Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25278results about "Filament handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

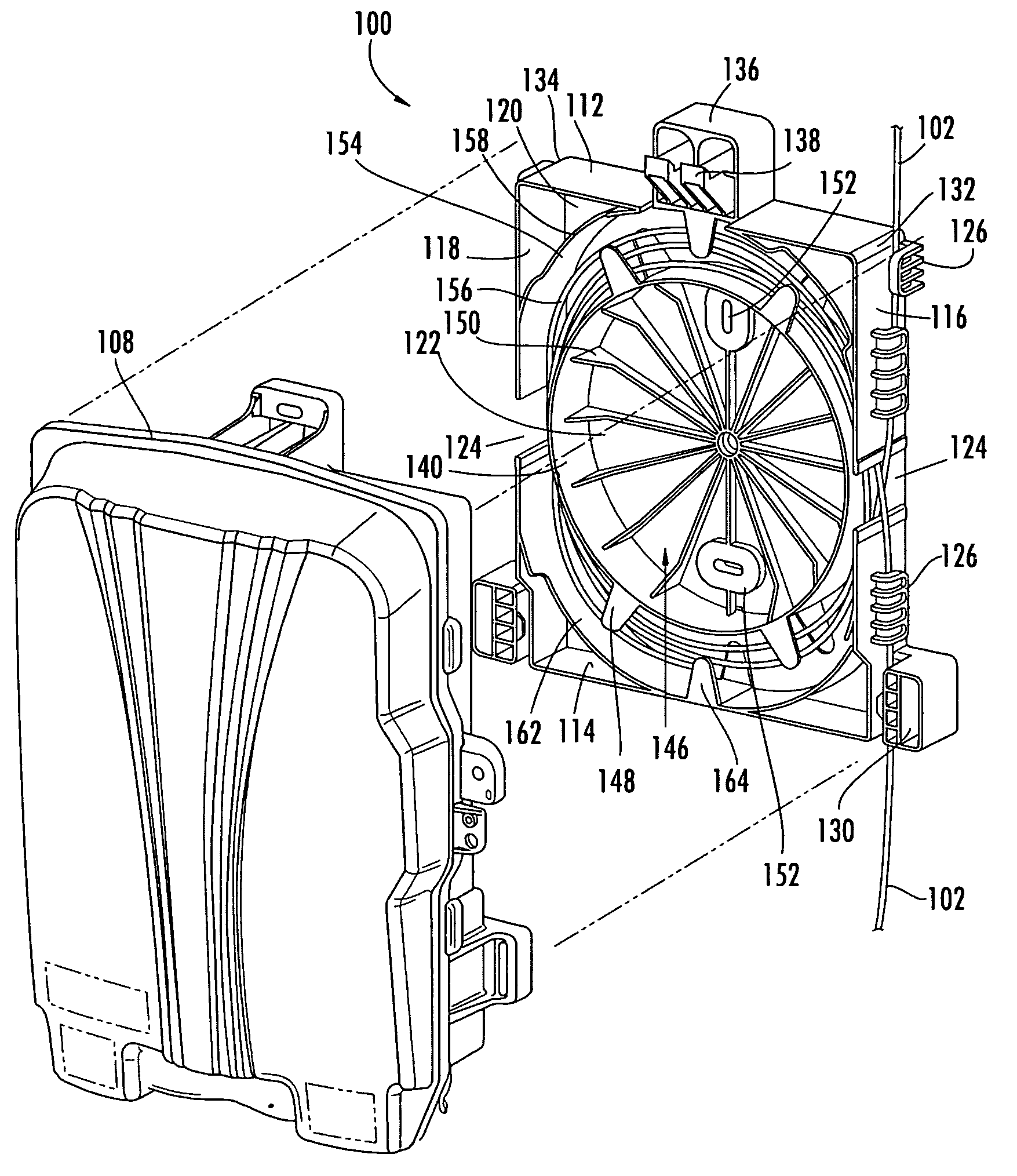

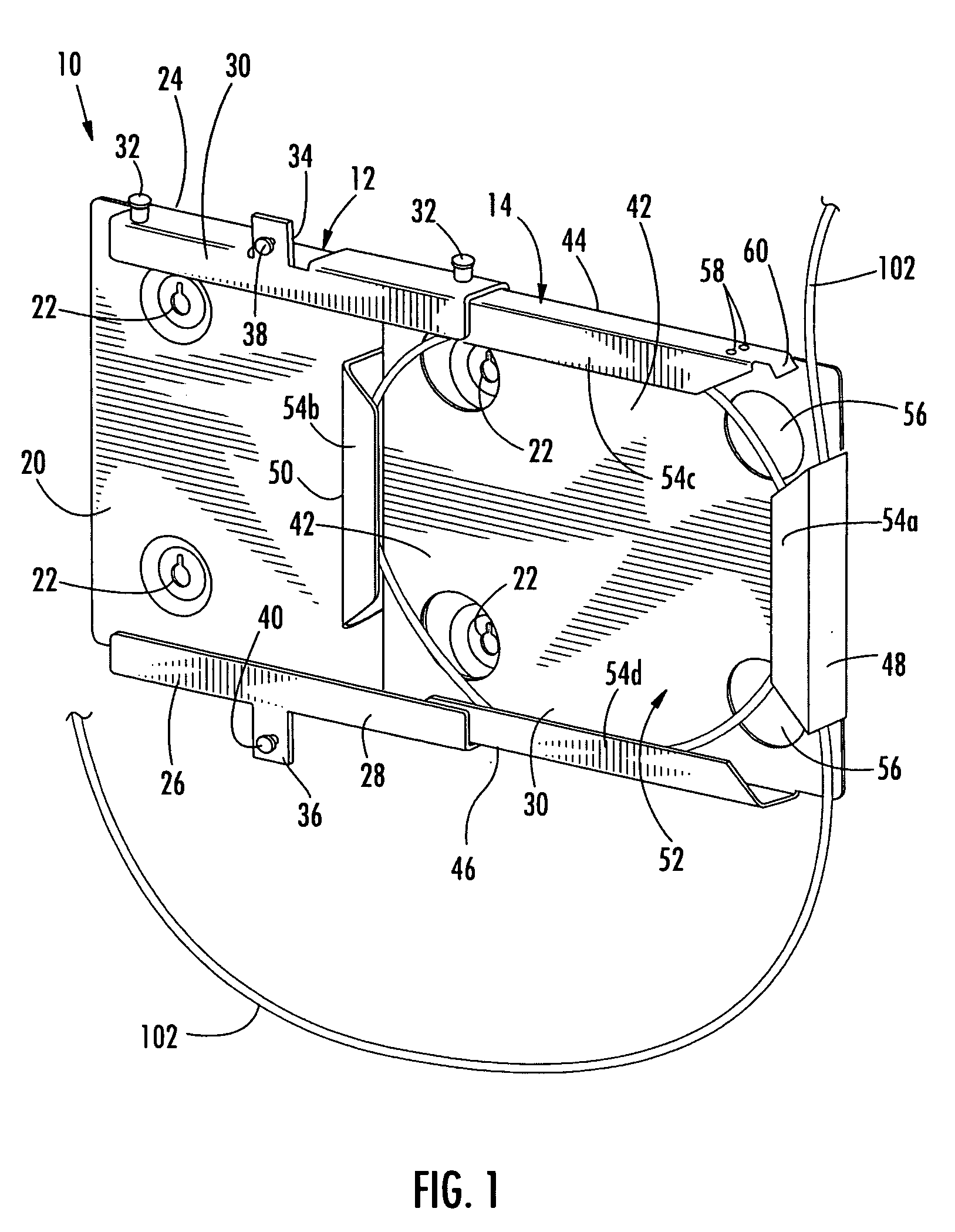

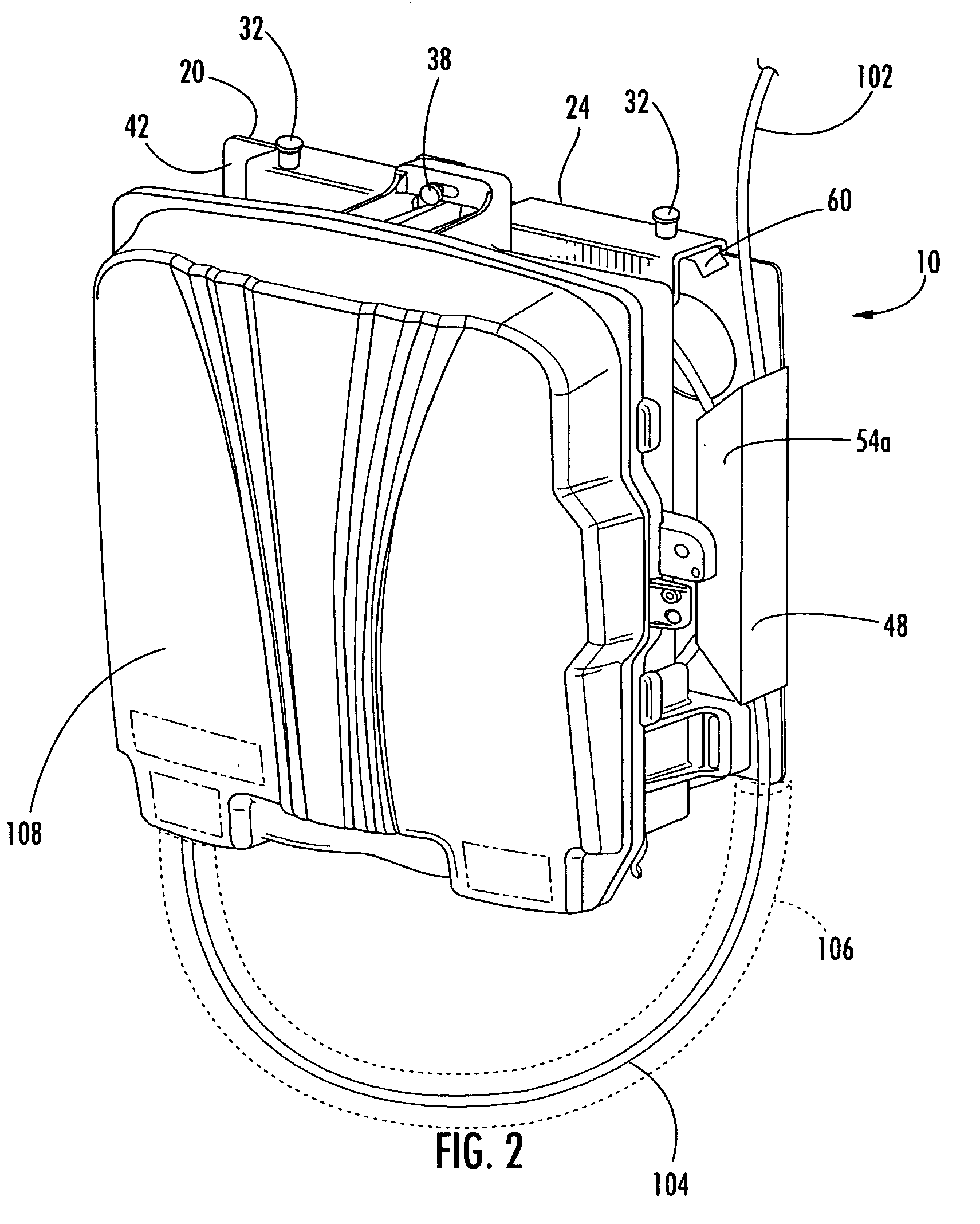

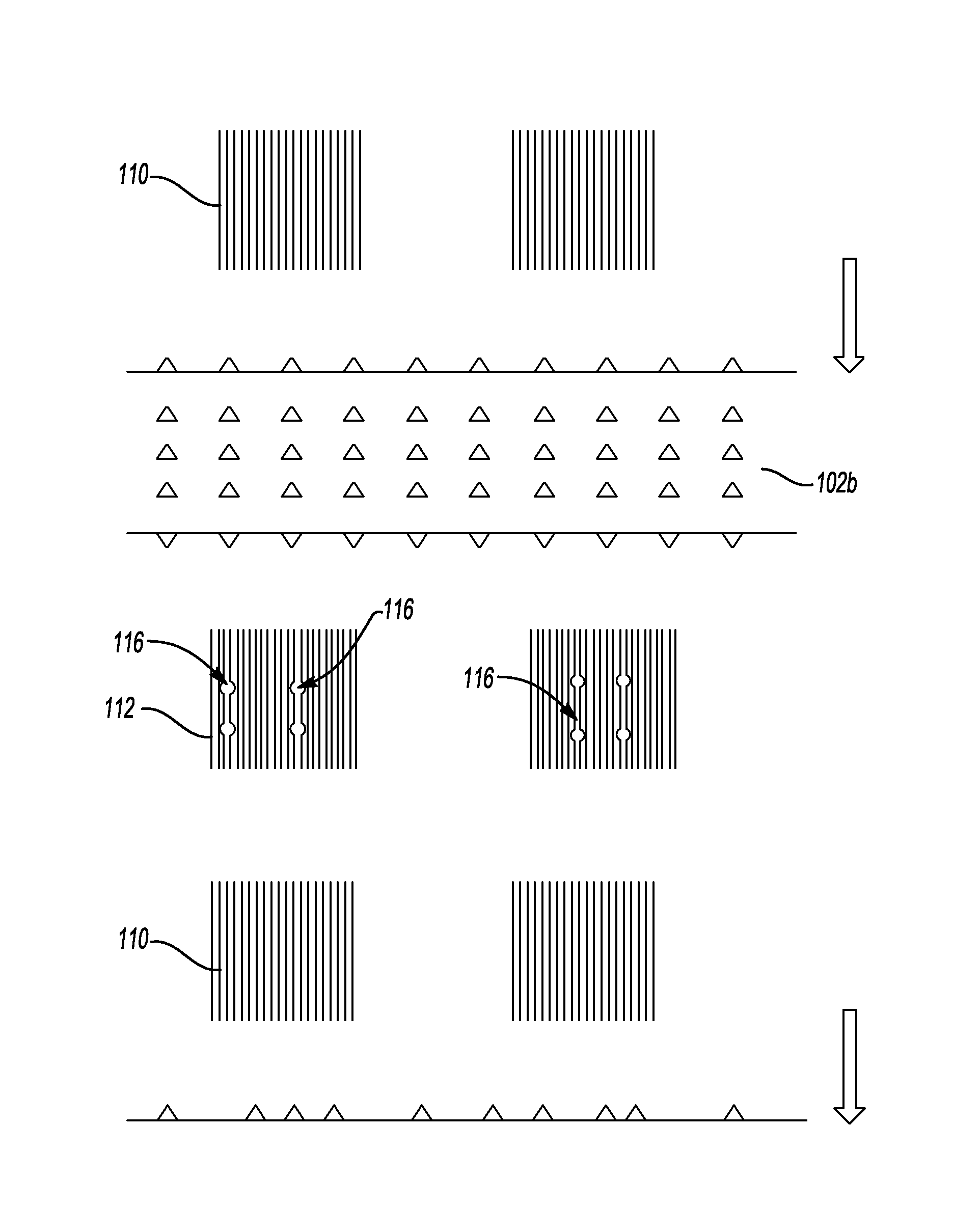

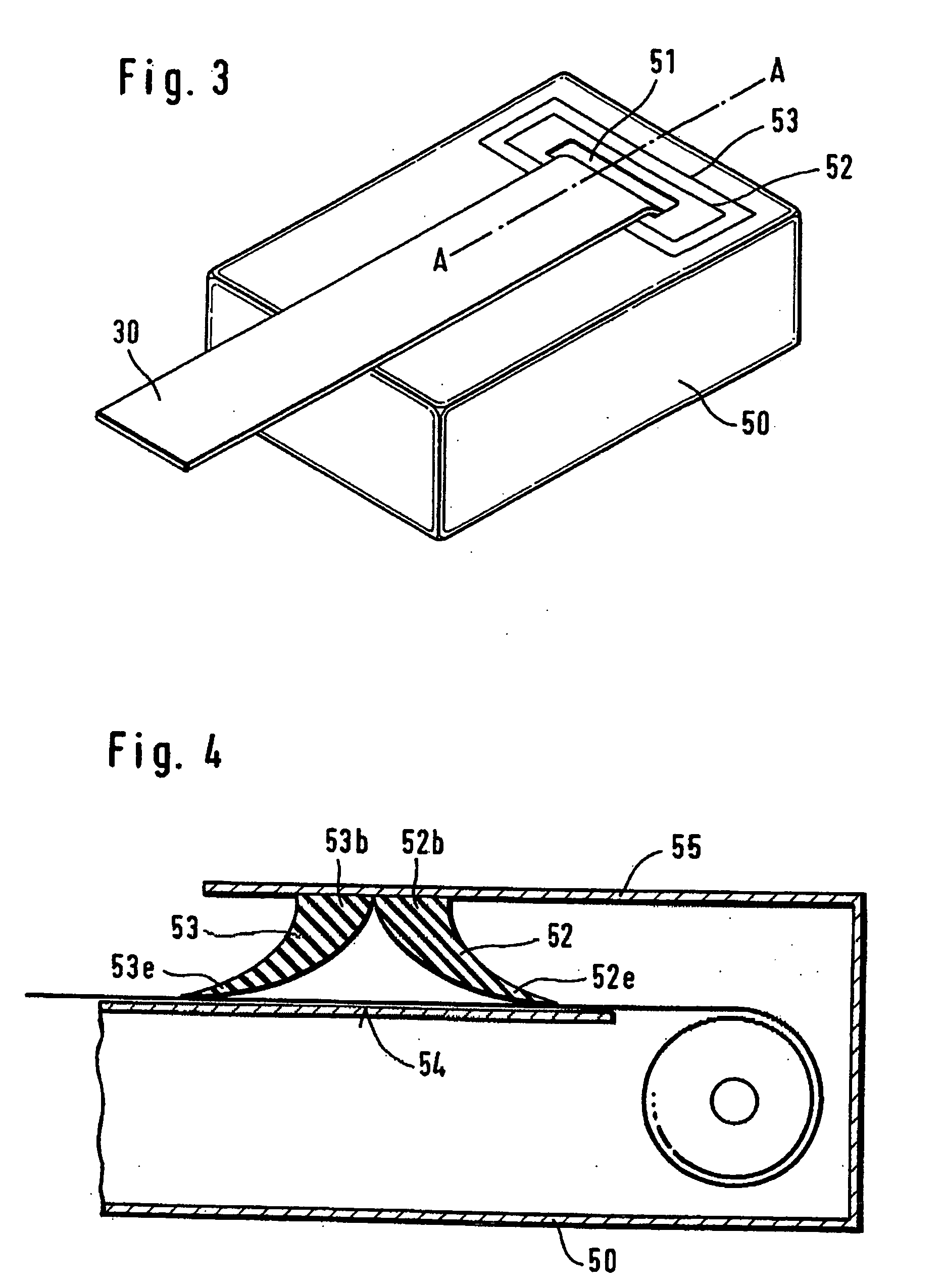

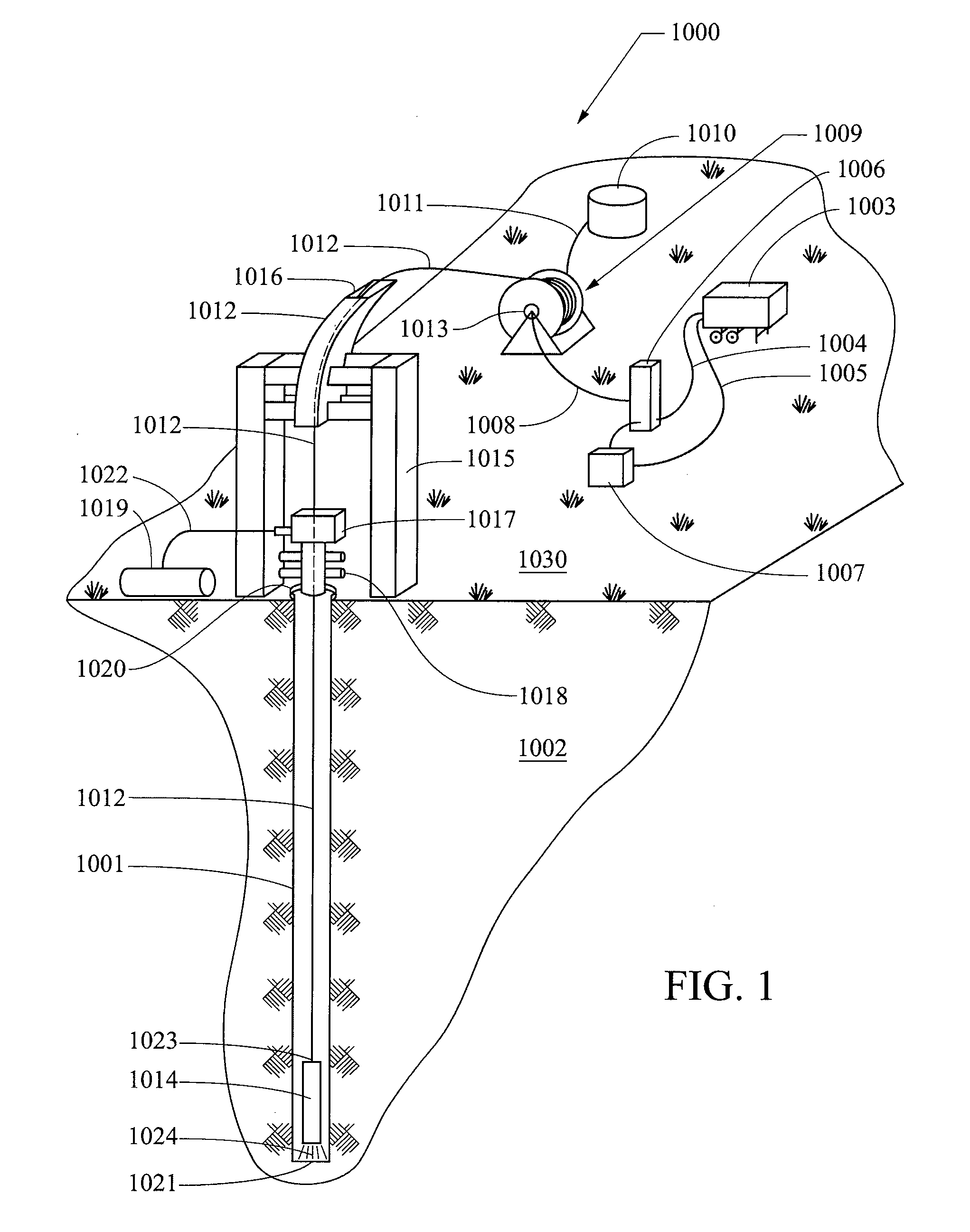

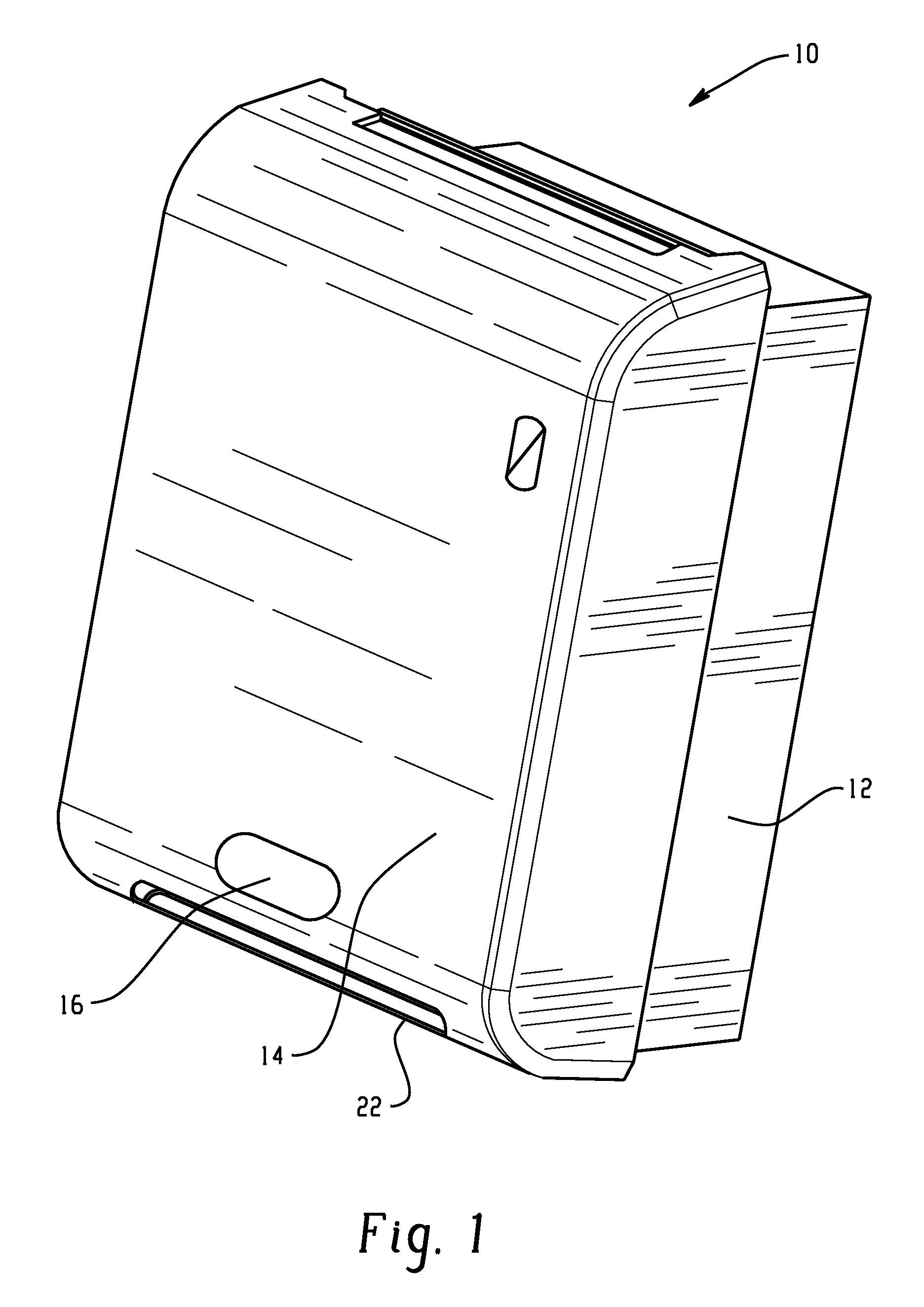

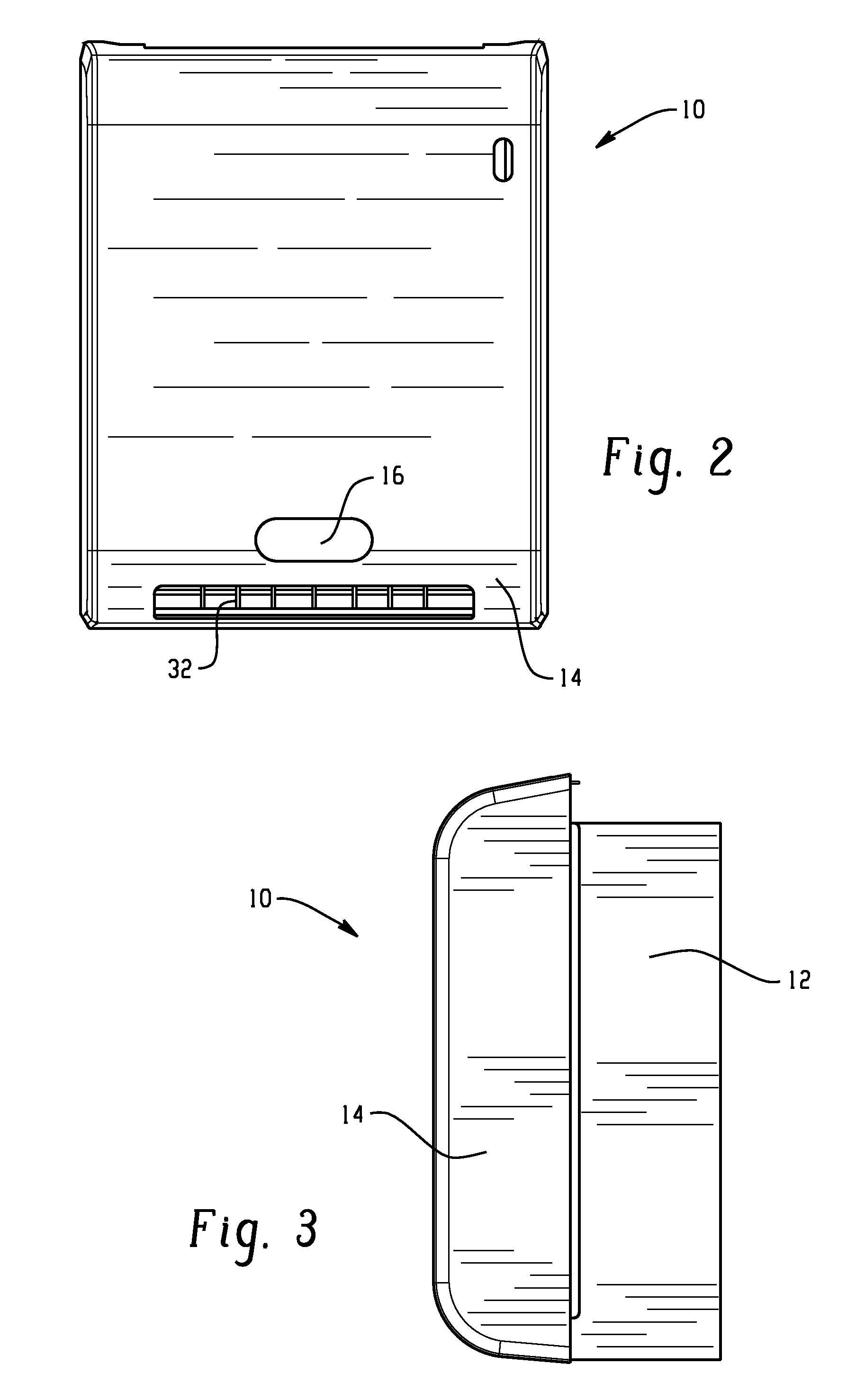

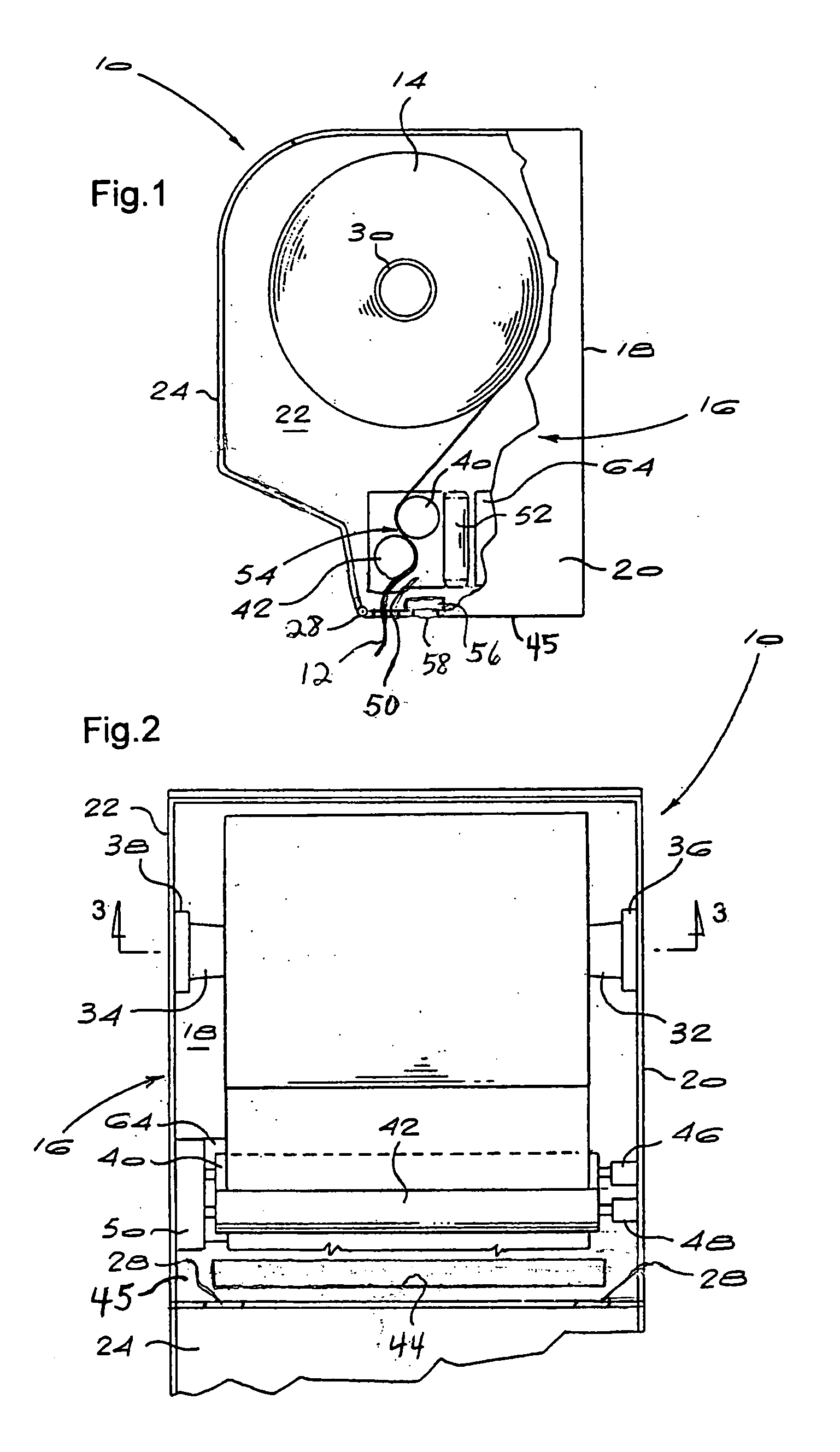

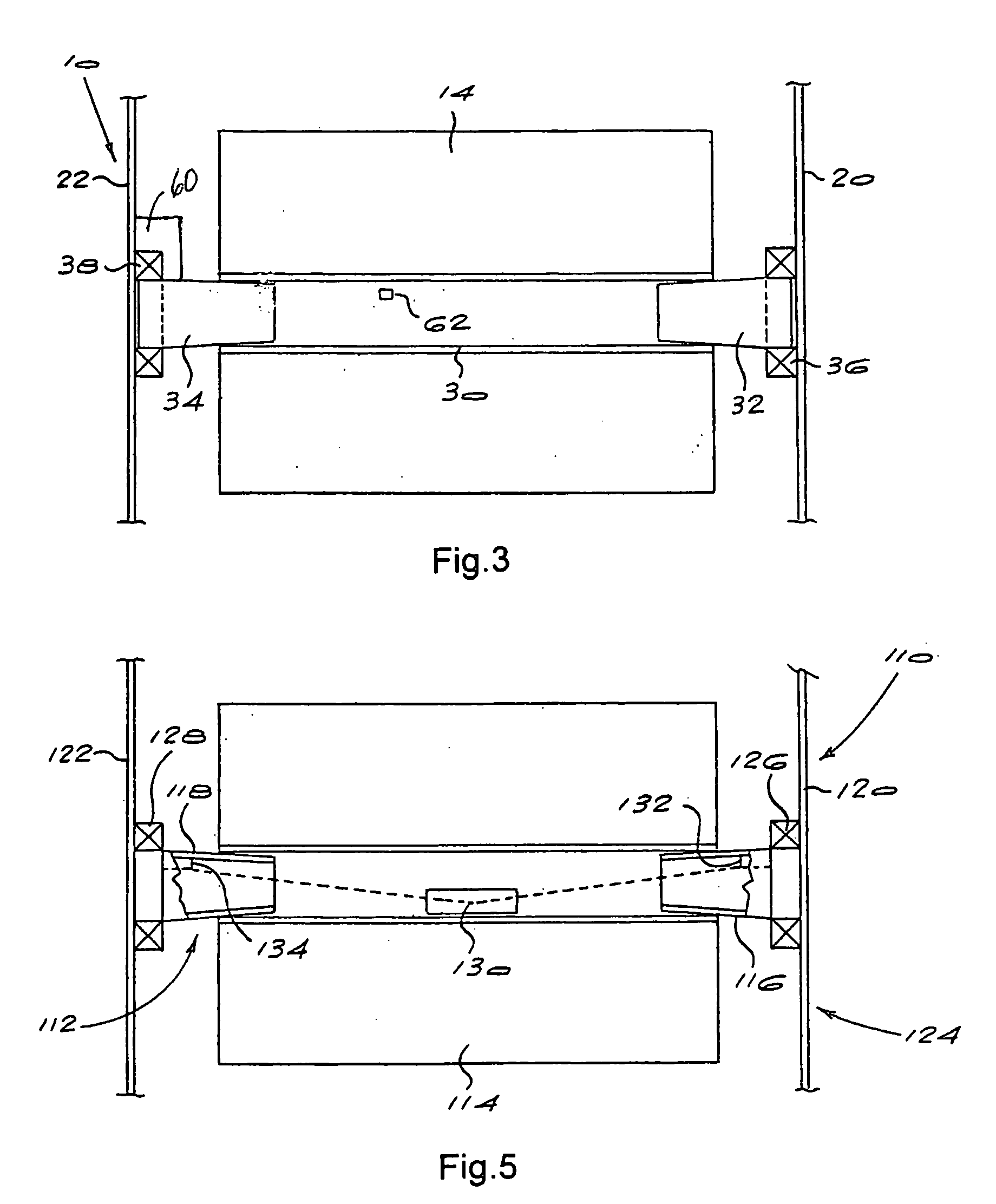

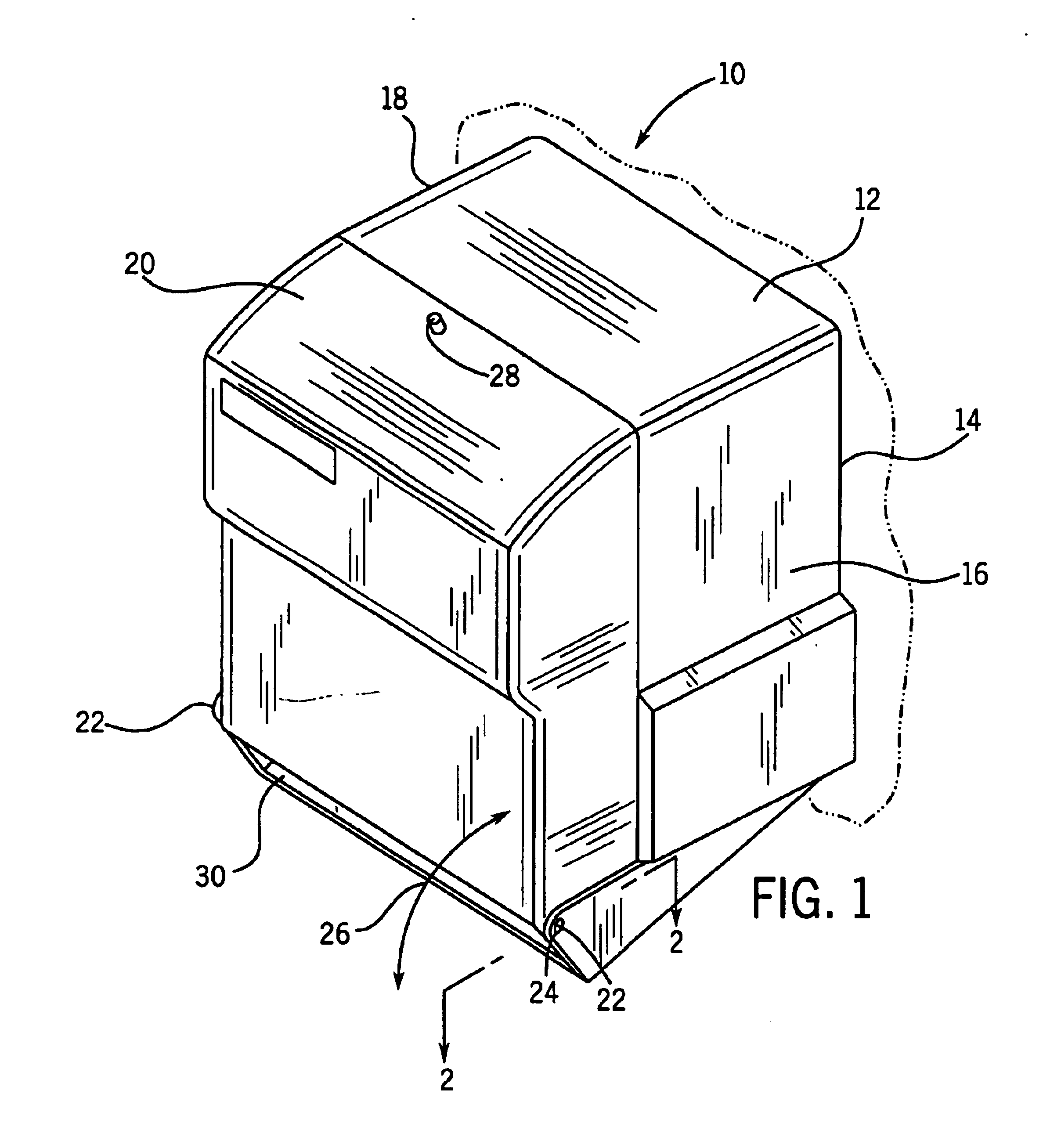

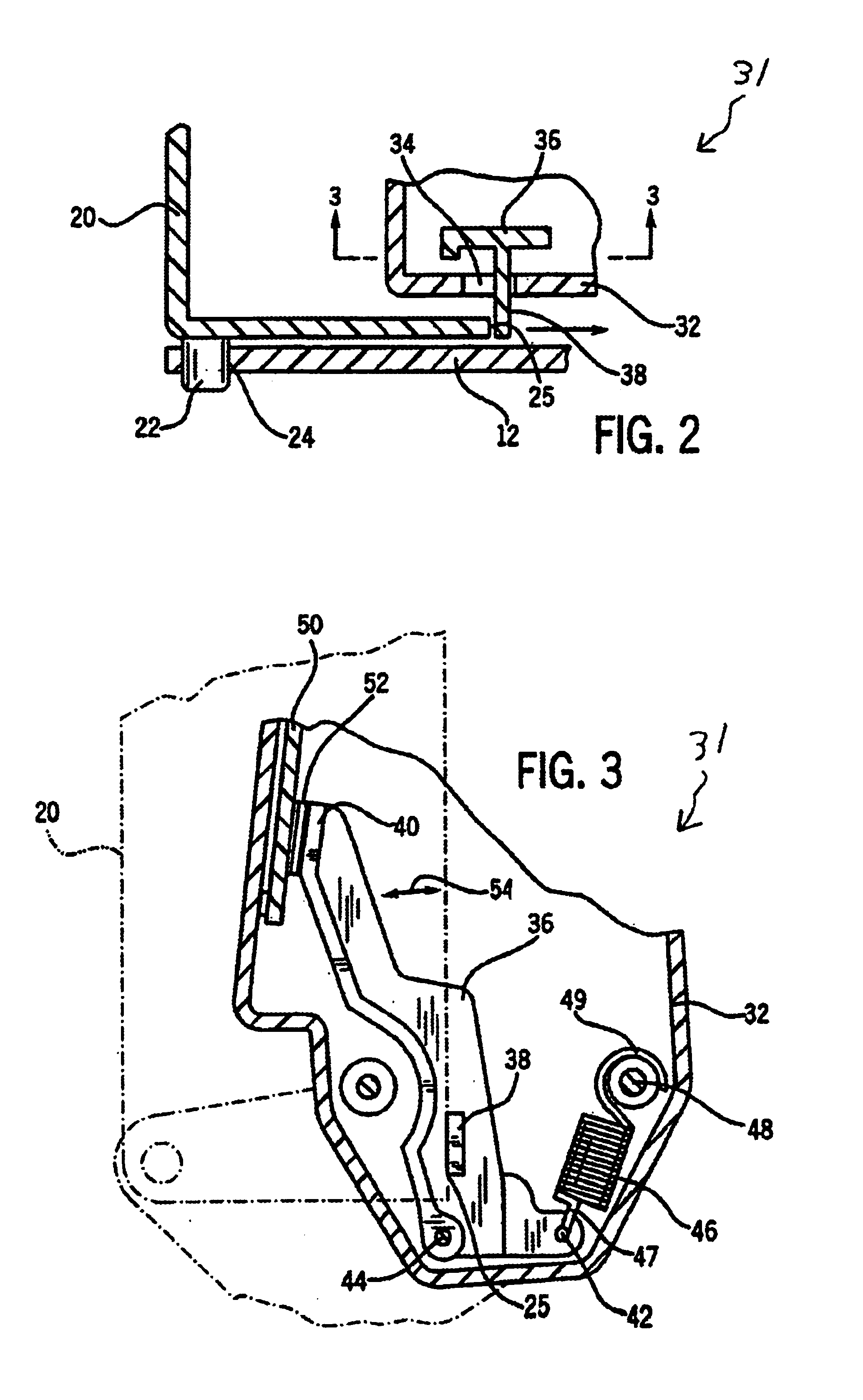

Fiber optic drop cable slack storage receptacle

ActiveUS20050145522A1Easy to deployEasy to installContainers for annular articlesFilament handlingFiberNetwork interface device

A slack storage receptacle for storing an excess length of a pre-connectorized fiber optic drop cable extending between an optical connection terminal and a network interface device (NID) includes a housing and a storage means disposed within the housing for receiving the drop cable such that the drop cable slack is stored external to the NID. The slack storage receptacle may be secured to an exterior wall of a subscriber premises and the NID mounted thereon. Alternatively, the slack storage receptacle may be positioned around and formed to the NID. Alternatively, the slack storage receptacle may be buried in the ground adjacent the NID. The drop cable slack may be wound onto the storage means after deployment. Alternatively, the slack storage receptacle may be pre-assembled, shipped to the subscriber premises, and the drop cable unwound from the storage means with the drop cable slack remaining wound on the storage means.

