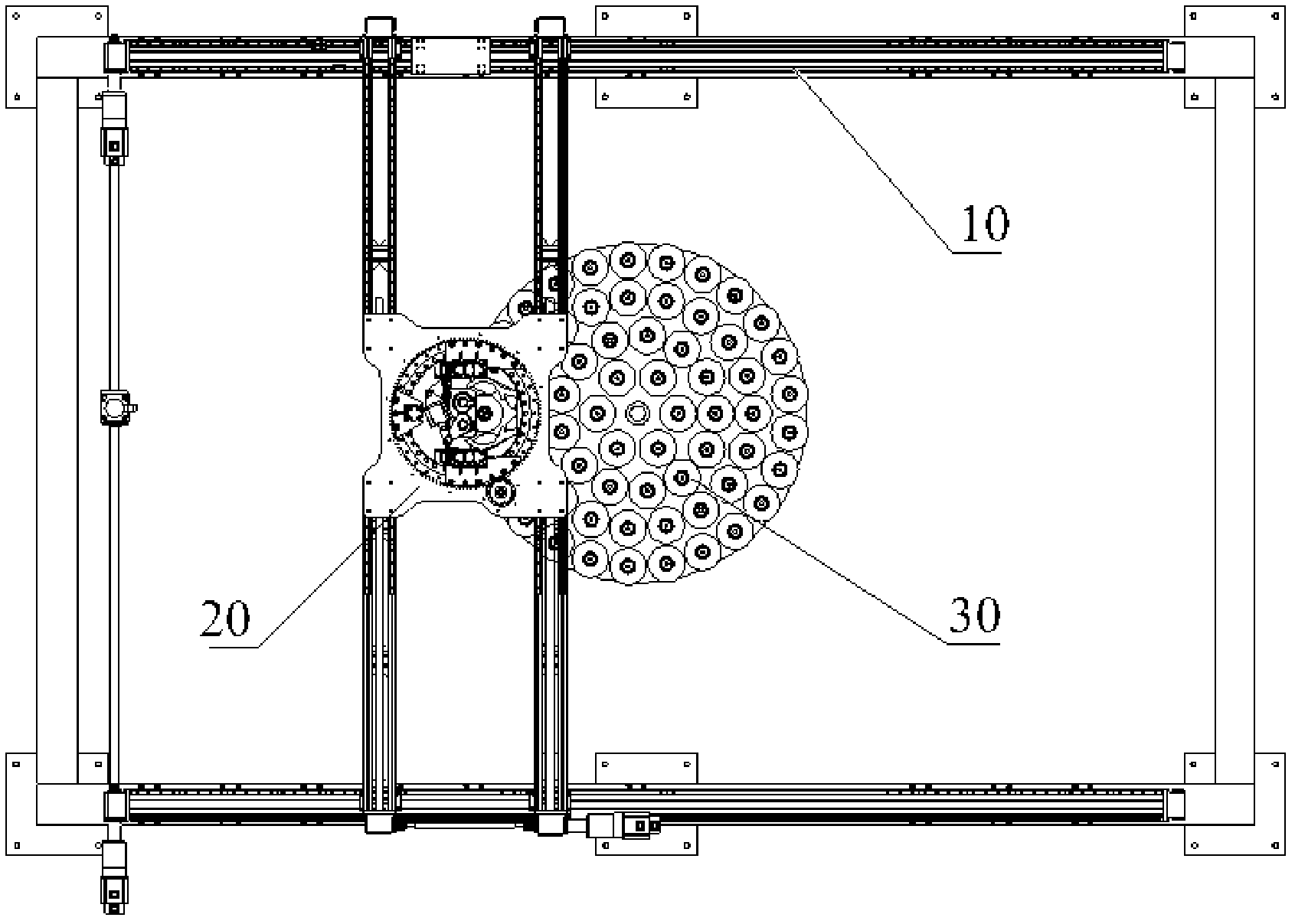

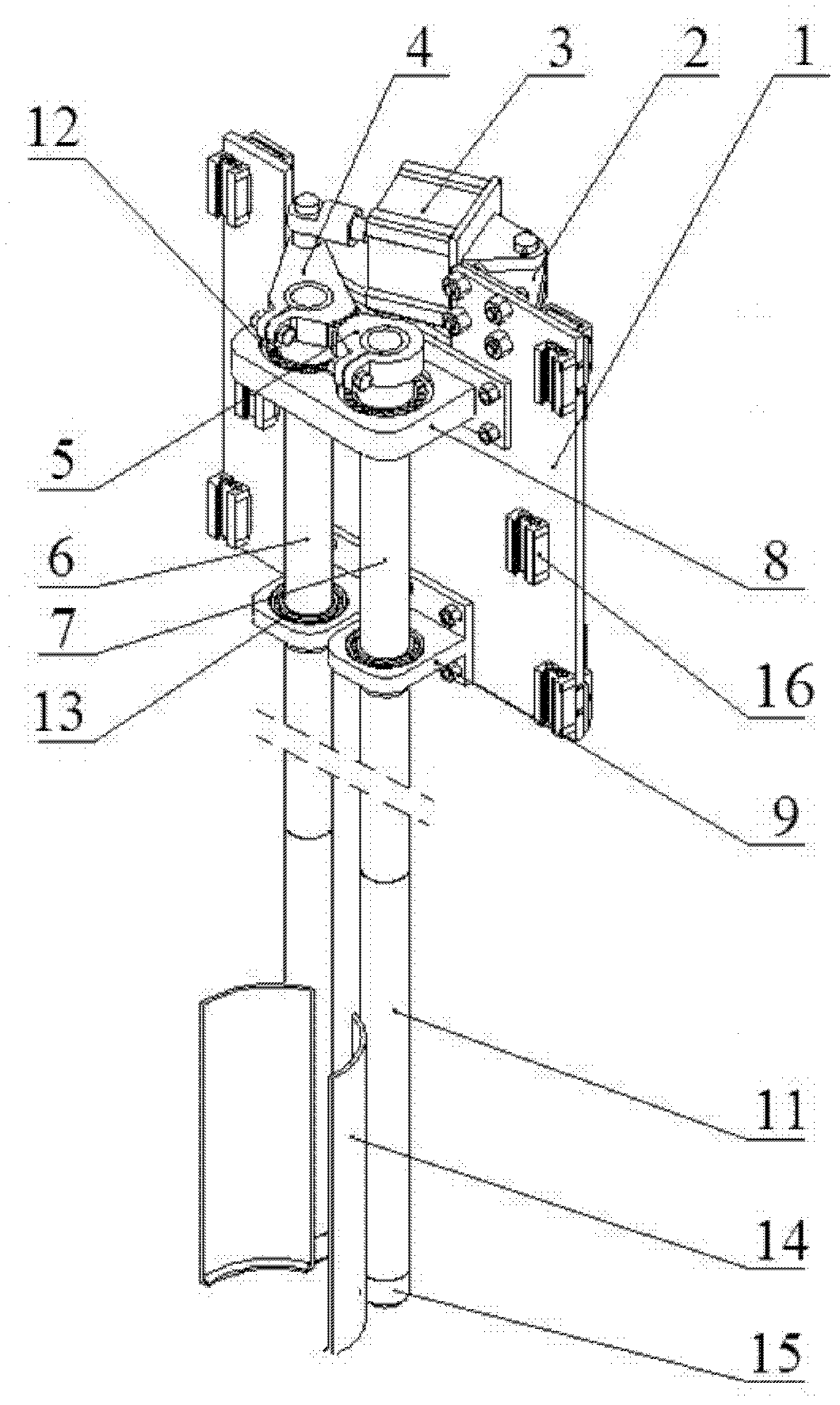

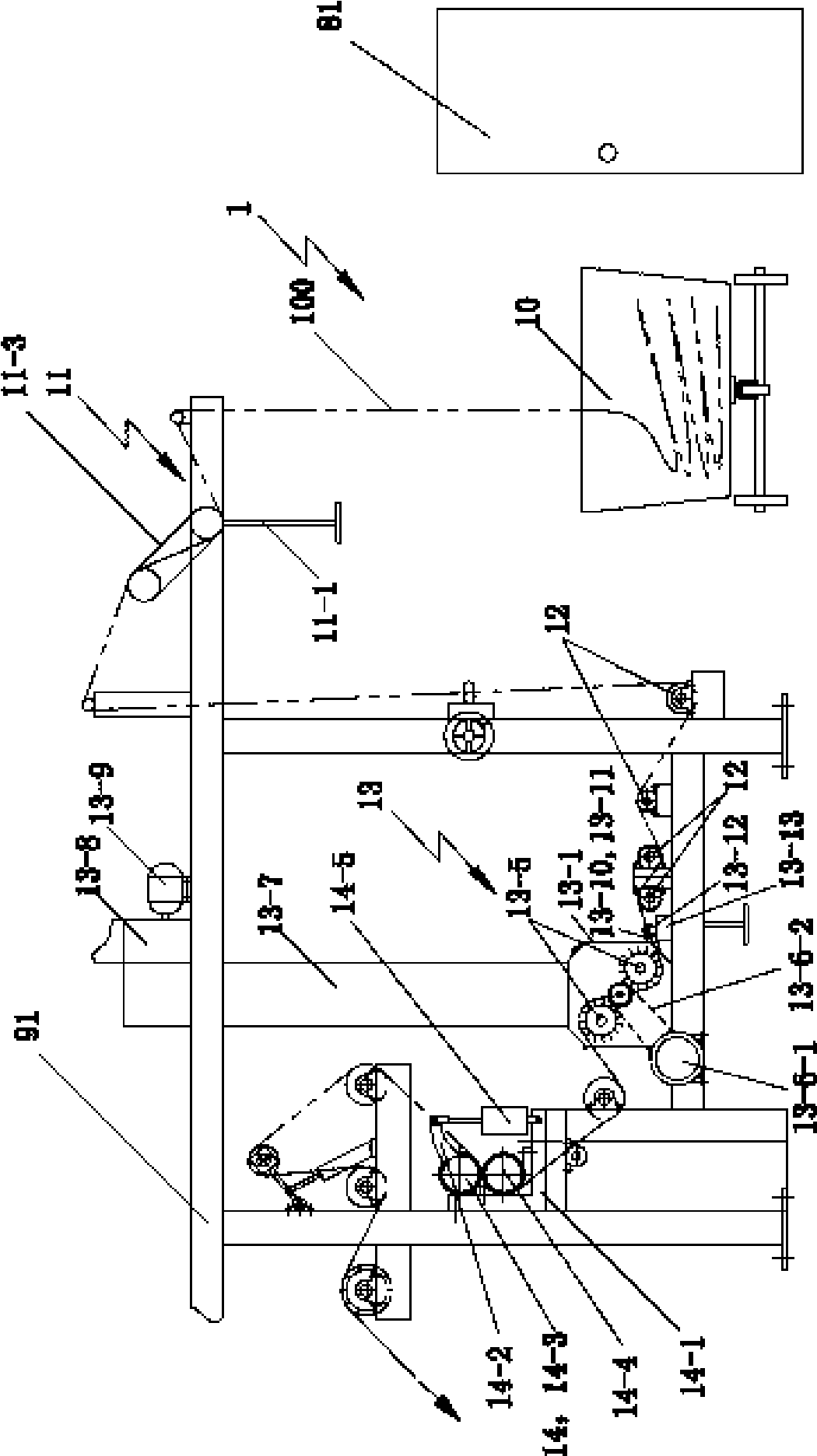

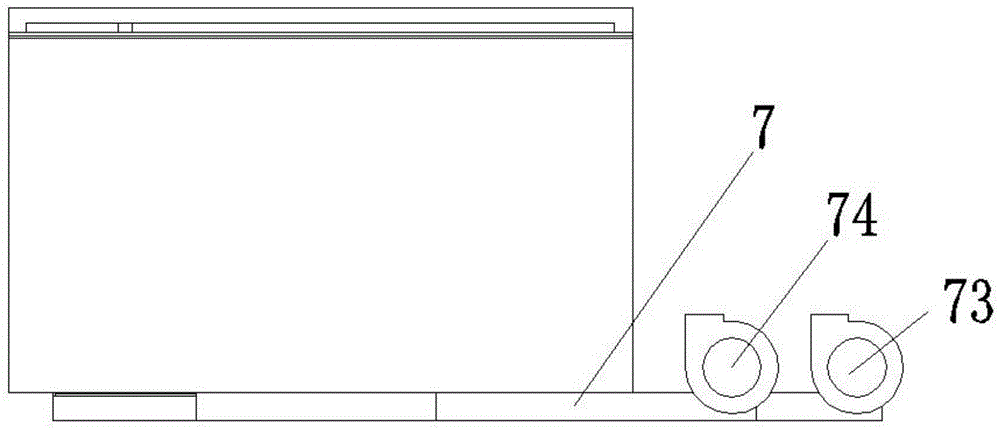

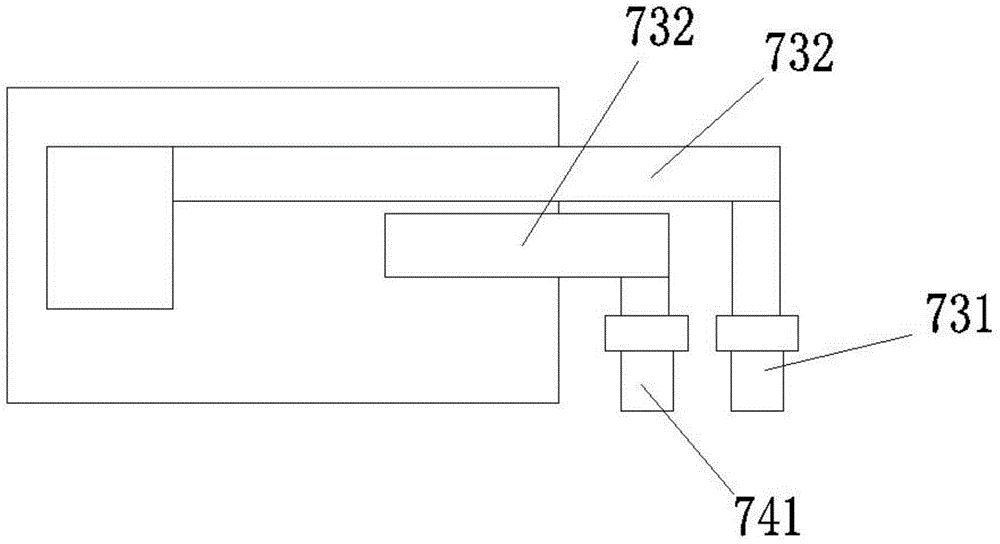

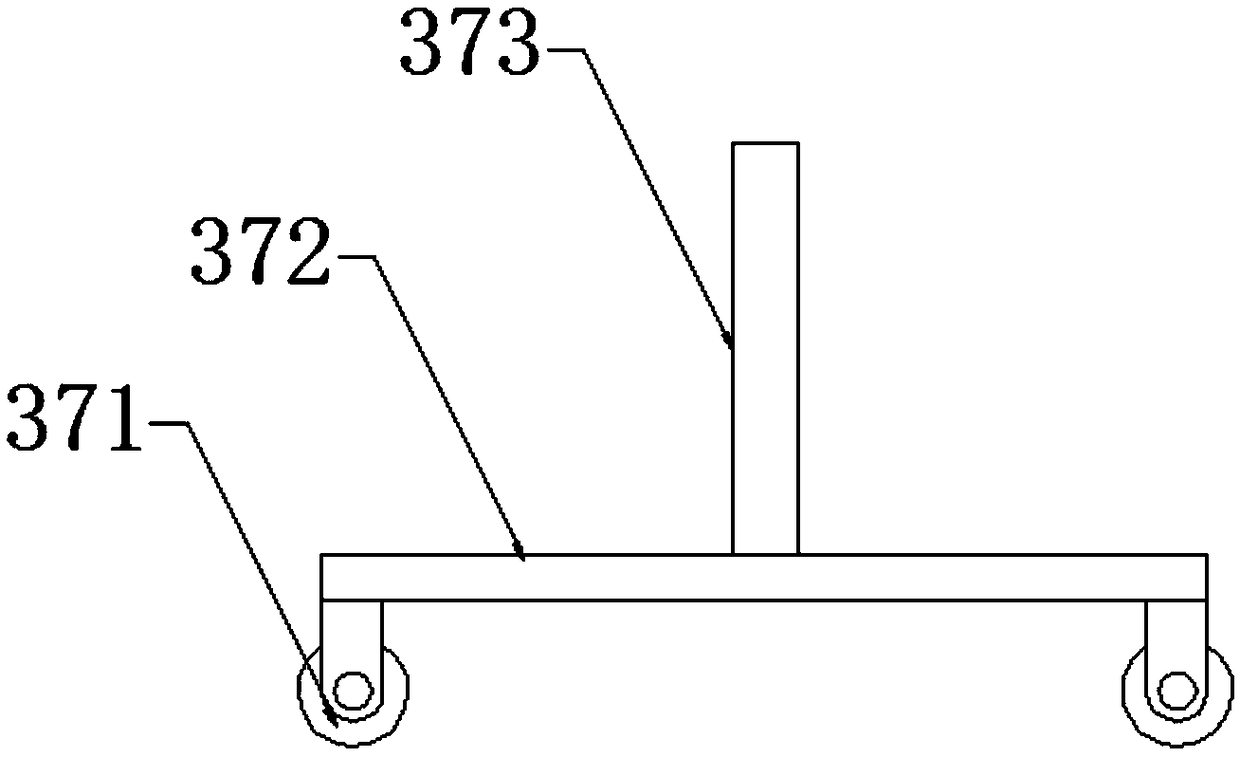

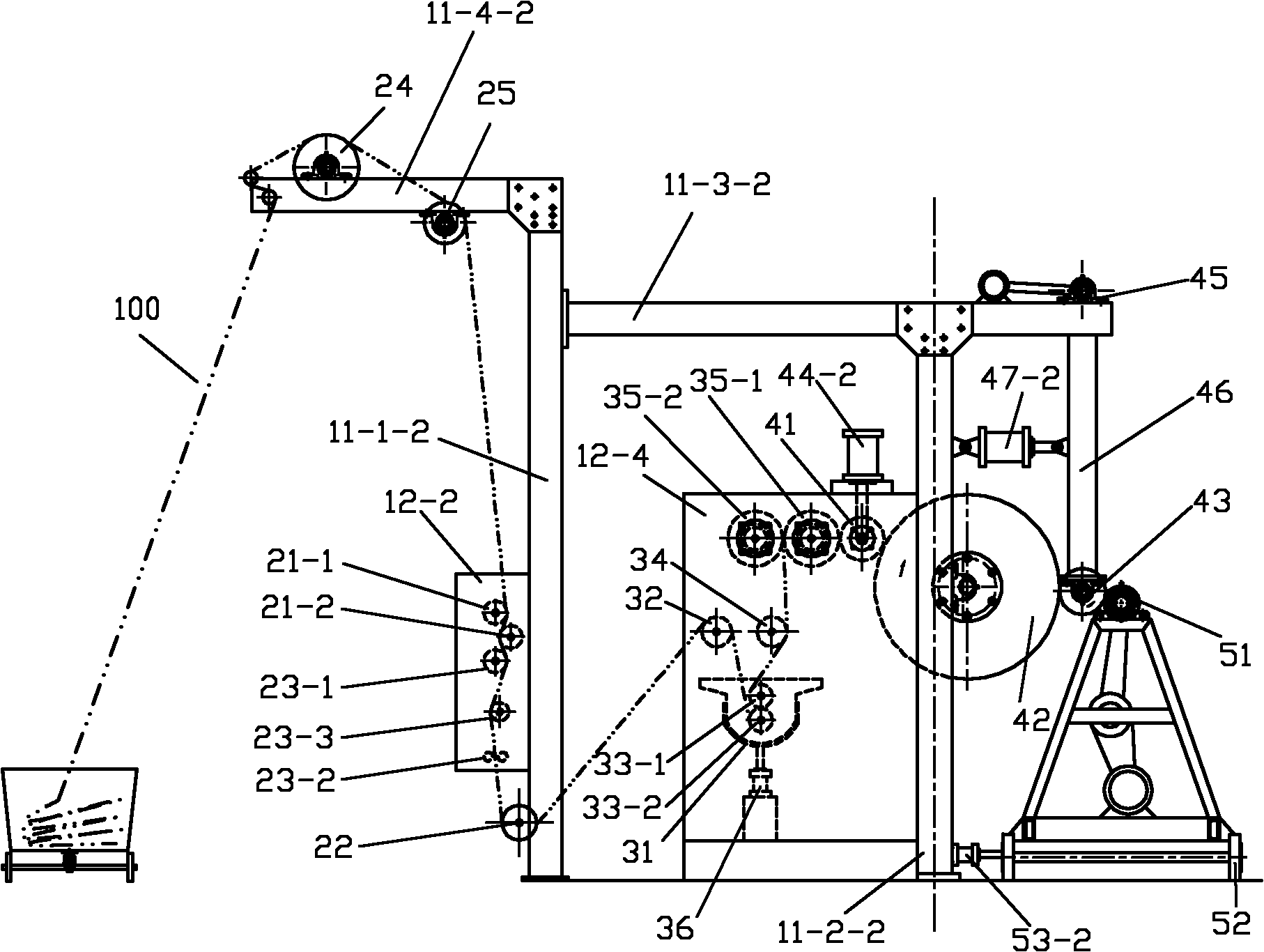

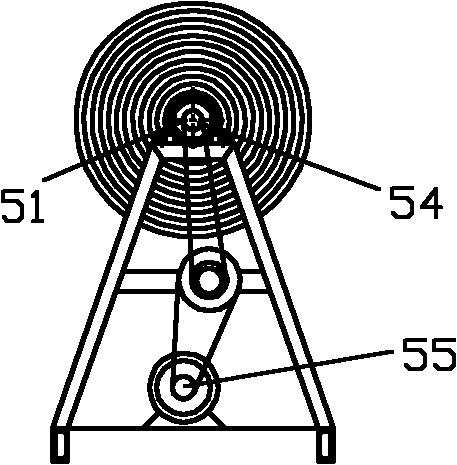

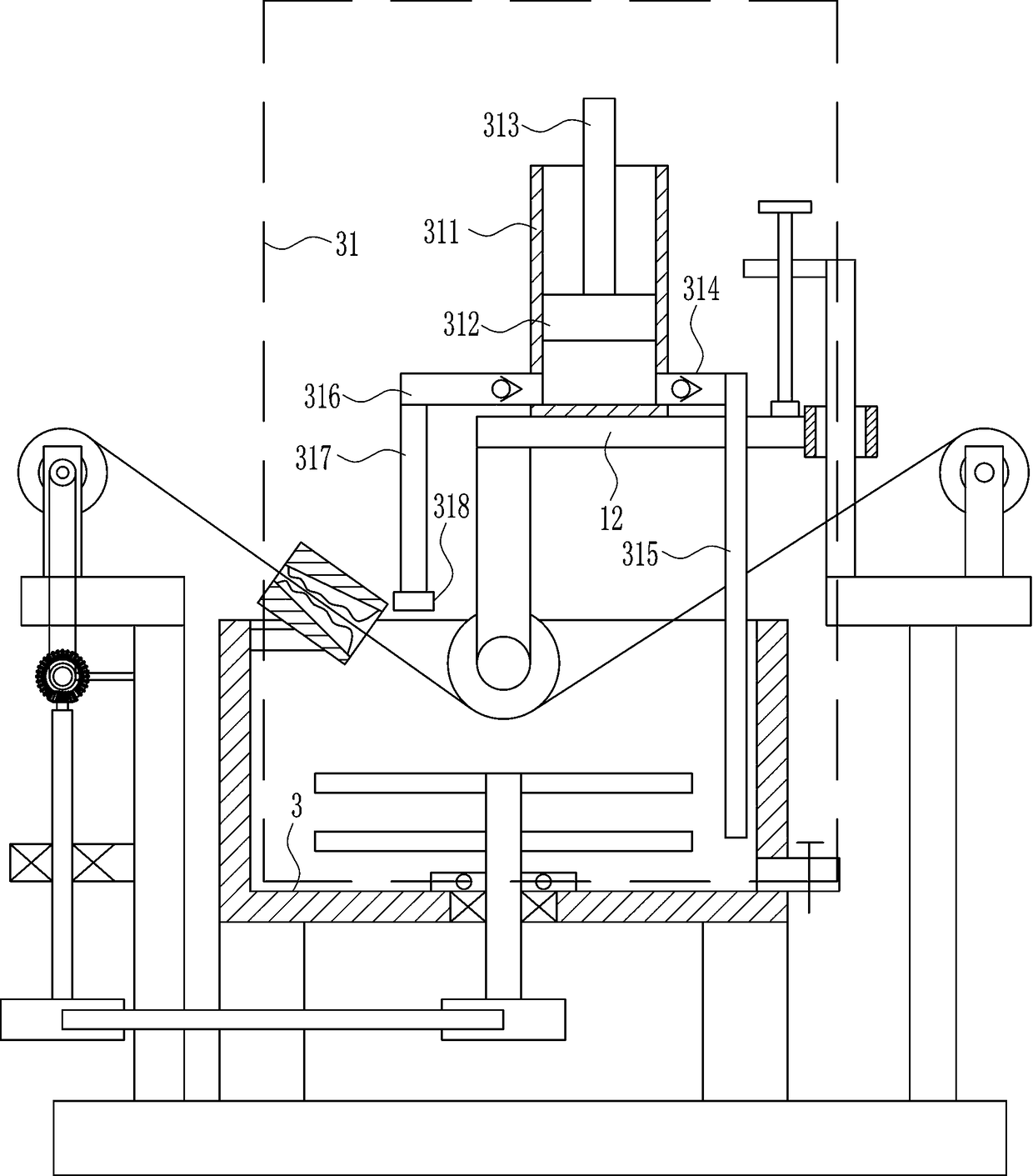

Automatic yarn grabbing machine and automatic yarn grabbing method

ActiveCN102583046AImprove efficiencyReduce labor costsProgramme-controlled manipulatorGripping headsYarnBobbin

The invention provides an automatic yarn grabbing machine and an automatic yarn grabbing method. The automatic yarn grabbing machine of the invention comprises a yarn grabbing unit comprising a clamping mechanism used for grabbing cheese and a rotary lifting mechanism used for driving the clamping mechanism to rotate and lift; and a planar moving mechanism used for driving the yarn grabbing unit to move on a horizontal plane. The automatic yarn grabbing machine of the invention mainly has the following advantages: yarns are grabbed in an automatic manner, so as to fill the blank in a bobbin dyeing procedure, improve efficiency and greatly save labor cost.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

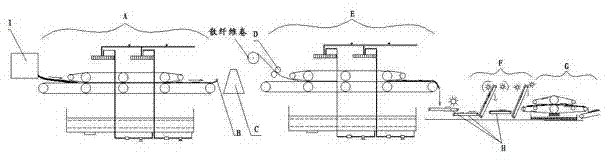

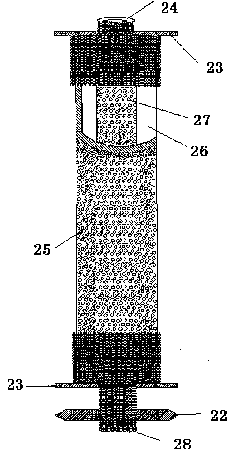

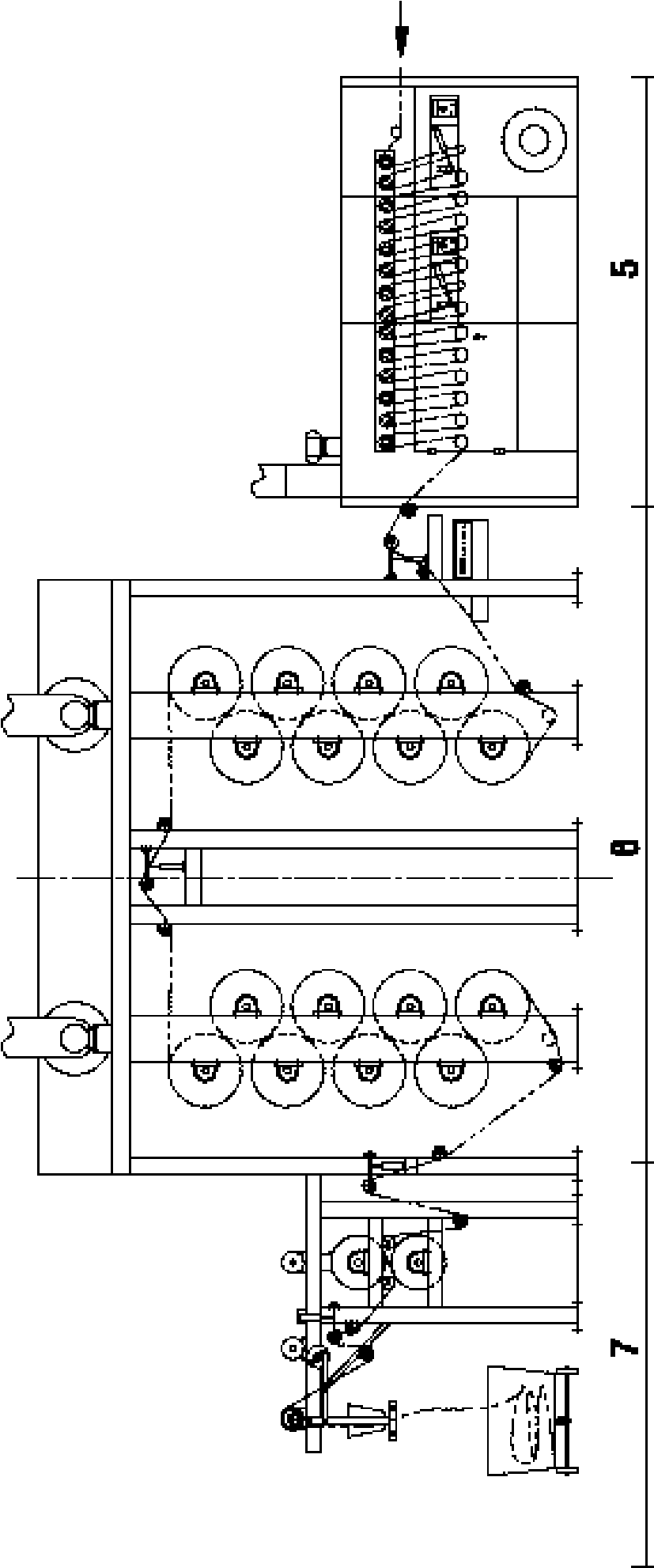

Continuous type colored loose fiber machining device

ActiveCN103774368ASolve uneven dyeingResolution cycleSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberEngineering

The invention relates to a continuous type colored loose fiber machining device, and belongs to the technical field of loose fiber dyeing. The continuous type colored loose fiber machining device comprises a spray-rolling type drying machine, a coiling roller, a cold-batch fixation device, cotton conveying rollers, a spray-rolling type washing machine, a conveyor belt and a squeezing device in sequence. Loose fibers are subjected to spraying dyeing by being horizontally clamped by a transmission component of the spray-rolling type drying machine, the coiling roller is arranged on the rear portion of a lower guide belt of the spray-rolling type drying machine and coils the dyed loose fibers to be loose fiber coils, the loose fiber coils are transferred to the cold-batch fixation device for cold-batch fixation, the loose fiber coils are conveyed to the spray-rolling type washing machine through the cotton conveying rollers, spray washing is carried out on the cotton conveying rollers when the cotton conveying rollers are conveyed by being horizontally clamped through the transmission component of the spray-rolling type washing machine, the washed loose fibers fall down on the conveyor belt behind the spray-rolling type washing machine under the gravity of the loose fibers themselves, and the loose fibers are conveyed to the squeezing device for dewatering. The continuous type colored loose fiber machining device can continuously produce colored loose fibers, and greatly lower processing cost.

