Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1489results about "Pattern making" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for creating and sharing purchasing lists on a network

InactiveUS6925444B1Minimize network communicationImprove securityAdvertisementsPattern makingPurchasingWorld Wide Web

A system and method create and share purchasing lists in a network system. The system and method utilize a consumer user interface. The consumer user interface provides the consumer the ability to create a purchase list by receiving advertisement data on the consumer device, selecting an item desired for purchase, identifying the purchase list for the item to be saved, creating the purchase list if the purchase list identified does not exist, and saving the item to the identified purchase list. The consumer user interface further provides the consumer the ability to share a purchase list by identifying a purchase list to be shared, converting the purchase list to the appropriate format, identifying a recipient of the purchase list, and transmitting the purchase list to the recipient.

Owner:KNAPP INVESTMENT

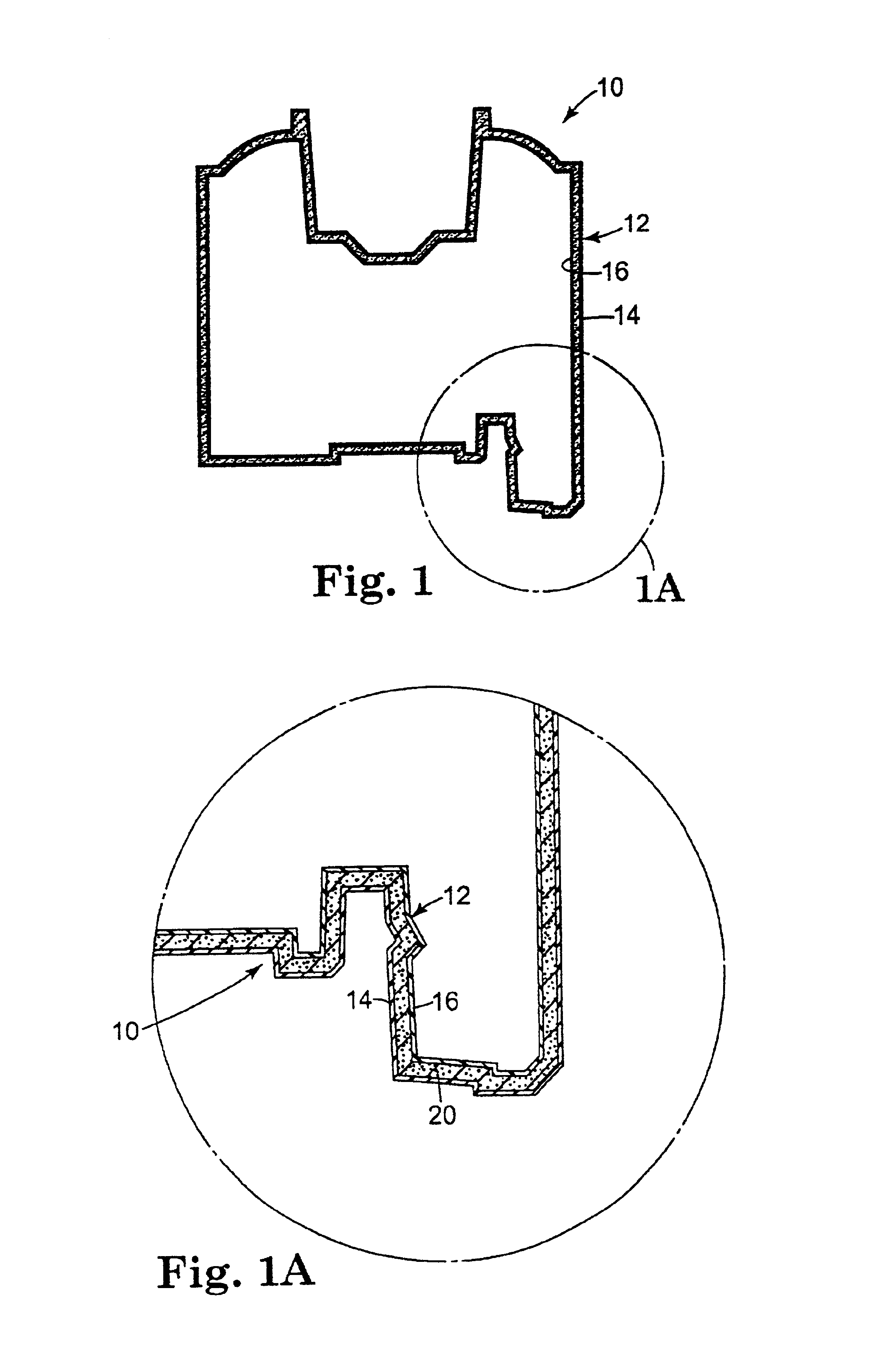

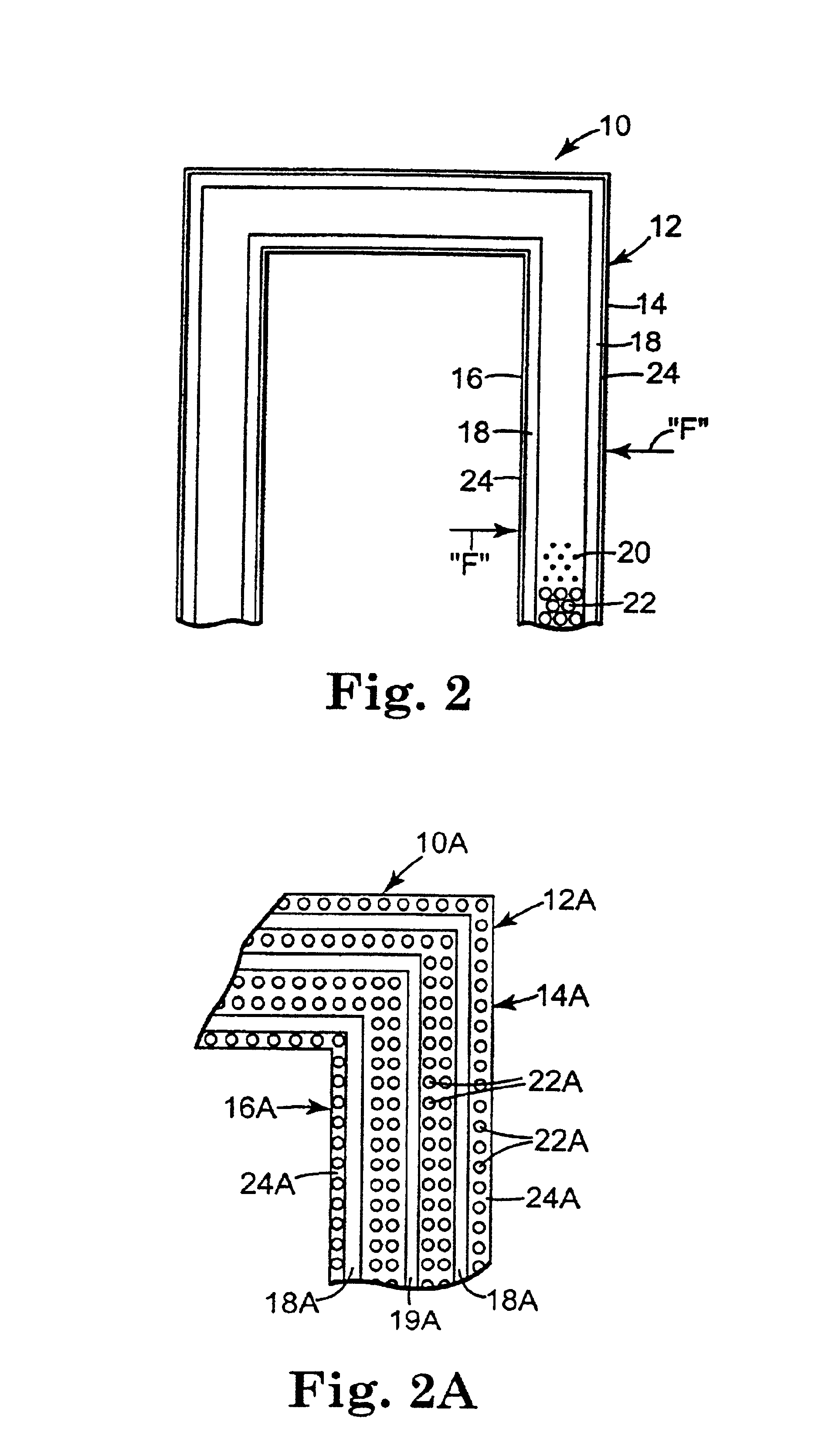

Dressing

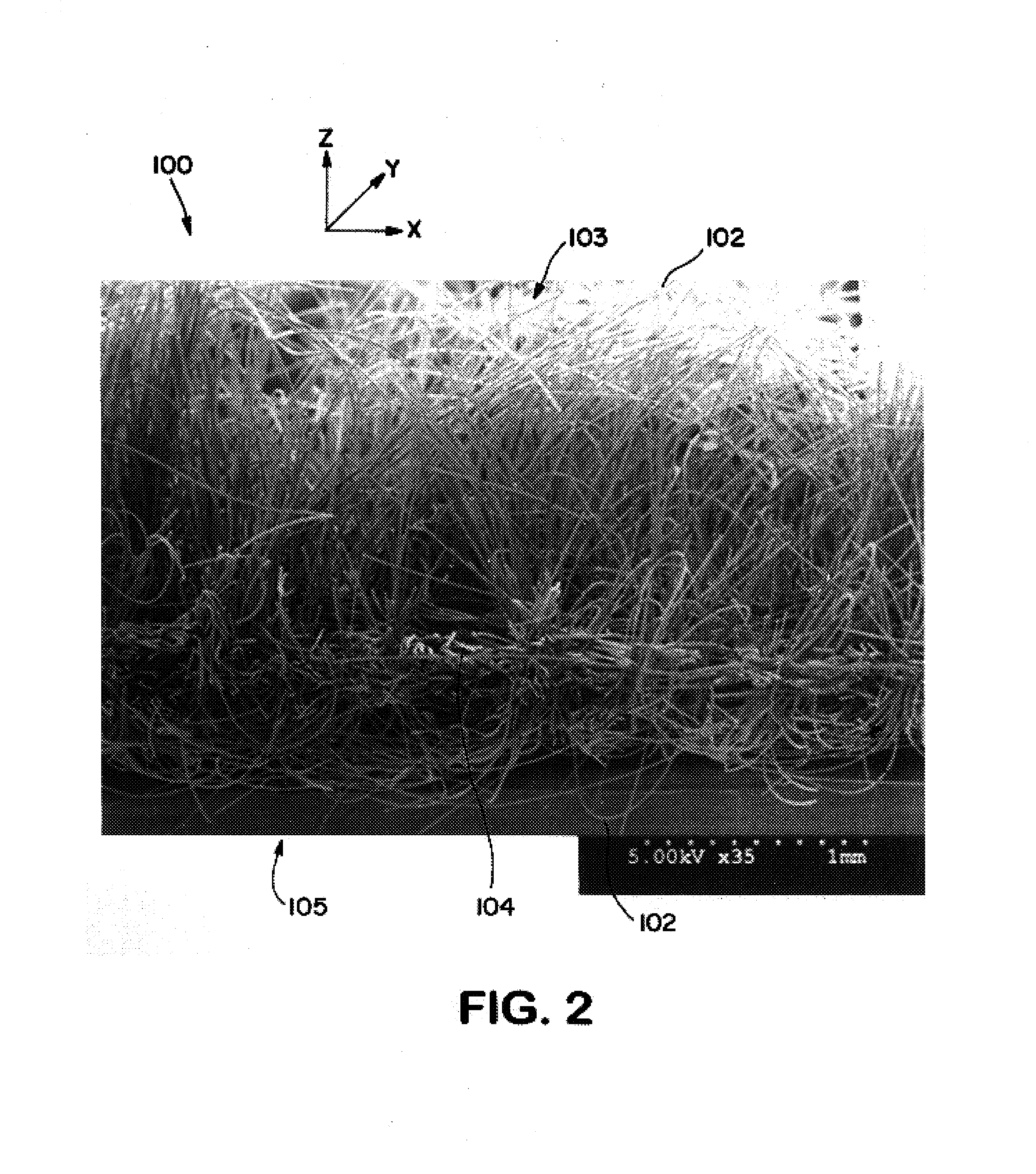

InactiveUS7112712B1Facilitates non-adhesionReduce absorptionNon-adhesive dressingsPattern makingPolyesterFiber

A dressing and a method of manufacturing a dressing. The dressing comprising an absorbent support fabric (2), and a polyester fiber sheet (1) attached to one surface of the absorbent support fabric to provide a wicking path such that exudates contacting an outer surface of the fiber sheet are wicked to the absorbent support fabric. The outer surface of the polyester fiber sheet is heat treated to hinder individual fibers from extending out of the surface and thereby produce a glazed effect. This glazed surface inhibits the dressing from sticking to a wound, and impedes exudate transported within the dressing from returning to the dressing surface.

Owner:PROTEX HEALTHCARE (UK) LIMITED

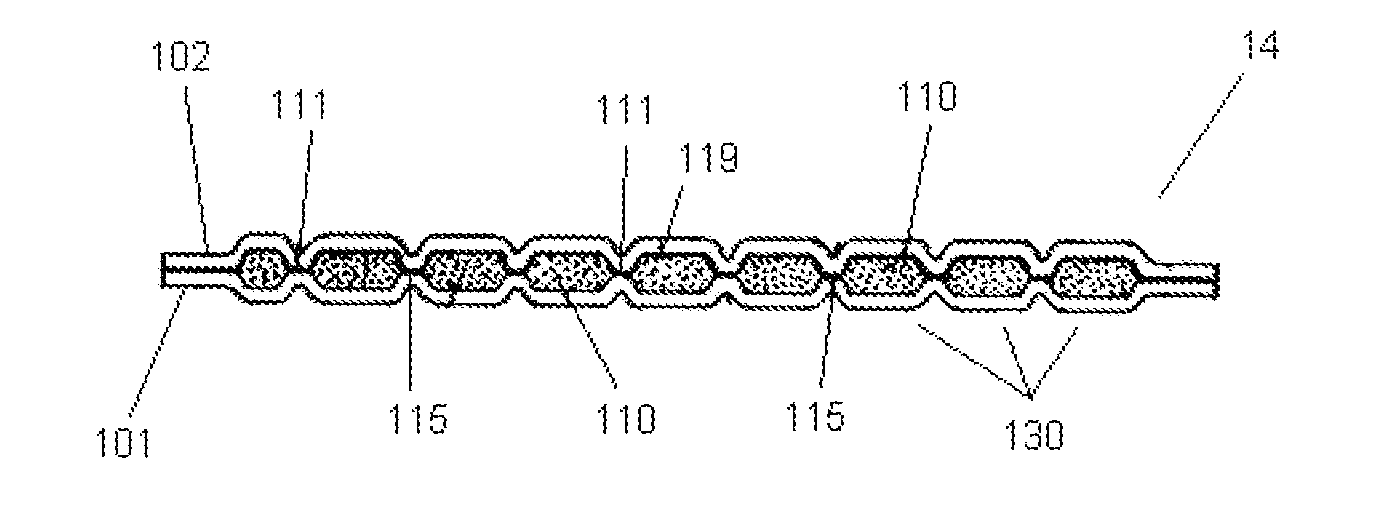

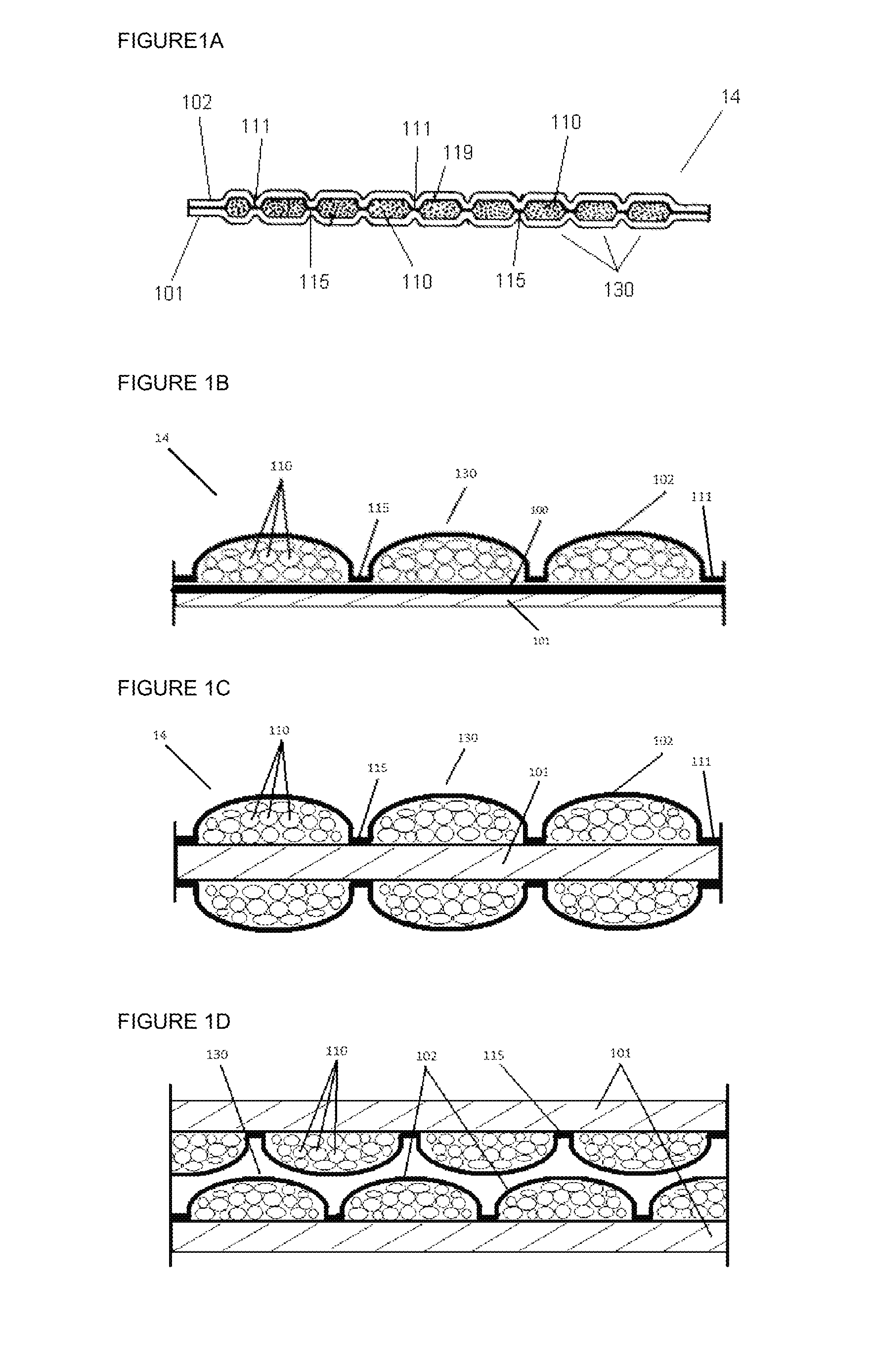

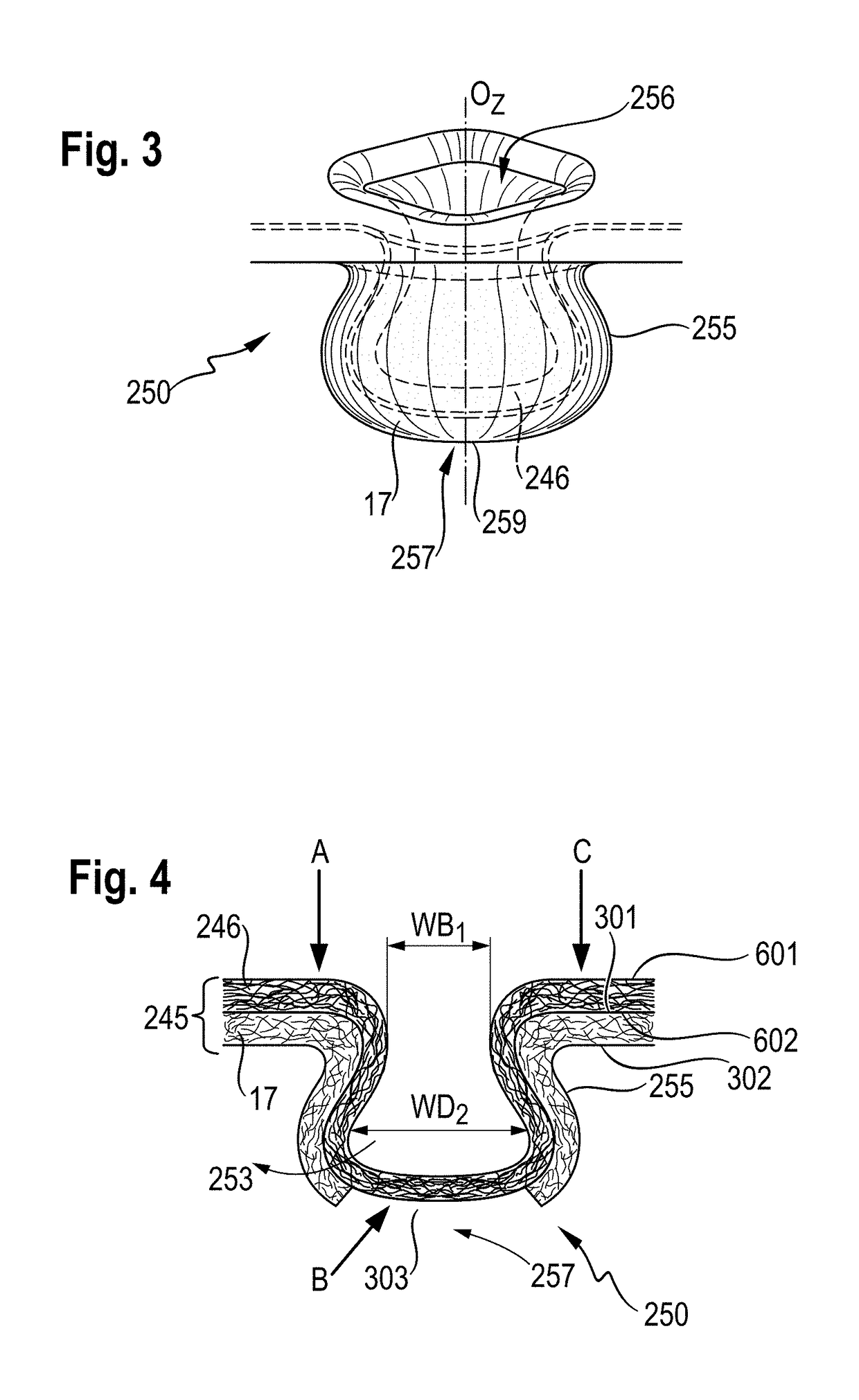

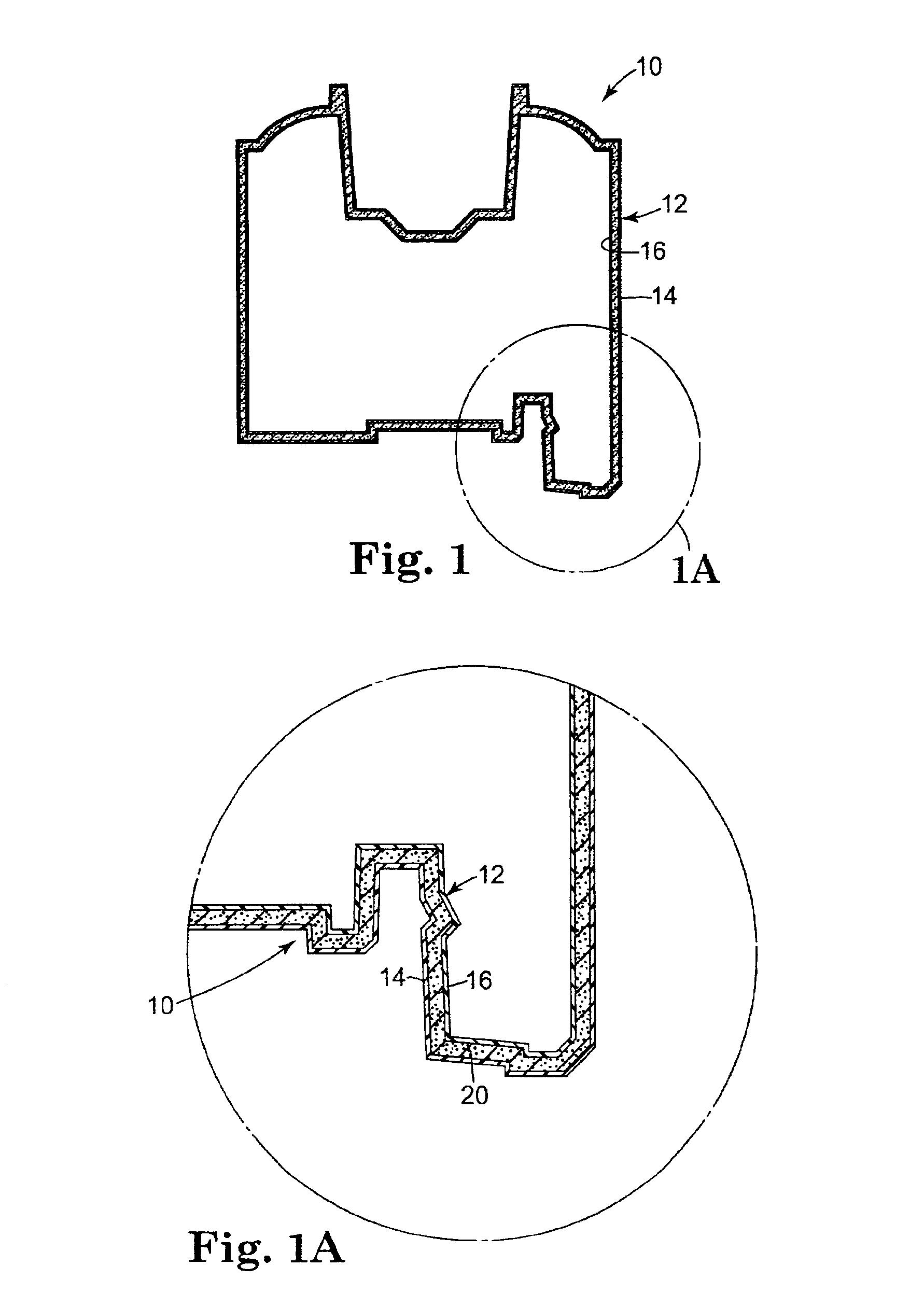

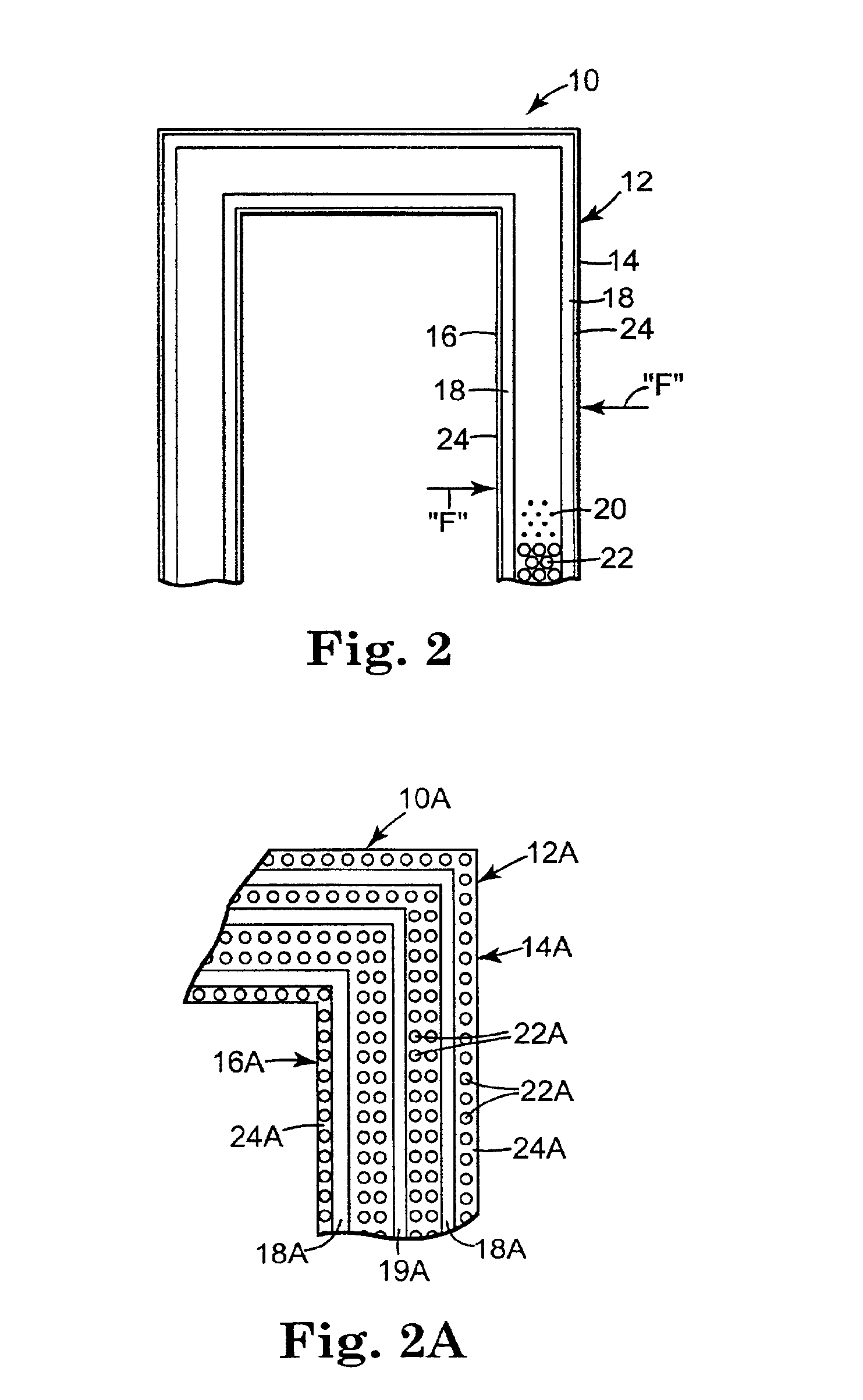

Absorbent structure

InactiveUS20130226120A1Excellent fluid managementInhibit migrationLiquid surface applicatorsPattern makingEngineeringFluid management

The present invention relates to an absorbent structure, preferably for use in absorbent products, such as used in the food, consumer, household, building and construction, beauty and medical industry, and as used in the personal hygiene industry. The substantially cellulose free absorbent structures continuously immobilise absorbent polymer material via initial smaller pockets and subsequently larger compartments allowing excellent fluid management of the absorbent polymer material in dry, partially and fully liquid loaded state. Preferably such absorbent structure volume increases are result of temporary secondary attachment patterns made in combination with substantially permanent primary attachment grids allowing the release of bigger volumes from the initial smaller volumes by detachment of the secondary attachments. Furthermore the absorbent structure according to an embodiment of the invention non-homogeneously swells to form a liquid-managing surface structure as a result of exposing the absorbent structure to liquid. The present invention foresees in the need for improved flexible, thin, lightweight absorbent structures which overcome the absorbency problems of the prior art during absorption, distribution and retention of liquids with optimal fit.