Owner:CORNING OPTICAL COMM LLC

Fiber tow treatment apparatus and system

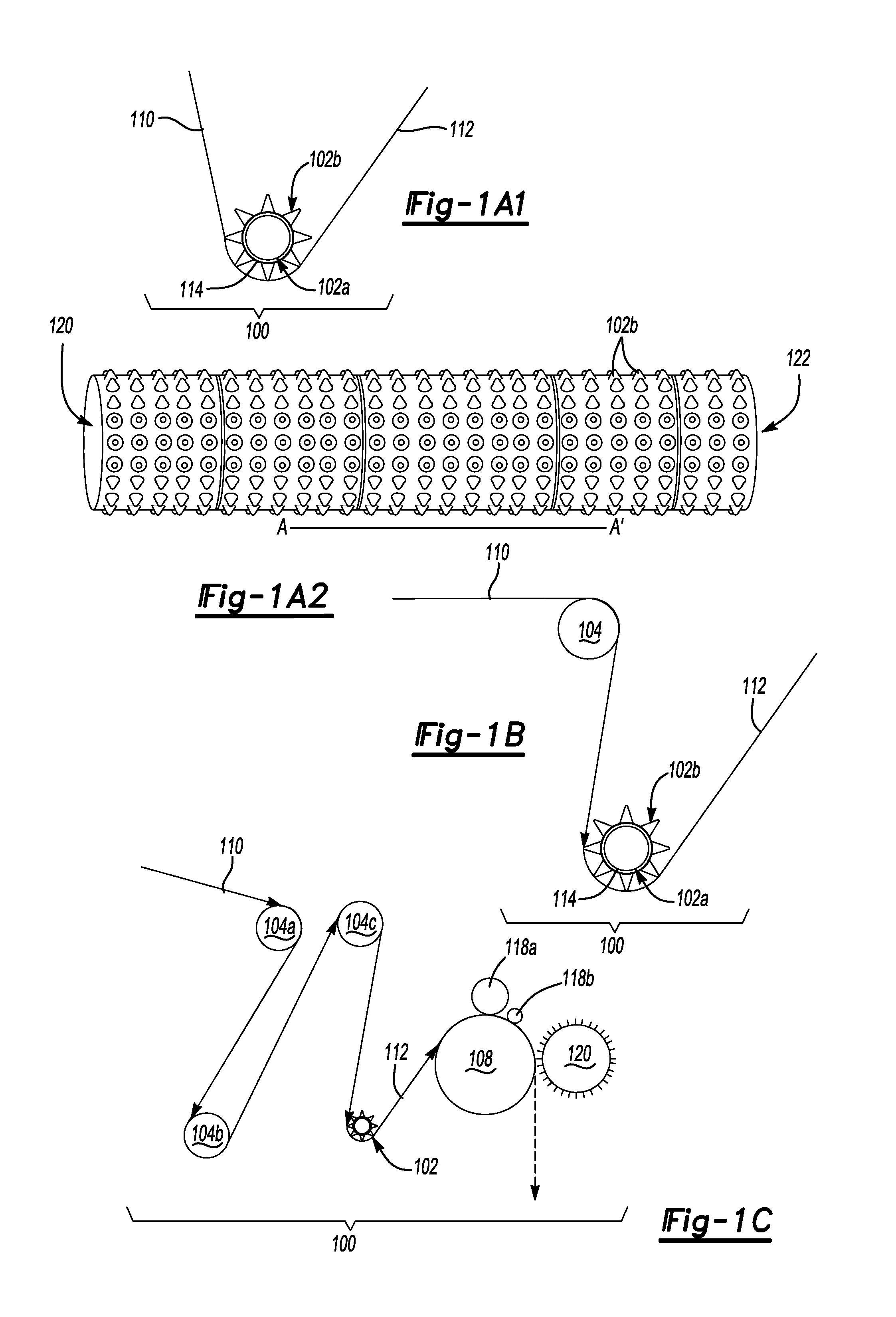

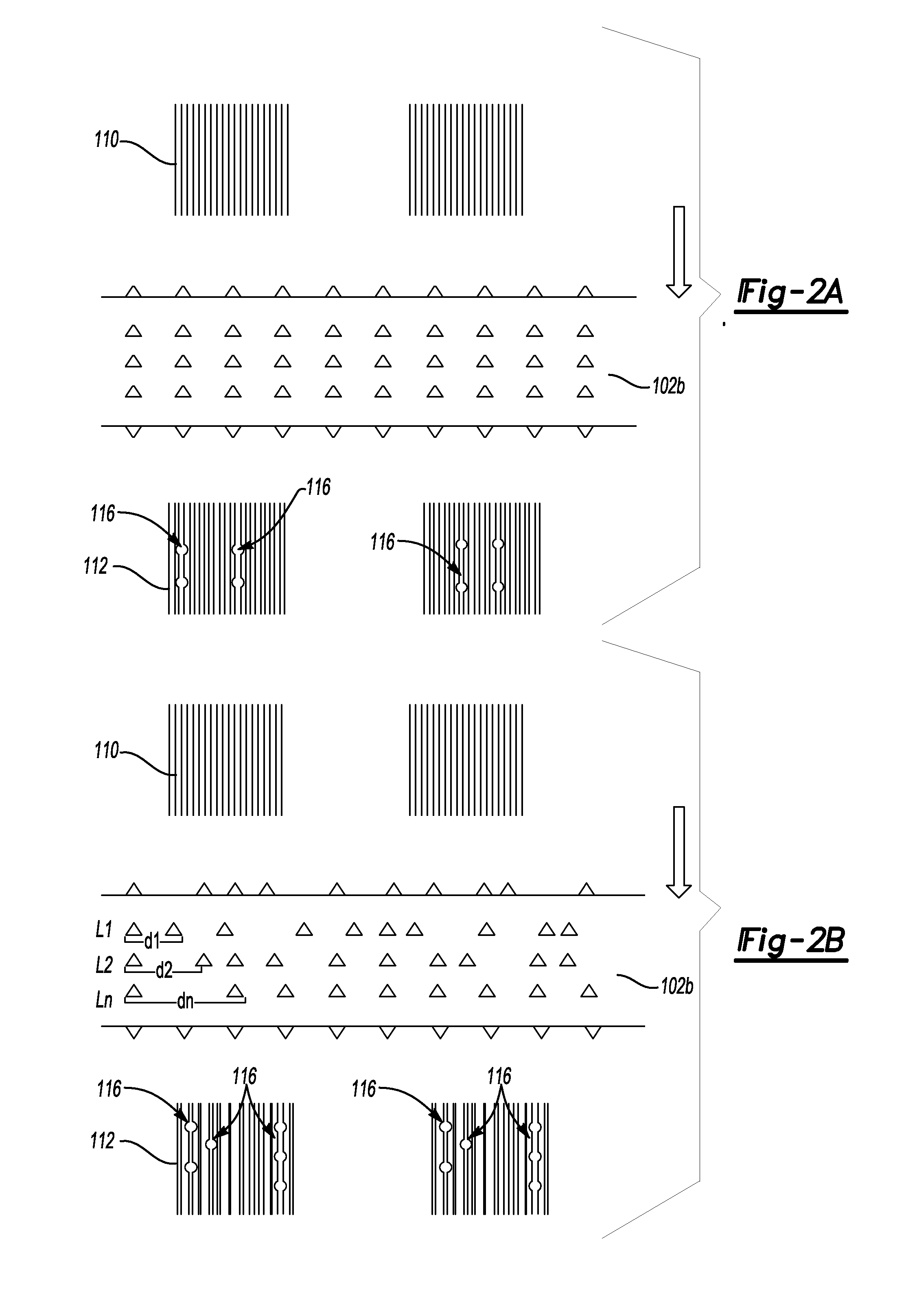

In one embodiment, a fiber treatment system includes a rotatable nubbed roller including an axis of rotation, a surface, and a number of spaced apart nubs projecting away from the surface, the number of spaced apart nubs imparting a number of spaced apart openings in a fiber tow. In another embodiment, the fiber treatment system further includes an optionally rotatable spreader roller for flattening the fiber tow. In yet another embodiment, the loosened, but still continuous fiber tow is chopped by a downstream chopper to form short fibers with reduced tow sizes.

Owner:US COUNCIL FOR AUTOMOTIVE RES

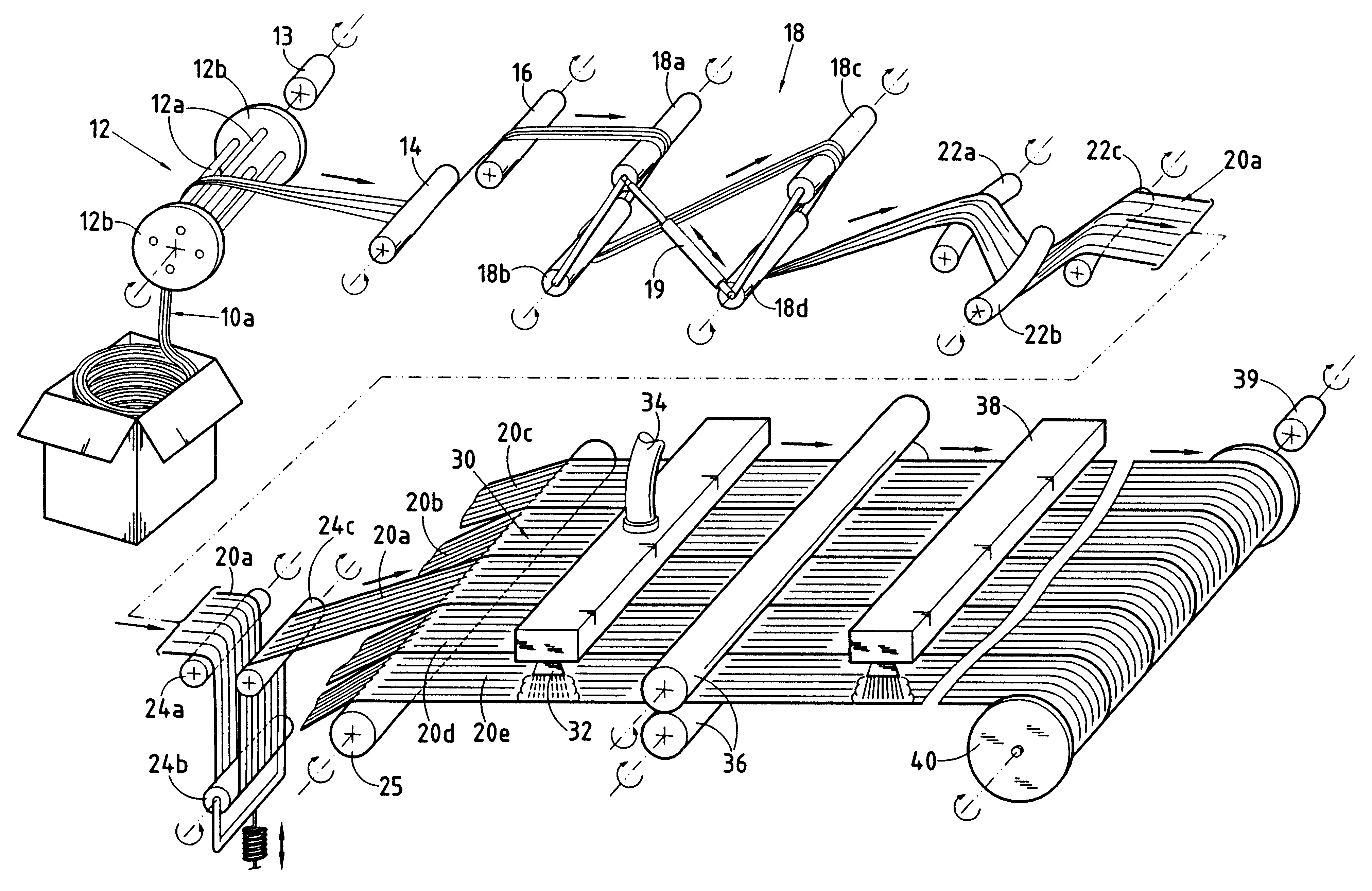

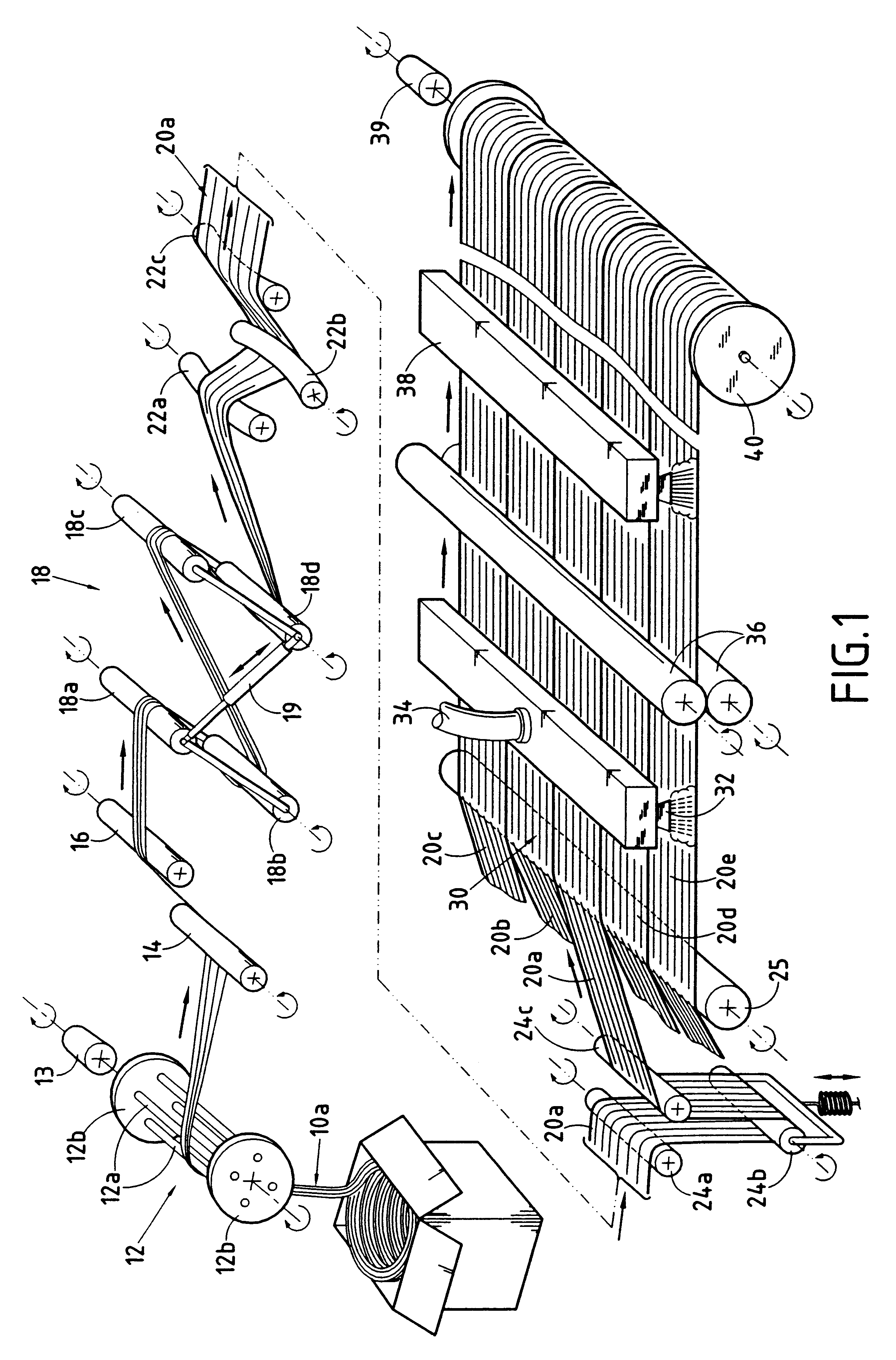

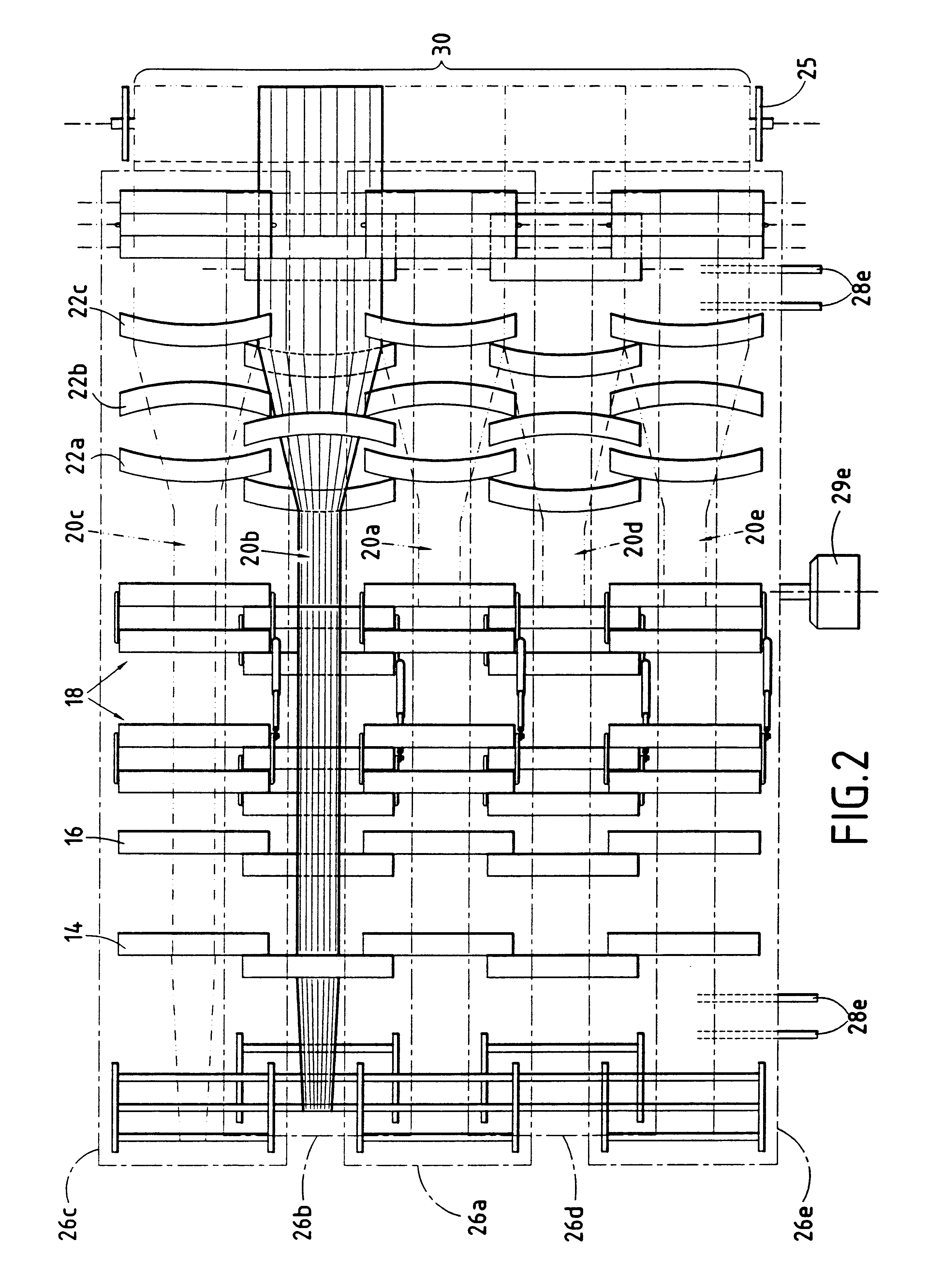

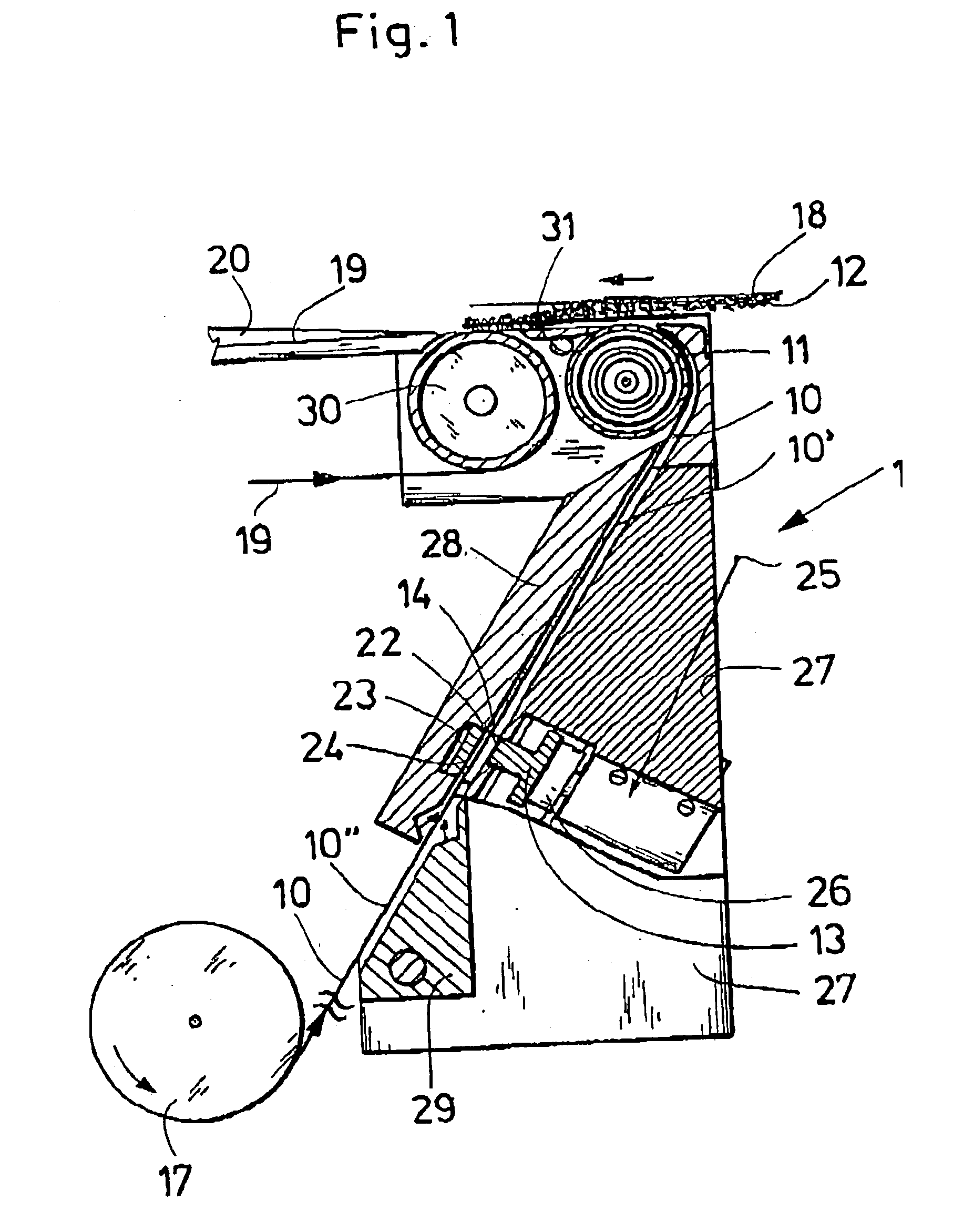

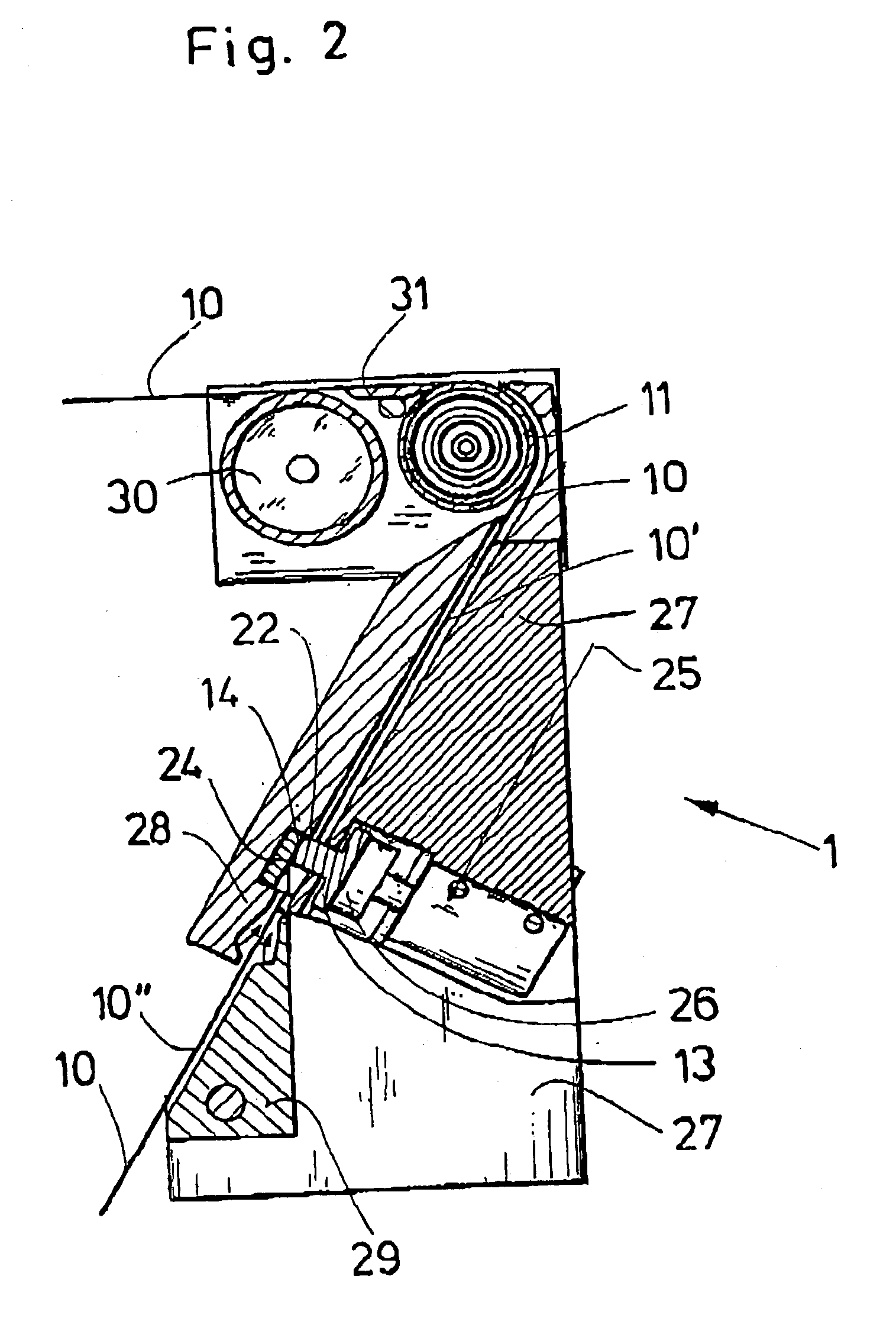

Method and machine for producing multiaxial fibrous webs

InactiveUS6585842B1Reduce manufacturing costLow costLamination ancillary operationsOrnamental textile articlesFiberCarbon fibers

A plurality of unidirectional sheets (30a, 30b, 30c) are superposed in different directions and they are bonded together. At least one of the unidirectional sheets is made by spreading a tow so as to obtain uniform thickness, width not less than 5 cm, and a weight of no more than 300 g / m2, cohesion being imparted to the sheet so as to enable it to be handled prior to being superposed with other sheets. Advantageously, the unidirectional sheets are made of carbon fibers and are obtained by spreading out large tows.

Owner:HEXCEL FABRICS +1

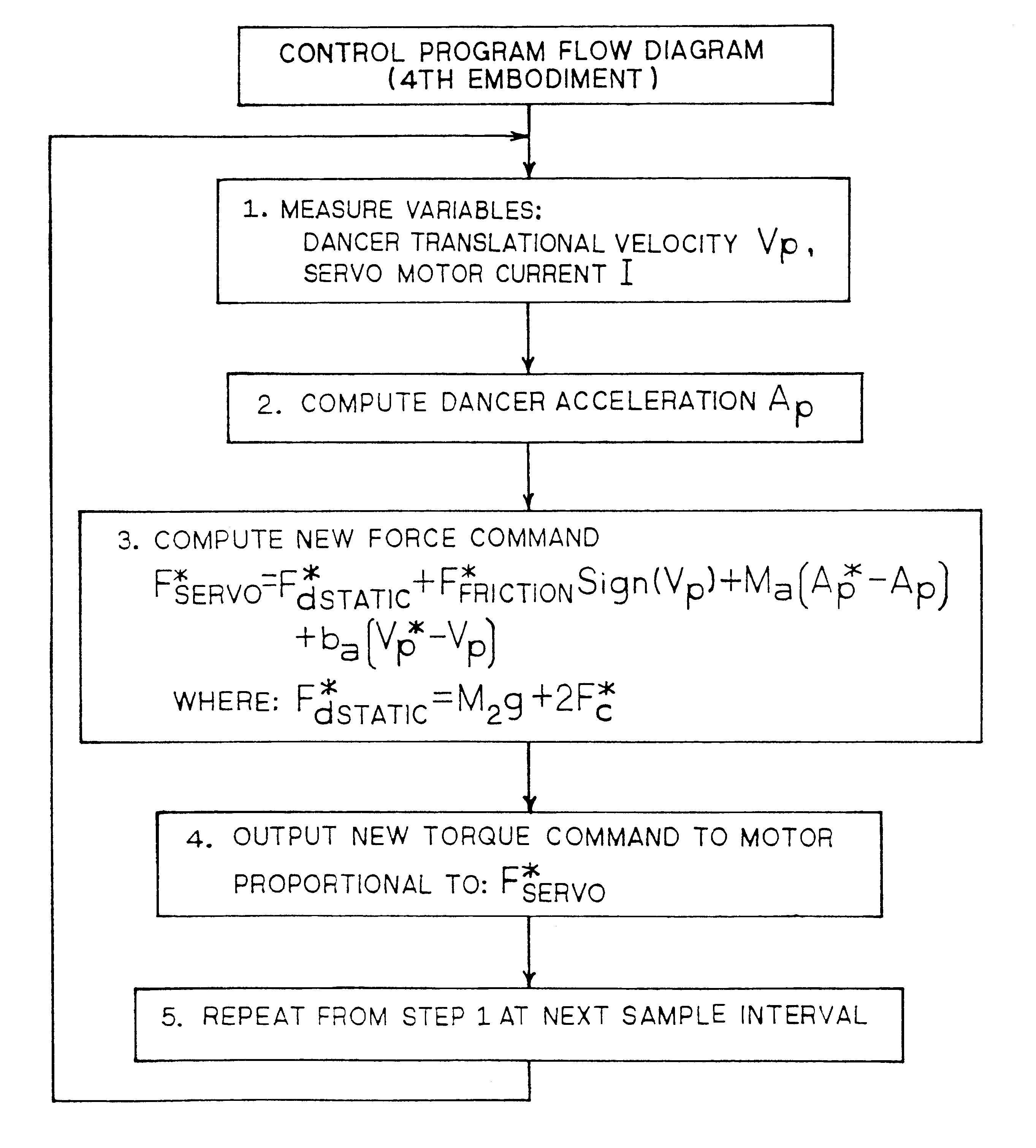

Method and apparatus for controlling web tension by actively controlling velocity and acceleration of a dancer roll

InactiveUS6314333B1The result is accurateAutomatic control devicesPrecision positioning equipmentControl systemEngineering

This invention pertains to processing continuous webs such as paper, film, composites, and the like, in dynamic continuous processing operations. More particularly, it relates to controlling tension in such continuous webs during the processing operation. Tension is controlled in a dancer control system by connecting a corresponding dancer roll to an actuator apparatus or the like, sensing variables such as position, tension, velocity, and acceleration parameters related to the web and the dancer roll, and providing active force commands, in response to the sensed variables, to cause translational movement, generally including a target acceleration, in the dancer roll to control tension disturbances in the web. In some applications of the invention, the dancer control system is used to attenuate tension disturbances. In other applications of the invention, the dancer control system is used to create tension disturbances.