Owner:绍兴国周针织科技有限公司

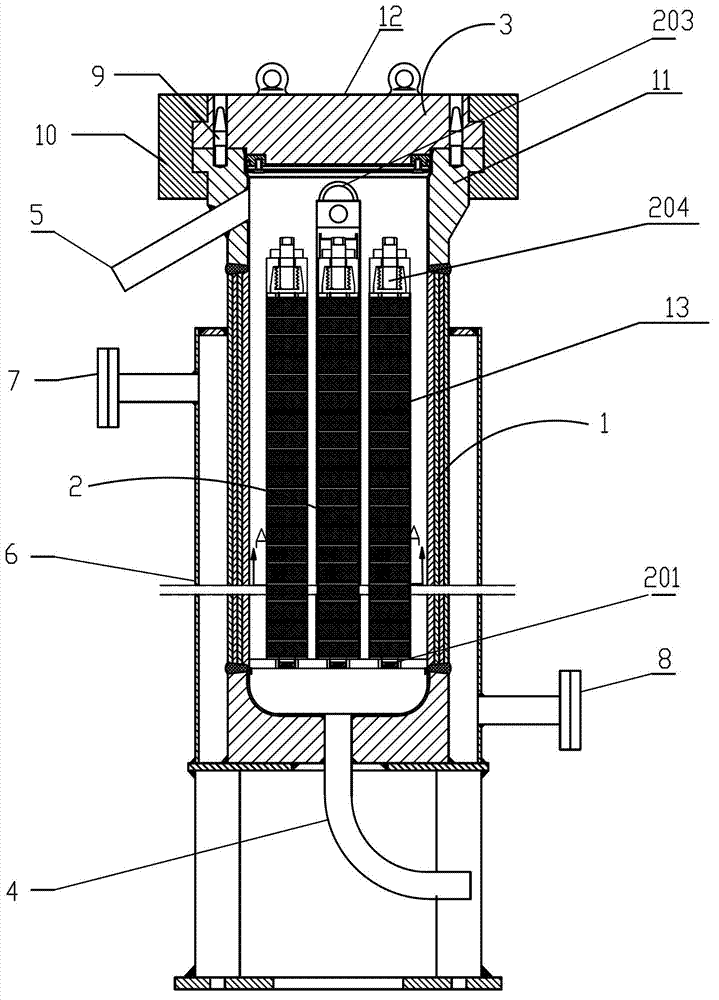

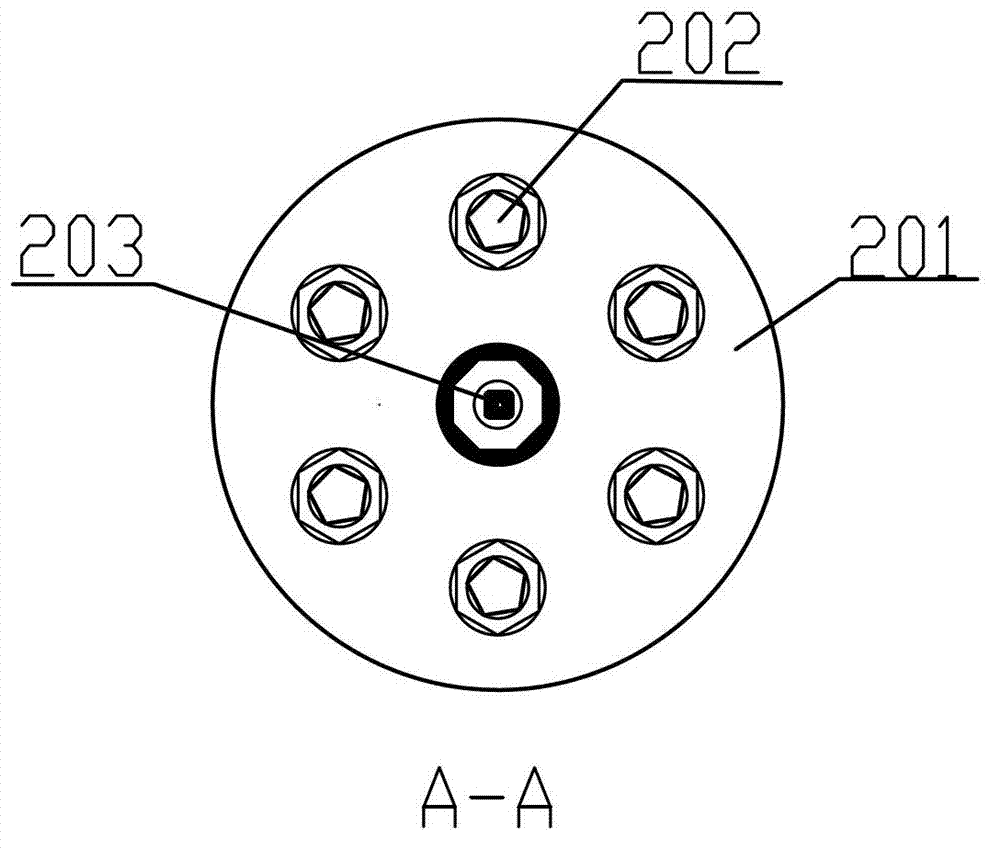

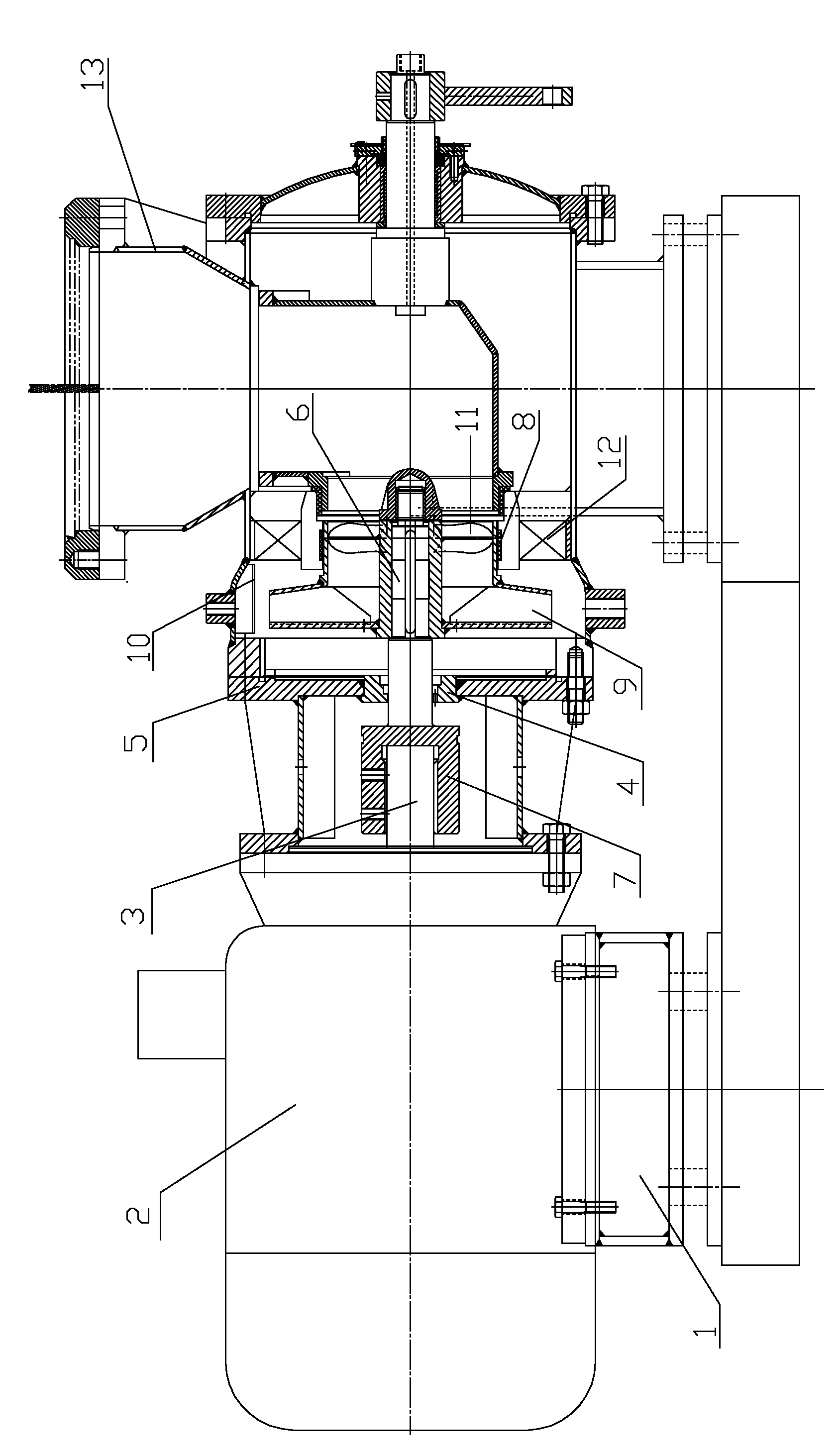

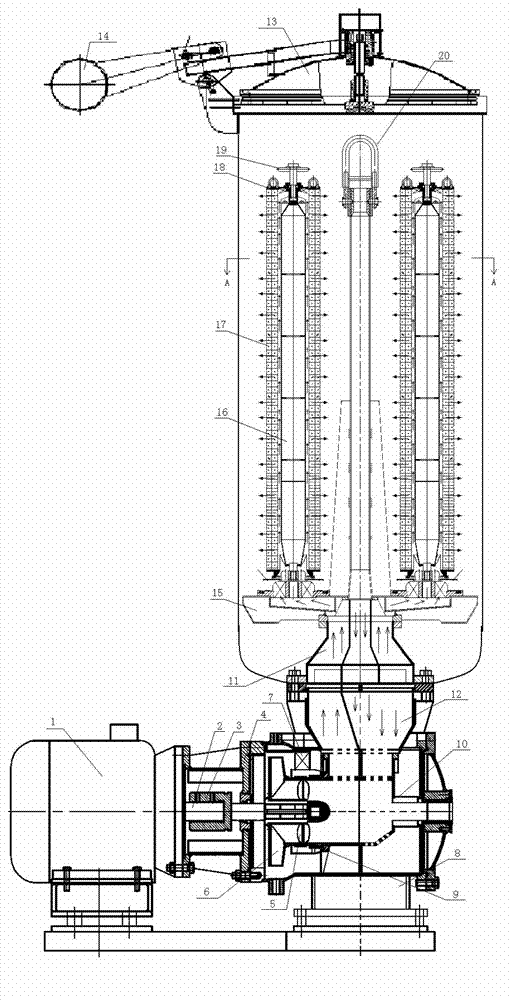

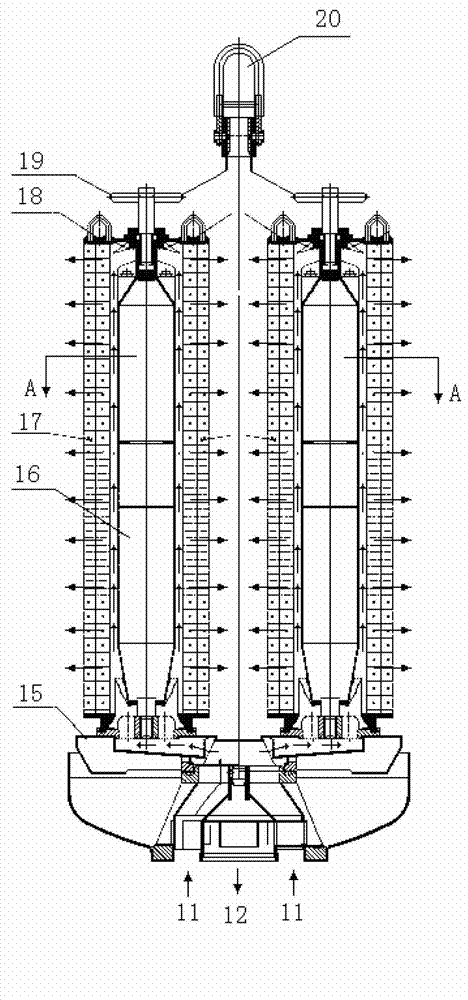

Ultralow bath-ratio yarn dyeing machine with three-level vane pump

InactiveCN102134793ACycle fastAvoid layer chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment machine arrangementsYarnThree level

The invention discloses an ultralow bath-ratio yarn dyeing machine with a three-level vane pump, comprising a dye vat, a yarn stand and a vane pump, wherein the bottom of the yarn stand is a yarn stand disk; the yarn stand disk is provided with a hole communicated with a dye liquor input channel in the dye vat; the vane pump is arranged below the whole dye vat and is a three-level vane pump; a shaft of the three-level vane pump is connected with an internal motor shaft coaxially; the dye vat is connected with the inlet of the three-level vane pump; the three-level vane pump comprises an axial flow level, a centrifugal level and a fixed guide vane level; the axial flow level and the centrifugal level are connected with the motor in sequence through the same transmission shaft; dye liquor flows into the axial flow level through an in-flow channel; the dye liquor flowing out of the axial flow level directly enters the inlet of the centrifugal level; and the dye liquor flowing out of the centrifugal level enters an out-flow channel after passing through the fixed guide vane level. During work, the dye liquor in the dye vat does not exceed the yarn stand disk all the time and the bath ratio is lower than 1:3. The ultralow bath-ratio yarn dyeing machine can achieve required lift when the dye liquor in the yarn dyeing machine is lower than a spindle, so as to realize the low bath ratio of the yarn dyeing machine as well as the purpose of saving energy and reducing emission.

Owner:高勋绿色智能装备(广州)有限公司

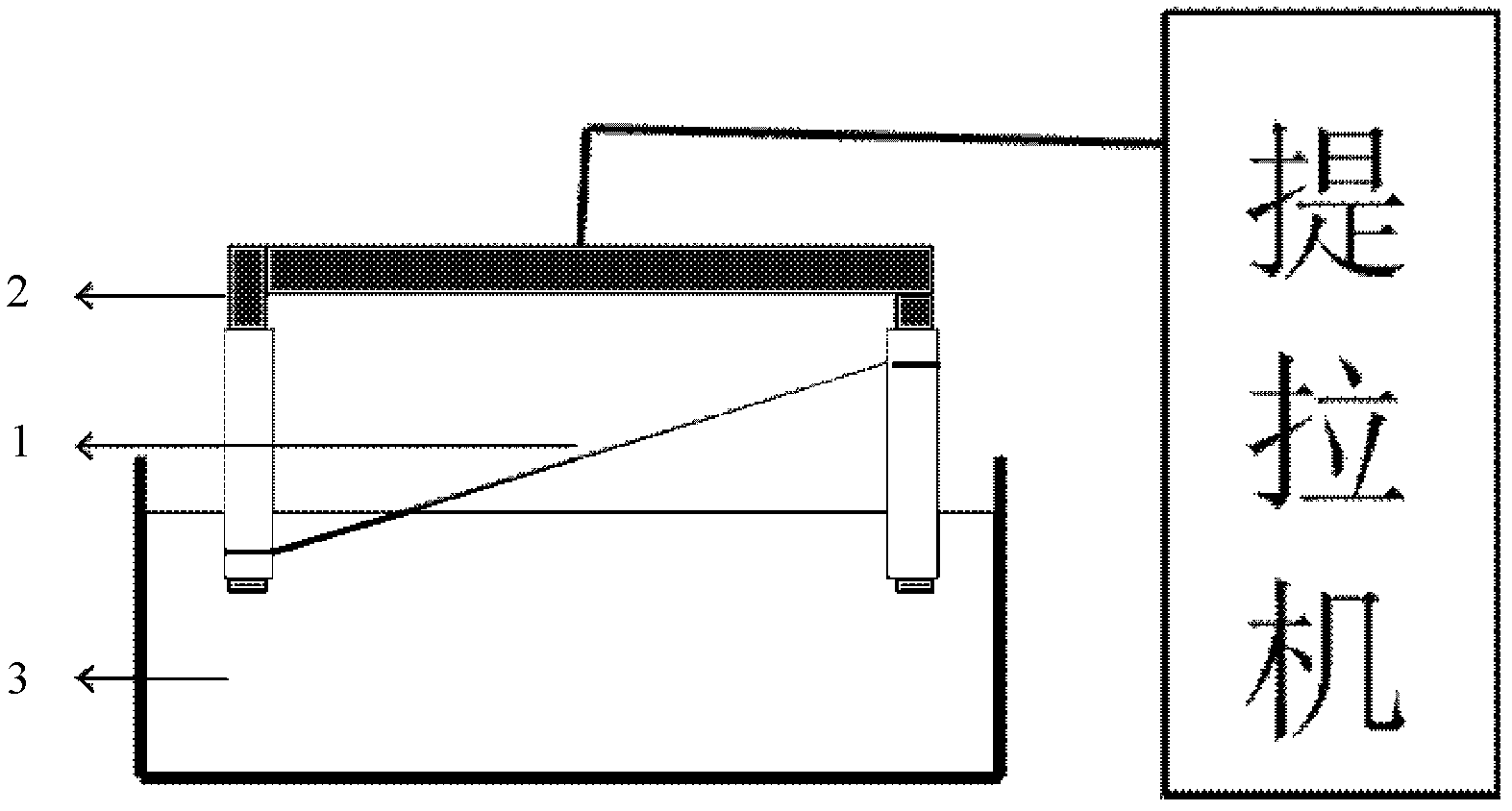

Preparation method of freshwater collecting fibers with transmission function and application thereof

The invention discloses a preparation method of freshwater collecting fibers with a transmission function and an application thereof and belongs to the technical field of chemical bionics. The preparation method comprises the following steps of: completely soaking a support fixed with the fibers in a prepared polymer solution with the mass fraction of 5-9% for lifting and pulling, wherein raised nodes, which are sequentially arrayed according to the size, are generated on the fibers, and finally drying to obtain the freshwater collecting fibers. The freshwater collecting fibers are woven intothe freshwater collecting fiber net for carrying out freshwater collection; and the freshwater collecting fiber net can be used for collecting freshwater in fog so that the visibility of air can be increased; and the freshwater collecting fiber net has high water collection efficiency and can be used for removing fog. The heights of the raised nodes on the surfaces of the fibers prepared by the method are uniformly increased from small to large and are controlled; the surfaces of the fibers are provided with more microscopic bulges or micropores so that the collision probability and the spreading speed of water drops in air can be increased, and the efficiency of collecting water is increased; and the freshwater collecting fibers are suitable for coastal deserts, islands, ocean ships, foggy mountain areas and the like; and the cost of the freshwater collecting fiber for collecting the freshwater is far lower than the cost for the desalination of sea water.