Owner:DRYLOCK TECHNILOGIES NV

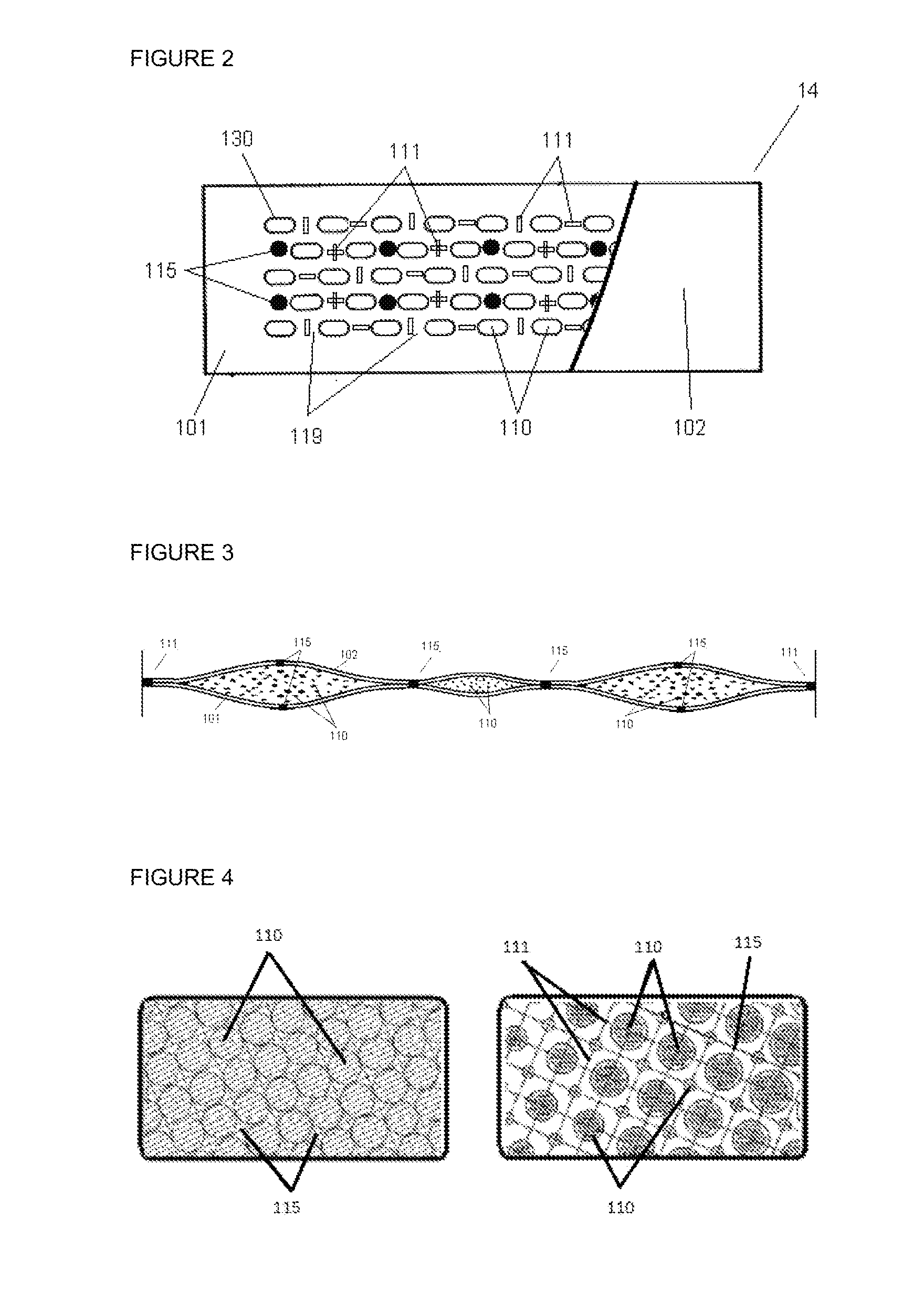

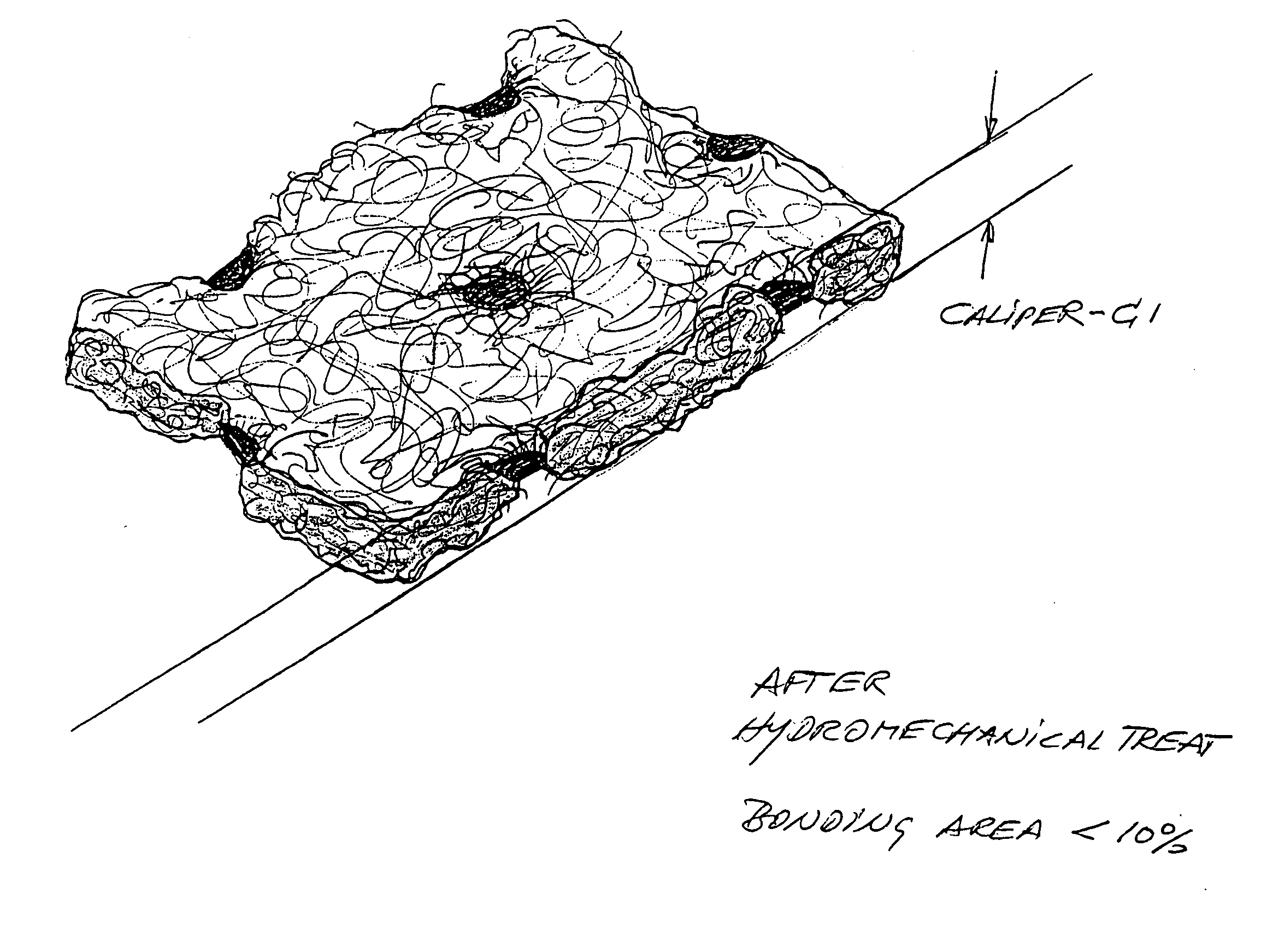

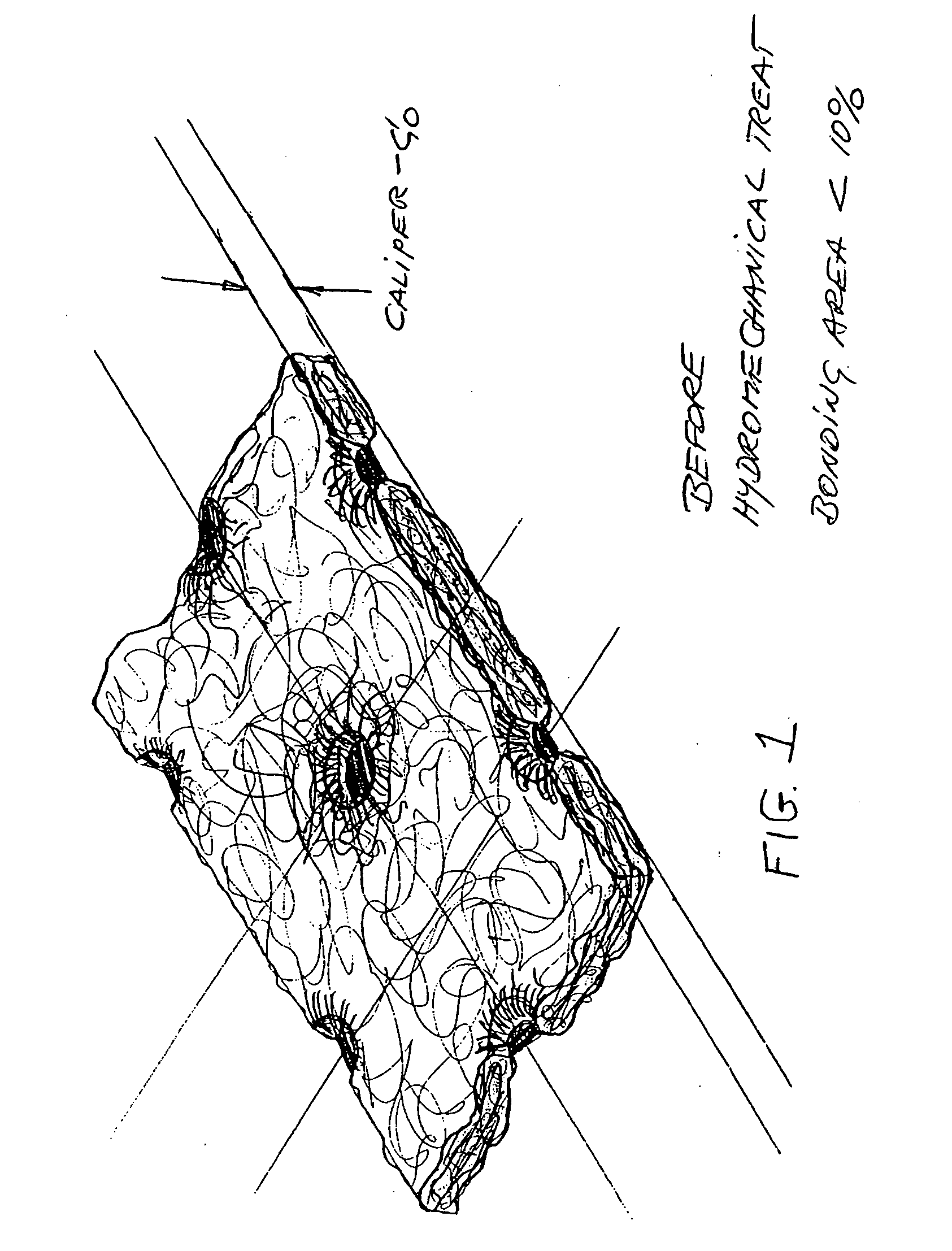

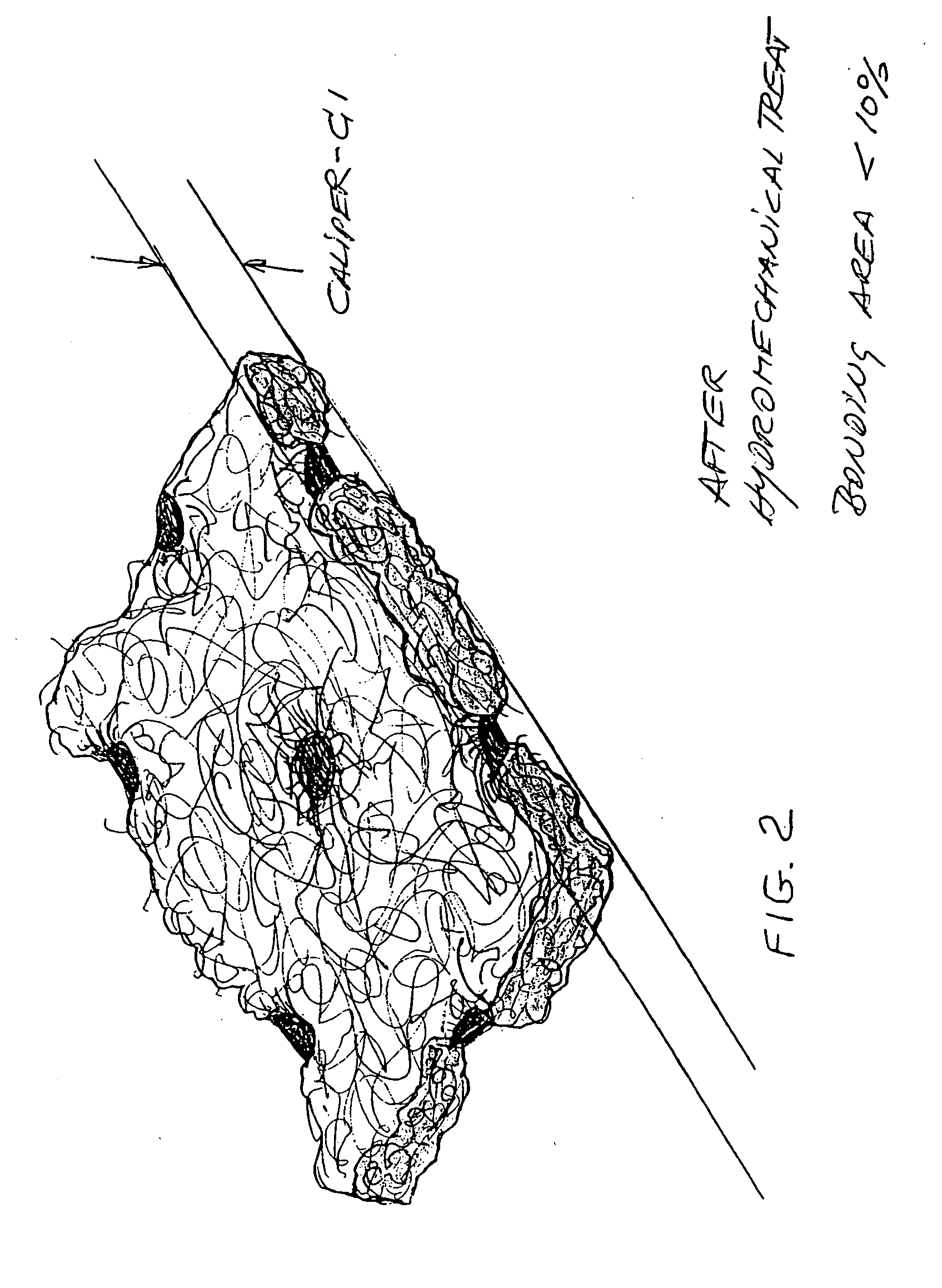

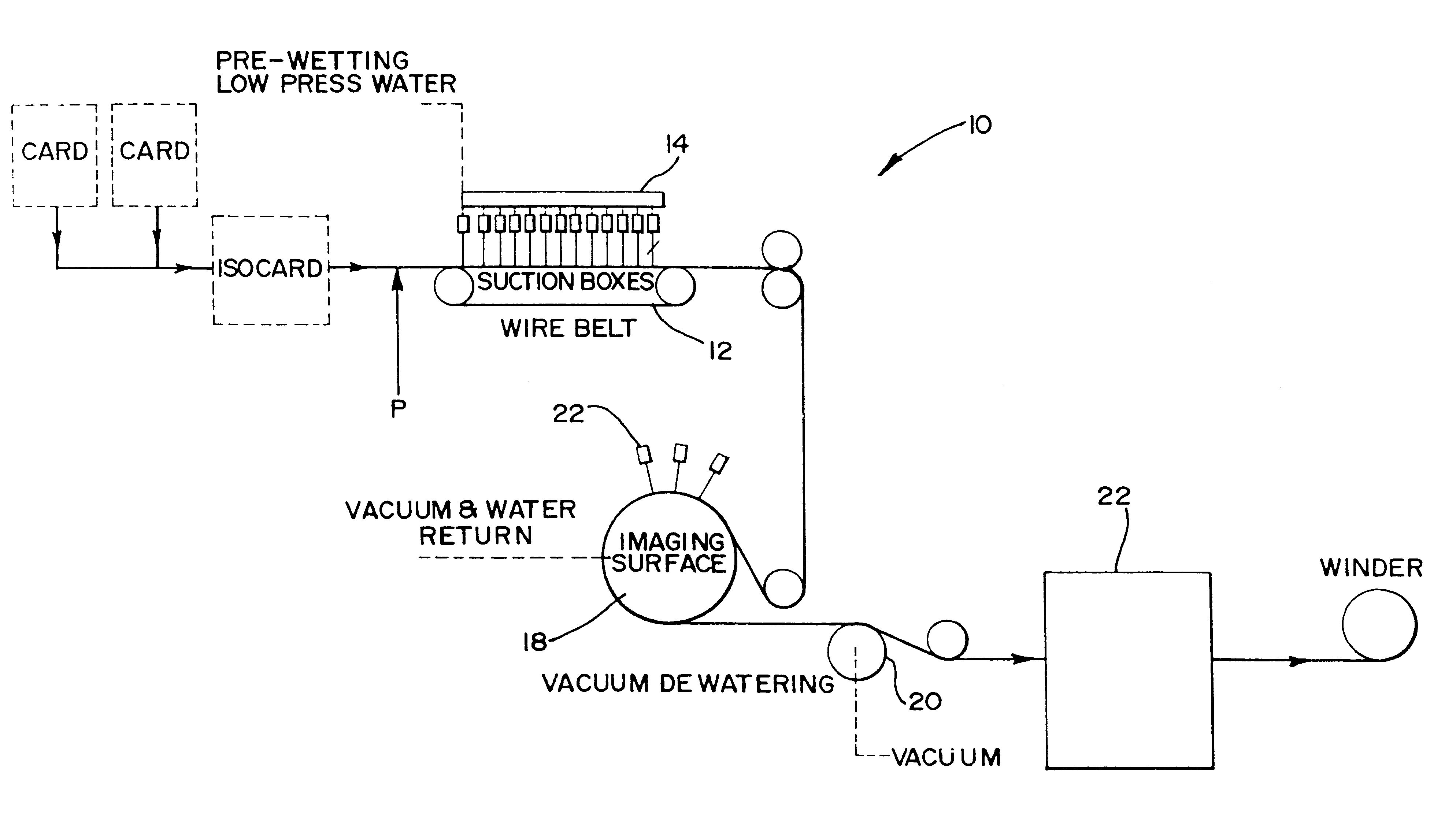

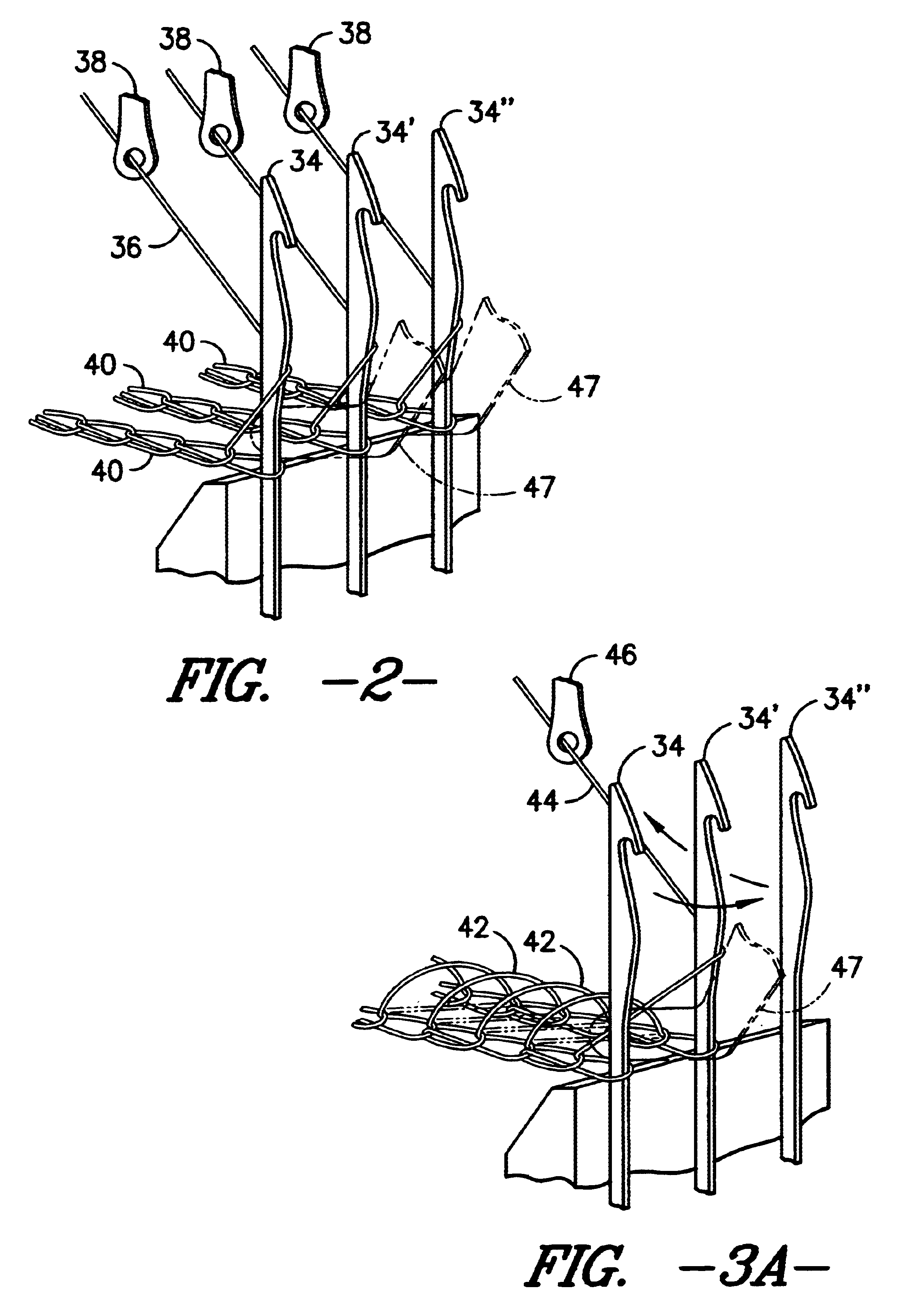

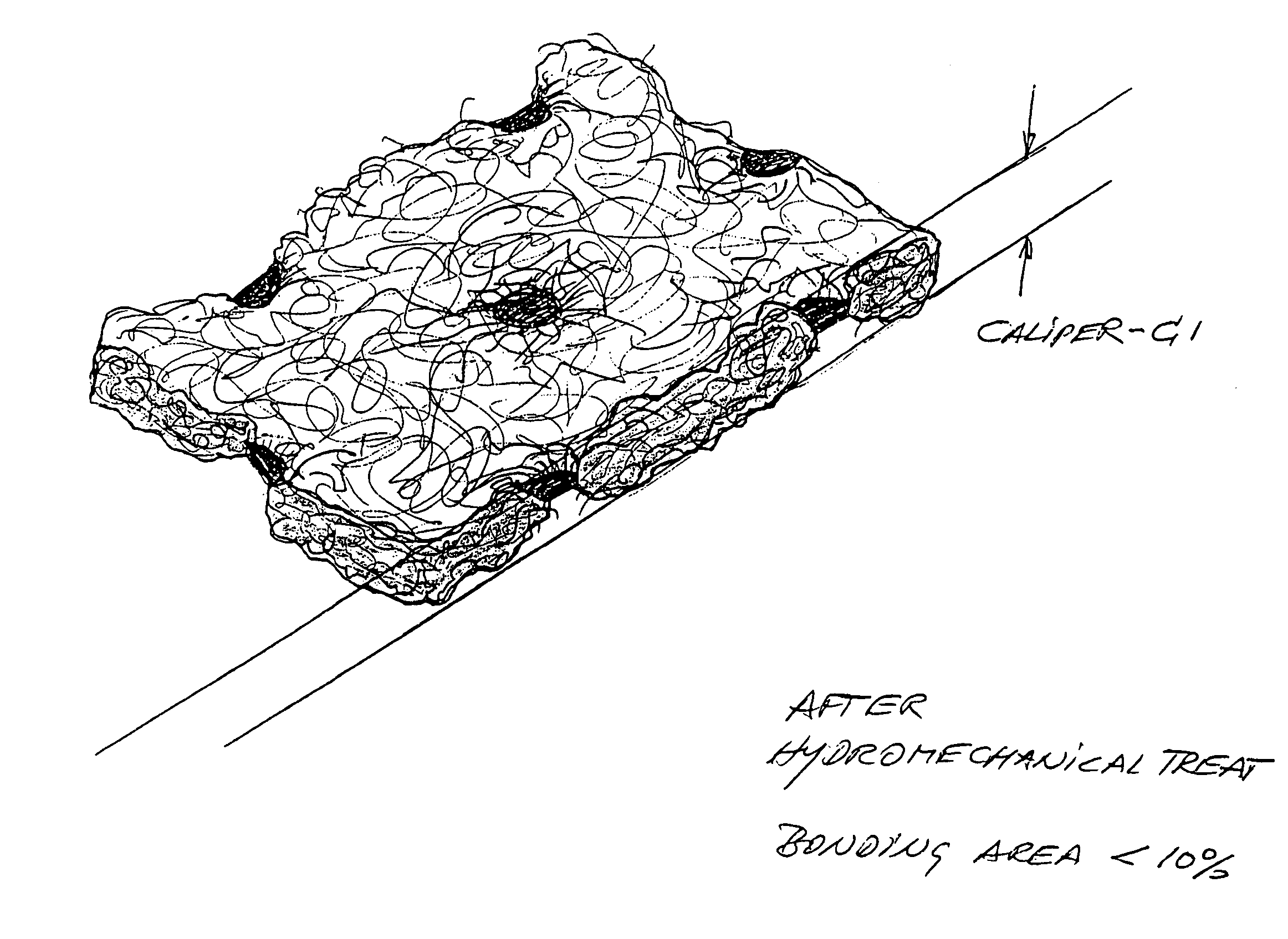

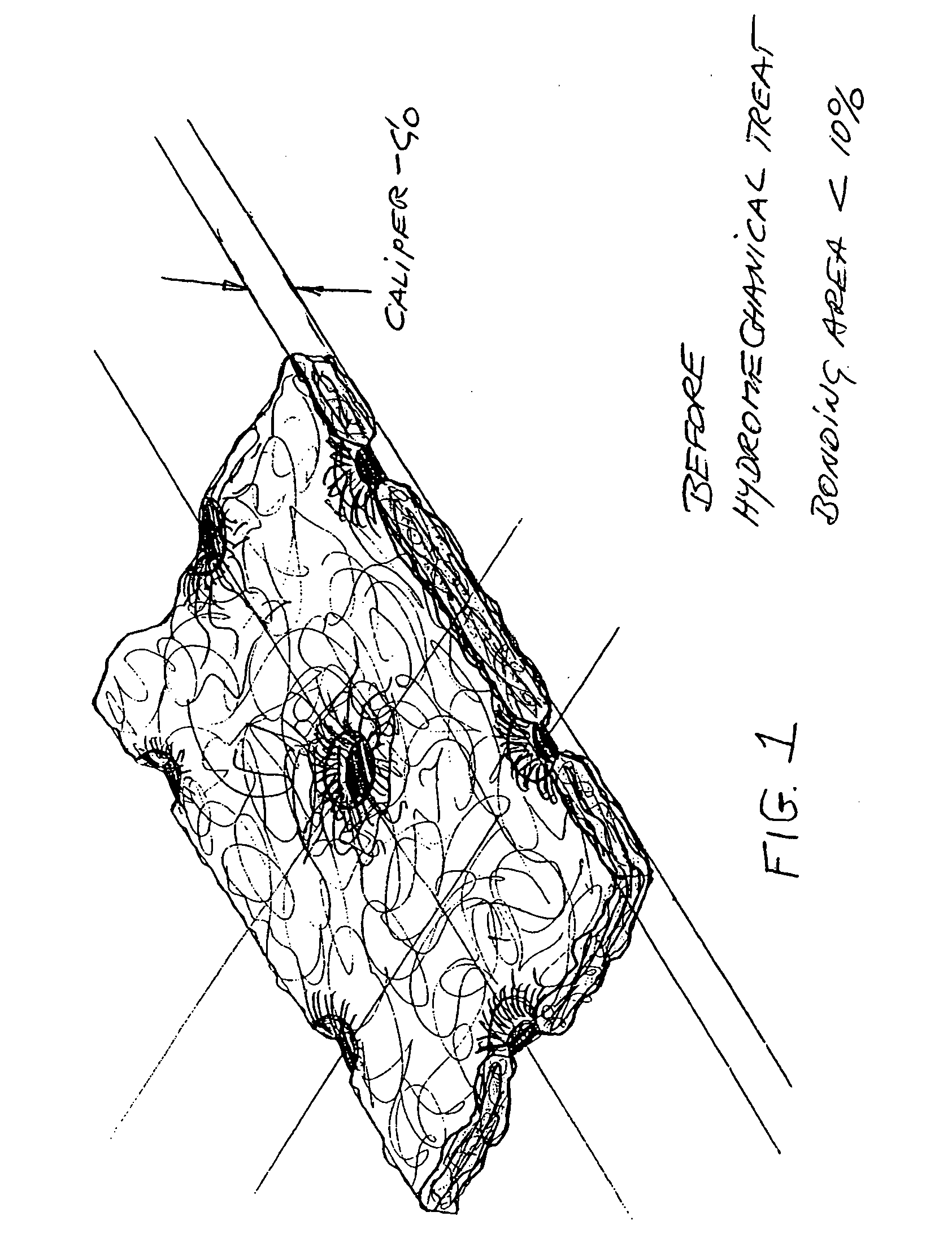

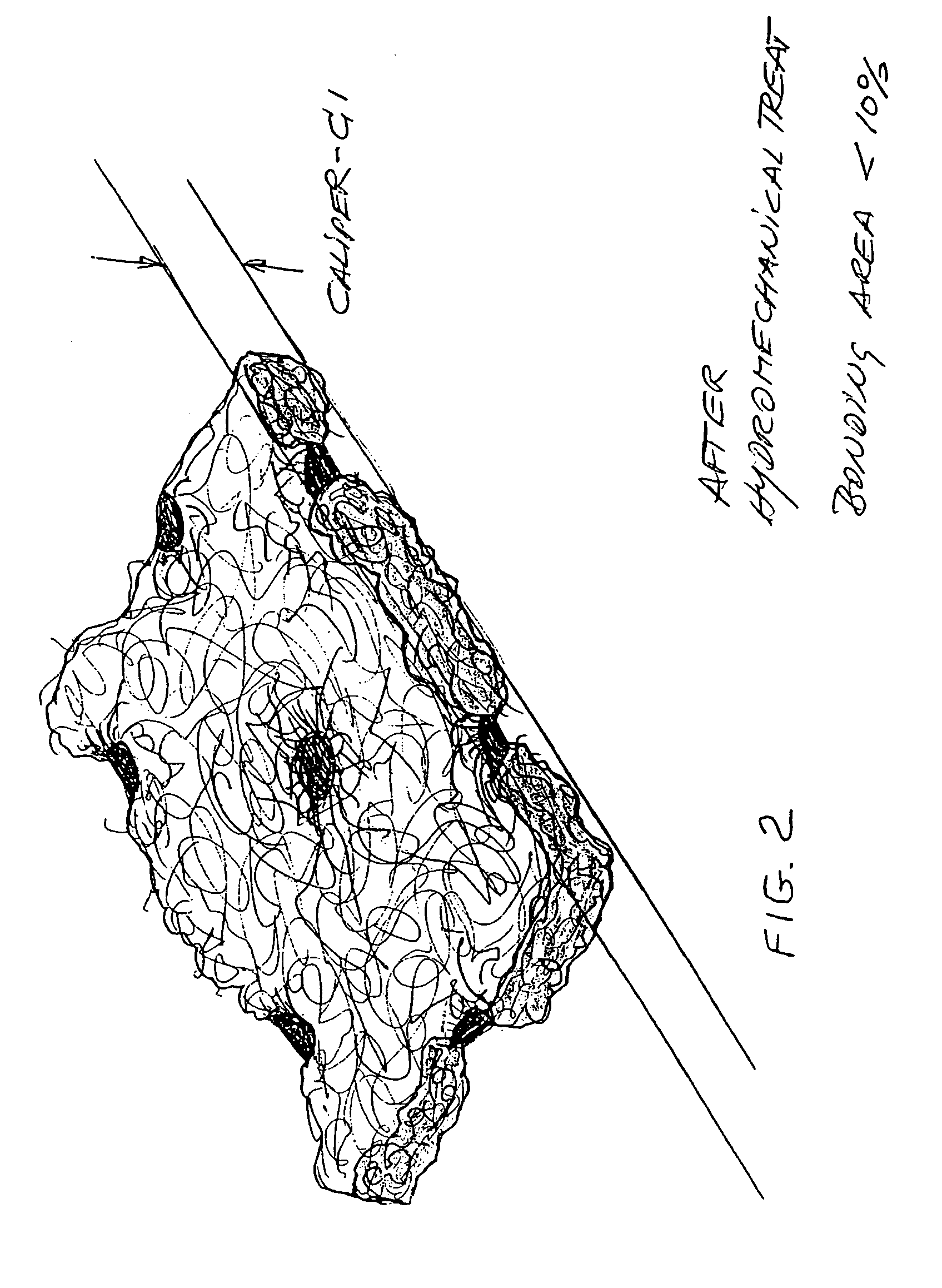

Hydroengorged spunmelt nonwovens

A hydroengorged spunmelt nonwoven formed of thermoplastic continuous fibers and a pattern of fusion bonds. The nonwoven has either a percentage bond area of less than 10 percent, or a percentage bond area of at least 10% wherein the pattern of fusion bonds is anisotropic.

Owner:FIRST QUALITY NONWOVENS

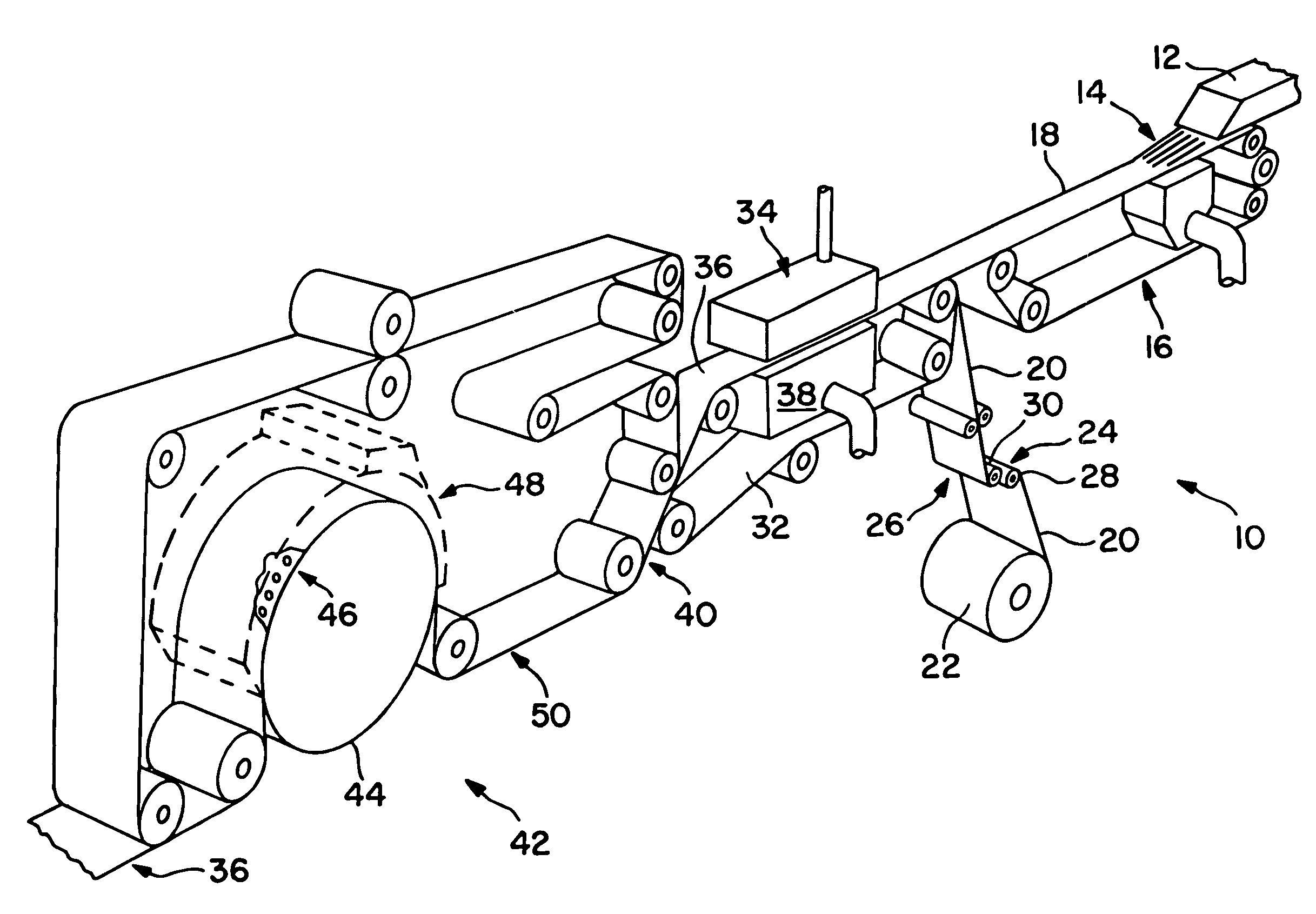

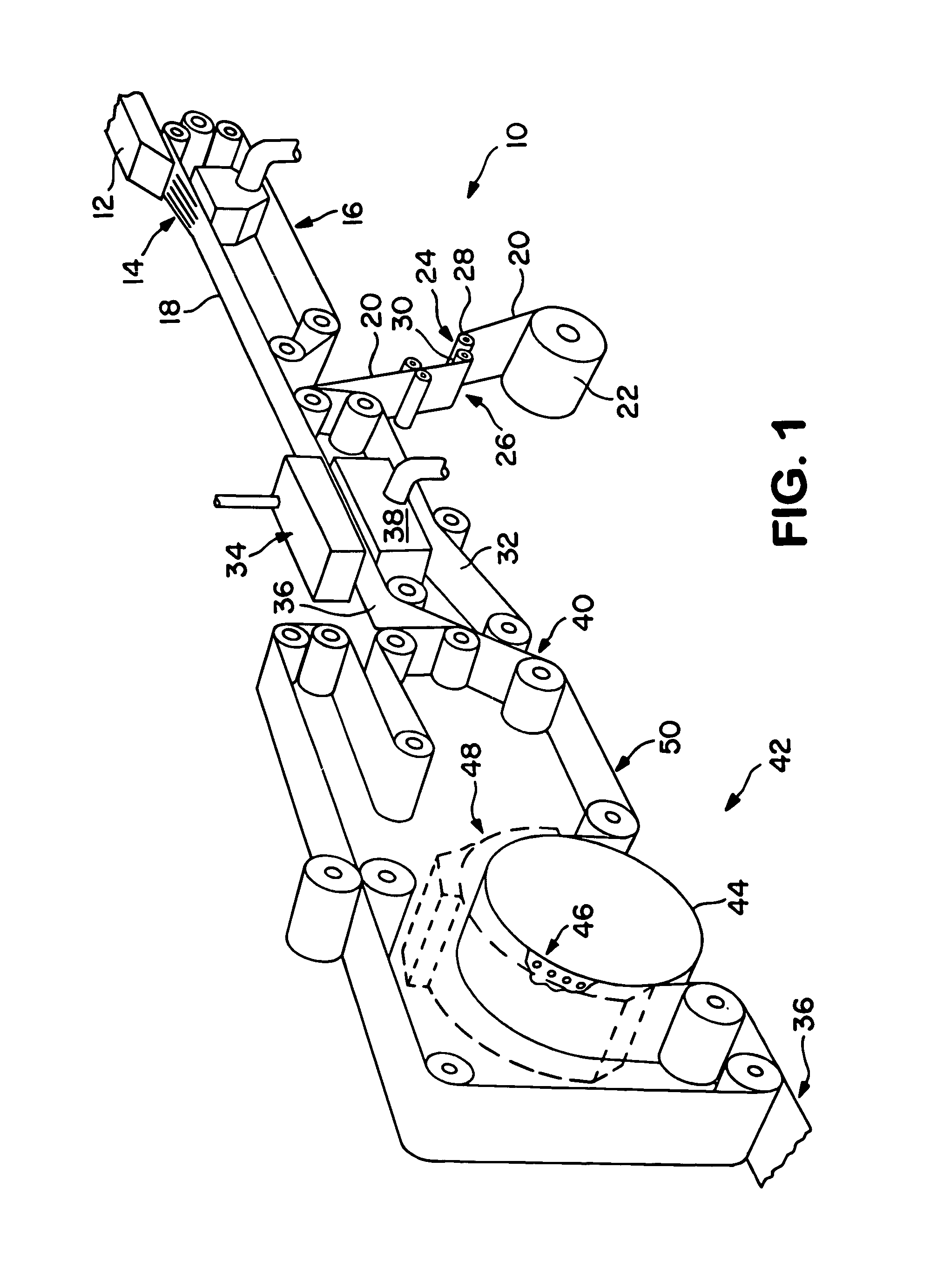

Soft and bulky composite fabrics

A composite fabric is provided that contains staple fibers hydraulically entangled with a nonwoven web formed from continuous filaments. A portion of the staple fibers is entangled with the web, while another portion protrudes through the web. The resulting surface topography has one surface with a preponderance of the smooth, staple fibers, and another surface with a preponderance of the continuous filaments from the nonwoven web, but also including some of the protruded smooth, staple fibers. Thus, each surface contains smooth staple fibers and is soft.