Owner:KIMBERLY-CLARK WORLDWIDE INC

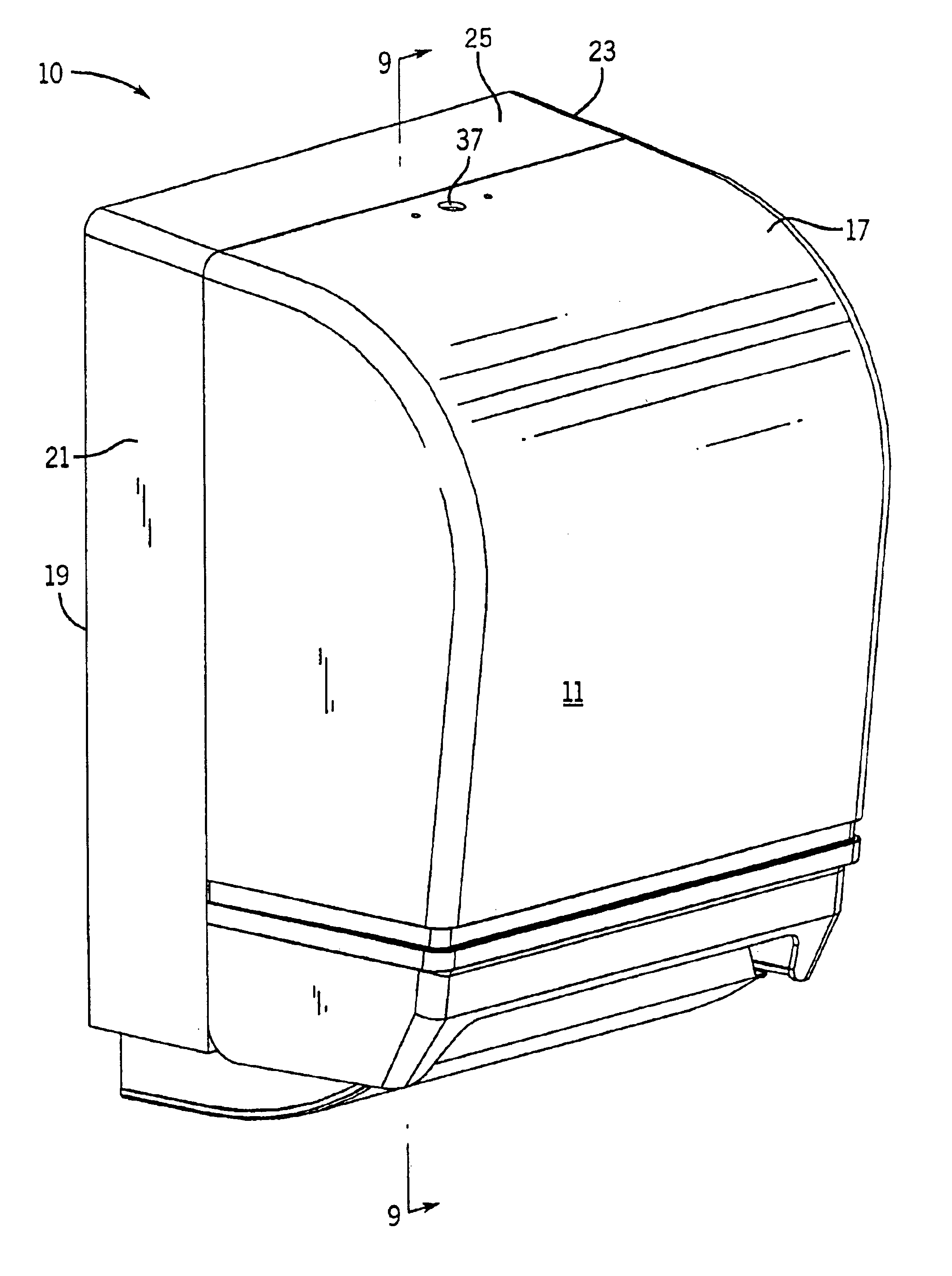

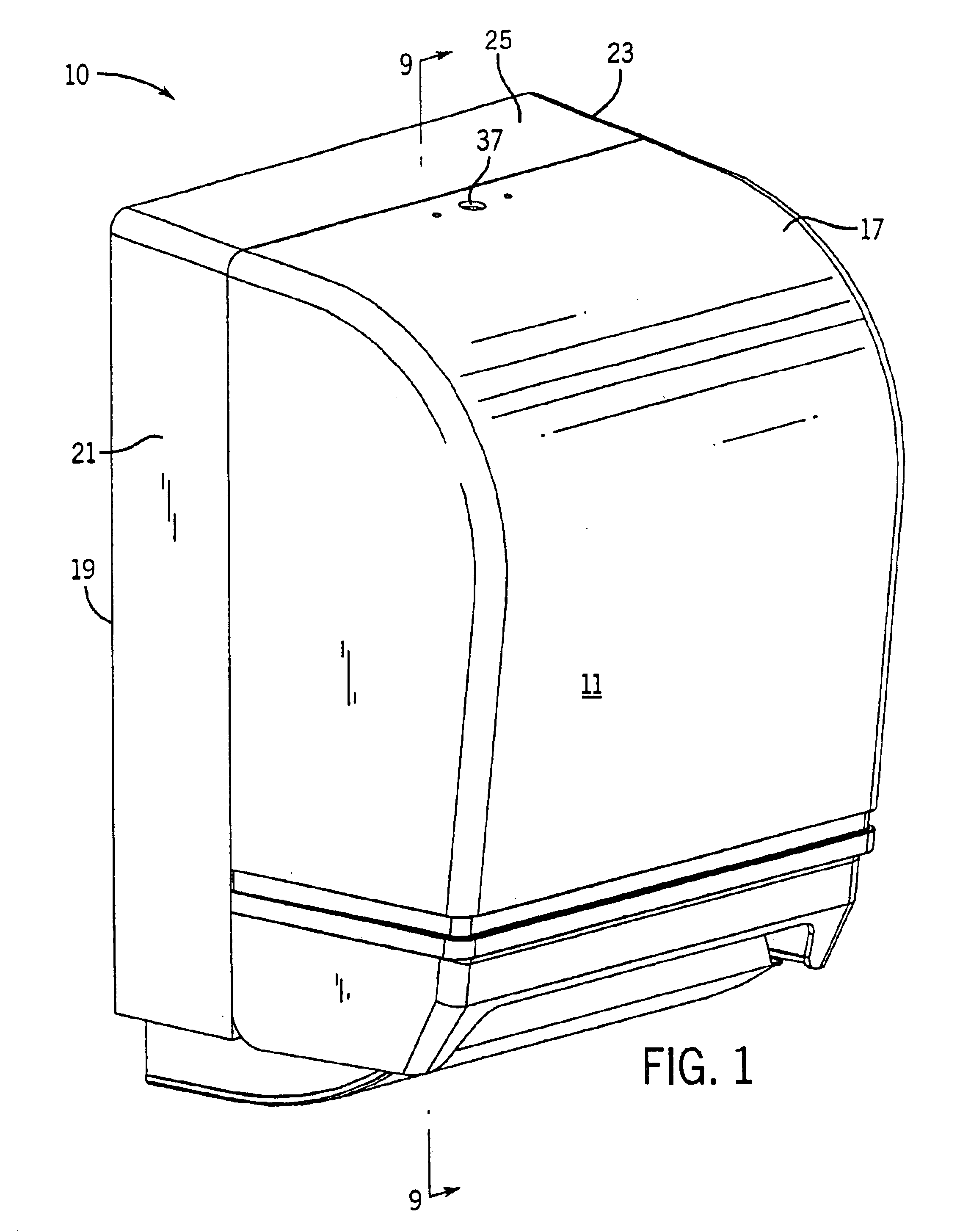

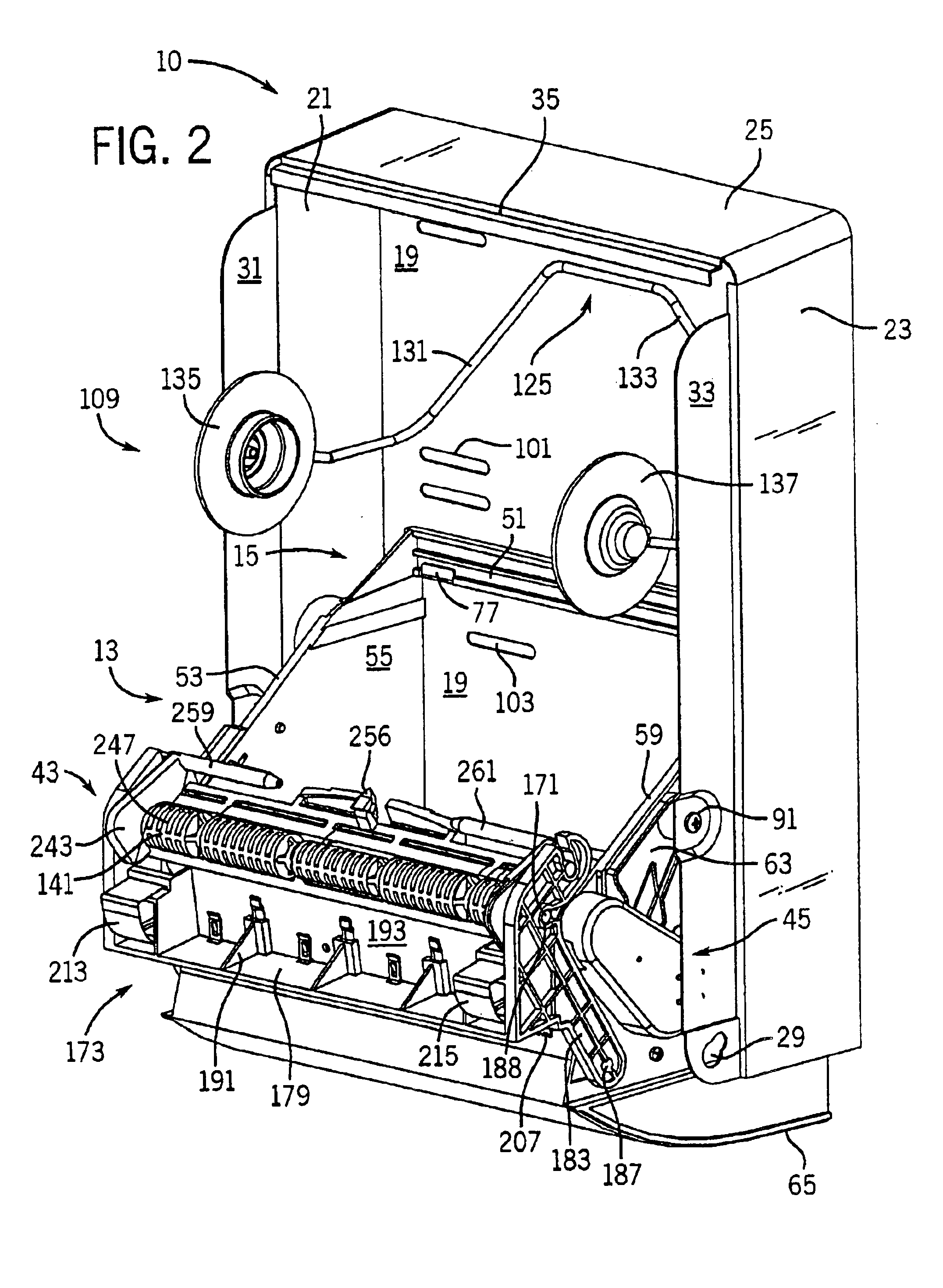

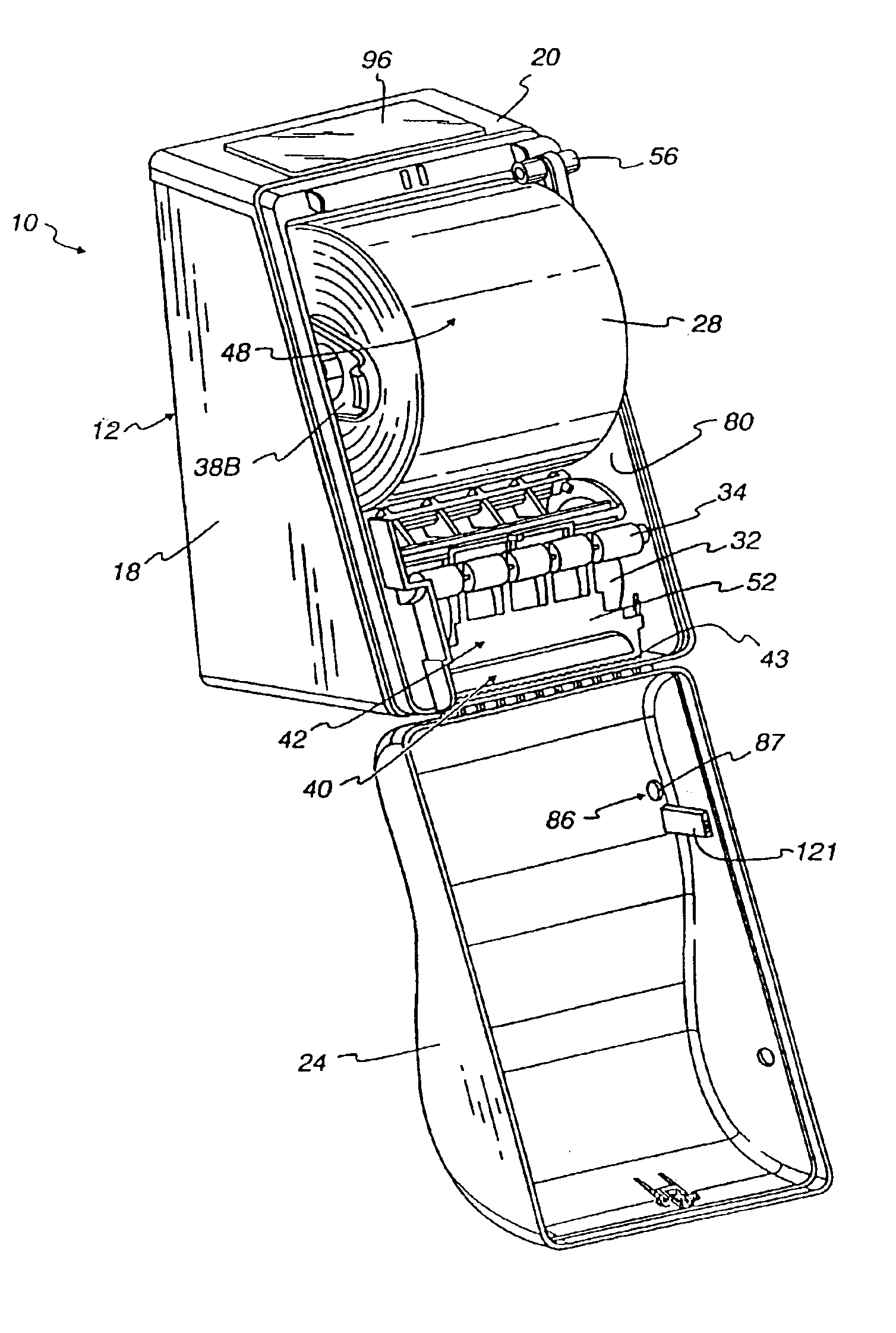

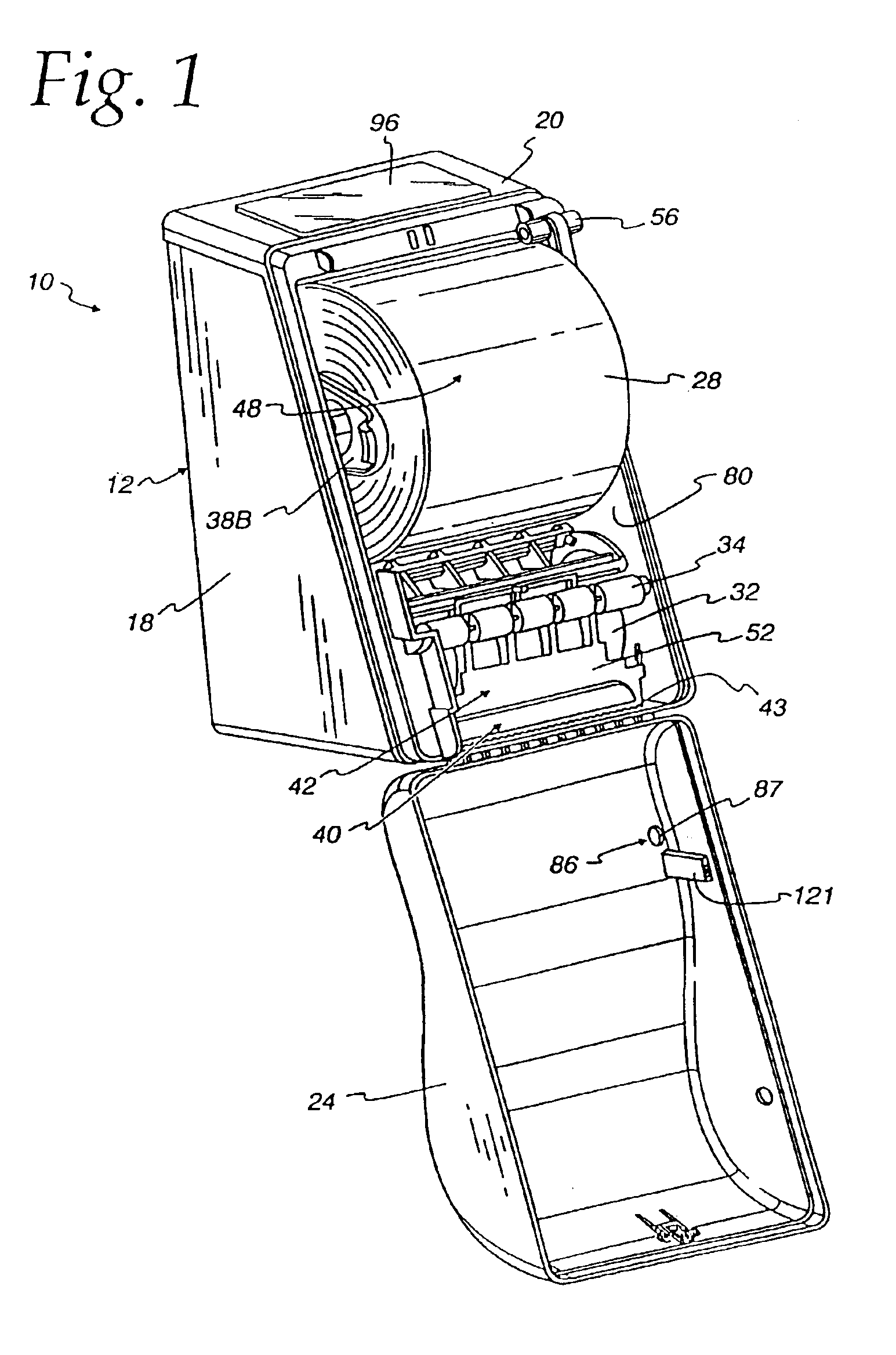

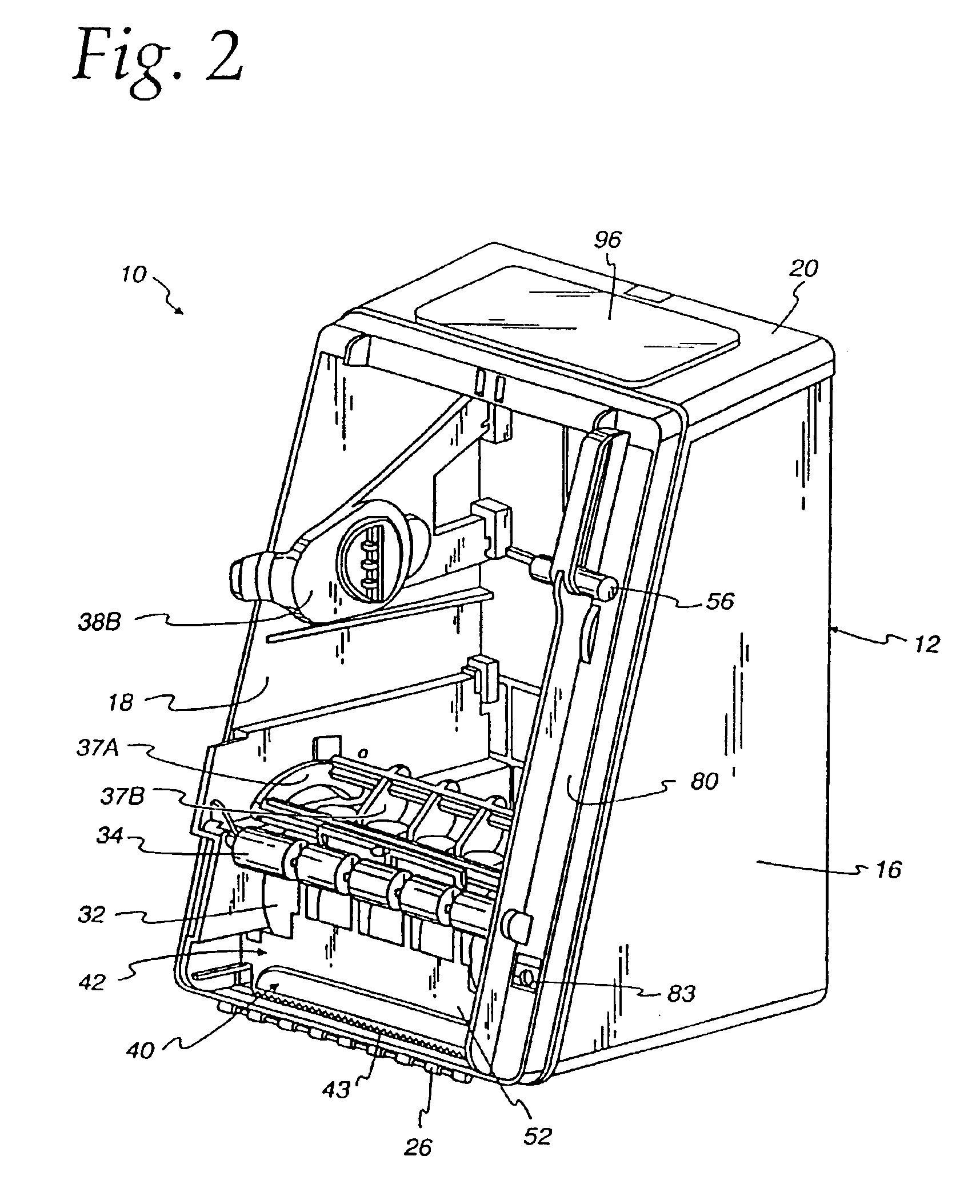

Static build up control in electronic dispensing systems

Apparatus for dispensing paper from rolls which feeds continuously, roll to roll, and does not require extra procedure to bring stub roll into position. The apparatus has device for holding and positioning at least first and second rolls of paper with respect to each other; device for dispensing paper from the first roll; device for dispensing paper from the first and second rolls simultaneously when the first roll reduces to a predetermined diameter of paper, device for positioning the depleted first roll for replacement without the necessity of removing the second roll; and device for dispensing from the second and replacement rolls simultaneously when the second roll reduces to a predetermined diameter of paper. The apparatus also has a proximity sensor, which senses when a hand is placed near the dispenser, and thereupon dispenses a set amount of towel. The dispenser incorporates device for dissipating static charges to a local ground.

Owner:GPCP IP HLDG LLC

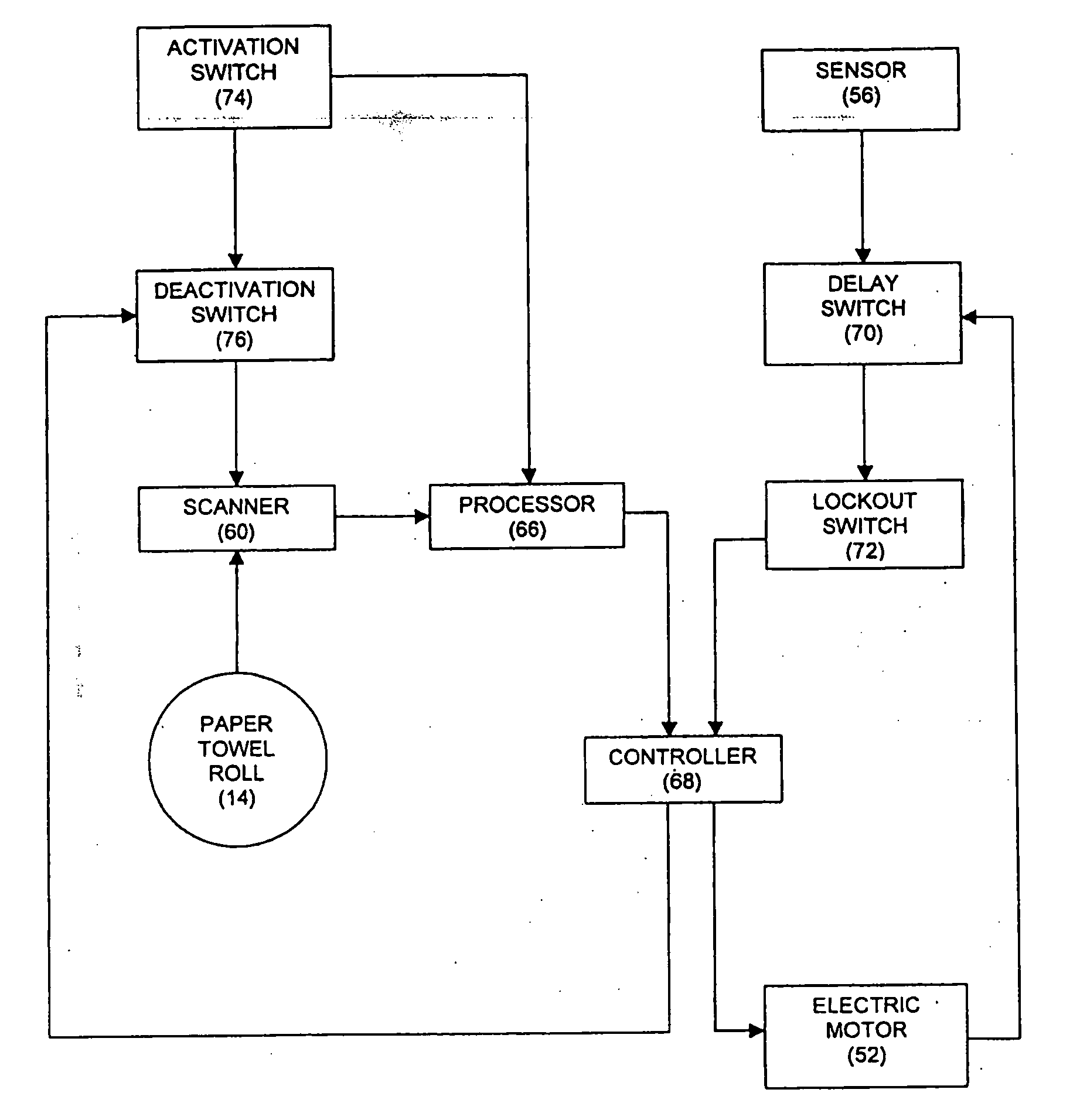

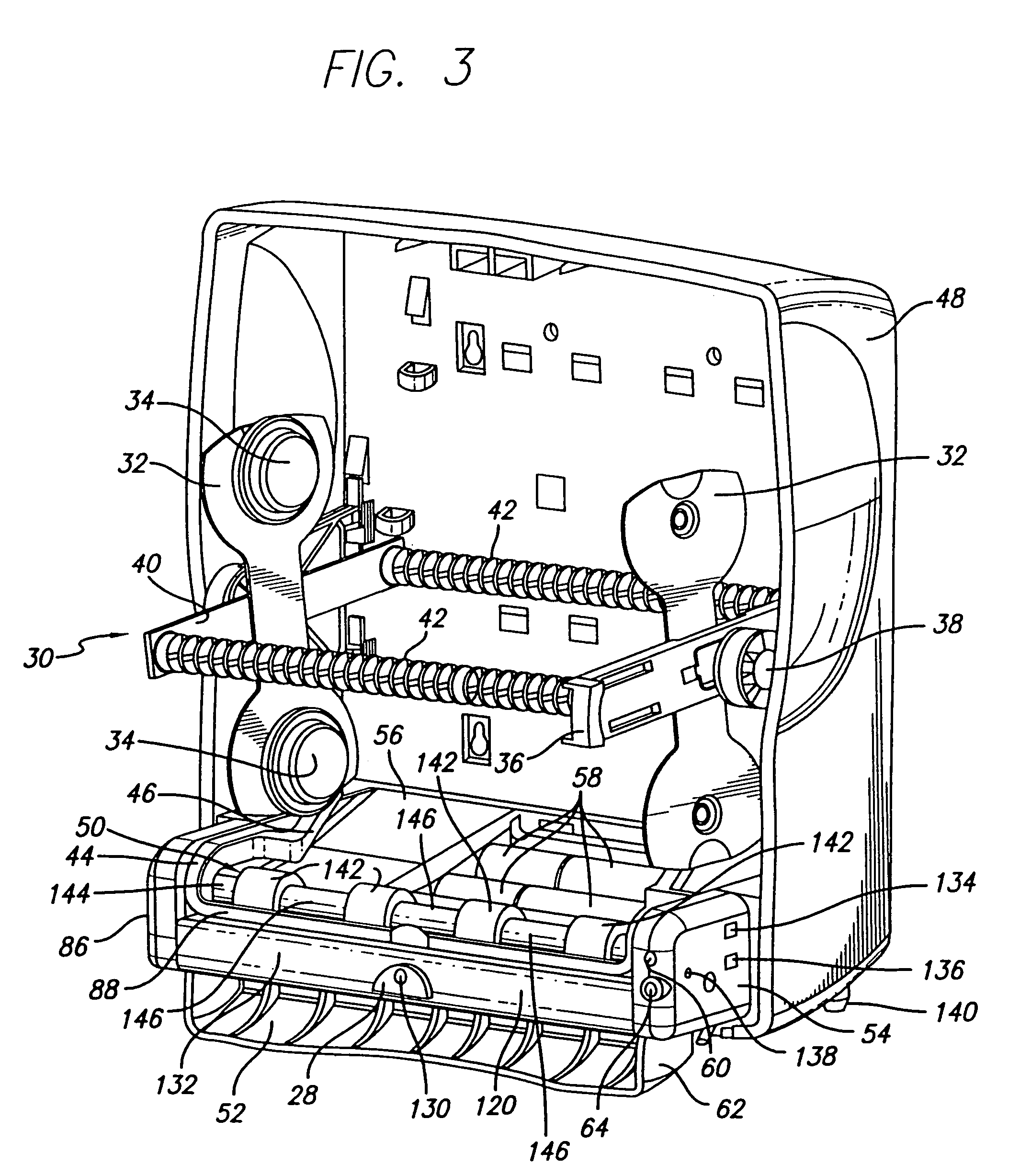

Dispenser with material-recognition apparatus and material-recognition method

InactiveUS7040566B1Risk minimizationEasy to operateFilament handlingDomestic applicationsMechanical componentsEngineering

Dispenser apparatus for dispensing flexible sheet material including material-recognition apparatus permitting the dispenser to recognize sheet material from an authorized source and to be enabled for operation with such material. The dispenser preferably includes standard mechanical components for dispensing sheet material from the dispenser including a housing, structure for supporting a roll of sheet material, drive and tension rollers forming a nip through which the sheet material is displaced as the drive roller rotates and drive apparatus in power-transmission relationship with the drive roller. The material-recognition apparatus includes a sensor mounted in the dispenser housing and in position to scan a code, preferably located on the core on which the sheet material is wound. The sensor generates a code signal corresponding to the code. A control circuit operatively connected to the sensor is adapted to receive the code signal and compare the code represented by said code signal to at least one code in a code database. The dispenser is placed in a dispenser-enabled state capable of dispensing sheet material corresponding to agreement between the codes and a dispenser-disabled state in which the dispenser is disabled when no such code agreement exists.

Owner:ALWIN MFG

Body fluid testing device

ActiveUS20050232815A1Easy to testAdvanced conceptContainers for annular articlesFilament handlingMagnetic tapeEngineering

Body fluid testing device for analyzing a body fluid comprises a test media tape adapted to collect the body fluid. The test media tape comprises a tape and test media portions. A free tape portion without test medium is located between successive test media portions. The testing device further comprises a supply portion. The supply portion comprises a housing in which uncontaminated test media tape is contained. The housing further has an opening for withdrawing test media tape from the housing. The testing device further has a sealing means for closing the opening against the surrounding. A free tape portion of the test media tape is located between a wall of the housing and the sealing means when the sealing means closes the opening. Further aspects concern a test media cassette with sealing means and a method for providing test media while holding them sealed against humidity during onboard storage.

Owner:ROCHE DIABETES CARE INC

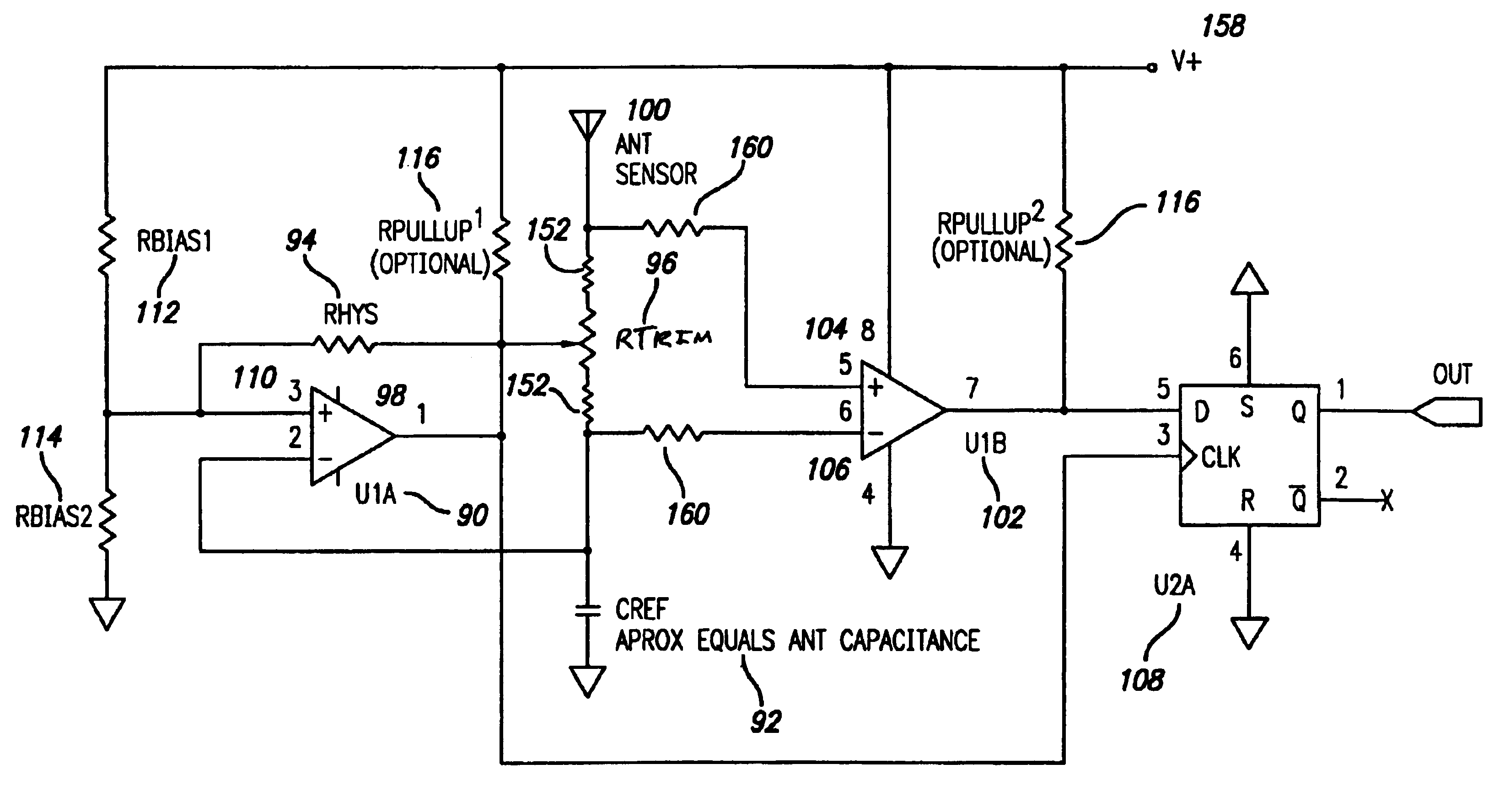

Proximity detection circuit and method of detecting small capacitance changes

InactiveUS6838887B2Guaranteed uptimeReduce wasteCurrent/voltage measurementResistance/reactance/impedenceCapacitanceProximity sensor

Apparatus for dispensing paper from rolls which feeds continuously, roll to roll, and does not require extra procedure to bring stub roll into position. The apparatus holds and positions at least first and second rolls of paper with respect to each other; dispenses paper from the first roll; dispenses paper from the first and second rolls simultaneously when the first roll reduces to a predetermined diameter of paper, positions the depleted first roll for replacement without the necessity of removing the second roll; and dispenses from the second and replacement rolls simultaneously when the second roll reduces to a predetermined diameter of paper. The apparatus also has a proximity sensor, which senses when a hand is placed near the dispenser, and thereupon dispenses a set amount of towel. The proximity sensor incorporates “static” and noise immunity circuitry.

Owner:GPCP IP HLDG LLC

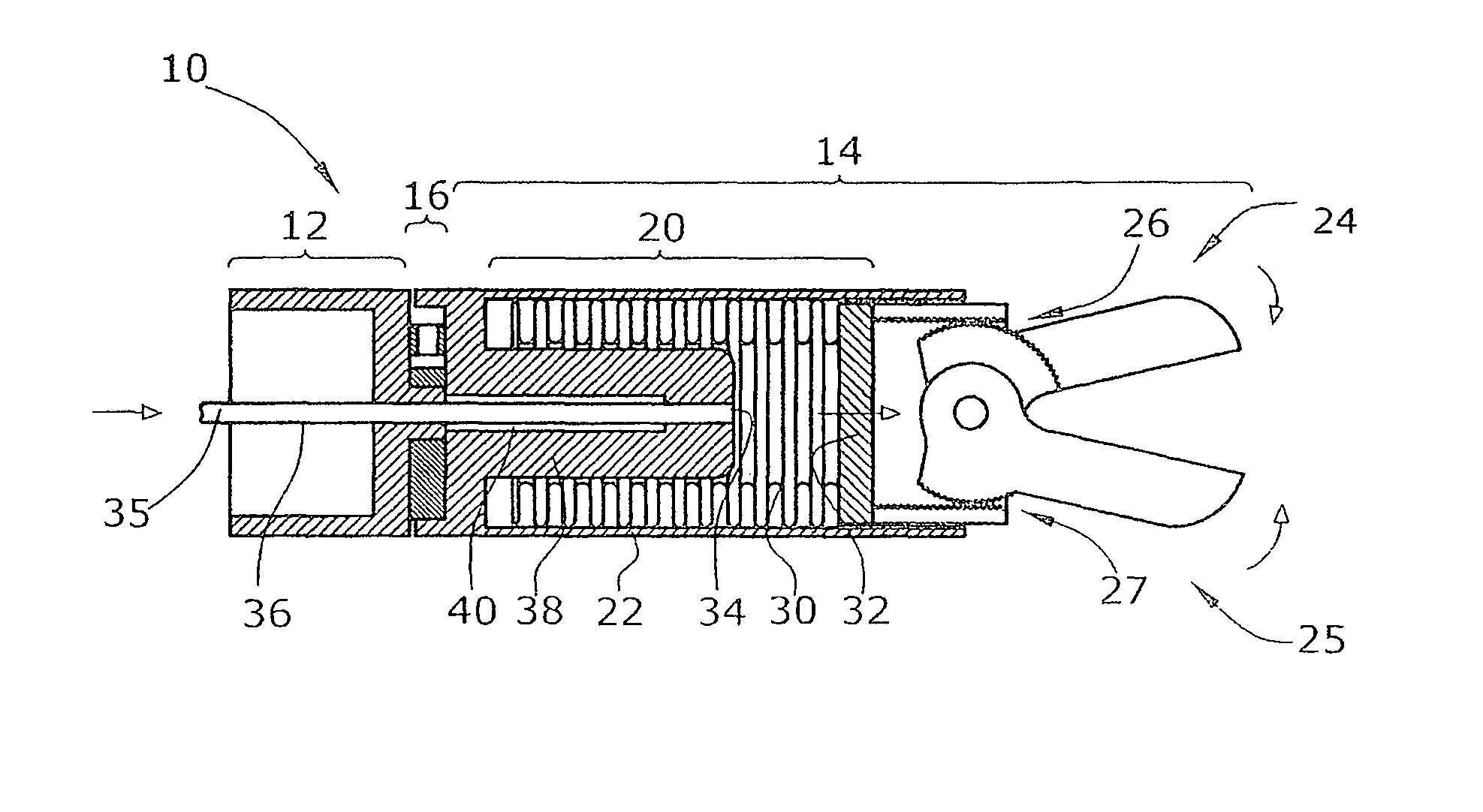

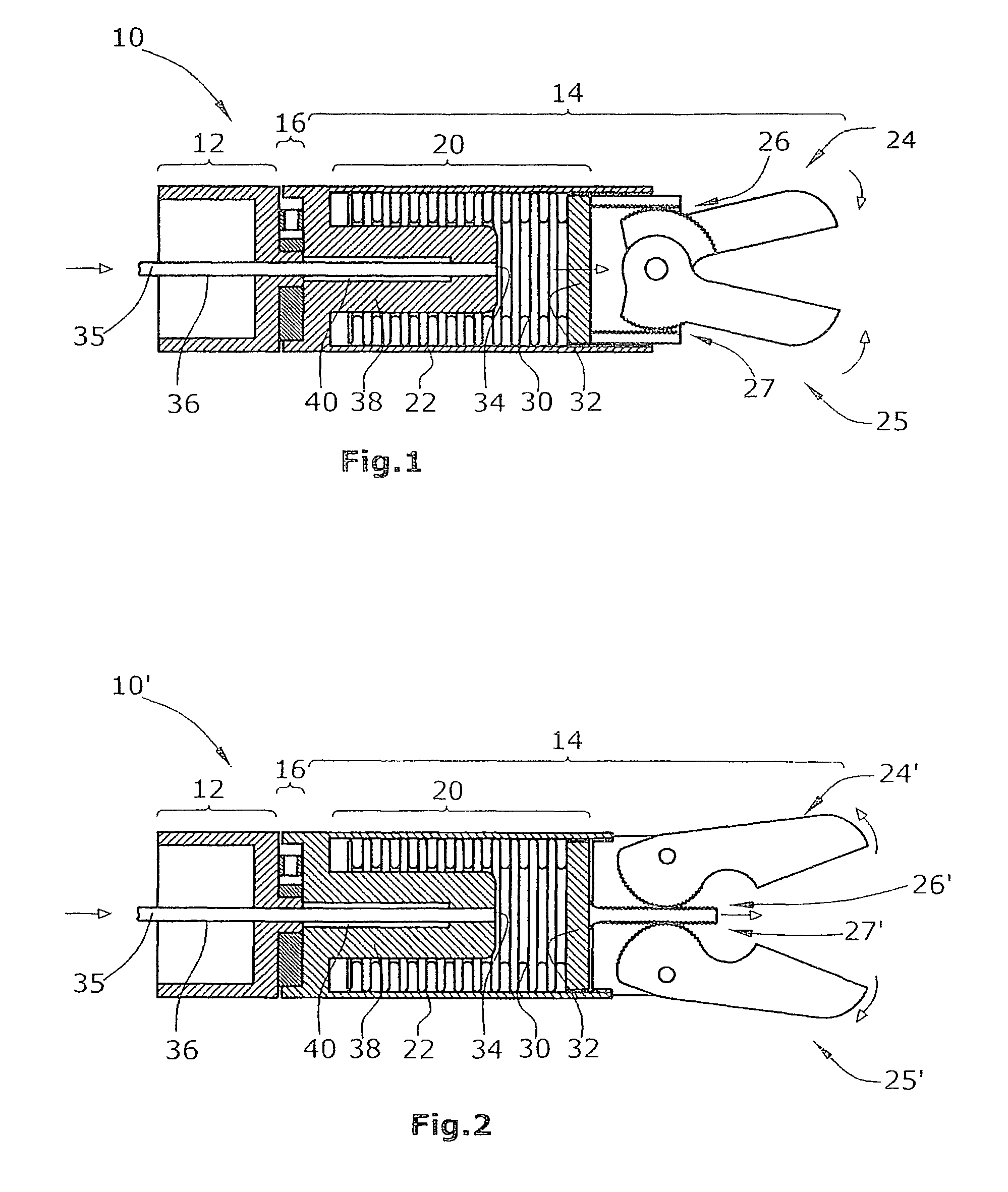

Method and apparatus for delivering high power laser energy over long distances

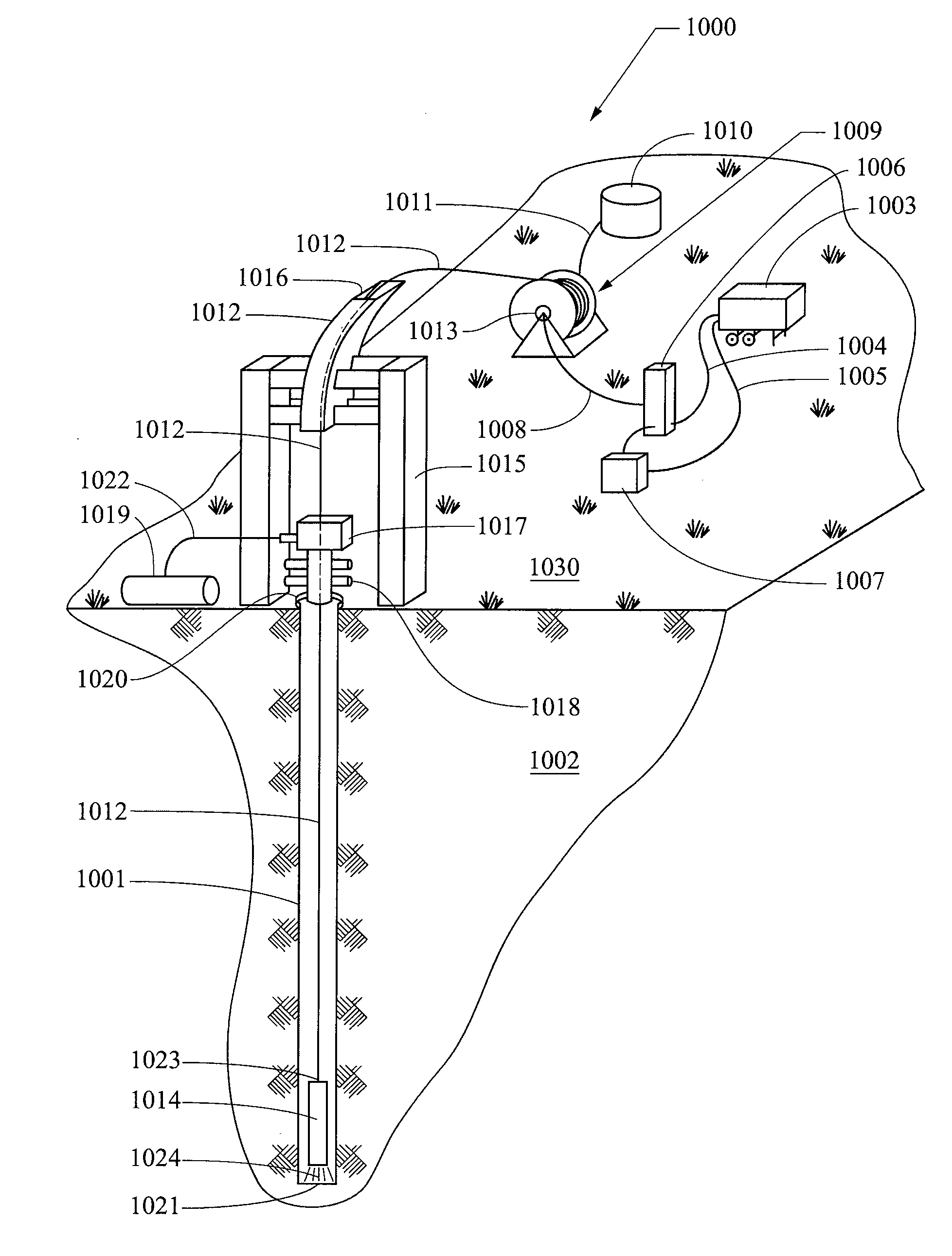

ActiveUS20100044106A1Suppressing nonlinear scattering phenomenonIncrease the lengthDrill bitsLaser using scattering effectsHigh power lasersOptoelectronics

There is provided a system, apparatus and methods for the laser drilling of a borehole in the earth. There is further provided with in the systems a means for delivering high power laser energy down a deep borehole, while maintaining the high power to advance such boreholes deep into the earth and at highly efficient advancement rates.