Owner:BEIHANG UNIV

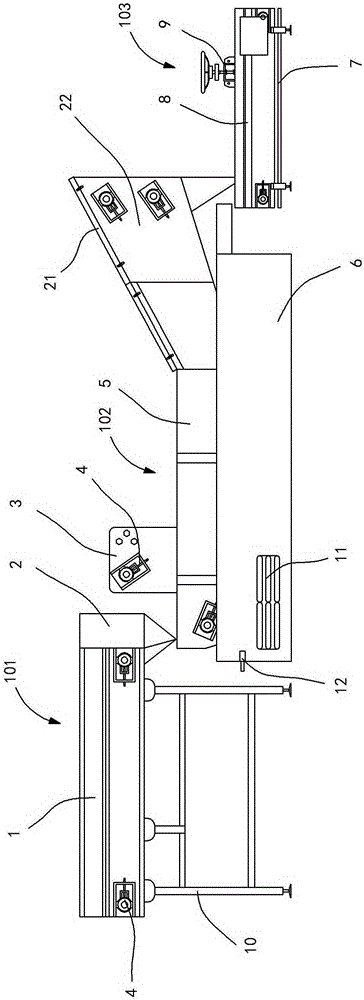

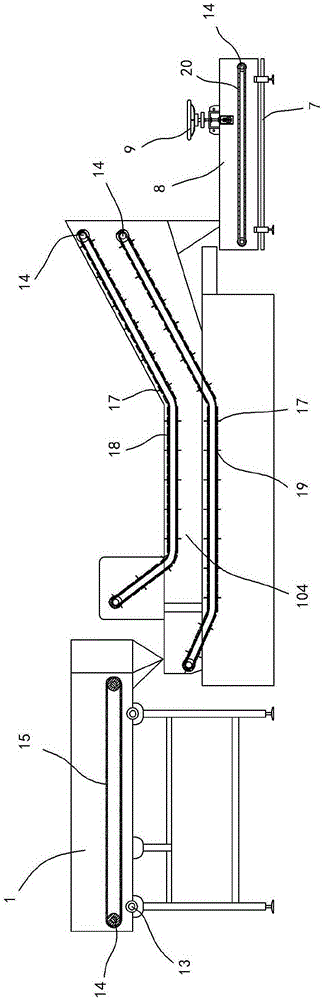

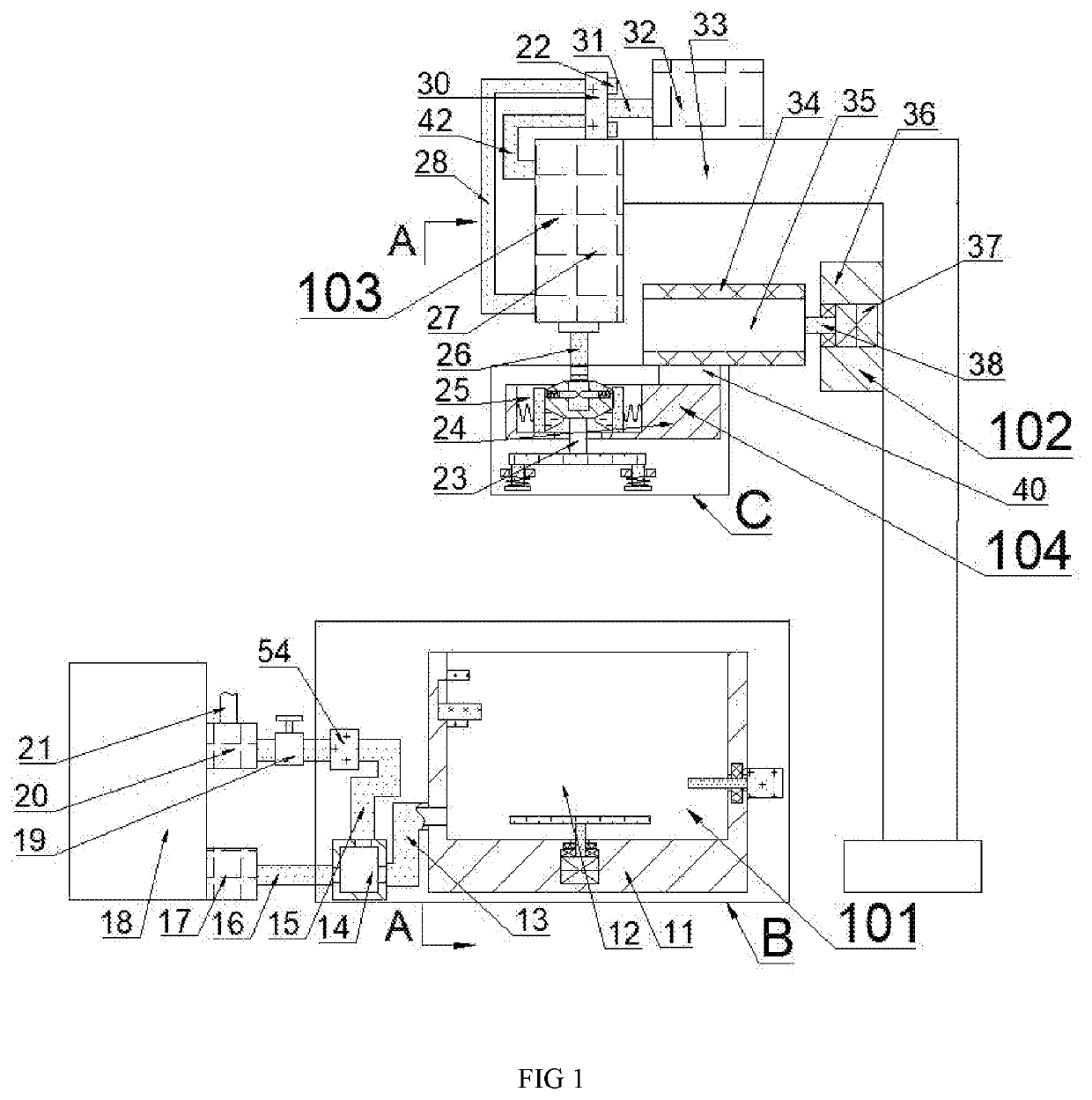

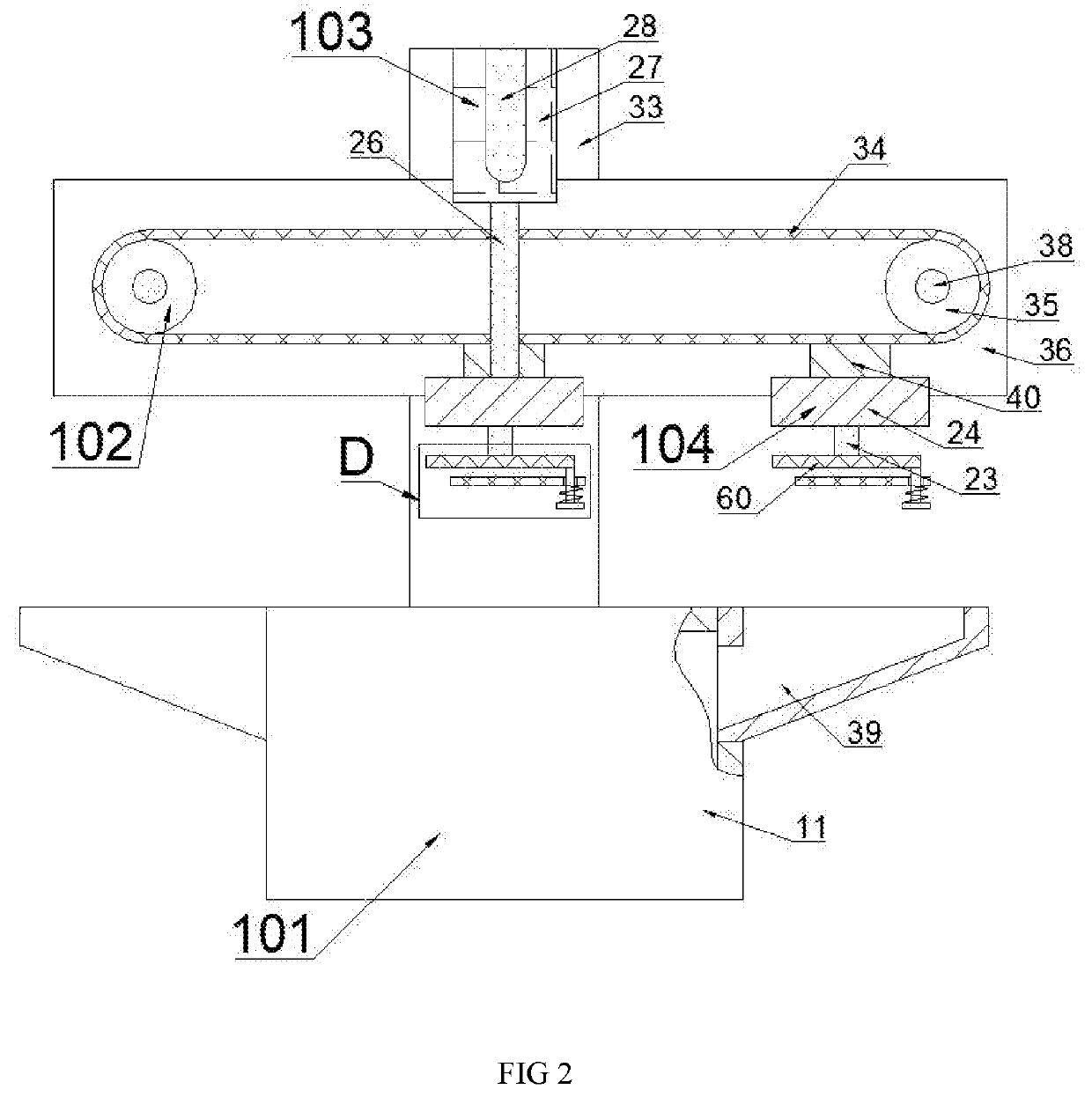

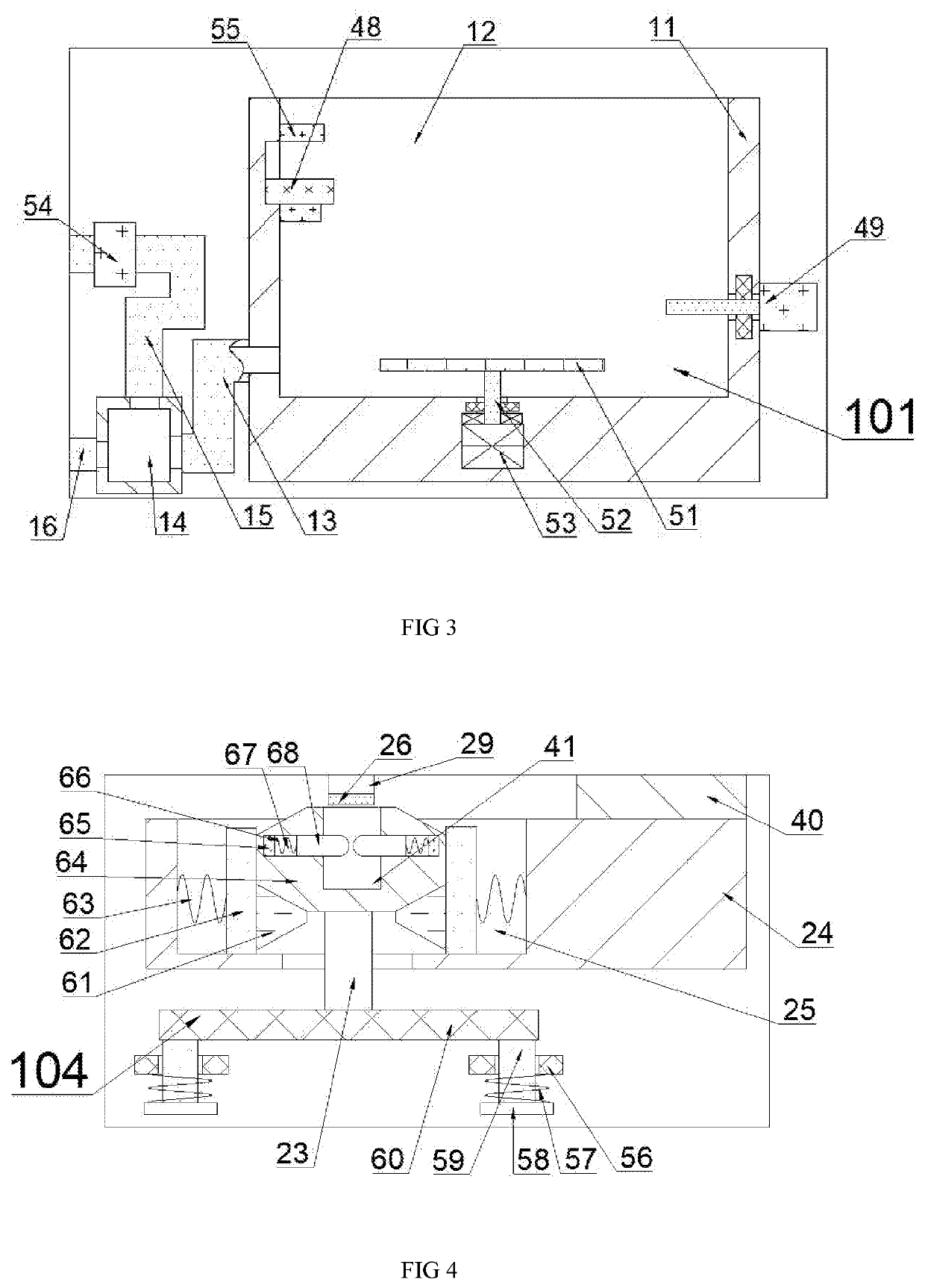

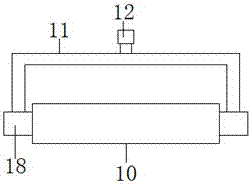

Fiber after-treatment equipment

ActiveCN105113160AIncrease productivityImprove qualityLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberAfter treatment

The invention discloses fiber after-treatment equipment which comprises a fiber input mechanism (101), a fiber soaking mechanism (102) and a fiber output mechanism (103). An outlet of the fiber input mechanism (101) is formed in an inlet of the fiber soaking mechanism (102). An outlet of the fiber soaking mechanism (102) is formed in an inlet of the fiber output mechanism (103). The fiber after-treatment equipment improves the production efficiency, greatly improves the quality of products, and reduces the product reject ratio in the production process.

Owner:JIANGSU XILUN NANO BIOTECH CO LTD

Device and method for fabric dyeing with supercritical carbon dioxide fluid

ActiveCN101824716AAvoid unwindingAvoid looseTextile treatment containersDyeing processTime ratioEngineering

The invention discloses a method for improving the level-dyeing property of fabric in supercritical carbon dioxide fluid and a device thereof. The method adopts special seamless warp beam which consists of an inner layer and an outer layer is adopted, a seamless woven wrapper of a cylindrical net shape is sleeved outside the outermost layer of wound fabric, and process parameters such as the time ratio between fluid circulation and static dyeing, and the like are controlled reasonably, thereby realizing the uniform dyeing of piece fabric in the supercritical carbon dioxide fluid. Since the method adopts the warp shaft mode with a reasonable structure, the fabric winding way and the process condition, the supercritical fluid containing a soluble dye can penetrate through the wound fabric uniformly, thereby reducing the non-uniform pressure loss in the fluid flow during circulation, the sudden change of the fluid path and the unevenness of the fluid circulation, and improving the uniform dyeing effect on the piece fabric. The technical method of the invention has the advantages of simple equipment and process, convenient operation, high efficiency, energy conservation and emission reduction.