Owner:KIMBERLY-CLARK WORLDWIDE INC

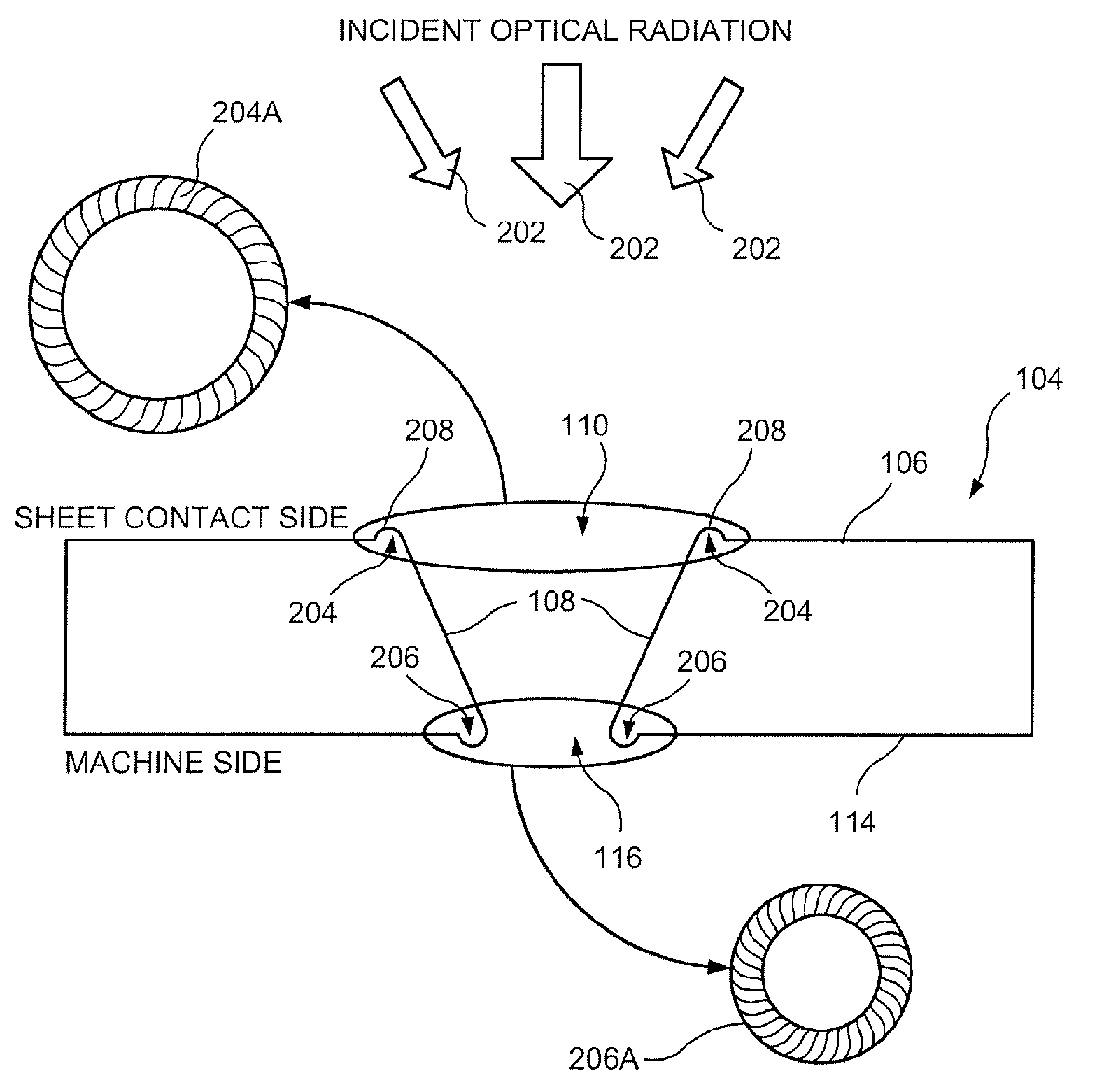

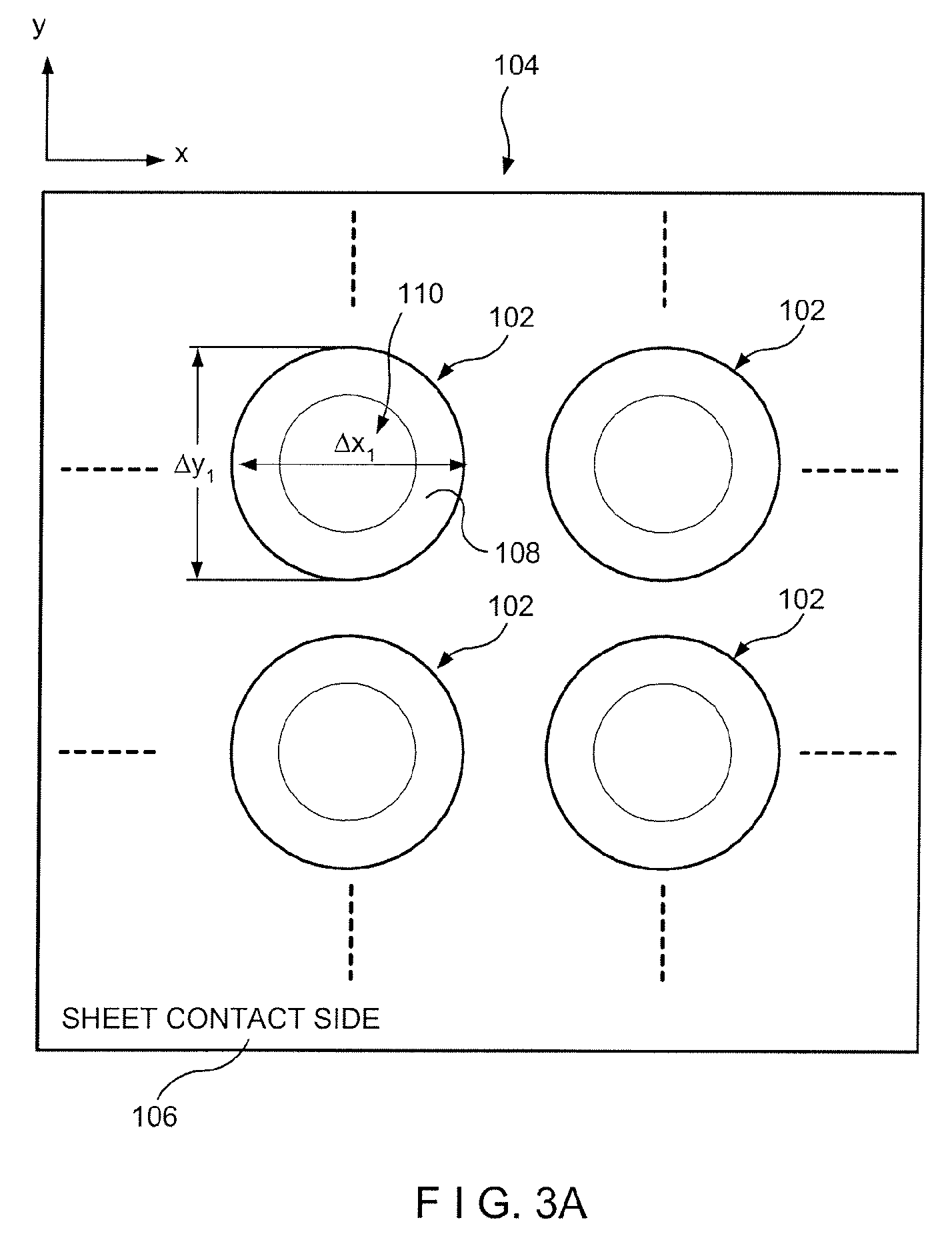

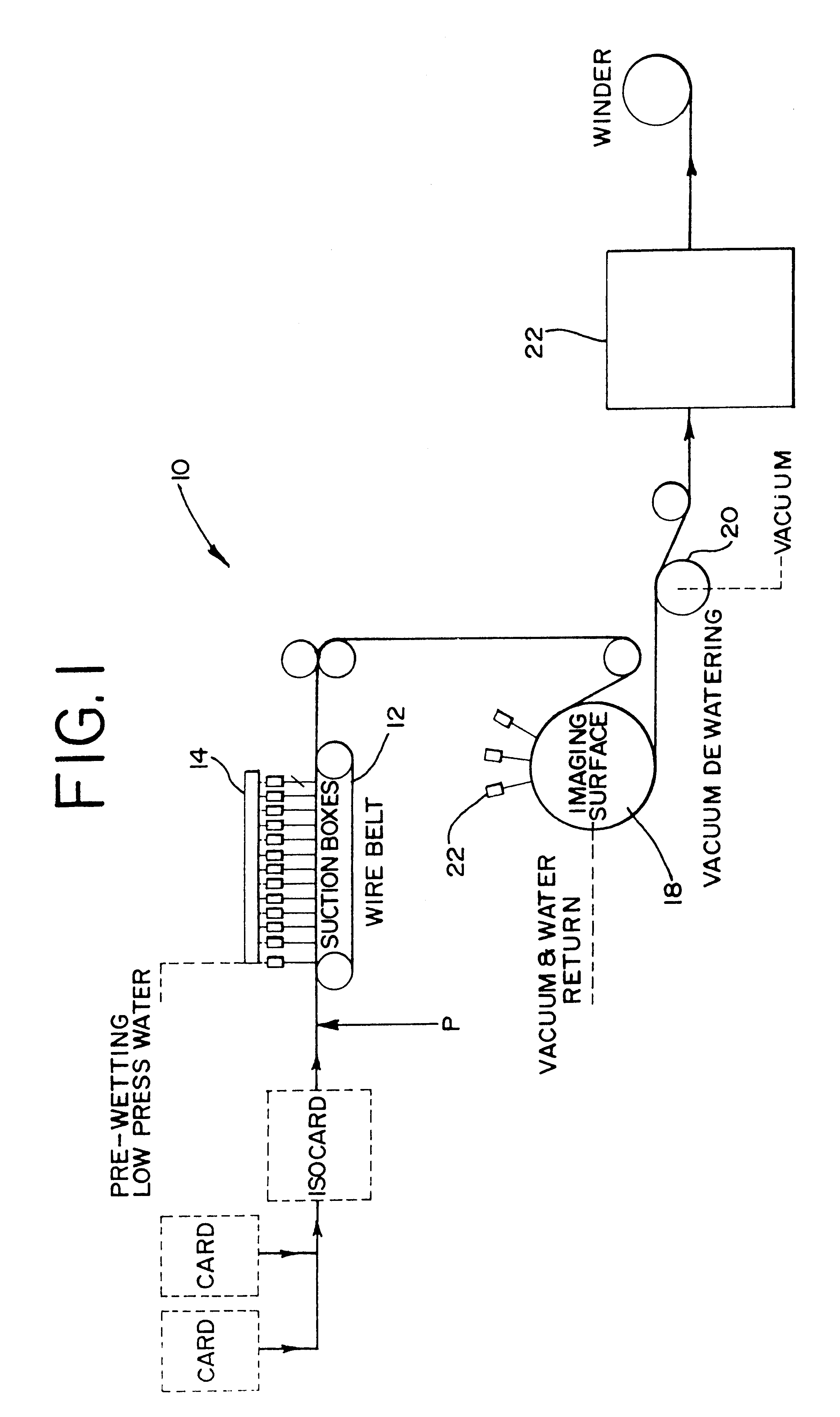

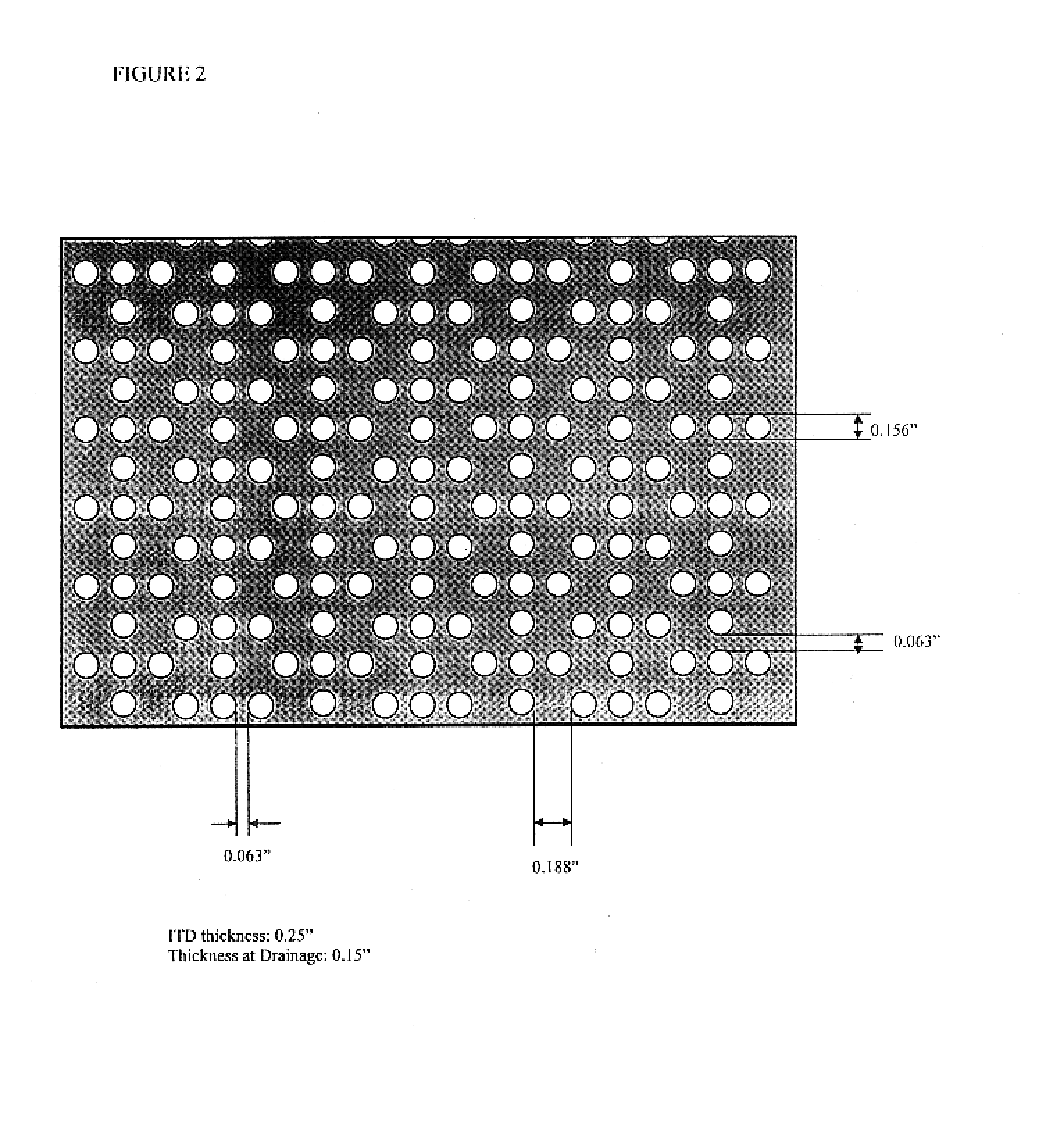

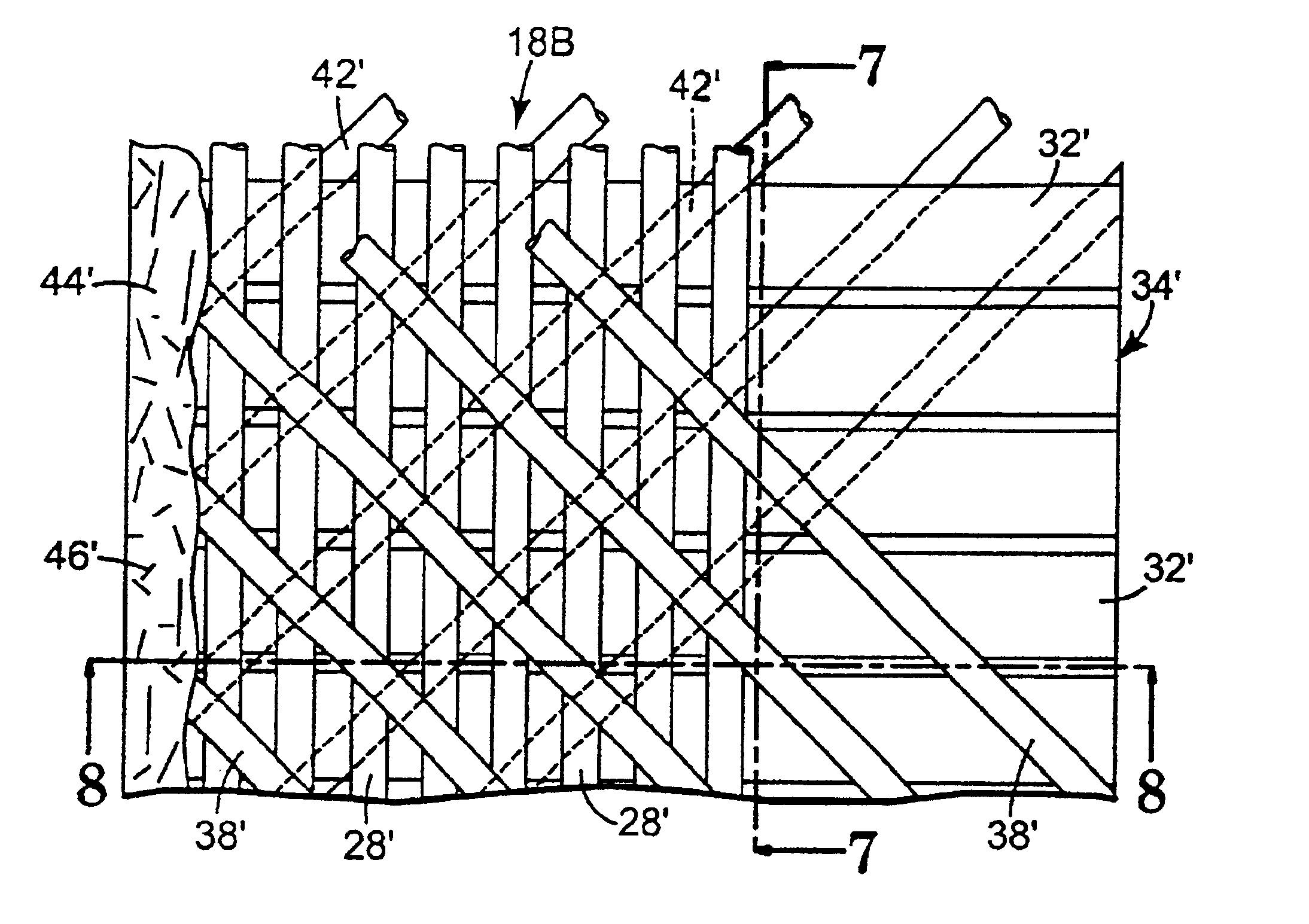

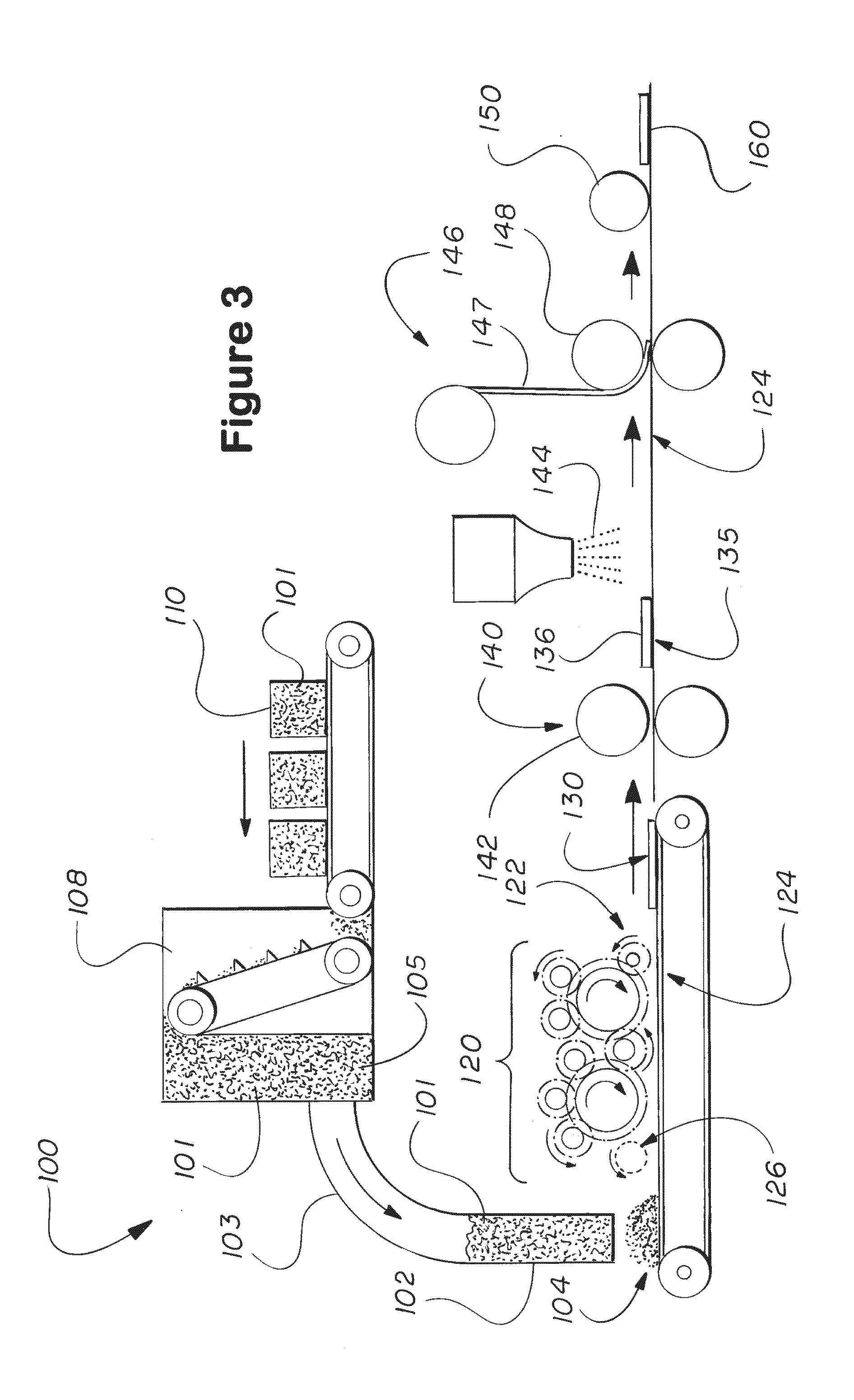

Industrial fabric, and method of making thereof

ActiveUS8822009B2Wet shapingEasy to cleanPattern makingSynthetic resin layered productsEngineeringMaterial Perforation

A support member such as a belt or sleeve includes a topographical pattern on its sheet contact side. A plurality of land areas, corresponding depressions, through voids, and / or groove areas are formed on the top surface of the support member to produce the topographical pattern. The land areas, corresponding depressions, through voids, and / or groove areas may be formed by graving, cutting, etching, embossing, mechanical perforation or a combination thereof. The improved belt or sleeve imparts desired physical characteristics, such as bulk, appearance, texture, absorbency, strength, and hand to a nonwoven product produced thereon.