Owner:FORO ENERGY

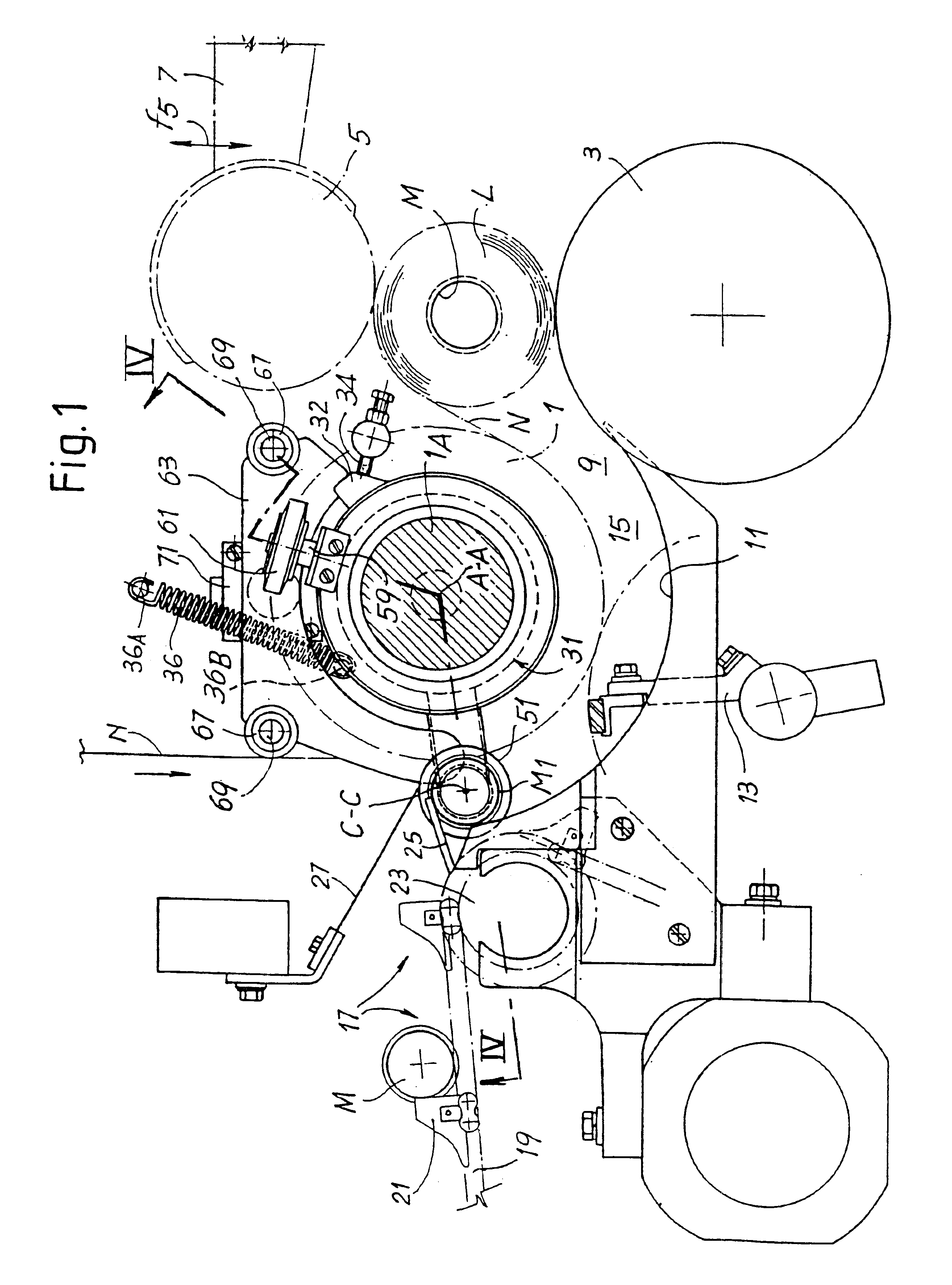

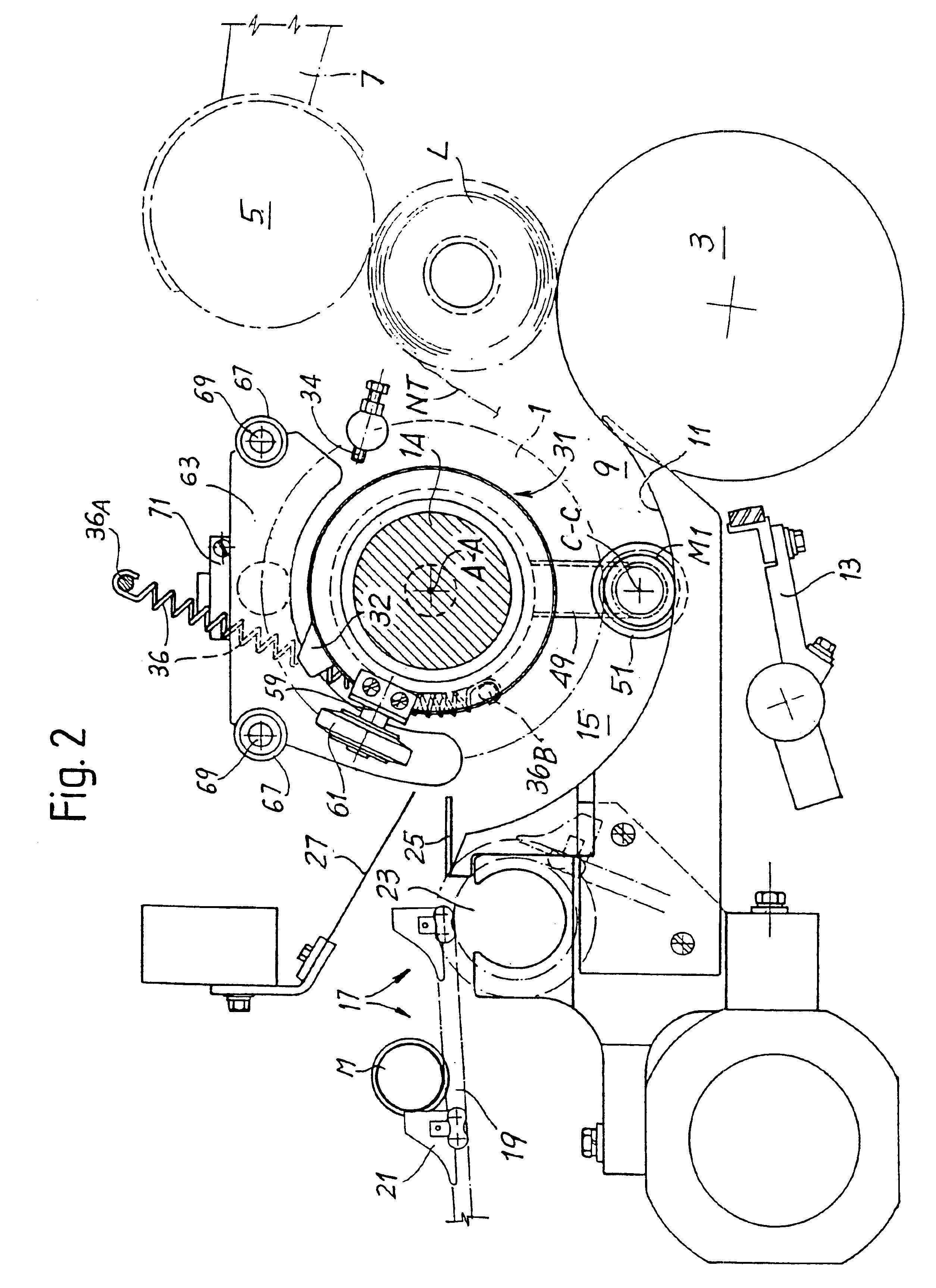

Process and device for conveying a wrapper strip in a machine of the tobacco processing industry

InactiveUS20030145866A1Little time takenGuaranteed uptimeCigar manufactureCigarette manufactureEngineeringMechanical engineering

Process and apparatus for operating a machine of the tobacco processing industry. The process includes guiding at least one wrapper strip along a conveyor path from a wrapping strip supply to a garniture device, and fixing the at least one wrapper strip in at least one preset position along the conveyor path The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:HAUNI MASCHINENBAU AG

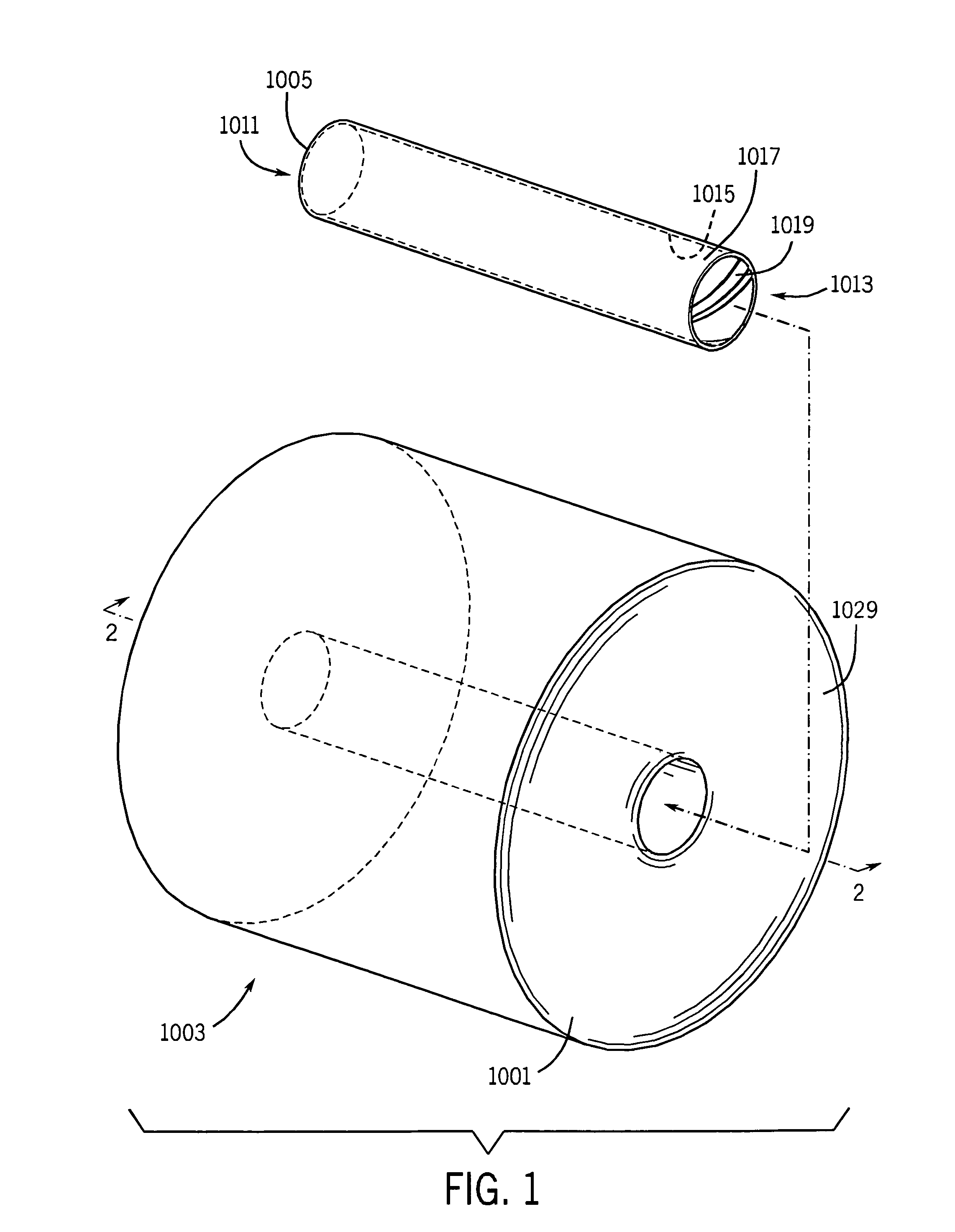

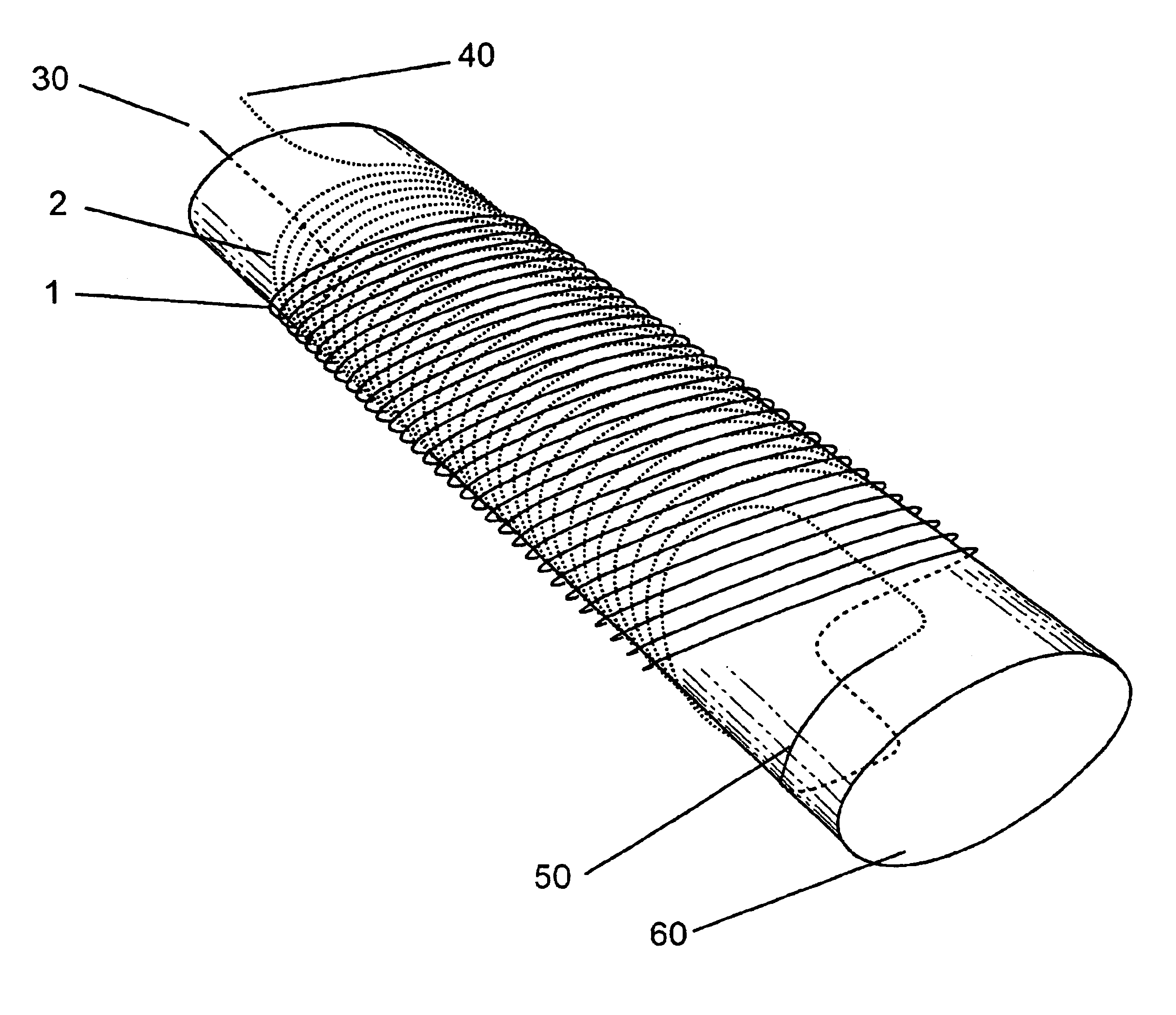

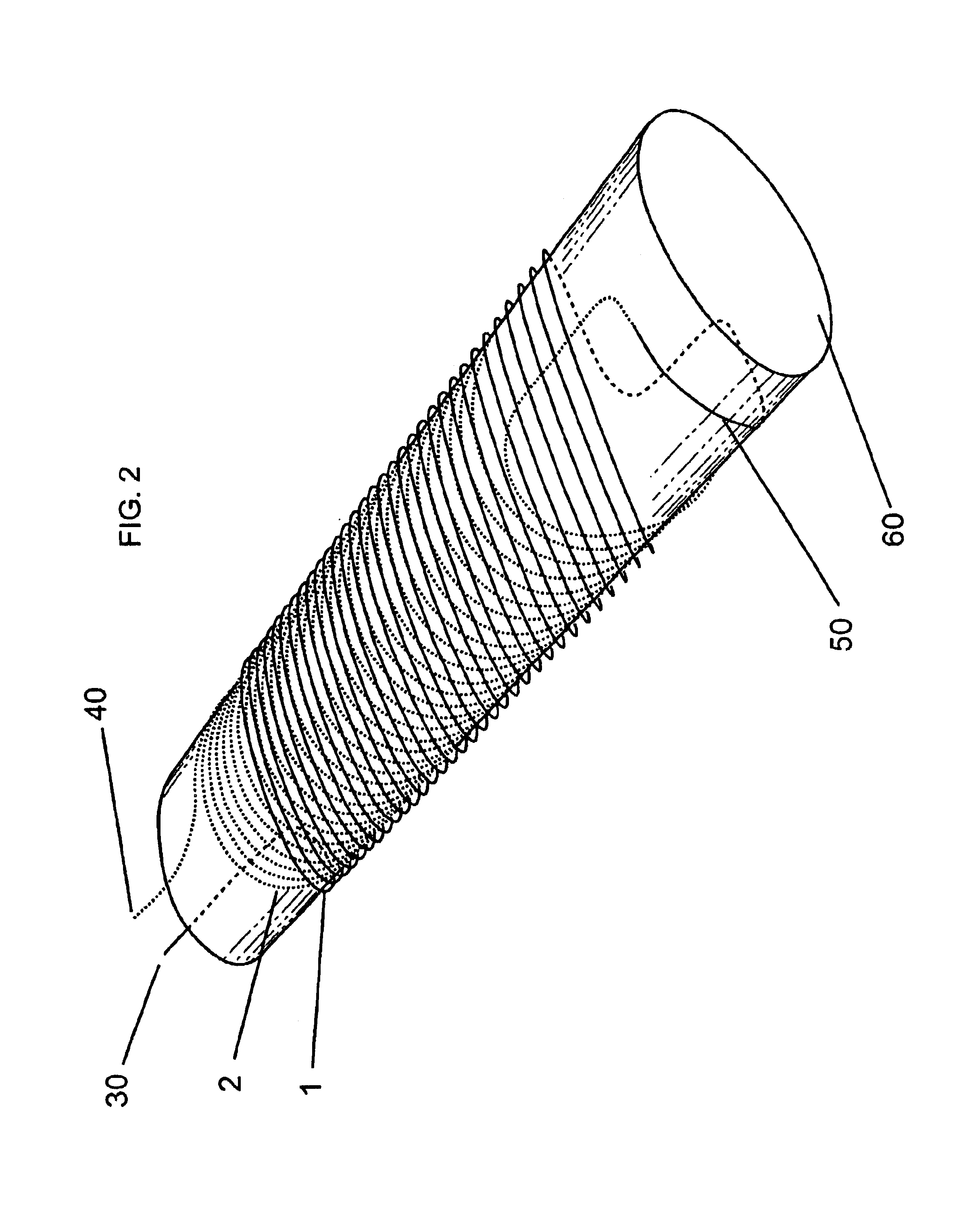

Concentric tilted double-helix dipoles and higher-order multipole magnets

InactiveUS6921042B1Simple processLess costlyElectromagnets without armaturesFilament handlingElectric machineryMagneto hydrodynamic

Concentric tilted double-helix magnets, which embody a simplified design and construction method for production of magnets with very pure field content, are disclosed. The disclosed embodiment of the concentric tilted double-helix dipole magnet has the field quality required for use in accelerator beam steering applications, i.e., higher-order multipoles are reduced to a negligibly small level. Magnets with higher multipole fields can be obtained by using a simple modification of the coil winding procedure. The double-helix coil design is well-suited for winding with superconducting cable or cable-in-conduit conductors and thus is useful for applications that require fields in excess of 2 T. The coil configuration has significant advantages over conventional racetrack coils for accelerators, electrical machinery, and magneto-hydrodynamic thrusting devices.

Owner:GOODZEIT CARL L +2

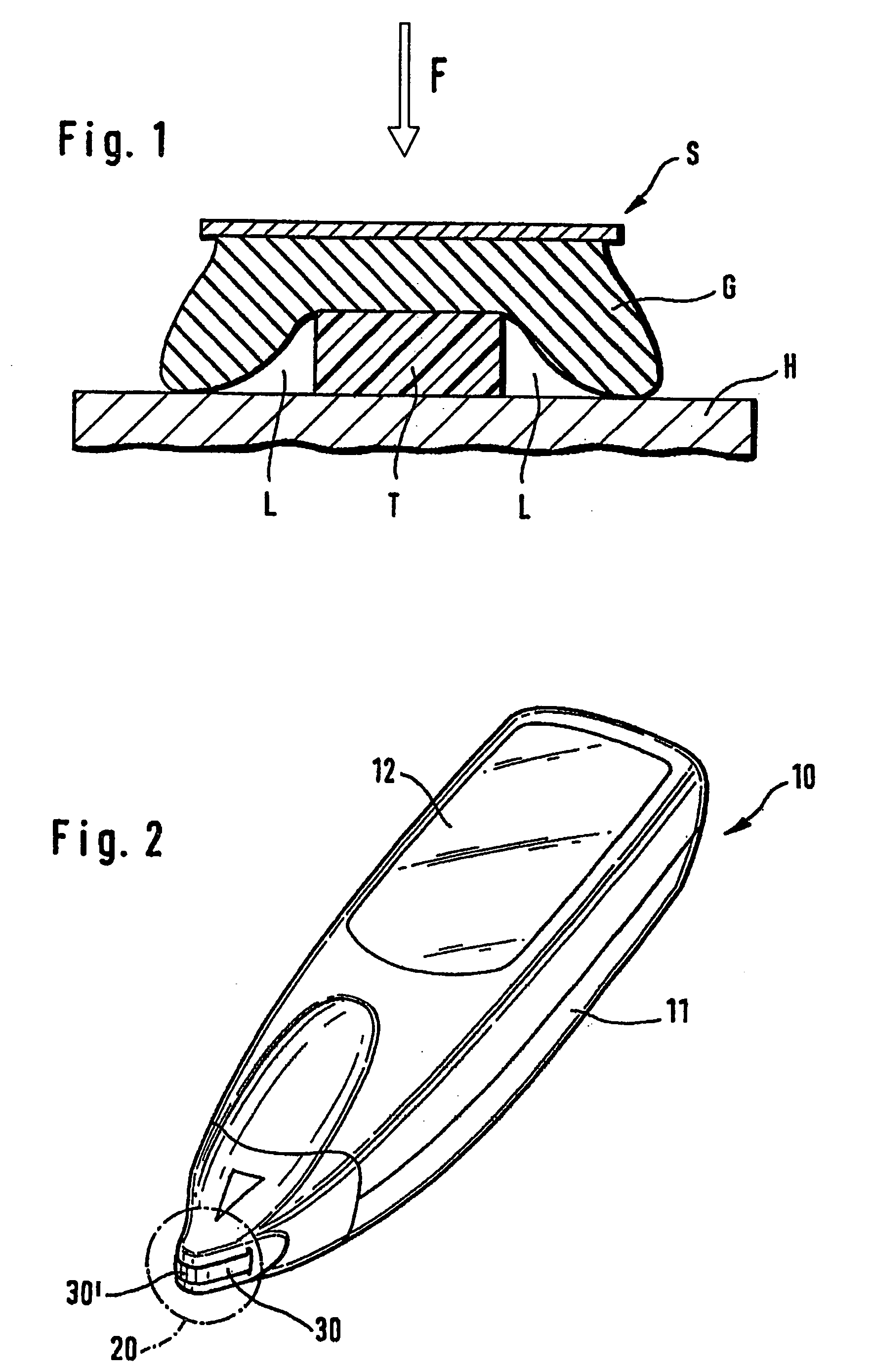

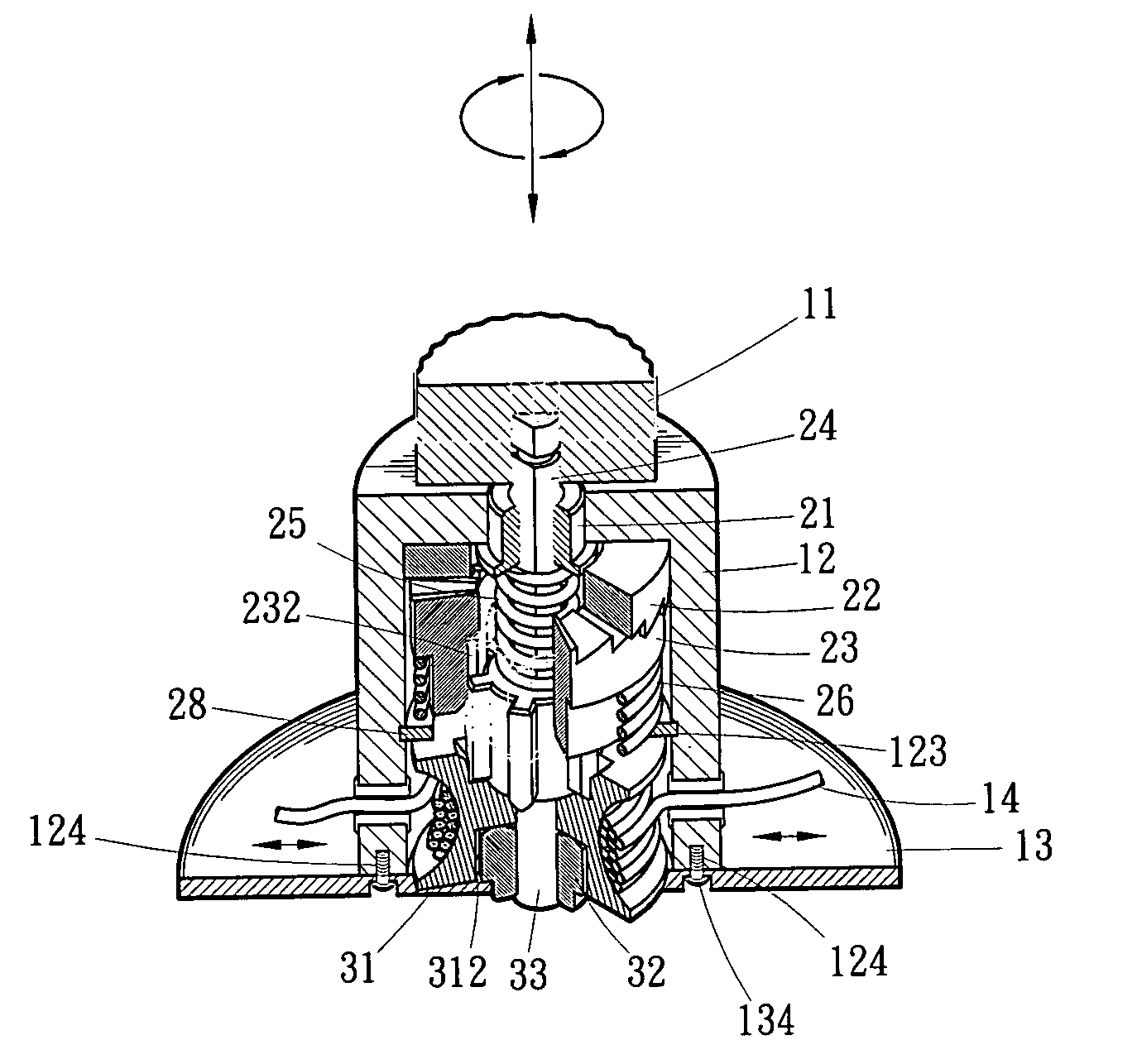

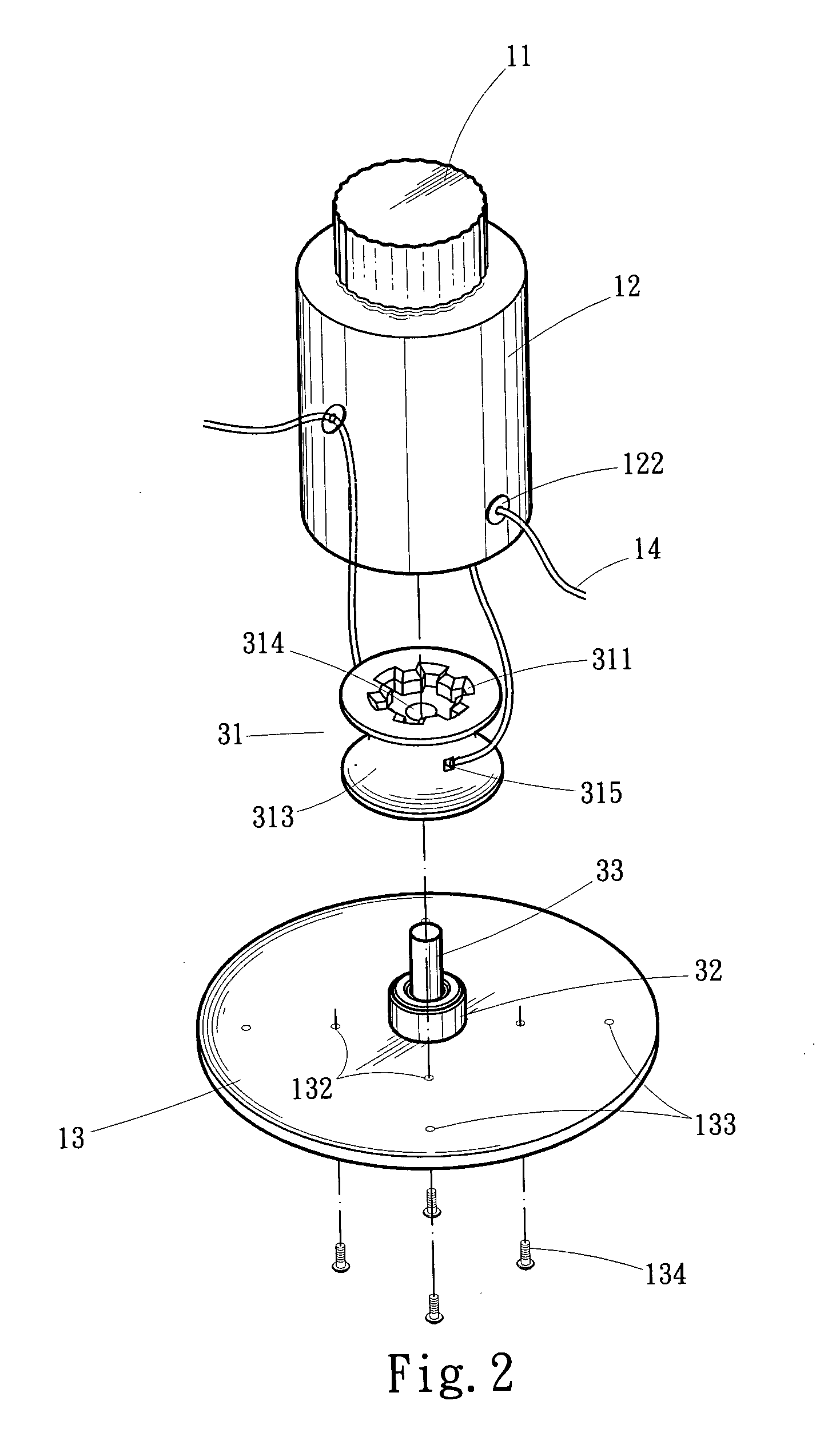

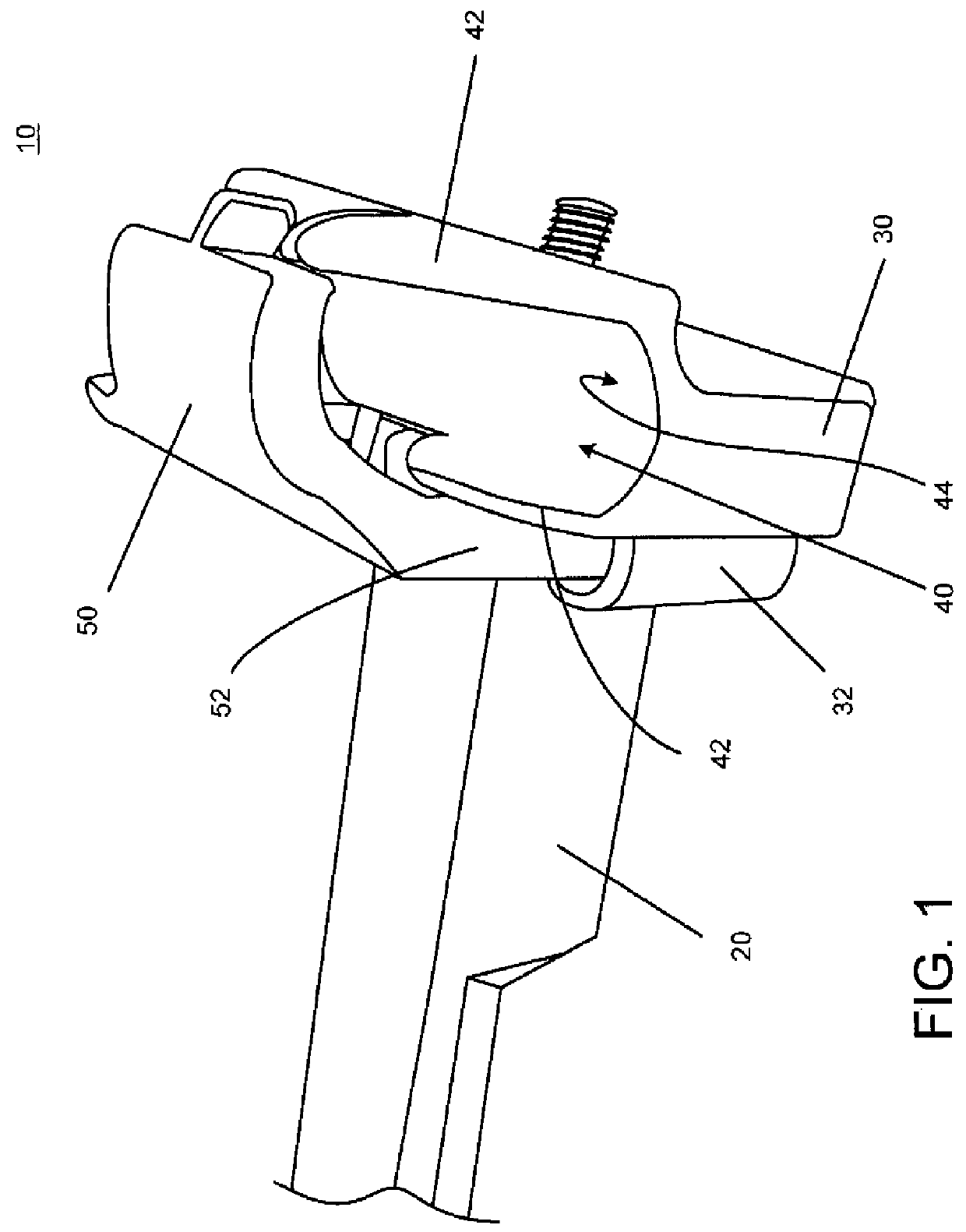

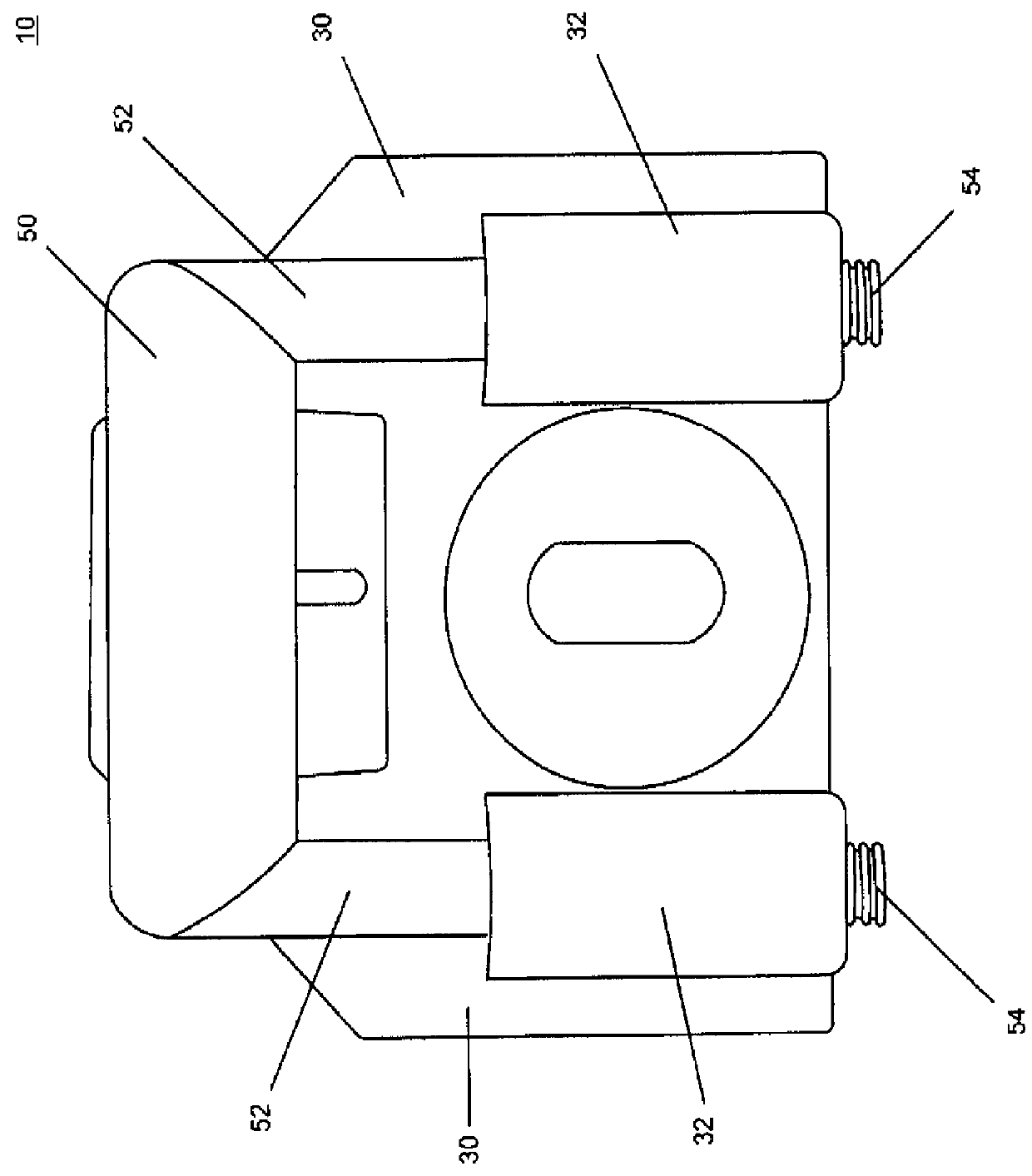

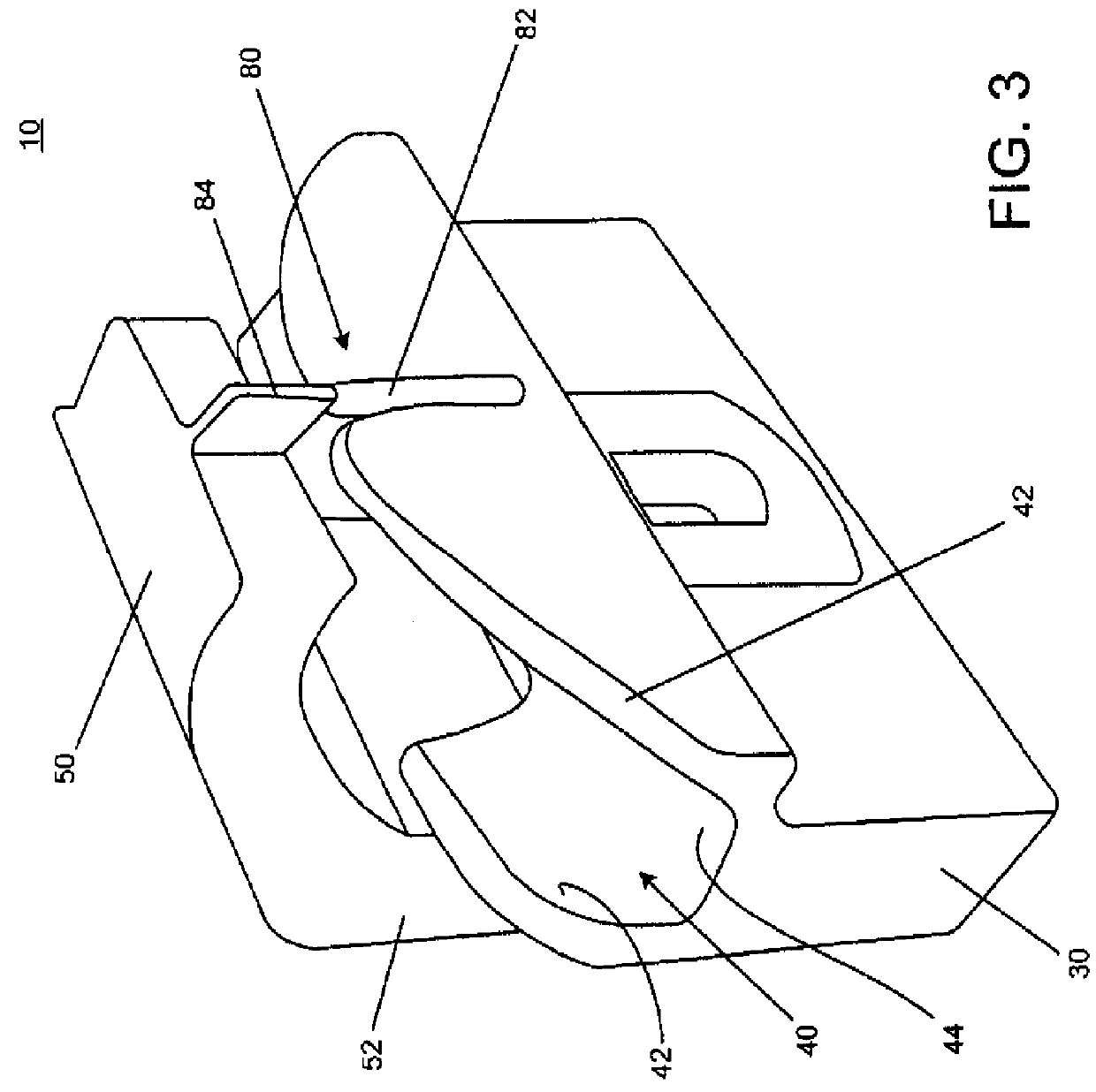

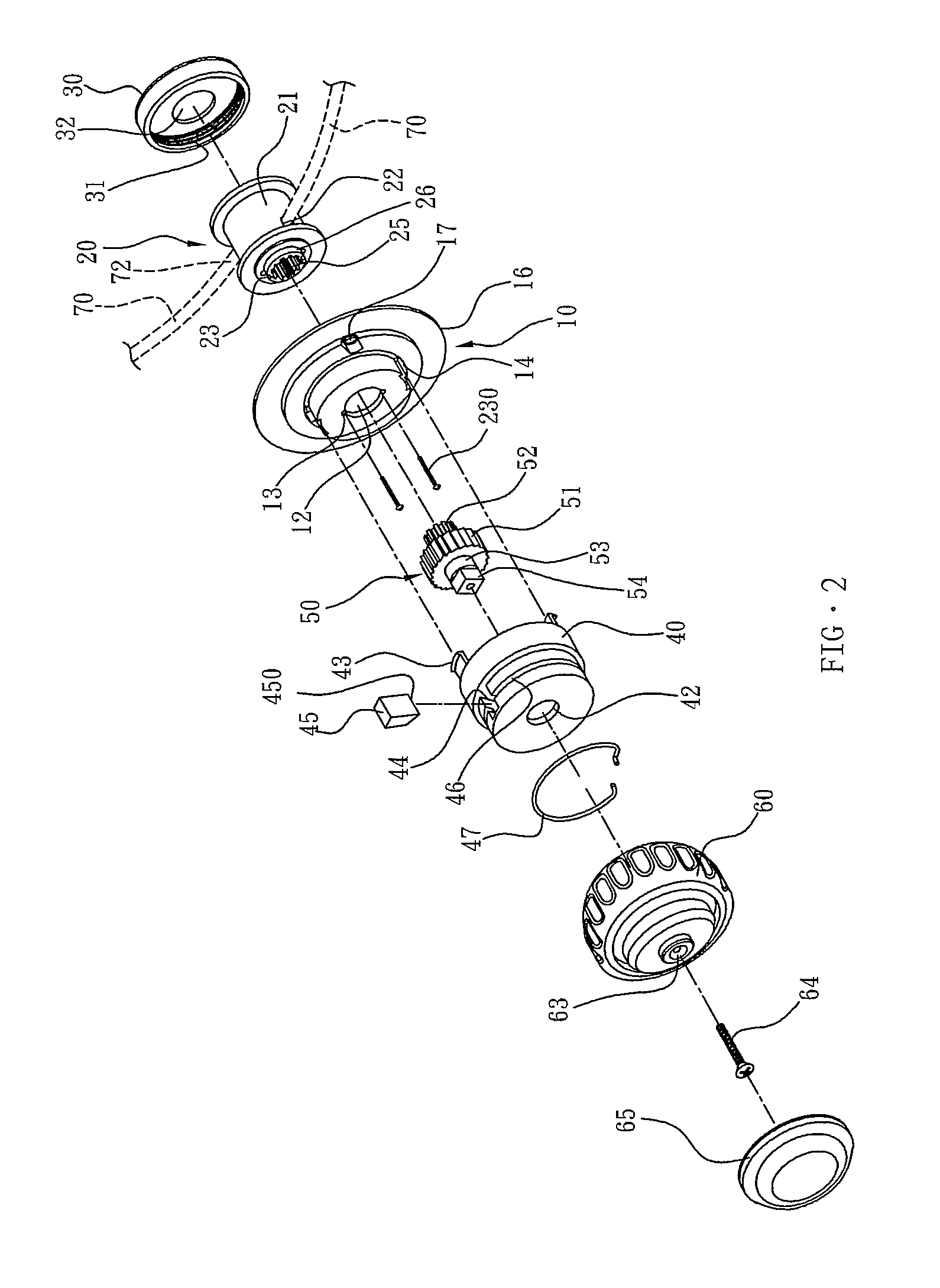

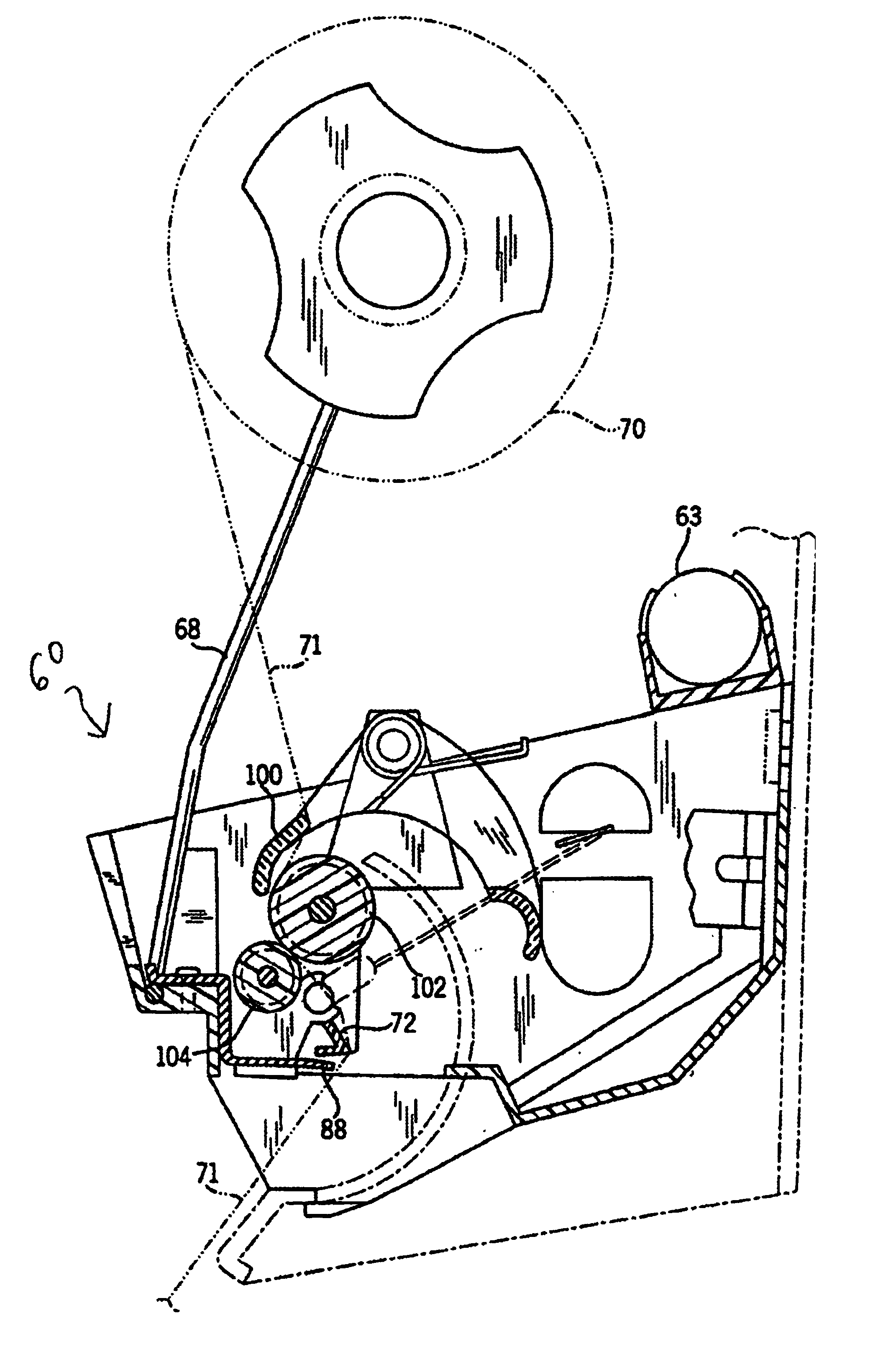

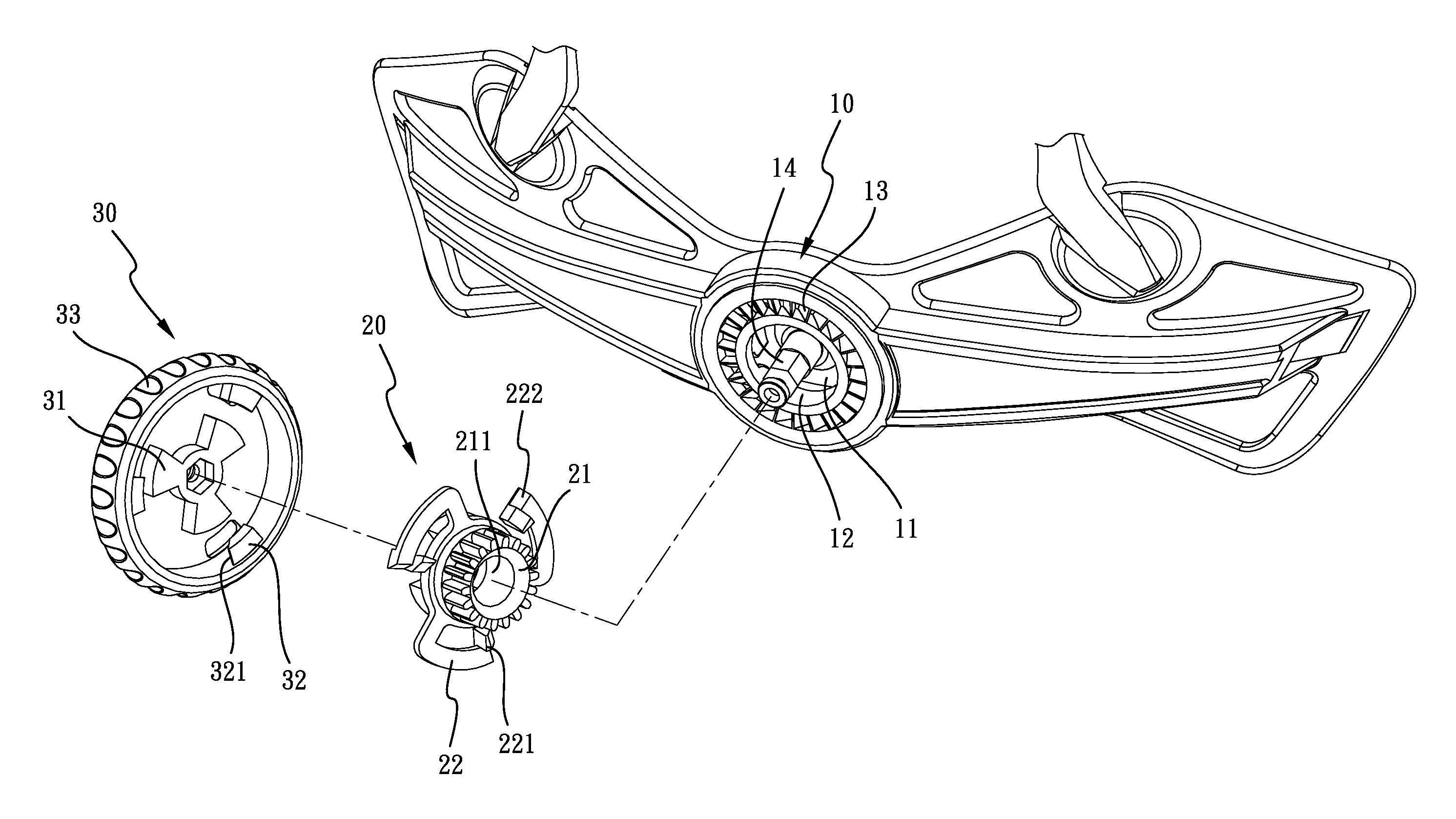

Cord taking-up and releasing device

InactiveUS20050098673A1Easy to operateFilament handlingShoe lace fasteningsEngineeringMechanical engineering