Owner:中科首望无水染色智能装备(苏州)有限公司

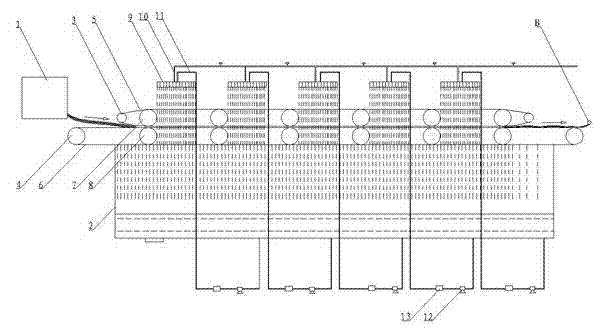

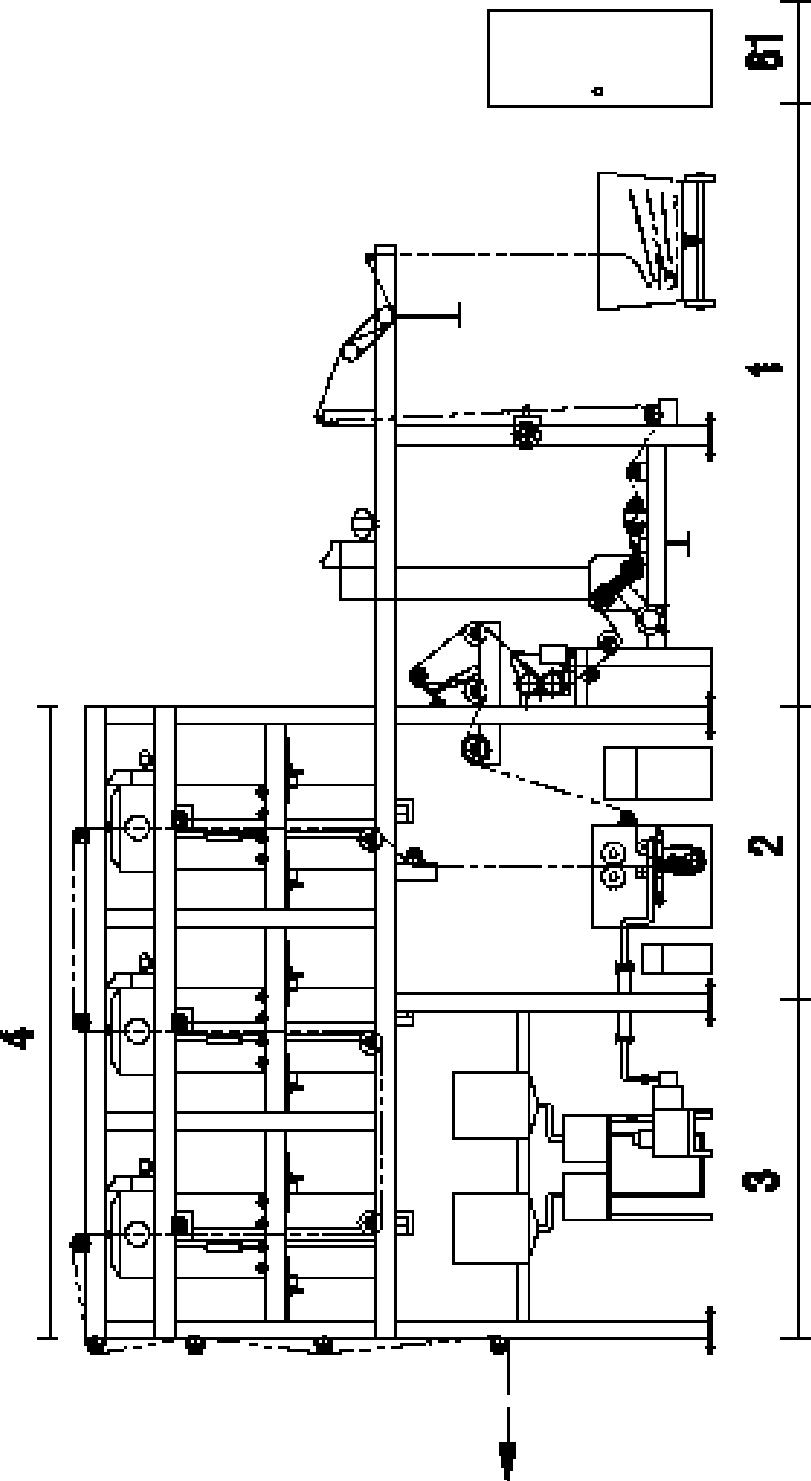

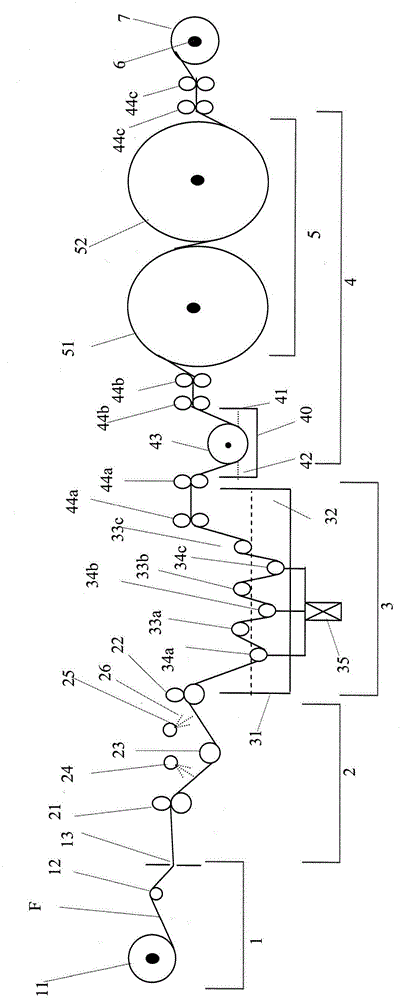

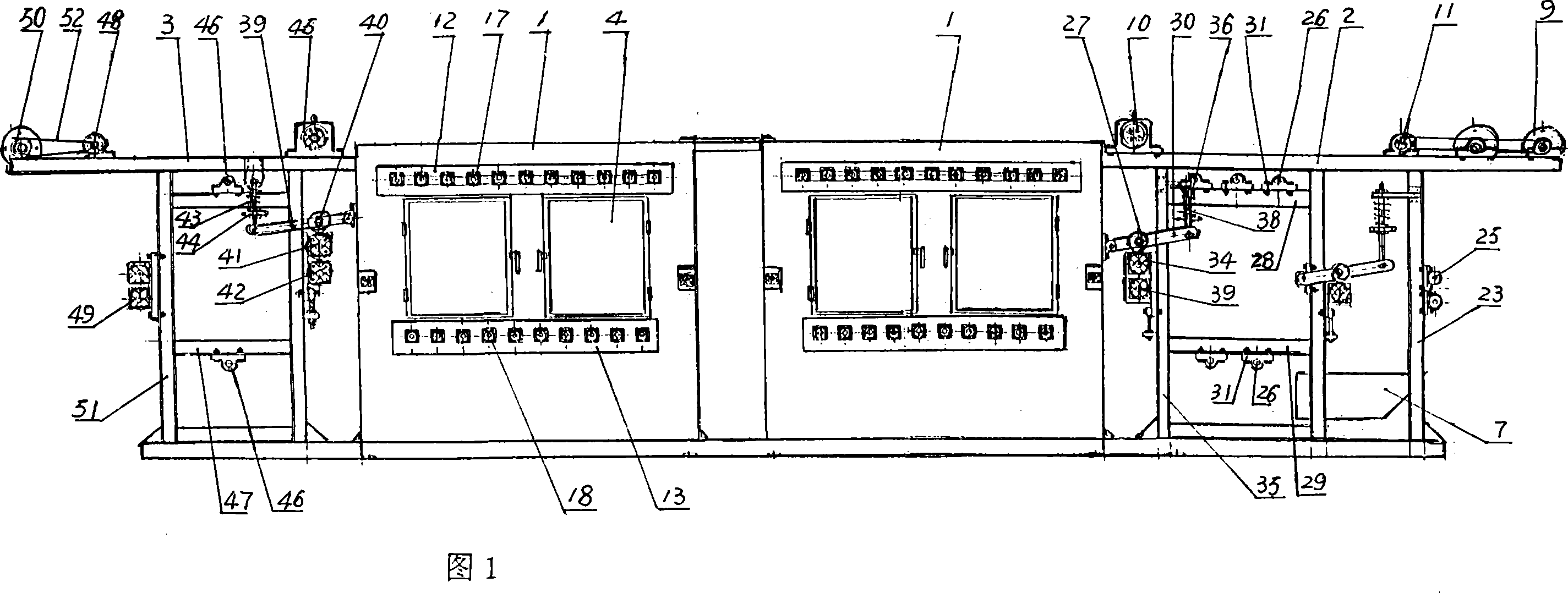

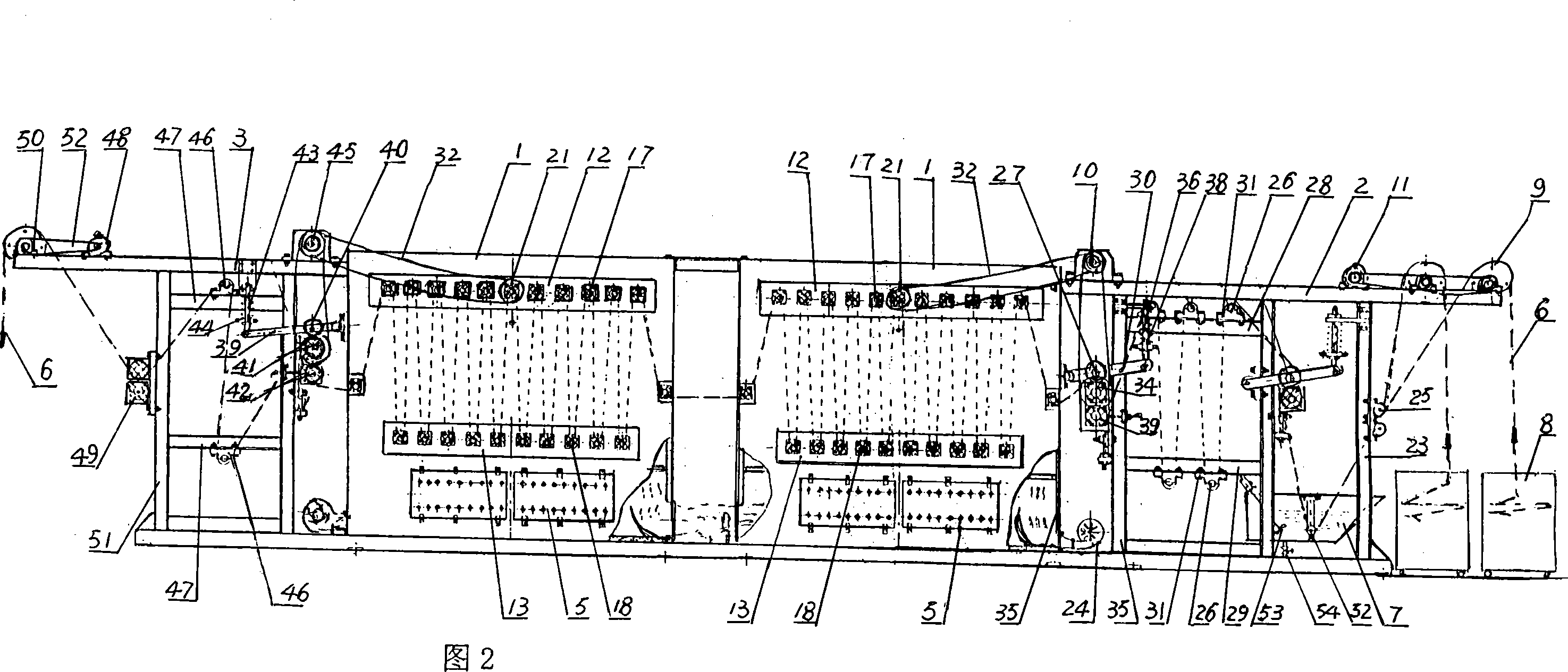

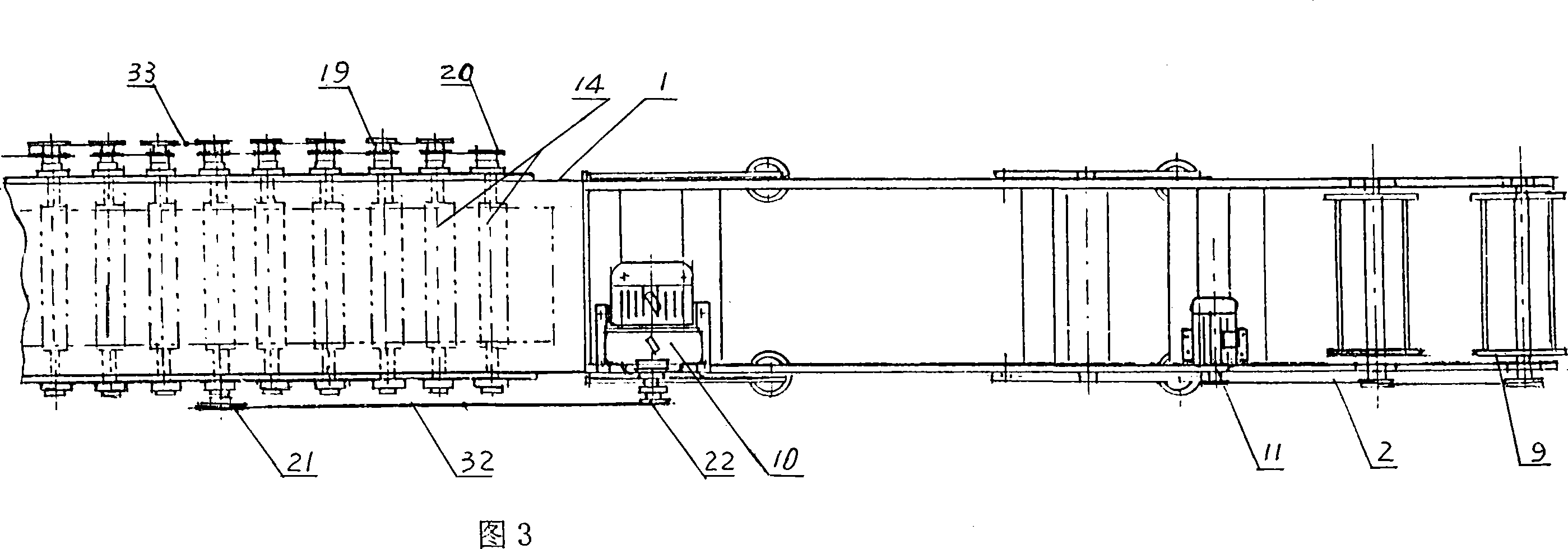

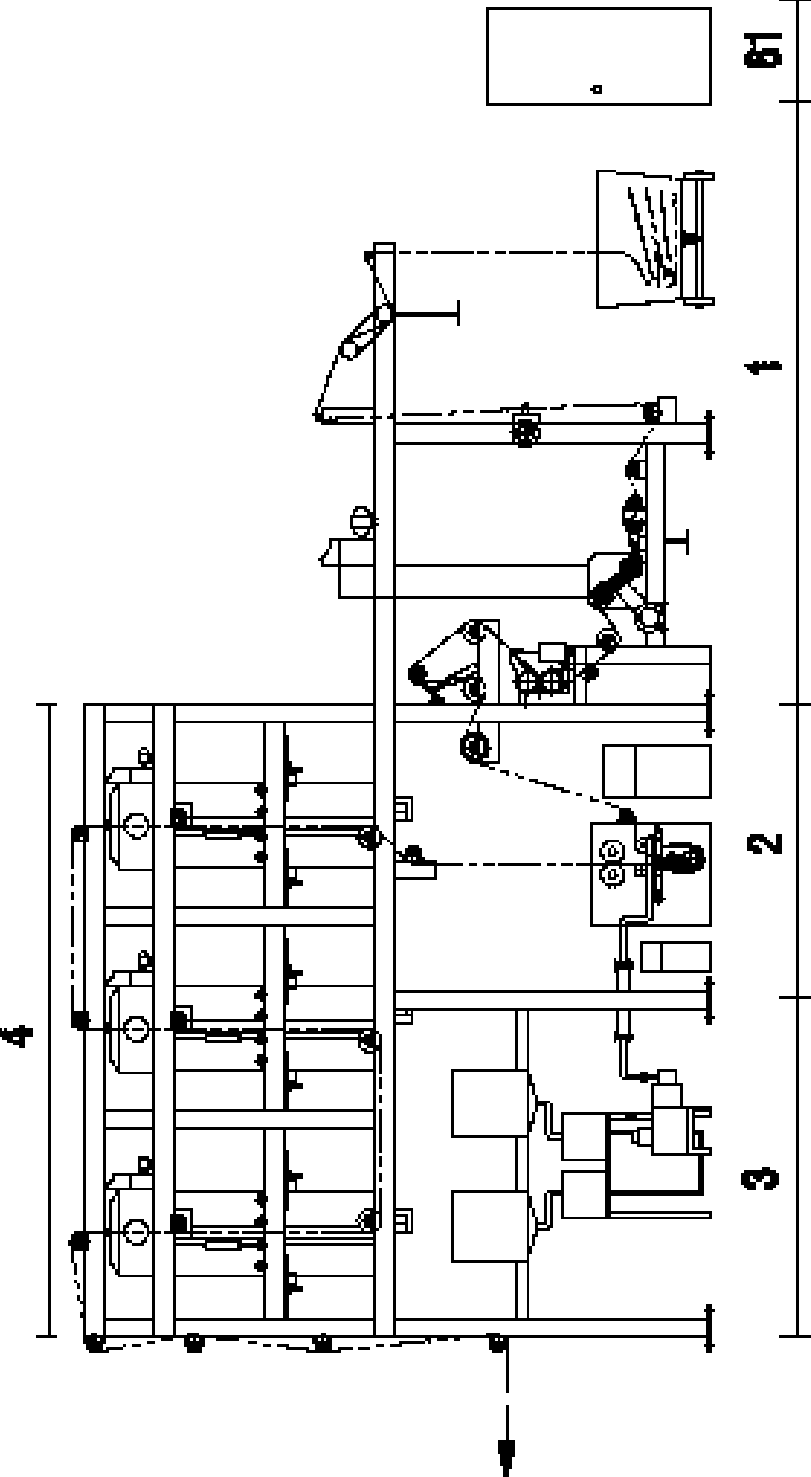

Non-woven fabric dying production line

InactiveCN103820962AAvoid shakingPrevent fallingSucessive textile treatmentsTextile treatment machine arrangementsEngineeringNonwoven fabric

The invention discloses a non-woven fabric dying production line which comprises an uncoiling device, a dying cylinder, a cleaning cylinder, dry-rolling device, a drying device, a coiling device, a plurality of guide rollers, net belts and a first frame body. The uncoiling device, the dying cylinder, the cleaning cylinder and the dry-rolling device are arranged on the first frame body in sequence. The coiling device is arranged in rear of the drying device, and the dying cylinder, the cleaning cylinder and the first frame body are provided with the guide rollers. The net belts are arranged on the guide rollers in a tensioning mode. Compared with the prior art, the good cleaning effect can be achieved, the dying quality of a product is not affected, the size of an exhaust opening can be adjusted, the normal temperature in drying non-woven fabric in a drying oven and the coherence of the whole production process are guaranteed, production efficiency is not affected, crimples are avoided, the overall attractiveness and the coiling quality of the non-woven fabric are ensured, slippage in transmission can also be avoided, the transmission rate is guaranteed, the uncoiling speed can be prevented from being higher than the belt supporting speed of the net belts, water removing is even, the normal water removing effect is achieved, and the drying effect is not affected.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

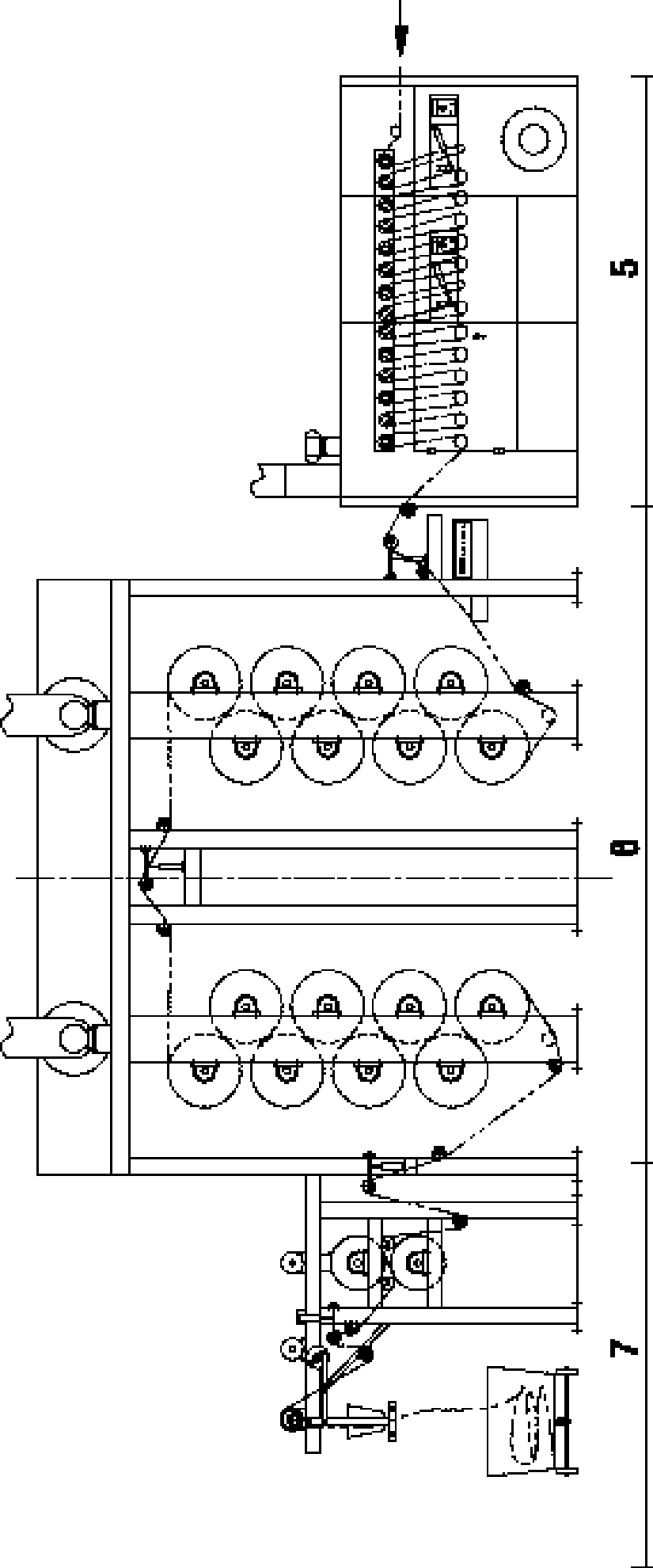

Continuous pigment dyeing pad dyer

InactiveCN101487175AOptimize layoutGuaranteed uptimeSucessive textile treatmentsDrying solid materials with heatEngineeringHot blast

The invention relates to a continuous paint dyeing padding machine. The padding machine comprises a device which brushes hair and collects dusts for the textile, a traction binding vehicle which can obstruct the tensile force of the textile, a padding device, an infrared pre-baking device, a hot-blast pre-baking device, a steam drying device and a fabric outlet disposing device, and all devices are sequentially arranged. All components of the dyeing padding machine are reasonably configured; and when in use, the energy resource is saved, the process is simple and the dyeing effect is good.

Owner:常州市东高染整有限公司

Spraying, dyeing and drying device for textile fabric

InactiveCN107574602AStir fully and evenlyStir wellTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringUltimate tensile strength

The invention discloses a spraying, dyeing and drying device for textile fabric. The device comprises a tank body, supporting vertical plates which are mutually symmetric are fixedly connected to twosides of the bottom of the tank body, and a bottom supporting plate is fixedly connected to the bottoms of the two supporting vertical plates; a dye stirring device is fixedly connected to the left side of the top of the bottom supporting plate, a liquid pumping pump placement tank is fixedly connected between the surface of the left side of the dye stirring device and the surfaces of the right sides of the supporting vertical plates, and a liquid pumping pump is fixedly connected to the bottom of the inner wall of the liquid pumping pump placement tank; a liquid pumping pipe is communicated with the right side of the liquid pumping pump. The invention relates to the technical field of textile machinery equipment. According to the spraying, dyeing and drying device for the textile fabric,the problems of high dyeing cost, environmental pollution, low use ratio and low cloth dyeing effect of an existing drying device for the textile fabric are solved, the use efficiency of dye is effectively improved, the device is safe and environmentally friendly, the pollution to the environment is lowered, manual operation is not needed, the labor intensity is lowered, and the economic efficiency is improved.

Owner:HUZHOU BOREN TEXTILES

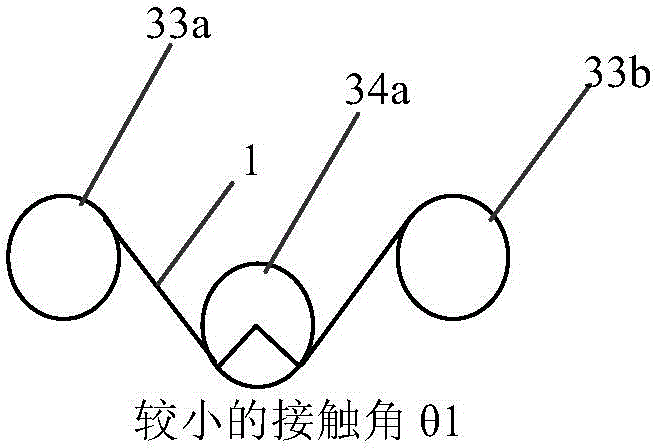

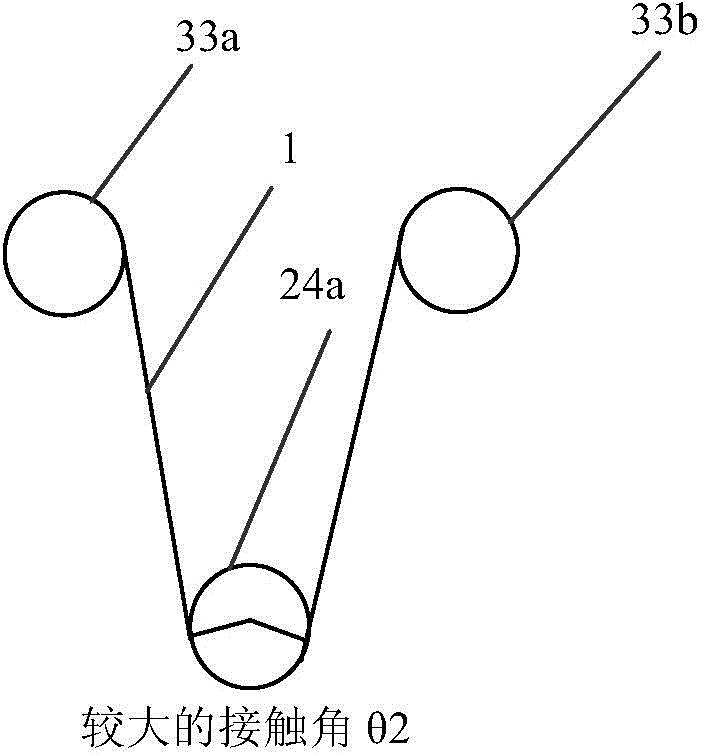

Processing equipment and method for continuous fiber tows

The invention relates to processing equipment and method for continuous fiber tows. The processing equipment comprises a desizing unit, an unfolding and dispersing unit and a sizing unit, wherein the desizing unit uses a fluid washing mode to enable fiber tows to desize, the unfolding and dispersing unit comprises round bars, tension braking rollers and a tension brake which are alternatively arranged, the round bars and the tension braking rollers are used for controlling the contact angles between the fiber tows and the adjacent round bars, the tension brake is connected to each tension braking roller and then used for regulating the tension generated when the tension braking rollers rotate, and the sizing unit is used for conducting re-sizing and drying on the fiber tows. The method for the continuous fiber tows is achieved through the above equipment, the fiber tows after being processed have lowered and uniform fiber distribution density and stable and consistent fiber tow widths, and therefore the fiber tows together with heat plastic plastics can directly be made into heat plastic composite materials or various types of composite material products.