Owner:ALBANY INT CORP

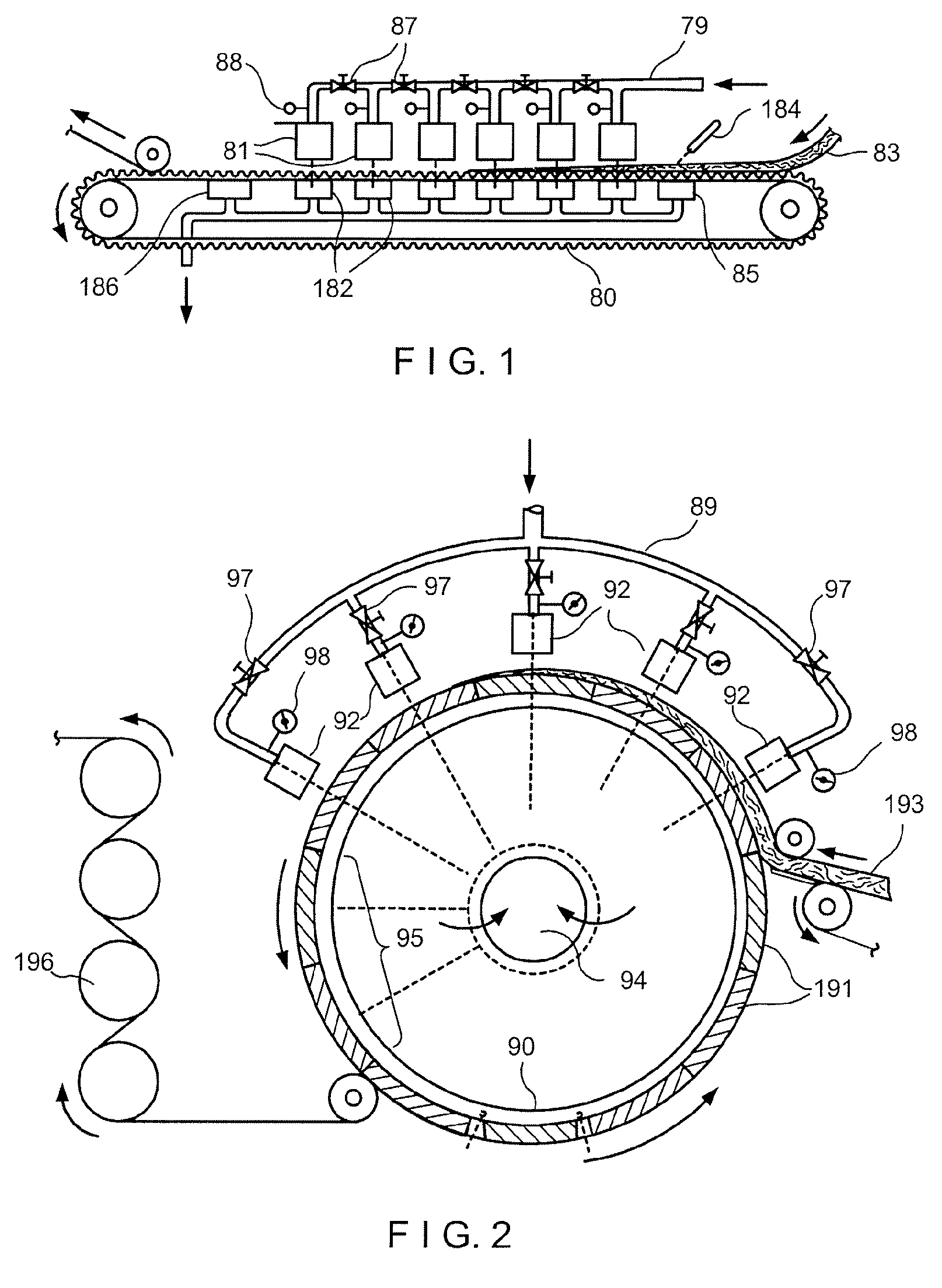

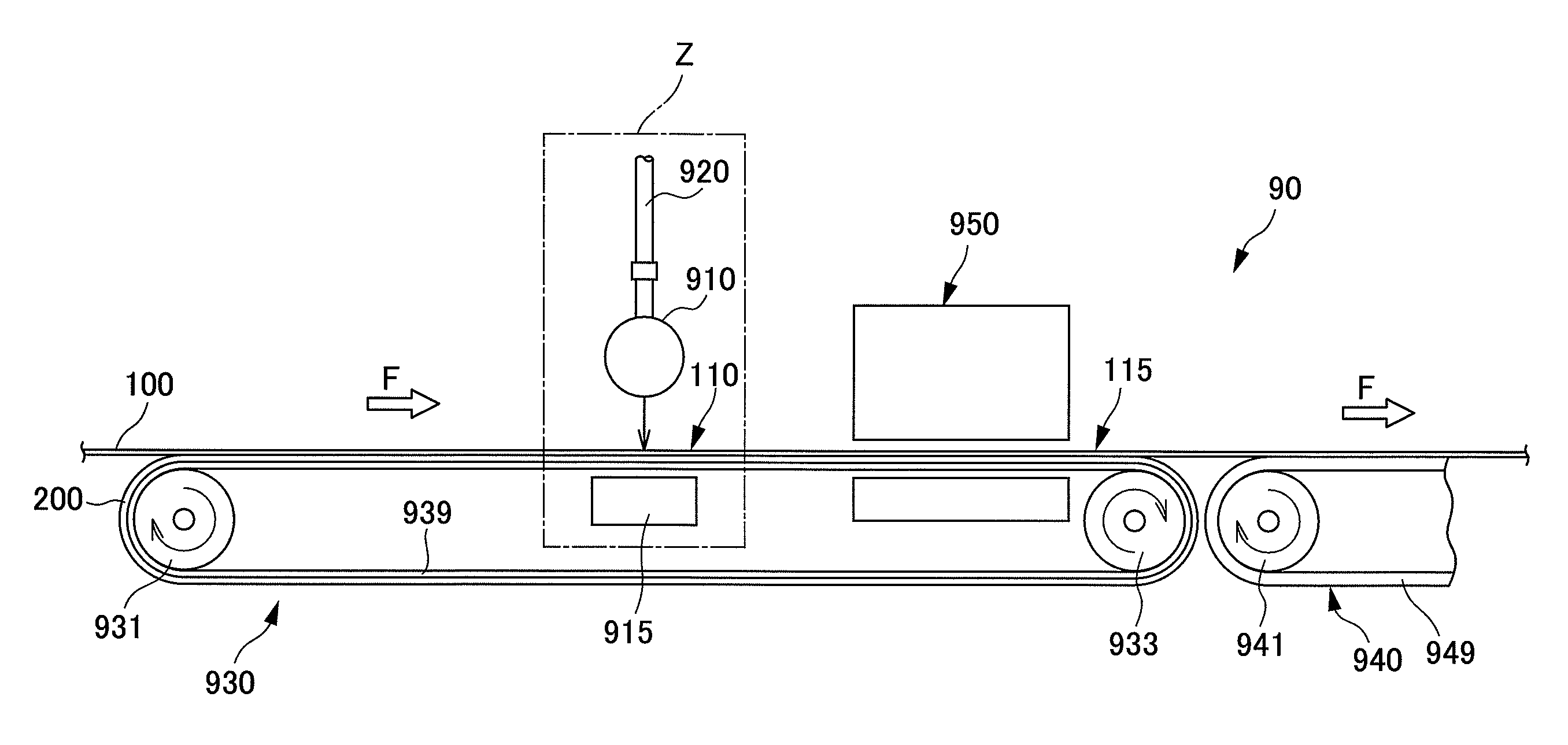

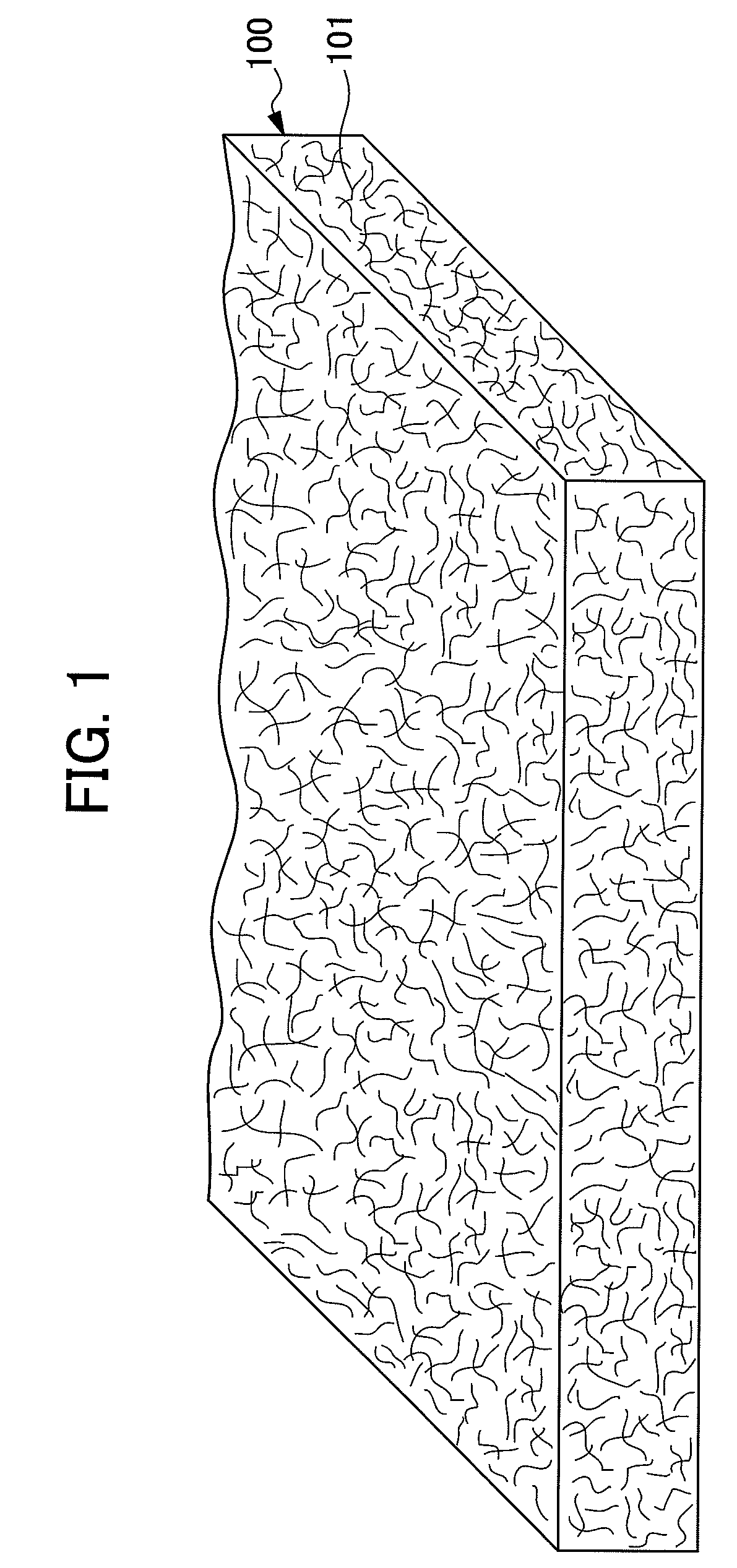

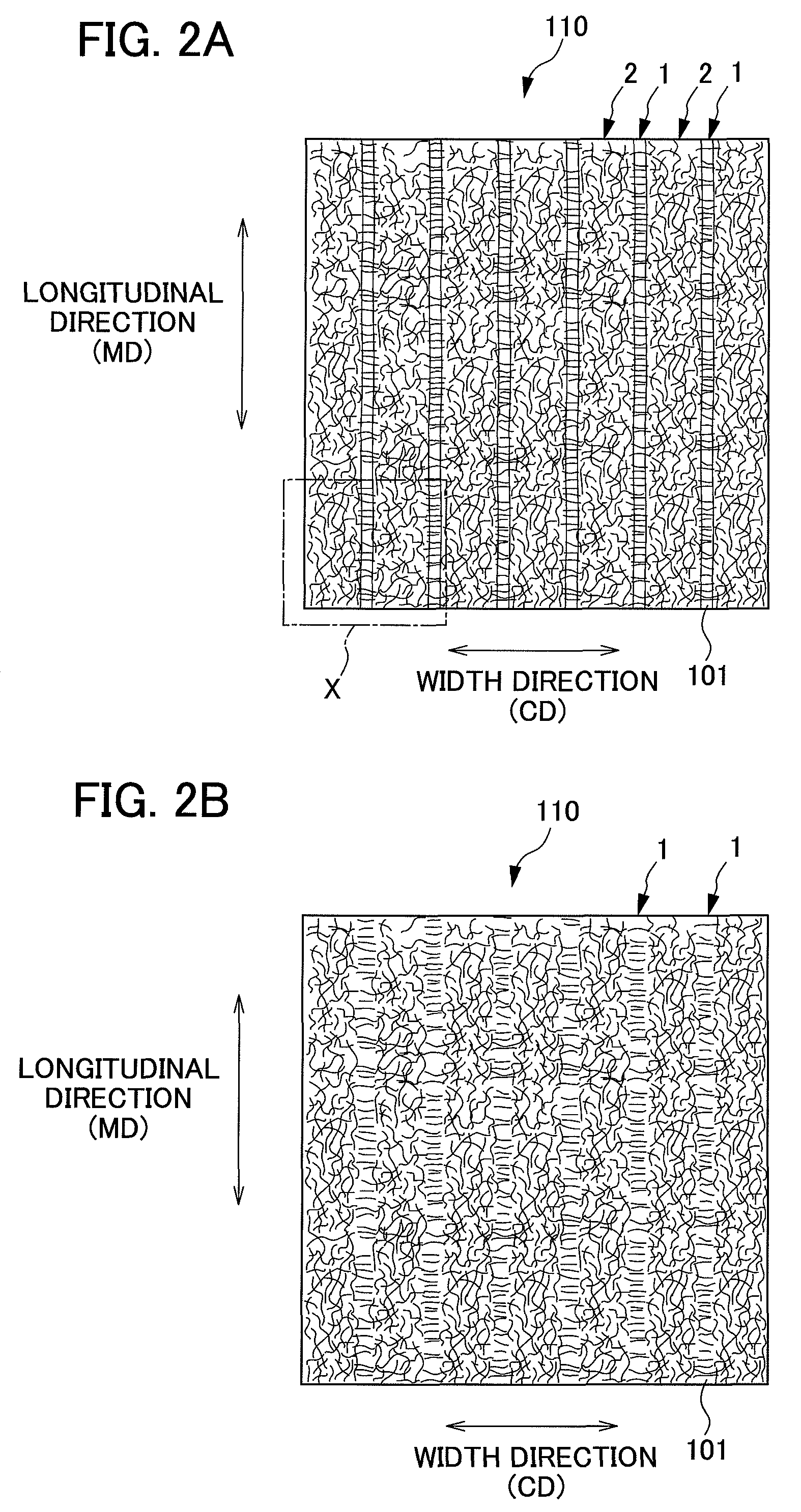

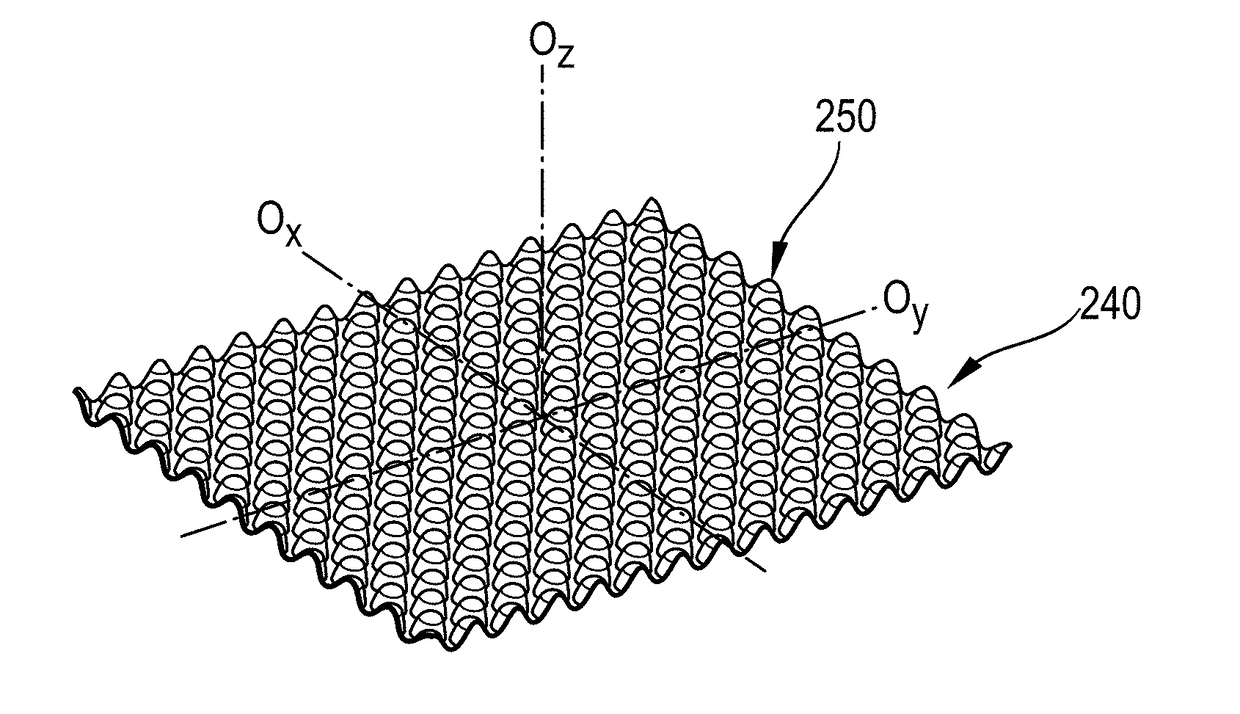

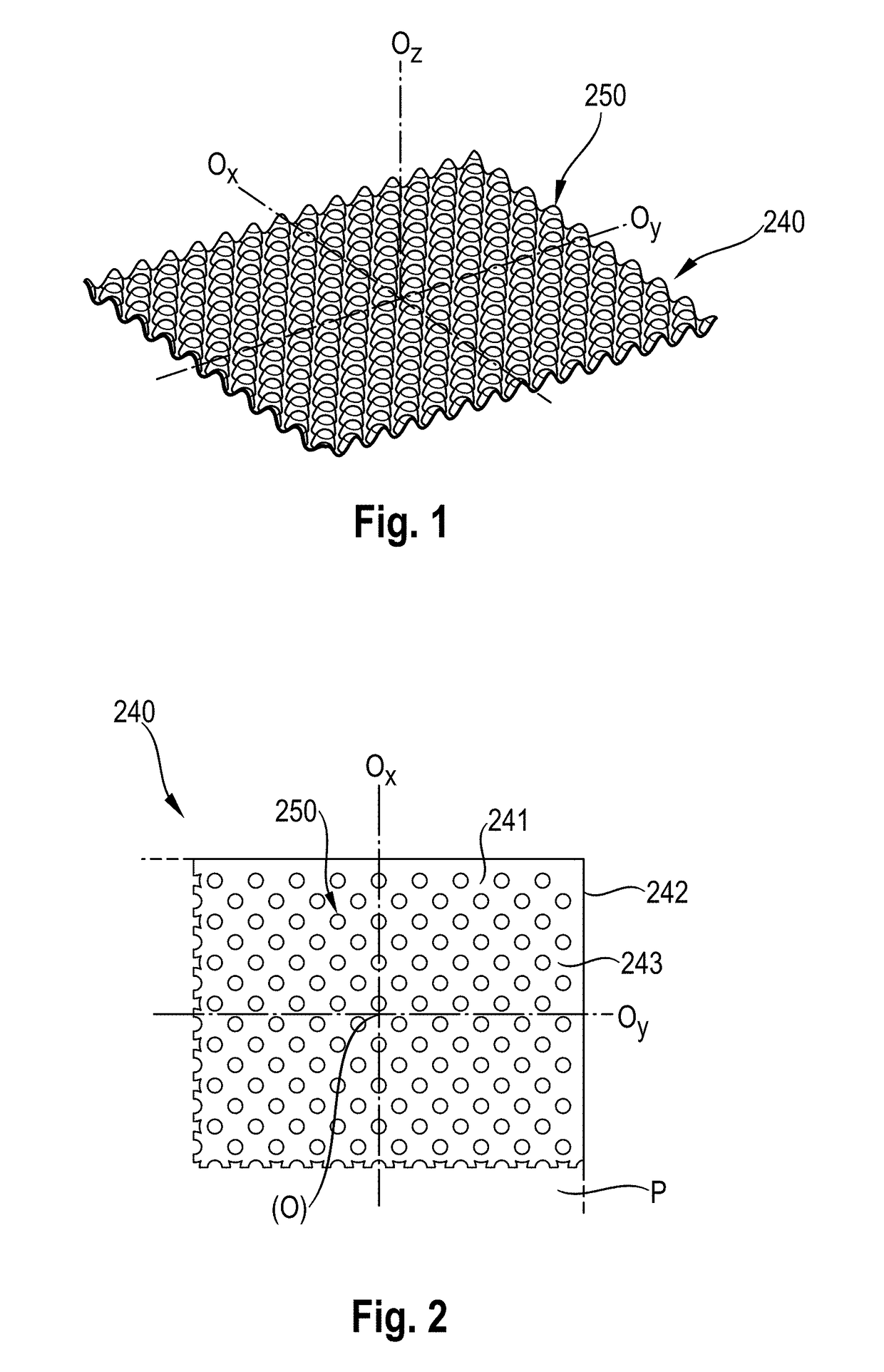

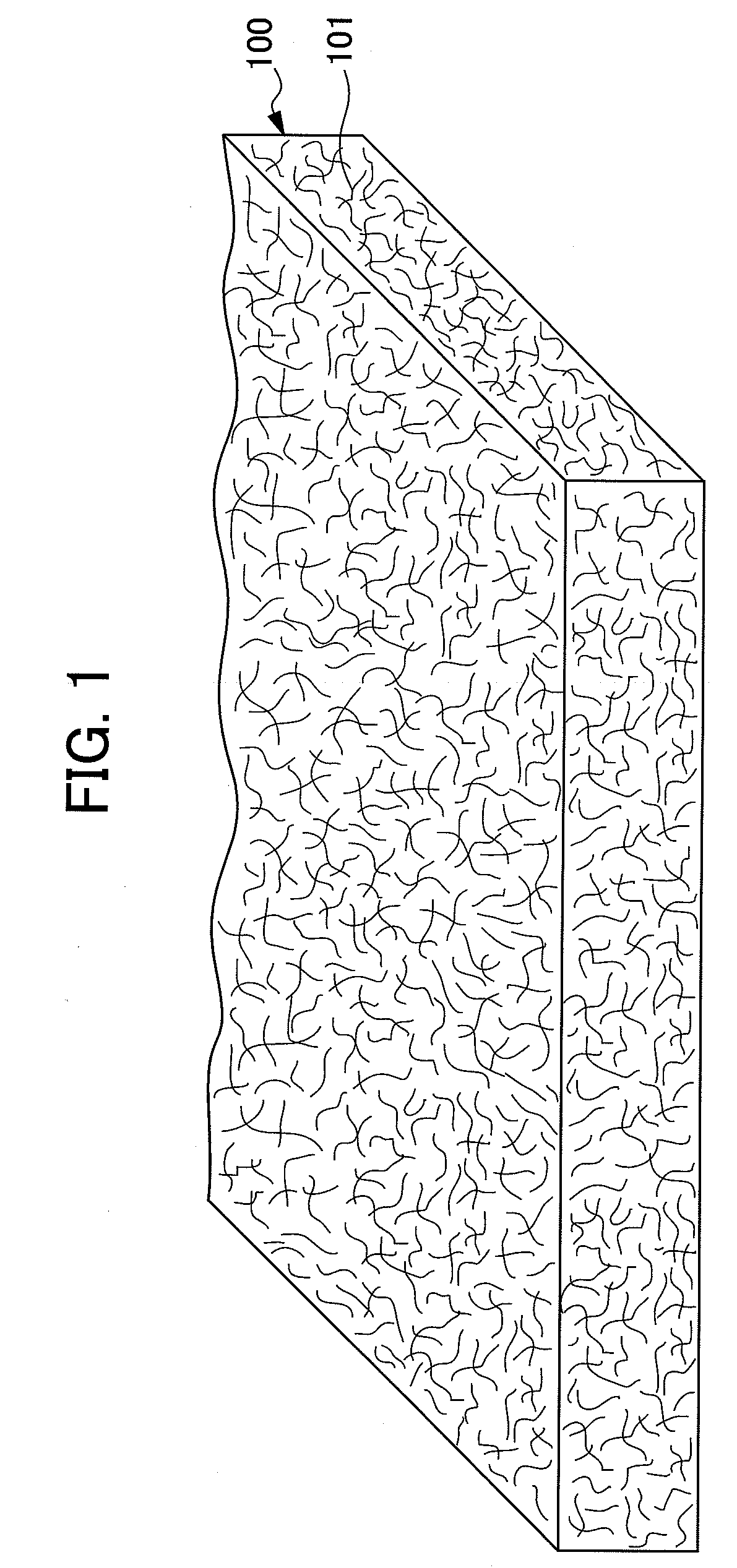

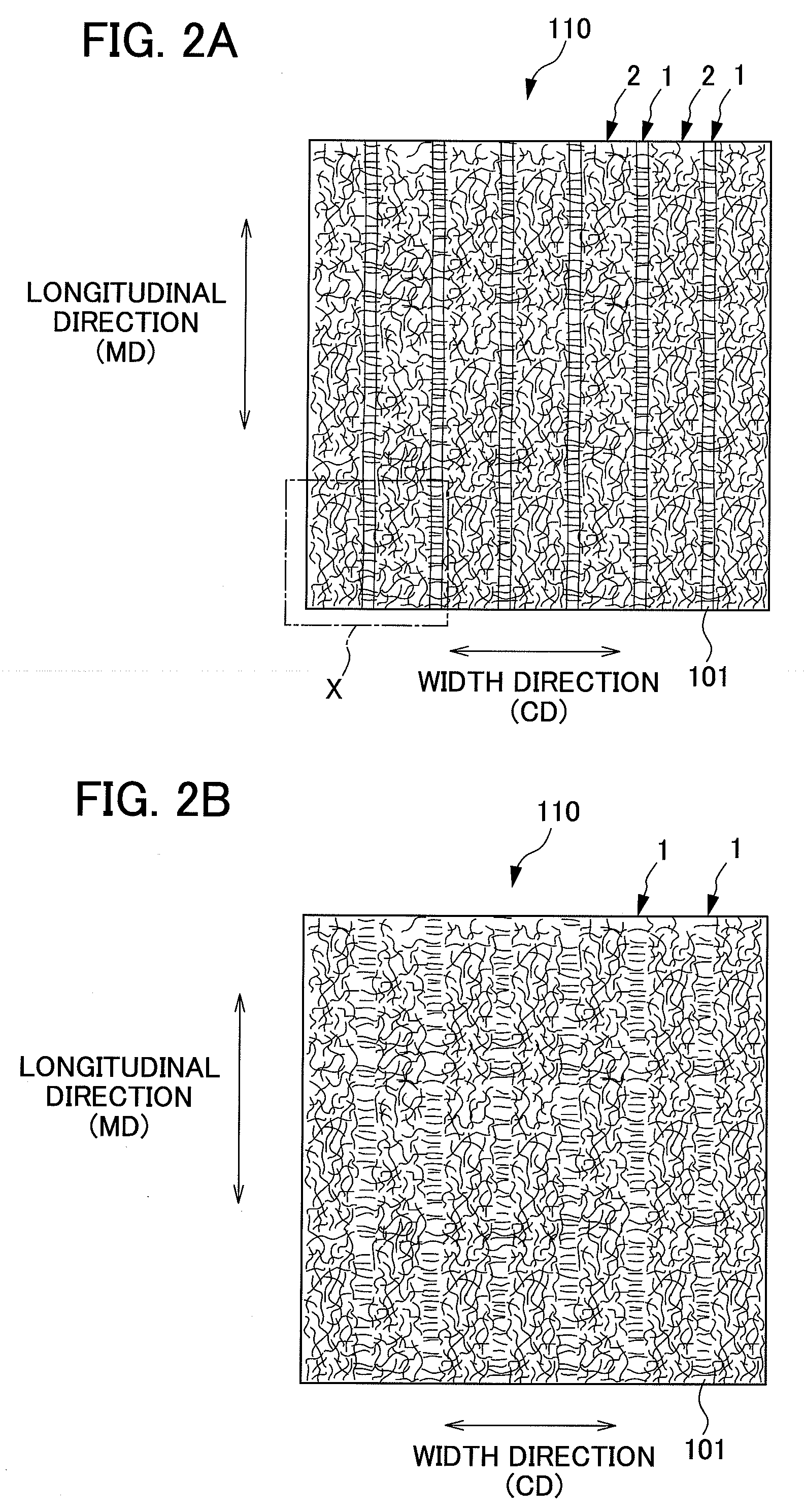

Nonwoven fabric, nonwoven fabric manufacturing method, and nonwoven fabric manufacturing apparatus

The present invention provides a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, and in which at least one of a predetermined groove portion, an opening, and a protrusion is formed, a manufacturing method for the nonwoven fabric, and a nonwoven fabric manufacturing apparatus. The nonwoven fabric manufacturing apparatus of the present invention manufactures a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, or in which at least one of a predetermined groove portion, an opening, and a protrusion is formed by blowing fluid mainly containing gas onto a fiber web which is formed in a sheet shape, and which is in a state where at least a portion of the fibers constituting the fiber aggregate has a degree of freedom.

Owner:UNI CHARM CORP

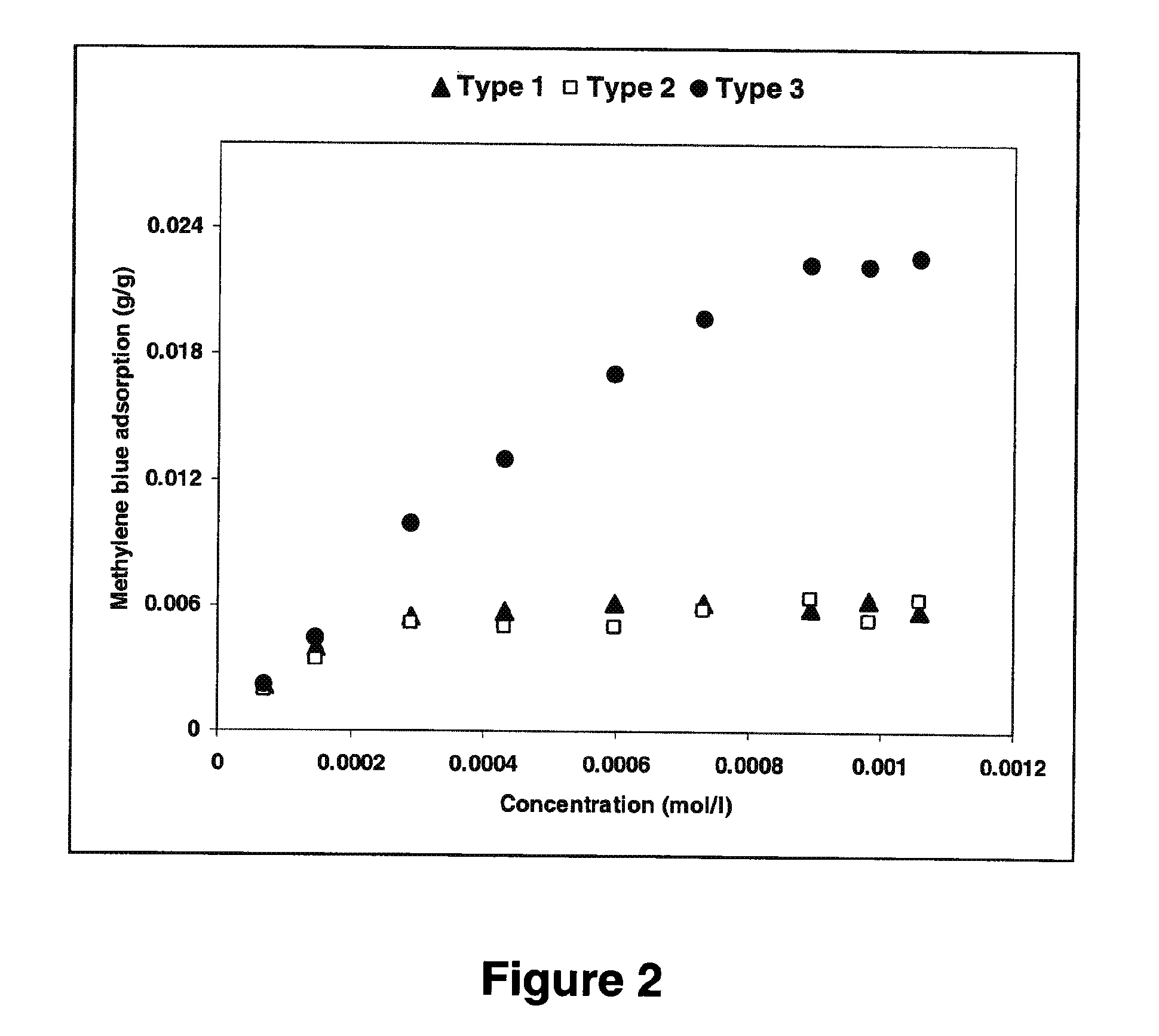

Nonwoven webs made from treated fibers

ActiveUS20080319407A1Superior initial tensile strengthIncrease surface areaPattern makingBaby linensFiberMedicine

The invention relates to a nonwoven web with superior initial tensile strength. The web constructed from at least one type of fiber that has been modified to increase its specific surface area. The fiber has a specific surface area of at least 55 m2 / g. The invention also relates to use of the nonwoven web with superior initial tensile strength for the making of a disposable absorbent article. These include, diapers, training pants, incontinence pants, tampons, female hygiene pads and wipes.

Owner:THE PROCTER & GAMBLE COMPANY

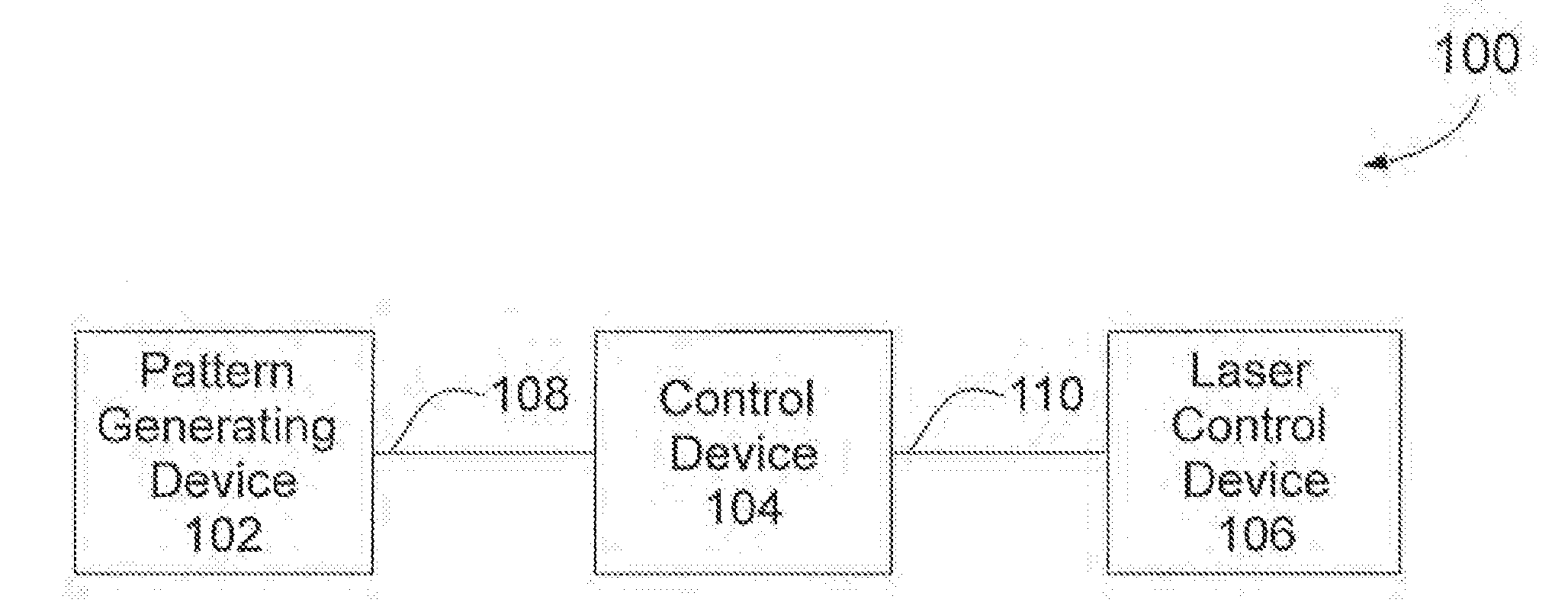

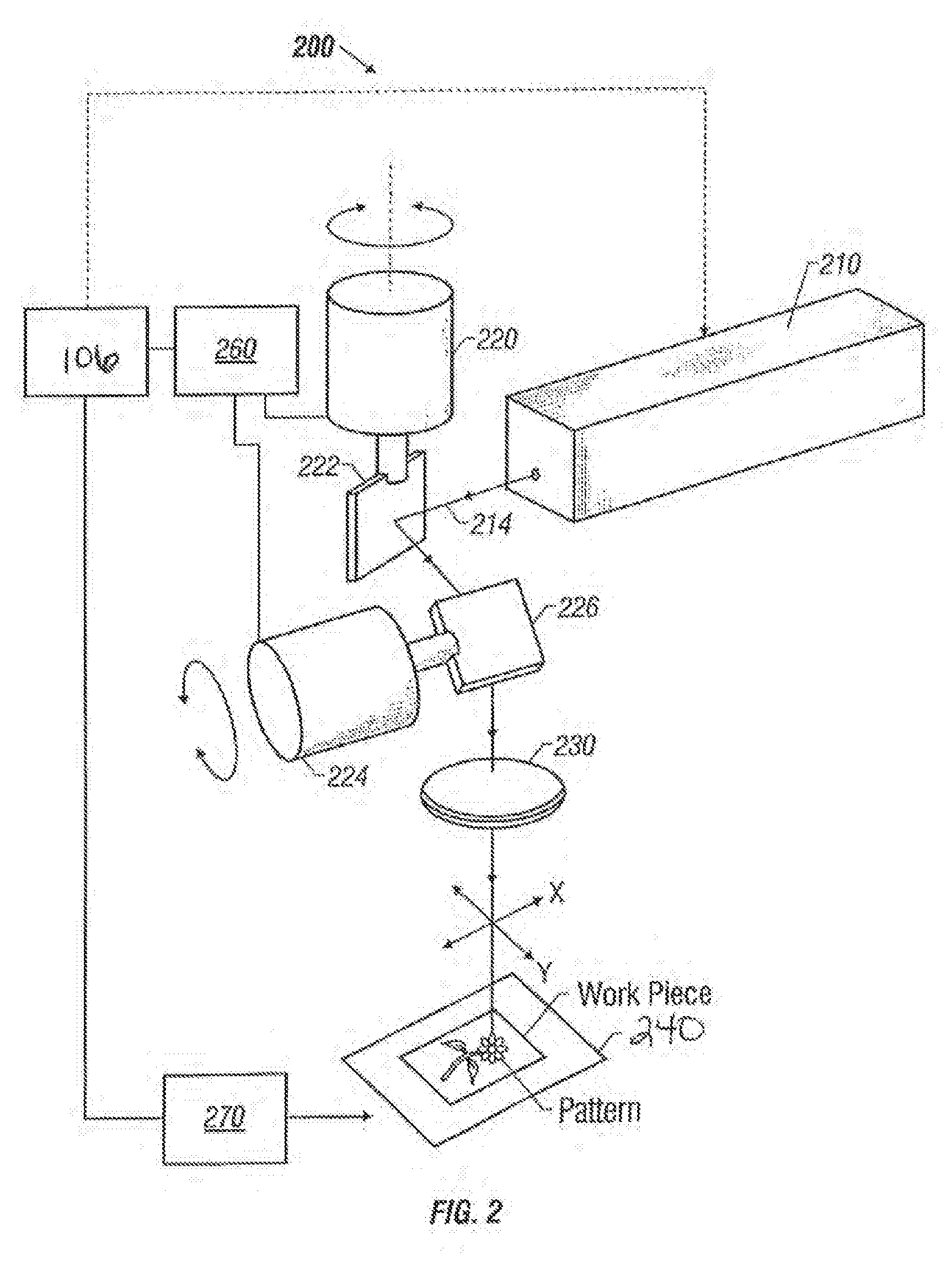

System and method of generating a pattern used to process a surface of a fabric through laser irradiation, and fabric created thereby

A method is provided of generating a pattern image used to form a pattern on a surface of a fabric using laser irradiation. A plurality of parameters associated with laser irradiation units are input into a user interface. The parameters include an area parameter, a laser irradiation unit density parameter, optionally a discontinuity parameter, and a dye removal parameter. A plurality of laser irradiation units arranged in a pattern area of a user interface based on computer processing of the inputted plurality of parameters is received for viewing at the user interface. The laser irradiation units collectively establish the pattern image for viewing by the user.