Owner:HUANG WEN SHENG

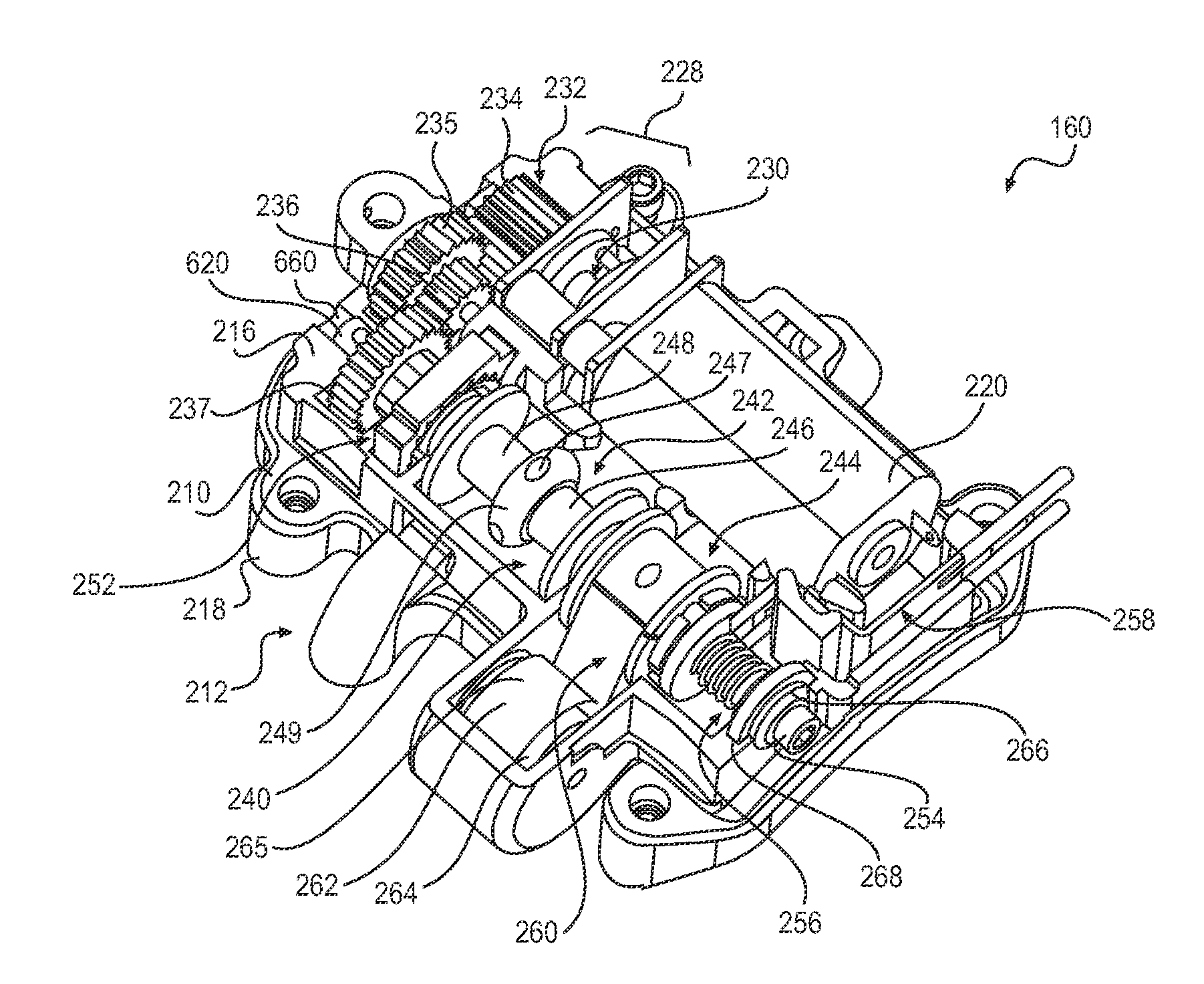

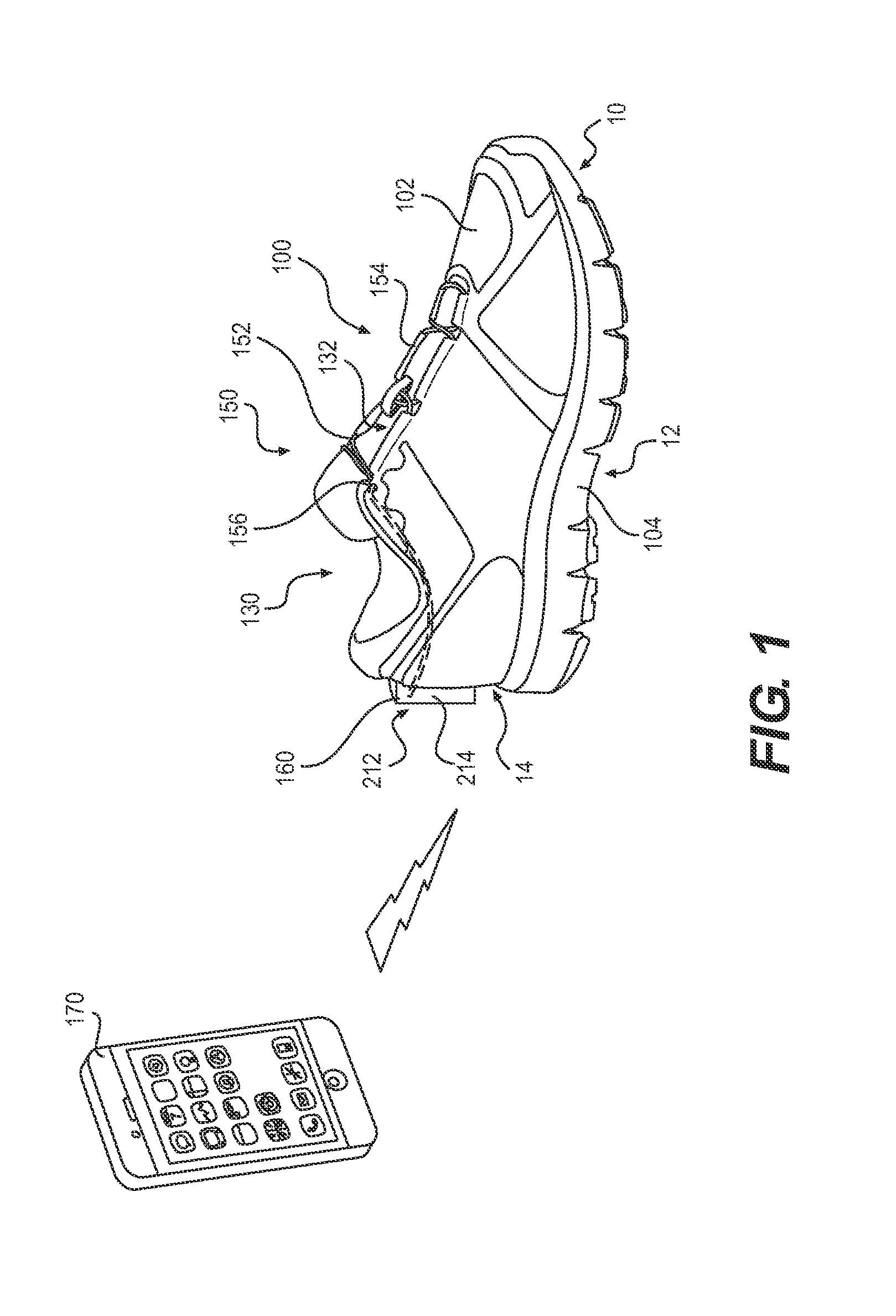

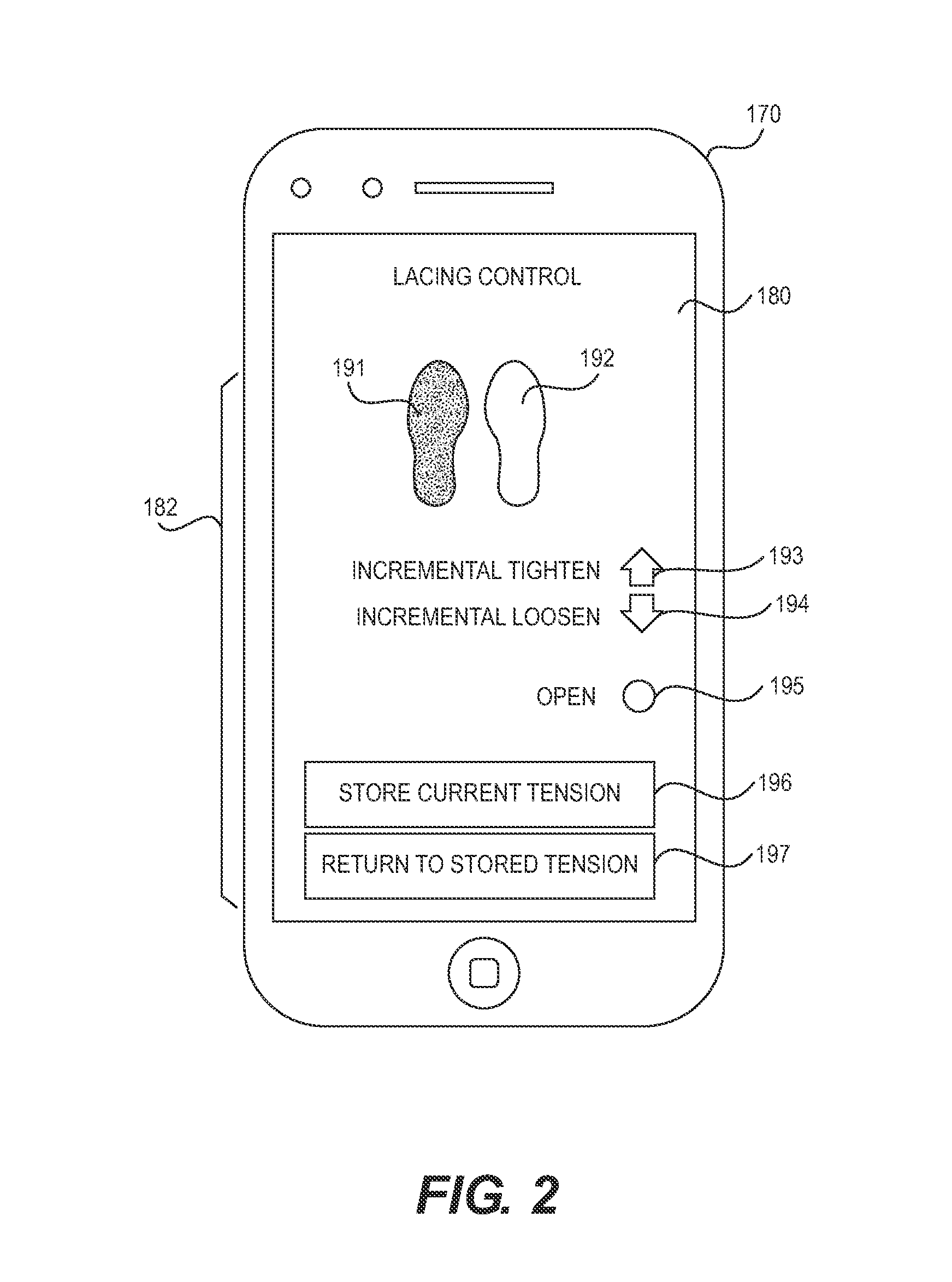

Motorized tensioning system for medical braces and devices

ActiveUS20140094728A1Adjustable tensionFilament handlingShoe lace fasteningsEngineeringMedical treatment

A tensioning system for medical braces and devices is disclosed. The tensioning system includes a tensioning member that is tightened or loosened using a motorized tensioning device for winding and unwinding the tensioning member on a spool. The motorized tensioning device includes a torque transmitting system that allows for incremental tightening, incremental loosening, and full loosening of the tensioning member.

Owner:WISCONSIN ALUMNI RES FOUND +1

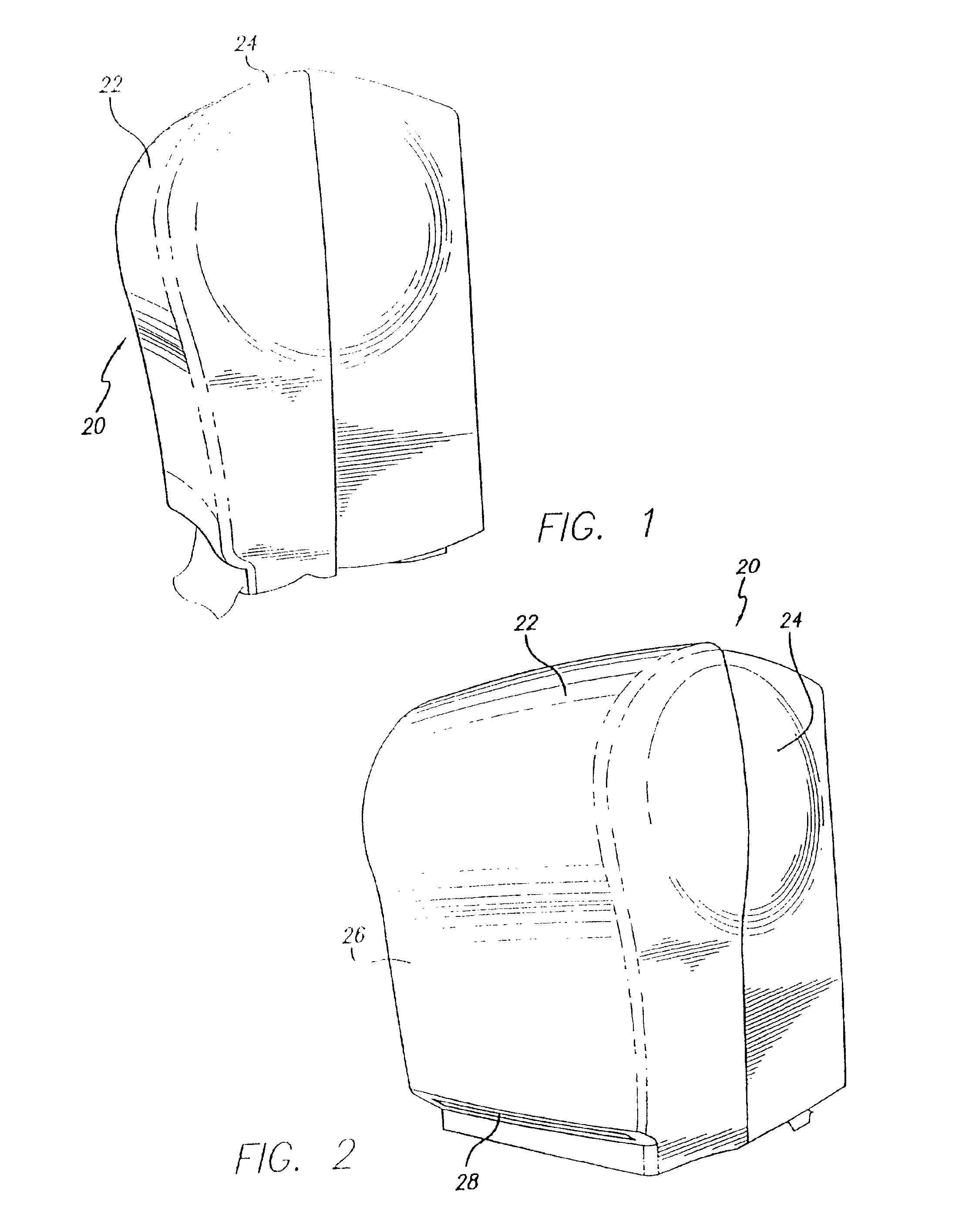

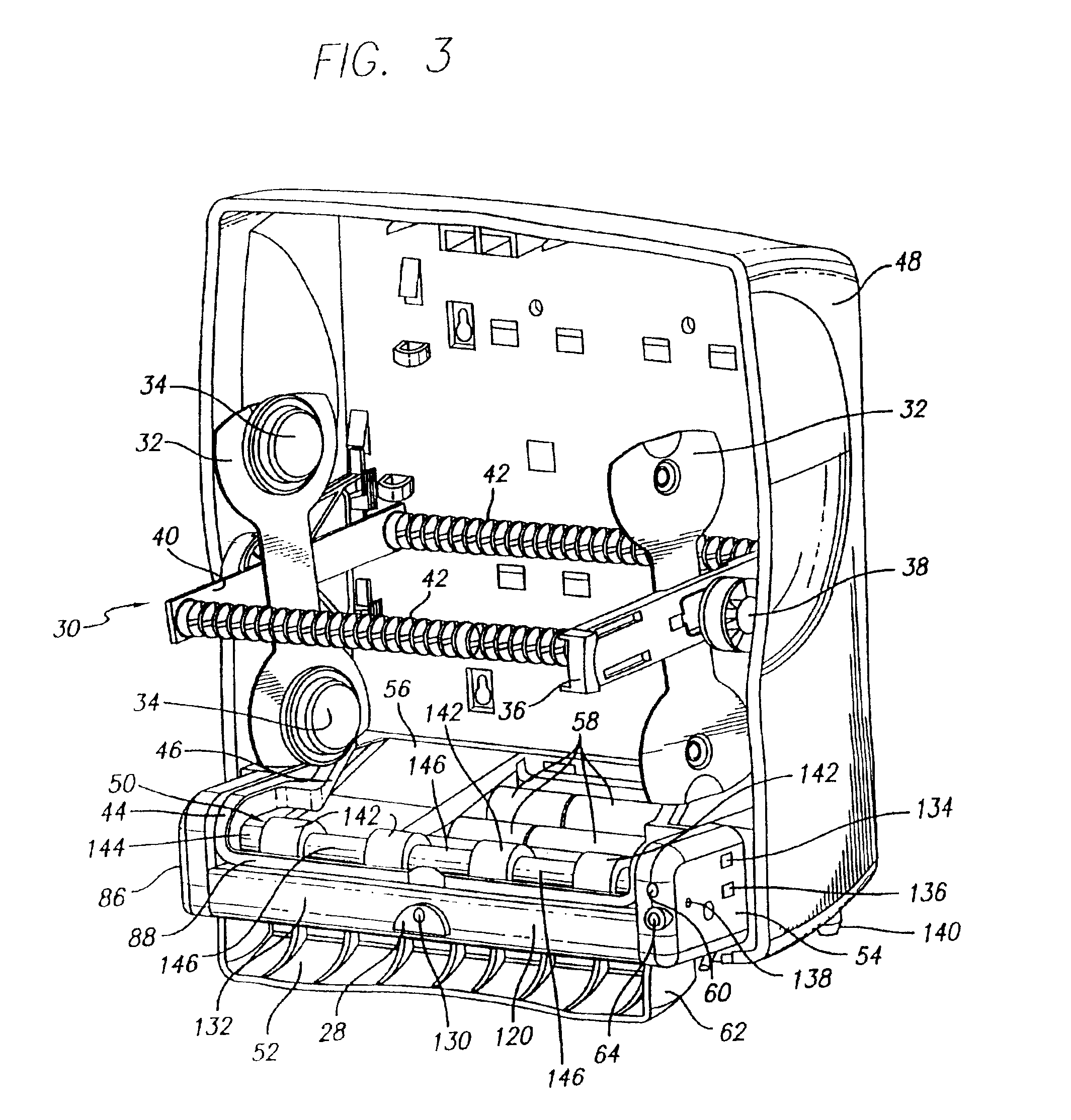

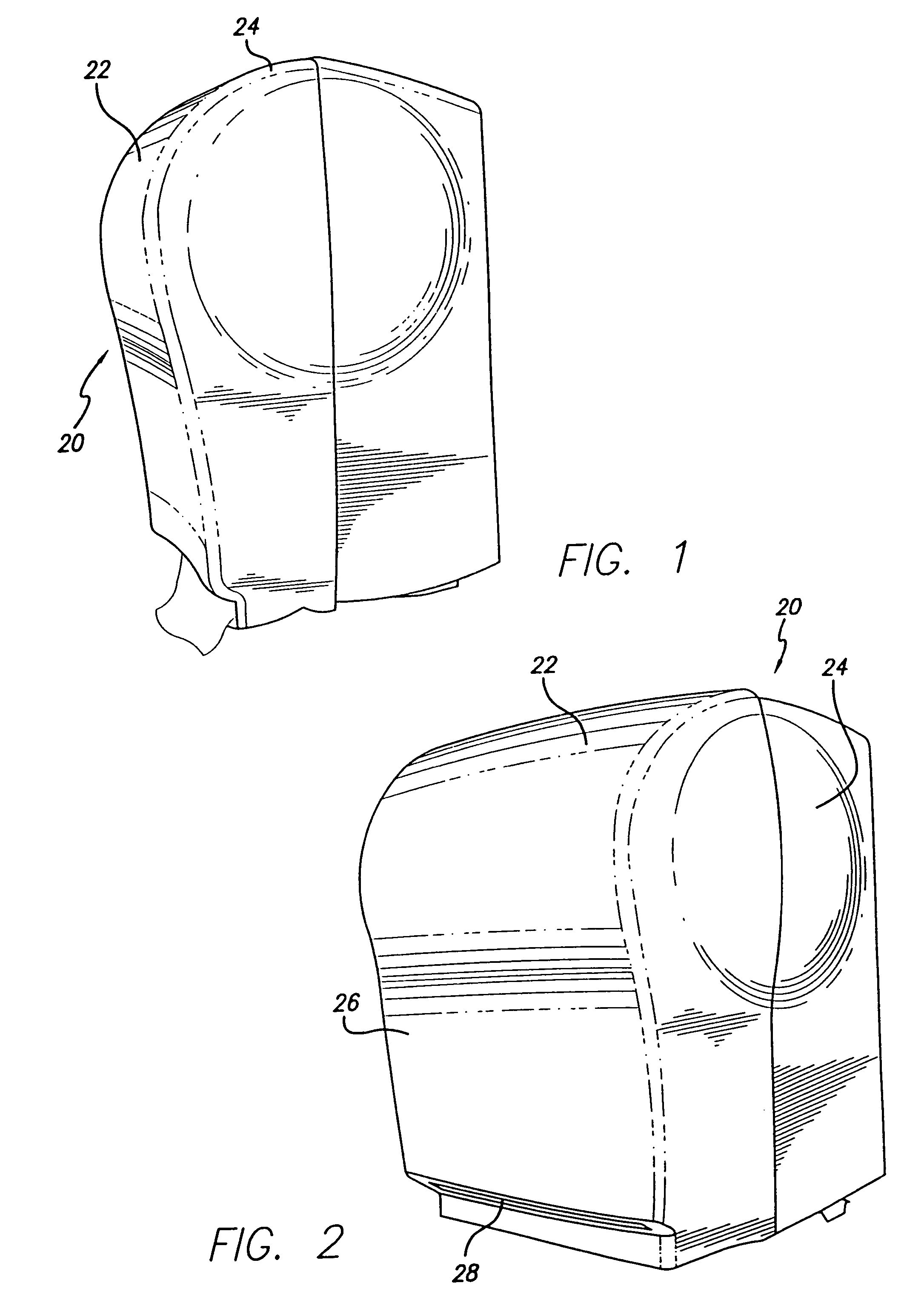

Automatic dispenser apparatus

InactiveUS6903654B2Easy to operateSame lengthCoin-freed apparatus detailsFilament handlingCapacitanceElectrical conductor

The invention is directed to improved automatic dispenser apparatus for dispensing sheet material and the like without contact between a user and the dispenser. Proximity detection apparatus is provided to detect the presence of a user in a detection zone generated outside the dispenser. Control apparatus controls actuation of the dispenser in response to the detected user. Preferred forms of the proximity detector include a sensor and a signal detection circuit operatively connected to the sensor. The sensor includes conductors configured to have a capacitance and positioned such that the capacitance is changed by the presence of a user within the detection zone. The signal detection circuit detects the change in capacitance and is provided with an oscillator having a frequency which is affected by the sensor capacitance and a differential frequency discriminator which detects changes in the oscillator frequency. The control apparatus receives the detected frequency change and generates a signal provided to actuate the dispenser to dispense the material. The dispenser control apparatus controls dispenser operation responsive to decreases in battery voltage which occur during the life cycle of the batteries and controls dispenser operation when the batteries near the end of such life cycle. Such control apparatus may be used with any type of battery powered dispenser, including hands-free dispensers and dispensers actuated by direct physical contact with the user.

Owner:ALWIN MFG

Surgical robotic system

ActiveUS7988215B2Simple and compact designReduce rateWaterborne vesselsDiagnosticsHydraulic cylinderRobotic arm

A surgical robotic system includes a robotic arm, an end effector movably connected thereto and provided with a movable end effector element driven by an actuator, and a force sensor arranged between the robotic arm and the end effector. The actuator is formed by a hydraulic cylinder. The robotic arm is provided with a hydraulic line connected to said hydraulic cylinder of the end effector.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

Stringing messenger clamp and methods of using the same

ActiveUS9379527B2Prevent radial displacementFilament handlingInsulatorsDistribution systemEngineering

A stringing messenger clamp for use in overhead transmission and distribution systems and method of installing a messenger cable is provided. The stringing messenger clamp includes a bracket and an assembly body supported by the bracket, wherein the assembly body has a cable channel sized to receive a portion of a messenger cable. An assembly clamp is movable with respect to the assembly body and closable upon the cable channel. When the assembly clamp is in a closed position, it retains in place the portion of the messenger cable within the cable channel.

Owner:MARMON UTILITY

Electronic Dispenser for Dispensing Sheet Products

An electronic dispenser for dispensing sheet products includes an infrared proximity sensor operative to detect a presence of a user's hand at a predetermined location near the dispenser and a feed mechanism configured to engage a sheet product roll to cause a quantity of sheet product to be dispensed therethrough. The infrared proximity sensor is configured to have an adjustable sensitivity to vary a detection range of the infrared proximity sensor. The feed mechanism has a motor operative in response to the infrared proximity sensor to engage the feed mechanism.