Owner:FORMOSA TAFFETA CO LTD

Blue calico printing and dyeing equipment imitating traditional process

InactiveUS20200181821A1Quality improvementIncrease productivityLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalProcess engineeringMechanical engineering

The invention discloses a blue printing cloth printing and dyeing device which imitates the traditional process, and includes a dye box. A dyeing device is provided on the right side of the dye box, and an L-shaped support post is provided on the right side of the dye box. A conveying device for conveying cloth is provided on the column, and a lifting device on the upper side of the conveying device is provided on the support column. The lifting device provides lifting movement for the dyeing cloth. As for the holding device for holding the cloth, the cloth dyeing cylinder of the present invention can indirectly detect the concentration of the dye solution through the PH value detection, and the liquid level detection mechanism and the PH value detector can be used to control the liquid pump supply to achieve automatic control of the dye solution concentration and The liquid level height improves the printing and dyeing quality. The conveying mechanism drives the two groups of clamping mechanisms to move to the upper side of the cloth dyeing cylinder and the air-drying place. The lifting mechanism can drive the clamping mechanism to lower into the cloth dyeing cylinder for dyeing. Therefore, the present invention can replace manual Printing and dyeing with traditional techniques can improve production efficiency.

Owner:WANG MING

Equipment for dyeing and finishing polyester fibre flat woven tape

InactiveCN101220549ANo deformationUniform thicknessSucessive textile treatmentsTextile treatment containersPolyesterEngineering

The invention discloses a dyeing and finishing device of a terylene flat meshbelt, relating to a high speed continuous dyeing and finishing device of the terylene flat meshbelt which is a dyeing dryer that collects coloring, dyeing, fixation, drying, ironing and sizing into a whole. The device comprises a front straining trestle, a back straining trestle, a carding belt device, a staining trough, a front draughting and pressing device, a drying box, a back draughting device, a cooling device, and a tape-out device. The front straining trestle is arranged on the front of the drying box while the back straining trestle is arranged on the back of the drying box; the carding belt device comprises a meshbelt freight lorry, a squirrel cage typed carding belt drum, a speed reduction motor, and a carding belt drum; and the staining trough is arranged on the lower part of the front straining trestle; the front draughting and pressing device which is arranged on a middle column of the front straining trestle comprises a frequency control motor I, a press roll, a draughting and driving roller, a pressure adjusting rod, a pressure spring, and a pressure adjusting ejector pin; the drying box is provided with a drying chamber and a heating chamber, and the back draughting device is arranged on a back column which is on the lower part of the back straining trestle, and the cooling device is provided with a plurality of cooling rollers.

Owner:杨军

Light conveying belt and preparation method thereof

ActiveCN101979283AHigh warp strengthQuality assuranceConveyorsSynthetic resin layered productsPolyesterEngineering

The invention relates to a light conveying belt and a preparation method thereof. The conveying belt comprises a Kevlar woven fabric, polyester woven fabrics and a polyurethane covering adhesive layer, wherein the Kevlar woven fabric is used as a middle framework layer; two layers of the polyester woven fabrics are used as a framework material of an upper framework layer and a framework material of a bottom framework layer; and three framework layers are respectively laminated with conductive polyurethane so as to obtain the three-fabric three-adhesive light conveying belt. The preparation method comprises the following steps of: (1) adopting Kevlar as warps of the Kevlar woven fabric and adopting ultra low shrink polyester multifilament yarns as weft yarns of the Kevlar woven fabric, wherein the basic weave is plain weave; (2) gluing the fabric and then sizing the glued fabric; and (3) coating the materials. The conveying belt of the invention has high strength. The integral tensile strength and the peel strength of the conveying belt are greatly improved. The preparation method is simple, has low cost and is suitable for industrial production.