Owner:REVOLAZE LLC

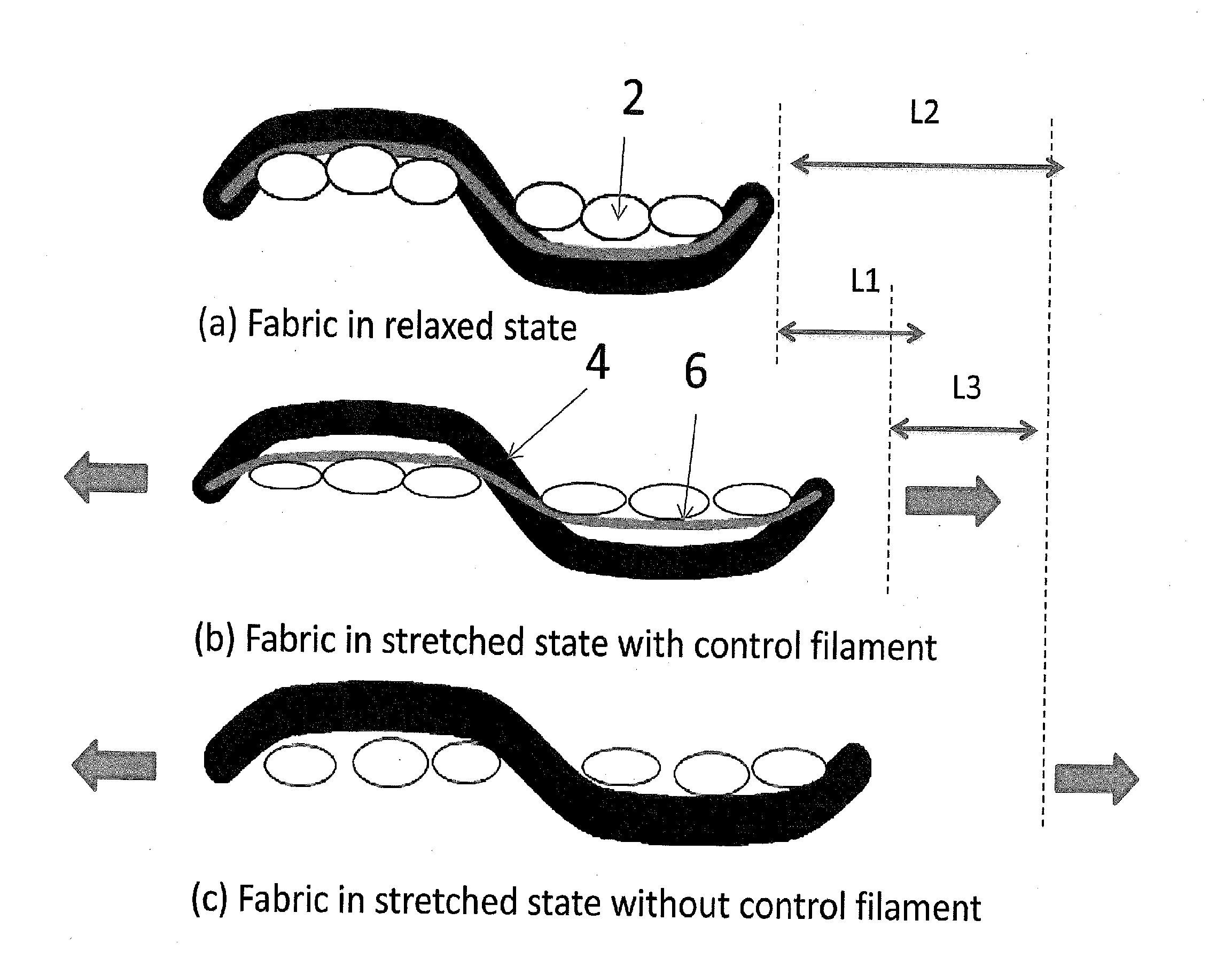

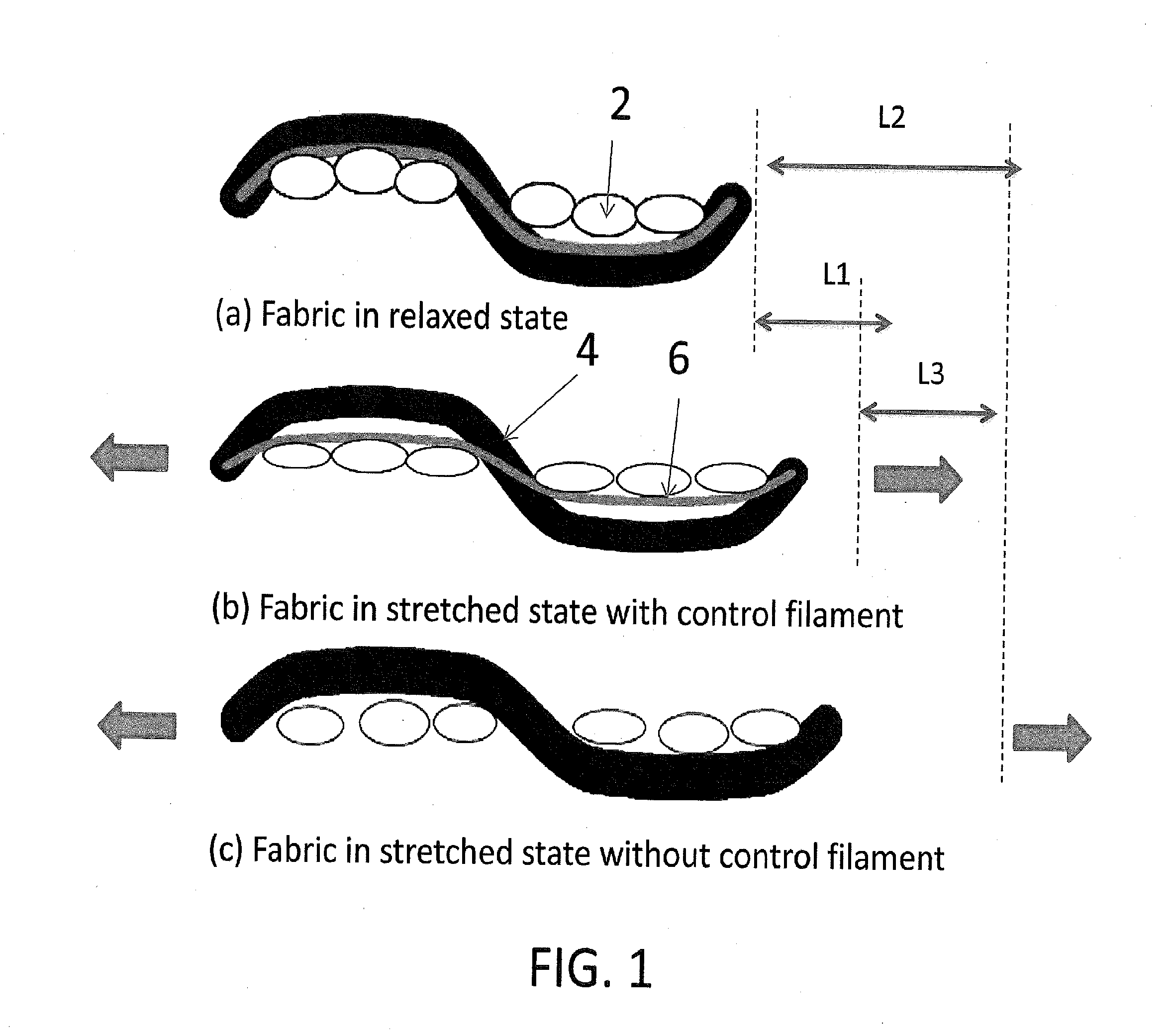

Stretch wovens with a control yarn system

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

Imaged nonwoven fabric for cleaning applications

The present invention is directed to enhancing the cleaning of surfaces by the contact application of a non-apertured nonwoven fabric having a three-dimensional image imparted therein. The three-dimensional image of the non-apertured nonwoven fabric induces the formation of lather due to pronounced surface projections that come in contact with the cleaning surface and provide air passageways that are parallel to the plane of the substrate. The imaged nonwoven fabric disclosed herein exhibits low linting qualities thereby reducing the potential of fiber contamination of the cleaned surface and is sufficiently durable that the sample can be used in a brisk manner.

Owner:POLYMER GROUP INC

Three-dimensional substrate comprising a tissue layer

ActiveUS20170258647A1Promote absorptionAccelerates the dehydration processPersonal carePattern makingBiomedical engineeringFiber

Owner:THE PROCTER & GAMBLE COMPANY

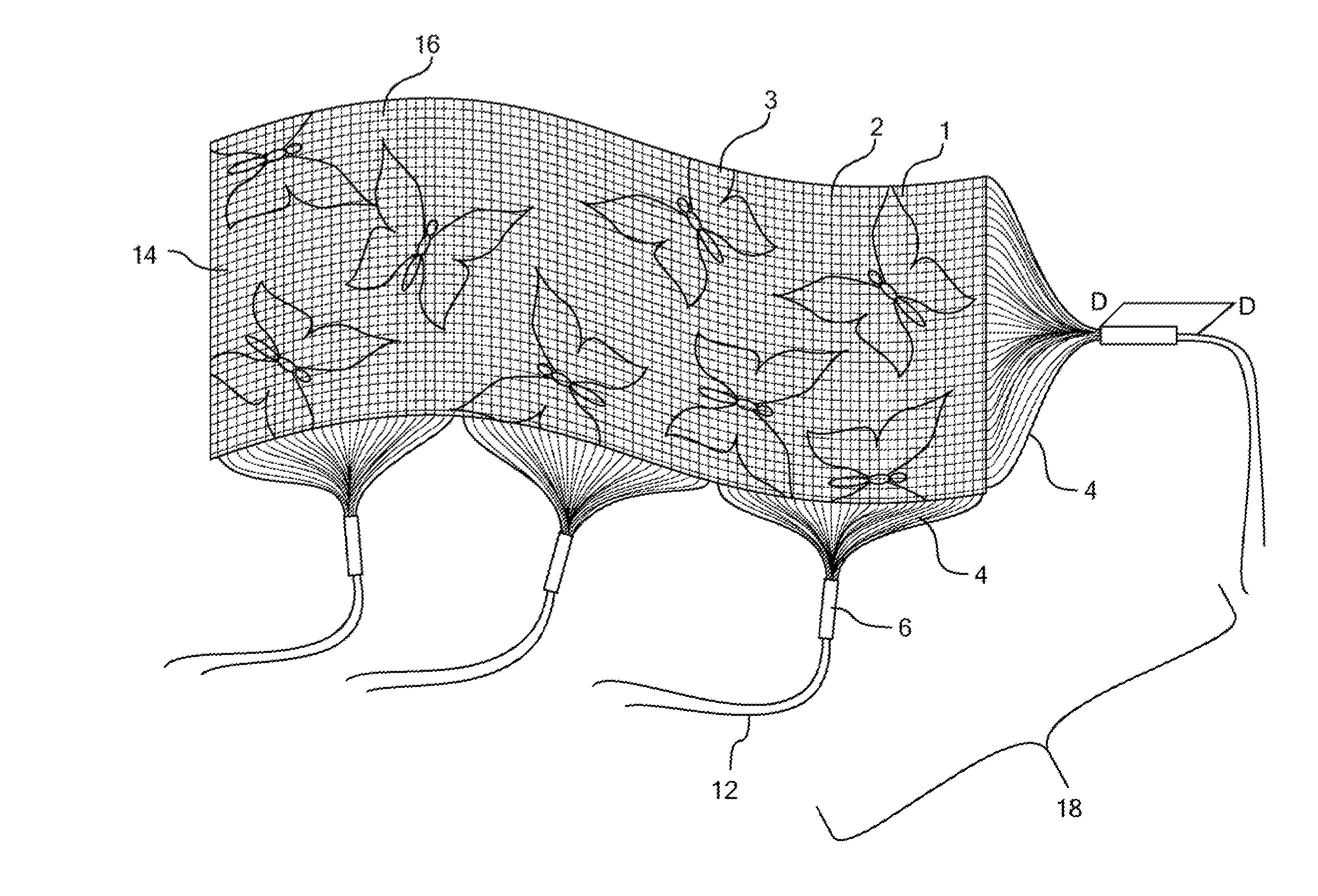

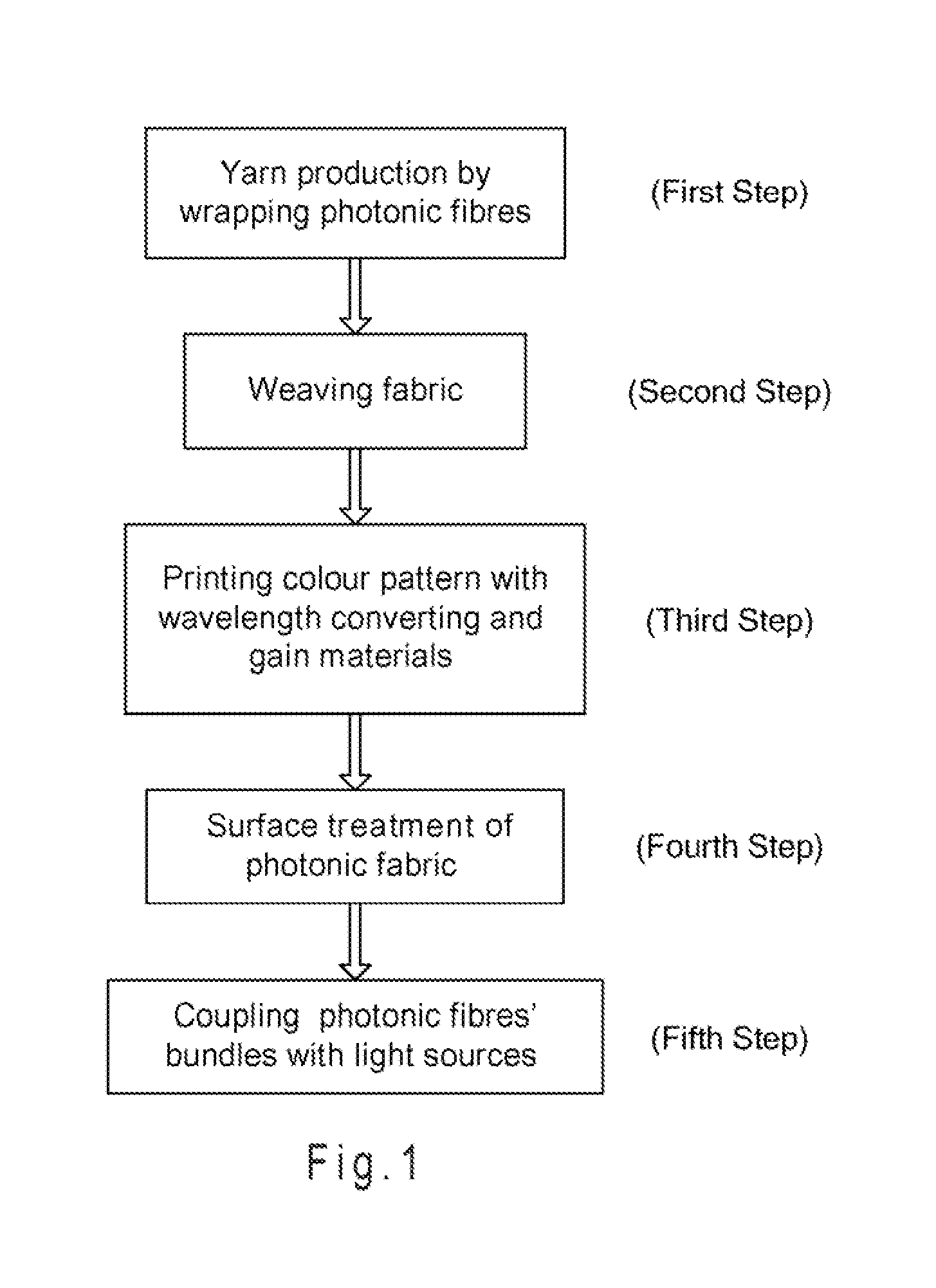

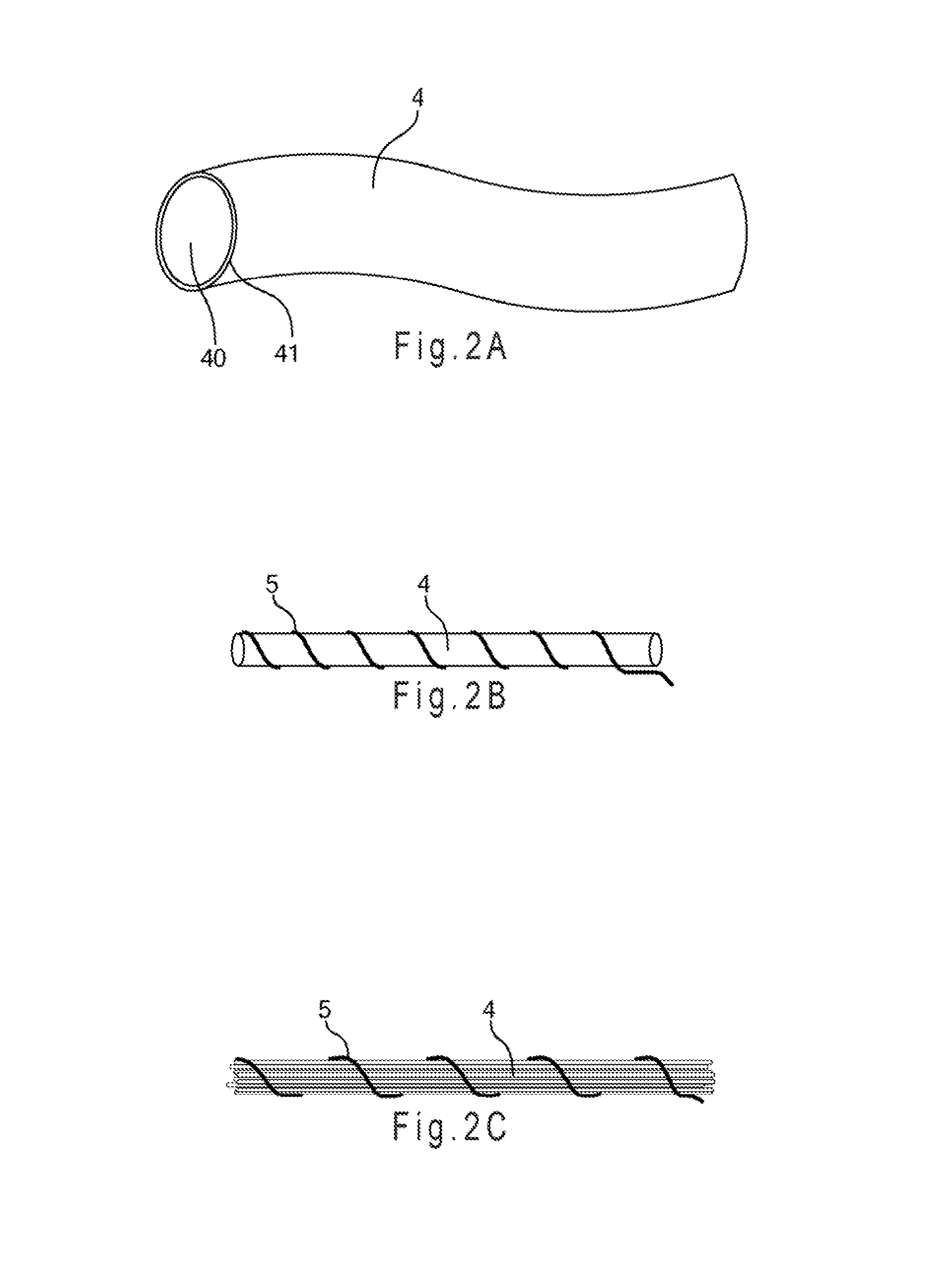

Photonic fabric display with controlled pattern, color, luminescence intensity, scattering intensity and light self-amplification

A method of making a photonic fabric display includes wrapping photonic fibers with a yarn, weaving the wrapped photonic fibers to form a fabric, printing a pattern on the fabric, surface treating the fabric, and coupling the photonic fibers with a light source to form a photonic fabric display.

Owner:THE HONG KONG POLYTECHNIC UNIV

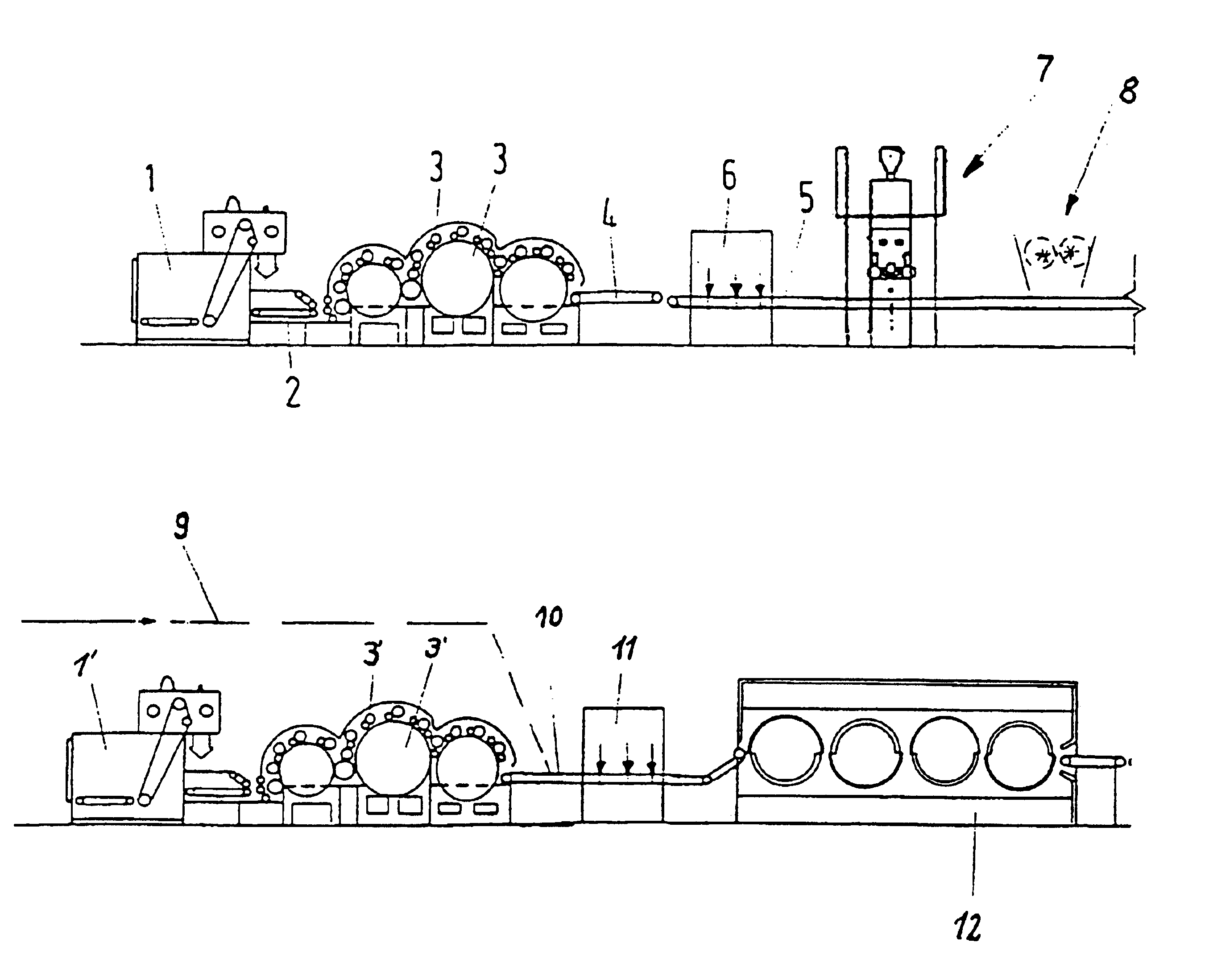

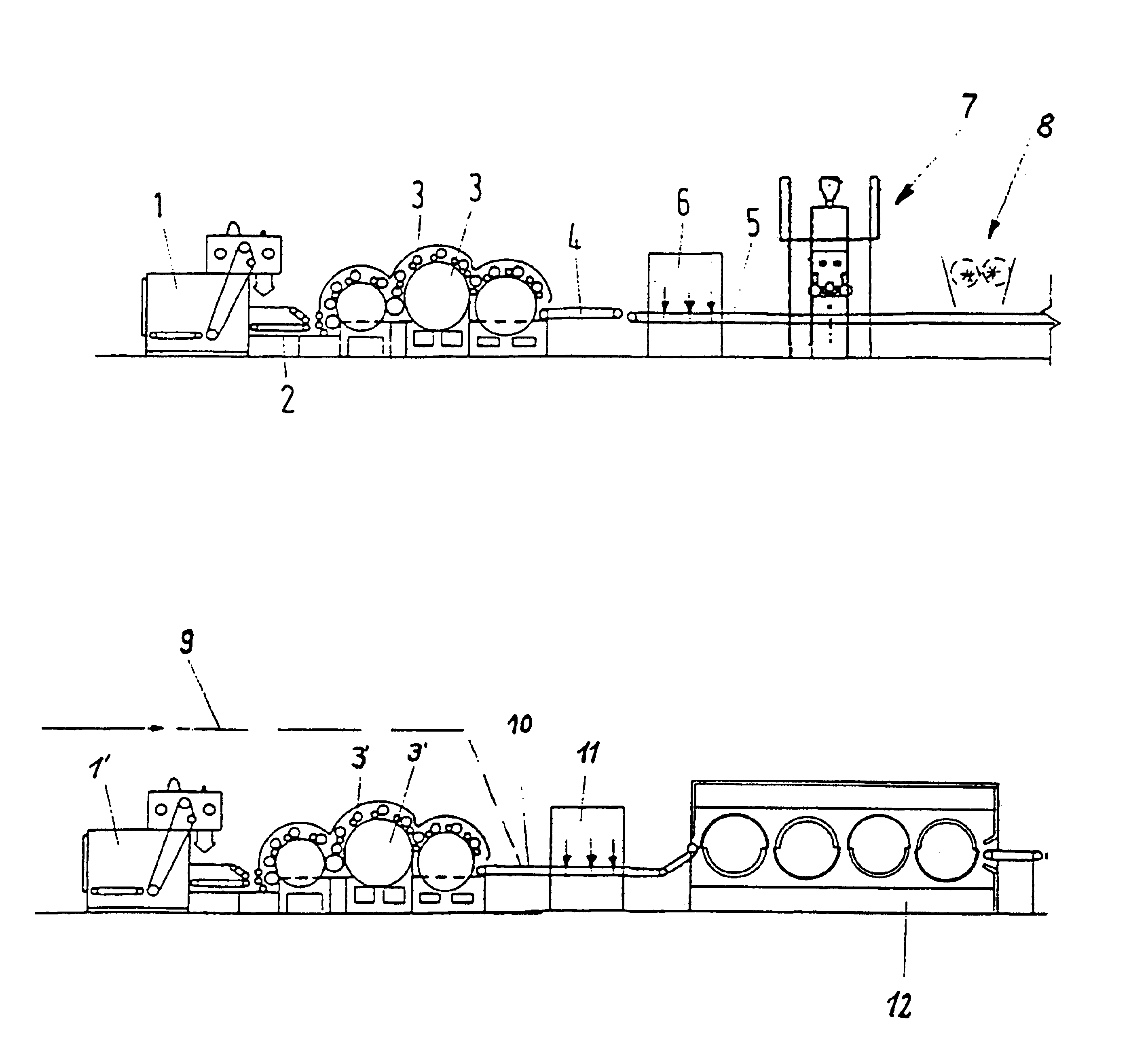

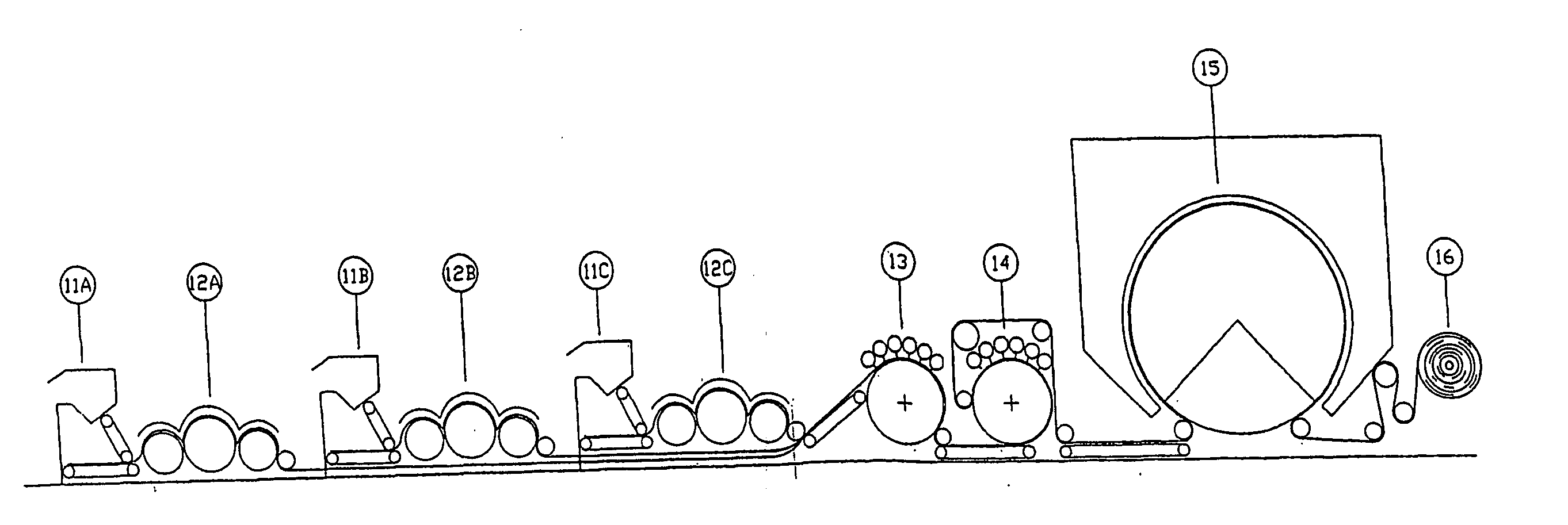

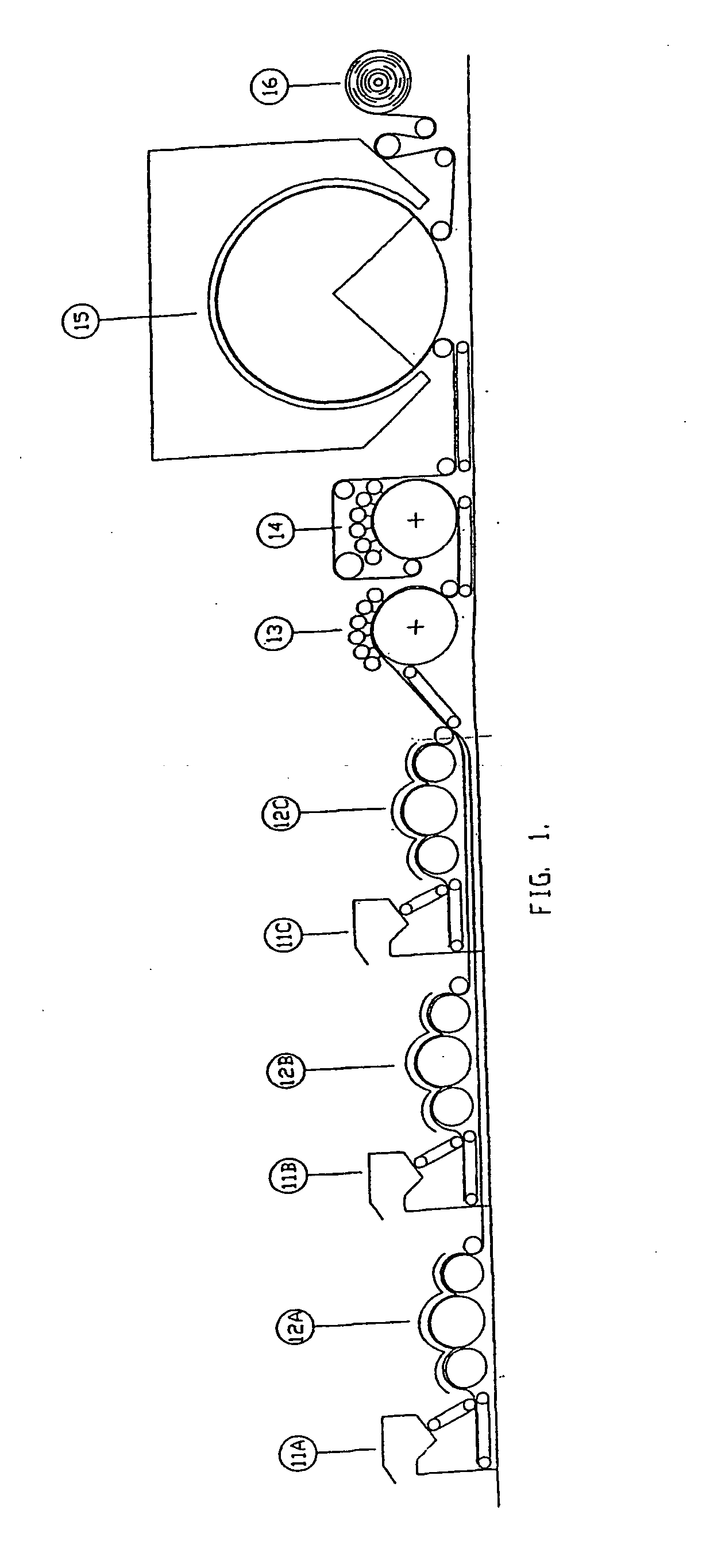

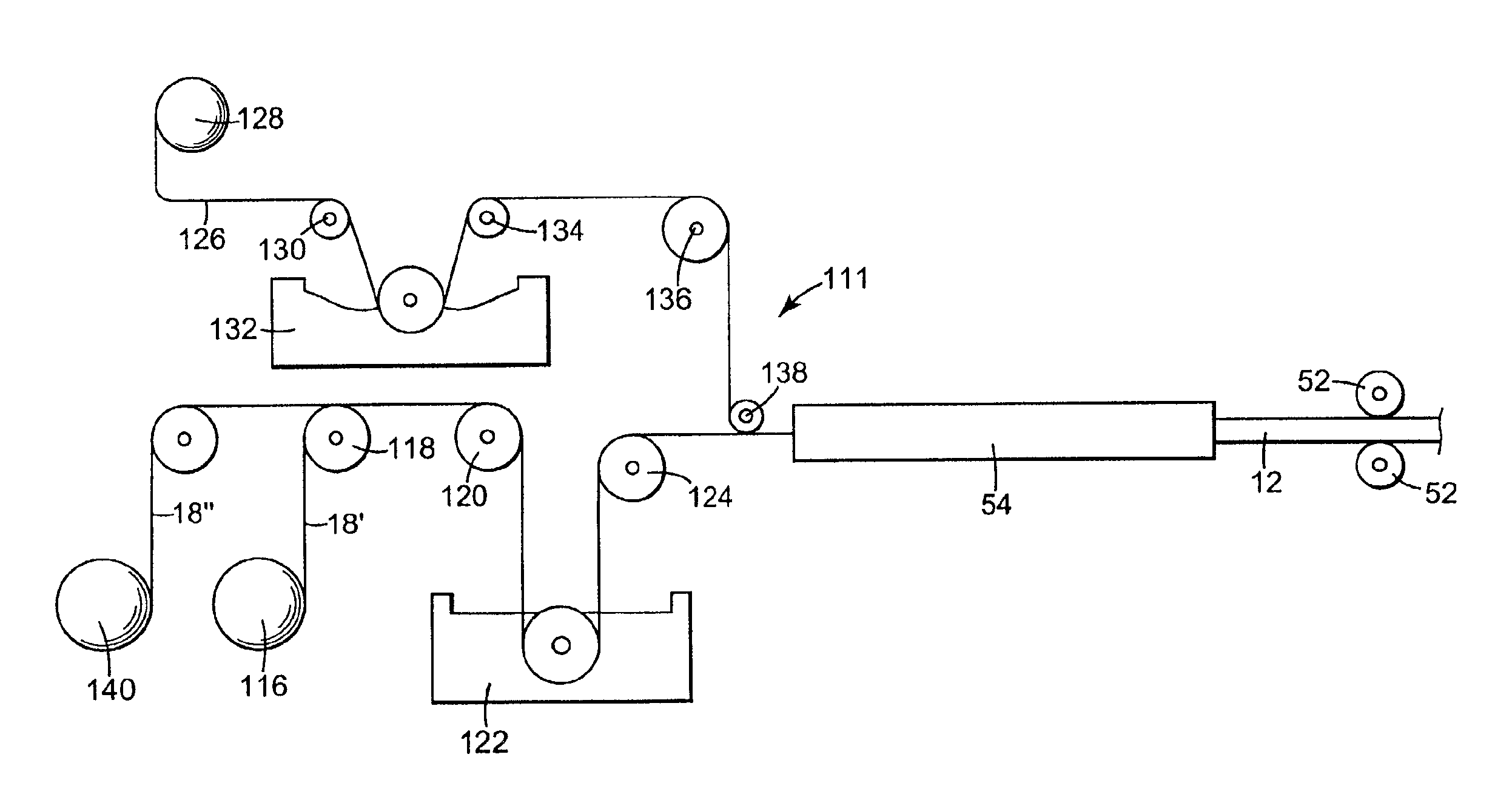

Method and device for producing a composite nonwoven for receiving and storing liquids

Known methods involve applying a layer of particularly highly absorbent fibers such as woodpulp on a carrier nonwoven and then compacting the composite nonwoven with the aid of water entanglement. One disadvantage of the compacting method is the high woodpulp fiber loss and the associated purification of the circulating water for the entanglement device. According to the invention, a fine layer of microfibers is initially applied before applying the woodpulp fibers. The microfibers are evenly distributed on the carrier nonwoven using, for instance, a meltblown process and the woodpulp fibers are only then applied in the separating layer. The water during entanglement can no longer merge the woodpulp fibers into the carrier nonwoven due to the fact that the microfibers act as a barrier.