Owner:GEORGIA PACIFIC CONSUMER PRODS LP

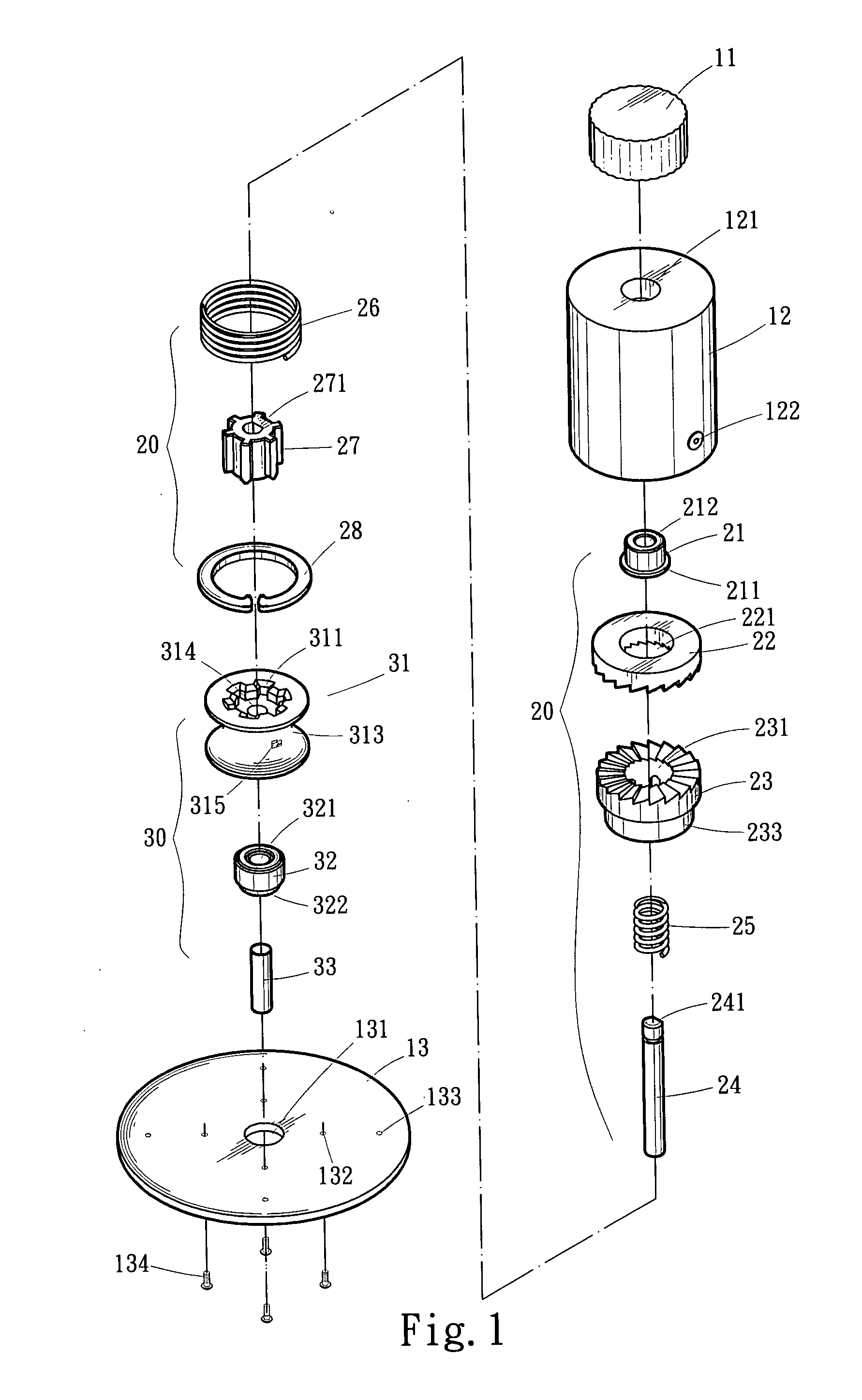

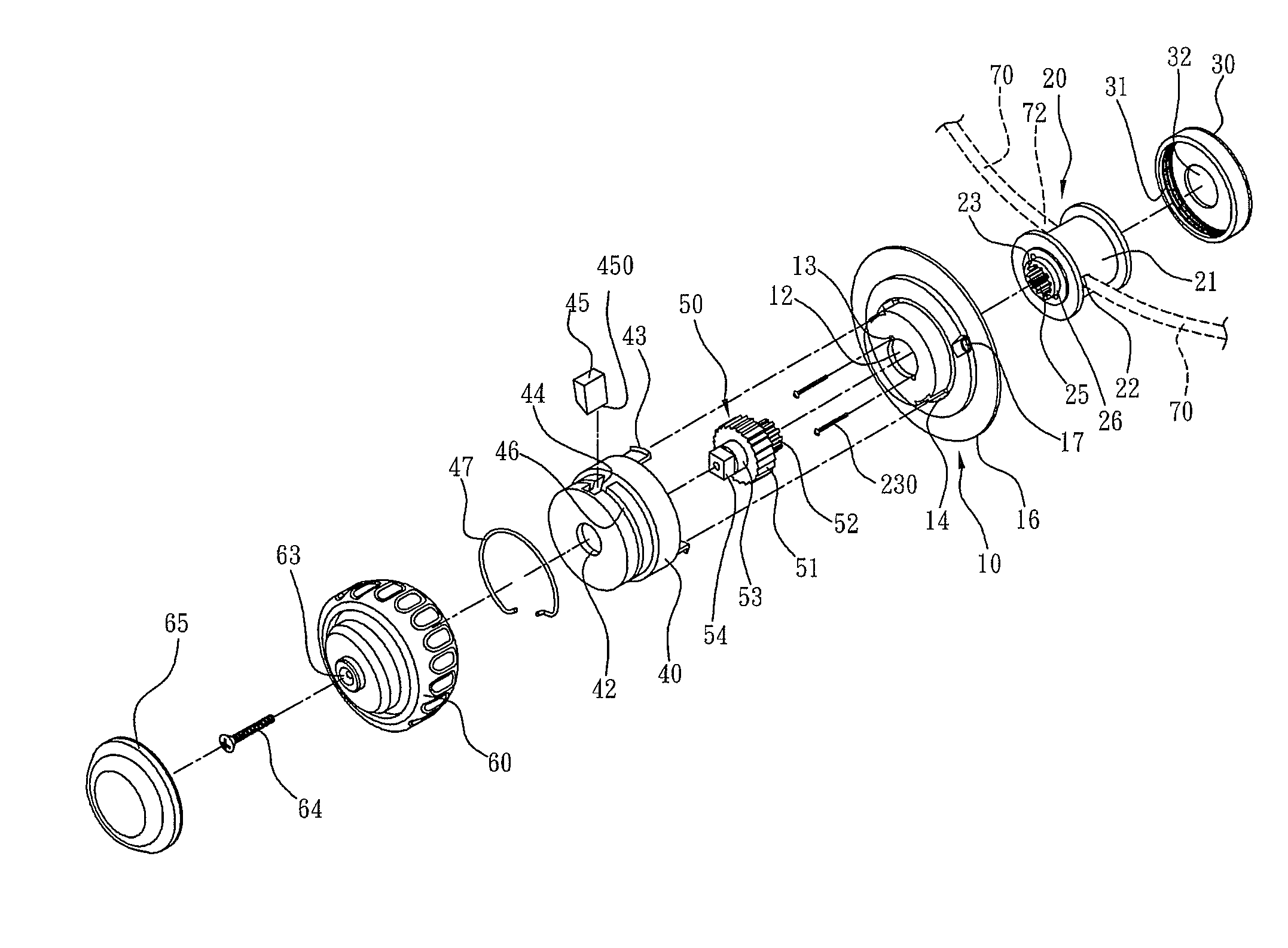

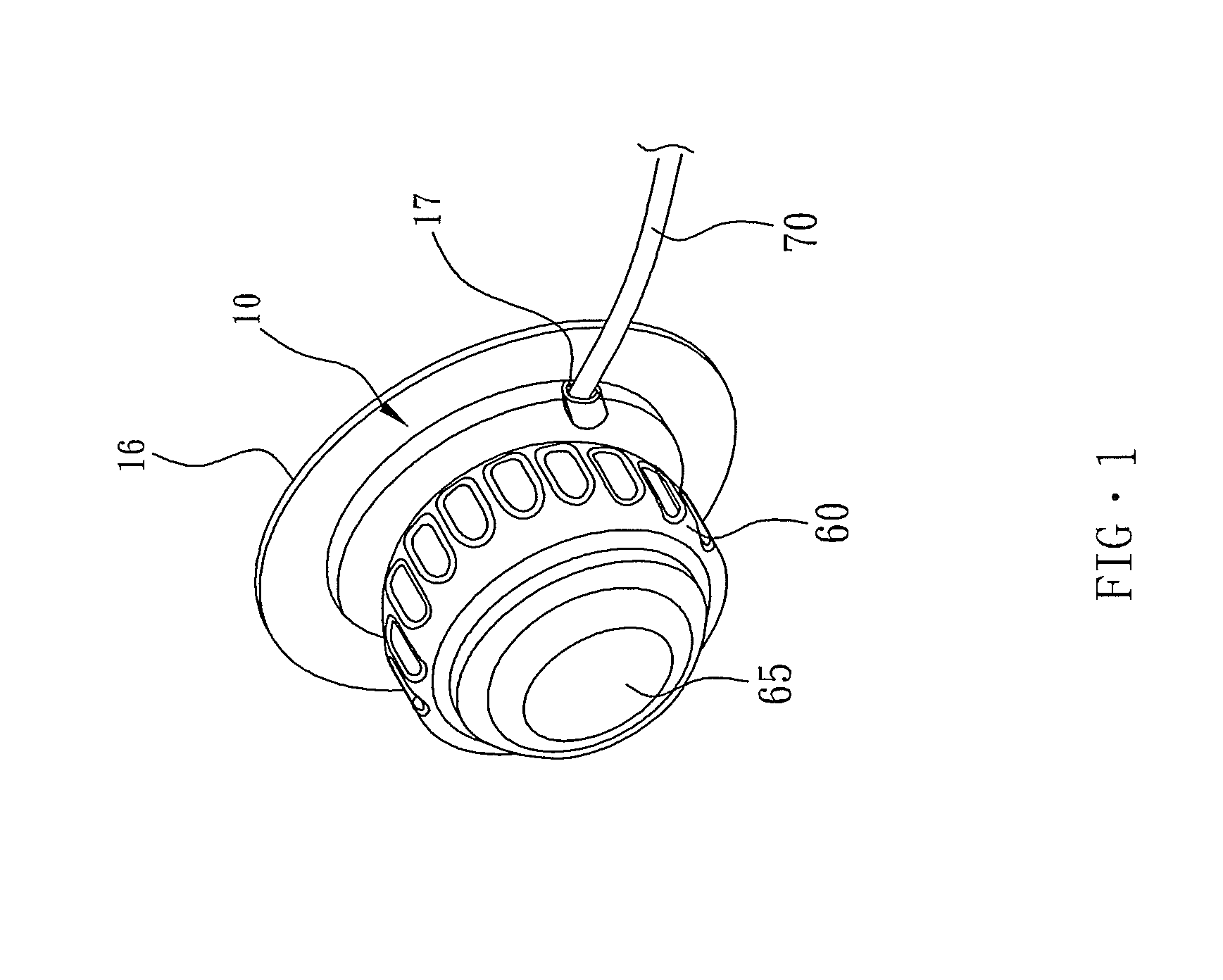

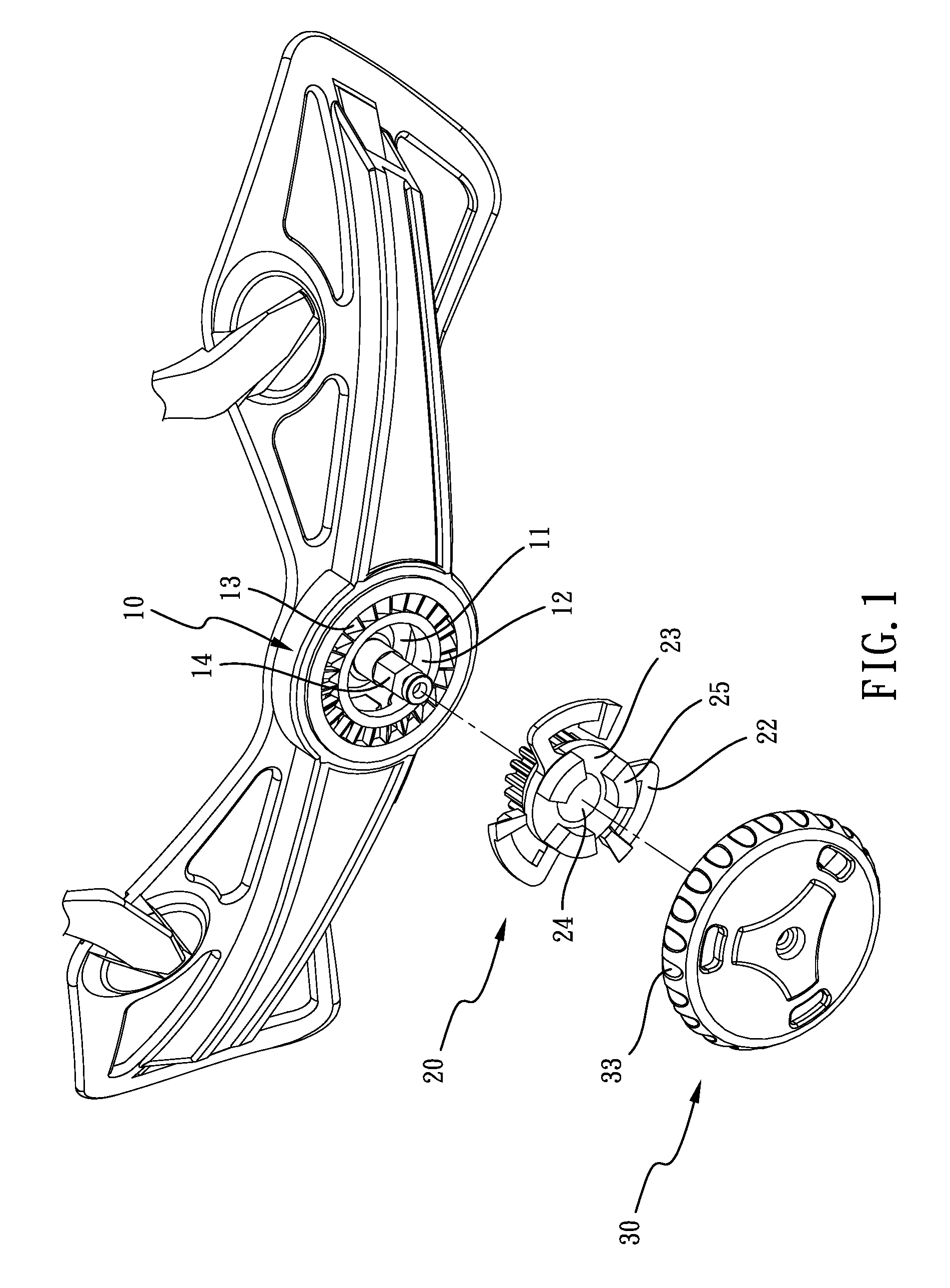

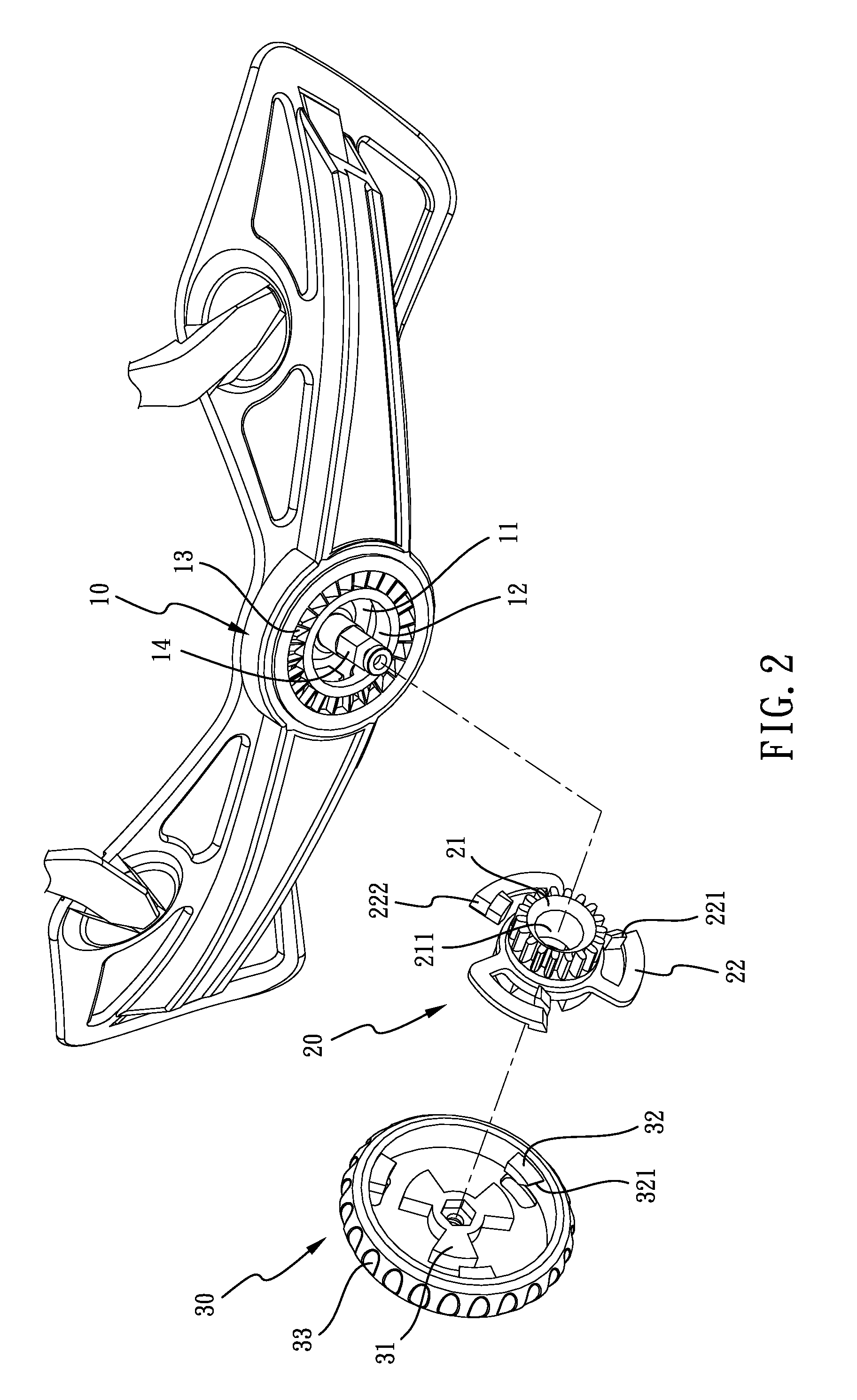

Lace winding device for shoes

InactiveUS8231074B2Stable and firmSmooth and stable windingSnap fastenersFilament handlingMechanical engineeringPositive direction

A lace winding device includes a base, a spool rotatably mounted in the base, a lace having two distal ends each extending through the base and each secured on the spool, a limit barrel mounted on the base, a drive member rotatably mounted in the limit barrel and connected with the spool to rotate the spool, and a ratchet block movably mounted on the limit barrel and engaging the drive member. Thus, the drive member is rotated in one direction only by limit of the ratchet block so that the spool is driven by the drive member to rotate in the positive direction only and cannot be rotated in the opposite direction so as to wind the lace easily and quickly.

Owner:HU RONG FU +1

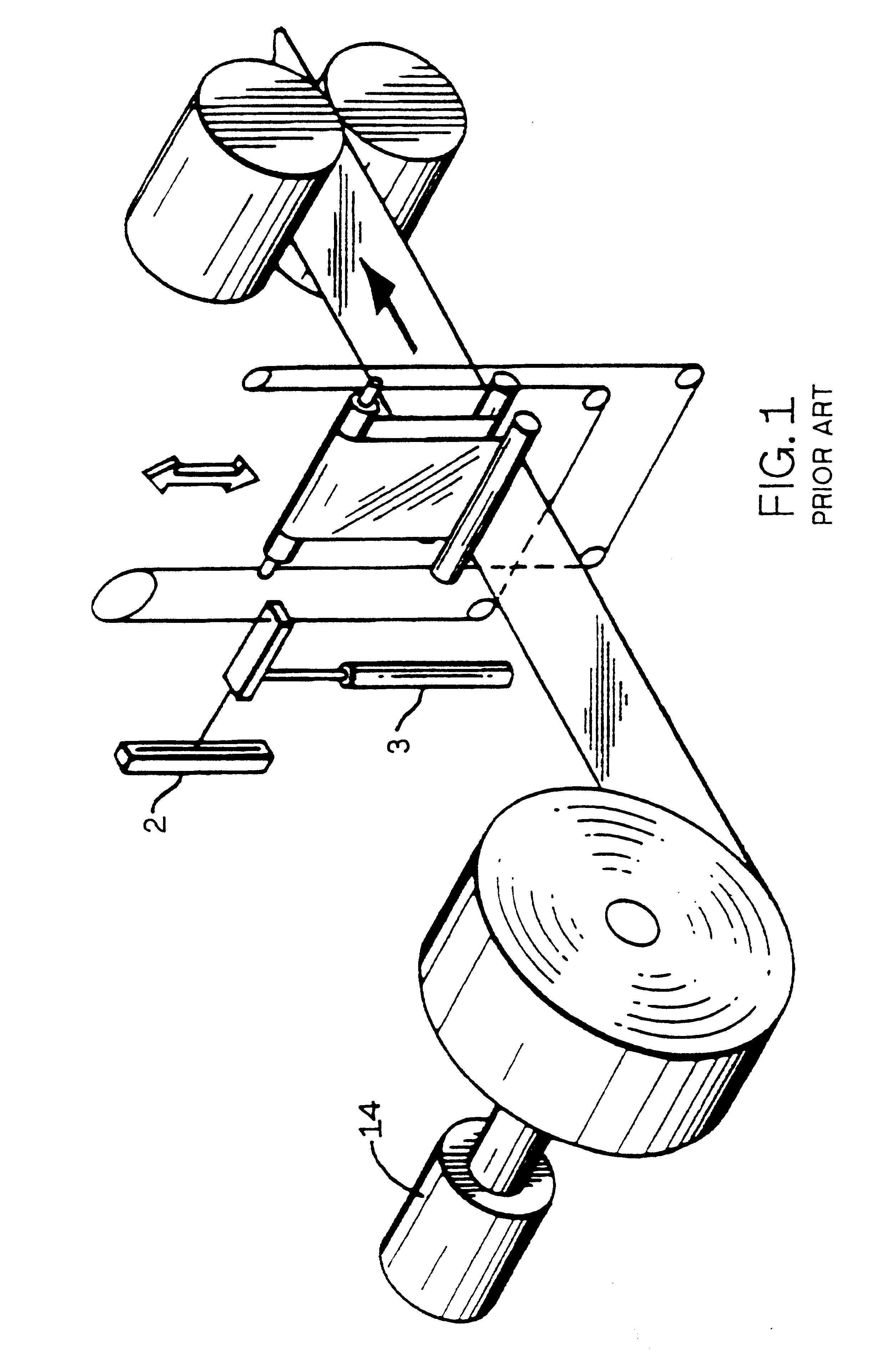

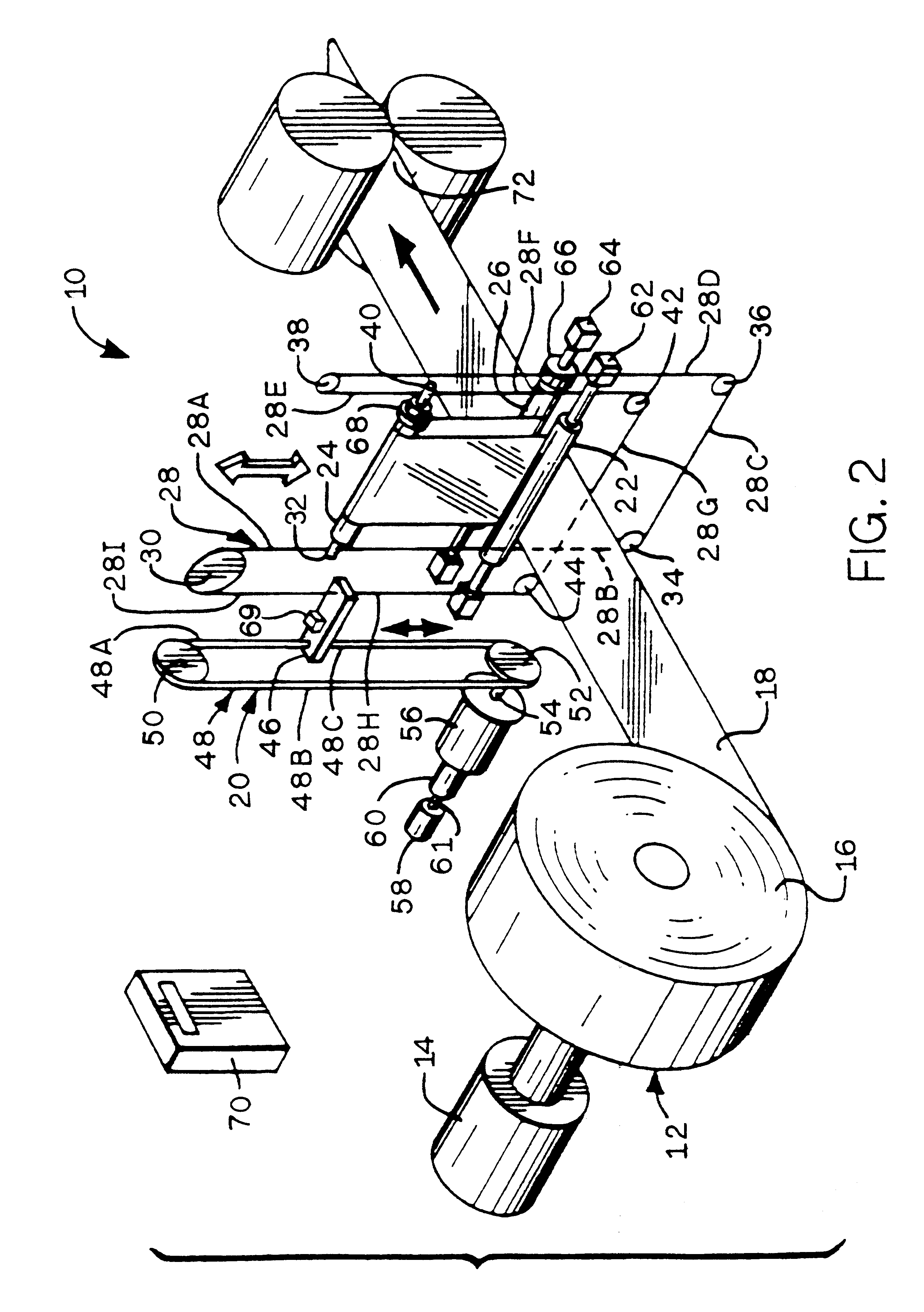

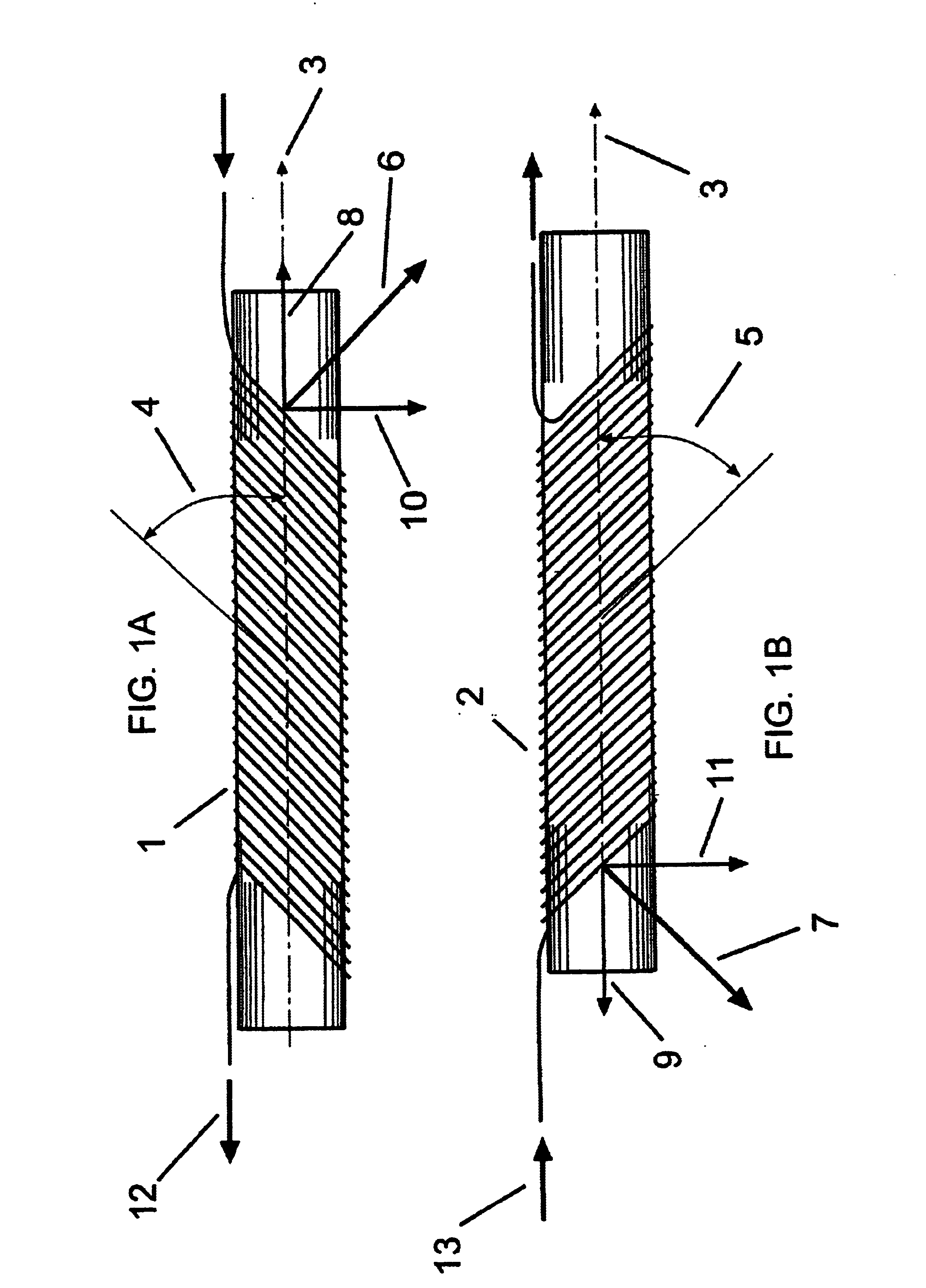

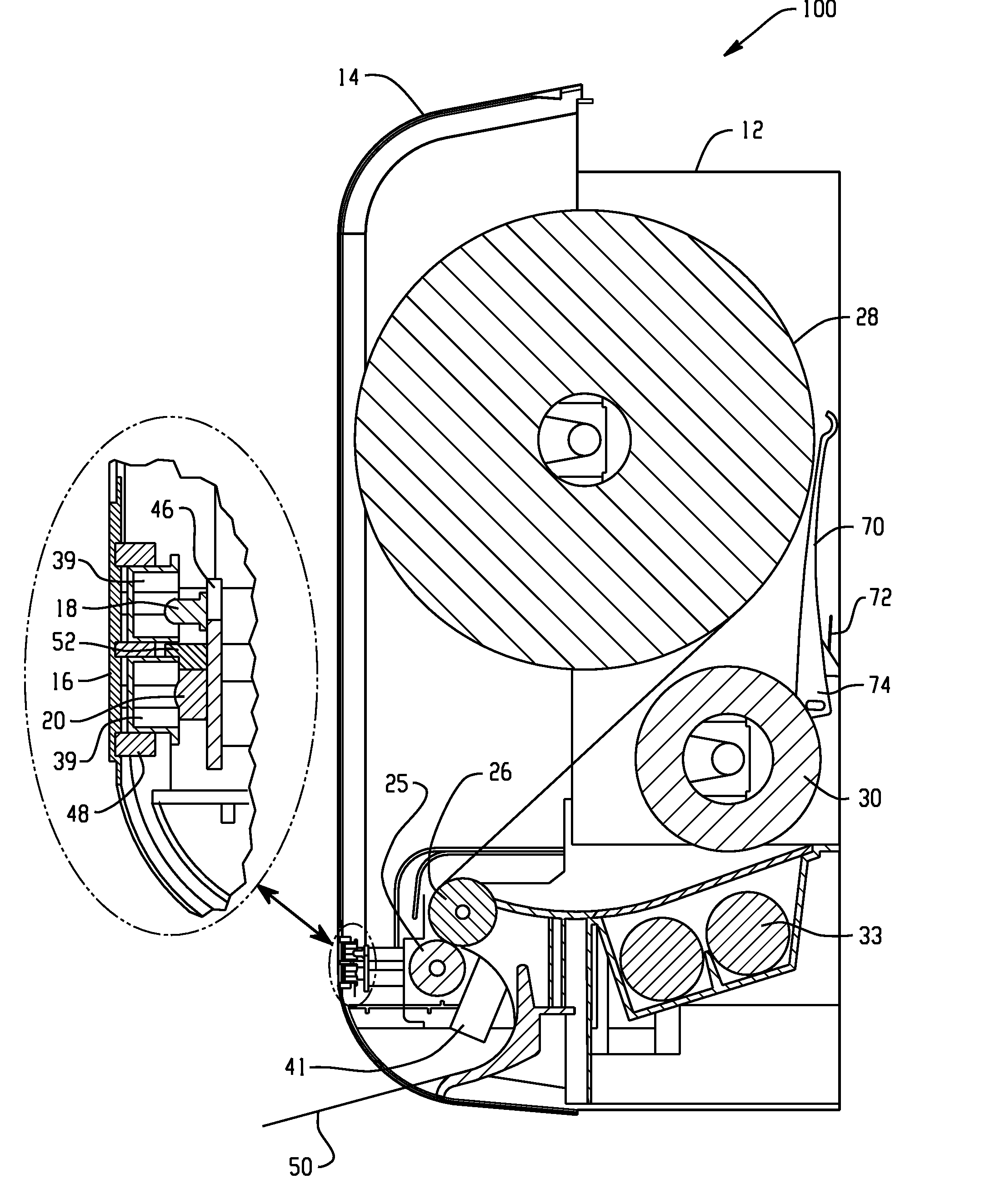

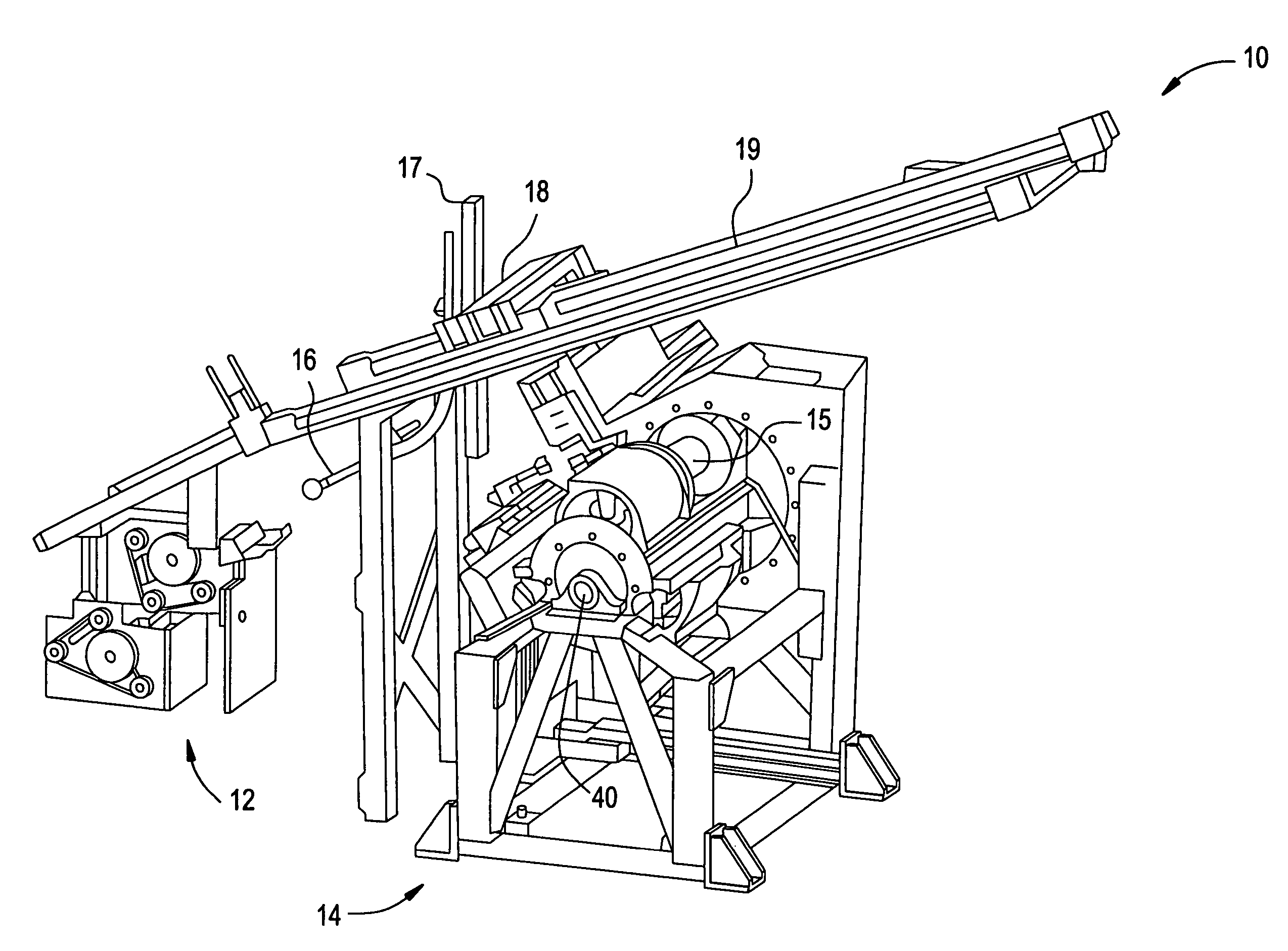

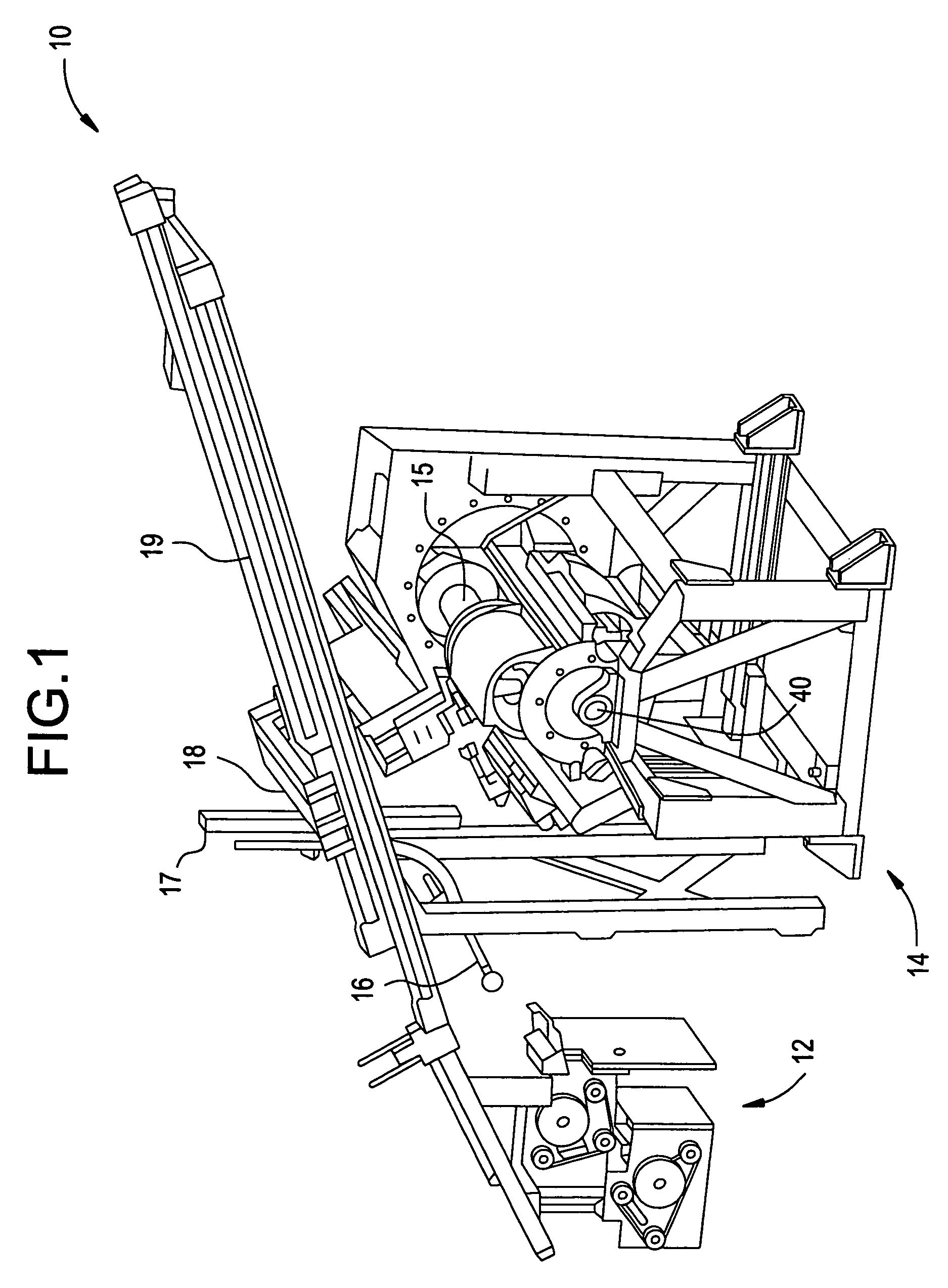

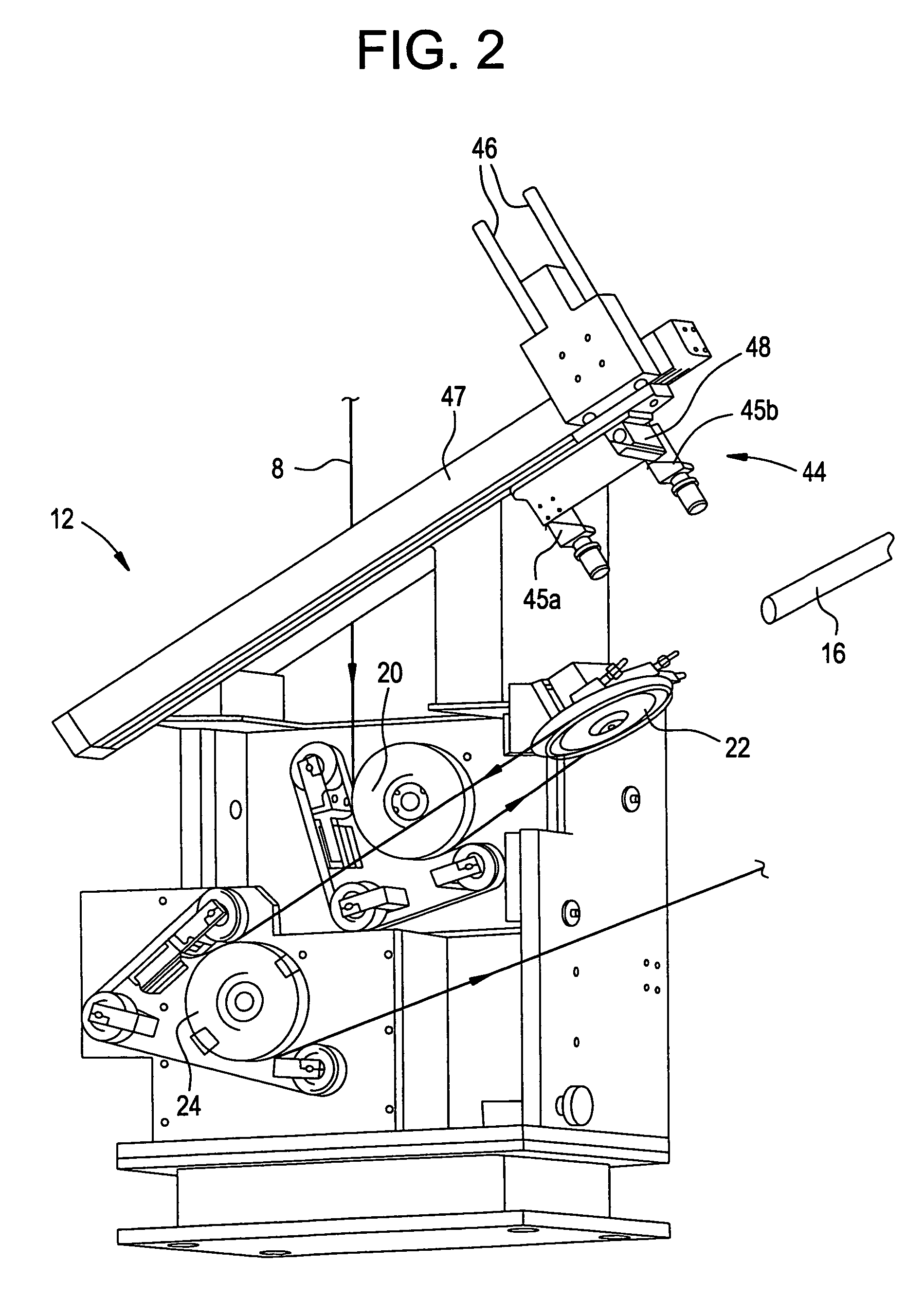

Method and apparatus for tensile testing and rethreading optical fiber during fiber draw

InactiveUS7832675B2Processing speedGlass fibre drawing apparatusFilament handlingFiber drawingTensile testing

A method and apparatus for automatic threading and winding of optical fiber onto various components in a fiber draw system, as well as methods and apparatus for conducting online tensile screening of optical fiber at high speeds. In a preferred embodiment, the fiber is tensile tested during fiber draw and wound directly onto a shipping spool to be shipped to a customer. The tensile stress can be imparted to the fiber during the draw process by feeding the fiber through a screener capstan, which works in conjunction with another capstan to impart the desired tensile stress to the fiber during the draw process. Another aspect is a method and apparatus for threading or rethreading of a moving length of fiber through a fiber draw or fiber testing process, in which fiber is wound onto a spool, comprising activating an aspirator to obtain the fiber at a first location and moving said aspirator in at least two dimensions to thereby move the fiber to a second location and thread the fiber through or onto at least one component in the fiber draw or testing process.

Owner:CORNING INC

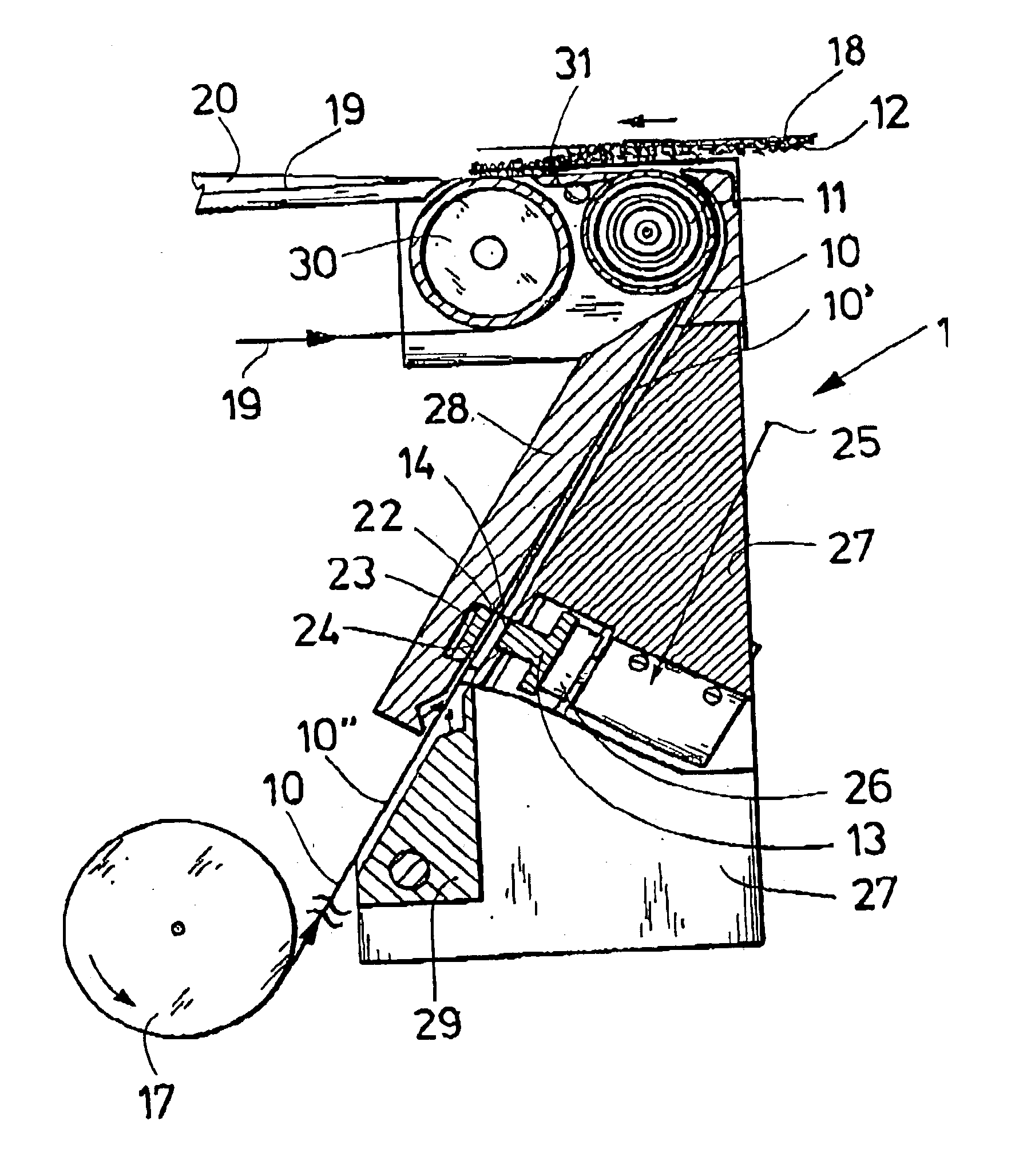

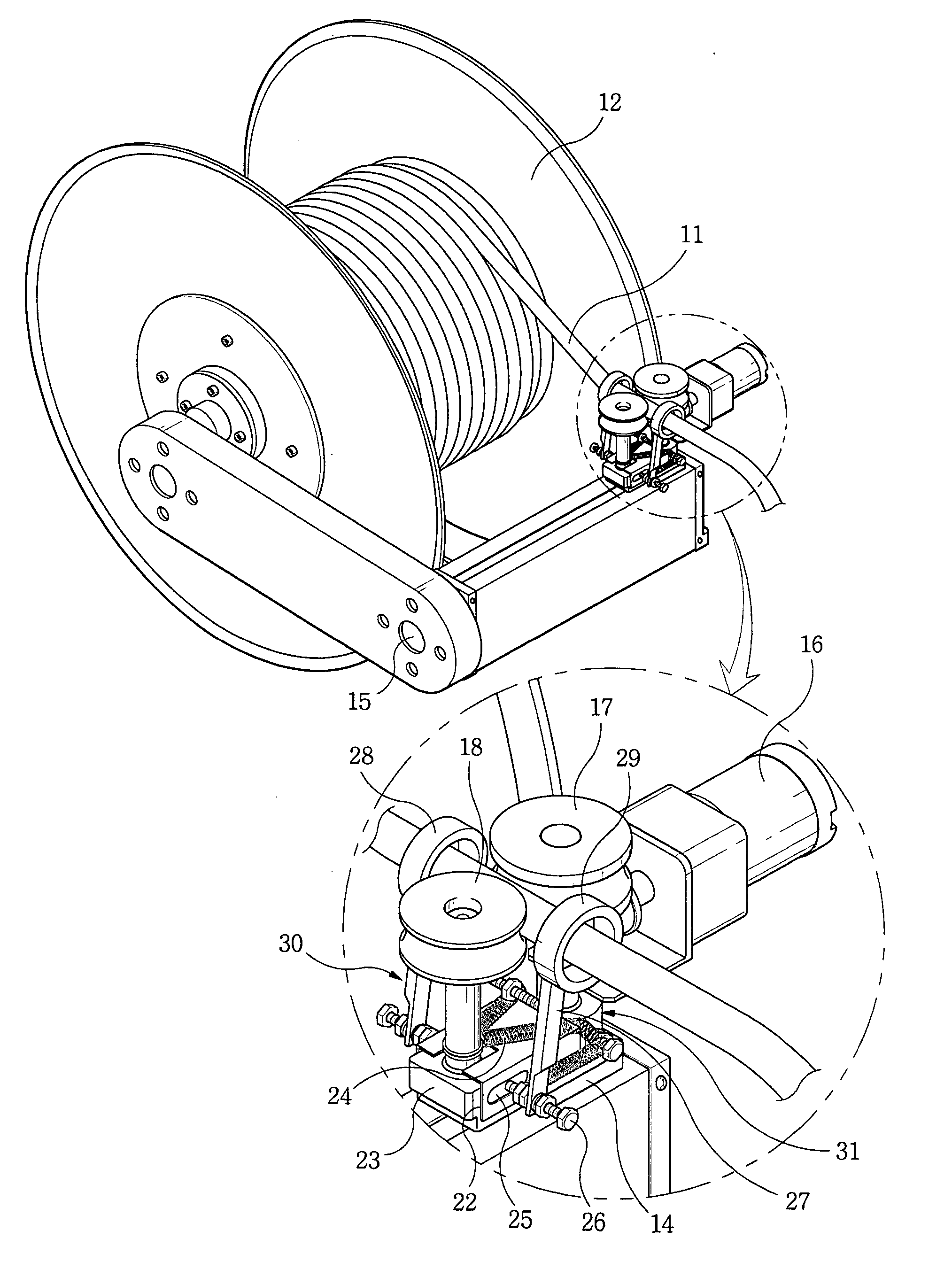

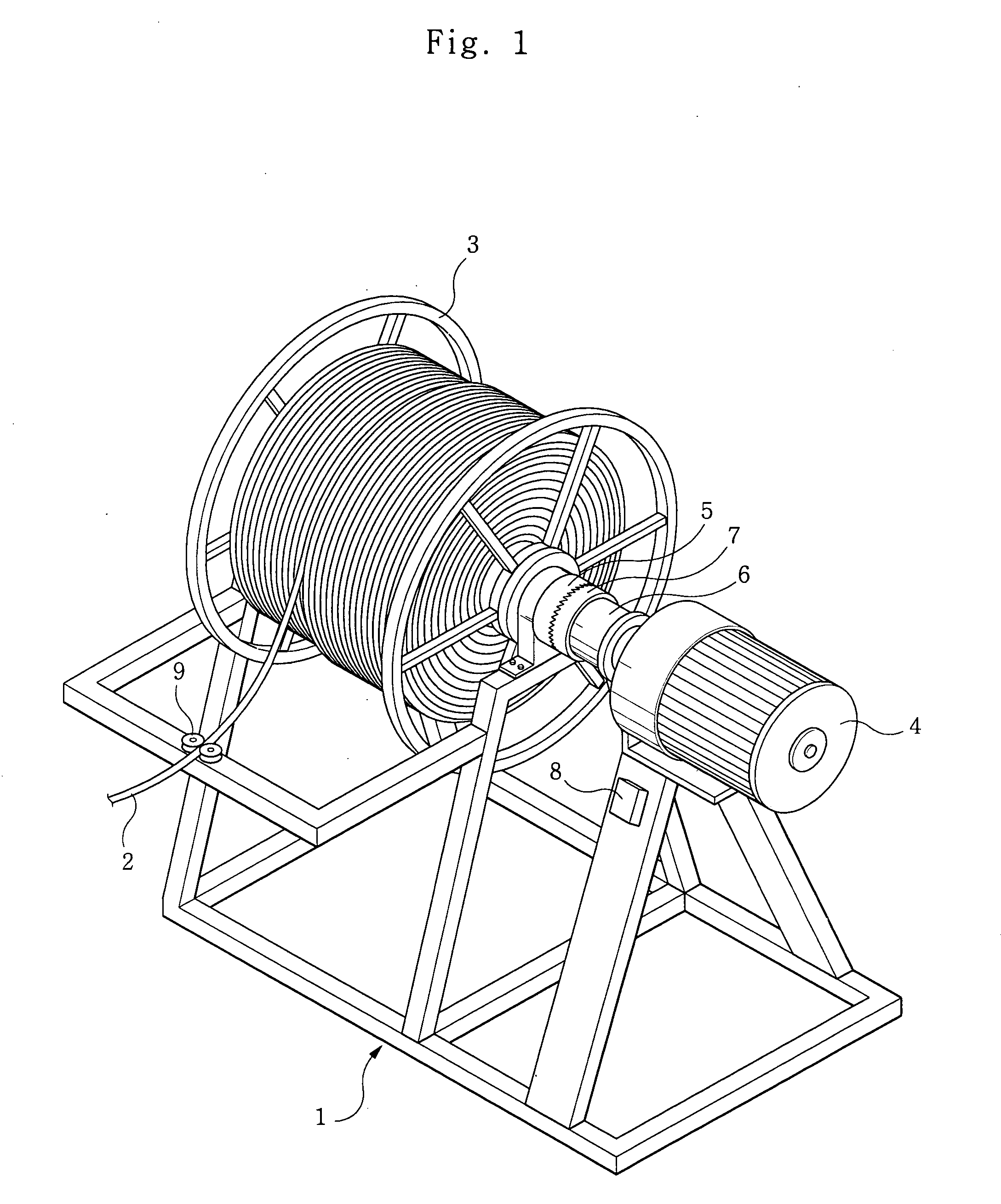

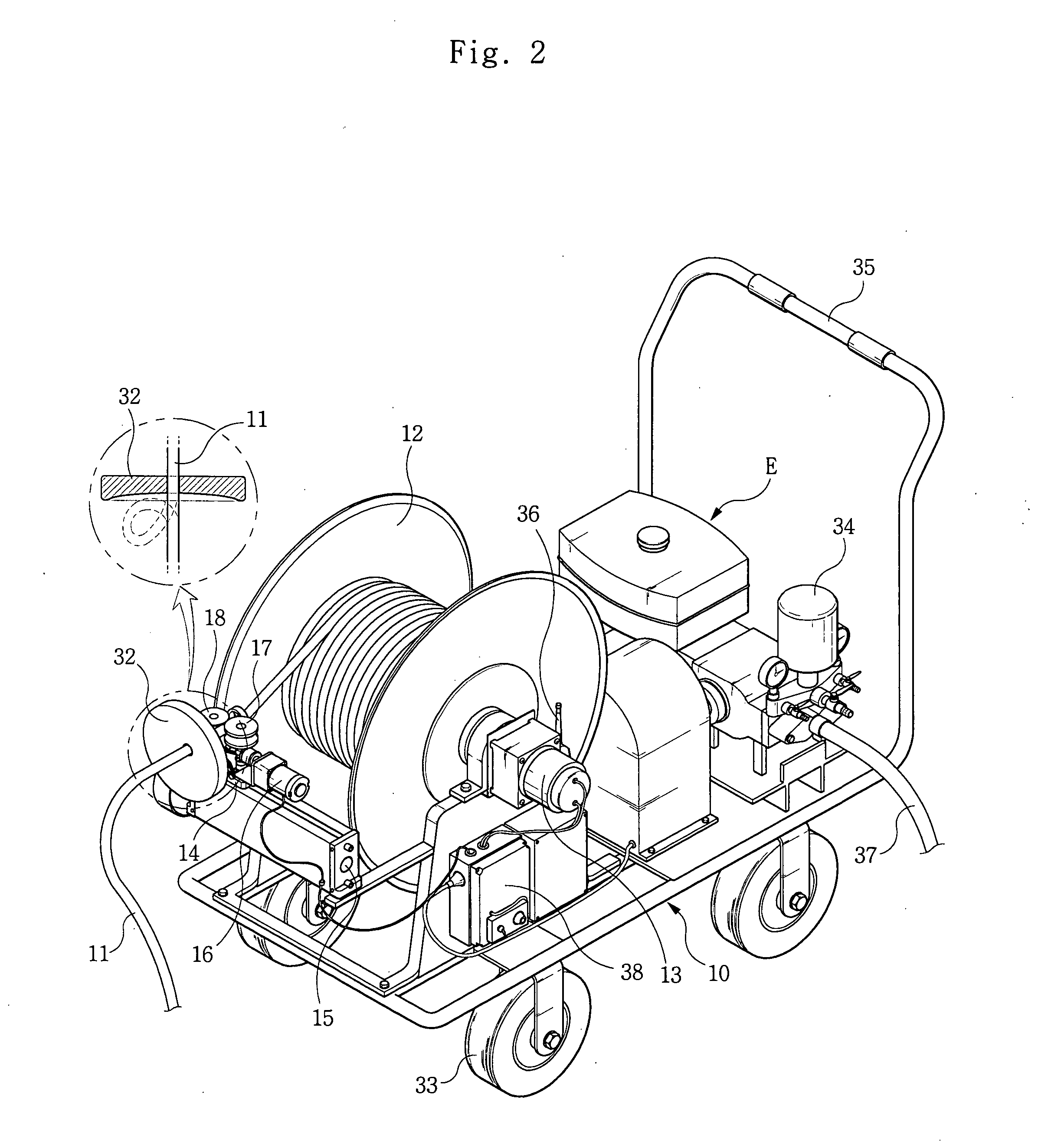

Labor reduction type agricultural chemical spraying system having automatic hose winding and unwinding apparatus