Owner:DONGHUA UNIV

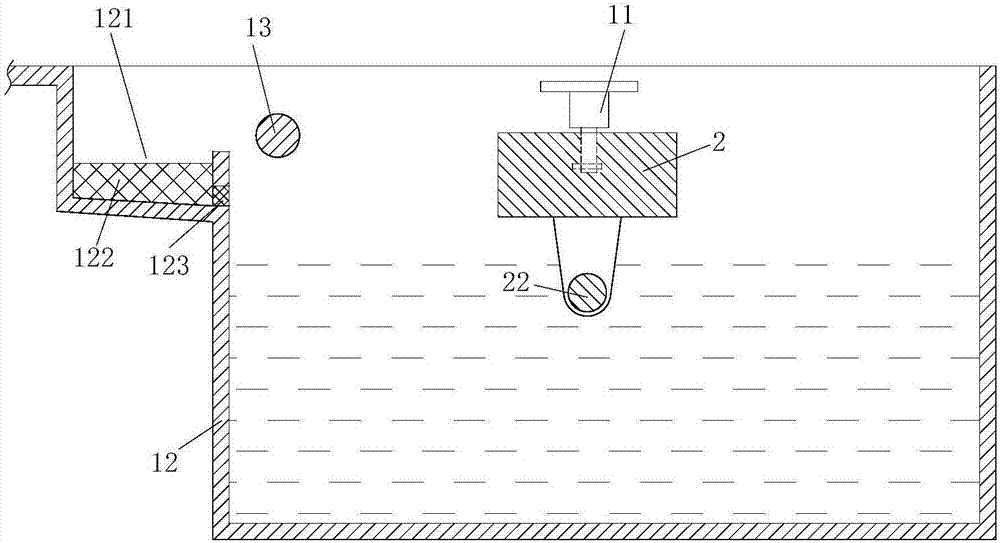

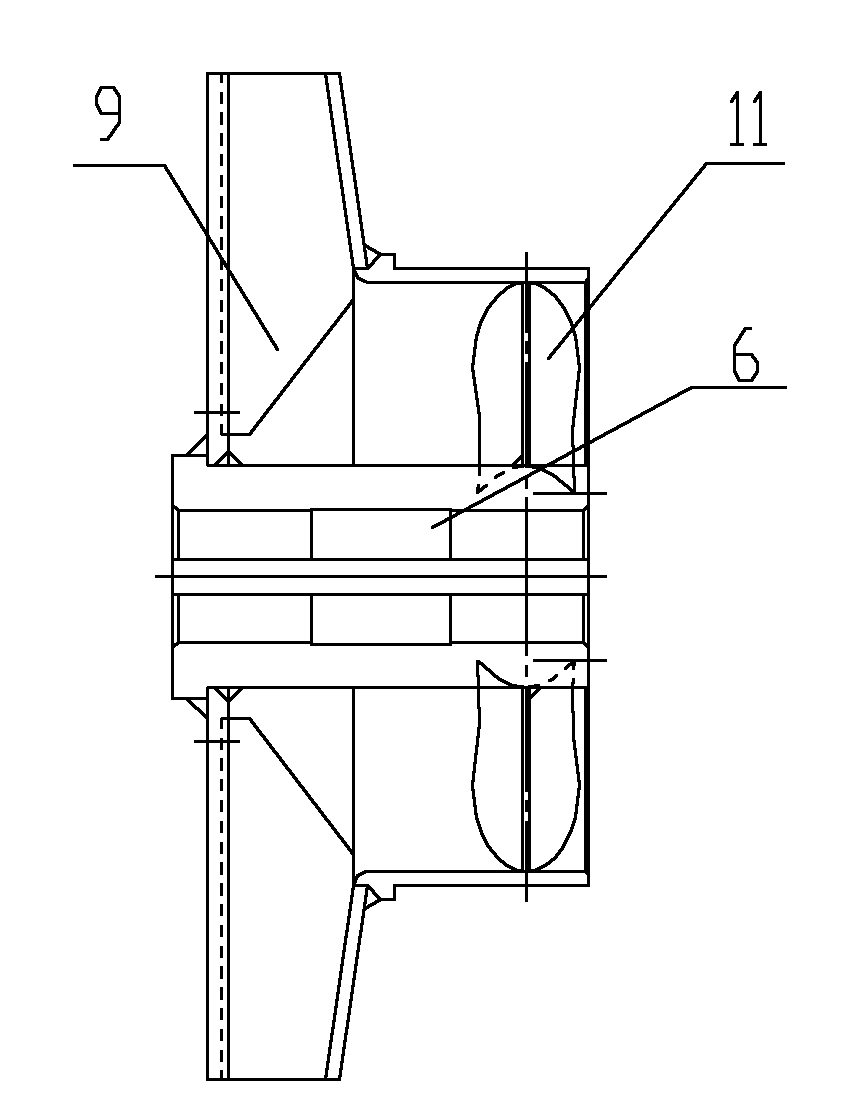

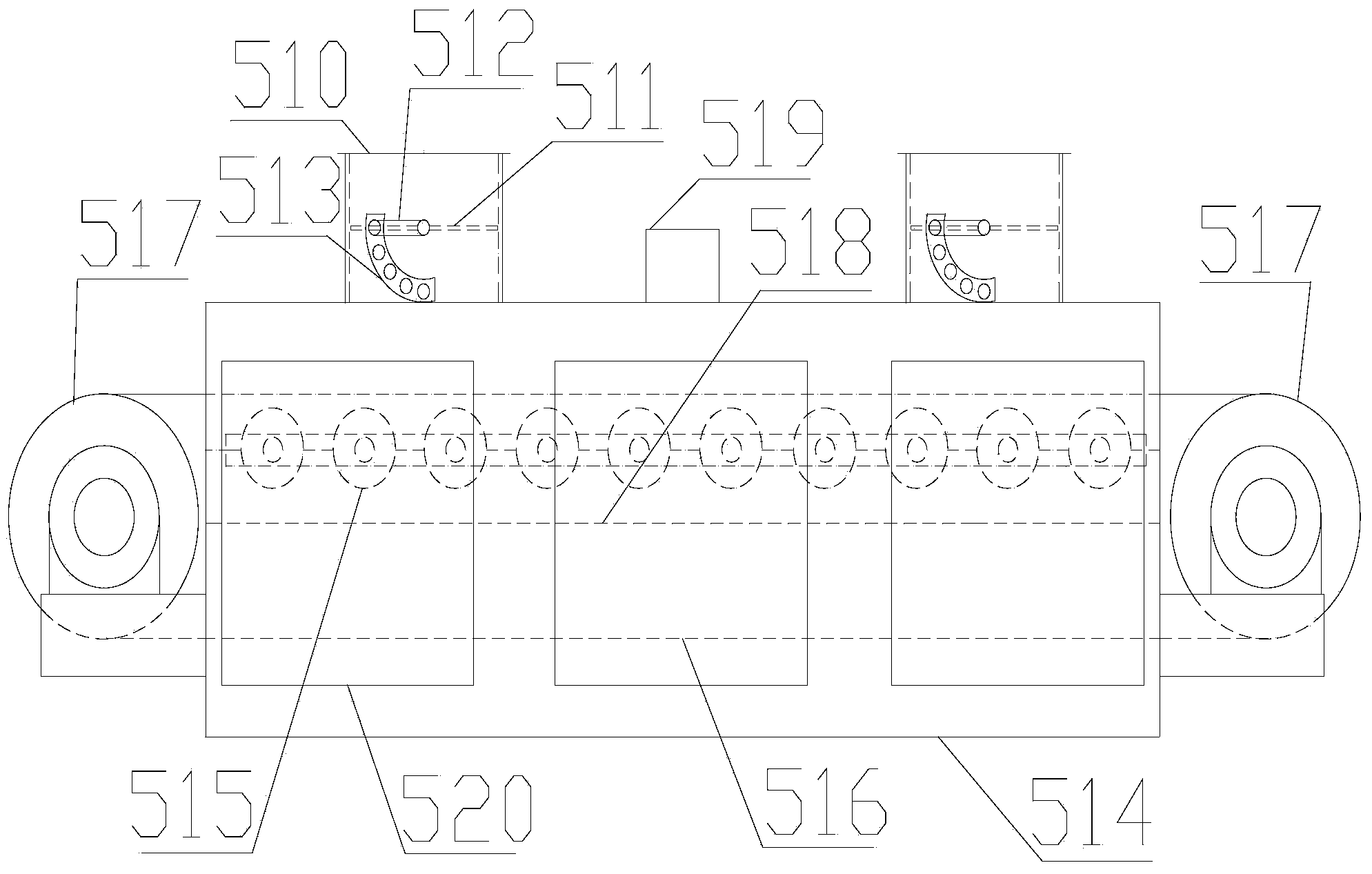

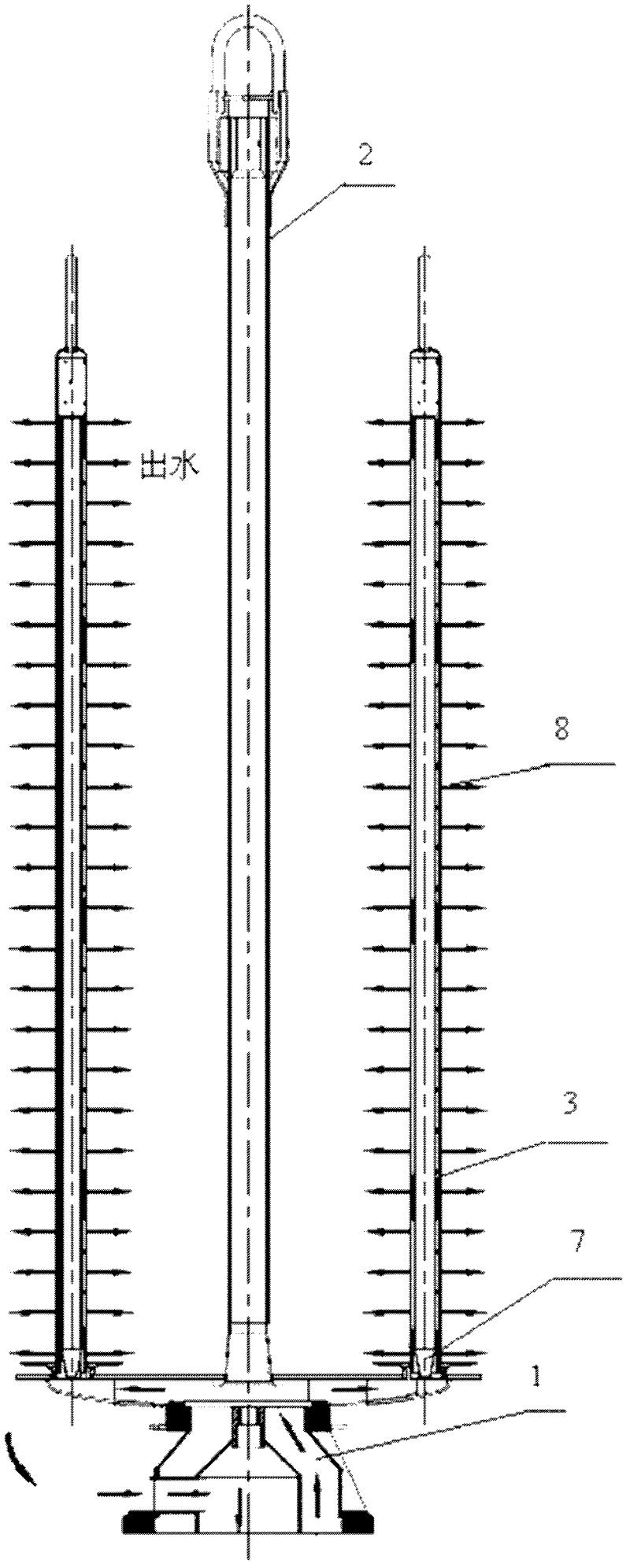

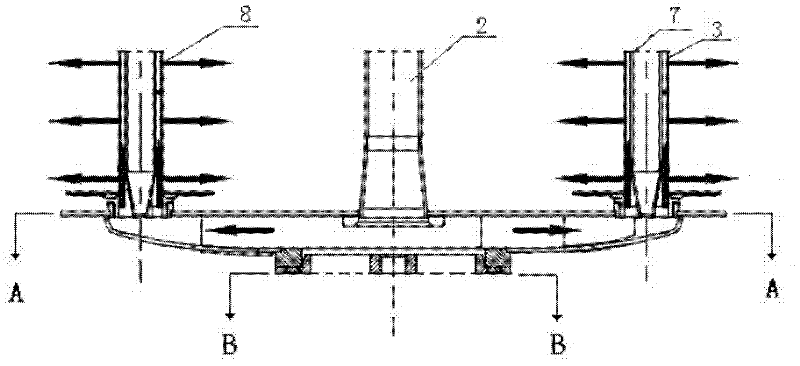

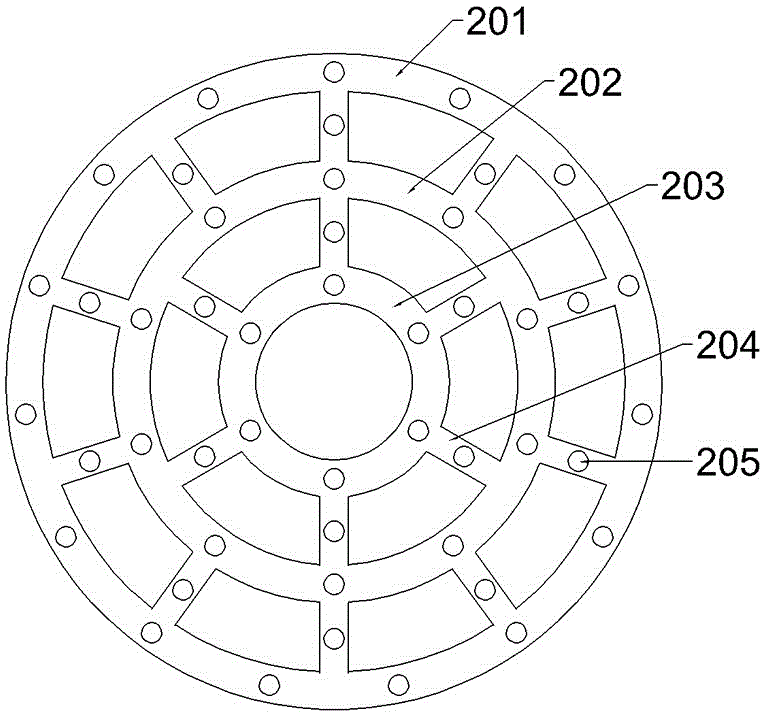

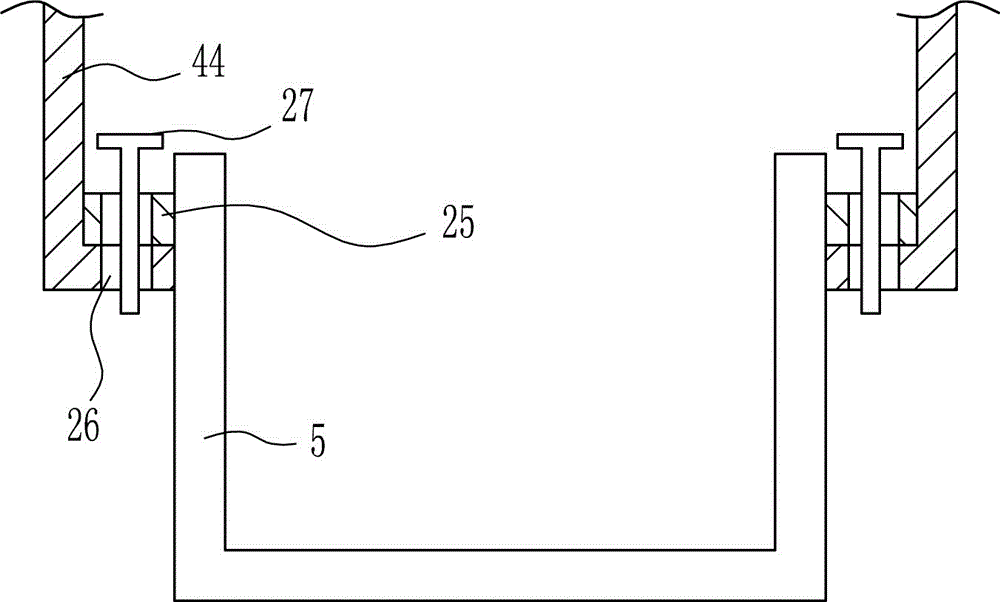

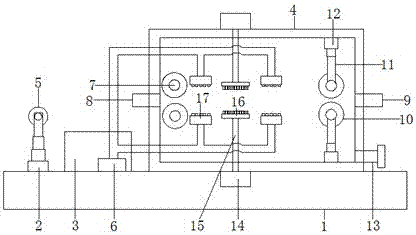

A creel device for an ultra-low liquor ratio yarn dyeing machine

InactiveCN102296436AReduce the cross-sectional areaGuaranteed coaxialityTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentWater bathsYarn

The invention discloses a creel device of a yarn dyeing machine with an ultra-low bath ratio, which comprises a sand table, a suspender and a yarn rod, wherein the upper surface of the sand table is in a disk shape; the lower end of the sand table is in a cavity structure; the yarn rod is in a hollow barrel structure; a water drum is arranged in the barrel of the yarn rod and is in a hollow or solid columnar structure; the center line of the yarn rod and the center line of the water drum are same; the ratio of the hollow internal diameter of the yarn rod and the external diameter of the waterdrum is 10:7-9; and the barrel of the yarn rod is evenly provided with a plurality of water outlets along the circumference of horizontal cross sections of different heights. The hollow barrel of theyarn rod disclosed by the invention is provided with the water drum, which is favorable for reducing the volume of dye liquor in the yarn rod and for reducing a water bath ratio; under the same main pump power, the water drum is favorable for improving the practical lift of a pipeline relatively, the flow rate of the dye liquor in the yarn rod is improved, the levelling property of cheeses of upper layers and lower layers can be better guaranteed, and the one-time success rate for dyeing is improved; and from the bottom to the top, the water outlets on the barrel of the yarn rod at the outer side of the water drum are thicker at the higher place of the yarn rod, which is favorable for realizing the purpose of even dye transfer.