Owner:FLEISSENER GMBH & CO MASCHFAB & ALBIS SPA +1

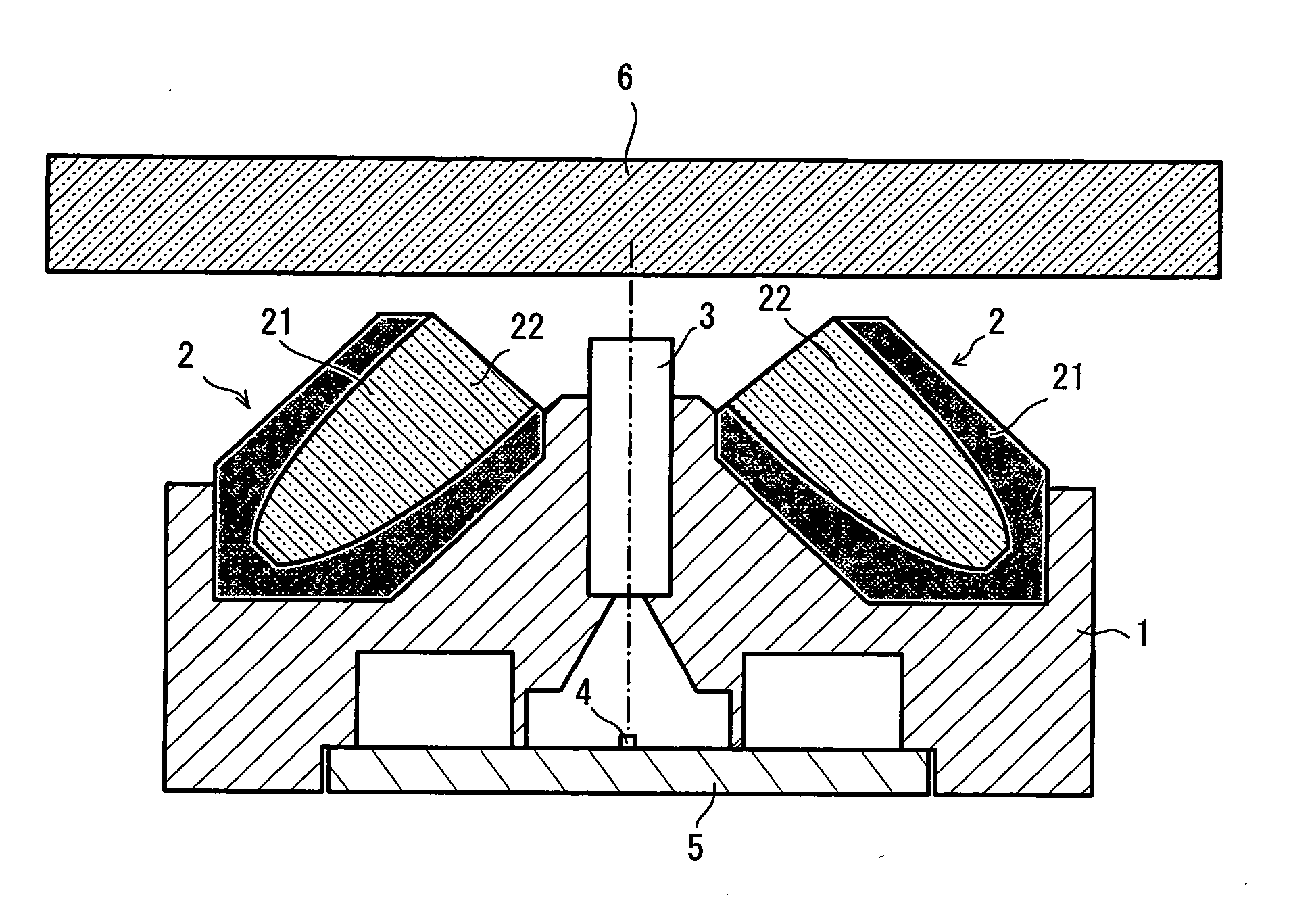

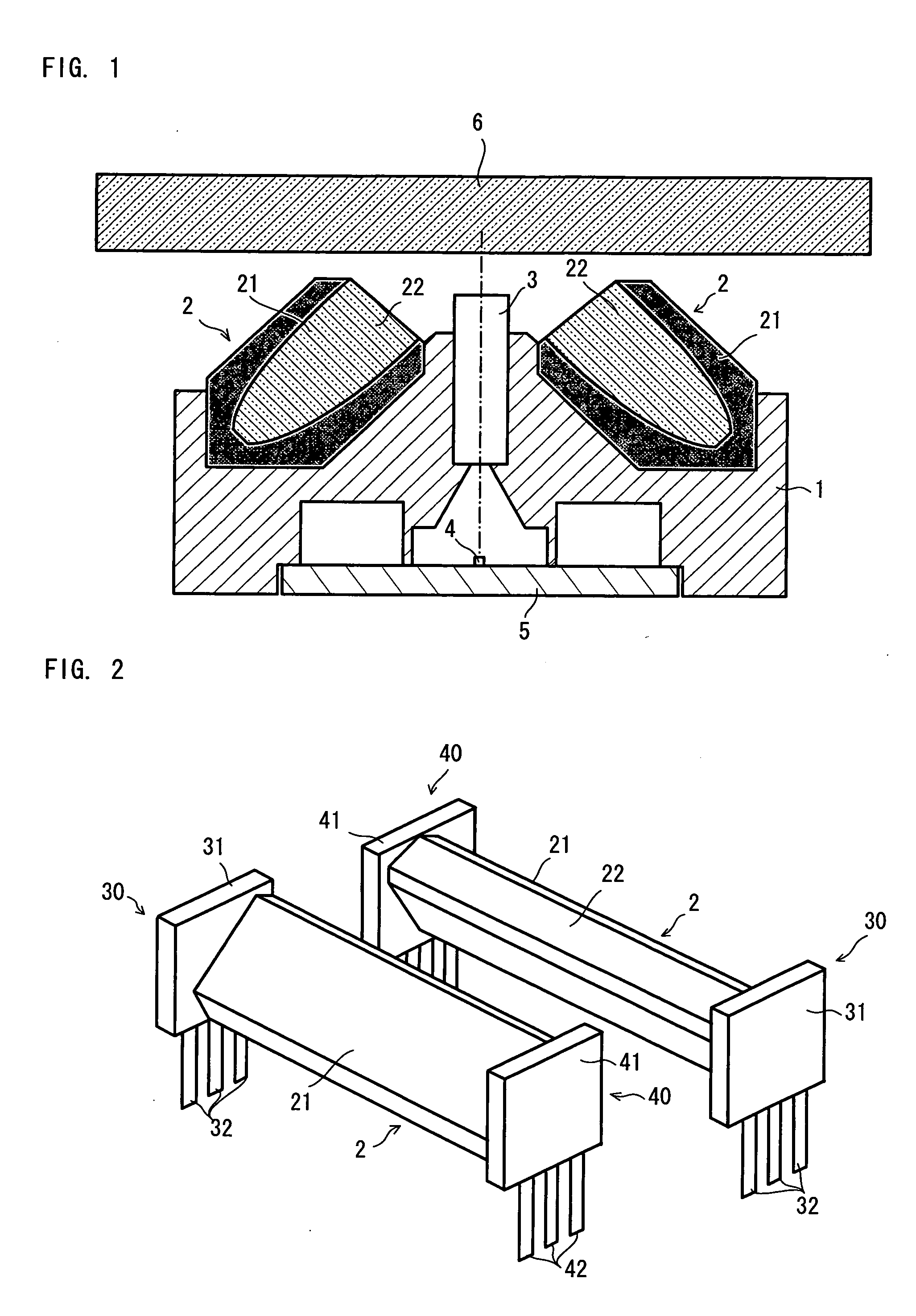

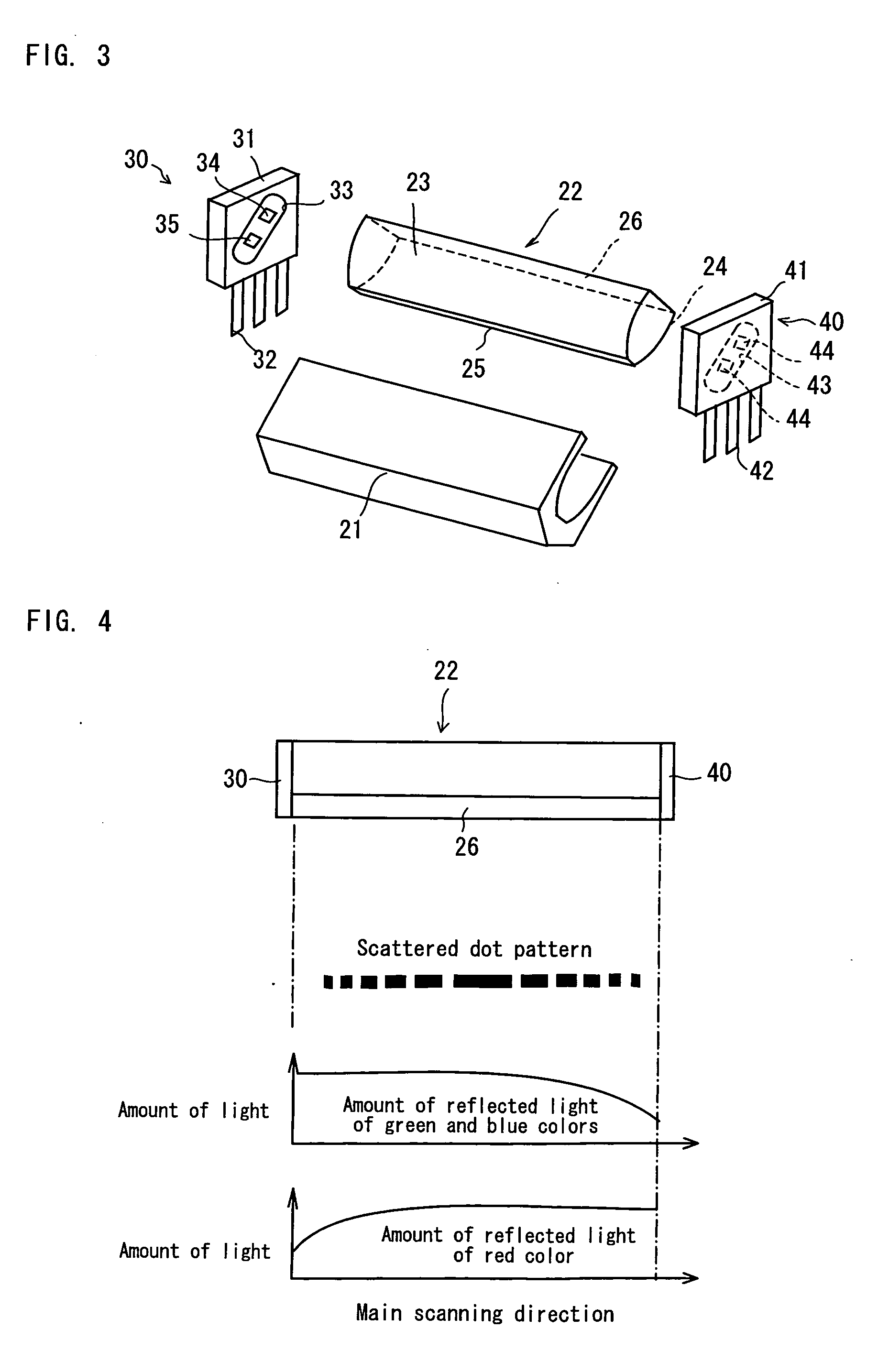

Line-illuminating device and image-scanning device

InactiveUS20050150956A1Improve accuracyHigh densityMechanical apparatusPattern makingLight guideEngineering

A line-illuminating device comprises a white casing, a bar-shaped light guide housed within the casing, and light-emitting units provided on opposite ends of the bar-shaped light guide. The light-emitting unit has a substrate forming a circuit on which a lead wire for power supply is installed. Formed on a surface of the substrate facing the bar-shaped light guide is a window for coupling in which a green-color light-emitting diode and a blue-color light-emitting diode are installed. Likewise, the light-emitting unit has a substrate on which a lead wire for power supply is installed. Formed on a surface of the substrate facing the bar-shaped light guide is a window for coupling in which two red-color light-emitting diodes are installed.

Owner:NIPPON SHEET GLASS CO LTD

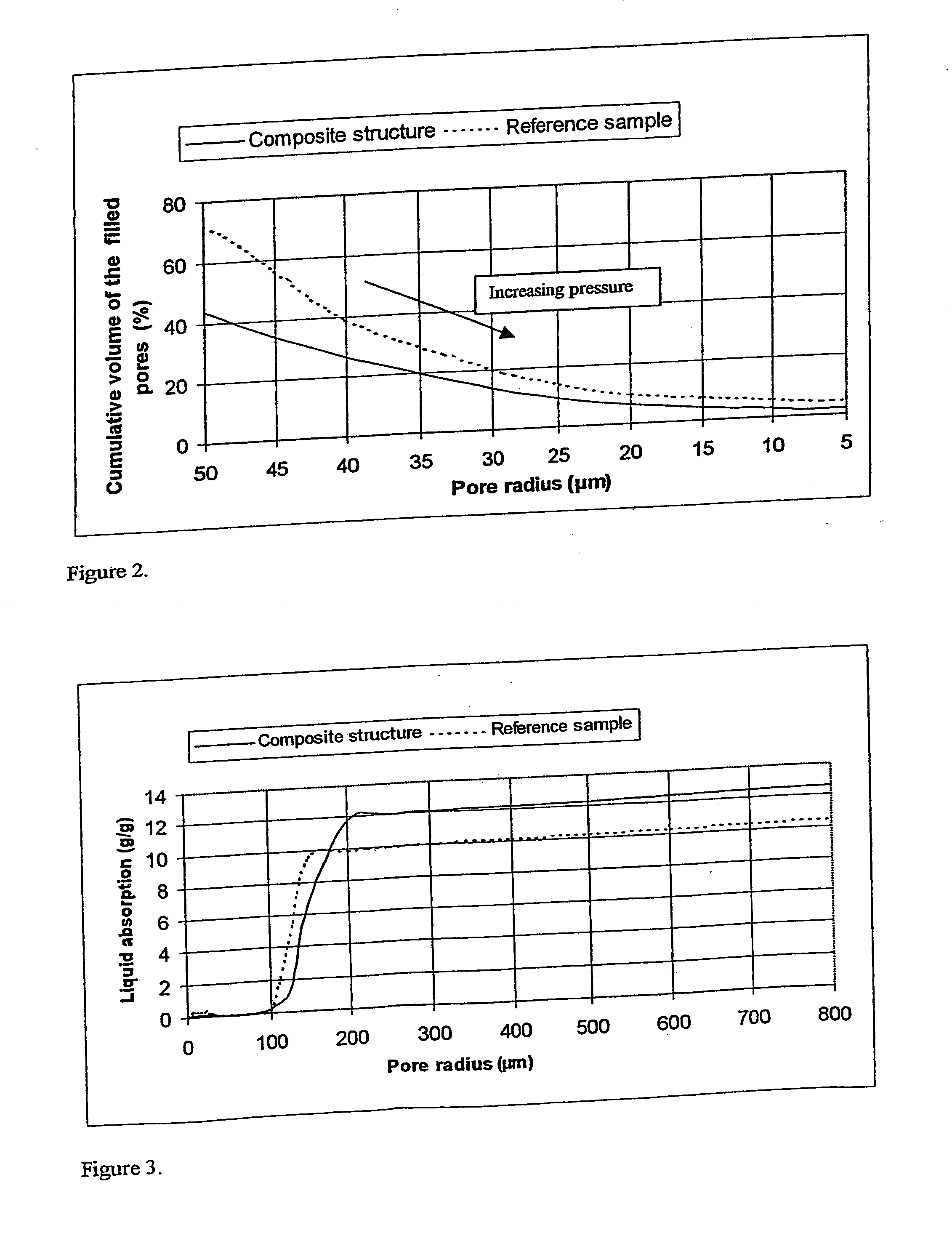

Composite nonwoven its use and method of manufacture

InactiveUS20050090175A1Excellent liquid absorptionGood release effectPattern makingNeedling machinesPolymer scienceFibrous layer

The invention concerns a composite nonwoven formed from fibrous layers bonded together by entanglement of fibers of the layers, wherein the fibrous layers comprise first and second outer layers each comprising a mixture of hydrophobic and hydrophilic fibers, as well as an intermediate layer of hydrophobic fibers sandwiched between the first and the second outer layers, the weight ratio between the hydrophobic and hydrophilic fibers in the first and the second layers being 20:80 to 80:20. The invention also concerns the manufacture of the nonwoven, as well as its use, especially as a wet wipe.

Owner:SUOMINEN NONWOVENS

Method of making a reinforcing mat for a pultruded part

A method of preparing a reinforcing structure for use in manufacture a pultruded part where the reinforcing structure is pulled through a pultrusion die in a continuous longitudinal pull direction. The method includes arranging a plurality of first reinforcing fibers in a transverse direction and attaching a permeable transport web of staple fibers to the first reinforcing fibers such that the portion of the first reinforcing fibers oriented in the direction transverse comprises at least 40% of a volume of materials comprising the reinforcing structure.

Owner:PELLA

Nonwoven fabric, nonwoven fabric manufacturing method, and nonwoven fabric manufacturing apparatus

The present invention provides a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, and in which at least one of a predetermined groove portion, an opening, and a protrusion is formed, a manufacturing method for the nonwoven fabric, and a nonwoven fabric manufacturing apparatus. The nonwoven fabric manufacturing apparatus of the present invention manufactures a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, or in which at least one of a predetermined groove portion, an opening, and a protrusion is formed by blowing fluid mainly containing gas onto a fiber web which is formed in a sheet shape, and which is in a state where at least a portion of the fibers constituting the fiber aggregate has a degree of freedom.

Owner:UNI CHARM CORP

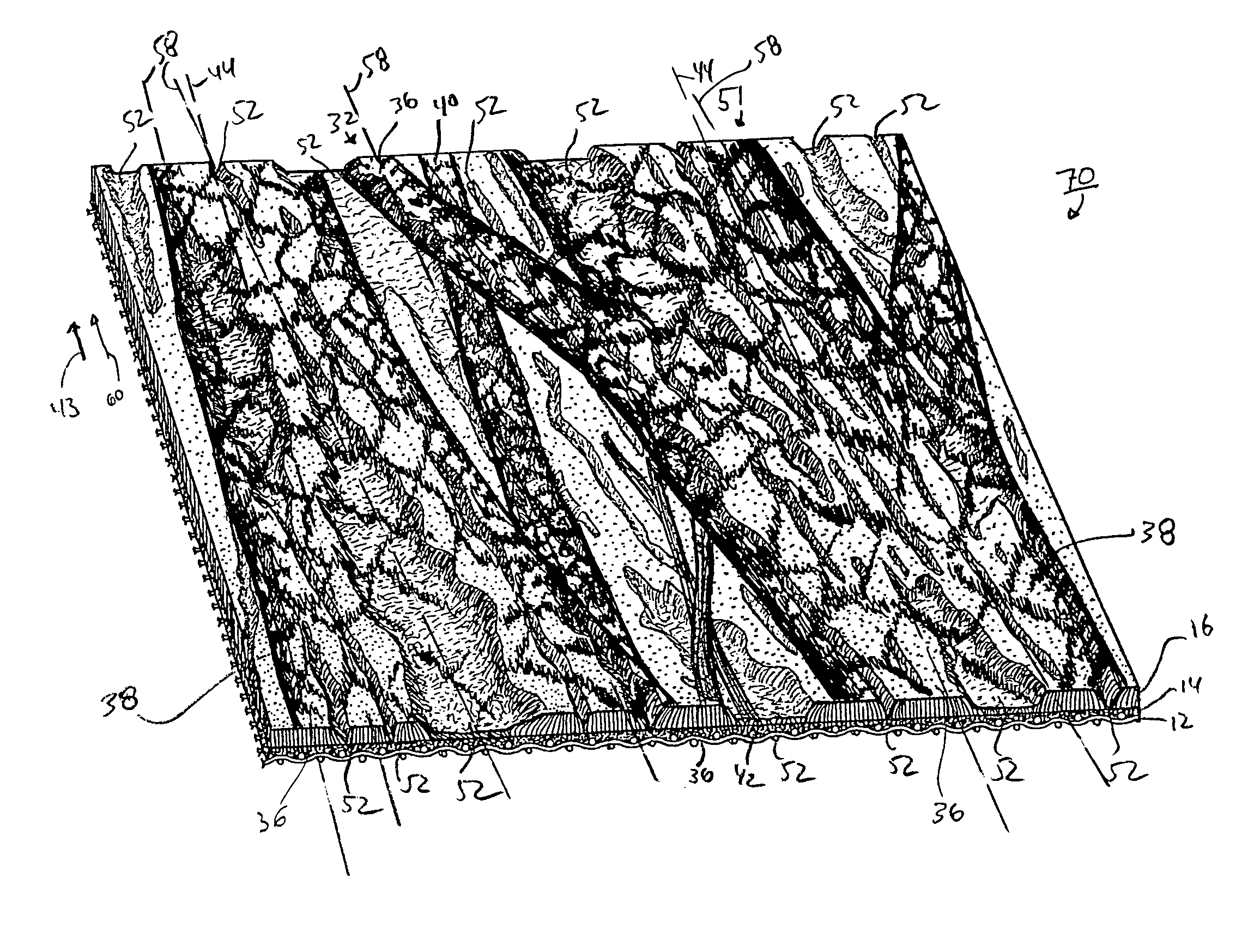

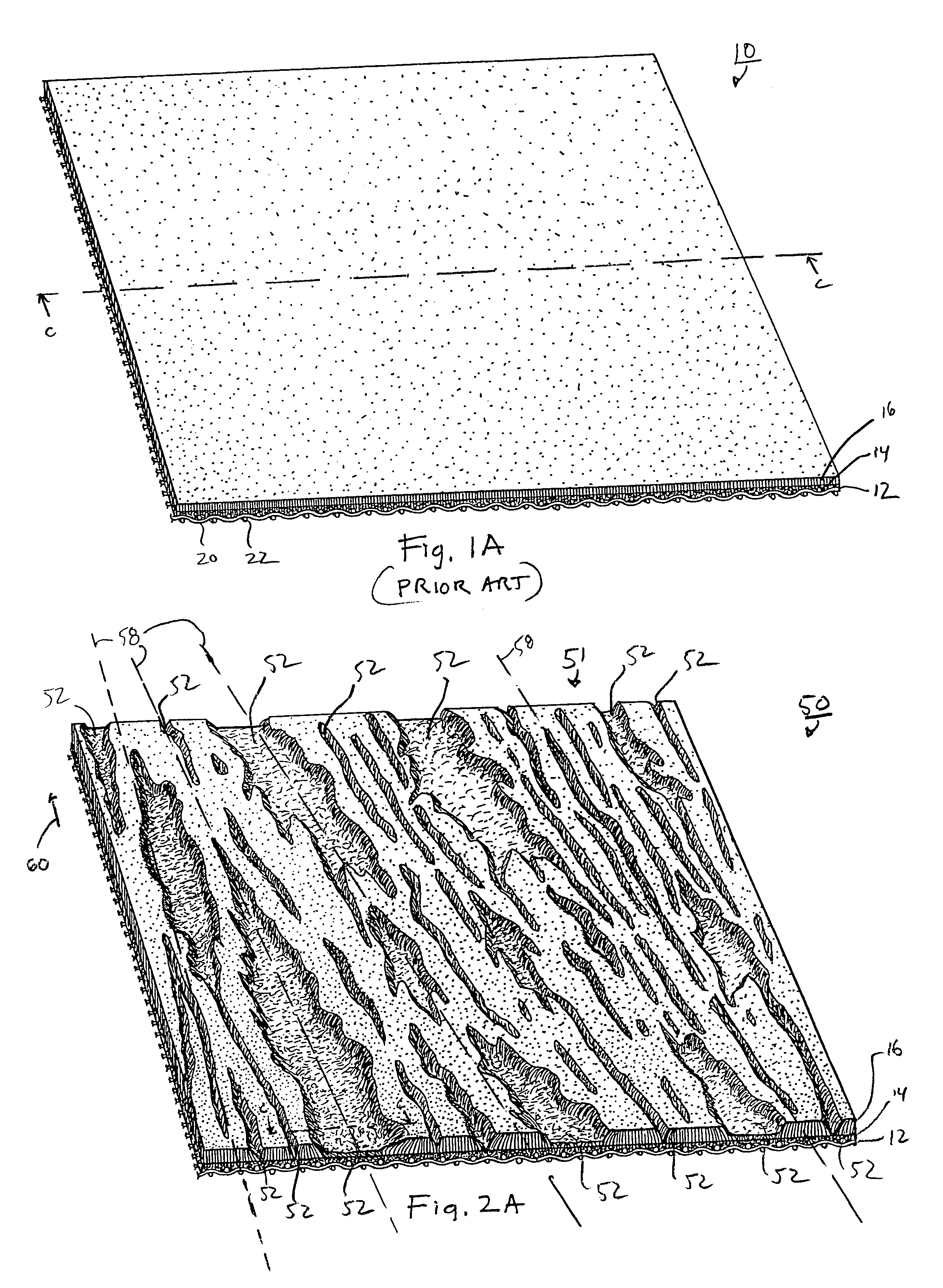

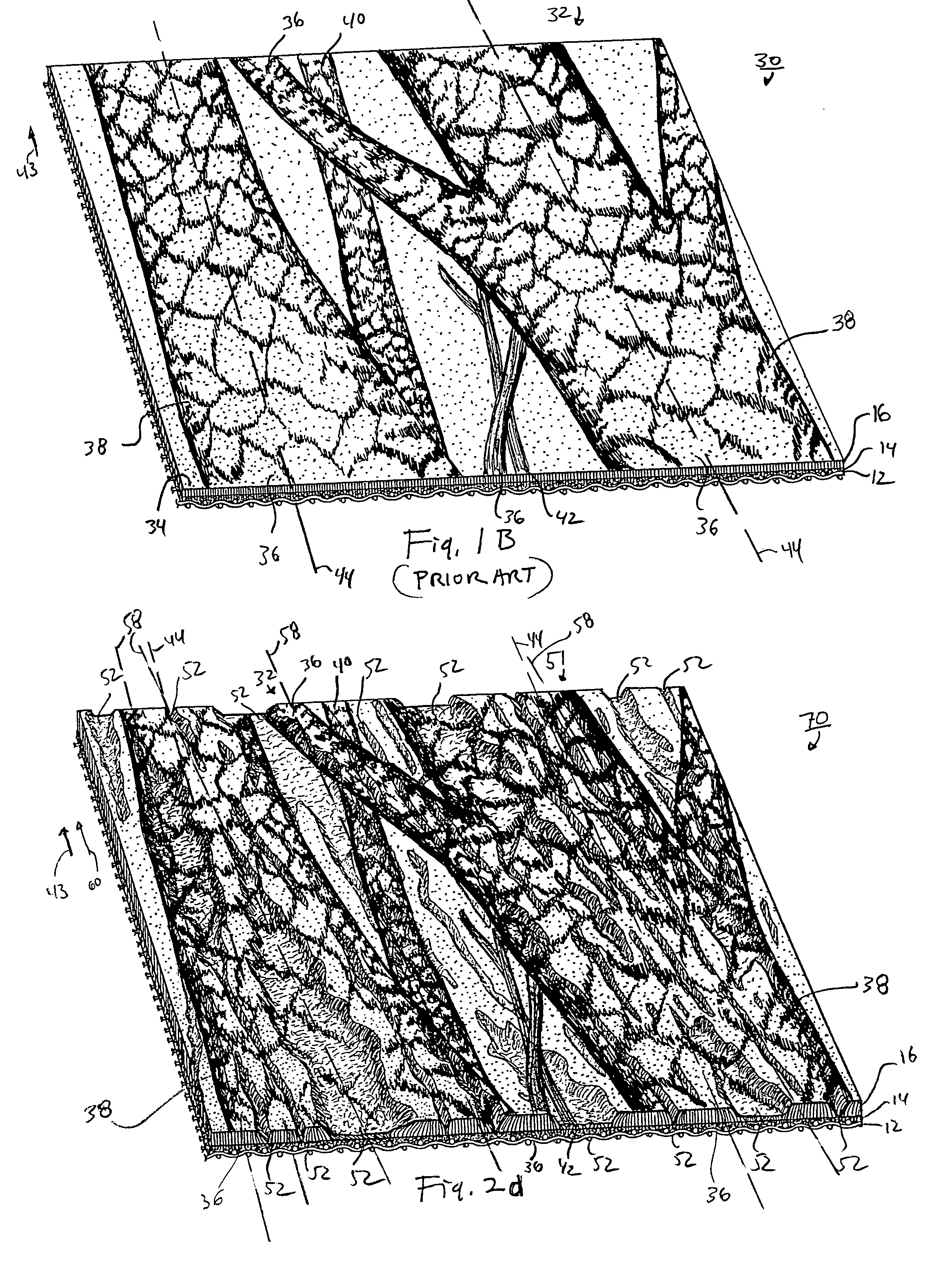

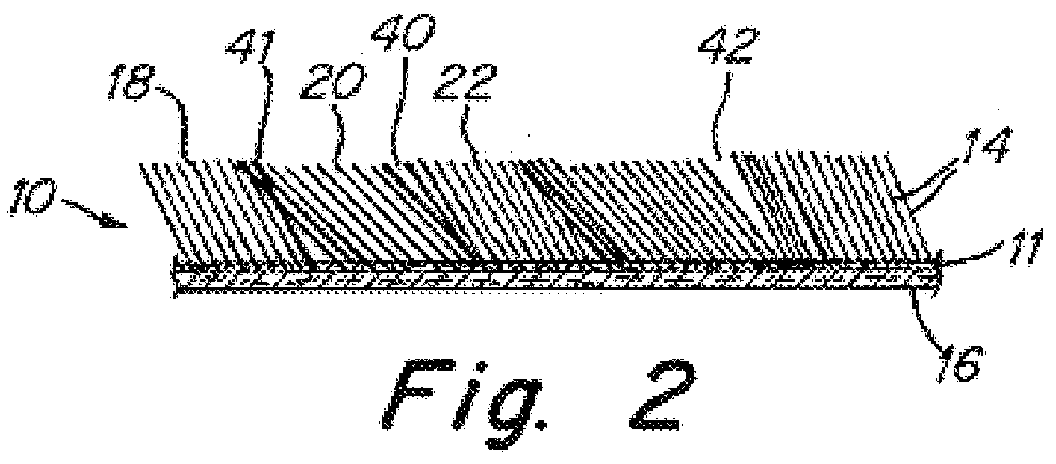

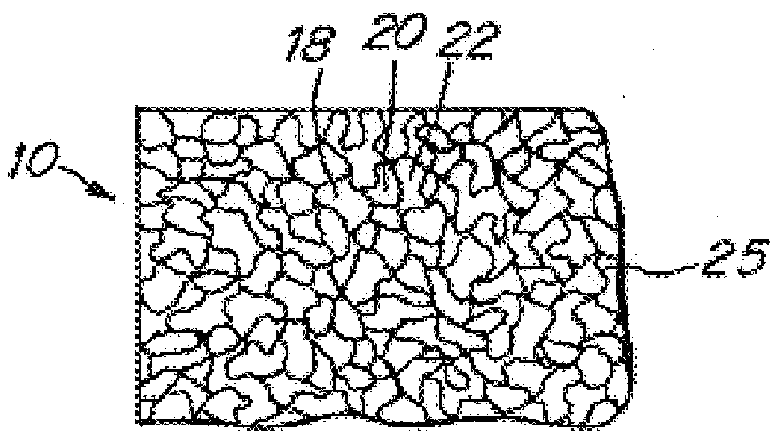

Realistically textured printed flocked fabrics and methods for making the fabrics

InactiveUS7229680B1Improve visual effectsDegree of reductionLiquid surface applicatorsLamination ancillary operationsEngineeringTransfer printing

The present invention is directed to unique flocked pile fabrics and methods for producing such fabrics. The fabrics provided according to one embodiment of the invention include an embossed pattern, characterized by a plurality of elongated depressions in the surface of the pile fabric, and a superimposed printed pattern, characterized by a scene or illustration including a plurality of visual features having elongated shapes. The inventive embossed, printed pile fabrics, having a superimposed embossed and printed pattern, advantageously superimpose the embossed pattern and the printed pattern upon the pile fabric so that the embossed pattern imparts a three-dimensional texture to the scene or illustration or pattern comprising the printed pattern. The texture provided by the embossed pattern can impart a visual effect to the scene or illustration which can render it more realistic than a similar scene or illustration printed upon a conventional unembossed pile fabric. In one embodiment, this unique texturing effect is accomplished by substantially aligning the longitudinal axes of the elongate features of the printed pattern and the elongate features of the embossed pattern. The pile fabric provided by the invention can be produced by utilizing a plurality of embossing and printing techniques. In one embodiment, the embossing technique comprises air embossing, and the printing technique comprises paper transfer printing utilizing a paper transfer sheet. The fabrics provided by the invention are especially useful as camouflage fabrics. Such fabrics typically include a printed scene or illustration representing a sylvan setting dominated by visual features such as trees, branches, bushes, leaves, flowers, berries, grass, rocks, moss, etc.