InactiveUS20050087644A1Avoid distortionLow costFilament handlingInsect catchers and killersMotor driveRemote control

The present invention relates to a labor reduction type agricultural chemical spraying system having an automatic hose winding and unwinding apparatus by which one worker is capable of spraying agricultural chemicals in such a manner that a hose is automatically wound and unwound from a reel based on a remotely controlled motor. The labor reduction type agricultural chemical spraying system having an automatic hose winding and unwinding apparatus comprises a frame in which a motored sprayer connected with an engine is installed; a reel rotatably installed in the frame wherein a hose is wound onto the reel; a first driving motor driven in both directions for rotating the reel in normal and reverse directions in accordance with a remote control signal; a rotary shaft rotating by a driving force from the rotary shaft of the reel and reciprocating a movable piece engaged to an upper side in the left and right directions with respect to the reel; a second driving motor installed on the movable piece in cooperation with the first driving motor and driven in the normal and reverse directions in accordance with a remote control signal; and a pair of rollers that are installed in the movable piece and are rotatably connected with the second driving motor and tension an outer surface of the hose, and unwind the hose from the reel.

Owner:HYUPWOO TRADING

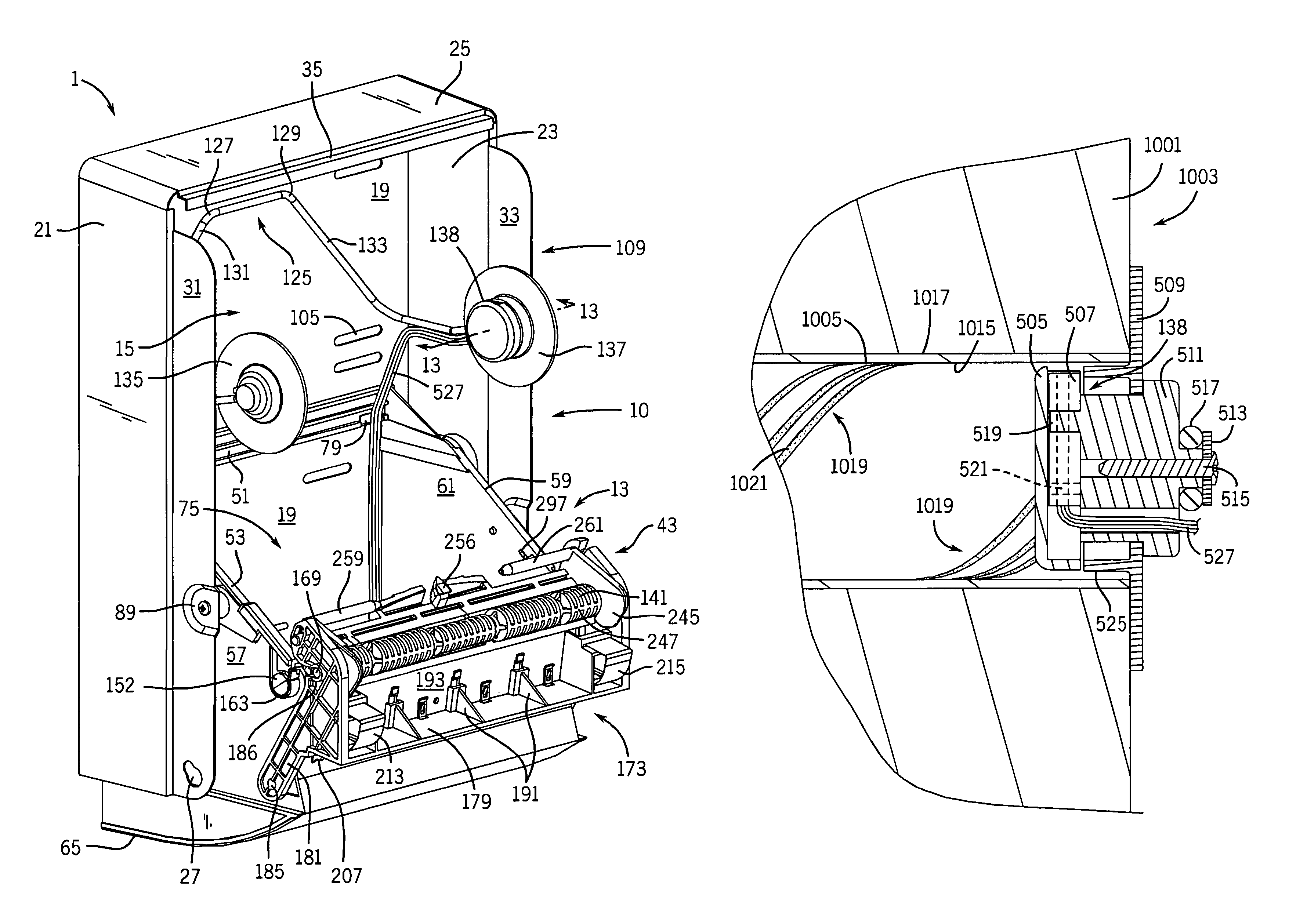

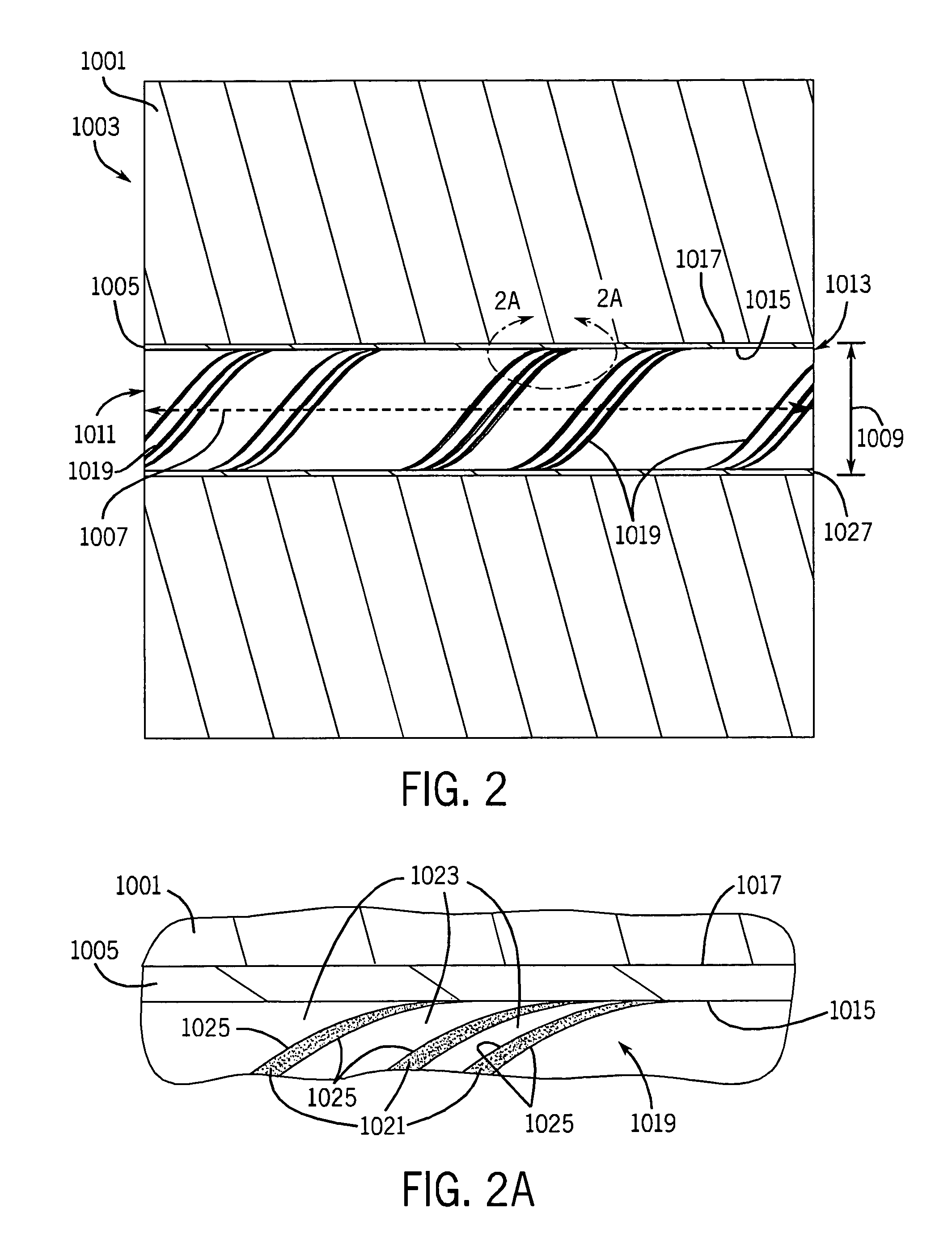

Apparatus and method for dispensing sheet material

A sheet material dispenser includes a controller for automatically controlling the lengths of sheet materials dispensed from a continuous roll by identifying the type of sheet materials on the roll and dispensing suitable lengths of the identified sheet material. The dispenser desirably has a support for rotatably supporting a roll of sheet material carrying identification relating to the type of sheet material on the roll, and an identifier positioned in or adjacent the dispenser for identifying the type of sheet material on the roll. A processor receives data from the identifier, processes the data and generates an output command, and a controller controls the lengths of sheet material dispensed from the roll in response to the output command. In this way, more absorbent products may be dispensed in shorter lengths and less absorbent products may be dispensed in longer lengths.

Owner:KIMBERLY-CLARK WORLDWIDE INC

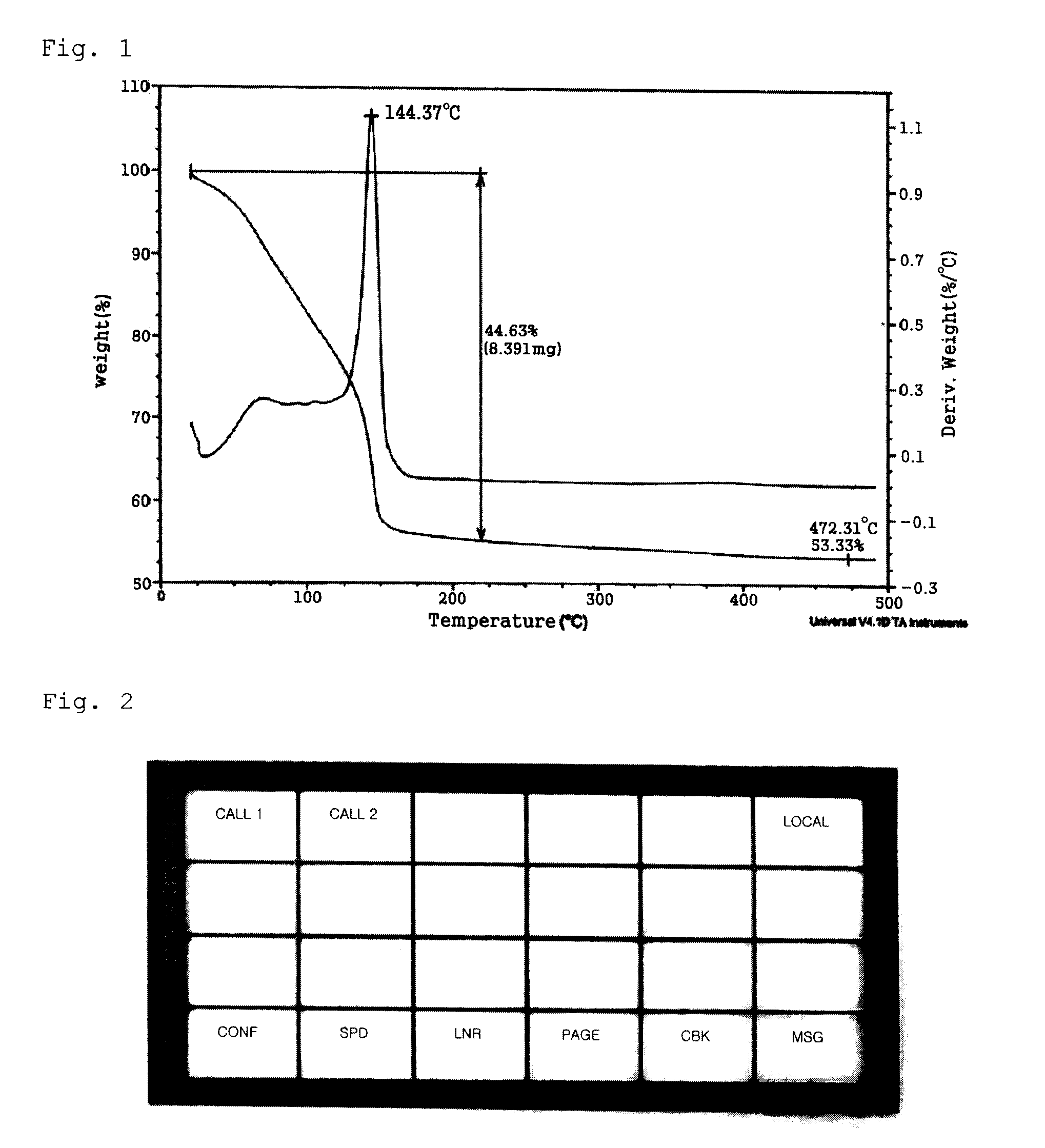

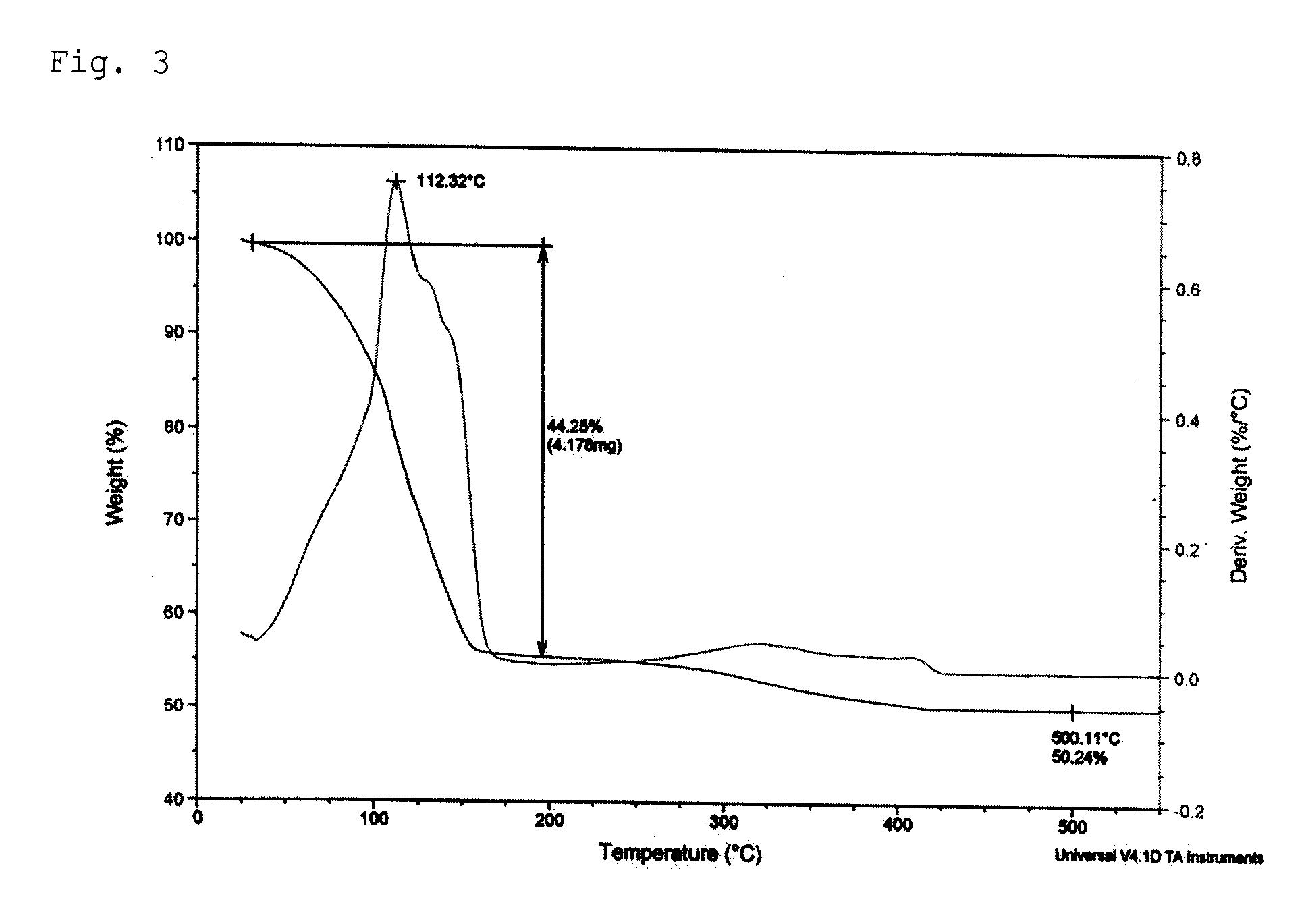

Conductive Inks and Manufacturing Method Thereof

ActiveUS20080206488A1Improve stabilityImprove solubilityElectric discharge heatingConductive materialAmmonium carbonateAmmonium carbamate

The present invention relates to a variety of conductive ink compositions comprising a metal complex compound having a special structure and an additive and a method for preparing the same, more particularly to conductive ink compositions comprising a metal complex compound obtained by reacting a metal or metal compound with an ammonium carbamate- or ammonium carbonate-based compound and an additive and a method for preparing the same.

Owner:INKTEC CO LTD

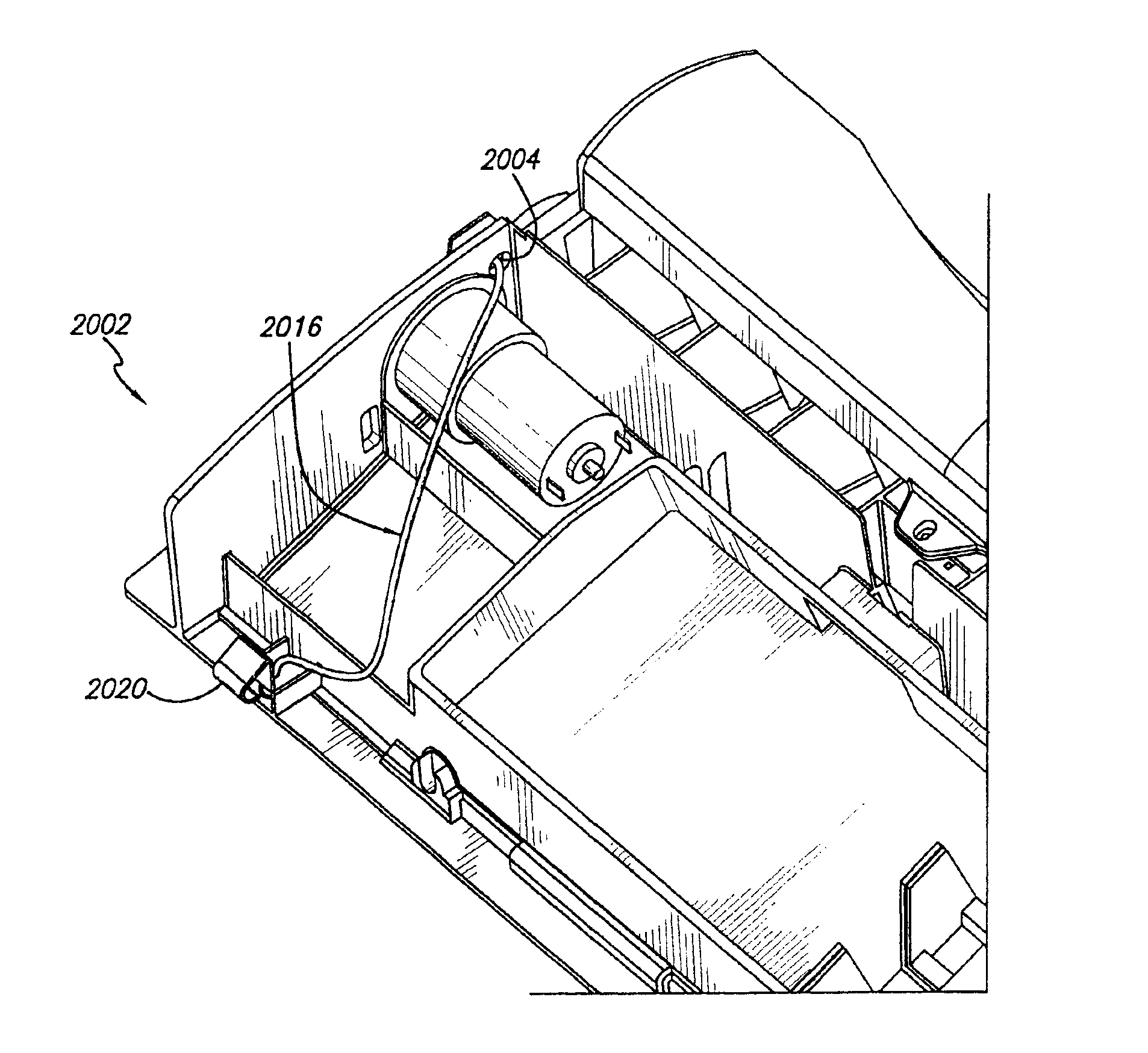

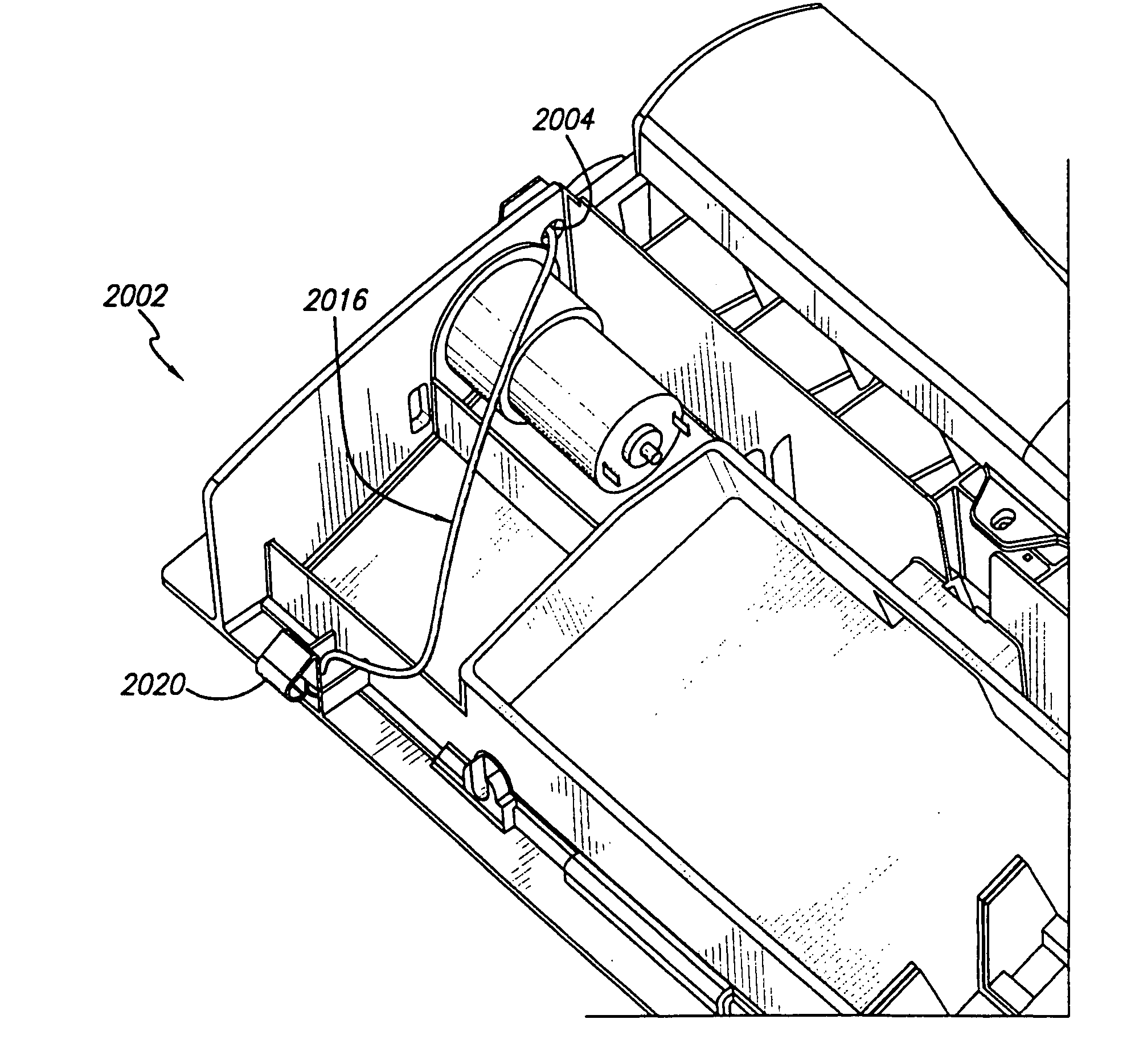

Electronically controlled roll towel dispenser with data communication system

InactiveUS7044421B1Easy to useLow costFilament handlingDomestic applicationsMicrocontrollerDigital data

An electronically controlled roll towel dispenser with a data communication system. The dispenser automatically dispenses a predetermined length of paper toweling from a supply roll after a length of toweling has been detached by a user pulling and tearing the protruding toweling against a stationary cutting blade. The dispenser is battery powered with an electric motor, an electromechanical dispensing mechanism, and an embedded microcontroller for controlling and monitoring operation of the dispenser. In addition to primary control functions, the microcontroller monitors parameters such as battery condition, towel usage, system status, system errors, and unsafe operating conditions. Pushbutton switches are also provided for programming towel length and the dispense delay. The dispenser further includes an optical transmitter for transmitting visual and infrared data to a receiving device. Useful information about the status of the dispenser can be visibly discerned by an operator through the use of primitive low-speed flash patterns, while high-speed infrared digital data can be simultaneously embedded in or multiplexed with the visible data.

Owner:SAN JAMAR INC +1

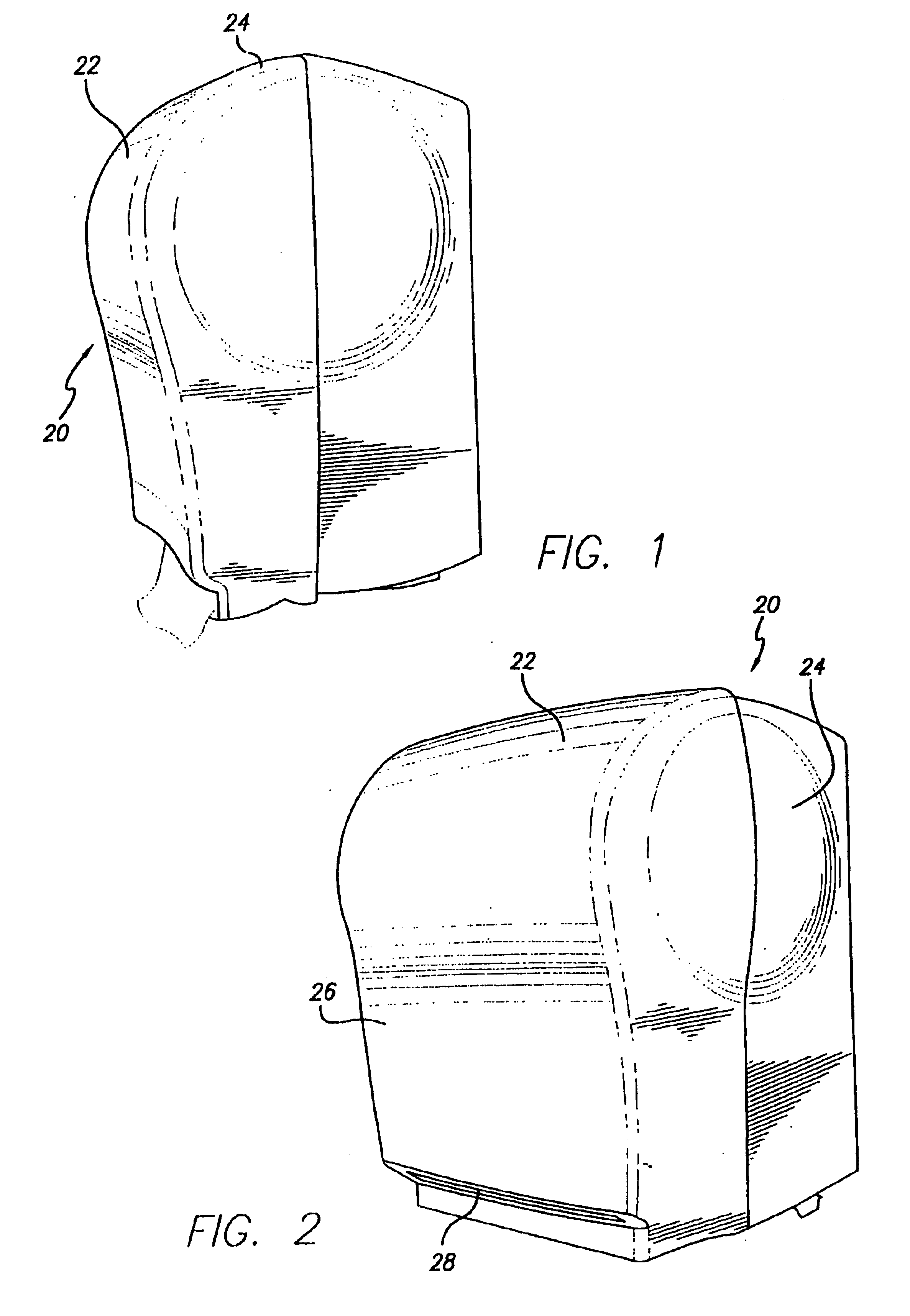

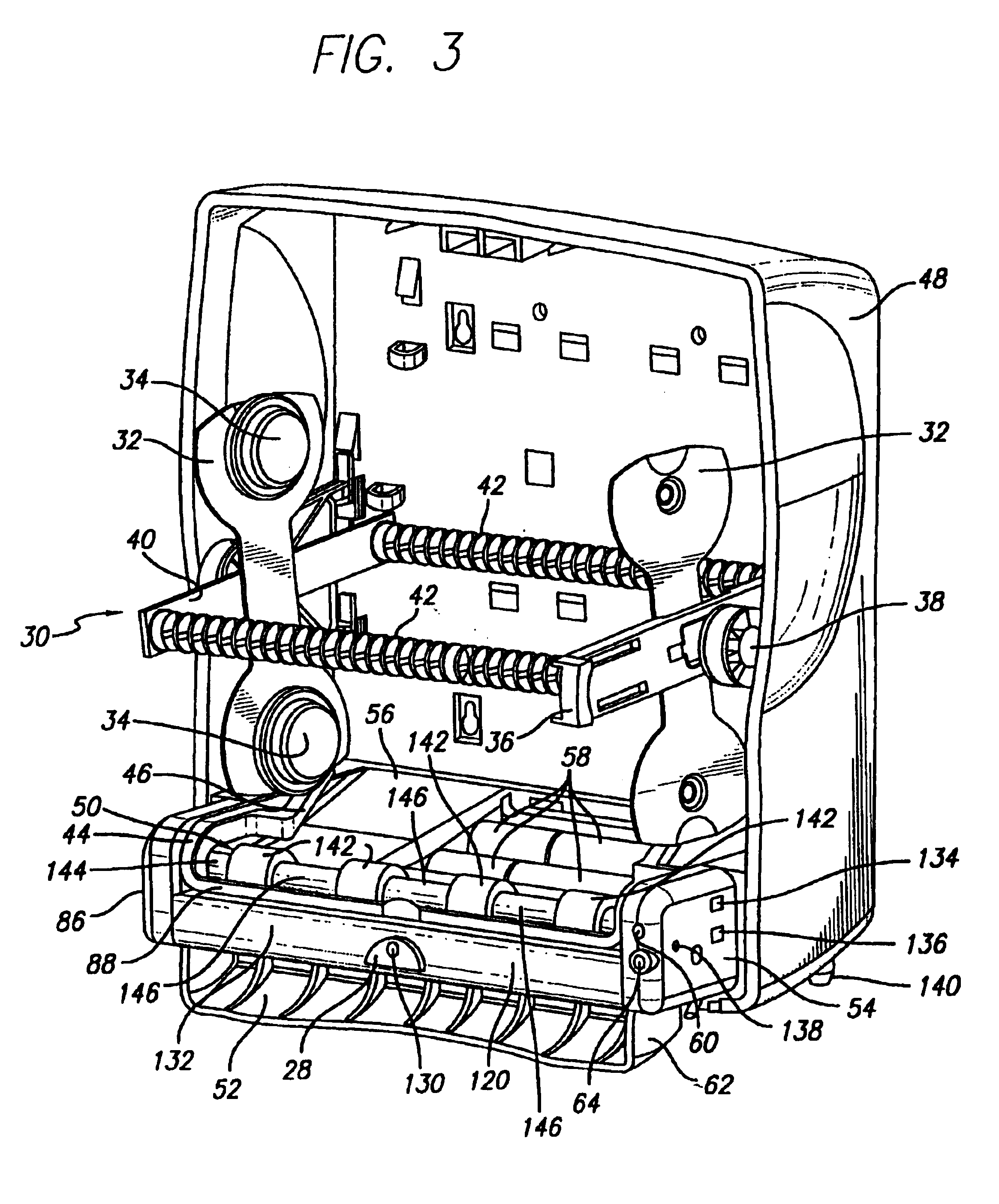

Hands-free paper towel dispensers

A hands-free paper towel dispenser including a housing with a front cover pivotally attached thereto. A sensor is disposed entirely within the housing, and mounted so that it is not attached to the front cover and oriented toward the front cover of the housing to detect an object adjacent the front cover of the housing without the object contacting the front cover. A dispensing mechanism is disposed within the housing for dispensing a length of towel, with the dispensing mechanism including a drive roller and a motor in driving engagement with the drive roller. Control circuitry controls operation of the sensor and the motor, with the control circuitry including a circuit to control the length of towel that is dispensed, and a circuit to provide a delay between dispensing cycles. The dispenser also includes an electric power source for powering operation of the dispenser.