Owner:高勋绿色智能装备(广州)有限公司

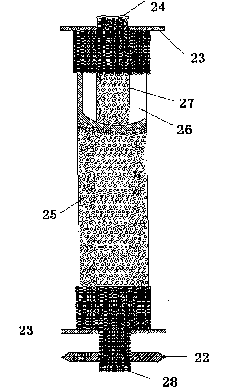

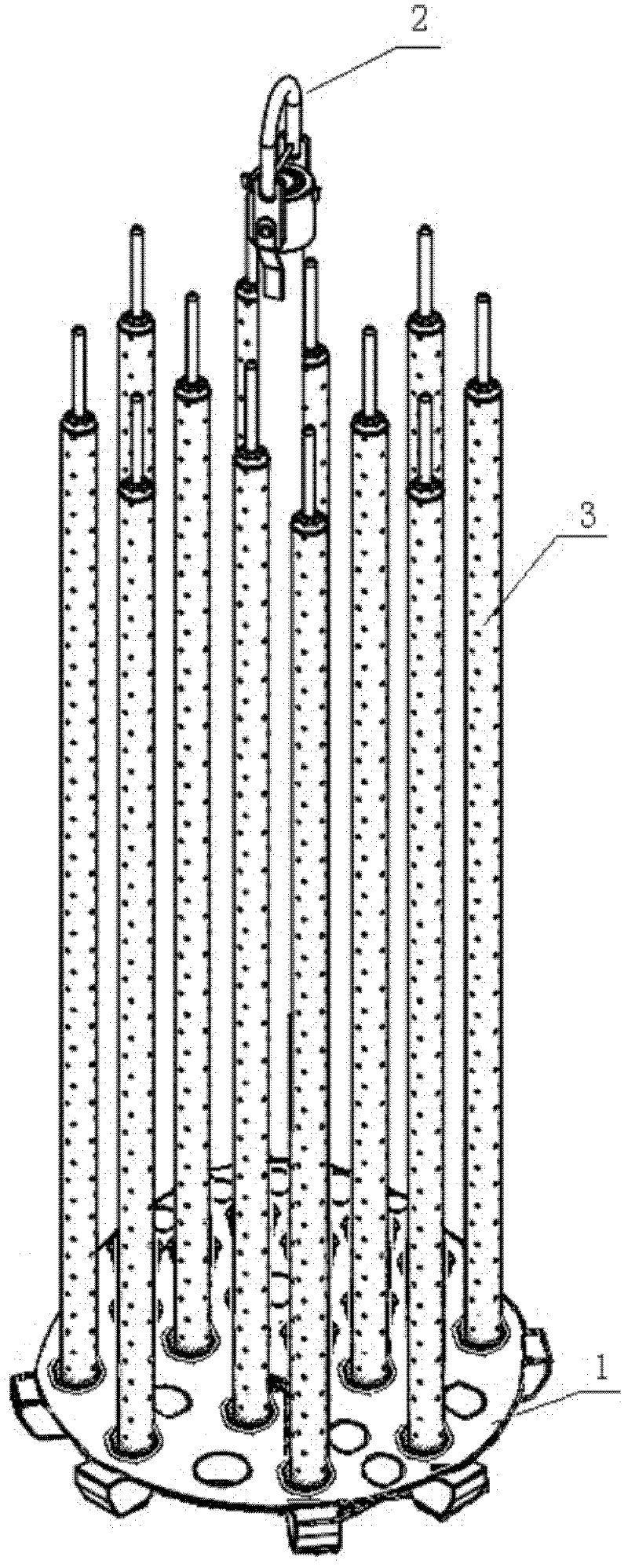

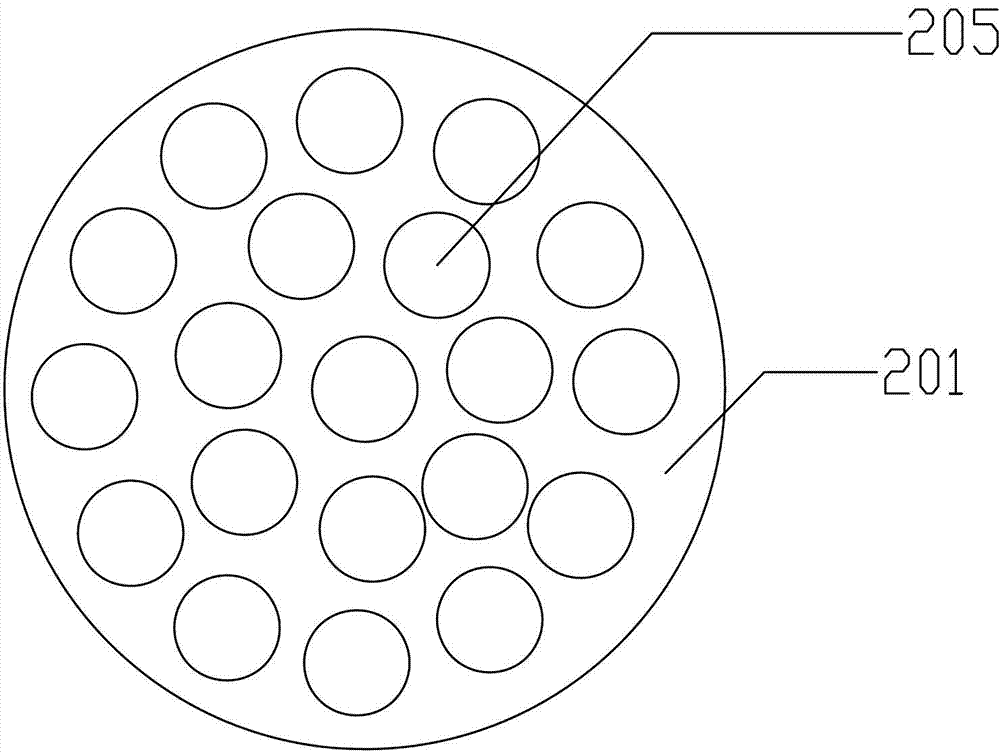

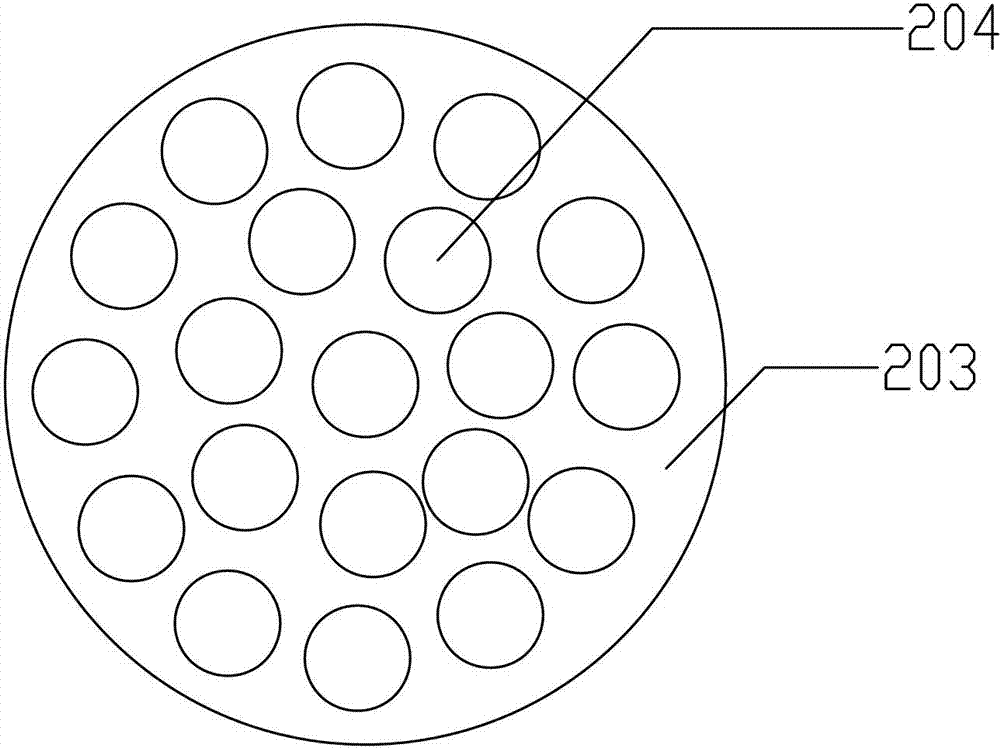

Supercritical carbon dioxide hairball dyeing kettle and waterless dyeing method thereof

ActiveCN102776738AMeet the development requirementsSimple and convenient production and processingTextile treatment containersSolvent treatment with solvent recoveryHairballSupercritical carbon dioxide

The invention relates to a supercritical carbon dioxide hairball dyeing kettle which comprises a cylinder body and a hairball dyeing barrel body fixed in the cylinder body, wherein a movable sealing cover is fixed at the upper end of the cylinder body, and the lower end of the cylinder body is provided with a carbon dioxide liquid outlet; a carbon dioxide liquid inlet is arranged at the upper part of the cylinder body; a heating clamping sleeve is fixed outside the cylinder body; a heating medium outlet is arranged at the upper end of one side of the heating clamping sleeve, and a heating medium inlet is arranged at the lower end of the other side of the heating clamping sleeve; the supercritical carbon dioxide hairball dyeing kettle is characterized in that a hole III is formed in the wall of the hairball dyeing barrel body; a central pipe is fixed to the centre of the hairball dyeing barrel body, and at least one upper limiting cover is fixed to the central pipe; the central pipe has a multi-pore shaft structure; a hole I is formed in a supporting plate at the bottom of the barrel body; a central hole Ia is corresponding to an internal chamber of the central pipe; and a hole II is formed in the upper limiting cover. According to the supercritical carbon dioxide hairball dyeing kettle increased, the direct contacting surface area of the a hairball and the dyeing liquid can be increased, and improves the influence due to the gravity in hairball dyeing can be improved, and the dyeing speed and the dye pickup can be improved, as well as the dyeing uniformity is improved.

Owner:晋江国盛新材料科技有限公司

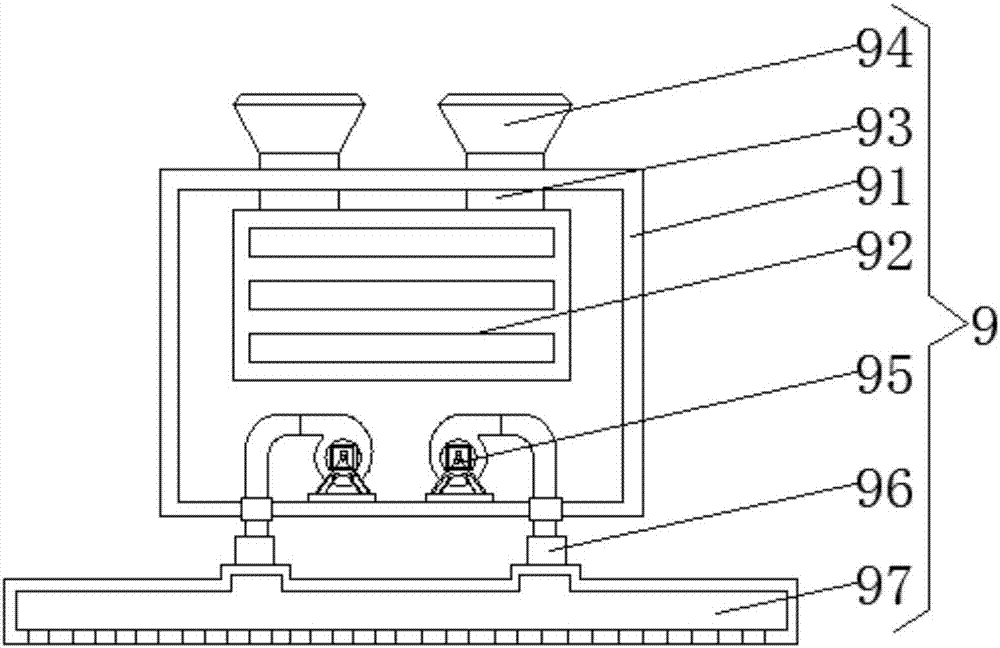

Integrated cleaning and drying apparatus for nonwoven fabric production

InactiveCN106087304AEasy to cleanImprove cleanlinessLiquid/gas/vapor removal by squeezing rollersTextile treatment carriersBristlePulp and paper industry

An integrated washing and drying apparatus for nonwoven fabric production comprises a washing device and a drying device, the washing device comprises a washing box, a feed roller is disposed on the upper right of the washing box, a first guide roller is provided in the washing box, a second guide roller is provided on the upper left of the washing box, nonwoven fabric runs sequentially through the feed roller, the first guide roller and the second guide roller, a motor is provided below the first guide roller and is fixedly connected with the inner bottom of the washing box, a rotary shaft is connected to the upper side of the motor and is provided with a washing brush, and the washing brush is provided with bristles; a squeezing roller is provided above the second guide roller, and a squeezing layer is provided outside the squeezing roller. The integrated washing and drying apparatus for nonwoven fabric production has the advantages that the bristles on the washing brush can effectively wash nonwoven fabric to ensure cleanness of the nonwoven fabric; the squeezing layer squeezes the nonwoven fabric so that most water in the nonwoven fabric is squeezed out to facilitate a subsequent drying step.

Owner:泉州中投文化发展有限公司

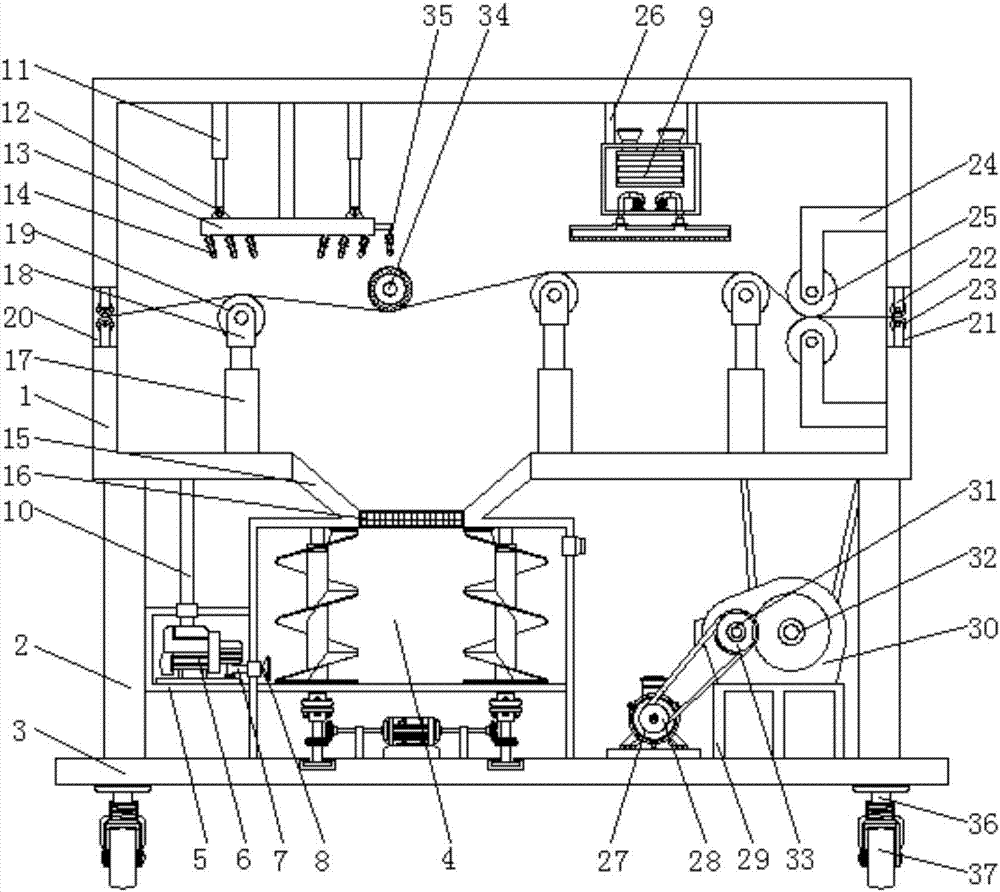

Automatic polishing and monkey washing device for jeans wear

ActiveCN105200694ASimple structureSmall footprintTextile treatment machine arrangementsTextile treatment carriersElectric machineryEngineering

The invention relates to an automatic polishing and monkey washing device for jeans wear. In the prior art, the working efficiency is relatively low since manual operation is carried out usually when jeans are polished. The automatic polishing and monkey washing device for jeans wear comprises a polishing room, a monkey washing room, jean fixing devices, polishing devices, monkey washing devices and a moving device and is characterized in that each polishing device comprises a fixing device, a brush, a control device and a driving motor; each control device comprises an adjusting plate and a driving device; each driving device comprises a lifting motor, a screw rod I and a sliding block connected with the adjusting plate; a connecting plate is arranged on each sliding block; an adjusting hole is formed in each of the connecting plate and the corresponding adjusting plate; a penetration hole corresponding to the adjusting hole is formed in the other one; each fixing device comprises a locking rod; each locking rod penetrates through the corresponding adjusting hole and the penetration hole sequentially. The automatic polishing and monkey washing device is simple in structure, reasonable in design, simple in operation and high in working efficiency.

Owner:嘉兴市金日不锈钢机械有限公司

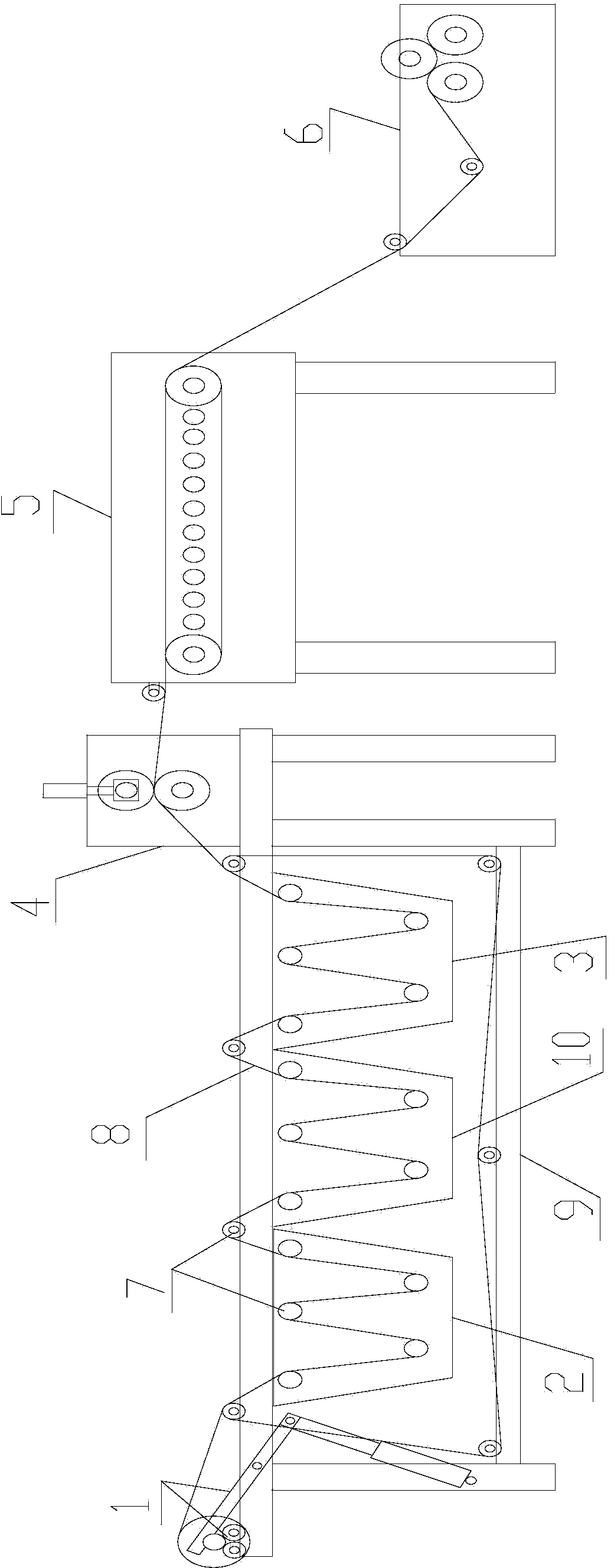

Non-woven lifting dye device for garment production

InactiveCN106835555AEasy to dyeEasy to rewindTextile treatment machine arrangementsTextile treatment carriersNonwoven fabricMechanical engineering

The invention relates to a dye device, particularly relates to a non-woven lifting dye device for garment production, and aims at solving the technical problem of providing a non-woven lifting dye device for garment production, which is capable of flatly putting non-woven into a dye for dyeing. In order to solve the technical problem, the invention provides the non-woven lifting dye device for garment production. The non-woven lifting dye device for garment production comprises a dye box, a connecting rod, a support rod, a lifting mechanism, a lifting frame, a guide roller and the like, wherein the upper part of the left side outside the dye tank is connected with the connecting rod; the top of the connecting rod is connected with the support rod; the support rod is connected with the lifting mechanism; and the lower side of the lifting mechanism is connected with the lifting frame. Through the lifting mechanism, the targets of driving the lifting frame to descend through the lifting mechanism, driving the guide roller at the inner side to descend through the lifting frame and flatly pressing the non-woven into the dye box for dip dyeing through the guide roller at the inner side are achieved.