Owner:MICROFIBERS

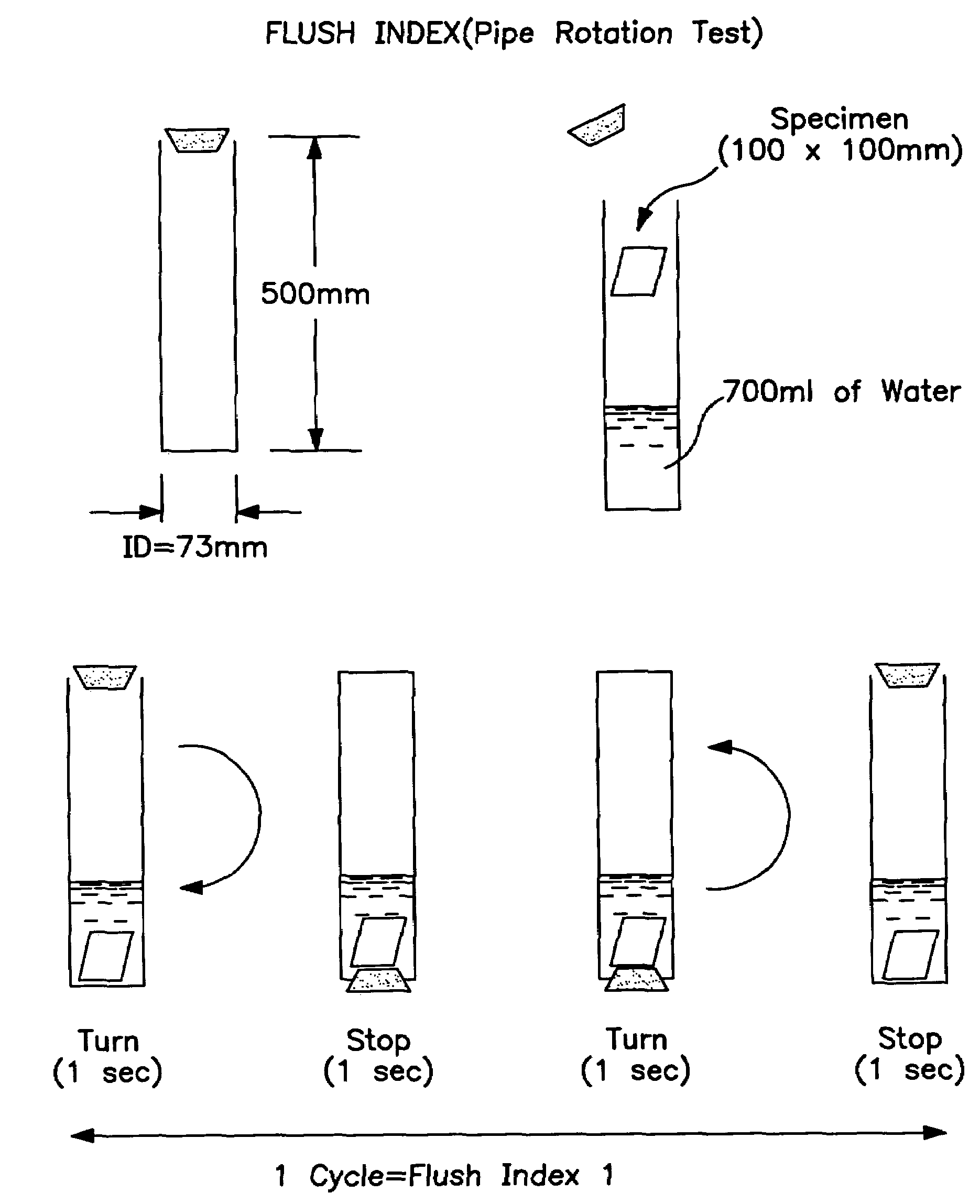

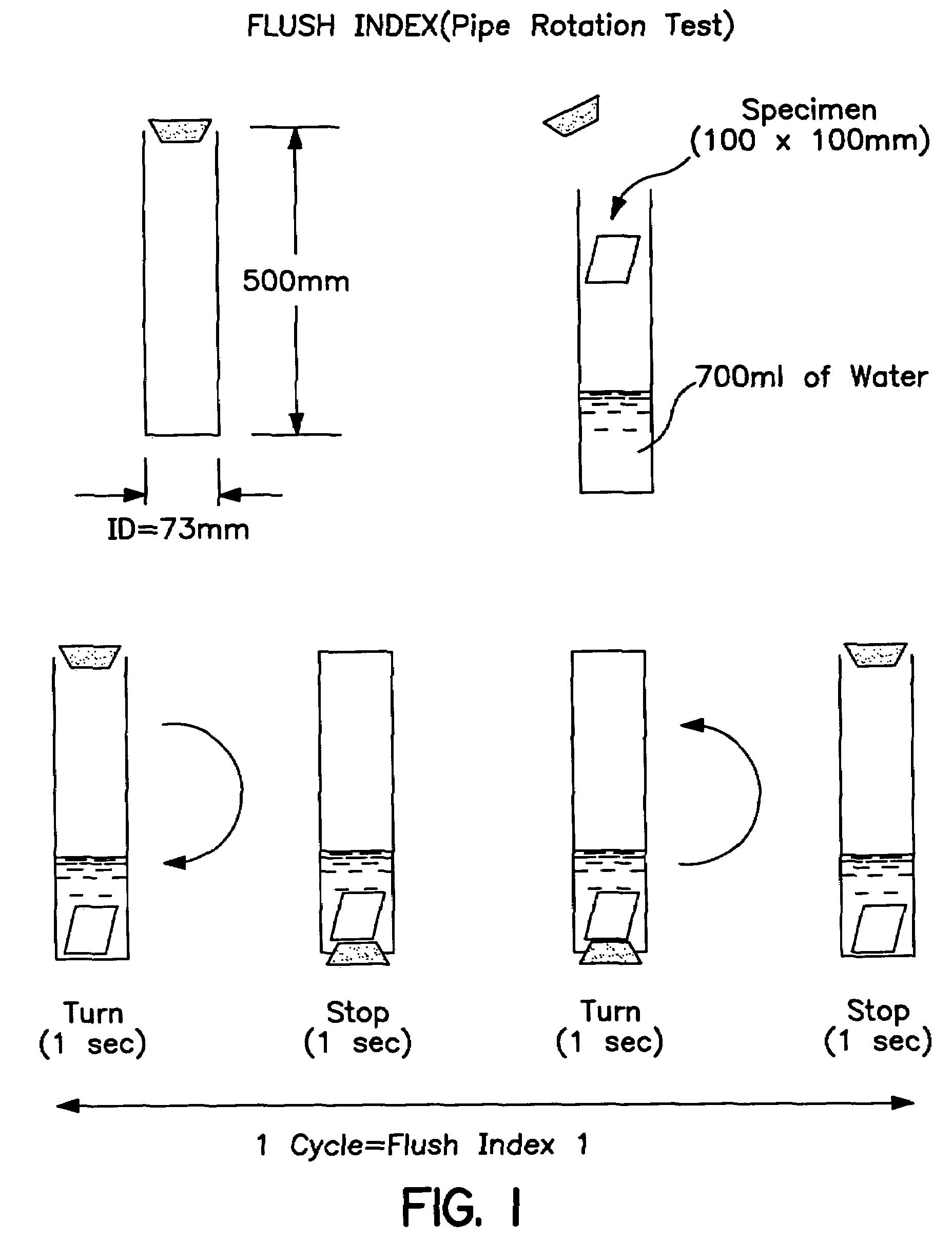

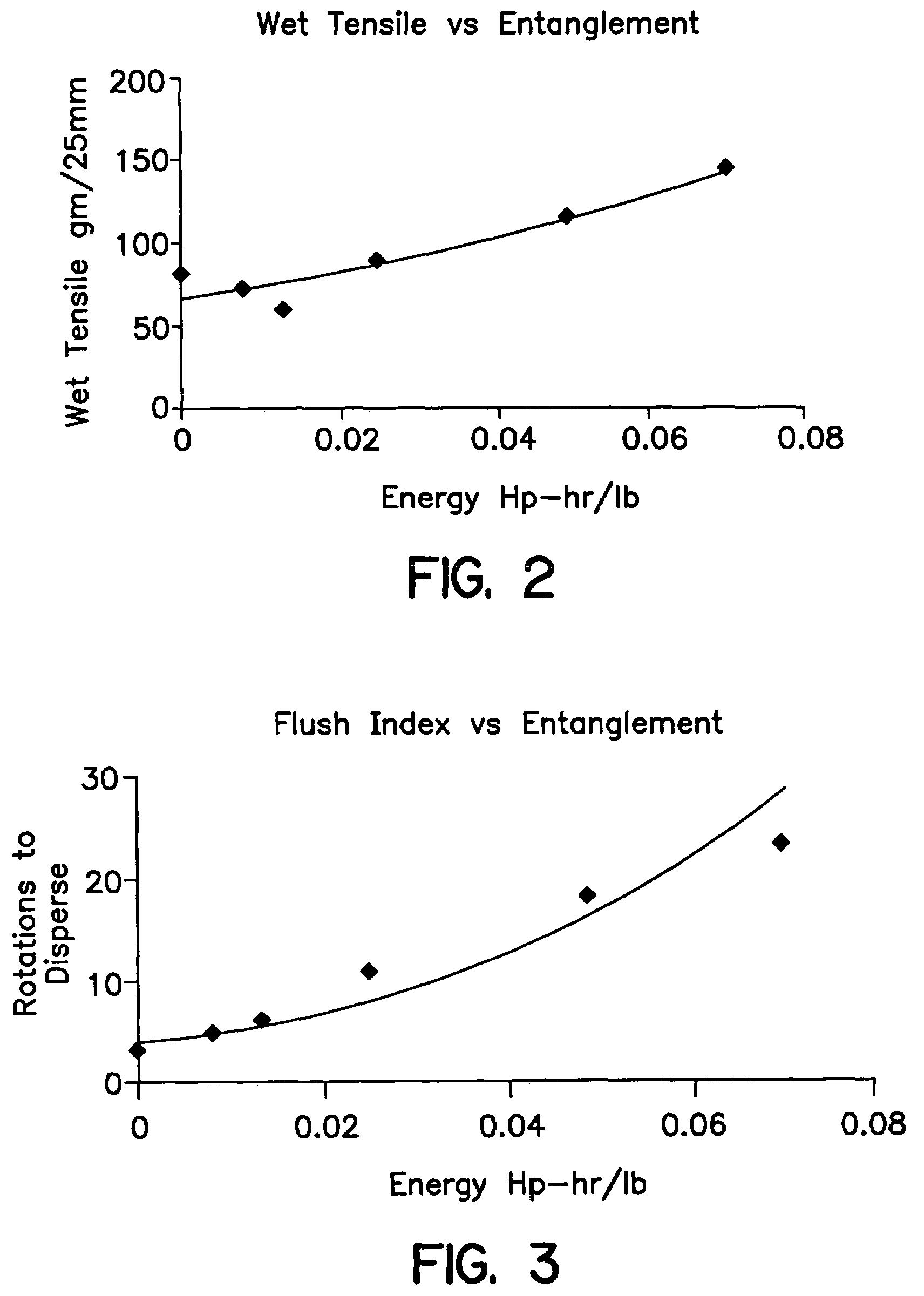

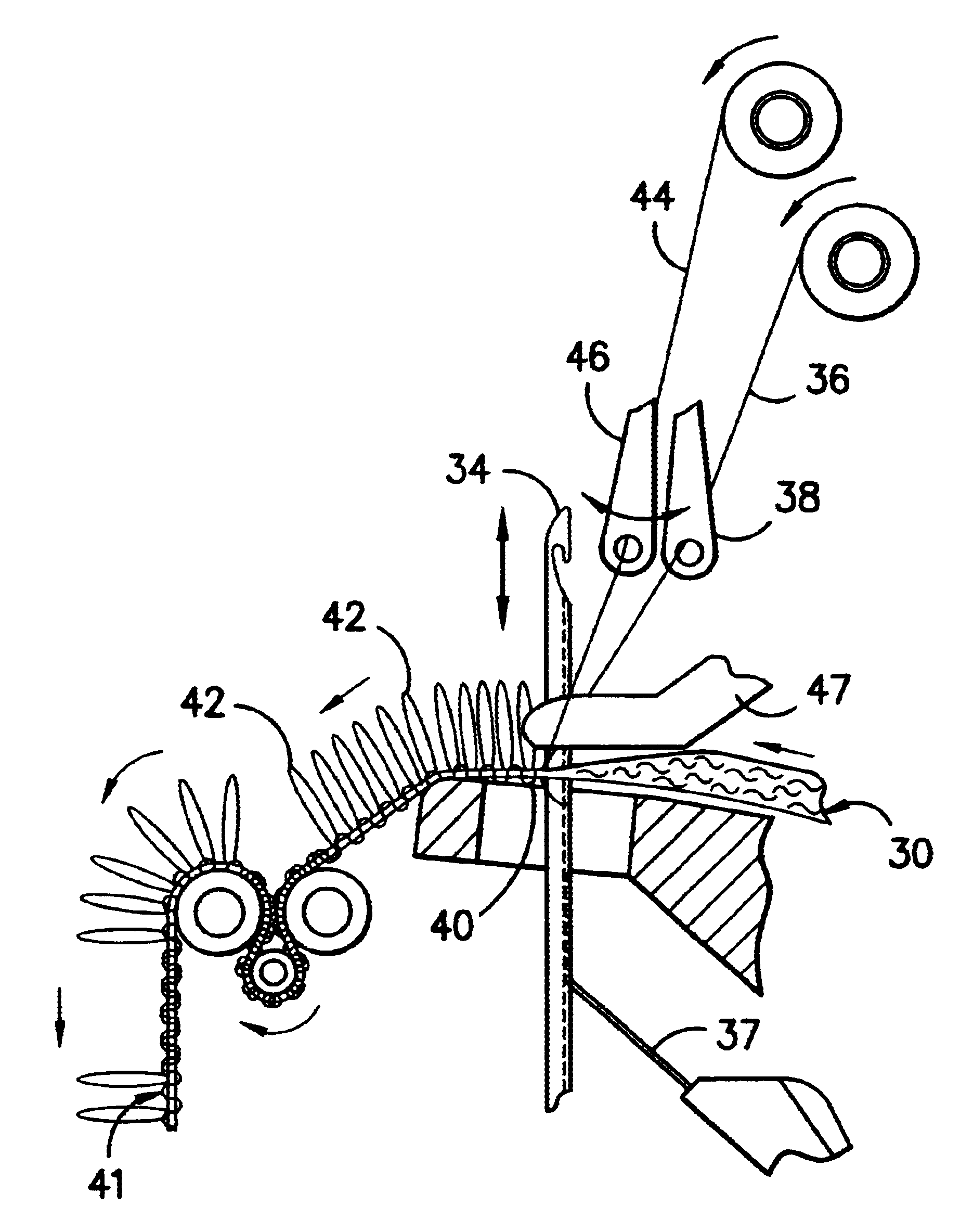

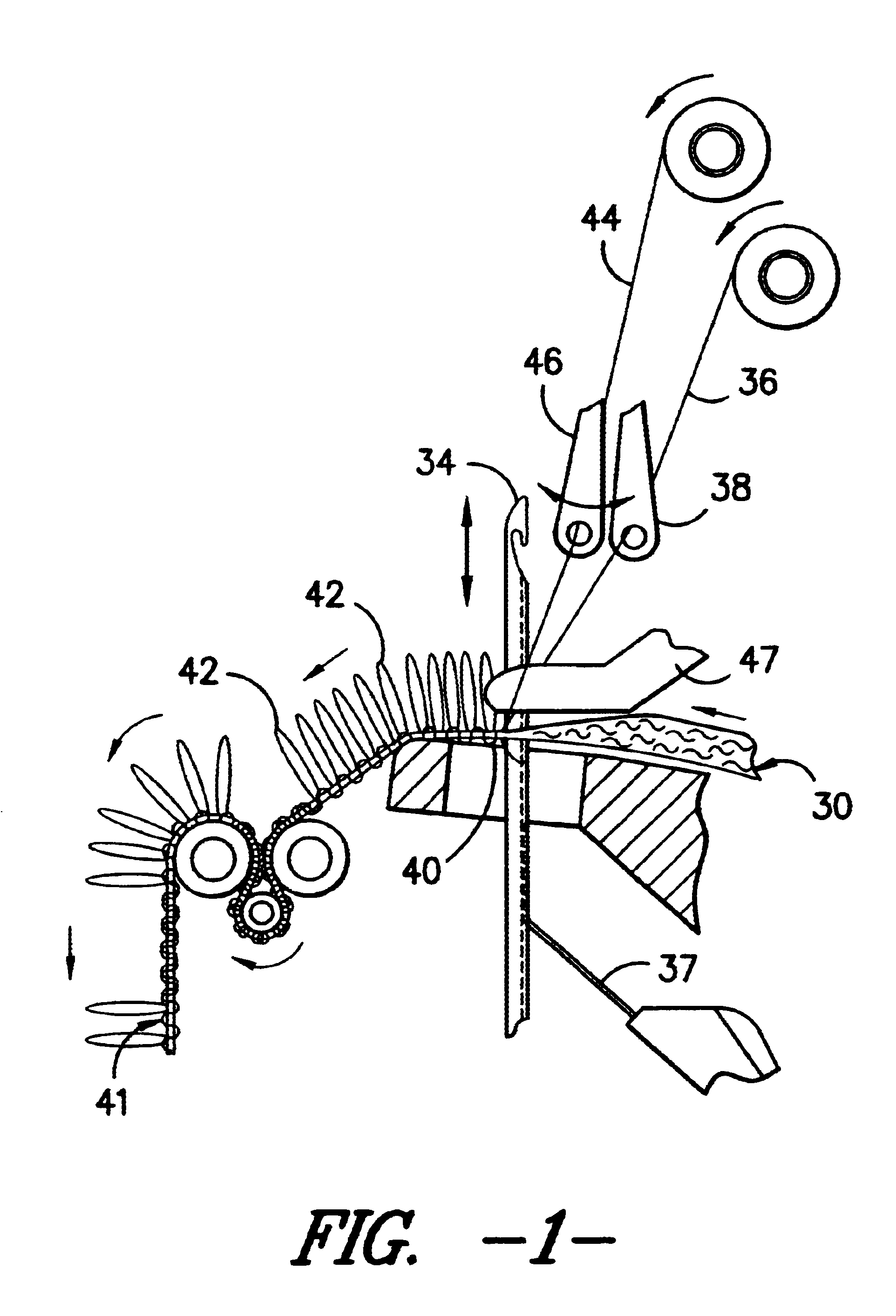

Disposable nonwoven wiping fabric and method of production

InactiveUS7732357B2Improve wet strengthImprove aestheticsCosmetic preparationsMake-upPolymer scienceCellulose fiber

Disclosed is a fibrous nonwoven web material and a method of manufacture thereof. The fibrous nonwoven web material includes natural cellulose fibers, manmade cellulose fibers and synthetic fibers. The manmade cellulose fibers are preferably high crystallinity cellulose fibers. The fibrous nonwoven web material has appreciable wet strength yet is capable of dispersing in most aqueous environments with only mild agitation. The fibrous nonwoven web material can be wet laid from an aqueous dispersion of fibers.

Owner:SUOMINEN CORP

Patterned stitch bonded pile fabric

A patterned pile fabric of stitch-bonded construction. The fabric includes a substrate layer with an arrangement of ground yarns extending in stitched relation through the substrate layer so as to define a ground covering across the substrate layer. An arrangement of pile forming yarns extend in stitched relation through the substrate layer such that the pile forming yarns define a patterned arrangement of looped elements projecting away from the ground covering in predefined three dimensional patterned arrays disposed across the fabric.

Owner:TIETEX INT

Hydroengorged spunmelt nonwovens

Owner:FIRST QUALITY NONWOVENS INC

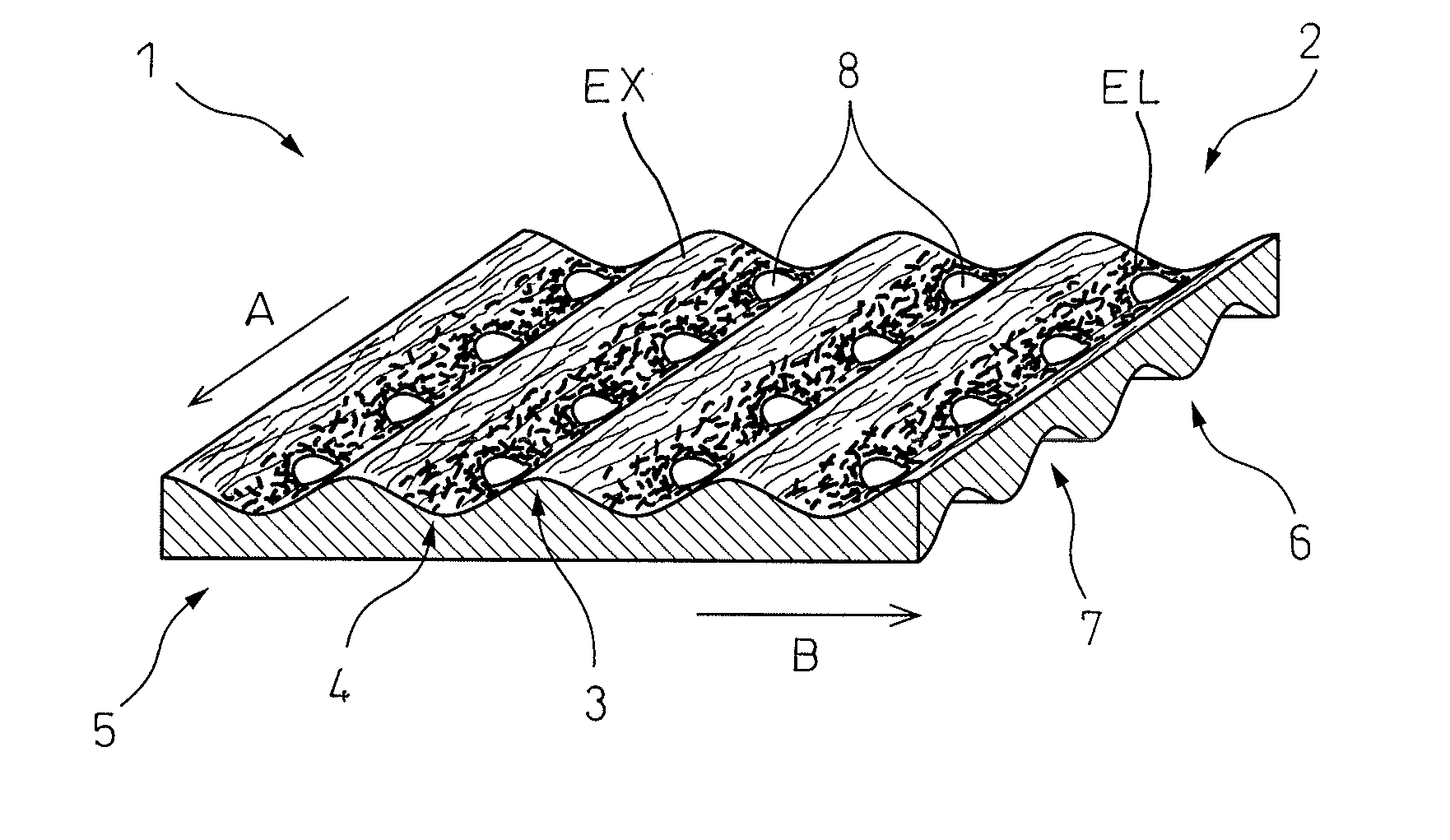

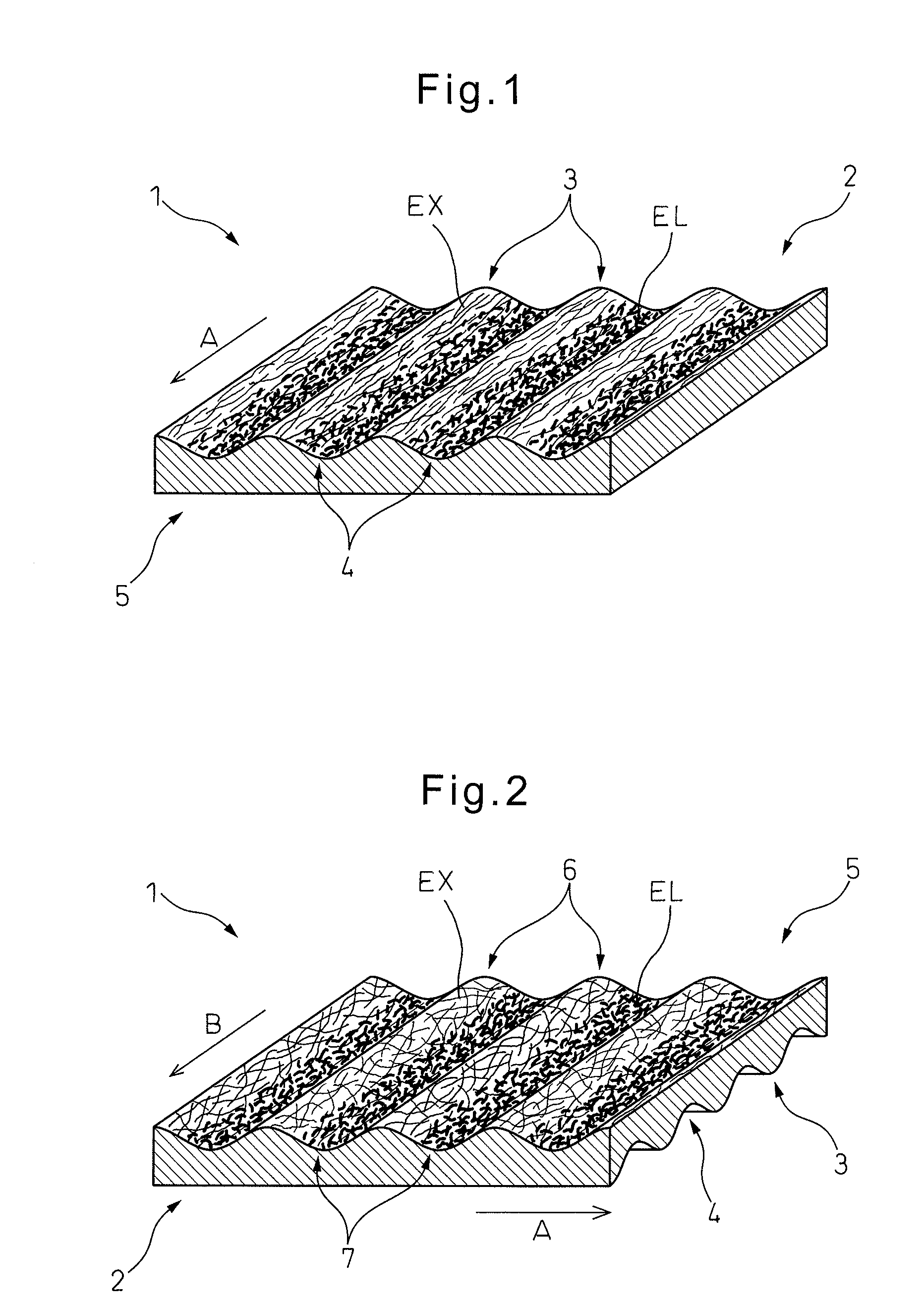

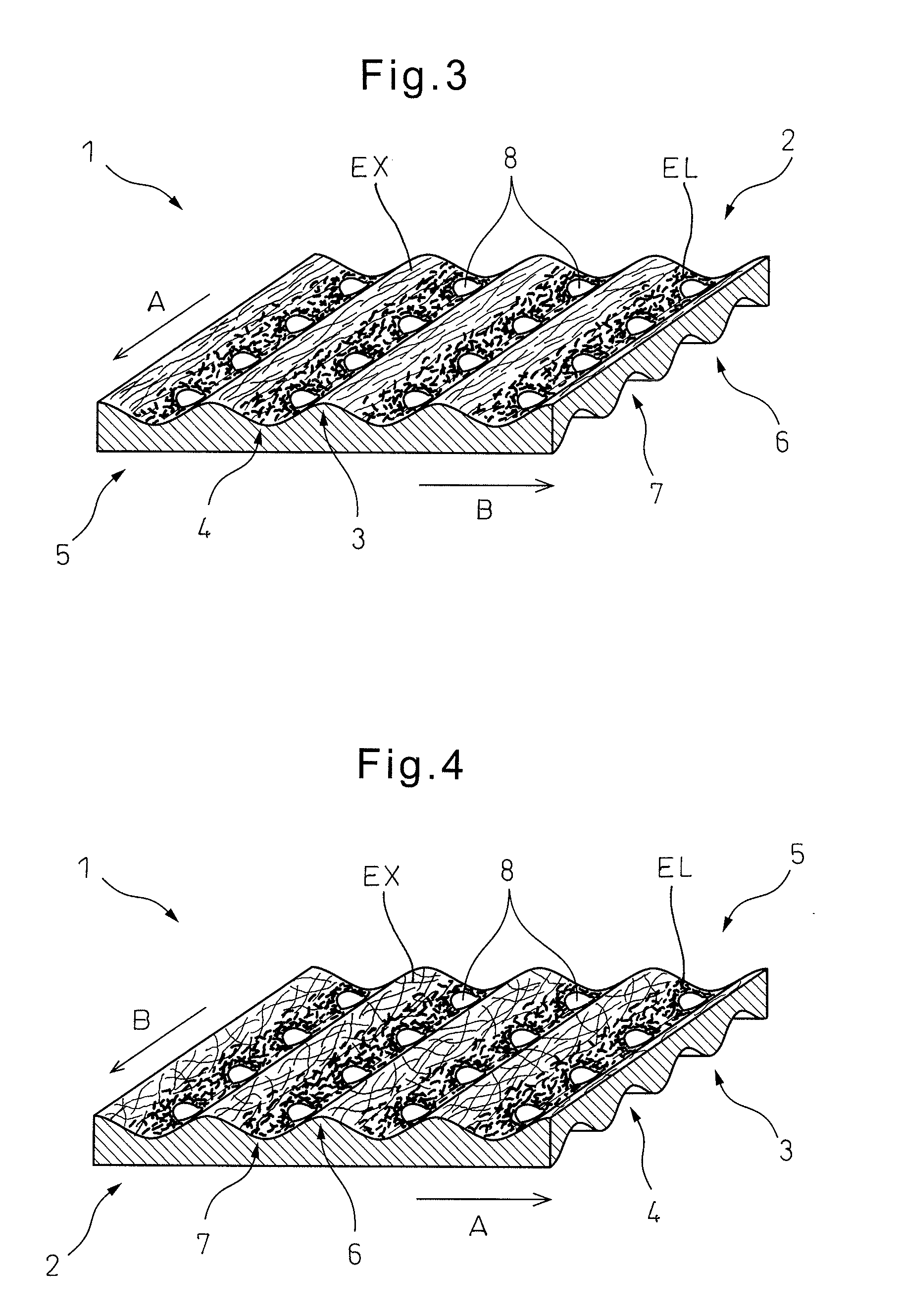

Nonwoven fabric having projections and recesses, comprising extensible fiber and elastic fiber, and method of producing nonwoven fabric

InactiveUS20130034686A1Good skin feelIncrease elasticityPattern makingLayered productsNonwoven fabricElastic fiber

It is an object of the invention to provide a nonwoven fabric having projections and recesses, comprising extensible fiber and elastic fiber, which has excellent feel on the skin and elasticity, and excellent air permeability in the planar directions and the thickness direction, as well as a method of producing the nonwoven fabric.A nonwoven fabric having projections and recesses, comprising extensible fiber and elastic fiber, wherein the first surface of the nonwoven fabric has a plurality of projections and a plurality of recesses, and the proportion of extensible fiber in the projections is higher than the proportion of extensible fiber in the recesses.

Owner:UNI CHARM CORP

Compositions and aqueous dispersions

An aqueous dispersion including (A) at least one base polymer selected from the group consisting of an ethylene-based co-polymer and a propylene-based co-polymer; (B) at least one polymeric stabilizing agent; and at least one filler; wherein the polymeric stabilizing agent is different from the at least one base polymer and is compatible with the at least one base polymer and the at least one filler, and wherein the dispersion has filler in the range of greater than 0 to about 600 parts per hundred parts of a combined amount of the at least one base polymer and the polymeric stabilizing agent is disclosed.

Owner:DOW GLOBAL TECH LLC +1

Printed flocked pile fabric and method for making same

InactiveUS6247215B1Soft handMore volumeLiquid surface applicatorsSucessive textile treatmentsFiberEngineering

Methods of forming a printed multicolor synthetic pile fabric having a substrate and pile formed of fibers arranged in random groups extending essentially unifomn-y across the entire width and along the entire length of the fabric are disclosed. The methods can be utilized to form fabrics wherein each of the above-mentioned groups comprises a random number of fibers extending at angles and in directions that randomly vary from the angles and directions of the fibers in adjacent groups. The methods can involve washing griege goods for selected times and at selected temperatures so as to randomly re-orient the fibers forming the flocked surface of the fabric. In preferred embodiments, the fabrics are printed after fiber re-orientation.

Owner:MICROFIBERS

Method of making a pultruded part with a reinforcing mat

A method of making a pultruded part having a uniform cross-section using a novel reinforcing mat. The method comprises orienting a plurality of longitudinal rovings along a longitudinal axis of a pultrusion die; providing a reinforcing structure comprising a permeable transport web of staple fibers attached to a plurality of first reinforcing fibers oriented so that the portion of the first reinforcing fibers oriented in a direction transverse to the longitudinal axis comprises at least 40% of a volume of materials comprising the reinforcing structure; shaping the reinforcing structure to generally conform with a profile of the pultrusion die; combining a resin matrix with the longitudinal rovings and the reinforcing structure in the pultrusion die so that the longitudinal rovings and the reinforcing structure are substantially surrounded by the resin matrix; at least partially curing the resin matrix in the pultrusion die; and pulling the pultruded part from the pultrusion die.

Owner:PELLA

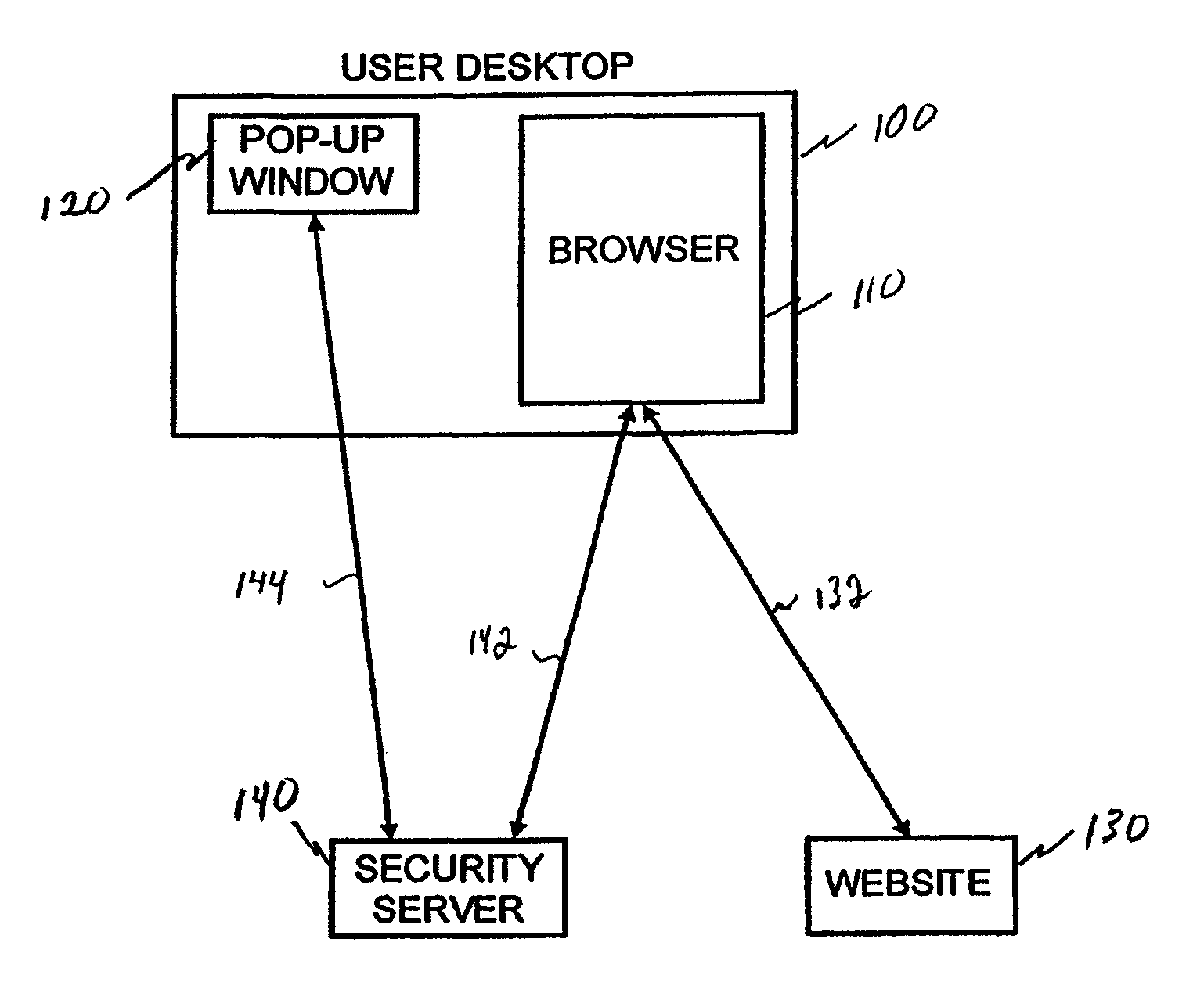

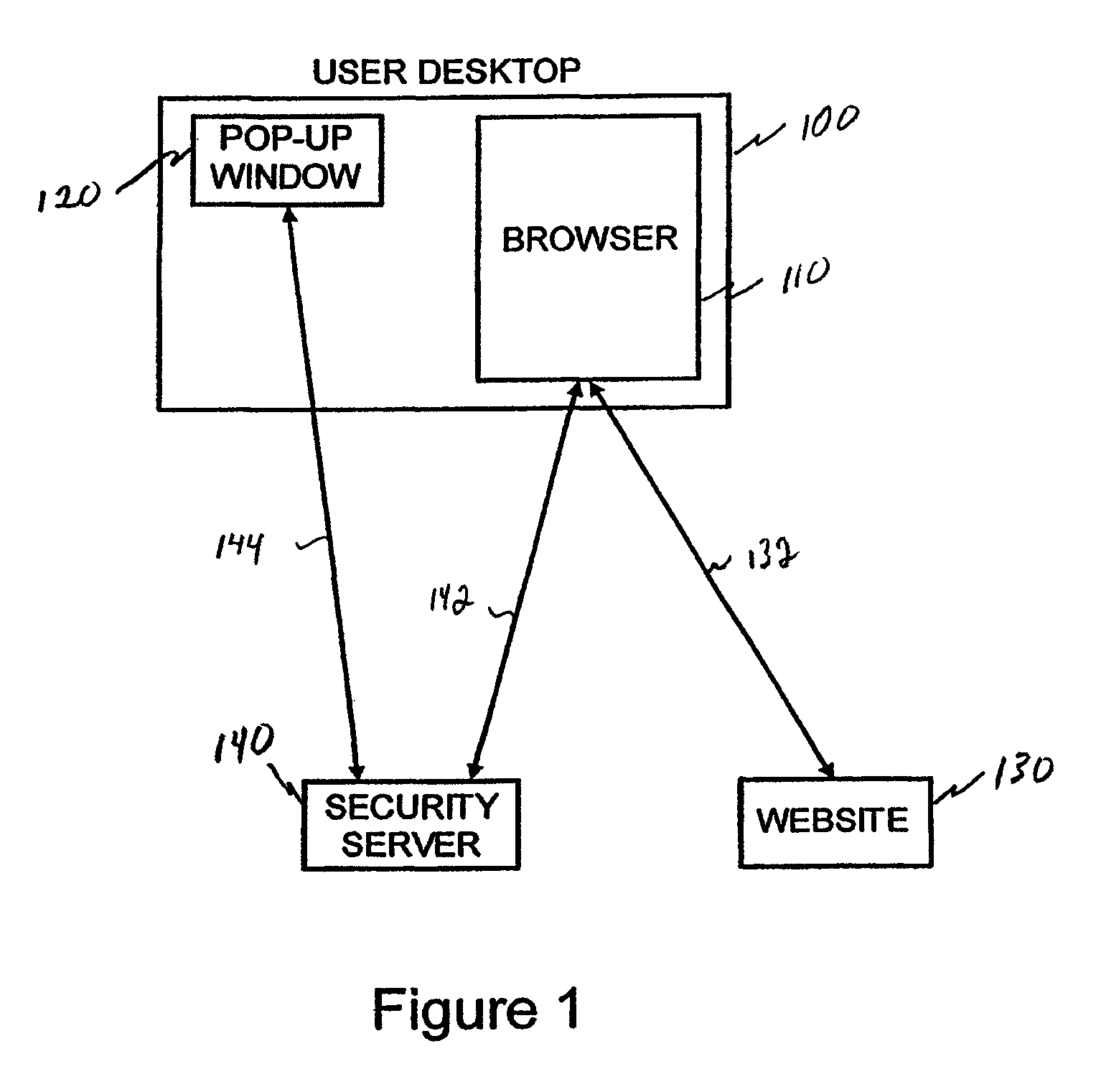

Secure and efficient authentication using plug-in hardware compatible with desktops, laptops and/or smart mobile communication devices such as iPhones

ActiveUS8769784B2Enhanced authenticationImproved transactionPattern makingDigital data processing detailsAuthorization certificateTelecommunications link

A portable apparatus is removably and communicatively connectable to a network device to communicate authentication or authorization credentials of a user in connection with the user logging into or entering into a transaction with a network site. The apparatus includes a communications port to connect and disconnect the apparatus to and from the network device and to establish a communication link with the network device when connected thereto. A processor receives a secure message from the network security server via the port. The message has a PIN for authenticating the user to the network site, and is readable only by the apparatus. The processor either transfers, via the port, the received PIN to an application associated with the network site that is executing on the network device or causes the apparatus to display the received PIN for manual transfer to the application associated with the network site.