Owner:WAUSAU PAPER TOWEL & TISSUE

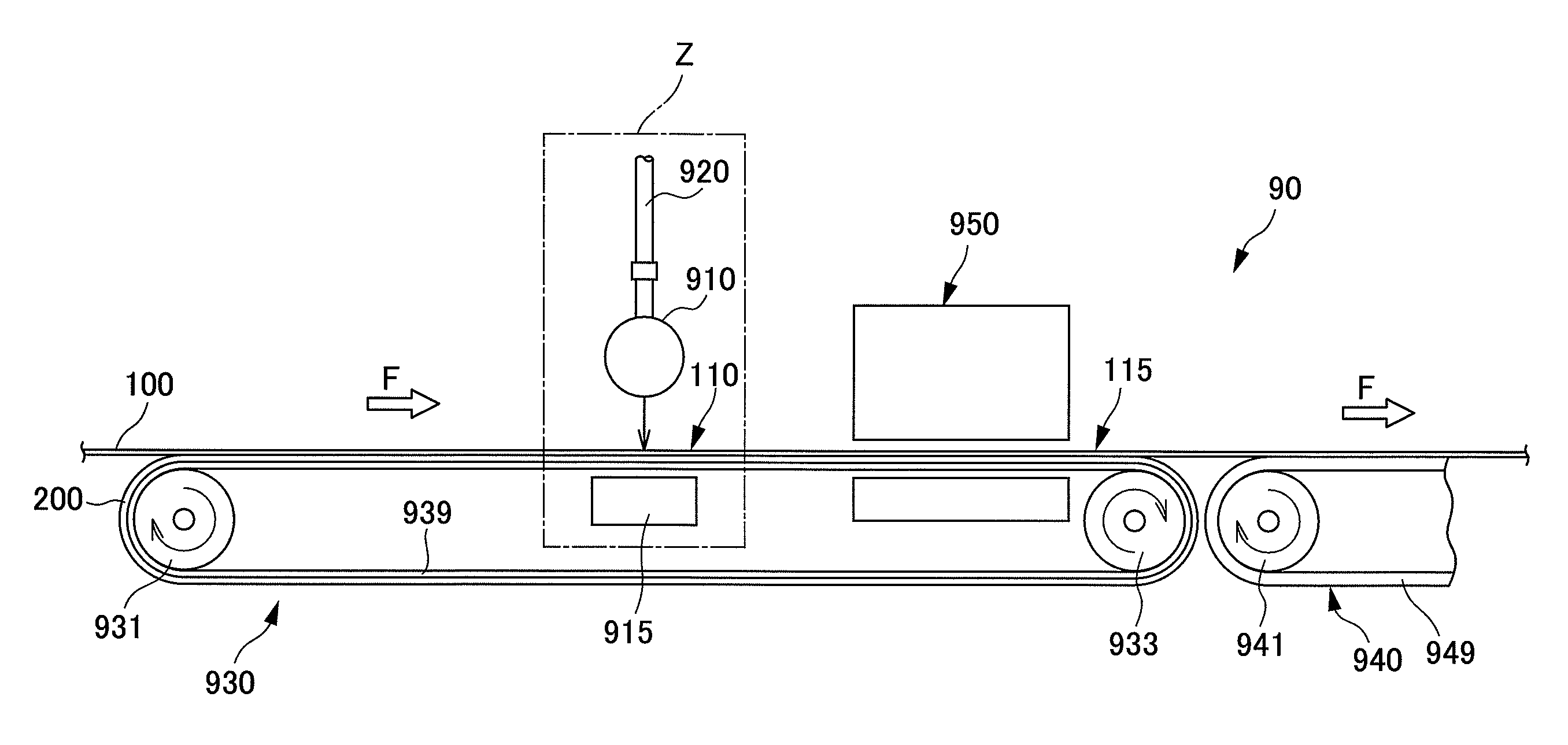

Nonwoven fabric, nonwoven fabric manufacturing method, and nonwoven fabric manufacturing apparatus

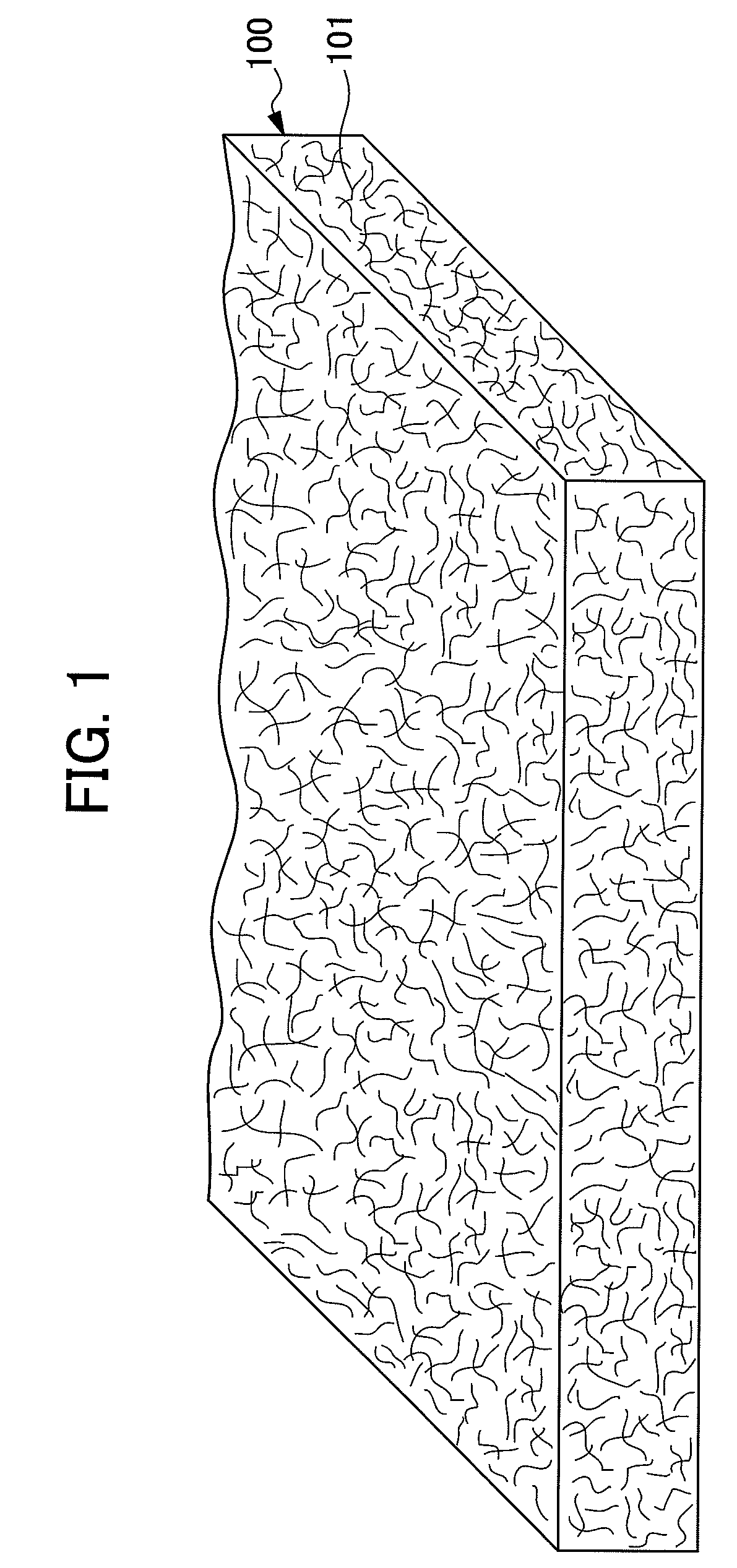

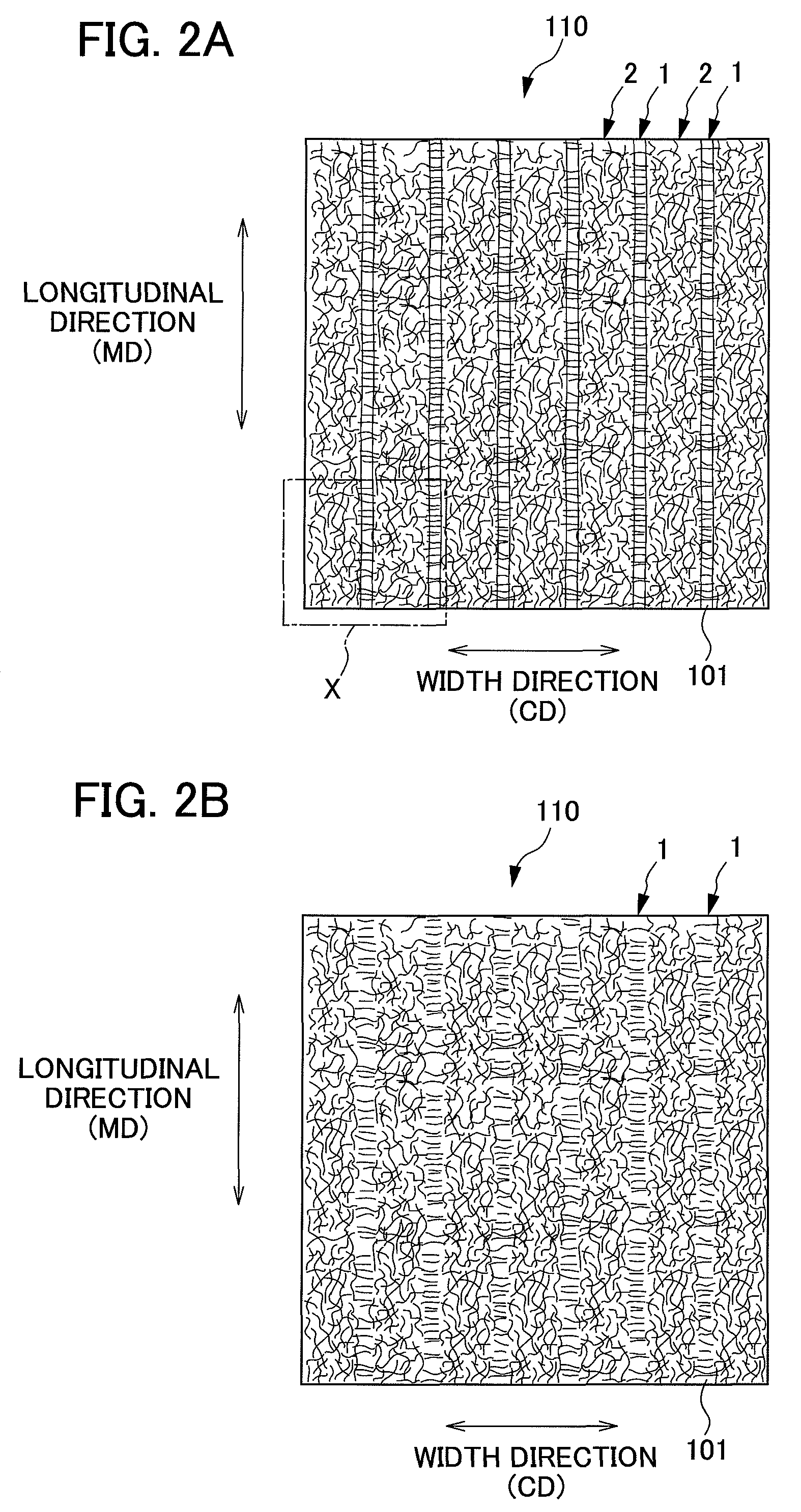

The present invention provides a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, and in which at least one of a predetermined groove portion, an opening, and a protrusion is formed, a manufacturing method for the nonwoven fabric, and a nonwoven fabric manufacturing apparatus. The nonwoven fabric manufacturing apparatus of the present invention manufactures a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, or in which at least one of a predetermined groove portion, an opening, and a protrusion is formed by blowing fluid mainly containing gas onto a fiber web which is formed in a sheet shape, and which is in a state where at least a portion of the fibers constituting the fiber aggregate has a degree of freedom.

Owner:UNI CHARM CORP

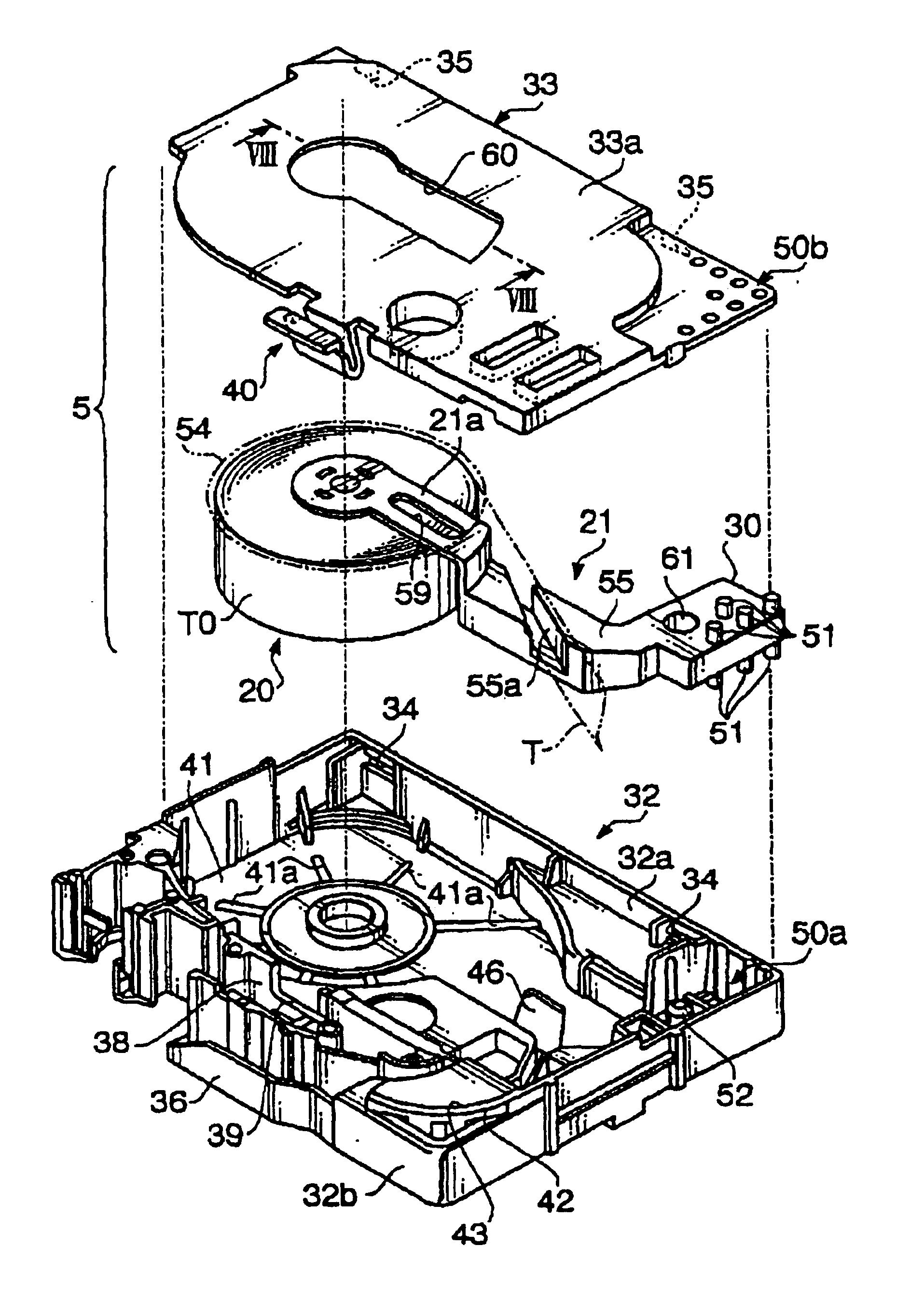

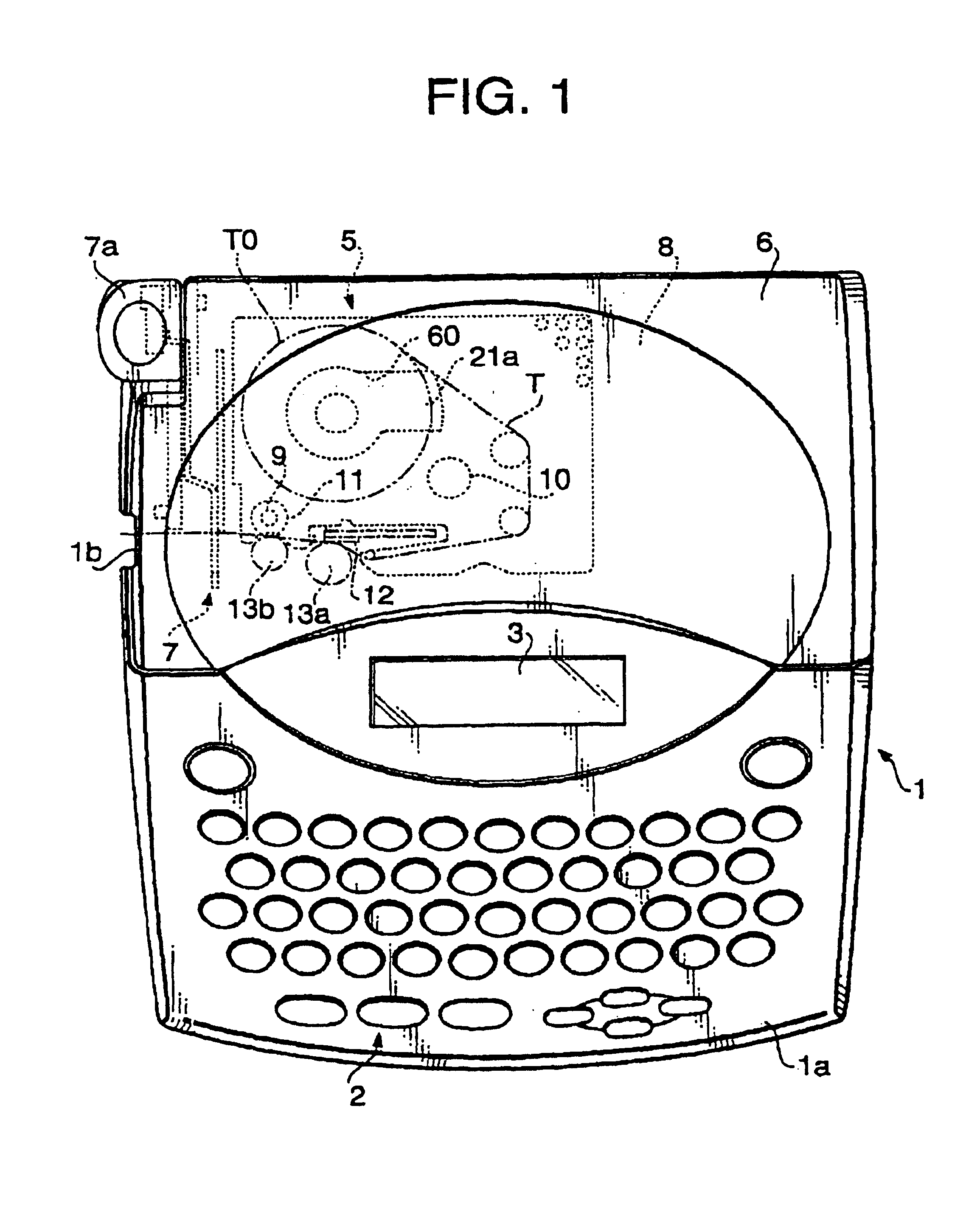

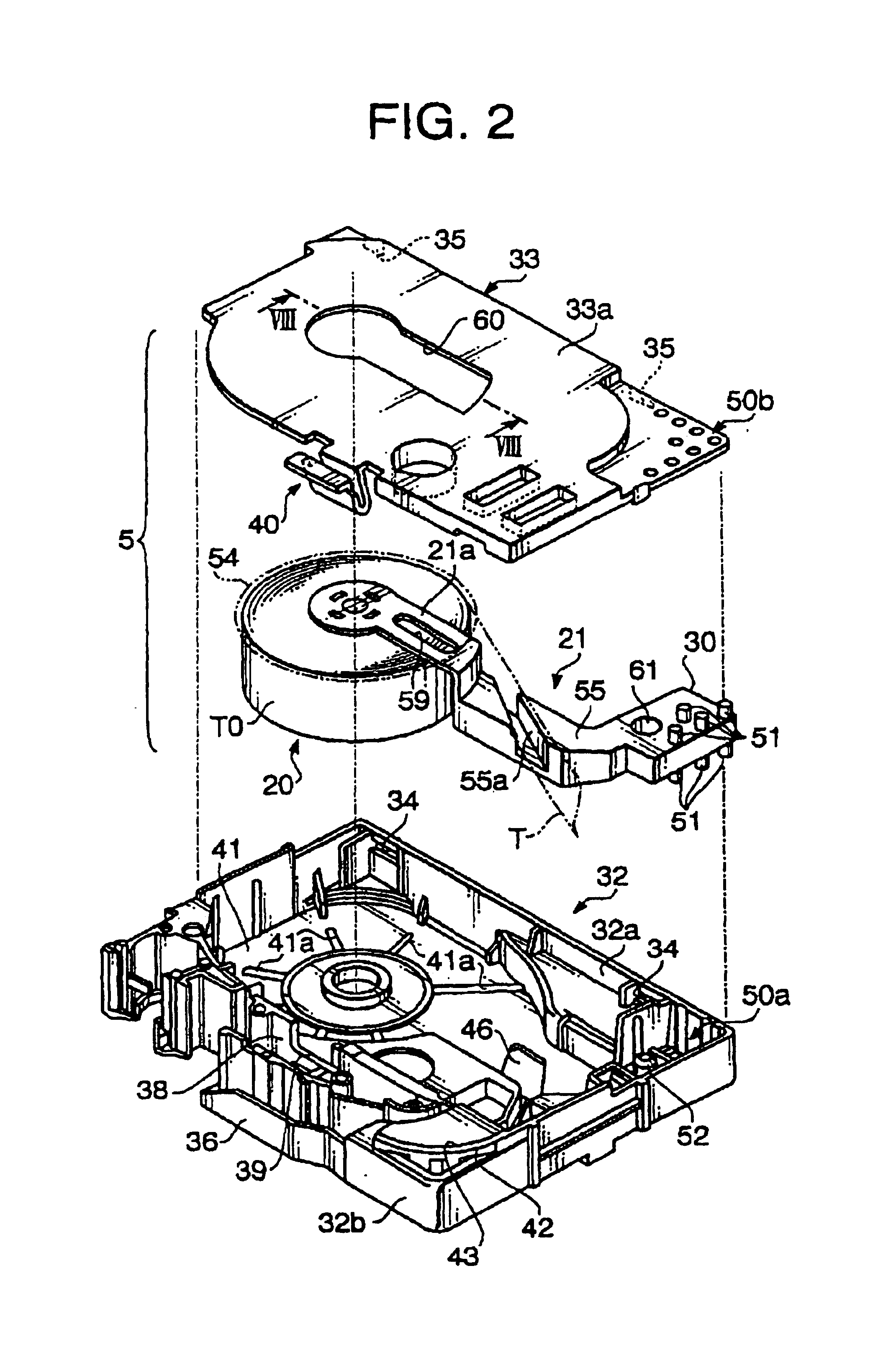

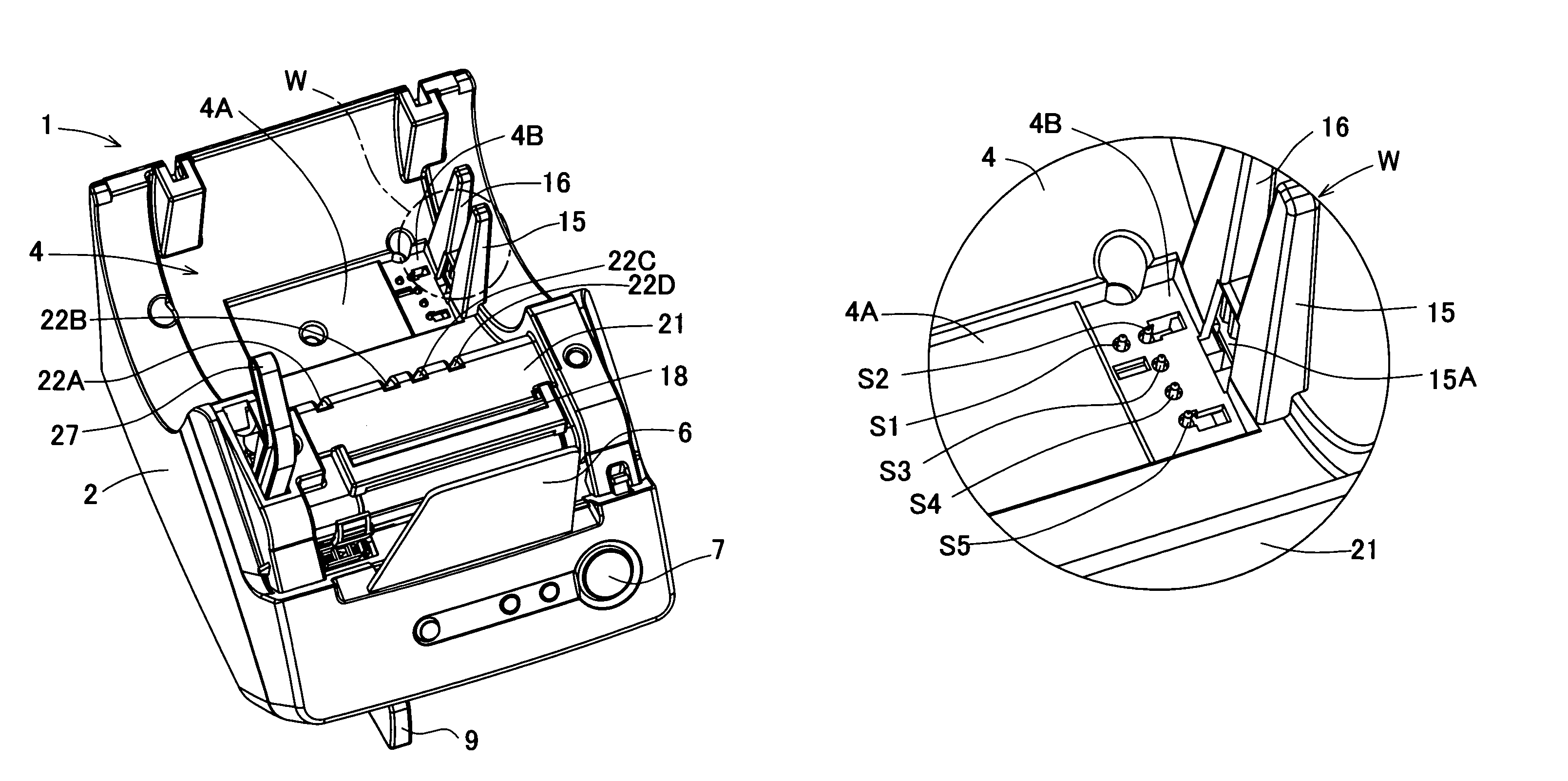

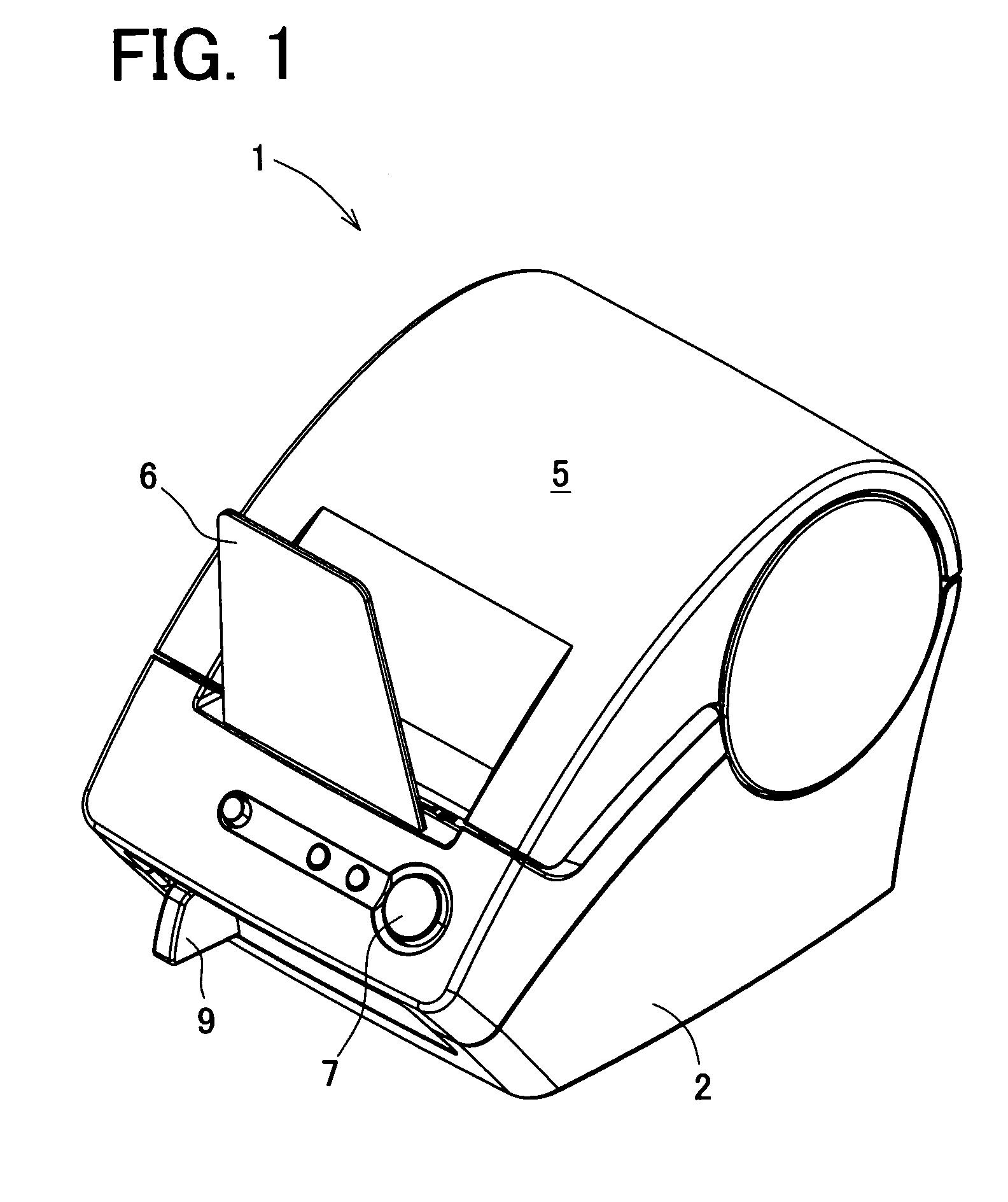

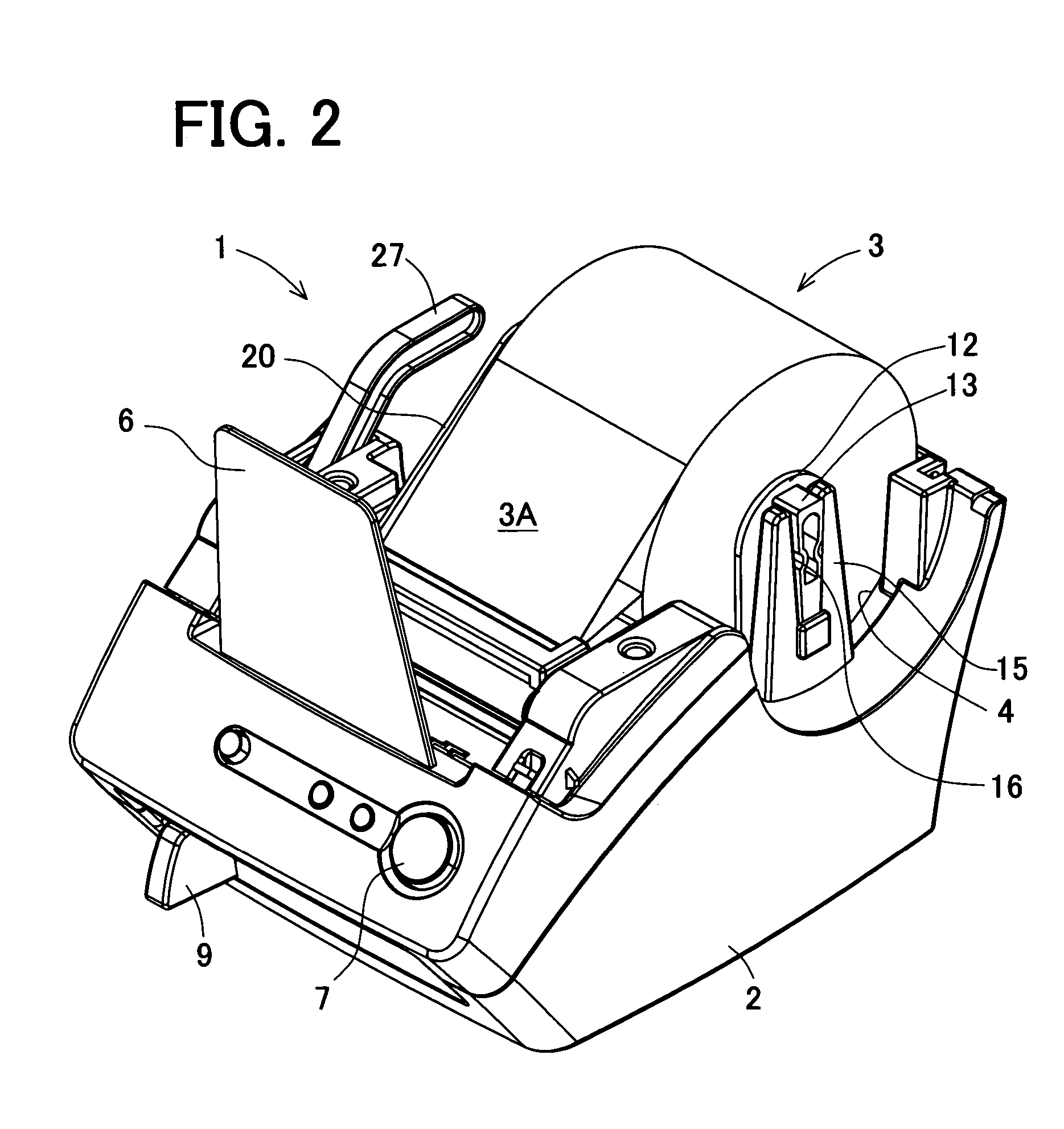

Tape cassette and tape unit

InactiveUS6955318B2Erroneous loadingPicture changing apparatusInking apparatusMagnetic tapeCassette tape

Owner:BROTHER KOGYO KK

Static build-up control in dispensing system

A method of grounding a dispenser. A low impedance path is connected to elements internal to the dispenser. The low impedance path is also connected to a surface contact spring which is adapted to contact an external mounting surface when the dispenser is affixed thereto. Static electrical charge accumulated on the elements is discharged through the low impedance path and the surface contact spring to the external mounting surface.

Owner:GPCP IP HLDG LLC

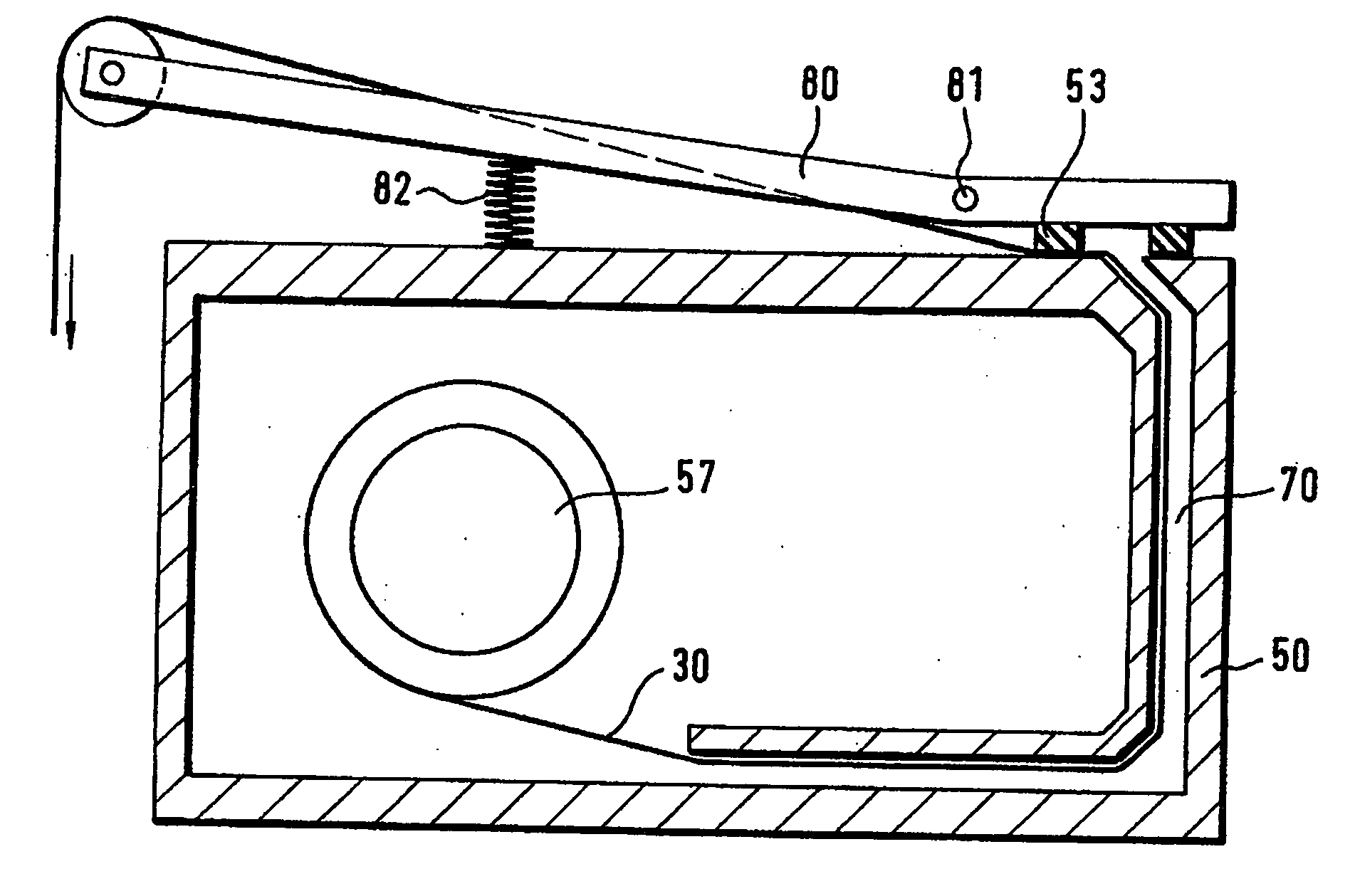

Adjusting device for tightening or loosing laces and straps

An adjusting device for tightening or loosing laces and straps includes a base, an actuating member and a knob. When a user rotates the knob clockwise, the adjusting device is tightening a flexible strap of the clothing or a lace of the footwear. However, when a user rotates the knob counterclockwise, the adjusting device is loosing a flexible strap of the clothing or a lace of the footwear. The knob never moves up and down along the axis during the operation for tightening or loosing the flexible strap or the lace.

Owner:CHEN CHIN CHU

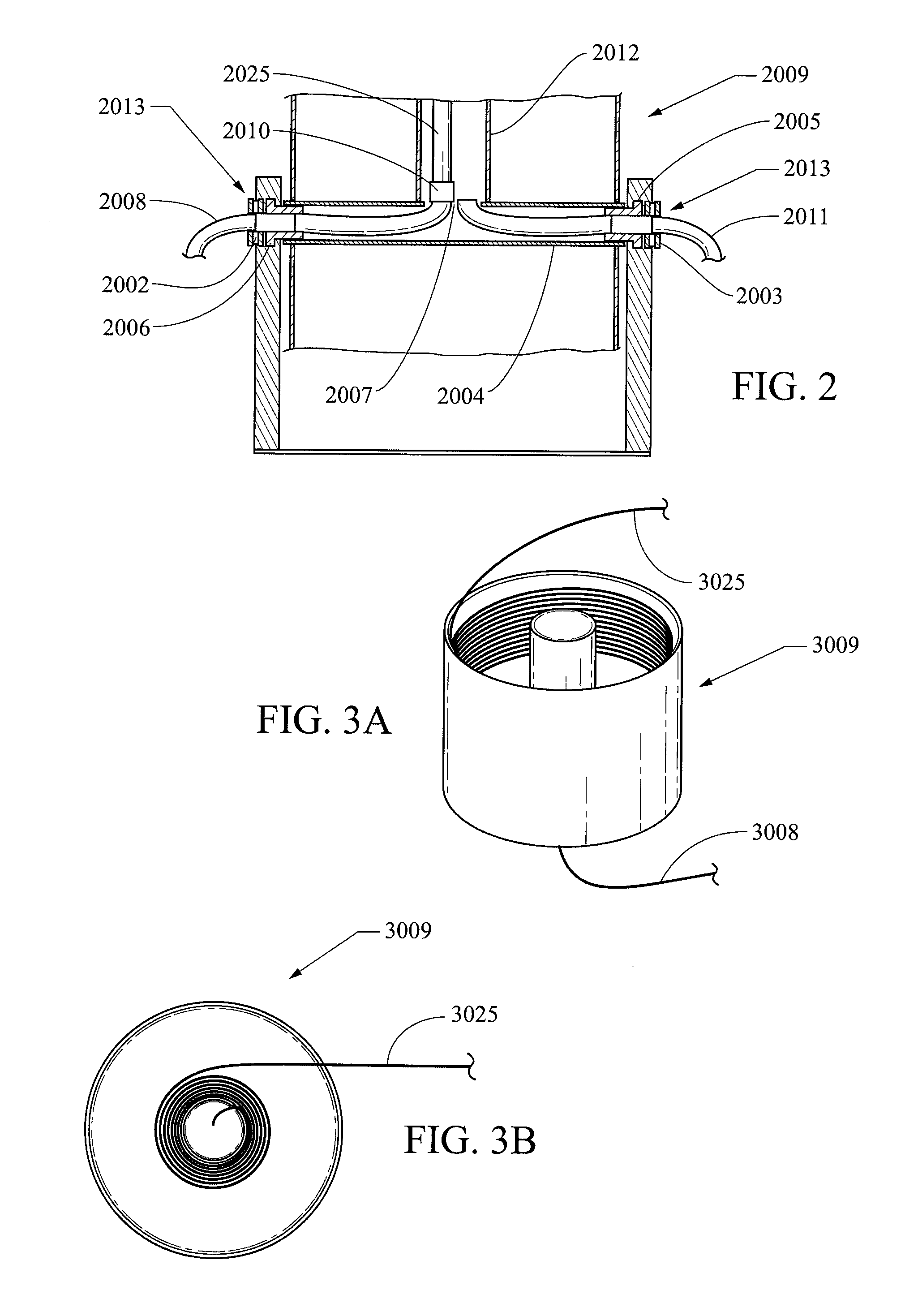

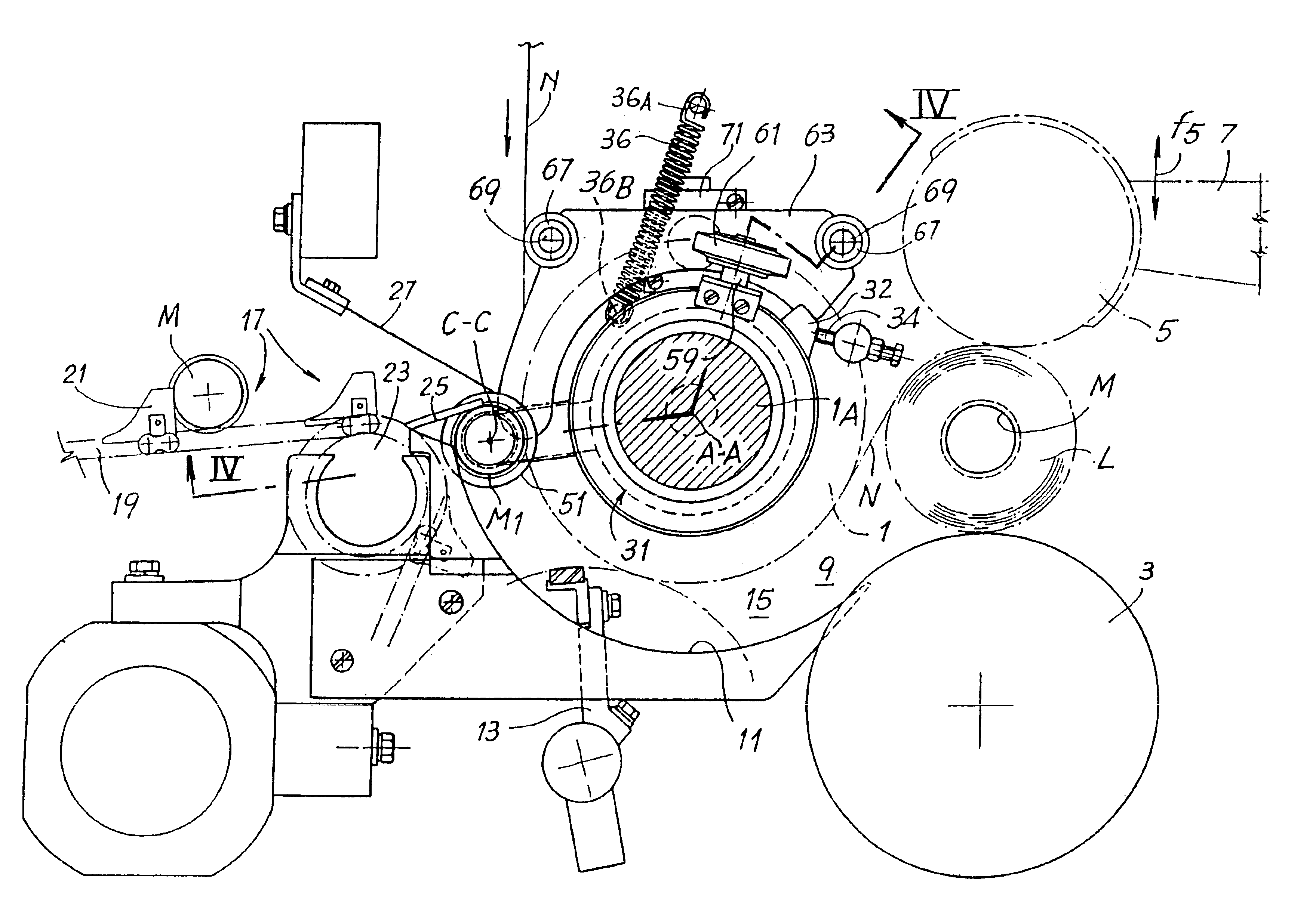

Method and device for the production of rolls of web material without a winding core

InactiveUS6595458B1Suitable for high production speedEfficient and fast and reliableFilament handlingWebs handlingEngineeringInsertion device

A surface rewinding machine for the production of rolls of wound web material is described. The machine comprises: a winding cradle (1, 3, 5) for winding the web material and sequentially forming rolls (R) of wound web material; an insertion device (25) for inserting sequentially, into said winding cradle, winding spindles (M1; M) on which the rolls are formed; an insertion path for the spindles inside the winding cradle. A suction system (51) which follows the spindles along at least one portion of the insertion path so as to produce a vacuum inside the spindles is also envisaged.

Owner:FABIO PERINI SPA

Roll sheet holder and tape printer

ActiveUS7070348B2Avoid partialImprove detection accuracyInking apparatusProjector film strip handlingRolling paperEngineering

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com