Owner:绍兴金祥惠纺织印染有限公司

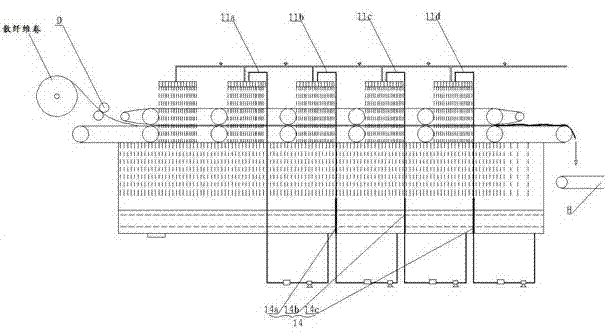

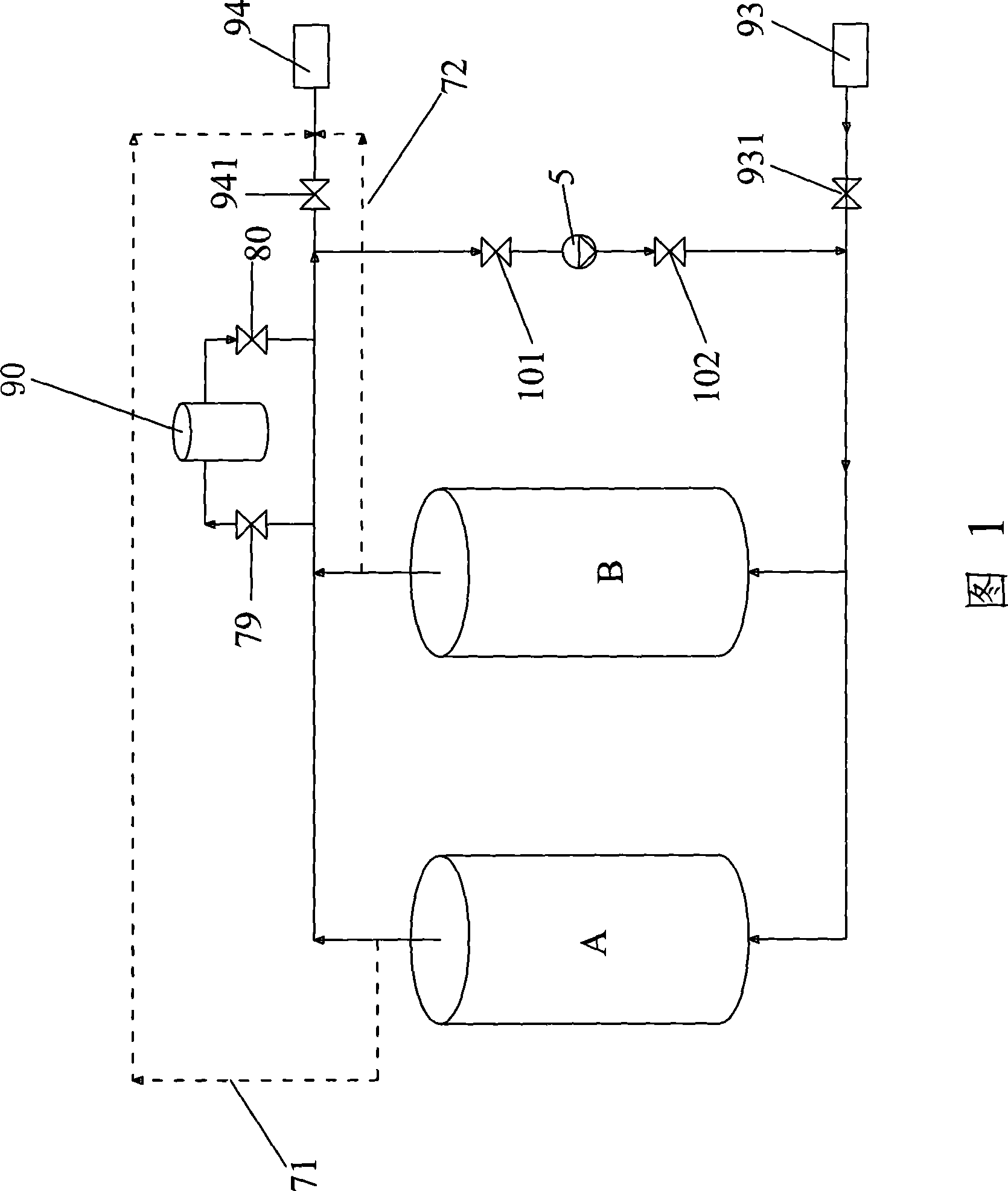

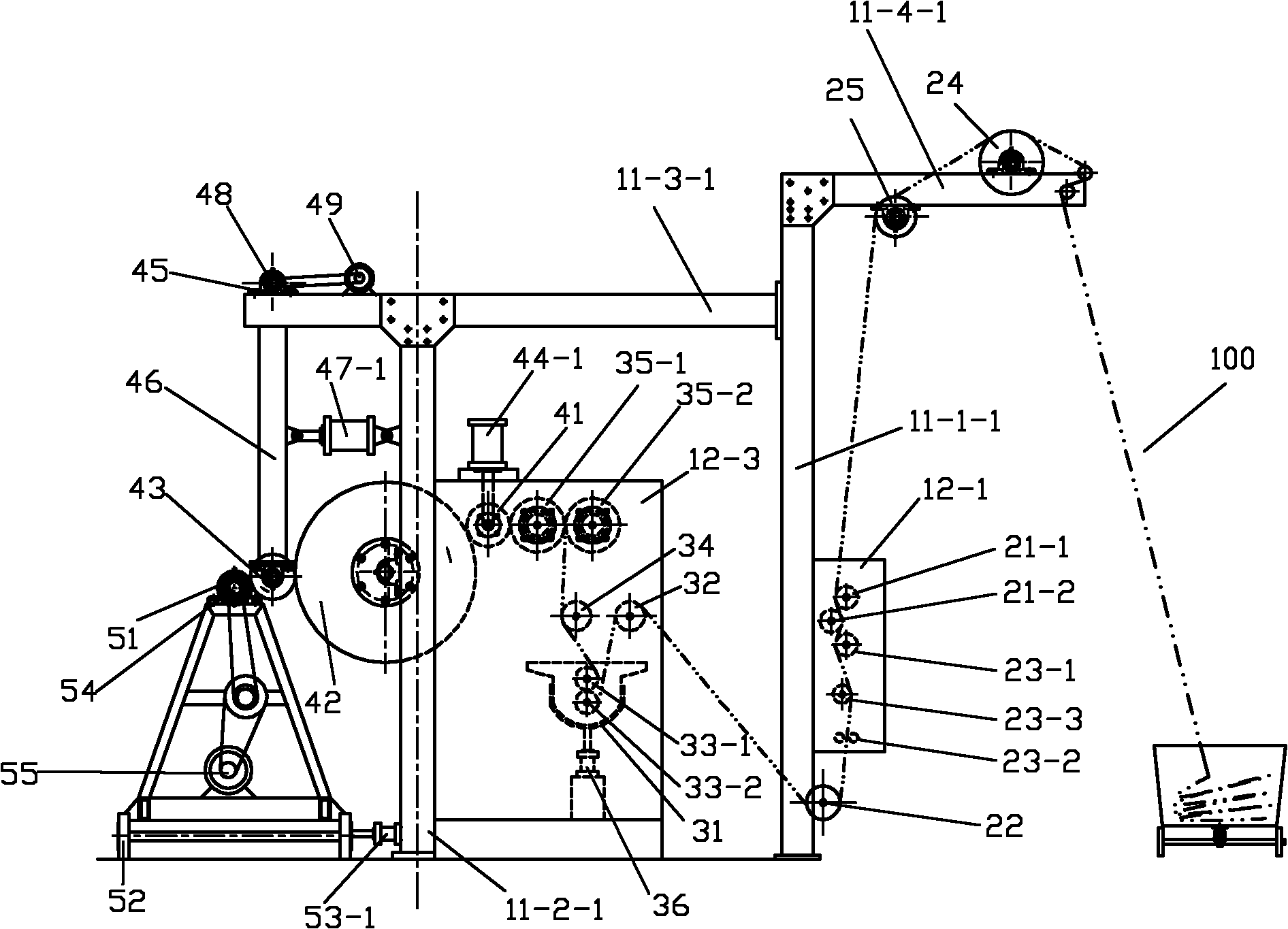

Supercritical CO2 anhydrous yarn warp dyeing system and dyeing method thereof

InactiveCN101413191ALow costIncrease capacityTextile treatment sample takingTextile treatment containersYarnProcess engineering

The invention discloses a supercritical CO2 anhydrous warp beam dyeing system and a dyeing method thereof. The system comprises a CO2 pressure supply device, a circulating pump, a separation and recovery device and two or more than two dyeing kettles which are arranged in parallel, wherein the dyeing kettles are arranged in parallel and connected in series with the circulating pump to form a closed dyeing circuit; a shutoff valve is respectively arranged on both ends of the circulating pump; the CO2 pressure supply device and the separation and recovery device are connected between the shutoff valves and the dyeing kettles respectively; and an outlet of each dyeing kettle is connected with an independent recovery bypass which is communicated with the separation and recovery device and independent of the closed dyeing circuit which is formed by the dyeing kettles and the circulating pump, so that different dyeing kettles can perform dyeing and recovery of CO2 simultaneously. The system can perform dyeing and recovery of the CO2 simultaneously and respectively, reduces consumption of the CO2 to the maximum degree, reduces the cost, can realize discontinuous operation and improve the production efficiency, and has quick dyeing speed.

Owner:HONG KONG PRODUCTIVITY COUNCIL

Polyester yarn dyeing device and method

InactiveCN109281097ARealize flow dyeingRealize streamlined dyeing processLiquid/gas/vapor open-width material treatmentSucessive textile treatmentsPolyesterYarn

The invention discloses a polyester yarn dyeing device and method. The polyester yarn dyeing device comprises polyester yarn, a dyeing mechanism, a washing mechanism and a drying mechanism; the washing mechanism and the drying mechanism are arranged on one side of the dyeing mechanism in sequence, the polyester yarn penetrates through the dyeing mechanism, the washing mechanism and the drying mechanism in sequence, and yarn guide wheels are arranged at the left and right ends of the upper surface of the dyeing mechanism and the left and right ends of the upper surface of the washing mechanismrespectively. According to the polyester yarn dyeing device and method, the polyester yarn is subjected to flow dyeing through the yarn guide wheels and dyeing guide wheels of the dyeing mechanism, surface dye of the polyester yarn is washed through the washing mechanism, finally, the polyester yarn is dried through the drying mechanism, and thus flow dyeing processing of the polyester yarn is achieved; no repeated dyeing operation is needed, and time and labor are saved; meanwhile, extruding rollers extrude out redundant dye carried by the polyester yarn, redundant dye is prevented from beingcarried out, and thus resource waste is greatly reduced.

Owner:福建省天和纺织实业有限公司

Continuous pigment dyeing pad dyer with infrared pre-baking apparatus

InactiveCN101487177AAvoid damageImprove mobilitySucessive textile treatmentsDrying solid materials with heatEngineeringPre treatment

The invention relates to a continuous paint dyeing padding machine with an infrared pre-drying device. The padding machine comprises a fabric inlet pre-processing device, a padding system, a drying system and a fabric outlet processing device which are sequentially arranged. The drying system comprises an infrared pre-drying device and a steam drying device. The infrared pre-drying device comprises two to five pre-dying mechanisms; each pre-drying mechanism comprises a pair of frame parts; and each pair of frame parts is provided with an infrared emitter. The continuous paint dyeing padding machine is characterized in that the front part of each row of infrared emitters is provided with a shielding device; when the padding machine is in use, the shielding device is arranged at a keep-clear position; and when the padding machine is in a shutdown state, the shielding device is arranged at a shielding position. Furthermore, each pair of frame parts can be arranged in a close state or an open state corresponding to the rolling of a first frame. Therefore, the padding machine has protection effect when in use, better dyeing effect and convenient maintenance.

Owner:常州慧杰电气技术有限公司

Cold pad-batch dyeing device for open-width knitted fabrics

InactiveCN101818422APrevent deviationAdjustable distanceTextile storage in wounded formLiquid/gas/vapor removal by squeezing rollersEngineeringControl circuit

The invention discloses a cold pad-batch dyeing device for open-width knitted fabrics, which comprises a frame, a cloth feeding device and a dyeing padding liquid device, and further comprises a wet supported cloth conveying device, a rollup device and a control circuit. The cloth feeding device, the dyeing padding liquid device and the wet supported cloth conveying device are arranged on the frame one after another; the cloth feeding device, the dyeing padding liquid device and the wet supported cloth conveying device are all provided with mechanical open-width components, and the open-width knitted fabrics are subject to open-width flattening before entering the units described above; the control circuit controls the rotating speed of electric motors in an active manner so that the cloth feeding device, the dyeing padding liquid device, the wet supported cloth conveying device and the rollup device realize the conveyance of the open-width knitted fabrics under bearable tension in a manner of synchronous operation, the open-width knitted fabrics are free from crumpling and curling in the entire treatment process, and eventually, the open-width knitted fabrics are flatly rolled onto a cloth roller in the form of big batch which can be rotatably piled up like woven fabrics, and the dyeing is completed during the rotatable pile-up, which not only reduces various consumptions and saves cost remarkably, but also improves the quality of the knitted fabrics.

Owner:蔡宗义

Textile cloth cleaning device for textile cloth production

InactiveCN107287783AAdjustable tensionAvoid pollutionLiquid/gas/vapor removal by squeezing rollersTextile treatment by spraying/projectingEngineeringMechanical engineering

The invention discloses a textile cloth cleaning device for textile cloth production in the technical field of textile cloth production equipment. A tension adjustment roller is installed on the top of the device, and the other end of the rotating shaft runs through the outer wall of the cleaning box to install a brush. The left and right sides of the cleaning box are respectively equipped with a cloth inlet and a cloth outlet, which can clean the two sides of the textile cloth. Washing, and in the process of washing, the motor drives the brush to rotate to wash the textile cloth, which improves the cleaning efficiency. Two sets of electric telescopic rods are used to drive two sets of extrusion rollers, which can squeeze out the washed textile cloth The remaining water stains on the surface can prevent water stains from polluting the workshop. The tension adjustment roller can be driven up and down by the hydraulic lifting device, which can realize the adjustment of the tension of the textile fabric and improve the cleaning efficiency.

Owner:湖州南浔贵丰纺织有限公司

Textile fabric dyeing equipment

ActiveCN108277594AAvoid color inconsistenciesNo precipitationLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringSediment

The invention relates to textile processing equipment, in particular to textile fabric dyeing equipment. The to-be-solved technical problem is to provide the textile fabric dyeing equipment capable ofstirring dye, so that no sediment occurs in the dye, the fabric is dyed uniformly, the upper and lower layers of the fabric both can be dyed with the dye at same depth in a dyeing process. In order to solve the above technical problem, the invention provides the textile fabric dyeing equipment, the textile fabric dyeing equipment comprises a bottom plate, brackets, a dye box, a discharging tube,a valve, a first supporting plate, a first mounting plate, a first connecting rod, and a first sleeve wheel, a guiding rail, a guiding sleeve, a second connecting rod and the like, wherein the left and right sides of the bottom plate both are connected to the brackets, and the dye box is connected between the upper ends of the brackets. According to the textile fabric dyeing equipment, the effectsthat the dye is stirred, so that no sediment occurs in the dye, the fabric is dyed uniformly, and the upper and lower layers of the fabric both can be dyed with the dye at same depth in the dyeing process are achieved.

Owner:嘉兴市永泰五金塑料有限责任公司

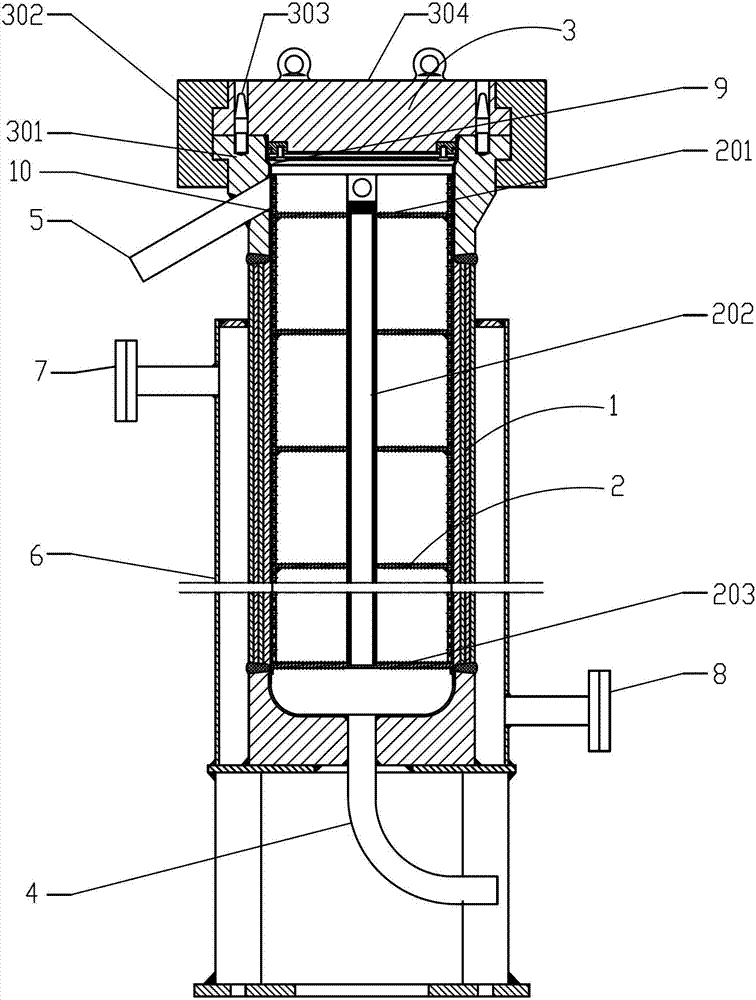

Ultralow liquor ratio zipper dyeing machine and dyeing process thereof

InactiveCN103088574AHollow volume reductionReduced cavity cross-sectional areaPump componentsTextile treatment machine arrangementsPolymer scienceEngineering

The invention discloses an ultralow liquor ratio zipper dyeing machine and dyeing process thereof. The dyeing machine comprises a tube cylinder, a cylinder cover and a zipper warp beam plate frame embedded into the tube cylinder. The zipper warp beam plate frame comprises a zipper plate seat, a hollow water drum, a zipper woven belt, a zipper tube sleeve, a locking bolt, and a zipper frame lifting ring. The lower end of the hollow water drum is fastened on the zipper plate seat, the zipper tube sleeve is sleeved on the outer side of the hollow water drum, and a diversion inlet and a diversion outlet are arranged below the zipper plate seat and connected with an infusion pump through a horn-shaped pipe sleeve. The dyeing process comprises the stages of scouring and bleaching, dyeing and water scrubbing. According to the ultralow liquor ratio zipper dyeing machine and the dyeing process thereof, a lift range required by zipper woven belt dyeing water level can be achieved when the height of dye liquor in the dyeing machine is lower than the zipper plate seat, the effect of ultralow liquor ratio zipper dyeing is achieved, the dyeing machine has a lower dying liquor ratio than a traditional zipper dying machine, and the purposes of saving electric energy, steam and the dye liquor, shortening dyeing and finishing periods, and saving energy and reducing emission are achieved.

Owner:高勋绿色智能装备(广州)有限公司

Popular searches

Textile solvent-dyeing Liquid/gas/vapor treatment of definite length materials Digital data processing details Filament handling Analogue secracy/subscription systems Color television details Computer security arrangements Selective content distribution Special data processing applications Liquid/gas/vapor textile treatment

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com