Owner:PAYFONE

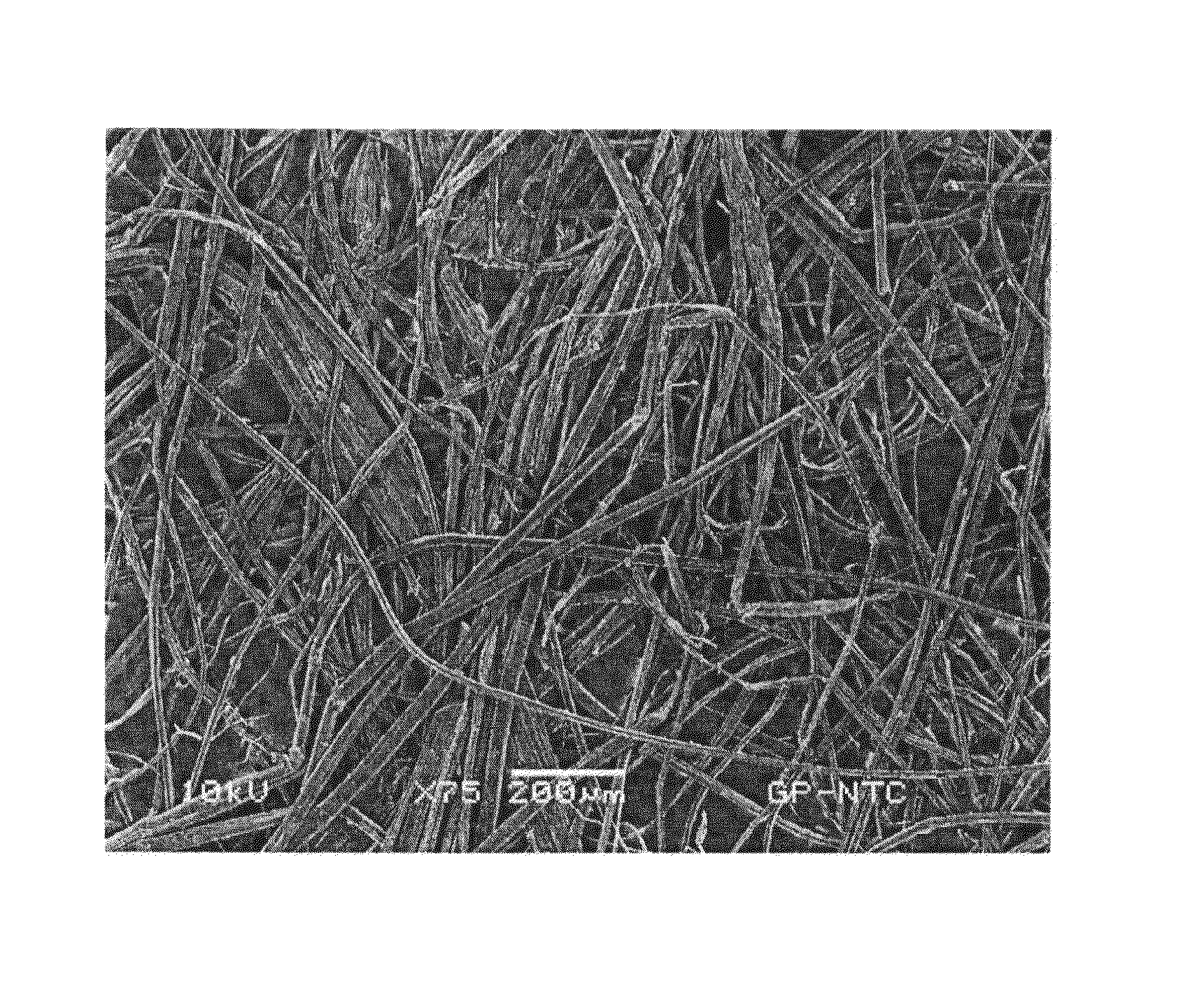

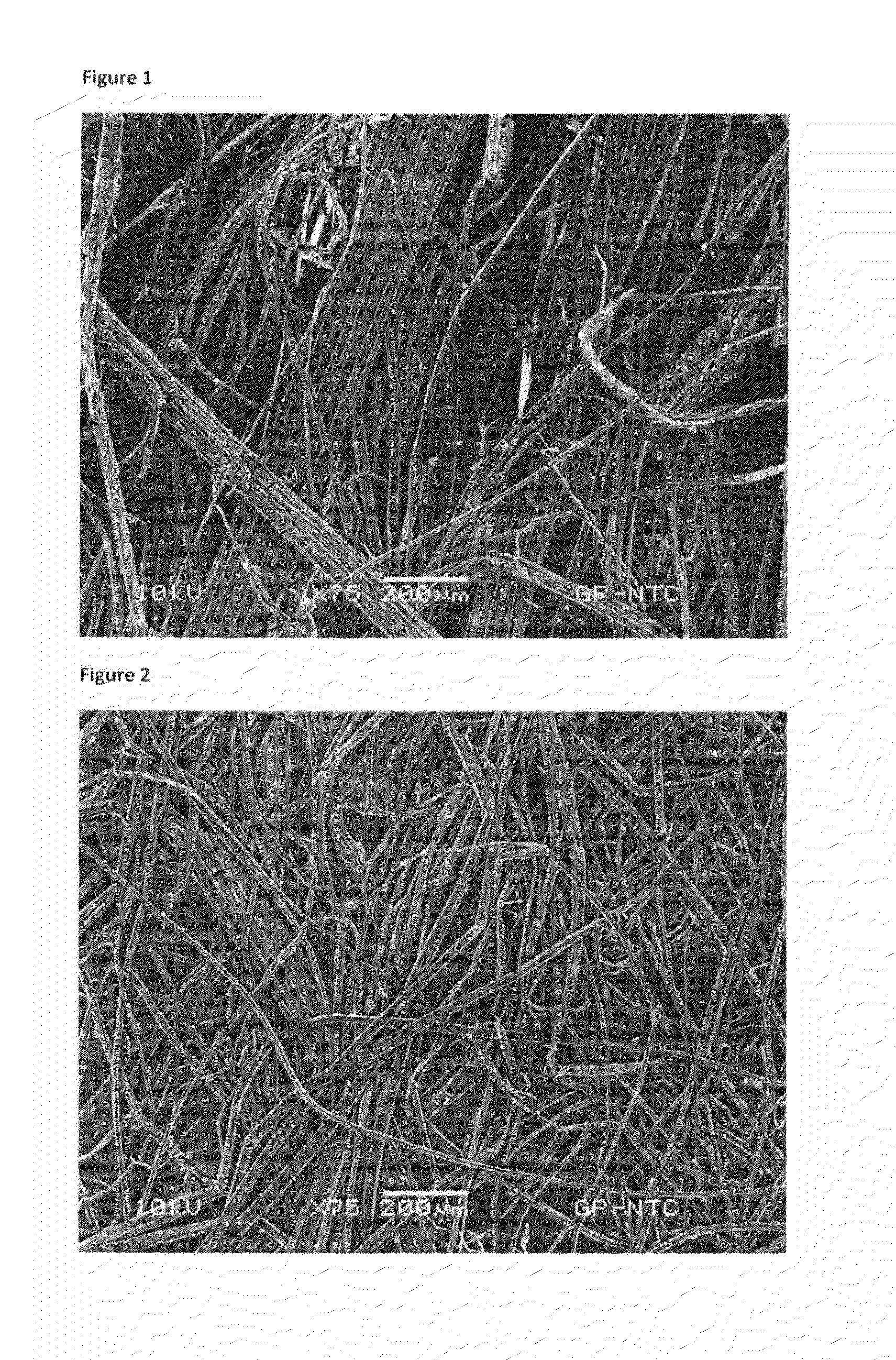

Nonwoven Fabrics Comprised of Individualized Bast Fibers

Nonwoven textile fabrics in accordance with the present invention are formed primarily of individualized bast fibers substantially free of pectin. The nonwoven fabric can include staple fibers to a lesser extent than the individualized bast fibers. Individualized bast fibers include fibers derived from the flax and hemp plants. The nonwoven textile fabric is formed into a web while in a dry state and subsequently bonded to produce a nonwoven fabric.

Owner:GPCP IP HLDG LLC

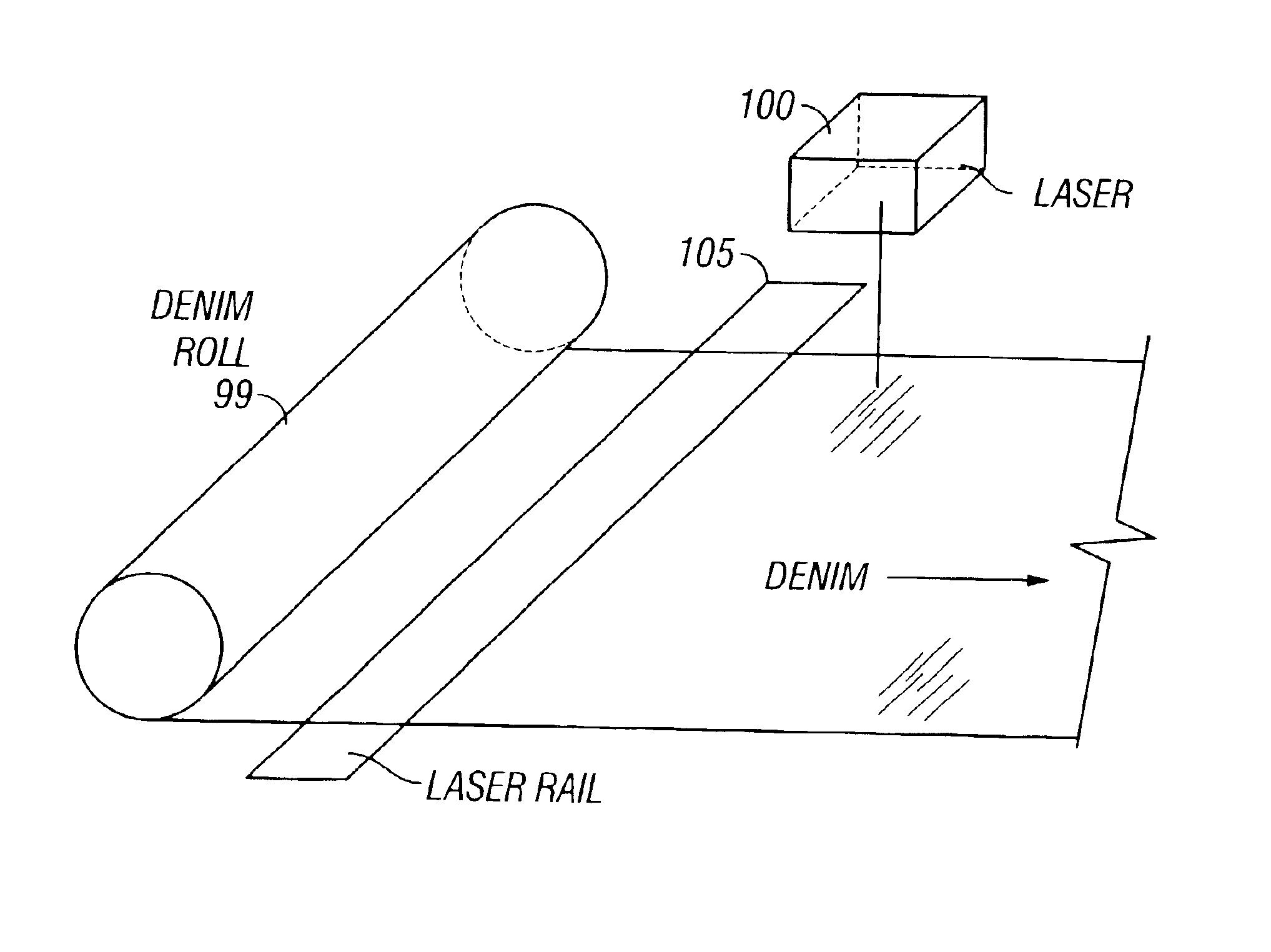

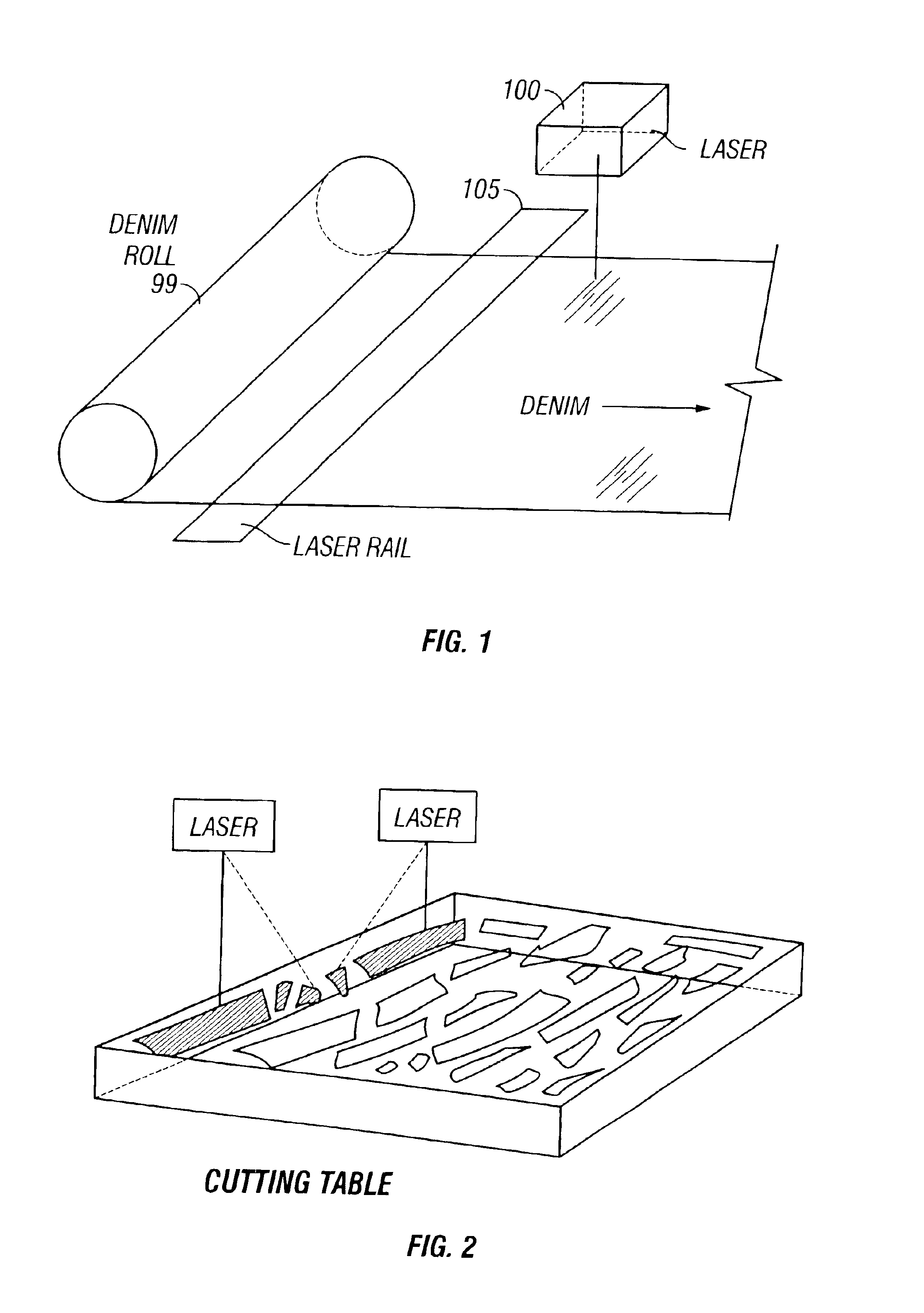

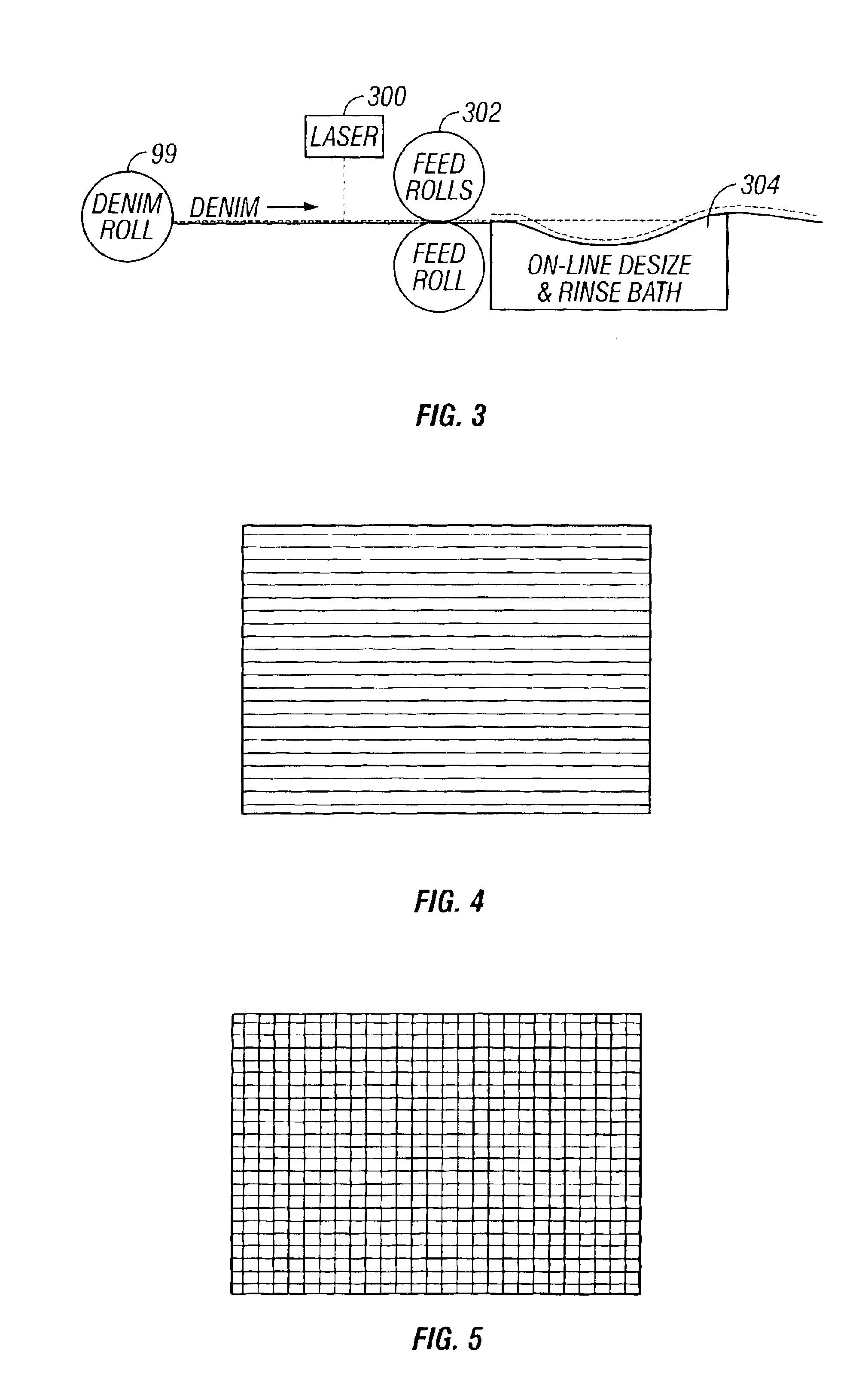

System and method of generating a pattern or image on fabric with linear laser irradiation, fabric made by said method, and products made with said fabric

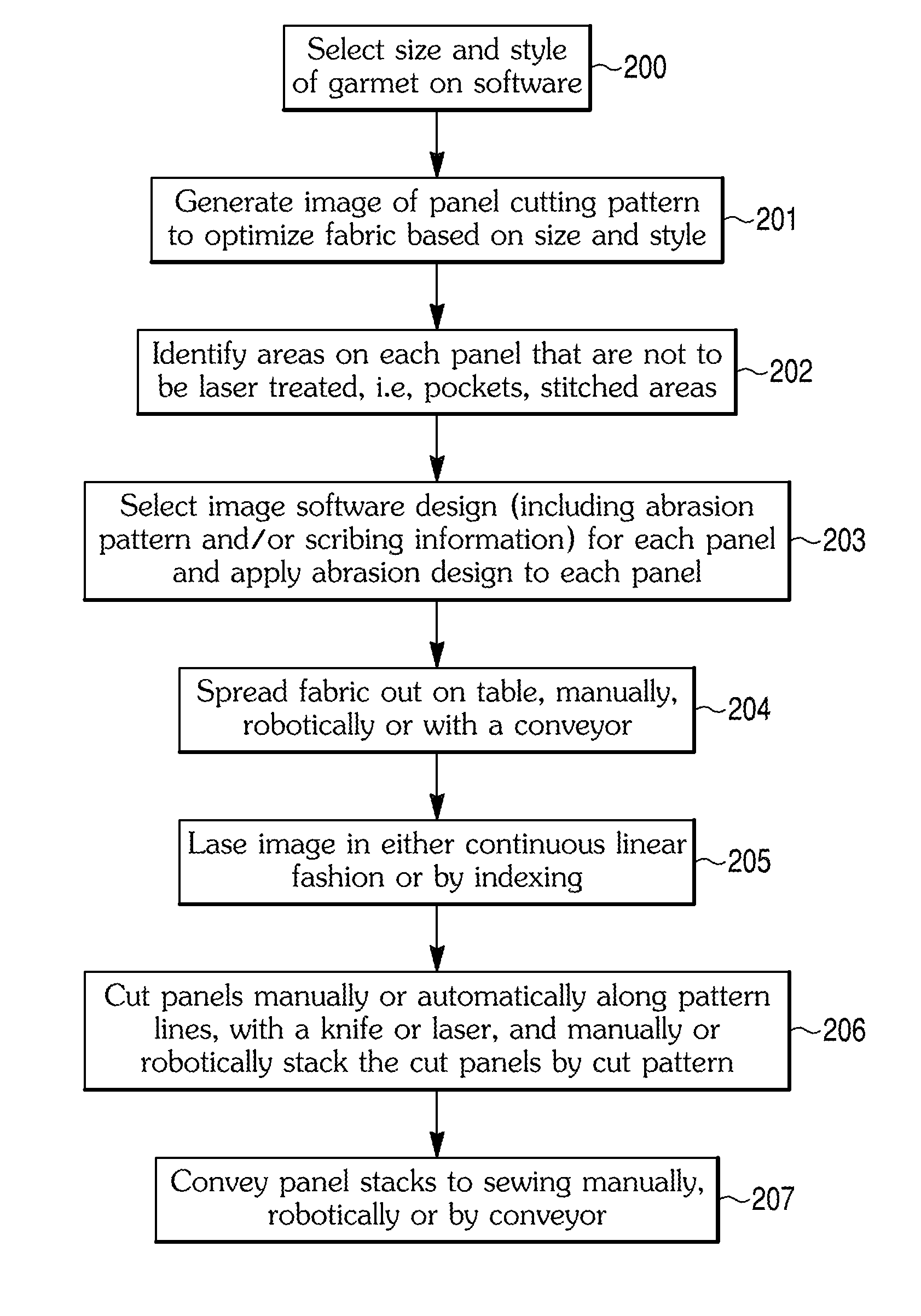

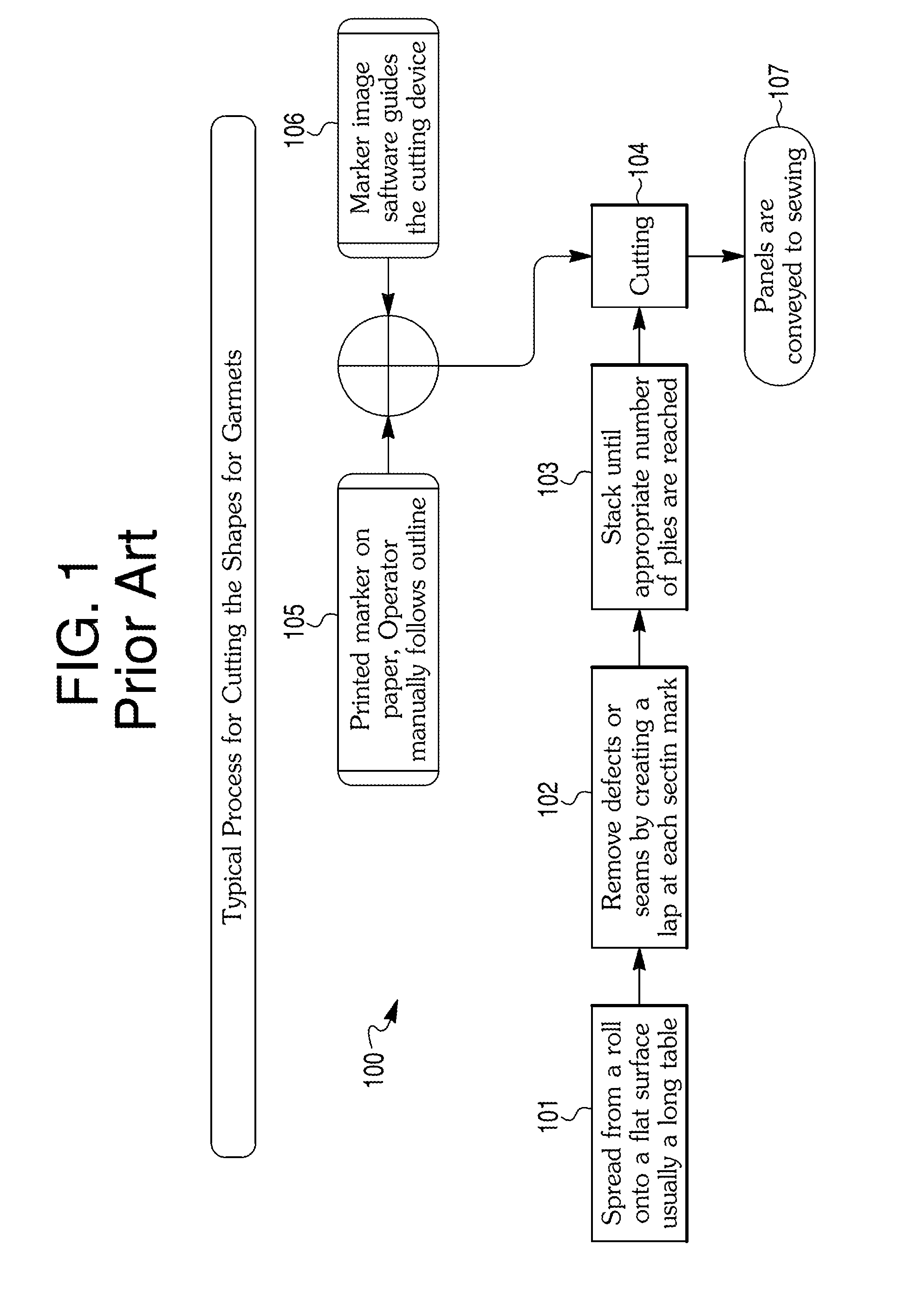

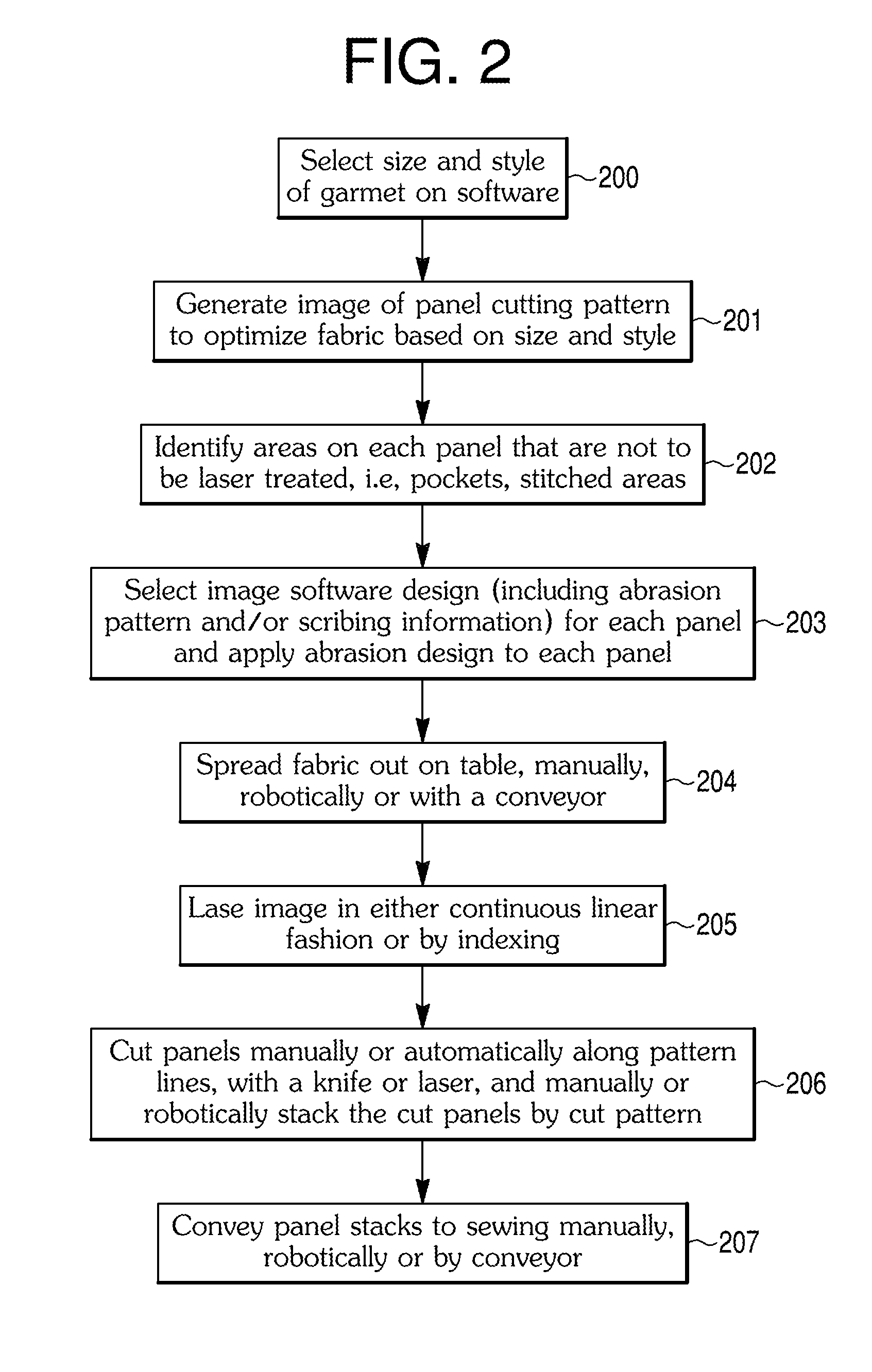

A method of scribing abrasion aesthetics, patterns, images, serial numbers, ply markings and / or other information, such as sizing or care information, on fabric such as denim, before or during the fabric cutting process is provided. The method comprises loading the panel abrasion software, pattern marker software, and fabric scribing software; placing the fabric on a flat surface under at least one laser; laser scribing ply numbers, serial labels, fabric markers, and panel abrasions on the fabric; cutting the fabric into fabric lengths; spreading the pre-abraded and pre-marked fabric lengths on top of each other to create multiple plies in precise alignment; cutting shaped panels along the lines of the pattern marker with a conventional knife, laser, or other appropriate cutting tool; and stacking the abraded, labeled and shaped panels robotically or manually for sewing.

Owner:REVOLAZE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com